Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Guaranteed uniform velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

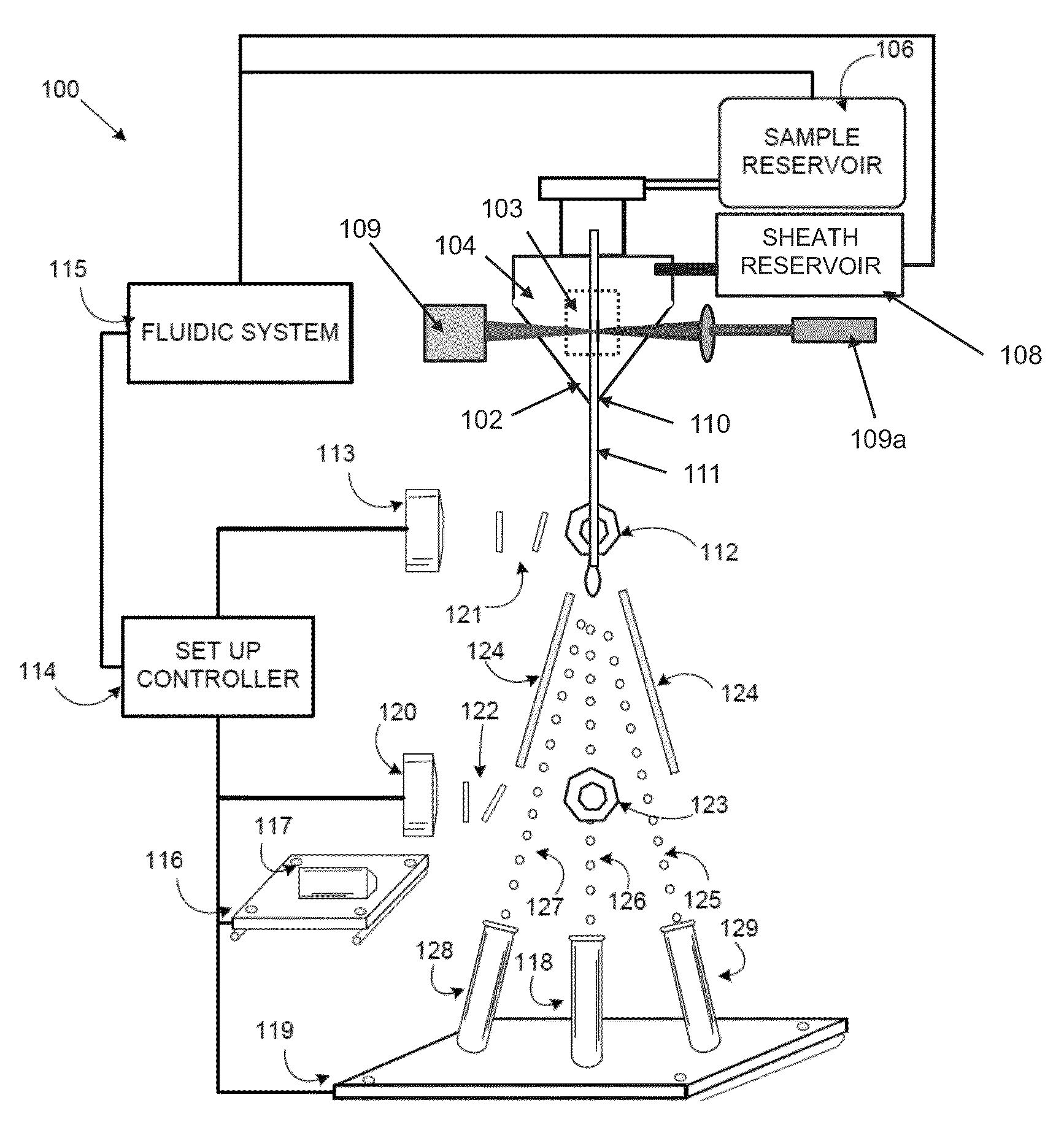

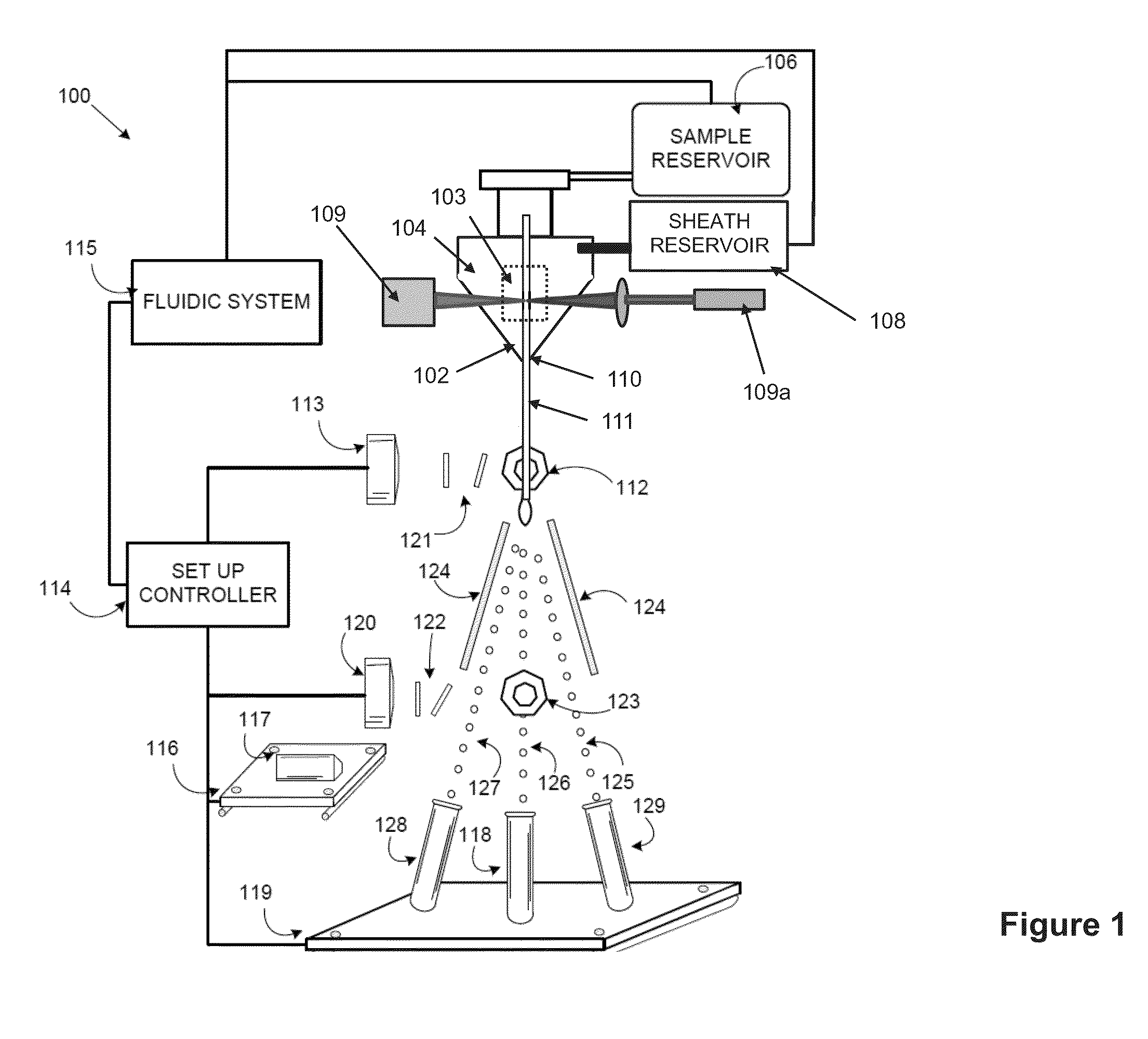

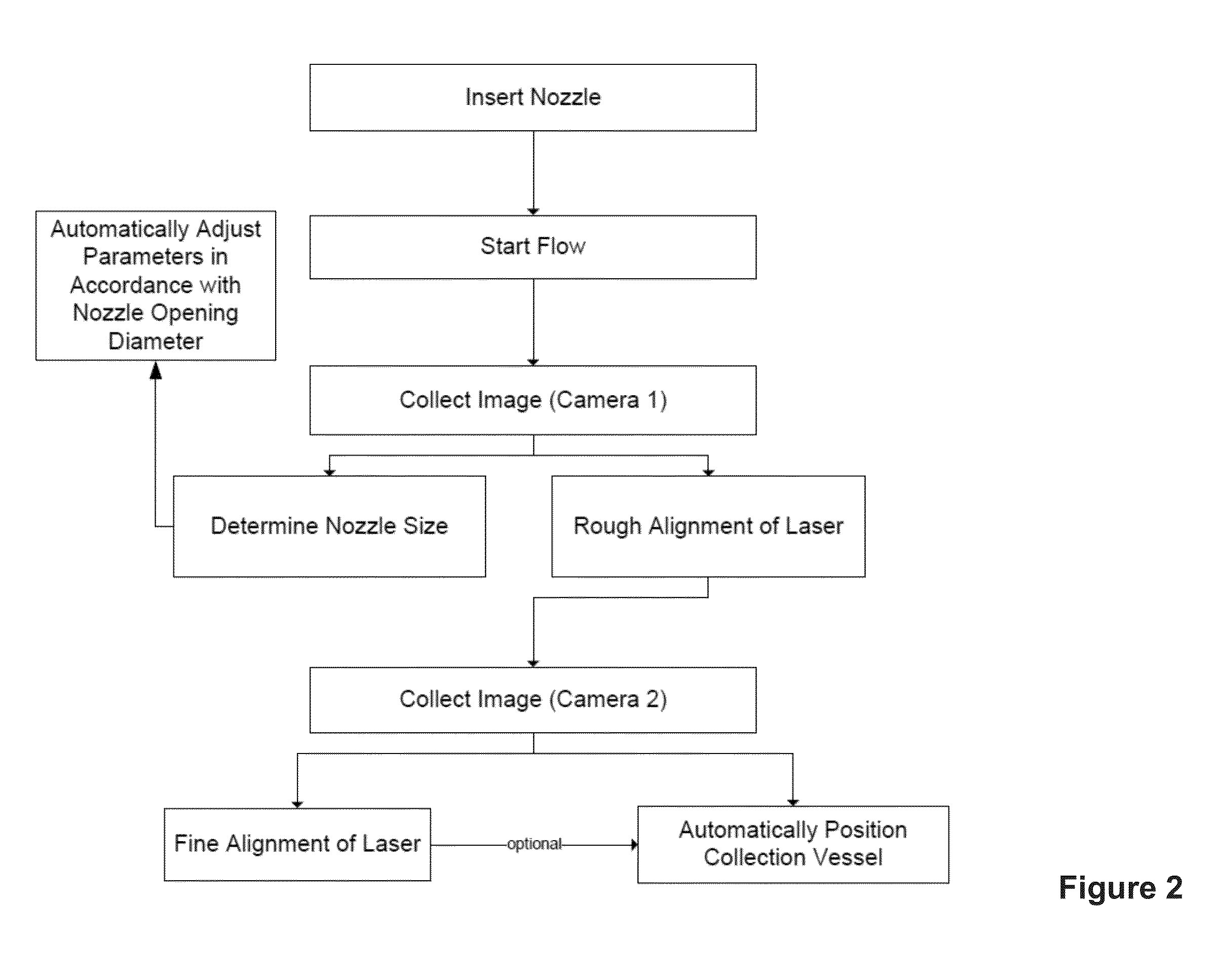

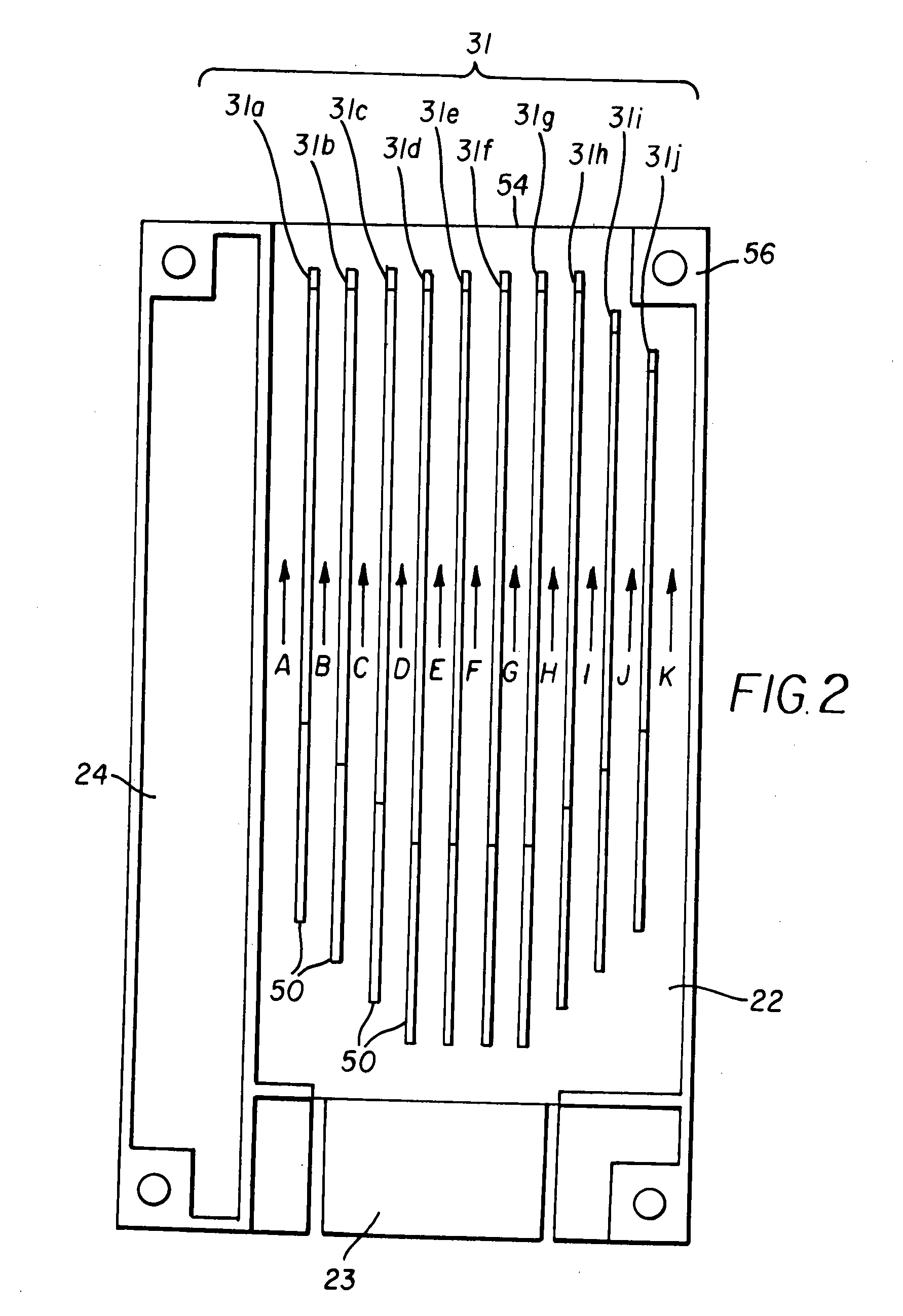

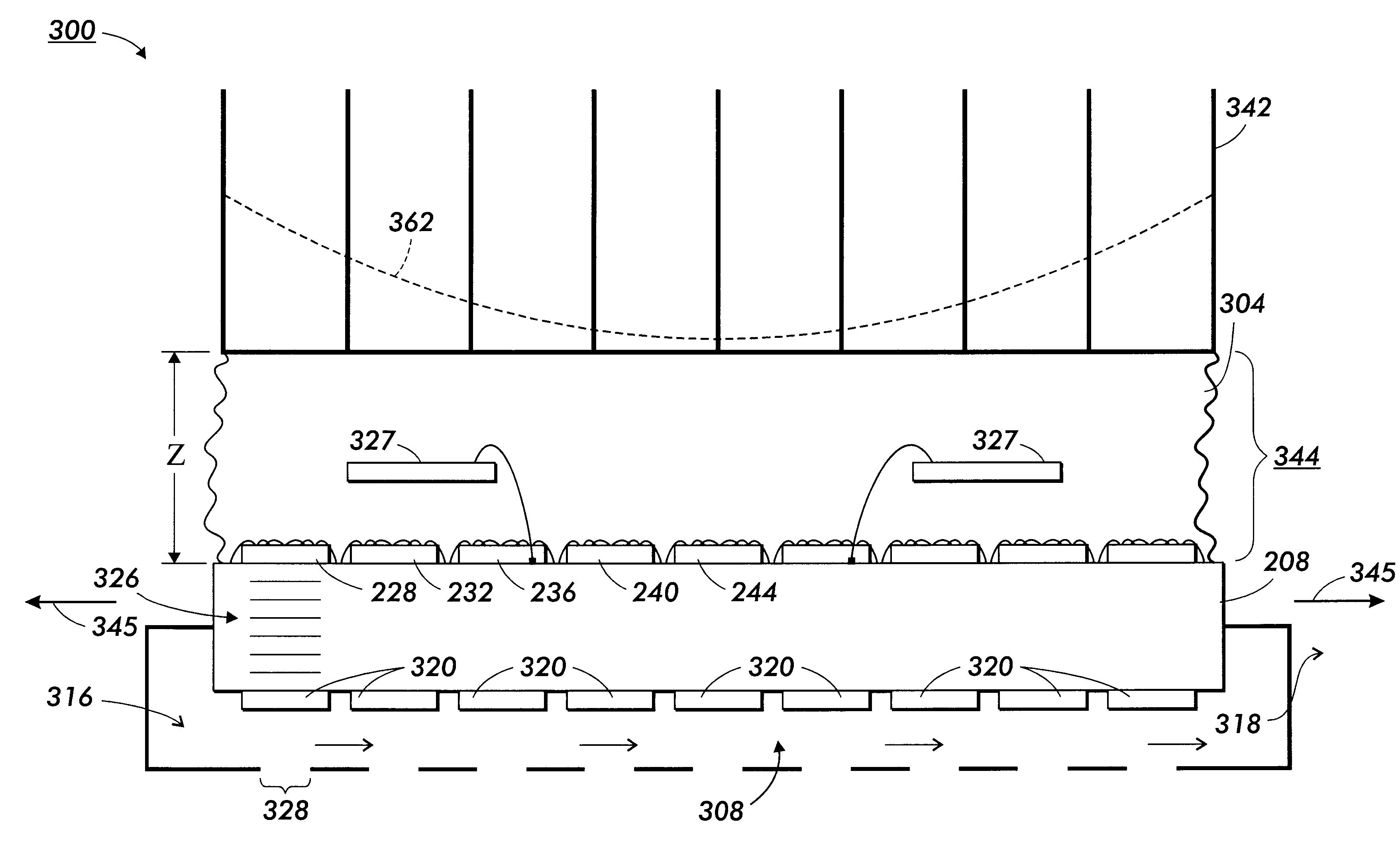

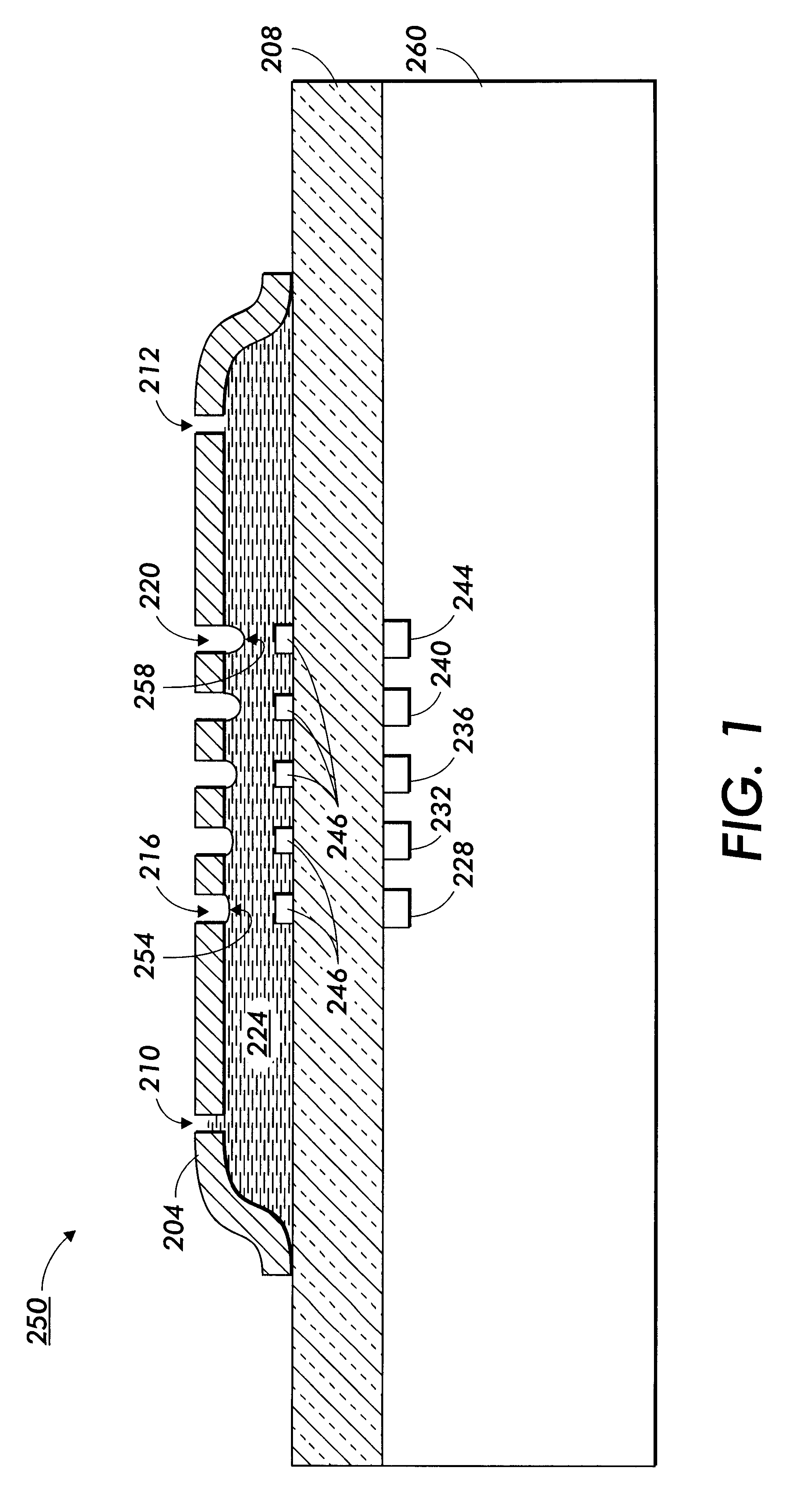

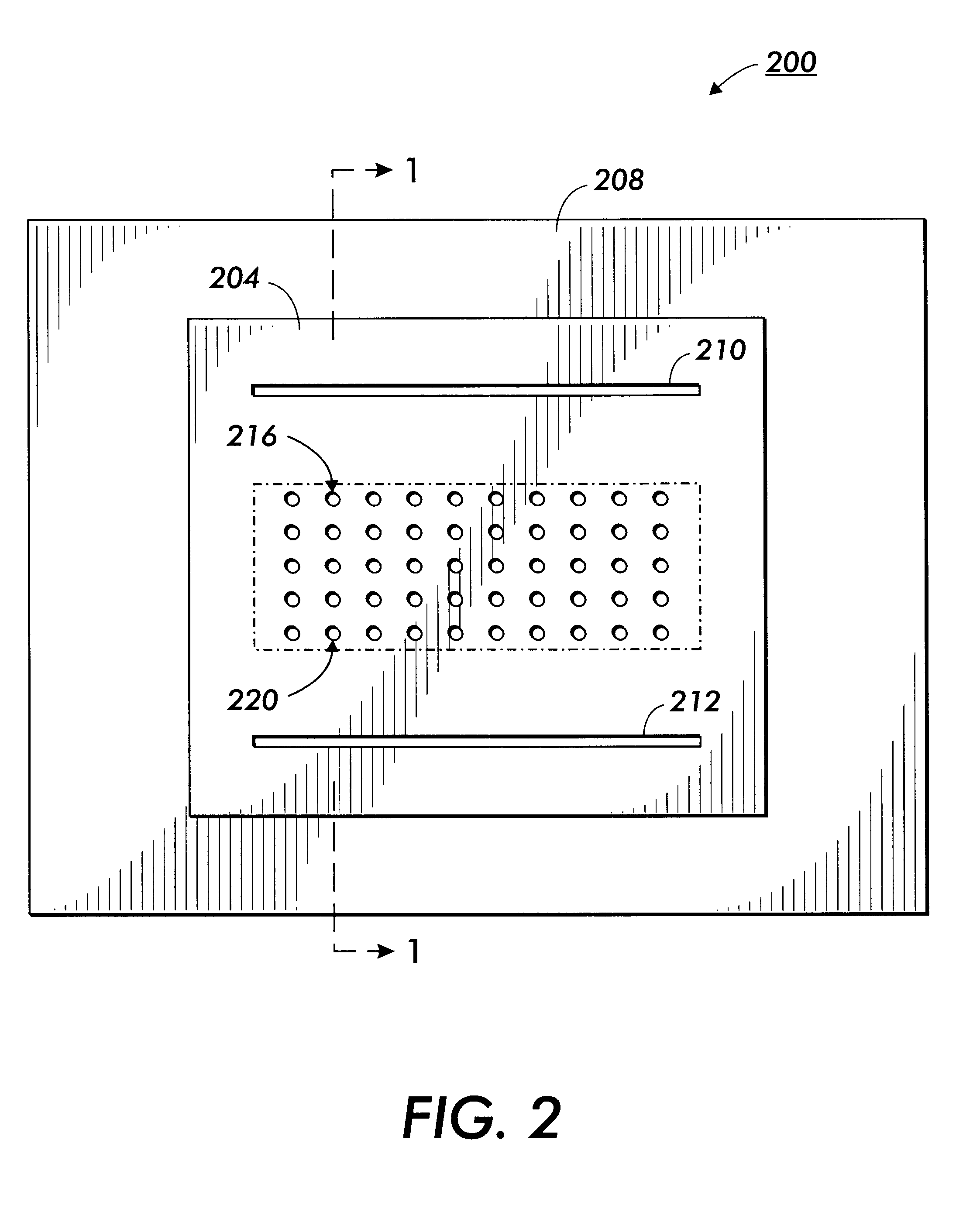

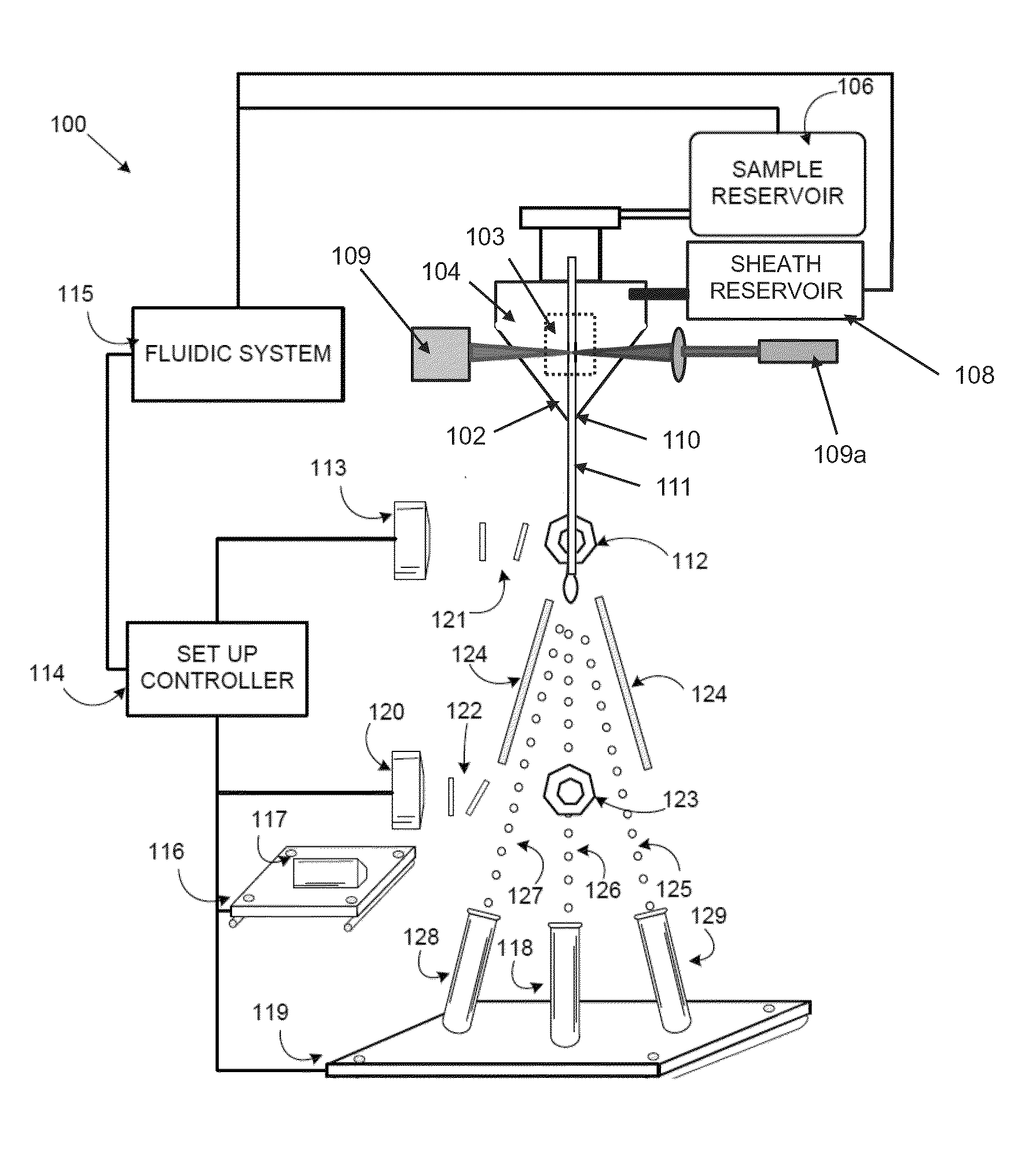

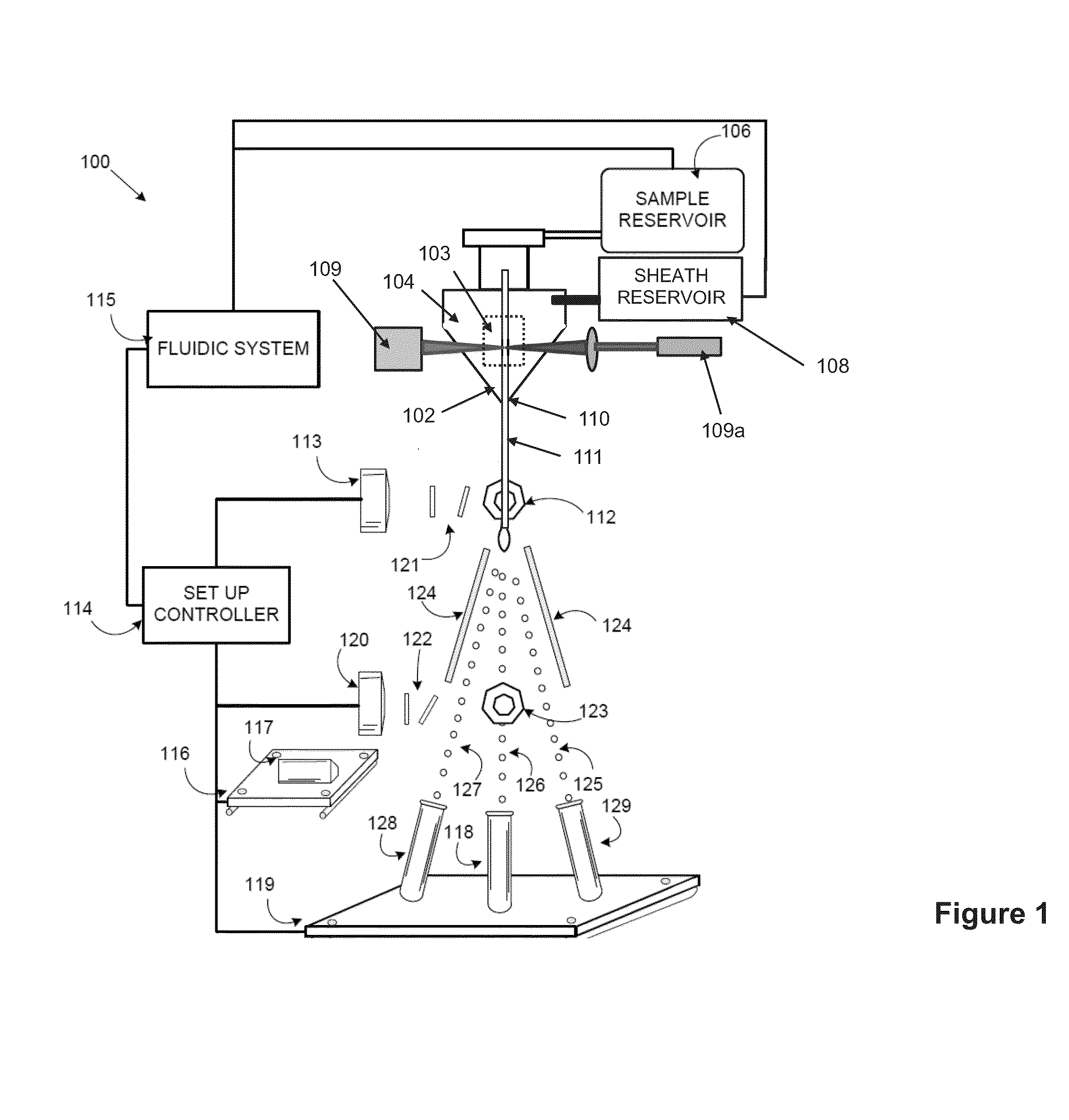

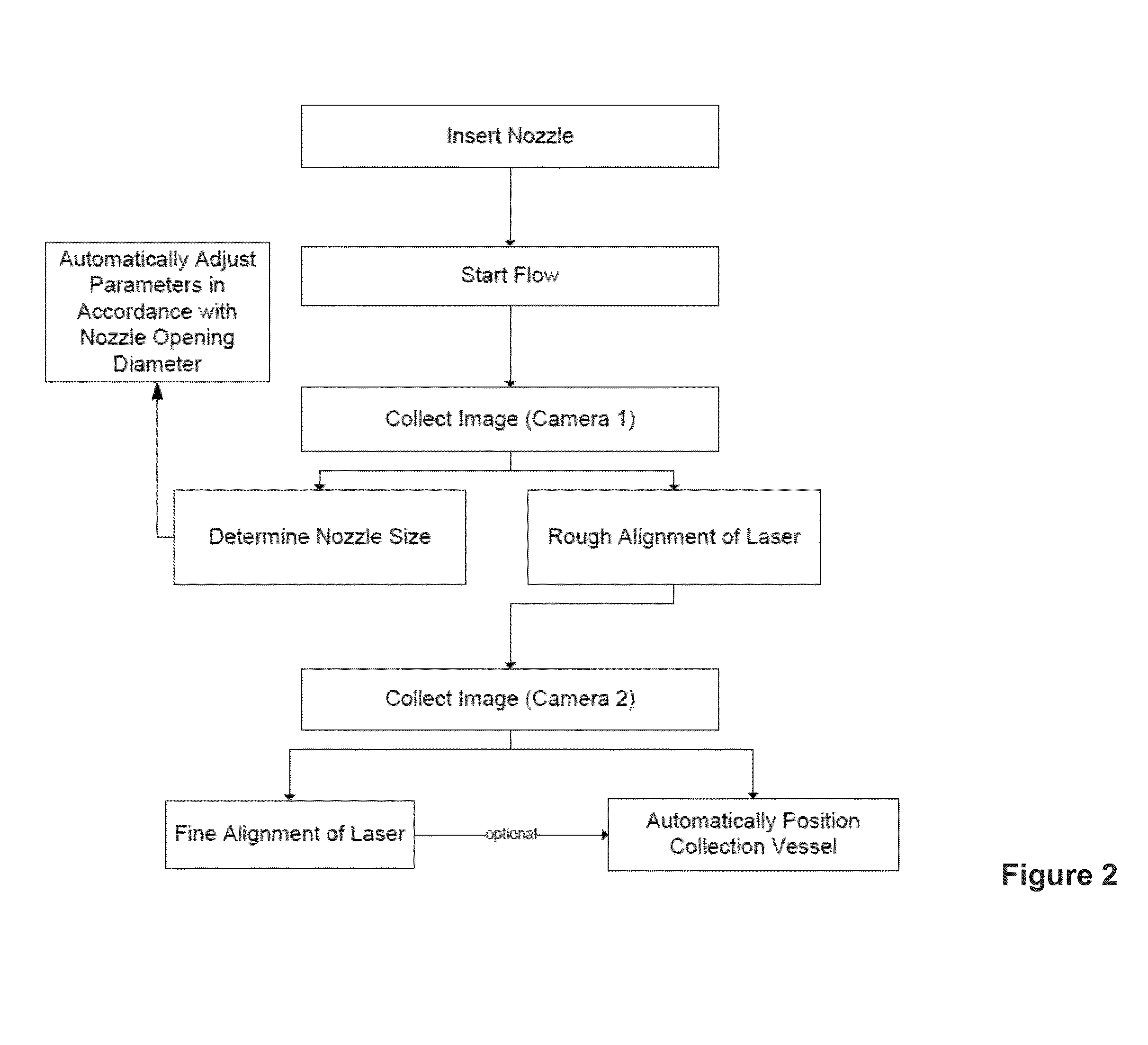

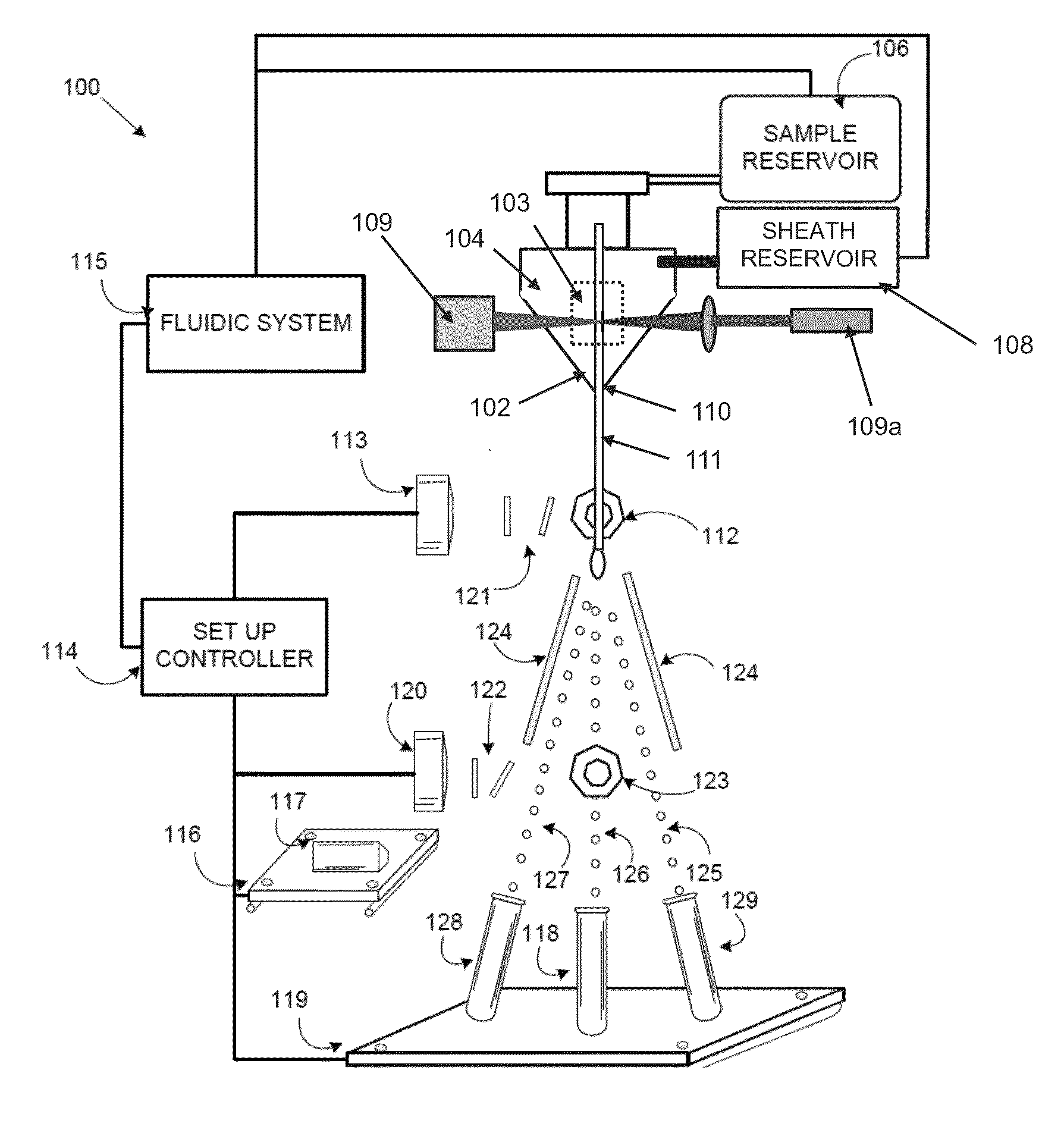

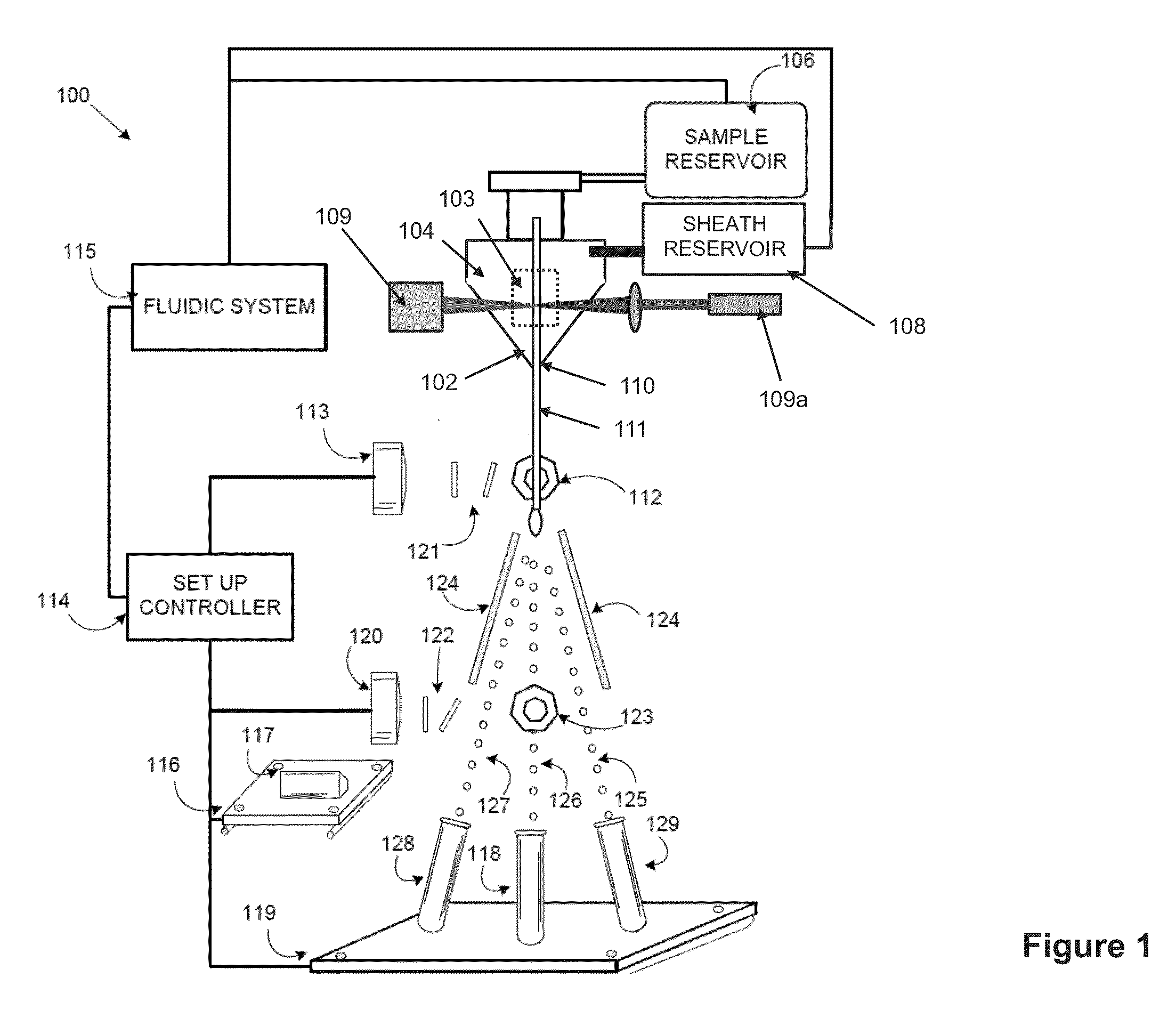

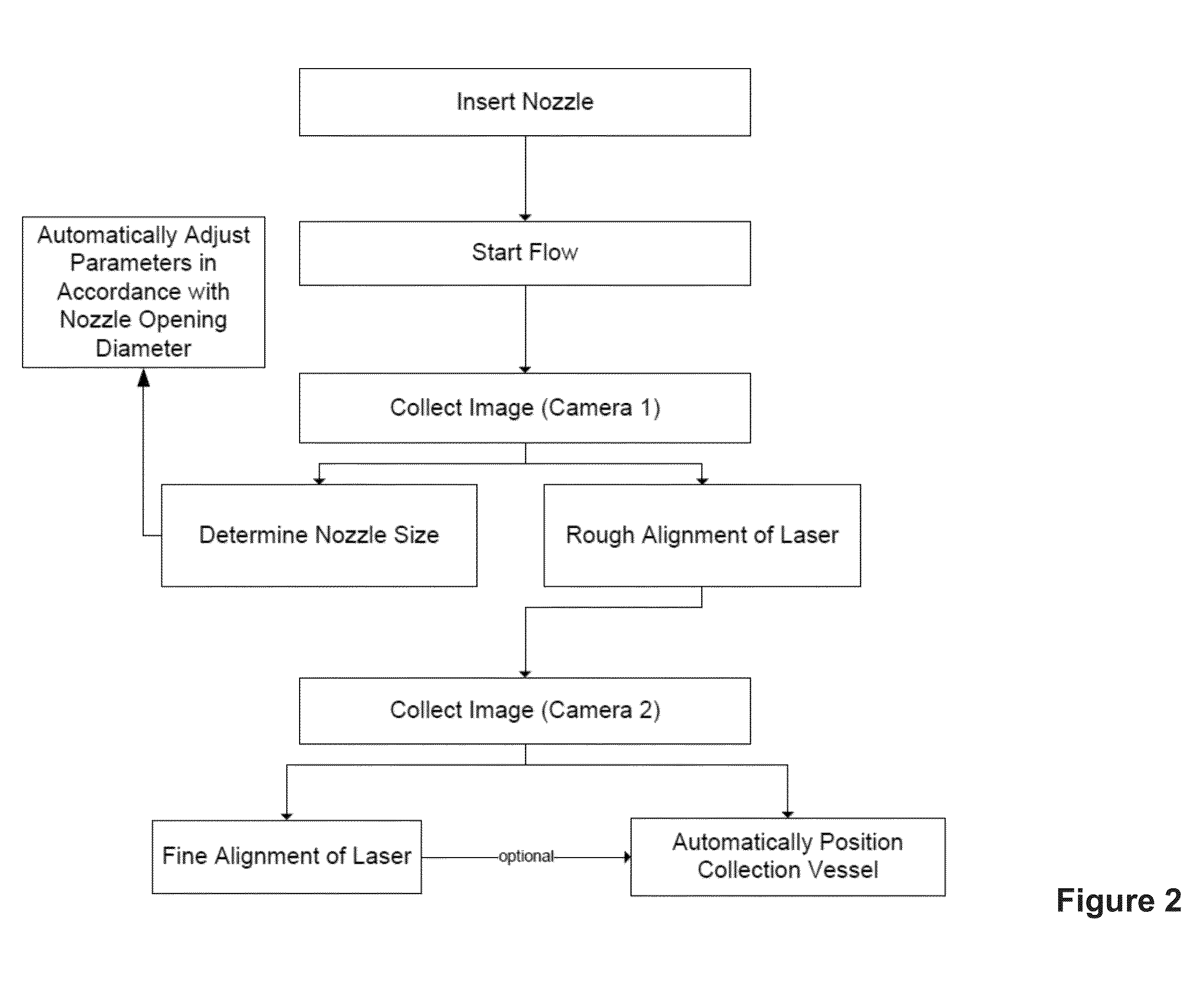

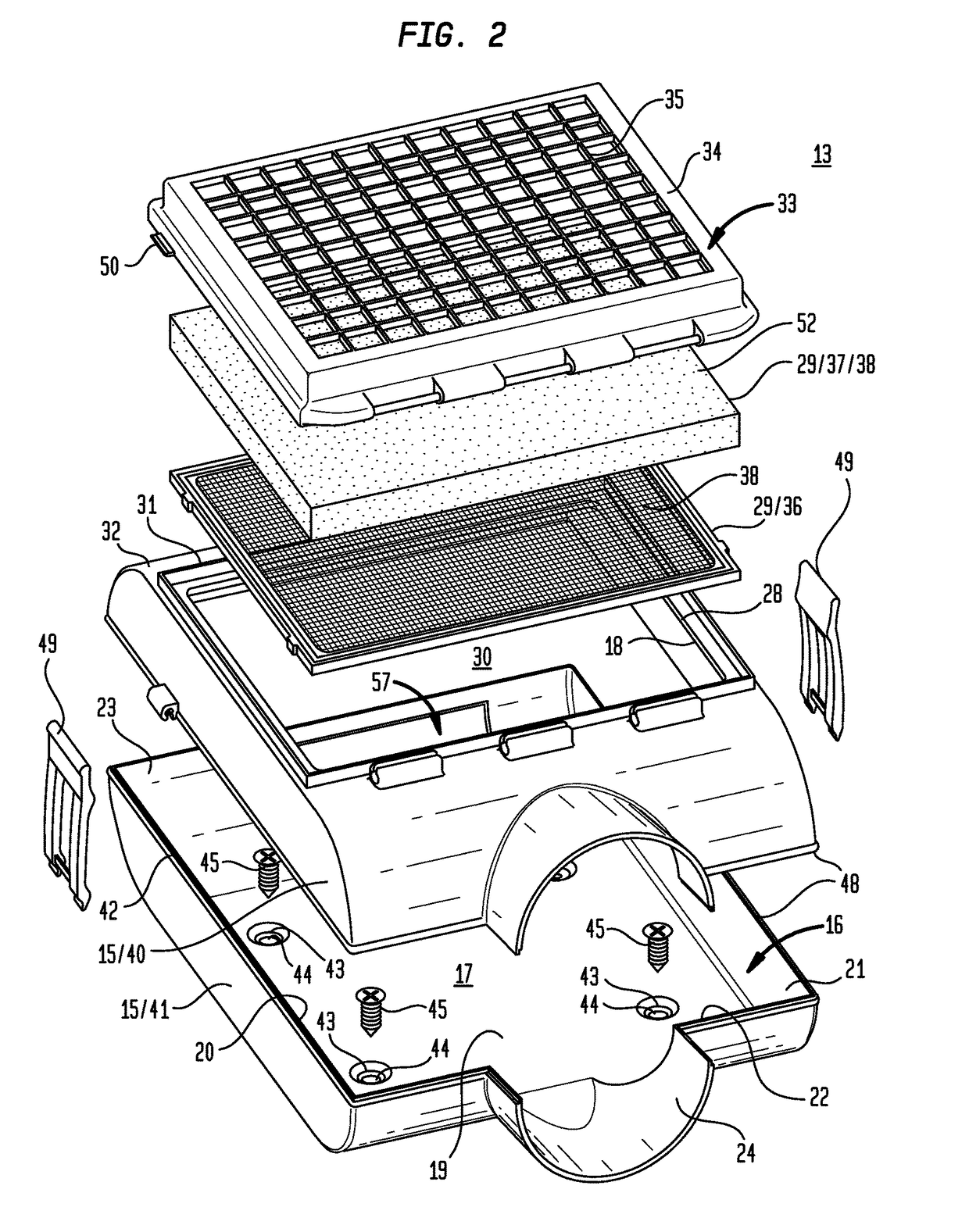

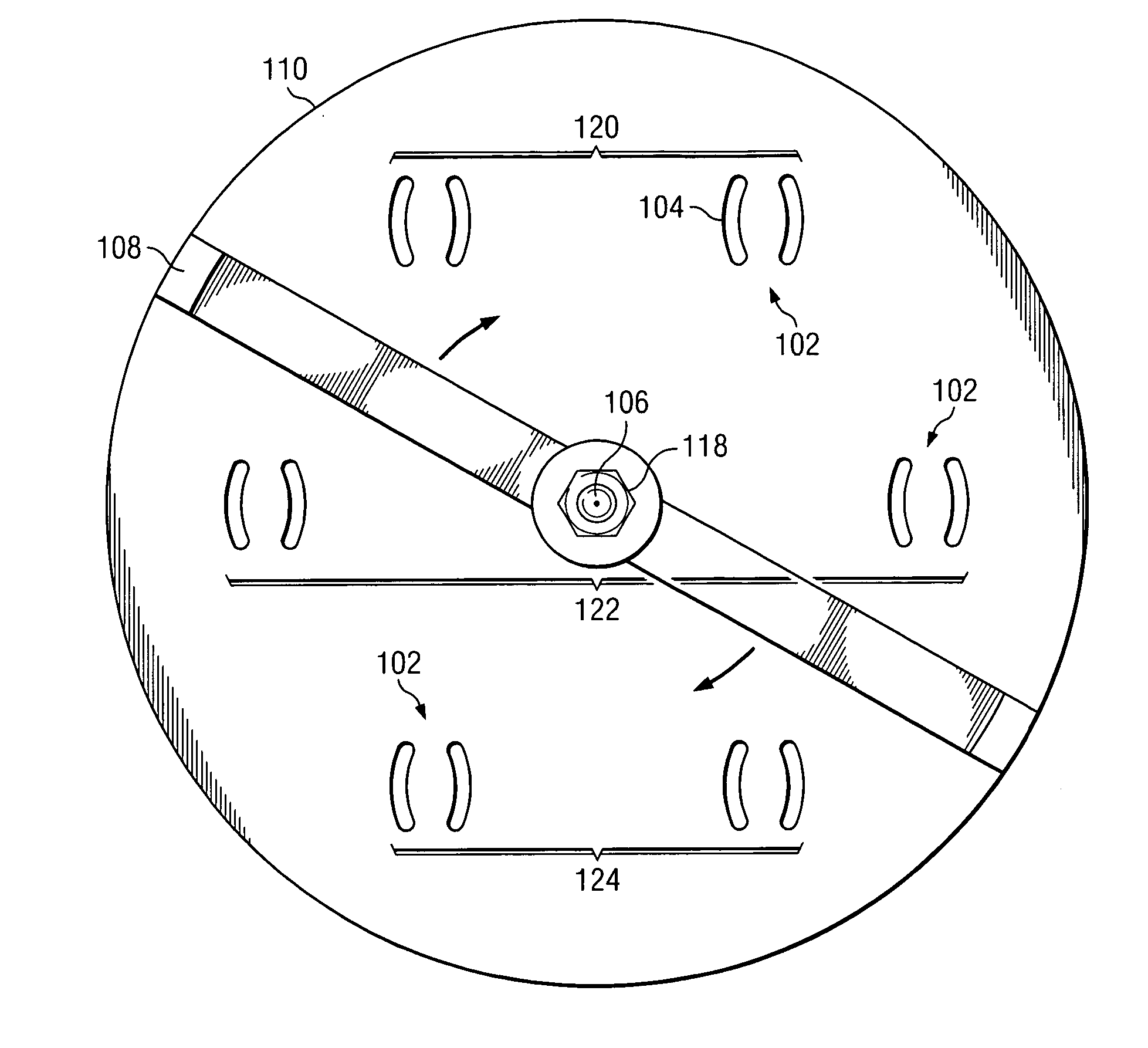

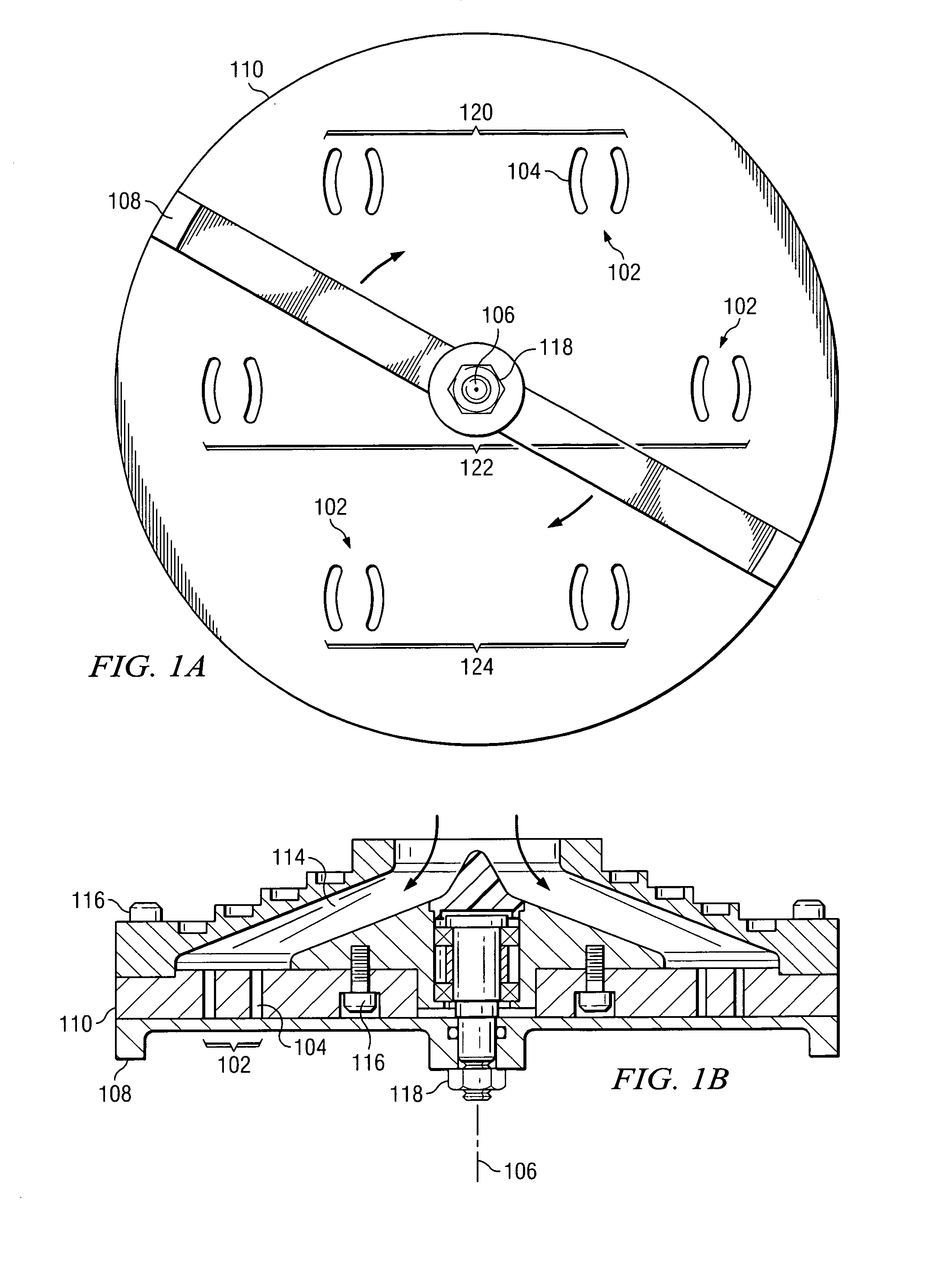

Automated set-up for cell sorting

ActiveUS8975595B2Guaranteed uniform velocityReduce needImage analysisVolume/mass flow measurementComputer scienceFlow Cytofluorometry

Apparatus and methods are described for automatically performing set-up steps for flow cytometry operations. The invention provides for the spatial determination of a flow stream and the subsequent automatic alignment of analysis devices and / or collection vessels. The automatic determination of flow stream properties provides for the automatic configuration flow cytometer parameters.

Owner:BECTON DICKINSON & CO

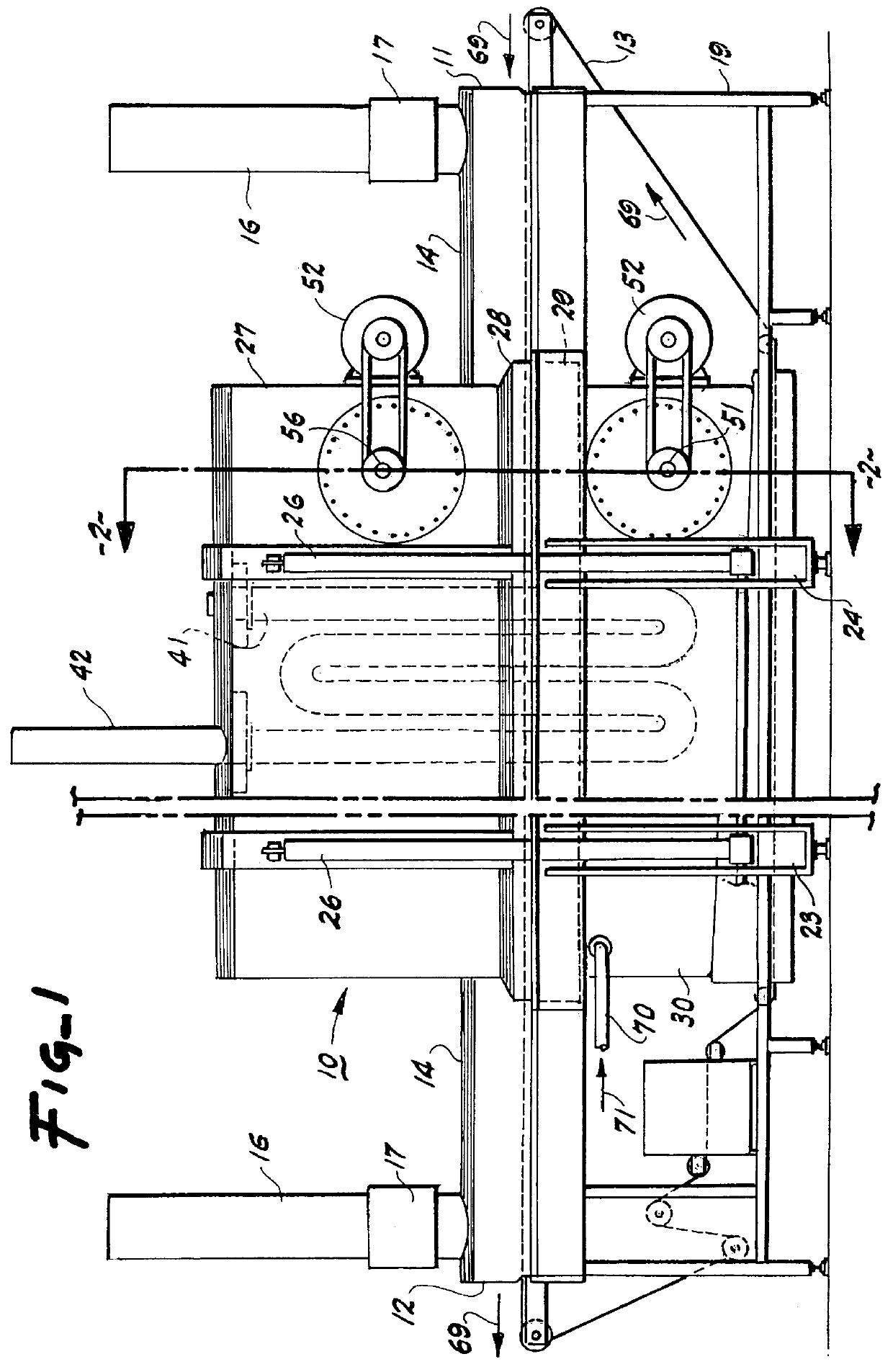

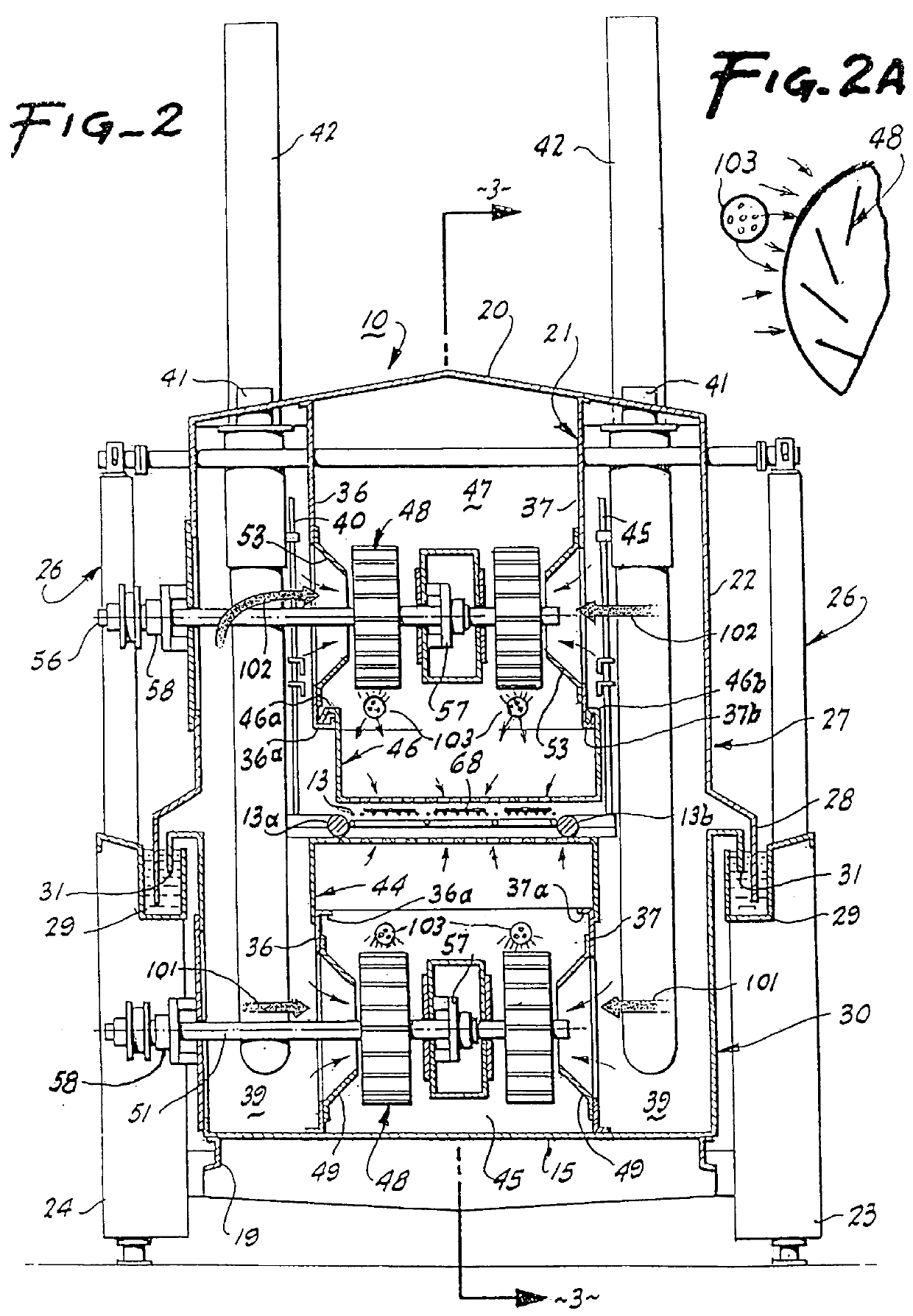

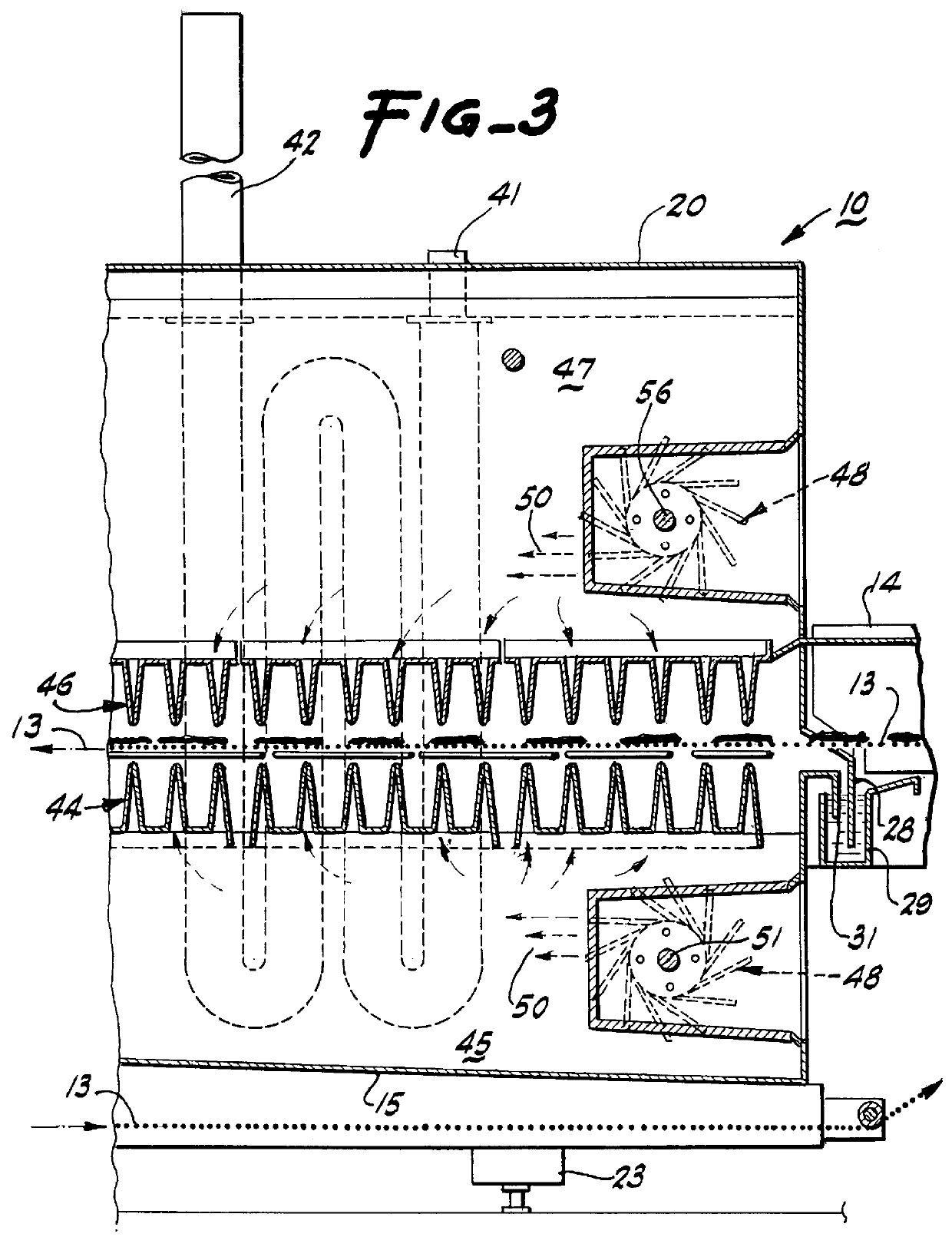

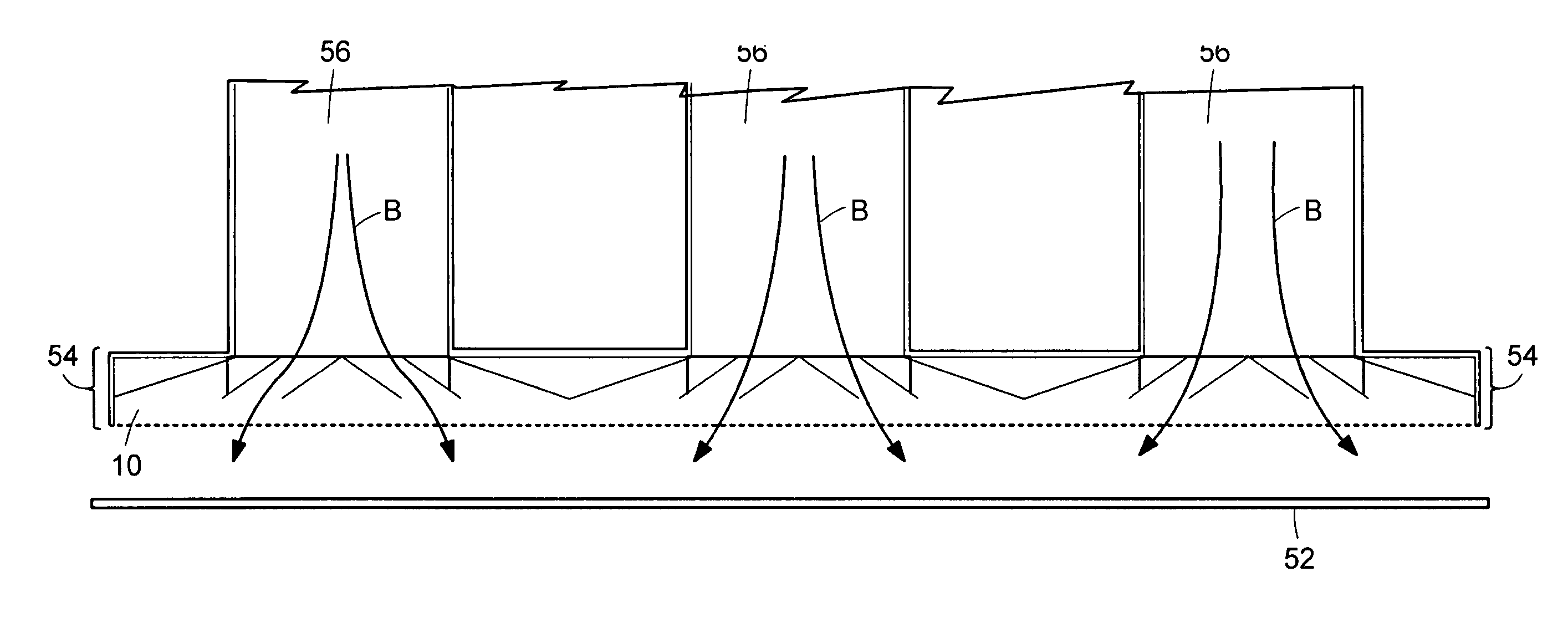

Method of cooking food products in an air impingement oven

InactiveUS6146678AIncrease heatGuaranteed uniform velocityMilk preservationDomestic stoves or rangesProduct gasEngineering

