Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4939results about How to "Easy clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

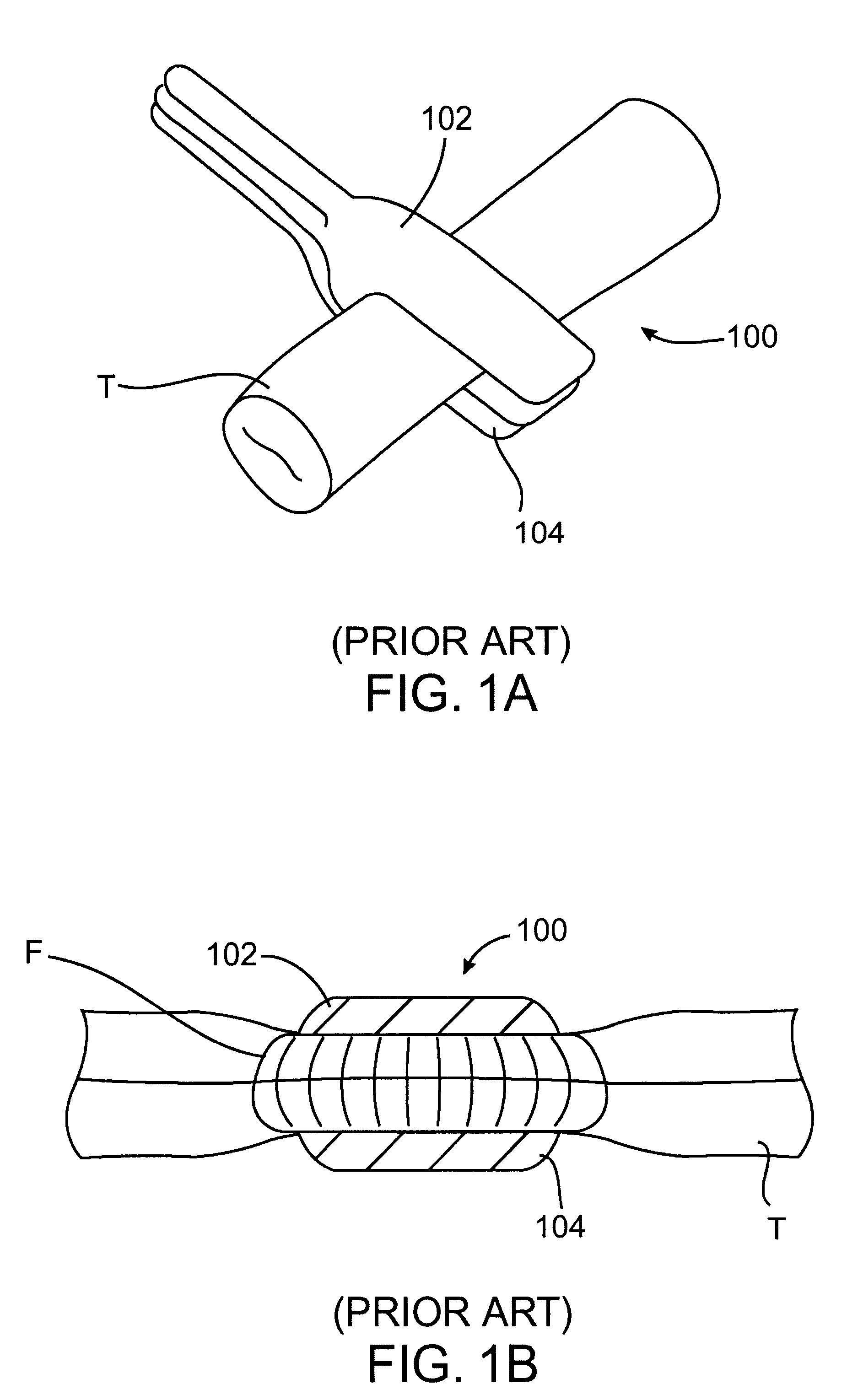

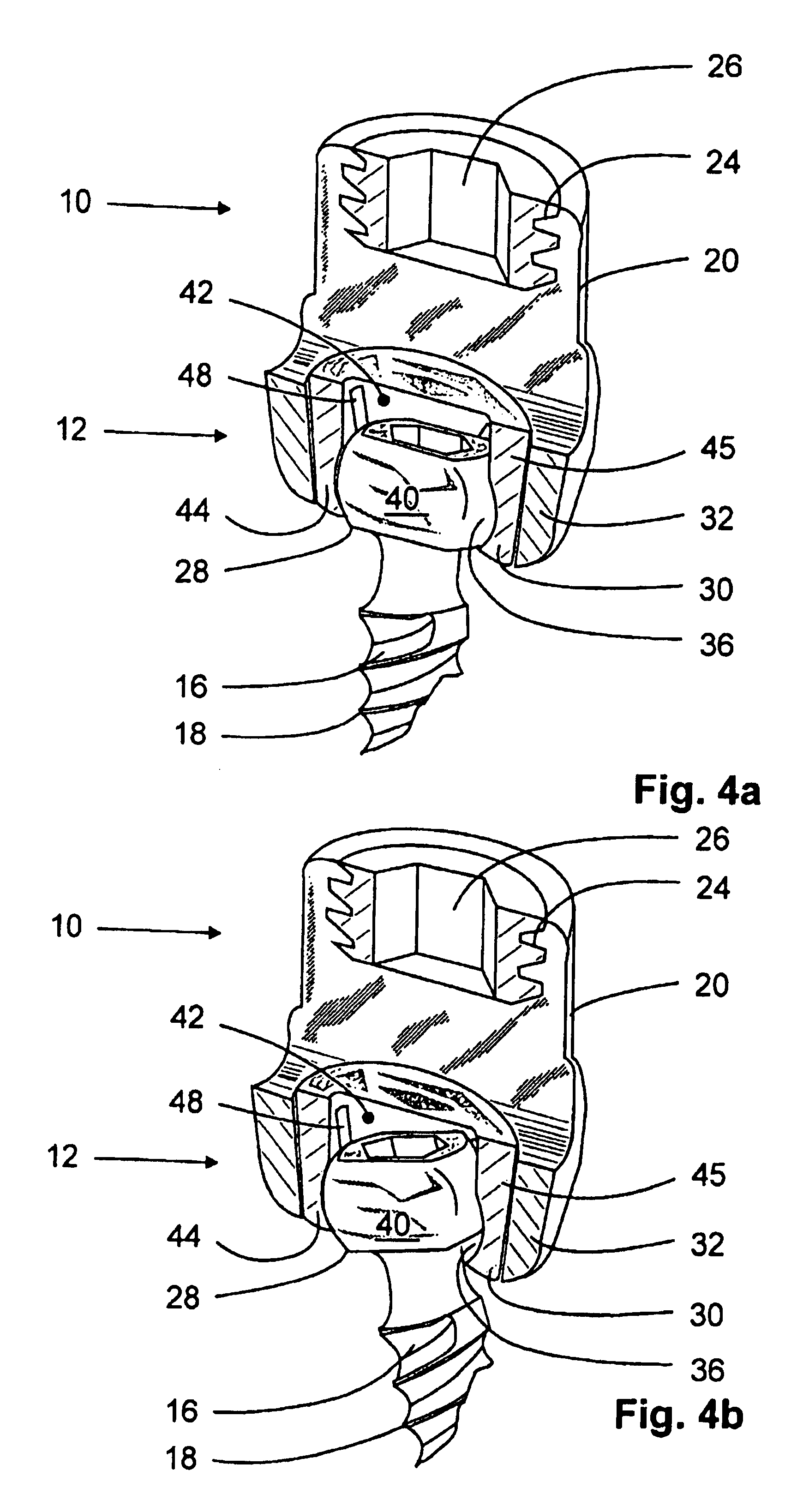

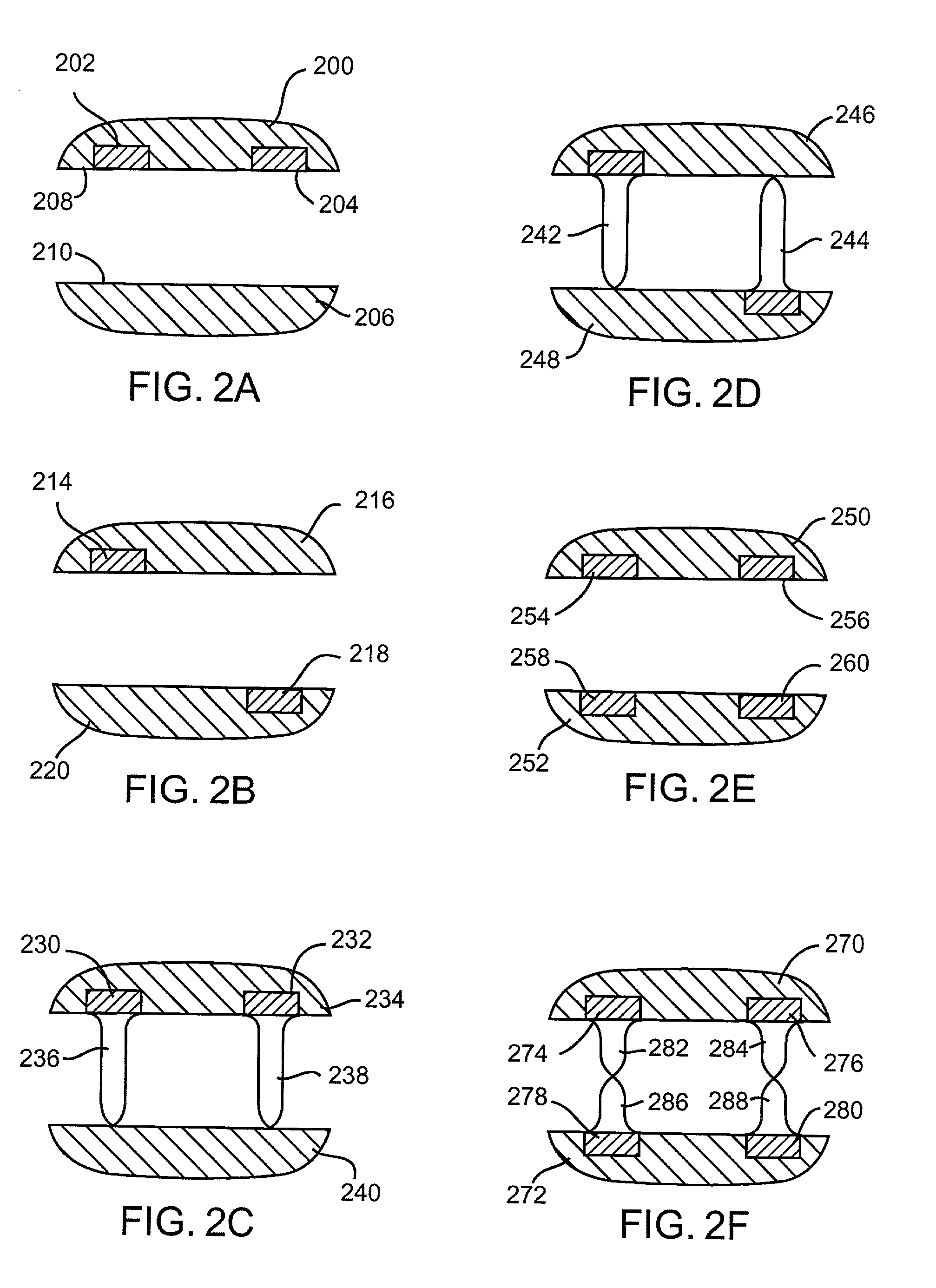

Bipolar surgical instruments having focused electrical fields

InactiveUS6514252B2Reduce capacityLower impedanceSurgical needlesSurgical instruments for heatingElectricitySurgical device

A bipolar surgical device comprises a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

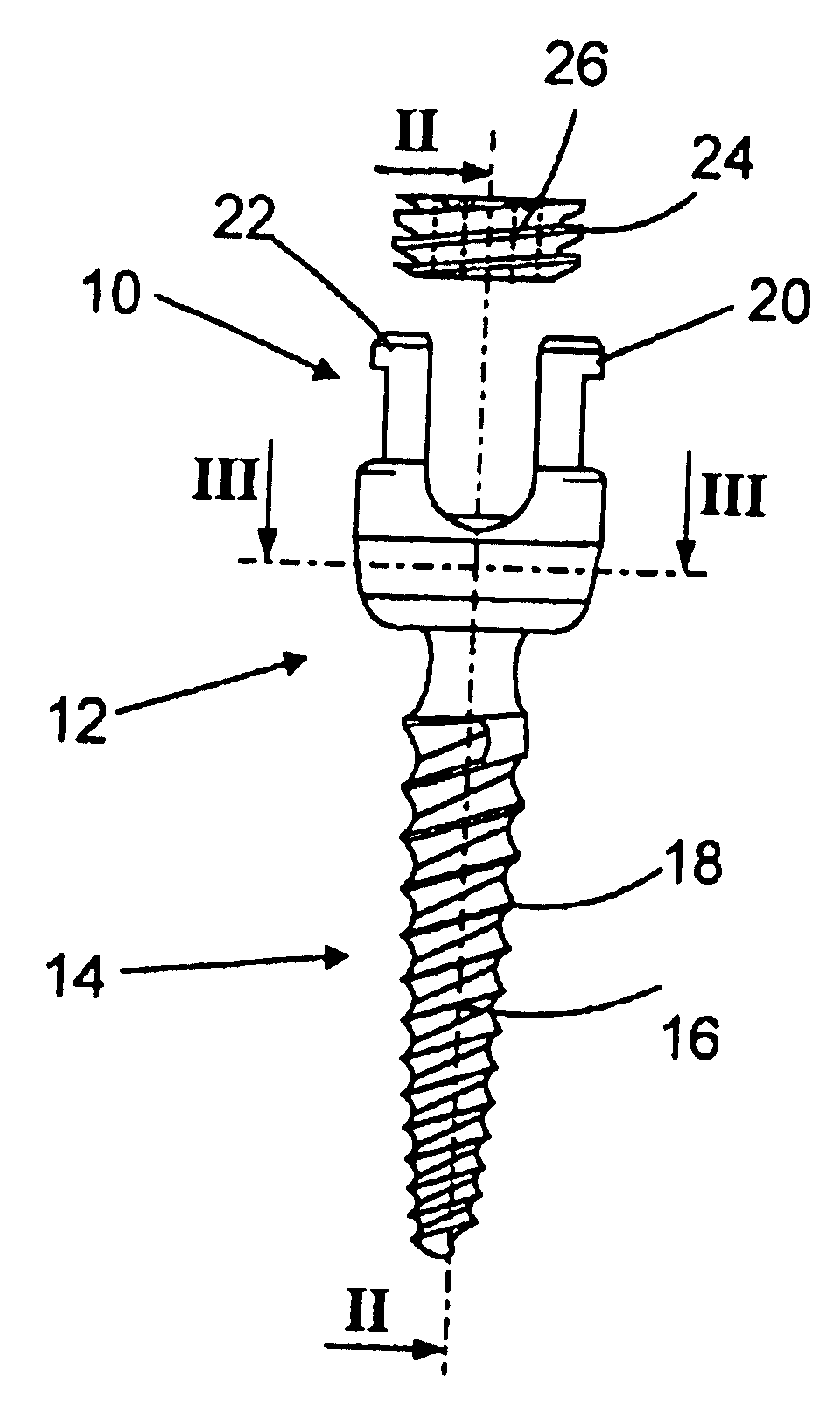

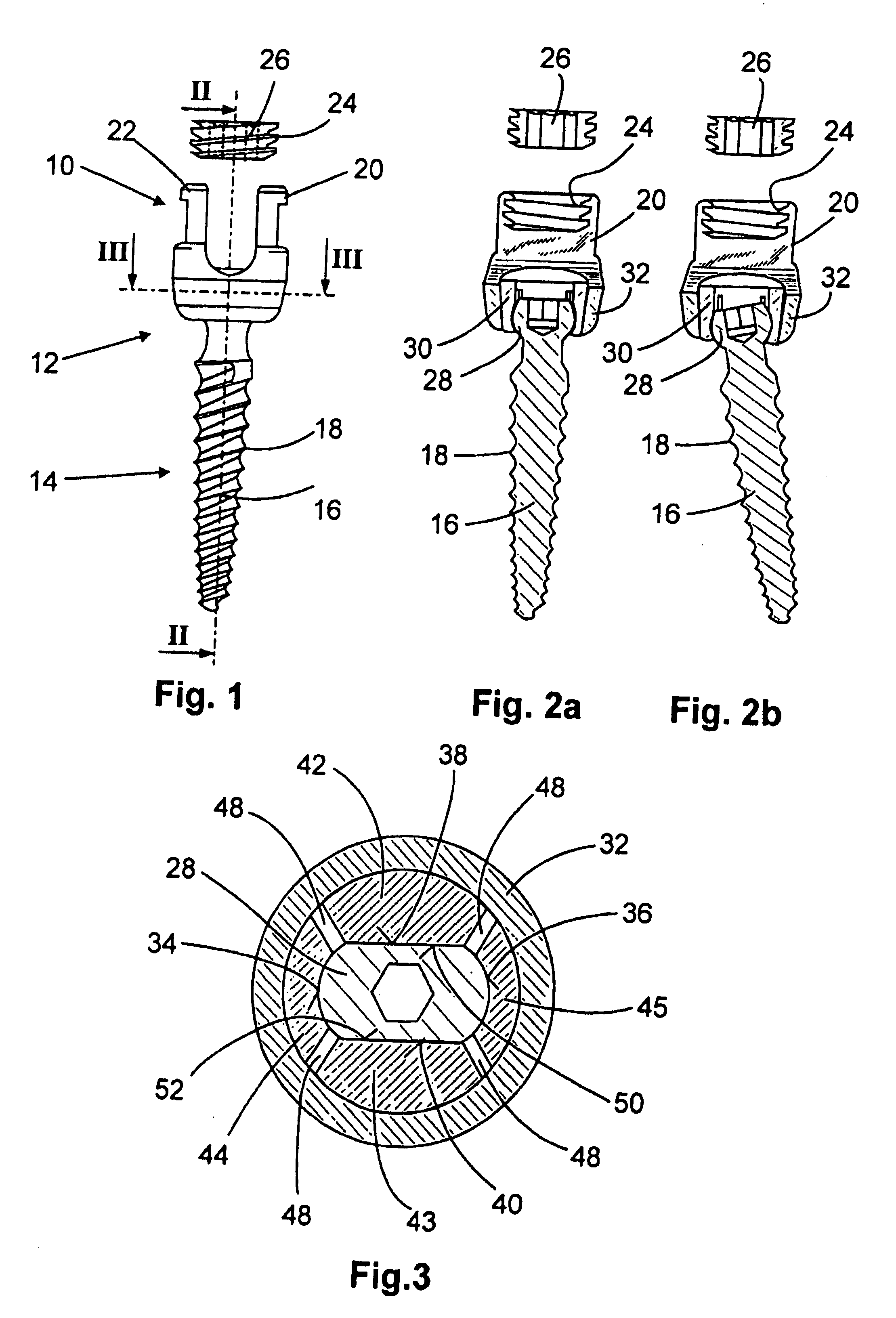

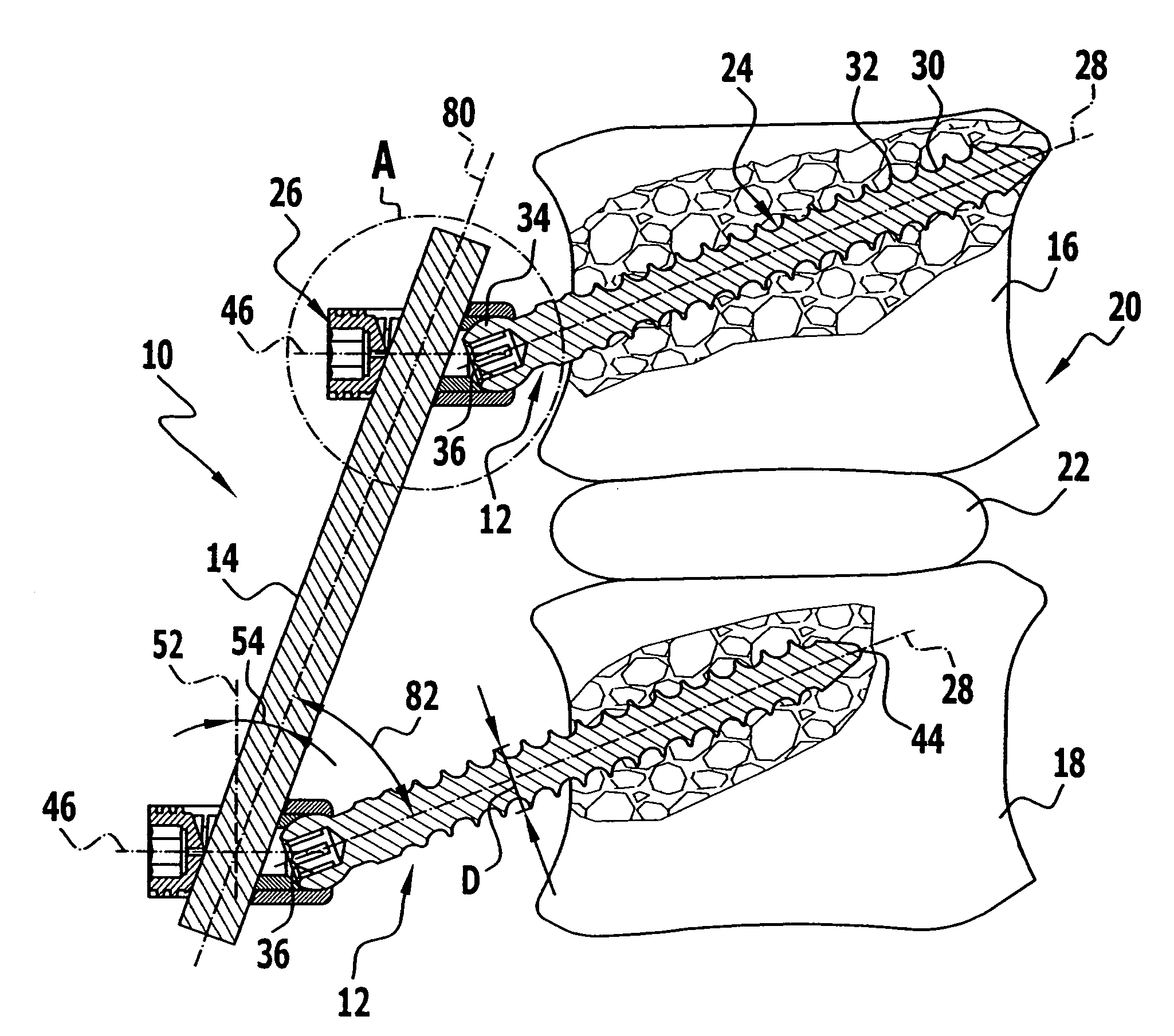

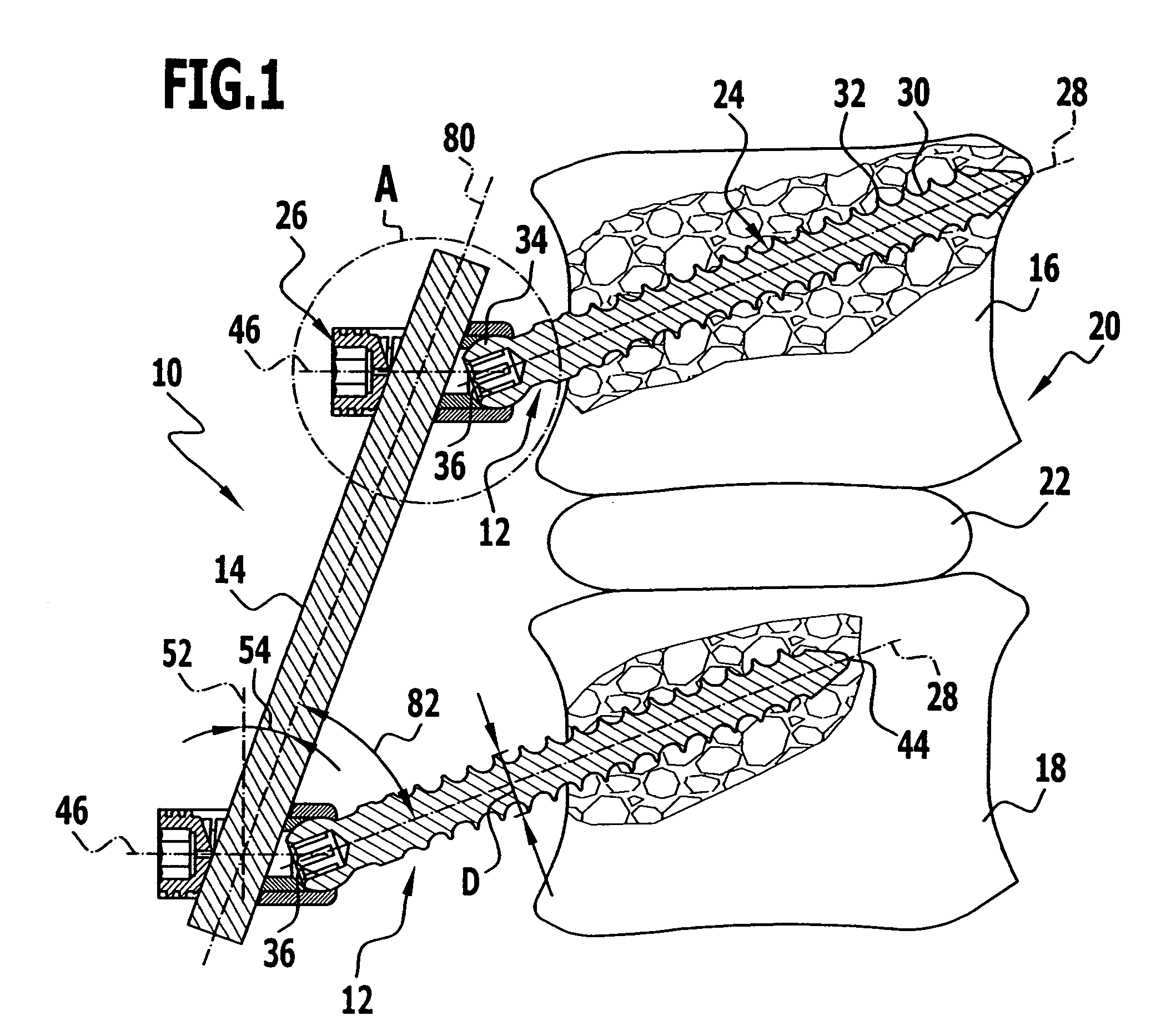

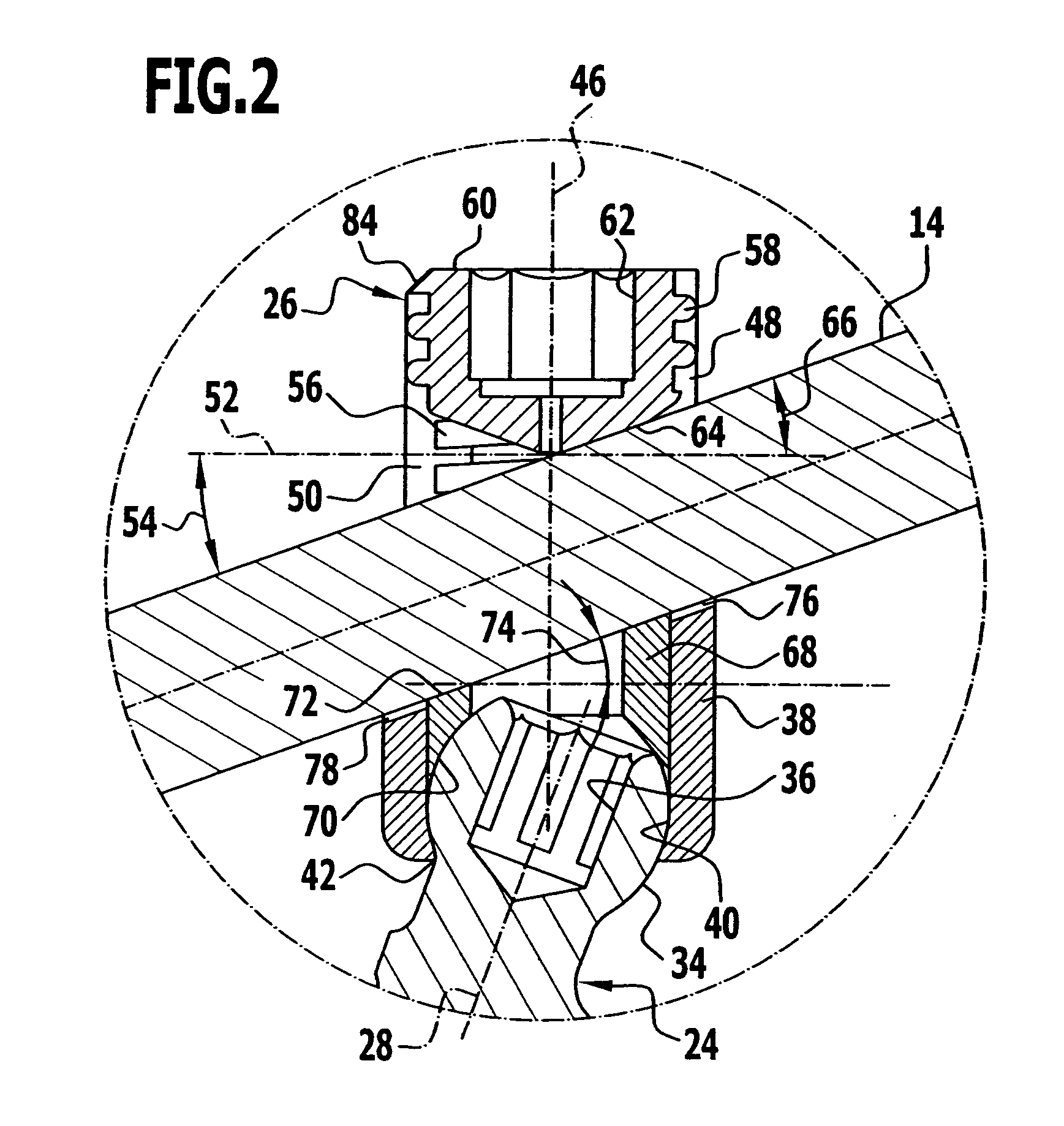

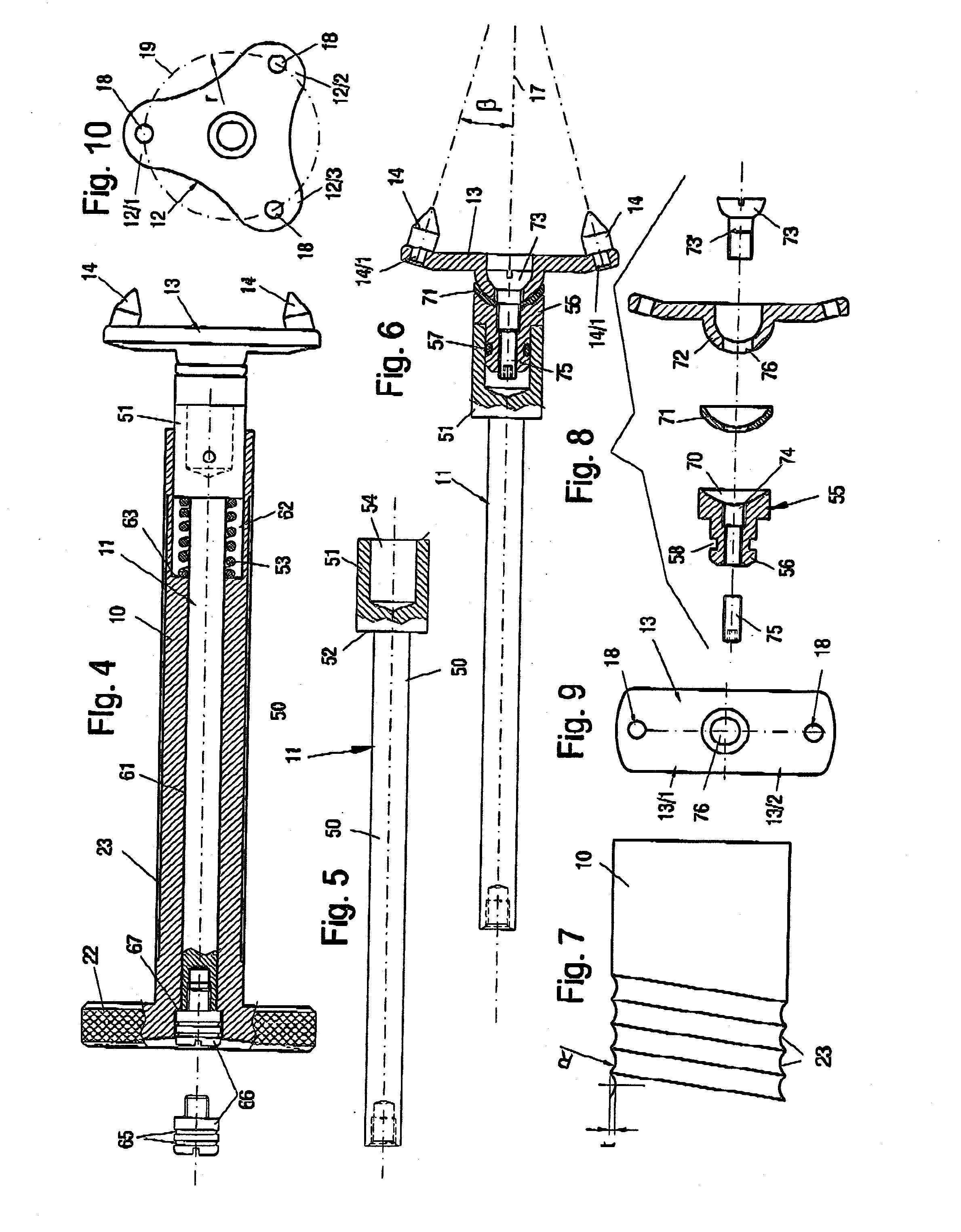

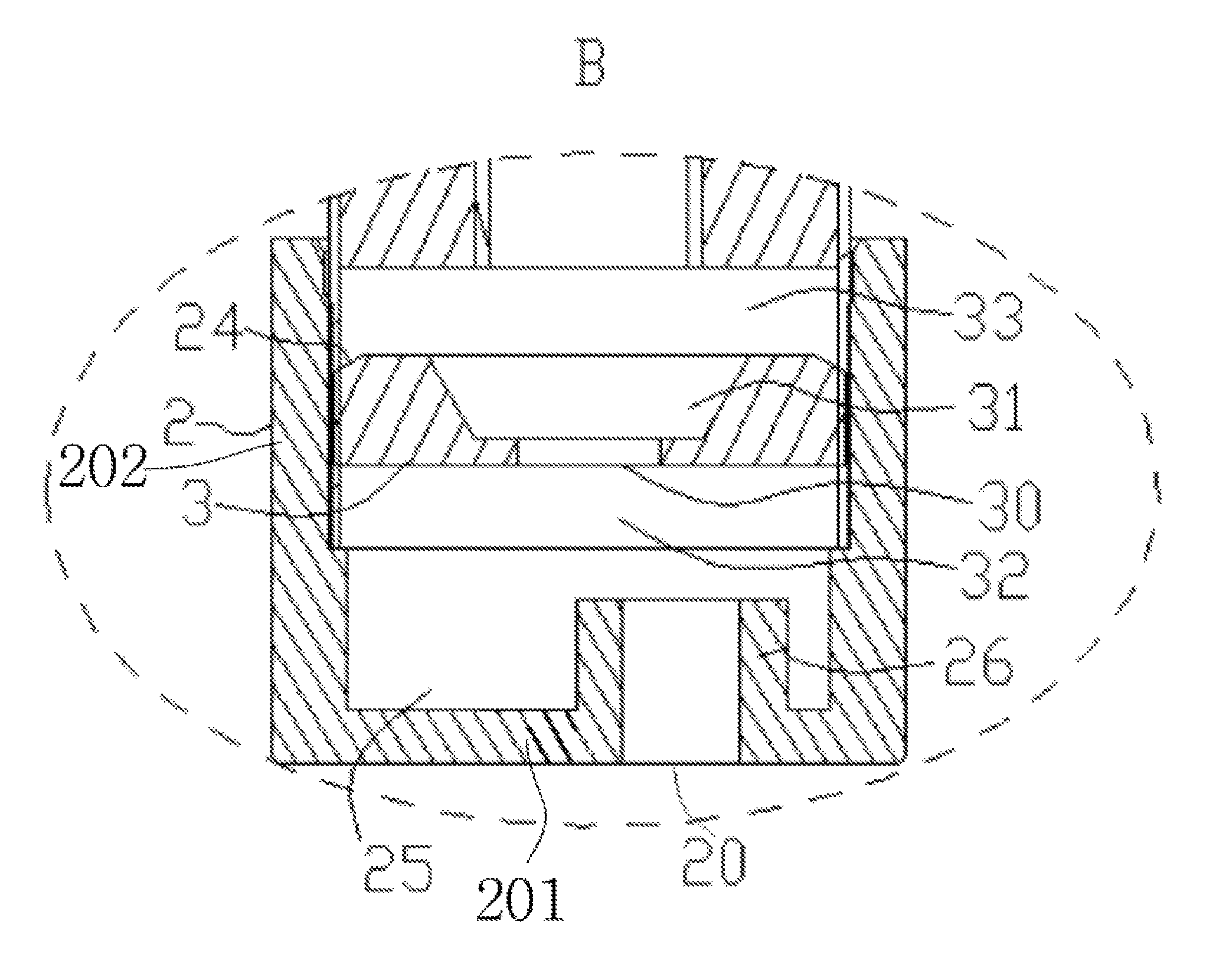

Anchoring element for securing a rod of a device for adjusting a human or animal vertrebal column on a vertreba

InactiveUS20060155277A1Lower clamping surfaceLower requirementInternal osteosythesisJoint implantsBiomedical engineeringLumbar vertebral column

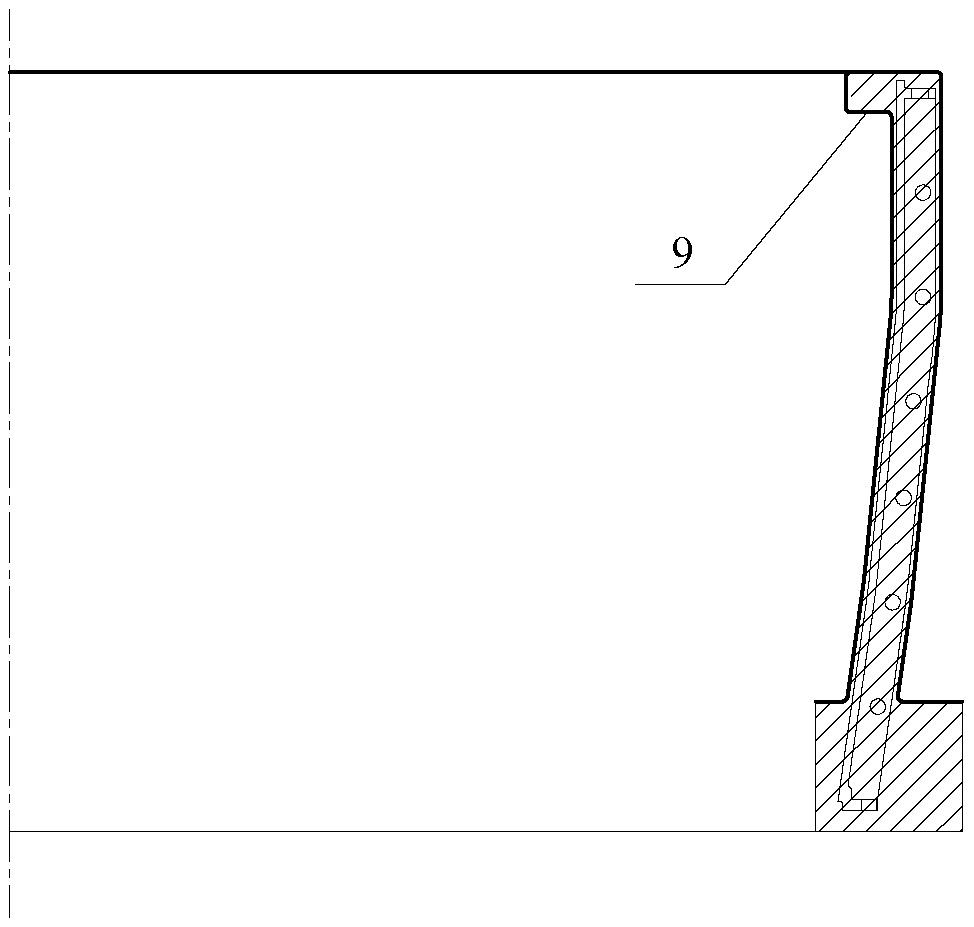

The invention relates to an anchoring element for securing a rod of a device for adjusting a human or animal vertebral column on a vertebra, comprising a retaining means (10) for receiving the rod, a safety element (26) placed on the retaining means and working against the rod, a securing element (14) which can be placed on the body of the vertebra, and a clamping device (12) which is arranged between the retaining means (10) and the securing element (14), comprising a ring-shaped mount (32), a partially conical-segment shaped bearing (28) and an intermediate element (30) which is embedded in the mount (32) and which engages the bearing, whereby the mounting (32) is moveable in a removed state in relation to the bearing (28), whereas the mount (32) is maintained in a clamped state on the bearing (28) by means of the intermediate element (30). The mount (32) is rigidly connected to the retaining means (10) and the bearing (28) is rigidly connected to the securing element (14). In order to enable said type of anchoring element, despite the fact that it is displaceably retained, to transmit relatively large amounts of force from the rod to the body of the vertebra without causing slipping, the bearing (28) comprises flat guiding surfaces (38, 40) which are formed laterally on two opposite sides (34, 36), and the intermediate element (30) is provided with corresponding counter surfaces (50, 52).

