Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3308results about "Pipe protection against corrosion/incrustation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

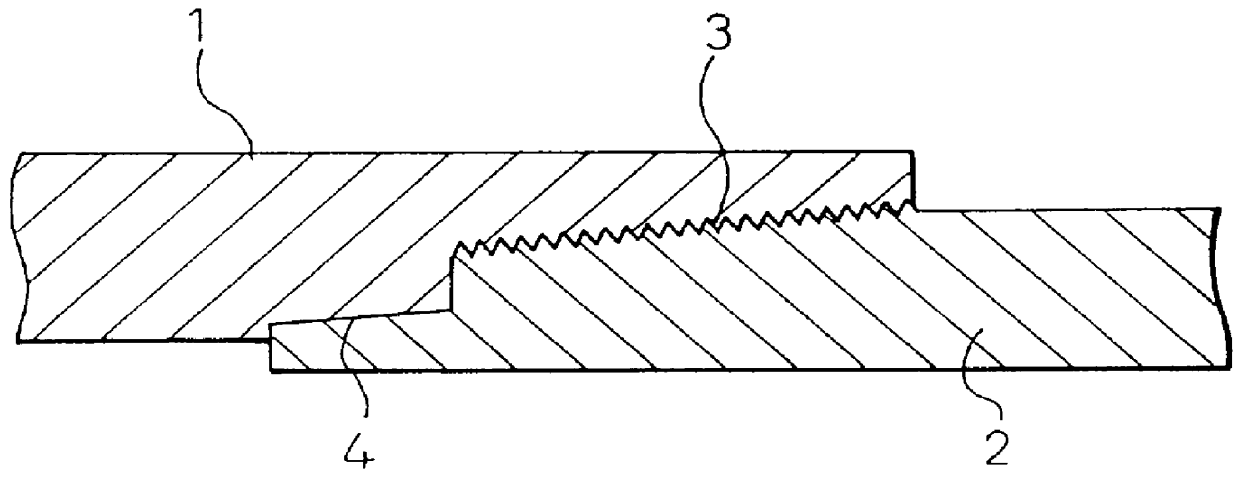

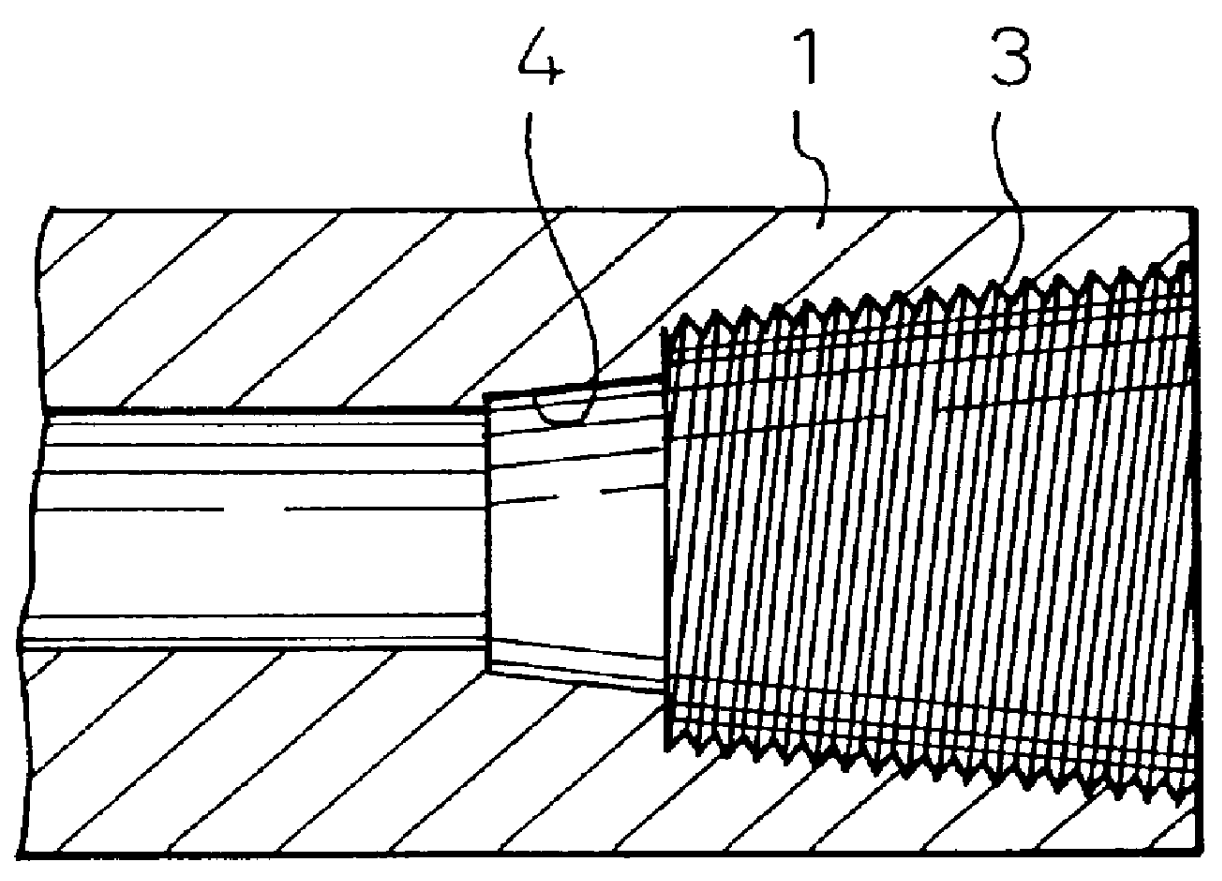

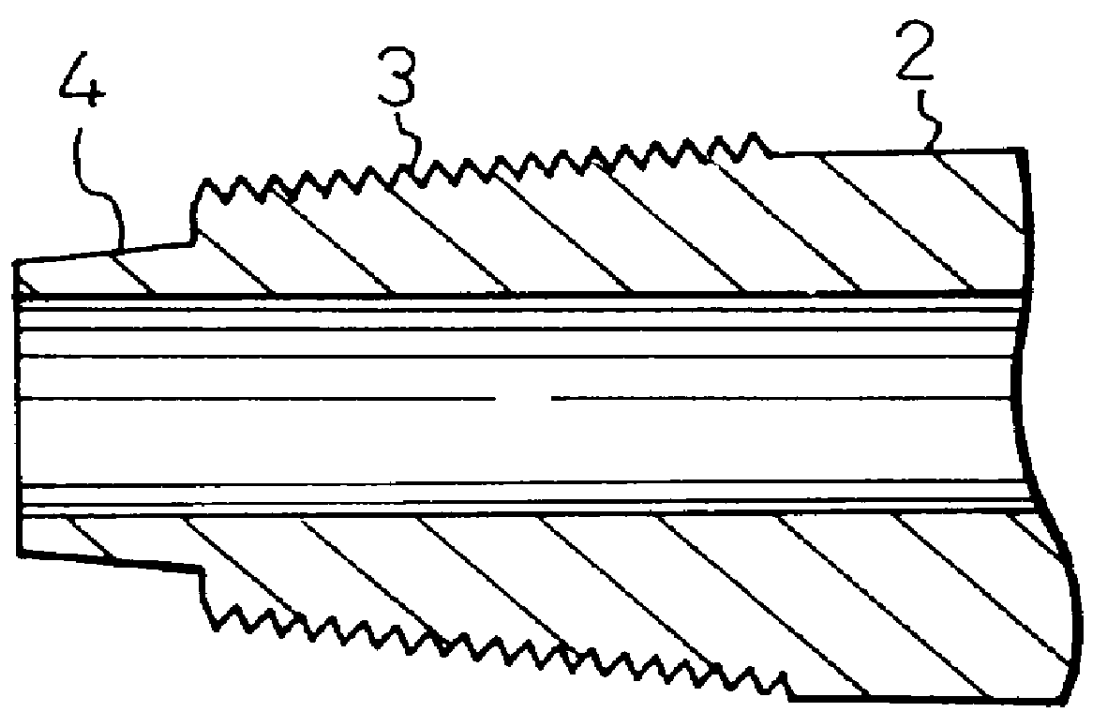

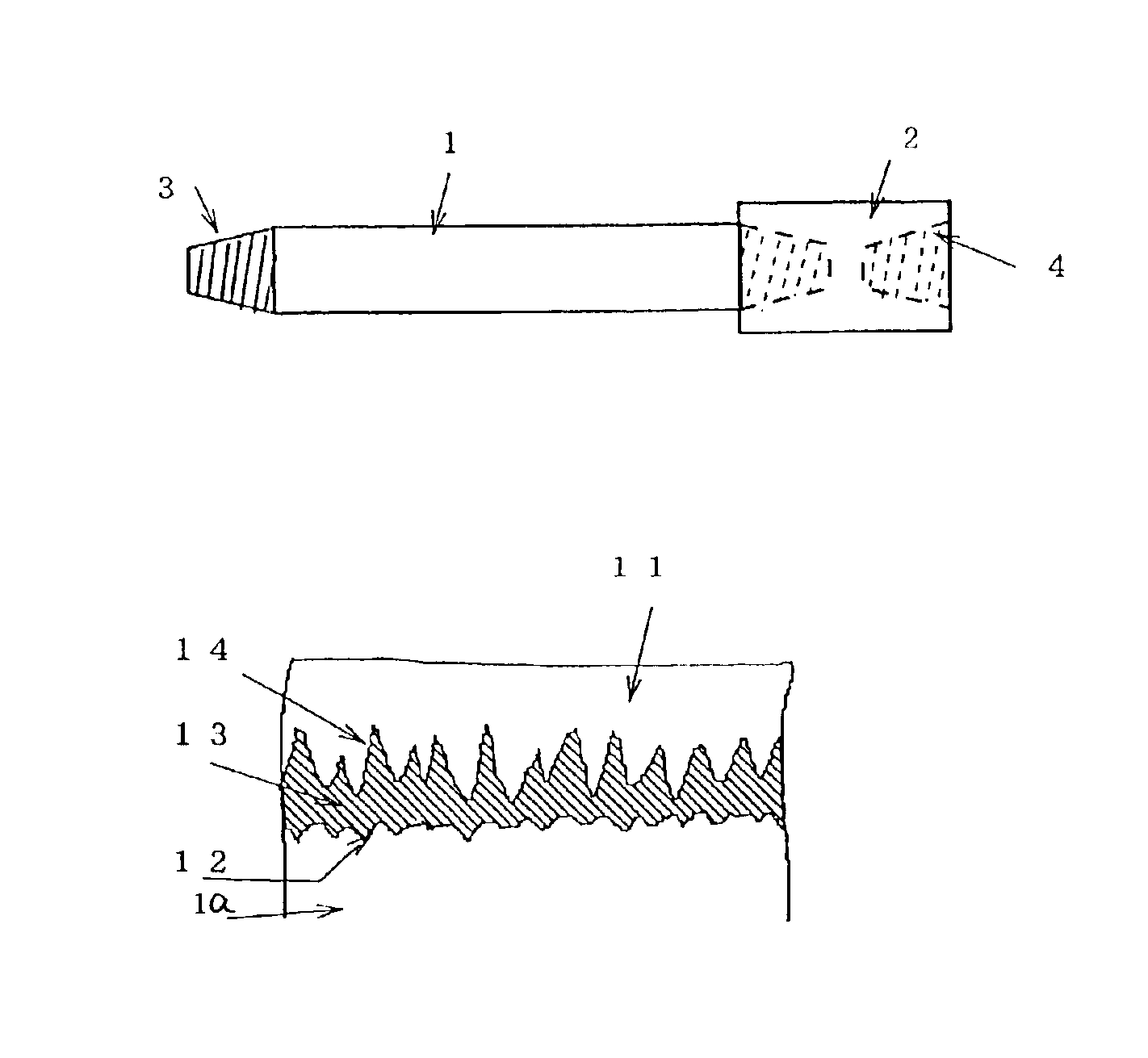

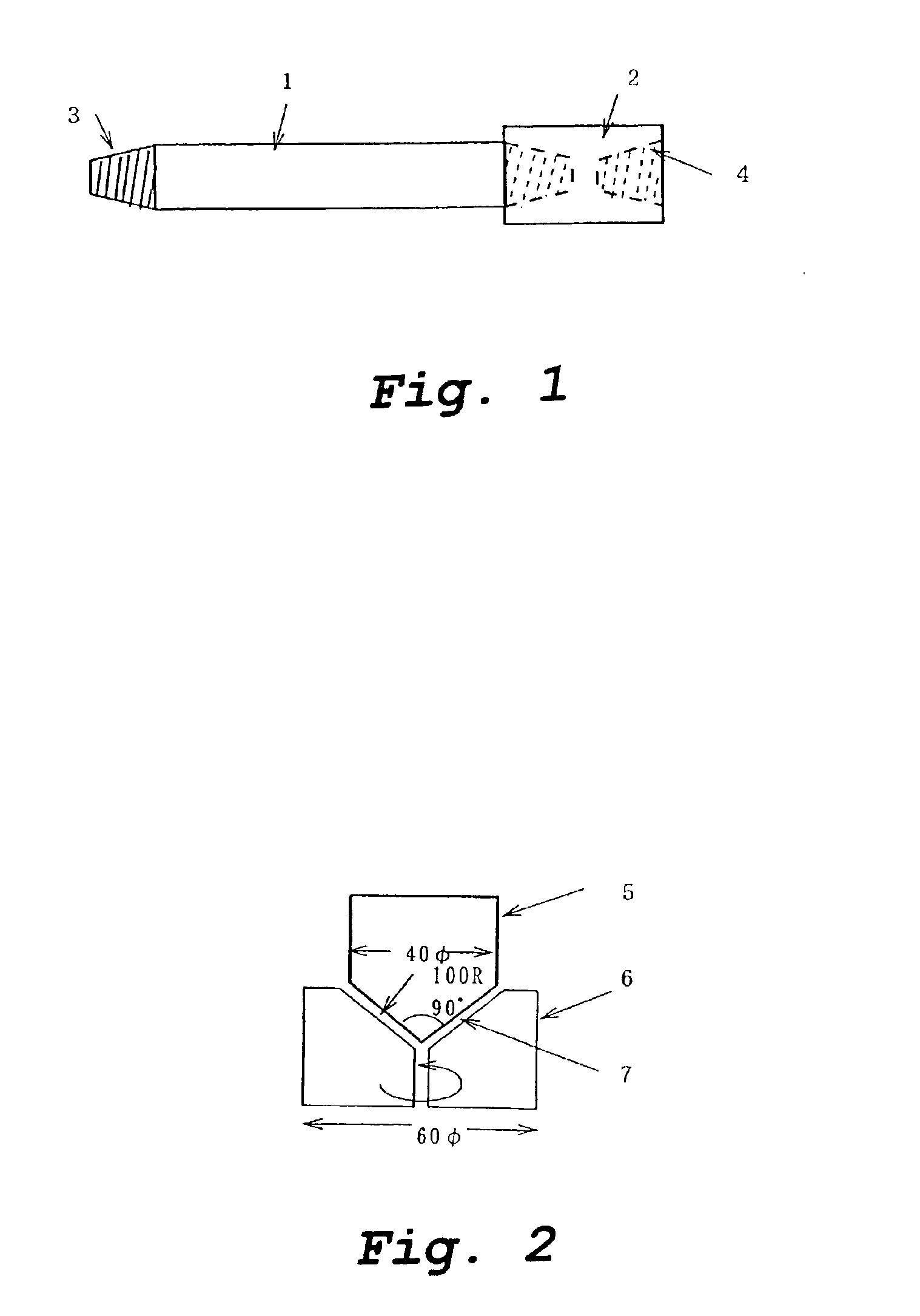

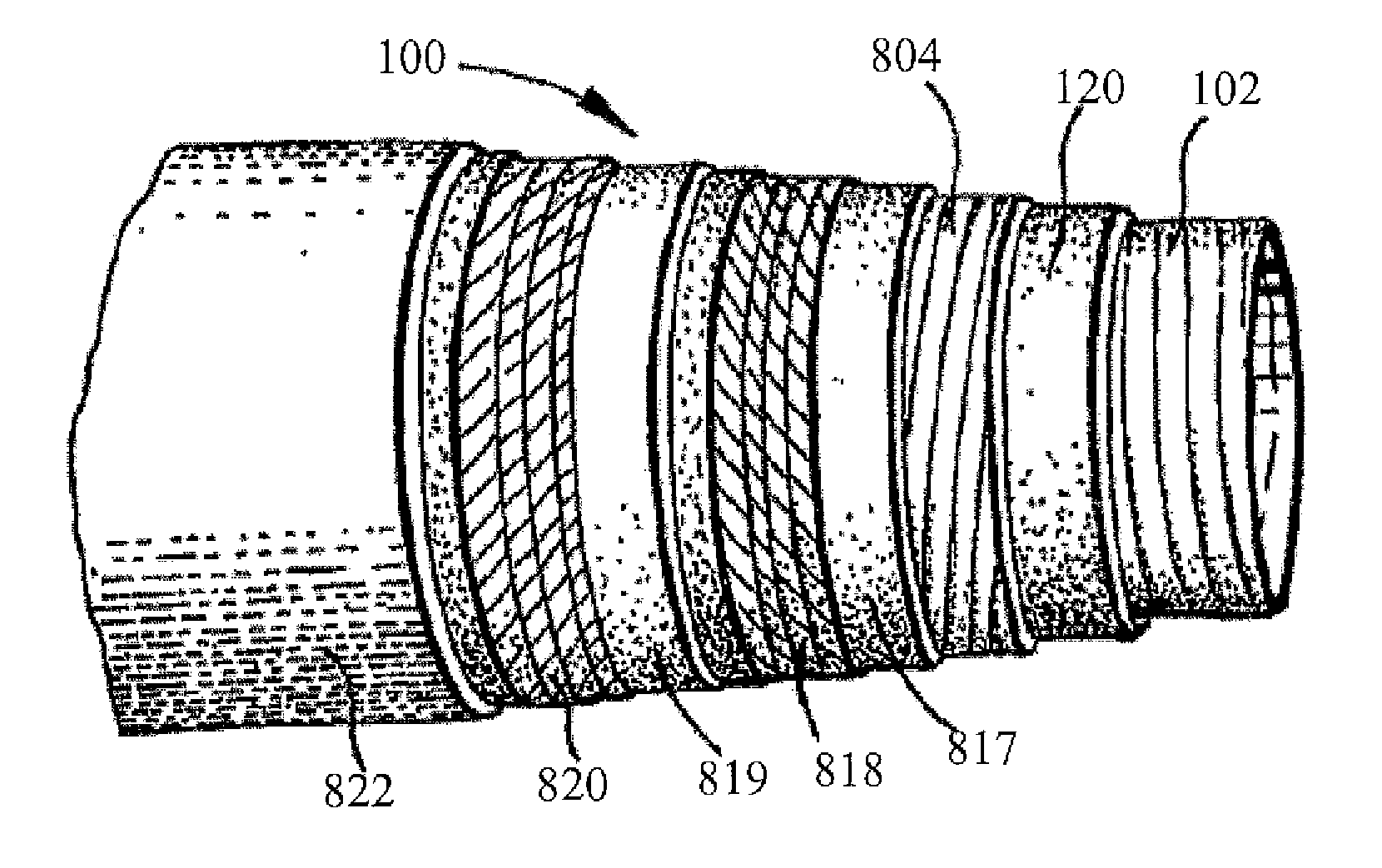

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

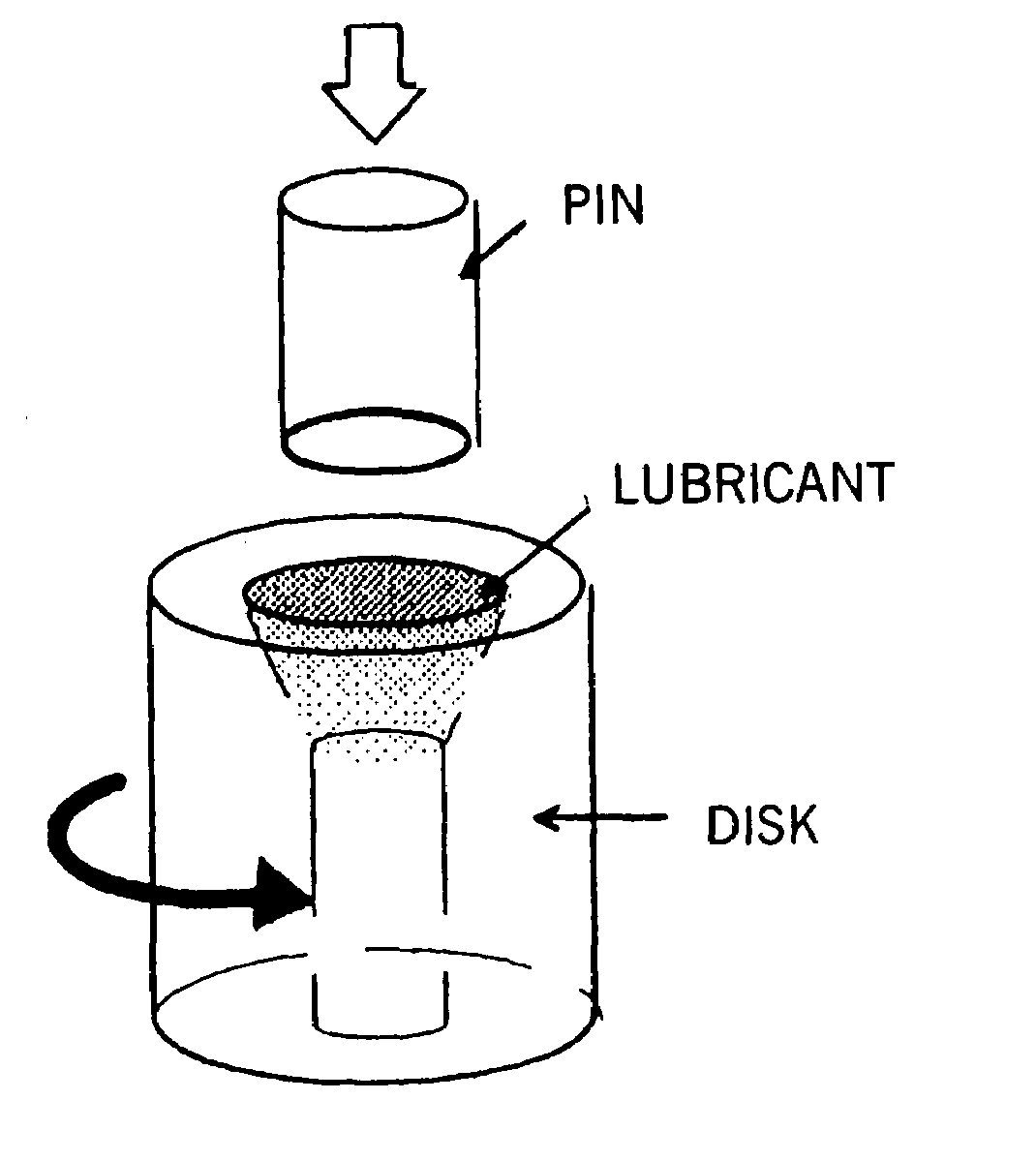

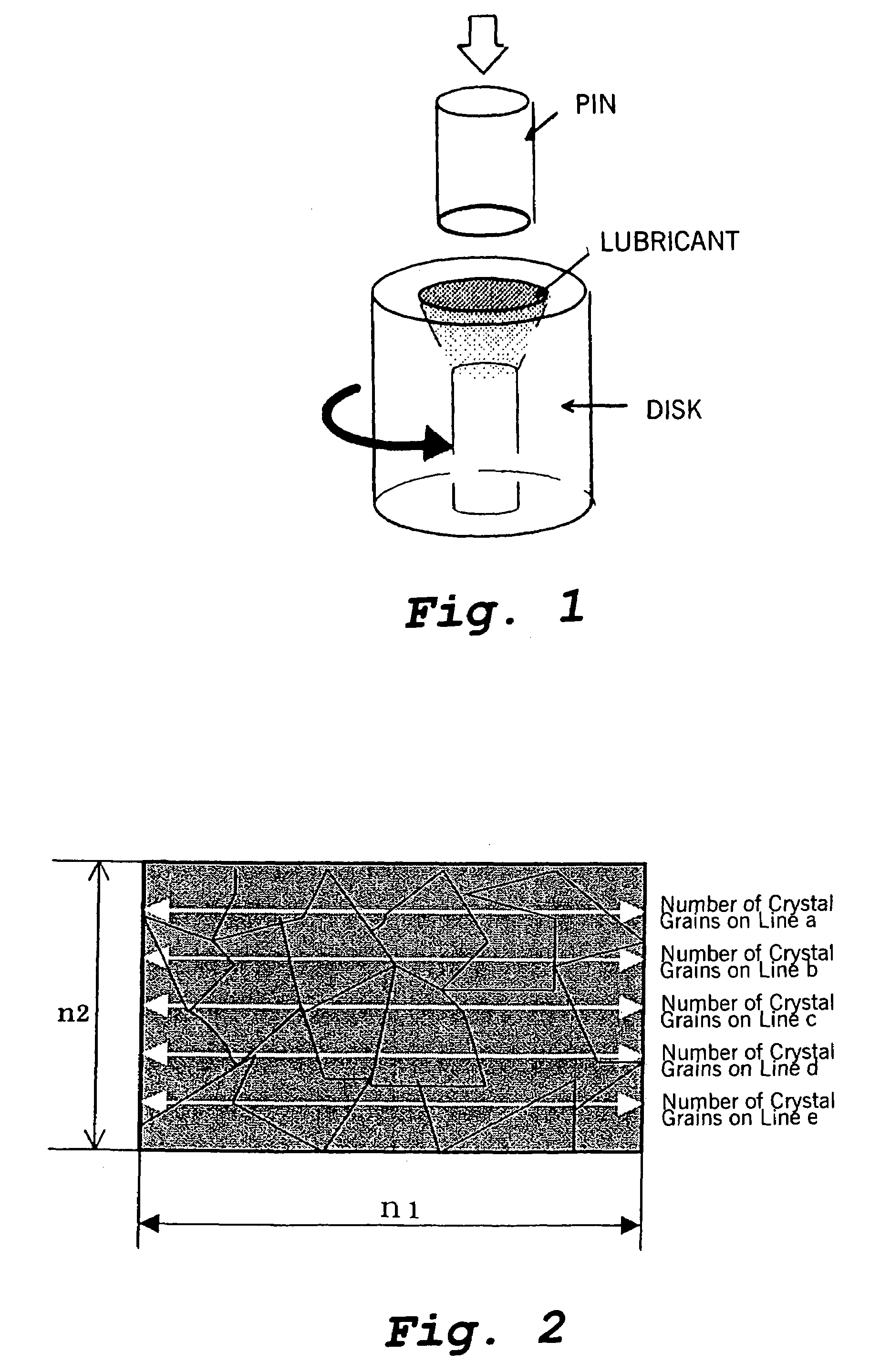

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

Surface conditioning prior to chemical conversion treatment of a steel member

ActiveUS7666266B2Optimized diameterShort timeOther chemical processesCorrosion preventionPotassiumMaterials science