An oven for continuous cooking of products carried upon a open mesh wire conveyor provides the impingement of a cooking vapor from air discharge structure having ports arrayed above and below the conveyor. The discharge ports extend laterally of the conveyor and communicate with upper and lower plenums each charged by blower fans which draw cooking vapor from low pressure corridors alongside the product conveyor. Gas, electric or thermo fluid heaters are disposed in the corridors. The discharge ports are in slot form disposed about the apex of a Vee shaped riser spaced from the adjacent riser to provide a low pressure flow channel communicating with the corridors giving a rapid velocity change of the cooking vapor from turbulent to a less turbulent flow. The distance for vapor travel between the upper discharge ports and the product carrying conveyor is variable. Temperature and moisture content of the process vapor can be changed to suit cooking conditions.

Owner:HEAT & CONTROL

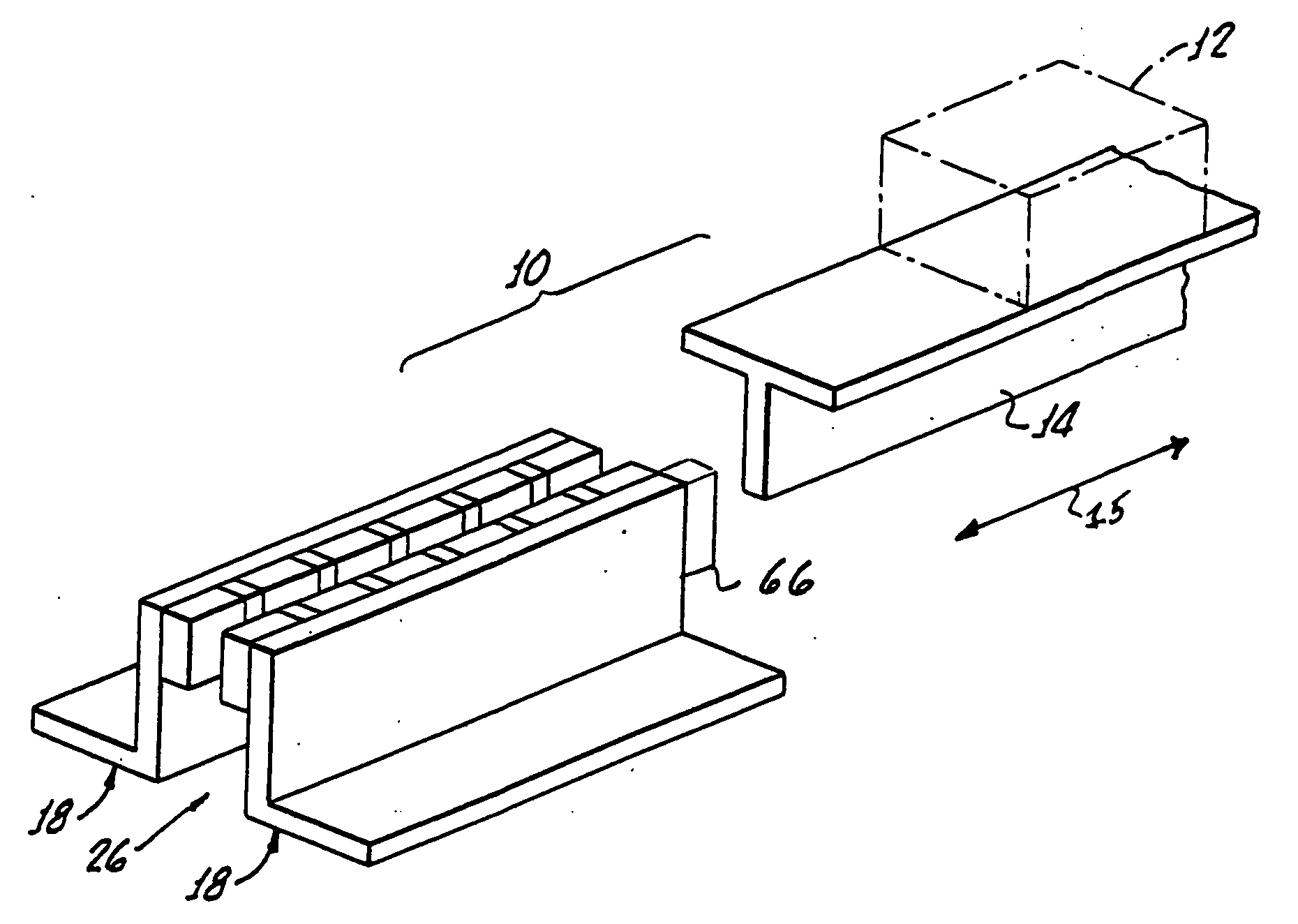

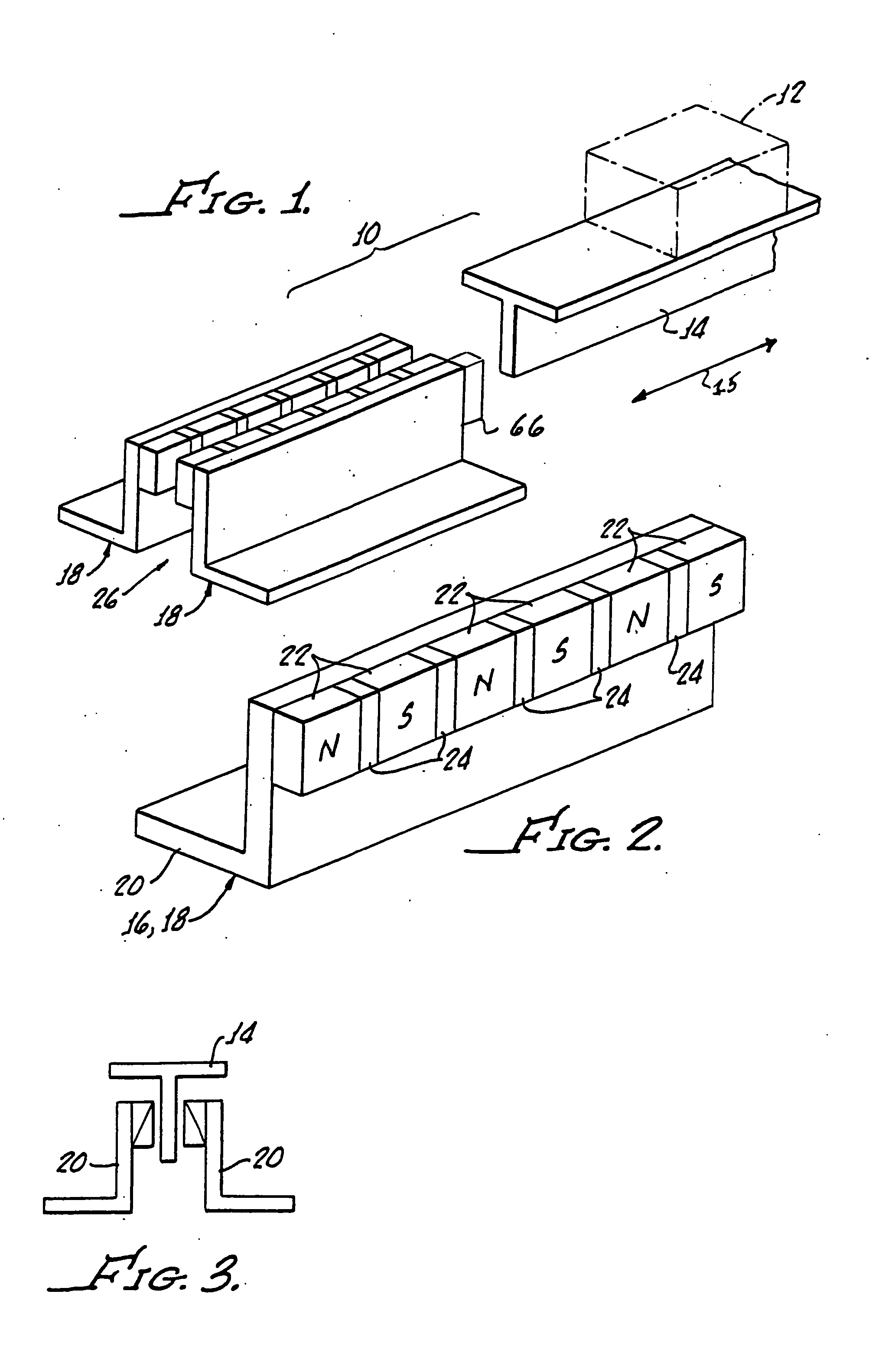

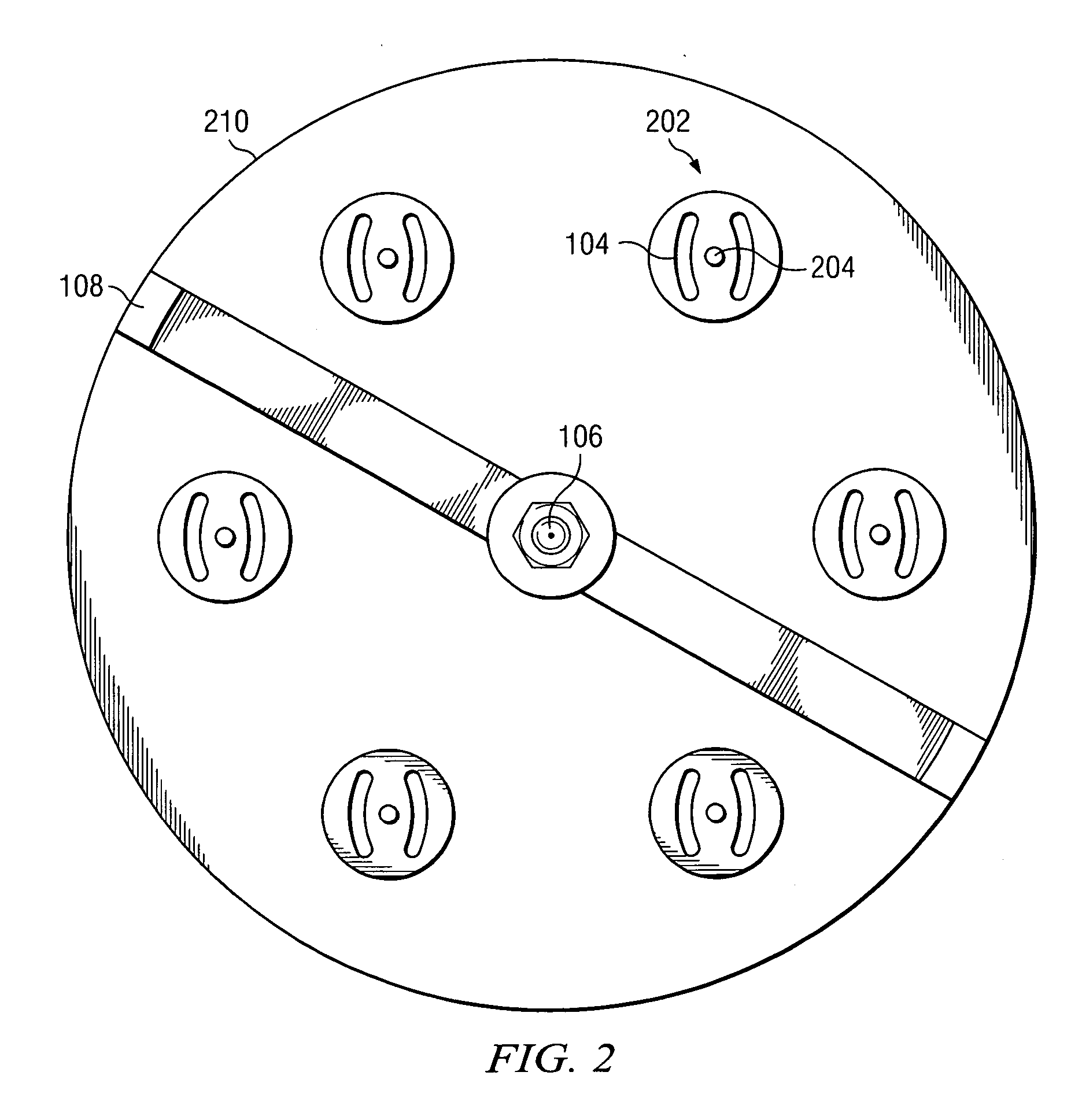

Eddy current braking apparatus with adjustable braking force

InactiveUS20060278478A1Adjustable distanceGuaranteed uniform velocityDynamo-electric brakes/clutchesElectrodynamic brake systemsEngineeringLinearity

An eddy current brake includes a diamagnetic member, a first support wall and a second support wall with the first and second linear arrays of permanent magnets disposed on the walls facing one another. Apparatus is provided for moving at least one of the walls in order to control eddy current induced in the member in the passage of the member therepast to adjust the braking force between the magnets and the member. Apparatus is also provided for causing the velocity of the member to change the braking force between the magnets and the member.