Owner:METZ STAVENHAGEN PETER

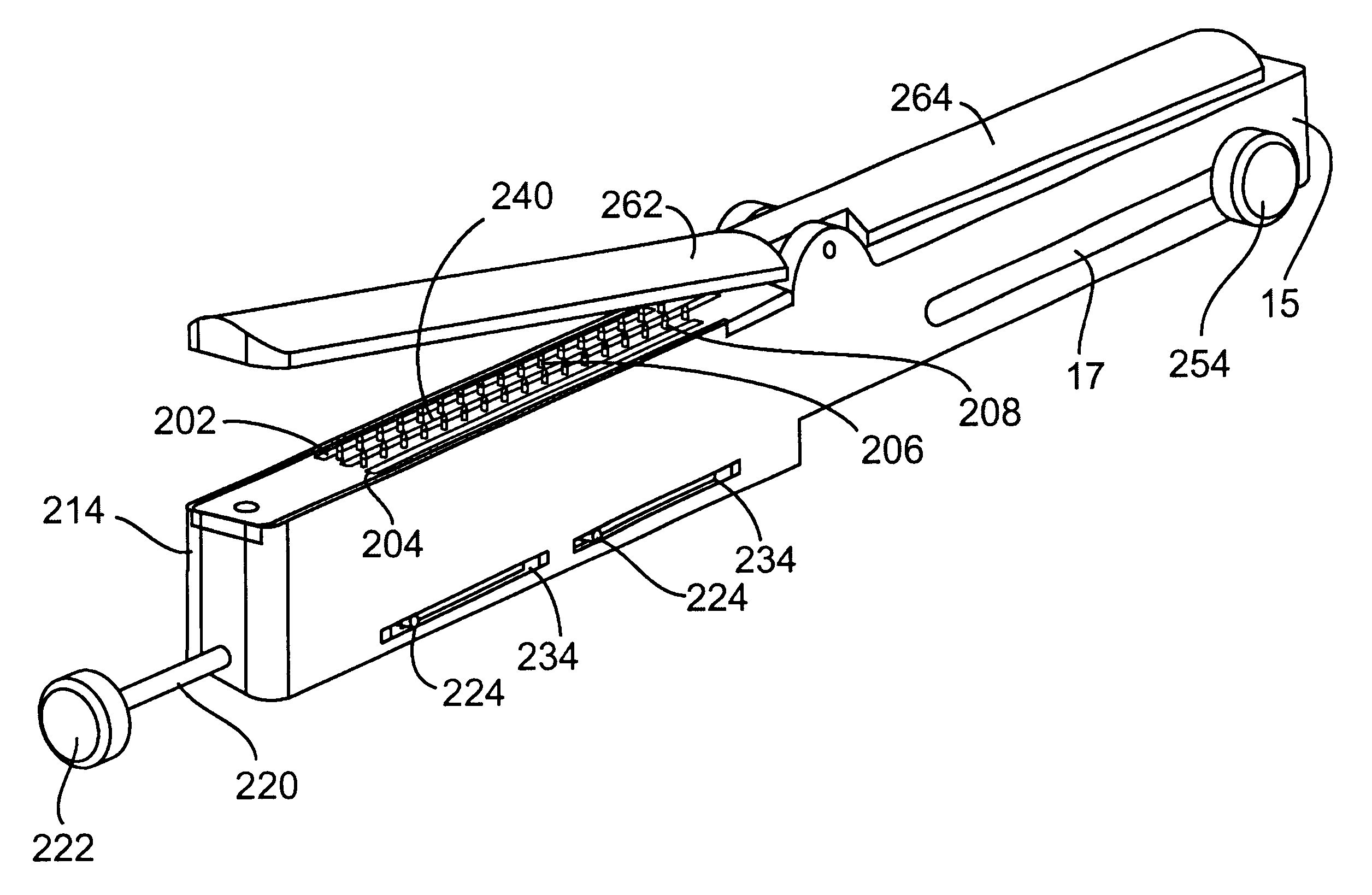

Bipolar surgical instruments having focused electrical fields

InactiveUS20020013583A1Reduce capacityLower impedanceSurgical needlesSurgical instruments for heatingElectricitySurgical device

A bipolar surgical device comprises a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

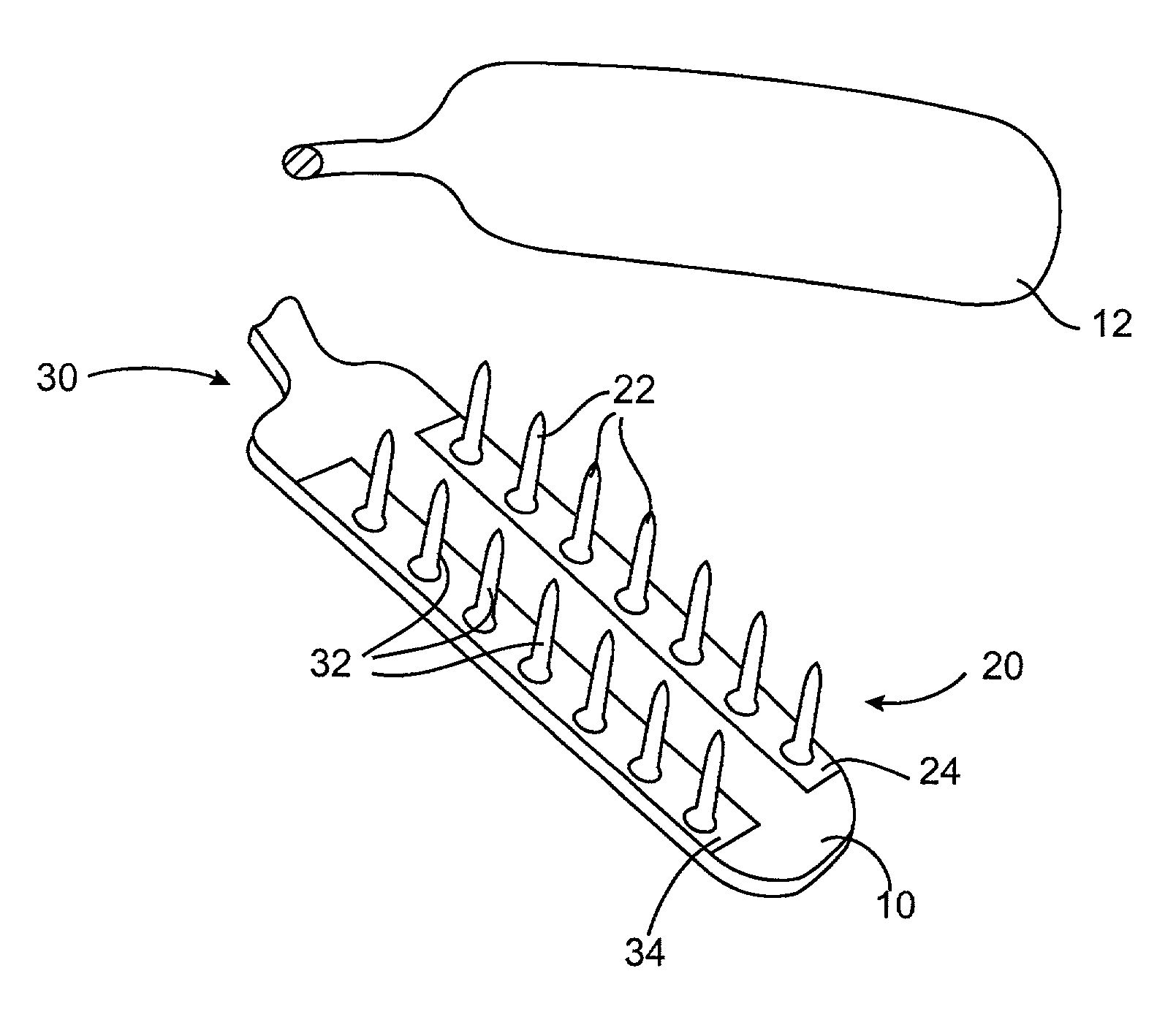

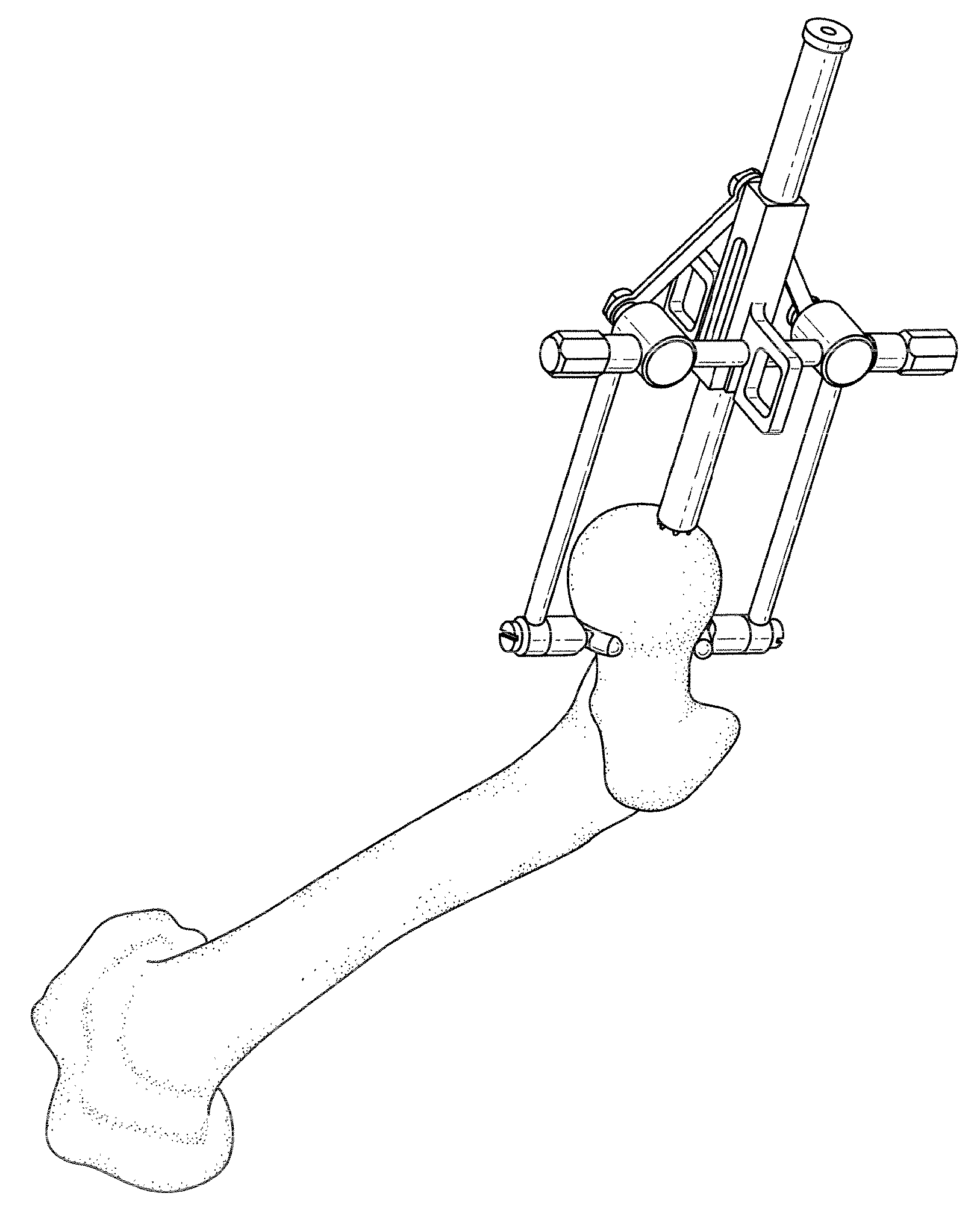

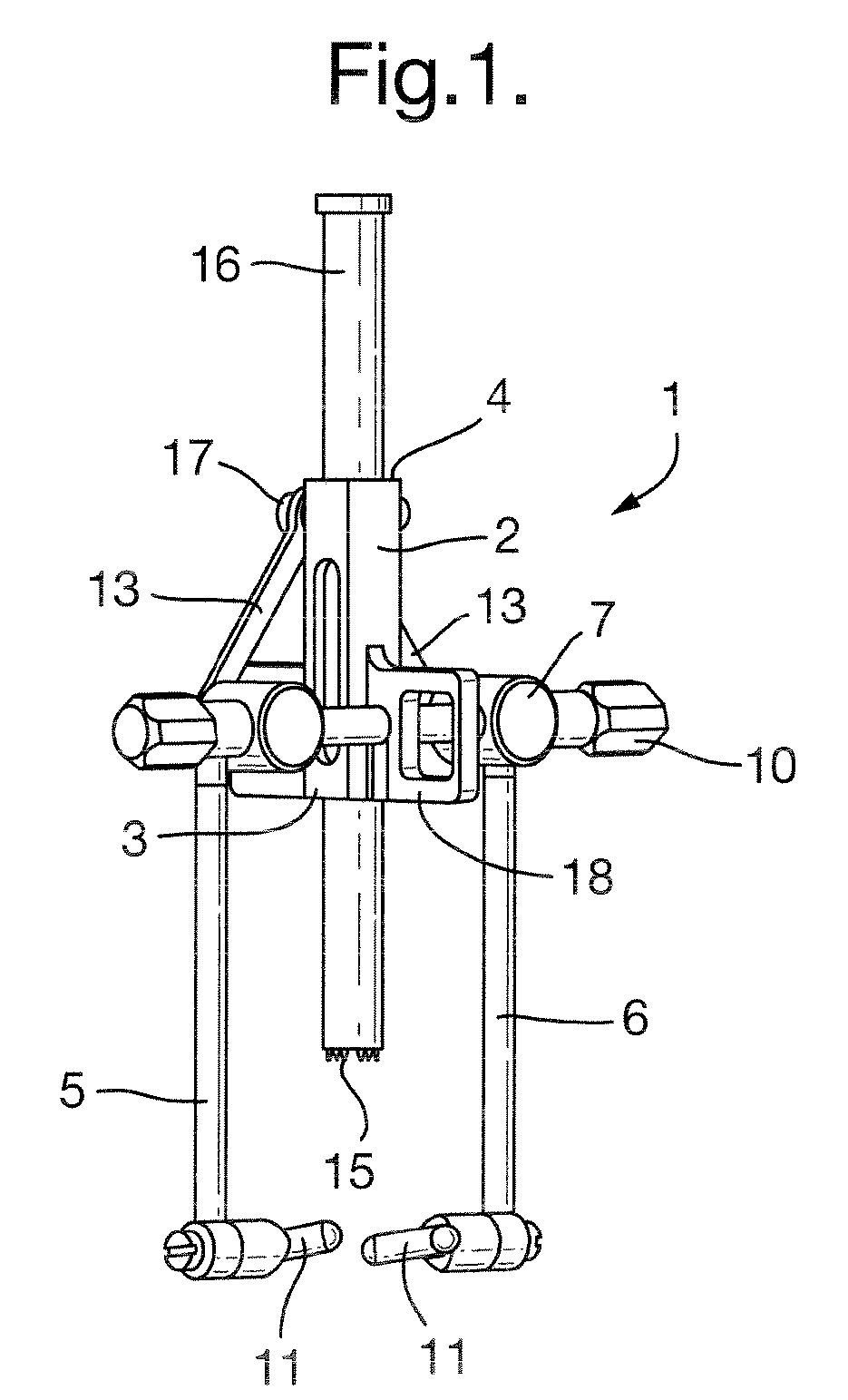

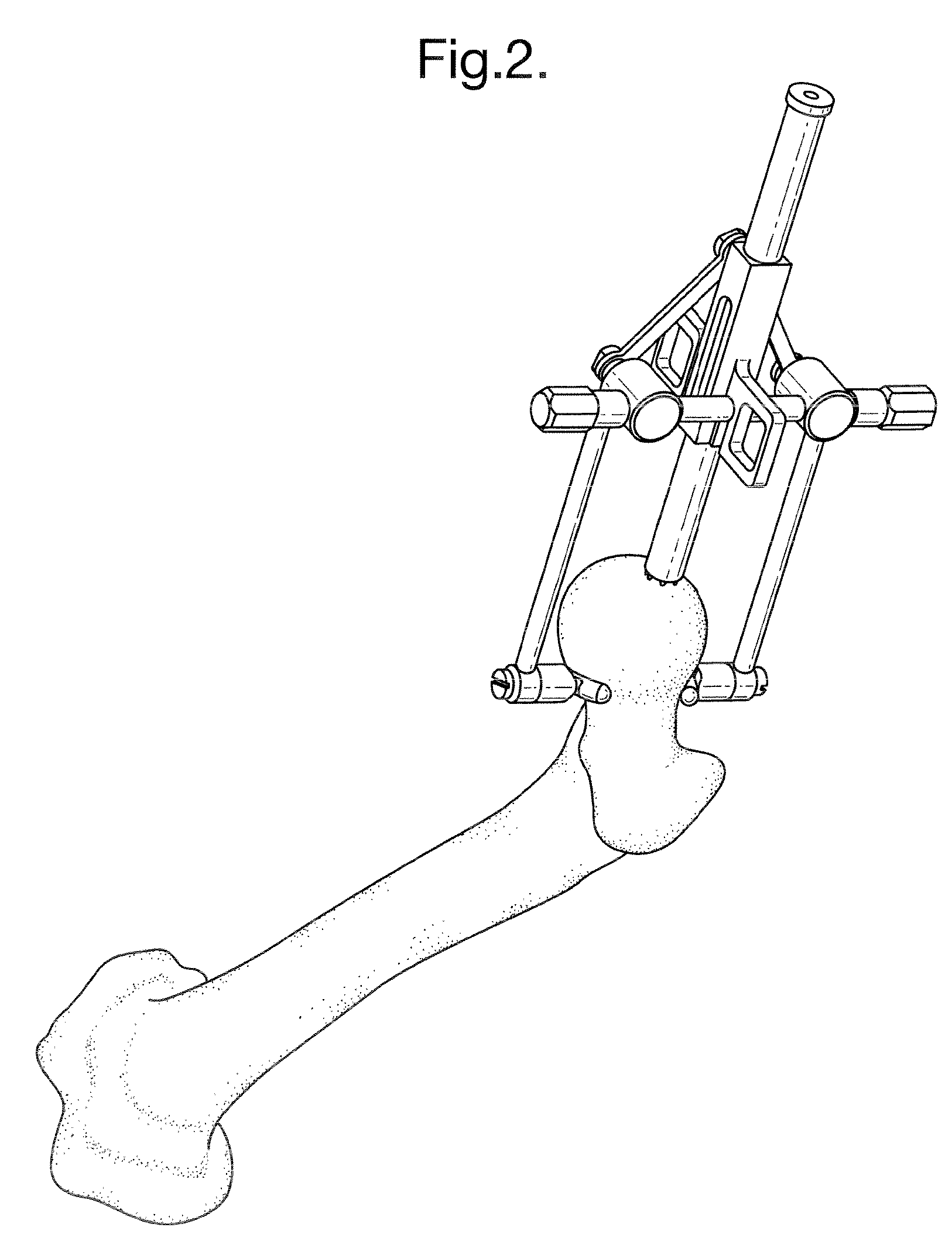

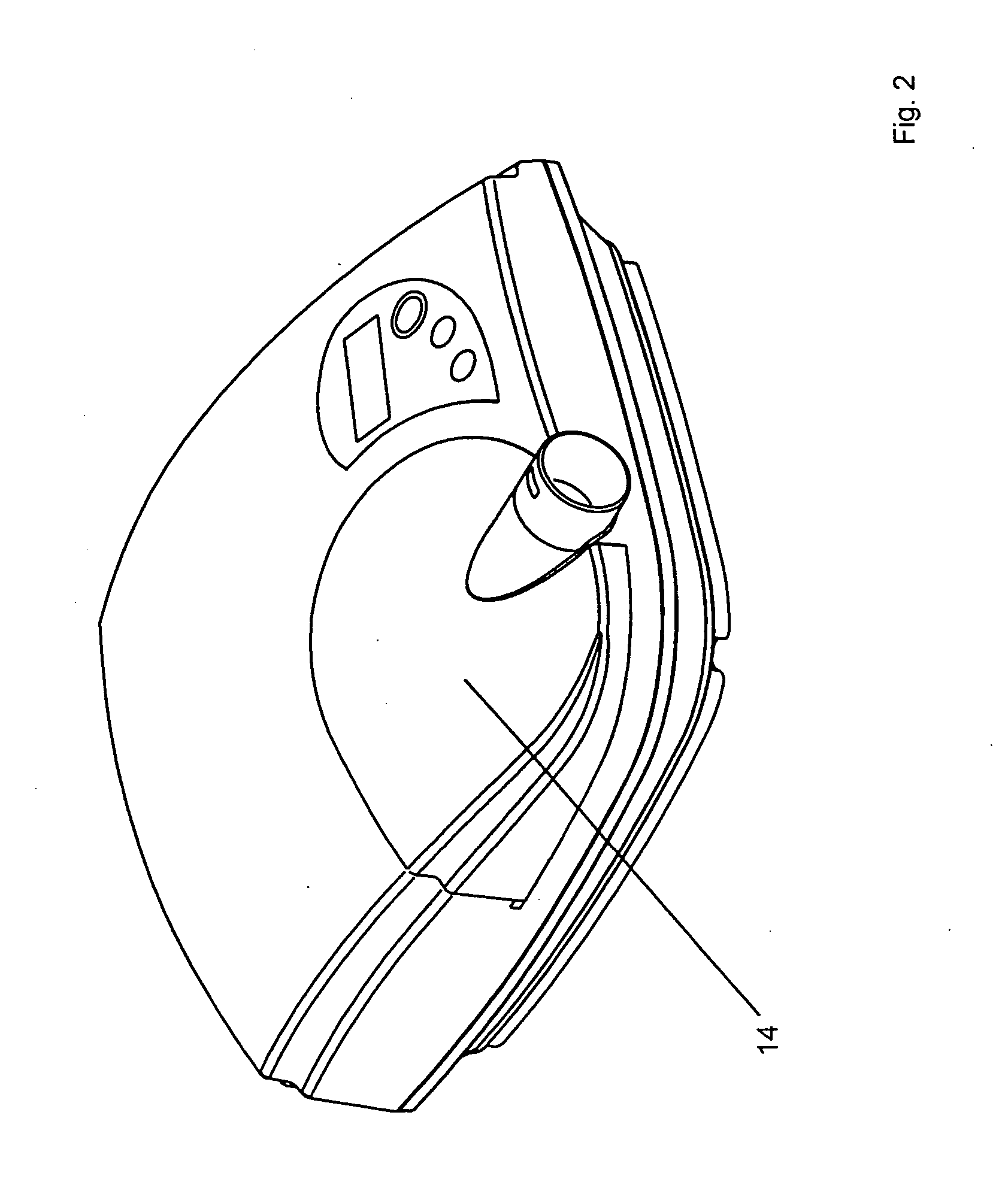

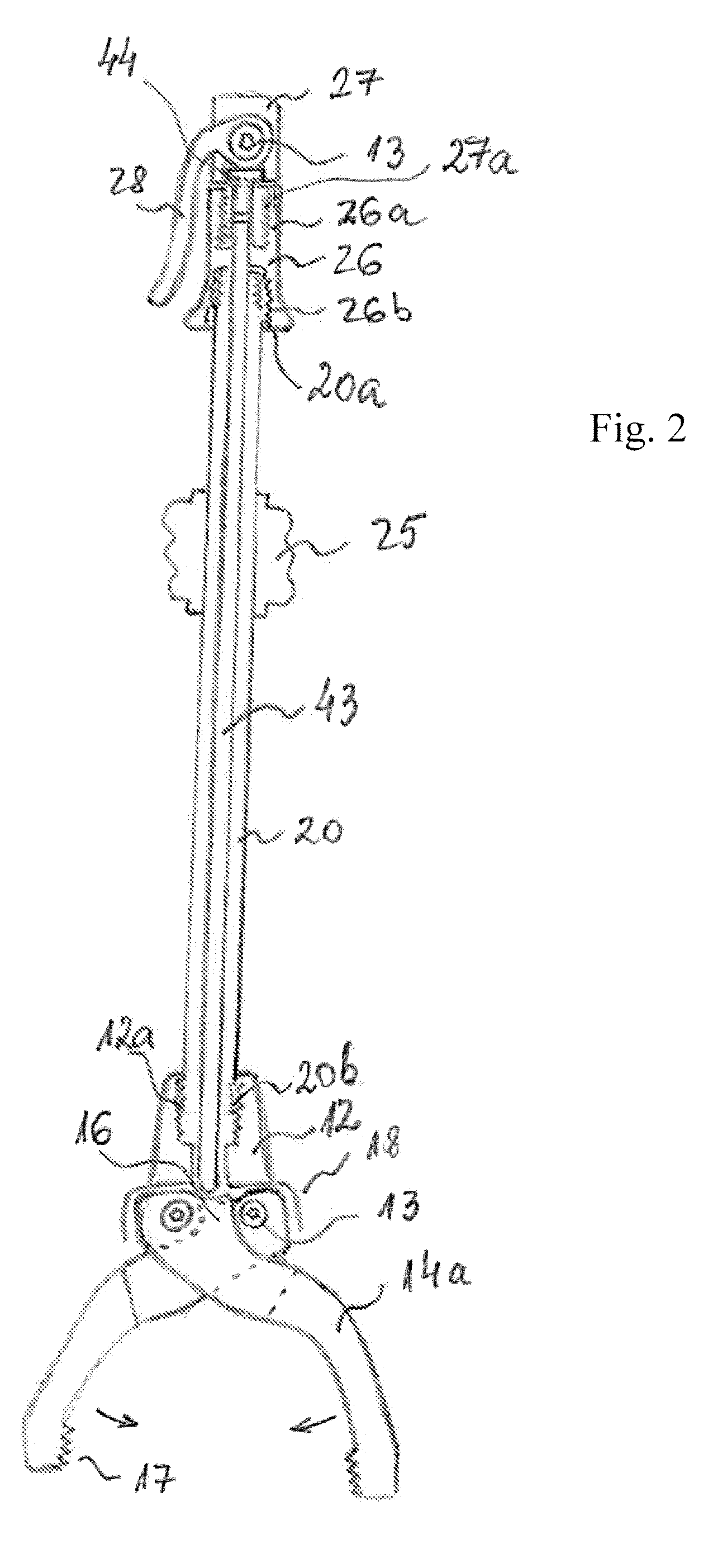

Tool

InactiveUS20100137924A1Stabilise toolEasy clampingJoint implantsSurgical sawsRight femoral headFemoral neck

In an alignment guide for use in femoral head surgery, a cannulated rod is supported by, and is adjustable with respect to, a support member of the alignment guide. The guide also includes two jaws, an anterior jaw and a posterior jaw, with each jaw having a proximal end connected to the support arm, and a distal end for clamping, in use, to the neck of the femur. At least one of the jaws is movable from a first open position to a second clamping position.

