Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13261results about "Rigid pipes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

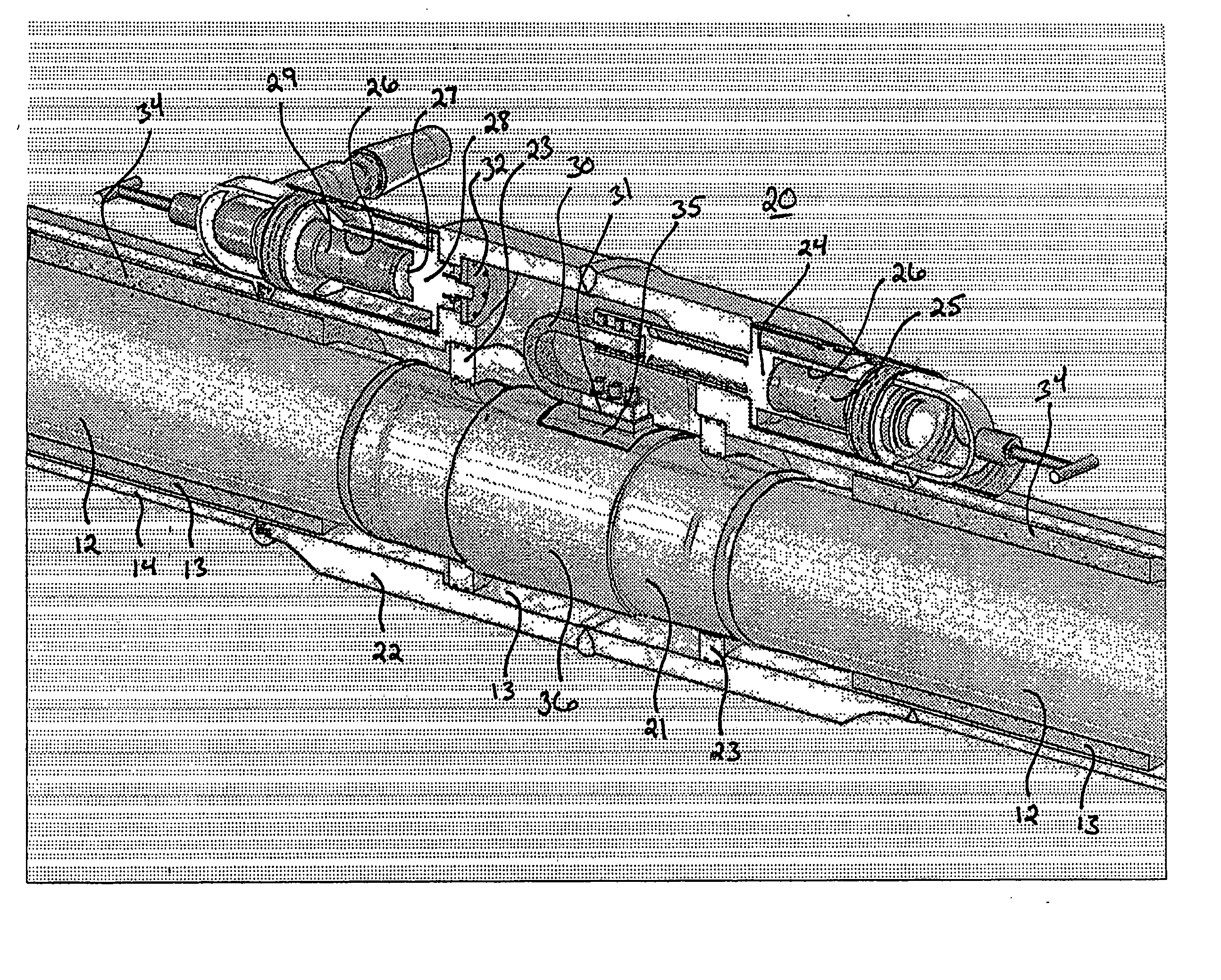

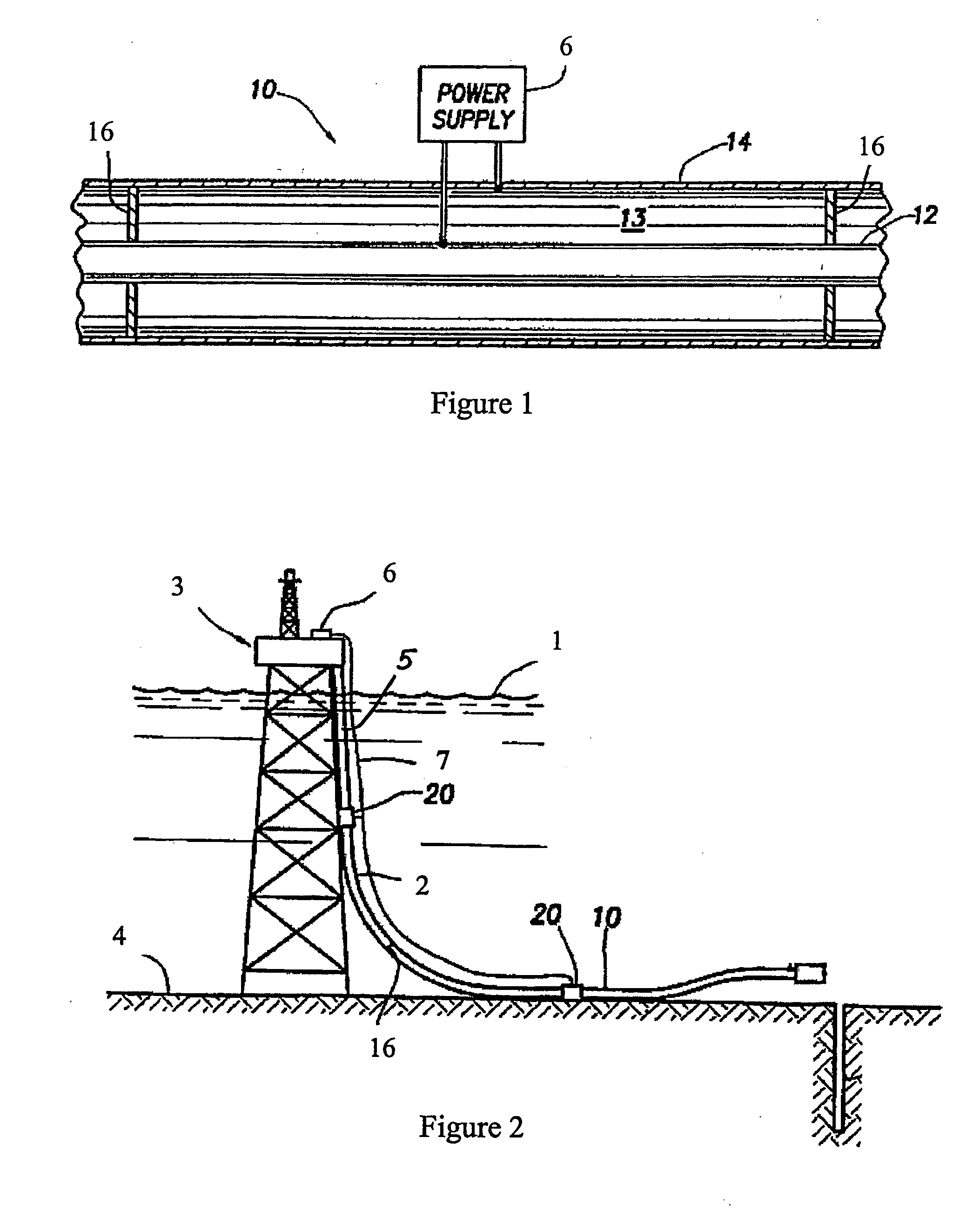

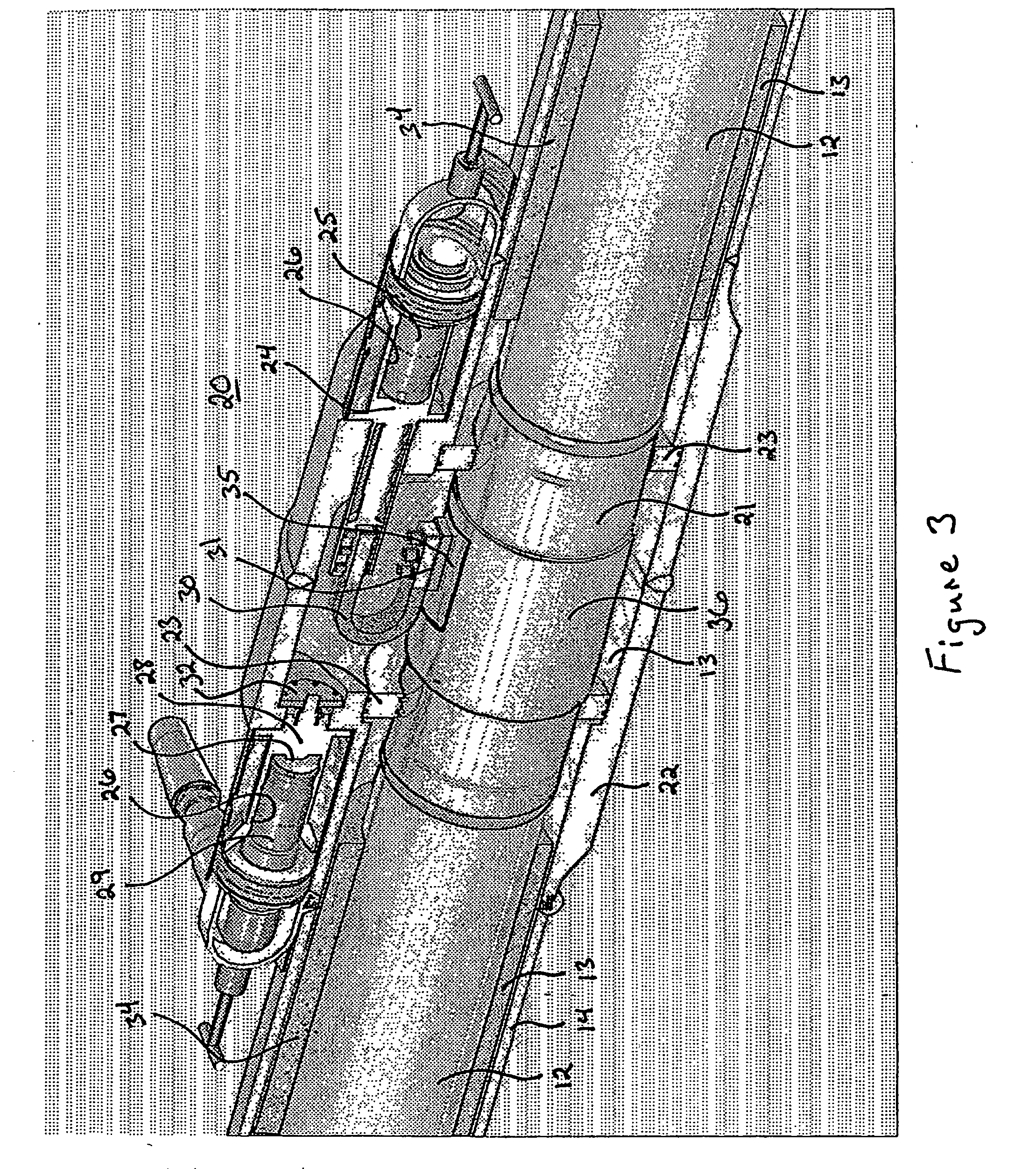

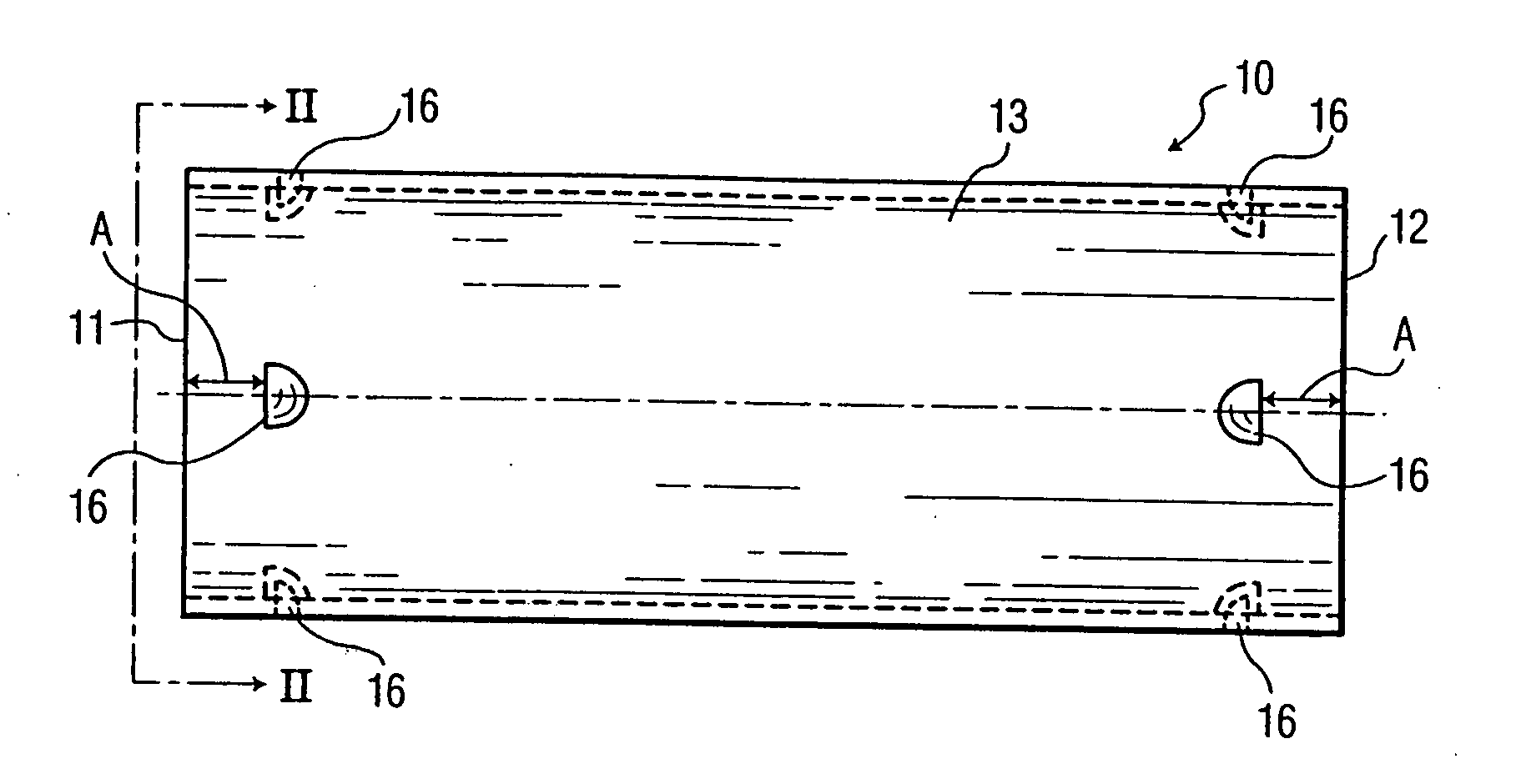

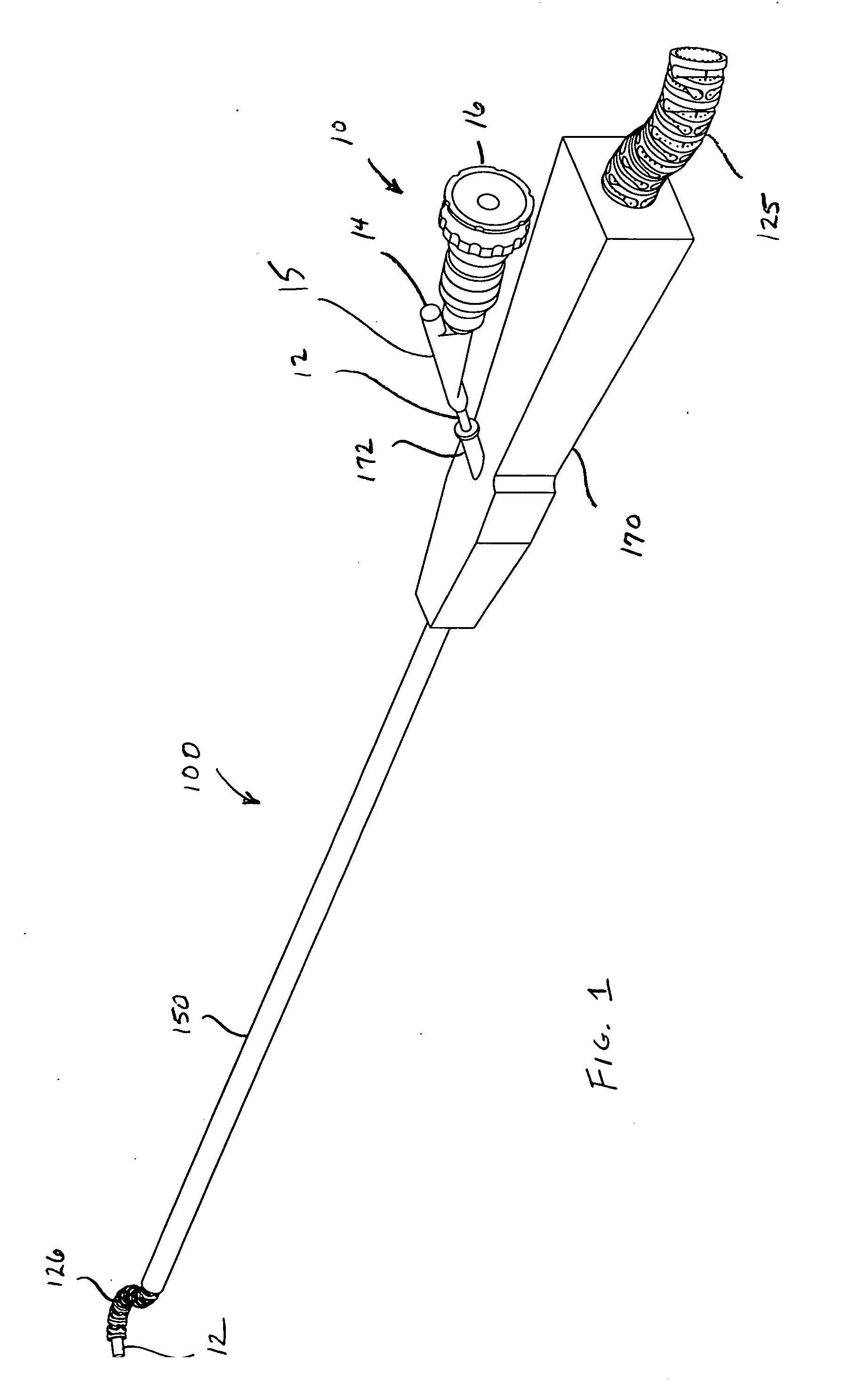

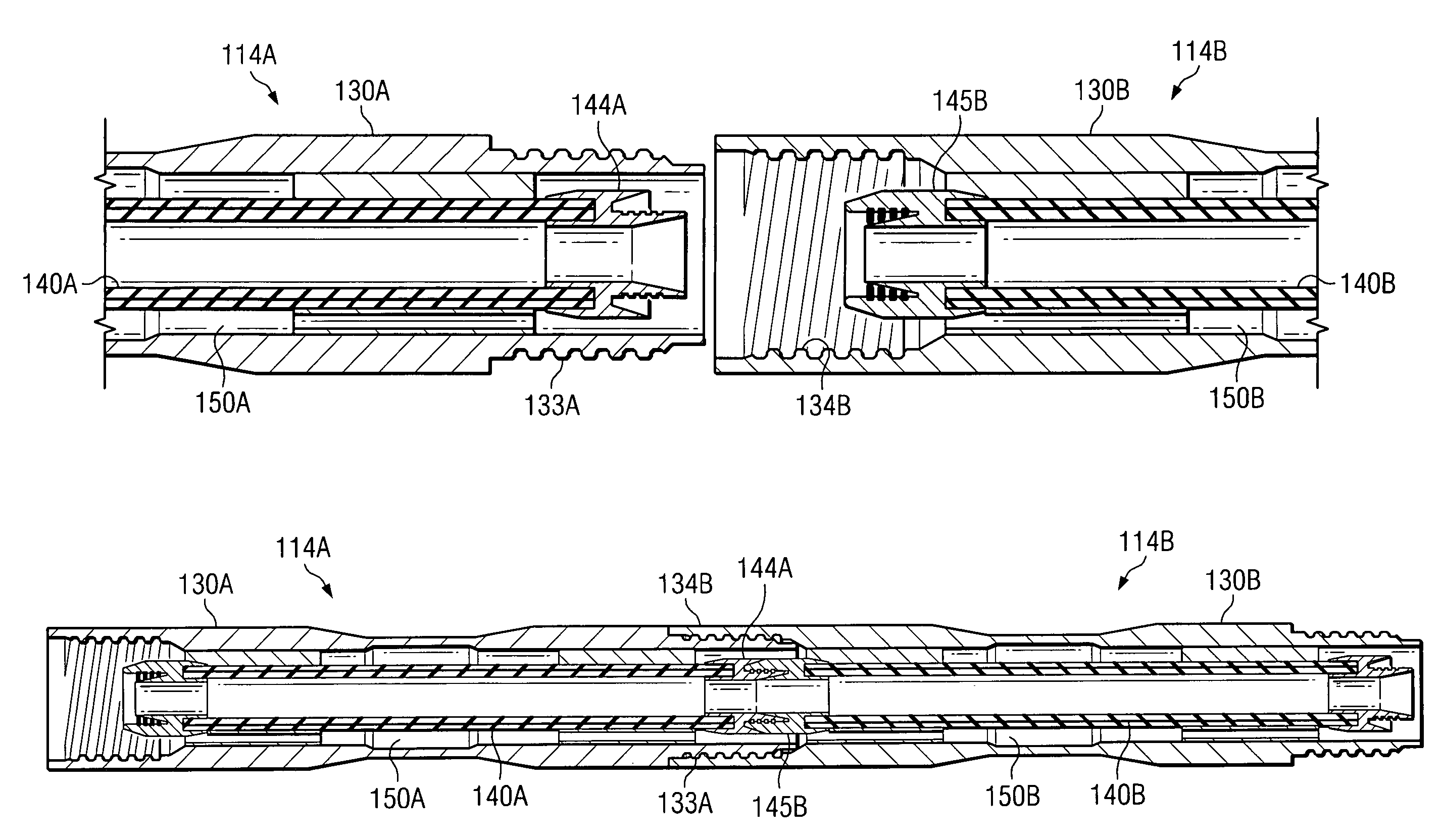

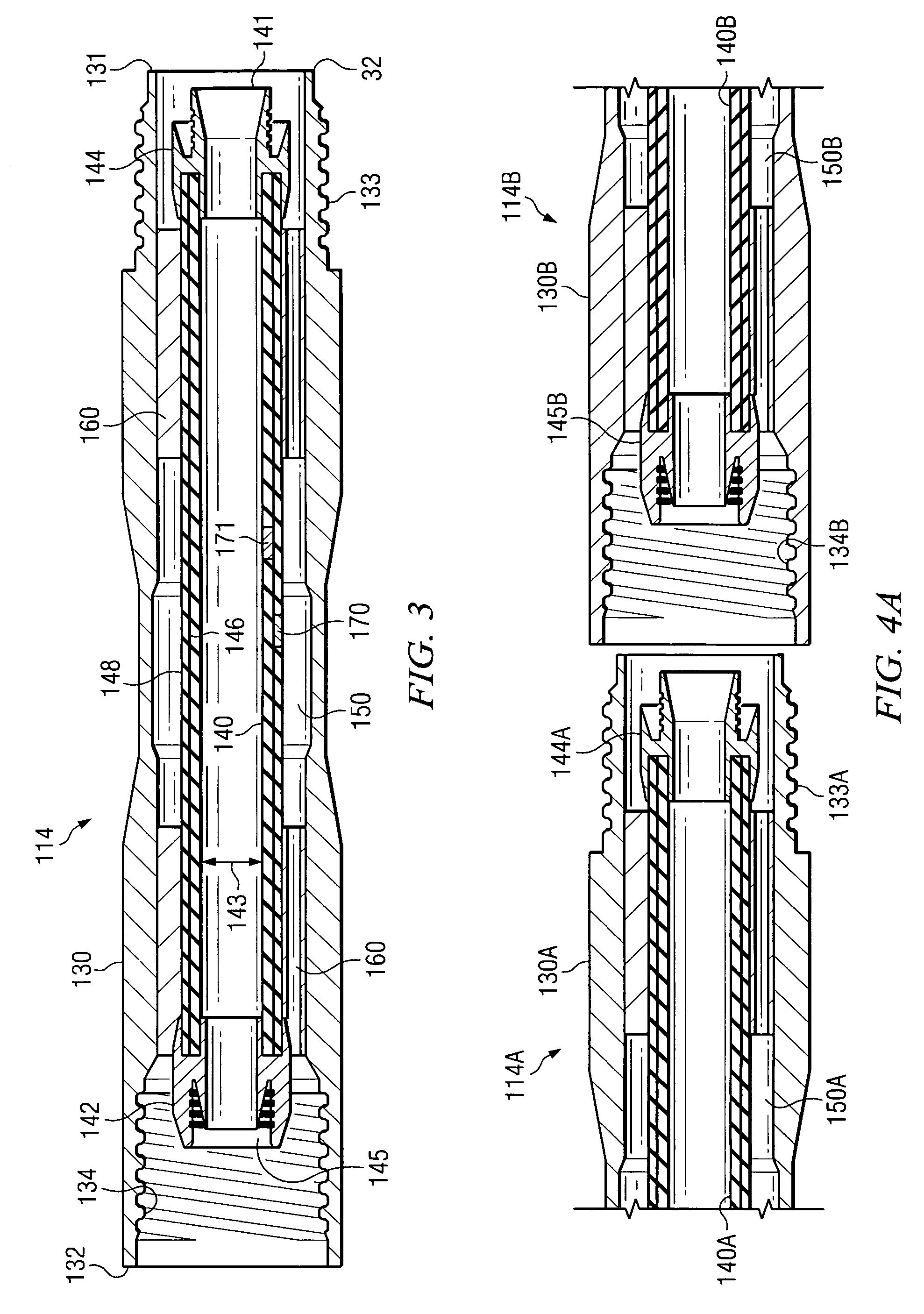

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS20050054228A1Increase axial loadAvoid local accumulationPipe heating/coolingPipe-jointsElectricityElectrical conductor

For heating a pipe-in-pipe pipeline with power provided through an electric cable, mid-line connector is provided including: a connector housing joinable to the outer pipe of the pipeline; a blank pipe positioned within the connector housing and joinable to the inner pipe of the pipeline; at least one pocket mounted in the connector housing, wherein the cable is mateable with the at least one pocket; a blank pipe conductor electrically coupled between the at least one pocket and the blank pipe; and an outer pipe conductor electrically coupled between the at least one pocket and the outer pipe.

