Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4200results about How to "Guarantee processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

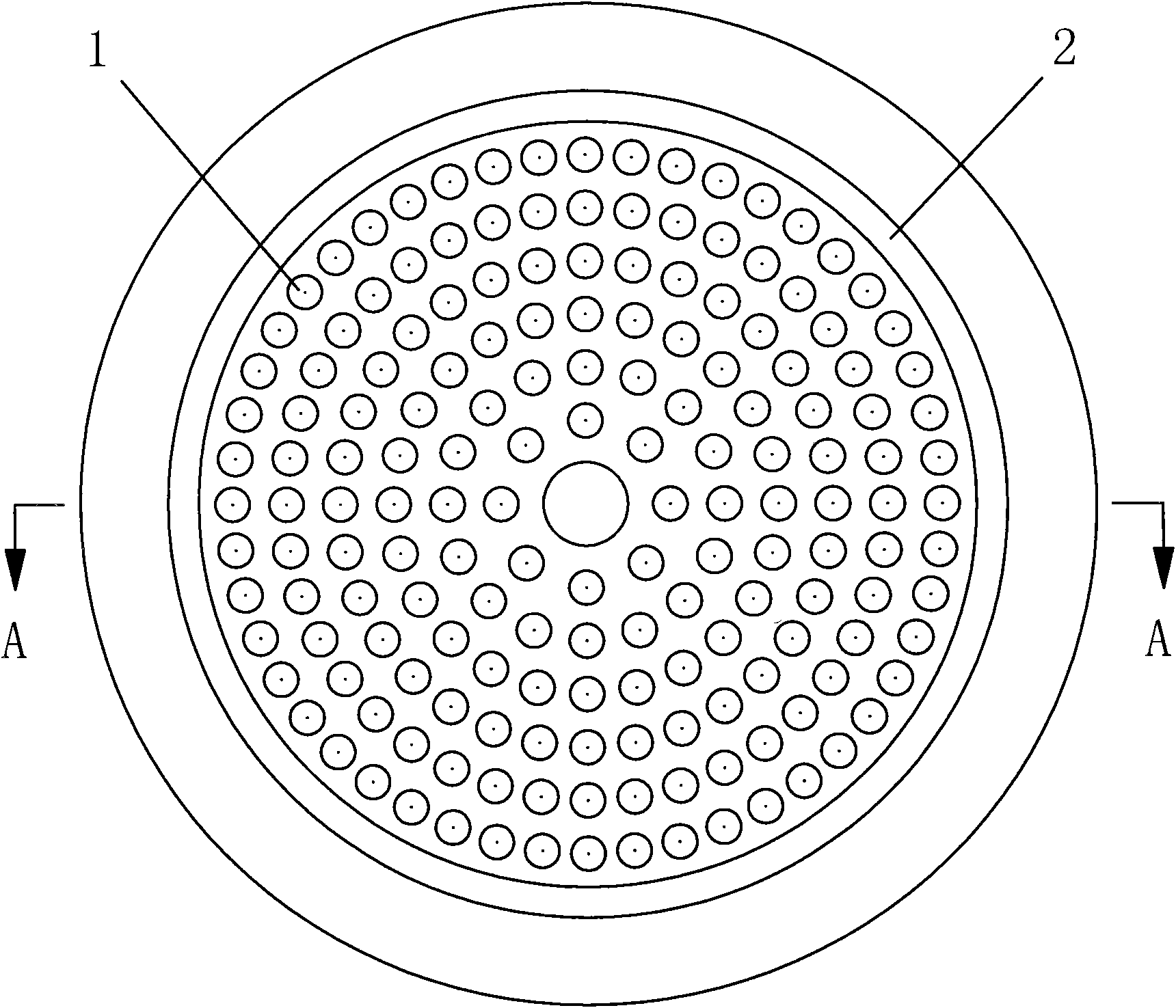

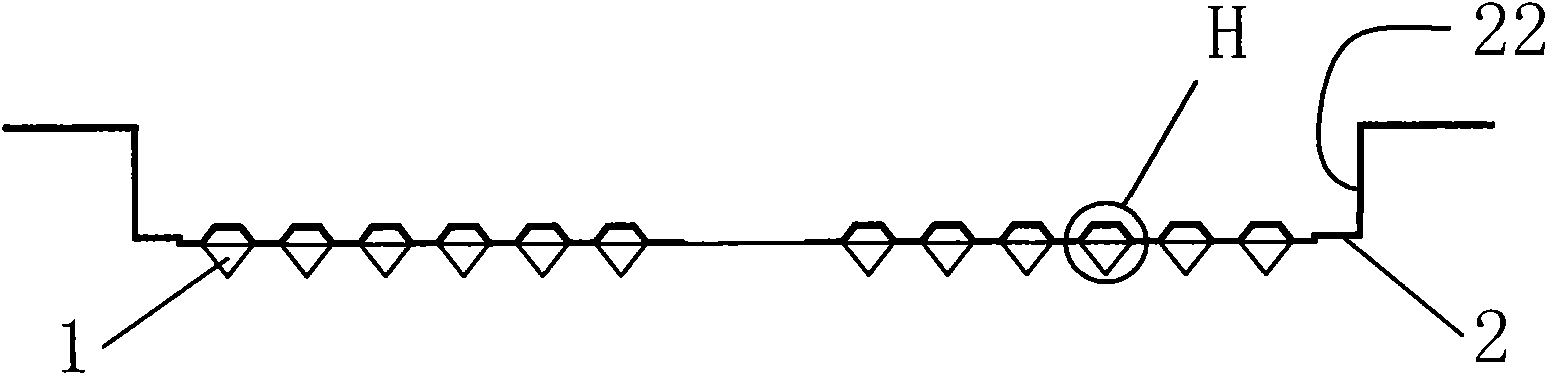

Method for plating surface of rhinestone and plastic-suction disk

ActiveCN101569447AEliminate the deplating processReduce management difficultyMetallic material coating processesJewelleryZinc alloysCopper

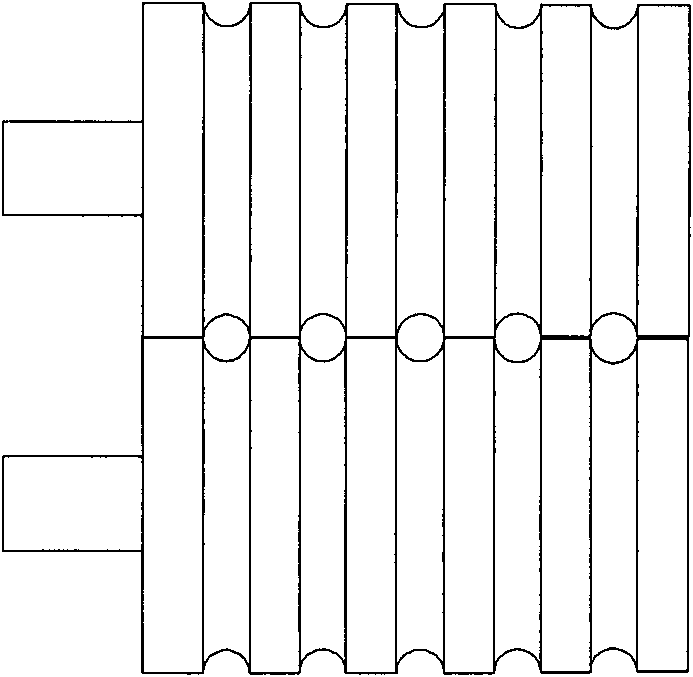

The invention discloses a method for plating the surface of a rhinestone. The method comprises the following steps: arranging a plurality of rhinestones in the same direction, and forming a plastic-suction disk by plastic suction, wherein, a plurality of absorption holes are formed on one surface of the plastic-suction disk, and the facial part of the rhinestone is embedded and fixed in the absorption hole; plating the surface of the plastic-suction disk with the embedded rhinestones with a reflection layer, wherein, the reflection layer is a silver, aluminum or chromium layer; coating the surface of the plastic-suction disk with the plated reflection layer with a protection layer, wherein, the protection layer is an anti-tarnishing paint, copper or copper-zinc alloy layer; and separating the rhinestones out from the plastic-suction disk. The invention further discloses a plastic-suction disk. By manufacturing the ground and polished rhinestones into a plastic-suction disk in a plastic-suction forming manner, the rhinestones can be fixed onto the plastic-suction disk, therefore, the plating treatment can be carried out on the entire disk of rhinestones, in this way, the invention can improve the processing efficiency, guarantee the processing quality, reduce the manual operation procedures and reduce the difficulties in plant management.

Owner:虞卫东

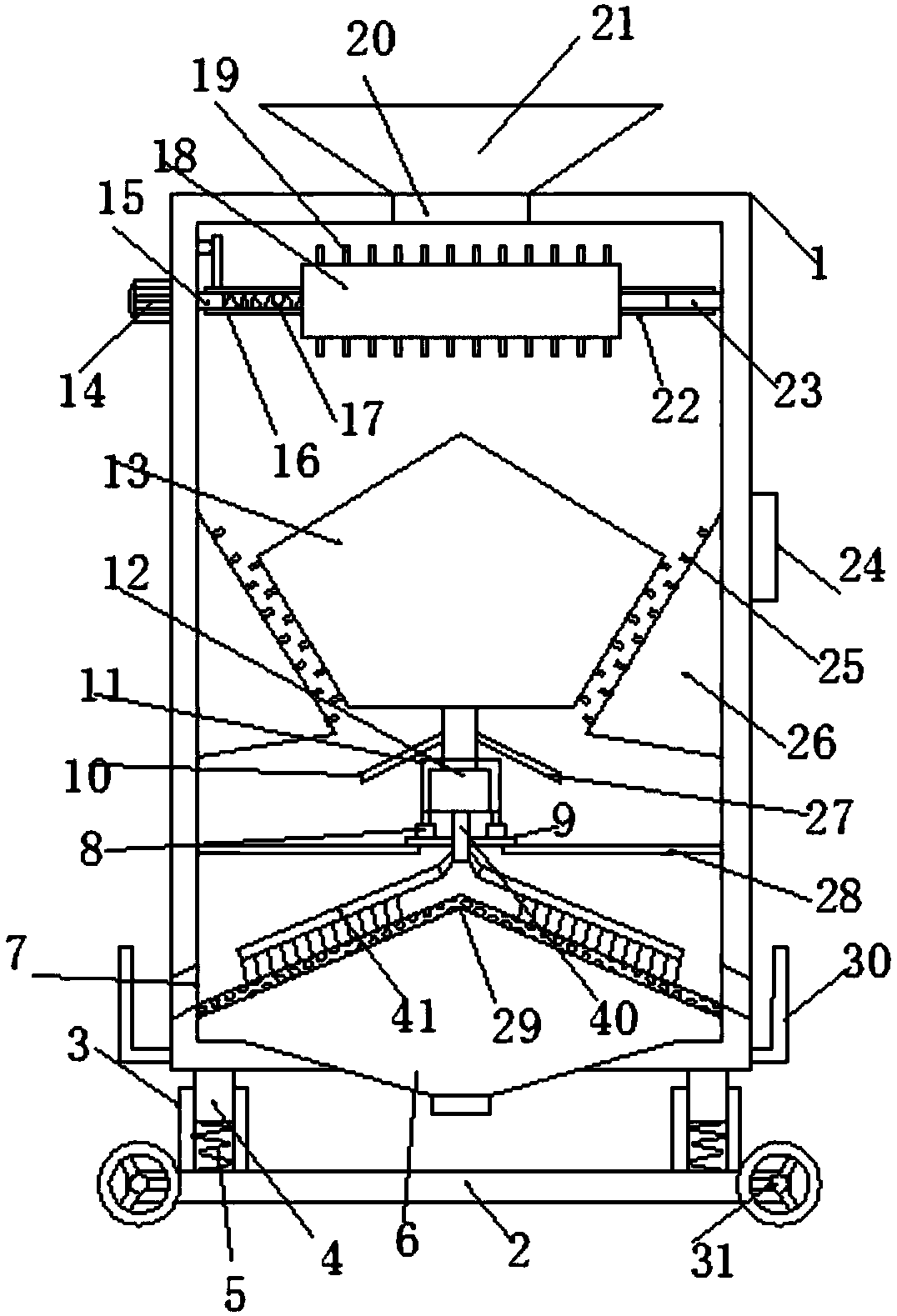

Grinding and sieving integrated traditional Chinese medicine processing device

InactiveCN108435357AImprove crushing effectEasy to processSievingScreeningEngineeringPulp and paper industry

The invention discloses a grinding and sieving integrated traditional Chinese medicine processing device. The device comprises a processing box, wherein a base is arranged below the processing box; rollers through which the device can be conveniently carried are symmetrically arranged at the left side and the right side of the base; supporting legs are symmetrically arranged at two sides of the lower end of the processing box; supporting sleeves sleeve the lower ends of the supporting legs in a sliding manner, and the lower ends of the supporting sleeves are connected and fixed to the base; buffering springs for connecting and fixing the supporting sleeves and the supporting legs are arranged in the supporting sleeves, and the abovementioned buffering mechanism is capable of effectively improving the damping performance of the device; a feeding port is formed in the middle of the upper end of the processing box; and a crushing mechanism comprising a crushing roller is arranged below the feeding port. The device is simple and reasonable in structure, convenient to carry, and high in damping performance; the crushing mechanism shakes leftwards and rightwards to improve the material crushing effect; the grinding effect is adjustable, and thus particular materials with different particle size can be conveniently processed; the processed materials can be sieved, so that the processing quality is ensured; and the practicability is high.