Owner:MAGNETAR TECH

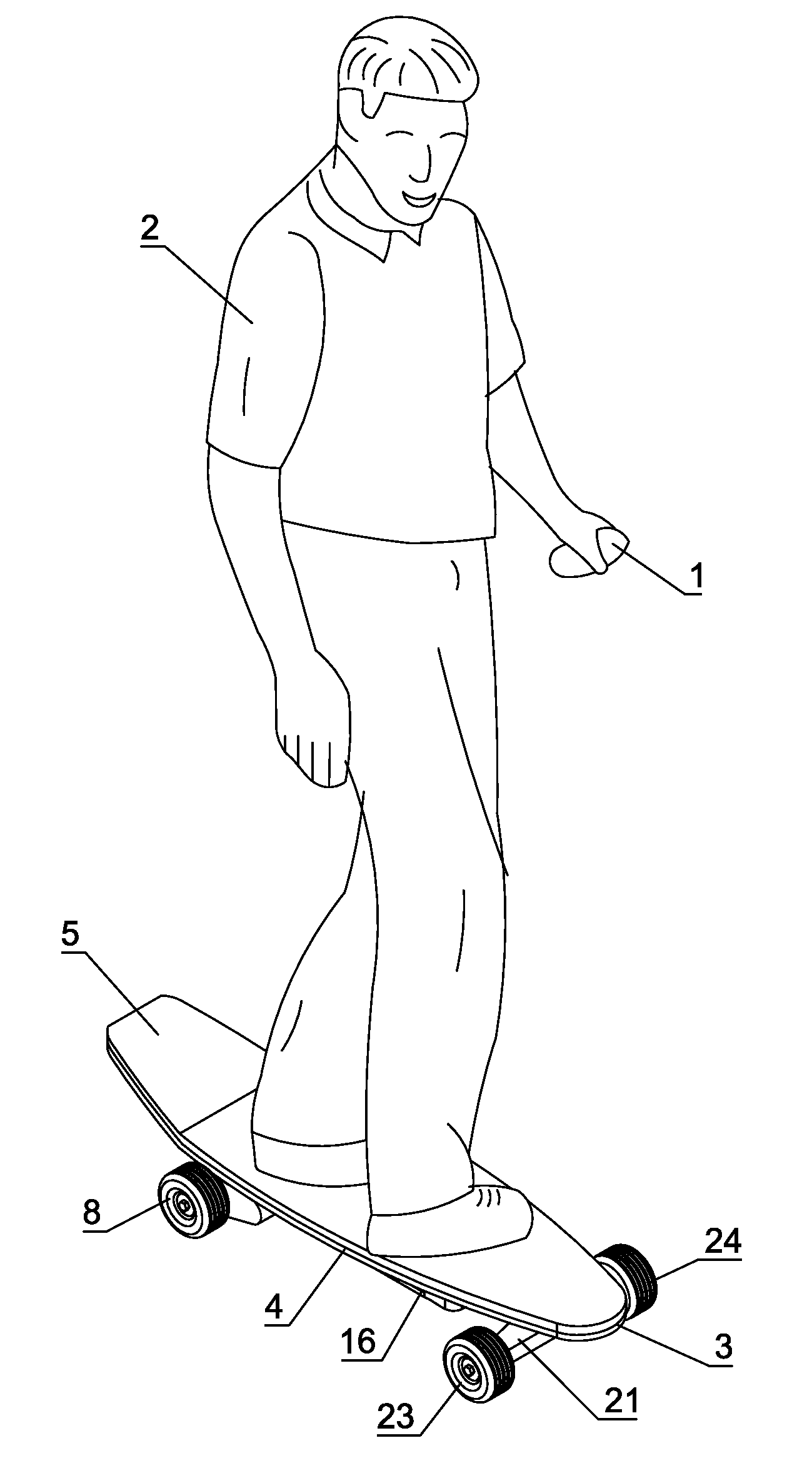

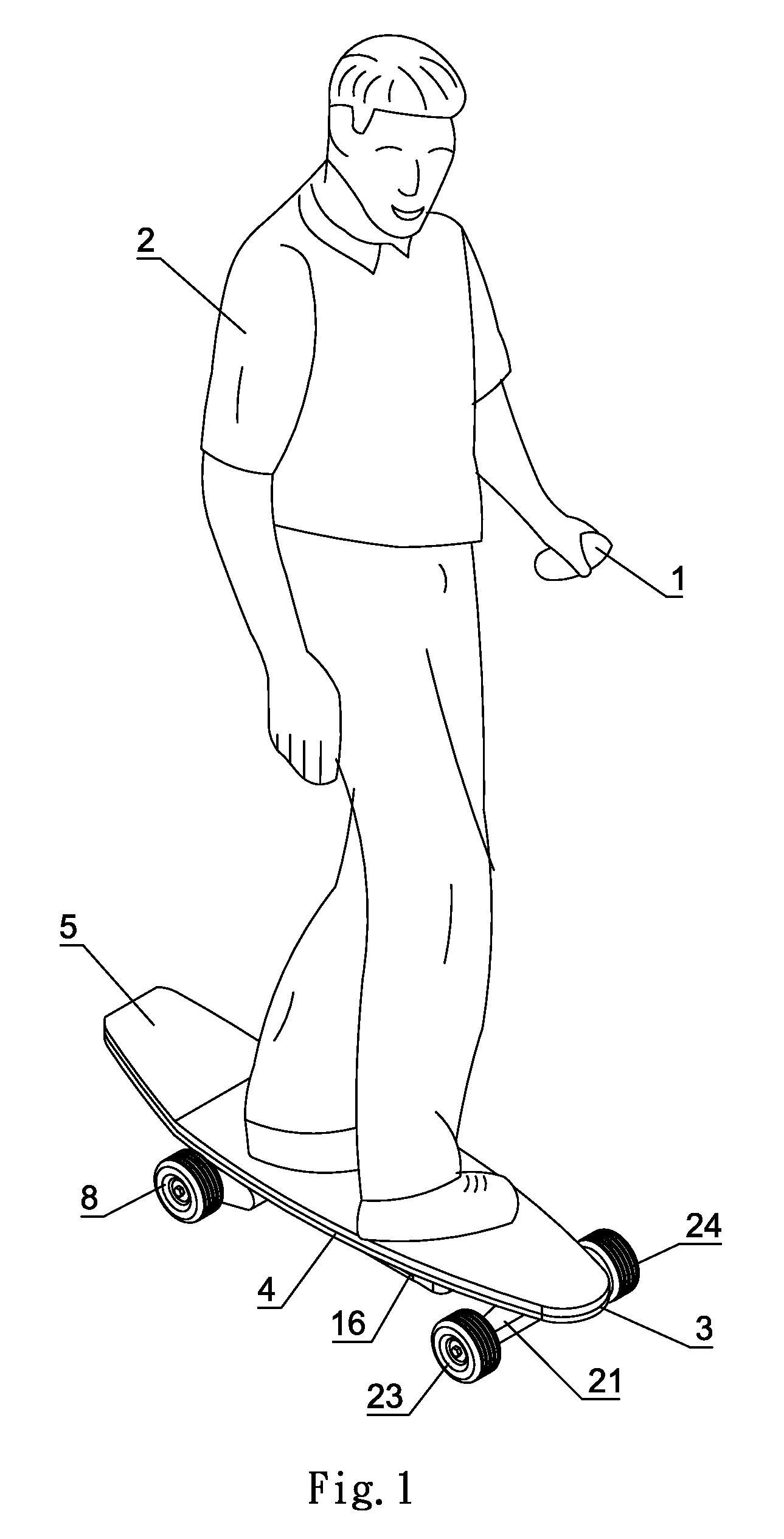

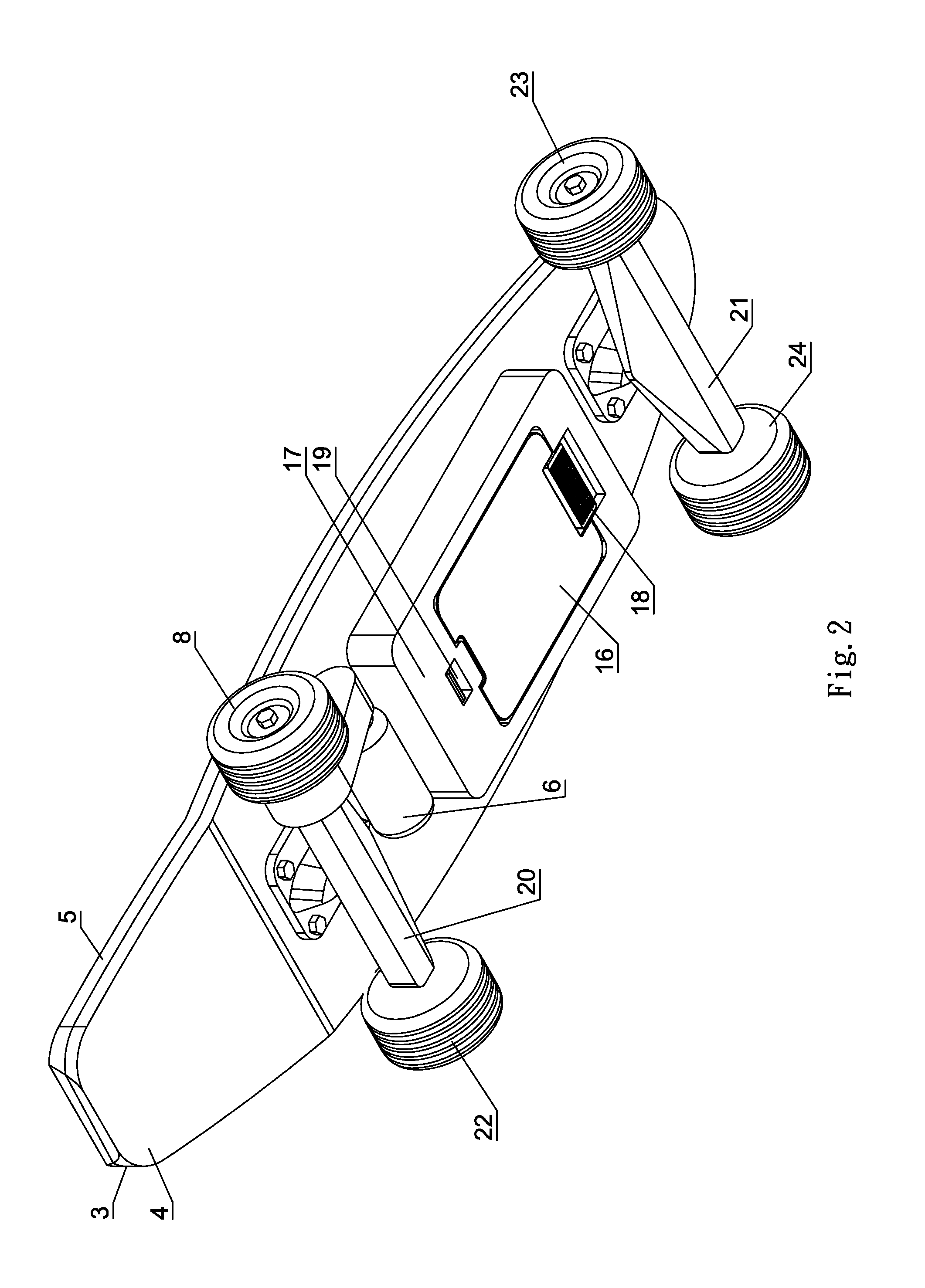

Remote Control Electric Powered Skateboard

InactiveUS20100222941A1High speedShort timeSynchronous motors startersAC motor controlBrushless motorsElectric machine

A remote control electric powered skateboard has a brushless motor or a brushless hub motor installed on the lower surface of the skateboard for connecting to a battery device through a controller, so that the motors could be electrified. A driving device disposed between either afore motors and at least one wheel is controlled by the remote control, thereby permitting an automatic comparison. When the electrification of the remote control executes, the remote control spontaneously generates an initial code for a receiver in the controller to robotically distinguish and lock the code. Turning off the remote control provides an automatic decoding. A receiver receives control signals from the remote control for the controller to interpret, and accordingly the controller generates and sends distinct commands to either motor, which allows the skateboard to implement various actions correspondingly. An auxiliary remote device disposed on the joint between a front support and a plywood is foldable or could stand on the skateboard; the height of the auxiliary remote device is adjustable for meeting divergent demands from dissimilar riders. A remote handle further provides the same operating means as that of the remote control for offering a supplementary supporting function.

Owner:CHANG WESLEY WENTI

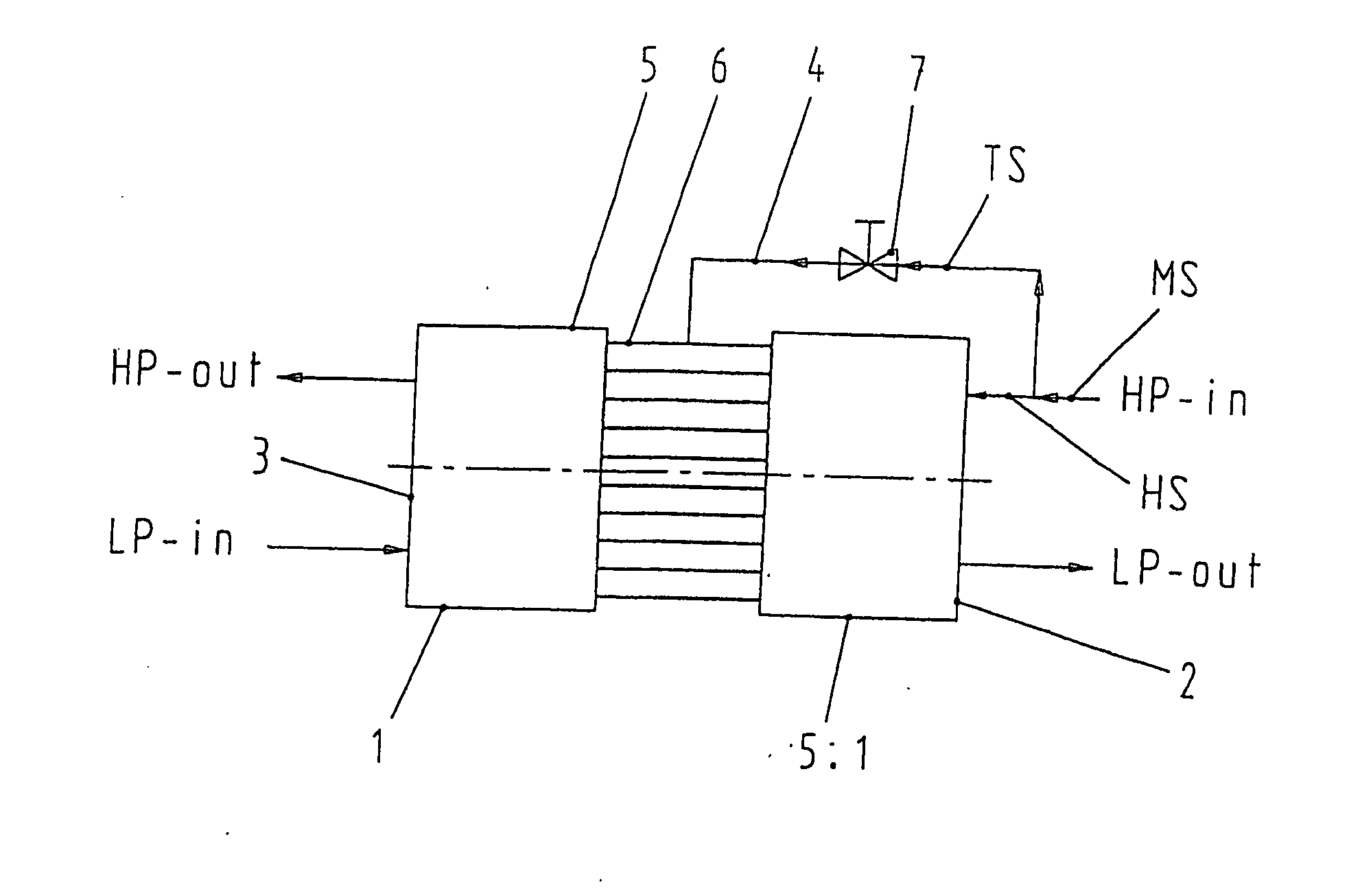

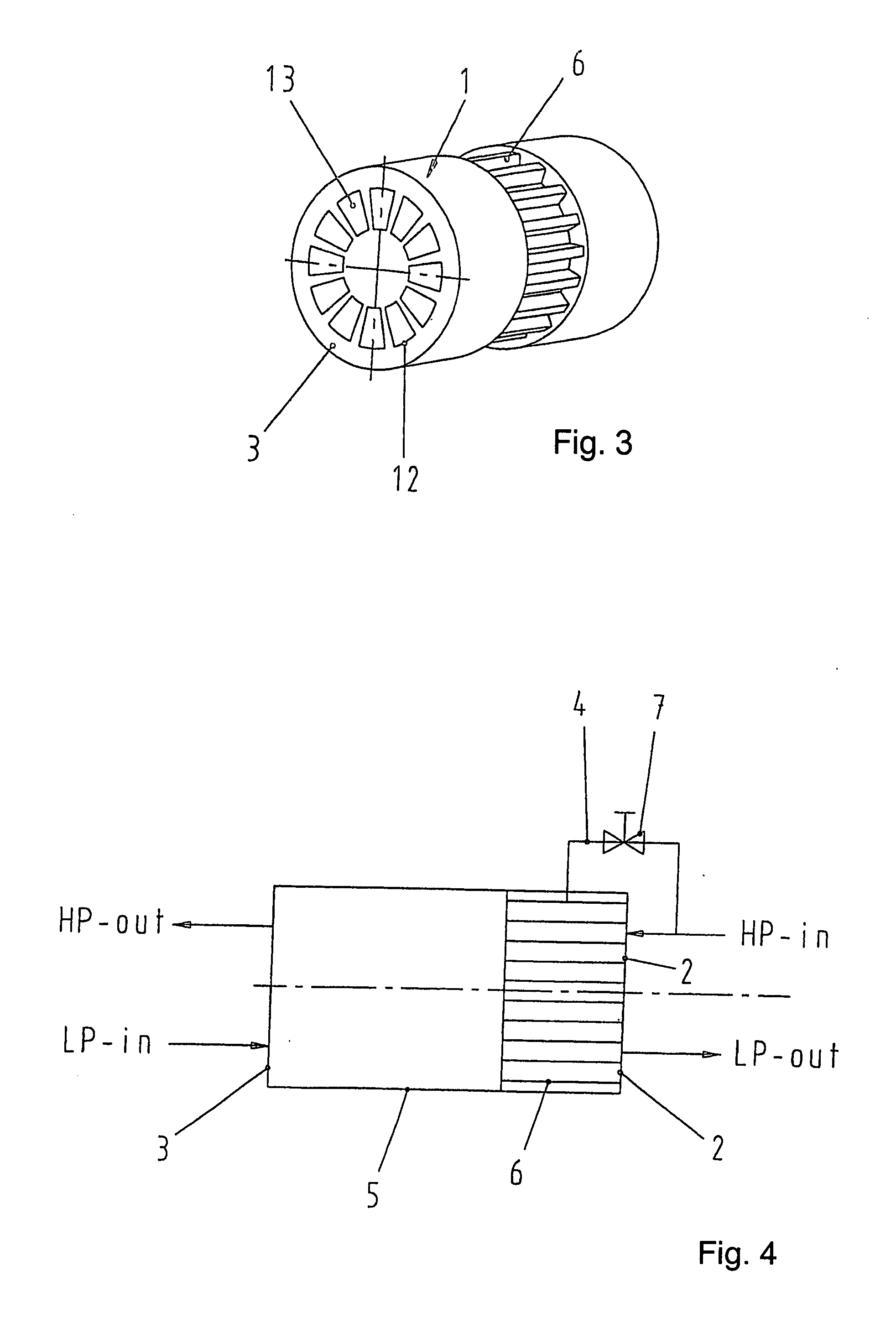

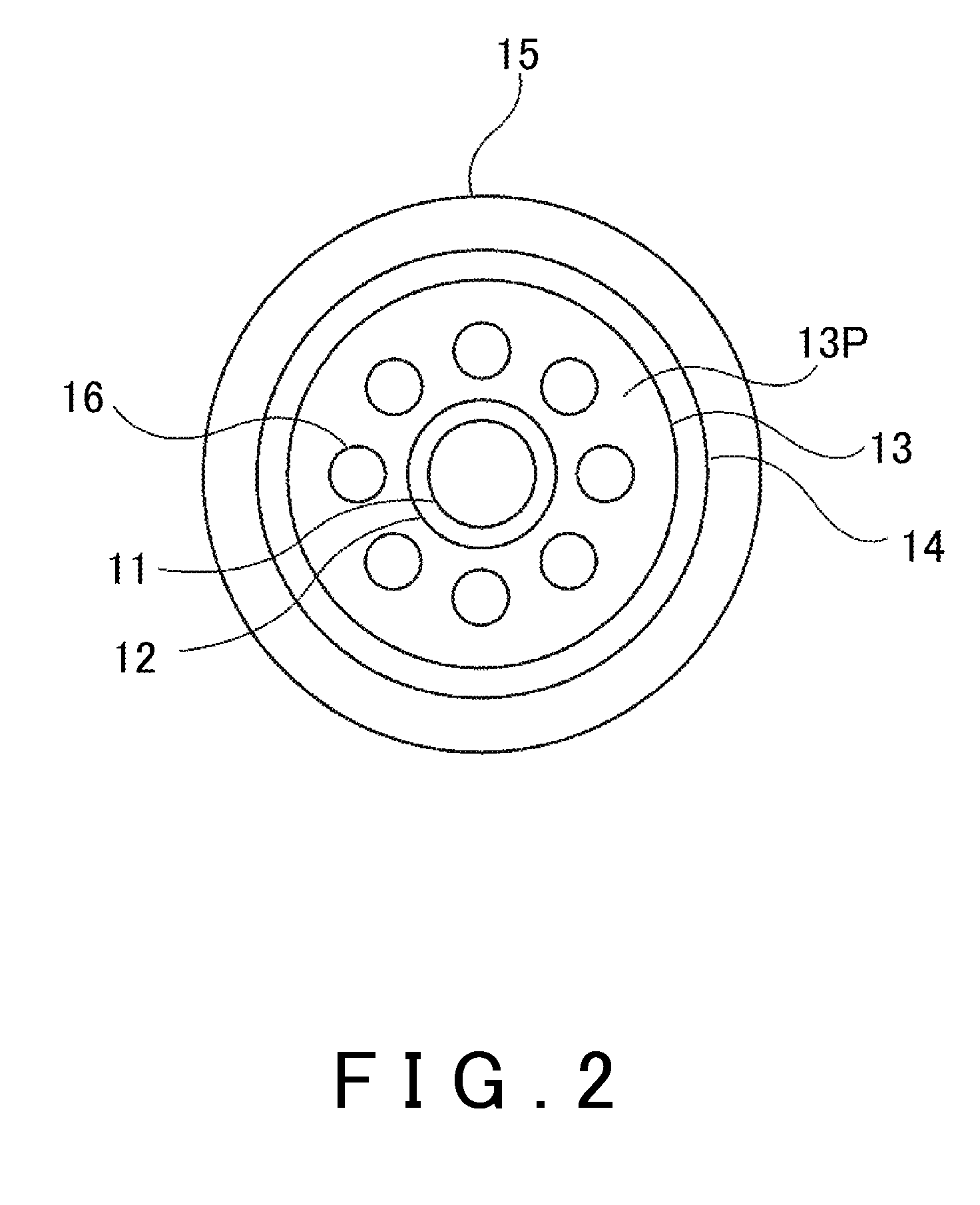

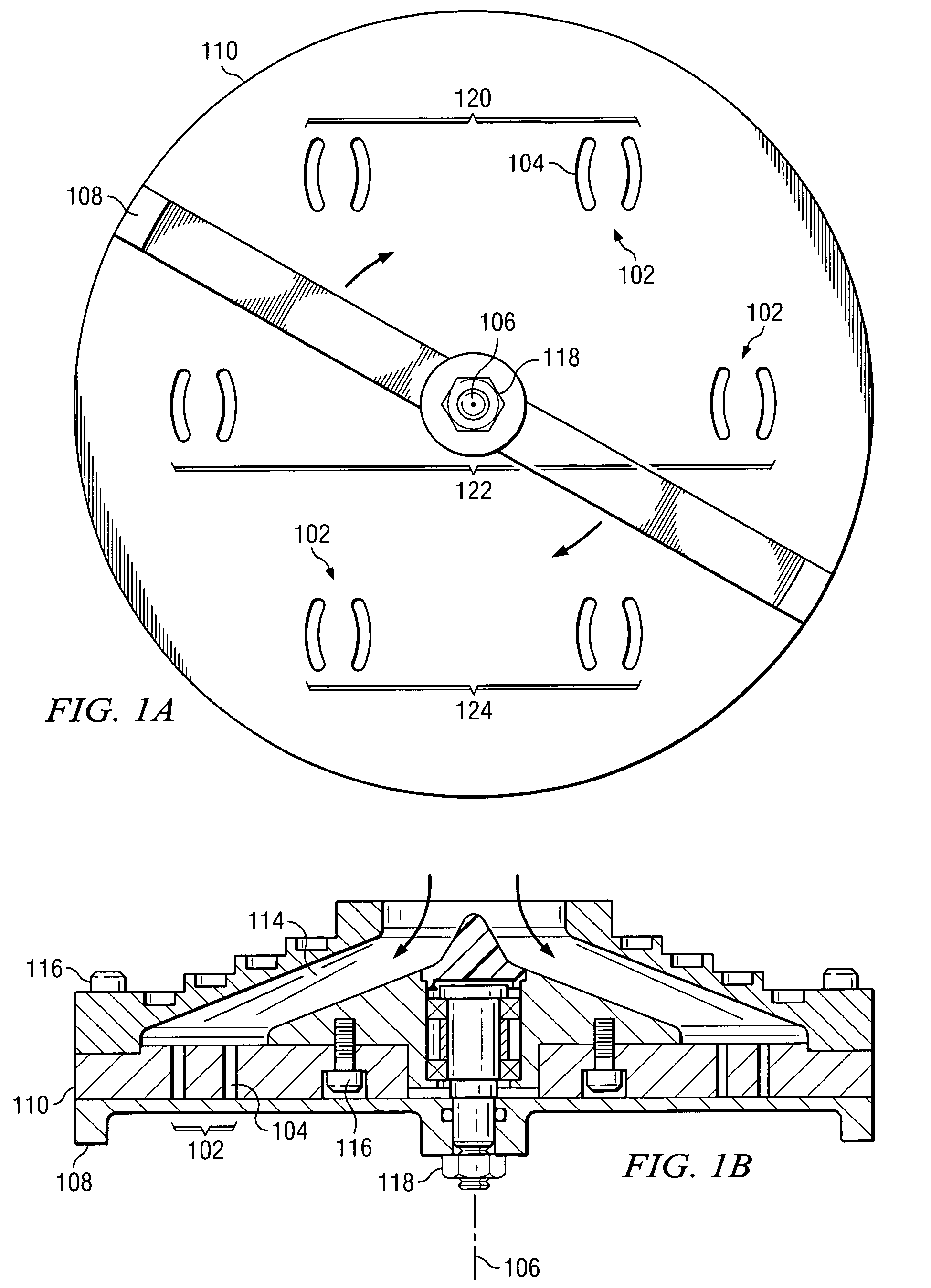

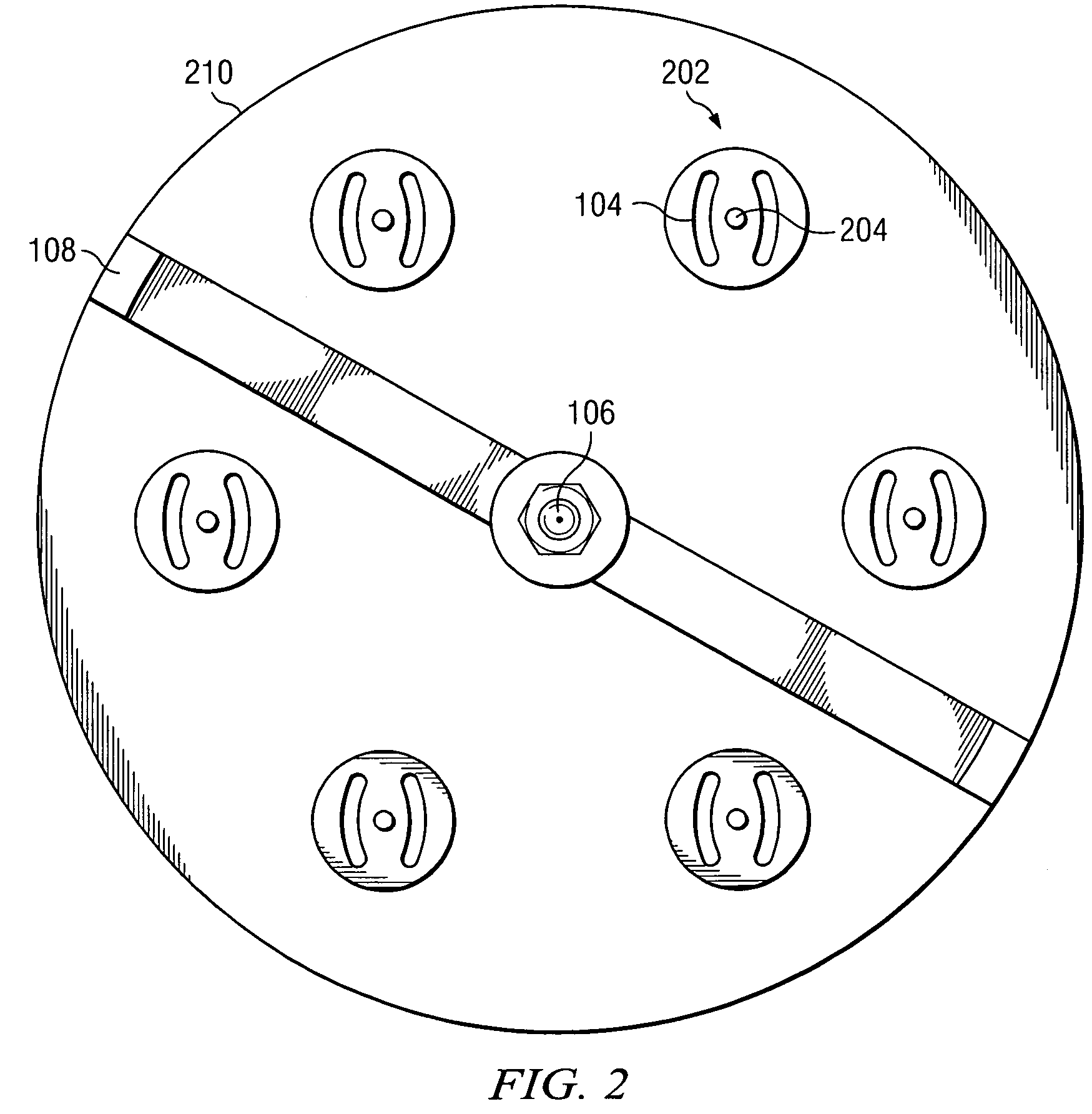

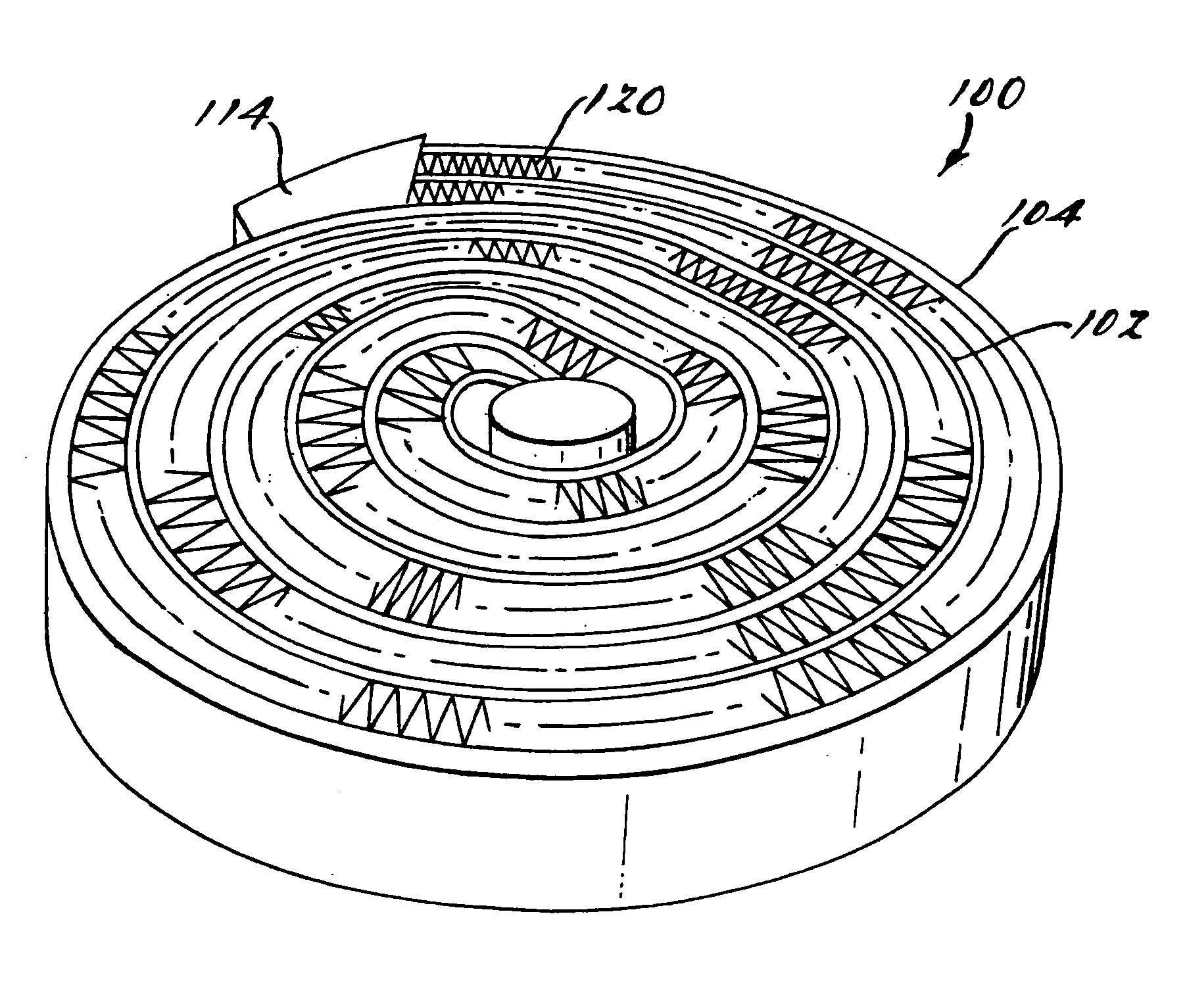

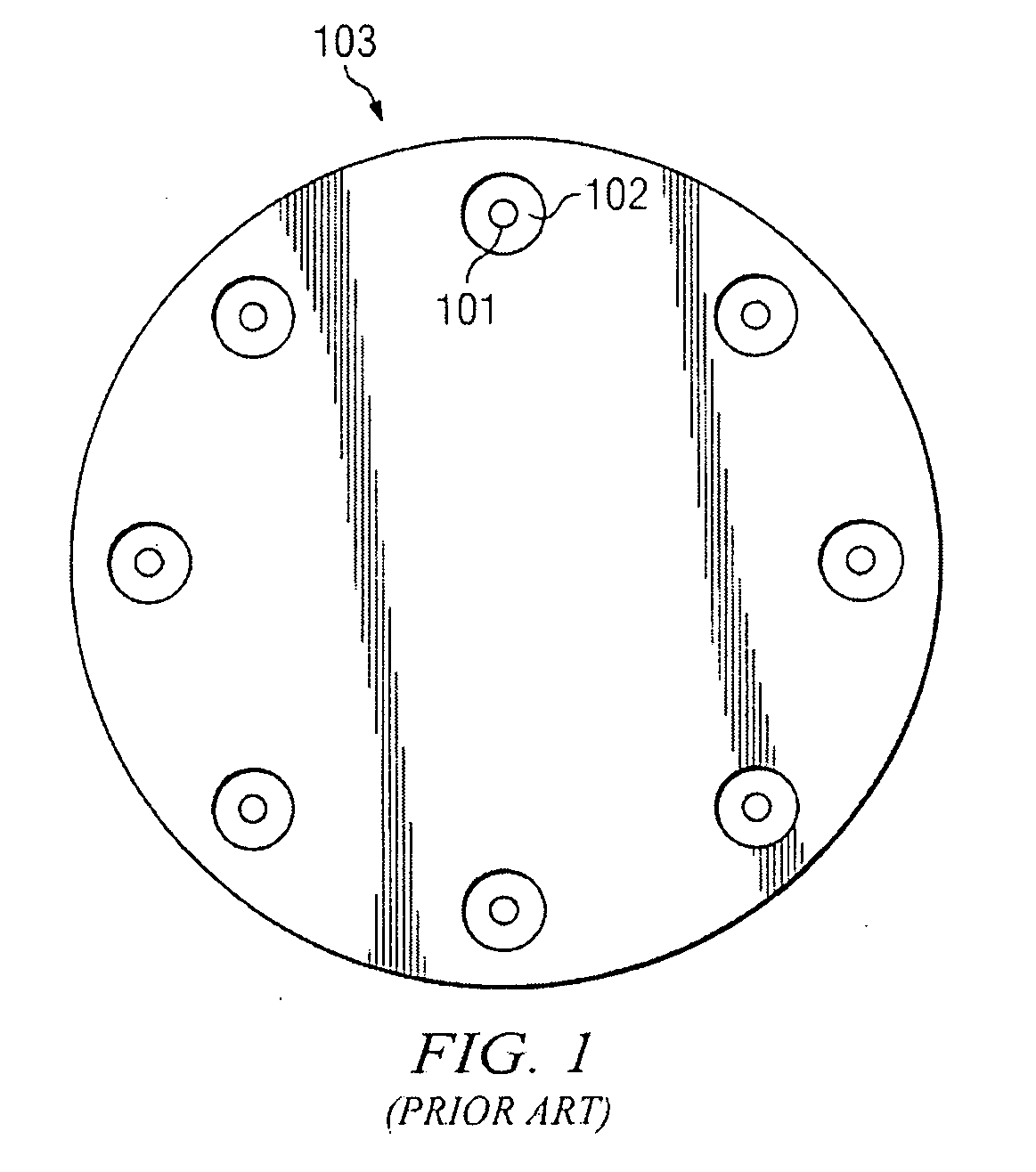

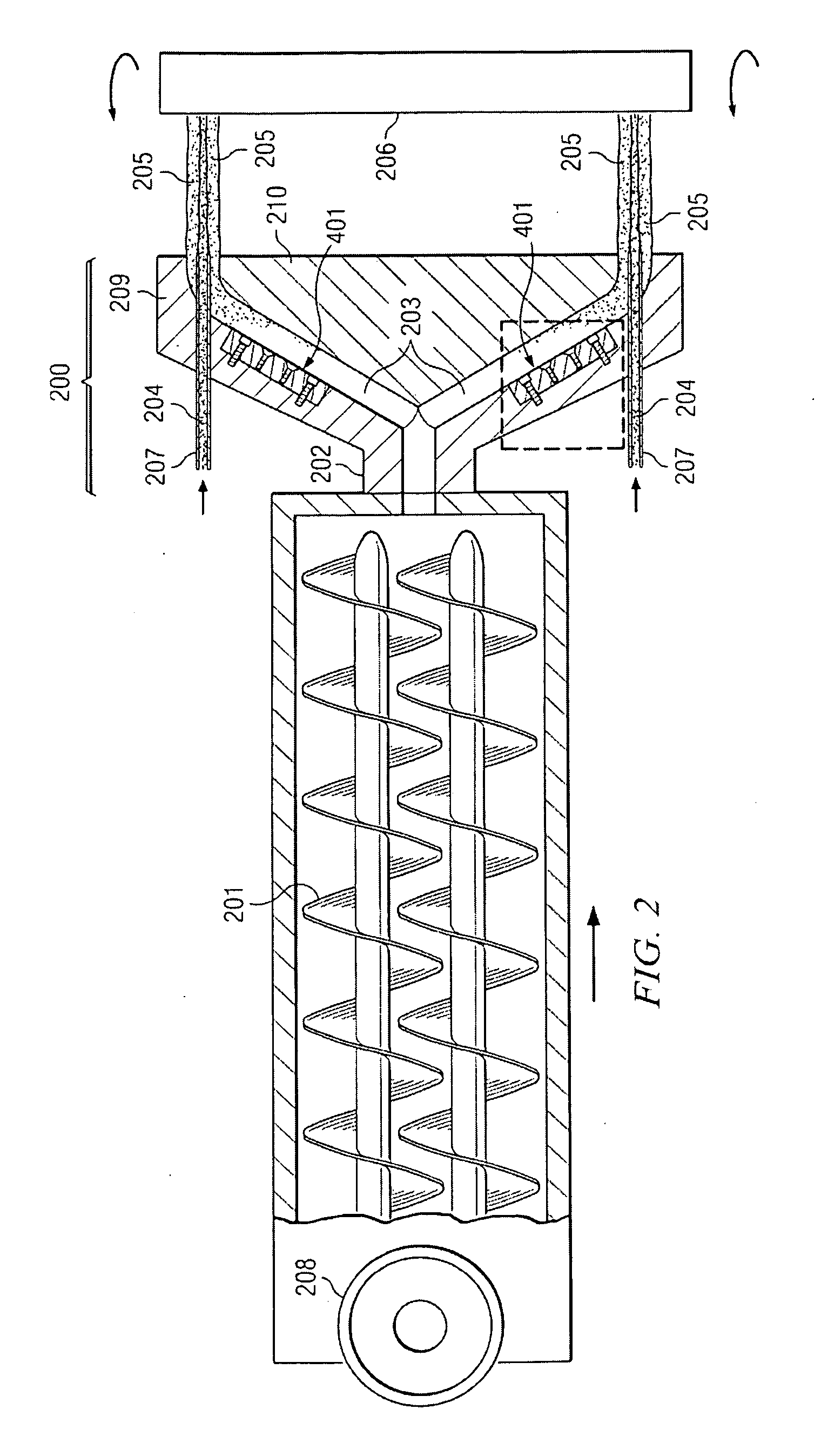

Speed-regulated pressure exchanger

InactiveUS20070137170A1Efficient operating stateMinimal mixing lossPump componentsGas turbine plantsMechanical engineeringPressure exchanger