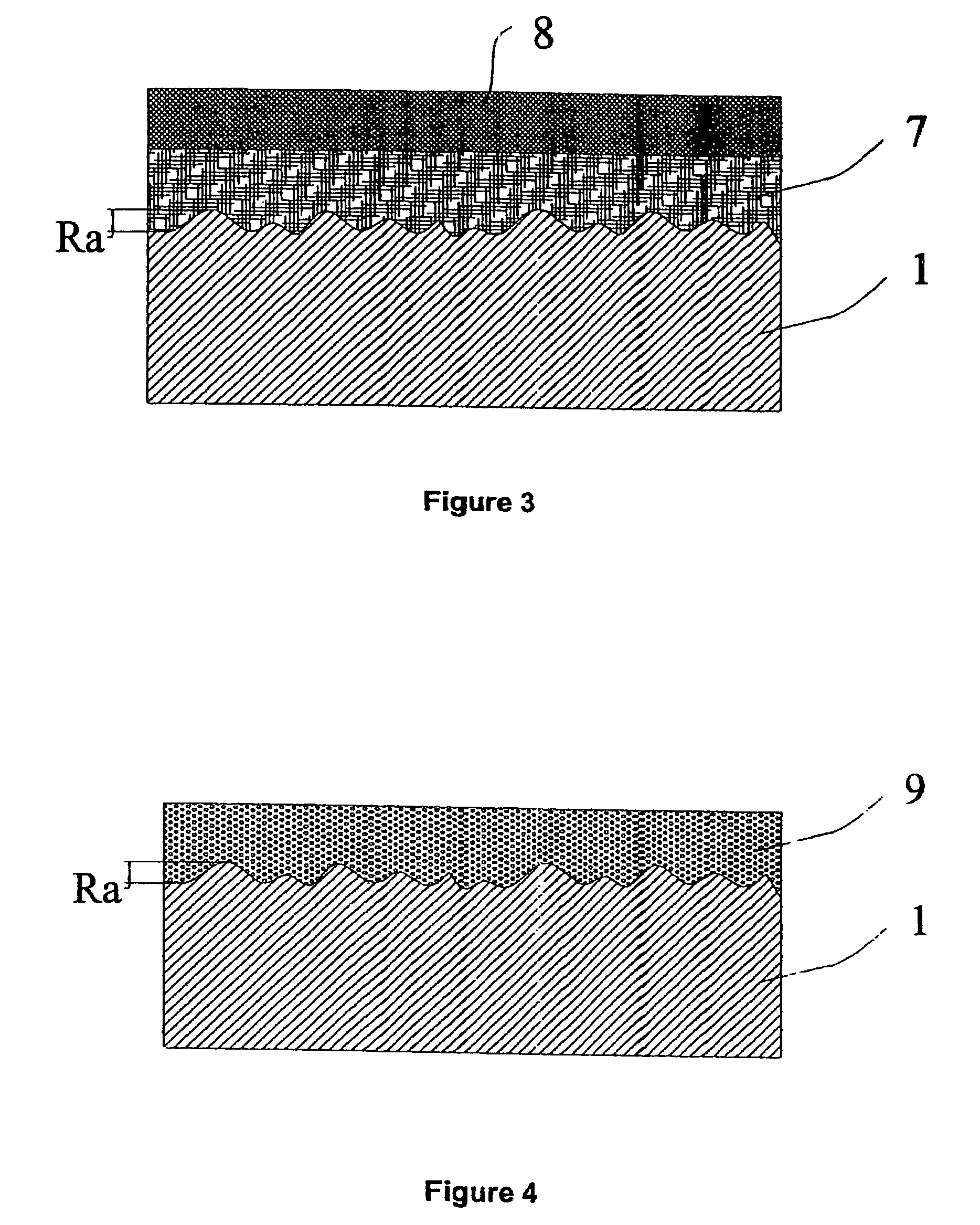

By subjecting a threaded joint for OCTG (oil country tubular goods) to surface conditioning with an aqueous solution of potassium tetraborate or sodium tetraborate prior to manganese phosphate chemical conversion treatment, a manganese phosphate chemical conversion coating having coarse crystal grains with an average crystal grain diameter of 10-110 micrometers is formed on the surface of the steel member which may be any steel including a high Cr steel. This manganese phosphate chemical conversion coating can hold a large amount of a liquid lubricant, and it is effective at preventing the occurrence of galling at the time of makeup of a threaded joint for OCTG.