Owner:安徽康和中药科技有限公司

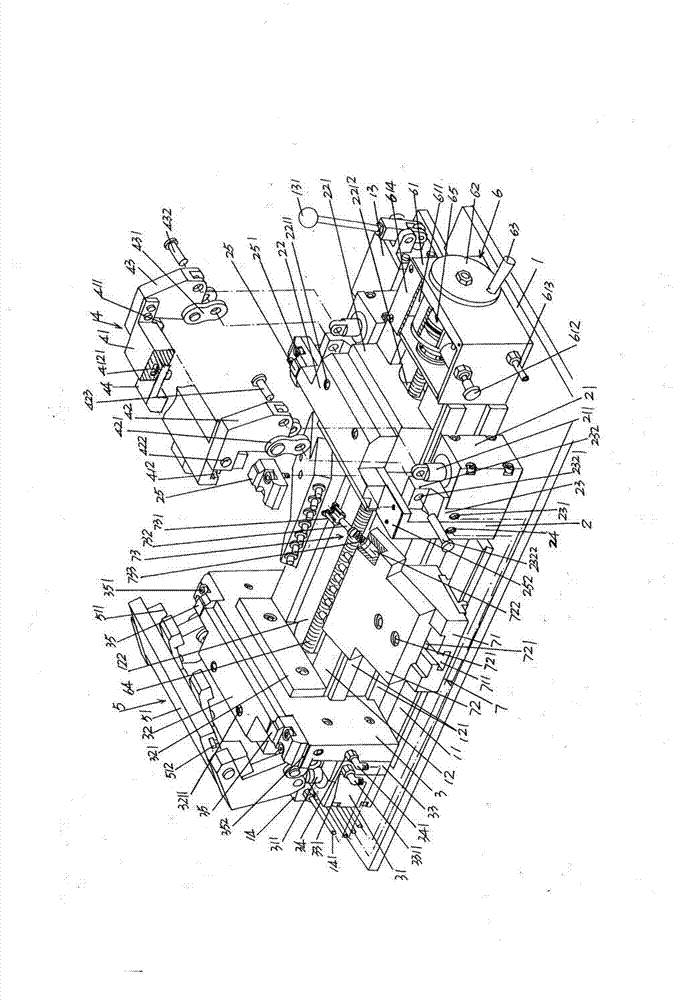

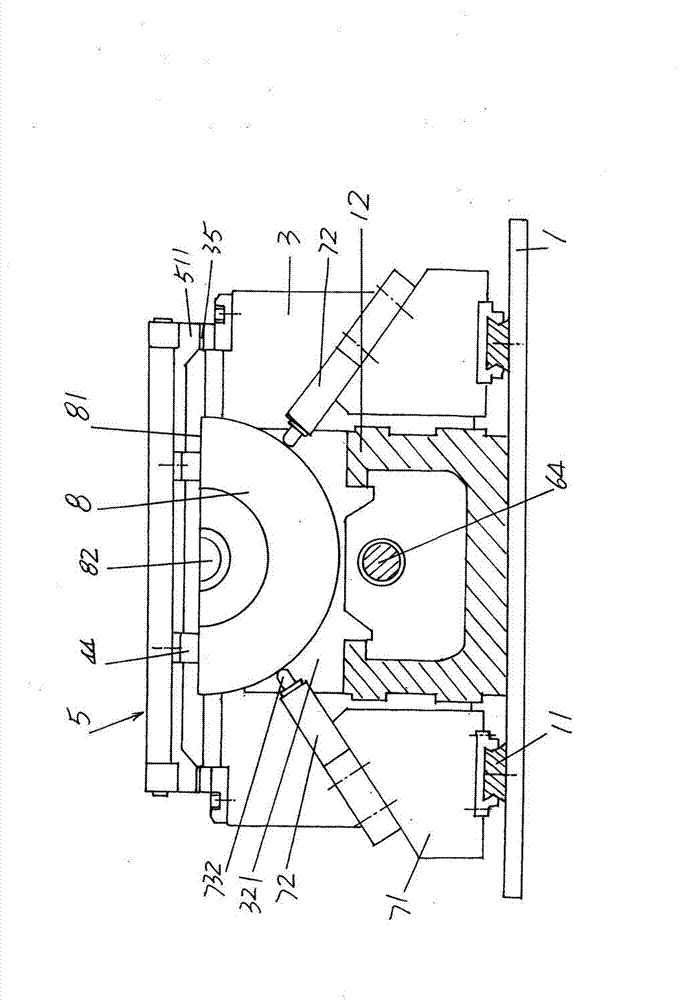

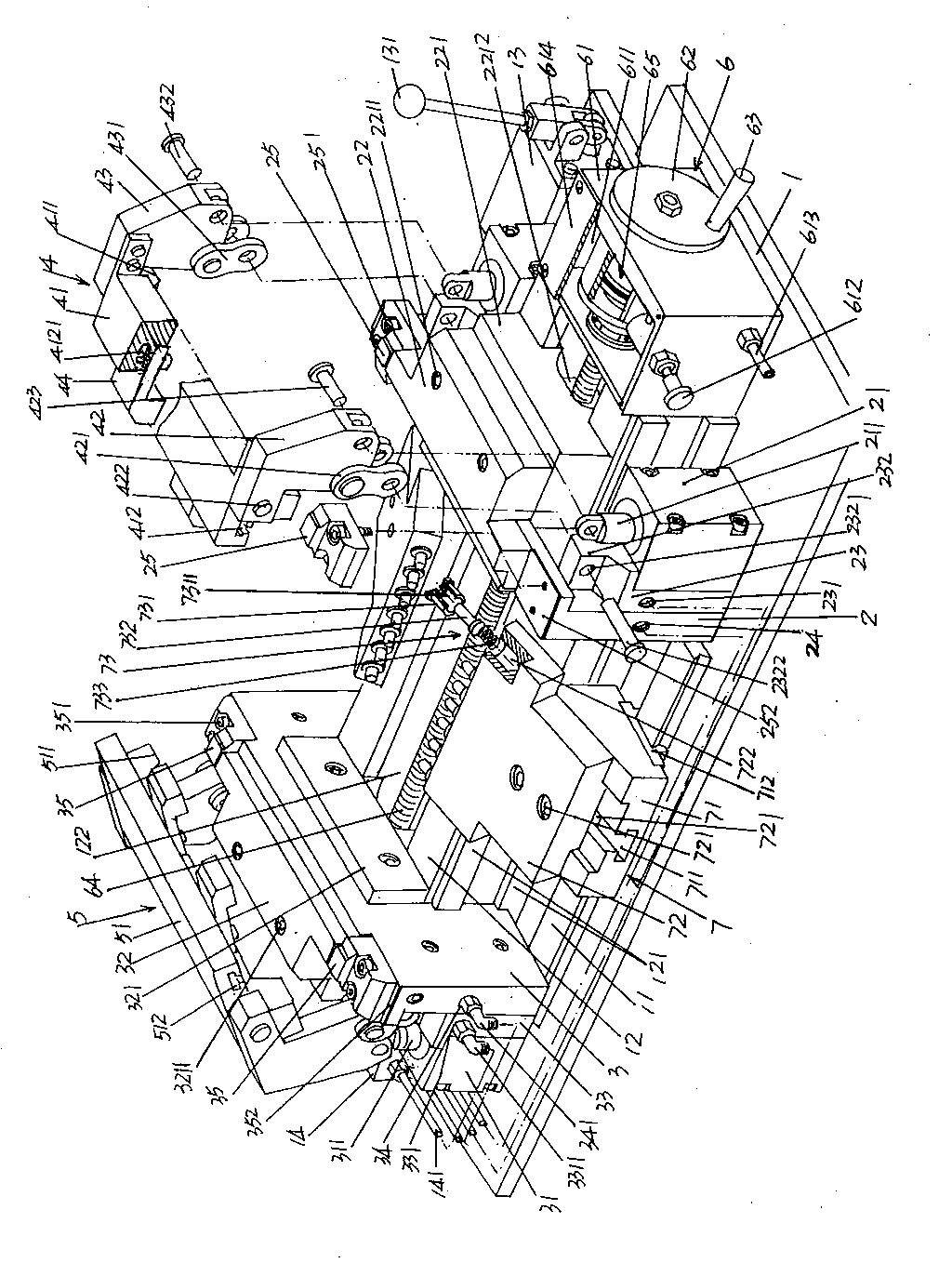

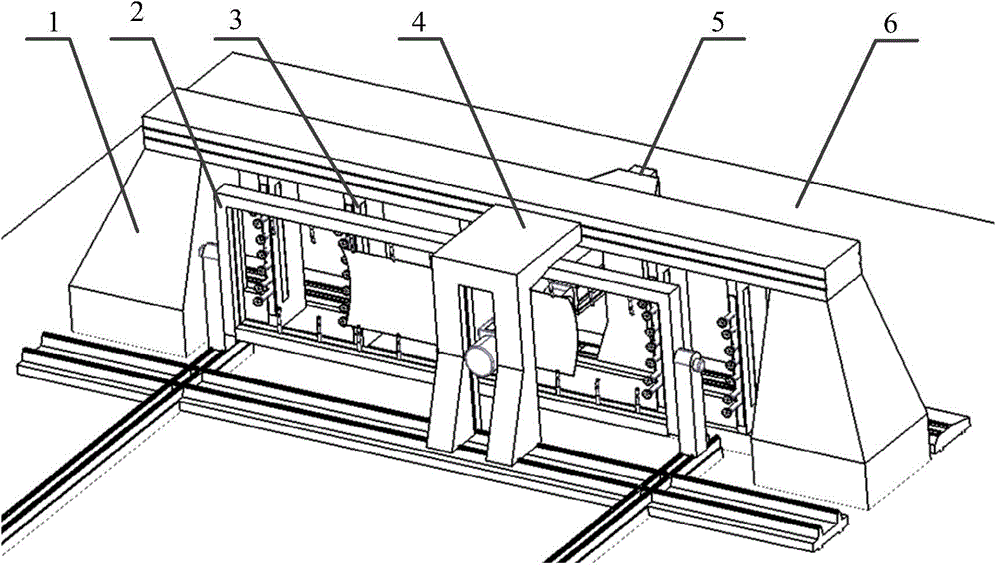

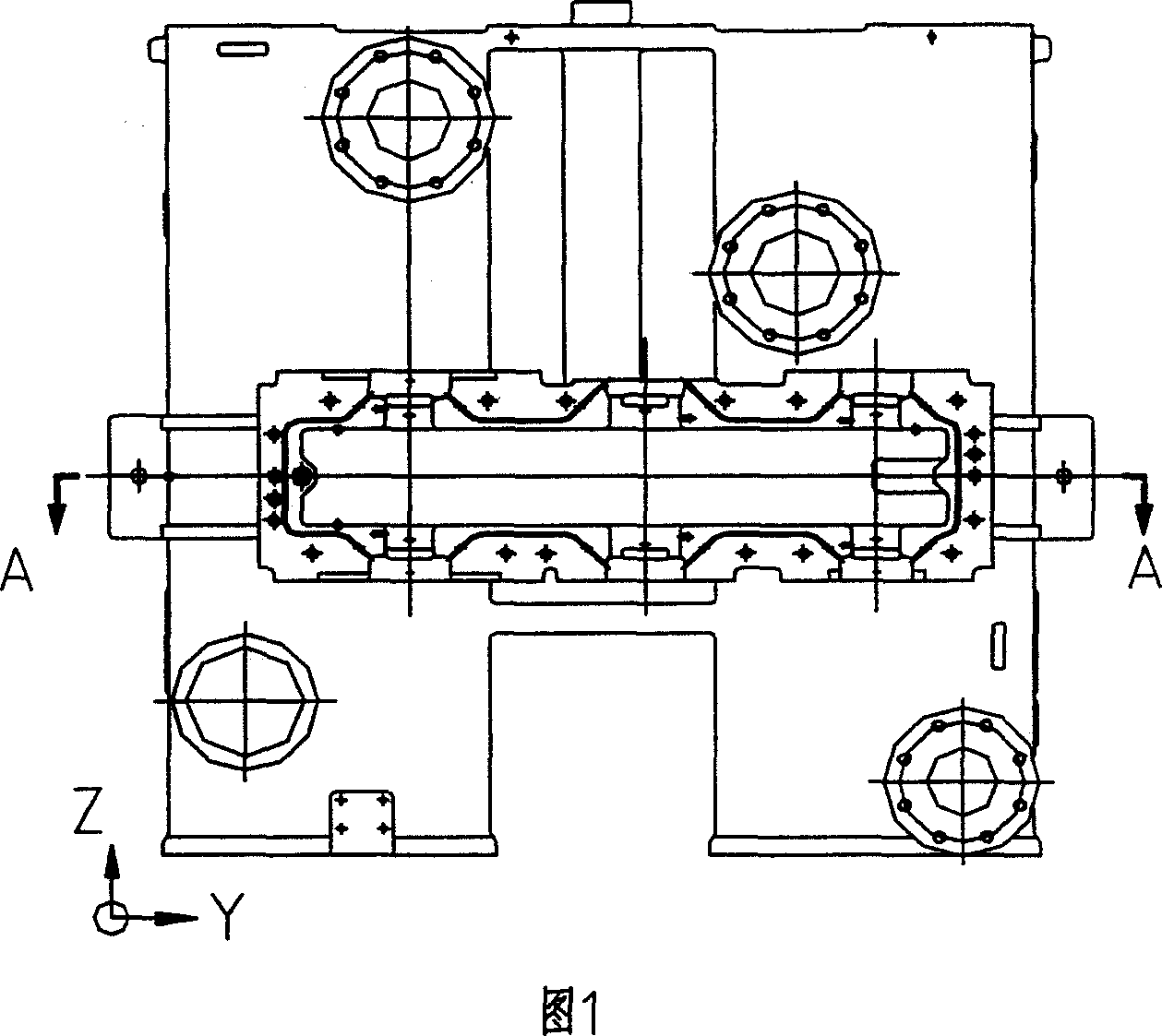

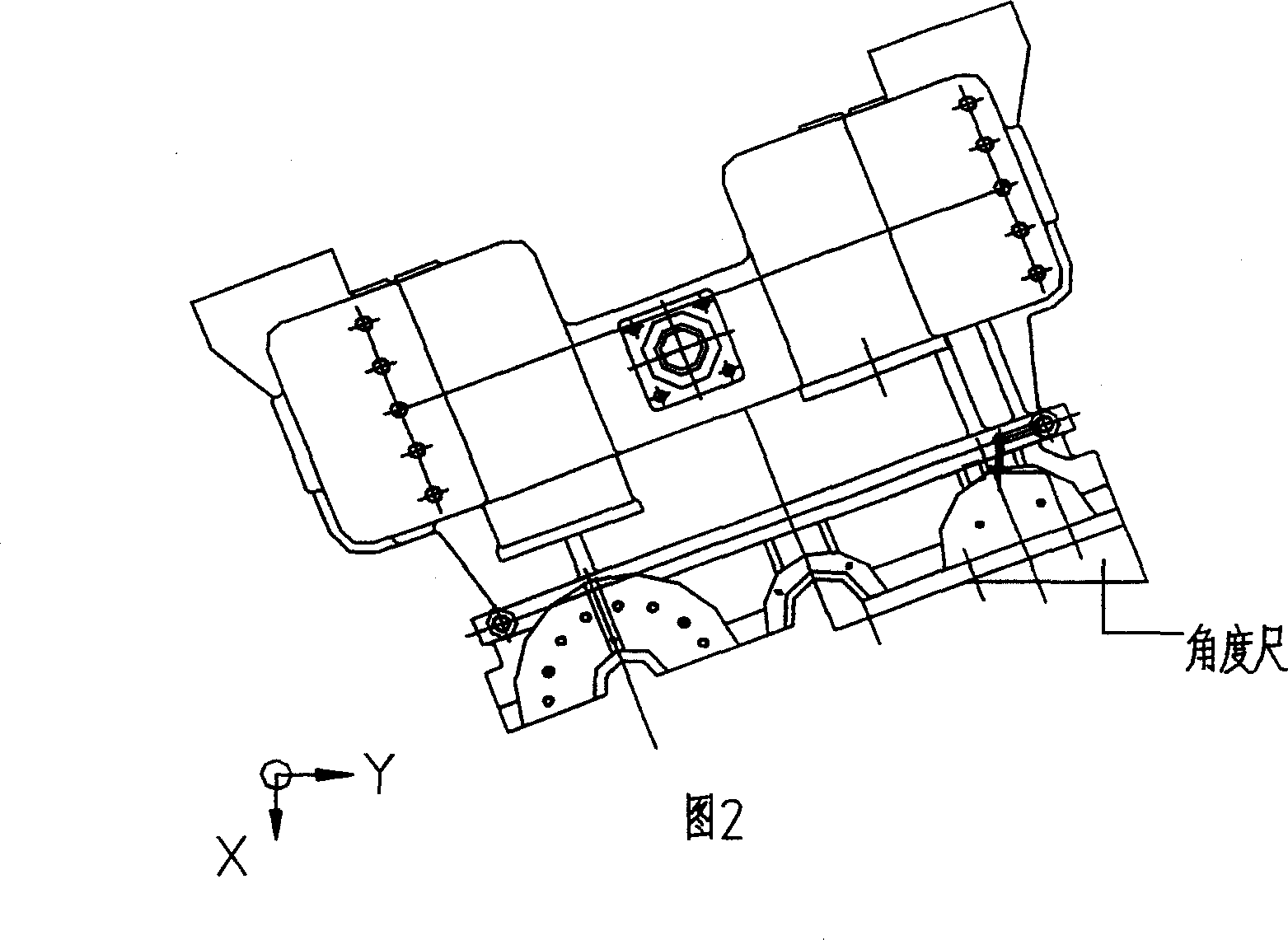

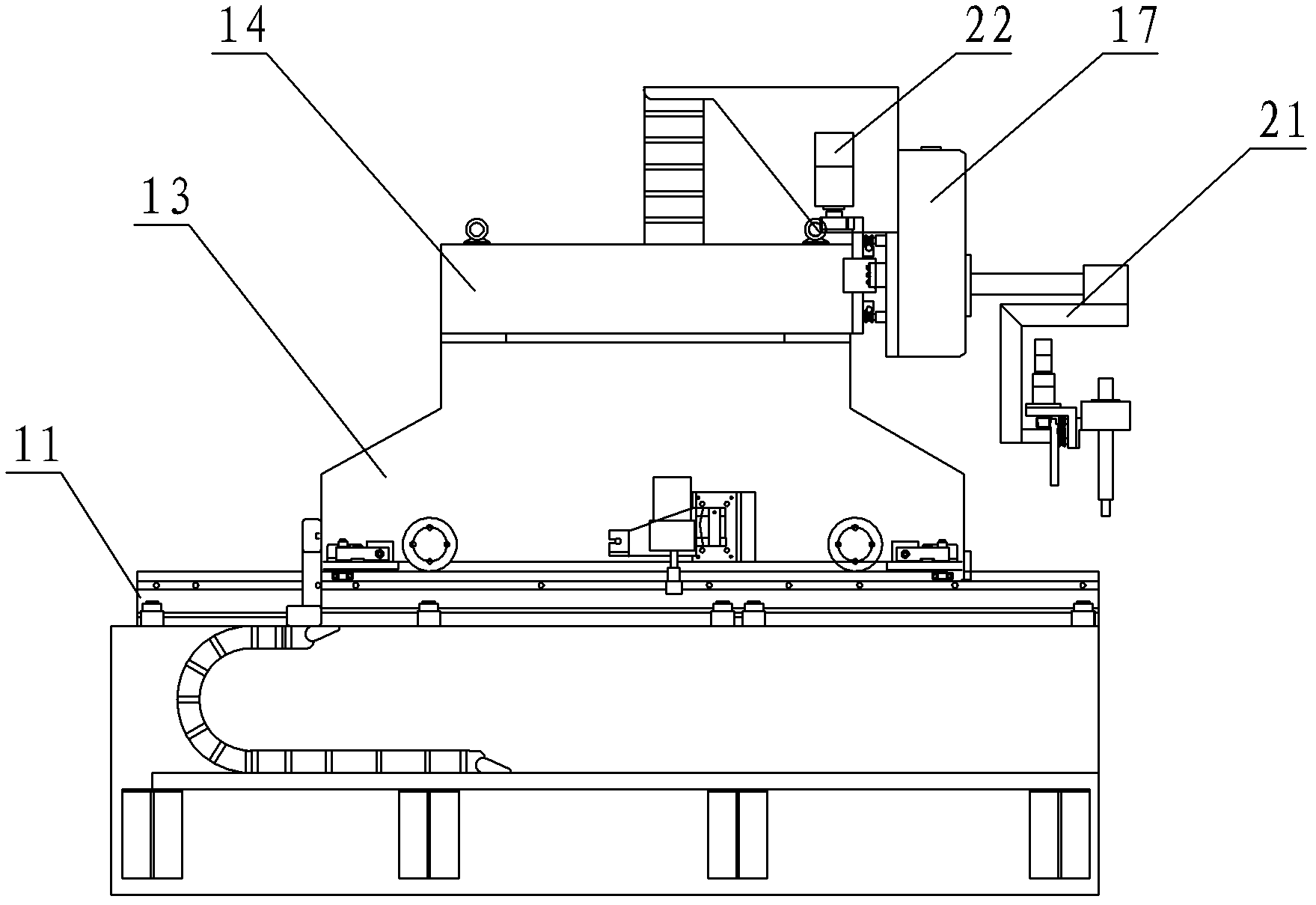

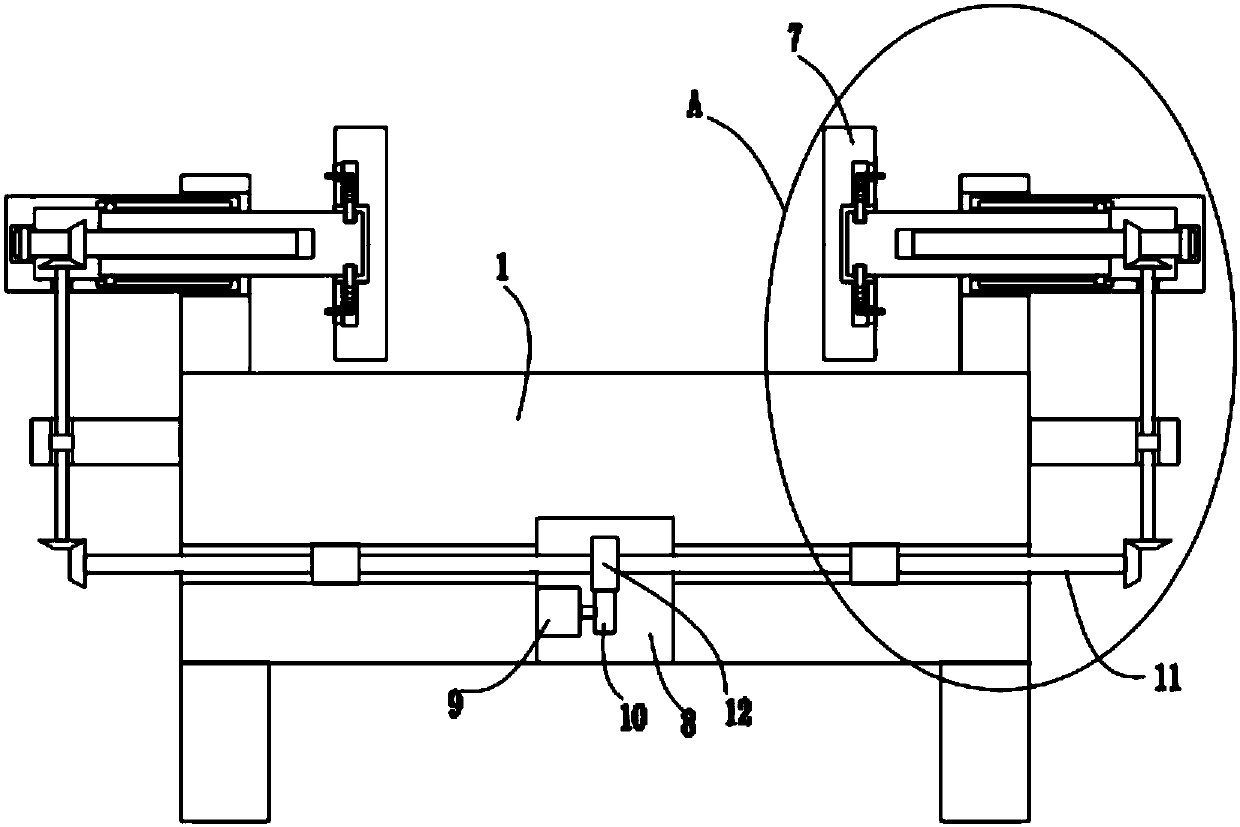

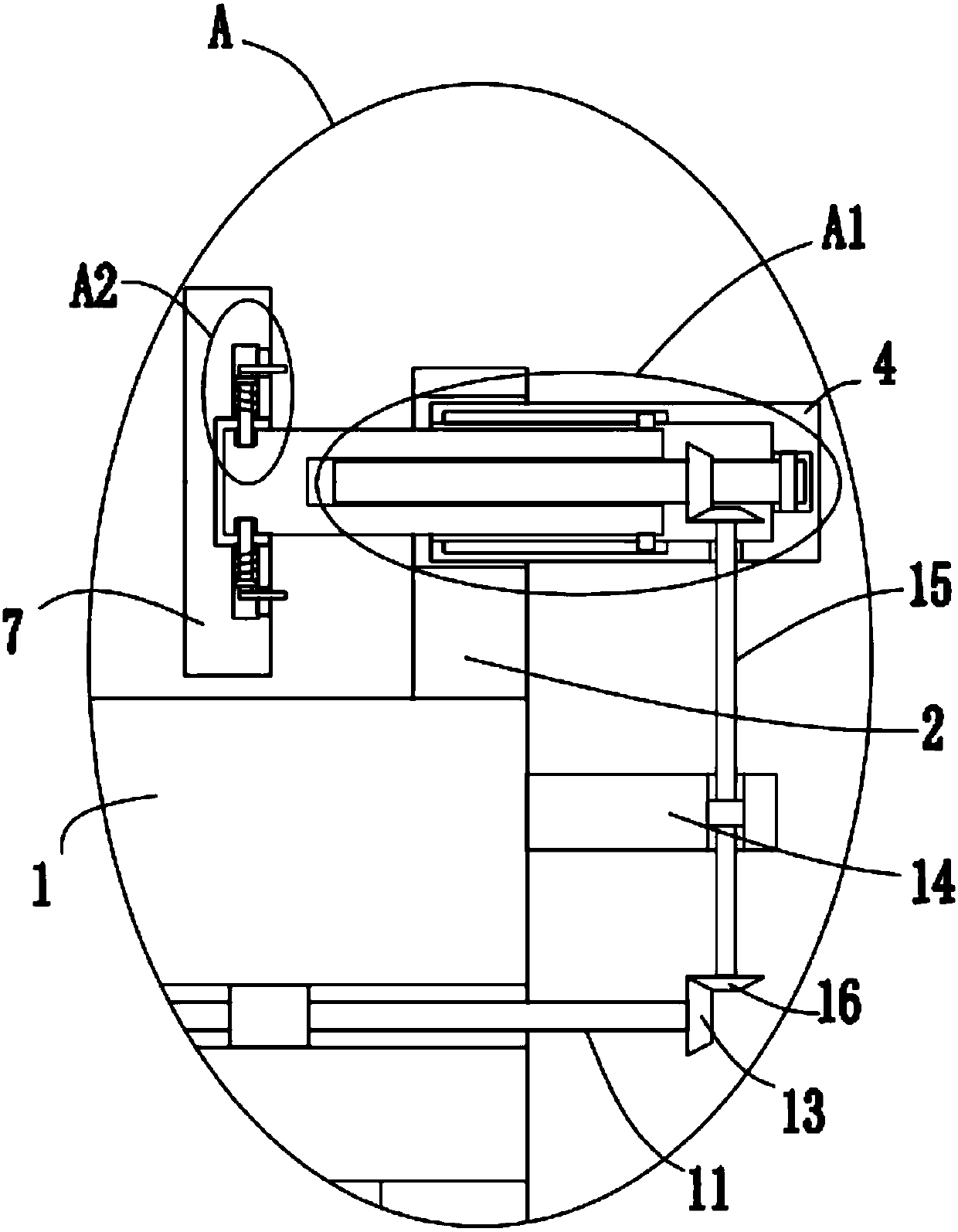

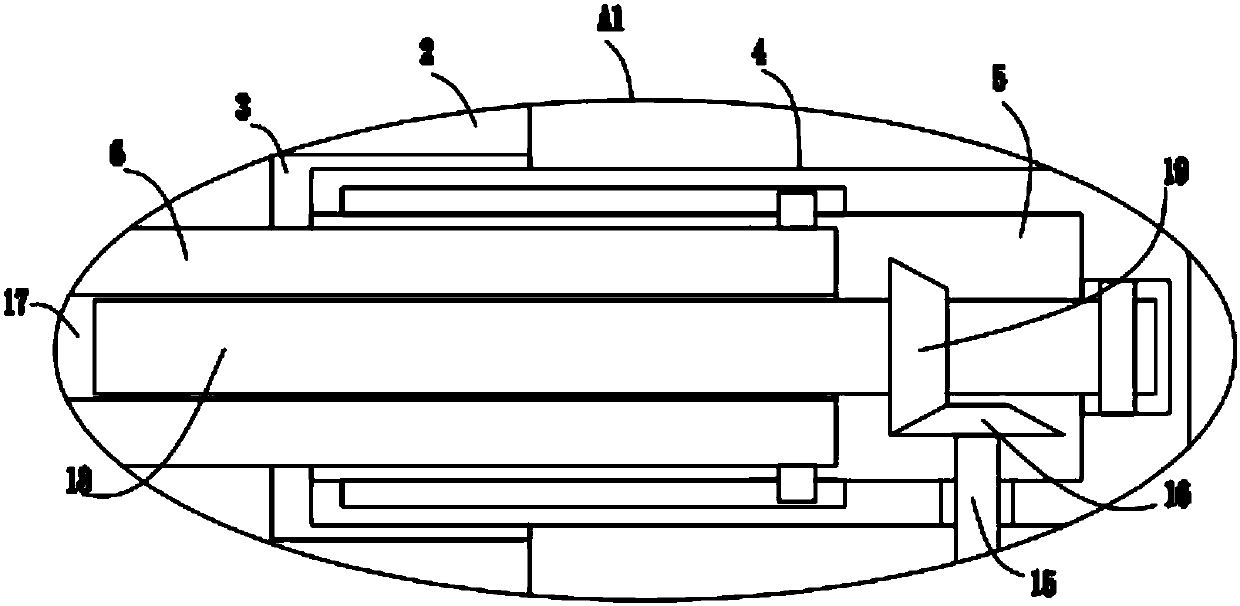

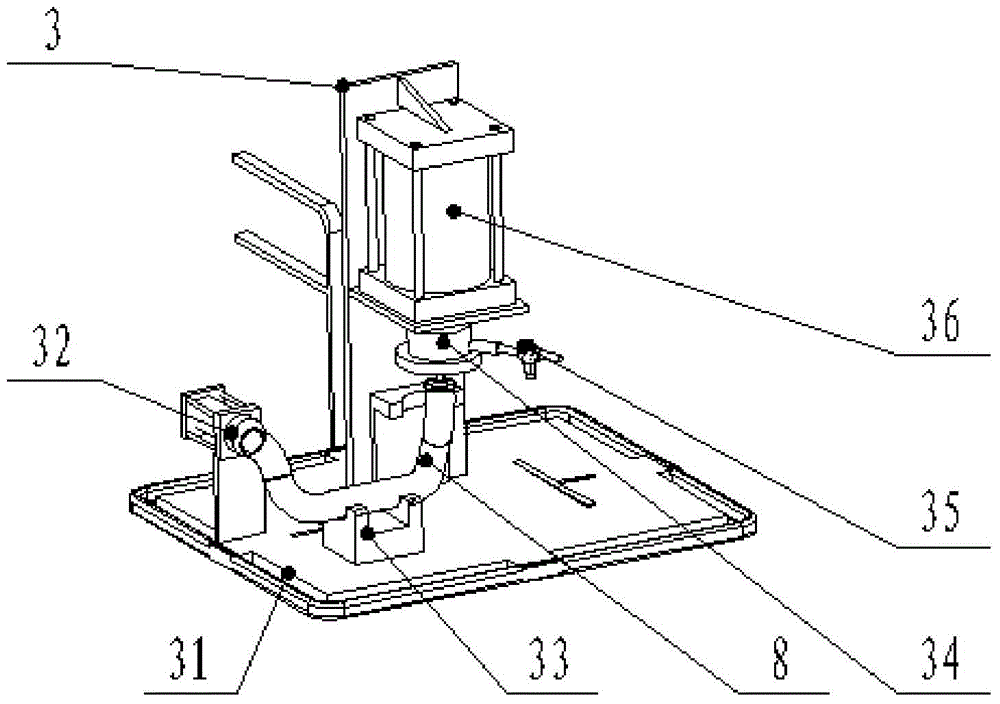

Fixture device for processing glass moulds

ActiveCN102380777BReduce work intensityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

A fixture device for processing glass moulds belongs to the technical field of work fixtures and comprises a base, a first vice bench holder, a second vice bench holder, a first mould horizontal adjustment mechanism, a second mould horizontal adjustment mechanism, a vice bench driving mechanism and a pair of horizontal adjustment mechanisms. Guide rail bars are arranged on two sides of the base, a vice bench holder sliding seat is arranged between the guide rail bars, a pair of guide rails and a vice bench moving cavity are formed on the vice bench holder sliding seat, a first acting cylinderand a second acting cylinder are fixed to two ends of each of the first vice bench holder and the second vice bench holder respectively, a first vice bench fixing seat and a second vice bench fixing seat are fixed to the middles of the first vice bench holder and the second vice bench holder respectively, a first vice bench and a second vice bench are fixed to the first vice bench fixing seat andthe second vice bench fixing seat respectively, the first mould horizontal adjustment mechanism and the second mould horizontal adjustment mechanism are arranged on the first vice bench holder and the second vice bench holder respectively, the vice bench driving mechanism is arranged on the base, one horizontal adjustment mechanism is fittingly arranged on one of the two guide rail bars, and the other horizontal adjustment mechanism is fittingly arranged on the other guide rail bar. The fixture device has the advantages that one-step clamping is realized, the operating intensity of workers can be relieved, processing efficiency is improved, and processing quality is guaranteed.

