Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1297results about How to "Improve clamping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

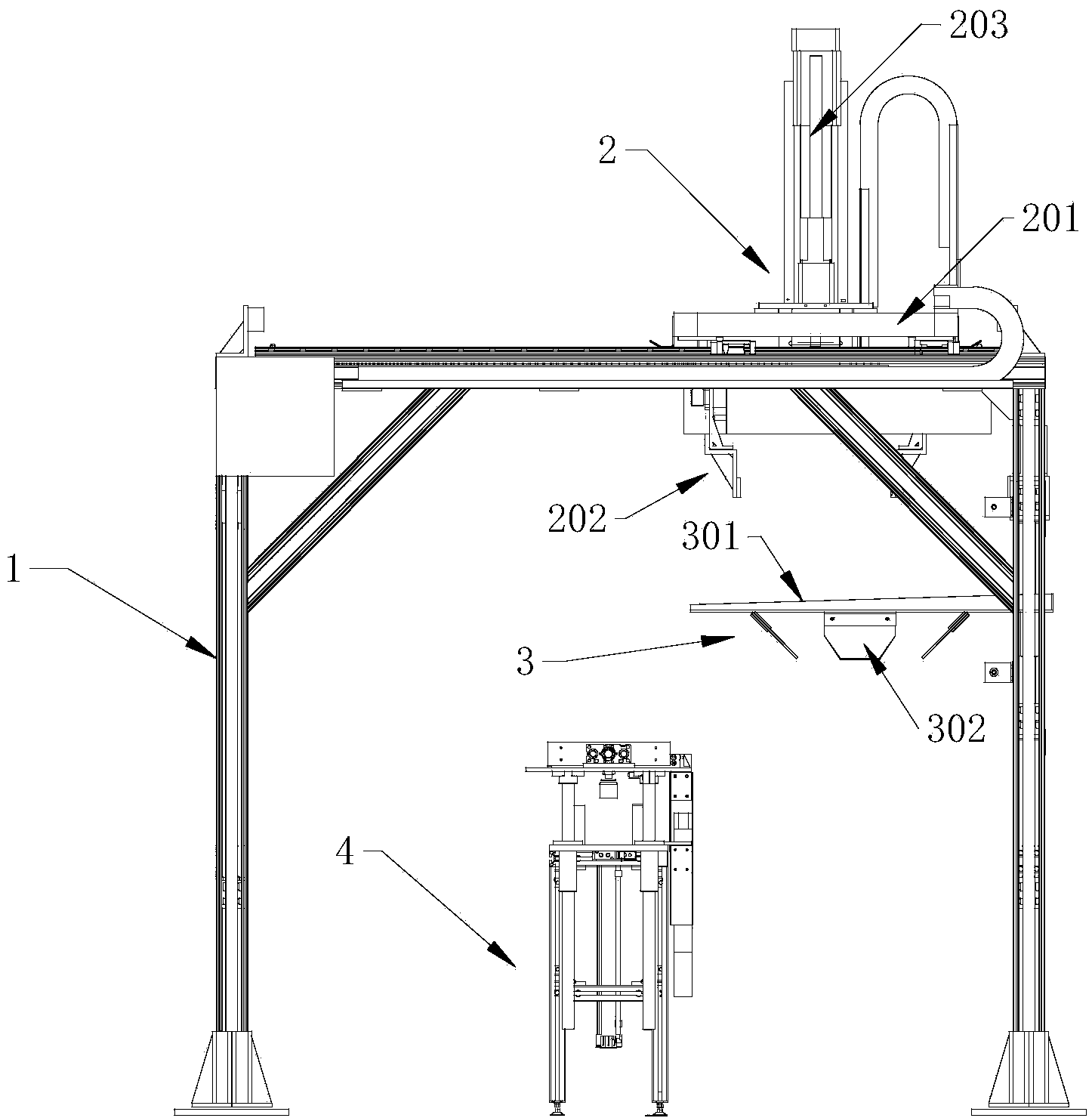

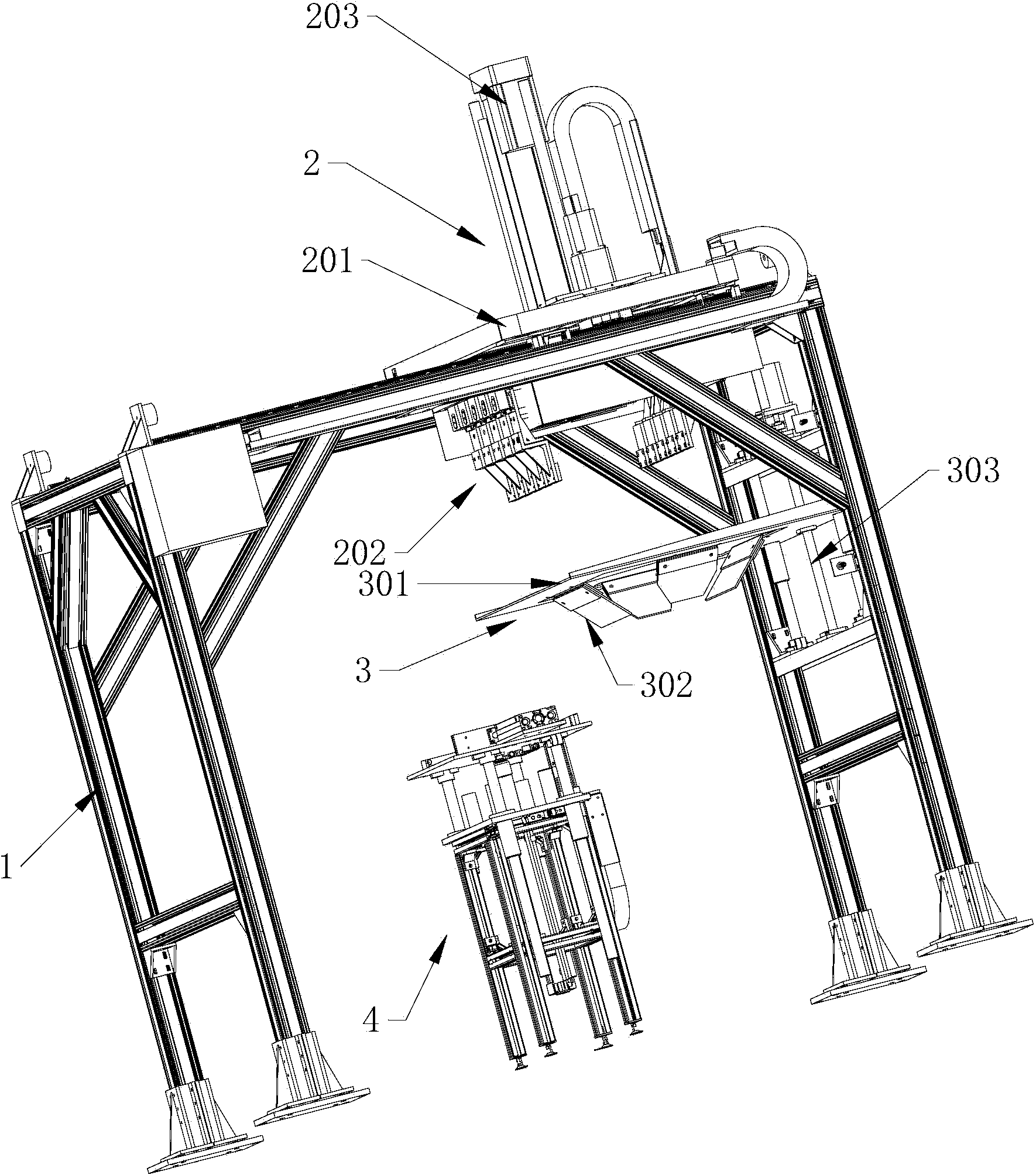

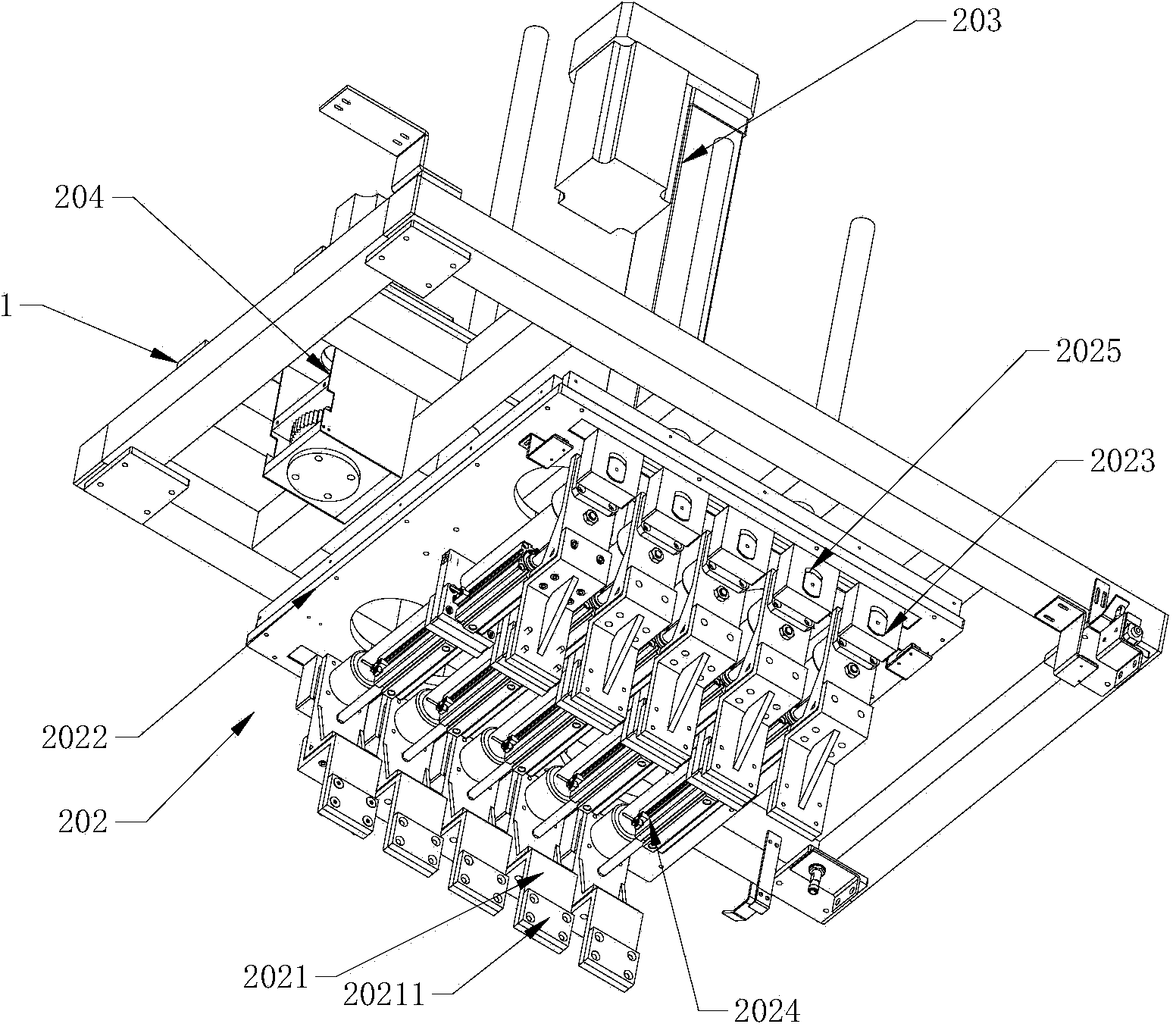

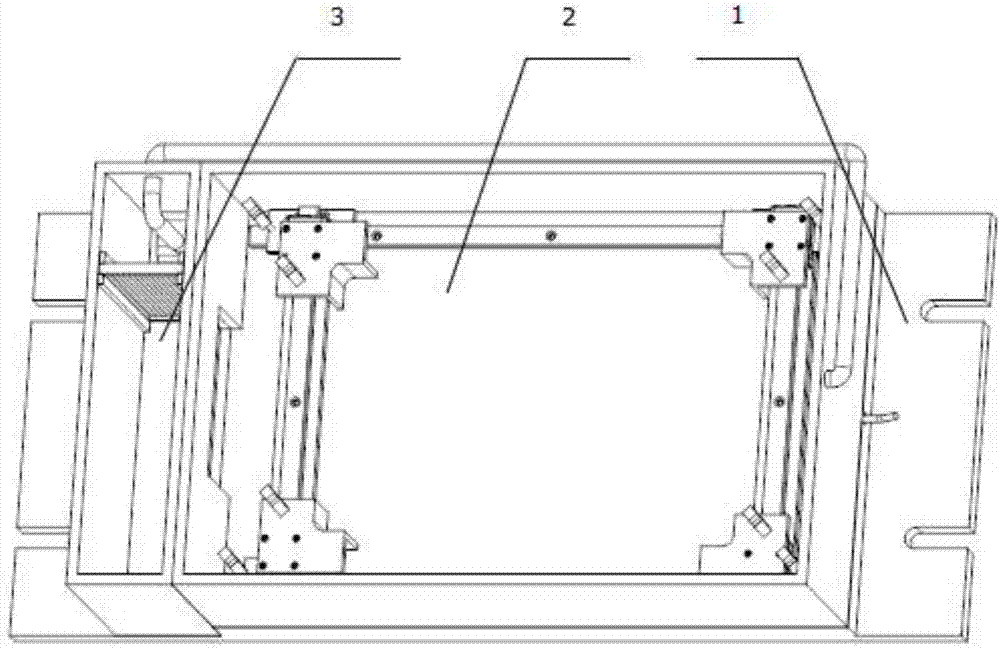

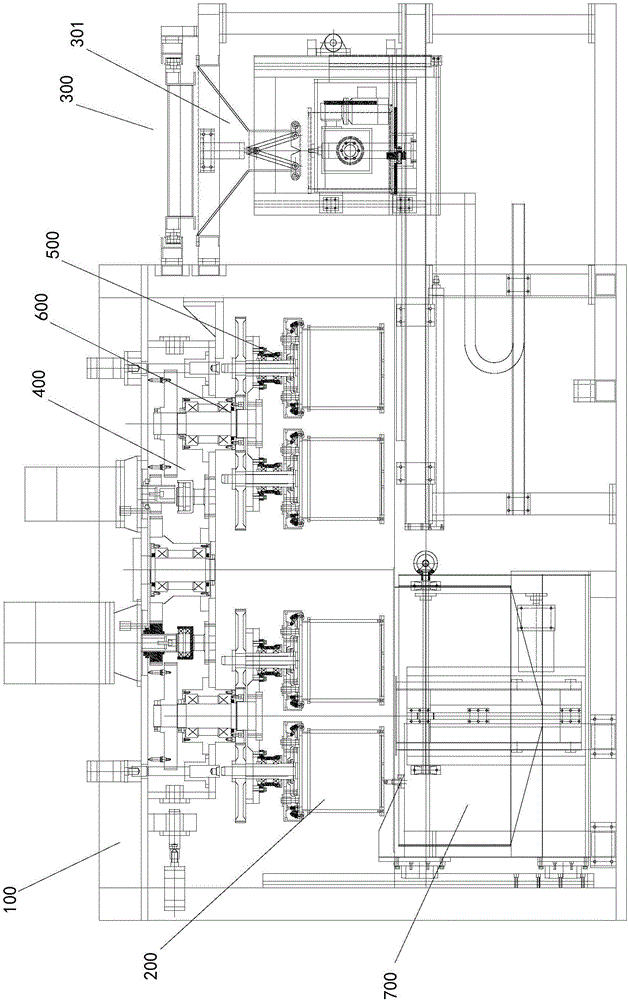

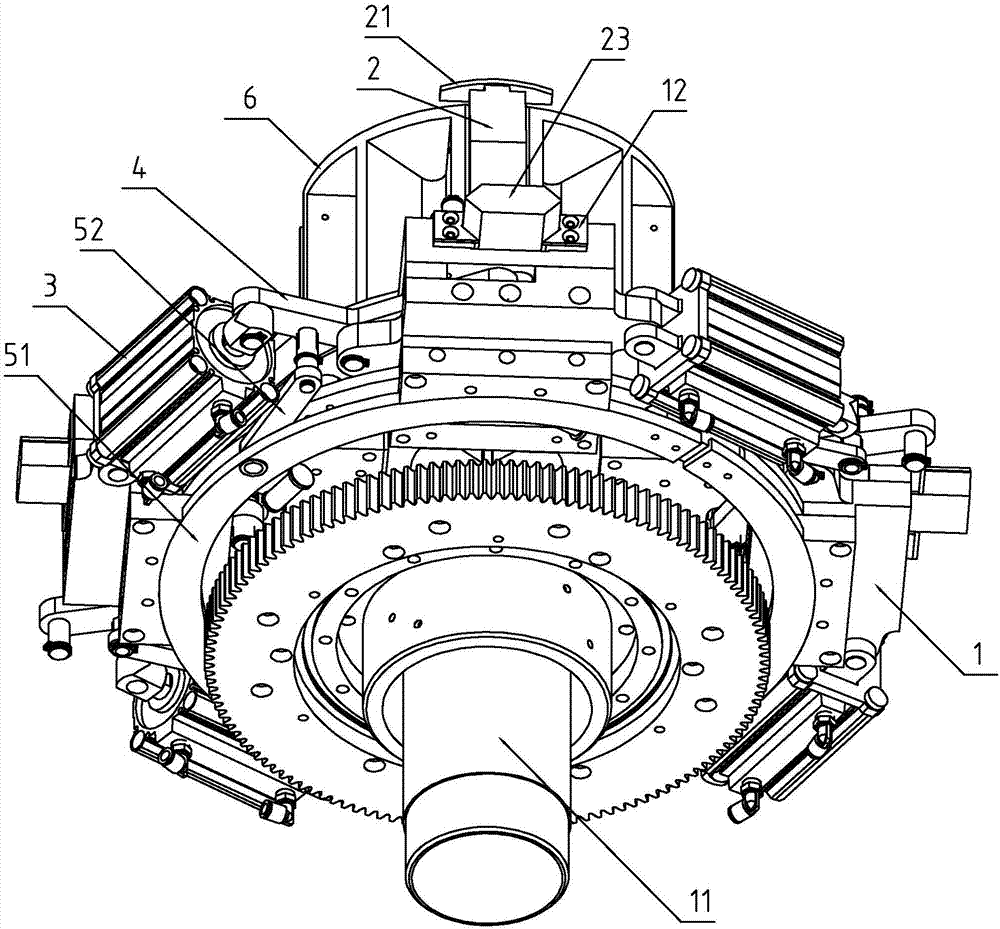

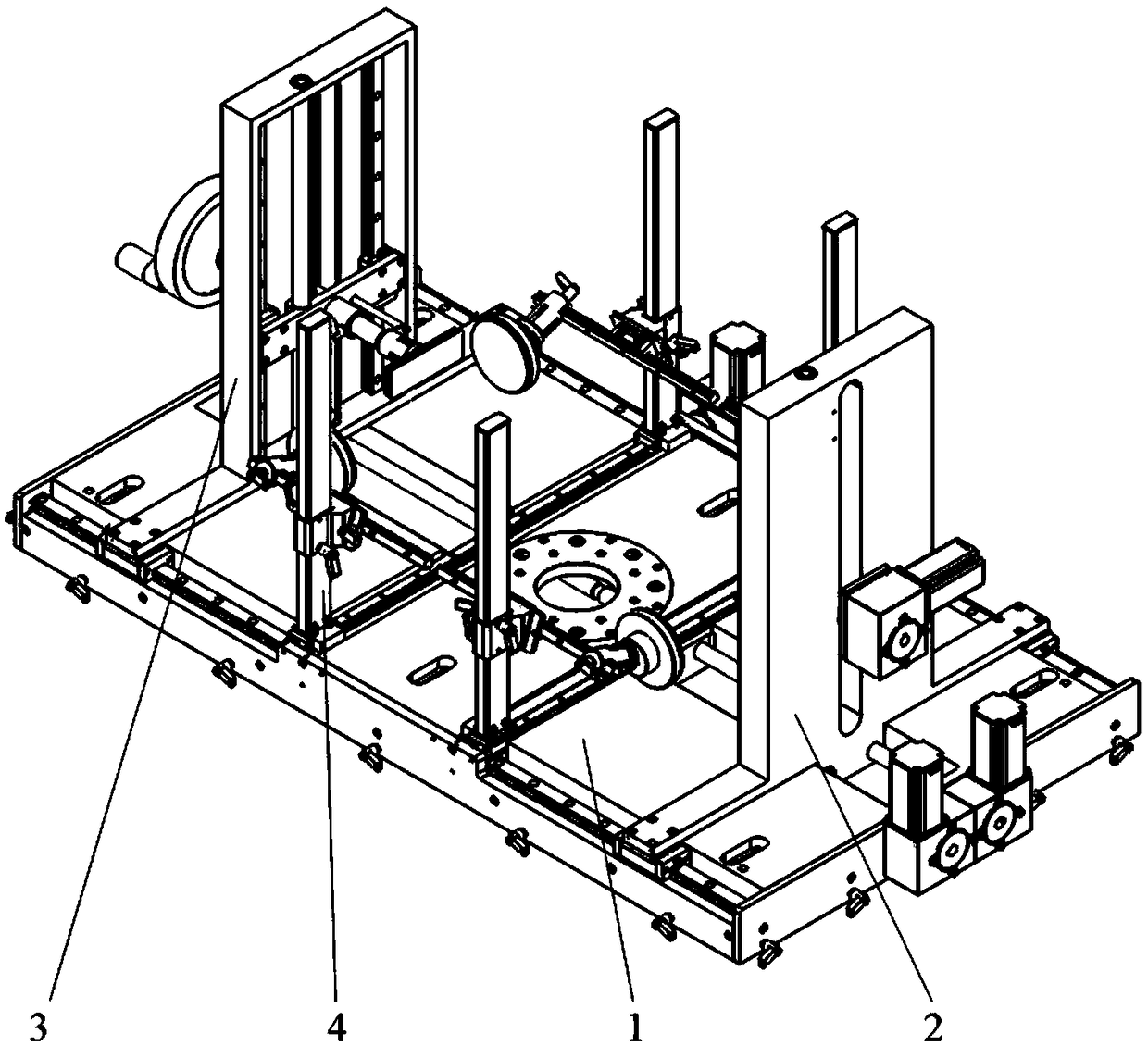

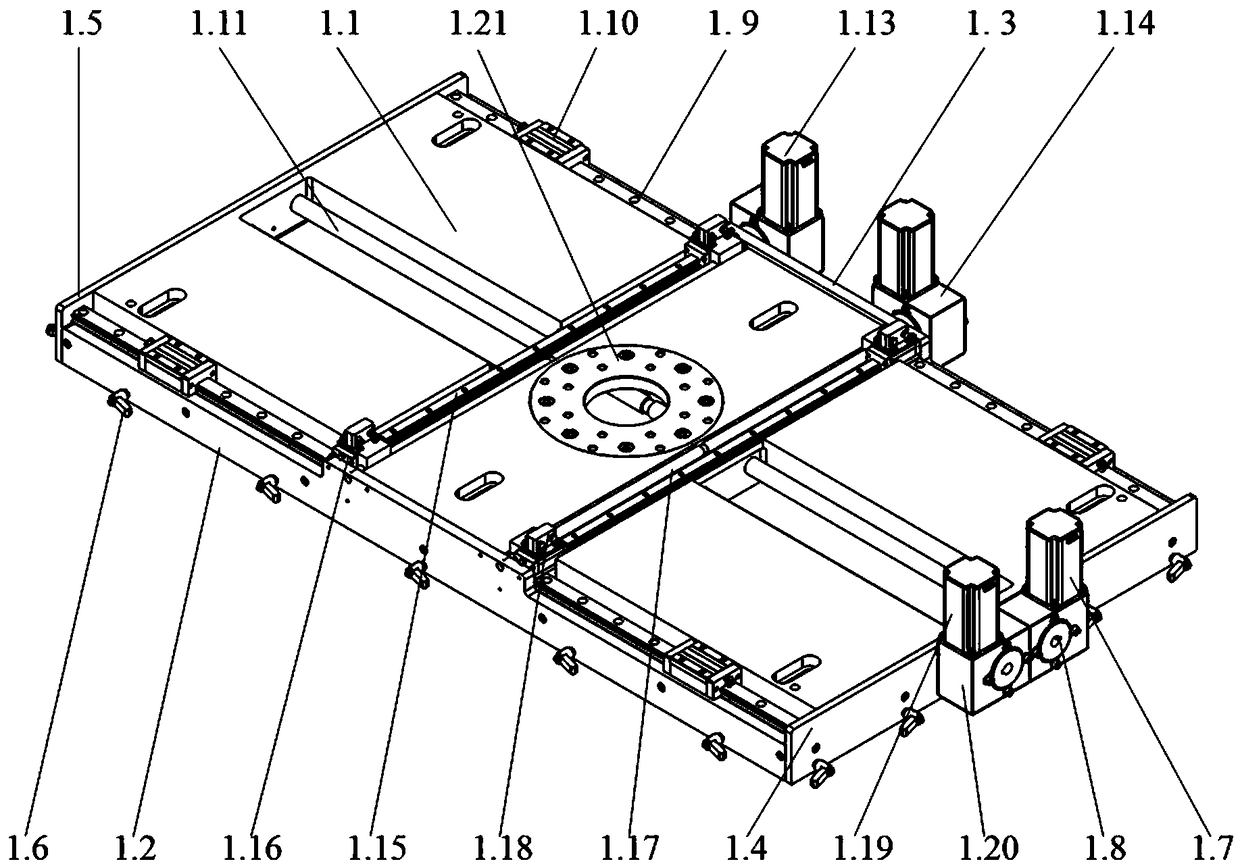

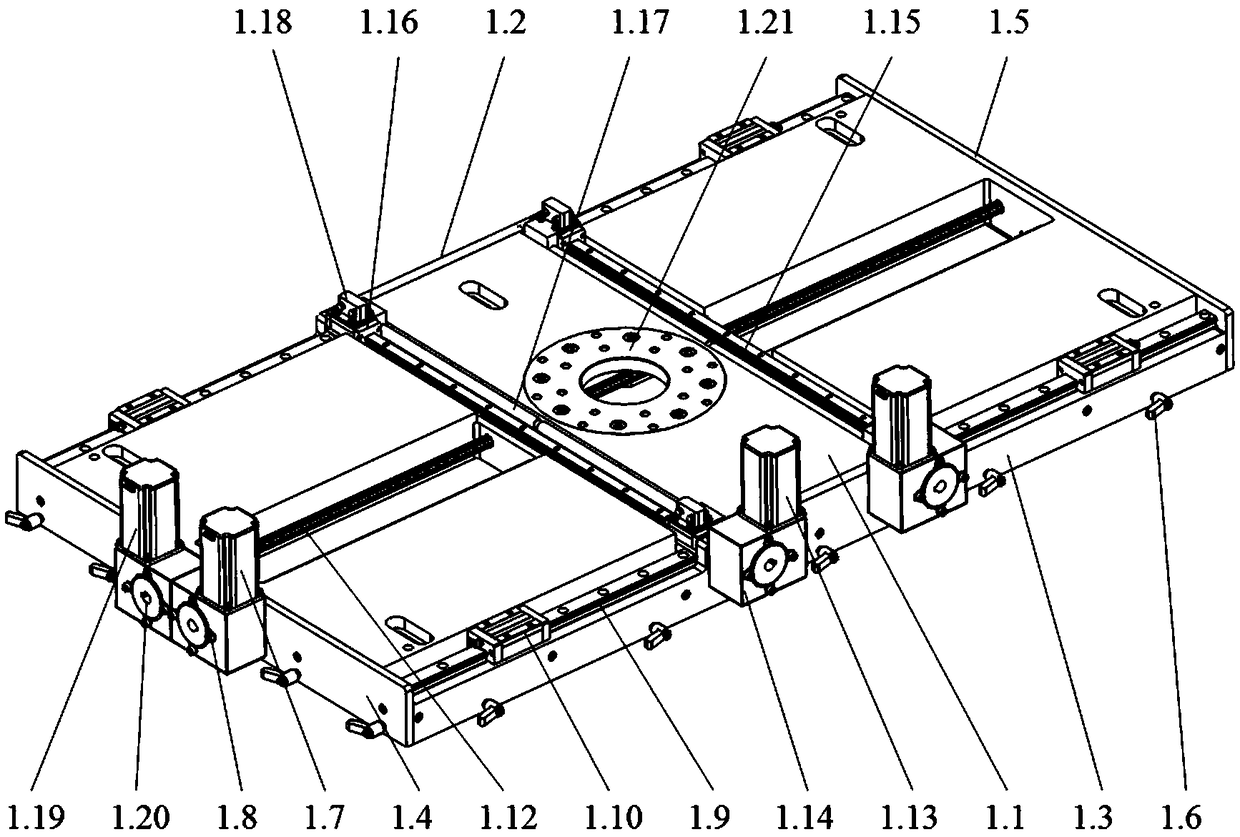

