Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3614results about "Flow control using electric means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

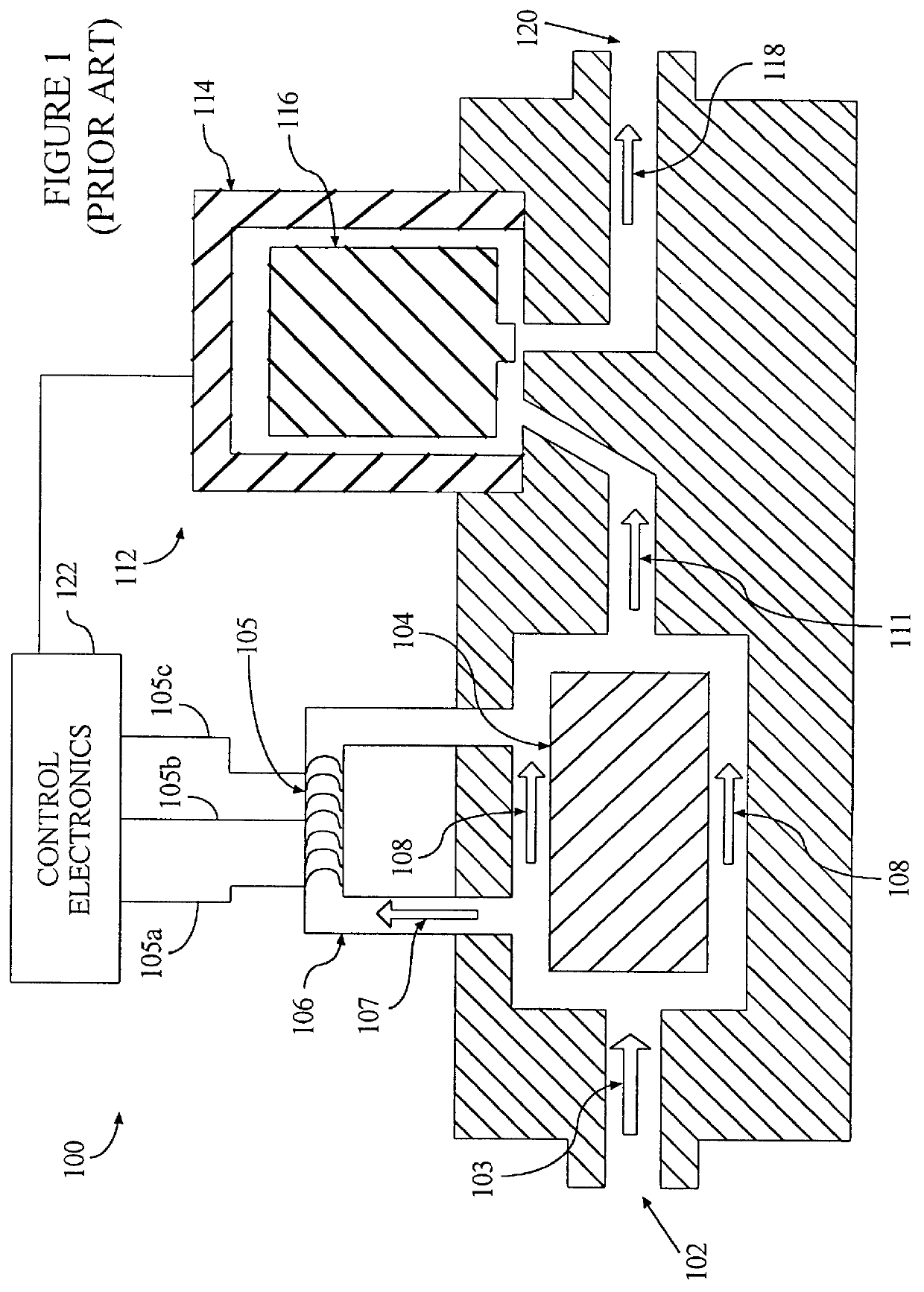

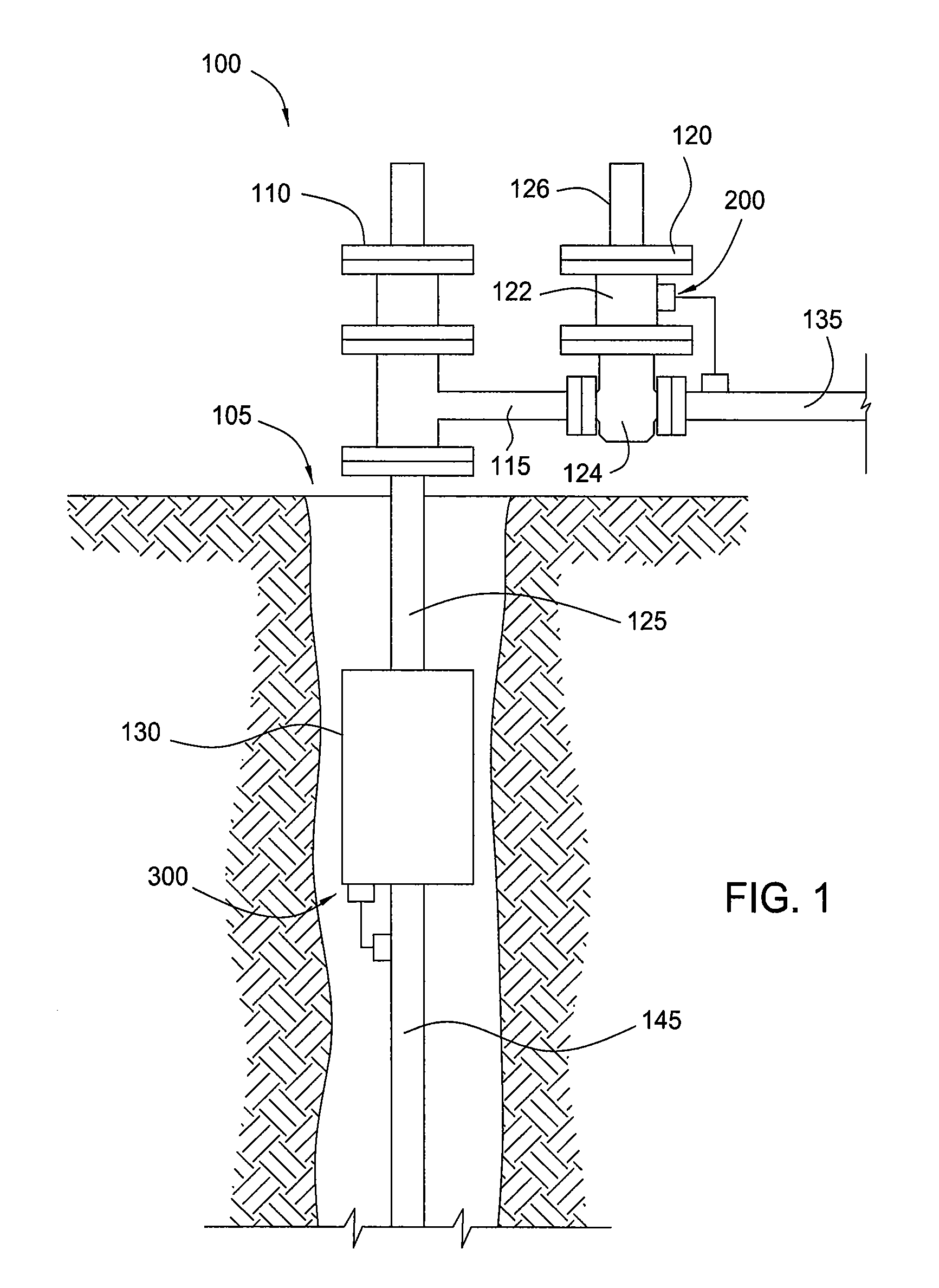

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

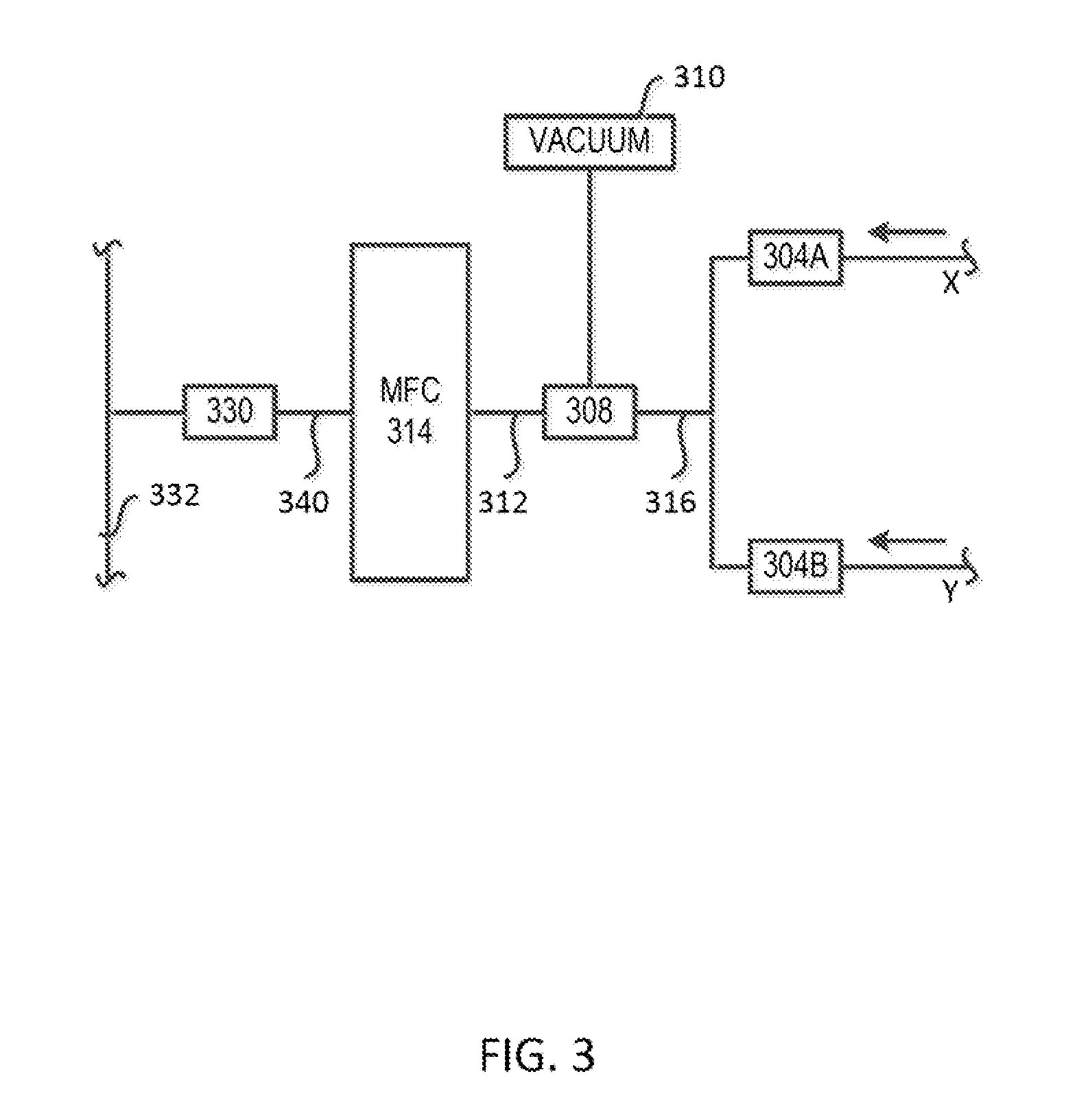

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

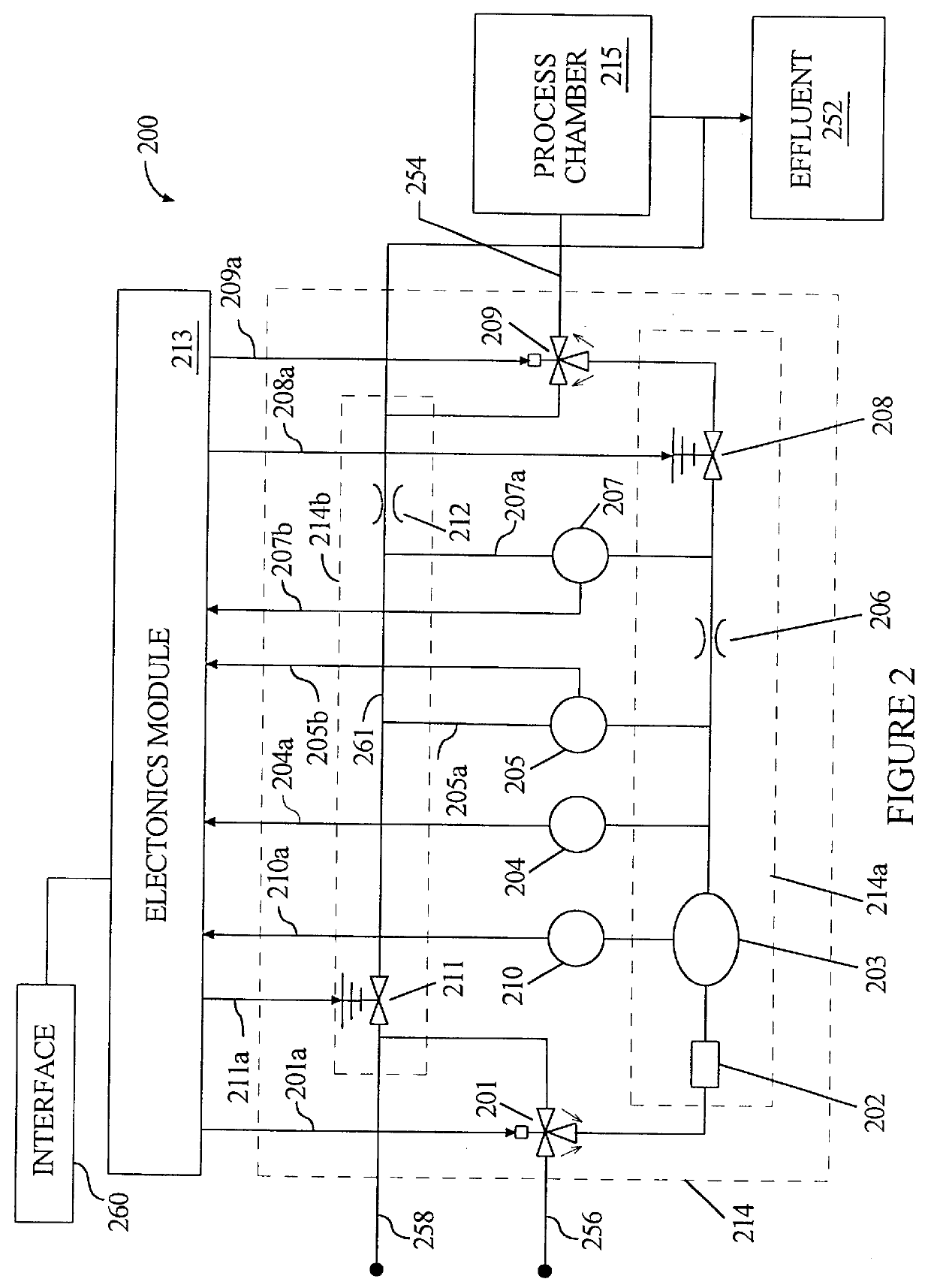

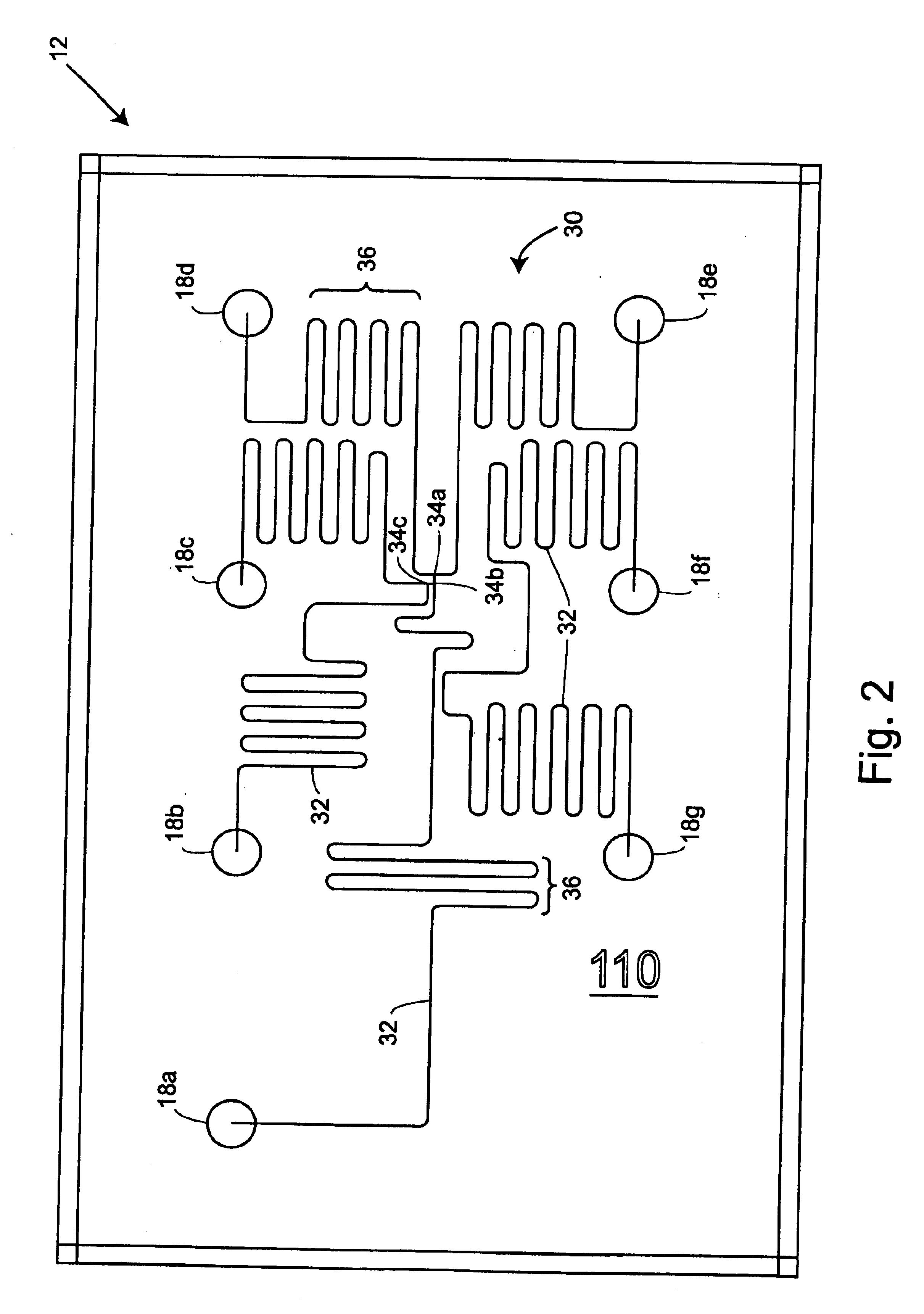

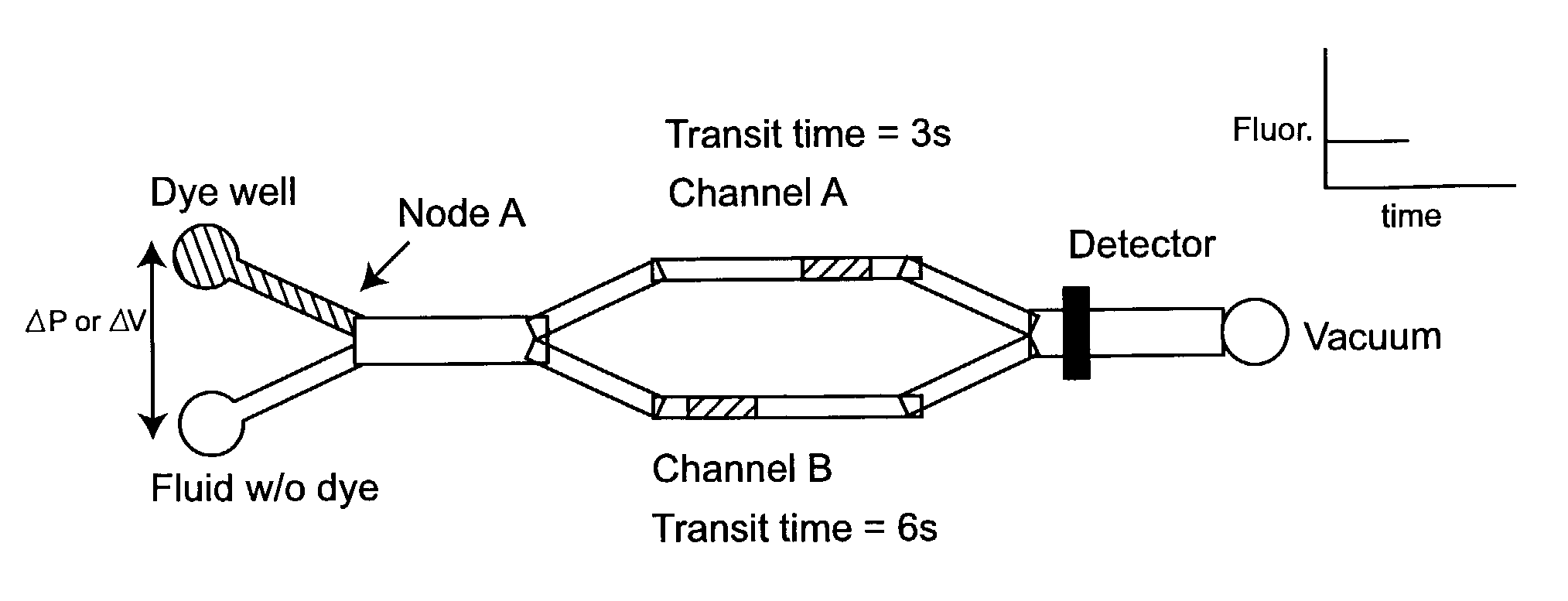

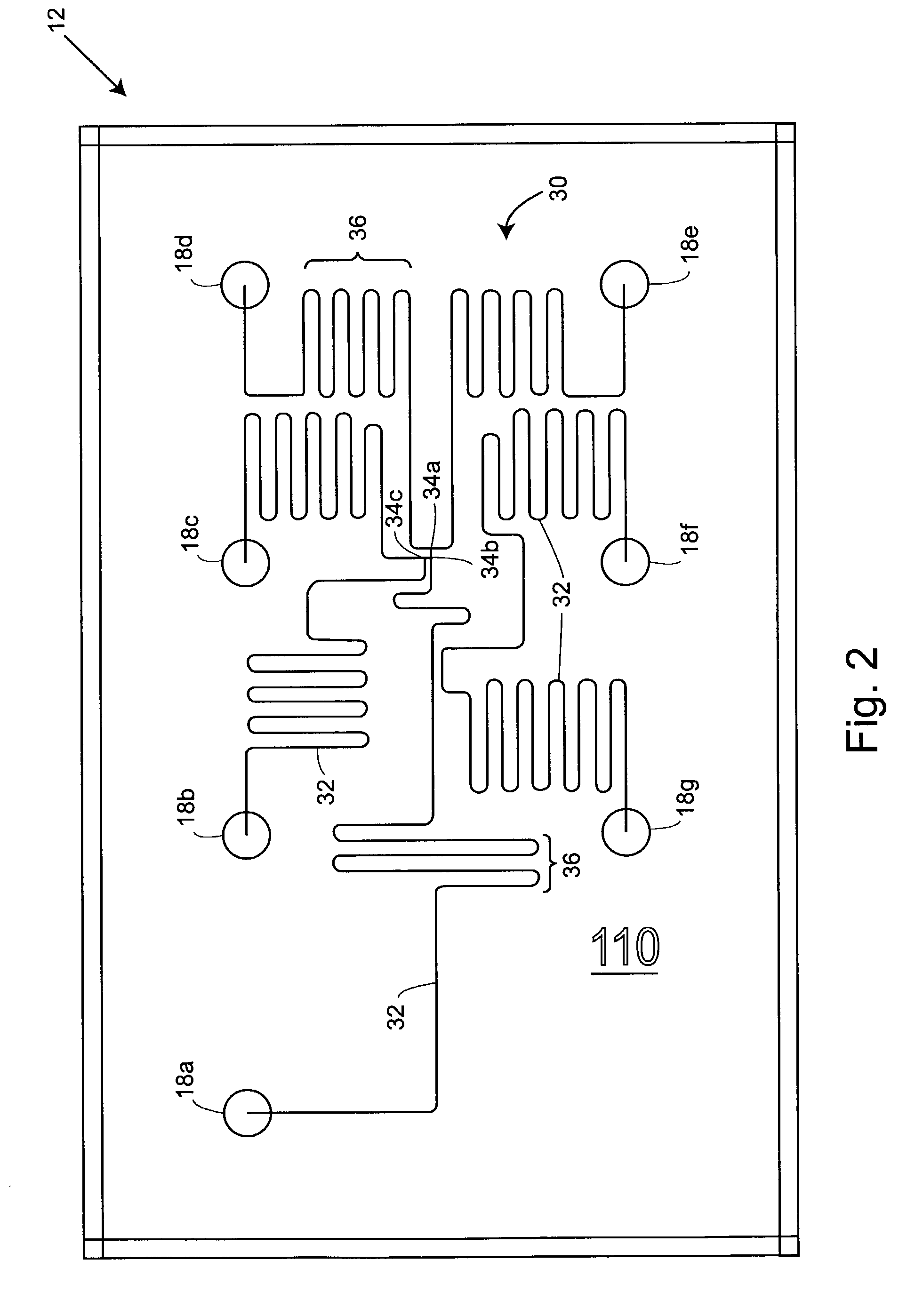

Multi-reservoir pressure control system

InactiveUS6915679B2Sufficient oscillationAccurate and stable and reliable assayAnalysis by electrical excitationLaboratory glasswaresFluid transportFlow resistivity

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

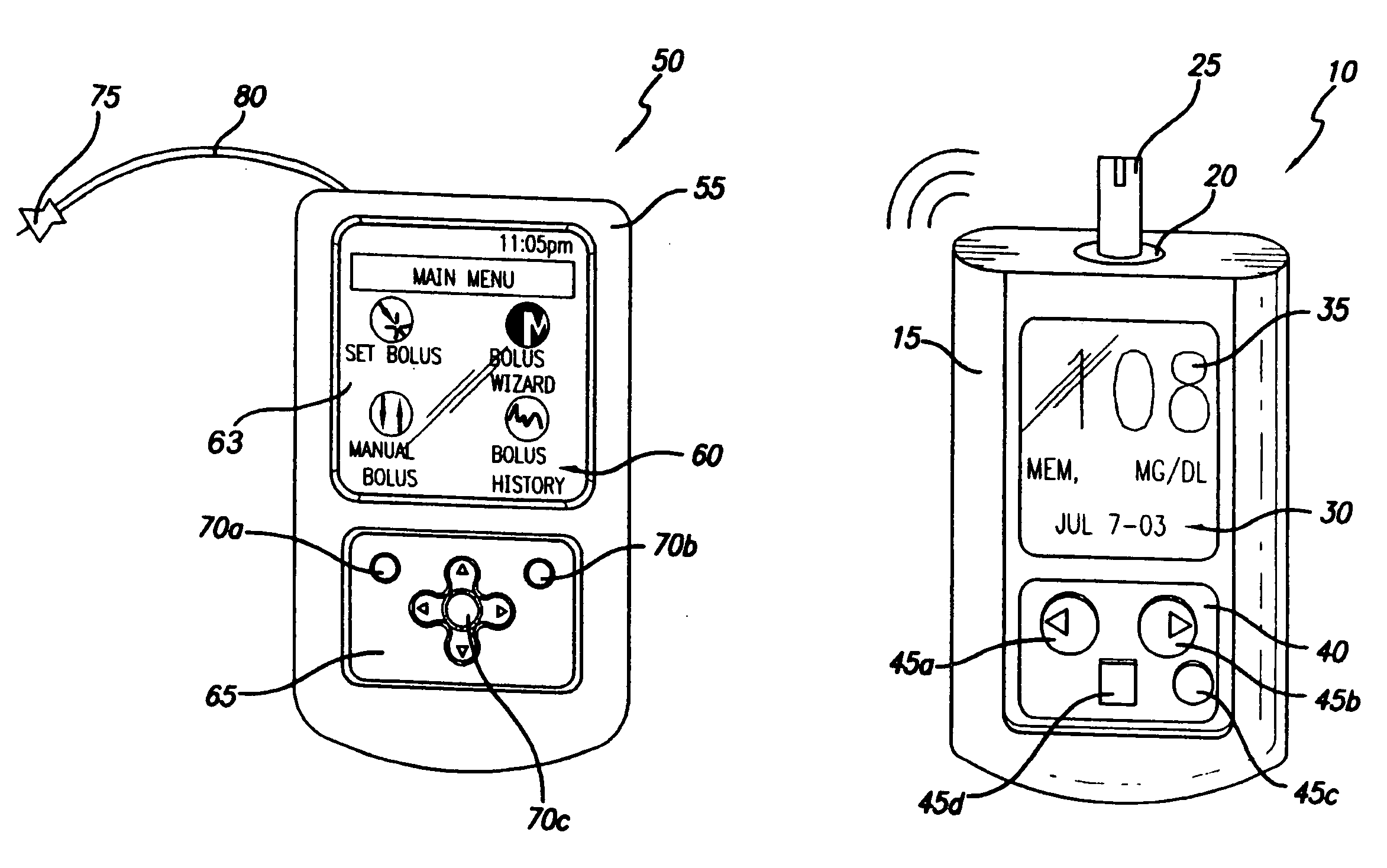

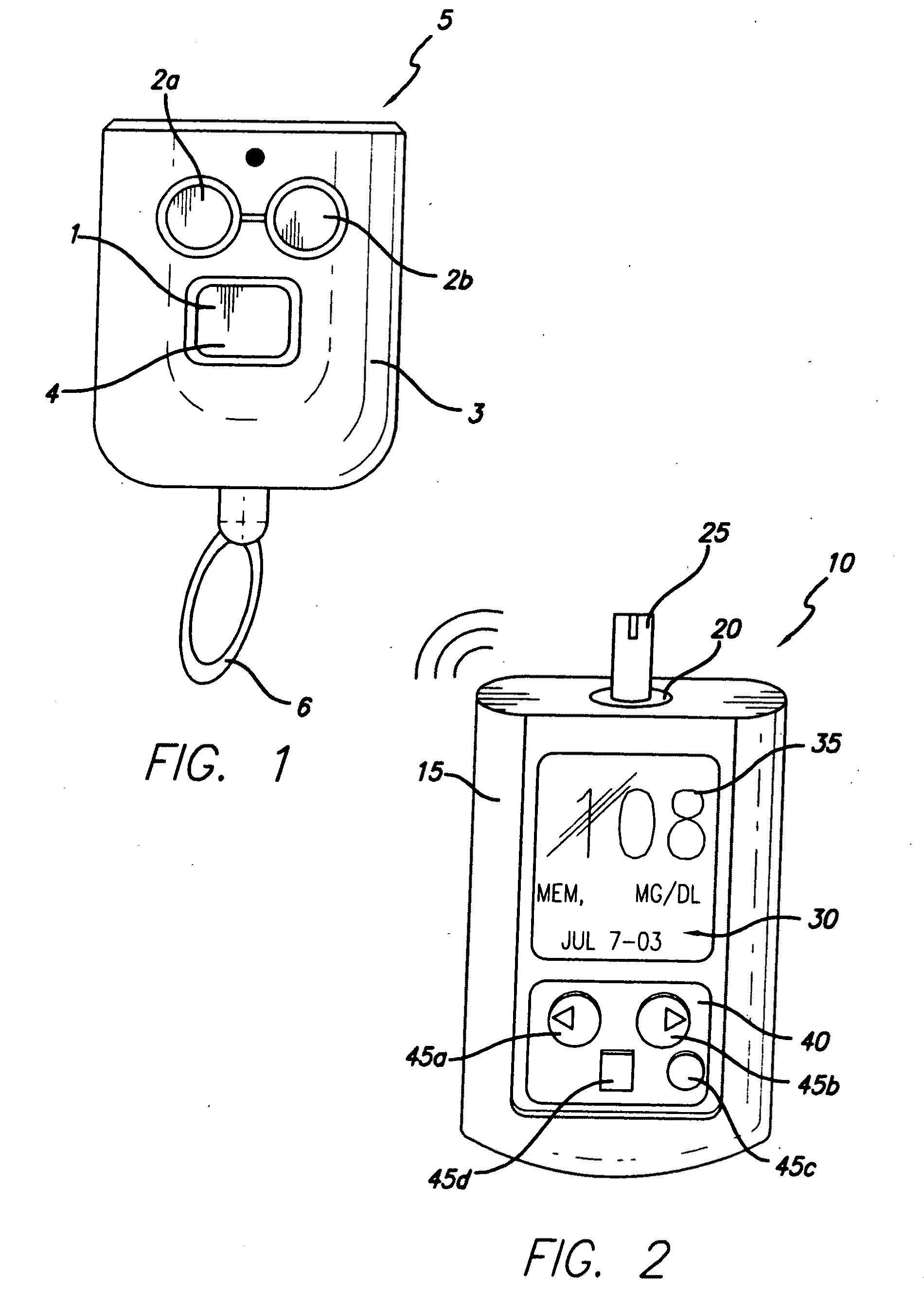

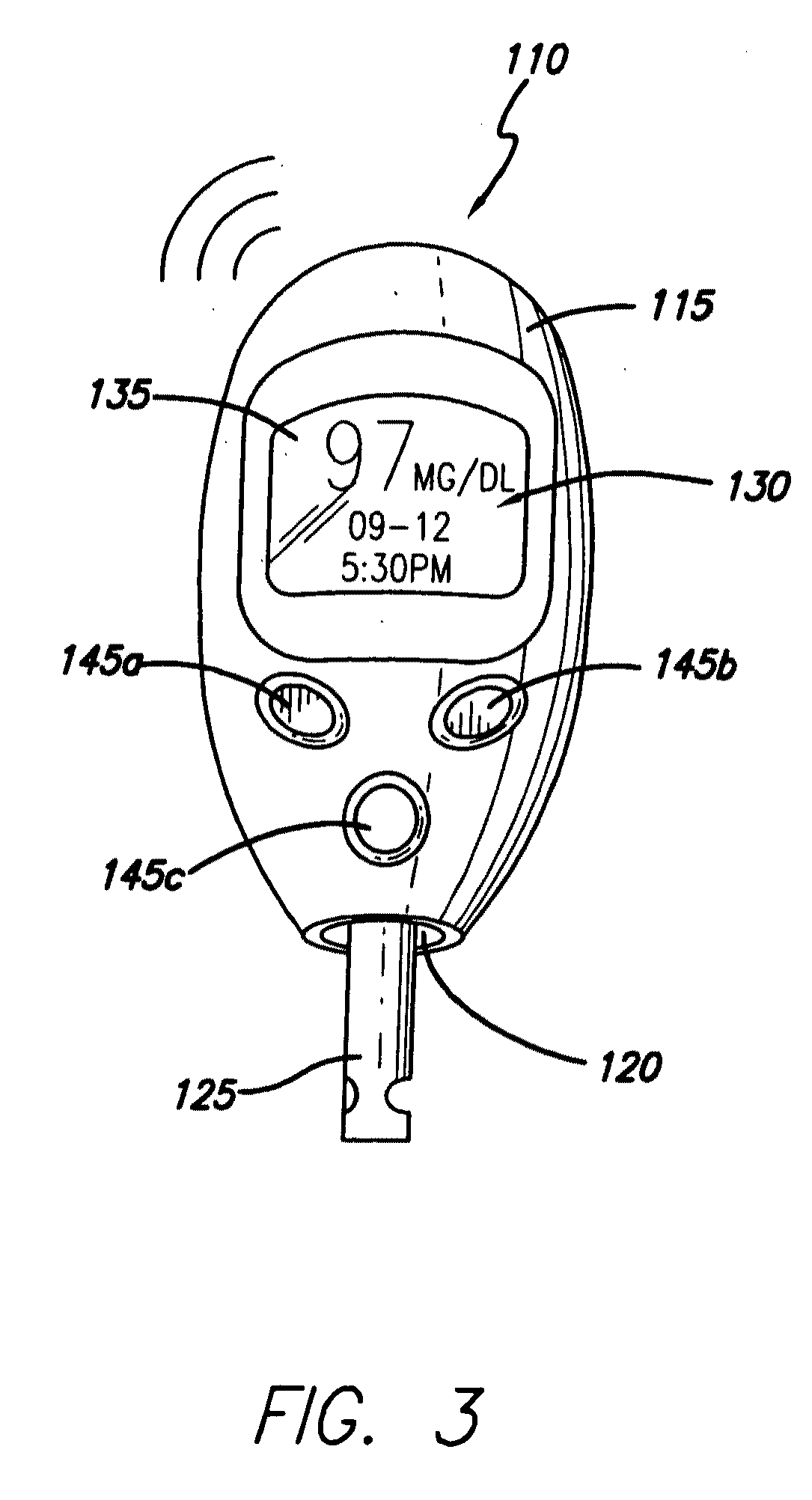

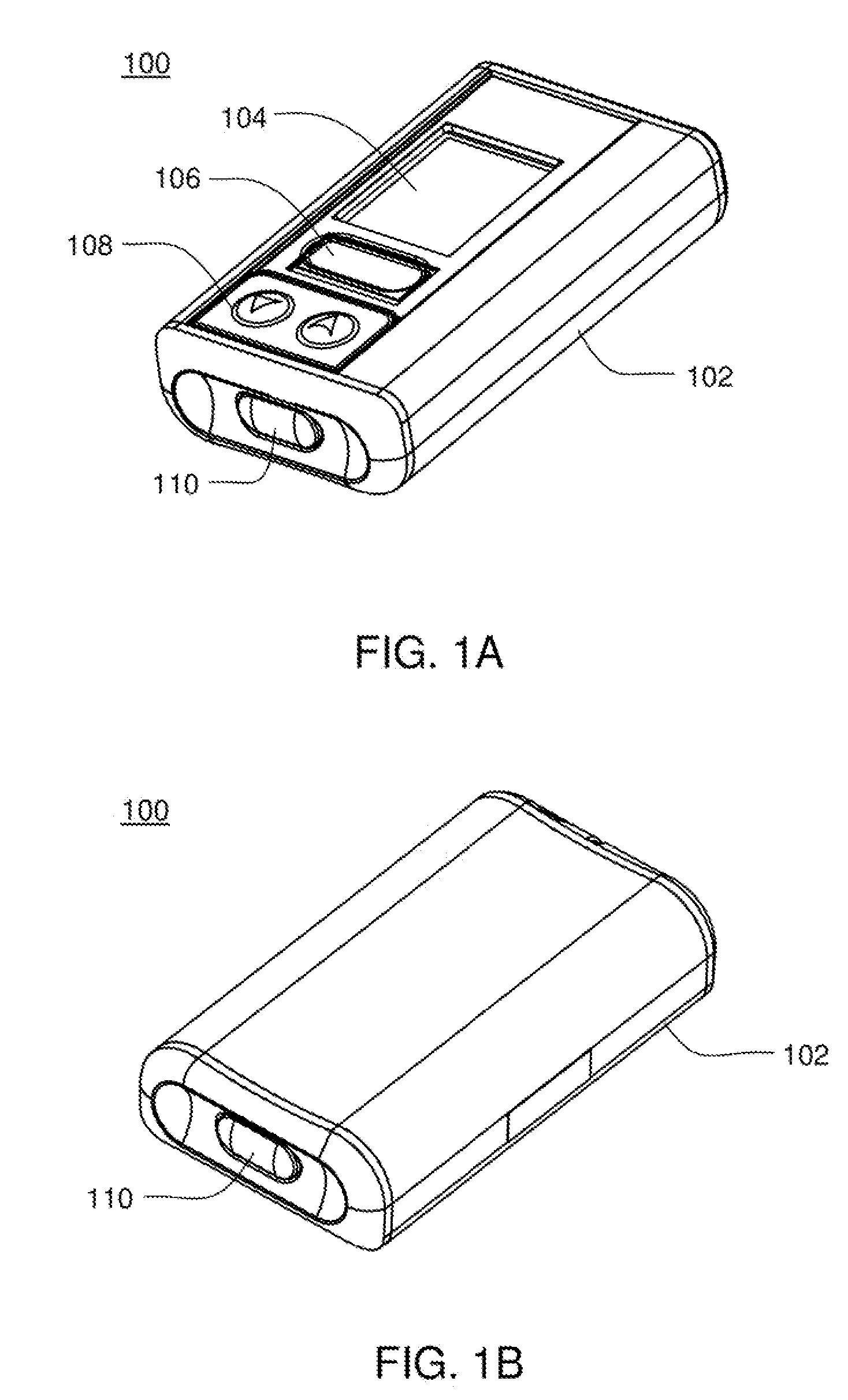

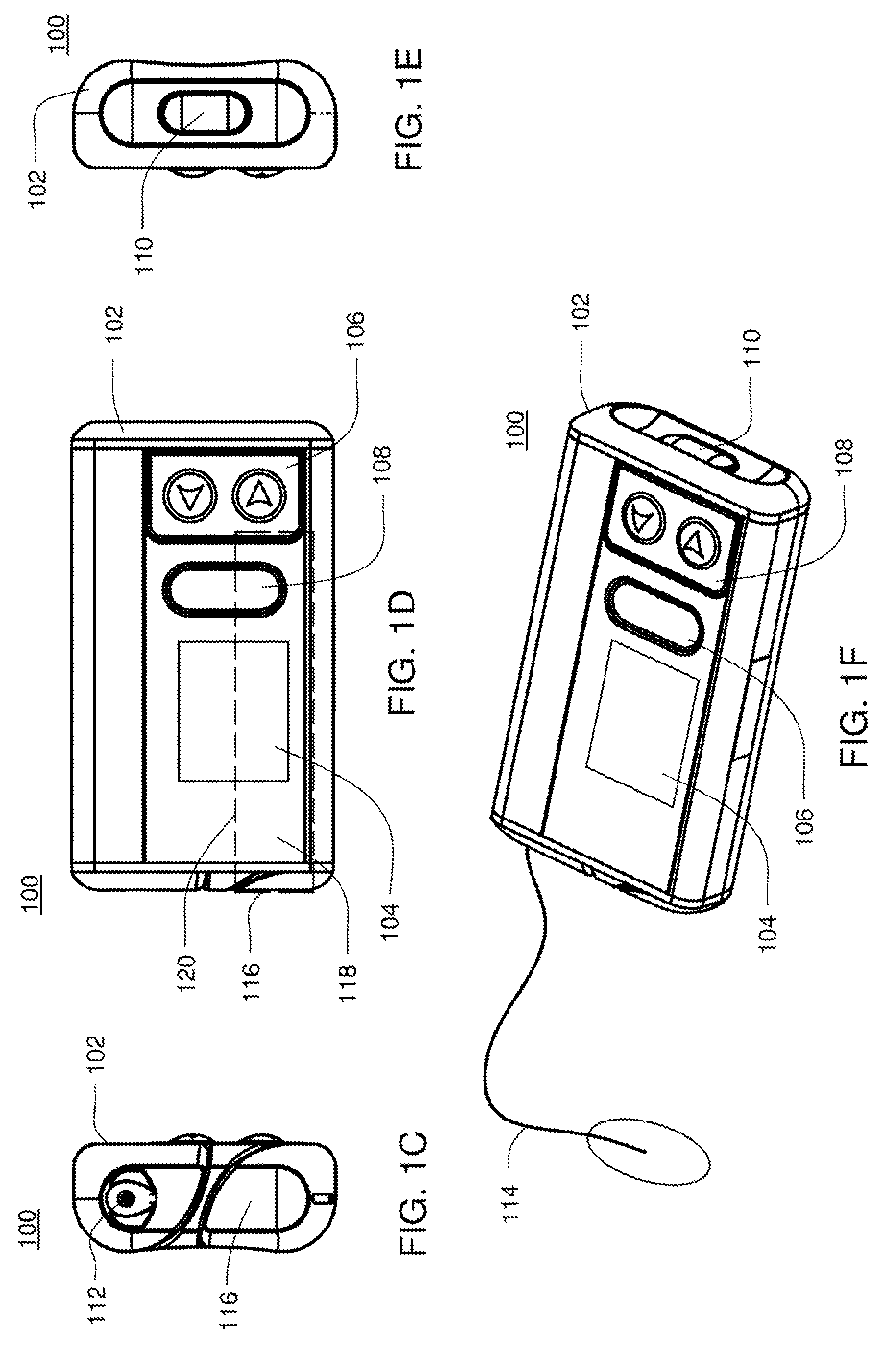

Controller device for an infusion pump

InactiveUS20090227855A1Minimizes potential for errorEasy to watchDrug and medicationsMedical devicesEngineeringInfusion pump

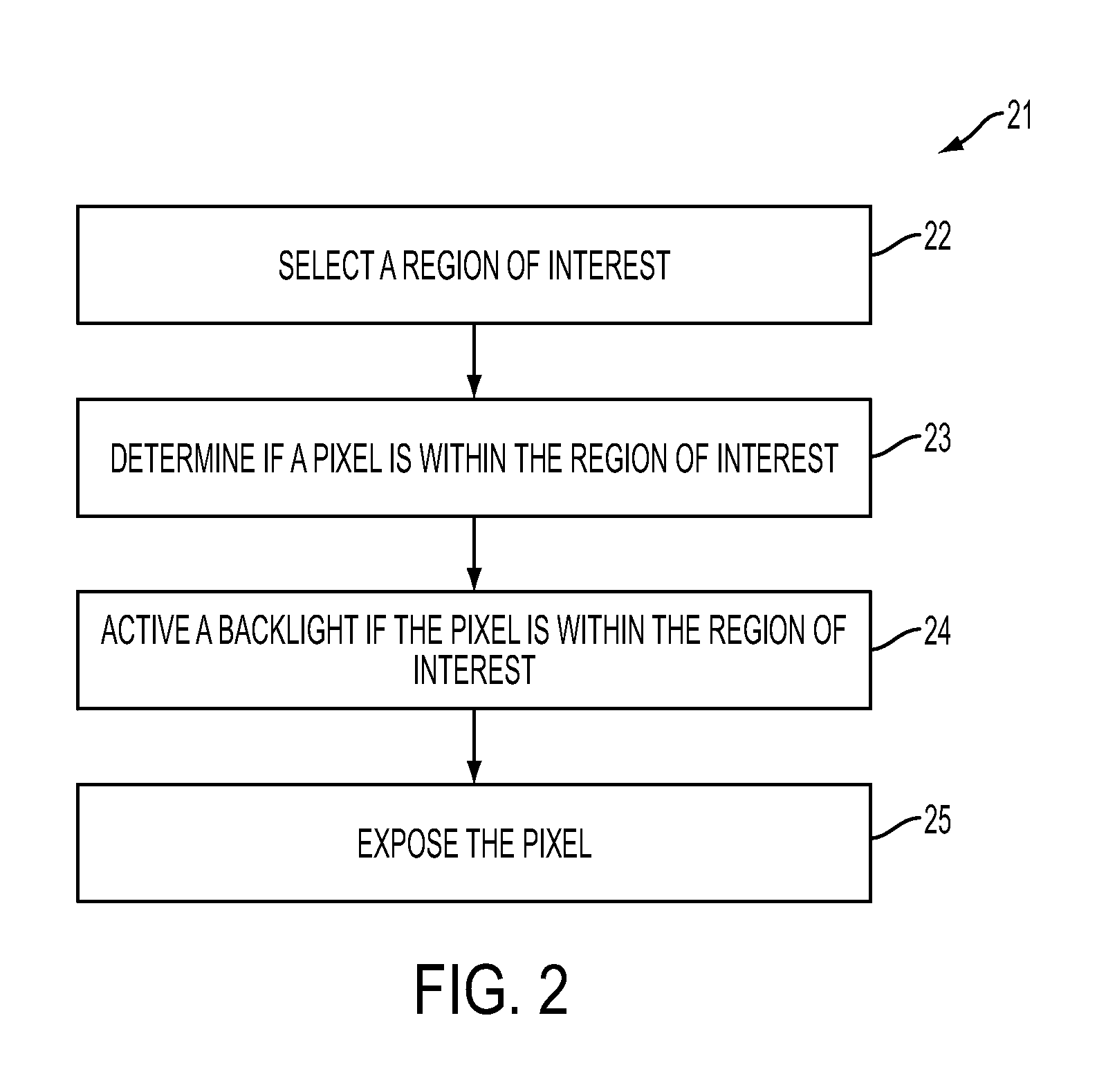

An infusion system that includes a controller device and a communication system to provide for two-way communication between the controller device and an infusion device that controls delivery of fluids to a user's body. Either the controller device or the infusion device may be integrated with a characteristic determining device in a single housing. The housing, in turn, may include a test-strip receptacle and an illuminator disposed so as to illuminate an area covering the receptacle and a test-strip inserted therein. The illuminator may be configured to be activated automatically when a test strip is inserted into the receptacle, selectively by the user via a button, key, or similar mechanism, and / or when the ambient light level, measured, e.g., with a light sensor, falls below a predetermined intensity. The illuminator may be a LED emitting white light, and may provide illumination at various levels of intensity.