Owner:SHELL OIL CO

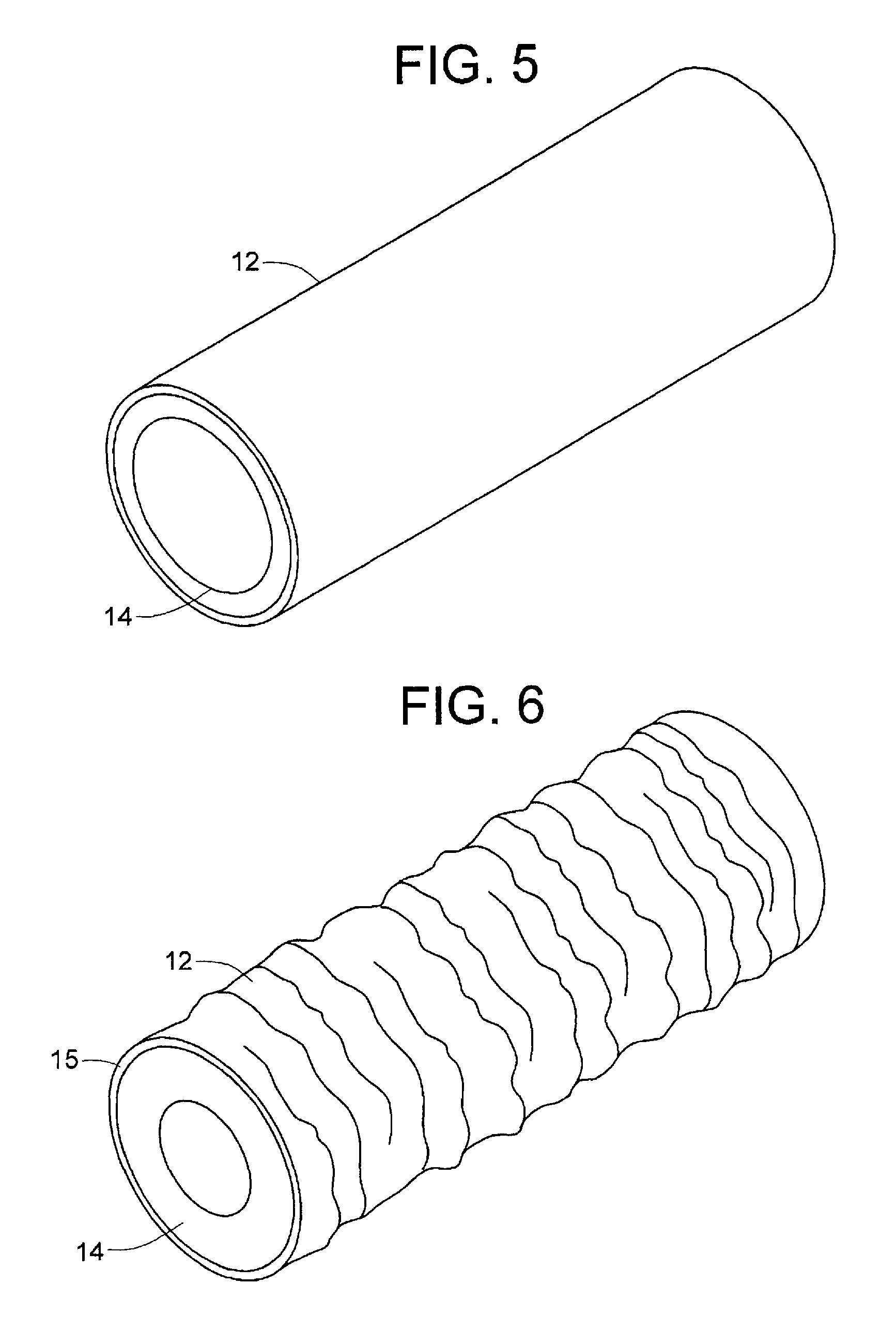

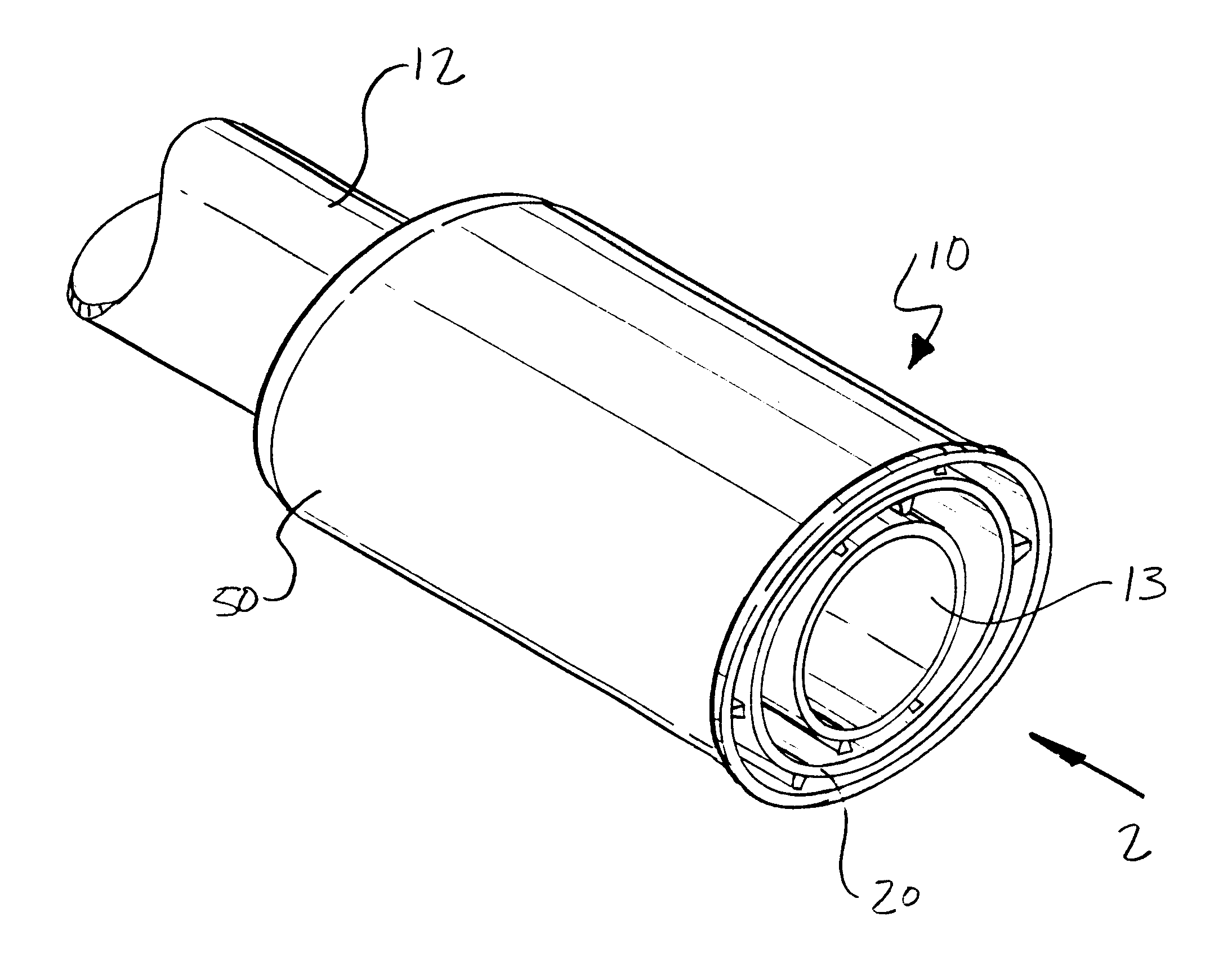

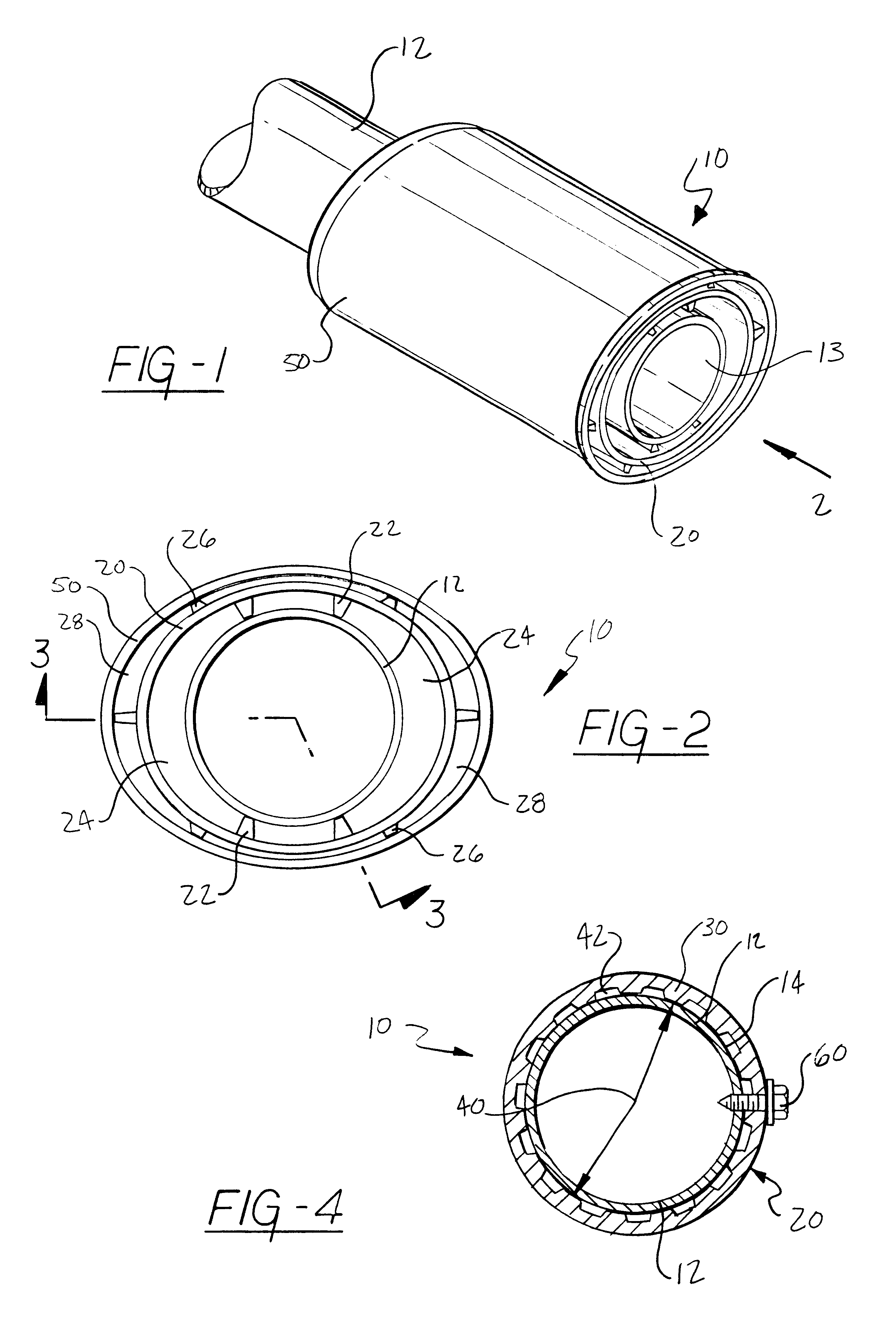

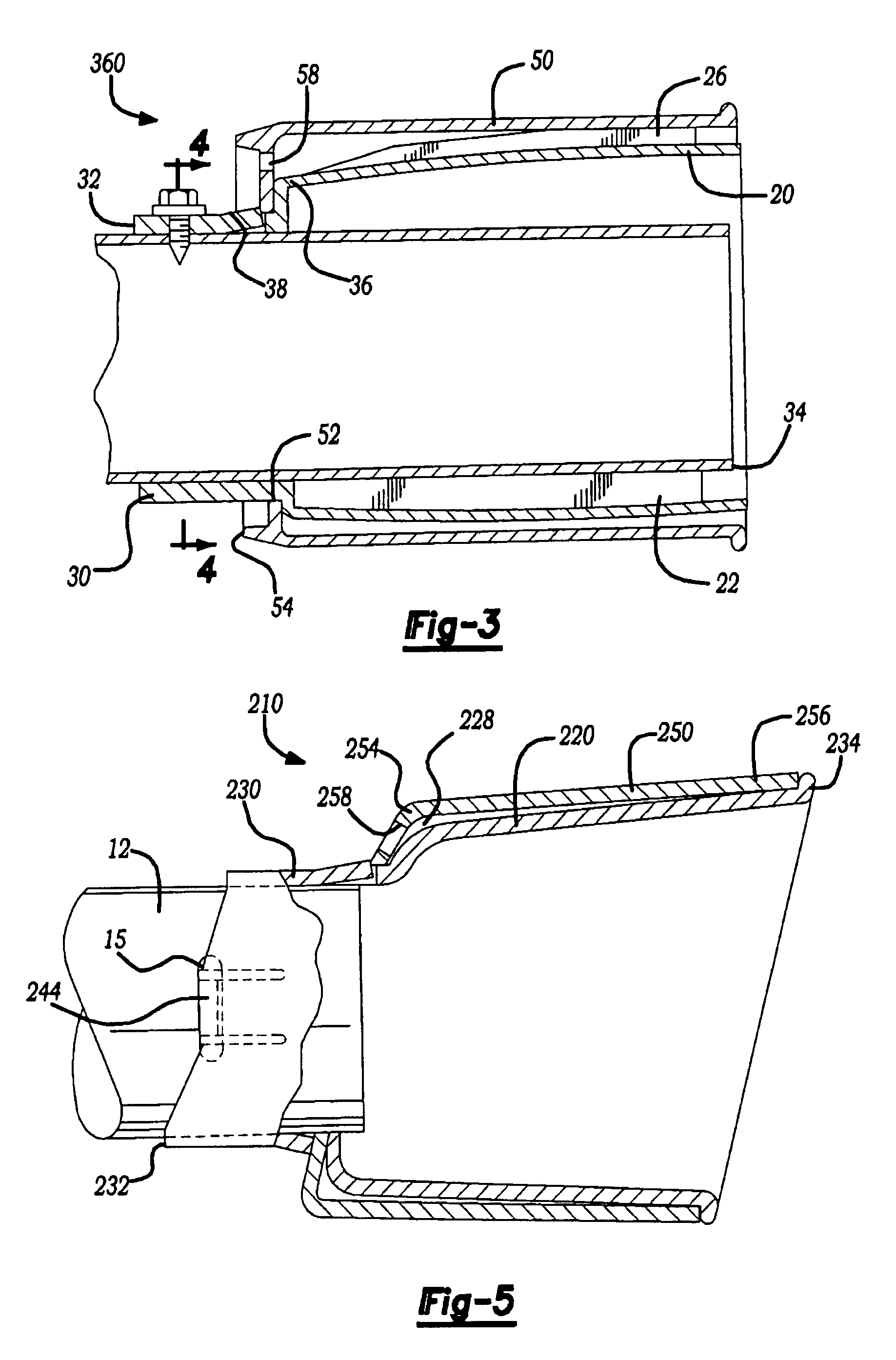

Electrical metallic tube, coupling, and connector apparatus and method

InactiveUS20050006122A1Shorten the timeEliminates time-consuming complexitySubstation/switching arrangement detailsRigid pipesCouplingBiomedical engineering

A labor saving system, method, and apparatus for connecting or coupling lengths of electric metallic tubing (“EMT”). The invention uses couplings / connectors that have barbs that are designed to engage corresponding indentations on EMT to ensure proper installation. In one aspect, the invention is an EMT having: an EMT inner surface forming an EMT cavity; an EMT outer surface; an EMT first end; and at least one indentation in the EMT outer surface at or near the EMT first end, the indentation adapted to receive a corresponding barb from a sleeve device. In another aspect, the invention is a sleeve device comprising; a sleeve inner surface forming a sleeve cavity adapted to receive an end of an EMT; a sleeve outer surface; a first sleeve end; at least one barb on the sleeve inner surface at or near the first sleeve end, the barb adapted to engage a corresponding indentation on the EMT.

Owner:JOHN MANEELY

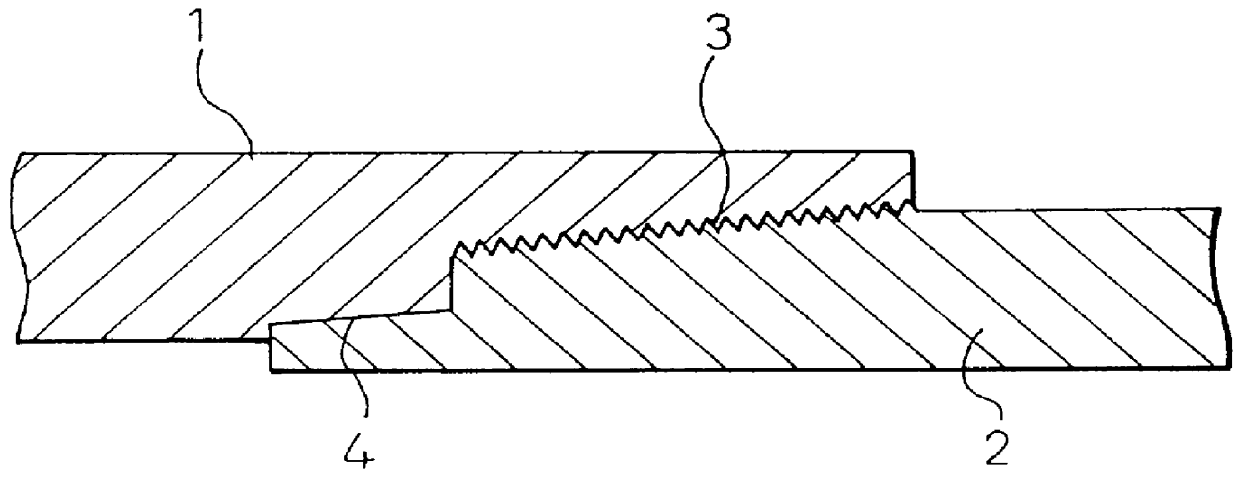

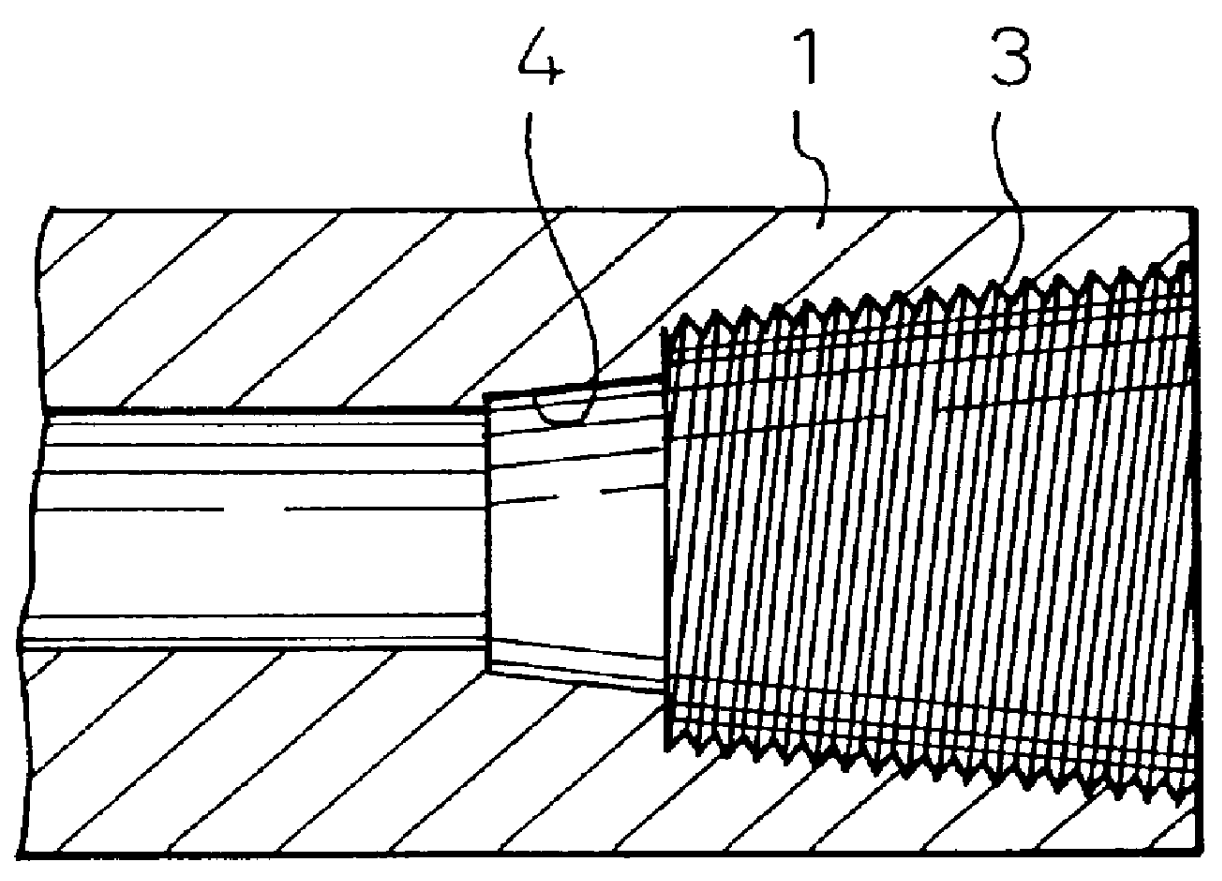

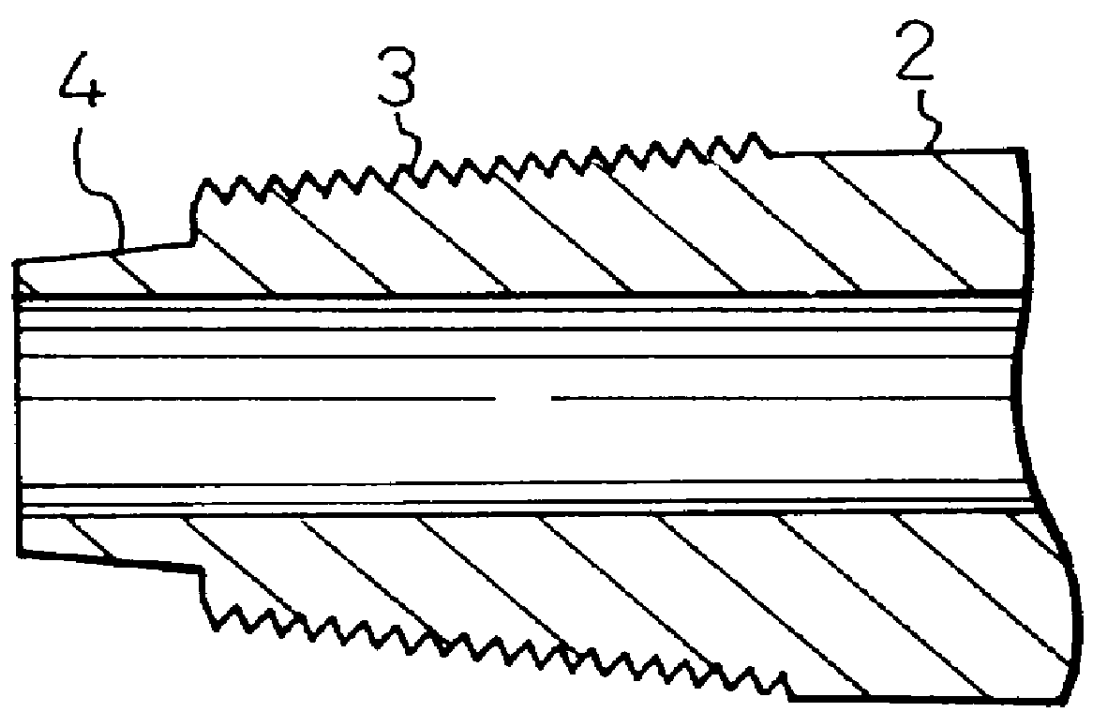

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

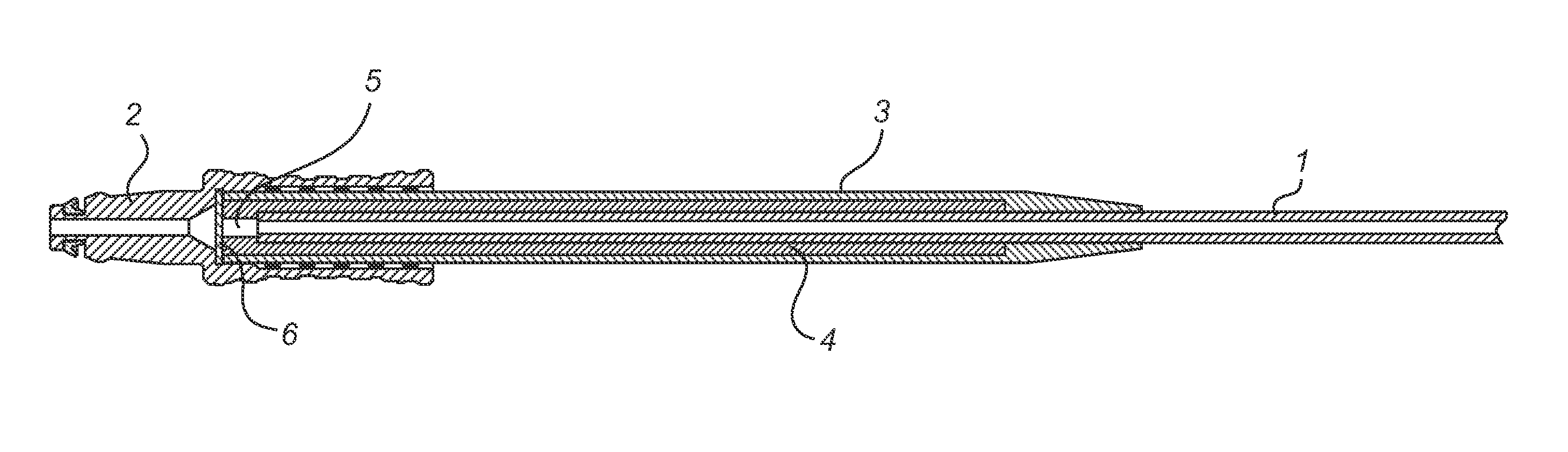

Articulating sheath for flexible instruments

A sheath useful for remote steering, guidance and / or manipulation of a flexible instrument, including e.g. an endoscope, received through the sheath.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

Method and apparatus for lining a conduit

Owner:HEAGY RICHARD T +3

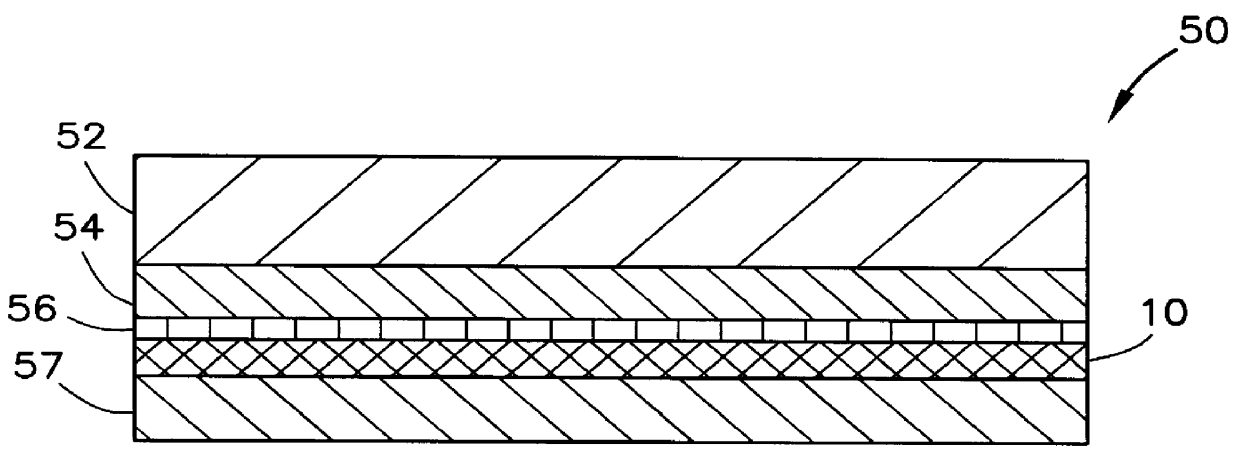

Composite modular barrier structures and packages

InactiveUS20050249901A1Improve barrier propertiesRemove moistureNanotechWrappersNanoparticleDesiccant

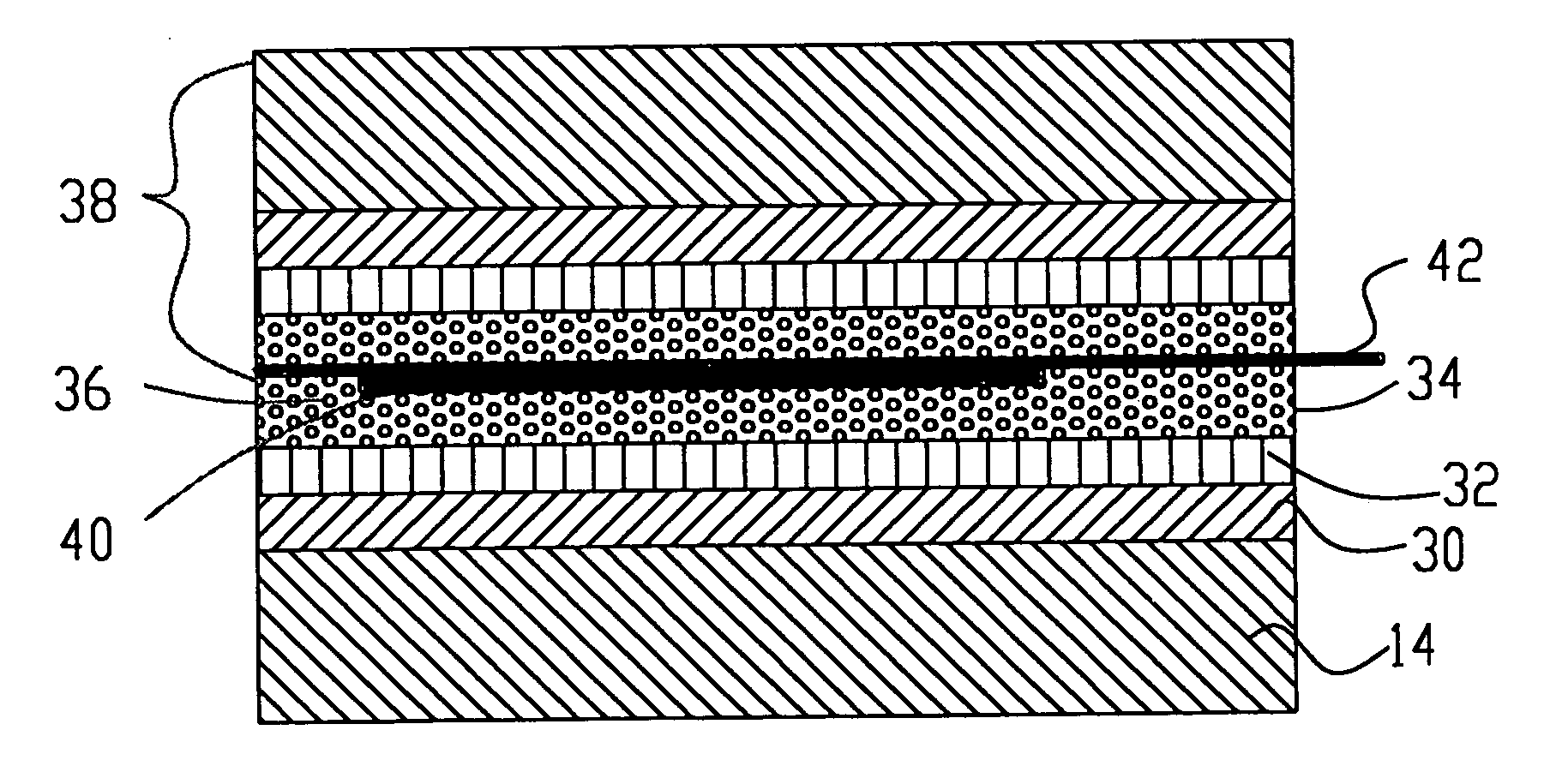

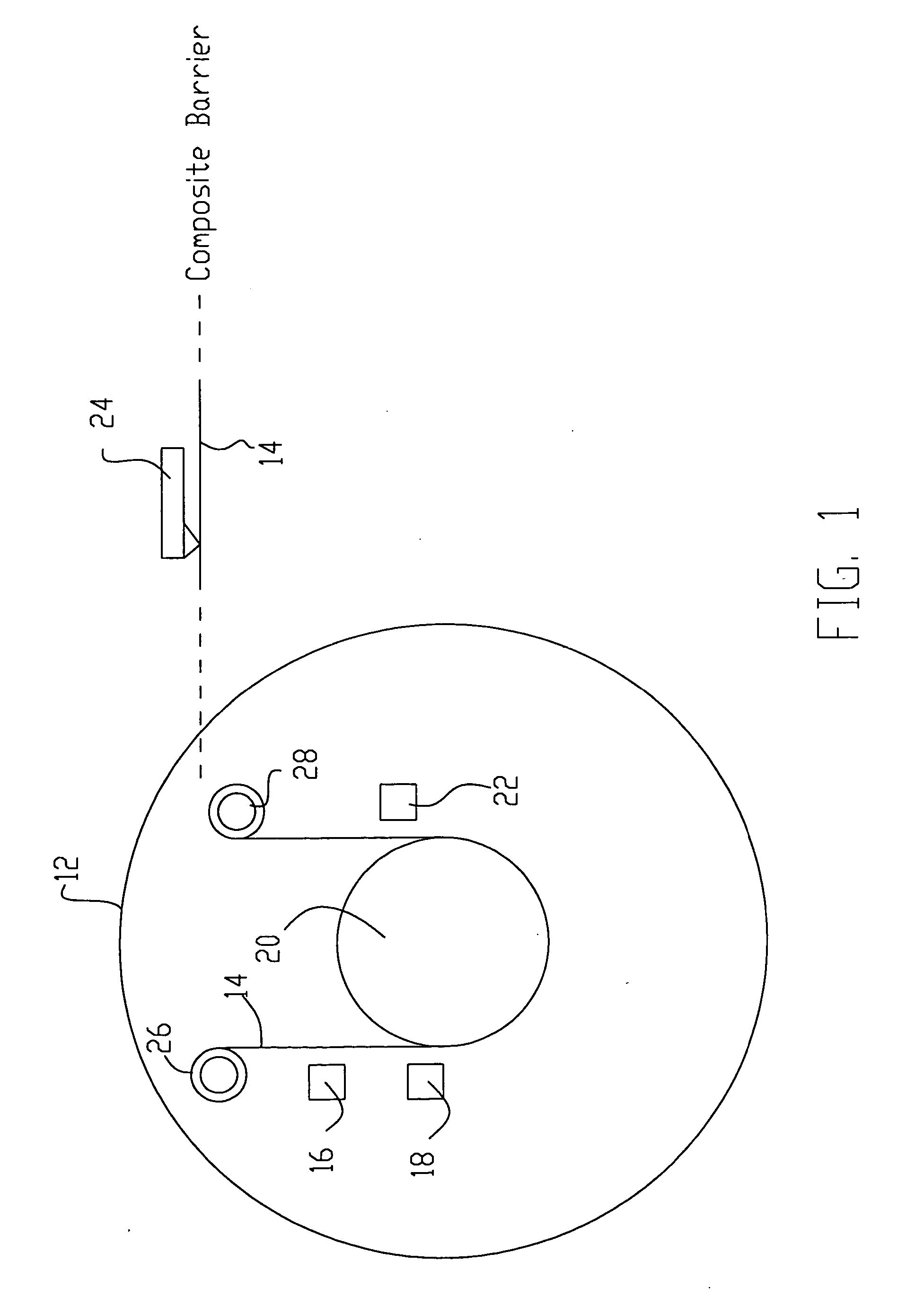

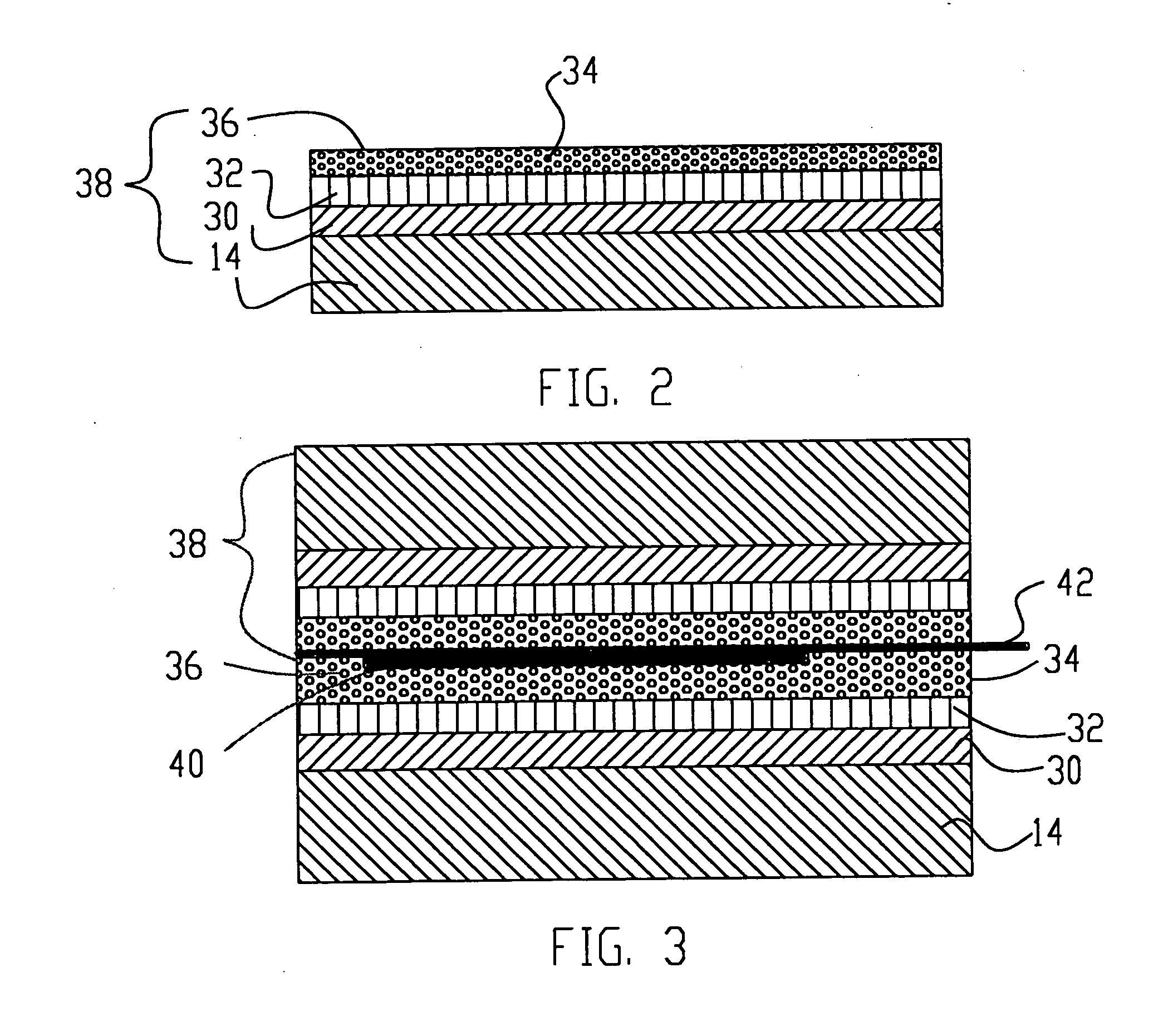

A composite multi-layer barrier is produced by first vapor depositing a barrier under vacuum over a substrate of interest and then depositing an additional barrier at atmospheric pressure in a preferably thermoplastic layer. The resulting multi-layer barrier is then used to coat an article of interest in a lamination process wherein the thermoplastic layer is fused onto itself and the surface of the article. The vacuum-deposited barrier may consists of a first leveling polymer layer followed by an inorganic barrier material sputtered over the leveling layer and of an additional polymeric layer flash evaporated, deposited, and cured under vacuum. The thermoplastic polymeric layer is then deposited by extrusion, drawdown or roll coating at atmospheric pressure. The resulting multi-layer barrier may be stacked using the thermoplastic layer as bonding agent. Nano-particles may be included in the thermoplastic layer to improve the barrier properties of the structure. A desiccant material may also be included or added as a separate layer.