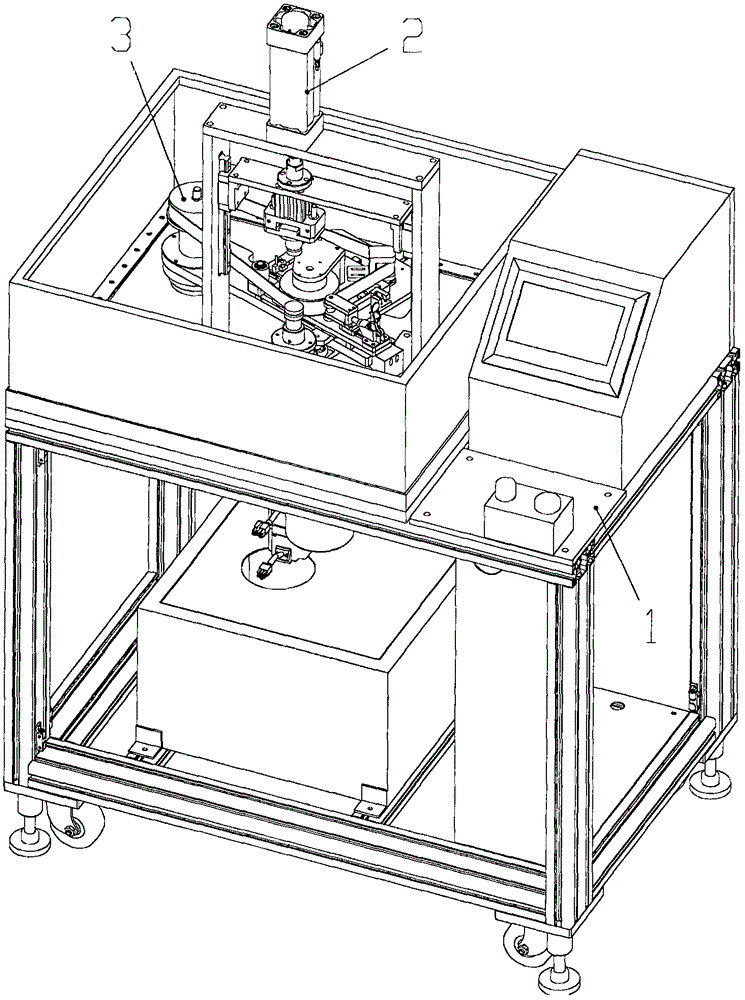

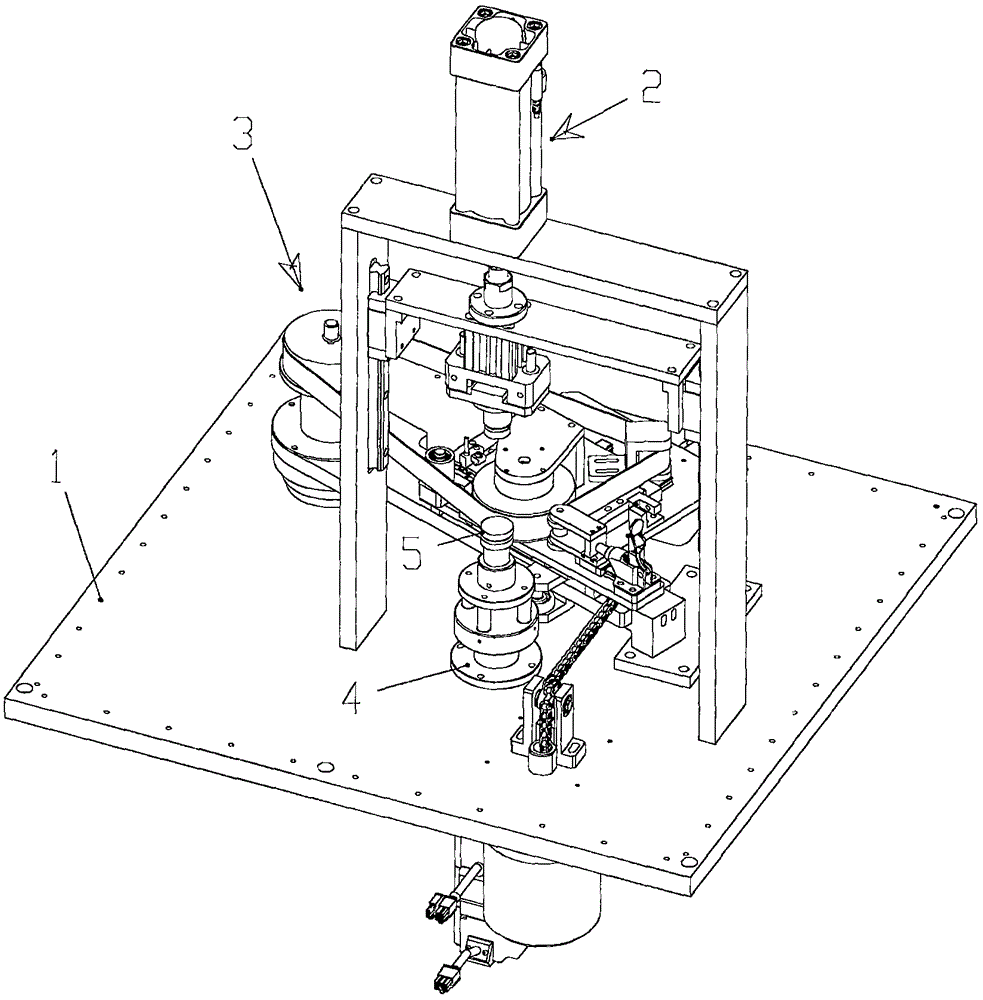

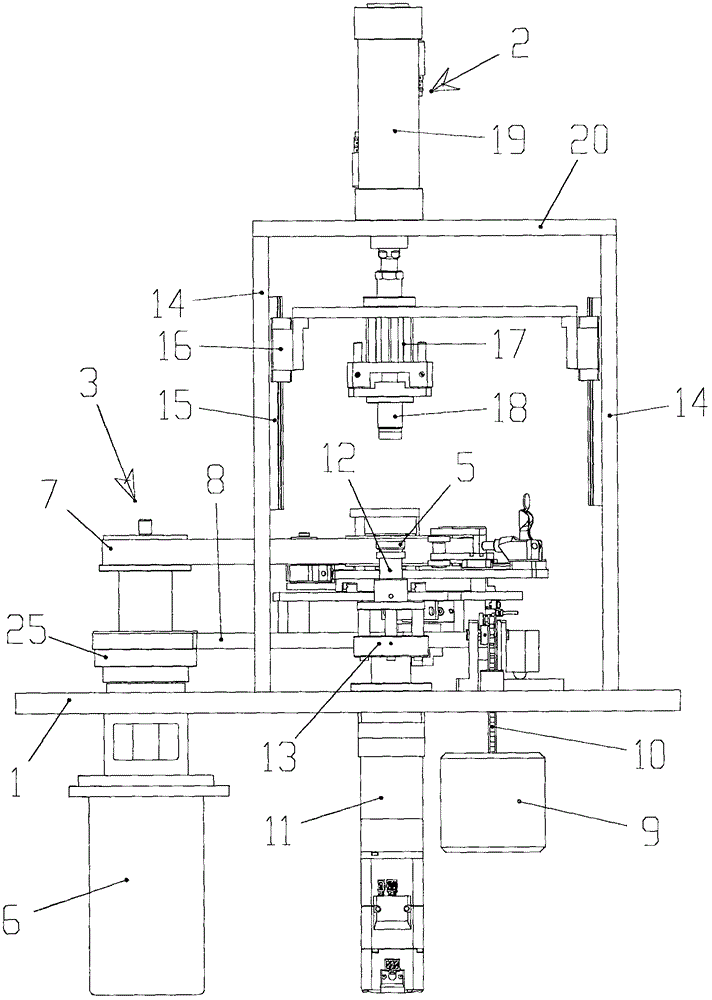

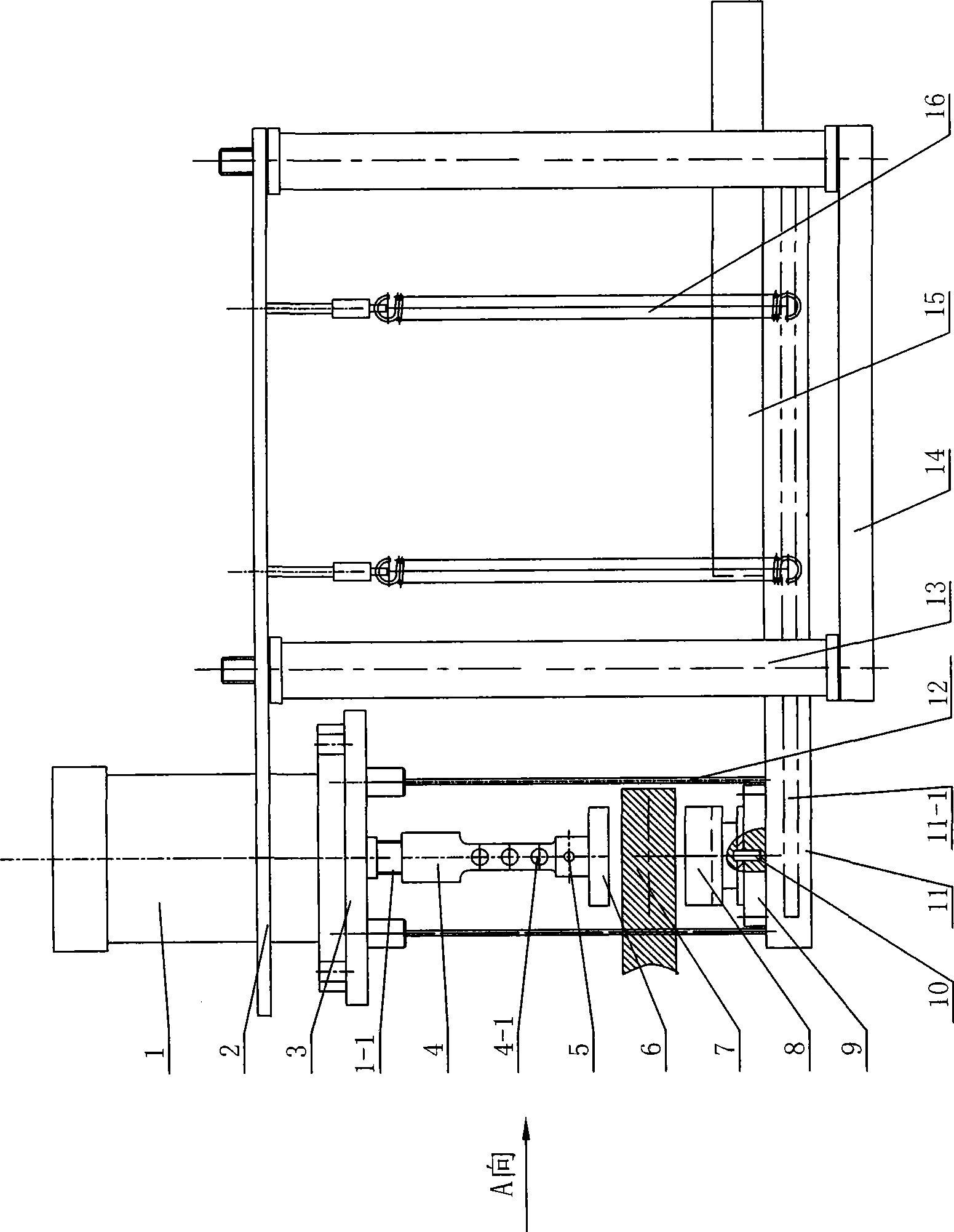

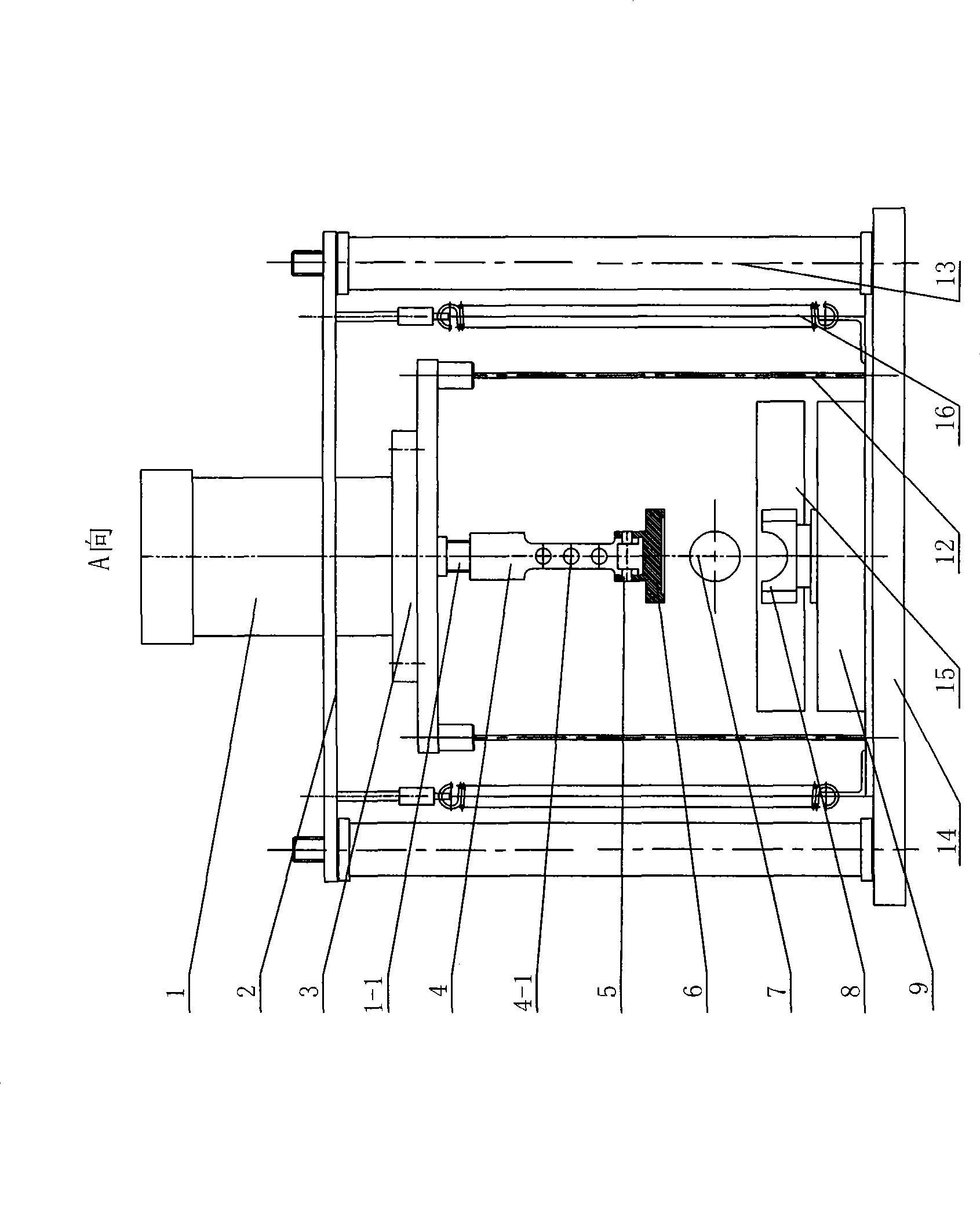

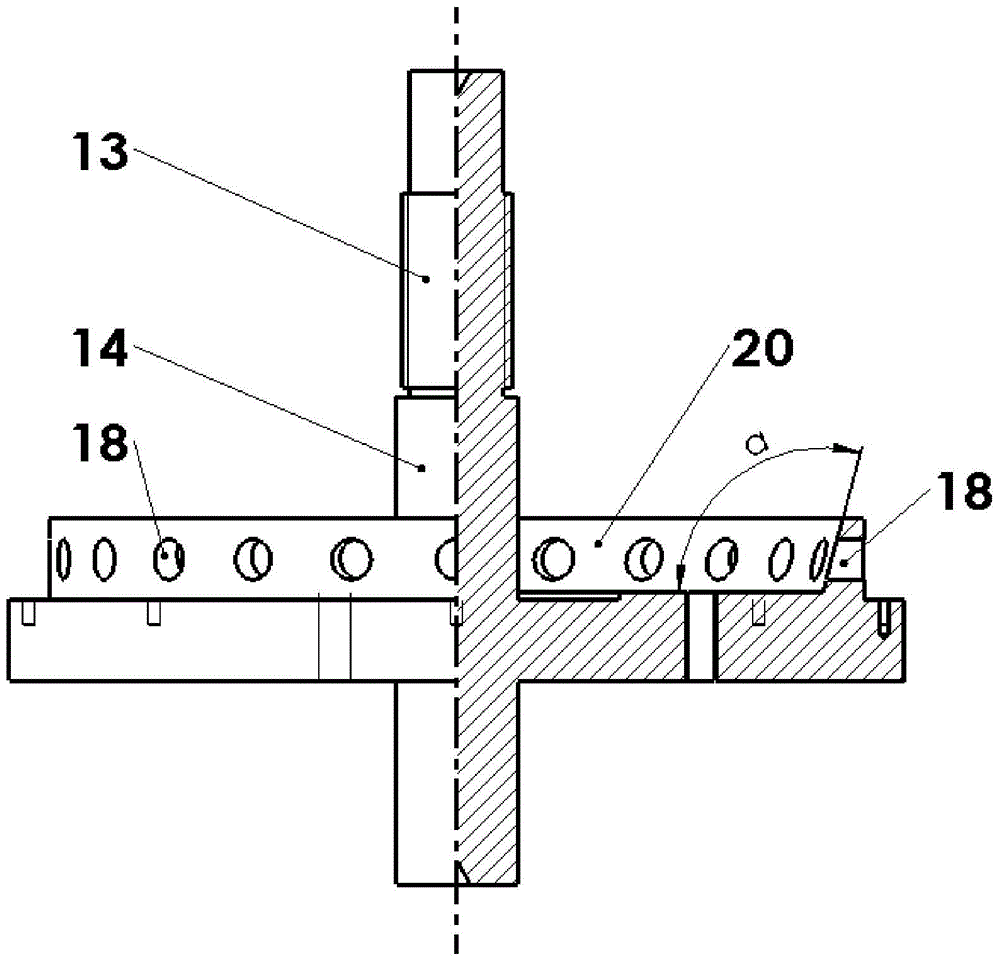

Aircraft skin mirror milling method and aircraft skin mirror milling device

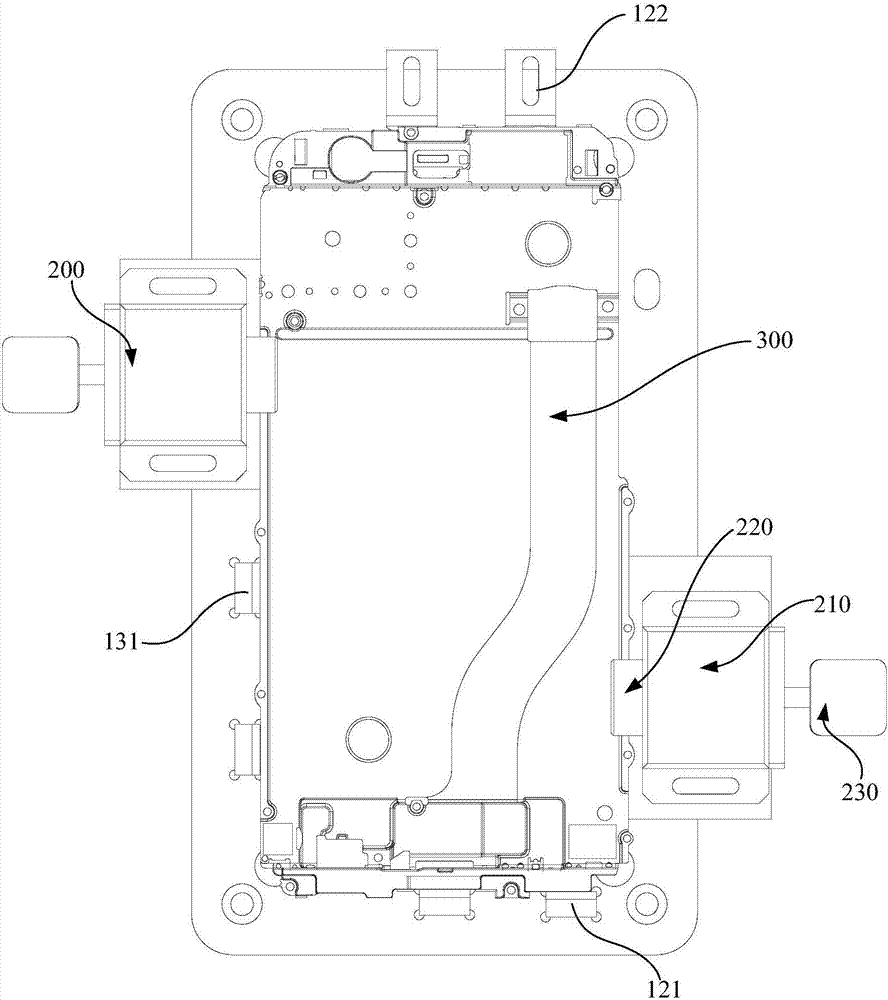

ActiveCN104400086AReal-time thicknessReal-time thickness compensationAutomatic control devicesWorkpiecesSelf adaptiveAirplane