Owner:MEDTRONIC MIMIMED INC

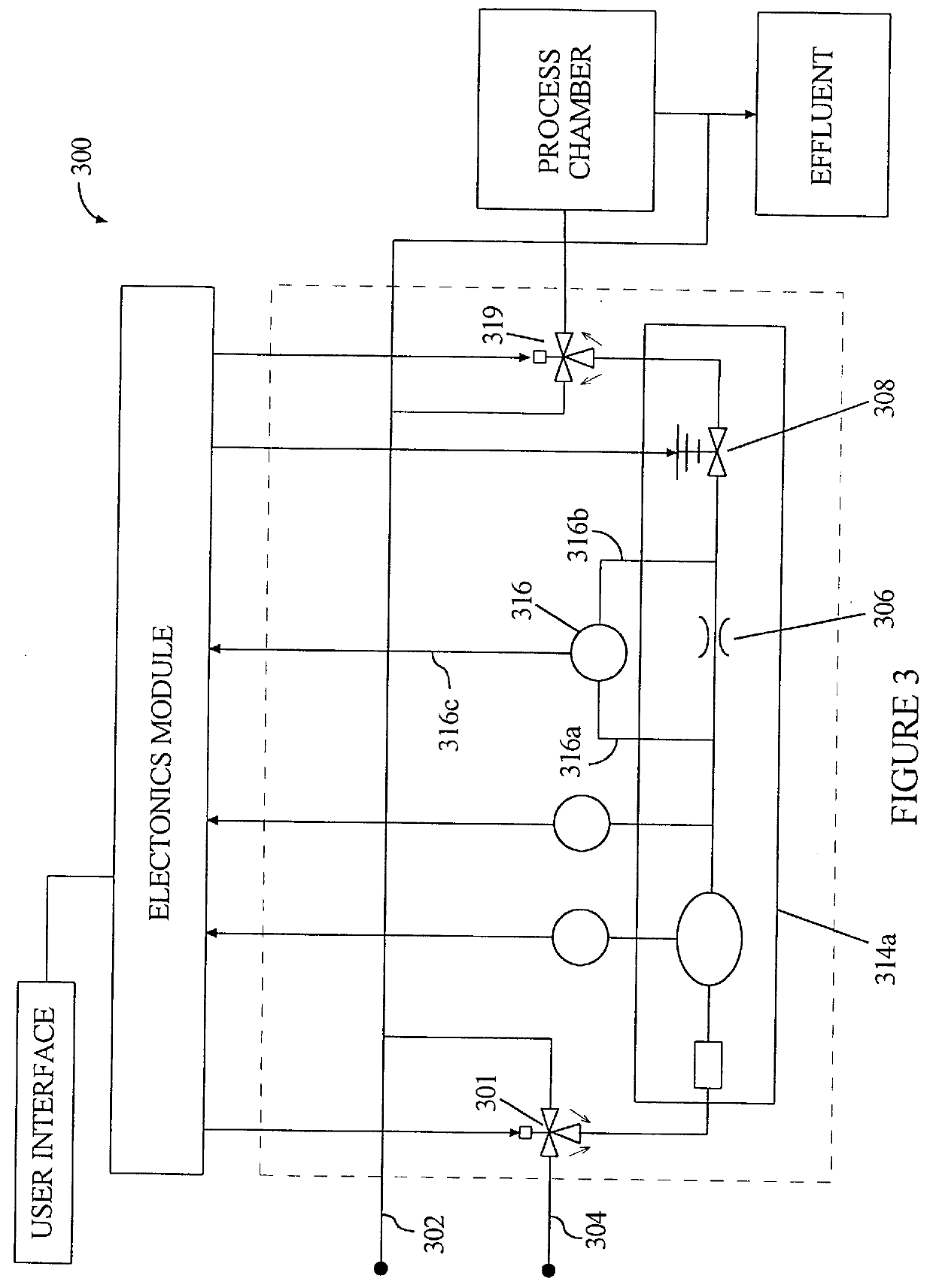

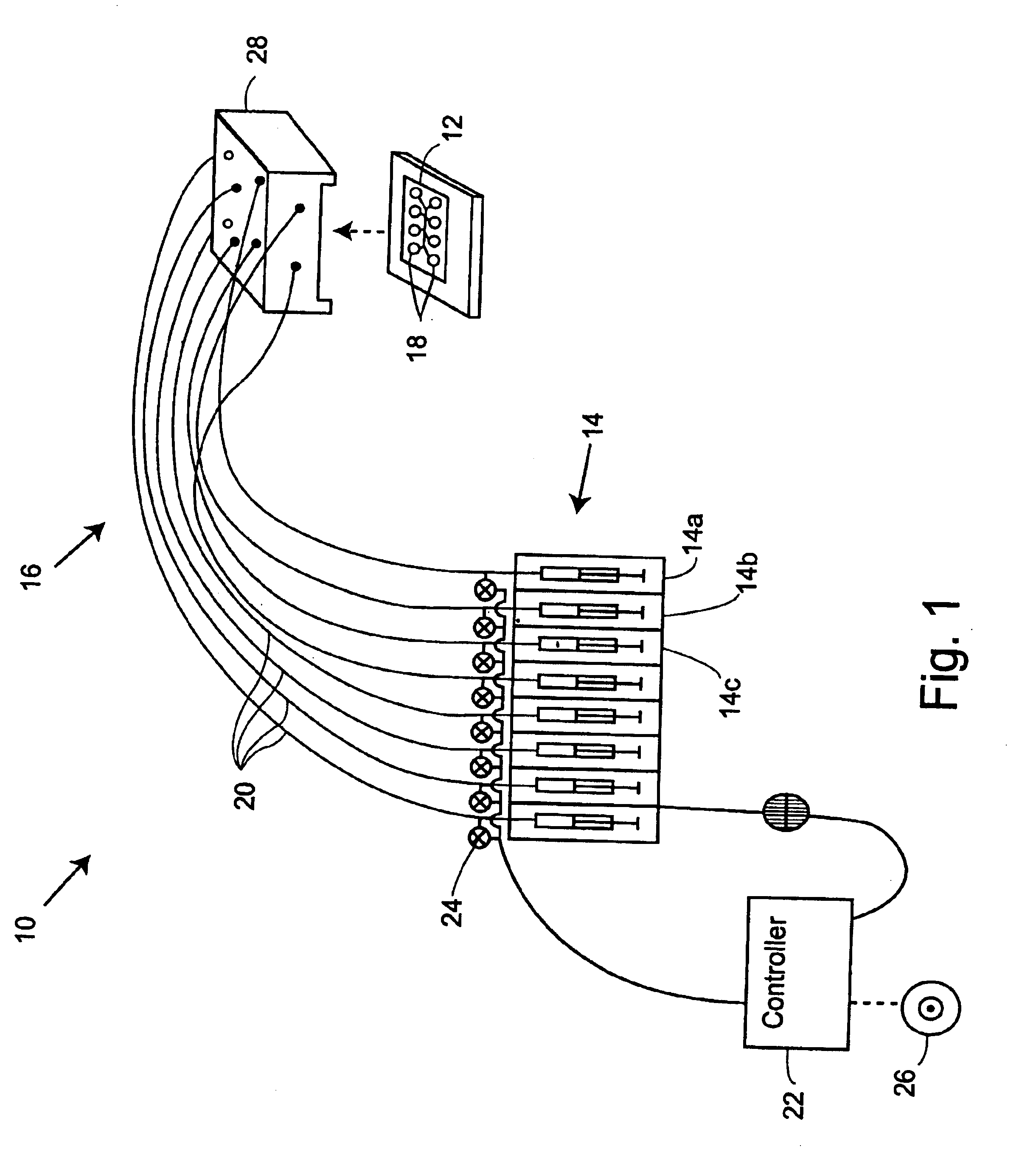

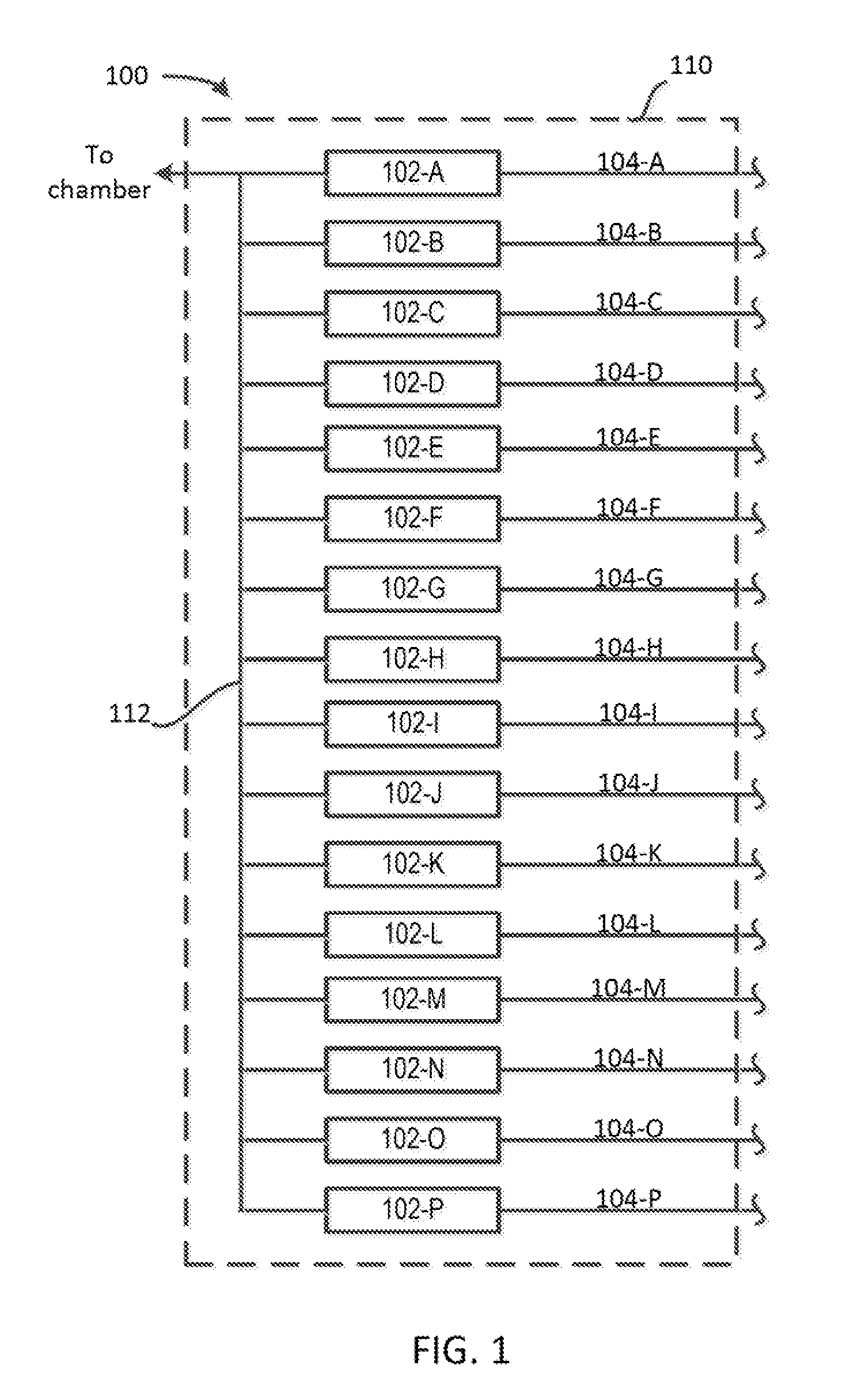

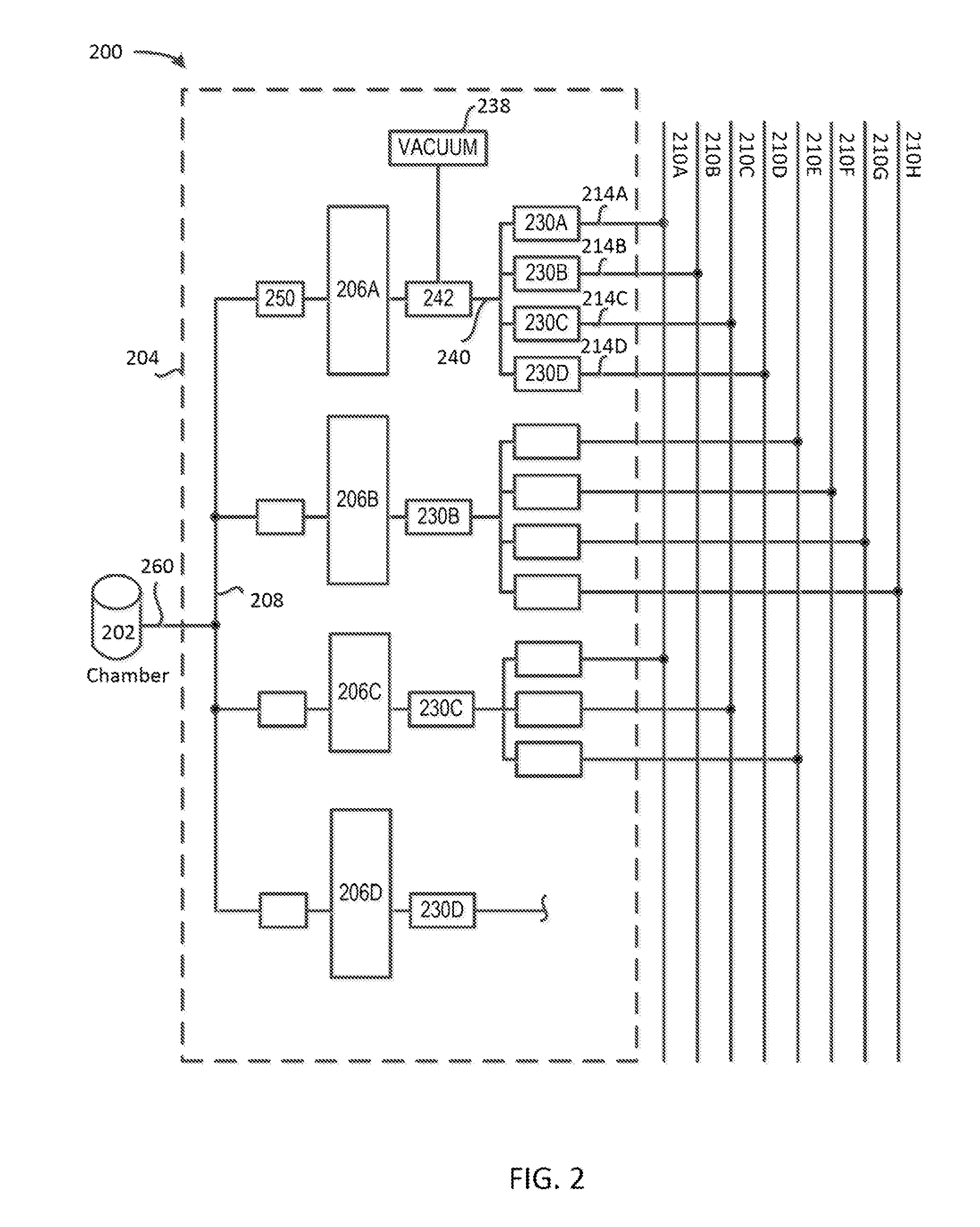

Gas supply systems for substrate processing chambers and methods therefor

ActiveUS20140182689A1Electric discharge tubesFlow control using electric meansMultiplexingProcess engineering

A gas supply subsystem for providing a set of process gases to a substrate processing chamber, the set of process gases being a subset of a plurality of process gases available to the substrate processing chamber. The gas supply subsystem has fewer multi-gas mass flow controllers than the number of available process gases, wherein multiple process gases are multiplexed at the input of one or more of the multi-gas mass flow controllers. Pump-purge may be employed to improve gas switching speed for the multi-gas mass flow controllers

Owner:LAM RES CORP

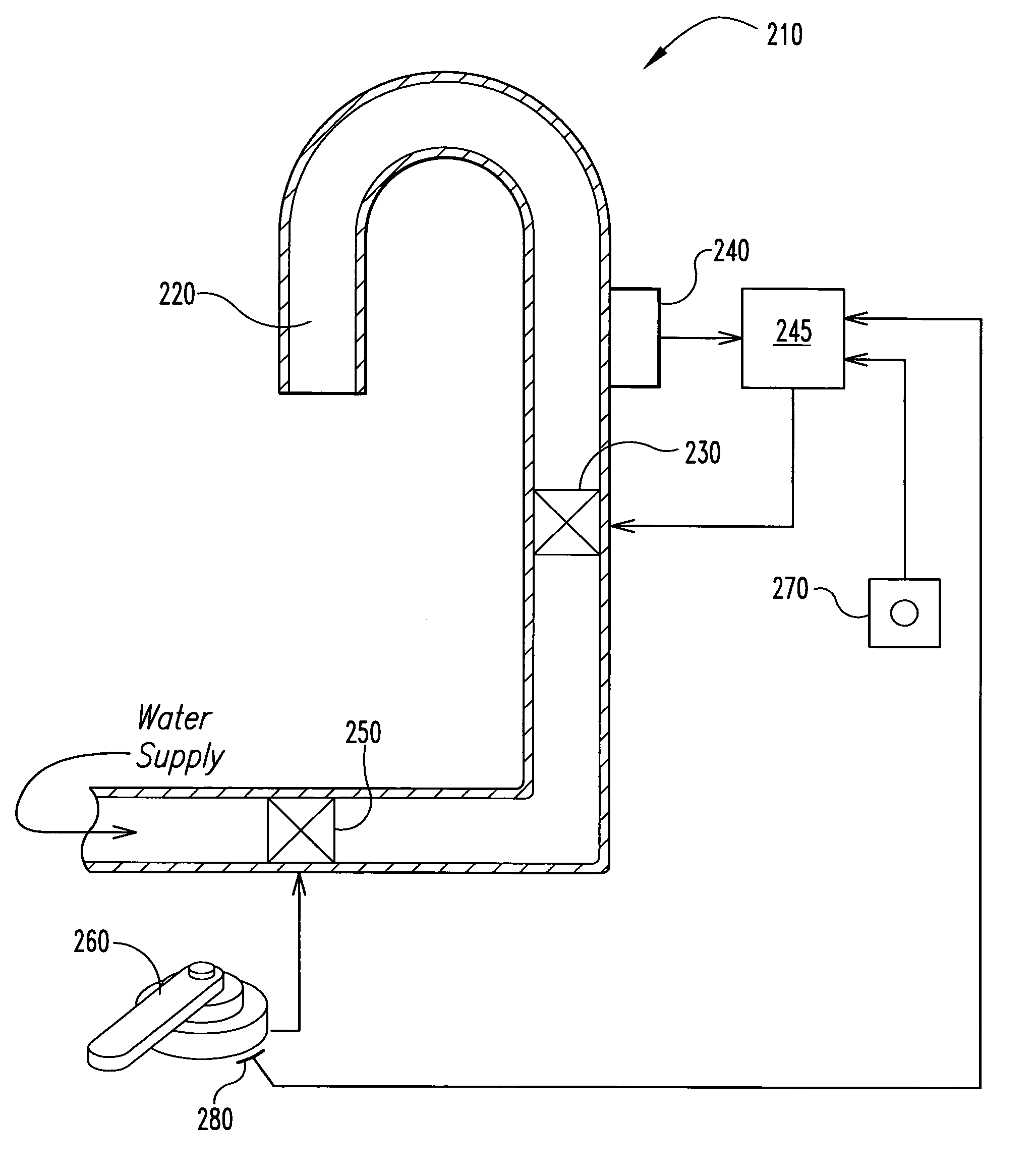

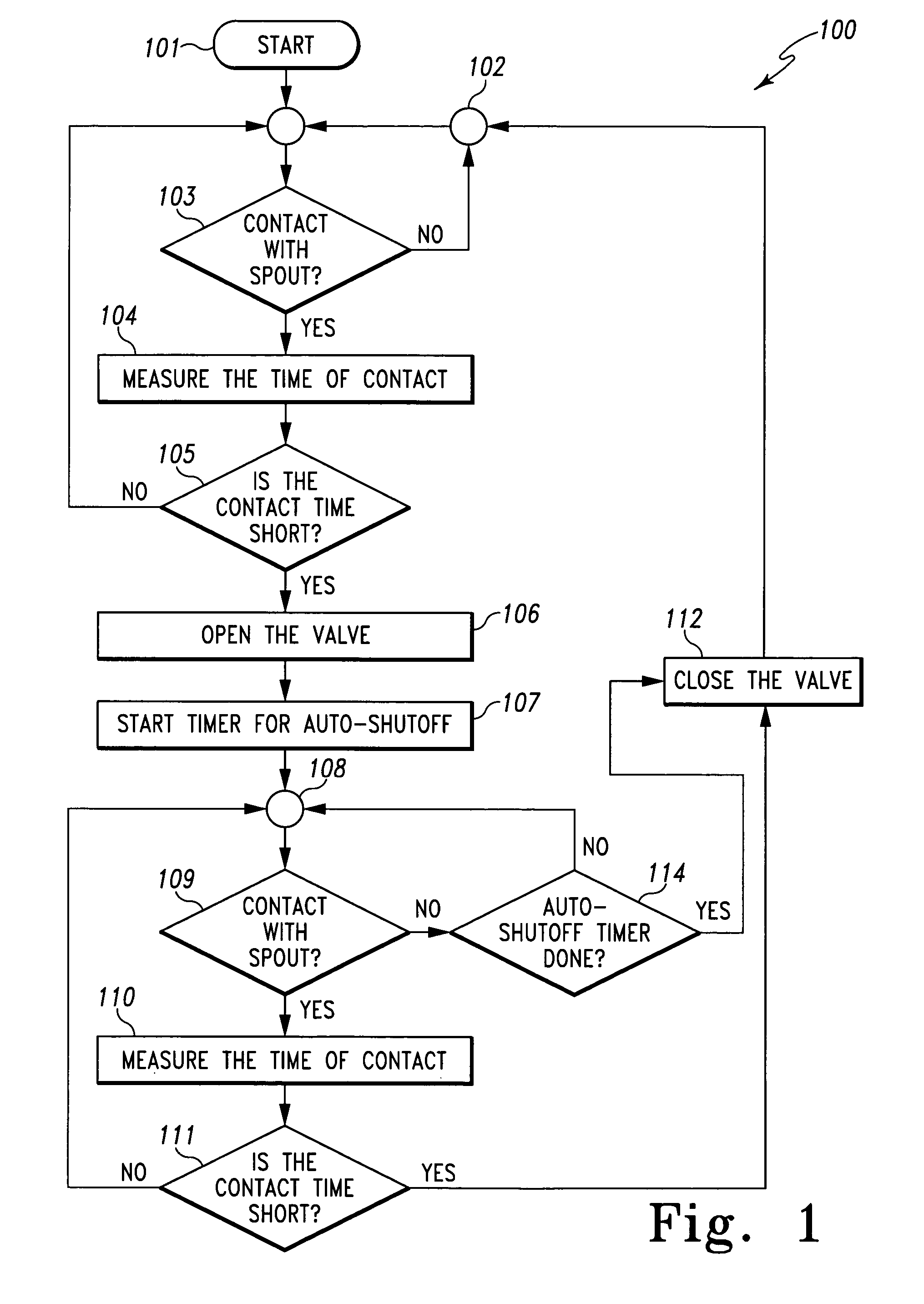

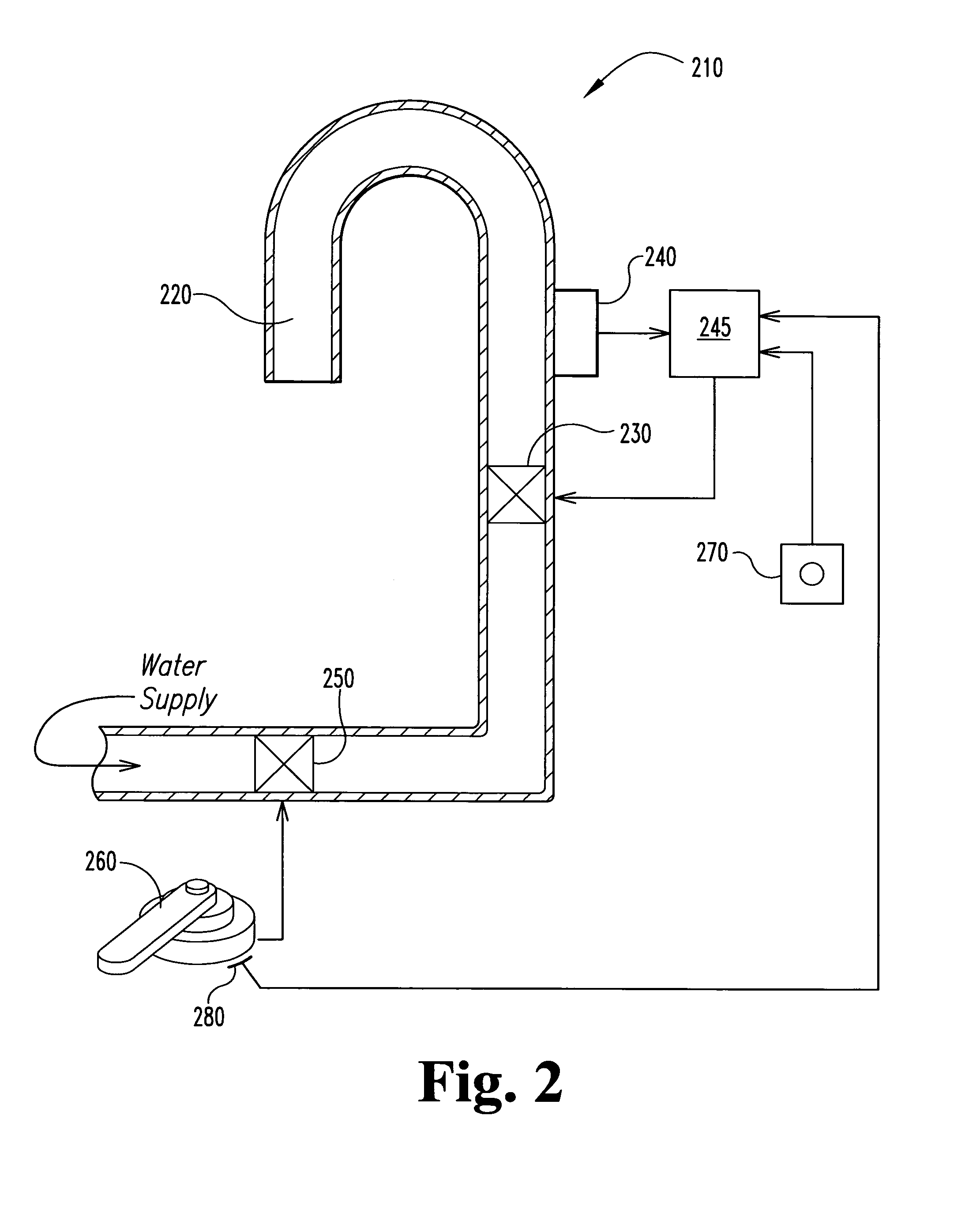

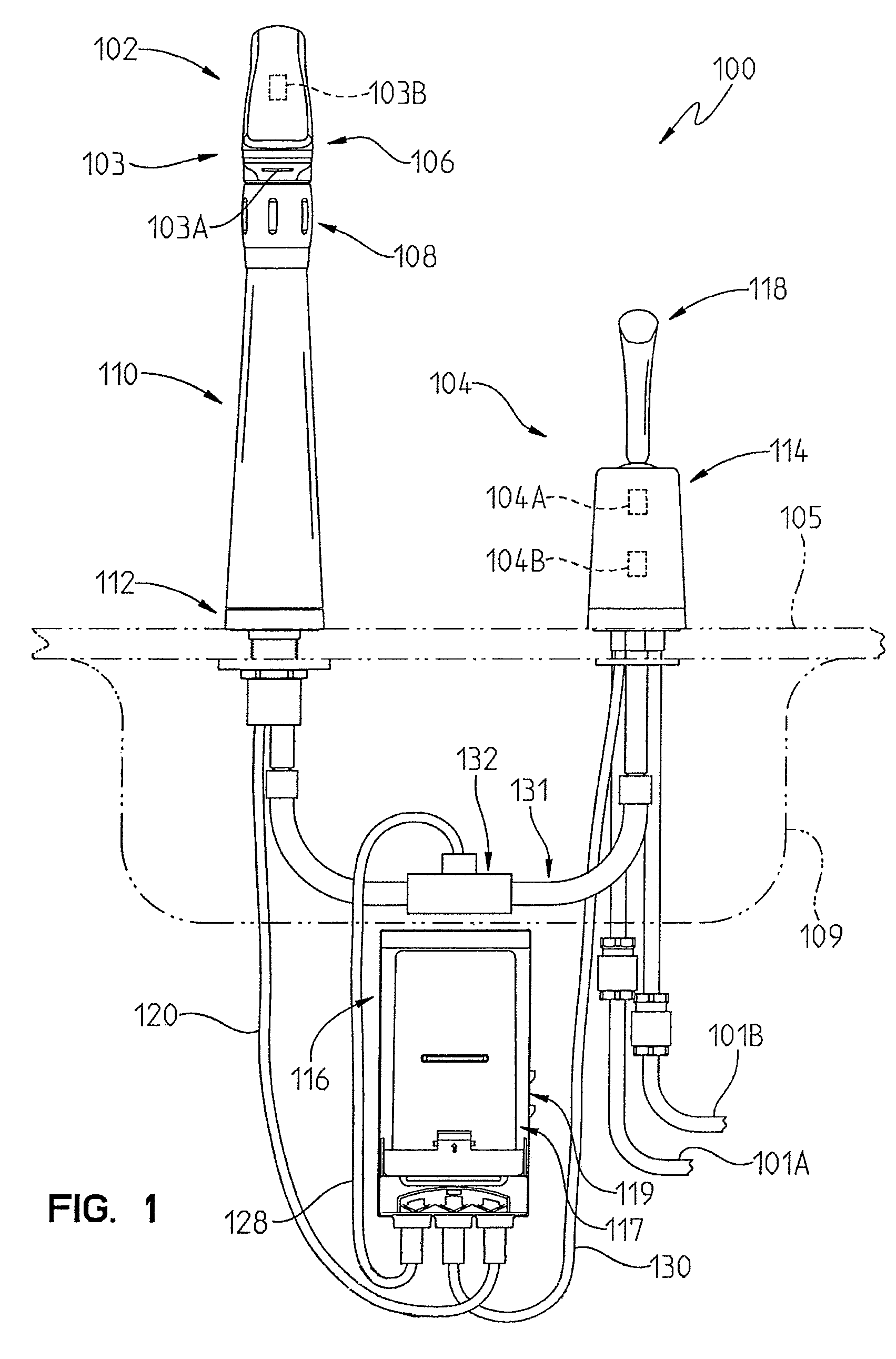

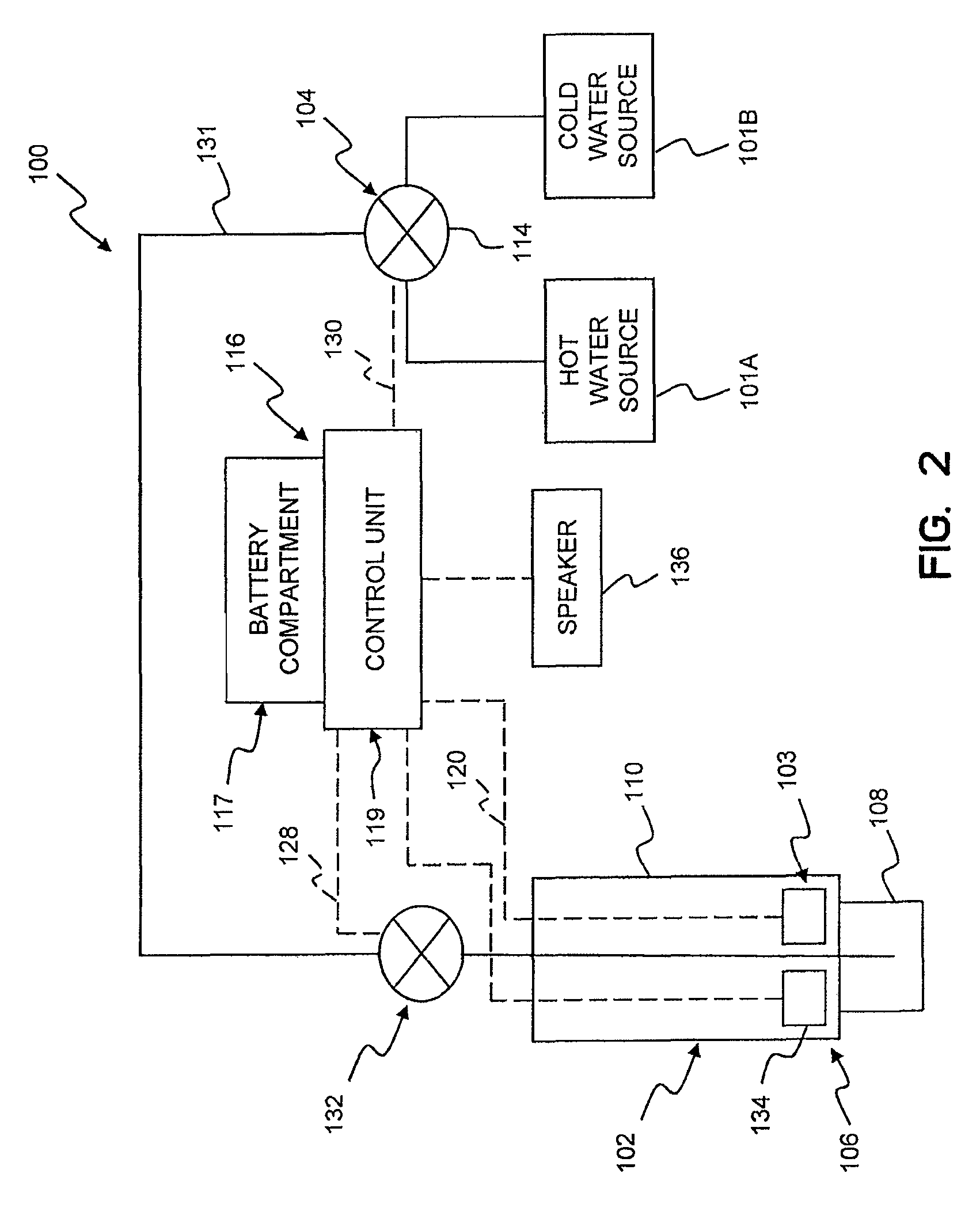

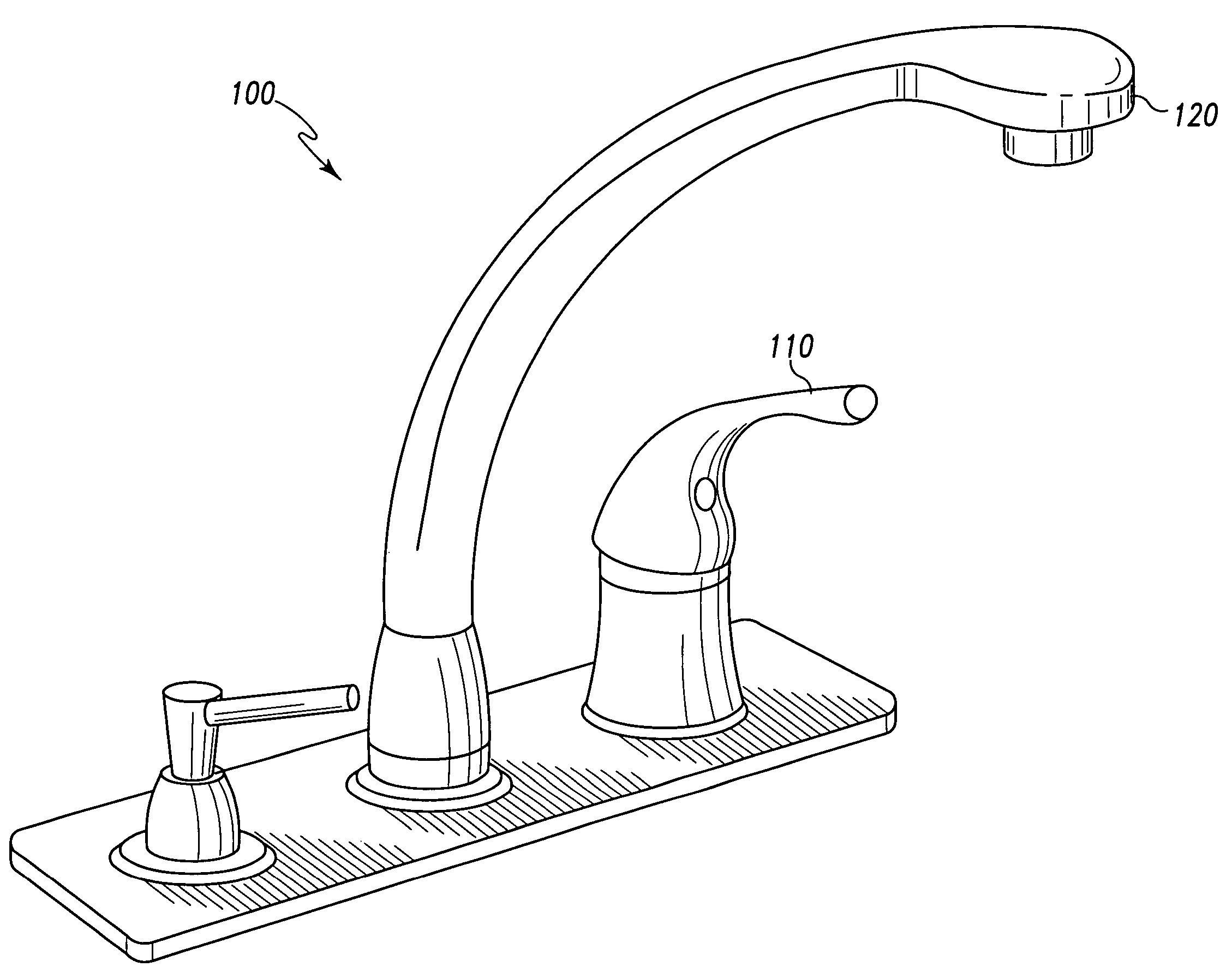

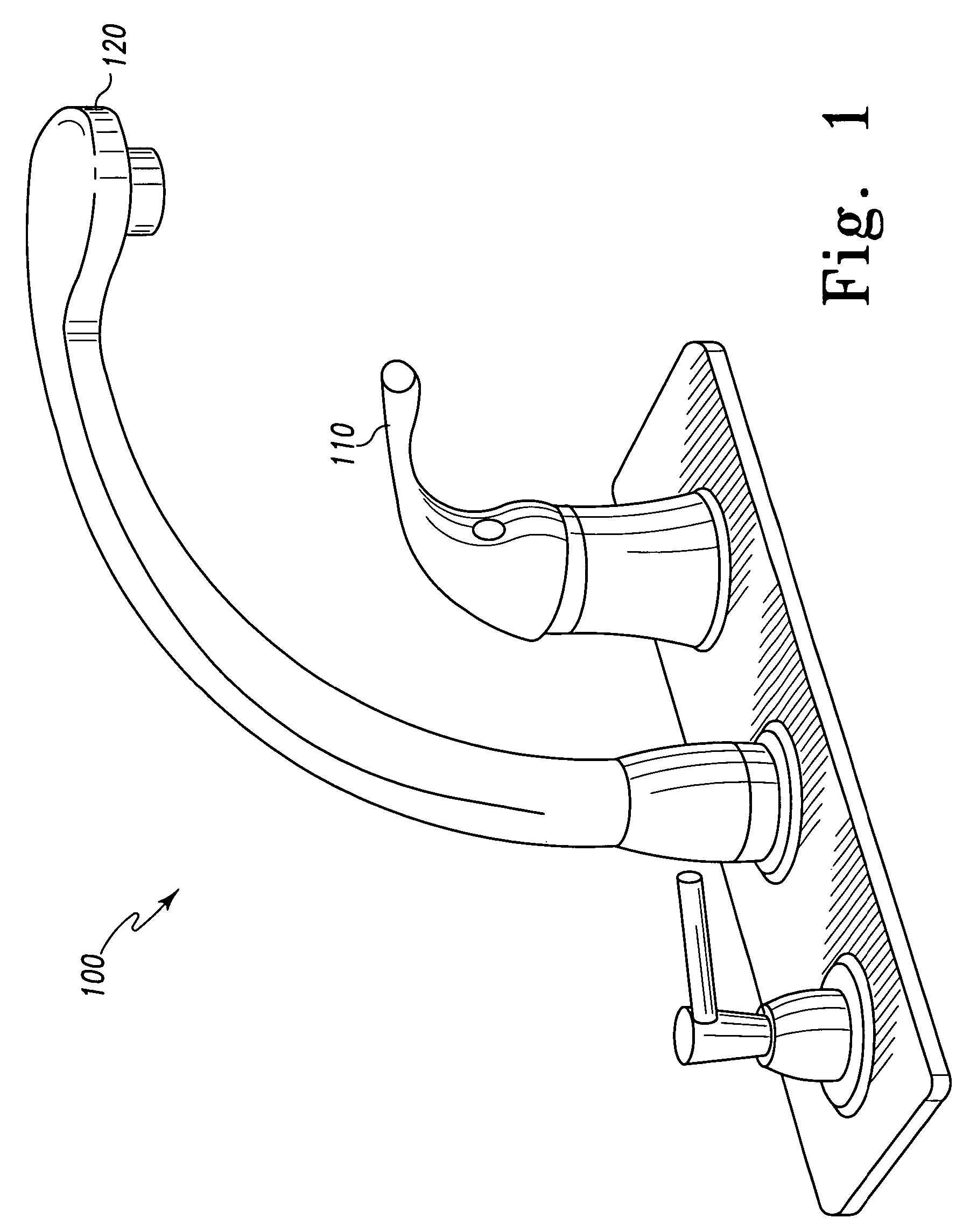

Capacitive touch on/off control for an automatic residential faucet

ActiveUS6962168B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A capacitive touch-controlled automatic faucet comprises: a spout, a magnetically latching valve, a proximity sensor, a handle, a capacitive touch-control, and a logical control. The proximity sensor is sensitive to motion of objects within a detection zone of the proximity sensor. The handle determines a water flow rate and temperature. The capacitive touch-control is positioned in the spout and generates an output signal while the touch-control is in contact with a user. The logical control receives the output signal, and toggles the magnetically latching valve when the output signal begins and ends within a period of time less than a predetermined threshold, but does not toggle the magnetically latching valve when the output signal persists for a period longer than the predetermined threshold. The faucet has a manual mode, wherein the proximity sensor is inactive, and a hands-free mode, wherein water flow is toggled in response to the proximity sensor.

