Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142 results about "Age forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

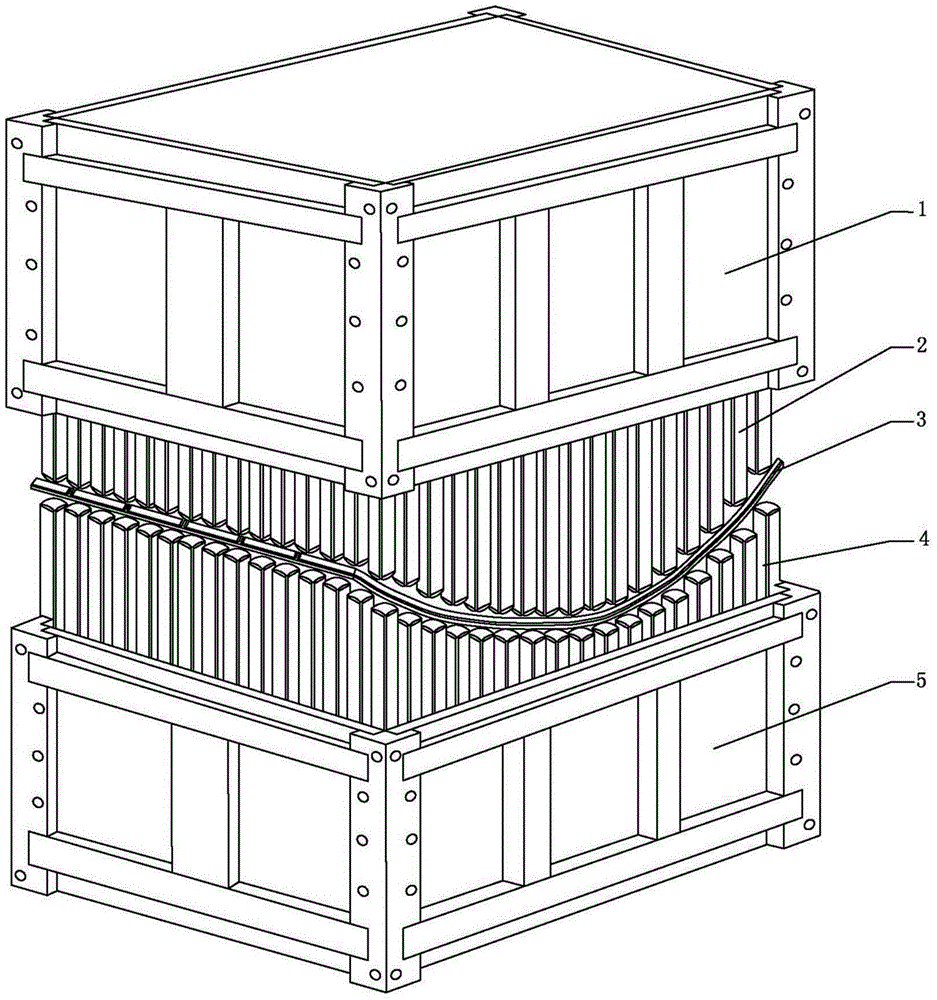

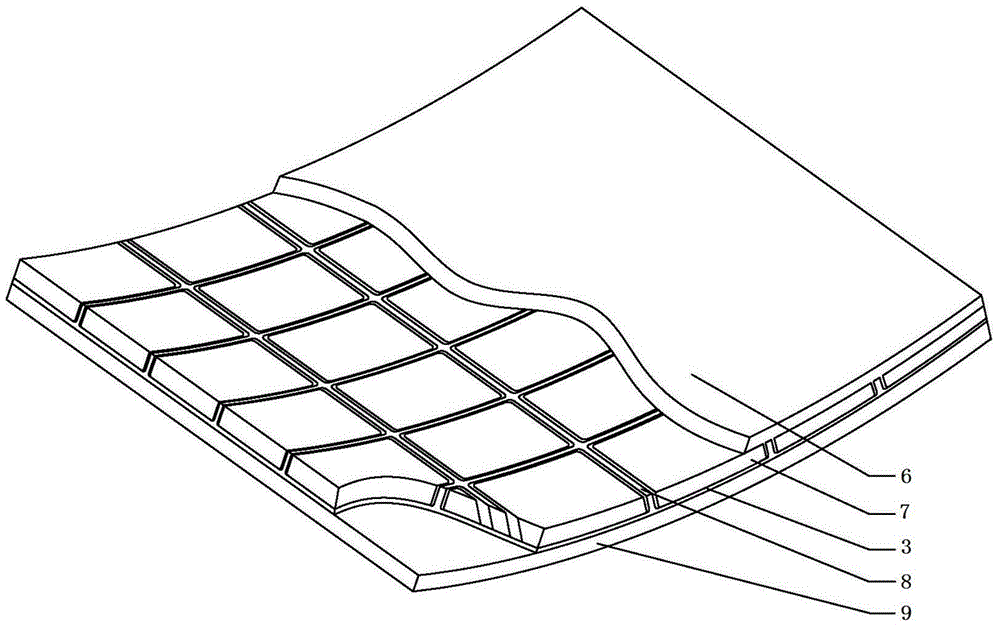

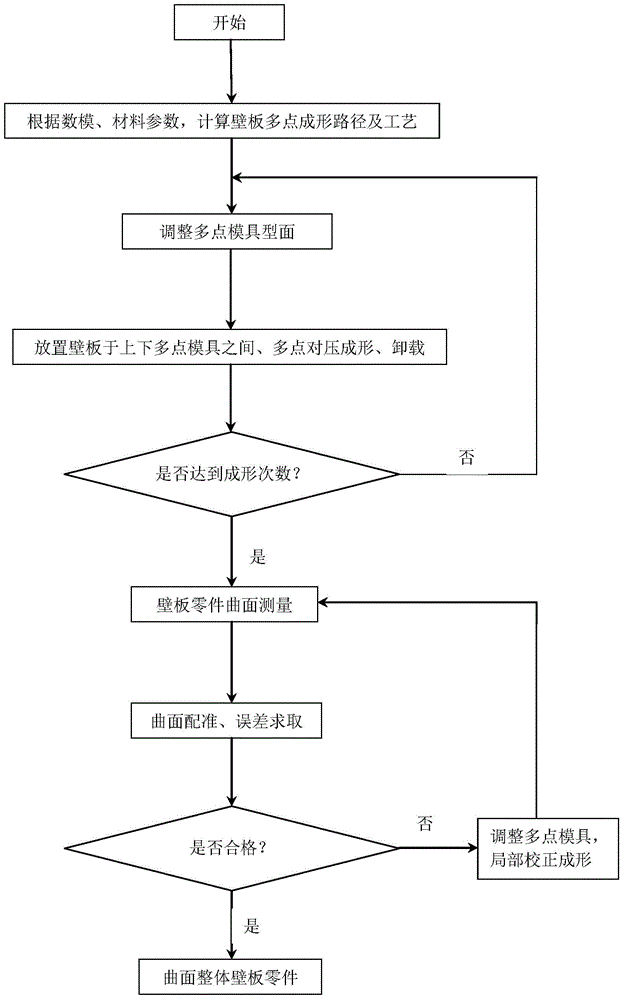

Multi-point forming method for whole aluminum alloy wall plate of aircraft

InactiveCN104646475ASolve efficiency problemsSolve the problem that cracks are prone to occur and cause the overall wall panel to be scrappedShaping toolsMetal working apparatusRocketDouble curvature

The invention discloses a multi-point forming method for a whole aluminum alloy wall plate of an aircraft. The multi-point forming method comprises the following steps of arranging the whole aluminum alloy wall plate with ribs between an upper multi-point die and a lower multi-point die of a quick reconstructing die surface, filling a filling material between the ribs, arranging an elastic cushion between the wall plate and the multi-point die, and gradually forming a whole aluminum alloy wall plate part with ribs by a die pressing method along a controllable deformation path. The multi-point forming method has the advantages that by utilizing the quick and adjustable characteristic of the reconstructing multi-point die surface, the wall plate parts with different geometric shapes and double curvatures can be processed by one set of equipment; compared with the traditional rolling and bending forming method and the pressing and bending forming method, the stress of the wall plate is uniform, and the forming quality can be guaranteed; compared with the shot peen forming method and the aging forming method, the deformation amount is large, and the forming efficiency is high; the method can be used for forming the whole aircraft wall plate with different rib structures and the double curvatures, the problems of large size and high rib in the whole wall plate forming process are solved, and the method can be applied to the manufacturing of other large ribbed curvature parts of aircrafts, rockets and the like.

Owner:JILIN UNIV

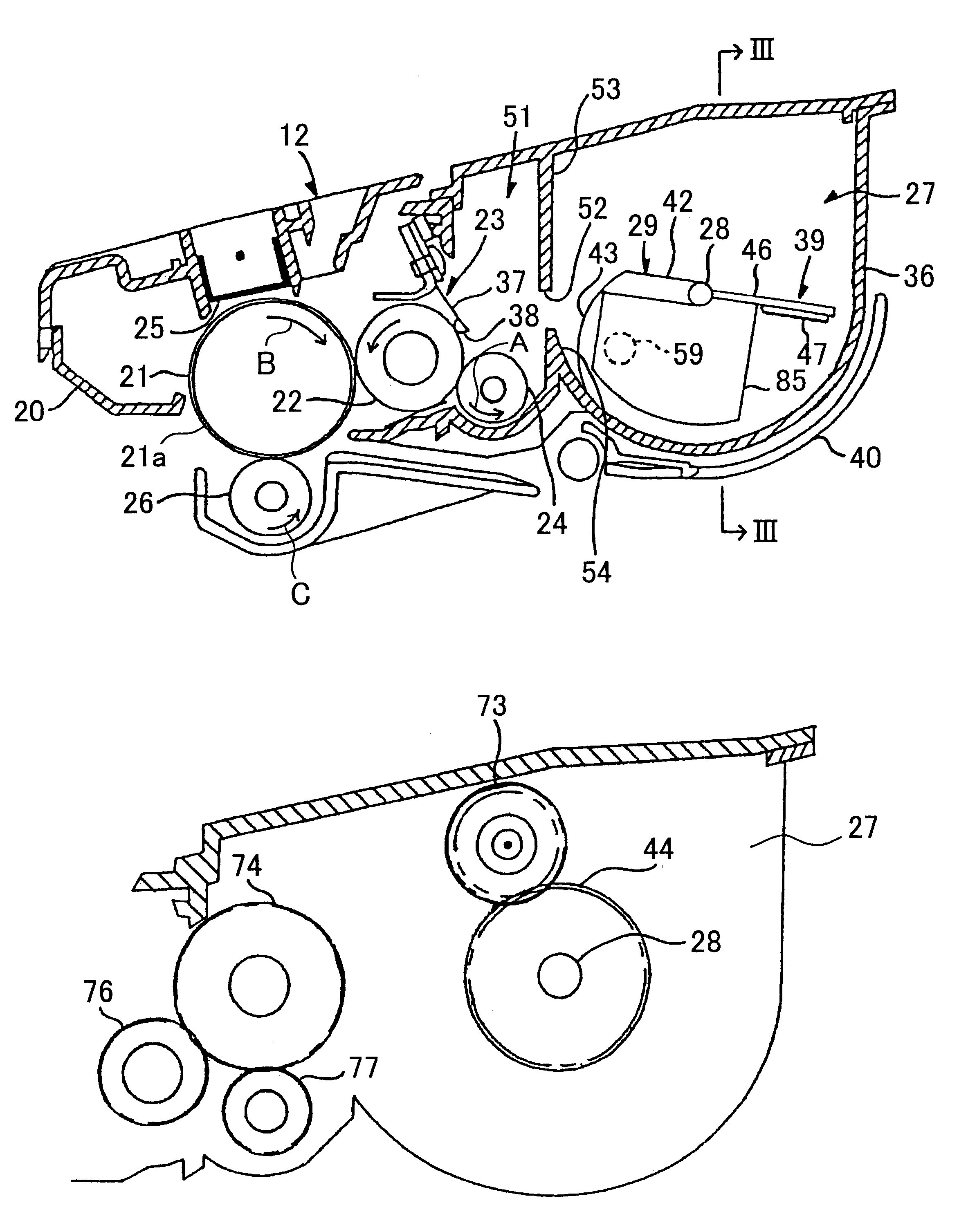

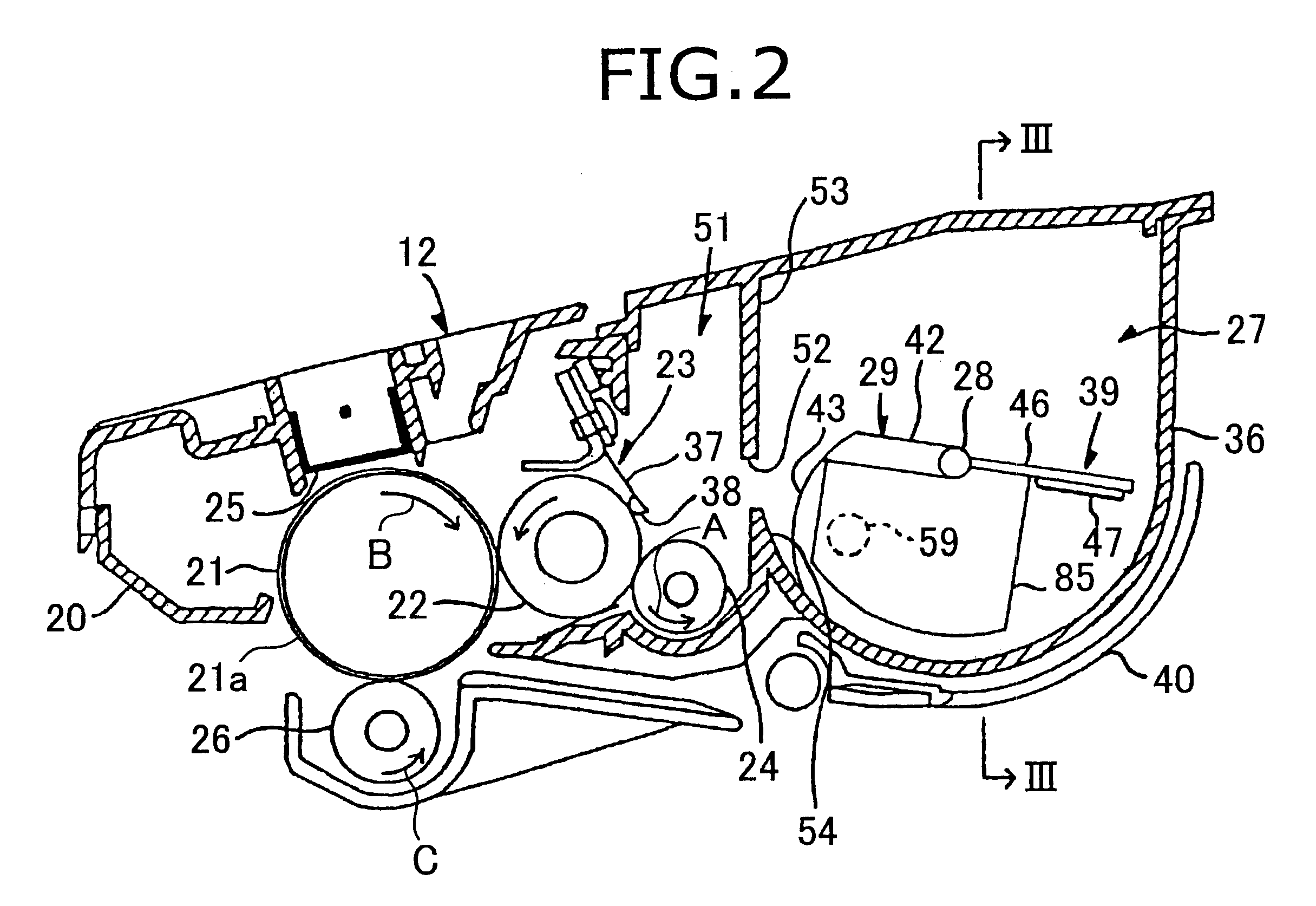

Developing cartridge with agitator driven to rotate independent from developing roller

To provide age forming device and a developing cartridge used in the image forming device capable of performing high-speed image forming operation for forming high-quality images and of reliably detecting an accurate amount of remaining toner. An agitator and a developing roller provided to a developing cartridge are driven to rotate independent from each other. During the detection of the remaining toner amount, the agitator is rotated at a lower speed so as not to stir up the toner. On the other hand, the agitator is rotated at a higher speed during the image forming operations, so that the toner efficiently circulates within the developing cartridge, thereby forming preferable images.

Owner:BROTHER KOGYO KK

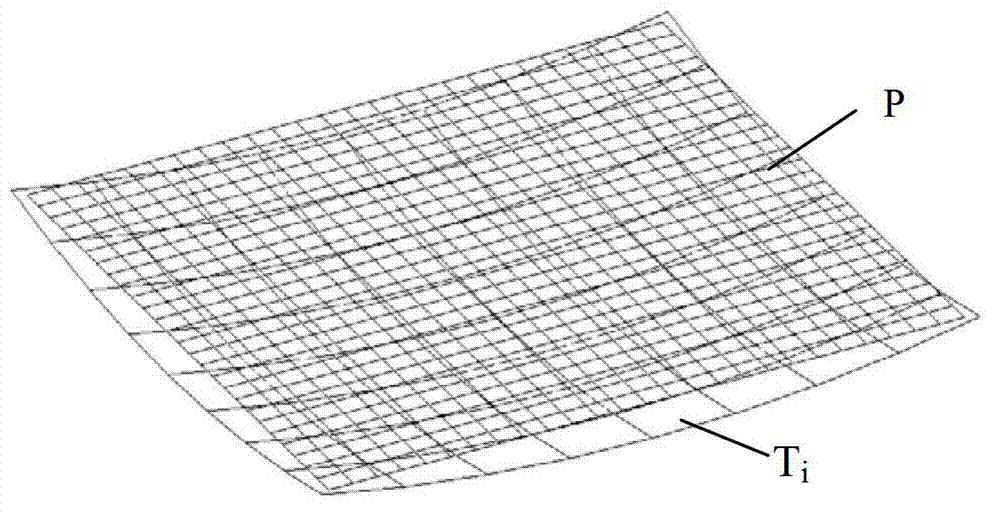

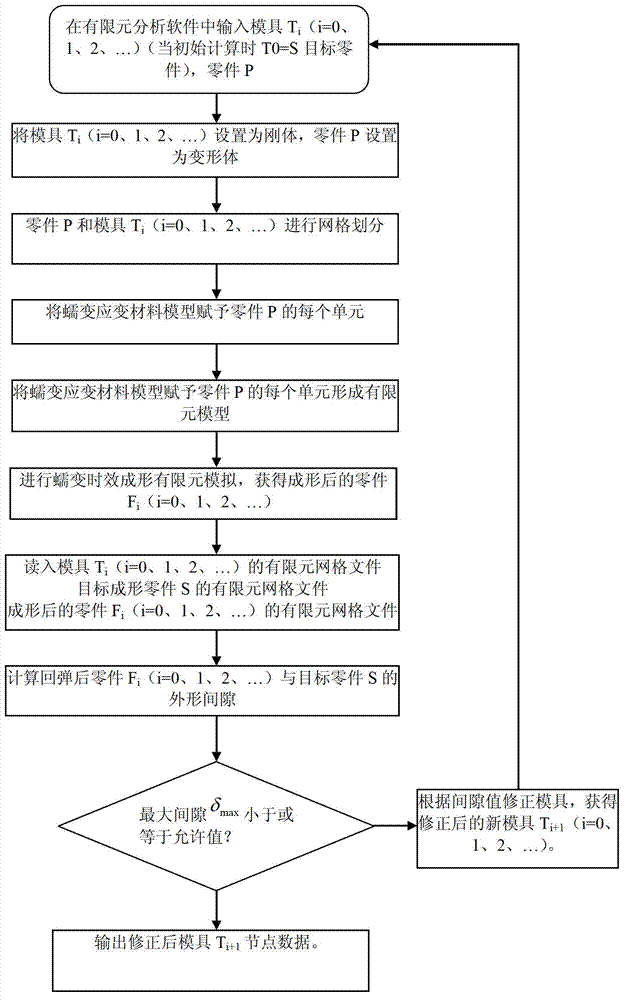

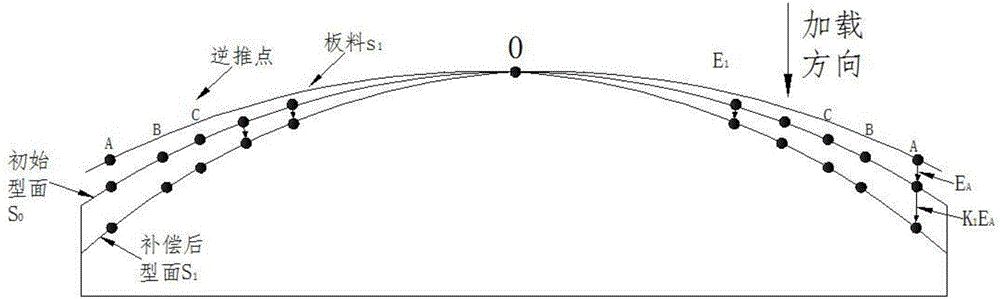

Wall board creep age forming method based on finite element mould profile rebound compensation

ActiveCN102930115AReduce auto-optimizationExtended service lifeSpecial data processing applicationsRepair timeWelding residual stress

The invention belongs to the technical field of metal plate forming, and relates to a wall board creep age forming method based on finite element mould profile rebound compensation. By the wall board creep age forming method, a finite element method is used for determining a mould profile, technological tests and mould repairing times are largely reduced, appearance control of formed parts can be realized, and forming precision is improved; according to the data through analog computation of forming process and rebound process of a formed piece, the mould profile is compensated, revised and optimized, so that rebound parts are the same as or close to the appearance of an ideal formed piece, and automatic optimization to the mould appearance during a creep age forming process is realized. The forming method can be applicable to various wallboard structures; except for overall wallboard parts, the forming method can be used for welding overall wallboards; welding residual stress can be effectively reduced, stress corrosion resistance capability is enhanced, and service lives of parts are prolonged.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

