Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

357results about How to "Good toughness strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

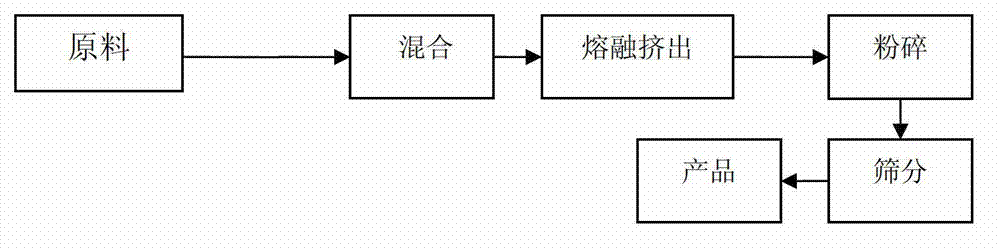

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

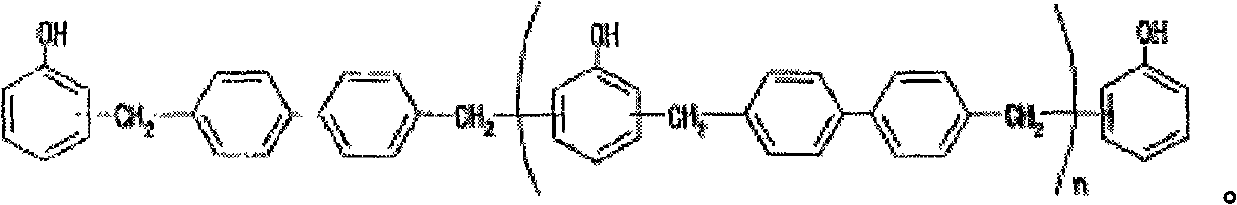

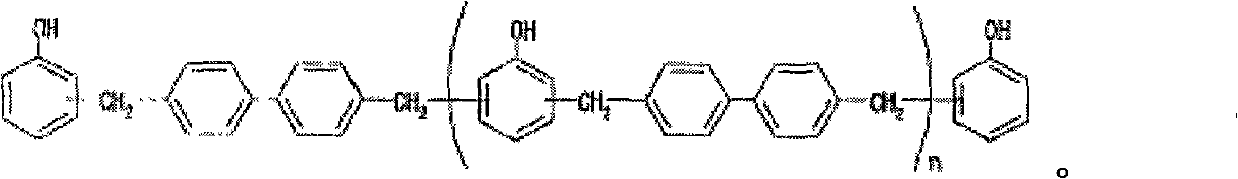

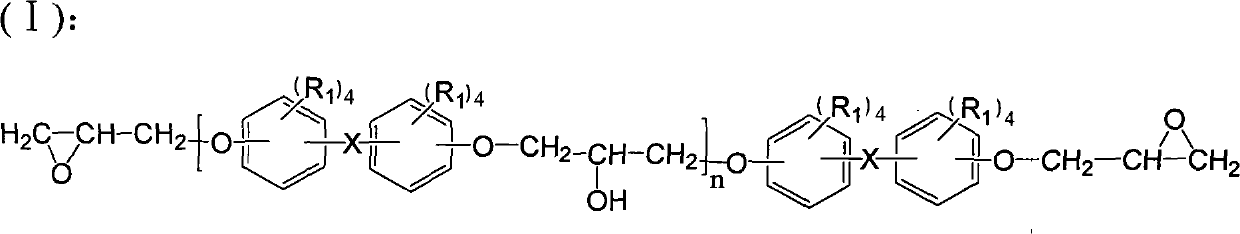

High thermal conductivity resin composition and high thermal conductivity coated metal foil board manufactured by using same

ActiveCN101974208AImprove thermal conductivityImprove heat resistanceMetal layered productsPolyesterEpoxy

The invention relates to a high thermal conductivity resin composition and a high thermal conductivity coated metal foil board manufactured by using the same. The high thermal conductivity resin composition comprises the following components of: epoxy resin, at least one phenoxy resin or carboxy terminal butadiene acrylonitrile, biphenyl phenolic resin and a high thermal conductivity packing material, wherein the biphenyl phenolic resin has the structure shown in the specification. The high thermal conductivity coated metal foil board manufactured by using the high thermal conductivity resin composition comprises a high thermal conductivity adhesive film and metal foils coated on both sides of the high thermal conductivity adhesive film, wherein the high thermal conductivity adhesive film comprises a carrier film and the high thermal conductivity resin composition coated on the carrier film, and the carrier film is a polyester film or a polyimide film. The high thermal conductivity coated metal foil board comprises a resin composite metal foil and a metal foil or another resin composite metal foil coated on the previous resin composite metal foil, and the resin composite metal foil comprises a metal foil and the high thermal conductivity resin composition coated on the metal foil.

Owner:GUANGDONG SHENGYI SCI TECH

Electronic element

ActiveCN101458975AIncreased durabilityImprove performanceMaterial nanotechnologyNanomagnetismCarbon nanotubeOptoelectronics

Owner:TSINGHUA UNIV +1

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

Carbon fiber reinforced toughened epoxy resin composite material and preparation method thereof

InactiveCN104277418AImprove toughnessReduce hot melt dissolution processSynthetic resin layered productsLaminationThermoplasticEpoxy

The invention belongs to the technical field of high polymer composite materials and relates to a carbon fiber reinforced toughened epoxy resin composite material and its preparation method. The high polymer material is prepared from the following components, by weight, 100 parts of epoxy resin, 8-120 parts of a curing agent, 0.5-1.5 parts of a promoter, 160-500 parts of carbon fiber and 5-55 parts of thermoplastic. According to the invention, engineering thermoplastic is selected as a flexibilizer, and an appropriate solvent is selected; the engineering thermoplastic is made into a solution, and the solution is uniformly mixed with epoxy resin, the curing agent and the promoter; the solvent is removed; the resin system with the solvent removed is made into a resin film; by a routine resin film melt impregnation method, the resin film and carbon fiber undergo hot melting to be combined so as to prepare a carbon fiber reinforced epoxy resin prepreg; and furthermore, the highly-toughened carbon fiber reinforced toughened epoxy resin composite material is prepared.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

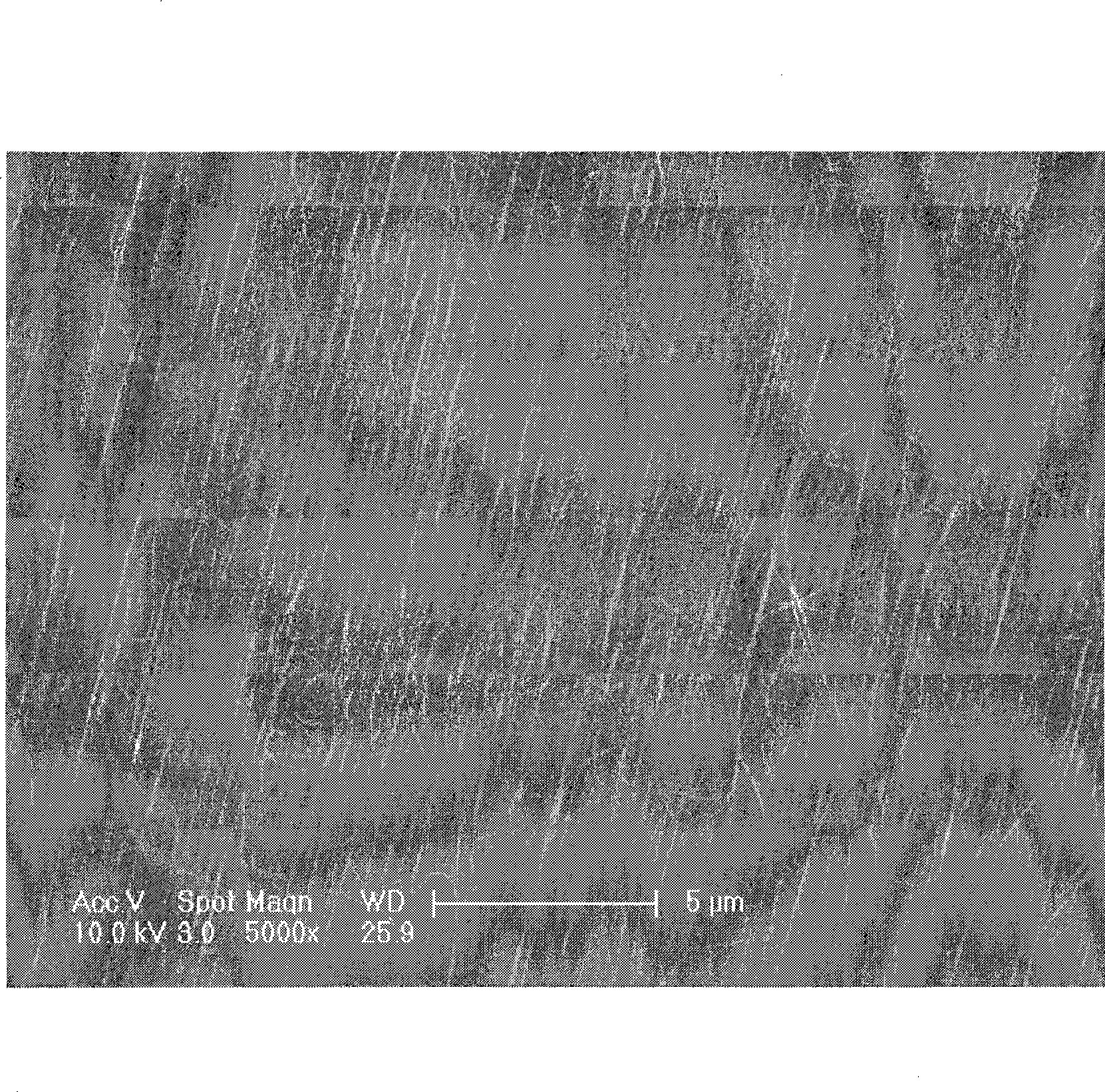

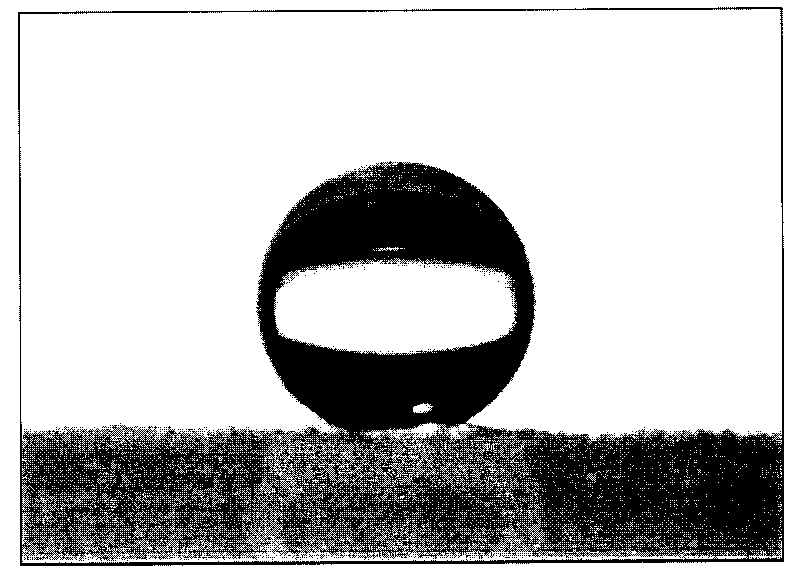

Method for preparing super-hydrophobic nano modified cellulose material

InactiveCN101694057AStrong toughnessHigh mechanical strengthDry-cleaning apparatus for textilesVegetal fibresCellulose fiberNatural fiber

The invention relates to a method for preparing a super-hydrophobic nano modified cellulose material, which comprises the following steps: adopting tetrabutyl titanate as a precursor, adopting a natural cellulose fiber as a substrate substance and depositing a nano-layer titanium dioxide film on the surface of the natural cellulose fiber by a sol-gel method; and then self-assembling a silane single layer containing long chain alkyl to obtain the super-hydrophobic nano modified cellulose material. The nano modified cellulose material has obvious super-hydrophobicity, durable chemical stability and self-cleaning capacity and wide application prospect in the production of the fiber materials for preventing water, damp, dirt, dust, and the like in a textile industry.

Owner:ZHEJIANG UNIV

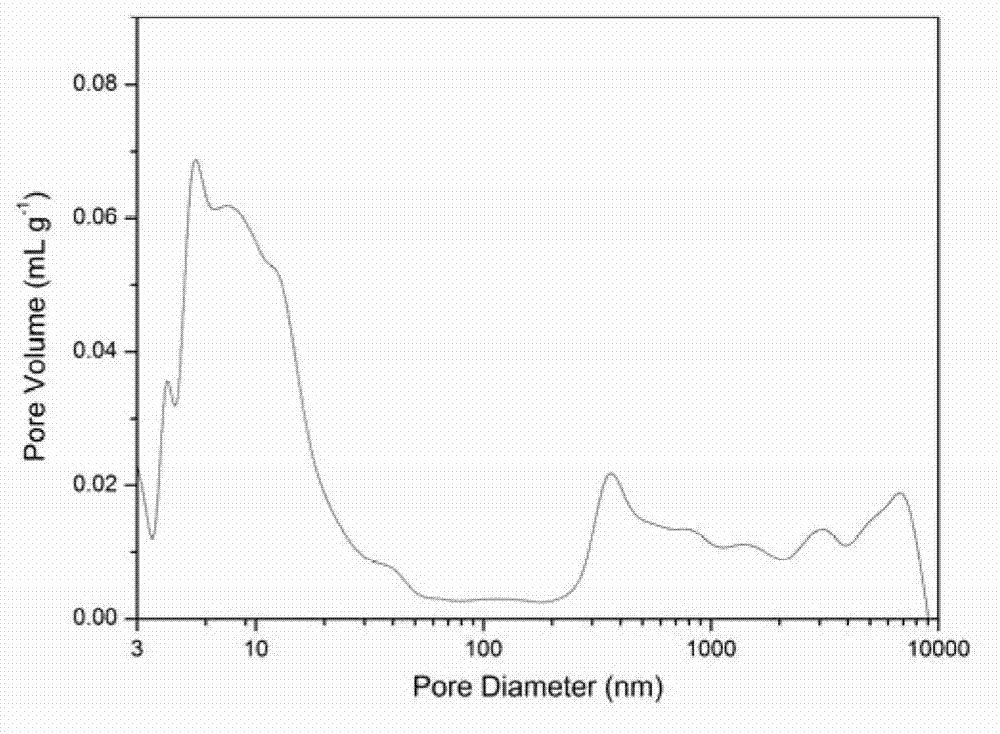

Thermal preparation method of solution of self-supported porous graphene-based membrane

ActiveCN104192836AFast oxidation-reduction reactionIncrease specific capacitance valueCvd grapheneElectrochemical energy storage

The invention relates to a thermal preparation method of a solution of a self-supported porous graphene-based membrane, relates to a preparation method of a self-supported porous graphene-based membrane, and aims to solve the technical problems that the size and the thickness of a conventional self-supported porous graphene-based membrane are limited and the electrochemical performance of the conventional self-supported porous graphene-based membrane is poor caused by severe interlay lamination of graphene sheets in the chemical reduction process. The thermal preparation method comprises the following steps: dispersing graphene oxide into water, adding or not adding a doped carbon material, concentrating, and spreading into a membrane, thereby obtaining a graphene oxide membrane; preparing a thermal treatment solution by using acid or alkali solute, putting the graphene oxide membrane into a reaction kettle with a polytetrafluoroethylene lining, adding the thermal treatment solution according to the standard that the membrane is submerged, sealing the reaction kettle, and subsequently performing thermal treatment, thereby obtaining the self-supported porous graphene-based membrane. The self-supported porous graphene-based membrane is prepared by orderly arranging graphene sheets in parallel, and due to the gaps among the graphene sheet layers, the self-supported porous graphene-based membrane can be used in electrochemical energy storage devices such as supercapacitors.