Owner:DELTA FAUCET COMPANY

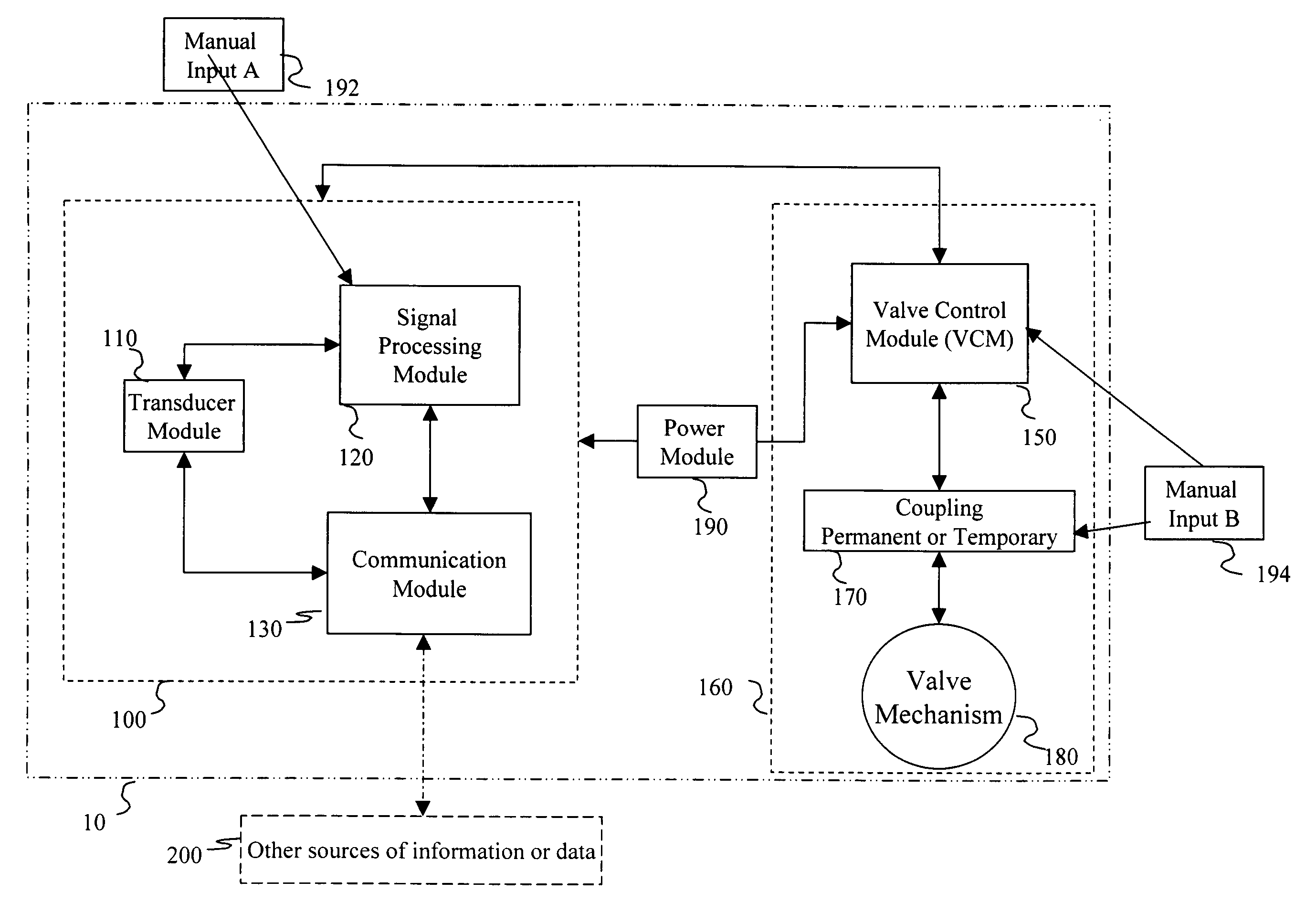

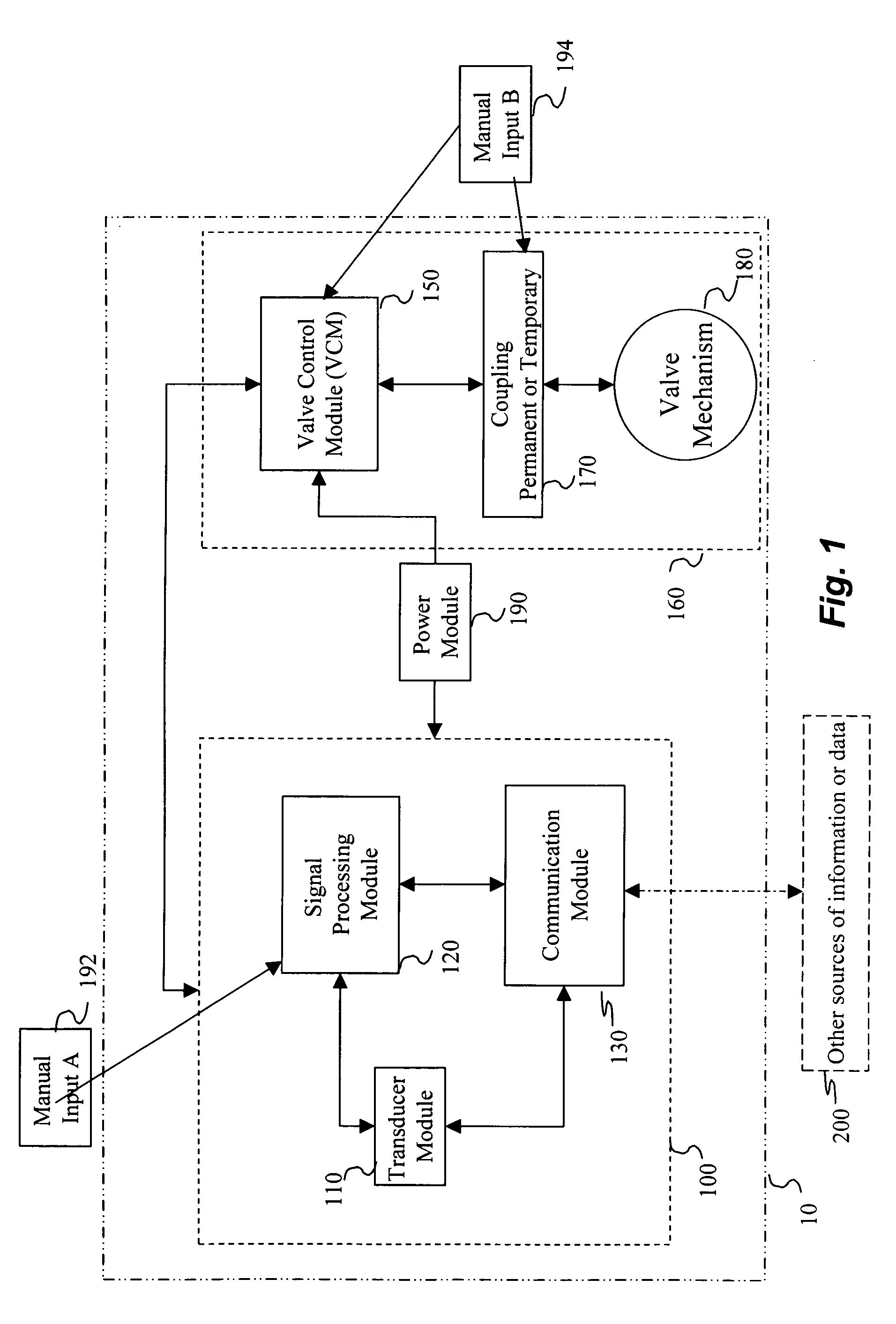

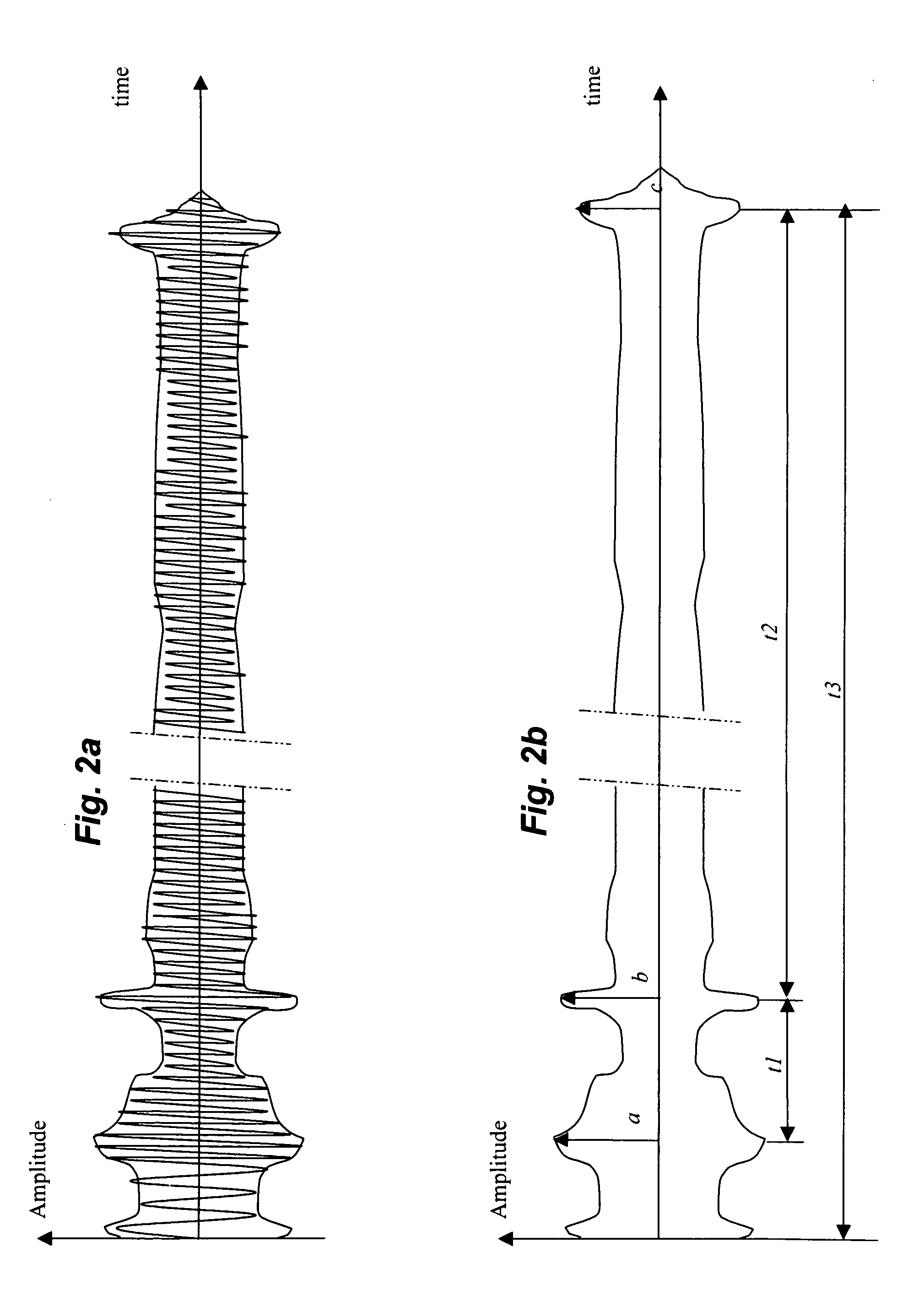

Intelligent valve control methods and systems

InactiveUS20060174707A1ConfidenceQuick couplingDetection of fluid at leakage pointVibration measurement in fluidSmoke detectorsElectricity

A method for determining a burst pipe that requires immediate feeding-valve closing using acoustic and / or vibration sensors coupled to the pipe lor detecting signals, a microprocessor for analyzing signals from said sensors in real-time, a memory coupled to said microprocessor for storing data, including digital signatures acoustic and / or vibration signatures, as well as an actuator electrically coupled to said microprocessor and mechanically coupled to said feeding-valve. When the sensor signals match stored leak-signatures or when a persistent sensor signal produces no match, the system of the present invention initiates a valve closing. To improve detection, signals from other sensors, i.e. water sensors, smoke detectors, heat sensors or acoustic / vibration sensors mounted on other pipes are also used. Some of the said systems have IP addresses and can communicate over the Internet or wirelessly with others.

Owner:ZHANG JACK K

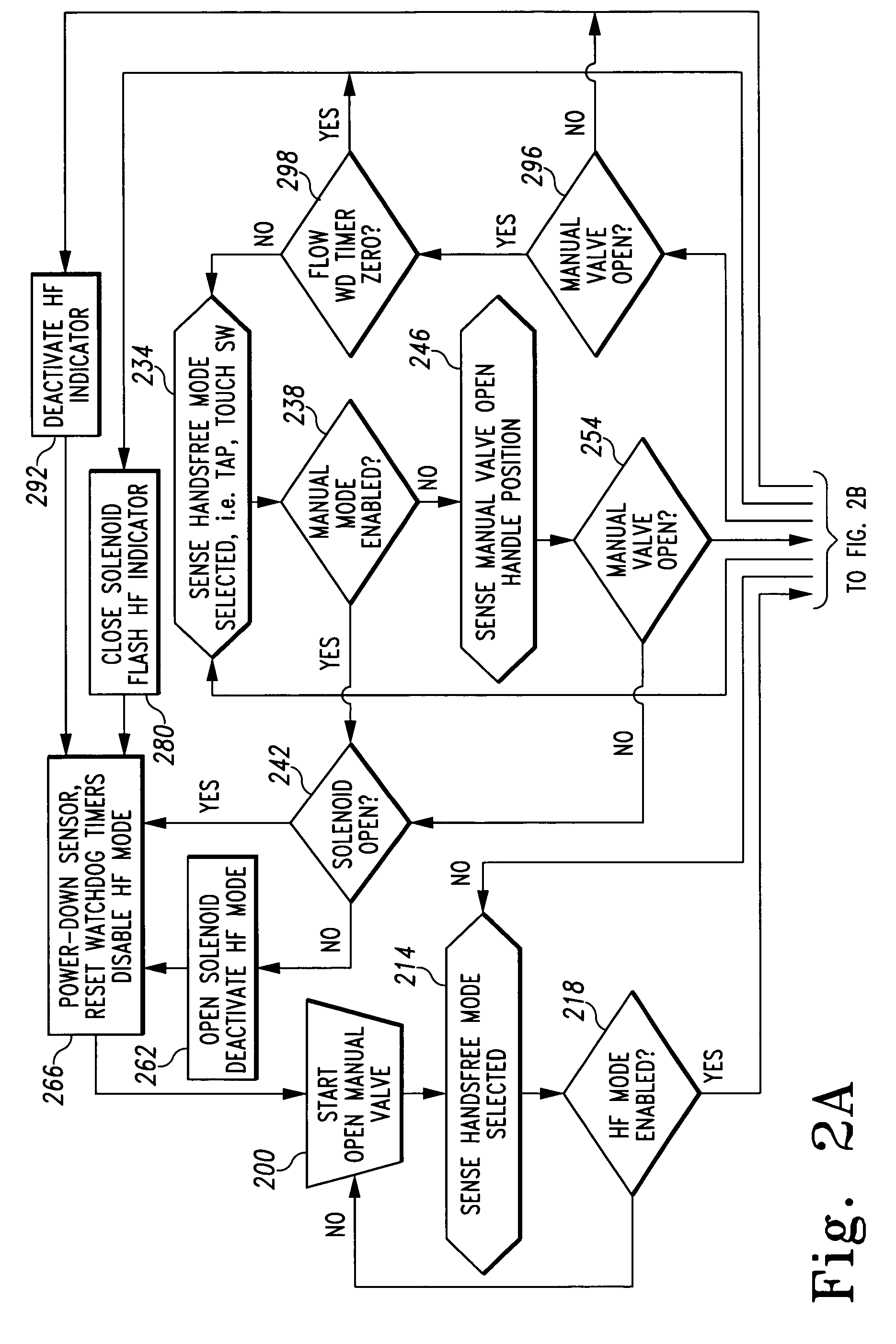

Multi-mode hands free automatic faucet

ActiveUS7690395B2Operating means/releasing devices for valvesFlow control using electric meansProximity sensorEngineering

A hands-free faucet comprises a proximity sensor, a logical control, a handle, a spout, and a touch control operably coupled to at least one of the spout and the handle.

Owner:DELTA FAUCET COMPANY

Multi-mode hands free automatic faucet

ActiveUS7150293B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A hands-free faucet comprises a proximity sensor, a logical control, a handle including a first touch control, a second touch control, and a mode indicator. The logical control has a manual mode (wherein the proximity sensor is inactive, and water flow is toggled on and off by positioning the handle) and a hands-free mode (wherein water flow is toggled on and off in response to the proximity sensor). The first touch control puts the faucet in the hands-free mode when touched by a user. The second touch control toggles the logical control between the hands-free mode and the manual mode when touched by a user. The mode indicator indicates which mode the faucet is presently in. The water flow has a temperature and a flow rate that are determined by the position of the handle.

