Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2652 results about "Scratching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scratching, sometimes referred to as scrubbing, is a DJ and turntablist technique of moving a vinyl record back and forth on a turntable to produce percussive or rhythmic sounds. A crossfader on a DJ mixer may be used to fade between two records simultaneously.

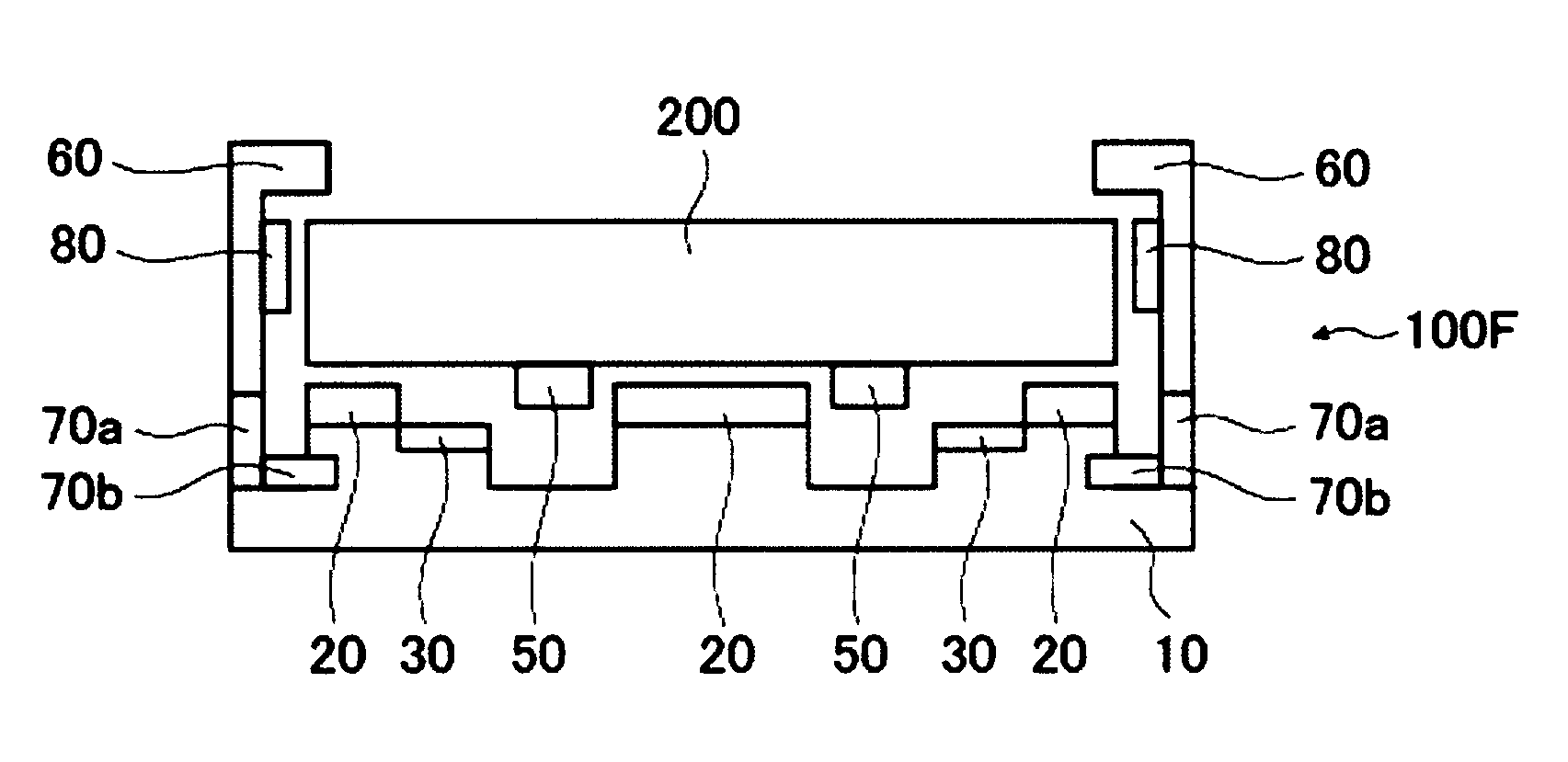

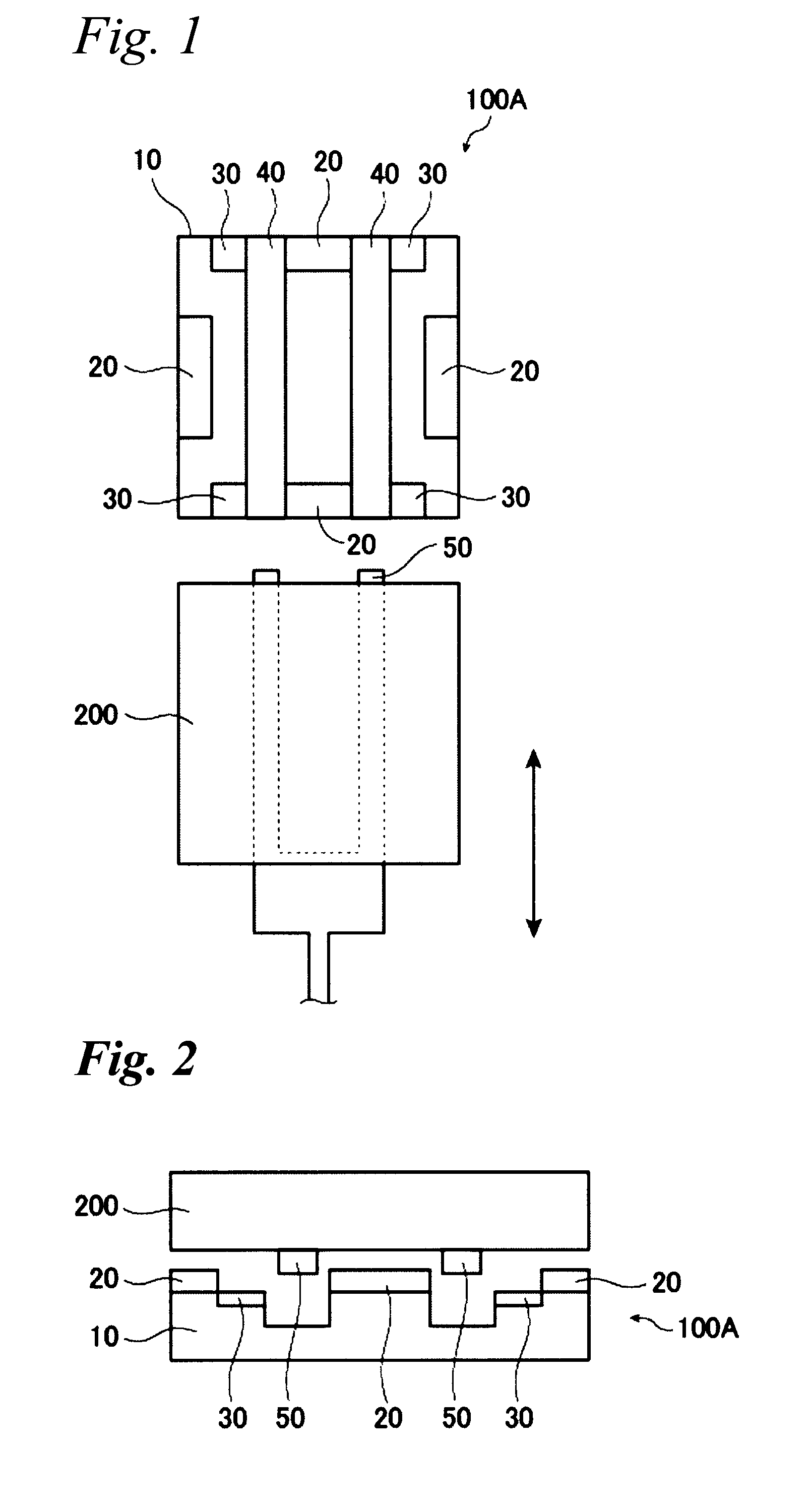

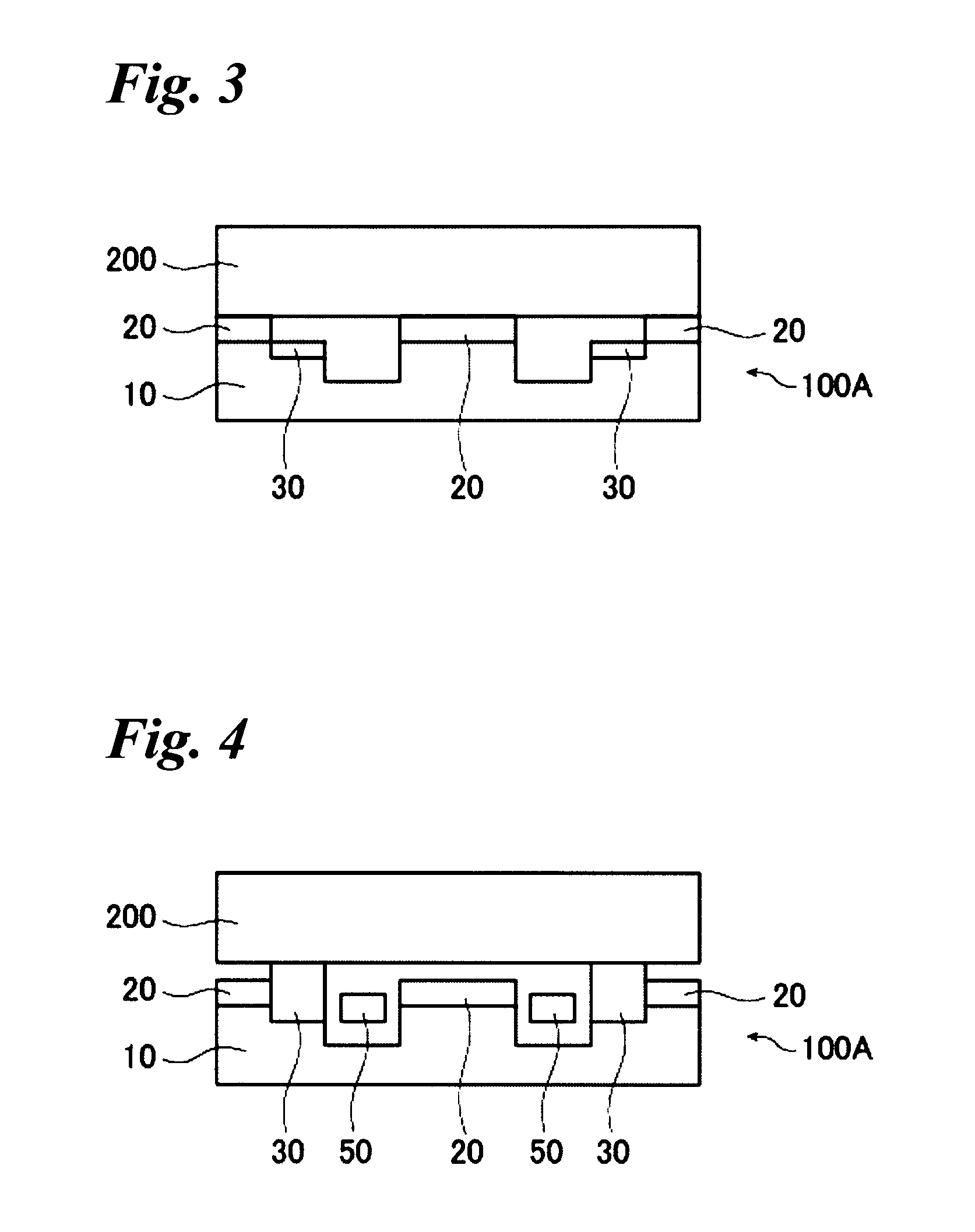

Glass substrate-holding tool

InactiveUS20120100464A1Avoid dustAvoid depositionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringScratching

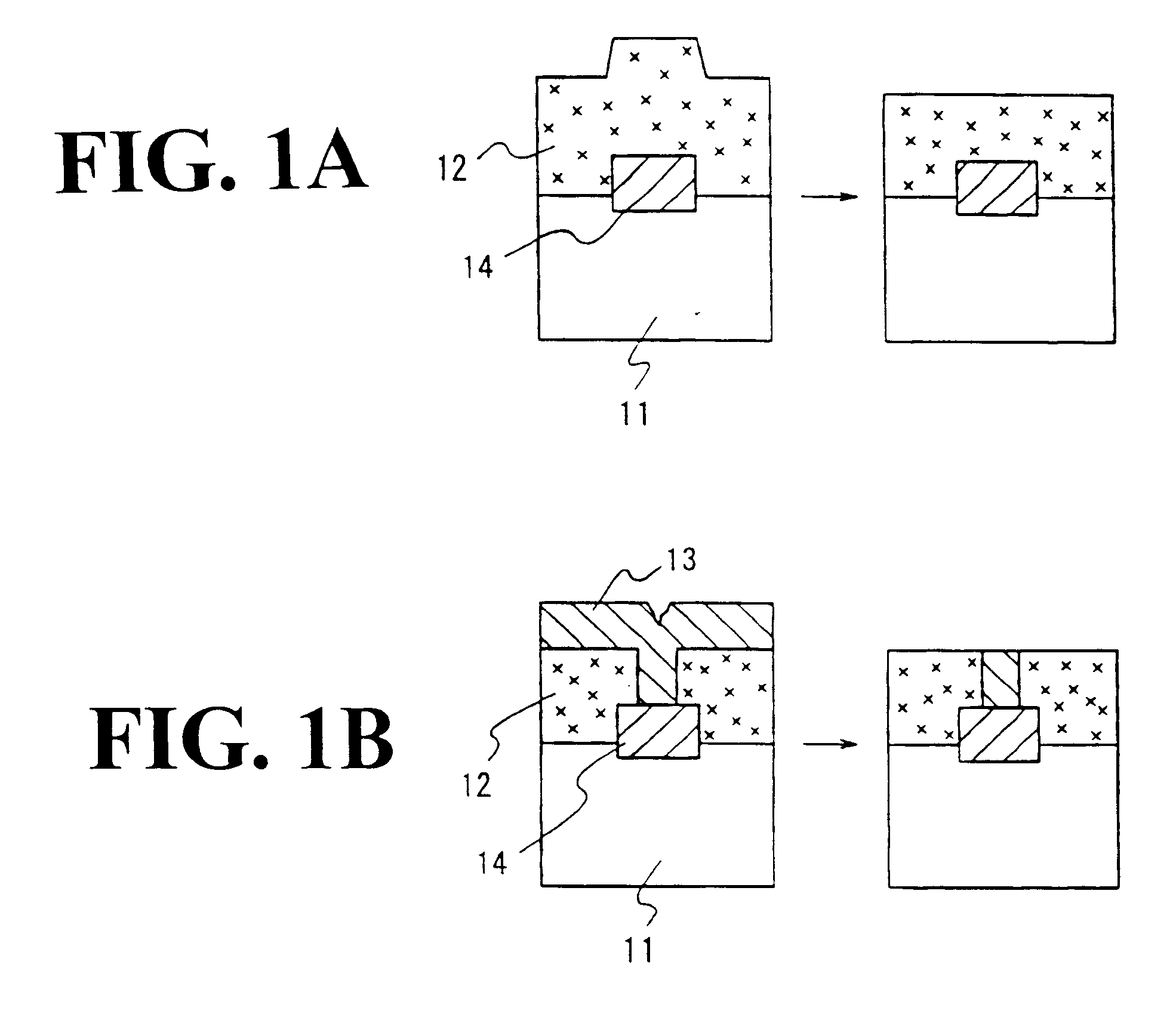

To provide a glass substrate-holding tool which is capable of avoiding scratching to the deposition surface of a glass substrate and dusting thereby caused as well as scratching and deposition of foreign substances at a center portion of the rear surface of the substrate and which is capable of suppressing dusting from the holding tool itself at the time of forming a multi-layered reflection film and an absorptive layer.A glass substrate-holding tool having, formed on a surface of a flat base, a catching portion for catching and holding by van der Waals forces, wherein the catching portion is in contact with only the periphery of the glass substrate.

Owner:ASAHI GLASS CO LTD

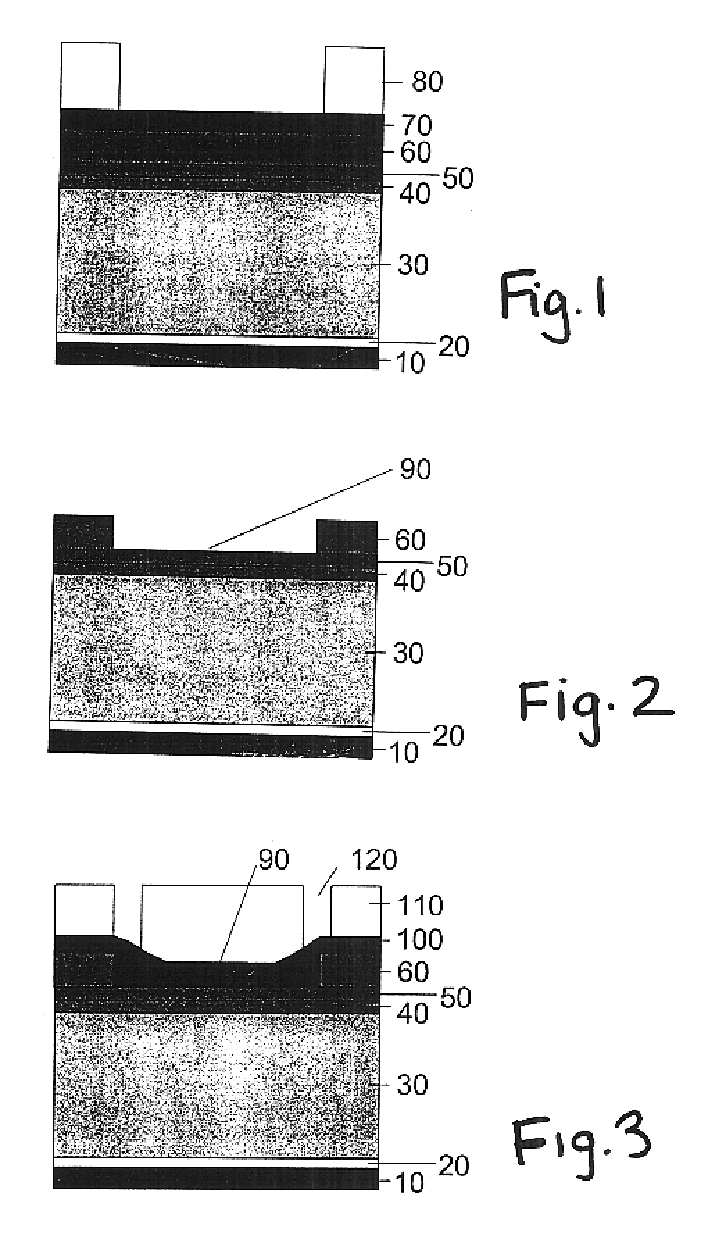

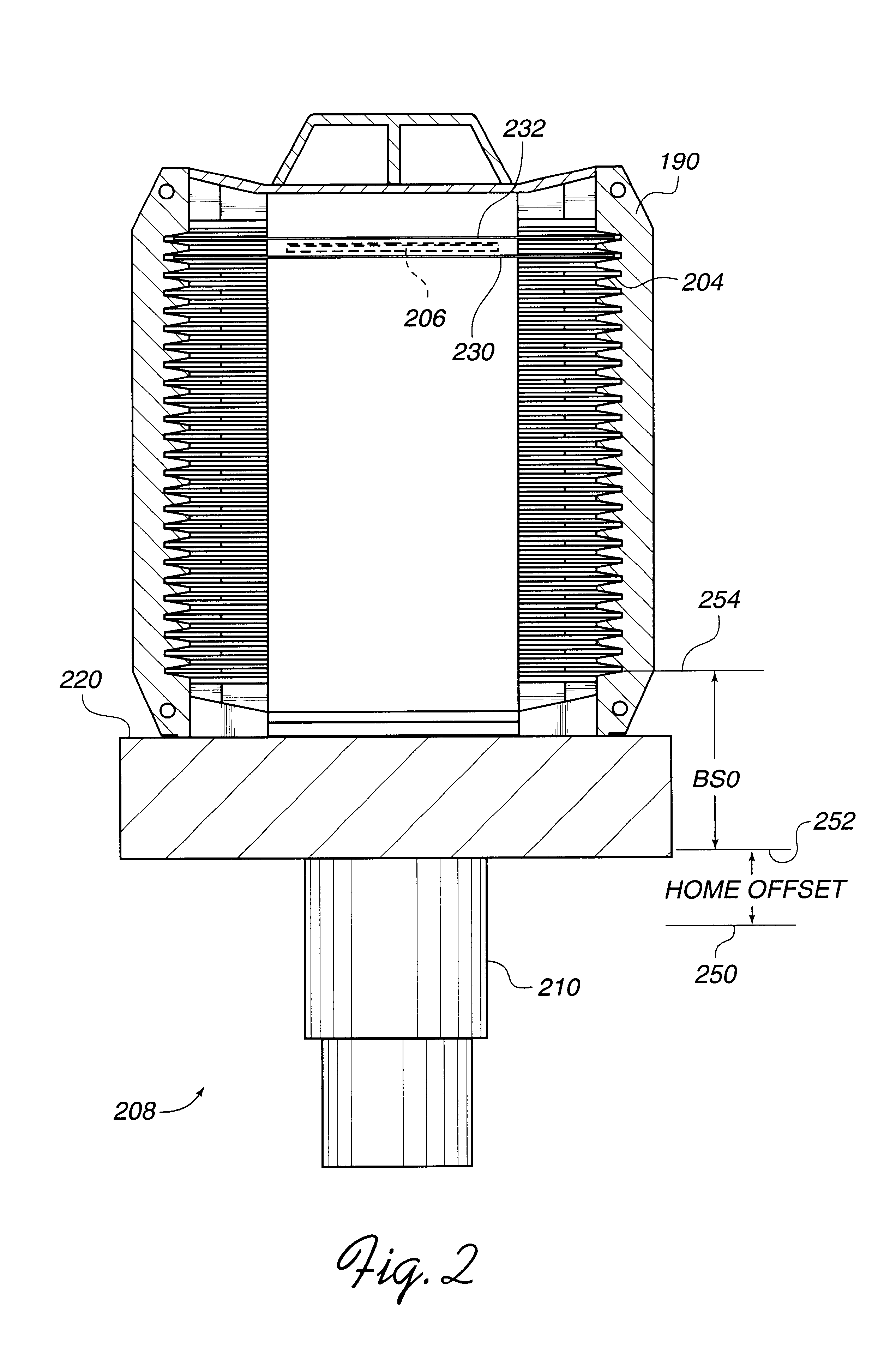

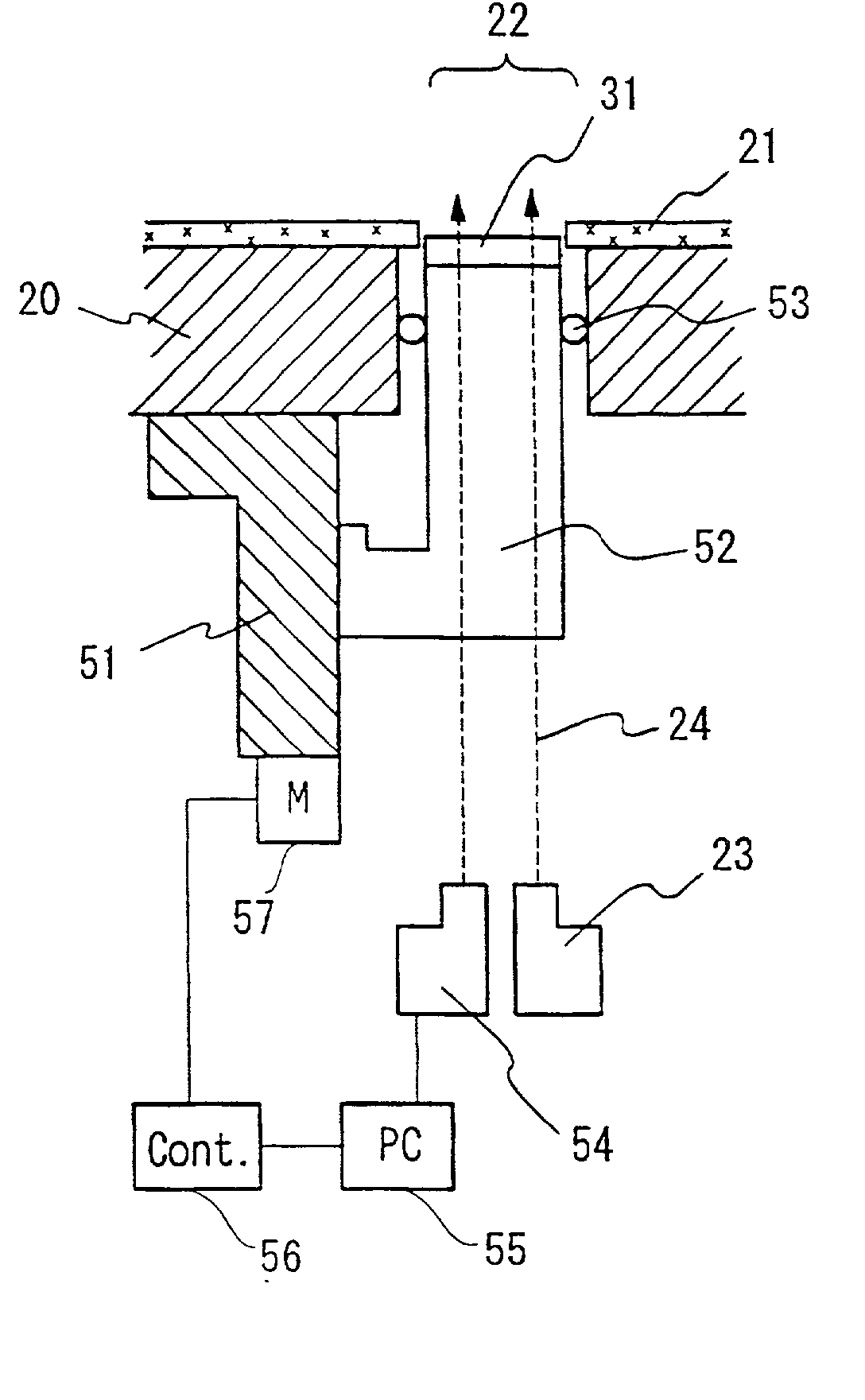

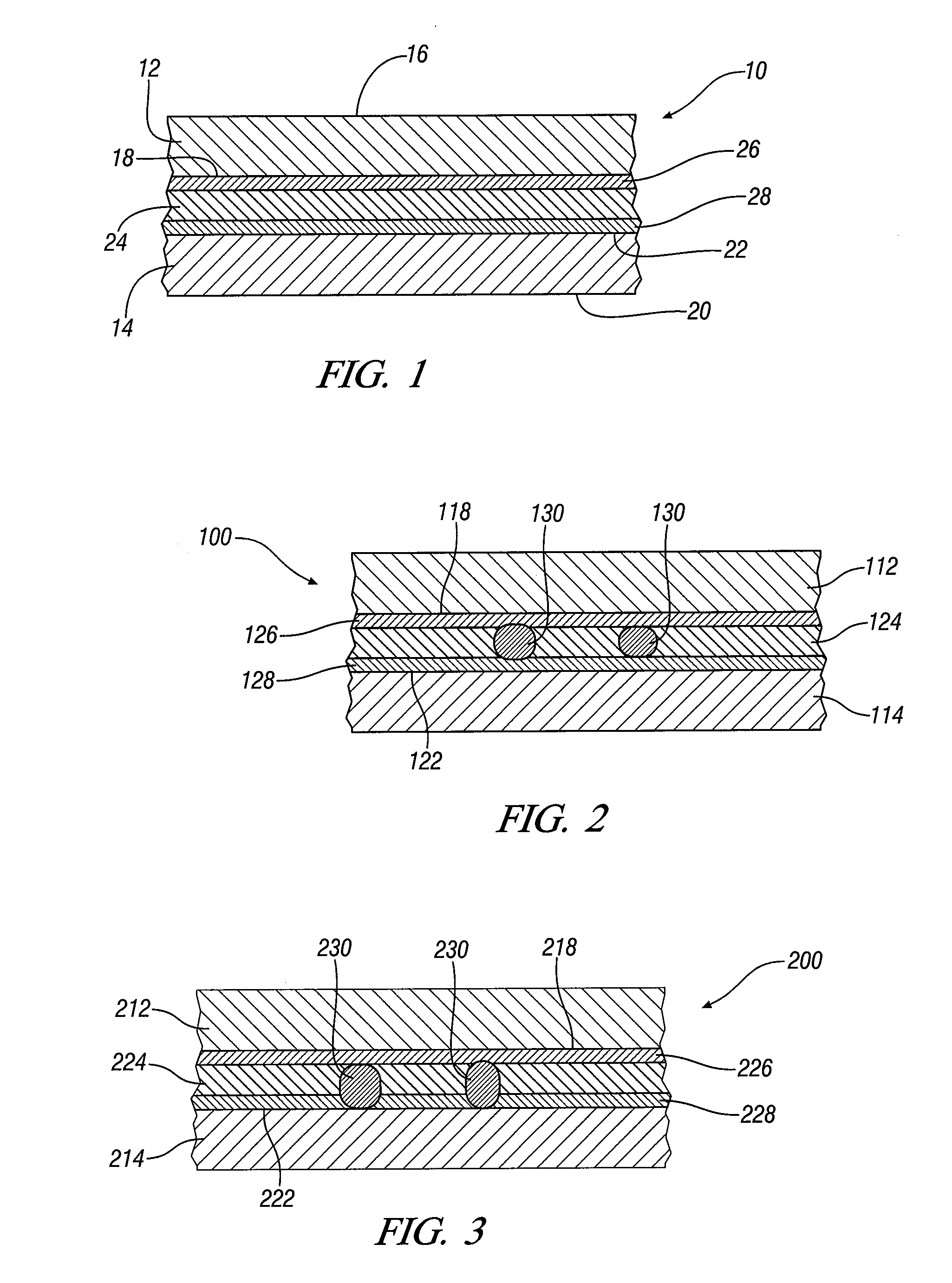

Polishing body, polishing apparatus, polishing apparatus adjustment method, polished film thickness or polishing endpoint measurement method, and semiconductor device manufacturing method