Owner:NIPPON STEEL CORP

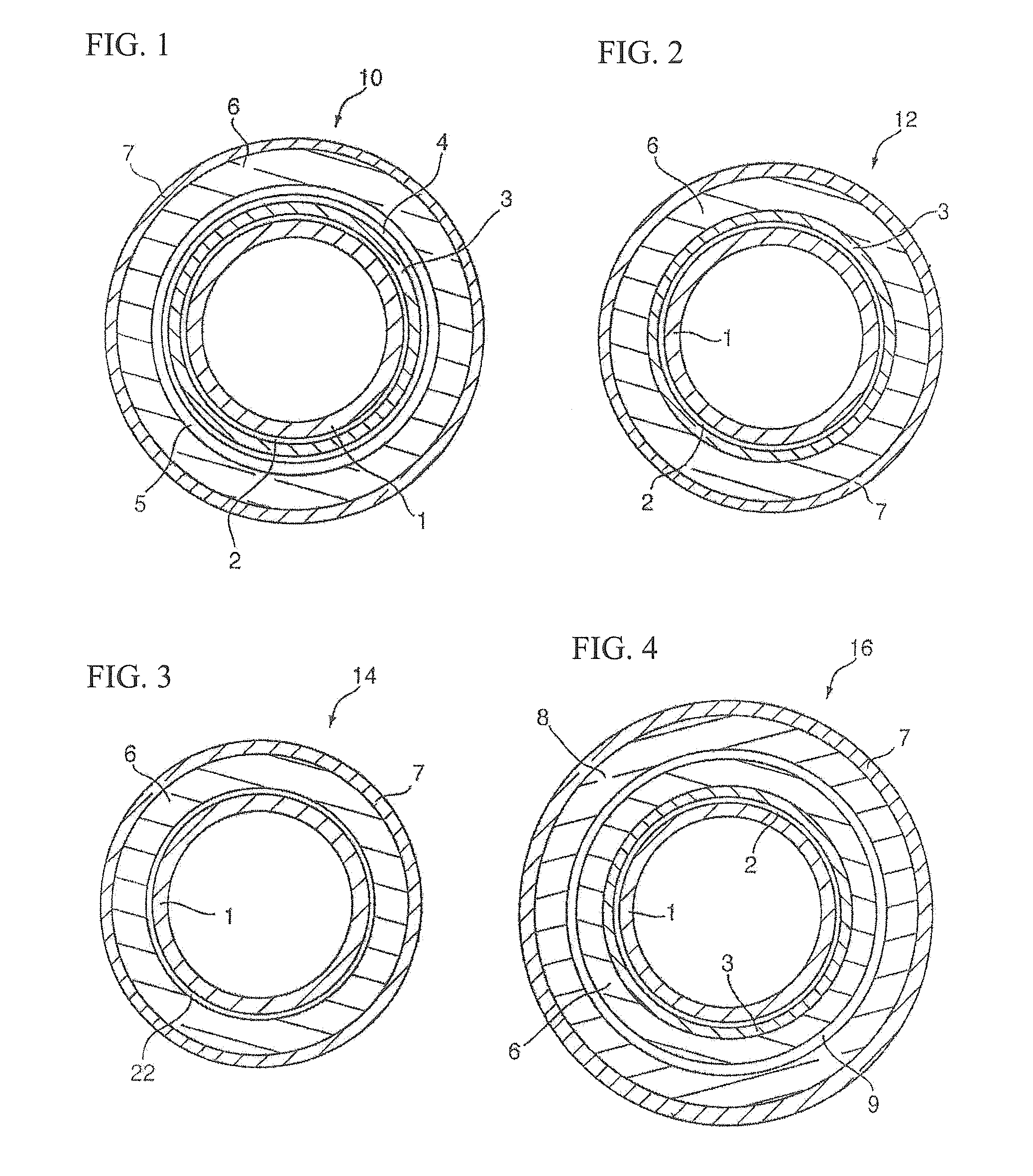

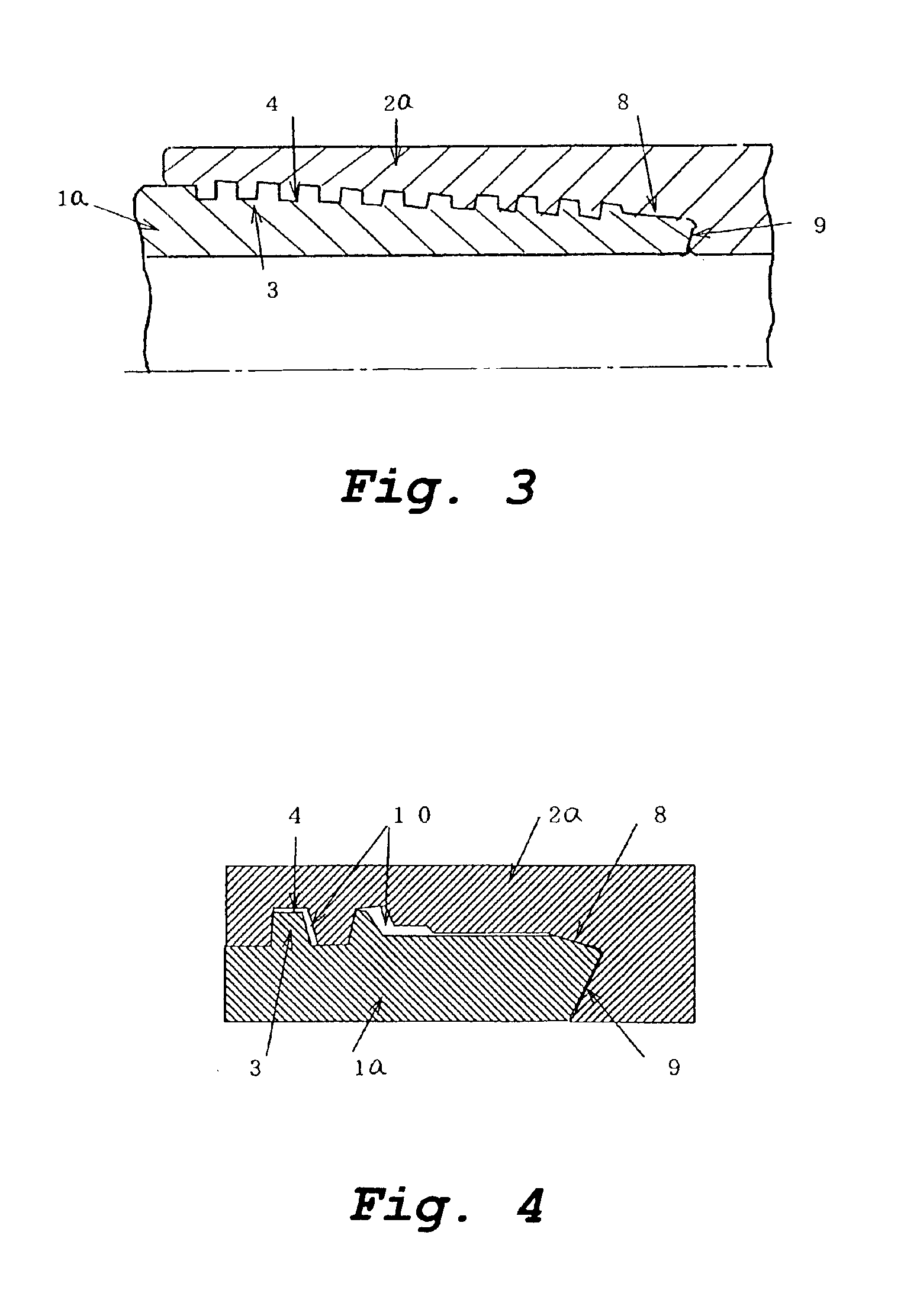

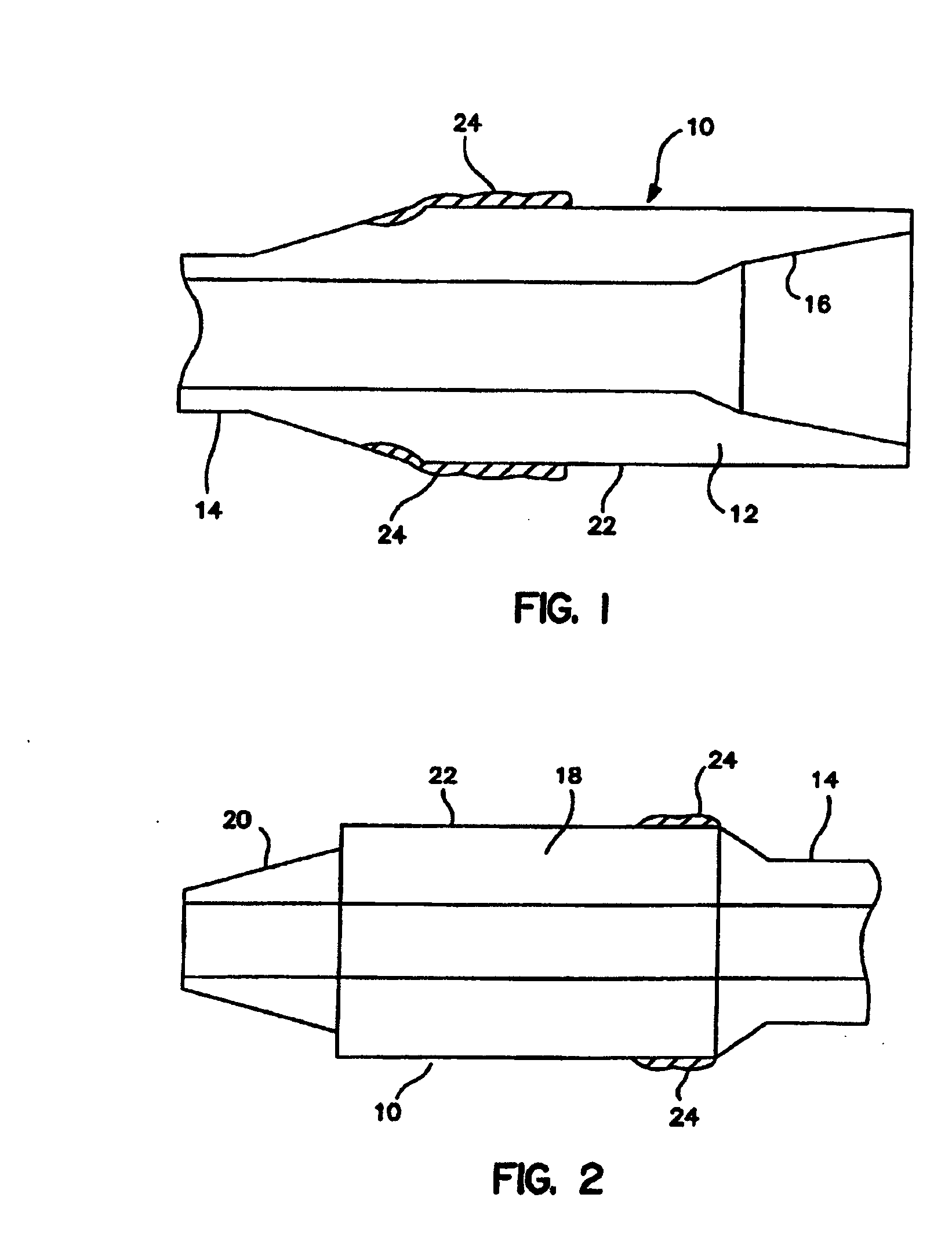

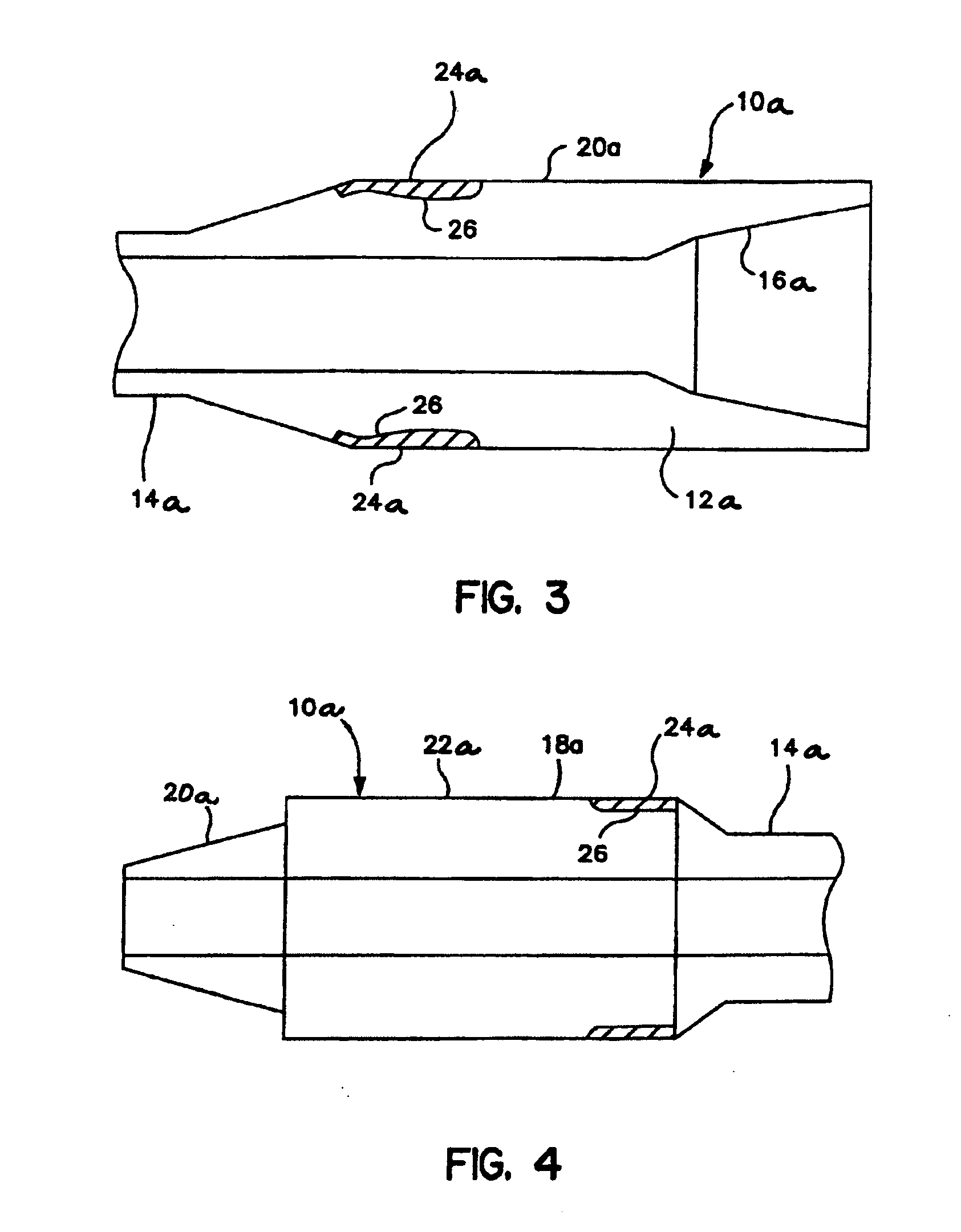

Threaded pipe with surface treatment

InactiveUS6971681B2Maintain good propertiesIncrease resistanceDrilling rodsPipe elementsThreaded pipeDry lubricant