Owner:FINSBURY DEV

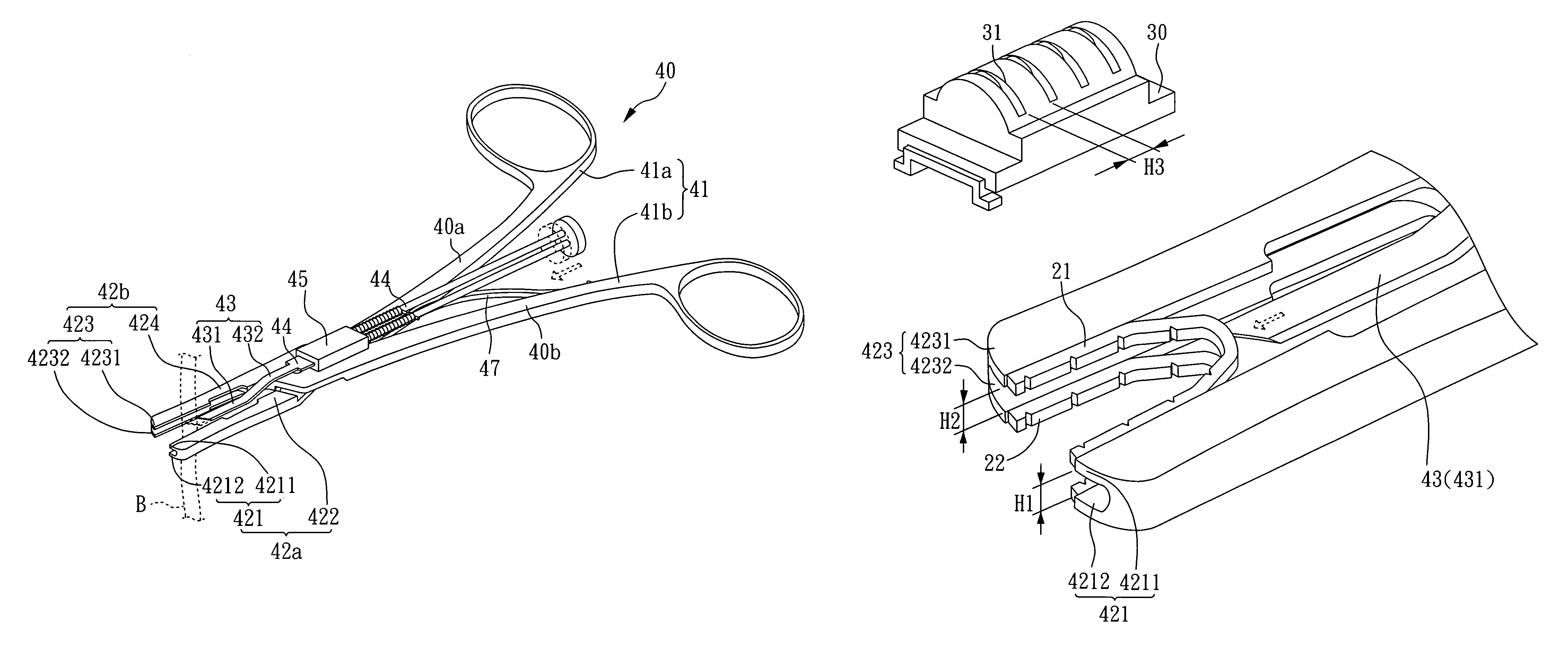

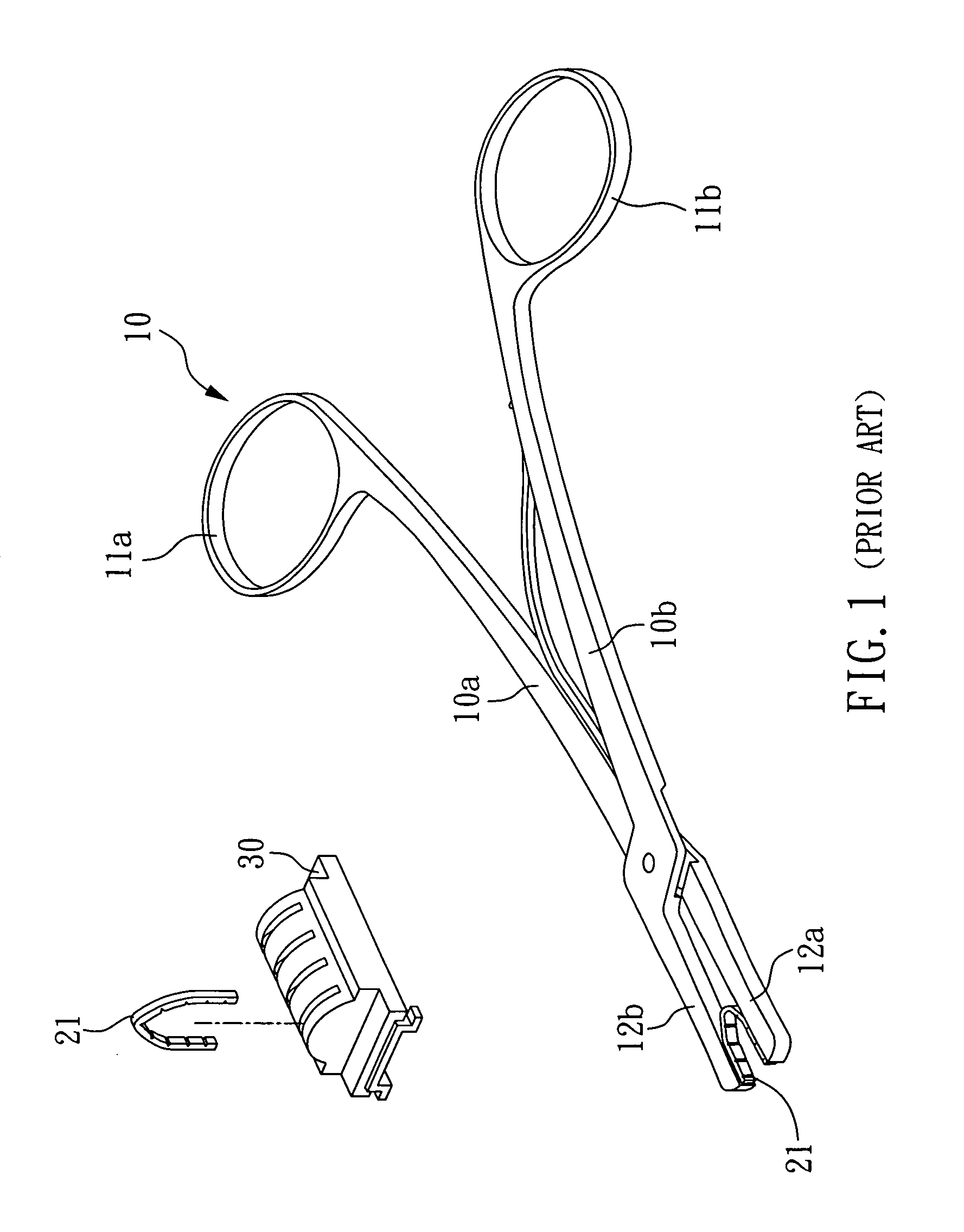

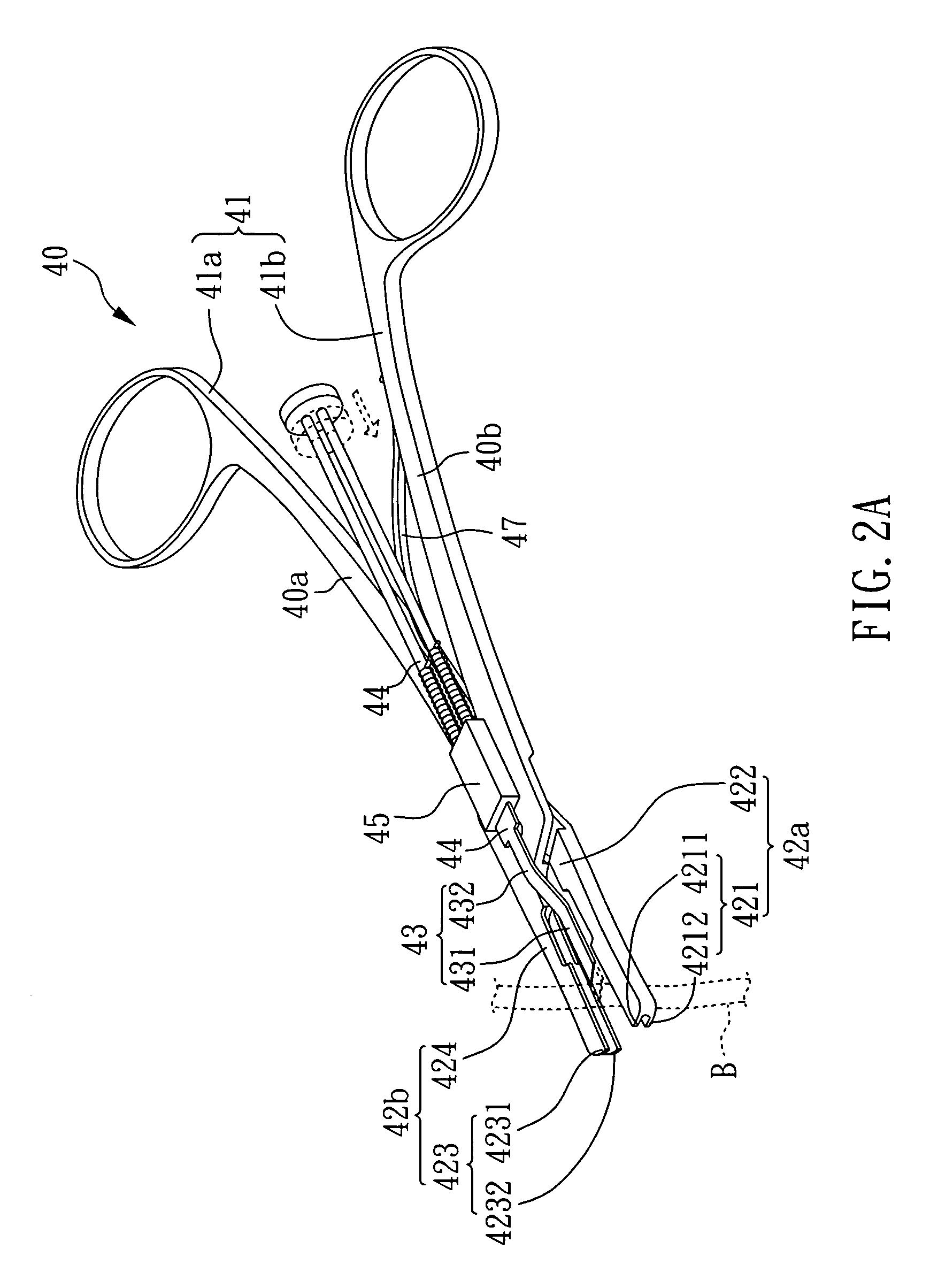

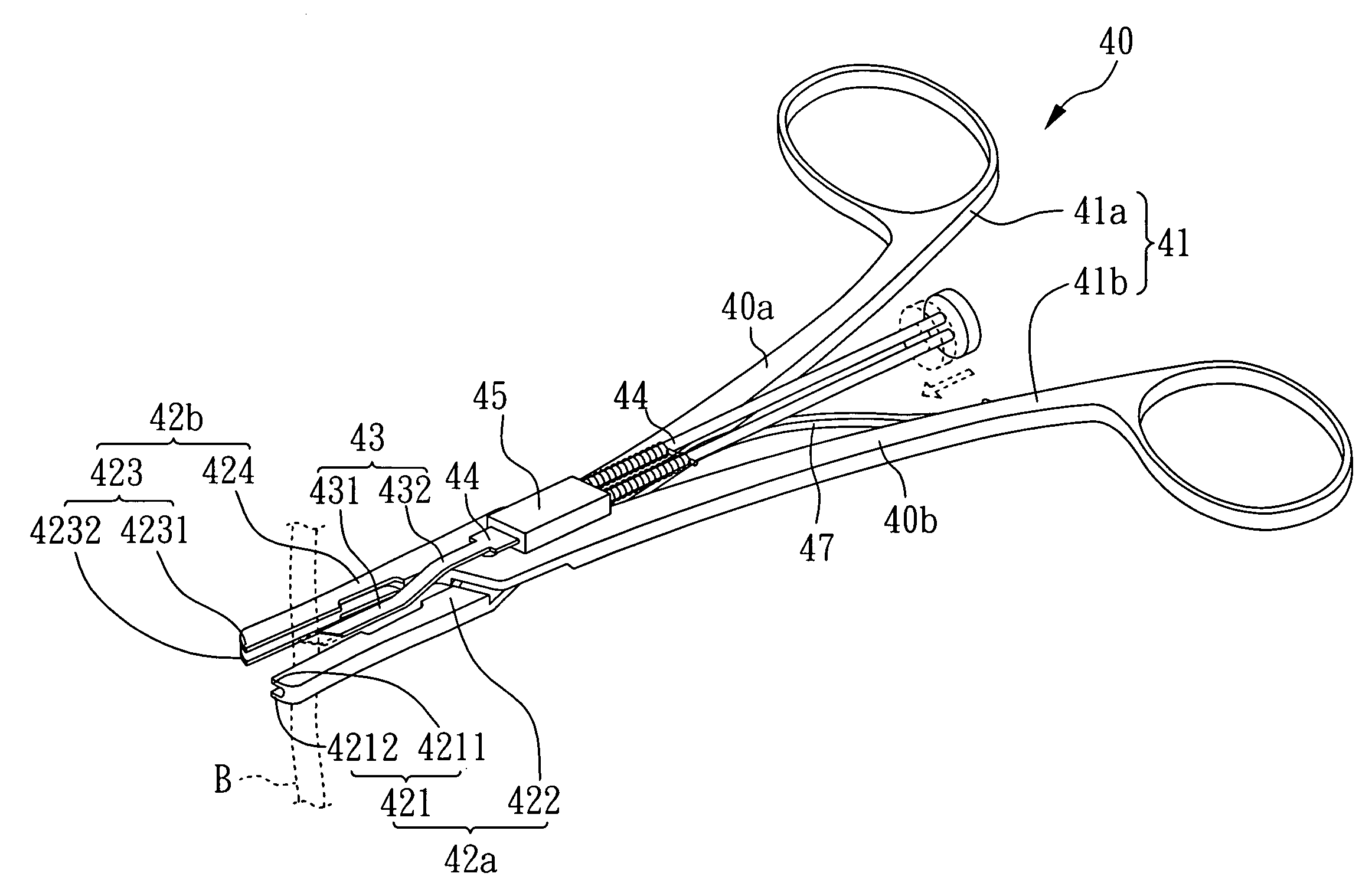

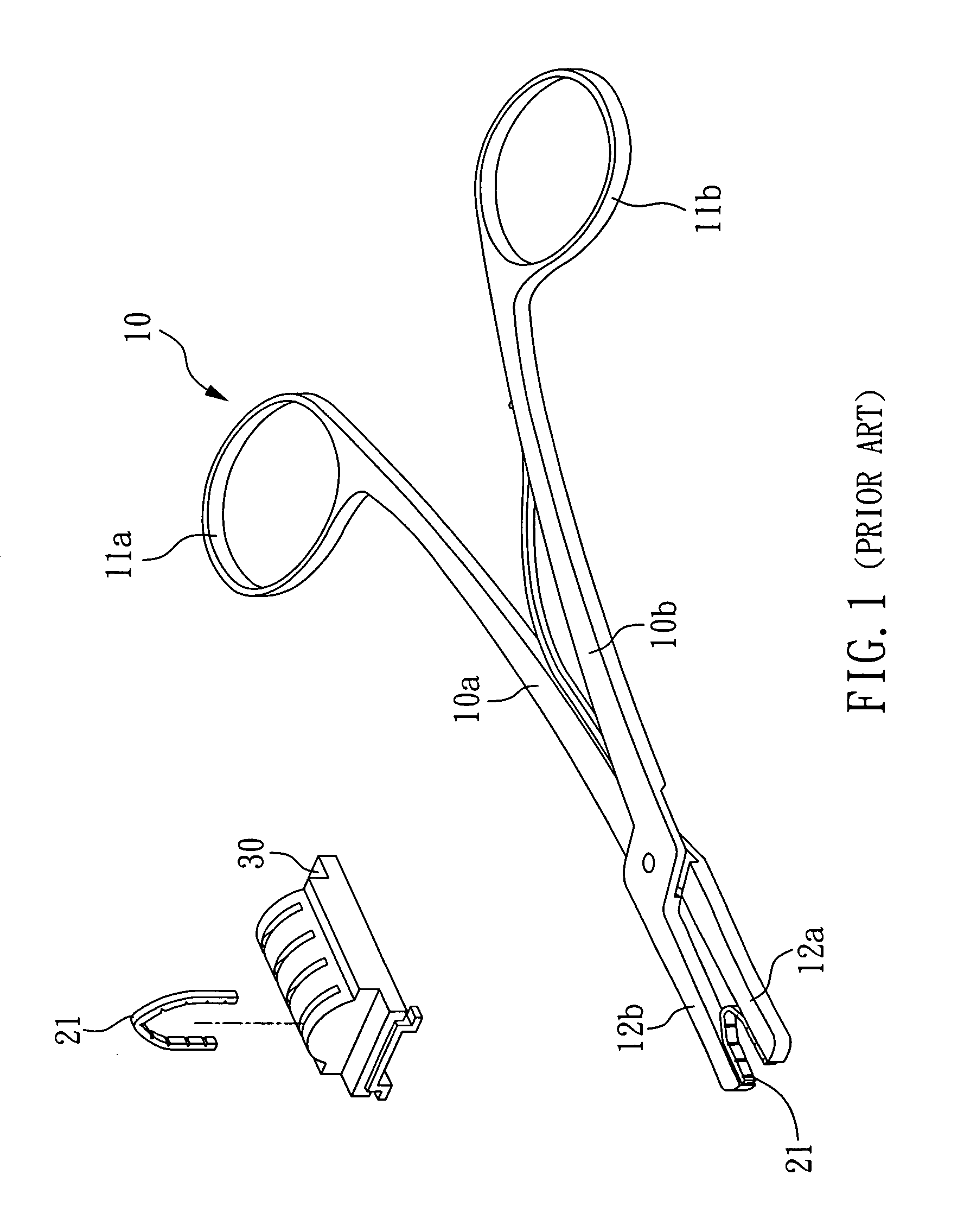

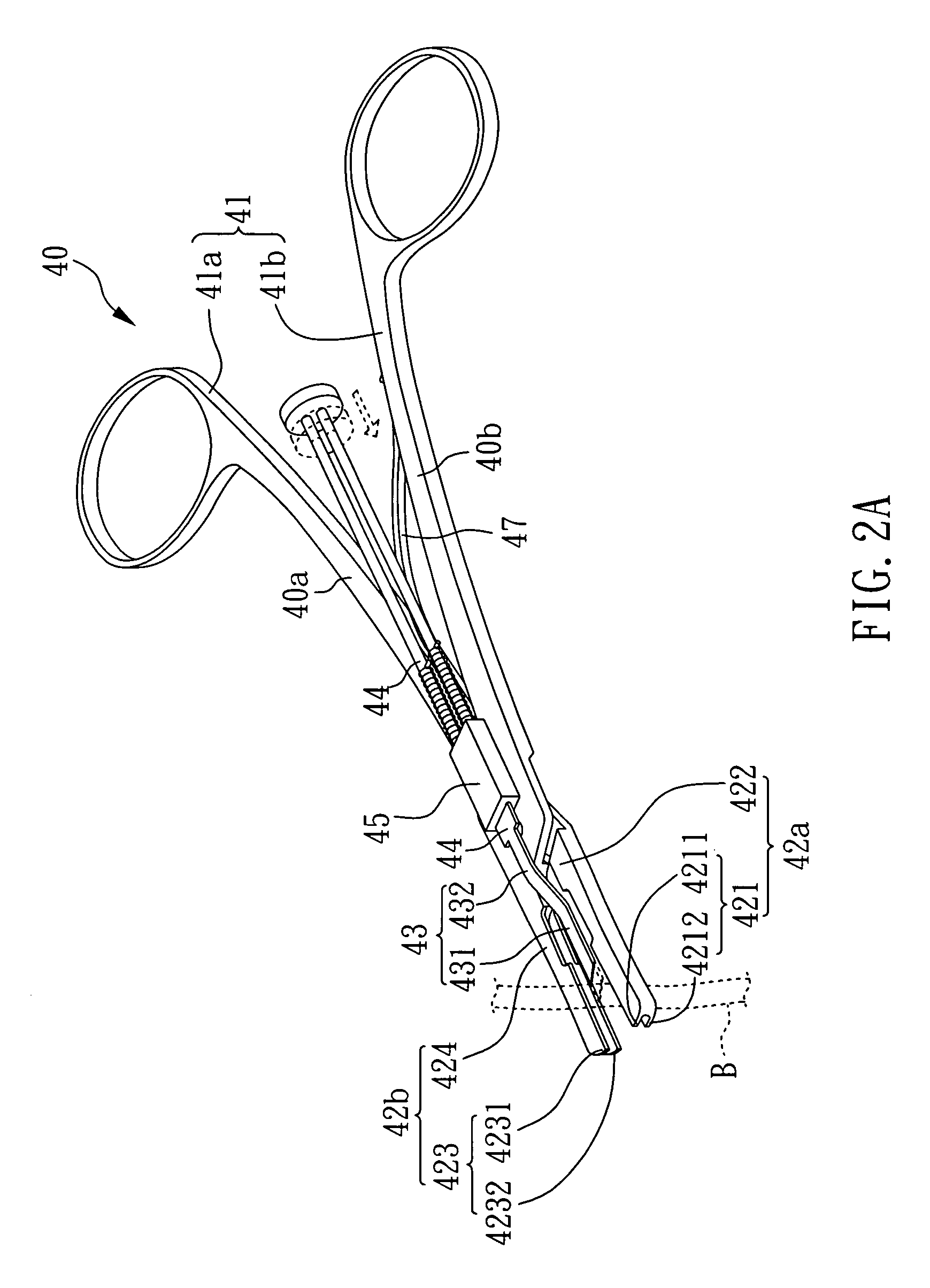

Integrated double clips applier with division device for clamping clips

The present invention relates to a clip applier for clipping and dividing blood vessels, including: a handle; a first jaw unit; and a second jaw unit. The clip applier of the present invention can bring up two ligating clips at the same time with the first jaw unit and the second jaw unit, whereas the two clamping positions of the blood vessel can be clamped with the ligating clips simultaneously by the clip applier of the present invention in a single step, and thus the operating steps can be simplified, and the time involved with the surgical operation can be shortened.

Owner:CHENG MING HUEI +2

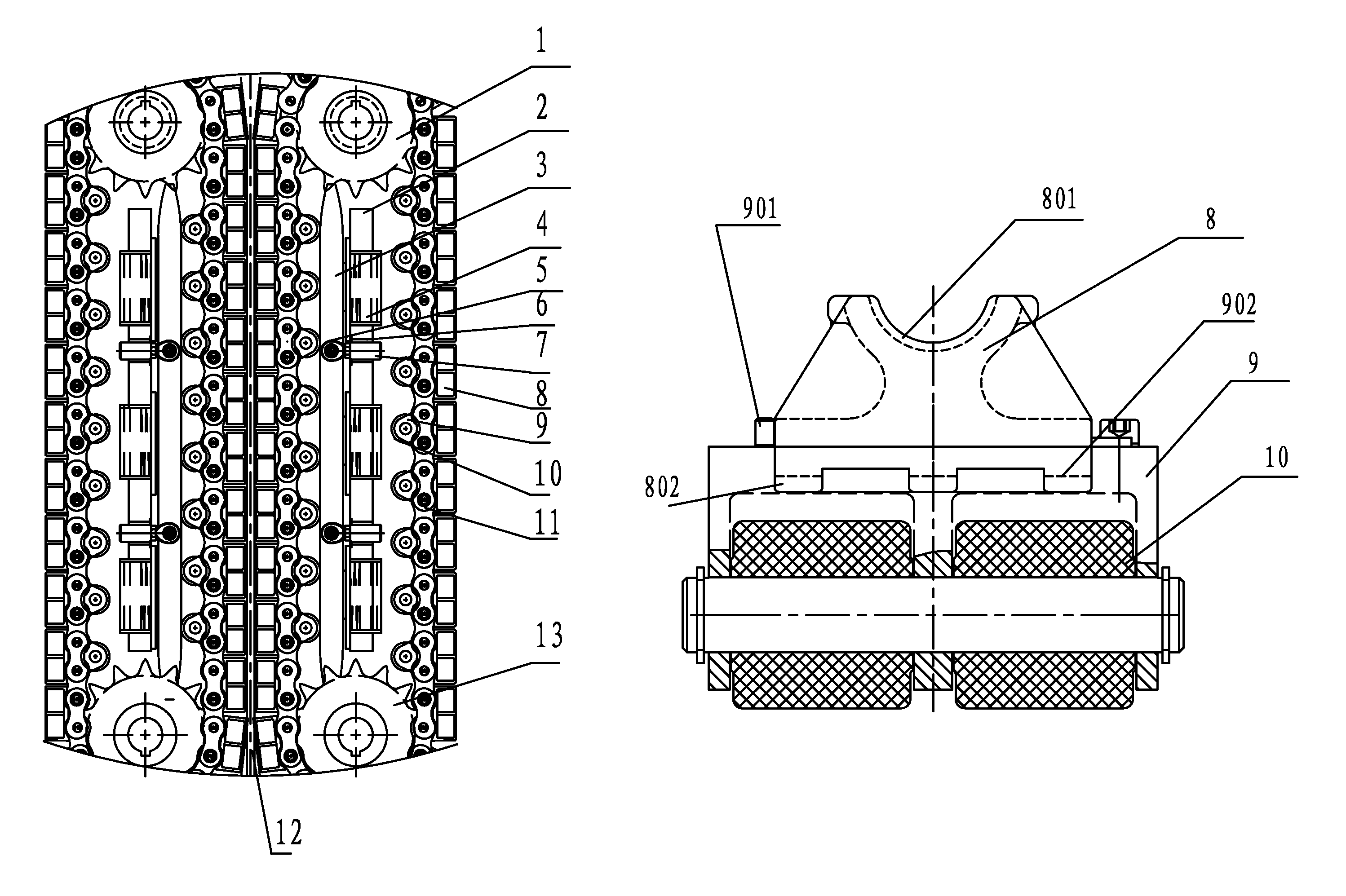

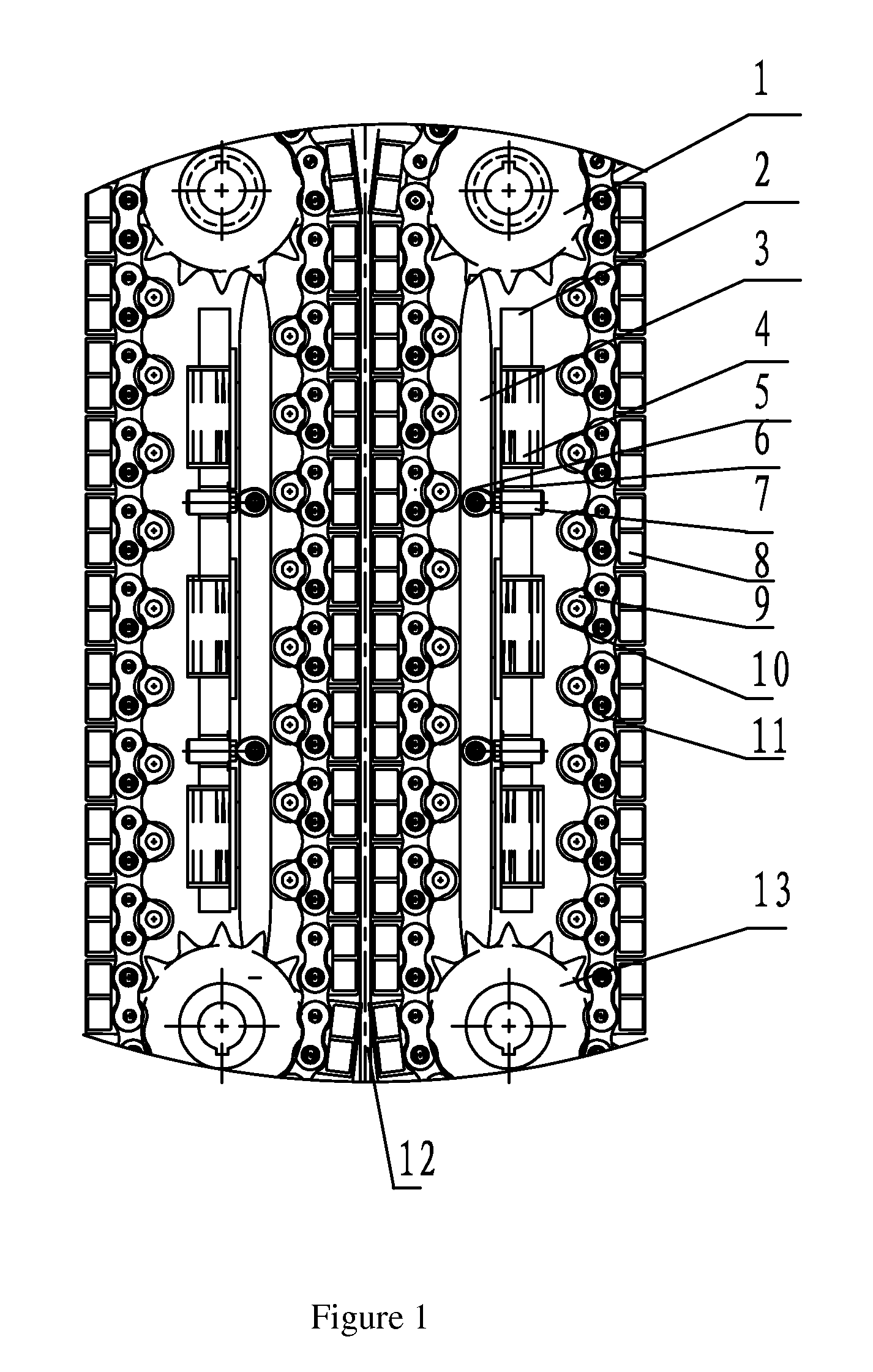

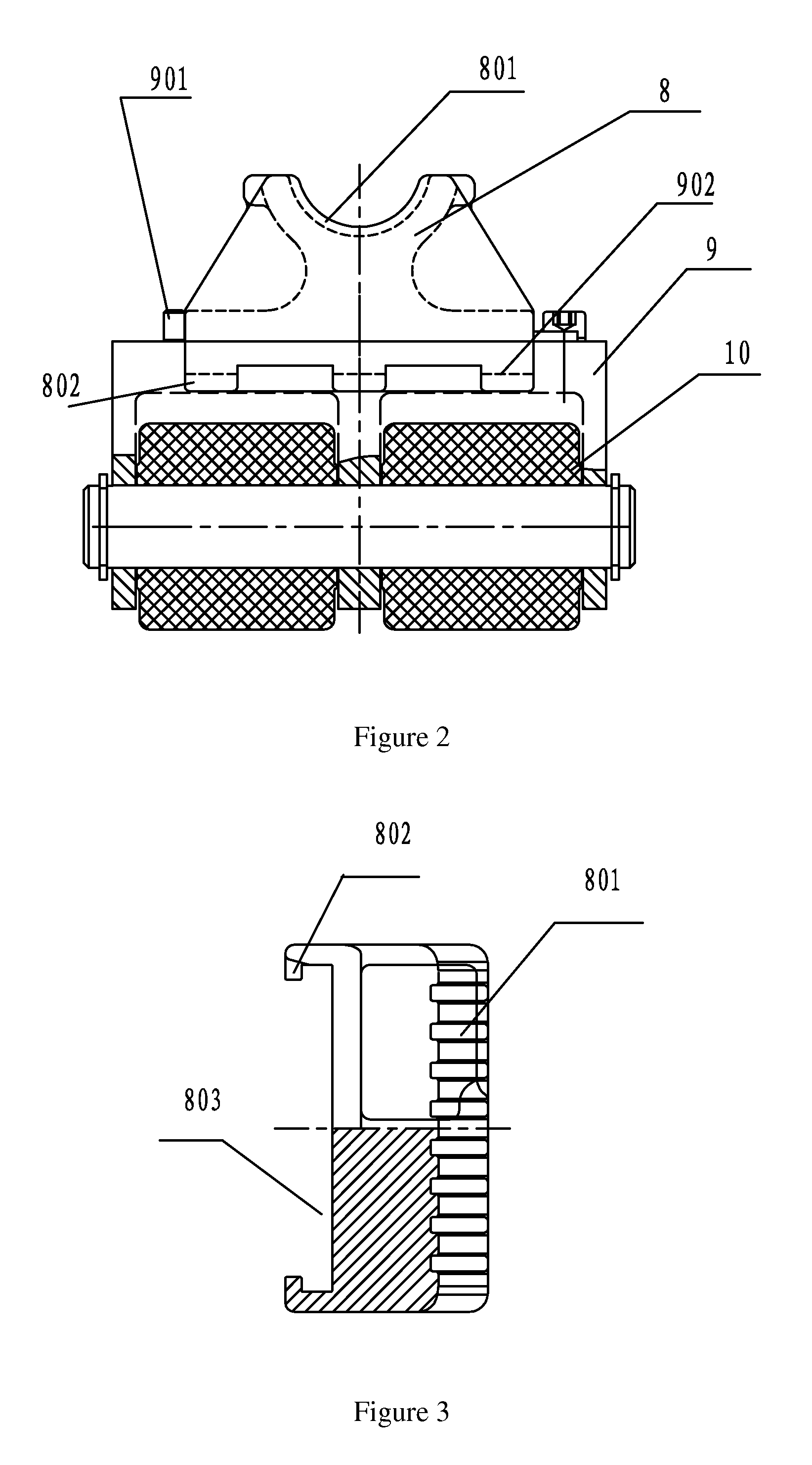

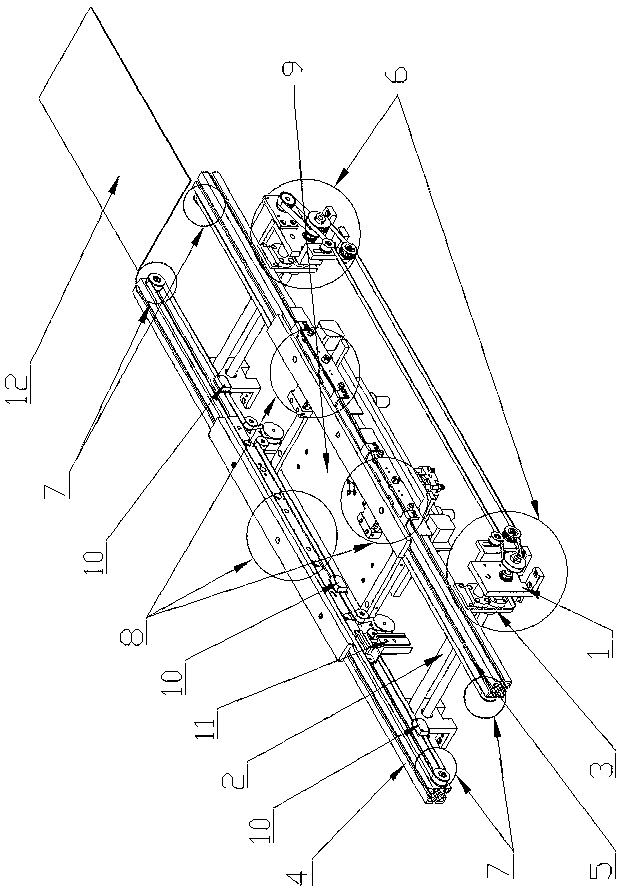

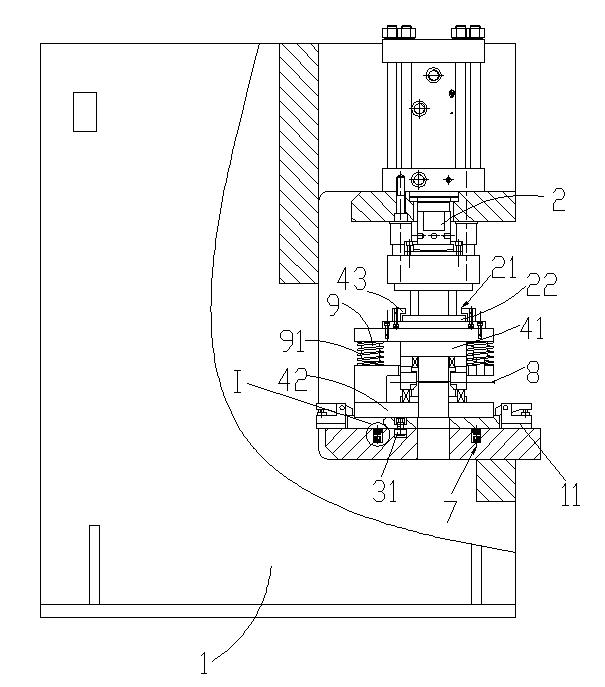

Floating clamping device for injection head of continuous oil pipe

ActiveUS9493997B2Easy to serviceEasy to operateDrilling rodsDrilling casingsCoiled tubingEngineering

A floating clamping device for an injection head of a continuous oil pipe, including a drive sprocket, a transmission chain, a supporting plate, a pushing plate, clamping oil cylinders and a clamping assembly. At least two clamping oil cylinders are installed on the supporting plate fixedly. The pushing plate is fixed on the supporting plate through a pin shaft. The clamping assembly includes a saddle-shaped clamping block, a clamping block seat and rollers which are mounted on the clamping block seat. The clamping assembly is mounted on the transmission chain. A piston rod of the clamping oil cylinder is pressed on one face of the pushing plate, while the other face of the pushing plate is pressed on the rollers. The pushing plate has a simple structure and is convenient for maintenance; the clamping device has a compact structure and a reduced volume.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

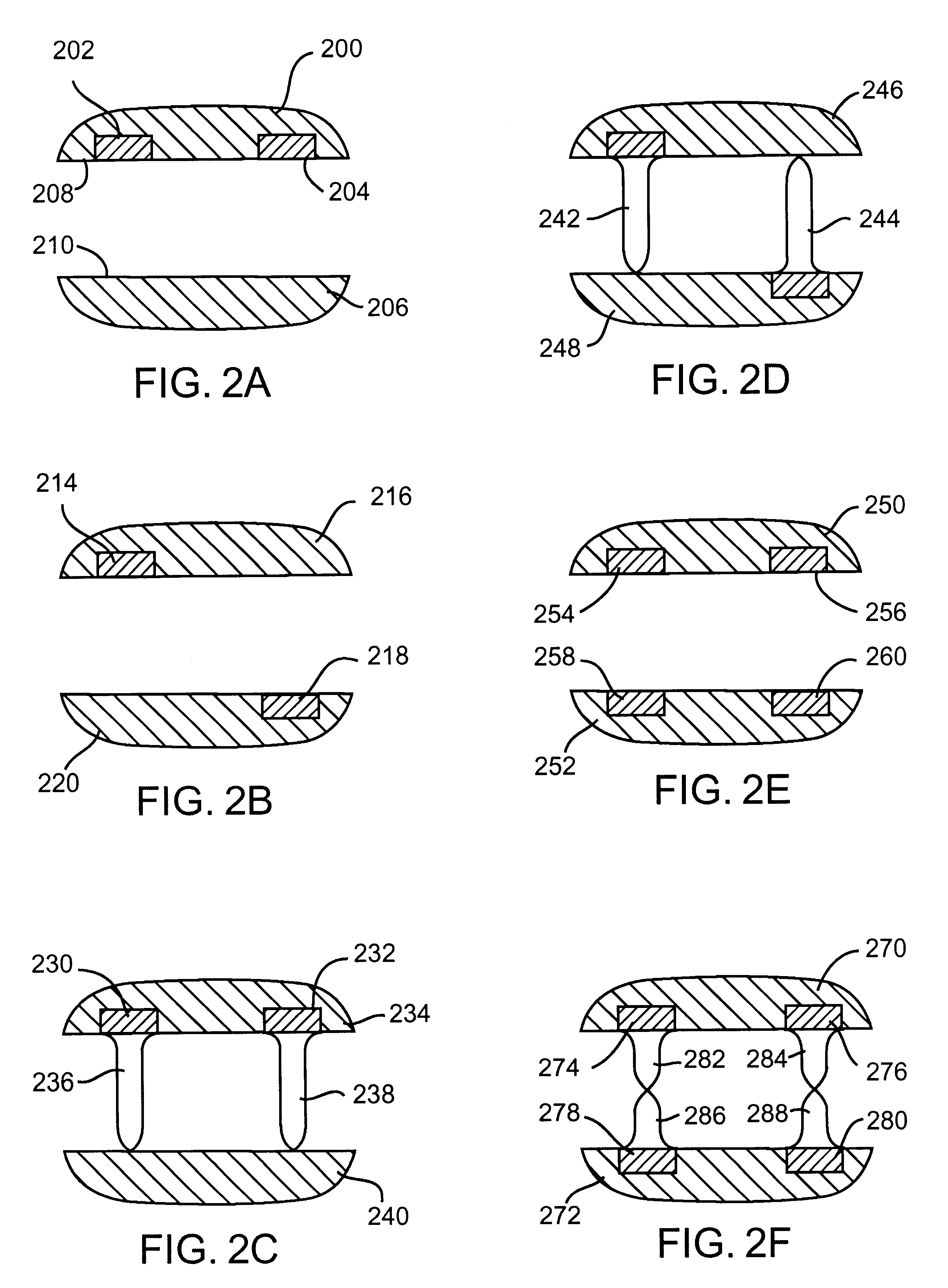

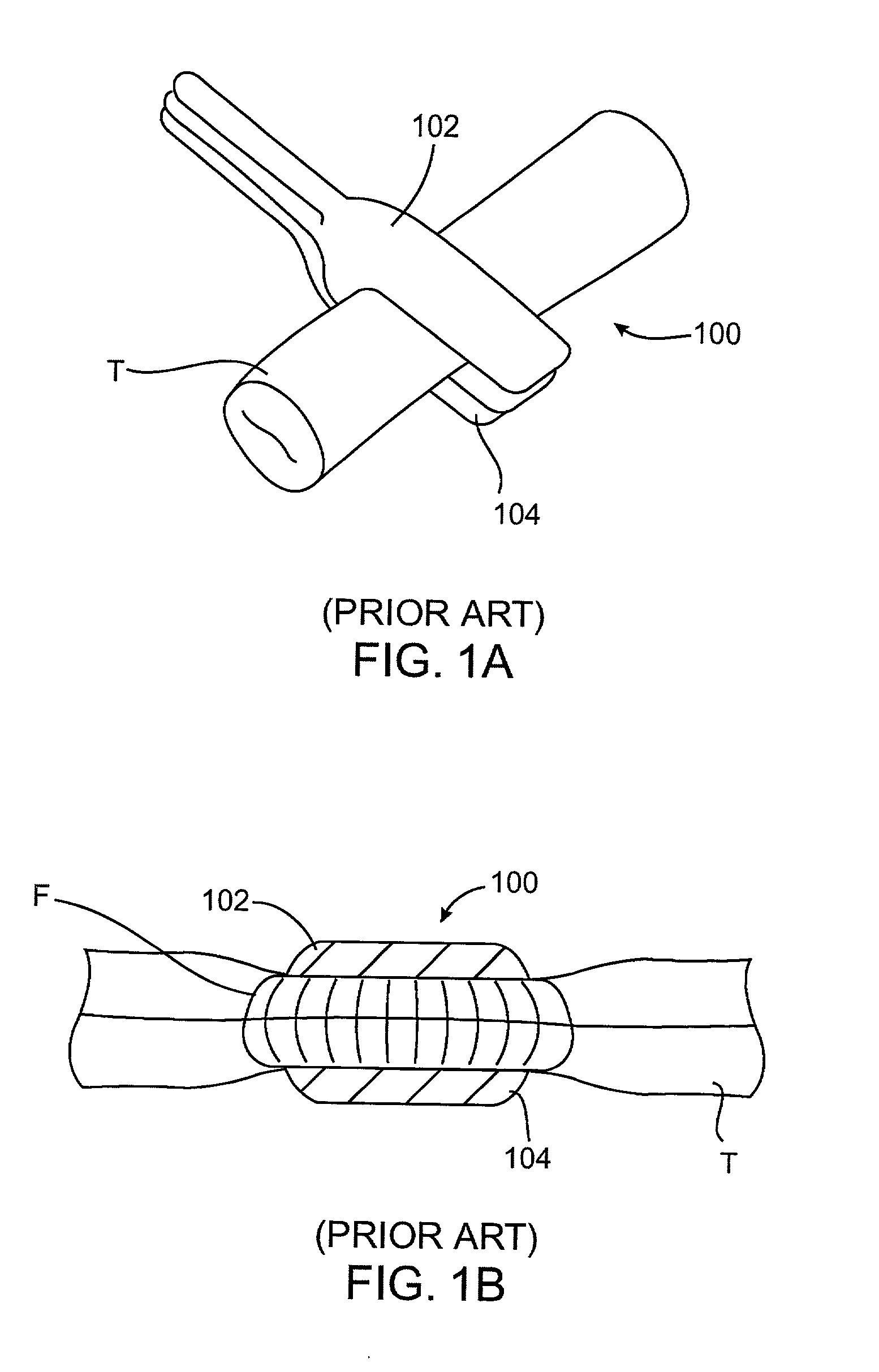

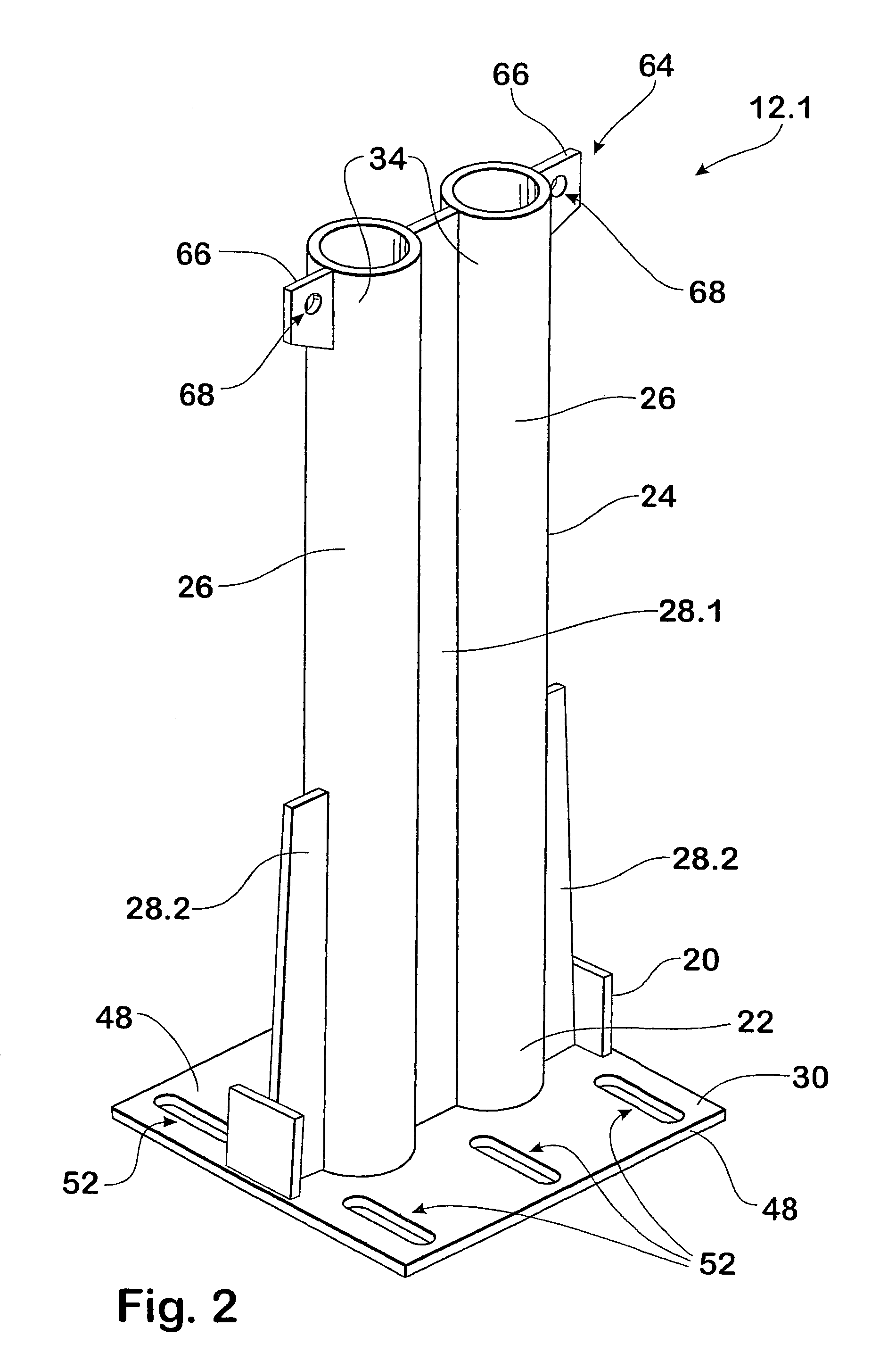

Implant system and fastening element for an implant system

InactiveUS20060195098A1Easy to optimizeStable supportSuture equipmentsInternal osteosythesisAxis of symmetryEngineering

The present invention relates to a fastening element for an implant system, which comprises at least two fastening elements fixable to bone parts or the like and at least one connecting element fixable to the at least two fastening elements, wherein the fastening element comprises a fastening part with a fastening portion at the distal end as well as a receiving part connected to the fastening part, wherein the receiving part comprises a connecting-element receiver for receiving the connecting element as well as a fixing element for fixing the fastening element in the connecting-element receiver, wherein the connecting-element receiver is designed asymmetrically in relation to an axis of symmetry or longitudinal axis of the fixing element.

