Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308results about How to "Reduce the number of welds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Installing method for main pipeline of coolant system of nuclear power station

ActiveCN102169736ASimple structureReduce elbowNuclear energy generationReactors manufactureNumerical controlPressurized water reactor

The invention relates to an installing method for a main pipeline of a coolant system of a nuclear power station, which is characterized in that the main pipeline of the coolant system of a reactor of the pressurized water reactor nuclear power station comprises a cool section (41) and a hot section (42), and a steam generator is directly connected with a main pump. According to the invention, the problem that the main pipeline is installed and welded by only a pressure container or steam generator in place by adopting the installing method of the main pipeline without a transition section issolved, and technical limit that the main pipeline is installed after the pressure container is in place and the steam generator or main pump is in place in the traditional main pipeline constructiontechnology is eliminated. A main pipeline groove is processed by adopting a site numerical control machining technology, the main pipeline and equipment connected with the main pipeline are subjectedto measurement, modeling and process monitoring by adopting a laser tracking measuring and 3D modeling technology, the main pipeline is regulated to meet the assembly welding requirement and is installed by using a narrow TIG (argon tungsten-arc welding) automatic welding technology, thus a feasible method is provided for shortening the construction period of the nuclear power station.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

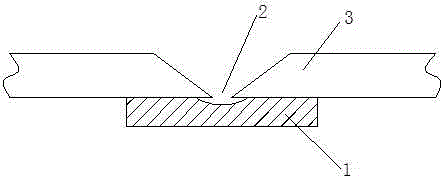

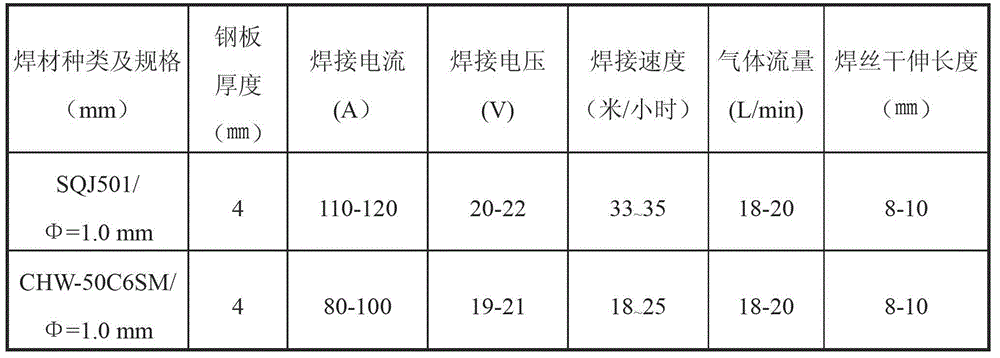

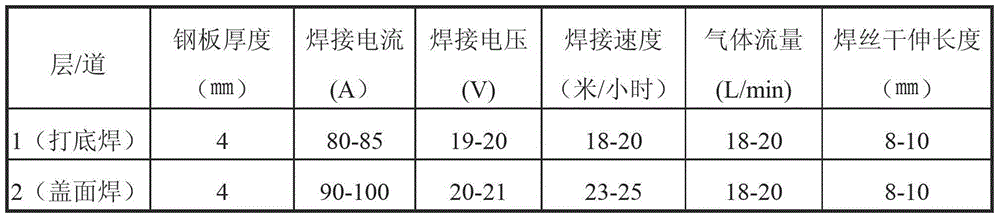

Single-side welding and double-side forming welding method for ceramic gasket

The invention discloses a single-side welding and double-side forming welding method for a ceramic gasket, and belongs to the welding field of material processing engineering. The method comprises the following steps of (1) treatment of grooves of abutted plates; (2) installation of the plates, and spot-welding fixing; (3) adding of the ceramic gasket; (4) baking for dehumidifying; (5) groove welding. The method does not need to carry out the operation that the welds of the back side are subjected to cleaning and welding operations after the structure is turned over, after the welds of the front side are welded, the double-side forming effect is directly realized, and the required matching of hoisting equipment and the required man-hours during turnover of the structure are reduced. The number of welds is reduced, and the operation of overhead welding positions is avoided. Therefore, the labor strength of workers is reduced, the welding difficulty is reduced, the production efficiency is greatly improved, and the production cost is reduced.

Owner:中船桂江造船有限公司

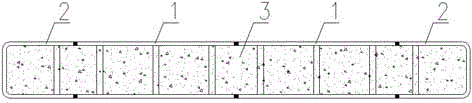

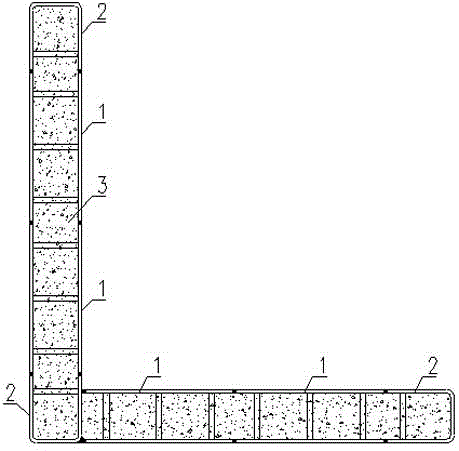

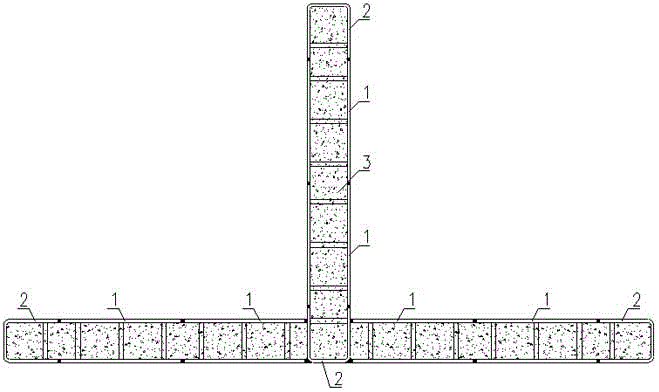

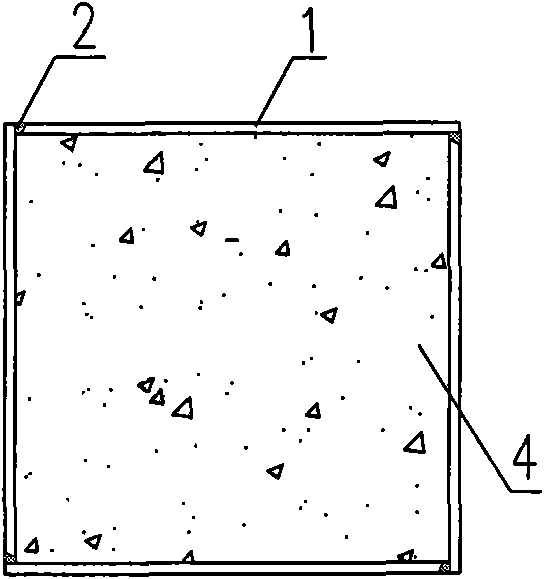

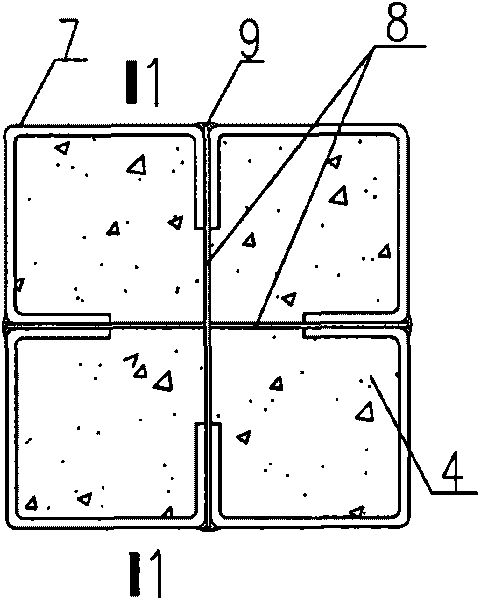

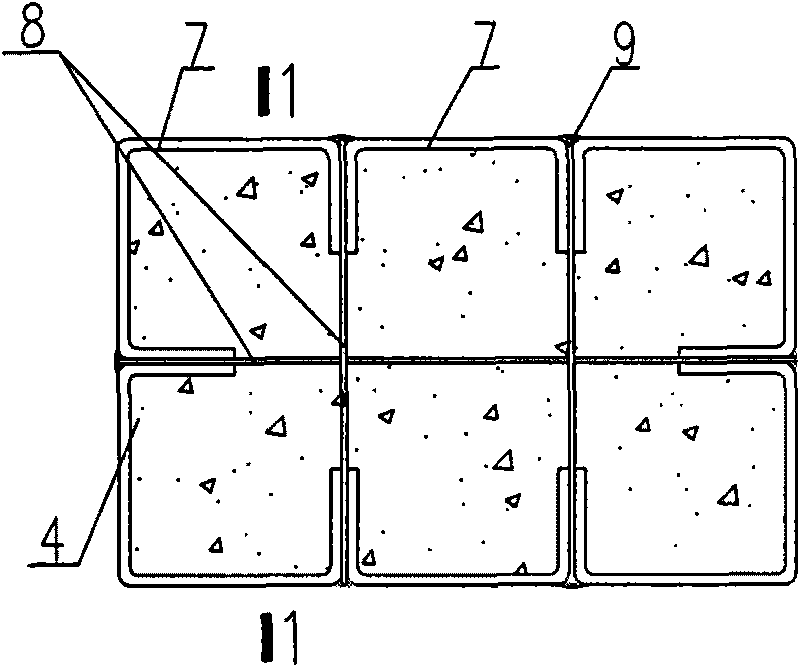

Double-steel-plate shear wall combined structure

The invention discloses a double-steel-plate shear wall combined structure. The double-steel-plate shear wall combined structure is formed by one or a plurality of double-steel-plate wall units and end members which are welded, concrete is poured into cavities formed by the double-steel-plate wall units and the end members, each double-steel-plate wall unit is formed by two steel plates and a connecting part which are welded, and the connecting part is arranged between the two steel plates. The cross section of the double-steel-plate shear wall combined structure can be in a straight line or L or T or Z or U shape. The double-steel-plate wall units and the end members can all be manufactured in a factory, welding operation and cutting operation can be finished by automatic equipment, a processing speed is quick, materials are saved, and the labor cost is saved. The double-steel-plate wall unit and the end members are utilized as concrete formworks, so that formwork construction is avoided, and the double-steel-plate shear wall combined structure is quick in constructing speed, convenient to construct and environmentally friendly.

Owner:石柏林

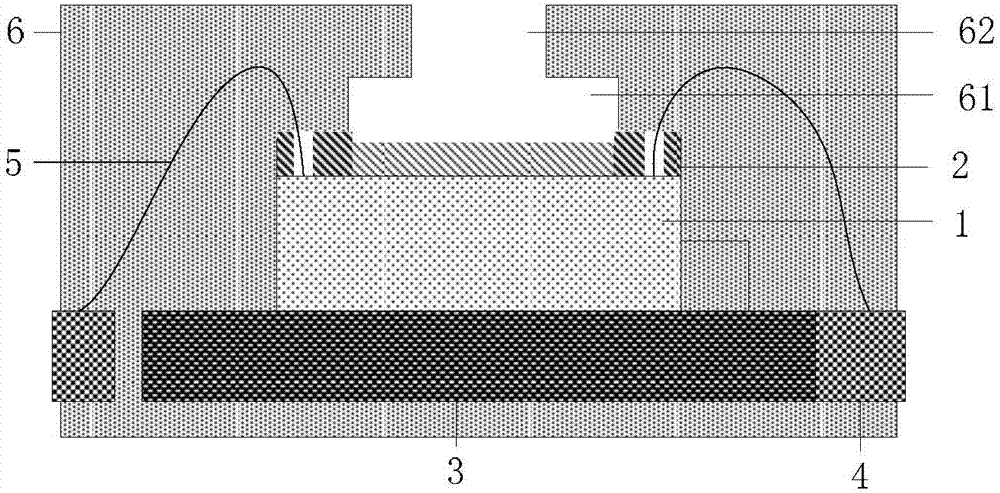

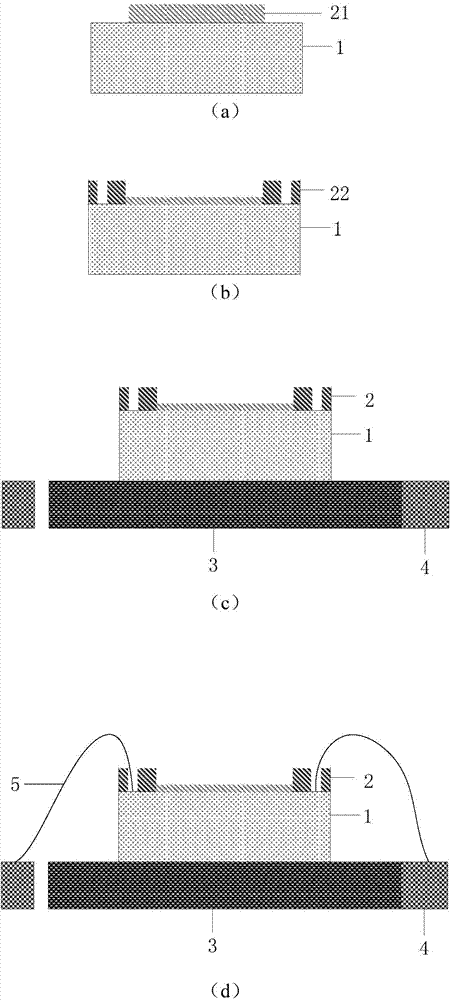

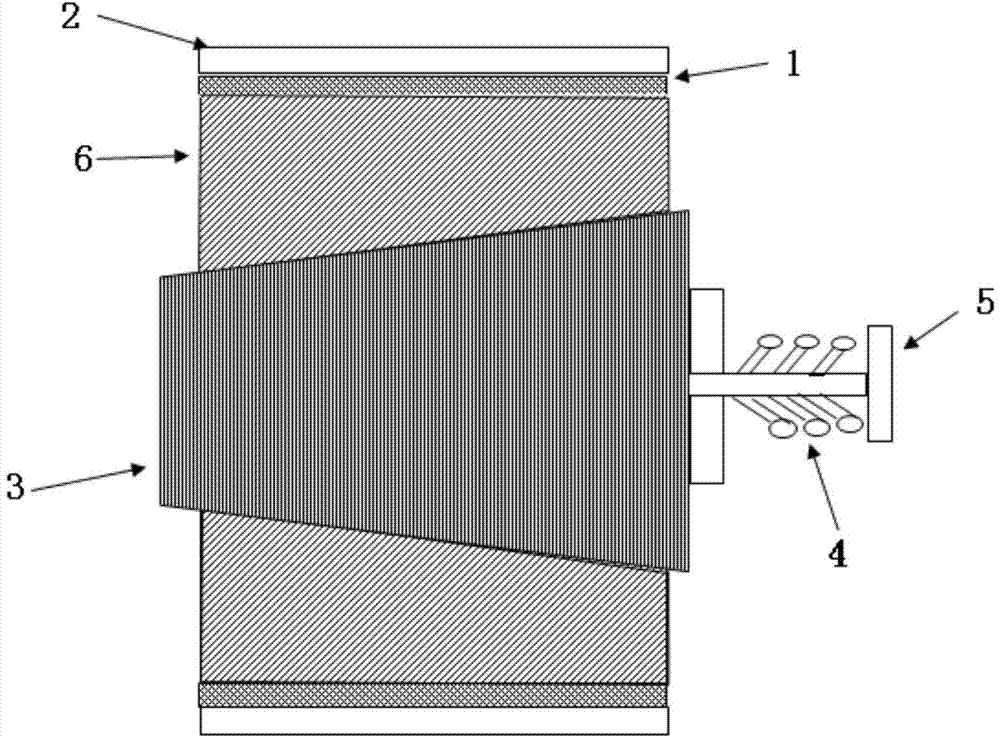

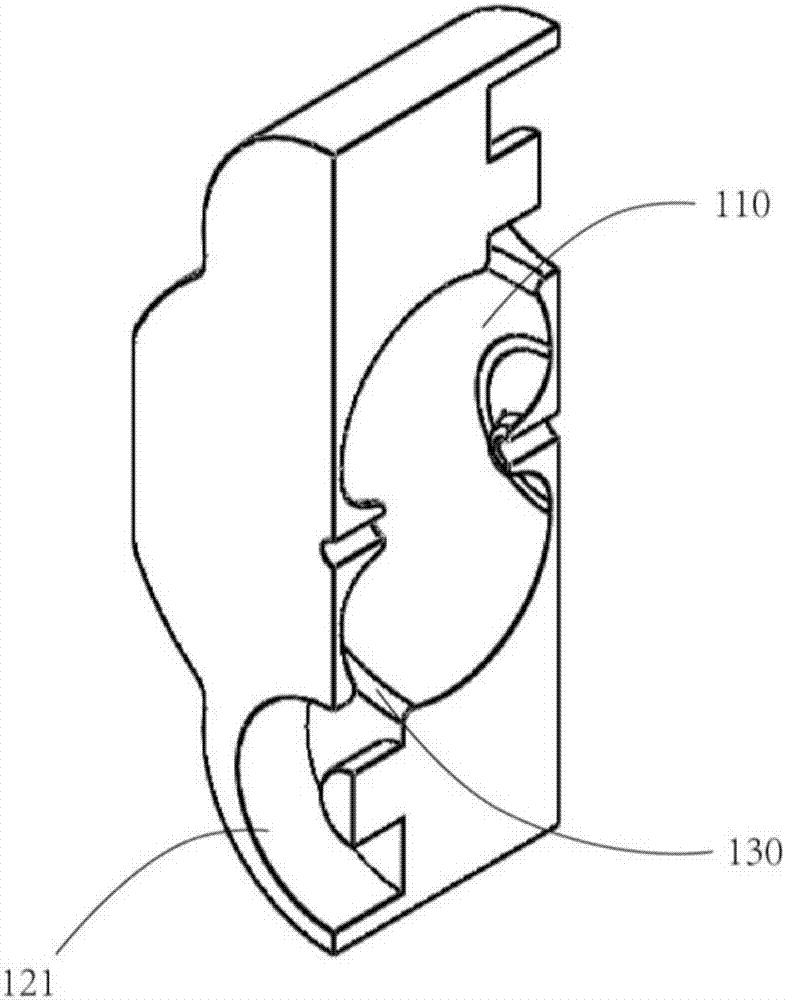

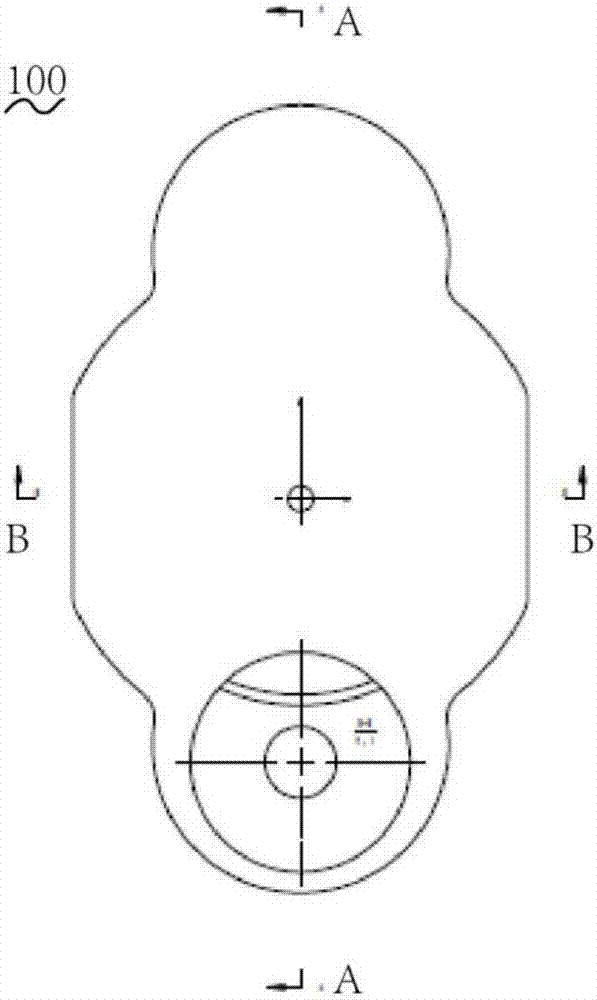

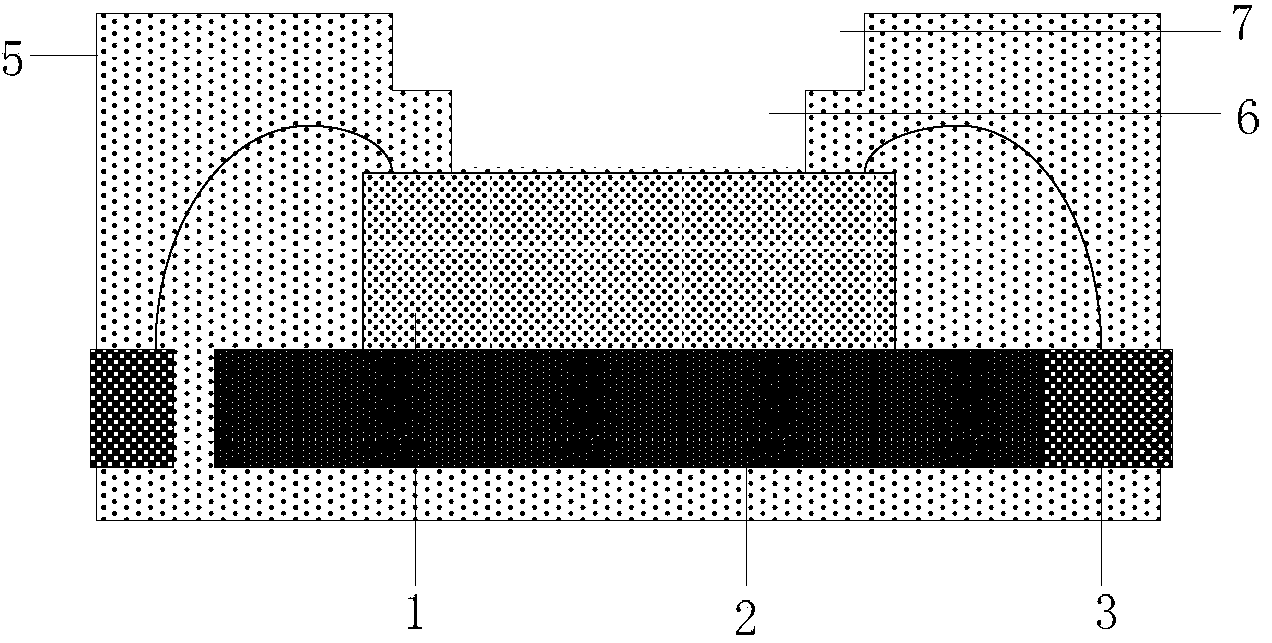

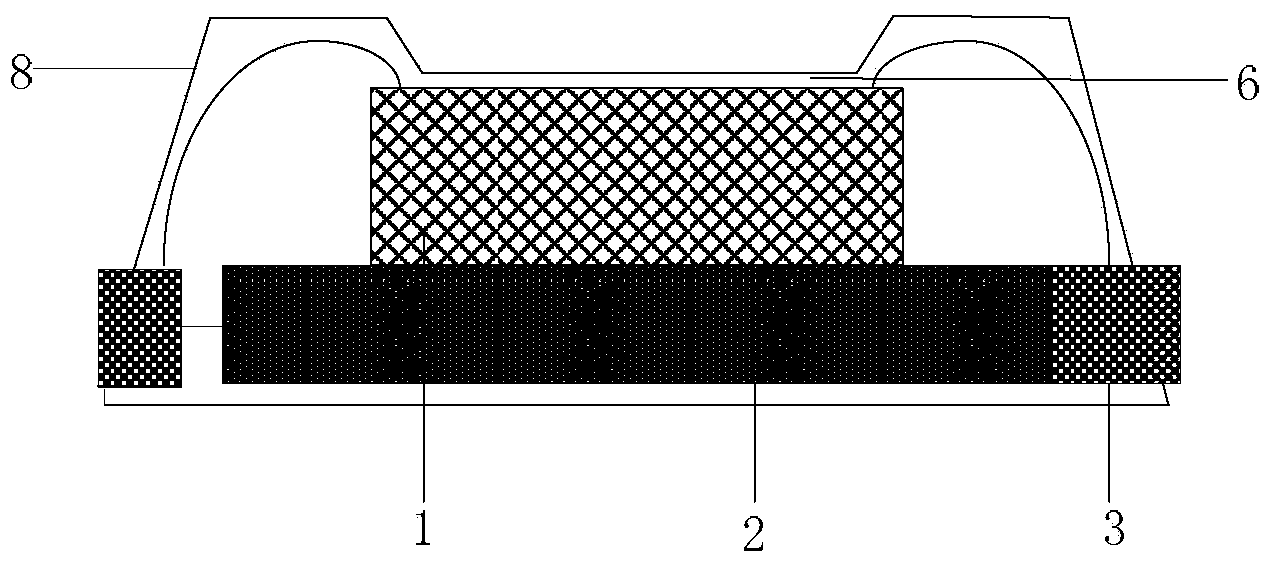

Stress dispersion MEMS (Micro-Electro-Mechanical Systems) plastic package pressure sensor and preparation method thereof

ActiveCN103674399AImprove ventilationImprove cooling effectPrecision positioning equipmentFluid pressure measurement using ohmic-resistance variationManufacturing technologyEngineering

The invention discloses a stress dispersion MEMS (Micro-Electro-Mechanical Systems) plastic package pressure sensor and a preparation method thereof. The plastic package pressure sensor disclosed by the invention comprises a pressure chip, a pressure buffer layer, a base plate, a pin frame, conducting wires and a plastic package body, wherein a flexible glue thin film is covered on the upper surface of the pressure chip, and welding points of the pressure chip and the conducting wires are exposed to form the pressure buffer layer; a cavity is arranged between the plastic package body and the pressure buffer layer, and a through hole is formed between the cavity and the outer surface of the plastic package body and communicated with the outside. According to the stress dispersion MEMS plastic package pressure sensor and the preparation method thereof, the pressure buffer layer with the flexible glue thin film is adopted for covering a sensitive structure of the pressure chip, and the pressure during plastic injection is reduced through stress dispersion of the pressure buffer layer; moreover, the cavity with large area is arranged on the pressure buffer layer, and is beneficial to ventilating and radiating the pressure chip, so that the function that the performance of the pressure chip is complete and normal is ensured; the plastic package pressure sensor has the characteristics that the manufacturing technology is simple and advanced, the pressure chip is not influenced by stress, the performance is complete, the size is relatively smaller, the radiation is good, and the like.