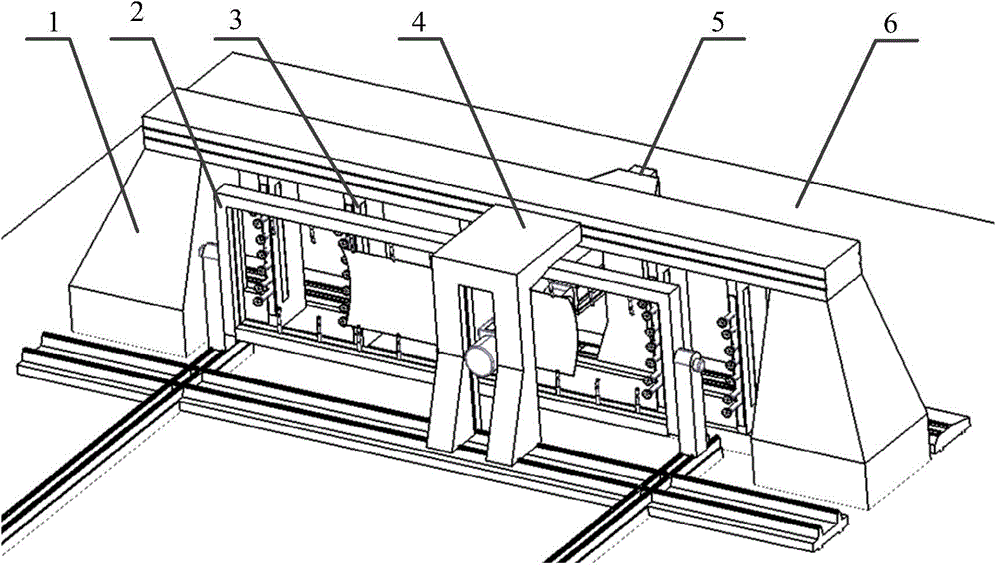

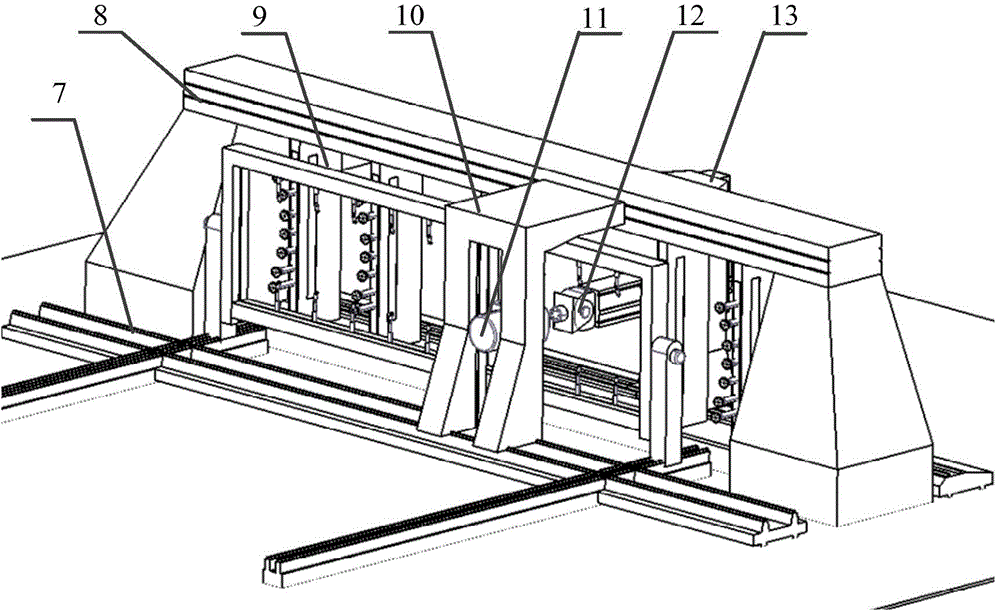

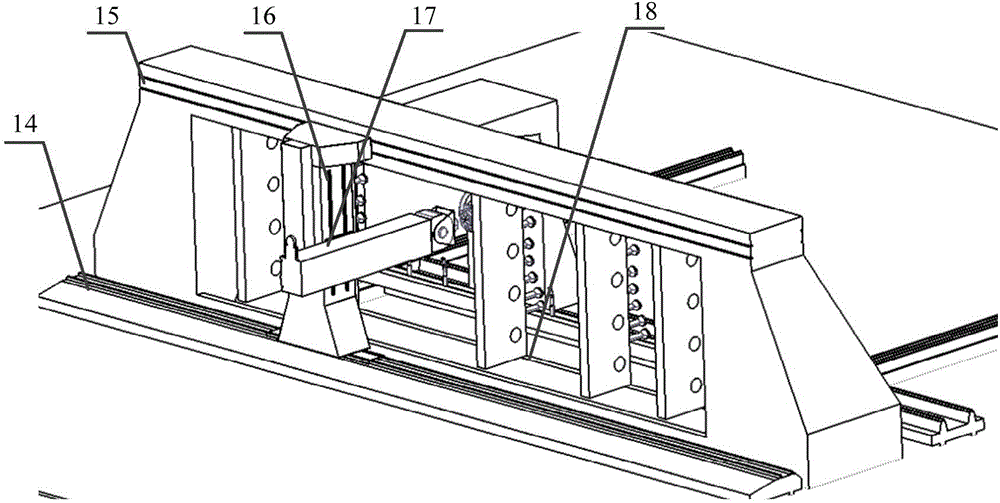

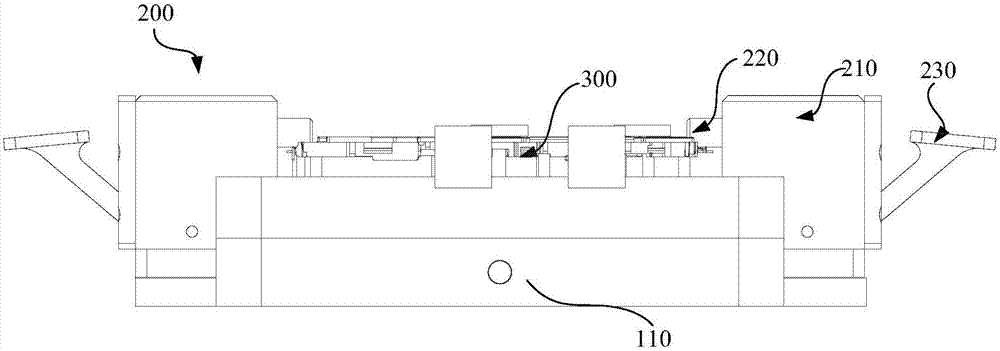

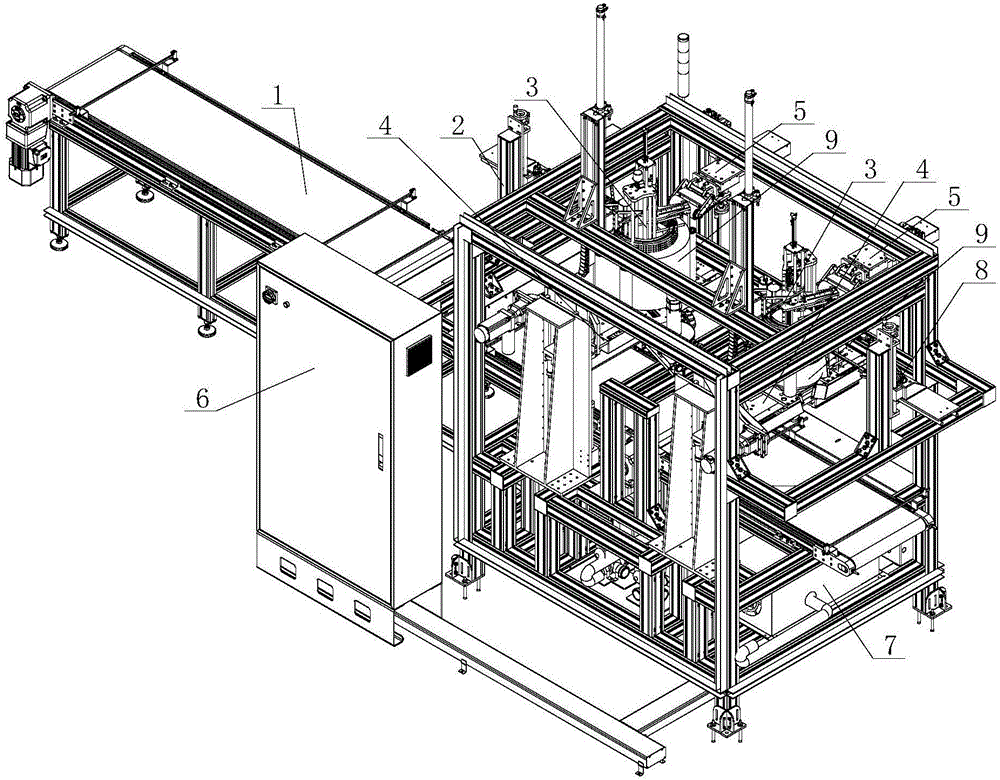

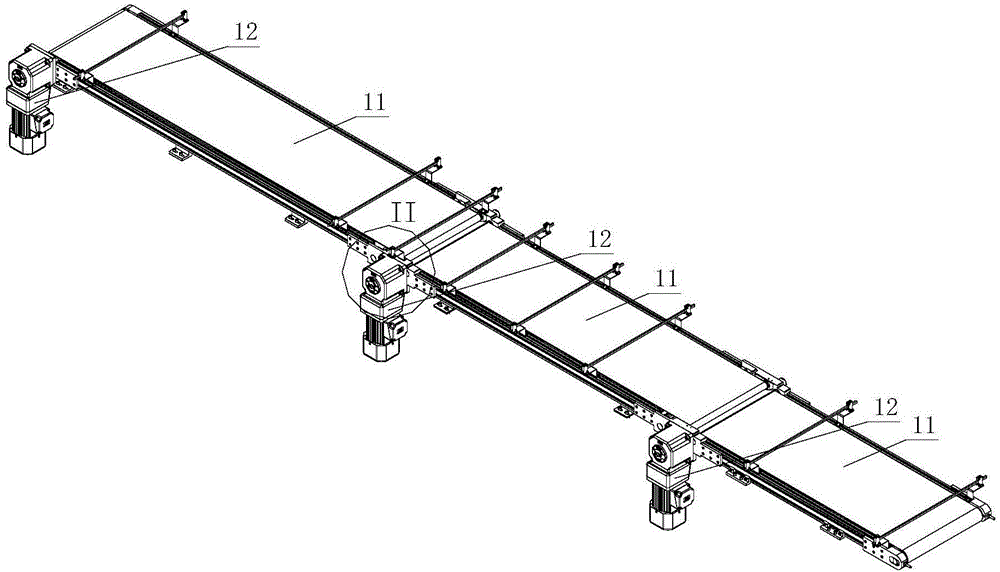

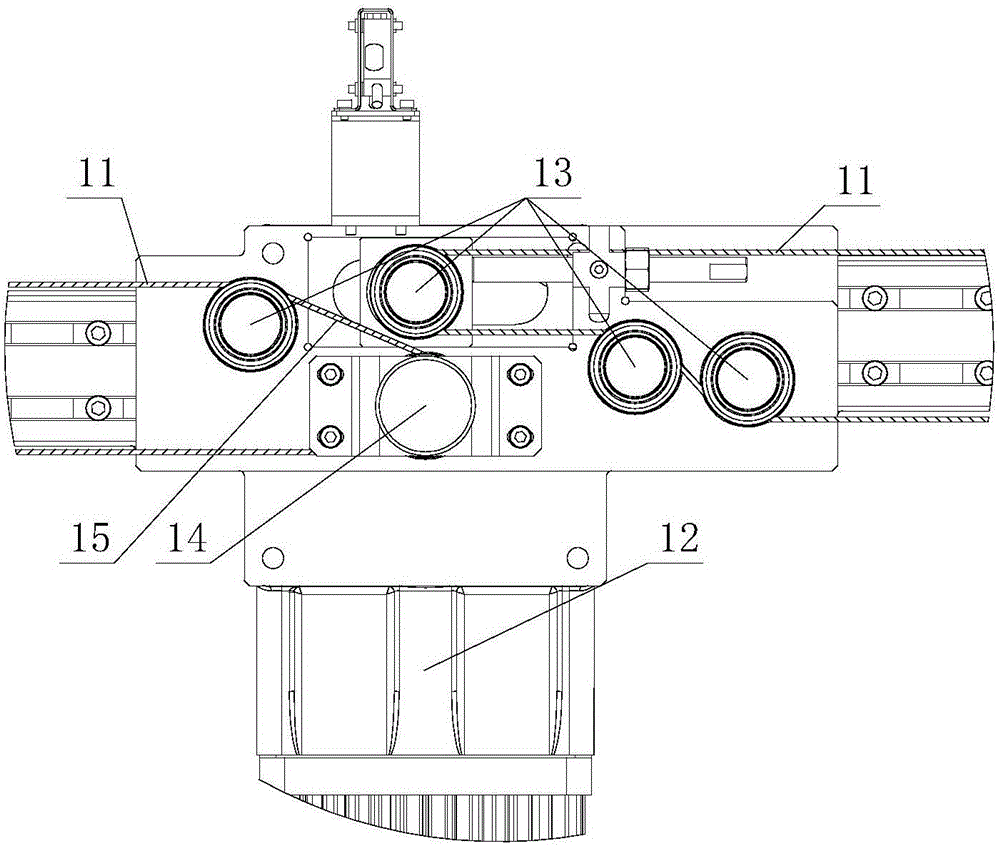

An aircraft skin mirror milling method and an aircraft skin mirror milling device. The device is characterized by mainly comprising a machine tool main framework, a milling apparatus, a vertical-horizontal conversion apparatus, a lug piece holding apparatus, a flexible adsorption apparatus, a top-shore apparatus, a detection apparatus and a thickness measuring apparatus. In the device, an aircraft skin is vertically clamped by the vertical-horizontal conversion apparatus for increasing the clamping efficiency of the aircraft skin and a positioning precision of the aircraft skin is further improved with combination of a vacuum adsorption apparatus so that deformation caused by gravity can be avoided. On the basis of on-line detection by a laser displacement sensor, actual curve surface of the aircraft skin can be detected before processing and aircraft skin processing tool path can be adjusted according to an actual clamping situation for achieving self-adapting numerically-control processing. The top-shore apparatus can support the aircraft skin from backside during a milling process of the aircraft skin, thereby avoiding vibration during processing and improving stability of processing. On-line monitoring of the thickness can be achieved during the processing and thickness compensation can be provided. By means of an integrated control system, cooperative operation of units in the machine tool can be ensured and interference can be avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

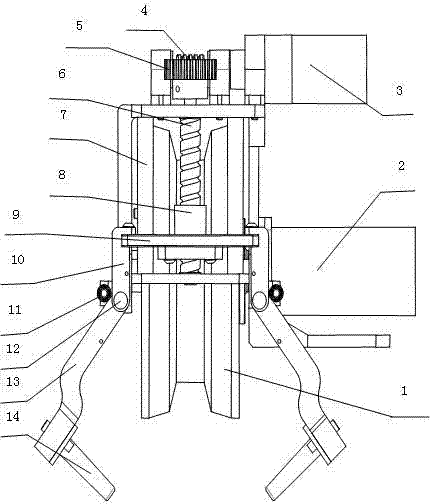

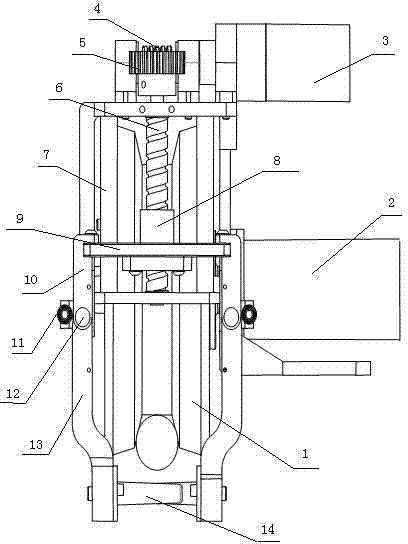

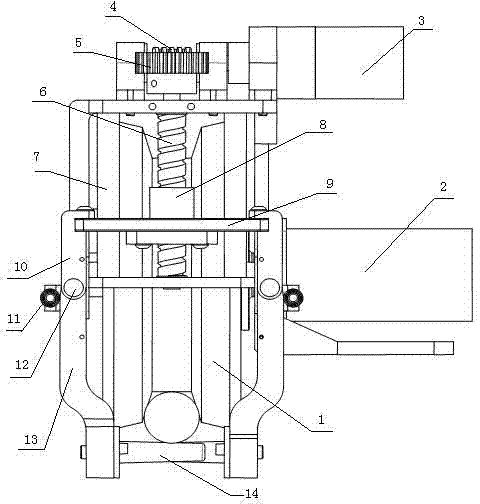

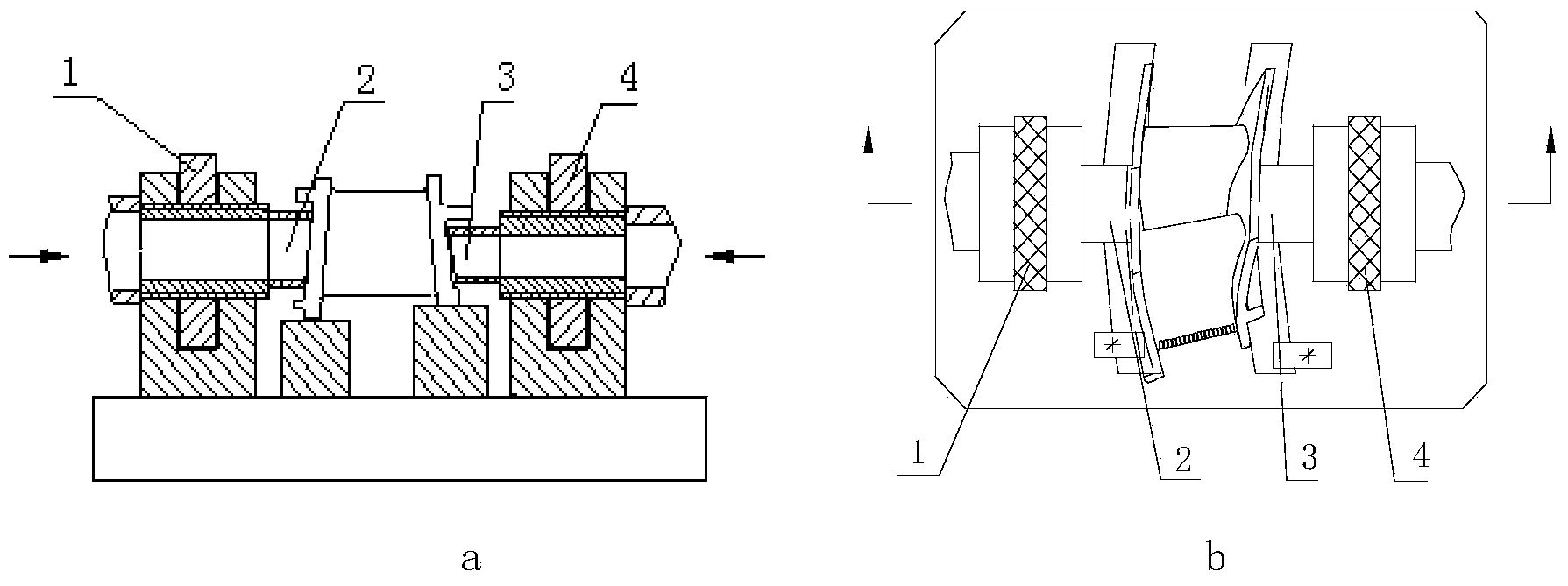

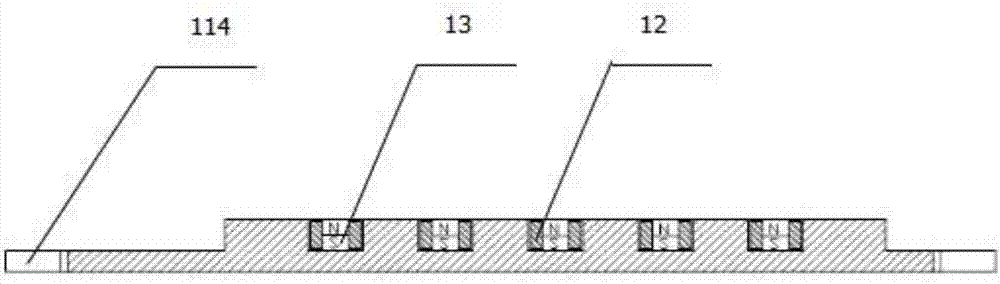

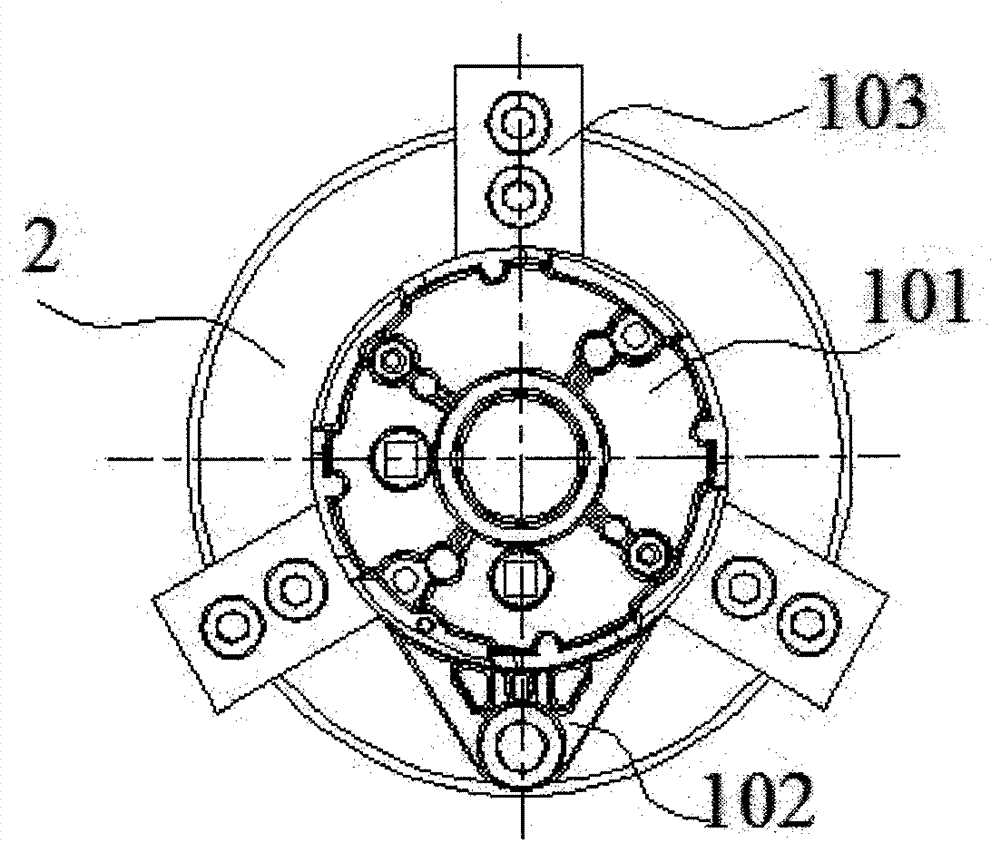

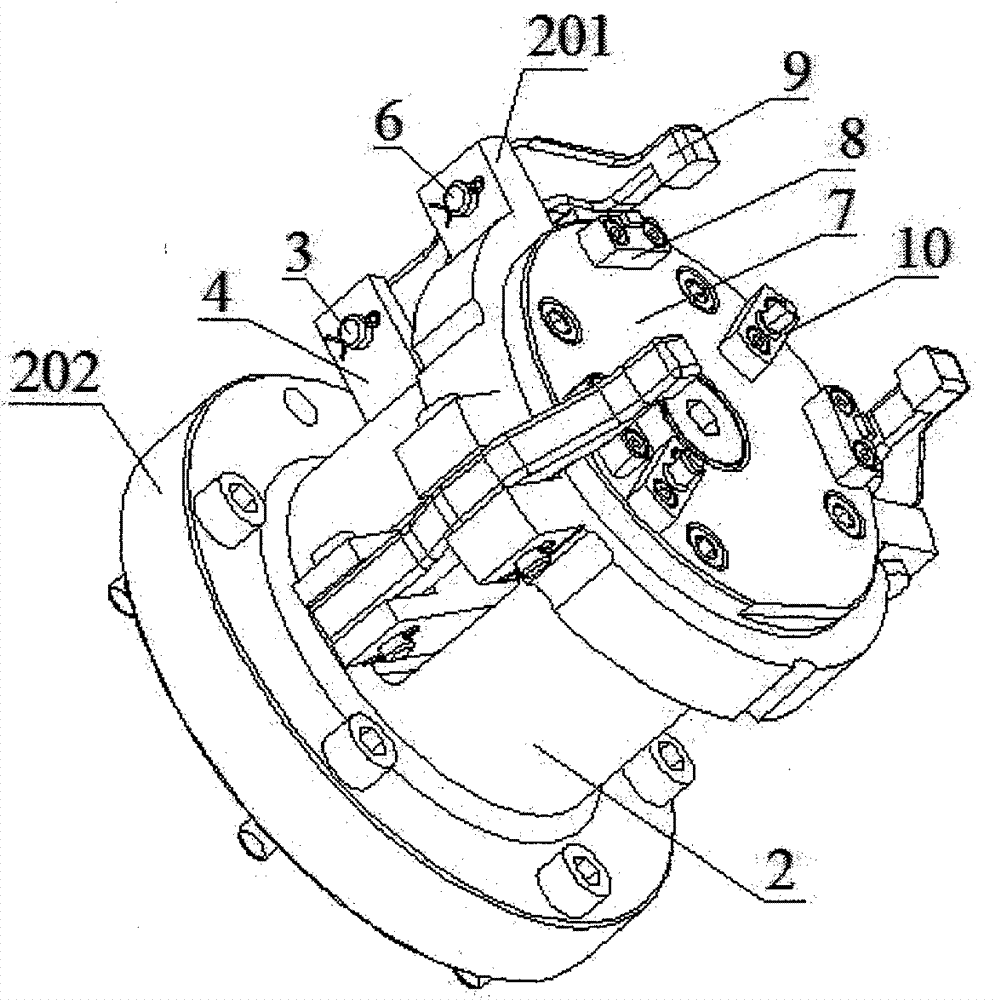

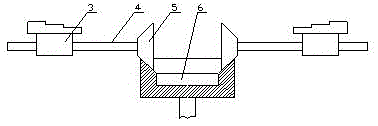

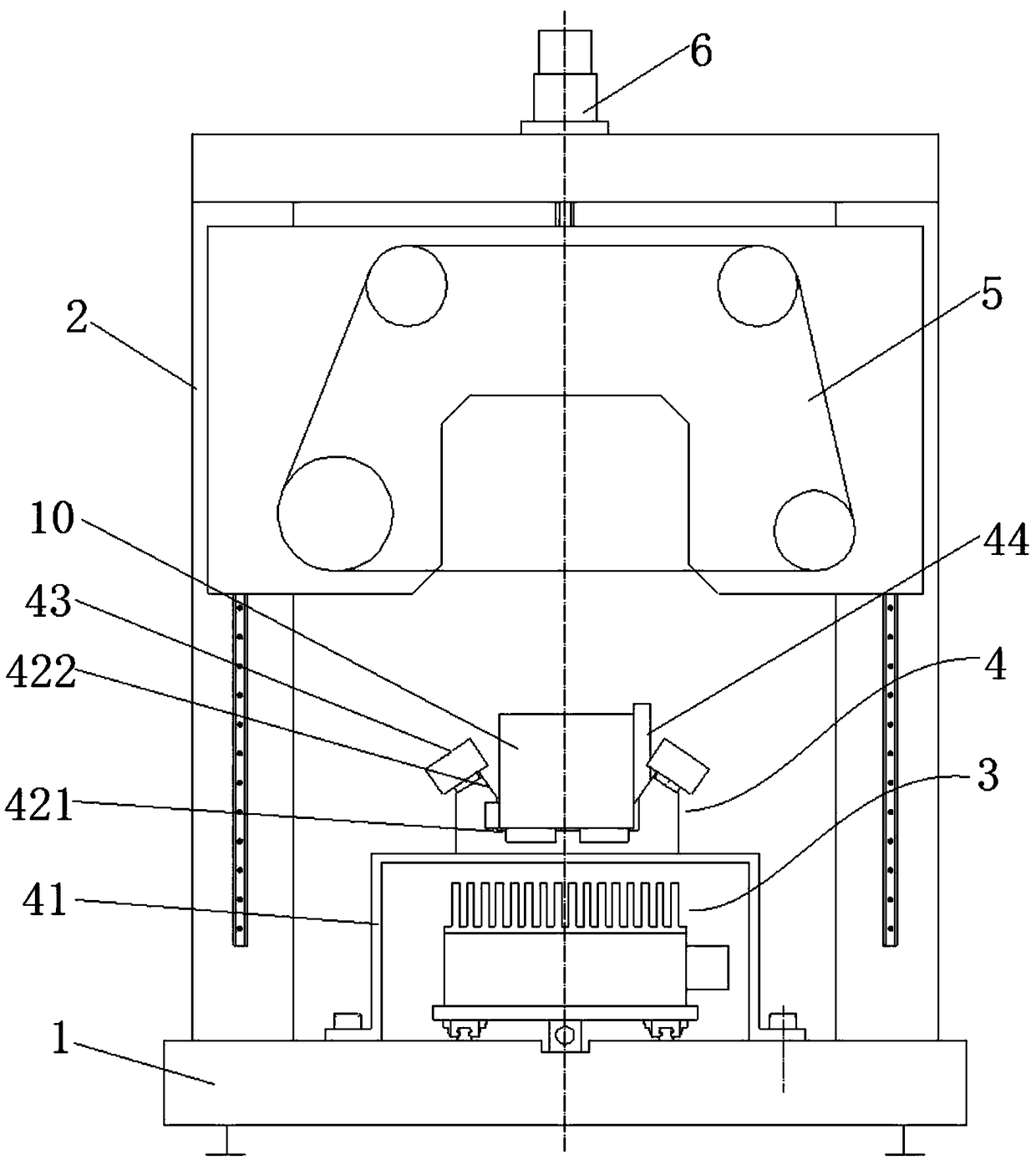

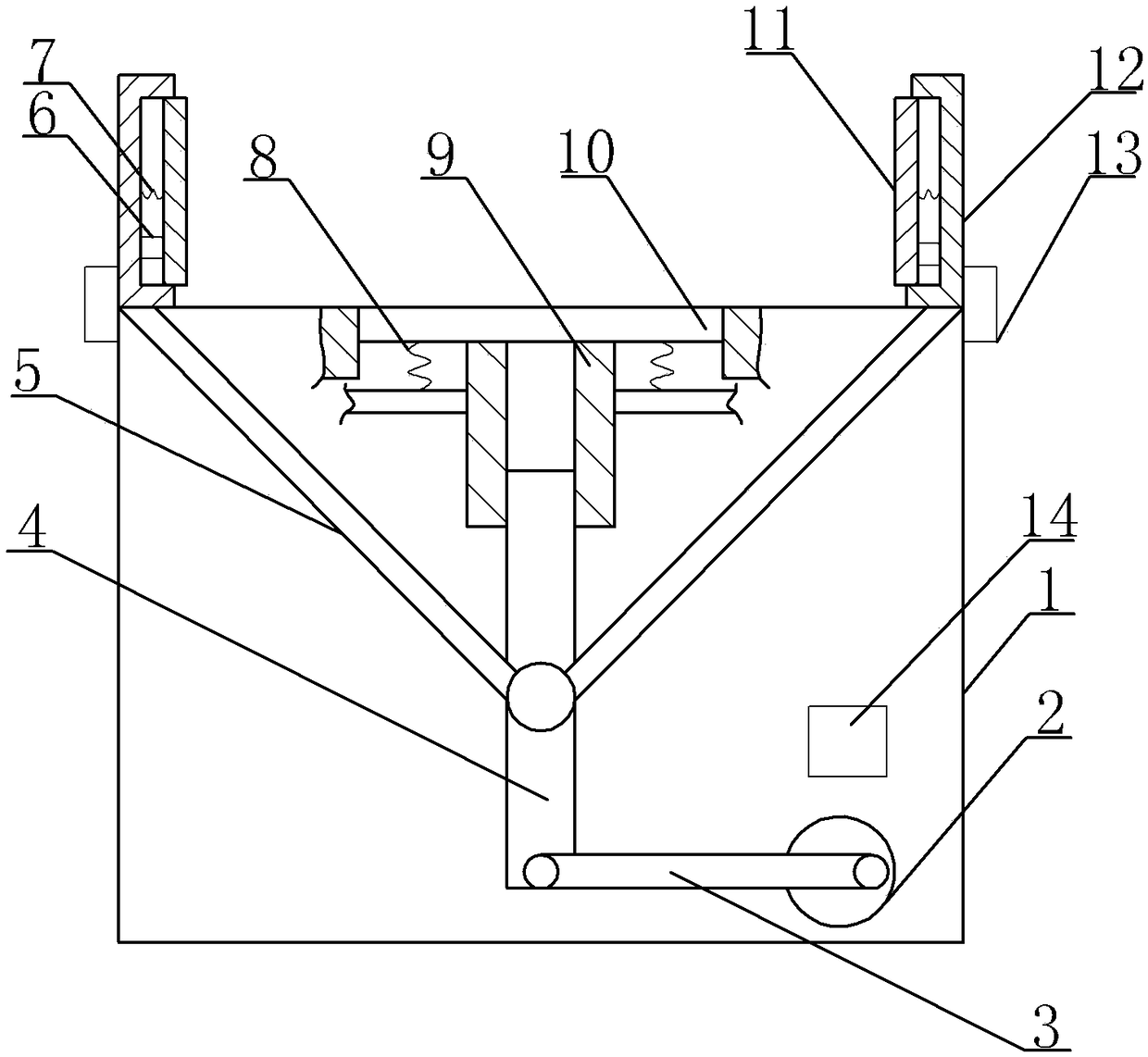

Bearing-type damage biomechanic three-point bending test device and bearing-type damage biomechanic three-point bending method

