Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3996results about "Volume/mass flow by differential pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

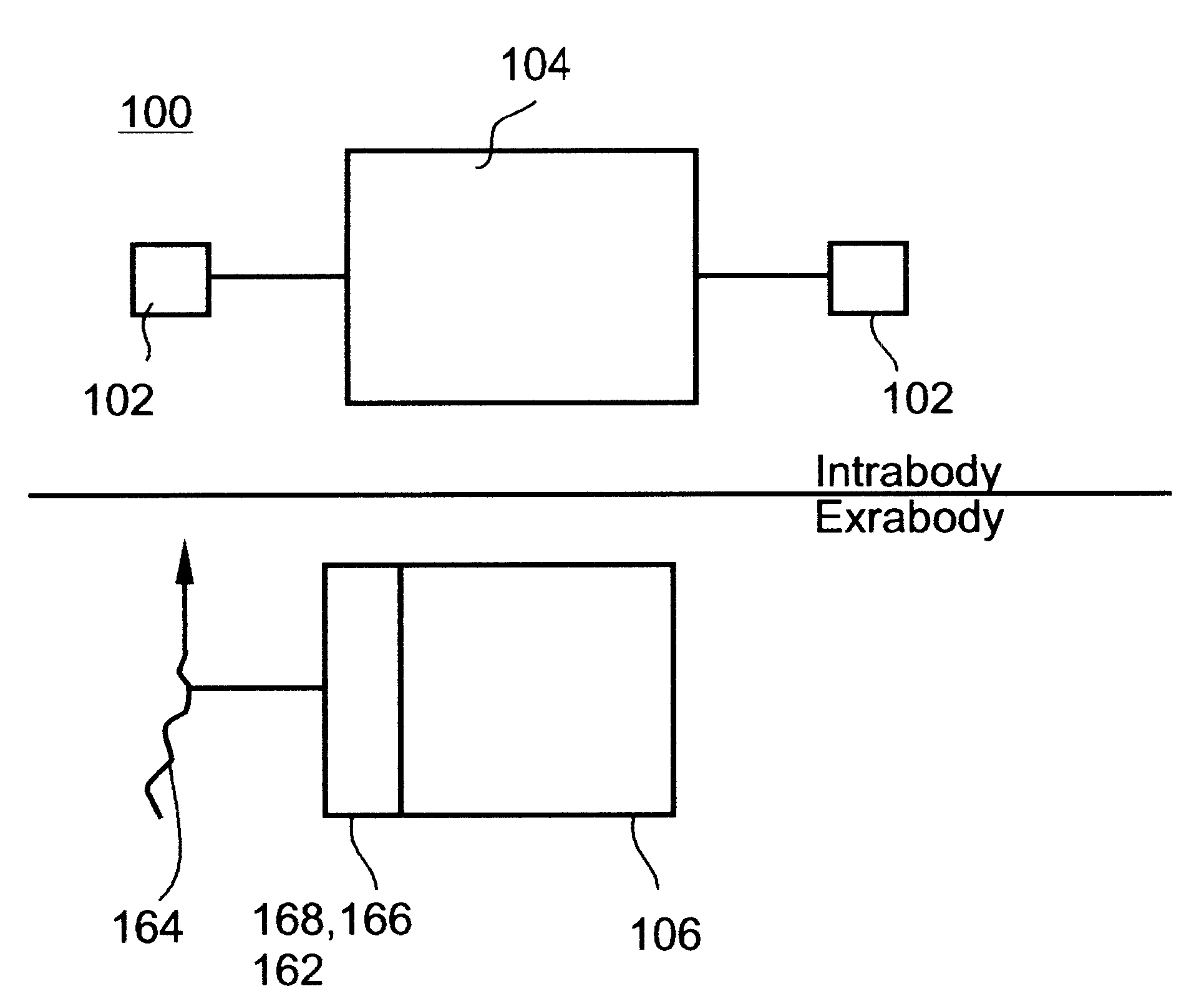

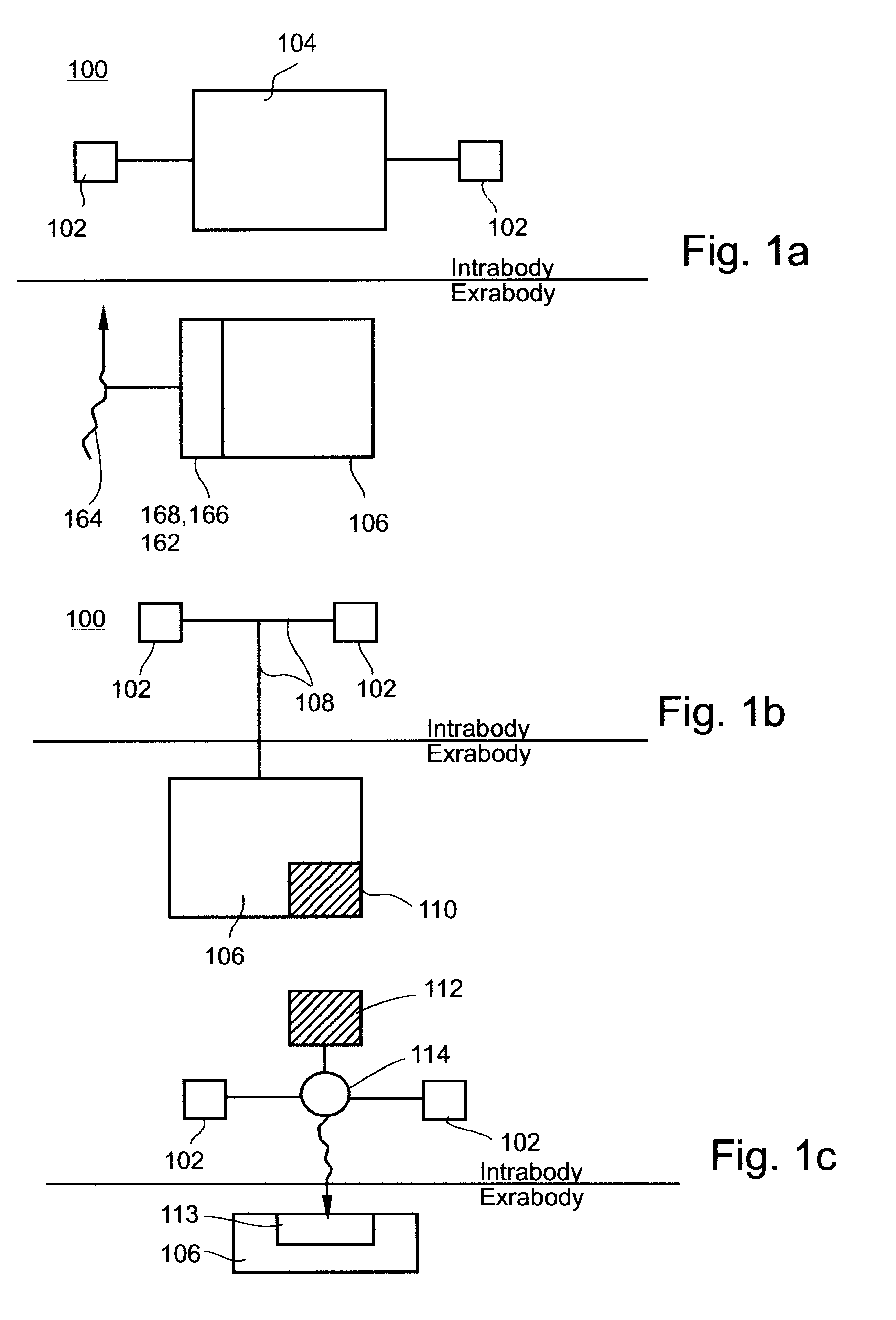

System and method for telemetrically providing intrabody spatial position

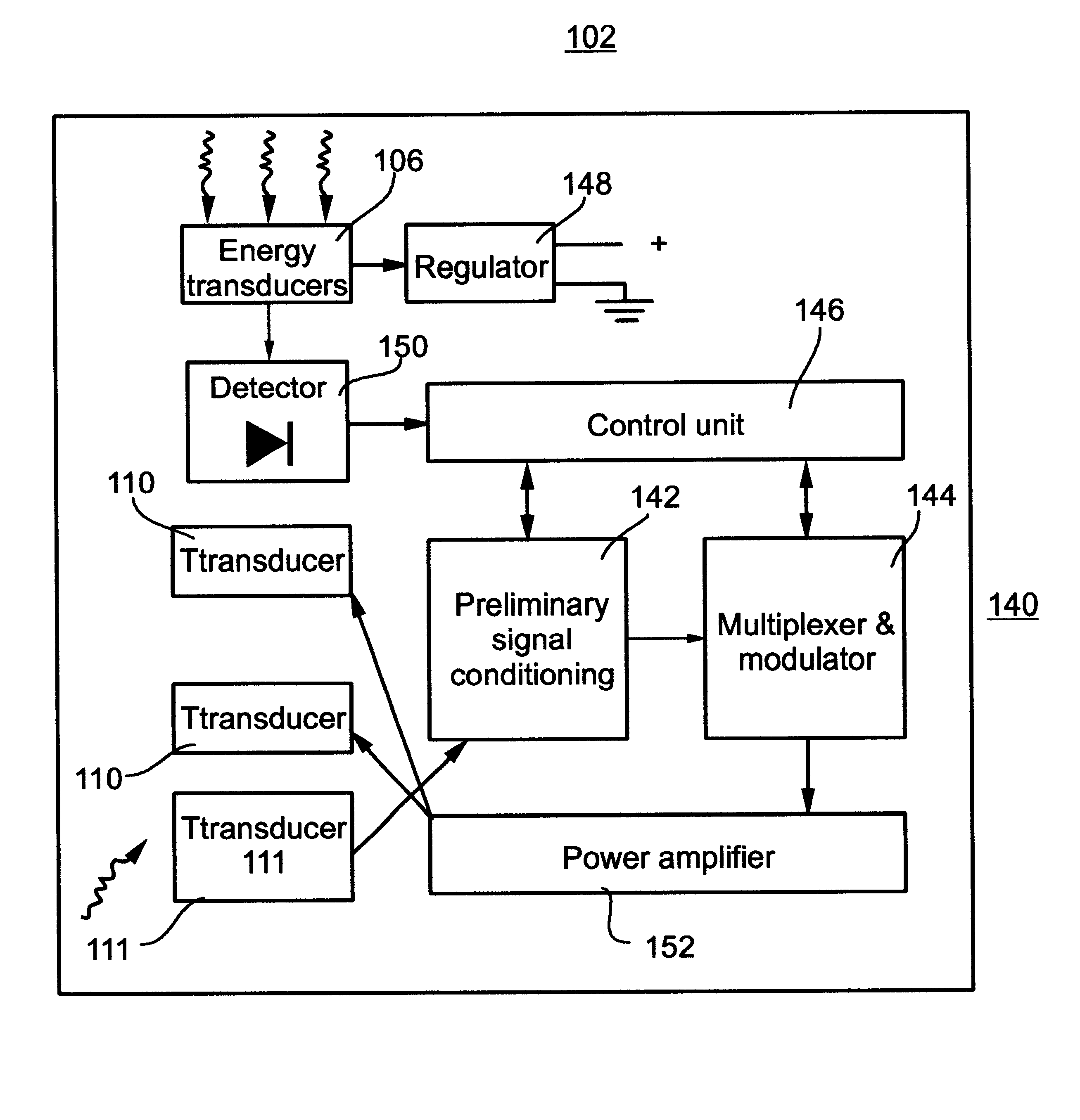

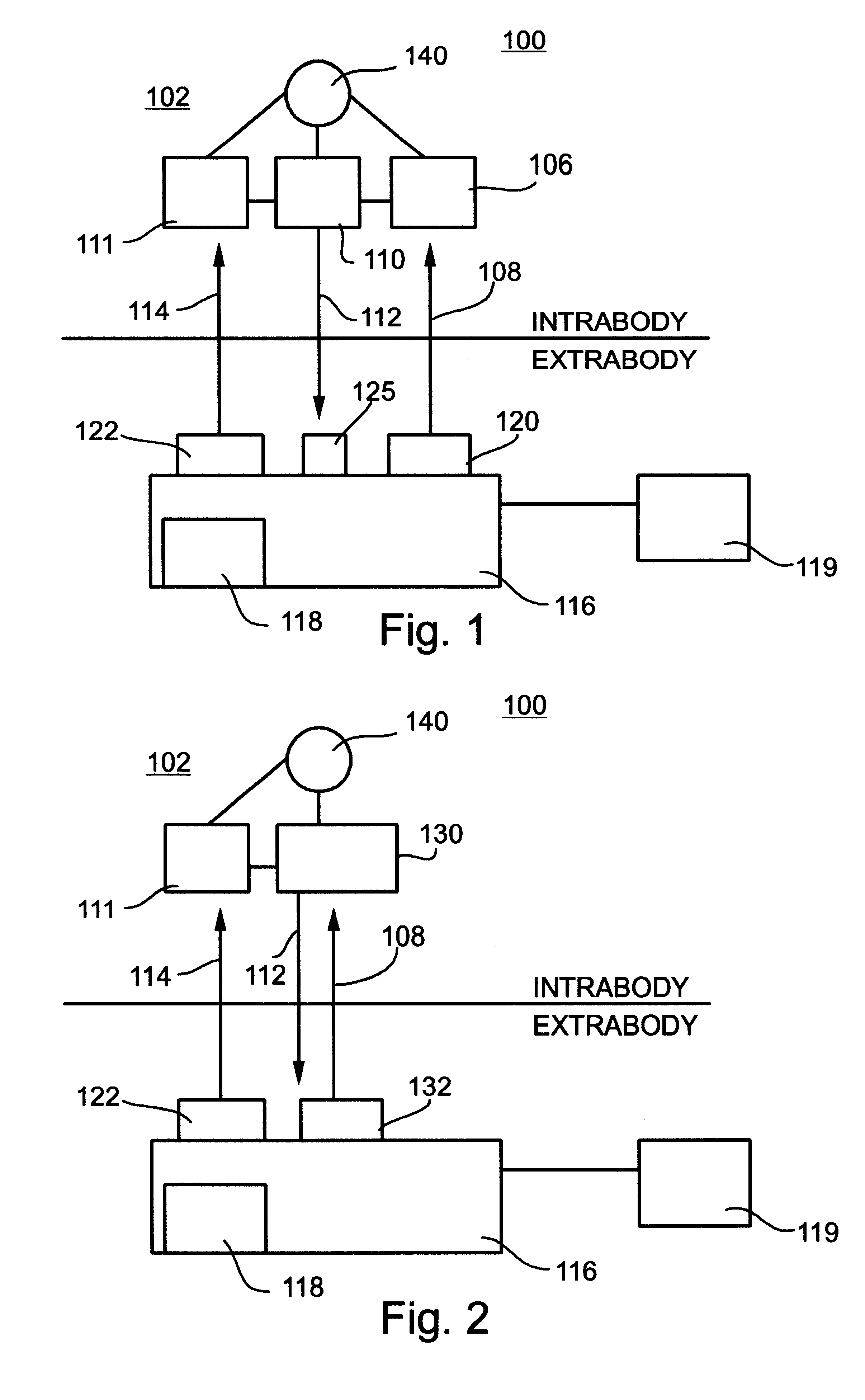

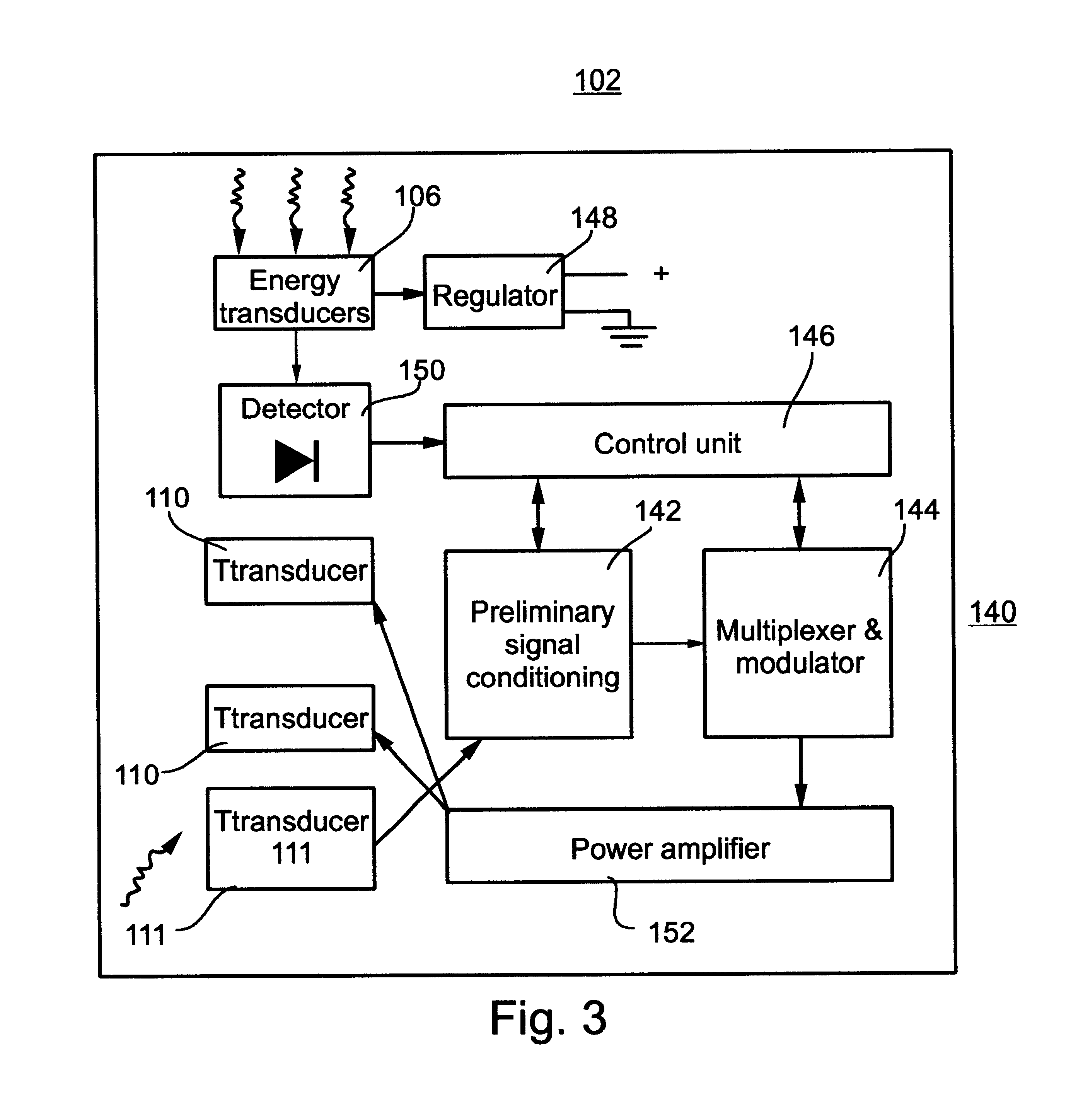

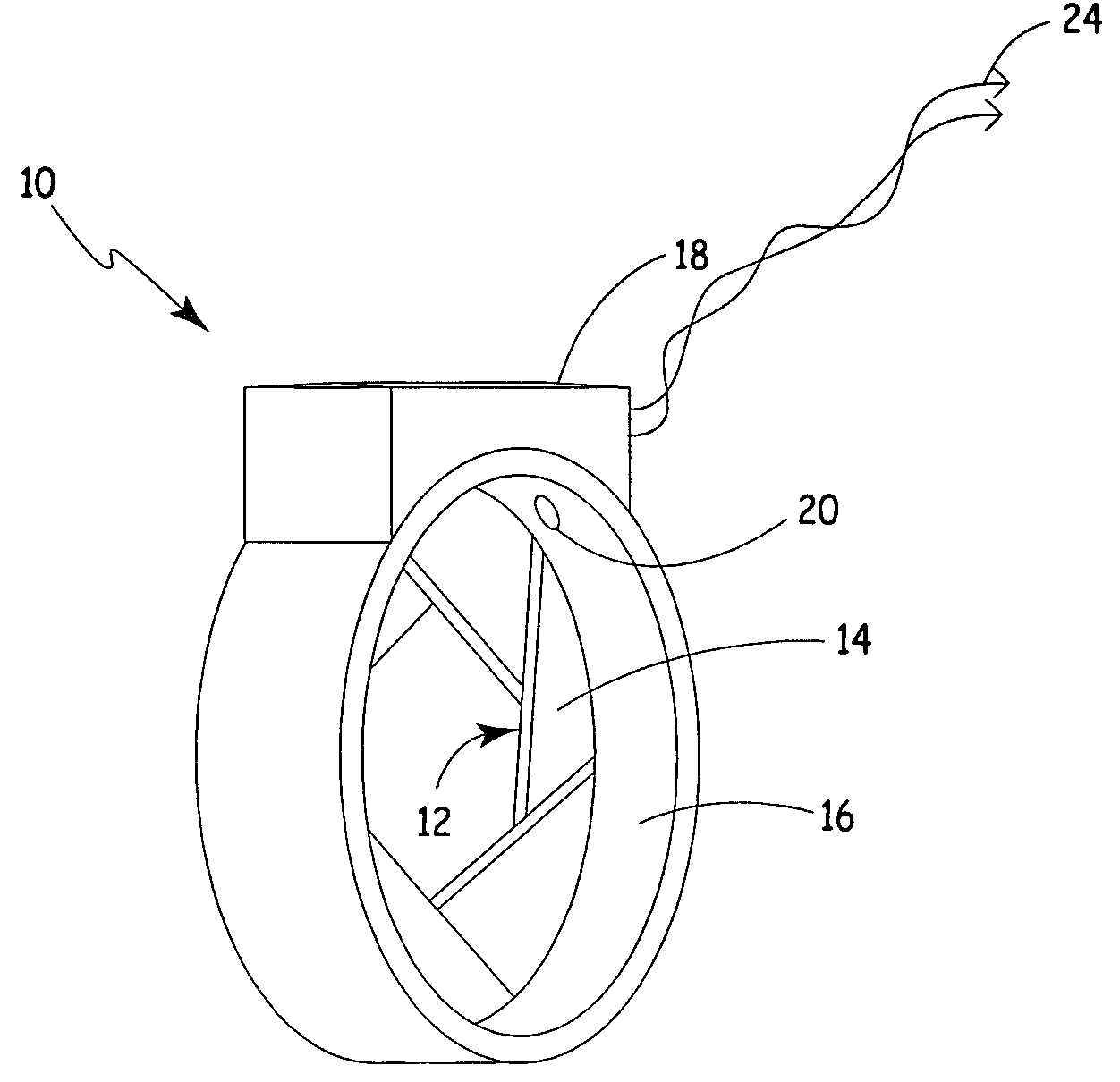

A telemetry system and method for providing spatial positioning information from within a patient's body are disclosed. The system includes at least one implantable telemetry unit which includes (a) at least one first transducer being for converting a power signal received from outside the body, into electrical power for powering the at least one implantable telemetry unit; (b) at least one second transducer being for receiving a positioning field signal being received from outside the body; and (c) at least one third transducer being for transmitting a locating signal transmittable outside the body in response to the positioning field signal.

Owner:REMON MEDICAL TECH

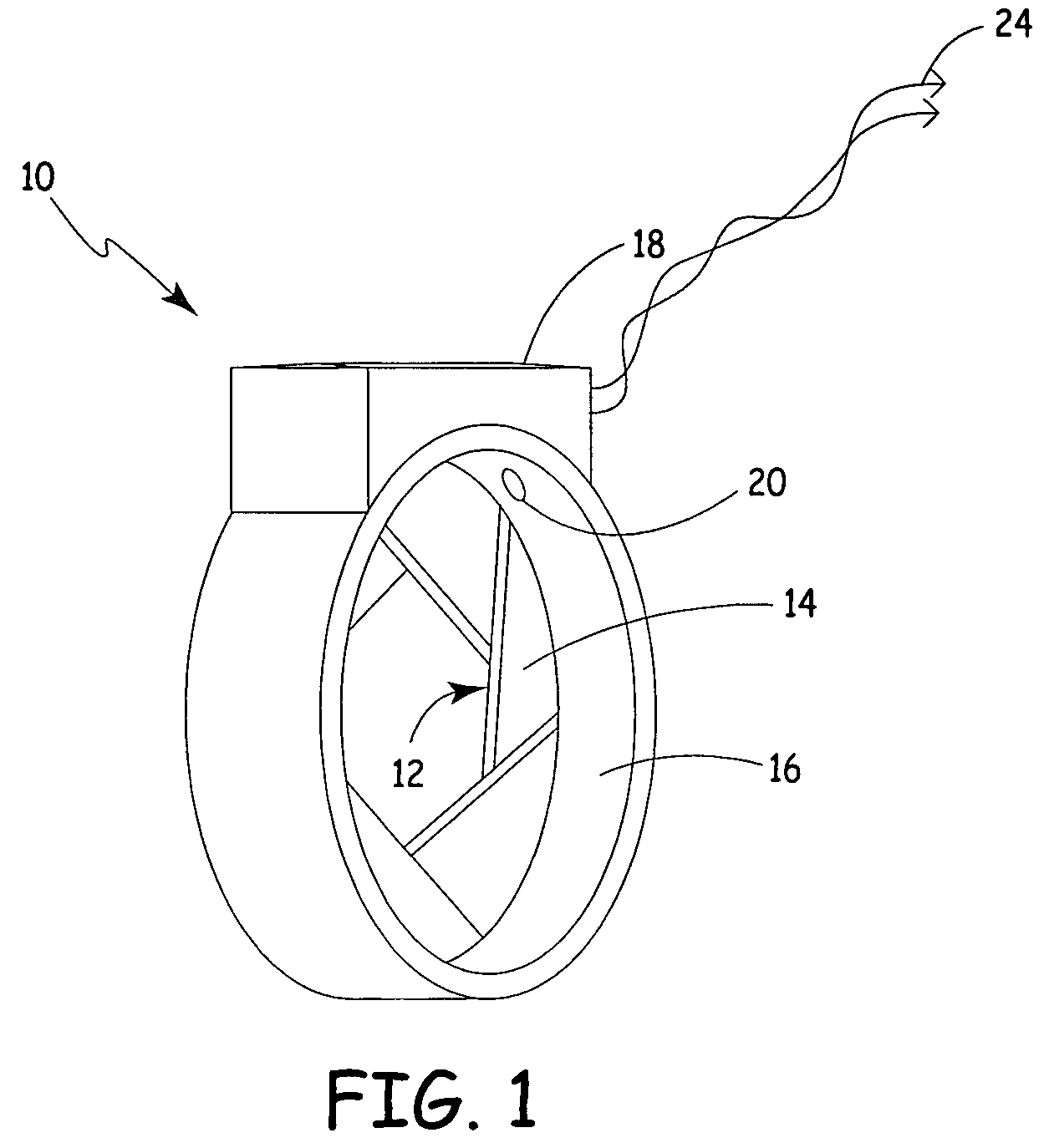

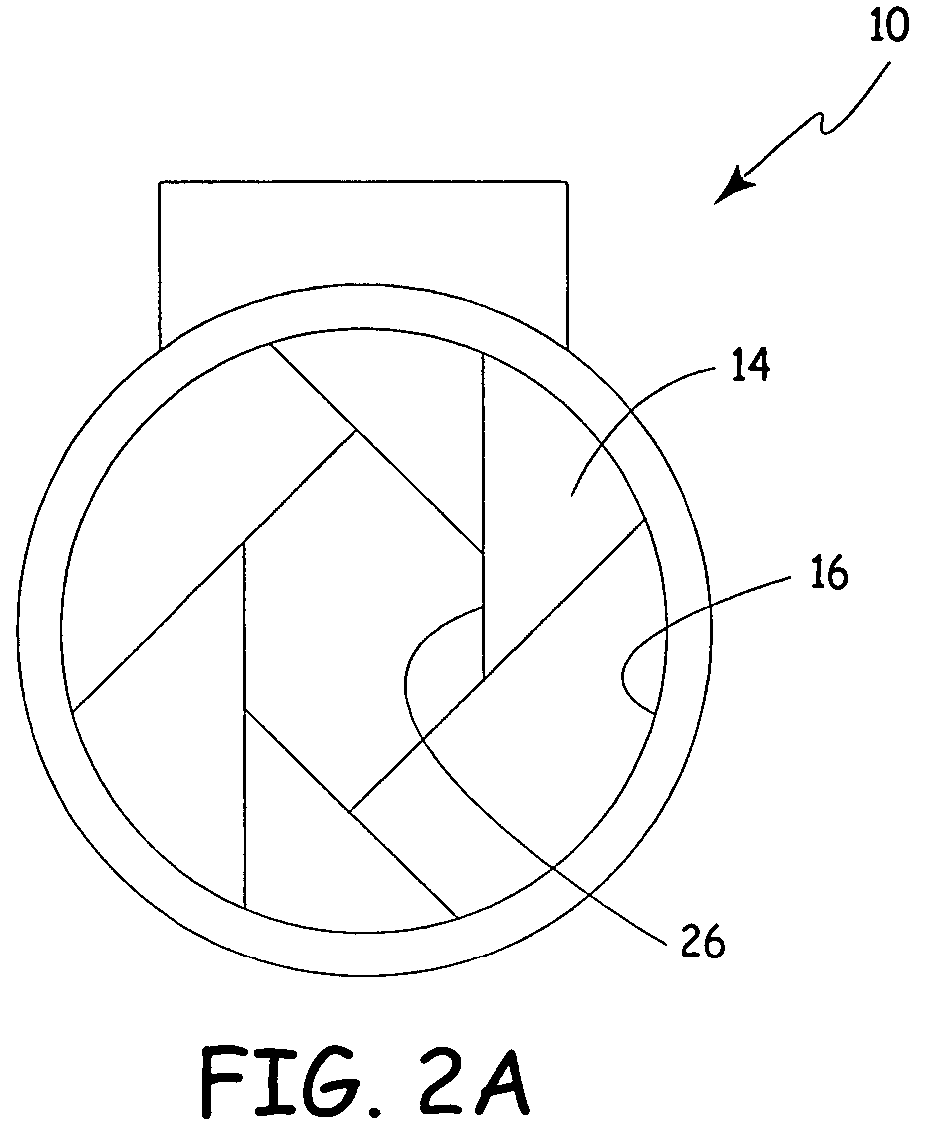

Process fluid flow device with variable orifice

A process device providing total fluid flow control is provided. The device includes a closure mechanism disposed in a flow conduit. The closure mechanism, which is preferably an iris-type diaphragm, provides a variable internal diameter. The device includes a differential pressure sensor for sensing the differential pressure on opposite sides of the diaphragm. A controller receives an indication of differential pressure and generates a control signal to an actuator that actuates the closure mechanism. The closure mechanism, differential pressure sensor and controller create a closed-loop flow controller in a single process device.