Owner:安徽京芯传感科技有限公司

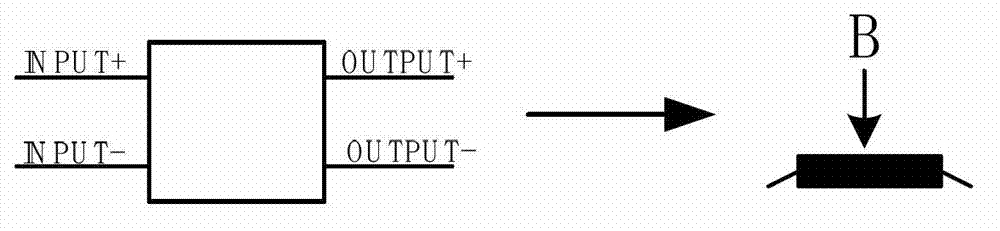

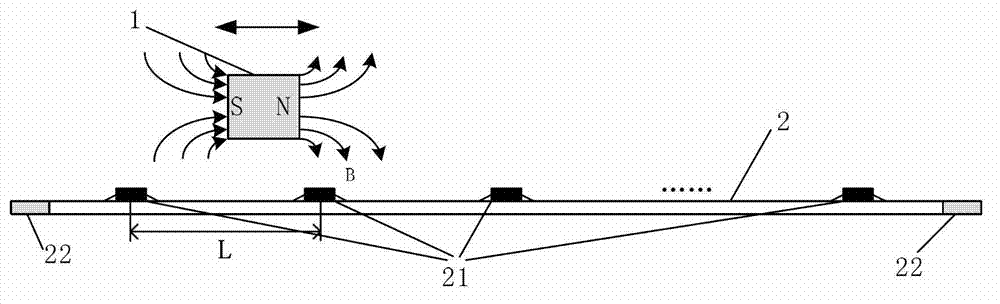

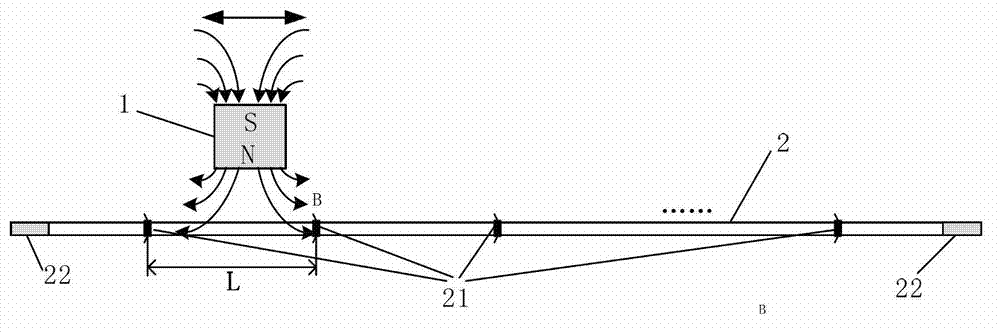

Device and method for measuring long stroke displacement based on Hall effect

InactiveCN102878916ALarge measuring rangeReduce the number of weldsUsing electrical meansLevel indicators by floatsTime-sharingConstant current source

The invention belongs to the technical field of physical parameter measurement and relates to a device for measuring long stroke displacement based on the Hall effect. The device comprises a single chip microcomputer, a constant current source, a signal processing circuit, an analog-to-digital converter and a sensor array, wherein the sensor array is at least one group of linear hall sensors; each group of the linear hall sensors are uniformly and linearly arranged on a PCB (Printed Circuit Board); the space between the adjacent linear hall sensors is not less than the size of a magnet on a magnetic float in the arrangement direction of the sensor array; the differential outputs of the linear sensors are multiplexed with two differential voltage signal transmission lines through an n-channel analog multiplexer; the two differential voltage signal transmission lines are connected with an input interface of the signal processing circuit; the two adjacent PCBs are connected through an expansion interface; and each group of the linear hall sensors are powered by one same constant current source in a time sharing manner. The device has the advantages of low power consumption, fewer adopted devices, convenience in maintenance and lower cost.

Owner:杨会峰

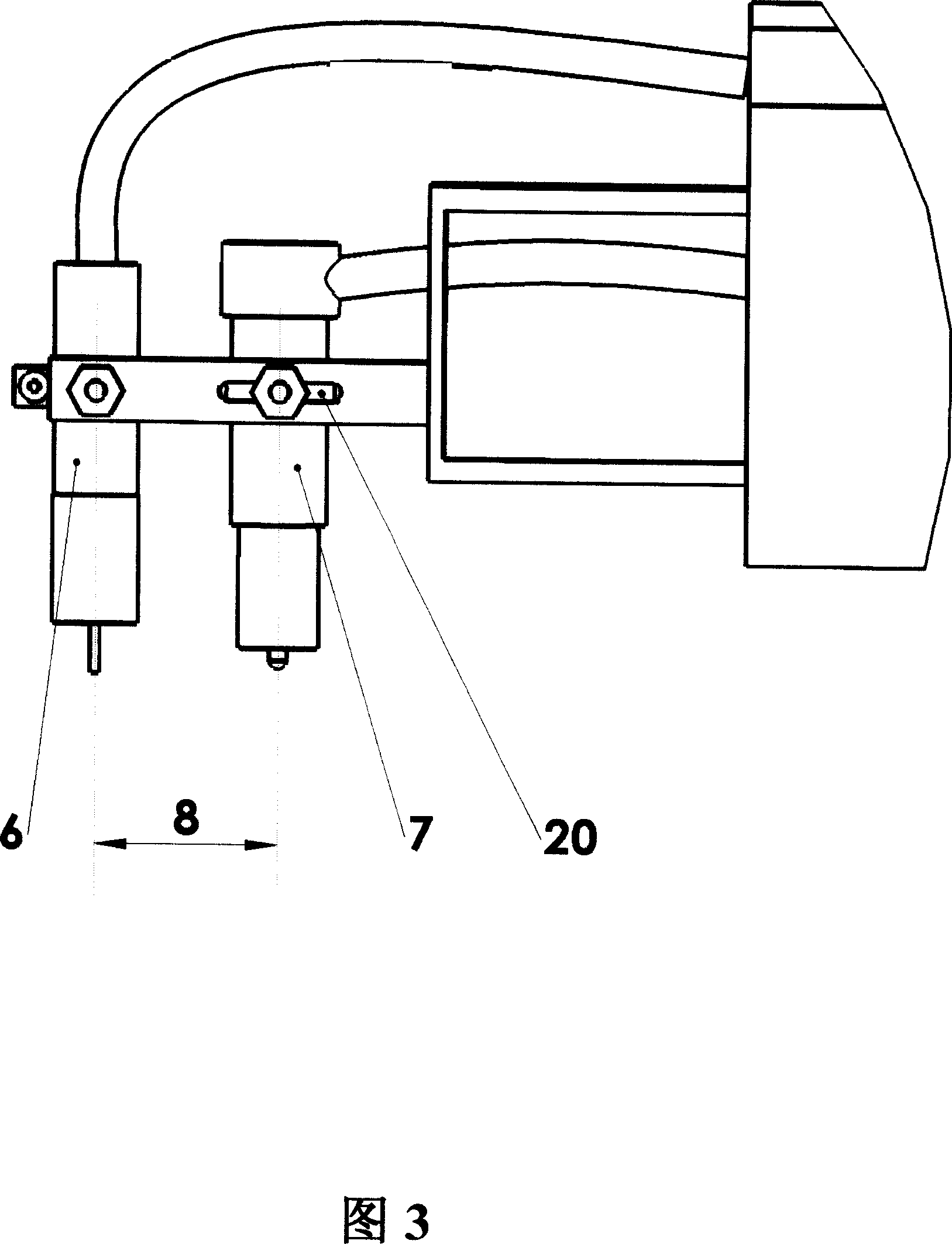

Single-side MIG and TIG synchronous automatic soldering method and device

ActiveCN101077545AReduce the number of weldsReduce welding distortionArc welding apparatusMolten bathMetallic materials

The present invention relates to automatic welding technology, and is especially automatic synchronous single side MIG and TIG welding method and apparatus. The present invention features that on the single welded surface, the front MIG welding gun and the rear TIG welding gun form two molten bath simultaneously, and after some time T, the TIG welding gun forms one TIG molten bath in the position with MIG molten bath. The present invention is suitable for automatic single side welding of homogeneous or hetreogeneous Al, Al alloy material as well as other metal material.

Owner:XIAN XD SWITCHGEAR ELECTIC CO LTD

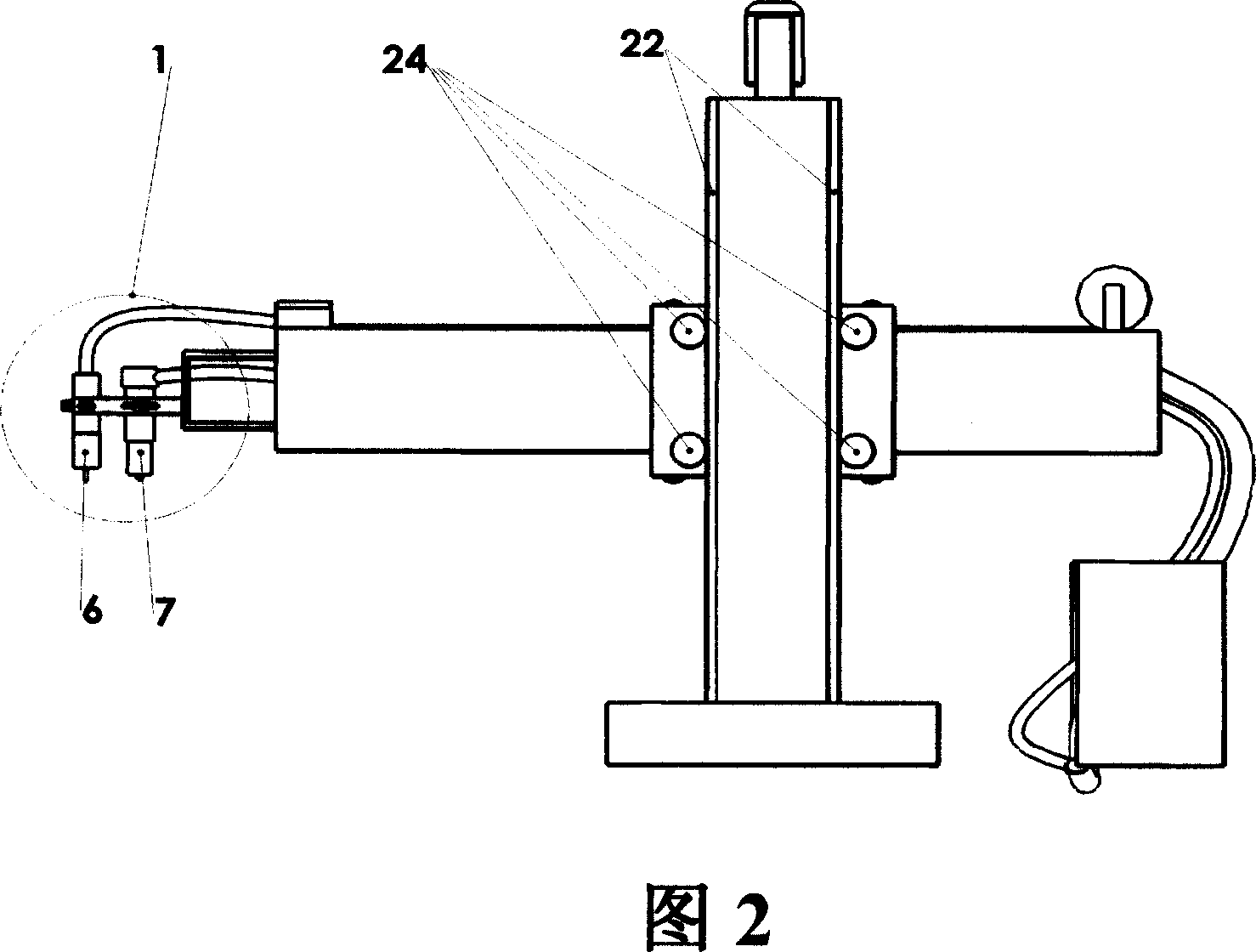

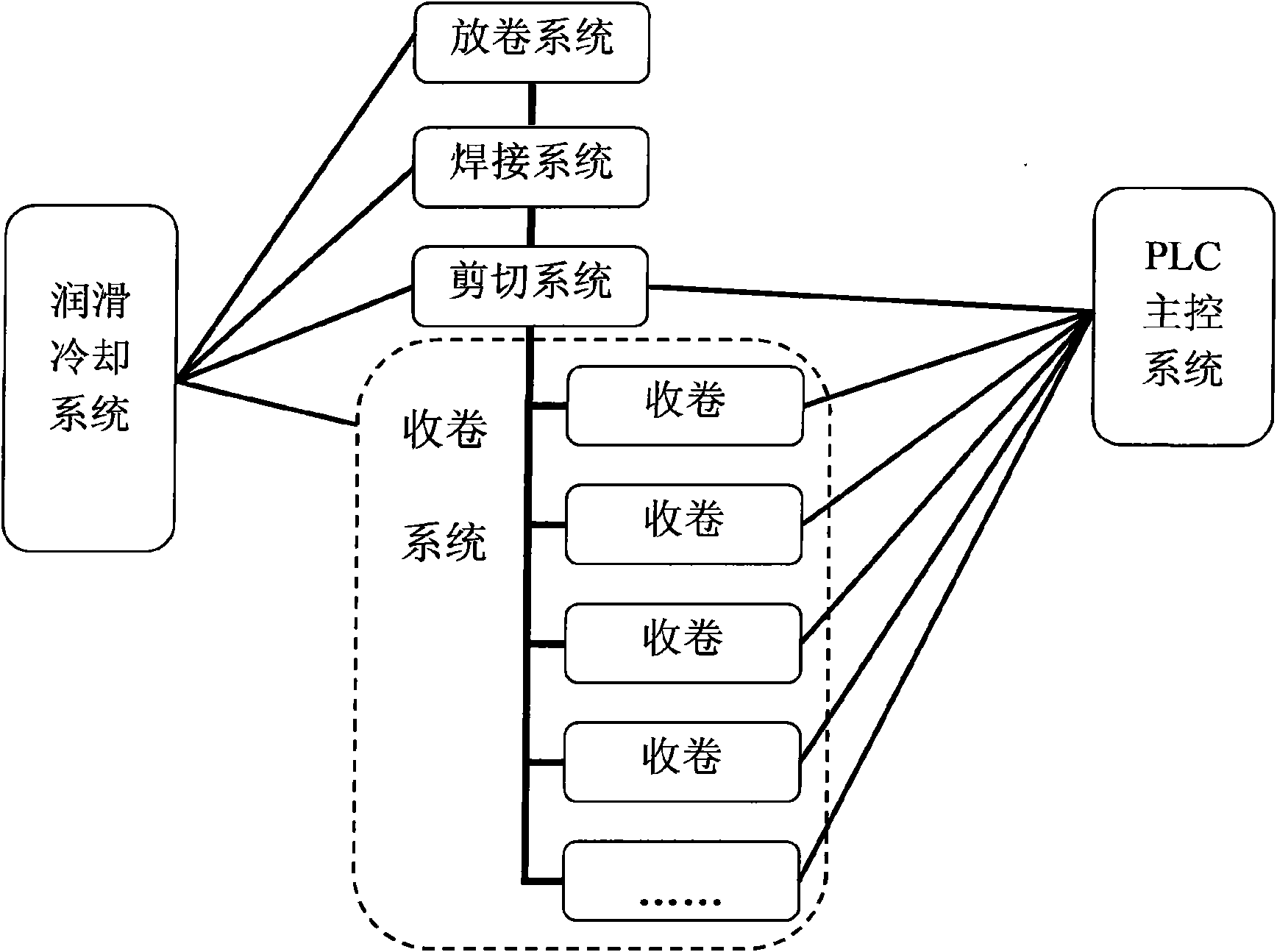

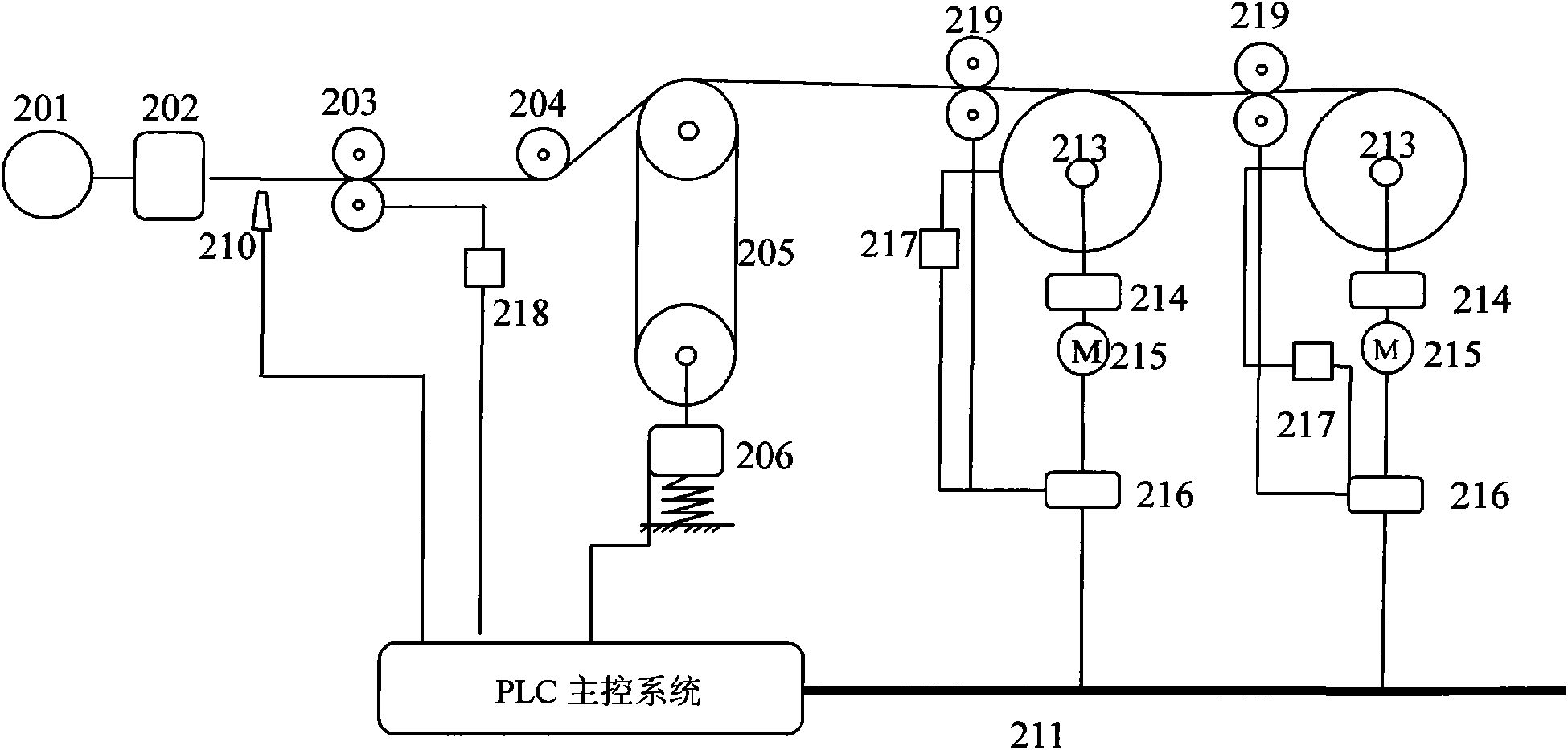

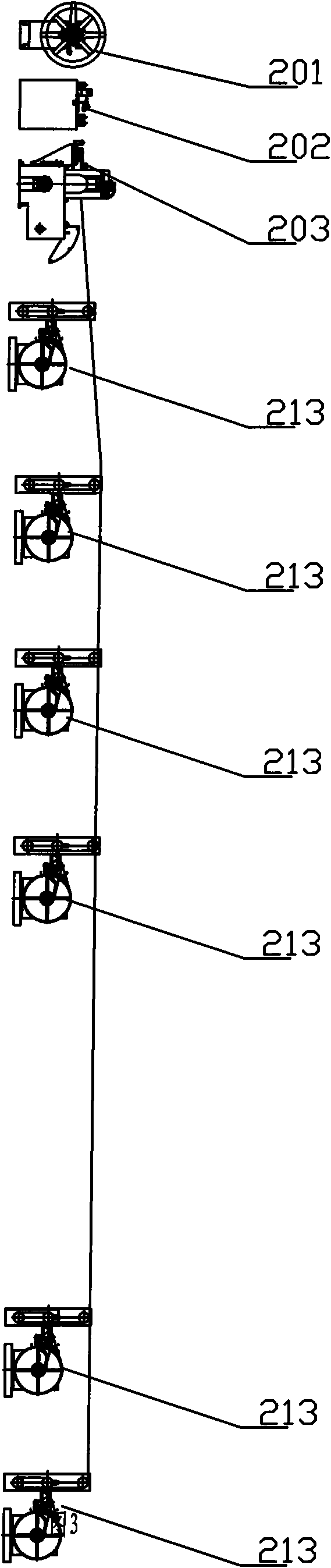

High-speed multithreading cutting-reeling-welding integrated production line and production method thereof

InactiveCN101618507AImprove work efficiencyReduce the number of weldsOther manufacturing equipments/toolsProduction lineControl system

The invention discloses a high-speed multithreading cutting-reeling-welding integrated production line comprising an unreeling system, a welding system, a cutting system and a reeling system. The cutting system and the reeling system are controlled by a main control system; the reeling system comprises a plurality of reeling devices, a tension device and a tension sensor, wherein each reeling device comprises a reeling machine, a first sensor for detecting the operation state of the reeling machine and a linear speed detection device; the first sensor, the linear speed detection device and a motor are connected with the main control system by a driver; the tension device is a tensioner, and the tension sensor is connected with the main control system; the cutting system comprises a cutting machine and a second sensor which is connected with the main control system; and a third sensor is arranged between the cutting machine and the welding system, is connected with the main control system and is used for detecting the states of raw materials. The production line can be utilized to be controlled by the main control system for all the production processes comprising unreeling, welding, cutting and synchronously reeling a plurality of reeling machines; and the main control system also monitors the safety conditions of the whole processing process in real time.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