Owner:DELTA FAUCET COMPANY

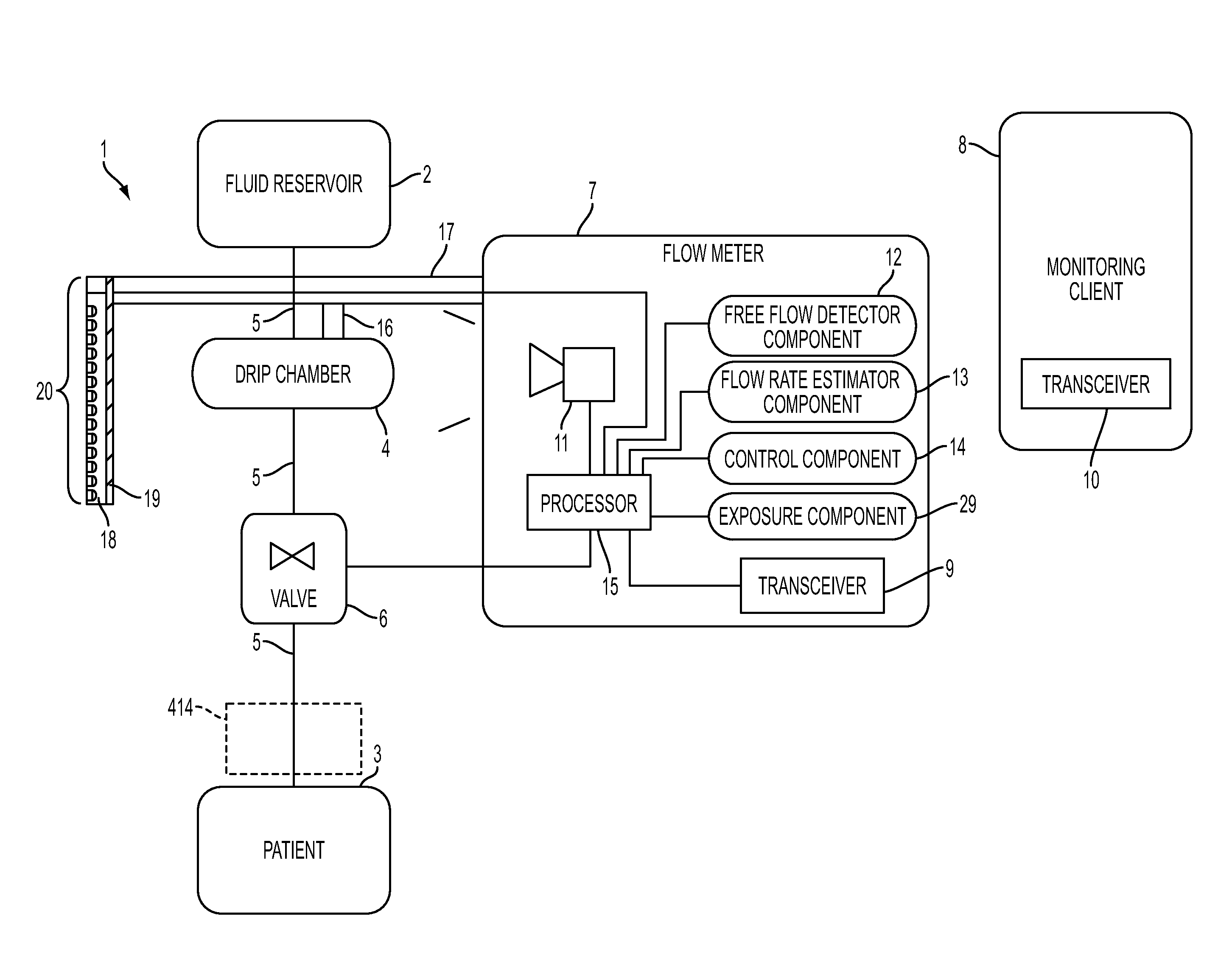

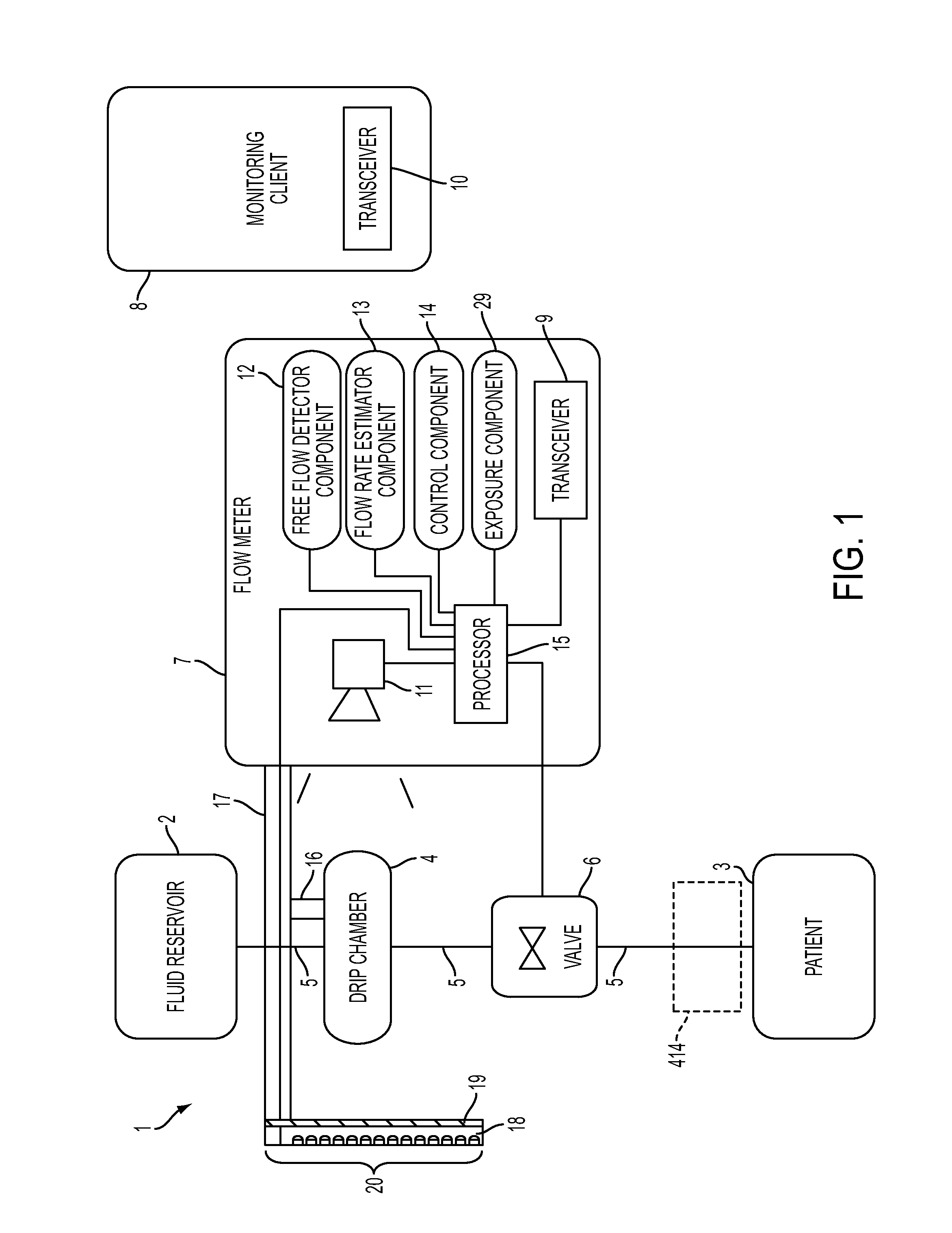

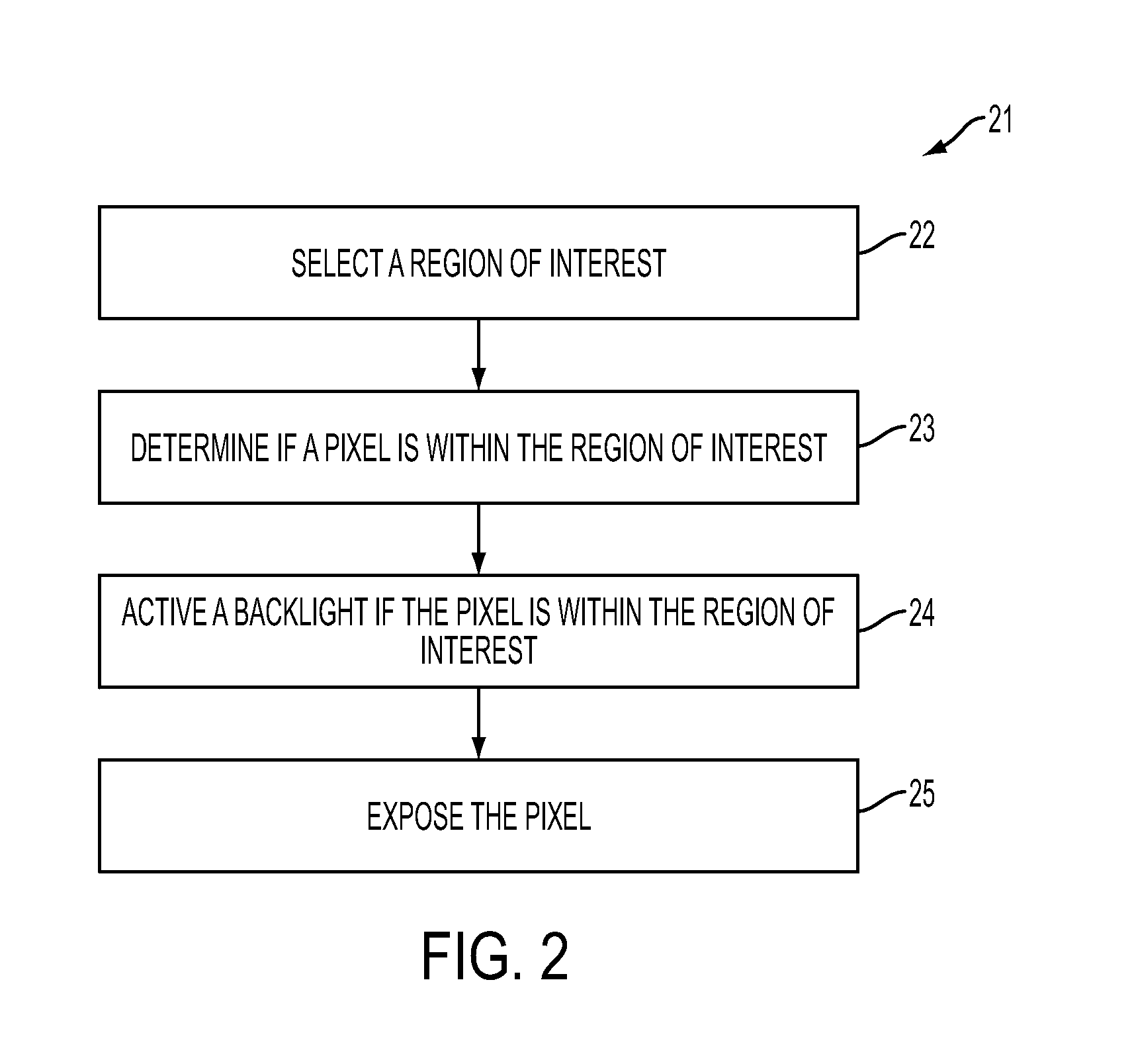

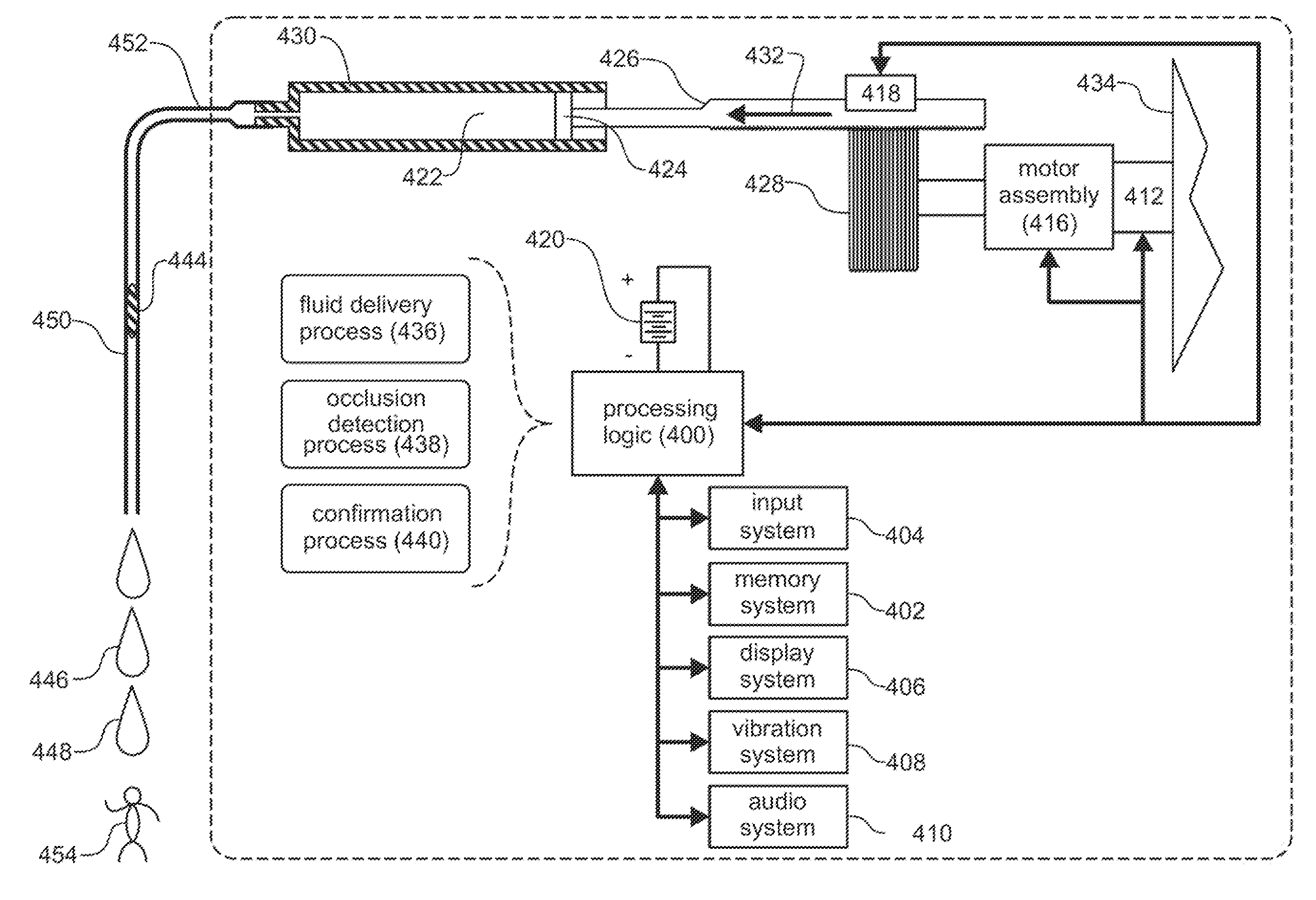

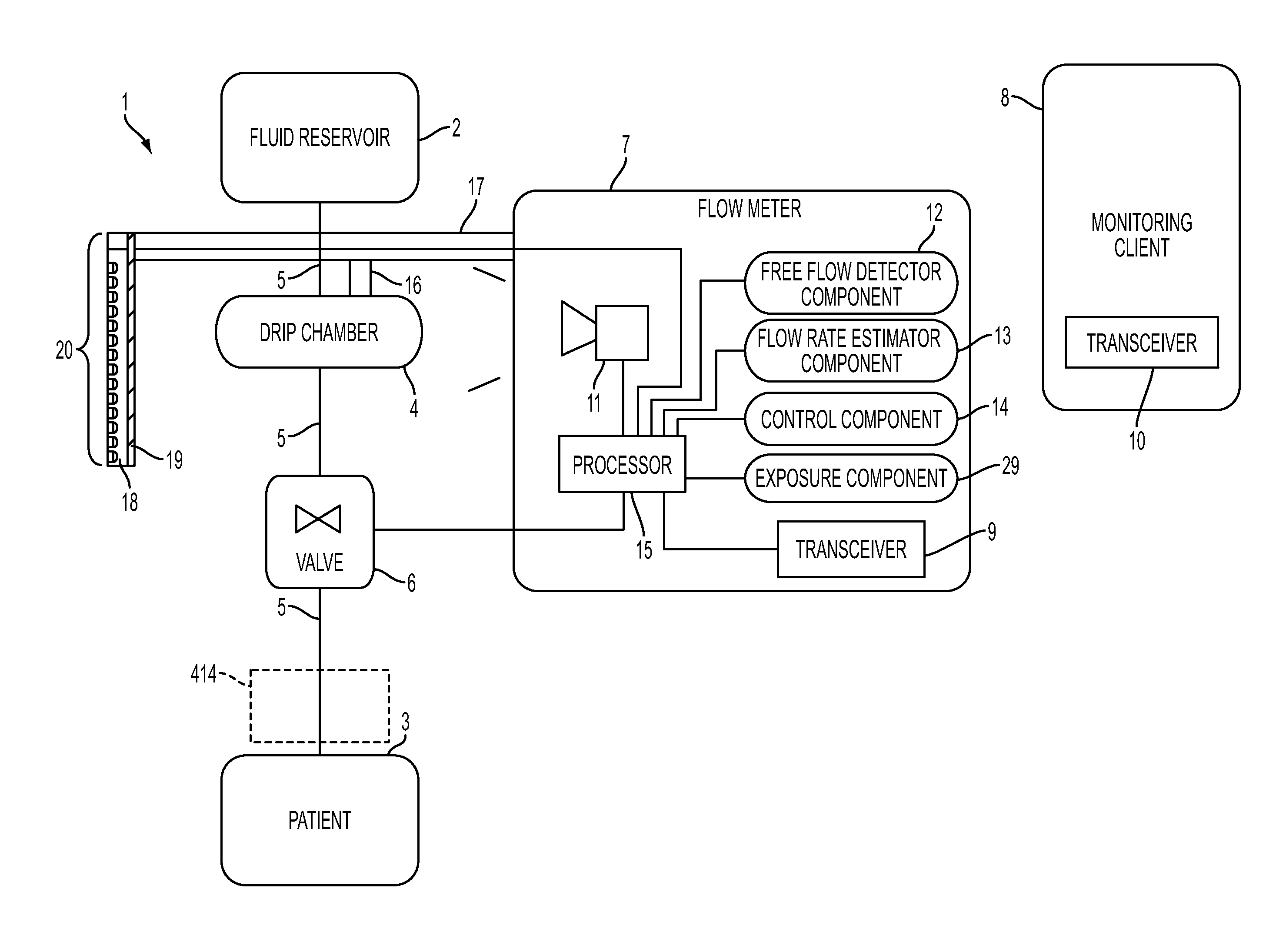

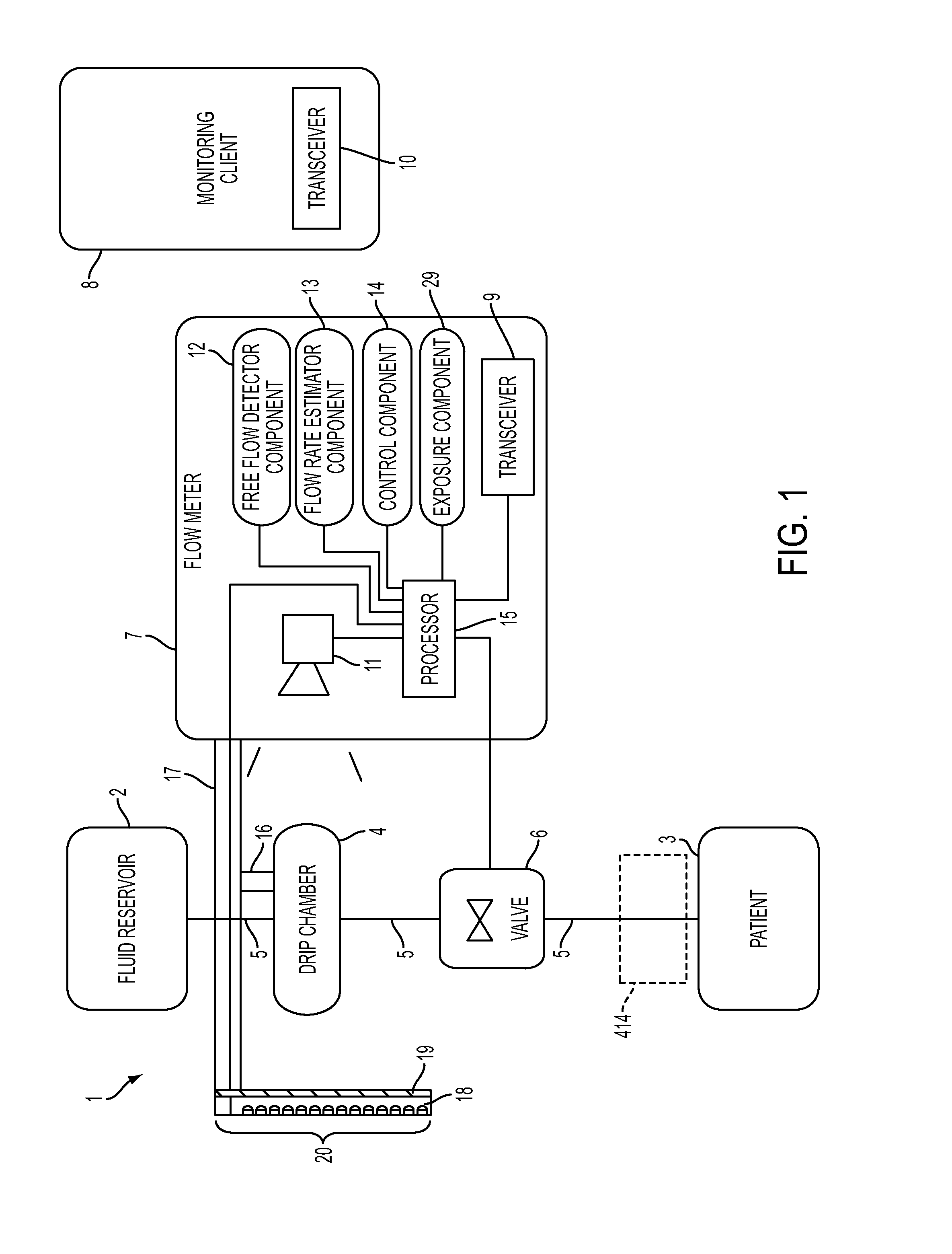

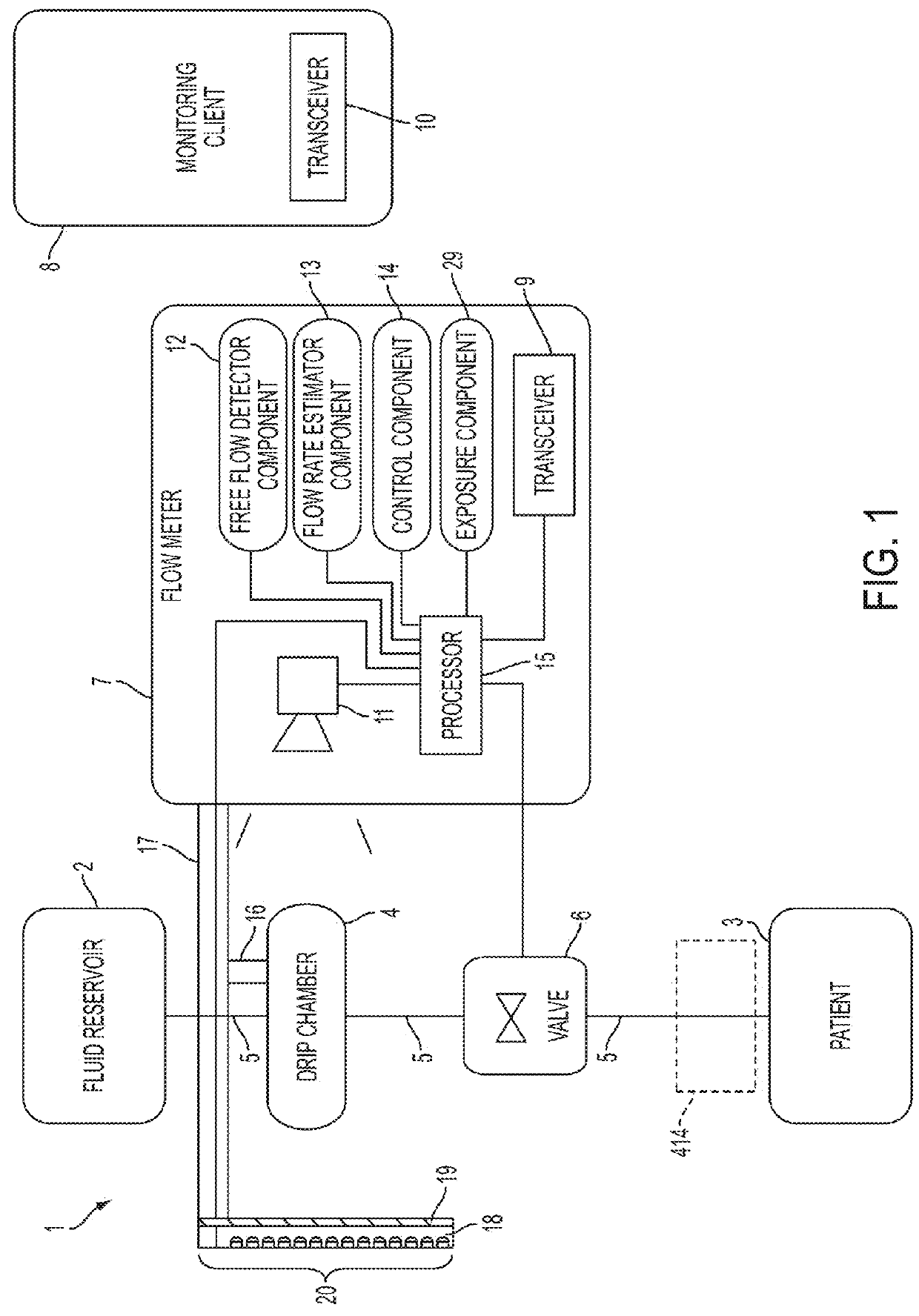

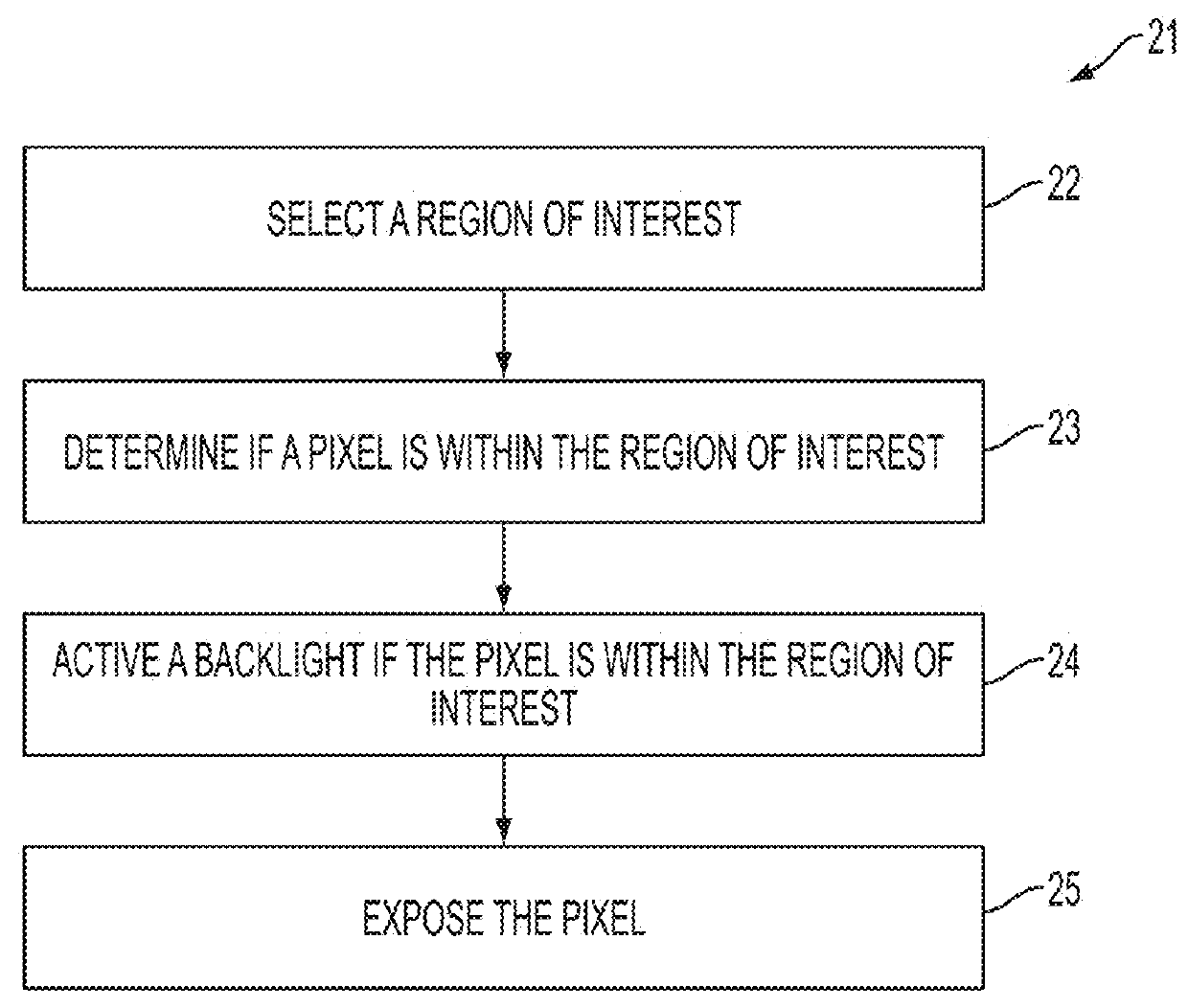

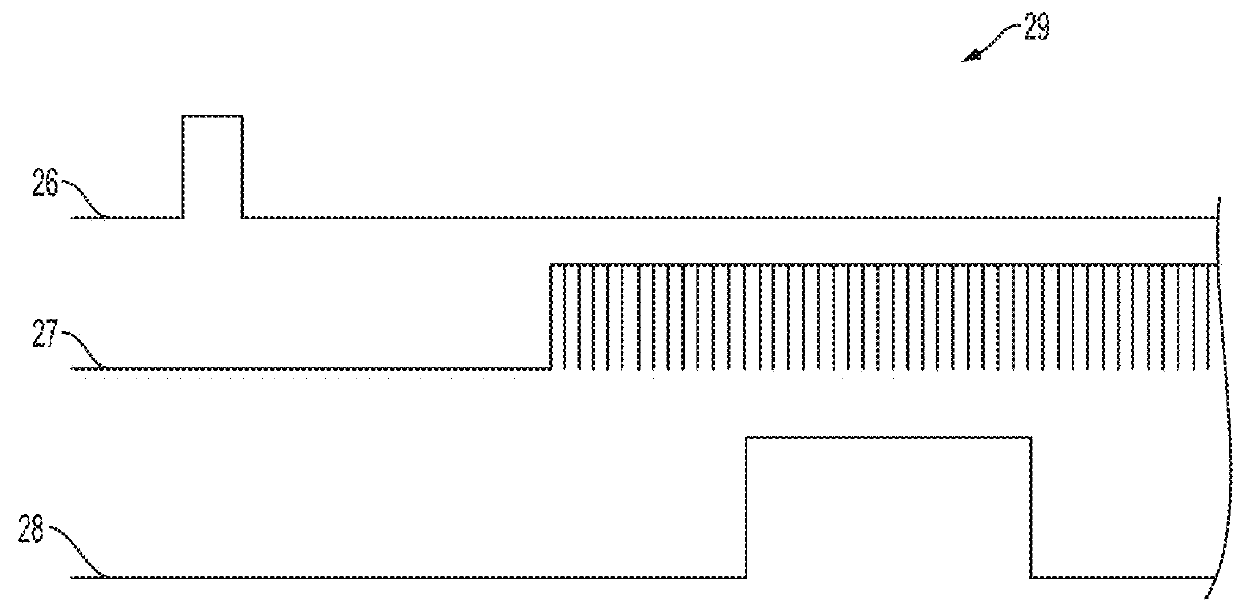

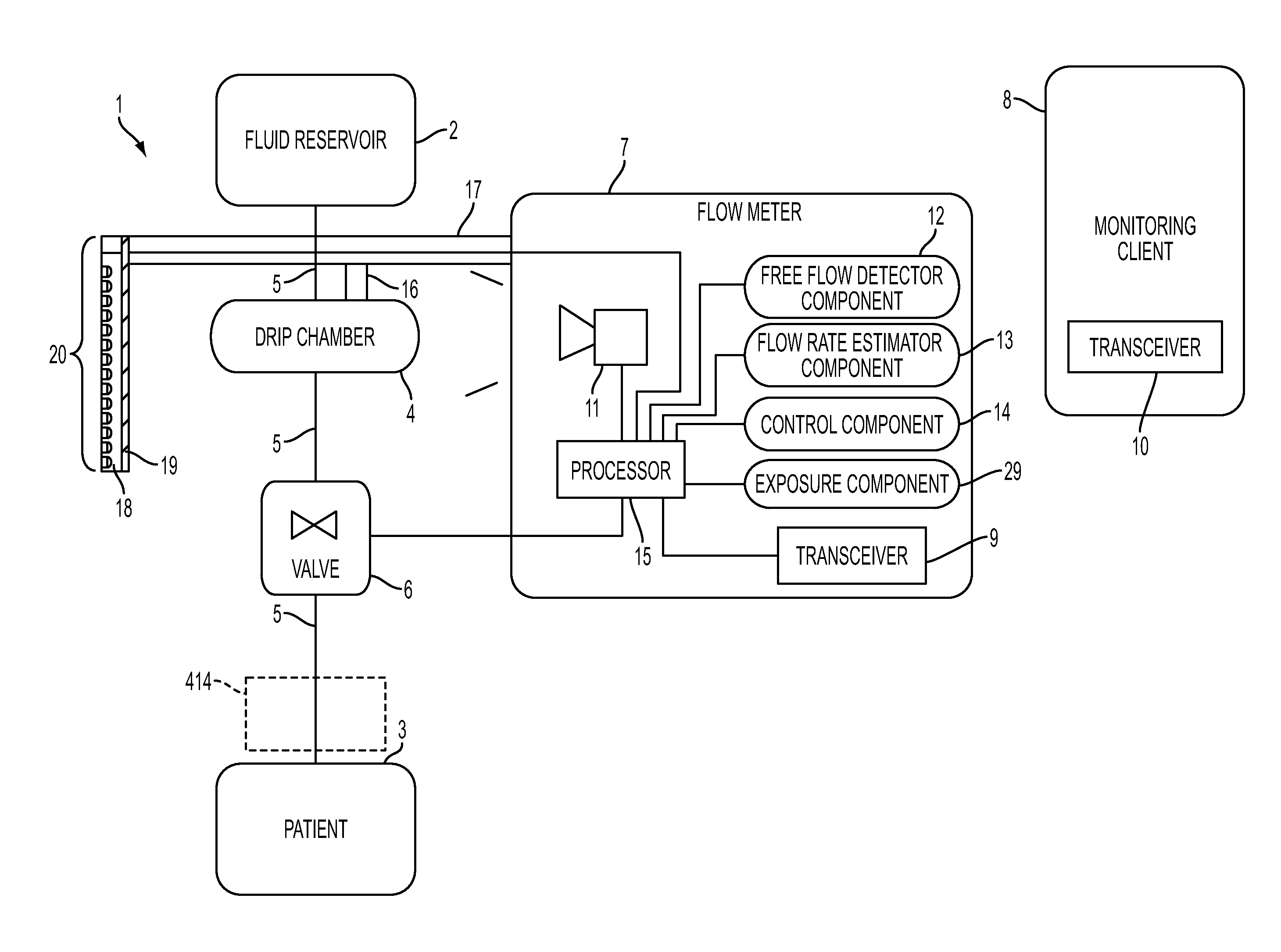

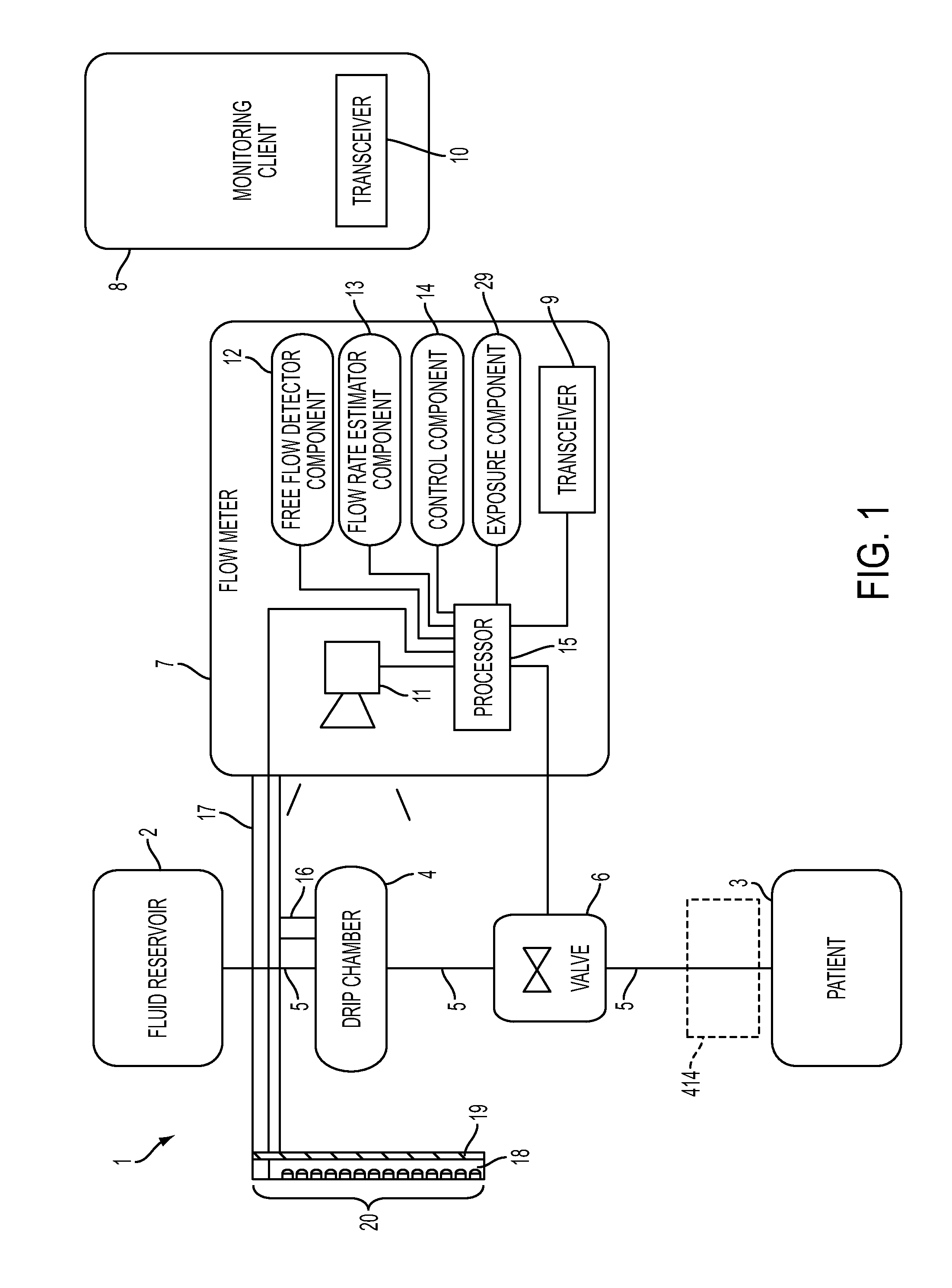

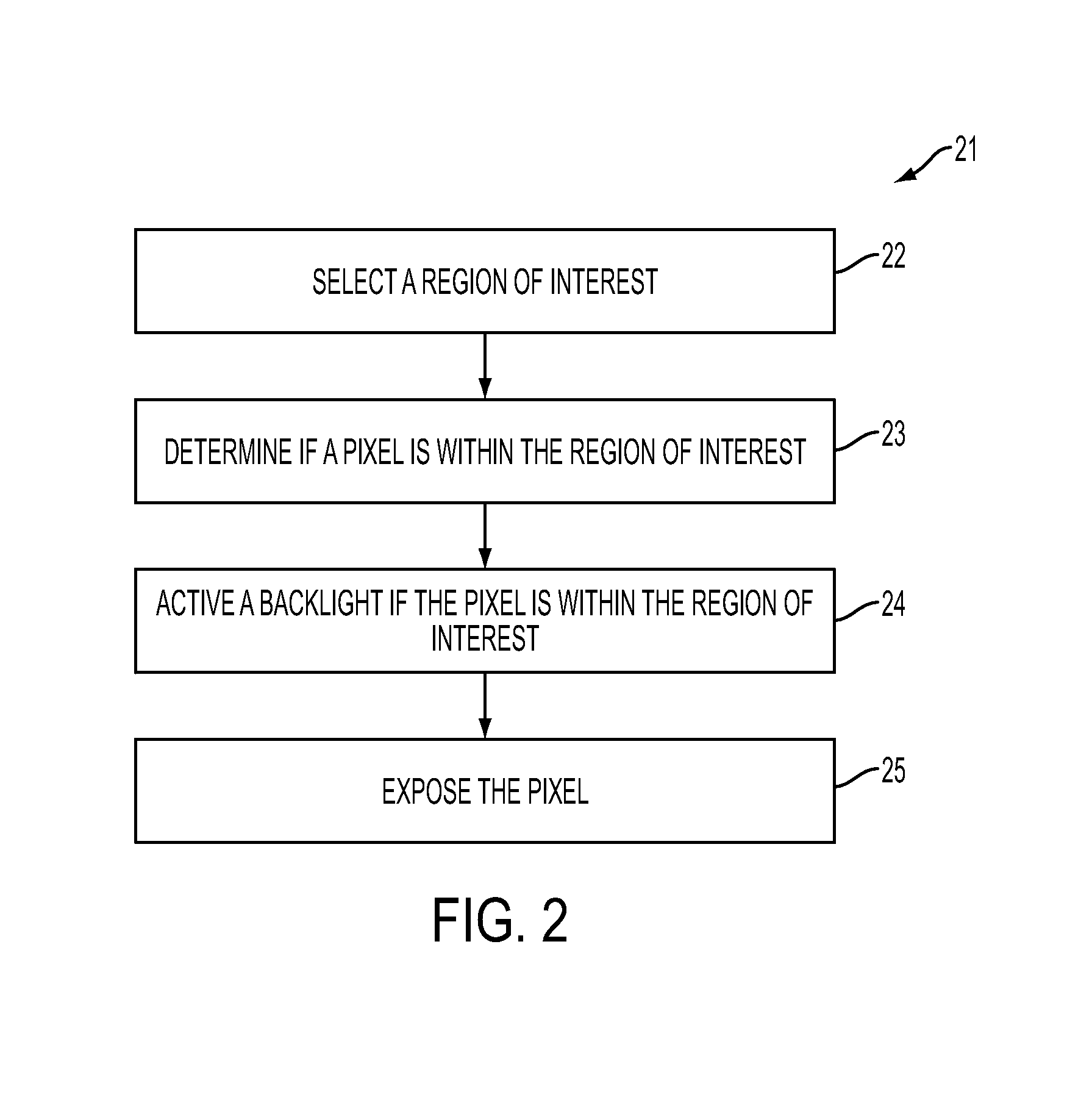

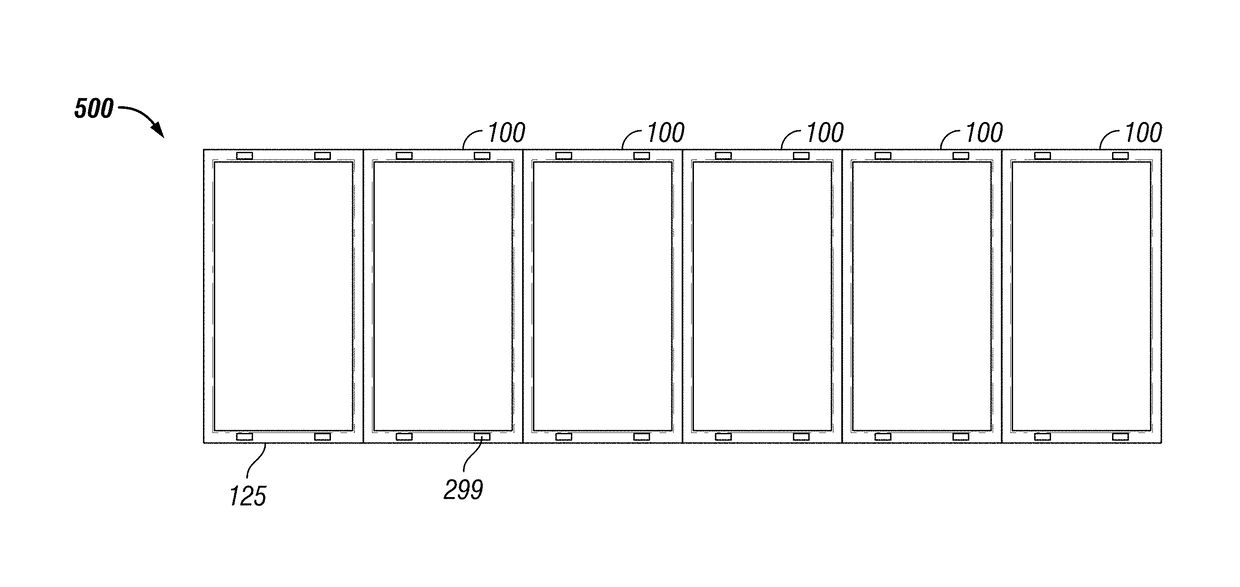

System, Method, and Apparatus for Monitoring, Regulating, or Controlling Fluid Flow

ActiveUS20130310990A1Reduce internal volumeReduce liquid volumeImage analysisEngine diaphragmsEngineeringActuator

A flow meter, and related system and method are provided. The flow meter includes a coupler, a support member, an image sensor, a valve, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within the field of view. The one or more processors are operatively coupled to the image sensor to receive image data therefrom and to the actuator to actuate the valve. The one or more processors are configured to estimate a flow of fluid through the drip chamber and to actuate the valve to control the flow of fluid through the drip chamber to achieve a target flow rate.

Owner:DEKA PROD LLP

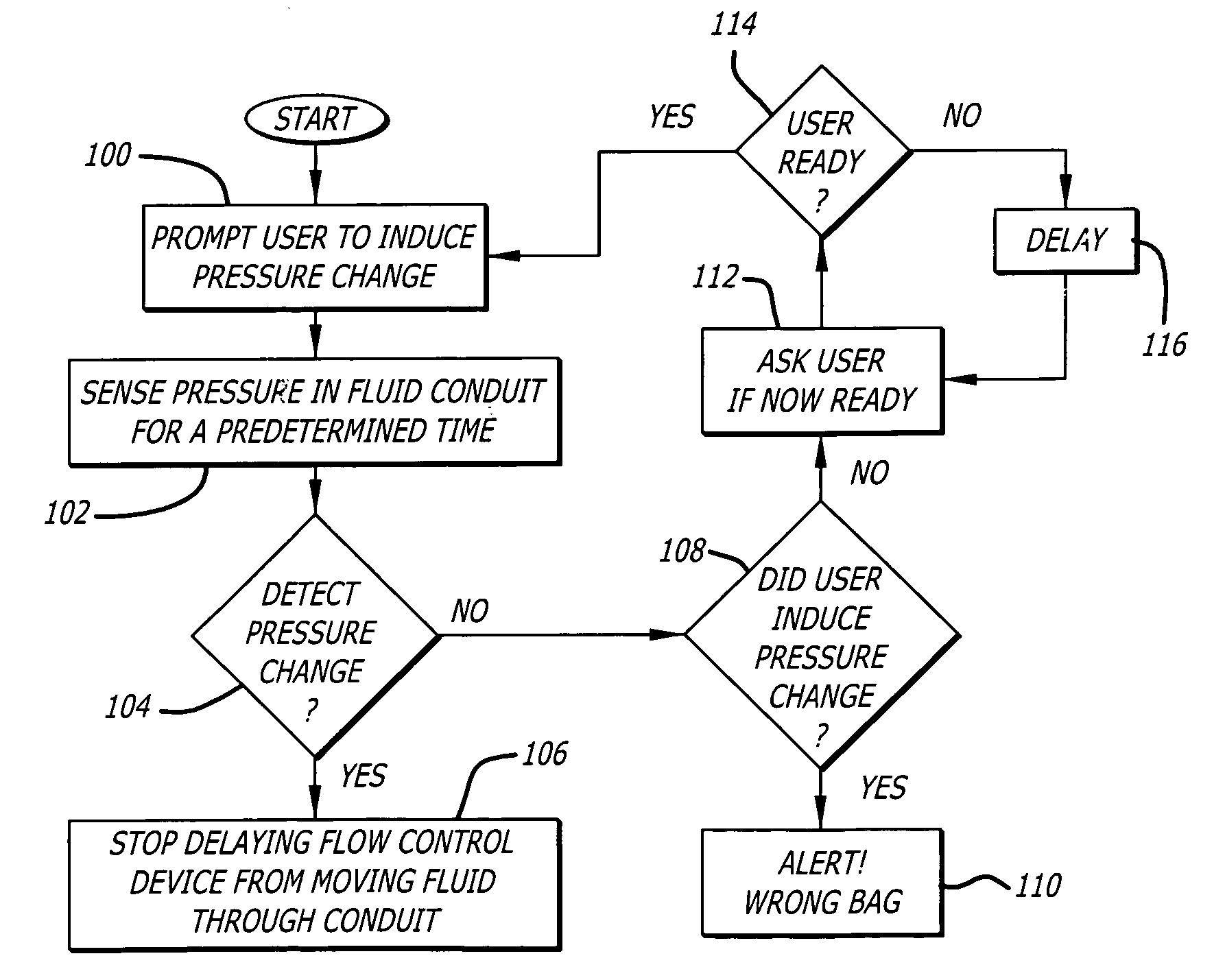

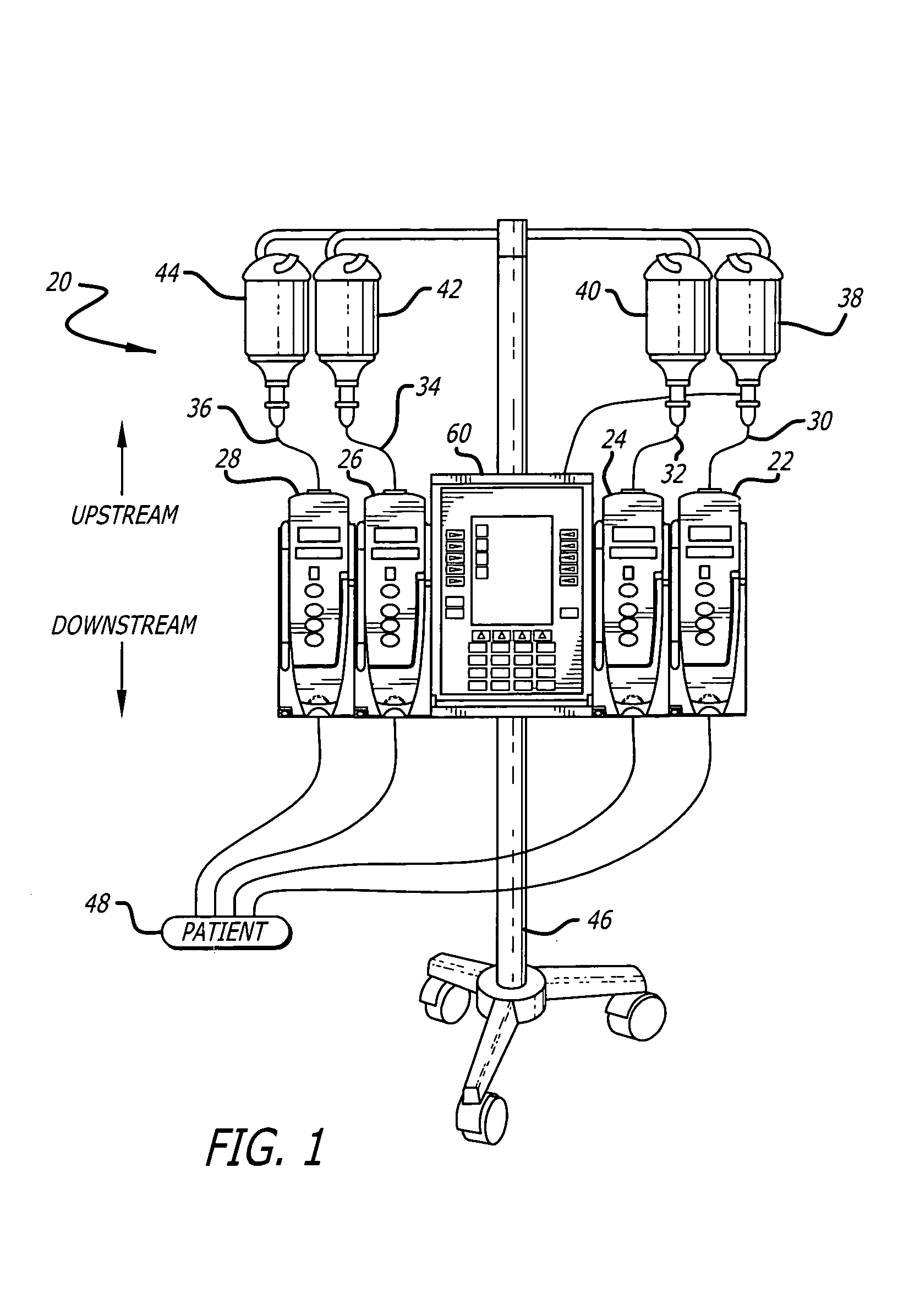

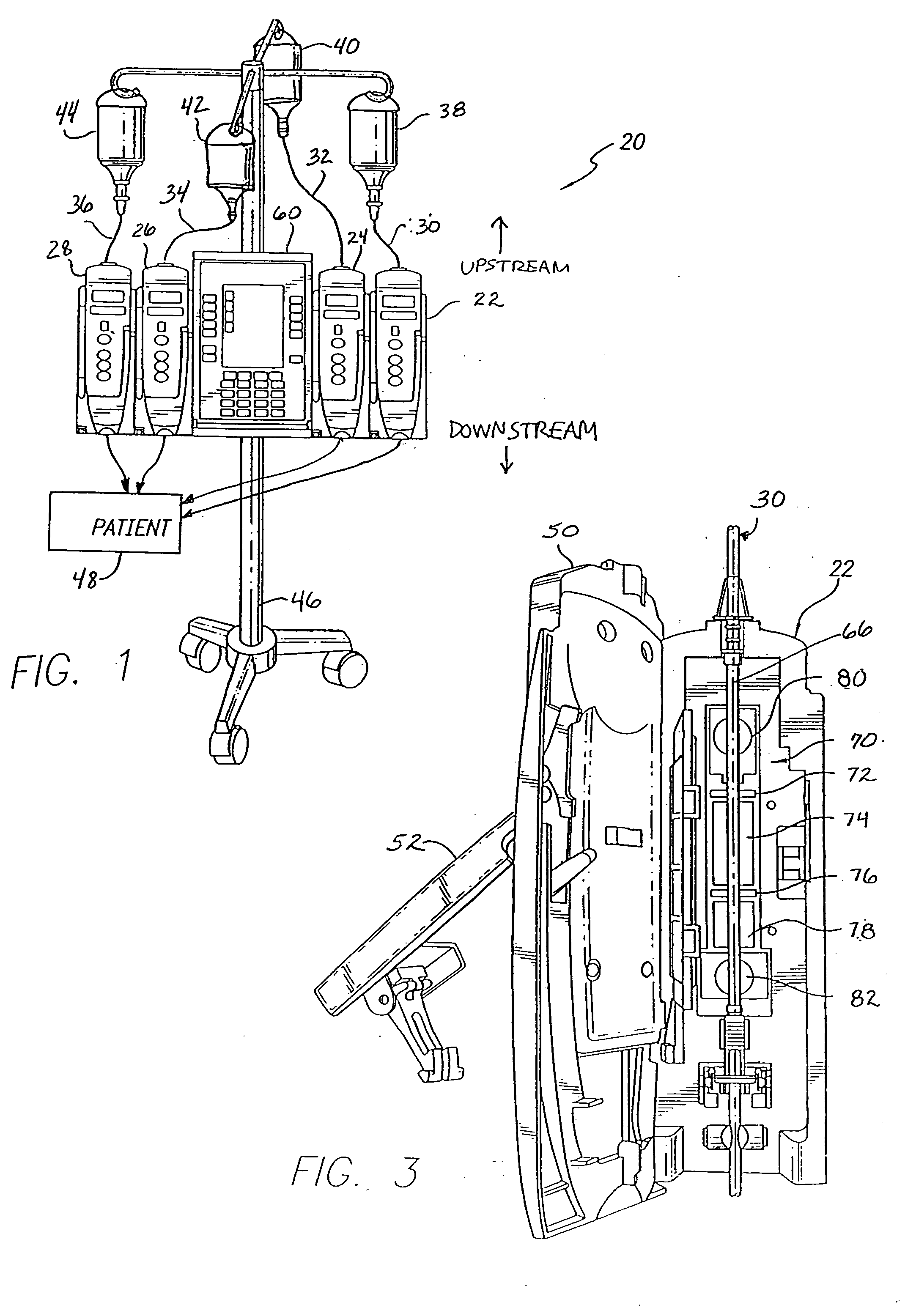

System and method for verifying connection of correct fluid supply to an infusion pump

A system and method for verifying that a particular fluid supply is connected to an infusion pump or pump channel. An upstream pressure sensor coupled to a fluid conduit associated with the fluid supply is used to provide pressure signals in response to pressure sensed in the conduit to a processor. In a connection verification mode, the processor is configured to receive the pressure signals and delay the flow control device of the infusion pump from moving fluid through the conduit until the processor detects a pressure change in the conduit indicated by the pressure signals to thereby verify that the particular fluid supply is connected to the infusion pump.