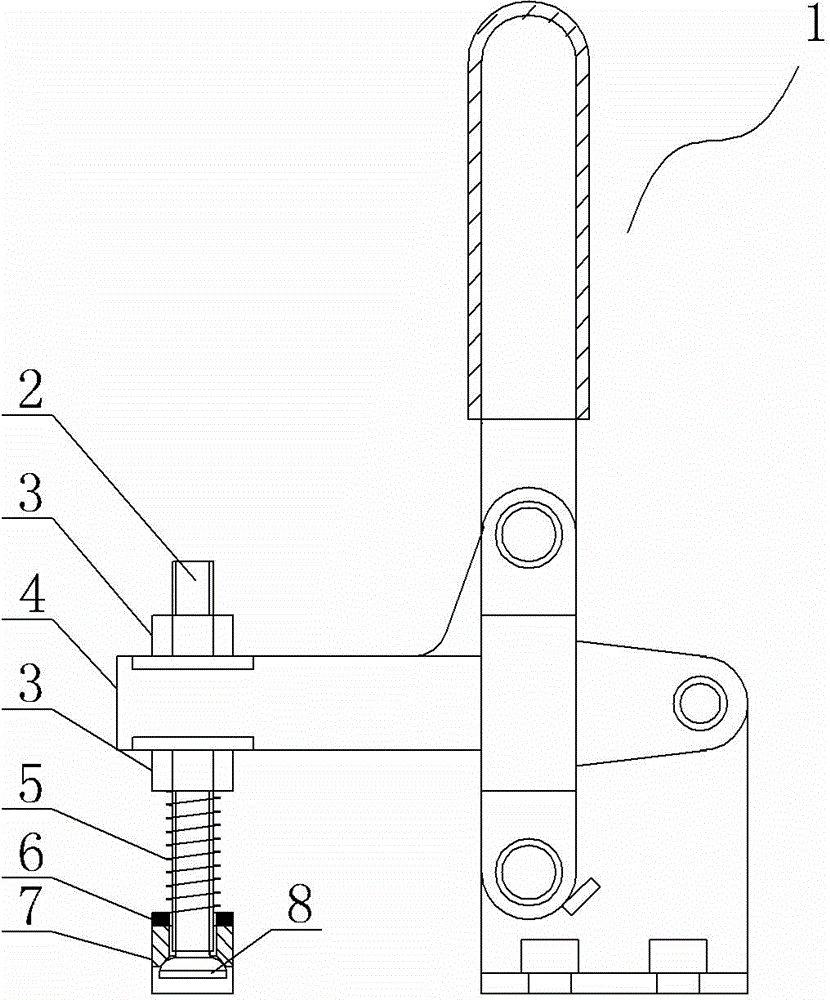

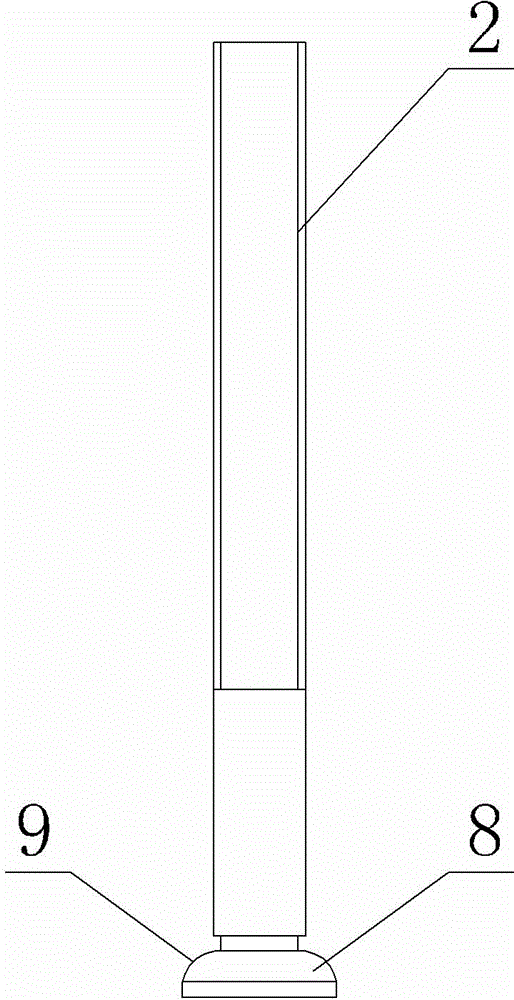

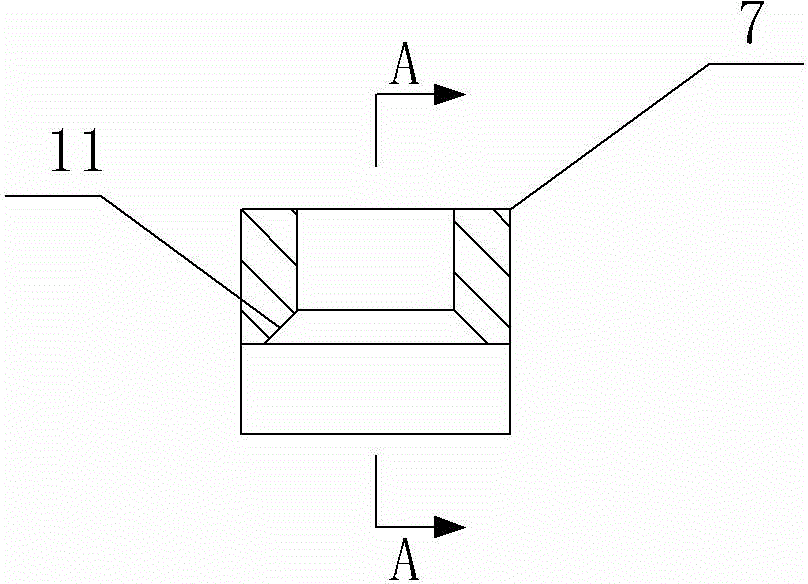

InactiveCN103760037AReduce distortionThe test data is accurateMaterial strength using steady bending forcesRolling resistanceElement model

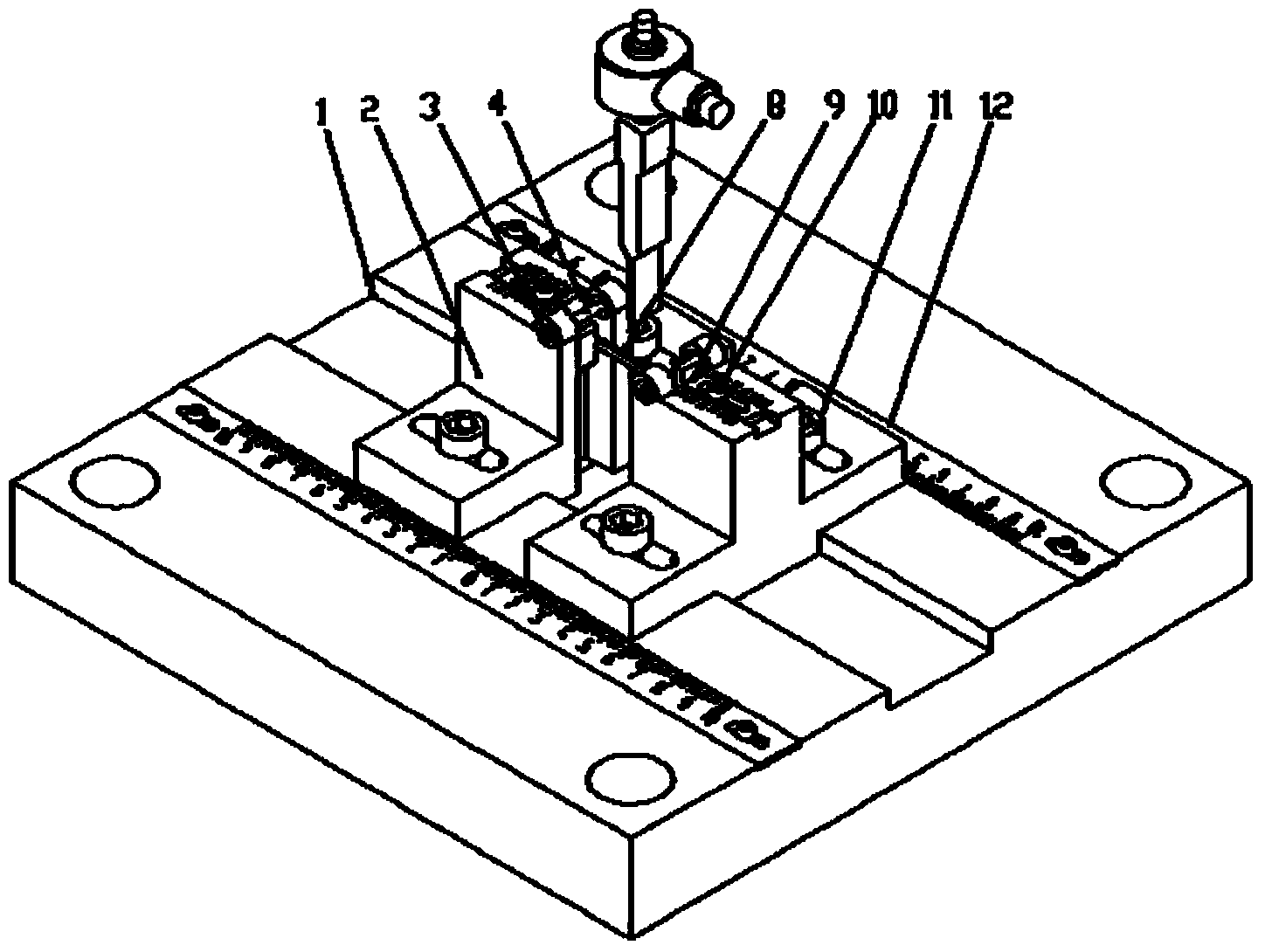

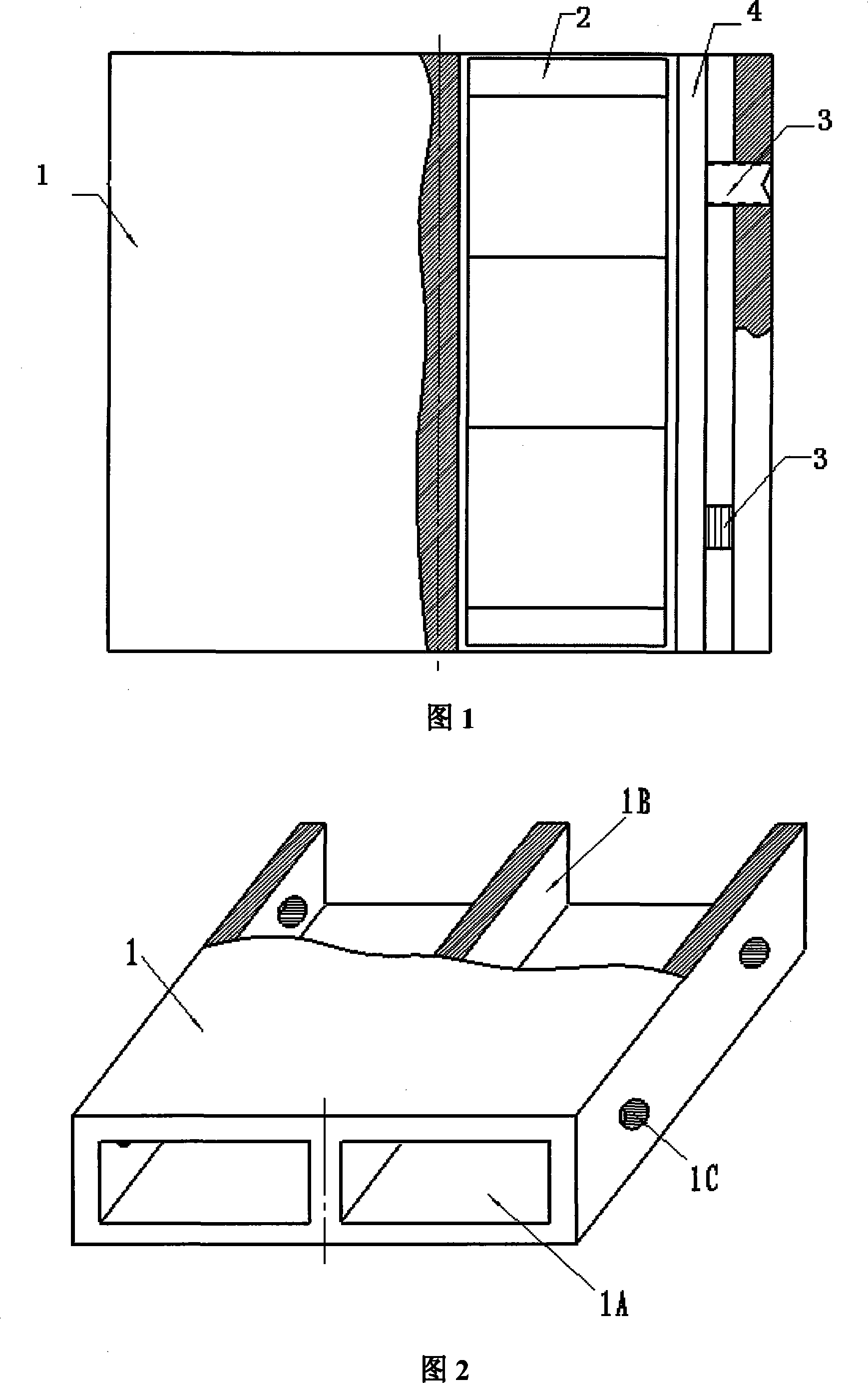

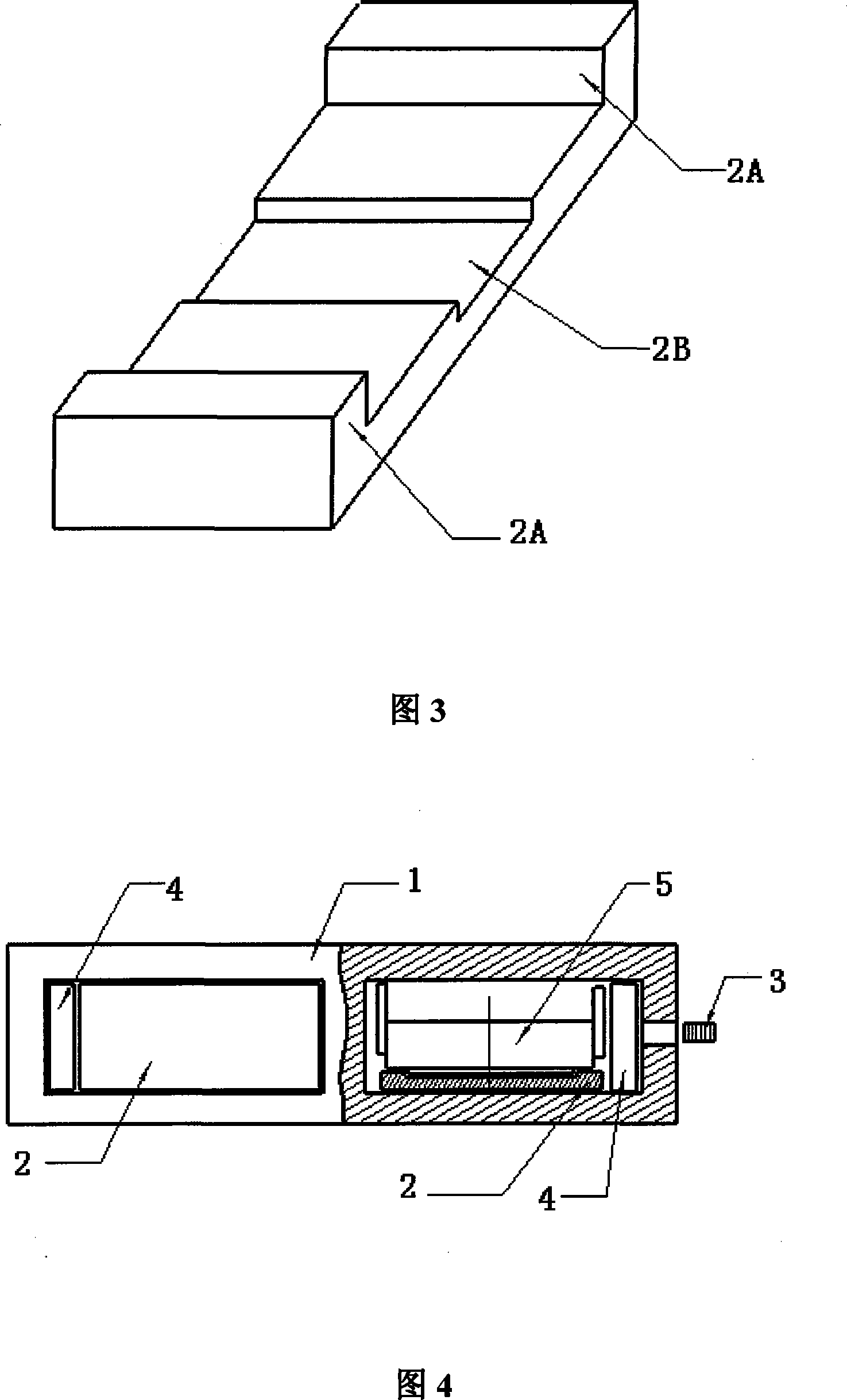

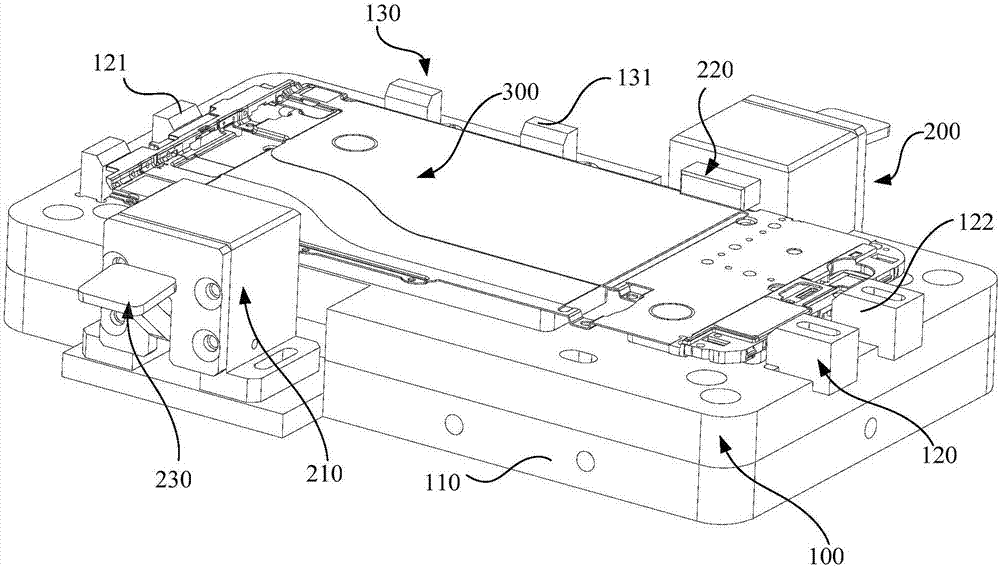

The invention provides a bearing-type damage biomechanic three-point bending test device. The bearing-type damage biomechanic three-point bending test device is characterized by comprising a base (1), a support base (2), support bearings (3), support shafts (4), a pressing head (5), a sensor (6), a connecting plate (7), a travel switch (8), a baffle (9), a baffle fixing screw (10), a support base fixing screw (11) and a dividing rule (12). The bearing-type damage biomechanic three-point bending test device provided by the invention has the advantages that a pair of support shafts and the support bearings can support a biological sample, the rolling friction is formed among the support shafts and the support base, the biological sample free bending constraint caused by the friction in a test process is reduced, the transformation of the biological sample on a supporting position is relieved, more accurate test data can be obtained, and a terminal condition more easily set in a finite element model so as to perform material parameter reverse engineering.

Owner:HUNAN UNIV

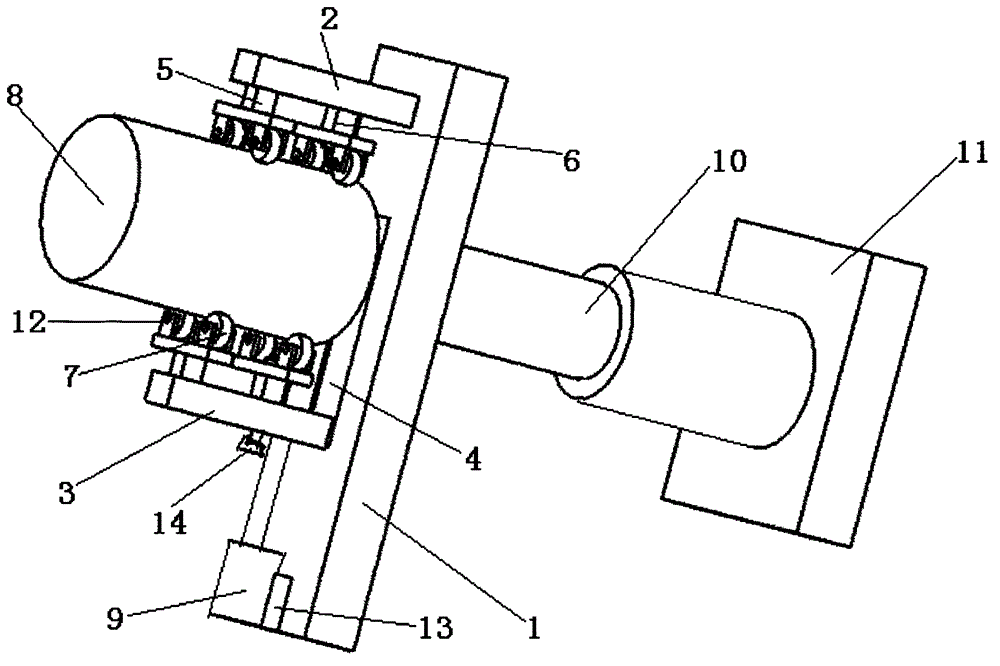

Combined mechanism of ratchet of high-voltage-cable walking robot

ActiveCN102259341AImprove driving abilityEasy to walkProgramme-controlled manipulatorGripping headsMotor drivePositive pressure

The invention relates to a combined mechanism of a ratchet of a high-volatage-cable walking robot. The combined mechanism is characterized by comprising a wheel type walking mechanism and claw-type clamping mechanisms, wherein the wheel type walking mechanism is used for walking on a high-voltage cable, the claw-type clamping mechanisms are used for clamping the high-voltage cable and provides positive pressure, the wheel type walking mechanism and the claw-type clamping mechanisms are arranged on a robot frame, and the claw-type clamping mechanisms are used in pairs. The combined mechanism disclosed by the invention utilizes a principle of an under-actuated mechanism, and two motion manners of rotation and movement are realized through one motor-driven clamping mechanism; through a self locking mechanism, the clamping mechanism is automatically locked after closed, thus the energy consumption is reduced; and the invention has the advantages of small and novel structure, high clampingefficiency and wide application range.