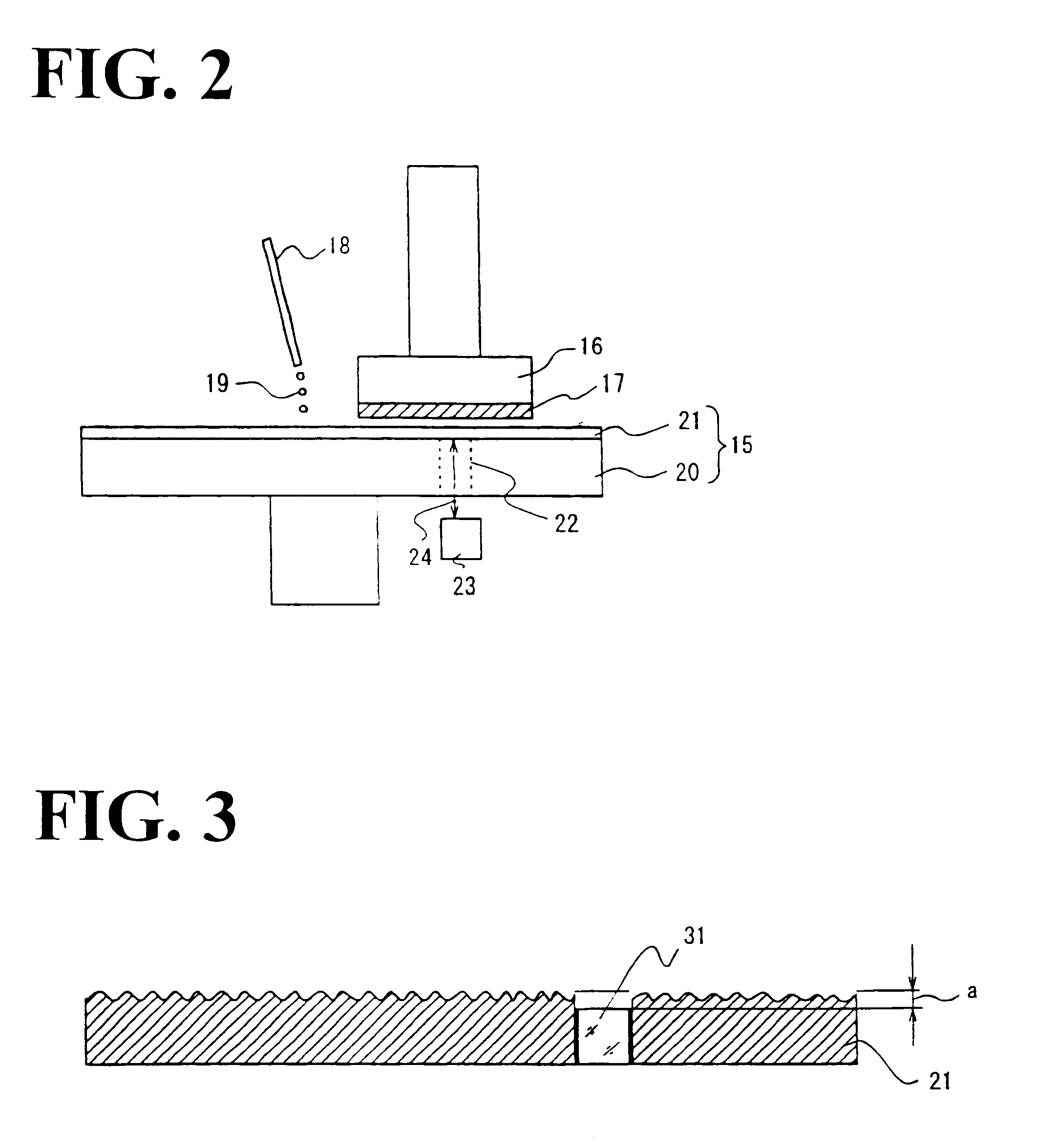

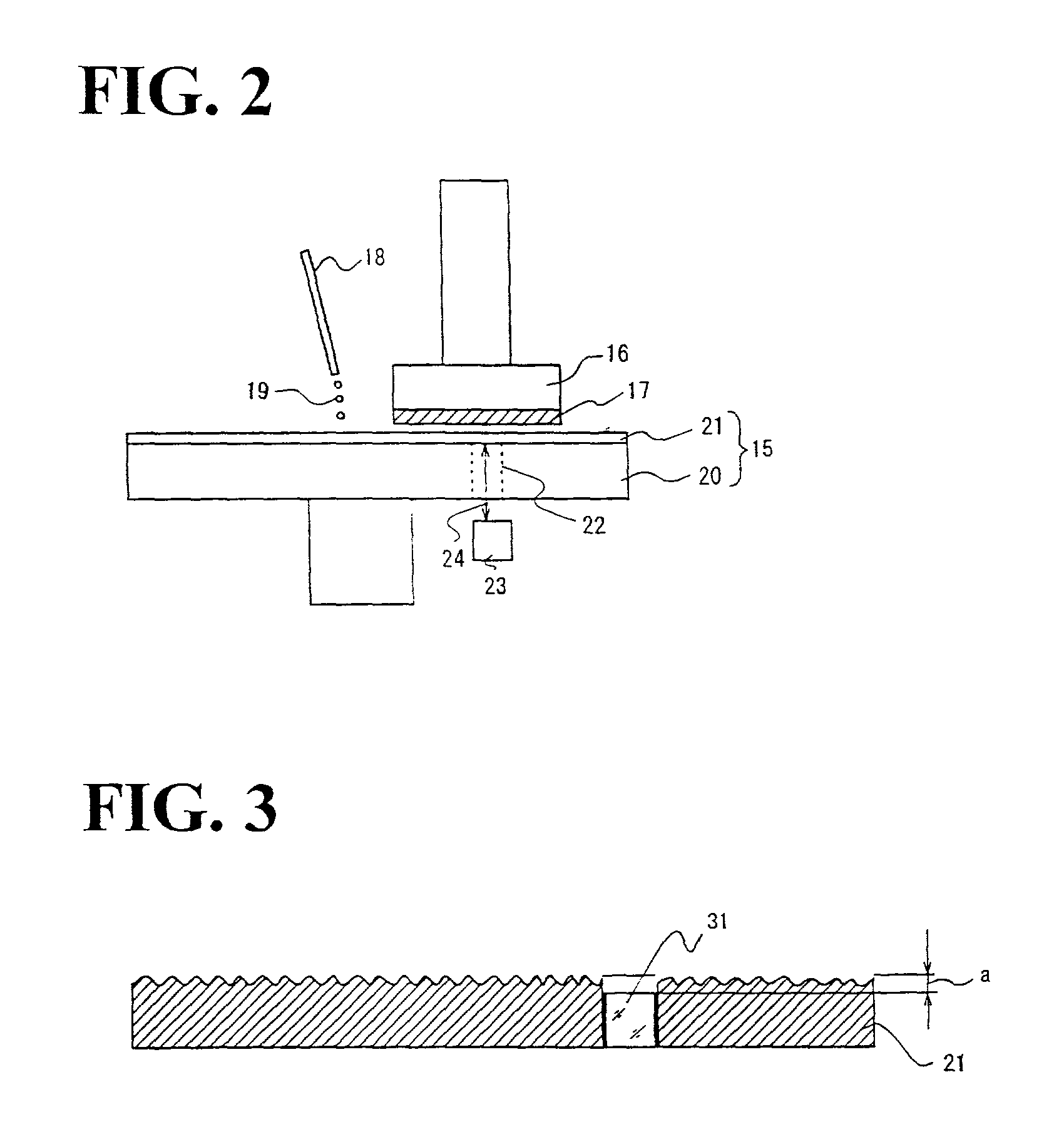

After a hole is formed in a polishing pad, a transparent window plate is inserted into the hole. Here, a gap is left between the upper surface of the transparent window plate and the outermost surface constituting the working surface of the polishing pad. During polishing, the polishing head holding the wafer applies a load to the polishing pad by means of a load-applying mechanism, so that the polishing pad and transparent window plate are compressed. In this case, the system is arranged so that the gap remains constant, and so that a dimension equal to or greater than a standard value is maintained. Since the upper surface of the transparent window plate is recessed from the upper surface of the polishing pad, there is no scratching of the surface of the transparent window plate during dressing. Accordingly, the polishing pad has a long useful life.

Owner:NIKON CORP

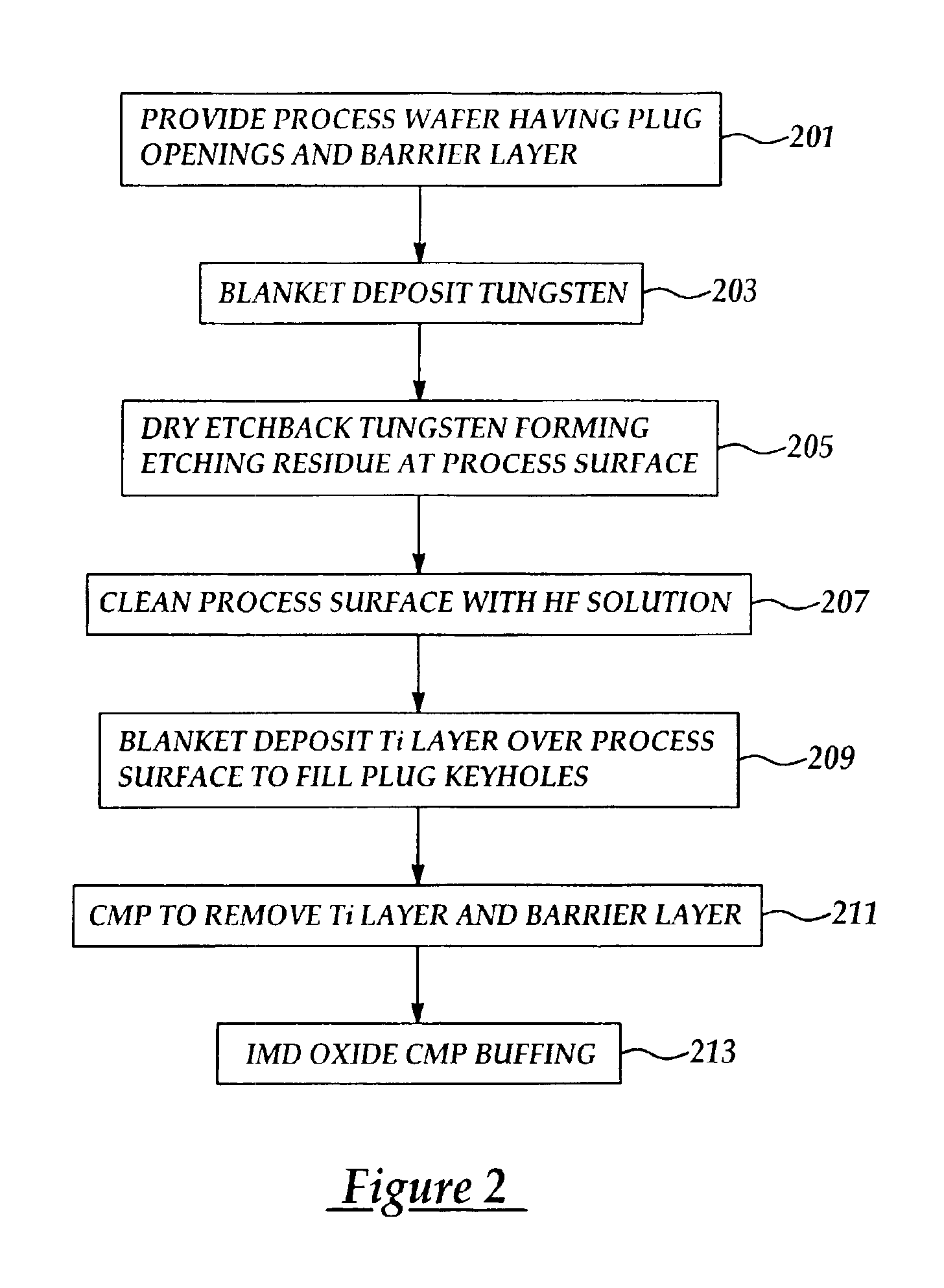

Method of removing metal etching residues following a metal etchback process to improve a CMP process

InactiveUS6936544B2Reduce scratchesSemiconductor/solid-state device manufacturingElectrostatic cleaningHydrofluoric acidCompound (substance)

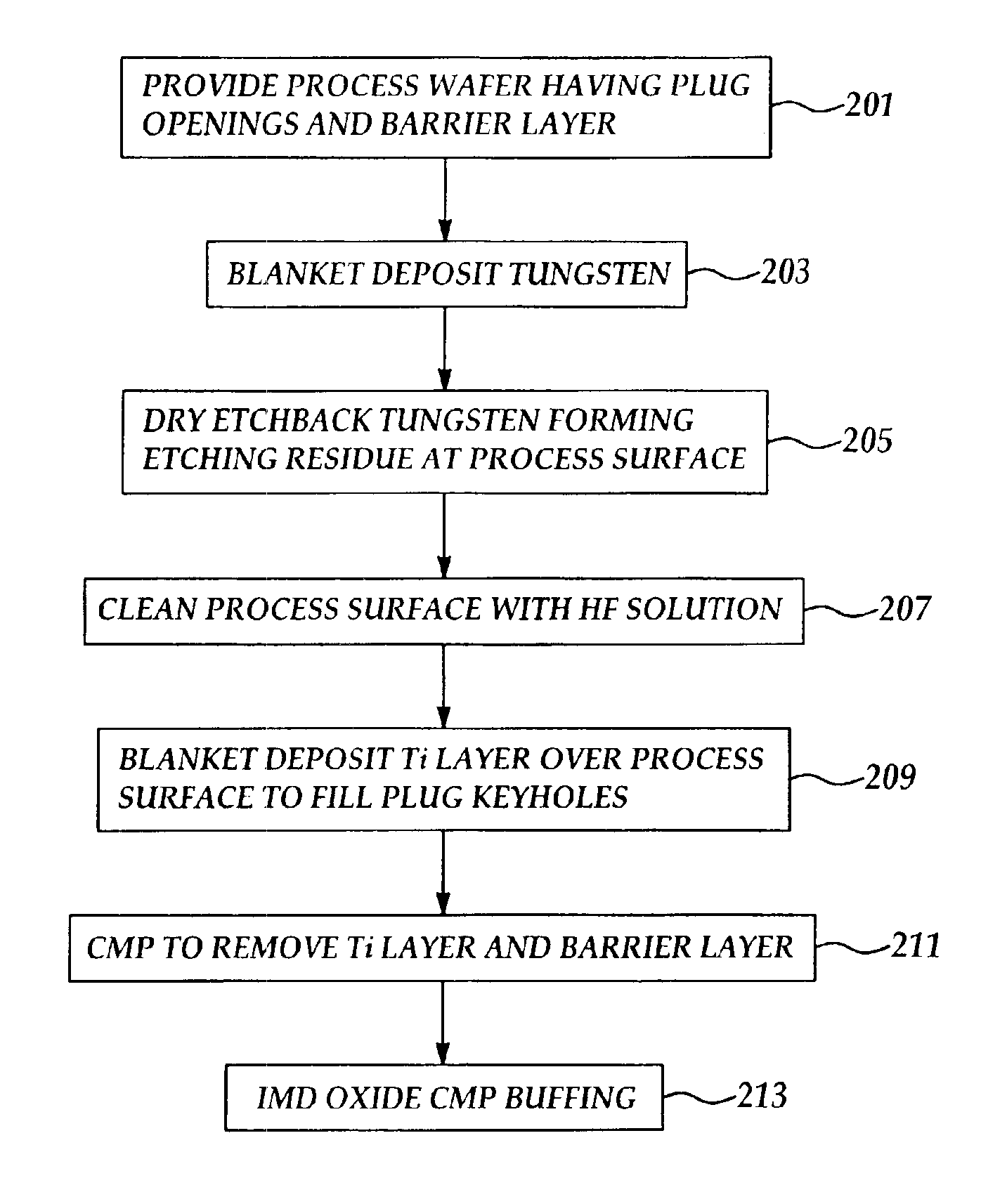

A method for reducing wafer surface scratching in a metal CMP process including providing a semiconductor wafer having a process surface comprising a blanket deposited metal layer; dry etching in an etchback process comprising a fluorine containing etching chemistry to remove at least a portion of the metal layer forming a metal and fluorine containing etching residue at the process surface; cleaning the process surface with a hydrofluoric acid (HF) containing cleaning solution; and carrying out a subsequent metal chemical mechanical polishing (CMP) process.