Owner:AESCULAP AG

Integrated double clips applier with division device for clamping clips

The present invention relates to a clip applier for clipping and dividing blood vessels, including: a handle; a first jaw unit; and a second jaw unit. The clip applier of the present invention can bring up two ligating clips at the same time with the first jaw unit and the second jaw unit, whereas the two clamping positions of the blood vessel can be clamped with the ligating clips simultaneously by the clip applier of the present invention in a single step, and thus the operating steps can be simplified, and the time involved with the surgical operation can be shortened.

Owner:CHENG MING HUEI +2

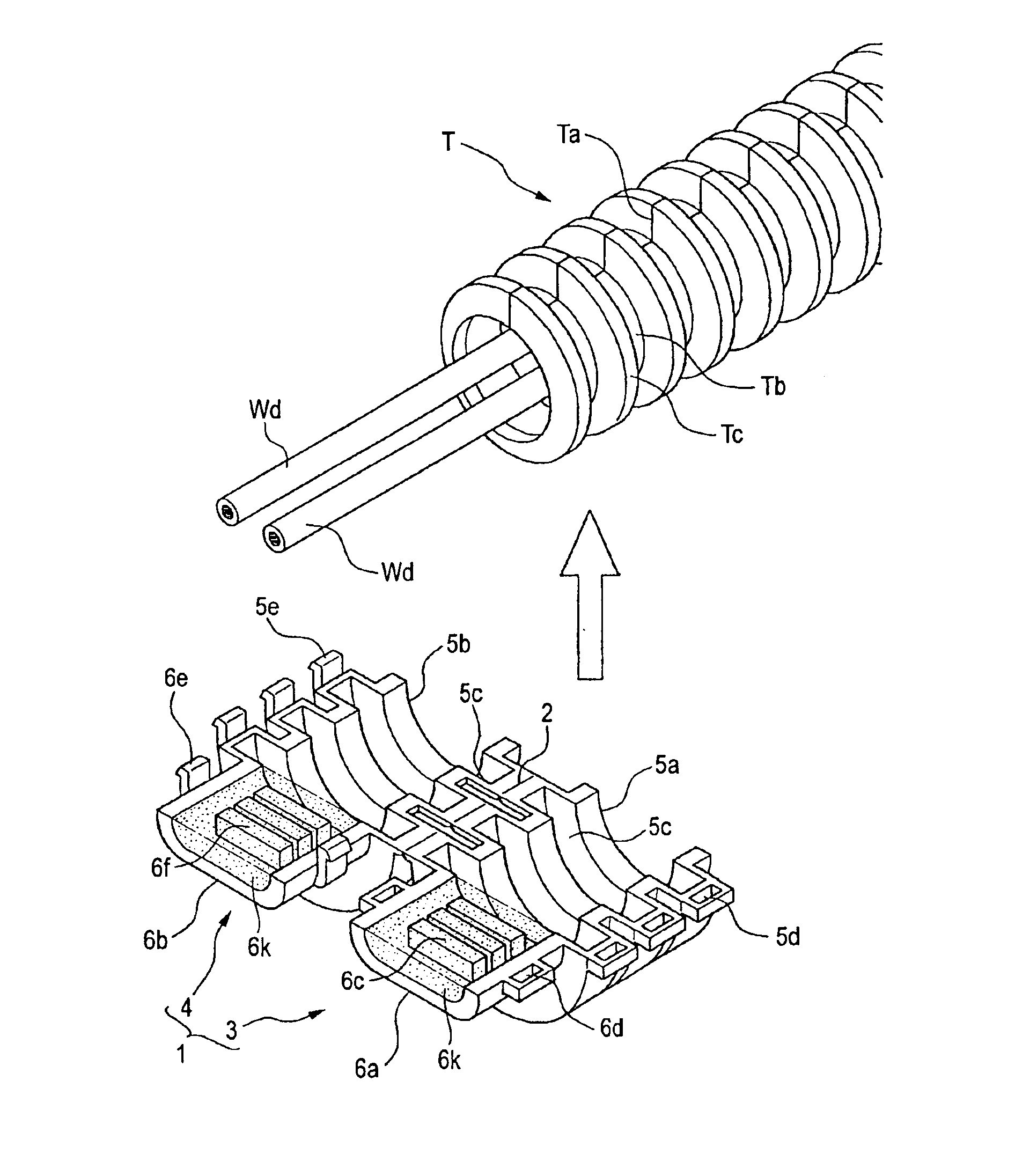

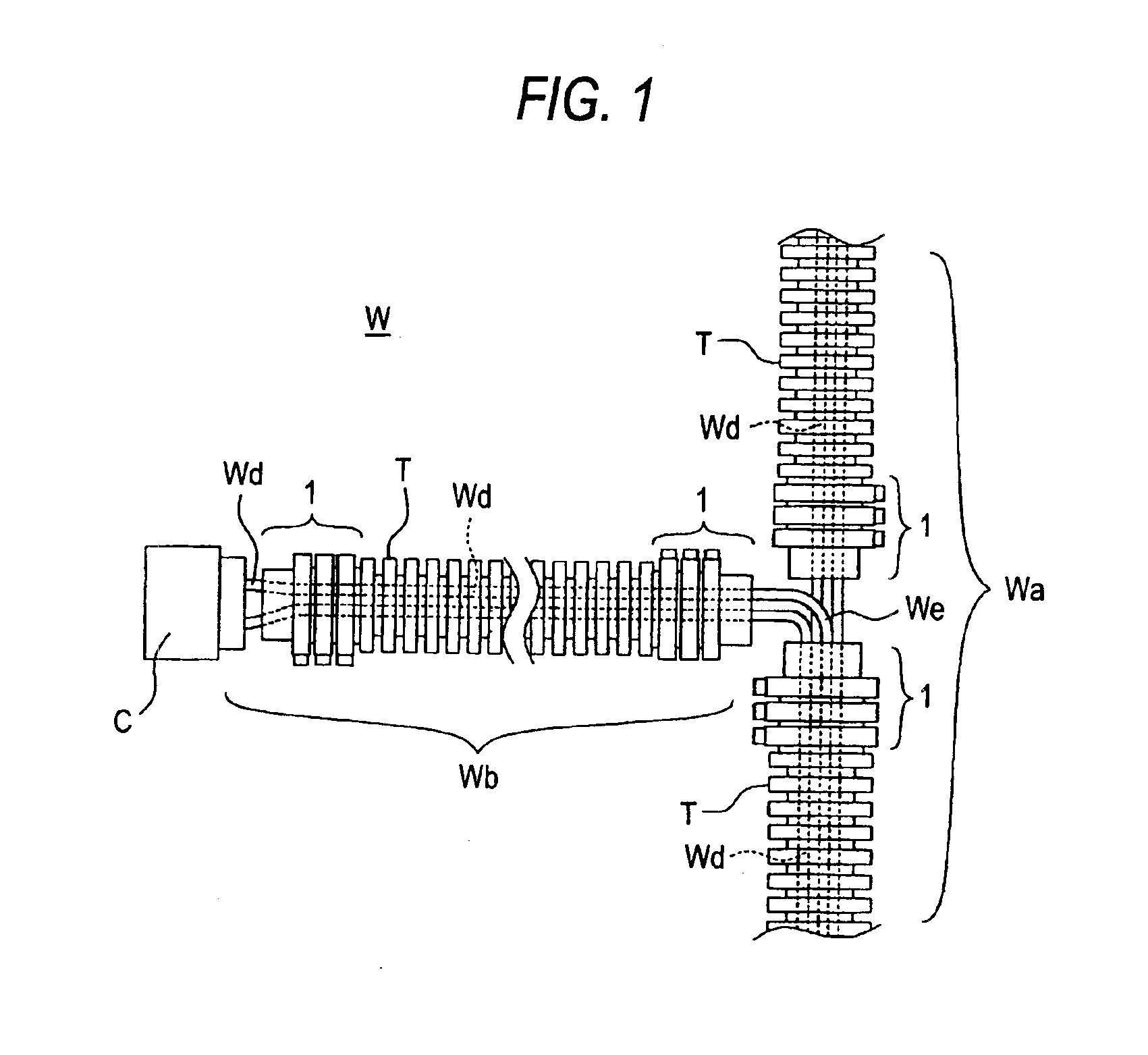

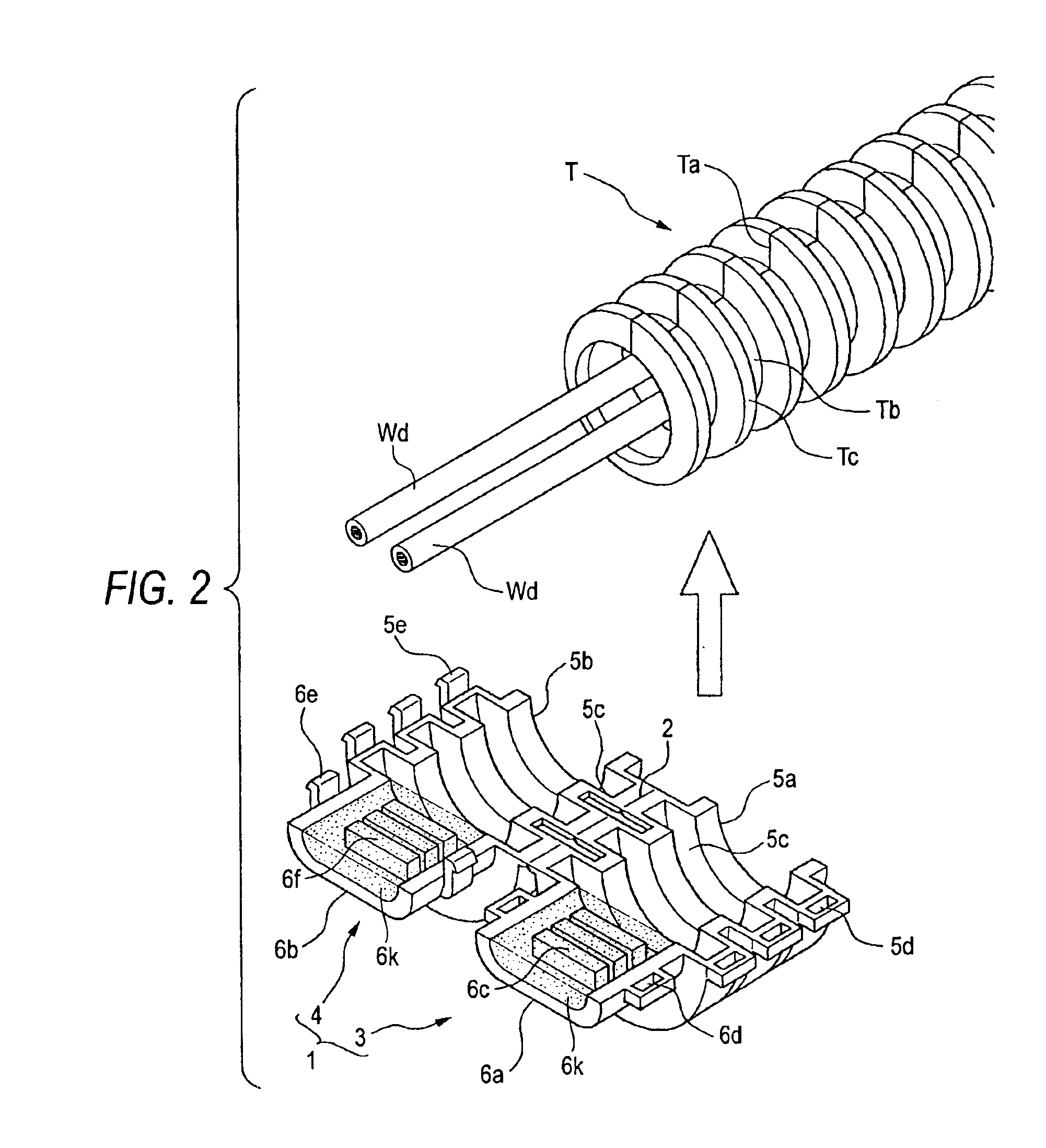

Joint for tubular cable cover

InactiveUS6875918B2Simple structureControl displacementElectrically conductive connectionsInsulated cablesEngineeringMechanical engineering

Owner:AUTONETWORKS TECH LTD +2

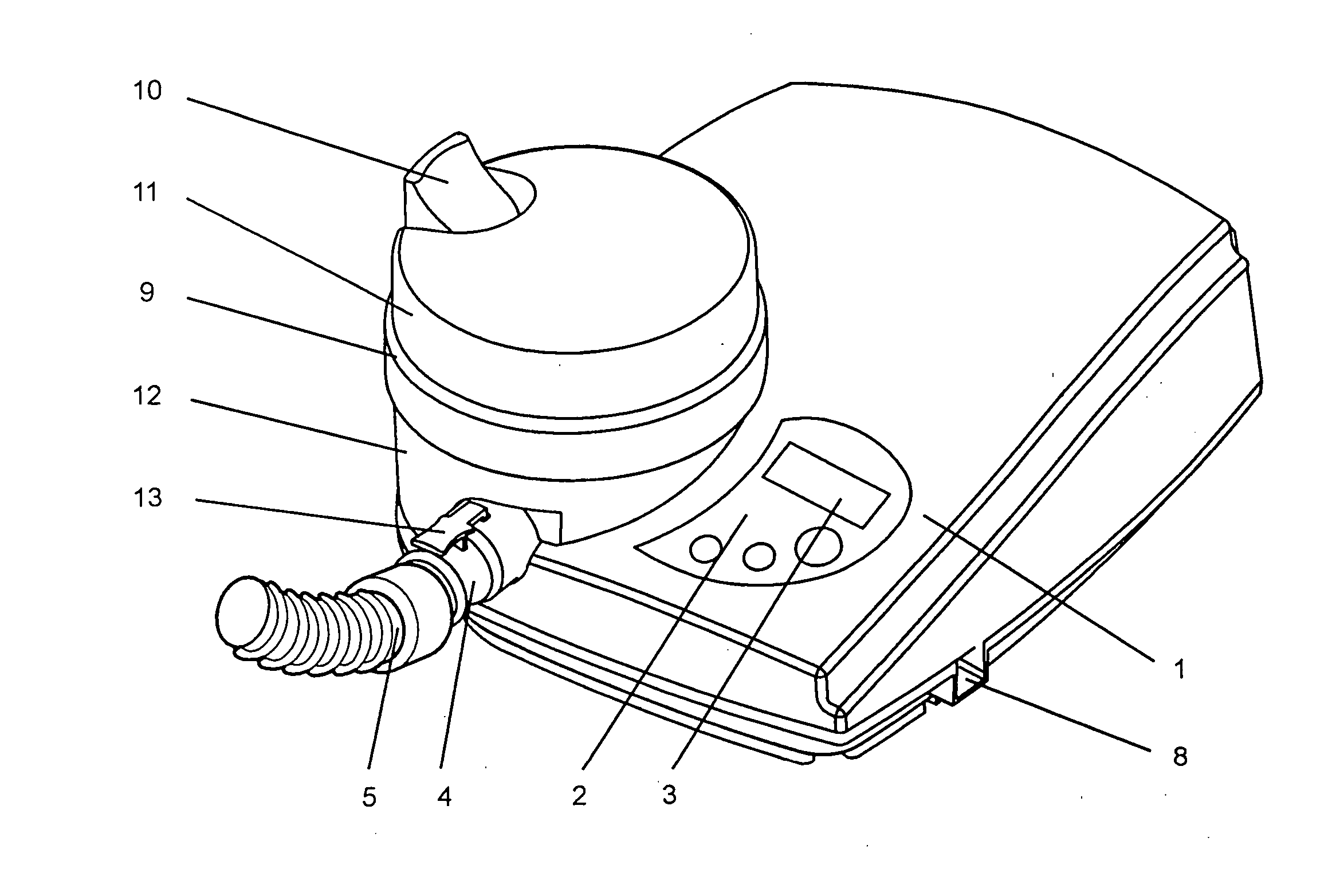

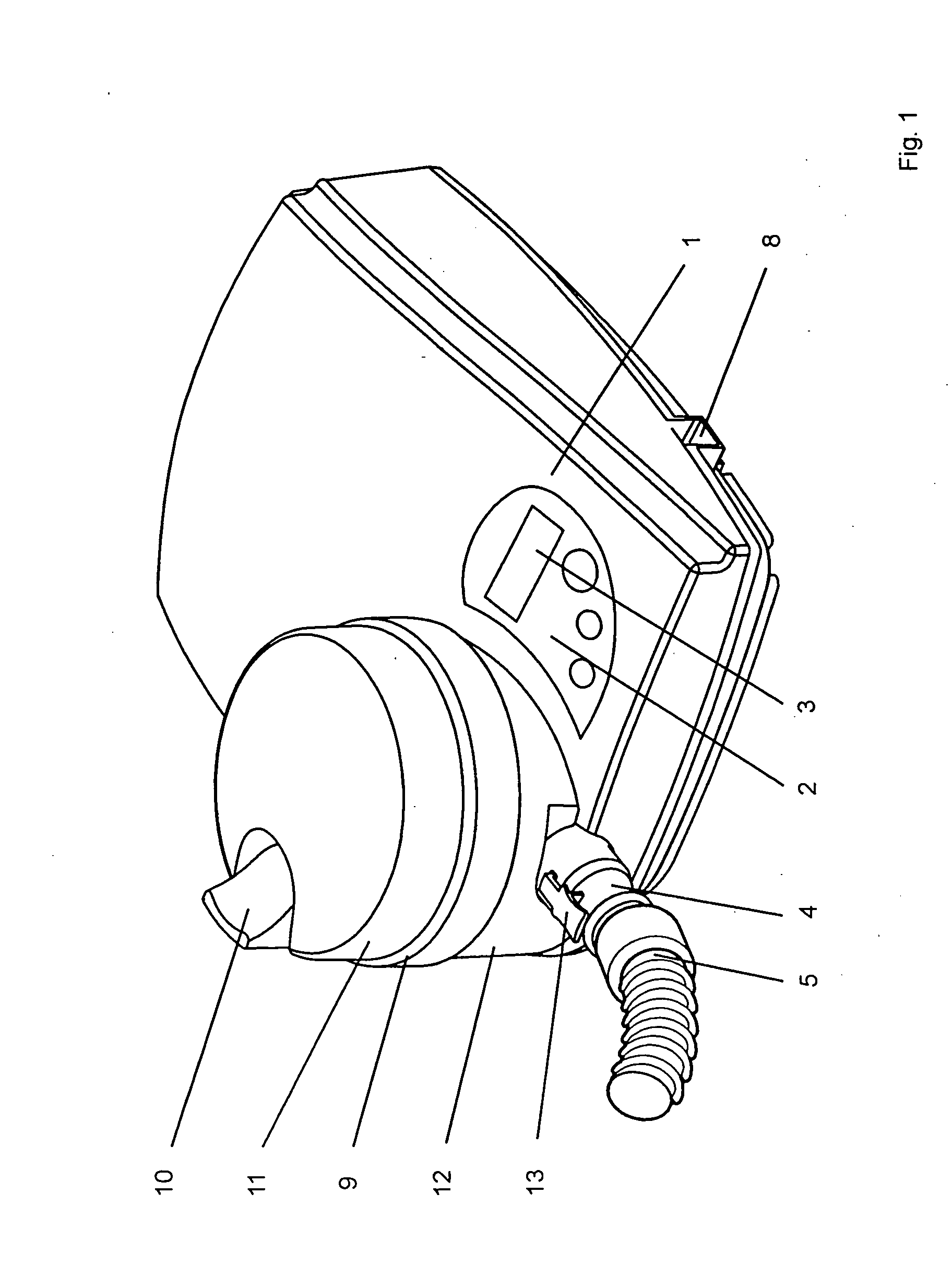

Ventilation device

ActiveUS20070193580A1Reduce mask soundIncrease in sizeRespiratorsMedical devicesFile deviceOperation mode

A ventilator with integrated breathing air humidifier has at least two defined air pathways provided in the breathing air humidifier, wherein the breathing air humidifier is installed and fixed on a horizontal surface of the ventilator. The ventilator with integratable breathing air humidifier has a breathing air humidifier with at least a top part and a bottom part, wherein a water reservoir is provided in the bottom part, and wherein the top part cannot be removed from the bottom part when the unit is in at least one operating mode. The ventilator may have an air humidifier with at least one water reservoir, and at least one filing device for the water reservoir in the breathing air humidifier, wherein the filing device can be operated with one hand and / or opened with one hand.

Owner:LOWENSTEIN MEDICAL TECH SA

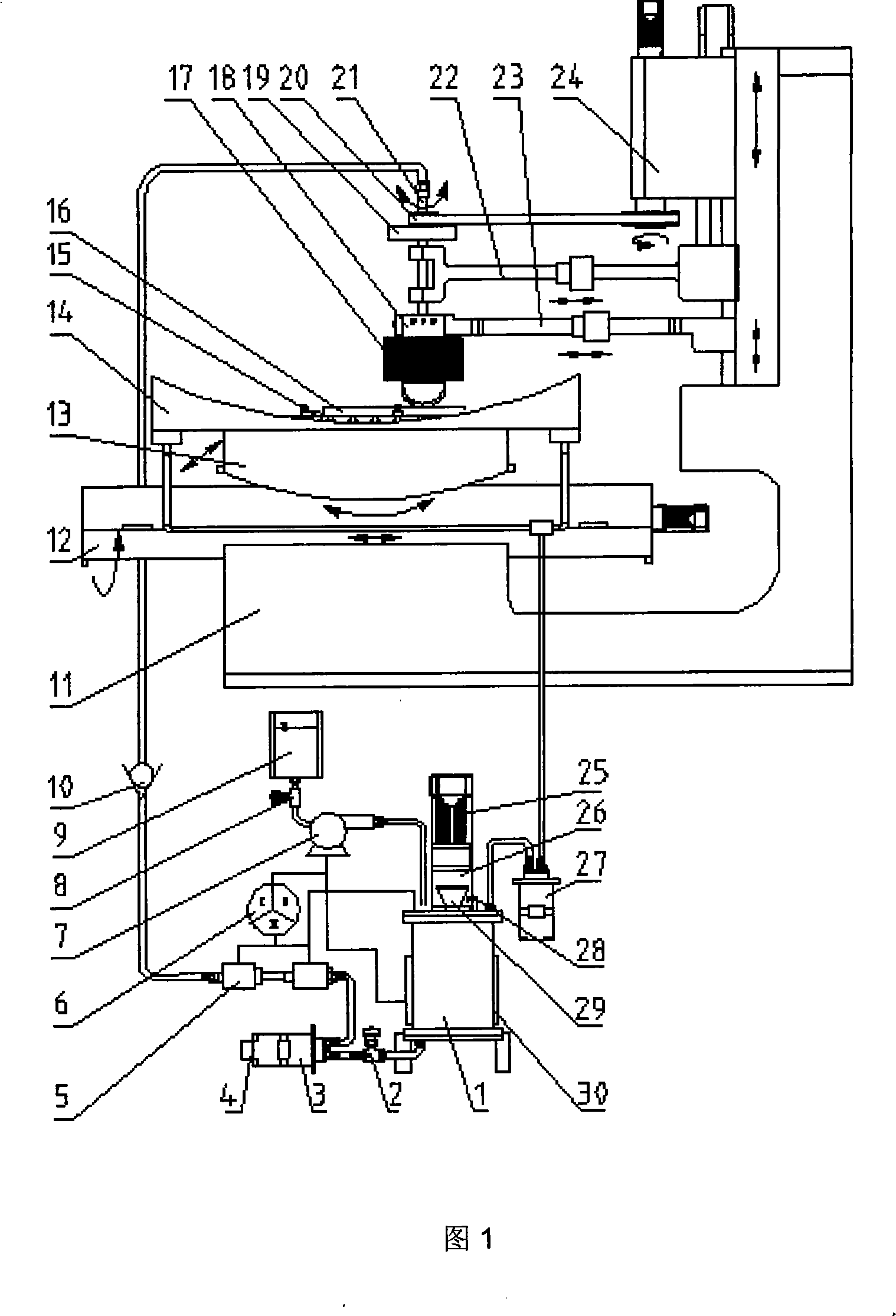

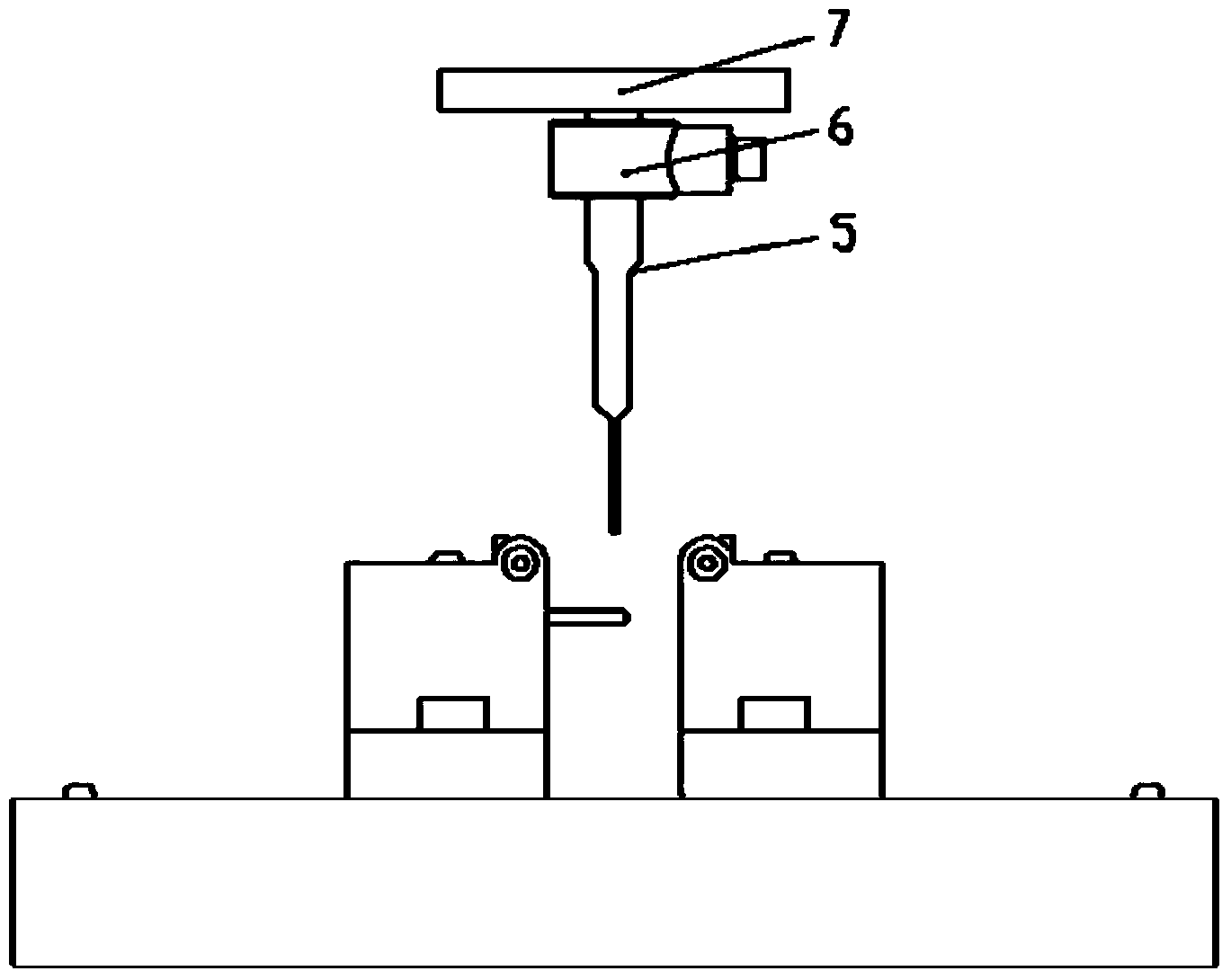

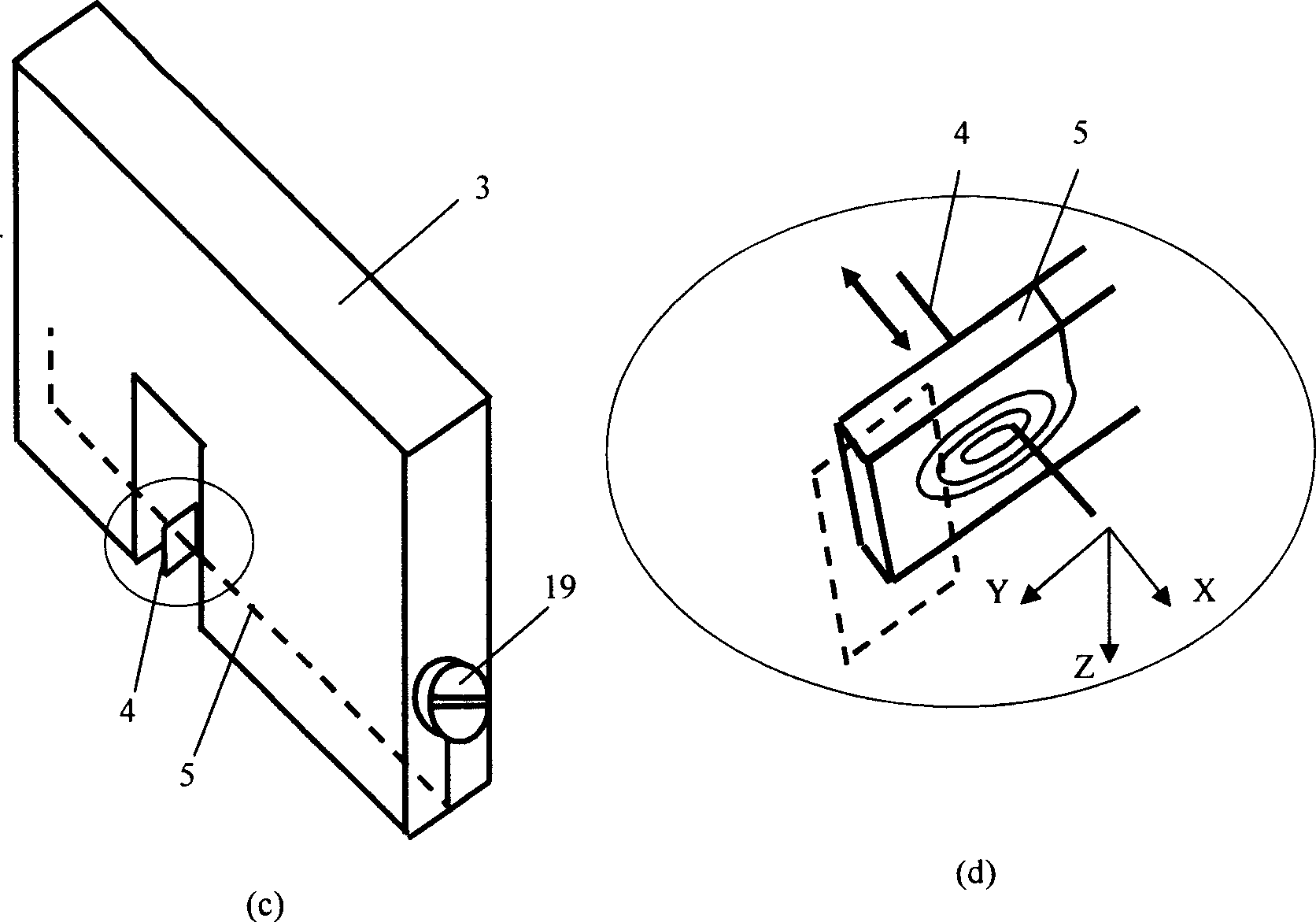

Precise magnetic flowage polishing system for optics parts and method thereof

InactiveCN101224556AImprove processing efficiencyEasy clampingOptical surface grinding machinesPeristaltic pumpTemperature control

The invention relates to an optical part magnetic rheologic precise polishing system and a method; magnetic rheologic liquid which flows out of a liquid storage cylinder is pressurized by a peristaltic pump and then enters a polishing head through a rotating connector and a guide pipe; the clearance between a workpiece and the polishing head is fully filled by the magnetic rheologic liquid; under the action of electromagnetic field, the magnetic rheologic liquid is transformed from the liquid state to the half-solid state so as to form a flexible grinding head used for polishing. The polishing head of the invention is not directly contacted with the workpiece; the polishing heads with different shapes and specifications can be replaced according to the processed workpiece; a computer automatic control device can realize the viscousity control and the temperature control of the magnetic rheologic liquid, and different polishing efficiency and precisions can be obtained by changing the factors such as magnetic field and rotation speed, etc.; the method of the invention can process the curved workpieces and plane workpieces with different shapes, more particularly the ultra-precise polishing of the large plane optical parts; the system has the advantages of high processing efficiency, wide applicable range, high processing precision and convenient operation.