Owner:CHANGSHU JIANHUA MOLD TECH

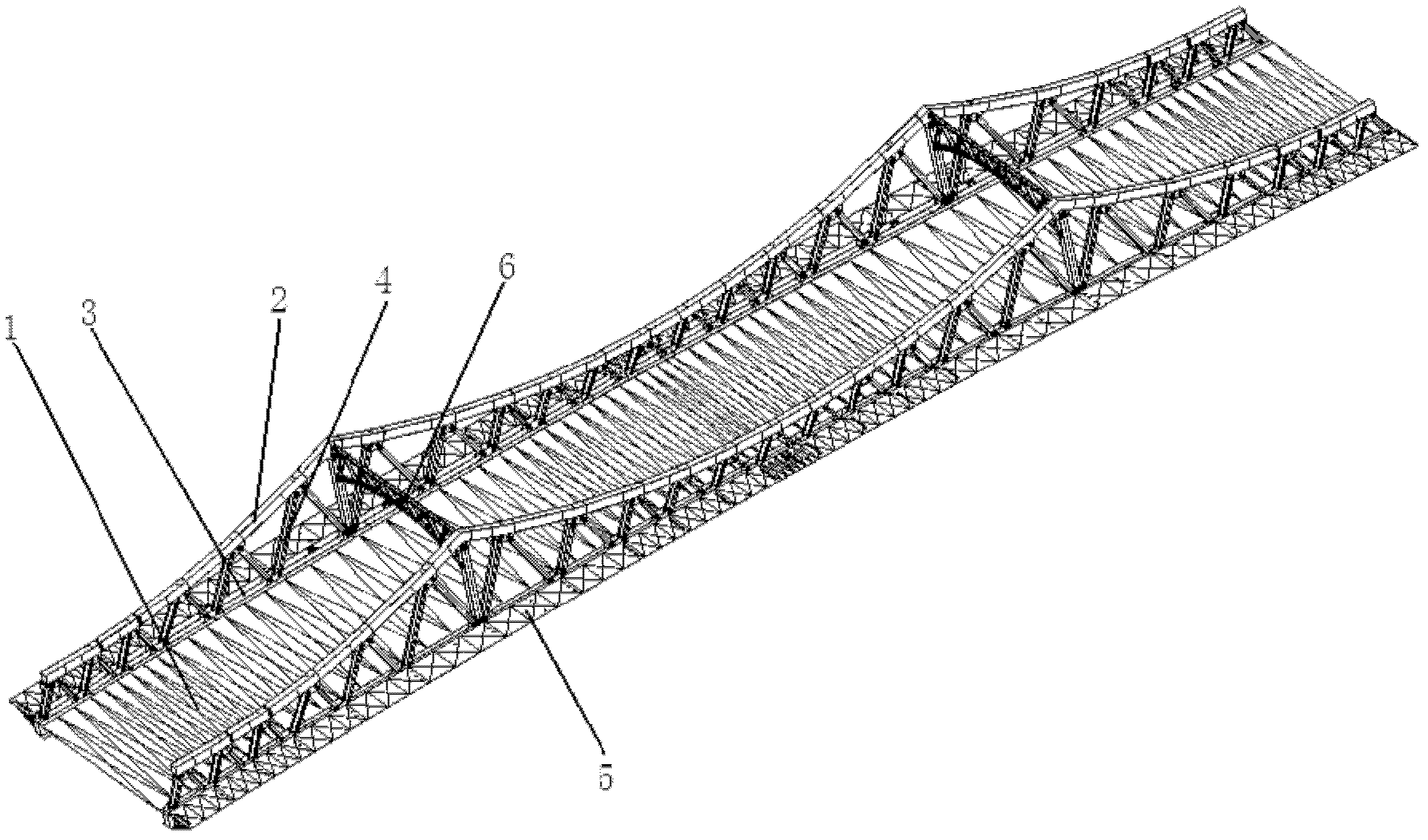

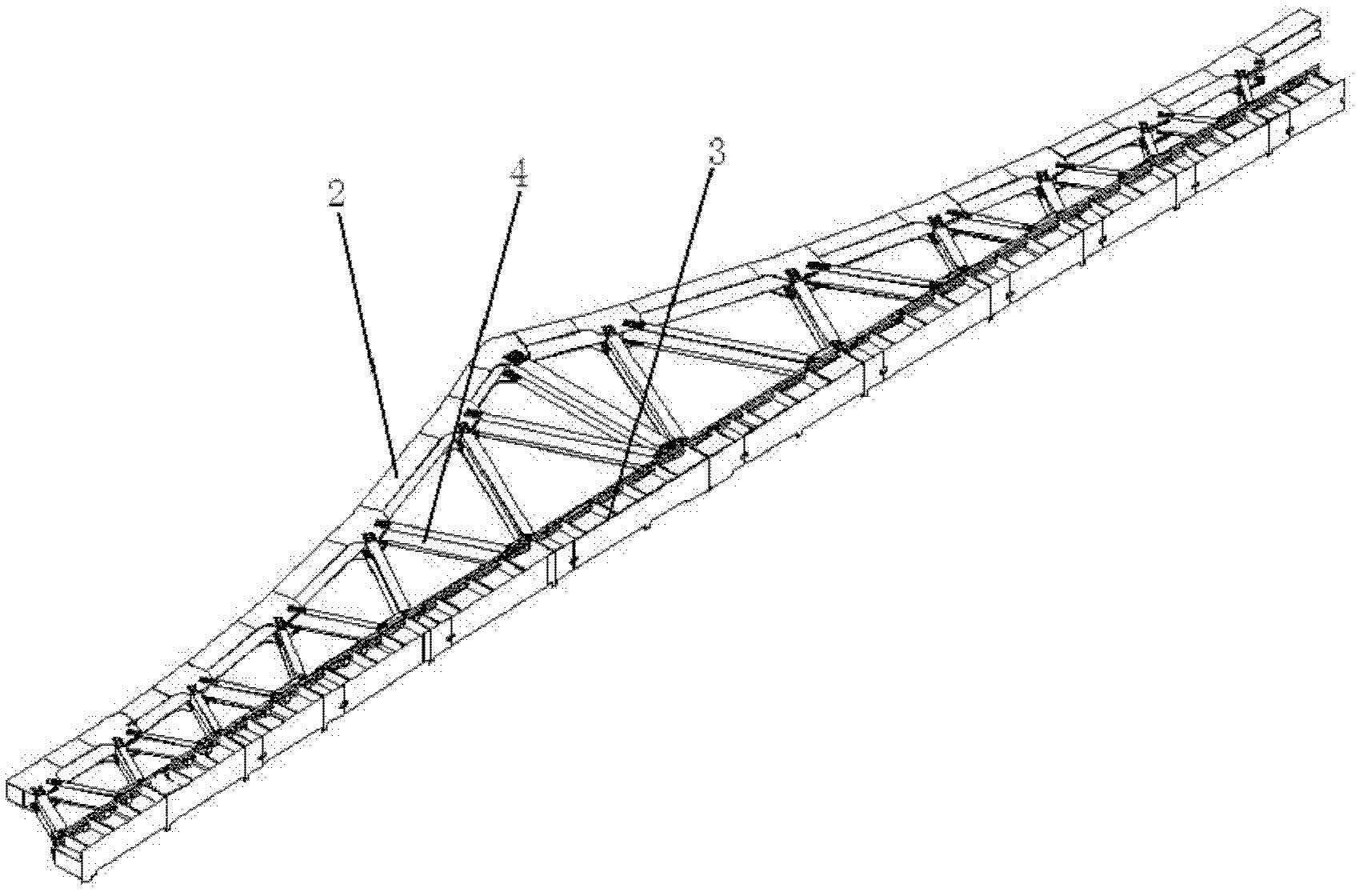

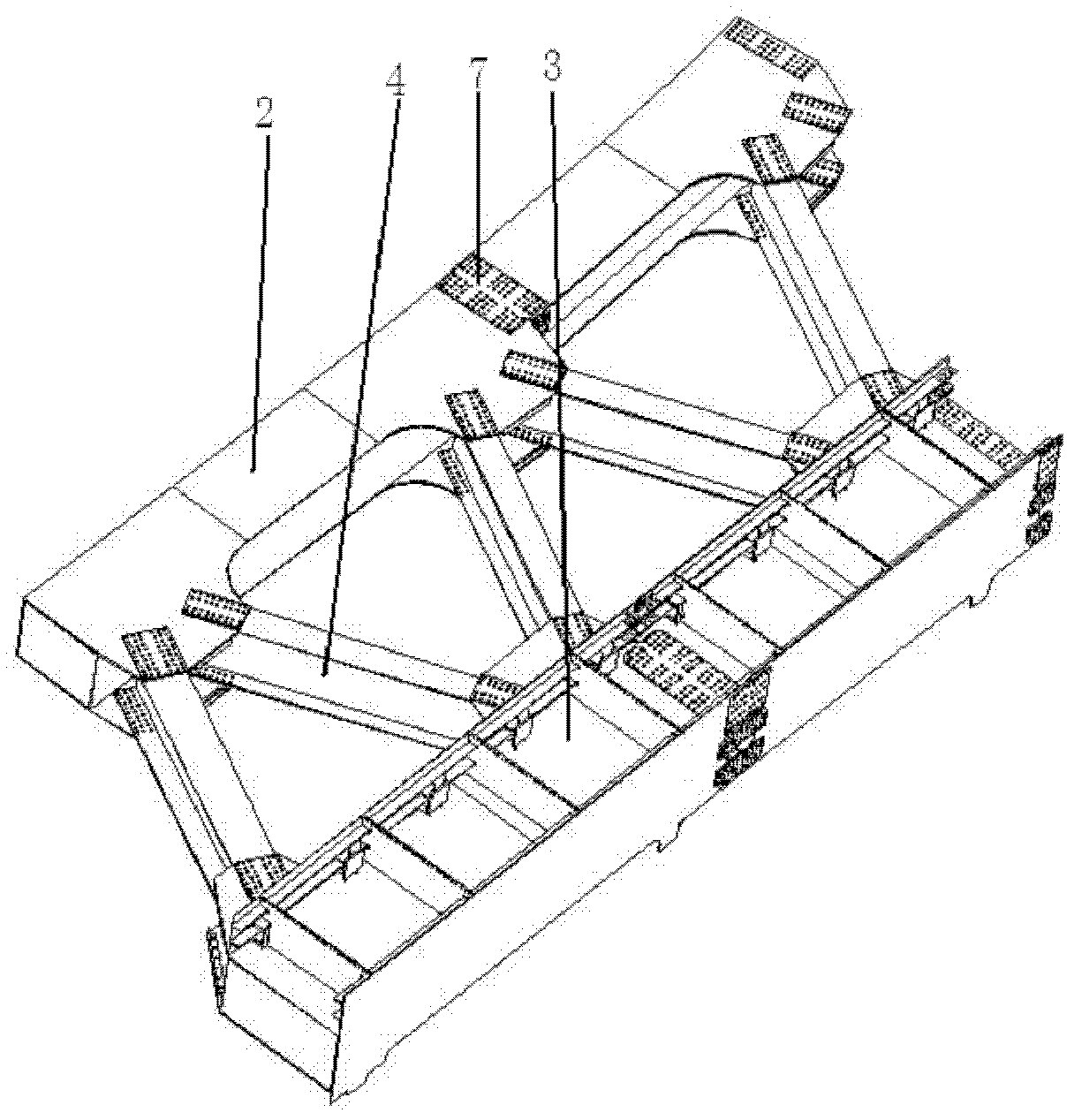

A kind of steel truss bridge and its manufacturing method

ActiveCN102277825AImprove stabilityImprove securityTruss-type bridgeBridge structural detailsBridge deckEngineering

The invention discloses a steel truss bridge and a method for fabricating the same. The steel truss bridge comprises a steel box girder bridge deck, a main truss composed of two steel trusses, and a steel portal frame. The steel truss comprises an upper chord member, a lower chord member, and a web member which is connected with the upper chord member and the lower chord member through bolts. A sidewalk bracket is arranged outside each steel truss. The lower chord member is connected to the steel box girder bridge deck and the sidewalk bracket, respectively. Besides, the two steel trusses are connected through the steel portal frame. During fabrication, all the sections of the steel trusses, the steel portal frame and the bridge deck are independently fabricated, respectively; all the sections of the upper and lower chord members of the steel truss are pre-assembled circularly with the corresponding web members, and all the sections of the steel box girder bridge deck are pre-assembled with the corresponding lower chord members by an orthotectonic method, respectively; and the steel portal frame is pre-assembled with the steel trusses. The steel truss bridge disclosed by the invention completely meets the design requirements so that the stability and safety factor of the bridge can be enhanced; and by employing the fabricating method, positioning is accurate so that the risks during the field assembling can be reduced; and the construction period can be shortened.