Owner:ROSEMOUNT INC

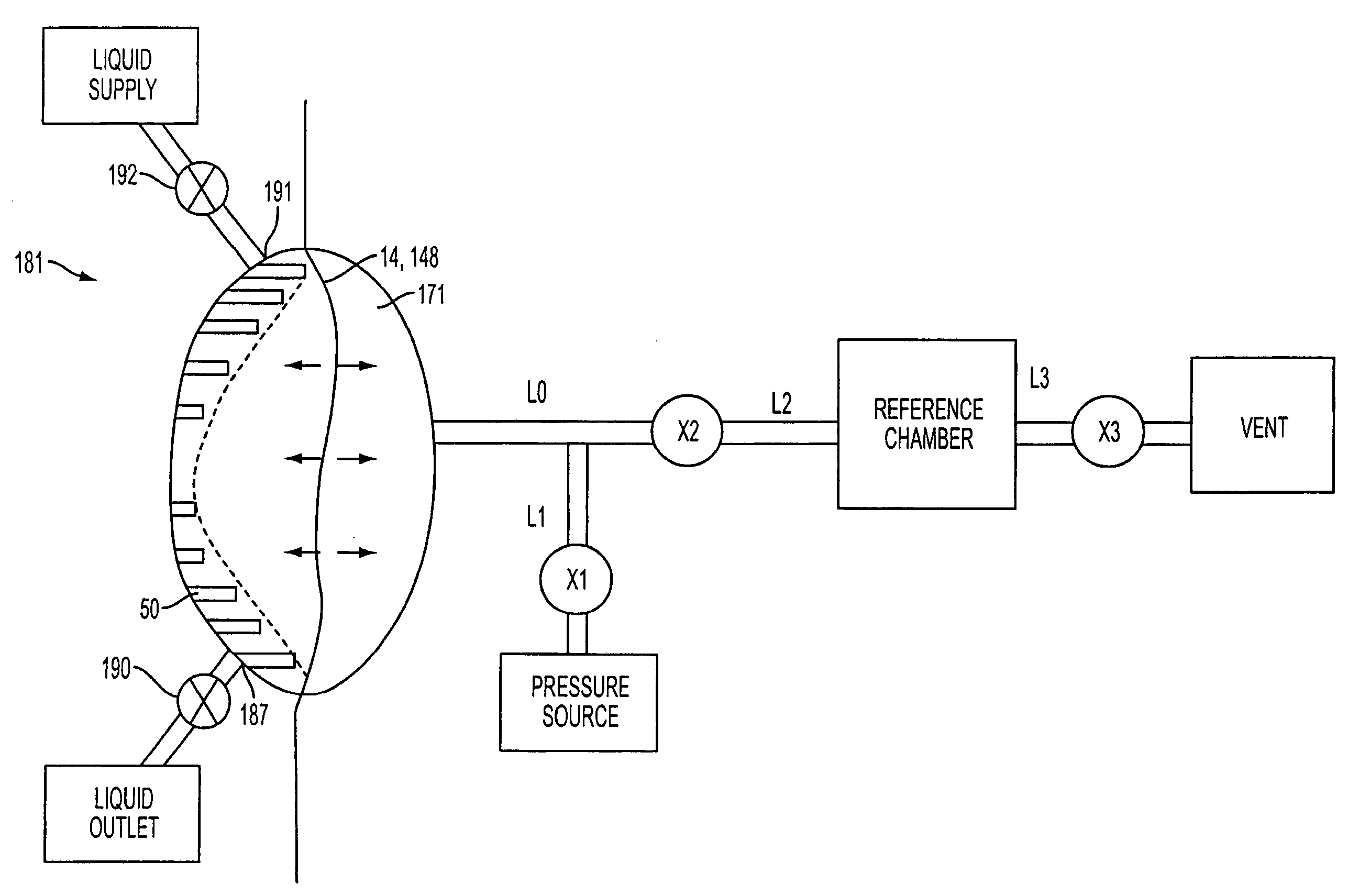

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

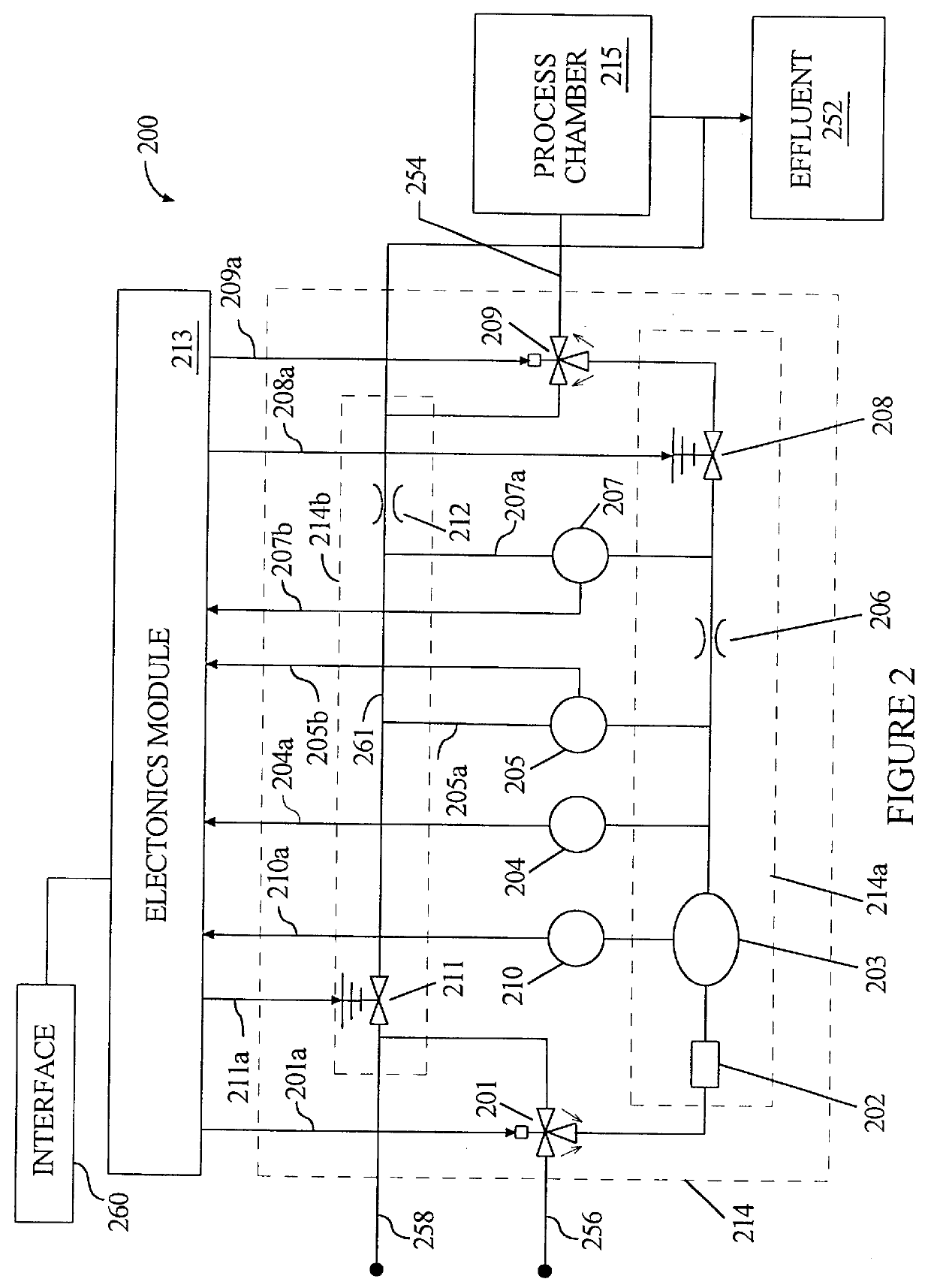

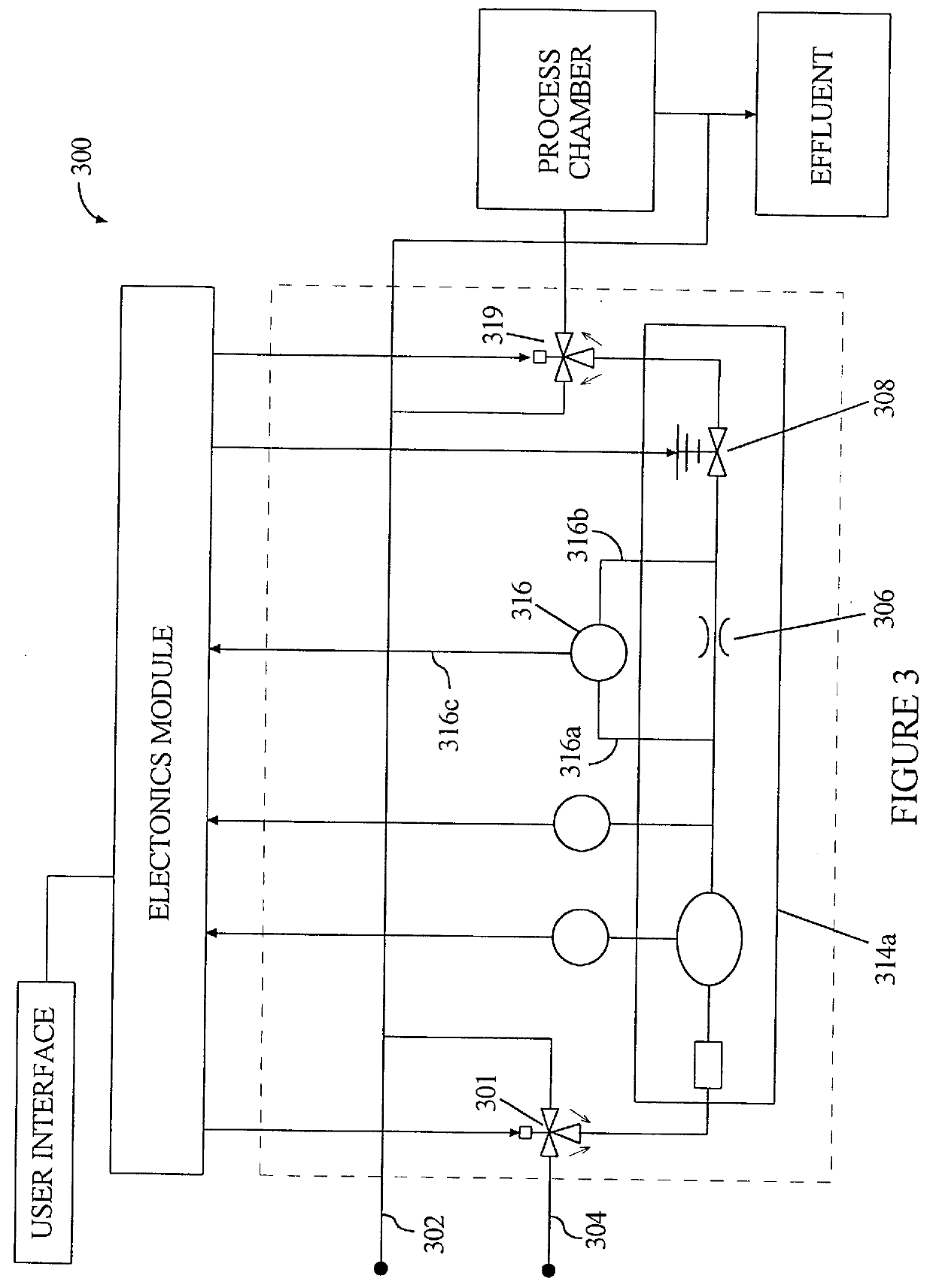

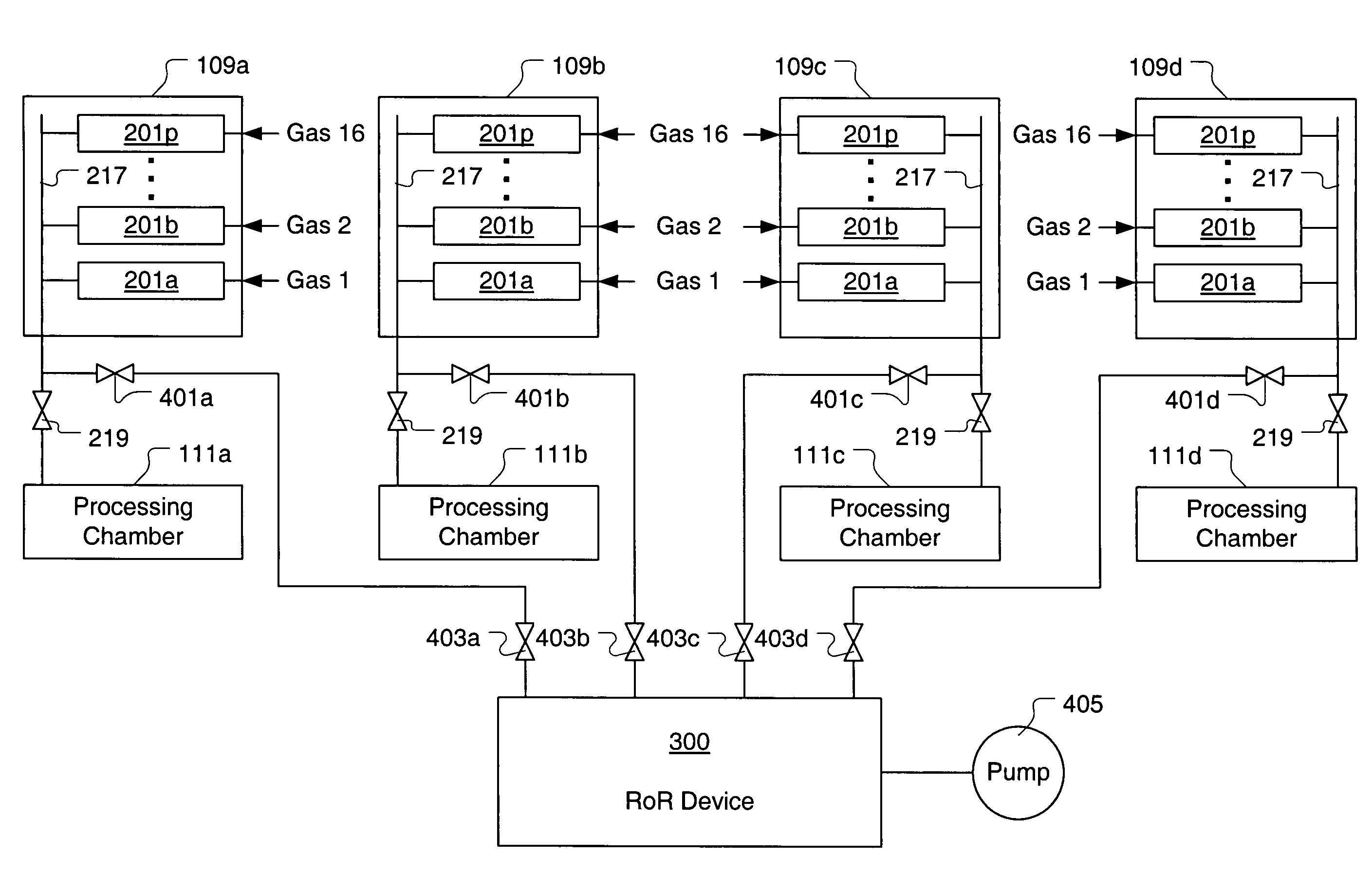

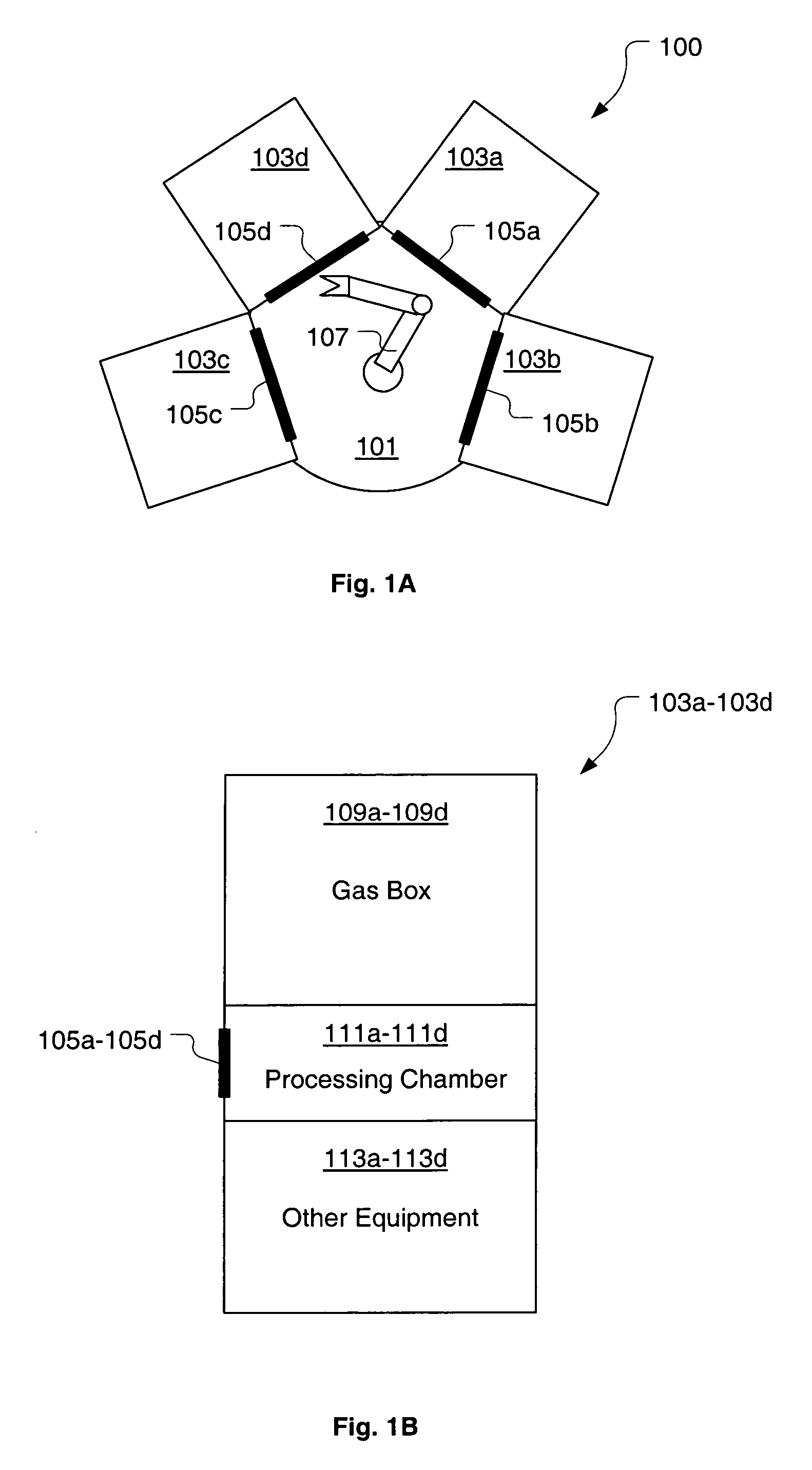

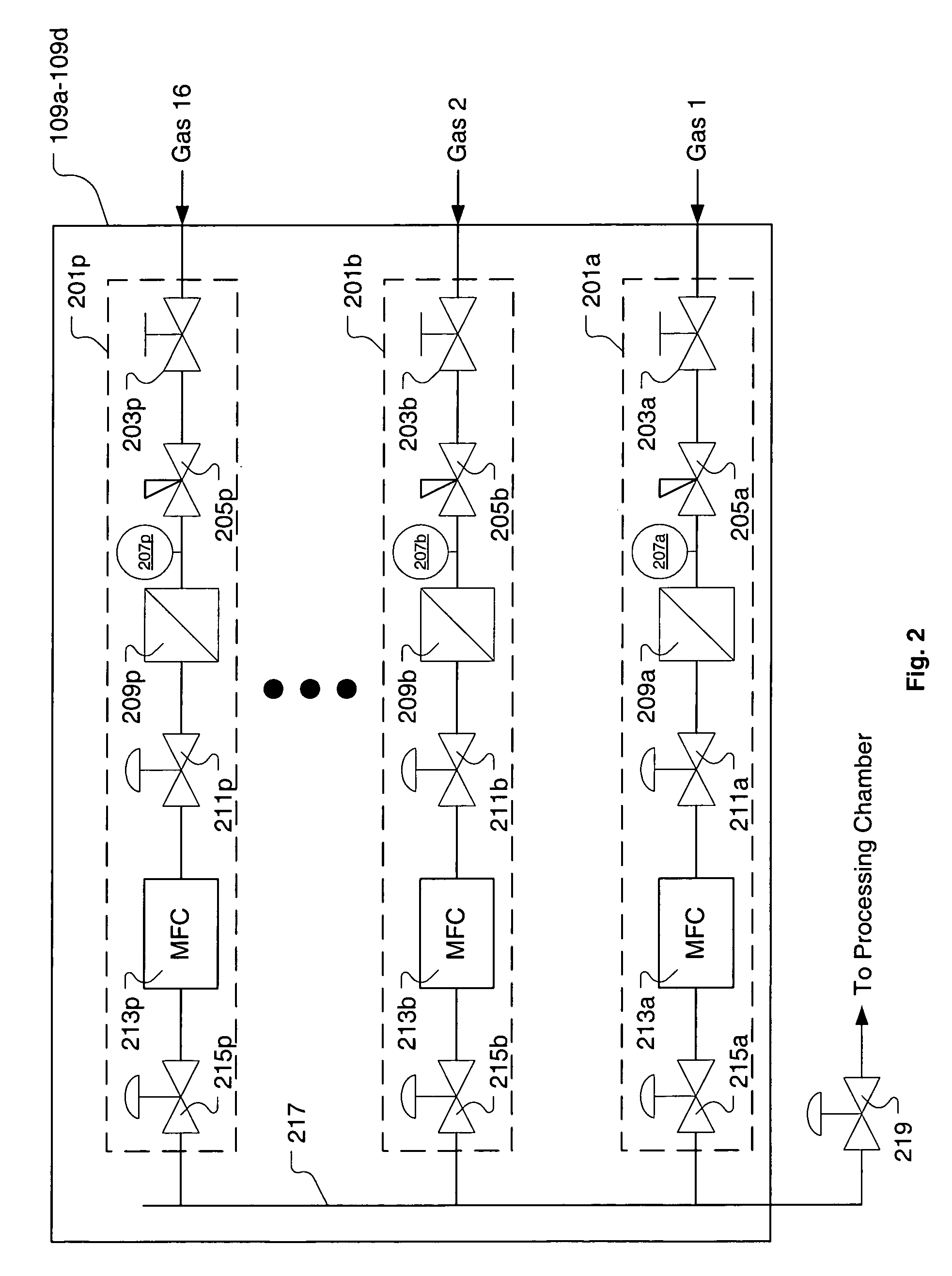

System and method for gas flow verification

A gas flow rate verification apparatus is provided for shared use in a multiple tool semiconductor processing platform. The gas flow rate verification apparatus is defined to measure a pressure rate of rise and temperature within a test volume for determination of a corresponding gas flow rate. The apparatus includes first and second volumes, wherein the second volume is larger than the first volume. The apparatus also includes first and second pressure measurement devices, wherein the second pressure measurement device is capable of measuring higher pressures. Based on the target gas flow rate to be measured, either the first or second volume can be selected as the test volume, and either the first or second pressure measurement device can be selected to measure the pressure in the test volume. Configurability of the apparatus enables accurate measurement of gas flow rates over a broad range and in an time efficient manner.

Owner:LAM RES CORP

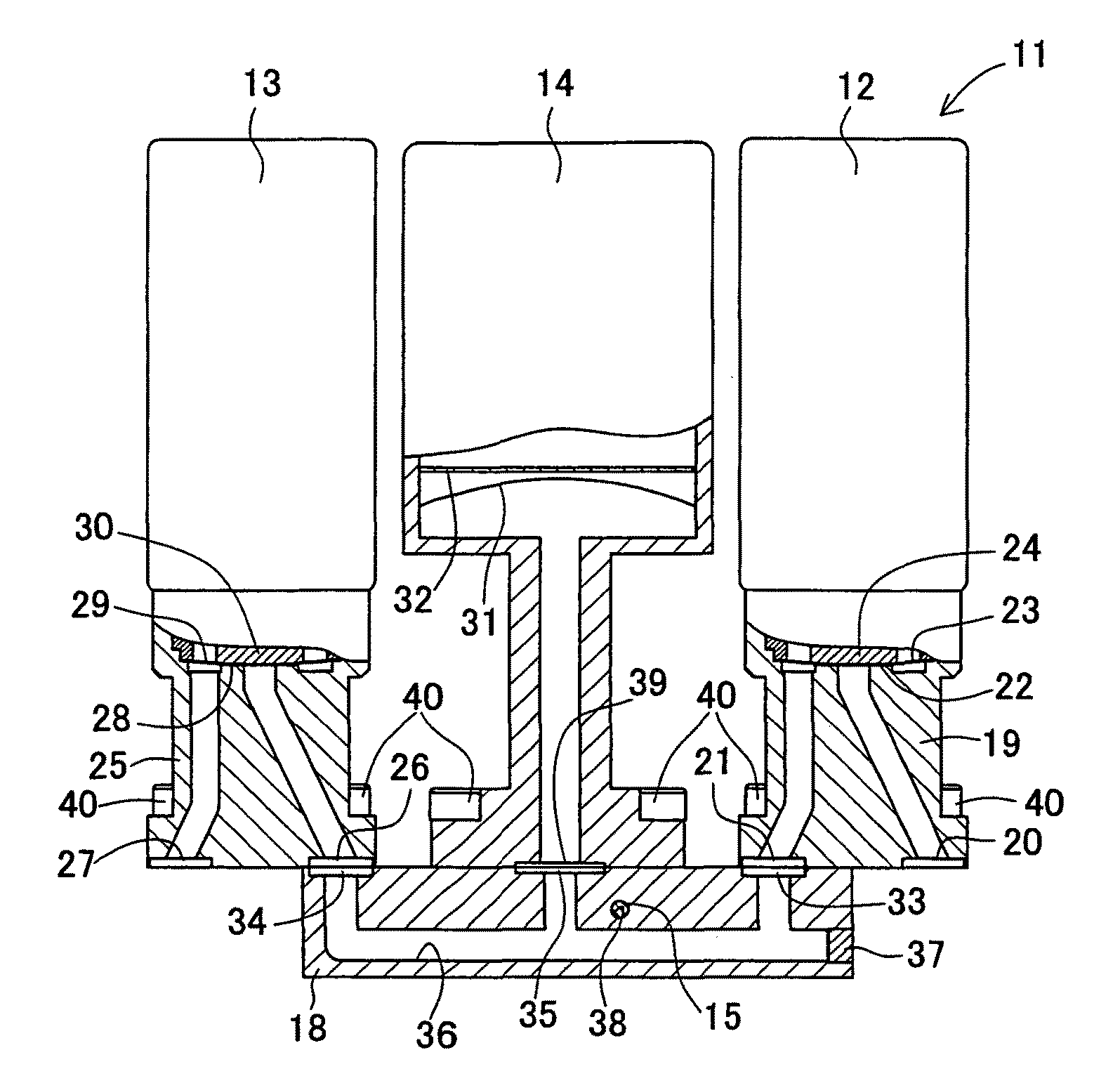

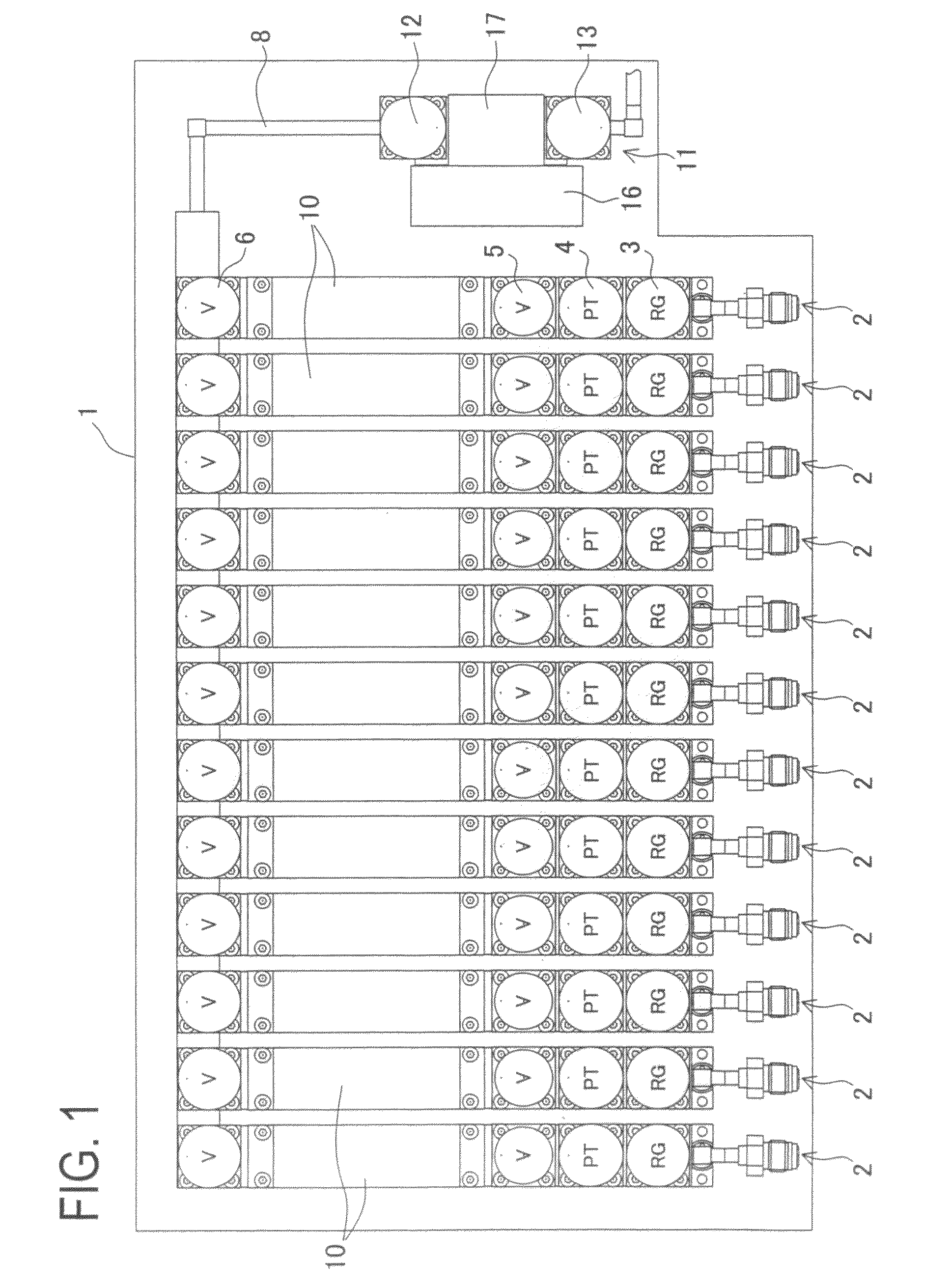

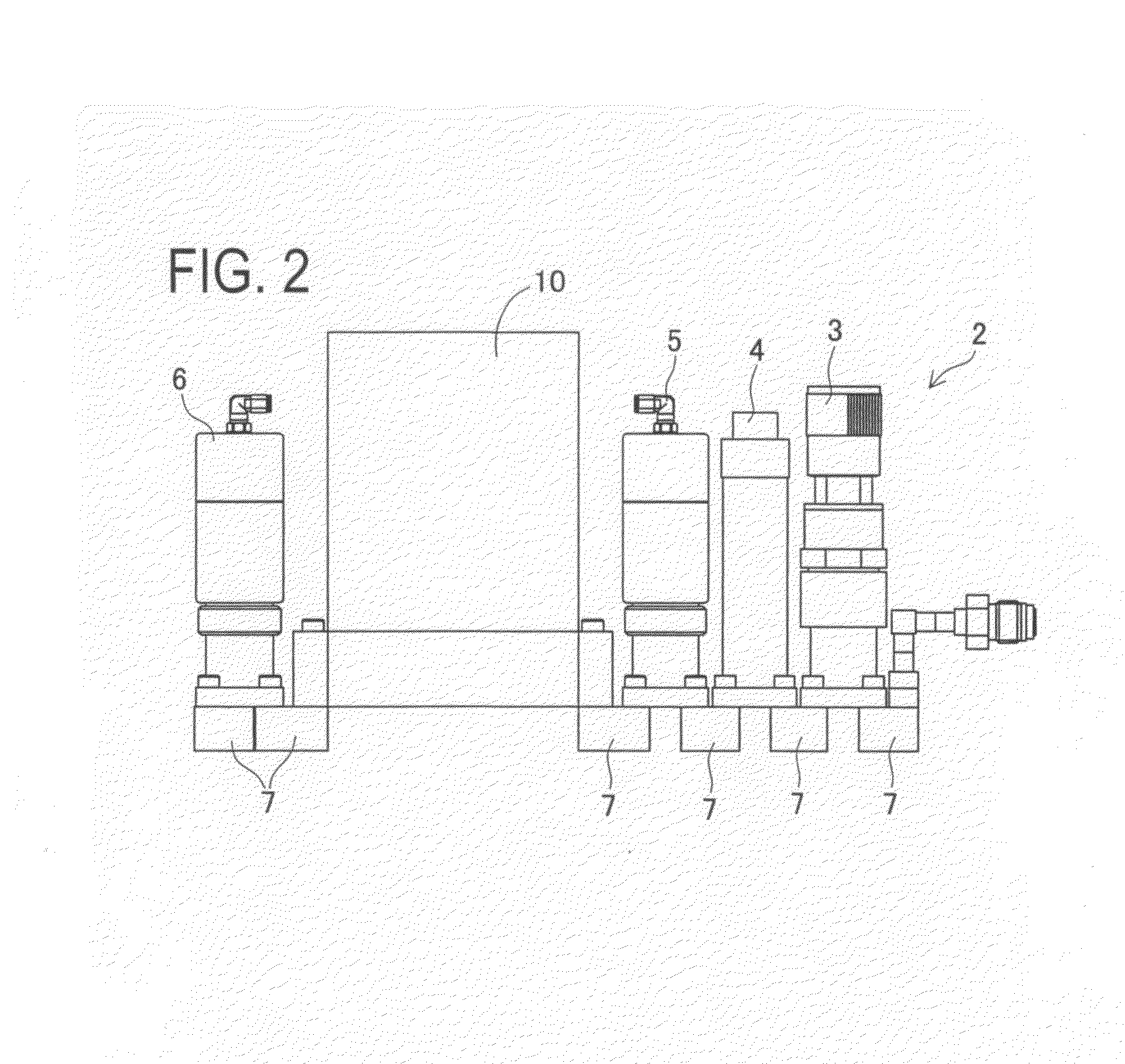

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

System and method for monitoring pressure, flow and constriction parameters of plumbing and blood vessels

InactiveUS6237398B1Ultrasonic/sonic/infrasonic diagnosticsMaterial analysis by optical meansEngineeringPulsatile flow

The present invention provides a system and method of quantifying flow, detecting a location of an obstruction and quantifying a degree of the obstruction in a pipe characterized in pulsatile flow. The method includes the steps of (a) attaching at least two spaced pressure sensors onto inner walls of the pipe; (b) using the at least two spaced pressure sensors for recording pressure records associated with each of the at least two pressure sensors within the pipe; and (c) using the pressure records for quantifying the pulsatile flow in the pipe, for detecting the location of the obstruction in the pipe and for quantifying the degree of the obstruction in the pipe.

Owner:TELESENSE

Apparatus and method for applying topical negative pressure

A method and apparatus for alerting a user of topical negative pressure therapy apparatus to a full waste canister condition are described, the apparatus comprising a device having vacuum pump means and a waste canister connected to the device and the waste canister operably connected to a wound dressing by aspiration conduit means for aspirating fluid from the wound, the aspiration conduit means, the waste canister and the device providing a fluid flow path therethrough and the vacuum pump means providing fluid flow through the apparatus, the apparatus further comprising fluid flow restriction means in the fluid flow path of said vacuum pump and fluid pressure sensing means upstream and downstream of said fluid flow restriction means.

Owner:SMITH & NEPHEW INC

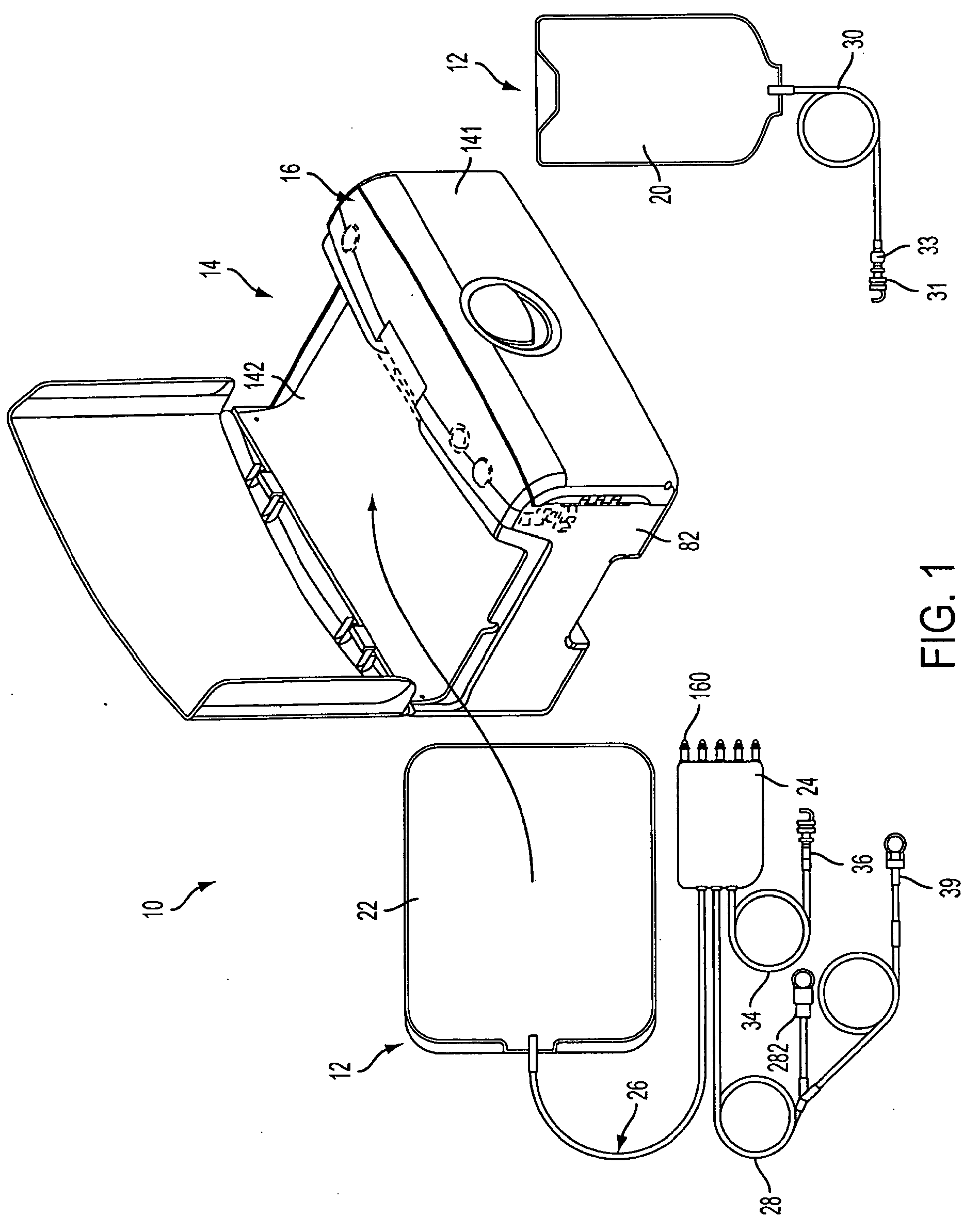

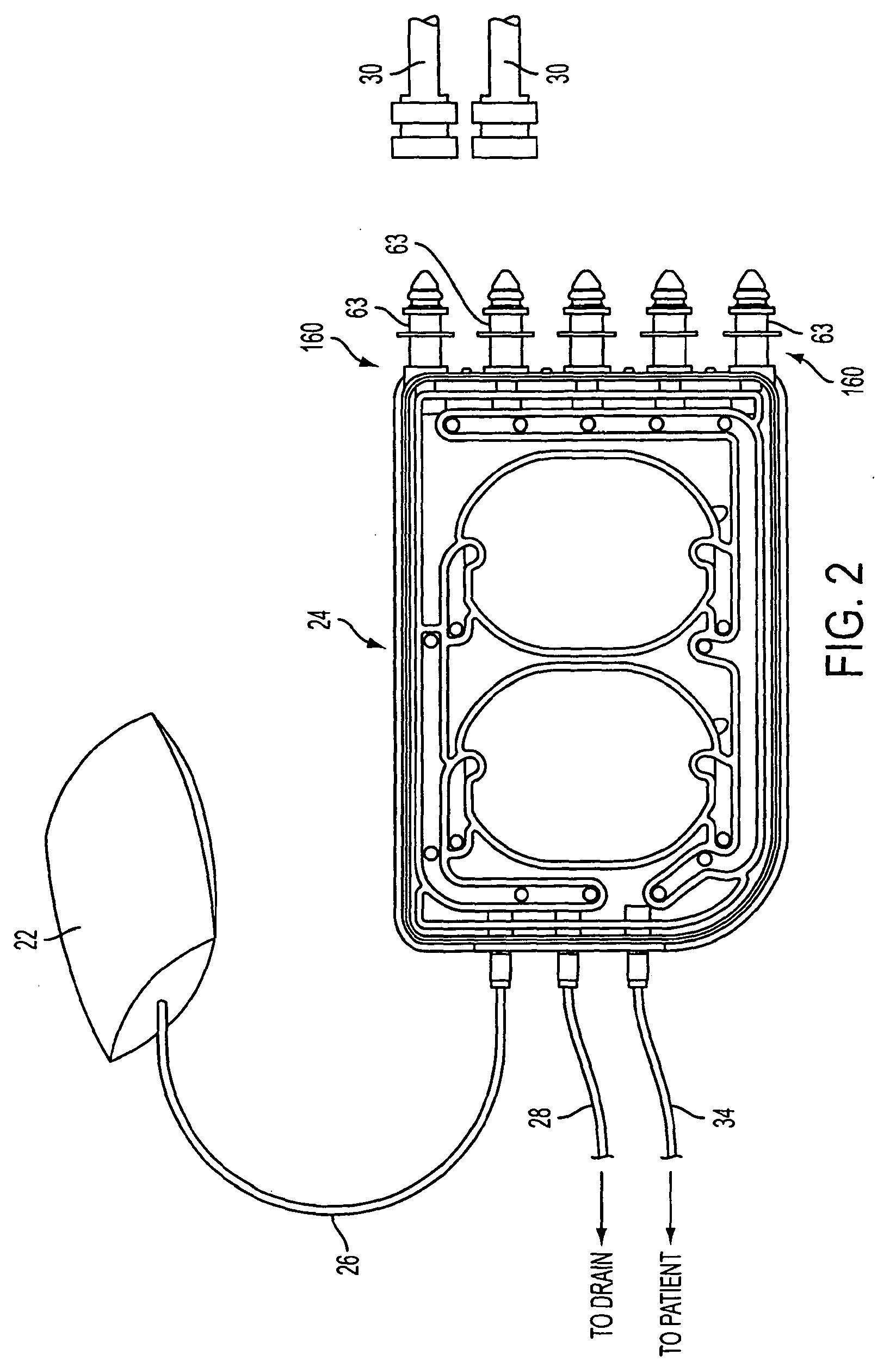

Fluid volume determination for medical treatment system

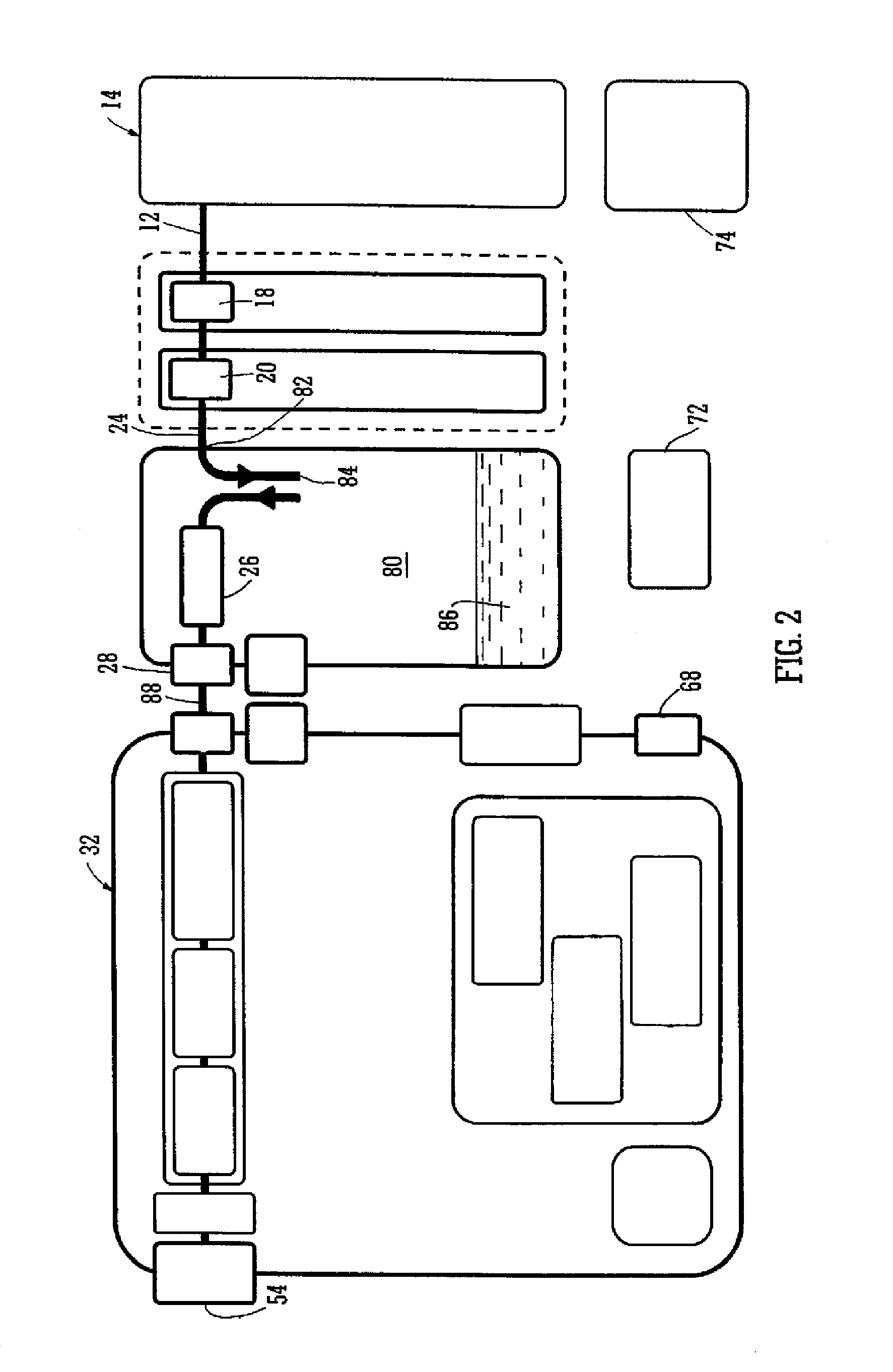

ActiveUS20110071465A1Deformation MinimizationPreventing sticking of the membraneMechanical/radiation/invasive therapiesFlexible member pumpsPump chamberMathematical model

A volume of fluid moved by a pump, such as a pump in an APD system, may be determined without direct measurement of the fluid, such as by flow meter, weight, etc. For example, a volume of a pump chamber (181) (having a movable element that varies the volume of the pump chamber) may be determined by measuring pressure in the pump chamber and a reference chamber, both while the two chambers are isolated from each other, and after the two chambers are fluidly connected so that pressures in the chambers may equalize. Equalization of the pressures may be assumed to occur in an adiabatic way, e.g., a mathematical model of the system that is based on an adiabatic pressure equalization process may be used to determine the pump chamber volume. In one embodiment, pressures measured after the chambers are fluidly connected may be measured at a time before complete pressure equalization has occurred, and thus the pressures for the pump and reference chambers measured after the chambers are fluidly connected may be unequal, yet still be used to determine the pump chamber volume.

Owner:DEKA PROD LLP

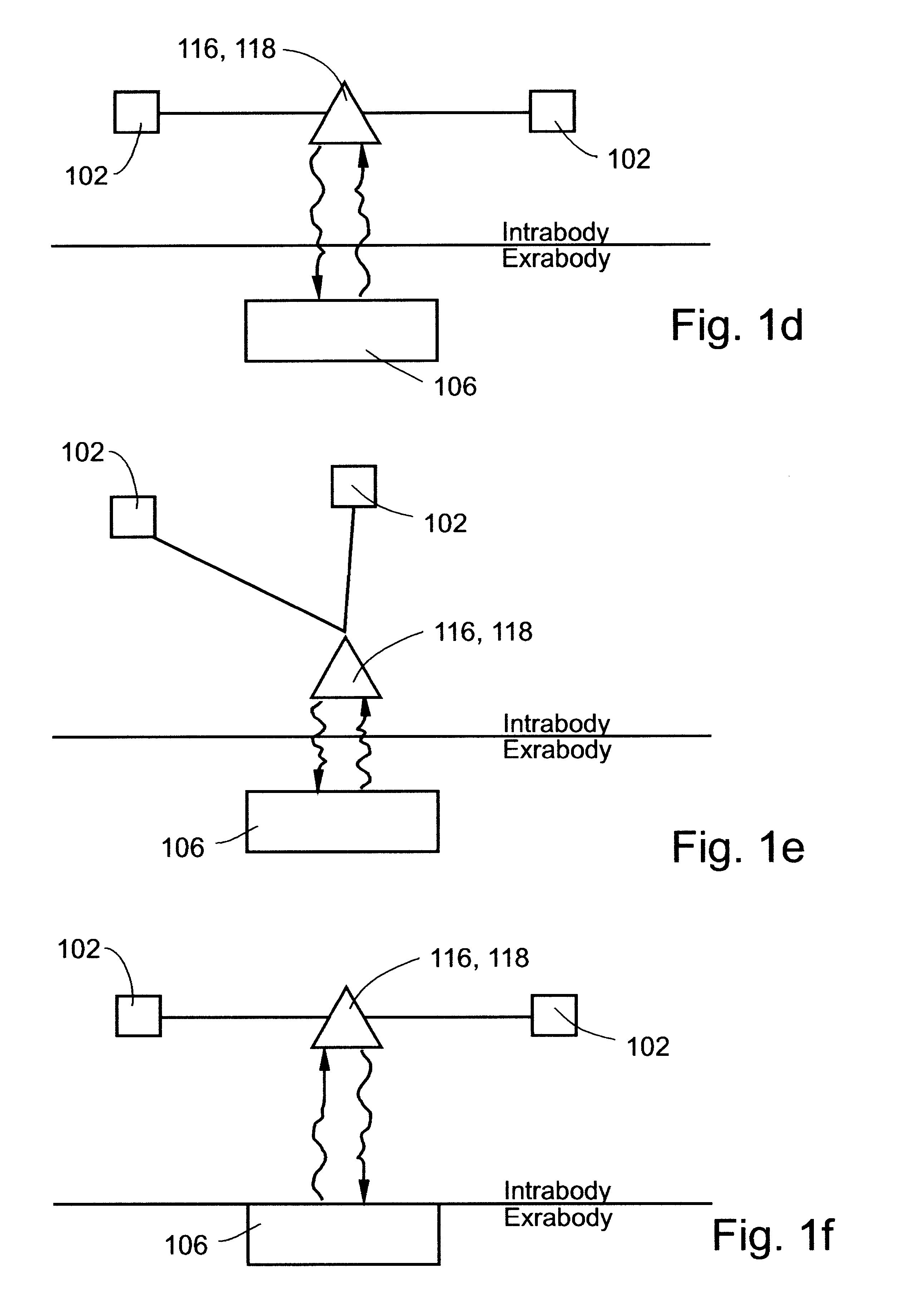

System and method for directing and monitoring radiation

A system for monitoring, directing and controlling the dose of radiation in a medical procedure for irradiating a specific region of a patient's body. In its generic form, the system includes at least one sensor being implantable within, or in proximity to, the specific region of the patient's body, the at least one sensor being for sensing at least one parameter associated with the radiation. The system further includes a relaying device which is in communication with the sensor(s). The relaying device serves for relaying the information outside of the patient's body.