Owner:HARBIN INST OF TECH

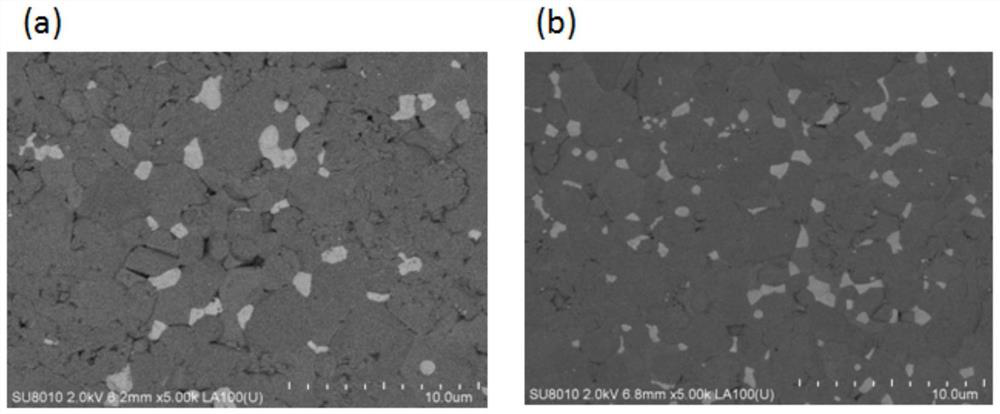

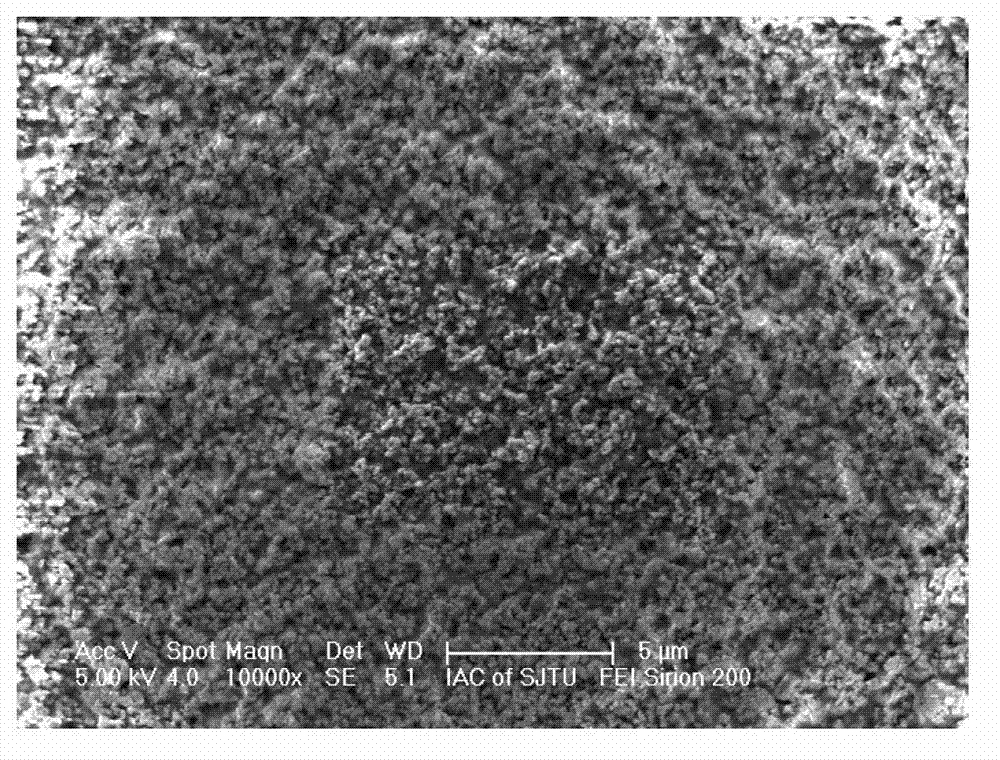

Graphene/carbon nano tube/graphite film composite material and preparation method thereof

InactiveCN104029461AImprove thermal conductivityGood toughness strengthLamination ancillary operationsLaminationHeat conductingCarbon nanotube

The invention discloses a graphene / carbon nano tube / graphite film composite material and a preparation method thereof. The composite material is formed by performing composite molding on a graphene layer, a carbon nano tube layer and a graphite film through a rewinding machine and has high heat-conducting property; the novel composite material has extremely high heat-conducting coefficient in the three-dimensional direction, and heat centralized to one point can be rapidly conducted to a composite heat-conducting plate, so that the temperature of a heat source in an electronic device is reduced, and the composite material has high flexibility, machinability, electro-magnetic interference (EMI) shielding property and absorption characteristics. Moreover, the preparation process is simple, the cost is low and the composite material is suitable for industrial production.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

Sliver-oxide ternary alloy electrical contact material and production method thereof

InactiveCN102747248AImprove electrical contact performanceImprove wear resistanceSolid state diffusion coatingElectric switchesWire rodLow voltage

The invention discloses a sliver-oxide ternary alloy electrical contact material and a production method thereof. The sliver-oxide ternary alloy electrical contact material comprises, by weight percent, 6%-24% of total ternary alloy oxides, 0.72%-5% of total added element oxides, and the balance of silver. The production method includes smelting the raw materials to obtain ingots by stepwise smelting process or atomizing to produce alloy powder; performing rolling and temperature differential oxidation, or high energy ball milling and temperature differential oxidation; and performing isostatic pressing to obtain primary ingots, subjecting the primary ingots to sintering, hot re-pressing and hot extrusion to obtain wires or strips, and thereby obtaining highly dispersible organizational structure with even and small crystal grains. The obtained material is high in conductivity, low in temperature rise, high in welding resistance, high in arc suppressing and high in electric corrosion resistance, electrical life is prolonged greatly, advantages of comprehensive property are highlighted, and the demands of high-end low-voltage electric appliances are fully met.

Owner:浙江乐银合金有限公司 +1

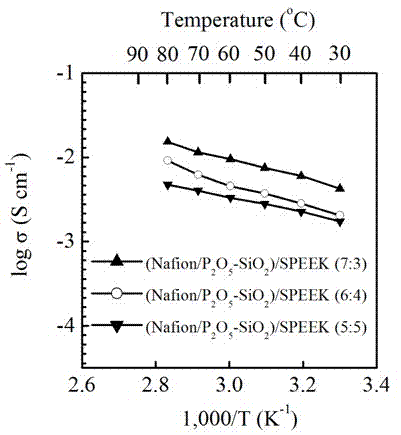

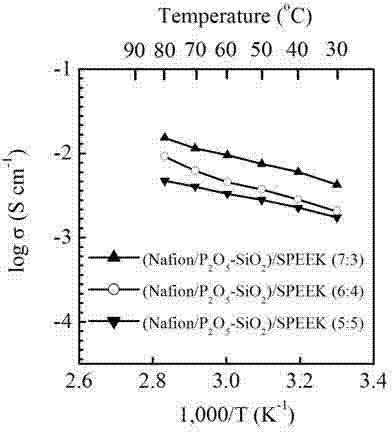

Preparation method for flexible inorganic/organic composite proton exchange membrane

InactiveCN102315463AHigh proton conductivityImprove heat resistanceCell component detailsFuel cell detailsVanadium redox batteryPolymer dissolution

The invention discloses a preparation method for a flexible inorganic / organic composite proton exchange membrane. The method comprises the following steps: 1, dissolving a proton conducting polymer in an organic solvent or water so as to obtain a proton conducting polymer solution; 2, mixing an inorganic proton conducting material or an inorganic proton conducting material containing organic components with the proton conducting polymer solution for mechanical ball milling so as to obtain a mixture in which the inorganic proton conducting material or the inorganic proton conducting material containing organic components disperses in the proton conducting polymer solution; 3, pouring the mixture on a substrate, and allowing the solvent to volatilize and the mixture to solidify so as to prepare the flexible inorganic / organic composite proton exchange membrane. The flexible inorganic / organic composite proton exchange membrane prepared in the invention has the characteristics of proton conducting capacity, flexibility, stable dimension, heat resistance and mechanical strength at a certain degree, and can be used in the field of fuel cells and related fields in need of proton exchange membranes like all-vanadium redox flow batteries, industrial electrolysis of chlor-alkali, super capacitors and sensors.