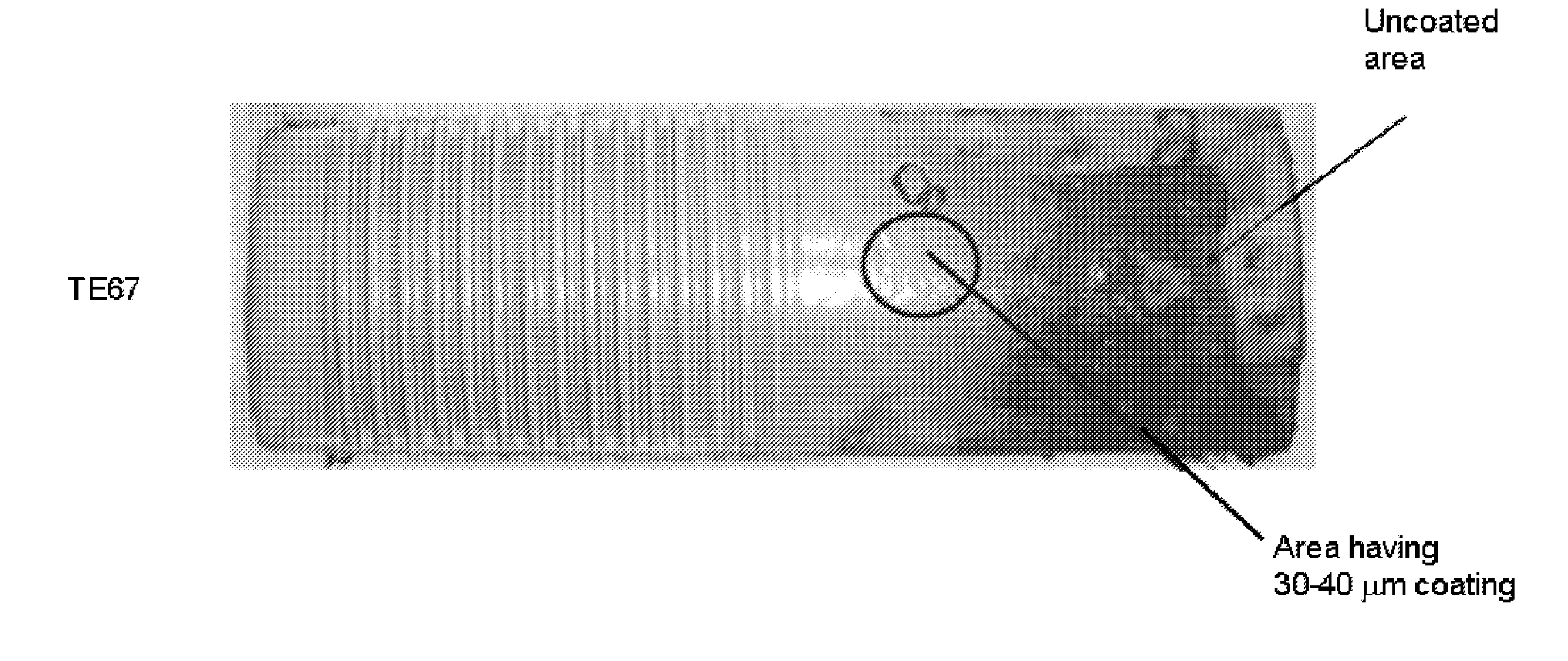

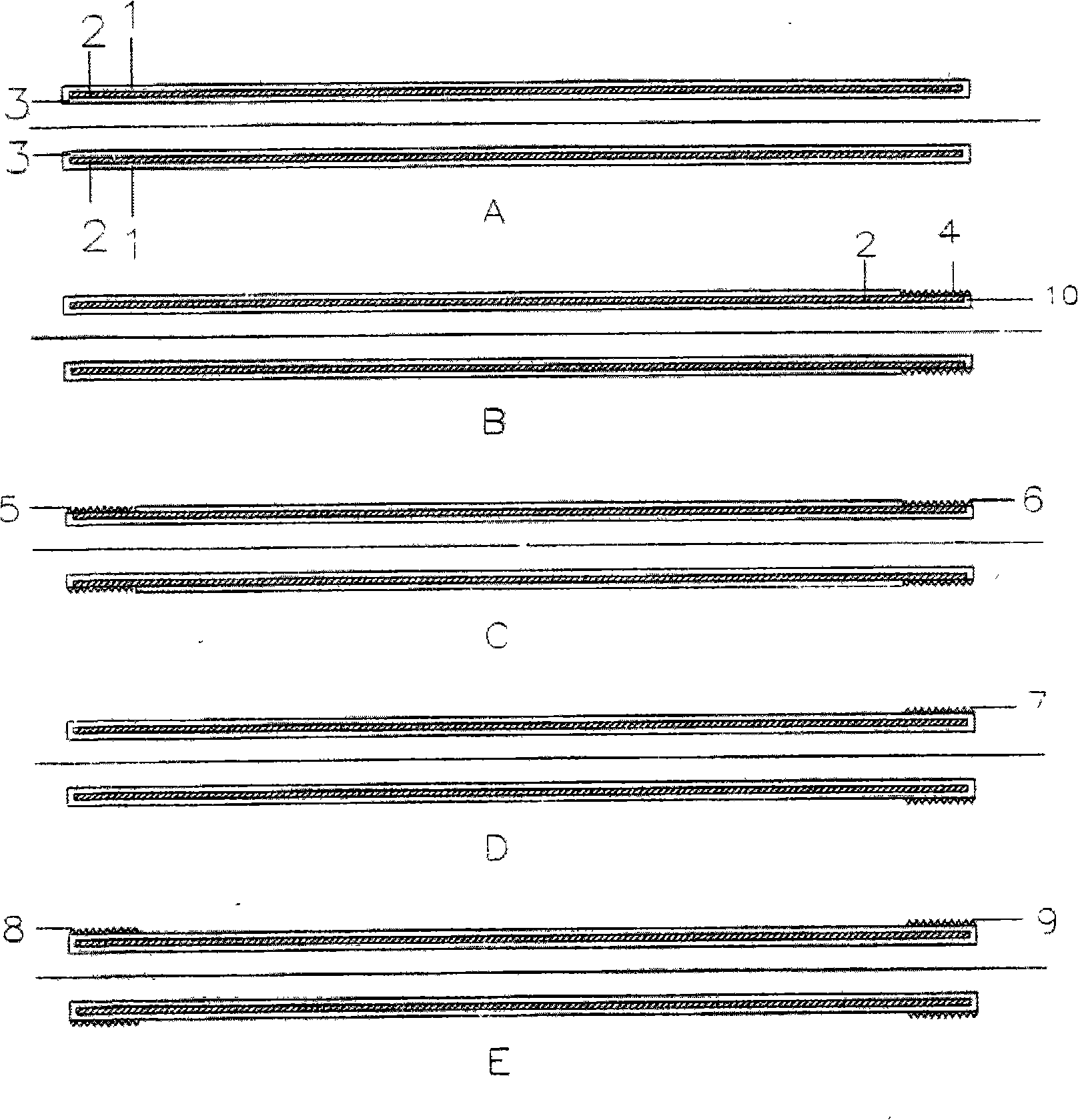

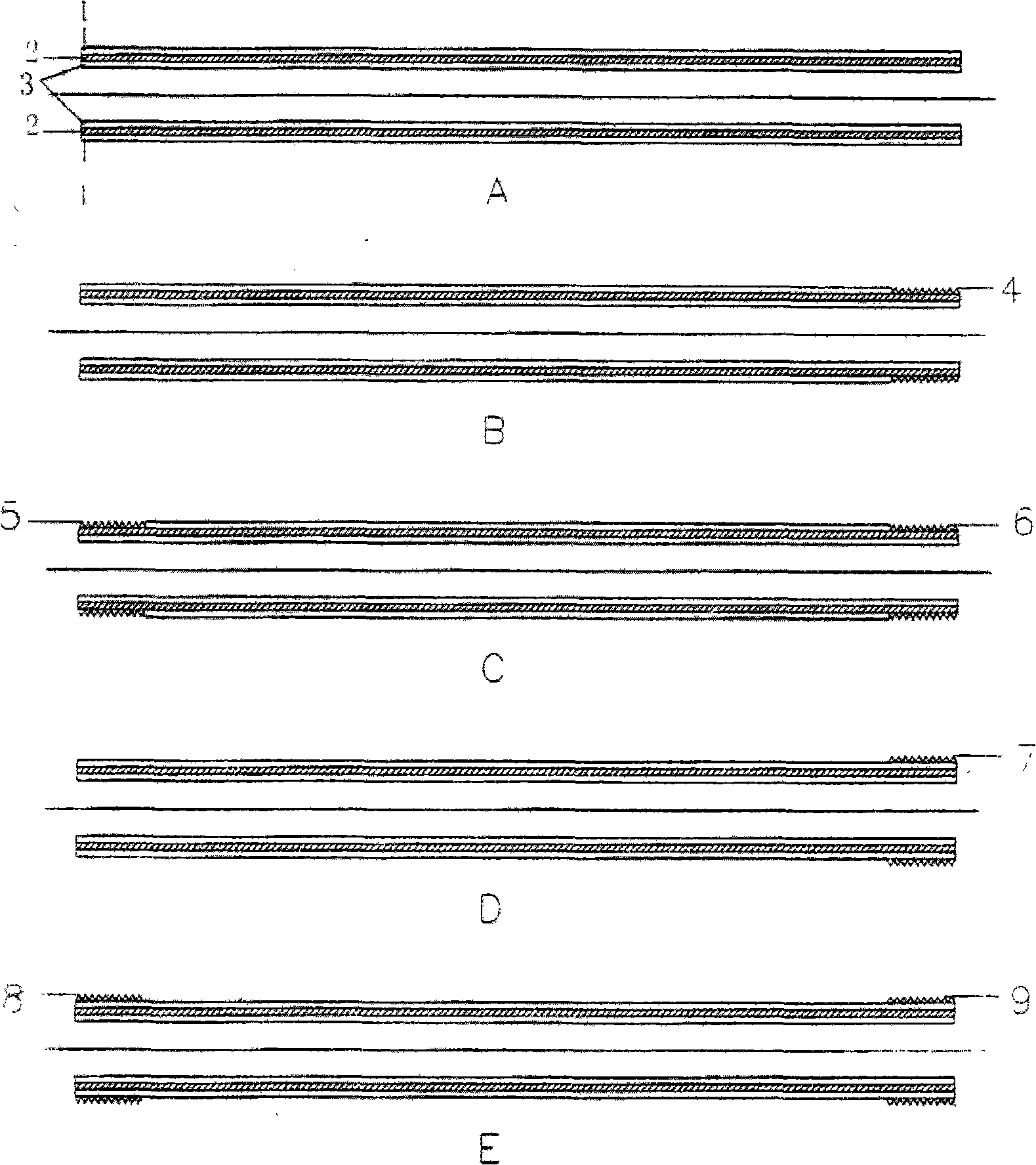

A threaded metallic pipe for oil extraction industry has a threaded end portion with treated surface in which the metal surface has a roughness (Ra) comprised of 2.0 μm and 6.0 μm, which is covered by a uniform layer (7) of a dry corrosion inhibiting coating and a second uniform layer (8) of dry lubricant coating. Alternatively the layers (8, 9) combined into one uniform layer (9) of a dry corrosion inhibiting coating containing a dispersion of particles of solid lubricant.

Owner:TENARIS CONNECTIONS

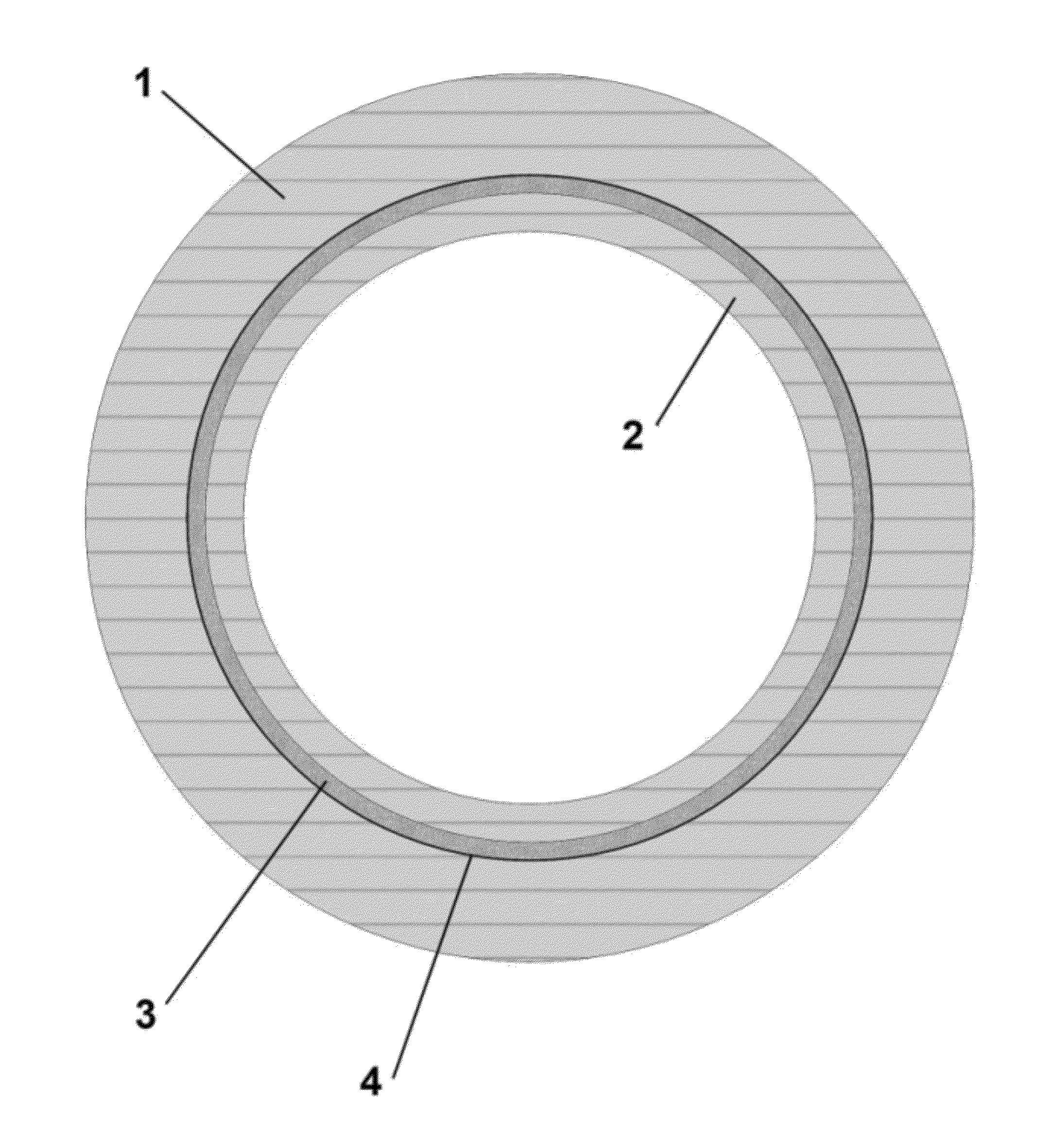

Nanocomposite coatings for threaded connections

Coating systems which provide corrosion resistance and, optionally, lubrication, for threaded connections are disclosed. The compositions comprise a first coating composition comprising polymer matrices of polyimides or epoxies which are modified with small amounts of a fluorine containing polymer. Also present in the coating compositions are corrosion inhibiting agents and inorganic particles having a mean diameter of between approximately 10 nm and 10 μm. Solid lubricants, which may include at least one of PTFE, HDPE, Graphite, and MoS2, are optionally added to provide the first coating with a low coefficient of friction. The coating systems may further comprise a second coating composition, comprising a solid lubricant dispersed within an epoxy resin and a solvent. The first and second coating compositions are deposited on at least a portion of at least one of the pin and box members of the threaded connections.