Owner:CAREFUSION 303 INC

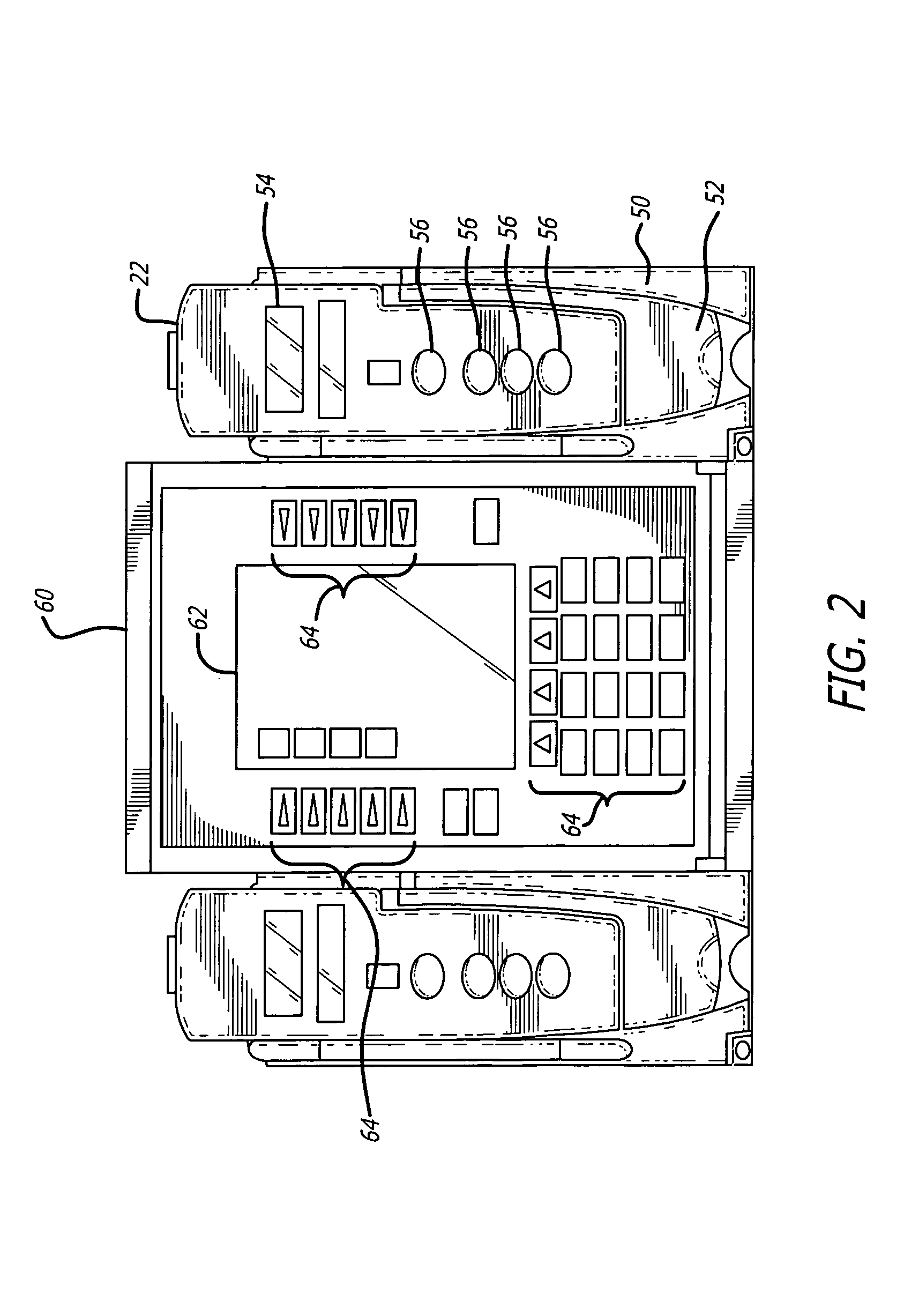

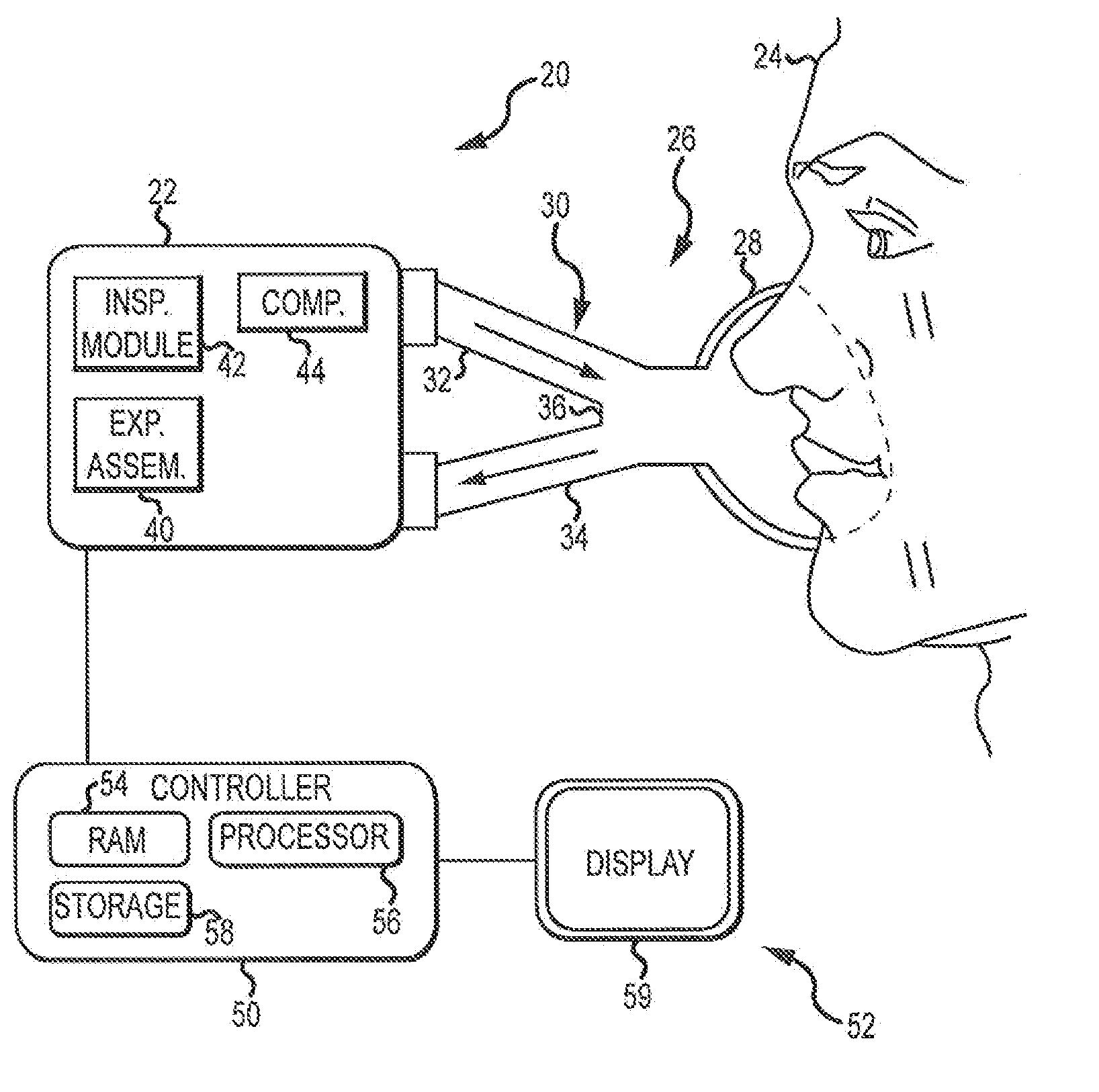

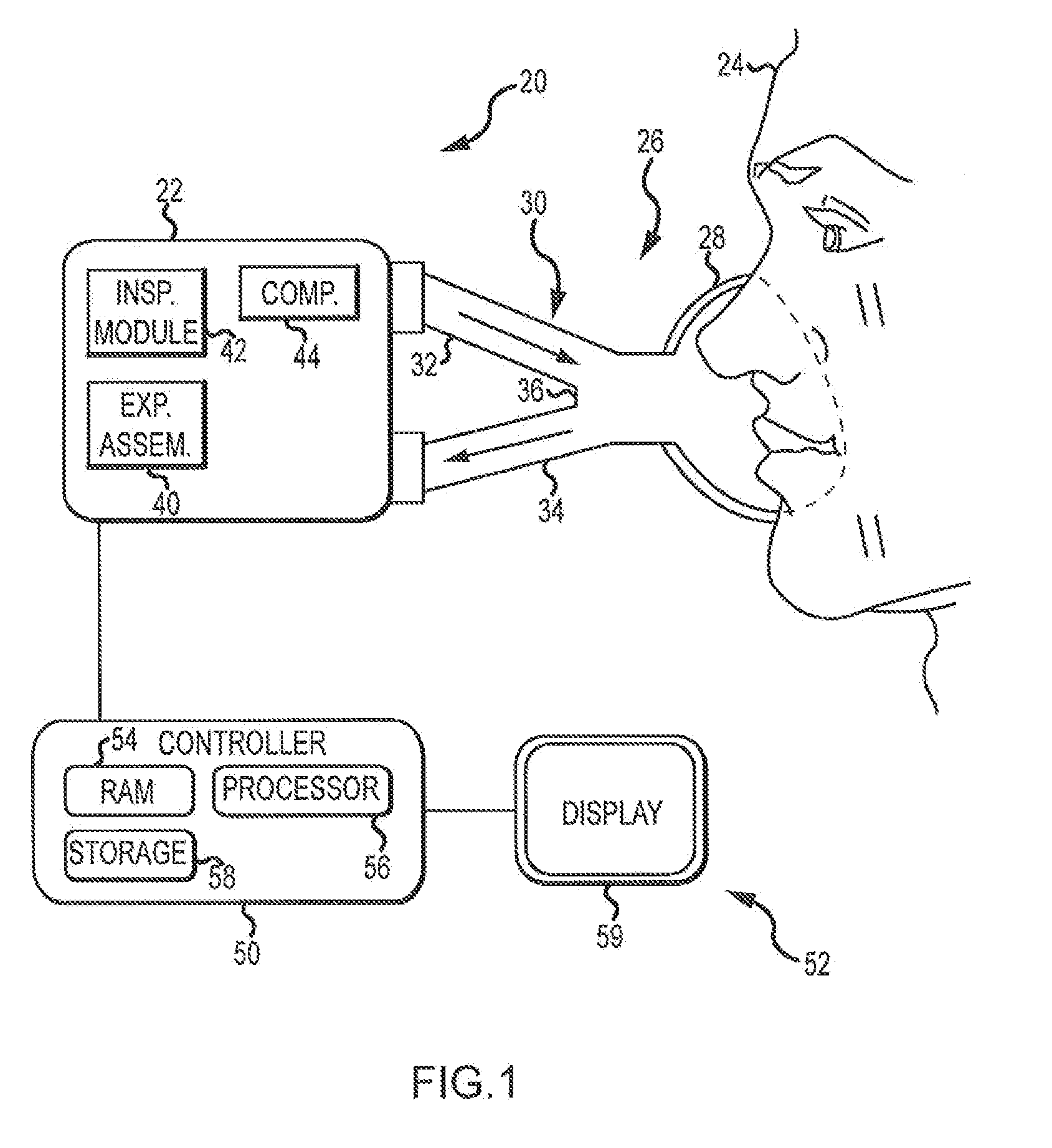

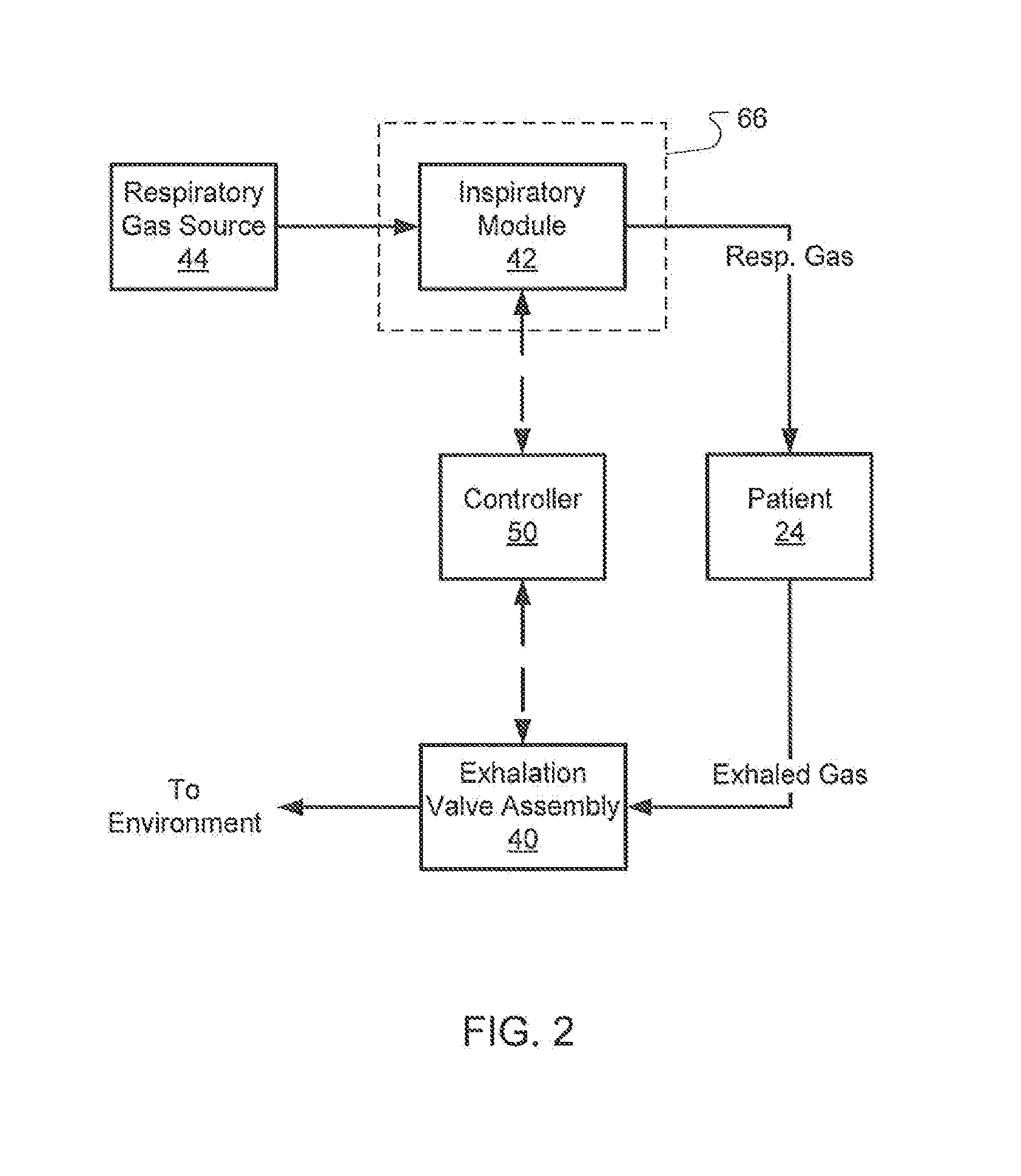

Exhalation Valve Assembly

An exhalation valve assembly that controls the pressure of exhaled gas in a ventilation system is described. The exhalation valve assembly includes an actuator module that may be fixed to the ventilation system and a valve module, removable for cleaning or disposal, through which the exhaled gas flows and that controls the pressure and release of the exhaled gas to the environment. Other components may also be incorporated into the assembly including a filter module, a flow meter and a condensate trap.

Owner:TYCO HEALTHCARE GRP LP

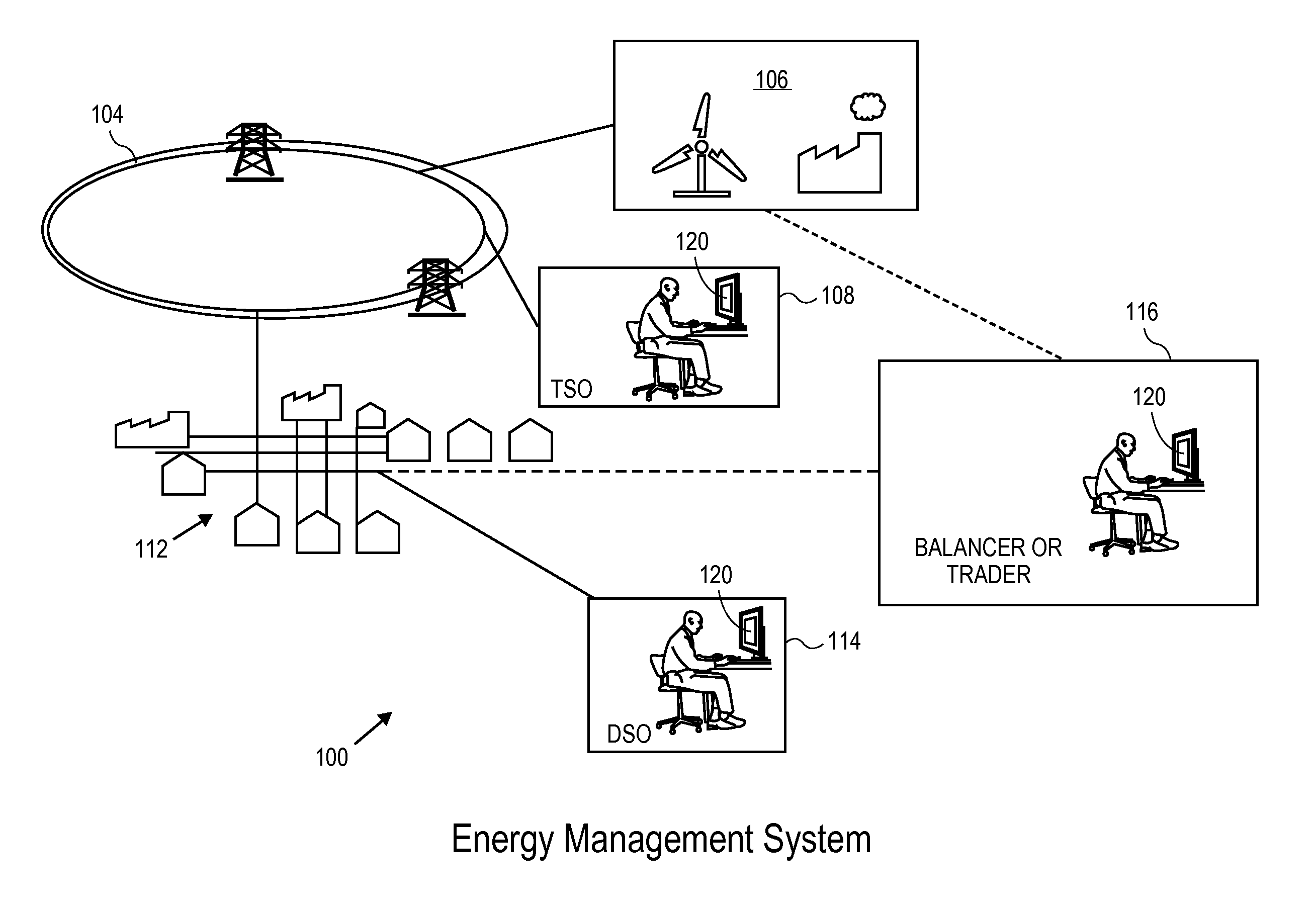

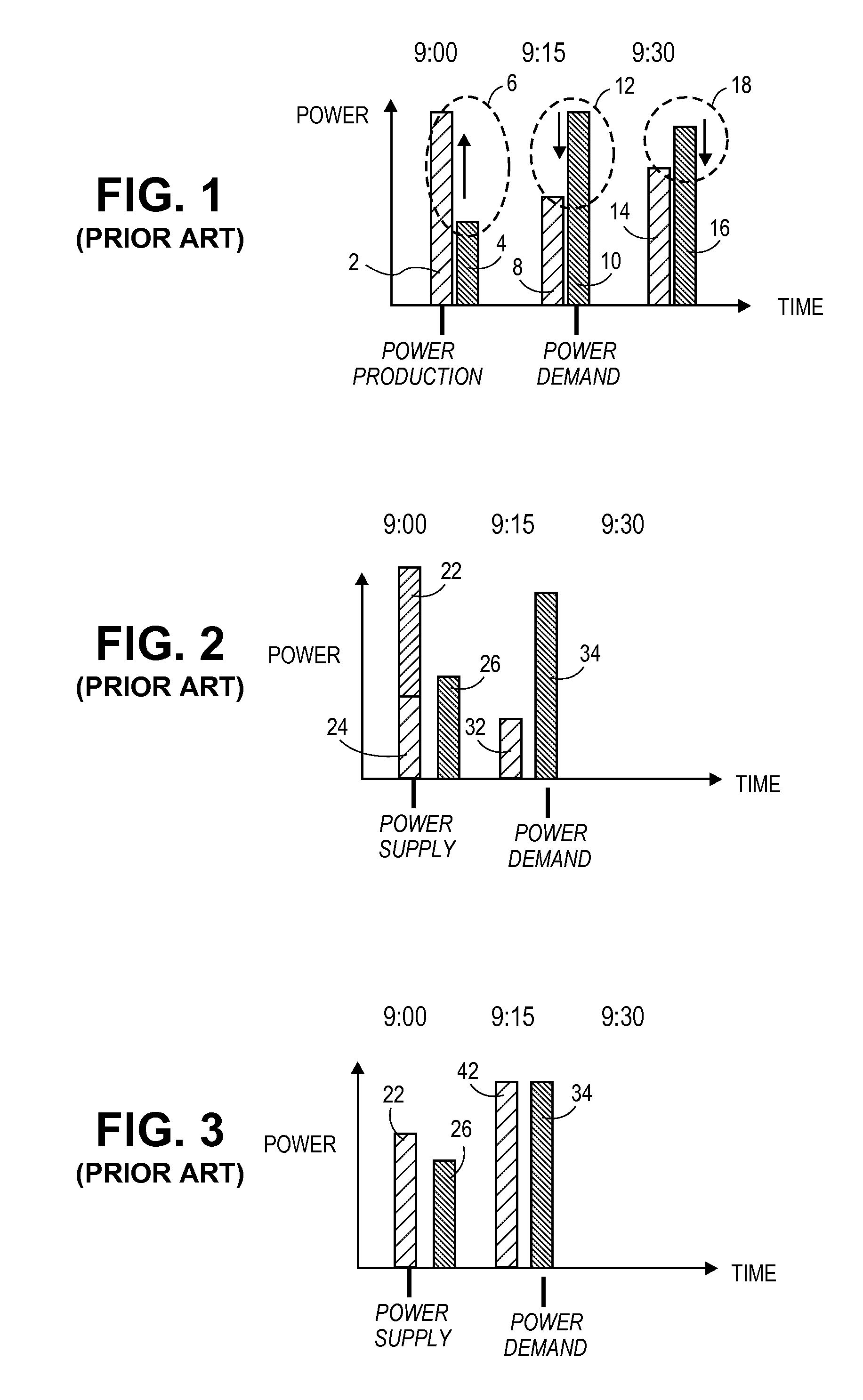

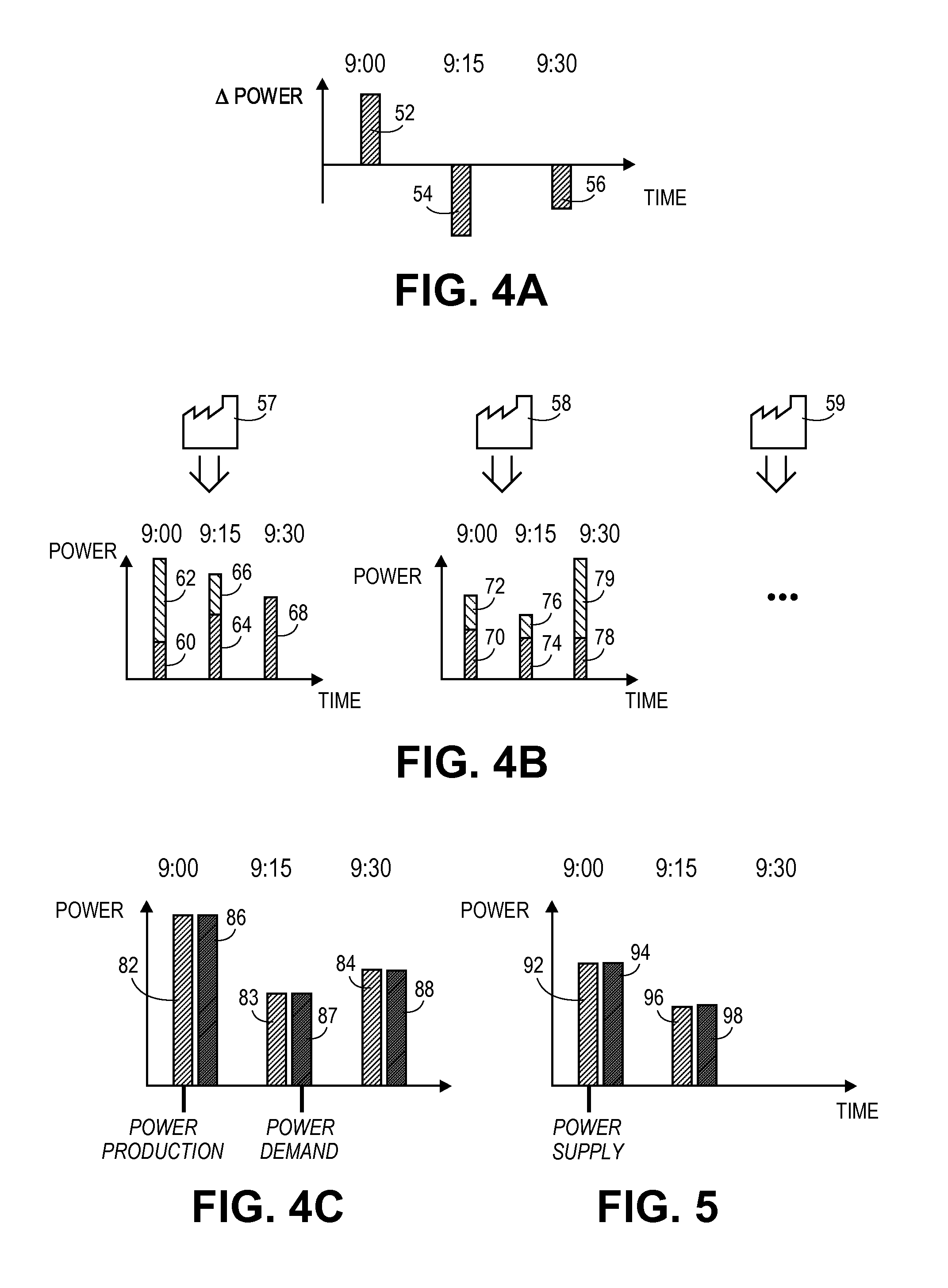

Automated demand response energy management system

The power flexibility of energy loads is maximized using a value function for each load and outputting optimal control parameters. Loads are aggregated into a virtual load by maximizing a global value function. The solution yields a dispatch function providing: a percentage of energy for each individual load, a time-varying power level for each load, and control parameters and values. An economic term represents the value of the power flexibility to different players. A user interface includes for each time interval upper and lower bounds representing respectively the maximum power that may be reduced to the virtual load and the maximum power that may be consumed. A trader modifies an energy level in a time interval relative to the reference curve for the virtual load. Automatically, energy compensation for other intervals and recalculation of upper and lower boundaries occurs. The energy schedule for the virtual load is distributed to the actual loads.

Owner:RESTORE

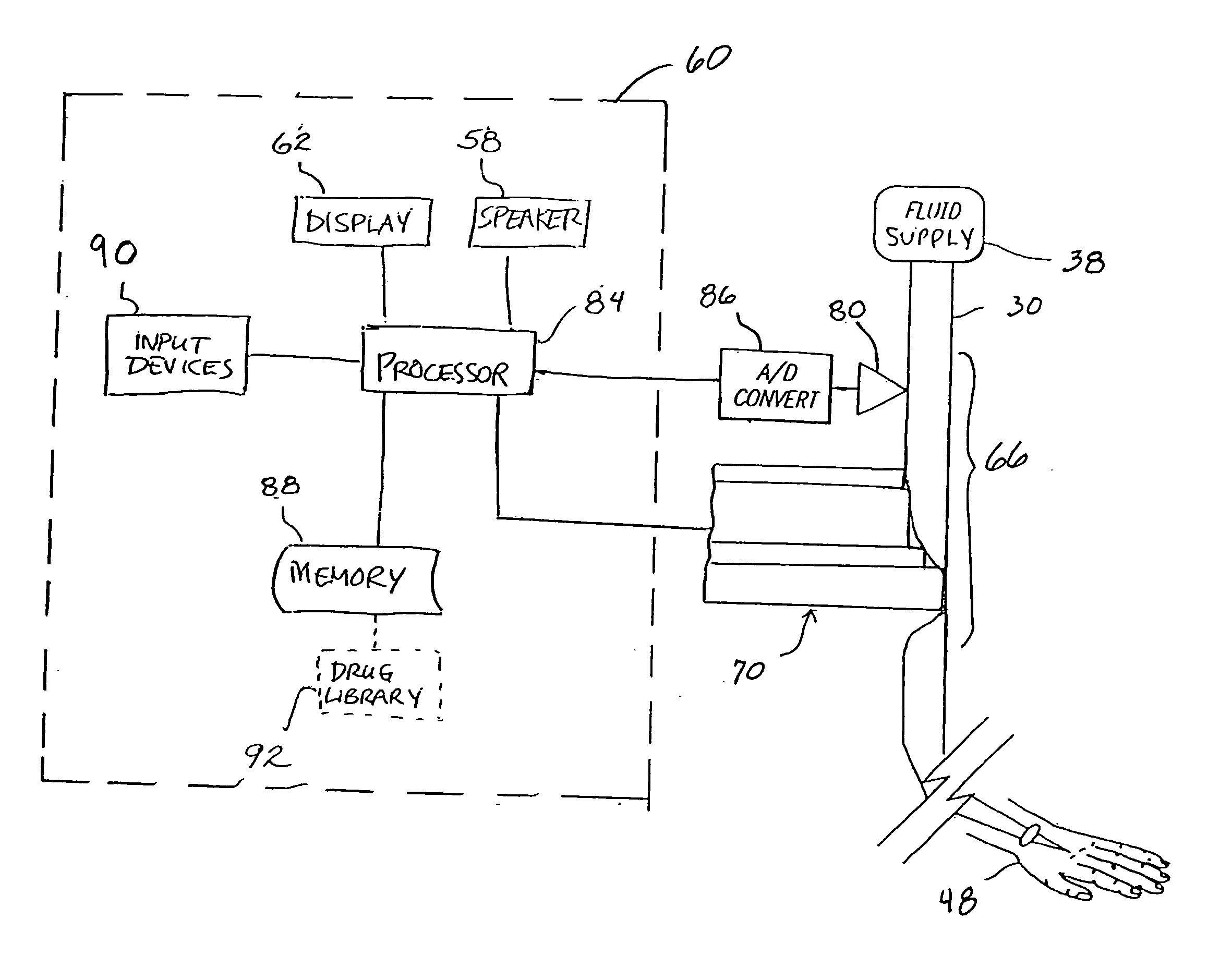

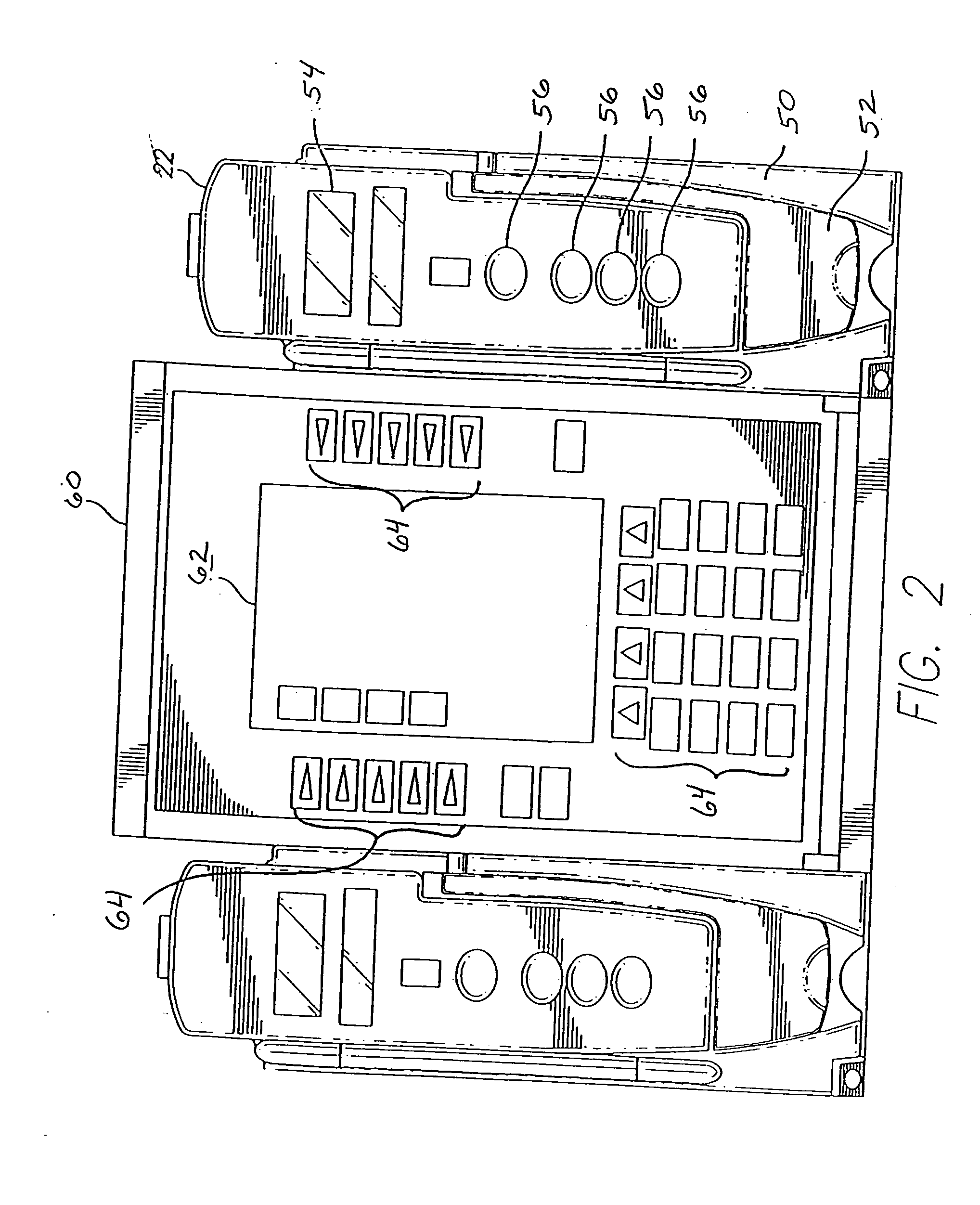

Methods and systems for controlling an infusion pump

A system for pairing a controller and an infusion pump is disclosed. The system includes an infusion pump, a controller device and a user interface residing on both the infusion pump and the controller. The user interface includes a pairing mode for enabling wireless communication between the infusion pump and the controller device, wherein the user interface requires both the infusion pump and the controller to be in the pairing mode simultaneously. Also, a method of changing a power source in an infusion pump is disclosed. The method includes placing the infusion pump in idle mode wherein the infusion pump stops delivery. Removing the first power source from the infusion pump. Replacing the first power source with a second power source in the infusion pump, and maintaining the insulin on board during the changing of the first power source with the second power source.

Owner:DEKA PROD LLP

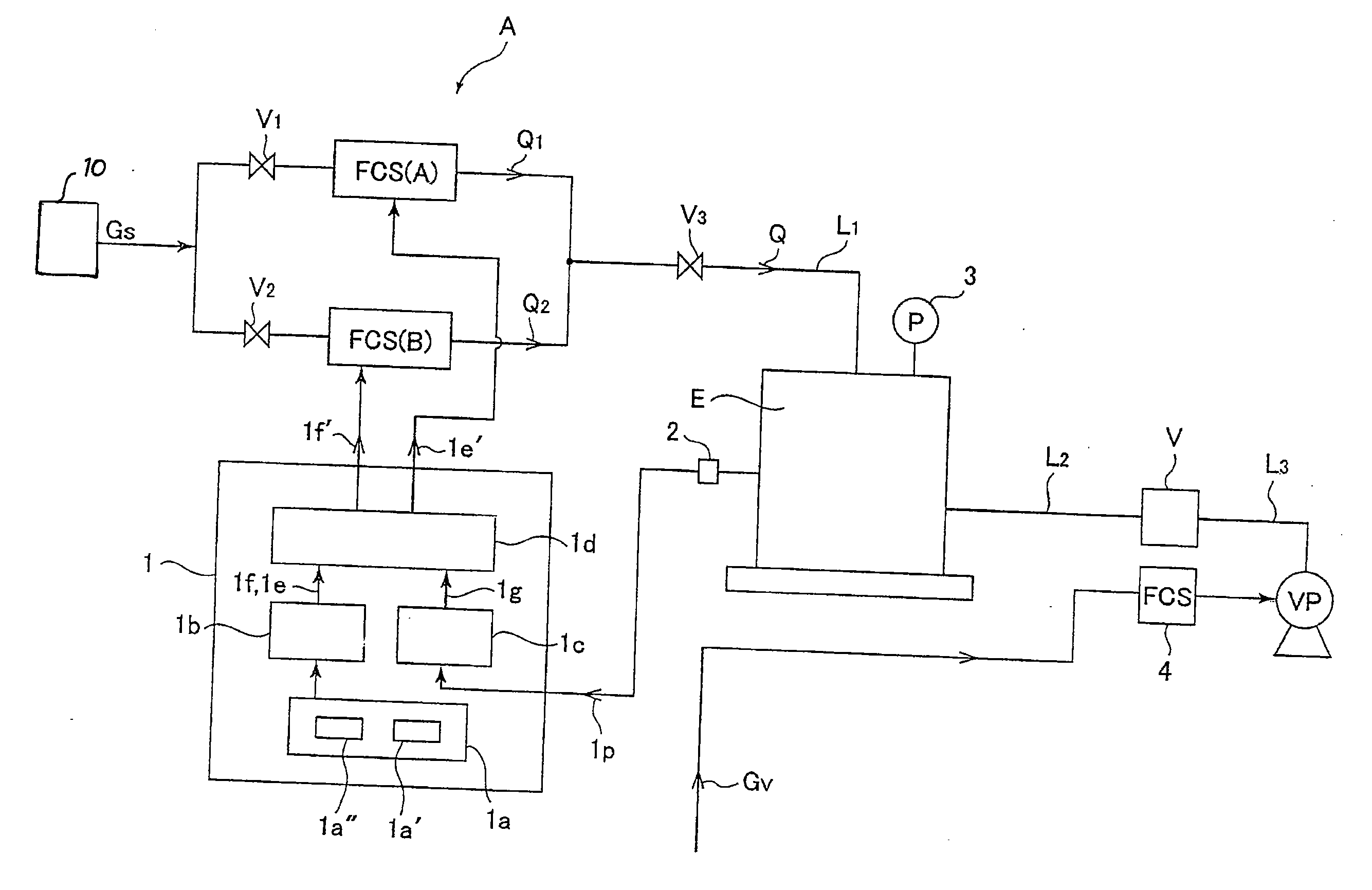

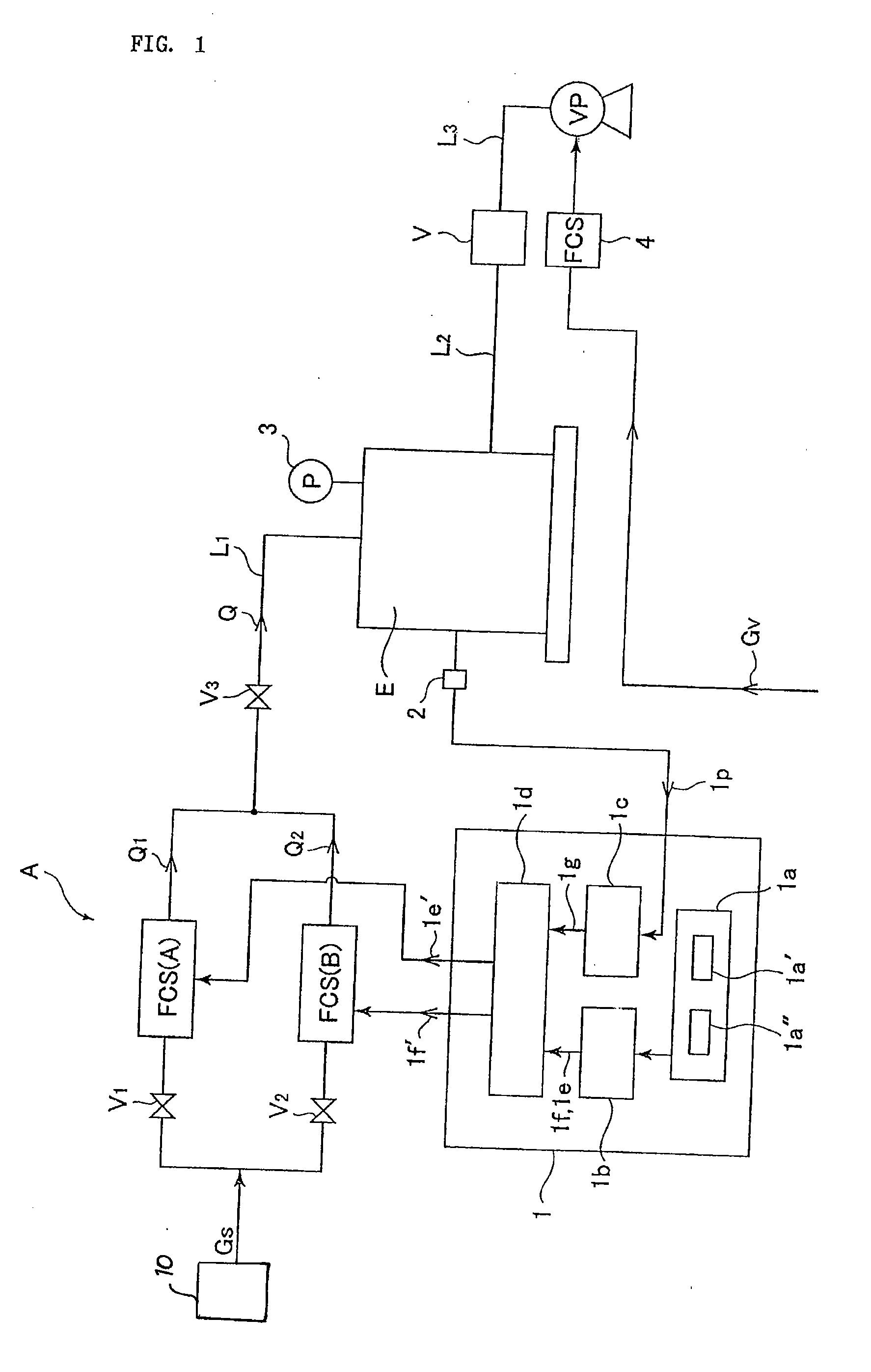

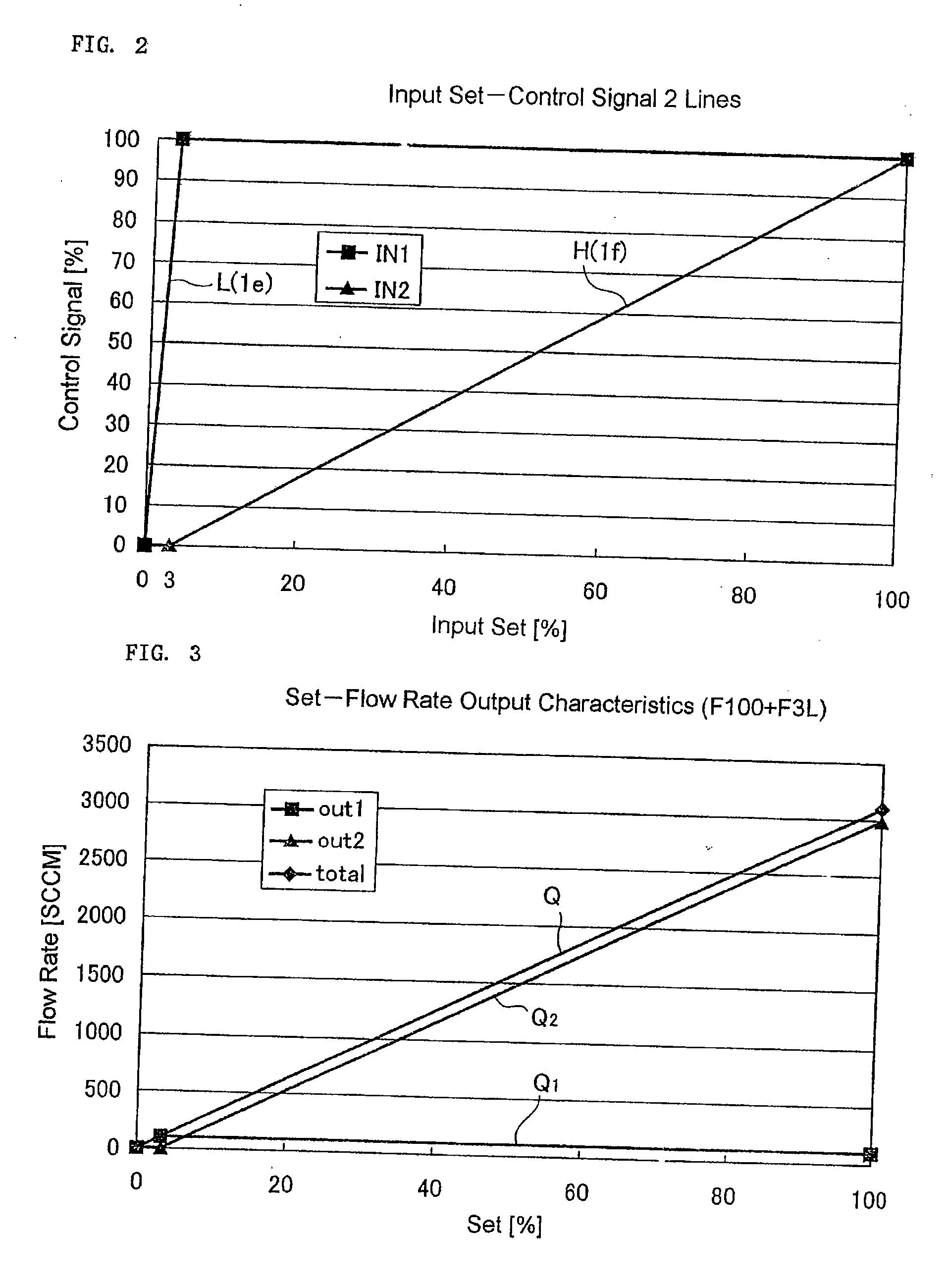

Internal pressure controller of chamber and internal pressure subject -to- control type chamber

InactiveUS20060207595A1Precise flow controlContinuous controlBreathing protectionOperating means/releasing devices for valvesInternal pressureControl signal

A gas supply facility includes a plurality of pressure type flow controllers connected in parallel, and a first controller to control operation of the plurality of pressure type flow controllers so as to supply a desired gas exhausted by a vacuum pump to a chamber while controlling its flow rate, one of the pressure type flow controllers operates as a second controller to control the gas flow rate range up to 10% of the maximum flow rate supplied to the chamber, while the remaining pressure type flow controllers are made to be ones that control the rest of the gas flow rate range. Furthermore, pressure inside the chamber is controlled by installing a pressure detector in the chamber, inputting the value detected by the detector to the controller, and by adjusting a control signal to the pressure type flow controllers.