Owner:SHANGHAI JIAO TONG UNIV

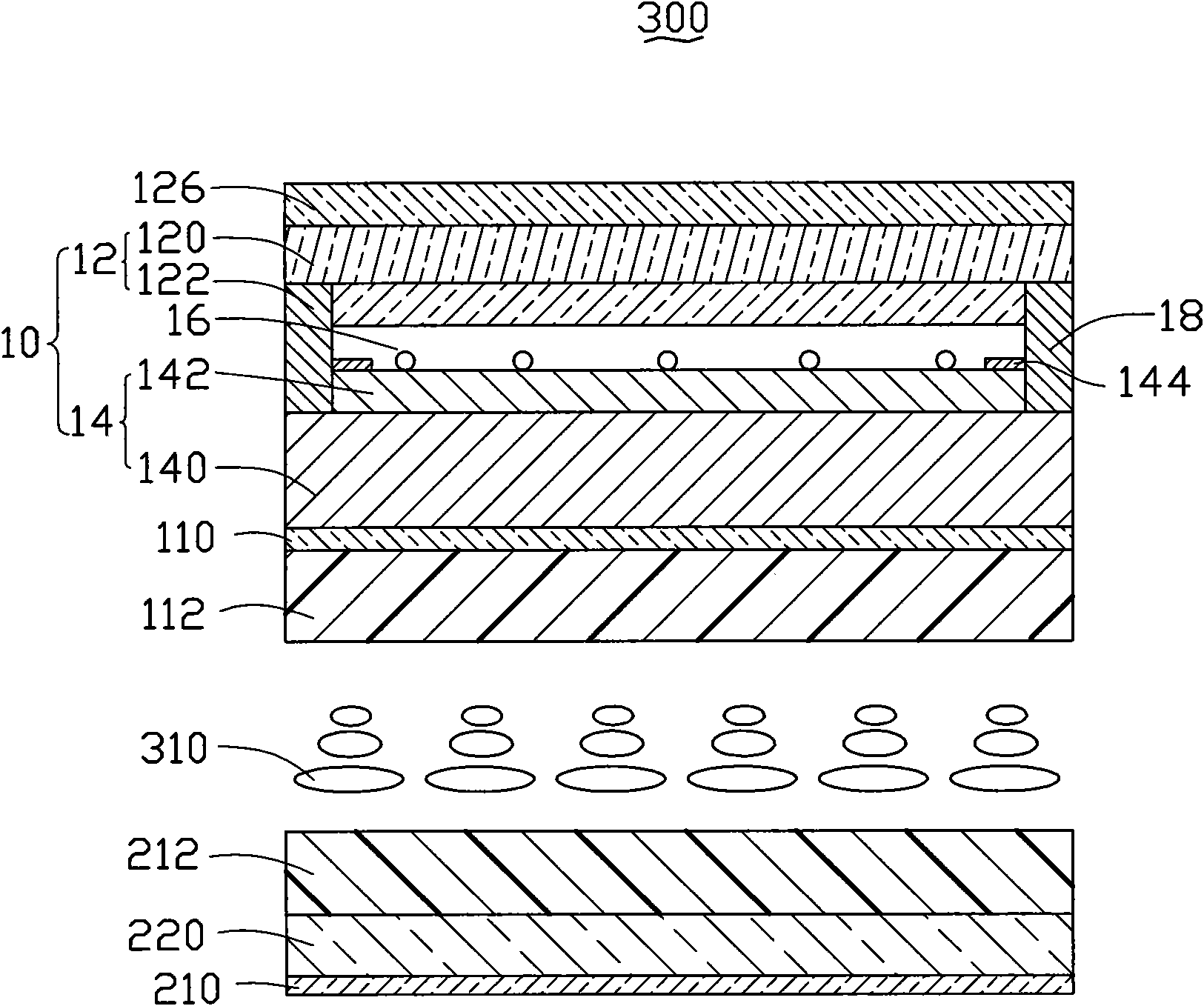

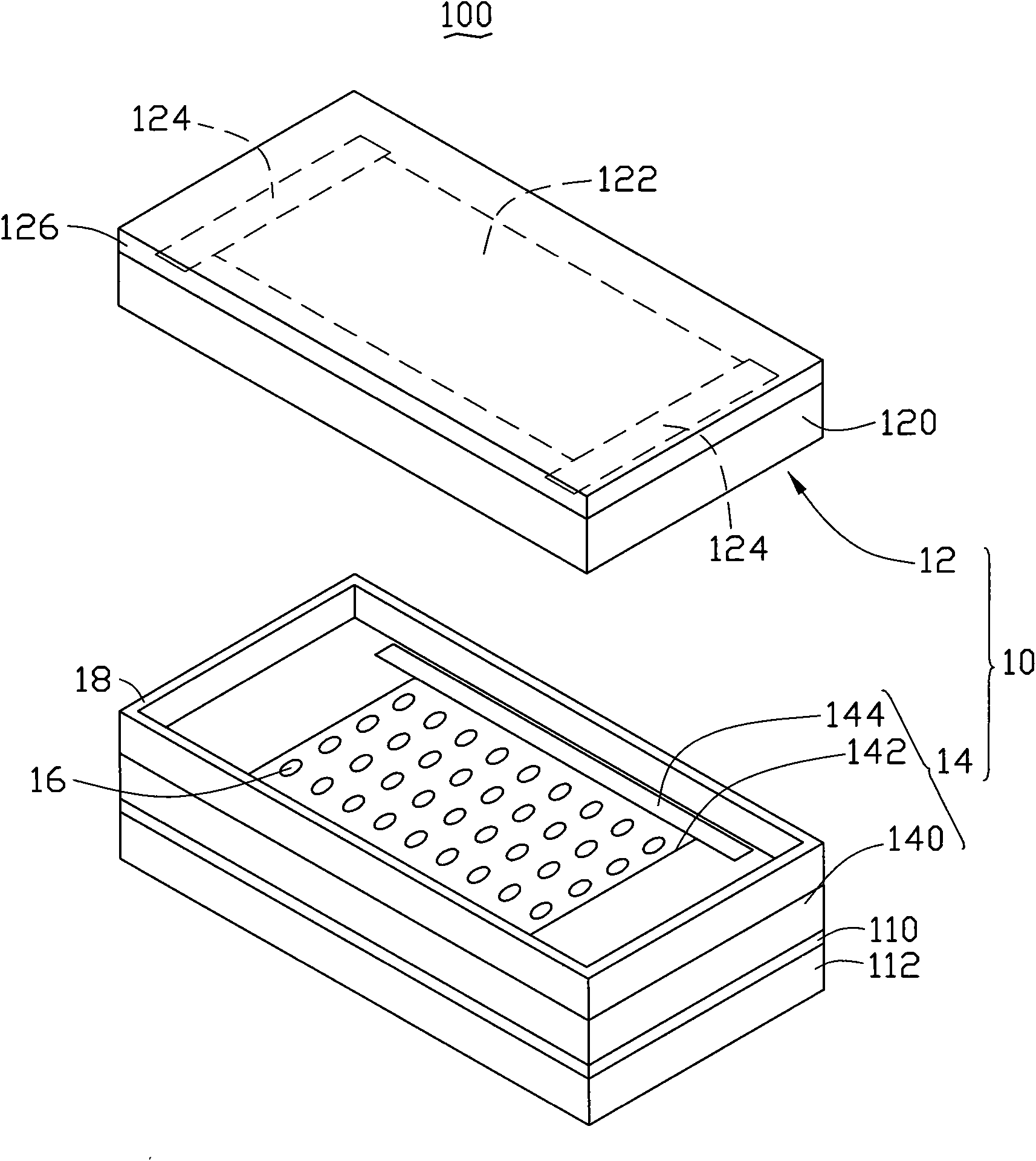

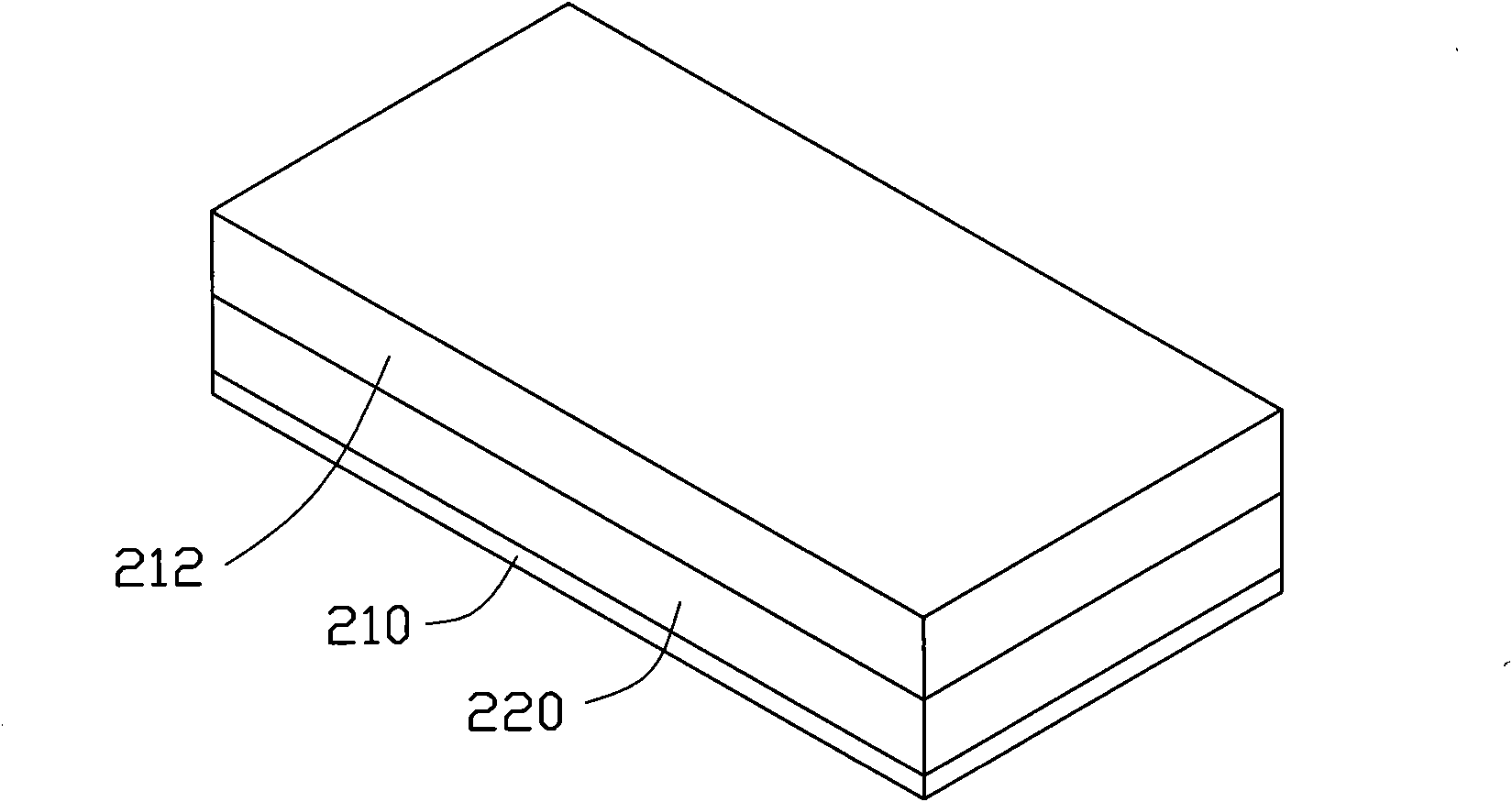

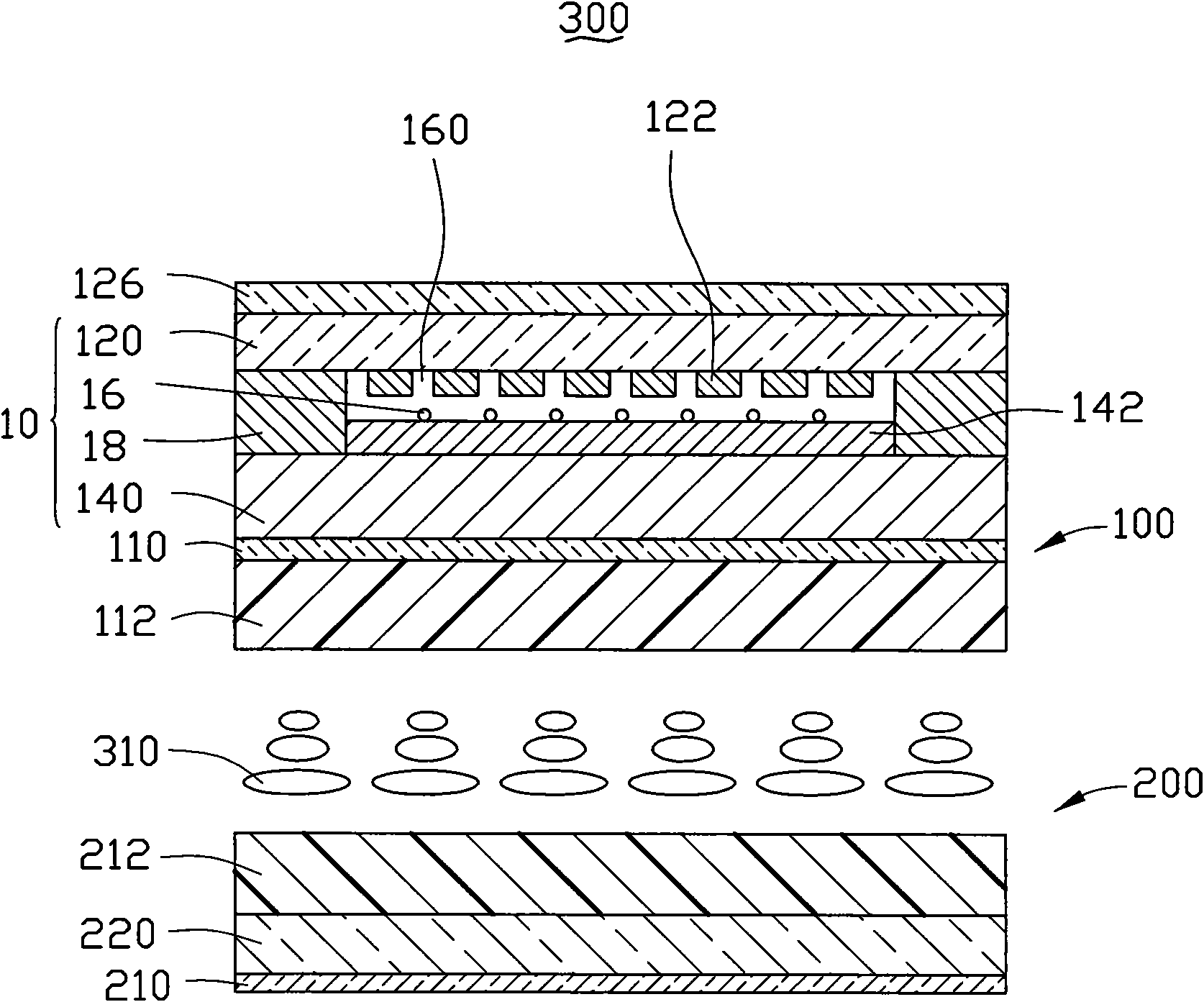

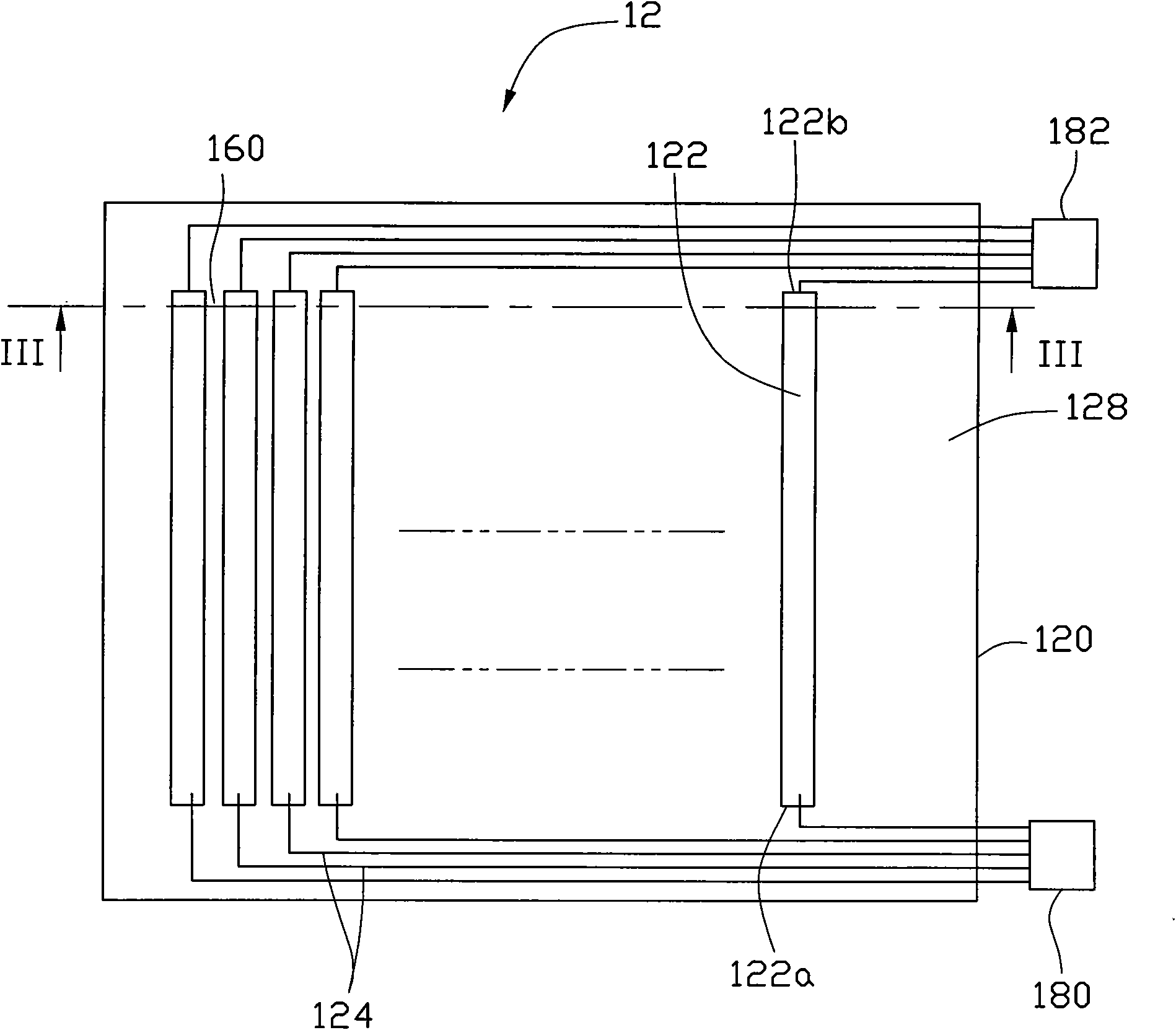

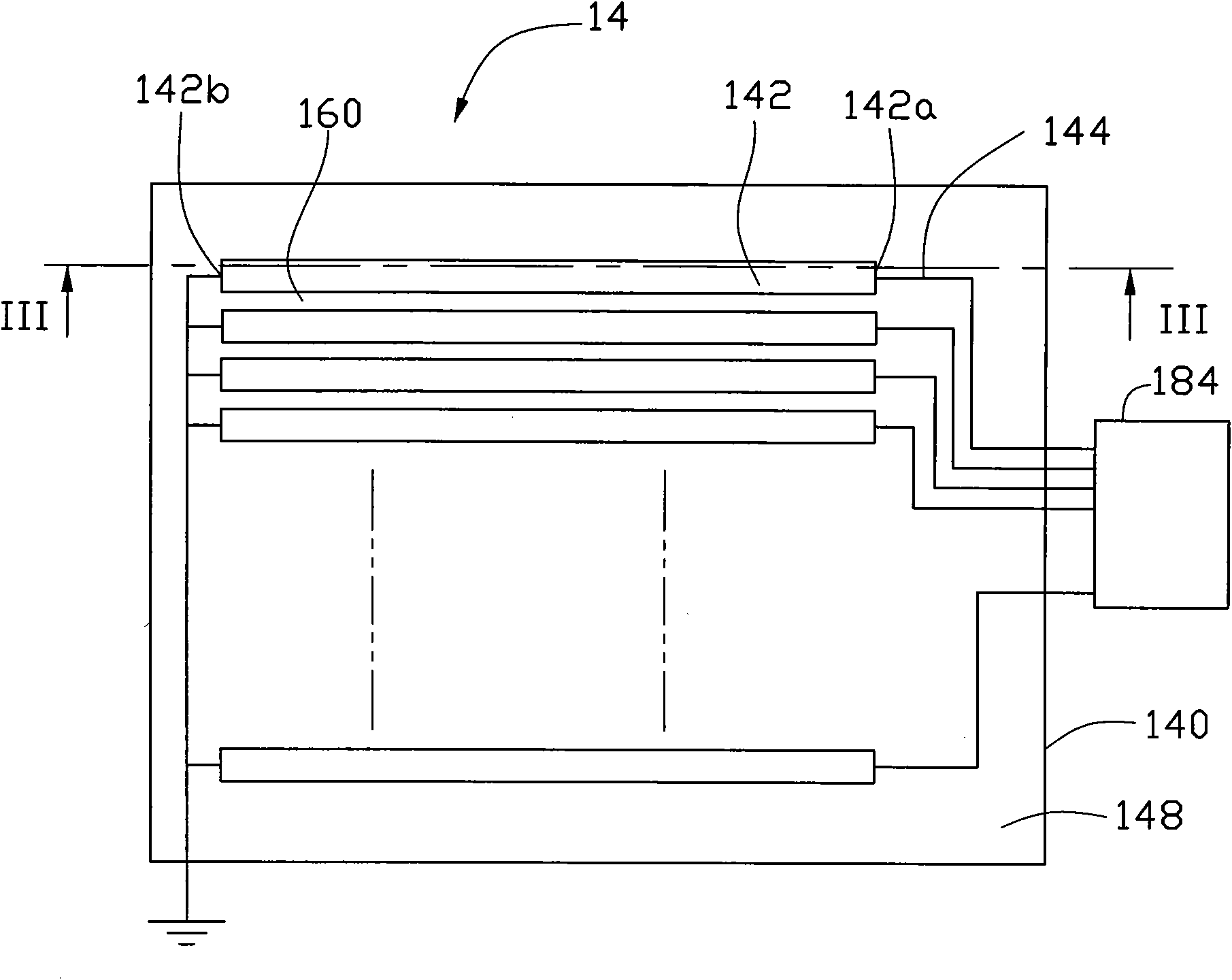

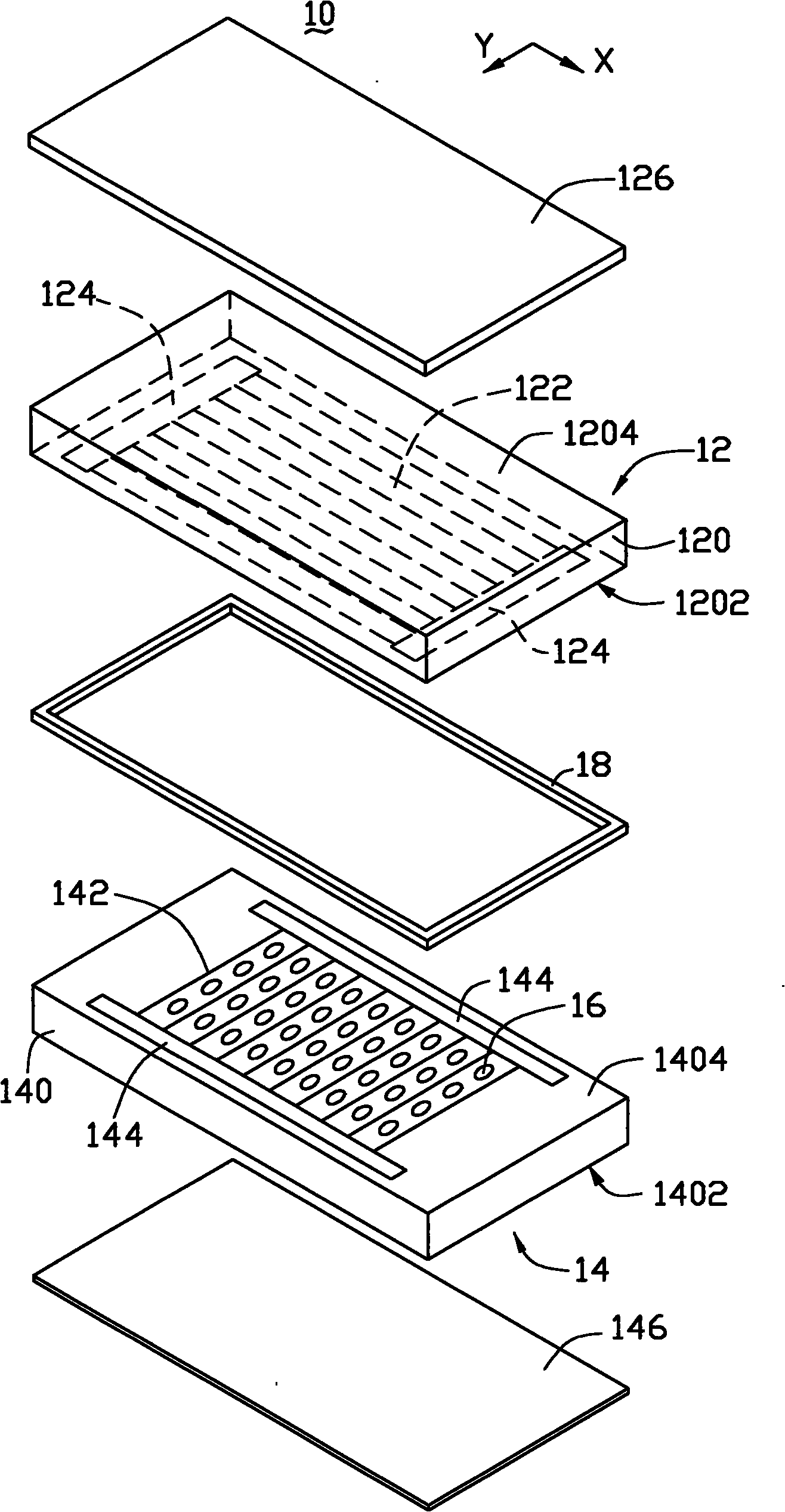

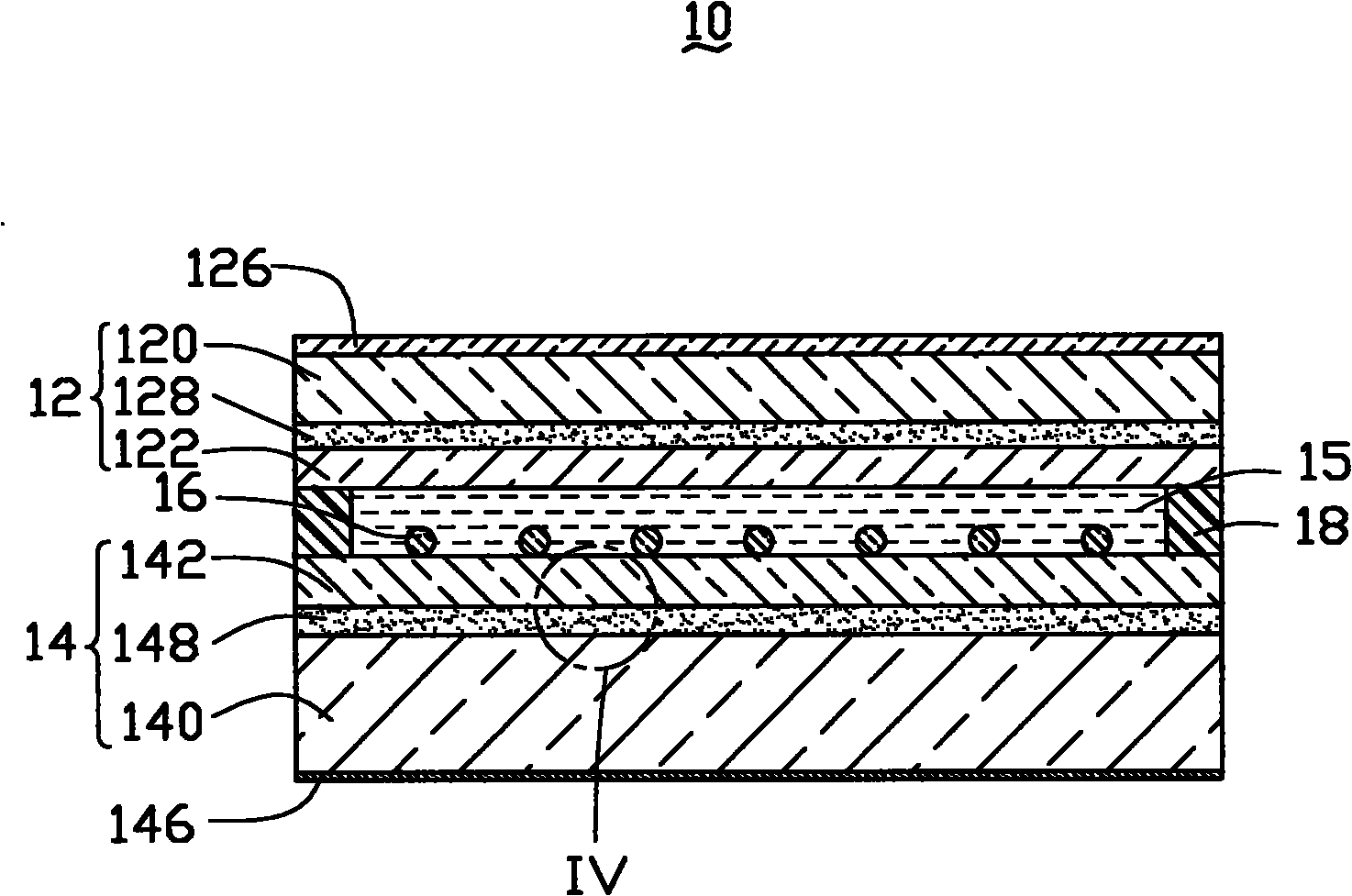

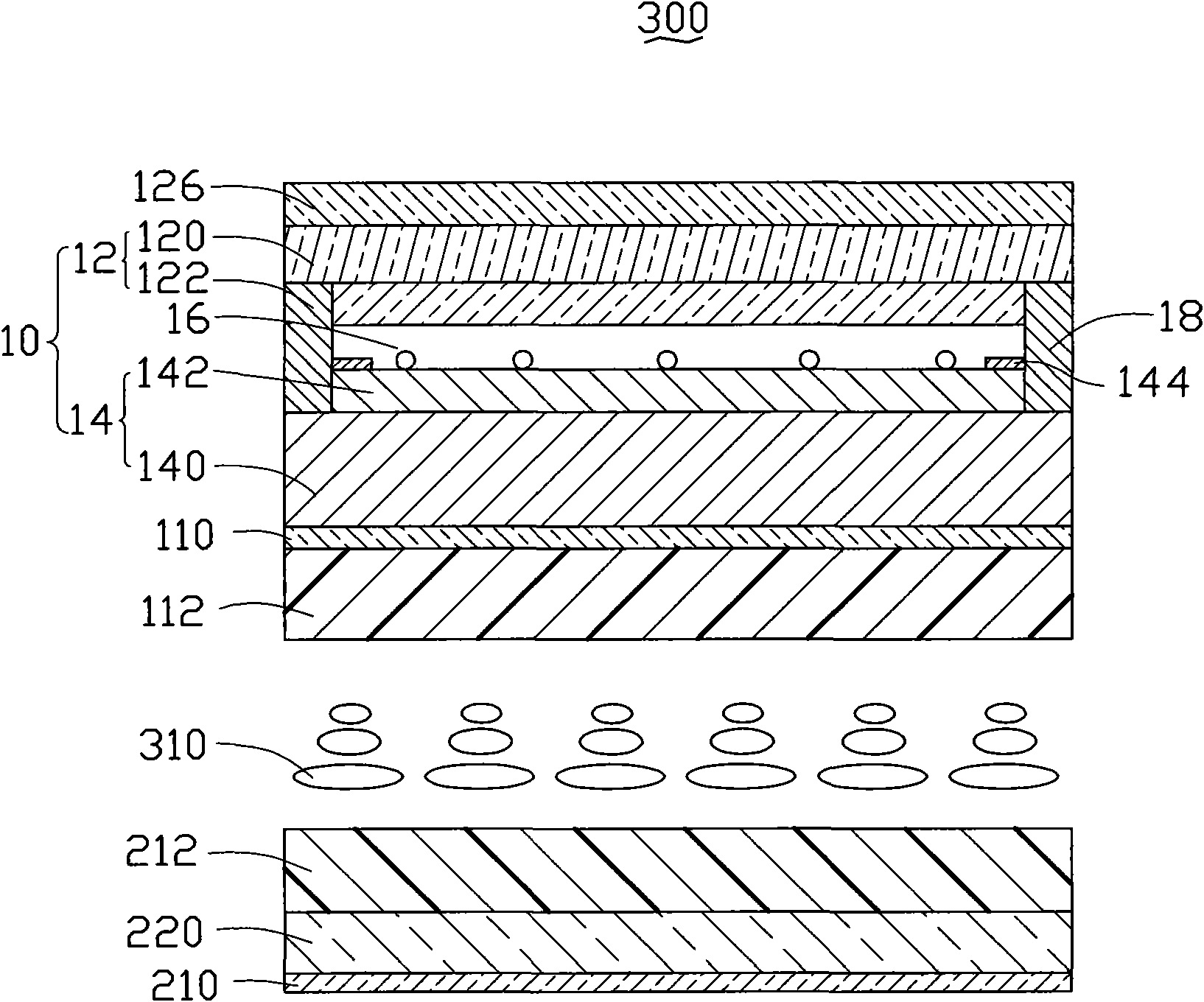

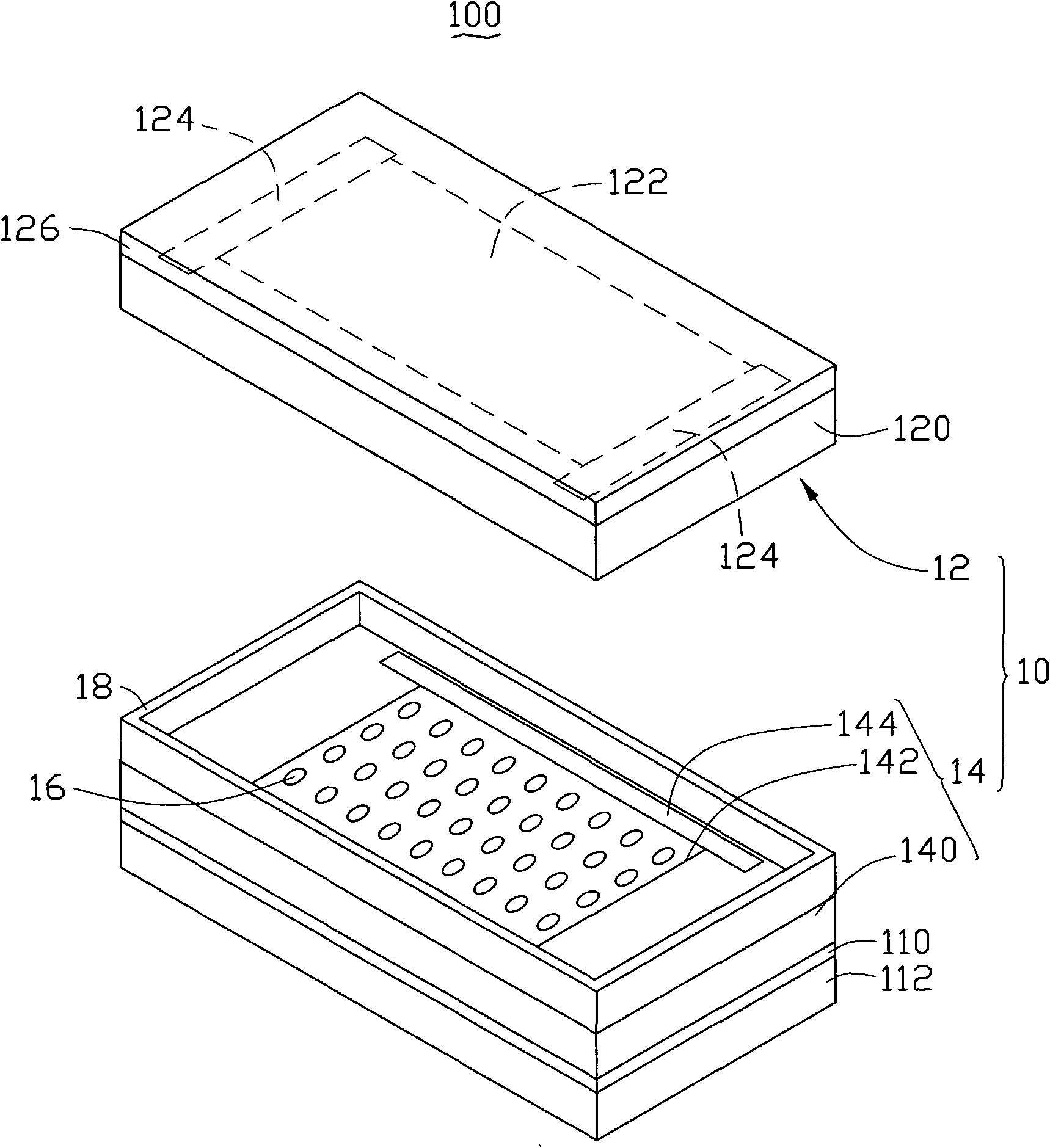

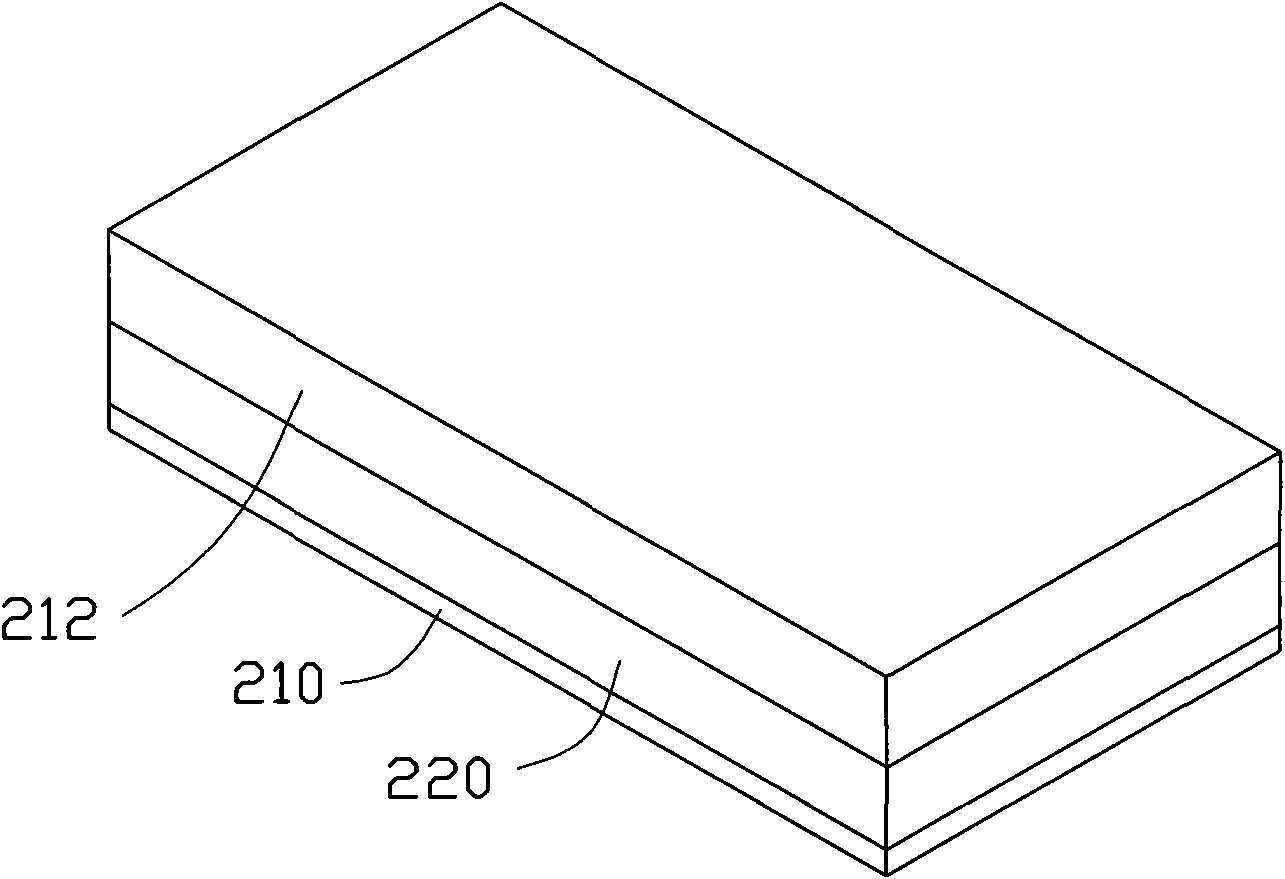

Touch LCD screen

ActiveCN101620327AIncreased durabilityHigh-resolutionStatic indicating devicesSolid-state devicesLiquid-crystal displayCarbon nanotube

The invention discloses a touch LCD screen, which comprises an upper substrate, a lower substrate, and a liquid crystal layer, wherein the upper substrate comprises a touch screen; the lower substrate and the upper substrate are oppositely arranged; the lower substrate comprises a thin film transistor panel; the liquid crystal layer is arranged between the upper substrate and the lower substrate; and a conducting layer of the touch screen comprises a carbon nanotube layer.