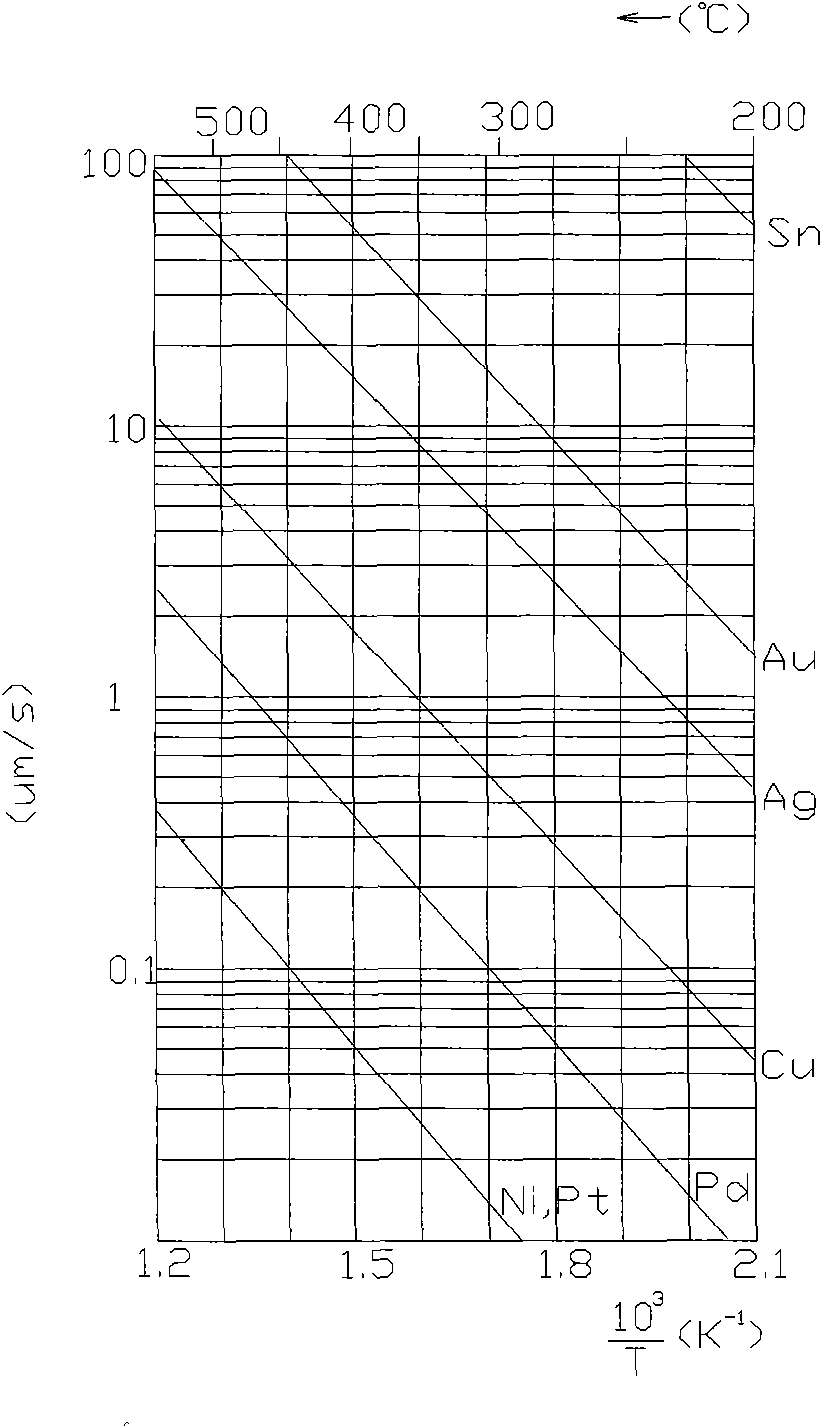

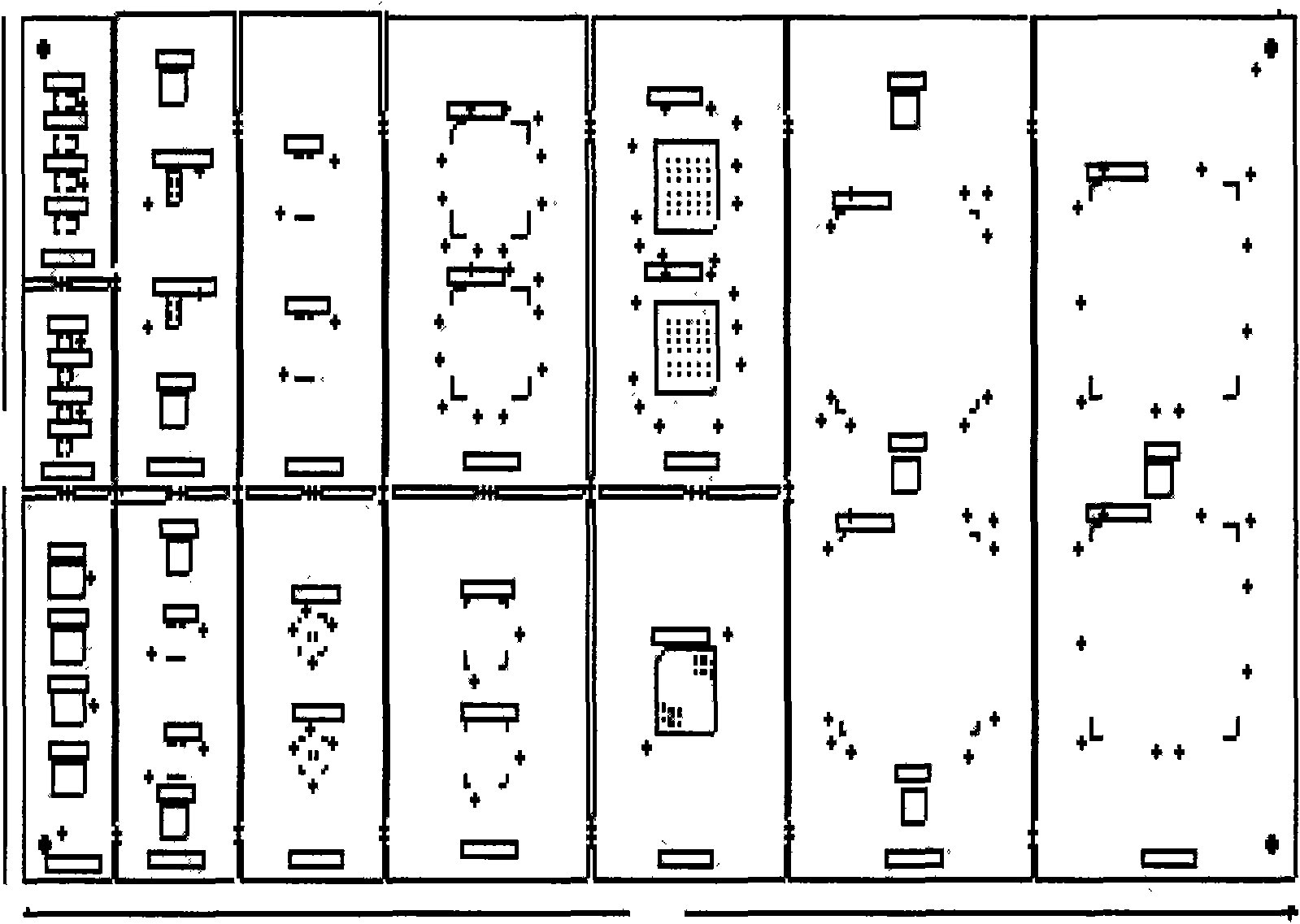

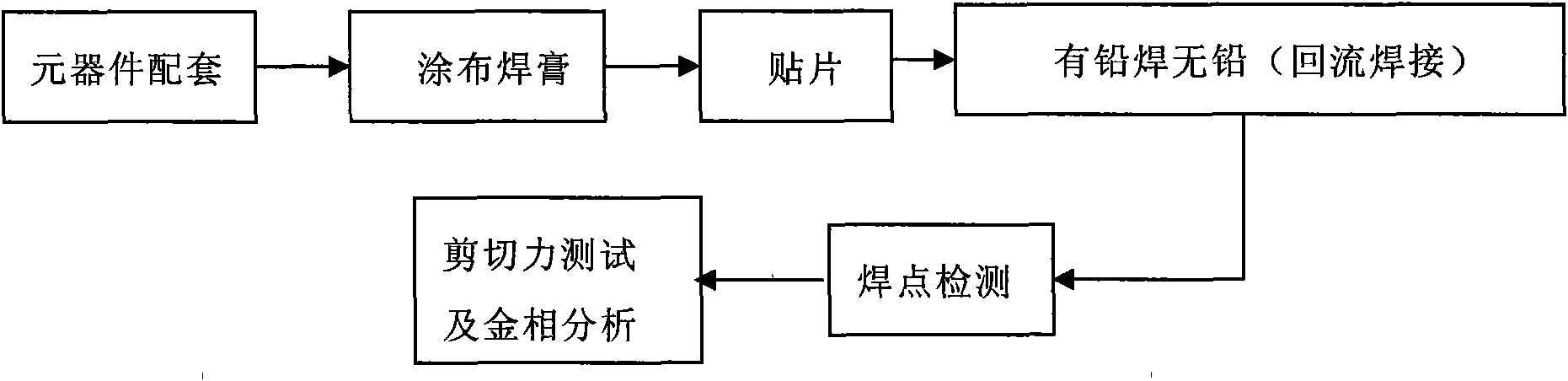

Method of welding printed circuit board containing mixed lead components and leadless components

ActiveCN101553092AIncrease soldering temperatureReliable weldingPrinted circuit assemblingWelding/cutting media/materialsTemperature curveEngineering

The present invention relates to a method of welding printed circuit board containing mixed lead components and leadless components, using lead solder and controlling welding temperature curve to improve welding peak temperature and prolong solder liquid phase time properly on the base of conventional lead welding technics to implement reliable welding of leadless components. Applying the invention provided technical scheme can implement solder paste coating, patching and welding in one time of most lead components and leadless components, of which the production efficiency is far higher than separate welding technics of lead components and leadless components. The invention provided method improves production efficiency and reduces materials control difficulty of production field while shorts production period of mixed products and reduces production cost.

Owner:BEIJING RES INST OF TELEMETRY +1

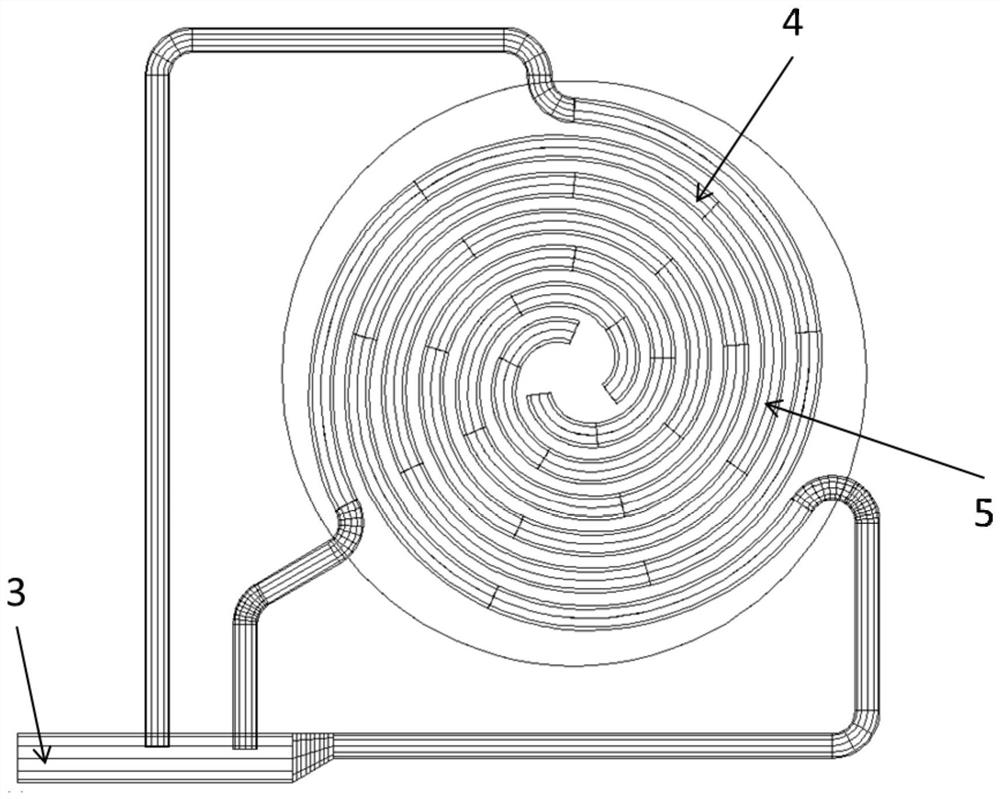

Double-layer pore plate type gas distributor easy to assemble

ActiveCN106640569AReduce the number of weldsReduce welding difficultyMachines/enginesUsing plasmaHollow cylinderEngineering

The invention discloses a double-layer pore plate type gas distributor easy to assemble. The double-layer pore plate type gas distributor easy to assemble comprises a gas guiding column, a distributor base, a first-layer pore plate, a second-layer pore plate, an outer baffle, an inner baffle and a fixing column. The gas guiding column, the distributor base, the outer baffle and the inner baffle are all hollow cylinders, the first-layer pore plate and the second-layer pore plate are both hollow circular plates, and the fixing column is a cylinder. One end of the distributor base is provided with holes for installation of the gas guiding column and the fixing column, the other end of the distributor base is provided with grooves for installation of the first-layer pore plate and the second-layer pore plate, and the first-layer pore plate and the second-layer pore plate are both provided with small holes for homogenizing gas. The outer baffle is fixedly connected with the outer side of the second-layer pore plate, the inner baffle is fixedly connected with the inner side of the second-layer pore plate, and the outer baffle and the inner baffle are further fixedly connected with the other end of the distributor base. Through the cooperation of the distributor base, the outer baffle and the inner baffle, the number of weld joints of the gas distributor is reduced, and the problem that a traditional gas distributor has multiple weld joints is solved.