Owner:FUJIKIN INC +1

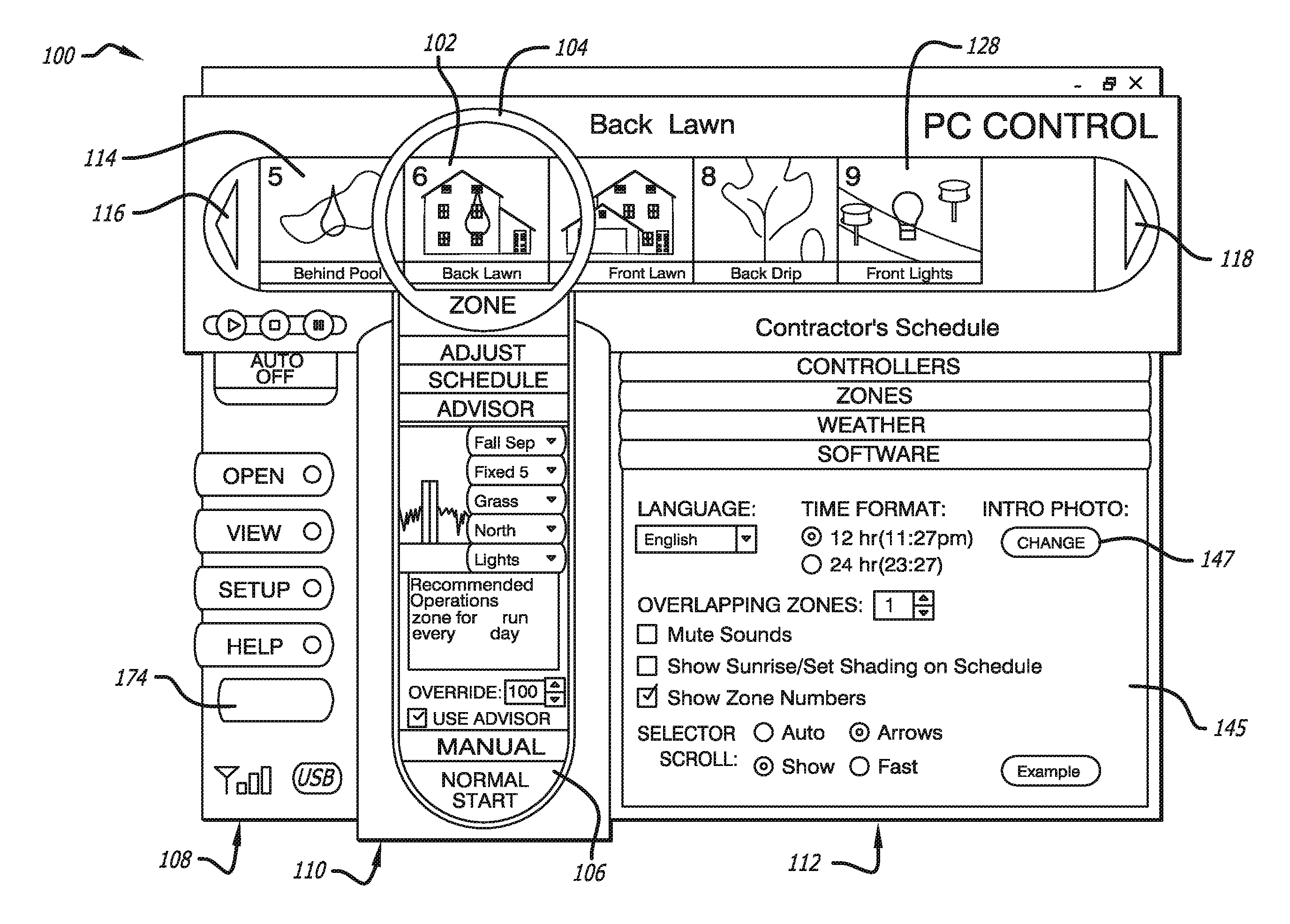

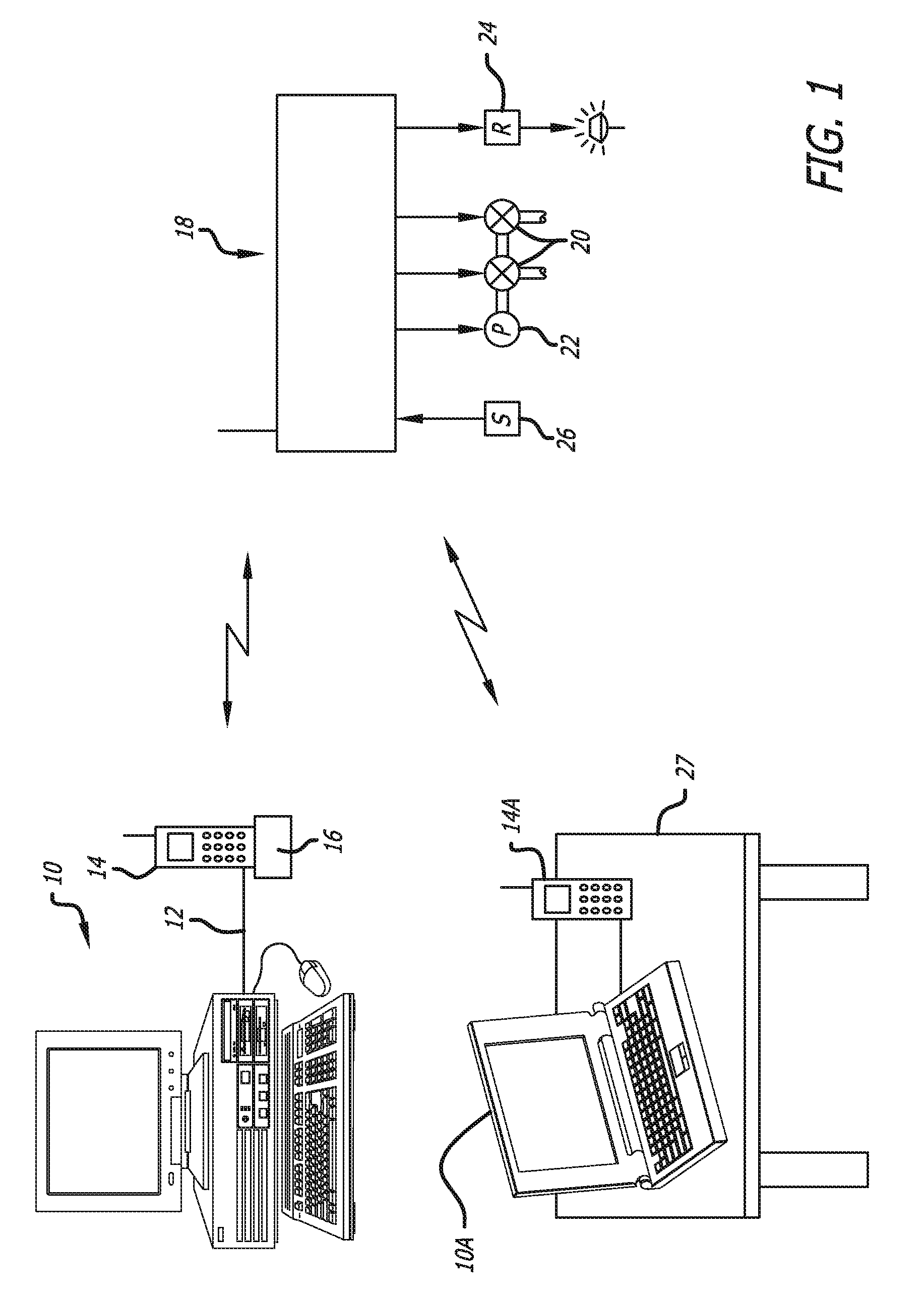

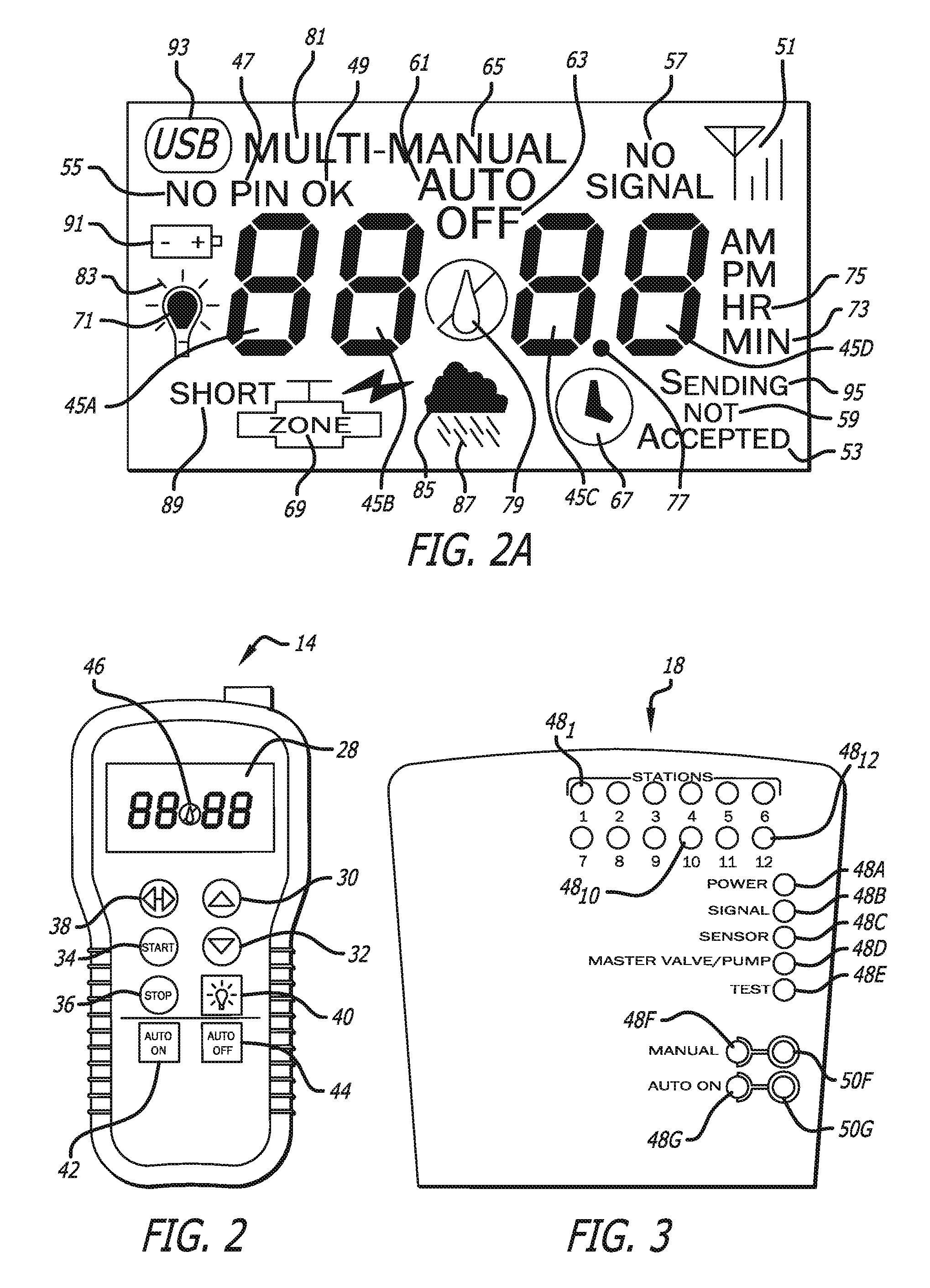

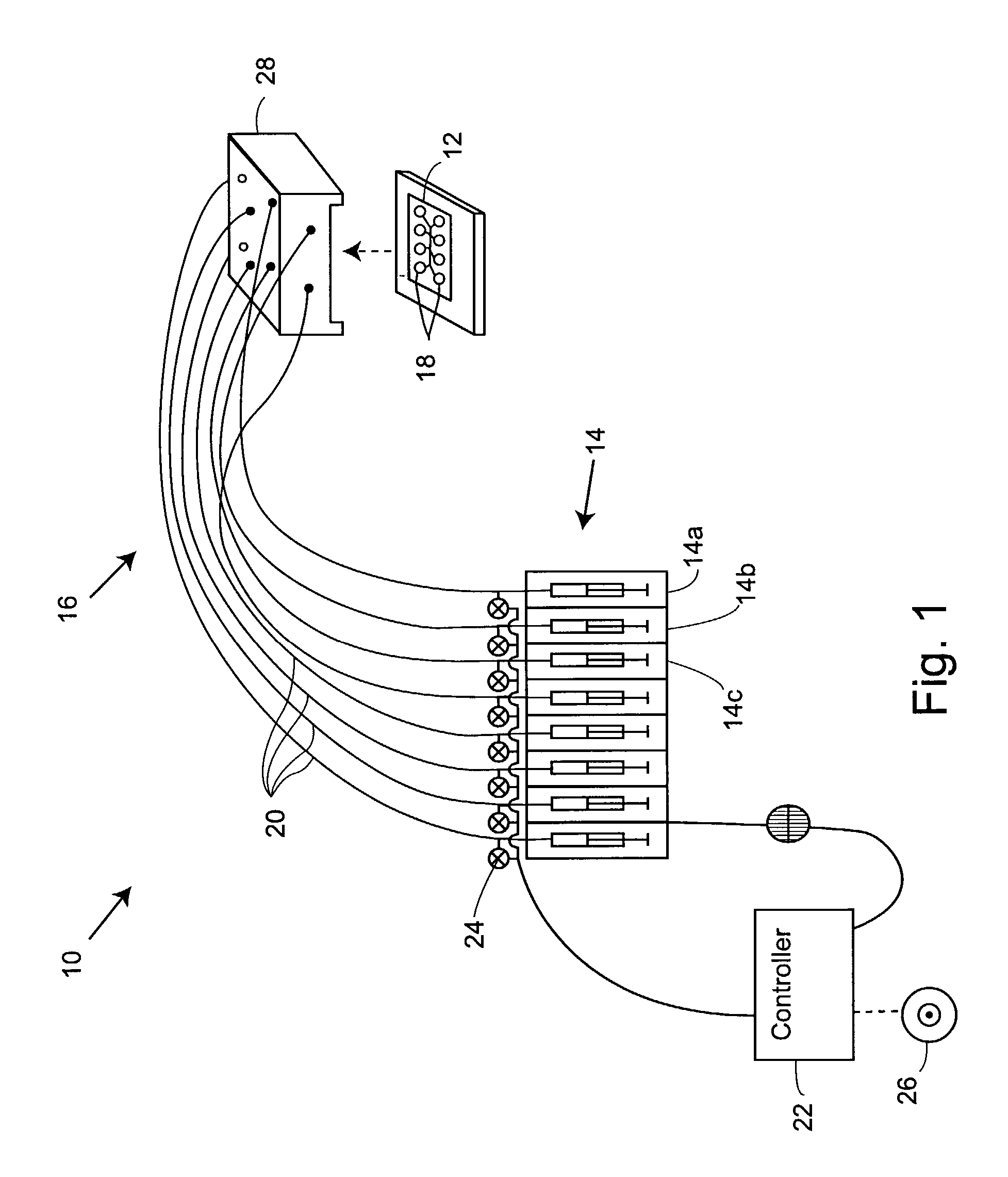

Computer-Operated Landscape Irrigation And Lighting System

A multi-zone landscape irrigation and lighting system includes a personal computer equipped with a detachable wireless remote, and a multi-station controller operating a plurality of irrigation valves and lighting circuits in accordance with schedules wirelessly transmitted to it by the computer through the remote. When detached from the computer, the remote can wirelessly operate selected irrigation or lighting zones manually. The computer has an intuitive graphic user interface capable of using actual zone photographs to identify individual zones in a strip of zone icons. The icon strip is movable past a lens-like window, the zone icon under the lens at a given time determining the zone currently programmable. A residential system can be operated by a contractor from the street, and the system can be programmed by e-mail from the contractor's shop. Fully automatic operation may be derived from data obtained over the Internet.

Owner:TORO CO THE

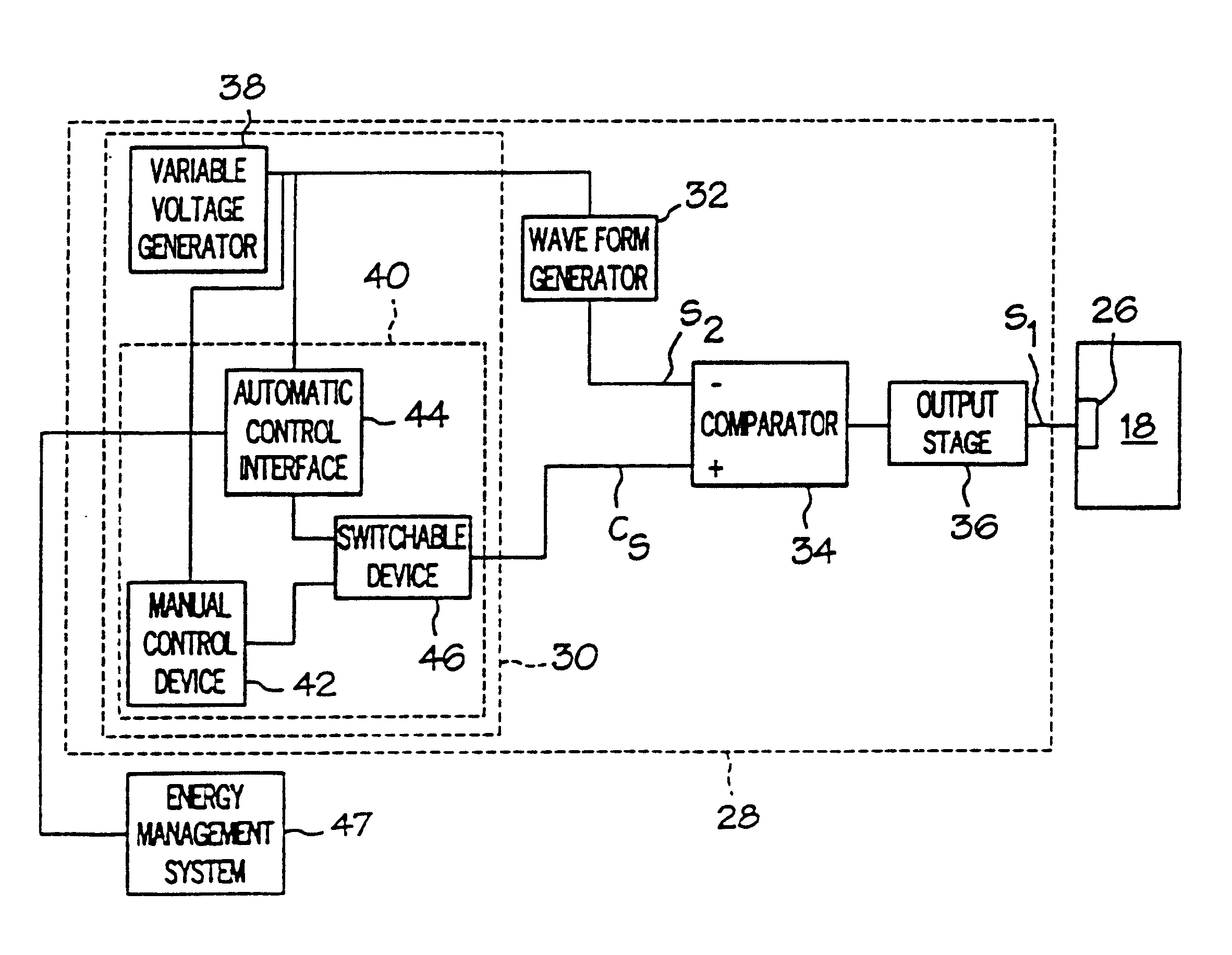

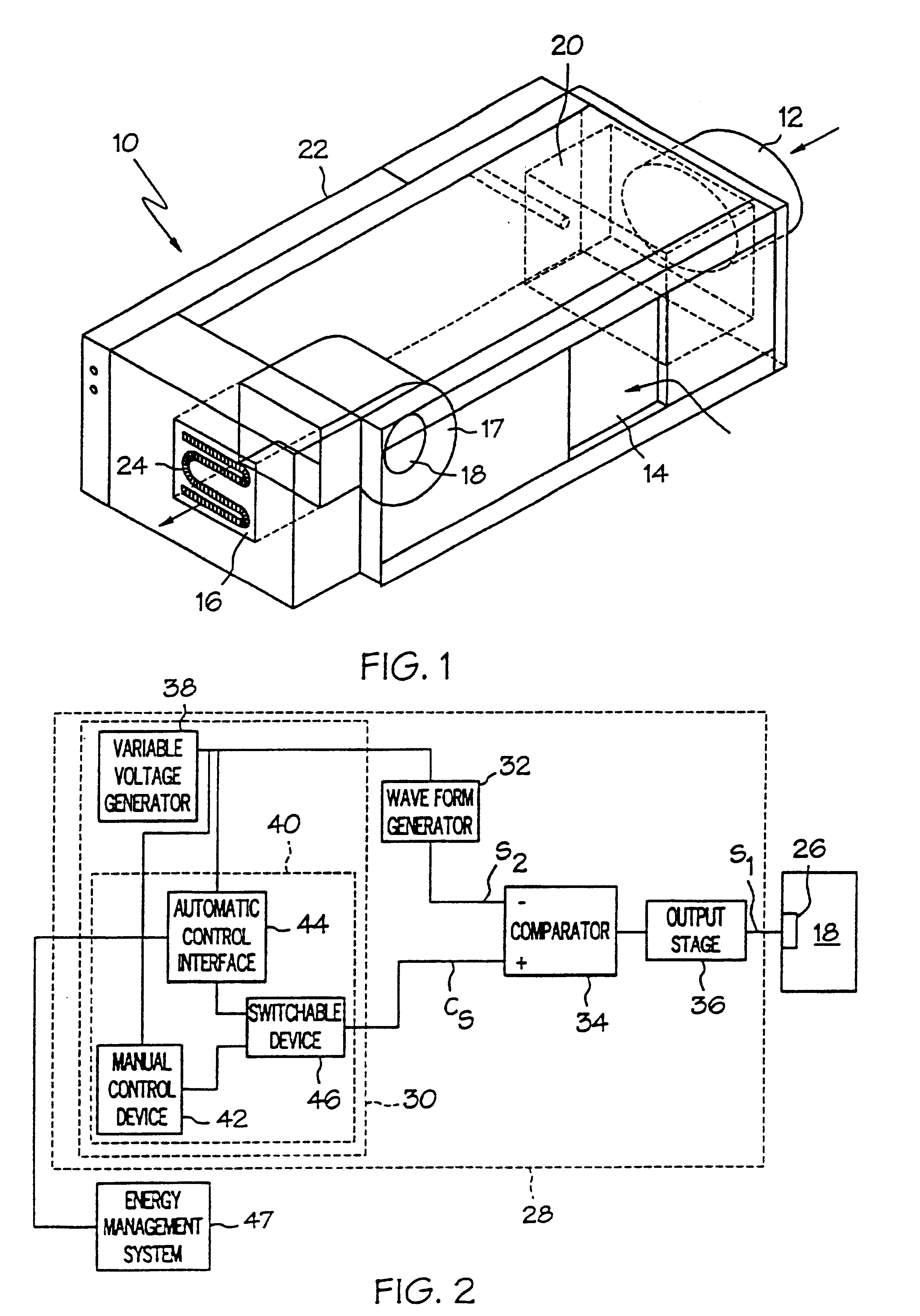

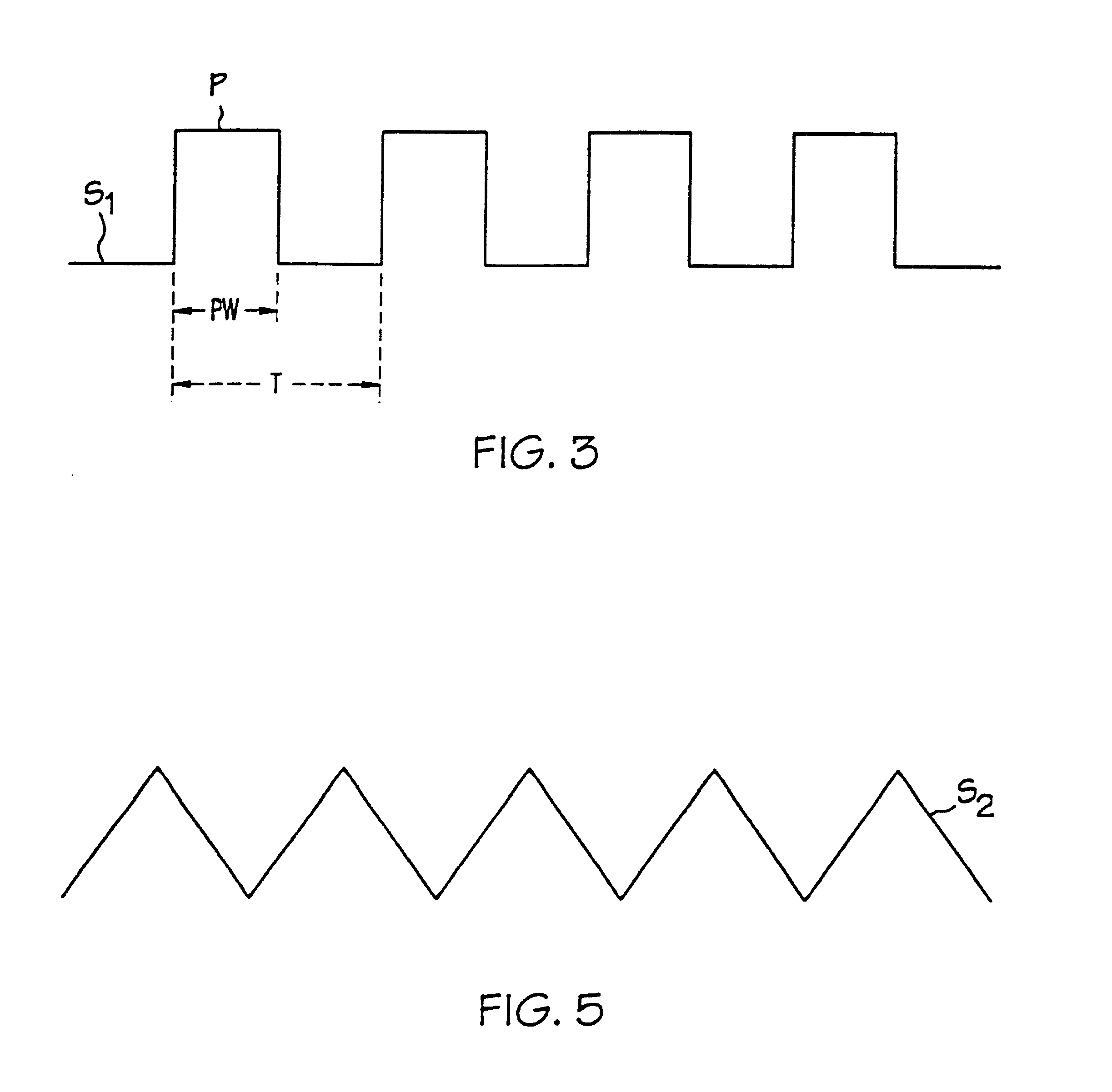

HVAC fan-powered terminal unit having preset fan CFM

InactiveUSRE38406E1Mechanical apparatusSpace heating and ventilation safety systemsVoltmeterEngineering

An arrangement is disclosed for controlling fan motors in fan-powered terminal units which permit the air flow of the terminal units to be factory preset and reset using a voltmeter. The fan motor is responsive to the pulse width of pulses of a pulse width modulated signal to provide an air flow which is proportional to the pulse width. By adjusting the pulse width, the air flow may be set as desired. A pulse width modulated signal having pulses with a set amplitude and frequency is generated. The dc voltage of the pulse width modulated signal is measured using a voltmeter. As the pulses have a set amplitude and frequency, the pulse width of the pulses may be adjusted by controlling the dc voltage of the pulse width modulated signal. The fan motor is programmed to deliver the set air flow over a range of static pressures.

Owner:NAILOR INDS OF TEXAS

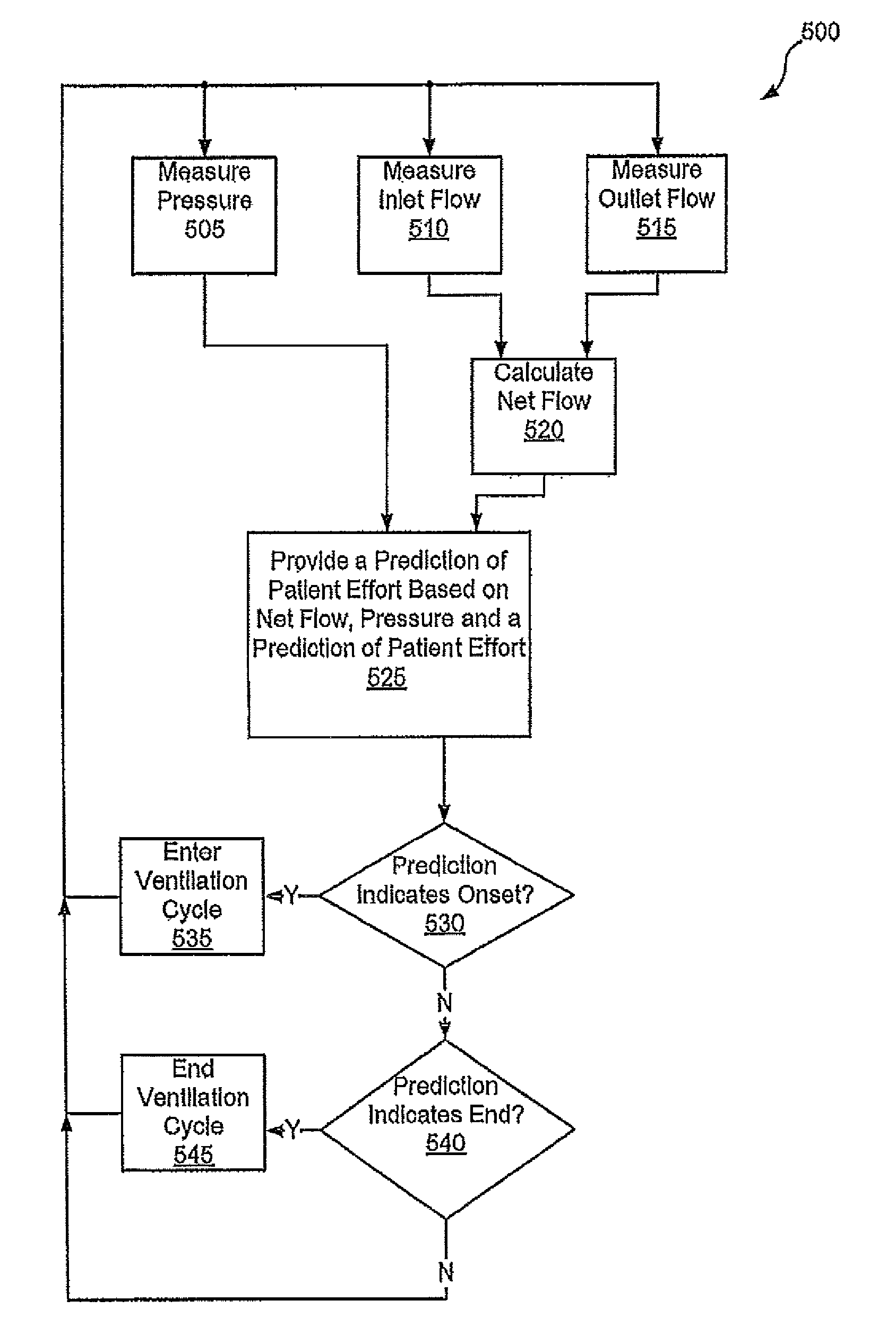

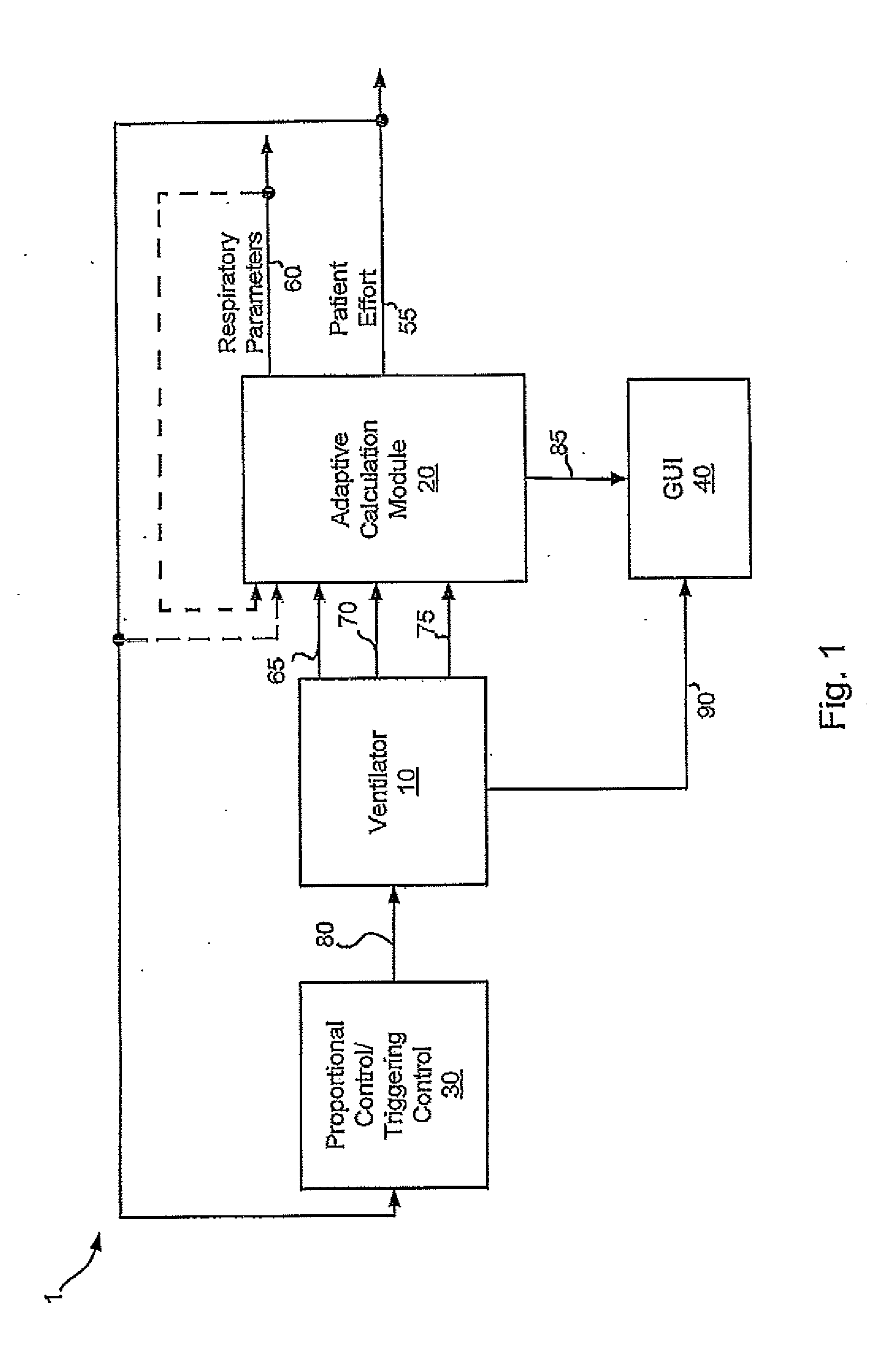

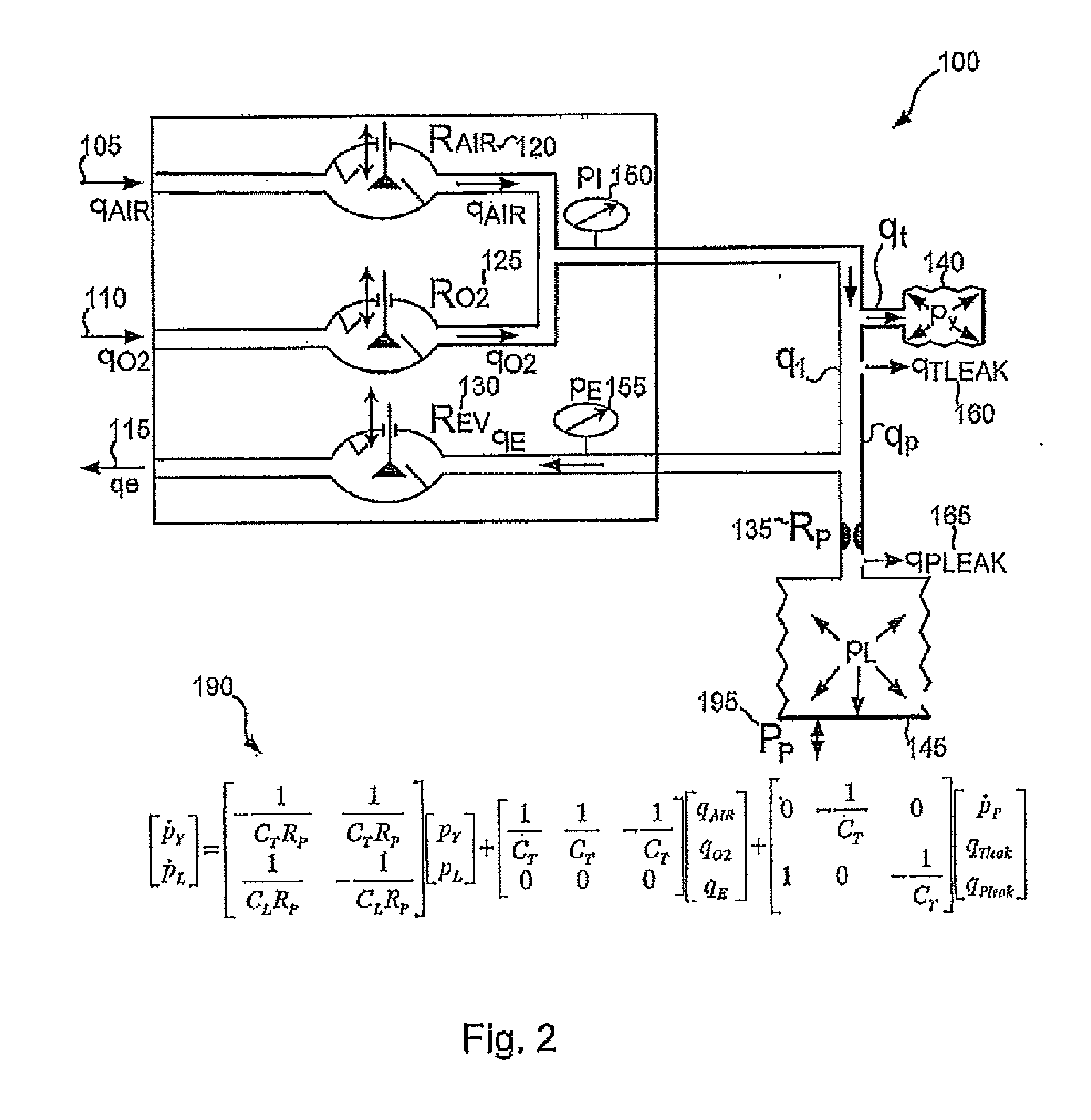

Systems and methods for ventilation in proportion to patient effort

Various embodiments of the present disclosure provide systems, methods and devices for respiratory support. As one example, a ventilation system is disclosed that includes a computer readable medium including instructions executable by a processor to receive a measured pressure value and a net flow value. A patient effort value is calculated based on a relationship between patient effort, the measured pressure value and the net flow value. The instructions are further executable to calculate a gas delivery metric that varies as a function of the patient effort value. Gas is then caused to be delivered consistent with the gas delivery metric.

Owner:TYCO HEALTHCARE GRP LP

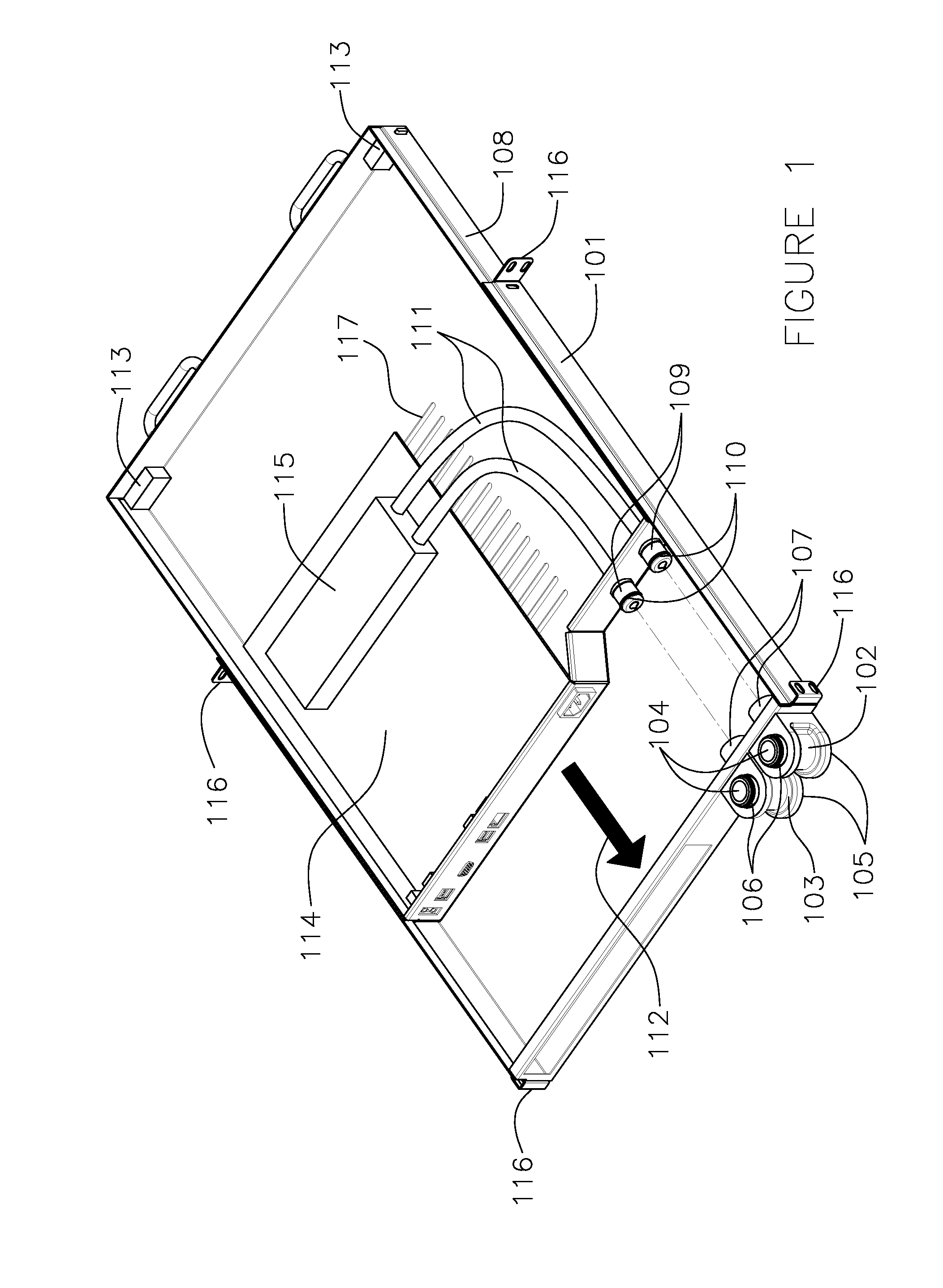

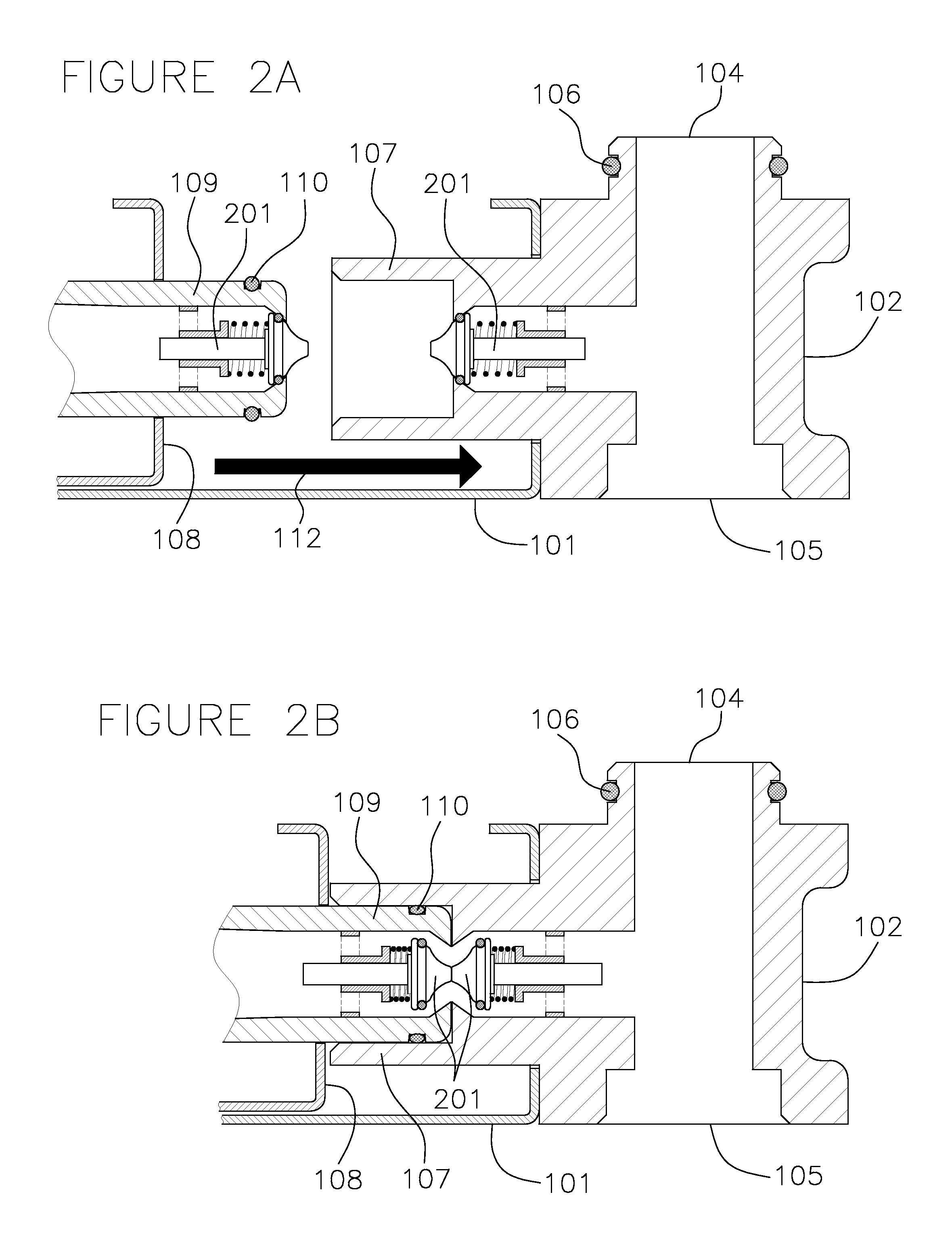

System, method, and apparatus for monitoring, regulating, or controlling fluid flow

An apparatus, system and method for regulating fluid flow are disclosed. The apparatus includes a flow rate sensor and a valve. The flow rate sensor uses images to estimate flow through a drip chamber and then controls the valve based on the estimated flow rate. The valve comprises a rigid housing disposed around the tube in which fluid flow is being controlled. Increasing the pressure in the housing controls the size of the lumen within the tube by deforming the tube, therefore controlling flow through the tube.