A pressure exchanger for transferring pressure from a higher pressure liquid in a first liquid system to a lower pressure liquid in a second liquid system having a housing (8) with inlet and outlet connection openings (10-10.3) for each liquid and a rotor (1) arranged in the housing for rotation about a longitudinal axis. The rotor has a plurality of through channels (13) arranged around the longitudinal axis with openings (12) on axial end faces (2, 3) of the rotor. The rotor channels (13) are connected to the connection openings (10-10.3) through flow openings (11-11.3) in the housing such that during rotation of the rotor high pressure liquid and low pressure liquid are alternately supplied to the respective systems. A predominantly axially extending flow transition is formed between the flow openings (11-11.3) in the housing and the openings (12) of the rotor channels (13), and the flow openings in the housing form part of curved cavities (19) with each cavity (19) simultaneously covering several rotor channel openings (12) and having a shape which equilibrates the liquid flow speed in the vicinity of the housing flow openings (11-11.3). External surfaces (5-5.3) of the rotor (1) have an energy converting or energy transmitting configuration (6), and a partial flow (TS) of high pressure and / or flow energy impinging on the configuration (6) produces rotation of the rotor (1). A regulator (7) the varies the amount of the partial flow (TS) and the rotational speed of the rotor (1) and controls the rotational speed of the rotor for substantially shock-free admission of the mass flow into the rotor channels (13).

Owner:KSB AG

Heat sink

InactiveUS20080144279A1Improve performanceReduce weightSolid-state devicesModifications for power electronicsAir velocityEngineering

A heat sink is provided that makes air velocity between cooling fins uniform in order to improve heat dissipation performance, thereby realizing a reduction in weight and achieving high cost performance. Distal ends of fins disposed substantially in front of a cooling fan are located on the uppermost stream side in the flowing direction of cooling air, and distal ends of fins on both sides in the width direction of the heat sink are located on the lowermost stream side. Each of the fins is preferably provided with a slope so that the height of the fin gradually increases from the distal end thereof in a direction from the upstream side to the downstream side in the flowing direction of cooling air.

Owner:FUJI ELECTRIC SYST CO LTD

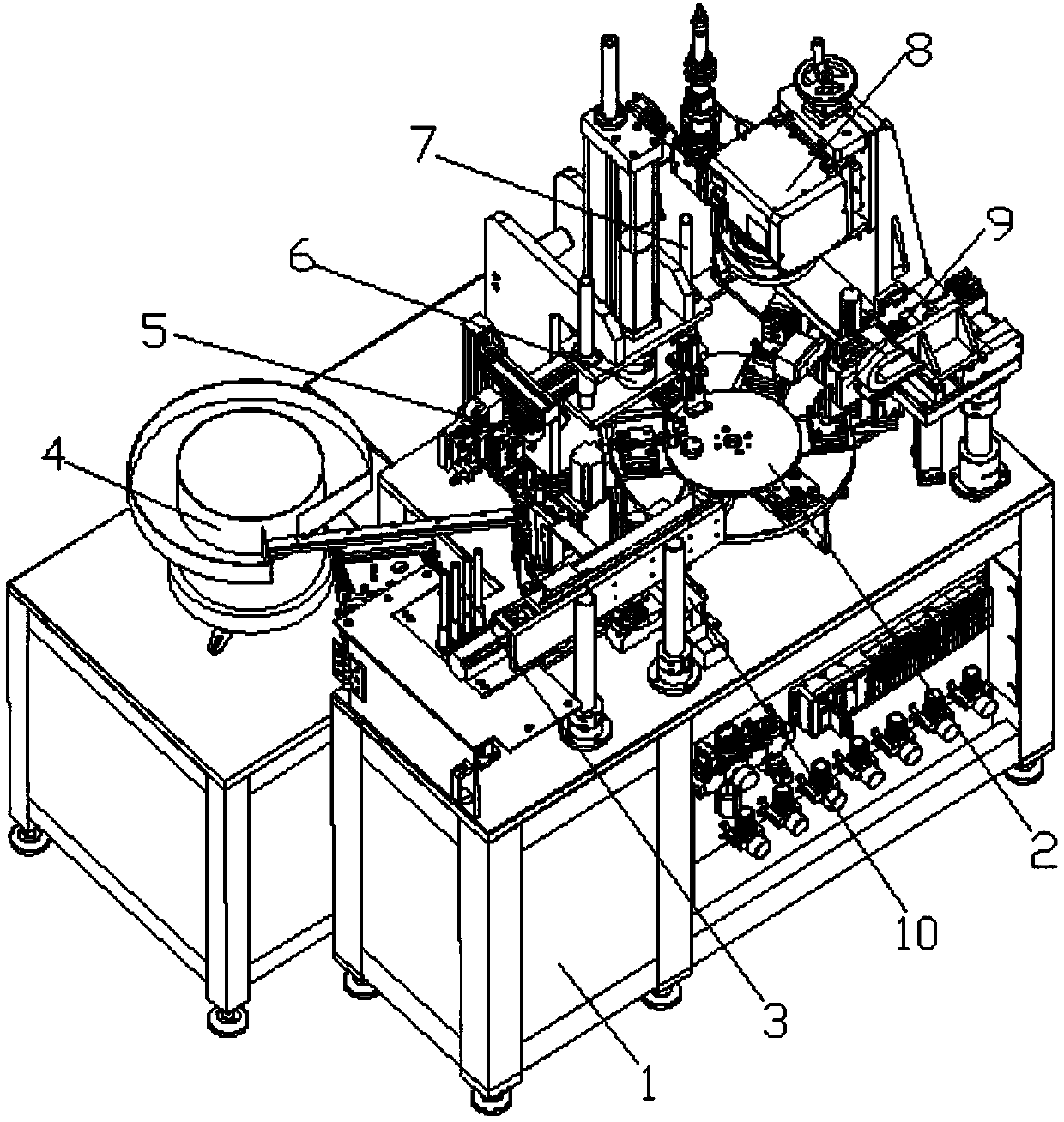

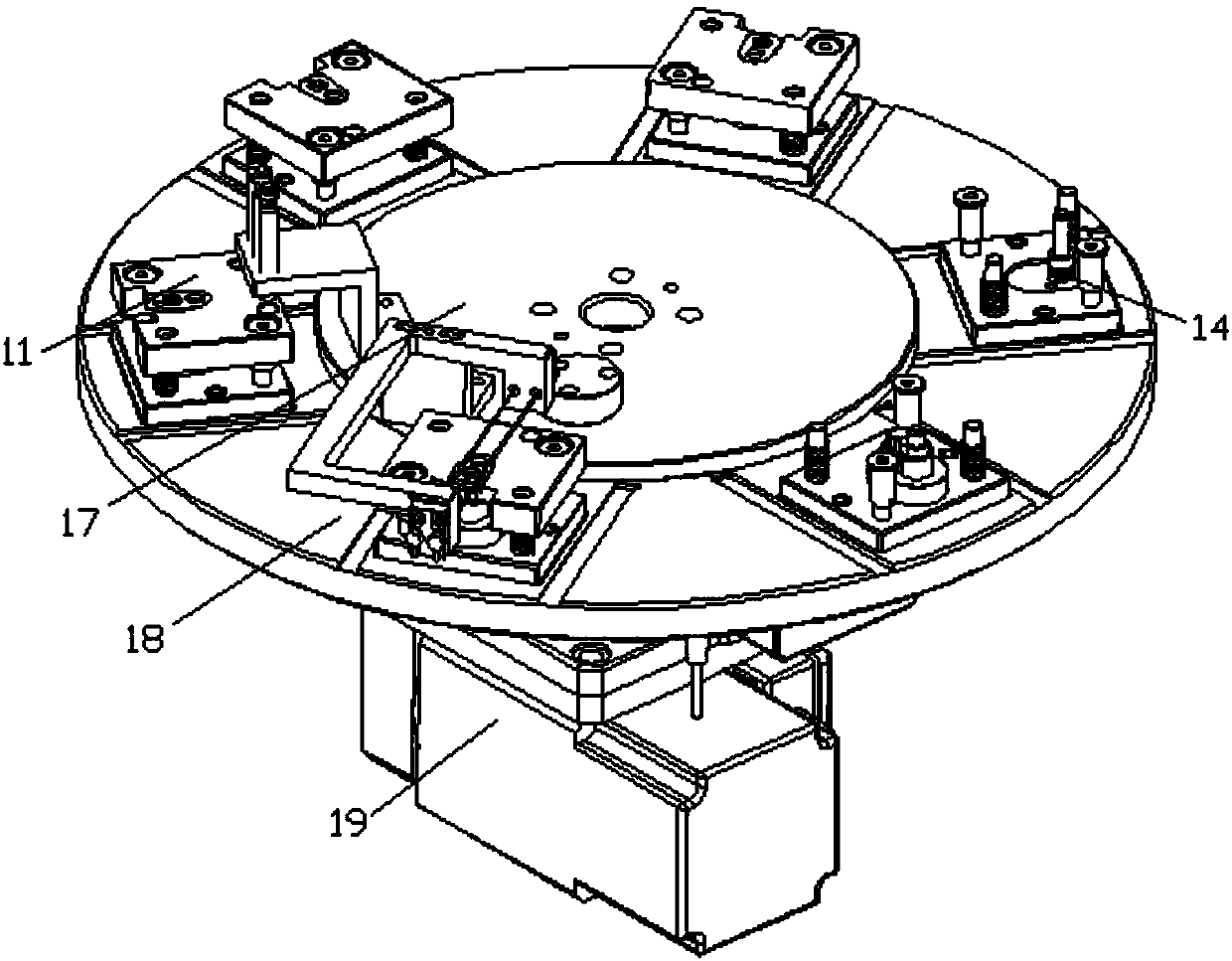

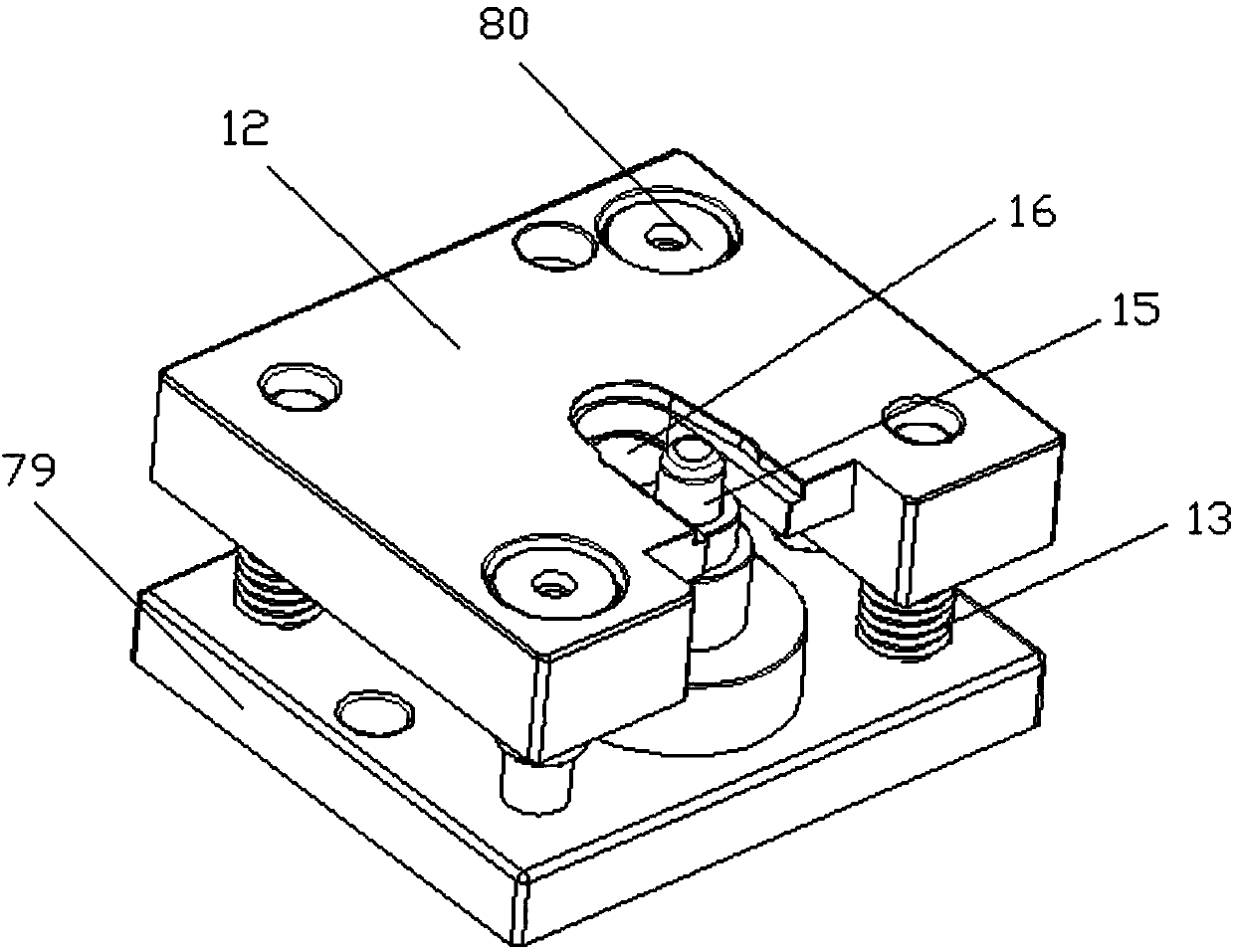

Full-automatic camshaft assembling machine

InactiveCN107717435ATimely detectionHigh positioning accuracyAssembly machinesLaser beam welding apparatusDistribution controlButt joint

The invention relates to a full-automatic camshaft assembling machine. The full-automatic camshaft assembling machine comprises a rack and a power distribution control cabinet arranged in the rack; arotating disk device is arranged on the middle portion above the rack; and a shaft feeding device, a cam vibrating feeding disk, a cam feeding device, a press-fitting device, a floating shaft pressingdevice, a laser welding device, a flaw detecting device and a discharging device in butt joint with carrier assemblies are sequentially arranged above the rack in the rotating direction of a rotatingdisk. According to the full-automatic camshaft assembling machine, by means of the shaft feeding device, a shaft is placed in the carrier assembly on the rotating disk device, and the carrier assembly rotates clockwise along the rotating disk and sequentially rotates onto the cam feeding device to perform cam feeding, onto the press-fitting device so as to press a cam into a matching groove of the shaft, onto the floating shaft pressing device to push down the shaft to be clamped with the matching groove, onto the laser welding device to perform laser welding on the matched portion of the shaft and the cam, onto the flaw detecting device to detect bruised damage and scratches, and onto the discharging device to perform discharging; and the assembling process of the cam and the shaft is completed, the positioning precision is high, and defective products are detected in time.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Method and apparatus to achieve uniform ink temperatures in printheads

InactiveUS6484975B1Uniform droplet sizeGuaranteed uniform velocityInking apparatusOther printing apparatusHeating effectEngineering

A system for improving the uniformity of ink droplets delivered from a plurality of droplet sources on a printhead is described. The system includes a cooling system that compensates for nonuniform heating effects in a printhead which results in nonuniform temperatures. The distribution of the cooling system, and the effectiveness of the cooling system is set to maintain an approximately uniform ink temperature across the printhead.

Owner:XEROX CORP

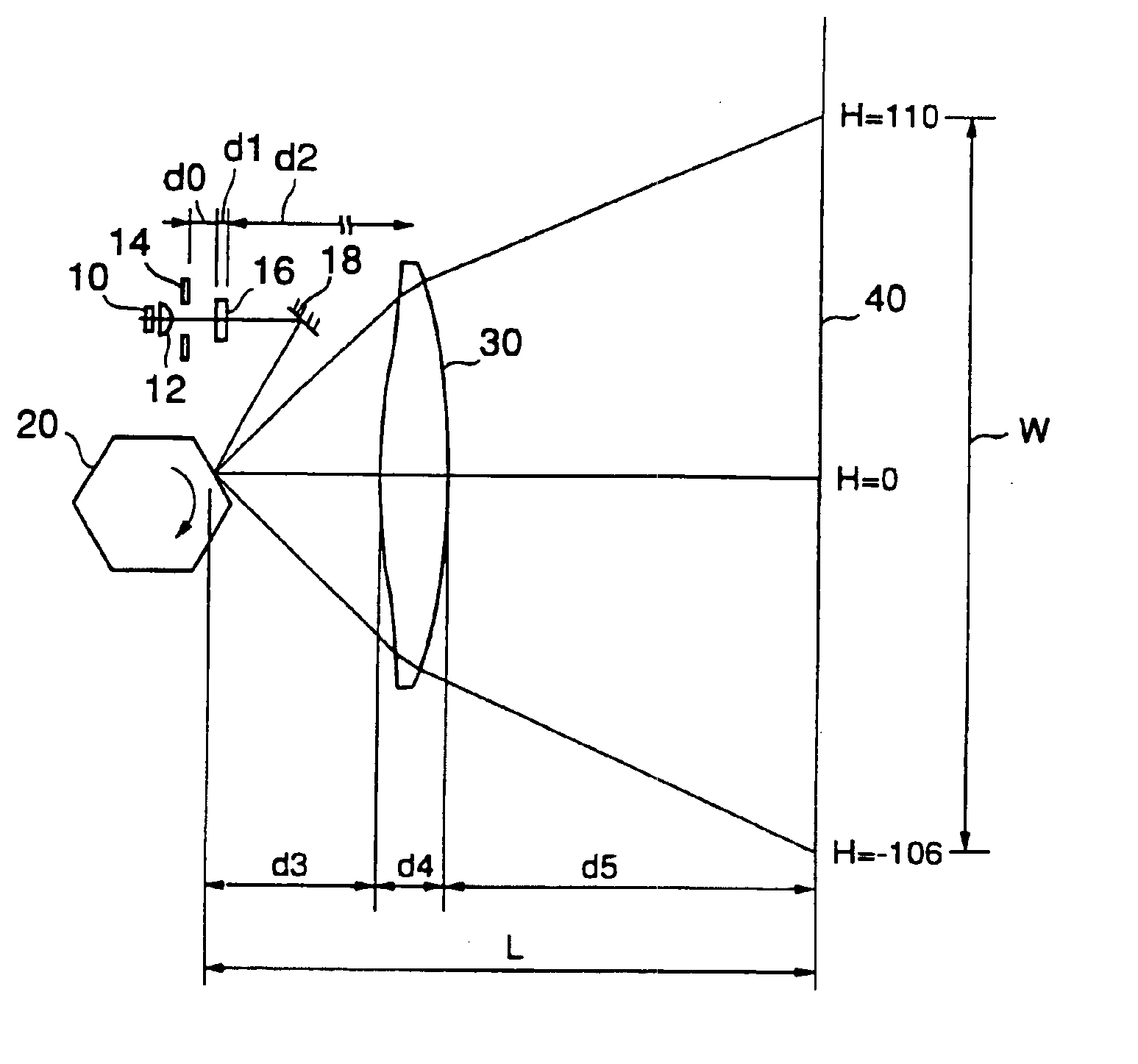

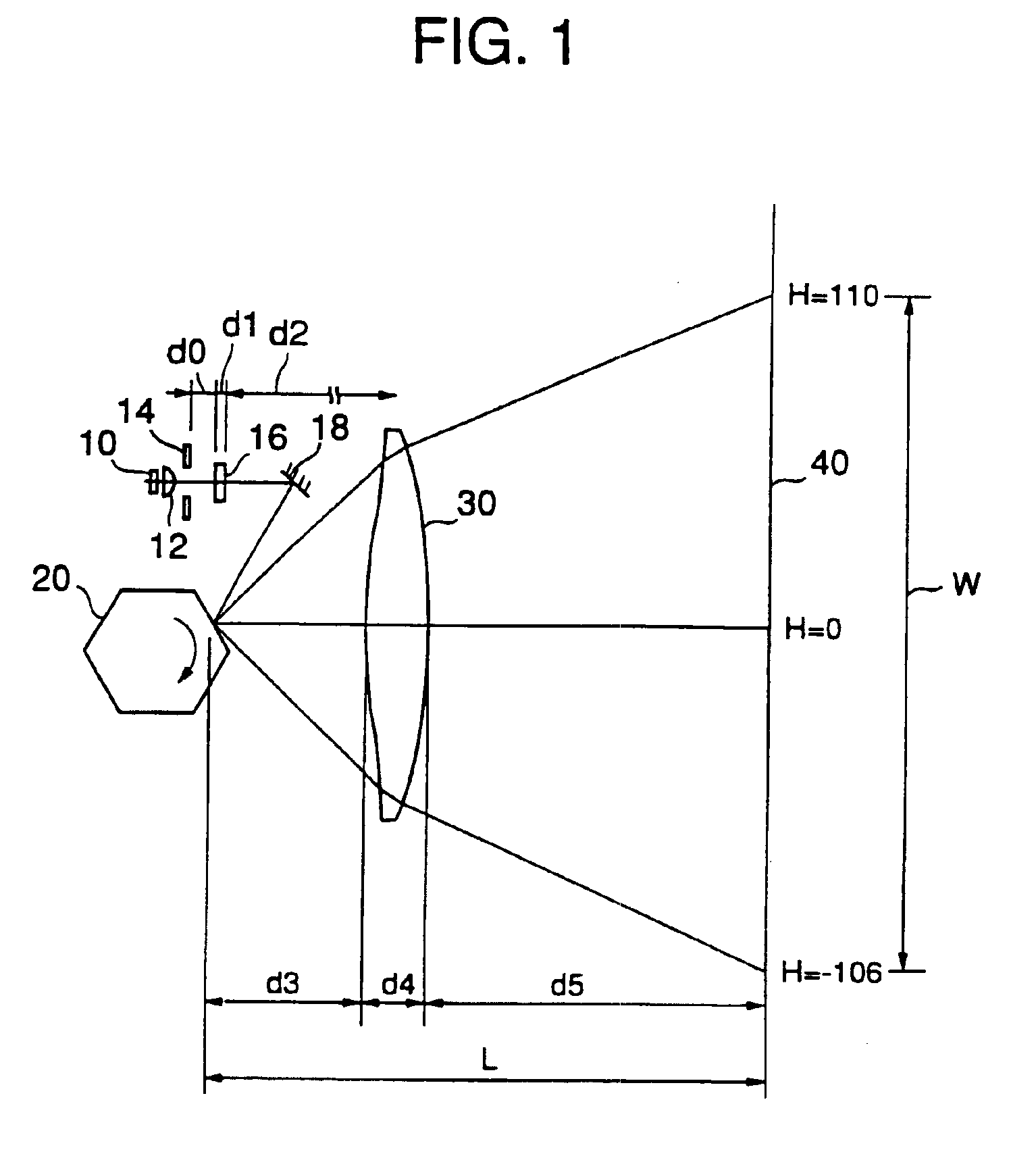

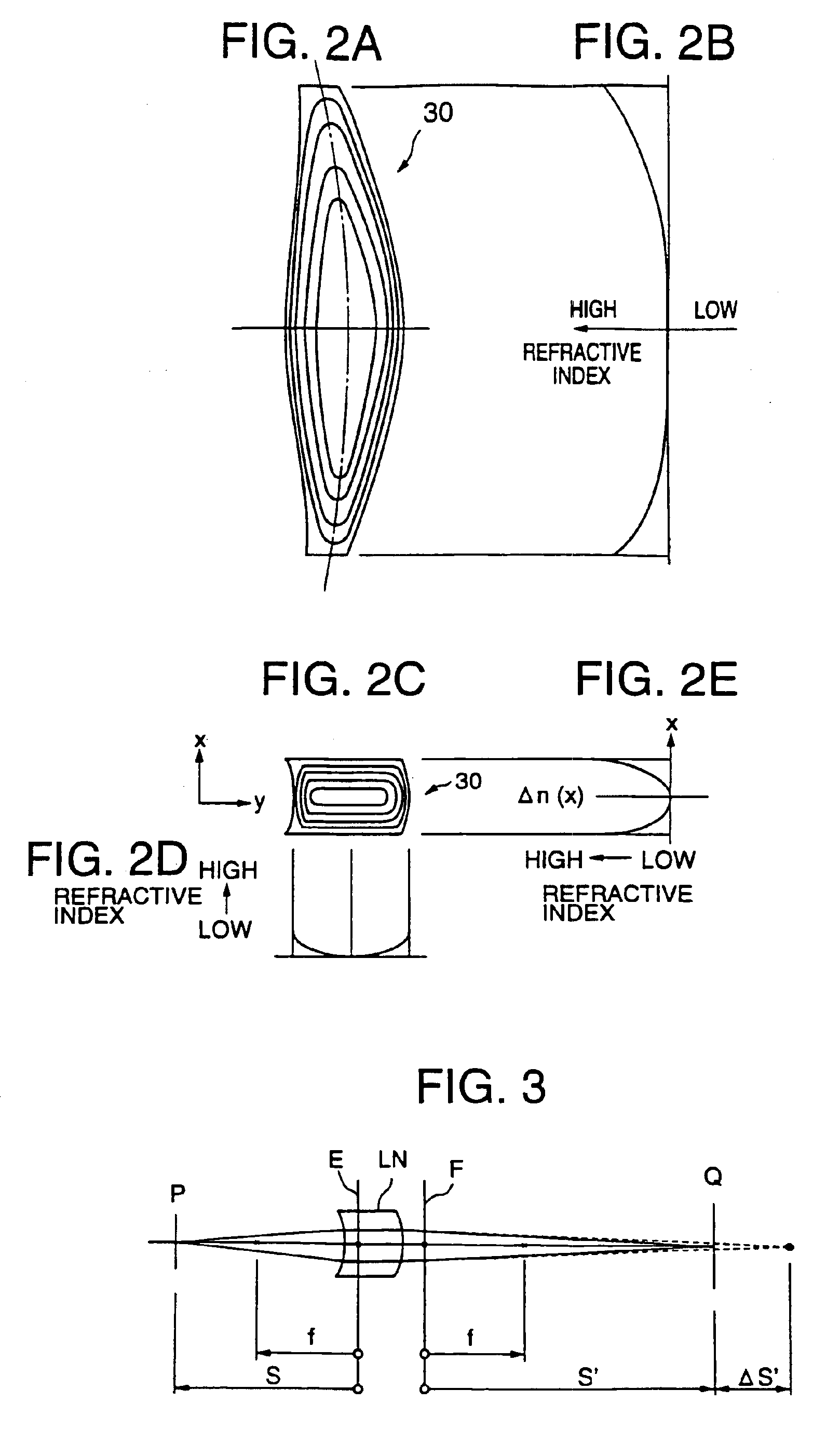

Optical scanning lens, optical scanning device and image forming apparatus

InactiveUS6870652B2Guaranteed uniform velocityAccurate inclinationInking apparatusLensPolyolefinLight flux

An optical scanning lens which is used in a scanning and age forming optical system which gathers a light flux deflected by a light deflector in the vicinity of a surface to be scanned. The lens is formed by plastic molding of polyolefin resin, and the following condition is satisfied: 0<|Deltan(x)-min[Deltan(x)]|<34X10<-5>, where Deltan(x) denotes a refractive-index distribution existing inside the lens, in a range which the light flux passes through, in the lens, and min[Deltan(x)] denotes the minimum value of the Deltan(x).

Owner:RICOH KK

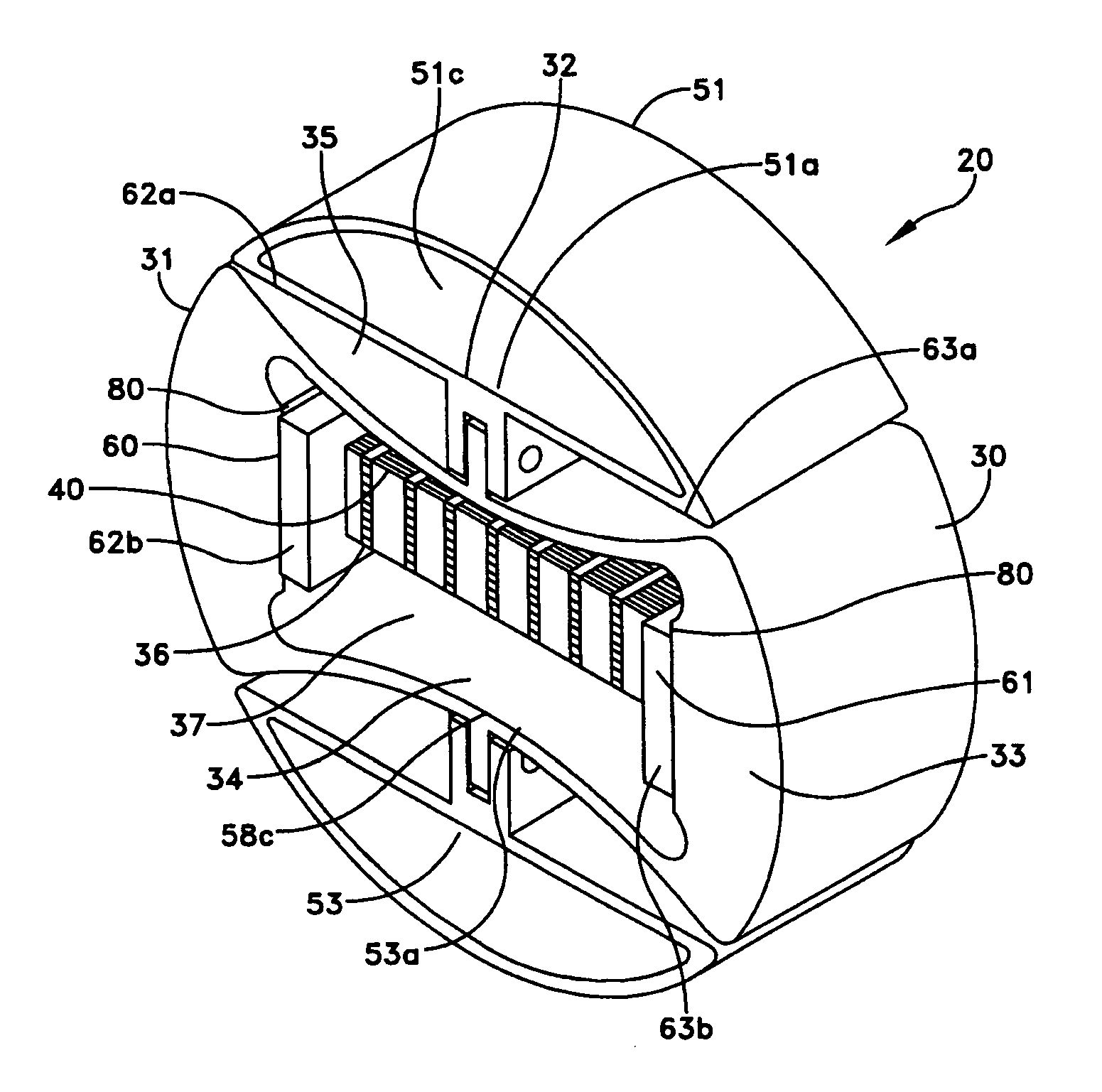

Automated set-up for cell sorting

ActiveUS20140306122A1Reduce needGuaranteed uniform velocityImage analysisVolume/mass flow measurementComputer scienceSorted Cells

Apparatus and methods are described for automatically performing set-up steps for flow cytometry operations. The invention provides for the spatial determination of a flow stream and the subsequent automatic alignment of analysis devices and / or collection vessels. The automatic determination of flow stream properties provides for the automatic configuration flow cytometer parameters.