Owner:SIGMA LAB OF ARIZONA

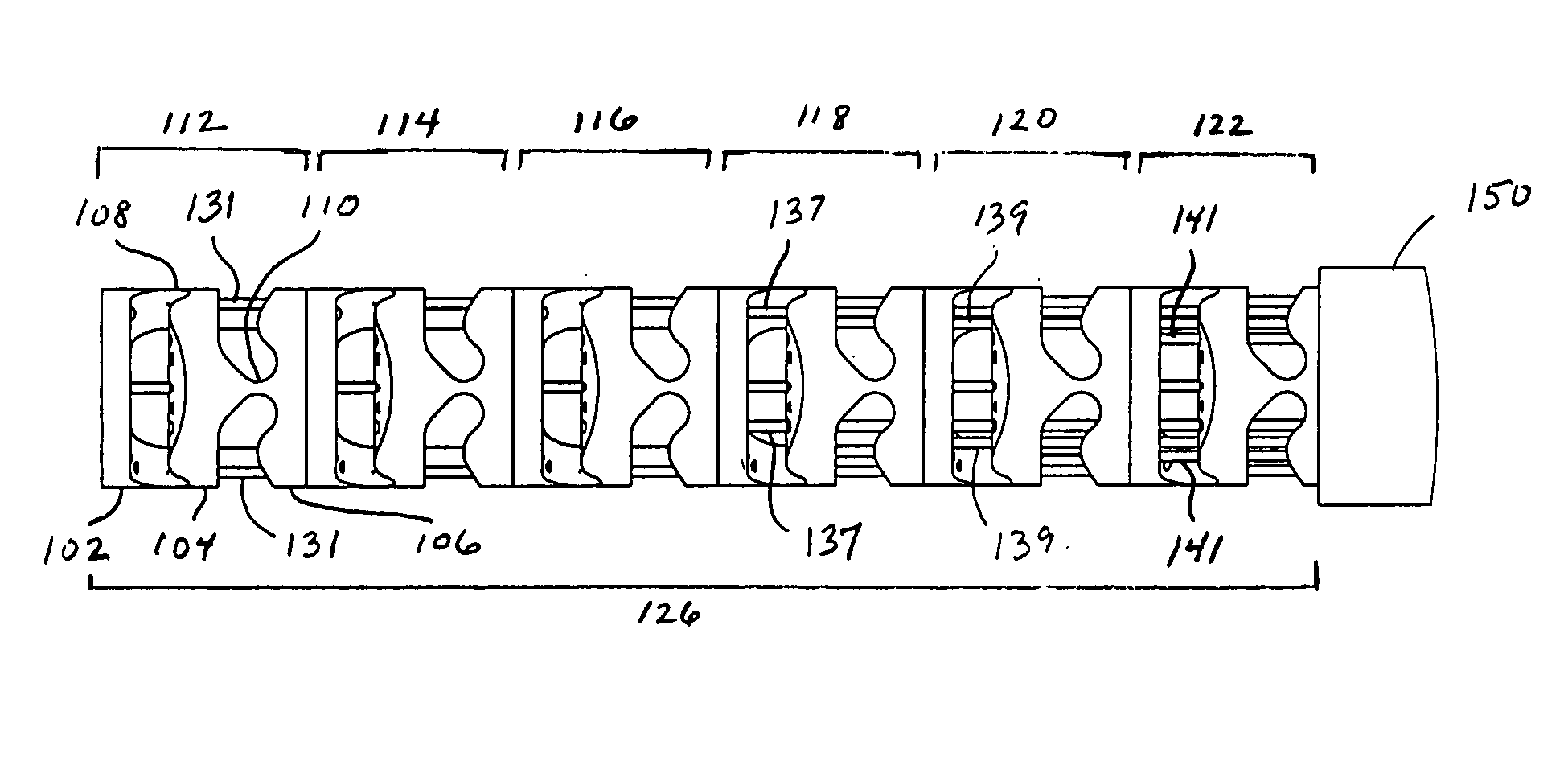

Guide catheter having selected flexural modulus segments

InactiveUS6858024B1Prevent guide catheter back-outIncreasing back-out resistanceGuide needlesFlexible pipesFlexural modulusAortic arch

A guiding catheter for use in coronary angioplasty and other cardiovascular interventions which incorporates a plurality of segment of selected flexural modulus in the shaft of the device. The segments which have a different flexibility than the sections immediately proximal and distal to them, creating zones in the catheter shaft which are either more or less flexible than other zones of the shaft. The flexibility and length of the shaft in a given zone is then matched to its clinical function and role. A mid-shaft zone is significantly softer than a proximal shaft or distal secondary curve to better traverse the aortic arch shape without storing too much energy. A secondary zone section is designed to have maximum stiffness to provide optimum backup support and stability.

Owner:BOSTON SCI SCIMED INC

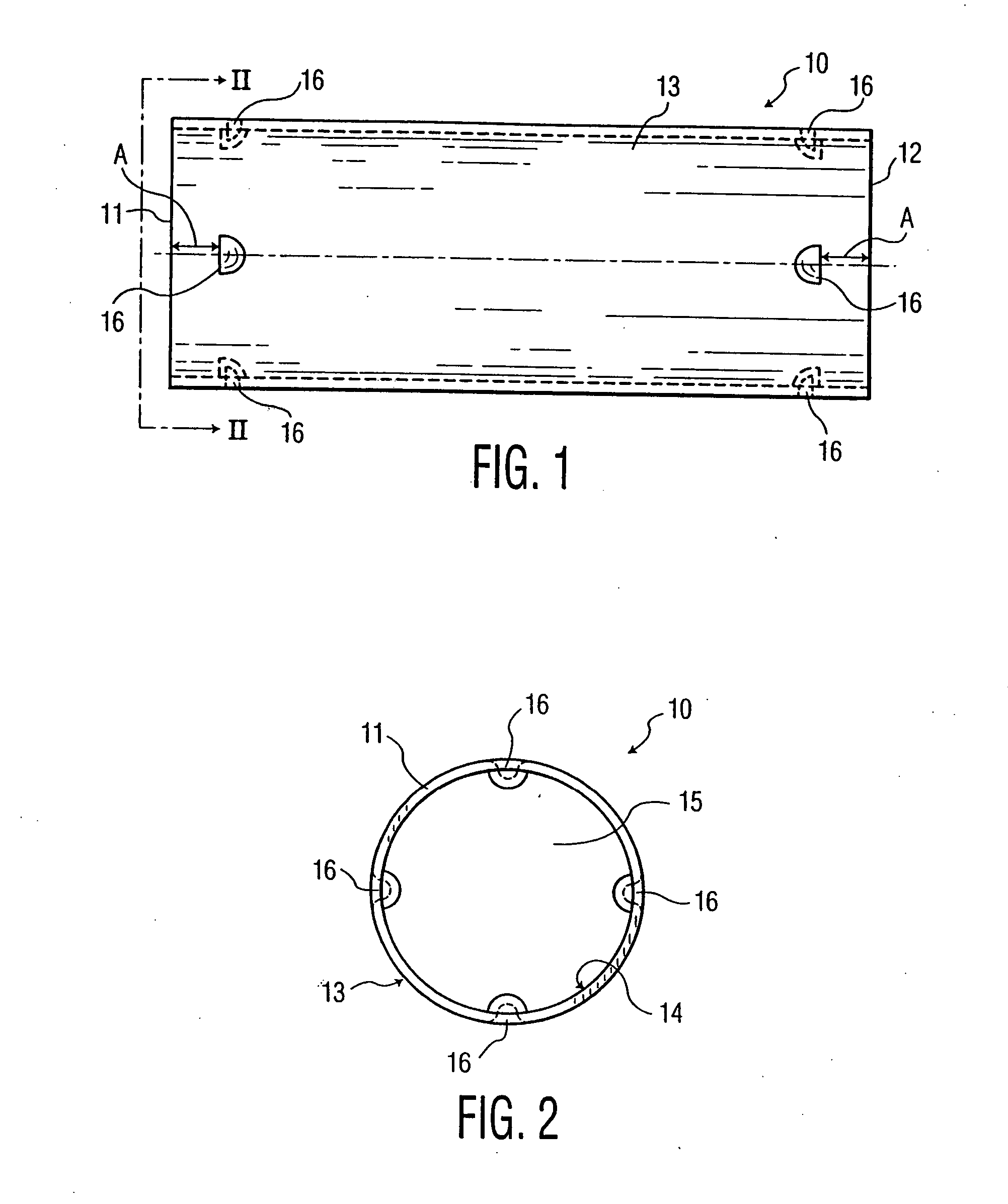

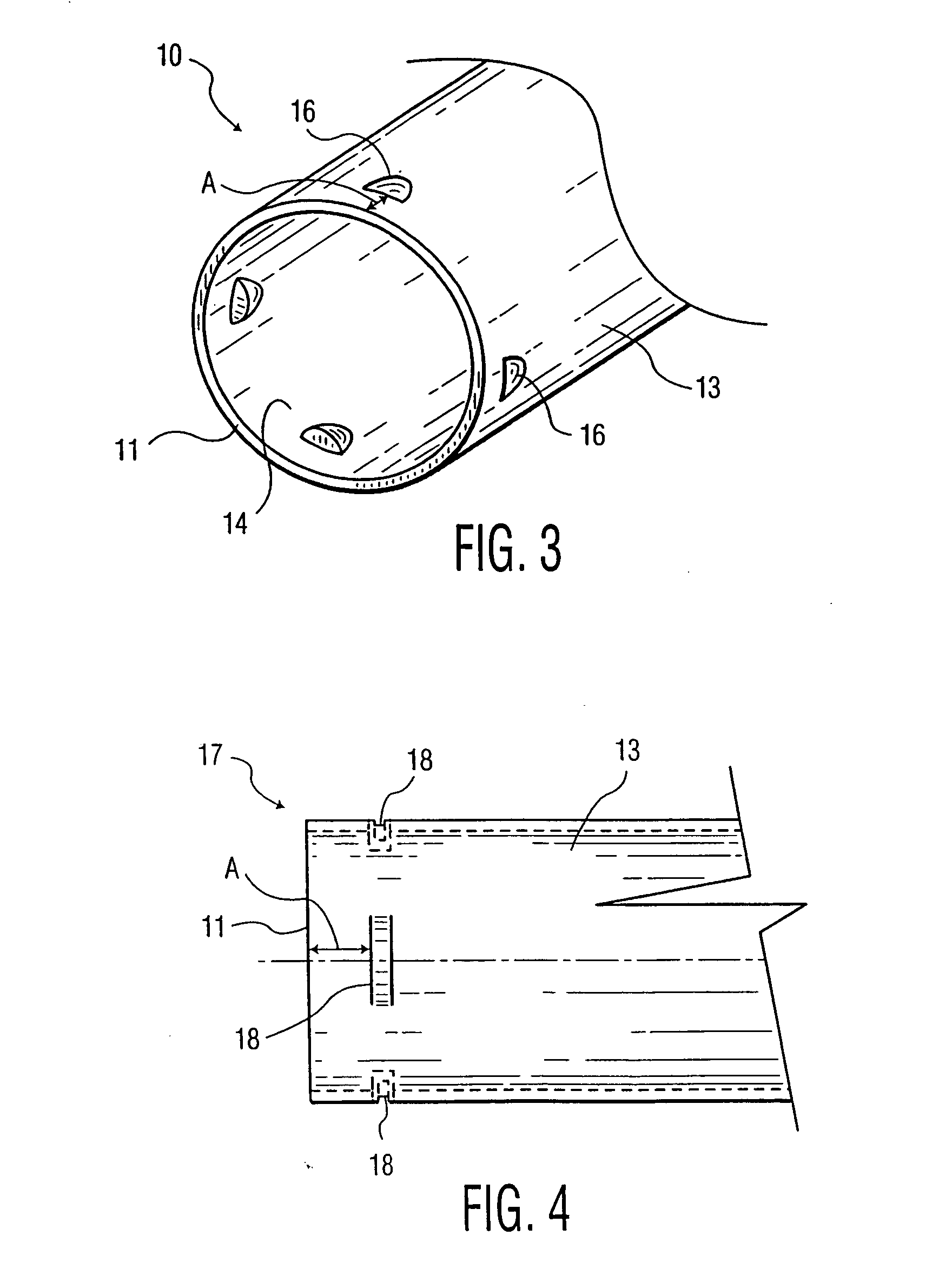

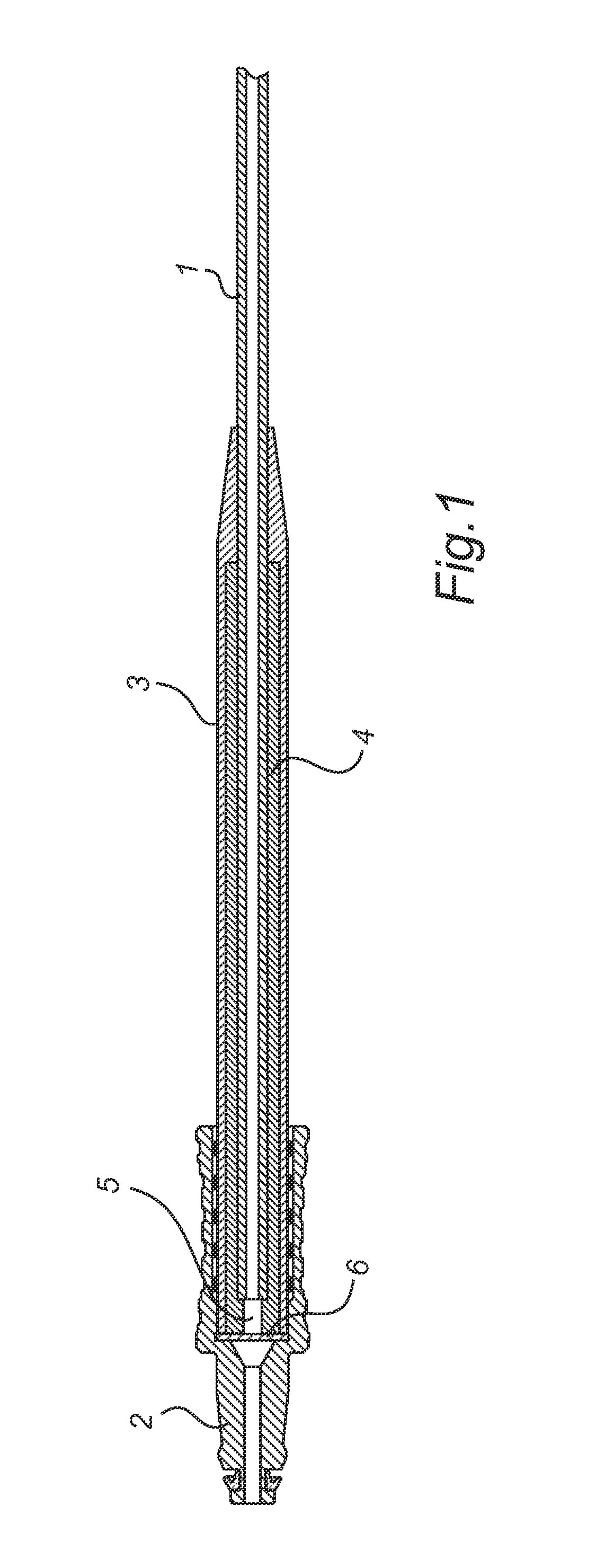

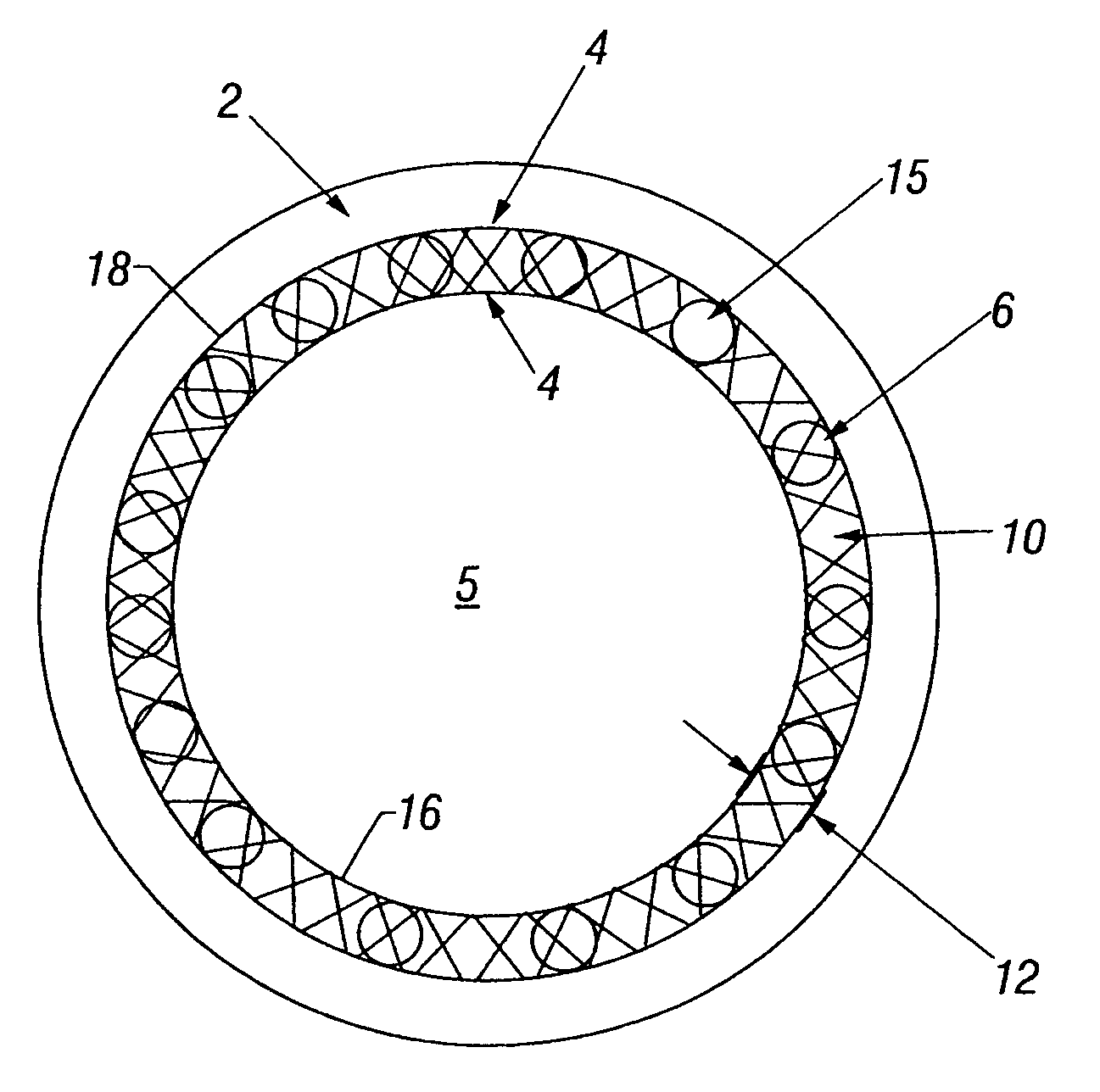

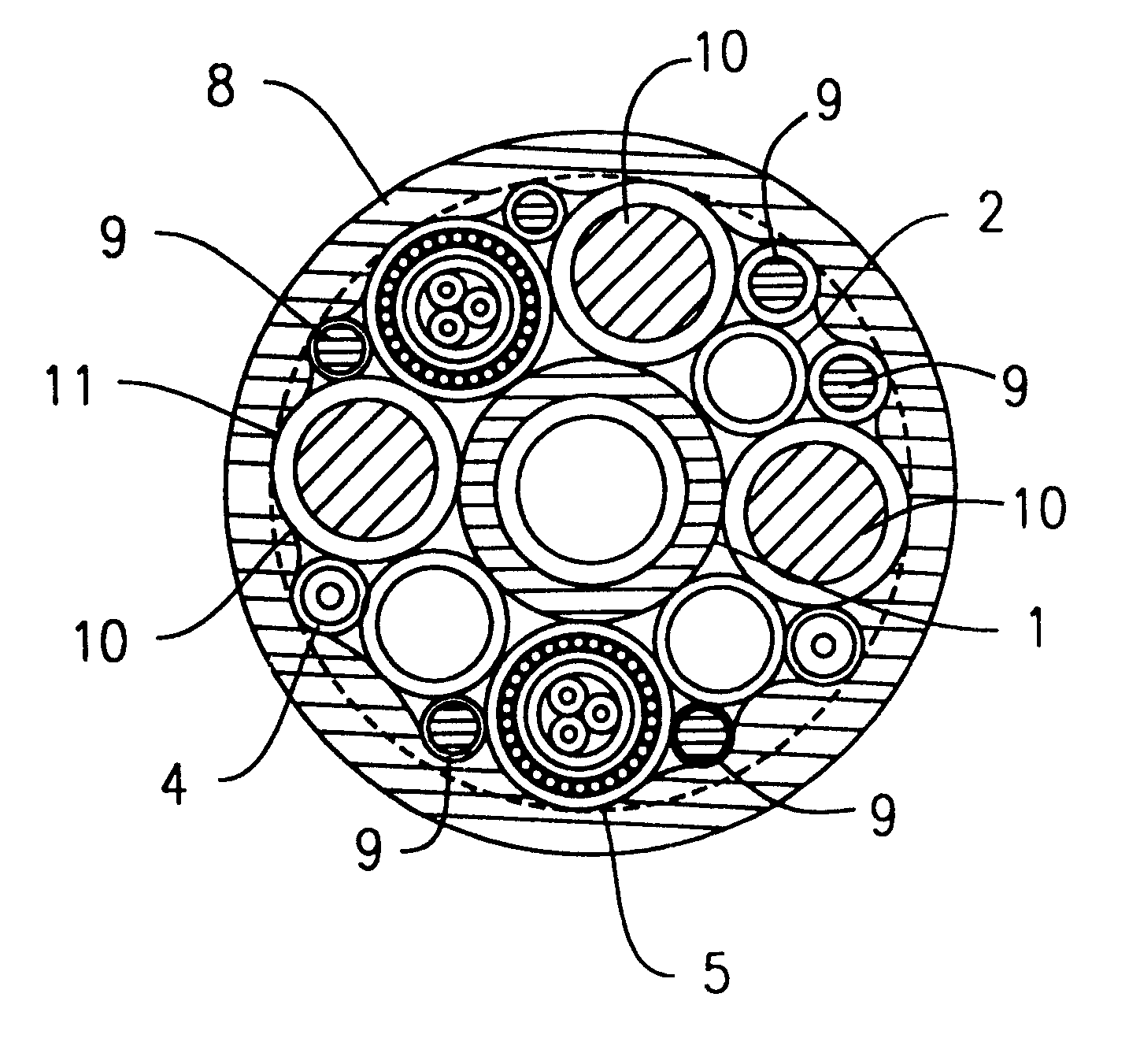

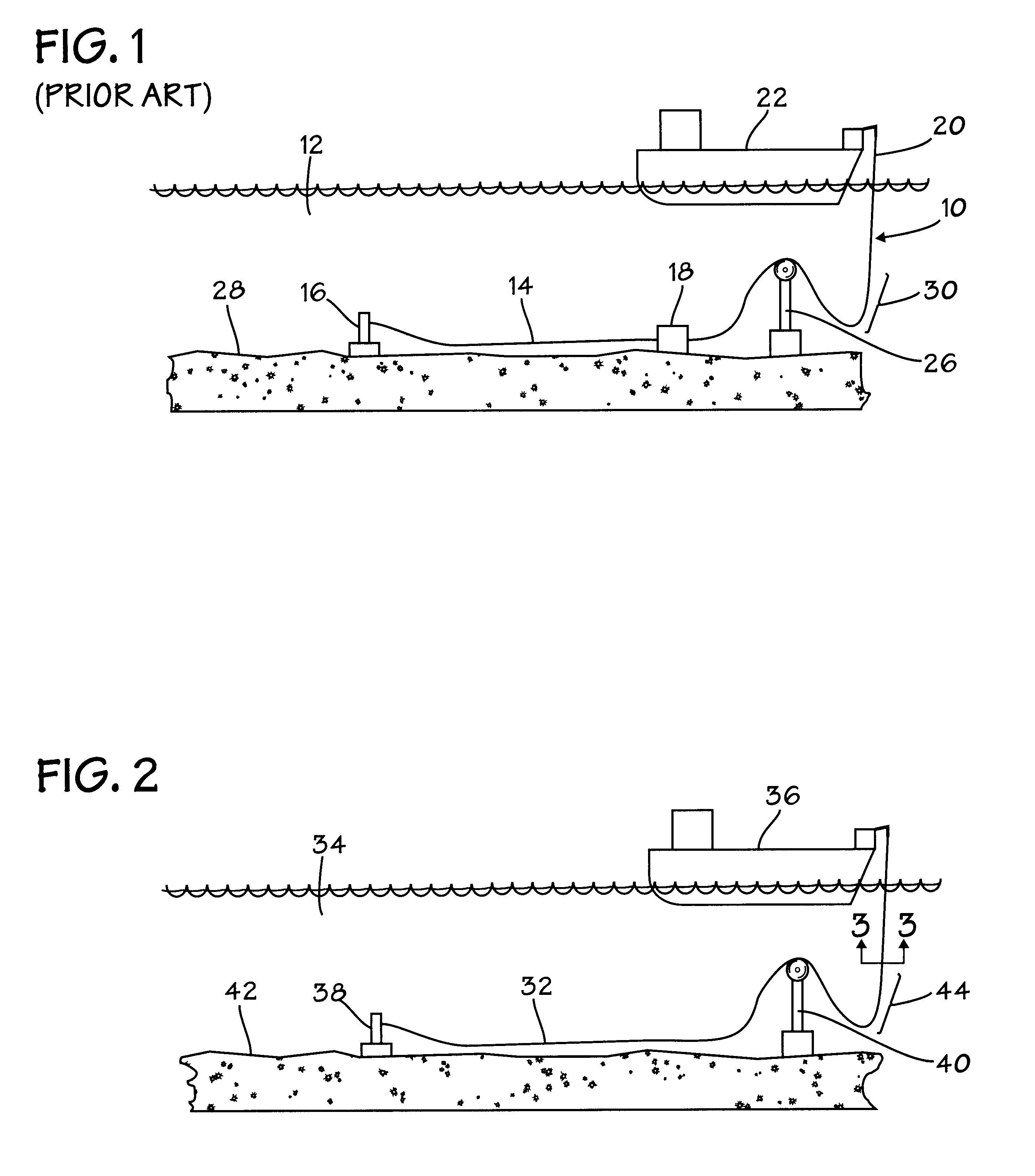

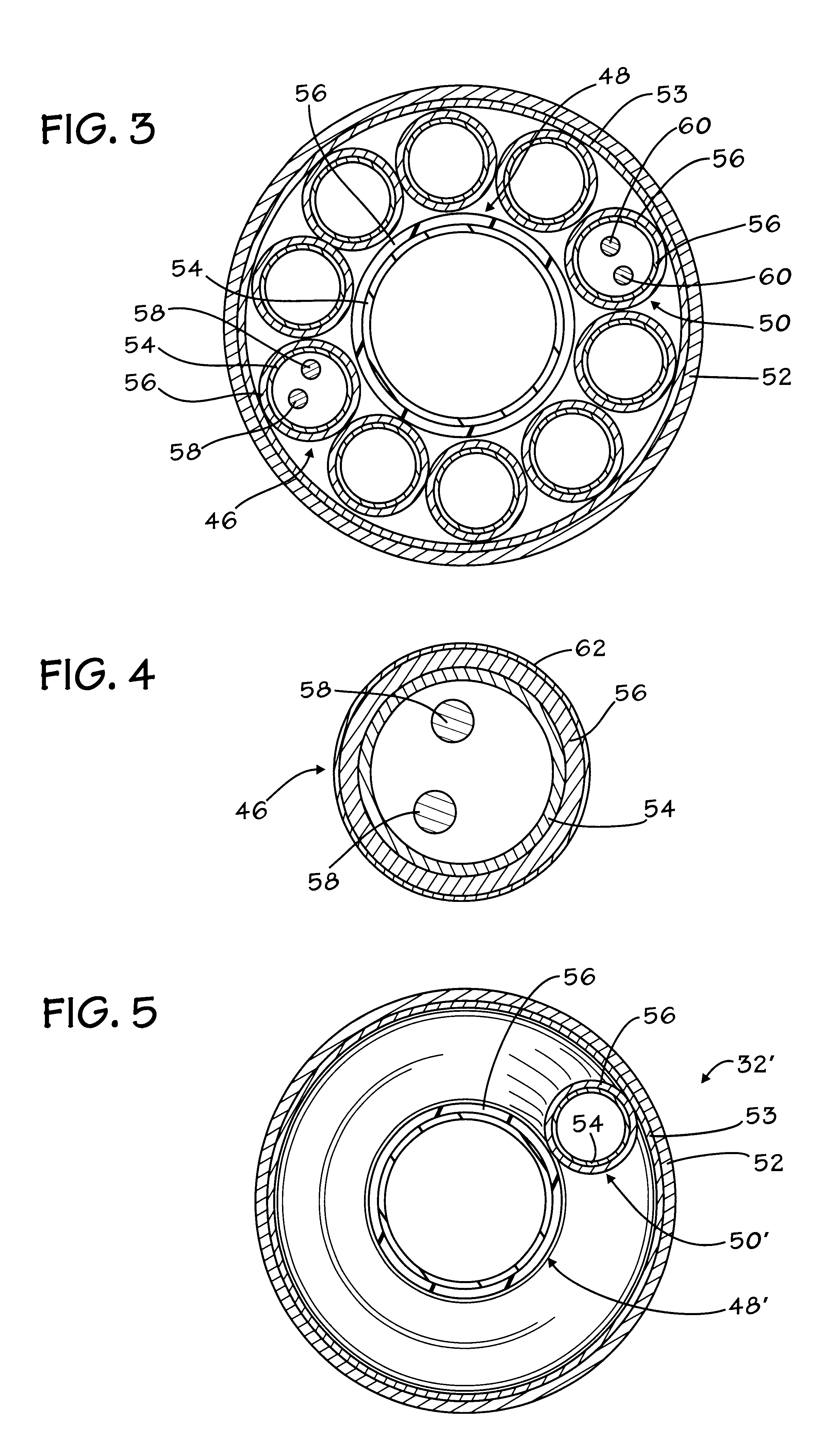

Dynamic umbilicals with internal steel rods

InactiveUS6472614B1Power cables including communication wiresPower cables including electrical controlUltimate tensile strengthBallast

In an umbilical, one or more steel rods, which provide strength and ballast, are wound helically within the umbilical along with the steel tubes and / or elongated active umbilical elements. These steel rods replace some or all of the thermoplastic filler elements that would otherwise be included within the umbilical. An umbilical according to an embodiment of the invention may include a plurality of steel tubes helically wound around a core, and at least one substantially solid steel rod helically wound around the core, the steel rod being arranged in a void between the steel tubes. Thus, the invention avoids the need to apply additional armoring layers to the outside of the umbilical for strength and ballast.