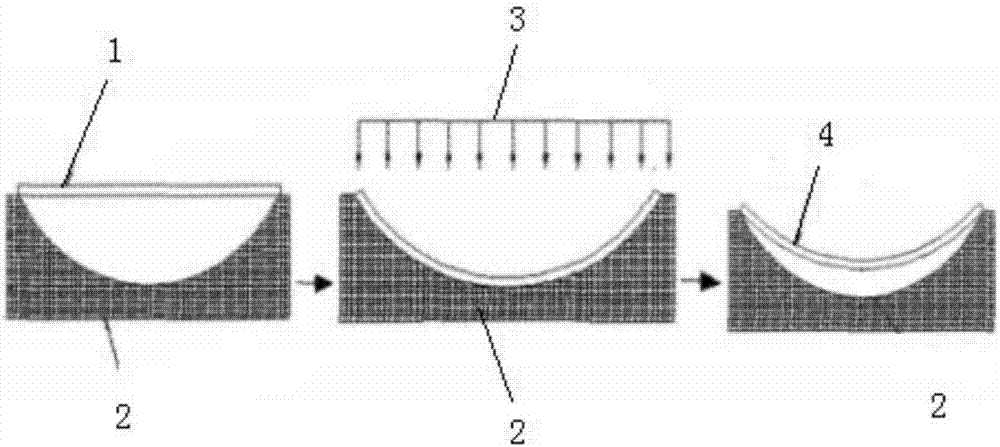

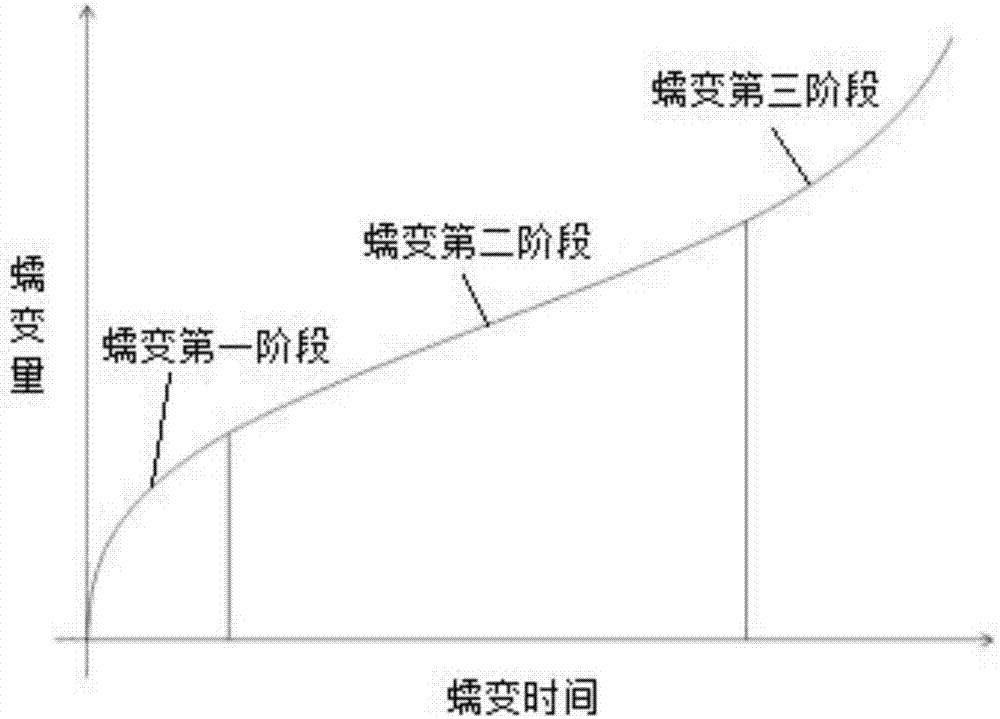

Creep age forming technological method

The invention provides a creep age forming technological method. The technological method comprises the following steps: obtaining molded surface characteristic data of a target part; prebending an initial sheet material according to the molded surface characteristic data, so as to obtain a prebent test piece; placing the prebent test piece to enable the molded surface of the prebent test piece to correspond to that of an age forming die, then jointly packaging the prebent test piece and the age forming die, and performing vacuum treatment on a gap between the prebent test piece and the age forming die; putting the prebent test piece and the age forming die into an autoclave, and changing environment parameters in the autoclave, so as to ensure that the prebent test piece is closely adhered to the molded surface of the age forming die; separating the prebent test piece from the age forming die; enabling the prebent test piece to rebound, so as to form the target part. Accordingly, parts with complex molded surfaces and good material comprehensive properties are formed, the application field of the creep age forming technology is broadened, the flexibility of the forming technology of wallboard components with complex molded surfaces is improved, and the part forming precision is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Age-tolerant face recognition method

InactiveCN108846350AExpand the training datasetReduce difficultyCharacter and pattern recognitionNeural learning methodsGenerative adversarial networkPhases of clinical research

The invention discloses an age-tolerant face recognition method. The depth network VGG-Face is trained to perform age-tolerant face recognition, and it is necessary to collect face data of different age stages for training, but collecting faces from the same person at different times is a difficult task, thus the invention completes the generation of human faces at different ages by means of the generation antagonism network, and a cross-age database composed of face pictures of a plurality of persons at different ages is constructed. Then, the faces at part of the different ages in the database form a training set, and the faces on the rest different ages form a testing set, and the network is trained by the two sets, the classification of different faces is achieved through softmax, so as to complete the age-tolerant face recognition. A main use of the invention is to realize cross-age face recognition under the condition of incomplete pictures of people at different times.

Owner:JIANGSU UNIV

Creep age forming method for aluminium alloy plate

The invention provides a creep age forming method for an aluminium alloy plate. The method comprises the steps as follows: a to-be-formed component is arranged on the molded surface of a mold firstly, and parts (the whole lower surface and the peripheral edge of the upper surface) of the component are covered with air-permeable felt; a plate is bent downwards by a mechanical loading device, and the mechanical loading device stops moving downwards after reaching the set force value; the load is unchanged, at least one circle of a sealant is sequentially bonded to the component and the edge of the mold, a vacuum bag is laid and bonded between the sealants, a closed space is formed, vacuum pumping treatment is performed, and the component is almost attached to the molded surface of the mold as far as possible or is kept to be attached to the molded surface of the mold; and then the mechanical loading device is detached, the component and the mold are placed into an autoclave for vacuum creep age forming, and the component and the mold are separated after ageing is completed. With the method, the time required for vacuum pumping is shortened, so that the forming efficiency is improved; less test materials are used, and thus the test cost is reduced; and the mold attaching error is reduced, and accordingly, the forming precision of the component is improved.

Owner:CENT SOUTH UNIV

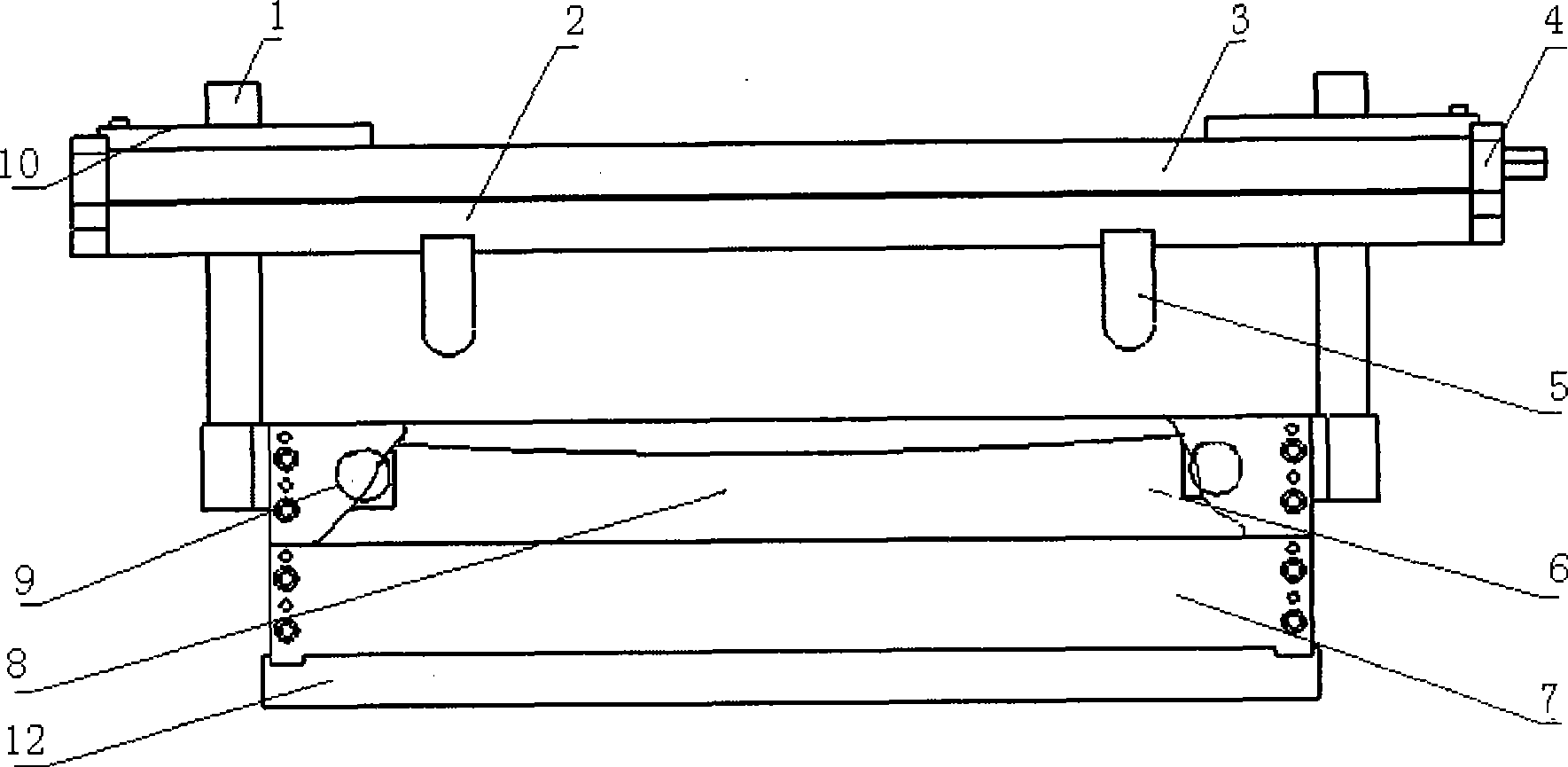

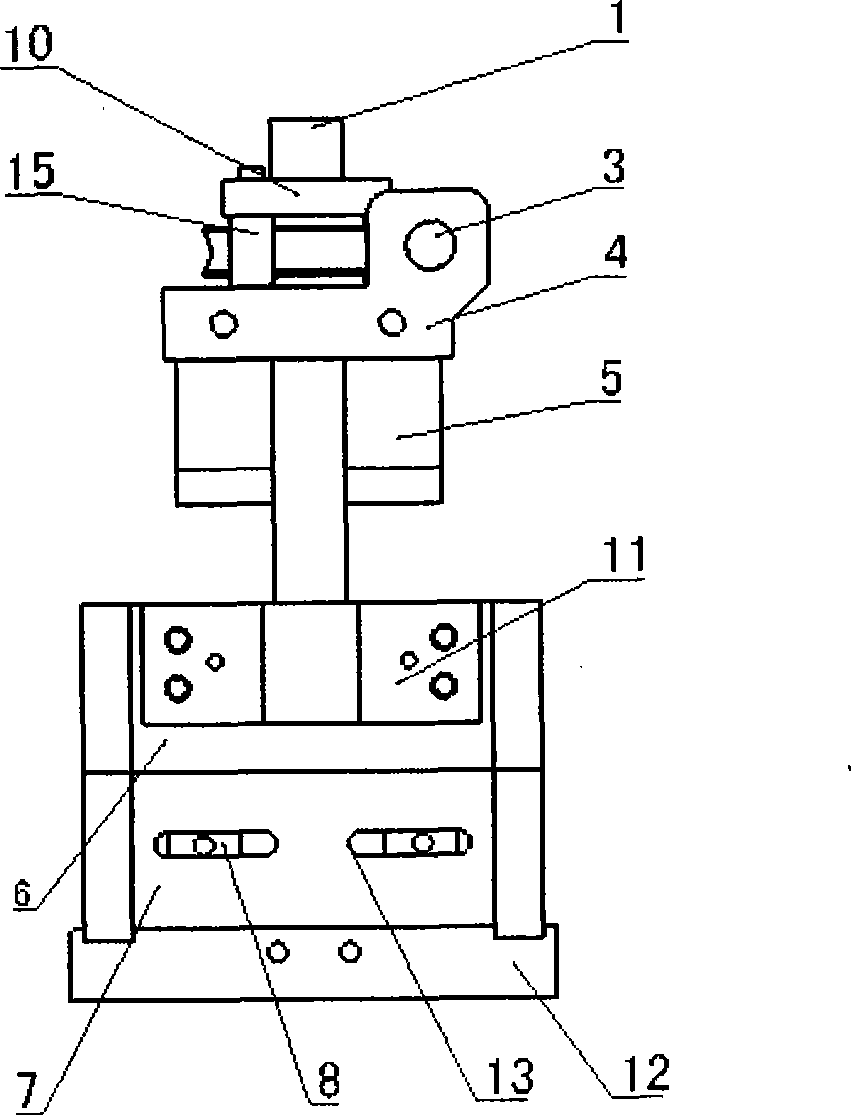

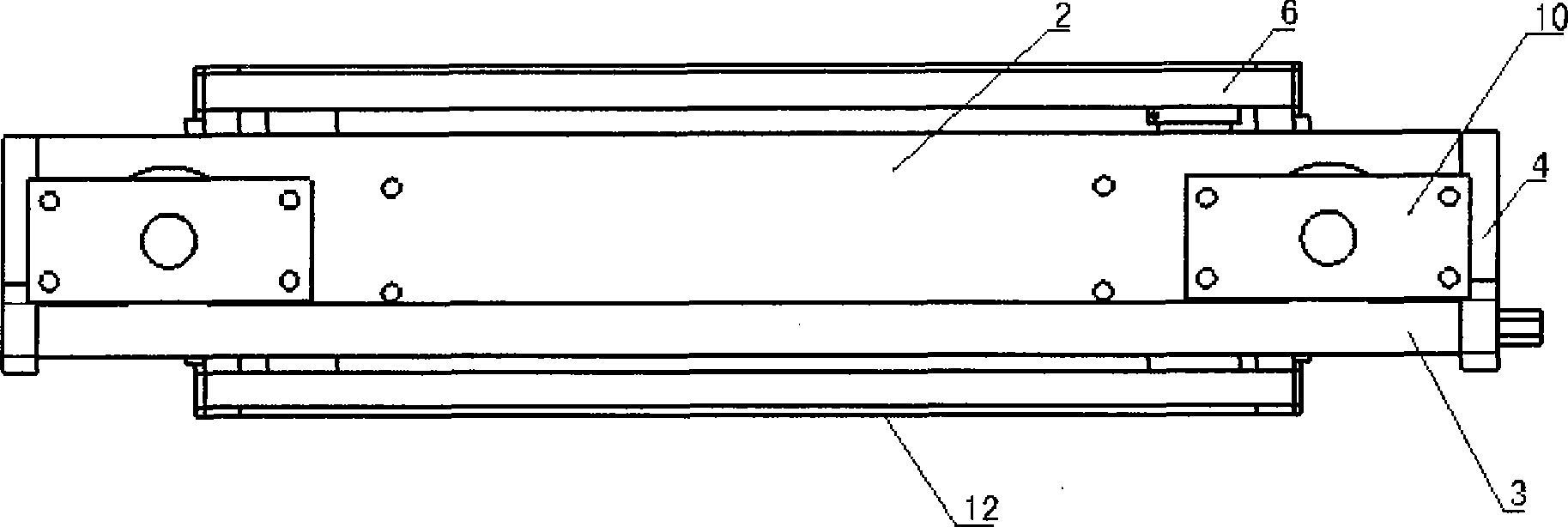

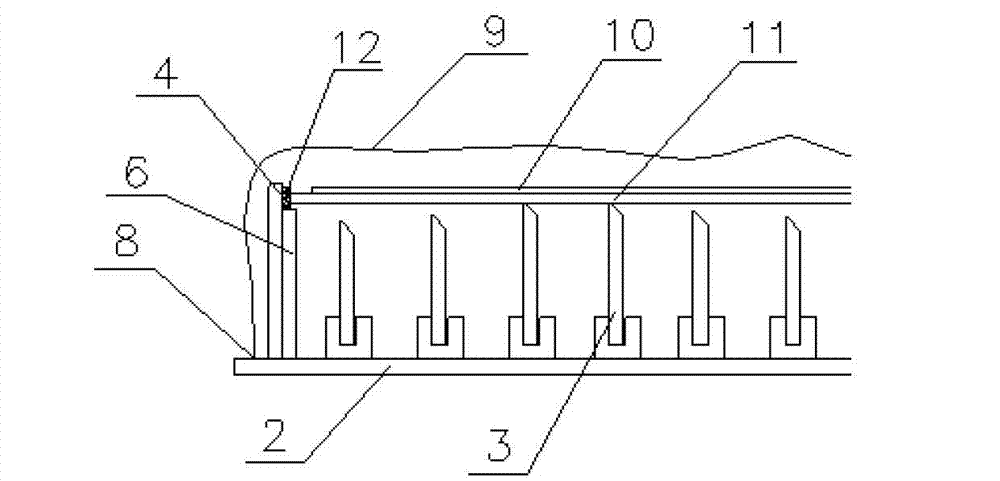

Pure bending age forming die

The invention discloses a pure bending age forming die, being a combination structure which combines four-point bending and a frame plate structure together and comprising a base plate (12), frame plates (6, 7), a pressing plate (2), a pressing block (5) and form plates (8); a lead screw seat (11) is fixed on an upper frame plate (6) at the two sides of a cavity; a worm (3) is installed on a supporting base (4); the two ends of the pressing plate (2) are provided with lead screw holes (17); a pair of pressing block slots (14) distributed symmetrically are arranged at the inner side of the lead screw holes and on the central line of the pressing plate; the pressing block (5) is fixed in the pressing block slots; a baffle supporting rod (15) is connected with the pressing plate (2); a turbine baffle (10) is fixedly connected with the baffle supporting rod (15); and two forming plates (8) are arranged in the cavity of the die, and the curvature of the upper surface thereof is determined according to the curvature requirement of a test piece. The invention uses a design way in which the distance between the forming plates is adjustable, is applicable to the pure bending load of the test piece, and has the advantages of simple structure and easy operation; in addition, the test piece still takes a round shape after rebounding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