Owner:JIANGSU JINGHU HEAVY IND

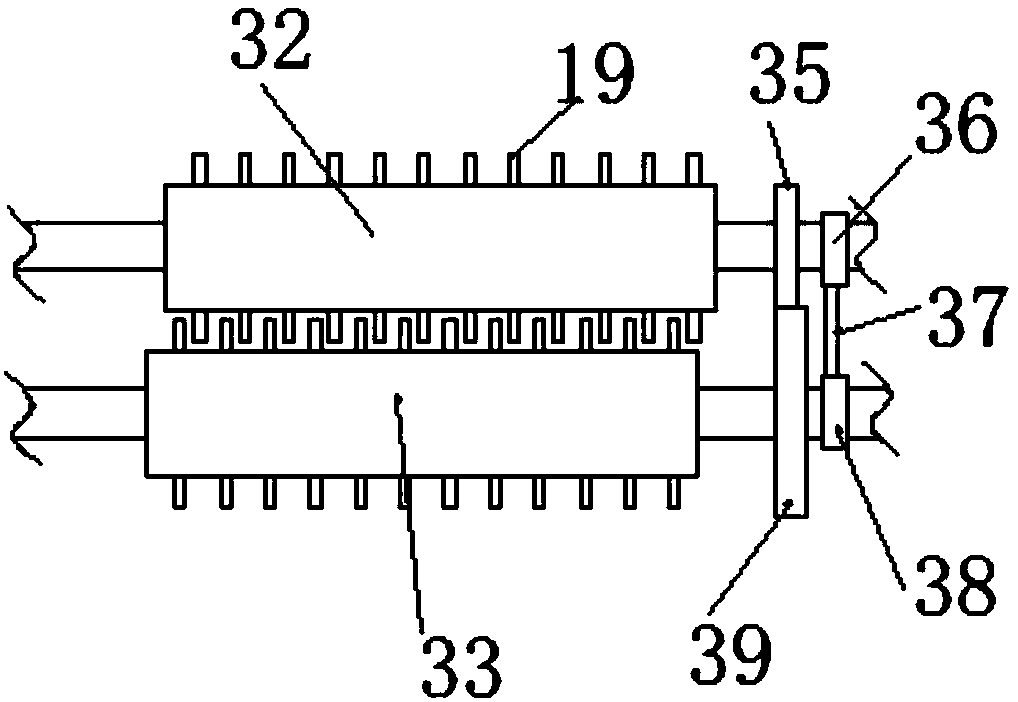

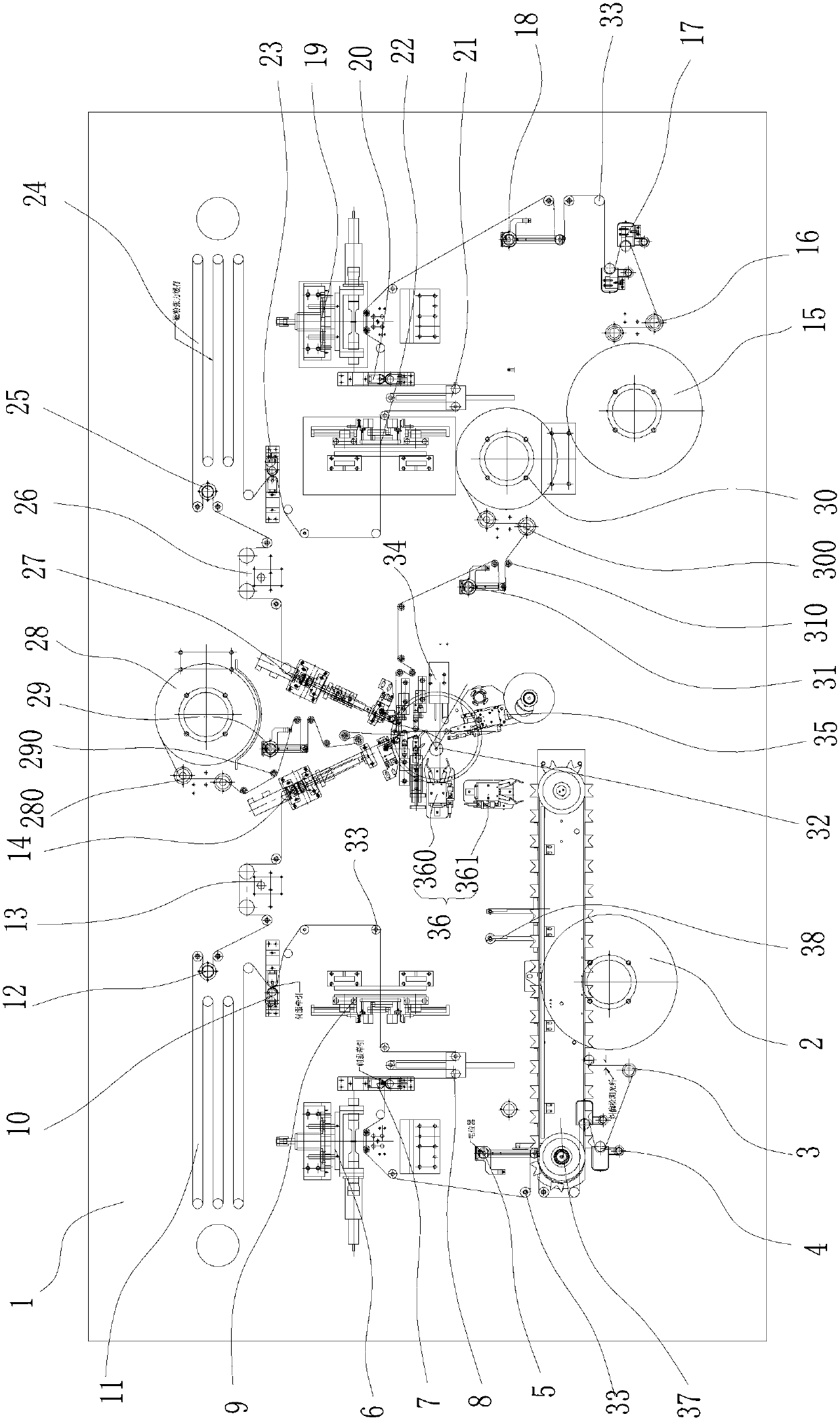

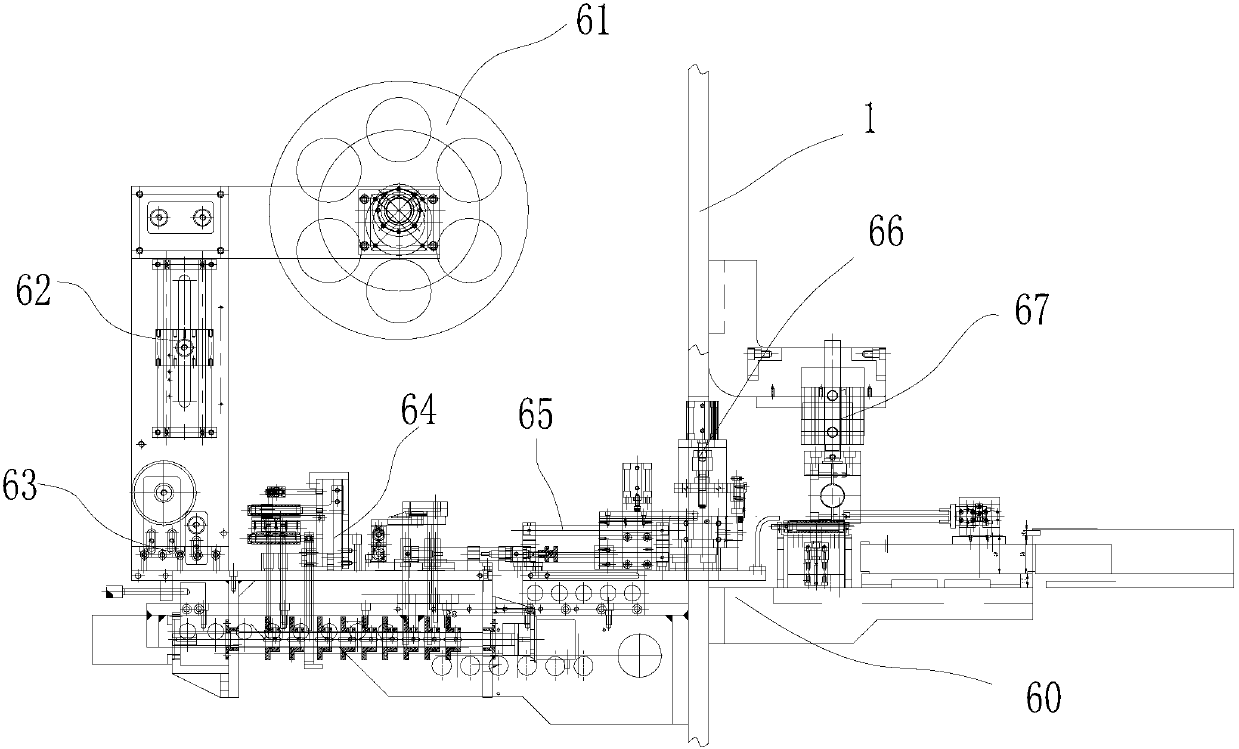

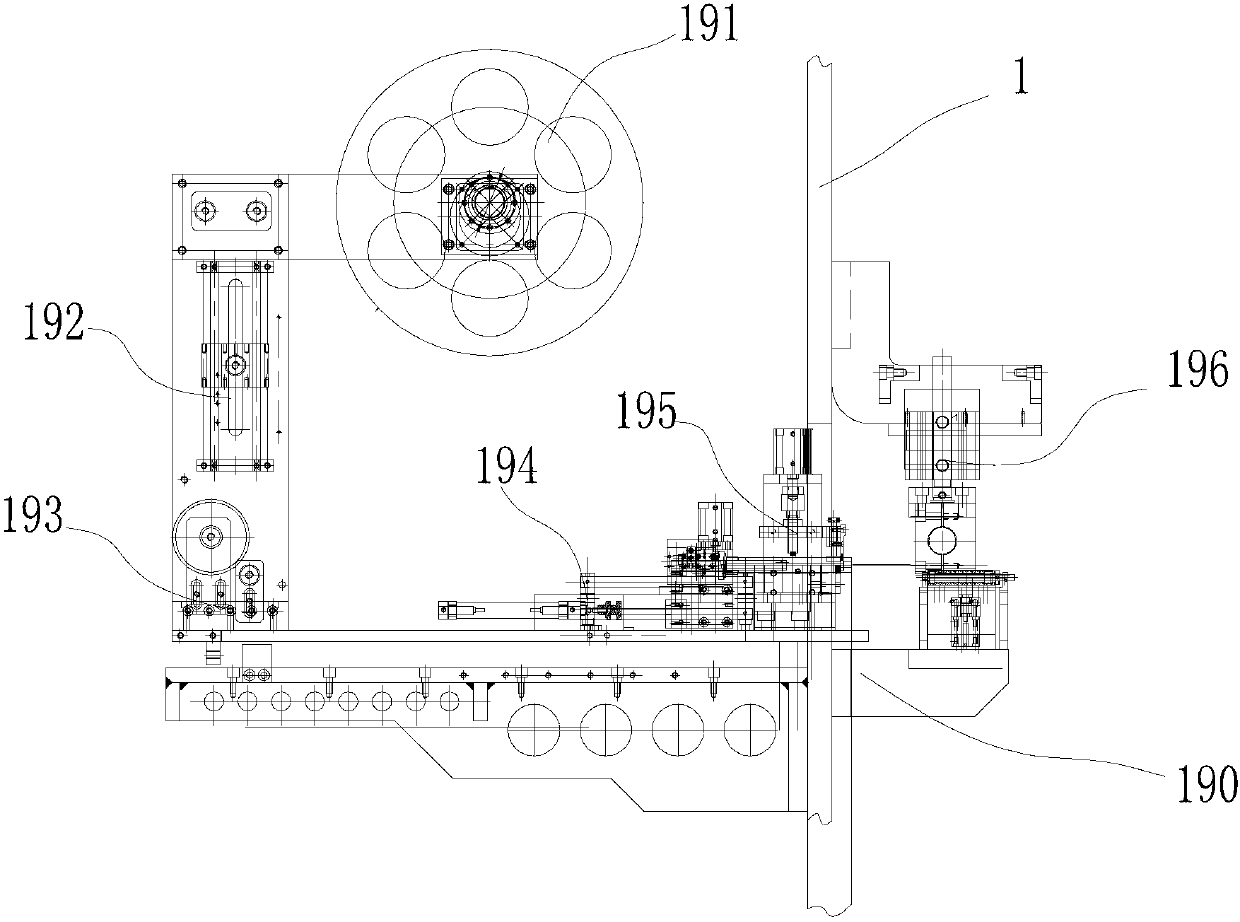

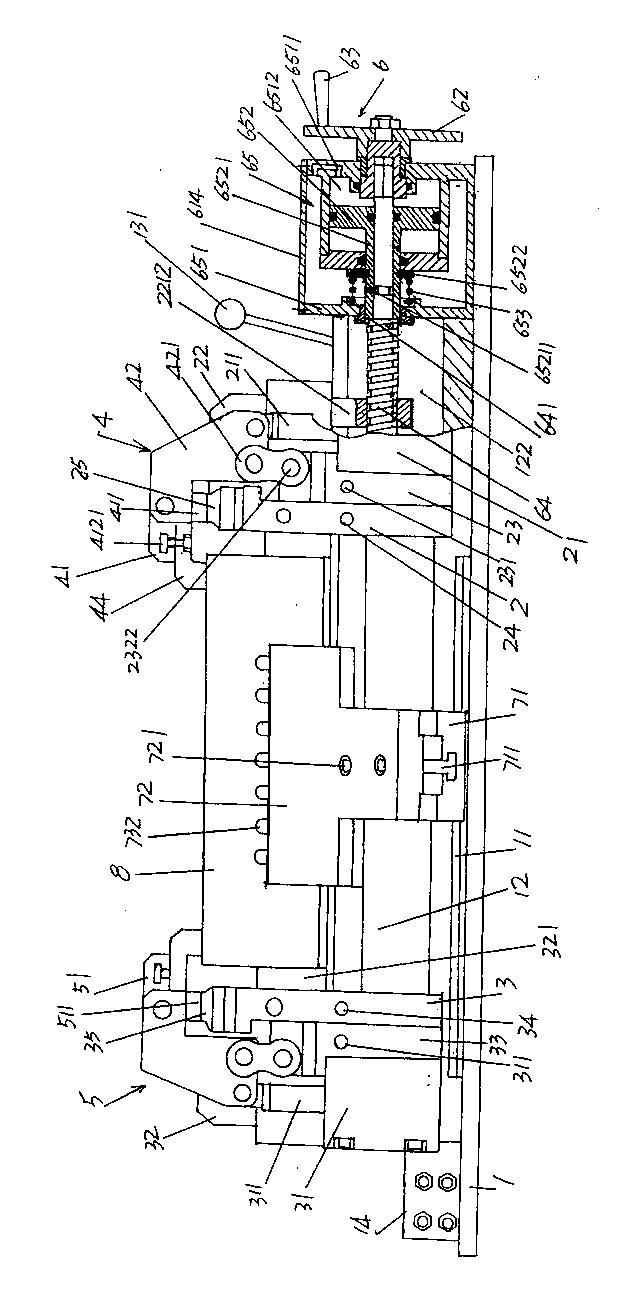

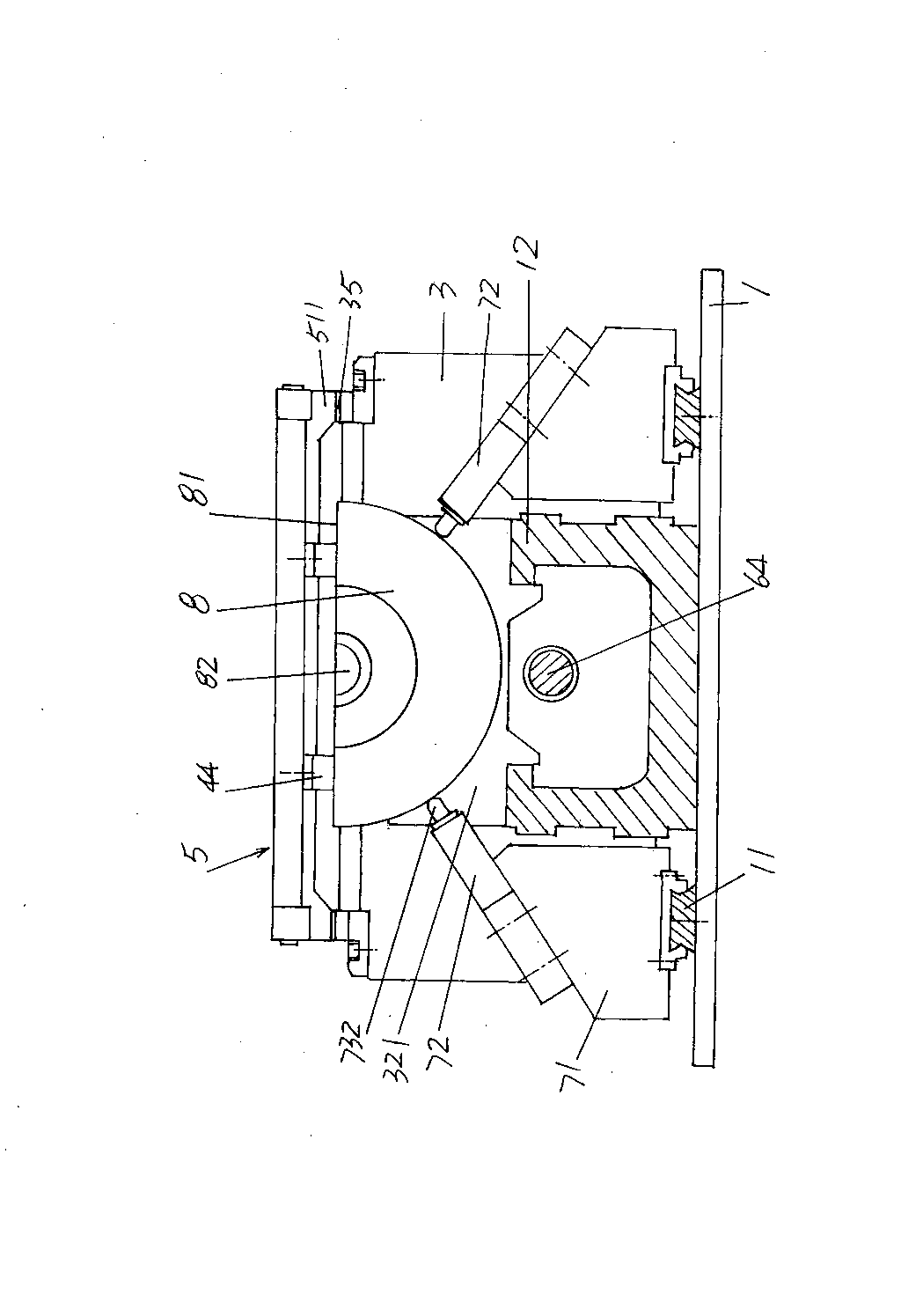

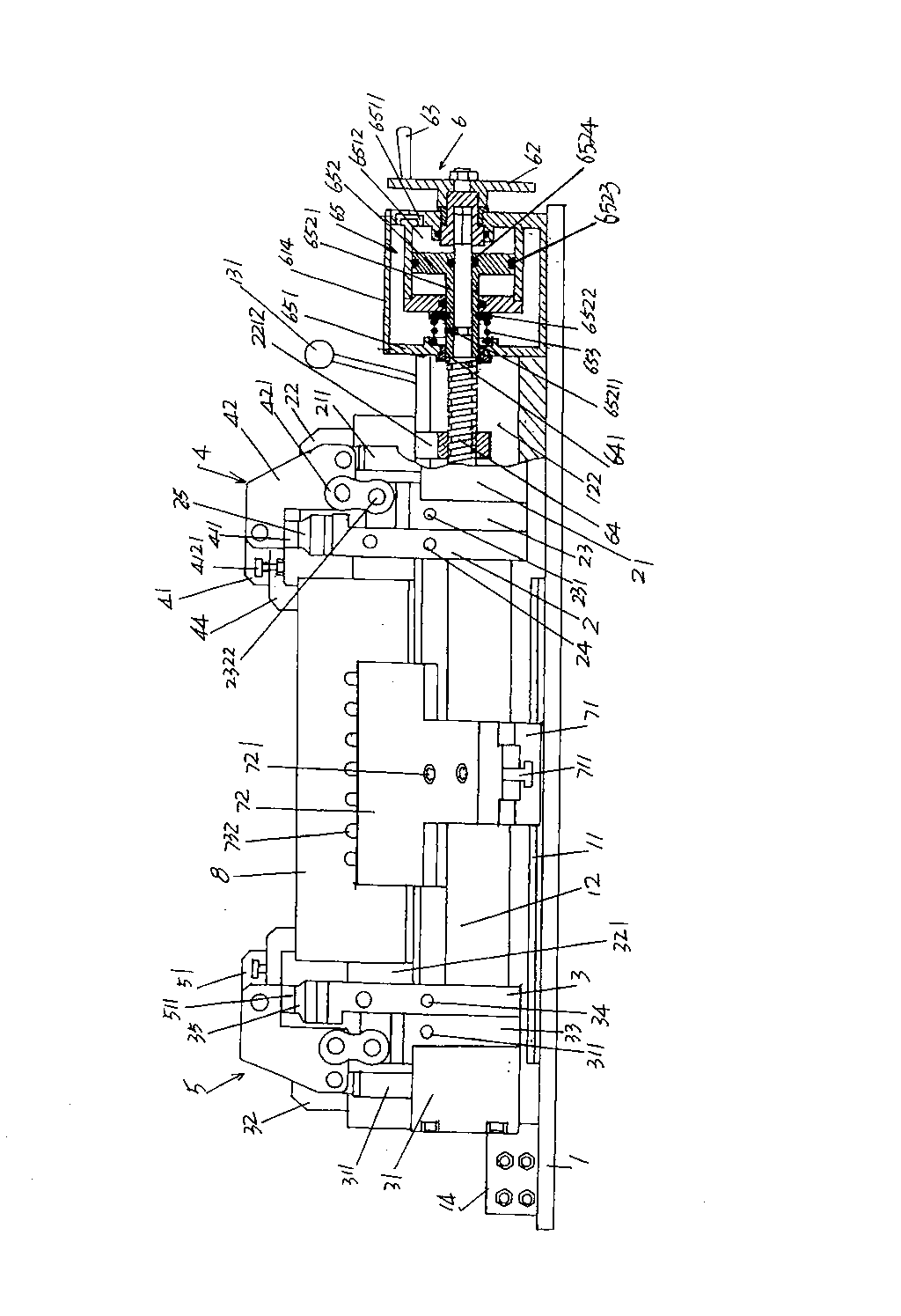

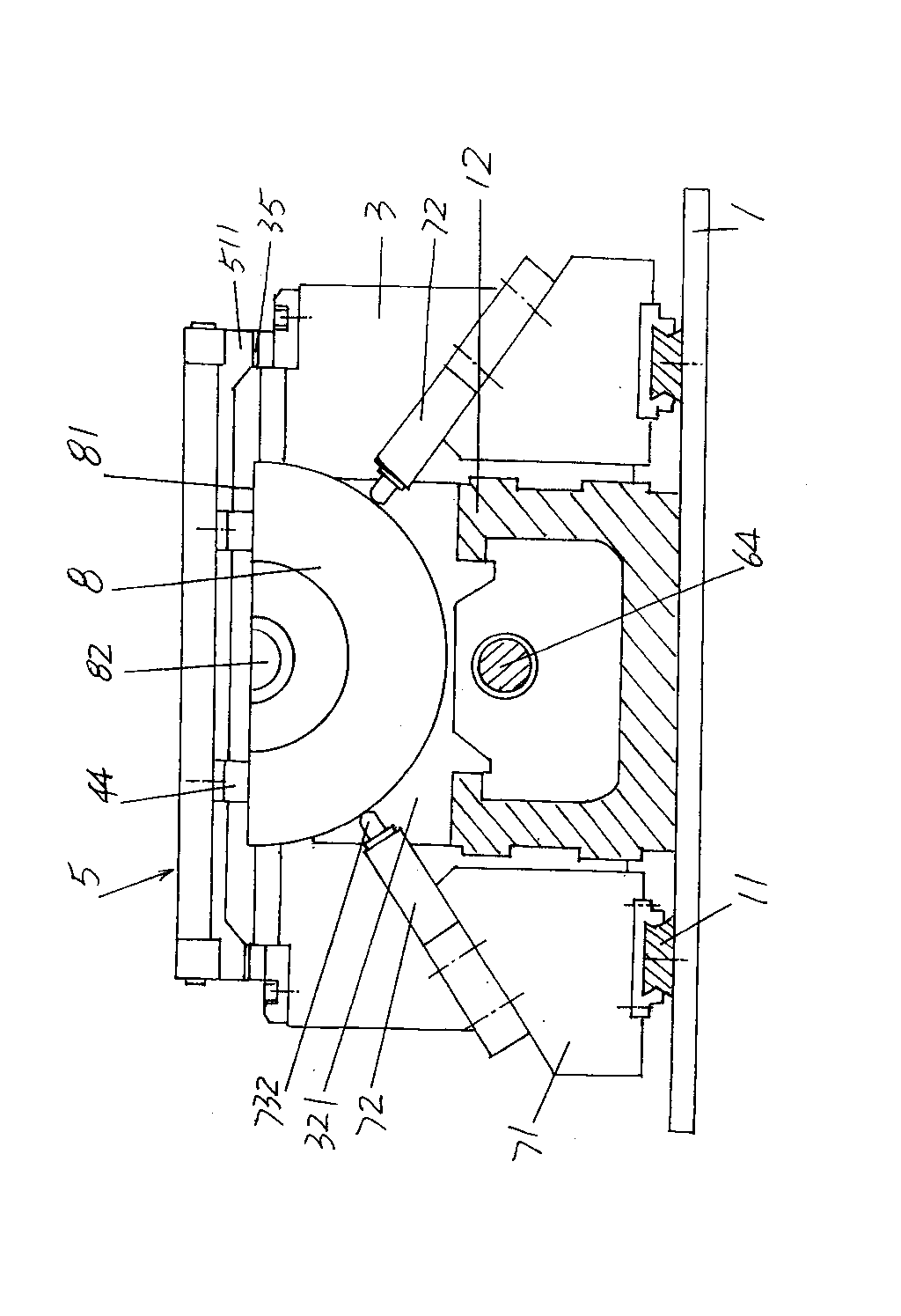

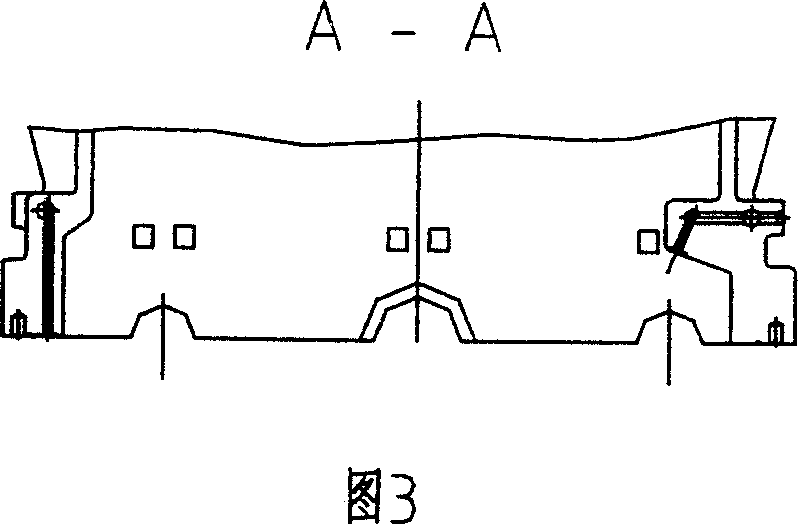

Battery pole piece making and battery cell coiling integrated equipment

ActiveCN102969479AReduce labor intensitySave time at workElectrode manufacturing processesFinal product manufactureControl systemPole piece

The invention discloses battery pole piece making and battery cell coiling integrated equipment, which comprises a rack and a control system. The center of the rack is equipped with a coiling device, which coils a positive pole piece transmitted by a positive pole piece supply device, a negative pole piece transmitted by a negative pole piece supply device, and diaphragms output by a first diaphragm supply device and a second diaphragm supply device into a battery cell according to the order of the positive pole piece, a diaphragm, the negative pole piece and a diaphragm. A secondary unloading manipulator and an unloading conveyor belt mechanism are arranged at left lower side of the coiling device. When the secondary unloading manipulator unloads, hole ironing processing is performed simultaneously, and the mode is convenient and effective. A glue wrapping mechanism of a positive lug welding device on the rack adopts a cam control structure, which has high precision and good stability. A positive lug support of the positive lug welding device passes through the rack of the equipment and is installed at the back side of the rack. A negative lug support of a negative lug welding device passes through the rack of the equipment and is installed at the back side of the rack. Thus, for the whole equipment, the layout of all the devices is more reasonable, and the overall size is decreased effectively.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

Clamp for processing glass mould

ActiveCN102350650BIdeal levelNo sheddingMetal working apparatusPositioning apparatusMechanical engineeringElectrical and Electronics engineering

Owner:CHANGSHU JIANHUA MOLD TECH

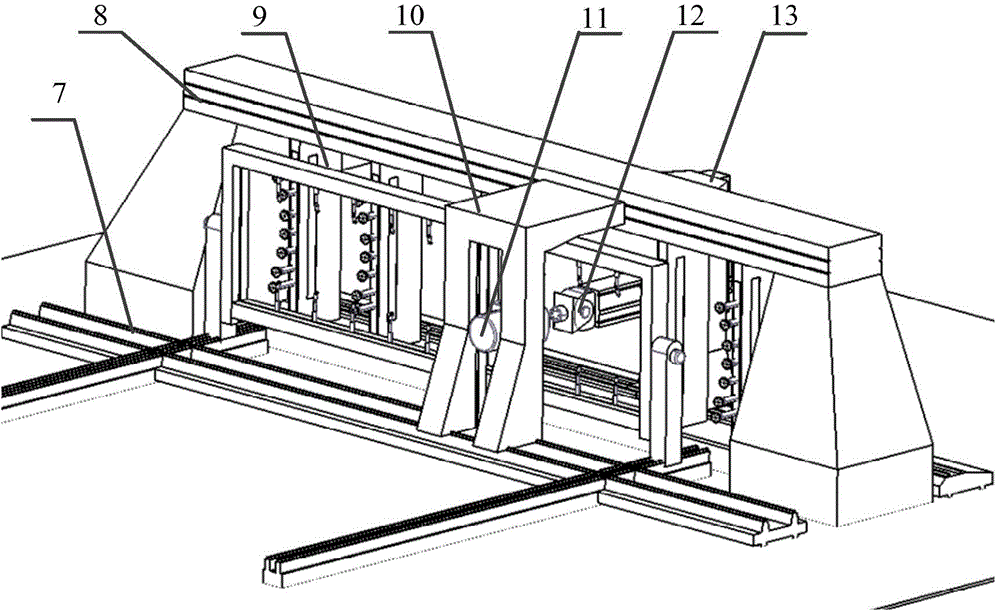

Clamp device with improved structure for processing glass mould

ActiveCN102350651BGuaranteed locking effectReduce work intensityPositioning apparatusMetal working apparatusEngineeringMechanical engineering

The invention discloses a clamp device with an improved structure for processing a glass mould, and belongs to the technical field of tooling clamps. The clamp device comprises a base, a first clamp platform fixed mount, a second clamp platform fixed mount, a first mould horizontal adjusting mechanism, a second horizontal adjusting mechanism, a clamp platform driving mechanism and a pair of horizontal adjusting mechanisms, wherein guide rail bars are arranged on two sides of the base respectively, a clamp platform fixed mount sliding seat is arranged between the guide rail bars, and a pair ofguide rails and a clamp platform moving chamber are formed on the clamp platform fixed mount sliding seat respectively; the first clamp platform fixed mount and the second clamp platform fixed mount are positioned on the base, a first acting cylinder and a second acting cylinder are fixed at two ends of the first clamp platform fixed mount and the second clamp platform fixed mount respectively, afirst clamp platform fixed seat and a second clamp platform fixed seat are fixed in the middle parts of the first clamp platform fixed mount and the second clamp platform fixed mount respectively, and a first clamp platform and a second clamp platform are fixed on the first clamp platform fixed seat and the second clamp platform fixed seat respectively; the first mould horizontal adjusting mechanism and the second mould horizontal adjusting mechanism are arranged on the first clamp platform fixed mount and the second clamp platform fixed mount; the clamp platform driving mechanism is arrangedon the base; the two horizontal adjusting mechanisms are arranged on a pair of guide rail bars; and the clamp platform driving mechanism comprises a box body, a handle plate, a handle, a screw rod and a clamp platform locking device. The clamp device has the advantages that: once clamping is embodied, the operating strength is reduced, and the working efficiency is improved.