Owner:REMON MEDICAL TECH

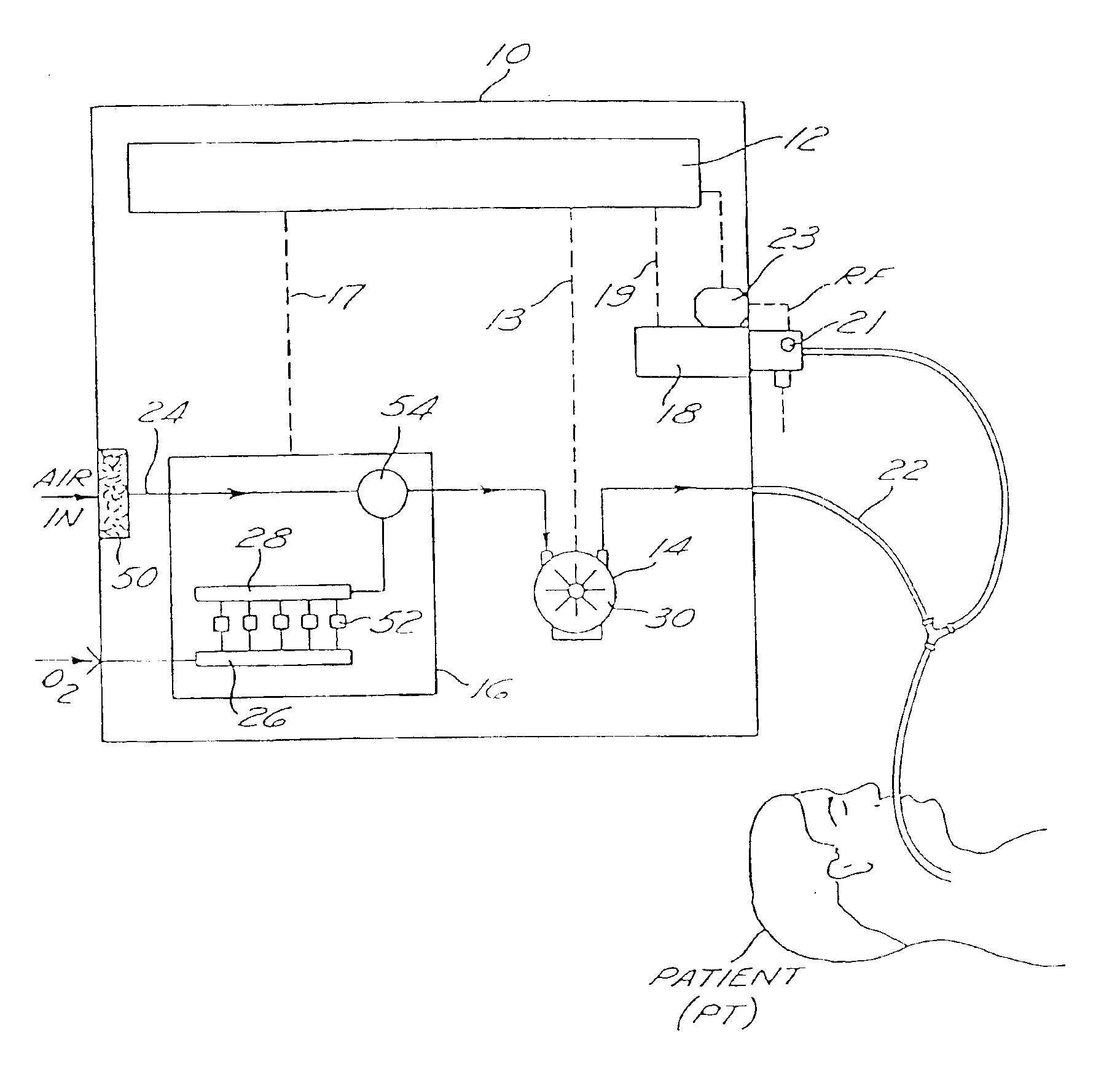

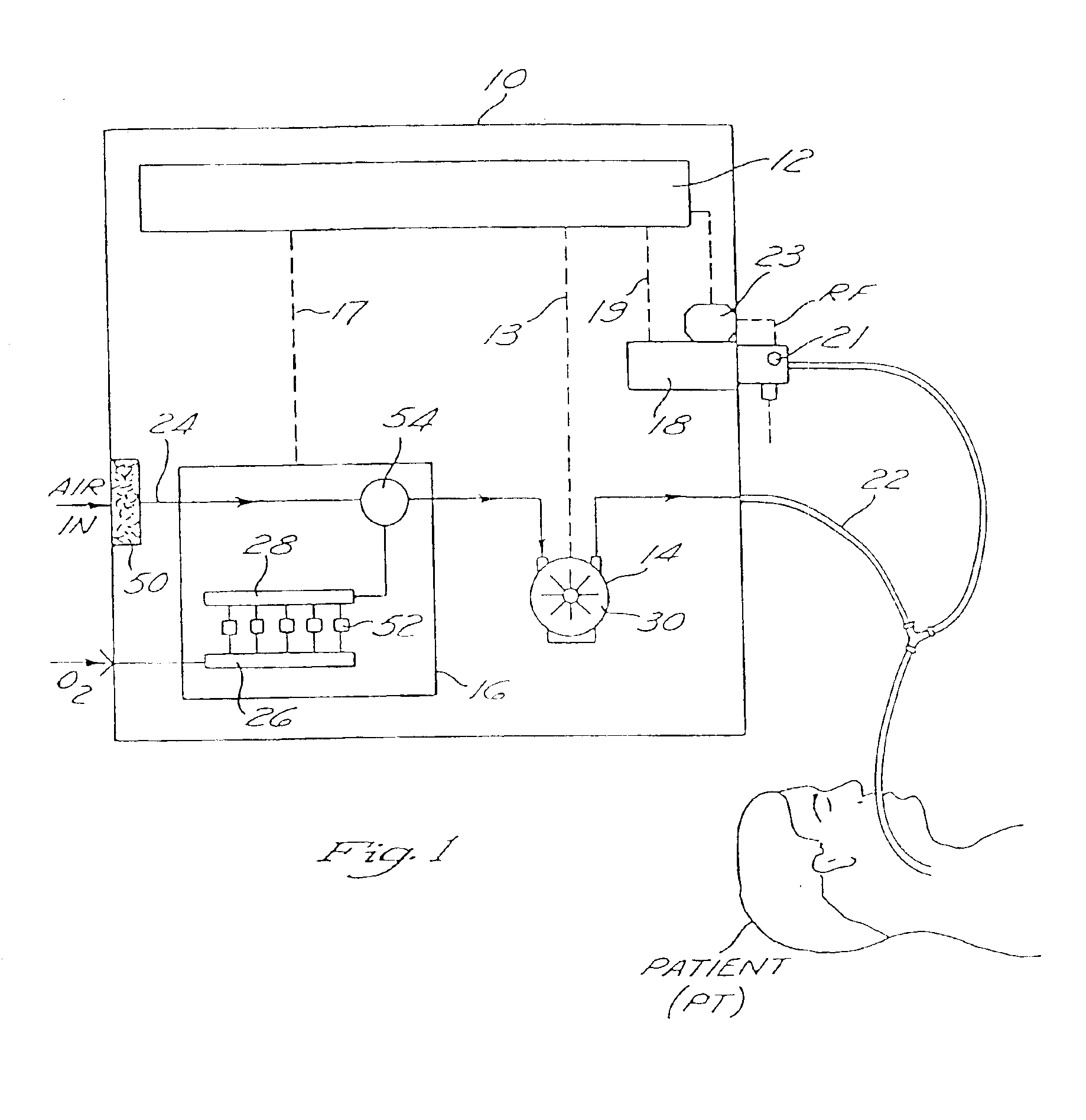

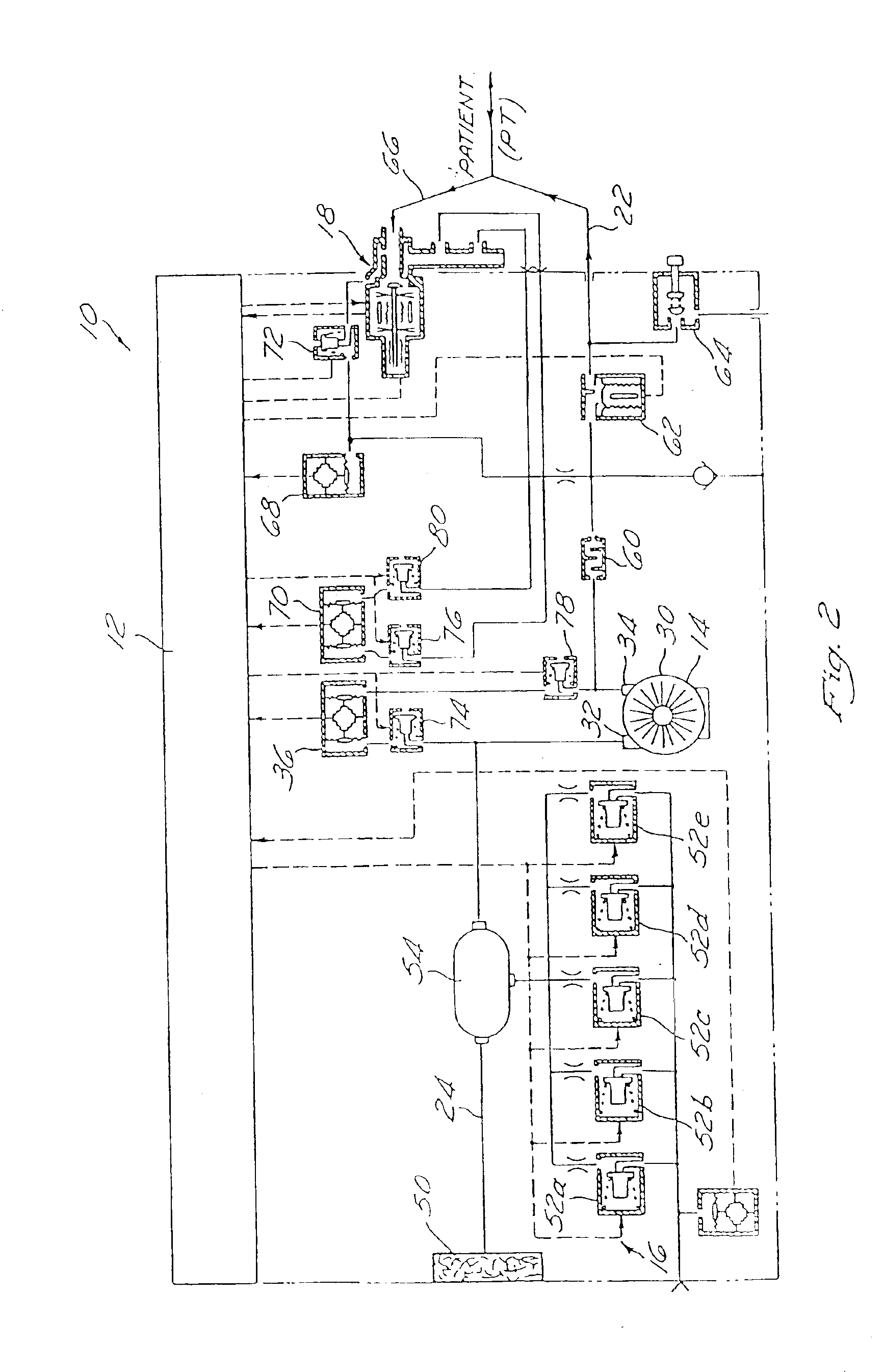

Portable drag compressor powered mechanical ventilator

InactiveUS6877511B2Accurate measurementMinimize fabrication inaccuracyRespiratorsOperating means/releasing devices for valvesSolenoid valveEngineering

A ventilator device and system comprising a rotating compressor, preferably a drag compressor, which, at the beginning of each inspiratory ventilation phase, is accelerated to a sufficient speed to deliver the desired inspiratory gas flow, and is subsequently stopped or decelerated to a basal flow level to permit the expiratory ventilation phase to occur. The ventilator device is small and light weight enough to be utilized in portable applications. The ventilator device is power efficient enough to operate for extended periods of time on internal or external batteries. Also provided is an oxygen blending apparatus which utilizes solenoid valves having specific orifice sizes for blending desired amounts of oxygen into the inspiratory gas flow. Also provided is an exhalation valve having an exhalation flow transducer which incorporates a radio frequency data base to provide an attendant controller with specific calibration information for the exhalation flow transducer.

Owner:BIRD PRODS

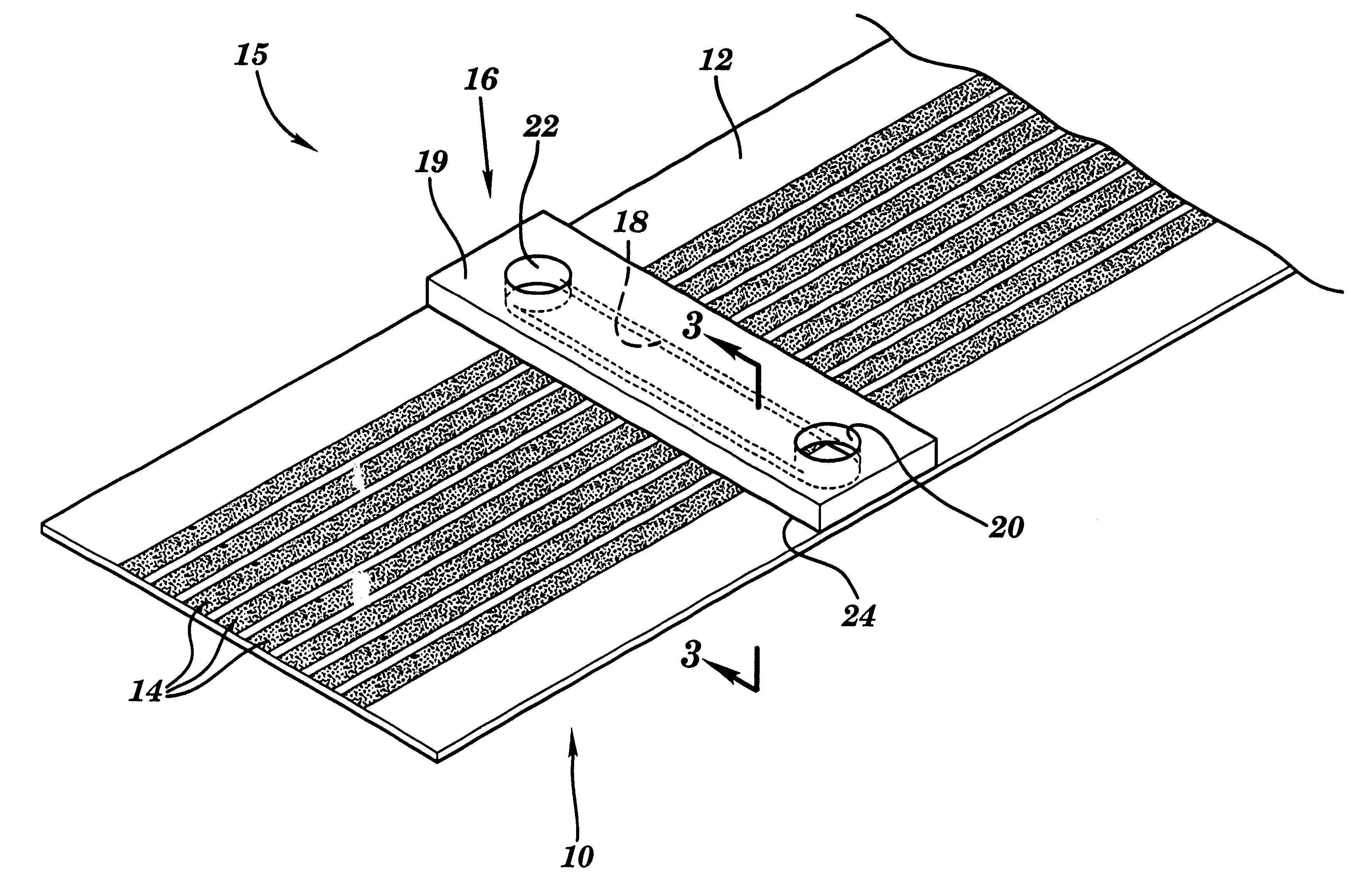

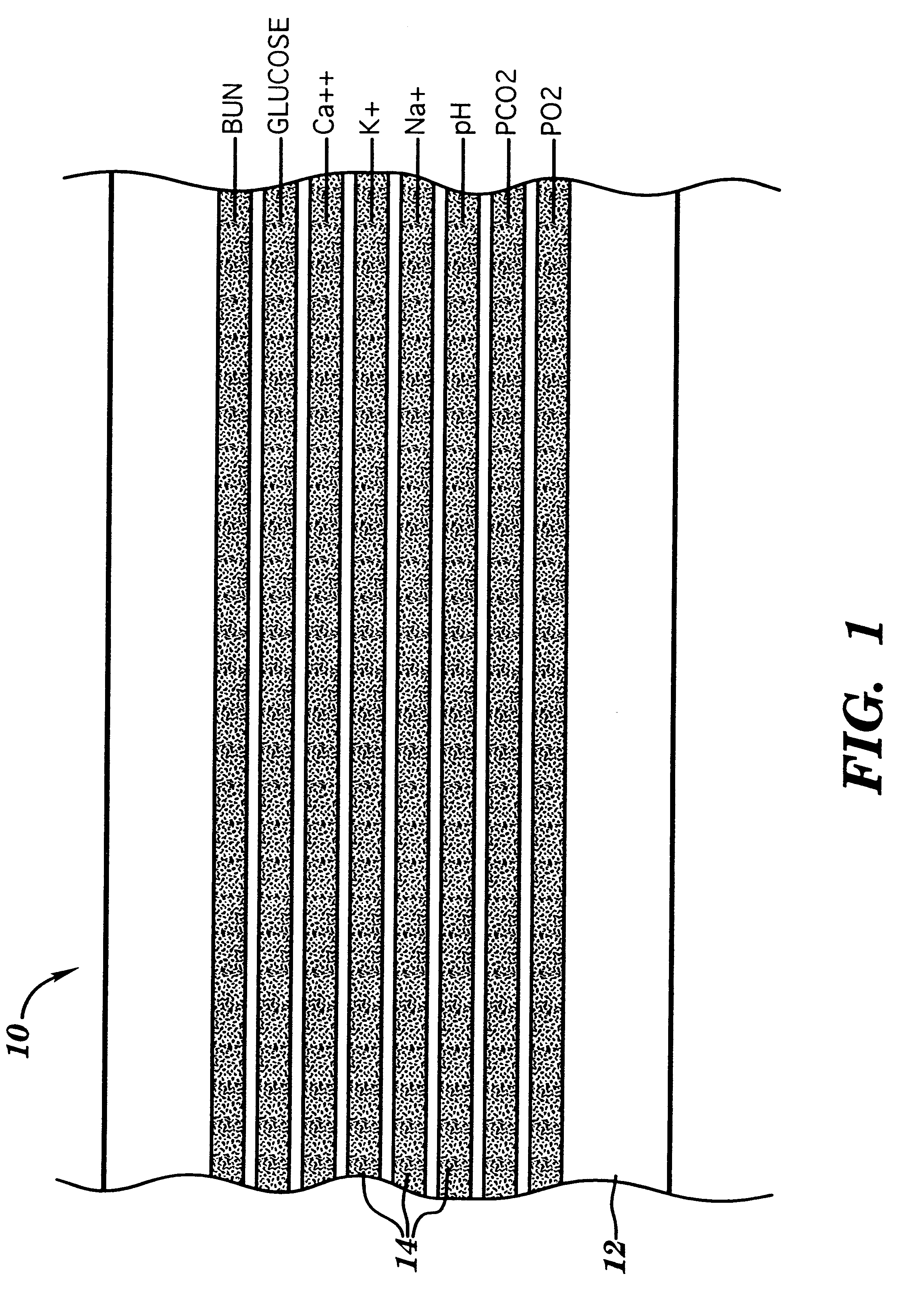

Optical sensor and method of operation

InactiveUS6488891B2Analysis using chemical indicatorsTesting/calibration apparatusOptical transducersSample chamber

A multiple single use optical sensor includes a series of continuous sensor stripes deposited on a substrate web. At least one sample chamber is adapted to extend transversely across a discrete portion of the series of sensor stripes to facilitate analysis of a sample disposed therein. The sample chamber may be moved, or additional sample chambers provided to enable subsequent measurements of additional samples at unused discrete portions of the sensor stripes. The continuous nature of the sensor stripes provides consistency along the lengths thereof to enable calibration data obtained from one discrete portion of the sensor stripes to be utilized for testing an unknown sample an other discrete portion of the sensor stripes. This advantageously eliminates the need for any particular discrete portion of the sensor stripes to be contacted by more than one sample, for improved sensor performance.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