Owner:TENARIS CONNECTIONS

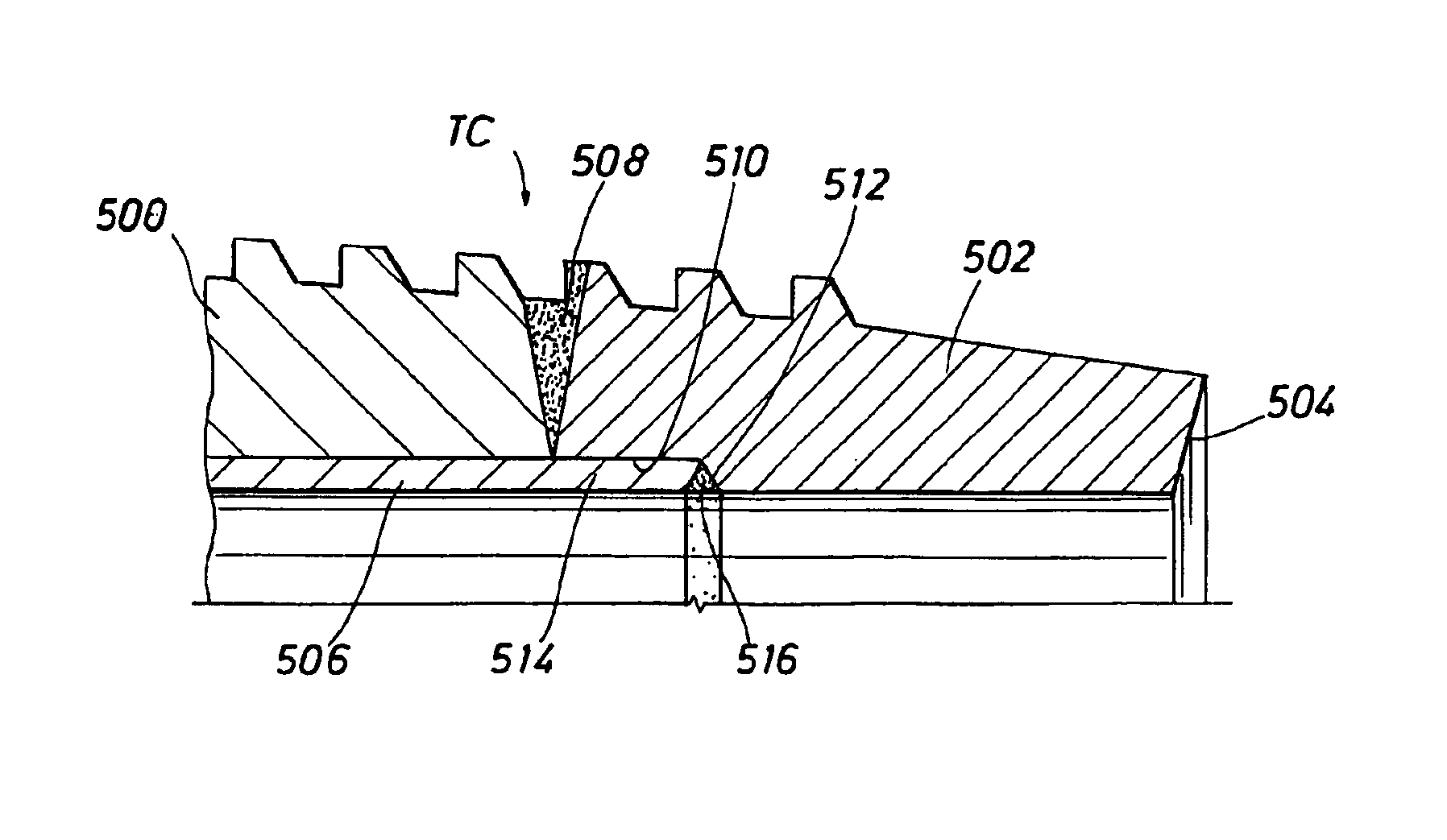

Hardfacing alloy, methods, and products

ActiveUS7361411B2Extended service lifeReduce coefficient of frictionDrill bitsDrilling rodsBorideCasing wear