Owner:DONGHUA UNIV

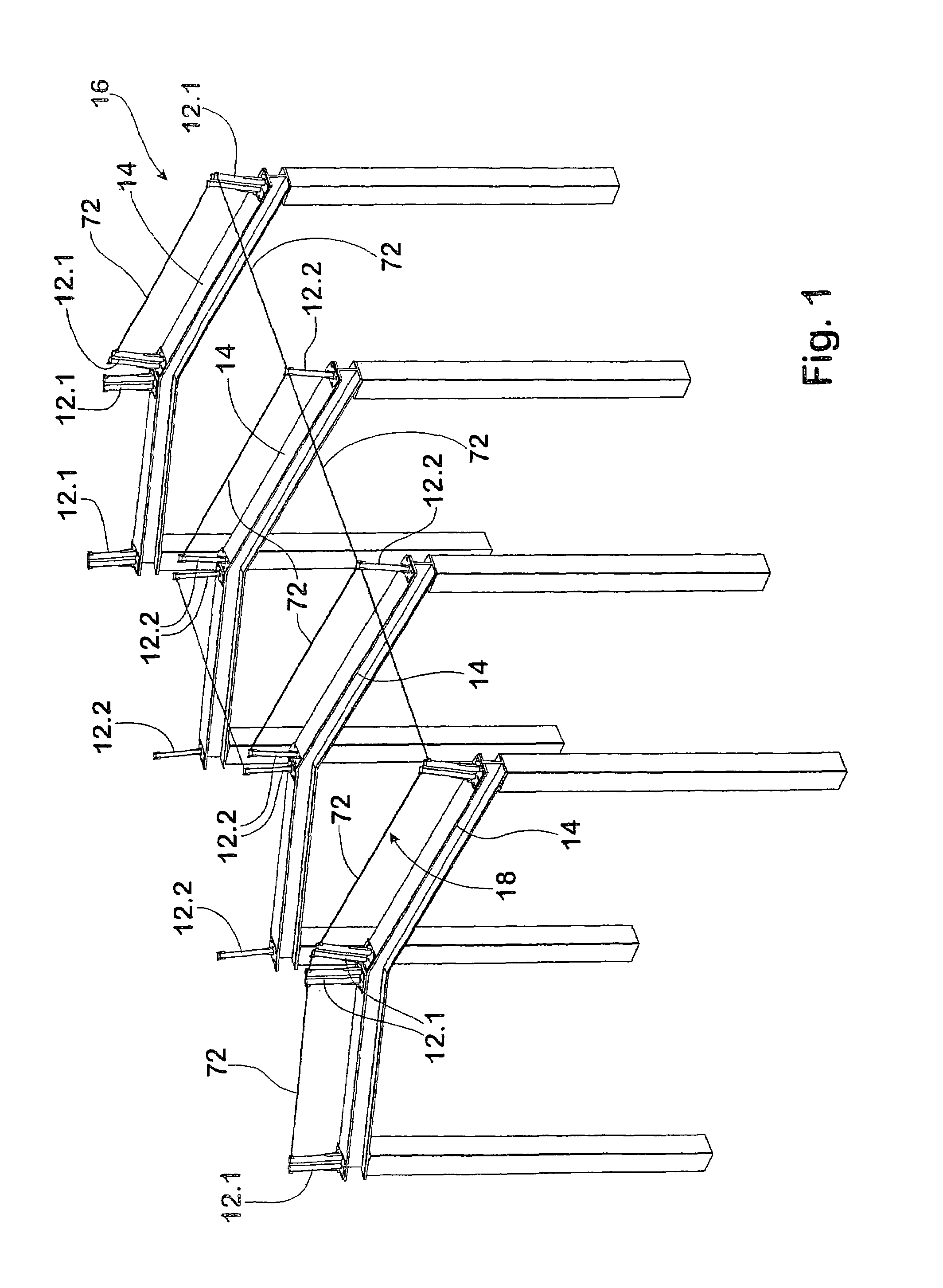

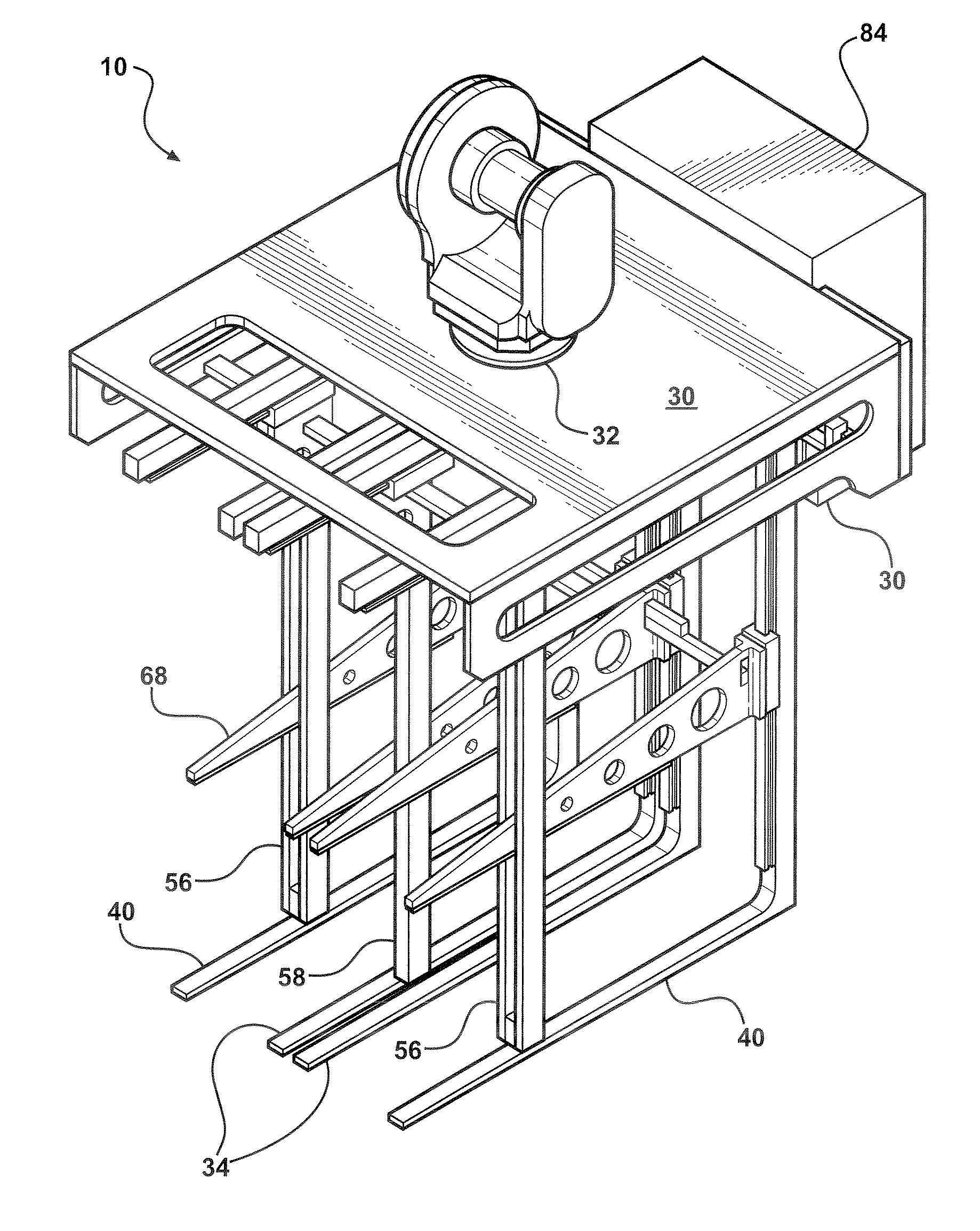

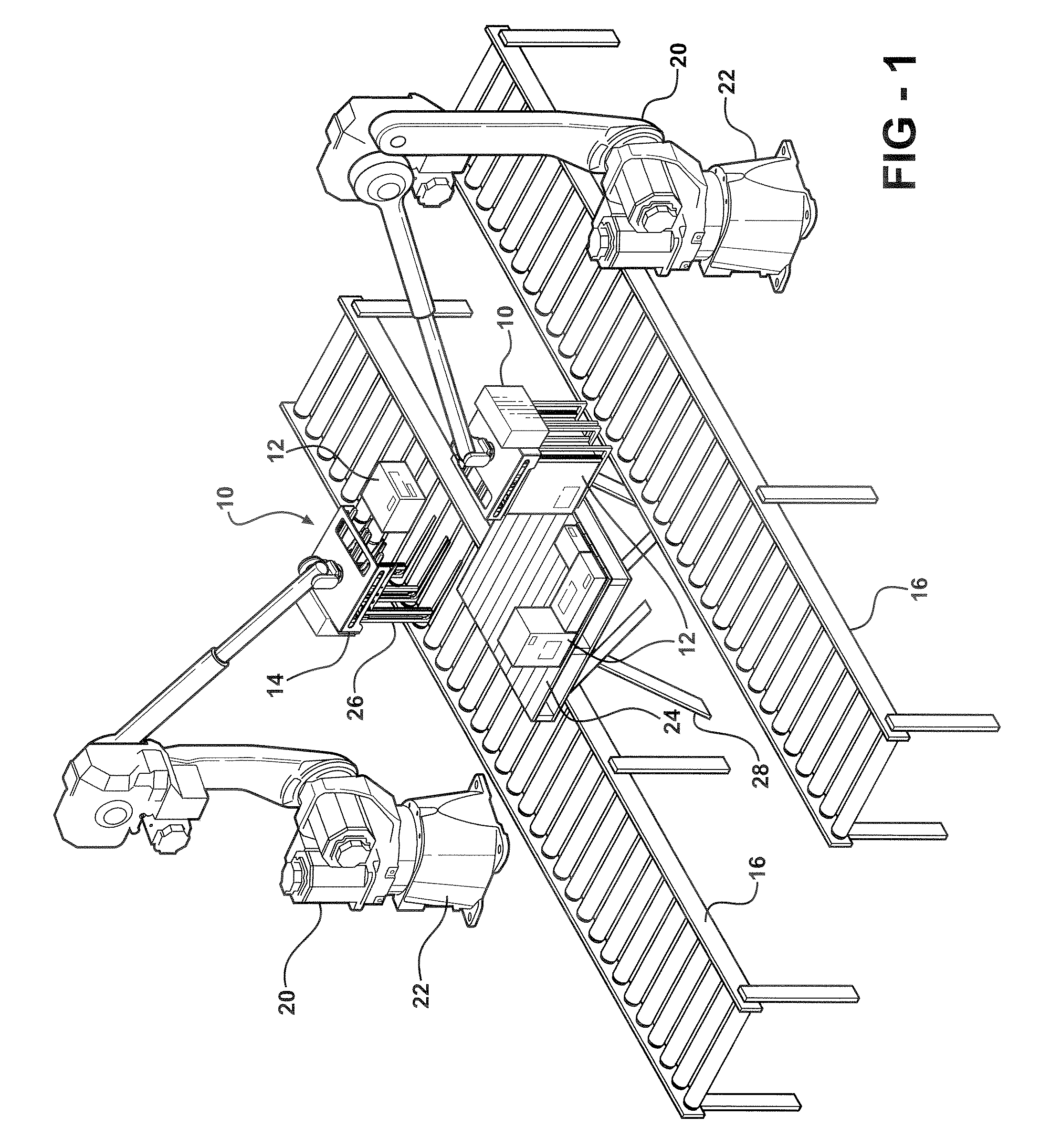

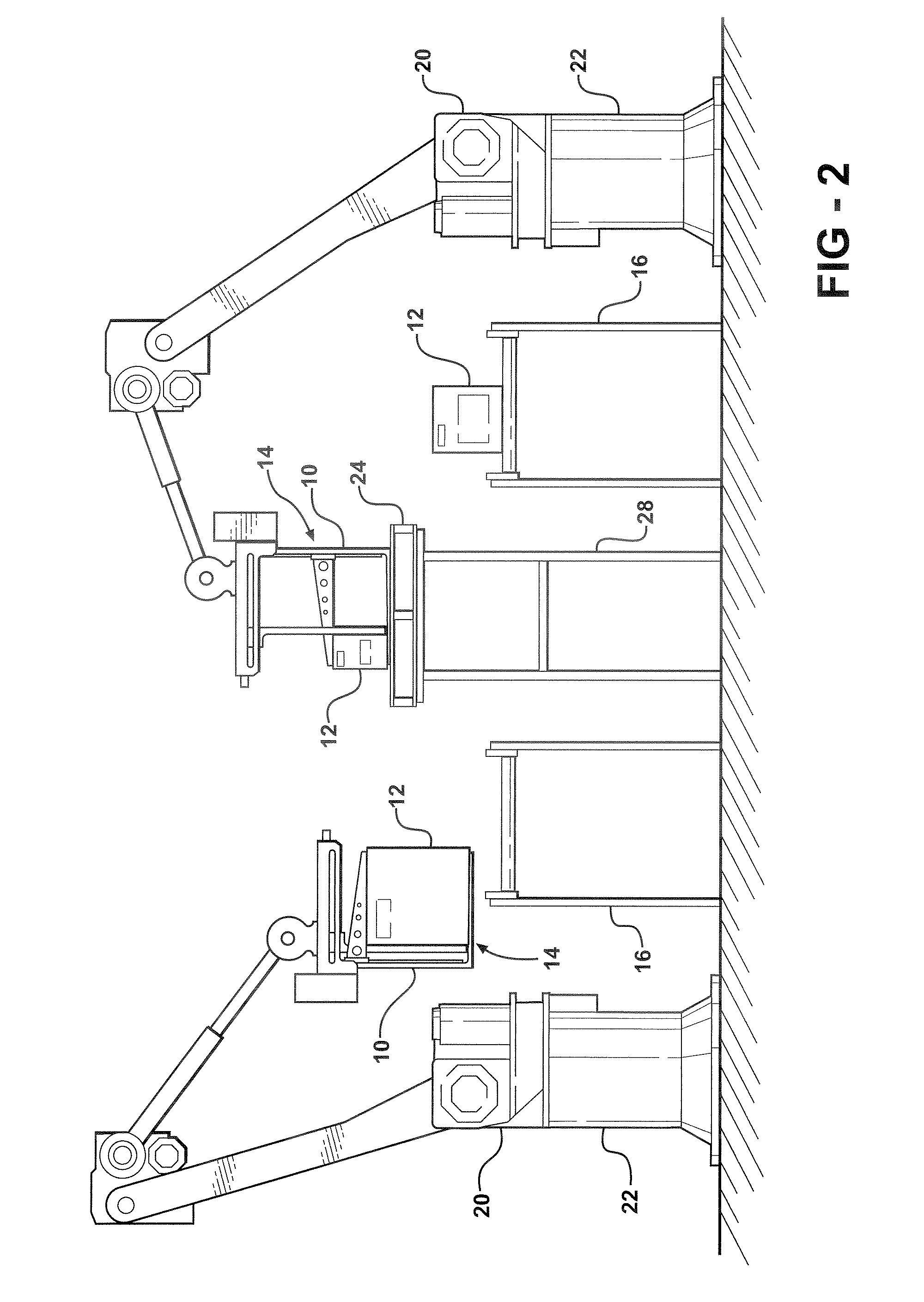

Mixed size product handling end of arm tool

InactiveUS7967354B2Safe handlingQuicker handling timeProgramme-controlled manipulatorGripping headsPalletRobot

A mixed size product end of arm tooling is used in conjunction with a robot to pick mixed size product and place the product onto a pallet or layers resting on top of a pallet. The end of arm tooling includes two center rails / forks mounted to a base. Two outer rails / forks are mounted to linear bearings that guide the outer rails / forks when moving inwardly or outwardly from the center rails for pre-sizing to the product. Pusher arms are formed of two outer pusher arms and one center pusher arm. These pusher arms are attached to linear bushings that guide the pusher arms forward and backward. The pusher arms push off the product simultaneously as the robot is withdrawing the rails.

Owner:FANUC ROBOTICS NORTH AMERICA

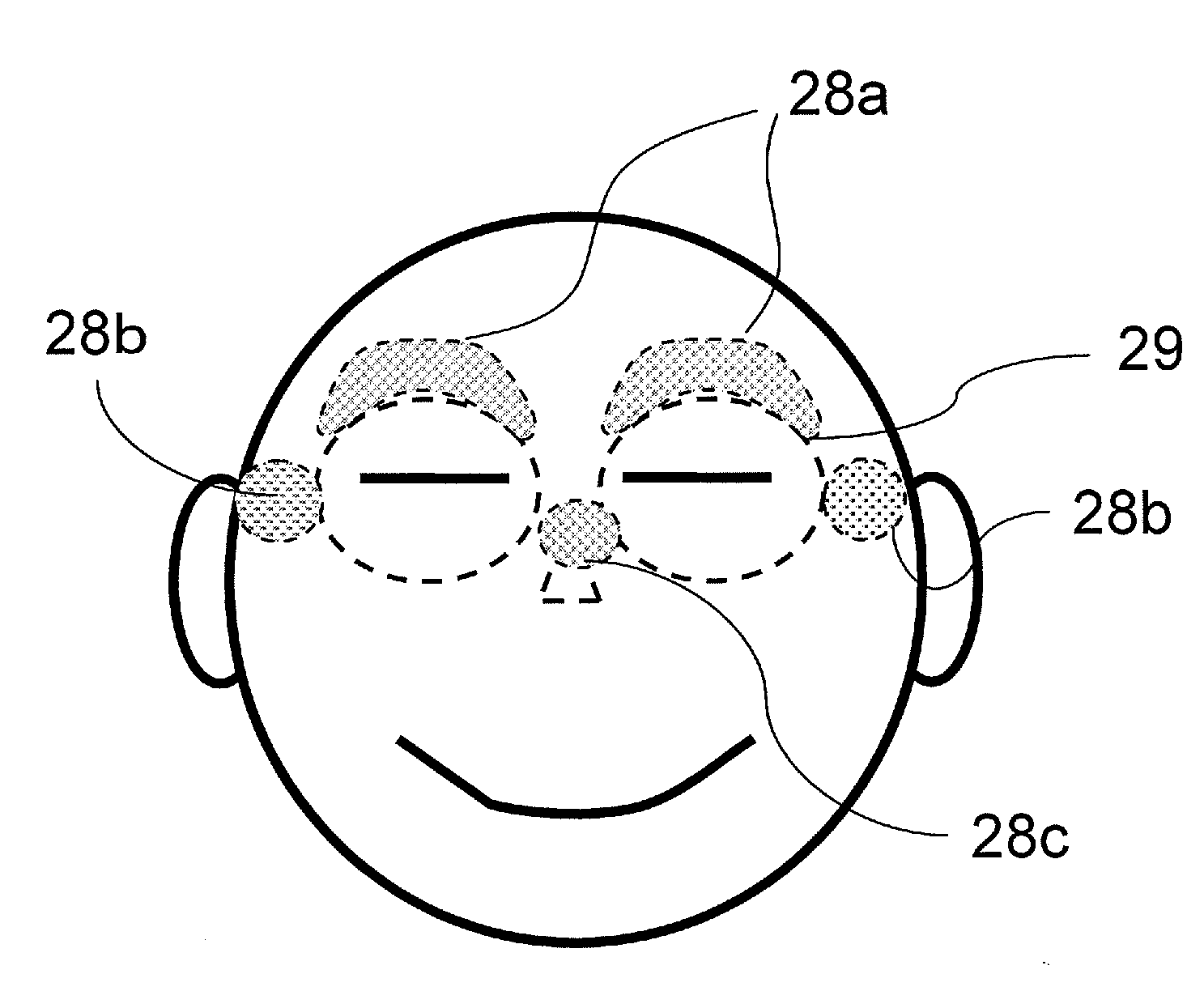

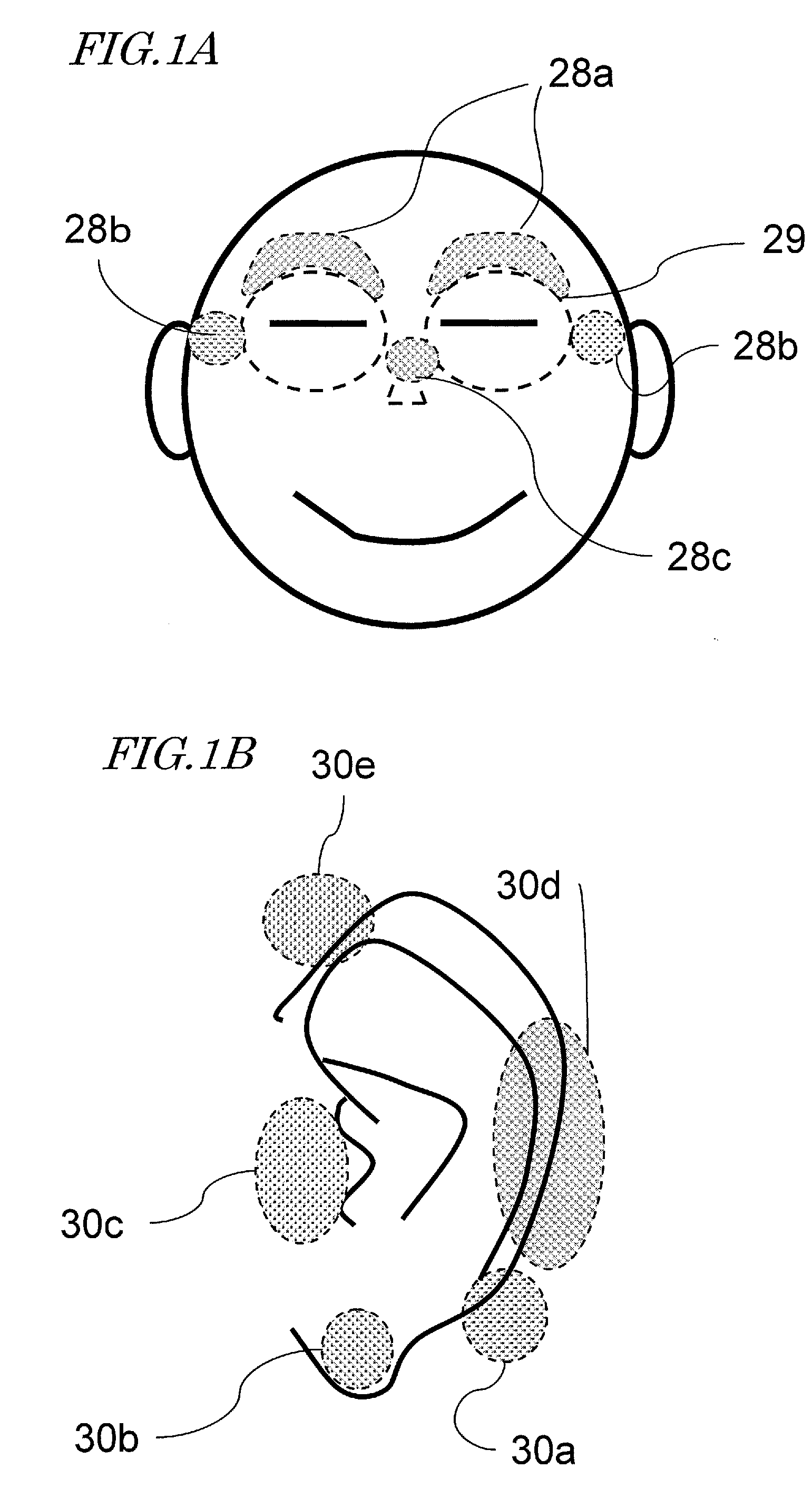

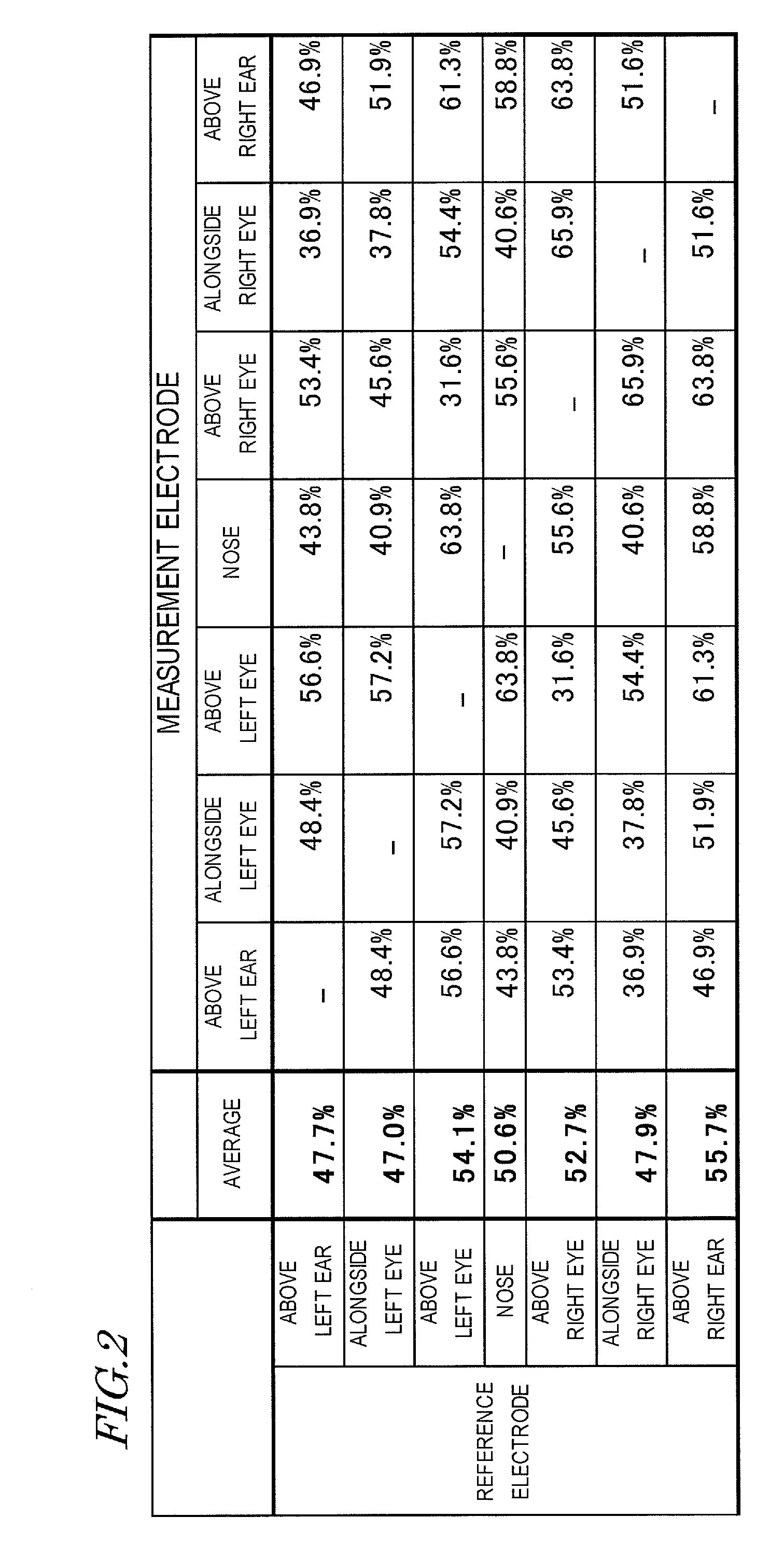

Electroencephalogram interface system

InactiveUS20110071416A1Stable electrode contactContact stabilityElectroencephalographySensorsPotential differenceEvent-related potential

An eyeglass-type electroencephalogram interface system is worn on the head of a user. The system includes: an output section for presenting a visual stimulation to the user; an ear electrode portion disposed at a position coming in contact with an ear of the user when the system is worn; a facial electrode portion disposed at a position coming in contact with the face below a straight line connecting an external canthus and an internal canthus of an eye of the user, such that the mass of the system is supported at the position, when the system is worn; and an electroencephalogram measurement and determination section for measuring an event-related potential on the basis of a potential difference between the ear electrode portion and the facial electrode portion based on the visual stimulation being presented by the output section as a starting point.

