Three-dimensional nozzle ring vane of variable geometry turbocharger and design method thereof

A technology for turbochargers and nozzle rings, applied in mechanical equipment, machines/engines, gas turbine devices, etc., to achieve the effects of widening the flow range, reducing vortex losses, and reducing flow losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] The variable geometry turbocharger nozzle ring three-dimensional vane of the present invention includes but not limited to variable geometry turbocharger (VGT). For the convenience of expression, VGT is used as an example for description in this specification.

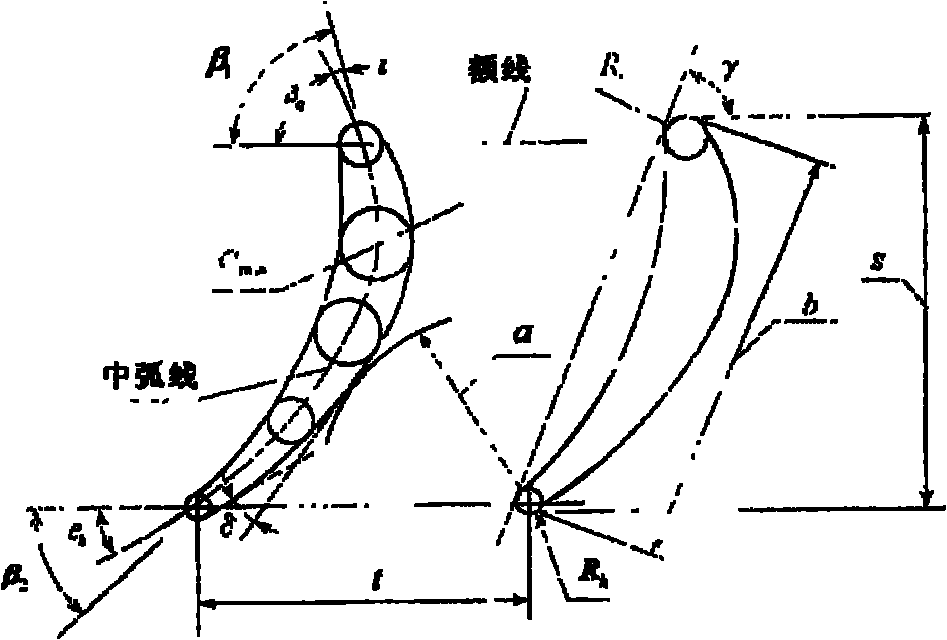

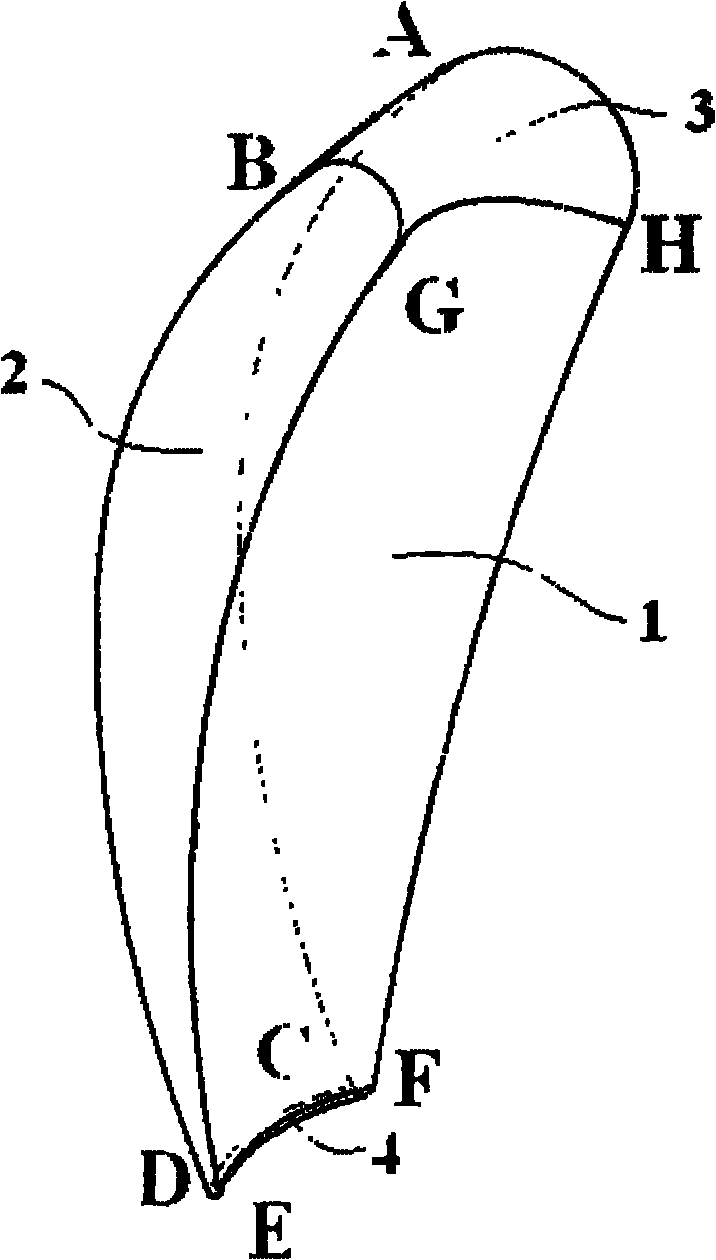

[0036] The present invention is designed on the basis of the axial-flow compressor blade cascade test of NASA between 1940 and 1960 according to the principle of aerodynamics. The design of the nozzle ring blade is mainly formed by stacking the blade shapes of several sections along the radial direction according to a certain rule. attached figure 1 Indicates the geometric parameters and flow parameters used in blade forming: leading edge construction angle β q , trailing edge construction angle β h , intake angle β 1 , outlet angle β 2 , angle of attack i, trailing edge b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com