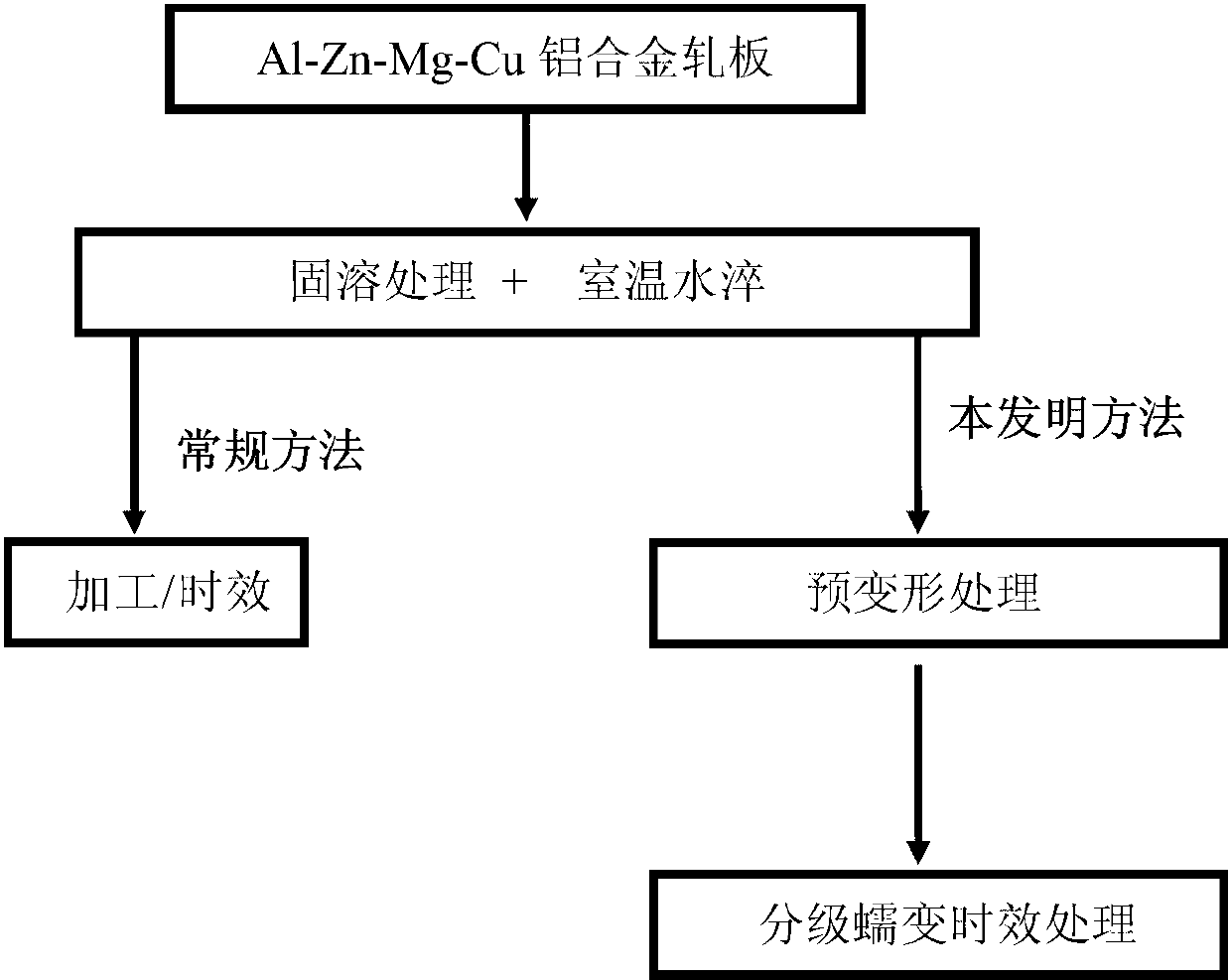

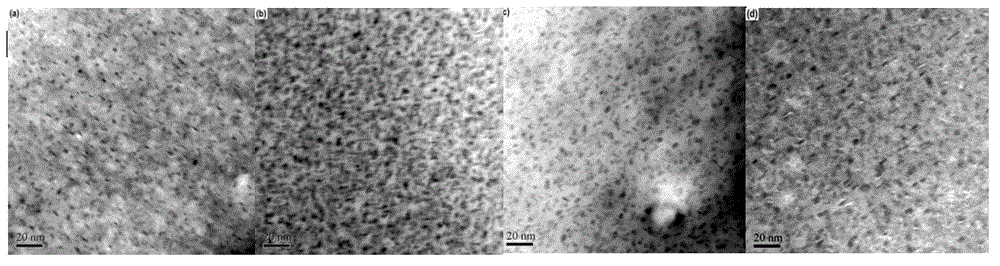

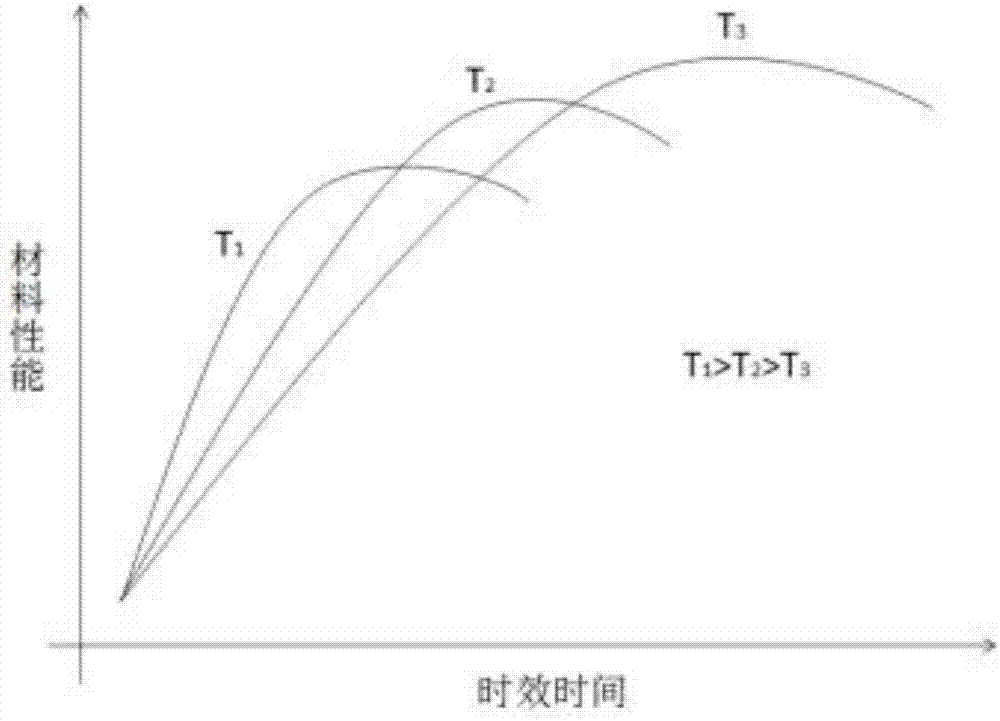

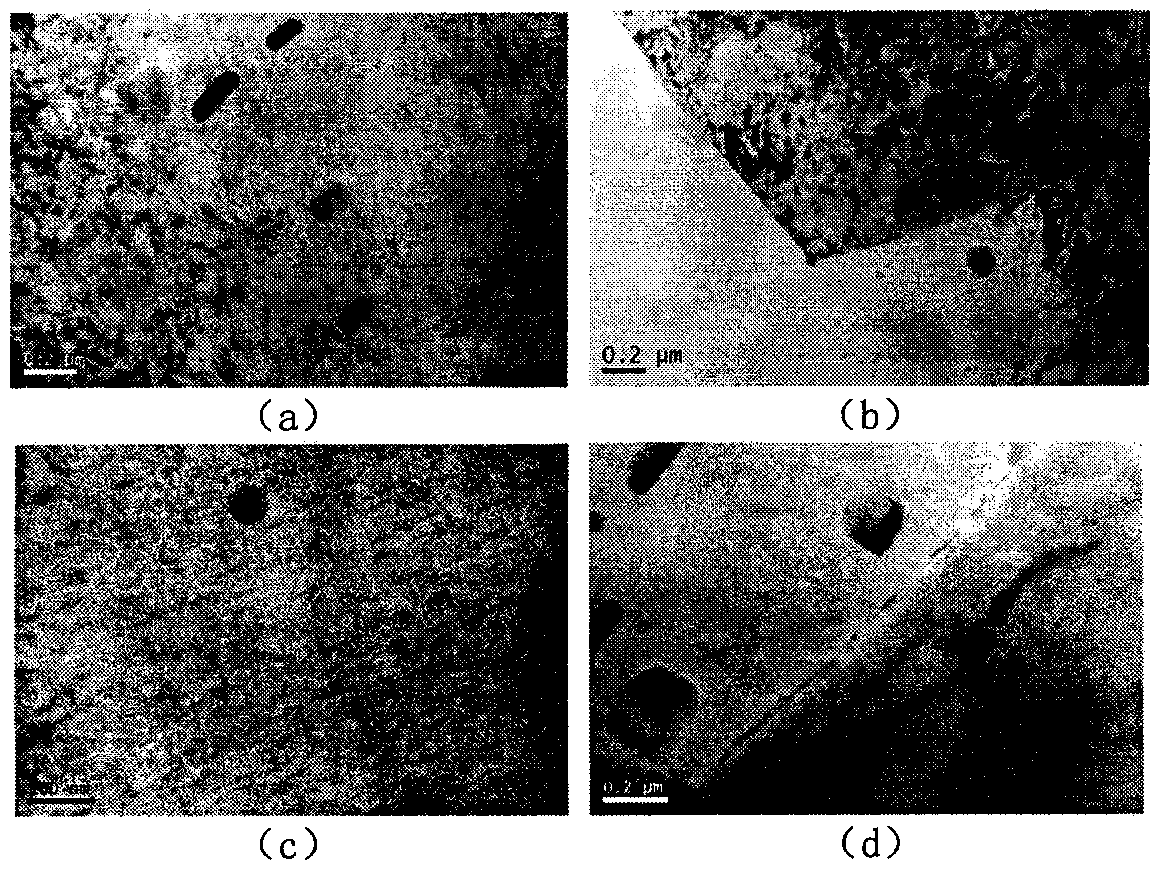

Method for multilevel creep age forming of Al-Zn-Mg-Cu series aluminium alloy plate

ActiveCN102978544AImprove mechanical propertiesImprove corrosion resistanceCreep stressThermal insulation

The invention relates to a method for multilevel creep age forming of an Al-Zn-Mg-Cu series aluminium alloy plate. The method is characterized in that a reasonable solid solution-quenching-pretreating-multilevel creep aging system is adopted, is suitable for plates with the thickness of 2 millimeters-30millimeters and comprises the following steps that solid solution is carried out at 470-485 DEG C for 30 minutes-120 minutes, quenching is then carried out, the quenched plate is subjected to 0-10% predeformation treatment and creep aging at 120 DEG C and is thermally insulated for 24 hours, the creep return temperature is between 150 and 170 DEG C, return thermal insulation is carried out for 20-240 minutes, and another creep aging is thermally insulated at 120 DEG C for 24 hours, wherein the creep stress is between 100 and 150 mega pascals, and the forming bending radius is between 800 millimeters and 5000 millimeters. The method is utilized to treat Al-Zn-Mg-Cu series aluminium alloy, so that the alloy creep aging strengthening phase can be effectively regulated, the mechanical property of the alloy plate and the alloy creep formability are improved, the residual stress of the alloy plate is reduced, and the alloy exfoliation corrosion resistance is improved.

Owner:CENT SOUTH UNIV

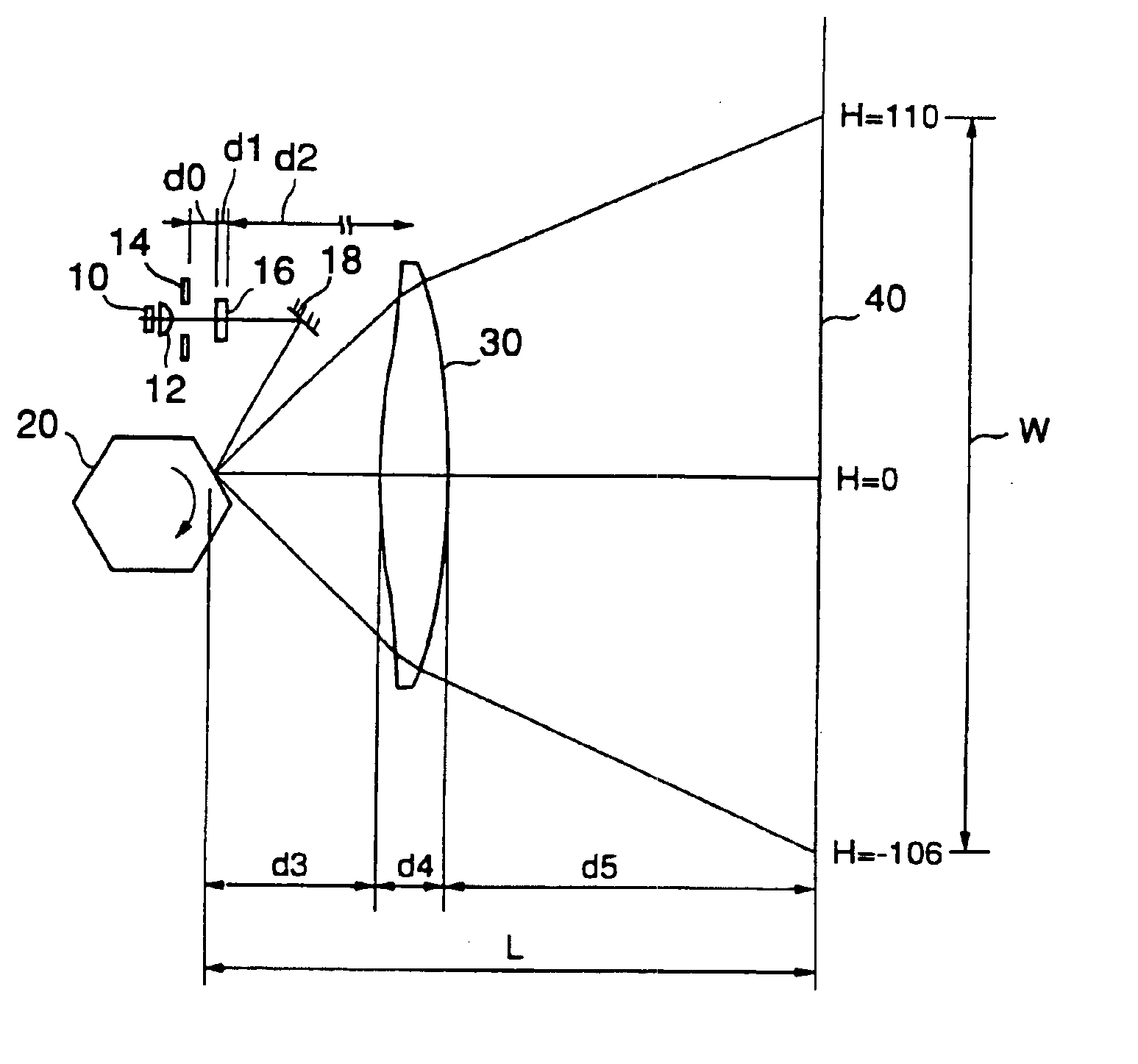

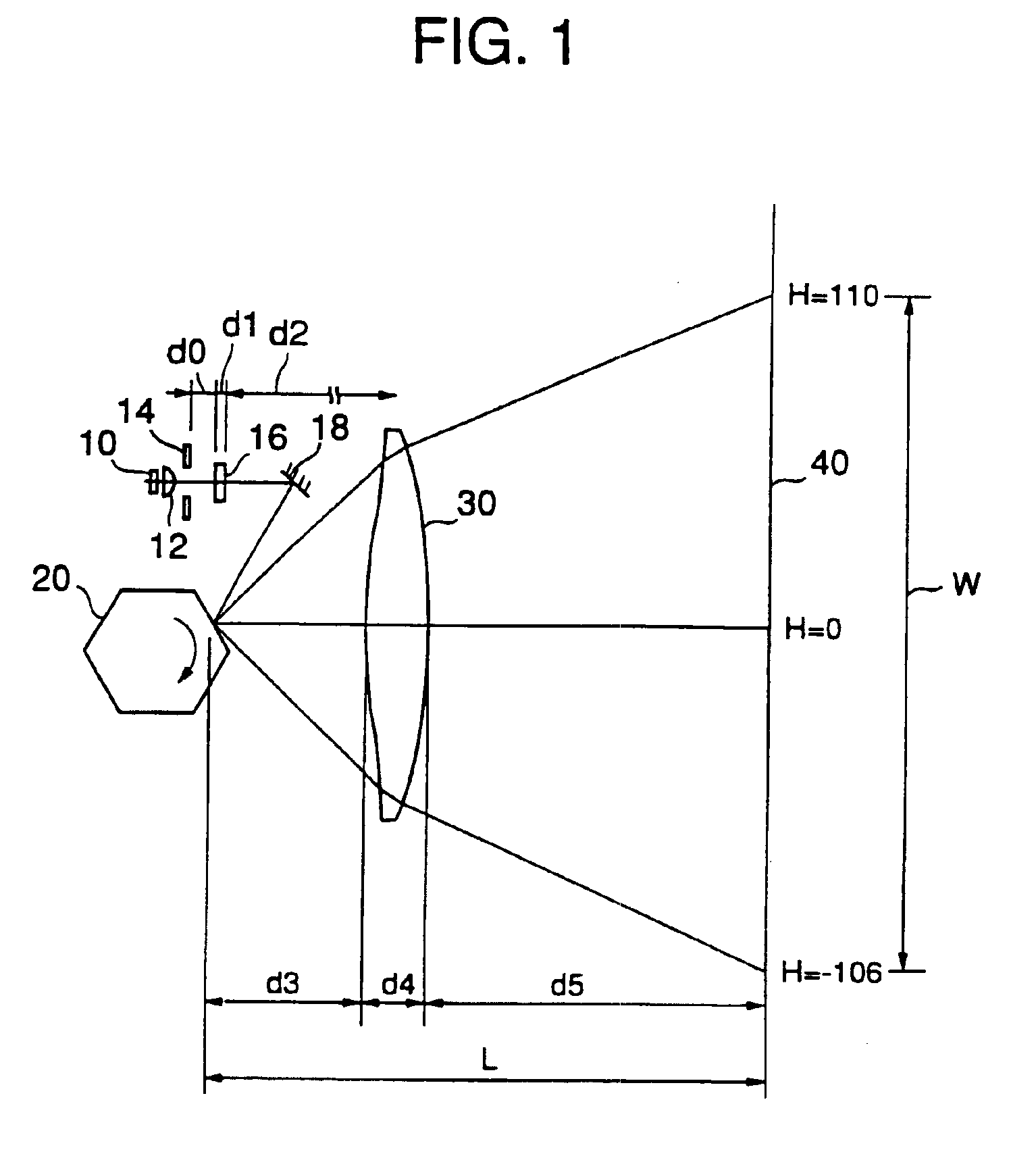

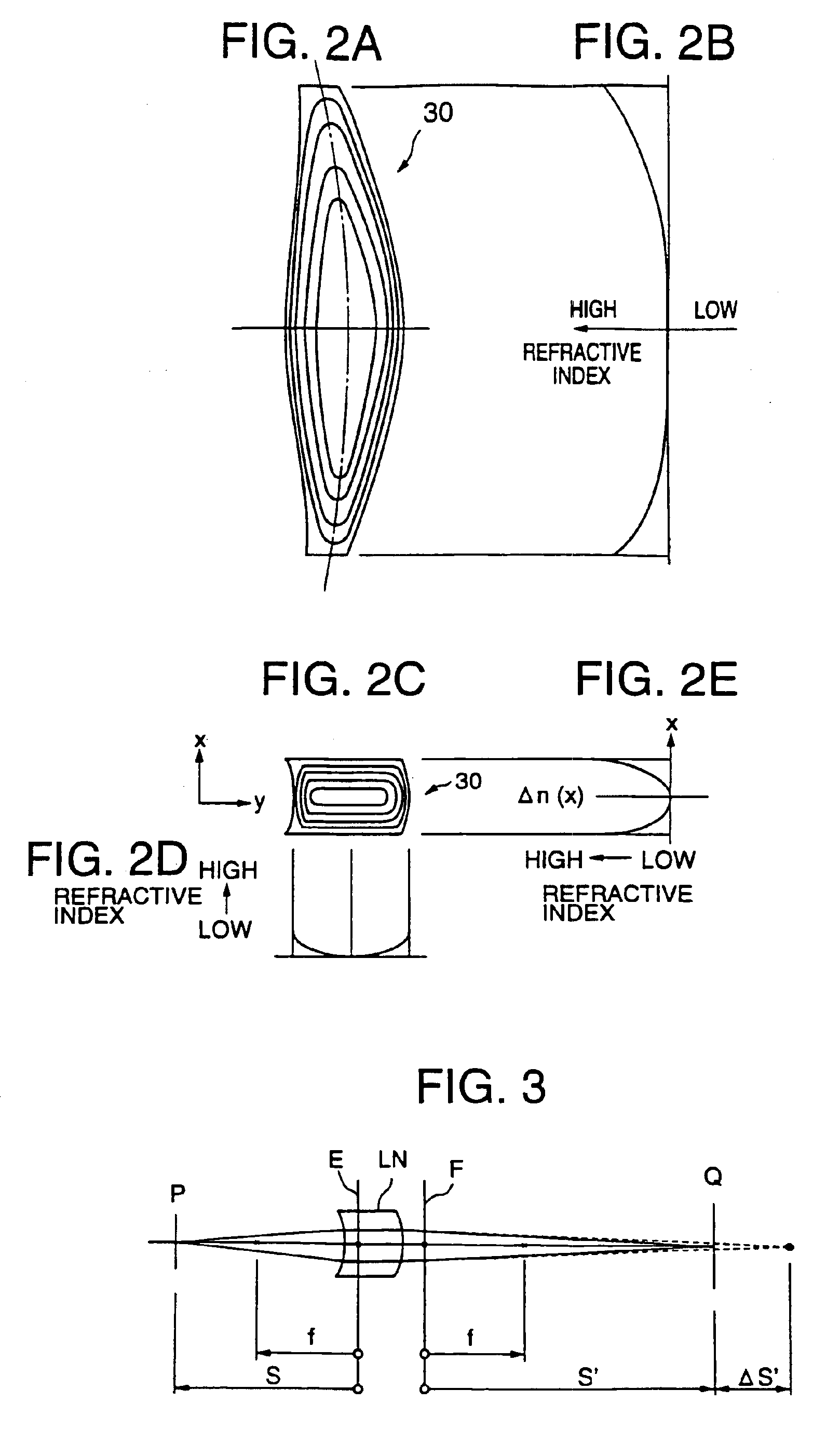

Optical scanning lens, optical scanning device and image forming apparatus

InactiveUS6870652B2Guaranteed uniform velocityAccurate inclinationInking apparatusLensPolyolefinLight flux

An optical scanning lens which is used in a scanning and age forming optical system which gathers a light flux deflected by a light deflector in the vicinity of a surface to be scanned. The lens is formed by plastic molding of polyolefin resin, and the following condition is satisfied: 0<|Deltan(x)-min[Deltan(x)]|<34X10<-5>, where Deltan(x) denotes a refractive-index distribution existing inside the lens, in a range which the light flux passes through, in the lens, and min[Deltan(x)] denotes the minimum value of the Deltan(x).

Owner:RICOH KK

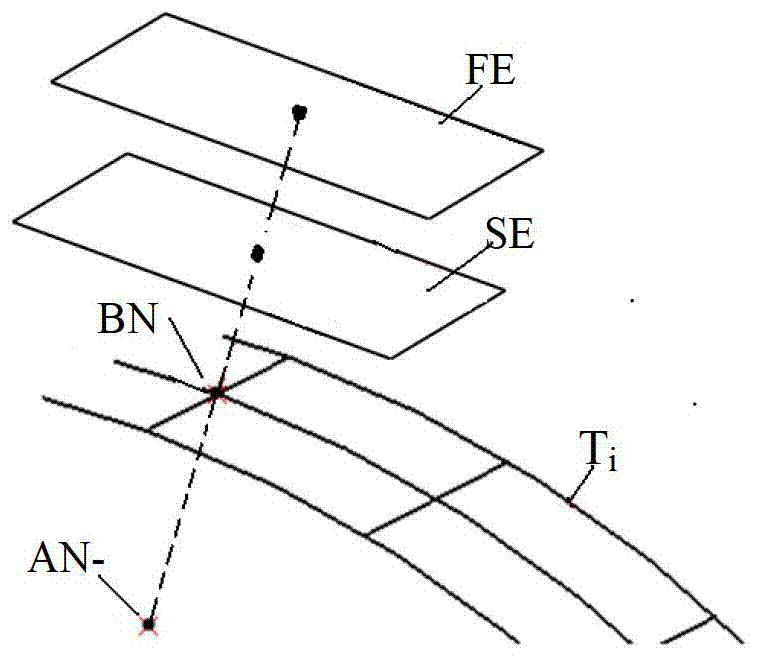

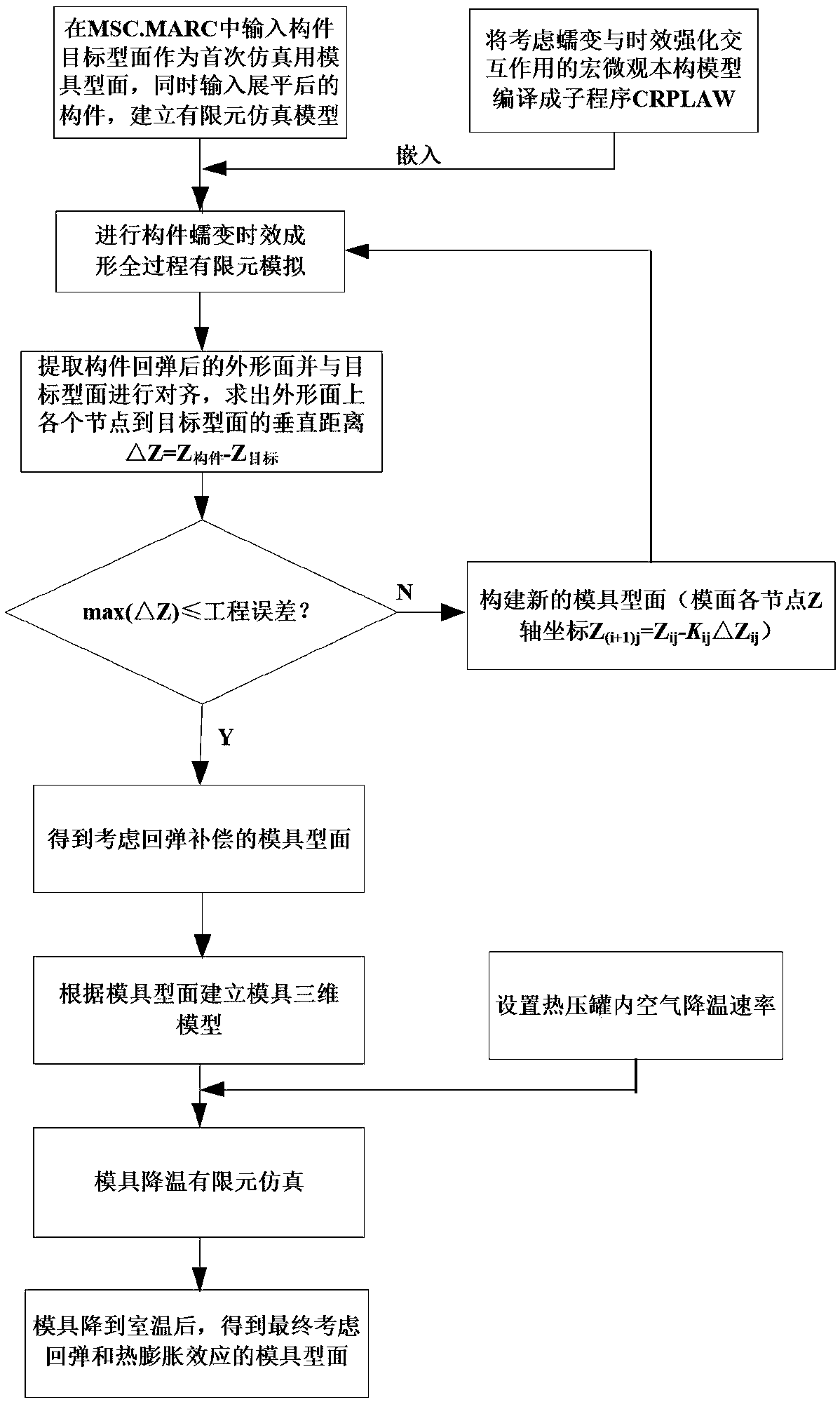

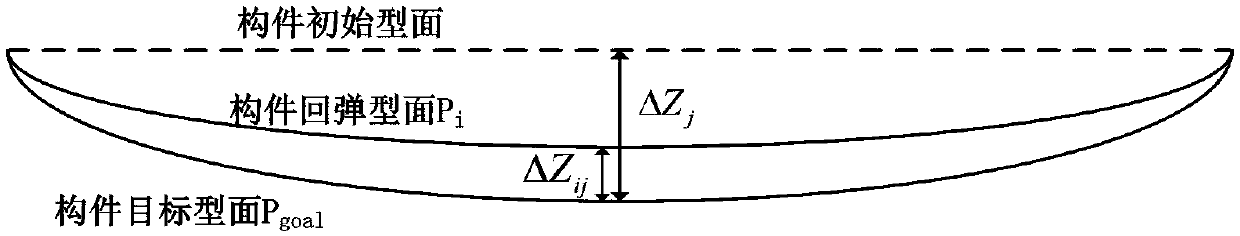

Springback compensation method for creep age forming

InactiveCN108920847AReduce the number of mold repairsPrecise Tooling Surface Design MethodDesign optimisation/simulationSpecial data processing applicationsThermal expansionEngineering

The invention provides a springback compensation method for creep age forming. The method comprises the following steps: Step S100, based on MSC.MARC commercial finite element software, constructing creep age forming finite element simulation; Step S200, weighting a springback iterative compensation process based on a molding surface of a finite element simulation result; and Step S300, considering a reverse compensation process of high temperature molding surface thermal expansion effect. The method considers the influence of the strength of a component on surface compensation, the influenceof a component feature structure on surface compensation, and reverse compensation of thermal expansion of a high temperature molding surface. A component formed by the model can still meet the engineering error requirement after being cooled.