Owner:SOVEREIGN PEAK VENTURES LLC

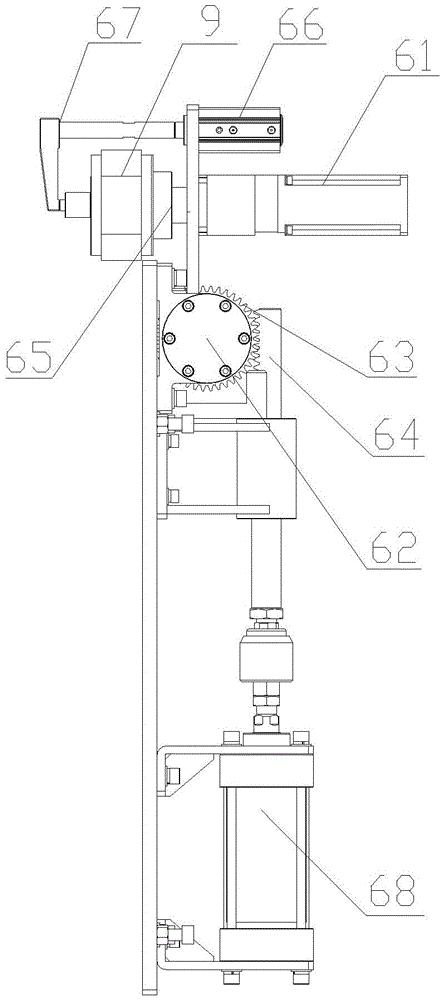

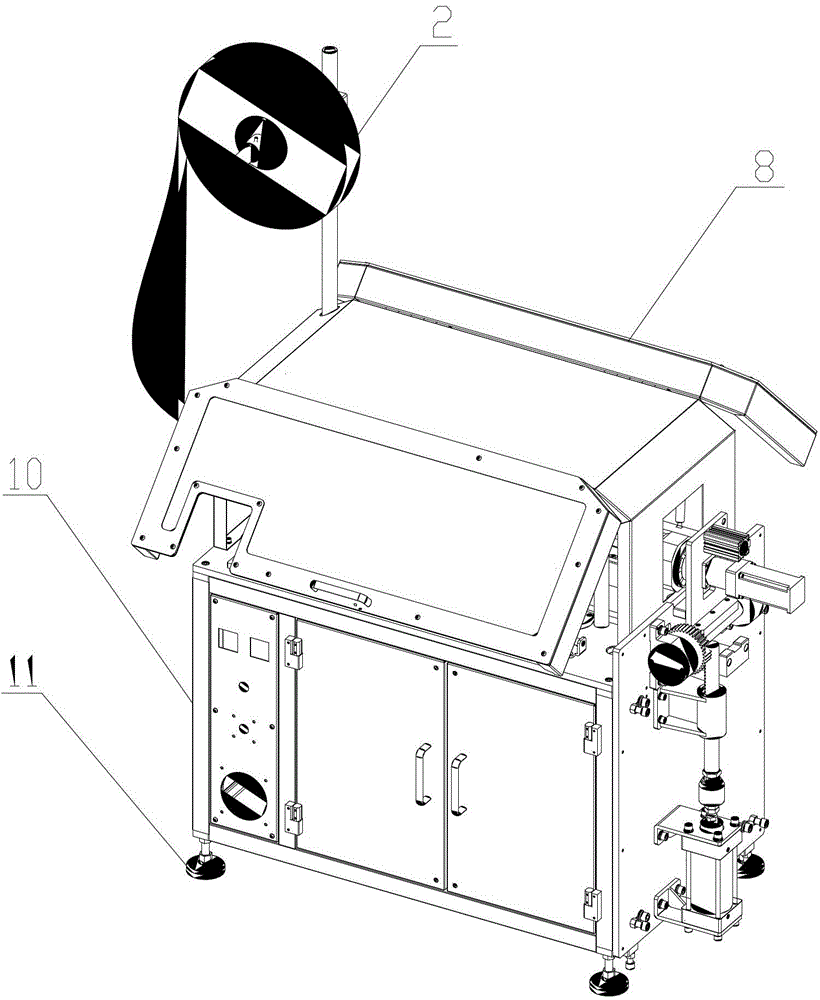

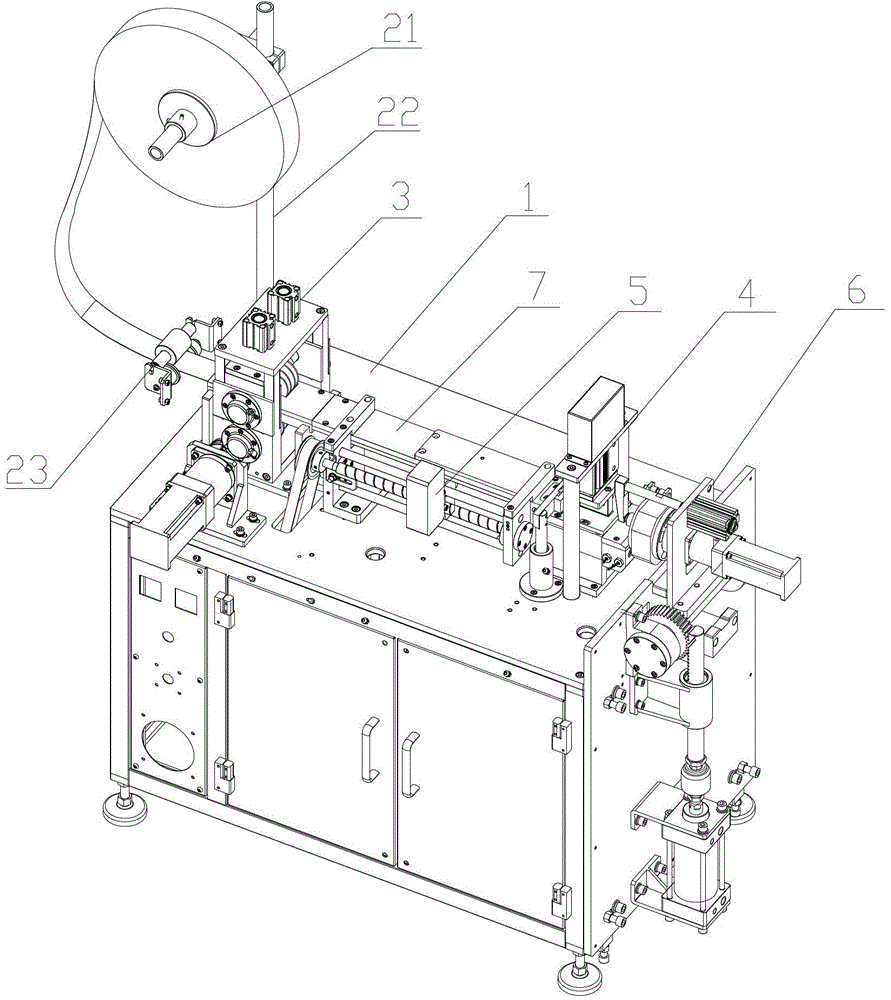

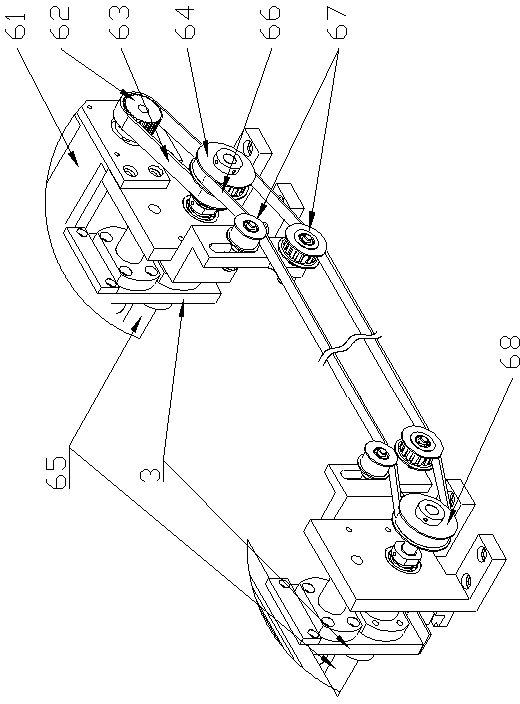

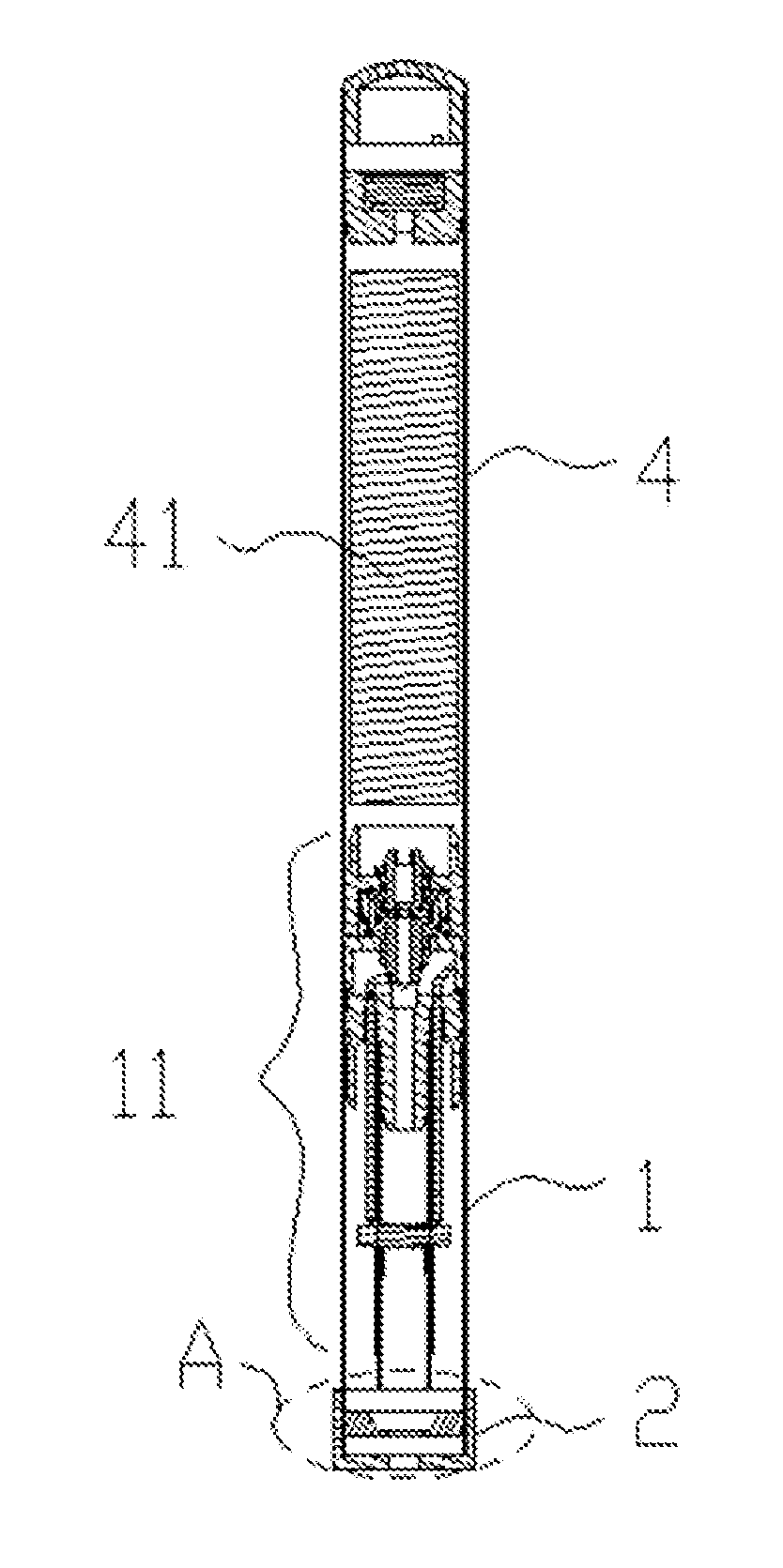

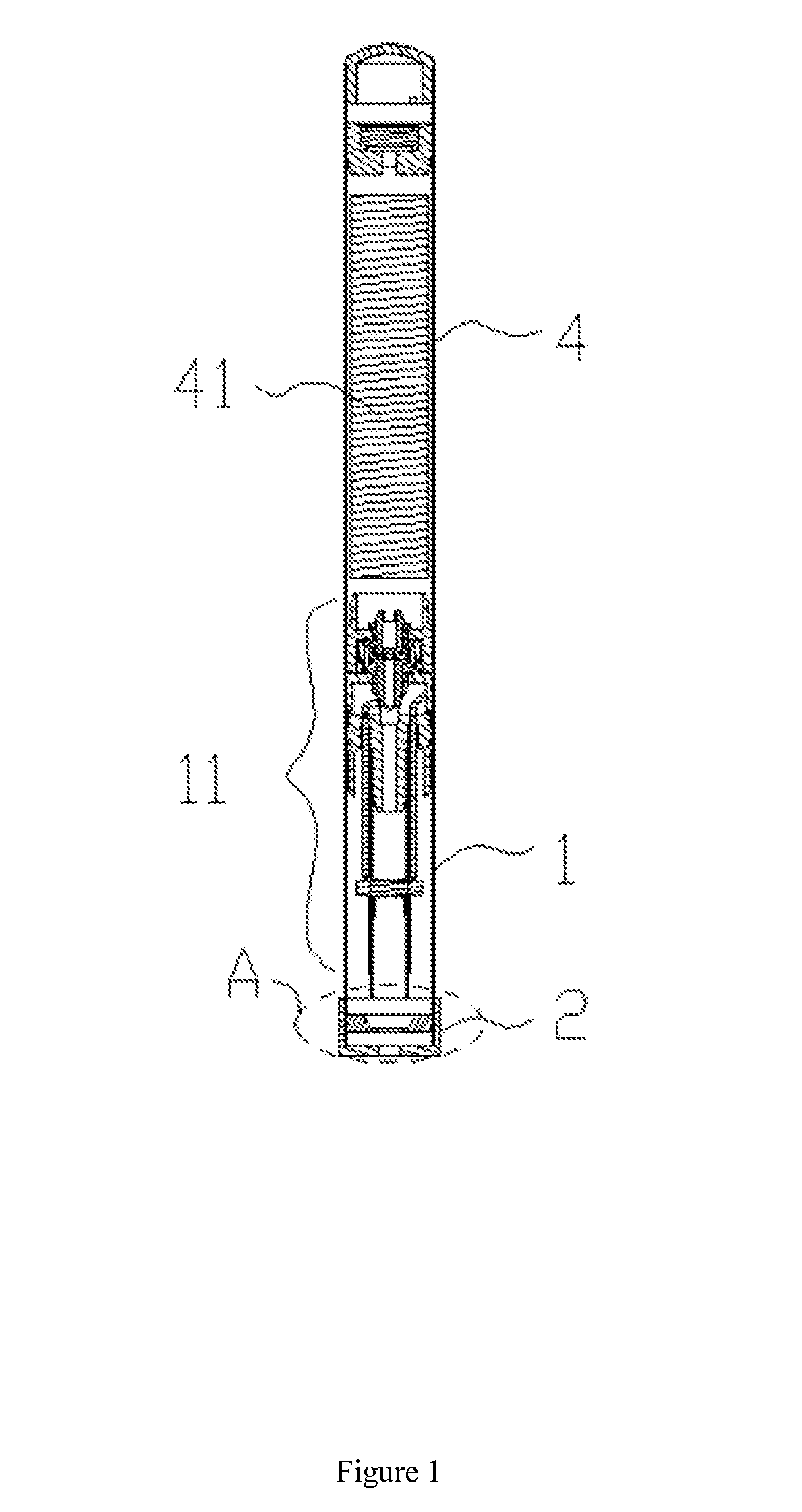

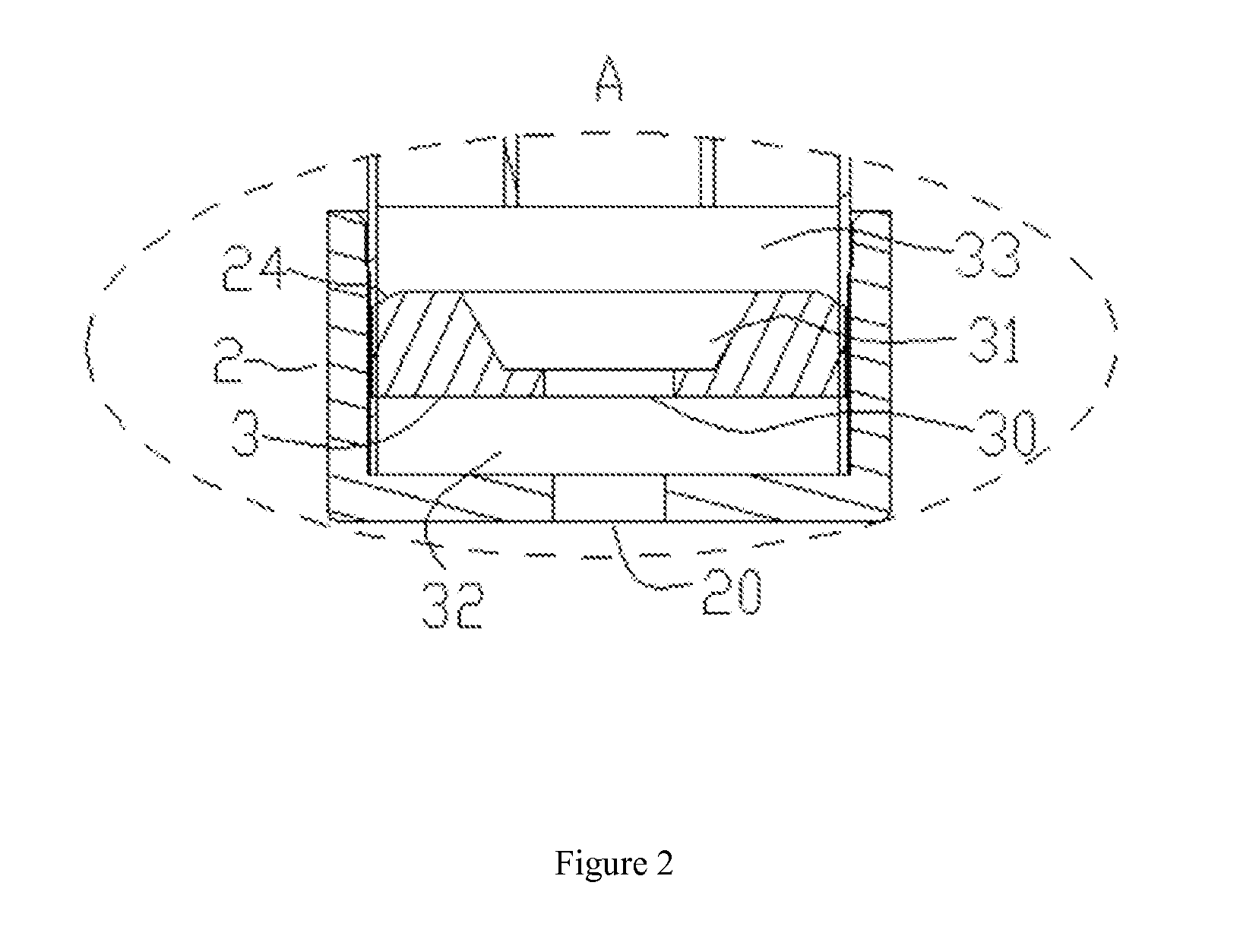

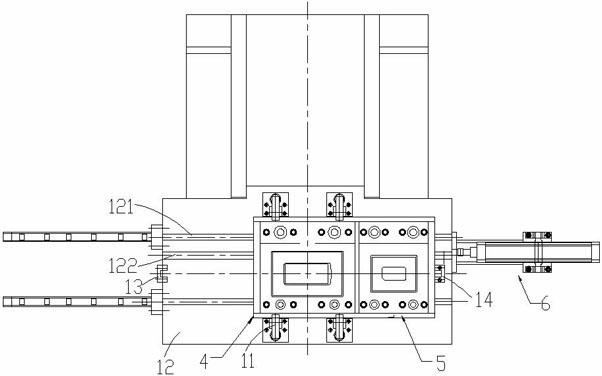

Insulation paper inserting machine for motor stator

InactiveCN103337935APrecise positioningEasy clampingApplying solid insulationManual insertionPulp and paper industry

The invention discloses an insulation paper inserting machine for a motor stator, which includes a working platform and a paper feeding device arranged on the working platform, wherein an indentation device and a cutting device are also mounted on the working platform; a paper guide slot is arranged between the indentation device and the cutting device; a paper pushing mechanism is matched with the cutting device; after the paper feeding device sends out a piece of insulation paper, the insulation paper passes through the indentation device, the paper guide slot and the cutting device sequentially, and then is pushed out of the cutting device by the paper pushing mechanism; the insulation paper finally enters the motor stator clamped on a stator clamping workbench on a side surface of the working platform; the stator clamping workbench is connected with the working platform via a rotating shaft, and can turn over around the rotating shaft. Through the manner, the insulation paper inserting machine for the motor stator not only has the insulation paper forming function, but also can push the clamped insulation paper into a groove of the motor stator, has efficient automatic performance, and puts an end to the low efficiency working manner of manual insertion.

Owner:NIDE MECHANICAL EQUIP

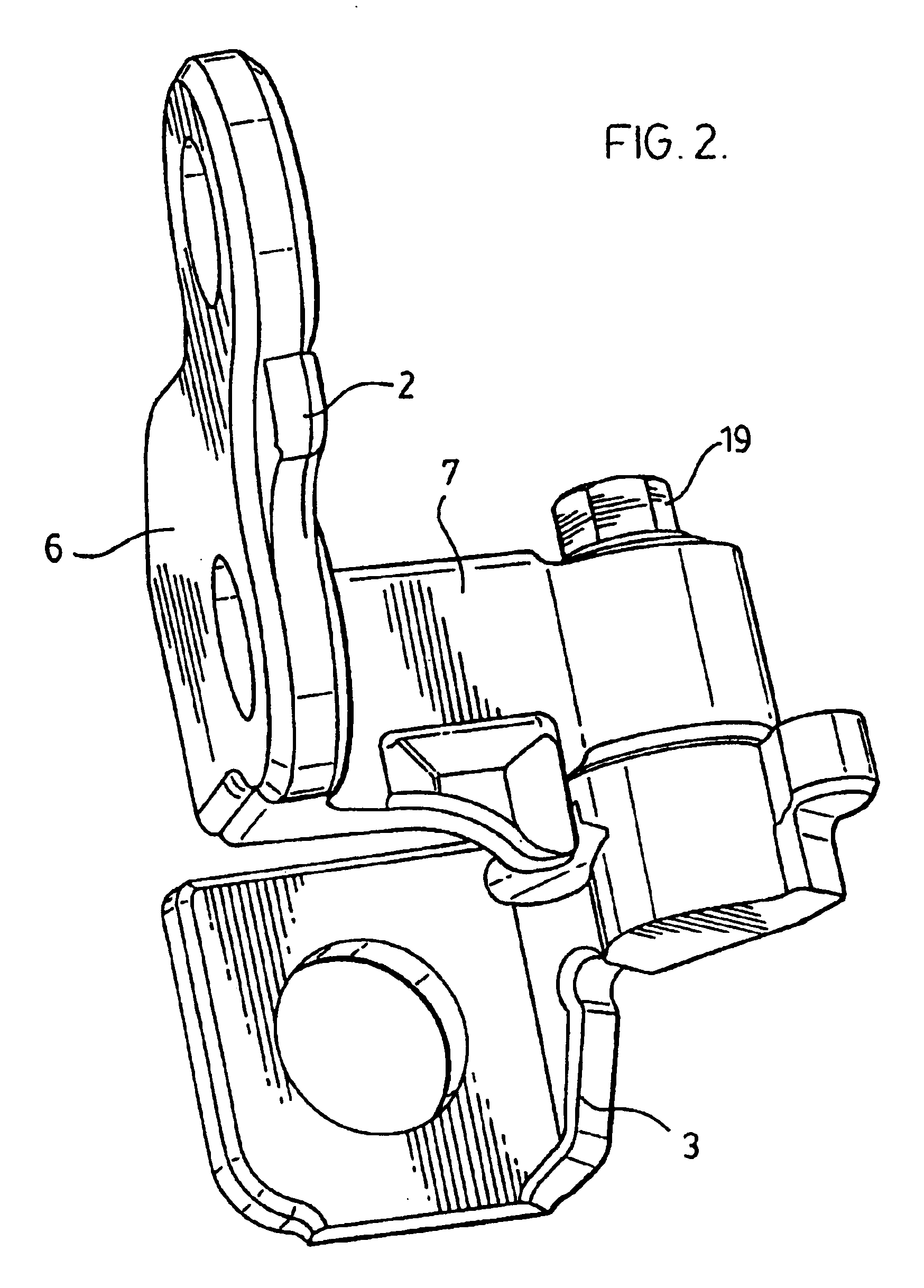

Surgical head clamp

InactiveUS20070250071A1Easy to handleEasy constructionDiagnosticsRigid tablesContact elementSpherical form

Owner:GOTTFRIED STORZ MEDIZINTECHN

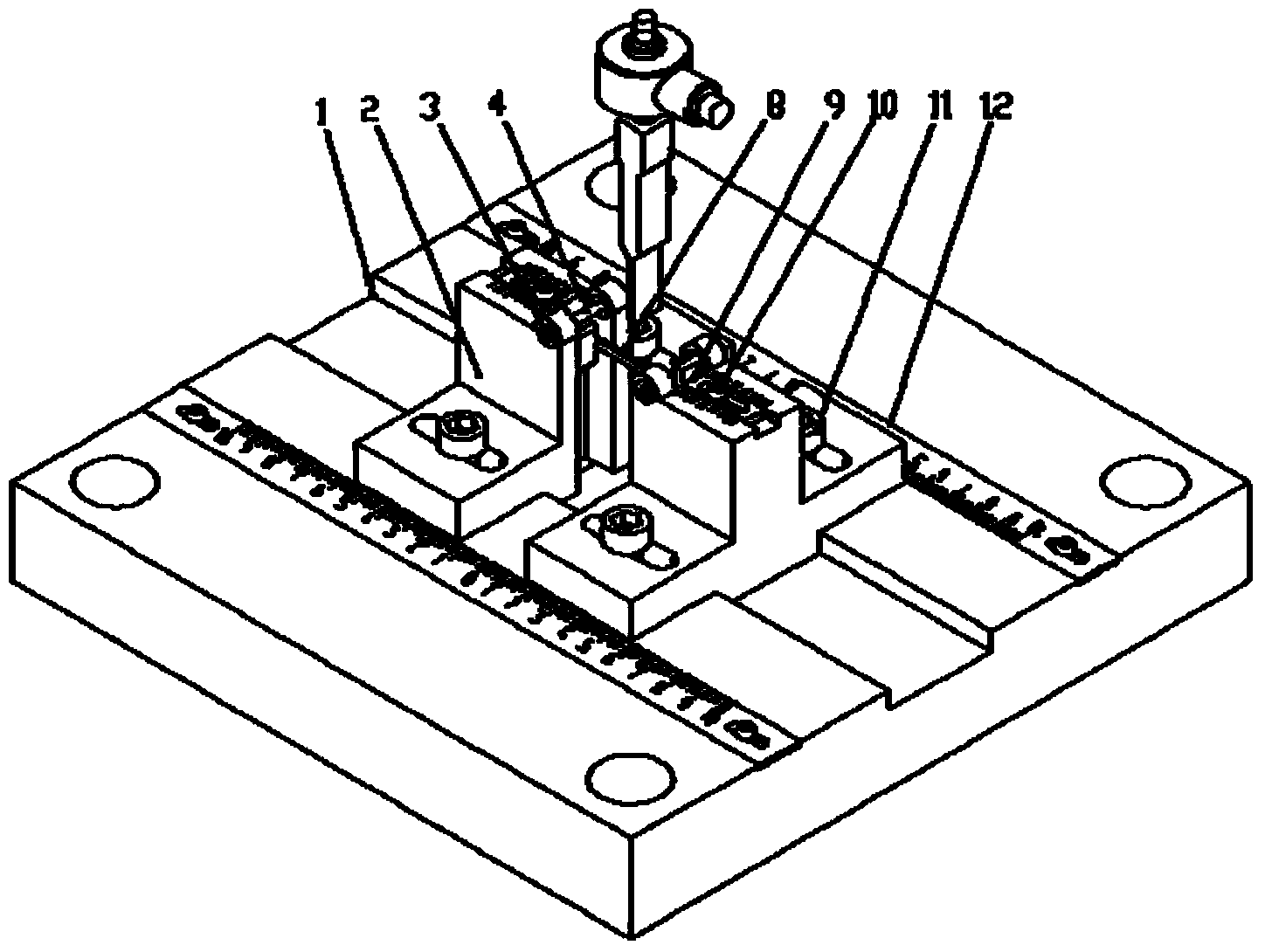

Full-automatic PCB (printed circuit board) positioning clamp

ActiveCN103025077AAccurate positioning and clampingReliable and easy positioning and clampingPrinted circuit assemblingPrinted circuit boardAssembly line

The invention provides a full-automatic PCB (printed circuit board) positioning clamp. The full-automatic PCB positioning clamp comprises a support seat, a support rod, a sliding support plate, a fixed-side railing, a movable-side railing, width adjusting mechanisms, conveying mechanisms, clamping mechanisms, a top plate mechanism, a detecting mechanism and a positioning mechanism, wherein the support rod and the width adjusting mechanisms are assembled on holes reserved on the lateral side of the support seat, the fixed-side railing is fixed on the support seat, the sliding support plate is slidably connected with the support rod, the movable-side railing is fixed on the sliding support plate which is connected with the width adjusting mechanisms, the conveying mechanisms are mounted on the inner sides of the fixed-side railing and the movable-side railing to form a PCB delivery rail, the clamping mechanisms are fixed on the fixed-side railing and the movable-side railing, the detecting mechanism is mounted on the fixed-side railing, and the positioning mechanism used for positioning the PCB when entering is fixed at a positioning position on the fixed-side railing. The full-automatic PCB positioning clamp can quickly automatically deliver the PCB, and can position and clamp the PCB accurately, reliably and conveniently, and production efficiency of an assembly line is improved.

Owner:广州弘高科技股份有限公司

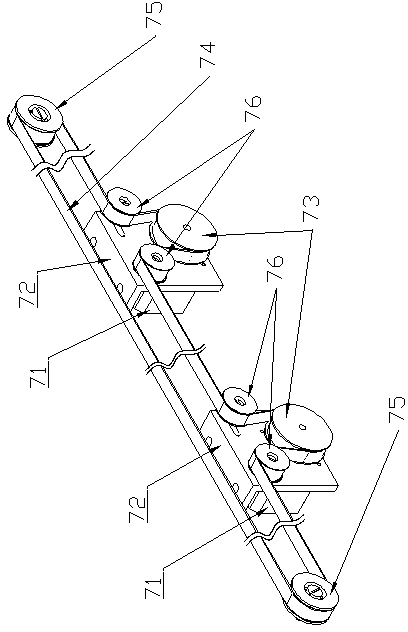

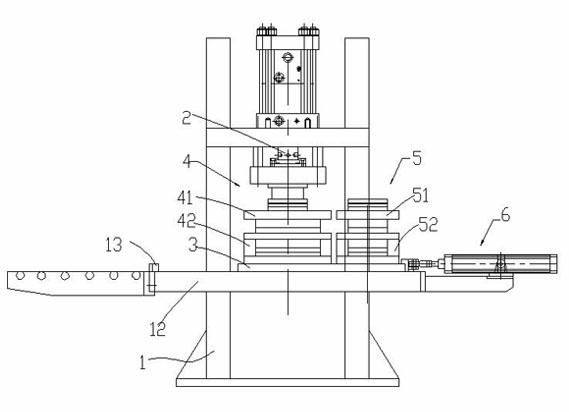

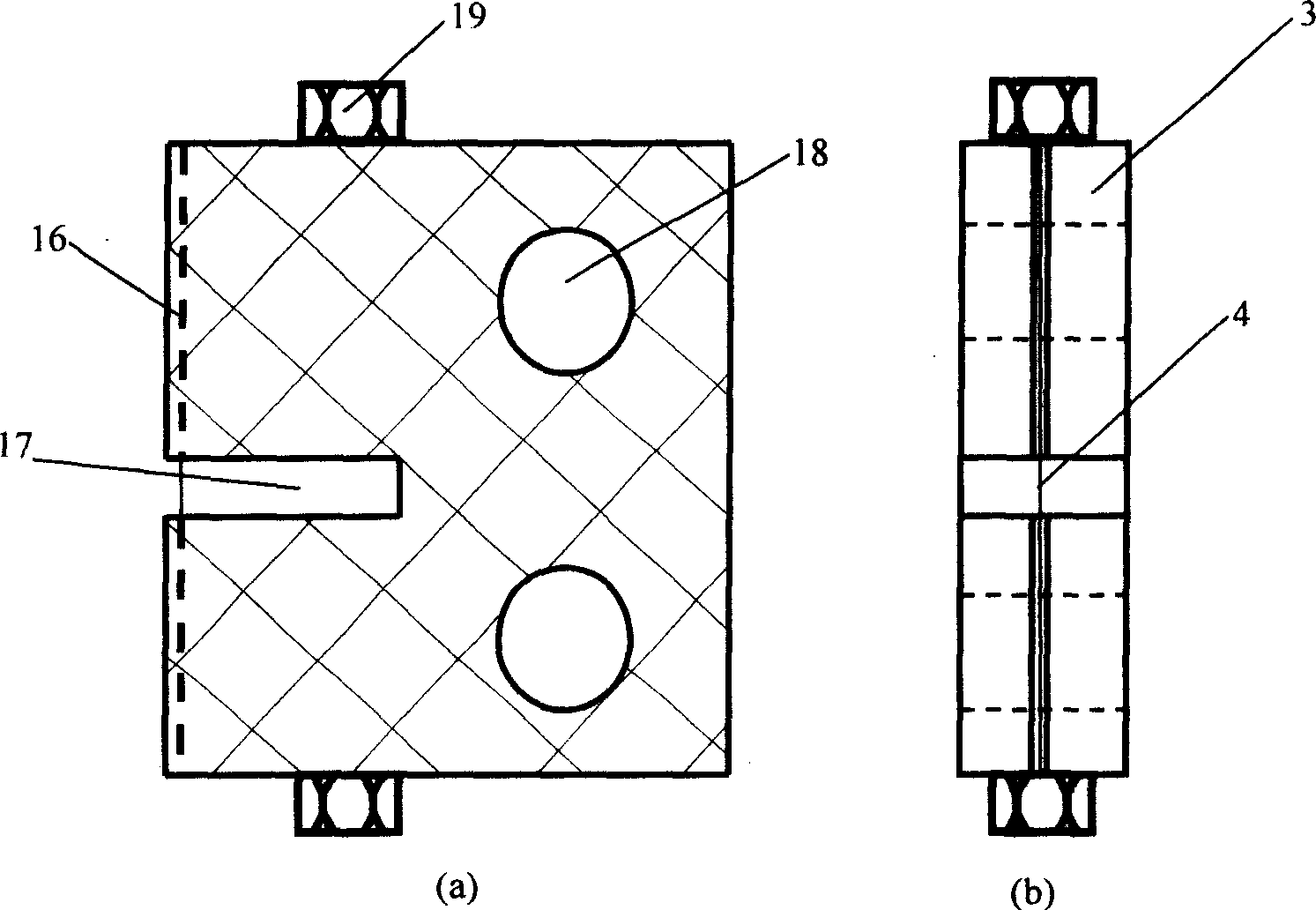

Bearing-type damage biomechanic three-point bending test device and bearing-type damage biomechanic three-point bending method

InactiveCN103760037AReduce distortionThe test data is accurateMaterial strength using steady bending forcesRolling resistanceElement model

The invention provides a bearing-type damage biomechanic three-point bending test device. The bearing-type damage biomechanic three-point bending test device is characterized by comprising a base (1), a support base (2), support bearings (3), support shafts (4), a pressing head (5), a sensor (6), a connecting plate (7), a travel switch (8), a baffle (9), a baffle fixing screw (10), a support base fixing screw (11) and a dividing rule (12). The bearing-type damage biomechanic three-point bending test device provided by the invention has the advantages that a pair of support shafts and the support bearings can support a biological sample, the rolling friction is formed among the support shafts and the support base, the biological sample free bending constraint caused by the friction in a test process is reduced, the transformation of the biological sample on a supporting position is relieved, more accurate test data can be obtained, and a terminal condition more easily set in a finite element model so as to perform material parameter reverse engineering.

Owner:HUNAN UNIV

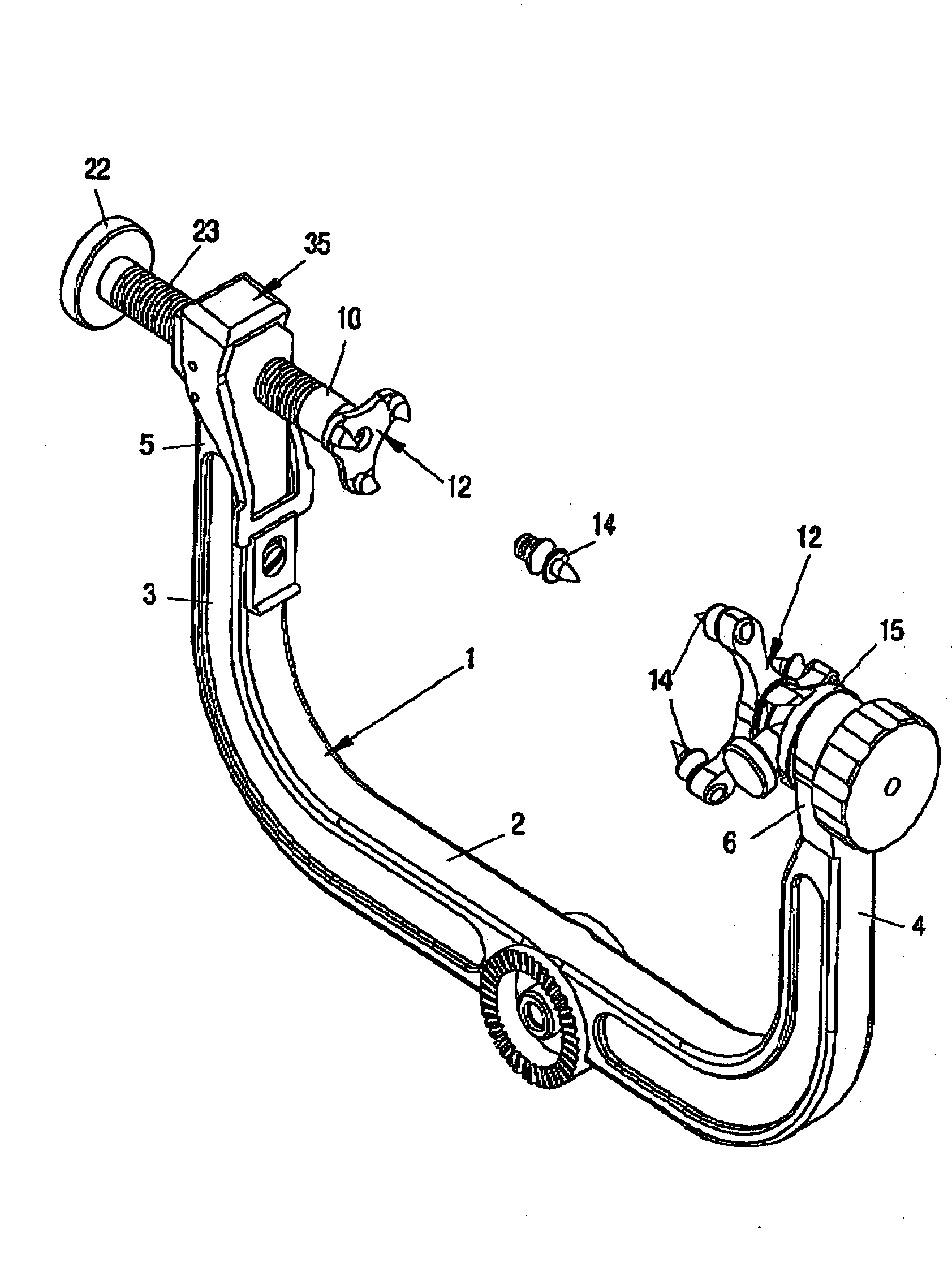

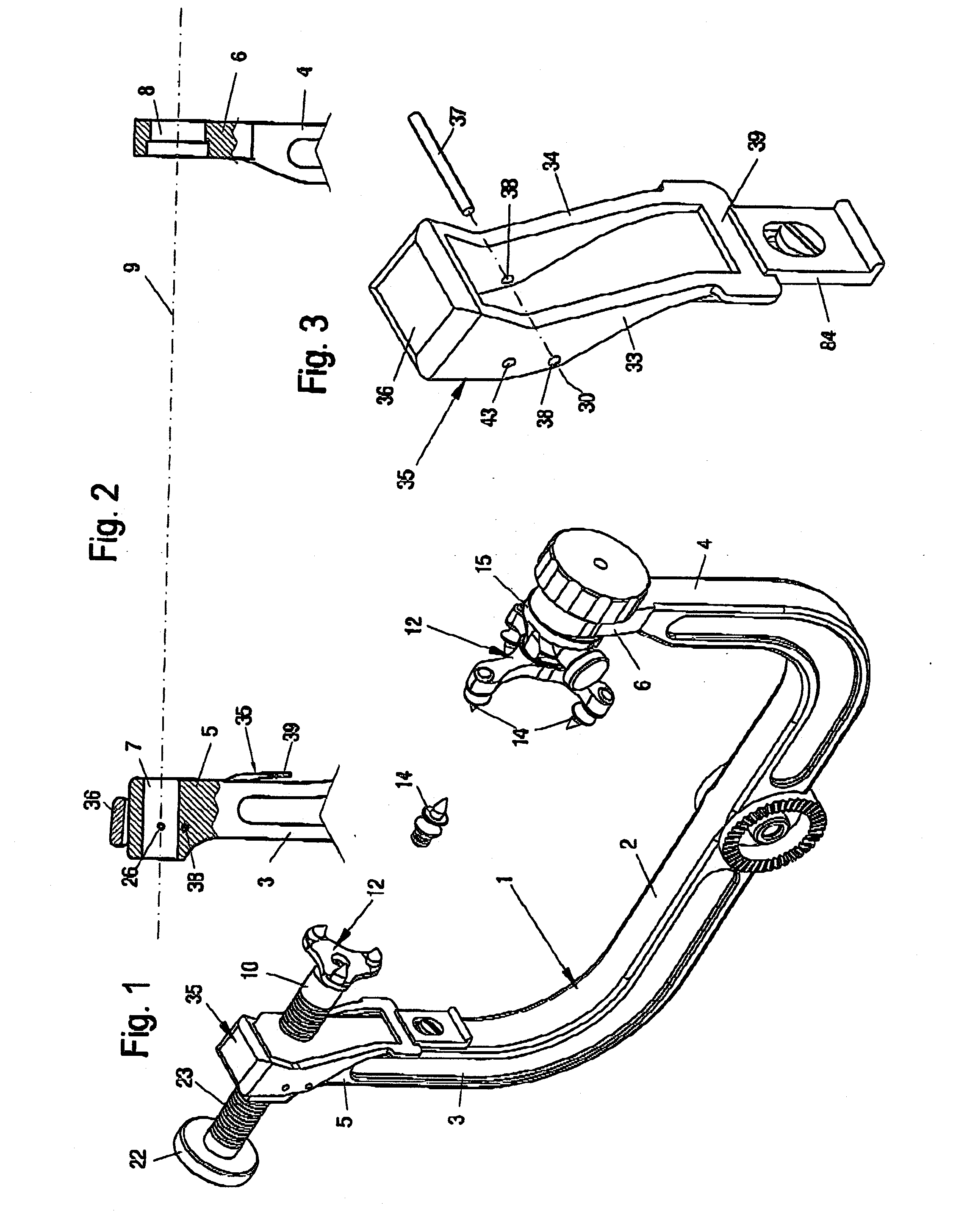

Rapid attach and release clamps

ActiveUS8167259B2Improve clampingQuickly attachCandle holdersLighting support devicesMechanical engineeringThreaded rod

Rapid attach and release clamps for attaching to supports include a threaded rod, an arm pivotally attached to the threaded rod, and a knob having an exterior surface and an interior surface. The knob defines a passageway sized to fit the threaded rod. A lock comprises at least one thread and is rotatably attached to the interior surface of the knob. The lock is constructed and arranged to move between a closed position with the thread entering the passageway and engaging the threaded rod and an open position with the thread not entering the passageway. A lever is moveably attached to the clamp and constructed and arranged to rotate the lock about a pivot point.

Owner:BAXTER HEALTHCARE SA +1

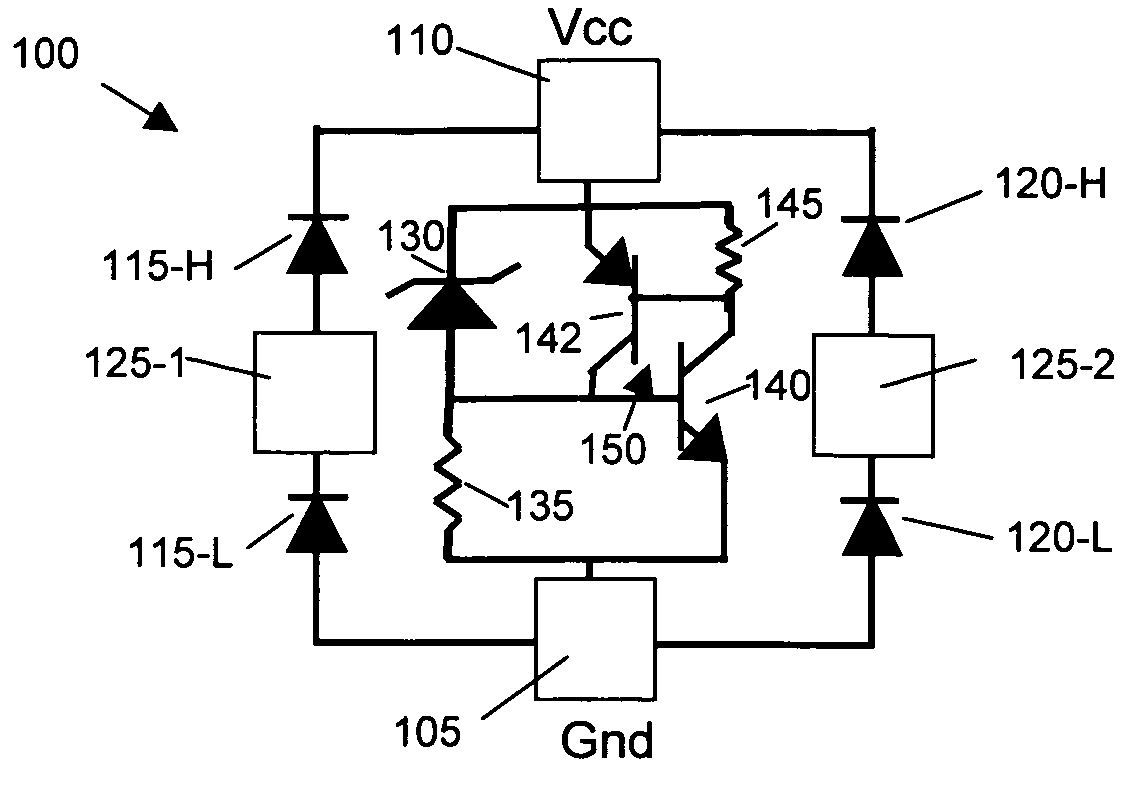

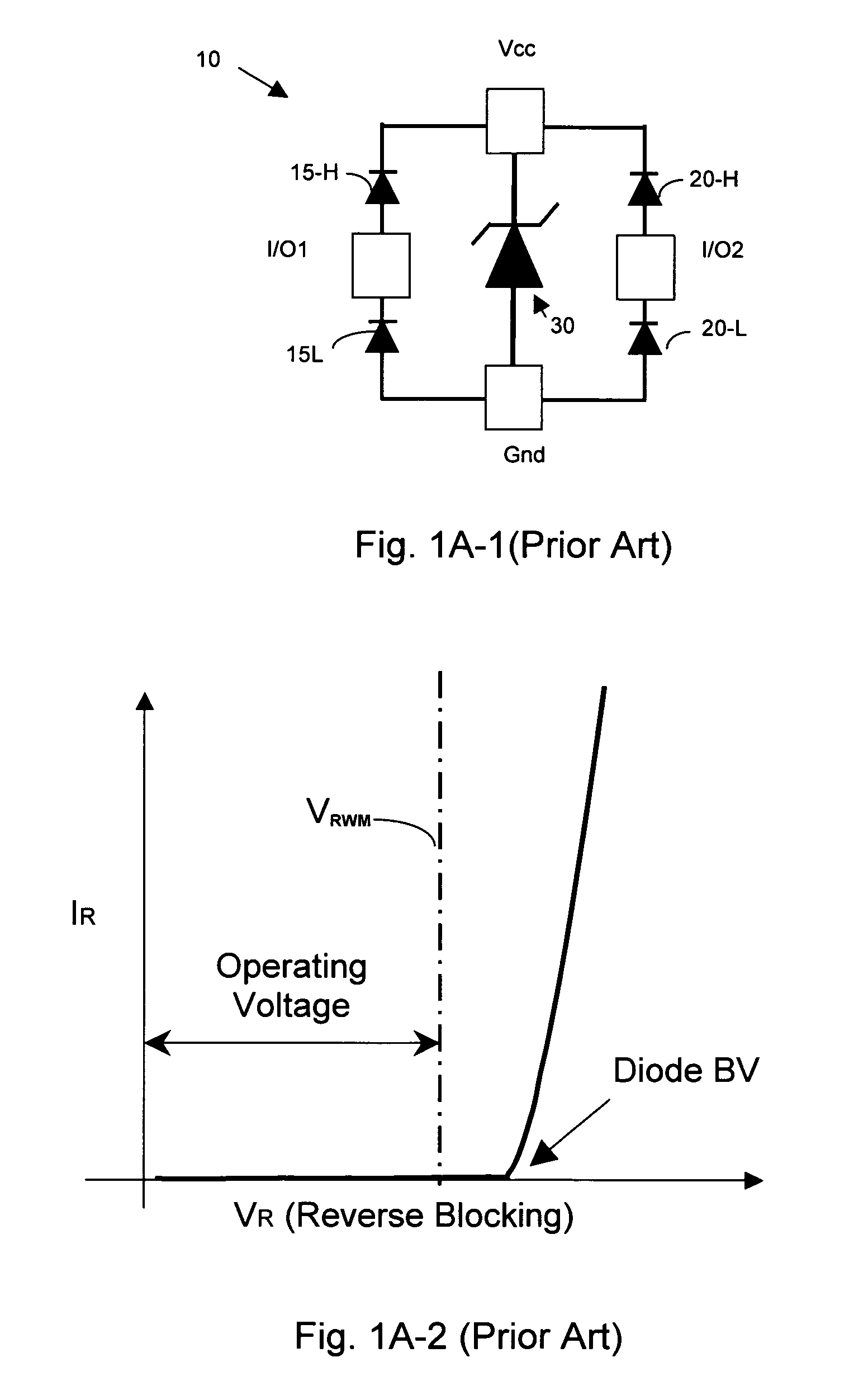

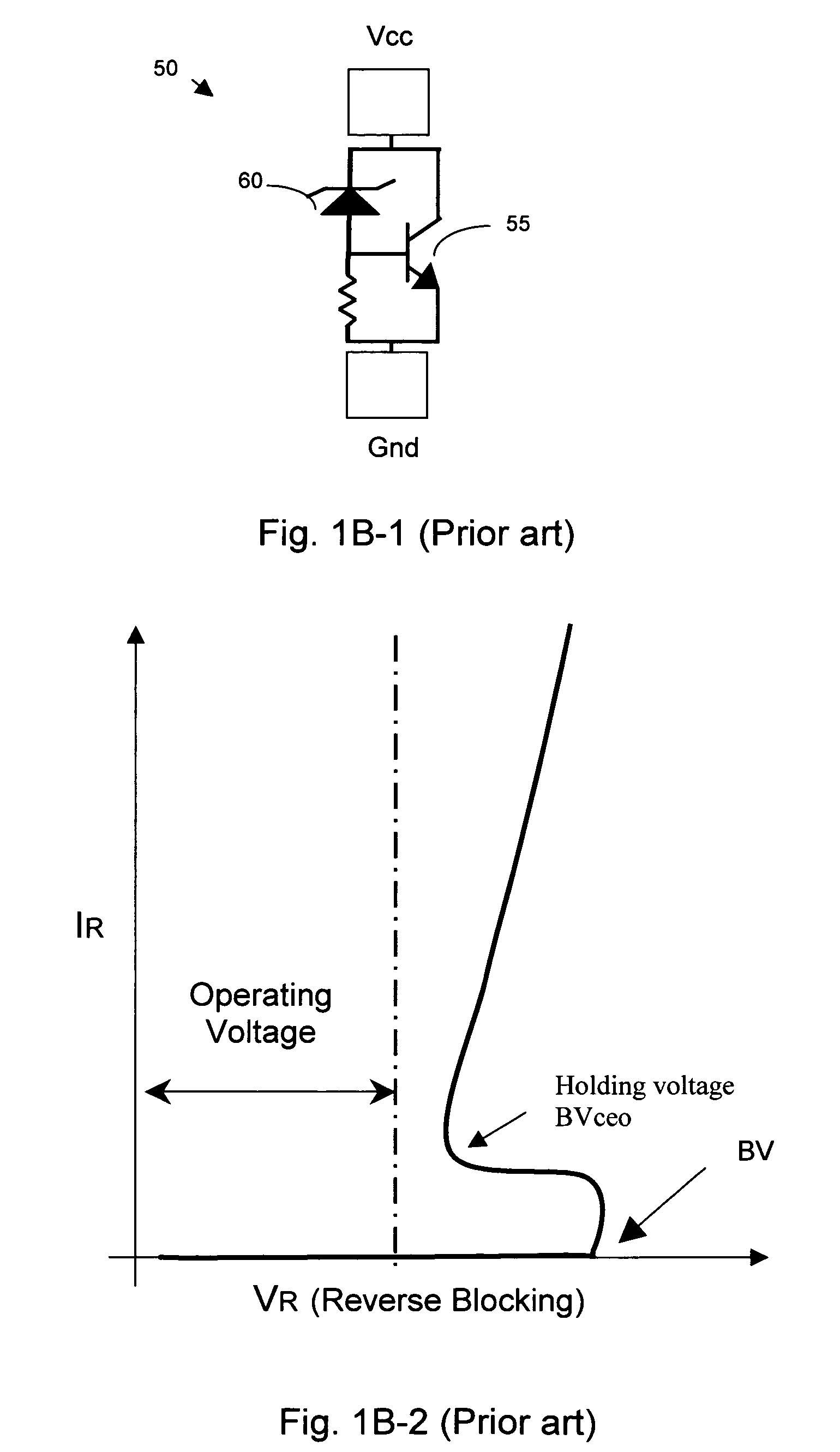

Circuit configurations to reduce snapback of a transient voltage suppressor

ActiveUS7538997B2Reduce voltage dropEasy clampingTransistorSolid-state devicesDevice formZener diode

Owner:ALPHA & OMEGA SEMICON LTD

Phase-change heat conductive material and preparation method thereof

The invention discloses a phase-change heat conducting material and the preparation method, mainly comprising the silicone 10 to 40 wt percent, the ethylene propylene diene rubber 2 to 20 wt percent, the heat conducting powder 40 to 70 wt percent, the paraffin 5 to 25 wt percent, the tackifier 5 to 35 wt percent and the resin acceptor 0.1 to 1.5 wt percent. The phase-change heat conducting material can be coated on the copper foil, the aluminum foil, the polyethylene naphthalatc film or the polyimide film in solution state in order to increasing the strength. The dissolved with the mixed refrigerant is solid in ambient temperature, so can be conveniently fixed between the radiator and the electronic device, GPU and CPU. When the temperature of the device is up to 40 to 70 degree C, the dissolved with the mixed refrigerant starts to soften and flow, so can fill with the air gap between the interfaces well, reduce the thermal resistance and accelerate the heat transference. The phase-change heat conducting material can be perfectly peeled off when maintaining or replacing the device and also can reuse.