Owner:TAIWAN SEMICON MFG CO LTD

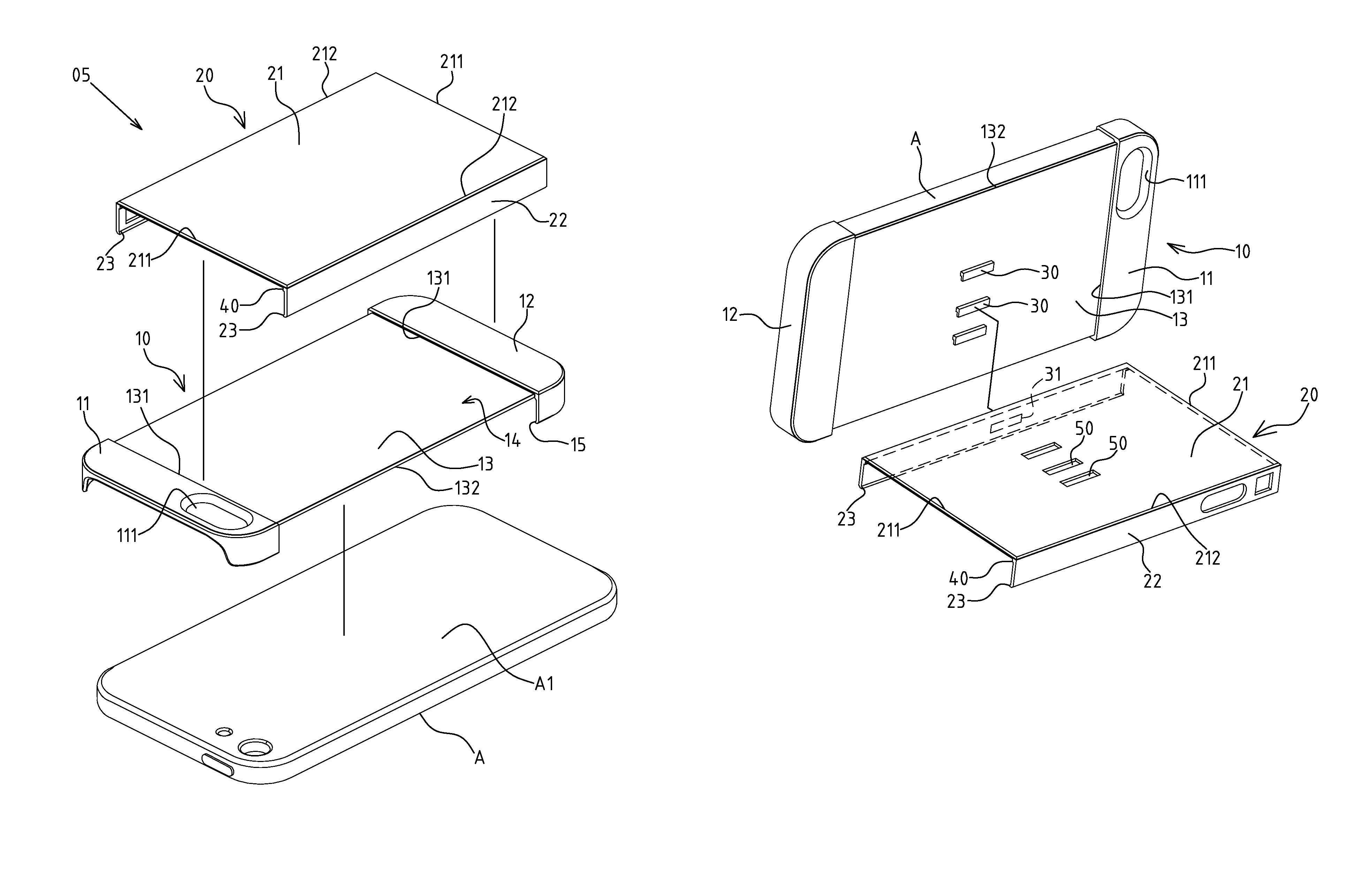

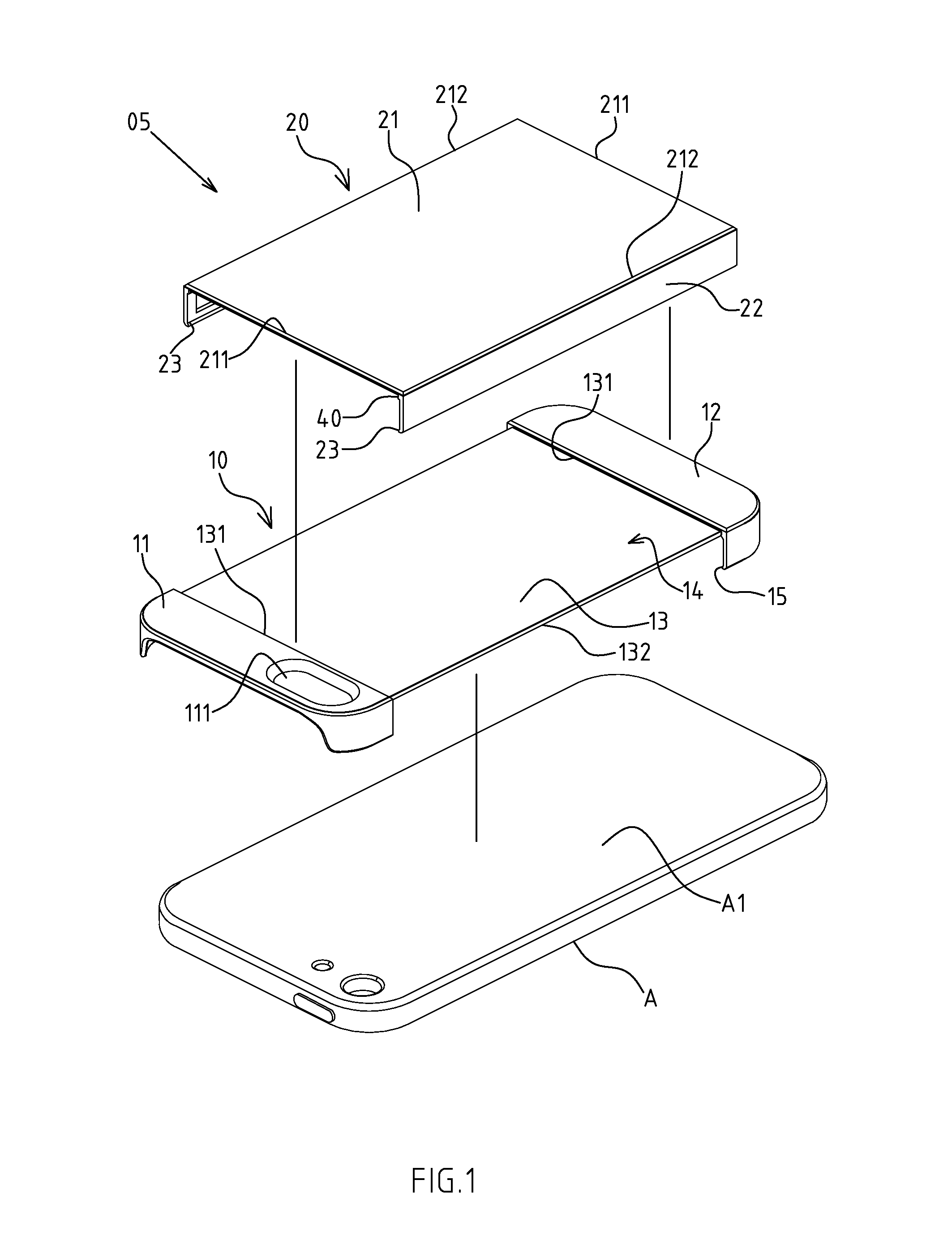

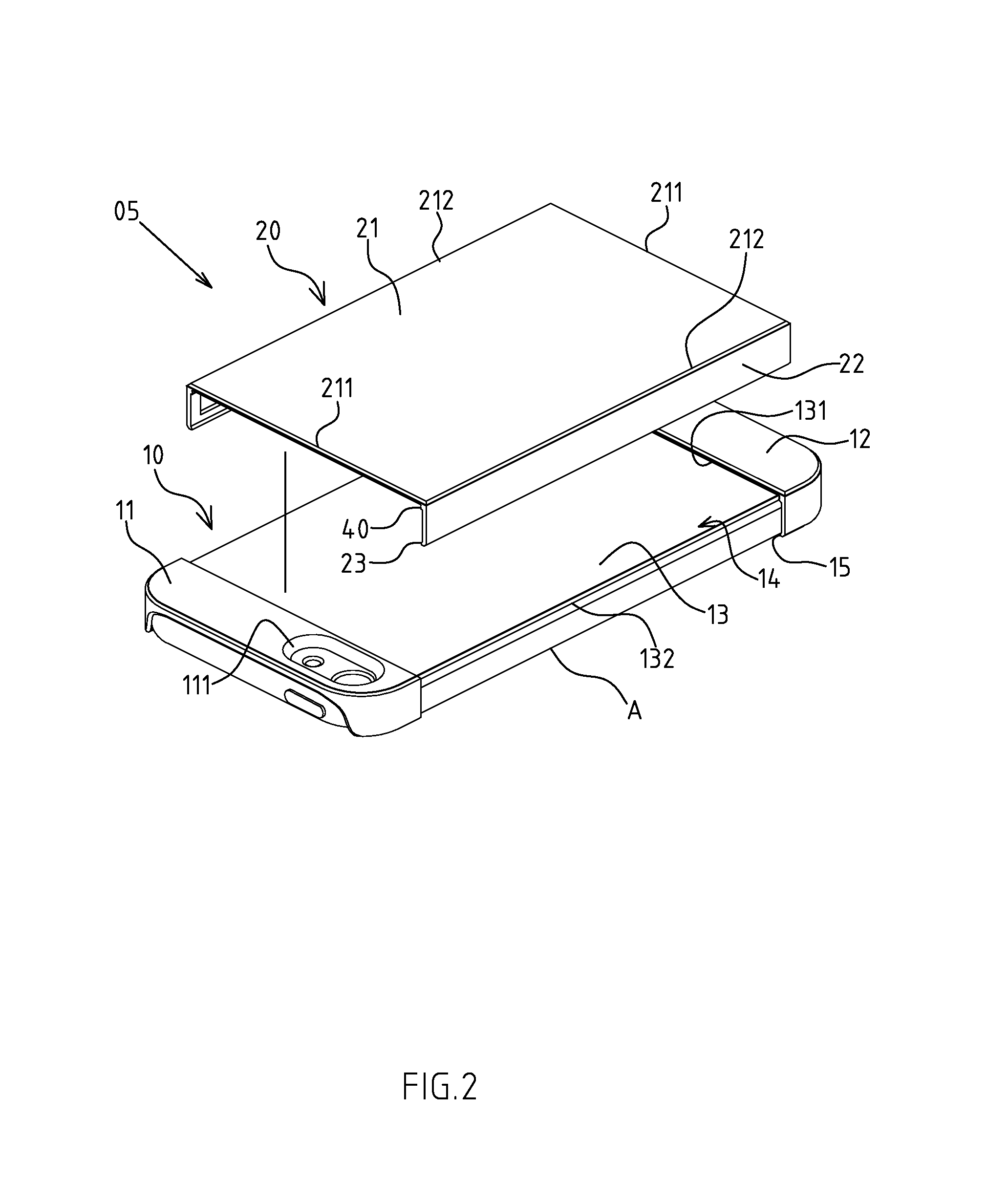

Protective housing assembly for electronic devices

InactiveUS8517172B1Convenient angleMore assembledDigital data processing detailsOther accessoriesEngineeringElectric equipment

Owner:MATCH U INT

Optical solidifying fluorine-carbon paint and its preparing method and use

InactiveCN101210145AHigh hardnessVariety of colorsLiquid surface applicatorsCoatingsScratchingPollution

Owner:ZHUHAI DONGCHENG UV MATERIALS

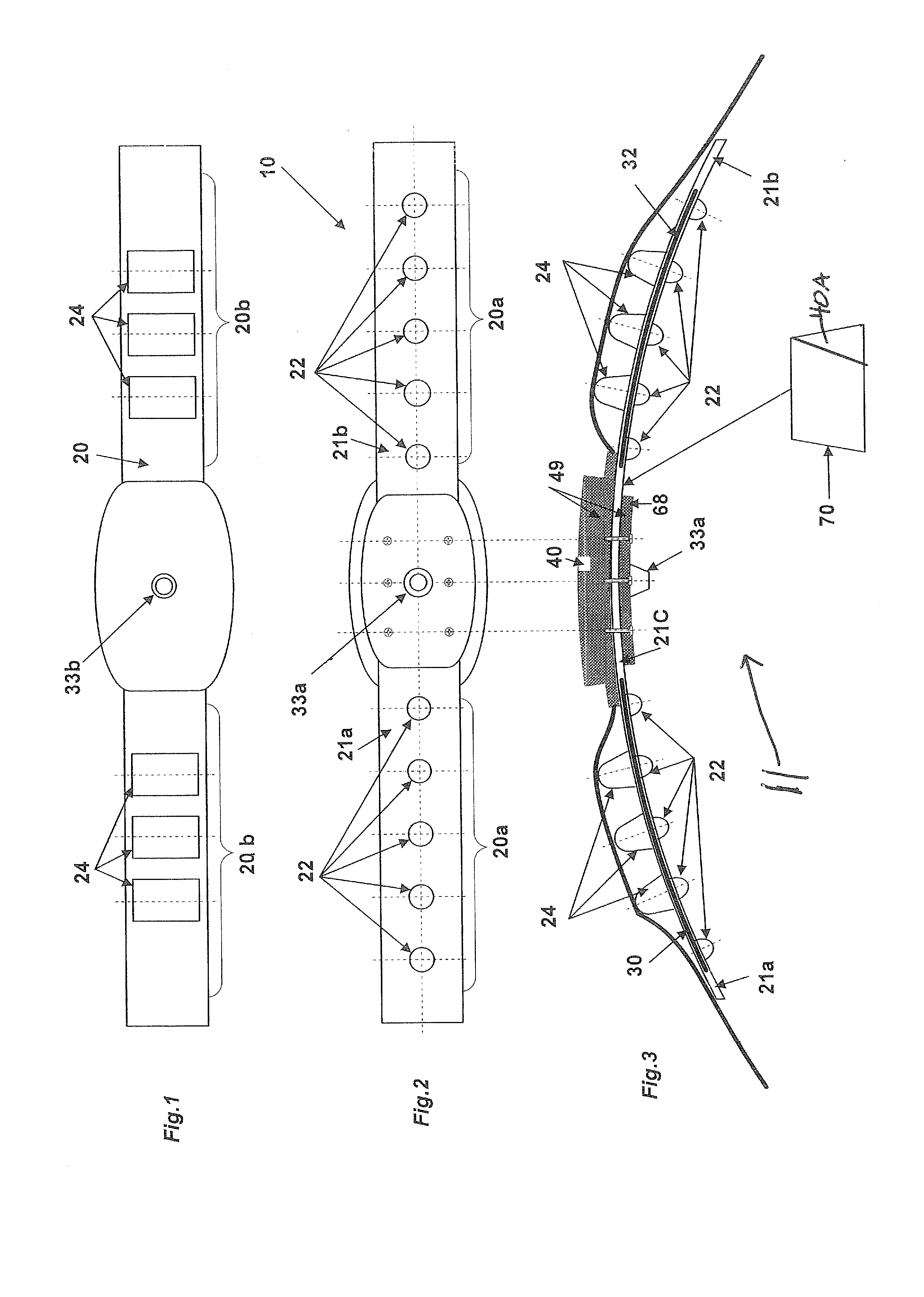

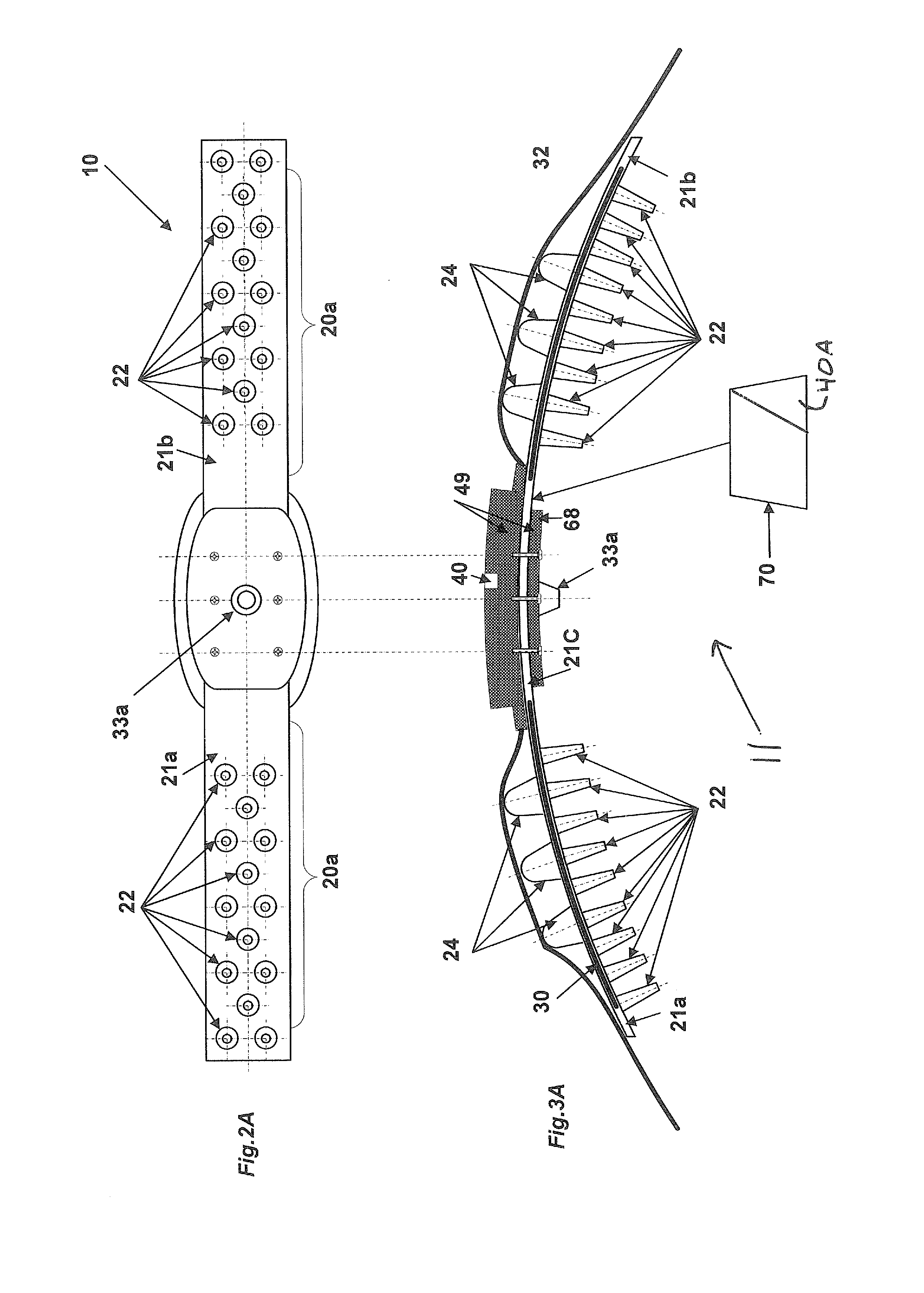

Pet Animal Collar for Health & Vital Signs Monitoring, Alert and Diagnosis

A system for monitoring vital signs of a pet animal comprises an annular band, an accelerometer configured to measure at least one of resting patterns, activity patterns, movement patterns, position patterns relating to, for example the pet animal relieving itself, lameness and scratching, and a non-accelerometer sensor configured to measure at least one of the following non-accelerometer-measured bioparameters of the pet animal: temperature, pulse rate, respiration rate. One or more processors are configured to receive sensor output data and reference data concerning the measured bioparameters of the pet animal or of a population of the pet animal, and determine a suspicion of a specific medical condition by: (i) scoring at least two bioparameters and comparing a cumulative score to a threshold cumulative score or to a threshold cumulative range; or (ii) identifying an abnormal pattern. The processor(s) may send an alert if at least one specific medical condition is suspected.

Owner:PETPACE

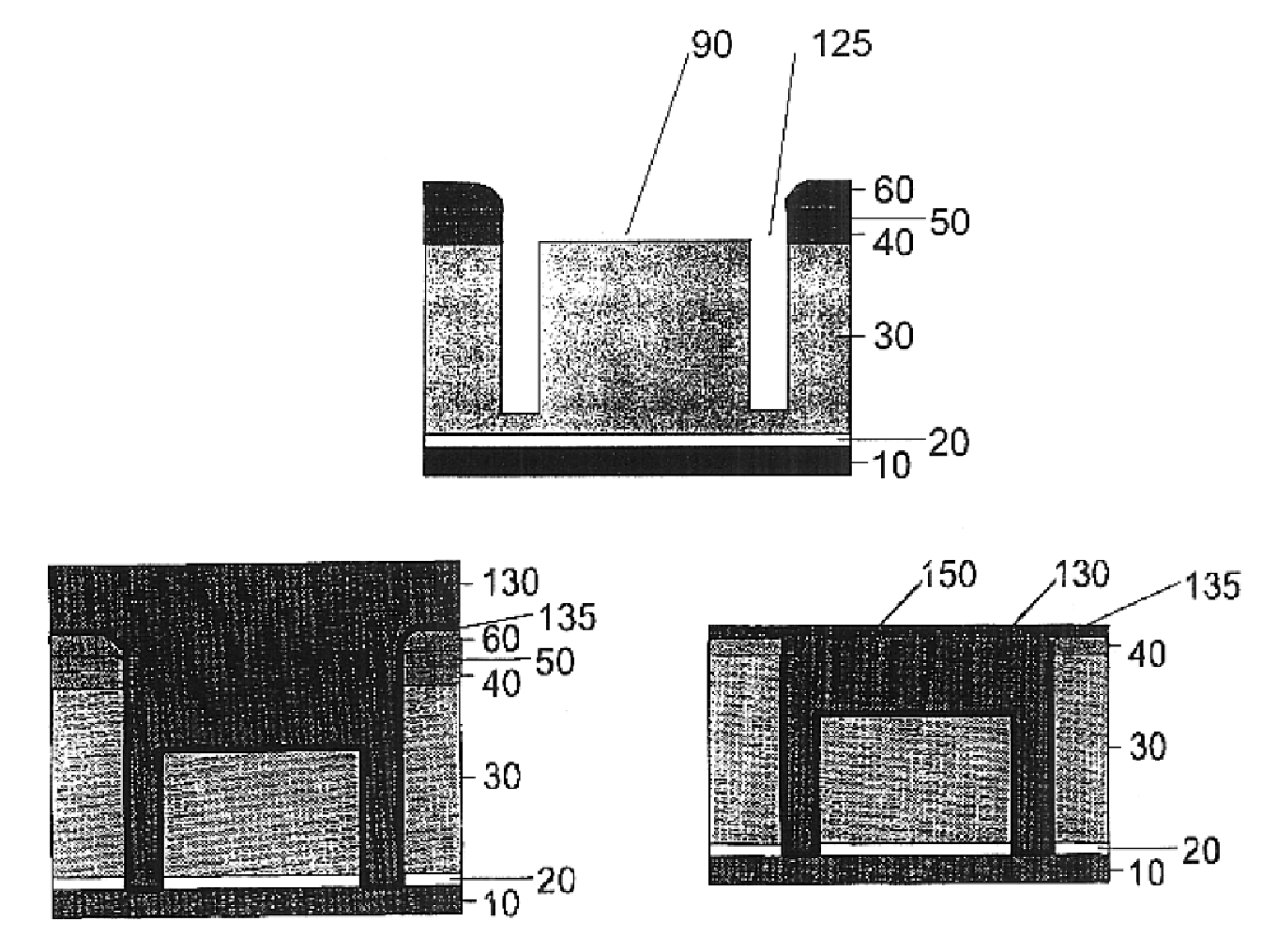

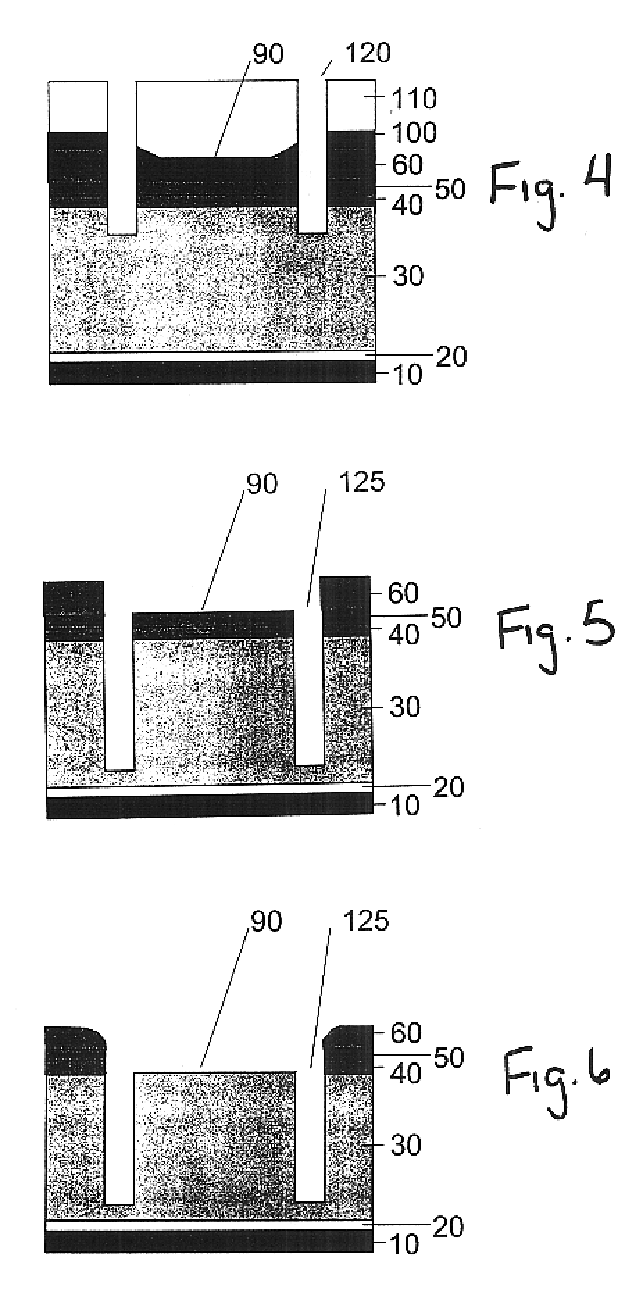

Protective hardmask for producing interconnect structures

InactiveUS6720249B1Deep unityAlteration can be preventedSemiconductor/solid-state device detailsSolid-state devicesSilicon dioxideScratching

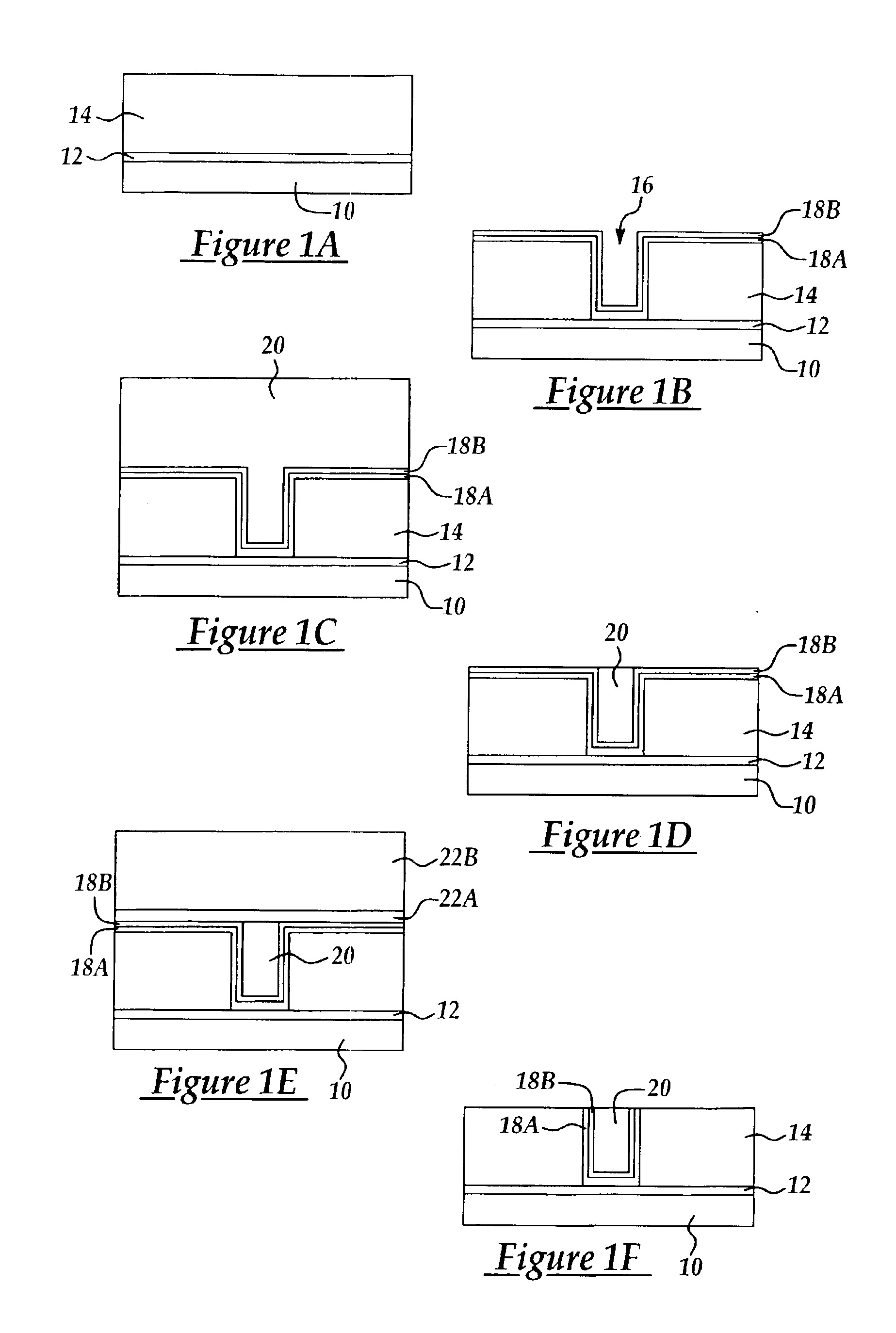

The present invention provides a permanent protective hardmask which protects the dielectric properties of a main dielectric layer having a desirably low dielectric constant in a semiconductor device from undesirable increases in the dielectric constant, undesirable increases in current leakage, and low device yield from surface scratching during subsequent processing steps. The protective hardmask further includes a single layer or dual layer sacrificial hardmask particularly useful when interconnect structures such as via openings and / or lines are formed in the low dielectric material during the course of making the final product. The sacrificial hardmask layers and the permanent hardmask layer may be formed in a single step from a same precursor wherein process conditions are altered to provide films of differing dielectric constants. Most preferably, a dual damascene structure has a tri-layer hardmask comprising silicon carbide BLoK(TM), PECVD silicon nitride, and PECVD silicon dioxide, respectively, formed over a bulk low dielectric constant interlevel dielectric prior to forming the interconnect structures in the interlevel dielectric.