Owner:CENT SOUTH UNIV

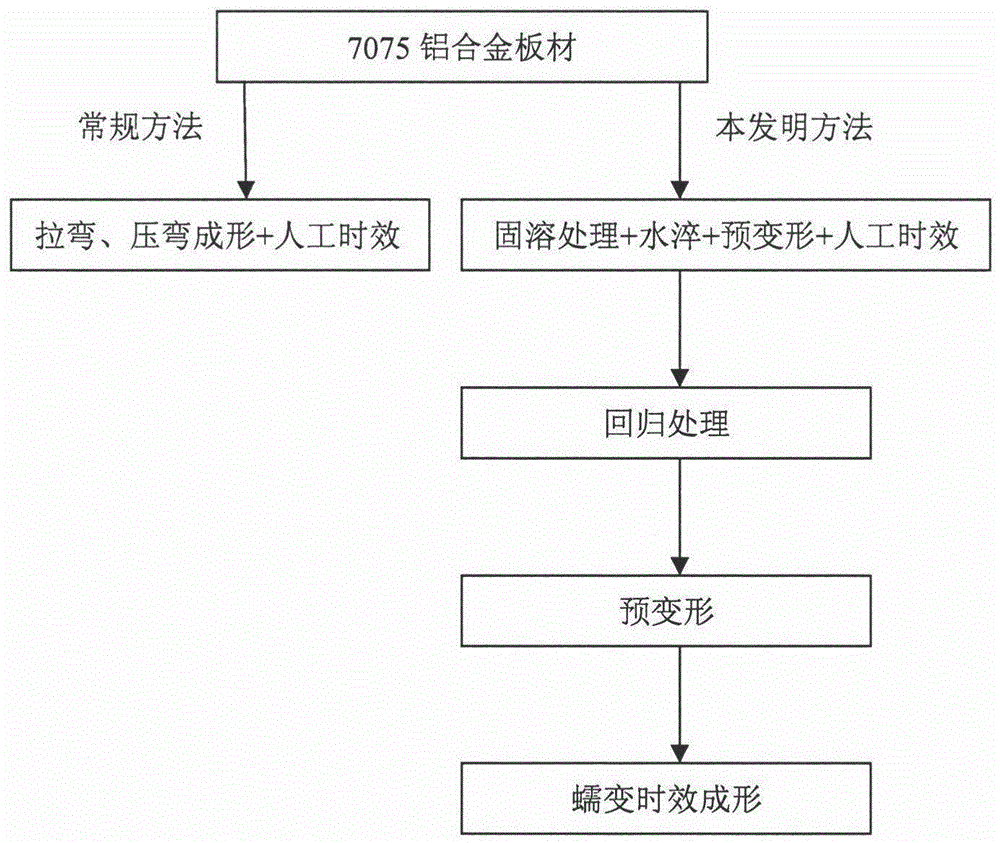

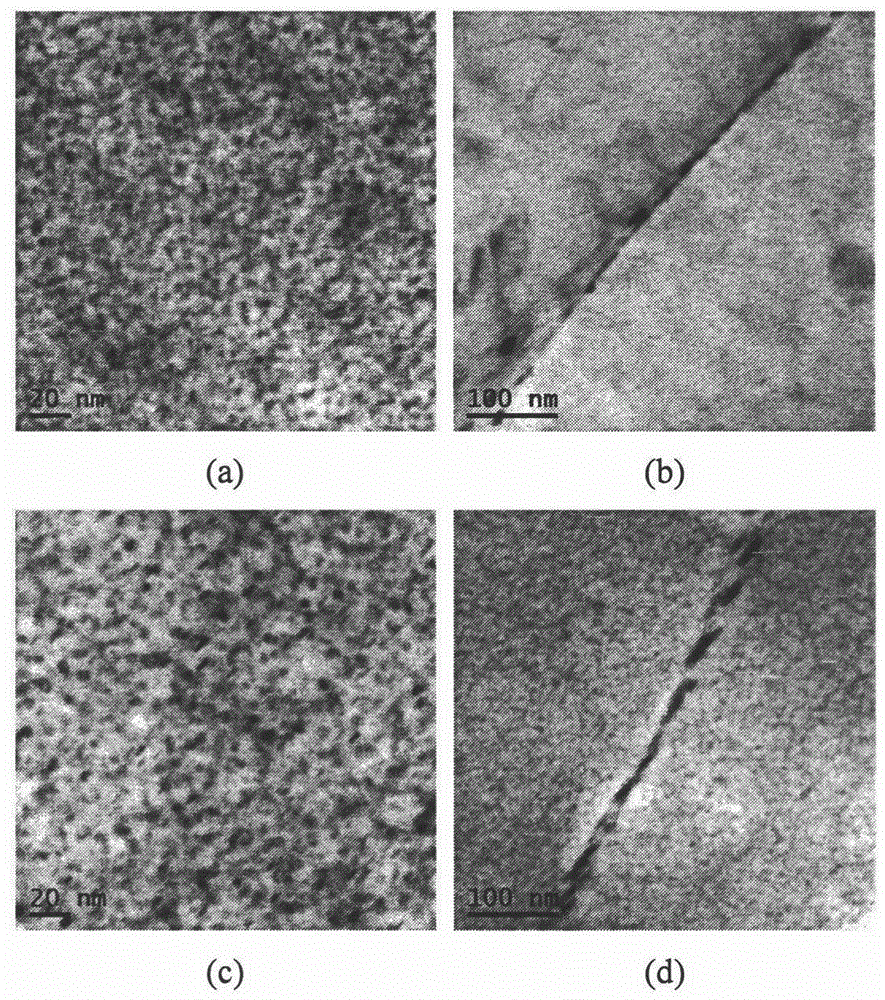

7075 aluminum alloy plate creep age forming method

InactiveCN104404414ARegulating Precipitation BehaviorImprove corrosion resistanceSolution treatmentPre deformation

The invention discloses a 7075 aluminum alloy plate creep age forming method. The method comprises the following steps: (1) carrying out solid-solution treatment on a 7075 aluminum alloy plate with a thickness of 2-40 mm for 30-90 minutes at a temperature of 466-480 DEG C, then water-quenching, subsequently carrying out 1-5 percent of pre-deformation and finally carrying out artificial aging treatment for 6-24 hours at a temperature of 80-120 DEG C; (2) carrying out retrogression treatment, wherein the retrogression treatment temperature is 160-200 DEG C, and the heat preservation time is 20-180 minutes, and then carrying out water quenching at a room temperature; (3) carrying out 1-5 percent of pre-deformation on the plate subjected to the retrogression treatment, then placing the plate in a mould and fixing; (4) carrying out creep age forming, wherein the creep age forming temperature is 120-160 DEG C, the applied stress is 200-260 MPa, and the forming time is 12-24 hours; (5) unloading the plate from the mould. When the method disclosed by the invention is utilized for processing the 7075 aluminum alloy plate, while the strength of the aluminum alloy plate is ensured, the corrosion resistance of the 7075 aluminum alloy plate can be effectively improved.

Owner:CENT SOUTH UNIV

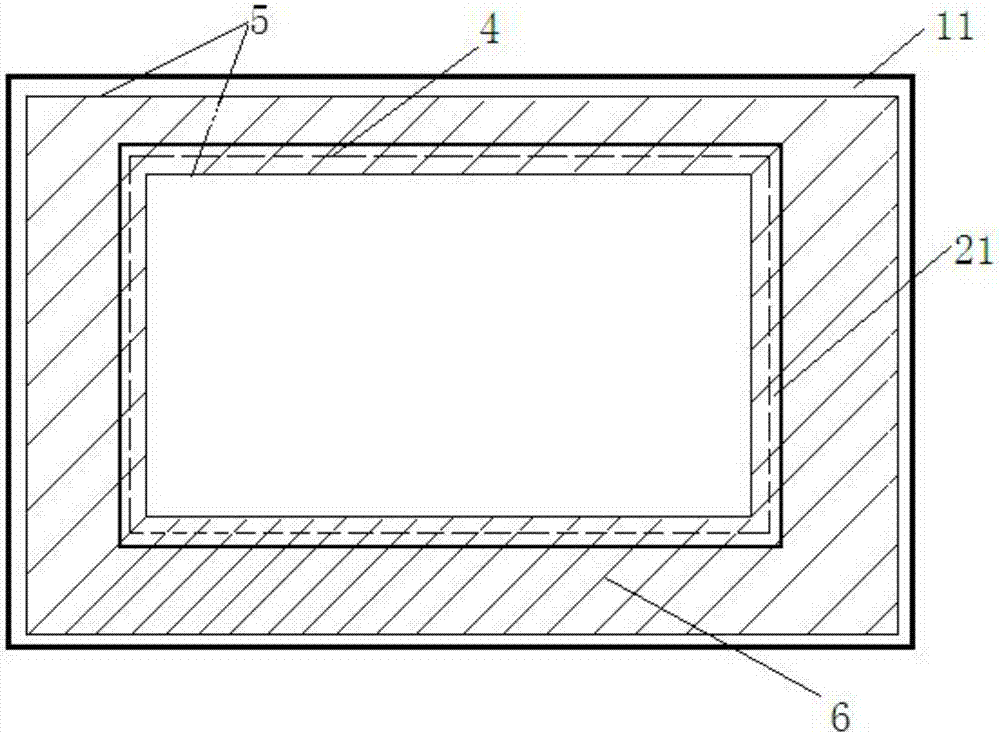

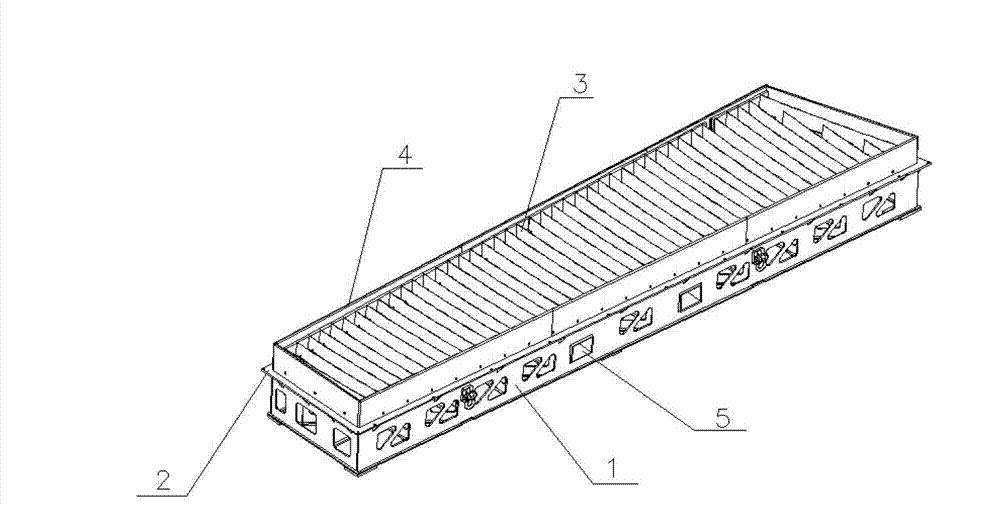

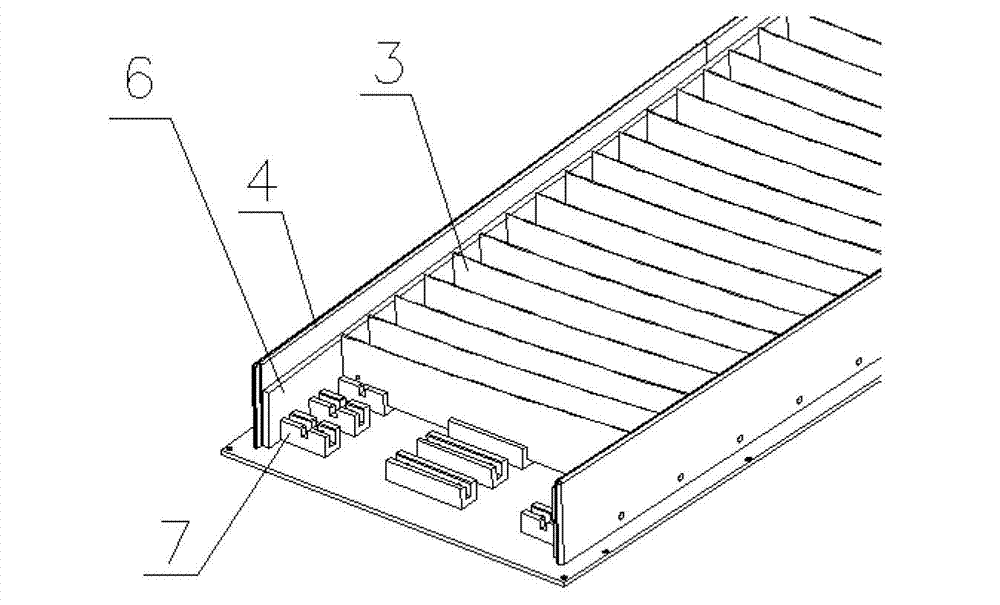

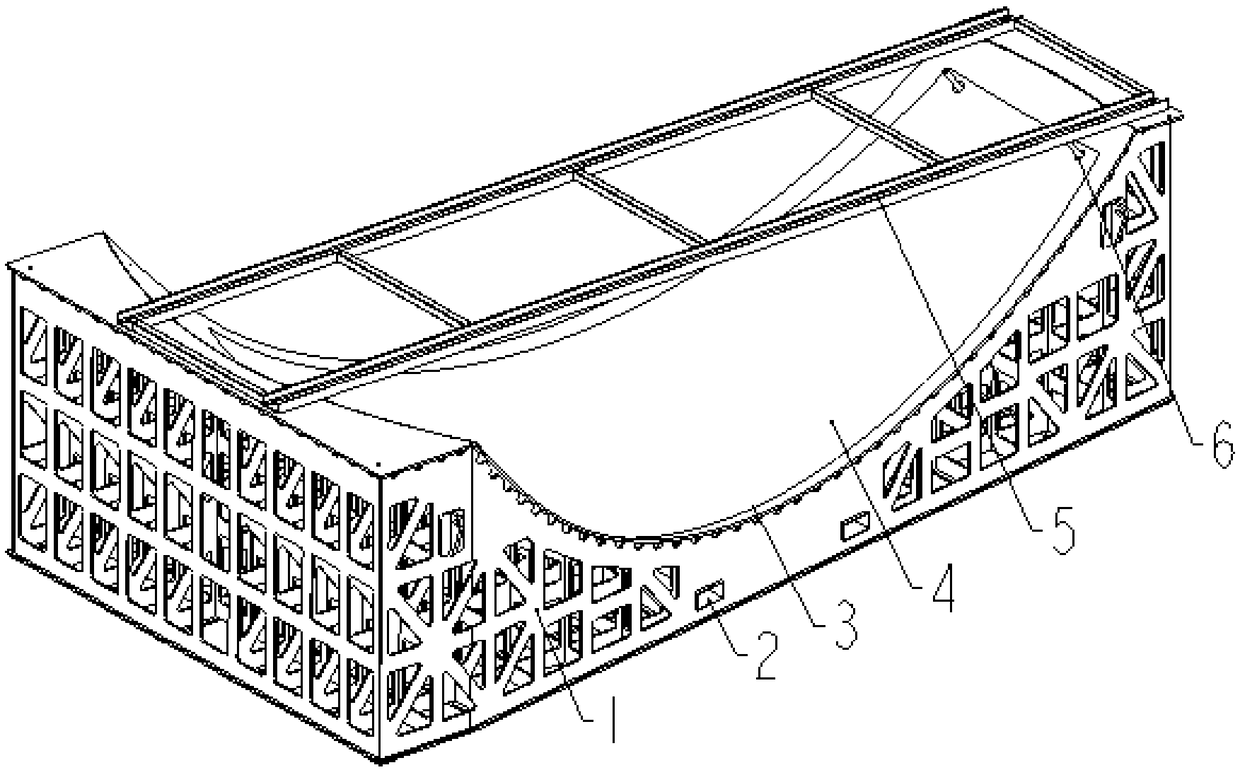

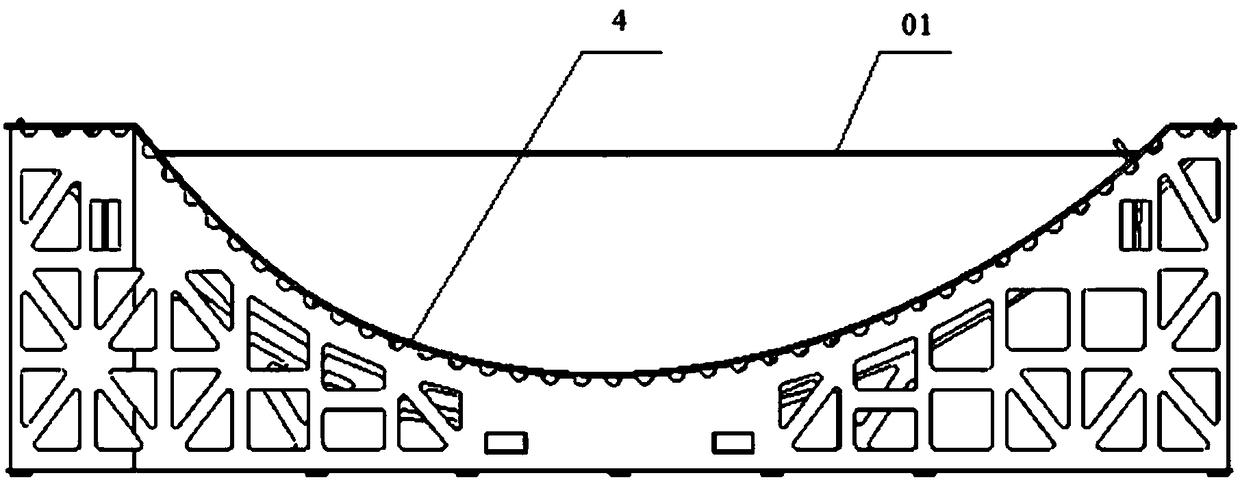

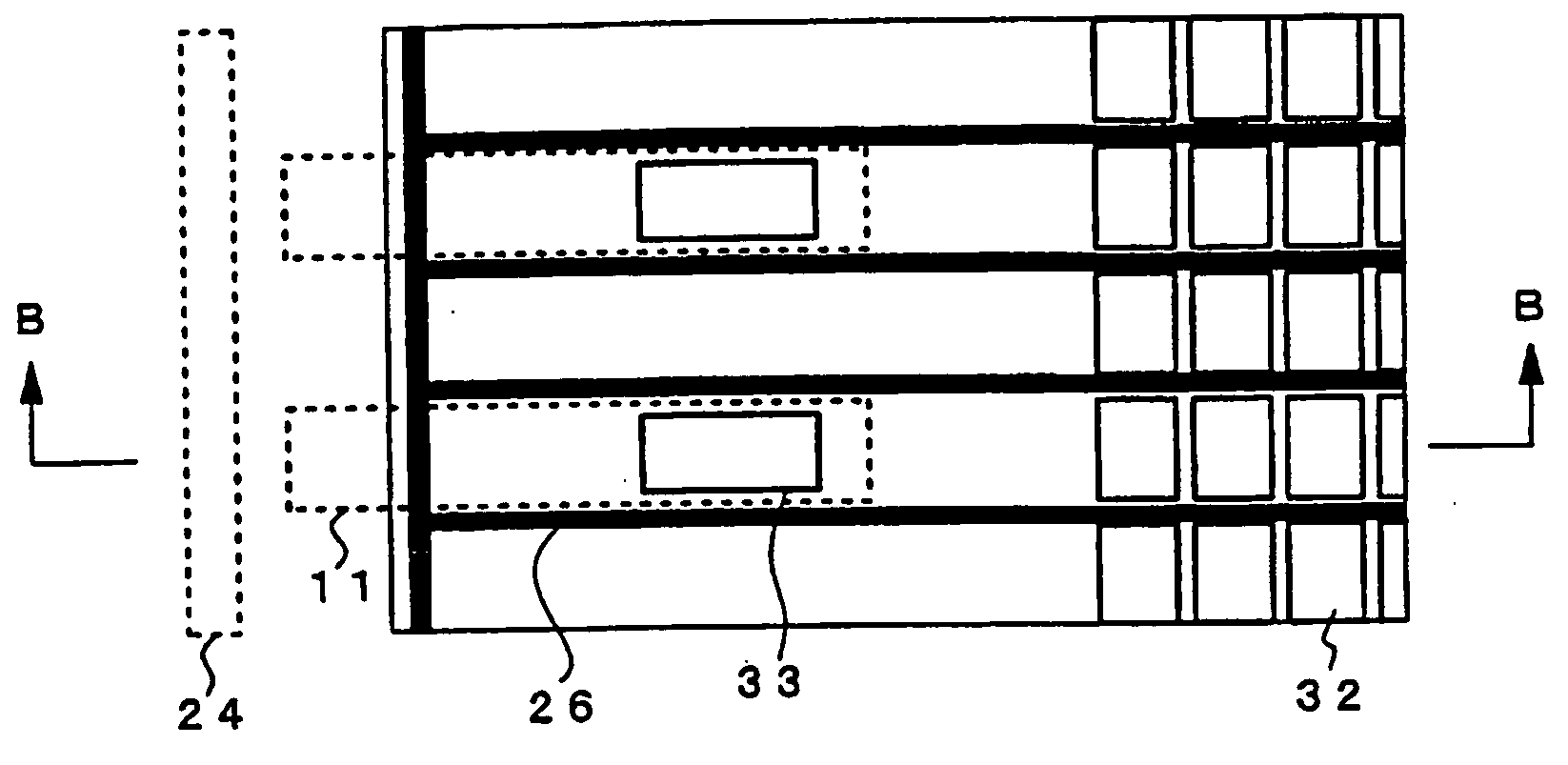

Integral panel creep aging forming tool based on autoclave

The invention belongs to the technical field of the metal plate forming and relates to an integral panel creep aging forming tool based on an autoclave. The tool comprises a support structure, a reference platform, a clamping plate, a limiting base, an internal side wall, an external side wall, a base plate and a sealing structure, wherein the support structure is of a frame structure, the reference platform is fixed on a plane of the support structure, the reference platform is provided with the limiting base, and the internal side wall and the external side wall are arranged around the reference platform. The integral panel creep aging forming tool adopts a detachable clamping mode to bring convenience to target profile adjustment and greatly save time and economic cost. The integral tool is large in size and high in precision, and an integral wall which is 5.5 meter long can be formed. The support structure of the tool adopts a mode of a frame so that not only the integral rigidity requirements can be met, but also the uniformity of a temperature field can be ensured. The side walls around the tool can be disassembled, so that the clamping plate can be conveniently replaced, and the deformation and heat processing problems caused by welding can be reduced. With the adoption of a unique sealing structure of the tool, a sealing bag cannot be damaged under the pressure of 1.5MPa of the autoclave so as to ensure the sealing effect.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Method for creep age forming of Al-Zn-Mg-Cu series aluminium alloy plate

InactiveCN102978545AImprove mechanical propertiesSimple and fast operationCreep stressSolid solution

The invention relates to a method for creep age forming of an Al-Zn-Mg-Cu series aluminium alloy plate. The method is characterized in that a reasonable solid solution-quenching-pretreating-creep aging system is adopted, is suitable for plates with the thickness of 2 millimeters-30millimeters and comprises the following steps that solid solution is carried out at 470-485 DEG C for 30 minutes-120 minutes, quenching is then carried out, and the quenched plate is subjected to 0-10% predeformation treatment and creep aging at 120 DEG C-150 DEG C and is thermally insulated for 2-36 hours, wherein the creep stress is between 100 and 150 mega pascals, and the forming bending radius is above 1000 millimeters. The method is utilized to treat Al-Zn-Mg-Cu series aluminium alloy, so that the Al-Zn-Mg-Cu series aluminium creep formability can be effectively improved, and the residual stress of the alloy plate is reduced.