Owner:DEKA PROD LLP

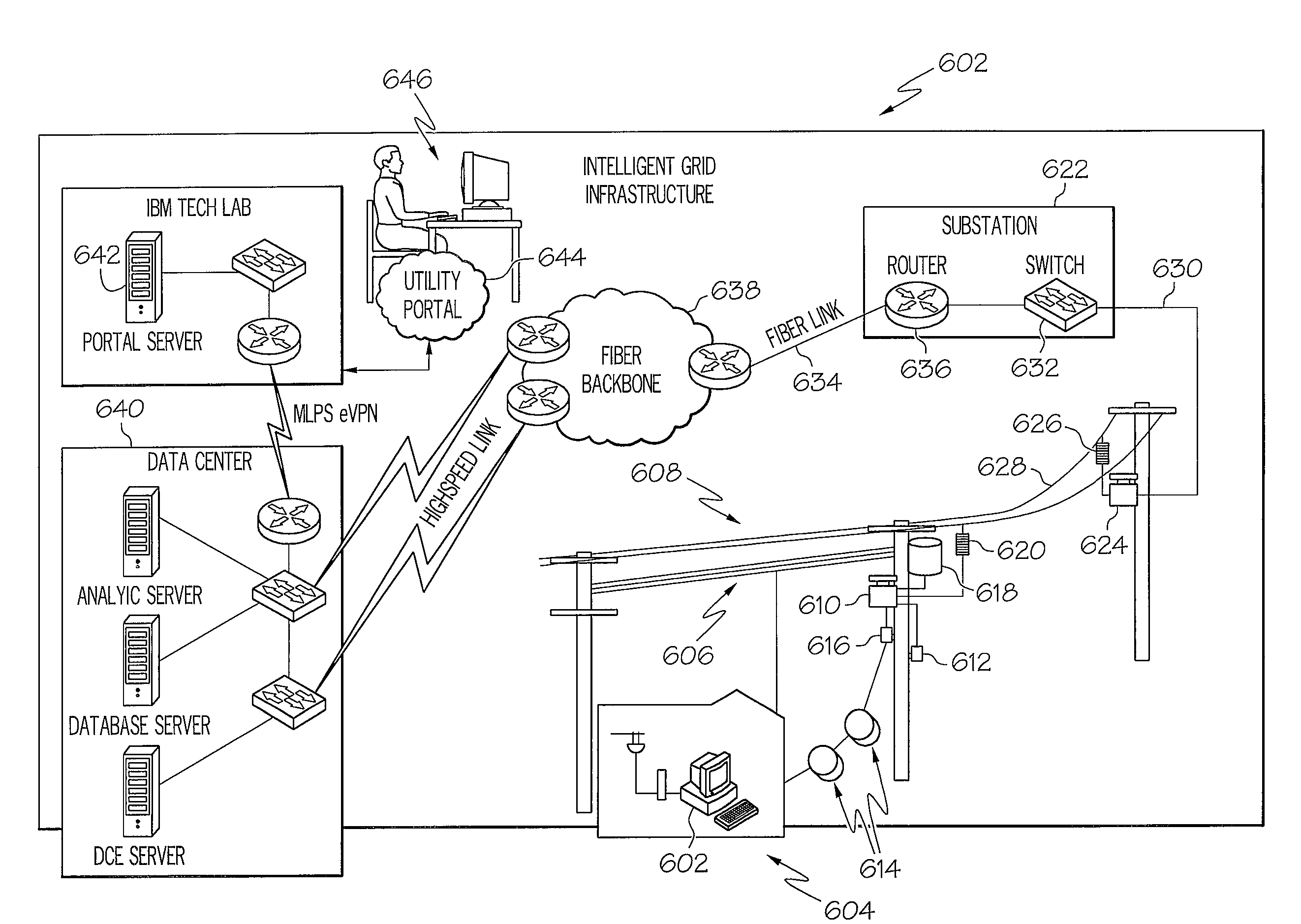

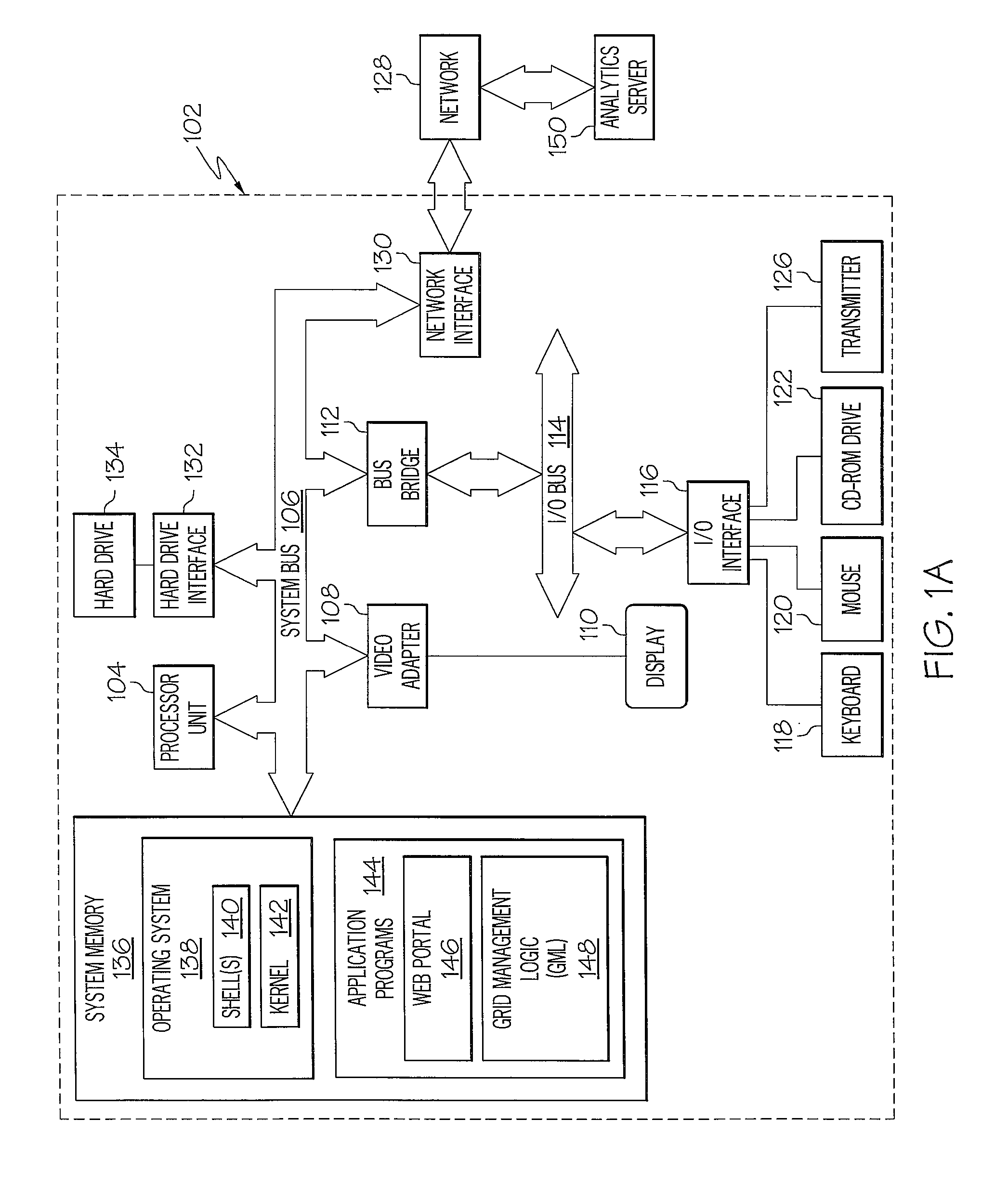

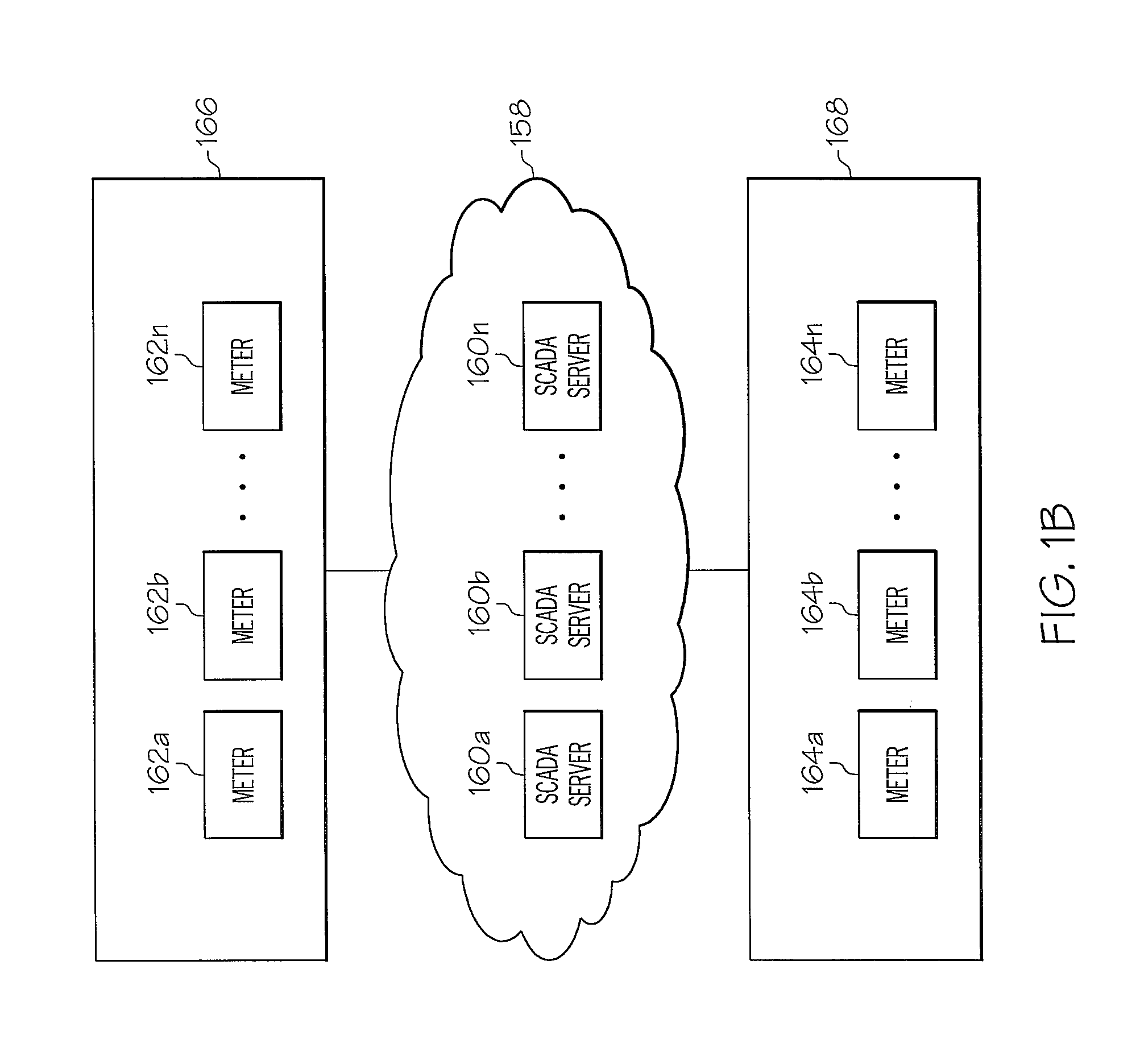

Intelligent monitoring of an electrical utility grid

A method of managing an electric utility grid includes geographically grouping a set of customer electric usage meters to create a set of fine sensors on a power grid. Each usage meter in the grouped set is capable of being remotely monitored, and each usage meter is at a different location along the power line. If a power anomaly is detected at the subset of meters, then power to the electric utility grid is adjusted to correct the anomaly.

Owner:TERRACE LICENSING LLC

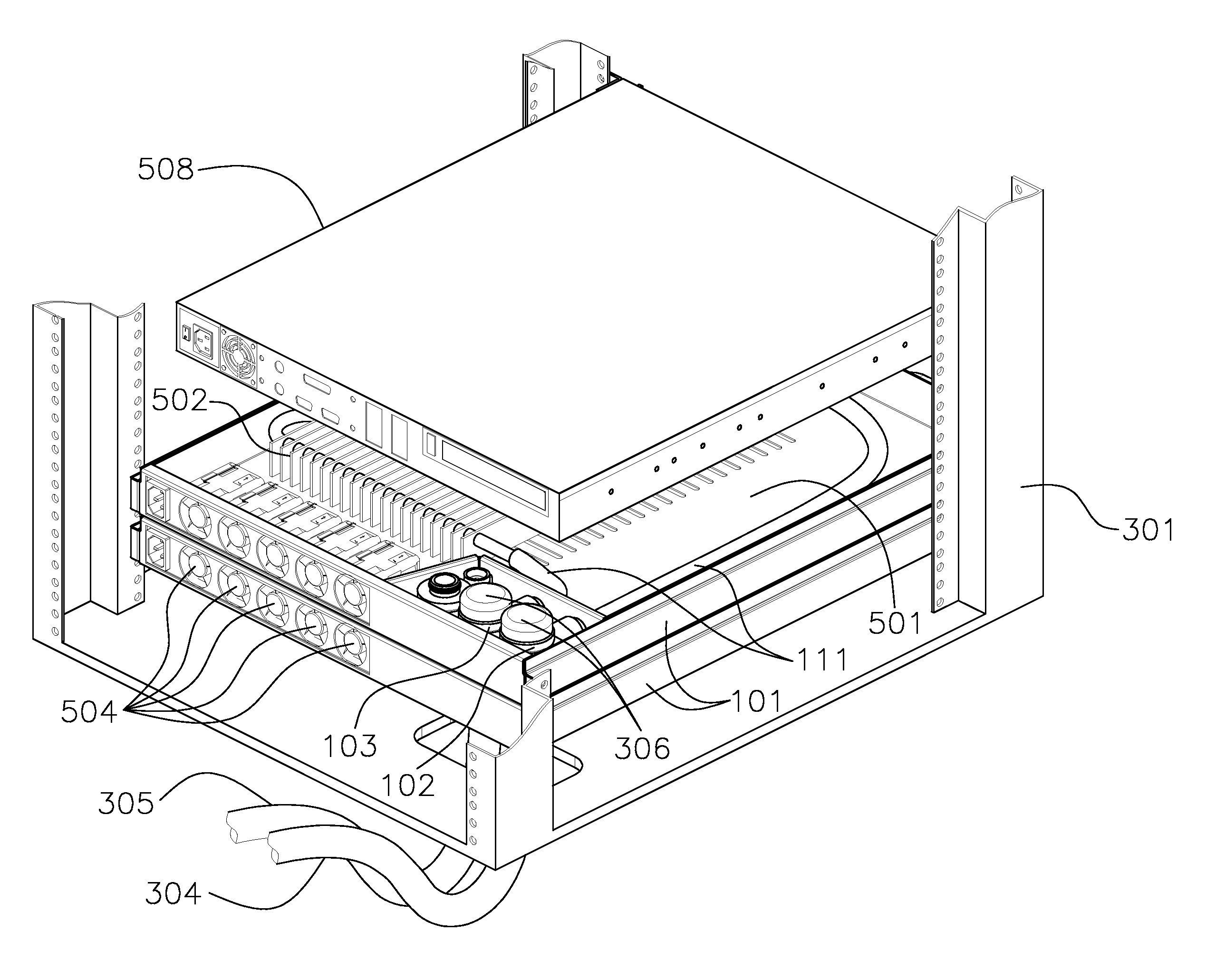

System and method for flowing fluids through electronic chassis modules

InactiveUS20110313576A1Safe removalCombustion enginesFluid dynamicsComputer moduleMonitoring and control

An electronic chassis distributes fluids to adjacent chassis and electronic modules housed within the chassis. Provision is made for the detection, containment, and removal of liquid spilled within the chassis. The fluids may be used as coolants, and provision is made for heat exchanger modules to be included within the chassis. Provision is further made to include fluid sensors and actuators, allowing for monitoring and control of fluid distribution by a controller.

Owner:NICEWONGER MARK RANDAL

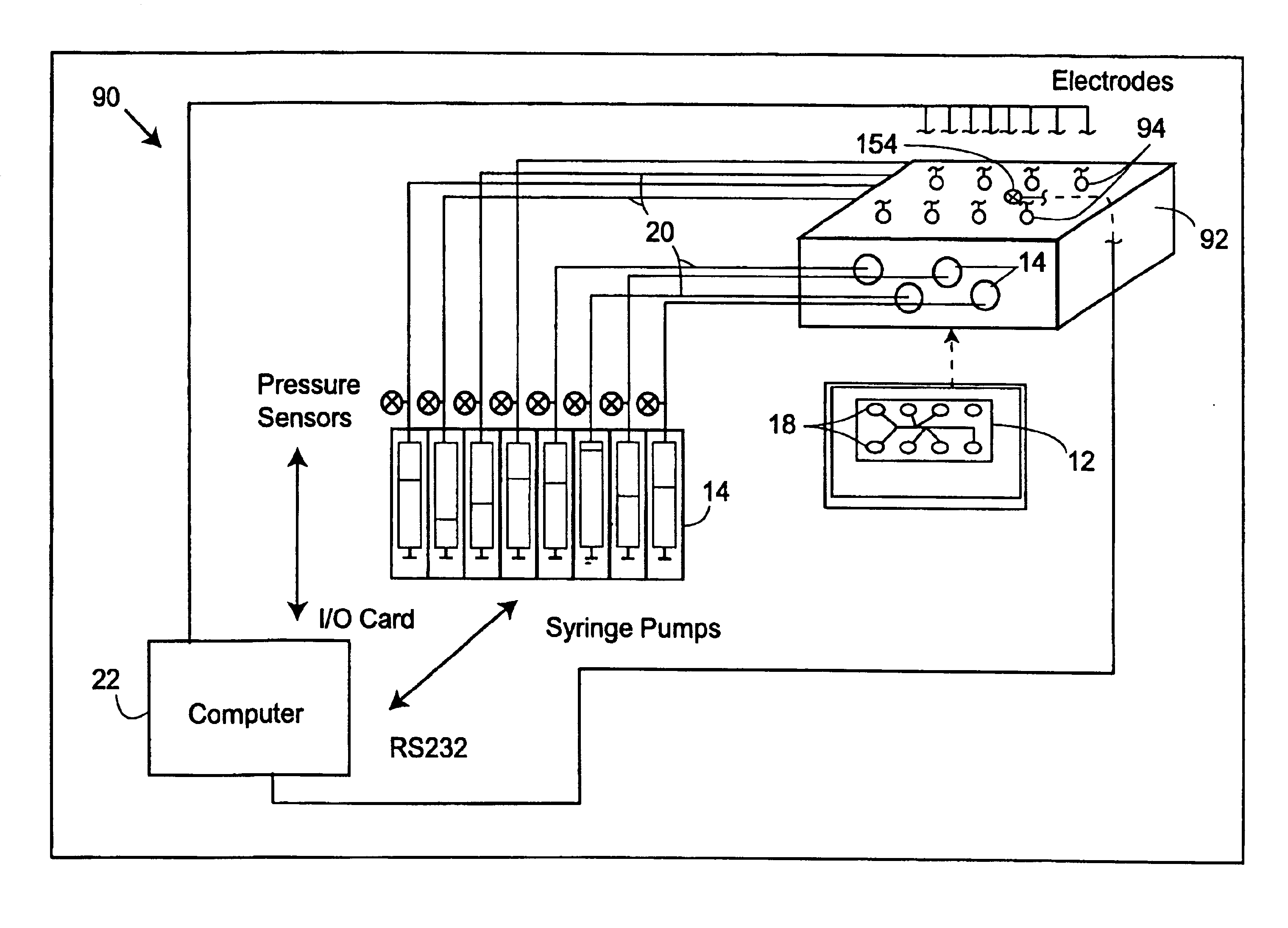

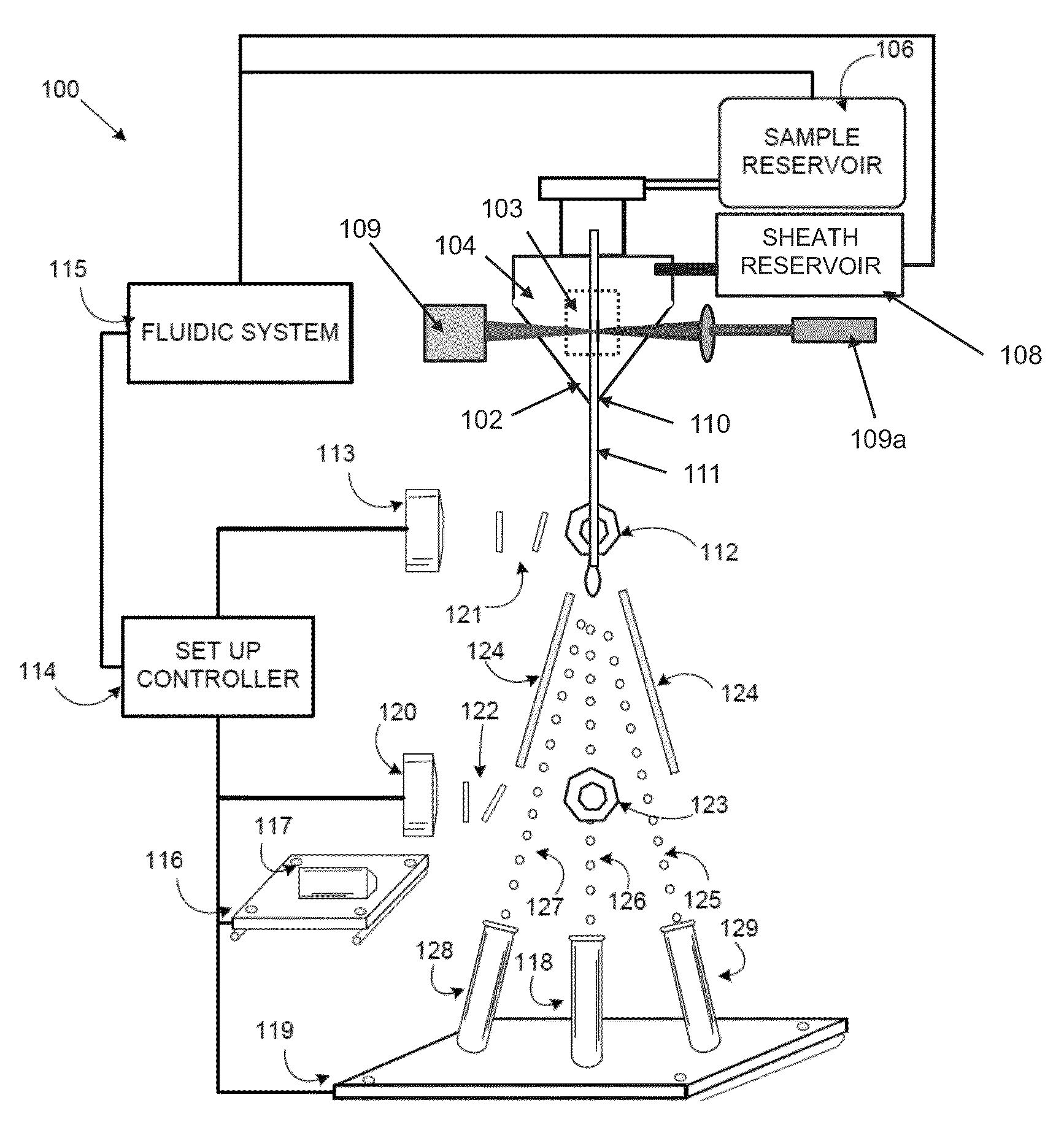

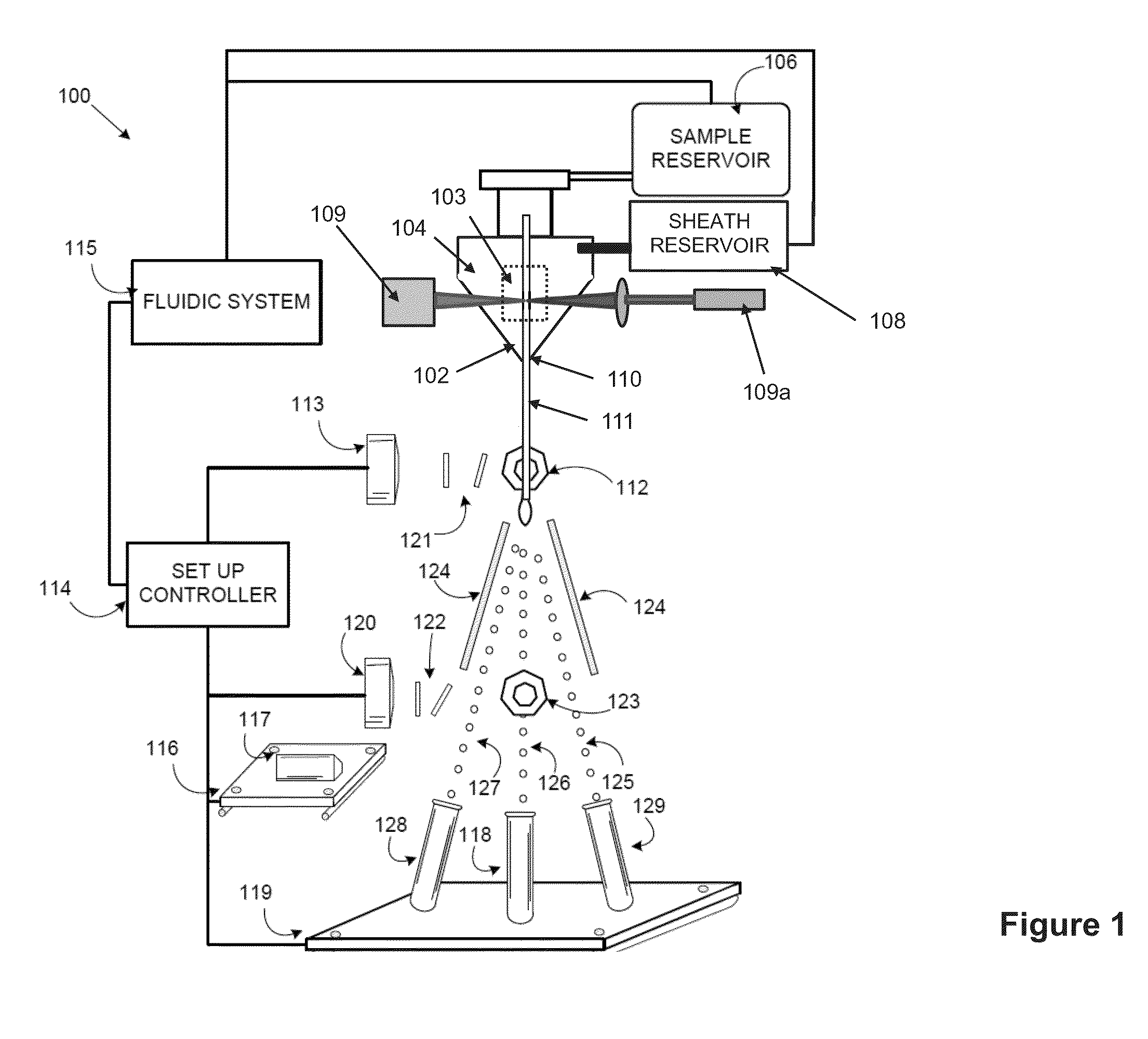

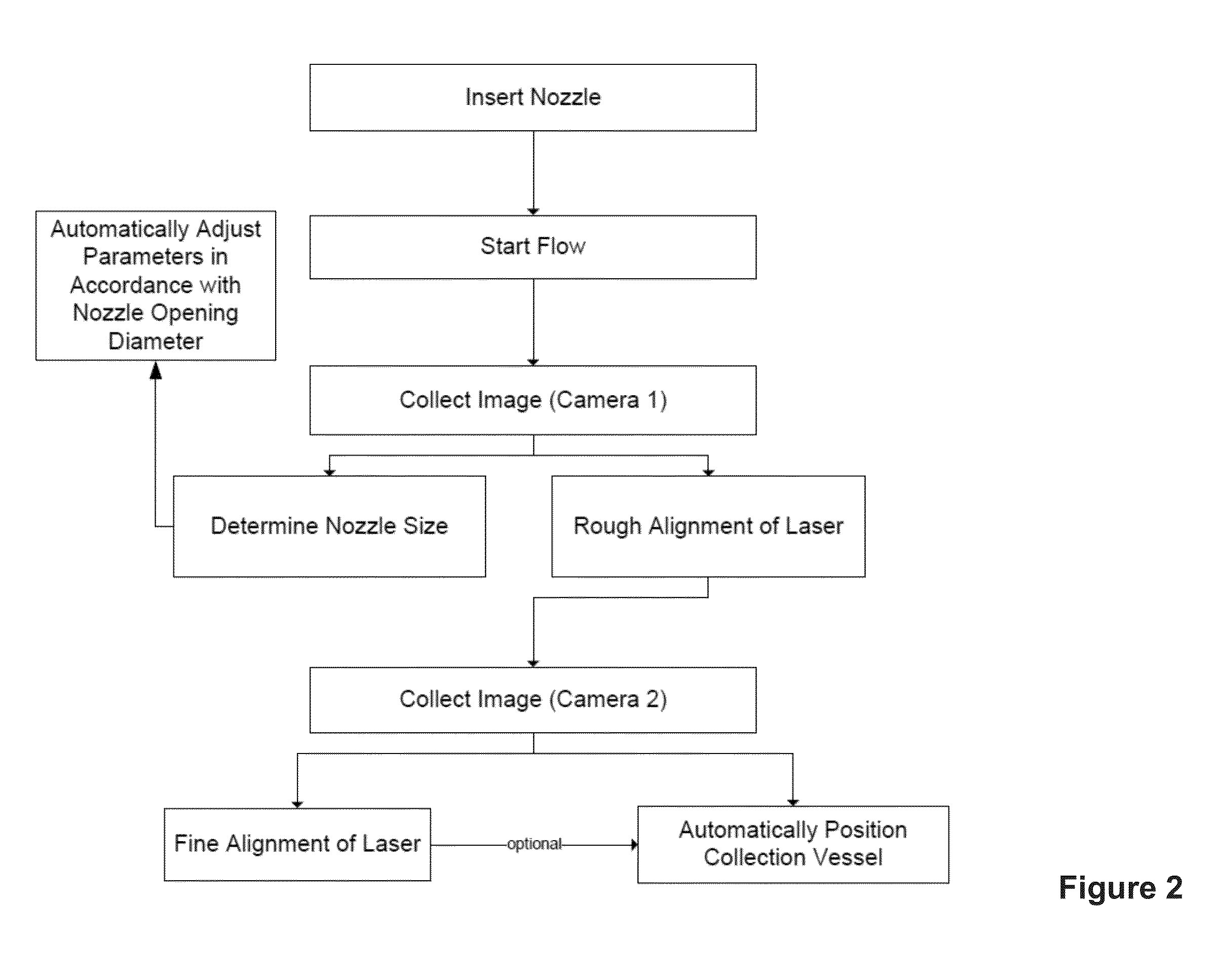

Automated set-up for cell sorting

ActiveUS8975595B2Guaranteed uniform velocityReduce needImage analysisVolume/mass flow measurementComputer scienceFlow Cytofluorometry

Apparatus and methods are described for automatically performing set-up steps for flow cytometry operations. The invention provides for the spatial determination of a flow stream and the subsequent automatic alignment of analysis devices and / or collection vessels. The automatic determination of flow stream properties provides for the automatic configuration flow cytometer parameters.

Owner:BECTON DICKINSON & CO

System and method for verifying connection of correct fluid supply to an infusion pump

A system and method for verifying that a particular fluid supply is connected to an infusion pump or pump channel. An upstream pressure sensor coupled to a fluid conduit associated with the fluid supply is used to provide pressure signals in response to pressure sensed in the conduit to a processor. In a connection verification mode, the processor is configured to receive the pressure signals and delay the flow control device of the infusion pump from moving fluid through the conduit until the processor detects a pressure change in the conduit indicated by the pressure signals to thereby verify that the particular fluid supply is connected to the infusion pump.

Owner:CAREFUSION 303 INC

System, Method, and Apparatus for Monitoring, Regulating, or Controlling FLuid Flow

A flow meter, and related system and method are provided. The flow meter includes a coupler, a support member, an image sensor, a valve, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within the field of view. The one or more processors are operatively coupled to the image sensor to receive image data therefrom and to the actuator to actuate the valve. The one or more processors are configured to estimate a flow of fluid through the drip chamber and to actuate the valve to control the flow of fluid through the drip chamber to achieve a target flow rate.

Owner:DEKA PROD LLP

System, method, and apparatus for monitoring, regulating, or controlling fluid flow

A flow meter, and related system and method are provided. The flow meter includes a coupler, a support member, an image sensor, a valve, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within the field of view. The one or more processors are operatively coupled to the image sensor to receive image data therefrom and to the actuator to actuate the valve. The one or more processors are configured to estimate a flow of fluid through the drip chamber and to actuate the valve to control the flow of fluid through the drip chamber to achieve a target flow rate.

Owner:DEKA PROD LLP

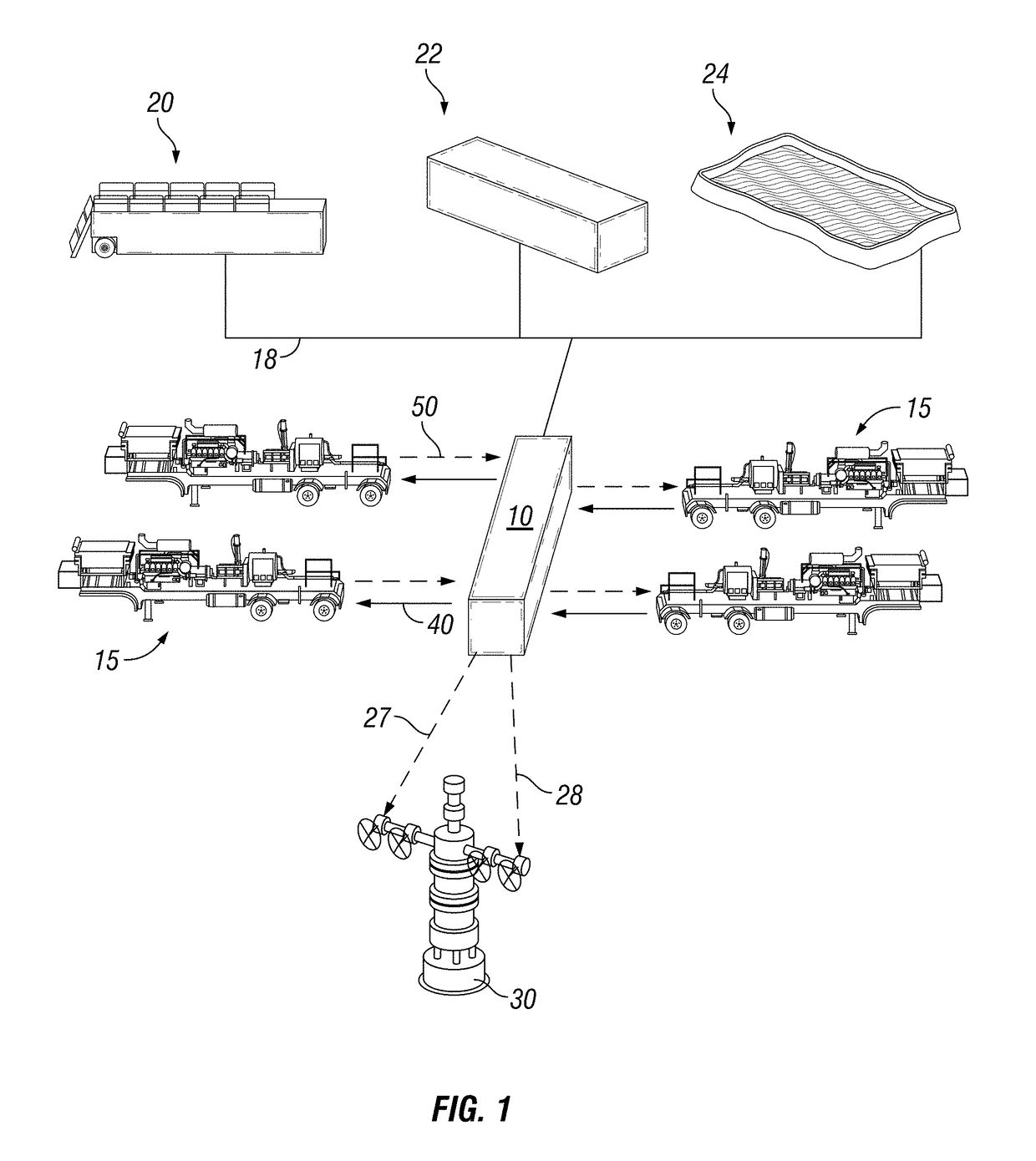

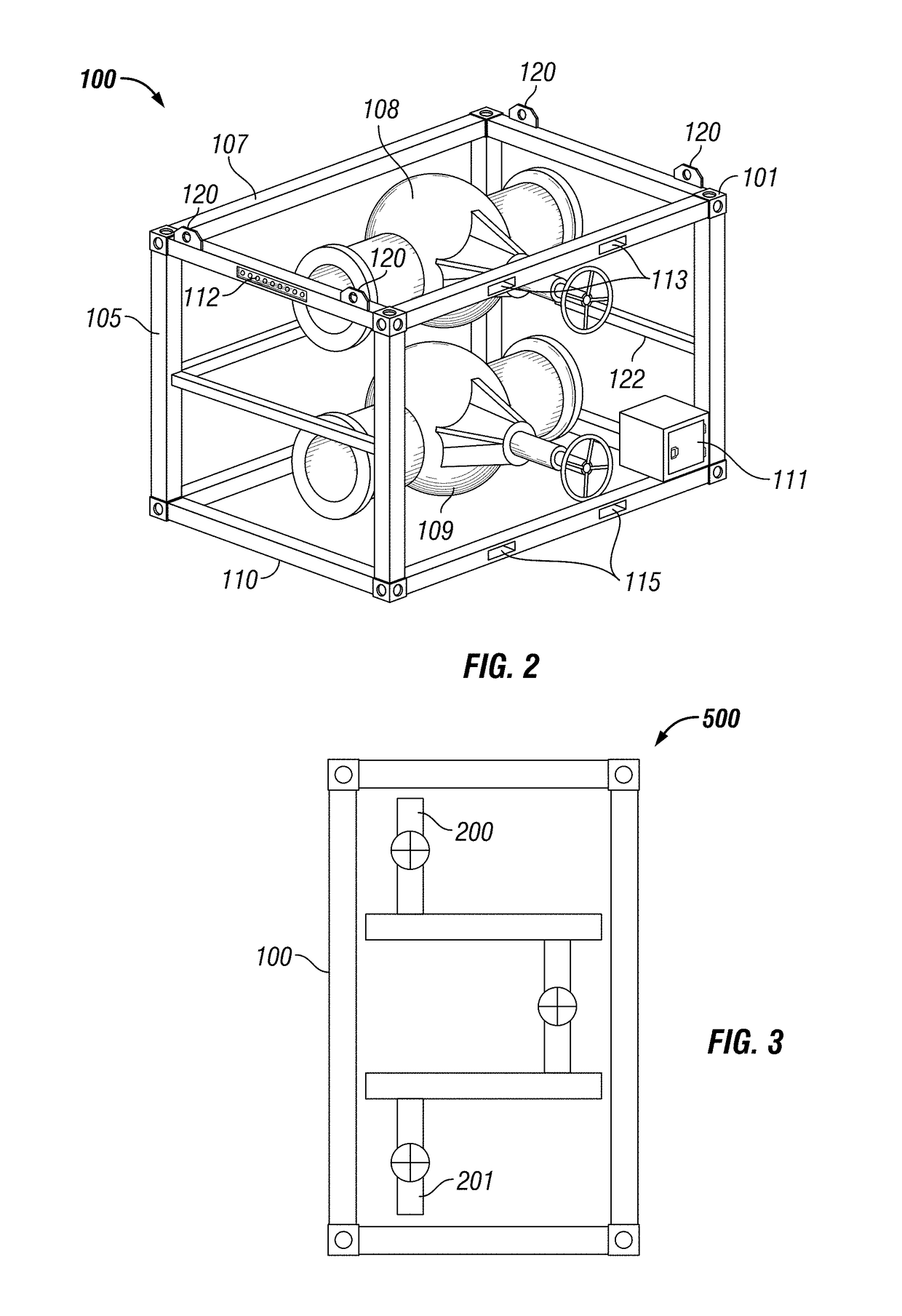

High pressure manifold, assembly, system and method

The present application is directed to a manifold system for low pressure and high pressure fluids. The manifold system may include one or more manifold sub-assemblies that may be assembled together, separated apart and replaced as desired. In oil and gas hydraulic fracturing operations, each manifold sub-assembly includes two or more low pressure fluid lines and two or more high pressure fluid lines for fluidly communicating with hydraulic fracturing pumps. High pressure fluid may exit the manifold system via a single line or multiple lines.