Owner:BEIJING INST OF CONTROL ENG

Welded pipe and manufacturing method thereof

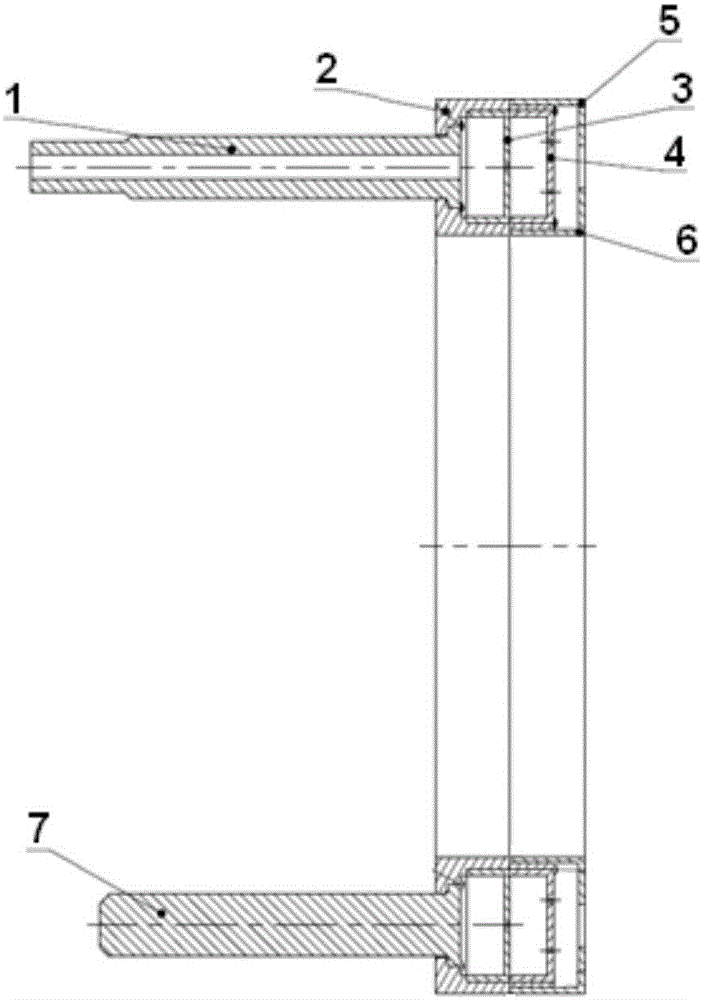

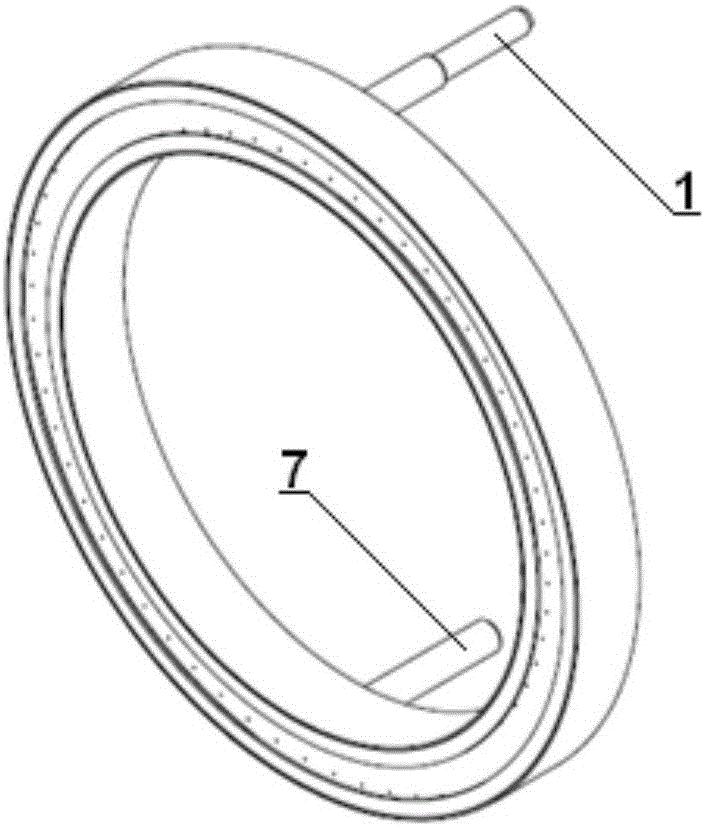

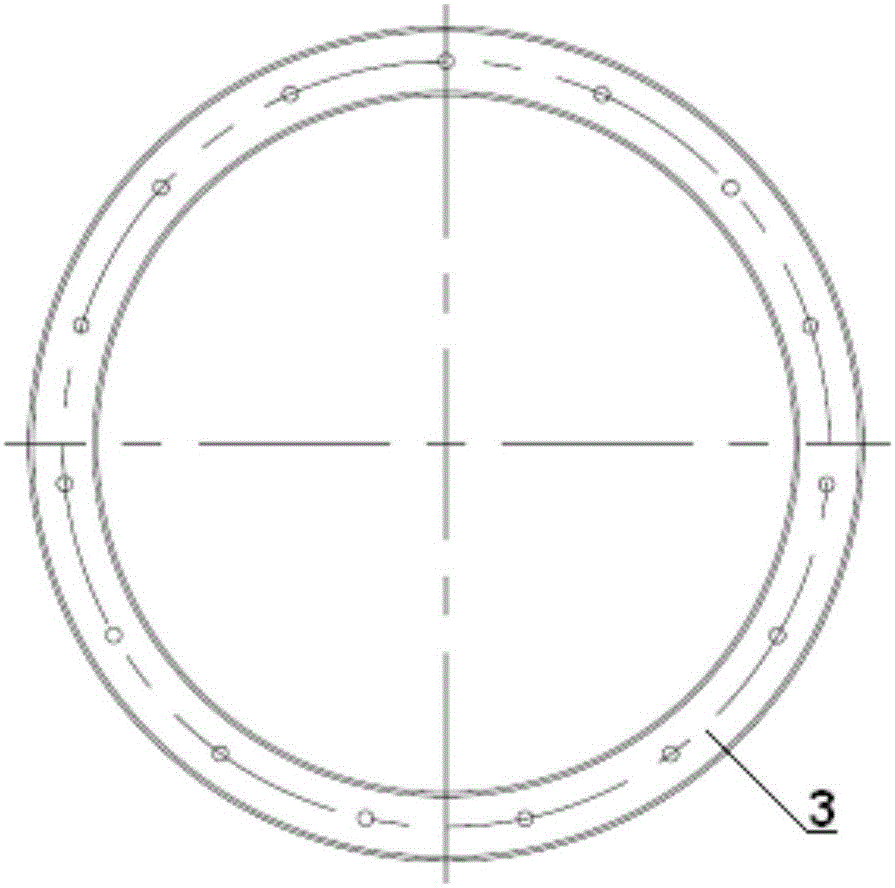

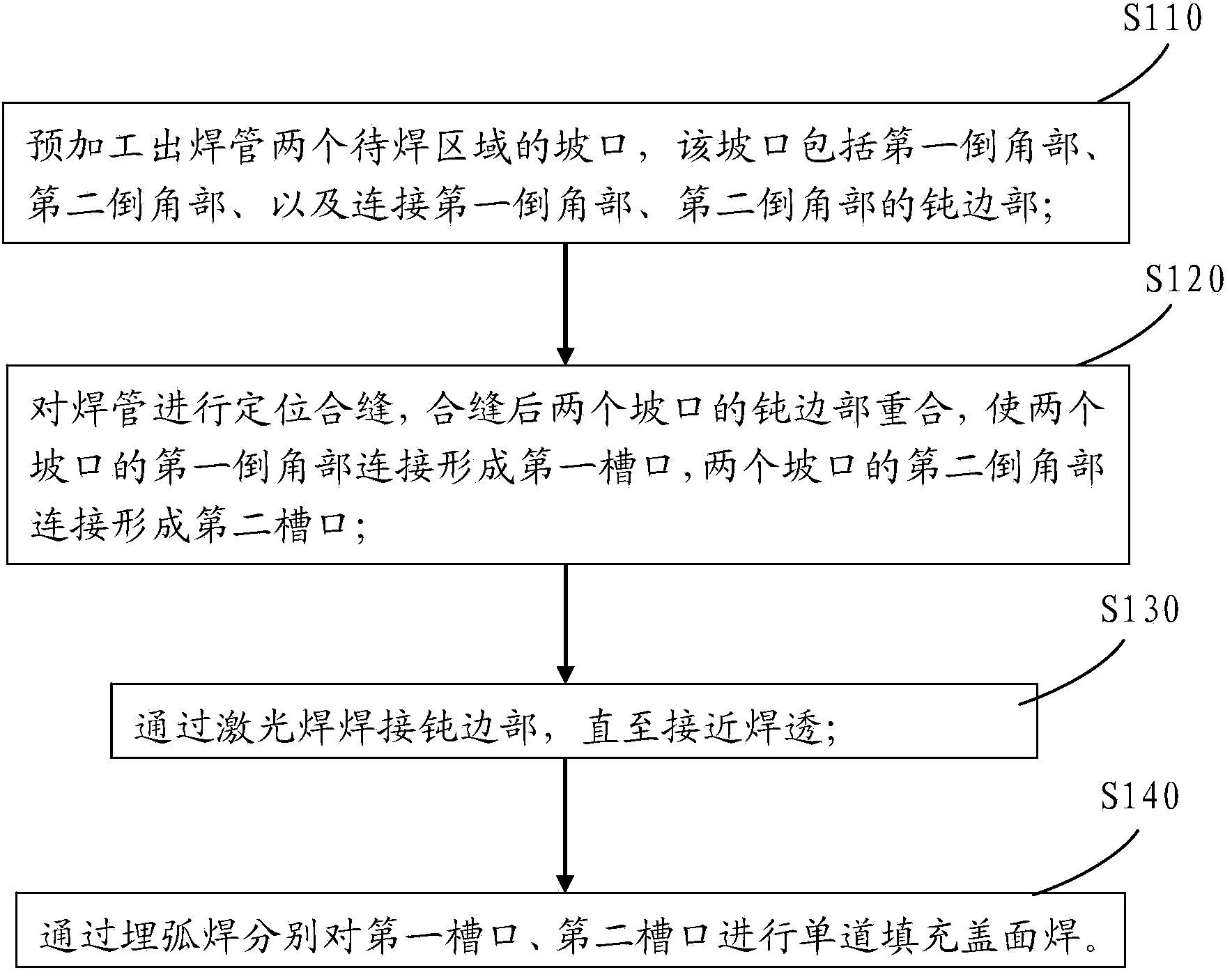

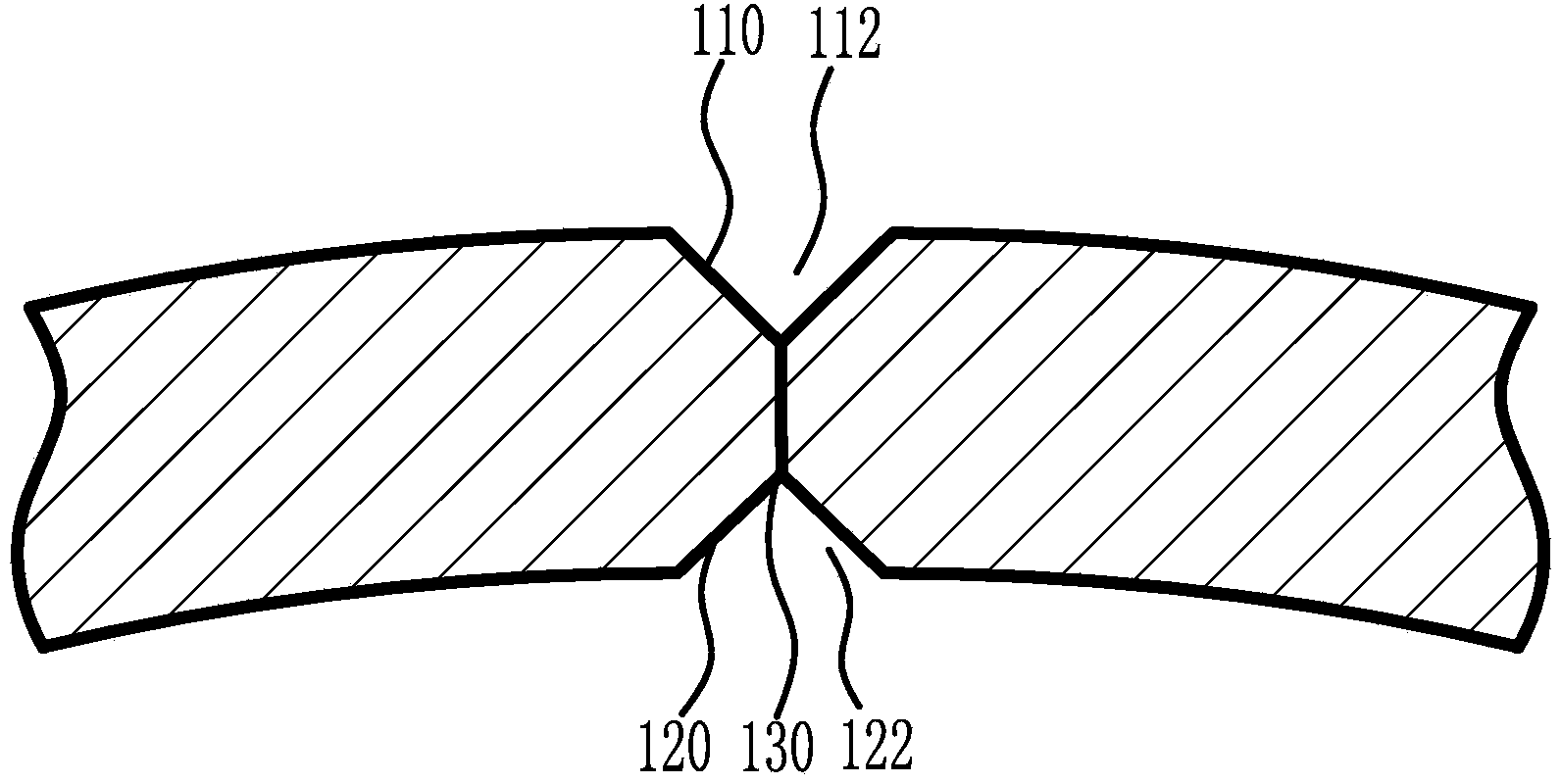

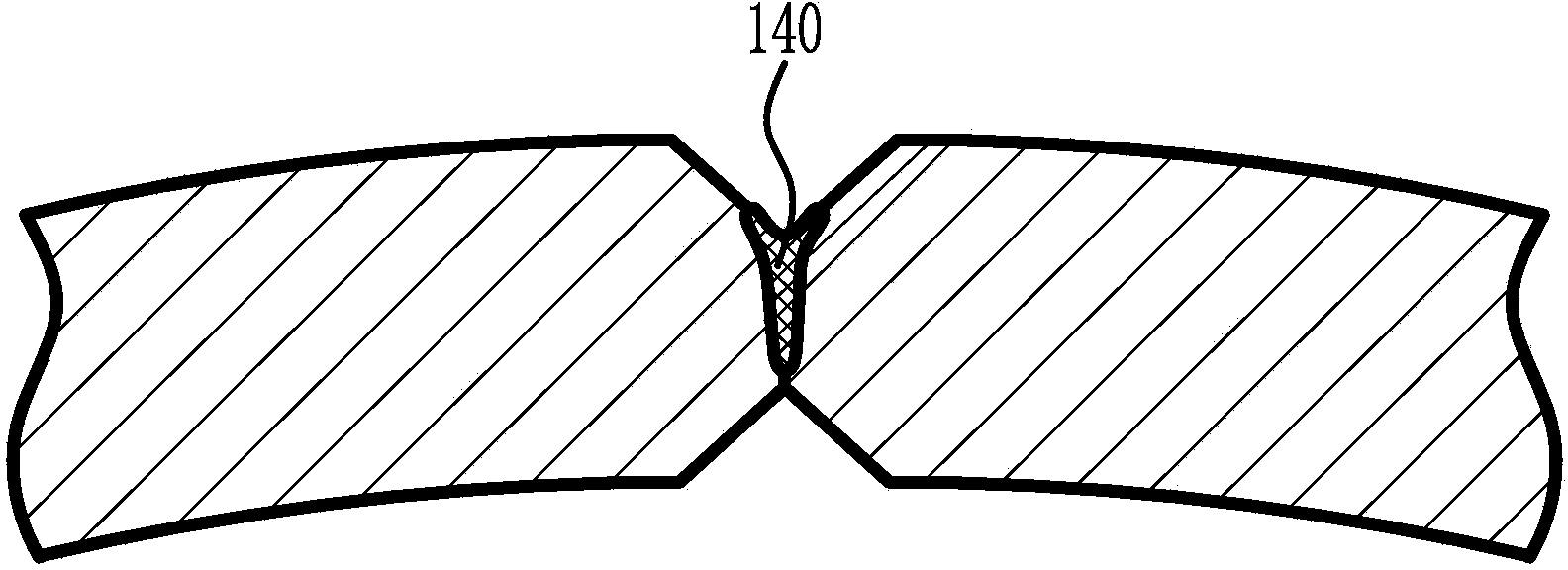

ActiveCN103551750AImprove welding efficiencyImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusEngineeringWeld seam

The invention discloses a welded pipe manufacturing method which includes preprocessing two grooves of an area to be welded of a welded pipe with each groove comprising a first chamfer portion, a second chamfer portion and a truncated edge portion connected with the first chamfering portion and the second chamfering portion; conducting location seam closure on the welding pipe, enabling the truncated edge portions of the two grooves to coincide after the seam closure, and enabling the first chamfer portions of the two grooves to be connected to form a first groove opening and the second chamfer portions of the two grooves to be connected to form a second groove opening; welding the truncated edge portions through laser welding till the truncated edge portions are almost subjected to weld penetration; conducting single-run filling cosmetic welding on the first groove opening and the second groove opening through submerged-arc welding. According to the welded pipe manufacturing method, butt connection of the truncated edge portions of the grooves in the middle of a welding seam is achieved through laser welding, then the submerged-arc welding is utilized to achieve single-run welding, welding times are reduced, preheating and heat insulation are not required, welding production efficiency can be greatly improved, post-welding surplus seam height and lossless yield of the welding seam are higher than those in the prior art, and the performances of the welding seam such as strength, toughness and bending performance are better than those in the prior art.

Owner:番禺珠江钢管(珠海)有限公司

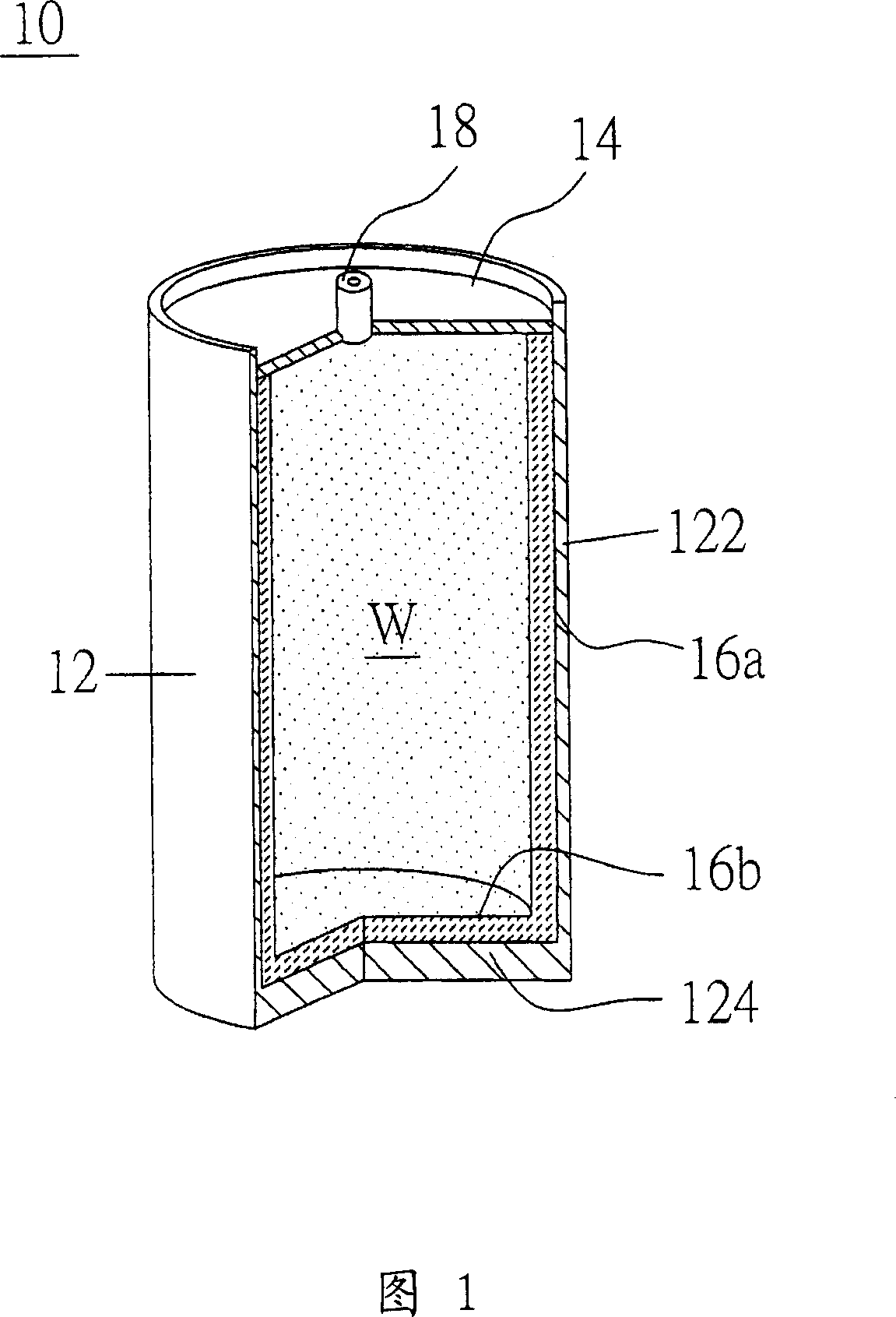

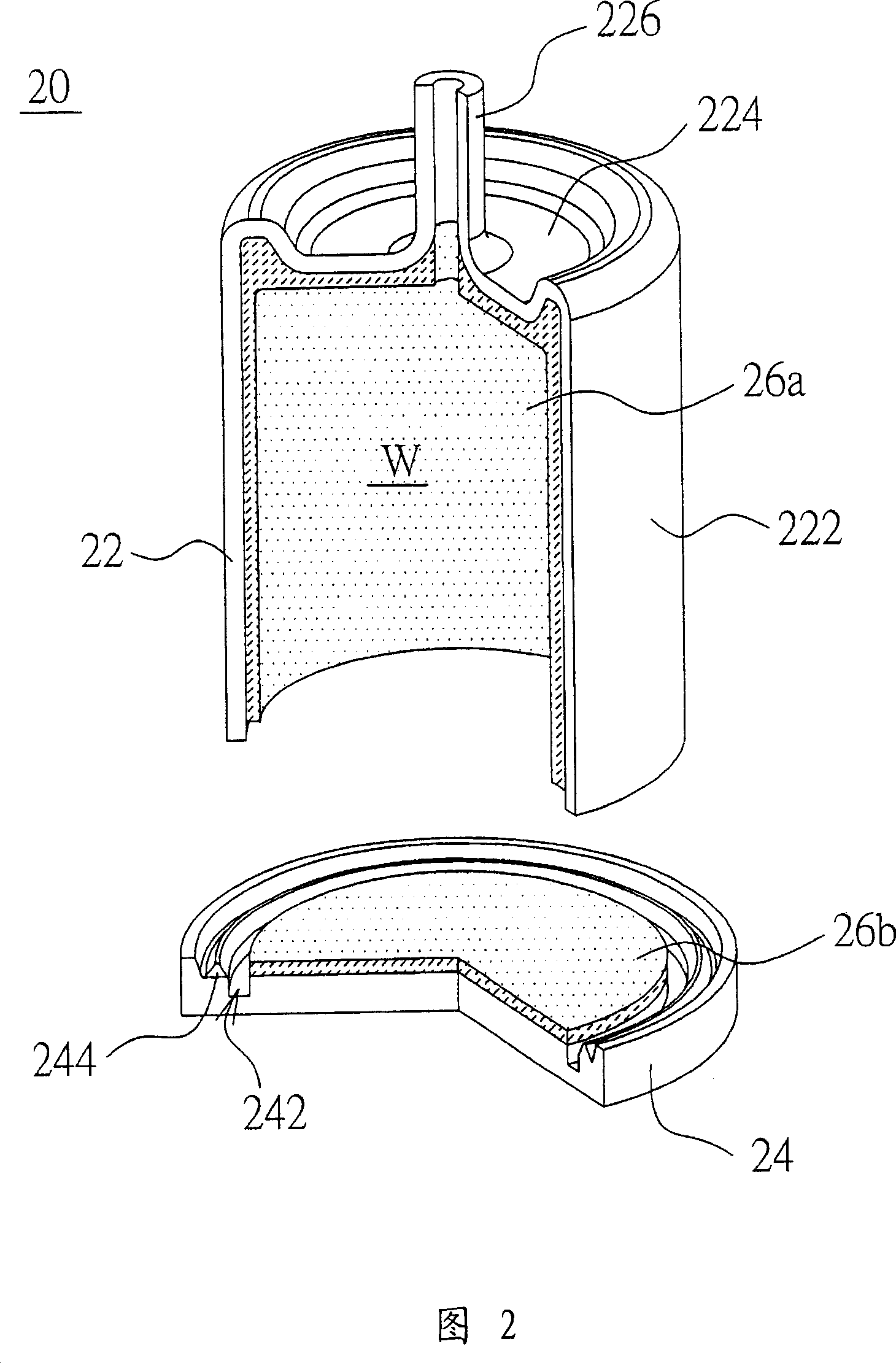

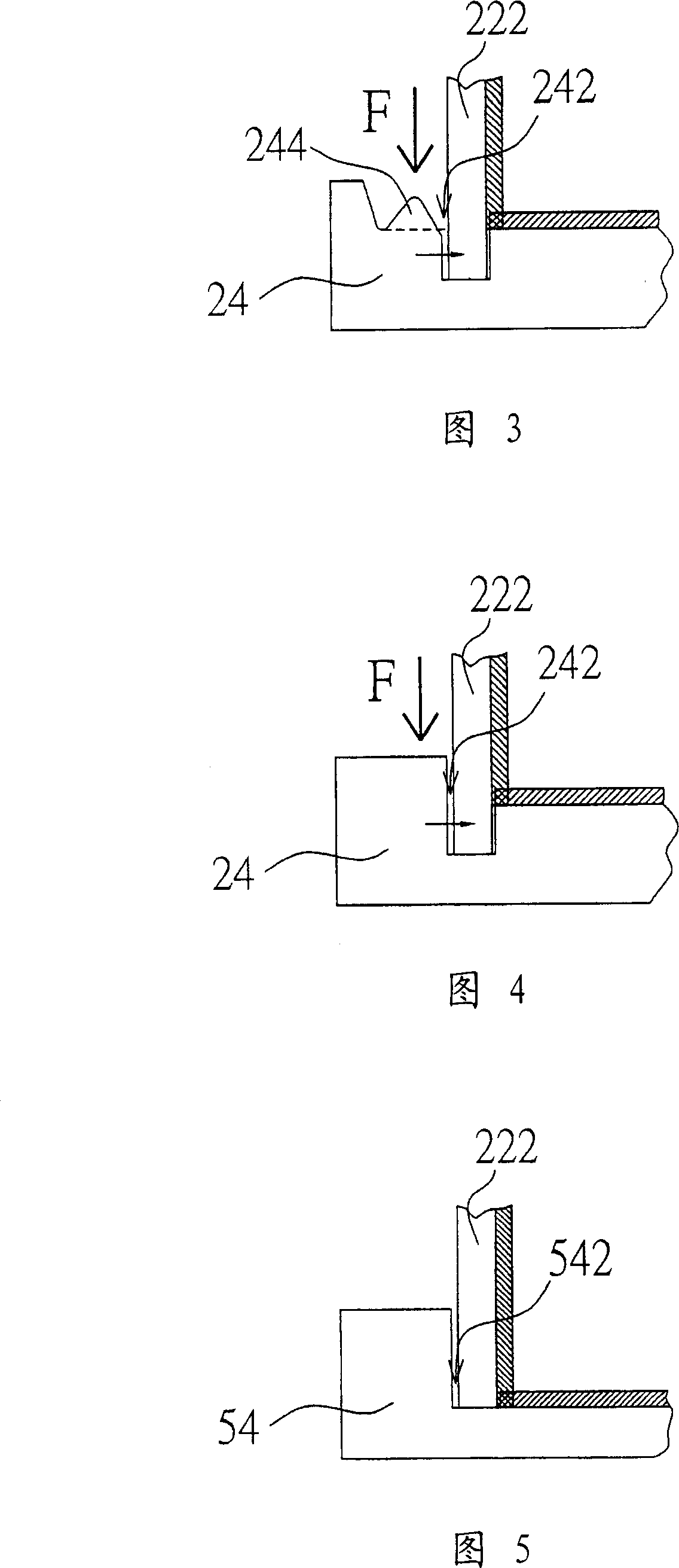

Lithium ion cylindrical battery and processing method thereof

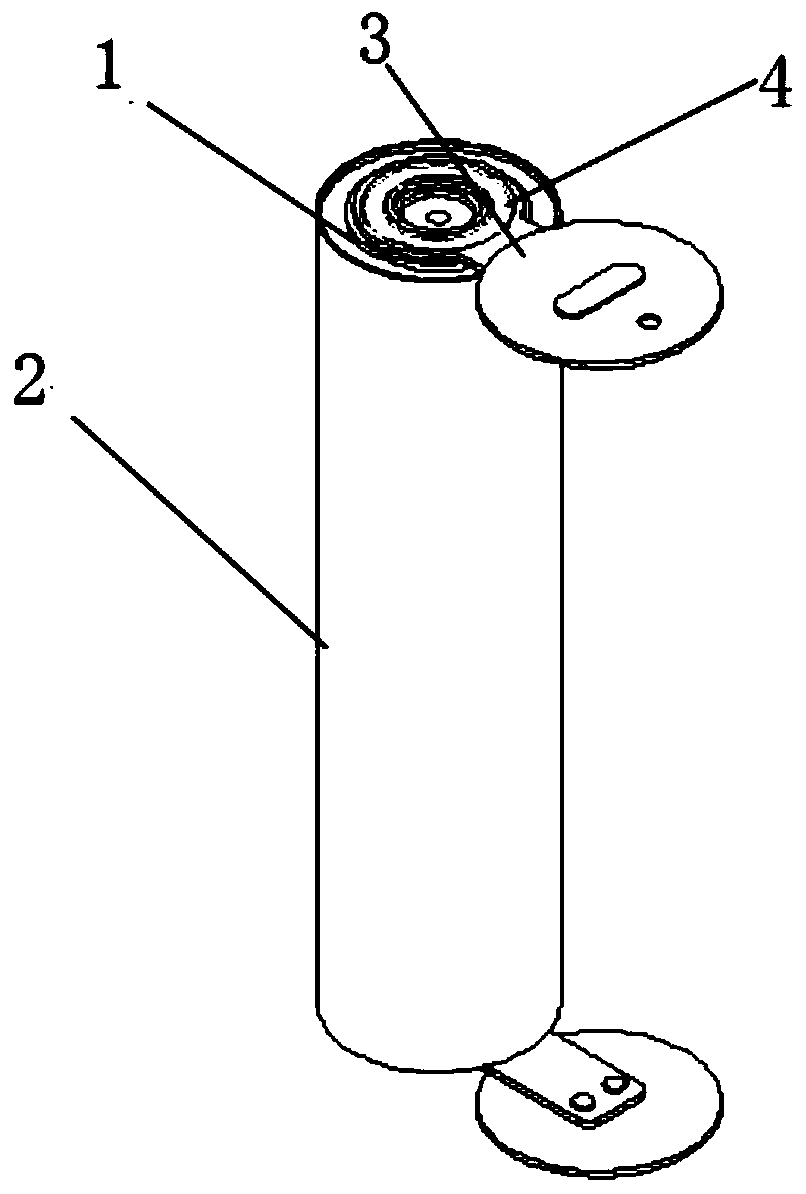

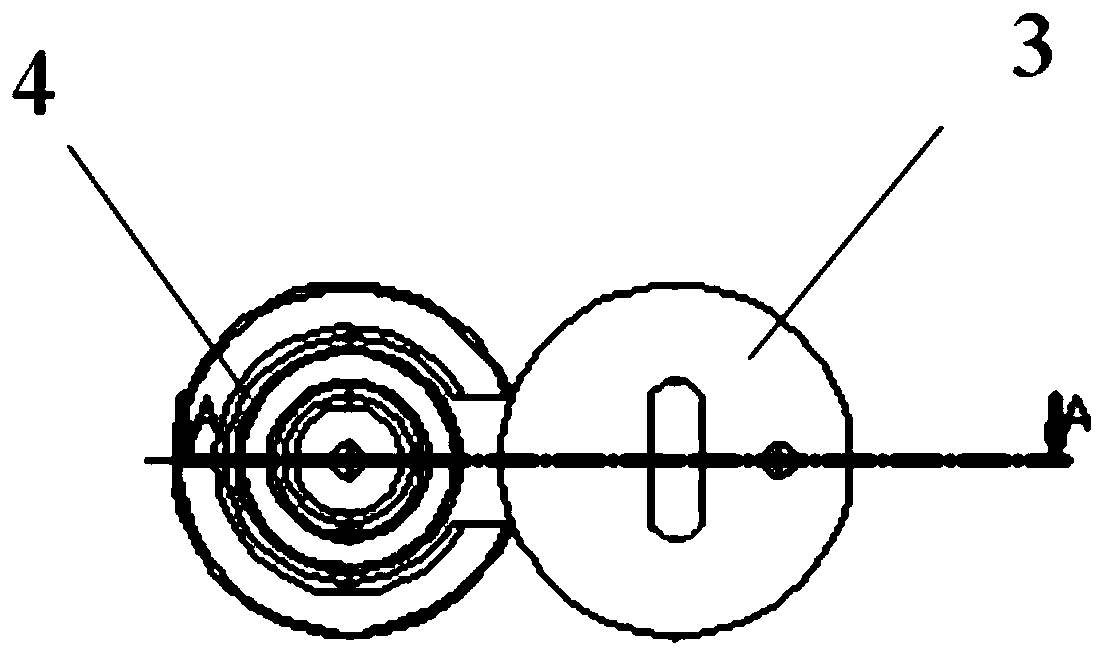

ActiveCN111081966AShorten the lengthReduce weightFinal product manufactureSecondary cellsStructural engineeringBattery cell

The invention discloses a lithium ion cylindrical battery. The lithium ion cylindrical battery comprises a shell and a roll core arranged in the shell; current collecting discs are fixedly connected to the two ends of the shell correspondingly; the roll core comprises a positive pole plate, an inner diaphragm, a negative pole plate and an outer diaphragm which are sequentially overlapped and woundinto a cylinder; a positive tab is arranged at one end of the positive pole plate; a negative tab is arranged at one end, far away from the positive tab, of the negative pole plate; the height of theroll core is smaller than that of the shell; the two ends of the roll core are of circular truncated cone structures; and annular grooves matched with the circular truncated cones on the roll core are formed in the current collecting discs. According to the lithium ion cylindrical battery of the invention, a part of the tabs are cut at the positive pole and the negative pole, so that the tabs arranged at intervals and connected with the pole plates can be obtained, and therefore, the length of the tabs is reduced, the length of the tabs is smaller than that of the pole plates, the weight of the battery is reduced; only one-time welding is needed, and therefore, welding frequency is reduced, welding quality is improved, and a reject ratio caused by welding breakdown is reduced.