Owner:CENT SOUTH UNIV

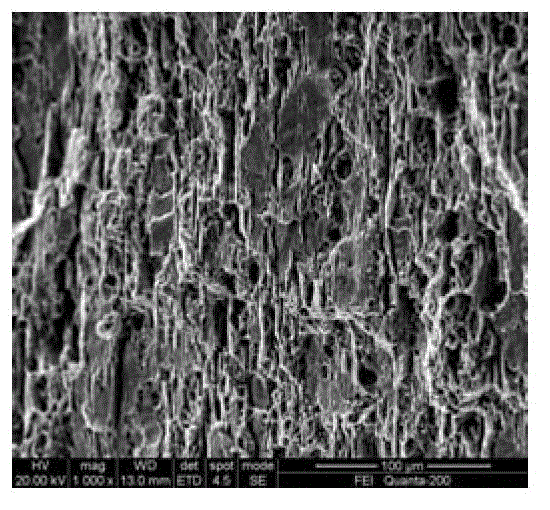

Preparation method for high-conductivity heat-resistant aluminium alloy conductor

ActiveCN105671374AIncrease productionQuality improvementConductive materialMetal/alloy conductorsFilter systemIngot

The invention discloses a preparation method for a high-conductivity heat-resistant aluminium alloy conductor, and relates to a preparation method for an alloy conductor. The method comprises the following processes: step 1, heating and melting commercially pure aluminium (containing Wt, not greater than 0.13% of Fe and not greater than 0.08% of Si) with a purity of greater than 99.7% in a heating furnace, and then adding Al-Zr intermediate alloy and Al-Er intermediate alloy in the melted pure aluminium melt; step 2, carrying out degassing, impurity removal, slagging-off, covering and other evolution treatments on the melt; step 3, discharging the melt subjected to heat insulation and standing from a heat-insulation furnace by virtue of a flow groove, and enabling the aluminium melt to sequentially flow through an online degassing system and a ceramic filtering system which are connected to the rear through the flow groove; step 4, carrying out 4-6 passes of continuous ECAE forming on an aluminium wire ingot obtained through continuous casting forming; and step 5, taking the aluminium alloy rod formed through the 4-6 passes of ECAE forming and with a diameter of 8.5-12mm as a raw material, and automatically rolling the aluminium alloy rod into a coil on a wire drawing machine. The method is a method for preparation of a high-strength high-conductivity heat-resistant aluminium alloy conductive wire, and continuous ECAE dynamic age forming, for obtaining a high-performance aluminium alloy conductive wire.

Owner:江苏和拓铝线有限公司

Quick creep aging forming (CAF) method

ActiveCN106862376AThe process steps are simpleGuaranteed efficiencyShaping toolsRoom temperatureAge forming

The invention provides a quick creep aging forming (CAF) method. The method comprises the steps as follows: Step 1, a component and a mold in an autoclave are closely attached to each other under the effect of a load; Step 2, the inside temperature of the autoclave is increased to be 10-50 DEG C higher than the creep aging temperature T and is kept for t1 hours; Step 3, the inside temperature of the autoclave is reduced to the creep aging temperature T and is kept for t2 hours, and the t2 is 3-4 times the t1; Step 4, the temperature is reduced to the room temperature, and a product after CAF is obtained after unloading; and the load in Step 1, the load in Step 2 and the load in Step 3 are identical. With the technical scheme, the method has the effects as follows: through combination of short-time temperature keeping after temperature increase to the temperature higher than the creep aging temperature and long-time temperature keeping after temperature reduction to the creep aging temperature, the forming rate can be substantially increased, and the creep product having performance better than that in an existing technology can also be obtained.

Owner:CENT SOUTH UNIV

Dedicated fertilizer for producing green nanguo pear and preparation and application method thereof

InactiveCN101747103ADrain controlIncrease productionFertilising methodsFertilizer mixturesTrace element compositionPear tree

The invention relates to nanguo pear cultivation, in particular to a dedicated fertilizer for producing green nanguo pear and a preparation and an application method thereof.The fertilizer is composed of urine-based nitrogenous fertilizer, phosphate fertilizer, potash fertilizer, medium elements and trace elements; in the preparation method, the urea-based nitrogenous fertilizer, phosphate fertilizer and potash fertilizer with a grain size of 1.5-4.5mm serve as solid raw materials; then the medium elements are added to humic acid or humic acid salt accounting for 60-100% of the mass percent of the medium elements to be mixed; afterwards, trace elements are added and mixed with the mixture, cementing agent is used for pelleting and producing solid raw materials with a grain size of 1.5-4.5mm for standby use; finally, the medium elements and trace elements mixed for pelleting are uniformly mixed with the urine-based nitrogenous fertilizer, phosphate fertilizer and potash fertilizer.The dedicated fertilizer is applied to the nanguo pear trees as spring base fertilizer at one time and no after manuring is not needed.The nitrogenous fertilizer use level in the fertilizer of the invention and different number of nanguo pear fruit indexes with proportion fully following nanguo pear of different tree ages form five-level supply speed of fertilizer nitrogen, thus remarkably controlling loss of nitrogenous fertilizer.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Multistage creep age forming method for Al-Cu-Mg series aluminum alloy panel

The invention discloses a multistage creep age forming method for an Al-Cu-Mg series aluminum alloy panel. The method includes the steps that firstly, water quenching is conducted on the Al-Cu-Mg series aluminum alloy panel with the thickness ranging from 2 mm to 35 mm after solid solution processing is conducted on the Al-Cu-Mg series aluminum alloy panel at the temperature ranging from 490 DEG C to 505 DEG C for 30 minutes to 90 minutes, 1 percent to 5 percent of cold rolling is conducted, and then natural aging processing is conducted for 100 hours to 200 hours; secondly, the first stage of creep age forming is conducted, wherein the creep age temperature ranges from 140 DEG C to 160 DEG C, the applied stress ranges from 170 MPa to 230 MPa, and the time ranges from 10 hours to 14 hours; thirdly, the second stage of creep age forming is conducted, wherein the creep age temperature ranges from 160 DEG C to 200 DEG C, the applied stress ranges from 170 MPa to 230 MPa, and the time ranges from 10 hours to 14 hours; fourthly, the panel is unloaded from a die. When the Al-Cu-Mg series aluminum alloy panel is processed through the method, the mechanical property and the corrosion resistance of the aluminum alloy panel can be effectively improved.

Owner:CENT SOUTH UNIV

Complex-curvature aluminum alloy component vacuum creep age forming method

ActiveCN108637081AWith precise positioning functionAchieve precise manufacturingShaping toolsMetal-working feeding devicesUltimate tensile strengthAge forming

The invention provides a complex-curvature aluminum alloy component vacuum creep age forming method. According to the complex-curvature aluminum alloy component vacuum creep age forming method, a device for complex-curvature aluminum component vacuum creep age forming is included. The device comprises a die surface with a complex curvature and a positioning structure arranged on the die surface. The die surface is provided with a through hole. The positioning structure comprises a fixing block correspondingly arranged in the through hole in a welded manner and cylindrical positioning columns arranged in the fixing block. The fixing block is provided with cylindrical blind holes into which the positioning columns are inserted. The material strength of the positioning structure is larger than the material strength of the die surface. The perimeter zone of a forming raw material aluminum alloy plate is provided with two kidney-shaped through holes for the two positioning columns to be inserted. By means of the device and method, an aluminum alloy component can be completely attached to the forming target zone on the die surface, and precise manufacturing of the component is achieved.

Owner:CENT SOUTH UNIV

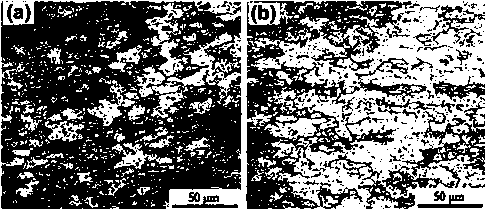

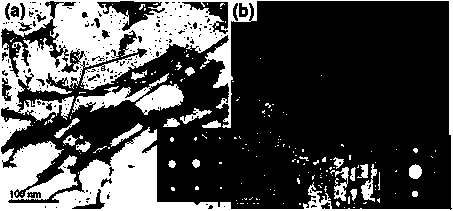

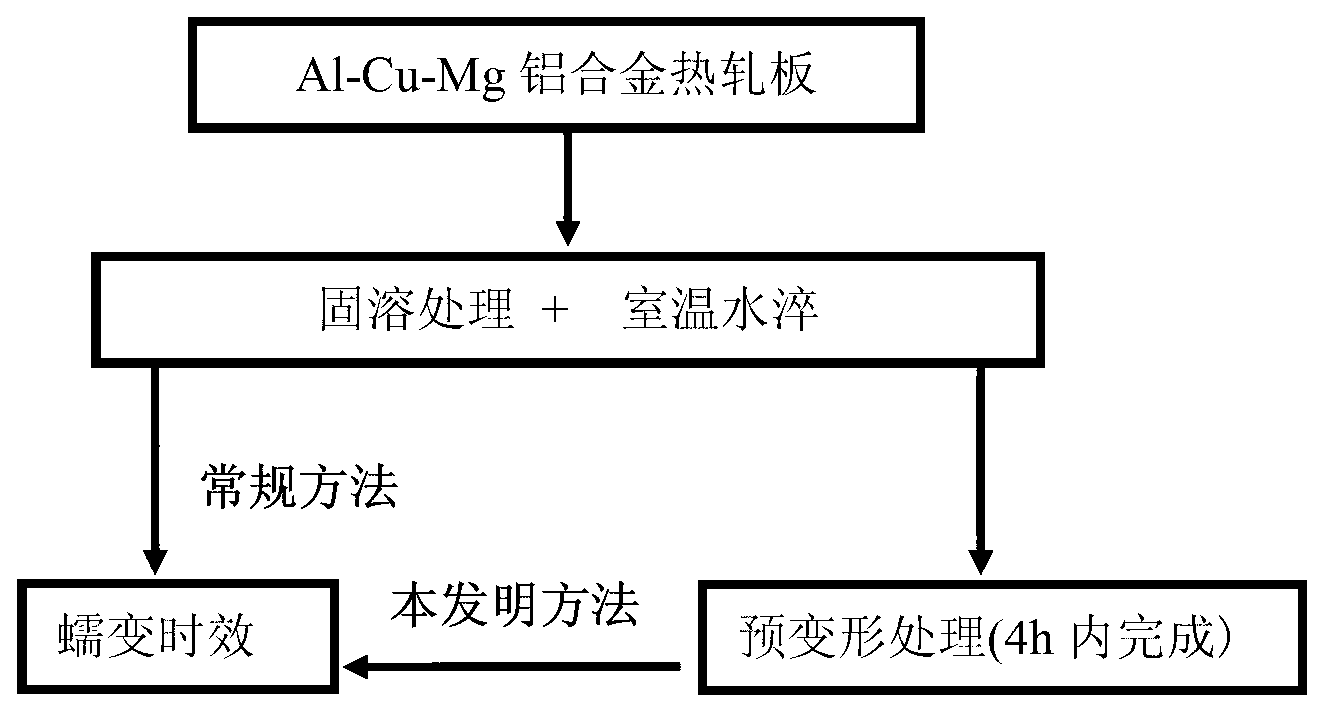

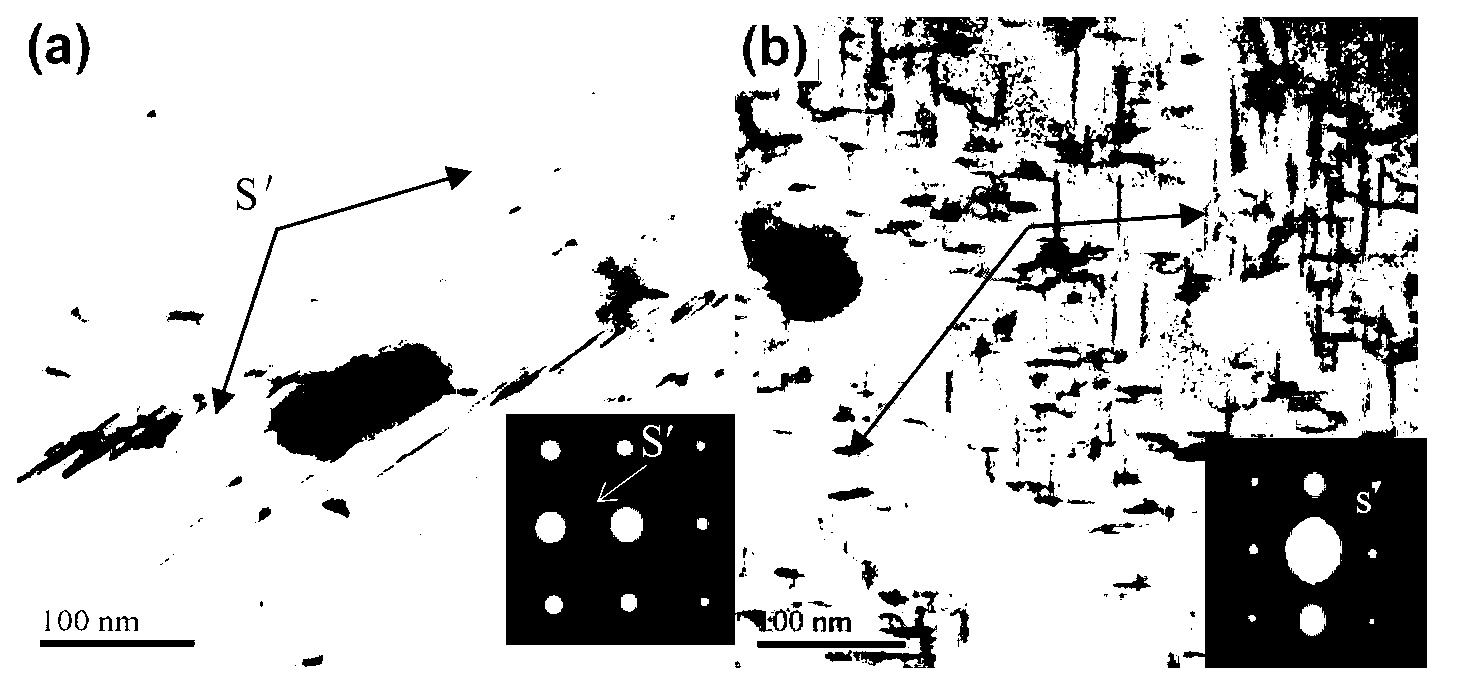

Creep aging forming method for Al-Cu-Mg alloy plate

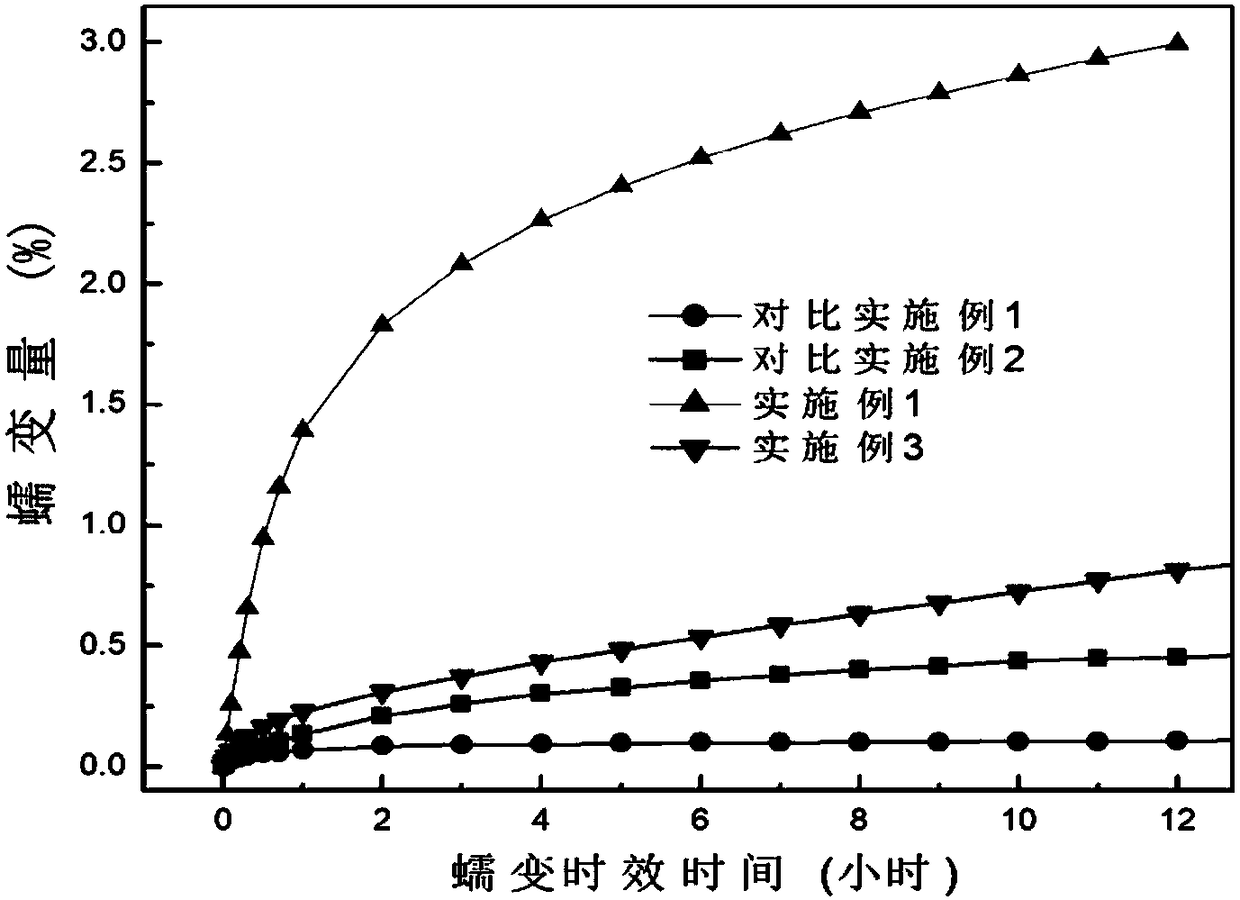

ActiveCN103422035ASuppression of precipitation phase effectLittle difference in mechanical propertiesCreep stressRoom temperature

The invention discloses a creep aging forming method for an Al-Cu-Mg series alloy sheet material. The creep aging forming method relates to a heat treatment method for reducing creep aging anisotropy of the Al-Cu-Mg alloy sheet material and improving an alloy performance. The method comprises the following steps of: water quenching after adopting solid-solution treatment at 490-505 DEG C for 30-70 minutes, carrying out 2-10% of predeformation processing on a quenched sheet material, and then carrying out creep aging, wherein a creep temperature is 150-200 DEG C; creep time is 0-12 hours; creep stress is 150-300 MPa, and predeformation processing time is controlled within 4 hours. By adopting the creep aging forming method to process an Al-Cu-Mg alloy, a mechanical property of the alloy sheet material can be improved and a degree of anisotropy of the sheet material can be reduced by controlling precipitation of an alloy creep aging strengthening phase. Compared with common thermal treatment, tensile strength of a room temperature is improved by at least 10%, and the anisotropy is reduced by at least 10% by adopting the creep aging forming method to process the Al-Cu-Mg alloy. The technique is simple in operation, and remarkable in effect. Compared with improvement of alloy microstructure components by a microalloying manner, cost is saved; the method is easy to achieve in industrial production, and comprehensive benefit is obviously higher than that of a reported processing method.