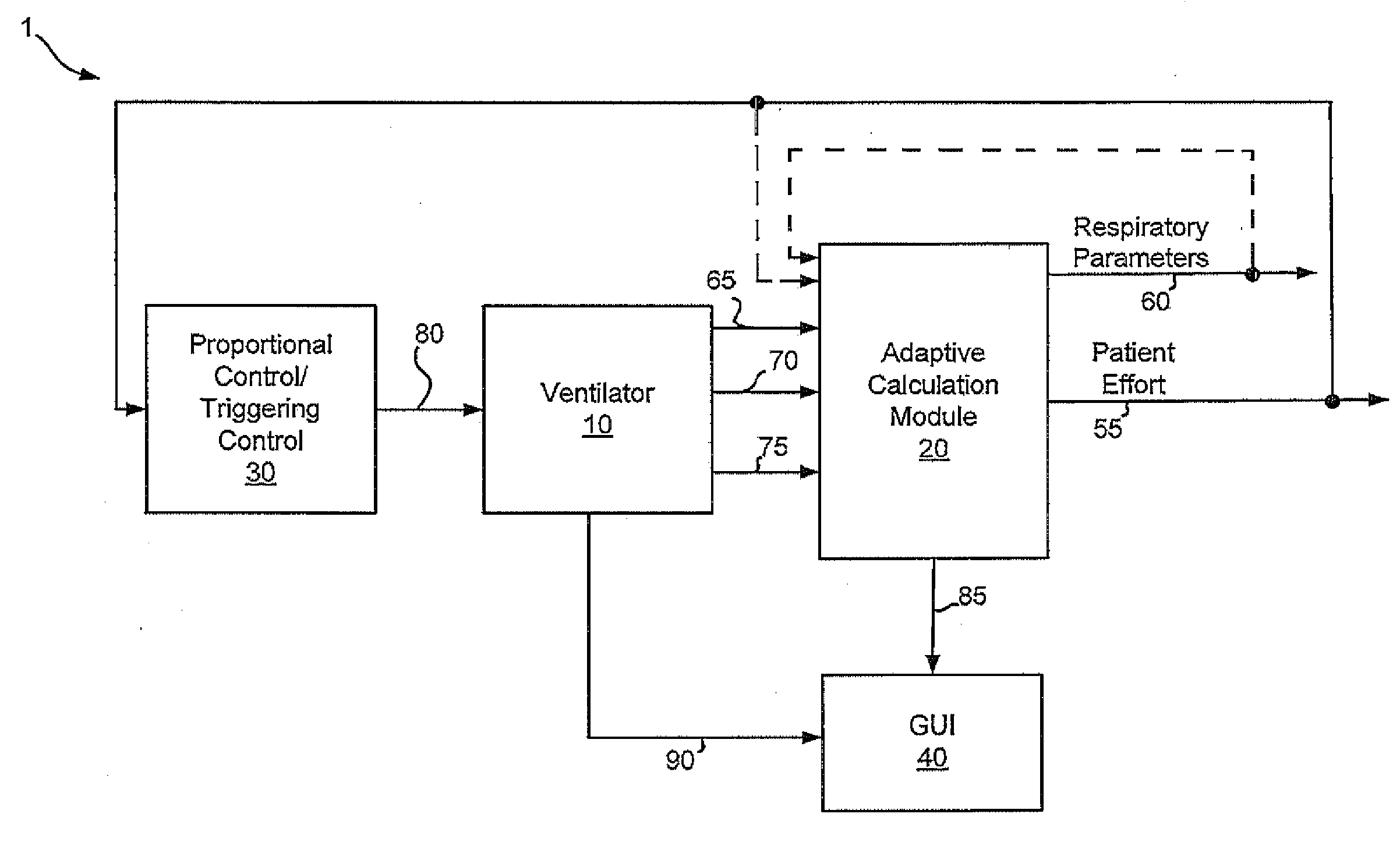

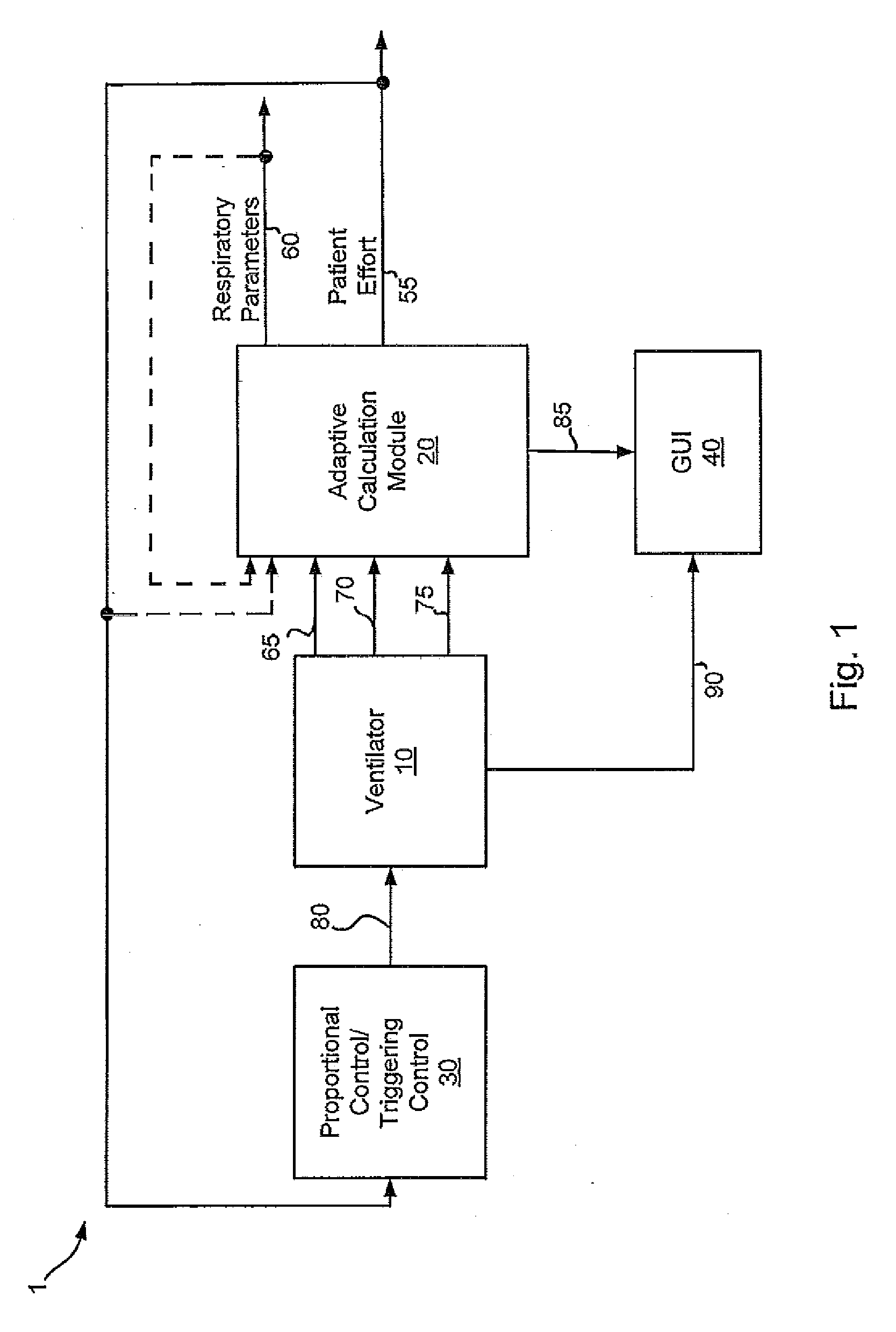

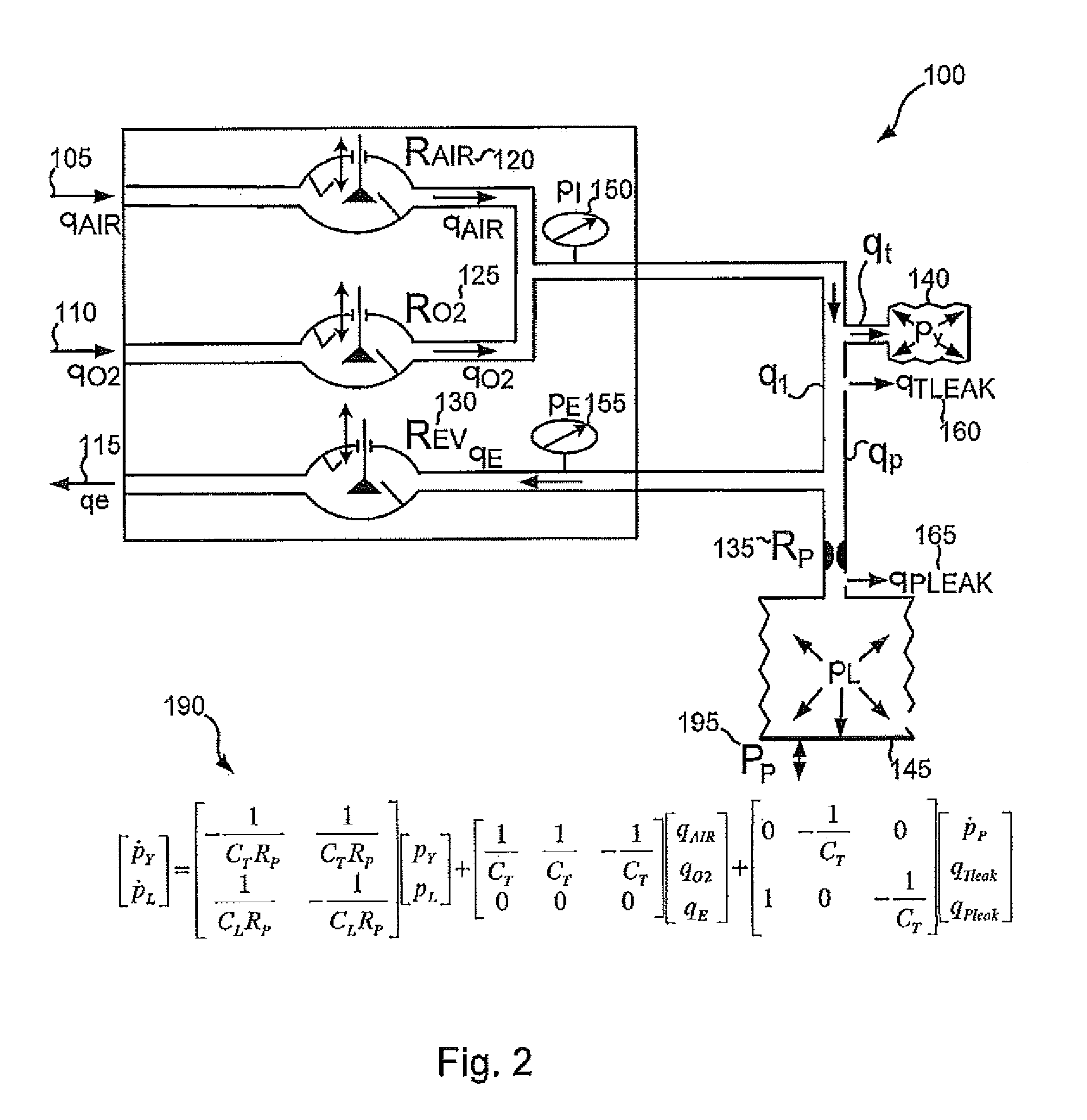

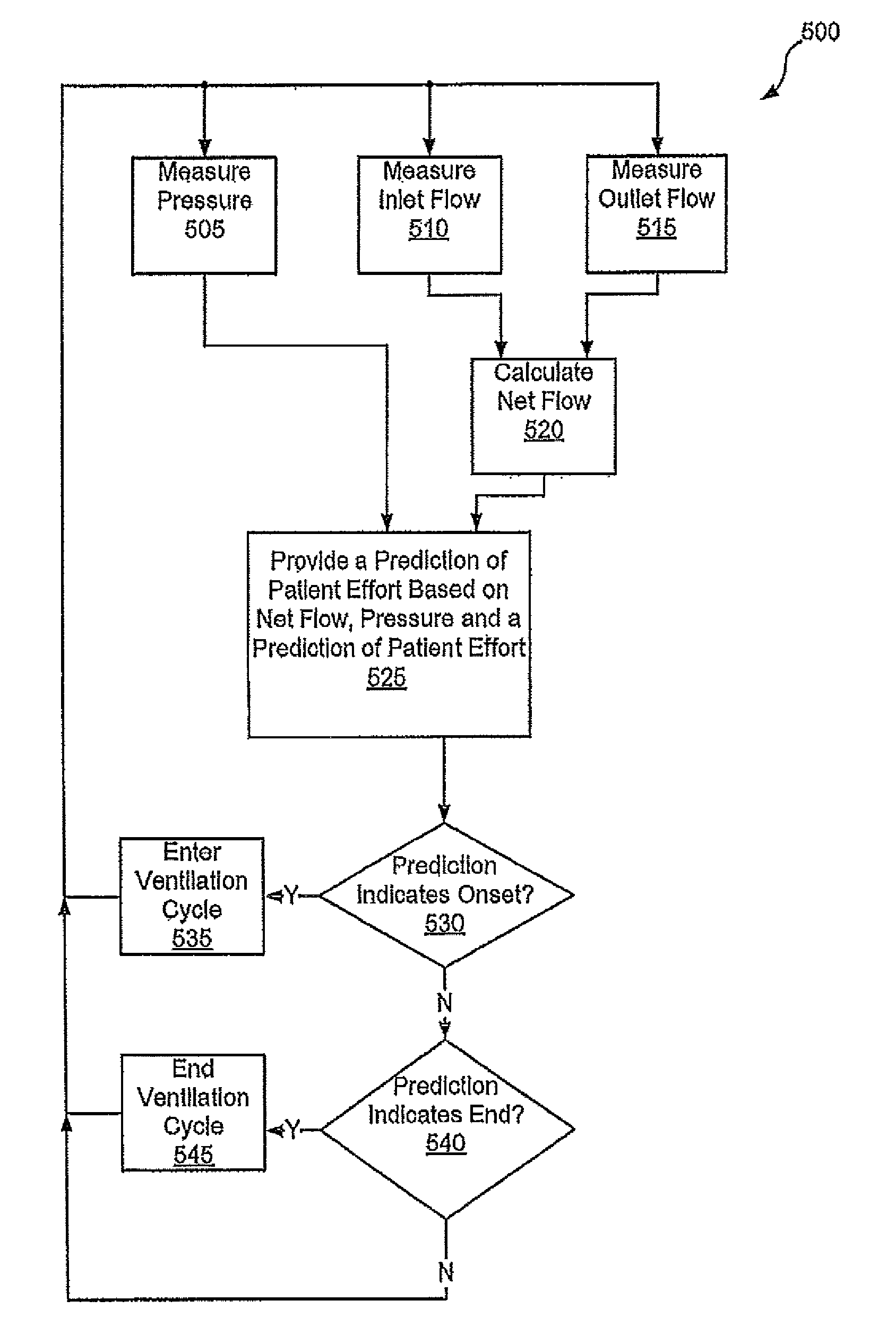

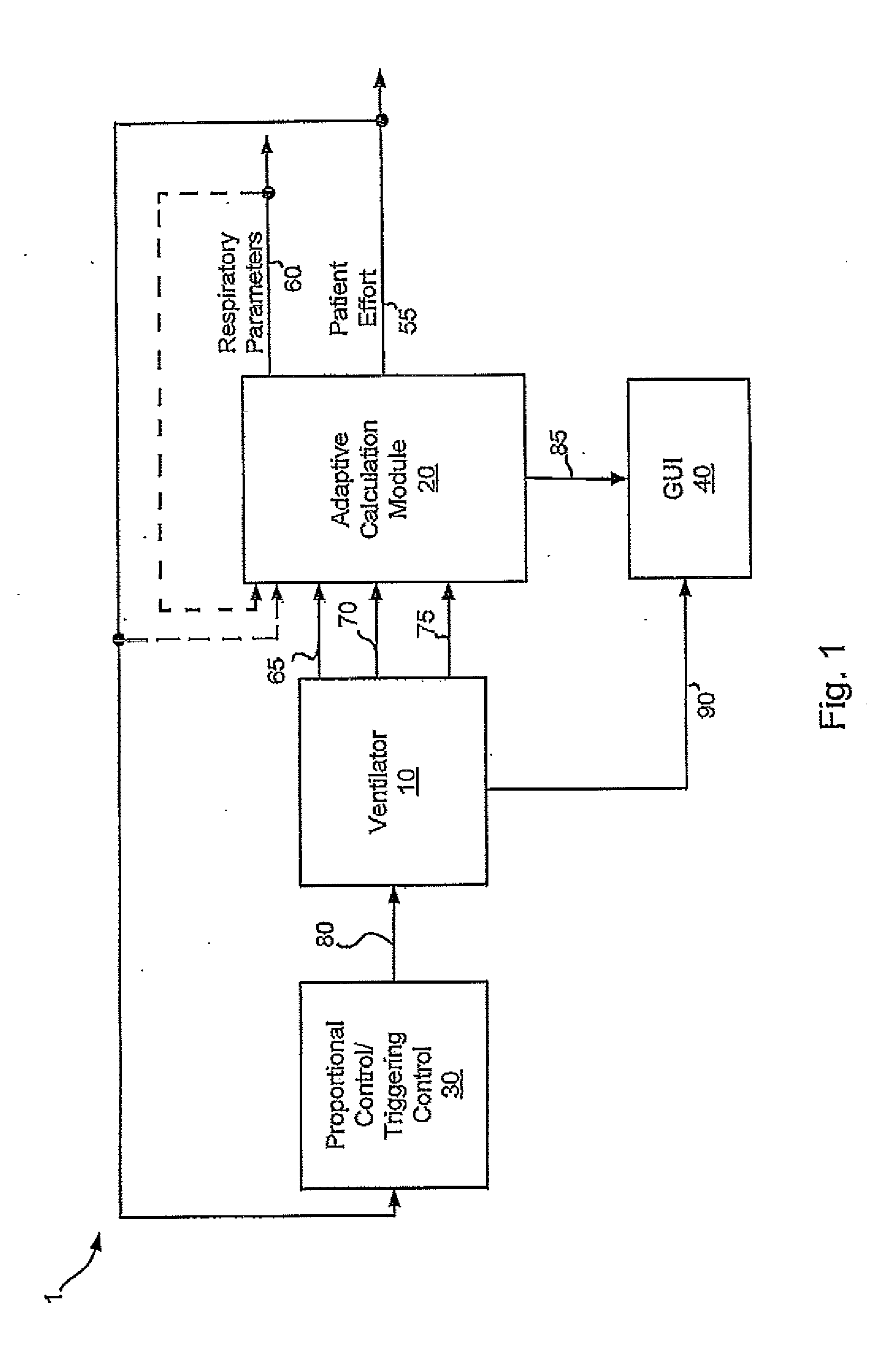

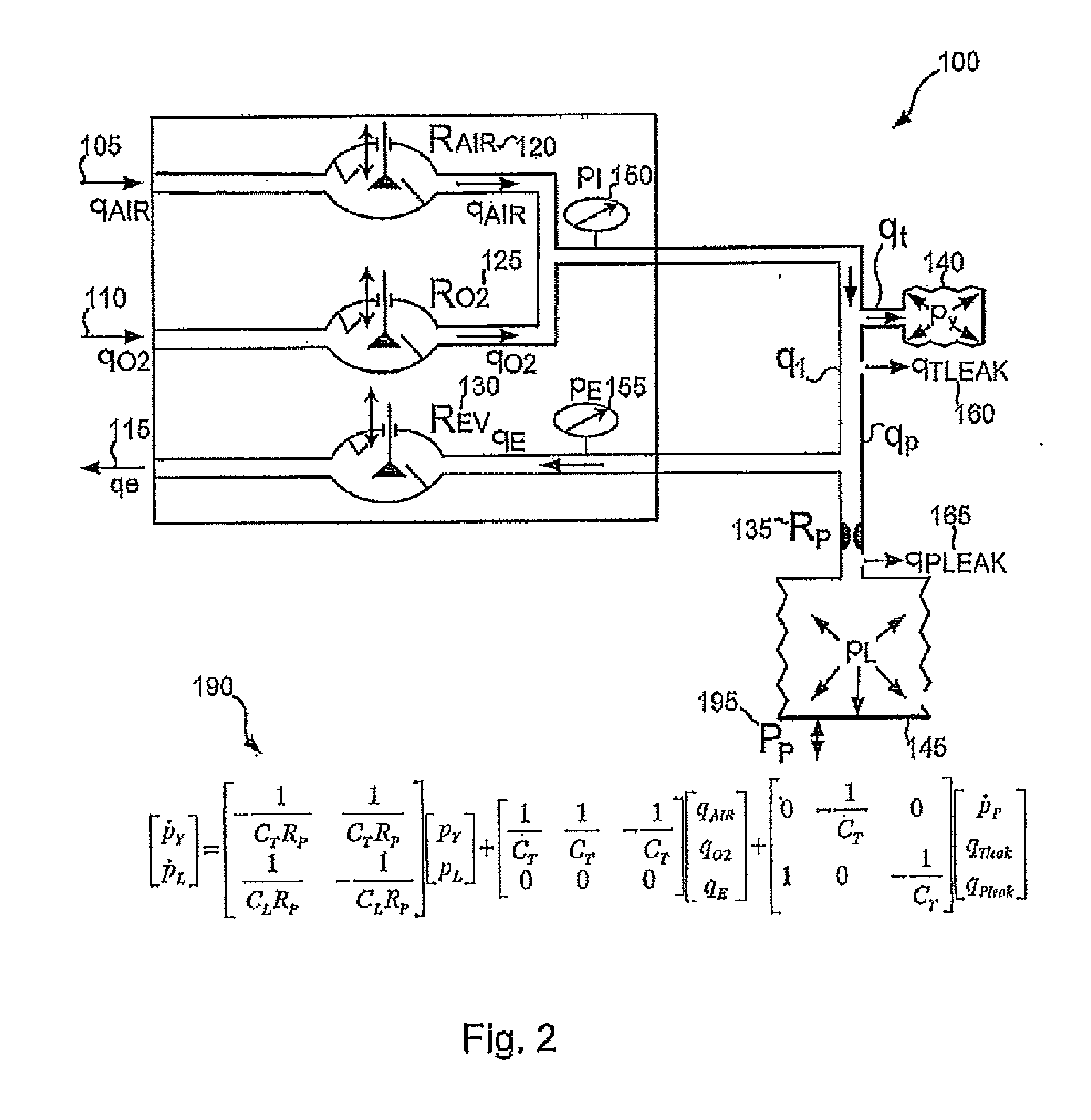

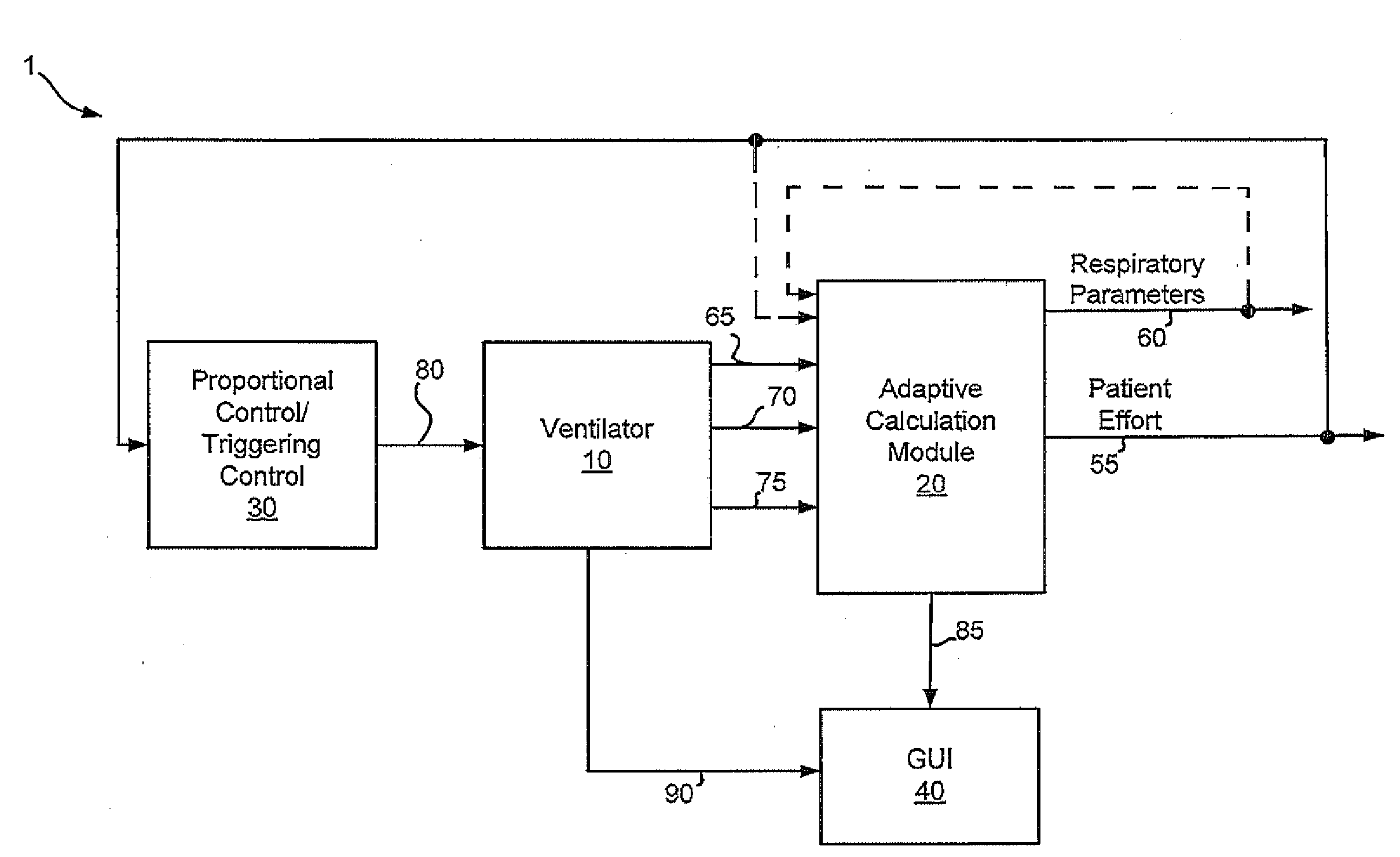

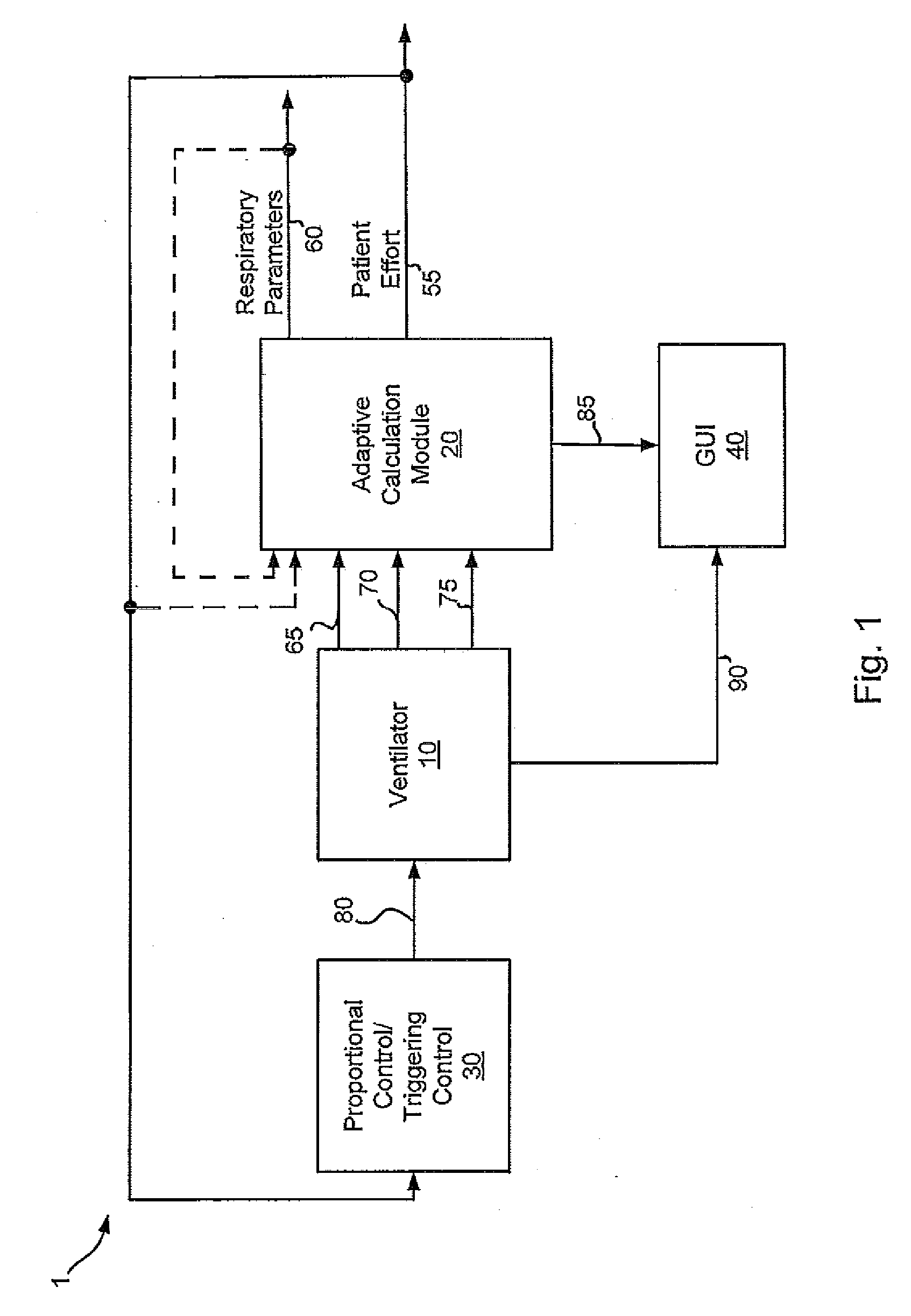

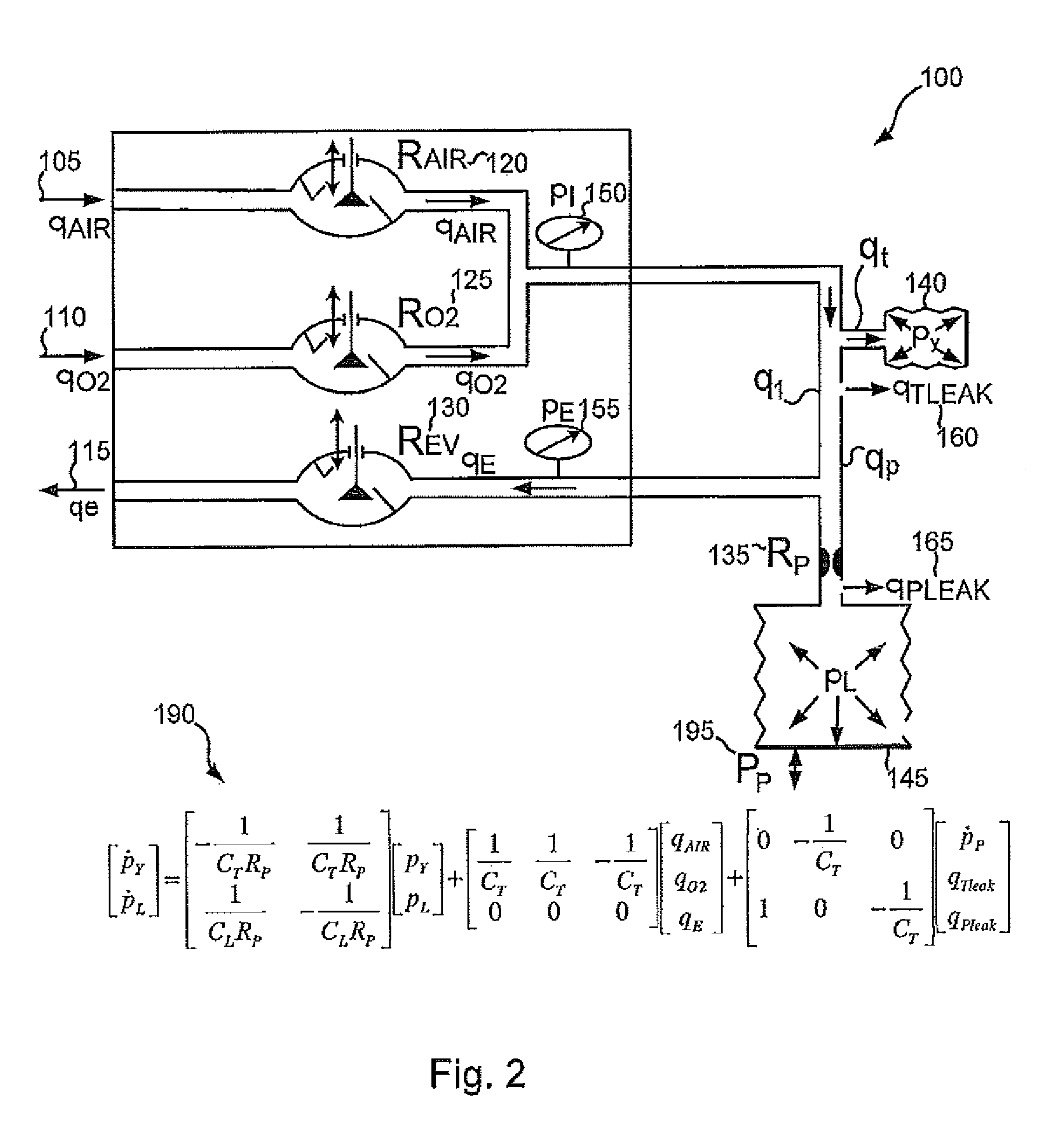

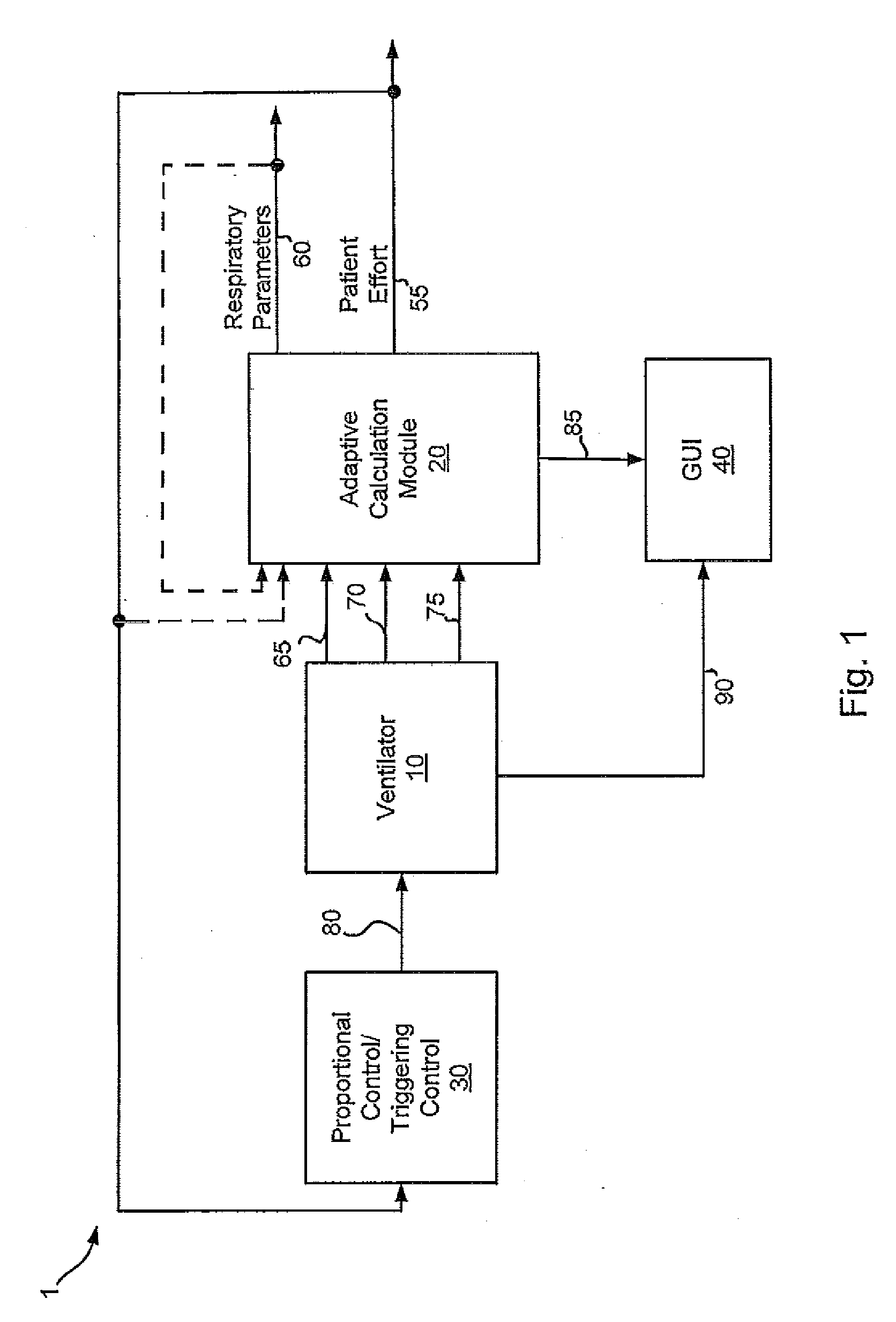

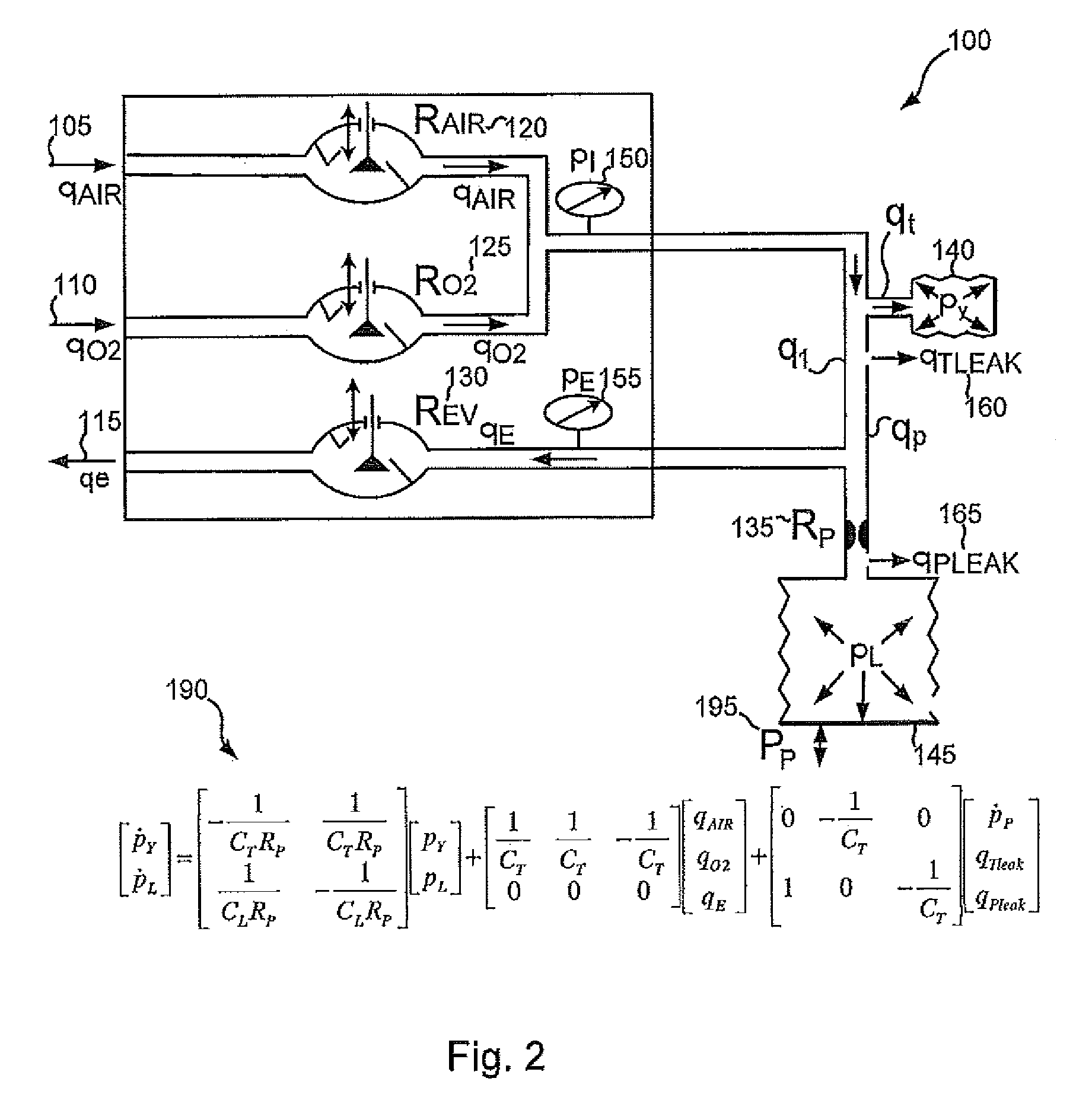

Systems and methods for triggering and cycling a ventilator based on reconstructed patient effort signal

ActiveUS20090301486A1RespiratorsOperating means/releasing devices for valvesRespiratory supportInlet flow

Various embodiments of the present disclosure provide systems, methods and devices for respiratory support. As one example, a method for respiratory support is described that includes providing a measured pressure, and calculating a net flow based on at least one measured inlet flow and measured outlet flow. A relationship between a first value related to the measured pressure, a second value related to the measured net flow and a third value related to patient effort is used to provide a prediction of patient effort. An interim value is updated based at least in part on the prediction of the patient effort, and used to help compute a patient effort. A ventilation cycle is initiated using the computed patient effort.