Owner:IBM CORP

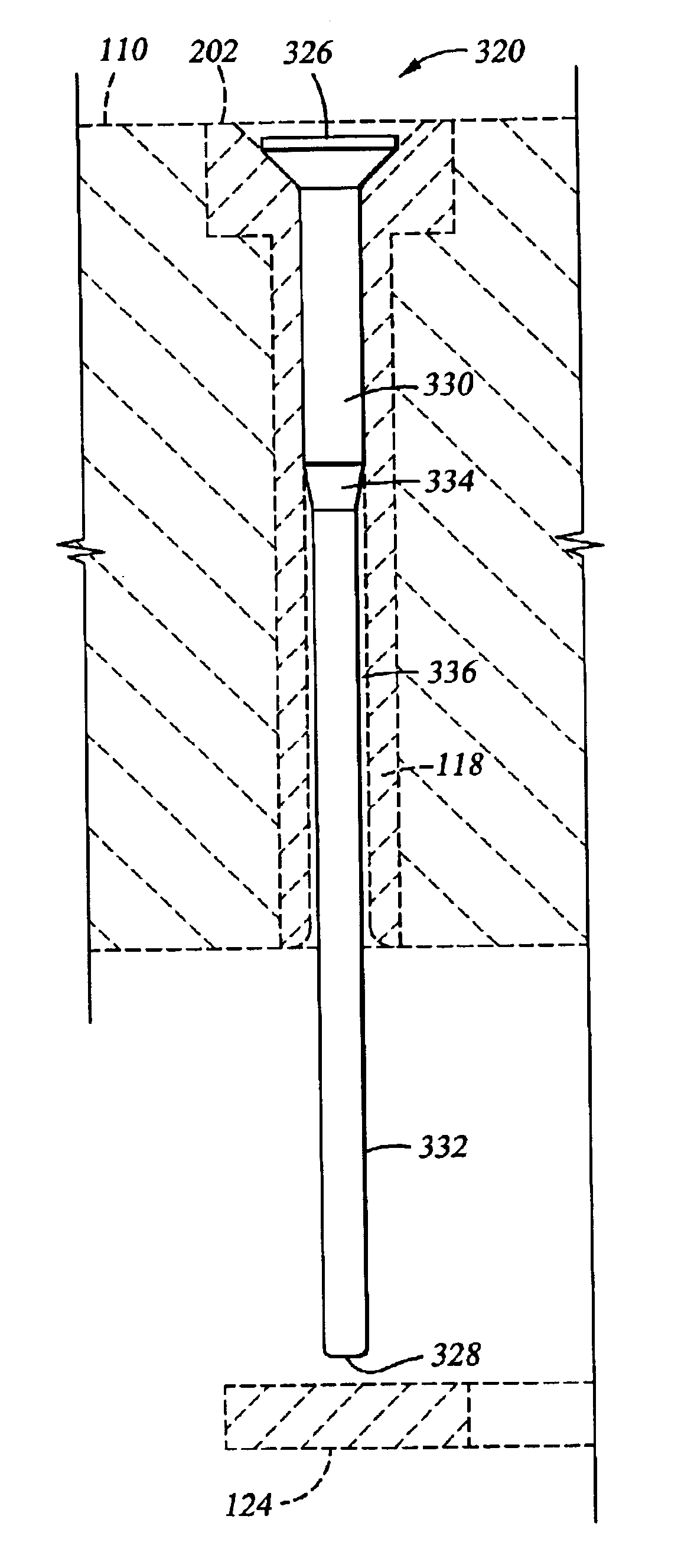

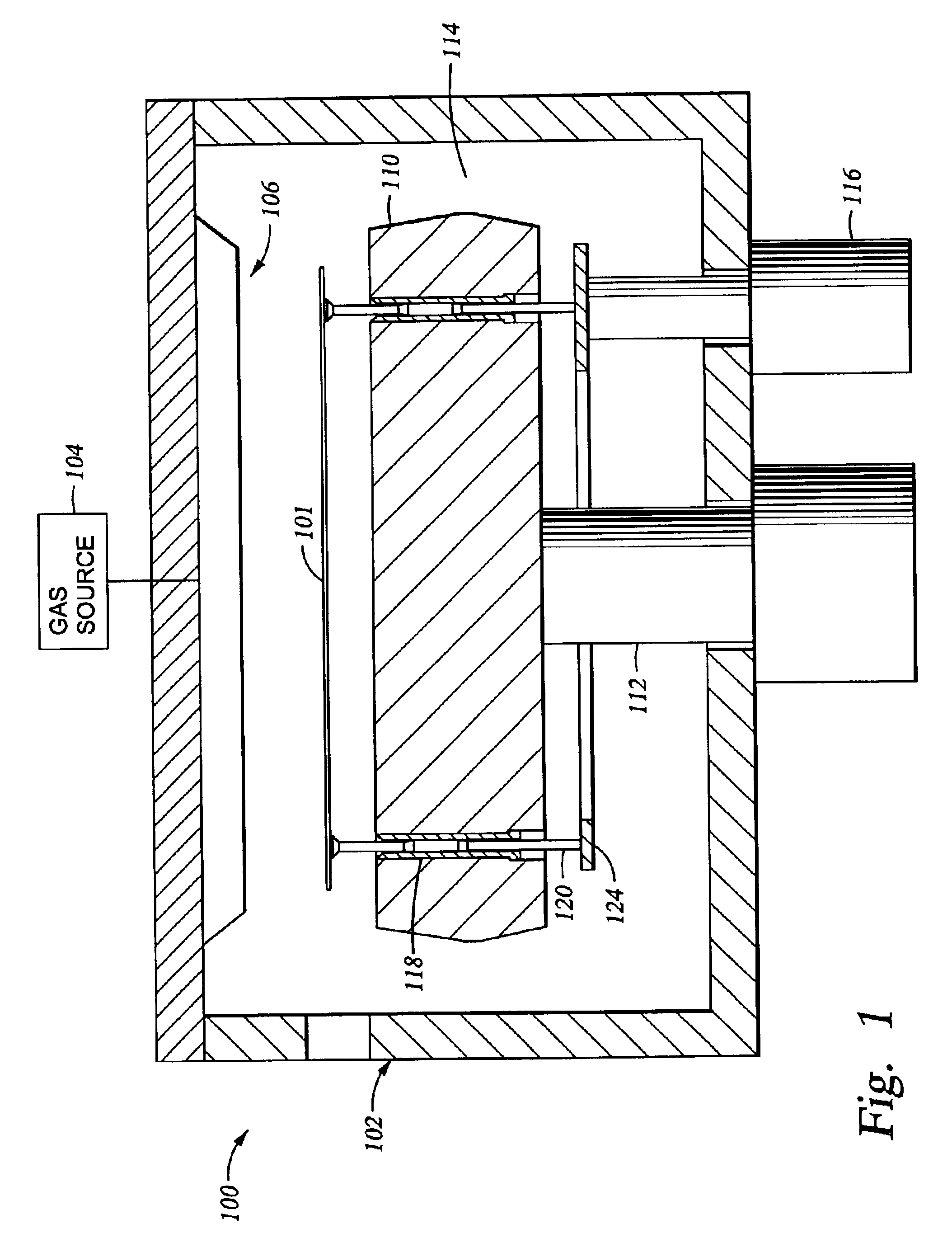

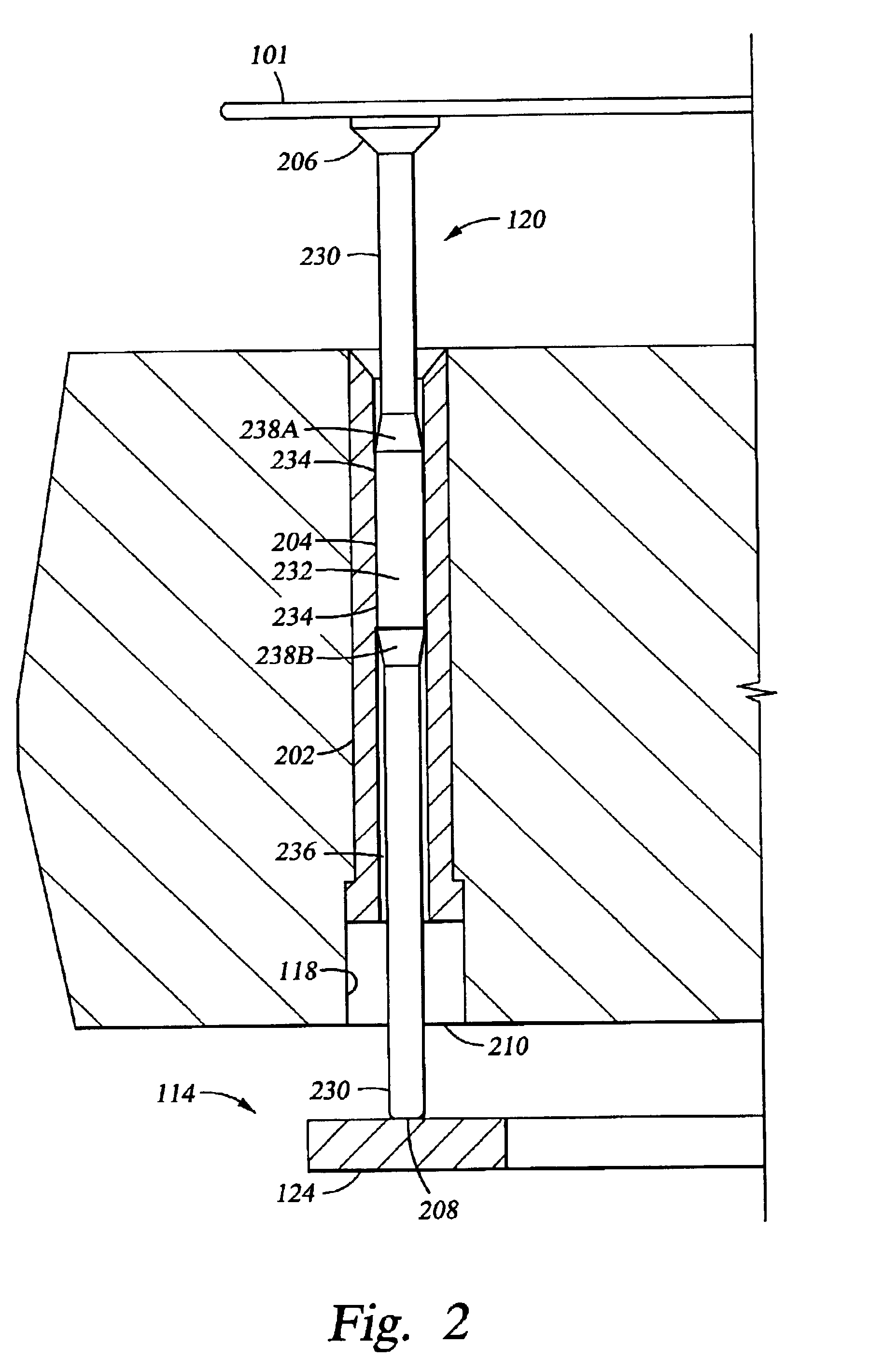

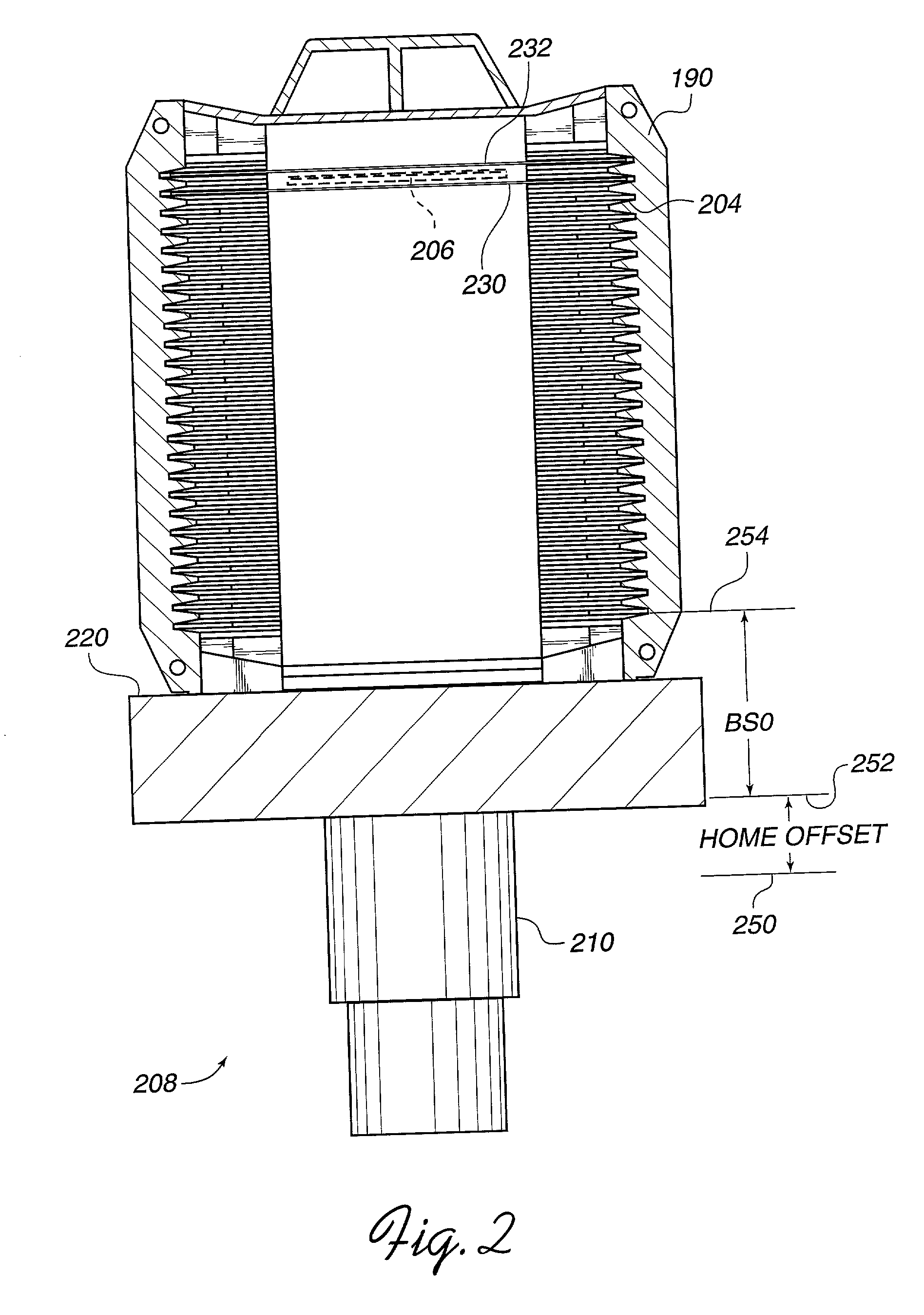

Reduced friction lift pin

InactiveUS6887317B2Increase design spaceReducing pin scratchingCellsLiquid surface applicatorsScratchingBiomedical engineering

A substrate support is provided that features a lift pin having at least one larger diameter shoulder section that forms a relief region between the lift pin and a guide hole disposed through a substrate support. The shoulder section minimizes contact between the substrate support and lift pin guide hole, thereby reducing pin scratching, particle generation, component wear, and increasing the useful life of the pin. In another embodiment, a flat-bottom tip is provided to promote self-standing of the lift pin, reducing pin tilting or leaning of the lift pin within the guide hole.

Owner:APPLIED MATERIALS INC

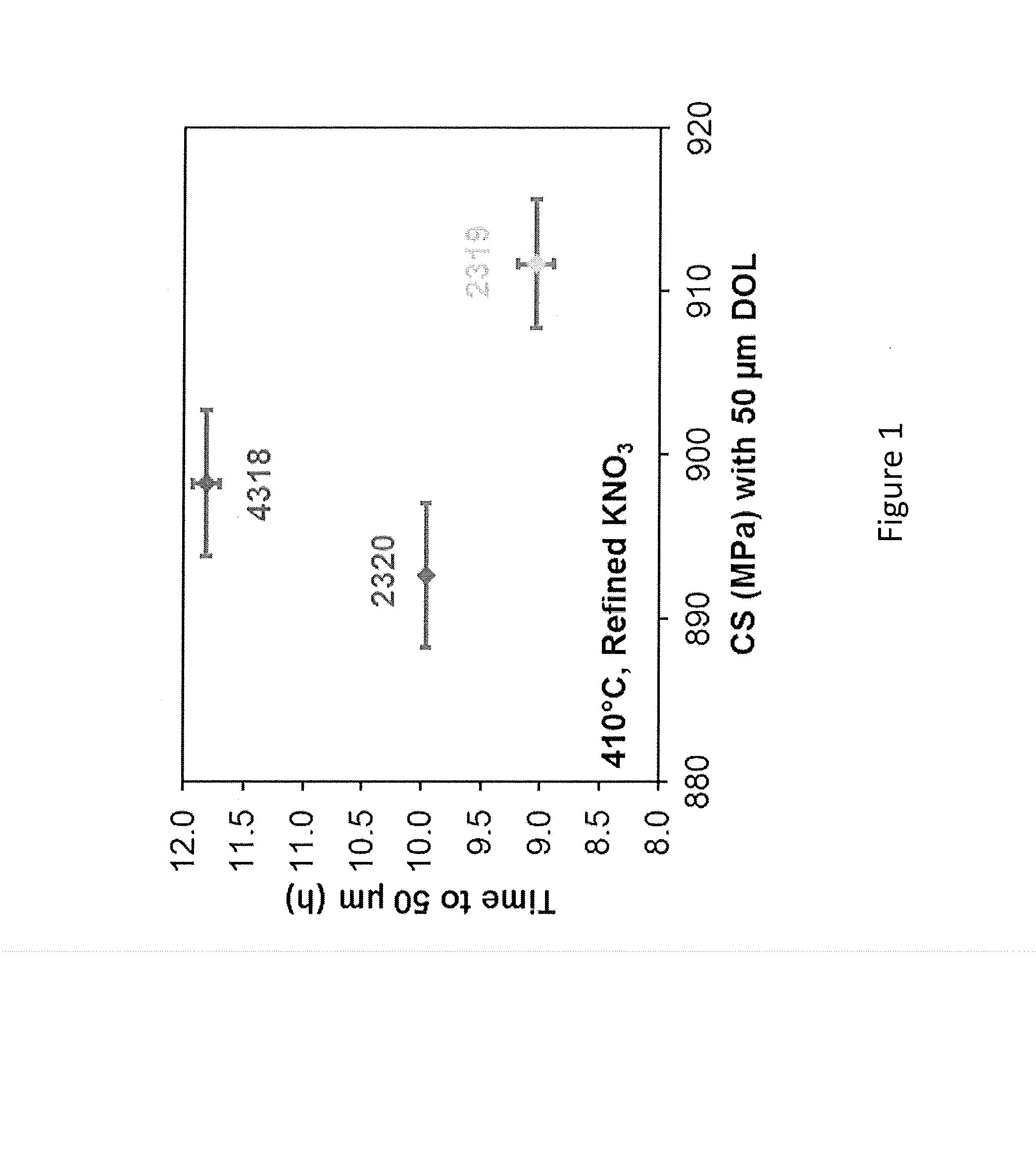

Zircon compatible, ion exchangeable glass with high damage resistance

An ion exchangeable glass having a high degree of resistance to damage caused by abrasion, scratching, indentation, and the like. The glass comprises alumina, B2O3, and alkali metal oxides, and contains boron cations having three-fold coordination. The glass, when ion exchanged, has a Vickers crack initiation threshold of at least 10 kilogram force (kgf).

Owner:CORNING INC

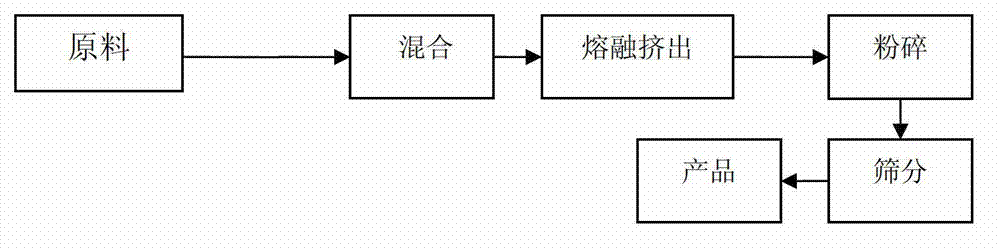

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

Sealants for Solar Energy Concentrators and Similar Equipment

InactiveUS20090032088A1Good sealantImprove performance and longevityPV power plantsSynthetic resin layered productsFresnel lensPlastic materials

Owner:RABINOWITZ MARIO

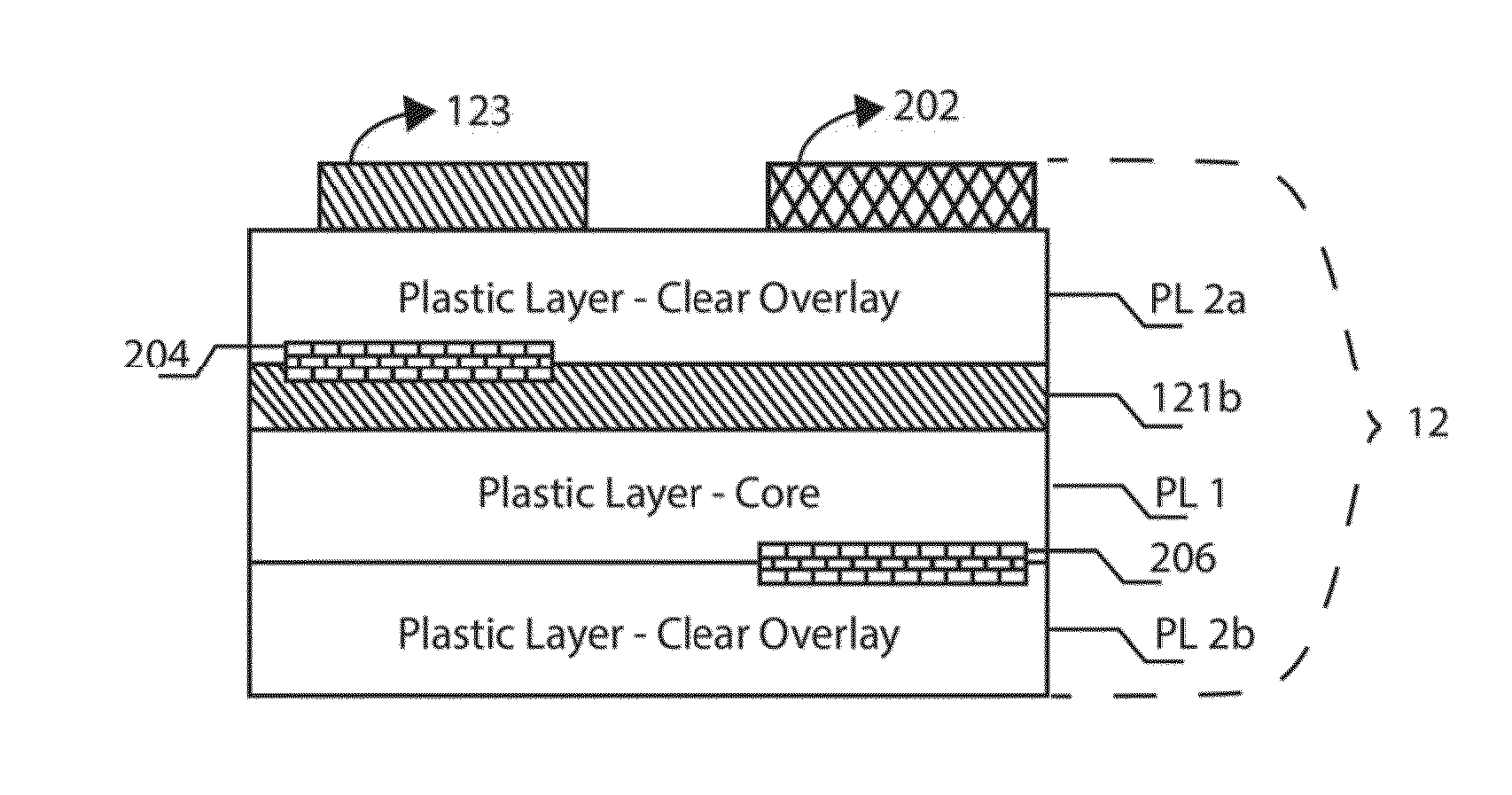

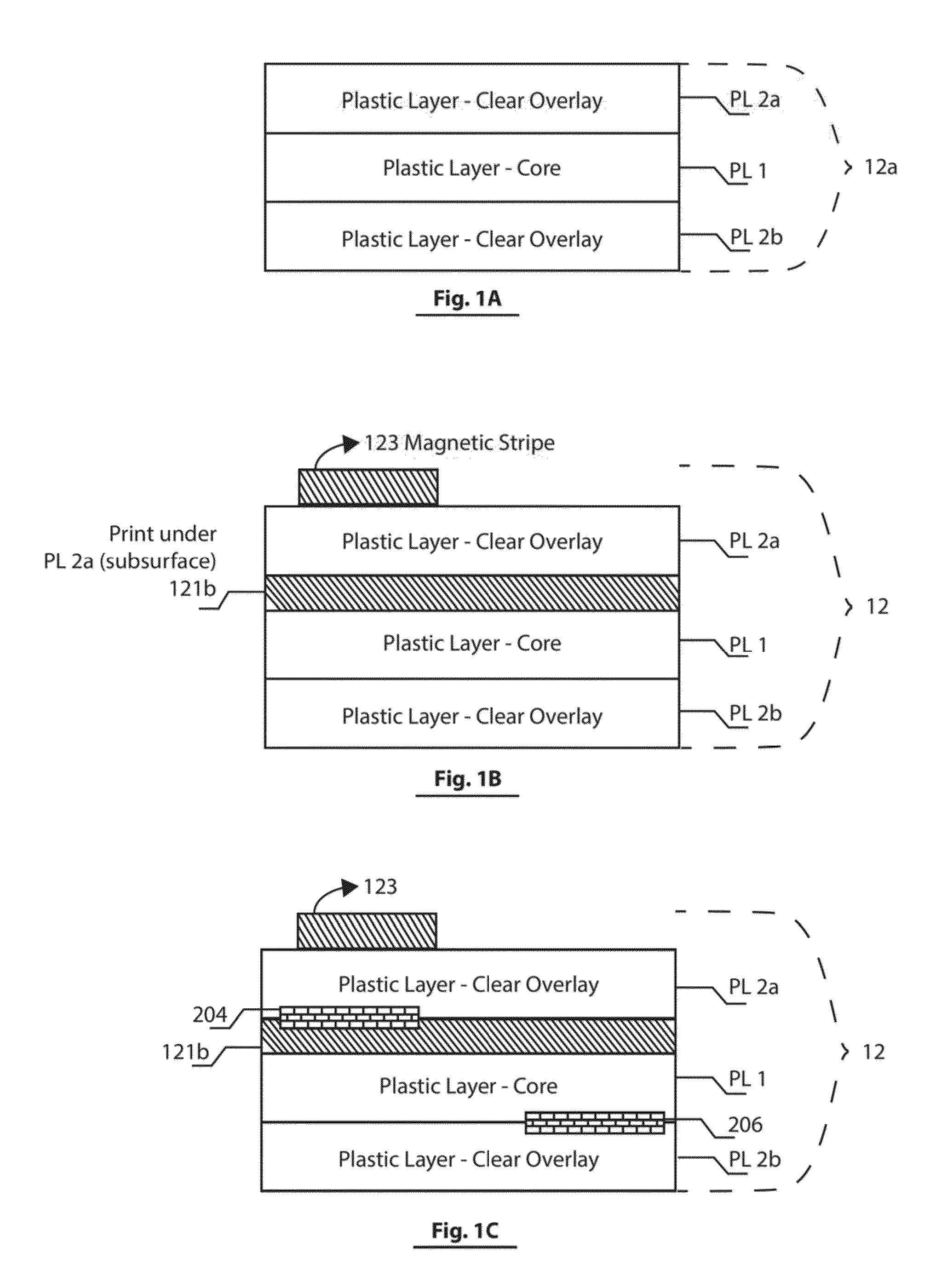

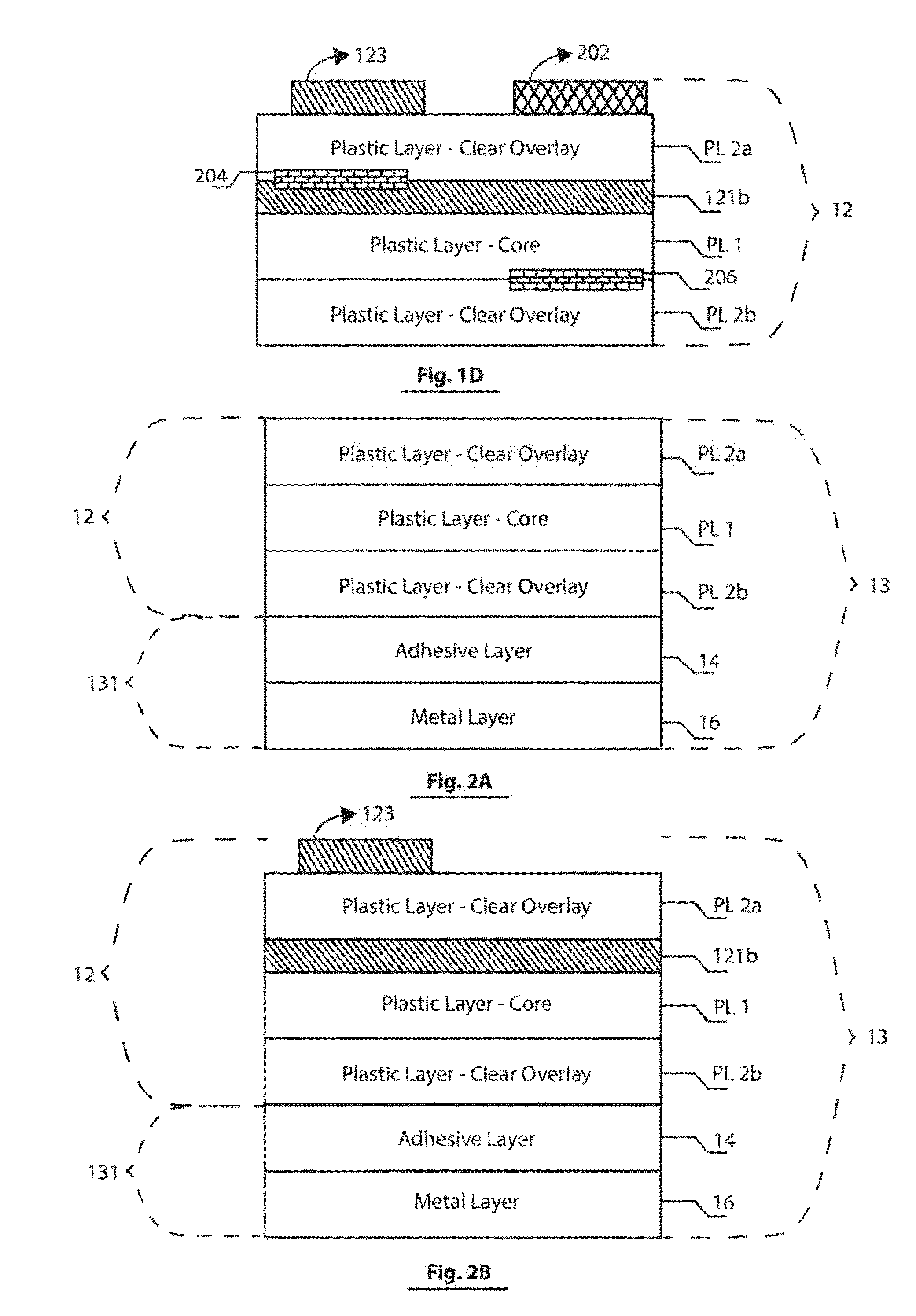

Card with metal layer and electrostatic protection

ActiveUS20150180229A1Minimize the possibilityReduce the possibilityLamination ancillary operationsSynthetic resin layered productsDual stageAcrylic resin

A metal card or a hybrid metal-plastic includes an acrylic resin protective clear coat layer and / or a “hard” nano-particle top-coat layer overlying any exposed metal surface in order to insulate the metal and reduce the likelihood of an electrostatic discharge (ESD) or a short circuit condition. In a particular embodiment the “hard” nano-particle top-coat layer overlies the clear coat layer. The dual stage protective layers which include a clear-coat layer and a top-coat ensure that the problem associated with an ESD and / or a short circuit condition is minimized. In addition, the dual stage protection imparted to a card by forming a clear-coat layer and a top-coat layer ensures that any card surface treatment or card decoration is protected over time from excessive wear or scratching due to use in conjunction with a POS device and / or handling.