Owner:TSINGHUA UNIV +1

Touch liquid crystal display screen

ActiveCN101625465AIncreased durabilityHigh-resolutionSilicaStatic indicating devicesLiquid-crystal displayCarbon nanotube

The invention relates to a touch liquid crystal display screen, which comprises an upper substrate, a lower substrate and a liquid crystal layer, wherein the upper substrate comprises a touch screen which comprises a plurality of transparent electrodes; the lower substrate is arranged opposite to the upper substrate and comprises a thin film transistor panel; and the liquid crystal layer is arranged between the upper substrate and the lower substrate, wherein the transparent electrodes in the touch screen comprise a carbon nano-tube layer.

Owner:TSINGHUA UNIV +1

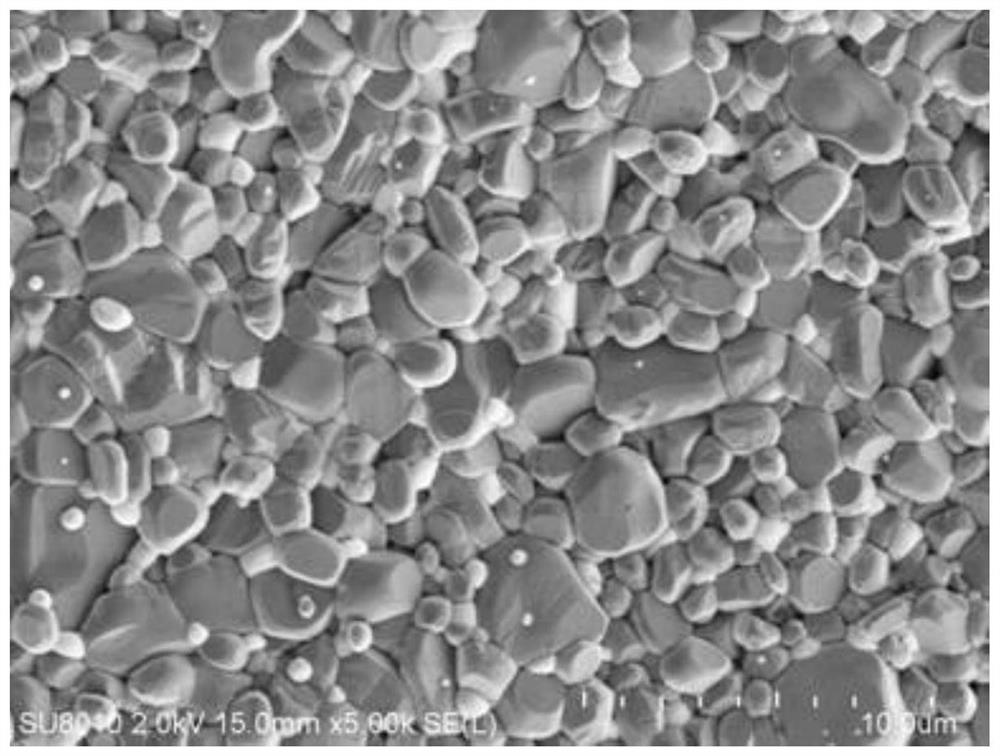

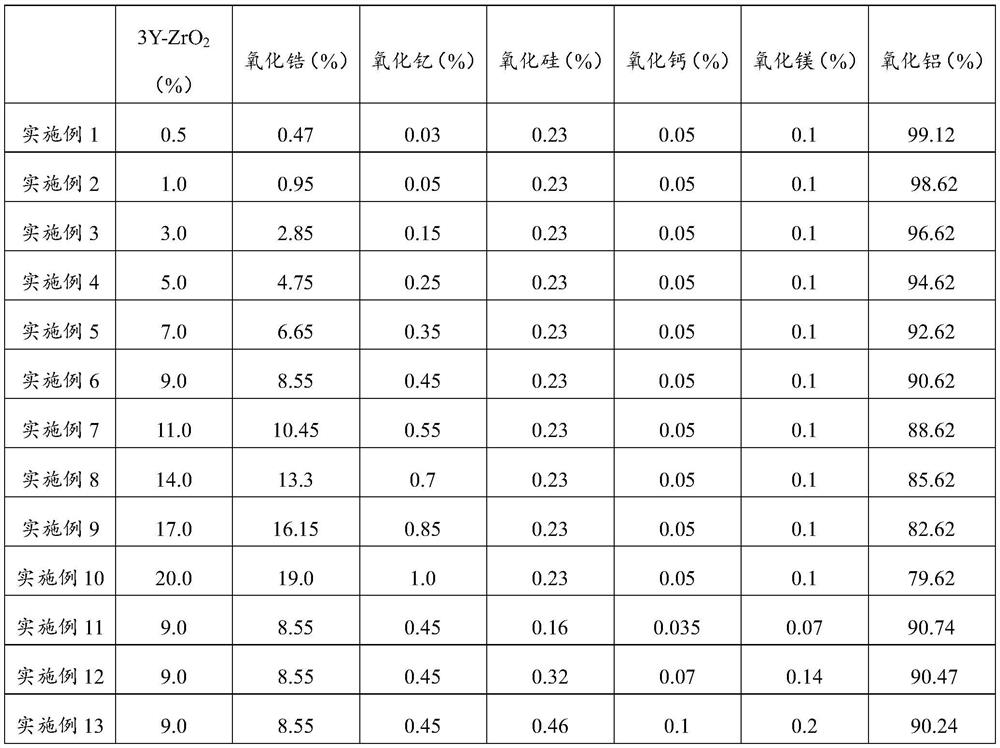

Zirconia composite alumina ceramic sintered body as well as preparation method and application thereof

The invention relates to a zirconia composite alumina ceramic sintered body. The zirconia composite alumina ceramic sintered body comprises the following components in percentage by mass: 0.01-19.0 wt% of a zirconium-containing compound (calculated in the form of zirconium oxide), 0.01-1 wt% of a yttrium-containing compound (calculated in the form of yttrium oxide), 0.16-4.6 wt% of a silicon-containing compound (calculated in the form of silicon oxide), 0.035-1.0 wt% of a calcium-containing compound (calculated in the form of calcium oxide), 0.07-2.0 wt% of a magnesium-containing compound (calculated in the form of magnesium oxide) and the balance of aluminum oxide. According to the zirconia composite alumina ceramic sintered body, 3Y-ZrO2 is taken as an additive, and the synergistic effect of multiple toughening modes such as phase change toughening, microcrack toughening, internal crystal structure strengthening toughening and surface strengthening toughening is achieved; CaCO3, SiO2and MgO are used as sintering aids, the sintering temperature of the aluminum oxide ceramic is reduced through liquid-phase sintering, the sintering rate is increased, sintering densification is promoted, and an aluminum oxide substrate prepared from the zirconia composite alumina ceramic sintered body has good fracture toughness and bending strength.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

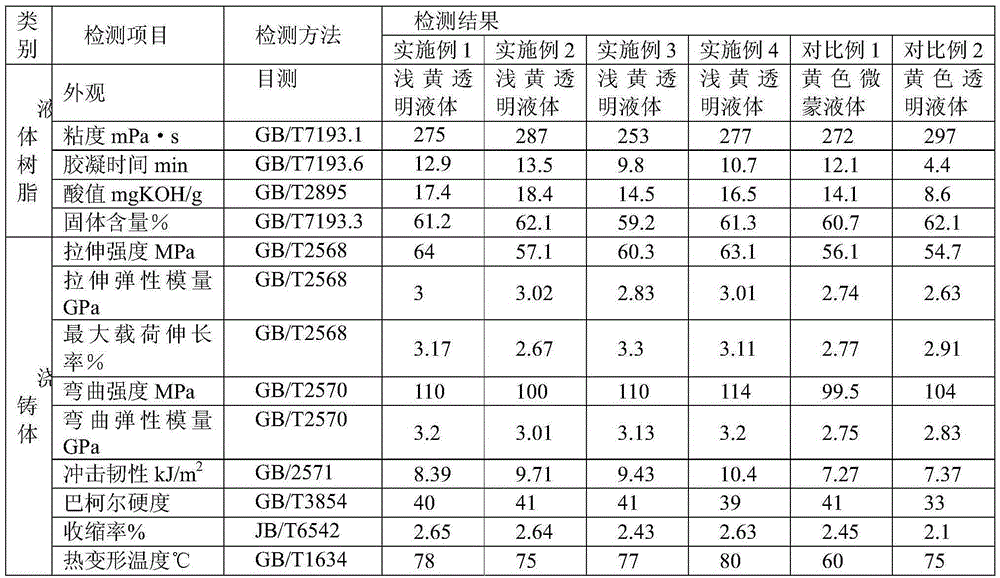

Method for synthesizing unsaturated polyester resin by utilizing PET

The invention provides a method for synthesizing unsaturated polyester resin by utilizing PET. The method comprises the following steps that 1, glycerol, dihydric alcohol with the boiling point exceeding 210 DEG C, waste PET and a catalyst are added and stirred at the speed of 250-300 r / min, under nitrogen protection, the temperature is raised to 210 DEG C to carry out a heat preserving reaction, after alcoholysis is carried out on PET completely, the temperature continues to be kept for 1-2 h, and cooling is carried out; 2, the temperature is lowered to below 150 DEG C, unsaturated dicarboxylic anhydrides, monohydric alcohol and residual dihydric alcohol with the boiling point lower than 210 DEG C are added, the temperature is raised to 150 DEG C-155 DEG C for carrying out the heat preserving reaction for 0.5 h, then the temperature is raised to 195 DEG C-200 DEG C step by step to carry out the constant temperature reaction, when the water yield reaches 85-90% of the theoretical amount, vacuumizing is carried out to force water to be drained, and the reaction is carried out until an acid value is smaller than 25 mgKOH / g; 3, the temperature is lowered to 155 DEG C-160 DEG C, a proper quantity of polymerization inhibitor is added, styrene is used for diluting, and cooling and filtering are carried out to obtain a finished unsaturated polyester resin product. According to the method, after being cured, the prepared resin has good toughness and physical strength, overcomes the defect of poor solubility of polyester and styrene, and is economical and environmentally friendly.

Owner:ZHAOQING FUTIAN CHEM IND

High-strength manhole cover

ActiveCN102633468AGood toughness strengthHigh tensile strengthArtificial islandsUnderwater structuresAlkali freePolystyrene

The invention provides a high-strength manhole cover. The manhole cover is characterized by being prepared from the following components in parts by weight: 25 to 30 parts of p-phenyl unsaturated polyester resin, 5 to 10 parts of styrene, 5 to 10 parts of polystyrene, 0.3 to 1.0 part of zinc stearate, 20 to 30 parts of calcium carbonate, 15 to 20 parts of alkali-free glass fiber cloth, 0.5 to 1.0part of calcium hydroxide, 0.6 to 1.0 part of coupling agent and 1 to 2 parts of carbon black. The manhole cover is low in production cost; the load-carrying capacity of the manhole cover can be greatly improved; and the load-carrying capacity can reach over 60 tons, so that the manhole cover can be applied to most pavement environments and solves the problem that the conventional manhole cover is easy to crack in use.

Owner:CHENGDU INFOEASY TECH

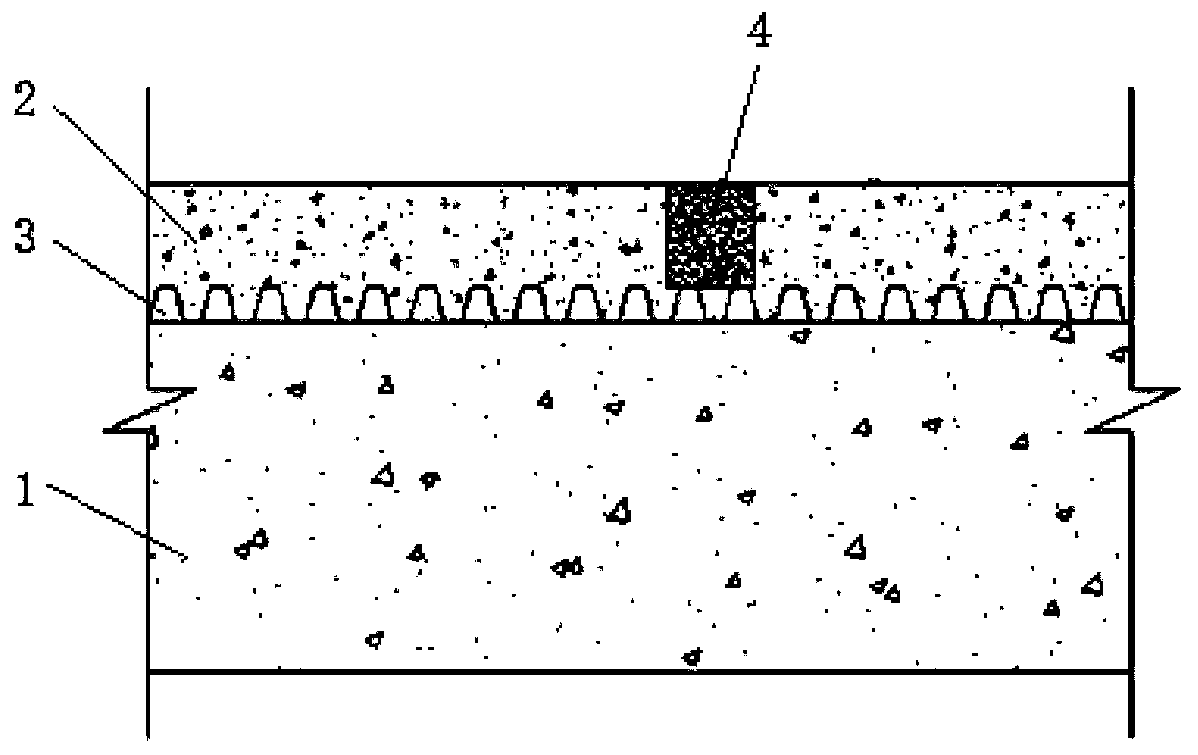

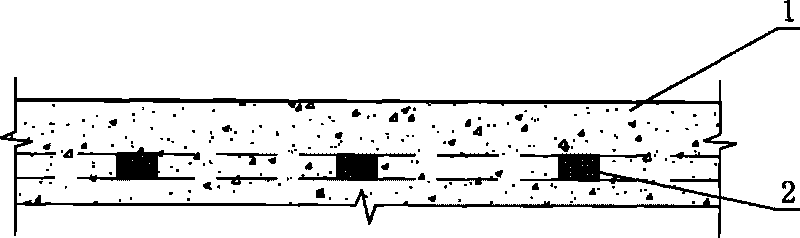

Construction method for terrace

The invention discloses a construction method for a terrace. The method includes the following steps that firstly, a ground basic layer is cleared, and multiple hydrophobic boards are flat laid on thecleared ground basic layer; then, a terrace formwork is erected, and ash cakes are arranged on the hydrophobic boards; then through a sequence method, concrete is poured on a pouring region; steel reinforcement net pieces are laid on the upper surface of concrete and settled to designated positions; then, the operation of polishing, maintaining, form stripping and expansion joint cutting is performed, and finally the concrete is maintained until the setting strength of the concrete meets designing requirements. With the construction method for the terrace, the terrace can be effectively prevented from cracking and peeling; the tenacity and mechanical strength of the terrace are good; the maintaining cost in the late period can be effectively lowered, and the service life of the terrace can be effectively guaranteed; construction is convenient, and construction efficiency is improved.