Owner:昆山市工业技术研究院有限责任公司

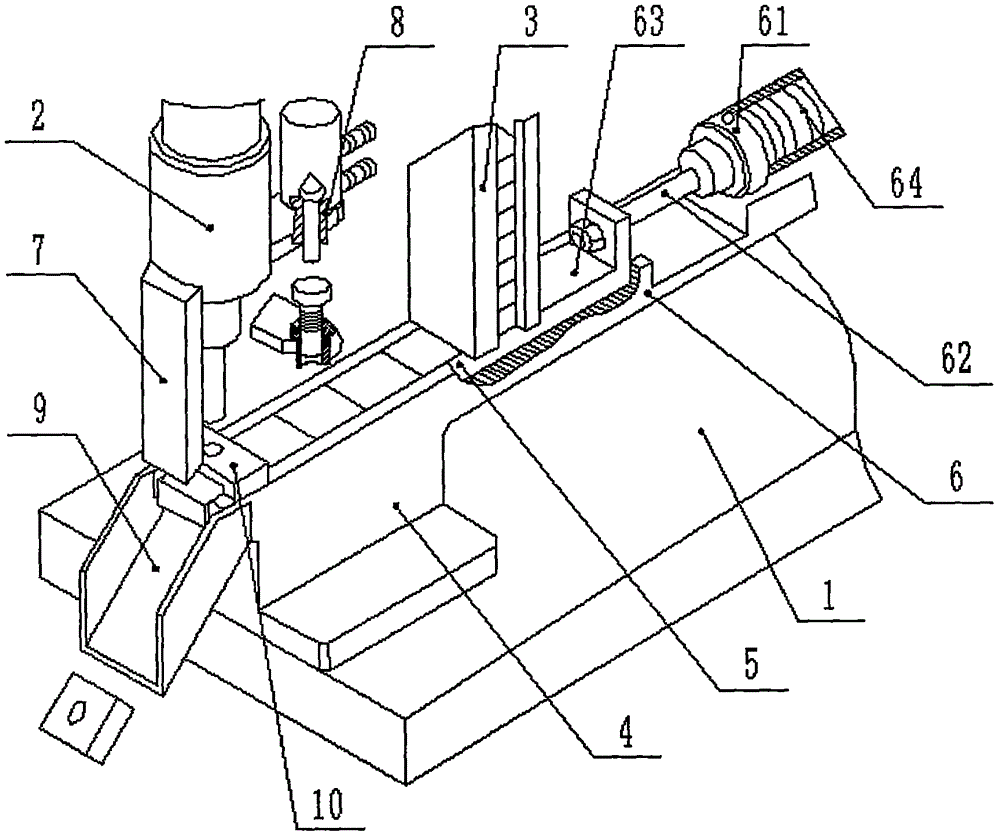

Machining tool for cylindrical workpieces

ActiveCN104985465AQuick clampingSmooth rotationWork clamping meansWelding/cutting auxillary devicesEngineeringMachine tool

The invention provides a machining tool for cylindrical workpieces. The machining tool comprises a bottom plate, a fixed support, a movable support, a first sliding groove, a fixed roller carrier, a sliding roller carrier, rollers, a first air cylinder, a second air cylinder and a locking bolt. By the adoption of the rollers, rapid workpiece clamping and accurate centering can be achieved, and workpieces can rotate conveniently in grinding or turning or welding or the like. By the adoption of the action of the air cylinders, automatic workpiece clamping can be achieved. By the arrangement of the first sliding groove and a second sliding groove, the distance between the fixed support and the movable support and the distance between the sliding roller carrier and the fixed roller carrier can be adjusted according to needs so that workpieces of different diameters can be clamped or different portions of workpieces can be clamped, and accordingly the universality and reliability of the tool are improved. The machining tool for the cylindrical workpieces is high in automation degree and clamping efficiency, greatly shortens the workpiece machining period, improves productivity and lowers the production cost.

Owner:ANHUI SCI & TECH UNIV

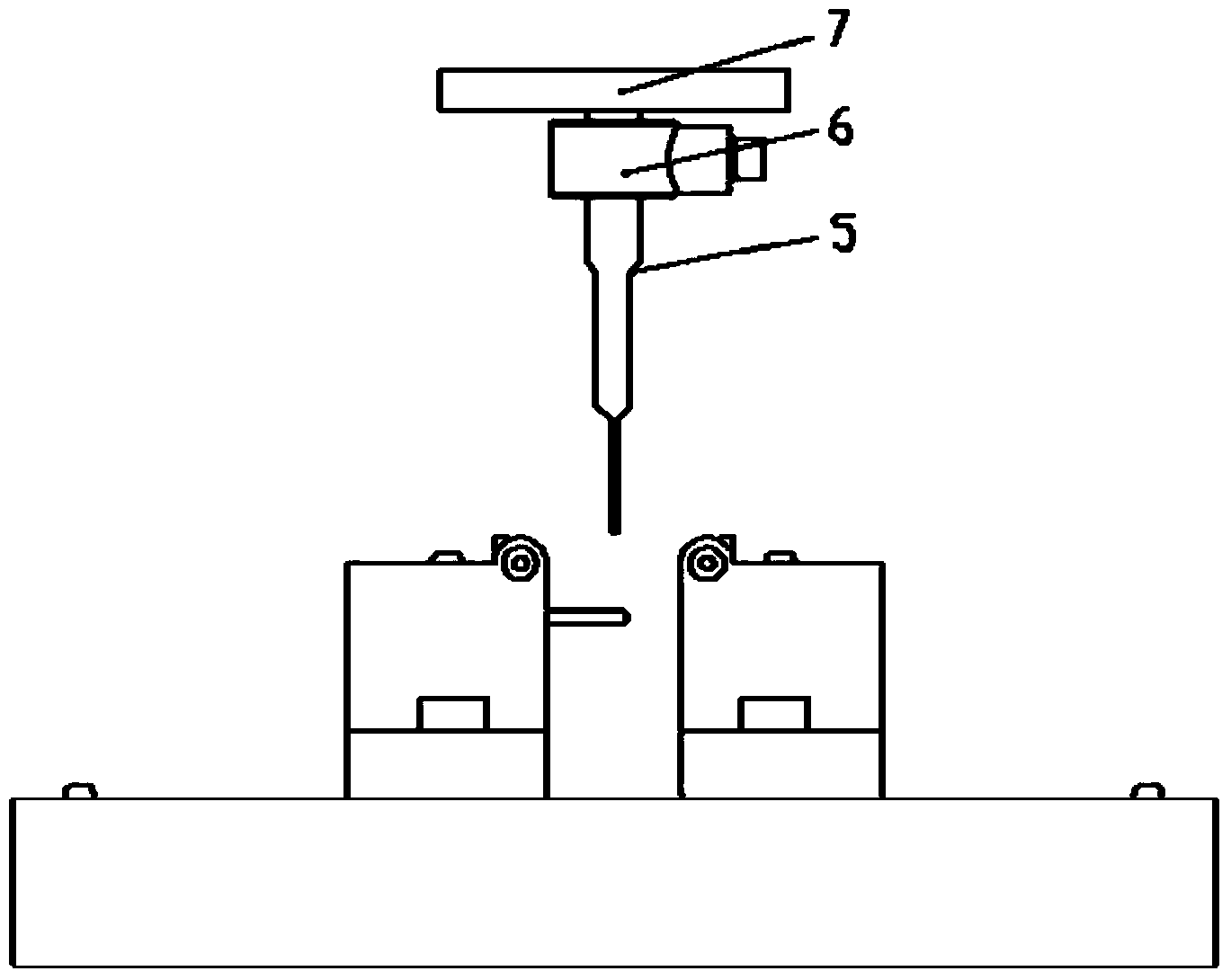

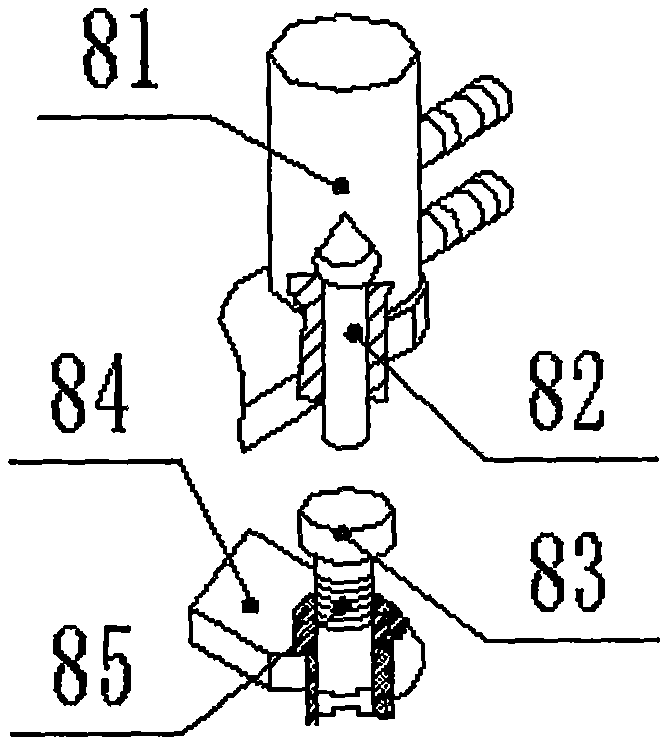

Drilling machine provided with automatic feeding device

InactiveCN105798689ARealize automatic feedingImprove clamping efficiencyMetal working apparatusEngineeringDrilling machines

The invention discloses a drilling machine provided with an automatic feeding device, belongs to the field of automatic drilling machines and solves problems that existing drilling machines cannot feed materials automatically and are low in drilling efficiency. The technical scheme is as follows: the drilling machine comprises a workbench and a drilling machine spindle, wherein a storage tank is fixedly arranged on one side of the drilling machine spindle, a feeding base is fixedly mounted on the workbench below the storage tank, a delivery guiding groove is formed in the feeding base in advance, a discharging port of the storage tank directly faces the delivery guiding groove, one side of the delivery guiding groove extends right below the drilling machine spindle, a push device is mounted on the other side of the delivery guiding groove, and a workpiece stop block is fixedly arranged on the drilling machine spindle, can slide up and down along the outer side surface of the drilling machine spindle and is located at the tail end of the delivery guiding groove after vertically falling.

Owner:WUXI INST OF COMMERCE

Guide blade water flow measuring clamp and guide blade water flow measuring method

ActiveCN103481219AReduce the number of clampingReduce mistakesMachine part testingWork holdersWater flowEngineering

The invention discloses a guide blade water flow measuring clamp and a guide blade water flow measuring method. Improvements on aspects of a sealing pad, a clamp passage structure and a water inlet waterway control are made. The sealing pad is changed into a mode that a blade is integrally contained and sealed and cavity passage docking is reserved, so that effective sealing is realized and the objective of multi-passage measuring is realized; four corresponding water incoming passages are designed for a clamp corresponding to the blade according to the position of a hole of the blade to be suitable for water incoming systems of four cavities of the blade. By the guide blade water flow measuring clamp and the guide blade water flow measuring method, the four cavities of the blade can be communicated with the four water incoming passages of a measuring system simultaneously only by clamping and mounting the blade for one time, and when measuring any cavity of the blade, water flow value of the cavity can be acquired only by opening a control valve. The guide blade water flow measuring method is simple and convenient to operate and stable in data, and the guide blade water flow measuring clamp is timesaving, laborsaving and good in sealability.

Owner:AECC AVIATION POWER CO LTD

Packing device of battery packaging line

ActiveCN103895900APrevent fallingSmooth movementIndividual articlesEngineeringMechanical engineering

The invention discloses a packing device of a battery packaging line. The packing device comprises a frame, a packing container conveying device, a container press device, a battery clamping handling device and a sorting platform. The container press device comprises a press frame, a packing opening is formed in the middle of the press frame, press plates are arranged on the edge of the packing opening, and the press frame is driven through a press frame lifting device; the sorting platform is used for temporarily storing and sorting a well arrayed battery pack; the battery clamping handling device comprises a sliding base which is driven through a driving device; a clamping base is vertically slidably mounted on the sliding base is driven through a clamping component and the lifting device; a plurality of mounting blocks are horizontally and slidably mounted at the bottom of the clamping seat, and each mounting block is provided with a detachable clamping jaw; the mounting blocks are driven to be connected through clamping jaw driving device. By the arrangement, the well arrayed batteries can be sorted through the packing device, then the sorted batteries are clamped to be packed accurately, and stable and normal operation of a battery packing line can be guaranteed.

Owner:蚌埠航宇知识产权服务有限公司

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

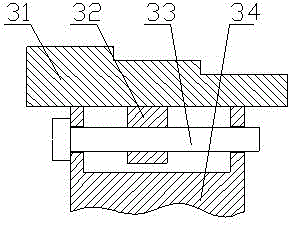

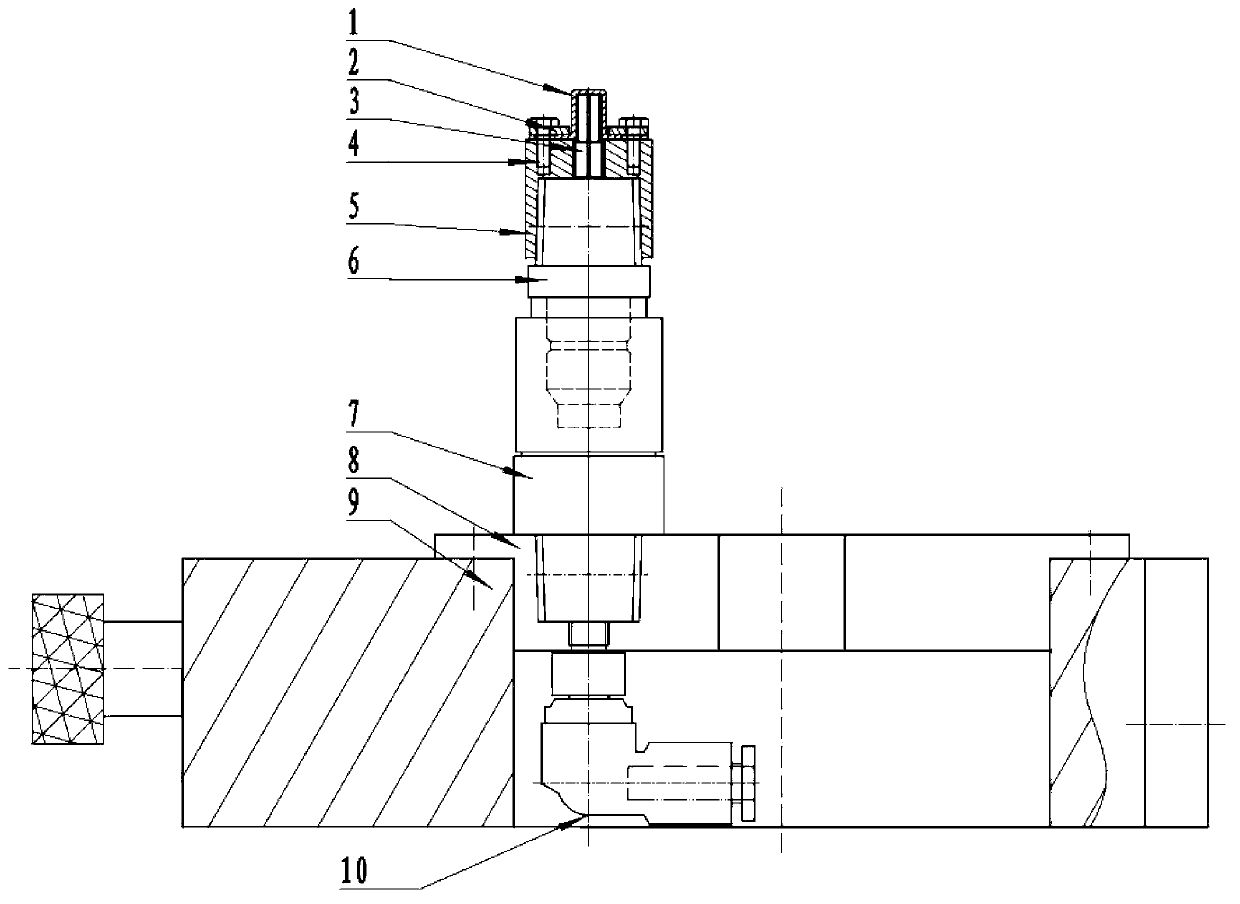

Turning fixture

ActiveCN103586705ARealize clamping and pressingEnsure correct clamping and positioningPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a turning fixture, and belongs to the field of machining fixtures. The turning fixture comprises a body (2), a positioning disc (7), positioning pins (10), a supporting block (8) and a pulling pressing mechanism, wherein the positioning pins (10) and the supporting block (8) are arranged on the positioning disc (7); and the pulling pressing mechanism consists of a pull rod (1), a short hinged shaft (3), a lever (4), a bush (5), a long hinged shaft (6) and a hook-shaped pressing plate (9). By the turning fixture, problems that in turning machining, the clamping efficiency of a fixture is low, workpieces are not flat or tilt due to improper clamping, and products are out-of-size are solved; actual clamping of the workpieces is guaranteed; and the clamping efficiency and the machining yield are improved.

Owner:CHANGSHA BODA MACHINERY PARTS CO LTD

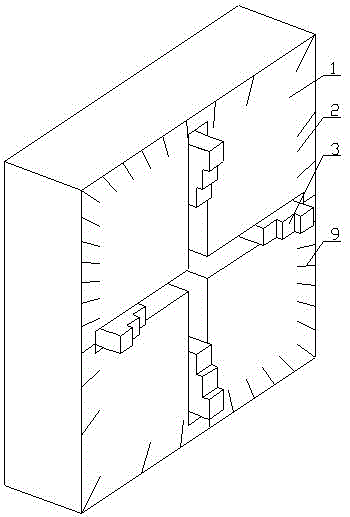

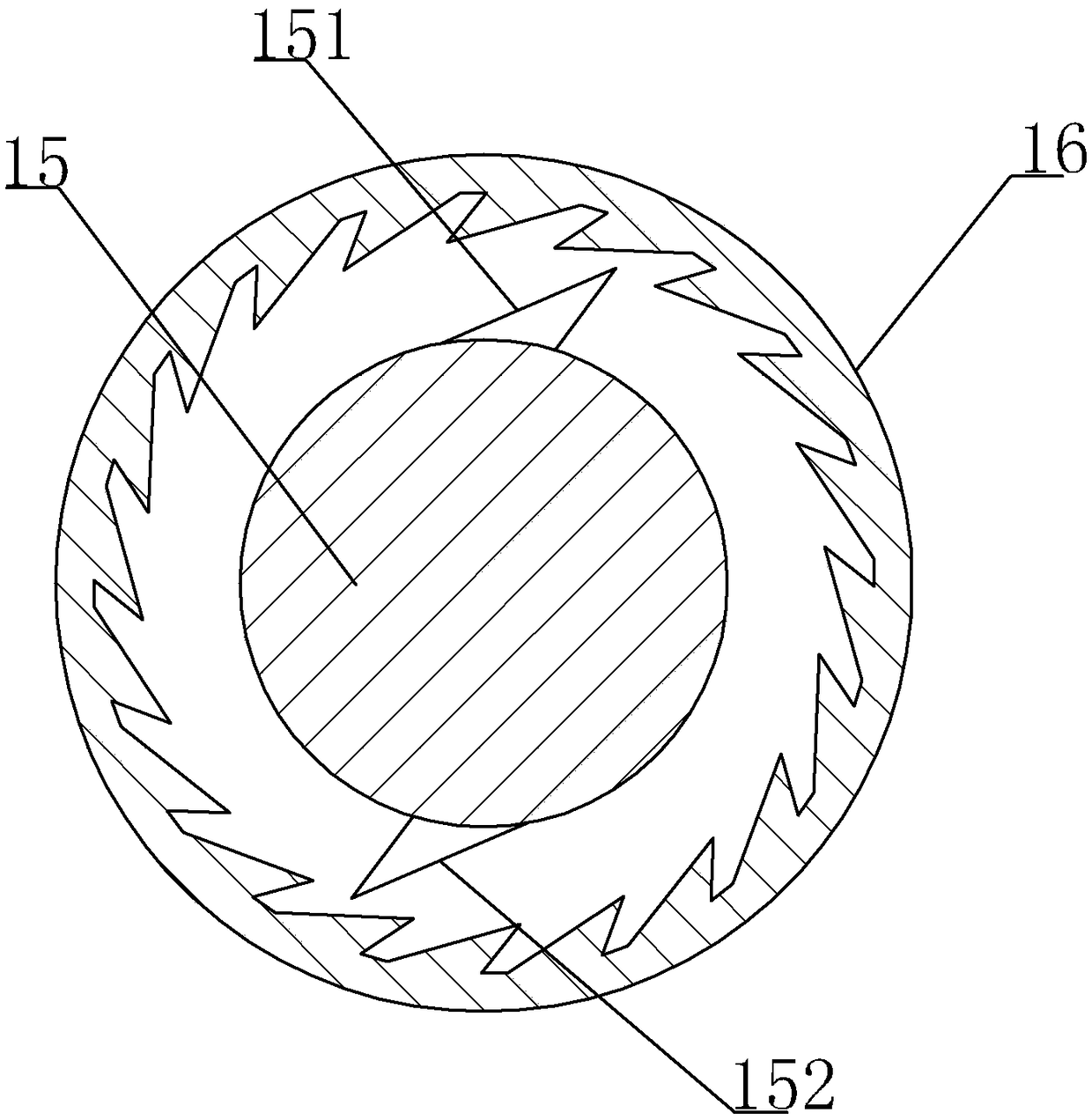

Precise indexing clamp special for turning

InactiveCN105583421AImprove clamping efficiencyEasy to holdMeasurement/indication equipmentsChucksEngineeringMachining

The invention discloses a precise indexing clamp special for turning, and belongs to clamps special for turning in the technical field of machining equipment. According to the precise indexing clamp special for turning, multipoint stress is achieved, and the clamp is suitable for clamping workpieces of multiple sizes. According to the technical scheme, the clamp comprises a clamp body, and a cross sliding groove is formed in the clamp body; a clamping jaw is arranged in each sliding groove body of the cross sliding groove, and a clamping jaw drive mechanism is arranged on the back face of the clamp body and comprises a large conical gear and a plurality of sets of lead screws; the large conical gear is mounted on the clamp body, and each lead screw is arranged at the position corresponding to the position of the corresponding clamping jaw; the lead screws are sleeved with threaded holes of the clamping jaws, and are in threaded connection with the clamping jaws; and a small conical gear is arranged on one side, close to the large conical gear, of each lead screw, and the small conical gears on the lead screws are meshed with the large conical gear. The precise indexing clamp is suitable for being used in turning.

Owner:新都区大丰鹏宇机械厂

Coating machine

ActiveCN105709990AGuaranteed synchronous actionImprove clamping efficiencyLiquid surface applicatorsCoatingsEngineeringAutomation

The invention discloses a coating machine which comprises a rack and a workpiece basket. The coating machine further comprises a feeding mechanism for adding workpieces into the workpiece basket. A working station rotating device for changing the work position of the workpiece basket is arranged on the rack and at least provided with two sets of clamping and rotating devices for clamping or loosening the workpiece basket and driving the workpiece basket to rotate, and centrifugal driving mechanisms arranged on the working station rotating device and used for driving the clamping and rotating devices to rotate. A dipping machine and a dipping machine lifting device for driving the dipping machine to enable the workpiece basket to be soaked therein, and a walking turnover device are arranged below the clamping and rotating devices, and the walking turnover device is used for conveying the fed workpiece basket to the positions of the clamping and rotating devices to be clamped by the clamping and rotating devices. The coating machine automatically conveys the workpieces needing to be coated into coating equipment, the coated workpieces are automatically discharged, the automation degree is high, and the coating efficiency is improved.