Owner:COMPOSECURE LLC

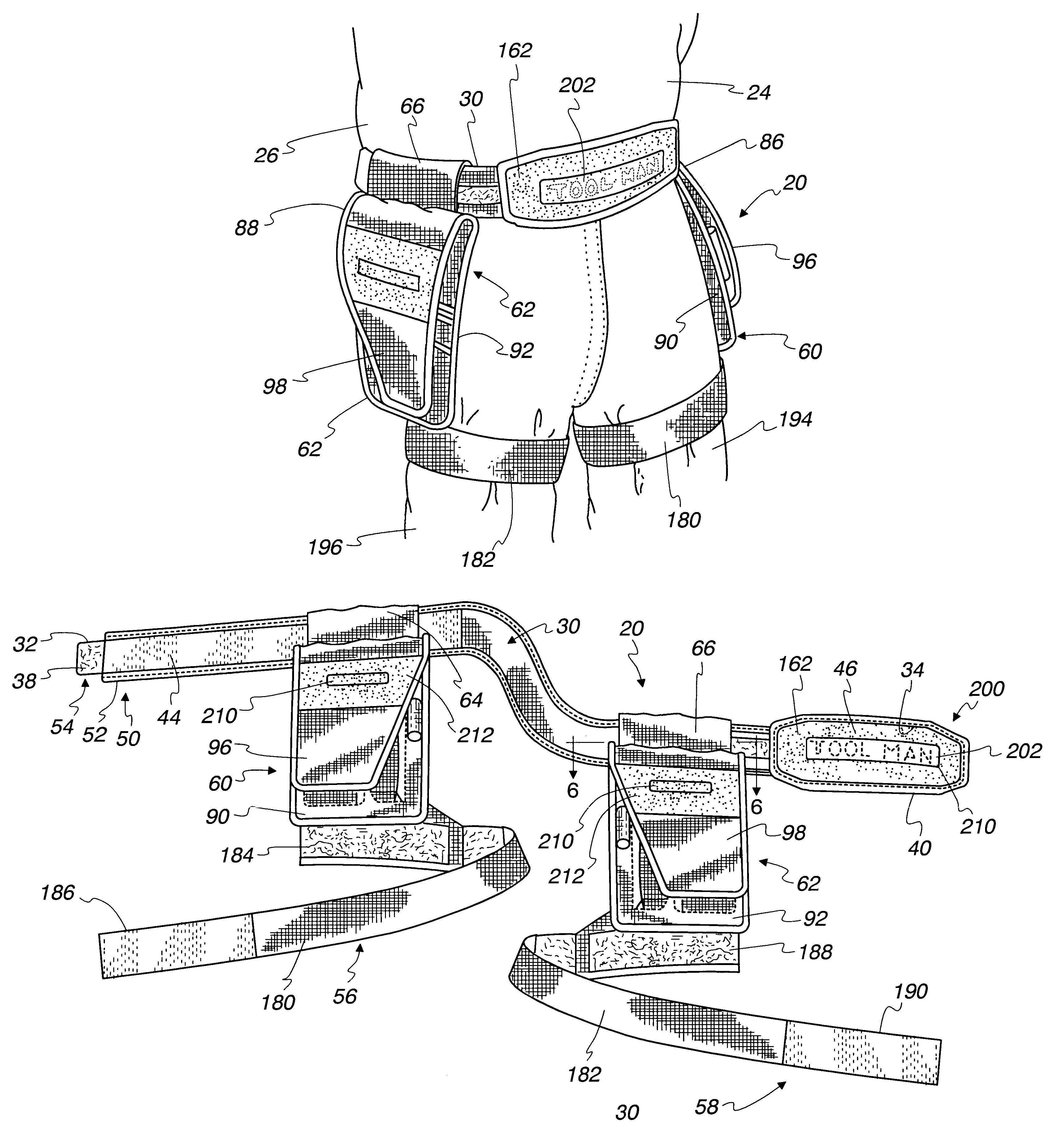

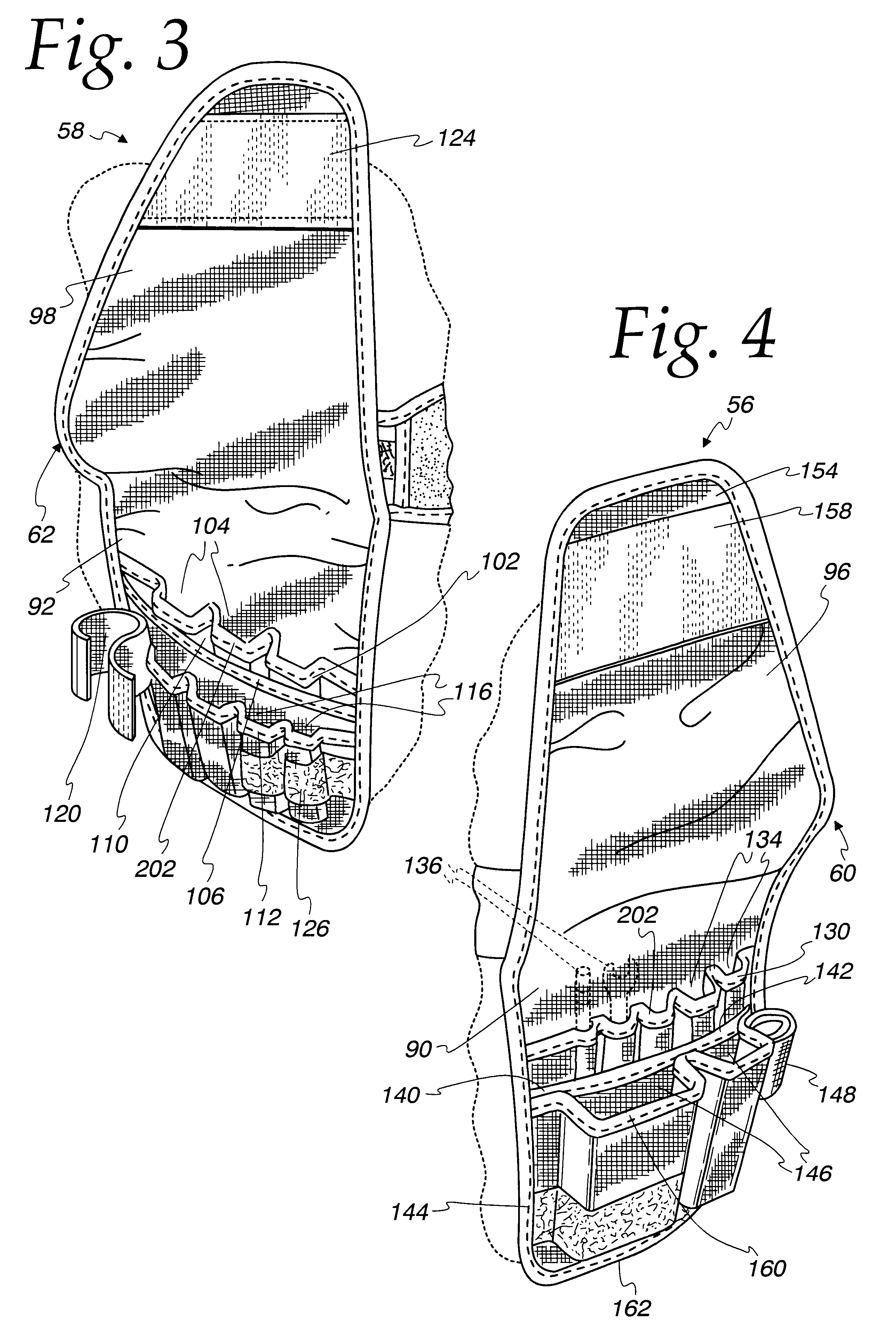

Belt assembly for storage and inventory of tools

InactiveUS6446852B1Surface damageEasy to repositionTravelling sacksTravelling carriersVisual markingEngineering

A tool-carrying assembly to be secured by a waist-encircling belt, and, additionally, by straps encircling the legs of a workman using the belt assembly. The assembly is thus stabilized, and enhanced weight distribution is achieved. Elements of the belt assembly include a waist-encircling band supporting a pair of laterally spaced, depending panels each carrying tool-accepting pockets. The pockets preferably carry visual markings and coding as well as other indicia identifying clearly the specific tools to be "housed" or carried in and to be returned to each pocket after use. Inventory control of the tools is thereby significantly enhanced. Pivotal flaps depending from the band-carried panels serve to cover the tools when not in use, and to prevent the tools from scratching or otherwise marring any article, or fixture, or "workpiece" requiring the workman's attention. The panels and the tools carried thereby are disposed in lateral, spaced zones at the wearer's sides (and not directly in the front of one's body) thus further to reduce any likelihood of the tools coming into damaging physical contact with an article being worked upon. That is, both frontal and rearwardly located zones about the wearer of the tool belt assembly are rendered essentially free and clear of all tools and other mechanical impediments. While wearing the tool assembly of the invention, a worker can, without any discomfort, lie upon and use a "creeper". Significantly, a frontal sector of the belt itself is covered with a relatively soft, non-marring protective pad, composition, or surface material effective to prevent possible damage from a workman's belt buckle. An additional feature of the invention is that the panels may be structured to constitute a core sandwiched between a pair of encasing sheet-like webs. The resulting composite is readily formable to provide selectable visual patterns, designs or indicia, for example, to identify product name or sources and / or to constitute decorations.

Owner:WMH TOOL GROUP

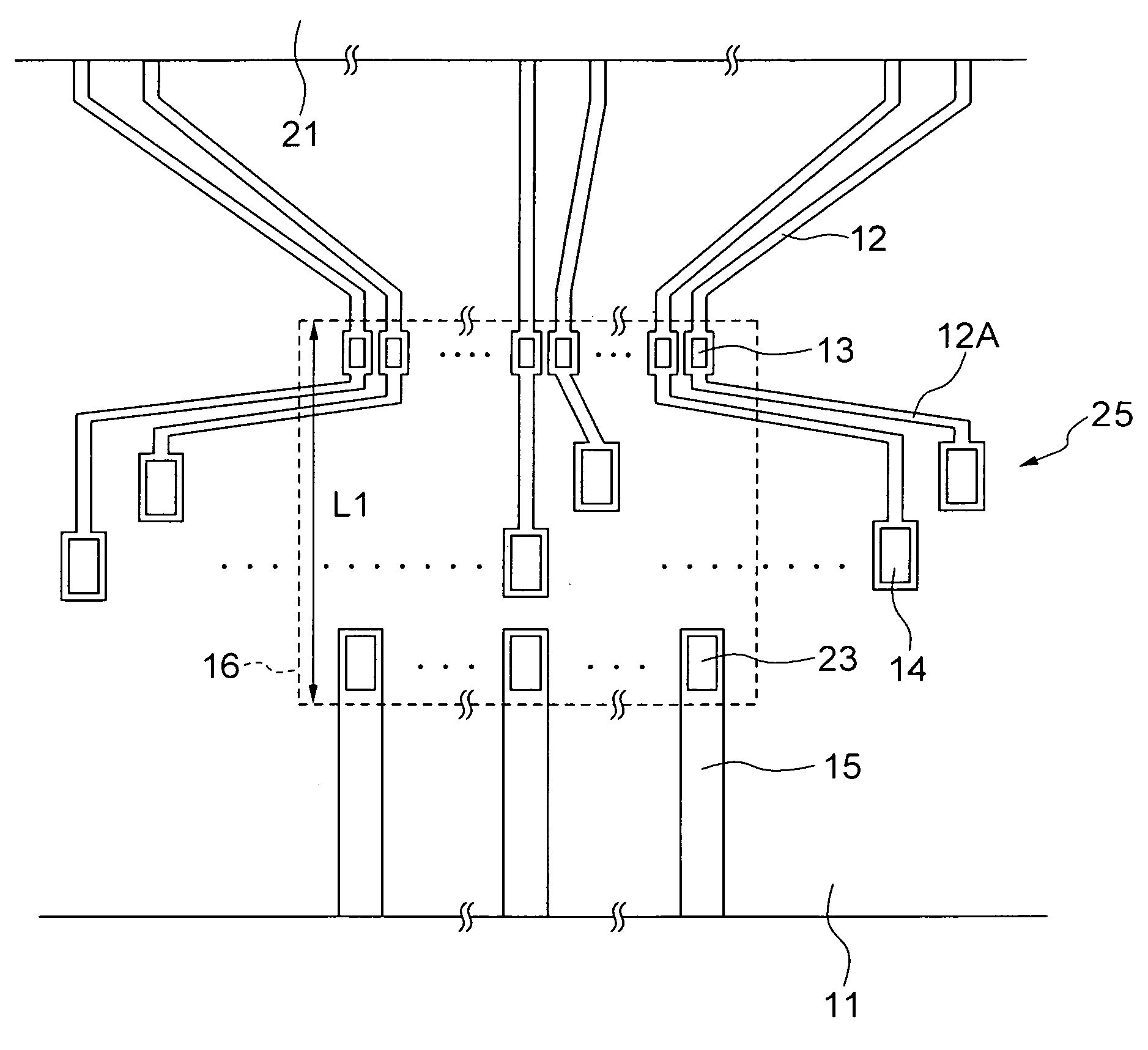

LCD device having test contact pads

InactiveUS6930744B1Safe test operationGuaranteed uptimeNon-linear opticsIndividual semiconductor device testingContact padSemiconductor chip

To make the test probe not directly in contact with the electrode pads for the semiconductor chip mounting, without using an advanced technology for making the pitch of electrode pads narrower, and remove the chip mounting failures such as scratching of electrode pads caused by testing, adherence of impurity particles, electrical corrosion.The electrode pads 13 formed on the distal ends of the external leads 5 for press-connecting the input electrodes 12 of the semiconductor chip 6 are disposed at both sides (shown as L1) of the semiconductor chip 6. The terminal-electrode leads 2 from the electrode pads 3 pass under the semiconductor chip 6 while keeping a pitch of the electrode pads 3. The test electrode pads 4 are disposed in alternate arrangement on the distal ends of terminal-electrode leads 2. The test electrode pads 4 may be disposed in alternate arrangement in three steps or more of multiple steps.

Owner:VISTA PEAK VENTURES LLC

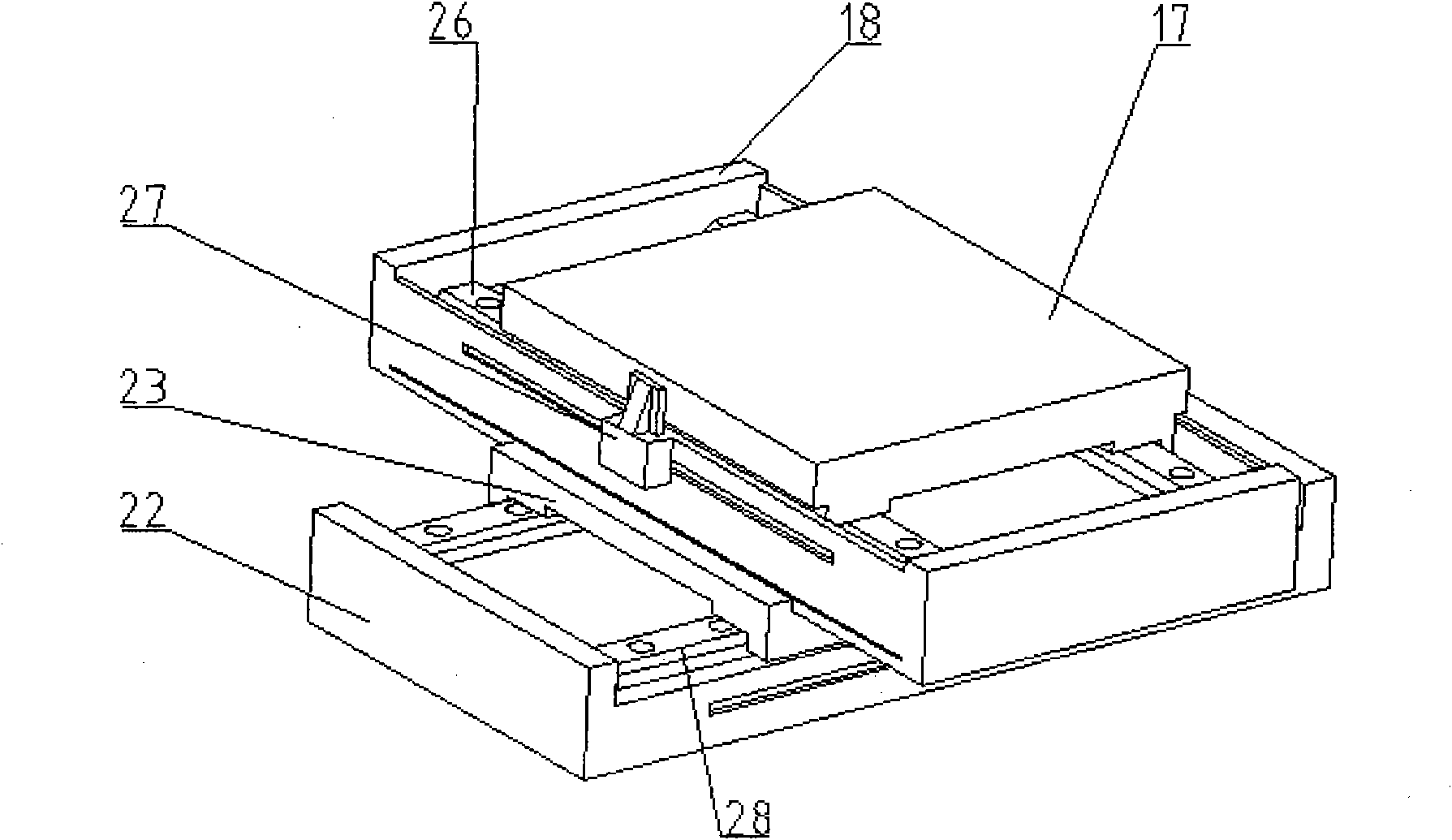

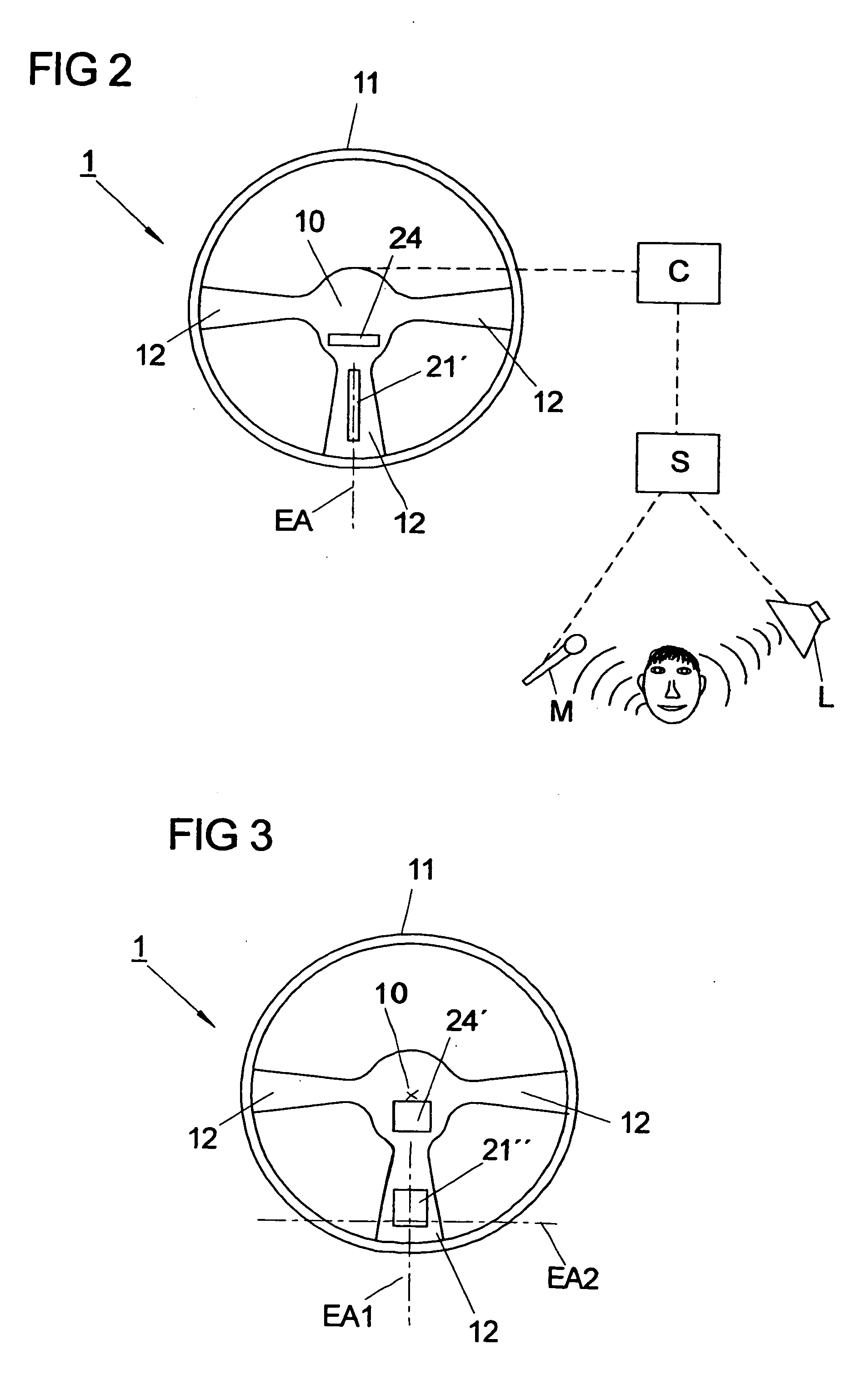

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

Siloxane-Based Coating Material, Optical Article, and Production Method of Siloxane-Based Coating Material

InactiveUS20070266896A1Excellent surface hardnessGood storage stabilityAntifouling/underwater paintsSynthetic resin layered productsSiloxaneScratching

The invention provides a coating material containing silica fine particles, a siloxane compound, and a curing agent and giving an even coating film in the case it is used for forming a coating film. The invention gives a siloxane-based coating material excellent in storage stability and giving high surface hardness of a coating film when the coating material is used for forming the coating film. The invention also provides an optical article excellent in anti-reflection property and scratching resistance.