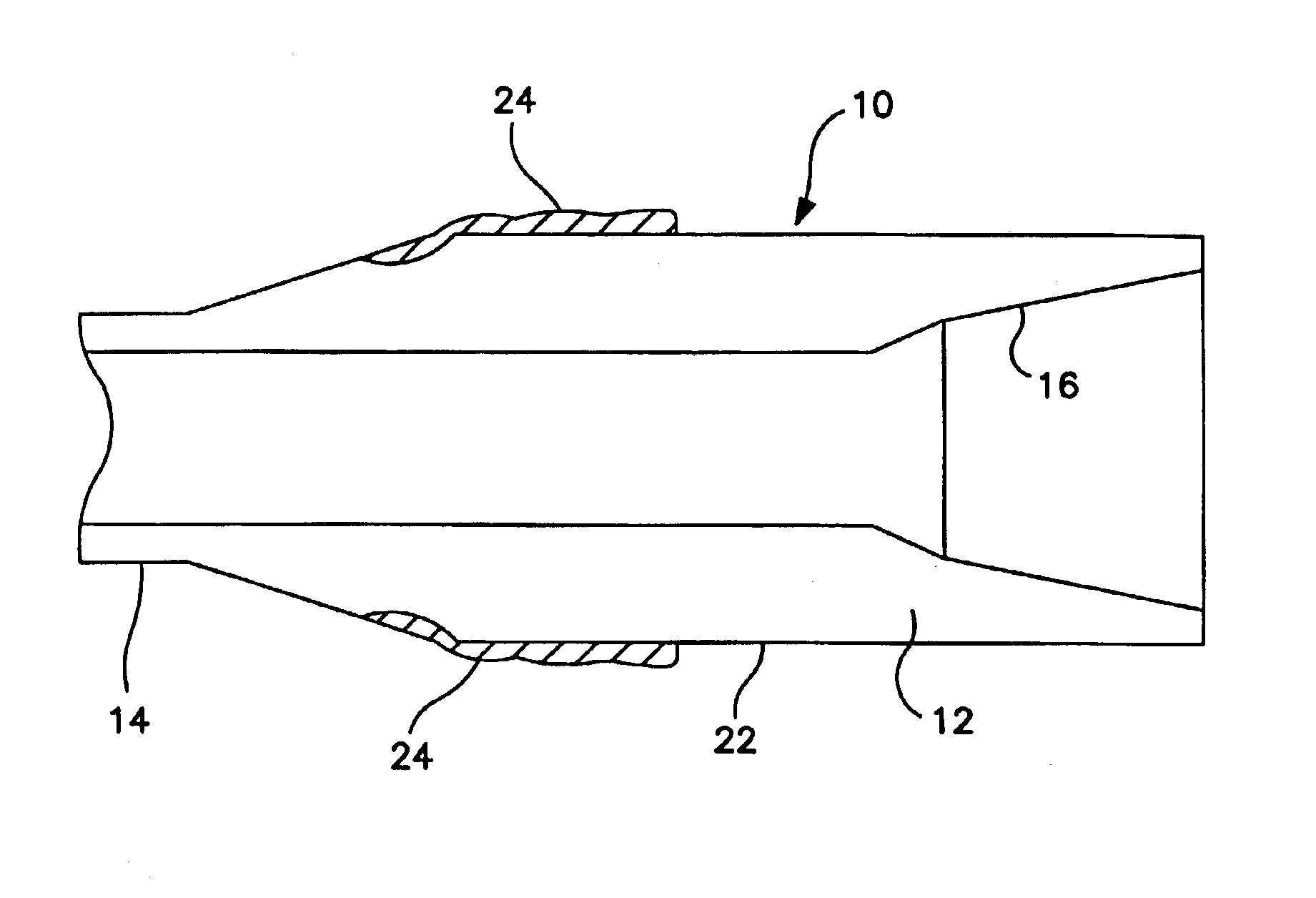

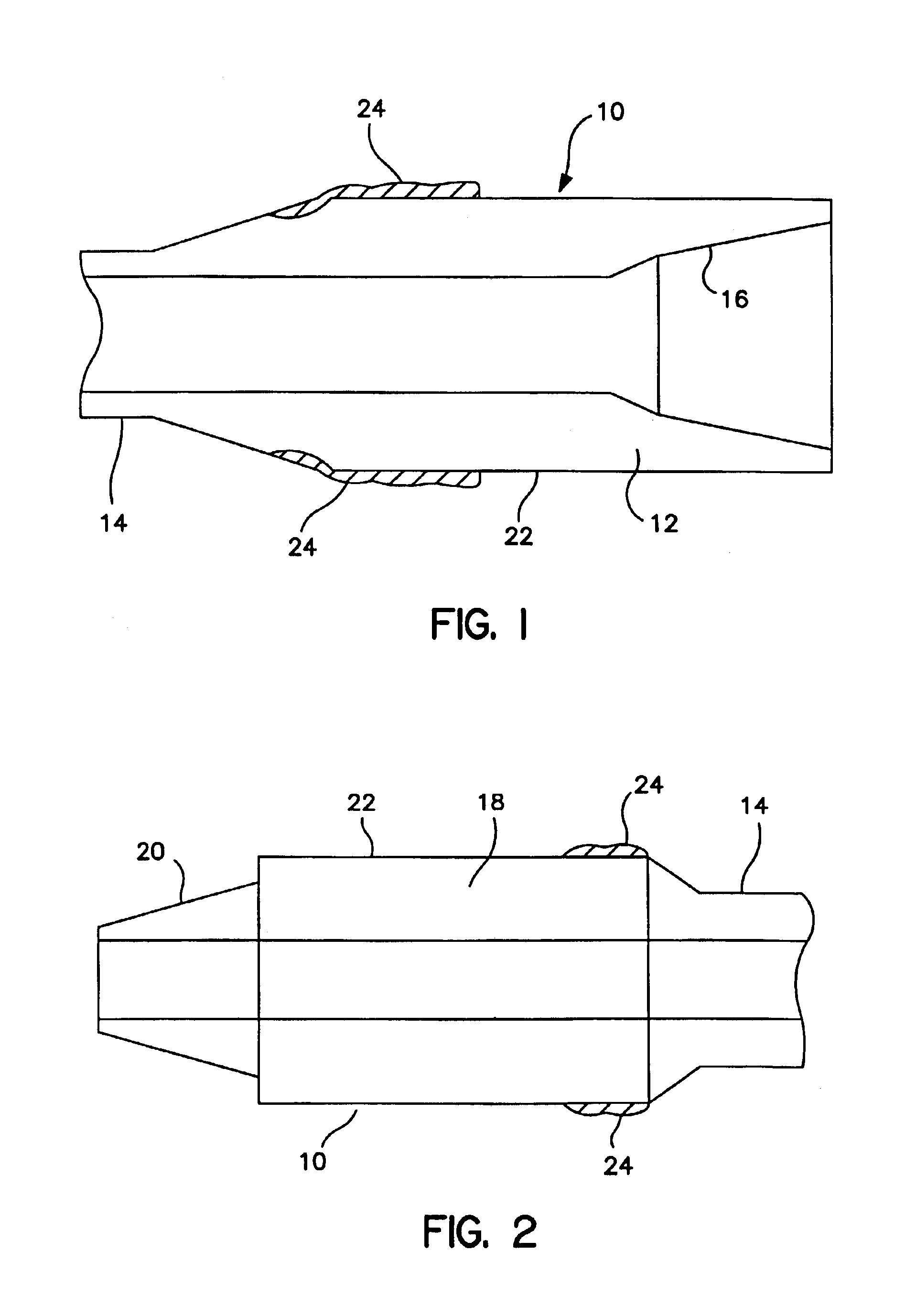

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD D B A ARNCO TECH TRUST +1

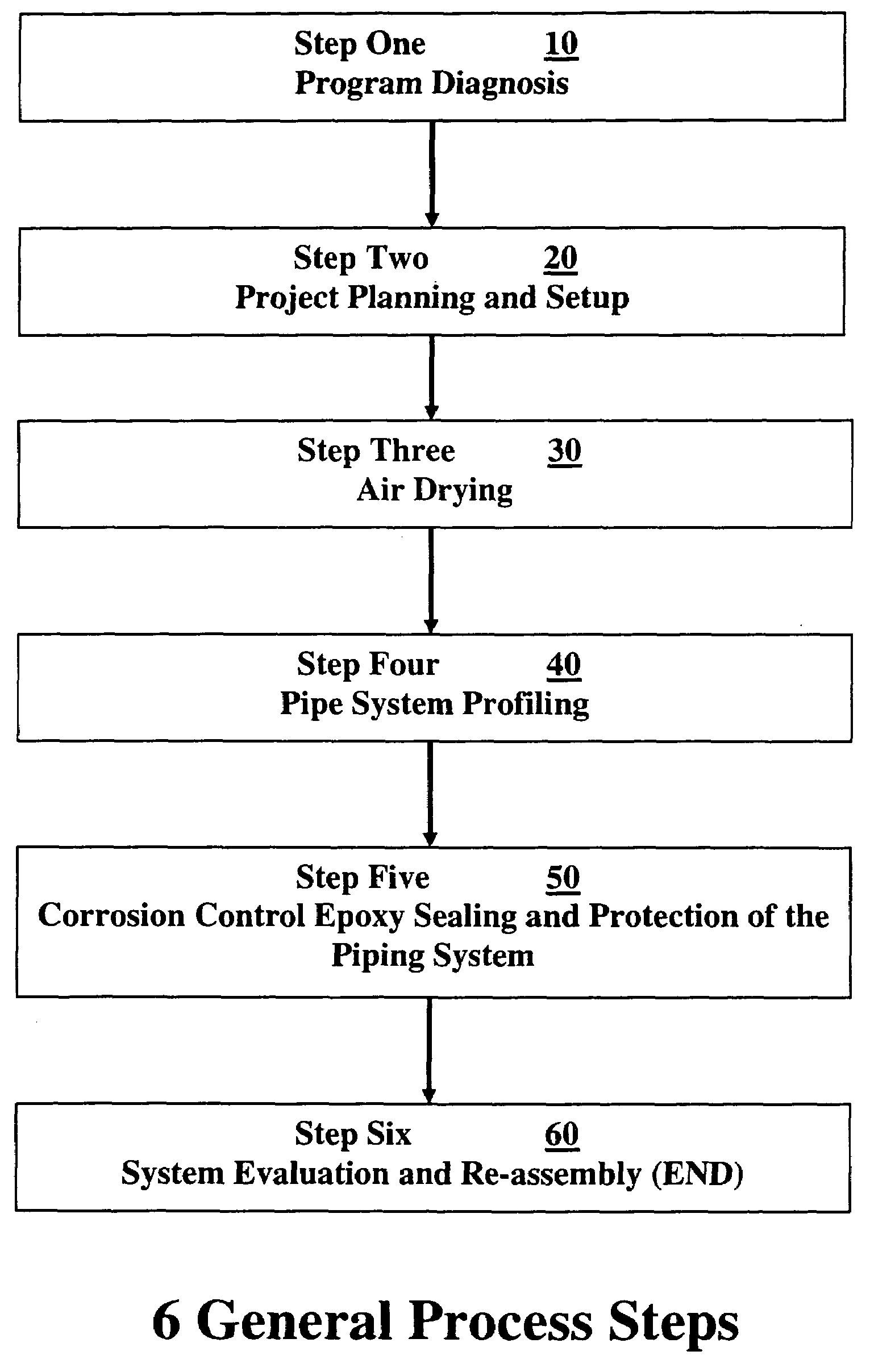

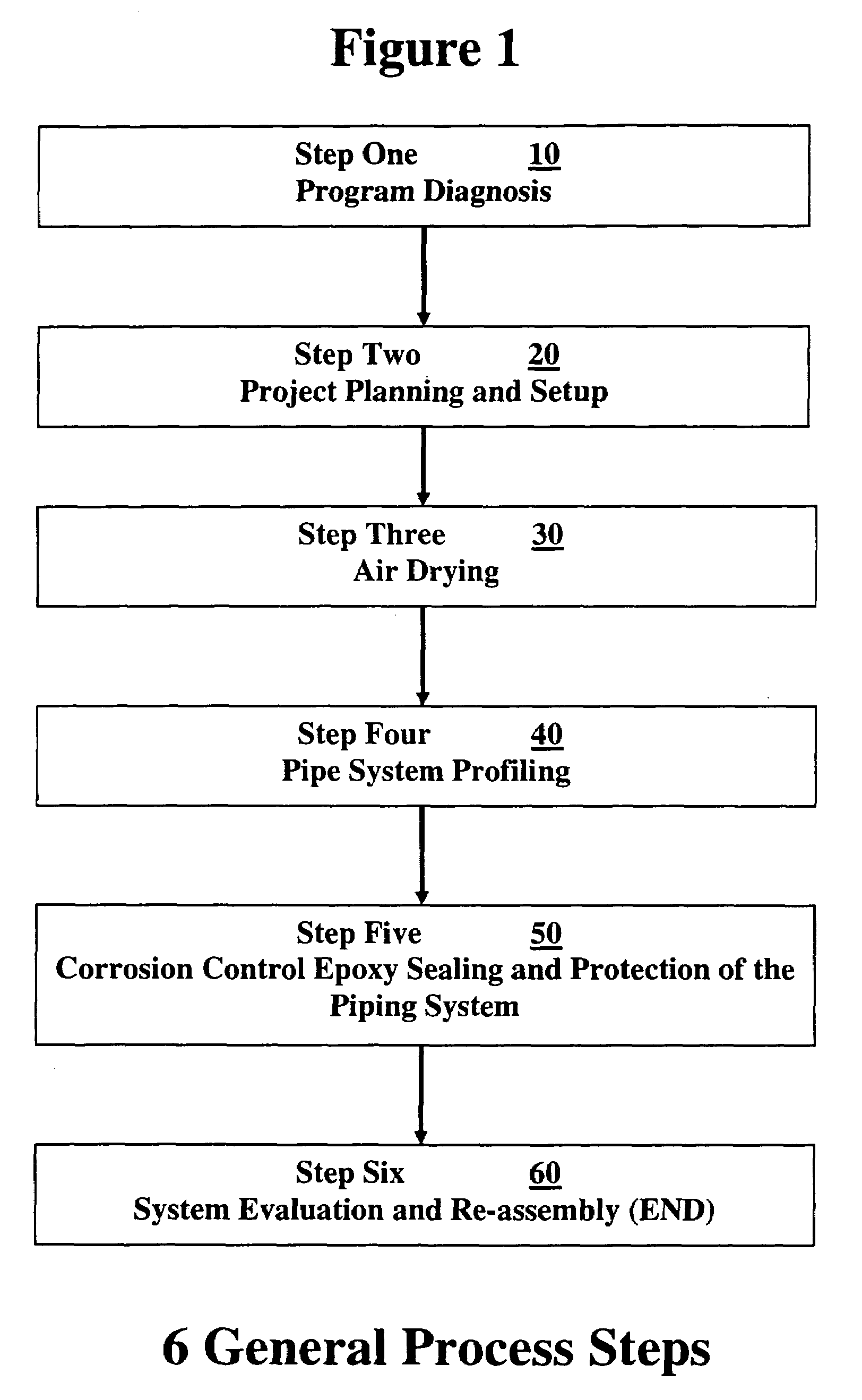

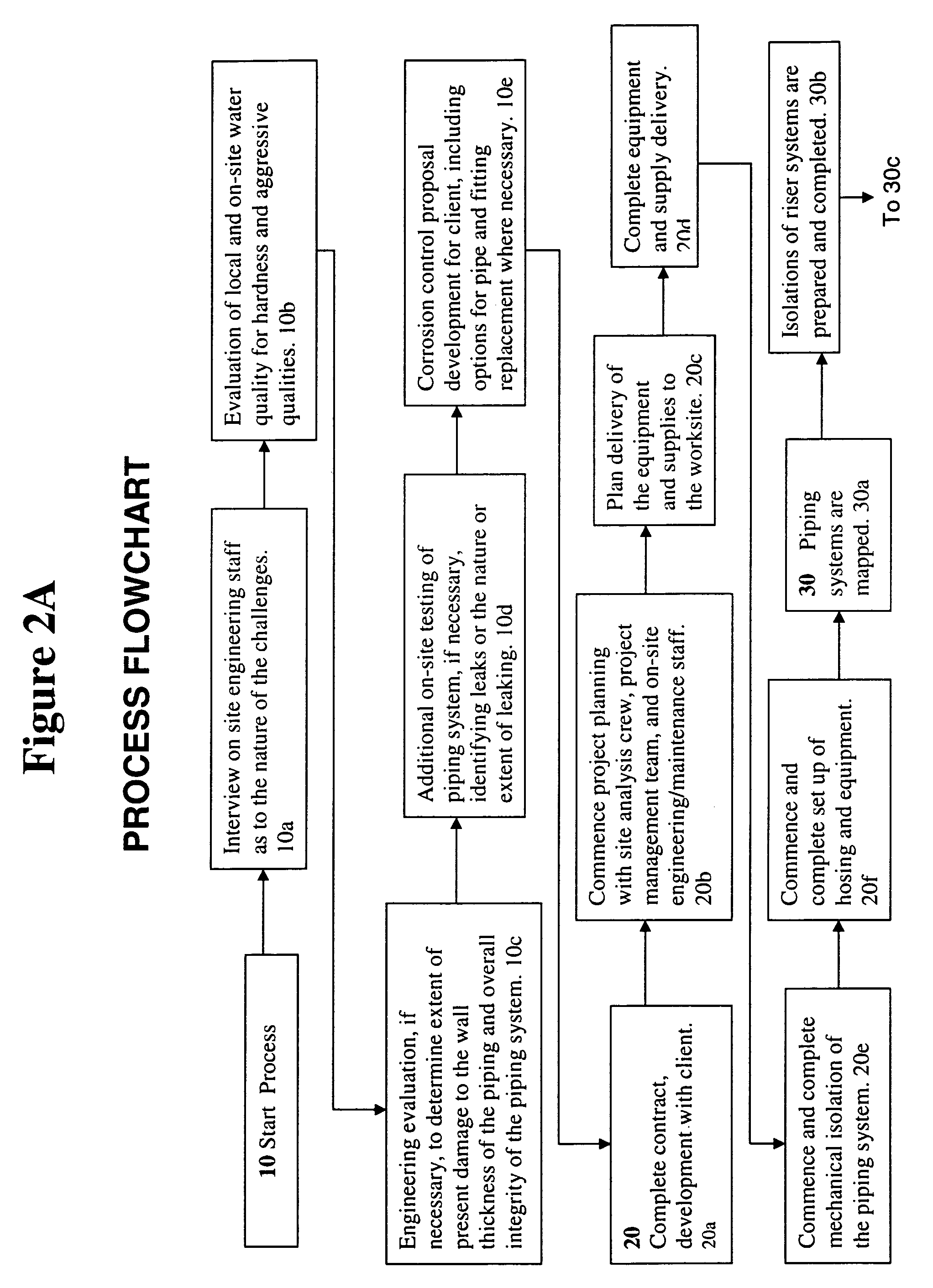

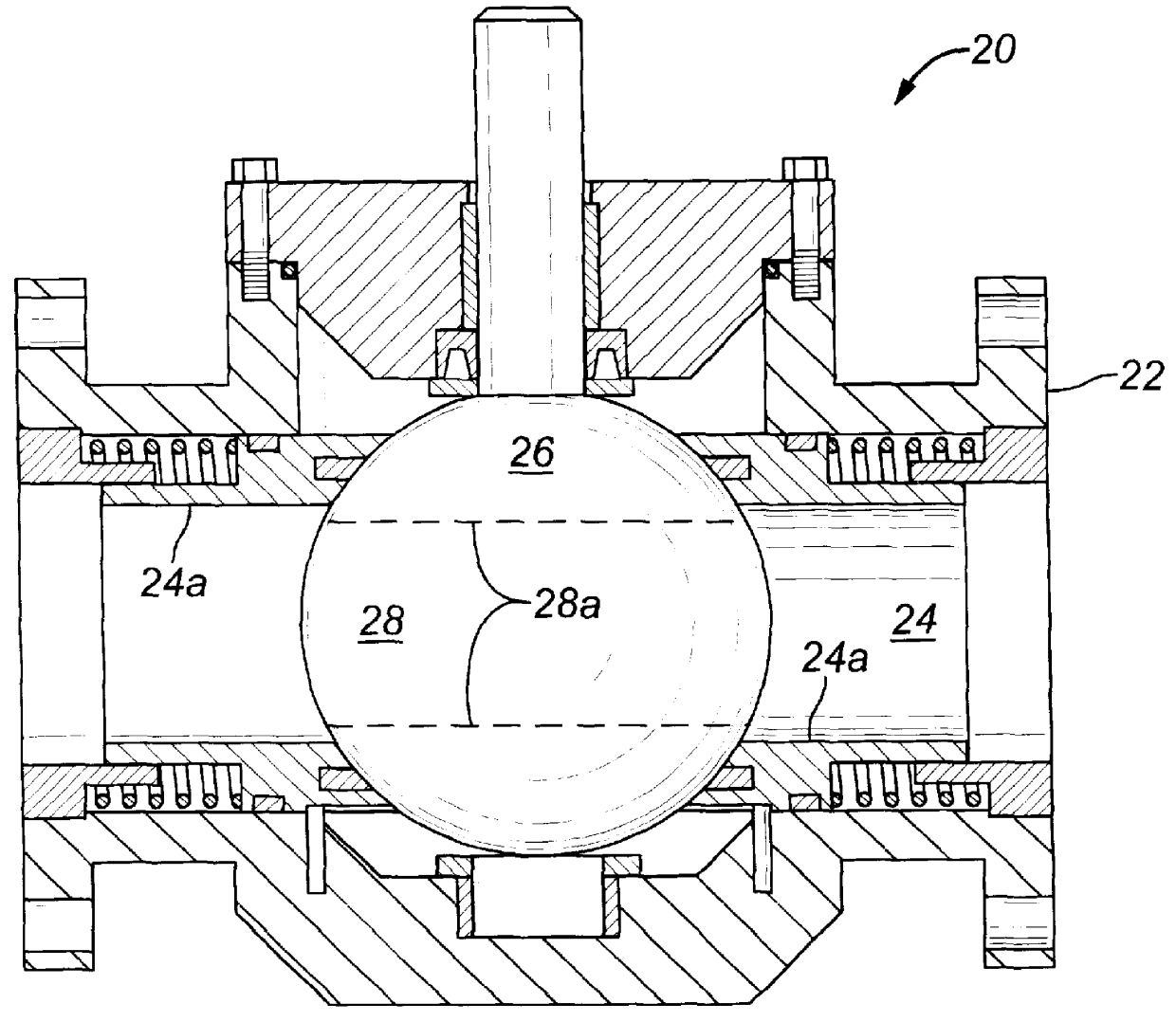

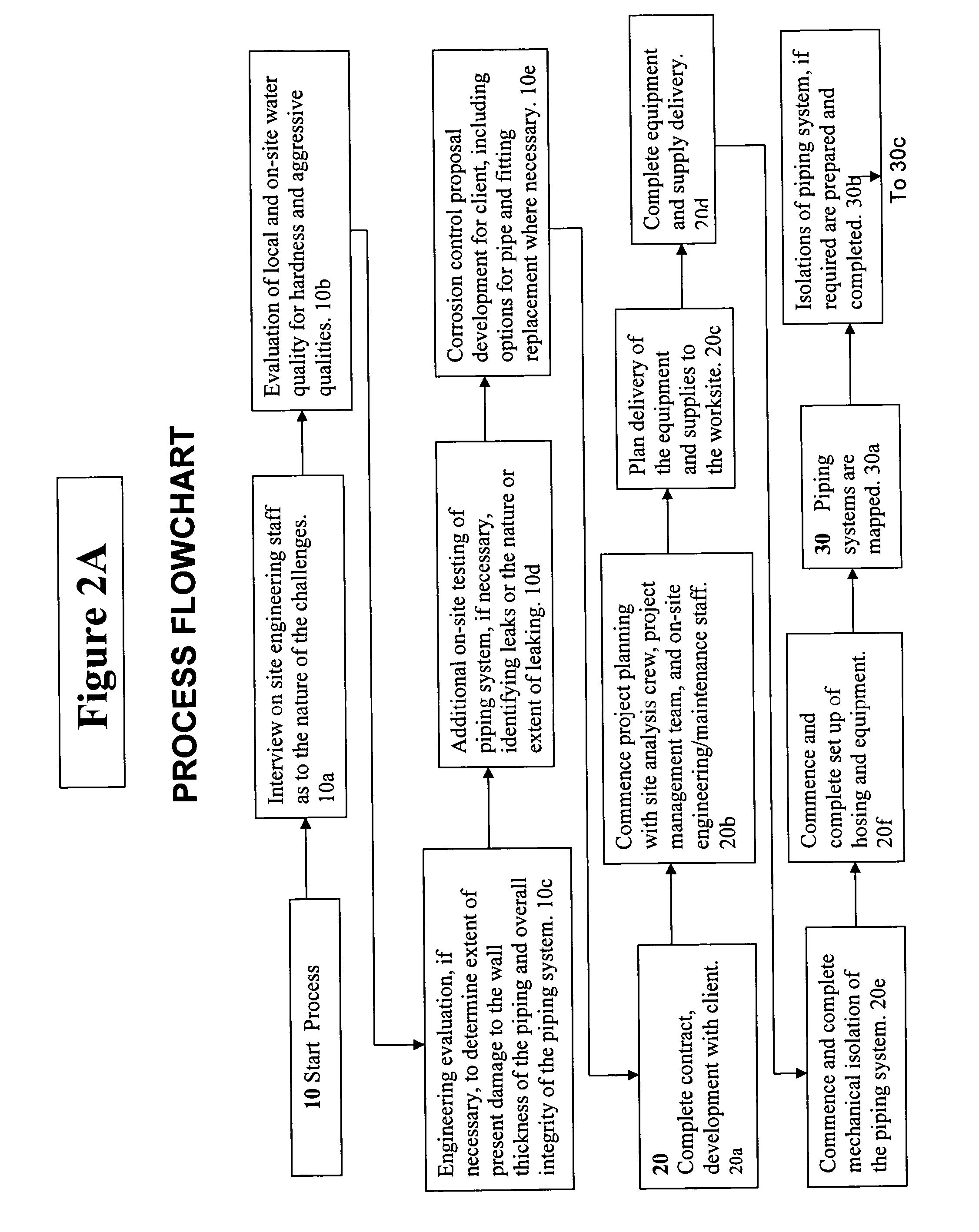

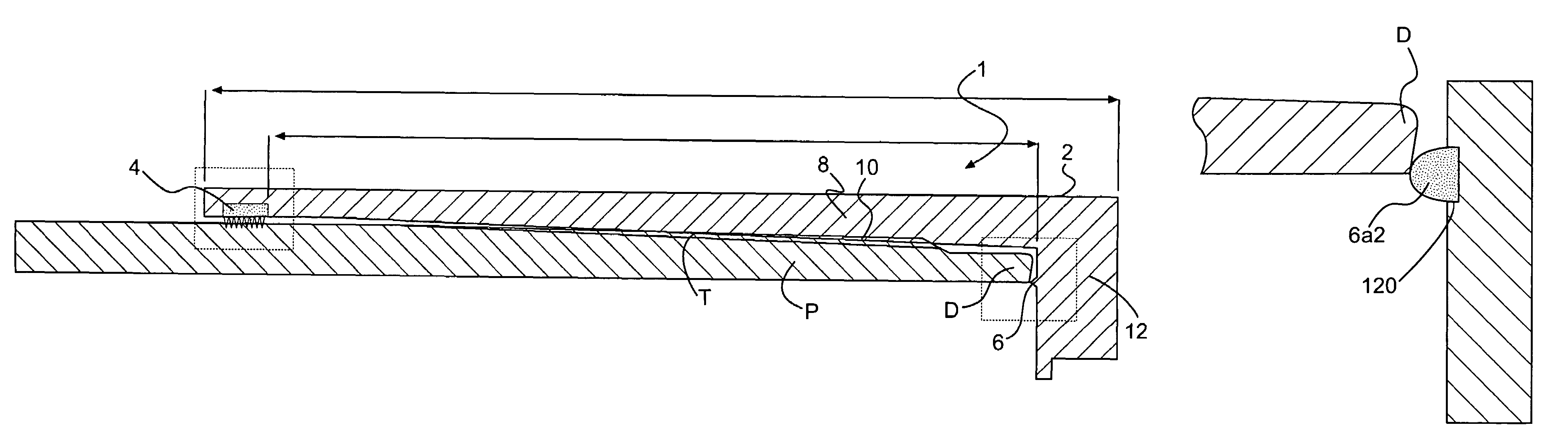

Barrier coating corrosion control methods and systems for interior piping systems

Methods and systems for cleaning and providing barrier coatings to interior walls of piping systems. An entire piping system can be cleaned in one single pass by dry particulates forced by air and the piping system coated in one single pass. Pipes can be protected from water corrosion, erosion and electrolysis. Pipes having diameters of approximately ⅜″ up to approximately 6″ are treatable. Piping systems such as potable water lines, natural gas lines, HVAC, drains, and fire sprinkler systems in homes, apartments, high-rise hotel / resorts, office towers, high-rise apartment and condominiums and schools, can be treated. The coating forms an approximately 4 mils or greater covering inside the pipes. Buildings can return to service within approximately 24 to approximately 96 hours.