Owner:TECH FRANCE SA

Metal material having good resistance to metal dusting

InactiveUS6623869B1Excellent in metal dusting resistanceIncreased durabilityChemical industryCorrosion preventionMetal dustingMetallic materials

A metallic material of the invention which comprises, in mass %, C: not more than 0.2%, Si: 0.01-4%, Mn: 0.05-2%, P: not more than 0.04%, S: not more than 0.015%, Cr: 10-35%, Ni: 30-78%, Al: not less than 0.005% but less than 4.5%, N: 0.005-0.2%, and one or both of Cu: 0.015-3% and Co: 0.015-3%, with the balance substantially being Fe, and of which the value of 40Si+Ni+5Al+40N+10 (Cu+Co), wherein the symbols of elements represent the contents of the respective elements, is not less than 50 and has excellent corrosion resistance in an environment in which metal dusting is ready to occur and, therefore, can be utilized as or in heating furnace pipes, piping systems, heat exchanger pipes and so forth to be used in a petroleum refinery or in petrochemical plants, and can markedly improve the equipment durability and safety.

Owner:NIPPON STEEL CORP

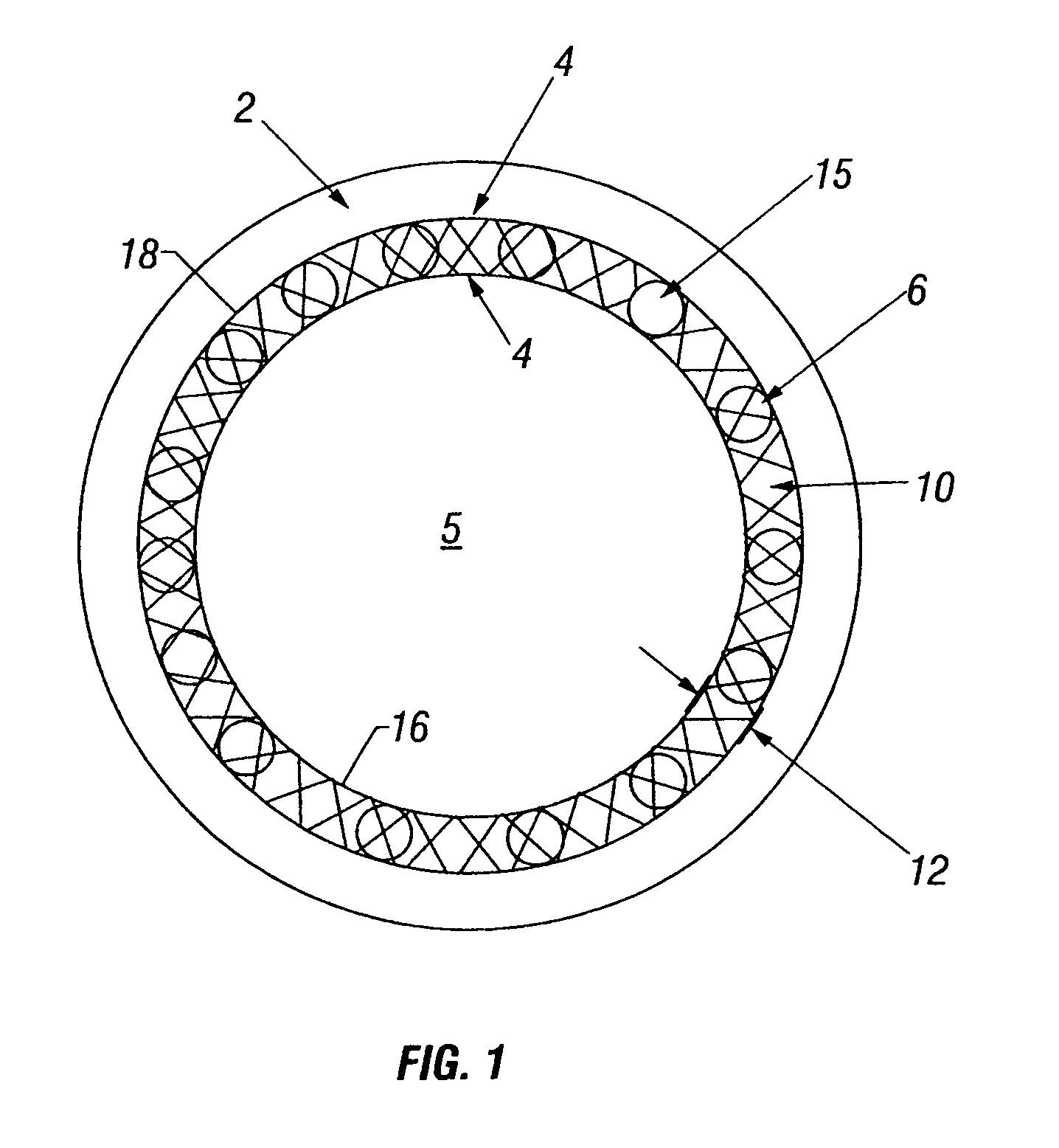

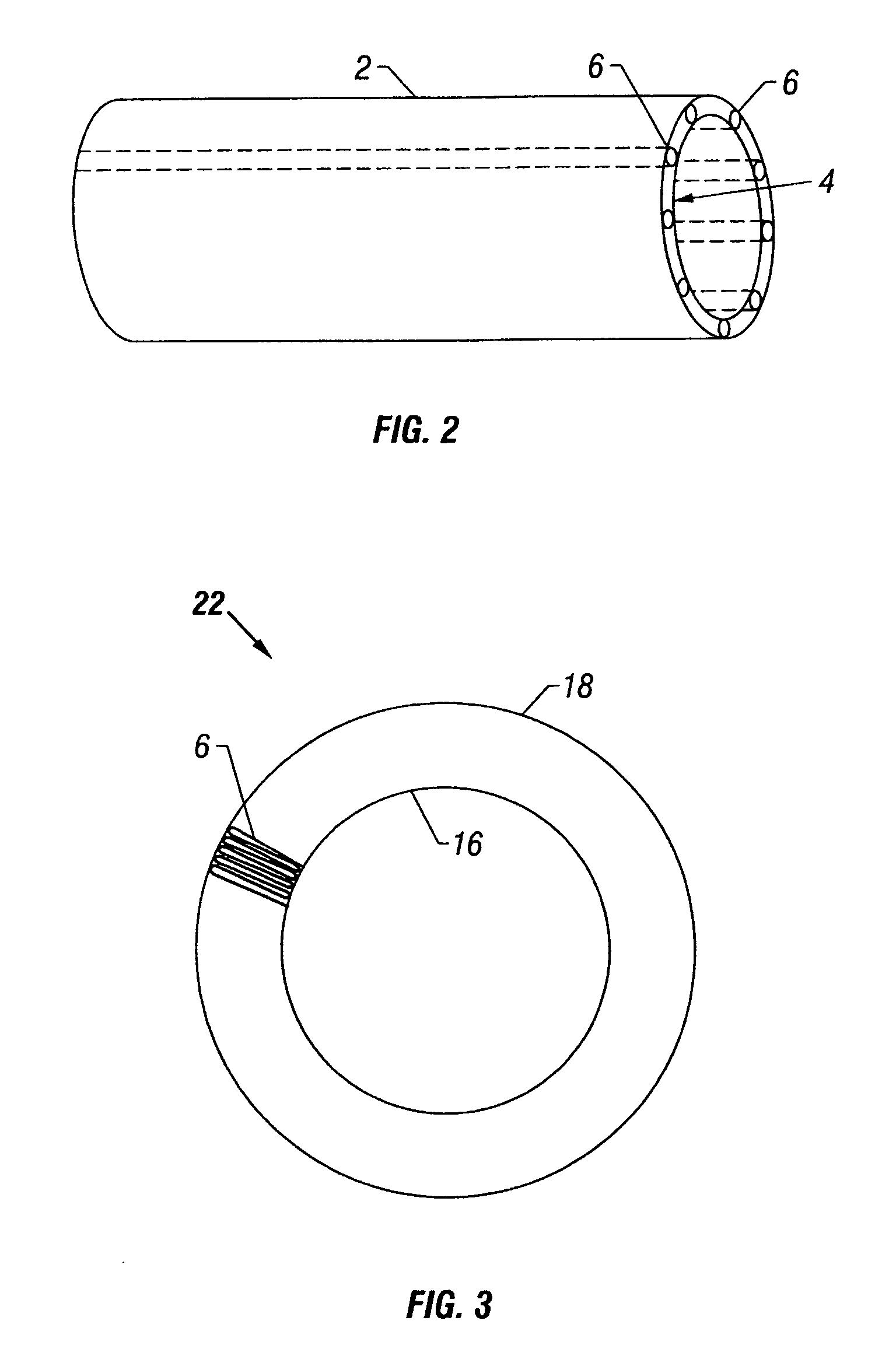

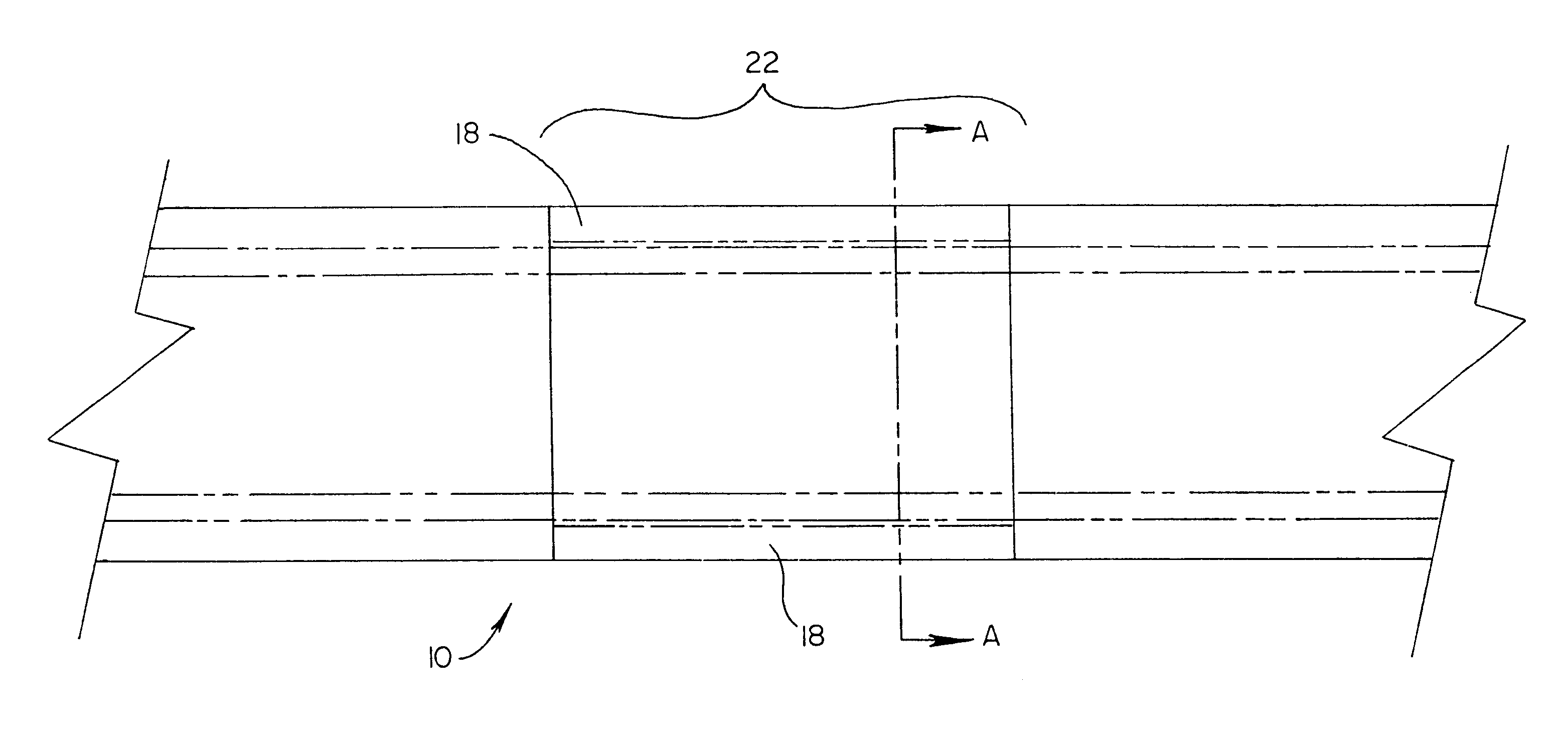

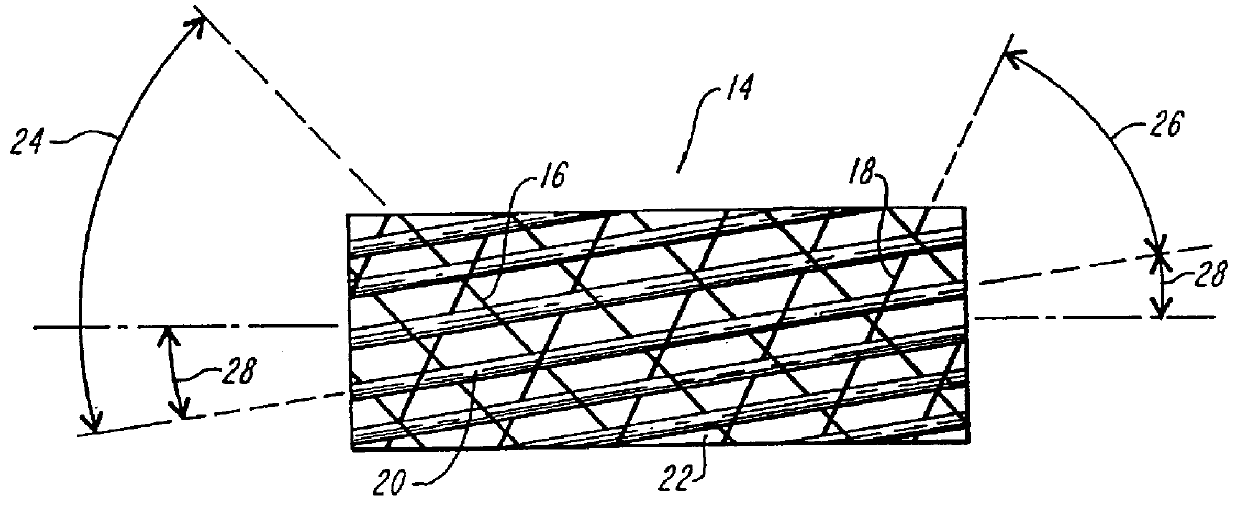

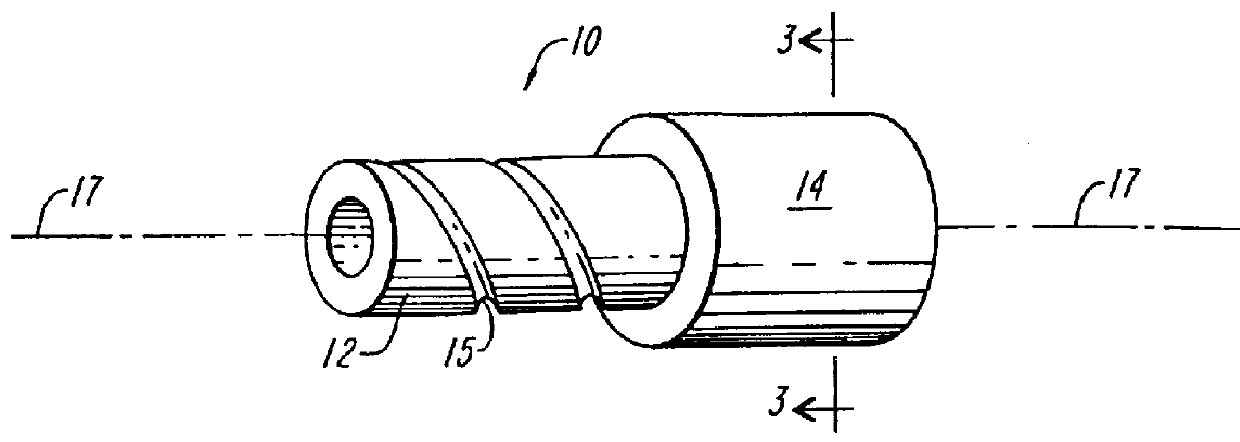

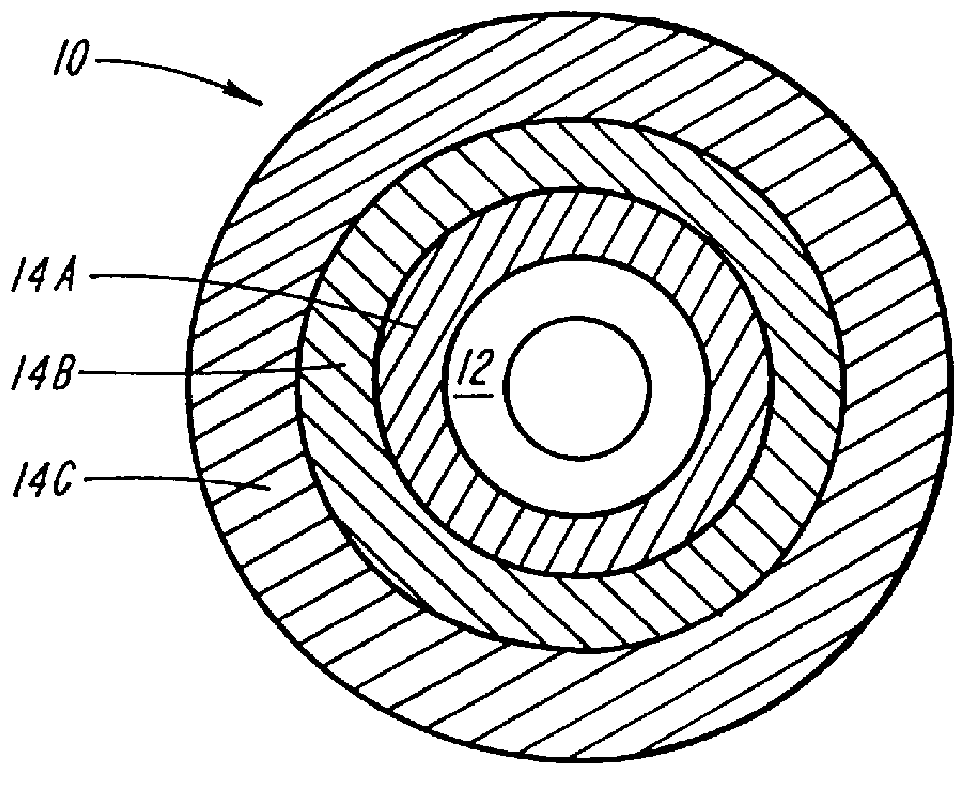

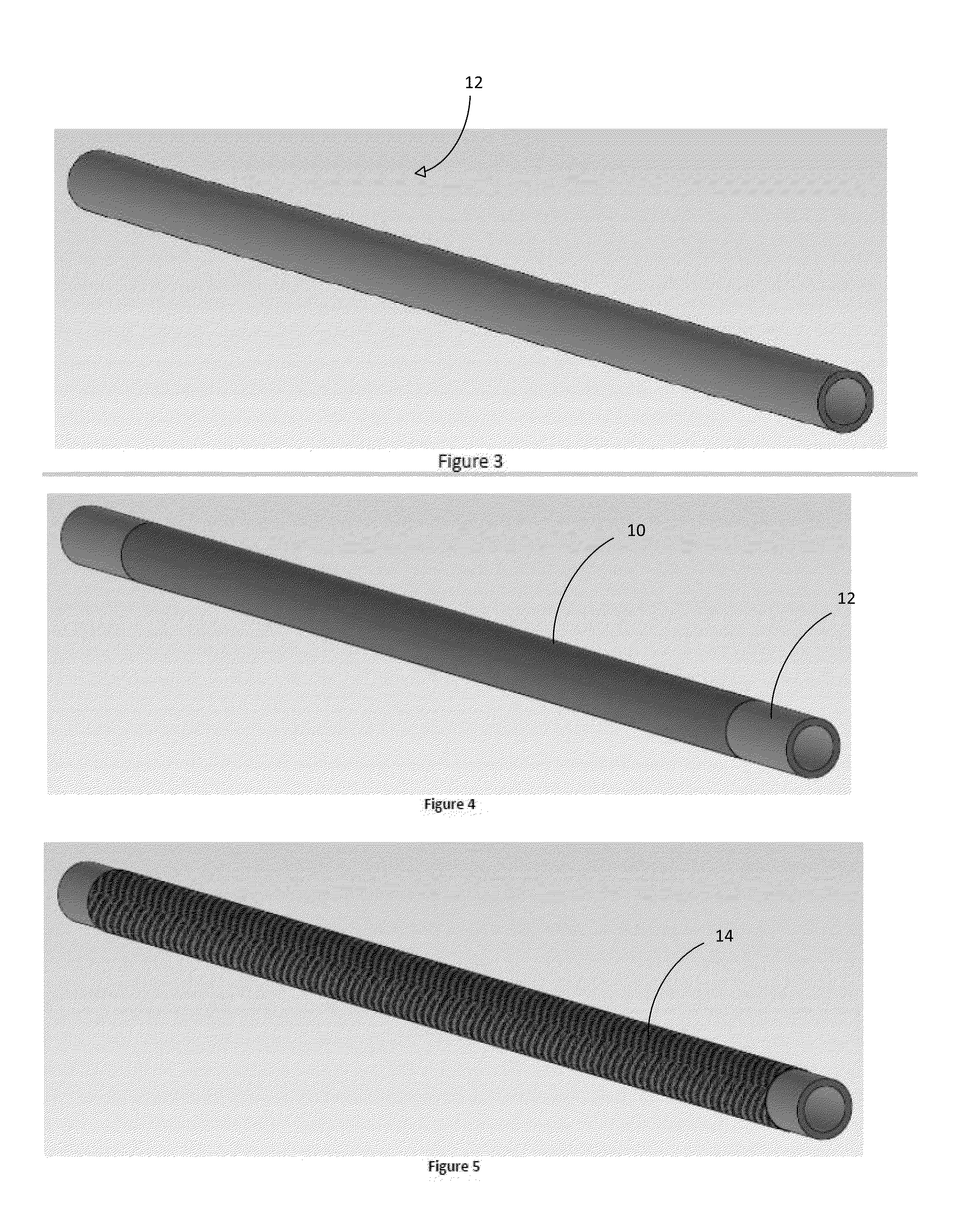

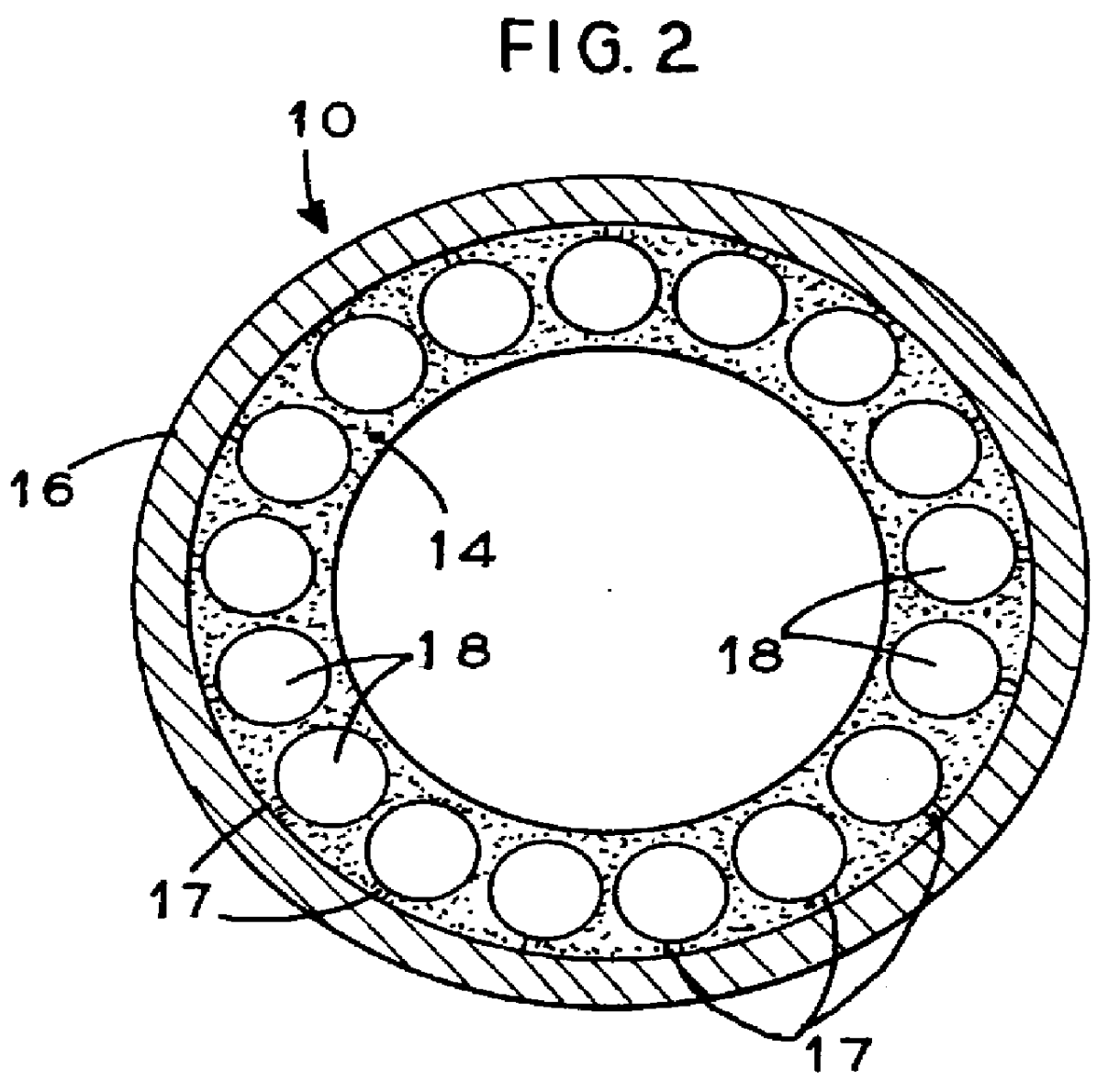

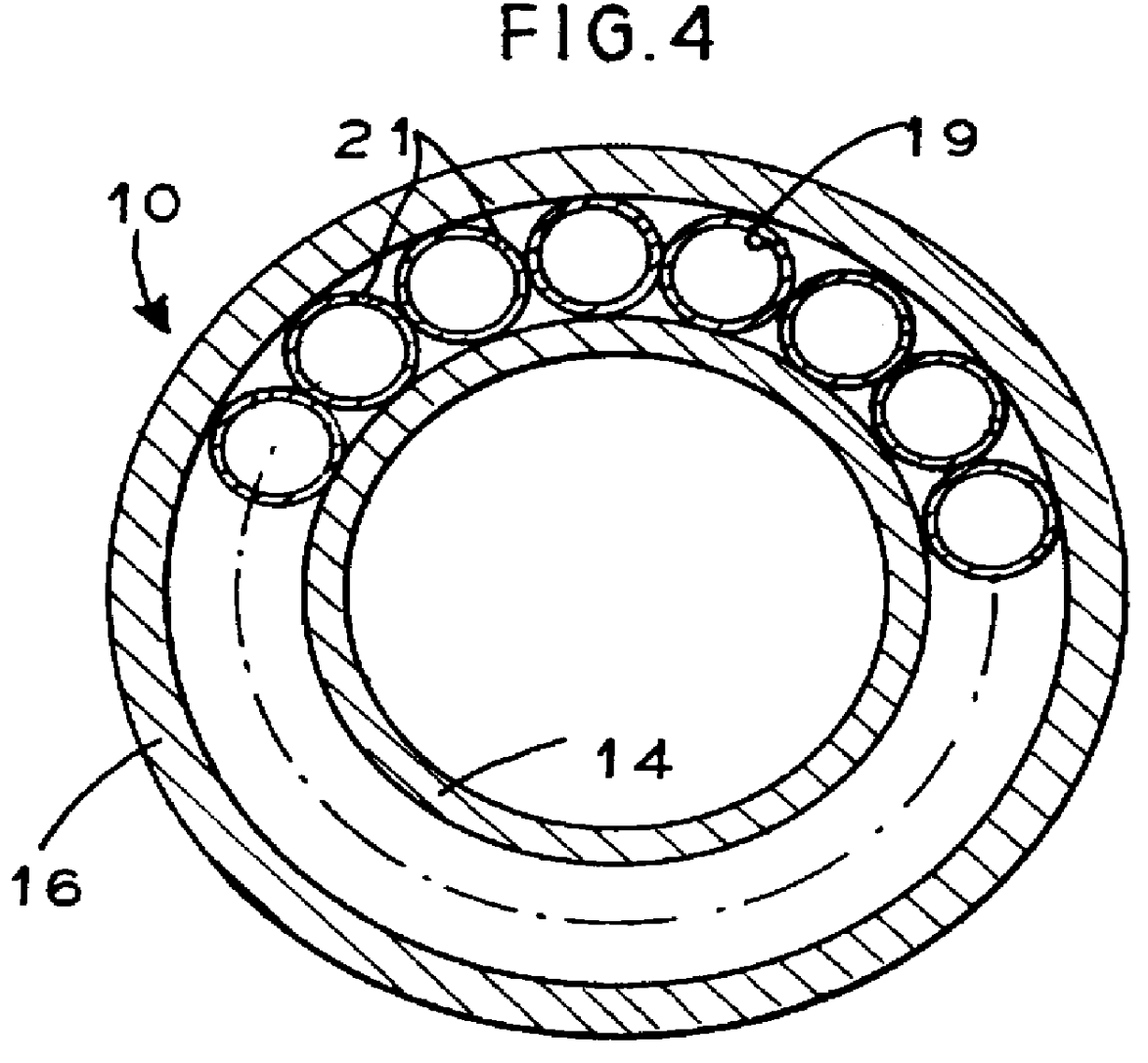

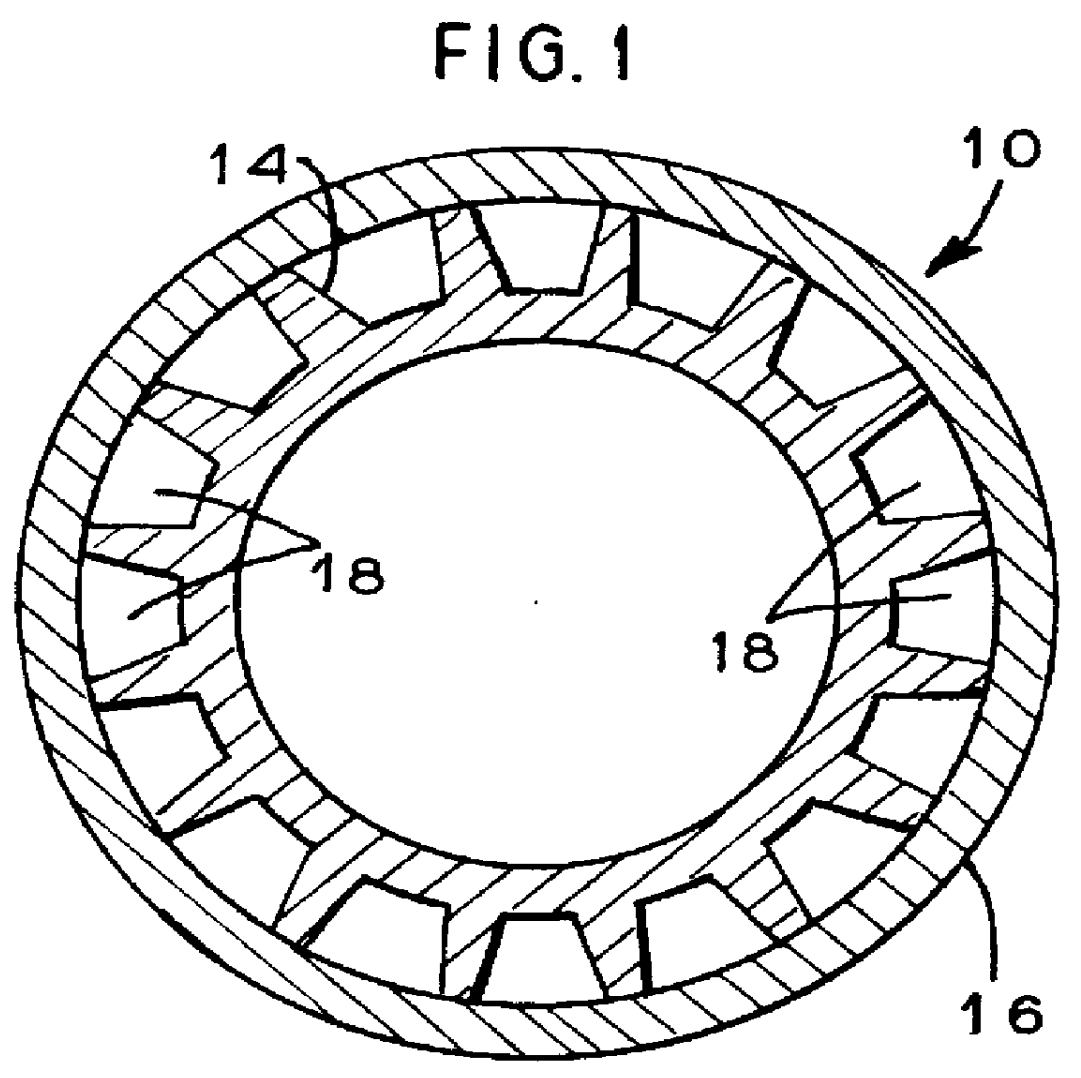

Composite spoolable tube

InactiveUS6016845AExtended service lifeExtending operational parameterDrilling rodsLayered productsInterface layerEngineering

A spoolable composite tube capable of being spooled onto a reel for storage and for use in oil field applications. The spoolable tube exhibits unique anistropic characteristics that provide improved burst and collapse pressures, increased tensile strength, compression strength, and load carrying capacity, while still remaining sufficiently bendable to be spooled onto a reel in an open bore configuration. The spoolable composite tube can include an inner liner, an interface layer, fiber composite layers, a pressure barrier layer, and an outer protective layer. The fiber composite layers can have a unique triaxial braid structure.