Owner:TORAY IND INC

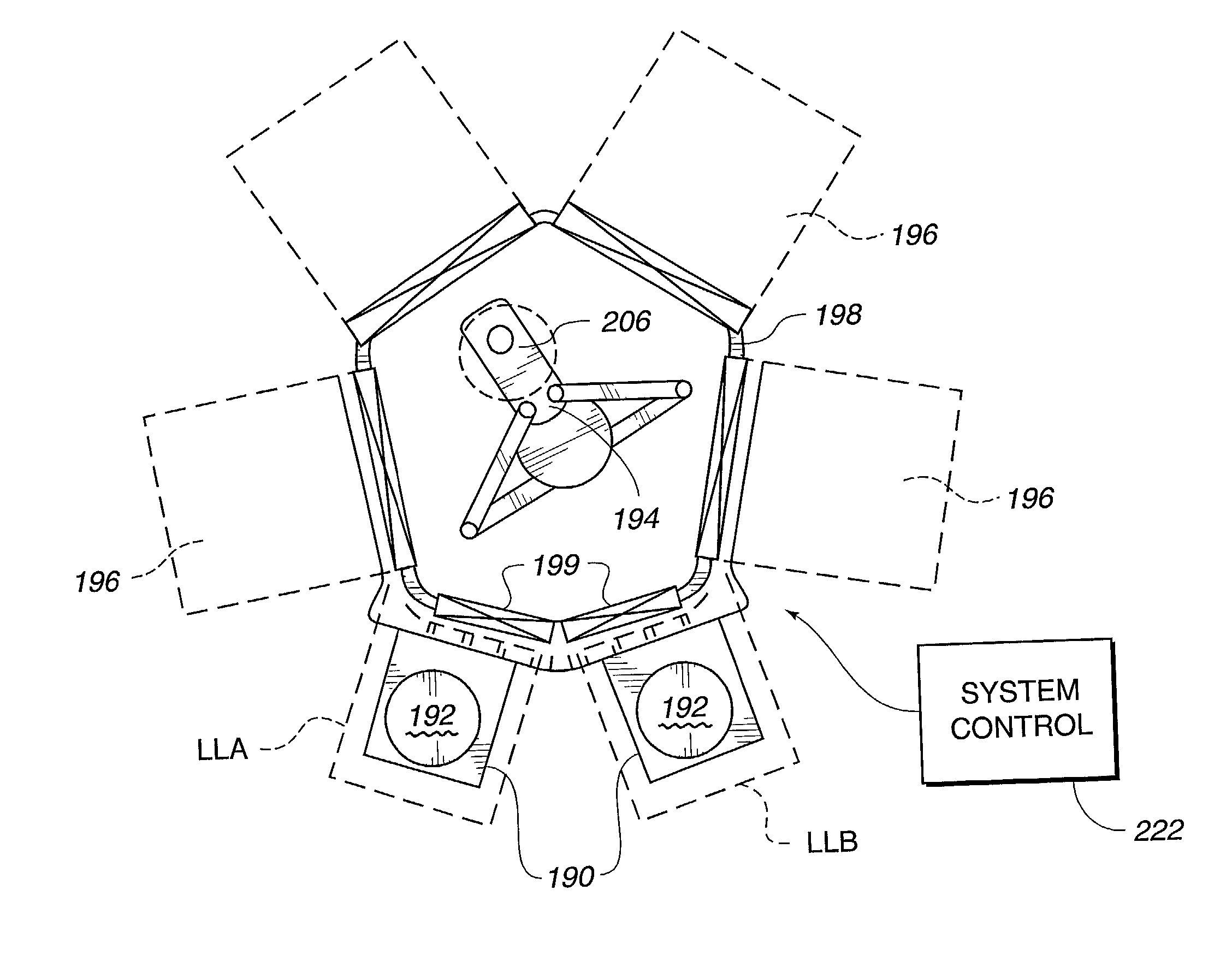

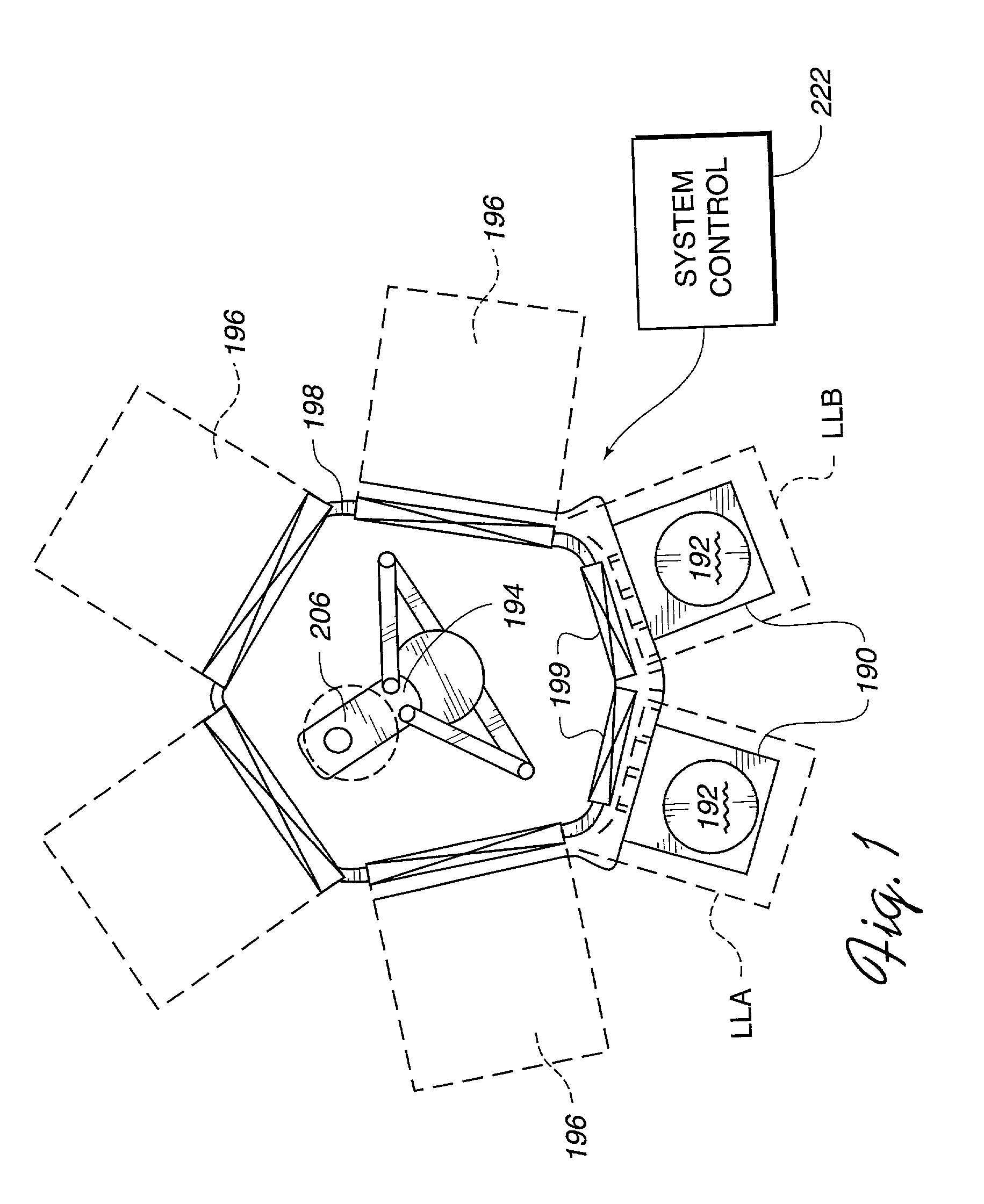

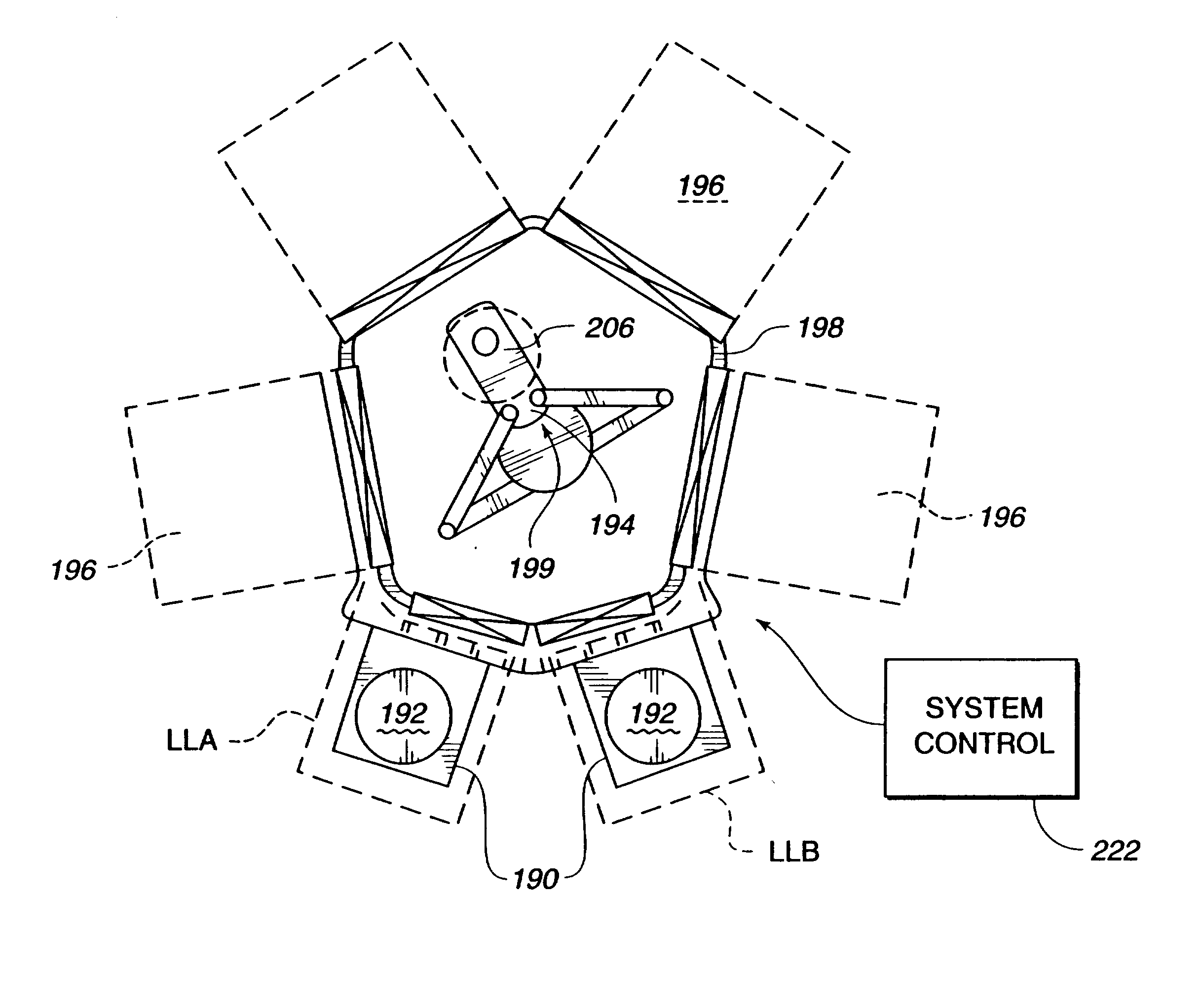

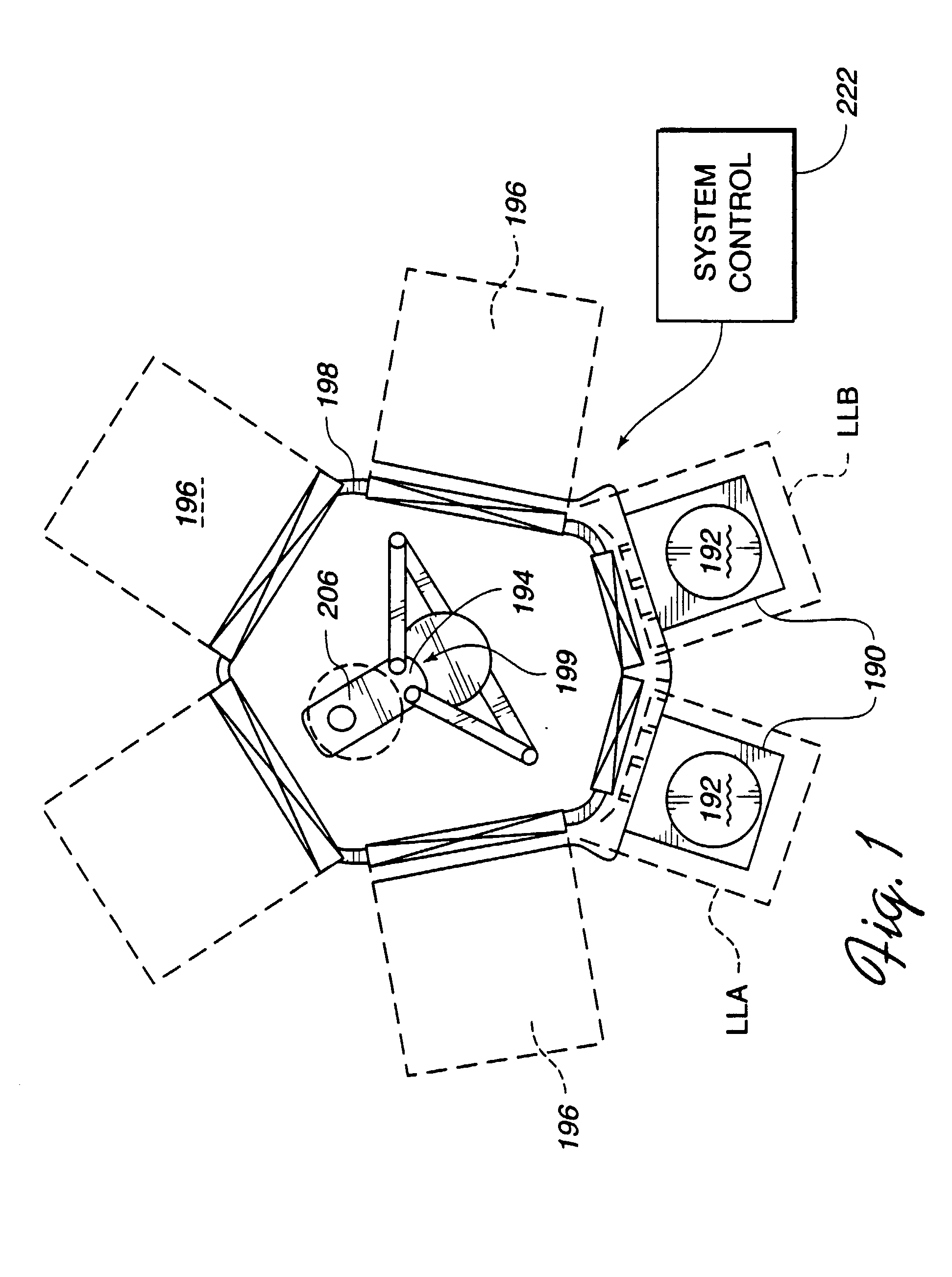

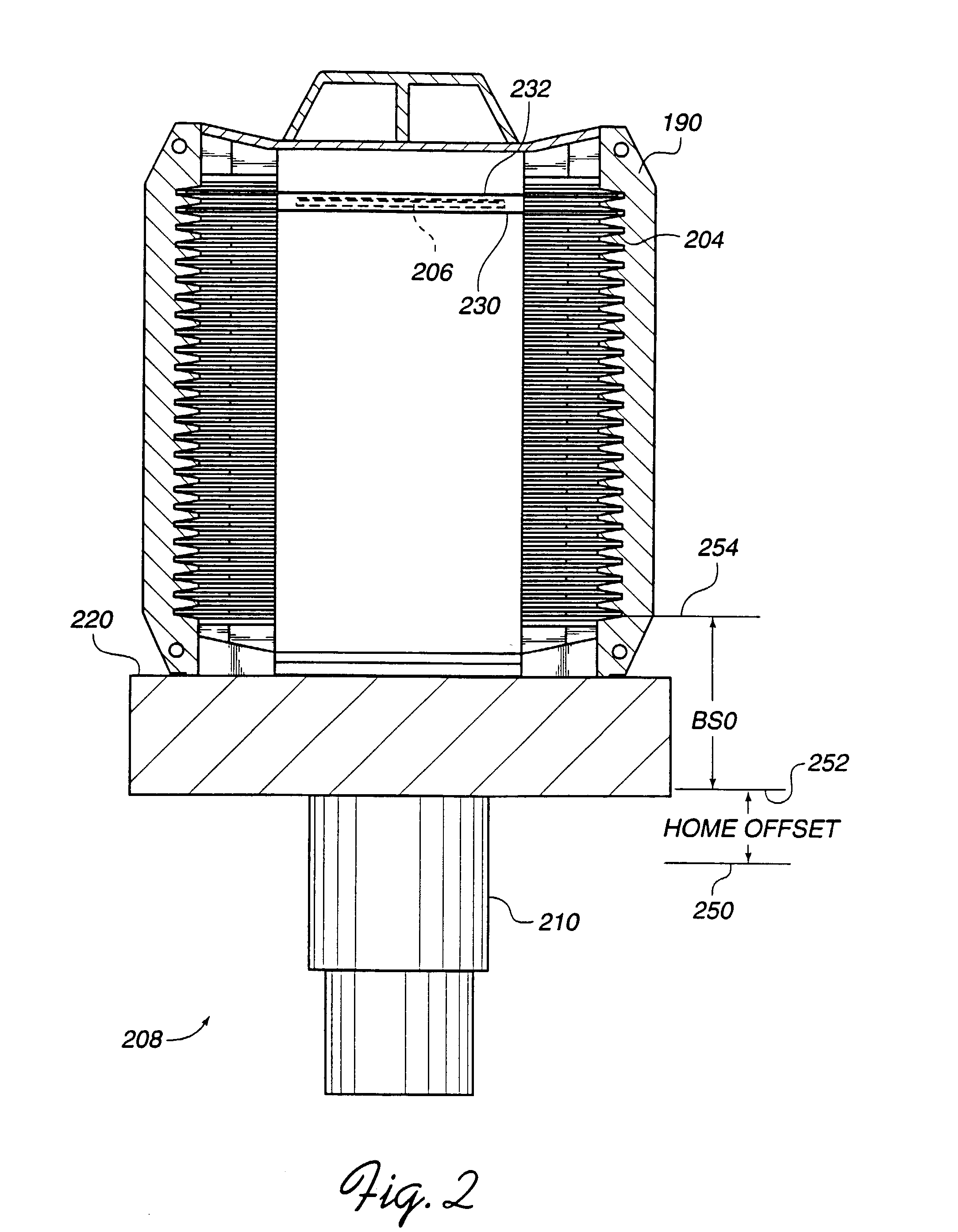

Apparatus for alignment of automated workpiece handling systems

InactiveUS6763281B2Facilitate accurately levelingBreakage can be reduced eliminatedDigital data processing detailsSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An alignment tool, method and system are provided for aligning a robot blade in a workpiece handling system, in which the tool comprises a frame or fixture adapted to be supported by a transfer chamber support surface or other support surface in the system, in which the frame has one or more non-contact distance sensors positioned to measure the distance of a workpiece or robot blade from the sensor or a predetermined reference point or surface. In one embodiment, the frame is used to align a robot blade relative to a robot support alignment surface in a robot chamber. In another embodiment, the frame emulates a workpiece cassette and the distance sensors provide an output to align the robot blade to a cassette support alignment surface. As a consequence, accidental scratching and breakage of workpieces such as semiconductor wafers and display substrates may be reduced or eliminated. In another embodiment, positions of distance sensors may be readily repositioned to accommodate alignment procedures for different sized wafers or other workpieces.

Owner:APPLIED MATERIALS INC

Method and apparatus for alignment of automated workpiece handling systems

InactiveUS20020021959A1Facilitate accurately levelingBreakage can be reduced eliminatedDigital data processing detailsSemiconductor/solid-state device manufacturingDisplay deviceHandling system

An alignment tool, method and system are provided for aligning a robot blade in a workpiece handling system, in which the tool comprises a frame or fixture adapted to be supported by a transfer chamber support surface or other support surface in the system, in which the frame has one or more non-contact distance sensors positioned to measure the distance of a workpiece or robot blade from the sensor or a predetermined reference point or surface. In one embodiment, the frame is used to align a robot blade relative to a robot support alignment surface in a robot chamber. In another embodiment, the frame emulates a workpiece cassette and the distance sensors provide an output to align the robot blade to a cassette support alignment surface. As a consequence, accidental scratching and breakage of workpieces such as semiconductor wafers and display substrates may be reduced or eliminated. In another embodiment, positions of distance sensors may be readily repositioned to accommodate alignment procedures for different sized wafers or other workpieces.

Owner:APPLIED MATERIALS INC

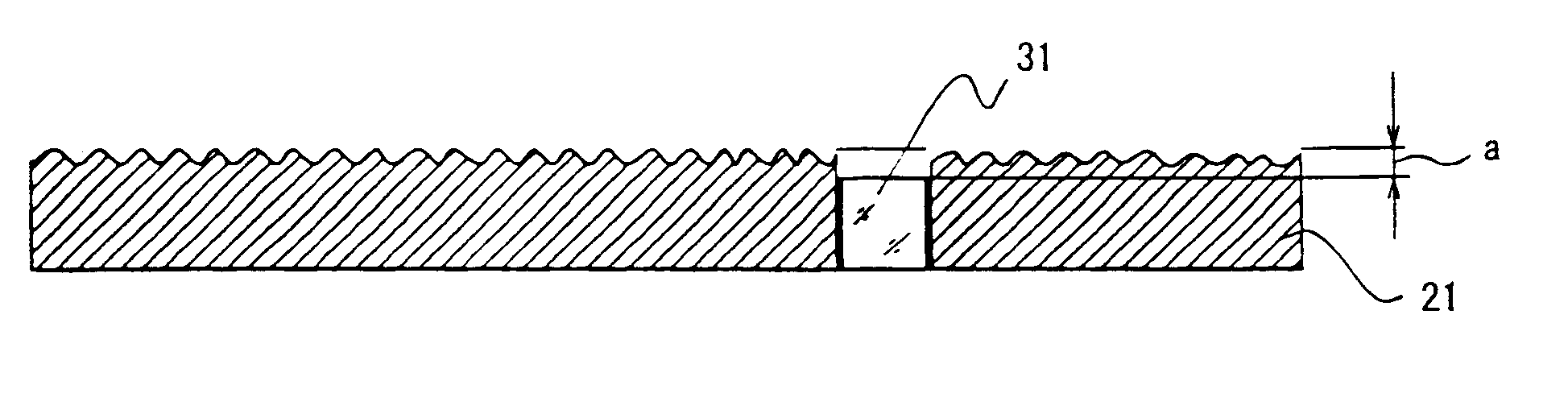

Polishing body, polishing apparatus, polishing apparatus adjustment method, polished film thickness or polishing endpoint measurement method, and semiconductor device manufacturing method

InactiveUS20020042243A1Low costGood precisionPolishing machinesRevolution surface grinding machinesEngineeringSemiconductor

After a hole is formed in a polishing pad, a transparent window plate is inserted into the hole. Here, a gap is left between the upper surface of the transparent window plate and the outermost surface constituting the working surface of the polishing pad. During polishing, the polishing head holding the wafer applies a load to the polishing pad by means of a load-applying mechanism, so that the polishing pad and transparent window plate are compressed. In this case, the system is arranged so that the gap remains constant, and so that a dimension equal to or greater than a standard value is maintained. Since the upper surface of the transparent window plate is recessed from the upper surface of the polishing pad, there is no scratching of the surface of the transparent window plate during dressing. Accordingly, the polishing pad has a long useful life.

Owner:NIKON CORP

Window member for chemical mechanical polishing and polishing pad

An object of the present invention is to provide a window member for chemical mechanical polishing, which is excellent in antifouling property and transparency and is excellent in anti-scratching and, further, can easily perform detection of a polishing endpoint of the surface of a semiconductor wafer by passing a light for endpoint detection, in polishing of a semiconductor wafer using an optical endpoint detecting apparatus and also to a polishing pad. A window member for chemical mechanical polishing of the present invention is provided with a substrate part (comprised of polyurethane resin and the like), which is transparent partly at least, an antifouling resin layer formed on at least one side of the substrate part. This antifouling resin layer is preferably comprised of a fluorine-based polymer having a polysiloxane segment in a main chain. A polishing pad may be the one that a window member is fitted in a through hole of a substrate for a polishing pad (comprised of polyurethane resin and the like, disc-like, belt-like or the like) provided with a through hole penetrating from surface to back, or adhered to a substrate for a polishing pad so as to cover an opening part of the through hole.

Owner:JSR CORPORATIOON

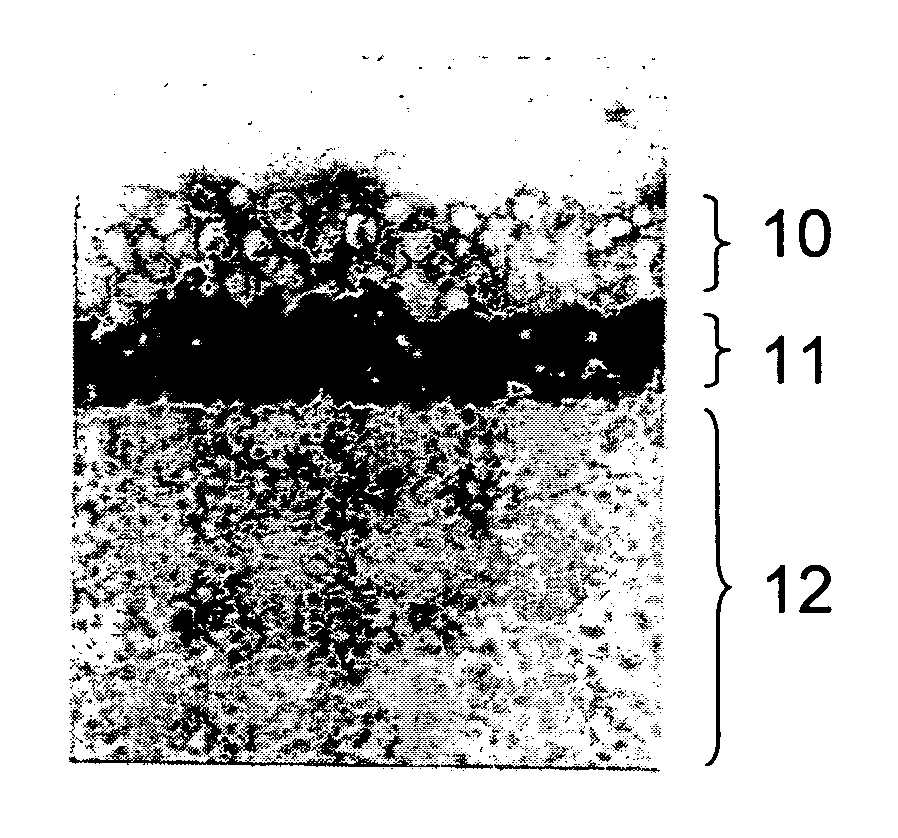

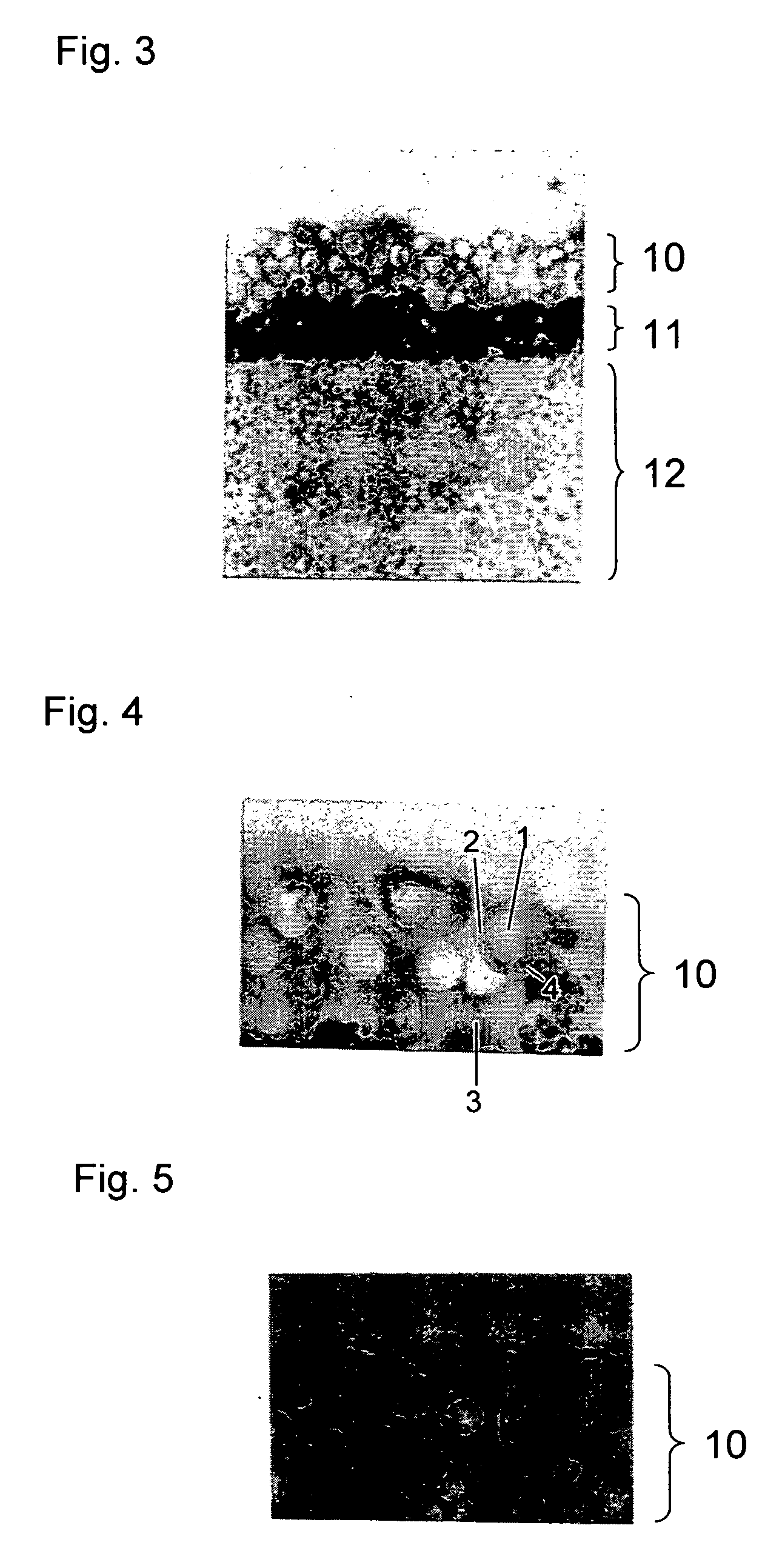

Coated pressing surfaces for abrasion resistant laminate and making laminates therefrom

A press plate for producing decorative laminate from resin impregnated paper, with alumina particles on its pressing surface, is coated with diborides selected from the group consisting of hafnium diboride, molybdenum diboride, tantalum diboride, titanium diboride, tungsten diboride, vanadium diboride, or zirconium diboride or mixtures thereof for making the press plate resistant to scratching. The preferred diborides are titanium and zirconium. The most preferred diboride is titanium. The color, gloss and surface appearance of laminate pressed with a titanium diboride coated press plate is substantially the same as laminate pressed with the press plate before coating.