Owner:PIPE RESTORATION TECH

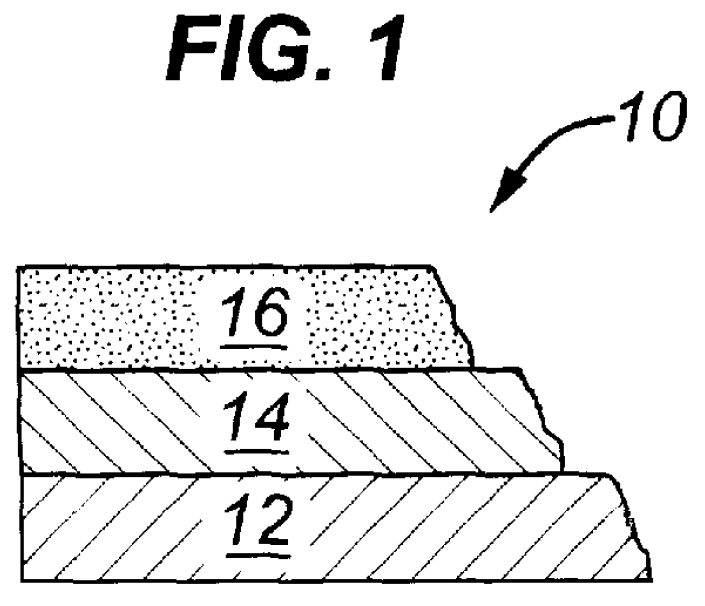

Metal element having a laminated coating

A laminated coating protects a metal substrate in a highly corrosive and highly erosive environment. A coating of a noble metal, such as gold, is bonded to the metal substrate, such as by electroplating or by flame spray. The noble-metal coating protects the metal substrate from the corrosive effects of a process fluid. A ceramic material, such as chromium oxide or titanium dioxide, is bonded to the noble-metal coating. Ceramic materials resist abrasion very well, which protects the underlying noble-metal coating from the erosive / abrasive effects of the process solution, which may contain suspended solids that are highly abrasive. However, the ceramic material is somewhat porous, which allows some seepage of the process fluid. The metal substrate is protected from the corrosive effects of the process fluid by the noble-metal coating.