Owner:CENT SOUTH UNIV +1

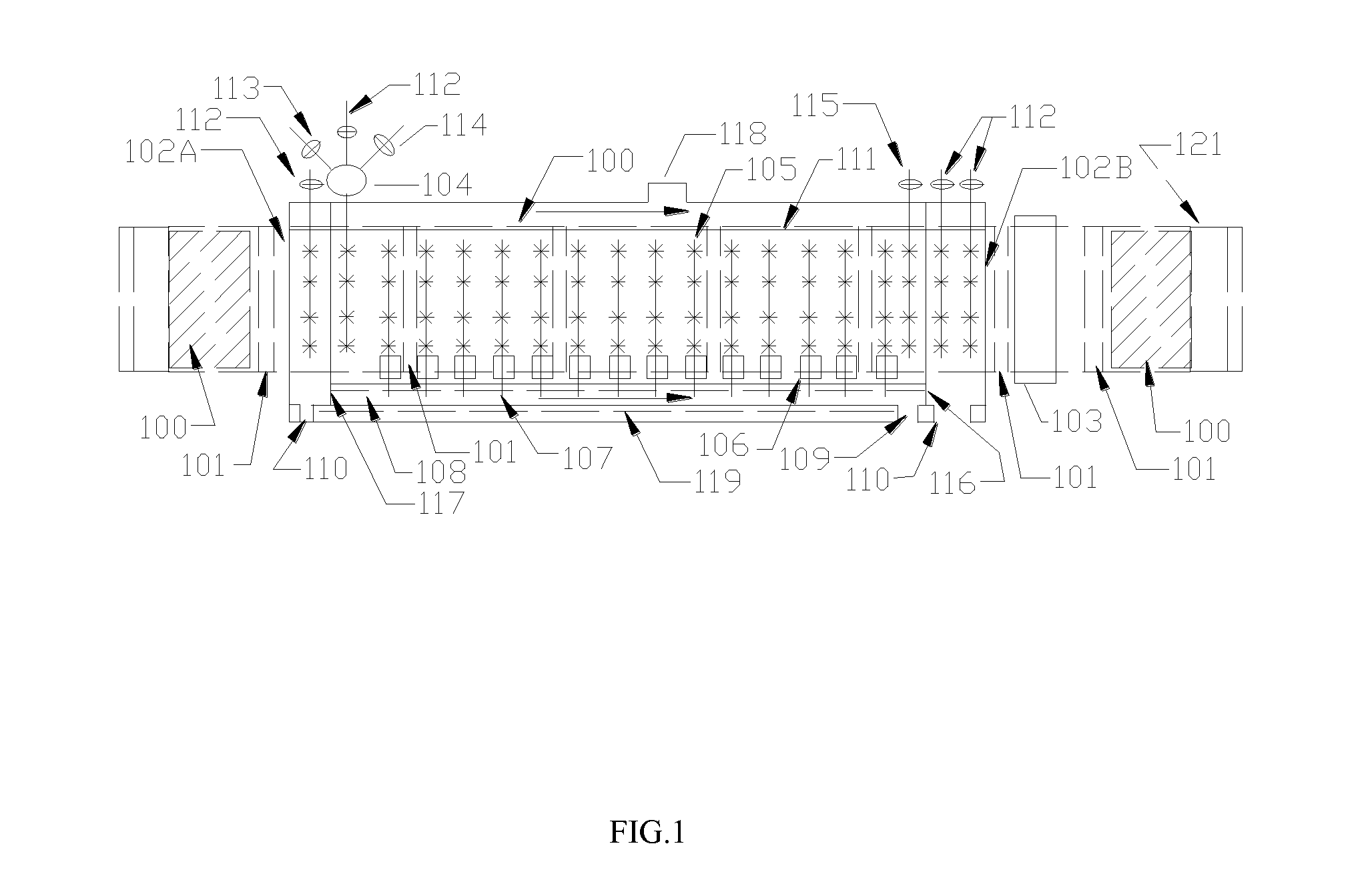

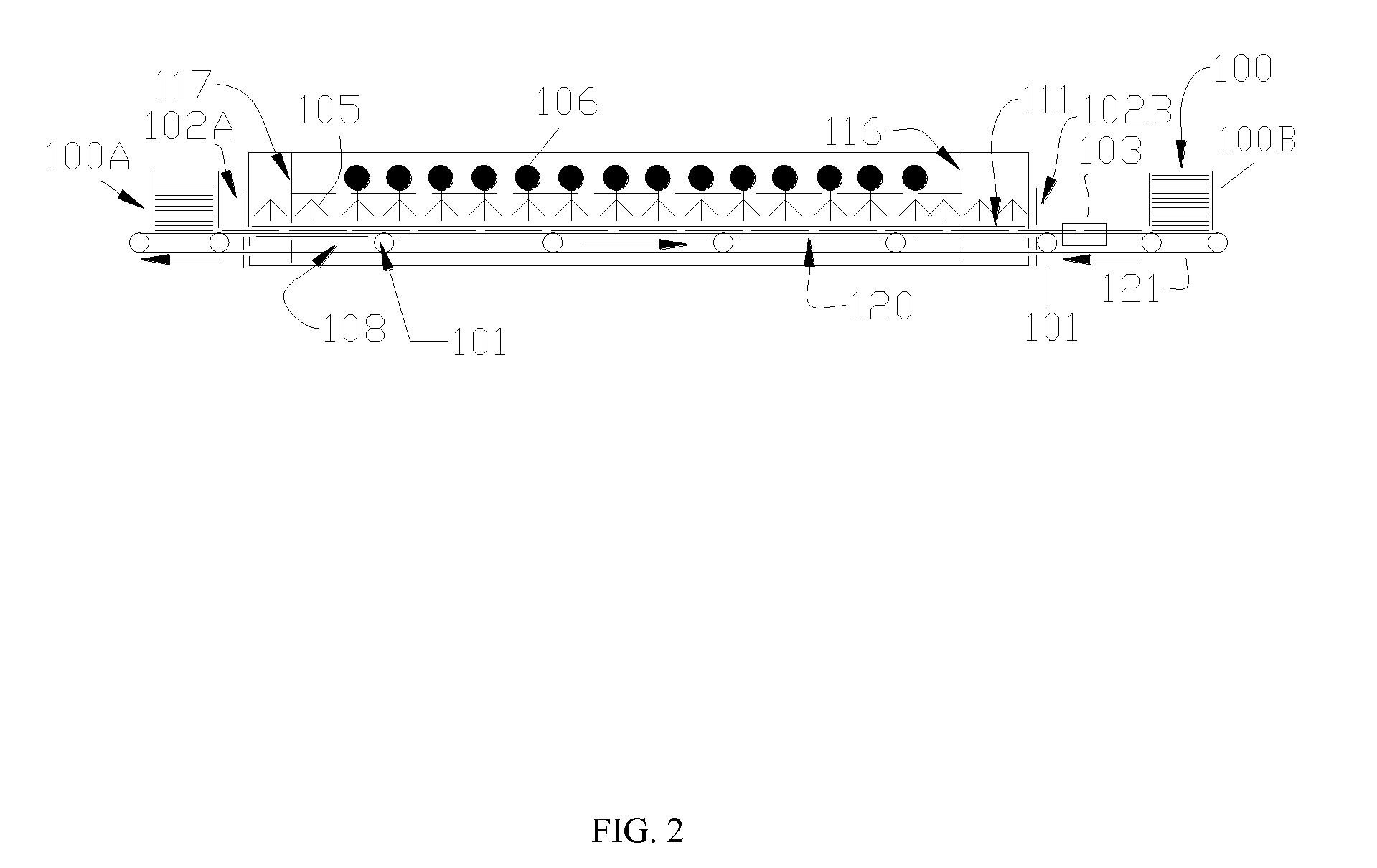

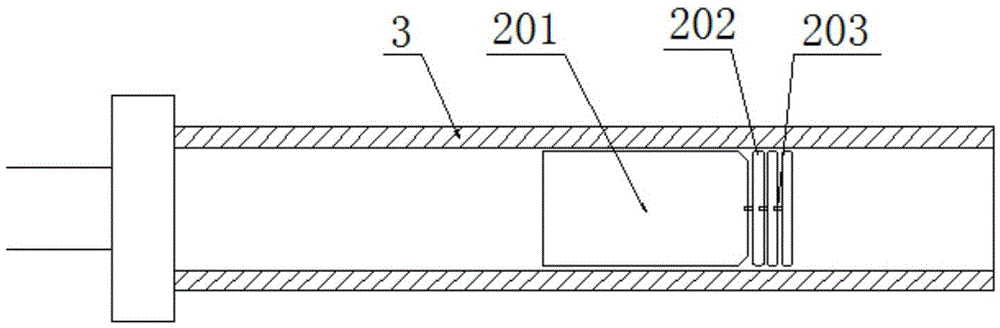

Chemical Bath Deposition Apparatus for Fabrication of Semiconductor Films

InactiveUS20130005073A1Save volumeReduce expensesLiquid surface applicatorsFinal product manufactureChemical treatmentReaction temperature

A chemical bath deposition method and a system are presented to prepare different thin films on plane substrates. In particular, they are useful to deposit CdS or ZnS buffer layers in manufacture of thin film solar cells. This method and the deposition system deposit thin films onto vertically travelling plane workpieces delivered by a conveyor belt. The thin films are deposited with continuously spraying the reaction solutions from their freshly mixed styles to gradually aged forms until the designed thickness is obtained. The substrates and the solutions are heated to a reaction temperature. During the deposition processes, the front surfaces of the substrates are totally covered with the sprayed solutions but the substrate backsides are remained dry. The reaction ambience inside the reactor can be isolated from the outside atmosphere. The apparatus is designed to generate a minimum amount of waste solutions for chemical treatments.

Owner:WANG JIAXIONG

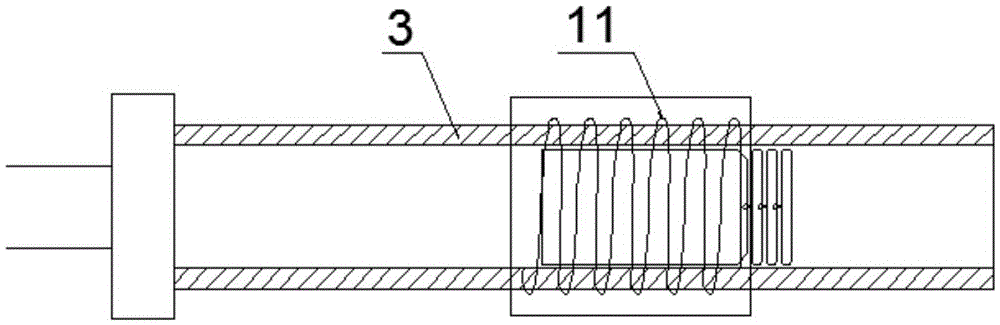

Solid solution-bending-aging forming device and method for vehicle body aluminum alloy pipe

The invention discloses a solid solution-bending-aging forming device and method for a vehicle body aluminum alloy pipe. The device comprises a heating mechanism and a bending mechanism. The heating mechanism comprises an induction coil and a high-frequency power source. The induction coil is arranged on the periphery of a bent part of the pipe in a sleeving mode and connected with the high-frequency power source. The bending mechanism comprises a bending die, a fixed clamp block, a crease-resistant block, movable clamp blocks and a rigid / flexible core die. The bent part of the pipe is placed on the bending die. One end of the pipe is clamped on the bending die through the fixed clamp block and the crease-resistant block, and the other end of the pipe is clamped by the movable clamp blocks. The rigid / flexible core die is arranged in the pipe. The fixed clamp block, the crease-resistant block and the movable clamp block are designed in a split mode, and the bending die is designed in an insert mode, so that water channels are processed conveniently and replacement after abrasion is convenient. The bending die, the fixed clamp block, the crease-resistant block and the movable clamp blocks are all internally provided with serpentine channels used for introducing cooling water. The solid solution-bending-aging forming device and method for the vehicle body aluminum alloy pipe can significantly improve the strength, the hardness and the forming precision of aluminum alloy pipes, and the springback problem of the pipes after bending and quenching is effectively solved.

Owner:WUHAN UNIV OF TECH

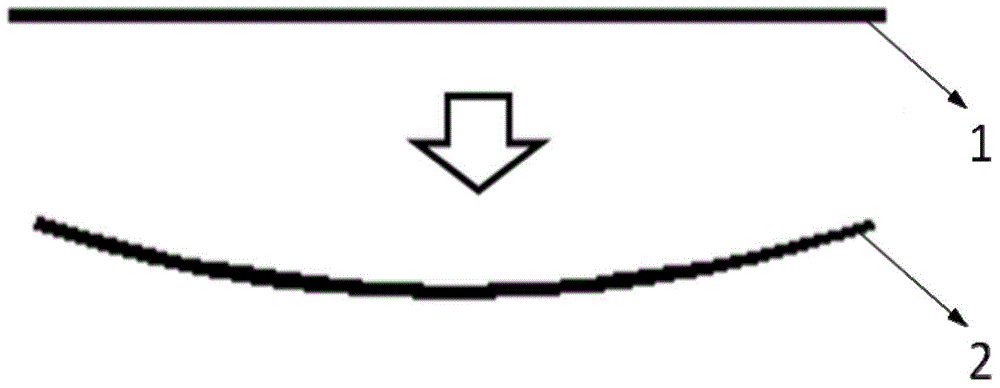

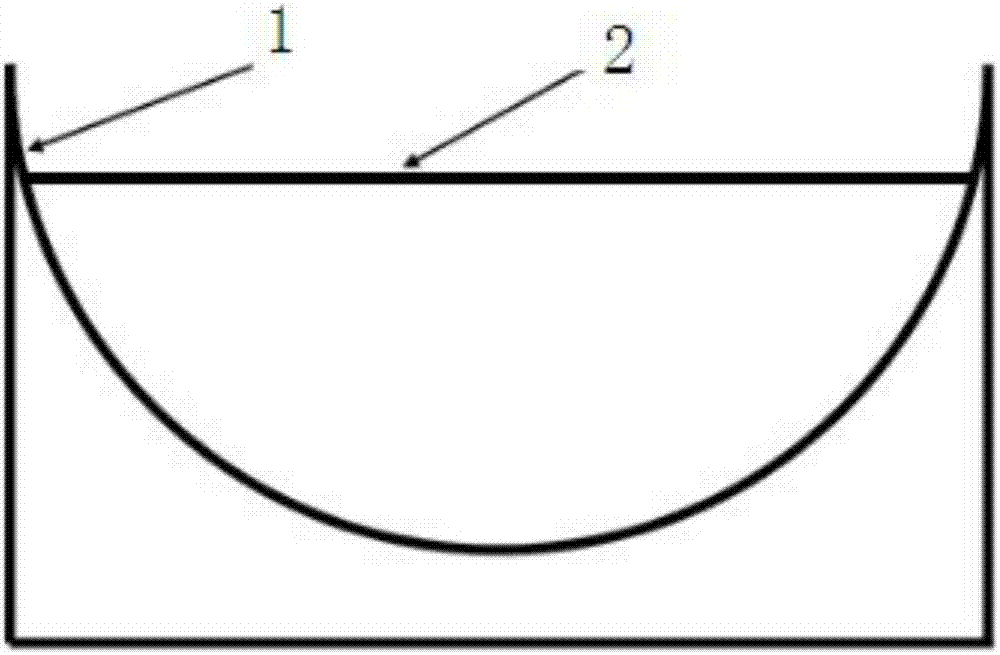

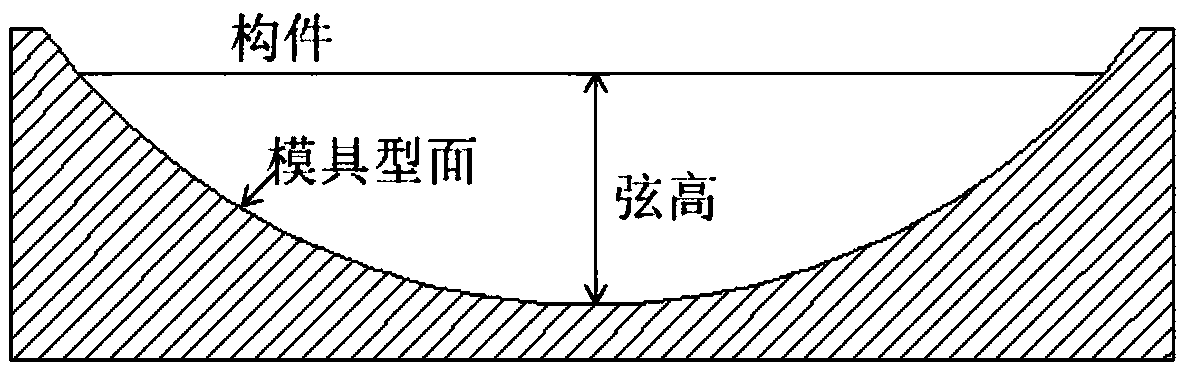

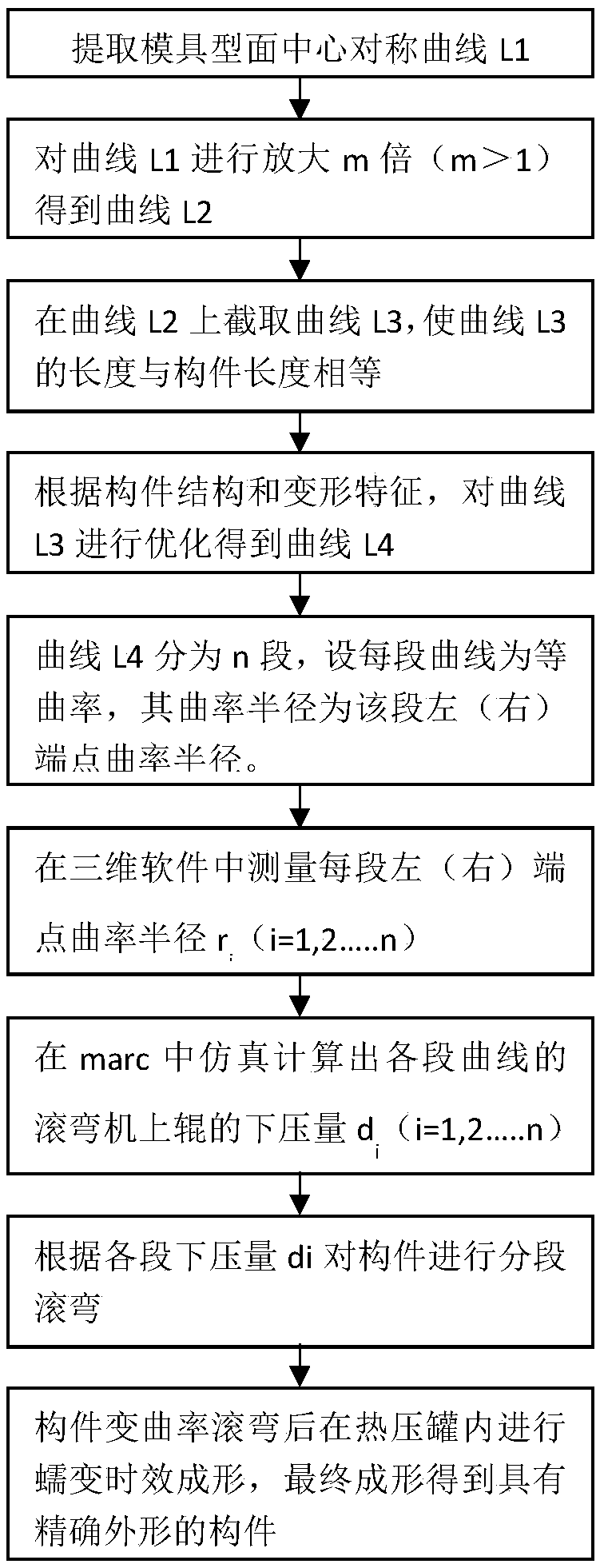

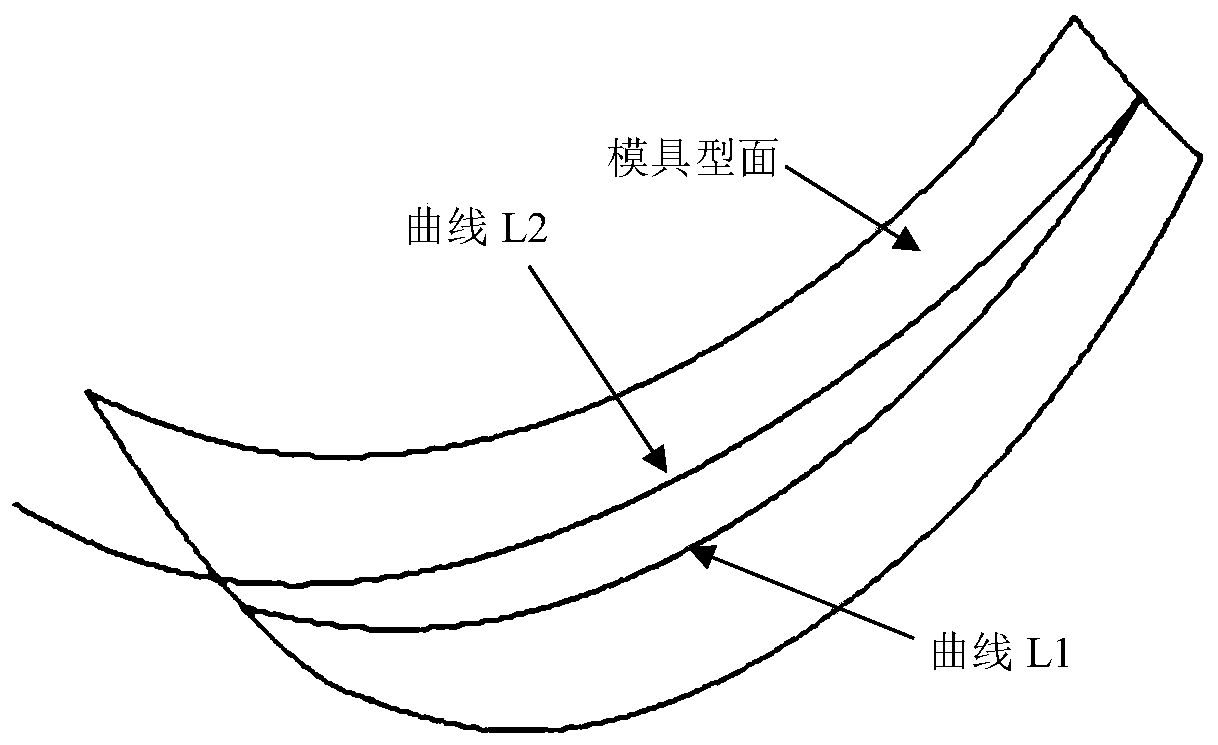

Large complex curvature component accurate forming method

ActiveCN109092944AHigh precisionIncrease the amount of plastic deformationManufacturing technologyMetal sheet

The invention belongs to the technical field of metal sheet manufacturing, and relates to a large complex curvature component accurate forming method. The large complex curvature component accurate forming method comprises the following steps of 1) performing roll bending treatment on the original plate of the large complex curvature component to be machined on the basis of the following variablecurvature of a mold profile; and 2) carrying out creep aging forming on the original plate after the original plate is subjected to the roll bending treatment so as to obtain the high-precision forming large complex curvature component. By virtue of the large complex curvature component accurate forming method, the creep aging forming operation is simple, and a phenomenon of breakage of a vacuum bag in the forming process can be avoided; and meanwhile, the potential safety hazard of hurting people caused by rebounding of the component can be eliminated.