Owner:CHANGZHOU JUNHE TECH

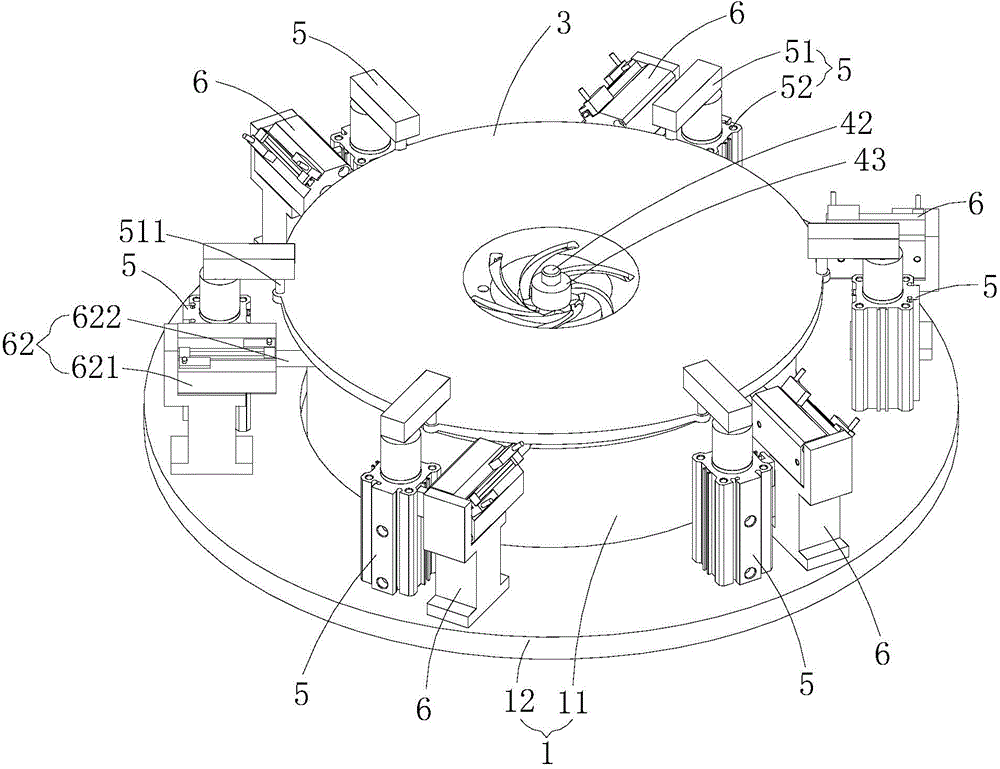

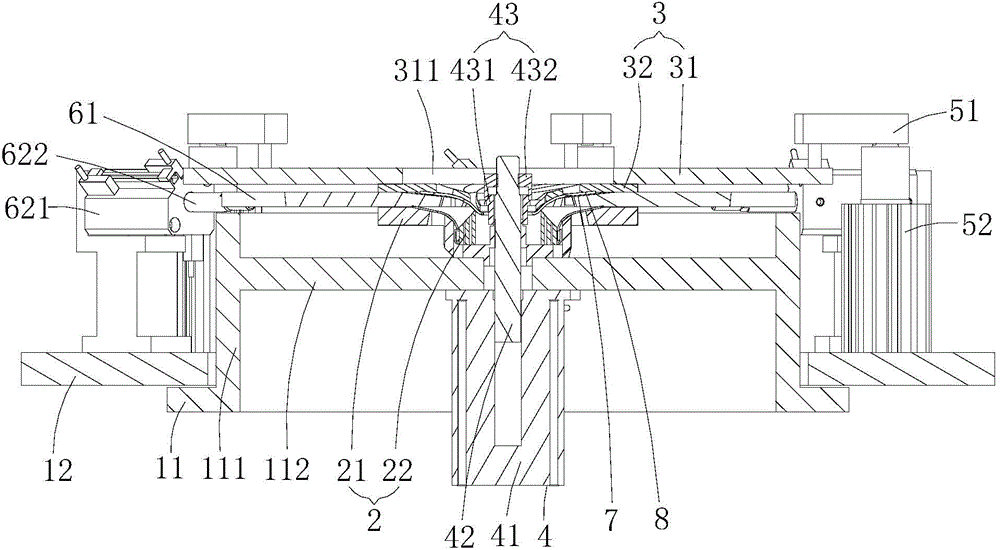

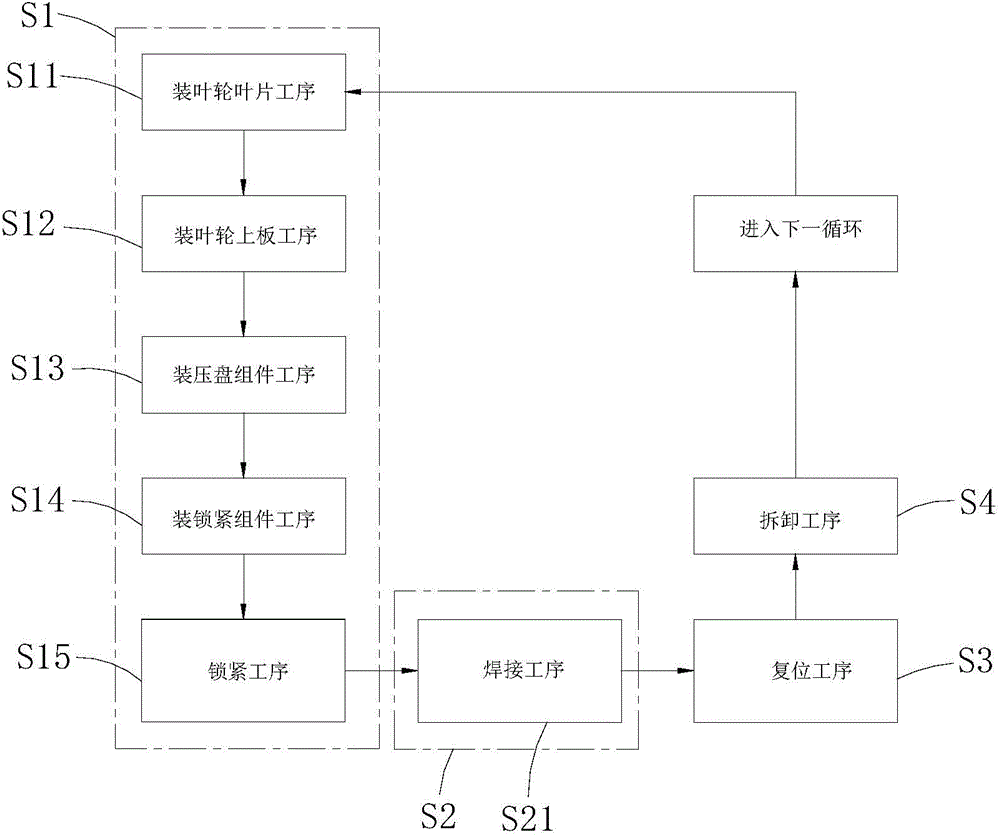

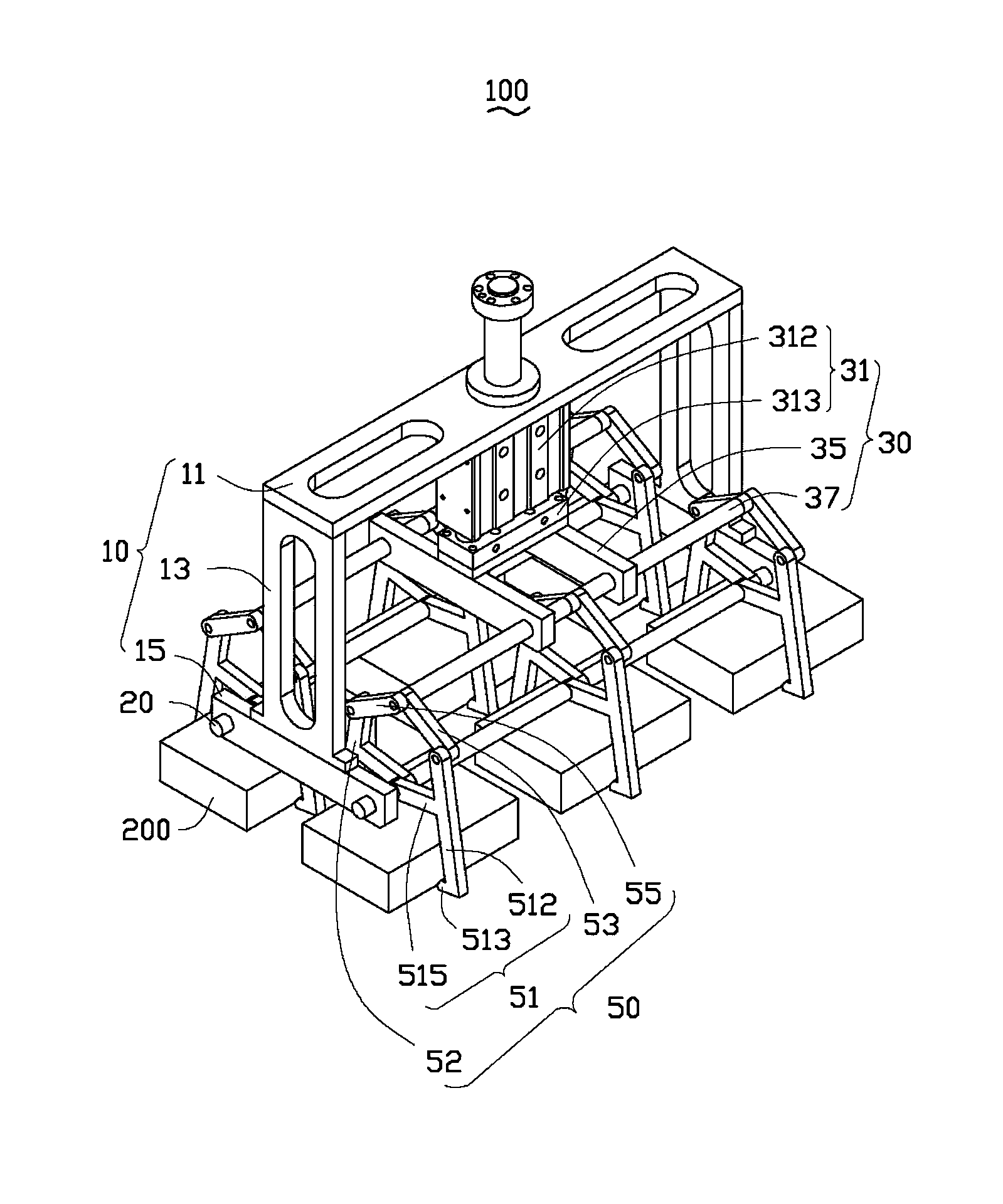

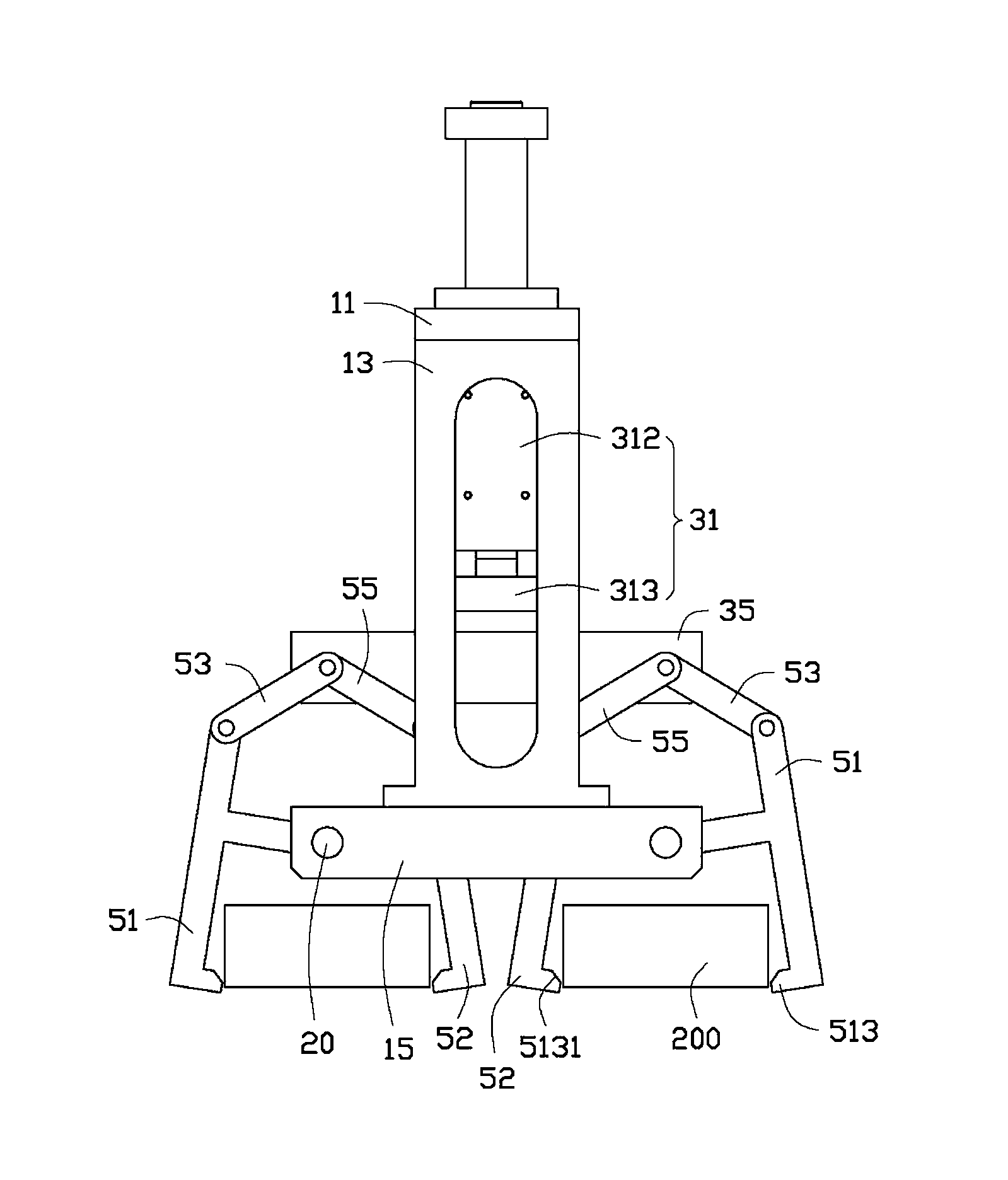

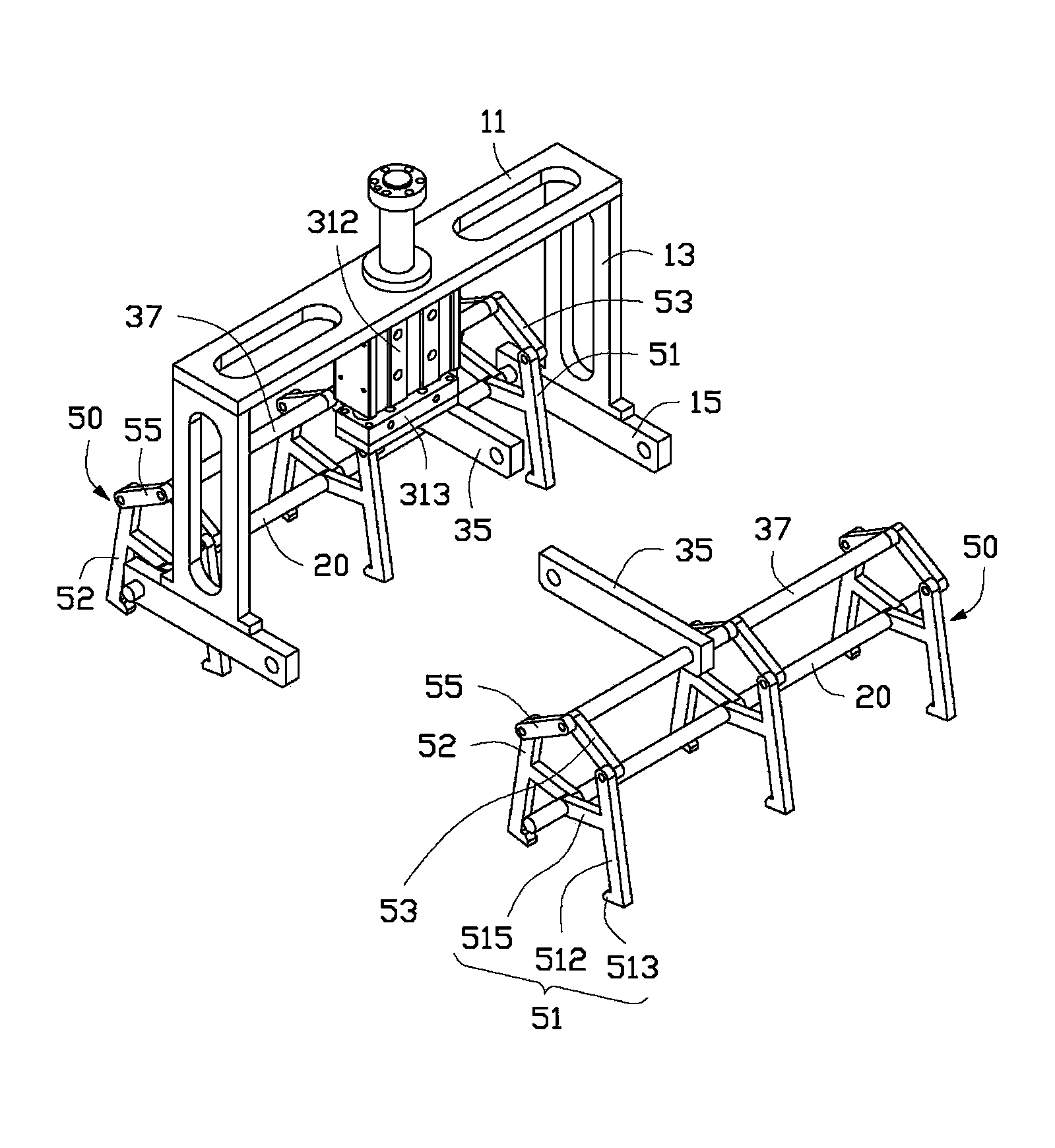

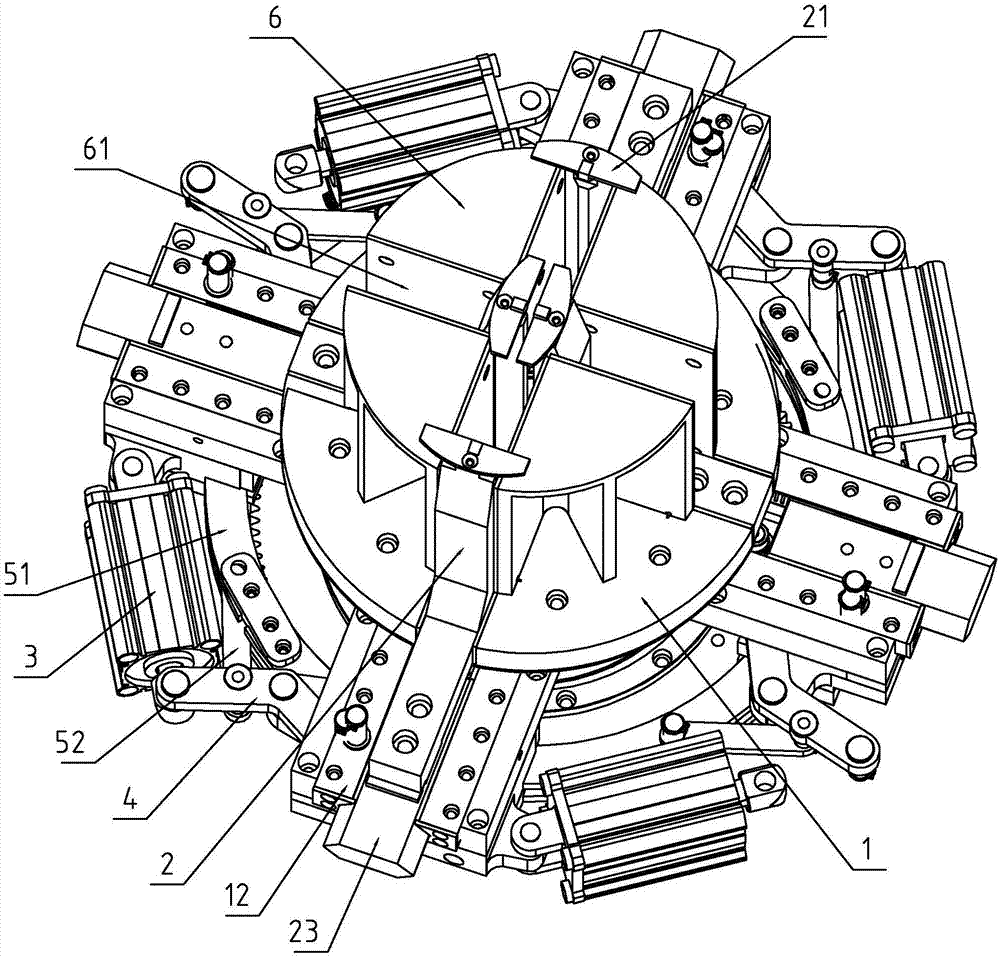

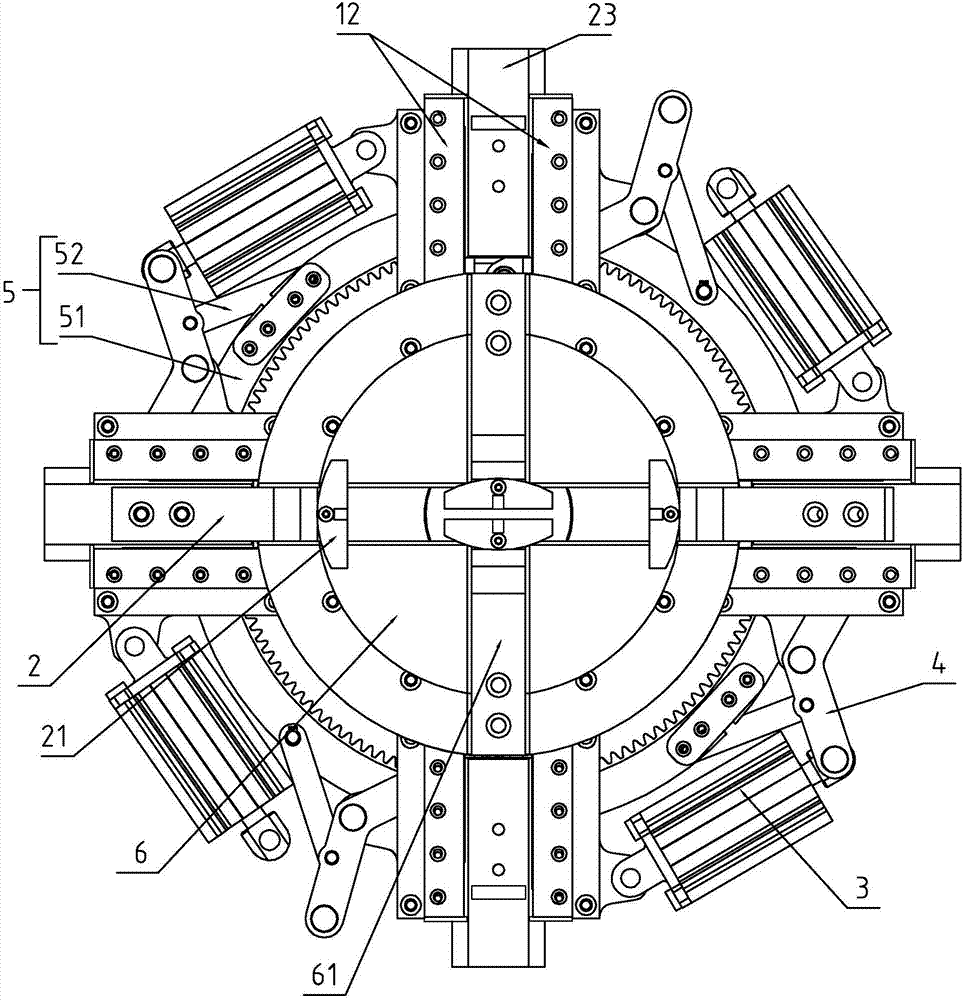

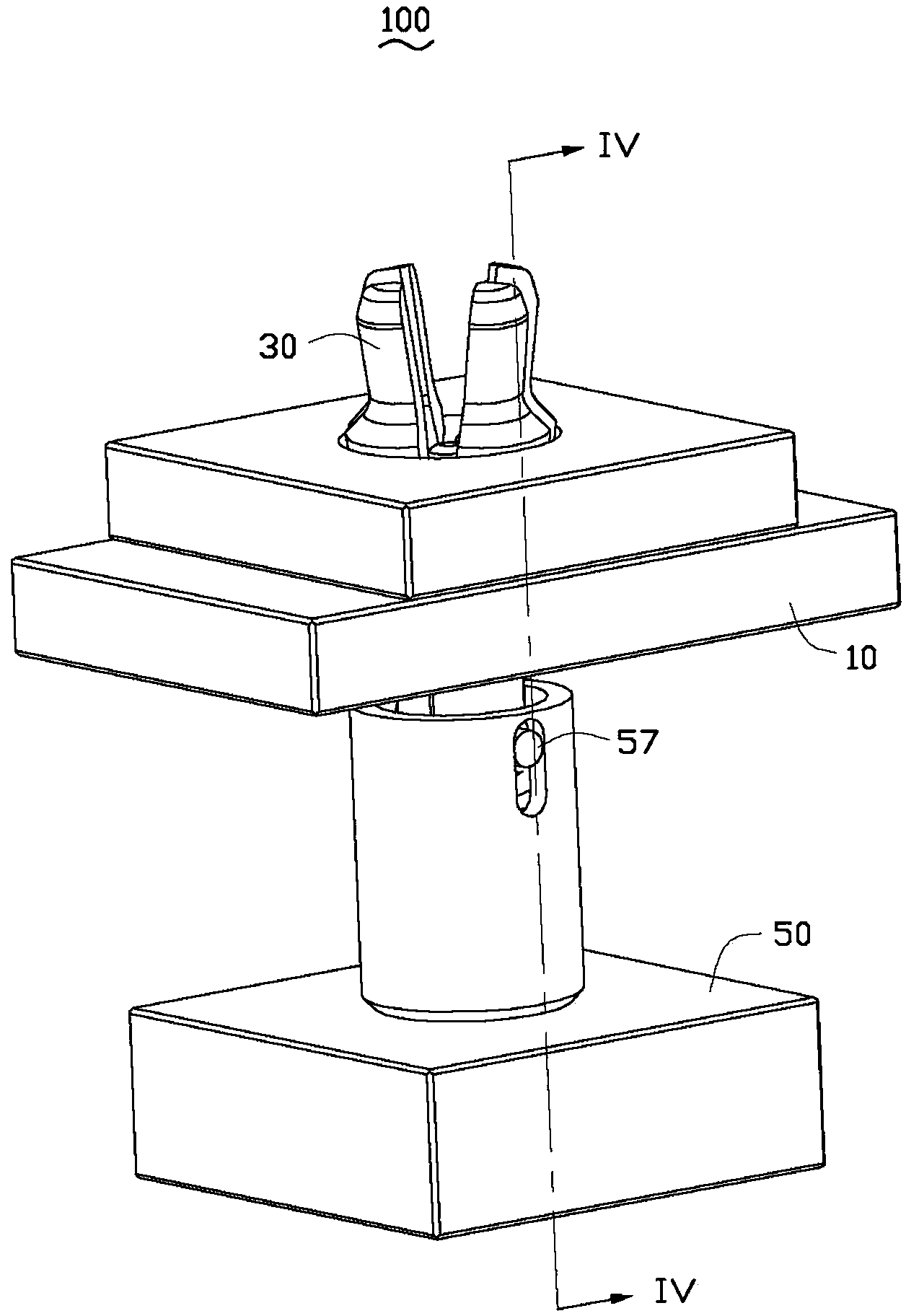

Impeller blade and impeller upper plate laser welding method and clamping method and jig

ActiveCN104384804AGuaranteed reliabilityEnsure positioning reliabilityTurbinesWelding/cutting auxillary devicesImpellerEngineering

The invention is applicable to the field of impeller laser welding and discloses an impeller blade and impeller upper plate laser welding jig, an impeller blade and impeller upper plate clamping method with the jig and an impeller blade and impeller upper plate laser welding method through the clamping method. The impeller blade and impeller upper plate laser welding jig comprises a base assembly, a support assembly mounted on the base assembly for placing and positioning an impeller blade and an impeller upper plate, a pressing plate assembly arranged above the support assembly for pressing the impeller blade and the impeller upper plate to the support assembly, a first telescoping assembly mounted on the base assembly for pressing the pressing plate assembly in the axial direction of the base assembly, a plurality of peripheral pressing structures mounted on the base assembly, and a plurality of lateral positioning structures mounted on the base assembly. The impeller blade and impeller upper plate laser welding jig, the impeller blade and impeller upper plate clamping method with the jig and the impeller blade and impeller upper plate laser welding method through the clamping method solve the technical problems of poor versatility, clamping difficulty and low clamping efficiency, clamping positioning reliability and automation degree of existing impeller laser welding jigs.