Owner:NANJING KAIHUI IND TECH

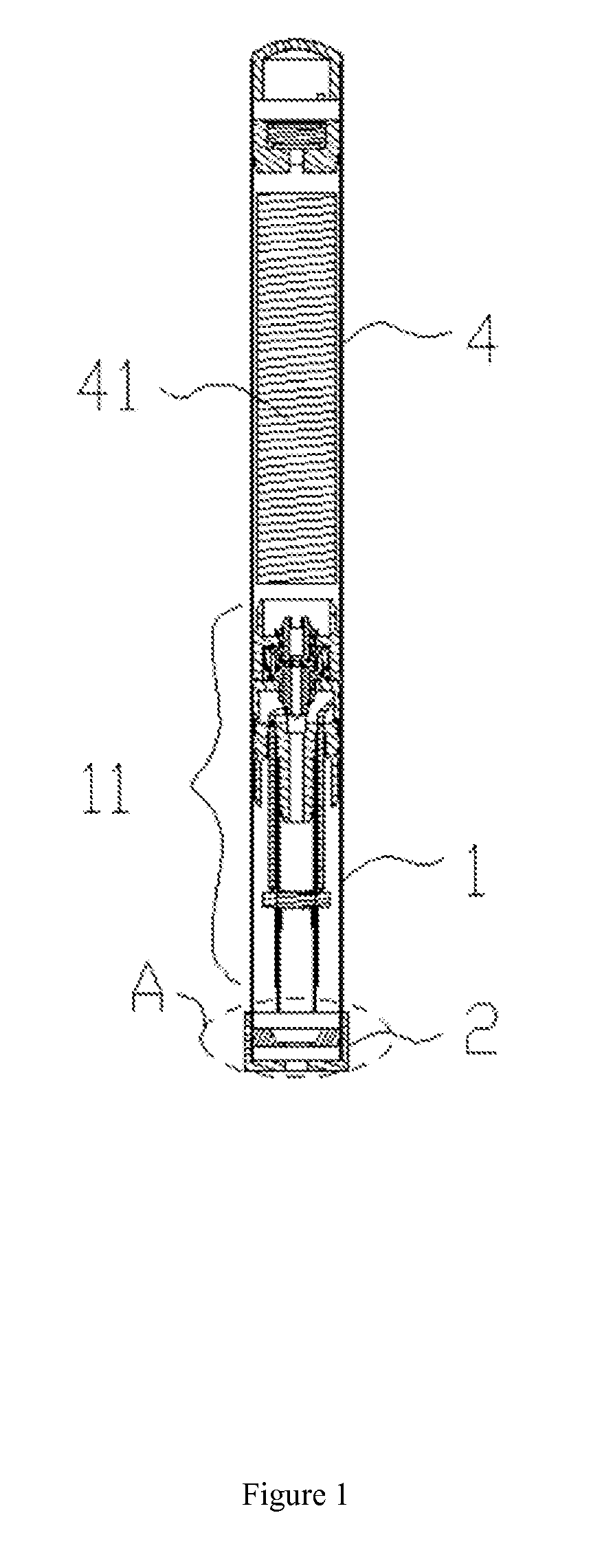

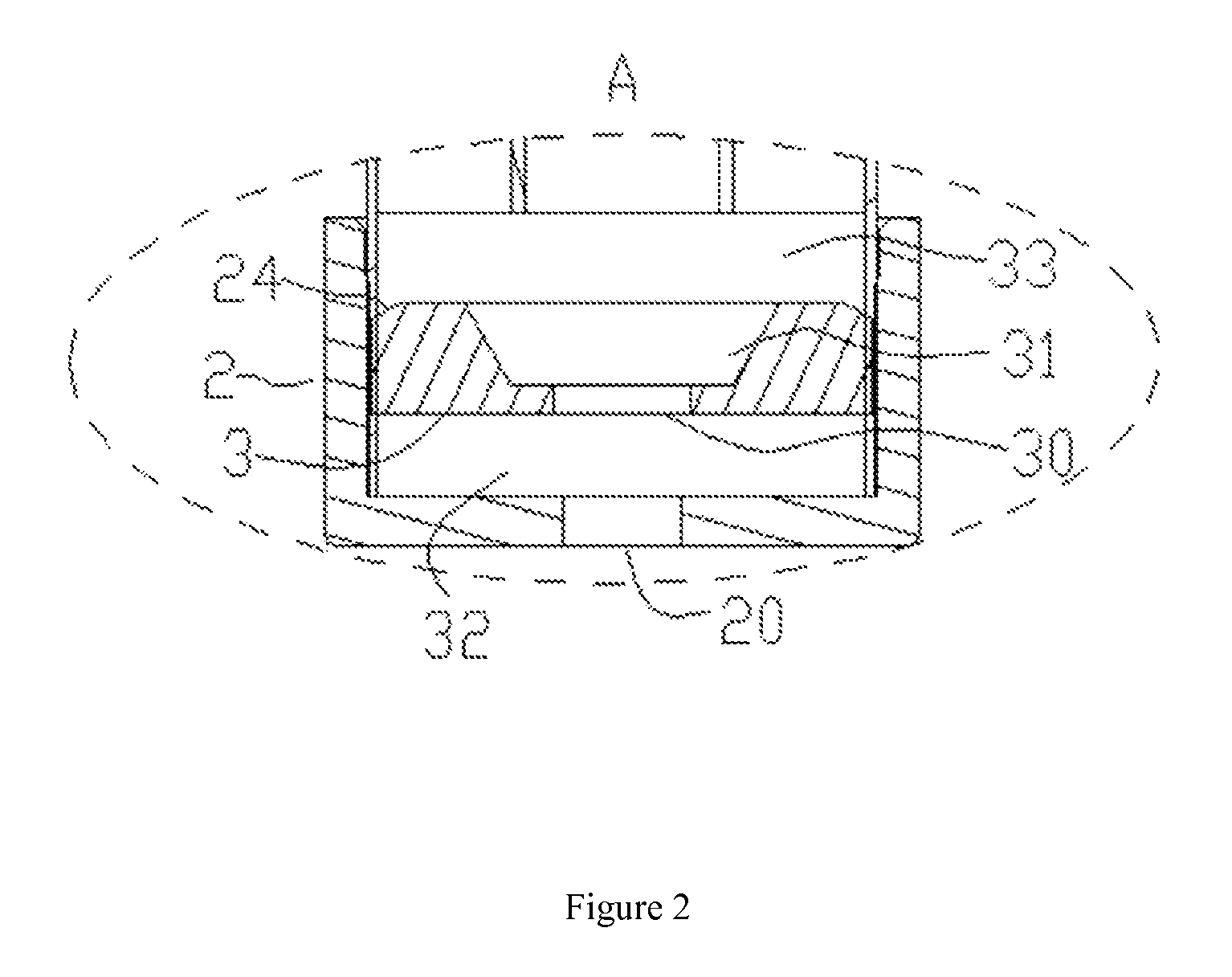

Electronic cigarette

InactiveUS9414627B2Great suctionStable and reliableTobacco pipesTobacco devicesElectronic cigaretteEngineering

Owner:HUIZHOU KIMREE TECH

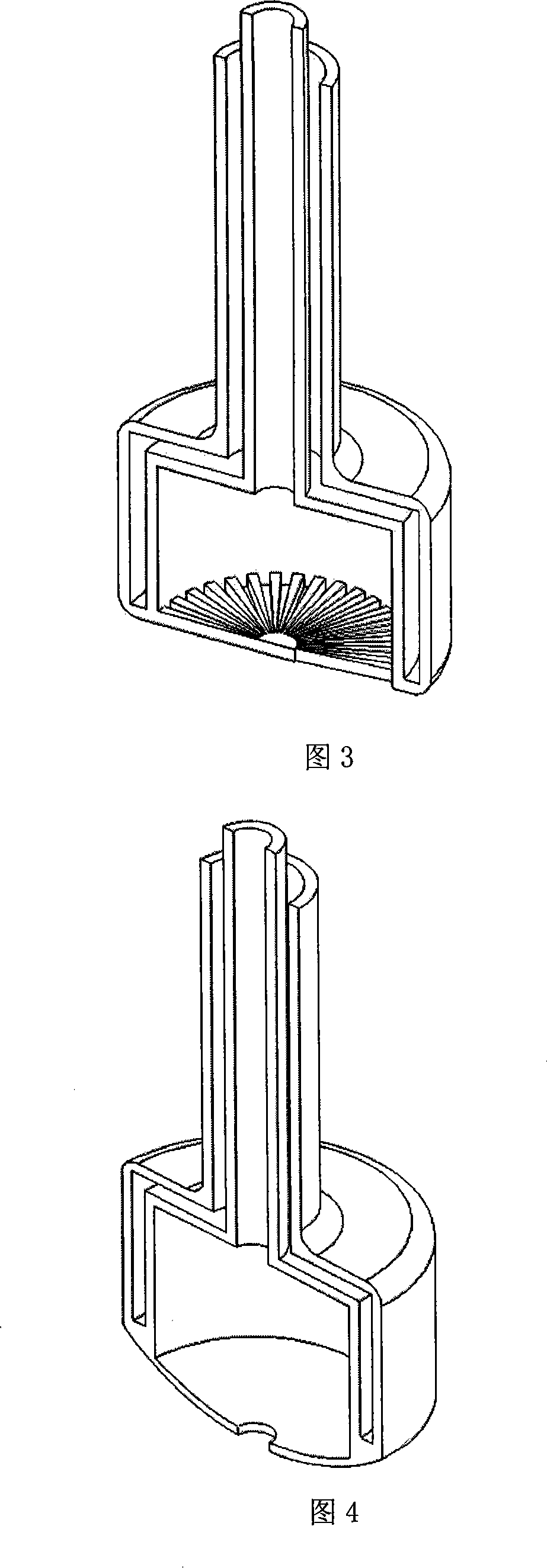

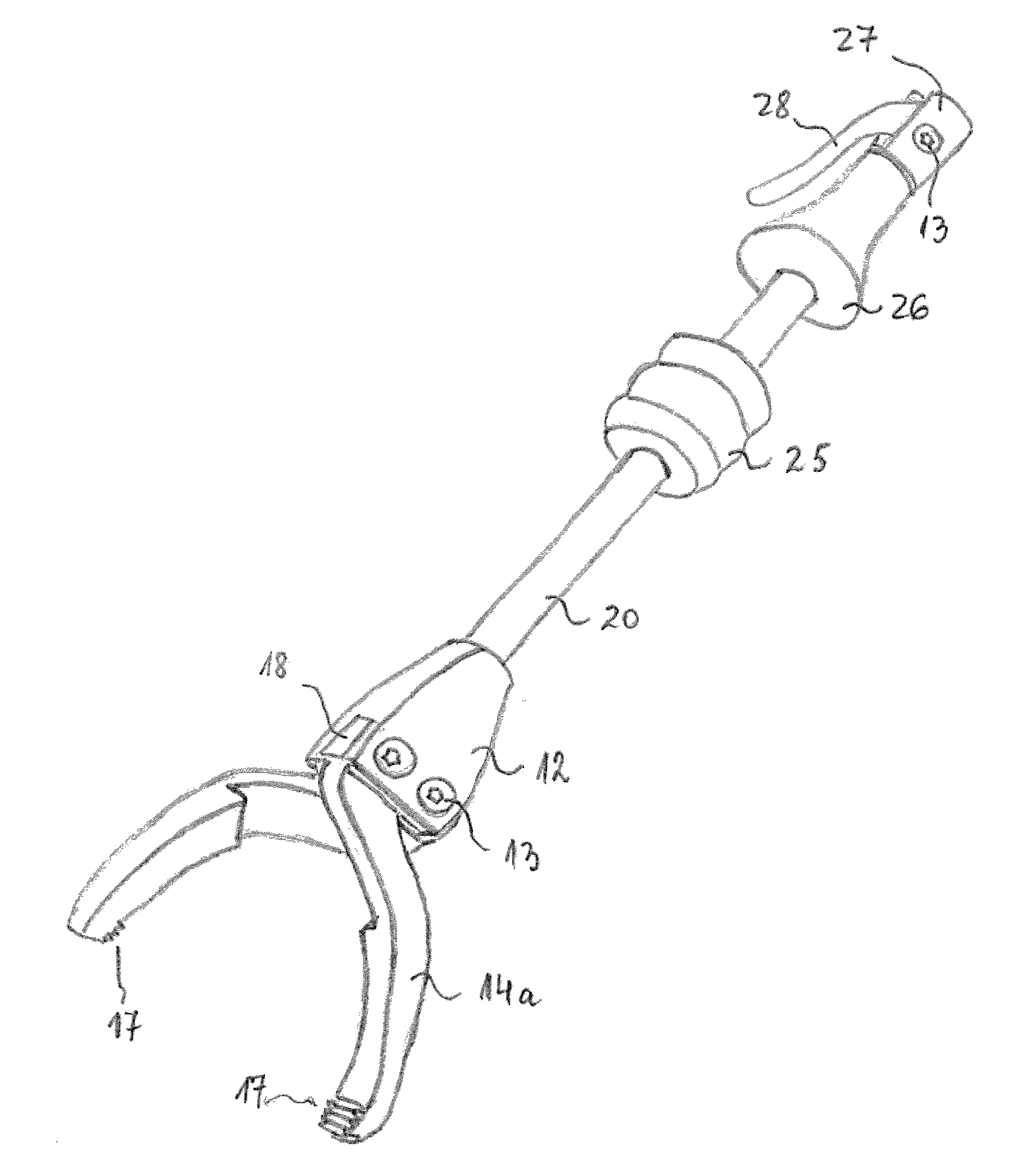

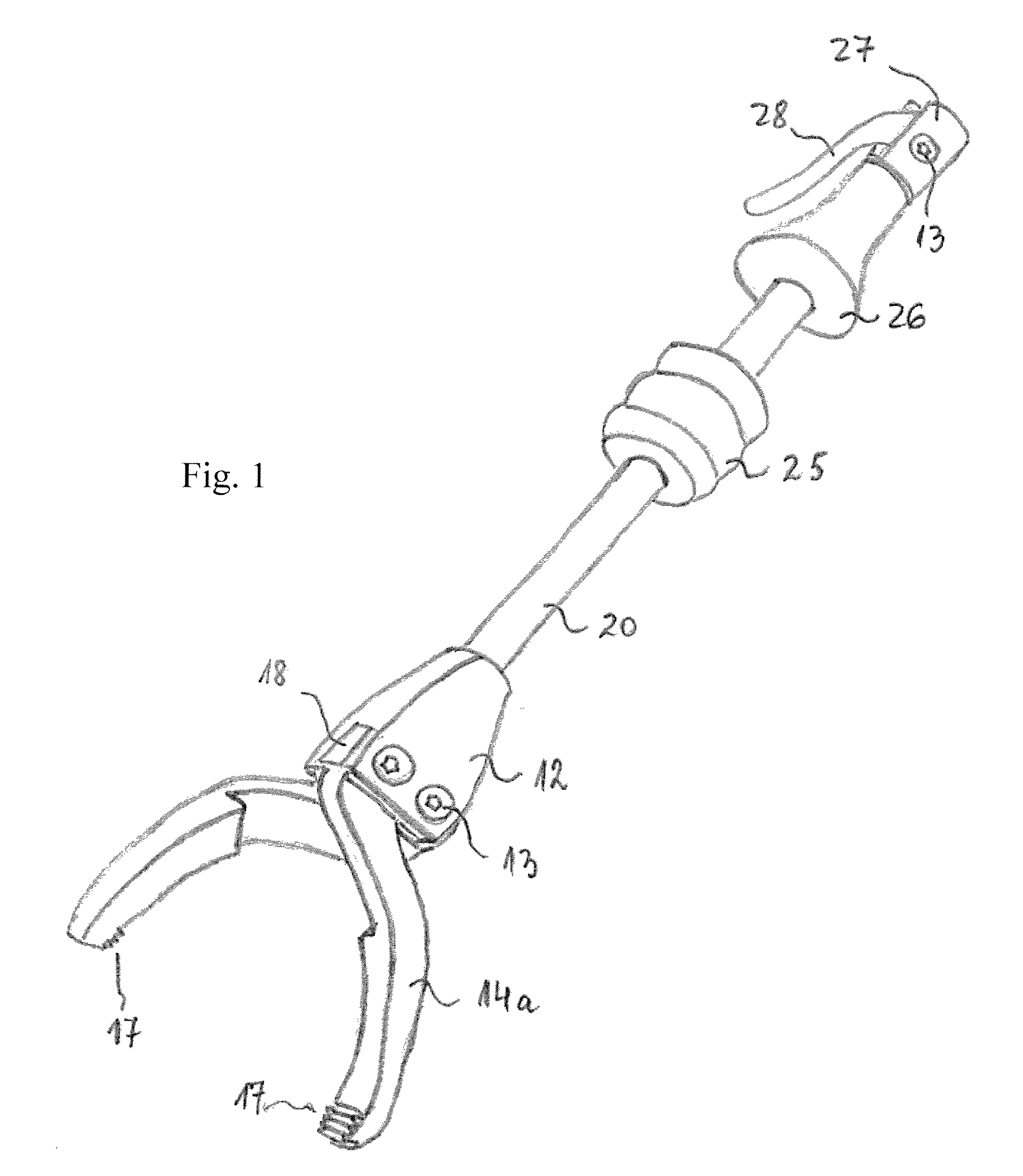

Knockout Tool for Minimally Invasive Prosthesis Revision

A tool head for a surgical tool for knockout and / or insertion of prostheses is disclosed, comprising a tool body (10, 11, 12) having at least two clamping jaws (14, 14a, 14b, 14c, 15, 15a, 15b, 41) for clamping a prosthetic part, wherein at least one of the clamping jaws is mounted to be movable in relation to the tool body (10, 11, 12); wherein at least one of the movable clamping jaws has at least one pressure area (16), which is arranged so that applying a pressure to the pressure area (16) of the at least one clamping jaw causes a movement of the clamping jaws (14, 14a, 14b, 14c, 15, 15a, 15b, 41) toward one another or away from one another, to thereby clamp the prosthetic part between the holding areas of the clamping

Owner:MUELLER ERICH JOHANN

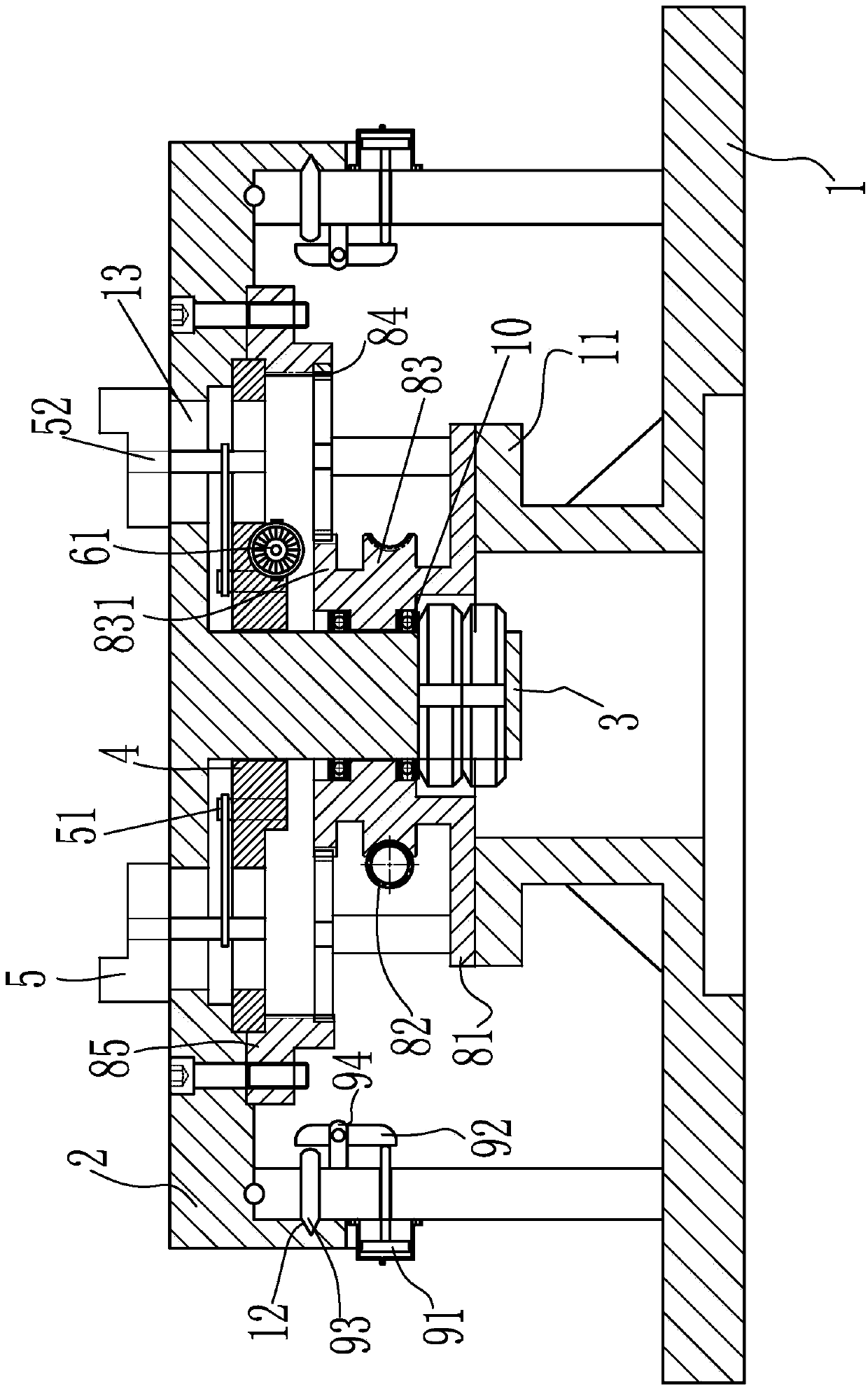

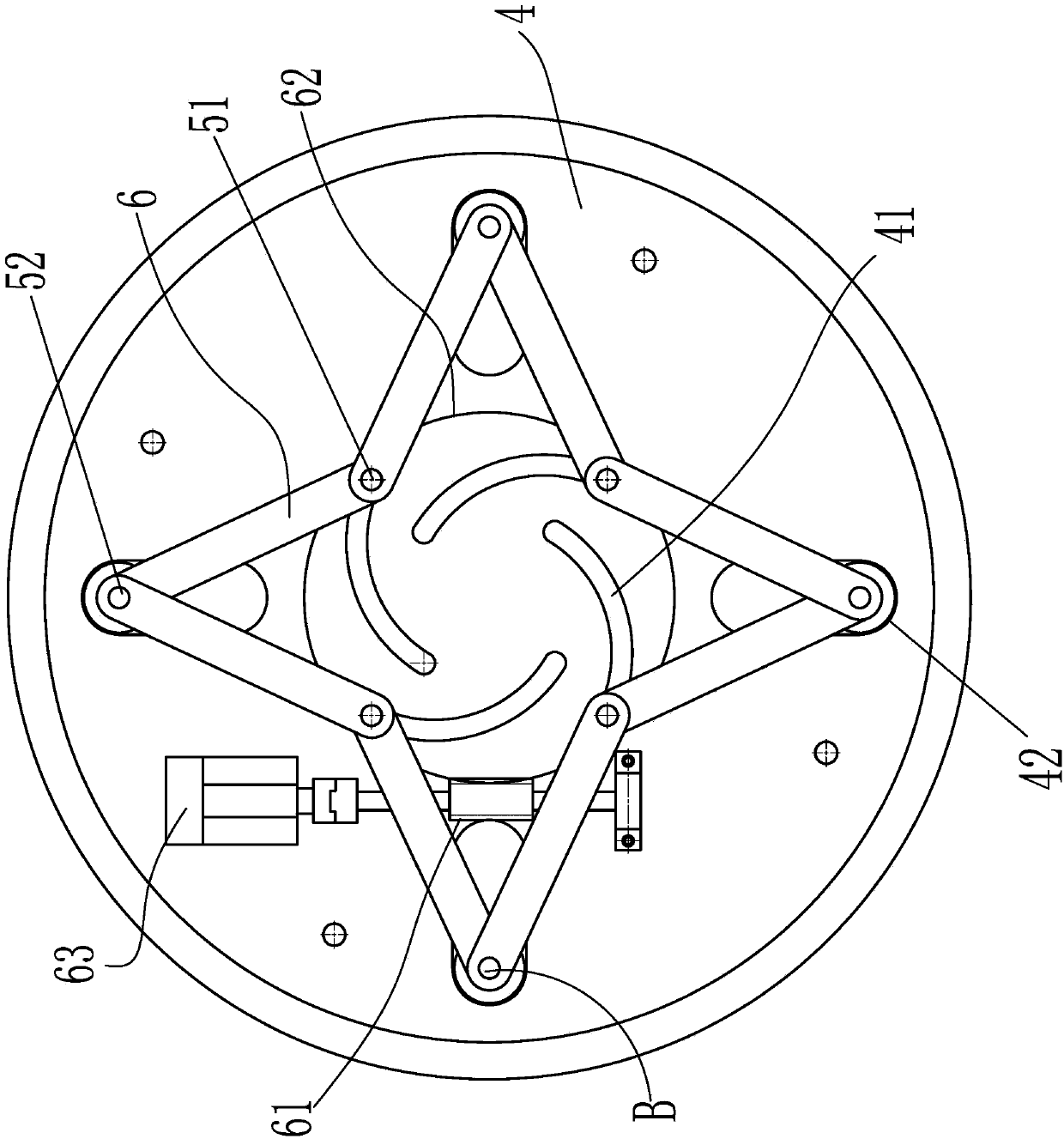

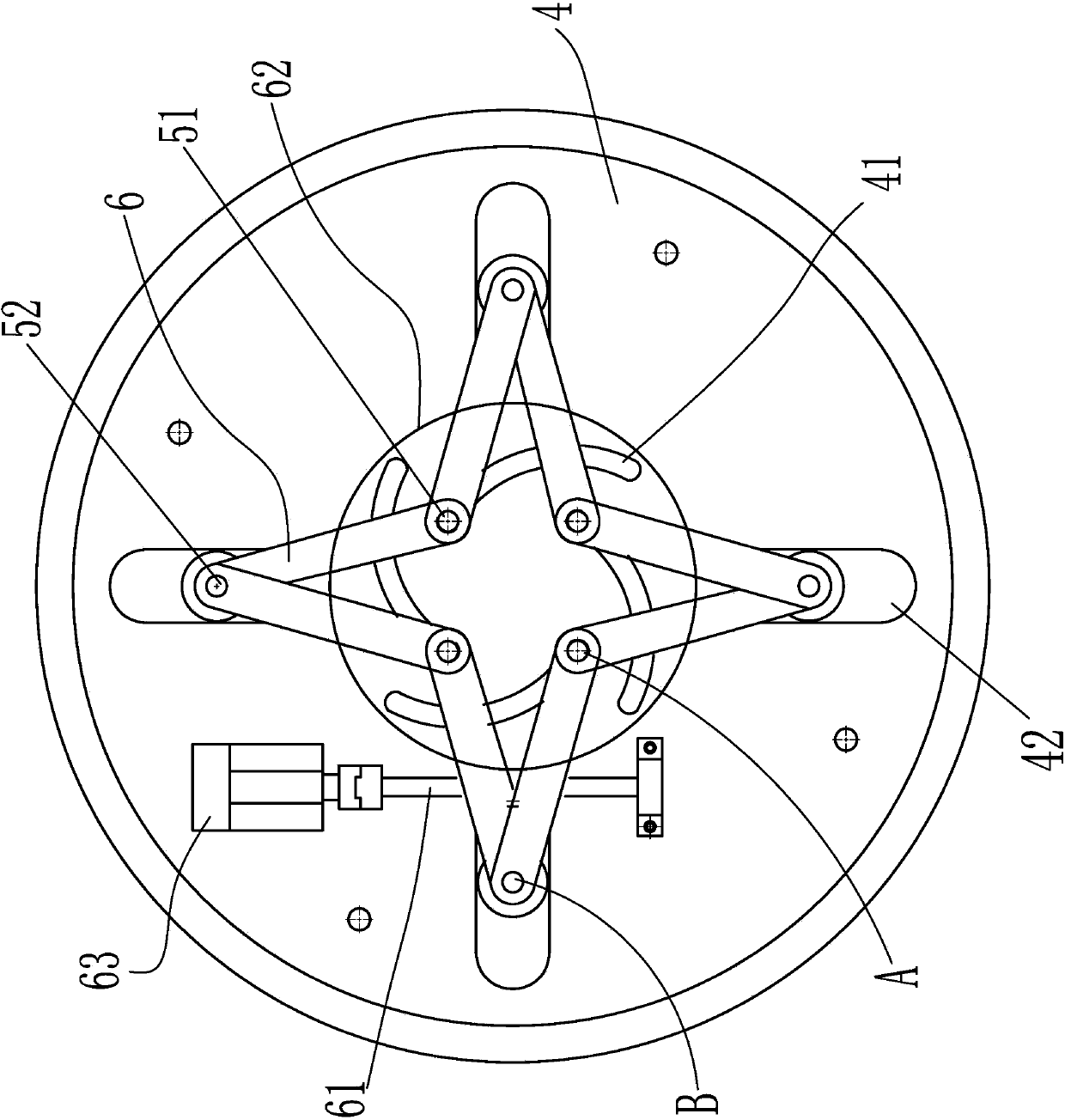

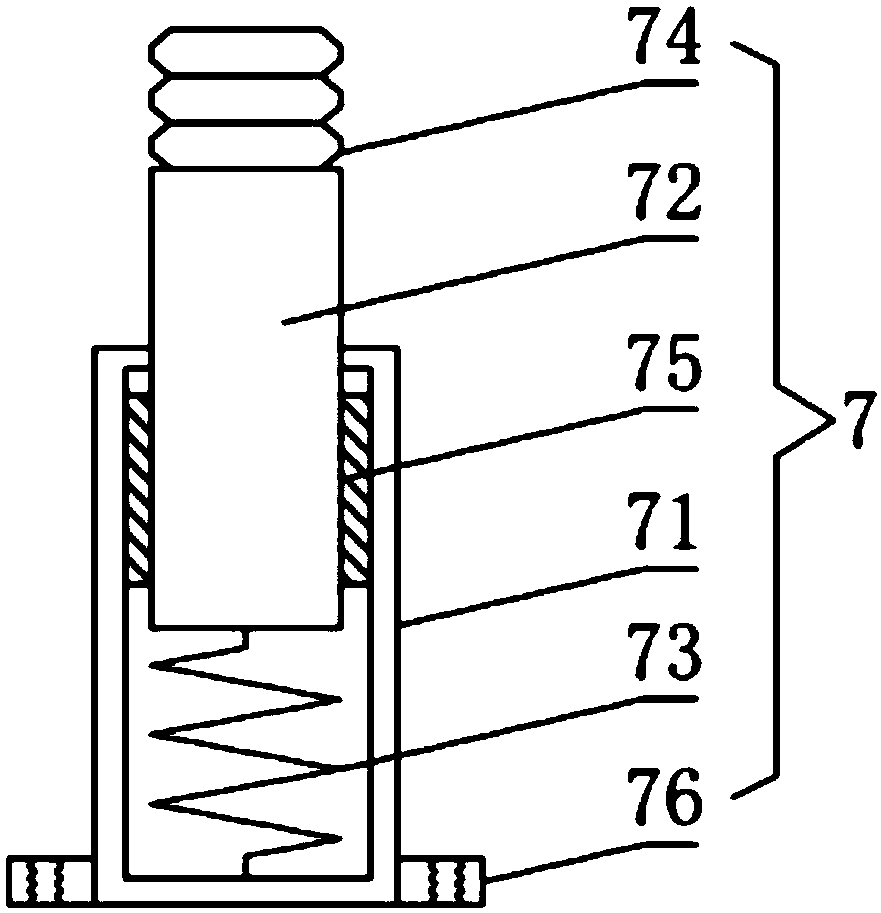

Self-centering clamping device of drill press workpiece

ActiveCN103801959AImprove processing efficiencyEasy to operateWork clamping meansFeeding apparatusLathe faceplateEngineering

The invention provides a self-centering clamping device of a drill press workpiece. The device can realize the self-centering function for a workpiece. The device comprises a connecting base, a workbench rotary disc, a main shaft, a parabola self-centering flower disc, a plurality of connecting rods and a plurality of positioning pawls, wherein the workbench rotary disc can be arranged above the connecting base in a rotary way, the main shaft is fixedly arranged below the middle part of the workbench rotary disc, the parabola self-centering flower disc can be arranged below the workbench rotary disc on the main shaft by a transmission mechanism in a rotary way, arc-shaped gradually slotting grooves are uniformly formed in the parabola self-centering flower disc in the radial direction, the head of one connecting rod is hinged to the end of the other connecting rod, both ends of each of the connecting rods are respectively a first hinging end and a second hinging end, the first hinging ends are respectively hinged to the arc-shaped gradually slotting grooves on the parabola self-centering flower disc, long hinging grooves corresponding to the positions of the peripheral sides of the arc-shaped gradually slotting grooves are respectively formed in the parabola self-centering flower disc, the second hinging ends are respectively hinged to the long hinging grooves in a hinge way, and the positioning pawls are respectively arranged above the second hinging ends of the connecting rods.