Owner:CENT SOUTH UNIV

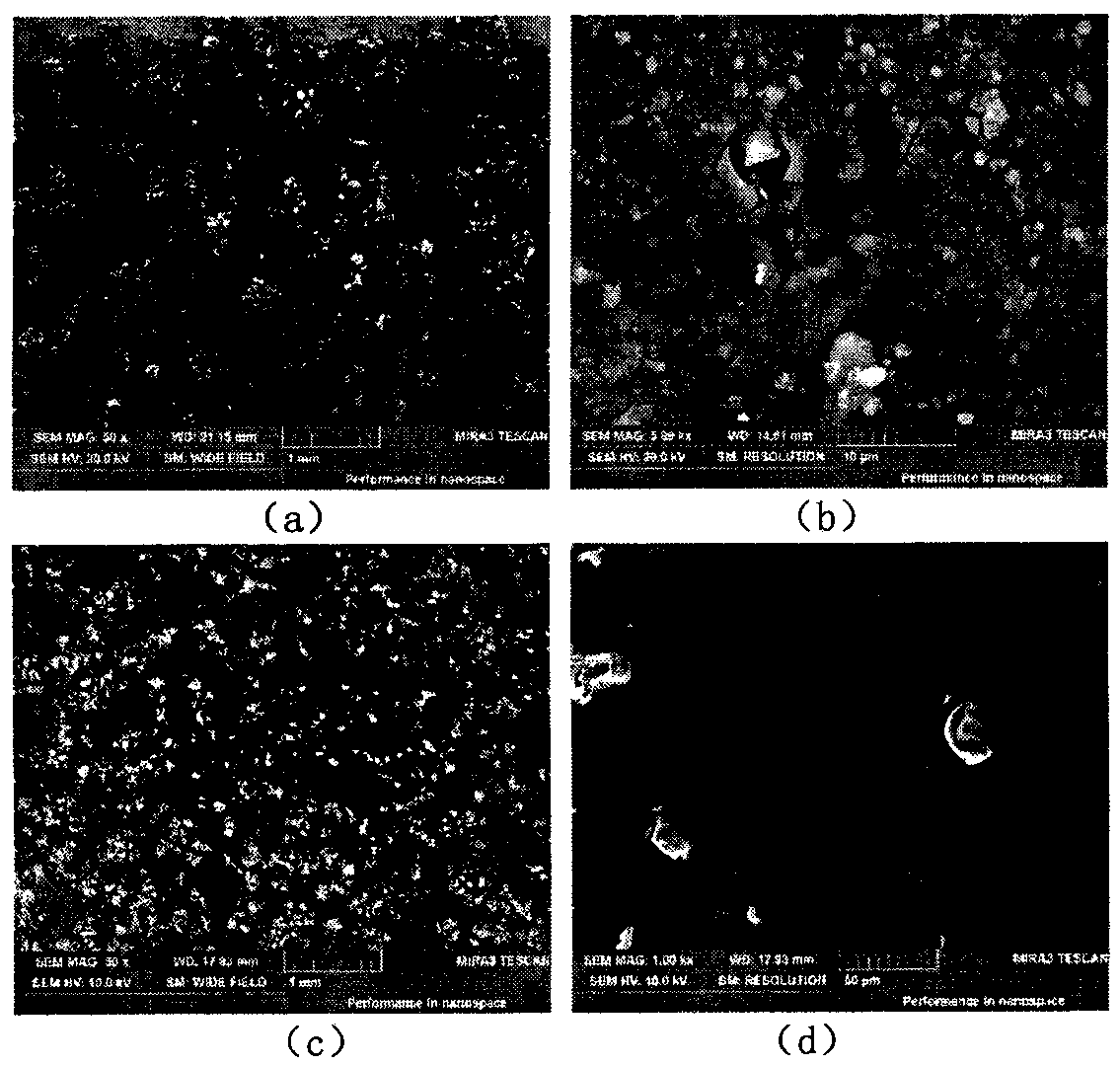

High-efficient creep age forming method for aluminum alloy

The invention relates to a high-efficient creep age forming method for an aluminum alloy. A hot-rolled aluminum alloy panel is subjected to solid solution and is then water-quenched, the quenched panel is placed in the middle and is subjected to cold deformation with the deformation being 20 to 90 percent at the room temperature until the required thickness is obtained, and then creep age formingis carried out. According to the high-efficient creep age forming method for the aluminum alloy provided by the invention, through cold deformation after alloy solid solution-quenching and before creep aging, a large number of dislocation, dislocation configuration and natural aging atom clusters are introduced into the alloy, and a part of dislocation and natural aging atom clusters can be used as a heterogeneous nucleation area of a precipitated phase, so that the precipitation of a main strengthening phase is promoted, the density of the precipitated phase is increased, the dimension is remarkably refined, and the creep rate and a mechanical property of creep aging are finally improve greatly. Through 20 to 90 percent of cold deformation, a large number of movable dislocation is introduced into the alloy, and the alloy creep quantity can be remarkably improved at lower temperature and stress through a creep age forming process, so that the age forming efficiency of the alloy is greatly improved.

Owner:CENT SOUTH UNIV

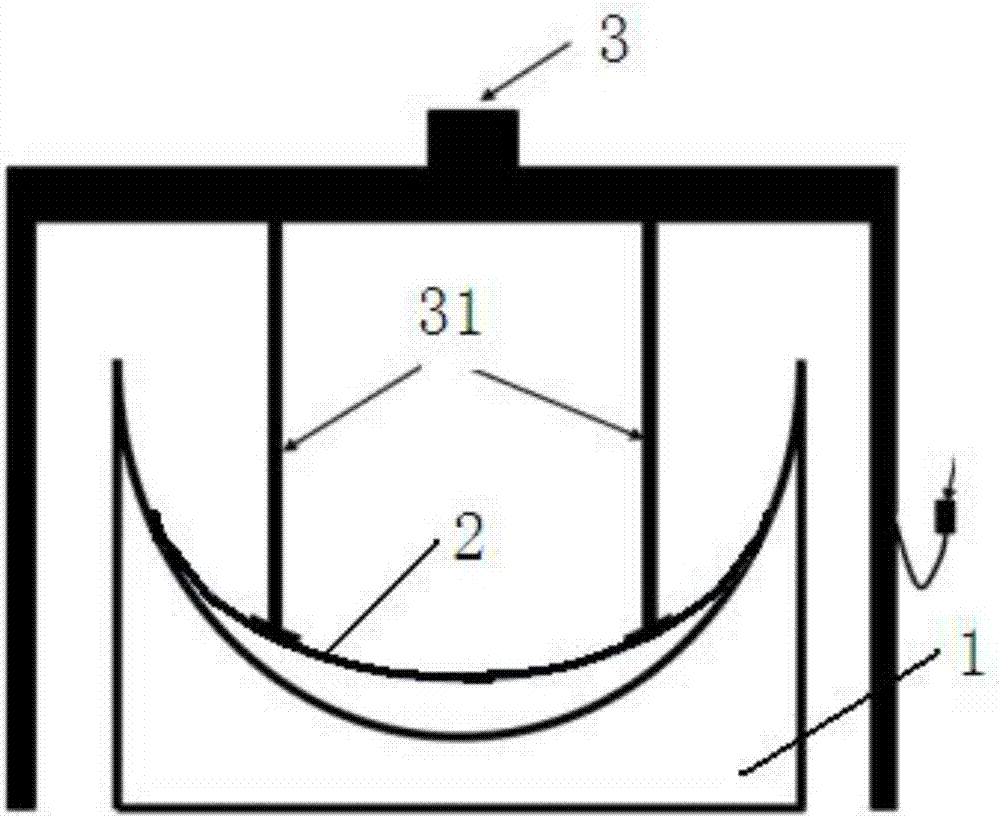

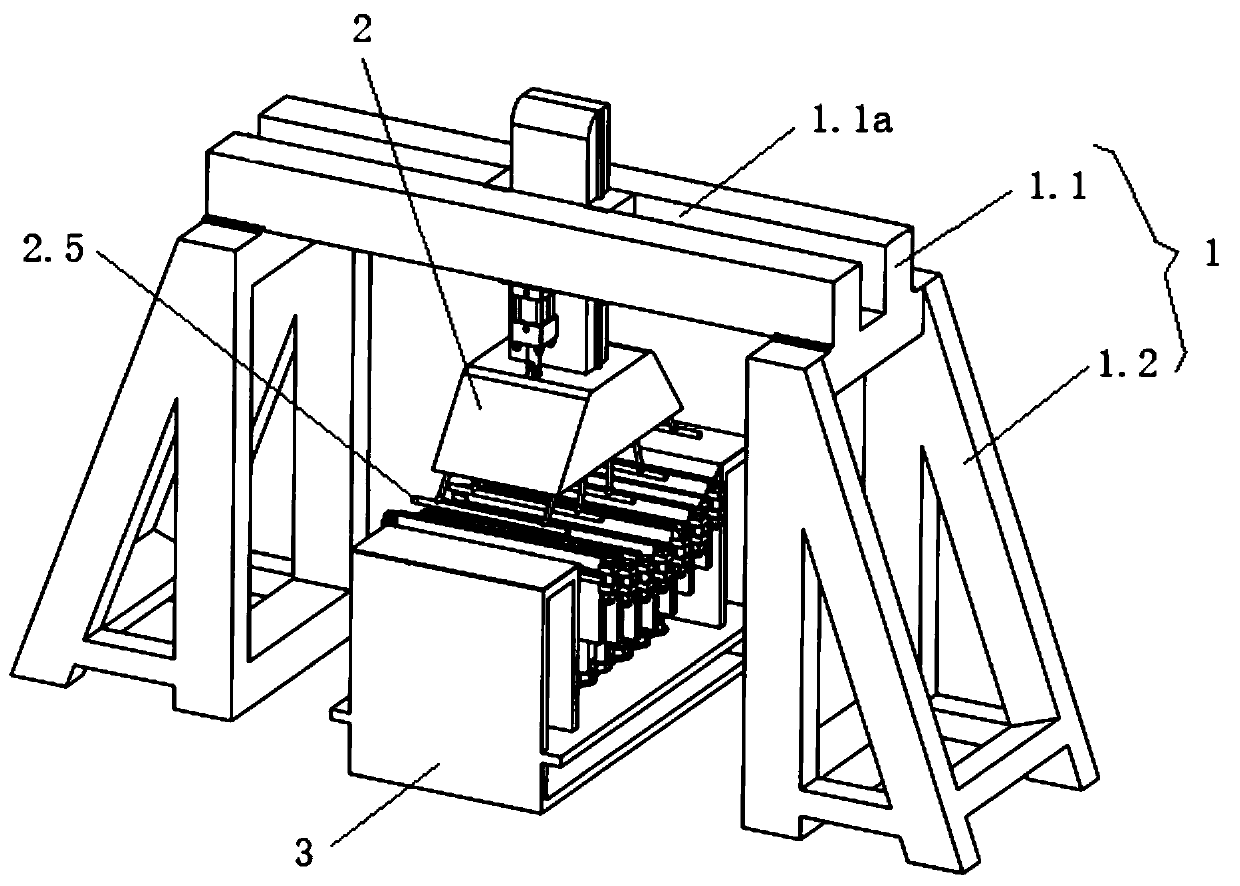

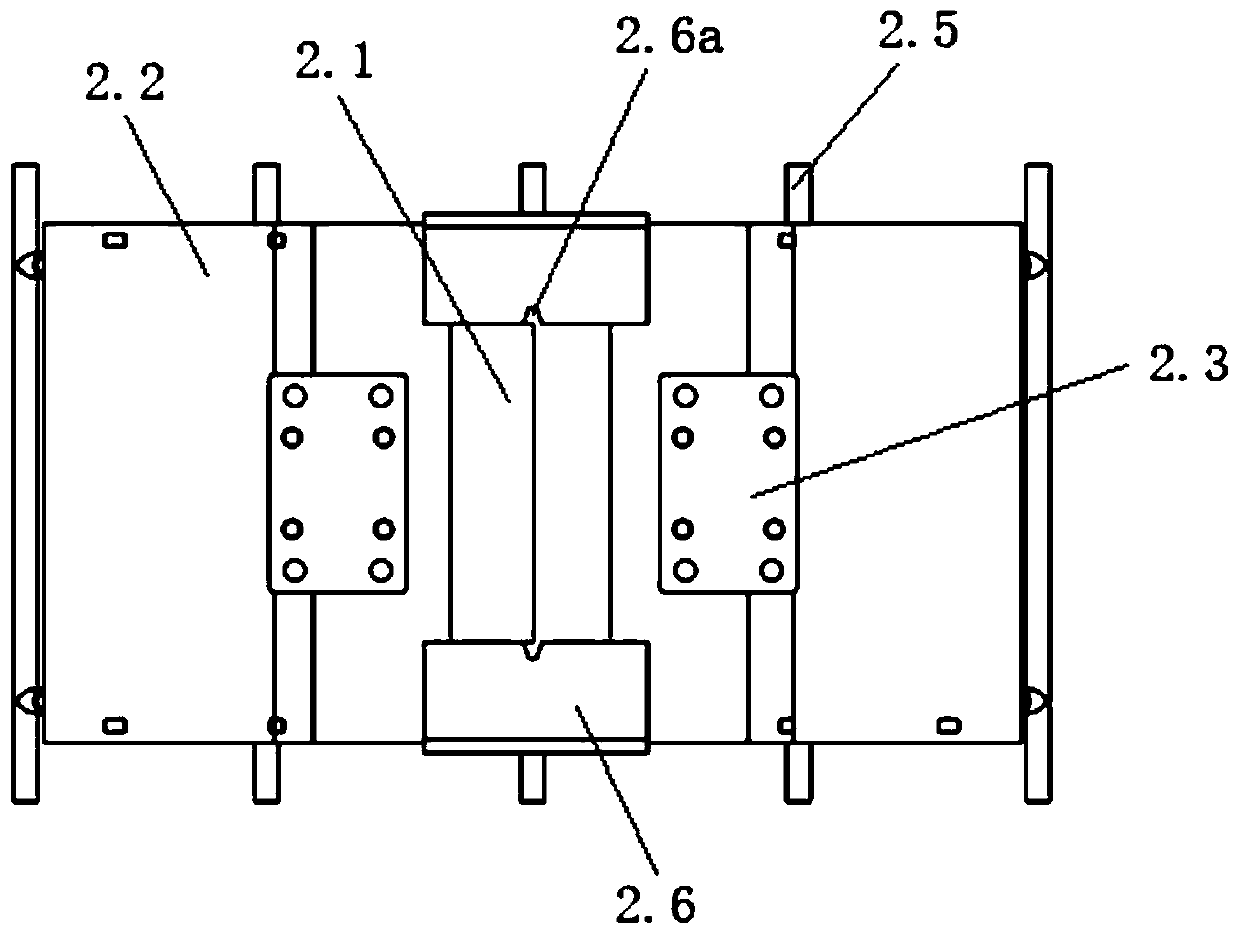

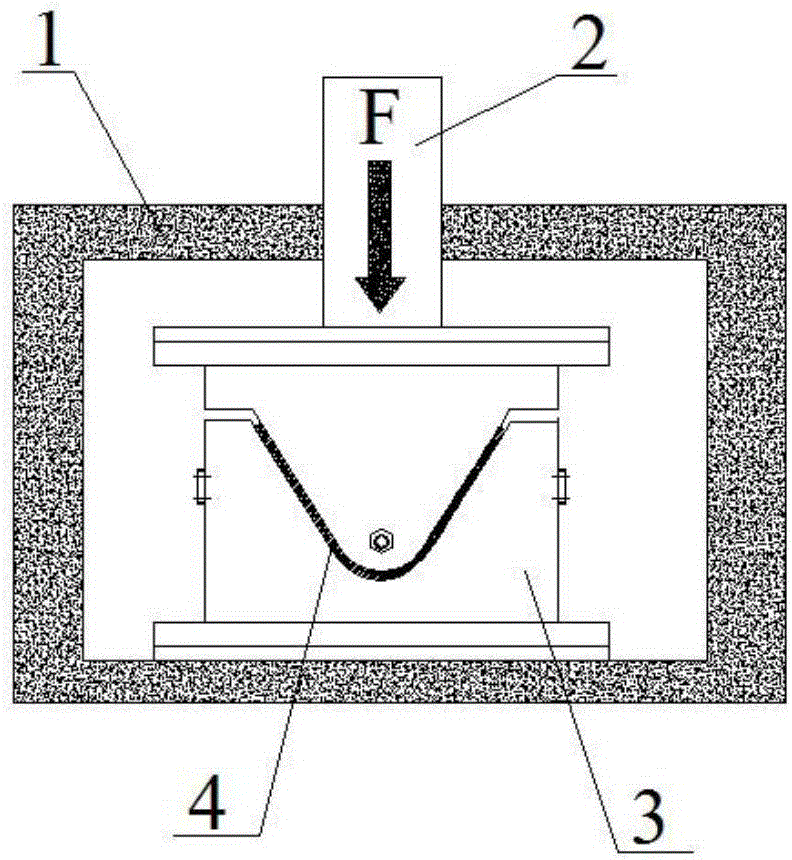

Creep age forming method based on mechanical loading

The invention discloses a creep age forming method based on mechanical loading. A mechanical-loading creep age forming device is used for carrying out mechanical loading on an aluminum alloy plate, and the forming method comprises the following steps that 1, a to-be-formed plate is placed on a die; 2, firstly, loads are applied to the upper surface of the to-be-formed plate through a main hydraulic cylinder and a loading hydraulic cylinder, so that the to-be-formed plate is deformed until the lower surface of the to-be-formed plate is tightly attached to the upper surface of a die shape plate,and then the to-be-formed workpiece is fixed to a die profile through a cover plate; 3, the to-be-formed workpiece and the die are placed in a hot-press pot, and the temperature is increased to an aging temperature and is kept; and 4, after cooling to room temperature, the workpiece after creep aging forming is unloaded and obtained. According to the forming method, the aluminum alloy plate is pressurized in a mechanical loading mode, so that a plurality of workpieces with different curvatures can be formed, and compared with vacuum film pasting in the prior art, the pre-preparation time canbe reduced by about 30%.

Owner:CENT SOUTH UNIV

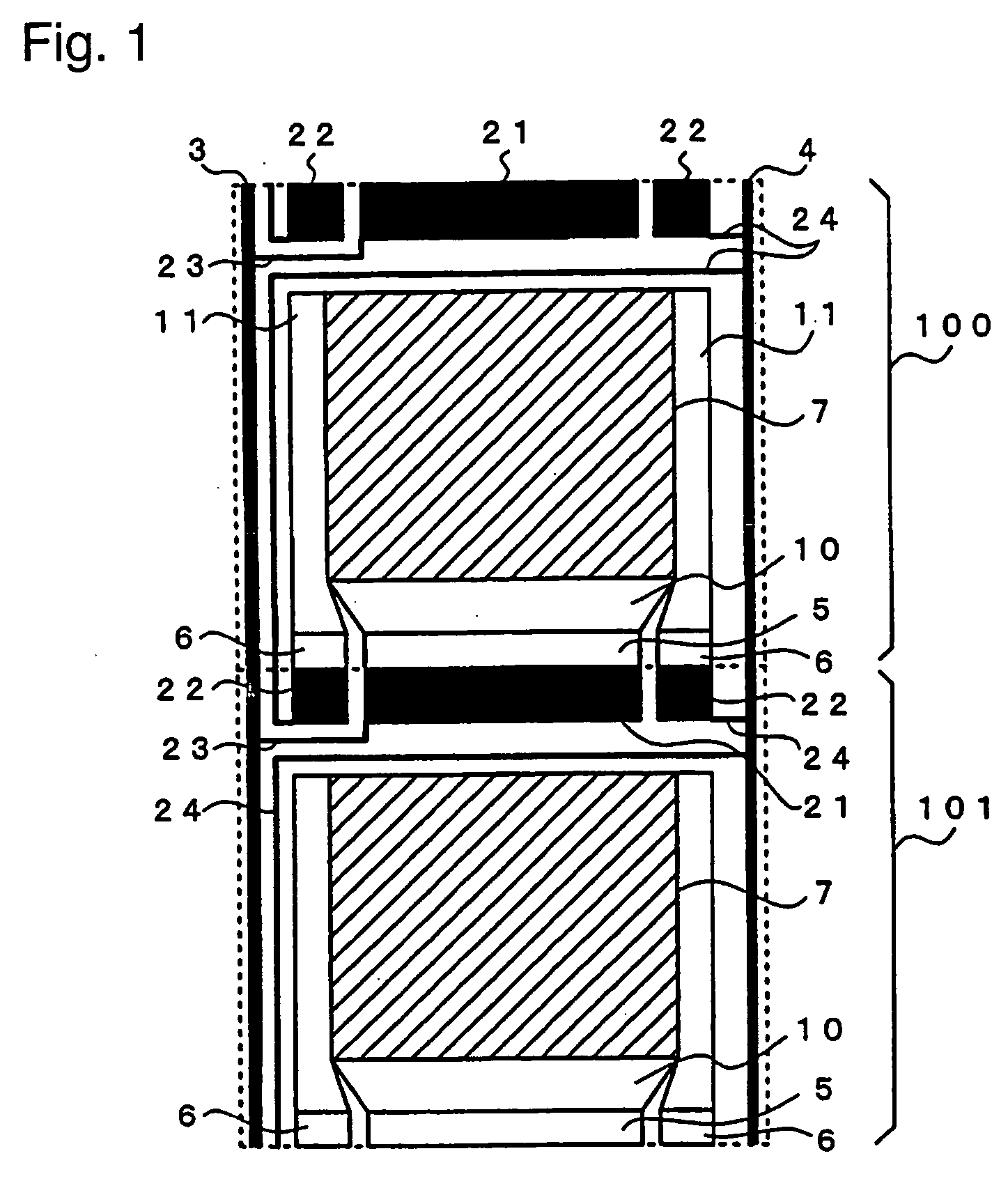

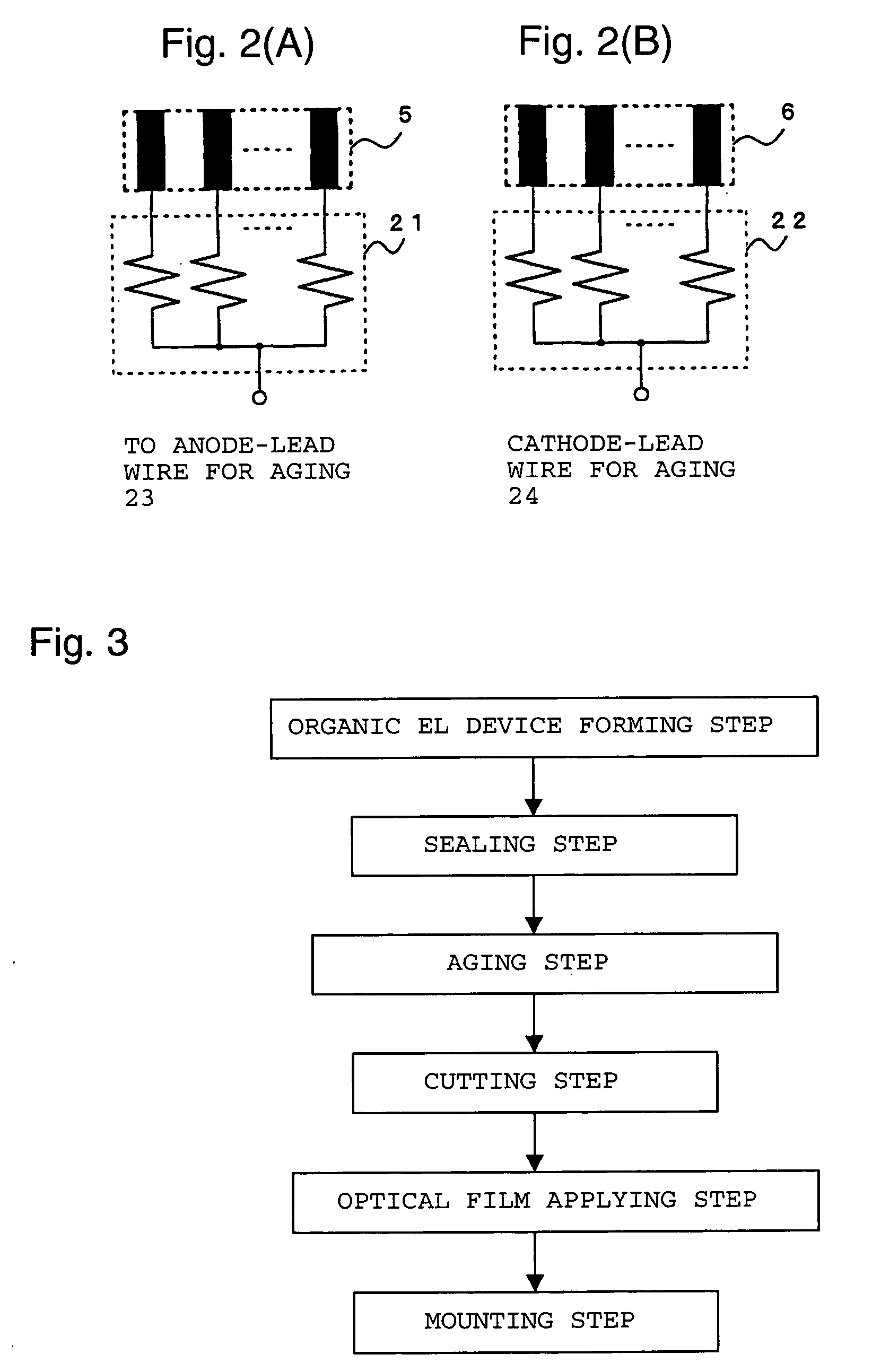

Substrate for organic EL display devices and organic EL display devices

InactiveUS20050264180A1Efficient executionIncrease resistanceDischarge tube luminescnet screensStatic indicating devicesDisplay deviceEngineering

A first organic EL display device has cathode-common wires for aging, first and second connection resistances at cathode side for aging, and a cathode-lead wire for aging formed thereon, the cathode-lead wire for aging connecting between a first connection resistance at cathode side for aging on a side remote from the cathode-common wires for aging and the cathode-common wires for aging. The cathode-lead wire for aging is drawn out of the first connection resistance at cathode side for aging, passes outside cathode circuitous wiring in a second organic EL display device adjacent the first organic EL display device, passes through a space defined by the second organic EL display device, first and second connection resistances at cathode side for aging of the second organic EL display device, and a connection resistance at anode side for aging of the second organic EL display device, and is connected to the cathode-common wires for aging.