Owner:TYCO HEALTHCARE GRP LP

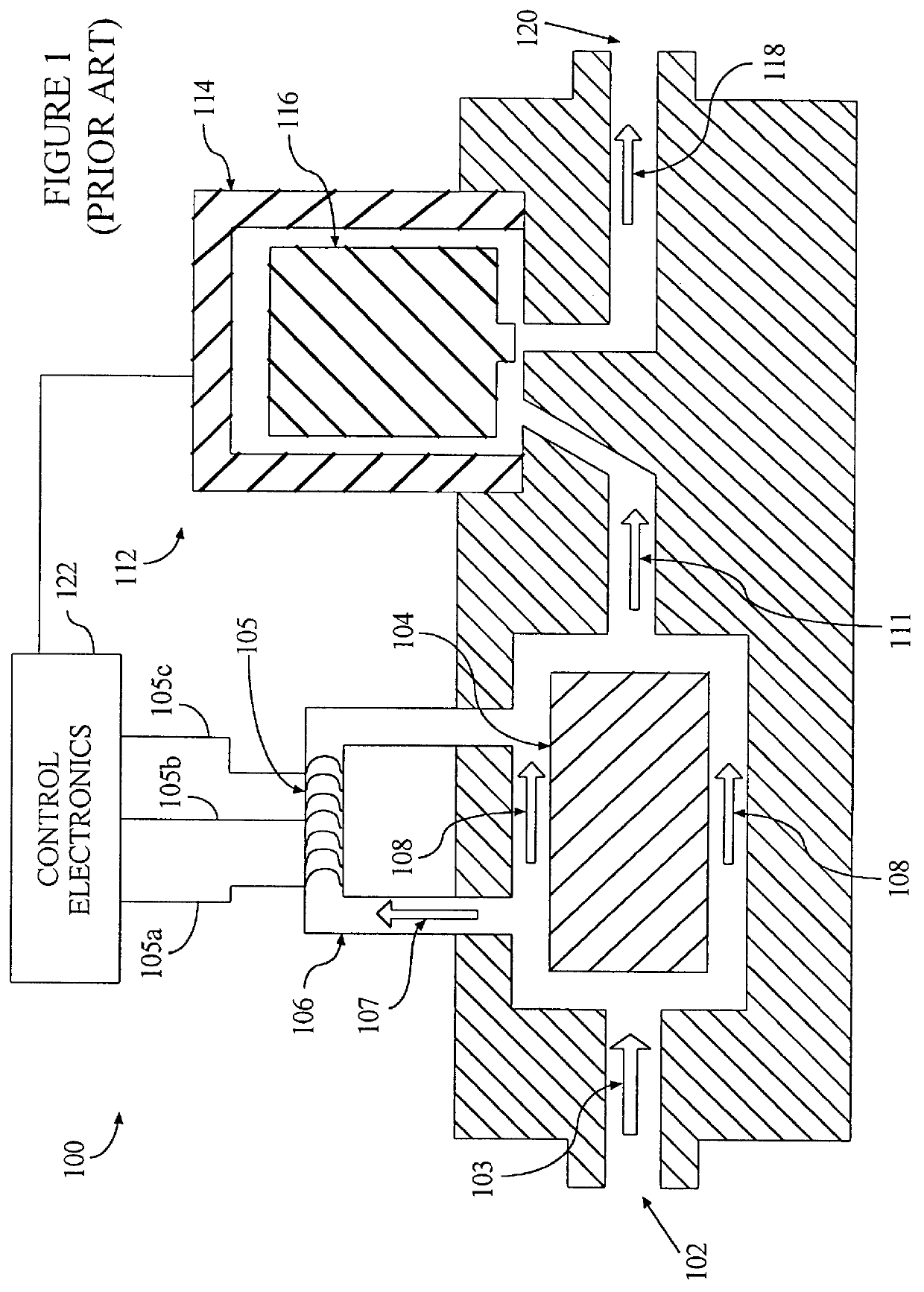

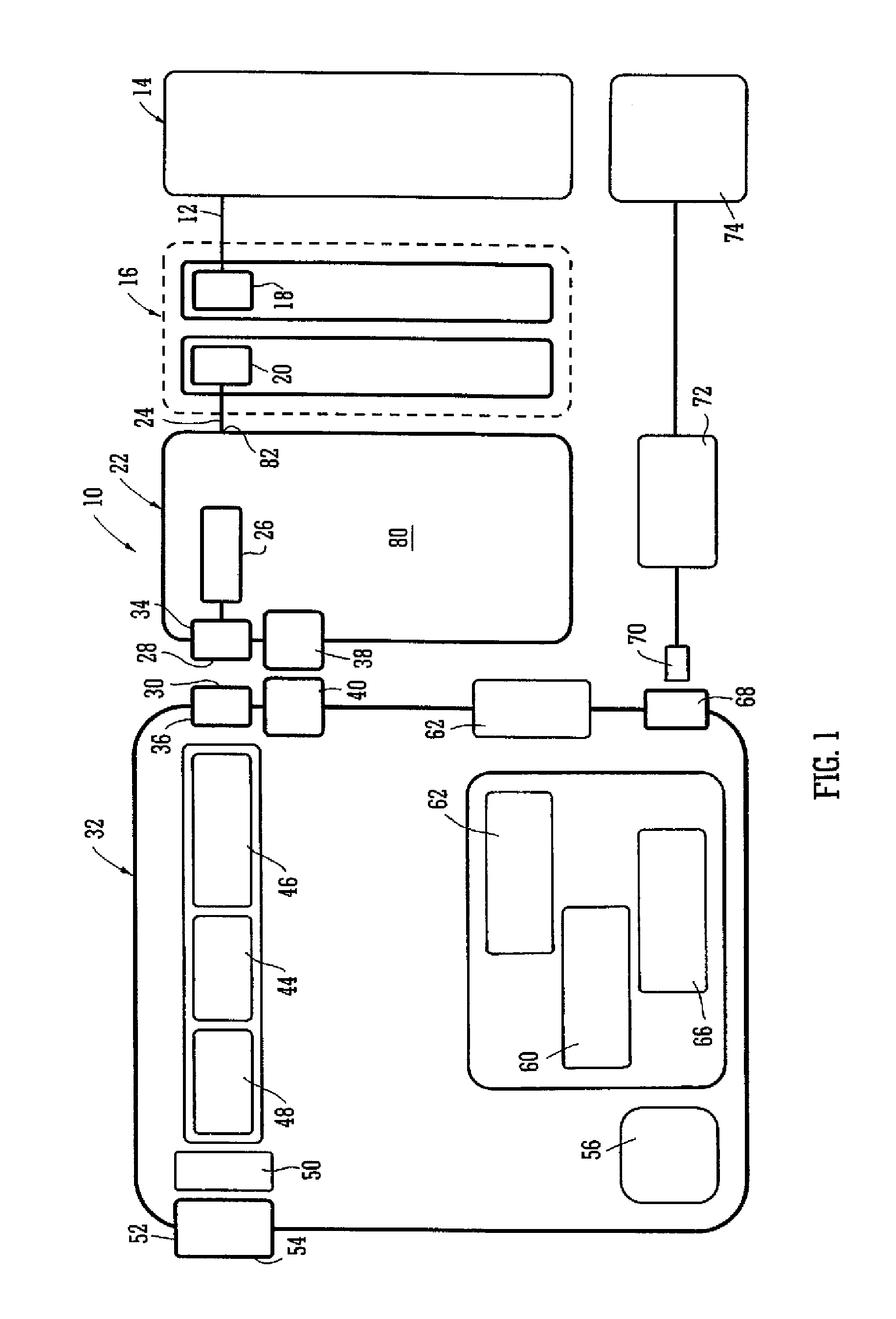

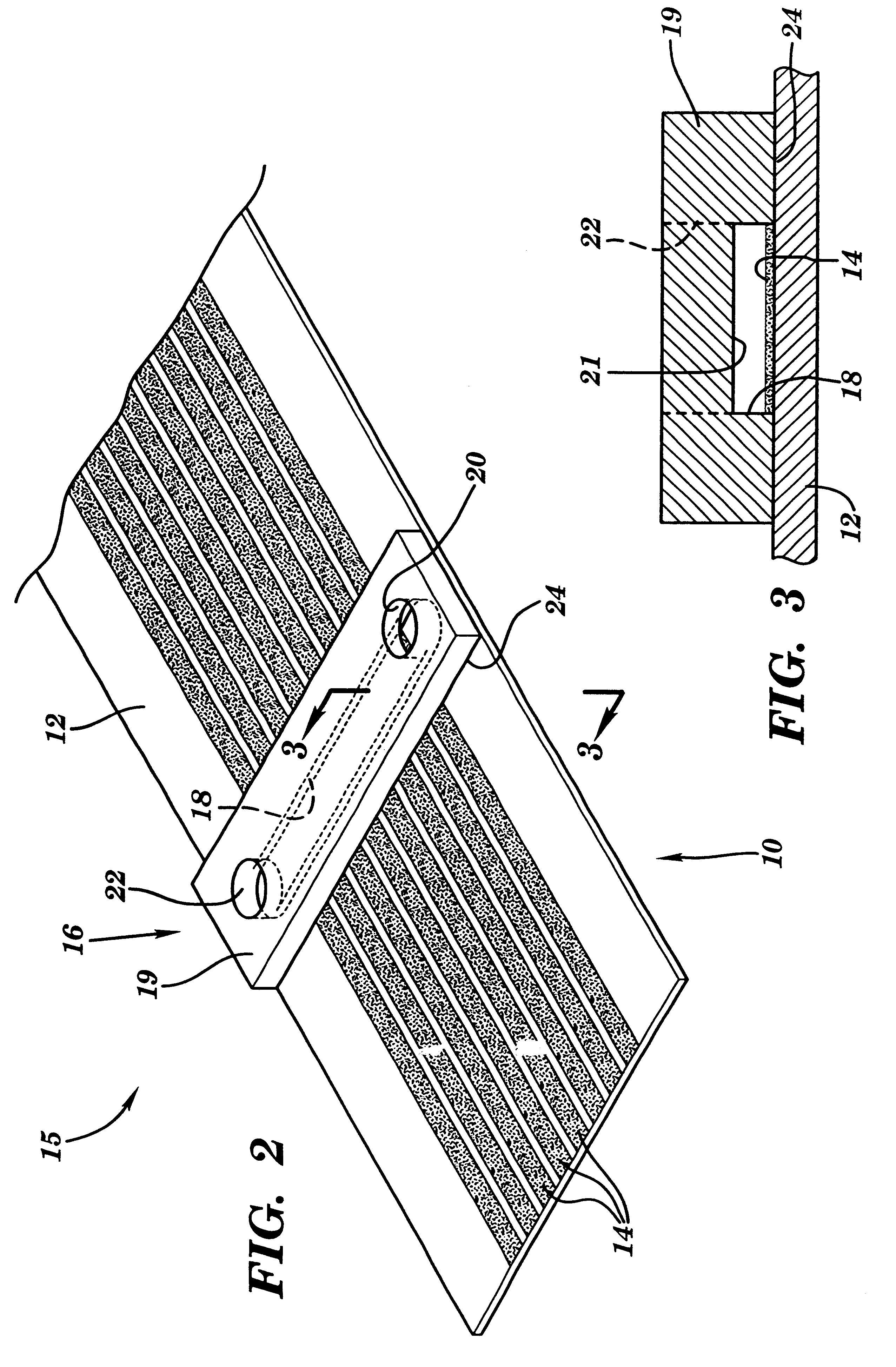

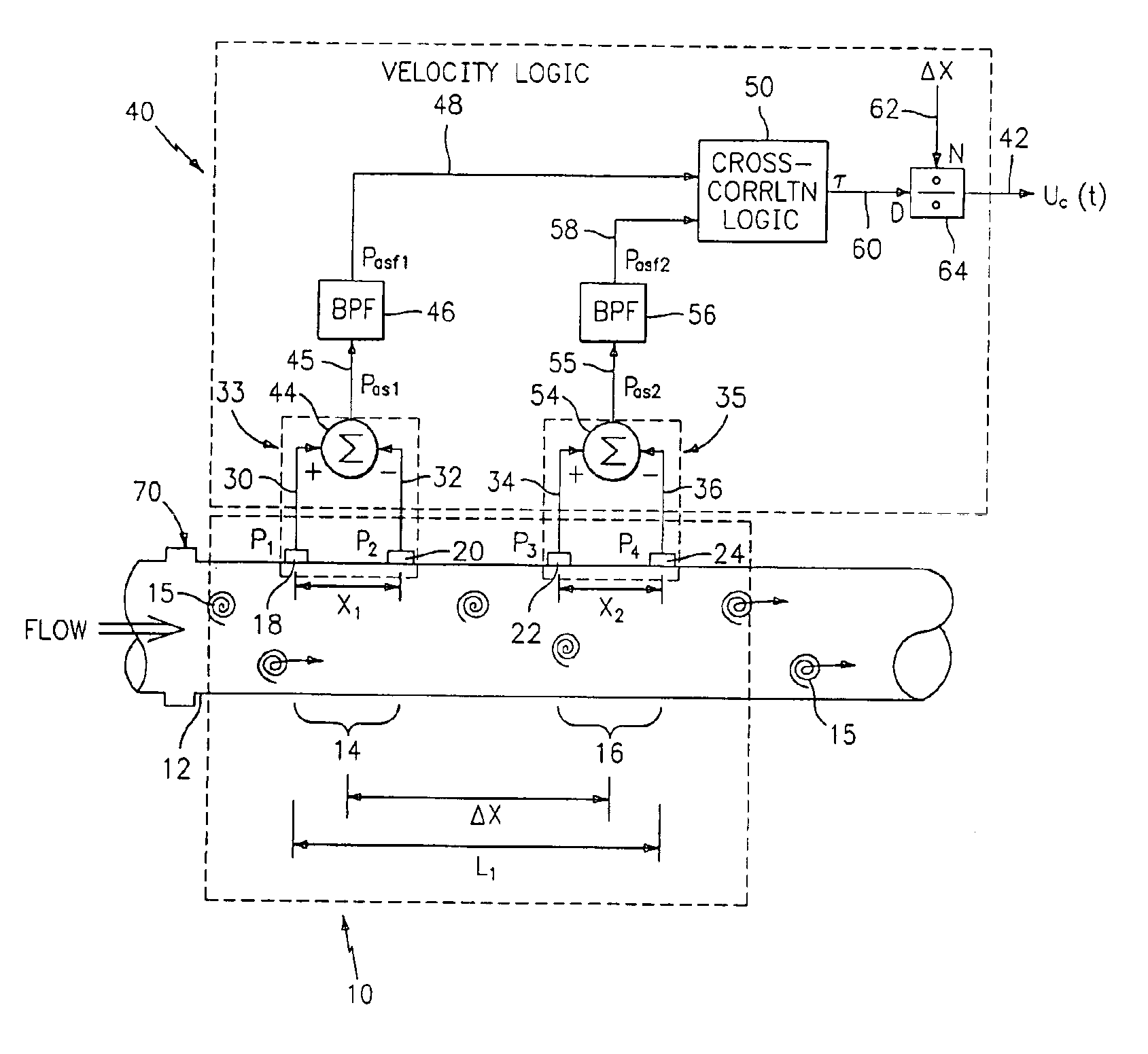

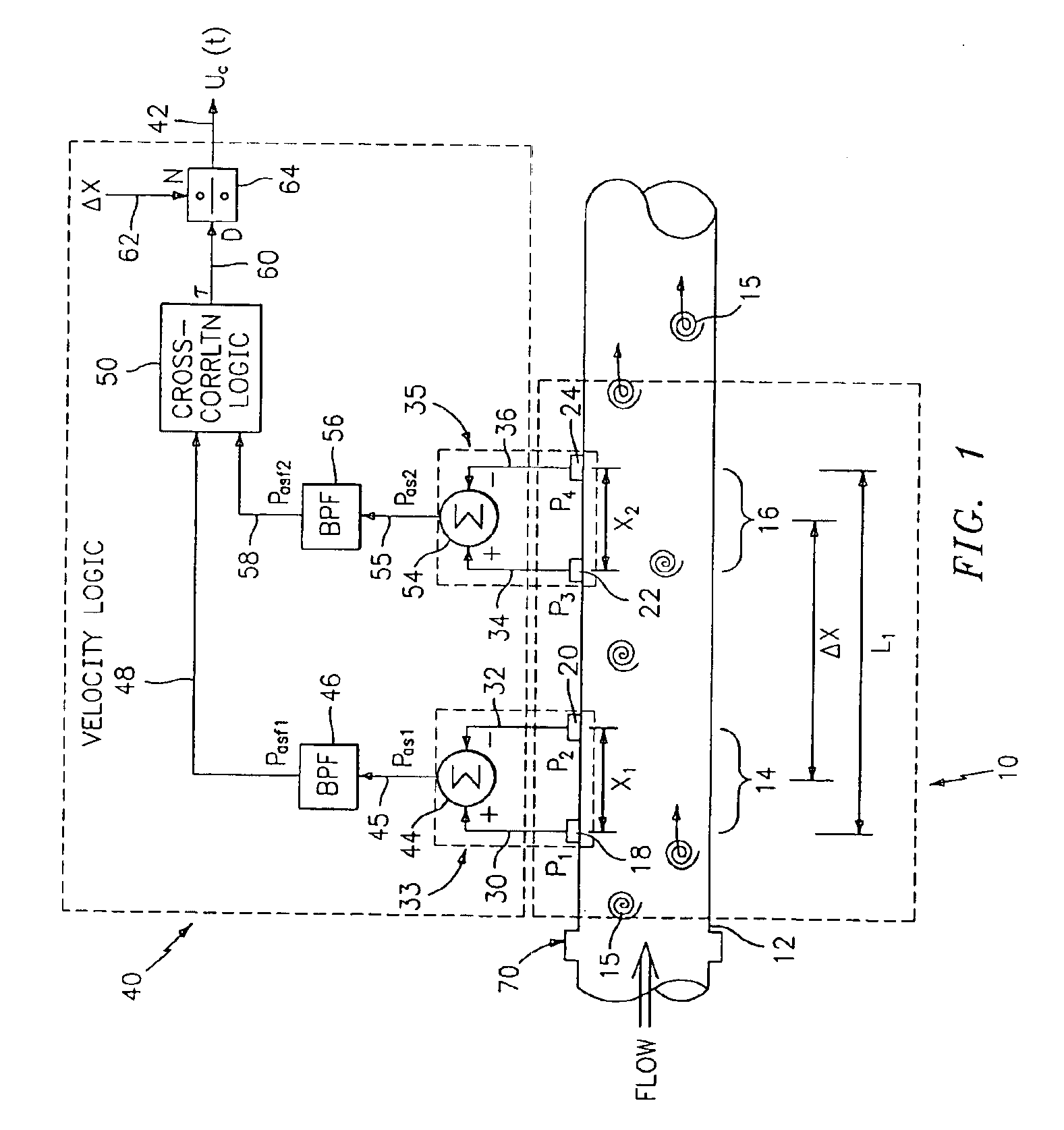

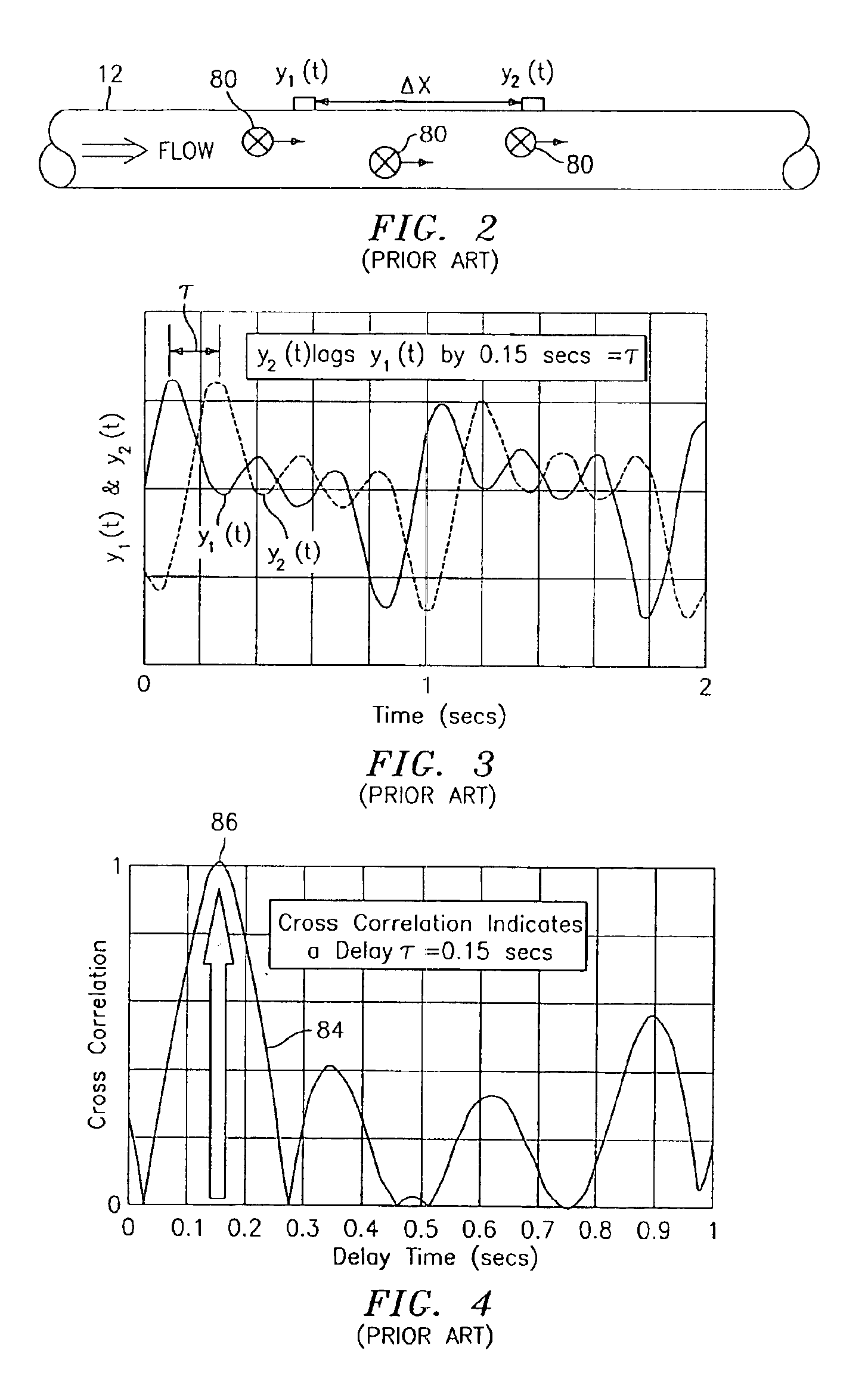

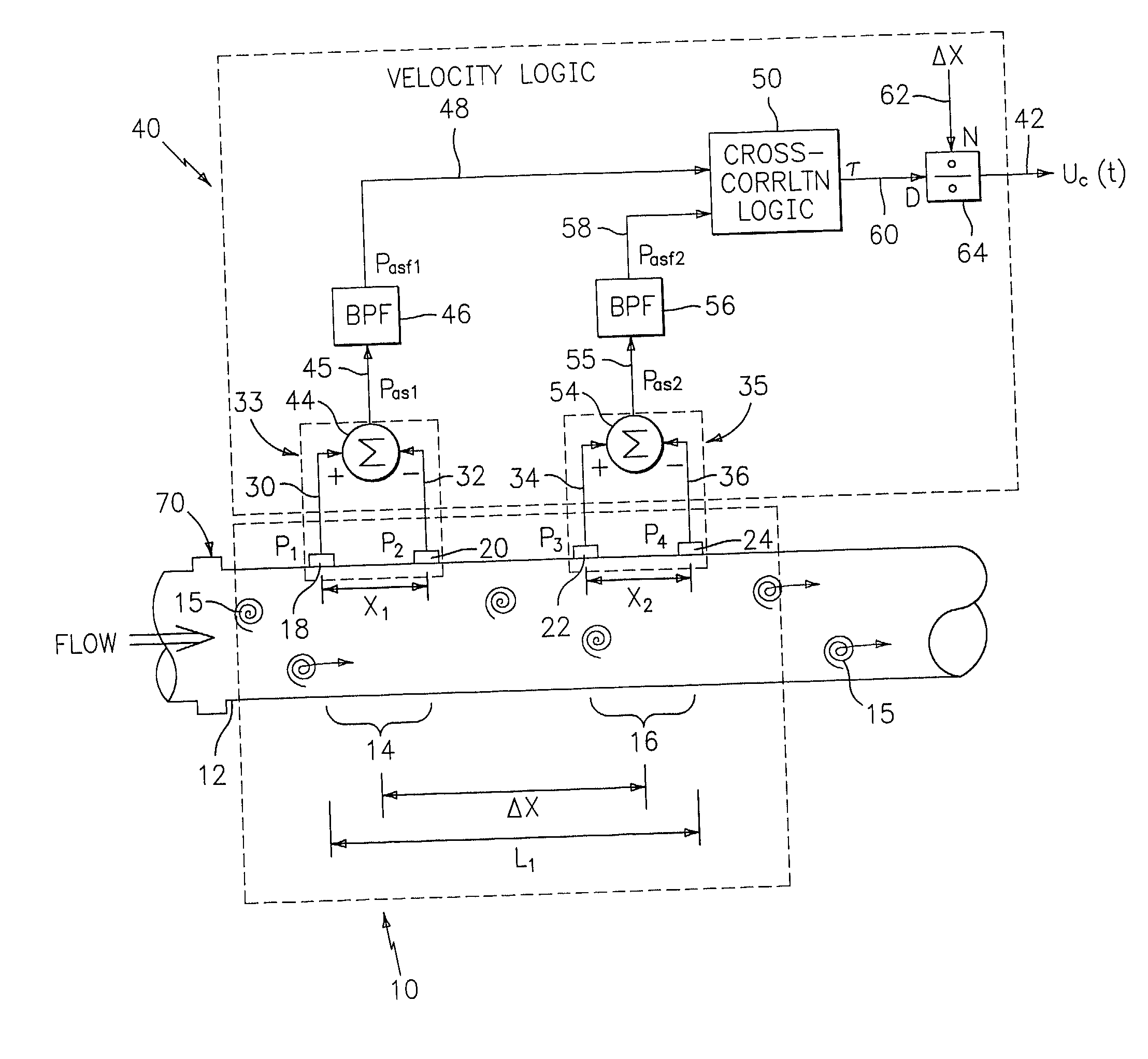

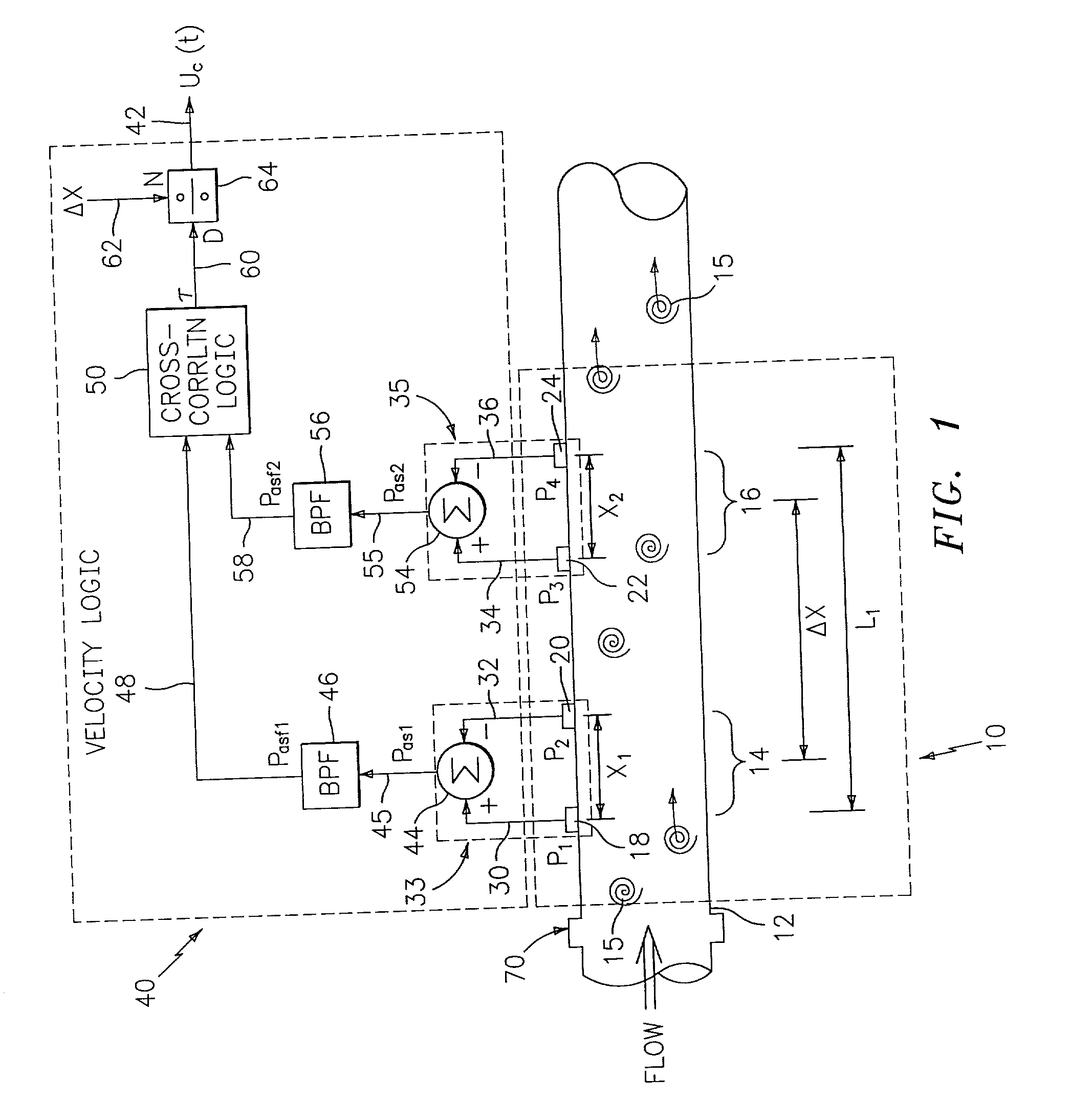

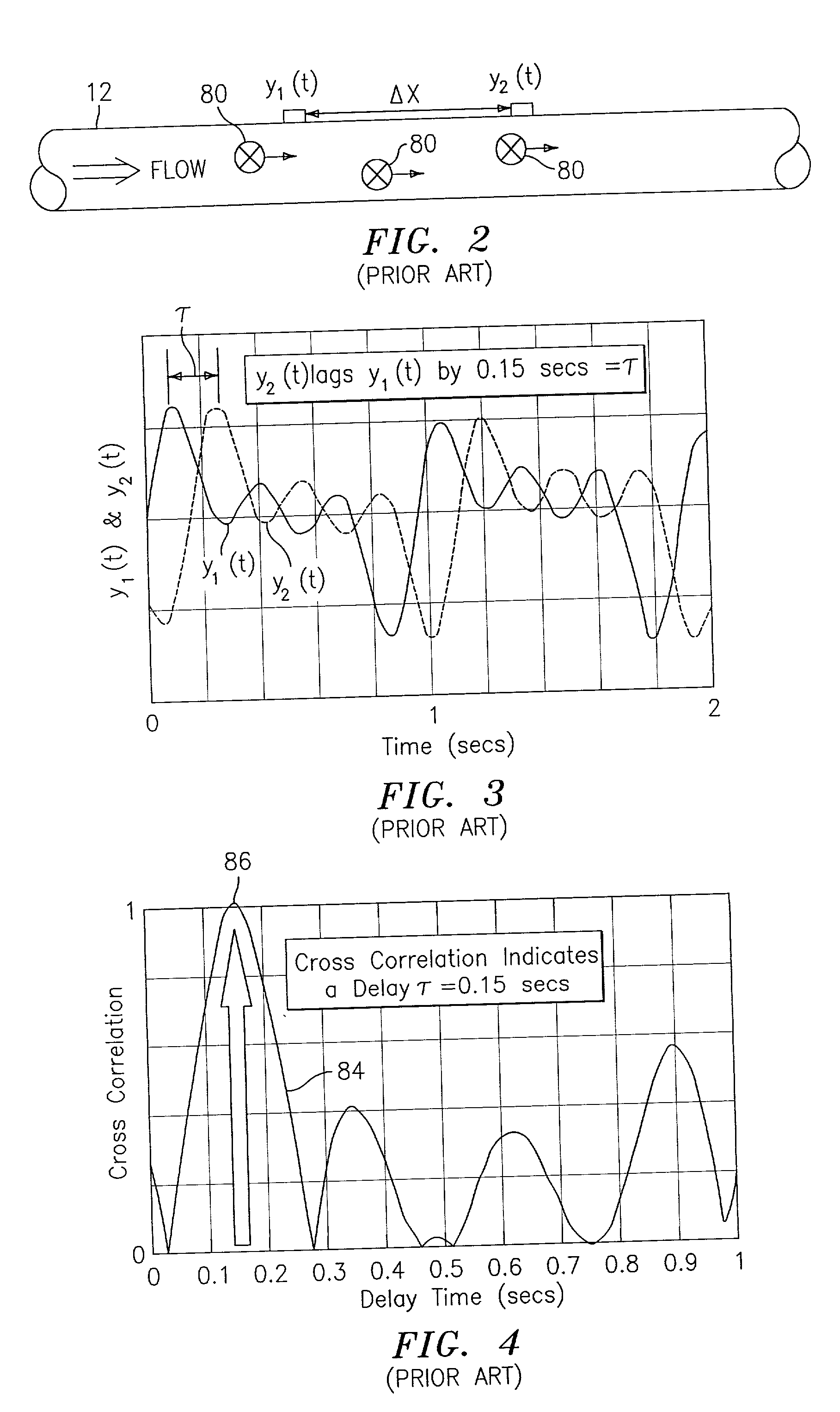

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance ΔX apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances Pacoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances Pvortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals Pas1,Pas2 to band pass filters 46,56 that filter out high frequency signals. The Pvortical -dominated filtered signals Pasf1,Pasf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay τ between the two sensing locations 14,16 which is divided into the distance ΔX to obtain a convection velocity Uc(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

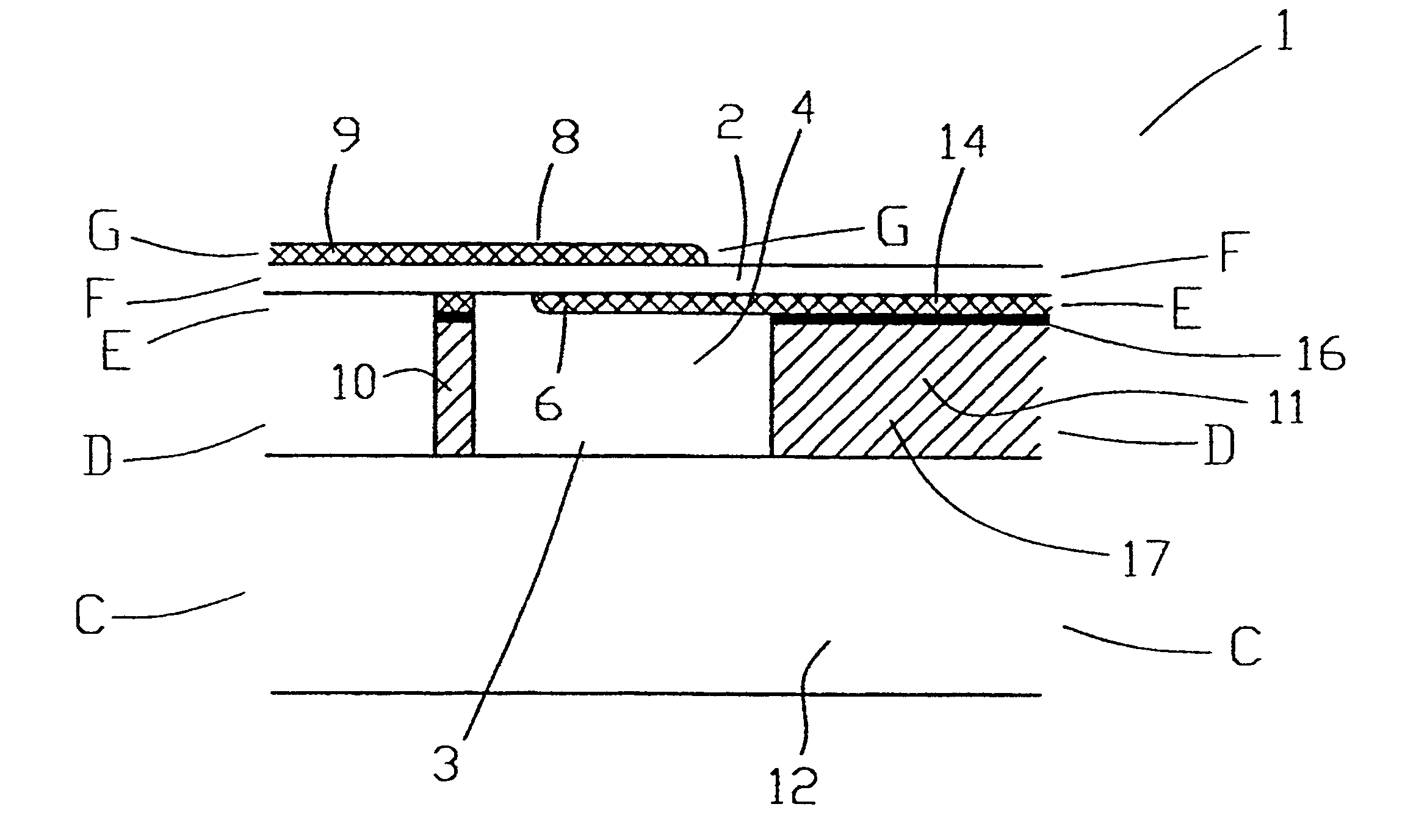

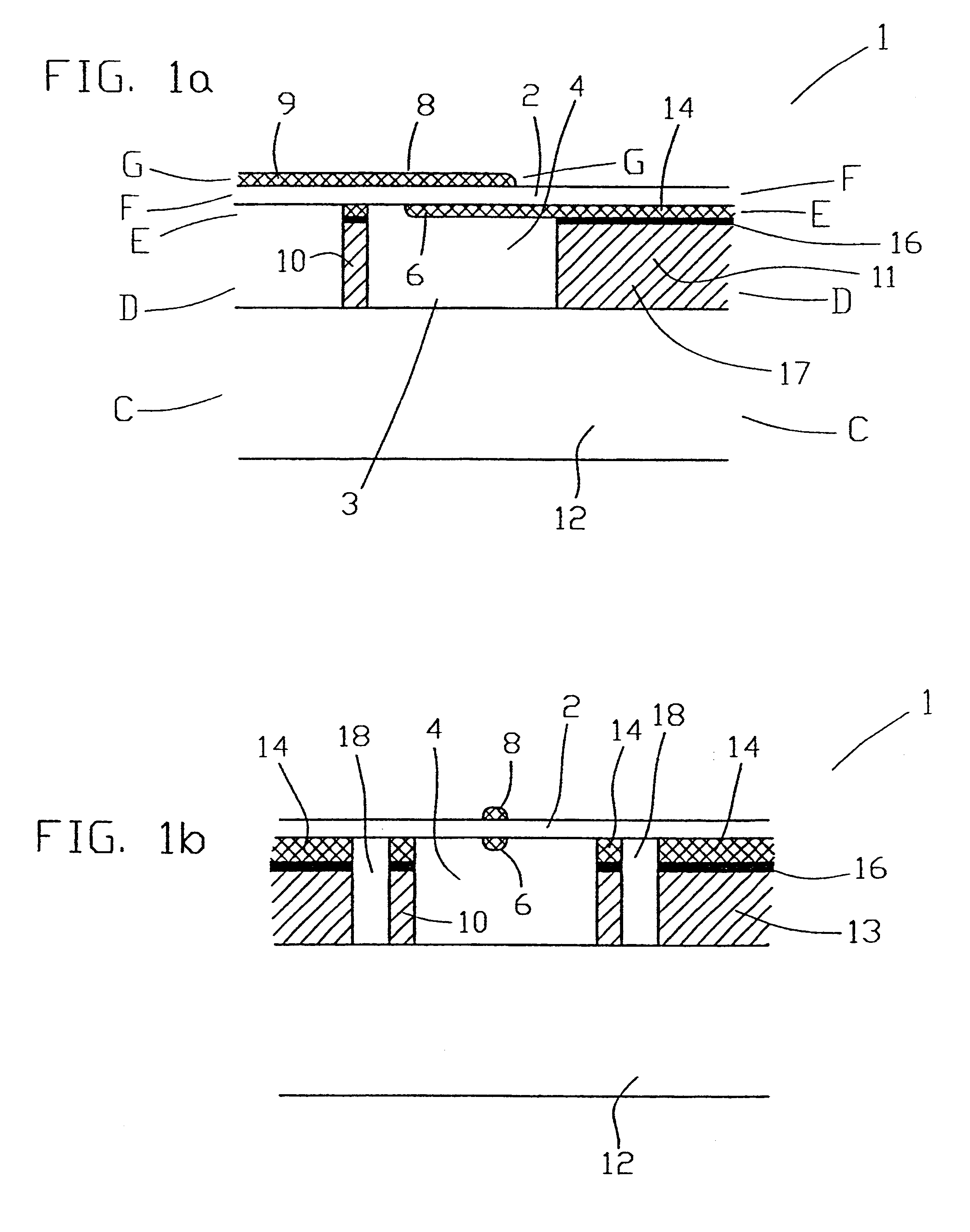

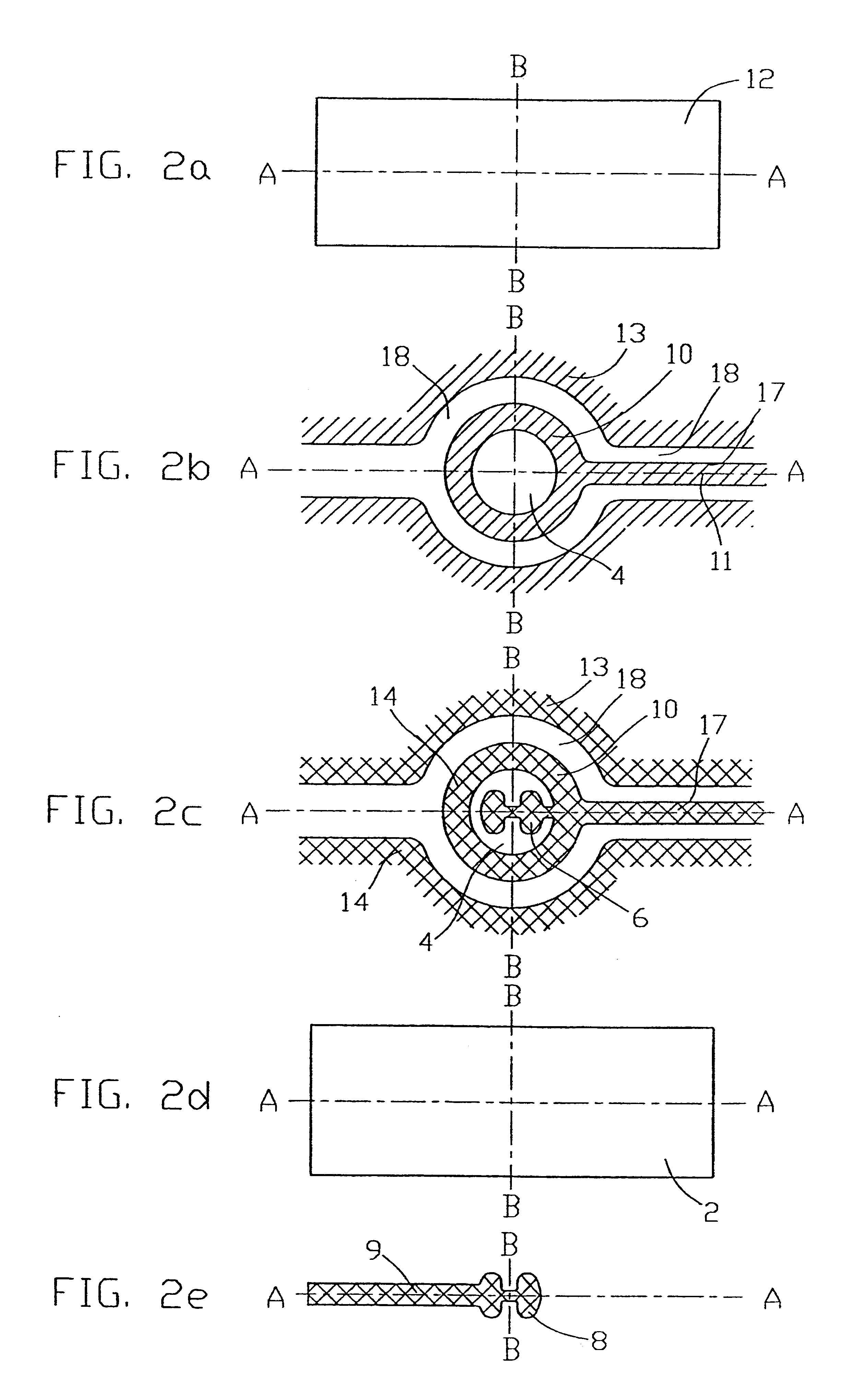

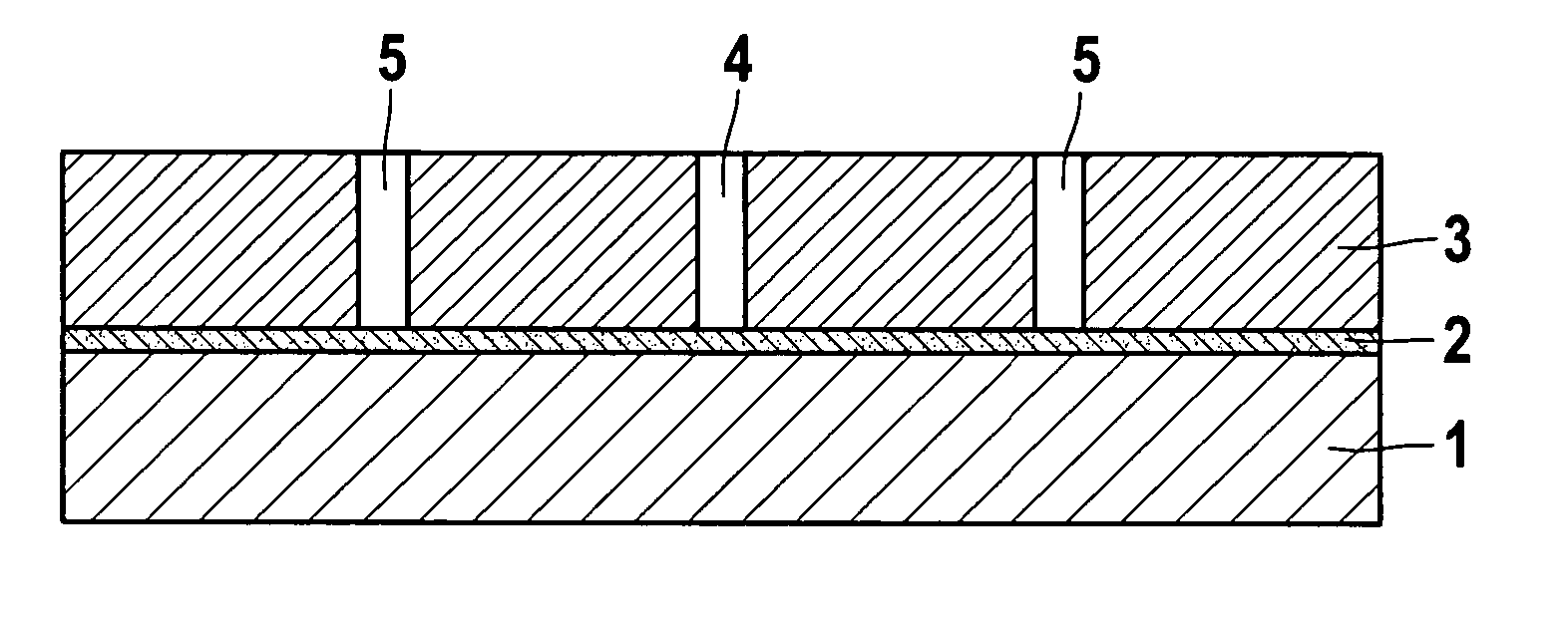

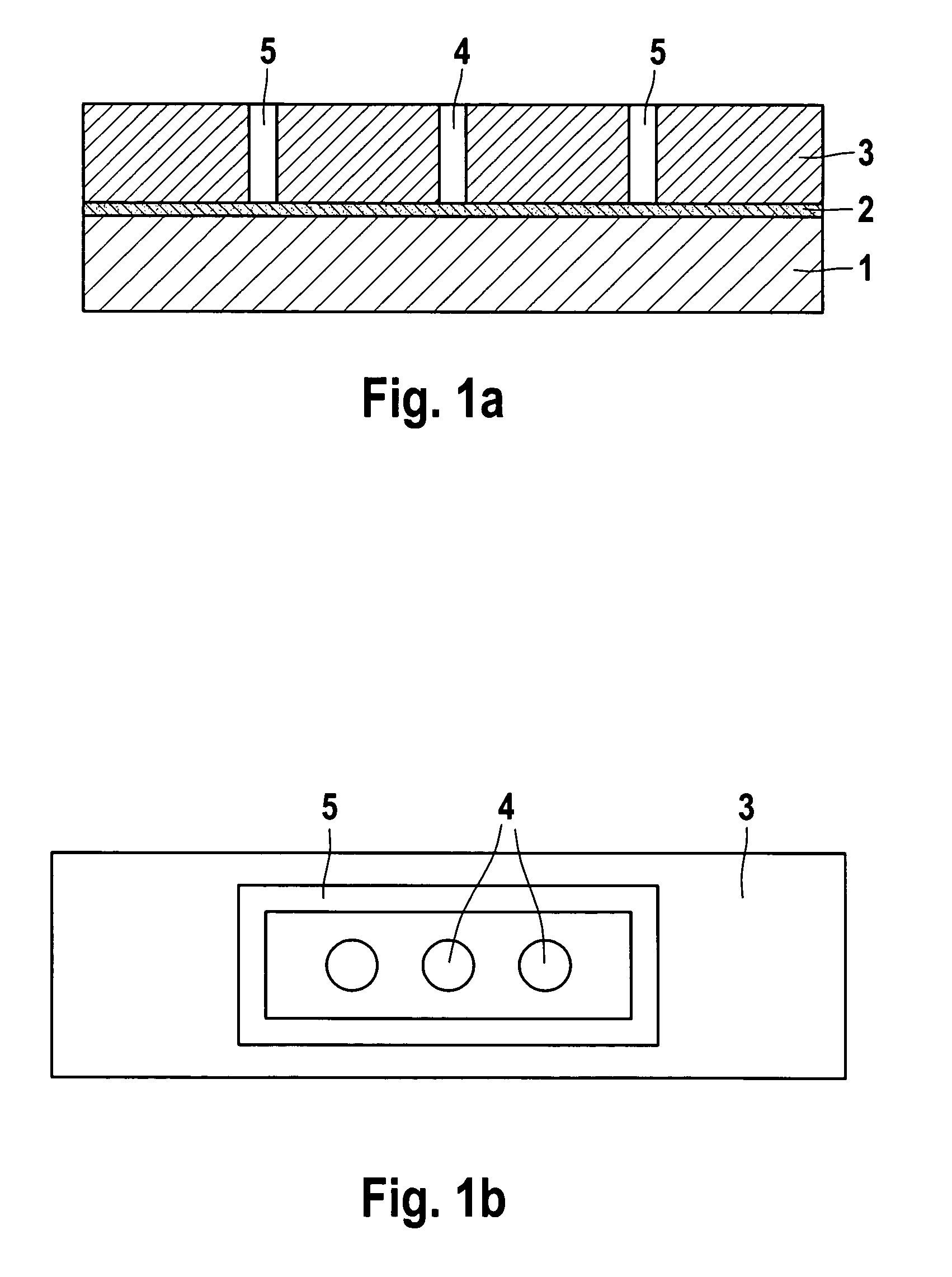

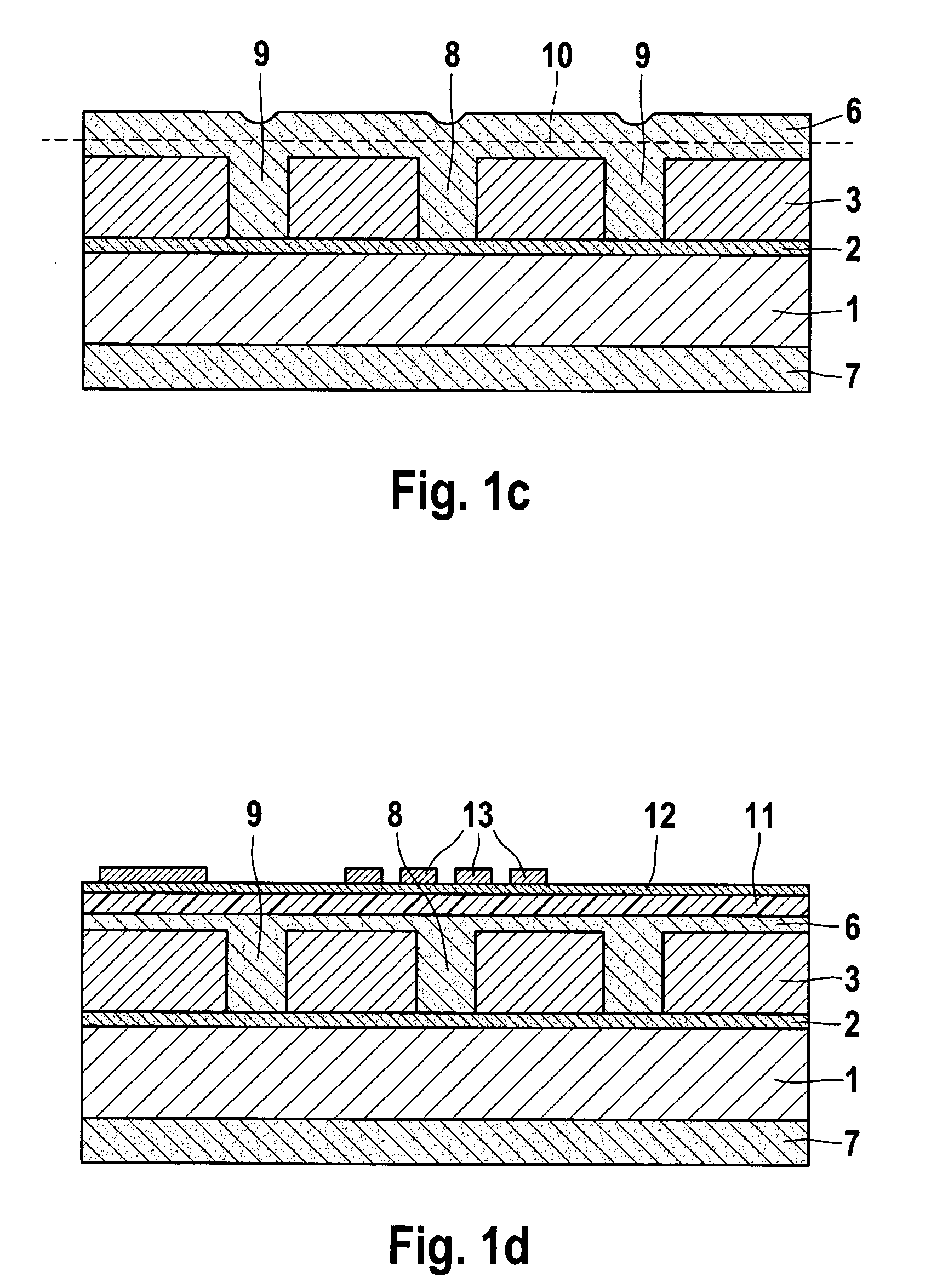

Micromechanical structural element having a diaphragm and method for producing such a structural element

ActiveUS20050098840A1Improve stabilityExtended service lifeDecorative surface effectsFluid pressure measurement using elastically-deformable gaugesEngineeringStructural element

A micromechanical structural element, having a very stable diaphragm, implemented in a pure front process and in a layer construction on a substrate. The layer construction includes at least one sacrificial layer and one diaphragm layer above the sacrificial layer, which is structured for laying bare the diaphragm and generating stabilizing elements on the diaphragm, at least one recess being generated for a stabilizing element of the diaphragm. The structure generated in the sacrificial layer is then at least superficially closed with at least one material layer being deposited above the structured sacrificial layer, this material layer forming at least a part of the diaphragm layer and being structured to generate at least one etch hole for etching the sacrificial layer, which is removed from the region under the etch hole, the diaphragm and the at least one stabilizing element being laid bare, a cavity being created under the diaphragm.

Owner:ROBERT BOSCH GMBH

Systems and methods for ventilation in proportion to patient effort

Various embodiments of the present disclosure provide systems, methods and devices for respiratory support. As one example, a ventilation system is disclosed that includes a computer readable medium including instructions executable by a processor to receive a measured pressure value and a net flow value. A patient effort value is calculated based on a relationship between patient effort, the measured pressure value and the net flow value. The instructions are further executable to calculate a gas delivery metric that varies as a function of the patient effort value. Gas is then caused to be delivered consistent with the gas delivery metric.