Owner:HANS LASER TECH IND GRP CO LTD

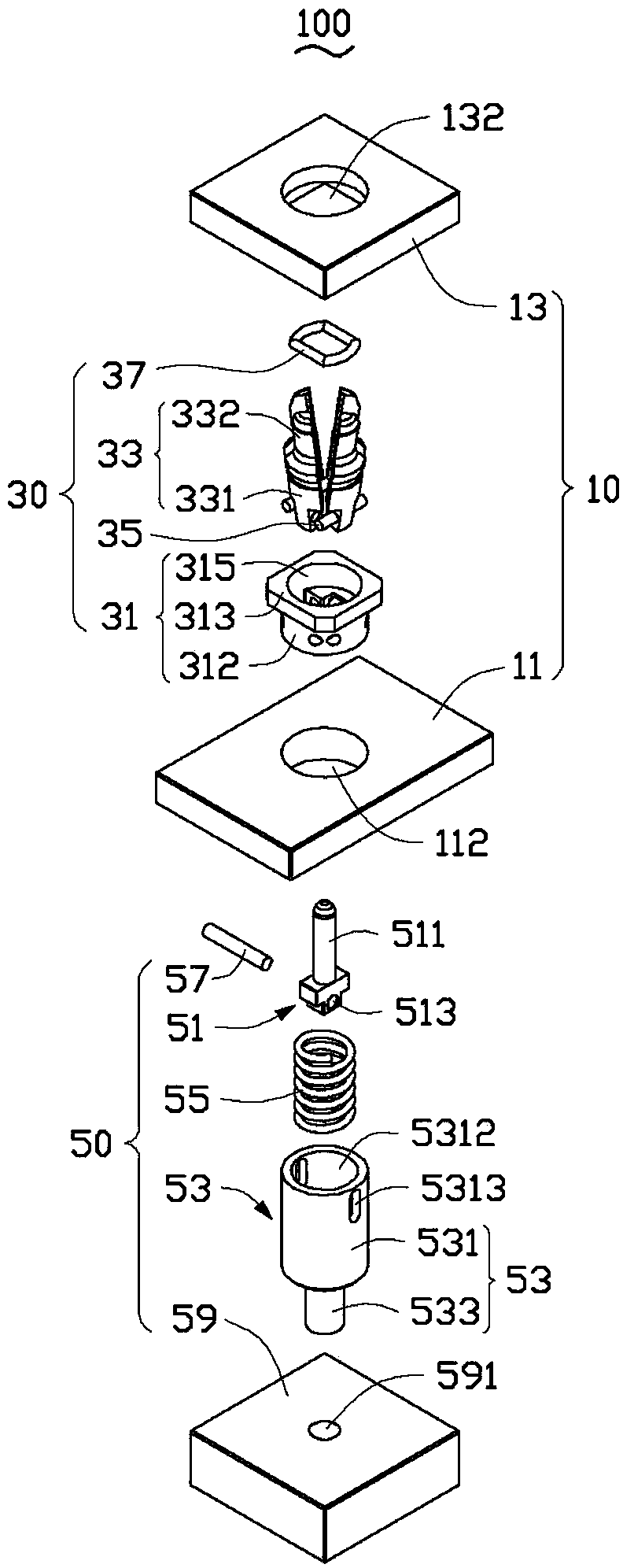

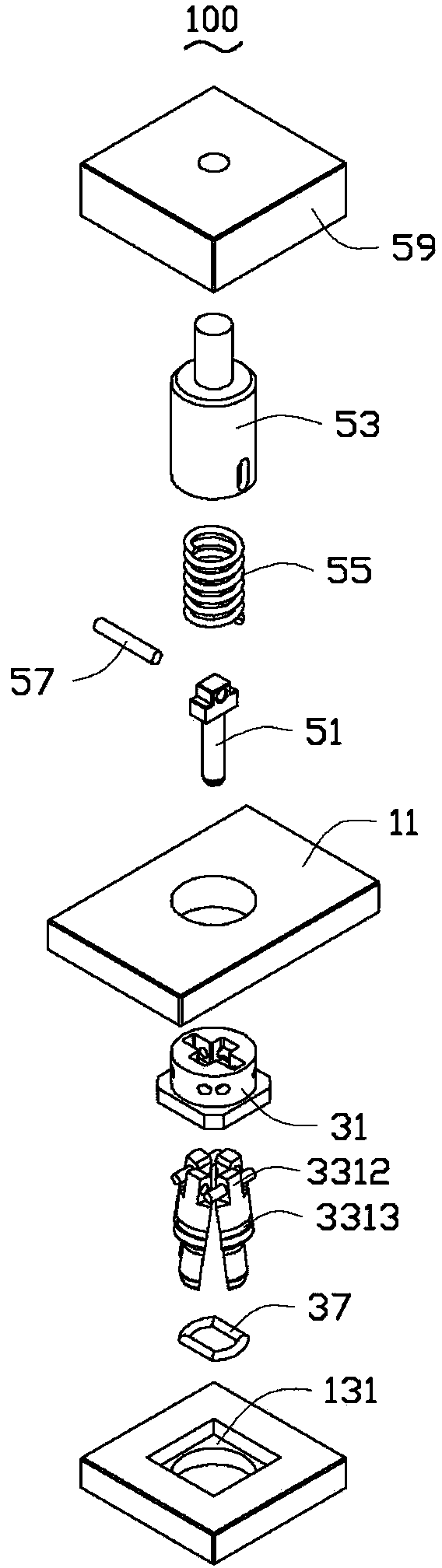

Clamping device

ActiveCN104227729ASimple structureImprove clamping efficiencyGripping headsMechanical engineeringEngineering

A clamping device comprises a supporting frame, a driving mechanism, fixed shafts and at least two clamping assemblies. The fixed shaft is fixedly installed on the supporting frame. The driving mechanism comprises a driving piece and movable shafts connected with the driving piece, and the driving piece is fixedly installed on the supporting frame. Each clamping assembly comprises a first clamping piece, a second clamping piece, a first connecting piece and a second connecting piece, the first clamping pieces and the second clamping pieces are respectively connected to the fixed shafts in a pivoting mode, the first connecting pieces and the second connecting pieces are respectively connected to the movable shafts in a pivoting mode, the first connecting pieces are connected with the first clamping pieces in a pivoting mode, the second connecting pieces are connected with the second clamping pieces in a pivoting mode, and the movable shafts drives the first connecting pieces and the second connecting pieces of the at least two clamping assemblies to move under the driving of the driving piece, so that the first clamping pieces and the second clamping pieces of the at least two clamping assemblies move close to or away from each other to clamp or release a workpiece. The clamping device has the advantage of being simple in structure.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

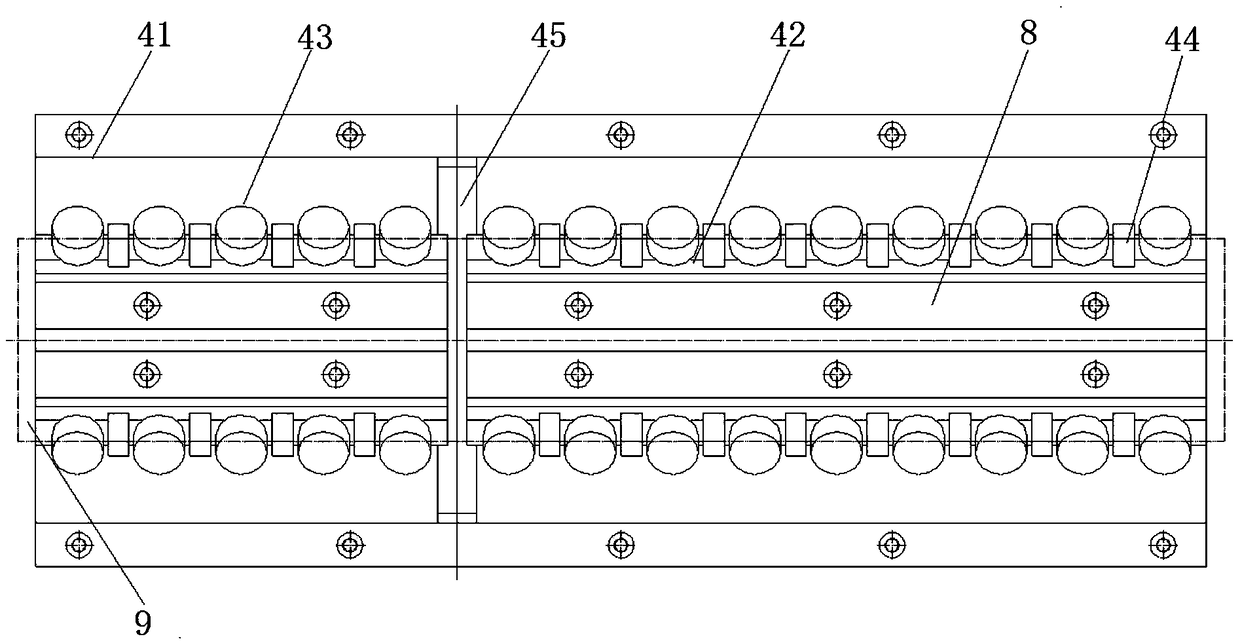

Ceramic double arrange packaging device high accelerate centrifugation experiment cramping apparatus

InactiveCN101135636AEven by forceAvoid deformationUsing mechanical meansCentrifugesCentrifugationEngineering

The fixture comprises a mother fixture, a daughter fixture used for placing the test piece, a fastening used for fastening the test piece and a fastening clamp plate. Said mother fixture has a through slot used for mounting the said daughter fixture by using a drawer way; on the side wall of the mother fixture there are screw type locking components.

Owner:NO 24 RES INST OF CETC

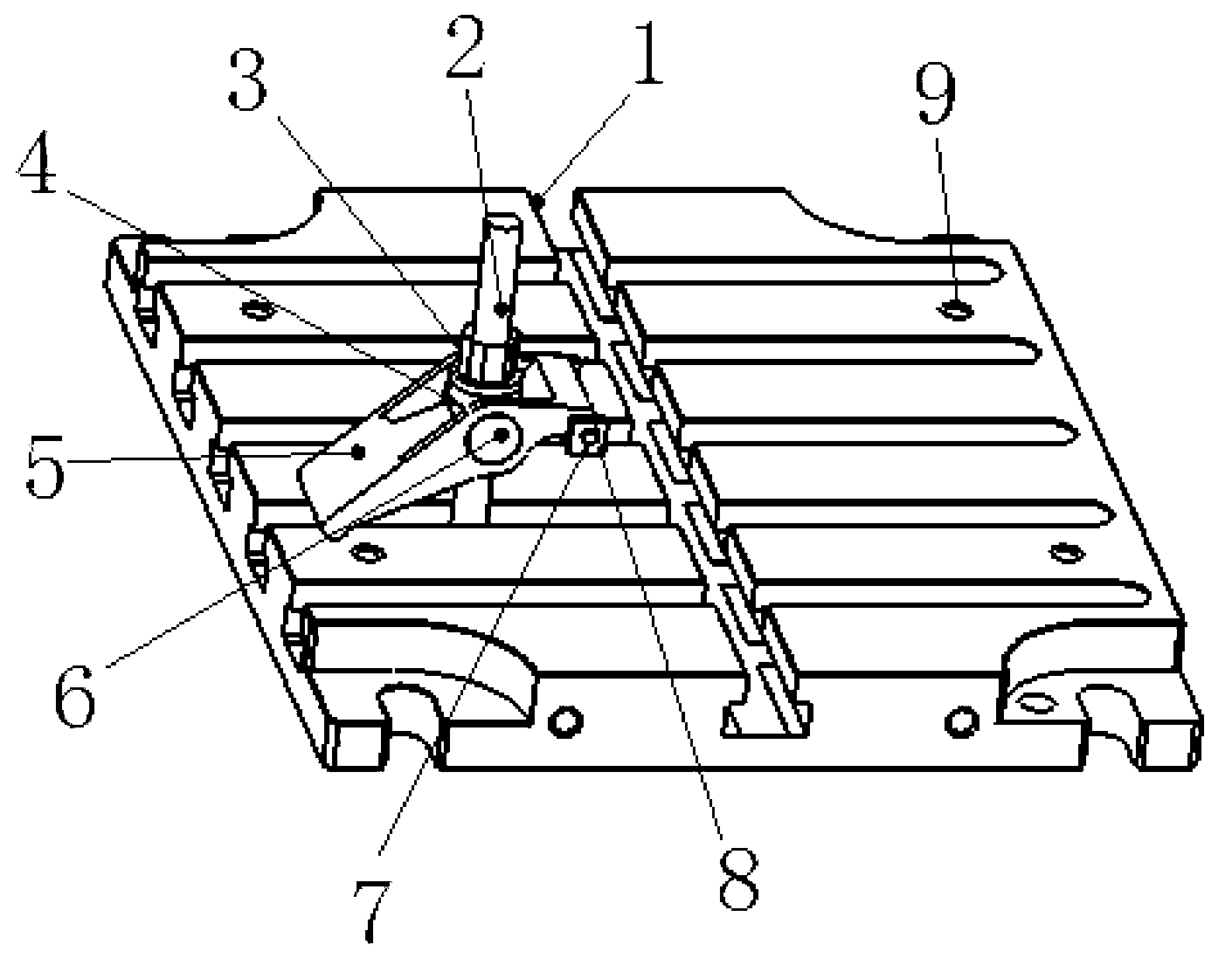

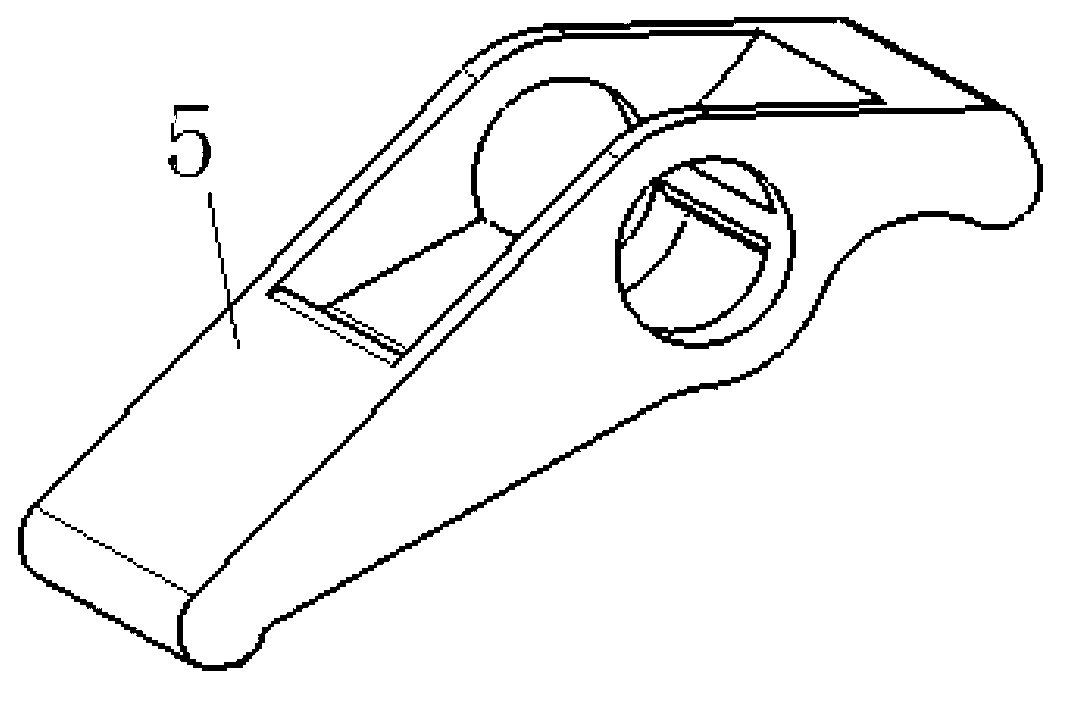

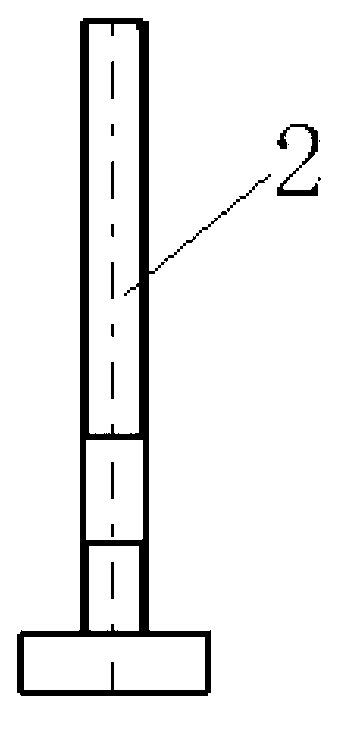

Rapid clamping device

ActiveCN106965009AQuick clampingQuick releaseWork holdersPositioning apparatusEngineeringMechanical engineering

The invention relates to a rapid clamping device. The rapid clamping device comprises a positioning mechanism and abutting mechanisms; the positioning mechanism comprises a base, first positioning assemblies and second positioning assemblies, wherein the base is used for bearing a workpiece, the first positioning assemblies are arranged on the base and used for positioning the workpiece in the first direction, and the second positioning assemblies are used for positioning the workpiece in the second direction; and the abutting mechanisms are connected to the base and each comprise a fixing base, an abutting part and a driving assembly, wherein the abutting parts are matched with the fixing bases in a sliding mode and can abut against the workpiece, and the driving assemblies drive the abutting parts to slide. The clamping device comprises the abutting mechanisms, the abutting mechanisms comprise the fixing bases, the abutting parts and the driving assemblies, the driving assemblies are driven to move, then the abutting parts abut against or keep away from the workpiece, and therefore the workpiece can be rapidly clamped, meanwhile, the machined workpiece can be rapidly loosened, and the clamping efficiency of the workpiece can be greatly improved on the basis of ensuring the clamping stability.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

Adjustable rapid clamp

Owner:MT PRECISION MACHINERY MFG

Clamping device and clamping and positioning method thereof

InactiveCN103264301AGuarantee product qualityRapid positioningPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a clamping device and a clamping and positioning method thereof. The clamping device is used for positioning workpieces of mold forging piece inserts, steel plates and the like and comprises an auxiliary working table and an arc-shaped pressing plate. A pressing screw is arranged on the auxiliary working table, a pressing plate rotation shaft is arranged on the arc-shaped pressing plate, the pressing screw penetrates the middle of the pressing plate rotation shaft, one end of the arc-shaped pressing plate contacts with the auxiliary working table, a pressing plate for pressing workpieces to be positioned is arranged at the other end of the arc-shaped pressing plate, and a locking nut matched with the pressing screw is installed on the pressing plate rotation shaft in a pressing mode. According to the clamping and positioning method, positioning of the workpieces is achieved through a clamping and positioning device. The clamping device and the clamping and positioning method of the clamping device can improve workpiece positioning efficiency, further improve working efficiency, and meanwhile can guarantee surface quality of products.

Owner:FUZHEN TECH RES ANHUI

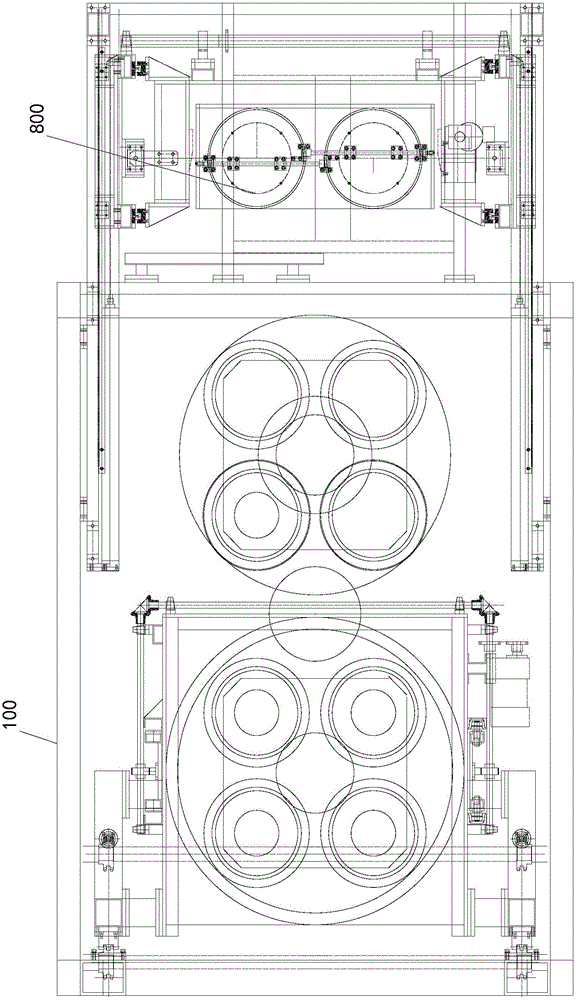

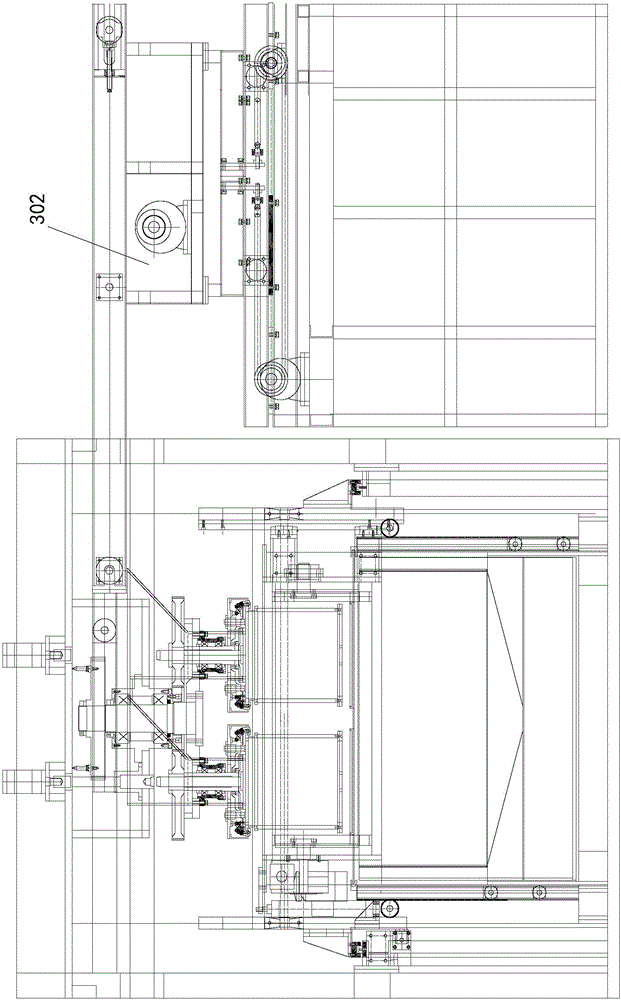

Silicon wafer processing device

ActiveCN108262869AAchieve truncationImplementor sliceWorking accessoriesFine working devicesEngineeringWire saw

The invention relates to a silicon wafer processing device. The silicon wafer processing device comprises a base, a rack, a squaring clamping mechanism, a silicon wafer cut-off clamping mechanism anda wire saw cutting machine, wherein the squaring clamping mechanism is used for clamping to-be-squared seed crystal rods, the silicon wafer cut-off clamping mechanism is used for clamping single-crystal silicon rods or polycrystalline silicon blocks to be cut-off, and the wire saw cutting machine is used for squaring the seed crystal rods and cutting off the single-crystal silicon rods or the polycrystalline silicon blocks. The silicon wafer processing device integrates the silicon wafer squaring and cut-off functions, not only can achieve squaring of the seed crystal rods, but also can achieve cutting off or slicing of the single-crystal silicon rods or the polycrystalline silicon blocks, the structure is simple and compact, the production cost and using cost of manufacturers are reduced,and the equipment utilization rate is increased.

Owner:福州天瑞线锯科技有限公司

Four-jaw chuck

ActiveCN107984157ASimple structureEasy to implementWelding/cutting auxillary devicesAuxillary welding devicesKinematic pairEngineering

The invention discloses a four-jaw chuck with a wide application range. The technical scheme of the four-jaw chuck is characterized by comprising a chuck body and four jaws, wherein four cylinders arehinged to the chuck body and correspond to the jaws respectively, a connecting rod is connected between a piston rod of each cylinder and the corresponding jaw, the middle of each connecting rod is hinged with the chuck body, and the jaw hinged to the other end of each connecting rod can be driven to radially slide along the chuck body when each cylinder pushes the corresponding connecting rod; two kinematic pairs used for limiting a group of two jaws to slide synchronously are arranged on the chuck body; each kinematic pair comprises a turning ring rotationally connected to the chuck body, the turning ring and the chuck body are coaxially arranged, a joint lever is connected between the turning ring and the corresponding connecting rod, two ends of the joint lever are hinged with the turning ring and the corresponding connecting rod, and the same group of two cylinders can drive two jaws to synchronously slide under the guidance of the joint lever and the turning ring when pushing the connecting rods.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

Pressing mechanism for airplane titanium alloy part processing tool table

ActiveCN108637724AGood repeatabilityImprove consistencyPositioning apparatusMetal-working holdersMotor driveEngineering

The invention relates to a pressing mechanism for an airplane titanium alloy part processing tool table, in particular to an auxiliary device for a machine tool processing part. The pressing mechanismcomprises four parts, which are separately a pedestal regulating and fixing mechanism, a left side lifting pressing mechanism, a right side lifting pressing mechanism and an X-direction pressing mechanism, wherein the left side lifting pressing mechanism and the right side lifting pressing mechanism are mounted and fixedly arranged on the pedestal regulating and fixing mechanism, and define a threaded-transmission and spline-transmission matching relationship with the pedestal regulating and fixing mechanism; and the X-direction pressing mechanism is mounted and fixed on the pedestal regulating and fixing mechanism. The pressing mechanism can be manually and quickly regulated, and a motor drives equipment to realize automatic regulation on a clamping dimension and a clamping position as well as clamping with set load; and the motor drives blank to lift and rotate, so that multi-surface processing is realized.

Owner:XIAN AIRCRAFT IND GROUP

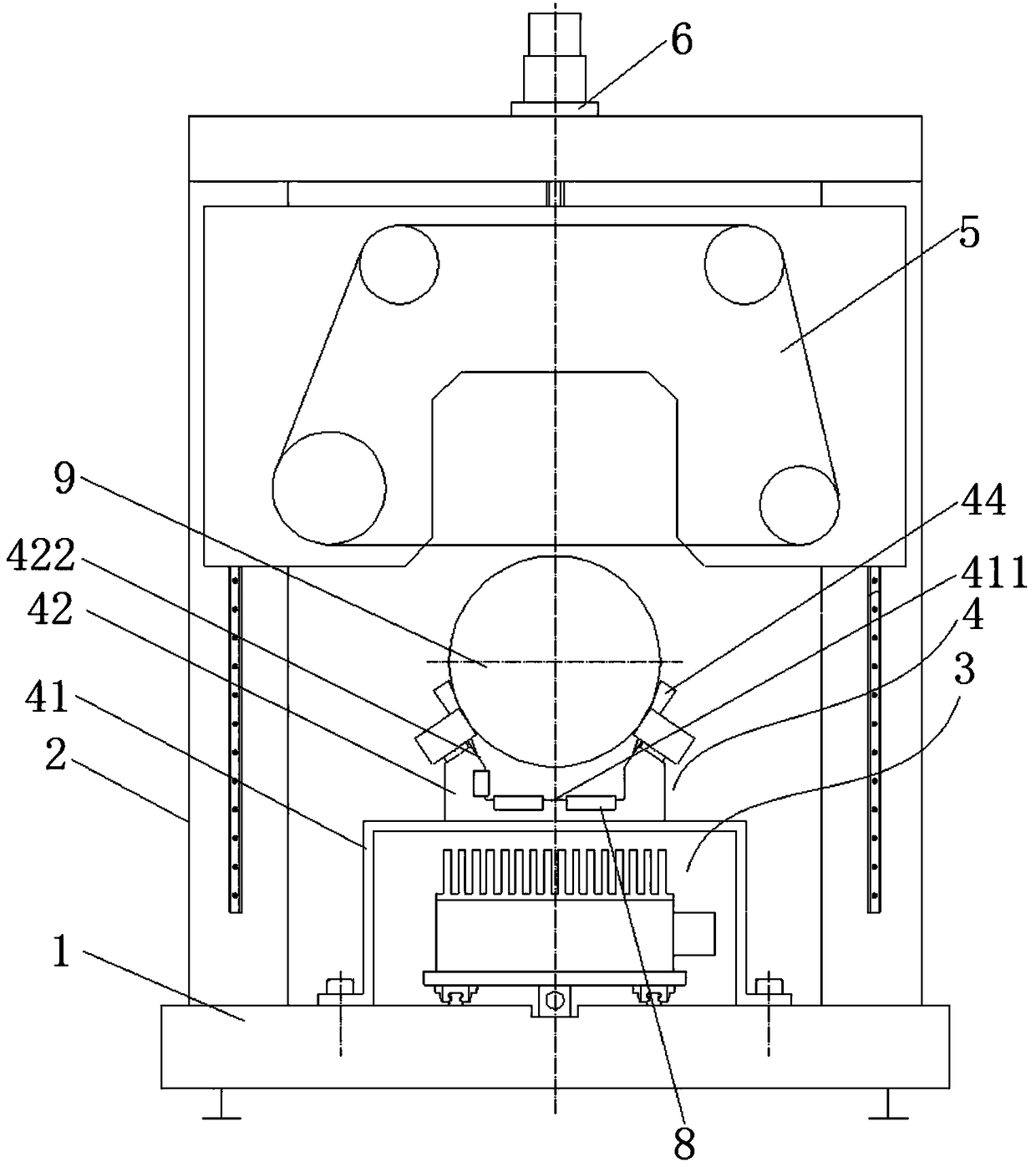

Outer surface force control type flexible polishing equipment of bearing outer ring

ActiveCN105773359AHigh strengthImprove stabilityBelt grinding machinesGrinding work supportsSurface finishConstant force

The invention relates to automatic polishing equipment, in particular to automatic polishing equipment of bearing fittings. The equipment comprises a worktable, a clamping mechanism for realizing clamping and positioning of the bearing outer ring, a polishing mechanism for realizing polishing of the outer surface of the bearing outer ring, and a fixture for mounting the bearing outer ring; the clamping mechanism, the polishing mechanism and the fixture are fixedly connected to the worktable; the fixture is positioned at the lower part of the clamping mechanism; and an abrasive belt of the polishing mechanism is contacted with the outer surface of the bearing outer ring. The outer surface force control type flexible polishing equipment of the bearing outer ring is used for polishing the outer surface of the bearing outer ring to improve the surface smoothness in a mode of not removing materials, realizes flexible contact between the abrasive belt and the outer surface of the bearing outer ring, realizes polishing by dint of constant force, monitors tangential force suffered by the bearing outer ring in real time, keeps constant tangential force and pressure of the bearing outer ring, and guarantees the polishing quality consistency; and after the bearing outer ring coats the fixture, the automatic mounting and polishing operation can be realized, and the automation degree is high.