Owner:WILSONART

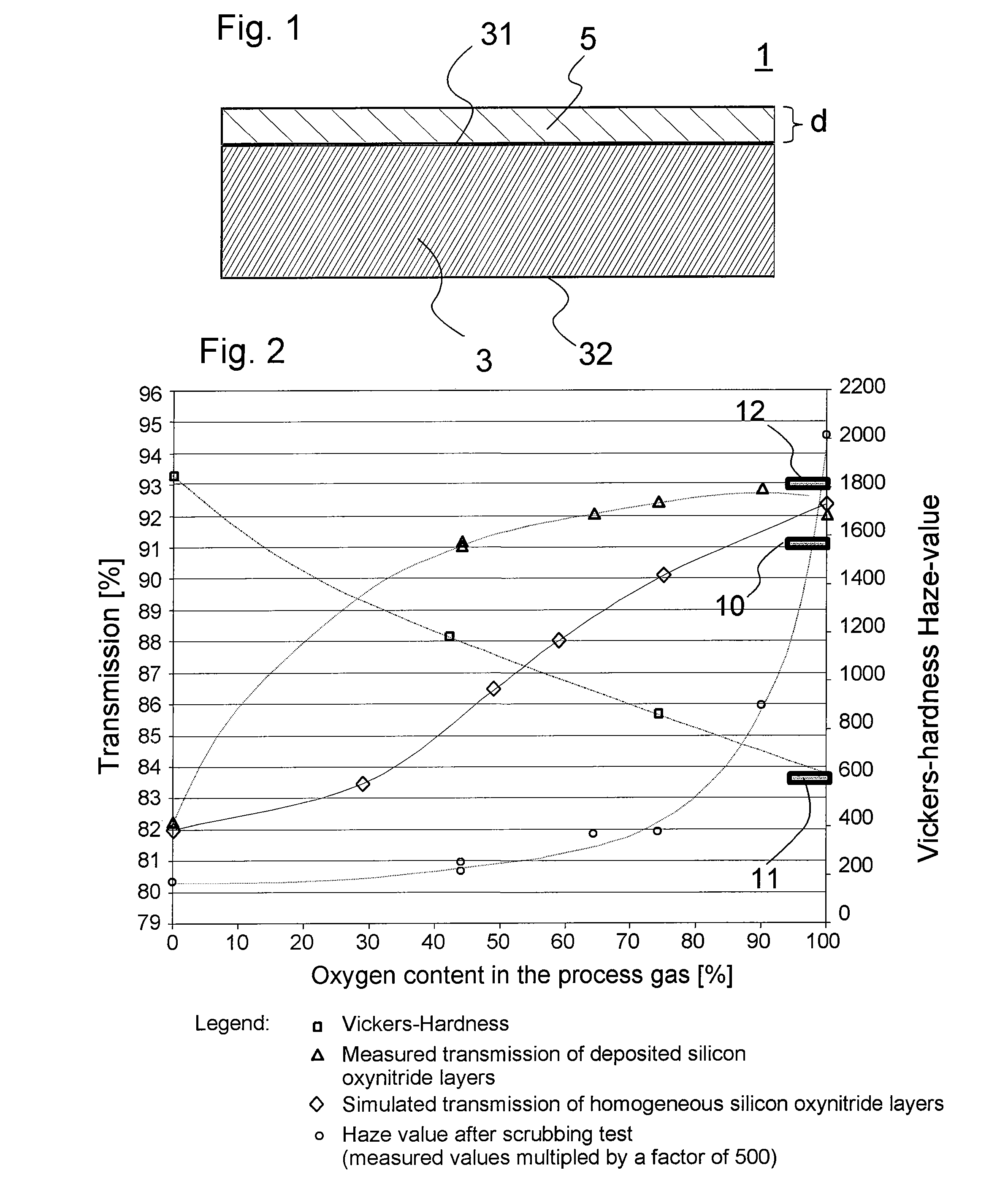

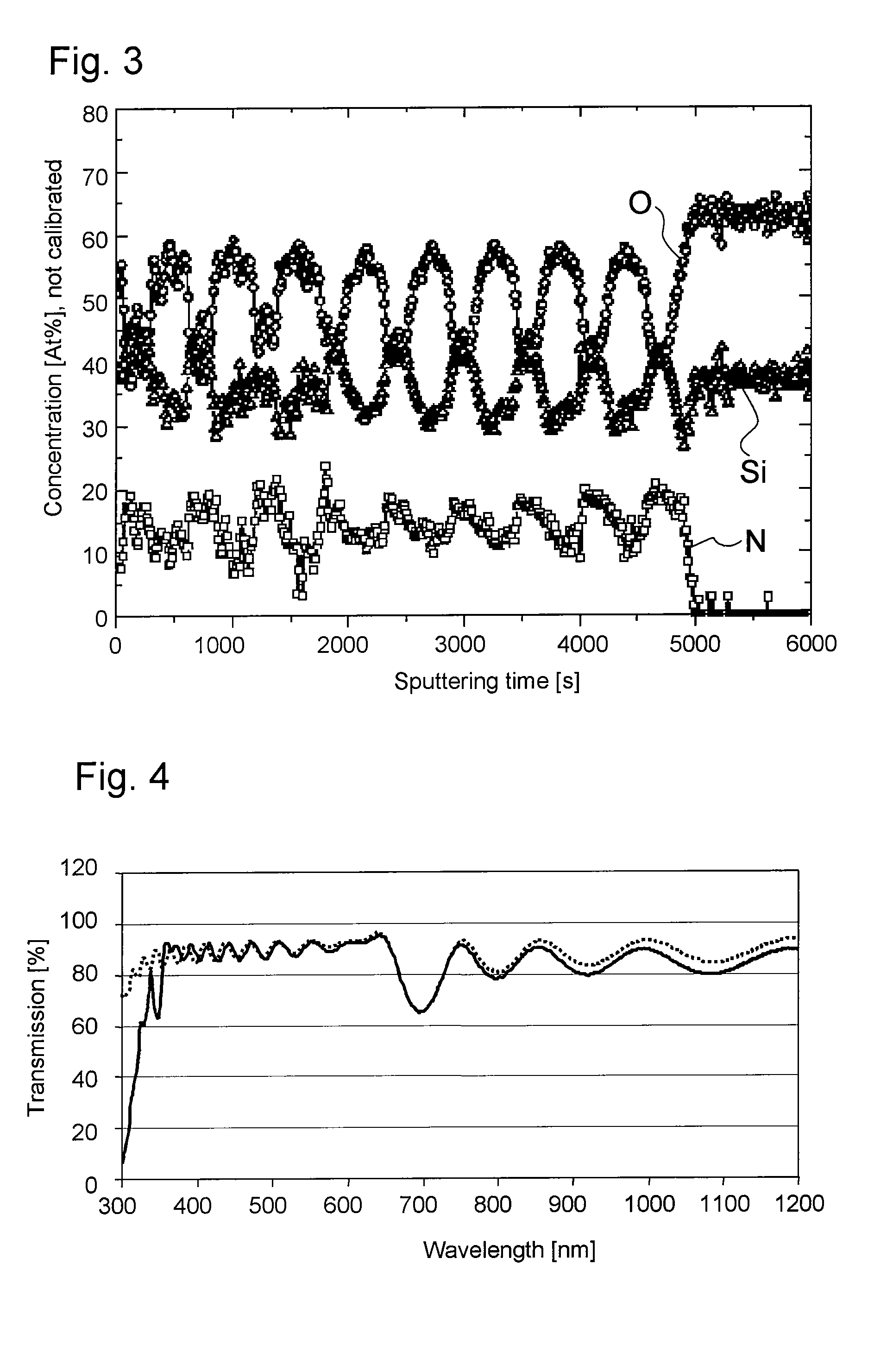

Glass or glass-ceramic substrate with scratch-resistant coating and method for the production thereof

ActiveUS8409716B2Facilitate transmissionAssured protectionVacuum evaporation coatingSputtering coatingMetallurgyGlass-ceramic

The invention in general relates to glass or glass-ceramic products. In order to protect the surface of such products against scratching, a silicon oxynitride coating with special composition is provided.

Owner:SCHOTT AG

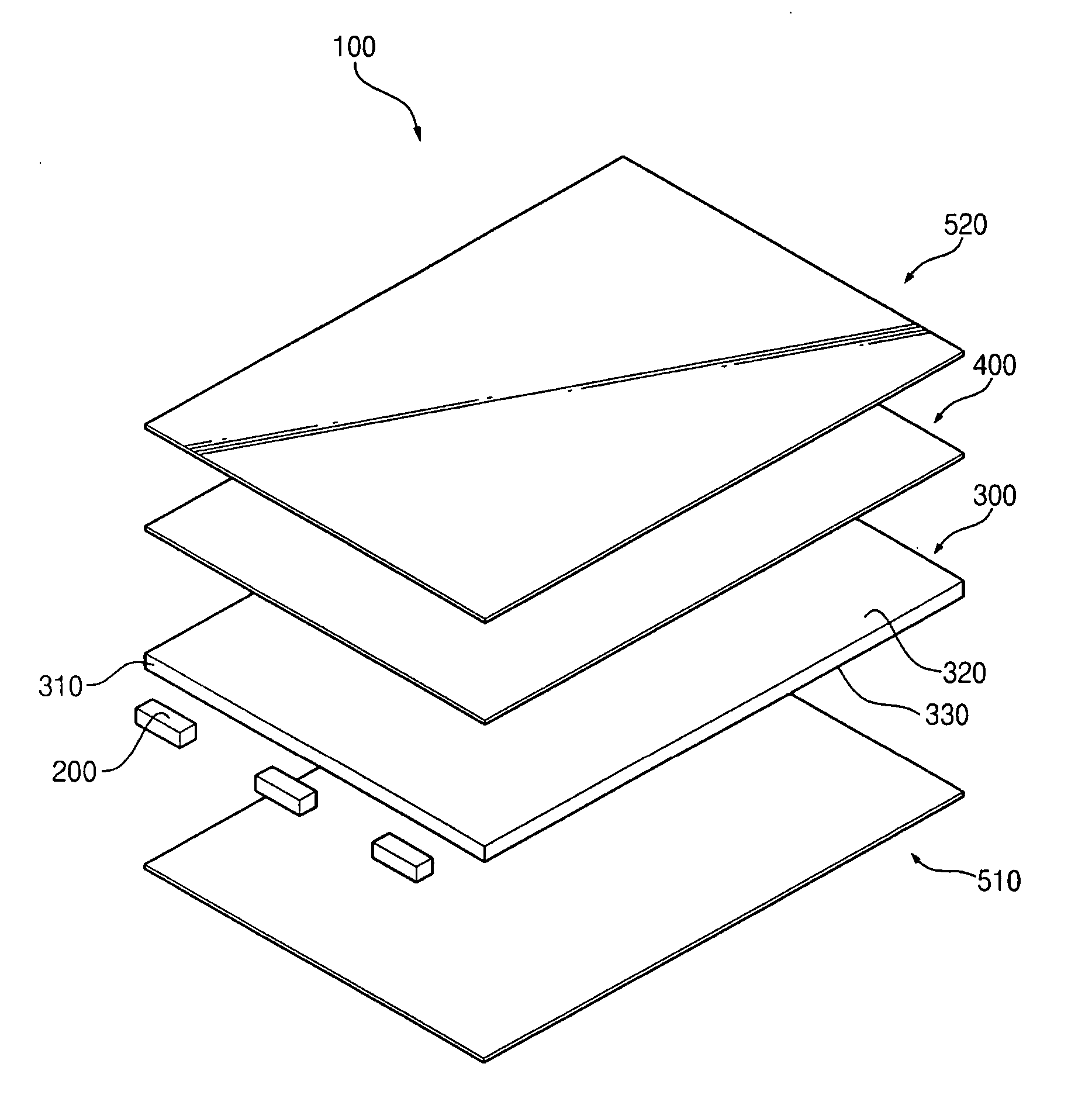

Backlight assembly and liquid crystal display device having the same

ActiveUS20060268579A1Avoid scratchesHigh strengthShow cabinetsImpedence networksLiquid-crystal displayLight guide

A backlight assembly includes a light source, a light-guiding plate and a diffusion sheet that includes a first bead layer on a lower surface of the diffusion sheet facing the light-guiding plate, and a second bead layer on an upper surface of the diffusion sheet. To improve image display quality, the hardness of the beads of the first bead layer facing the light guide plate are equal to or less than that of the light guide plate to prevent scratching of the light guide plate.

Owner:SAMSUNG DISPLAY CO LTD

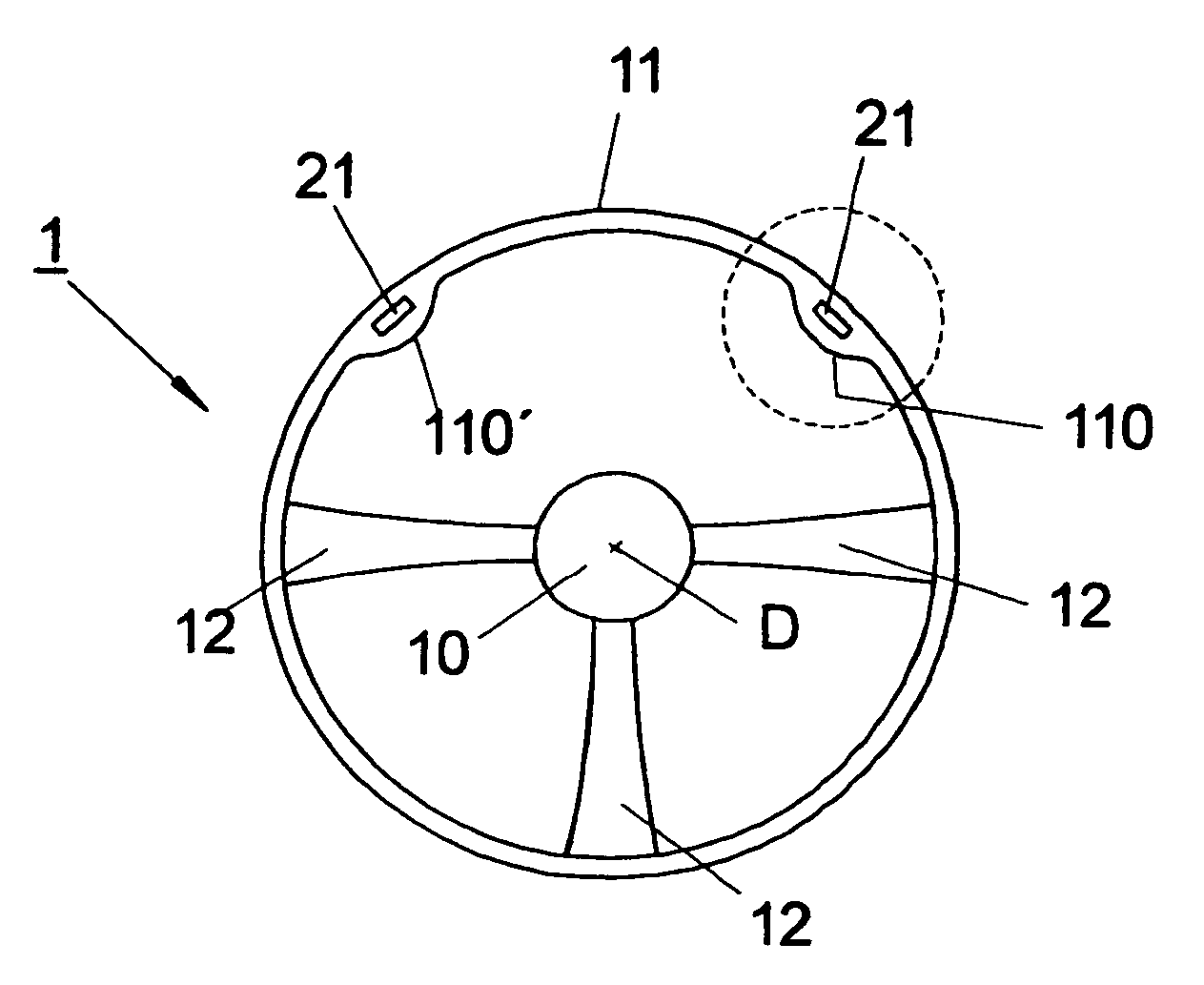

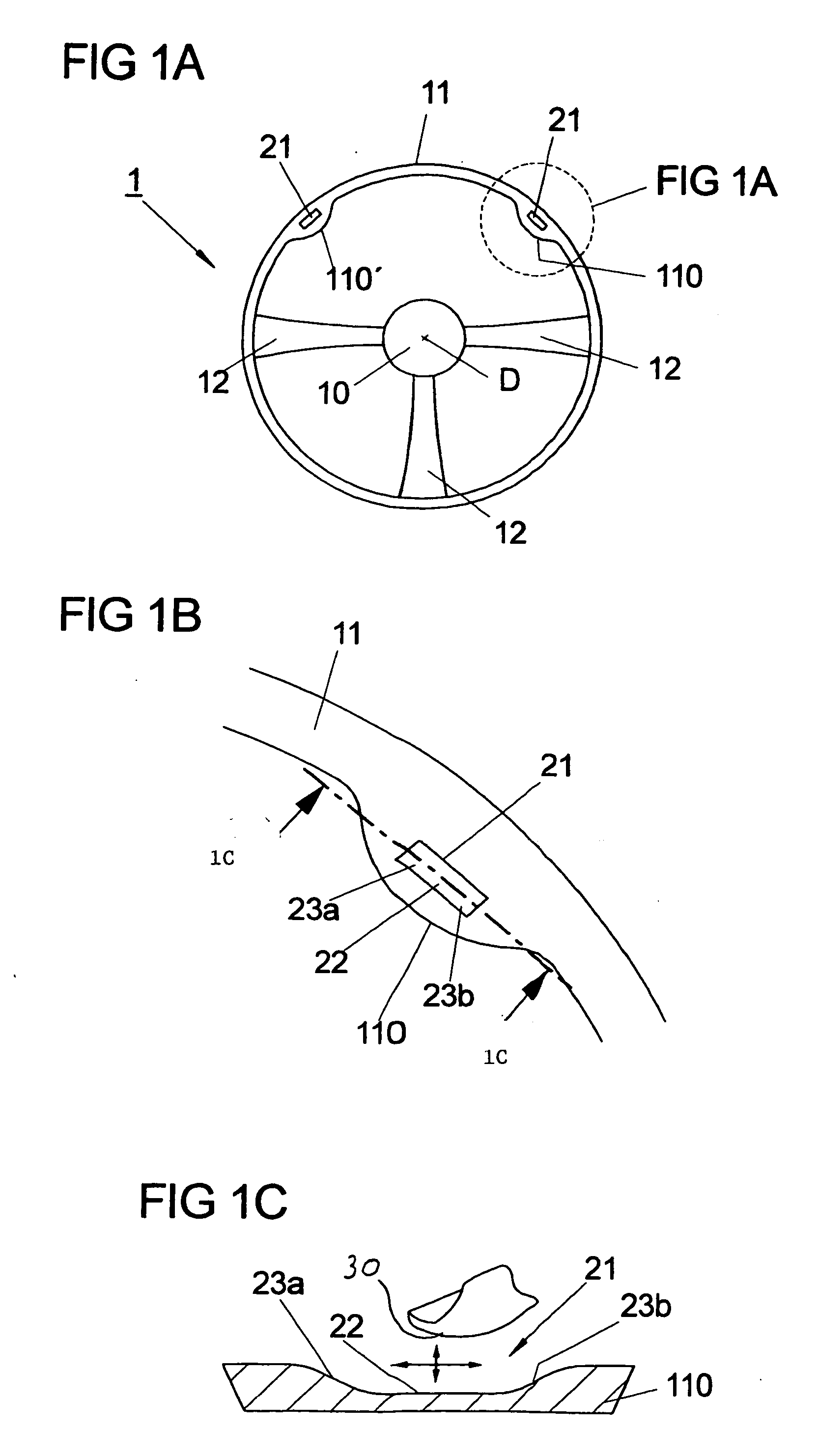

Steering wheel for a motor vehicle

InactiveUS20050189159A1Increasing impairmentSimpler and cost-effective manufactureControlling membersMechanical apparatusOptical reflectionSteering wheel

A steering wheel for a motor vehicle is provided having a hub element, a steering wheel rim, at least one steering wheel spoke for attaching the steering wheel rim to the hub element and at least one activation device which is arranged on the hub element, the steering wheel rim or the steering wheel spoke for controlling and / or regulating an assembly of a motor vehicle. The activation device is preferably embodied as an optical reflection sensor device with a functional face. Such a sensor device operates without mechanically moving parts and during the service life of the steering wheel it is independent of general scratching and soiling of its functional faces. In addition, the functionality of the measurement of distances and / or speeds of the objects located above the functional faces of the sensor device permits further functions to be integrated without requiring further separate devices in order to do so.

Owner:TAKATA PETRI AG

Method and apparatus for aligning a cassette

InactiveUS20030083776A1Leveling precisionBreakage can be reduced eliminatedDigital data processing detailsSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An alignment tool, method and system are provided for aligning a cassette handler to a robot blade in a workpiece handling system, in which the tool comprises a frame or fixture adapted to be supported by the cassette handler support surface, in which the frame has one or more distance sensors positioned to measure the distance of a workpiece or robot blade from the sensor or a predetermined reference point or surface. In a preferred embodiment, the frame emulates a workpiece cassette and the distance sensors provide a numerical output of the distance to the workpiece. As explained in greater detail below, these distance measurements facilitate accurately leveling and aligning the cassette handler support surface relative to a workpiece supported by the robot blade such that when the frame is replaced by an actual workpiece cassette, the workpiece cassette will also be level and aligned with respect to the robot blade and the workpiece held by the blade. As a consequence, accidental scratching and breakage of workpieces such as semiconductor wafers and display substrates may be reduced or eliminated.

Owner:APPLIED MATERIALS INC

Corrosion resistant precoated laminated steel

InactiveUS20090142538A1Reduce weightCorrosion of environmentVehicle componentsCoatingsSheet steelScratching

Two steel sheets joined face-to-face with a core layer form a laminated workpiece that may be shaped, for example, into automotive components. Depending on the nature of the core layer the laminated workpieces may be used for sound and vibration damping or as light weight structural panels. Before joining of the steel sheets, their facing surfaces may each be provided with a polymeric (organic or inorganic) corrosion resistant film that resists physical degradation such as tearing or scratching as the laminate is formed into a desired component shape. The pre-applied protective layer may also provide a bonding layer for the viscoelastic core or a structural core material. Conductive particles may be incorporated into the viscoelastic layer to assist in electrical resistance welding involving the laminated steel workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Glass substrate for information recording medium, process for producing the glass substrate, information recording medium, and process for producing the same

InactiveUS20050244656A1Improve heat resistanceImprove thermal shock resistanceBase layers for recording layersRecord information storageHeat resistanceScratching

A glass substrate for an information recording medium, which has high heat resistance, has such high thermal shock resistance that it does not break when exposed to a sharp change in temperature and has high strength against scratching, and which is formed of a glass comprising SiO2, Al2O3, ZrO2, CaO, BaO, Li2O and Na2O as essential components and comprises, by mold %, 50 to 70% of SiO2, 1 to 10% of Al2O3, over 0% but not more than 12% of ZrO2, 2 to 24% of CaO, over 0% but not more than 15% of BaO, 0 to 10% of MgO, 0 to 15% of SrO, provided that the content of CaO+BaO+MgO+SrO is over 10% but less than 25%, over 0% but not more than 6% of Li2O, over 0% but not more than 10% of Na2O, 0 to 5% of K2O, and 0 to 10% of TiO2.

