Clamping mechanism

A technology of clamping mechanism and clamping parts, which is applied in the direction of collets, manipulators, metal processing, etc., can solve the problems of excessive deformation of clamping parts, limited driving force of pushing parts, and affecting clamping efficiency, etc. The effect of improving service life and clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

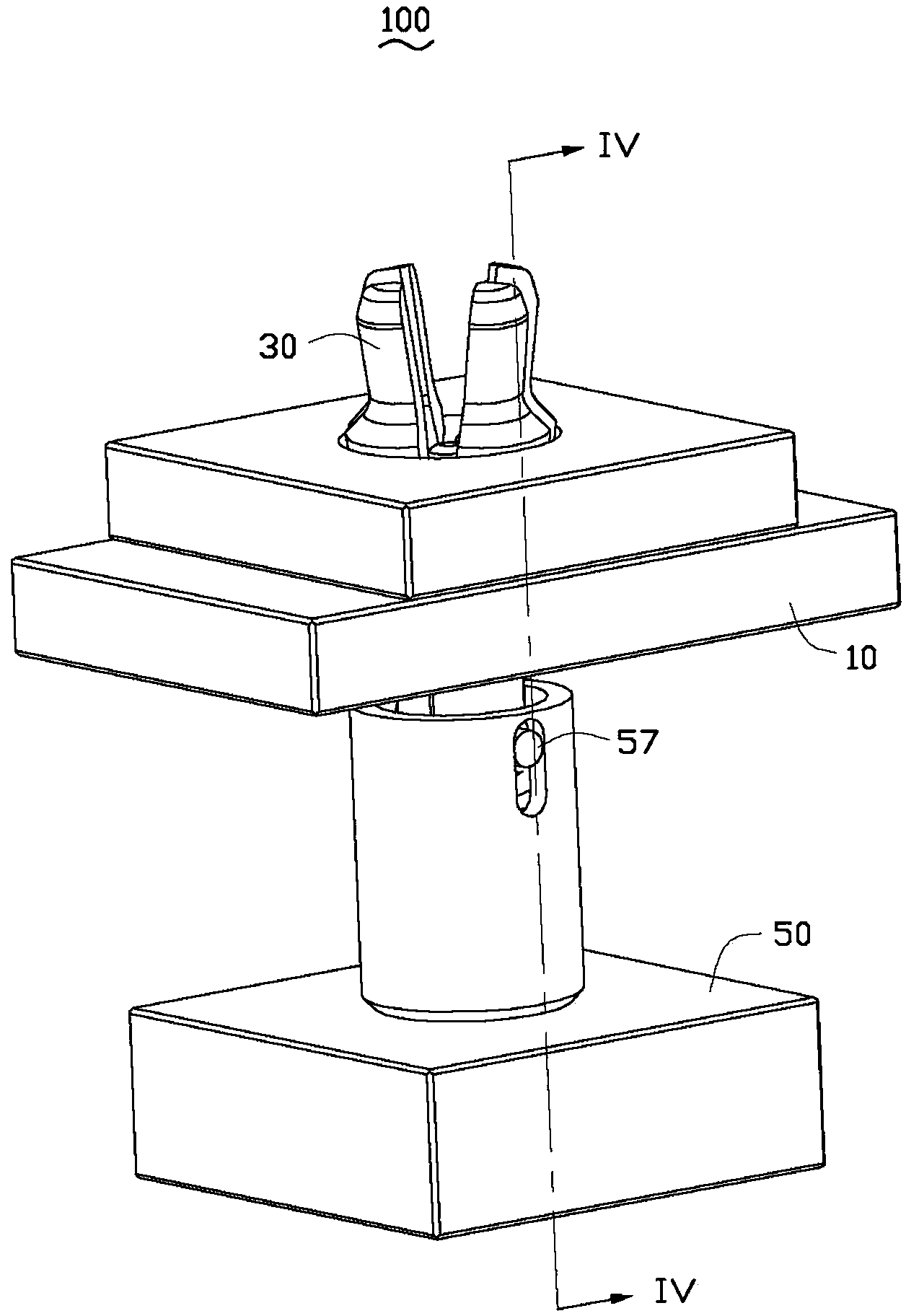

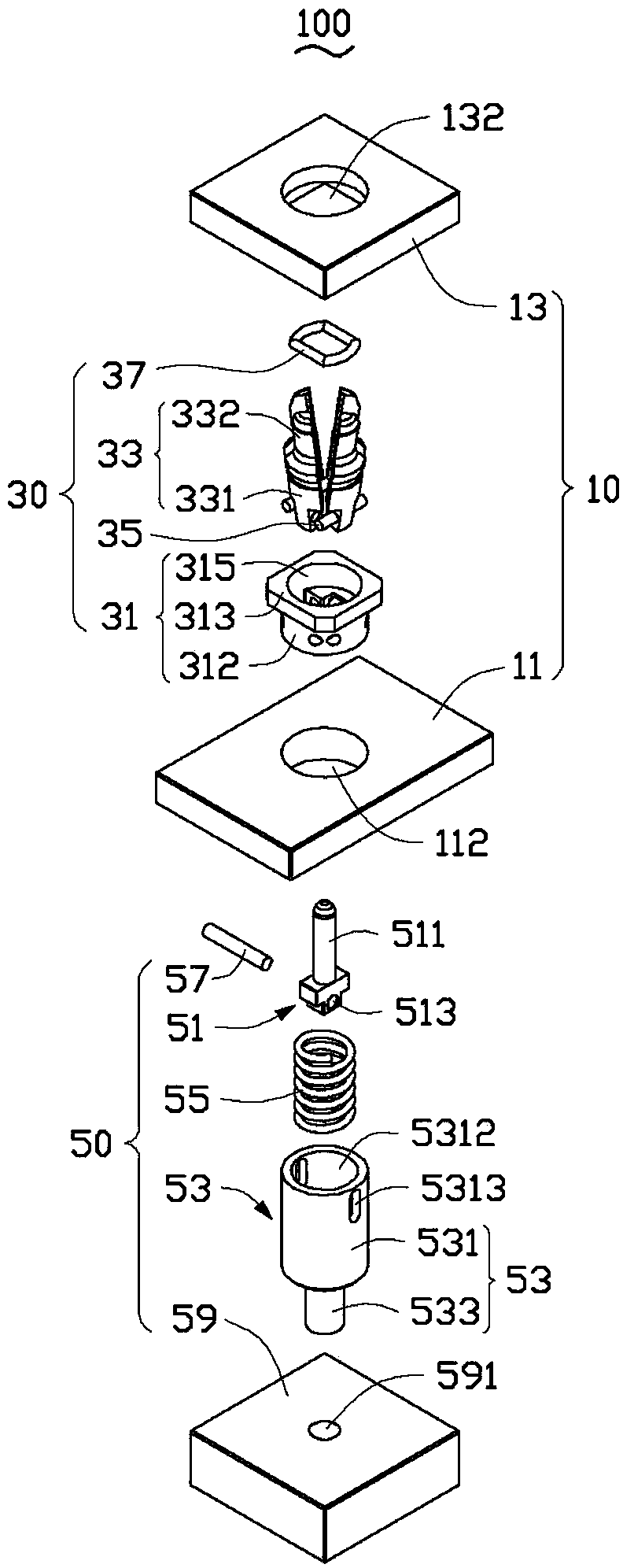

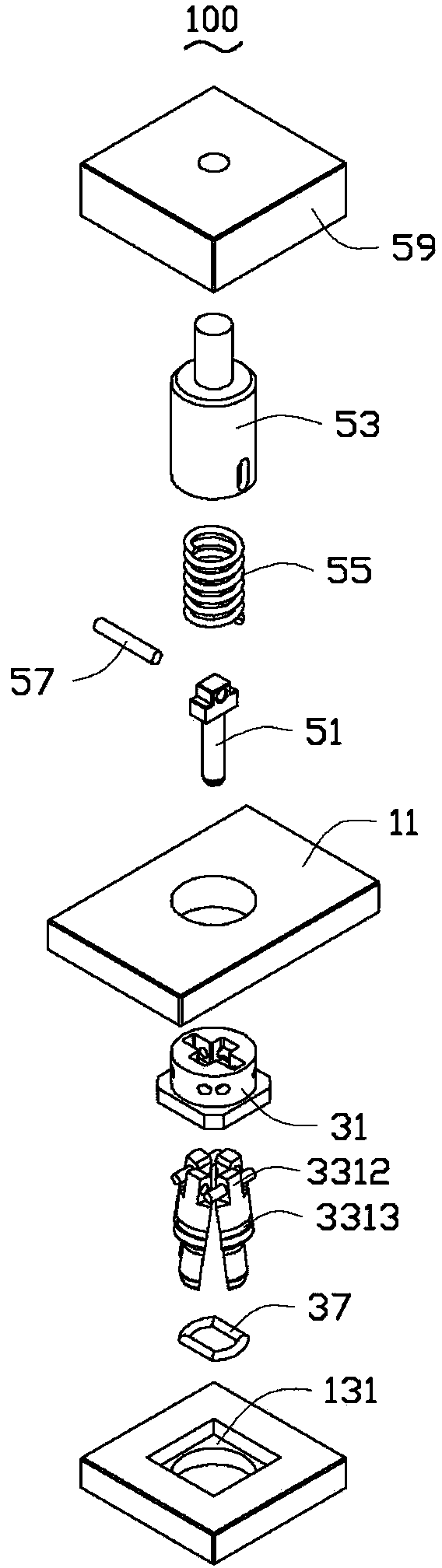

[0013] see figure 1 , the clamping mechanism 100 of the embodiment of the present invention is used to clamp a workpiece with a through hole (not shown in the figure). The clamping mechanism 100 includes a bearing base 10 , a clamping component 30 and a pushing component 50 . The bearing base 10 is connected with the mechanical arm (not shown in the figure), the clamping assembly 30 is passed through the bearing base 10 , the pushing assembly 50 is connected with the clamping assembly 30 , and can push the clamping assembly 30 to clamp the workpiece.

[0014] Please also refer to figure 2 , the bearing seat 10 includes a first mounting plate 11 and a second mounting plate 13 . The first mounting plate 11 is substantially in the shape of a rectangular plate, and a first through hole 112 is opened in the middle thereof. The second mounting plate 13 is mounted on one side of the first mounting plate 11 , and a fixing groove 131 is recessed on the side facing the first mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com