Owner:国轩新能源(庐江)有限公司

Novel LNG (Liquefied Natural Gas) vehicle-mounted gas bottle liner support structure

ActiveCN102865456ALow thermal conductivityAvoid contactContainer filling methodsContainer discharging methodsGas cylinderEngineering

The invention relates to a novel LNG (Liquefied Natural Gas) vehicle-mounted gas bottle liner support structure which is characterized in that a liner of a gas bottle is supported and fixed on a housing of the gas bottle; the support structure mainly consists of a liner end closure, a housing end closure, a manifold header, a support neck tube, an extension tube and a glass reinforced plastic ring; a reinforcing tube is sleeved outside the extension tube; one end of the reinforcing tube is fixedly connected with the inner wall of the liner end closure and the other end is fixedly connected with a second tube cap; and a vacuum cavity is formed between the reinforcing tube and the extension tube through vacuumizing. The novel LNG vehicle-mounted gas bottle liner support structure provided by the invention has few welding seams and is convenient to manufacture, and at the same time heat transfer is reduced and heat leakage amount is greatly reduced.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

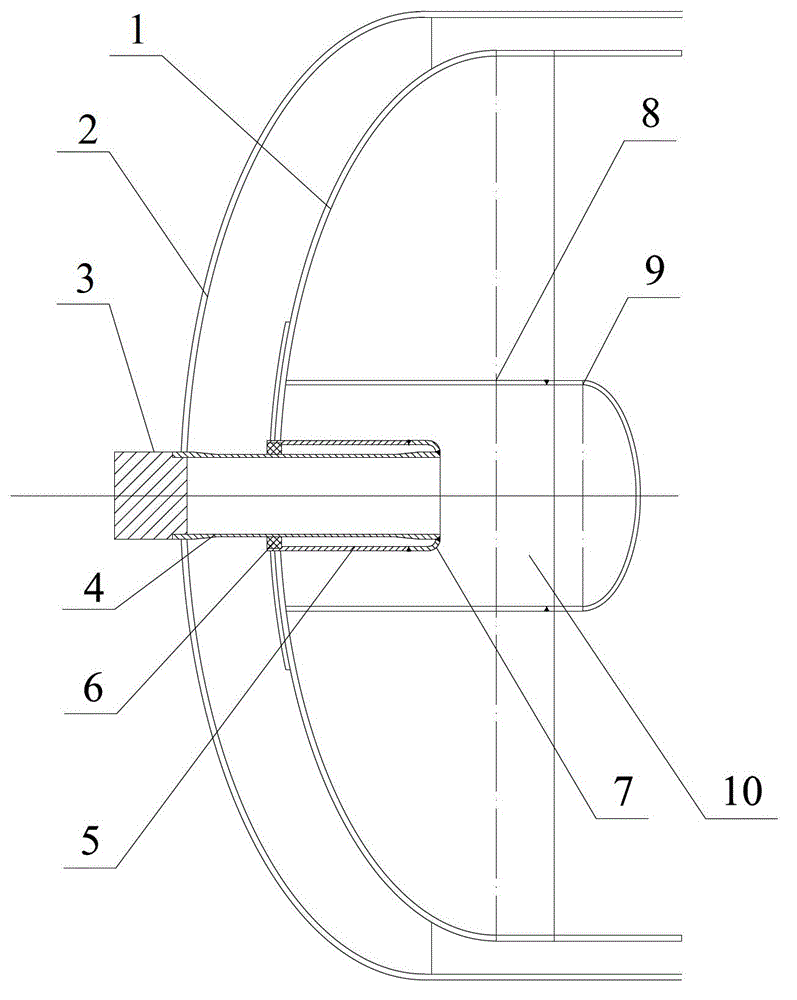

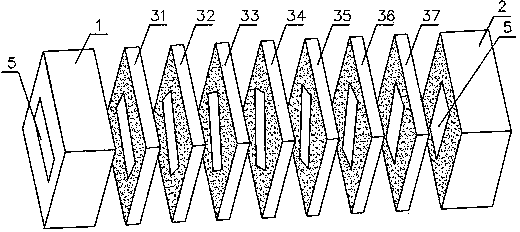

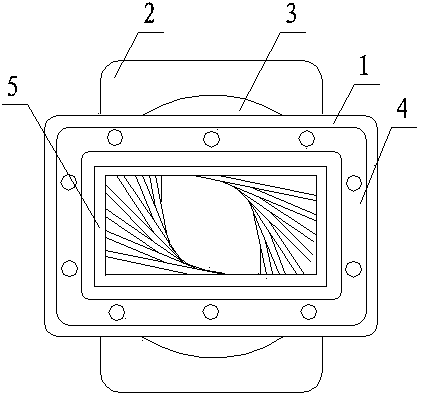

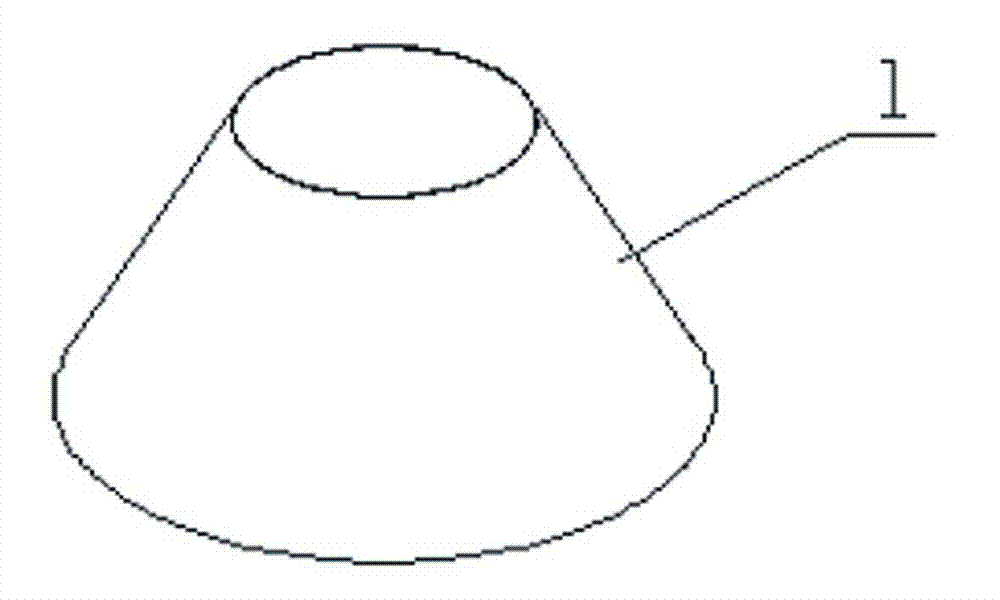

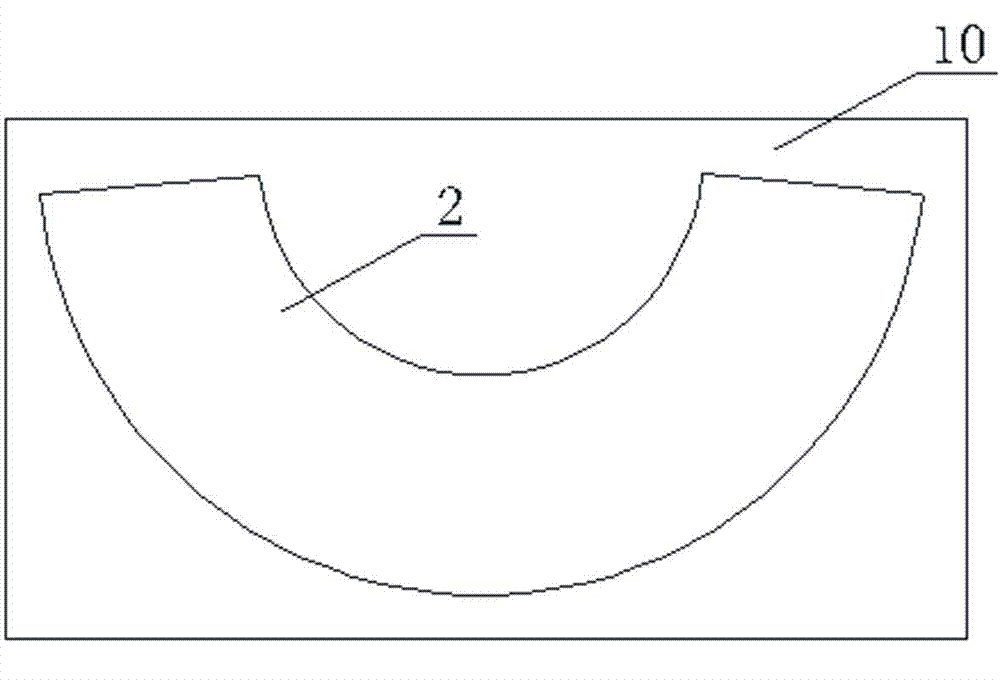

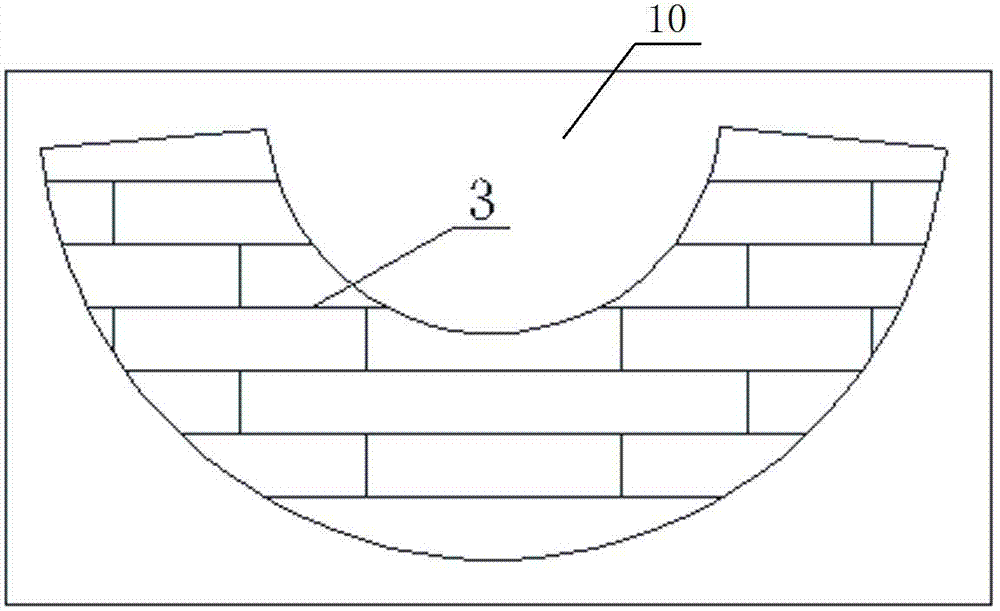

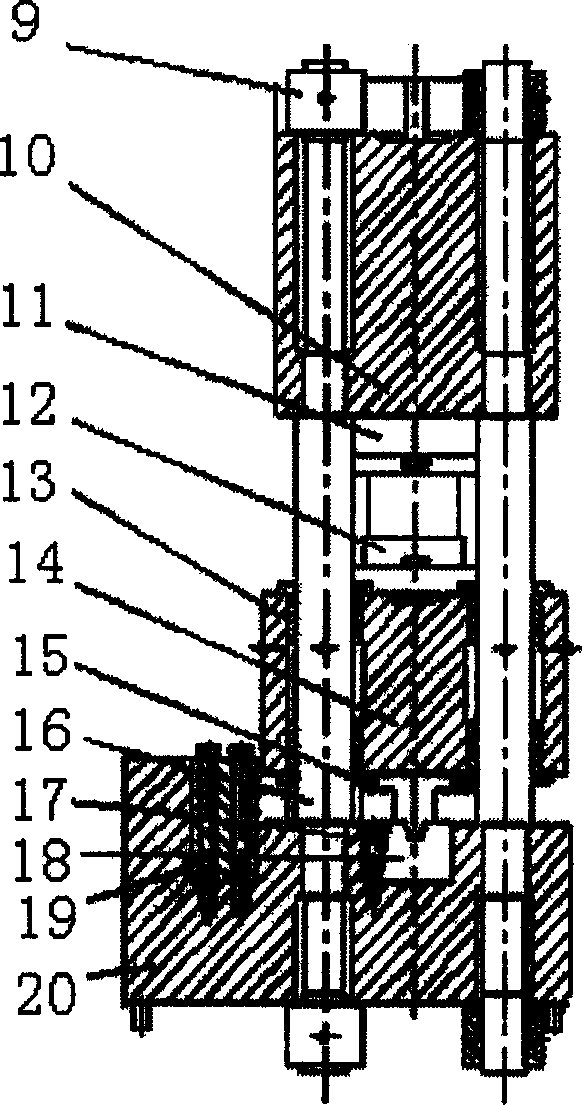

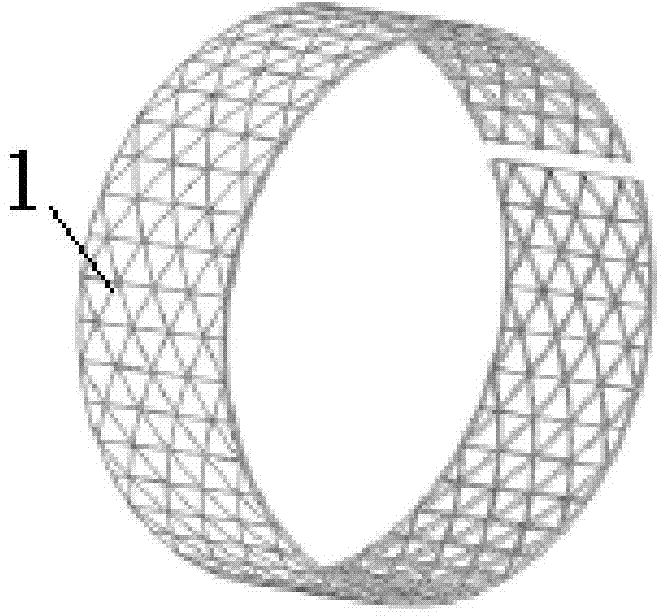

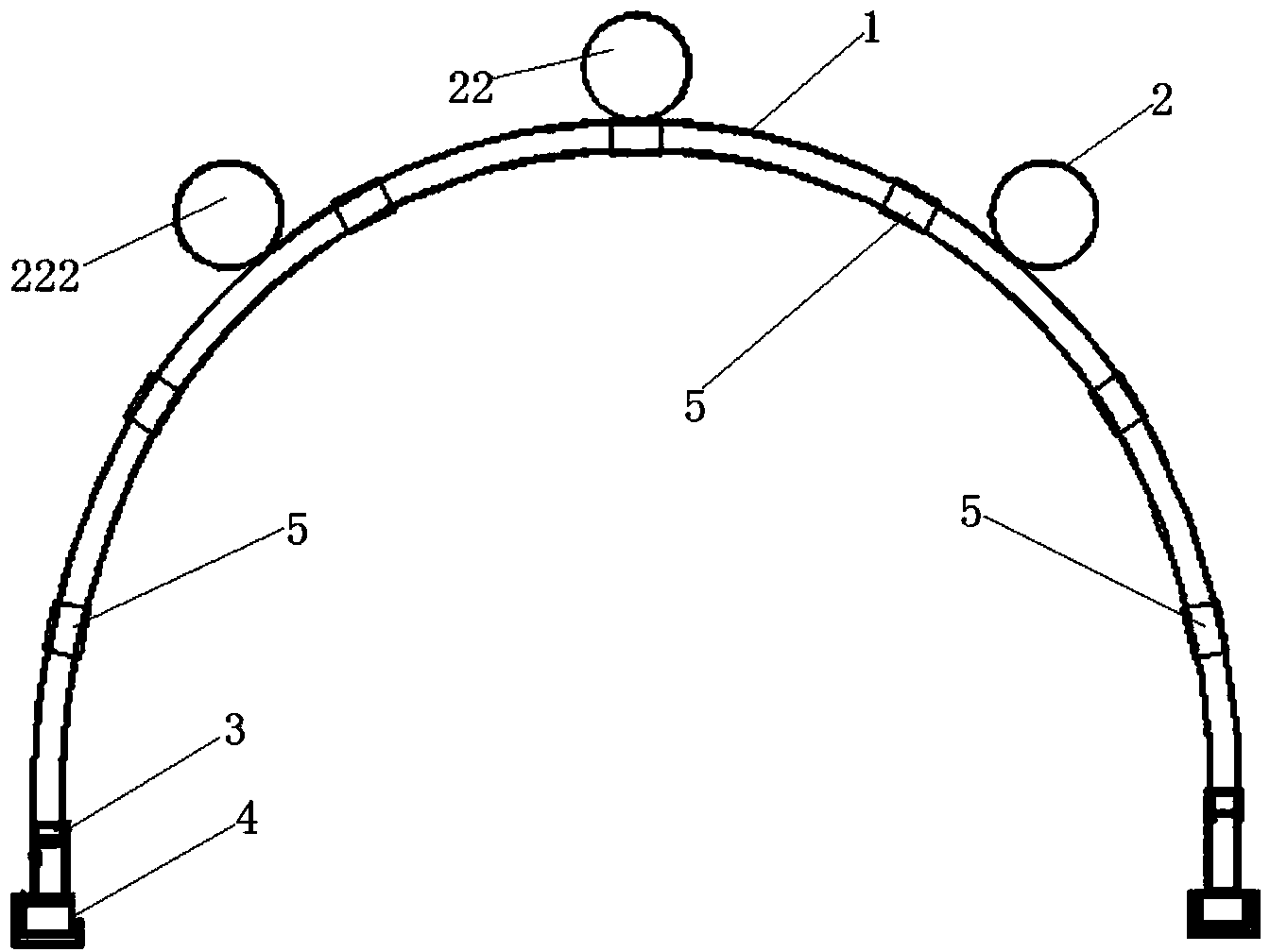

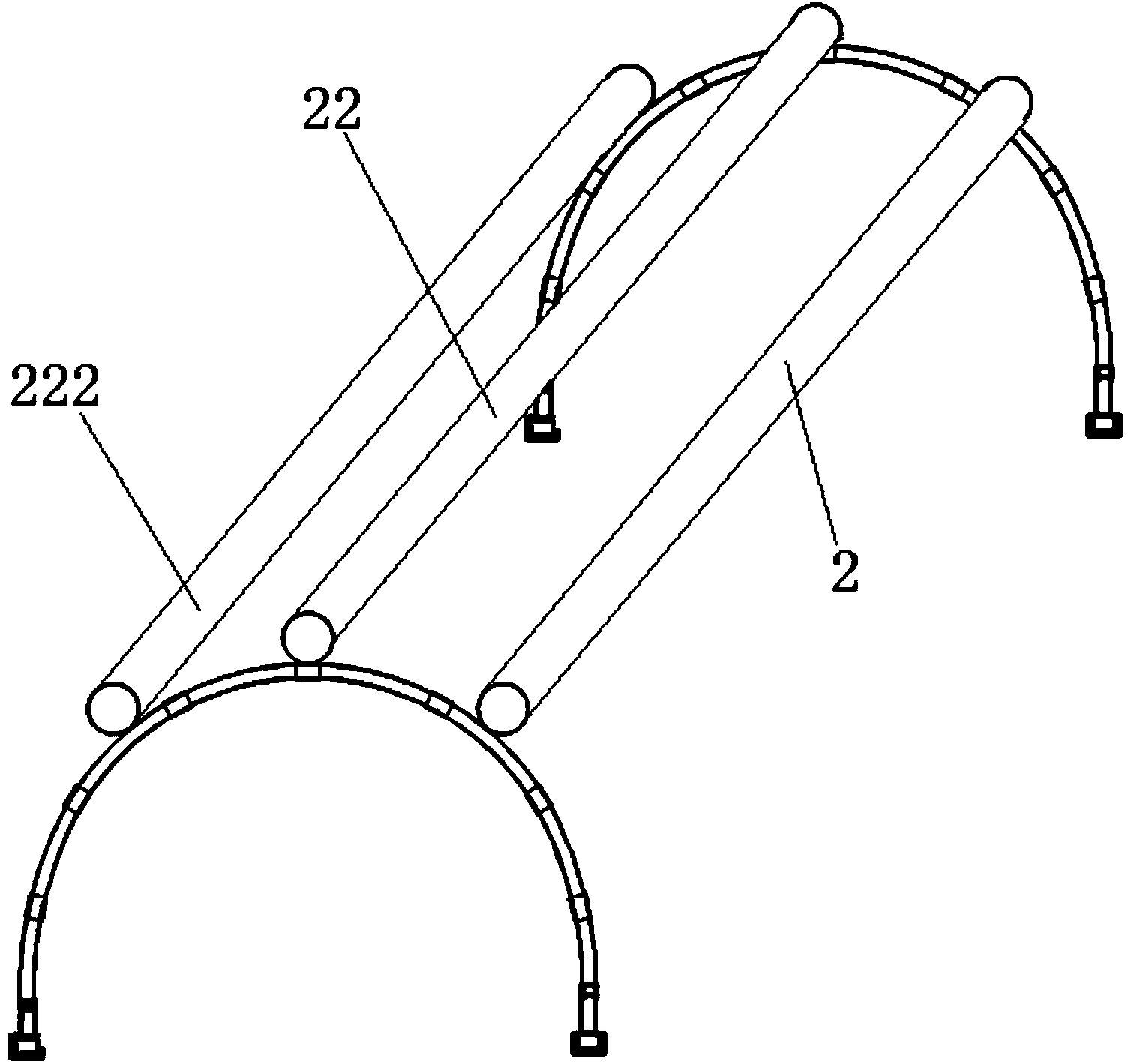

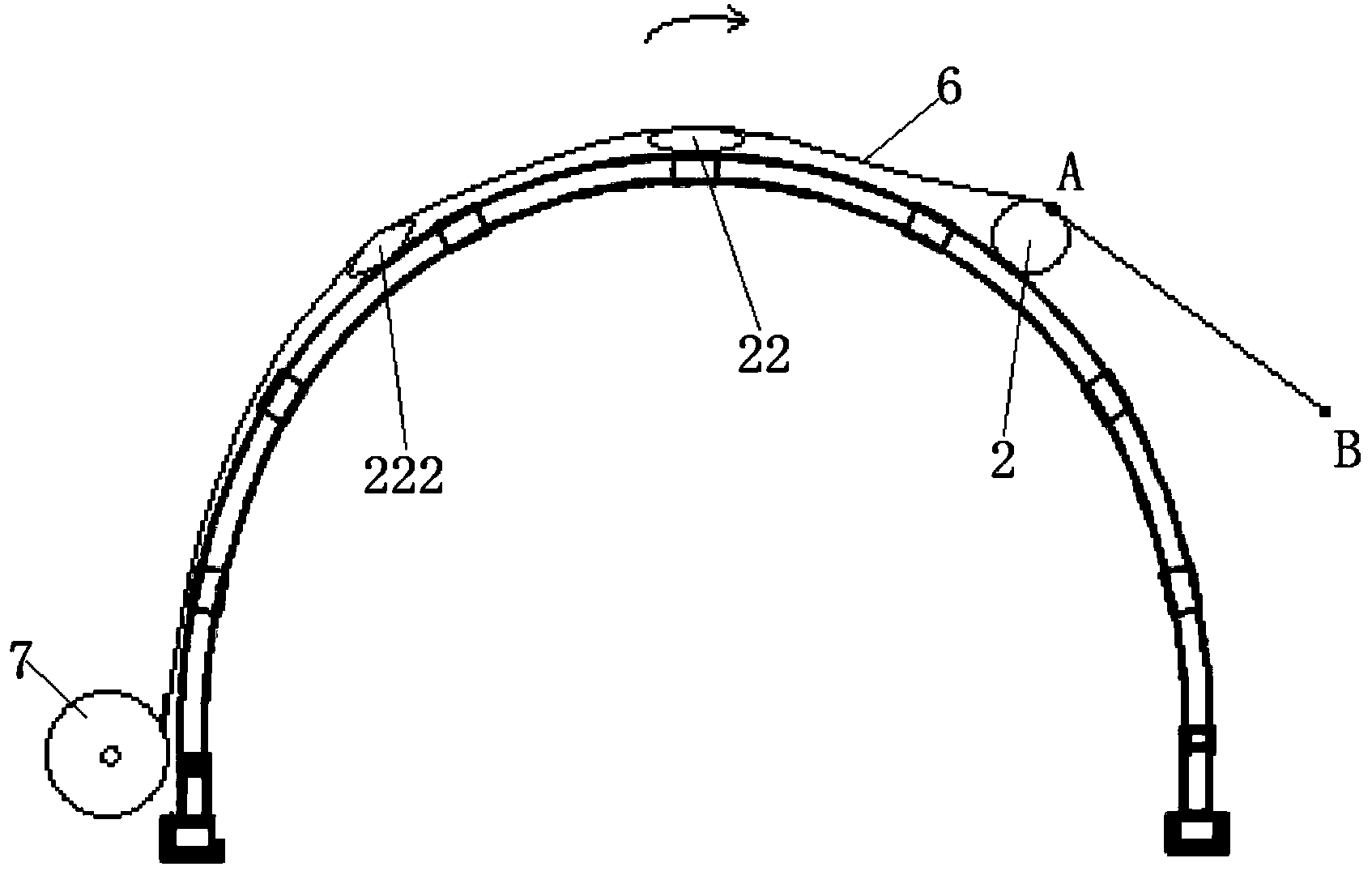

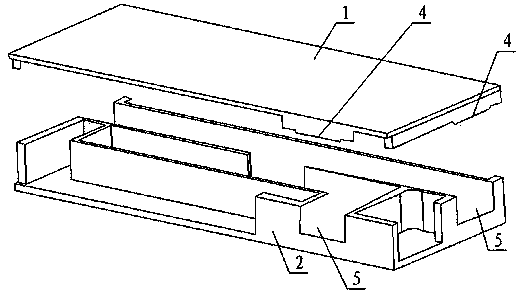

Self-positioning stepped twisted waveguide and vacuum brazing process thereof

InactiveCN103972628AControllable rotation angleRealize self-positioningSoldering apparatusWaveguidesEngineeringWaveguide