Owner:HOYA CORP

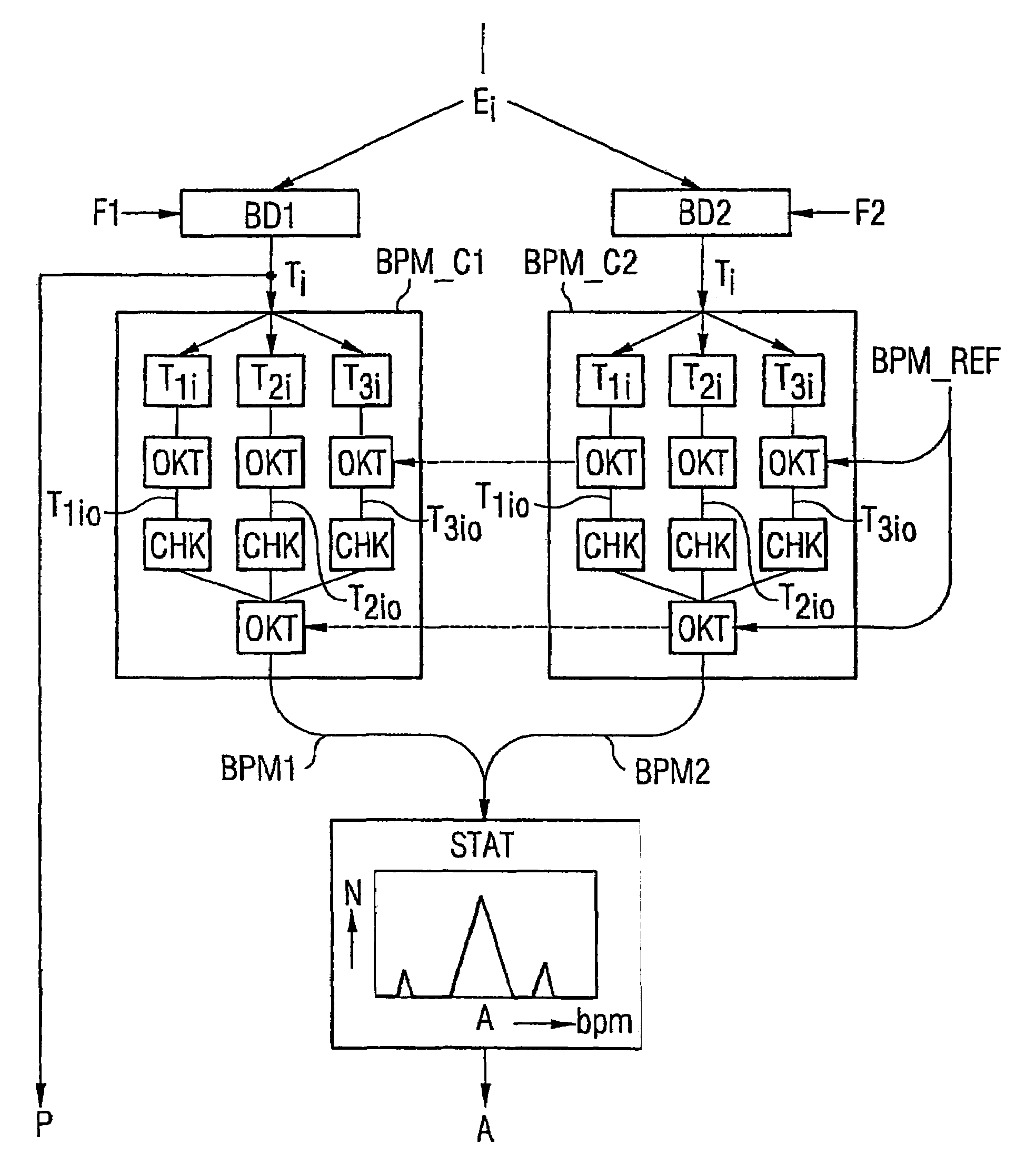

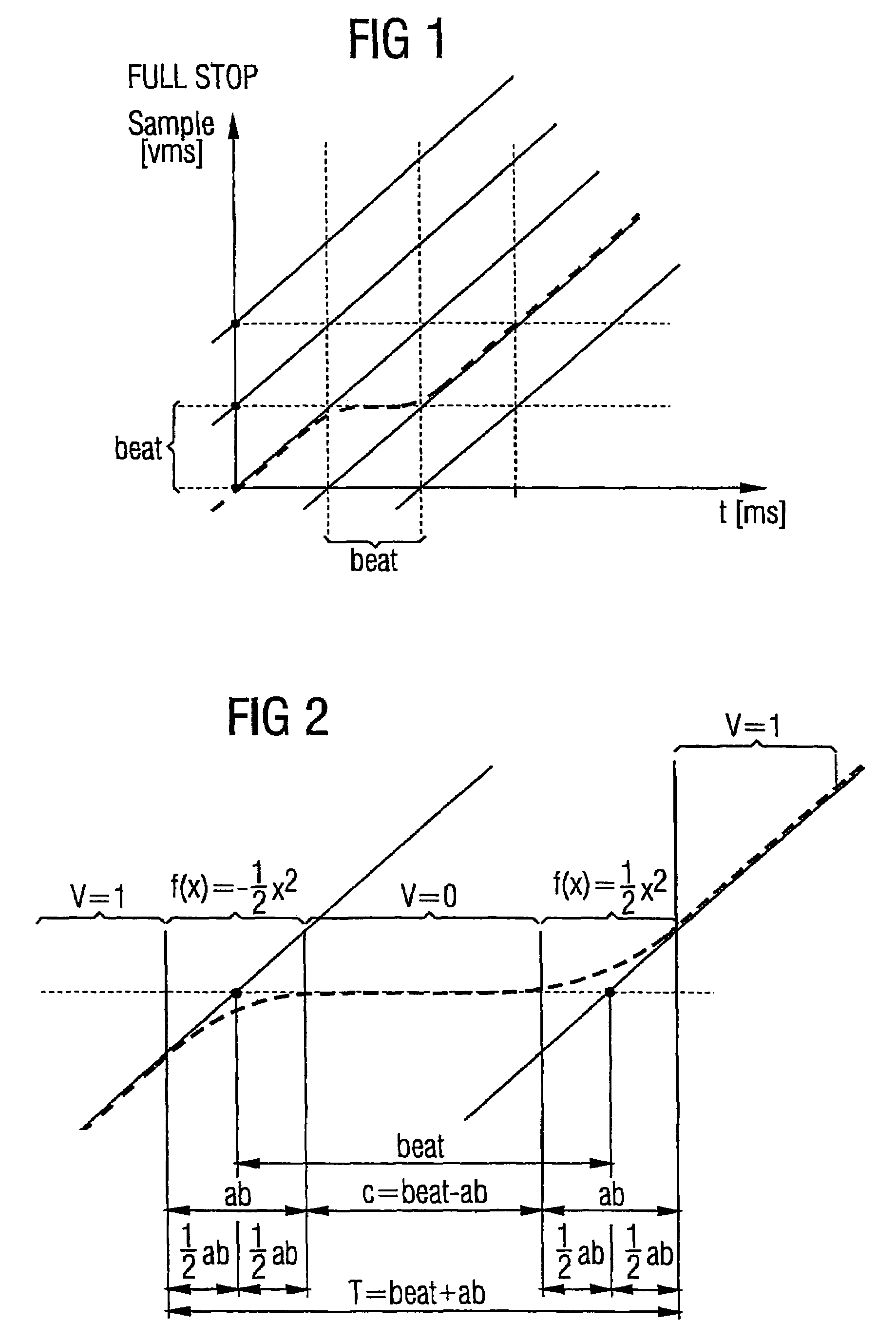

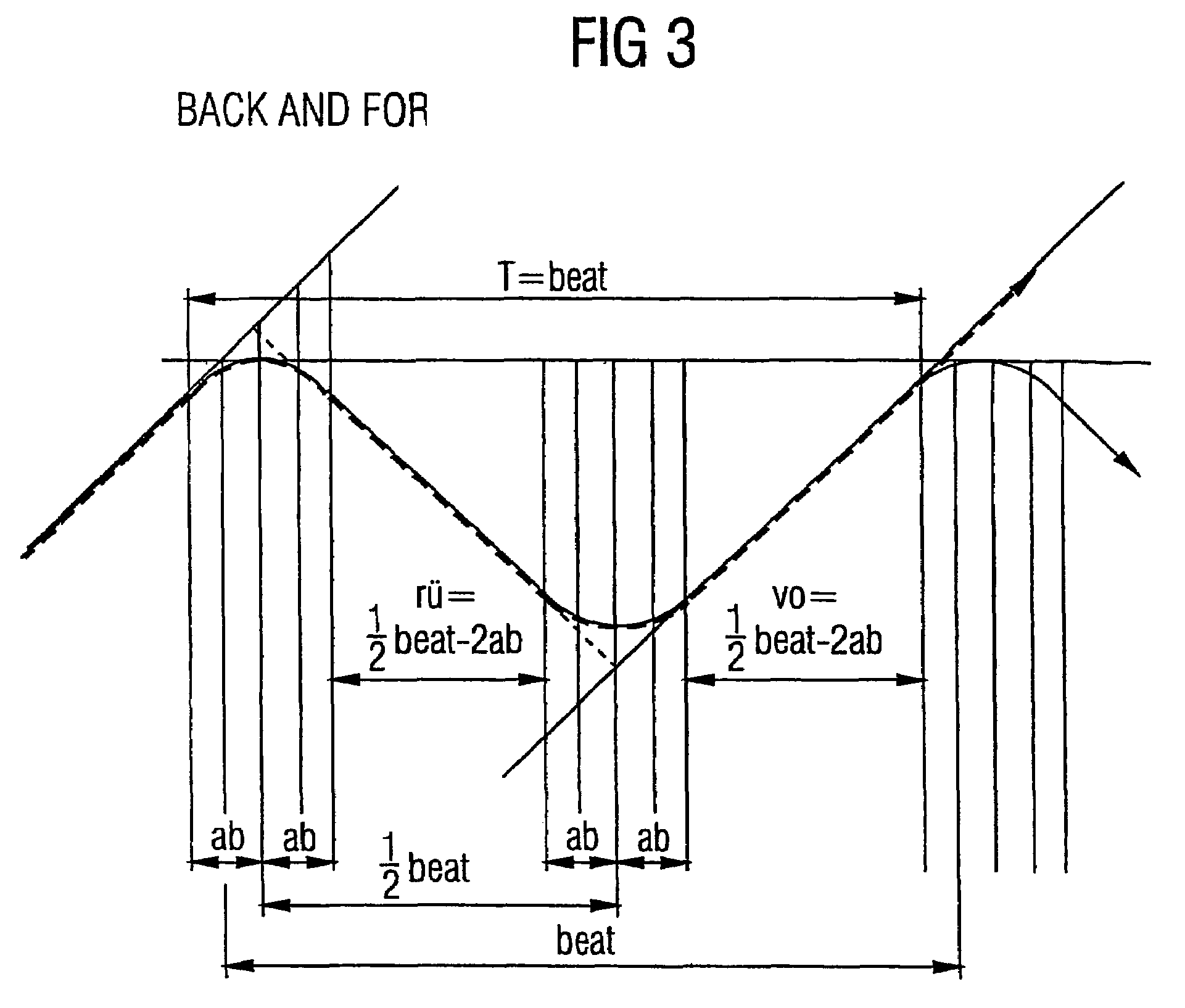

Automatic generation of musical scratching effects

InactiveUS7041892B2Production Process AutomationElectrophonic musical instrumentsReproduction speedGenerative music

The invention relates to a method for generating electrical sounds and to an interactive music player. According to the invention, an audio signal in digital format, which lasts for a predeterminable length of time, is used as the starting material. The reproduction position and / or the reproduction direction and / or the reproduction speed of said signal is / are modulated automatically with respect to the rhythm using control information in different predeterminable ways, based on information concerning the musical tempo.

Owner:NATIVE INSTR SOFTWARE SYNTHESIS

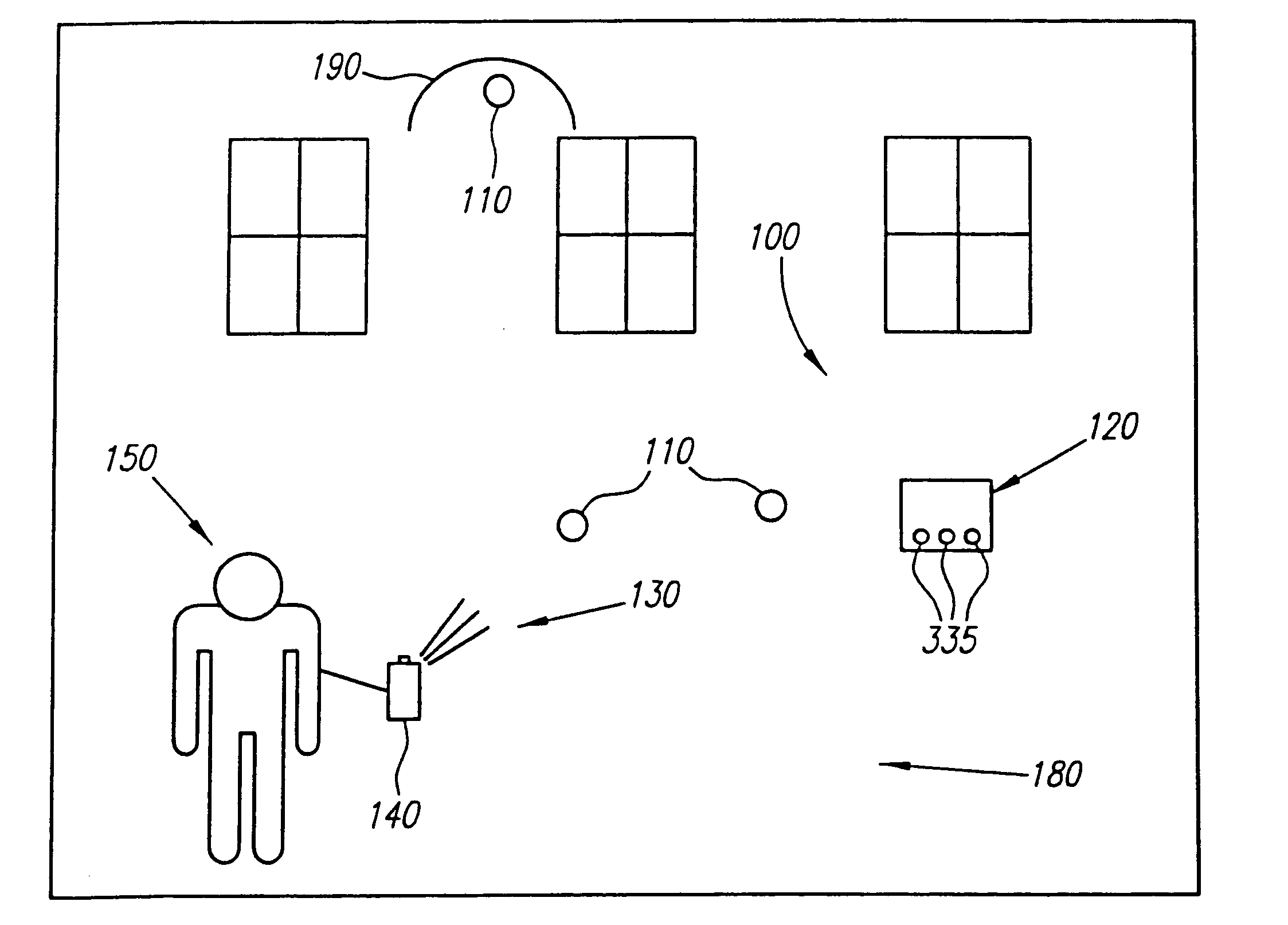

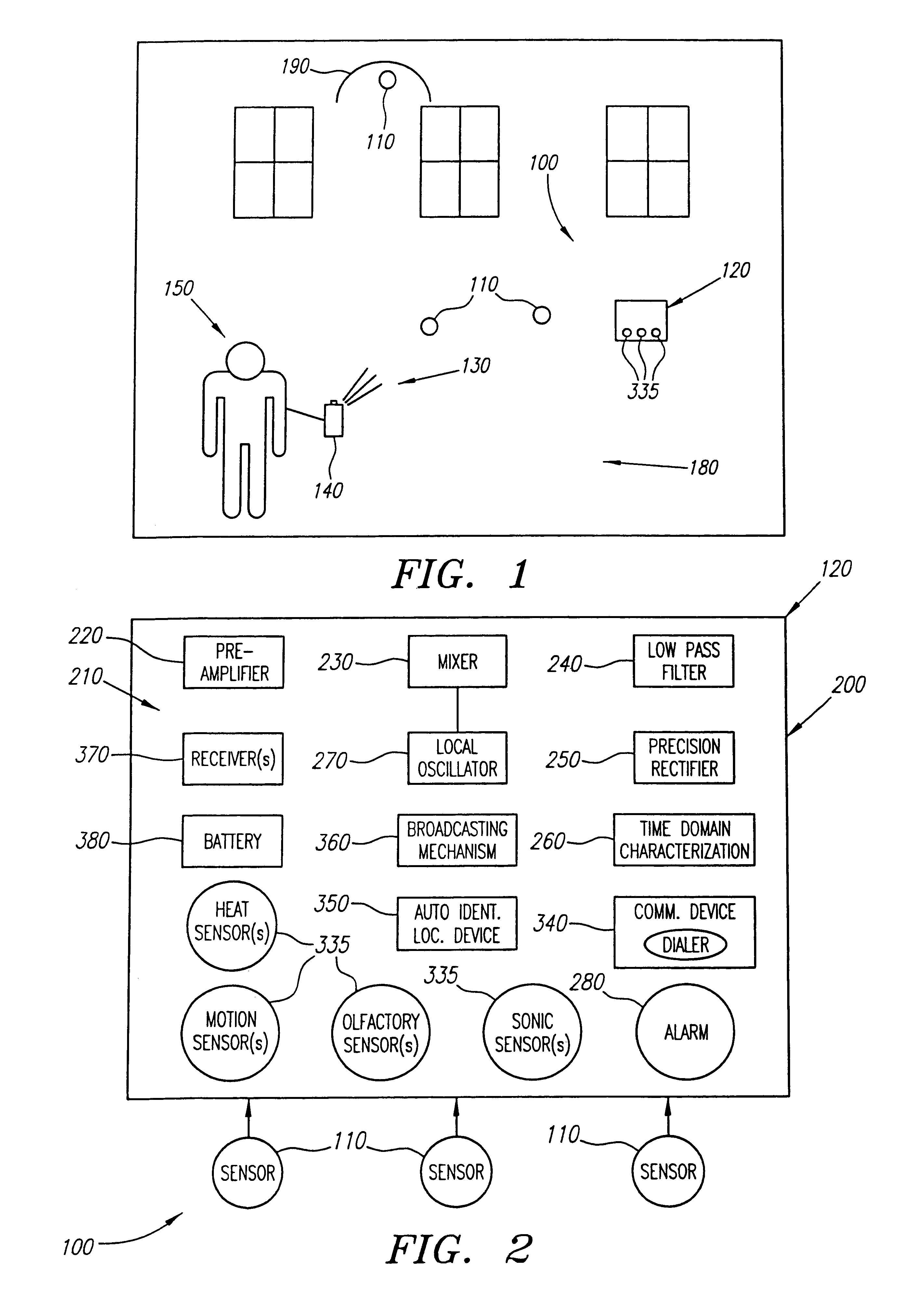

Graffiti detection system and method of using the same

InactiveUS6600417B2Signalling system detailsVisible signalling systemsEngineeringCommunication device

The present invention involves a system and method for detecting a graffiti-making act such as the spray of a spray paint can, the writing with a felt-marker pen on a surface, and the scratching with an abrasive instrument on a surface. The system includes one or more sensors adapted to sense the graffiti-making act and transmit a signal representative of the graffiti-making act, and a base unit including electronics adapted to process the signal and determined whether the signal represents a graffiti-making act, and a communication device coupled to the electronics and adapted to communicate to one or more entities that a graffiti-making act has been detected. The method includes sonically detecting the graffiti-making act, and initiating an alarm indicating that the graffiti-making act took place.

Owner:TRAPTEC CORP

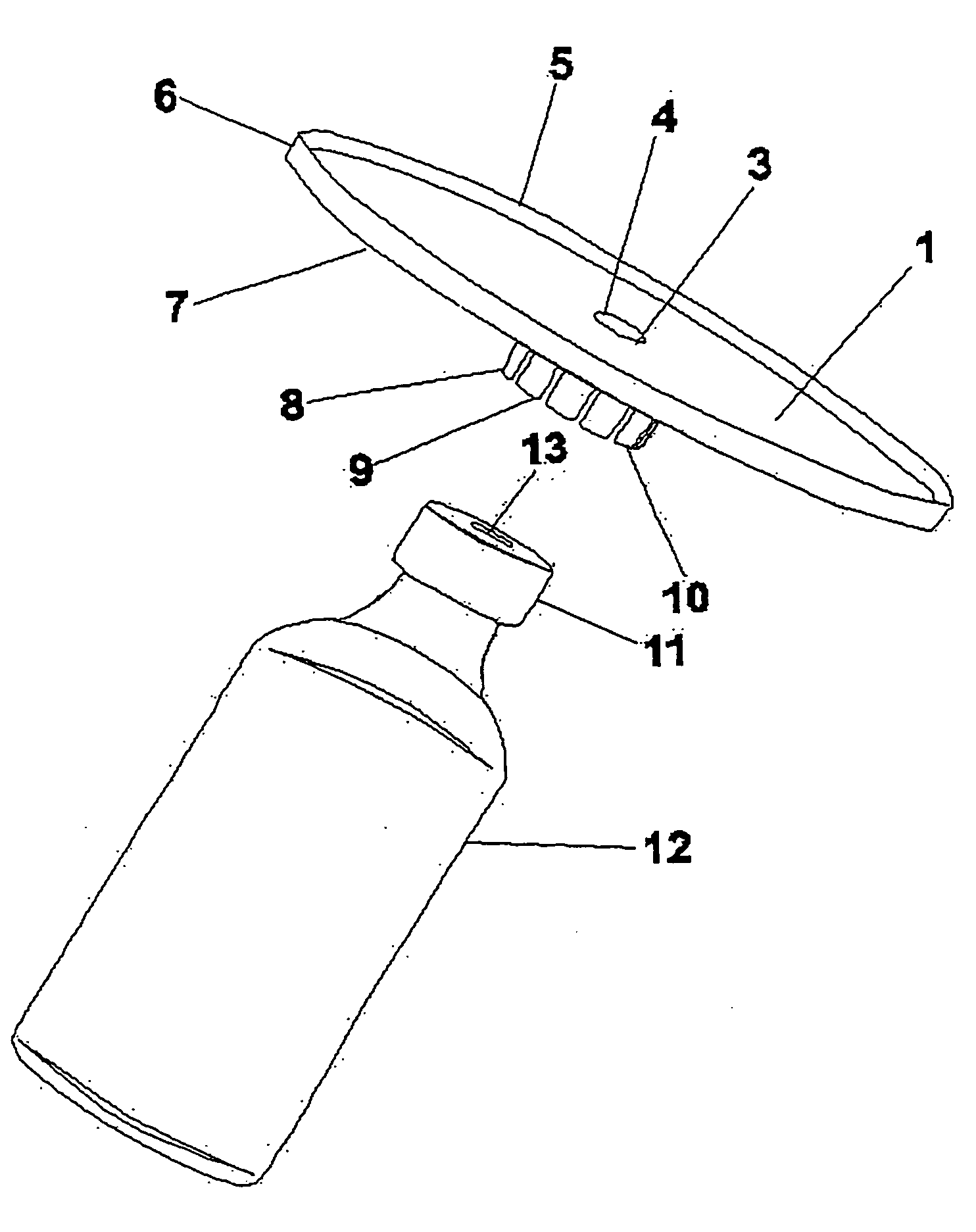

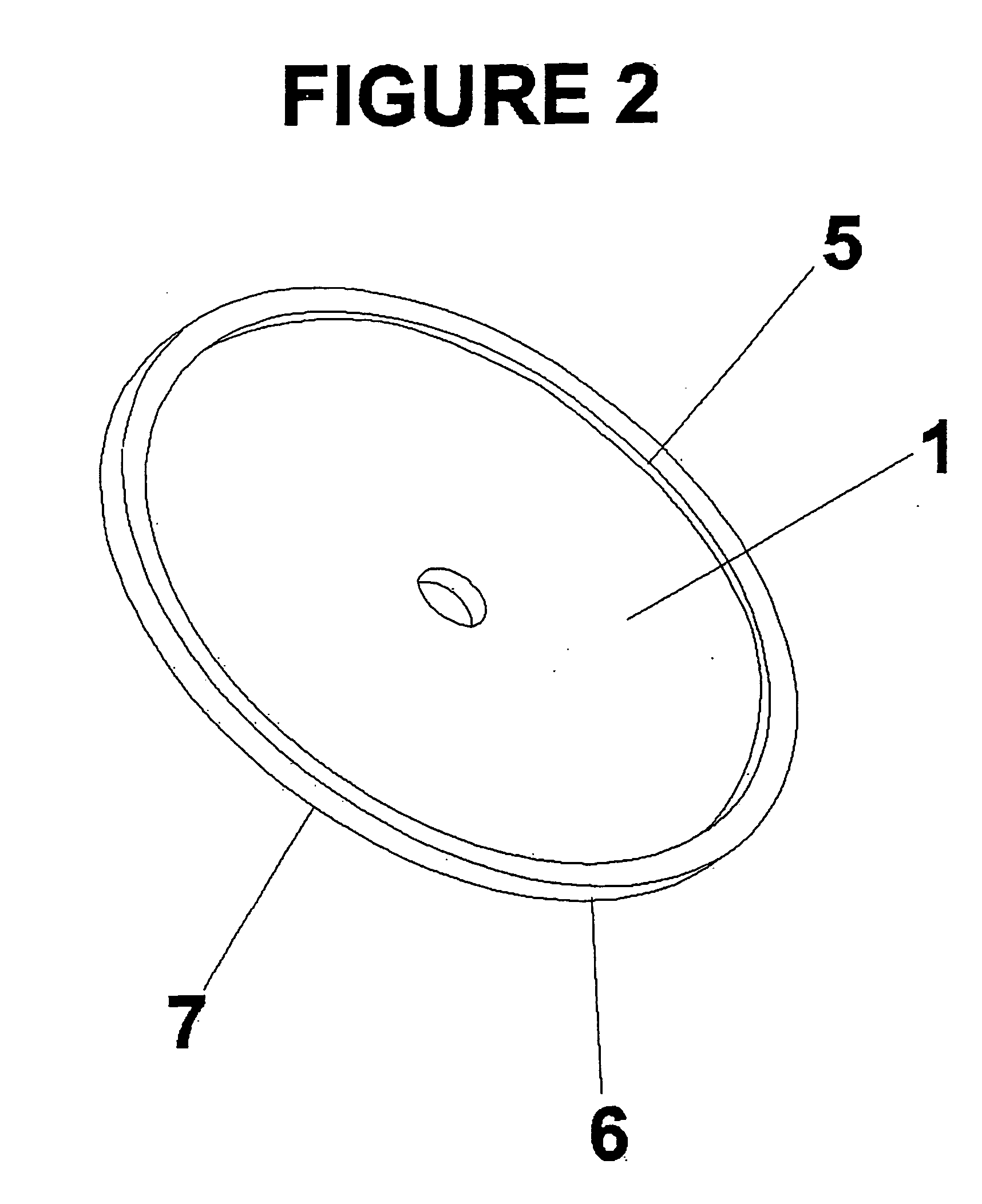

Vial attachment to prevent needle sticks

InactiveUS20060108319A1Easy to produceNot time-consume to putSmall article dispensingBottlesEngineeringBiomedical engineering

A clear protective disc shield that attaches to vial that protect medical personnel hand from being injured and contamination of the needle. The protective disc shield has a circular orifice that effectuates attachment of the disc shield to a vial for the dispensing of medicine or other material. The disc shield is designed so that any contact between the needle and the upper surface of the shield will guide the needle to the circular orifice and further prevents the needle from slipping of the disc shield. The disc shield further has a smooth underside and edges to prevent scratching and other injuries to the user.

Owner:MEITTUNEN ERIC JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com