Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

A technology for 3D printing and molding materials, applied in the field of high-bonding 3D printing molding materials and their preparation, can solve the problems of printing molding, high printing conditions, brittle and fragile parts, etc., and improve the bonding fastness and strength , high bond strength and fastness, increase the effect of bond strength and fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A tough and highly cohesive 3D printing molding material, its formula is as follows:

[0033] 1. Powder material (by weight)

[0034] Polyamide resin (melting point about 230-260°C, BASF, Germany): 40 parts

[0035] Titanium dioxide: 15 parts

[0036] Lithopone: 10 parts

[0037] Talc powder: 23 parts

[0039] Polymethyl methacrylate 701: 0.3 parts

[0040] Polypropylene wax: 0.2 parts

[0041] Benzoin: 0.5 parts

[0042] 2. Adhesive material (by weight)

[0043] Epoxy resin SK-0430 (Jiangsu Changzhou Shangke Special Polymer Material Co., Ltd.): 60 parts

[0044] Wollastonite: 5 parts

[0045] Castor Oil: 10 parts

[0046] Polymethyl methacrylate 701: 0.1 parts

[0047] Polyethylene wax: 4 parts

[0048] Benzoin: 0.1 parts

[0049] Vapor-phase SiO 2 : 0.5 parts

[0050] Preparation:

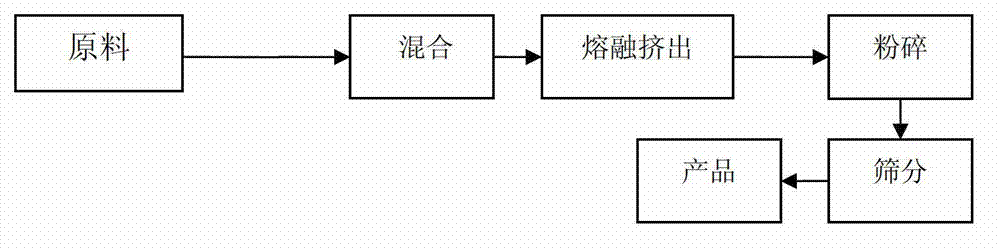

[0051] A. The powder material is prepared by the melting method production process: put the raw material of the formula into the batching tan...

Embodiment 2

[0059] A tough and highly cohesive 3D printing molding material, its formula is as follows:

[0060] 1. Powder material (by weight)

[0061] Polyamide resin (melting point: 285-300°C, American Dow Chemical): 60 parts

[0062] Titanium dioxide: 20 parts

[0063] Lithopone: 20 parts

[0064] Talc powder: 5 parts

[0065] Polyethylene wax: 4 parts

[0066] Hydrogenated pinoresinol: 0.1 parts

[0067] PTFE modified polypropylene wax: 2 parts

[0068] Benzoin: 0.1 parts

[0069] 2. Adhesive material (by weight)

[0070] Epoxy resin SK-0430 (Changzhou Shangke Special Polymer Material Co., Ltd., Jiangsu): 70 parts

[0071] Kaolin: 40 parts

[0072] Triphenyl phosphite: 3 parts

[0073] Polymethylmethacrylate 701: 1 part

[0074] Polyethylene wax: 1.5 parts

[0075] Benzoin: 0.3 parts

[0076] Precipitated SiO 2 : 0.2 parts

[0077] Preparation:

[0078] A. The powder material is prepared by the melting method production process: put the raw material of the formula int...

Embodiment 3

[0087] A tough and highly cohesive 3D printing molding material, its formula is as follows:

[0088] 1. Powder material (by weight)

[0089] Polyamide resin (melting point: 310-320°C, BASF, Germany): 85 parts

[0090] Titanium dioxide: 2 parts

[0091] Lithopone: 3 parts

[0092] Talc powder: 30 parts

[0093] Polyamide wax: 1 part

[0094] Polyethylene wax: 0.3 parts

[0095] Hydrogenated pinoresinol: 1.5 parts

[0096] Benzoin: 0.2 parts

[0097] 2. Adhesive material (by weight)

[0098] Epoxy resin DER667-20 (U.S. Dow Chemical): 95 parts

[0099] Kaolin: 18 parts

[0100] Castor oil: 1 part

[0101] Polymethyl methacrylate 701: 1.5 parts

[0102] Polyethylene wax: 1 part

[0103] Benzoin: 0.5 parts

[0104] Precipitated SiO 2 : 0.1 part

[0105] Preparation:

[0106] A. The powder material is prepared by the melting method production process: put the raw material of the formula into the batching tank, stir and disperse at a speed of 1500rpm for 30min; pass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com