Owner:TYCO HEALTHCARE GRP LP

Systems and methods for monitoring and displaying respiratory information

ActiveUS20090301487A1RespiratorsOperating means/releasing devices for valvesGraphicsRespiratory support

Various embodiments of the present disclosure provide systems, methods and devices for respiratory support. As one example, a ventilation system is disclosed that includes a graphical display, a processor and a computer readable medium. The computer readable medium is communicably coupled to the processor and includes instructions executable by the processor to receive a measured pressure value, and receive a net flow value. The instructions are further executable to calculate a patient effort value based on a relationship between patient effort, the measured pressure value and the net flow value; and to plot the patient effort value to the graphical display.

Owner:TYCO HEALTHCARE GRP LP

Systems and methods for determining patient effort and/or respiratory parameters in a ventilation system

ActiveUS20090301490A1RespiratorsOperating means/releasing devices for valvesRespiratory supportInlet flow

Various embodiments of the present disclosure provide systems, methods and devices for respiratory support. As one example, a method for respiratory support is described that includes measuring a pressure, providing a measured pressure, measuring an inlet flow and an outlet flow, and providing a measured net flow. A relationship between a first value related to the measured pressure, a second value related to the measured net flow and a third value related to patient effort is used to provide a prediction of patient effort. An interim value is updated based at least in part on the prediction of the patient effort.

Owner:TYCO HEALTHCARE GRP LP

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance .DELTA.X apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X.sub.1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X.sub.2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances P.sub.acoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances P.sub.vortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals P.sub.as1,P.sub.as2 to band pass filters 46,56 that filter out high frequency signals. The P.sub.vortical -dominated filtered signals P.sub.asf1,P.sub.asf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay .tau. between the two sensing locations 14,16 which is divided into the distance .DELTA.X to obtain a convection velocity U.sub.c(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

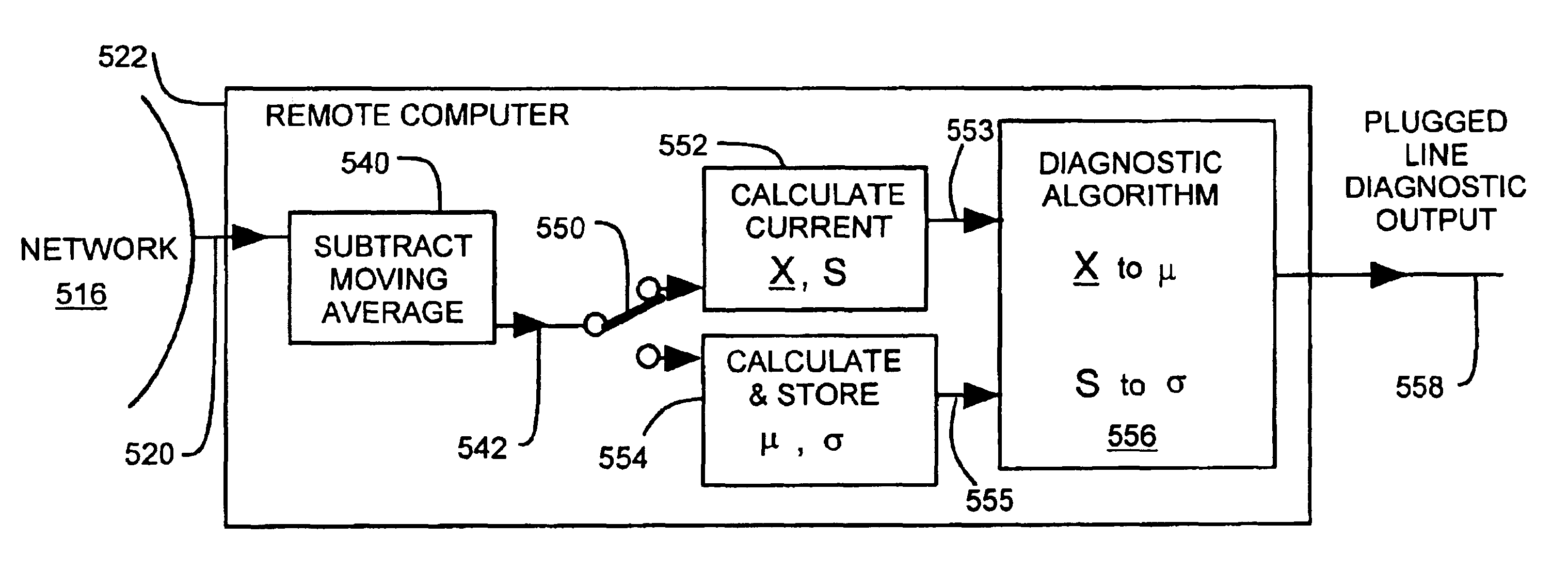

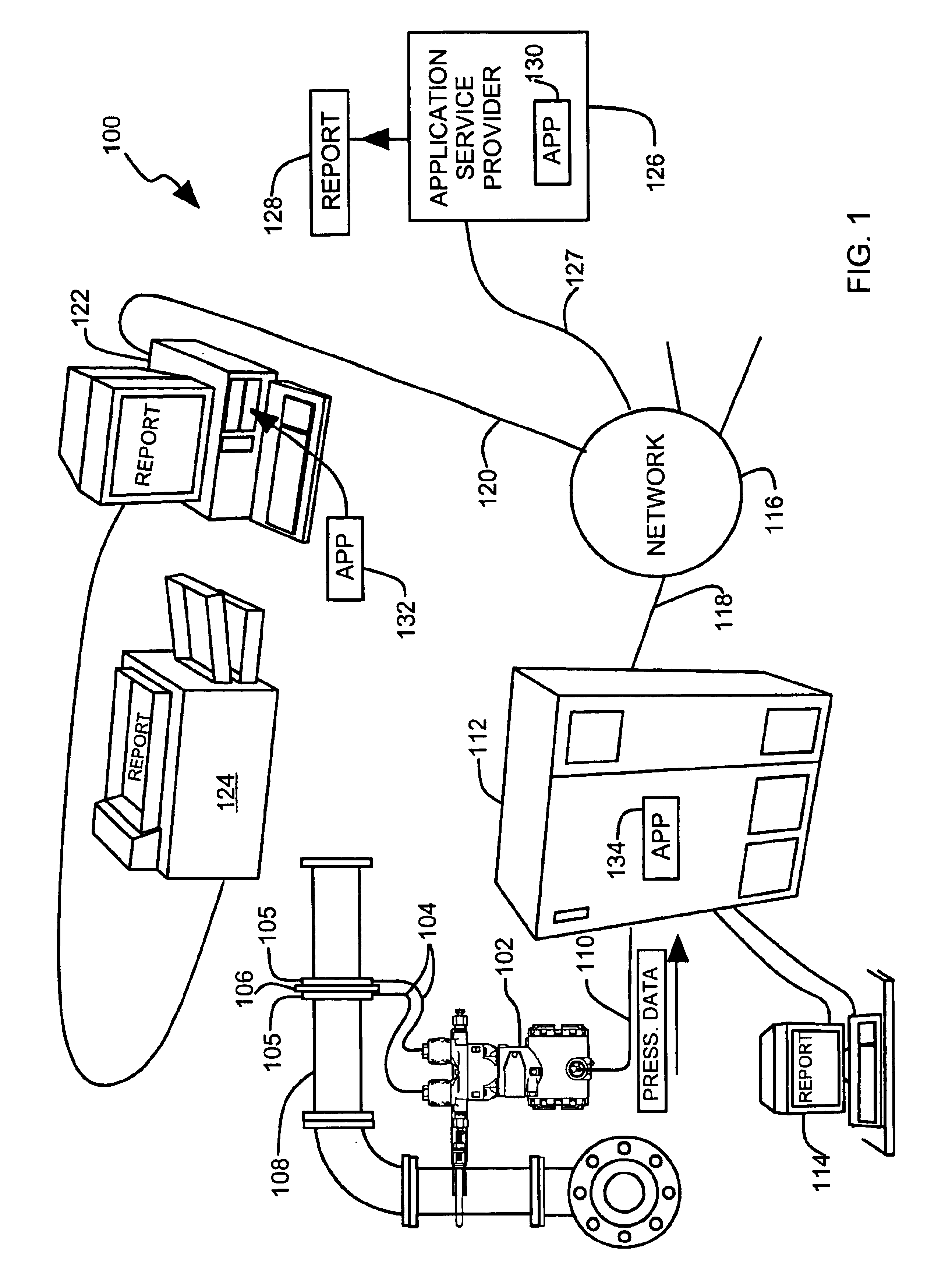

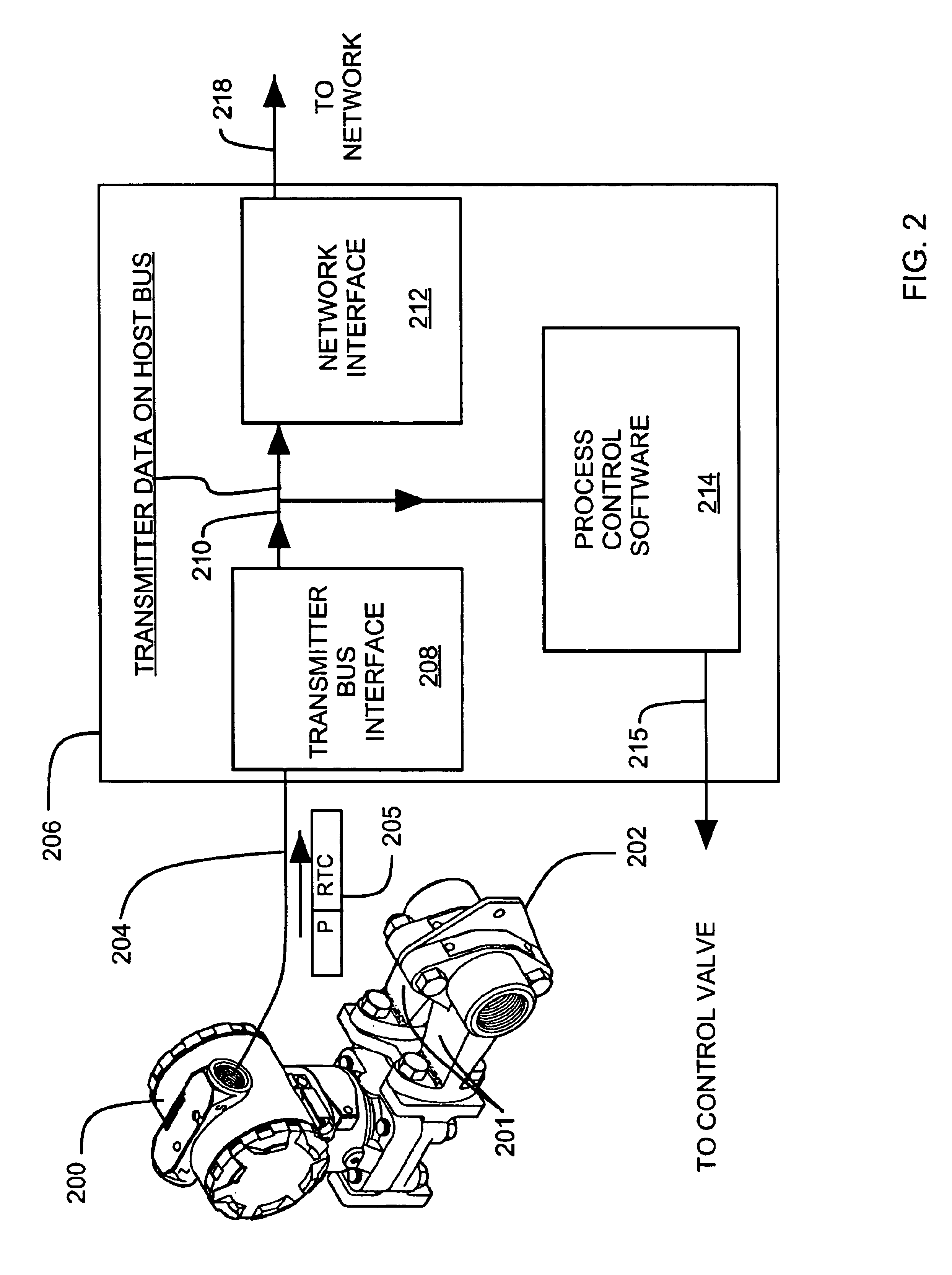

Flow diagnostic system

InactiveUS6907383B2Sampled-variable control systemsFlow control using electric meansMoving averageReal-time clock

A flow diagnostic system for a flow sensing element and impulse lines. A pressure transmitter coupled to the impulse lines provides digital pressure data to a control system. The control system provides the pressure data and real time clock readings to a diagnostic application. The diagnostic application calculates a difference between current pressure data and its moving average. A condition of the primary element or impulse lines is diagnosed from a current pressure data set relative to an historical data set. The diagnostic application is downloadable from an application service provider (ASP). The application can run on the control system, a remote computer or the ASP. A diagnostic report is preferably provided.

Owner:ROSEMOUNT INC

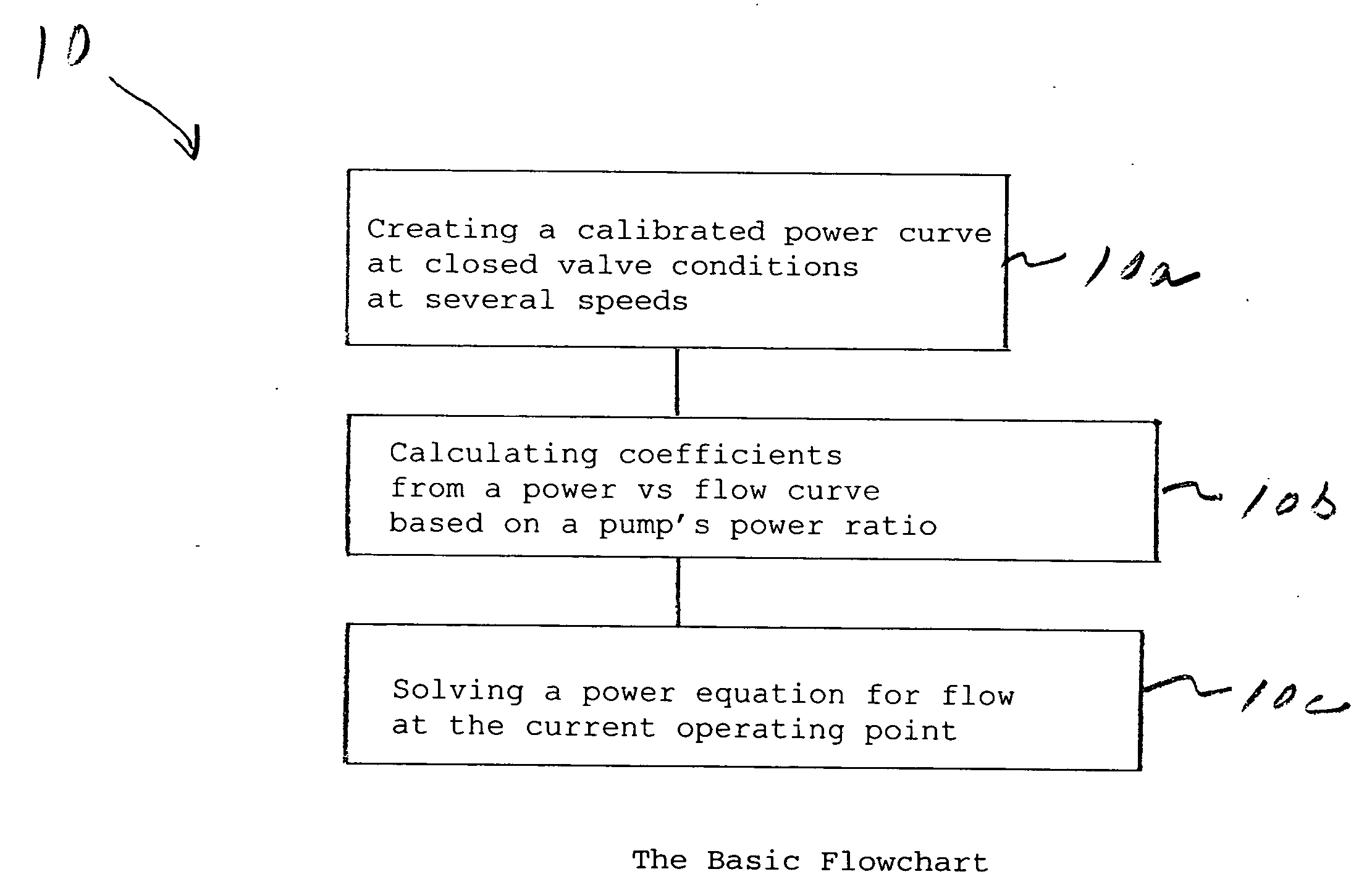

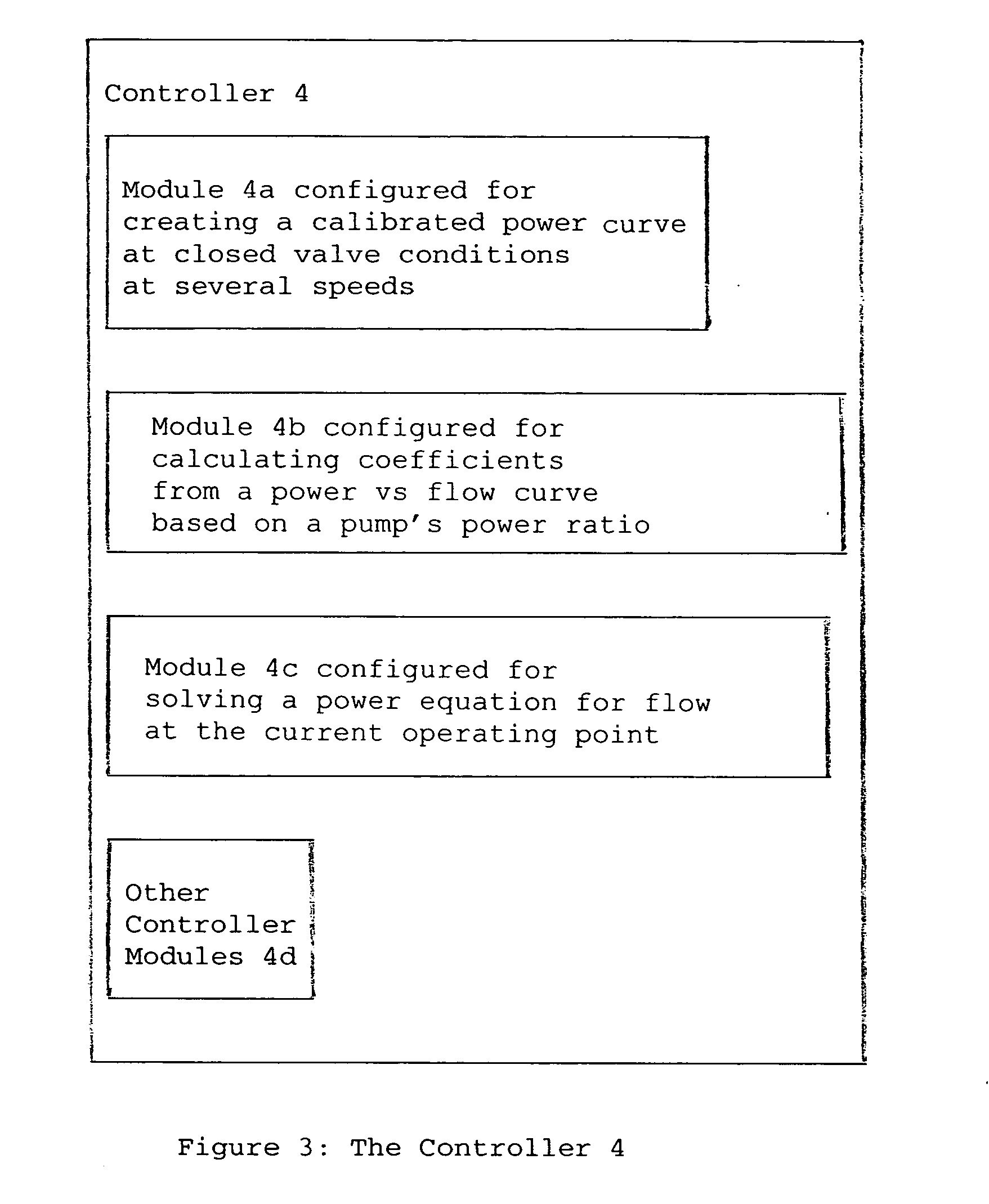

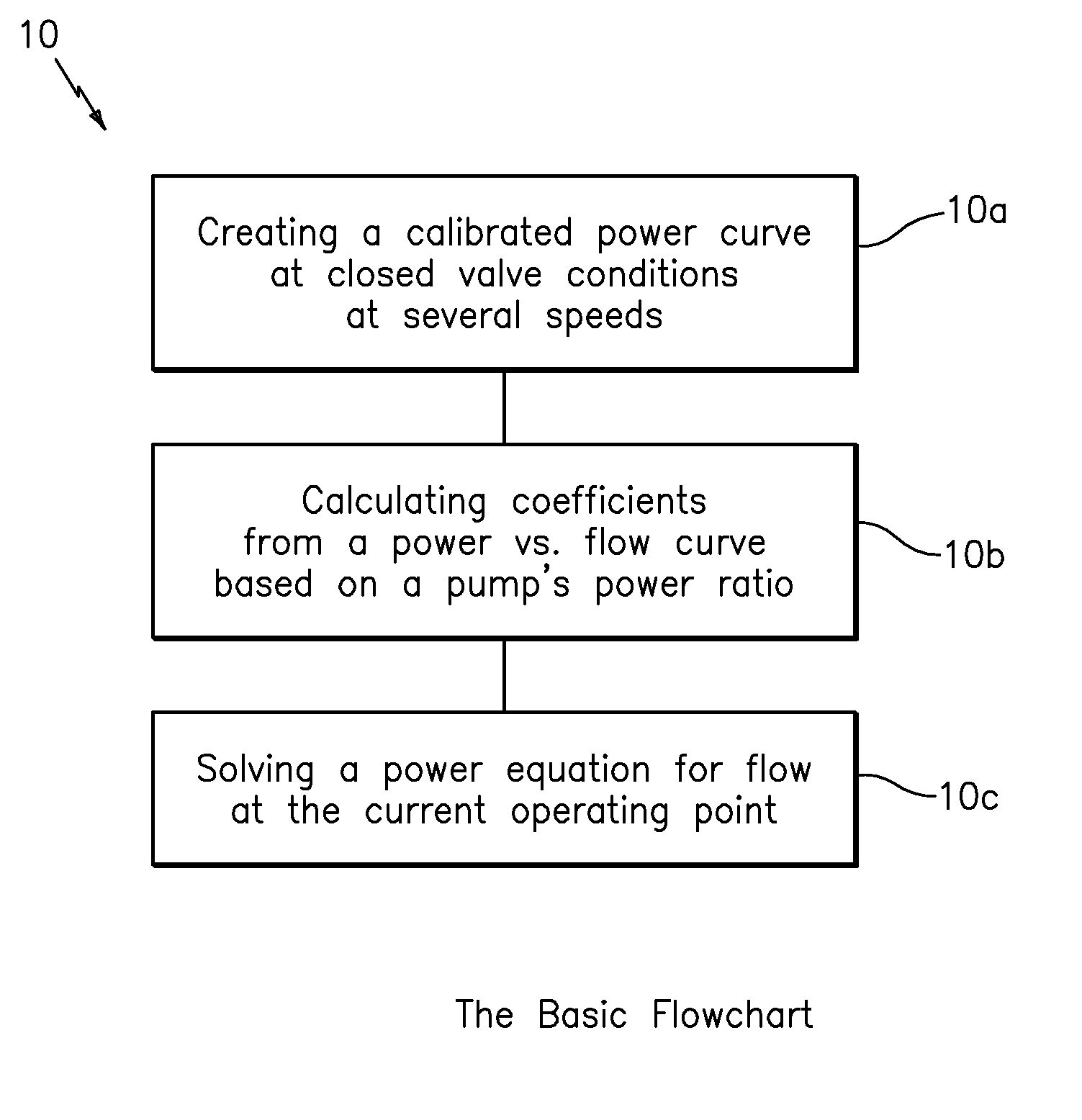

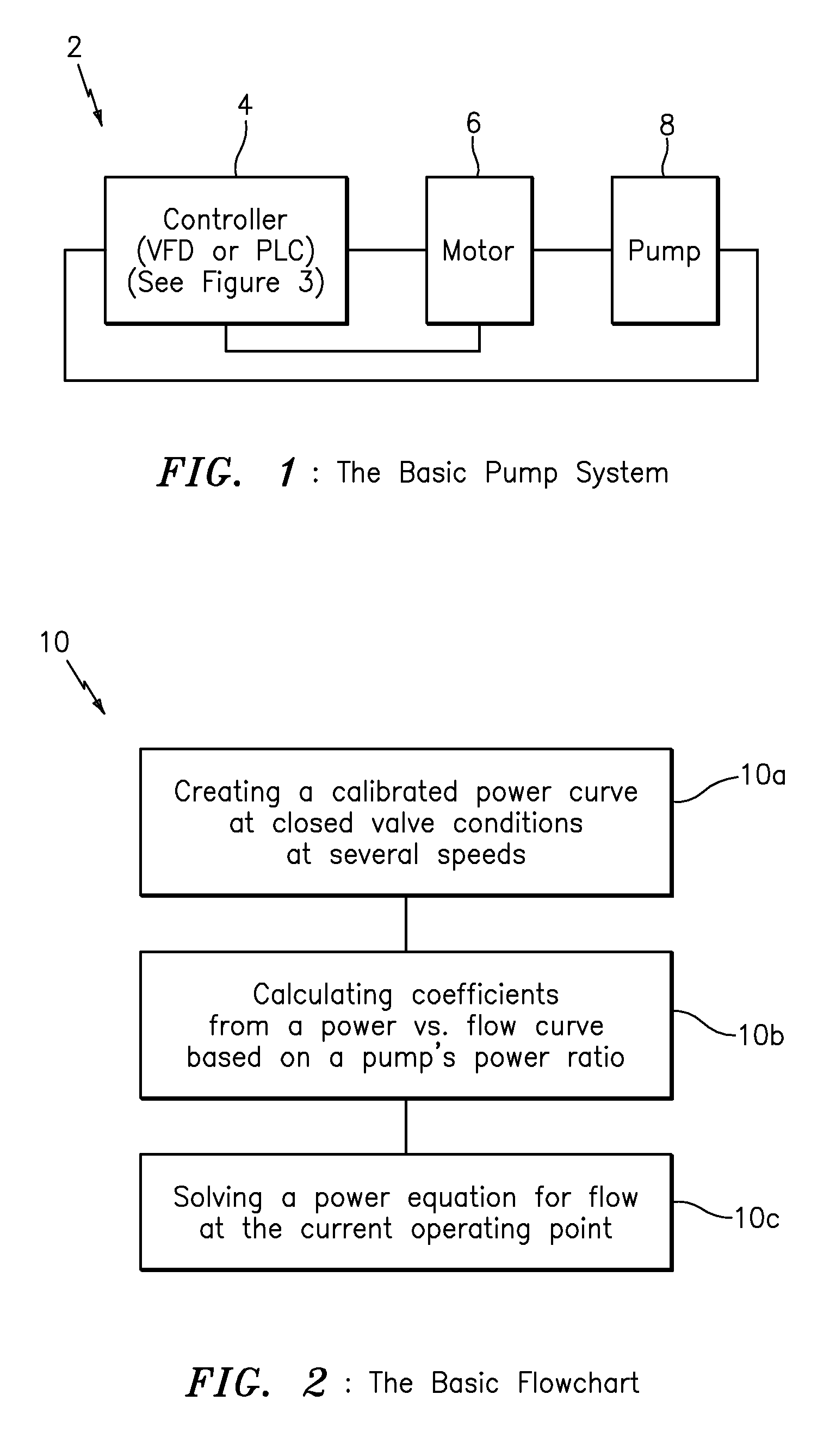

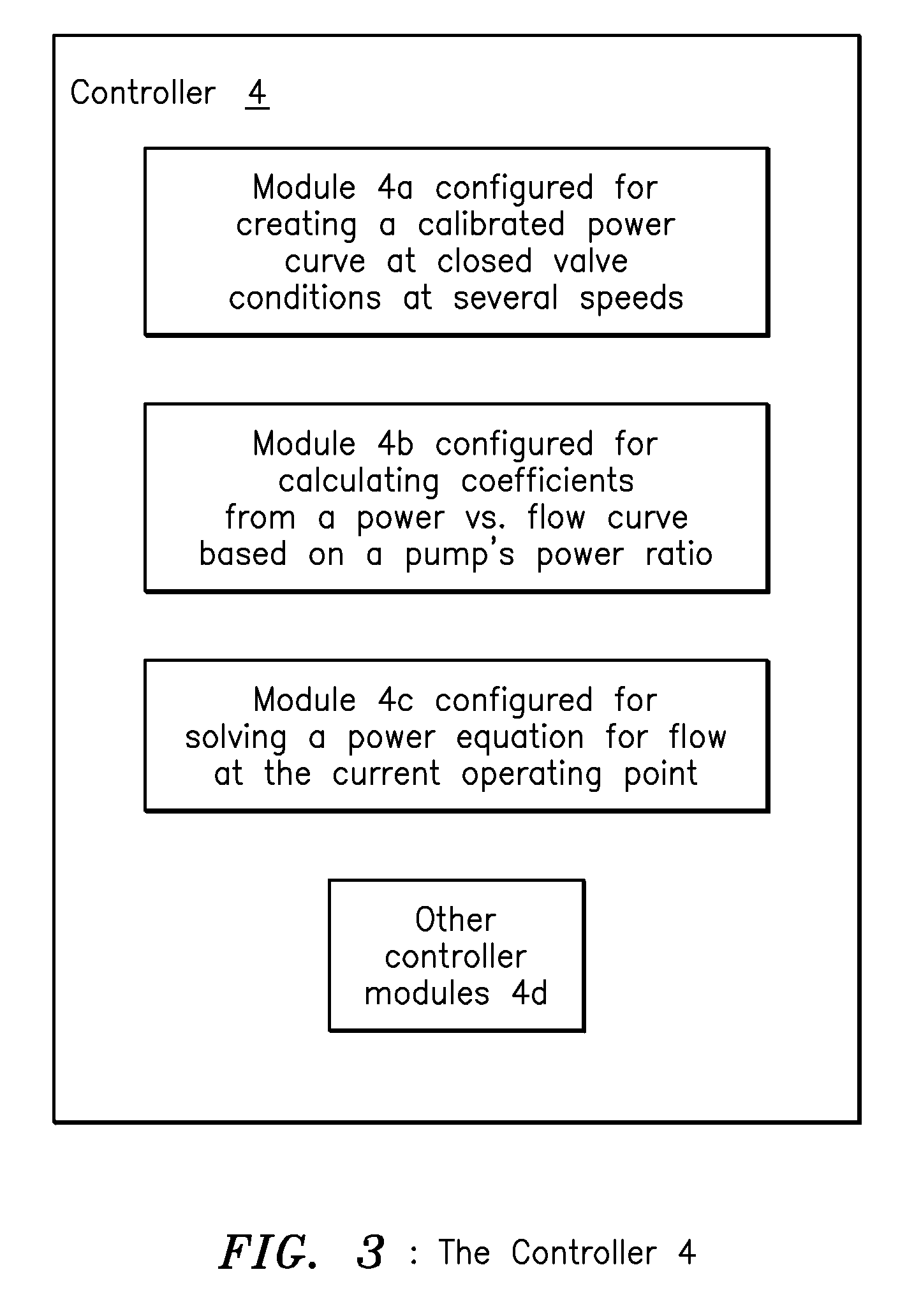

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

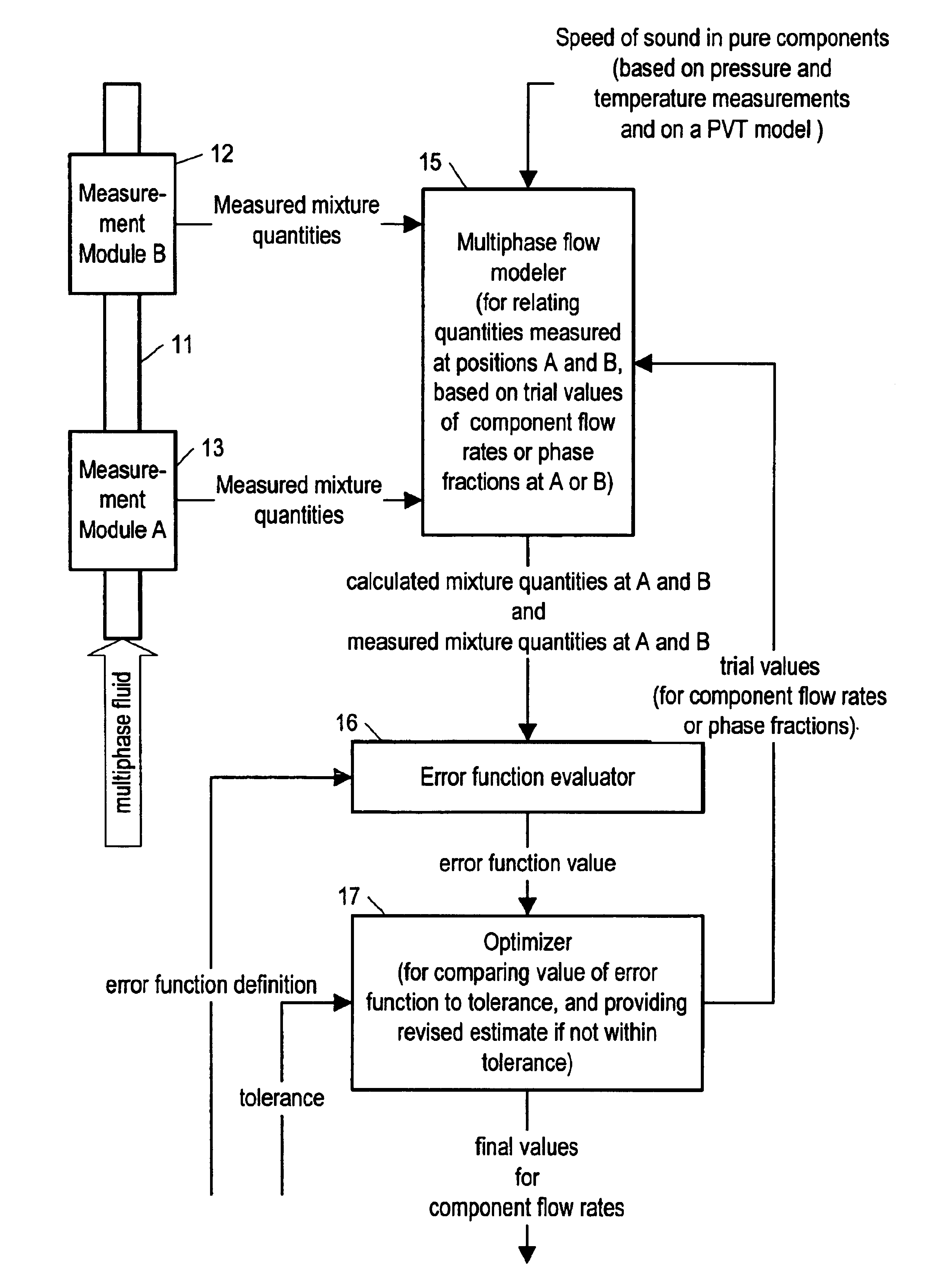

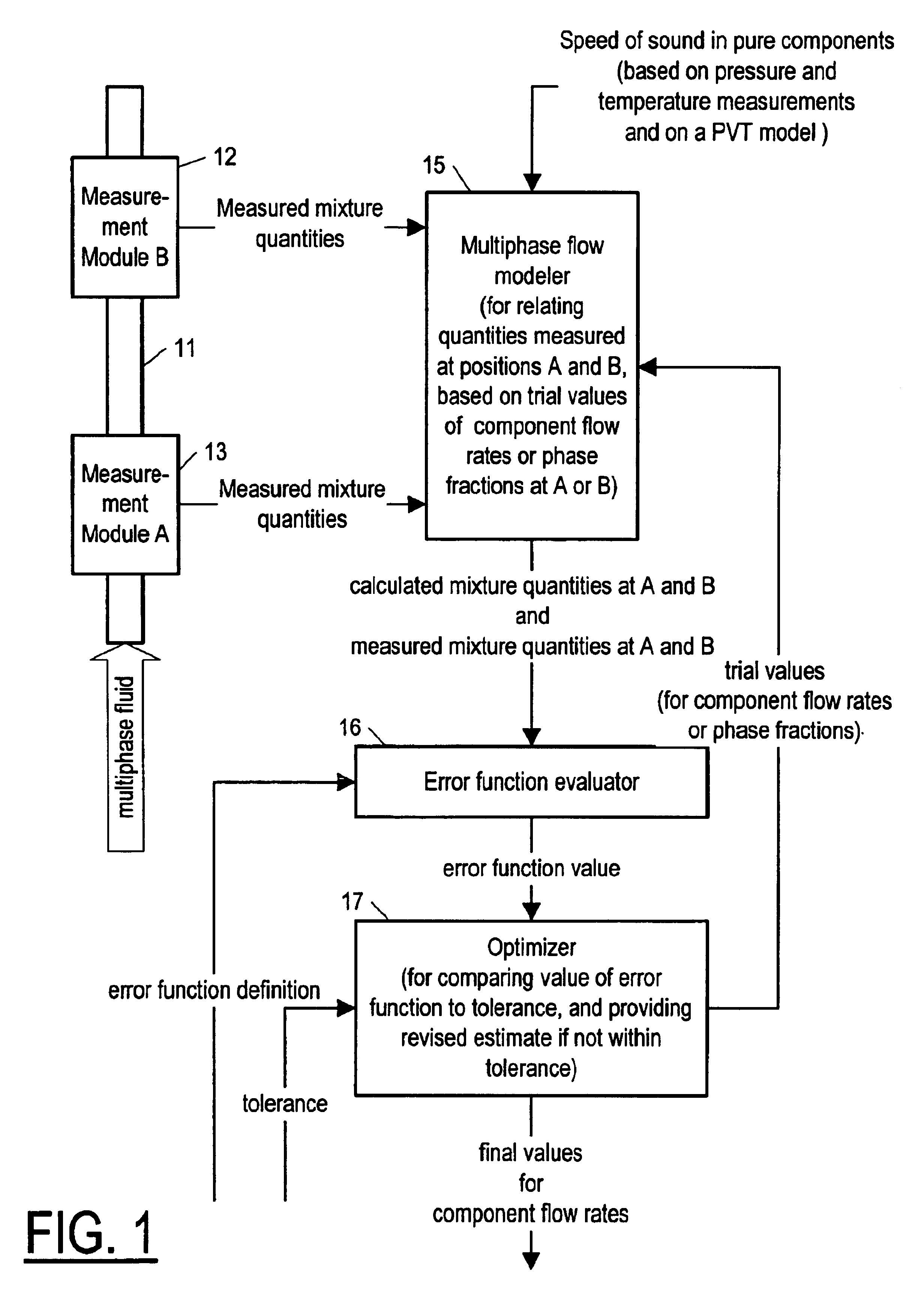

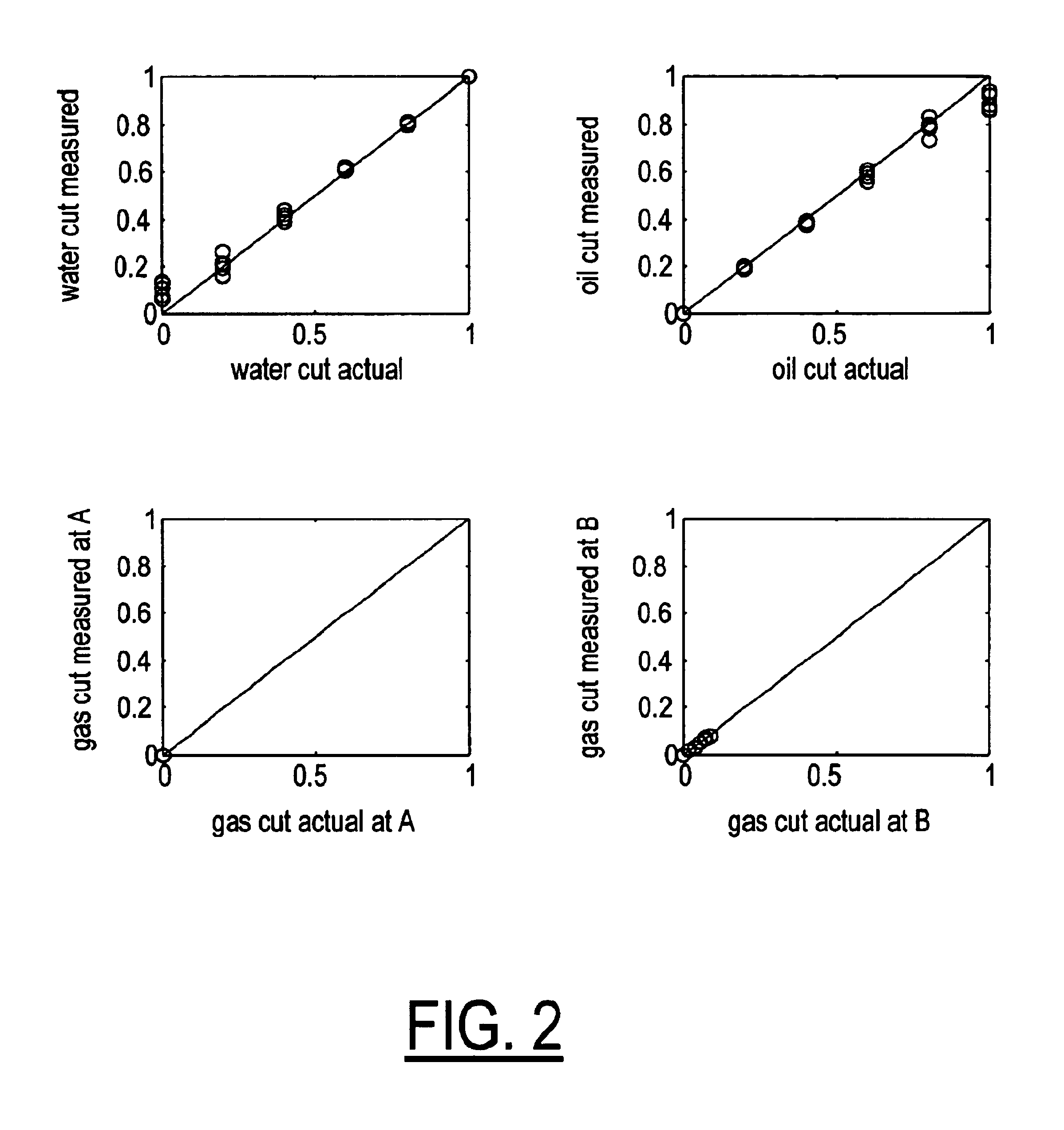

Method and apparatus for determining component flow rates for a multiphase flow

An apparatus and corresponding method for determining component flow rates of a multiphase fluid in a conduit, the fluid consisting of at least three known components, the method including the steps of: measuring at each of two different positions along the conduit at least four mixture quantities, typically the sound speed, the flow velocity of the multiphase fluid, the pressure and the temperature; providing a speed of sound in each of the components at the measured pressures and temperatures; providing a trial value for each of either the component flow rates or the phase fractions; using a predetermined model to calculate values for the measured mixture quantities based on the trial values for each of either the component flow rates or the phase fractions; using a predetermined error function to determine an error value; and using a predetermined optimizing algorithm to determine whether the calculated values are acceptable, and, if they are not, to provide a new trial value for each of either the component flow rates or the phase fractions. In some applications, the error function is the sum of the squares of the difference between the measured and calculated values at each point.