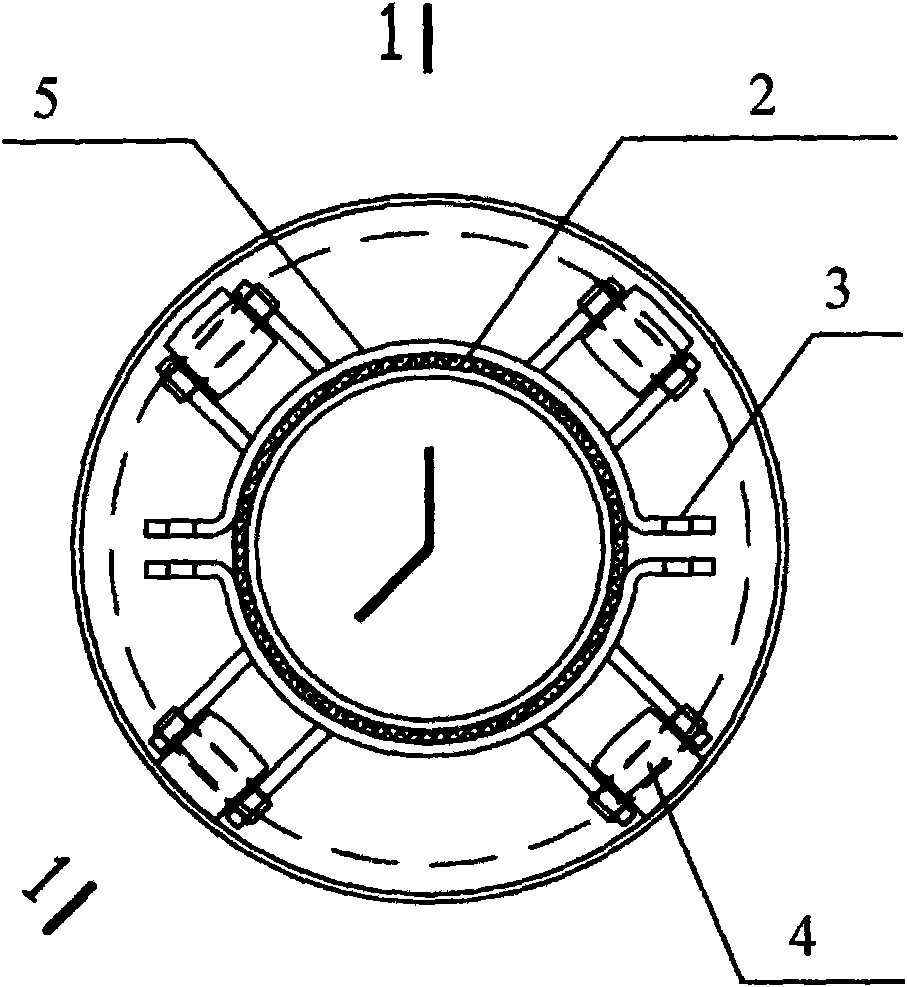

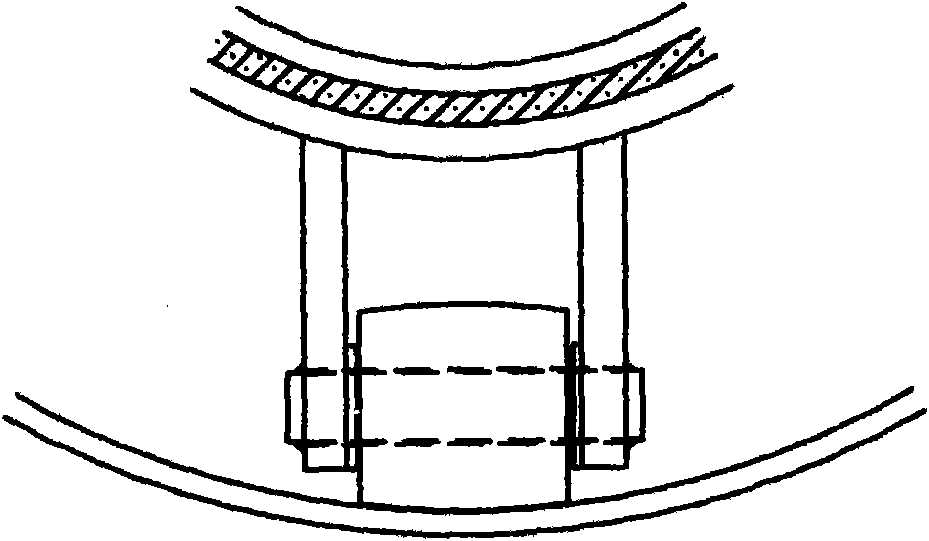

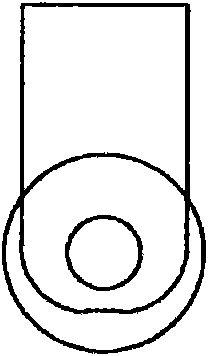

The invention discloses self-positioning stepped twisted waveguide and a vacuum brazing process thereof. The self-positioning stepped twisted waveguide comprises a cover plate (1), a bottom plate (2) and a cavity (3) installed between the cover plate (1) and the bottom plate (2). The cavity (3) is formed by a plurality of assembling plates which are mutually buckled, each assembling plate is provided with a transmission port, the transmission ports are obliquely arranged in the assembling plates, and inclination angles increase progressively and sequentially or decrease progressively and sequentially; the outer side of the port of the cover plate (1) and the outer side of the port of the bottom plate (2) are respectively provided with a flange plate (4), one side of the frame wall of each assembling plate is provided with a groove (6), and the other side of the frame wall of each assembling plate is provided with a boss (7) matched with the corresponding groove (6). According to the self-positioning stepped twisted waveguide, the assembling plates which are mutually buckled are adopted and are provided with the transmission ports at different inclination angles so that the cavity of the twisted waveguide is formed; the transmission ports of the assembling plates are combined together to form an inner cavity of the cavity of the twisted waveguide so that the stepped inner cavity can be formed; because the cavity is divided into multiple assembling plates, rotating angles of the twisted waveguide can be easily controlled.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

Manufacturing and installing method for upper cone on dry quenching furnace shell

ActiveCN104759856ASimplify the manufacturing processSimplify the installation processCoke quenchingWelding apparatusButt jointQuenching

The invention discloses a manufacturing and installing method for an upper cone on a dry quenching furnace shell. The method includes the following steps that the upper cone on the dry quenching furnace shell is set out into a fan-shaped sample plate, and the outline of the fan-shaped sample plate is drawn on a manufacturing plane according to the practical proportion; a steel plate is fully laid on the outline of the whole fan-shaped sample plate, and a fan-shaped steel plate is formed in a welding mode. Four lifting lugs are arranged on the fan-shaped steel plate, the two middle lifting lugs are connected with a crane lifting hook through steel wire ropes, and the lifting lugs on the two sides are connected with the crane lifting hook through chain blocks and steel wire ropes. After the fan-shaped steel plate is lifted through the crane, three lifting lugs are arranged on the inner side of the fan-shaped steel plate and adjust contracting of the lower end of the fan-shaped steel plate through pulleys, chain blocks and steel wire ropes, and a conical steel plate is formed. The conical steel plate is welded to be manufactured into the upper cone of the dry quenching furnace shell, the upper cone of the dry quenching furnace shell is lifted and is in direct butt joint with the dry quenching furnace shell, and installation is completed. According to the manufacturing and installing method for the upper cone on the dry quenching furnace shell, the upper cone of the dry quenching furnace shell can be integrally spliced on the ground to be used, a temporary platform does not need to be erected, and time, labor and materials are saved.

Owner:CHINA FIRST METALLURGICAL GROUP

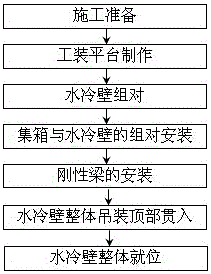

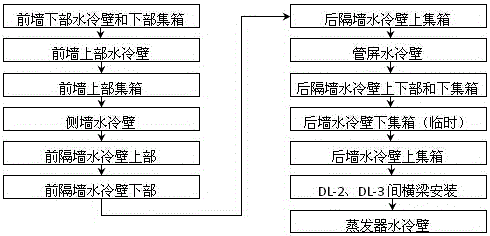

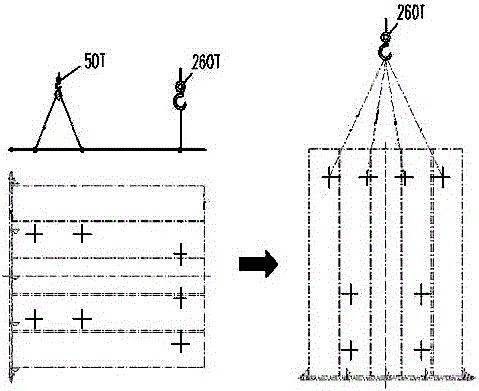

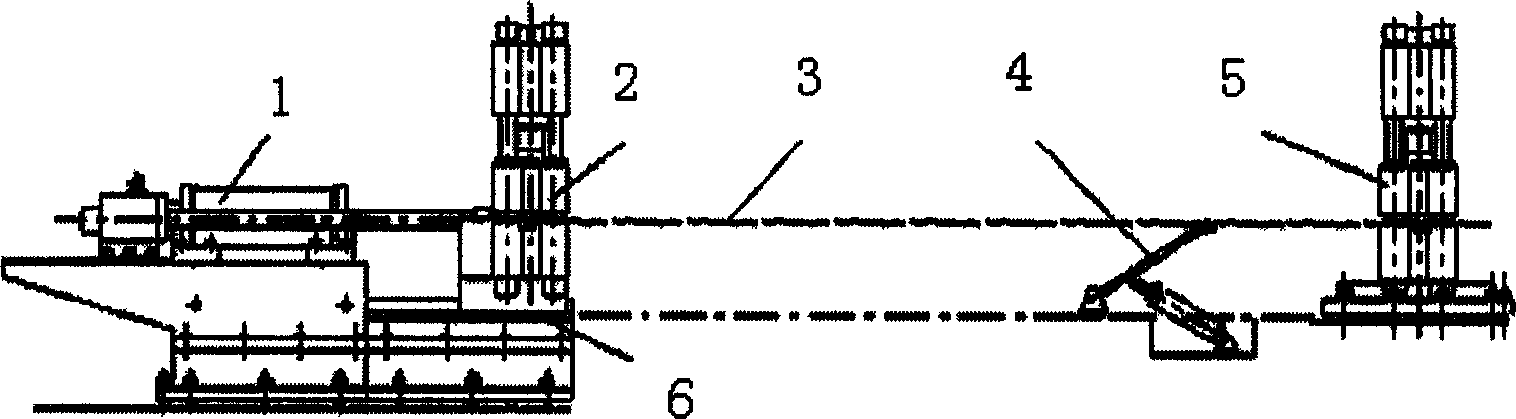

Construction method for enabling water-cooling walls of refuse incineration power generation waste heat boiler to integrally penetrate from top

ActiveCN106322347AReduce the number of liftingEasy to controlBoiler water tubesCasings/liningsButt weldingQuality control

The invention relates to a construction method for enabling water-cooling walls of a refuse incineration power generation waste heat boiler to integrally penetrate from a top. The construction method is characterized by comprising the following steps: step 1, manufacturing a water-cooling wall tool platform; step 2, assembling the water-cooling walls in a segmental mode on ground; step 3, mounting collecting boxes and the water-cooling walls in pairs; step 4, mounting rigid beams; step 5, enabling the water-cooling walls to integrally penetrate from the top; step 6, hoisting the water-cooling walls to the positions; and step 7, arranging an overhead row of tubes in pairs. With the adoption of a mounting method for the water-cooling walls of the waste heat boiler, water-cooling wall hoisting times and quantity of the overhead row of tubes welded in pairs are reduced, pipeline butt-welding quality control is convenient, the problem that part of the water-cooling walls are difficult to put in positions after a boiler steel structure is mounted can be efficiently solved, the construction period is effectively shortened, and potential safety hazards caused by overhead mounting operation and welding operation are further reduced. Meanwhile, a special clamping device for ground pipeline aligning and an overhead pipe row aligner are applied, so that working efficiency and project quality are effectively improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

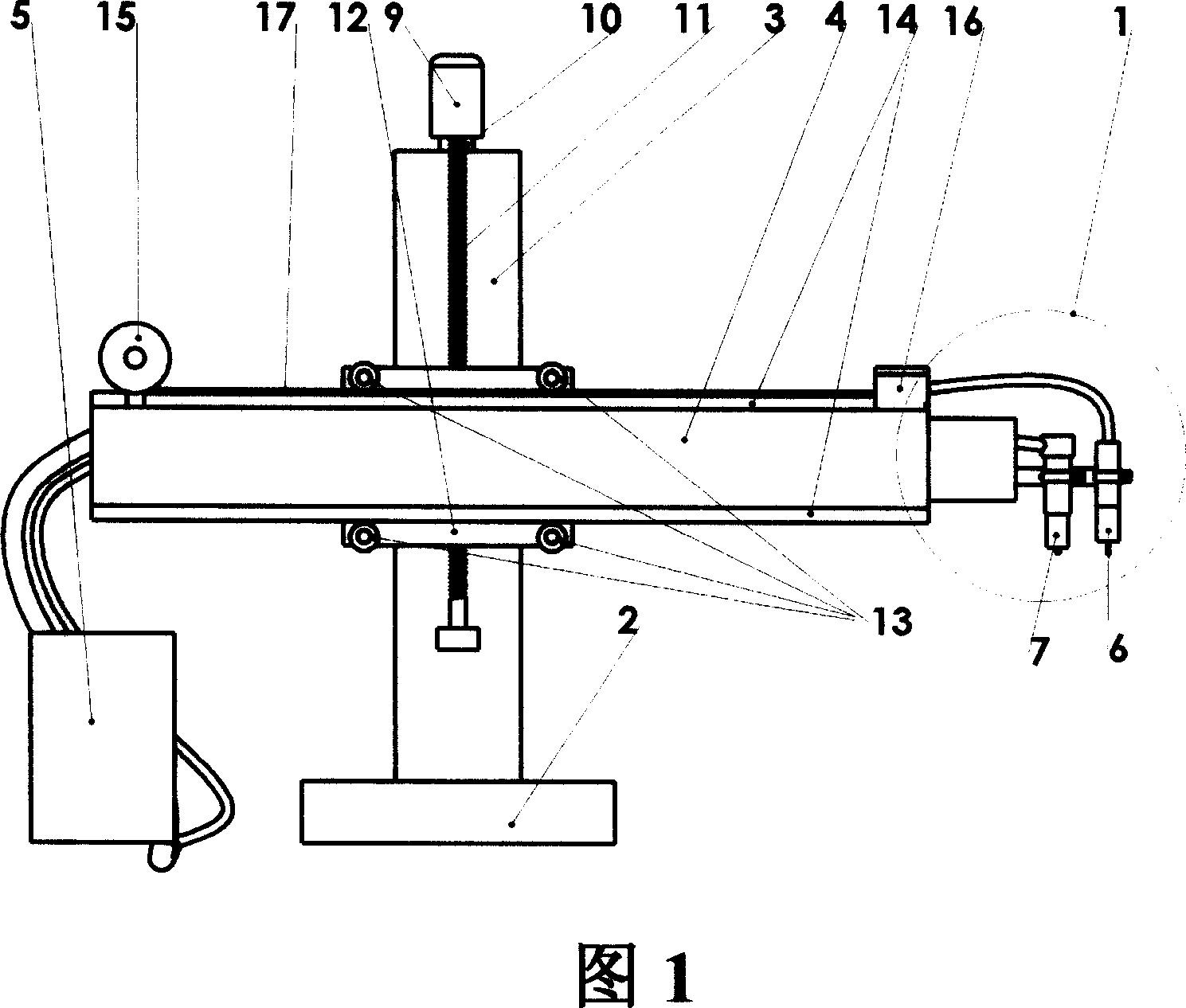

Hydraulic large plate leveling device

A hydraulic leveling-up machinefor large-size thin sheet is composed of stretching unit, sliding clamp unit, fixed clamp unit, working platform, feeding-stripping unit, slide table unit, hydraulic station and console.

Owner:JILIN UNIV

Combination of battery protection board and battery core as well as combination method thereof

InactiveCN102035038AUse less materialReduce the number of weldsFinal product manufactureActive material electrodesElectricitySurface mounting

The invention discloses a combination of a battery protection board and a battery core as well as a combination method thereof. The combination method comprises the following steps of: providing a battery protection board equipped with conductive bodies, welding a pair of positive connecting blocks and a pair of negative connecting blocks on a surface of the battery protection board in a SMT (Surface Mounting Technology) mode, electrically connecting each positive connecting block and each negative connecting block with the corresponding conductive bodies; covering the battery protection board on an end surface which is provided with a positive plate and a negative plate of the battery core, enabling the positive connecting blocks and the negative connecting blocks to correspond to the positive plate and the negative plate; and propping the positive bar and the negative bar of a DC (Direct Current) spot welding machine in the conductive body position at the other surface of the battery protection board, pressing the battery protection board on the battery core, and welding the battery protection board on the positive plate and the negative plate of the battery core via the positive connecting blocks and the negative connecting blocks so that the battery protection board is electrically connected with the battery core. The combination method of the battery protection board and the battery core enhances the efficiency and improves the welding quality.