Owner:SHANGHAI BAOYE GRP CORP

Tough epoxy resin curing system and preparation method thereof

The invention belongs to the technical field of high-molecular materials, and relates to a tough epoxy resin curing system and a preparation method thereof. The high-molecular material is prepared from the following compositions in parts by weight: 100 parts of epoxy resin, 8-120 parts of a curing agent, 0-1.5 parts of a promoter and 5-55 parts of thermoplastic. High-toughness high-heat-resistance thermoplastic engineering plastic toughened epoxy resin is selected in the epoxy resin cure system, and curing and toughening of epoxy resin can be realized under the premise of not reducing or slightly reducing mechanical properties and thermal properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method of lithium battery diaphragm

ActiveCN102790195AImprove heat resistanceHeat resistantCell component detailsOrganic solventHeat resistance

The invention relates to a preparation method of a lithium battery diaphragm. The method comprises the following steps: 1, dissolving an organic polymer in an organic solvent to obtain an organic polymer solution; 2, adding an inorganic material to the organic polymer solution obtained in step 1, uniformly mixing, heating, and carrying out ball milling to obtain a mixture; and 3, casting the mixture obtained in step 2 on a substrate, and drying to obtain the final product inorganic / organic composite diaphragm. The method has the advantages of simple steps and low cost, and the prepared diaphragm has the advantages of porousness, flexibility, mechanical strength, good stability, good uniformity, and good heat resistance, has a good popularization prospect, and can be applied to the lithium ion battery field.

Owner:JIANGMEN LONGSHIJI TECH CO LTD

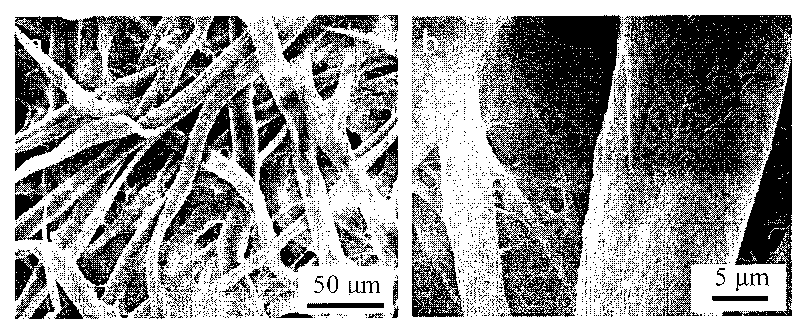

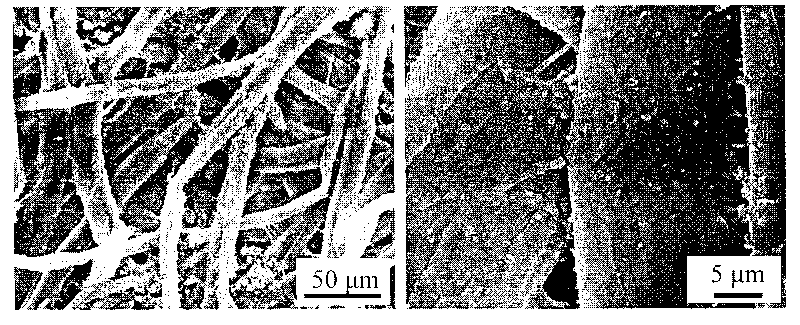

Method for preparing polycaprolactone-keratin composite nanometer fiber pipe

InactiveCN104005179AAdjustable inner diameterGood biocompatibilityNon-woven fabricsFiberElectrospinning

The invention relates to a method for preparing a polycaprolactone-keratin composite nanometer fiber pipe. The method includes the steps of firstly, dissolving polycaprolactone in a solvent, stirring the solvent to dissolve the polycaprolactone, and obtaining a polycaprolactone solution; secondly, dissolving keratin in a solvent, stirring the solvent to dissolve the keratin, and obtaining a keratin solution; thirdly, mixing the polycaprolactone solution with the keratin solution according to the mass ratio of 95:5 to 5:95, stirring the mixture to mix the mixture evenly, and obtaining a spinning solution; fourthly, conducting electrostatic spinning, and obtaining the polycaprolactone-keratin composite nanometer fiber pipe with a cylindrical collection roller serving as a receiver. The tubular material obtained through the method not only keeps good biological activity of the keratin, but also has good tenacity and mechanical strength of the polycaprolactone; meanwhile, the tubular material has the advantages of being adjustable in inner diameter, simple in preparation method and the like and is expected to be used for the field of artificial blood vessels and the like.

Owner:DONGHUA UNIV

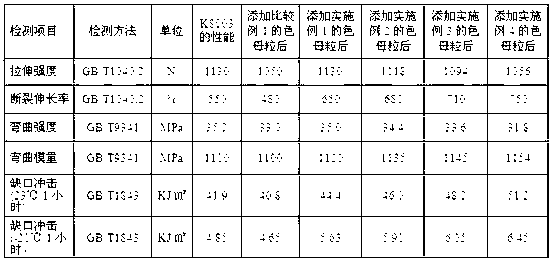

Novel high-efficiency PPR (pentatricopeptide repeat) pipe cold-resistant toughening color master batch

InactiveCN102850658APlay a coloring roleGood toughness strengthRigid pipesPentatricopeptide repeatPolypropylene

The invention discloses a novel high-efficiency PPR (pentatricopeptide repeat) pipe cold-resistant toughening color master batch. The color master batch comprises the following components in parts by weight: 5-25 parts of polypropylene, 5-10 parts of pigment, 35-65 parts of cold-resistant modifying agent and 1-15 parts of reinforced modifying agent, wherein the cold-resistant modifying agent is one substance or a mixture of more of styrene-butadiene-styrene ternary segmented copolymer, ethylene-vinyl acetate copolymer and ethylene-octylene copolymer, and the reinforced modifying agent is one substance or a mixture of more of nano calcium carbonate, nano silicon and the nano barium sulfate. According to the color master batch, the formula components of the color master batch can be optimized and improved, so that the novel high-efficiency PPR pipe cold-resistant toughening color master batch can be prepared. The color master batch provided by the invention not only can play a role in coloring, but also can obviously improve the flexibility and the shock strength of the PPR pipe under the condition of low temperature, so that the cold resistance of the pipe can be improved, and the service life of the pipe can be prolonged.

Owner:CHONGQING AOCAI NEW MATERIAL CORP LTD

Preparation method of tubular polyurethane/keratin composite nanofiber material

InactiveCN104018247AImprove the lack of low mechanical propertiesAdjustable inner diameterFilament/thread formingConjugated cellulose/protein artificial filamentsFiberPorosity

The invention relates to a preparation method of a tubular polyurethane / keratin composite nanofiber material. The preparation method comprises the steps of dissolving polyurethane in solvent and stirring until dissolving completely to obtain a polyurethane solution; dissolving keratin into a solvent and stirring until dissolving completely to obtain a keratin solution; mixing the polyurethane solution and the keratin solution with mass ratio of 95:5-5:95, stirring uniformly to obtain a polyurethane / keratin spinning solution, performing electrostatic spinning and using a cylindrical collecting roller as a receiver. The method can compound natural biomacromolecular keratin and polyurethane into the tubular nanofiber material through electrostatic spinning, so that the material has high porosity and good mechanical and biological functions.