Owner:WEATHERFORD TECH HLDG LLC

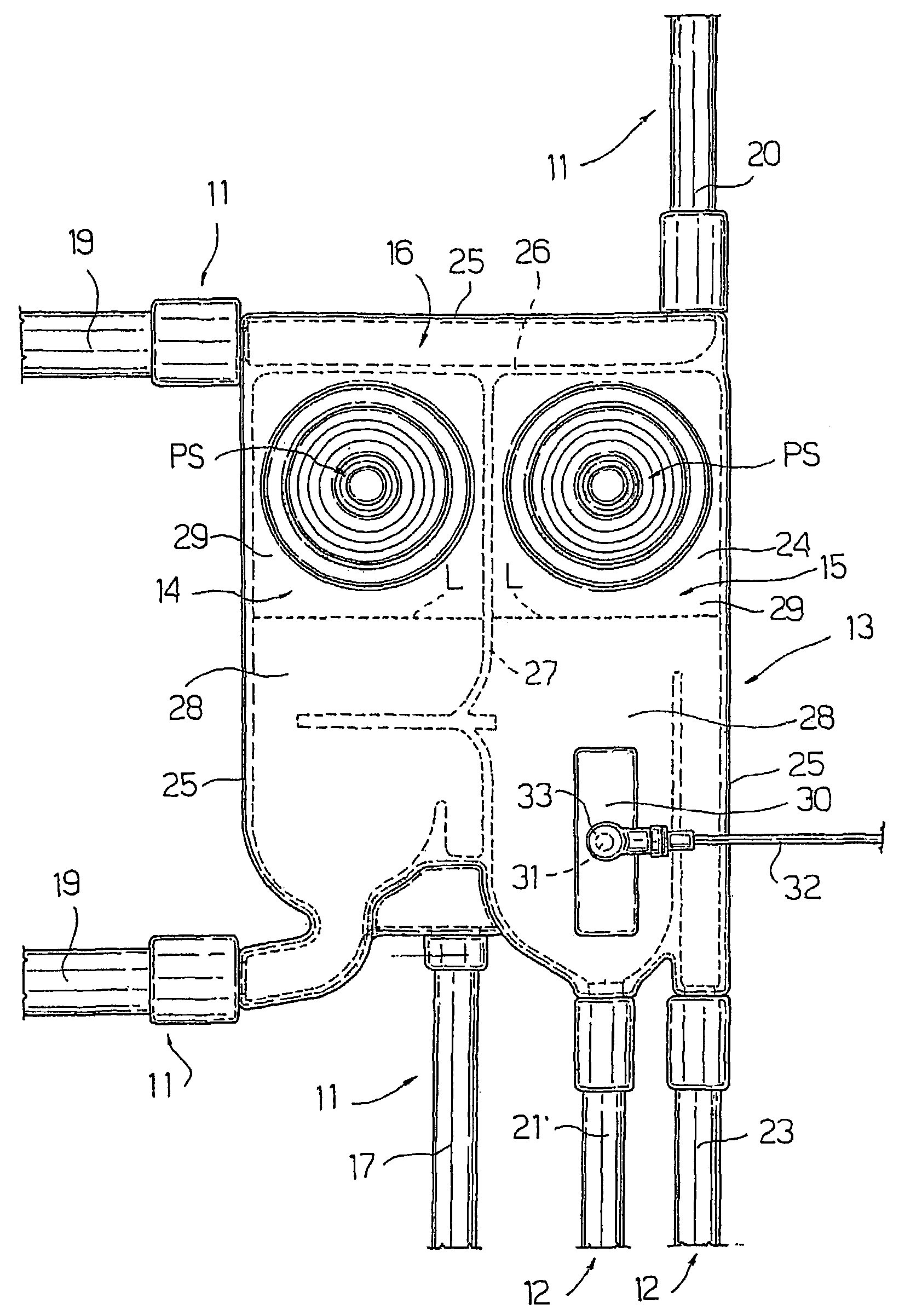

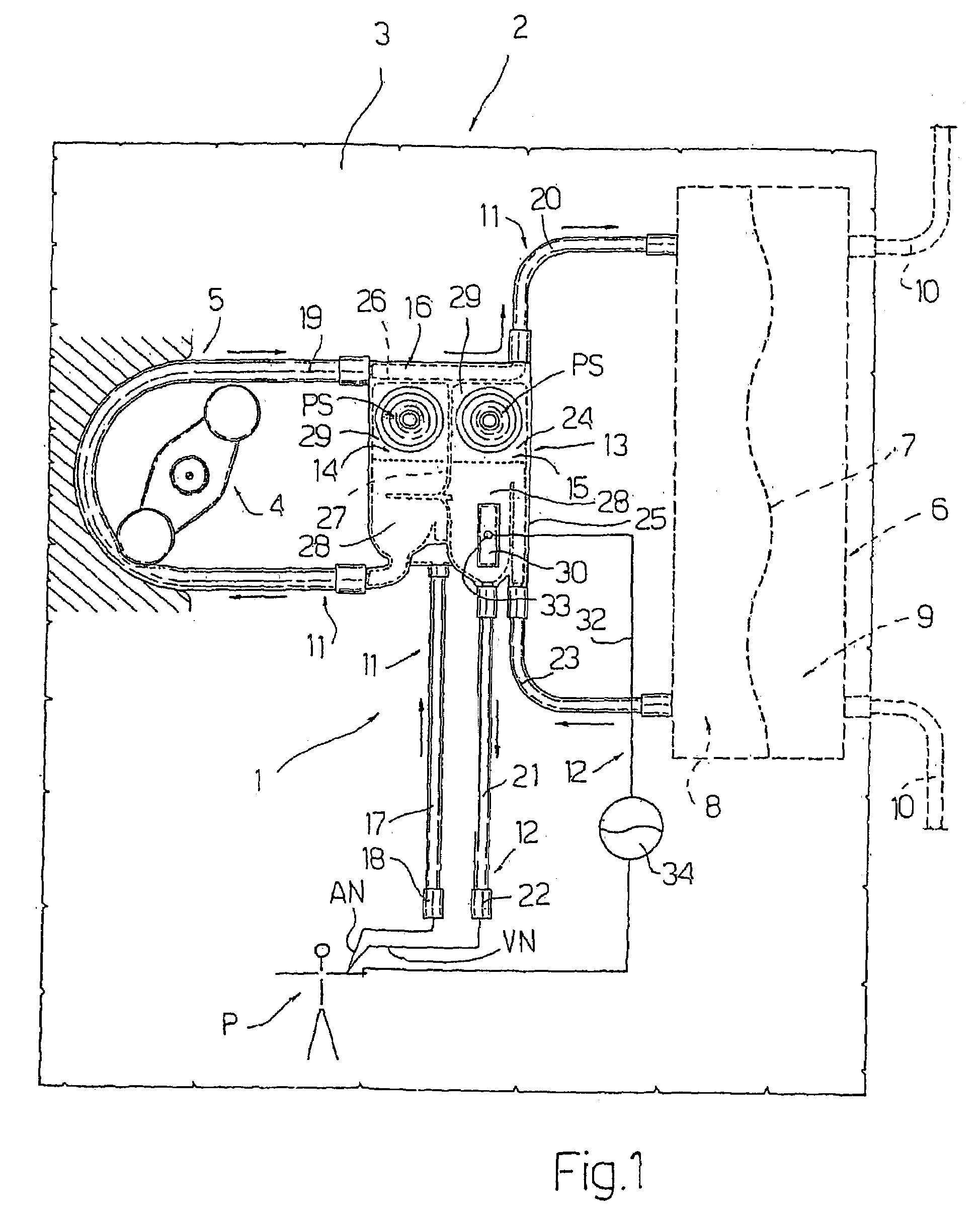

Blood circuit for a dialysis machine and corresponding dialysis machine

InactiveUS7115107B2Practical and convenientSimple methodSemi-permeable membranesOther blood circulation devicesDielectricVoltage generator

A blood circuit (1) for a dialysis machine is made form plastic material and is provided with a metallic plate (30), which is applied to an external face of the blood circuit (1) and is connectable to a voltage generator (34) in such a way as to form a capacitor, in which the plate (30) and the blood act as the capacitor plates and the plastic material acts as the dielectric.

Owner:GAMBRO LUNDIA AB

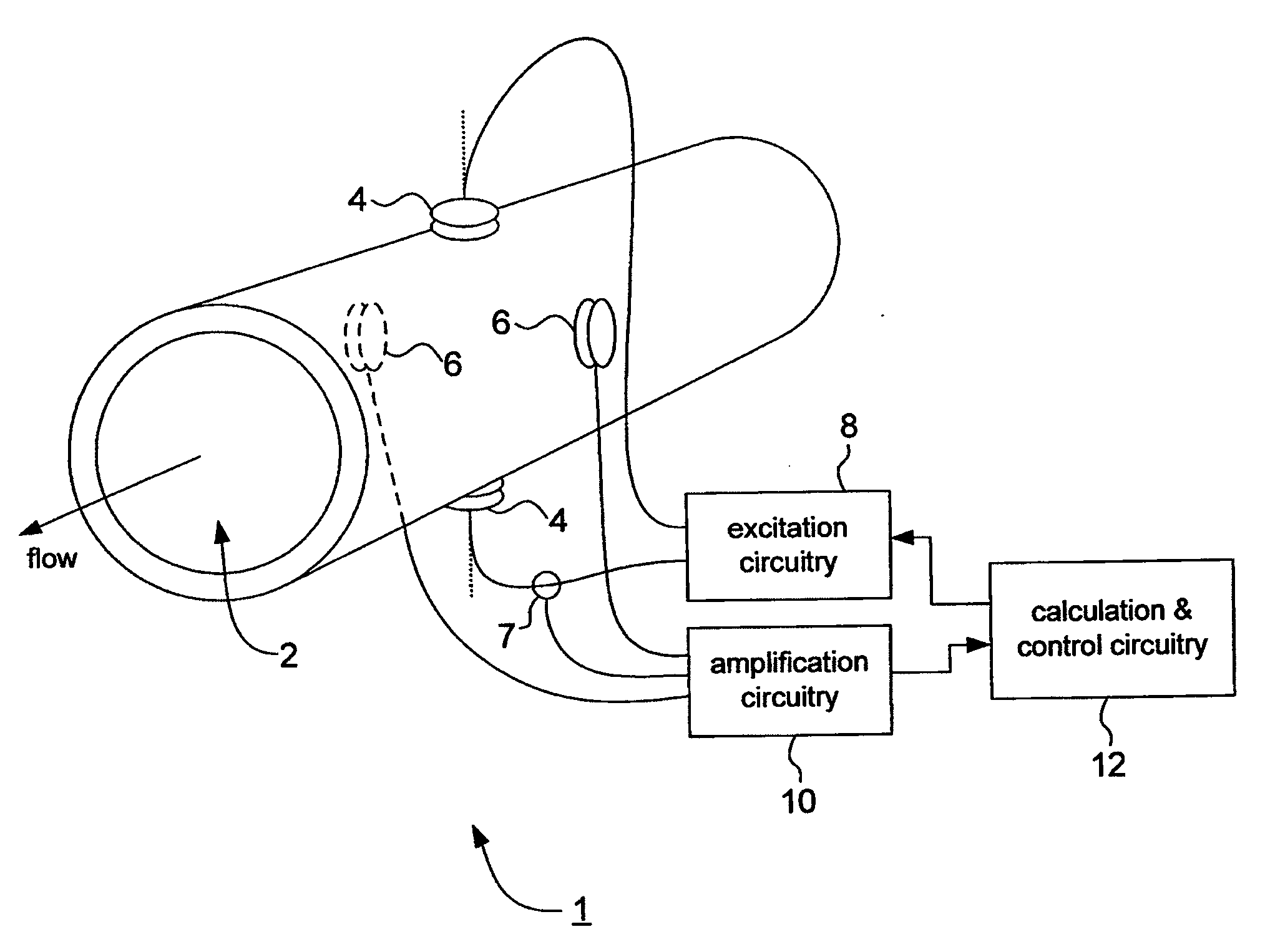

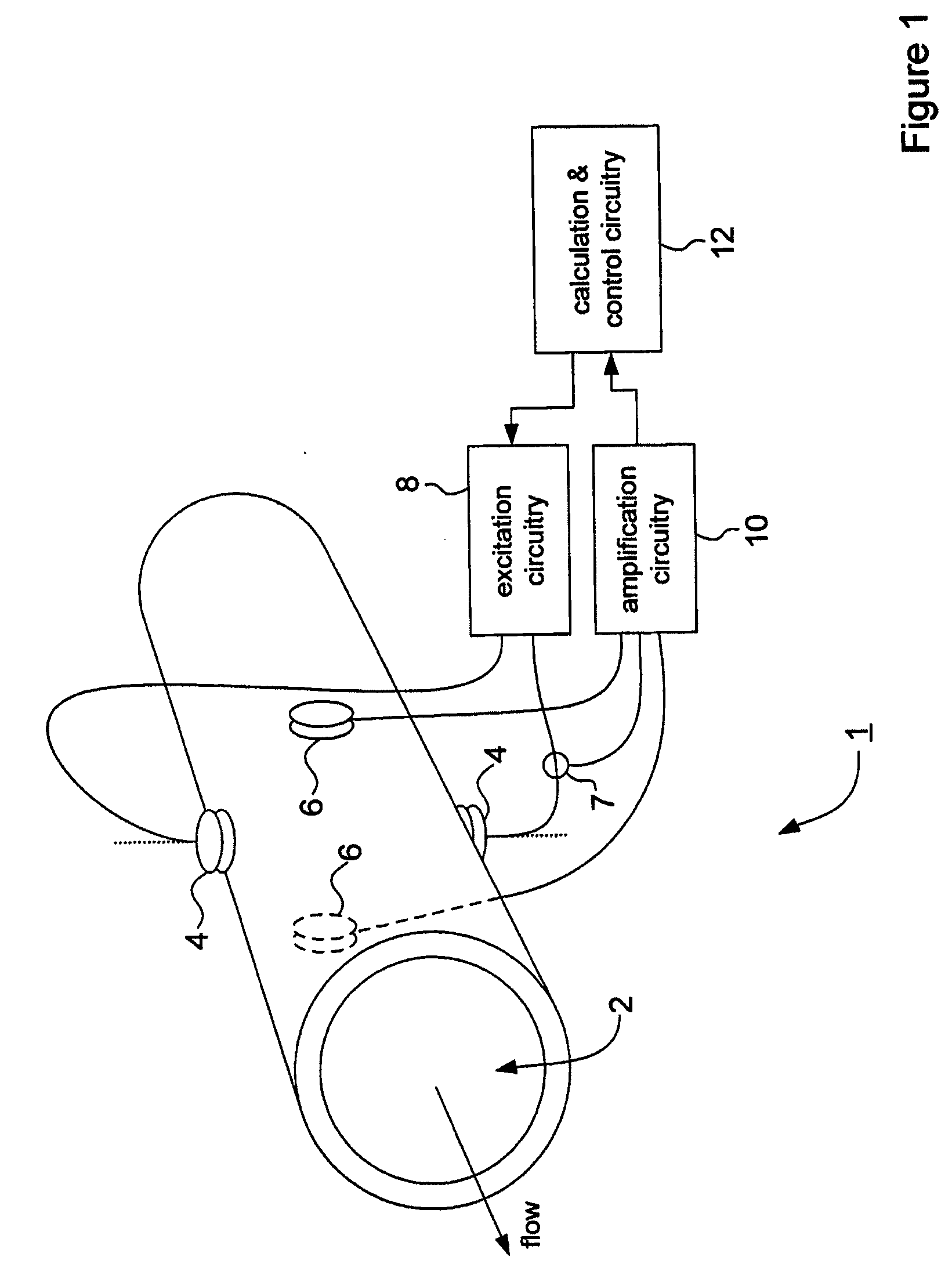

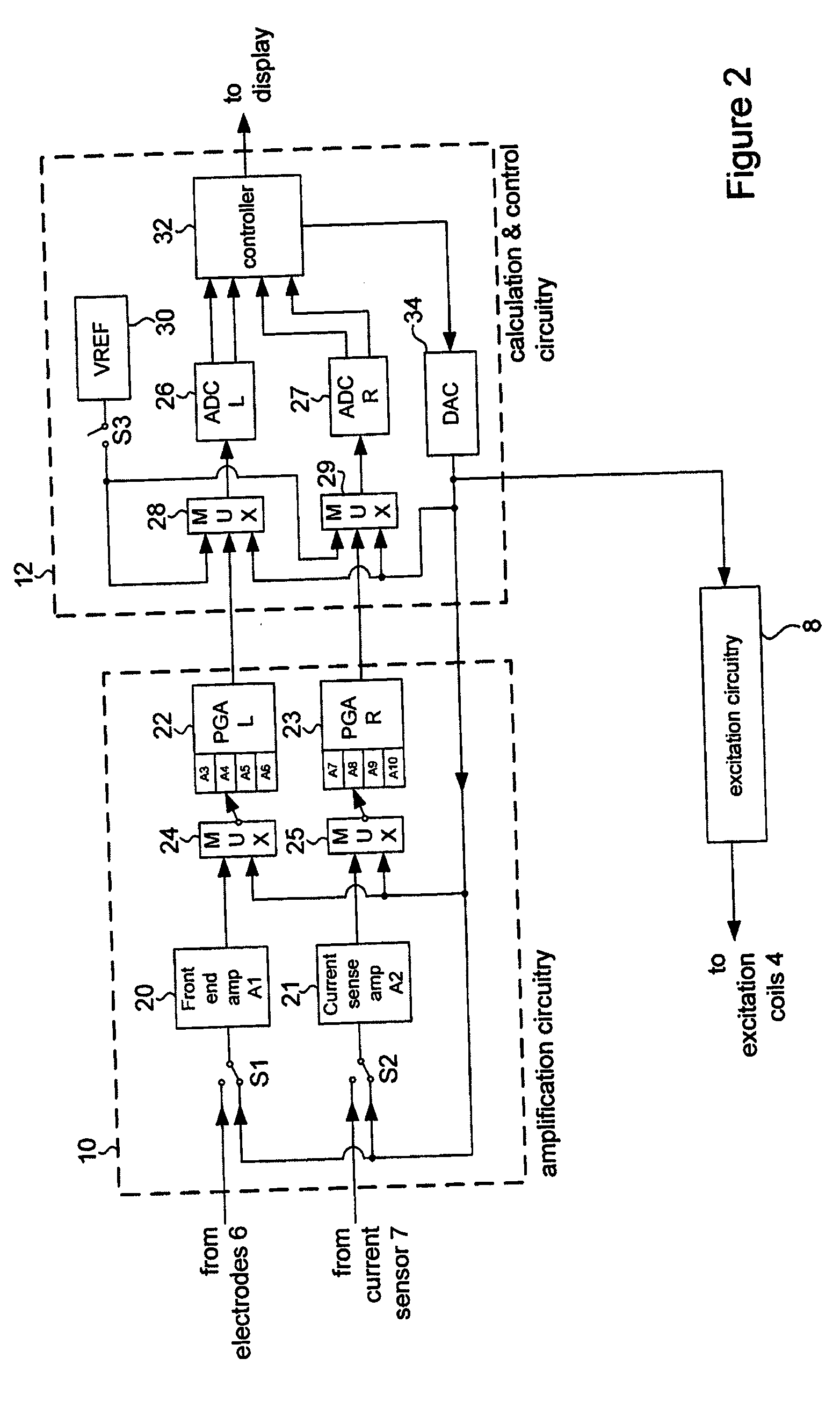

Flowmeter

ActiveUS20090071264A1Interference minimizationReduce the amount requiredFluid pressure measurementTesting/calibration for volume flowElectromagnetic fieldStreamflow

An electromagnetic flowmeter assembly is described in which an excitation field is set up across a flow conduit and electrodes are used to sense the electromagnetic field generated across the flow conduit as a result of interaction between the excitation field and fluid flowing along the flow conduit. The signals obtained from the electrodes are processed, together with stored calibration data, by processing circuitry to determine flow measurements and means is provided for dynamically updating the calibration data.

Owner:ABB LTD

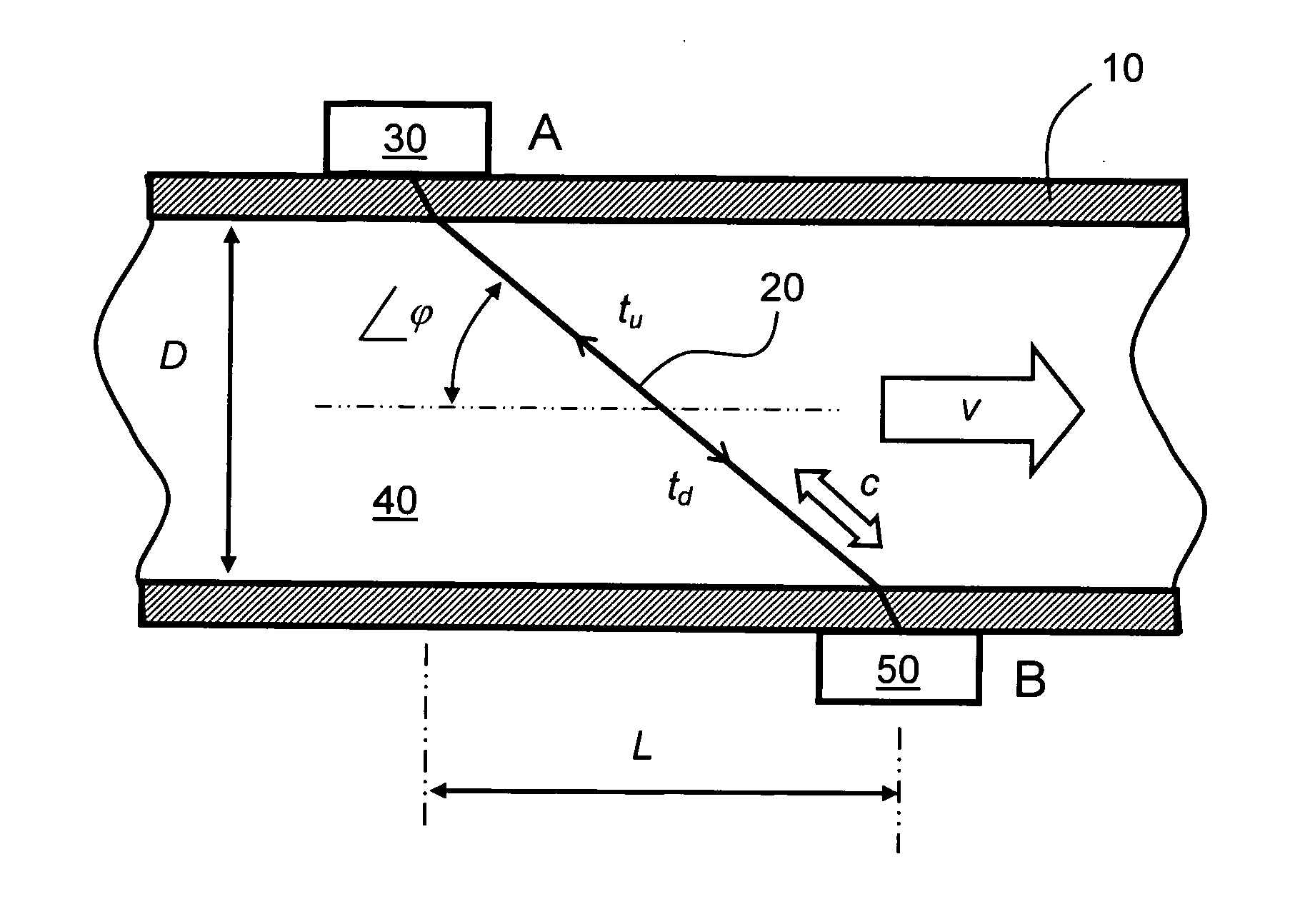

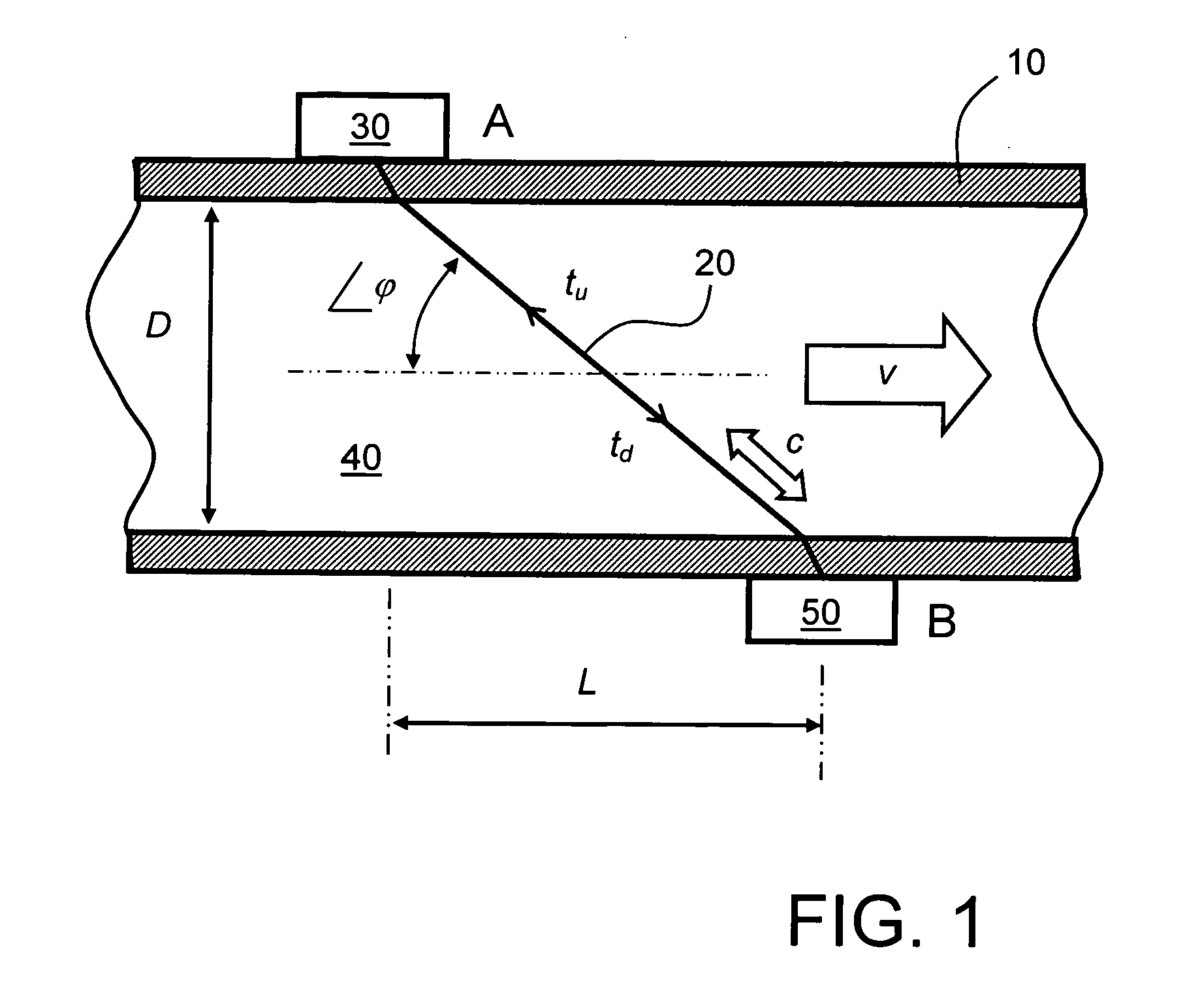

Flow measuring apparatus

ActiveUS20110271769A1Reliable and accurate measurementImprove energy transferFlow propertiesVolume flow measuring devicesPropagation timeUltrasonic radiation

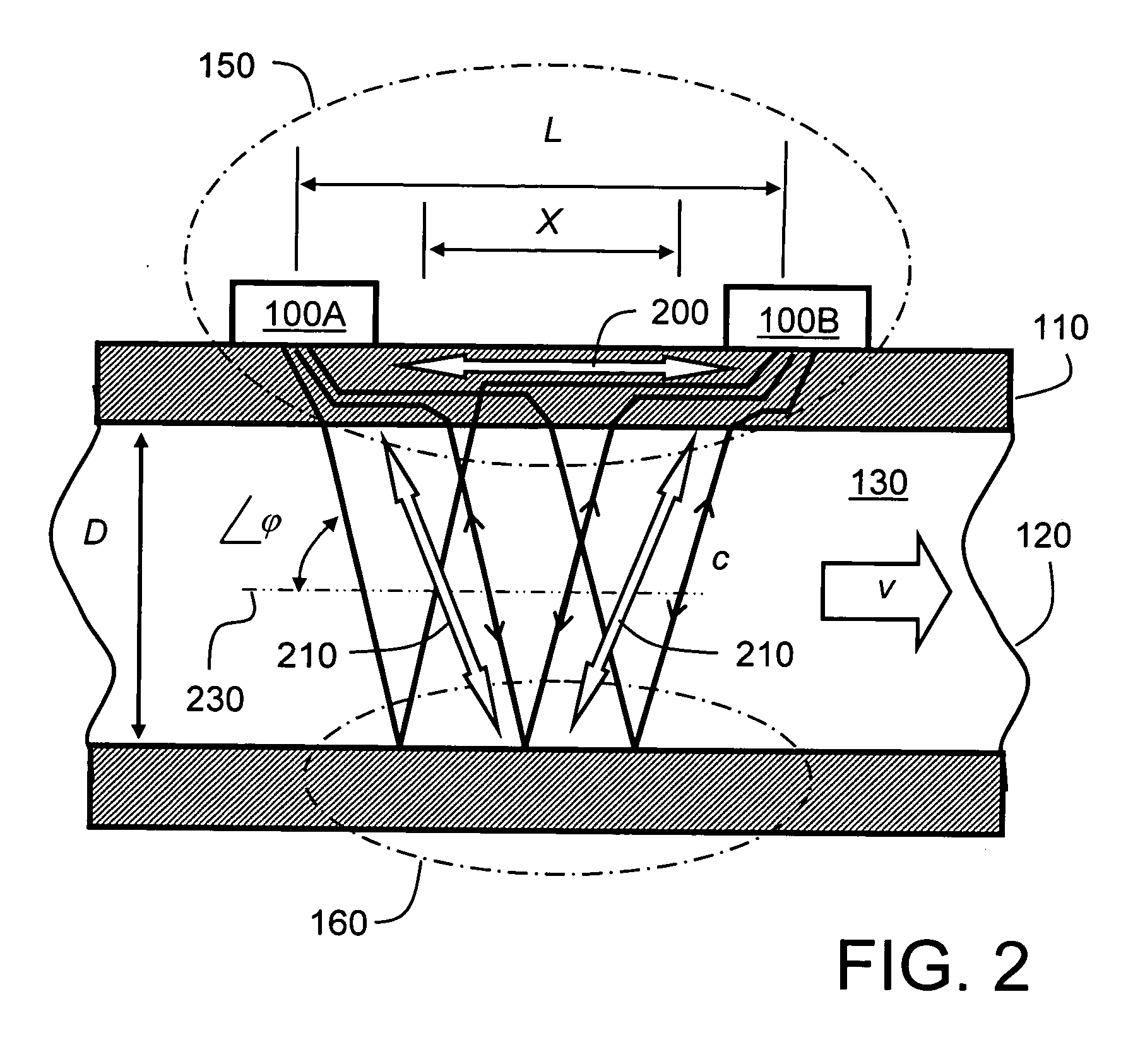

A flow measuring apparatus (300, 500) measures a fluid flow (130) within a conduit (120) including a wall (110). The apparatus (300, 500) includes a transducer arrangement including at least two transducers (100A, 100B) for alternately emitting and receiving ultrasonic radiation through the conduit wall (110) and the flow (130). The apparatus (300, 500) also includes a signal processing arrangement (310) for generating signals to excite the transducer arrangement (100A, 100B) and for processing received signals provided by the transducer arrangement (100A, 100B) for generating output signals from the signal processing arrangement (310) indicative of properties of the flow. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides a first path (200) for Lamb-wave ultrasonic radiation coupling directly from a first of the at least two transducers (100A, 100B), to a second of said at least two transducers to generate a first received signal. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides at least one second path (210) for ultrasonic propagation along the wall (100) via Lamb waves coupling to at least a portion of the flow (130) from a first of the at least two transducers (100A, 100B) to a second of the at least two transducers (100A, 100B) to generate a second received signal. The signal processing arrangement (310) determines from said first and second received signals ultrasonic radiation propagation time periods through the first path (200) and through the at least one second path (210), and to perform computational operations on the propagation time periods to determine properties of the flow including, but not limited to, at least one of: fluid flow velocity (v) in the conduit (120), a sound velocity (c) through the fluid (130).