Owner:KYOCERA CORP

Creep age forming method for wallboard and pre-pressing mold

The invention discloses a method for creep aging forming of wall panels and a pre-pressing mold. First, the pre-pressing mold is set on the workbench of a thermoforming machine tool, and then the wall panel blank is placed on the discharging platform of the pre-pressing mold. Close the pre-compression mold; then provide the temperature required for the creep aging of the wall panel under the pressure-holding state, and keep the temperature exceeding the preset time threshold; finally, when the temperature drops to no higher than 60°C, take out the wall panel pieces. The pre-press mold is loaded by a press, with uniform load and fast speed, especially suitable for rapid press forming of large-size and large-curvature wall panels. The invention breaks through the limitation that the existing creep aging forming must rely on pressure and heating in an autoclave.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

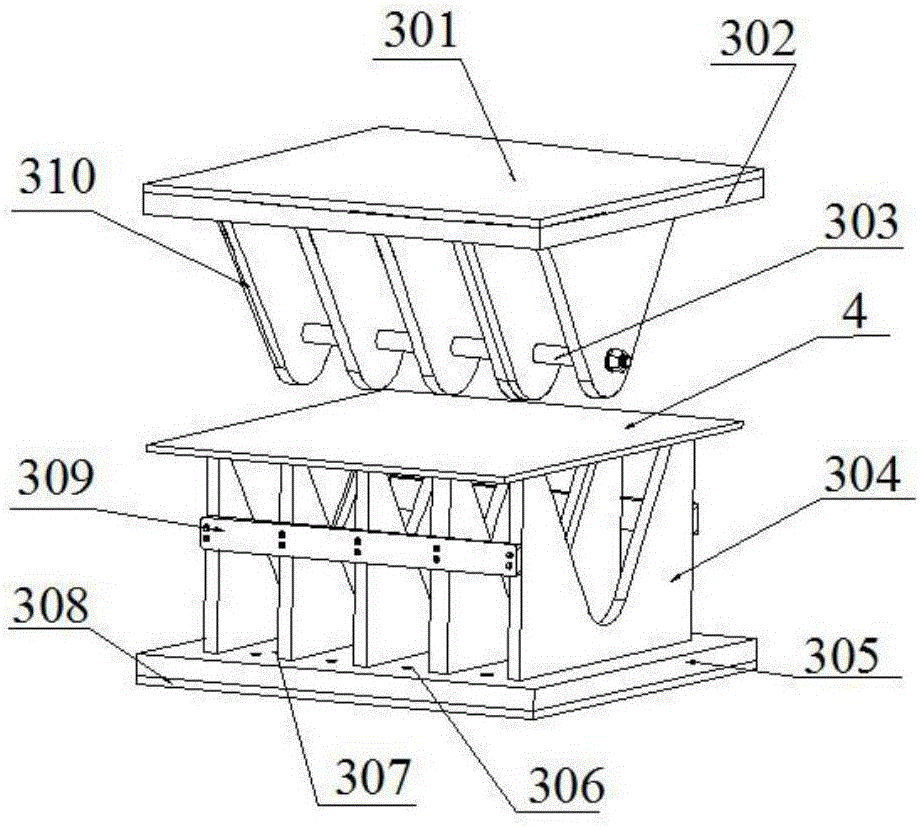

Combined type mechanical loading creep age forming device

The invention discloses a combined type mechanical loading creep age forming device which comprises an upper die plate, loading bolts, a male die and a female die. Two sides of the upper die plate aresupported through multiple stand columns; the multiple loading bolts are arranged on the upper die plate; the lower ends of the loading bolts contact the top surface of the male die; the male die andthe female die are formed by hinging multiple bidirectional shaped plate connecting units; and two sides of the male die and the female die are connected with the stand columns on two sides of the upper die plate. The combined type mechanical loading creep age forming device provided by the invention can flexibly adjust the shapes and the sizes of the curved surfaces of the male die and the female die so as to be suitable for parts with complicated-curvature curved surfaces and conventional single-curvature parts, and suitable for forming small-sized parts and large-sized parts. The combinedtype mechanical loading creep age forming device provided by the invention can be used for correcting a piece to be formed deformed due to resilience, and is simple in structure, low in production cost, and not only suitable for small-batch scientific research tests but also suitable for industrial production.

Owner:HUNAN UNIV OF SCI & TECH

Creep aging forming method for Al-Cu-Mg series alloy sheet material

InactiveCN102912268AImprove mechanical propertiesReduce the degree of anisotropyCreep stressRoom temperature

The invention discloses a creep aging forming method for an Al-Cu-Mg series alloy sheet material. The creep aging forming method relates to a heat treatment method for reducing creep aging anisotropy of the Al-Cu-Mg alloy sheet material and improving an alloy performance. The method comprises the following steps of: water quenching after adopting solid-solution treatment at 490-505 DEG C for 30-70 minutes, carrying out 2-10% of predeformation processing on a quenched sheet material, and then carrying out creep aging, wherein a creep temperature is 150-200 DEG C; creep time is 0-12 hours; creep stress is 150-300 MPa, and predeformation processing time is controlled within 4 hours. By adopting the creep aging forming method to process an Al-Cu-Mg alloy, a mechanical property of the alloy sheet material can be improved and a degree of anisotropy of the sheet material can be reduced by controlling precipitation of an alloy creep aging strengthening phase. Compared with common thermal treatment, tensile strength of a room temperature is improved by at least 10%, and the anisotropy is reduced by at least 10% by adopting the creep aging forming method to process the Al-Cu-Mg alloy. The technique is simple in operation, and remarkable in effect. Compared with improvement of alloy microstructure components by a microalloying manner, cost is saved; the method is easy to achieve in industrial production, and comprehensive benefit is obviously higher than that of a reported processing method.

Owner:CENT SOUTH UNIV

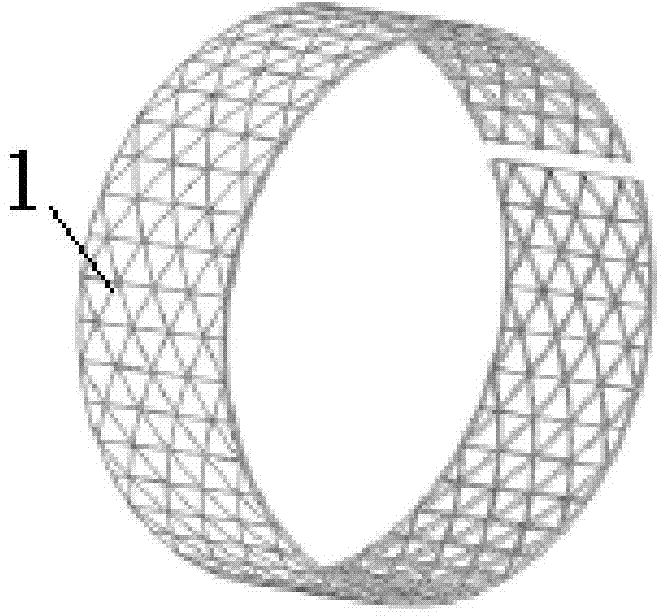

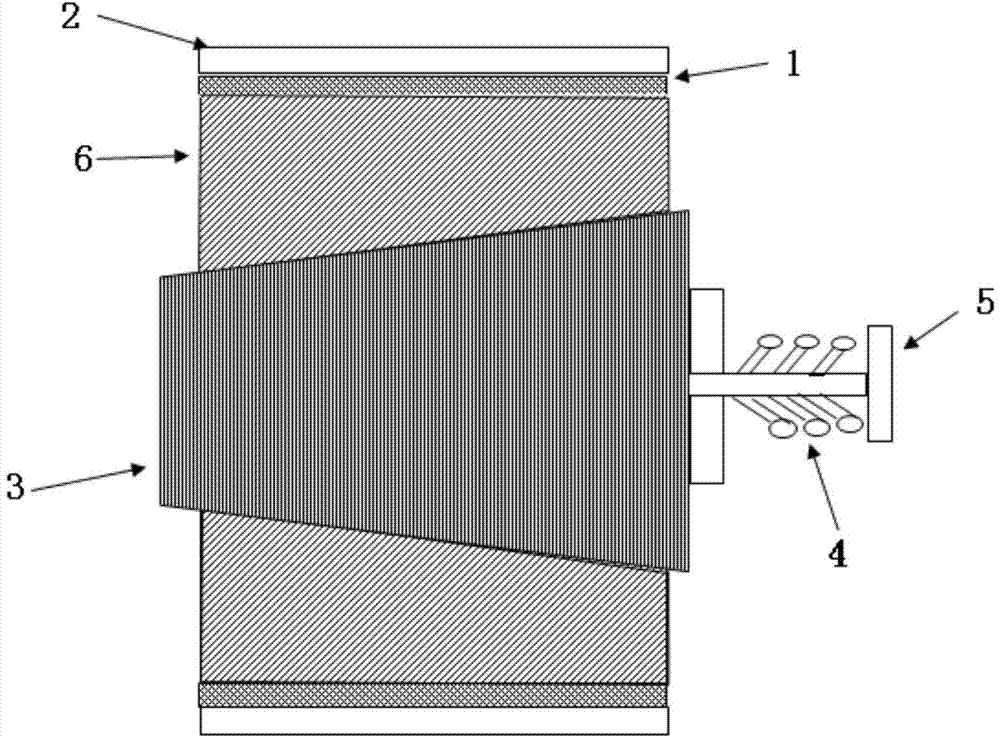

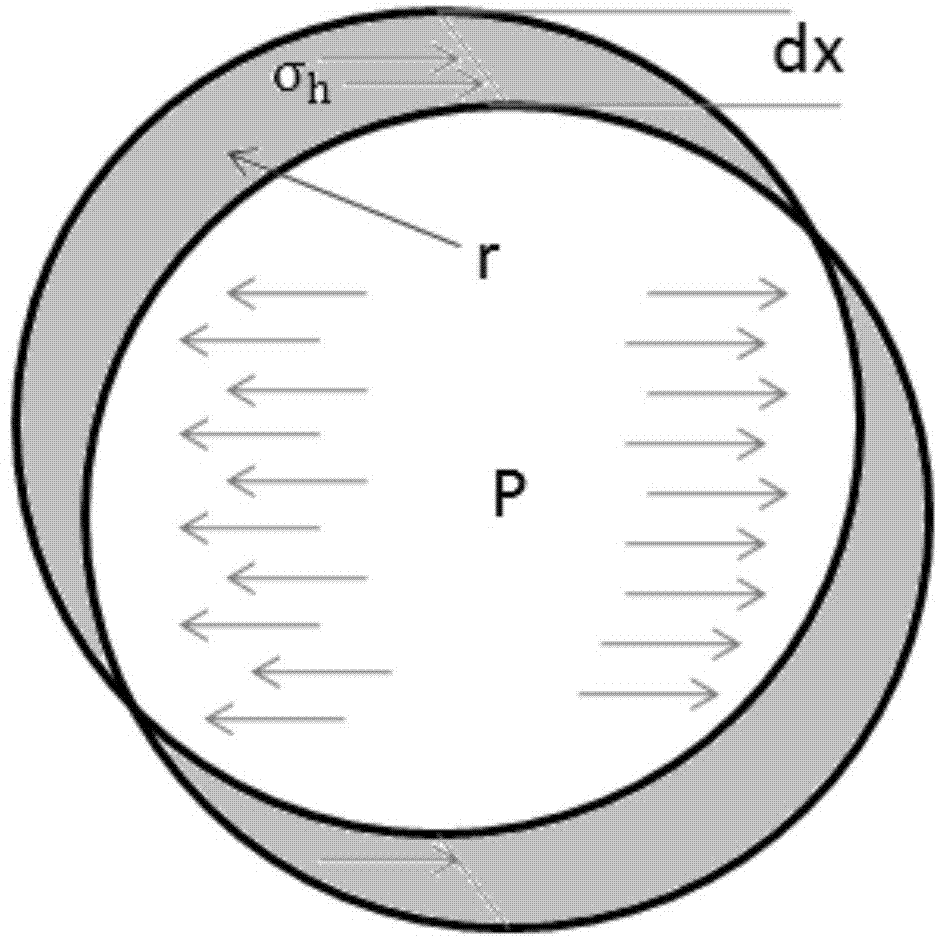

Storage-tank cylindrical-section integral wallboard creep aging forming method

ActiveCN104493430AImprove reliabilityReduce the number of weldsShaping toolsEngineeringElement modeling

The invention provides a storage-tank cylindrical-section integral wallboard creep aging forming method. The method includes the steps of a), subjecting a storage-tank cylindrical-section wallboard to machining according to drawing dimension, milling an interior grid or an exterior grid of the wallboard to dimensional requirements and then subjecting the wallboard to pre-roll bending on roll bending equipment; b), welding the wallboard to an integral cylindrical wallboard along a longitudinal joint; c), performing finite element modeling subjected to creep aging forming, calculating stress to be borne by a sticking mold of the cylindrical-section wallboard after welding, meanwhile, calculating rebound quantity and manufacturing a forming mold according to the stress and the rebound quantity; d), placing the wallboard into the mold and applying forming pressure by the mechanical mode; e), placing the assembled mold into an aging furnace for heat preservation at the temperature ranging from 150 to 200 DEG C for 10-30 hours, and then taking out the mold from the aging furnace to obtain a cylindrical-section wallboard product. With the method, the storage-tank cylindrical-section integral wallboard is formed and welded at one step, the number of welding joints is reduced, and reliability in tank storage is improved.

Owner:CAPITAL AEROSPACE MACHINERY +1

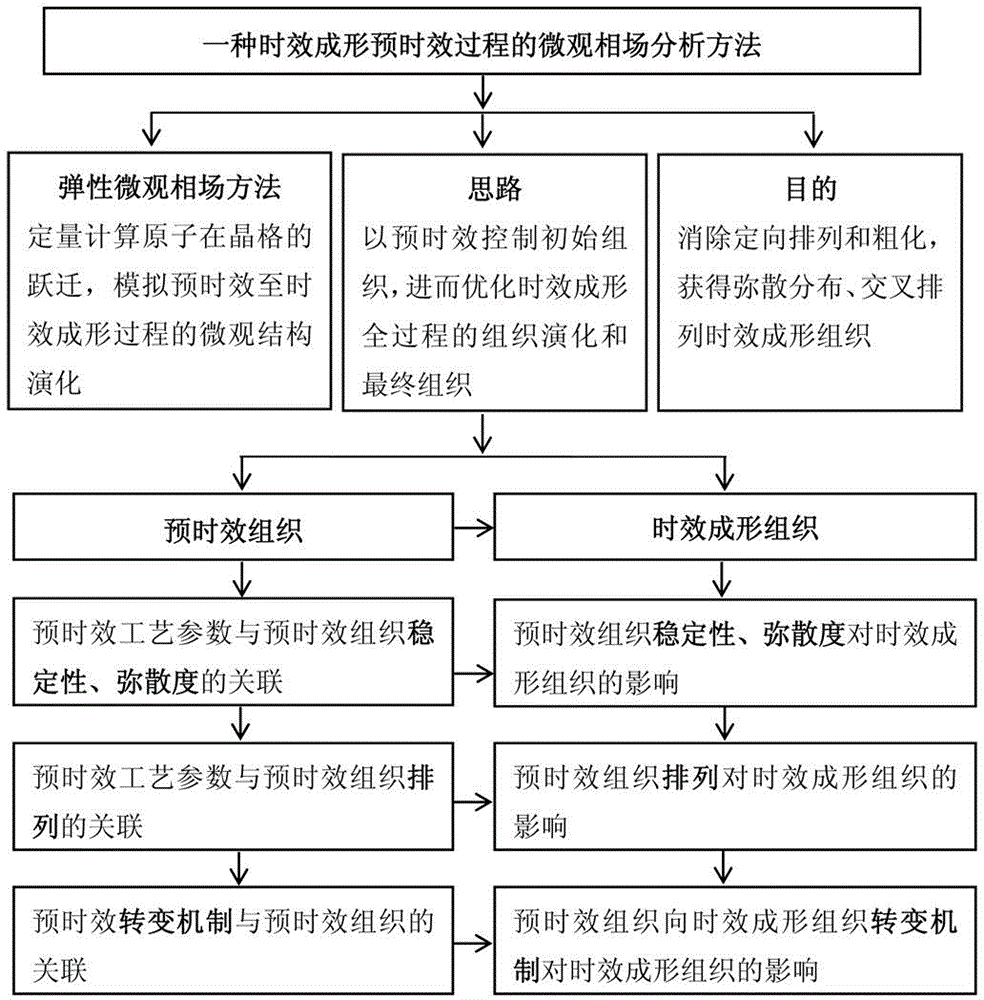

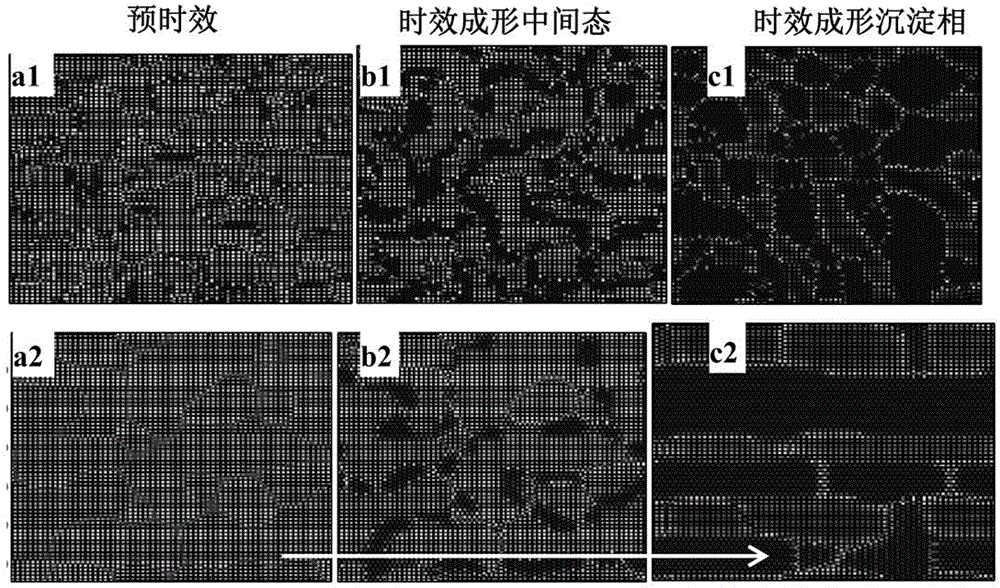

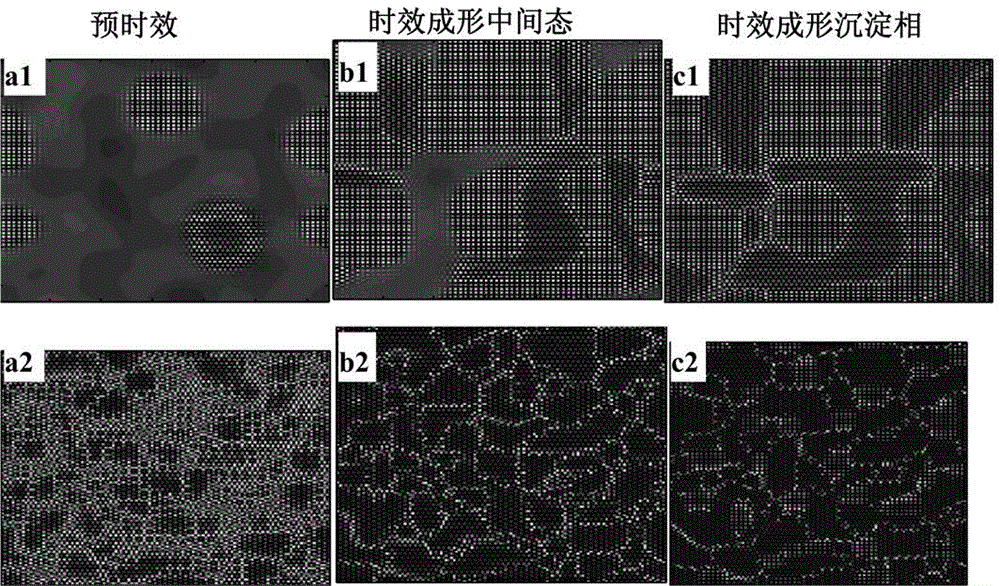

Microcosmic phase field analysis method in age forming and pre-ageing process

The invention discloses a microcosmic phase field analysis method in the age forming and pre-ageing process. A phase field model with the atomic scales of a macroscopic / nano stress field coupled is adopted, pre-ageing tissue hereditary of age forming is simulated, the influence rule of a pre-ageing tissue forming mechanism to a pre-ageing tissue structure is analyzed according to different precipitation tissue transformation mechanisms, the influence of the pre-ageing tissue forming mechanism and the mechanism used for transforming pre-ageing tissue to age forming tissue on the hereditary effect is obtained, and the response relation of the age forming tissue dispersity and layout is obtained. The method includes the step of first pre-ageing tissue control and the step of the hereditary effect of the second pre-ageing tissue on the age forming tissue. According to the method, the age forming precipitated phase early-stage shape is changed fundamentally, hence, age forming ending tissue is optimized, crystalline grain largeness and orientation arrangement are eliminated, and the tissue shape of dispersion distribution and cross arrangement with the refined crystalline strengthening effect and the dispersion strengthening effect is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com