Owner:BECTON DICKINSON & CO

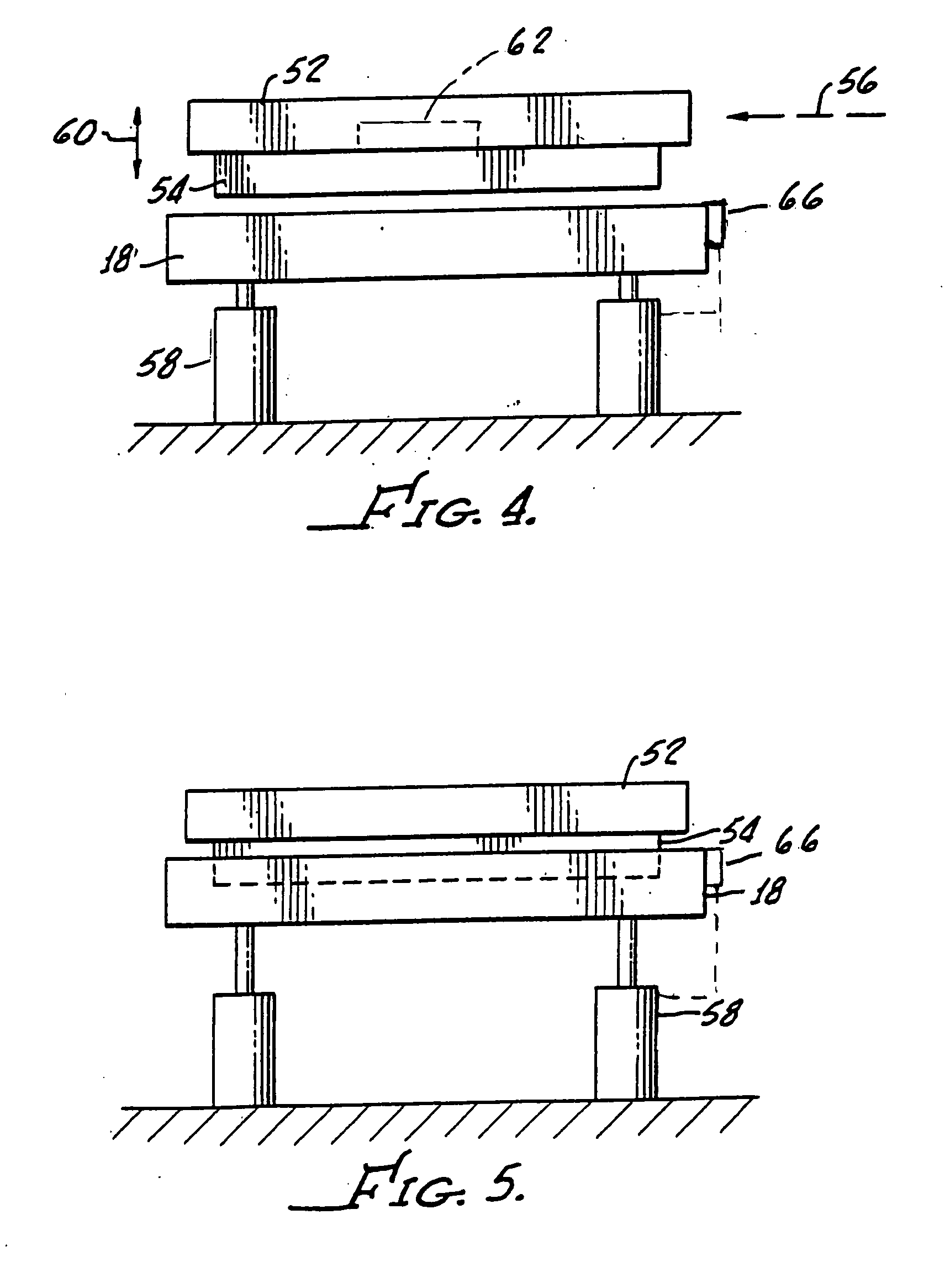

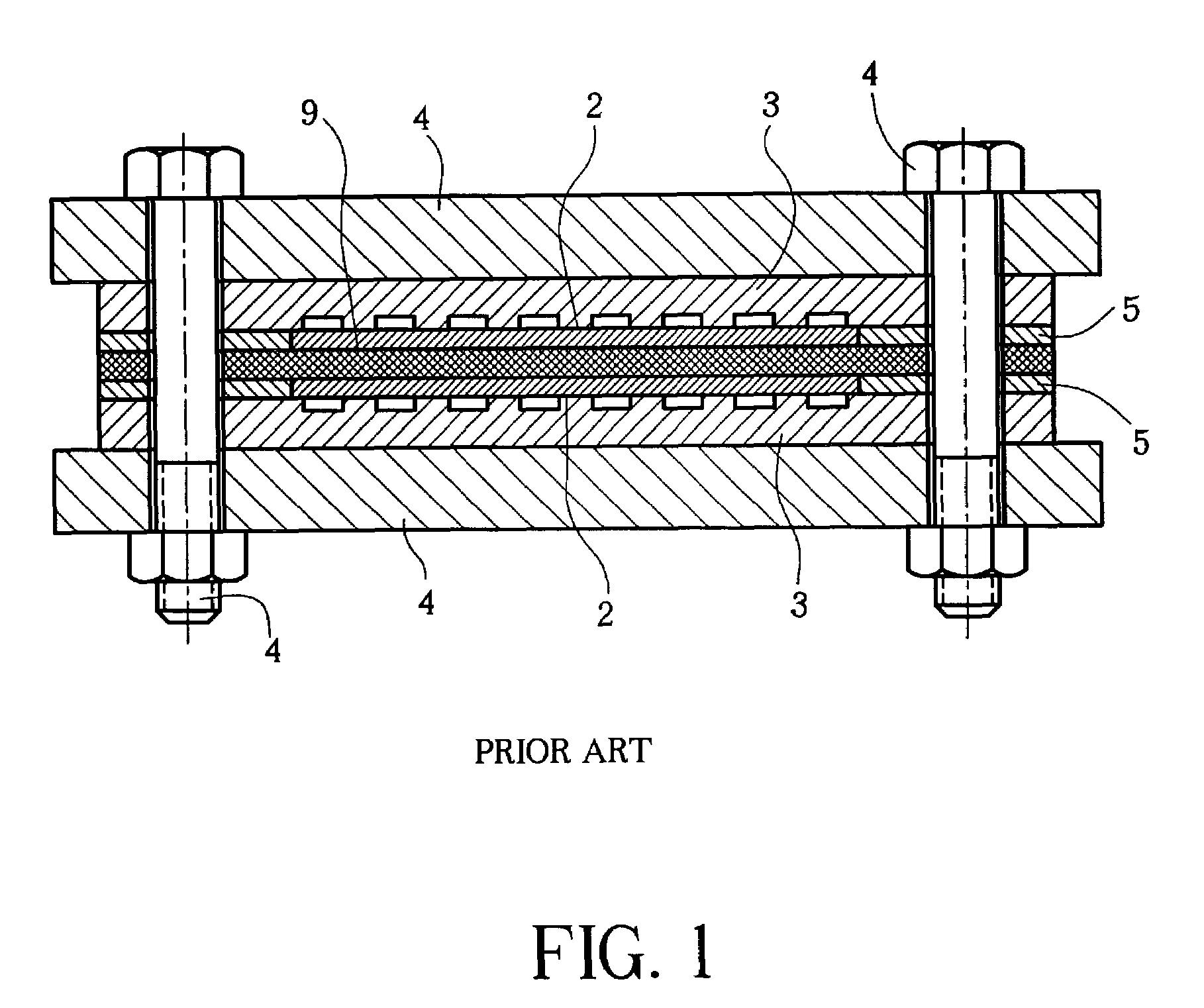

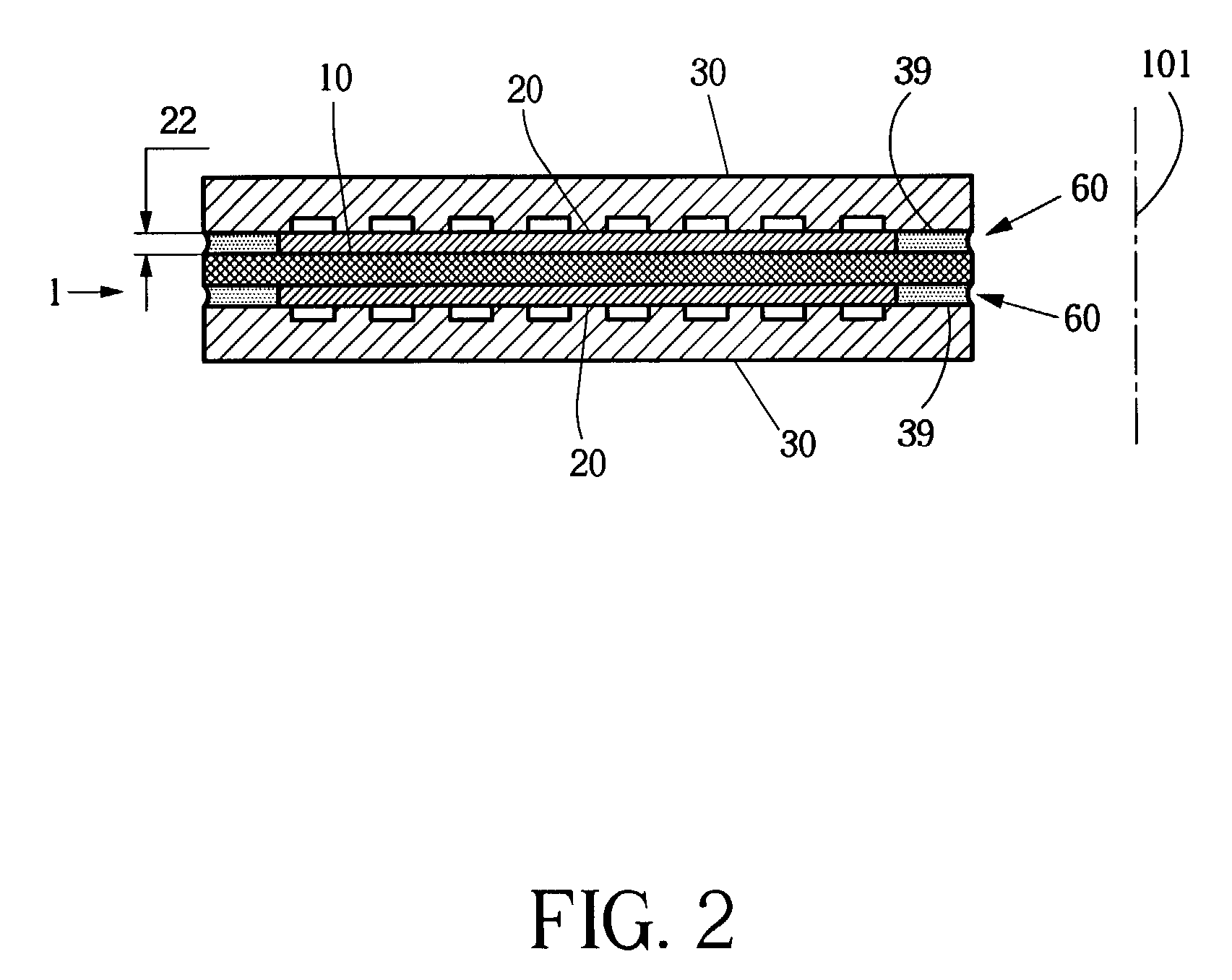

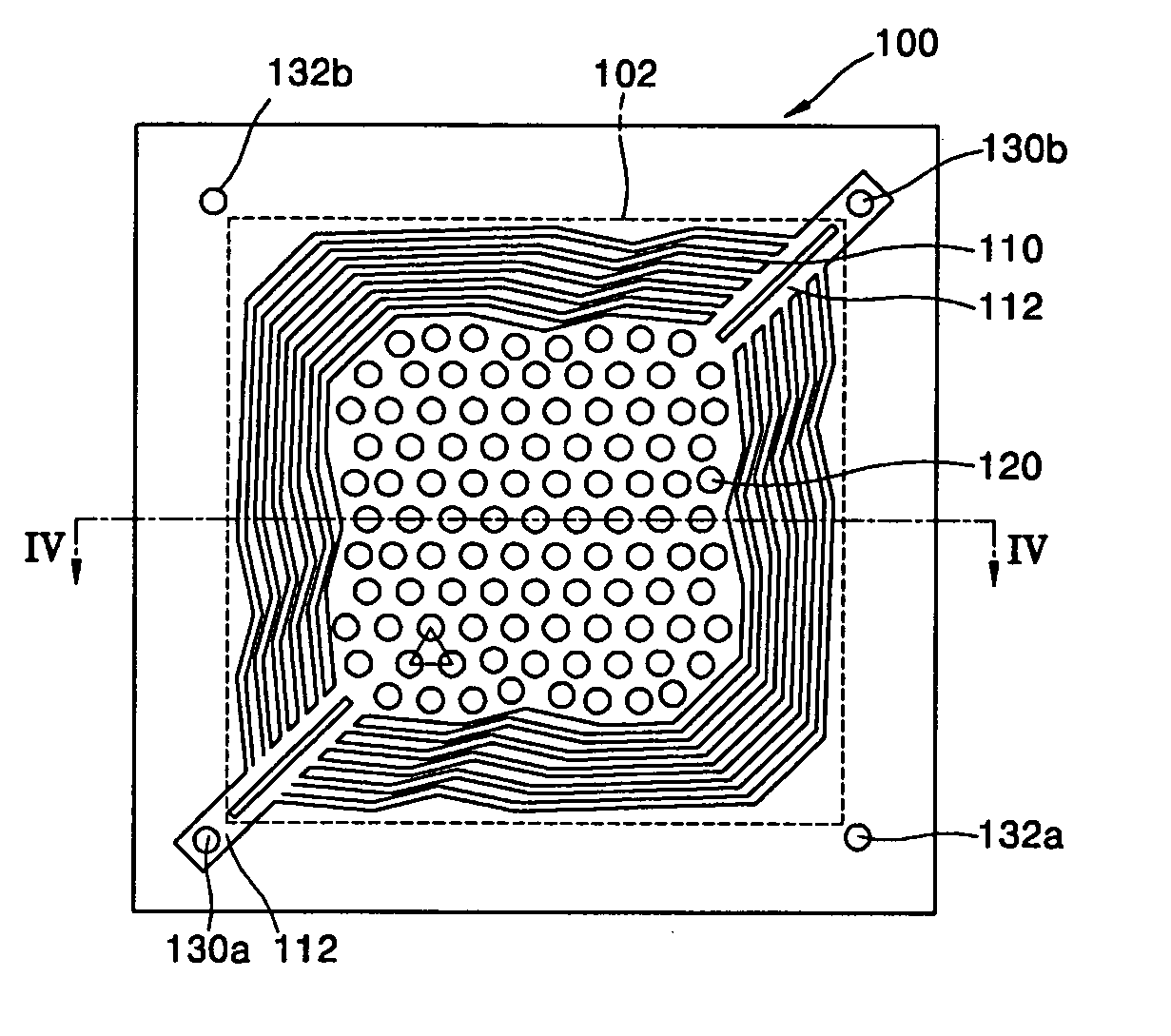

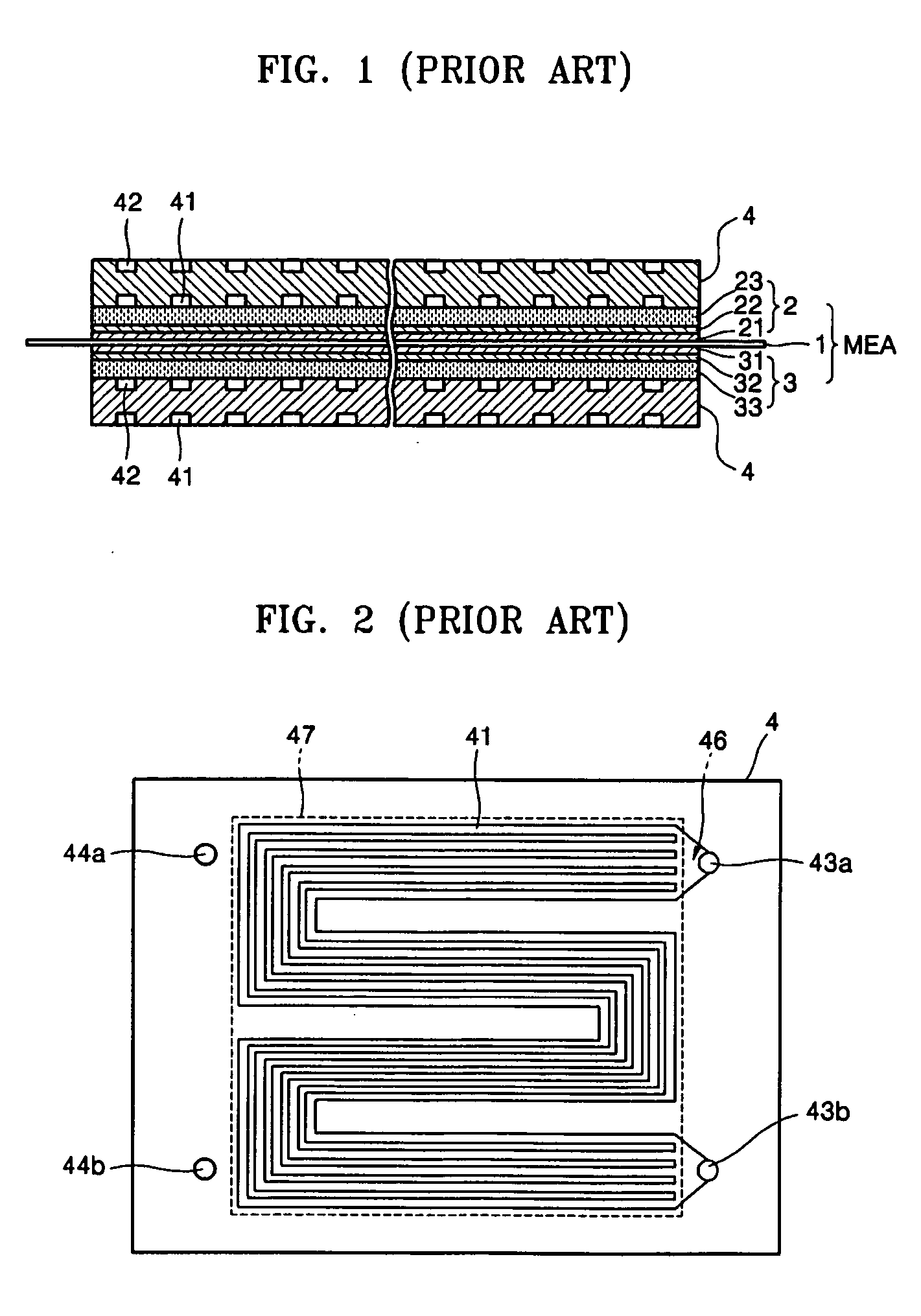

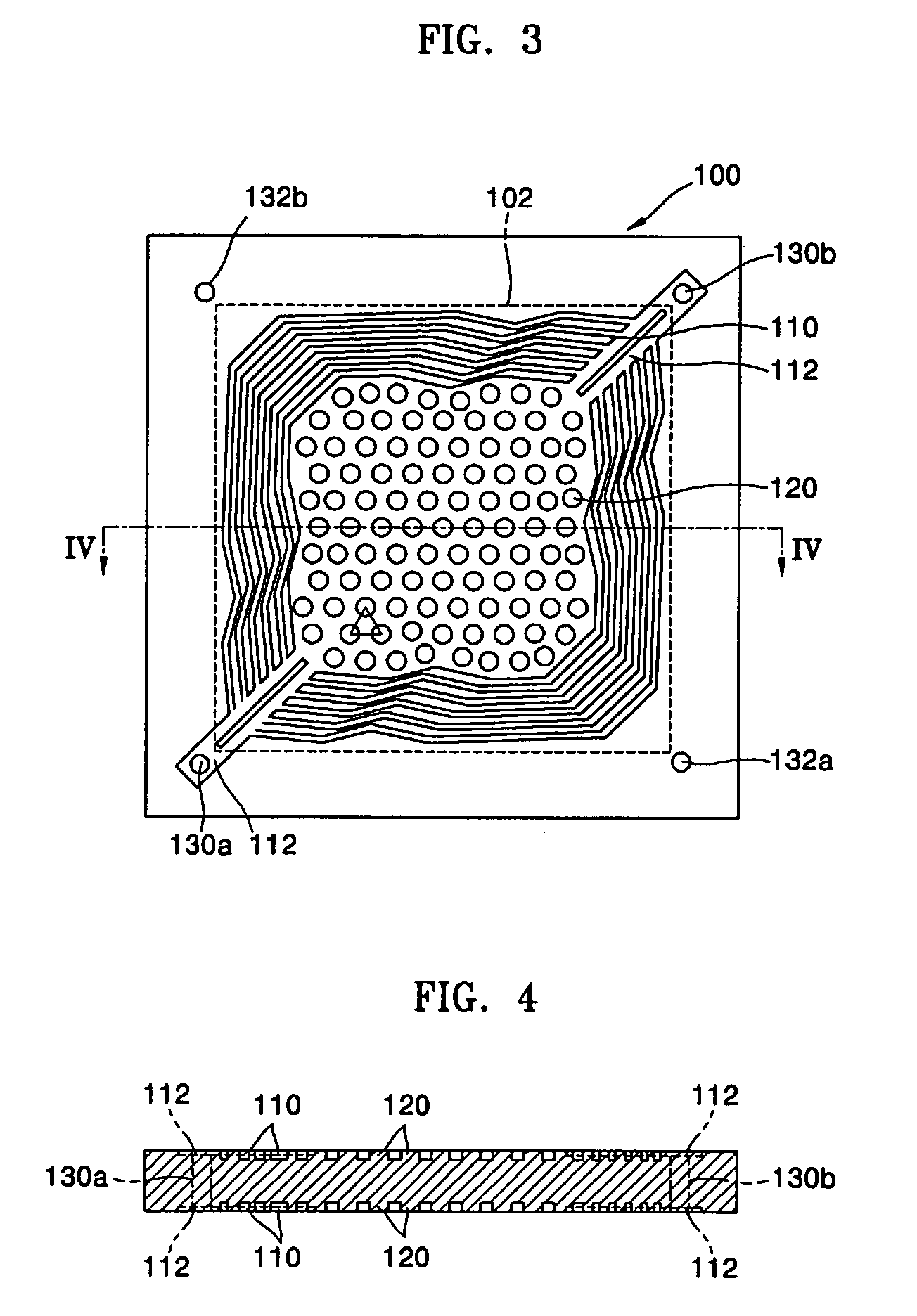

Fuel cell

InactiveUS7341800B2Bonded firmlyIncreased durabilityFuel cells groupingCell electrodesIn planeFlow resistivity

A simple, inexpensive and highly efficient fuel cell has boundary structures made of a photo-sensitive material in combination with selective patterning. Printed circuit board (PCB) fabrication techniques combine boundary structures with two and three dimensional electrical flow path. Photo-sensitive material and PCB fabrication techniques are alternately or combined utilized for making micro-channel structures or micro stitch structures for substantially reducing dead zones of the diffusion layer while keeping fluid flow resistance to a minimum. The fuel cell assembly is free of mechanical clamping elements. Adhesives that may be conductively contaminated and / or fiber-reinforced provide mechanical and eventual electrical connections, and sealing within the assembly. Mechanically supporting backing layers are pre-fabricated with a natural bend defined in combination with the backing layers' elasticity to eliminate massive support plates and assist the adhesive bonding. Proton insulation between adjacent and electrically linked in-plane cell elements is provided by structural insulation within the central membrane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Gas flow control arrangement

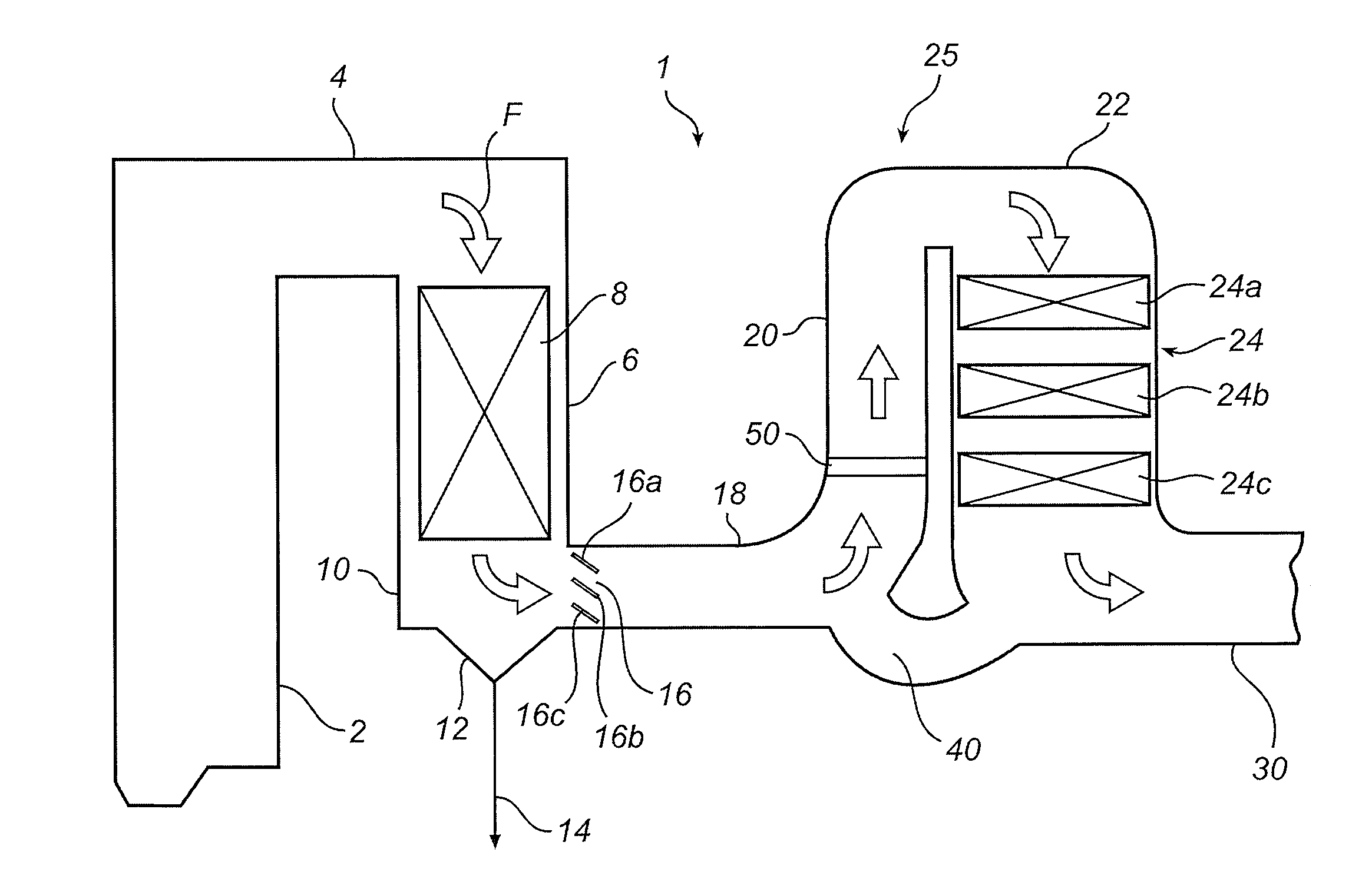

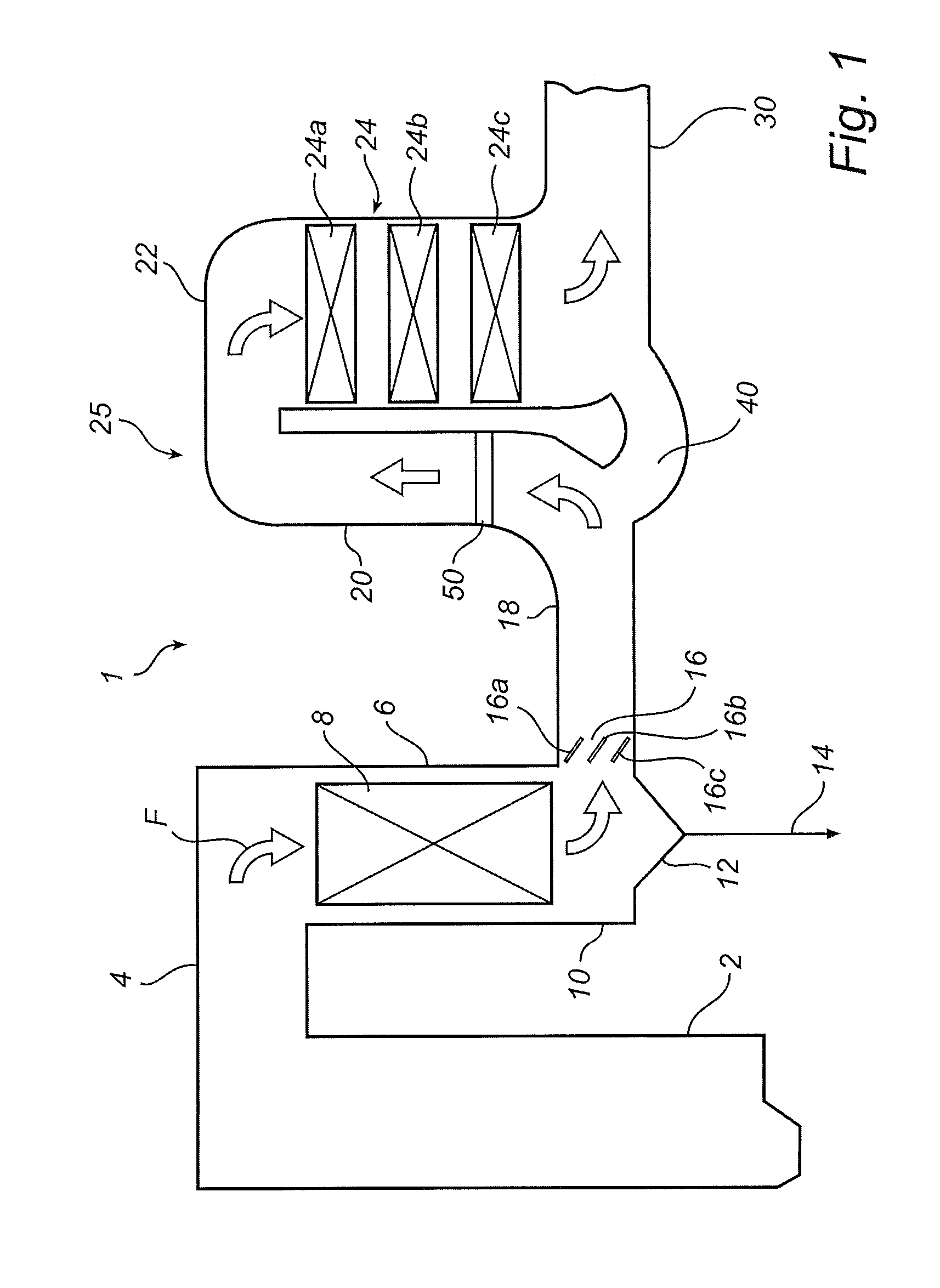

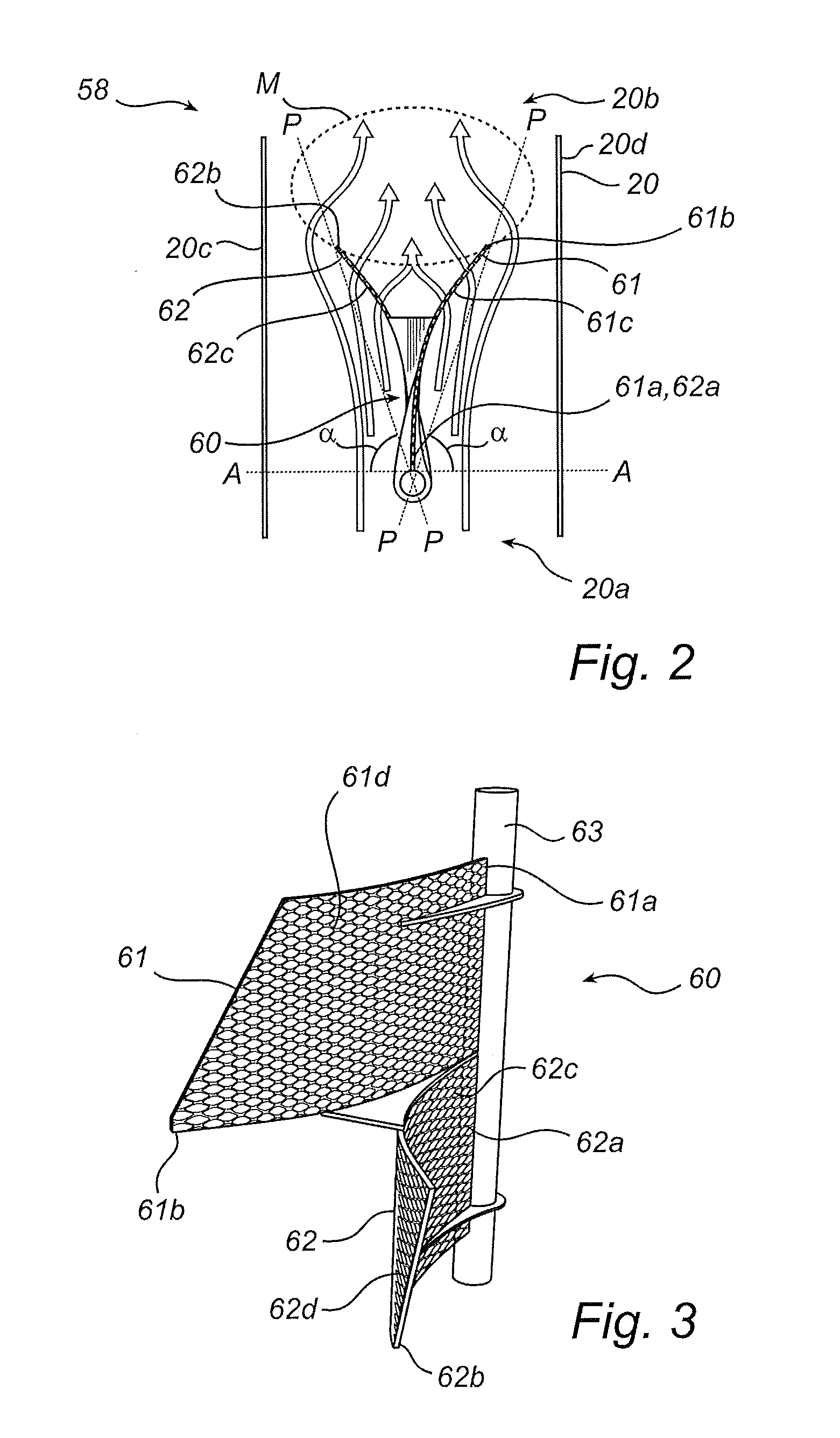

InactiveUS20120073666A1Decrease pressure dropEnhance performanceCombination devicesFlow mixersExhaust gasFlue

A gas flow control arrangement for use in an exhaust gas cleaning system, comprising a duct (20) through which flue gases flow from a first end (20a) toward a second end (20b). The duct is configured to have a longitudinal expanse between its first end and its second end, and a gas flow control device (80) arranged therein. The gas flow control device further comprises at least one expanded screen (81, 82, 83, 84) arranged at an angle within the duct to distribute gas flow. A method for controlling gas flow in an exhaust gas cleaning system is also described.

Owner:ALSTOM TECH LTD

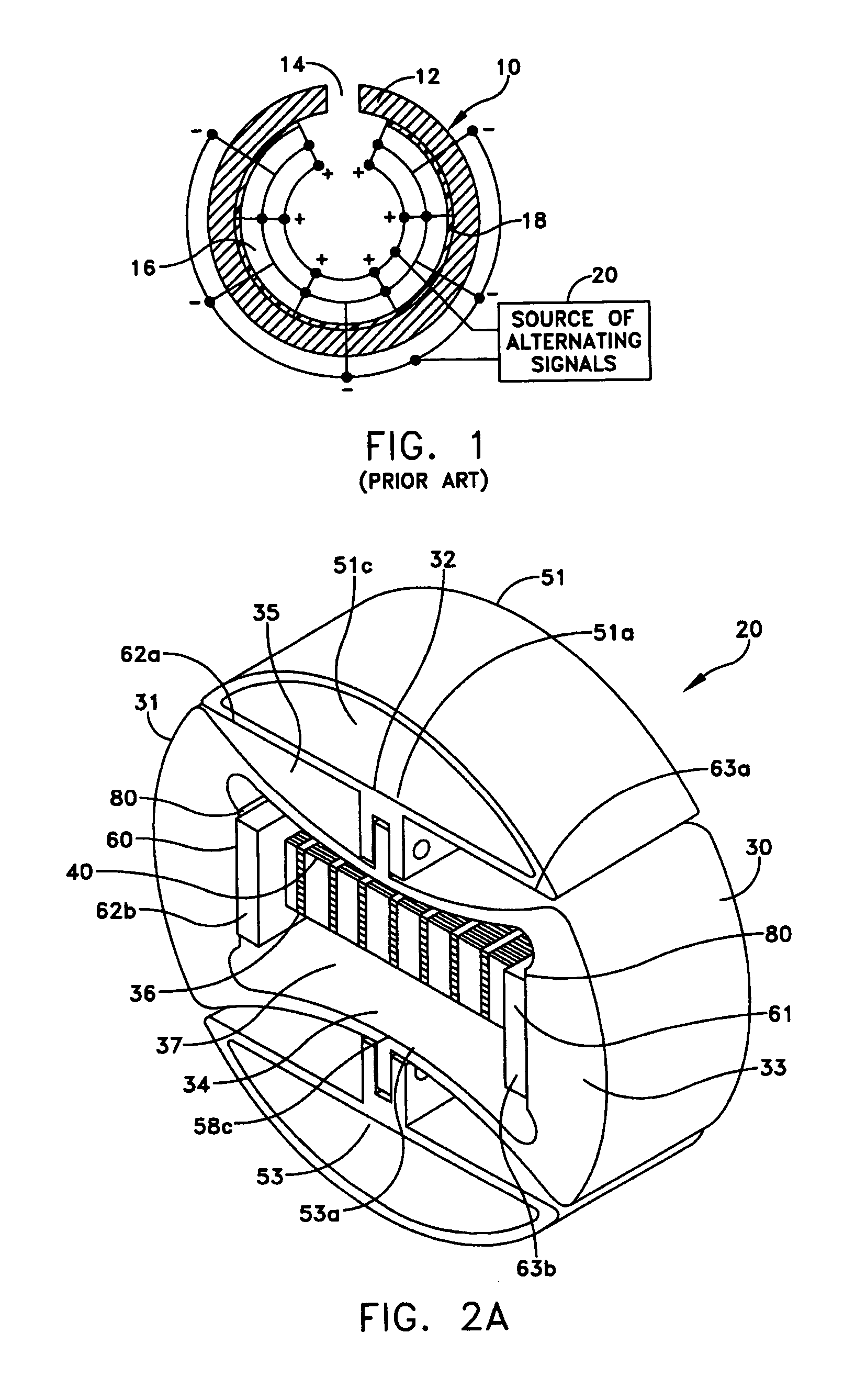

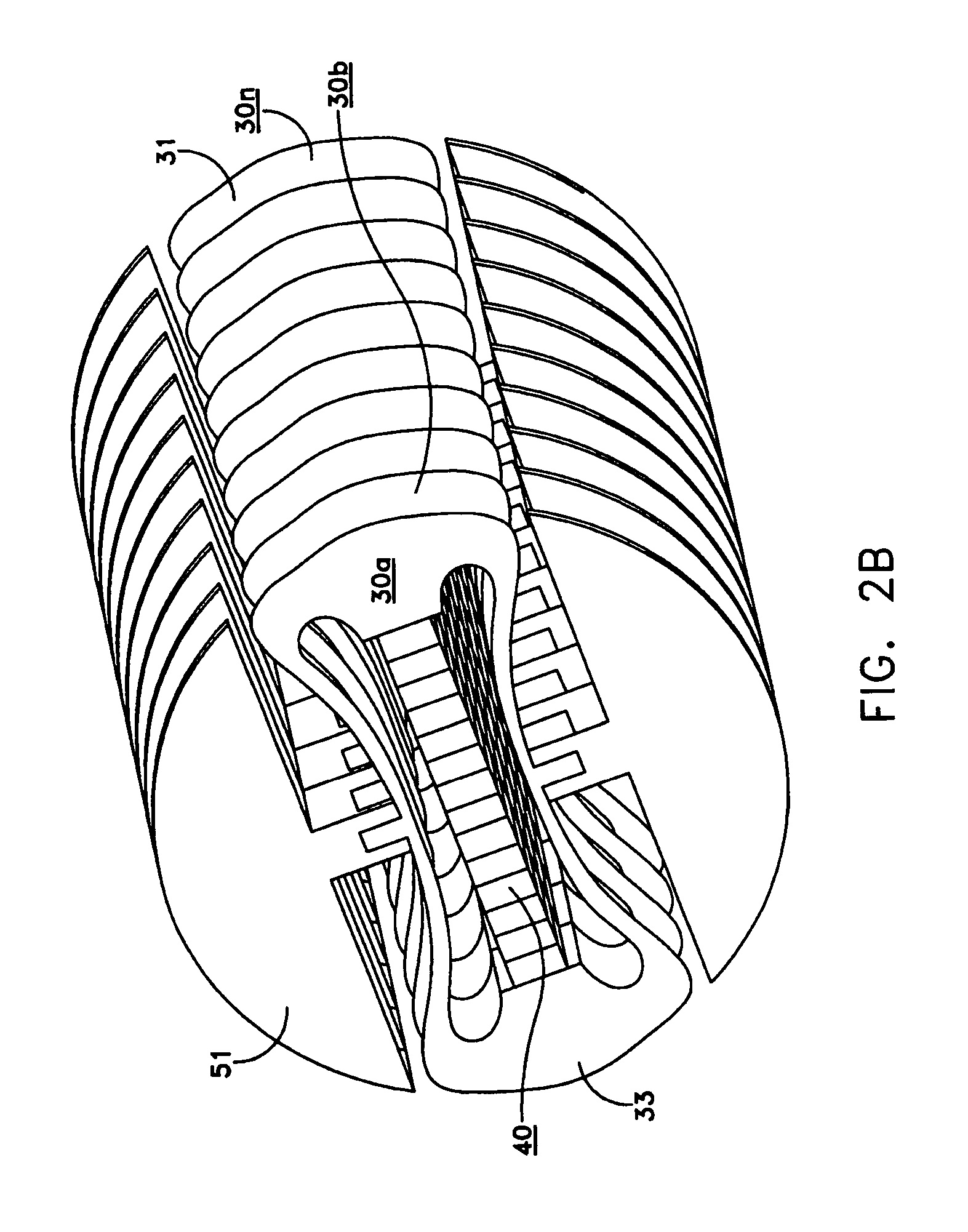

Flexural cylinder projector

InactiveUS20070206441A1Uniform radiation velocityLess susceptible to cavitation limitationPiezoelectric/electrostrictive transducersMechanical vibrations separationBroad bandHigh frequency

An inverse flextensional projector exhibits a low frequency flexural mode and a higher frequency “breathing” mode to defeat stealthy targets and to conduct short and long range detection and tracking in littoral waters. The device has much broader bandwidth than conventional flextensional transducers, slotted cylinders and conventional cylinder transducers. The device has a low frequency capability similar to slotted cylinder projectors (SCP) but is broader band and does not suffer from the unsupported gap of SCP projectors. The invention has a more uniform radiation velocity than both SCP and flextensional transducers, making it much less susceptible to cavitation limitations.