Owner:FUGANG ELECTRONICS KUNSHAN +1

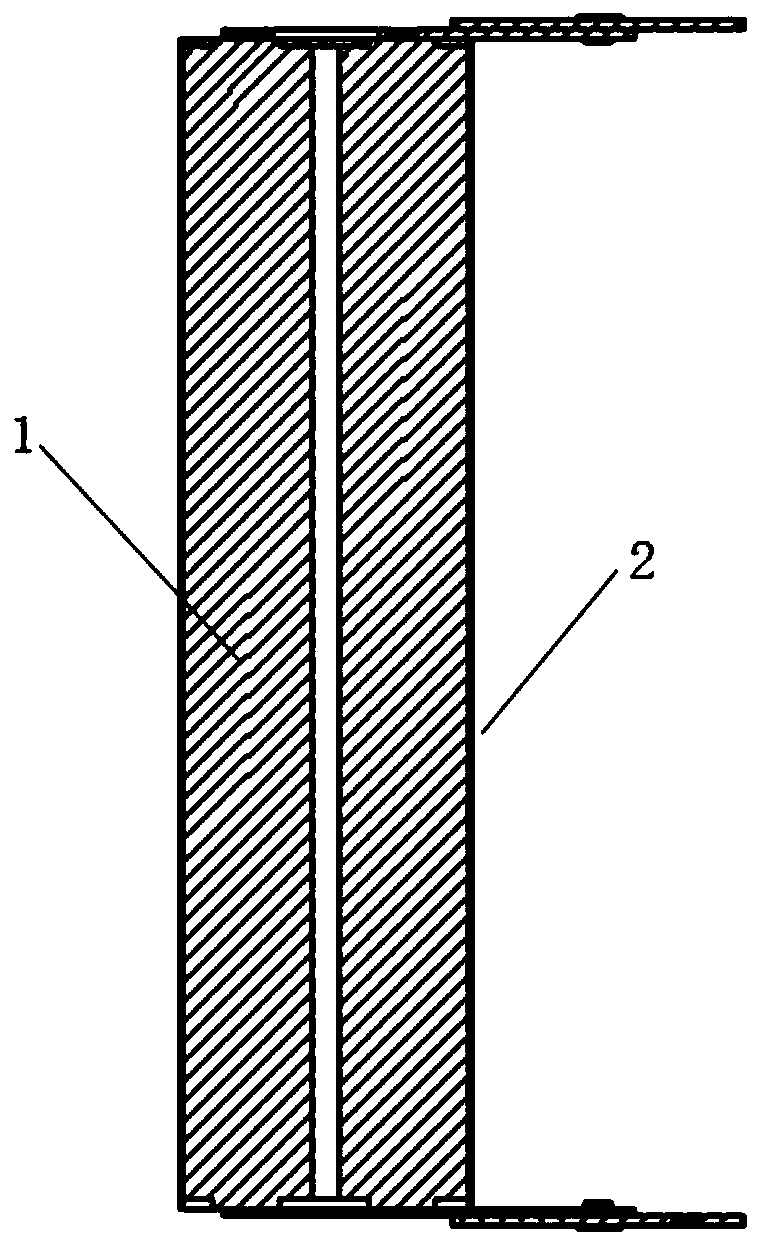

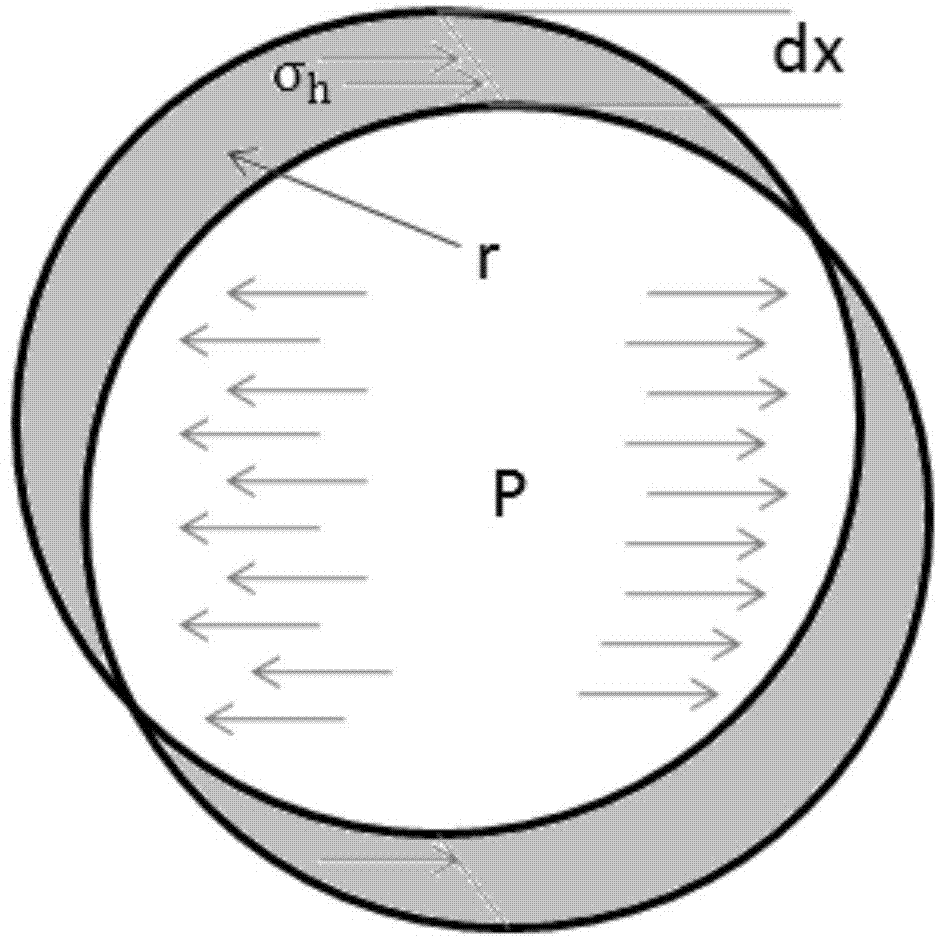

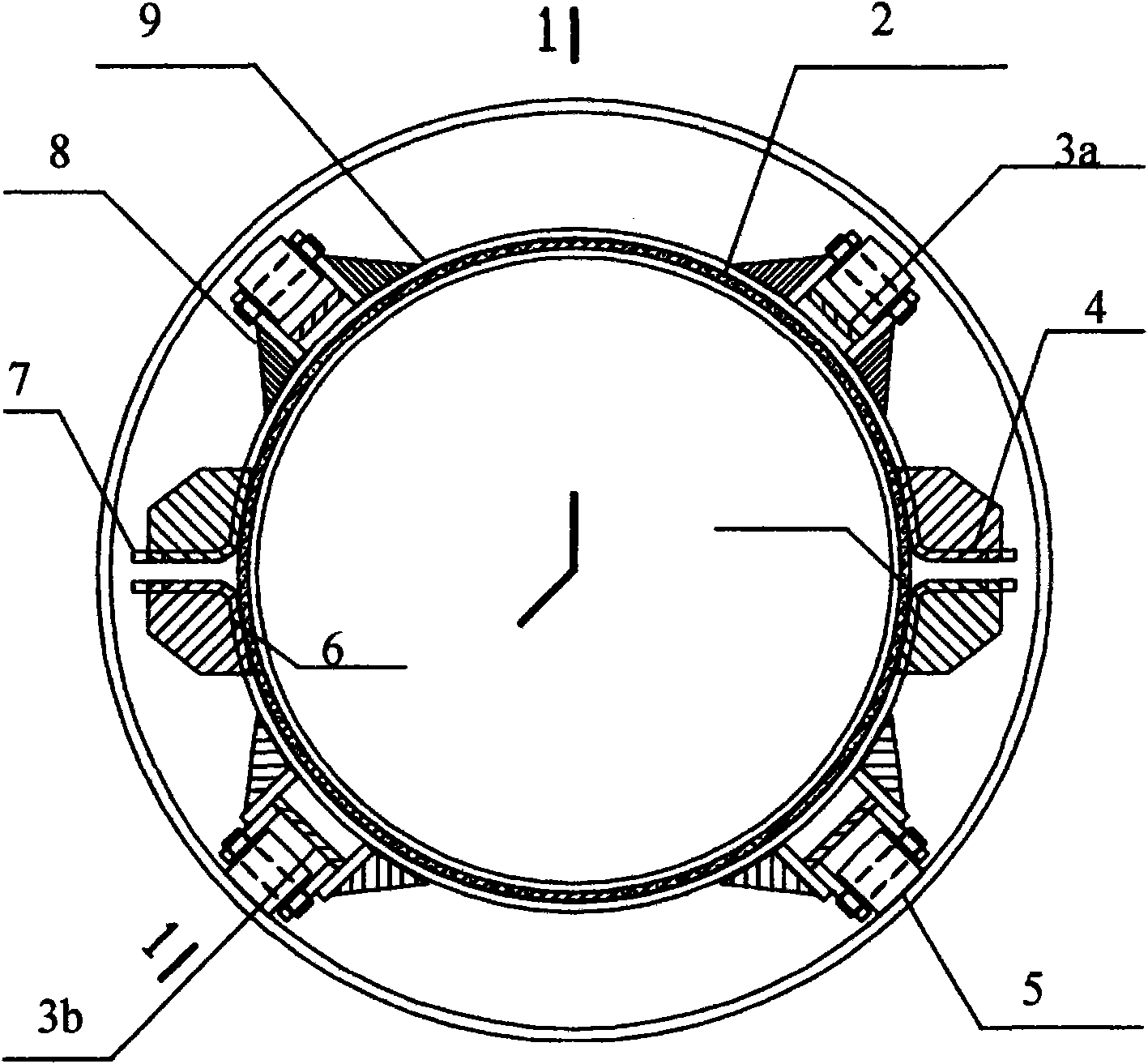

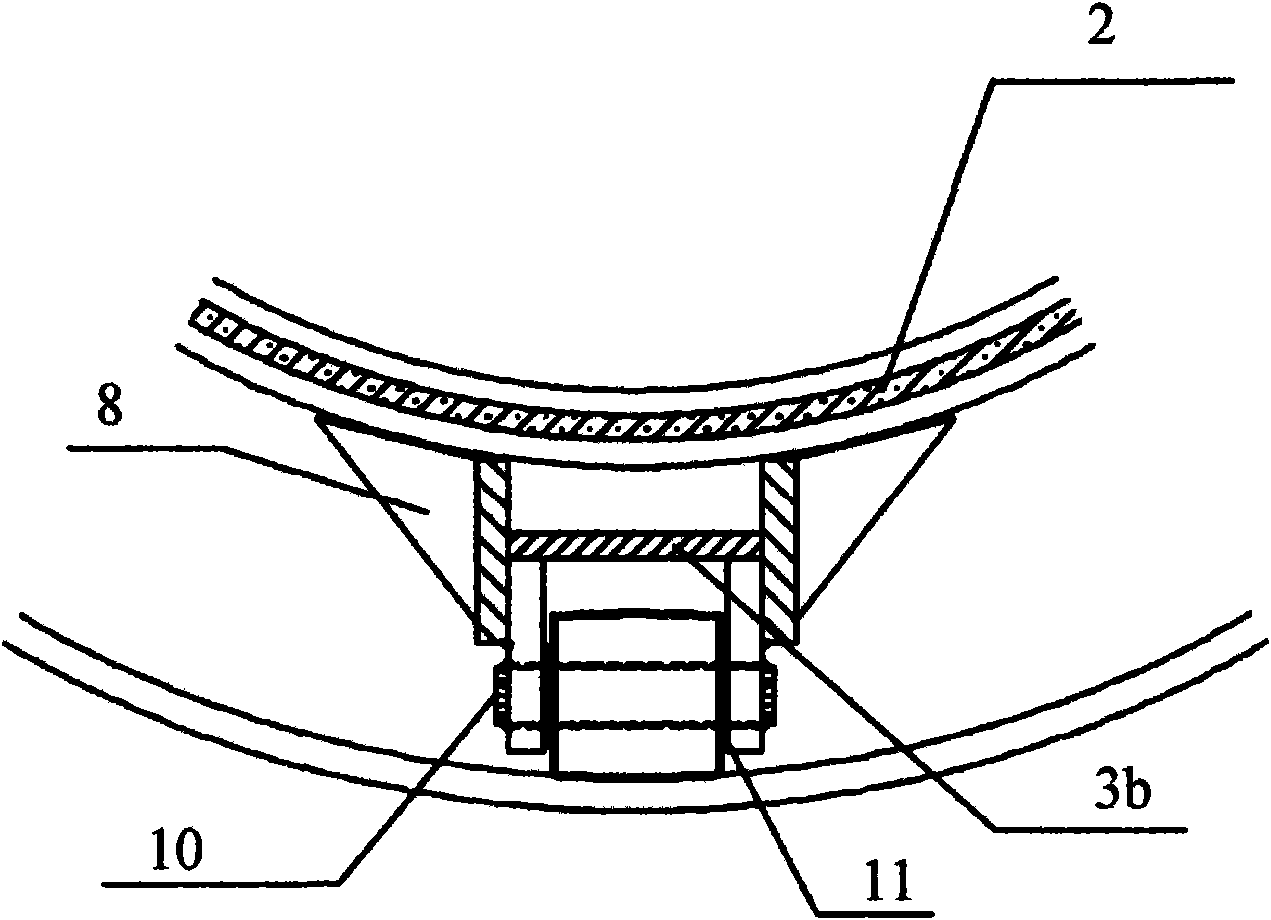

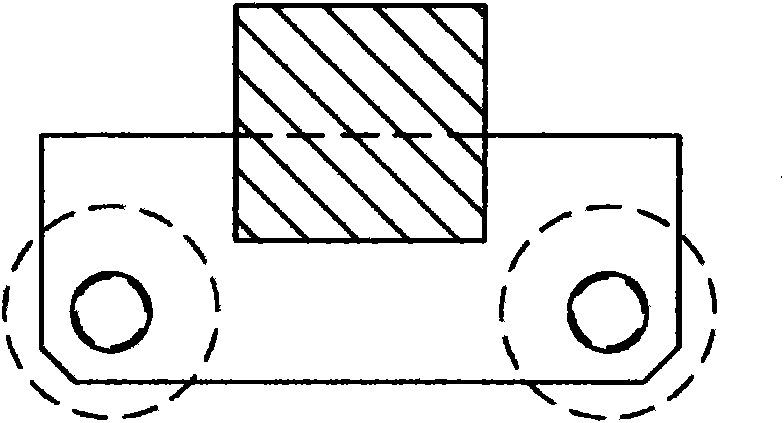

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

InactiveCN101666419AReduce processImprove insulation effectPipe supportsThermal insulationRolling resistanceEngineering

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steel steam insulation pipe is DN 250-DN 500. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels and two lower idler wheels, wherein the upper idler wheels and the lower idler wheels are respectively arranged on the upper steel hoop and on the lower steel hoop and distributed symmetrically; the end parts of the upper steel hoop and the lower steel hoop are clamped tightly by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the two lower idler wheels and the inner wall of the outer sleeve steelpipe are contacted in a rolling friction way, and fit-up gaps are left between the upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steam insulation pipe comprises the inner sleeve steel pipe, the outer inner sleeve steel pipe, the rolling supporting mechanism, insulation material and heat-preservation material, wherein the external diameter of the heat-preservation layer is smaller than the internal diameter of the outer sleeve steel pipe and an air layer is formed between the heat-preservation layer and the sleeve steel pipe. The rolling supportingmechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

Radiation module and its heat pipe

ActiveCN101089537AIncrease the heat exchange areaOvercome the defect of high scrap rateIndirect heat exchangersCooling/ventilation/heating modificationsComputer moduleEngineering

A heat-sink module is prepared as setting heat -sink fin at external of heat pipe and connecting the two with each other, forming heat pipe body by unified top unit and side wall being set around said top unit, setting base with ring-shaped groove to be opposite to said unified top unit and enabling to insert side wall of heat pipe body into ring-shaped groove of base for jointing said base with heat pipe body firmly.

Owner:DELTA ELECTRONICS INC

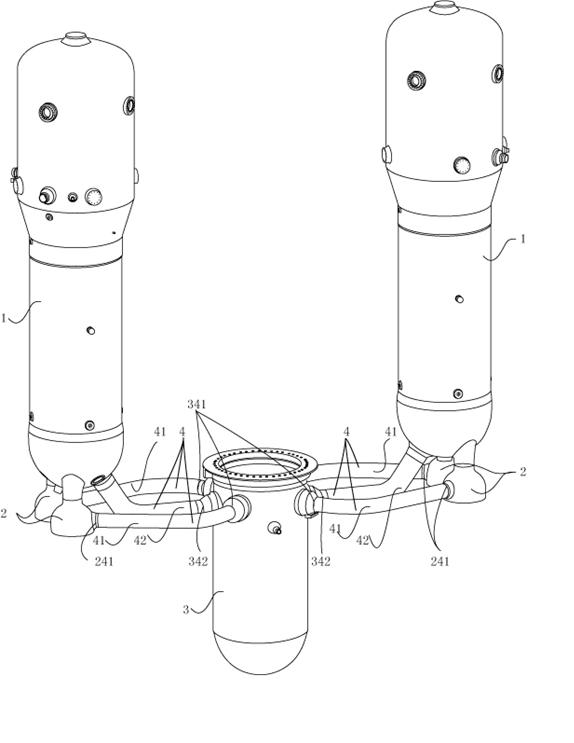

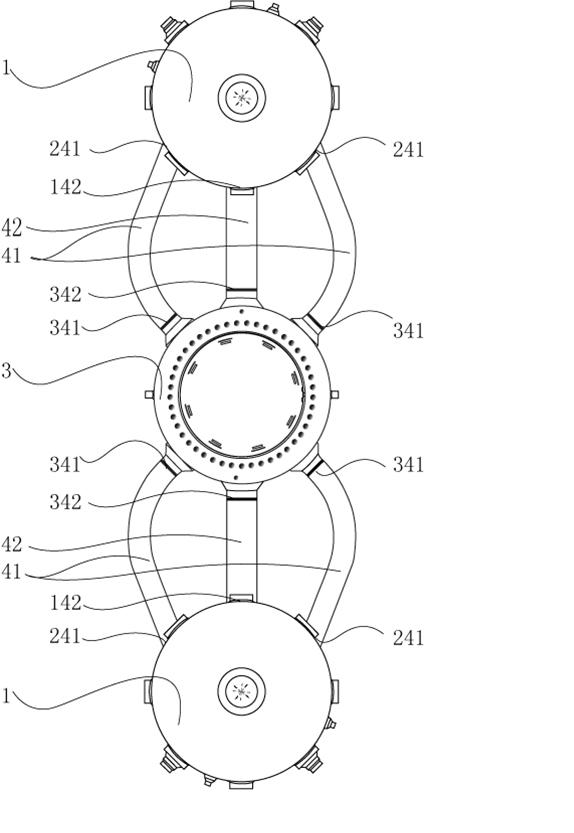

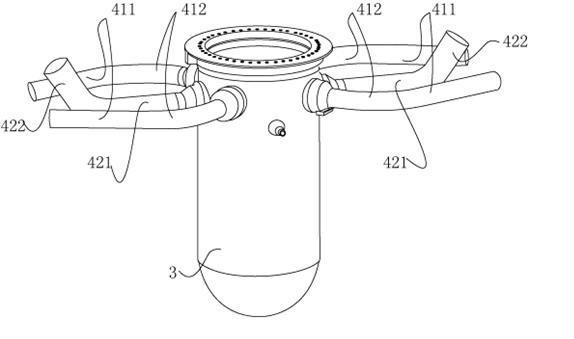

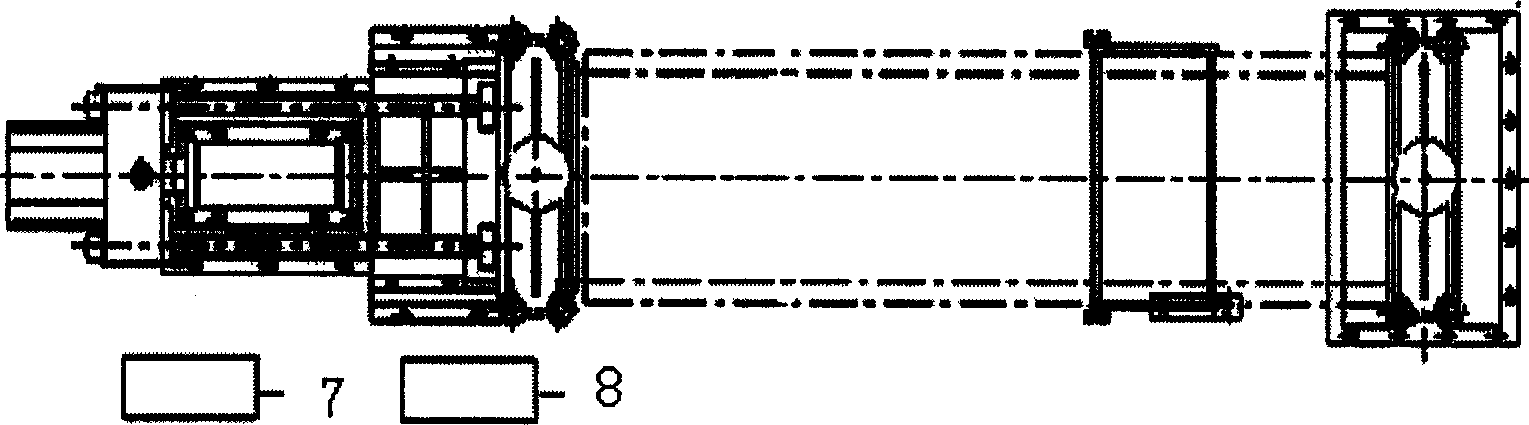

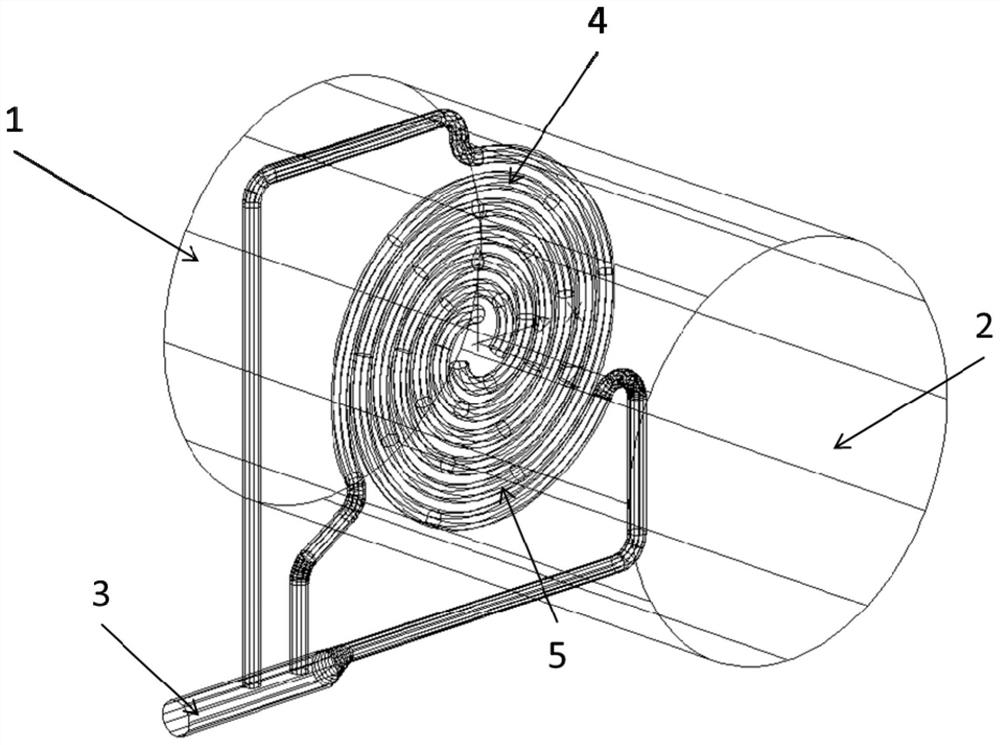

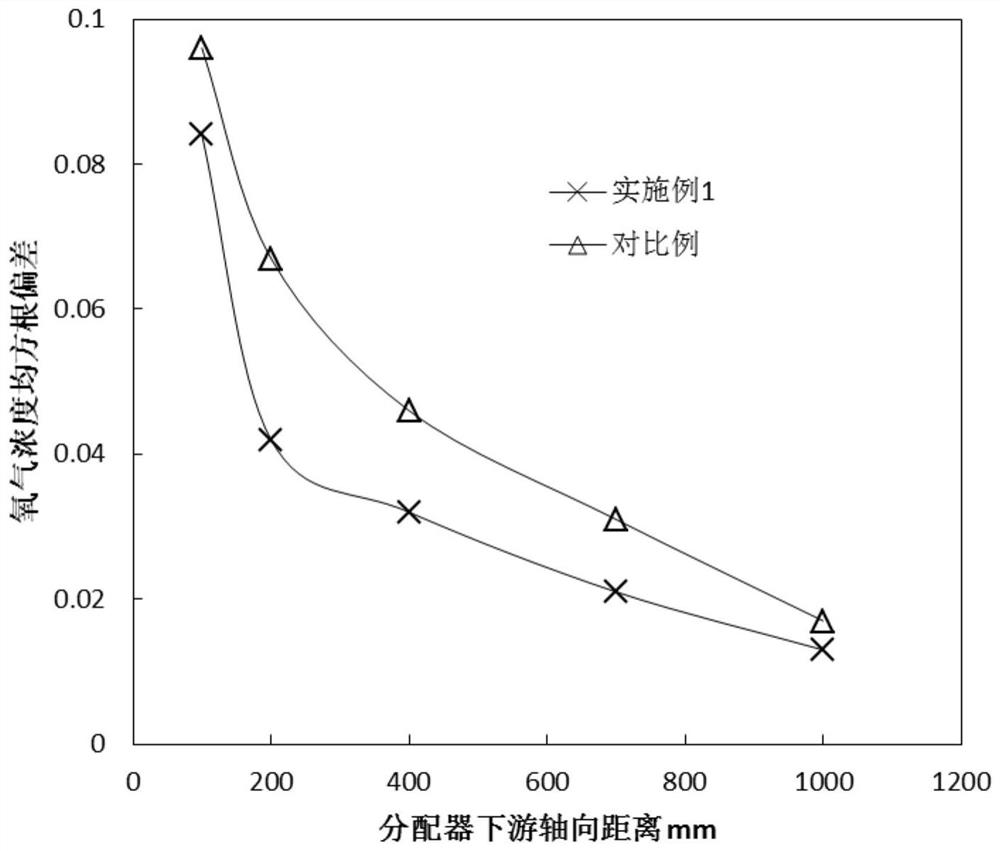

Rapid mixing equipment for ethylene and oxygen

ActiveCN108310989BFlexible structureSimple structureFlow mixersTransportation and packagingAlkeneMaterials science

The invention relates to a rapid mixing device for ethylene and oxygen, which mainly solves the problem of unsatisfactory mixing effect of olefin and oxygen in the prior art. The present invention adopts a kind of rapid mixing equipment of ethylene and oxygen, comprising ethylene main pipe and mixing chamber, the end of ethylene main pipe is connected to the mixing chamber, a number of oxygen spiral distribution pipes are arranged in the mixing chamber, the plane of the spiral distribution pipe is perpendicular to the flow direction of ethylene, A number of oxygen nozzles are evenly distributed on each spiral distribution pipe. The direction of the nozzles is consistent with the flow direction of ethylene. The oxygen feed pipe is divided into several branch distribution pipes in the main pipe and enters the main pipe of ethylene, so that the ethylene entering from the main channel and the nozzle of the spiral distribution pipe are sprayed. The technical scheme of rapid mixing of the oxygen produced in the mixing zone solves the above problems well, and can be used in the mixing of ethylene and oxygen.

Owner:SINOPEC SHANGHAI ENG +1

Storage-tank cylindrical-section integral wallboard creep aging forming method

ActiveCN104493430AImprove reliabilityReduce the number of weldsShaping toolsEngineeringElement modeling

The invention provides a storage-tank cylindrical-section integral wallboard creep aging forming method. The method includes the steps of a), subjecting a storage-tank cylindrical-section wallboard to machining according to drawing dimension, milling an interior grid or an exterior grid of the wallboard to dimensional requirements and then subjecting the wallboard to pre-roll bending on roll bending equipment; b), welding the wallboard to an integral cylindrical wallboard along a longitudinal joint; c), performing finite element modeling subjected to creep aging forming, calculating stress to be borne by a sticking mold of the cylindrical-section wallboard after welding, meanwhile, calculating rebound quantity and manufacturing a forming mold according to the stress and the rebound quantity; d), placing the wallboard into the mold and applying forming pressure by the mechanical mode; e), placing the assembled mold into an aging furnace for heat preservation at the temperature ranging from 150 to 200 DEG C for 10-30 hours, and then taking out the mold from the aging furnace to obtain a cylindrical-section wallboard product. With the method, the storage-tank cylindrical-section integral wallboard is formed and welded at one step, the number of welding joints is reduced, and reliability in tank storage is improved.

Owner:CAPITAL AEROSPACE MACHINERY +1

Manufacturing method of super austenitic stainless steel seamless steel pipe with large diameter

The invention discloses a manufacturing method of a super austenitic stainless steel seamless steel pipe with the large diameter, and relates to the technical field of production of seamless steel pipes with the large diameters. The manufacturing method comprises the steps that first a super austenitic stainless steel hollow ingot cylindrical tube blank is prepared by adopting an electroslag remelting technology, then surface treatment of an inner circle and an outer circle, heating, diameter enlarging and perforation and skew rolling are conducted, then intermediate heat treatment, cold rolling, intermediate heat treatment and cold rolling again, and heat treatment of a finished product are conducted, and finally, finishing is conducted. According to the manufacturing method of the superaustenitic stainless steel seamless steel pipe with the large diameter, the electroslag remelting technology is utilized to manufacture the hollow blank, and intermediate casting, forging and mechanical punching processes are reduced; and the perforation difficult problem that the center of the blank cannot form the Mannesmann effect during perforation of super austenitic stainless steel is solvedby using the hollow blank for perforation, the yield is high, the finished steel rate is more than 85%, the production cost is reduced, and the production efficiency is high.

Owner:YANGZHOU CHENGDE STEEL PIPE

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steam insulation pipe is DN 600-DN 700. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels arranged on the upper steel hoop and distributed symmetrically, and four lower idler wheels arranged on the lower steel hoop and distributed symmetrically, wherein the four lower idler wheels are evenly divided into two groups; the end parts of the upper steel hoop and the lower steel hoop are connected by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the four lower idler wheels and the inner wall of the outer sleeve steel pipe are contacted in a rolling friction way, and gaps are left between the two upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steaminsulation pipe comprises the rolling supporting mechanism and also comprises insulation material positioned between the rolling supporting mechanism and the inner sleeve steel pipe, heat-preservation material with the external diameter smaller than the internal diameter of the outer sleeve steel pipe, an air evaporation valve arranged on the outer sleeve steel pipe, and erosion resistant coatingsleeved outside the outer sleeve steel pipe. The rolling supporting mechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

Concrete post provided with counter pulling sheet profile steel welding rectangular steel tube

InactiveCN101748860AAvoid weak spotsEliminate adverse effects on bearing capacityStrutsPillarsWelding residual stressCounter-pull

The present invention discloses a concrete post provided with a counter pulling sheet profile steel welding rectangular steel tube, which relates to a rectangular steel-tube concrete post which is composed of a steel tube and concrete, wherein the steel tube is welded by belt rib profile steel and counter pulling sheets arranged transversely. The counter pulling sheet profile steel welding rectangular steel-tube concrete post enables welding seam positions not at four angle positions stressed largely and while at positions stressed little at the middle of a pipe wall. At the same time, the wall thickness and welding seam volume of the steel tube can be reduced, the constraint force of the middle of the pipe wall for the concrete is increased, and the bearing force of the total component is improved.