Owner:FIBERSPAR

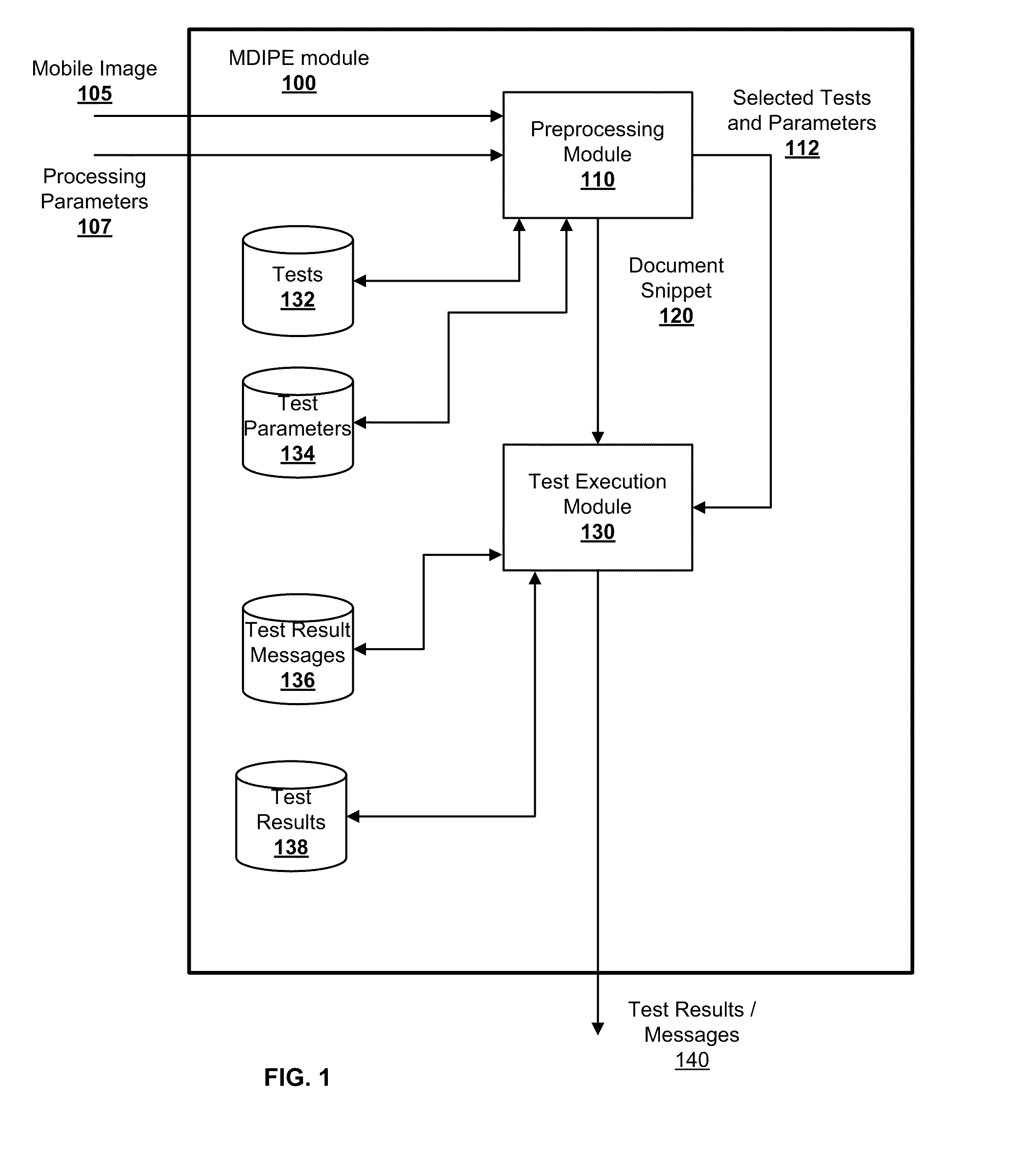

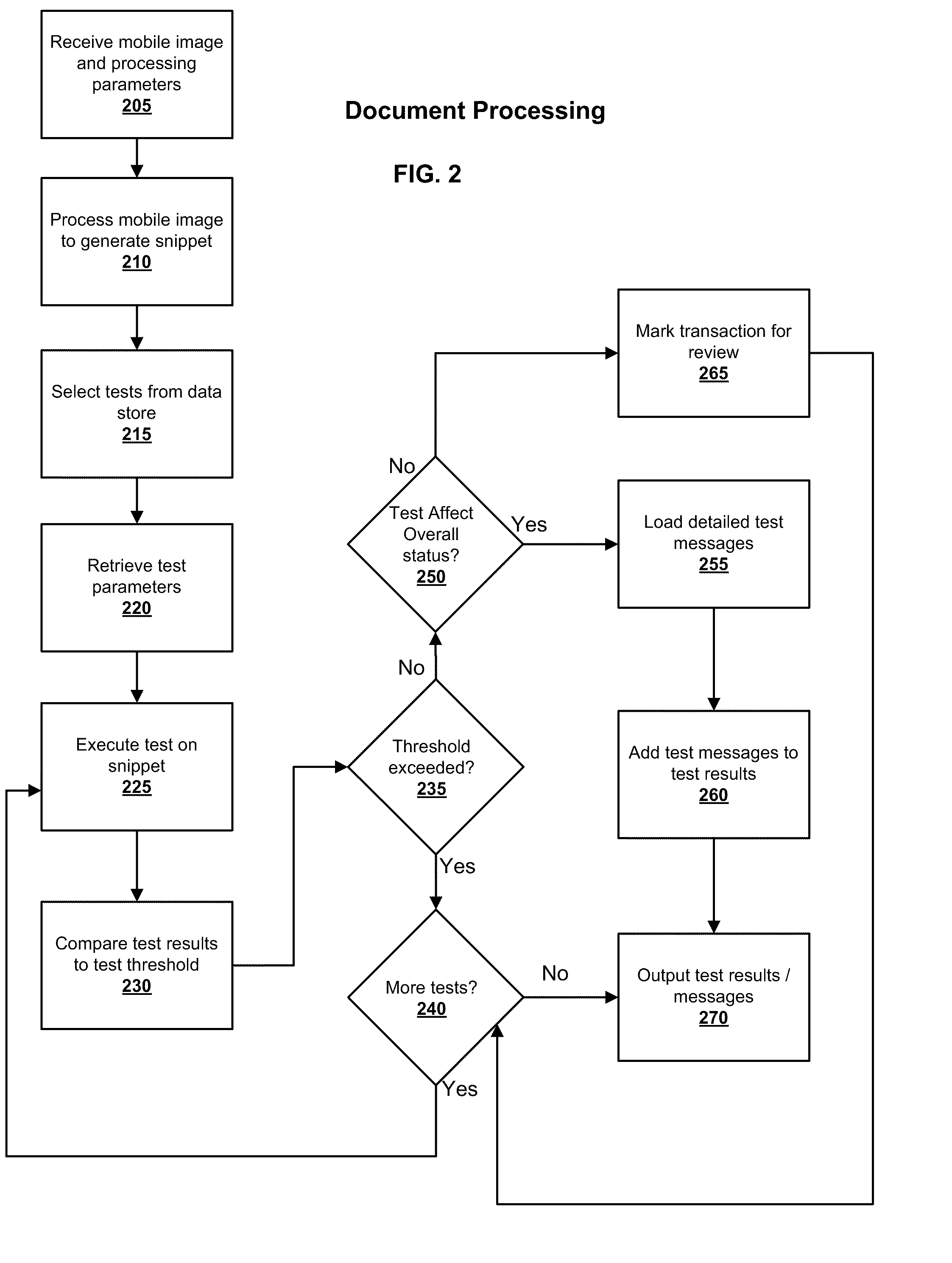

Mobile image quality assurance in mobile document image processing applications

Techniques for assuring the quality of mobile document image captured using a mobile device are provided. These techniques include performing one or more tests to assess the quality of images of documents captured using the mobile device. The tests can be selected based on the type of document that was imaged, the type of mobile application for which the image quality of the mobile image is being assessed, and / or other parameters such as the type of mobile device and / or the characteristics of the camera of the mobile device that was used to capture the image. The image quality assurance techniques can also be implemented on can be implemented on a mobile device and / or on a remote server where the mobile device routes the mobile image to the remote server processing and the test results are be passed from the remote server to the mobile device.

Owner:MITEK SYST

Multilayer plastic composition having an electrically conductive inner layer

InactiveUS6090459AAvoid disadvantagesAvoid accumulationSynthetic resin layered productsCeramic shaping apparatusMobile vehicleFiber

A multilayer plastic composition having (I) an outer layer of a thermoplastic molding composition and (II) an inner layer of an electrically conductive thermoplastic molding composition containing graphite fibrils, which are useful for the transport of (petro)chemical materials and also in the motor vehicle sector for conveying brake, cooling and hydraulic fluid and also fuel.

Owner:EVONIK DEGUSSA GMBH

Thermoplastic elastomer composition, process for the preparation there of, hose made by using the composition, and process for the production thereof

InactiveUS6179008B1Improvement of hose flexibilityLow production costSynthetic resin layered productsFlexible pipesElastomerVulcanization

A thermoplastic elastomer composition which, when used for the inner tube and / or outer cover of a hose, can improve the hose flexibility at an ordinary temperature and low temperature, oil resistance, and cold resistance and can reduce the production costs since it does not require a vulcanization step and a hose having said properties using this elastomer composition for its inner tube and / or outer cover and a process and apparatus for the production thereof.

Owner:YOKOHAMA RUBBER CO LTD

Camera device and method and program for starting the camera device

ActiveUS7385631B2Reduce startup timeTelevision system detailsDigital computer detailsOperational systemOperation mode

A camera device comprises a movable optical system, a driving unit which drives the optical system, and a control unit which makes the driving unit start driving of the optical system to a predetermined state by an initialization of the optical system by using an interrupt processing which is executed by setting an interrupt processing routine before the operating system is started, when the camera device is started up in a state in which an operation mode for photographing is set.

Owner:CASIO COMPUTER CO LTD

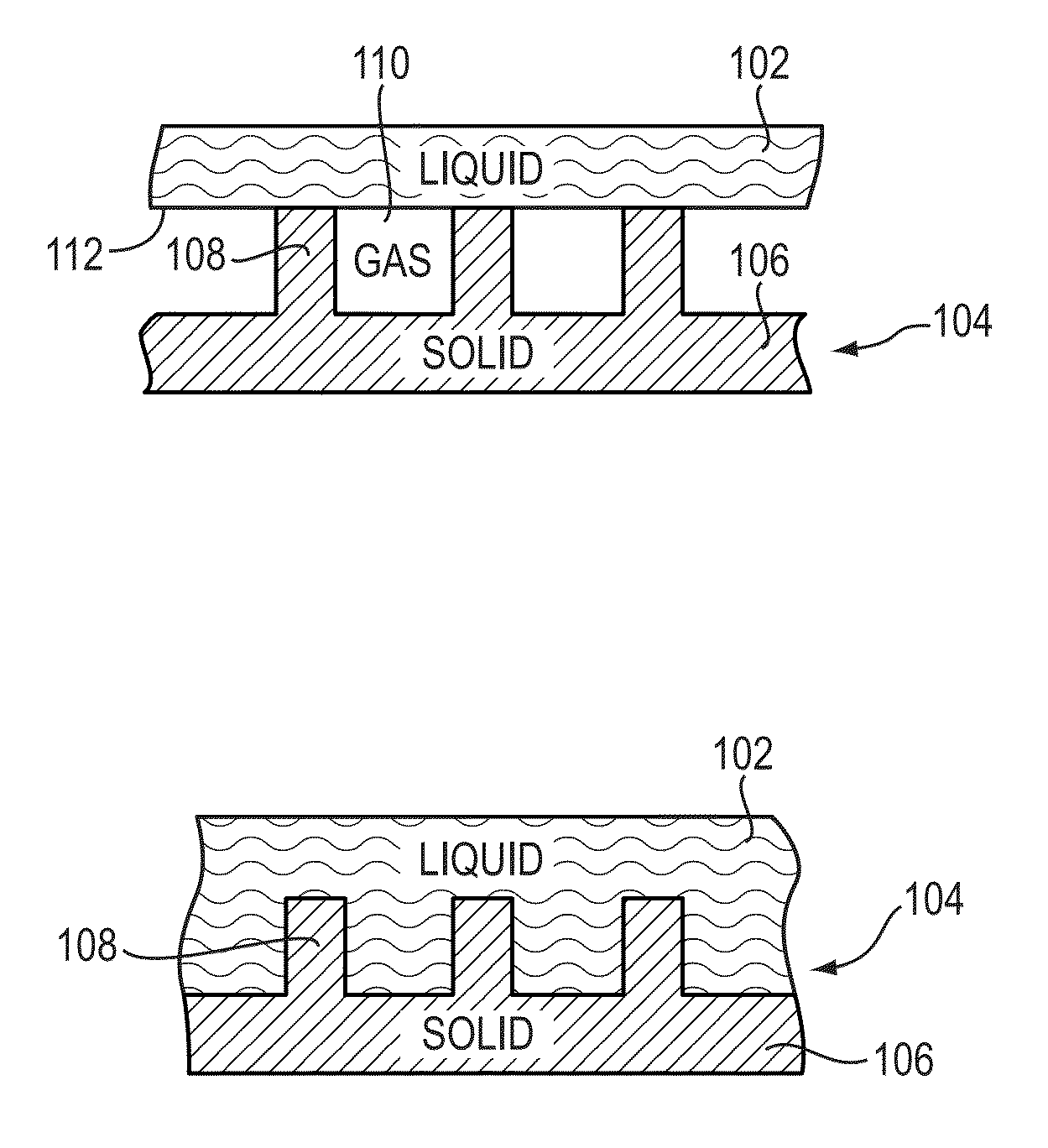

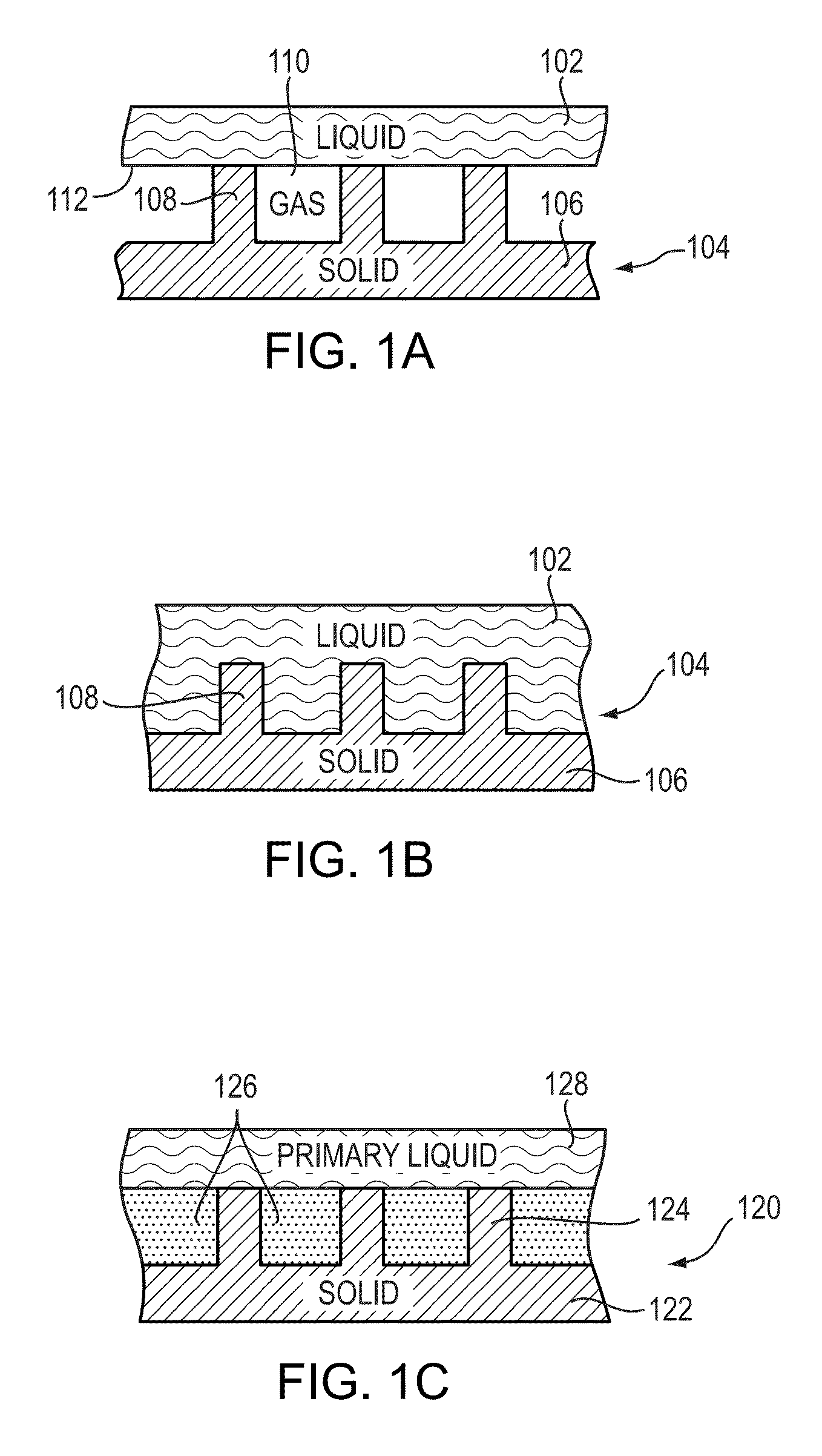

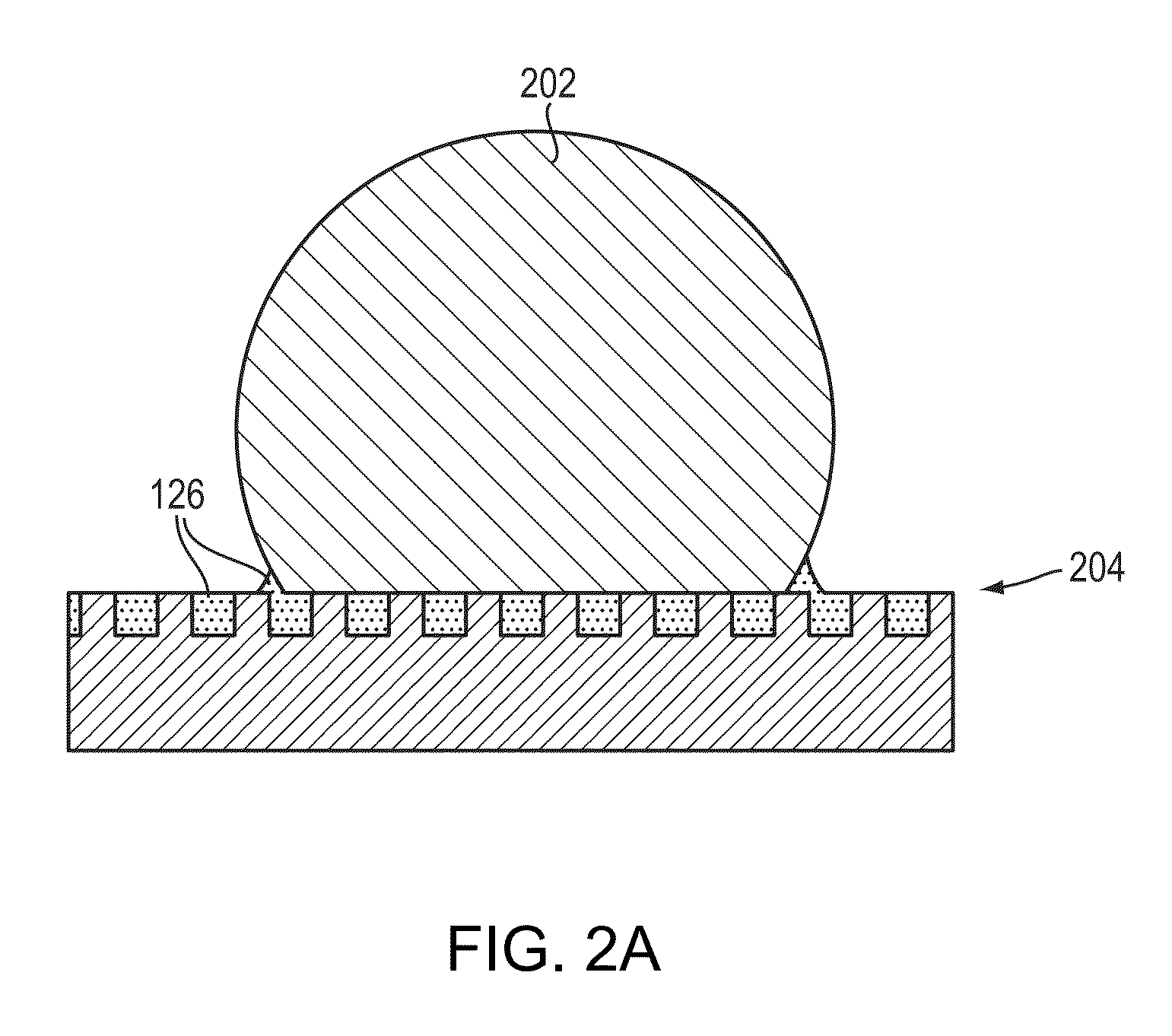

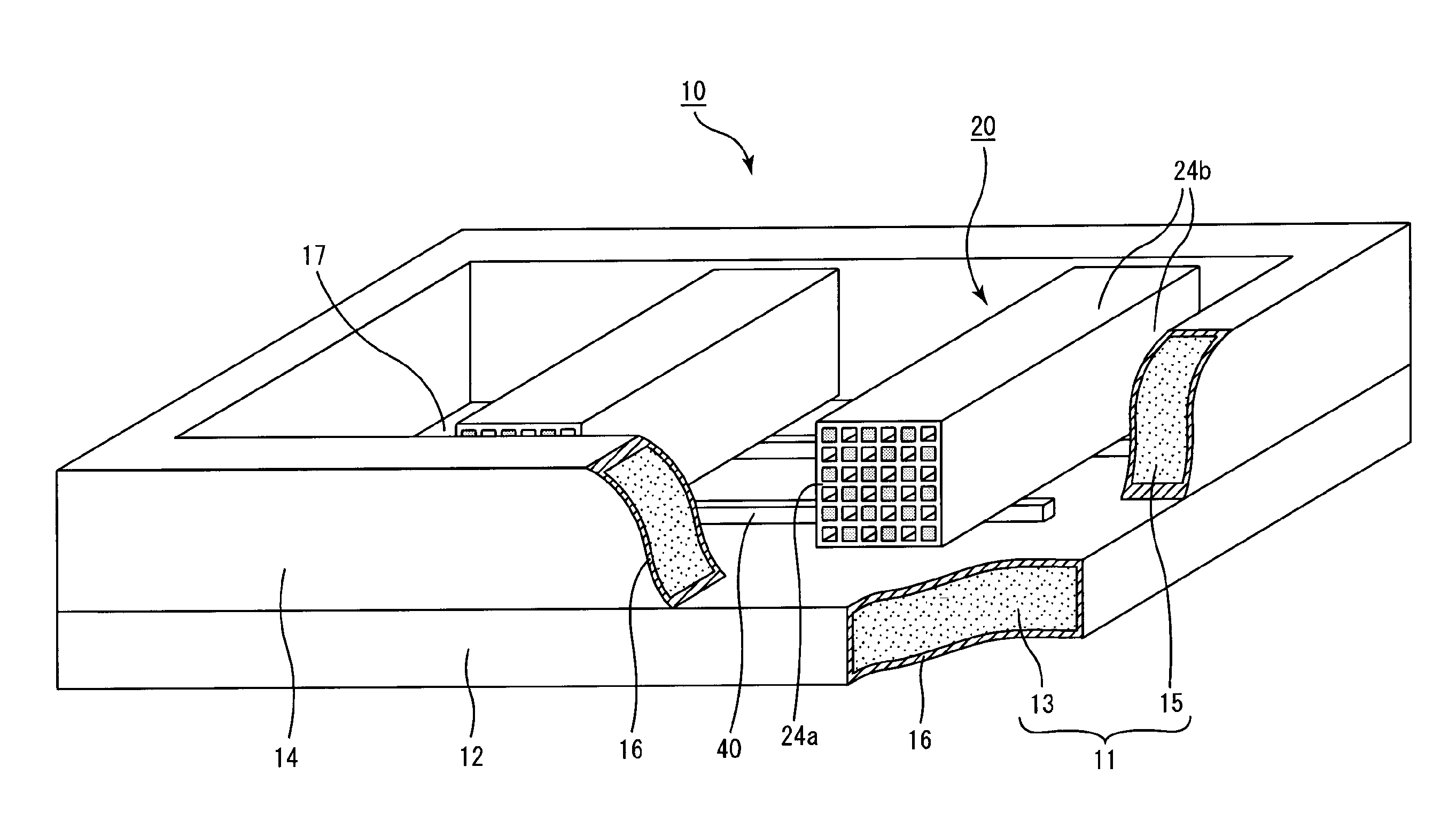

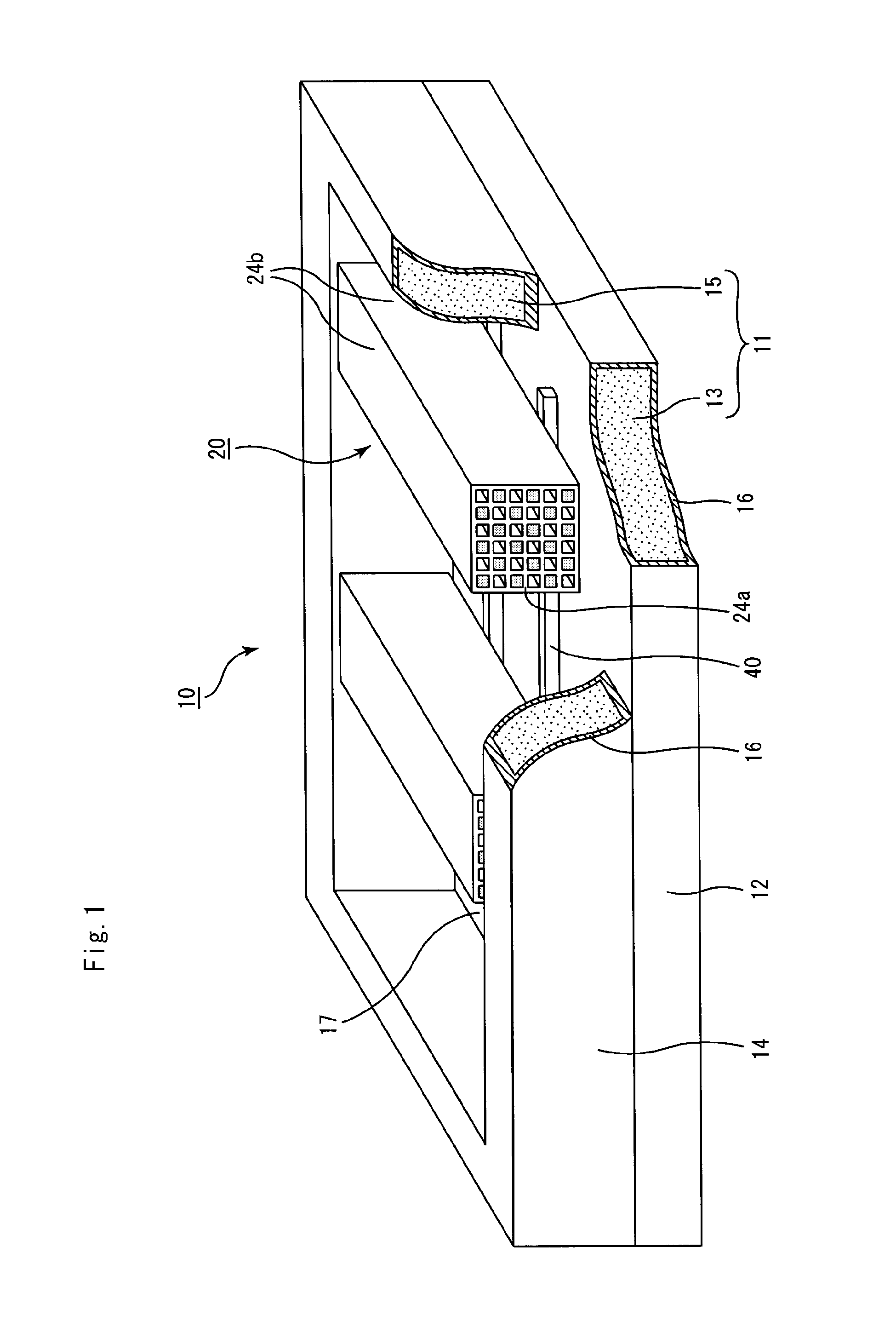

Liquid-Impregnated Surfaces, Methods of Making, and Devices Incorporating the Same

InactiveUS20130032316A1Improve skidReduce resistanceFouling preventionDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

