Bearing-type damage biomechanic three-point bending test device and bearing-type damage biomechanic three-point bending method

A biomechanical and three-point bending technology, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve the problems of large deformation resistance, large influence of test results, and large friction force, and meet the requirements of material performance impact. Satisfying the diversity of geometric dimensions and reducing the impact of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

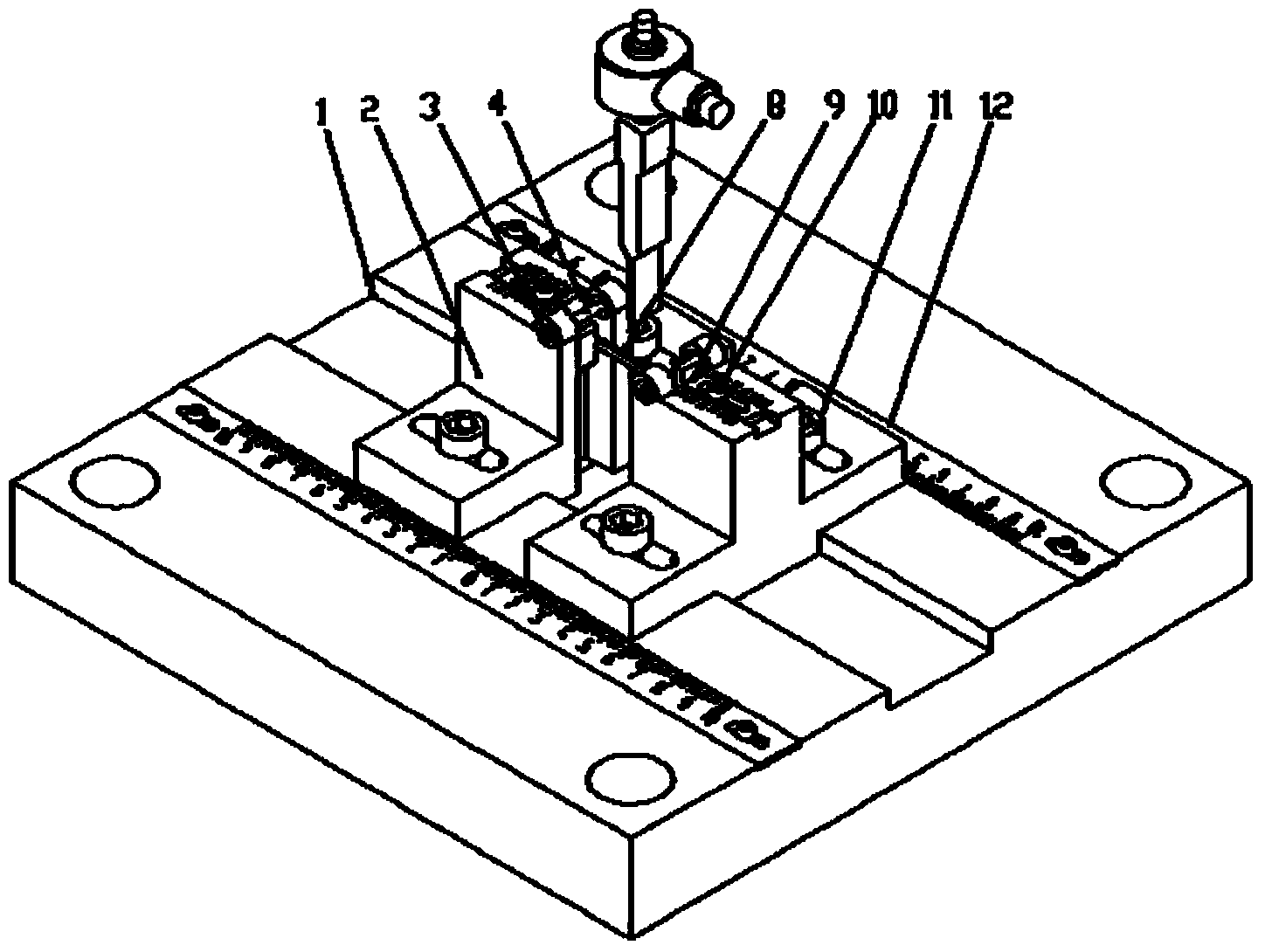

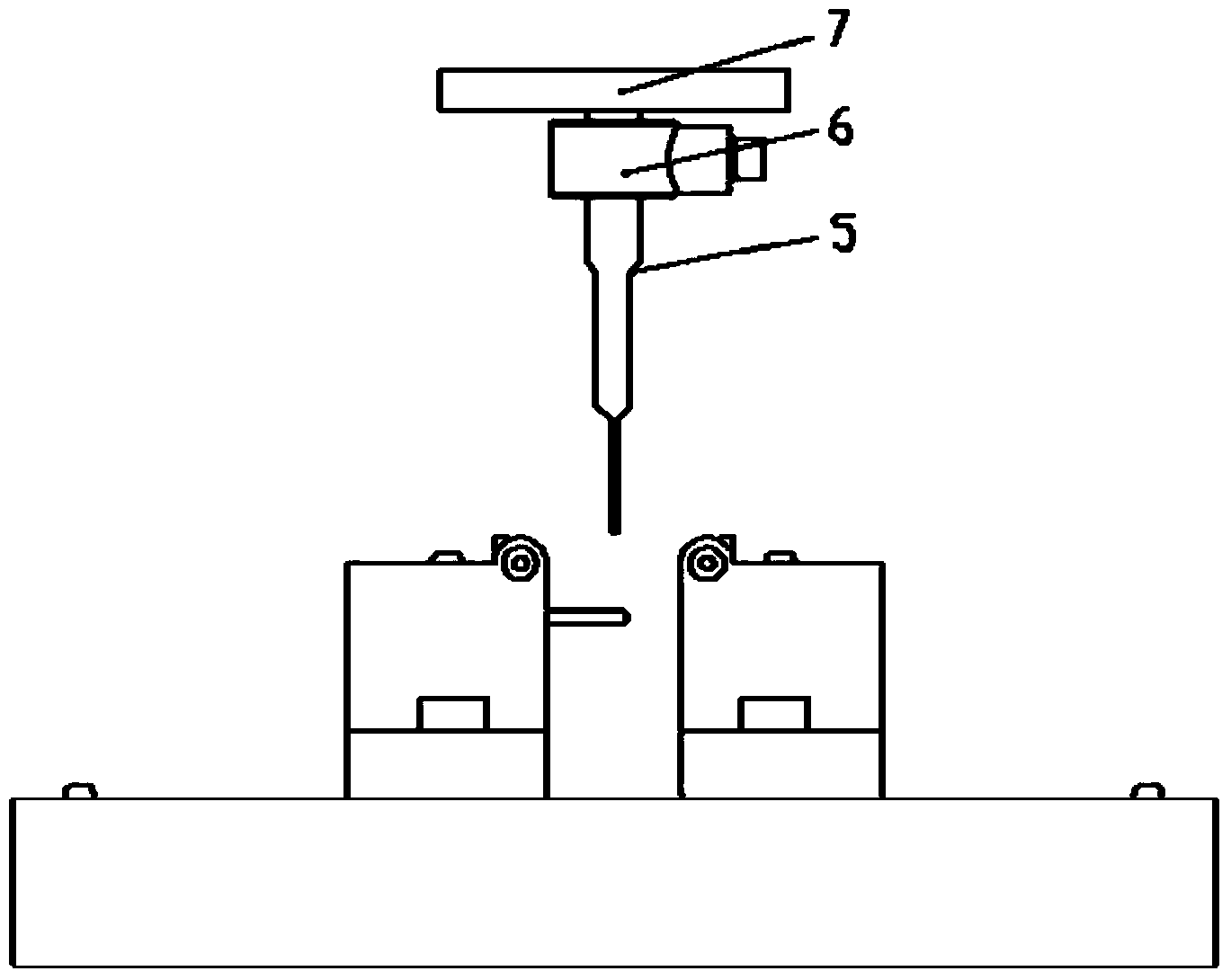

[0058] The following will be combined with figure 1 and figure 2 The specific technical solutions of the present invention are described in detail.

[0059] Biomechanical test is a kind of mechanical test carried out on biological tissue, and the material parameters of biological tissue can be calculated by using the test data. Compared with the mechanical tests of commonly used metal materials, biomechanical tests have their own characteristics:

[0060] 1) The material properties of biological tissue are greatly affected by the strain rate, and the mechanical responses measured at different loading rates are quite different. Therefore, the biomechanical test device not only needs to meet the static test requirements, but also must meet the dynamic test requirements.

[0061] 2) Using the biomechanical test data obtained from the three-point bending test, the material parameters of biological samples are mostly obtained by using the material parameter reverse method based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com