Owner:HUHANG TECH GRP CO LTD

Electronic cigarette

InactiveUS20150027462A1Great suctionStable and reliableTobacco pipesTobacco devicesEngineeringElectronic cigarette

An electronic cigarette is provided, comprising an outer sleeve and a suction nozzle cap mounted at one end of the outer sleeve; wherein, the suction nozzle cap is sheathed on the outer sleeve, and an inner wall of the suction nozzle cap is located at the outside of an outer wall of the outer sleeve. The suction nozzle cap is sheathed on the outer sleeve, the disassembly of the suction nozzle cap is more convenient, and the structure design of the suction nozzle cap is diversified.

Owner:HUIZHOU KIMREE TECH

Automatic die-changing processing equipment

ActiveCN102601245AQuick die changeImprove processing efficiencyShaping toolsIndustrial engineeringSelf weight

The invention relates to automatic die-changing processing equipment which comprises a frame, a punch, a working table and at least two dies arranged horizontally on the working table. The frame is provided with a bearing table for fixing the working table. A lifting track extending horizontally is arranged on the bearing table in a liftable way. The working table is arranged above the lifting track. The lifting track has two working positions. When the lifting track is located in the first working position, the upper part of the lifting track protrudes out of the upper surface of the bearing table, the lifting track is supported below the working table, and the lower surface of the working table is separated from the upper surface of the bearing table. When the lifting track is in the second working position, the lifting track is held in the bearing table, the upper part of the lifting track is not higher than the upper surface of the bearing table, and the bearing table is supported below the working table. The automatic die-changing processing equipment lifts the working table through the lifting track and is fixed by the self-weight of the die, so that a plurality of dies can be changed rapidly.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

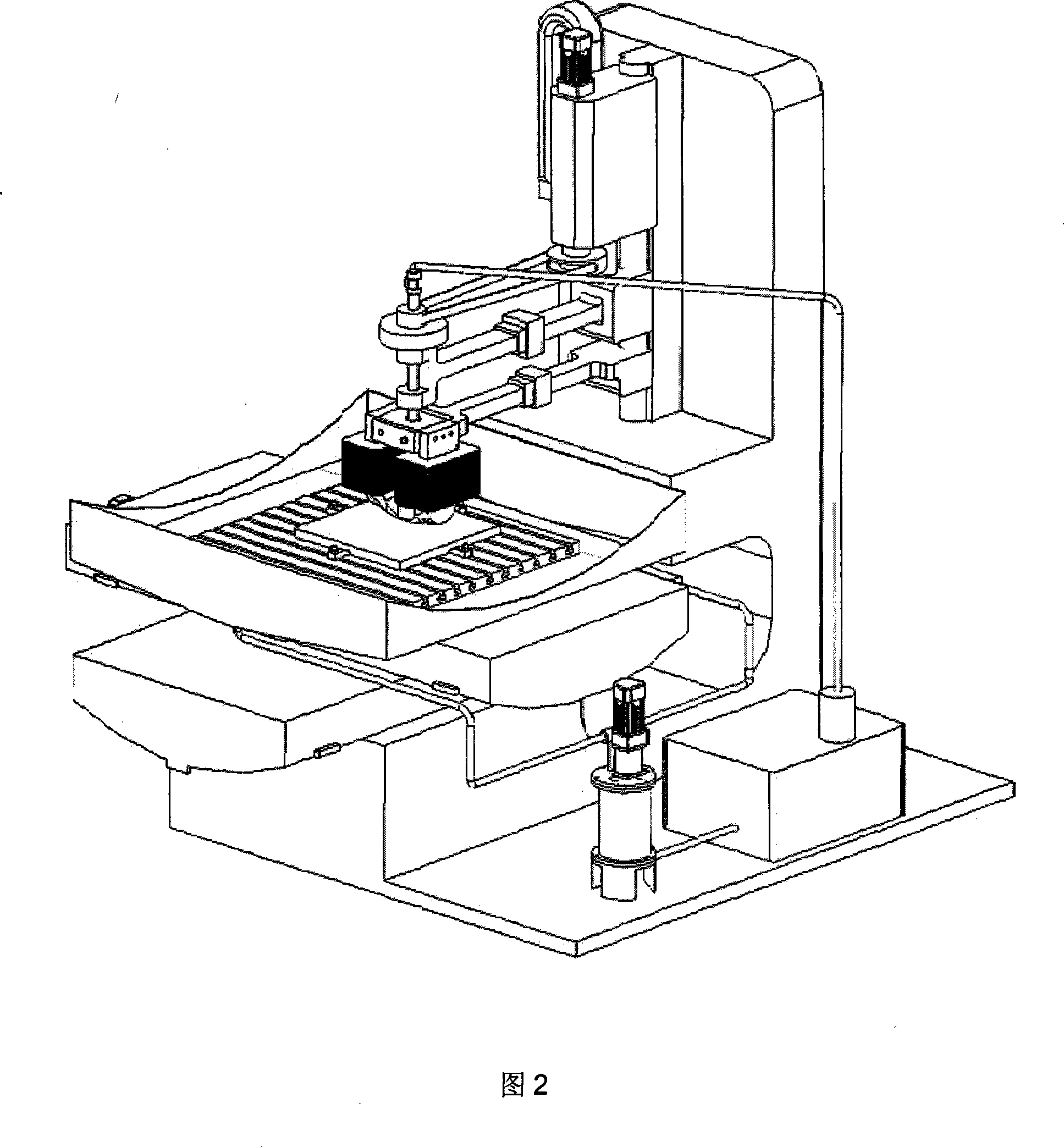

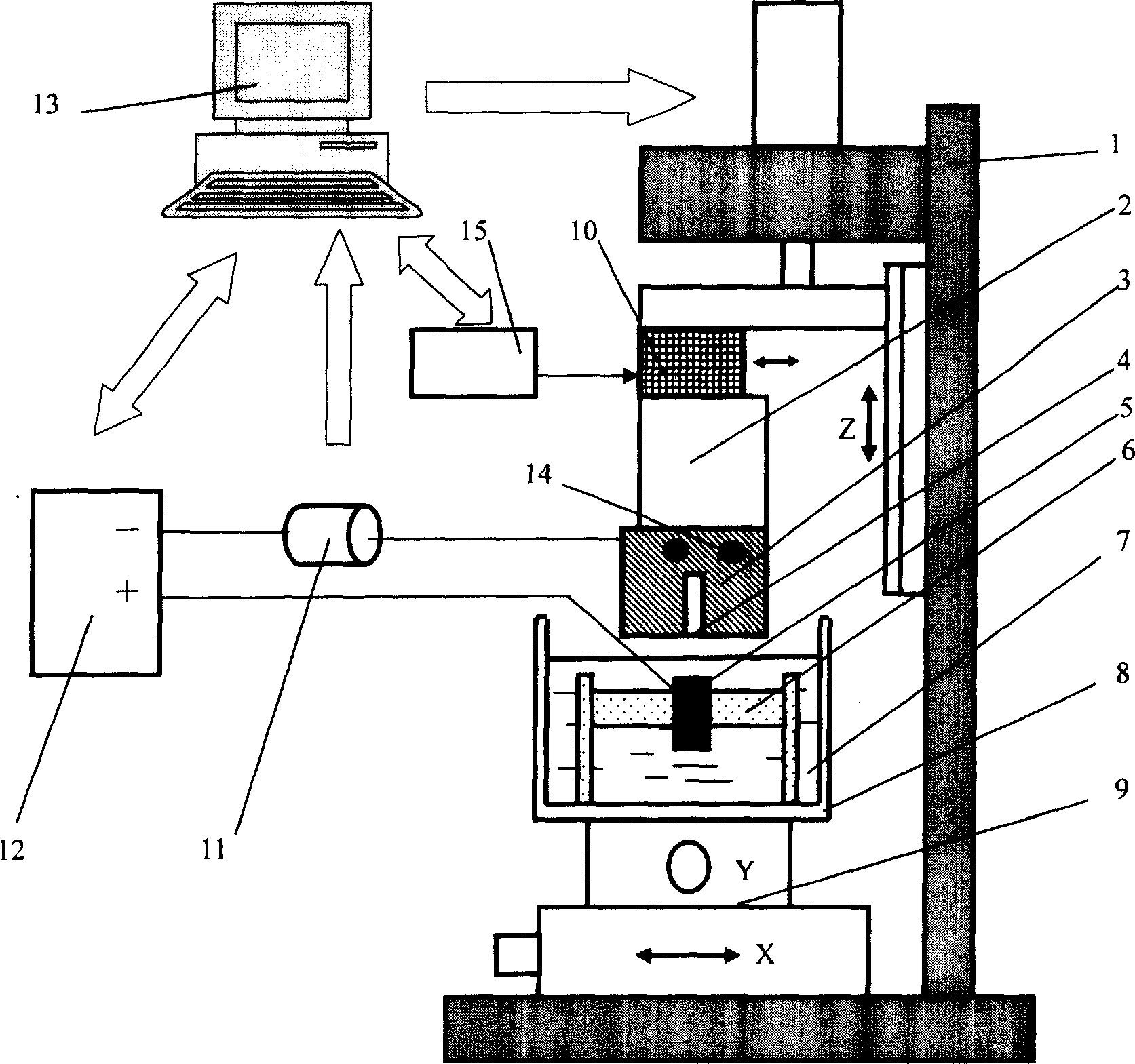

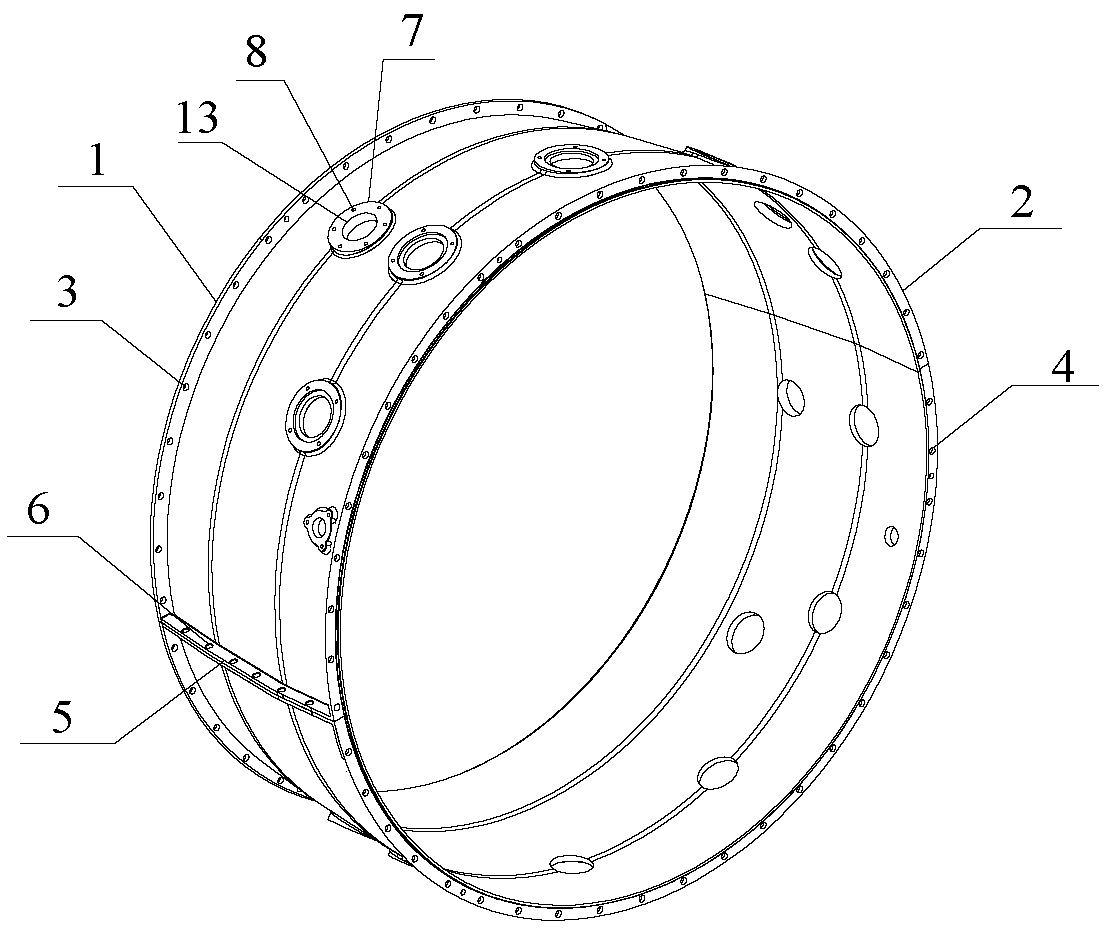

Micro-scale line electrode electrolysis machining method and micro-vibration line electrode system

InactiveCN1850411AEasy to excludeAvoid short circuitMechanical vibrations separationElectrical-based machining electrodesNumerical controlElectrolysis

The present invention relates to a microdimesion wire electrode electrolytic machining method. It is characterized by that in the course of electrolytically microcutting metal material by using wire electrode it utilizes a microvibration device to make the wire electrode produce microvibration perpendicular to its feeding direction, so that it is favourable for discharging electrolytic product from machining gap so as to prevent the short circuit from producing and greatly raise electrolytic quality. Said microvibration wire electrode system is mounted on the Z-axis of numerical control machine tool and is formed from wire electrode frame, microdimension wire electrode mounted on the wire electrode frame and microvibation device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

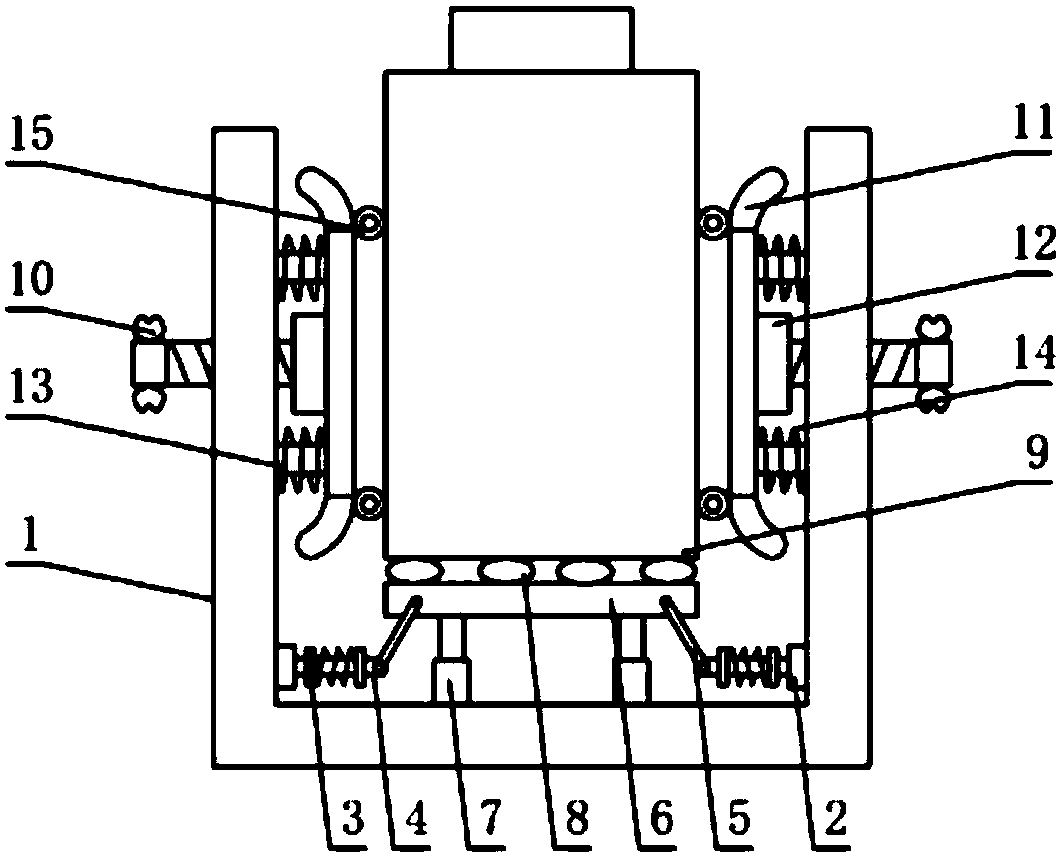

Mining excavator with cabinet body damping device

InactiveCN107869548AEasy clampingProtection securitySoil-shifting machines/dredgersVibration suppression adjustmentsCushioningAtmospheric pressure

The invention discloses a mining excavator with a cabinet damping device in the technical field of excavators, comprising a damping shell, the other end of the air pressure damping rod is hinged to a transmission rod through a connecting piece, and the shock absorbing base The four corners of the bottom are equipped with shock-absorbing feet, the top of the shock-absorbing base is uniformly provided with shock-absorbing airbags, the outer walls of the left and right sides of the shock-absorbing shell are symmetrically provided with two sets of adjusting screws with the same structure, and the guide plate is opposite to the top of the inner wall. There are two sets of guide pulleys with the same structure symmetrically to the bottom. The device is easy to operate. Rotate the adjustment screw to make the guide pulleys clamp the frequency conversion cabinet to prevent the frequency conversion cabinet from shaking left and right in the inner cavity of the shock-absorbing shell. The shock-absorbing base passes the shock-absorbing The airbag is equipped with a frequency conversion cabinet, and the shock-absorbing airbag evenly transmits the vibration of the frequency conversion cabinet to the shock-absorbing base. , to improve the stability of the frequency conversion cabinet.

Owner:高邮市迅达工程机械集团有限公司

Machining method of aircraft engine crankcast

The invention provides a machining method of an aircraft engine crankcast. The machining method can solve the problems that when an existing crankcast machining method is used, crankcast deformation is large, machining precision is low, the manufacturing period is long, and the machining difficulty is large. The method comprises the following steps of blank dimension re-inspection, rough turning of a large end and a small end, rough milling of shape contour, stress relief heat treatment, trimming of a large end datum and a small end datum, finish milling of two side faces of a longitudinal installing side and longitudinal installing side holes, segmentation, grinding and trimming of wire-electrode cut end faces, pre-assembling, semi finish turning of the large end and the small end, drilling of angular locating holes, semi finish milling of the shape, finish turning of the small end, finish milling of the shape and a small end installing side hole, finish reaming of the longitudinal installing side holes, finish turning of the large end, finish milling of a large end installing side hole, thread tapping, laser marking, dying check, fluorescence penetrant inspection and final inspection.

Owner:无锡航亚科技股份有限公司

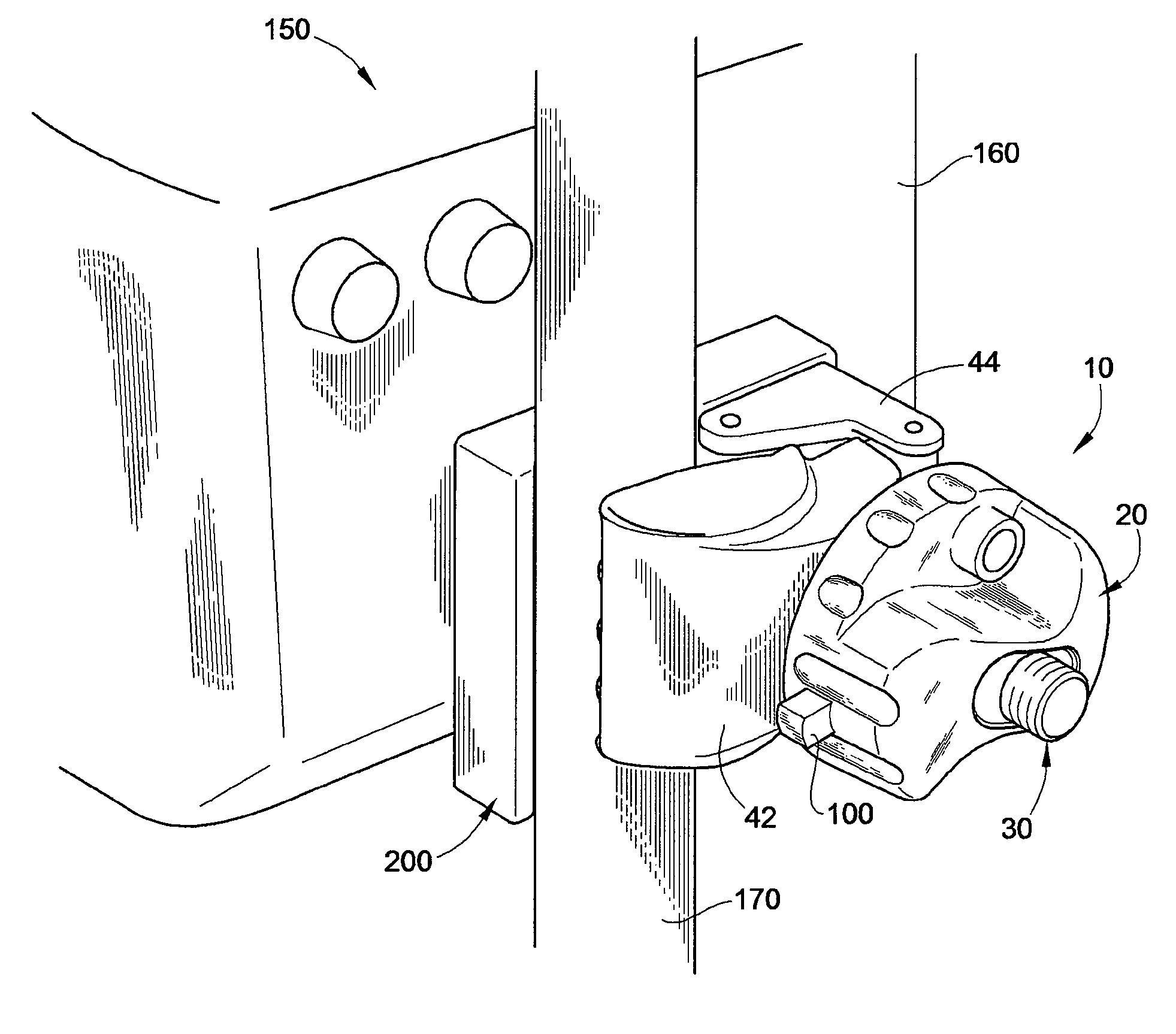

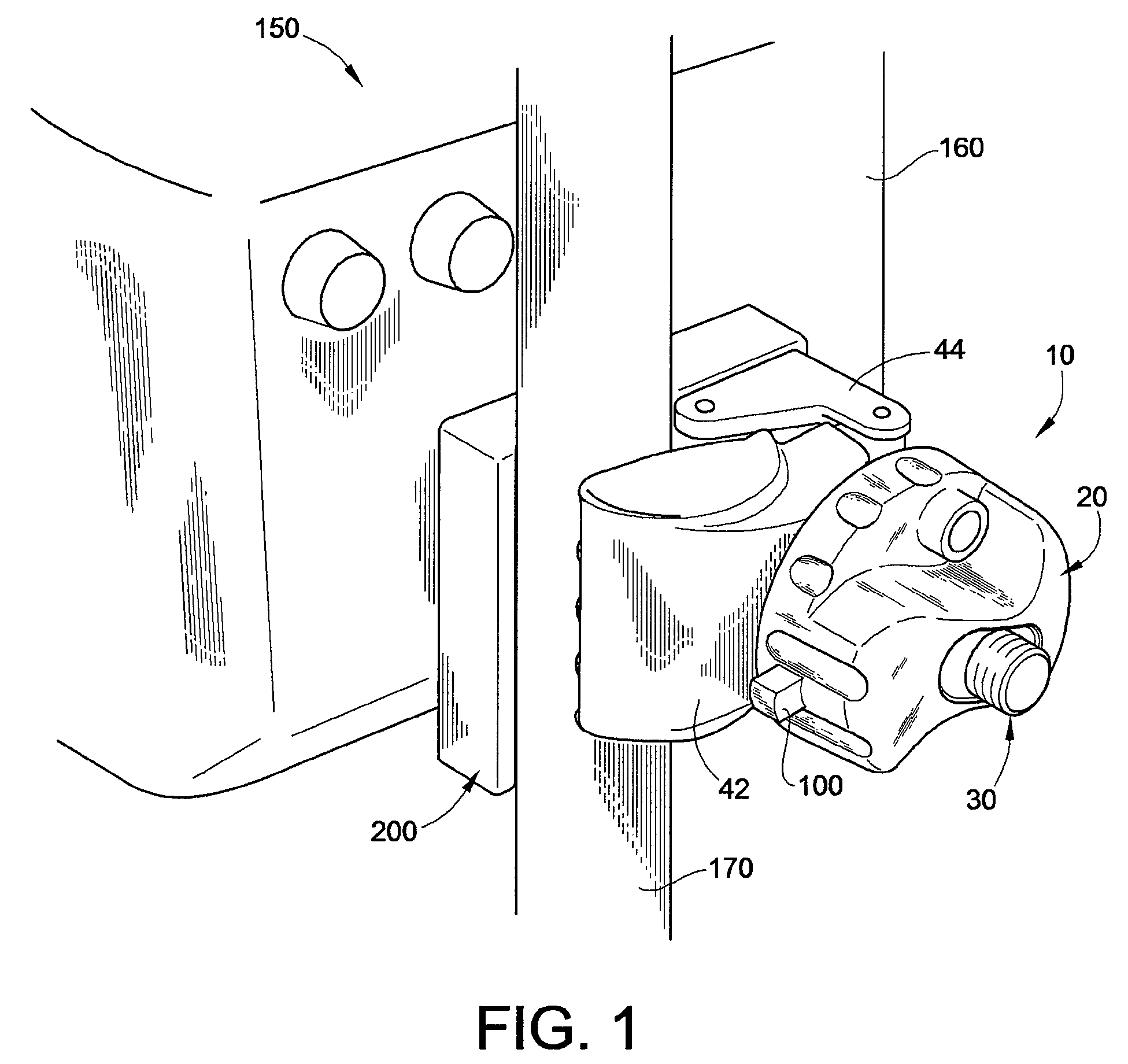

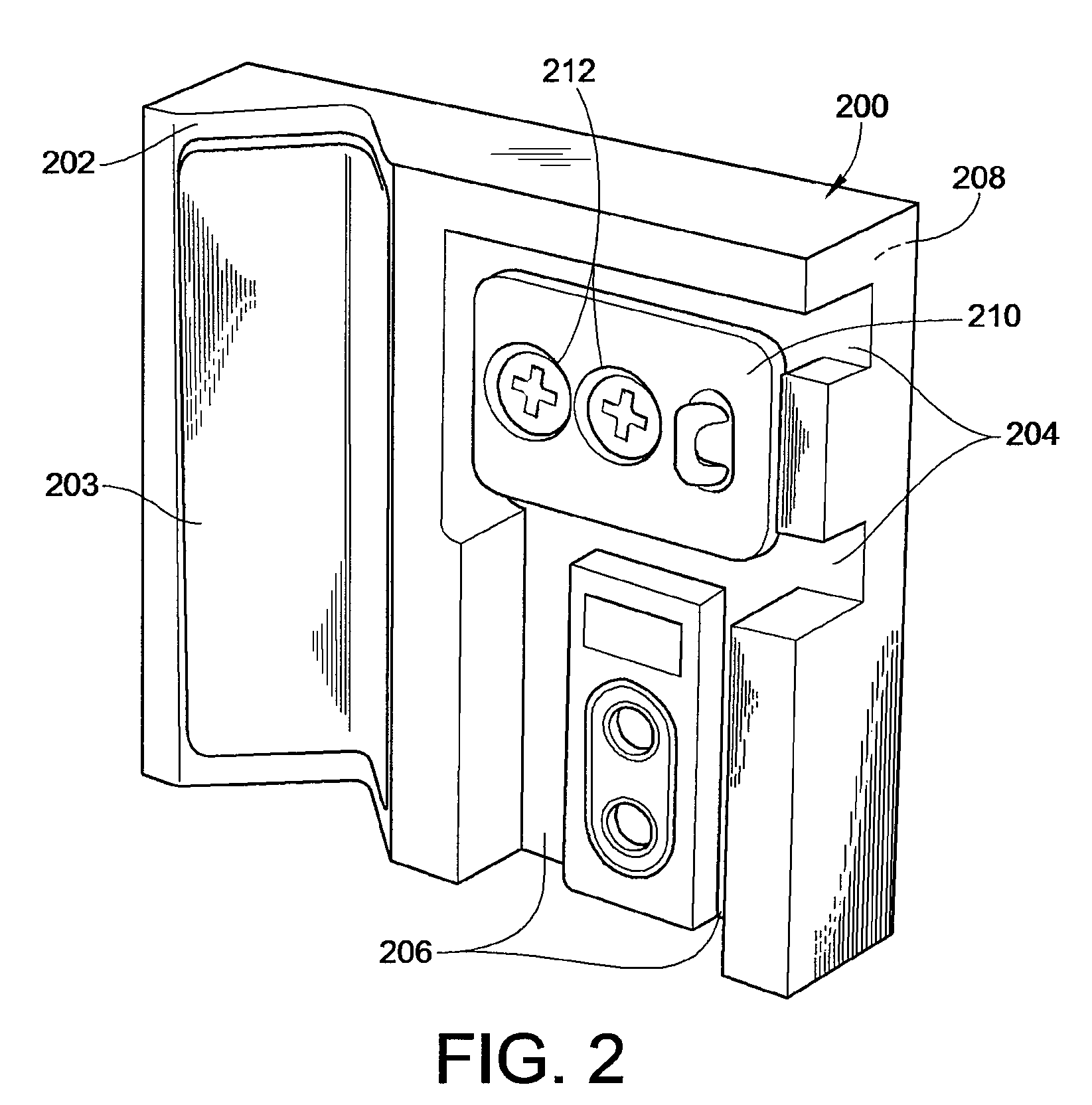

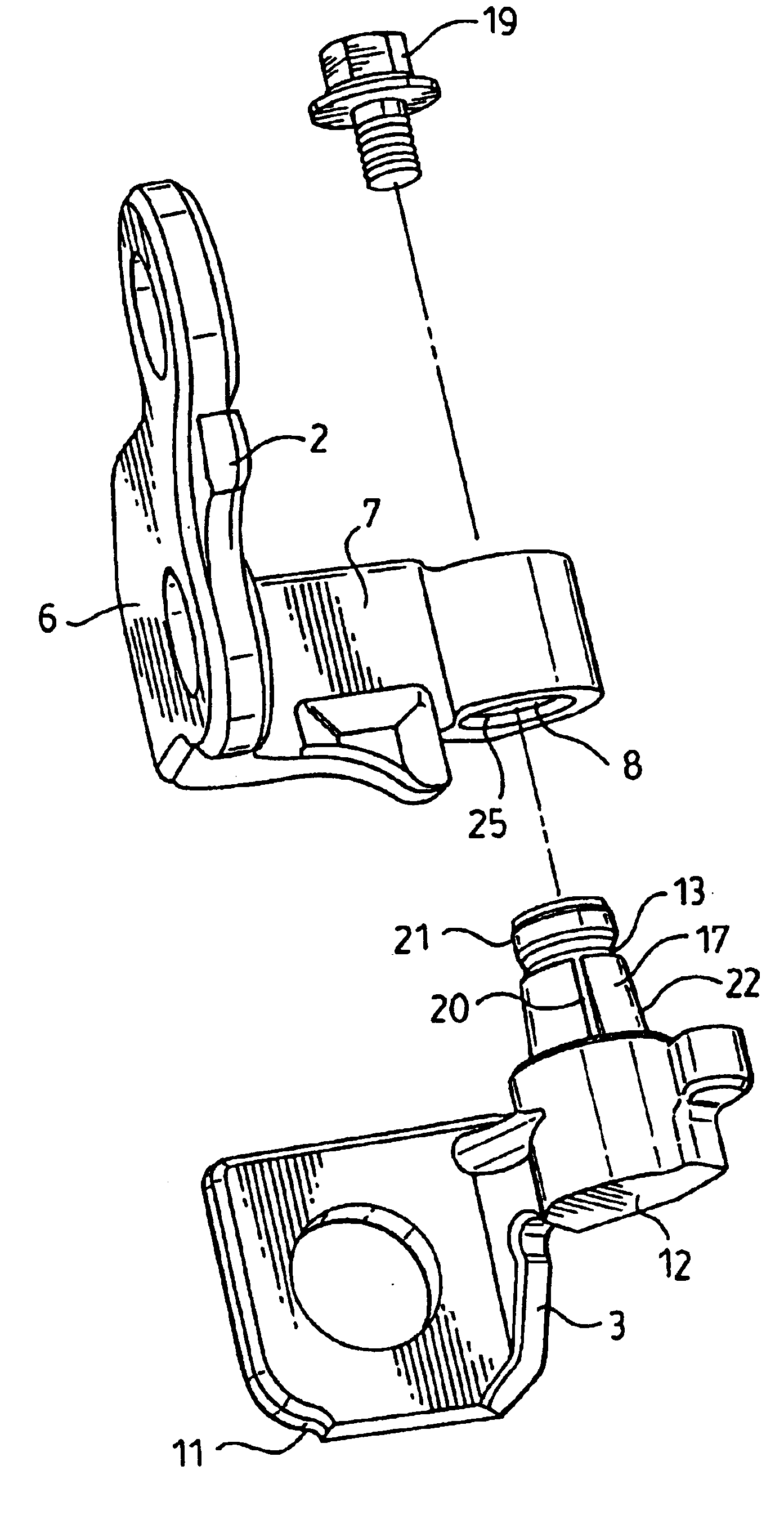

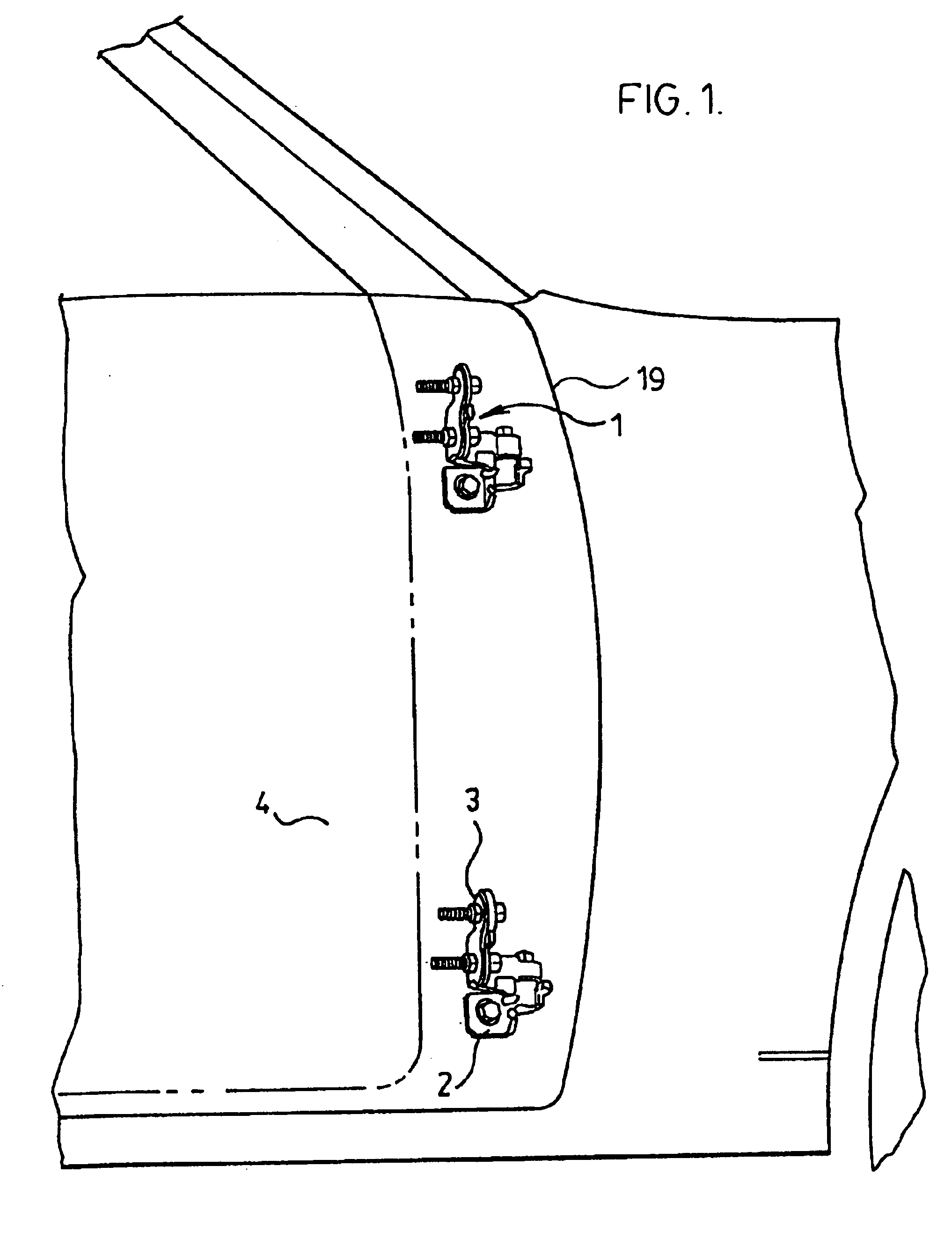

Automotive door hinge with structurally integrated pivot

An automotive hinge comprises: a door component adapted to be mounted to a vehicular closing panel, the door component comprising a conical pivot axis aperture; a body component adapted to be mounted to a vehicular body structure, said body component comprising a pivot arm; the door component and the body component being adapted to rotate about a pivot axis; the body component comprising an upstanding, conical structural feature extending from the body component and adapted to be coaxially aligned with the pivot axis and structurally fixed to the pivot arm of the body component; the conical structural feature comprising an external conical bearing surface; such that when the hinge is assembled, the door component interleaves over the body component, dimensionally locating the door and body components by means of the walls of the conical pivot axis aperture of the door component interacting with the external conical bearing surface of the conical structural feature. In an alternative embodiment, the conical structural feature is located on the door component and the body component is adapted to receive it.

Owner:MULTIMATIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com