Owner:CHANGSHU JIANHUA MOLD TECH

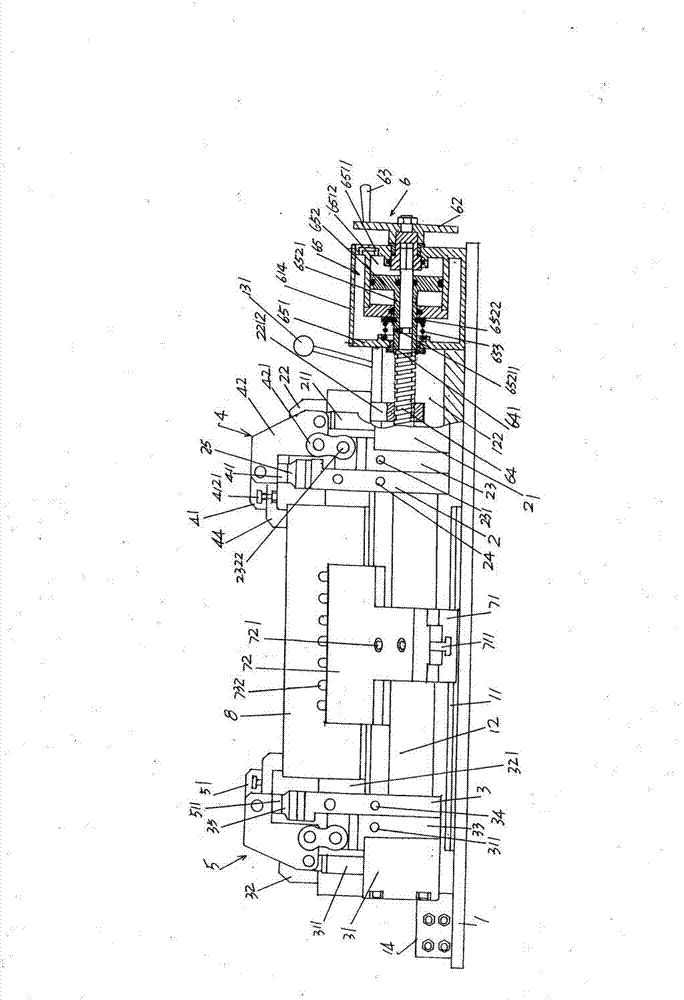

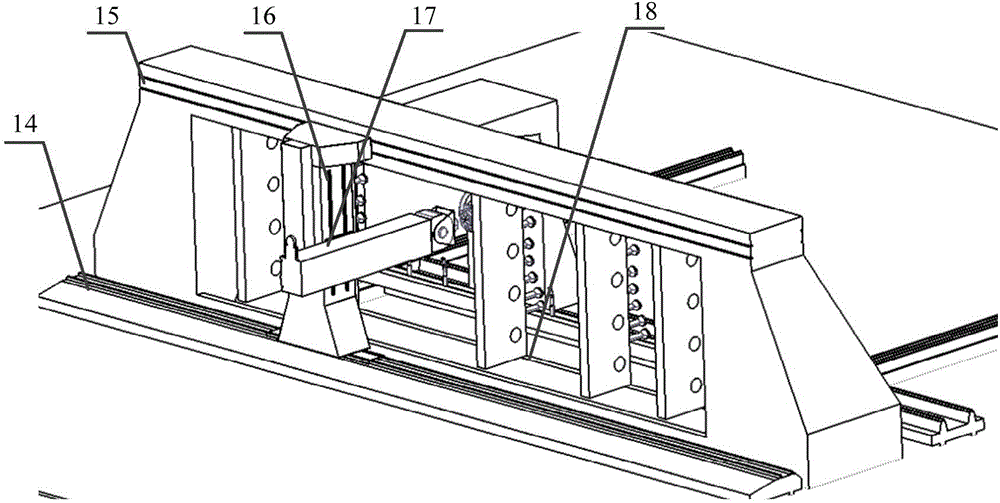

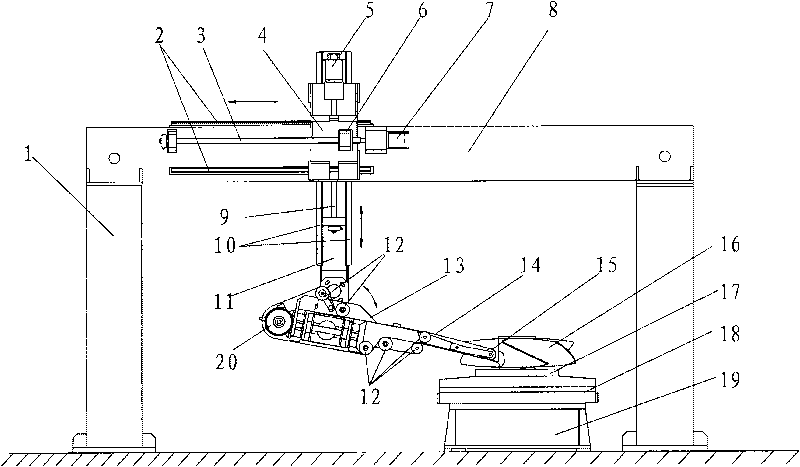

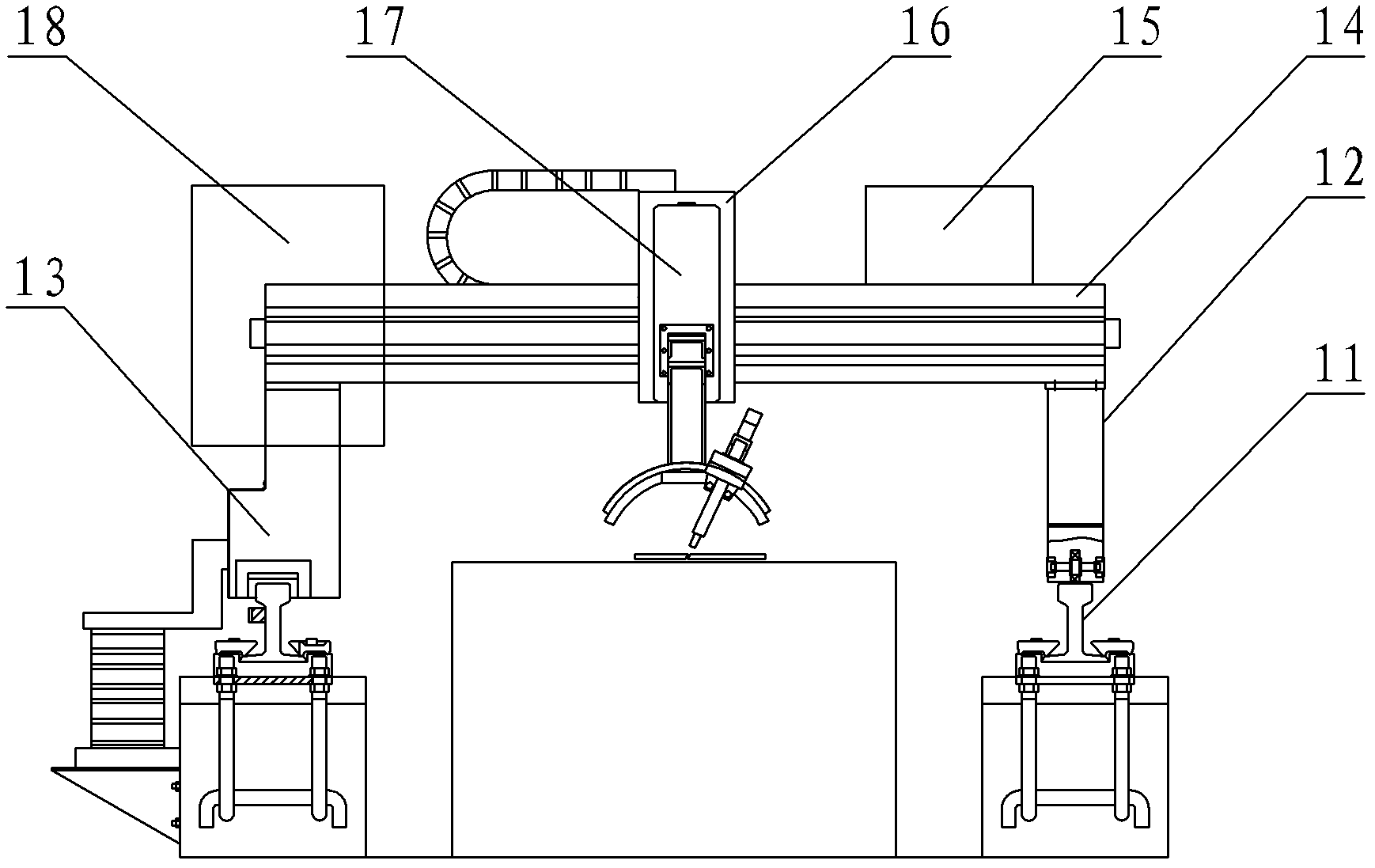

Aircraft skin mirror milling method and aircraft skin mirror milling device

ActiveCN104400086AReal-time thicknessReal-time thickness compensationAutomatic control devicesWorkpiecesSelf adaptiveAirplane

An aircraft skin mirror milling method and an aircraft skin mirror milling device. The device is characterized by mainly comprising a machine tool main framework, a milling apparatus, a vertical-horizontal conversion apparatus, a lug piece holding apparatus, a flexible adsorption apparatus, a top-shore apparatus, a detection apparatus and a thickness measuring apparatus. In the device, an aircraft skin is vertically clamped by the vertical-horizontal conversion apparatus for increasing the clamping efficiency of the aircraft skin and a positioning precision of the aircraft skin is further improved with combination of a vacuum adsorption apparatus so that deformation caused by gravity can be avoided. On the basis of on-line detection by a laser displacement sensor, actual curve surface of the aircraft skin can be detected before processing and aircraft skin processing tool path can be adjusted according to an actual clamping situation for achieving self-adapting numerically-control processing. The top-shore apparatus can support the aircraft skin from backside during a milling process of the aircraft skin, thereby avoiding vibration during processing and improving stability of processing. On-line monitoring of the thickness can be achieved during the processing and thickness compensation can be provided. By means of an integrated control system, cooperative operation of units in the machine tool can be ensured and interference can be avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

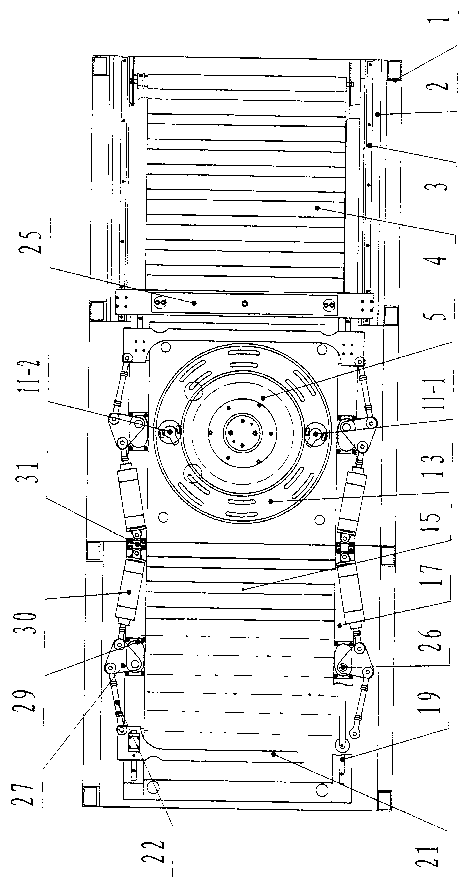

Full-automatic wheel hub deburring machine

InactiveCN102848282AImprove processing qualitySolve the problem of declining production efficiencyEdge grinding machinesCouplingElectric machinery

The invention belongs to technical equipment for machine manufacturing, and particularly relates to a full-automatic wheel hub deburring machine. The lower end of a lower brush feed rod (12) is vertically mounted on a bottom plate of a shell (1), and the upper end is fixed on a machining platform (13); upper and lower brush motor lifting plates (6) and a lower brush motor support plate (9) are respectively hinged on the upper end and the lower end of a support plate connection bar (8); a lower brush (5) is connected with the output shaft of a lower brush motor (10) through a coupling (43); a left locking device (11-1) and a right locking device (11-2) of a wheel hub lock (11) are respectively mounted at the left side and the right side of the machining platform (13); an upper brush motor support plate (36) provided with an upper brush motor (35) is movably sleeved on an upper brush feed rod (33) through a feed rod sleeve; an upper brush (32) is arranged in a dust shield (34) and is connected with the output shaft of the upper brush motor (35) through the coupling (43); and the shell (1) is provided a feeding path (15) and a discharging path (4) which are arranged at the left side and the right side of the machining platform (13). The full-automatic wheel hub deburring machine realizes the automatic unmanned production and improves the production efficiency.

Owner:FUXIN TONGSHENG HYDRAULIC MACHINERY MFGCO

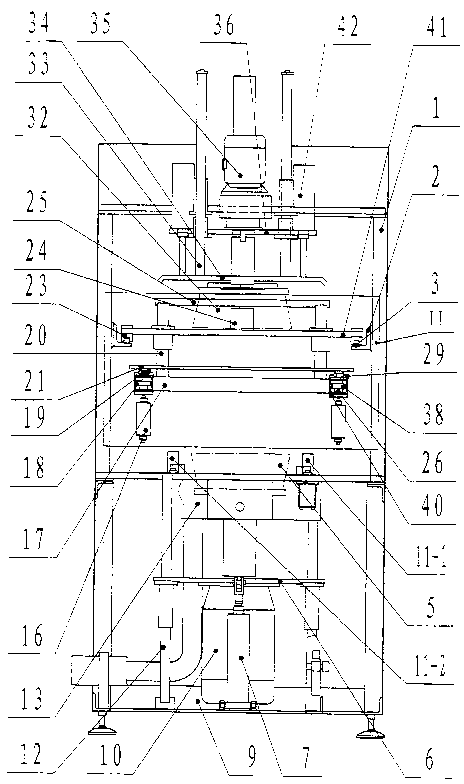

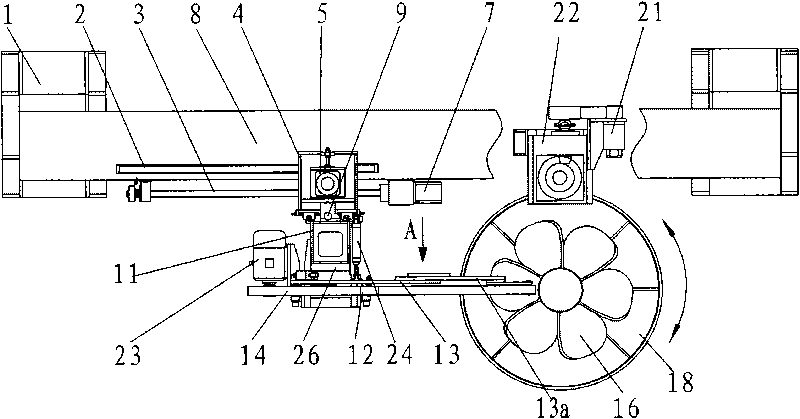

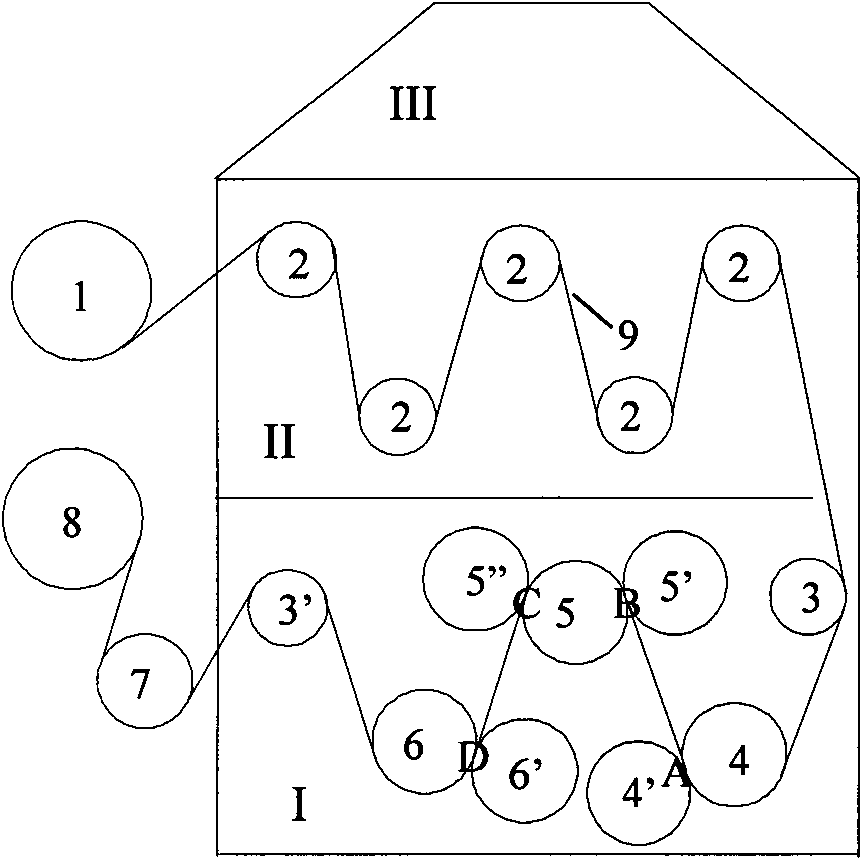

Gantry propeller integral blade abrasive belt grinding machine

InactiveCN101733690AImprove stabilityImprove rigidityBelt grinding machinesPropellerDegrees of freedom

The invention discloses a gantry propeller integral blade abrasive belt grinding machine, which comprises a machine body, a grinding head mechanism, a grinding head feed mechanism and a workpiece azimuth adjusting mechanism. The grinding head feed mechanism comprises an axial feed mechanism, a radial feed mechanism with respect to a work piece, and a grinding head deflection driving mechanism. The whole grinding machine has high stability and ensures the grinding precision. By reasonably distributing grinding head feed and adjusting the work piece azimuth and through the combination of four spatial degrees of freedom by a relatively short transmission chain, the grinding head mechanism has high and low degrees of freedom of pitch in a relatively small range, the integral blade can be directly ground, and the blades on the integral blade and other parts are all completely machined. The grinding head mechanism and a work piece clamping mechanism have good rigidity, the working efficiency is improved, and synchronously, the machining precision and the surface quality can be ensured. The grinding thickness in the process of polishing a curved surface is uniform, the quality of a molded surface is ensured, the labor intensity of workers is decreased, and the management cost and the production cost are reduced.

Owner:CHONGQING SANMO HAIDA GRINDING MACHINE

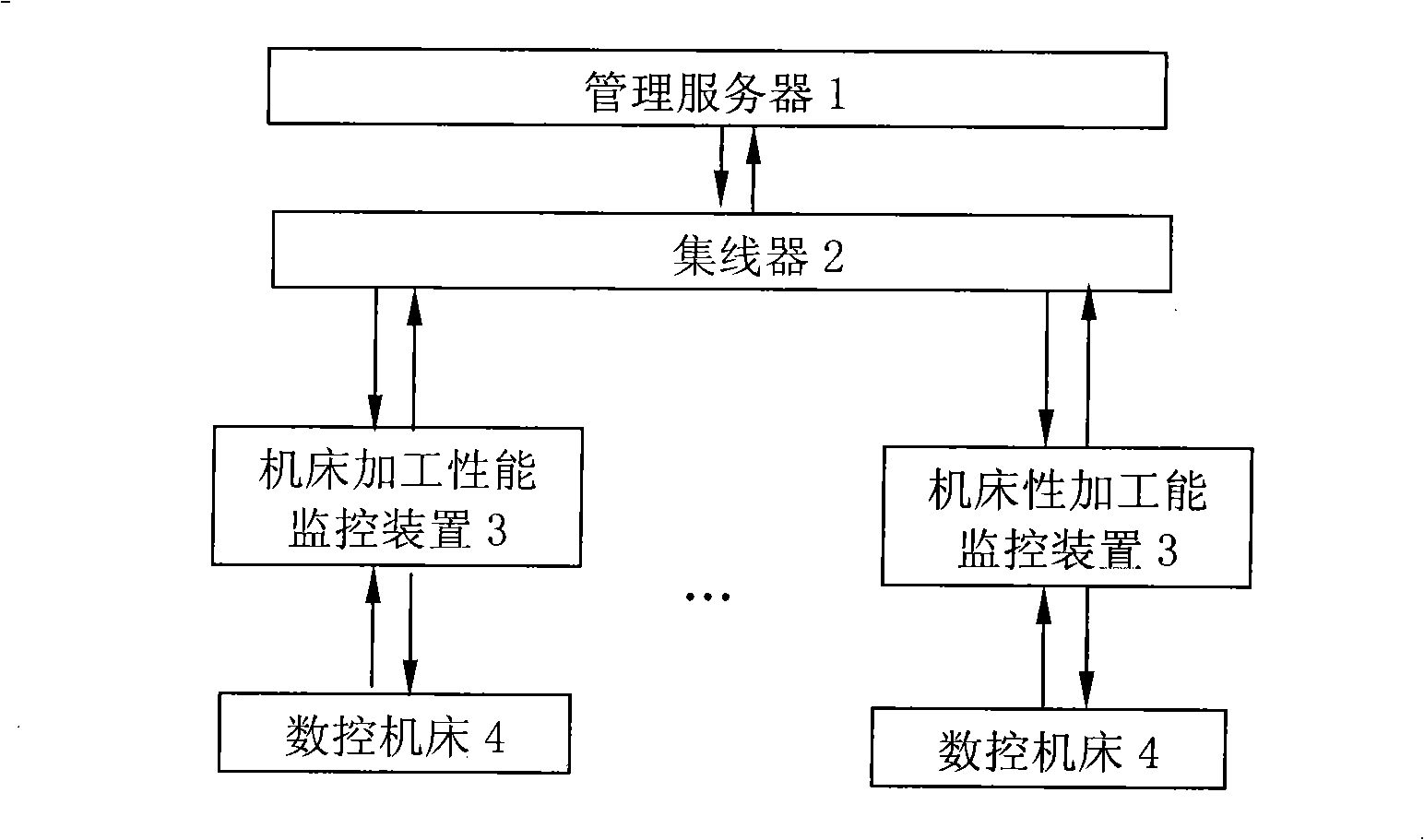

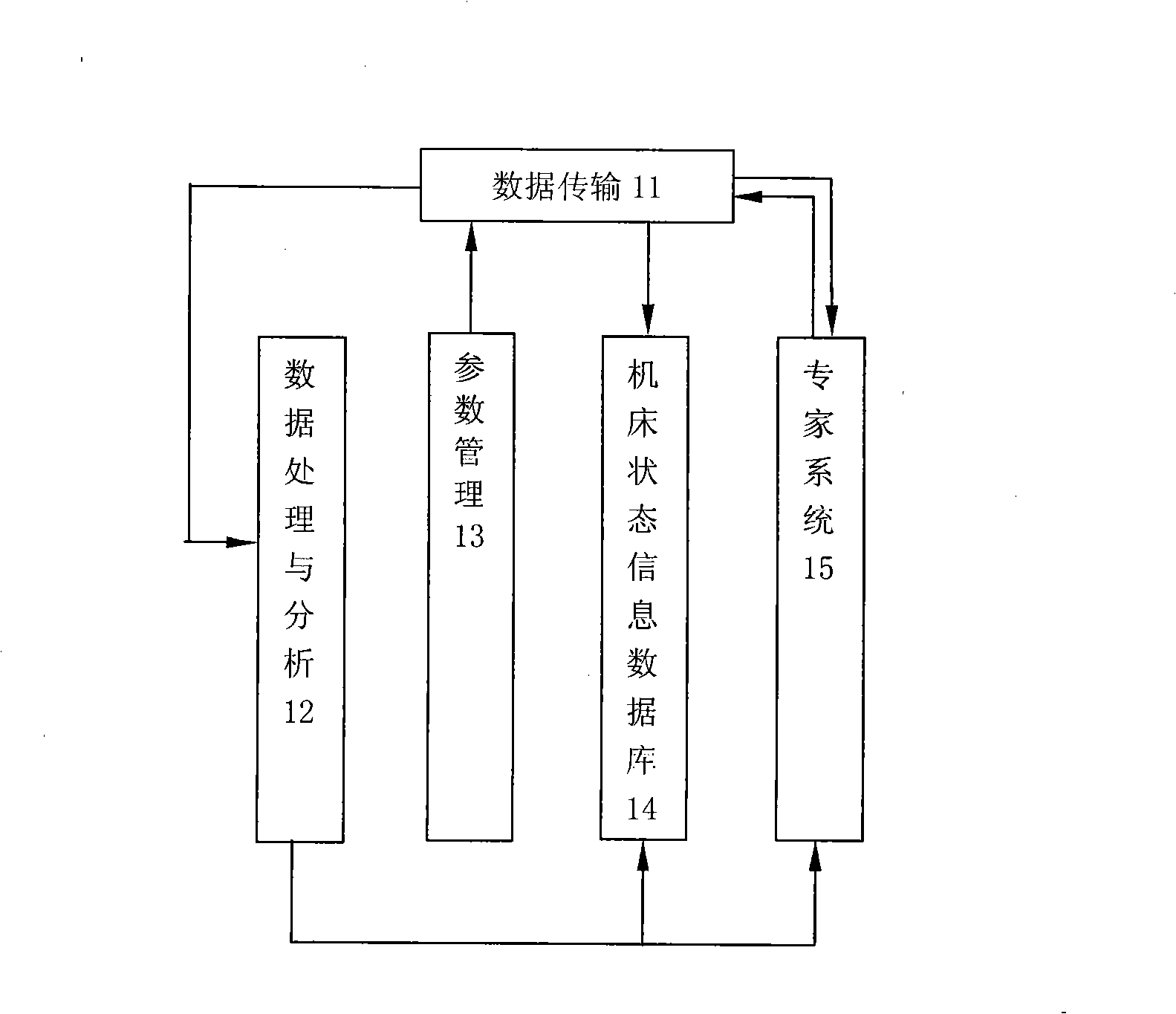

Numerical control machine processability monitoring system

InactiveCN101334656AFocus on statusFocus on processabilityProgramme controlComputer controlIndustrial EthernetNumerical control