Owner:XSENS

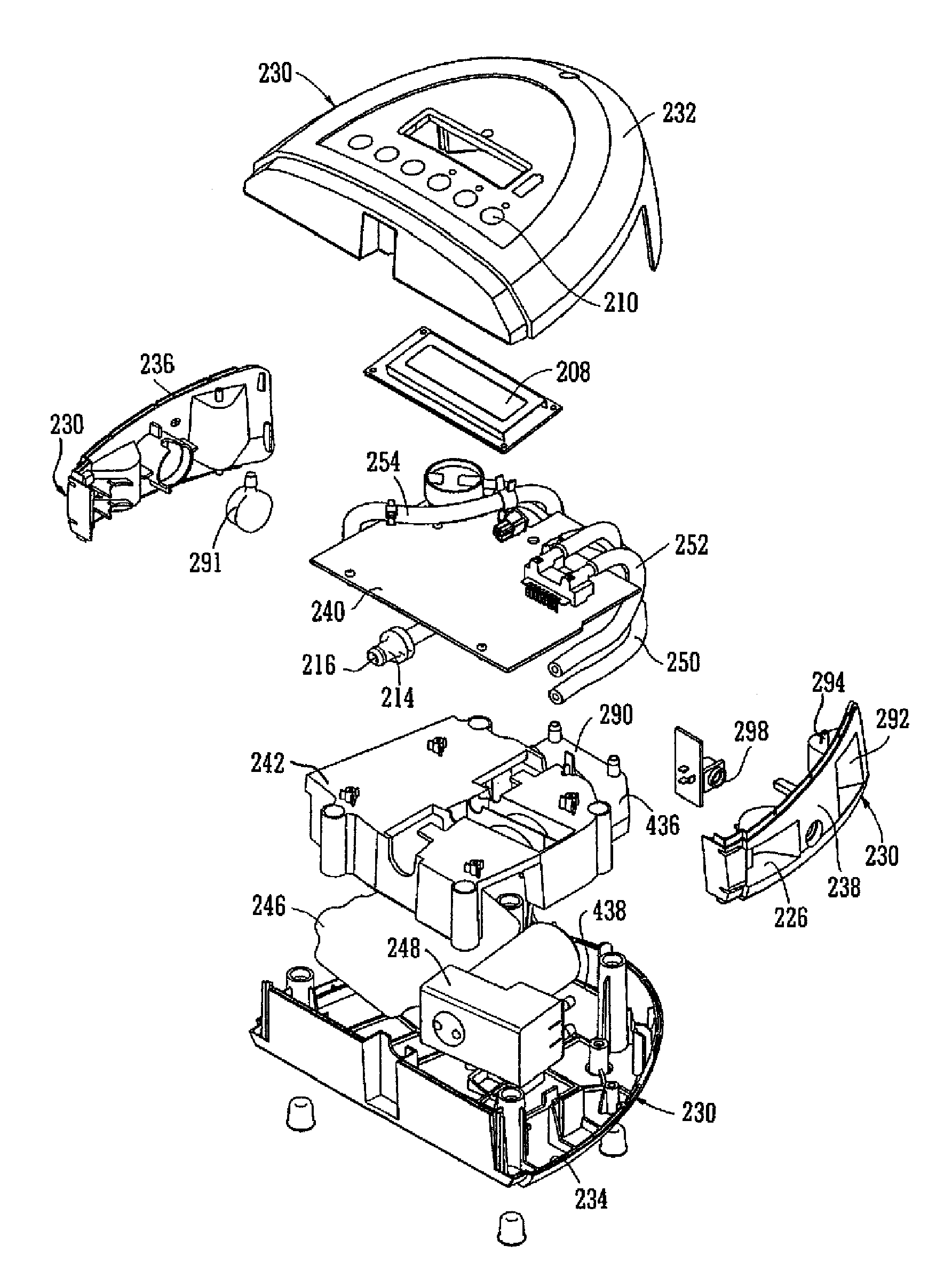

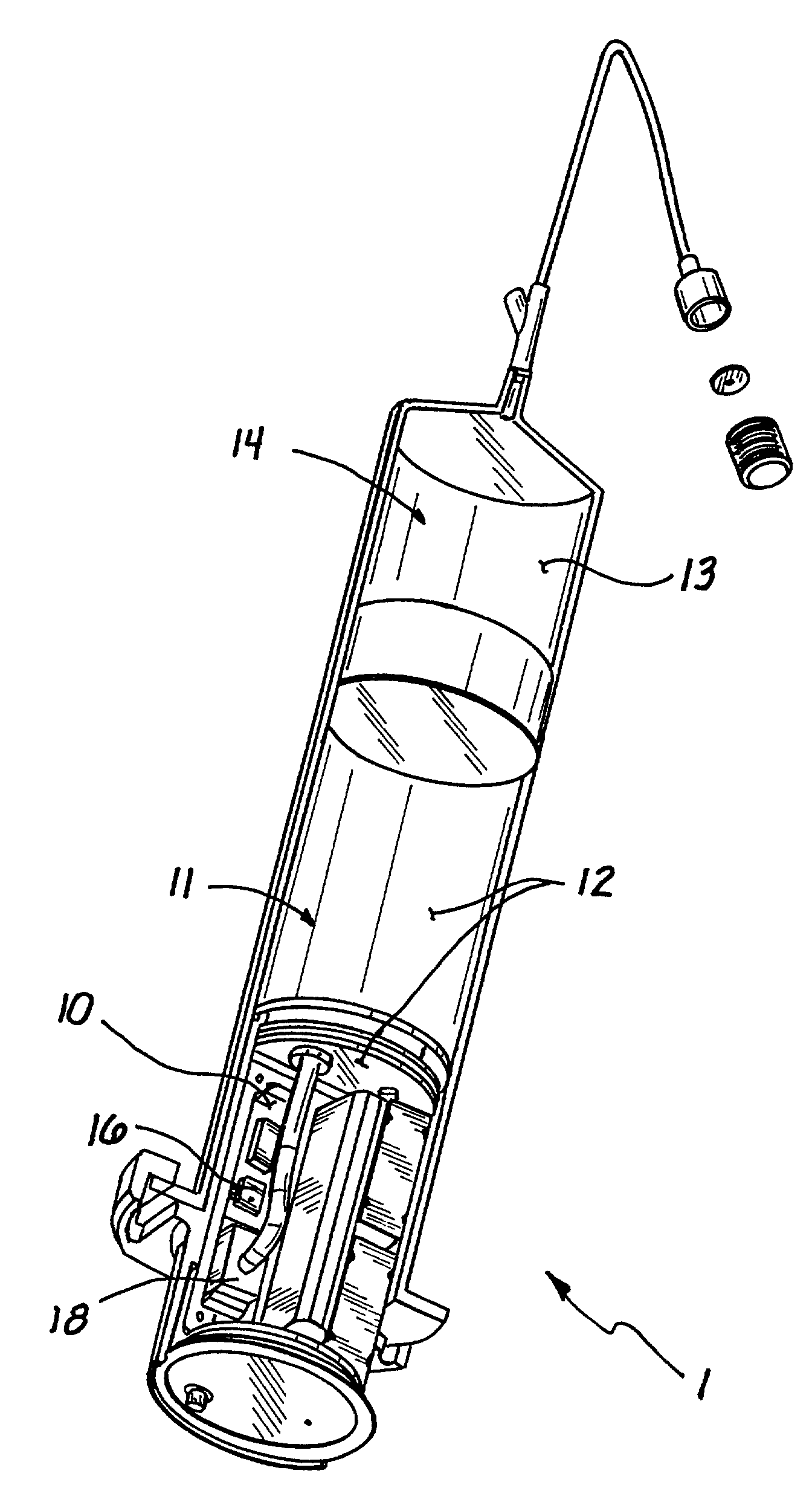

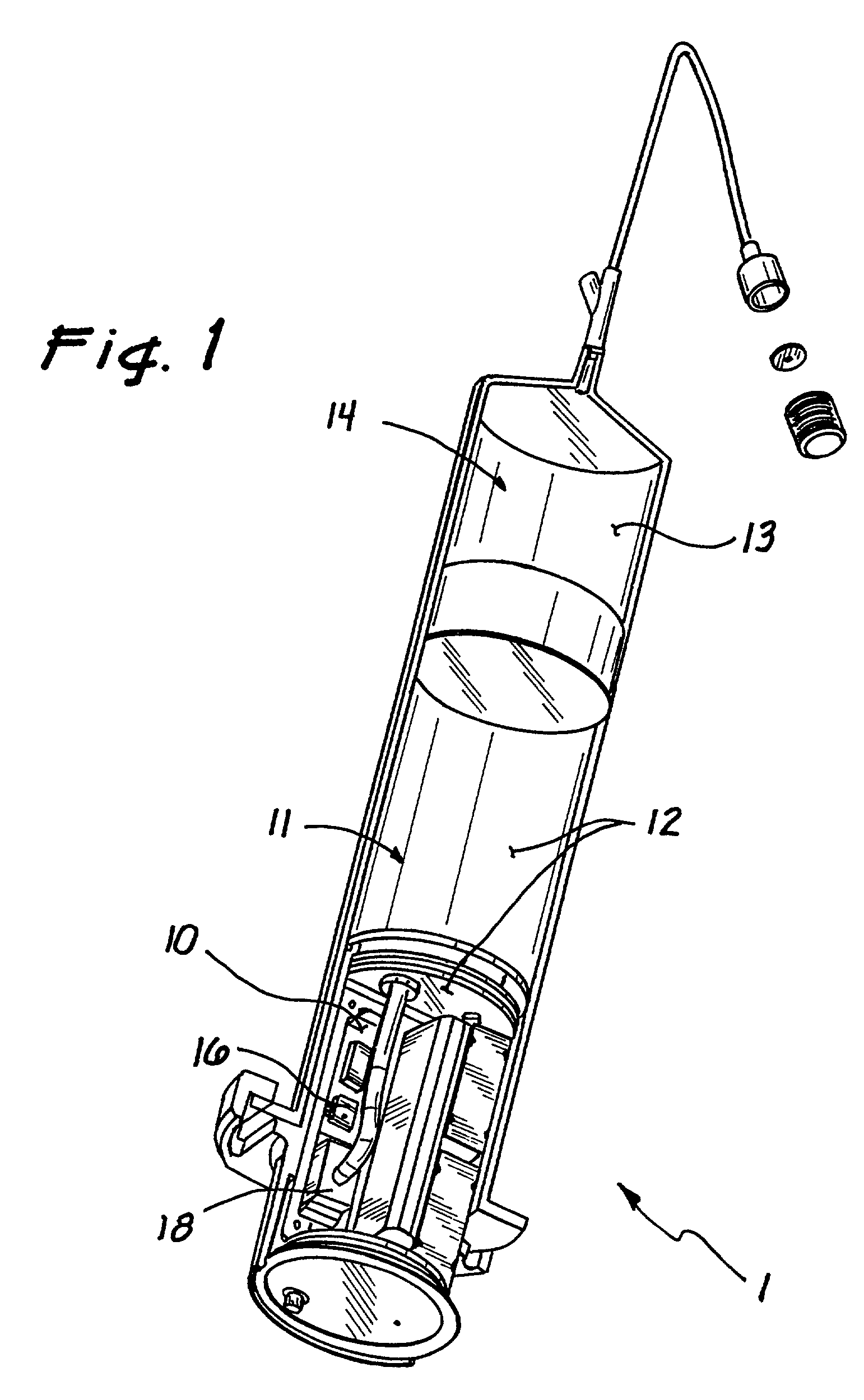

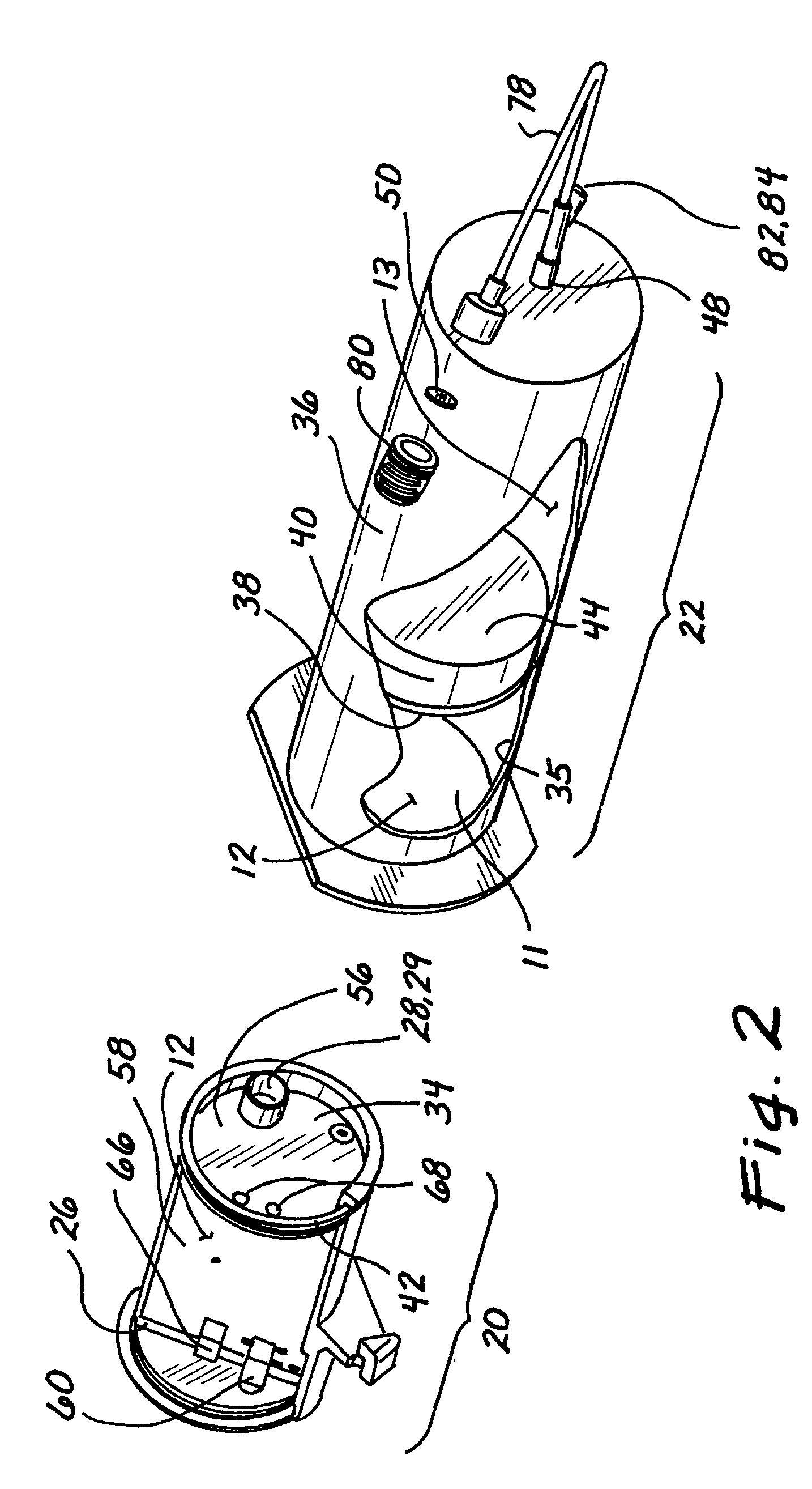

Infusion pump and method for use

InactiveUS7008403B1Small and lightLess componentsContracting/expanding measuring chambersVolume variation compensation/correction apparatusSolenoid valveContact method

A fluid dispensing system provides a non-contact method of monitoring the change in the fluid volume over time. This approach avoids the use of probes or sensors that come into direct contact with the fluid to be dispensed. The system comprises an apparatus comprising three chambers. The first chamber has a fixed volume and contains a pressurized gas. A solenoid valve is used to control the flow of gas from the first chamber into the second. The second chamber is sealed so that the combined mass of air in the first and second chambers remains fixed. The third chamber is adjacent to the second and contains medication in the form of incompressible fluid that is to be administered to a human or animal subject via a suitable delivery port. A piston is disposed between the second and third chambers and is movable responsive to the flow of gas into the second chamber to dispense fluid from the third chamber as desired. By sensing the pressure in the first and second chambers at any point in time, a processor is programmed to calculate the flow rate or dispensed volume of the fluid being delivered using principles derived from the Ideal Gas Law.

Owner:TANDEM DIABETES CARE INC

Medicament dosing system

InactiveUS6129702ALow production costFunction increaseFlow control using electric meansVolume measurement and fluid deliveryBiomedical engineeringResistor

PCT No. PCT / EP97 / 06574 Sec. 371 Date Jun. 6, 1999 Sec. 102(e) Date Jun. 6, 1999 PCT Filed Nov. 25, 1997 PCT Pub. No. WO98 / 24496 PCT Pub. Date Jun. 11, 1998A medicament dosing system comprises a replaceable unit and a permanent unit. The replaceable unit comprises a fluid reservoir for receiving therein a pressurizable liquid medicament, a temperature sensor for detecting the temperature of said liquid medicament, a fluid channel which is provided with a flow resistor and which is in flow communication with the fluid reservoir, and a hose means which is connected to the fluid channel. The permanent unit comprises a squeezing valve means for squeezing the hose means together, and a control means which is coupled to the temperature sensor and the squeezing valve means so as to control a flow rate of the liquid medicament by clocked actuation of said squeezing valve means depending on the temperature detected. Alternatively, the temperatur sensor can be arranged in the permanent unit.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

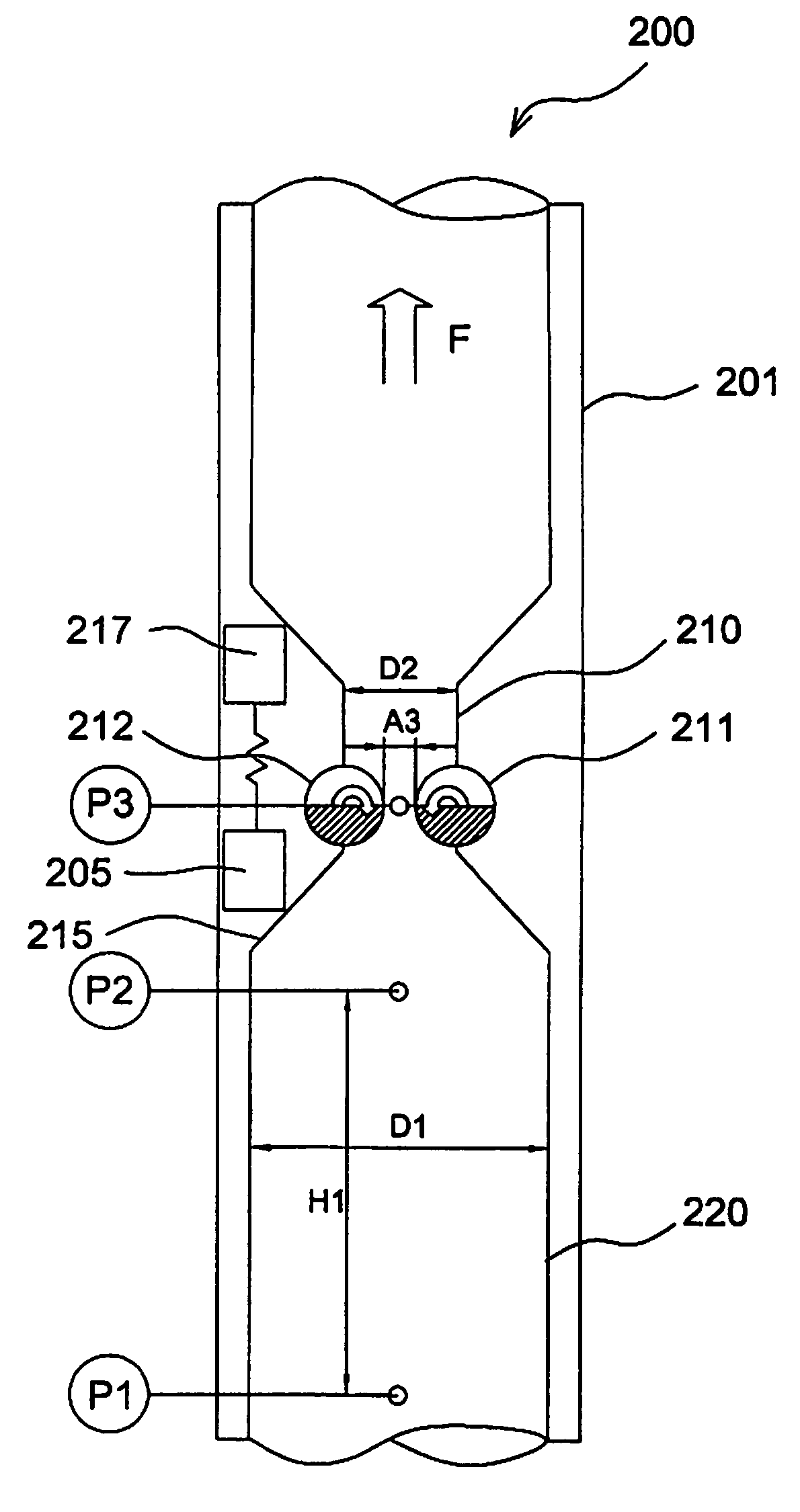

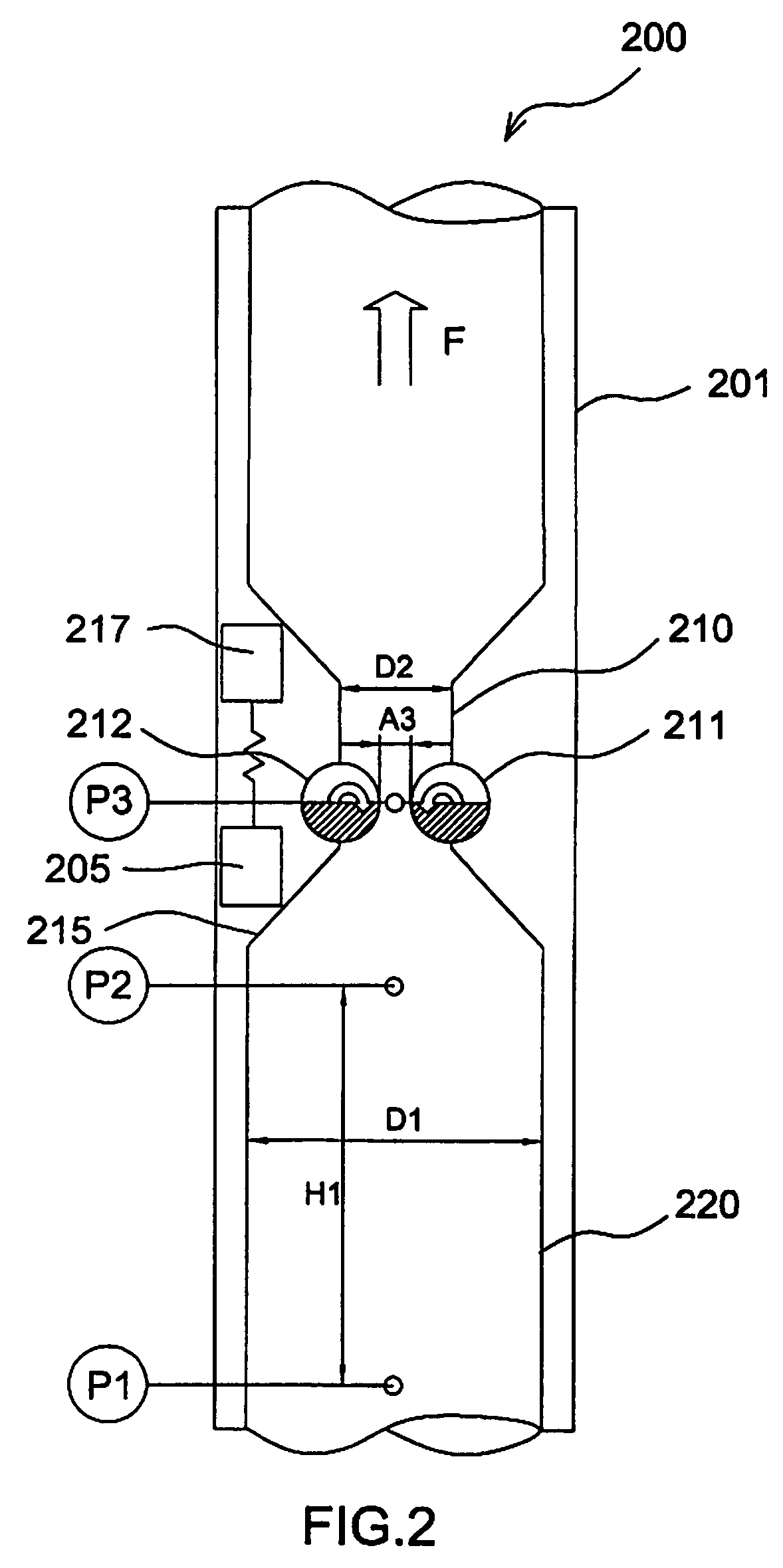

Variable throat venturi flow meter having a plurality of section-varying elements

A variable throat Venturi flow meter includes an upstream pipe section having an upstream cross-sectional area, a throat section having a variable throat cross-sectional area that is smaller than the upstream cross-sectional area, and a plurality of section-varying elements adapted to temporarily vary the throat cross-sectional area to allow a downhole tool to pass through the throat section.

Owner:SCHLUMBERGER TECH CORP

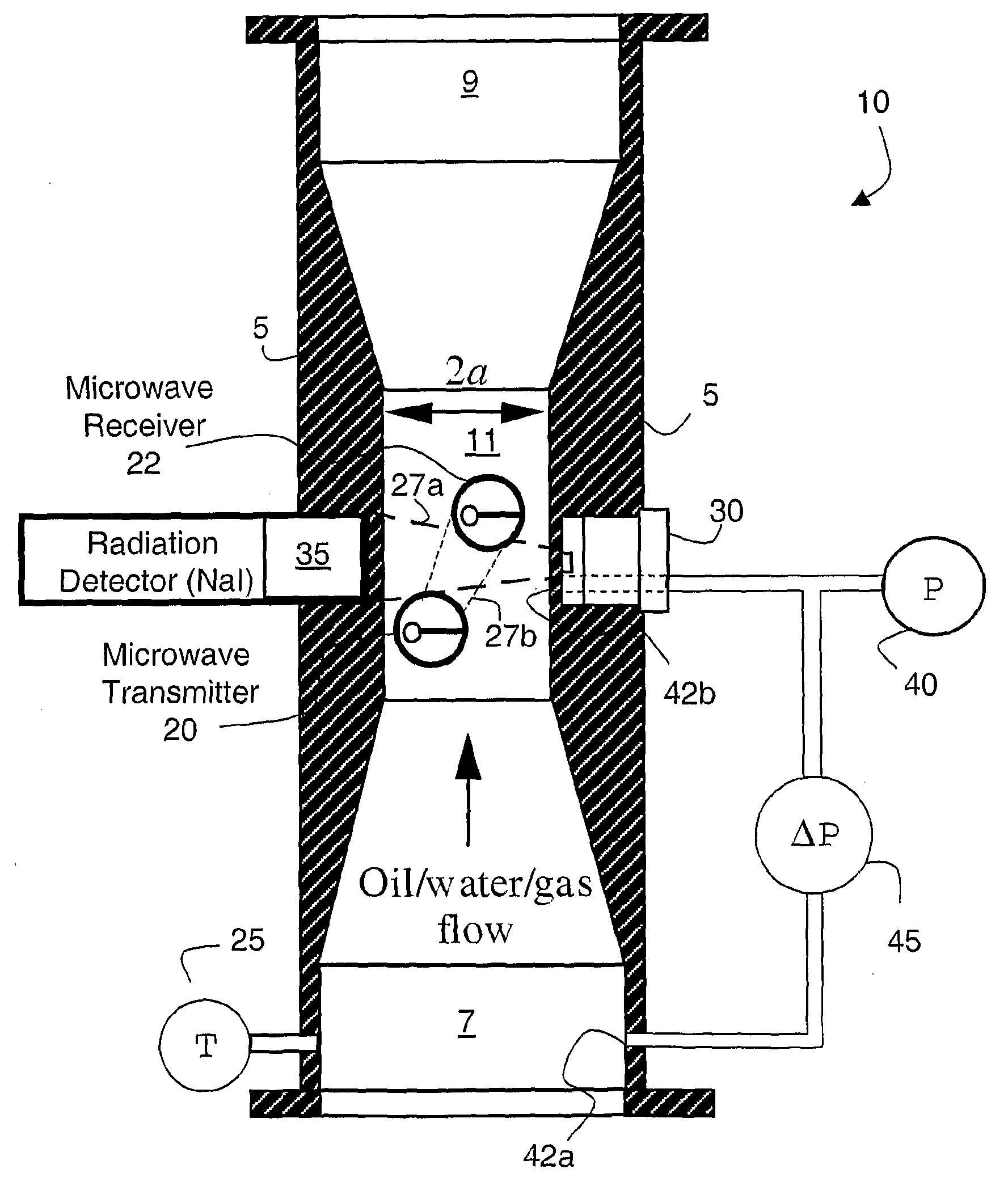

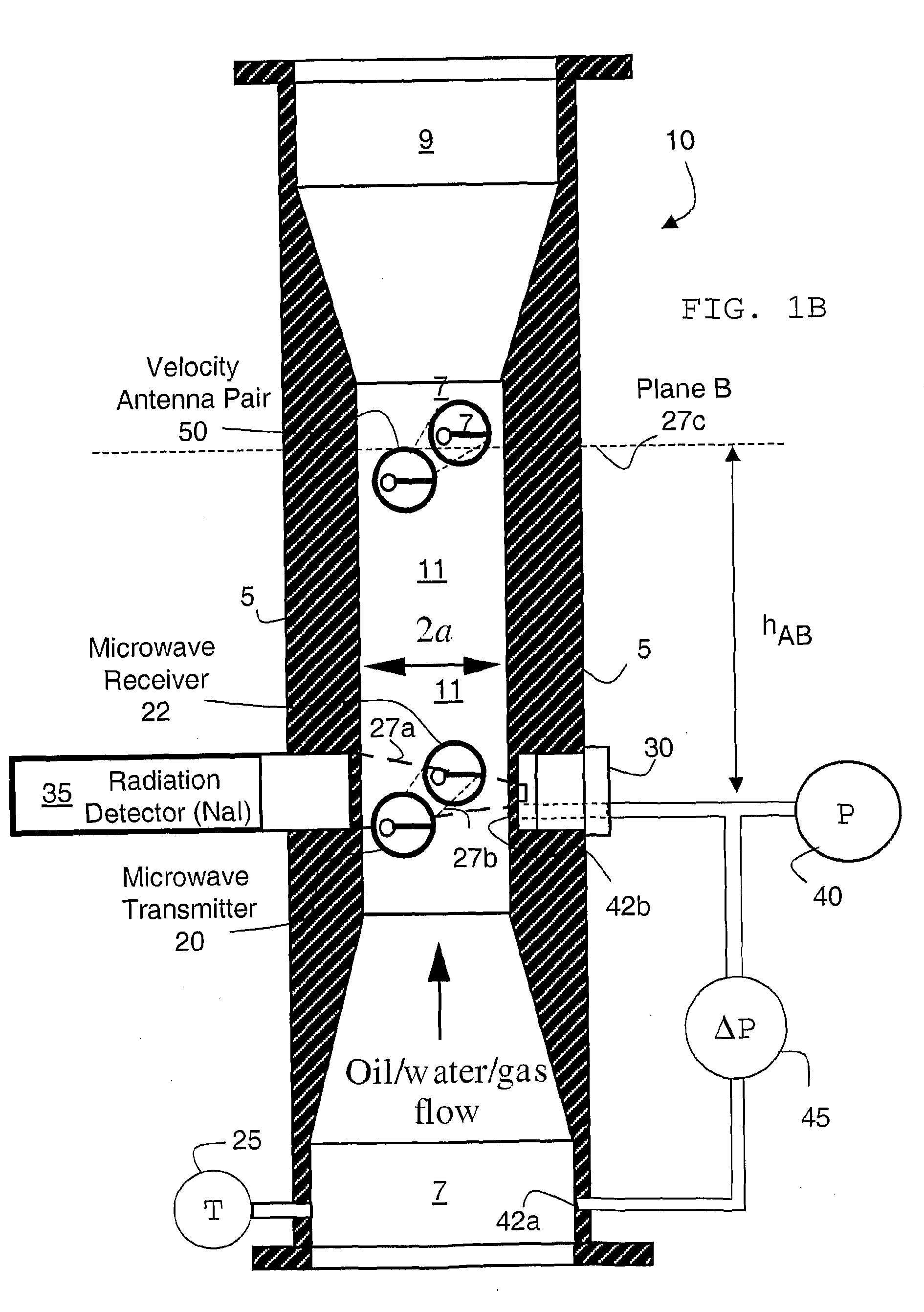

Systems and Methods For Measuring Multiphase Flow in a Hydrocarbon Transporting Pipeline

ActiveUS20080319685A1Material analysis using microwave meansMaterial testing goodsLow activityPressure difference

This disclosure relates in general to methods and systems for measuring multiphase flows in a pipeline using a combination of venturi, microwave and radiation techniques, where the pipeline is configured to transport hydrocarbons. More specifically, but not by way of limitation, certain embodiments of the present invention provide methods and systems in which low activity radiation sources may be used in combination with one or more microwave transmitter-receiver pairs and pressure differential sensors to measure the flow rates and fractions of phases in multiphase flows in a pipeline, such as may be encountered in producing hydrocarbon wells. Additionally, other embodiments of the present invention provide for the arrangement of one or more microwave transmitter-receiver pairs, one or more radiation source-detector pairs and / or one or more pressure sensor ports in the same cross-section of the throat of a venturi to measure multiphase flow in a hydrocarbon transporting pipeline.

Owner:SCHLUMBERGER TECH CORP

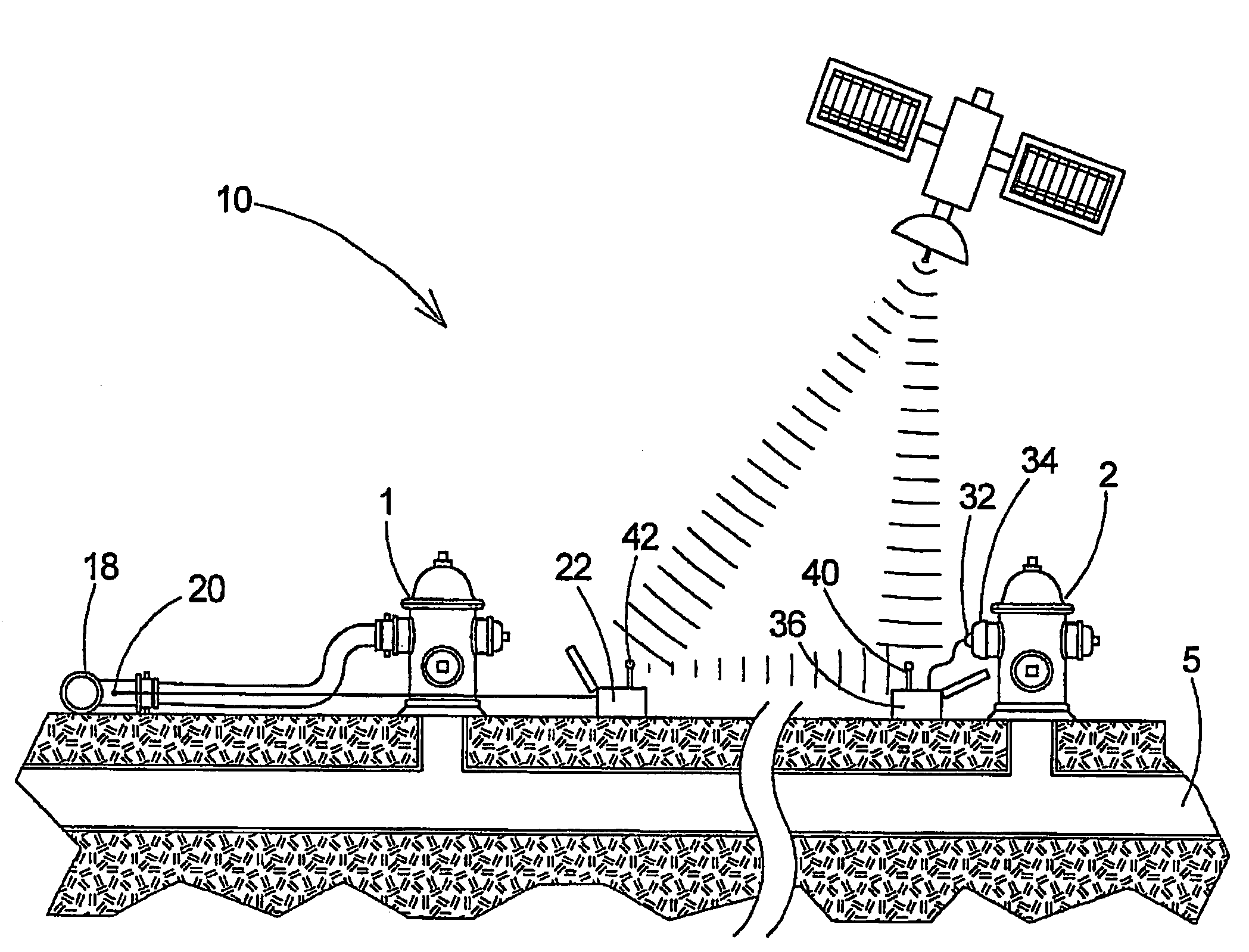

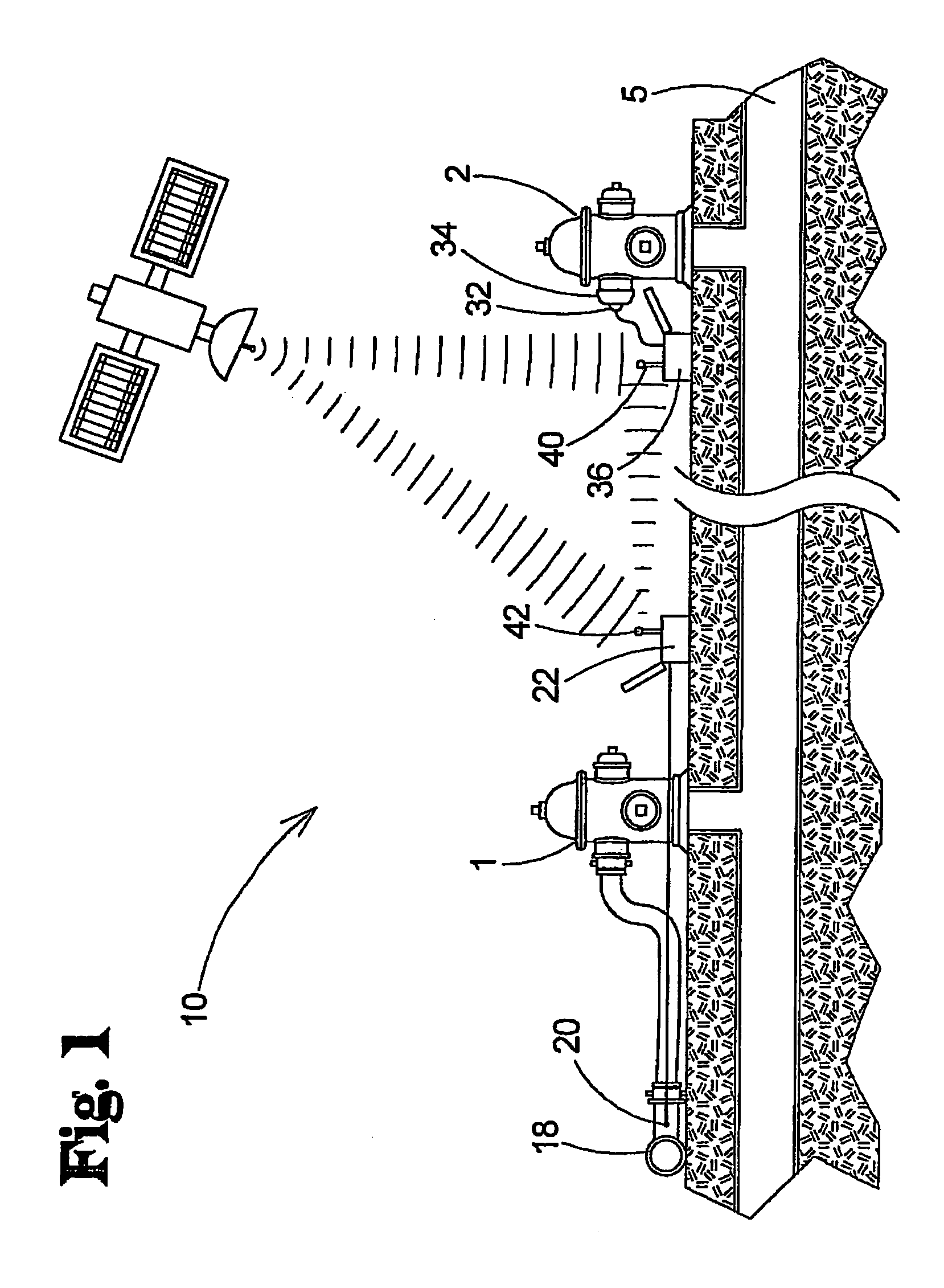

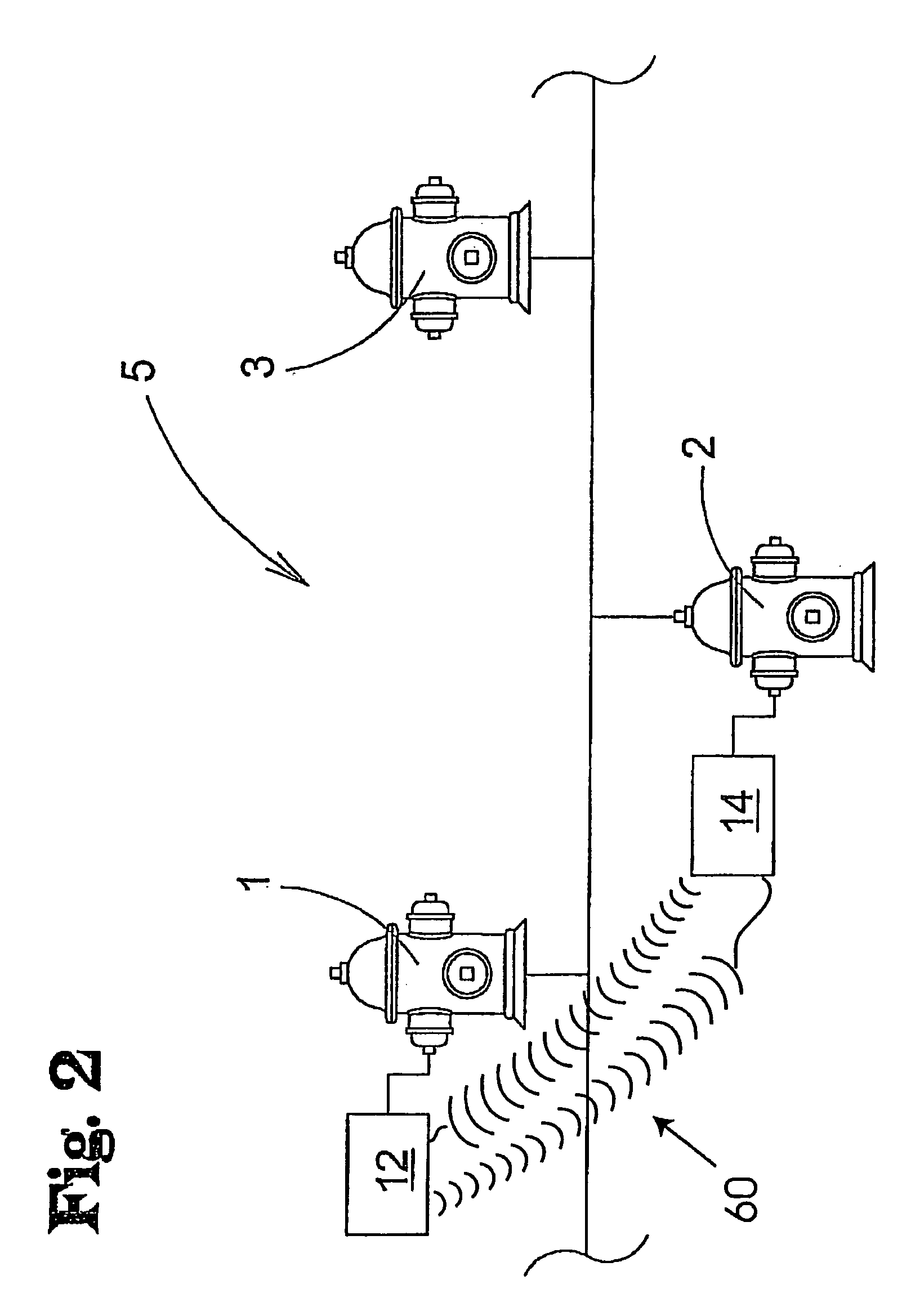

Flow testing system for fluid networks

ActiveUS20080281534A1Way accurateEasy to useVehicle testingAerodynamic testingEngineeringData transmission

An apparatus, system, method and kit for testing fluid flow and pressure is provided. The apparatus, system, method and kit include or include the use of a flow unit which is configured to measure flow rate and / or flow velocity when interfaced with a flow valve or hydrant and a pressure unit configured to measure at least residual pressure when interfaced with a test valve or hydrant. At least one of the units is configured to wirelessly send data transmissions to the other unit which is configured to receive such transmissions.

Owner:HURCO TECH

Method for determining pump flow without the use of traditional sensors

ActiveUS7945411B2Testing/calibration apparatusProcess and machine controlOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com