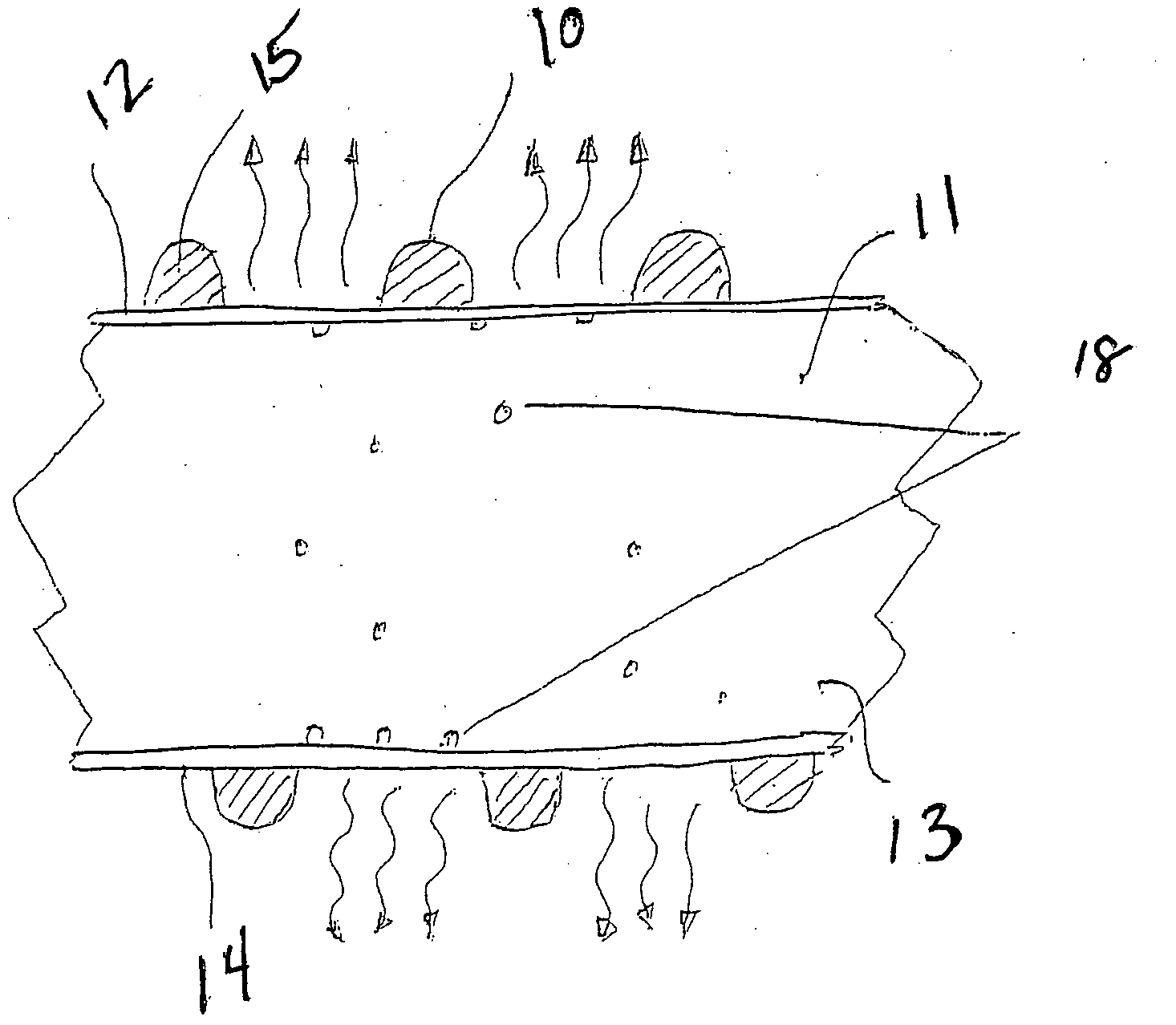

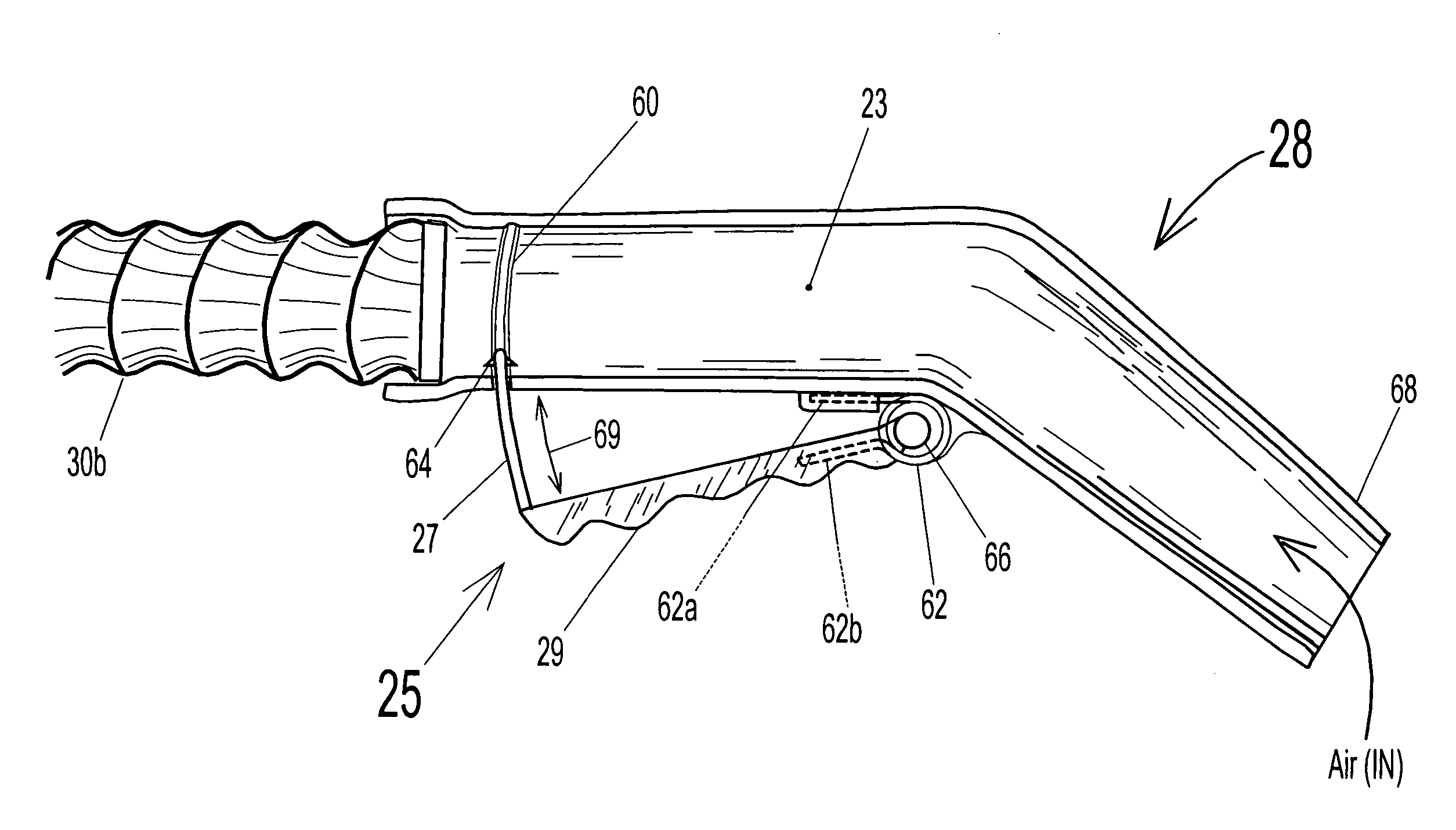

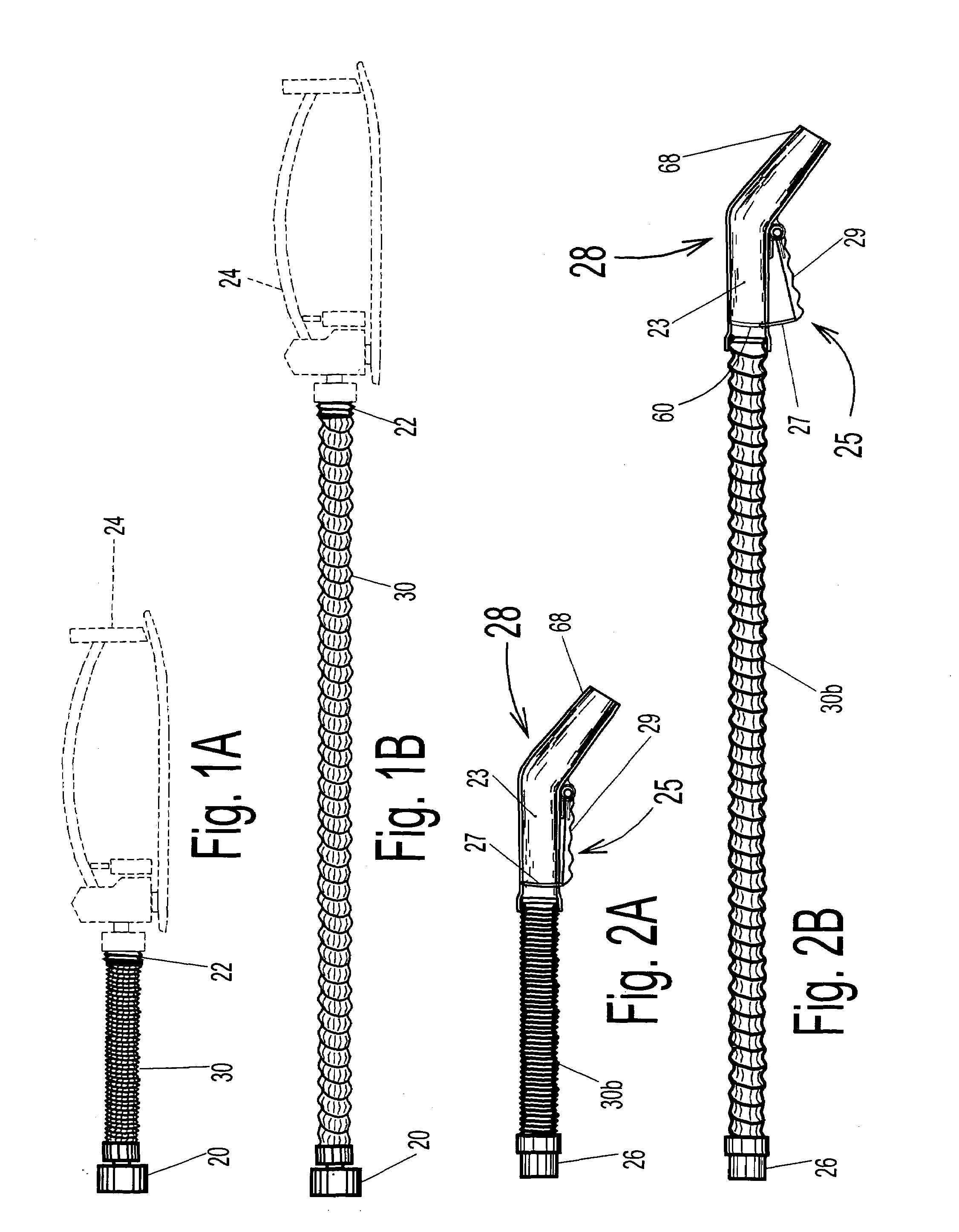

System for removal of water from a hose and the hygroscopic hose utilized

InactiveUS20090025724A1Prevent moistureRespiratorsMedical devicesRespiratorThermoplastic polyurethane

A respirator system and hygroscopic hose used in the system is disclosed. The system includes a means for generating a flow of air, a hose connected to the generating means and a mask adapted to be secured to a patient. The mask connected to the hose such that air generated by the generating means passes through the hose to the mask. The hose is a hygroscopic hose made up of a thermoplastic polyurethane. The thermoplastic polyurethane permits water formed by the respiration of the patient to permeate through a sidewall of said hose from an inner surface of the hose to an outer surface of the hose. The sidewall of the hose does not permit air generated by the generating means to pass through the sidewall.

Owner:FLEXIBLE TECH INC

Expandable and contractible hose

A hose which automatically expands longitudinally and automatically expands laterally upon the application of a fluid pressure is disclosed. The hose can automatically expand longitudinally up to six times its unexpanded or contracted length. Upon release of the fluid pressure within the hose, the hose will automatically contract to a contracted condition. The hose includes an inner tube made from an elastic material and an outer tube made from a non-elastic material. The inner tube is positioned concentrically within the outer tube in both a contracted condition and an expanded condition. The outer tube is secured to the inner tube only at a first end of the inner and outer tubes and at a second end of the inner and outer tubes. The outer tube moves laterally and longitudinally with respect to the inner tube when the tubes are transitioning between a contracted condition and an expanded condition.

Owner:TELEBRANDS CORP

Exhaust tip

InactiveUS7007720B1Severe design restrictionOverall design flexibilityThermal insulationSilencing apparatusEngineeringThermal effect

An exhaust tip for attachment to a tailpipe that includes a thermoset heat shield at least partially surrounding and fastened to the tailpipe, and a thermoplastic decorative cover at least partially surrounding and fastened to the thermoset heat shield. The thermoset heat shield insulates the thermoplastic decorative cover from thermal effects of the tailpipe and spaces the thermoplastic decorative cover a predetermined distance away from the tailpipe.

Owner:LACKS INDUSTRIES INC

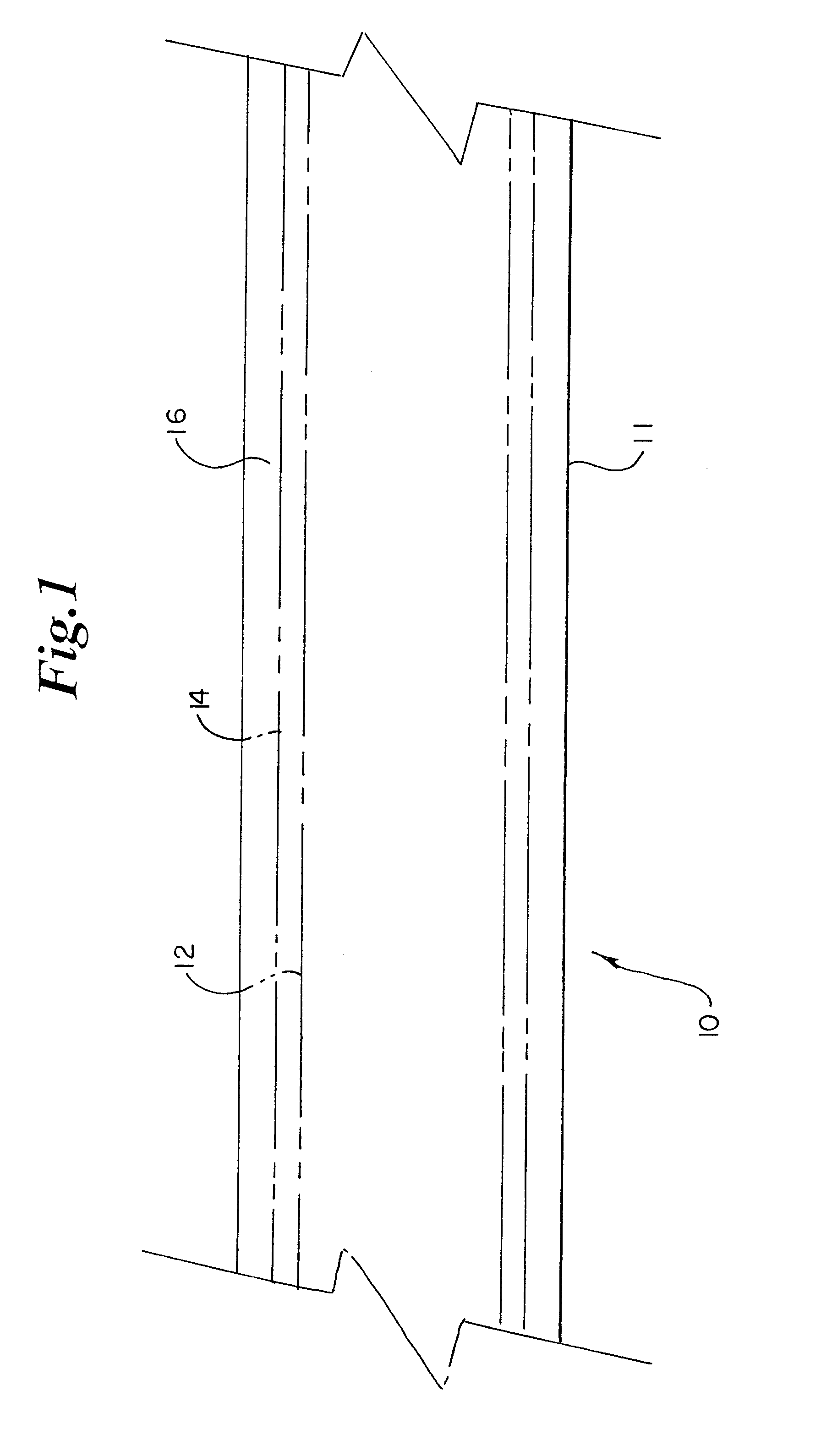

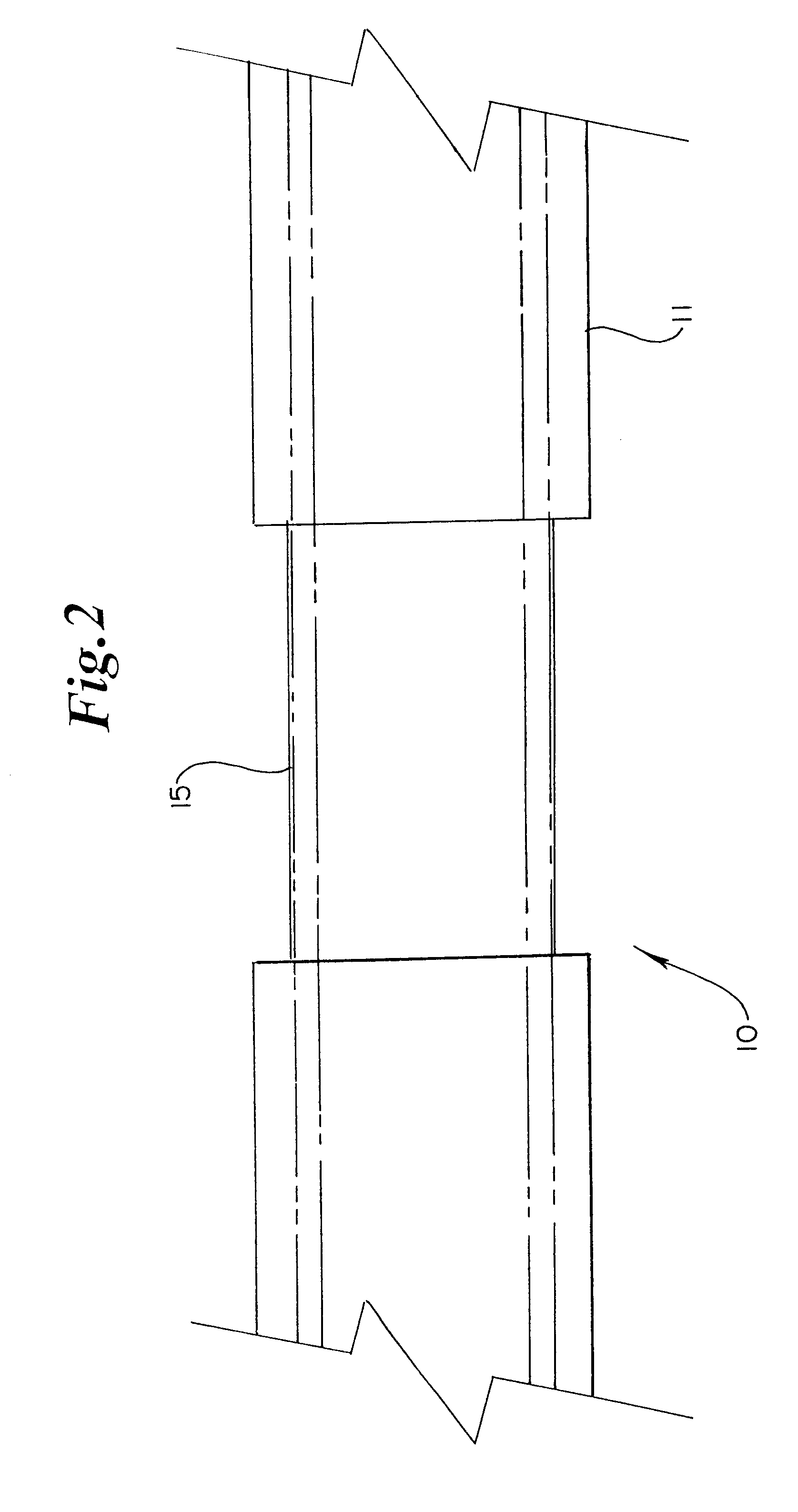

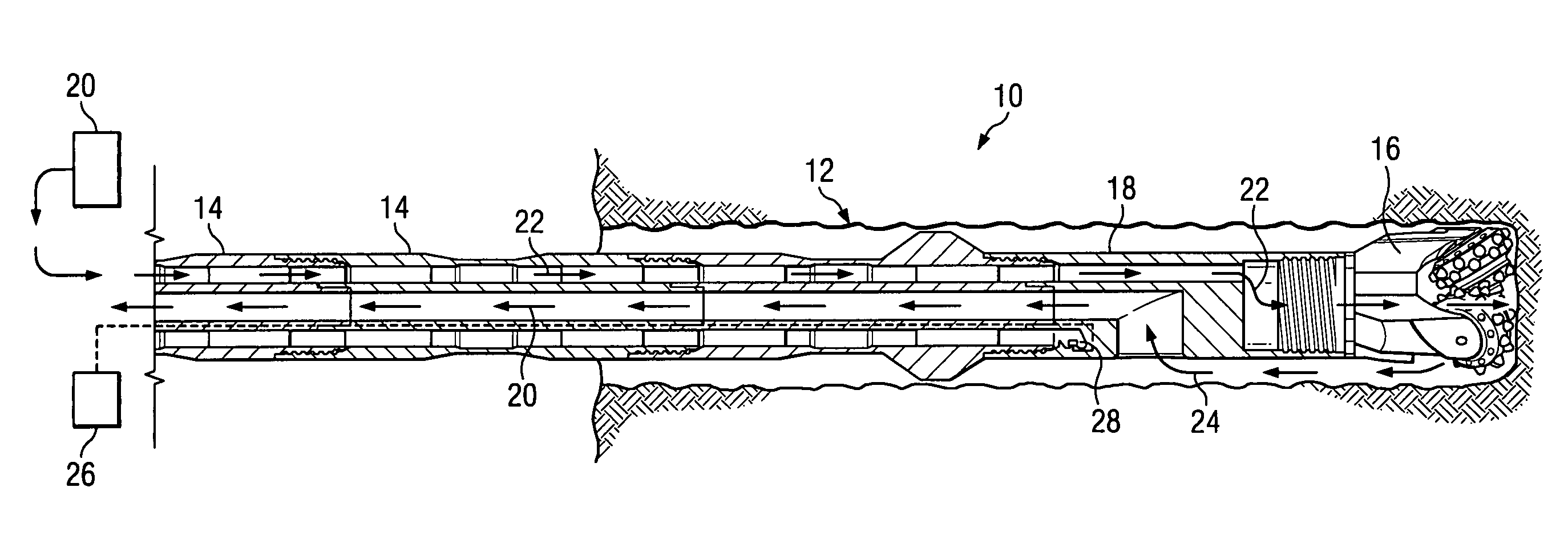

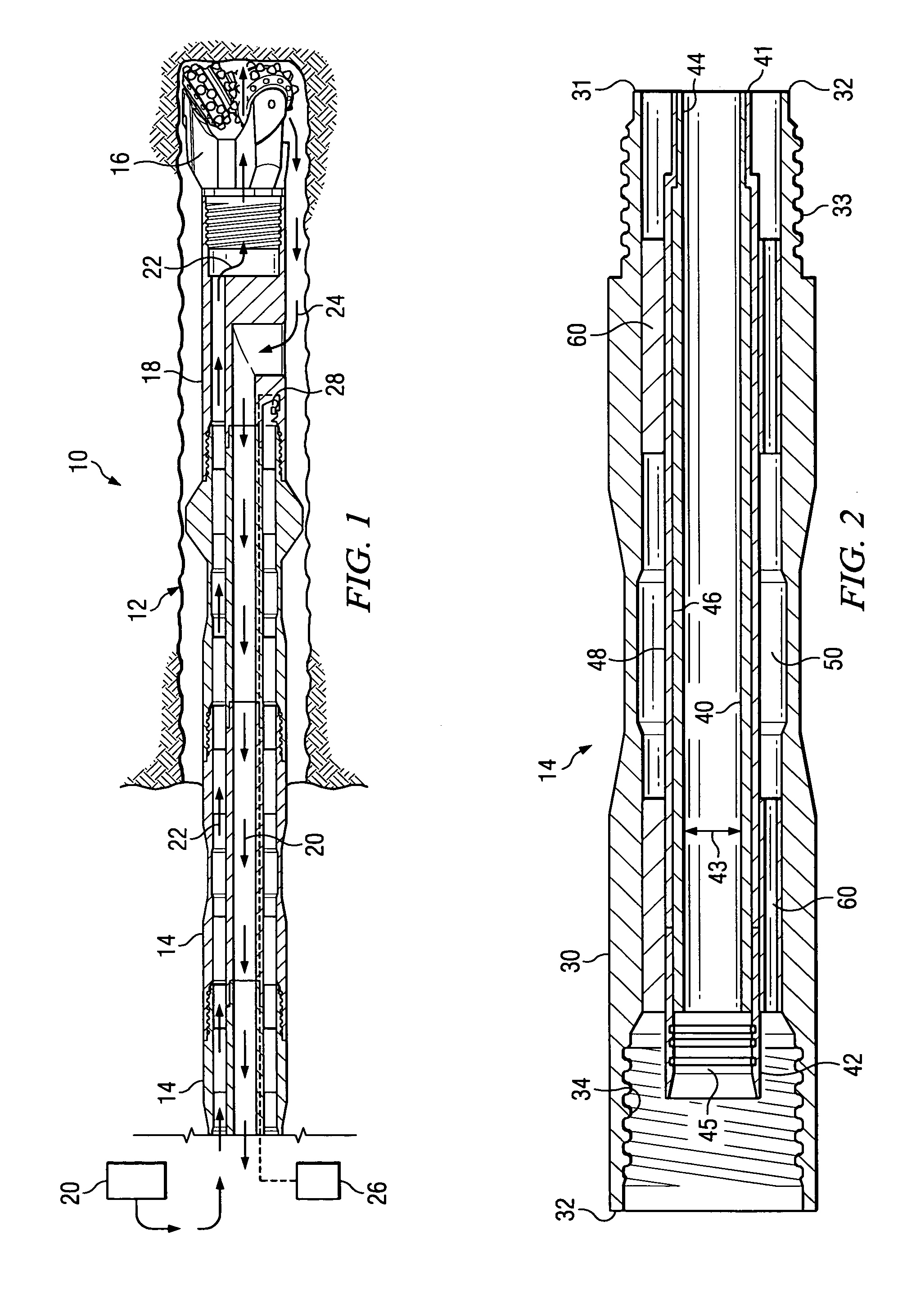

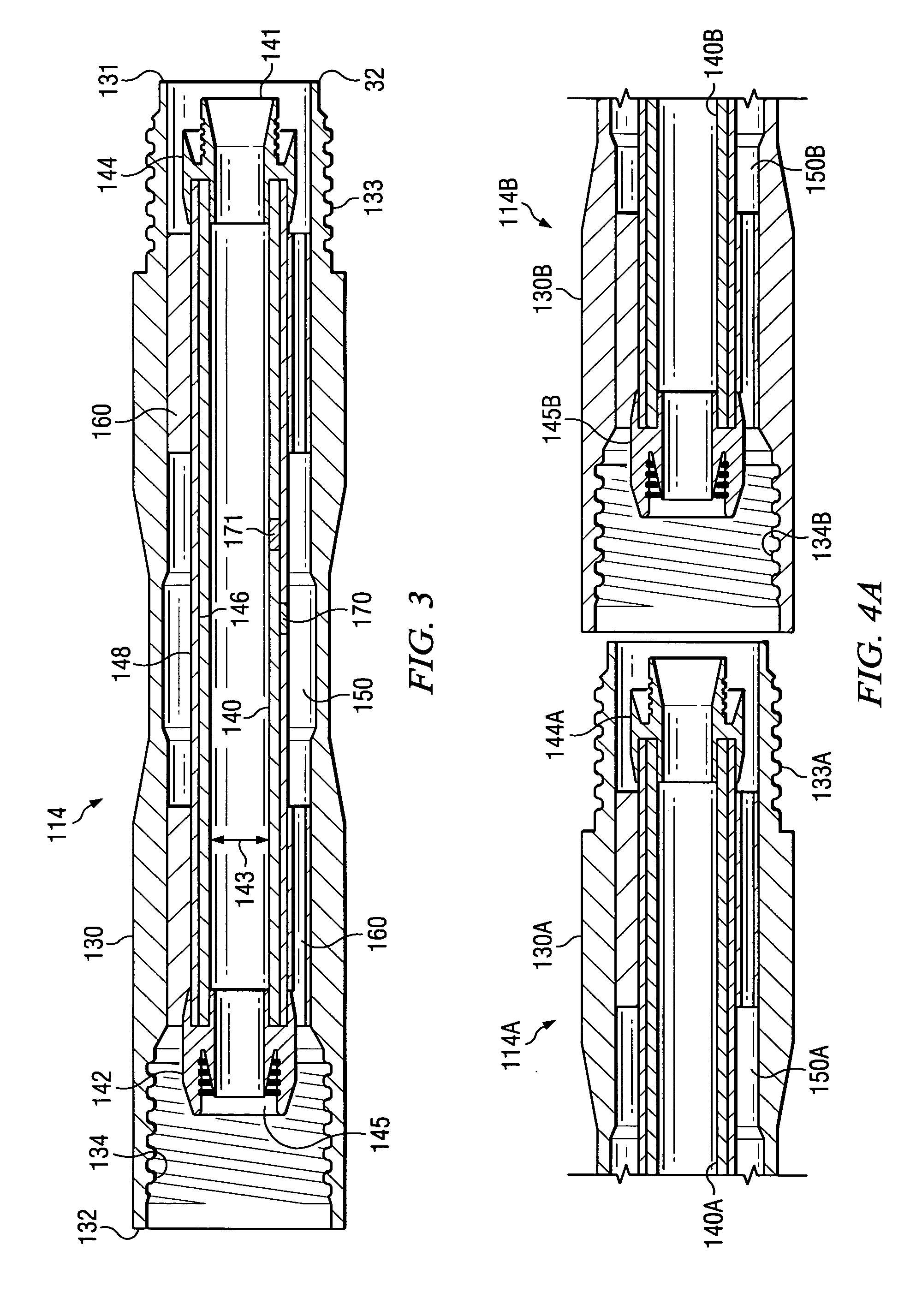

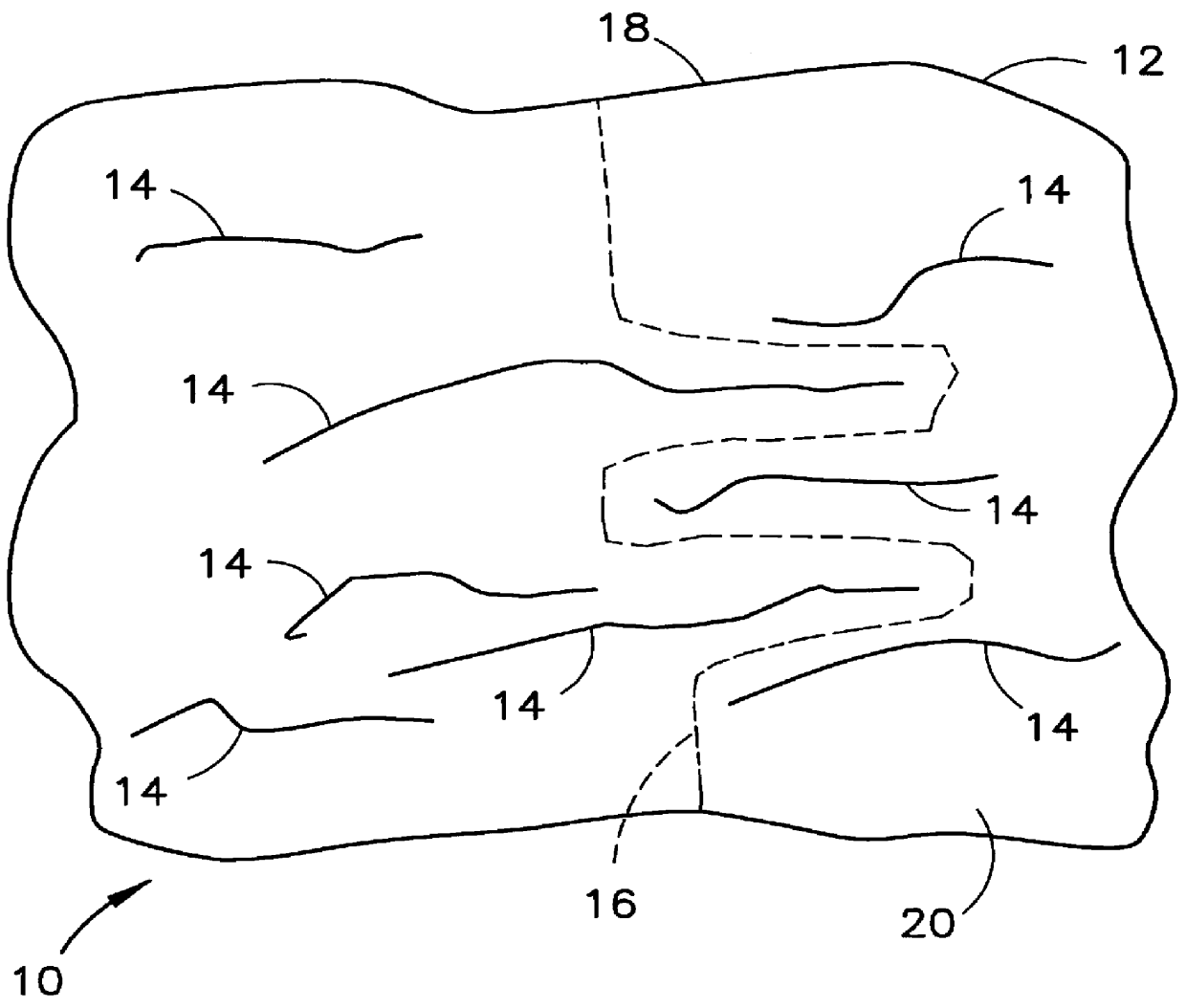

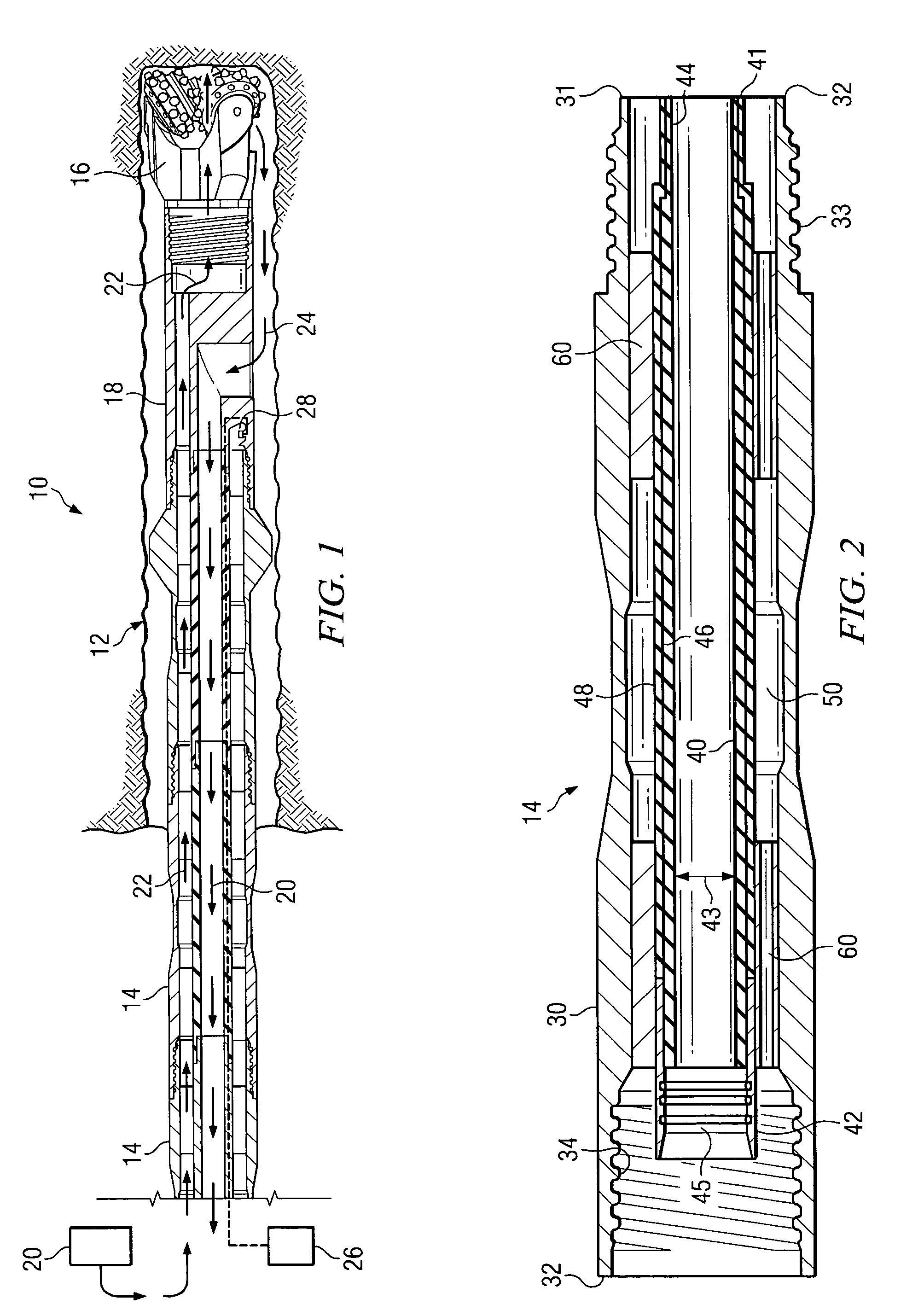

Dual wall drill string assembly

ActiveUS20050103527A1Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingEngineering

A coil tubing or jointed dual wall drill string assembly for subsurface drilling. The drill string assembly includes a metallic outer tube having an outer tube first end and an outer tube second end opposite the outer tube first end. The assembly also includes a flexible, substantially non-metallic inner tube that is substantially enclosed within and generally coaxially aligned with the outer tube. The flexible, substantially non-metallic inner tube has an inner tube first end, an inner tube second end opposite the inner tube first end, and an inner tube inner diameter. The inner tube and the outer tube define an annular channel therebetween. The drill string assembly also includes a means for conveying fluid through the annular channel toward the inner tube first end. The annular channel is adapted to convey drilling fluid under pressure toward the inner tube first end and the inner tube is adapted to convey cuttings toward the inner tube second end.