Owner:DONGHUA UNIV

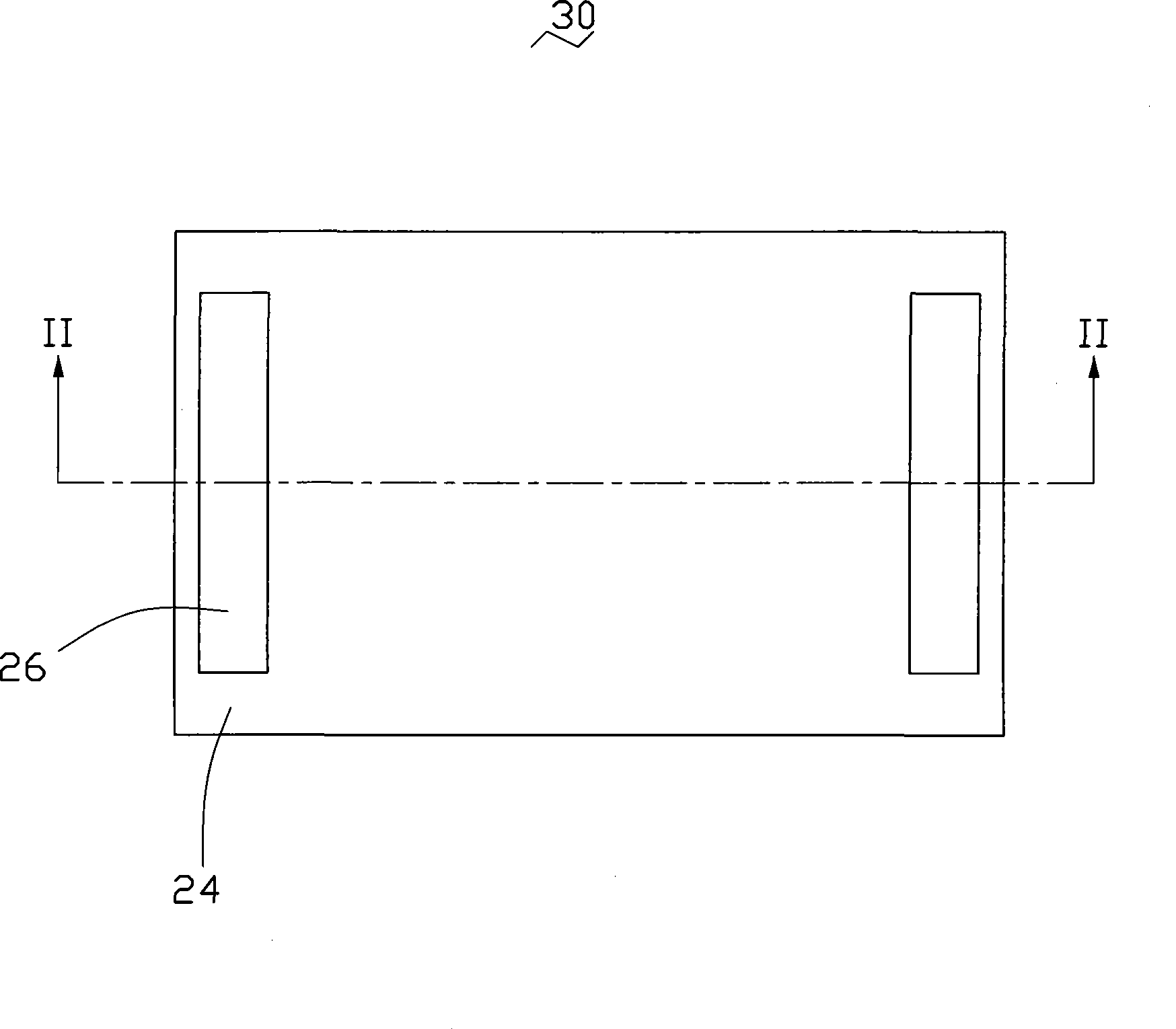

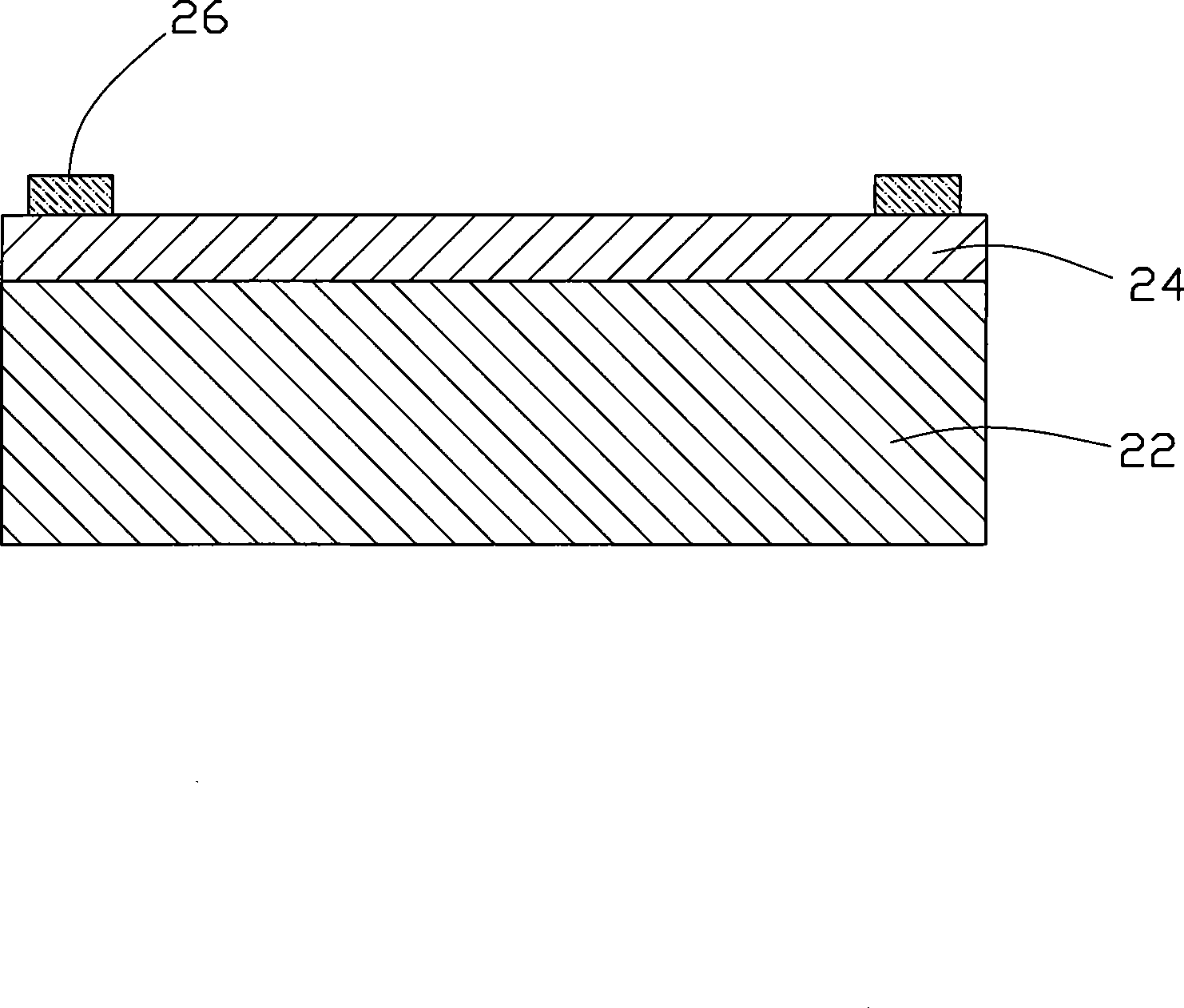

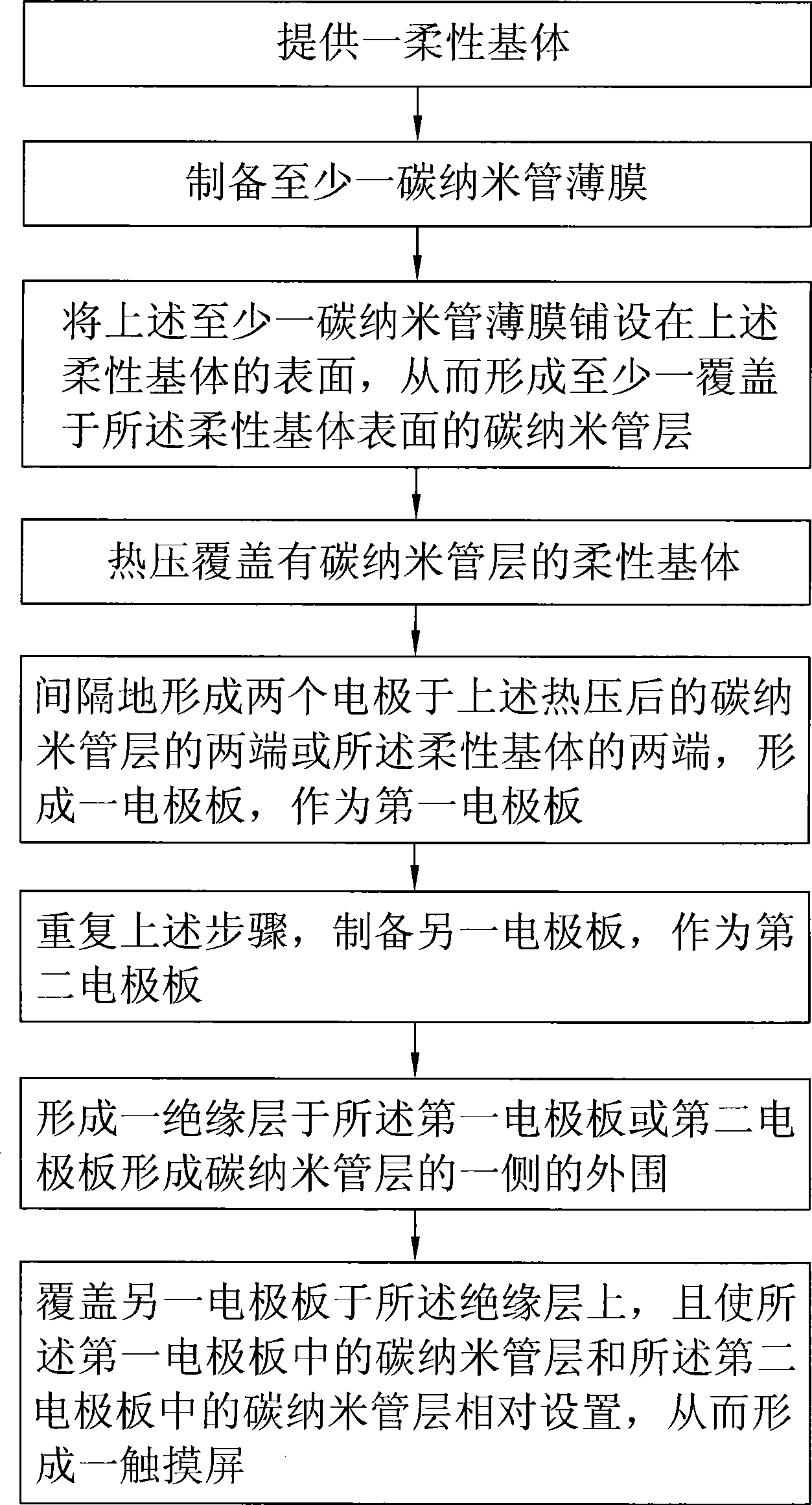

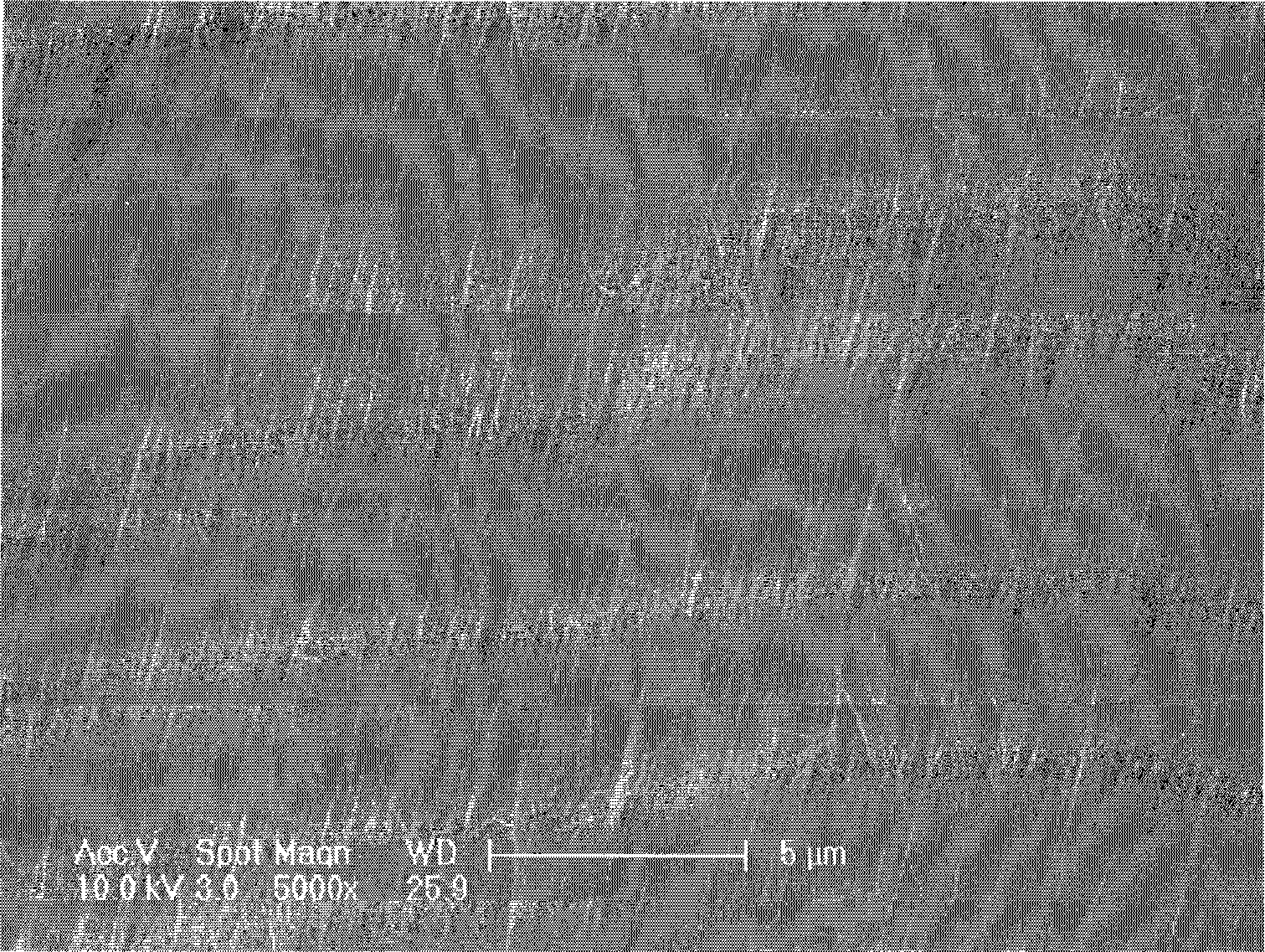

Production method of touch screen

ActiveCN101464763AExcellent mechanical propertiesGood toughness strengthLayered productsIndividual molecule manipulationCarbon nanotubeElectrode

The invention relates to a method for preparing a touch screen, which includes steps as follows: providing a flexible matrix; preparing at least one carbon nano tube film; laying the carbon nano tube film on the surface of the flexible matrix, thereby forming at least one layer of carbon nano tube film covering the surface of the flexible matrix; hot-pressing the flexible matrix with the layer of carbon nano tube film; forming two electrodes at internals at two ends of the layer of carbon nano tube film after hot-pressing or two ends of the flexible matrix, thereby forming an electrode plate taken as a first electrode plate; repeating the steps and preparing another electrode plate taken as a second electrode plate; forming an insulating layer on the periphery of one side of the layer of carbon nano tube film formed by the first electrode plate or the second electrode plate; and covering the insulating layer with another electrode plate to arrange the layer of carbon nano tube film in the first electrode plate and the layer of carbon nano tube film in the second electrode plate in an opposite manner, thereby forming the touch screen.

Owner:TSINGHUA UNIV +1

Ultra-light, ultra-thin, flexible and breathable ultra-fine fiber composite membrane with multi-spectrum electromagnetic wave protection performance and preparation method thereof

The invention relates to an ultra-light, ultra-thin, flexible and breathable ultra-fine fiber composite membrane with multi-spectrum electromagnetic wave protection performance and a preparation method thereof, belonging to the technical field of electromagnetic wave protection materials. An electrospinning method is combined with a metal chemical depositionmethod (or electrodeposition, ion sputtering vacuum plating), inorganic metal nanoparticles which are closely packed are fabricated on the surface of the organic ultrafine fiber, so that the organic ultrafine fiber has a specific shape, anda single-layer ultrathin fiber membrane carrying metal nano-alloy / metal oxide is formed, and a metal nano-alloy / metal oxide / ultrafine fiber composite membrane with a multilayer structure is preparedby a hot-pressing or resin-based reinforcer superposing method. The density of the composite membrane is only 2% ~ 15% of that of pure metal, but the composite membrane has good metal conductivity. Under the absorption loss of the metal nano-alloy / metal oxide, the multiple reflections of interlayer and intra-membrane voids, the diffraction of nano-structure and the scattering of macro-structure,the transmission and return of the incident electromagnetic waves are difficult, so as to achieve the purpose of absorbing and shielding the electromagnetic waves effectively.

Owner:吉林省贞靓科技有限公司

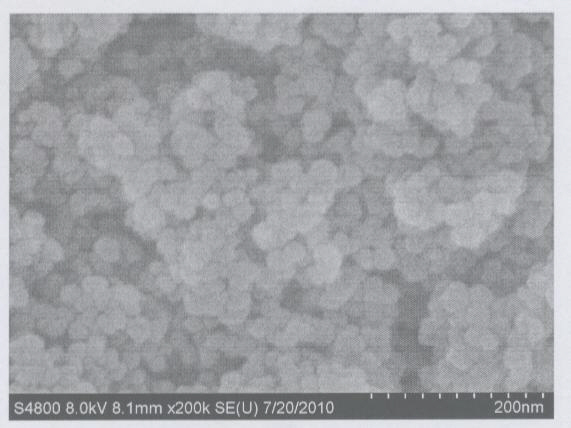

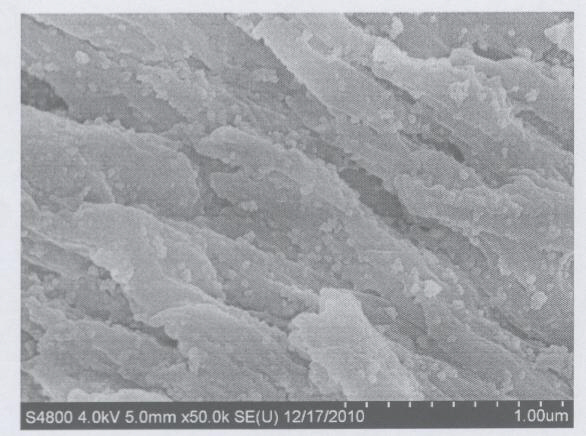

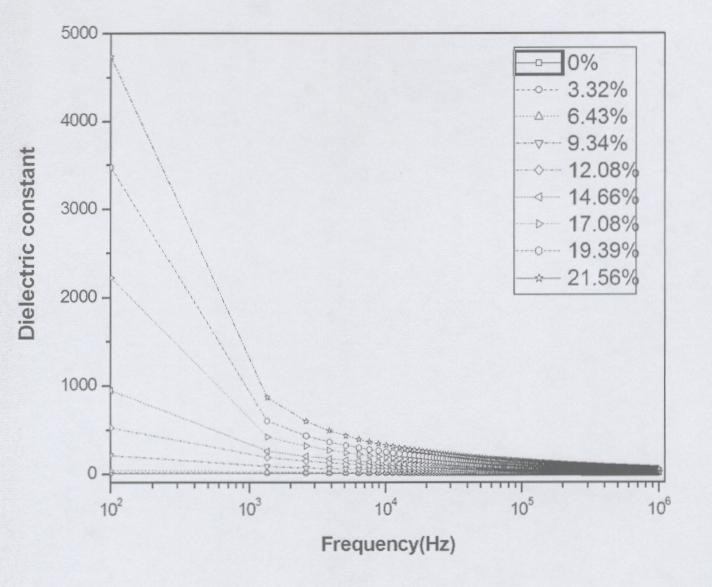

Composite material with high dielectric constant and preparation method for composite material

InactiveCN102653621AGood flexibilitySimple processFixed capacitor dielectricPolyvinylidene fluorideHigh dielectric permittivity

The invention relates to a composite material with a high dielectric constant and a preparation method for the composite material. The composite material with the high dielectric constant is formed by hot-pressing and molding polyvinylidene fluoride powder which serves as a base material and nano Fe3O4 particles which serve as a filling material, wherein the volume of the nano Fe3O4 particles accounts for 3-22% of the composite material. The method comprises the following steps of: preparing the nano Fe3O4 particles by adopting a hydrothermal method; converting the volume percentage of 3 to 22 percent of nano Fe3O4 particles into a mass ratio; mixing and uniformly stirring the nano Fe3O4 particles and the polyvinylidene fluoride powder; and obtaining the composite material with the high dielectric constant by hot-pressing and molding at a temperature of 180 to 220 DEG C under a pressure of 6 to 15 Mpa to obtain composite material with high dielectric constant. The preparation process is simple, low in power consumption, low in cost and molded conveniently; and the obtained raw materials are not required to be subjected to further chemical treatment.

Owner:NINGBO UNIV

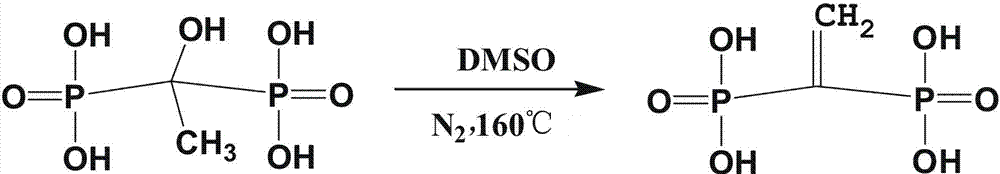

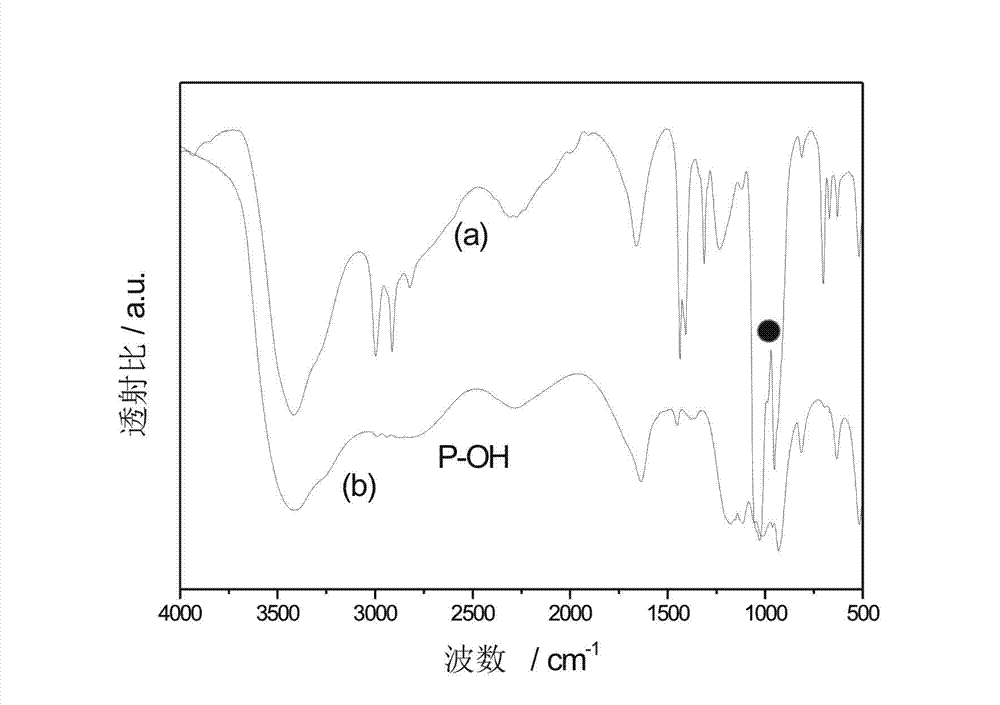

Chemically-bonded HEDP (1-hydroxy ethylidene-1, 1-diphosphonic acid) medium-temperature organic polysiloxane phosphate based proton exchange membrane and preparation method thereof

The invention relates to a chemically-bonded HEDP (1-hydroxy ethylidene-1, 1-diphosphonic acid) medium-temperature organic polysiloxane phosphate based proton exchange membrane. The membrane is prepared by the following steps: firstly, under protection of nitrogen, mixing dimethyl sulfoxide and HEDP, stirring to obtain clear and transparent mixture, and performing reflux reaction at 160 DEG C; removing the dimethyl sulfoxide after the solution is cooled to 110 DEG C to obtain 1,1-vinyl diphosphonic acid liquid; secondly, mixing 1, 1-vinyl diphosphonic acid, 3-(methacryloxy) propyl trimethoxyl silane, 2, 2'-azobisisobutyronitrile and ethanol, stirring at 60-80 DEG C to react, cooling to room temperature, adding diluted hydrochloric acid, and stirring to obtain clear and transparent sol; thirdly, performing gelation to the sol to obtain a gel membrane; and fourthly, drying the gel membrane to obtain the chemically-bonded HEDP medium-temperature organic polysiloxane phosphate based proton exchange membrane. The membrane has high proton conductivity under medium temperature and low humidity and has excellent flexibility and mechanical property.