Owner:MGB OILFIELD SOLUTIONS LLC

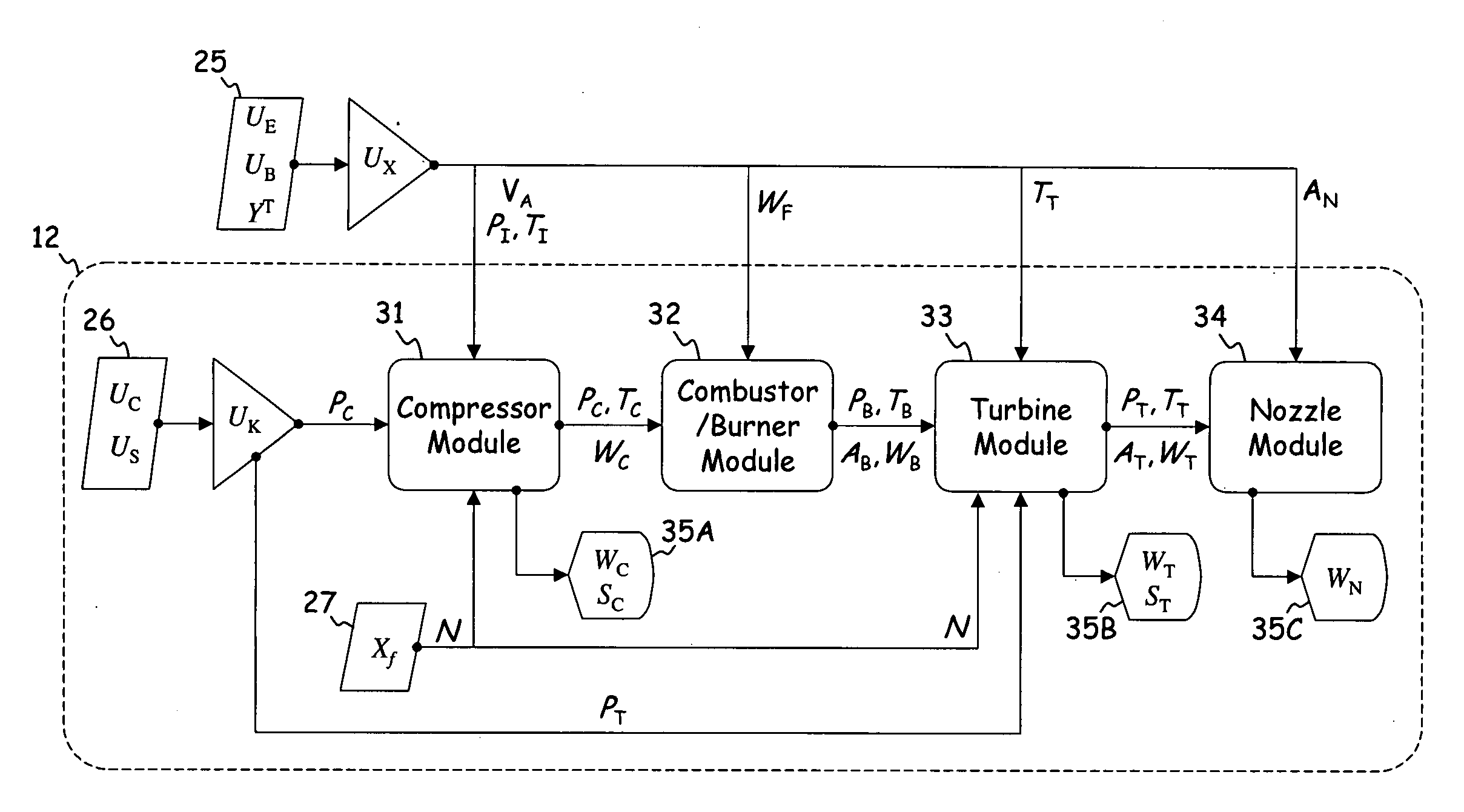

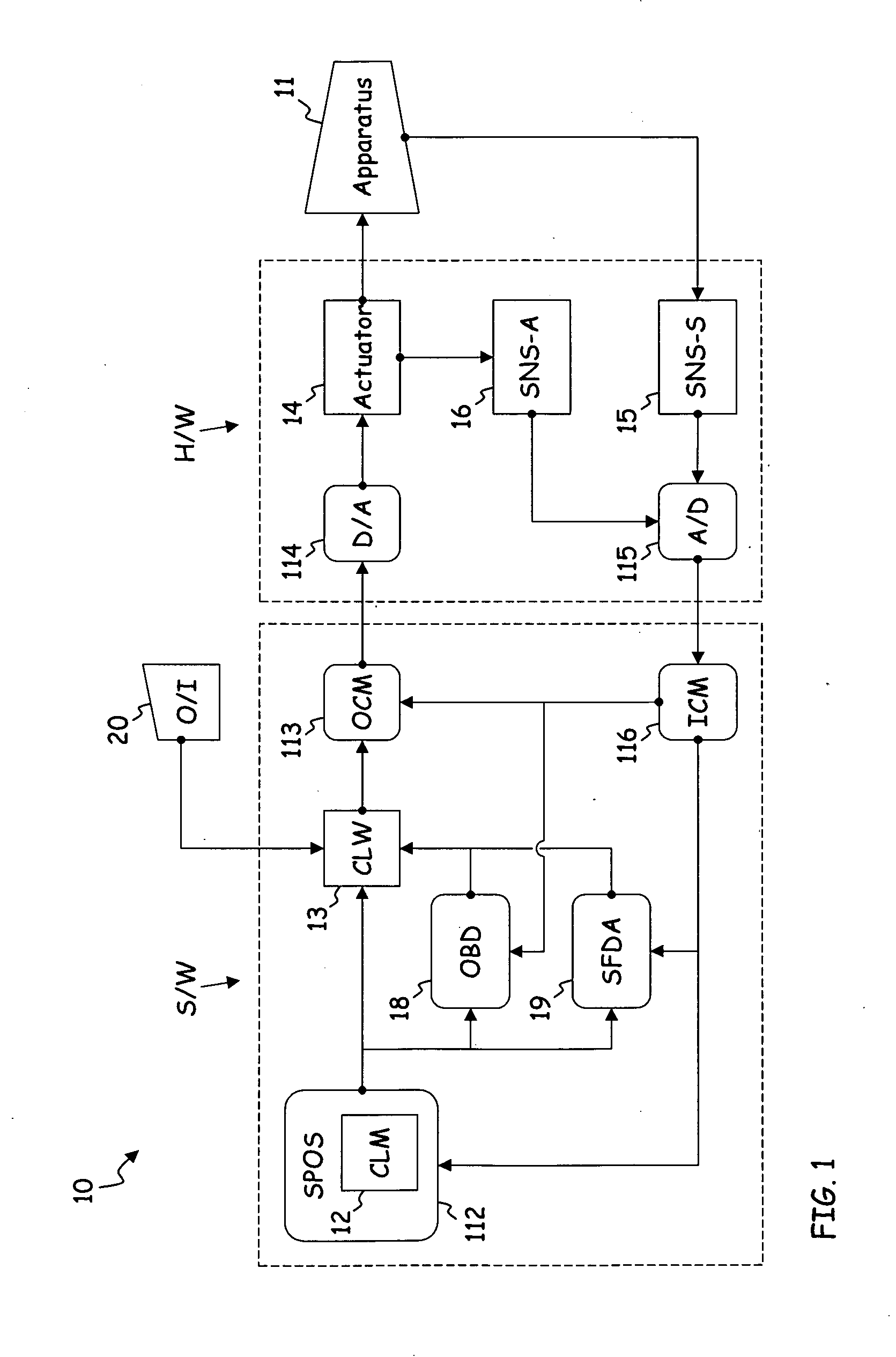

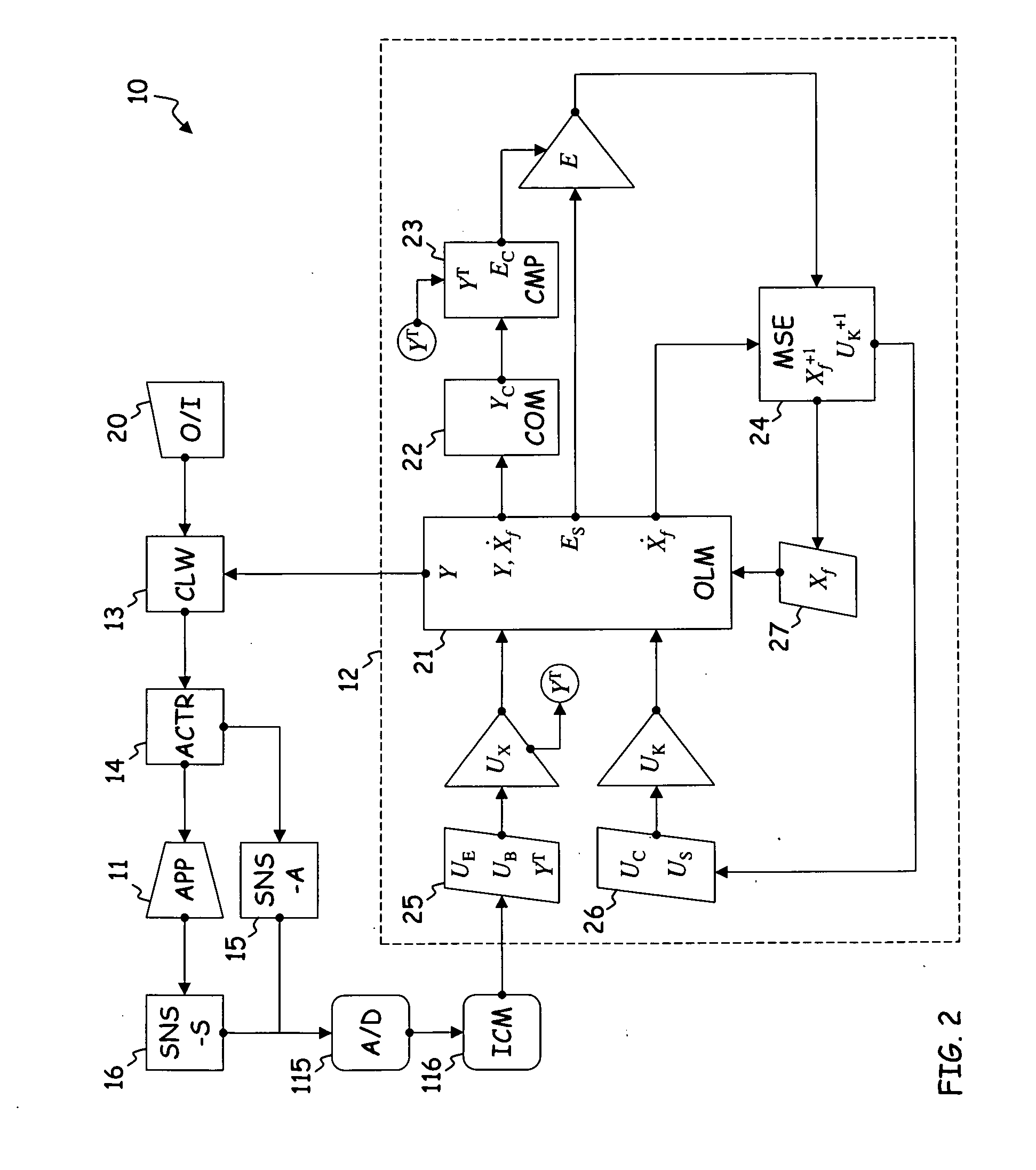

System and method for design and control of engineering systems utilizing component-level dynamic mathematical model

ActiveUS20110077783A1Error minimizationSimulator controlFlow control using electric meansWorking fluidMathematical model

A control system comprises a controller for positioning an actuator in a working fluid flow and a model processor for directing the controller as a function of a model feedback. The model processor comprises an output module, a comparator and an estimator. The output module generates the model feedback as a function of a constraint, a model state and a model input describing fluid parameters measured along the working fluid flow. The comparator generates an error by comparing the model feedback to the model input. The estimator generates the constraint and the model state, such that the error is minimized.

Owner:RTX CORP

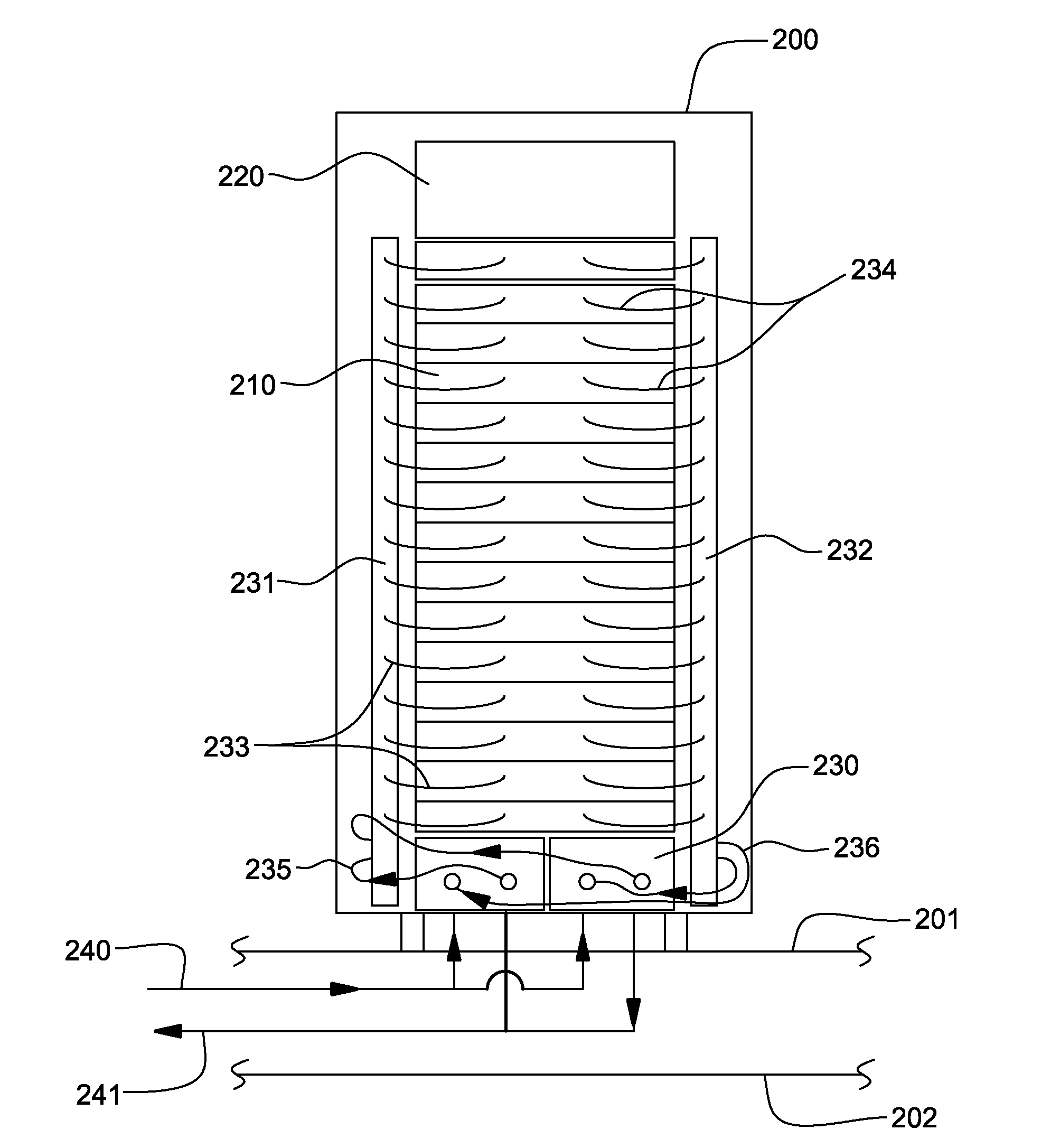

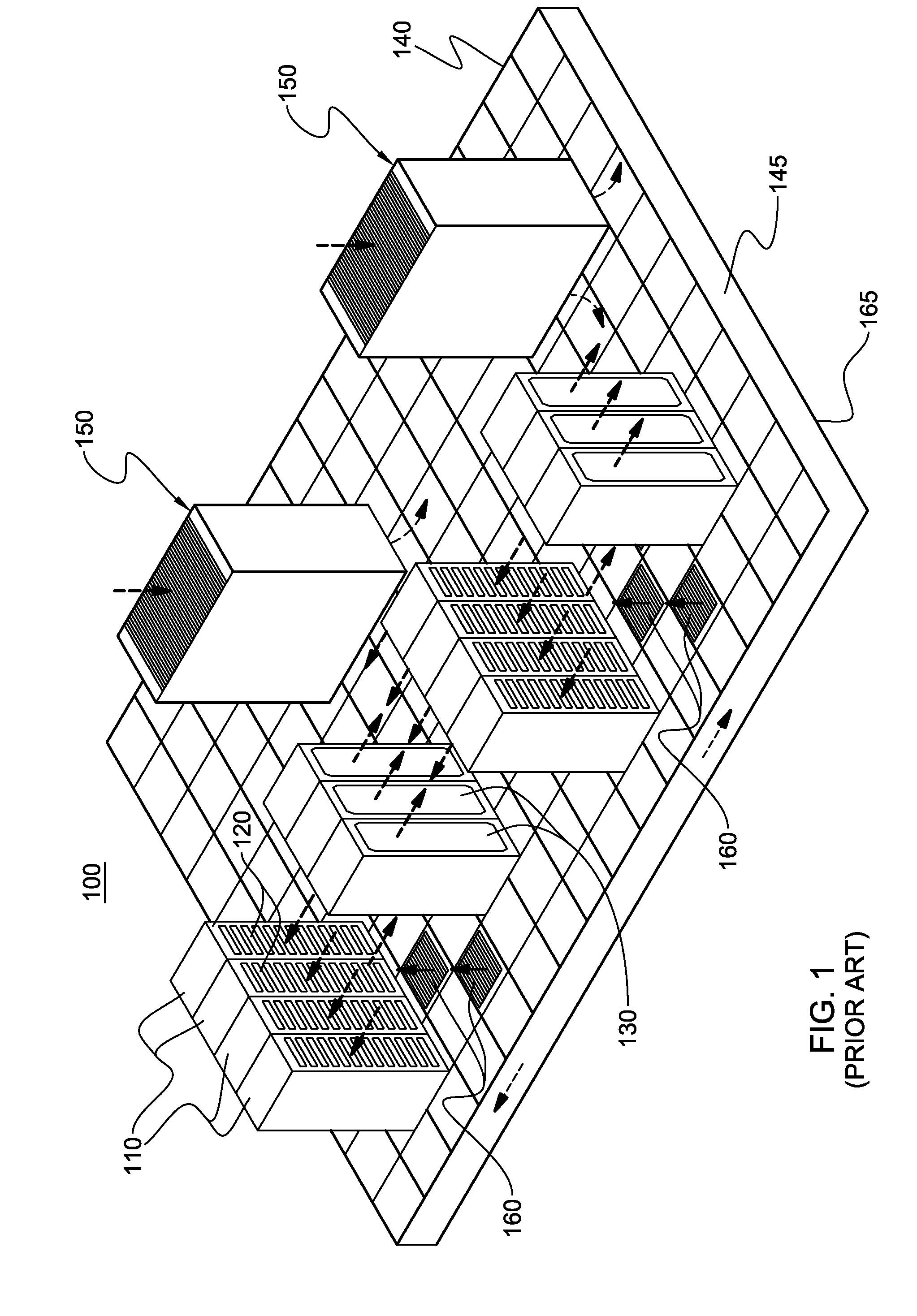

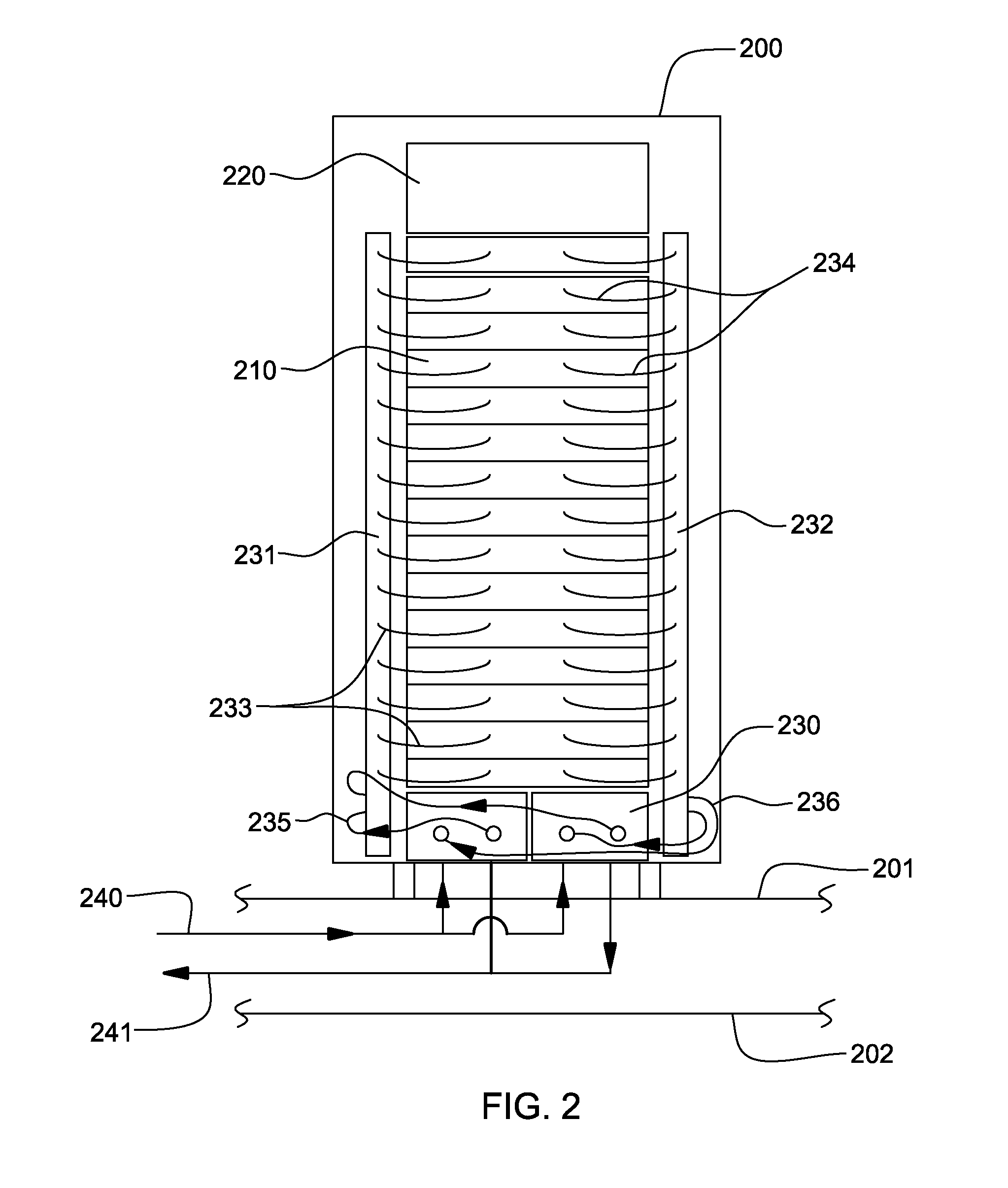

Cooling system and method minimizing power consumption in cooling liquid-cooled electronics racks

InactiveUS20110060470A1Reduce power consumptionOvercomes shortcomingMechanical power/torque controlEnergy efficient ICTControl flowPower dissipation minimization

A cooling system and method are provided for facilitating cooling of a liquid-cooled electronics rack. The cooling system includes a coolant flow controller, a modular cooling unit and a pressure controller. The flow controller is associated with a respective electronics rack and controls flow of coolant through that electronics rack based on its changing cooling requirements. The cooling unit includes an adjustable coolant pump for facilitating supply of coolant to the rack. The pressure controller is associated with the cooling unit for controlling pressure of coolant at an output of the cooling unit via control of pump speed of the pump. Responsive to adjusting coolant flow through the electronics rack, the pressure controller automatically adjusts pump speed of the adjustable pump to maintain pressure about a constant coolant pressure set point at an output of the cooling unit, thereby conserving power while still cooling the liquid-cooled electronics rack.

Owner:IBM CORP

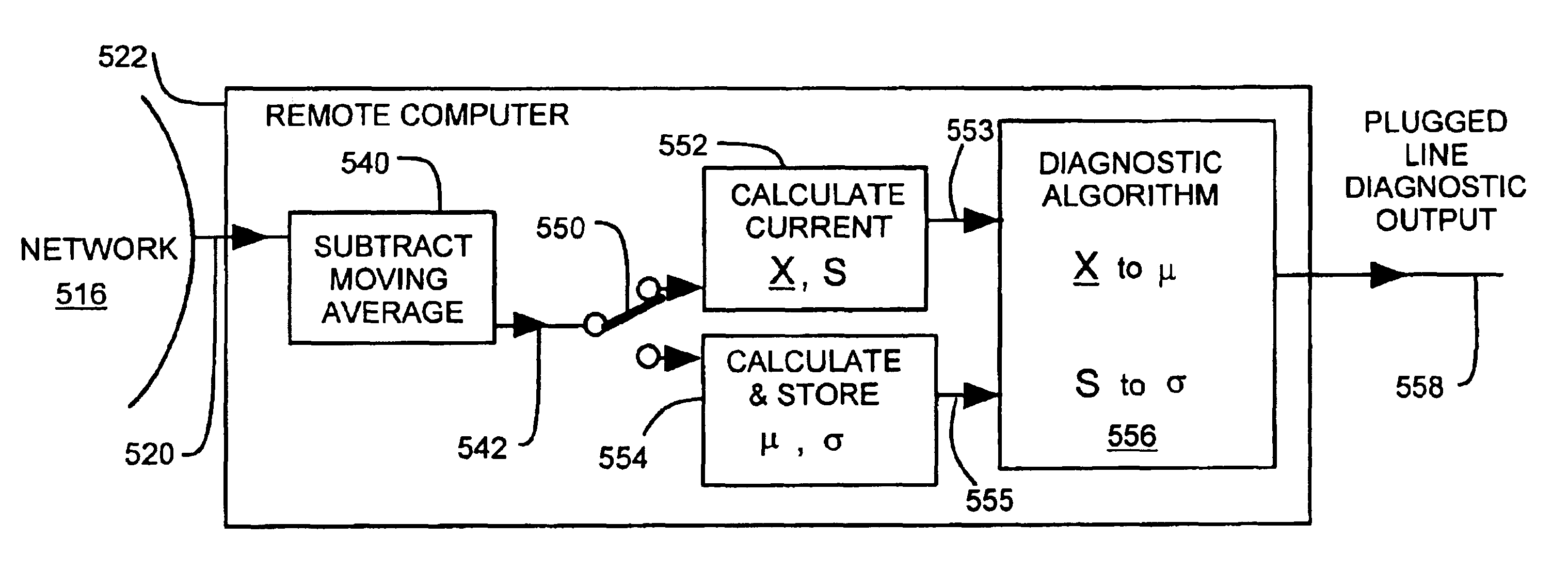

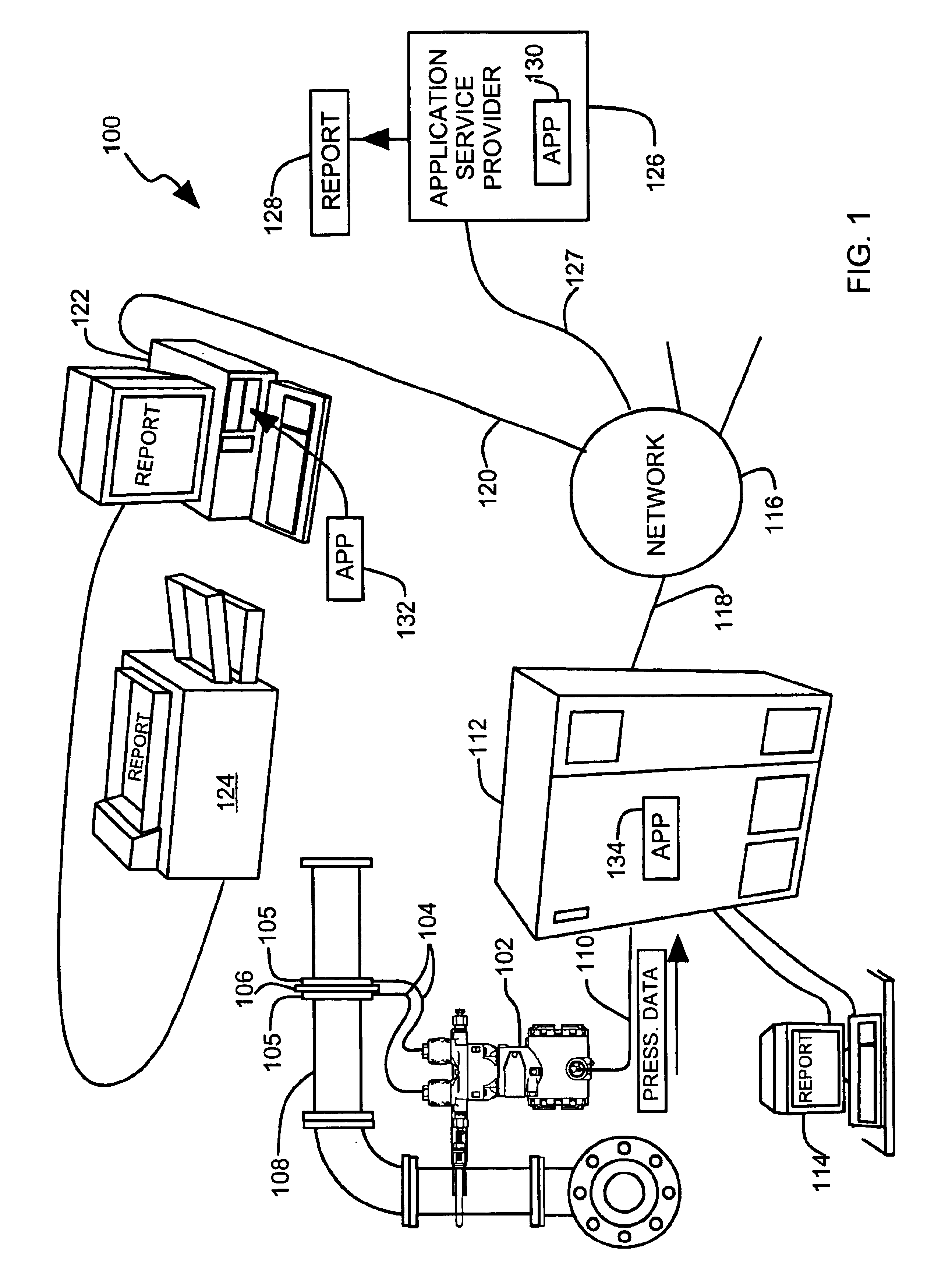

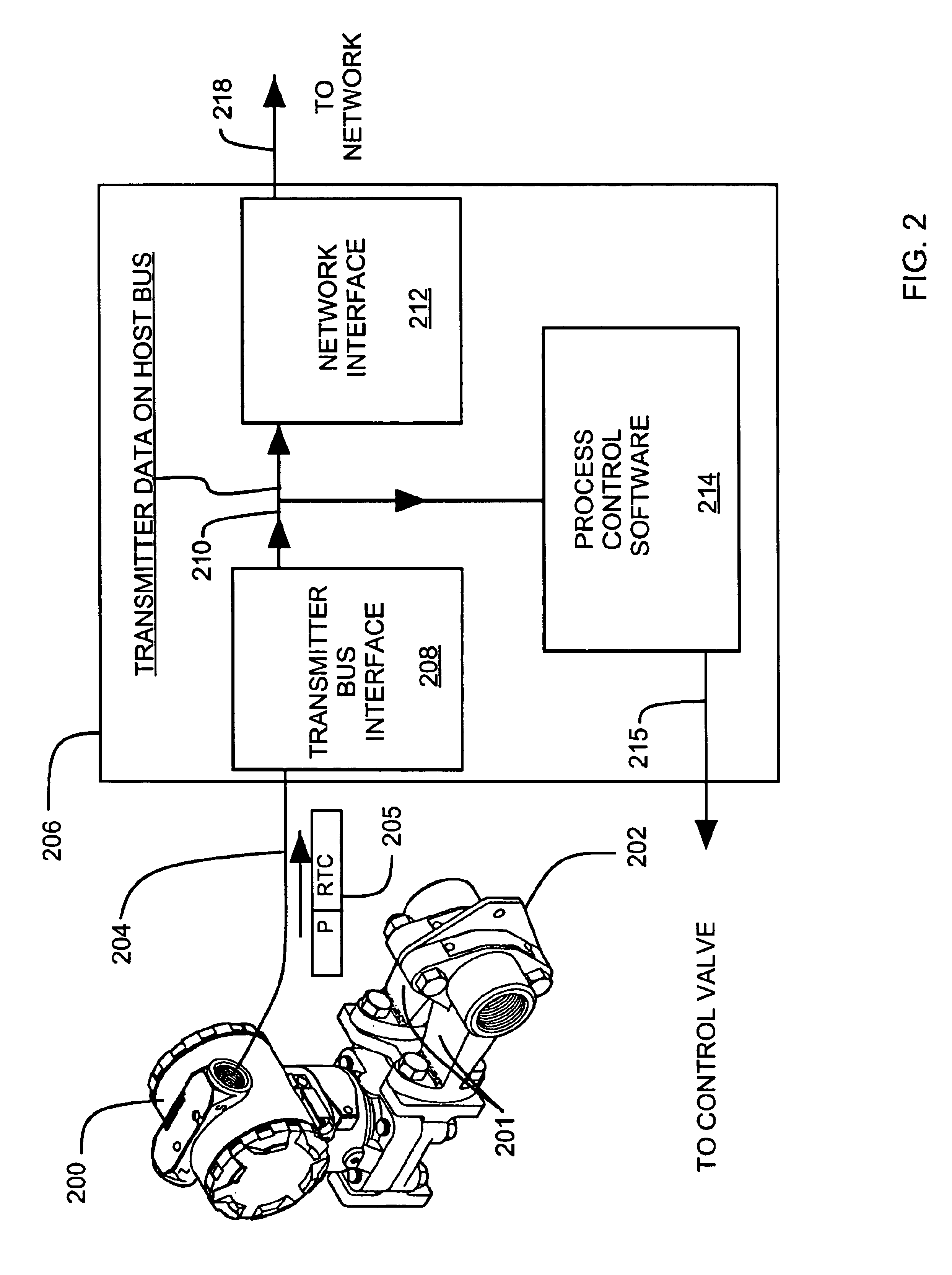

Flow diagnostic system

InactiveUS6907383B2Sampled-variable control systemsFlow control using electric meansMoving averageReal-time clock

A flow diagnostic system for a flow sensing element and impulse lines. A pressure transmitter coupled to the impulse lines provides digital pressure data to a control system. The control system provides the pressure data and real time clock readings to a diagnostic application. The diagnostic application calculates a difference between current pressure data and its moving average. A condition of the primary element or impulse lines is diagnosed from a current pressure data set relative to an historical data set. The diagnostic application is downloadable from an application service provider (ASP). The application can run on the control system, a remote computer or the ASP. A diagnostic report is preferably provided.

Owner:ROSEMOUNT INC

Microfluidic viscometer

InactiveUS7040144B2Determine viscosityVolume/mass flow measurementFlow control using electric meansFluid transportEngineering

Microfluidic devices, systems, and methods measure viscosity, flow times, and / or pressures, other flow characteristics within the channels, and the measured flow characteristics can be used to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems, electrokinetic systems and / or other fluid transport mechanisms can generate the flow, controllably mix fluids, and the like.

Owner:CAPLIPER LIFE SCI INC

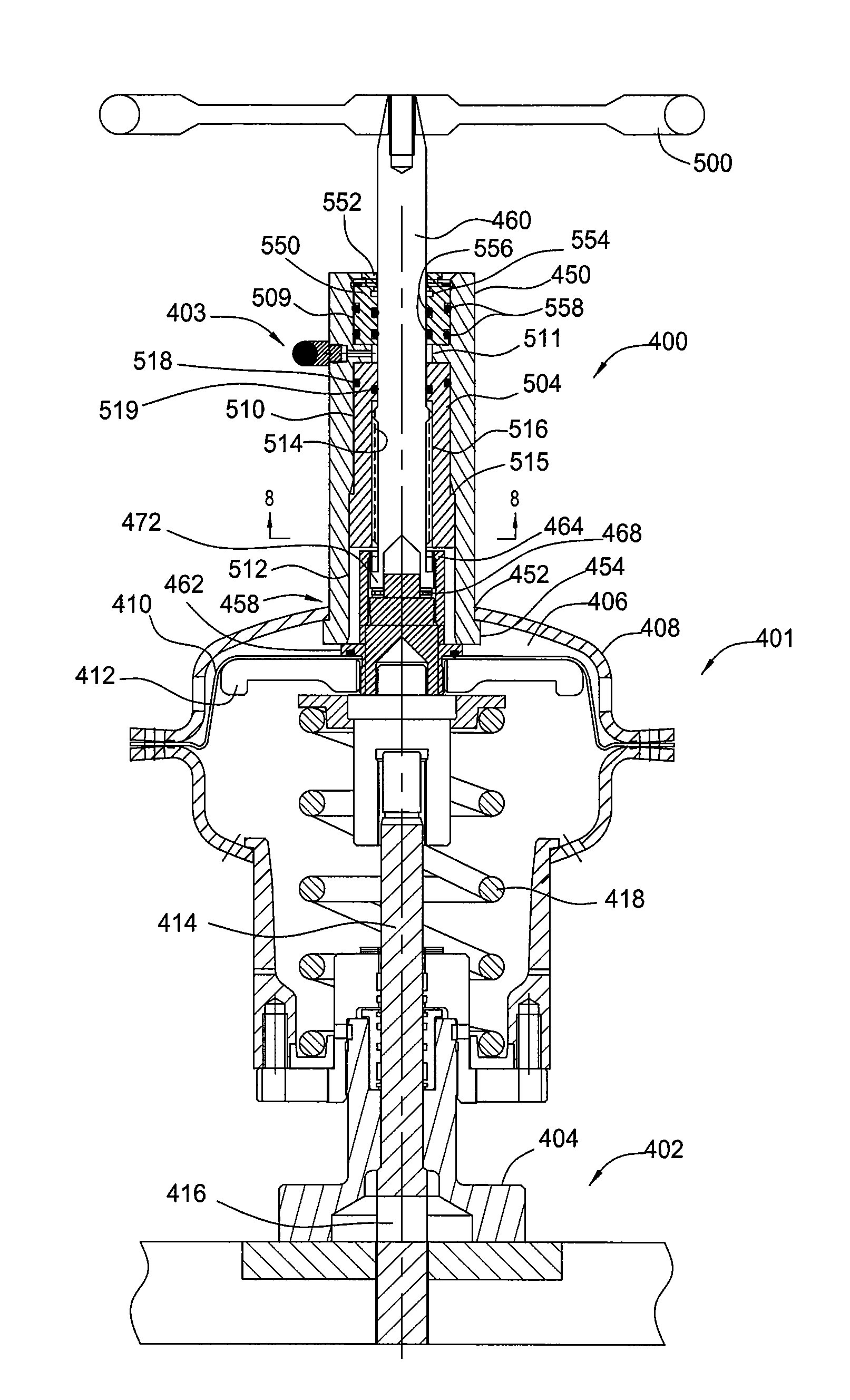

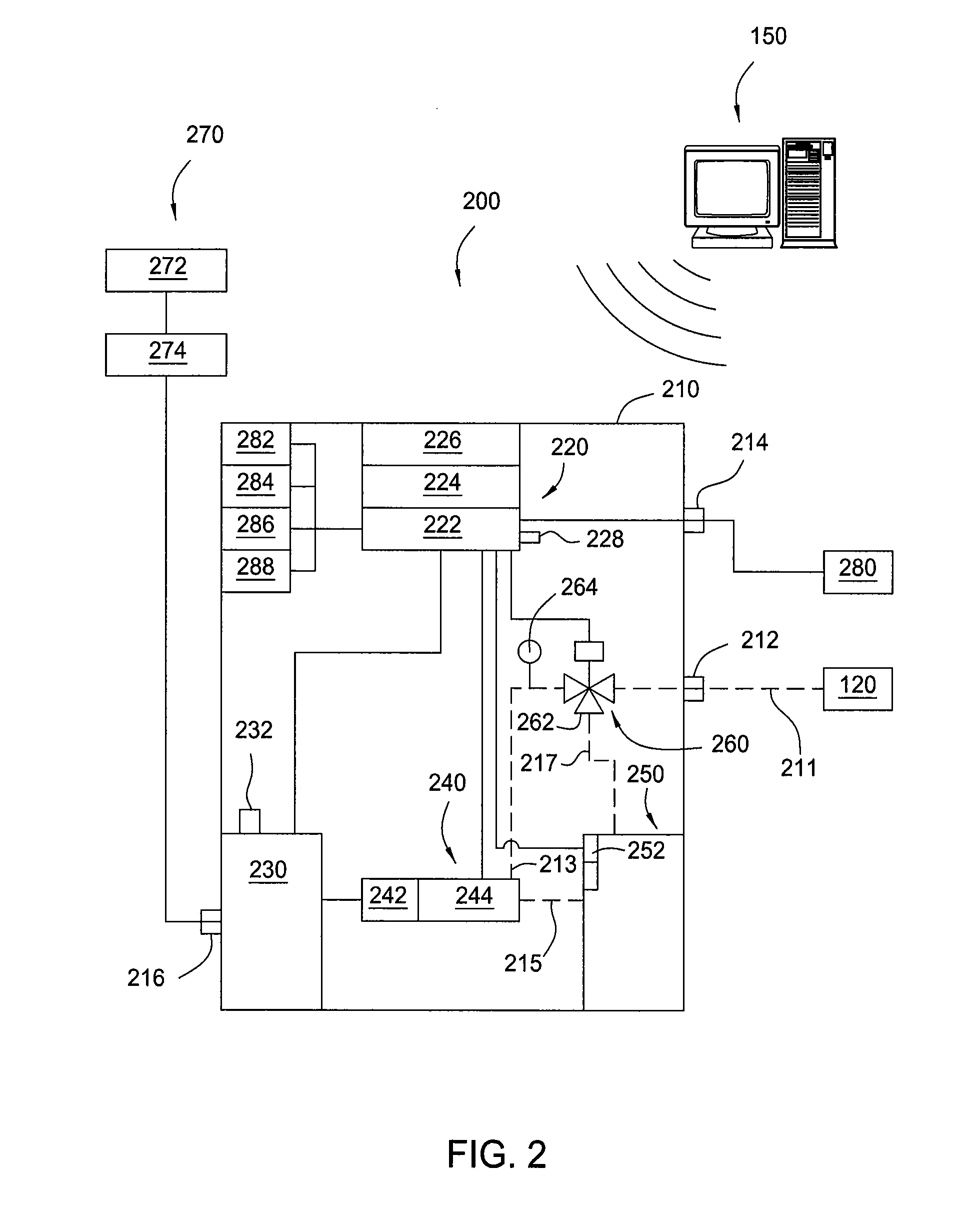

Safety valve control system and method of use

ActiveUS20120227983A1Reduce fluid pressureFluid-pressure actuator safetyEqualizing valvesControl systemTransducer

A safety valve control system may include a remotely operable control assembly, a first transducer, a valve assembly, and a compressor assembly in communication with the control assembly. The control assembly is operable to actuate the pump and valve assemblies to supply fluid to actuate the safety valve into open and closed positions, in response to one or more signals received from the first transducer. A method of operation may include maintaining the safety valve in an open or closed position while sensing a physical property with the control system; communicating a signal corresponding to the sensed physical property to the control system; and automatically closing or opening the safety valve in response to a comparison of the sensed physical property to a pre-set condition.

Owner:SAFOCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com