Owner:LOCKHEED MARTIN CORP

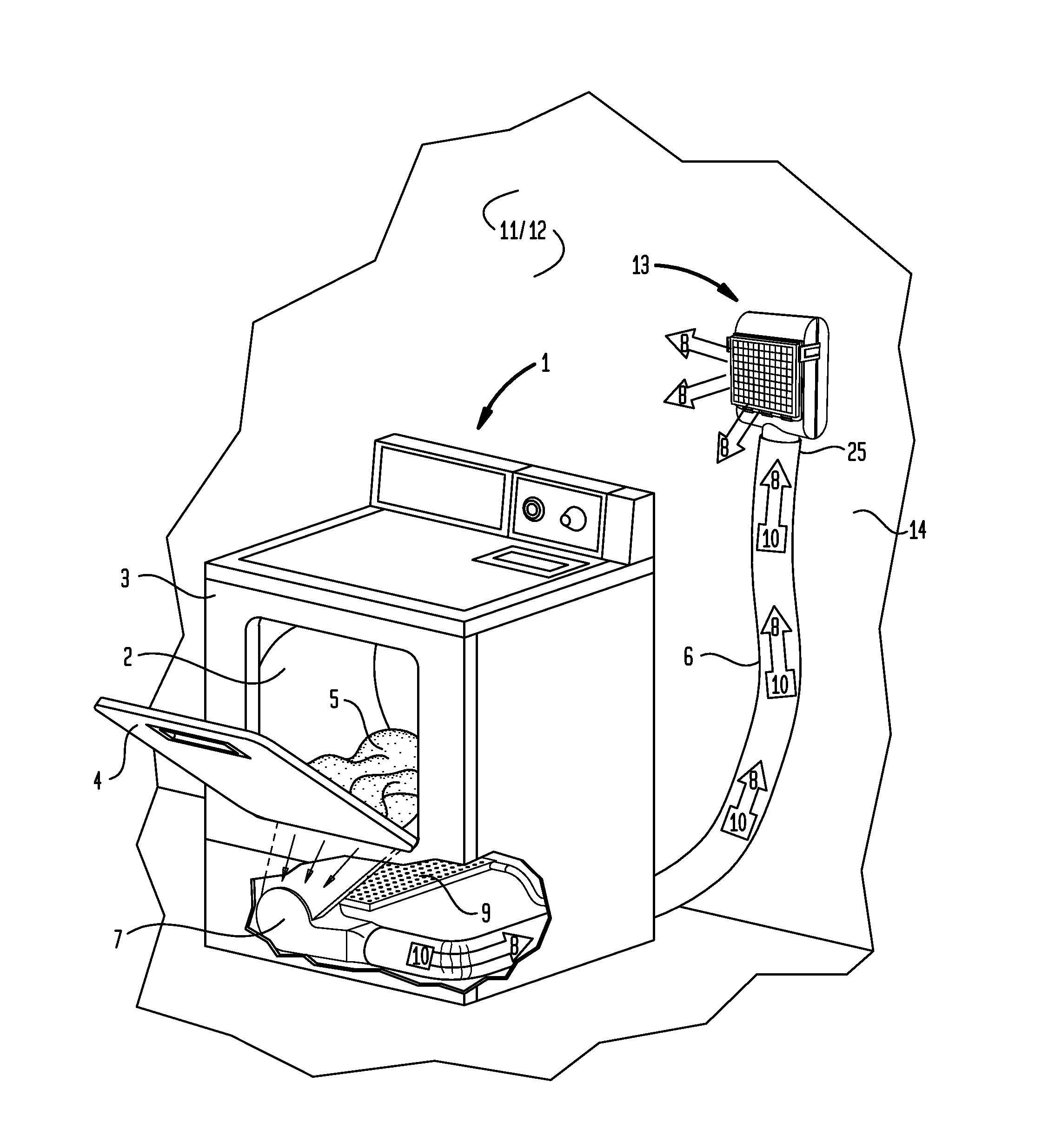

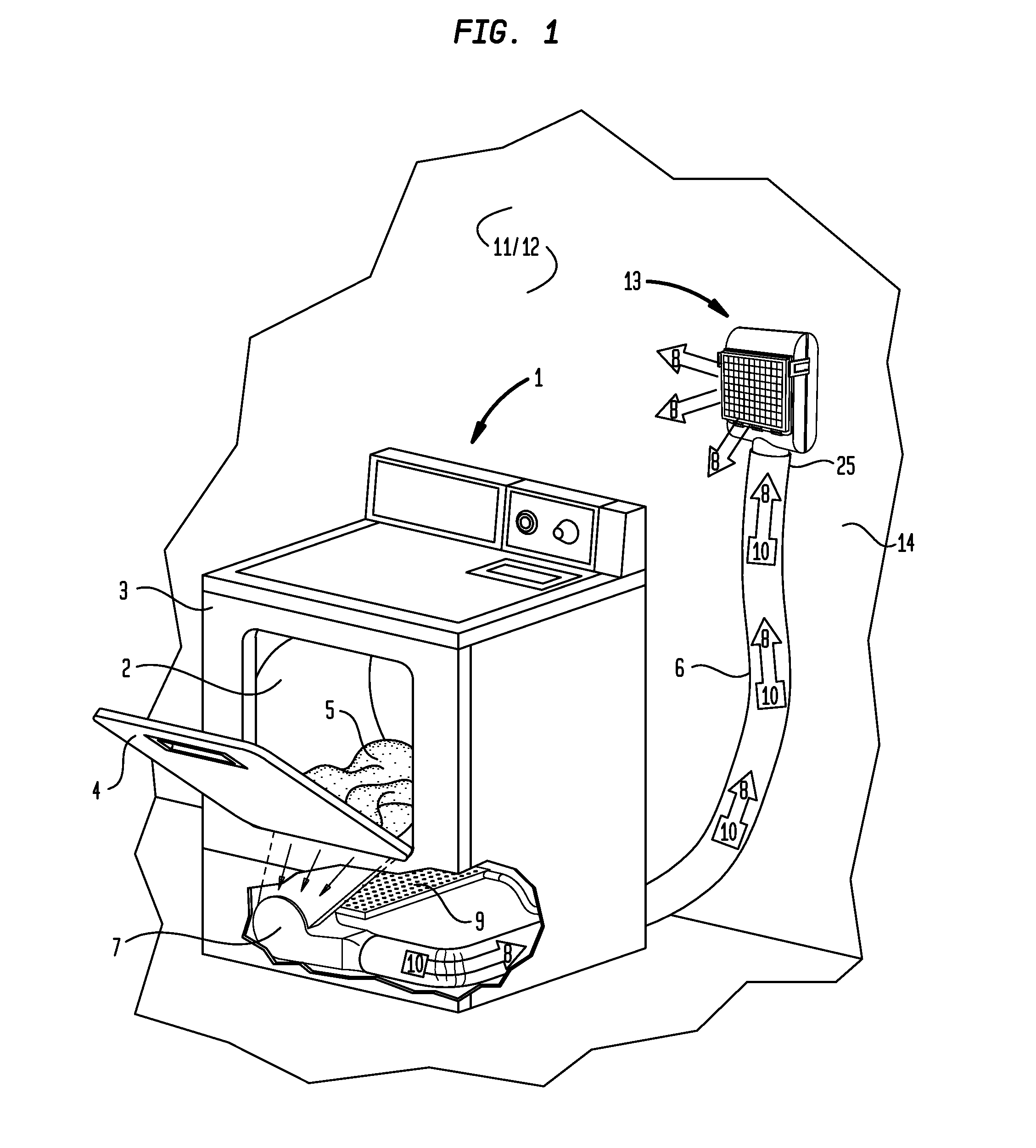

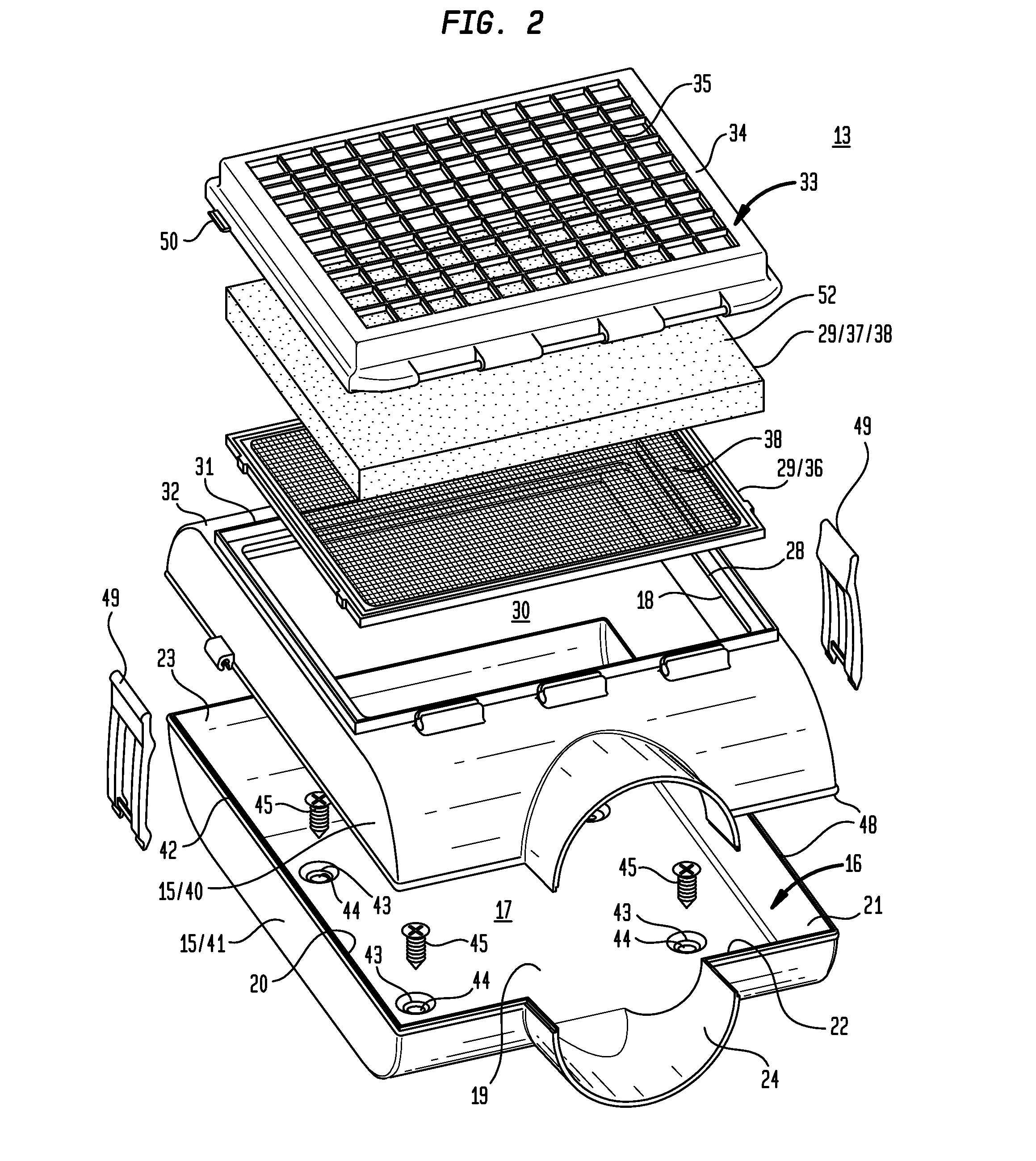

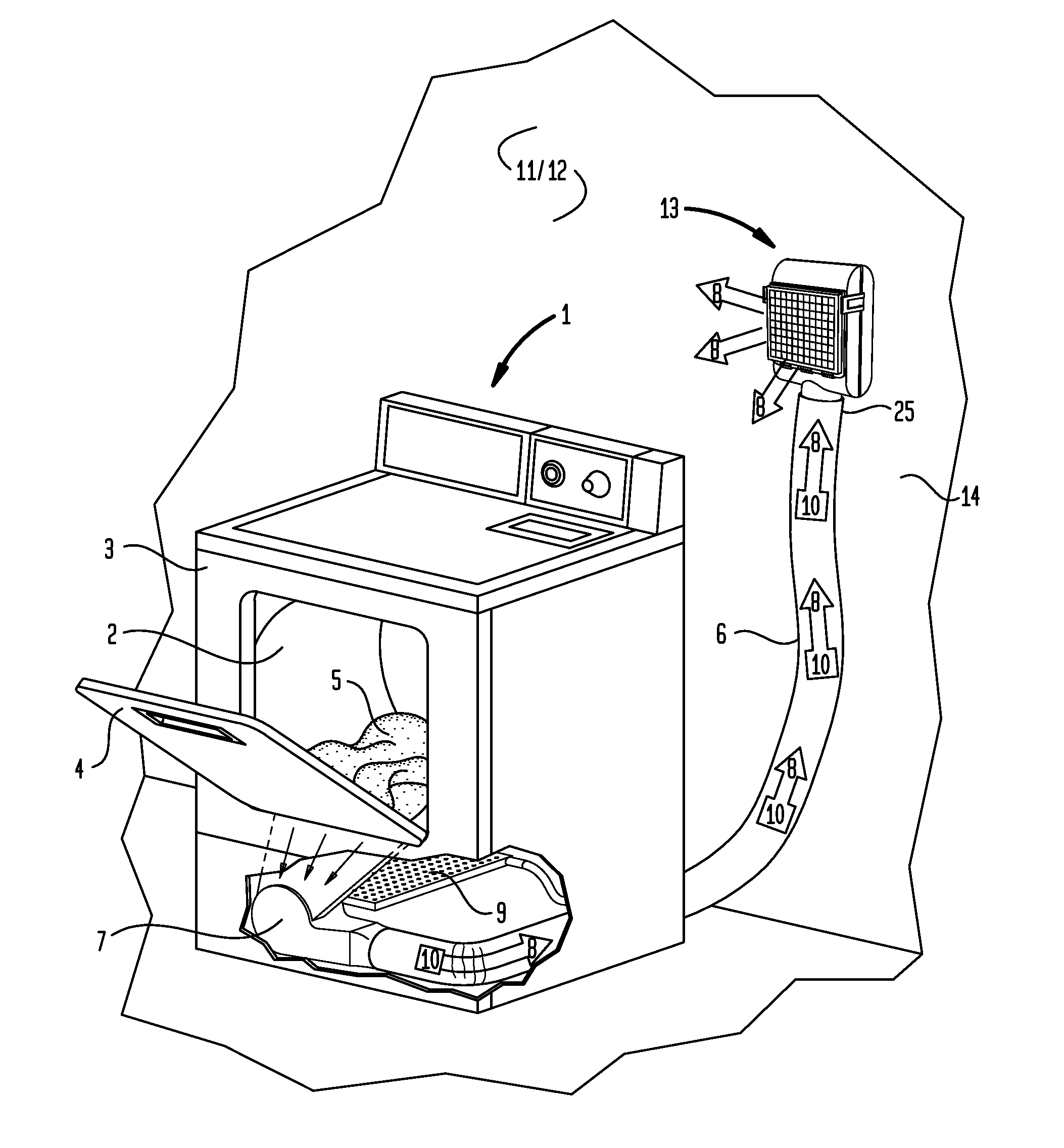

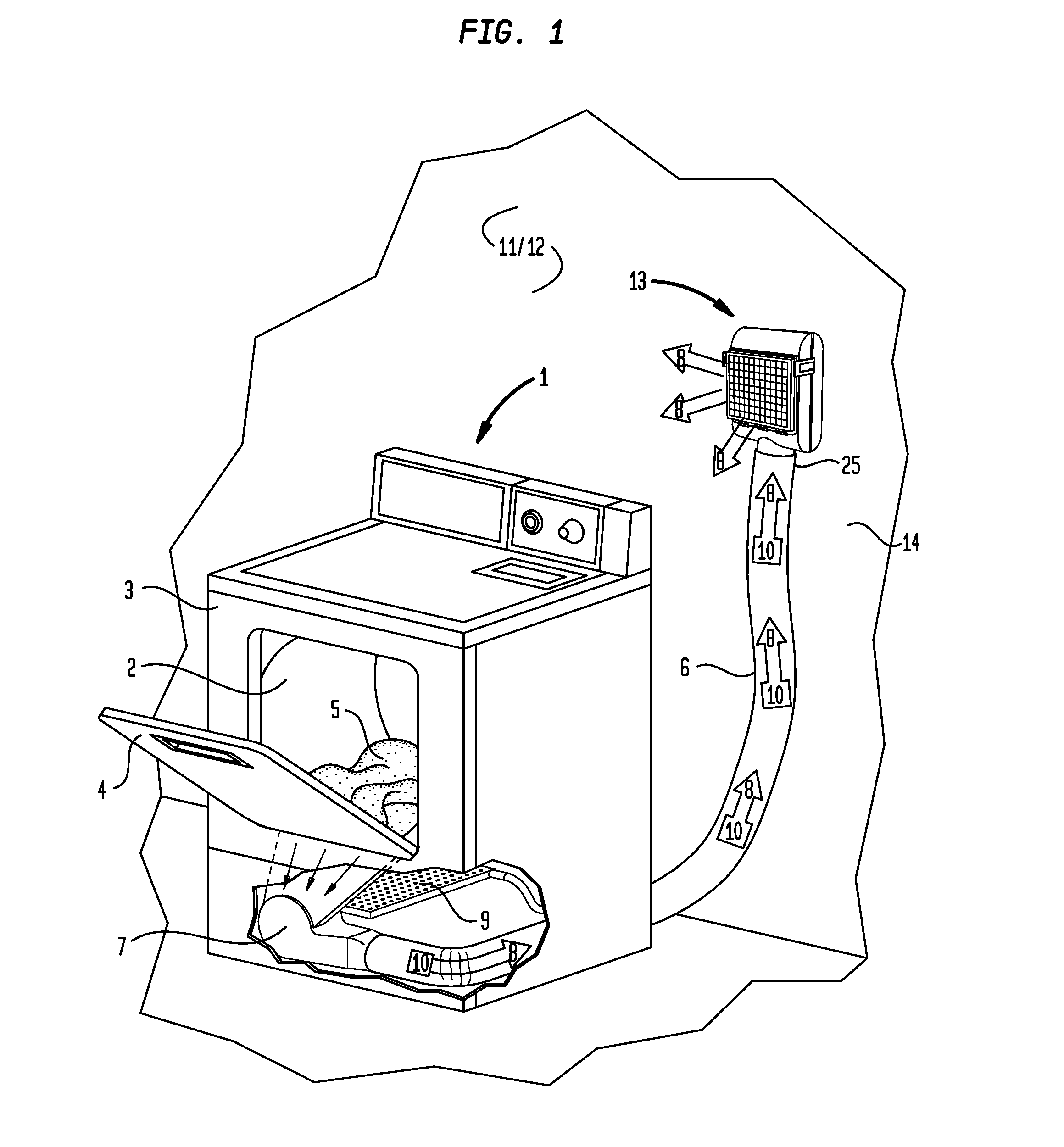

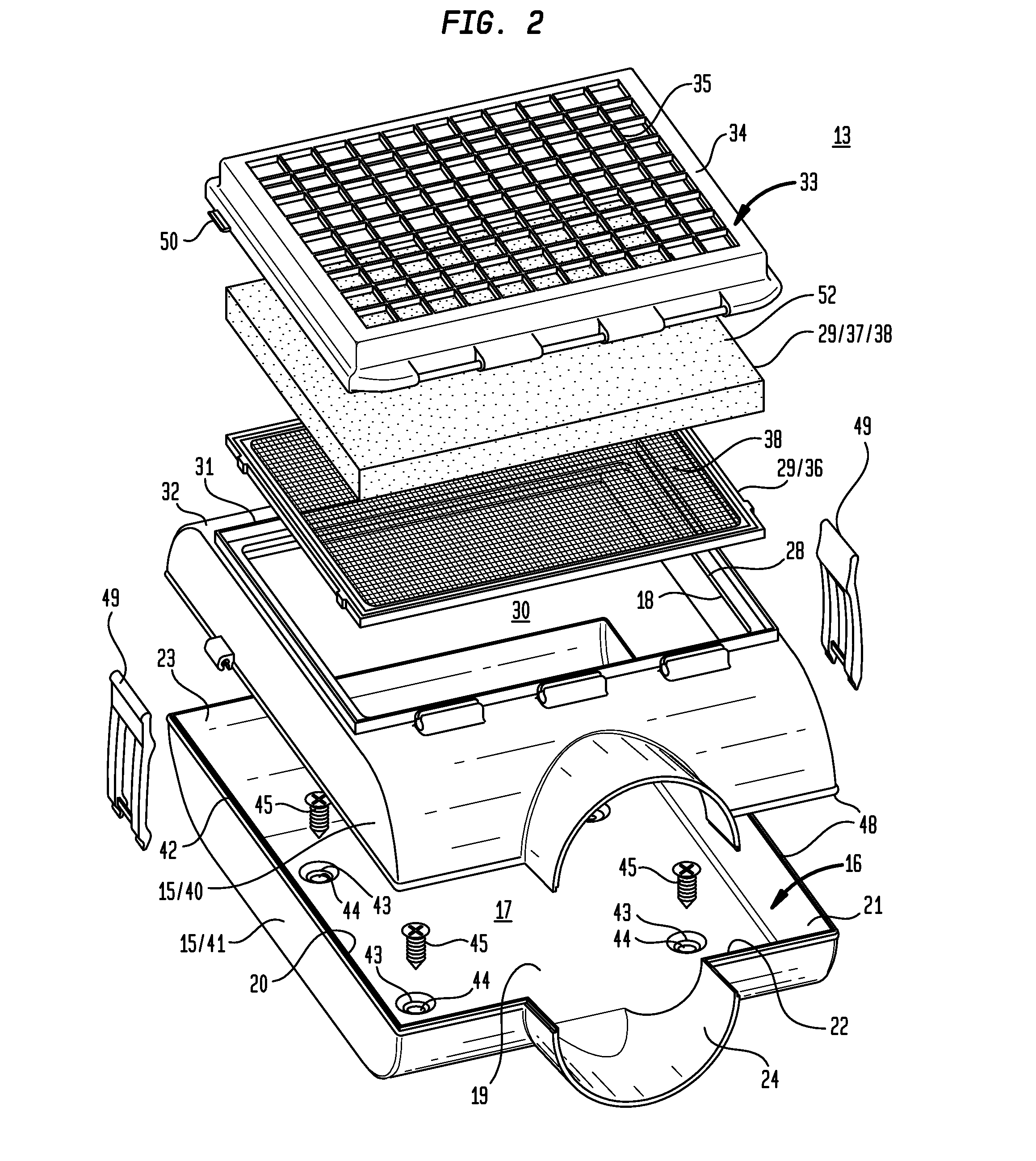

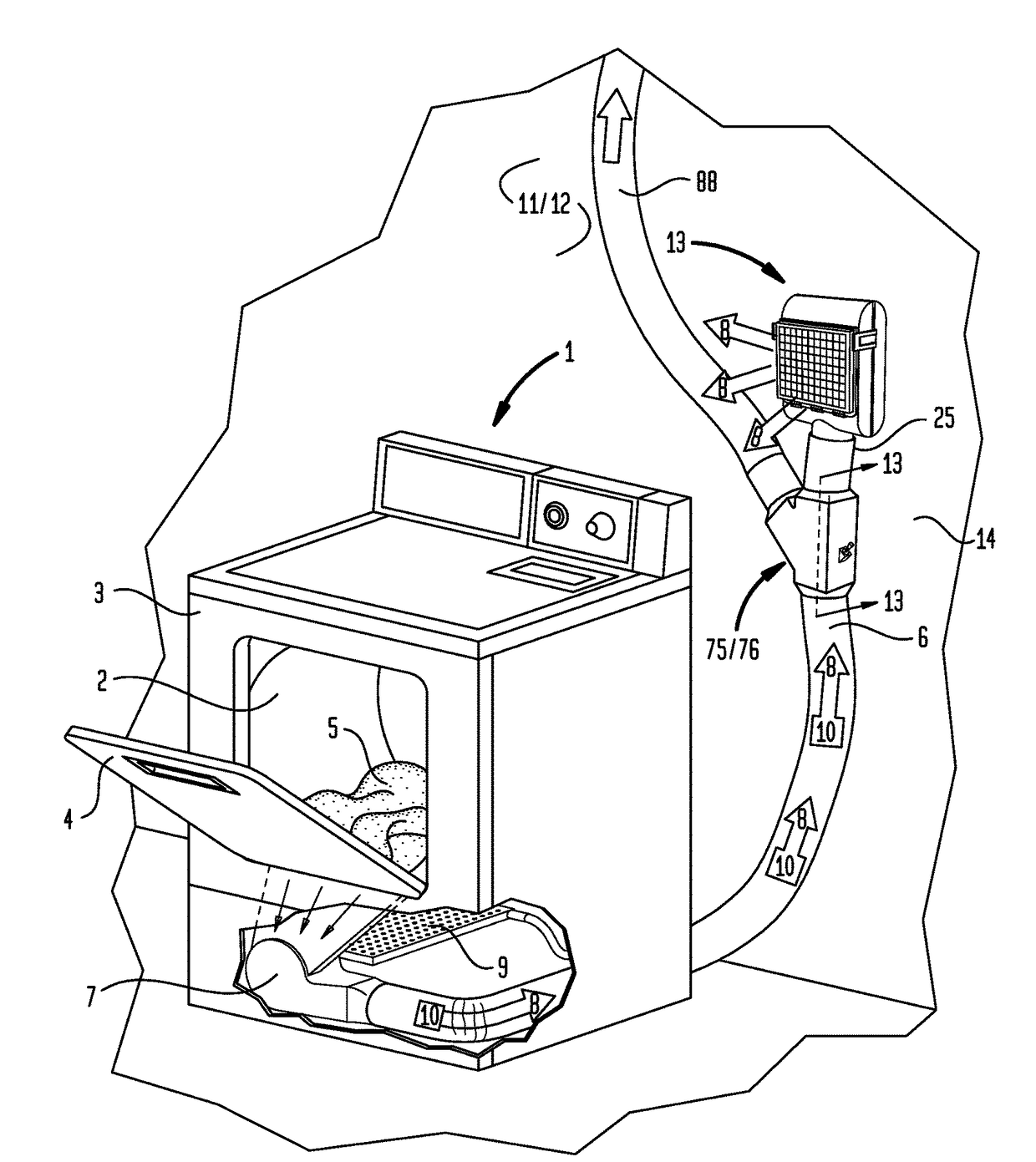

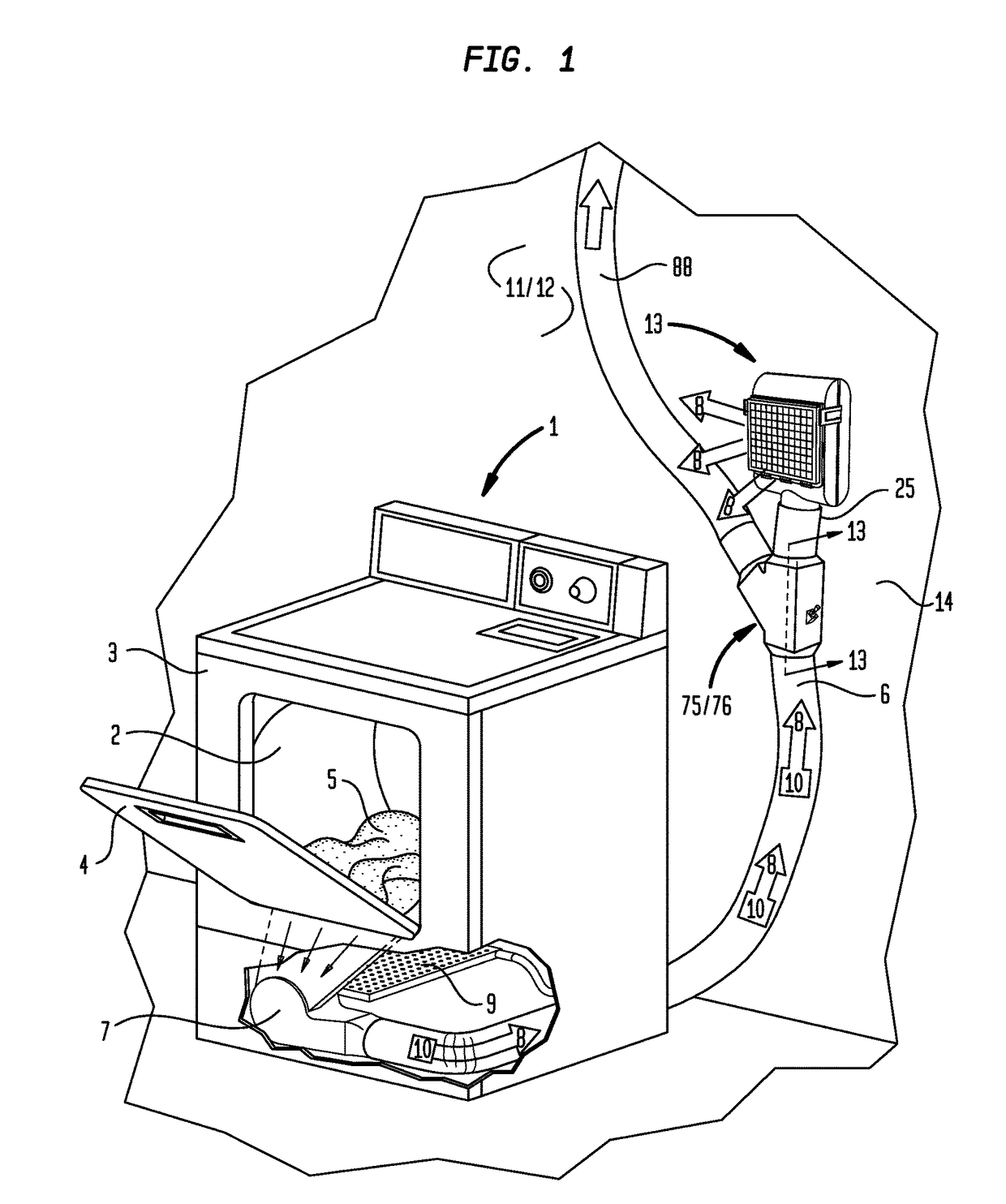

Lint catching system

ActiveUS8893399B2Increase depositionIncrease exhaust flowDrying using combination processesDrying solid materials with heatWaste management

Owner:ADR PROD

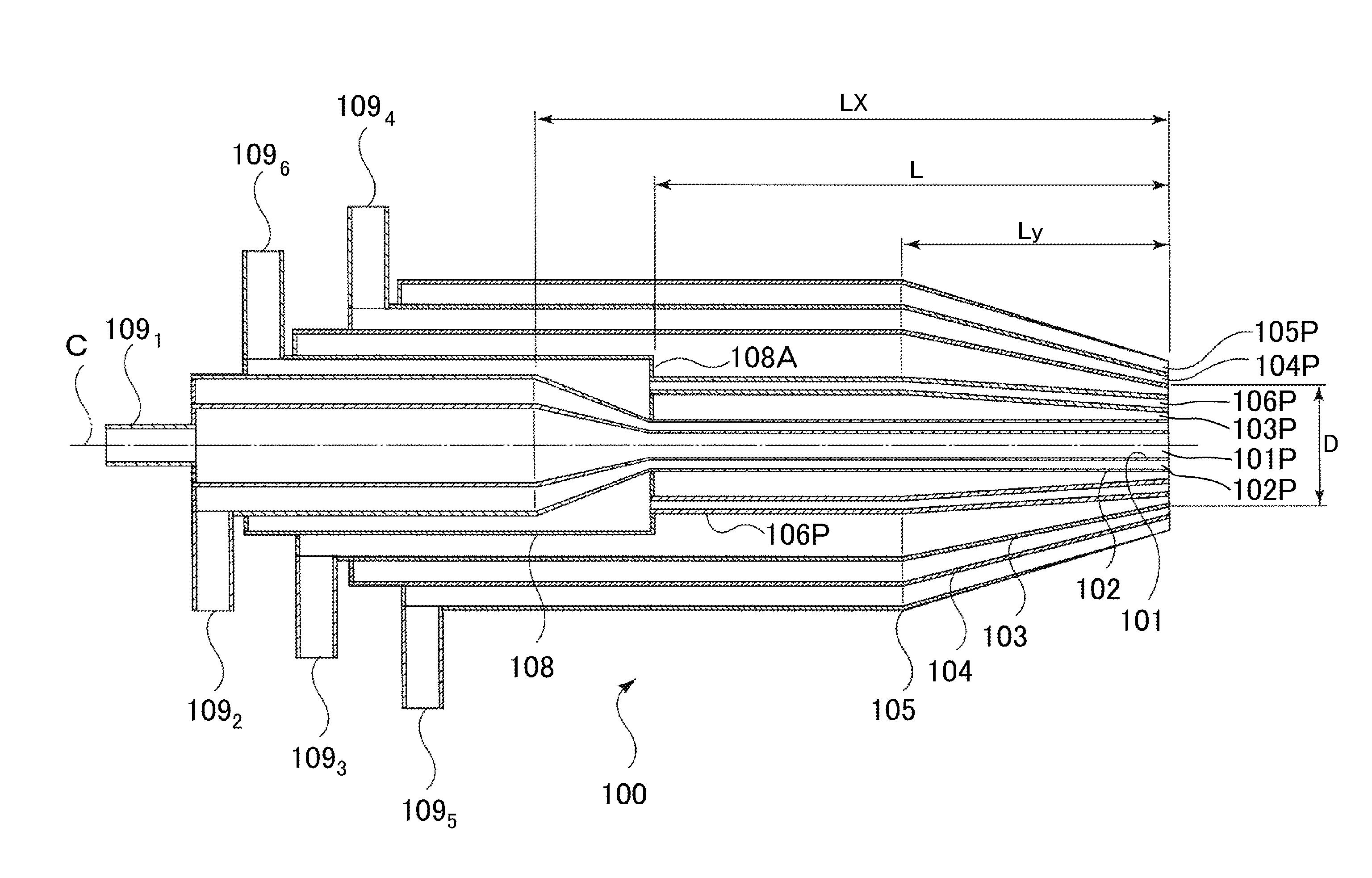

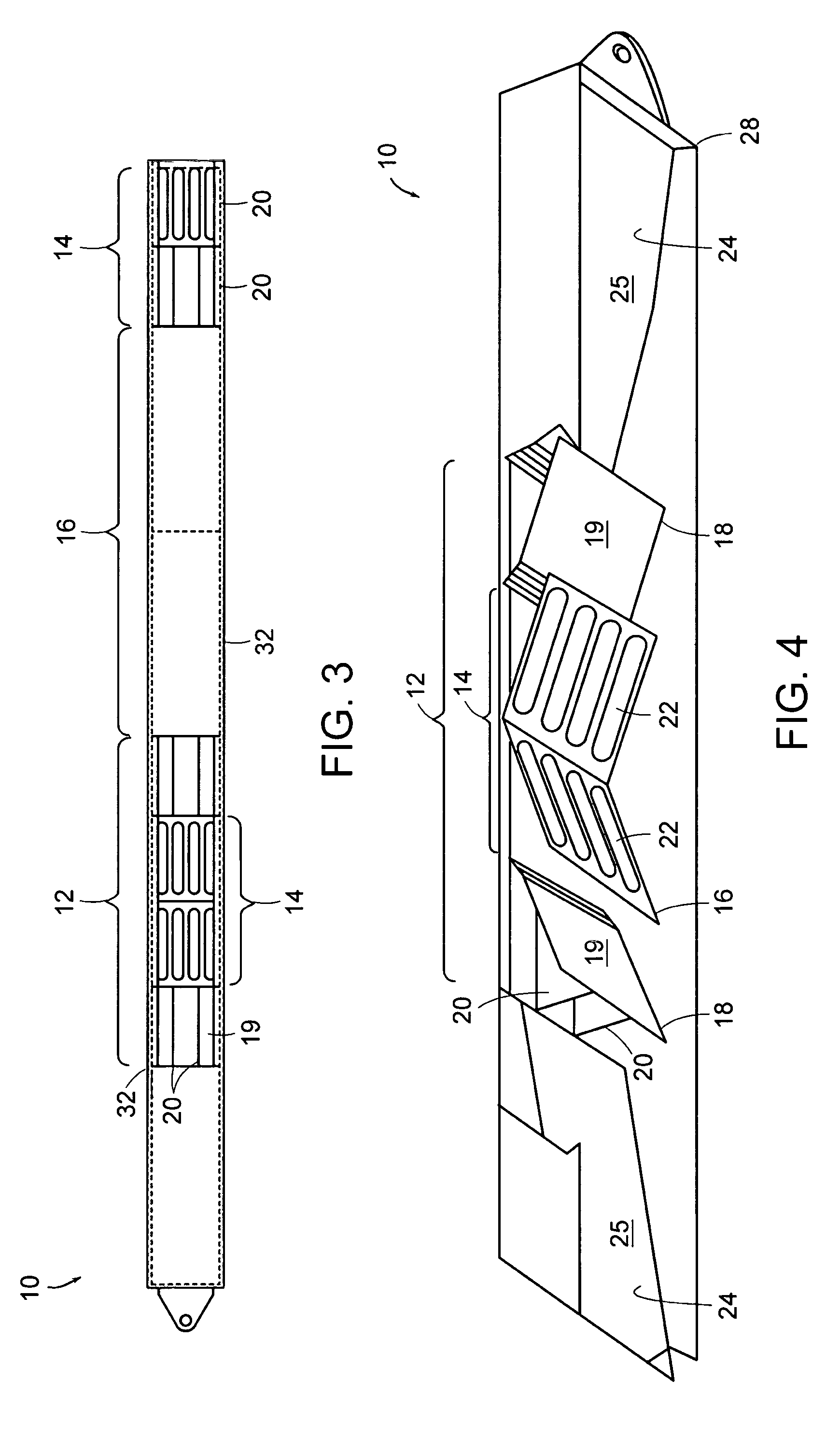

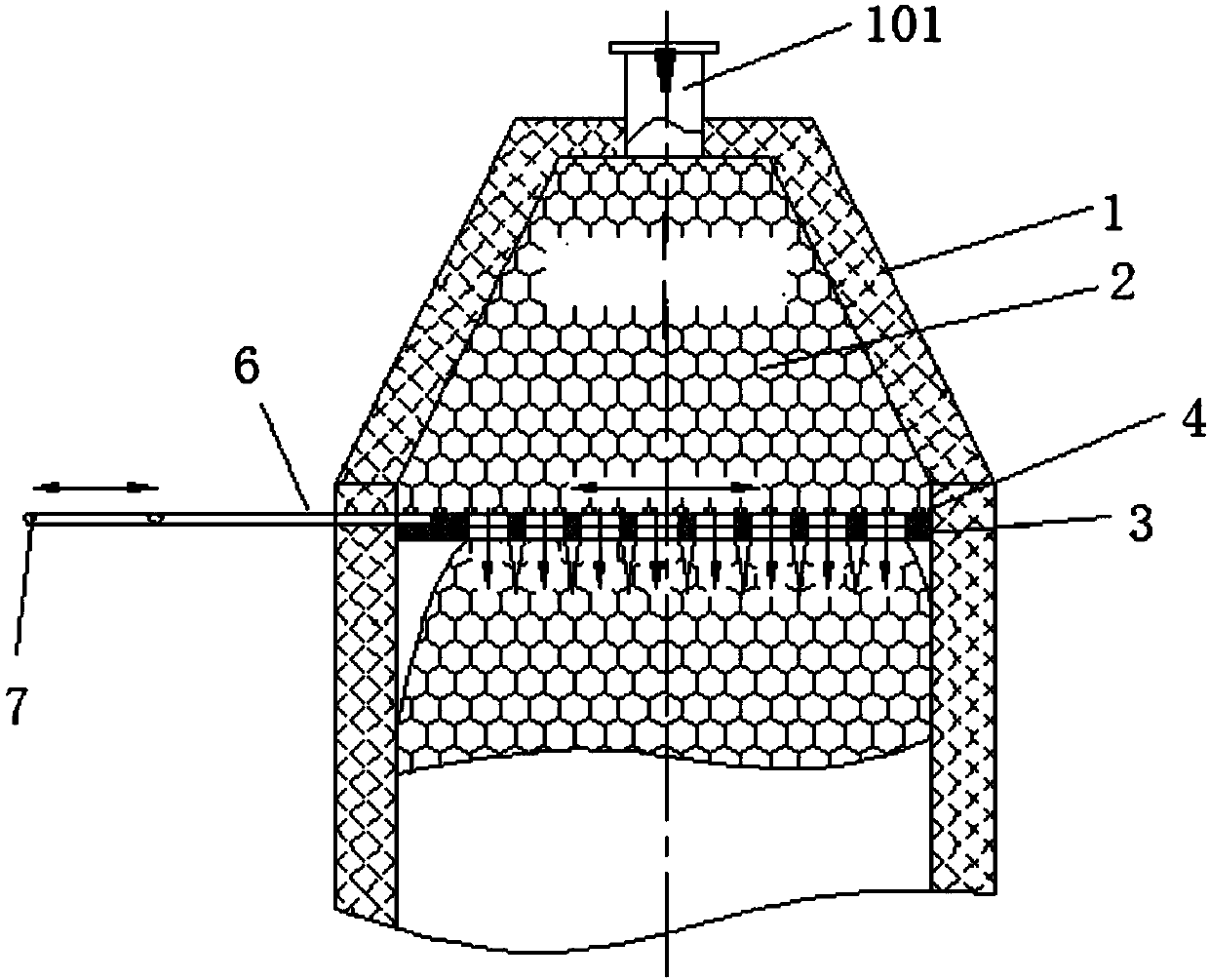

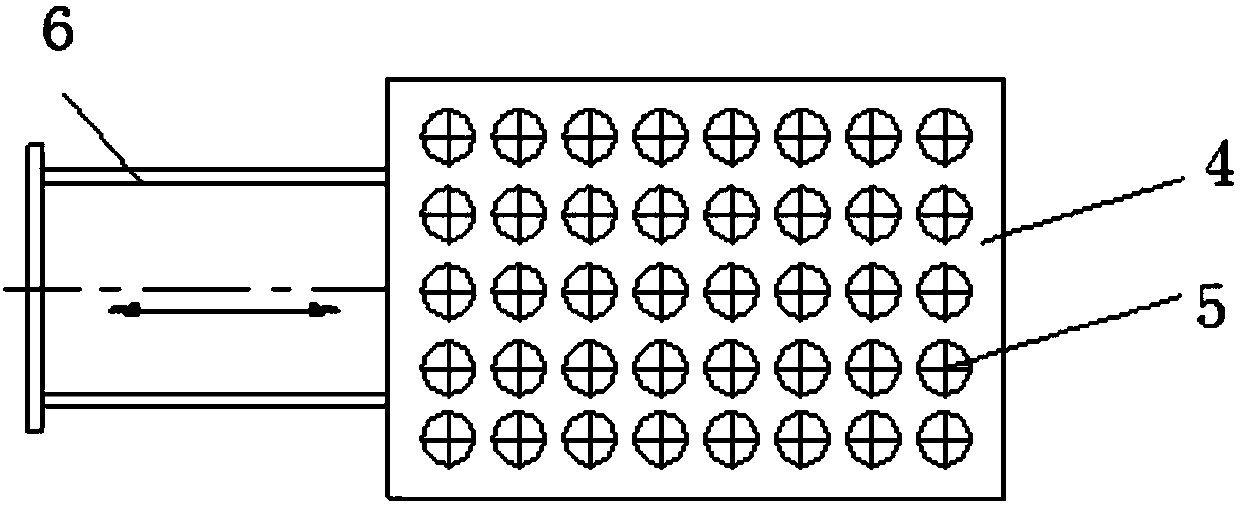

Burner for manufacturing porous glass base material

ActiveUS20100323311A1Flame stabilizationGuaranteed uniform velocityGlass shaping apparatusGlass deposition burnersPorous glassEngineering

The present invention provides a burner for manufacturing a porous glass base material that has small-diameter gas discharge ports and that achieves uniform linear velocity at the gas discharge ports, a uniform reaction, and a stable flame, and improved deposition efficiency. In the burner for manufacturing a porous glass base material, inner diameters of the pipes forming the gas discharge ports positioned farther inward in a radial direction than the gas discharge ports in which the small-diameter gas discharge port nozzles are arranged contract beginning from a position farther on a burner source side than the prescribed length L position, the contraction being greater closer to a burner tip side, and inner diameters of the pipes forming the gas discharge port in which the small-diameter gas discharge port nozzles are arranged and the gas discharge ports that are positioned farther outward in the radial direction than this gas discharge port contract beginning from a position farther on a burner tip side than the prescribed length L position, the contraction being greater closer to a burner tip side.