The invention provides a numerical control machine tool processing performance monitoring system which is characterized in that monitoring devices on a plurality of machine tools are connected with each other by Ethernet network by a management server; the monitoring device receives the data of the self-state of the machine tool, collects the current of a mainshaft motor and a feeding motor and the vibration quantity of a mainshaft, processes the collected data, compares the processing result with the judgment standard of the machine tool processing performance, emits control instructions to control the processing process according to the given control strategy, and feeds back all relevant information to the management server; the management server analyses the processing performance state and the development trend of the machine tool. The system carries out monitoring to the self-parameters and the in-situ processing state of a plurality of the machine tools, analyses the current processing performance the development trend of the machine tool, and self-adaptively controls the complex processing process, thus effectively ensuring the processing safety and quality.

Owner:HUAZHONG UNIV OF SCI & TECH +1

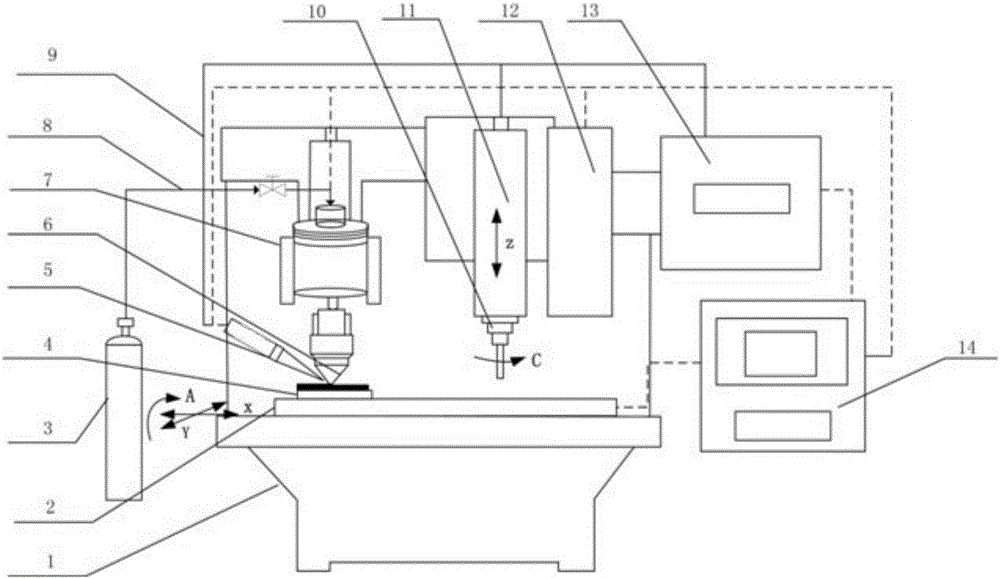

Composite forming device of molten coating added and decreased materials

InactiveCN105817625AAvoid dependenceConvenient location changeAdditive manufacturing apparatusIncreasing energy efficiencyMachiningAdditive layer manufacturing

The invention discloses a composite forming device of molten coating added and decreased materials. The composite forming device comprises a coating added material forming part and a decreased material machining part arranged on the same one motion platform; the coating added material forming part includes an atmosphere protecting device; the atmosphere protecting device is connected with the top of a smelting device; a coating head and a laser are arranged at the bottom of the smelting device; a coating forming platform is arranged below the laser and the coating head; the decreased material part includes a main shaft; a cutter clamping device is arranged at the bottom of the main shaft; the main shaft drives the cutter clamping device to rotate; and the main shaft is connected with a cooling unit. The added material manufacturing and the decreased material manufacturing are combined; and after the coating added material forming is performed, the decreased material machining is used, the workpiece precision is improved, and the workpiece machining speed is accelerated.

Owner:XI AN JIAOTONG UNIV

Precision numerical control milling method for thin-wall parts

InactiveCN101602122AReduce stiffnessGuaranteed machining accuracyMilling equipment detailsNumerical controlEngineering

The invention discloses a precision numerical control milling method for thin-wall parts, and provides a processing method for reducing the milling deformation of the thin-wall parts and improving processing precision and surface quality. When a thin-wall part is finished by fine processing through end milling, the machining allowances of the side wall and a web plate are larger than those of the prior process, and are between 2 and 5mm respectively; when the side wall is processed, the axial depth ap is between 0.2 and 0.8mm, and the radial cutting width is 60 to 80 percent of the diameter of a cutting tool; and when the web plate is processed, the axial depth ap is between 2 and 5mm, and the radial cutting width ae is 10 to 20 percent of the diameter of the cutting tool. The processing method effectively slows down the reduction of the self-rigidity of workpieces and control the cutting force in the thin-wall direction when the processing efficiency is ensured, thereby effectively reducing and controlling the processing deformation of the thin-wall parts, and ensuring the processing precision and surface quality of the parts.

Owner:TIANJIN UNIV OF COMMERCE

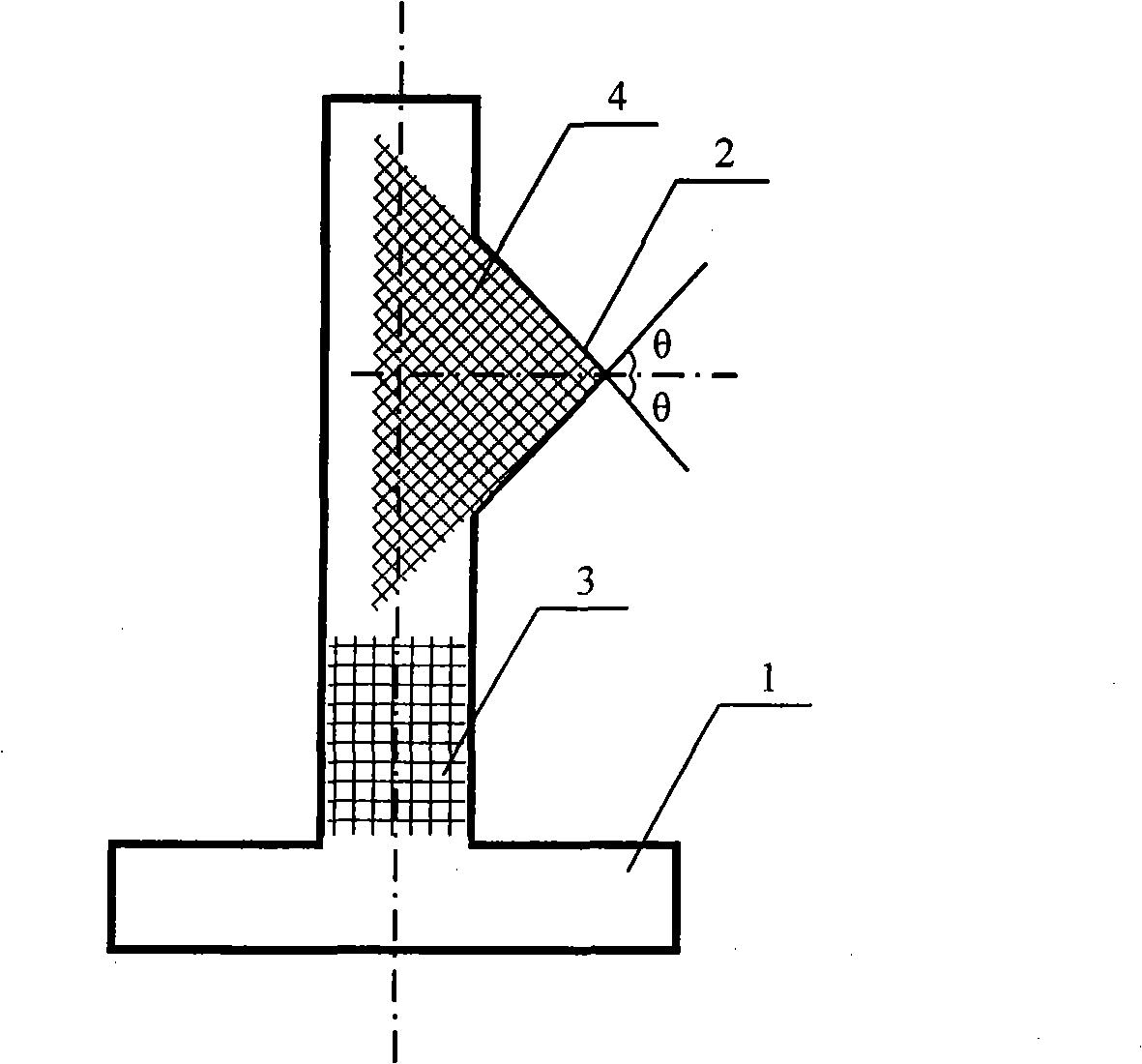

Ceramic base compound material bolt preparation method

The invention discloses a preparation method for a ceramic matrix composite bolt, which is characterized in that the method comprises the following steps: producing a fiber prefabricated product by shaping with a graphite plate after alternatively laminating a 1K carbon fiber 0 / 90 degree positive ply and a plus / minus Theta inclined ply; depositing a pyrolysis carbon interface layer on the prefabricated product and then depositing a silicon carbide matrix on the two-dimensional sheet with a deposited pyrolysis carbon interface layer to produce a semi-finished product of ceramic matrix composite sheet which is cut to form a bolt blank; grinding wheel and tapping the bolt blank; lastly obtaining the product of C / SiC composite bolt after many times of infiltration pyrolysis of polycarbosilane and continuing CVI depositing of SiC anti-oxidation coating. By the method, the bolt is processed and tapped on the semi-finished ceramic matrix composite prefabricated product which is not fully deposited and dense, so that the diamond grinding wheel wear is slow and the production cost is reduced. The technology of CVI combining with PIP process enables the elongation breaking strength of composite bolts to improve from 180 to 190MPa in prior art to 210 to 230MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

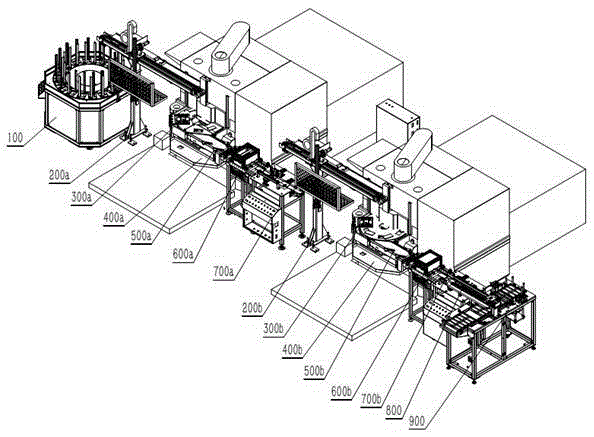

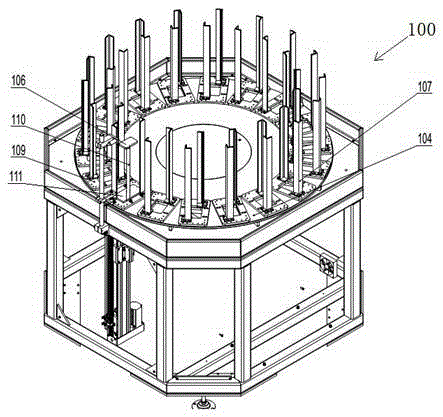

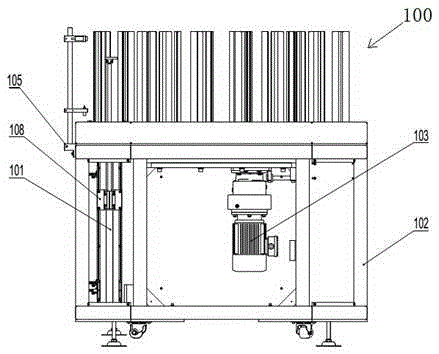

Full-automatic double-end-face grinding production line

ActiveCN105382650AGap adjustmentLow processing and manufacturing costsGrinding feedersPlane surface grinding machinesProduction lineManipulator

The invention discloses a full-automatic double-end-face grinding production line. The production line is arranged in a straight line and sequentially comprises a feeding mechanism, a feeding mechanical arm, a first double-end-face grinding machine, a first transfer conveying belt, a first washing mechanism, a first detecting device, a transfer mechanical arm, a second double-end-face grinding machine, a second transfer conveying belt, a second washing mechanism, a second detecting device, a discharging mechanical arm and a discharging mechanism, wherein the first double-end-face grinding machine is provided with a first grinding machine material drop plate which is engaged with the feeding mechanical arm; the second-end-face grinding machine is provided with a second grinding machine material drop plate which is engaged with the transfer mechanical arm. The full-automatic double-end-face grinding production line disclosed by the invention can be used for grinding a wide range of materials, is capable of implementing feeding, grinding, washing, detection and discharging of a work piece material by one time, is high in automation degree and has the effects of guaranteeing the machining quality, reducing the rejection rate, also greatly alleviating the labor strength, reducing the labor and lowering the machining cost and the manufacturing cost for enterprises.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

Method for machining thin-wall bearing housing part

The invention relates to the field of machining, in particular to a method for machining a thin-wall bearing housing part. The method comprises the following steps that a blank is forged, and a process construction chuck is reserved; rough turning is carried out, wherein the appearance of a workpiece is roughly turned on a common lathe, a ladder hole of the workpiece is roughly turned, stabilizing treatment is carried out, and the internal stress of the workpiece is eliminated; finish turning is carried out, finish turning is carried out on the workpiece on a numerically controlled lathe, the working allowance of 0.9 mm is reserved on the single side of the outer circle and the single side of an inner hole; rough grinding is carried out, wherein the two end faces of the workpiece are ground on a surface grinding machine, and the depth of parallelism between the two end faces is kept within 0.05 mm; rough grinding is carried out, wherein the construction chuck end face of the workpiece is sucked by a suction cup on a universal grinding machine, alignment is carried out according to the outer circle, and the outer circle, the inner hole and the end faces of the workpiece are ground roughly. The machining process is simple, the scheme is simple and practical, clamp design is reasonable, application is convenient, manufacturing cost is low, the part is easy to dismount, the use effect is good, the machining quality of the workpiece can be ensured, workpiece efficiency can be improved, and the method is suitable for batch production of the large-diameter thin-wall part.

Owner:祝云

Making process of gear box casing for centrifugal compressor

InactiveCN1931512ASolve processing problemsImprove processing qualityAutomatic control devicesGearboxesNumerical controlAgricultural engineering

The present invention is machining process of gear box casing for TM type centrifugal compressor, and belongs to the field of metal machining technology. The gear box casing consists of one upper casing and one lower casing mainly. The lower casing is machined through fine milling the bottom, drilling hole, machining the combining surfaces, sides and holes, washing, oiling and other steps; the upper casing is machined through fine milling the combining surfaces, drilling holes, fine boring the bearing holes, cleaning, oiling and other steps. The present invention has simple machining process, low production cost, high machining precision and other advantages.

Owner:WUXI COMPRESSOR CO LTD

Phase extraction method and detecting device for single width carrier frequency interference fringes

Provided are a phase extraction method and a detecting device for single width carrier frequency interference fringes. The phase extraction method and the detecting device are used for large plane optical element detection. The method is mainly based on virtual grating phase shifting moire fringes and two-dimensional Fourier transformation, two-dimensional wave surface phase information of a detected optical element is extracted from a single carrier frequency interference pattern within a full aperture range, and a computing method for a GRMS value of a circular aperture component surface shape is put forward. In addition, the plane optical element surface shape detecting device constructed on the basis of the method can be applied to procedure interference detection of optical manufacturing workshops. According to the phase extraction method and the detecting device, the requirement for detection of plane optical element transmission / reflection low frequency surface shape deviation can be met, and precision and efficiency of manufacturing detecting are improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

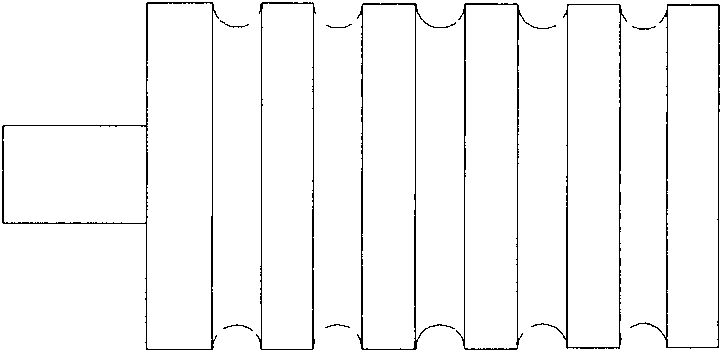

Polytetrafluoroethylene hollow fiber stretching device

The invention discloses a polytetrafluoroethylene hollow fiber stretching device. Cylindrical surfaces of two guide rollers, a plurality of stretching rollers and a cooling roller of the device are provided with uniform grooves of which the number is the same as that of the uniform grooves of degreasing rollers; and a baking oven consists of a stretching baking oven, a degreasing baking oven and a baking oven exhaust hood. An unwinding roller, the cooling roller and a winding roller are positioned outside the baking oven; a plurality of the degreasing rollers which are staggered up and down are arranged in the degreasing baking oven; a plurality of the guide rollers and a plurality of the stretching rollers two of which form a group are arranged in the stretching baking oven; the polytetrafluoroethylene hollow fibers which are wound on the unwinding roller and have the same number as the groove number of the degreasing rollers pass through the degreasing rollers in the degreasing baking oven, and the degreased hollow fibers enter the stretching baking oven, pass through the guide roller, the stretching rollers arranged in pairs and the other guide roller, and then the degreased hollow fibers is wound on the winding roller through the cooling roller. The device has the following advantages that: degreasing and stretching are performed in the baking oven to save energy resources; the degreasing and stretching of a plurality of the hollow fibers are performed, and the efficiency is high to ensure the processing quality; and stepwise stretching is adopted to effectively realize pore control of a hollow fiber membrane.