Owner:AMERICAN AUGERS +1

Polyolefin material integrated with nanophase particles

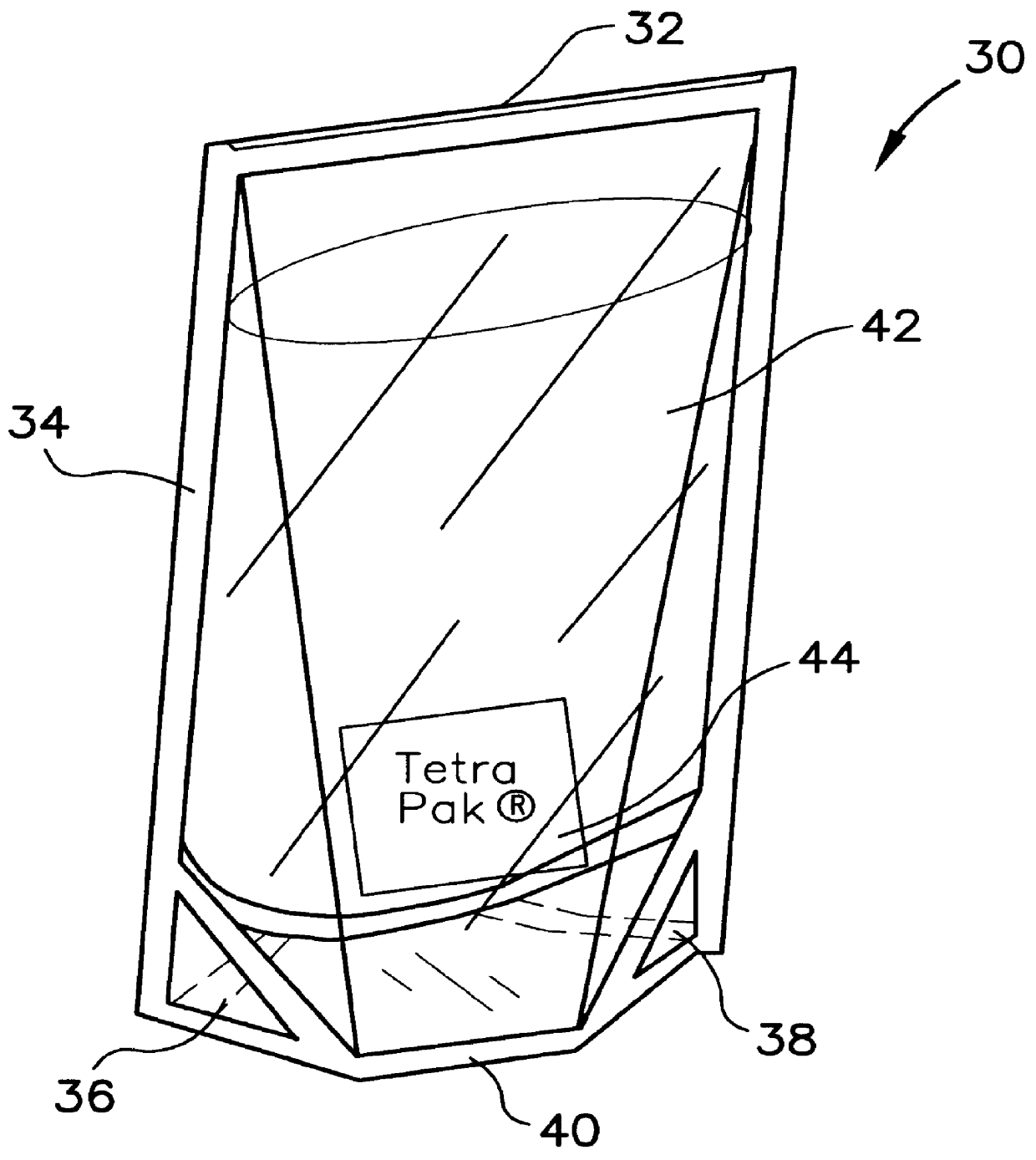

Owner:TETRA LAVAL HLDG & FINANCE SA

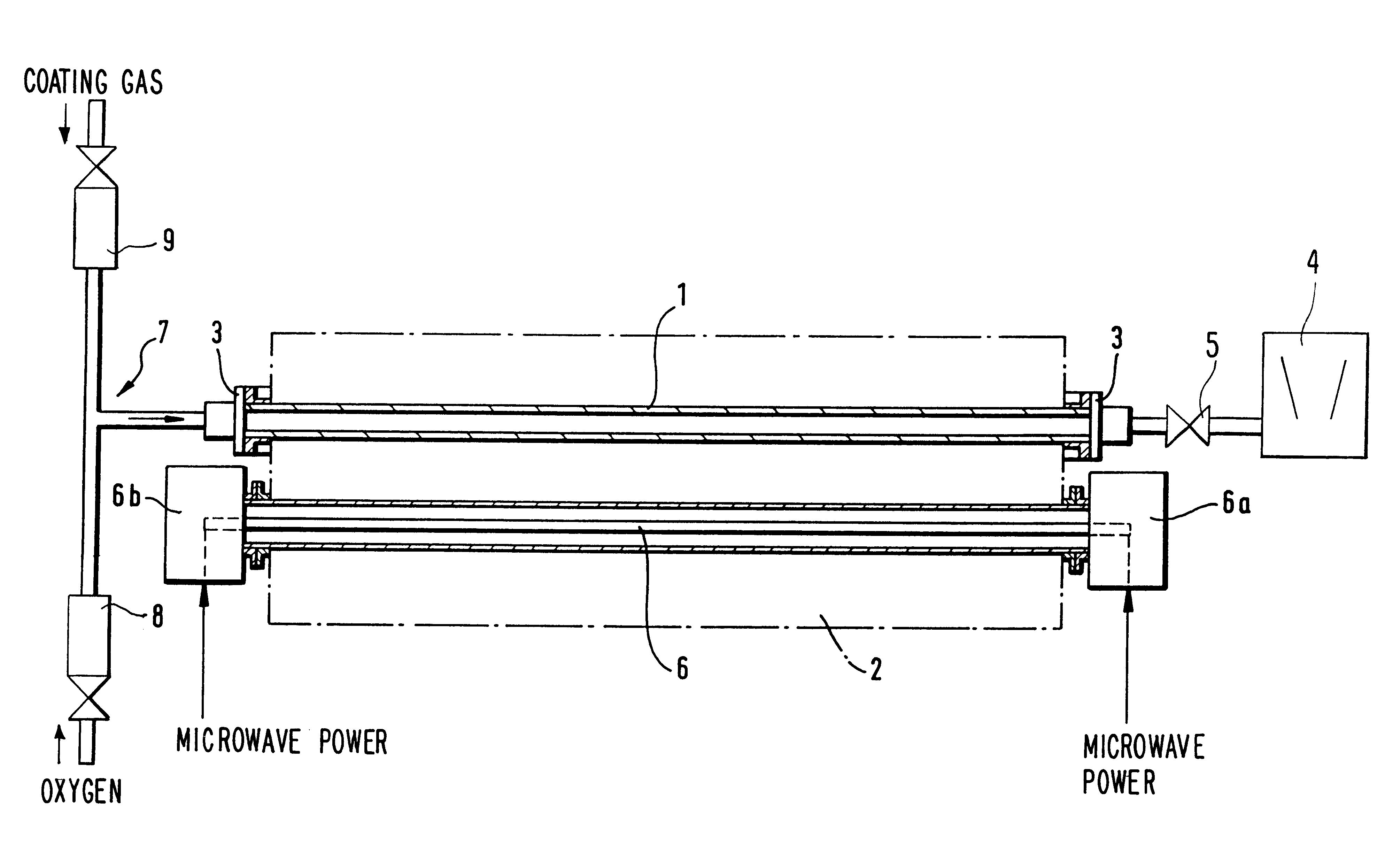

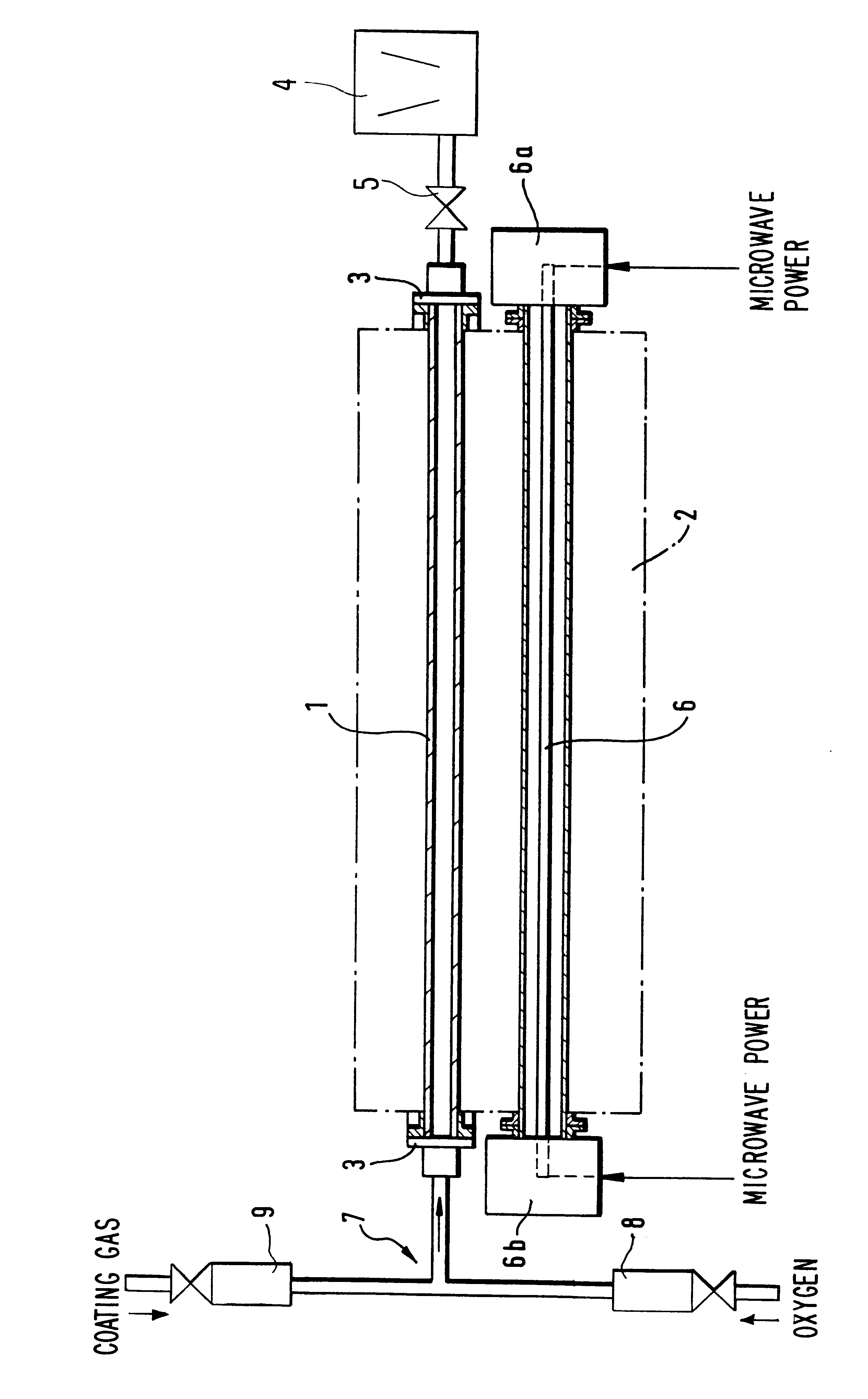

Method of making a hollow, interiorly coated glass body and a glass tube as a semi-finished product for forming the glass body

InactiveUS6200658B1Layered productsLiquid/solution decomposition chemical coatingVitreous BodiesWork in process

Numerous applications for hollow glass bodies made from low melting glass material require an increase in the chemical resistance of the interior surface of the glass body. In order to avoid a disadvantageous de-alkalizing process the hollow glass body must be provided with an interior coating in a comparatively expensive prior art process. In an improved process according to the invention a glass tube acting as a semifinished product from which the hollow glass body is made is provided with an interior coating of oxide material, preferably SiO2, Al2O3, TiO2 or mixtures thereof, having a predetermined coating thickness according to the required chemical resistance or working conditions for forming the glass body and then the hollow glass body is made from the glass tube. The coating is advantageously provided by means of a PICVD process.

Owner:SCHOTT AG

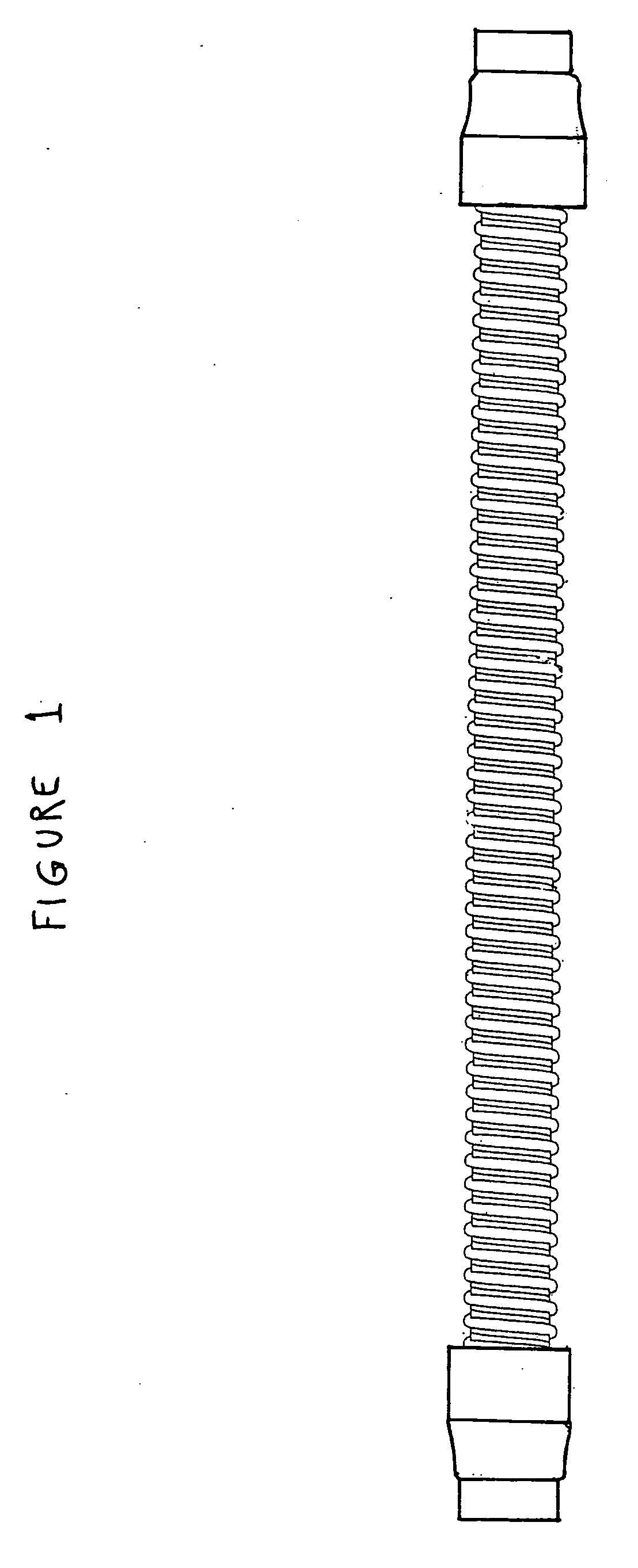

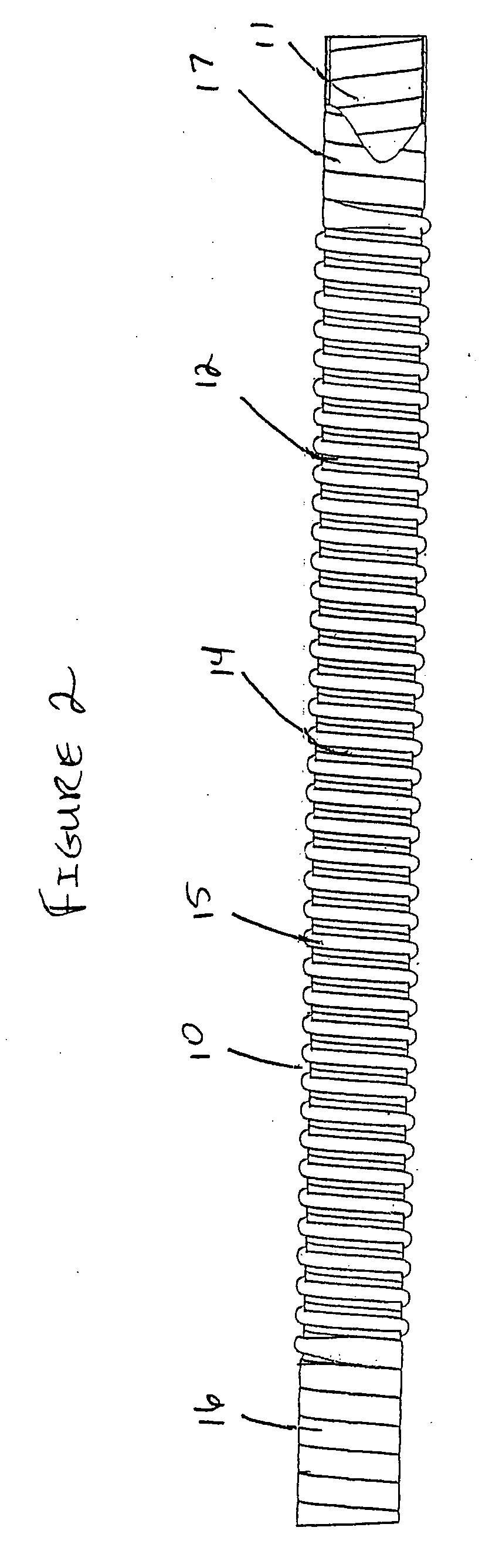

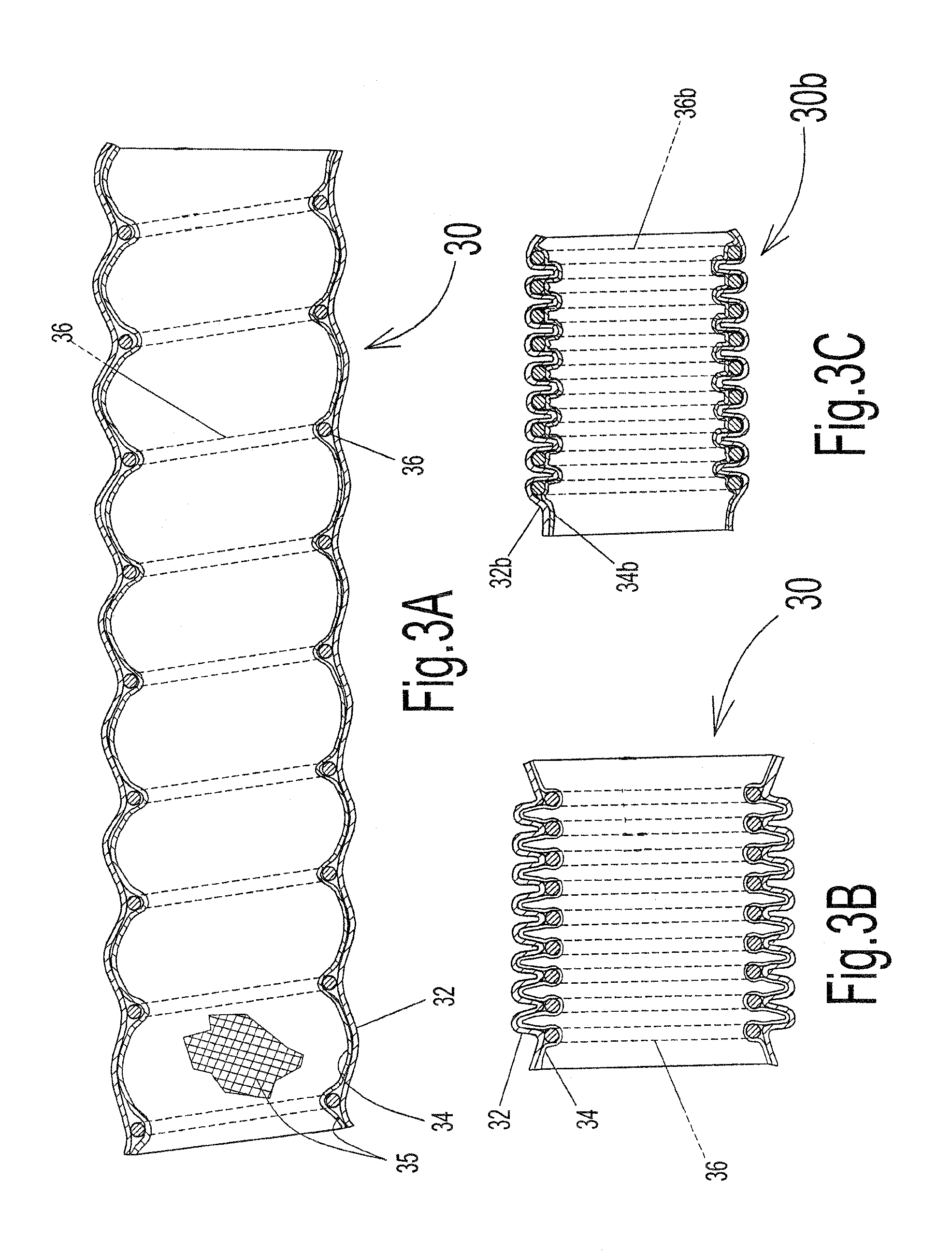

Linearly retractable pressure hose

A linearly self-actuated hose for use in transporting fluids (liquids, gases, solid particles, and combinations of these three). Hose (30) has a biasing spring (36) that extends along its full length, and can comprise single or multiple springs and / or multiple diameter spring coils. Spring (36) is covered with hose cover material (32) on the outside and hose cover material (34) on the inside to form a sealed hose and are bowed inward or outward radially between the individual spring coils depending on the intended use of hose (30) to give the cover materials room to move out of the way when the hose retracts and the coils of spring (36) are forced close together. The Linearly Retractable Hose is operated by changing internal pressure within the hose relative to the ambient pressure on the exterior of the hose. Control of fluid pressure within hose (30) is what allows the hose to operate as an automatically extendable and retractable hose. The biasing of spring (36) depends on the type of use for the hose. For hose (30b), which will be used as a vacuum hose then the biasing spring (30b) must exert an extending force on the cover material (opposite that for a pressure hose). If the hose is to be used as a pressure hose (garden hose, etc.), spring (36) will need to have a bias that exerts a retracting force on cover materials (32) and (34).

Owner:TELEBRANDS CORP

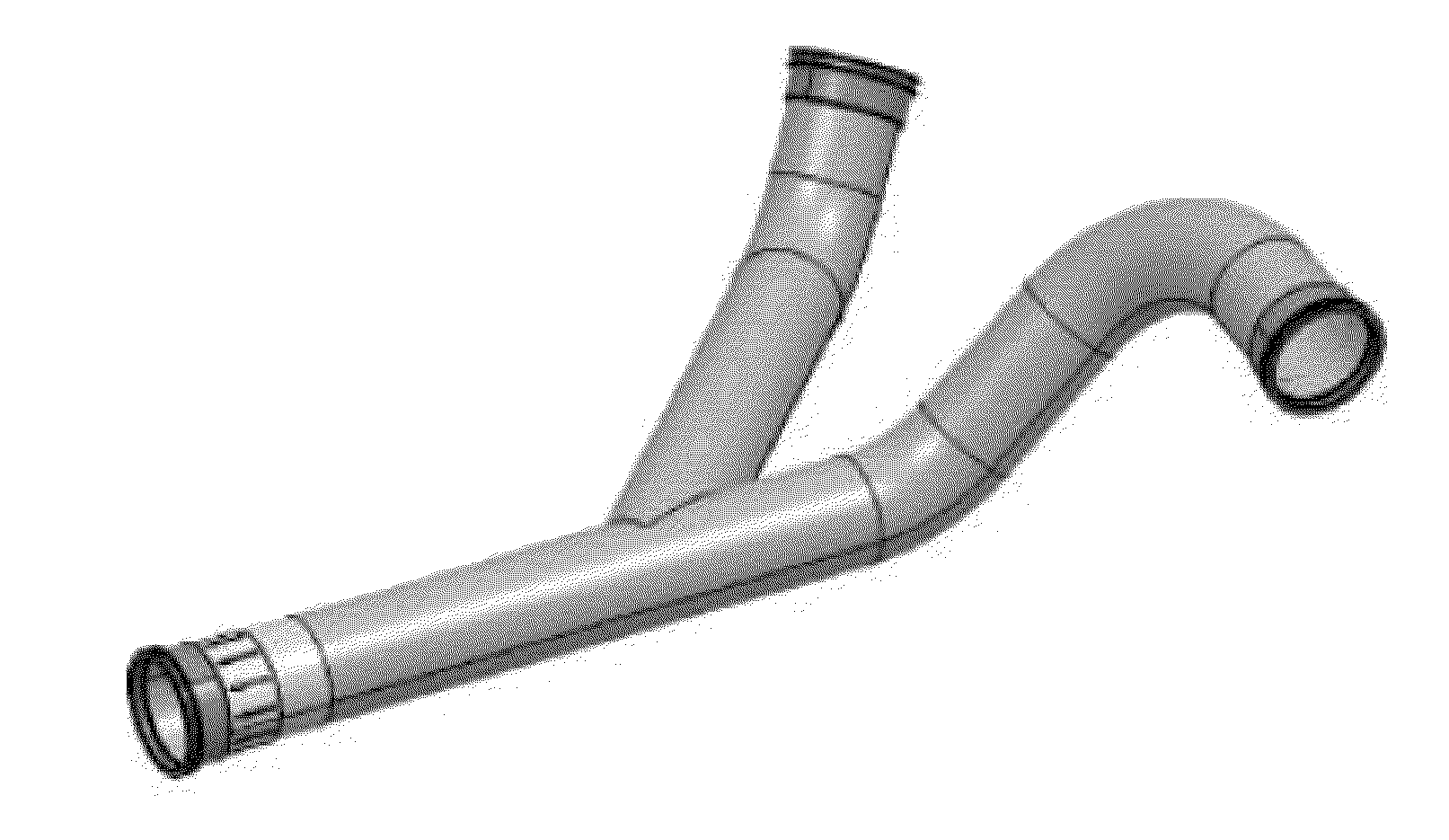

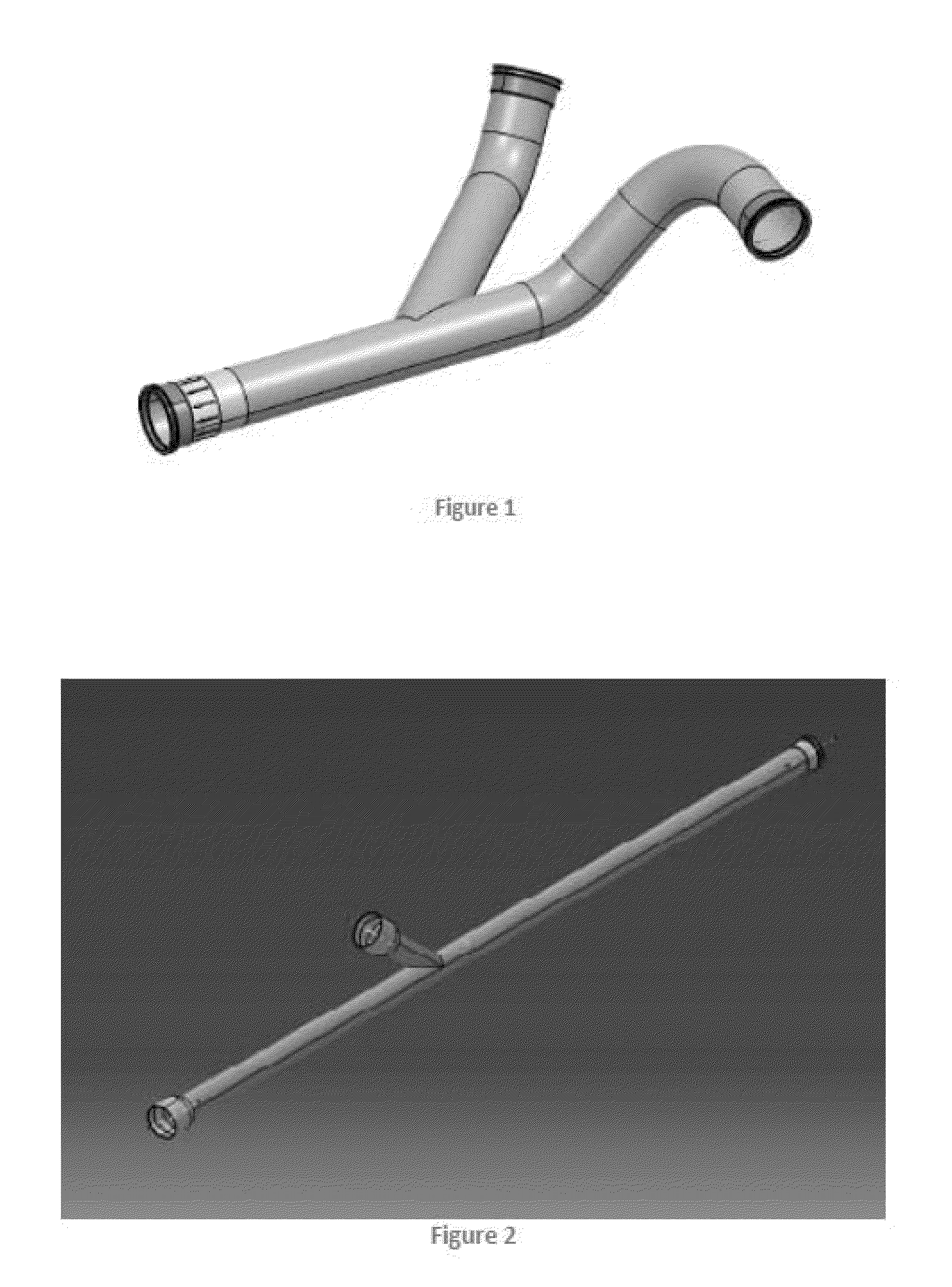

Composite waste and water transport elements and methods of manufacture for use on aircraft