Owner:SHIN ETSU CHEM IND CO LTD

Lint Catching System

ActiveUS20130125410A1Increase depositionIncrease exhaust flowDrying gas arrangementsOther manufacturing equipments/toolsWaste management

Owner:ADR PROD

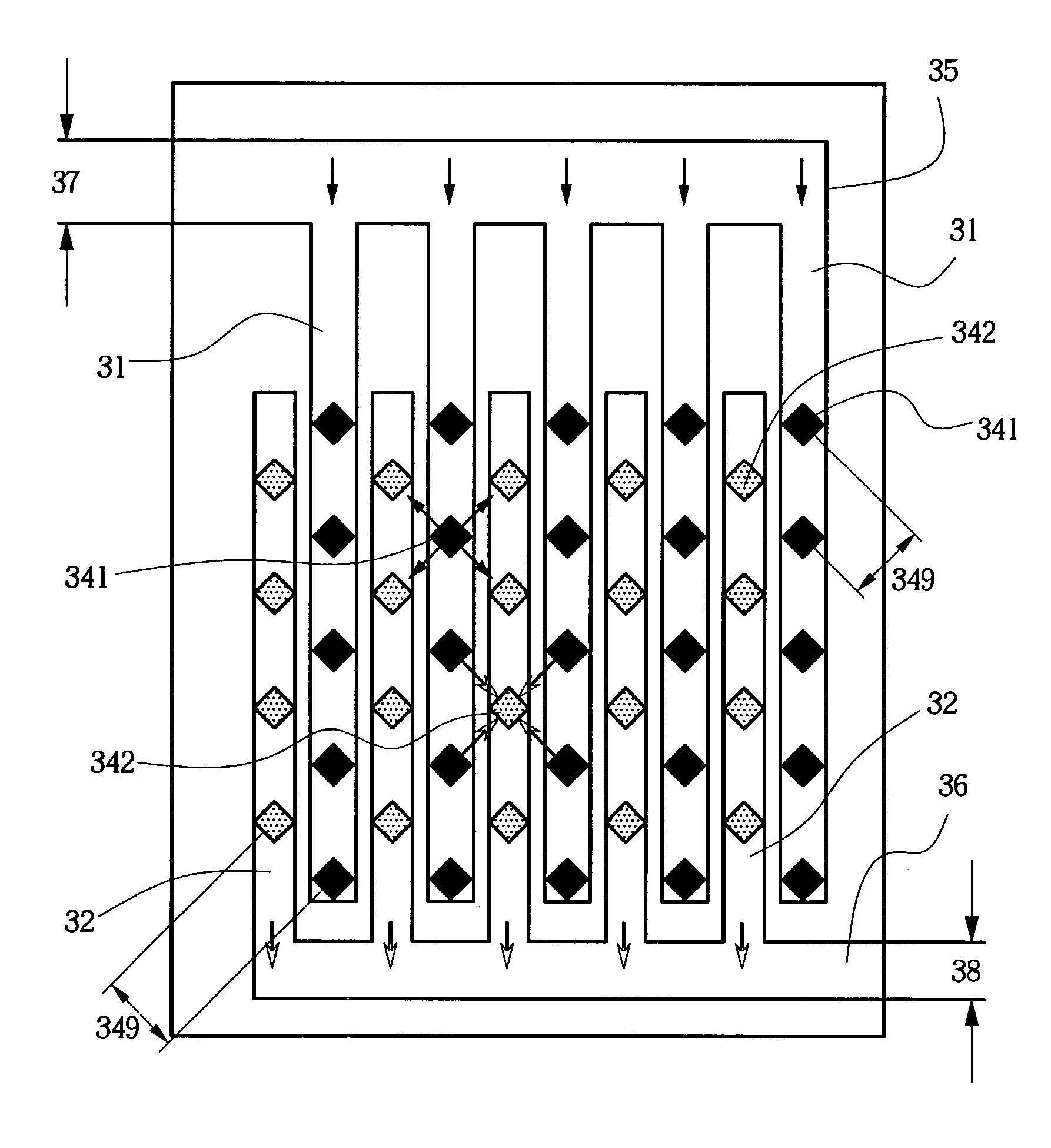

Bipolar plate and direct liquid feed fuel cell stack

InactiveUS20060105223A1Reduce total pressure lossUniform fluid velocityFuel cells groupingElectrode carriers/collectorsFuel cellsLiquid fuel

A bipolar plate for fuel cells includes a plurality of flow paths in which fuel flows. The flow paths include a first flow path formed by a plurality of flow channels and a second flow path formed by a plurality of islands. A direct liquid fuel cell stack comprises the bipolar plate.

Owner:SAMSUNG SDI CO LTD

Automated set-up for cell sorting

ActiveUS20140307940A1Reduce needGuaranteed uniform velocityImage analysisVolume/mass flow measurementComputer scienceFlow Cytofluorometry

Apparatus and methods are described for automatically performing set-up steps for flow cytometry operations. The invention provides for the spatial determination of a flow stream and the subsequent automatic alignment of analysis devices and / or collection vessels. The automatic determination of flow stream properties provides for the automatic configuration flow cytometer parameters.

Owner:BECTON DICKINSON & CO

Externally adjustable insert for extrusion manifold

Owner:FRITO LAY NORTH AMERICA INC

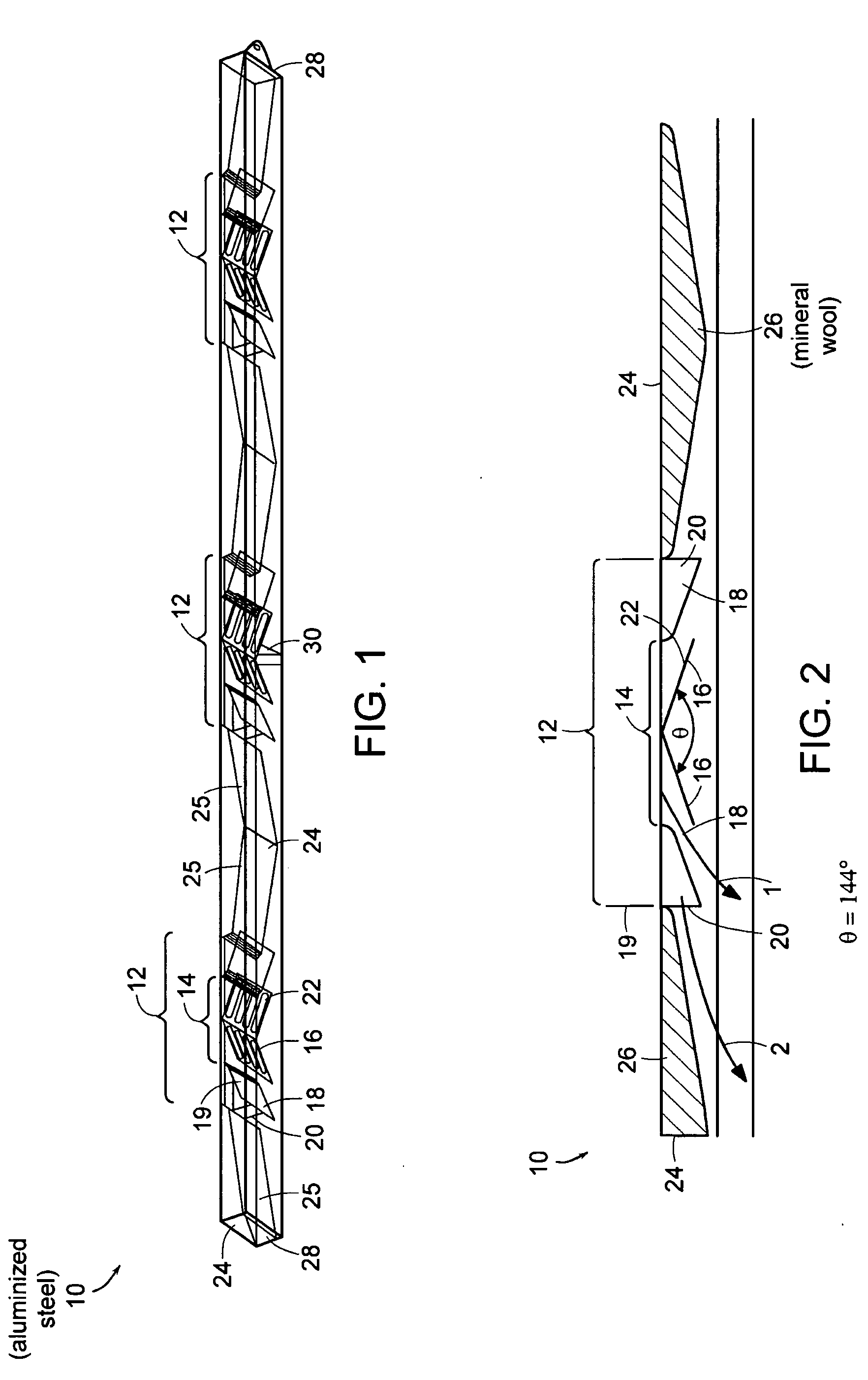

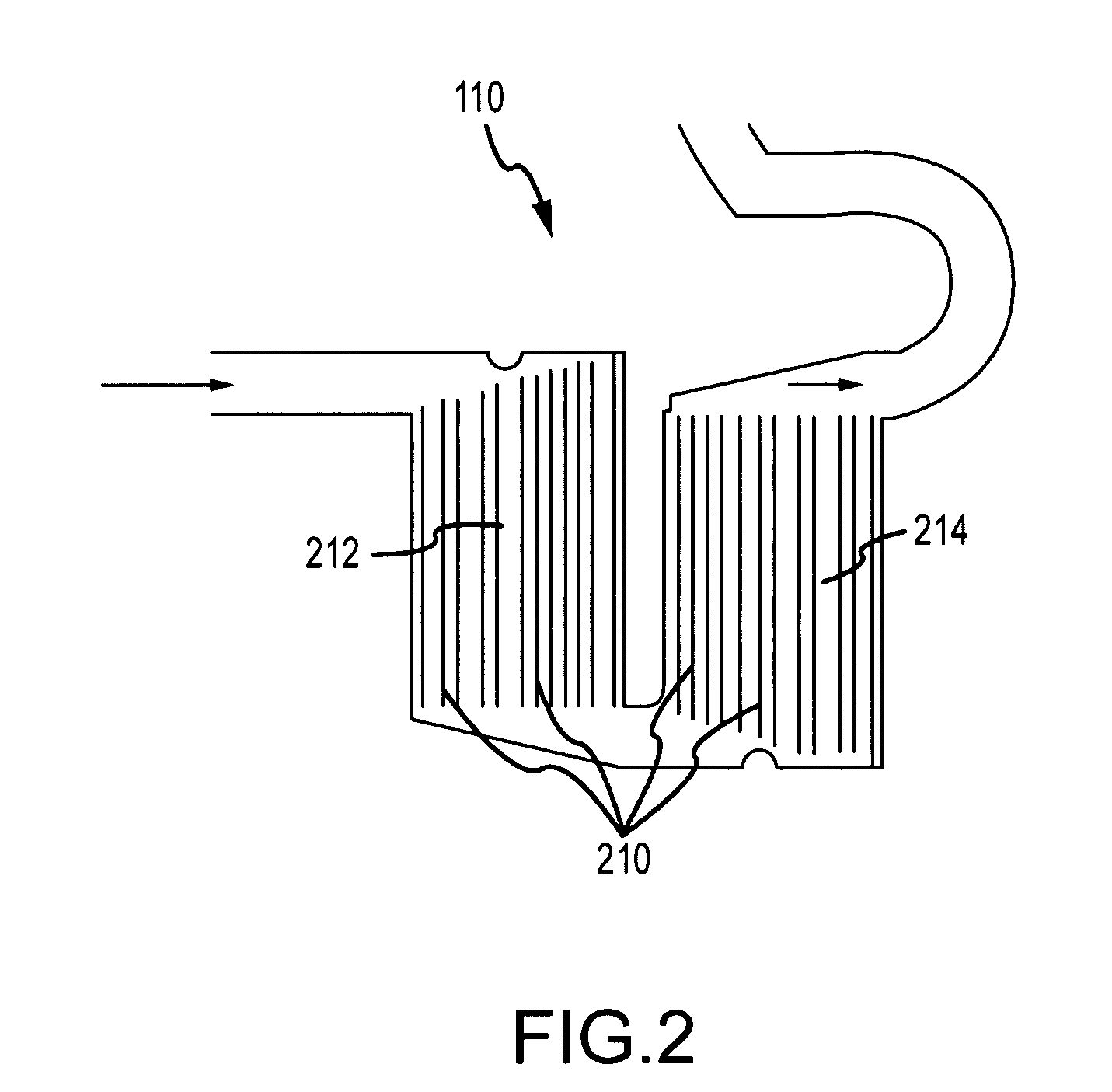

Nozzle insert for a Yankee impingement hood

ActiveUS20060107549A1Uniform temperatureGuaranteed uniform velocityDryer sectionDrying gas arrangementsHeat lossesYankee

The present invention includes a nozzle insert for use in a drying machine of the type used in paper web drying. The nozzle insert of the present invention includes at least one intake having a central portion, wherein a pair of center vanes is disposed for directing airflow. The central portion is bounded by at least one turning vane adapted for directing airflow in a lateral direction. For each turning vane, there is at least one straightening vane adapted for curtailing swirling of the airflow. The vanes are oriented at optimal angles for directing the flow of the nozzle in a lateral direction, while permitting some air to penetrate the central portion through a series of ports. The intakes are bounded by a series of insulated bulkheads, which serve to direct airflow and contain heat-loss through thermal emission.

Owner:VALMET OY

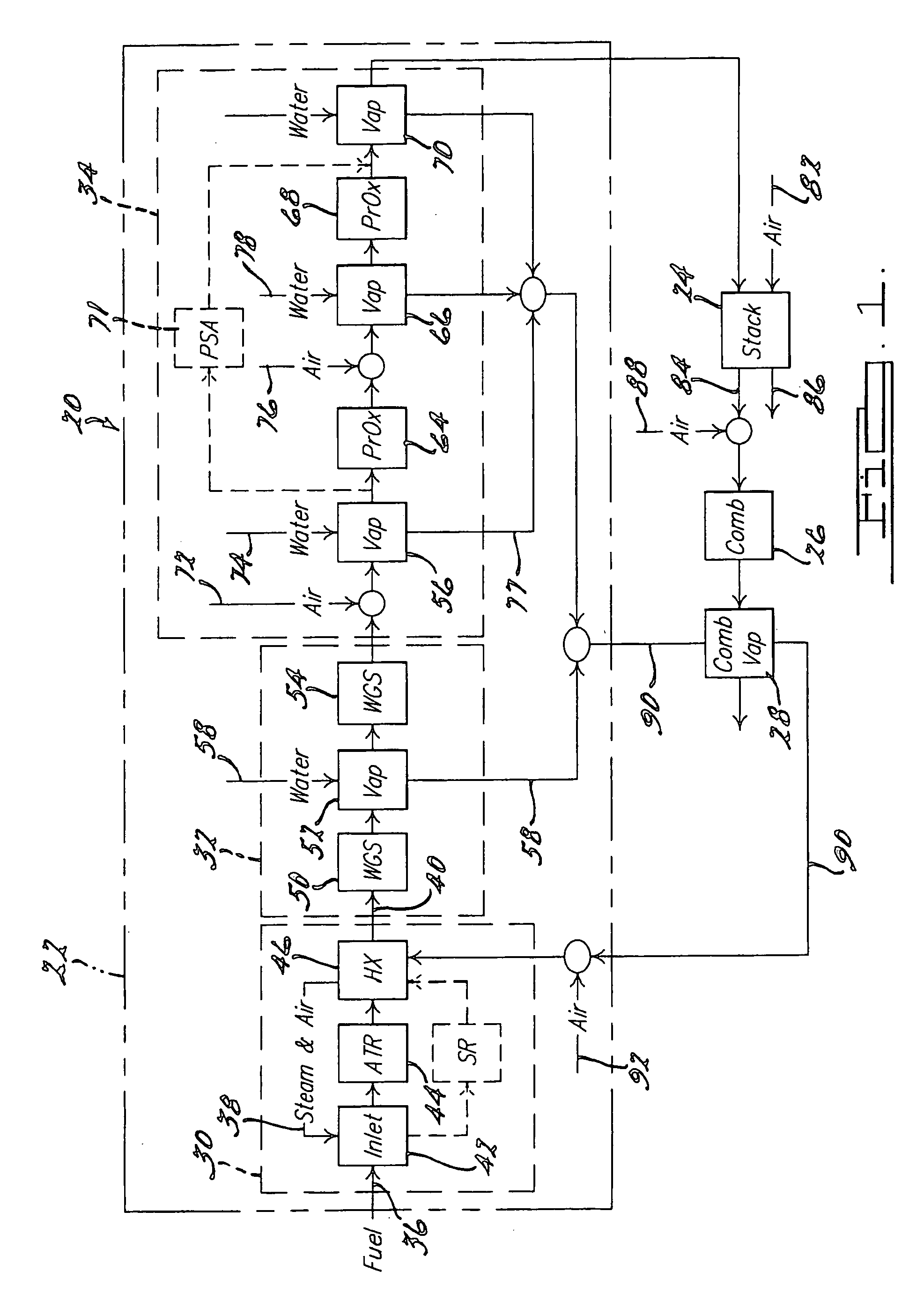

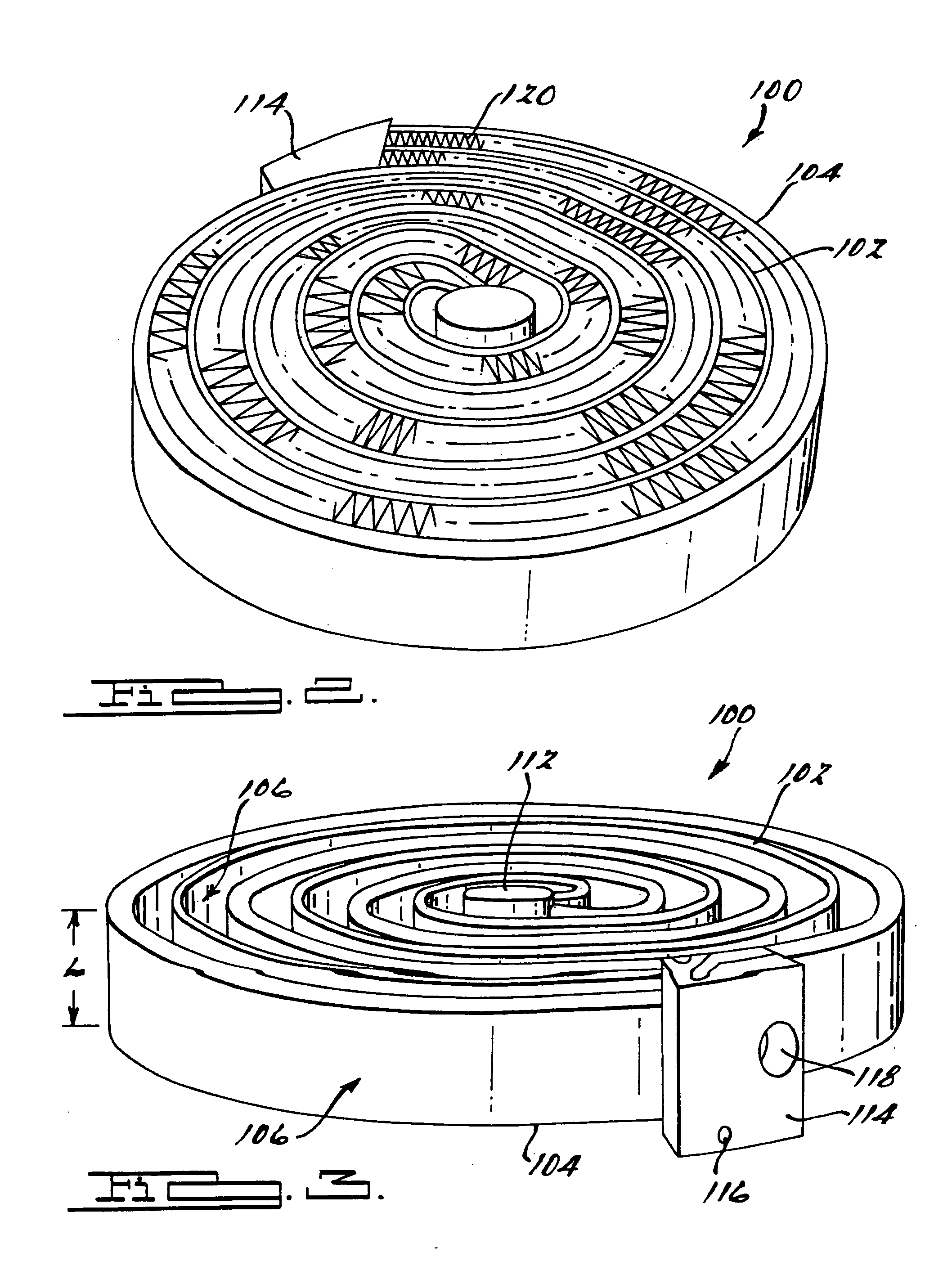

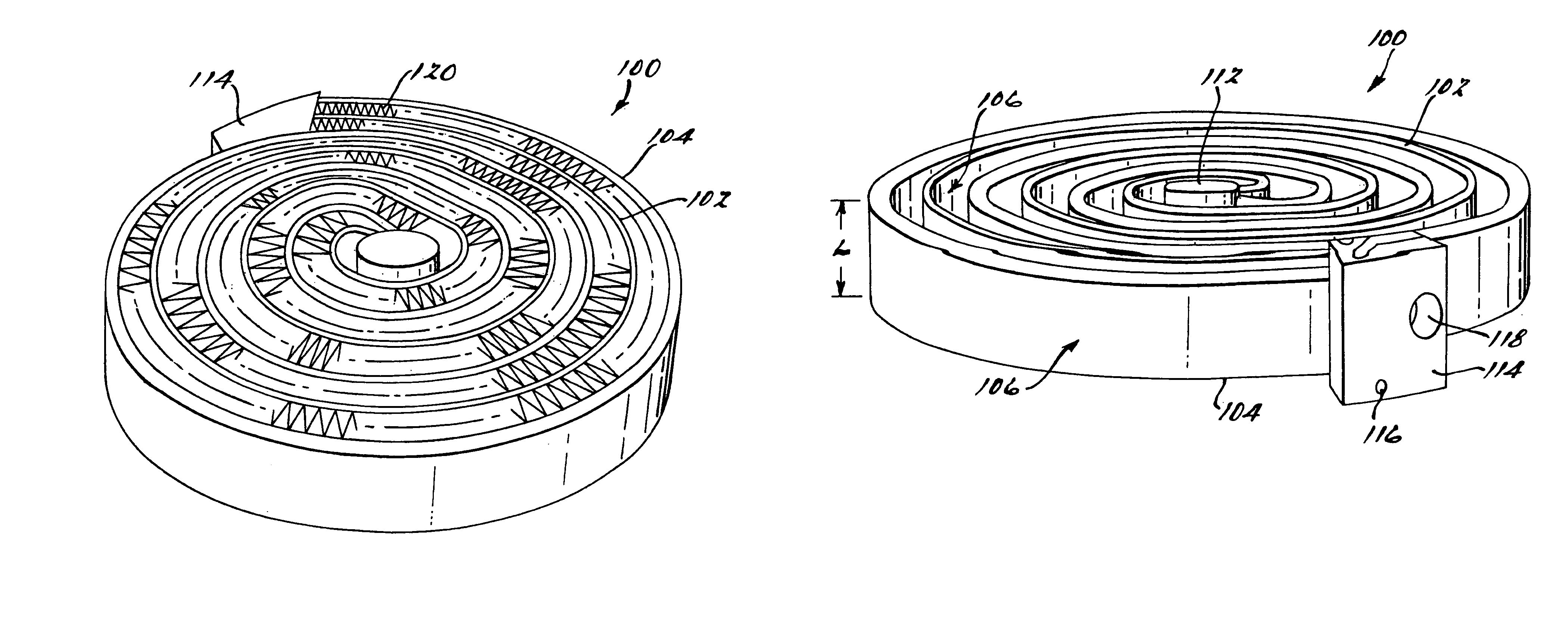

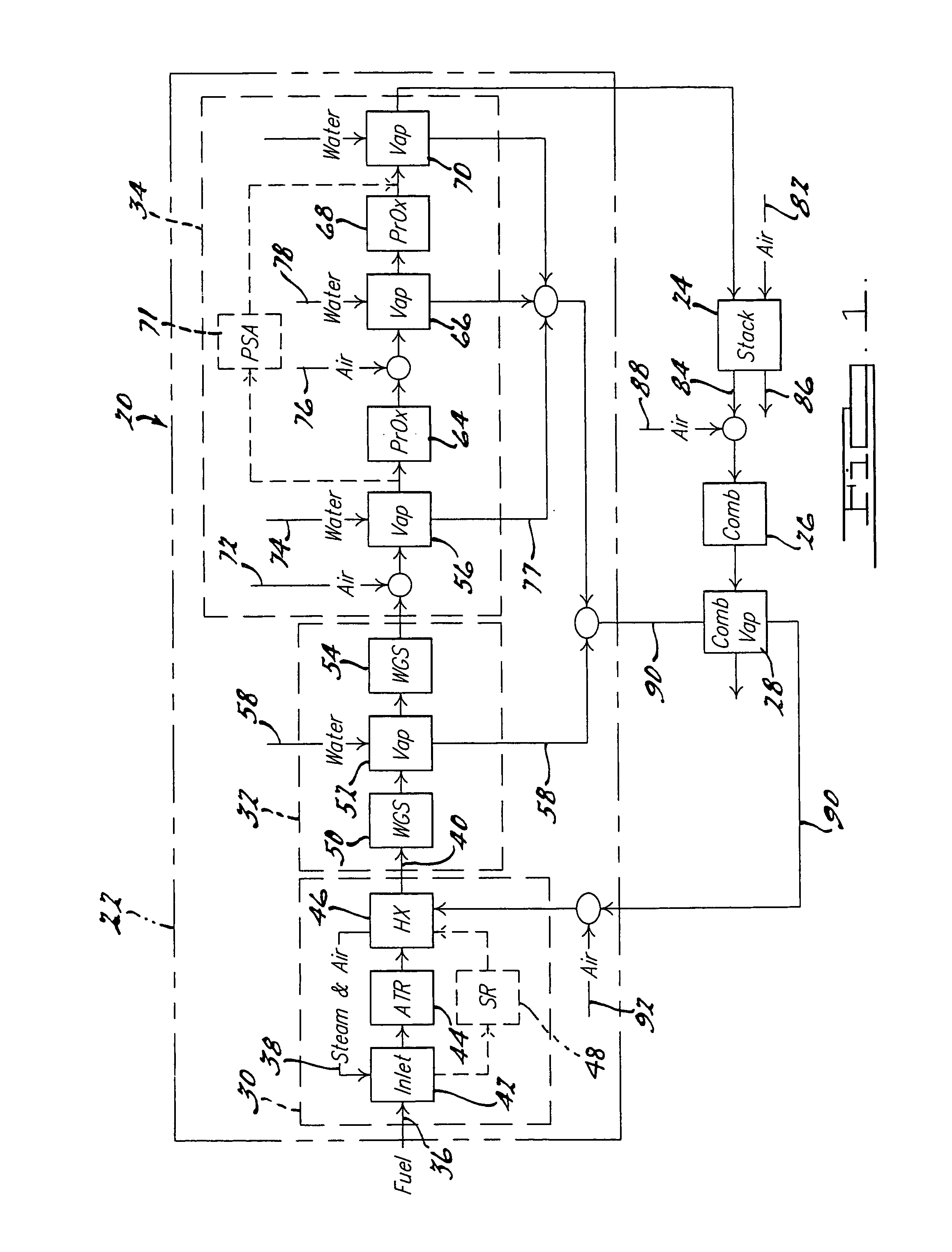

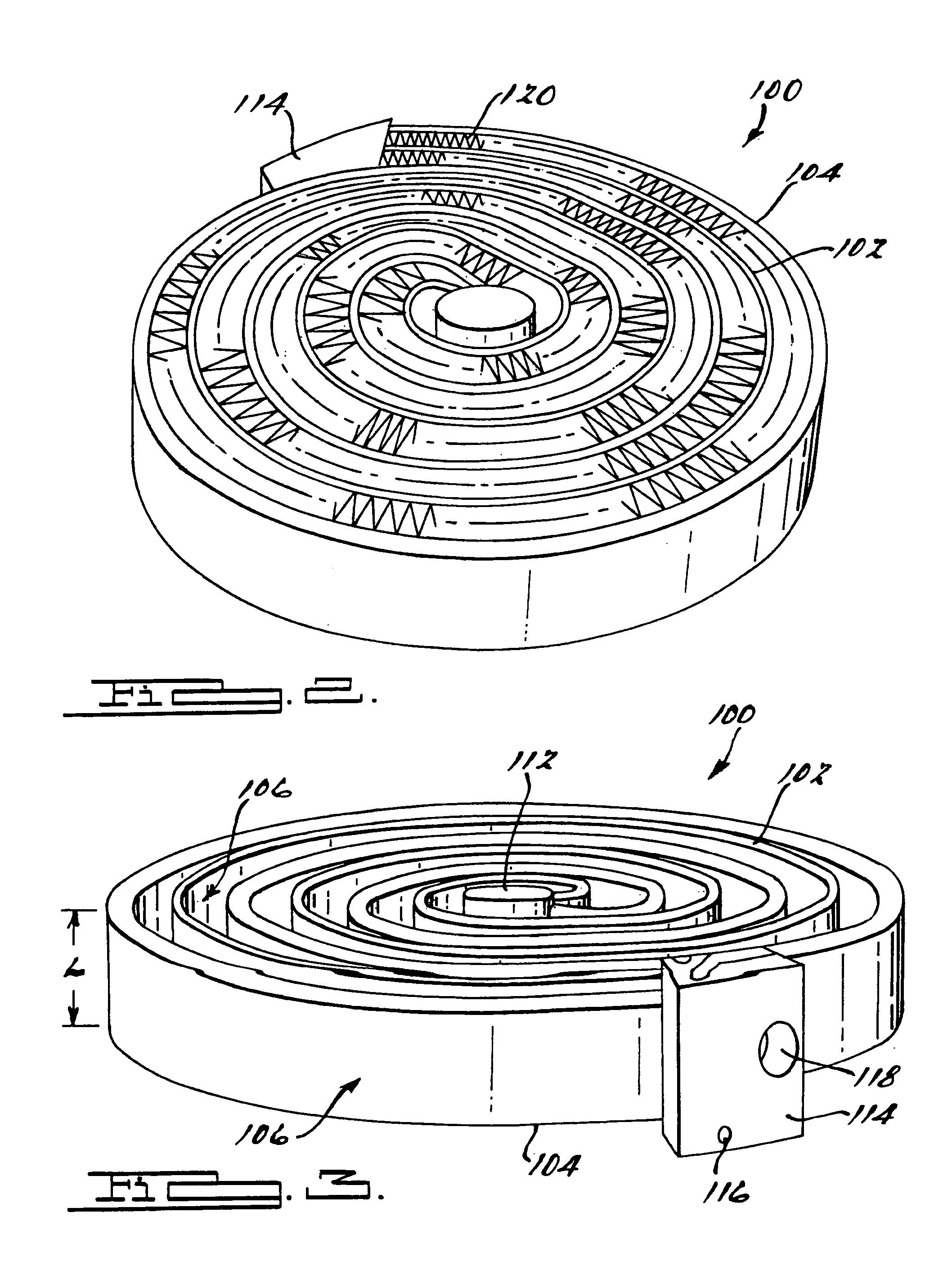

Compact water vaporizer for dynamic steam generation and uniform temperature control

ActiveUS20050100490A1Lower the volumeMinimal complexityBoiler water tubesSolid waste disposalTemperature controlCounter flow

A compact cylindrical vaporizer for simultaneous reduction of a reformate stream temperature and generation of a process stream is disclosed. The vaporizer utilizes counter flowing nested tubular portions that spiral between an outer section of the vaporizer and a central section of the vaporizer. The return spiral has a larger cross-sectional area than the inward spiral to accommodate a higher volumetric flow rate of the water flowing there through as it vaporizes while keeping the fluid velocity below erosion design constraints. The counter spiraling flow provides a substantially uniform spatial temperature profile of a reformate stream flowing on the exterior of the tubular portions. The vaporizer can be sized to be substantially the same as that of an upstream reactor to minimize velocity losses and pressure drops in the reformate stream flowing there through. A plurality of fins are positioned between the opposing tubular portion to enhance the heat transfer.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Lint catching system and exhaust assembly

ActiveUS9593441B2Increase depositionIncrease exhaust flowDrying solid materialsTextiles and paperWaste management

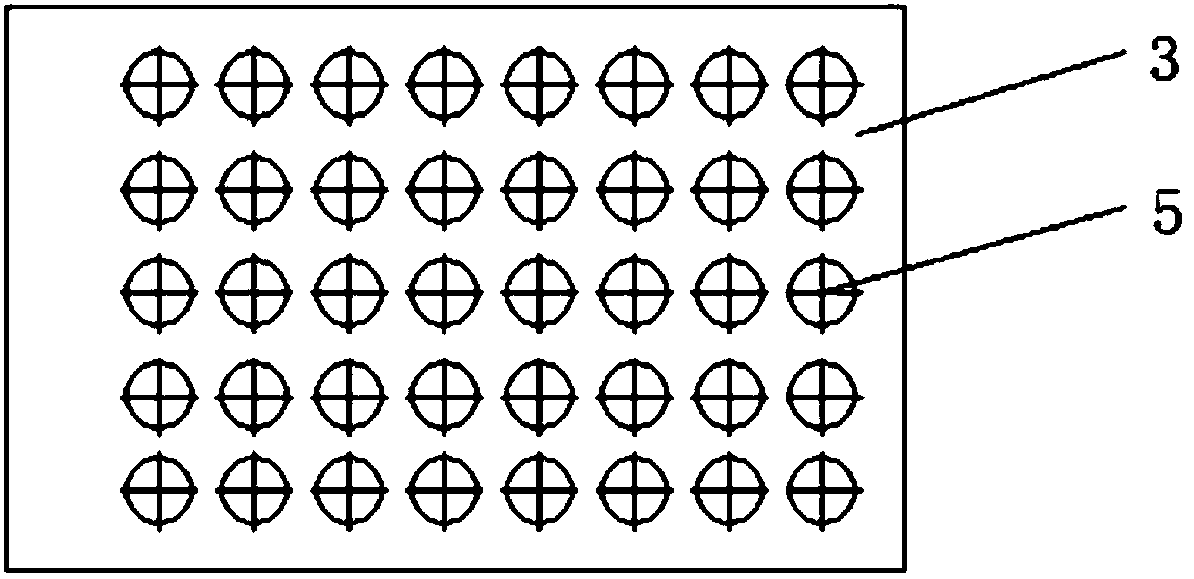

Falling type uniform material distributing system

The invention provides a falling type uniform material distributing system. The falling type uniform material distributing system comprises a furnace body, a stock bin, a material distributing deviceand a driving device, wherein the material distributing device is arranged at an unloading port of the stock bin along the horizontal direction and comprises a material distributing stationary plate and a material distributing movable plate; the material distributing stationary plate is fixedly connected to the inner wall of the furnace body, the material distributing movable plate is arranged above the material distributing stationary plate and is connected to the driving device, and the driving device drives the material distributing movable plate to move to distribute materials. The systemprovided by the invention achieves uniform material distribution of particle materials on a plane, and the material distributing uniformity is guaranteed by means of uniform porous material distribution, so that the stability of production quality is guaranteed; meanwhile, by adjusting the size of a blank hole, the material distributing uniformity at different falling amounts is achieved, and thesealing reliability in the furnace during material distribution is achieved.

Owner:SHENWU TECH GRP CO LTD

Biodegradable Heat-Shrinkable Production Method Thereof

InactiveUS20090162630A1Avoid mixingGuaranteed uniform velocityPigmenting treatmentSynthetic resin layered productsPolyesterMechanical property

The present invention relates to a biodegradable heat-shrinkable film for shrinkable label of vessel having printing property, sealable, transparency and superior mechanical property, capable of decomposing in a nature environments, and the present invention provides a biodegradable heat-shrinkable film comprising a biodegradable polylactic acid series polymer and an aliphatic polyester in the weight ratio range of 70:30-95:5.