Owner:ZHEJIANG SCI-TECH UNIV

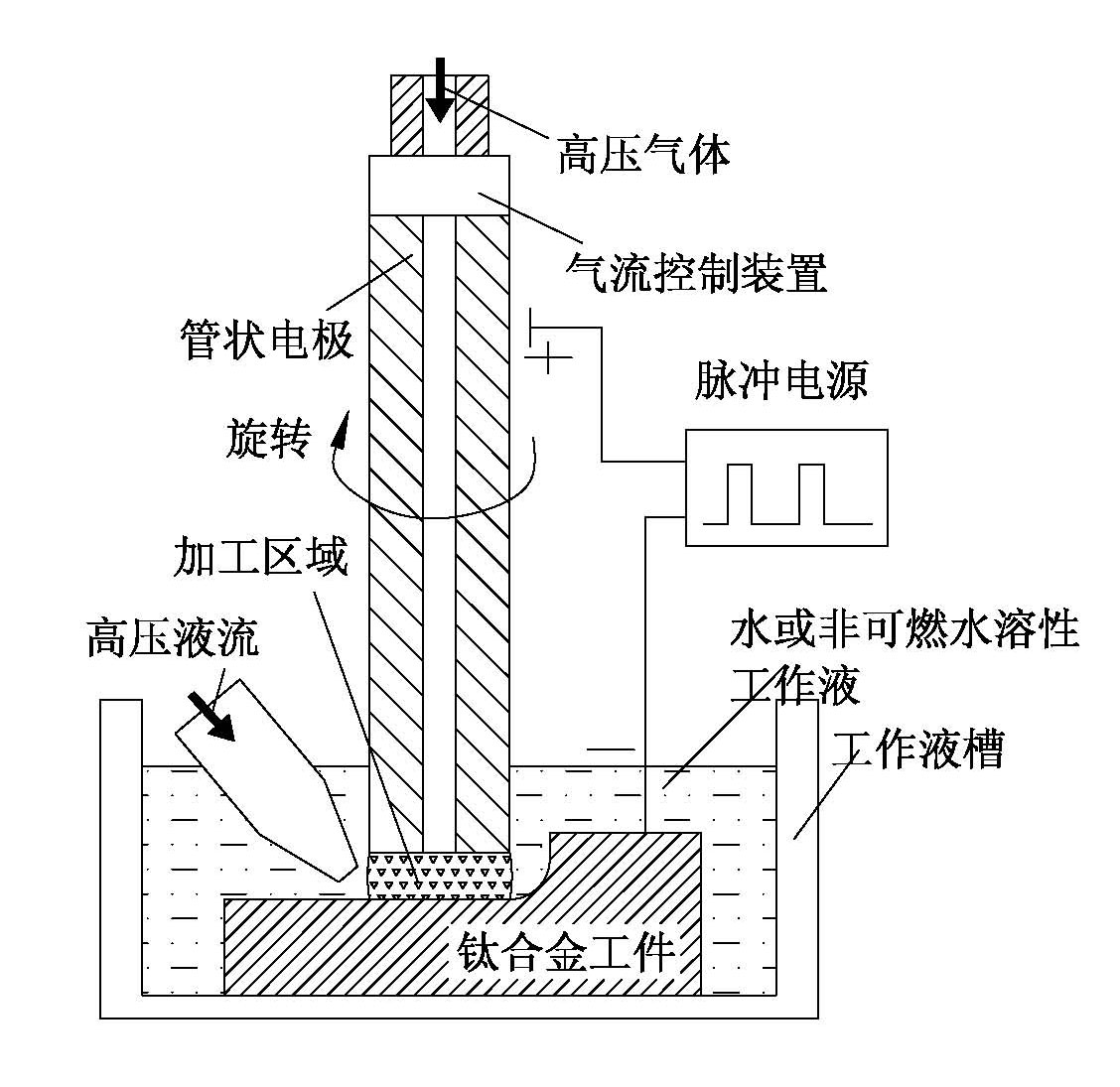

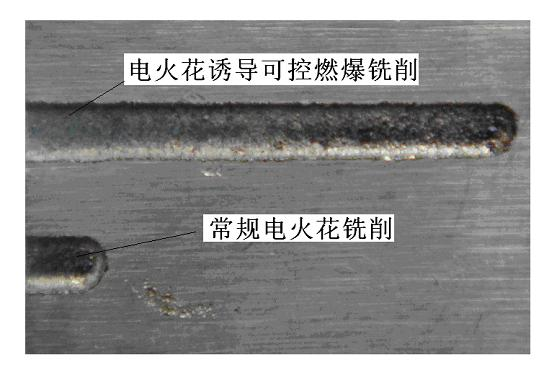

Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

The invention relates to a processing method for corroding titanium or a titanium alloy by burning and exploding under the electric spark induction effect, which is characterized in that a gas which can generate vigorous exothermic oxidation and burning and exploding effects with a titanium or titanium alloy materal to be processed is introduced in a processing area intermittently in the conventional process for processing the titanium or titanium alloy under the electric spark induction effect so that the titanium or titanium alloy of which the surface is activated under the electric spark induction effect and the introduced gas are subjected to burning and exploding reactions and a new activated layer can be exposed, and the process is carried out repeatedly so that the surfaces of titanium or titanium alloy substrate materials can be corroded rapidly and continuously in large quantities. Compared with the conventional method for corroding the titanium or titanium alloy under the electric spark induction effect, the invention can improve the material corroding rate by dozens of times or even hundreds of times. The invention can be used for processing through the relative motion of small-scale equipment on a large-scale structural component, can solve the problems on the size, the rigidity and the like of a large-scale structural component processing machine tool and has the advantages of high efficiency, low loss, low cost, safety and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Numerical control cutting machine

InactiveCN102303175AFull range of mobilityQuality improvementGas flame welding apparatusControl systemEngineering

The invention discloses a numerical control cutting machine, which comprises a longitudinal guide rail, a machine frame arranged on the longitudinal guide rail, and a numerical control system, a cutting control system, a transverse movement system, a lifting mechanism and a deflection device which are arranged on the machine frame, wherein a longitudinal driving rack is arranged on the longitudinal guide rail and is matched with a longitudinal driving gear; the longitudinal driving gear is arranged on the machine frame; the lifting mechanism is arranged on the transverse movement system; and the deflection device is arranged on the lifting mechanism. The numerical control cutting machine has the advantages of high production efficiency, quality of beveled edges and accuracy, low labor intensity of workers and the like and is controlled automatically in the whole process, angles of the beveled edges are easy to ensure, and the generality of workpieces is high.

Owner:昆山芬特机器制造有限公司

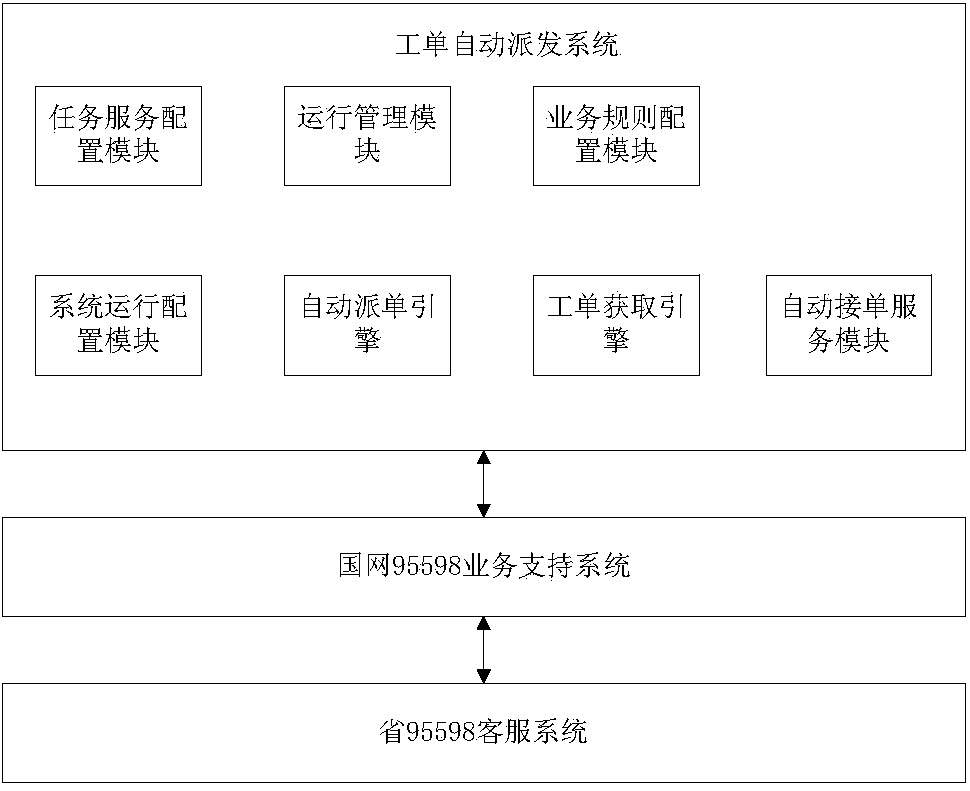

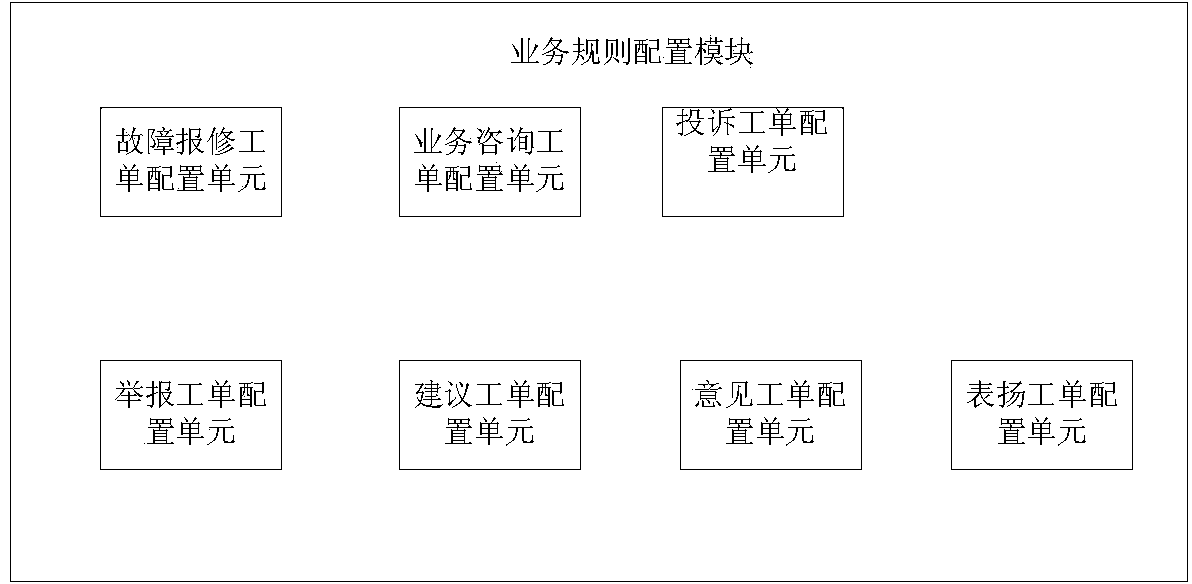

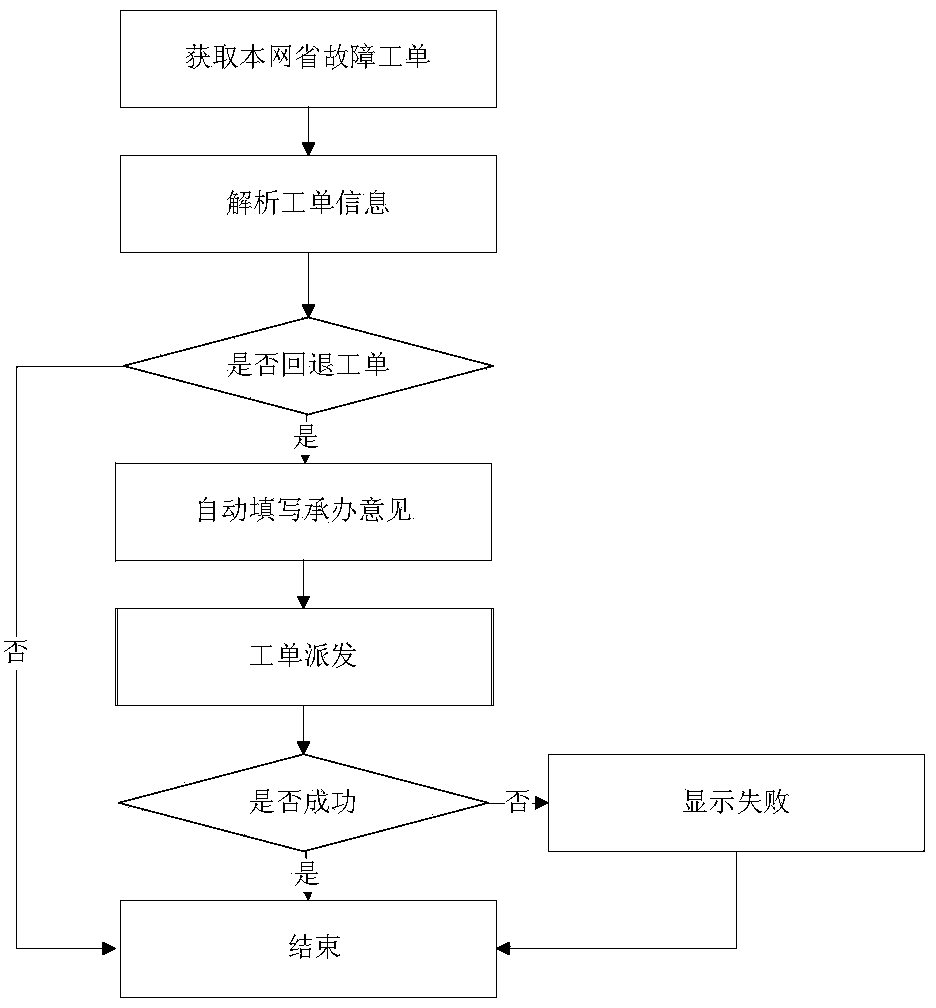

Automatic distributing system and method of work order

ActiveCN104182821AImprove the timely delivery rateImprove service levelResourcesBusiness ruleService configuration

The invention discloses an automatic distributing system and method of a work order. The system comprises a system operation configuration module, a task service configuration module, an operation management module and a service rule configuration module, wherein the system operation configuration module is used for providing system operation parameters which comprise switch configuration, work order issuing resource positioning, alerting ring file configuration and whether a ring alerting switch is turned on or not; the task service configuration module is used for providing timed task service configuration functions which comprises job number information configuration, time interval configuration, work order address resource information acquisition configuration and time interval configuration support for automatically obtaining national network work order information; the operation management module is used for carrying out log management for a system to automatically process a work order situation, and order sending failure reminding; the service rule configuration module is used for configuring conditions of fault repair, service consultation, complaint, informing, suggestion, opinions and automatic distribution of various types of work orders. The integral working quality of a remote workstation of a provincial customer service center is guaranteed, the working efficiency of staff is improved, and each index of high quality service is improved.

Owner:国网山东省电力公司营销服务中心(计量中心) +2

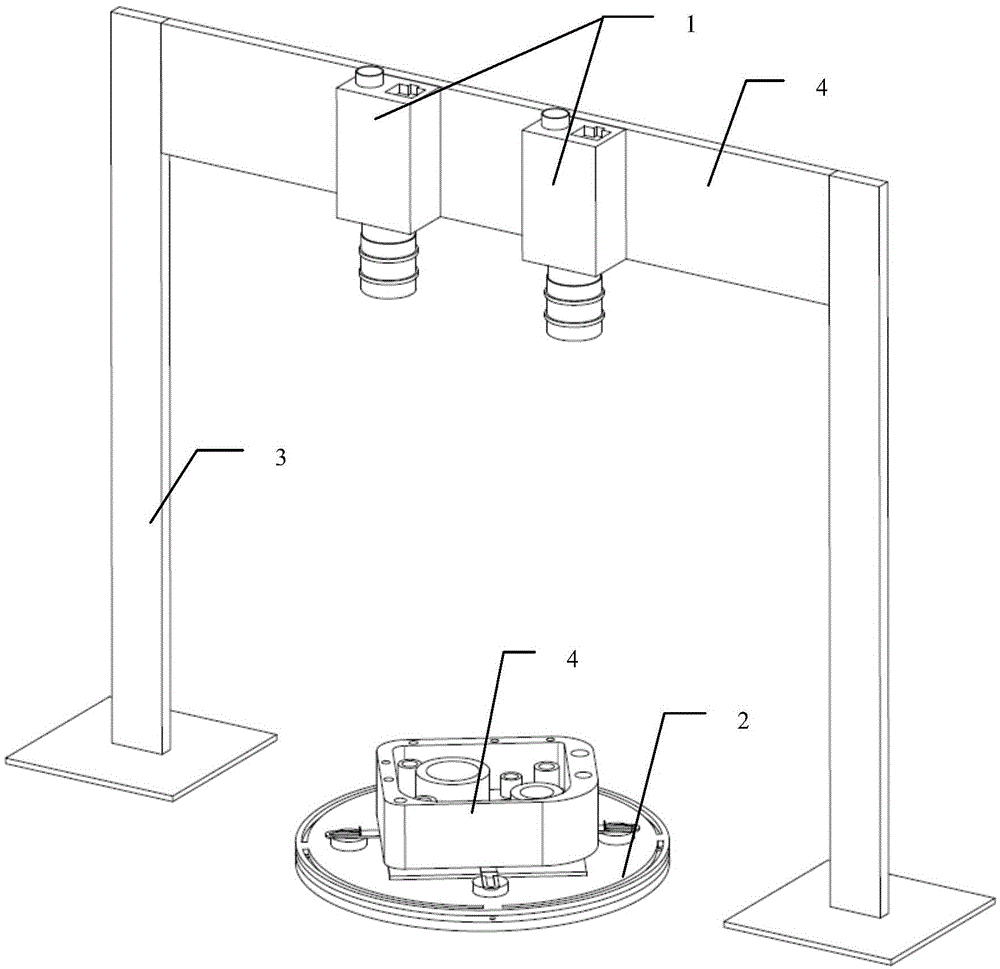

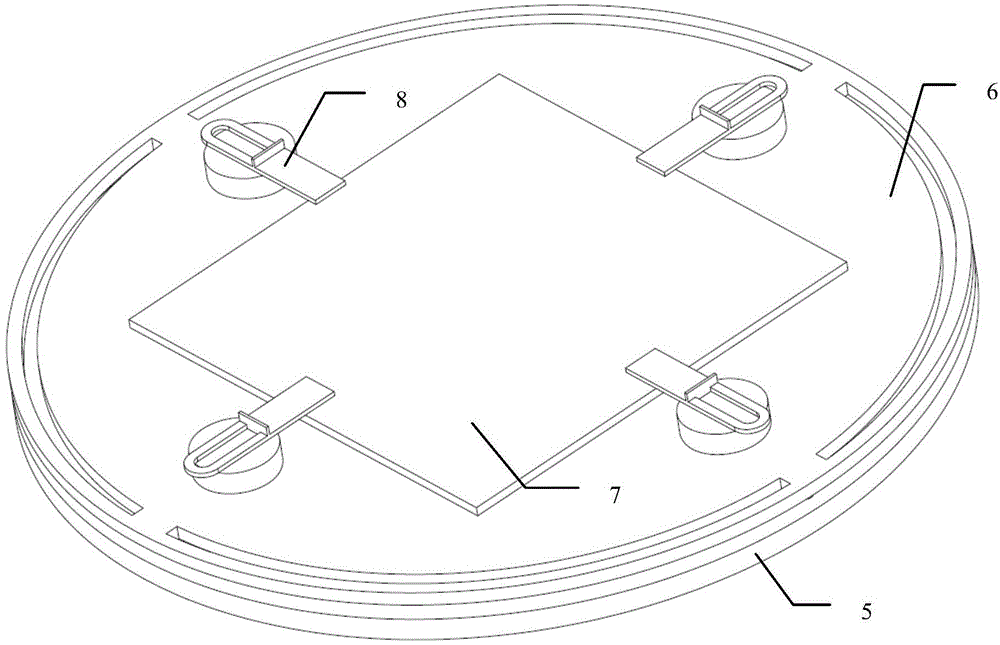

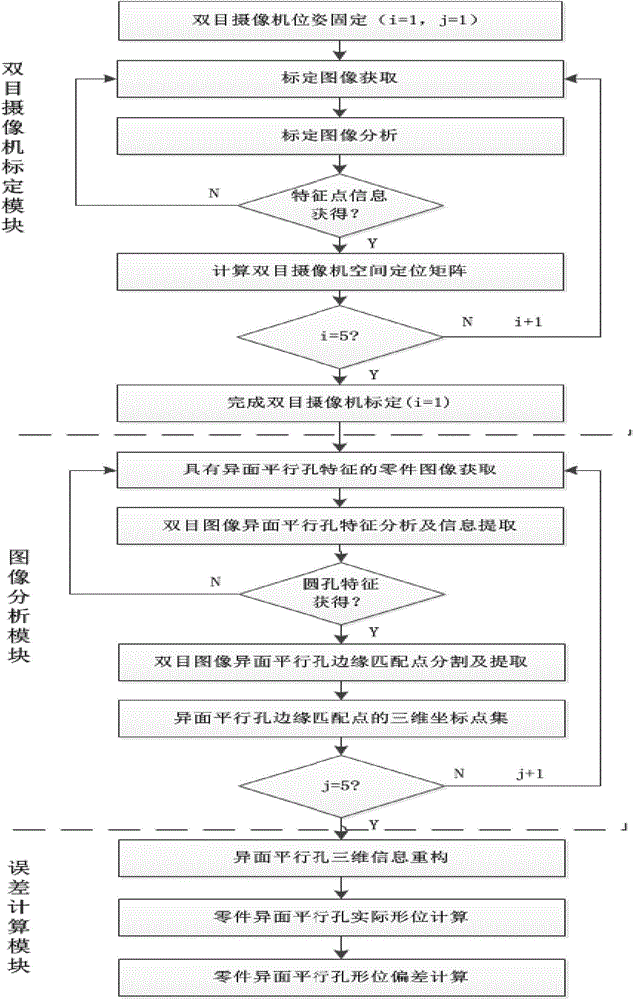

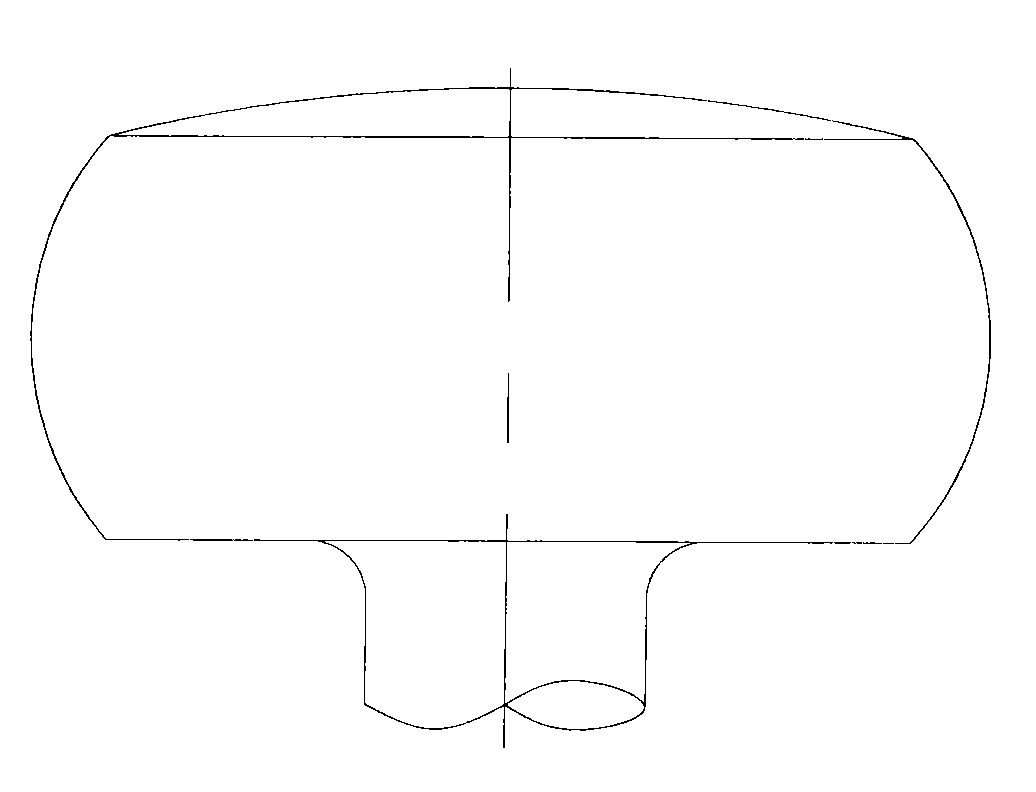

Component different-surface-parallel-hole form and position deviation visual measuring method and device

InactiveCN104897062AAvoid surface damageHigh measurement accuracyUsing optical meansAlgorithmEngineering

The invention provides a component different-surface-parallel-hole form and position deviation visual measuring method and device. The method comprises the following steps which are carried out in sequence: [1] binocular camera parameter calibration; [2] different-surface-parallel-hole feature analysis and treatment of a component entity image; [3] different-surface-parallel-hole match feature point extraction of the component entity image; [4] component different-surface-parallel-hole three-dimension information reconstruction, and analysis and calculation of form and position deviation parameters such as diameter, circular degree, hole pitch and depth distribution of holes. According to the invention, measurement of the component feature hole form and position deviation can be completed rapidly and effectively, precision requirements of high-precision measurement can be met, and advantages of simple measurement operation, low equipment maintenance cost and the like can be achieved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Forging molding method for million kilowatt nuclear power main pipe

InactiveCN101670416AReduce weightGuaranteed Grain SizeEngine componentsOther workshop equipmentNuclear powerIngot

The invention discloses a forging molding method for a million kilowatt nuclear power main pipe. The forging process of the method comprises the following steps of a, upsetting; b, stretching; c, single-side marking; d, stretching at two ends and a middle part respectively; and e, final fire stretching. The method adopts the single-side marking technology in the forging process so that a forge piece has two-side asymmetrical deformation in the forging process and then a required eccentric shaft neck can be formed. The forge piece formed by the method can be forged on the main pipe in the forging process to form two joint pipes between which an angle of 45 degrees is arranged, so the processing quality of products can be ensured and the weight of the forge piece can be lightened. Because the size of the forge piece has deformation quantity in the final fire forging process, the grain size of austenitic stainless steel can be ensured. The forging molding method for manufacturing the million kilowatt nuclear power main pipe has the advantages of light required steel ingot weight, low cost and small processing allowance.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Milling process parameter optimization method

ActiveCN104076733AExcellent milling process parametersImprove productivityNumerical controlProduction rateProcess engineering

The invention provides a milling process parameter optimization method and belongs to the field of cutting machining processes. The coupling effect of a machining device dynamic behavior and the high-speed milling process is considered in the method, the maximum milling extreme cutting depth changing with the rotating speed of a machine tool spindle and shortest machining time of single part are regarded as optimization targets, a milling process parameter optimization model based on cutting stability and productivity is established, and optimal milling process parameters of a milling process parameter combining scheme under the condition that a cutting state is stable when the productivity is maximum are calculated. The milling process parameter optimization method can improve the cutting depth to the most extent during milling, decrease feed times, obtains maximum productivity, meanwhile ensures the cutting stability and avoids flutter. In addition, the milling process parameter optimization method can be applied to the high-speed milling process, the defect that the interactive effect of the machining device dynamic behavior and the milling process parameters is not considered in the high-speed milling process at present is overcome, and optimal high-speed milling process parameters can be obtained.