ActiveUS9458955B2Reduce weightSimple methodAdditive manufacturing apparatusAdditive manufacturing with liquidsWater transportWaste management

Owner:MAG AEROSPACE IND INC

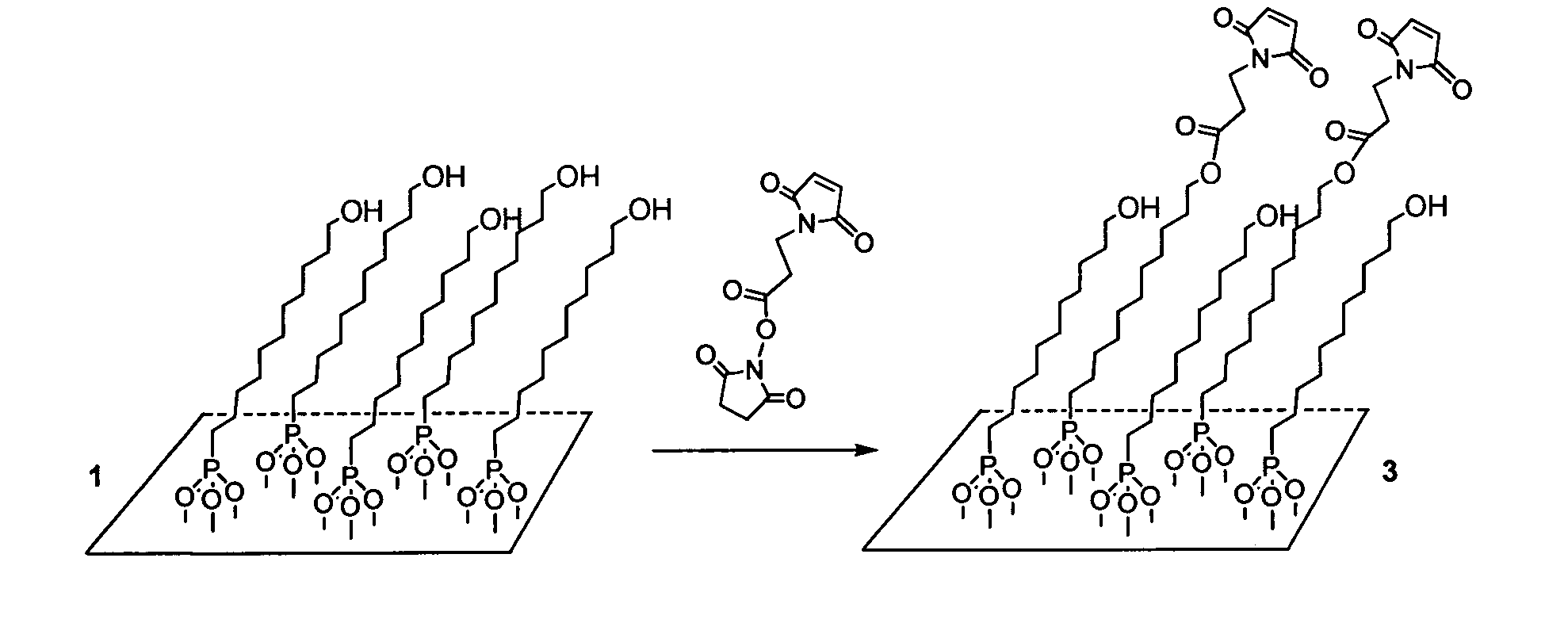

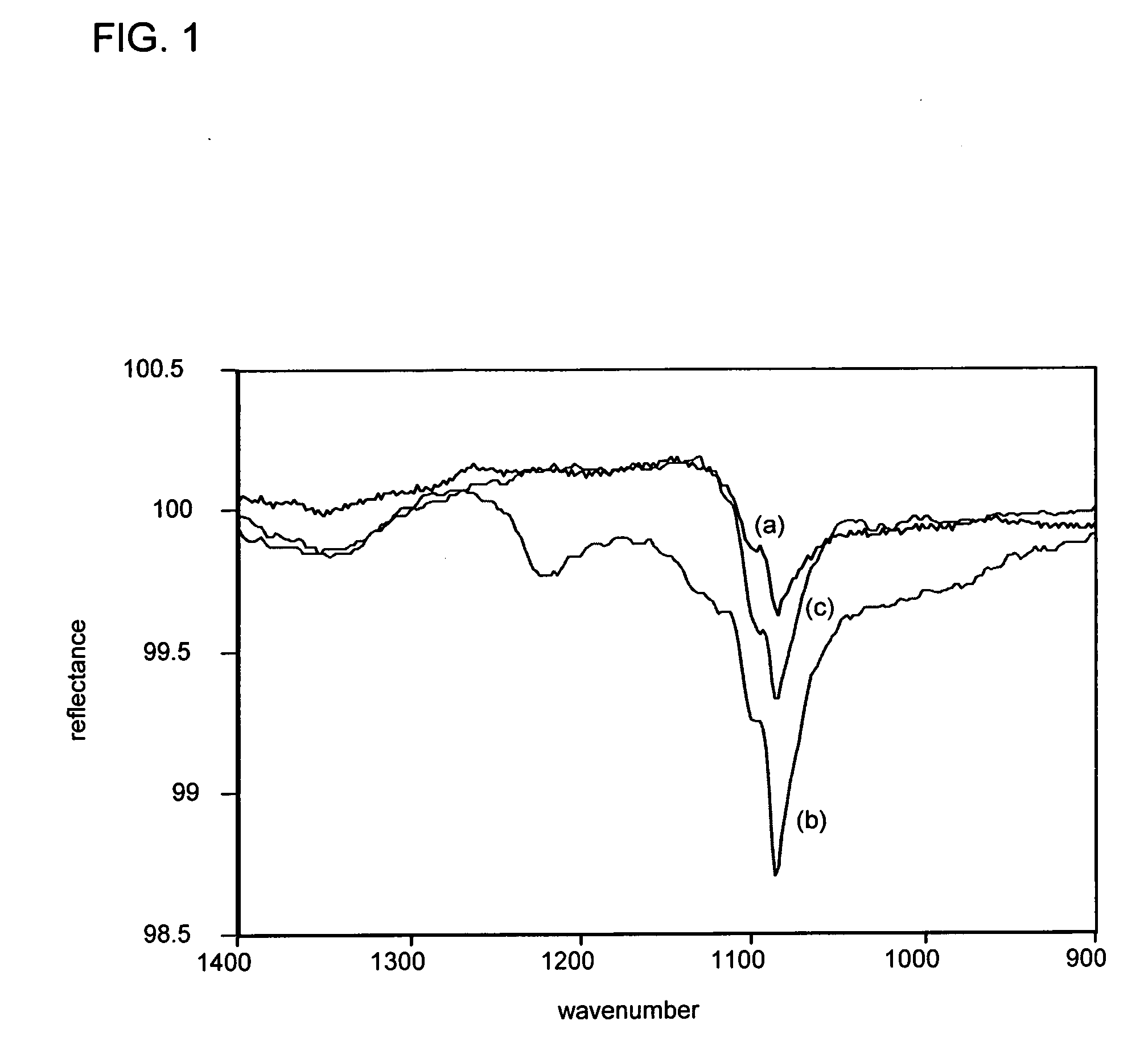

Devices with multiple surface functionality

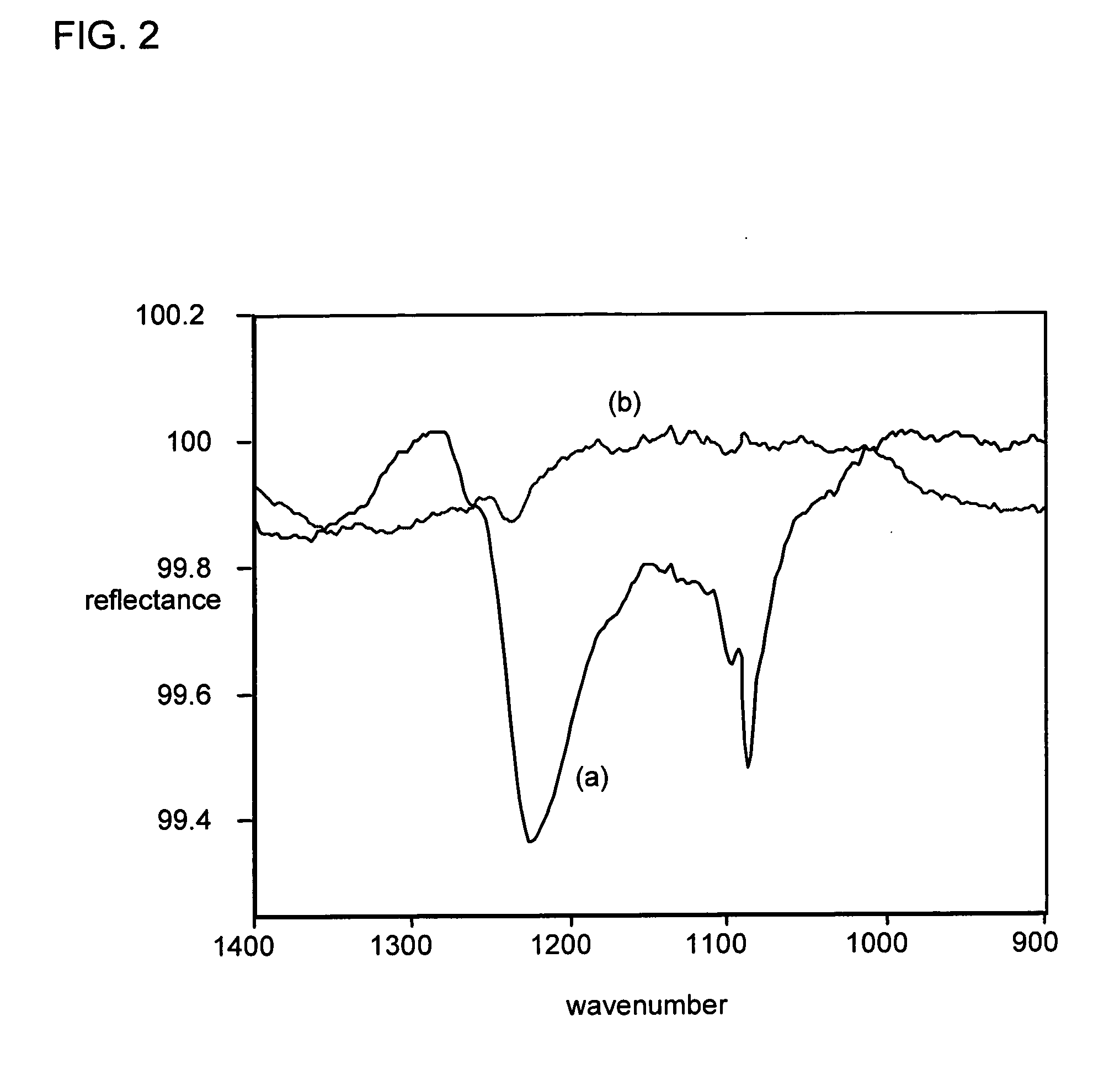

InactiveUS20060194008A1Desirable surface propertyMaterial nanotechnologyLiquid surface applicatorsImplanted deviceP phosphate

Phosphorus-based coatings having a plurality of phosphate moieties, a plurality of phosphonate moieties, or both, covalently bonded to an oxide surface of an implantable substrate exhibiting one or more of the following characteristics: (a) the surface phosphorus-containing group density of the coated regions of the substrate is at least about 0.1 nmol / cm2; (b) the phosphorus-based coating has a thickness of less than about 10 nm; or (c) the surface phosphorus-containing group density of the coated regions of the substrate is equal to or greater than the surface hydroxyl group density of the oxide surface of the substrate. Implantable devices embodying the coated substrates are also disclosed.

Owner:PRINCETON UNIV

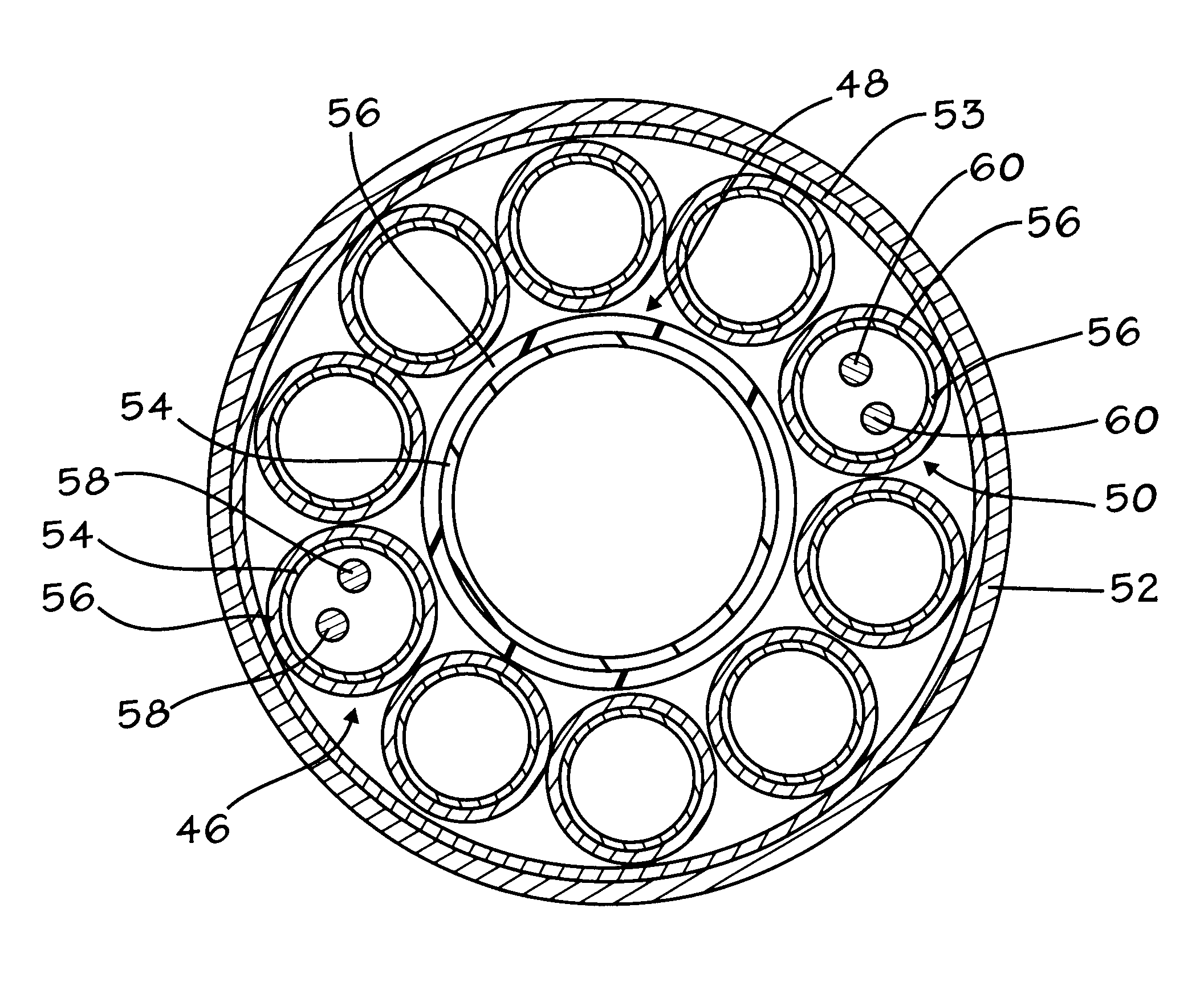

Marine umbilical

Various embodiments of an umbilical are provided. In one aspect, an umbilical is provided that includes a first tube, a second tube positioned in the first tube and a plurality of third tubes positioned in the first tube. Each of the plurality of third tubes has an inner polymer sleeve and an outer sleeve of carbon fibers in an epoxy matrix positioned around the polymer sleeve. The composite tubes yield a lighter umbilical that is easier to handle than a comparably sized conventional umbilical incorporating steel inner tubing and is more tolerant of dynamic bending and hydrostatic pressure loading.

Owner:MARINE INNOVATIONS

Internally insulated, corrosion resistant pipeline

An internally insulated, corrosion resistant pipeline. An inner fluid barrier is formed preferably by a polymer liner. The outer pipe may be a steel pipe. The liner is provided with a plurality of passages or an open annulus. The passages in the liner or annulus between the pipe and liner are filled with an insulation material.

Owner:J RAY MCCDERMOTT SA

Dual wall drill string assembly

InactiveUS7152700B2Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingDrilling fluid

Owner:AMERICAN AUGERS +1

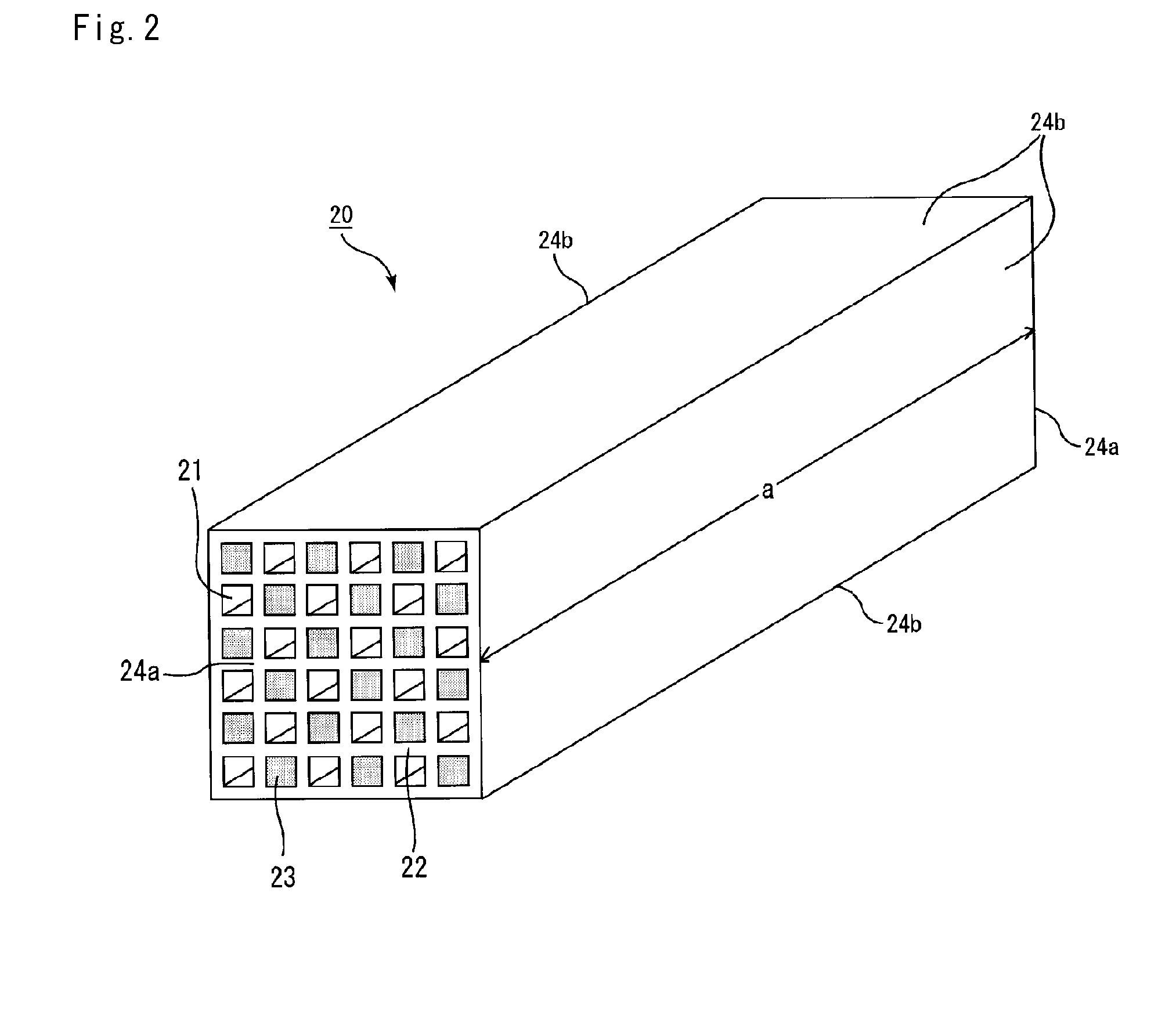

Firing jig and method for manufacturing honeycomb structure

InactiveUS20080305259A1Reduce yieldReduced strengthLayered productsCharge supportsHoneycomb structureSilicon carbide

A firing jig for a honeycomb molded body includes a housing body configured to place a pillar-shaped honeycomb molded body including silicon carbide as a main component with a side face of the honeycomb molded body facing down, and a coat layer formed on at least a placing face of the housing body configured to place the honeycomb molded body thereon. A main component of the coat layer is silicon carbide, the coat layer having an arithmetic average height Ra of about 10 μm or less obtained in conformity with JIS B 0601 (2001).

Owner:IBIDEN CO LTD

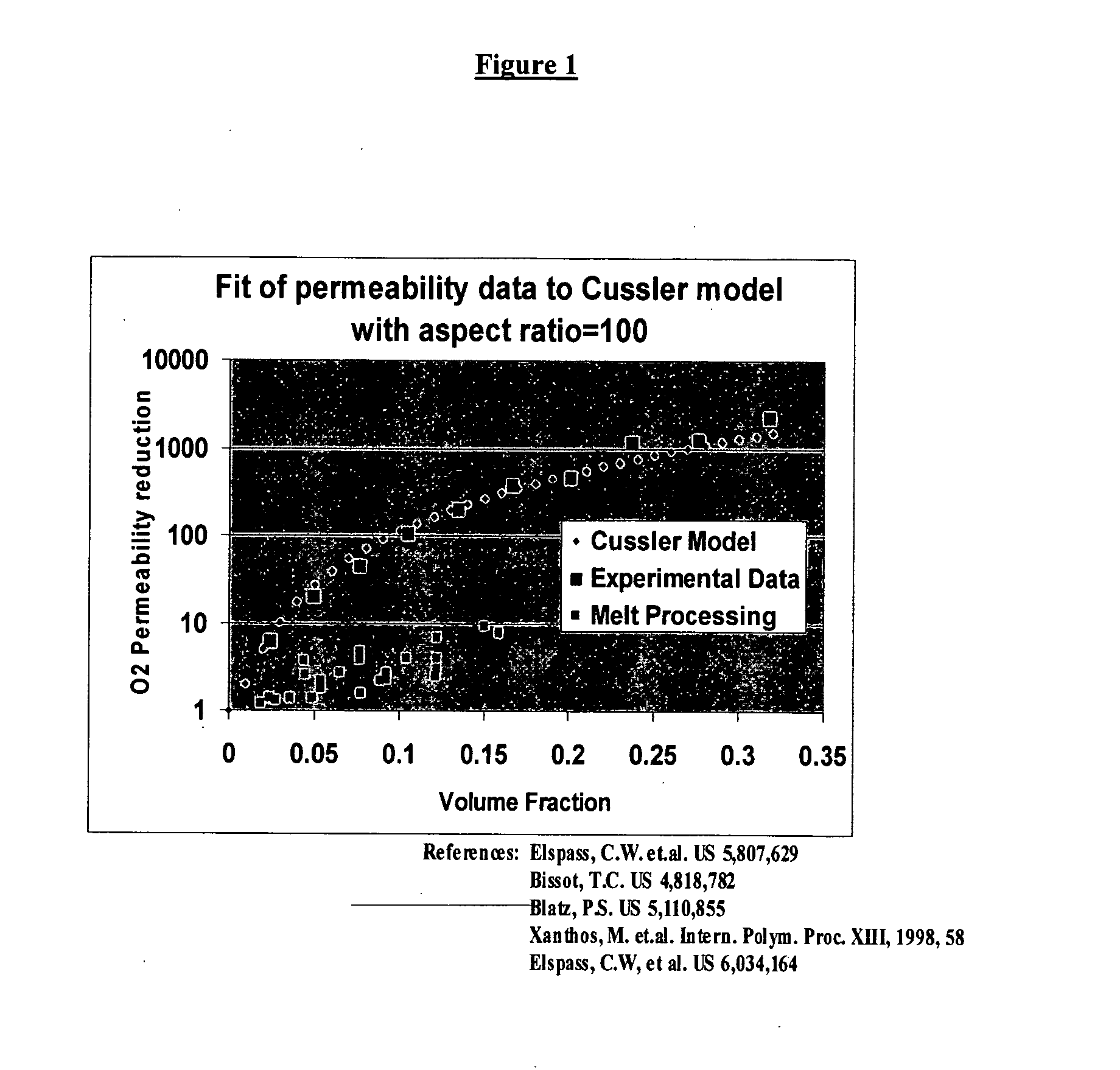

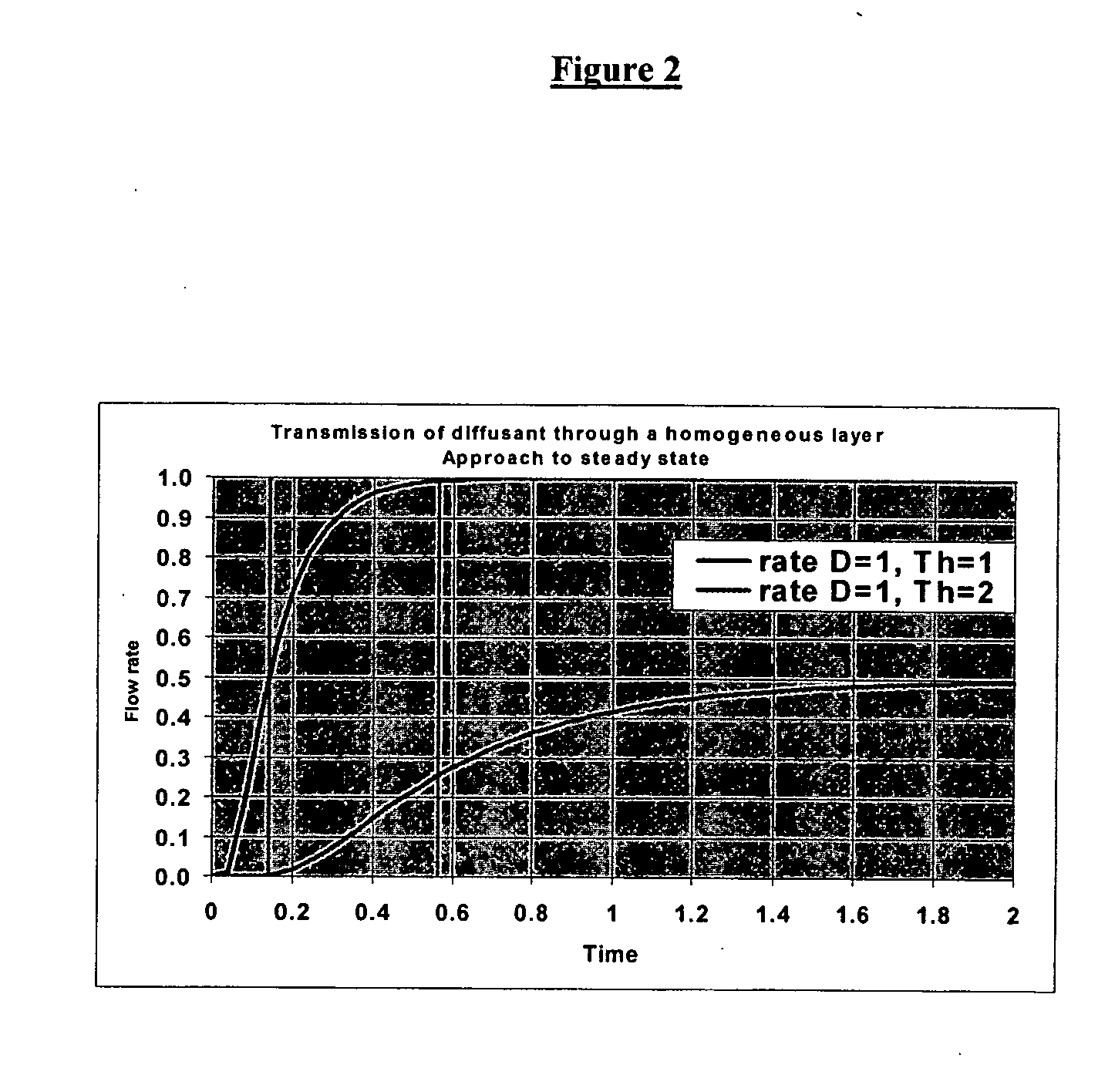

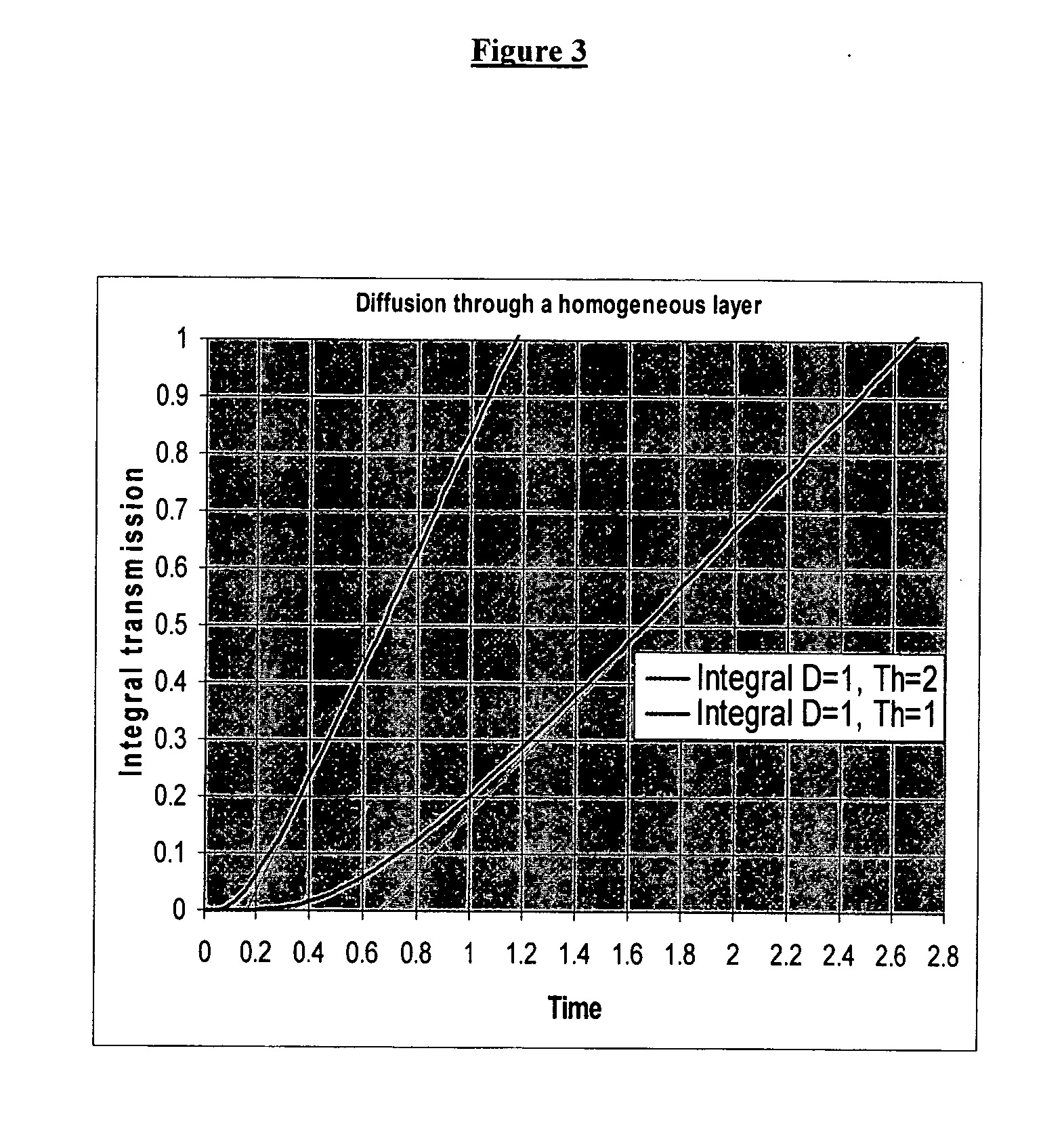

Multilayer nanocomposite barrier structures

InactiveUS20060110615A1Reduce penetrationInhibited DiffusionSynthetic resin layered productsDomestic containersElastomerNanometre

A multilayer barrier structure includes a plurality of relatively thin nanocomposite layers separated by one or more relatively thick intermediate layers selected from synthetic elastomers or non-elastomeric polymers. The composites exhibit remarkably long breakthrough and lag-times and are useful for packaging or protective apparel.

Owner:INMAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com