Owner:滁州辉煌无纺科技有限公司

Clamping mechanism

InactiveCN103831660AExtended service lifeAvoid deformationGripping headsMetal working apparatusEngineeringMechanical engineering

A clamping mechanism comprises a bearing base, a clamping assembly and a pushing assembly. The clamping assembly comprises at least two clamping parts, a fixed part and a limiting part, wherein the fixed part is fixedly arranged on the bearing base, a containing hole is formed in the fixed part in a through mode, the containing hole contains the clamping parts, part of each clamping part is exposed outside the fixed part, and the clamping parts are sleeved with the limiting part. The pushing assembly comprises a pushing part, an adjusting base and an elastic part, one end of the pushing part abuts against the clamping parts, one end, far away from the clamping parts, of the pushing part is movably arranged in the adjusting base, and the elastic part is arranged in the adjusting base and elastically abuts against the pushing part. The clamping mechanism has the advantages of being long in service life and high in clamping efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

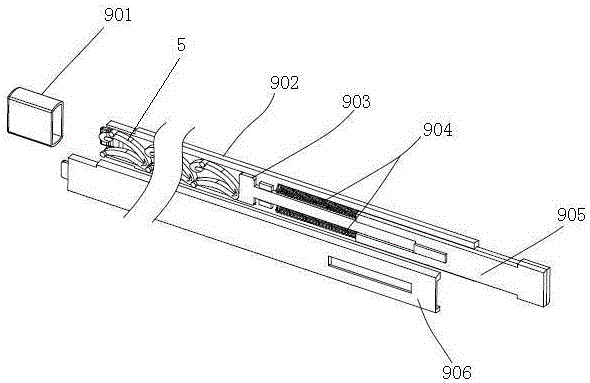

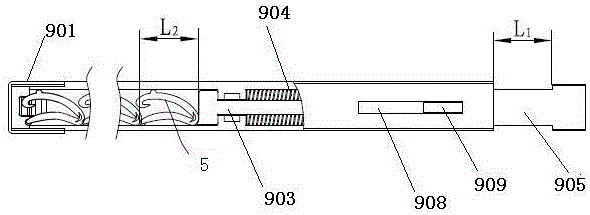

Medical biological clamping box for hair connecting

ActiveCN105997183APrecise clampingRealize the clinical function of ligationWound clampsEngineeringBlood vessel

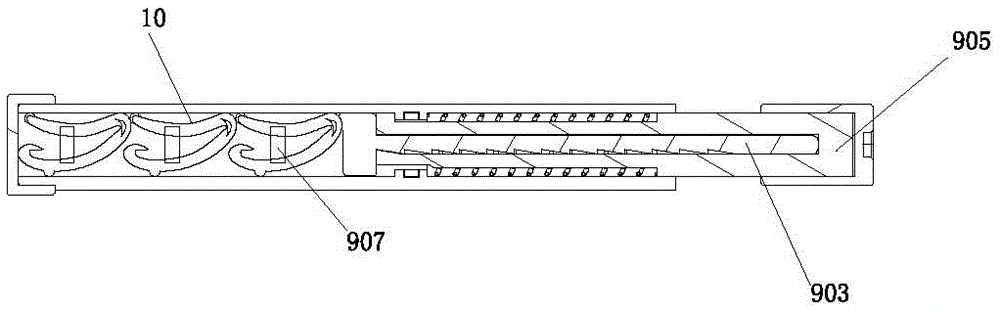

A medical biological clamping box for hair connecting is characterized by comprising a box cap (901), a box bottom (902), a biological clamping and pushing head (903), a push piece reset spring (904), a reciprocating push piece (905), a box cover (906), and a box body formed by buckling the box bottom (902) and the box cover (906), one end of the box body is provided with biological blood vessel clamps (5), the outlet end of the box body is sleeved with the box cap (901) so that the biological blood vessel clamps (5) can be guided between an upper jaw and a lower jaw, the last biological blood vessel clamp (5), away from the outlet end, in the box body abuts against one end of the biological clamping and pushing head (903), the other end of the biological clamping and pushing head (903) is provided with ratchet teeth which abut against pushing teeth on the reciprocating push piece (905), the force exerting end of the reciprocating push piece (905) extends out of the box body to abut against a push rod (4), one end of the push piece reset spring (904) abuts against the reciprocating push piece (905), and the other end of the push piece reset spring (904) abuts against a boss in the box body. The medical biological clamping box is simple in structure, safe and reliable.

Owner:JIANGSU HAIZE MEDICAL TECH DEV

Film-coating method for glass fiber yarn cluster

ActiveCN106586060ATransport impactImprove coating efficiencyWrapper folding/bending apparatusWrapping with article rotationGlass fiberYarn

The invention discloses a film-coating method for a glass fiber yarn cluster, and belongs to the technical field of glass fiber production equipment. The invention aims to provide the film-coating method for the glass fiber yarn cluster, and the coating method is relatively good in coating effect and is high in film-coating efficiency. The film-coating method comprises the following steps: step I: conveying yarn clusters; step II: grabbing the yarn clusters; step III: pressing the yarn clusters; step IV: coating a film, wherein a coating film is pushed to a specific position through a film feeding device, a gas blowing tube of a film cutting mechanism of the film feeding device works to blow the coating film; and the coating is adhered on the yarn cluster in a sticky mode, and the coating film is pressed onto the yarn cluster through a film-pressing thin sheet of the film pressing device; a clamping rotating device drives the yarn cluster to rotate, the coating film is continuously guided out and is coated on the cluster yarn; and the film is cut off through a blade of a film cutting mechanism; step V: pushing a film, wherein the film pressing device moves upwards and the film pressing device works to level the coating film exceeding the upper end surface of the yarn cluster to the upper end surface of the yarn cluster; and step VI: outputting finished products. The film-coating method is a film-coating method suitable for coating a layer of film outside the glass fiber yarn cluster.

Owner:福德机器人(成都)有限责任公司

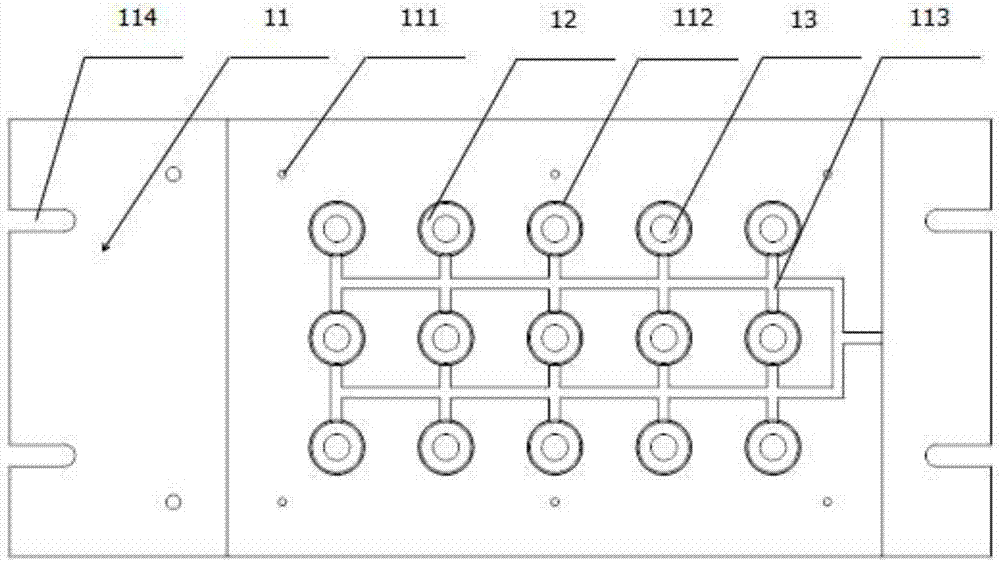

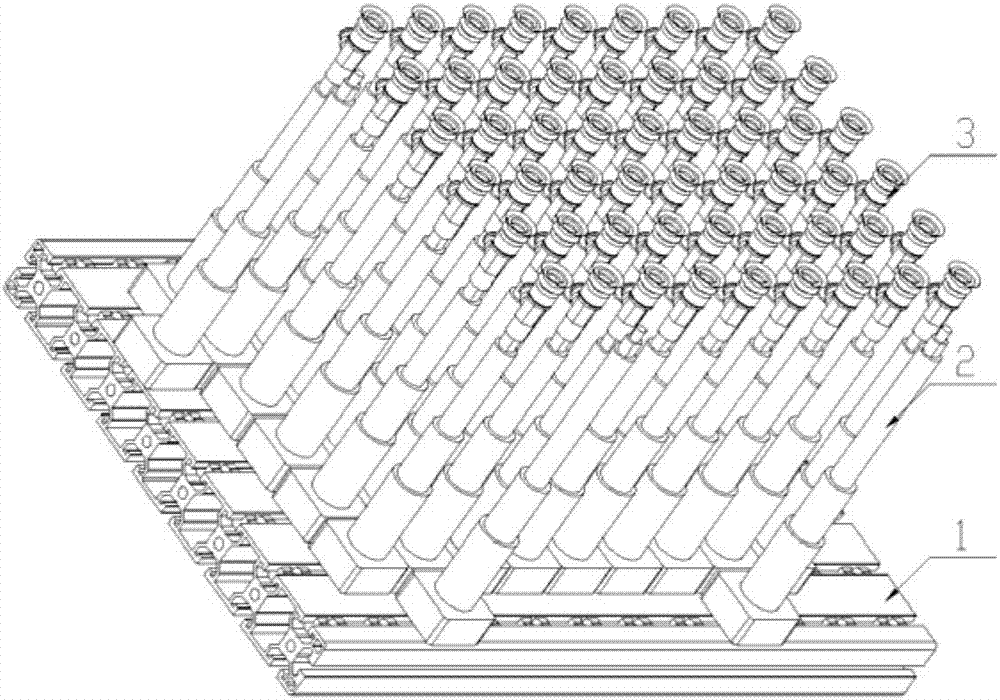

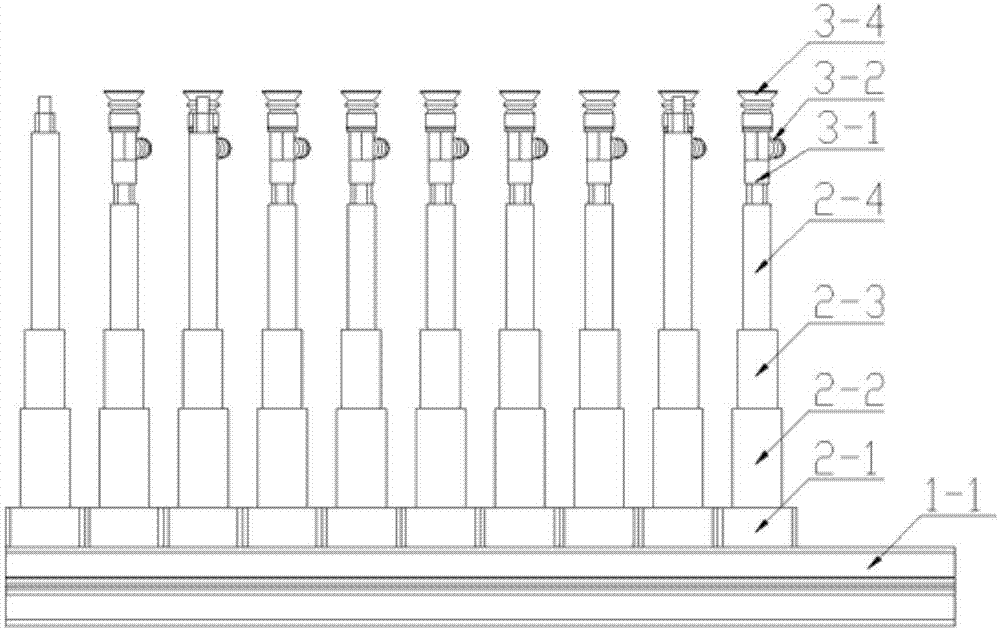

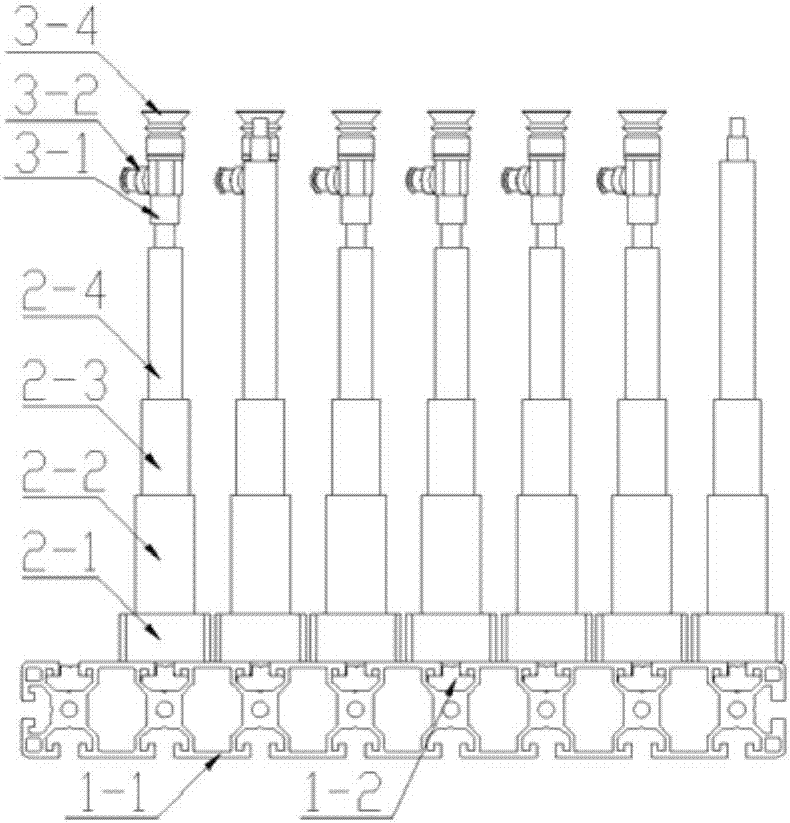

Array type two-degree-of-freedom adjustable flexible fixture

InactiveCN107263363AIncrease flexibilityAchieve height adjustable functionWork holdersSingle supportDISC assembly

Owner:XIAMEN UNIV

Clamping device for automobile parts

PendingCN108188770AImprove efficiencyImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringDrive shaft

The invention relates to the technical field of automobile part clamping and discloses a clamping device for automobile parts. The clamping device for the automobile parts comprises a rack and a clamping mechanism. The clamping mechanism comprises clamping blocks arranged on the two sides of the rack. The clamping blocks are in sliding connection with the rack. The clamping blocks are provided with sliding grooves, the sliding grooves are internally provided with vertical clamping plates, the clamping plates are in sliding connection with the clamping blocks, the clamping plates are provided with springs abutting against the clamping blocks, and the clamping blocks are provided with button switches which can be abutted by the clamping plates. The rack is provided with a sliding block in sliding connection with the rack. The clamping blocks are fixedly connected with the sliding block through connection rods. The rack is fixedly provided with a motor and a ratchet wheel. A drive shaft of the motor is provided with a drive pawl and a check pawl which coordinate with a ratchet wheel. The drive shaft is further fixedly provided with a rotary table. A connection rod is arranged betweenthe rotary table and the sliding block. One end of the connection rod is hinged to the eccentricity position of the rotary table, and the other end of the connection rod is hinged to the sliding block. The rack is further provided with an electric control box electrically connected with button switches. The clamping device for the automobile parts is simple in structure and conveniently clamps theautomobile parts.

Owner:宁波高新区新柯保汽车科技有限公司

Electrode clamping and positioning device for bar heating

InactiveCN101519715AFast and accurate positioning and clampingThe installation surface requirements are not highFurnace typesHeat treatment furnacesProduction lineEngineering

The invention relates to an electrode clamping and positioning device for bar heating, which comprises a connecting plate, a floating machine frame, a flexible current-conducting plate and a floating clamping mechanism, wherein the floating machine frame comprises a current-conducting seat and a tension spring, one end of the tension spring is in insulated connection with the connecting plate, the other end of the tension spring is connected with the current-conducting seat, and the flexible current-conducting plate is arranged on the current-conducting seat and extends to the front part of the current-conducting seat; and the floating clamping mechanism comprises an elastic supporting rod, an oil cylinder seat, an electrode, a pressure plate and an air cylinder, wherein two ends of the elastic supporting rod are arranged on the current-conducting seat and an air cylinder seat respectively, the air cylinder is arranged on the air cylinder seat, the piston rod of the air cylinder is connected with a radiating rod, the pressure plate is connected with the radiating rod through a horizontal shaft pin, the electrode of which the top is provided with a cambered surface is arranged on the current-conducting seat through a vertical rotating pin, and a distance for mounting a workpiece is reserved between the pressure plate and the electrode. The device can automatically adjust clamping positions according to the mounting surface of a bar workpiece, allows both ends of the bar workpiece to contact the electrode, and is high in loading and clamping efficiency, convenient in maintenance and suitable to be used on an automatic production line for large-scale production.

Owner:江苏南汽常随汽车零部件有限公司

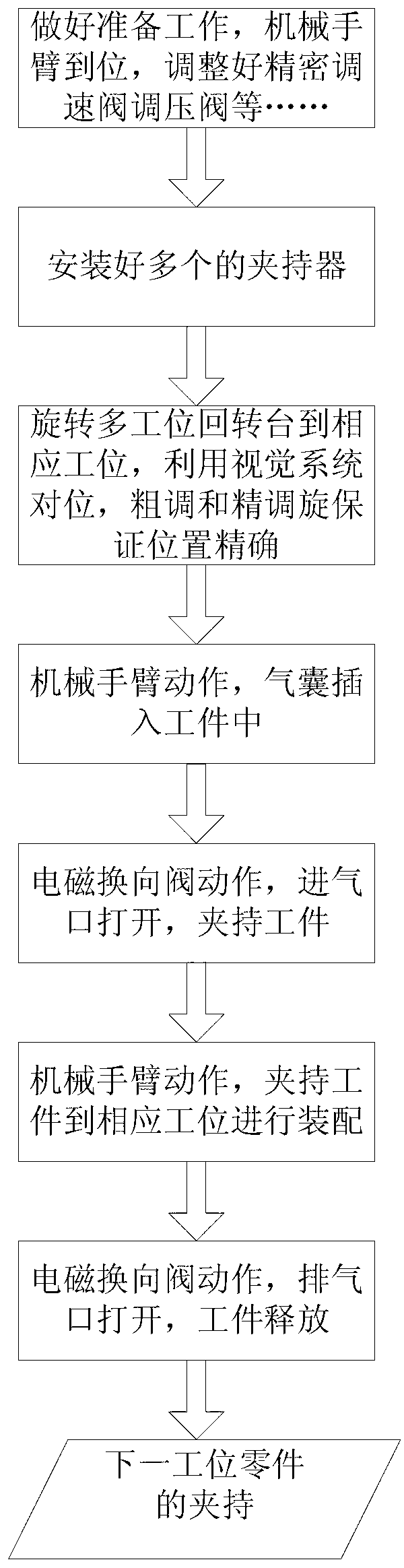

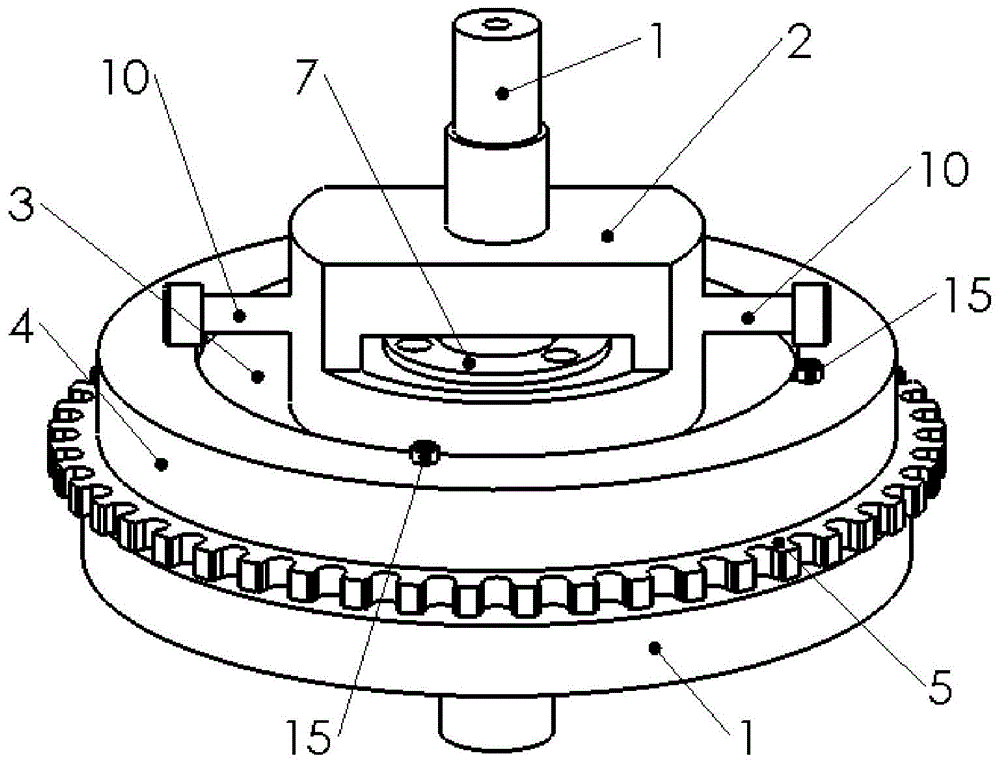

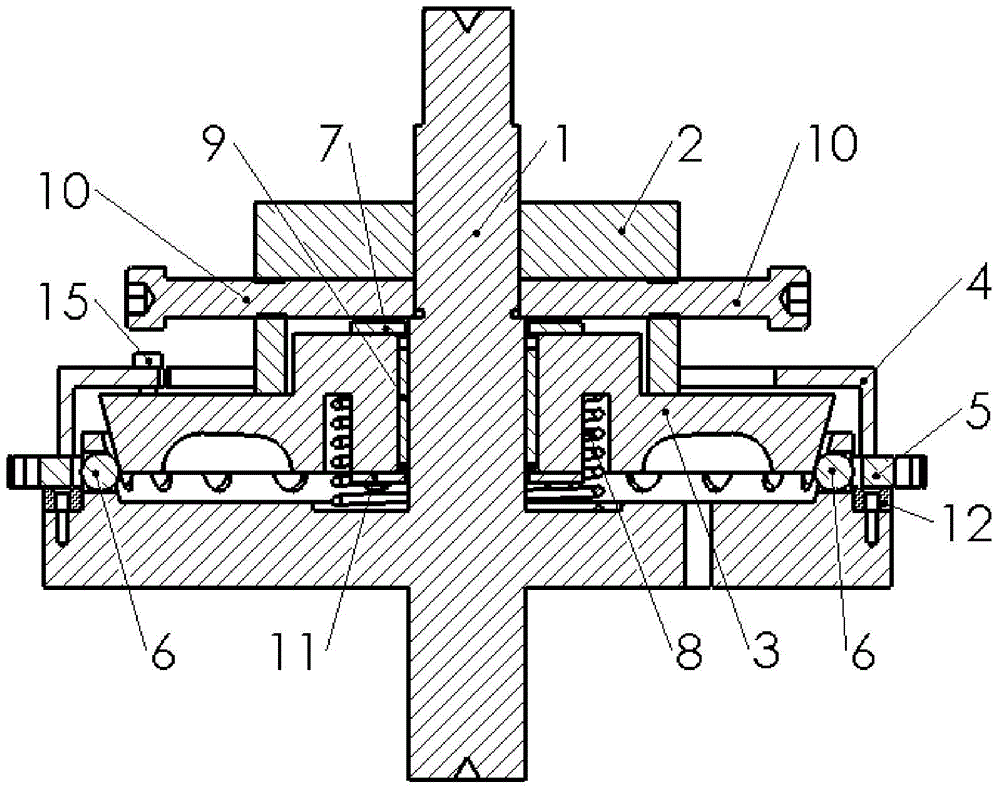

Multi-station silica gel air bag clamping device for clamping ultrathin wall deep cylinder part

ActiveCN103341861ARealize flexible clampingImprove clamping efficiencyGripping headsMetal working apparatusMagnetic exchangeEngineering

The invention relates to a multi-station silica gel air bag clamping device for clamping an ultrathin wall deep cylinder part and belongs to the field of microoperation and the micro electromechanical technology. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part particularly comprises an air bag clamping head, a conical surface quick-insertion connector, a multi-station rotary table and a gas circuit system. The air bag clamping head comprises an air bag, a center retainer, a ring fastening gasket and a connection transition part. The conical surface quick-insertion connector comprises a quick-change connector plug and a quick-change connector socket. The multi-station rotary table comprises a 360-degree manual rotary table and a pinboard. The gas circuit system comprises a gas source, a filter, a pressure regulating valve, a speed controlling valve, a magnetic exchange valve and a gas pipe connector. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part solves the problems that clamping of thin-wall parts is small in strength, poor in intensity, and deformation, invalidation and even damage are prone happening. Use of the quick-change connector and the multi-station rotary table can effectively achieve quick and flexible clamping and assembling of parts of different sizes and the same kind, facilitate operation and improve assembling precision and assembling efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Thin-wall gear ring self-centering tensioning installation fixture

InactiveCN104589230AAvoid deformationReduce distortionMachine gearing/transmission testingWork holdersEngineeringSteel ball

Owner:XI AN JIAOTONG UNIV

Clamping structure of circuit board

InactiveCN108012498AEasy take-out and feed-inEasy to install and fixSupport structure mountingSoftware engineering

Owner:曹诗晴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com