Owner:中国建筑东北设计研究院有限公司

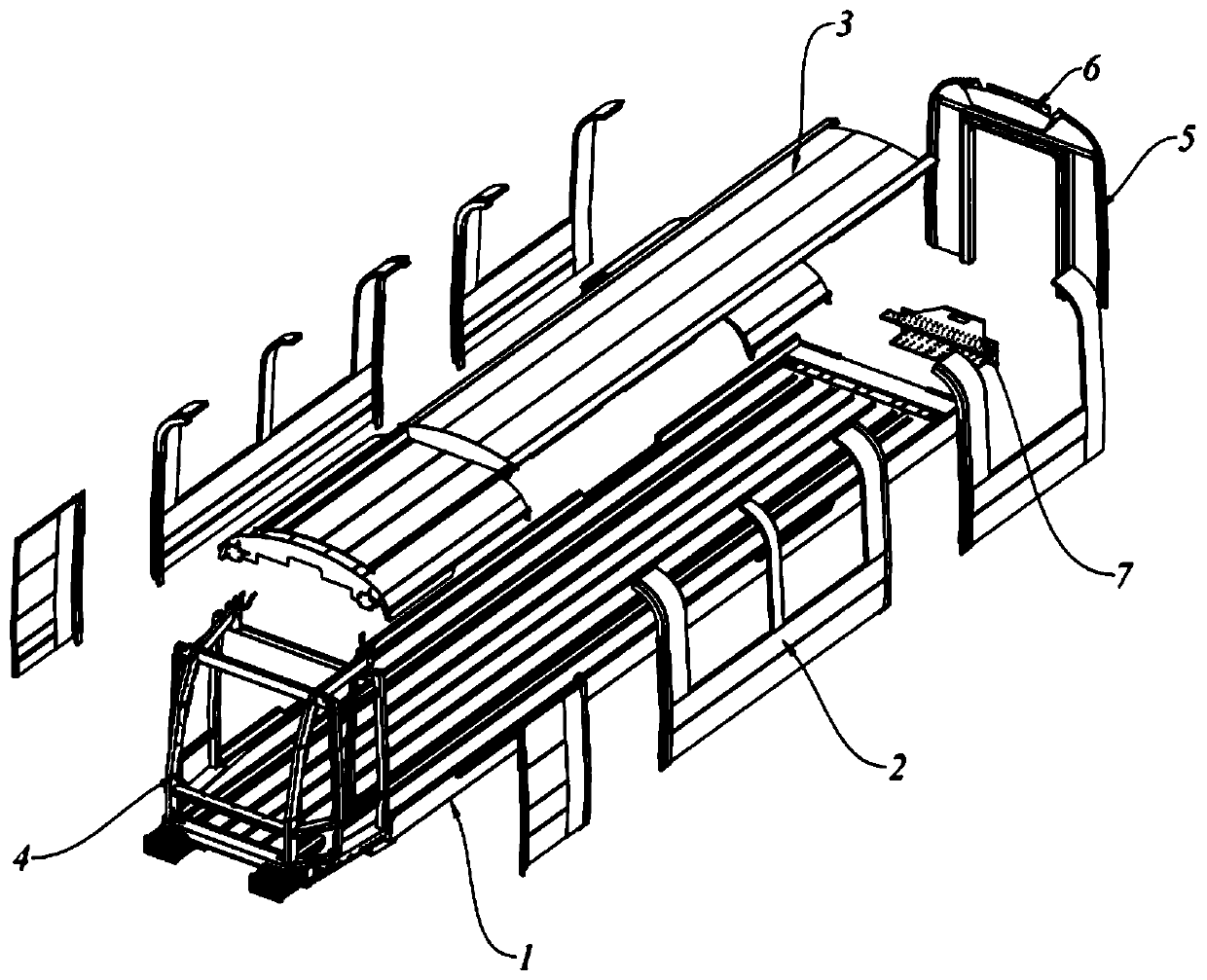

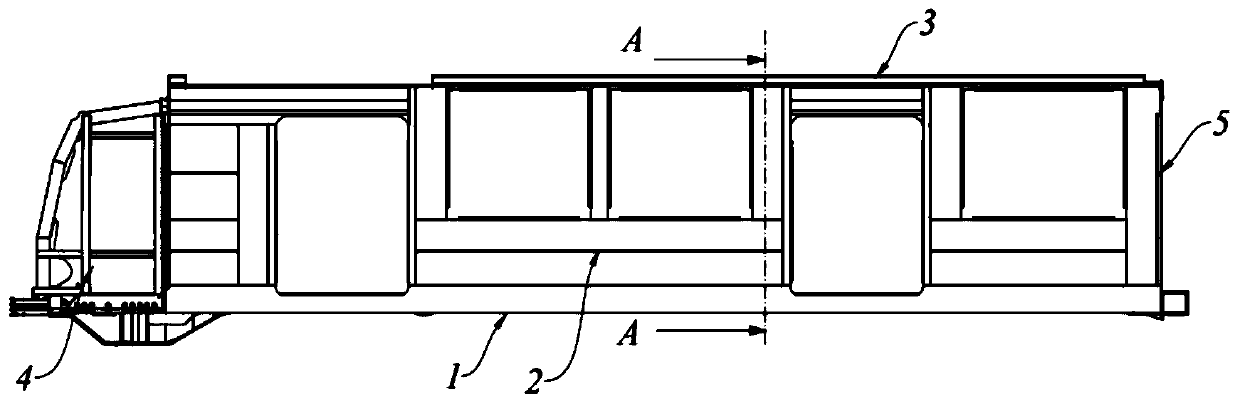

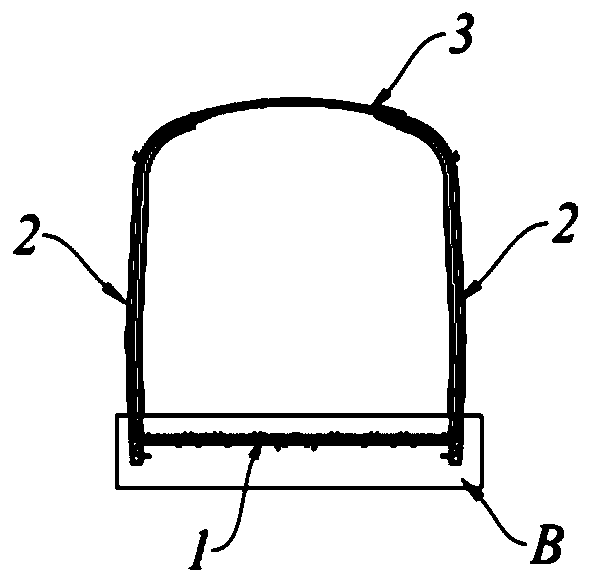

Head car body structure of high-floor tramcar

InactiveCN110667617AGive full play to carrying capacityReduce usageRailway roofsUnderframesBolt connectionAutomotive engineering

The invention discloses a head car body structure of a high-floor tramcar. The head car body structure comprises a base frame, side walls, a roof, a driver cab, an end wall, and an upper / lower hinge seat. The base frame, the side walls, the roof and the end wall are connected by welding, the driver cab is connected to the base frame and the roof by bolts, and the upper / lower hinge seat is rivetedto the end wall and the base frame respectively. The car body structure is mainly made by welding of hollow-section extrusion aluminum-type materials. In the manner, the car body structure has a goodlightweight effect and a good noise isolation performance while meeting the requirements of strength; and at the same time, window columns adopt an arc design, so that the area of a window frame is increased, and passengers can enjoy more wild field of vision to meet the needs of tour and sightseeing. In addition, the upper and lower hinge seats are riveted and cooperate with each other to effectively improve the connection strength with the car body. Even if the car body is larger than 12 meters, the car body structure can ensure sufficient connection strength.

Owner:中铁轨道交通装备有限公司

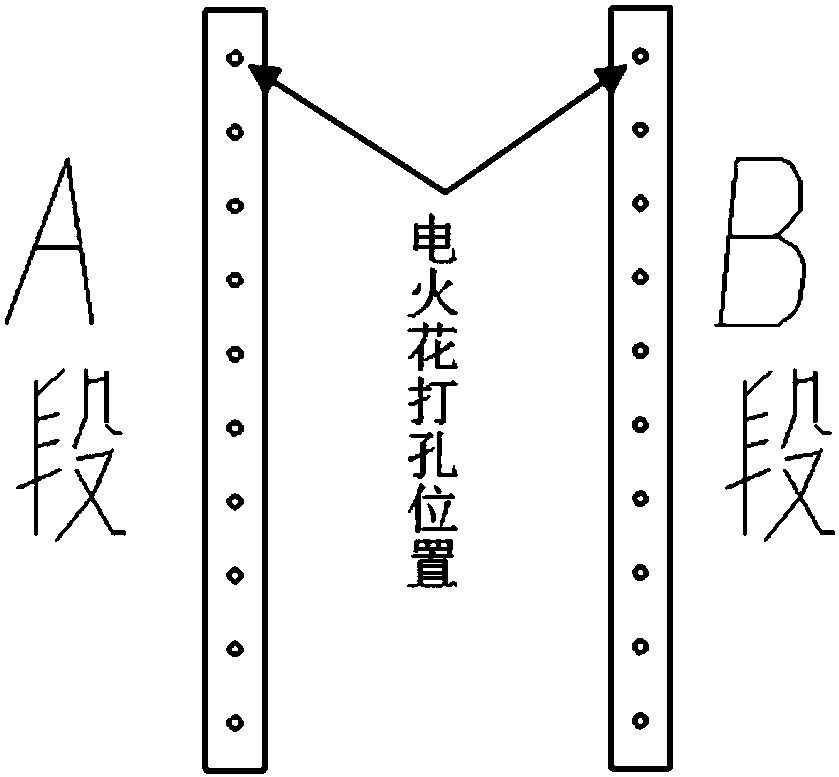

Processing and manufacturing method for ultra-long ultra-fine special-shaped multi-channel cooling plate

The invention relates to the design technology of an international thermonuclear fusion experimental reactor, and particularly discloses a processing and manufacturing method of an ultra-long ultra-fine special-shaped multi-channel cooling plate. After raw materials for cooling plate processing are prepared, holes are drilled by electric sparks. Then a special-shaped channel is cut, and a rectangular strip is welded. Each of the raw material plates processed blind holes are welded into a whole plate. And drilling again by the electric spark, a molybdenum wire is passed through the through holes, the centers of small holes are taken as dead centers, and the small holes are cut into square holes with flow channels of 2.5 mm in length and 4.5 mm in width. The welding method and nondestructivetesting adopted in the processing technology are simple, easy to operate, the processing quality of the ultra-long ultra-fine special-shaped multi-channel cooling plate is effectively ensured and theprocessing success rate is improved.

Owner:SOUTHWESTERN INST OF PHYSICS

Edge coupling standing wave accelerating tube manufacture method and edge coupling standing wave accelerating tube

ActiveCN107396528AImprove high frequency performanceReduce welding difficultyAdditive manufacturing apparatusLinear acceleratorsStanding wave3D printing

The invention provides an edge coupling standing wave accelerating tube manufacture method, and relates to the field of medical electron linear accelerators. The invention provides an edge coupling standing wave accelerating tube manufacture method which has the advantages of simple manufacture process and high operating stability of a manufactured accelerating tube, and an edge coupling standing wave accelerating tube. The edge coupling standing wave accelerating tube has a main accelerating chamber without weld joints, has the chamber body with low ignition risk, and is not limited by machining molding conditions. The edge coupling standing wave accelerating tube manufacture method provided by the invention has the advantages that an integrally formed single-cycle accelerating chamber body unit is manufactured through a 3D printing technology; a first time of heating is carried out on the printed single-cycle accelerating chamber body unit; the single-cycle accelerating chamber body unit is mechanically ground and polished through a grinding material; the mechanically ground and polished single-cycle accelerating chamber body unit is cleaned; and the cleaned single-cycle accelerating chamber body unit is assembled to form the edge coupling standing wave accelerating tube.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

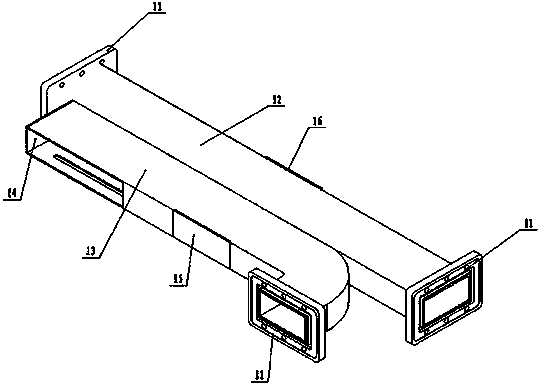

Inflating device for mounting tunnel wide-width waterproof board and construction method and mounting method

InactiveCN103899336AImprove construction efficiencyImprove construction qualityUnderground chambersTunnel liningStructural engineeringBuilding construction

Owner:CHANGSHU JIAFA CHEM

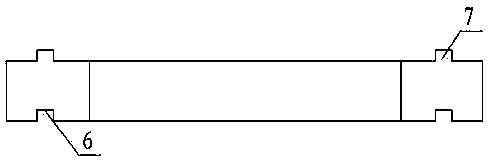

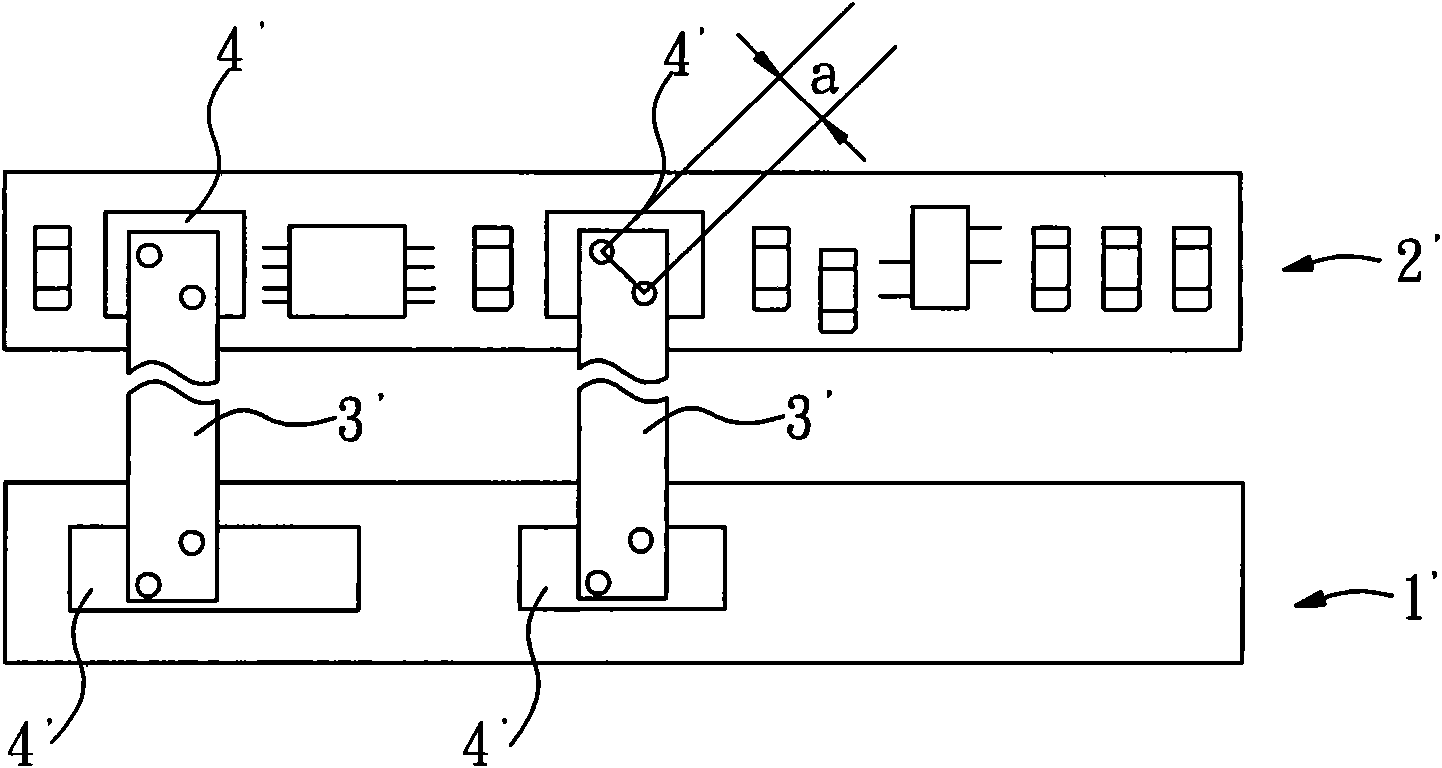

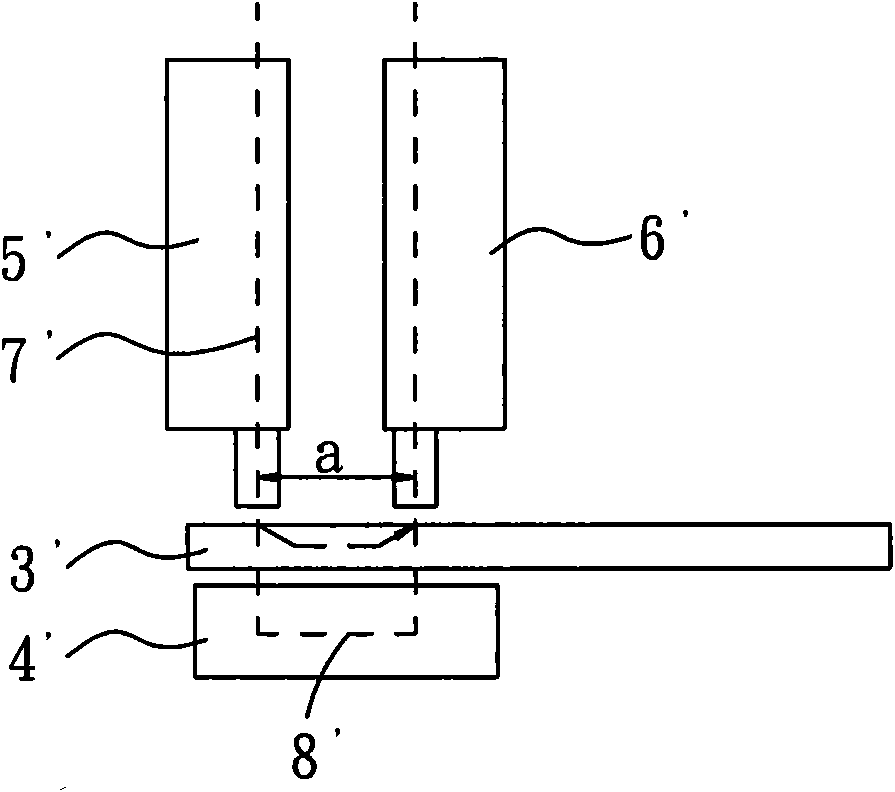

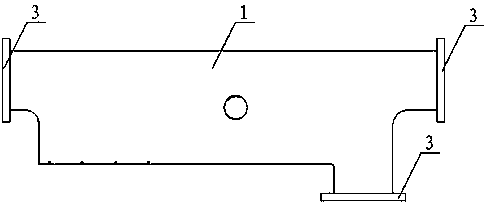

Self-positioning narrow-side bridge waveguide and vacuum brazing technology thereof

InactiveCN103928736AReduce production processReduce the number of partsWaveguidesCoupling devicesCorrosionEngineering

The invention discloses a self-positioning narrow-side bridge waveguide and a vacuum brazing technology thereof. The self-positioning narrow-side bridge waveguide comprises a cover plate (1), a cavity (2) and a flange (3), wherein the flange (3) comprises an upper flange body and a lower flange body, the upper flange body and the cover plate (1) are formed integrally, the lower flange body and the cavity (2) are formed integrally, bosses (4) are arranged around the cover plate (1), grooves (5) matched with the bosses (4) are formed around the cavity (2), and the cover plate (1) and the cavity (2) are welded together through vacuum brazing. Due to the adoption of the vacuum brazing technology in which the cover plate and the cavity are combined in a self-positioning mode, the accuracy of the whole waveguide is improved, the problem of deformation of the waveguide caused by flame welding is solved, and the corrosion resistance of the waveguide is improved due to the fact that electrochemical treatment is conducted on the waveguide subjected to vacuum brazing.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

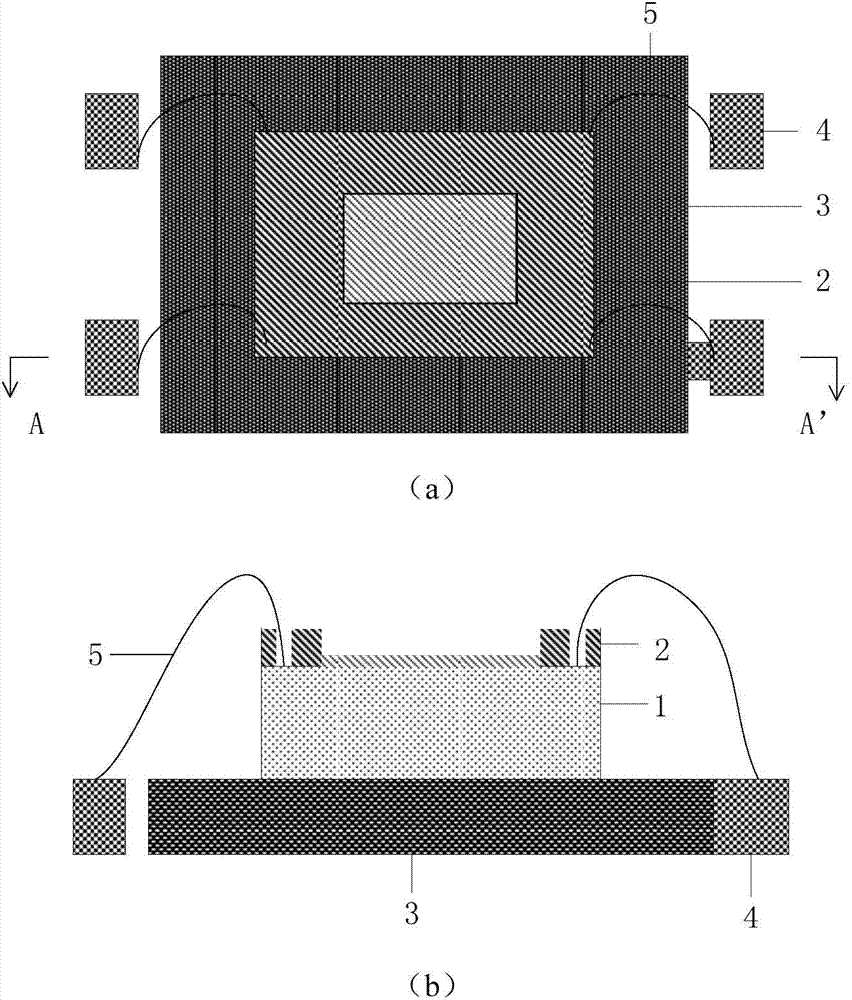

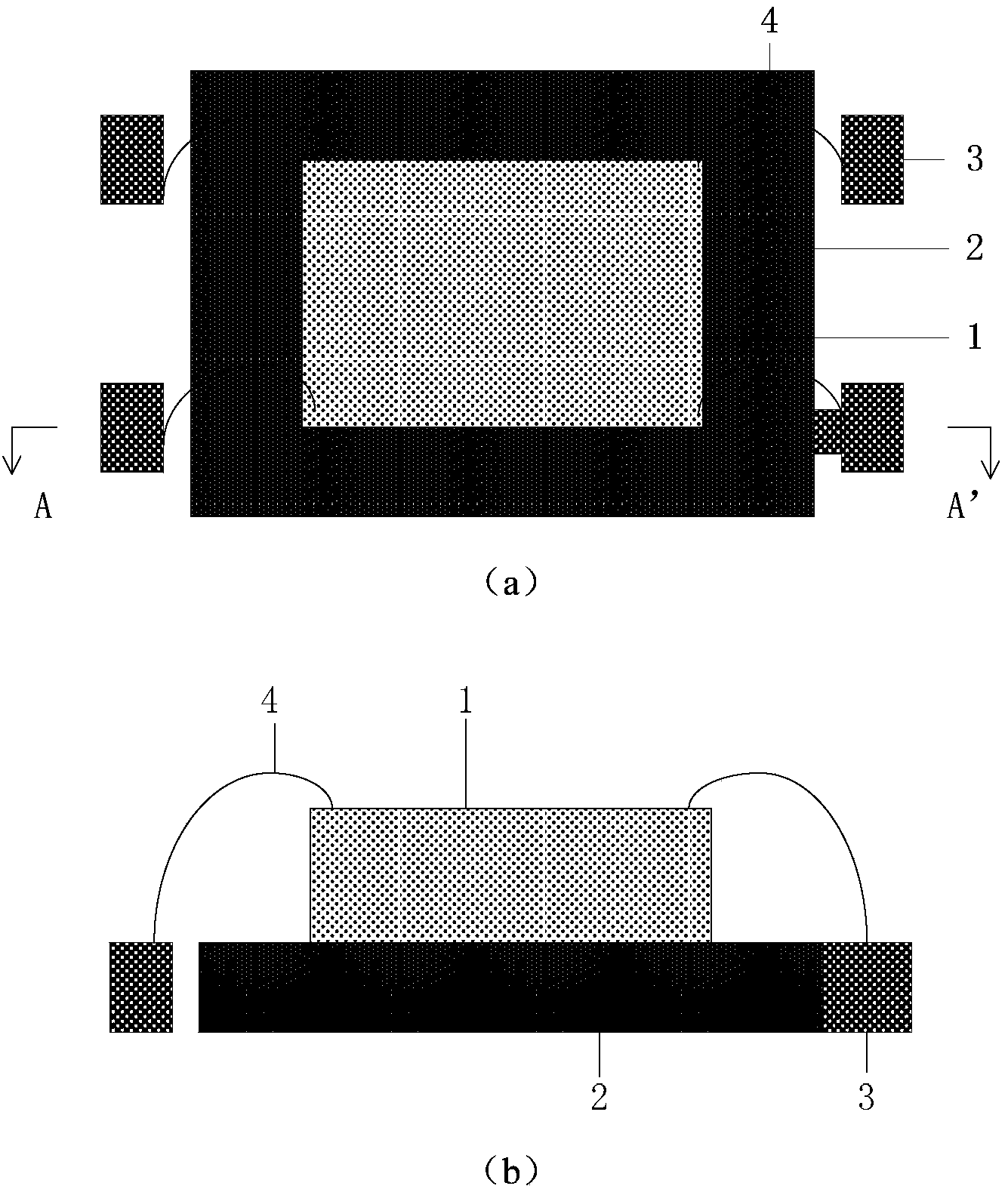

Chip packaging structure with cavity and packaging method thereof

ActiveCN103700635AReduce stress effectsReduce the number of weldingSemiconductor/solid-state device detailsSolid-state devicesRadiationElectrical and Electronics engineering

The invention discloses a chip packaging structure with a cavity and a packaging method thereof. The chip packaging structure comprises a chip, a substrate, a pin frame, a wire and a plastic package body, wherein the lower surface of the chip is arranged on the substrate; the chip is connected with the pin frame by the wire; the plastic package body is used for packaging the chip, the pin frame and the substrate; the pin frame is exposed out of the bottom surface or the side face of the plastic package body; the cavity is arranged between the plastic package body and the chip, so that one surface which does not contact with the plastic package body at least exists in the side face and the upper surface of the chip. The cavity is arranged between the plastic package body and the chip, so the sensitive part of the surface of the chip does not contact with the plastic package body, the sensitive part is not covered by the plastic package body, and the stress influence on the internal structure of the chip, which is caused by the packaging structure is reduced; the chip packaging structure further comprises a through hole which is beneficial for the ventilation and the heat radiation of the chip; the packaging structure has the characteristics that the manufacturing process is simple and advanced, the size is relatively small, the heat radiation is excellent and the like, and the reliability in the using process of the electronic chip is improved.

Owner:北京必创科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com