Owner:WUHAN UNIV OF TECH

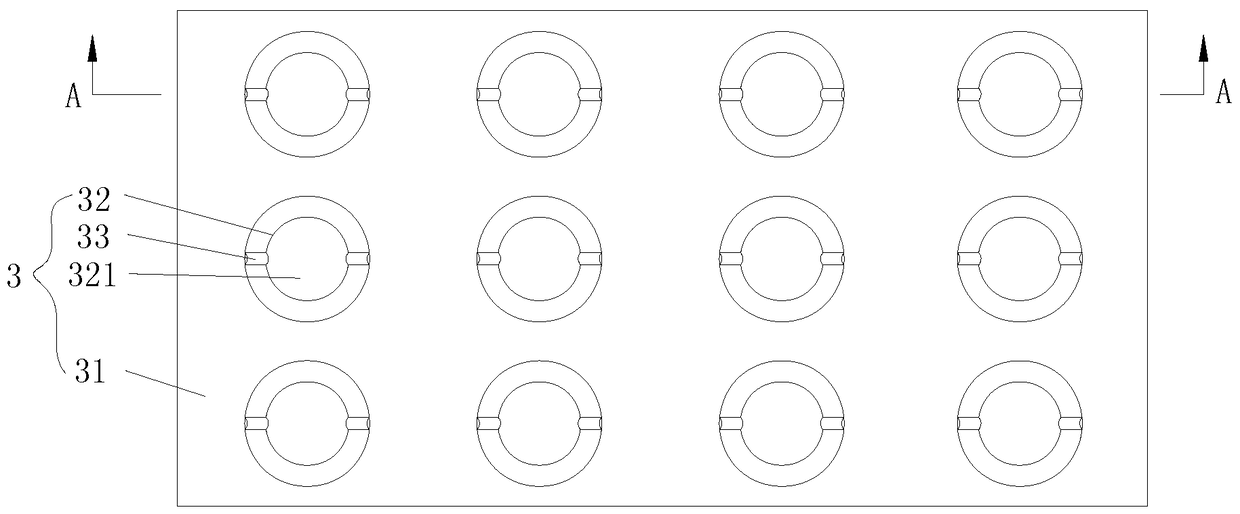

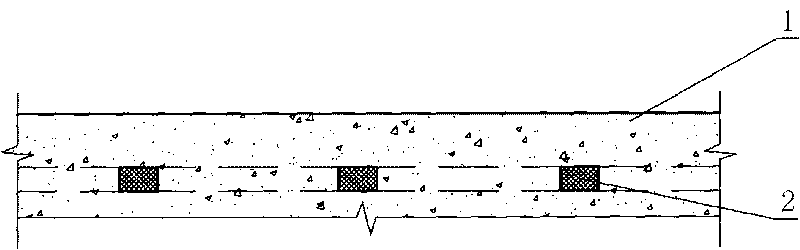

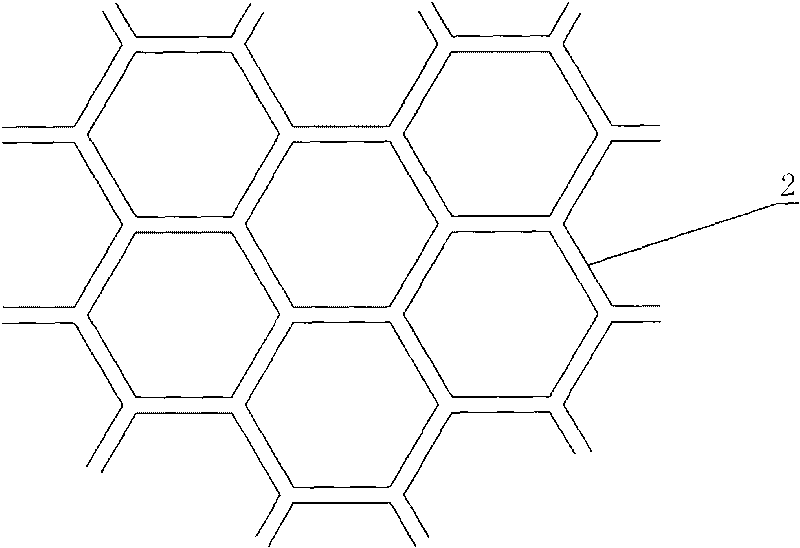

Honeycomb tendon drawing type anti-crack road surface

InactiveCN101761011AHigh tensile strengthHigh compressive strengthPaving reinforcementsIn situ pavingsHoneycombSurface layer

The invention relates to the technical field of urban traffic, in particular to a honeycomb tendon drawing type anti-crack road surface. The road surface consists of a surface layer and a honeycomb tendon. The material of the surface layer is compact type bituminous concrete. The honeycomb tendon is a netty structure which is formed by a plurality of regular hexagon frames with the circumcircle diameter of 40-60mm. The cross sectional area of each frame edge formed into the regular hexagon frames is 6-10 mm<2>, the material of the frame edge is low-pressure polyethylene engineering plastics. The honeycomb tendon is arranged in the surface layer, and the distance from the upper surface of the honeycomb tendon to the covered road surface is 10-15mm. The honeycomb tendon drawing type anti-crack road surface can greatly reduce the frequency for the maintainance and the constructure of the road surface and the corresponding investment, and can greatly prolong the service life of the road surface.

Owner:CHENGDU JUNFENG TECH DEV

Toughened environmental-friendly back mesh glue as well as preparation method and application thereof

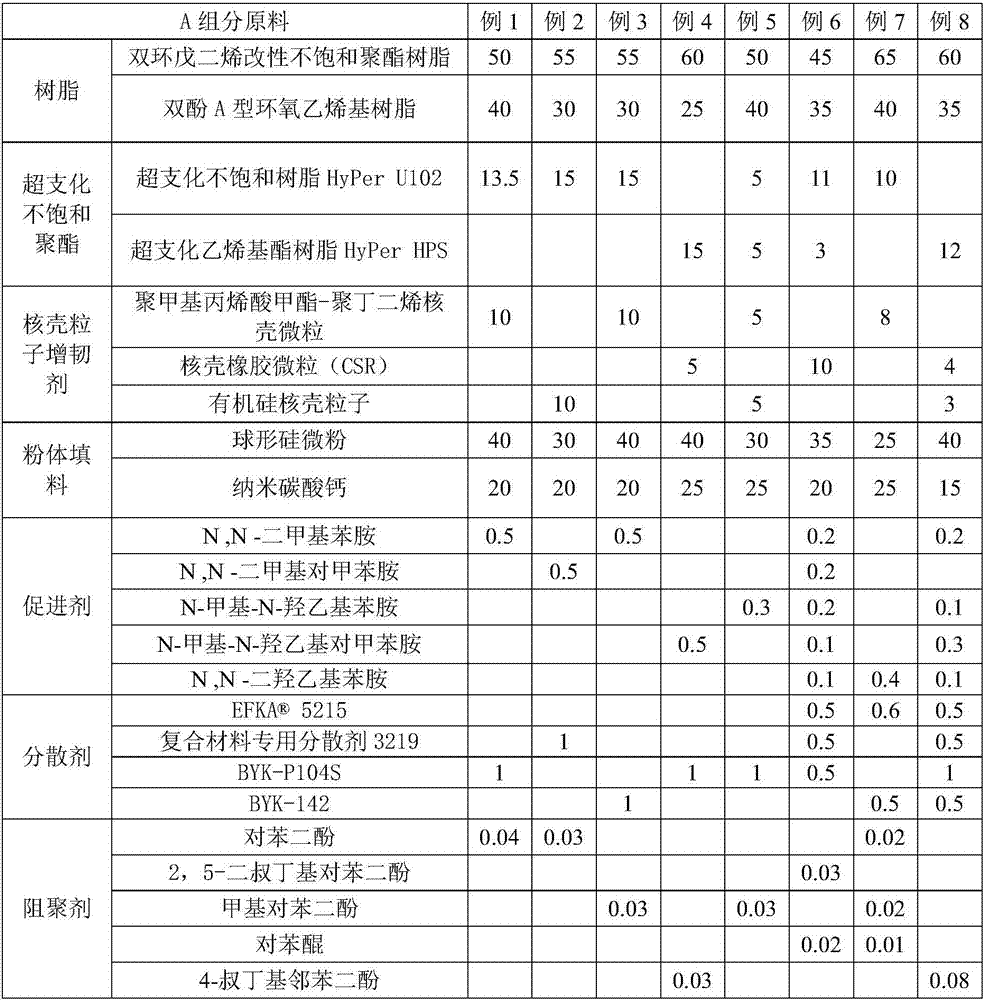

ActiveCN107090264AFast aggregationFast curing at room temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterToughening

The invention discloses toughened environmental-friendly back mesh glue as well as a preparation method and application thereof. A component A is prepared from the following components in parts by weight: 45-65 parts of dicyclopentadiene modified unsaturated polyester resin, 25-40 parts of bisphenol-A epoxy vinyl ester resin, 10-15 parts of hyperbranched unsaturated polyester, 1-2.5 parts of a dispersant, 5-10 parts of a core-shell particle toughening agent, 25-40 parts of spherical fine silicon powder, 15-25 parts of nano calcium carbonate, 0.2-0.8 part of an accelerator and 0.02-0.08 part of a polymerization inhibitor. A component B is prepared from the following components in parts by weight: 10-70 parts of a solidifying agent, 30-40 parts of a blending agent, 30-50 parts of an inorganic filler and 3-10 parts of a stabilizer. After the component A and the component B are mixed, the solidifying agent accounts for 0.5-3.5 percent of the total weight of the mixture. The back mesh glue is small in viscosity, good in permeability, moderate in rheology and low in content of total volatile organic compounds (VOCs); and the mechanical strength, particularly the impact resistance, of a back mesh stone is remarkably superior to that of the existing product.

Owner:江苏大力士云石护理材料有限公司

Touch screen and display device

ActiveCN102063213AIncreased durabilityHigh sensitivityAdhesivesInput/output processes for data processingDisplay deviceRefractive index

The invention relates to a touch screen. The touch screen comprises a first electrode plate and a second electrode plate, wherein, the first electrode plate comprises a first transparent conducting layer, the second electrode plate comprises a second transparent conducting layer, and the second transparent conducting layer is oppositely spaced from the first transparent conducting layer; at leastone of the first transparent conducting layer and the second transparent conducting layer is a carbon nanotube layer composed of a plurality of carbon nanotubes, and the carbon nanotubes are arrangedin a preferred orientation manner along the same direction; and a transparent insulator is arranged between a first substrate and a second substrate, and the refractive index of the transparent insulator is greater than that in vacuum. The carbon nanotube layer has the characteristics of lower resistance and good flexibility, and the refractive index of the transparent insulator is greater than that in vacuum, therefore the touch screen has the advantages of better durability, better sensitivity and better accuracy. The invention further provides a display device using the touch screen.

Owner:BEIJING FUNATE INNOVATION TECH

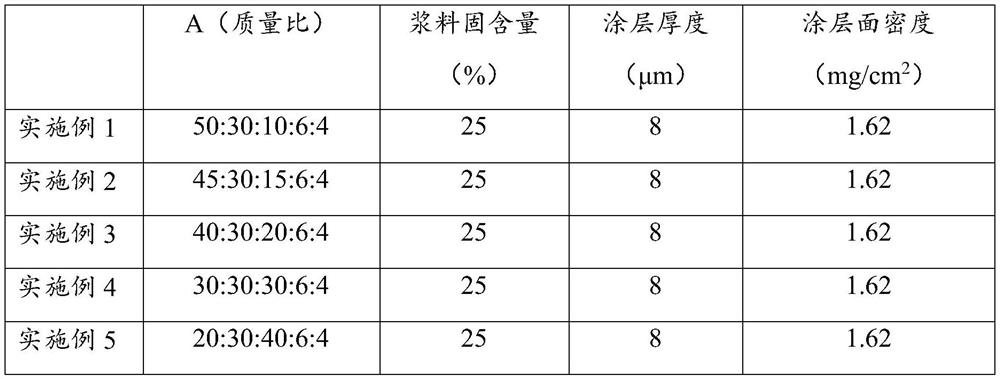

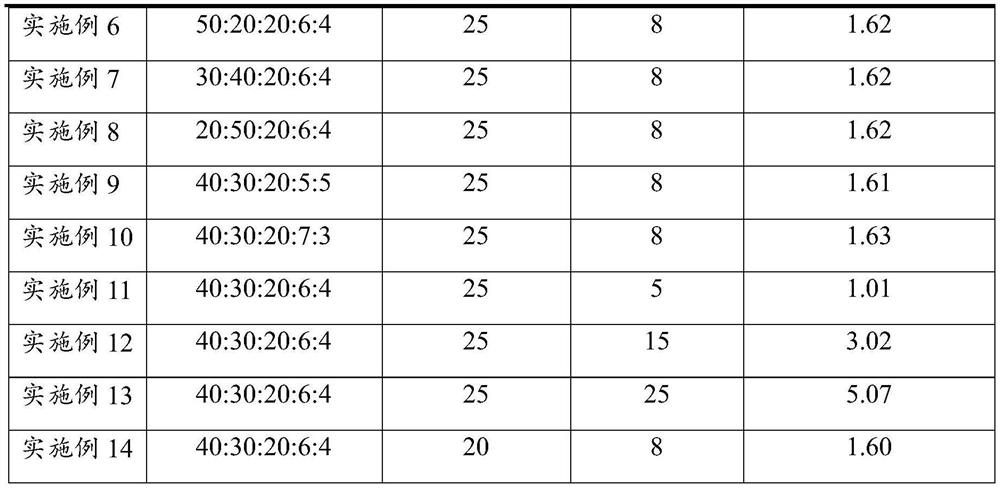

Safety coating, electrode plate, preparation method of electrode plate and lithium ion battery

PendingCN113488609AGood toughness strengthHigh mechanical strengthNon-aqueous electrolyte accumulator electrodesCell component detailsLithium-ion batteryPolymer

The invention provides a safety coating, an electrode plate, a preparation method of the electrode plate and a lithium ion battery. The safety coating comprises a polymer, a lithium salt, a flexibilizer, an inorganic filler and a plasticizer. The safety coating has the characteristics of electronic insulation and lithium ion conduction. Compared with the prior art, the safety coating provided by the invention takes the polymer as a film forming substrate, and then the polymer acts together with the lithium salt, the flexibilizer, the inorganic filler, the plasticizer and other substances, so that the safety coating not only has the characteristics of electronic insulation and lithium ion conduction, but also has good toughness and mechanical strength; and when the plate is punctured or extruded by an external object, the plate can be better protected, and the double isolation effect with the diaphragm is achieved, so that the situation of thermal runaway caused by short circuit of the battery is avoided.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Touch LCD screen

ActiveCN101620328AIncreased durabilityHigh transparencyStatic indicating devicesSolid-state devicesLiquid-crystal displayCarbon nanotube

The invention discloses a touch LCD screen, which comprises an upper substrate, a lower substrate, and a liquid crystal layer, wherein the upper substrate comprises a touch screen; the lower substrate and the upper substrate are oppositely arranged; the lower substrate comprises a thin film transistor panel; the liquid crystal layer is arranged between the upper substrate and the lower substrate; a conducting layer of the touch screen comprises a first carbon nanotube layer; and a semiconductor layer of a thin film transistor on the thin film transistor panel comprises a second carbon nanotube layer.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com