Owner:WEDUSCHEM

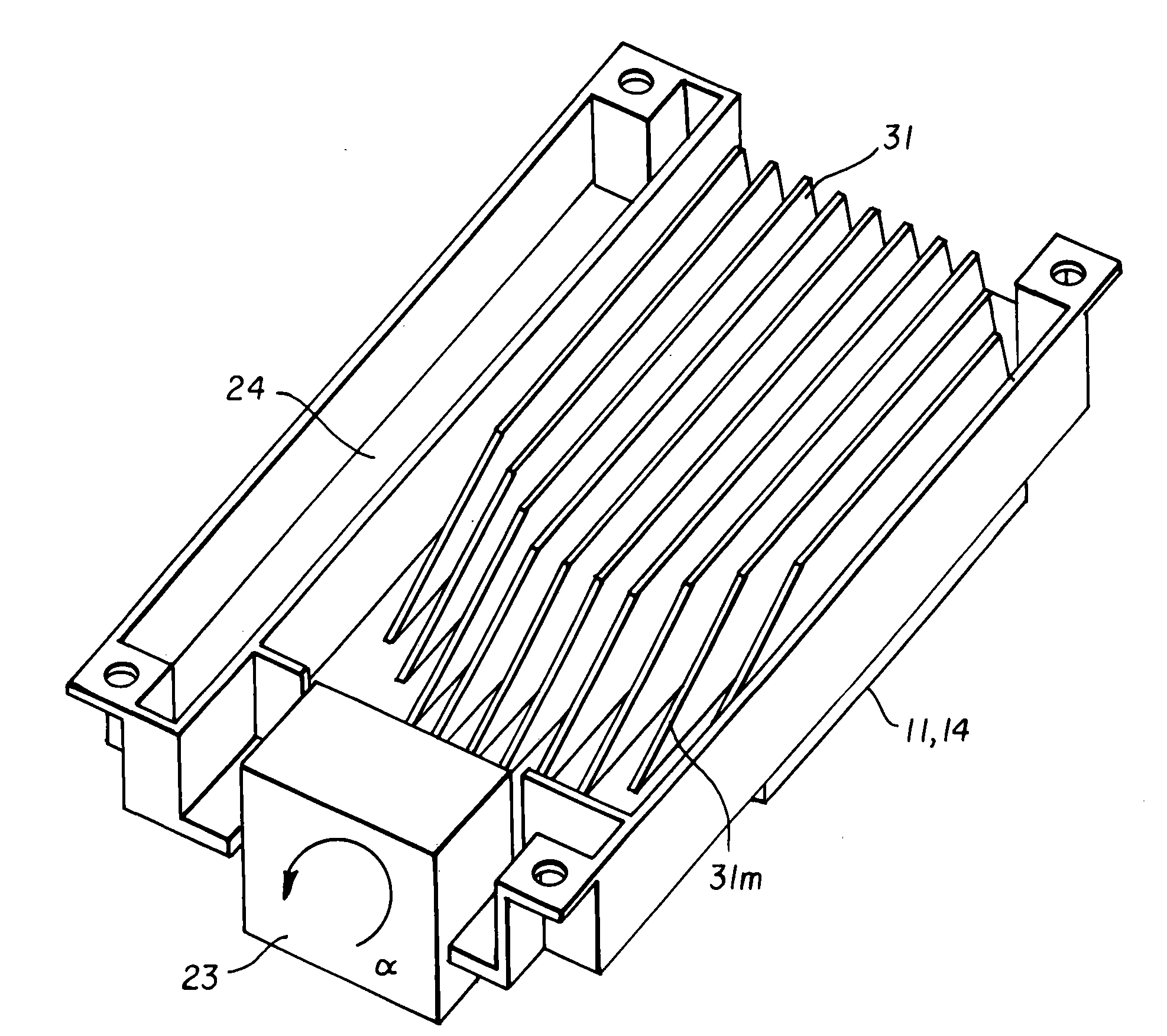

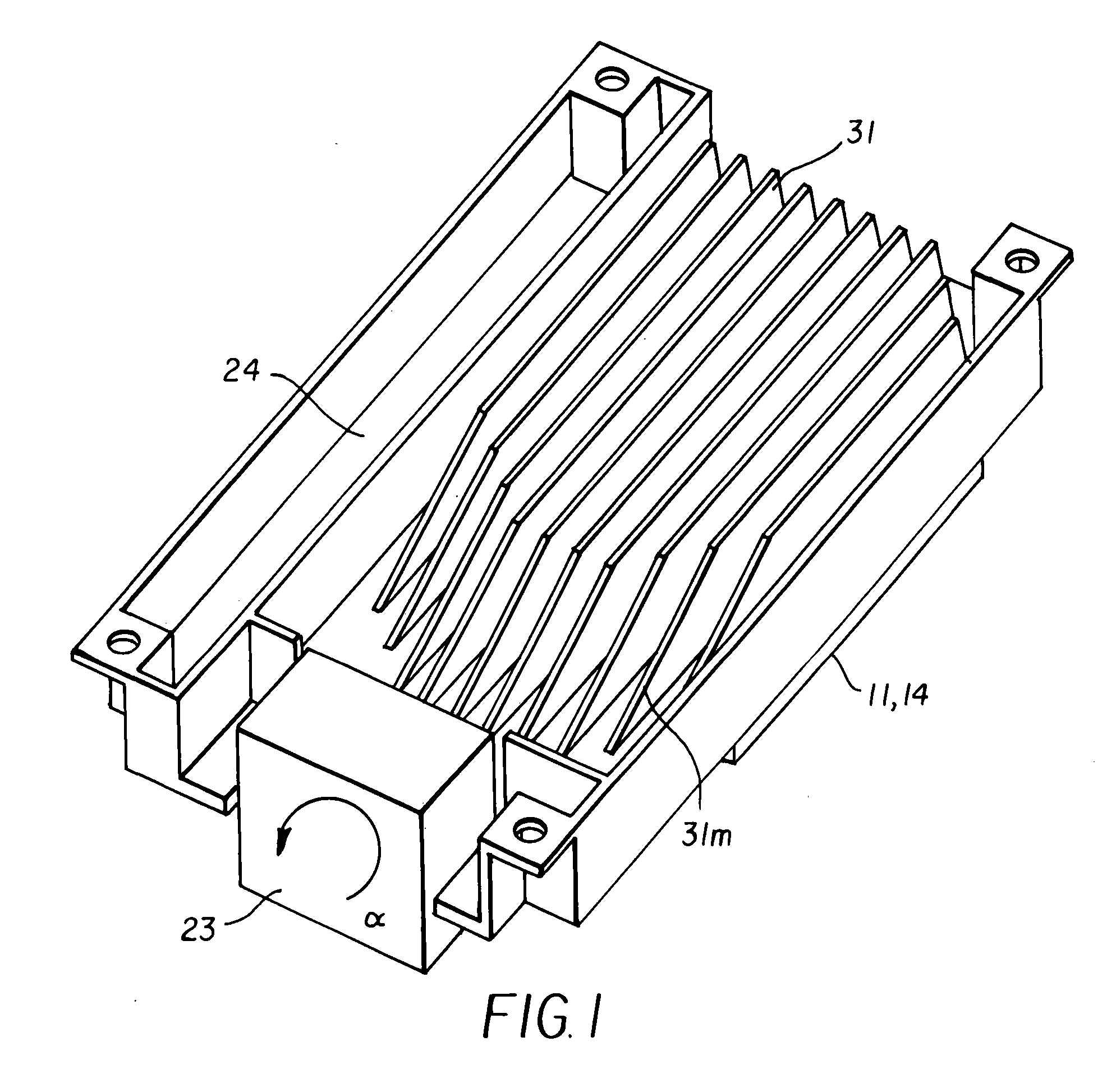

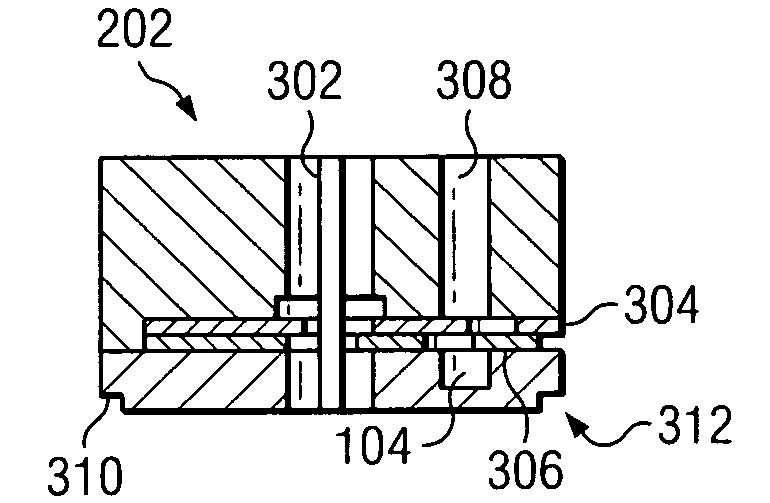

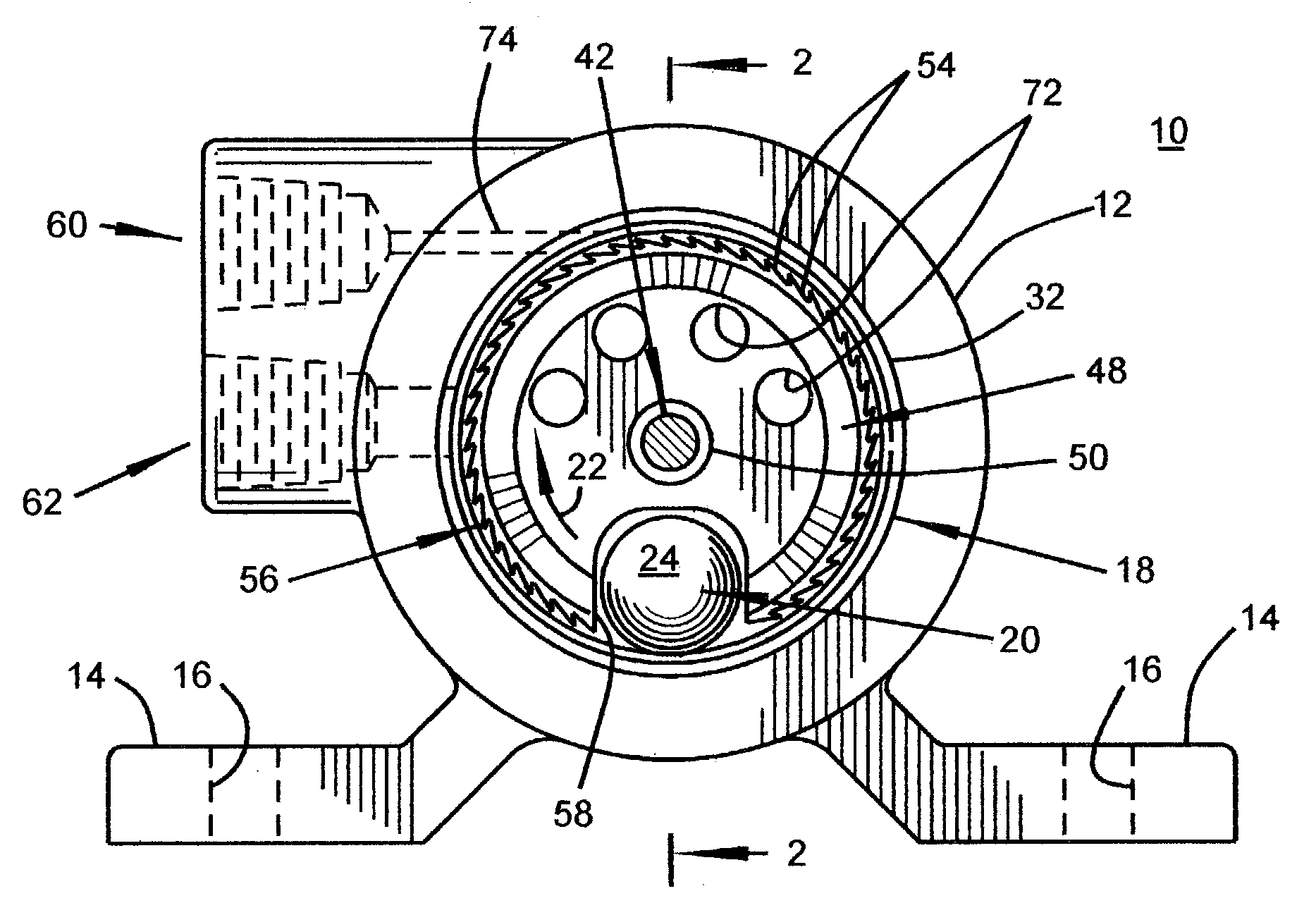

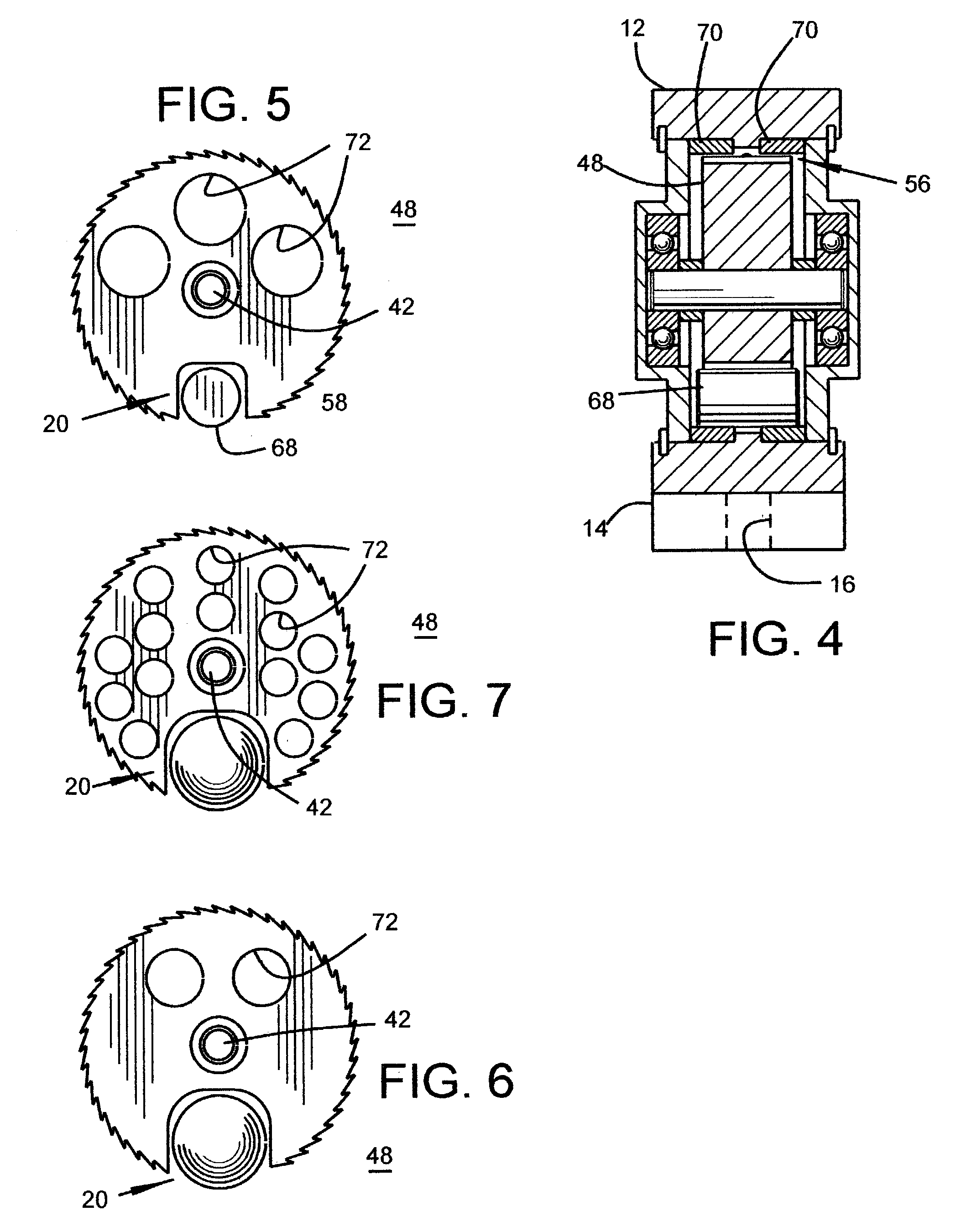

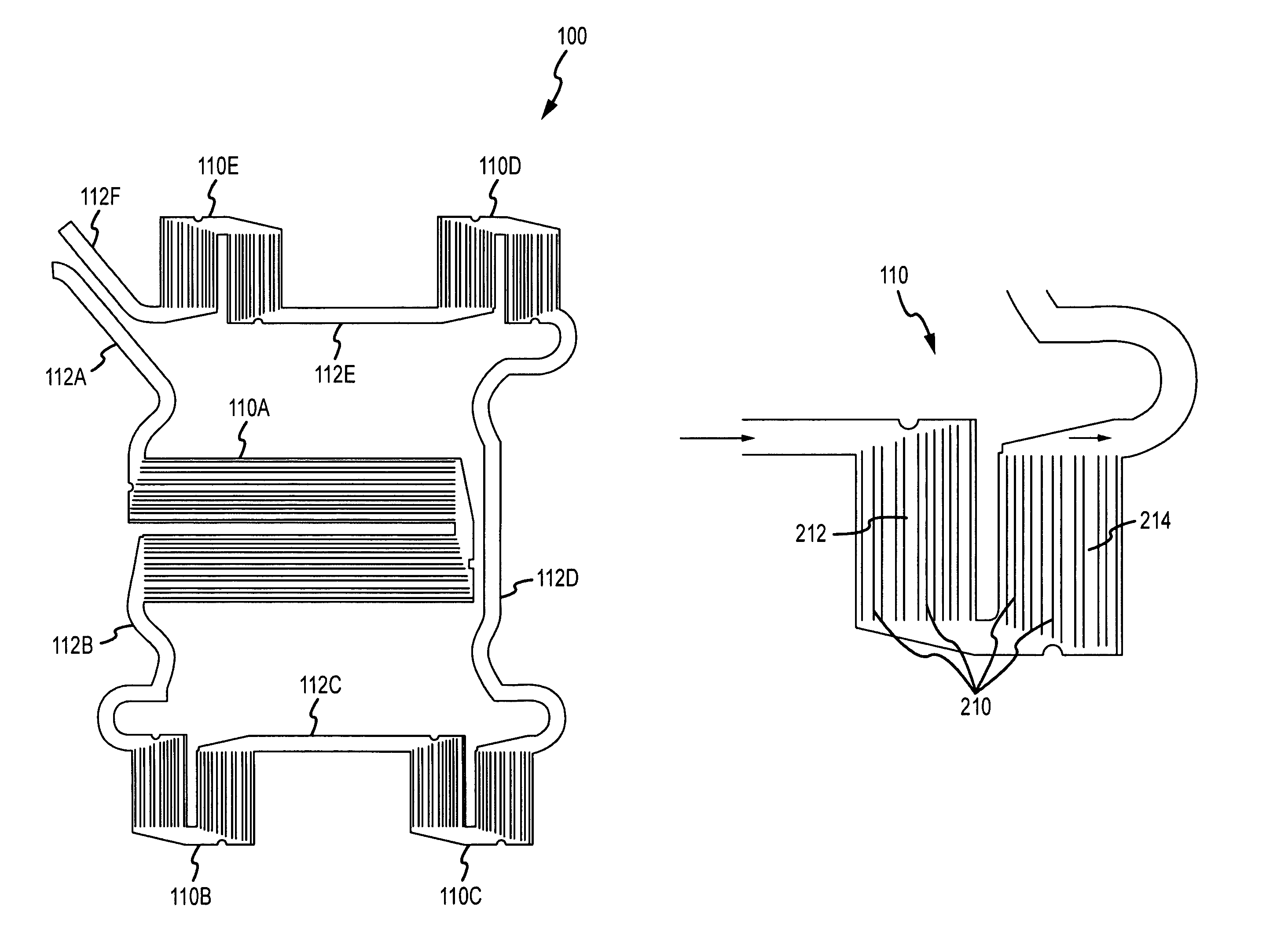

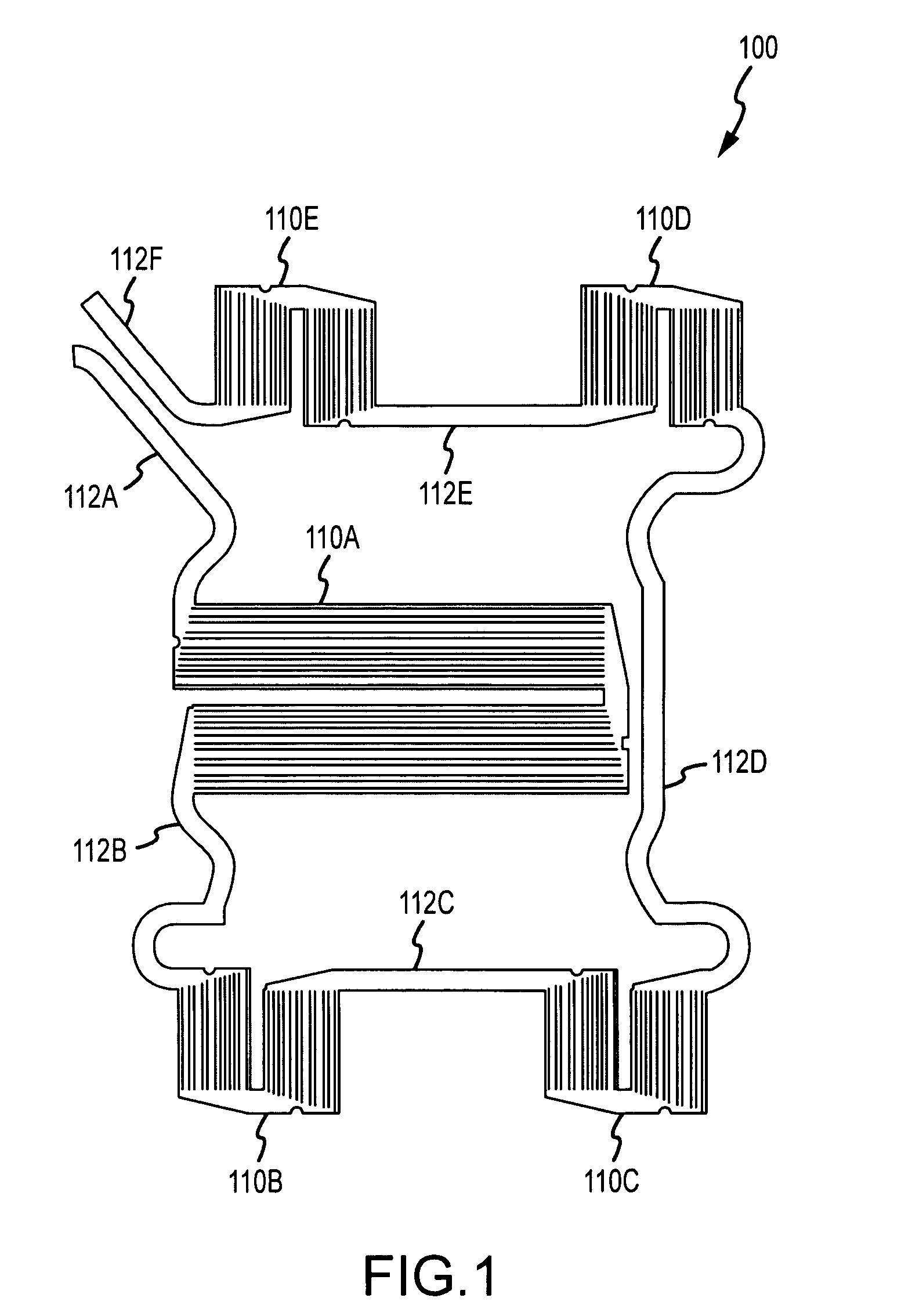

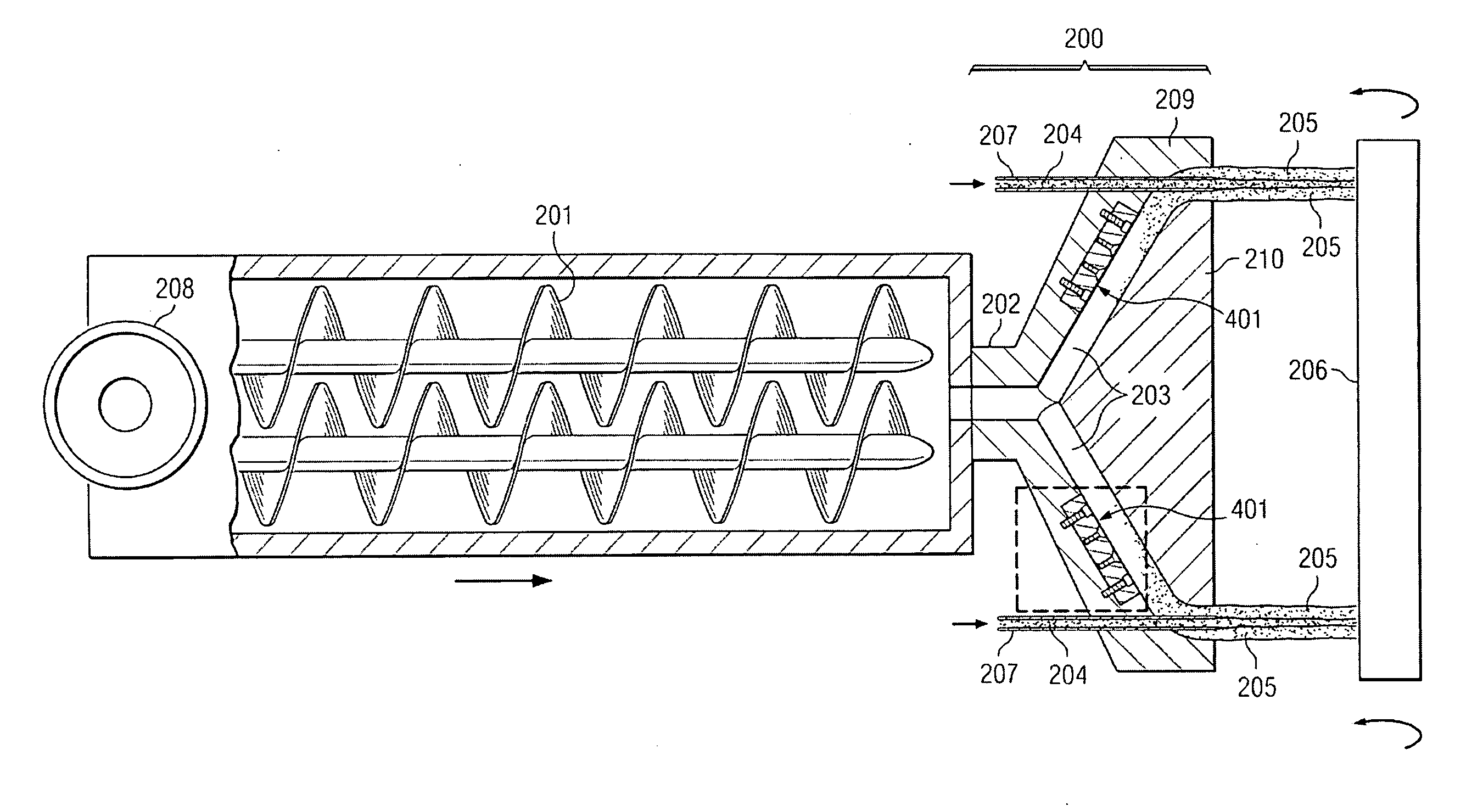

Externally adjustable insert for extrusion manifold

InactiveUS20070087070A1Uniform exit velocityGuaranteed uniform velocityMouldsConfectioneryEngineeringCam

Externally adjustable extrusion insert for a multiple-orifice extrusion manifold. Adjustments to an extrusion insert precisely controls the extrusion path leading to one or more extrusion orifices of the manifold. Each insert is adjusted to reduce or eliminate variations in extrudate exit velocity among orifices in the extrusion manifold. Precisely tuned inserts provide extruded products of uniform length. Choke plates controlling the flow of extrudate to each orifice. Choke plates are manipulated with an externally adjustable cam. Such adjustment compensates for variations in temperature, pressure, surface properties, geometric variations, and other conditions which may affect extrudate flow rates through the orifices and extrusion manifold.

Owner:FRITO LAY NORTH AMERICA INC

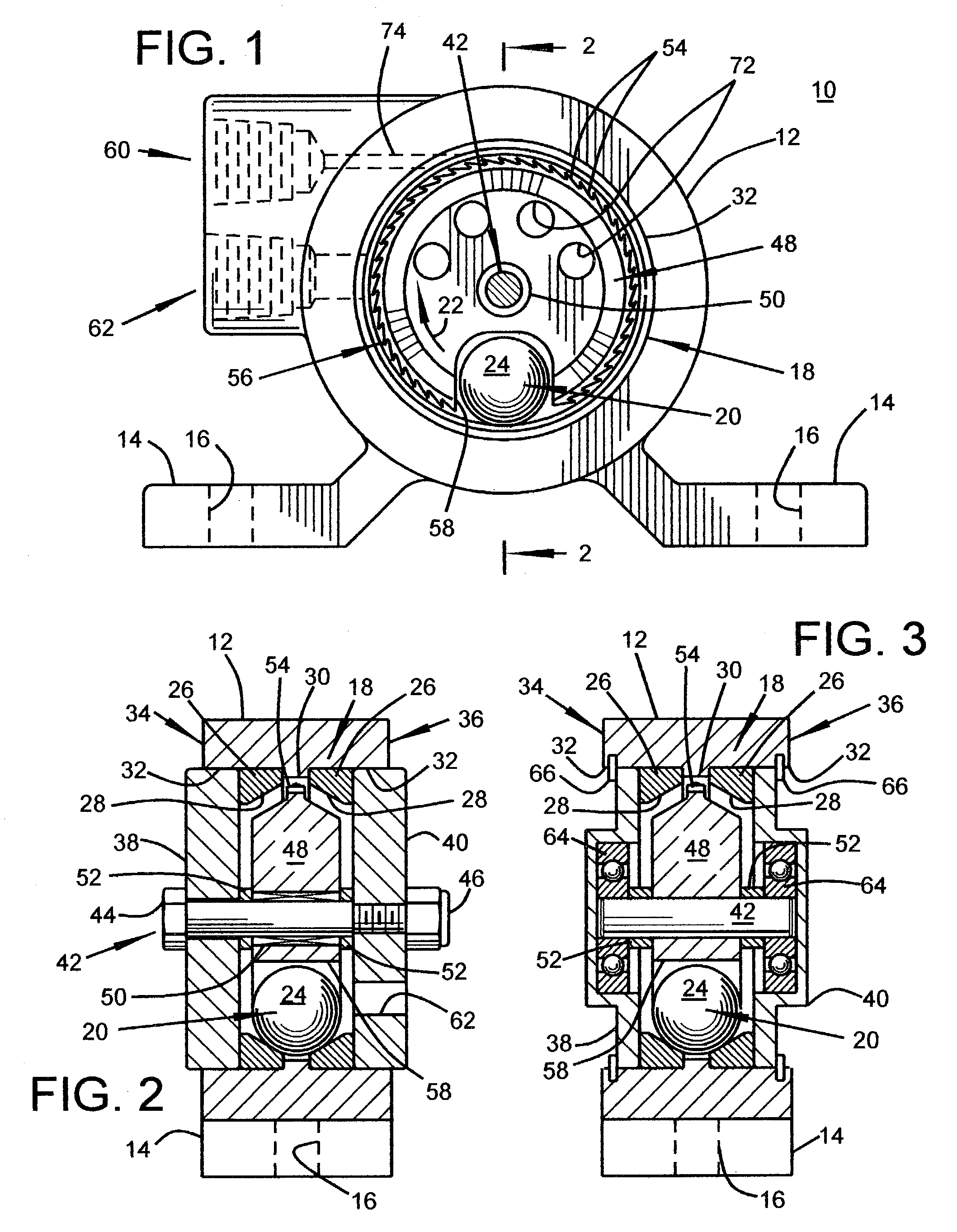

Compressed gas operated orbital rolling member vibrator having low noise properties

ActiveUS6857773B1Minimize consumptionReduce consumptionShaking/oscillating/vibrating mixersMechanical vibrations separationImpellerInternal rotation

A compressed air or gas operated vibrator that has a cylindrical housing with a raceway located and formed therein. The raceway is sized and shaped for guiding a rolling member along an orbital path. The vibrator also includes at least one removable end cap for closing any open ends of the housing. The cylindrical housing has an inlet port for directing a flow or jet of the compressed gas to and towards a selected point of the raceway. The vibrator also has an outlet port for exhausting gas from the housing. The vibrator further includes a turbine wheel that rotates inside of the housing with a predetermined clearance. The turbine wheel has a plurality of blade members formed along its outer diameter and a recess portion that is formed into its outer diameter for allowing the rolling member to reside therein while also allowing the rolling thereof. The turbine wheel with the rolling member residing therein rotates interior of the housing by the action of the compressed gas flowing from the inlet port thereby generating an unbalanced vibratory motion with low noise.

Owner:VIBCO

Multi-orientation single or two phase coldplate with positive flow characteristics

ActiveUS8833438B2Improve cooling effectReducing localized regionStationary conduit assembliesLaminated elementsDouble phaseEngineering

Owner:RAYTHEON CO

Multi-orifice extrusion die and method for obtaining uniform flow

InactiveUS20100123262A1Guaranteed uniform velocityIncrease decrease flowTailstocks/centresConfectioneryEngineeringExtrusion

A method for normalizing the exit velocity of multiple extrudate strands from a multiple die extruder and apparatus for producing the same. The invention describes utilizing a die with individual channels, and installing metering assembly on each individual channel. The metering assembly can then be adjusted to independently increase or decrease the velocity of product through an orifice. By independently adjusting individual velocities of extrudate strands, after successive iterations of adjusting, measuring, and readjusting, a plurality of extrudate stands can be produced having substantially uniform velocity. Further the invention can comprise a single extruder or a co-extruder used to make a co-extruded product wherein uniform velocity becomes more desirable.

Owner:FRITO LAY NORTH AMERICA INC

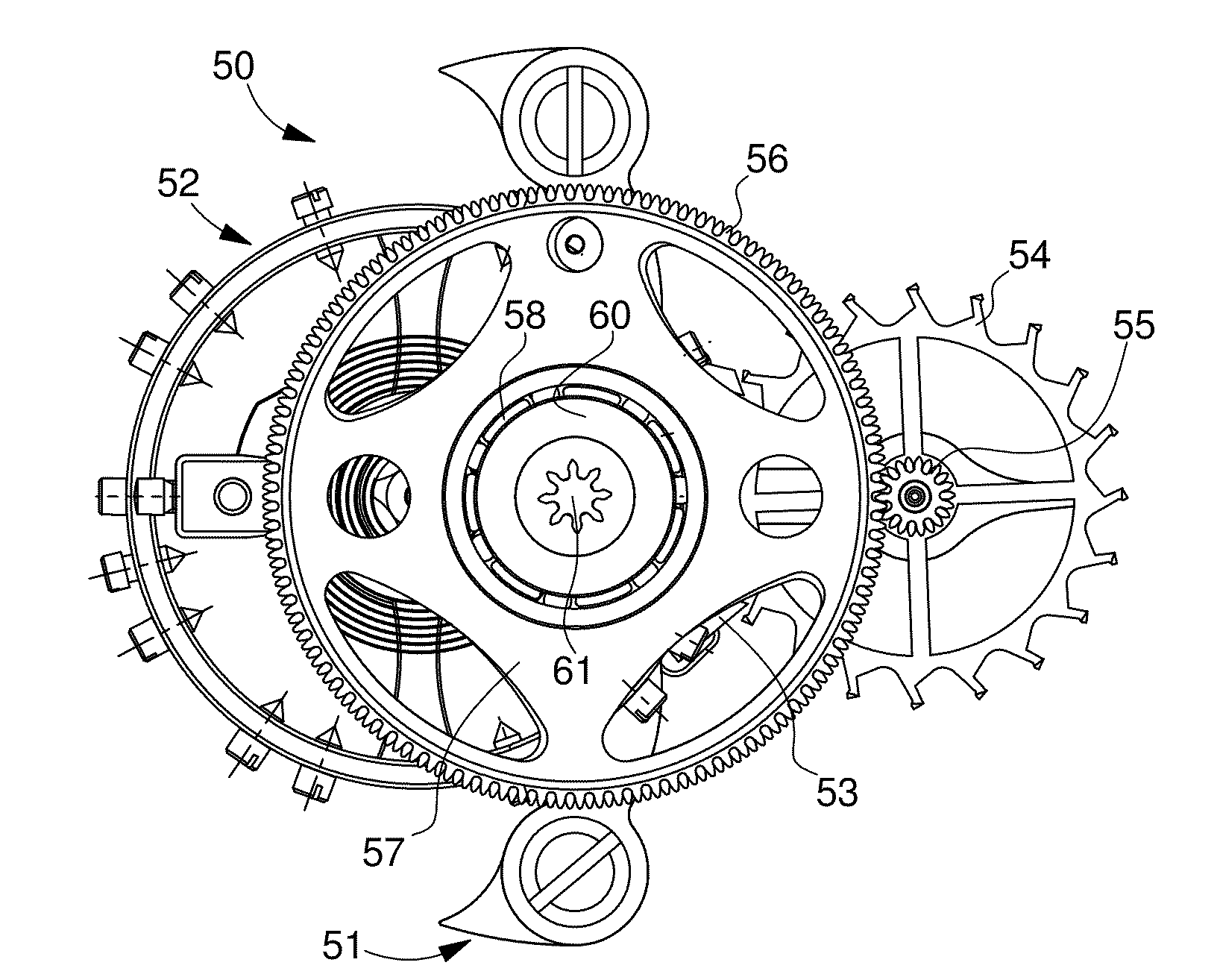

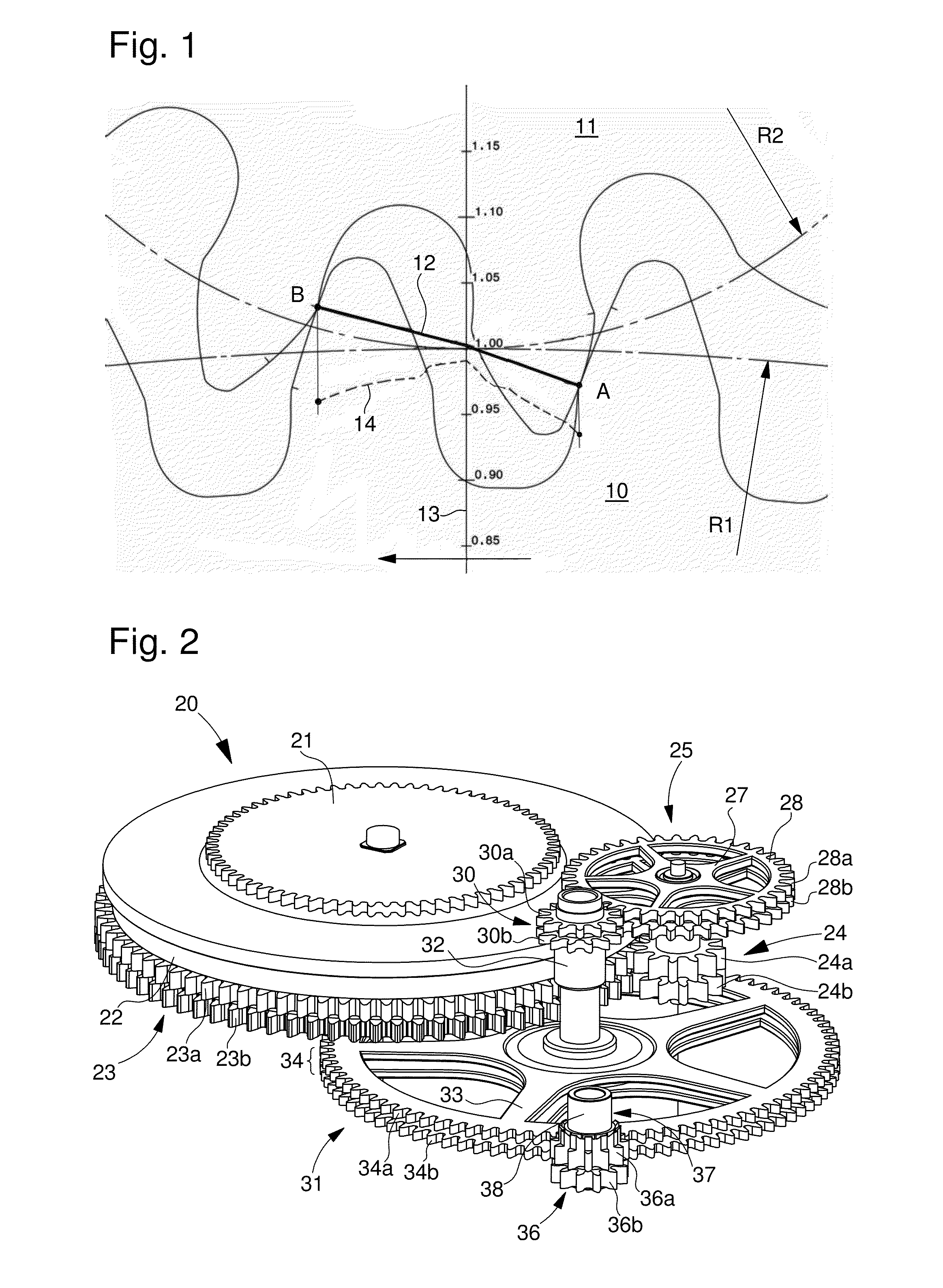

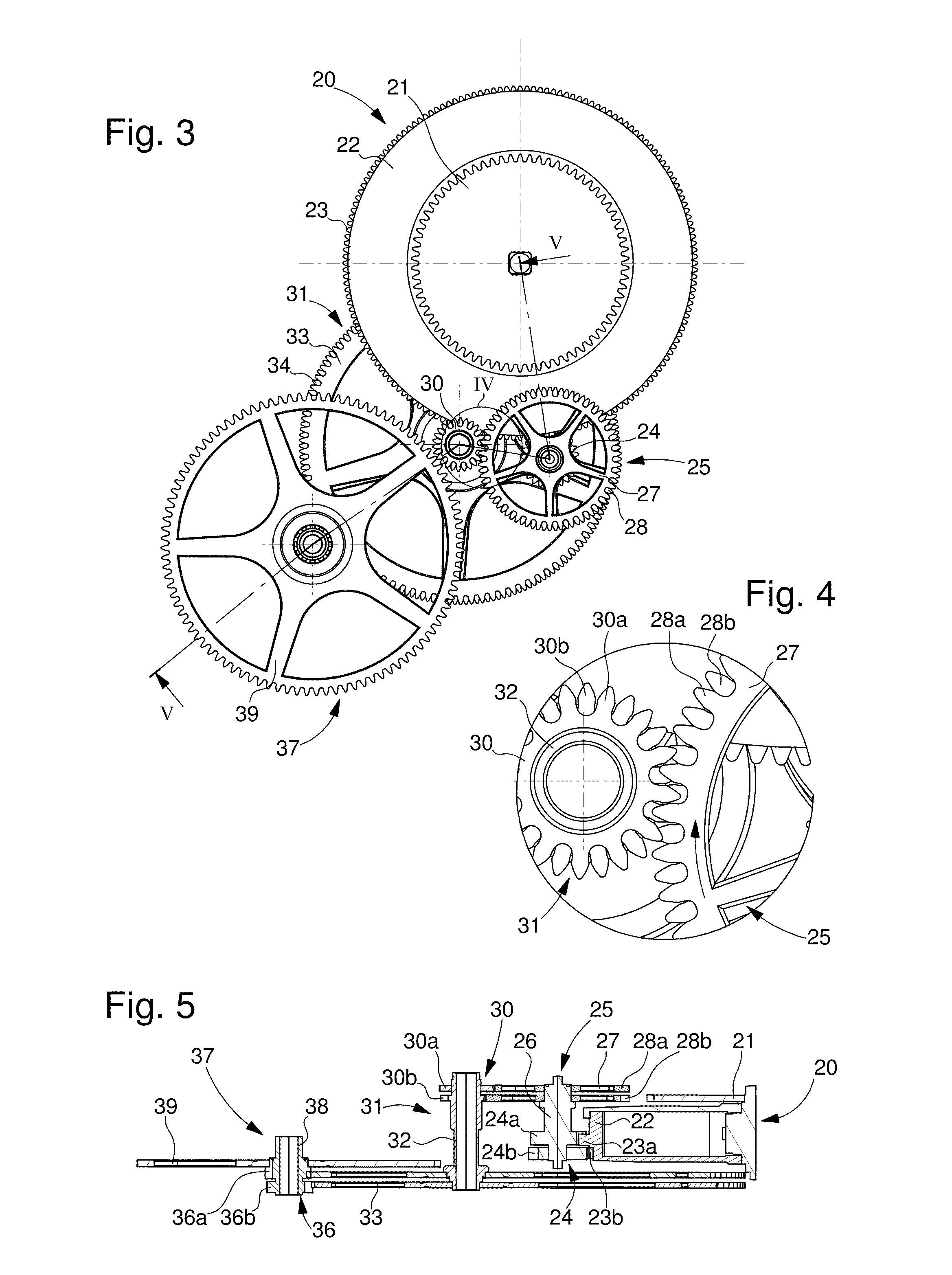

Timepiece gear train

InactiveUS20100091617A1Without weaken manufacture assemblyImprove trainingVisual indicationGearworksEngineeringEscapement

The invention concerns a timepiece gear train including at least one pair of circular toothed elements (25, 31) with parallel axes, the elements being provided with respectively toothings that are meshed with each other so that one (25) of the elements drives the other. In order to improve transmission conditions within the gear without reducing the toothing module, the corresponding toothings of each of the two elements are multiple, each of them being formed of N coaxial, toothed rings (28a, 28b; 30a, 30b) angularly shifted relative to each other by a fraction of a pitch of the toothing. In the simplest version, each of the toothings is double (N=2), the two rings being angularly shifted by a half-pitch. The invention prevents gearing in areas located relatively far from the line connecting the centres of the toothed elements, thus reducing torque and velocity variations during the lead of a tooth. Applications are envisaged in particular in a going train, a display train and a rotating escapement, such as a tourbillon.

Owner:MONTRES BREGUET +1

Compact water vaporizer for dynamic steam generation and uniform temperature control

ActiveUS7258081B2Lower the volumeMinimal complexityBoiler water tubesFuel cell auxillariesTemperature controlCounter flow

A compact cylindrical vaporizer for simultaneous reduction of a reformate stream temperature and generation of a process stream is disclosed. The vaporizer utilizes counter flowing nested tubular portions that spiral between an outer section of the vaporizer and a central section of the vaporizer. The return spiral has a larger cross-sectional area than the inward spiral to accommodate a higher volumetric flow rate of the water flowing there through as it vaporizes while keeping the fluid velocity below erosion design constraints. The counter spiraling flow provides a substantially uniform spatial temperature profile of a reformate stream flowing on the exterior of the tubular portions. The vaporizer can be sized to be substantially the same as that of an upstream reactor to minimize velocity losses and pressure drops in the reformate stream flowing there through. A plurality of fins are positioned between the opposing tubular portion to enhance the heat transfer.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com