Owner:TONGJI UNIV

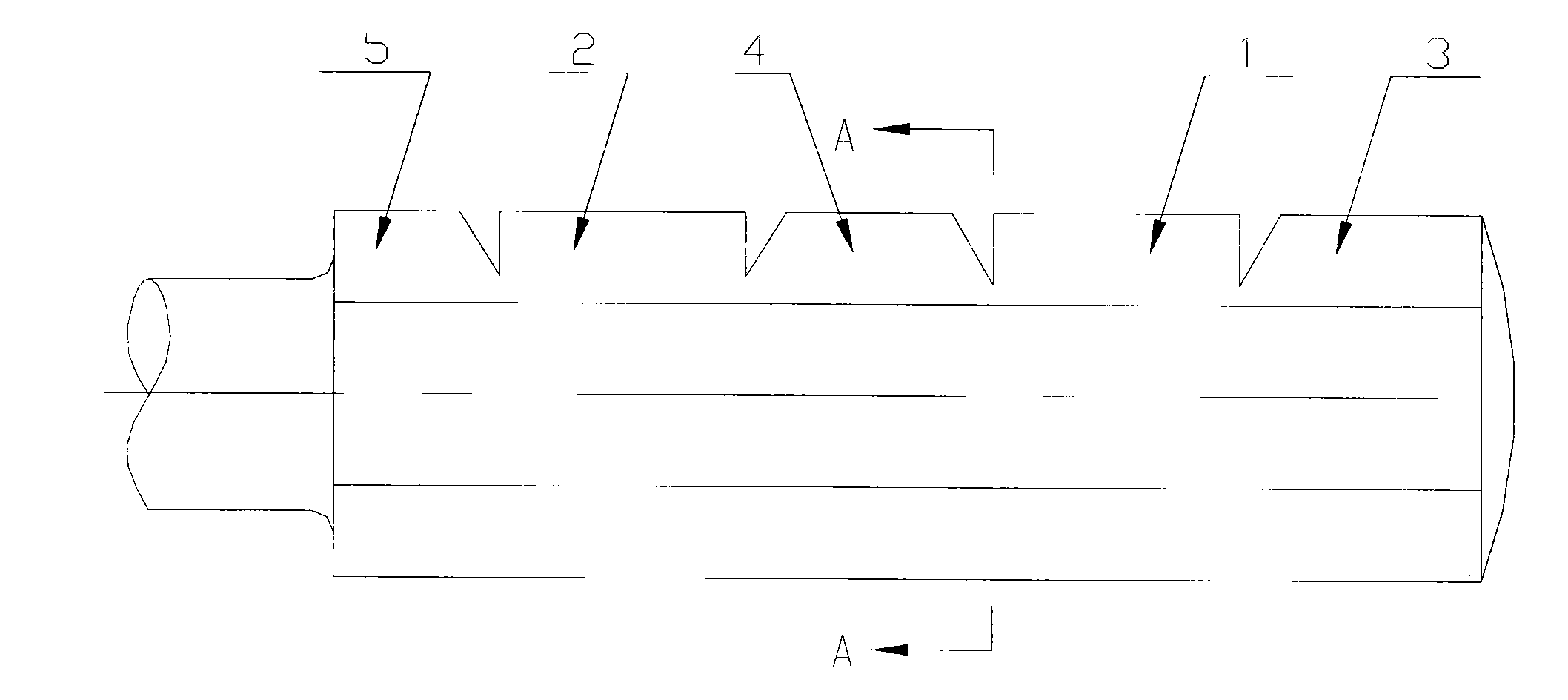

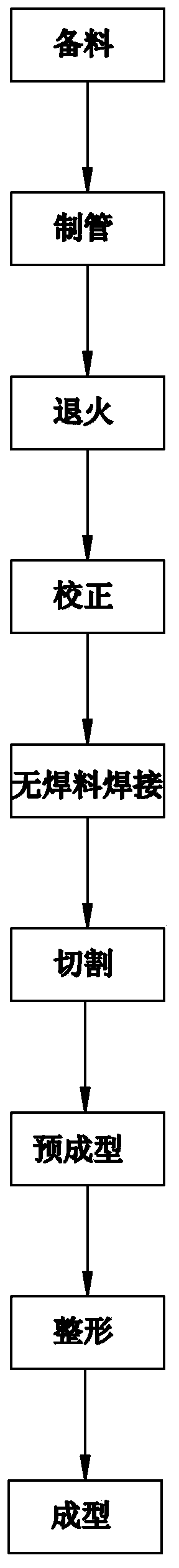

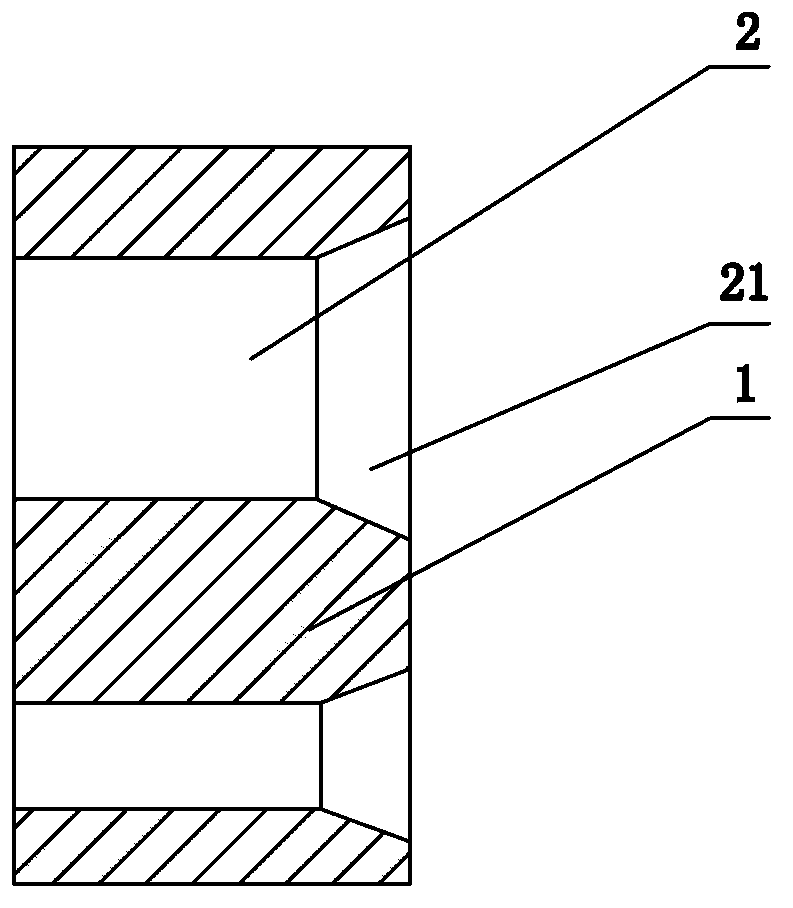

Gold and silver hollow bracelet processing technology

ActiveCN103416925AReduce processing technologyGuaranteed purity and colorJewelleryNanotechnologySheet material

The invention discloses a gold and silver hollow bracelet processing technology and belongs to the technical field of jewelry processing technologies. The processing technology comprises the following steps: preparing material: according to the specifications for processing gold and silver hollow bracelets, preparing sheet material with corresponding specifications; manufacturing a pipe: processing the sheet material into a round pipe with a gap and straightening the round pipe; annealing; calibrating: straightening the gap; welding without welding material: eliminating gap through high-temperature heating to form a gapless round pipe; cutting: cutting the gapless round pipe according to the finished size of a gold and silver hollow bracelet, and polishing two ends of the gapless round pip; pre-forming: processing the gapless round pipe into an open type circular ring, and forming a closed circular ring by performing high-temperature heating on the open type circular ring; shaping: shaping the shape of the closed circular ring until specified requirements are met; forming: processing the closed circular ring into a hollow bracelet with elliptic sections. Through the processing steps, since a only a piece of sheet material is needed, the hollow bracelet can be manufactured, the processing technology is reduced, the processing efficiency is improved, the forming effect is good, and meanwhile, the gap is closed automatically through high temperature, so that welding without welding material is achieved, and the purity and fineness are guaranteed.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD +1

Processing table for automobile part

The invention discloses a processing table for an automobile part. The processing table comprises a processing table body, and two fixed seats are symmetrically and fixedly mounted at the top of the processing table body; first through holes are formed in the sides, close to each other, of the two fixed seats; fixed rods are fixedly mounted in the first through holes; the ends, away from each other, of the two fixed rods separately extend to the outer parts of the two first through holes; first grooves are formed in the ends, close to each other, of the two fixed rods; movable rods are mountedin the first grooves in a sliding manner; and a driving assembly used for controlling the movable rods to move is arranged between the processing table body and the fixed seats. According to the processing table, the automobile part can be conveniently and quickly clamped between two clamping blocks, processing quality of the automobile part is guaranteed, besides, the different clamping blocks can be conveniently changed to clamp the automobile parts of different shapes and specifications, and the processing table has relatively high practicability.

Owner:柳州市钜嘉机械有限公司

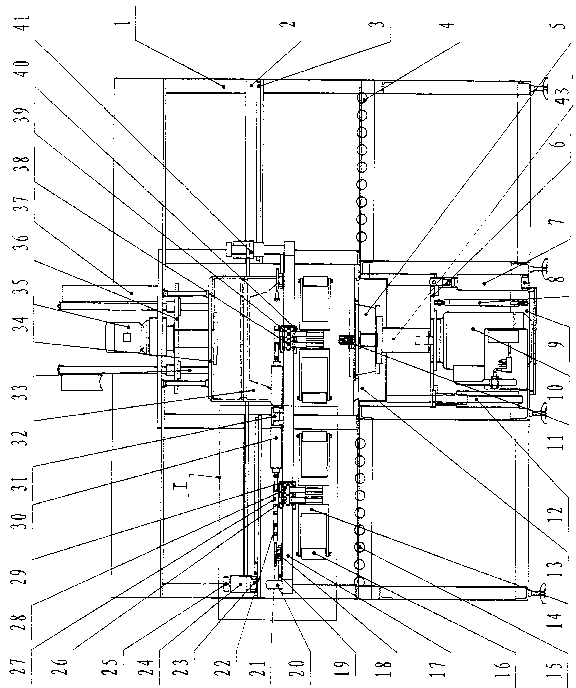

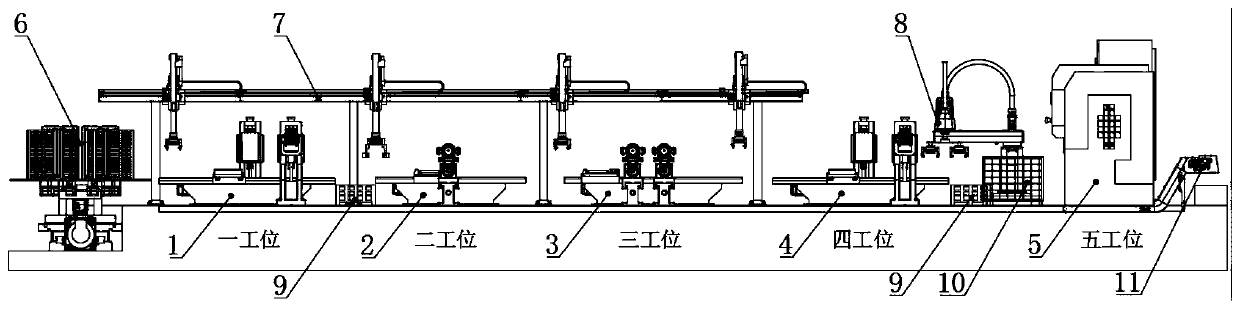

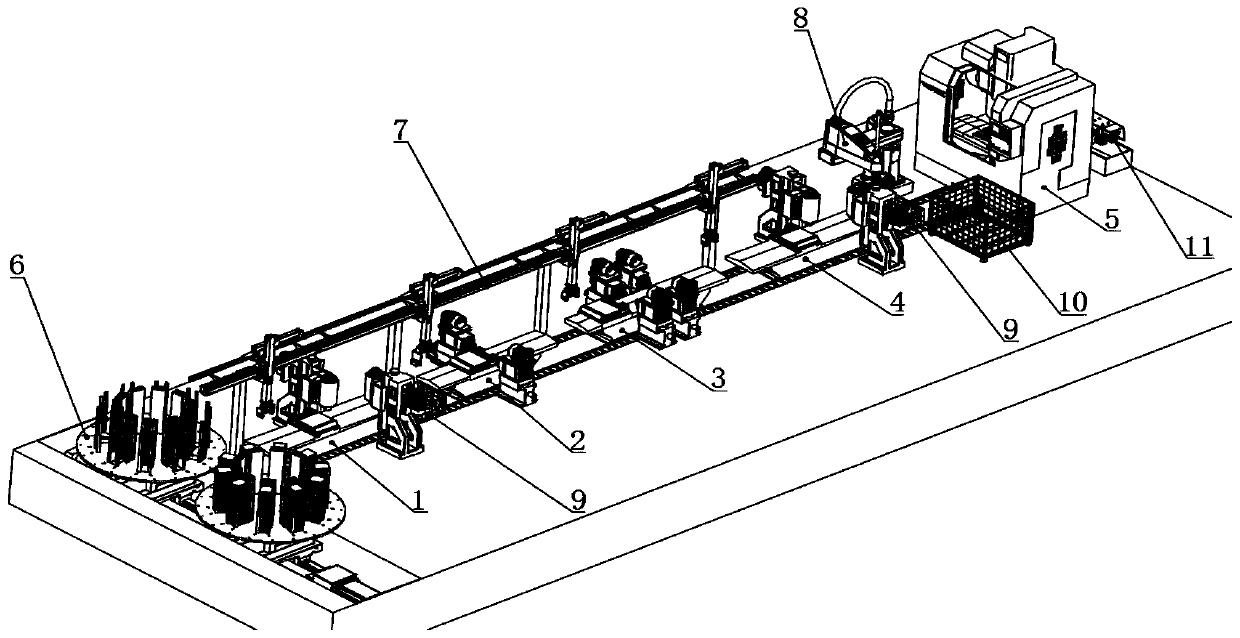

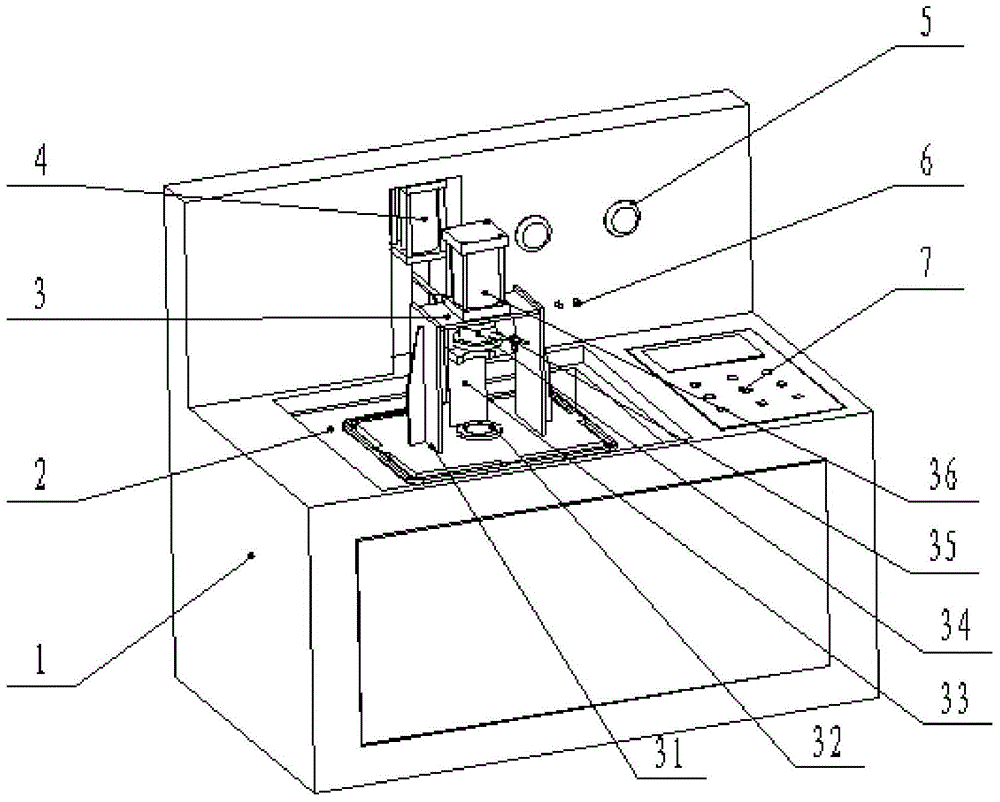

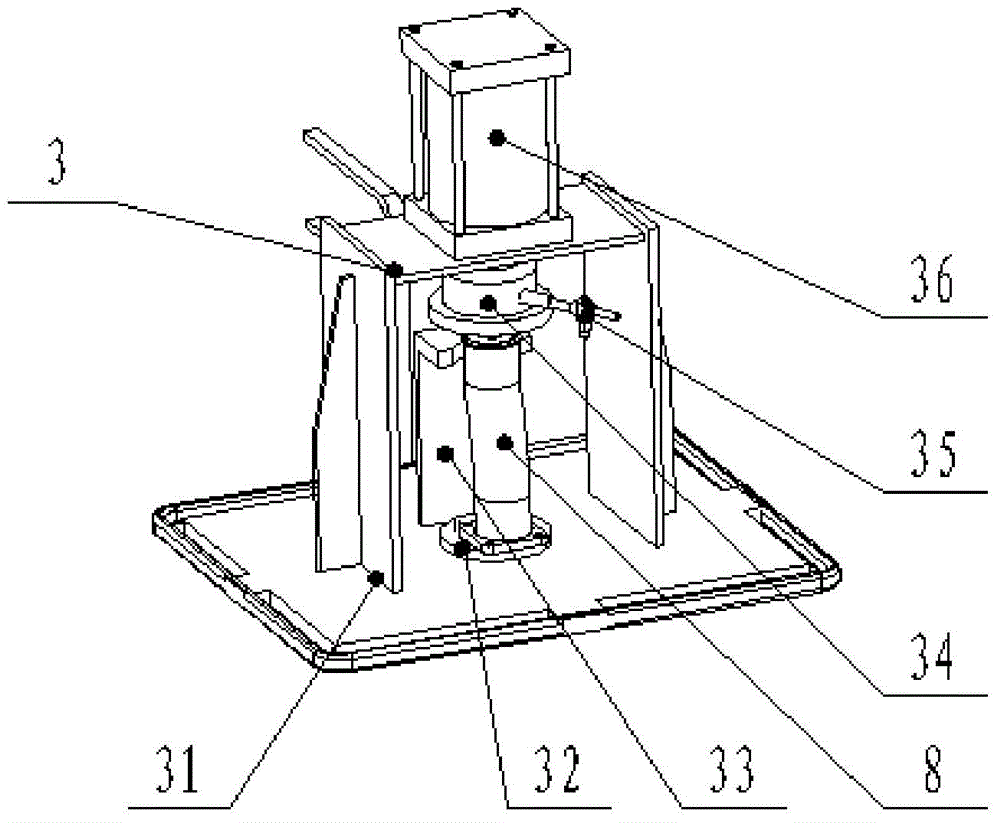

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

Automatic processing technology and system for traditional Chinese medicinal material pre-processing

ActiveCN103637911AUniform flowUniform and stable feedingPharmaceutical product form changeAutomatic controlControl system

Disclosed is an automatic processing technology and system for traditional Chinese medical material pre-processing. The processing technology sequentially comprises the procedures of unpacking, clean selecting, washing, medicine infiltrating, cutting, drying and box packaging or bagging. All the procedures are connected through a belt conveyor or a feeding machine or a vibration conveyor or material separating equipment. An automatic control system is used for controlling processing equipment in all links of the processing technology and automatic continuous production is realized. According to the automatic processing technology and system, an assembly line production mode is adopted, all main procedures in the current traditional Chinese medicine pre-processing process are connected organically through conveying equipment, caching conveying equipment and the material separating equipment, an automatic detecting technology and an automatic control technology are adopted to conduct real-time detection and control on the production process, the degree of automation of traditional Chinese medicine pre-processing is greatly improved, the labor intensity of workers can be lowered, the processing environment can be improved and the stability of the product quality can be maintained.

Owner:云南昆船电子设备有限公司

Automobile intake pipe air tightness detection device and detection method

InactiveCN105067197AImprove air tightnessGuaranteed air tightnessDetection of fluid at leakage pointElectricityHydraulic cylinder

The present invention relates to the pipe fitting performance detection equipment manufacturing technology field, in particular to an automobile intake pipe air tightness detection device and a detection method. The device comprises a rack, a water tank, an elevating device and a detection bench, and also comprises a gas source interface and a control device. The detection bench comprises a clamp arranged on a pedestal, one end of the clamp is equipped with a plug, and the other end is equipped with an inflation device. The inflation device is communicated with the gas source interface via a reducing valve, an elevating hydraulic cylinder is connected above the inflation device, and the inflation device moves up and down under the driving of the elevating hydraulic cylinder. The control device is electrically connected with the elevating device, the inflation device and the elevating hydraulic cylinder separately. The air tightness detection device of the present invention is reasonable in structure and high in detection efficiency, guarantees the processing quality of an intake pipe, realizes the automatic control of a whole process, realizes the air tightness detection by being equipped with a pressure sensor and the vent valve and without needing to be immersed in the water tank, enables the suitable range and the practicality to be improved, and also realizes the air tightness automatic determination.

Owner:曲靖维拓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com