Owner:WATSON GRINDING & MFG

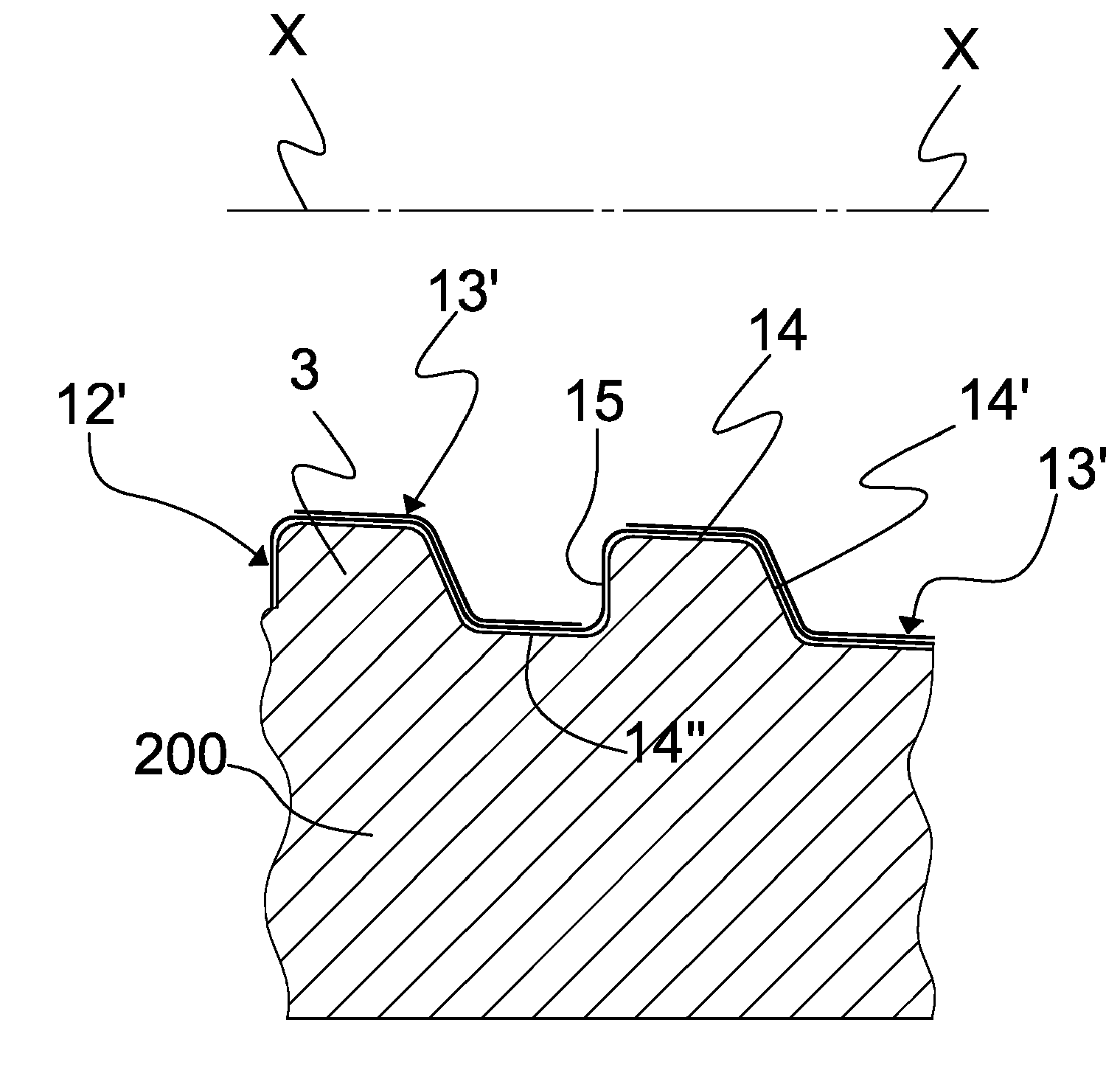

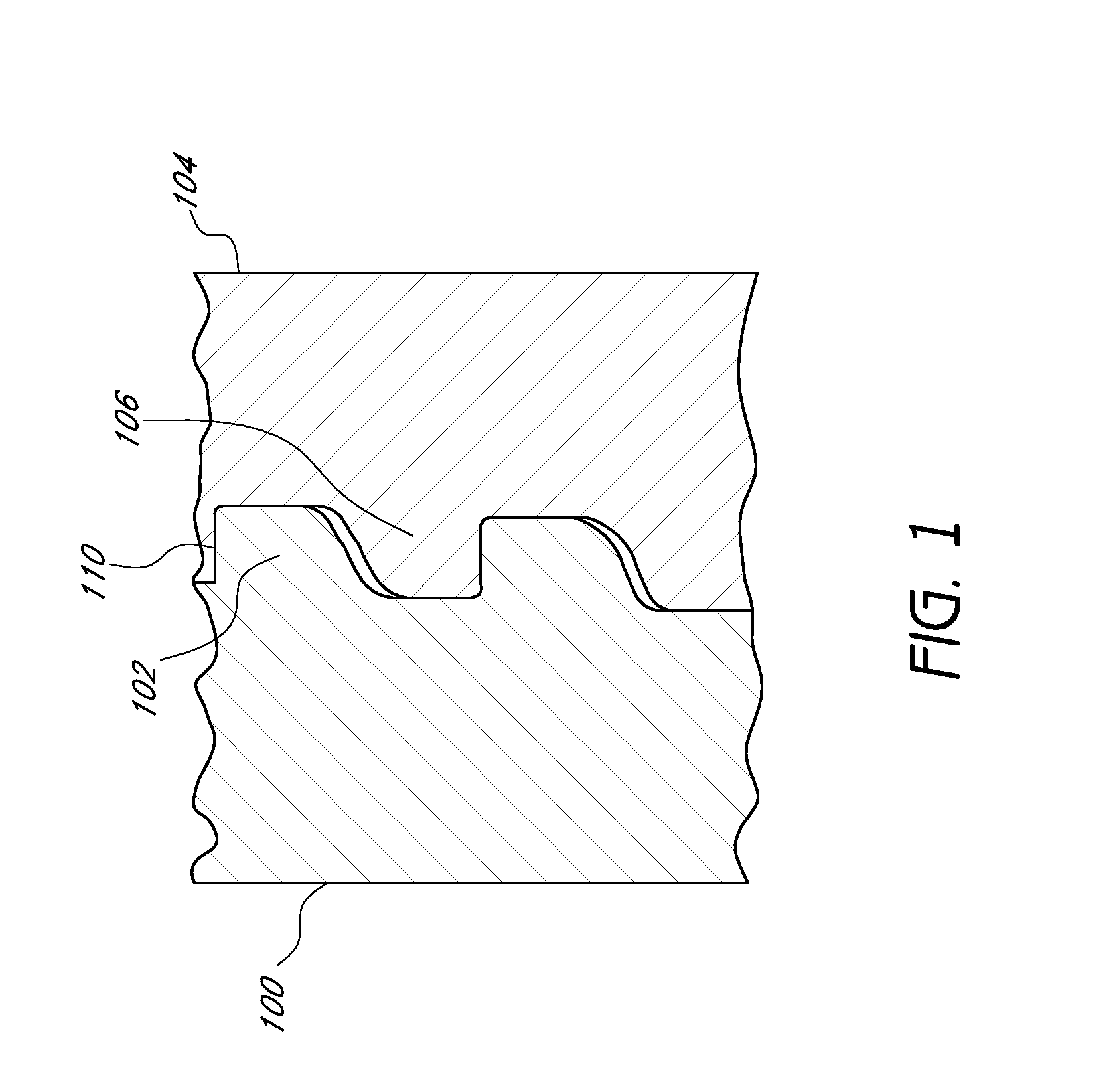

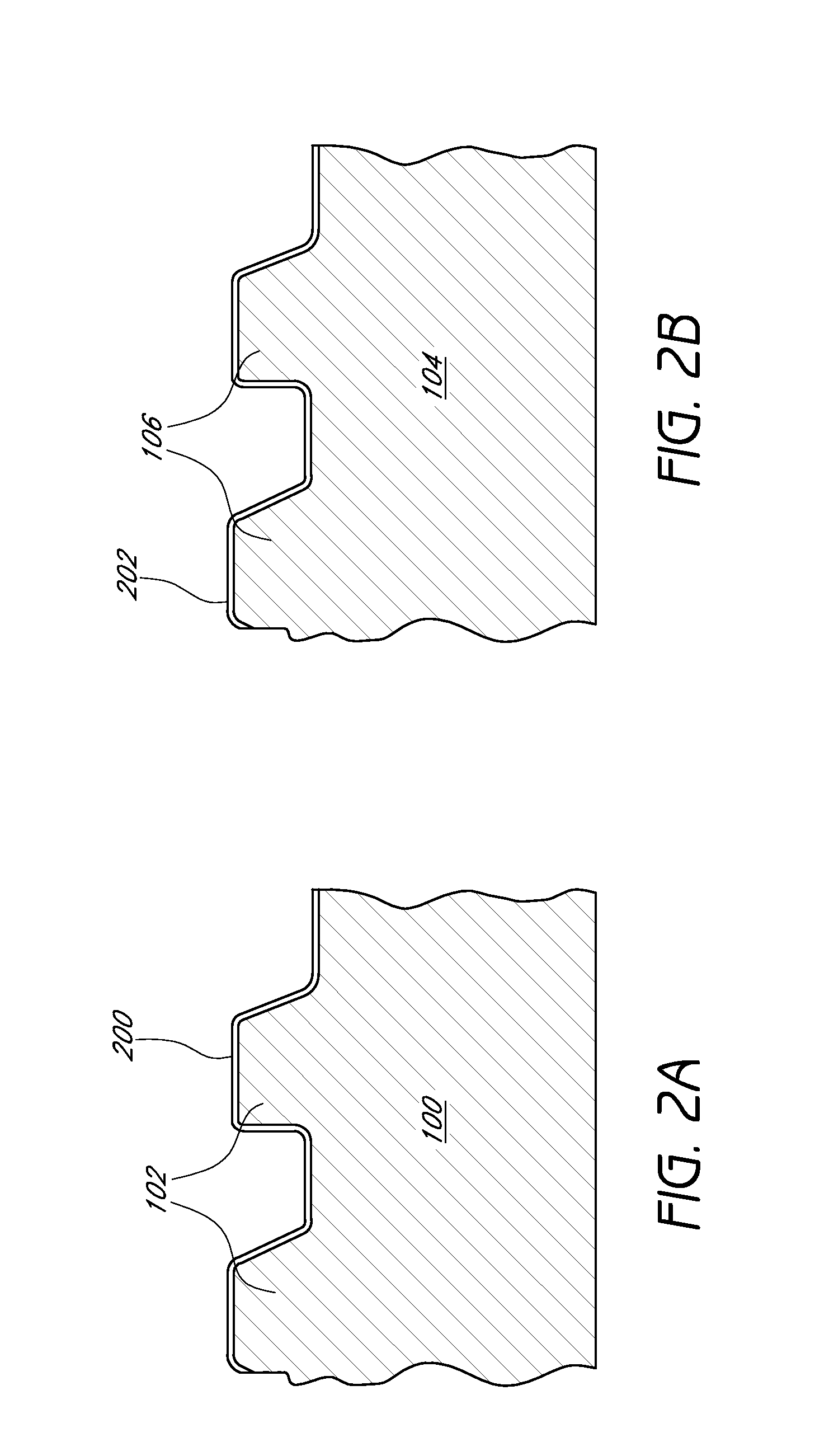

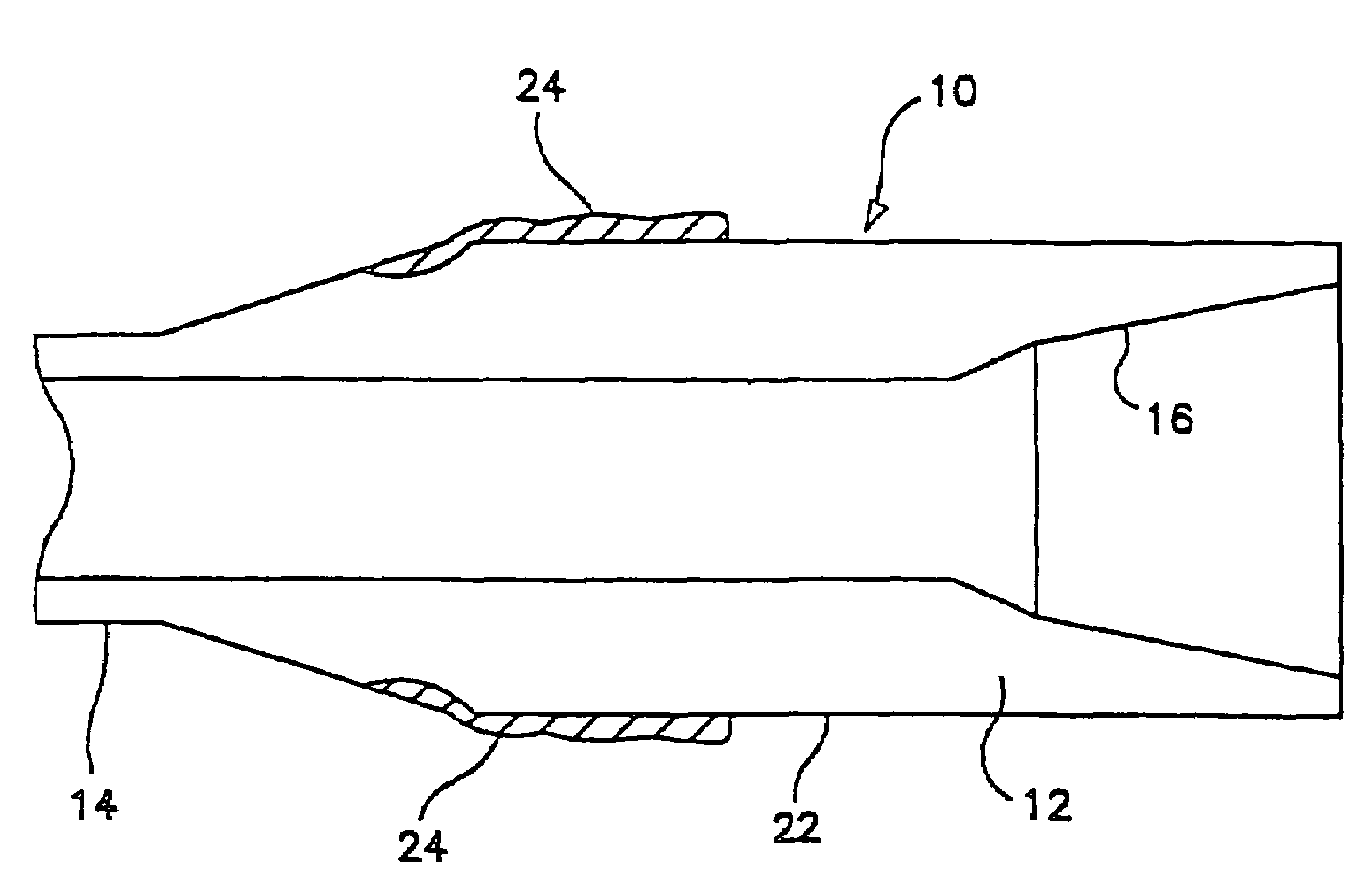

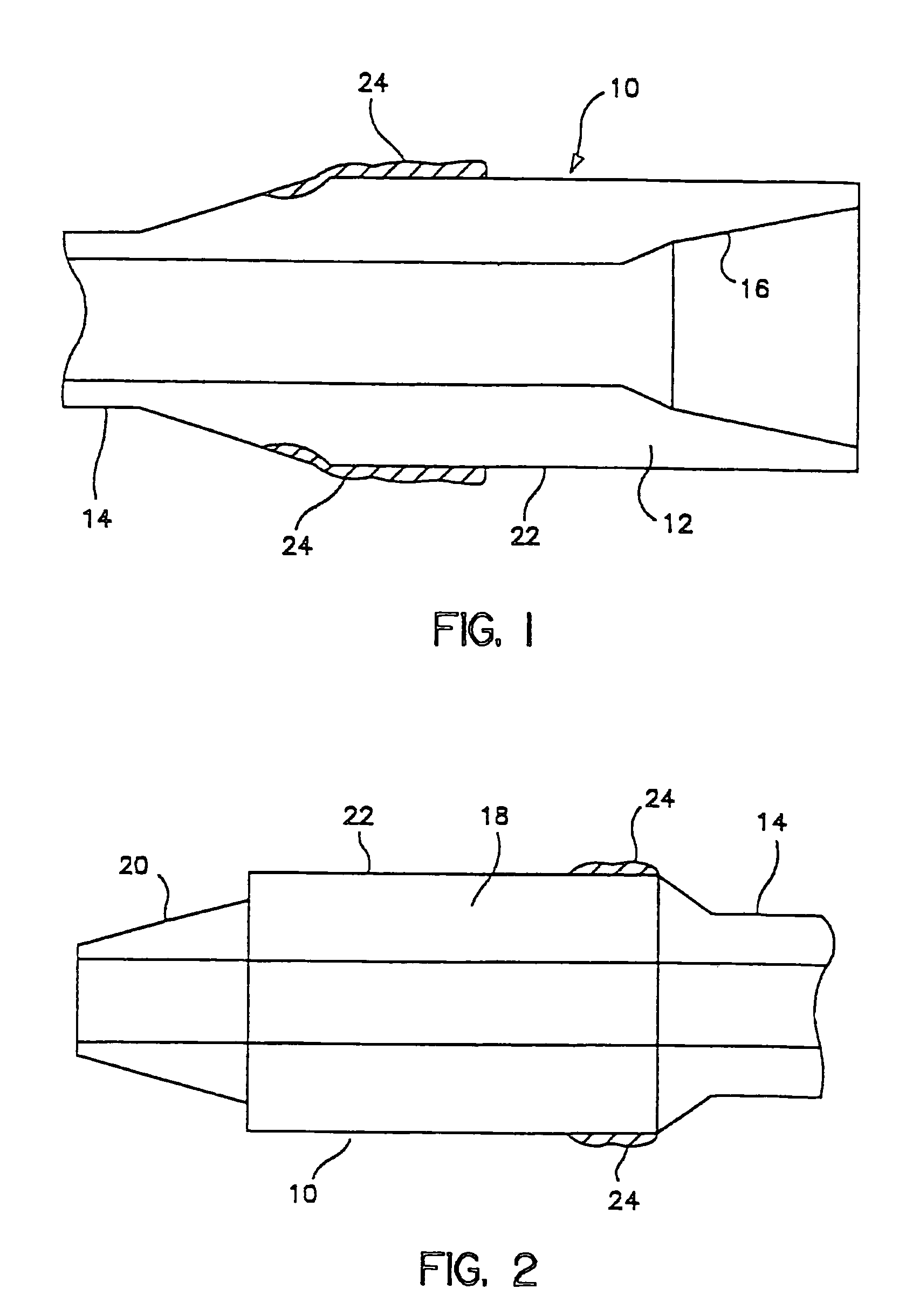

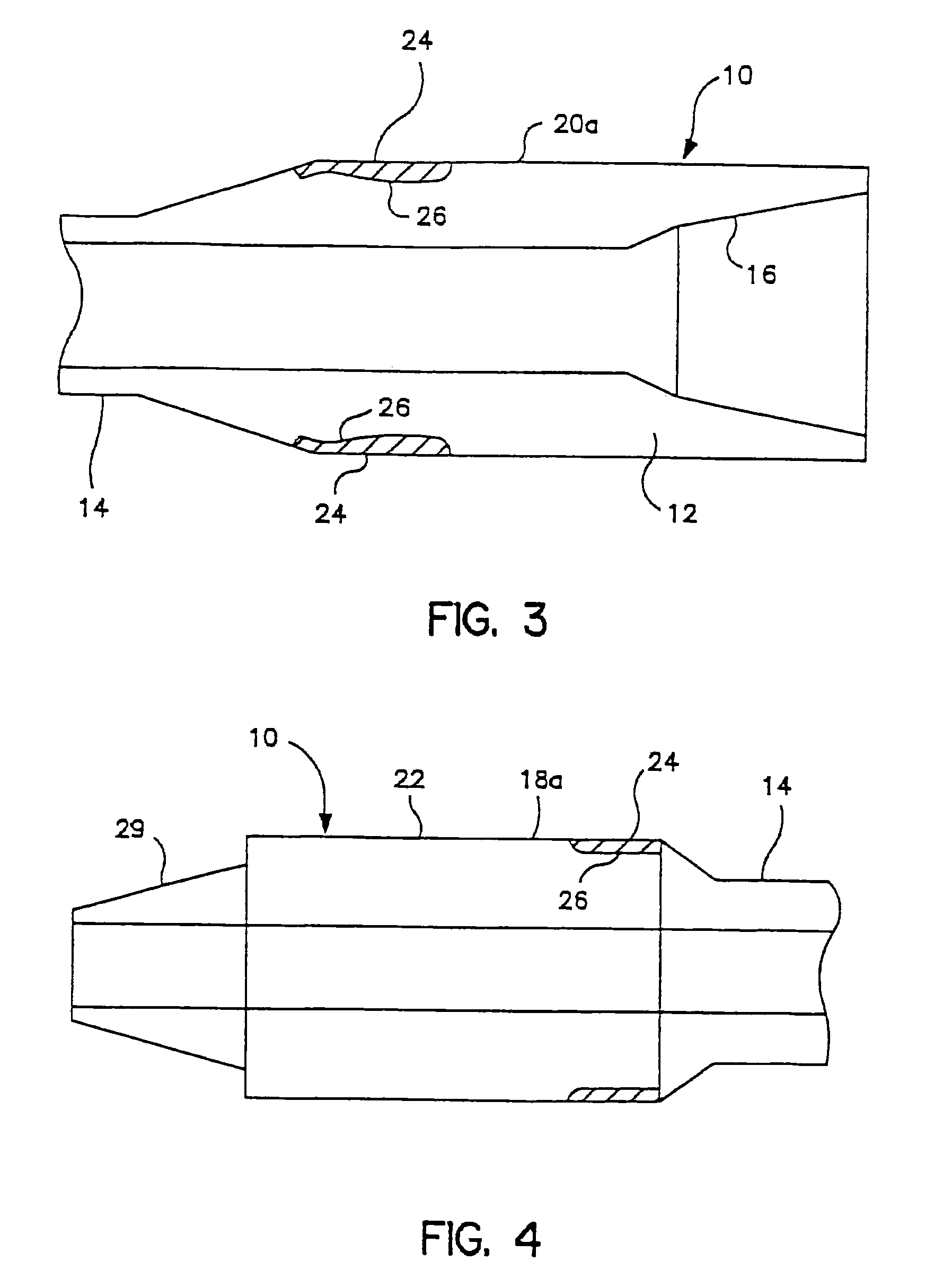

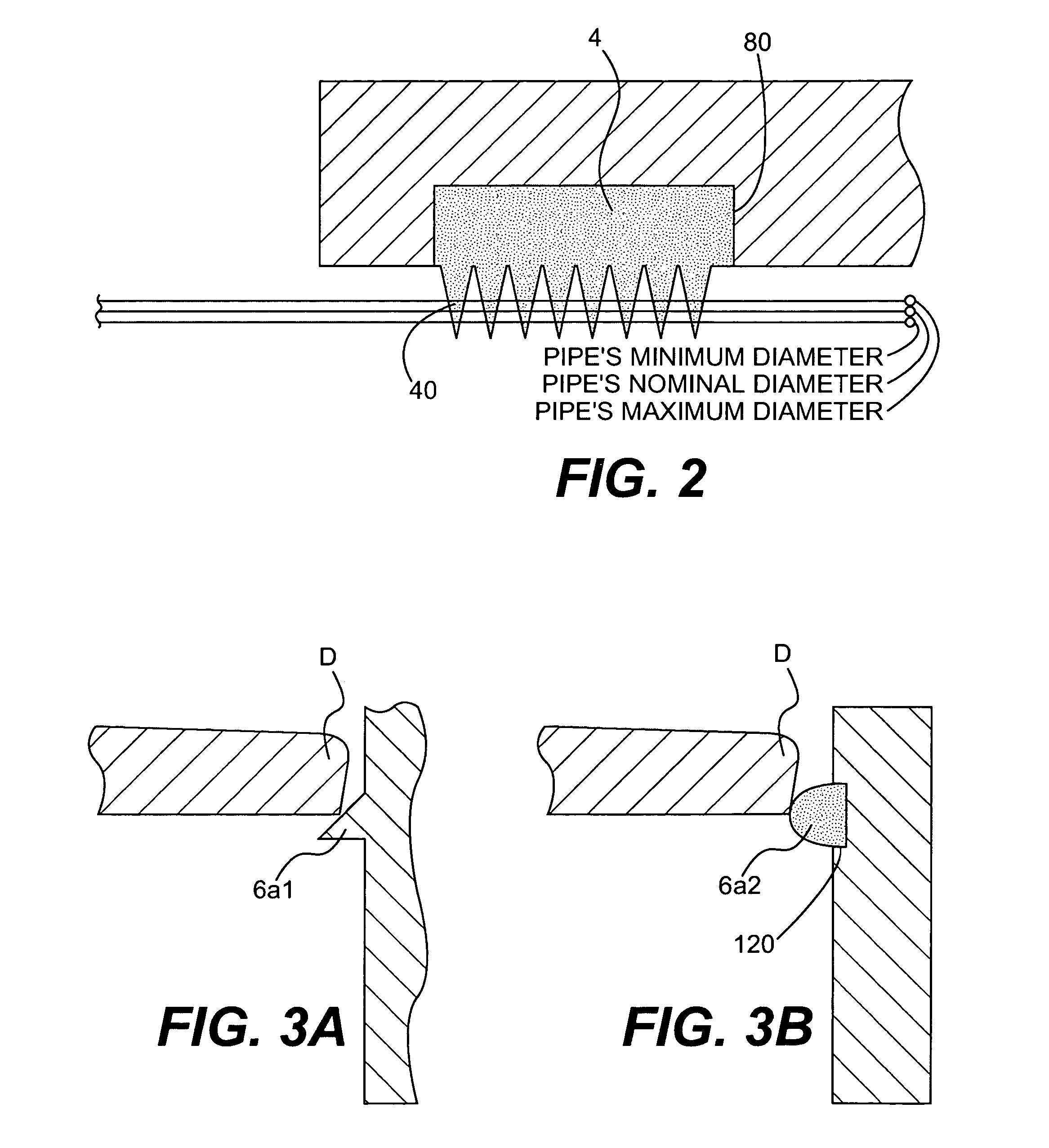

Threaded connections with high and low friction coatings

ActiveUS20090033087A1Increased torsional strengthImprove accuracyDrilling rodsPipe elementsBiomedical engineeringMetal

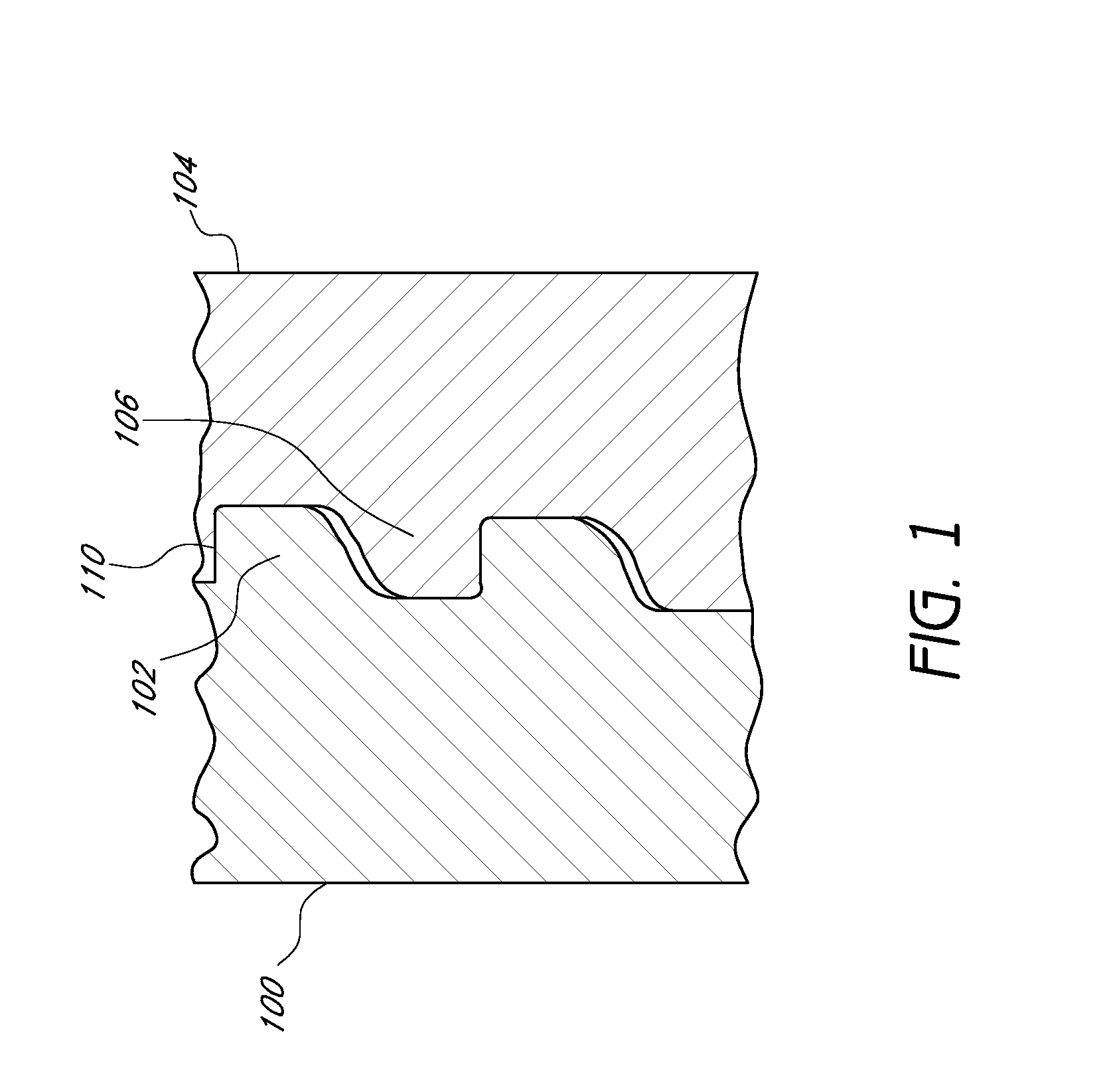

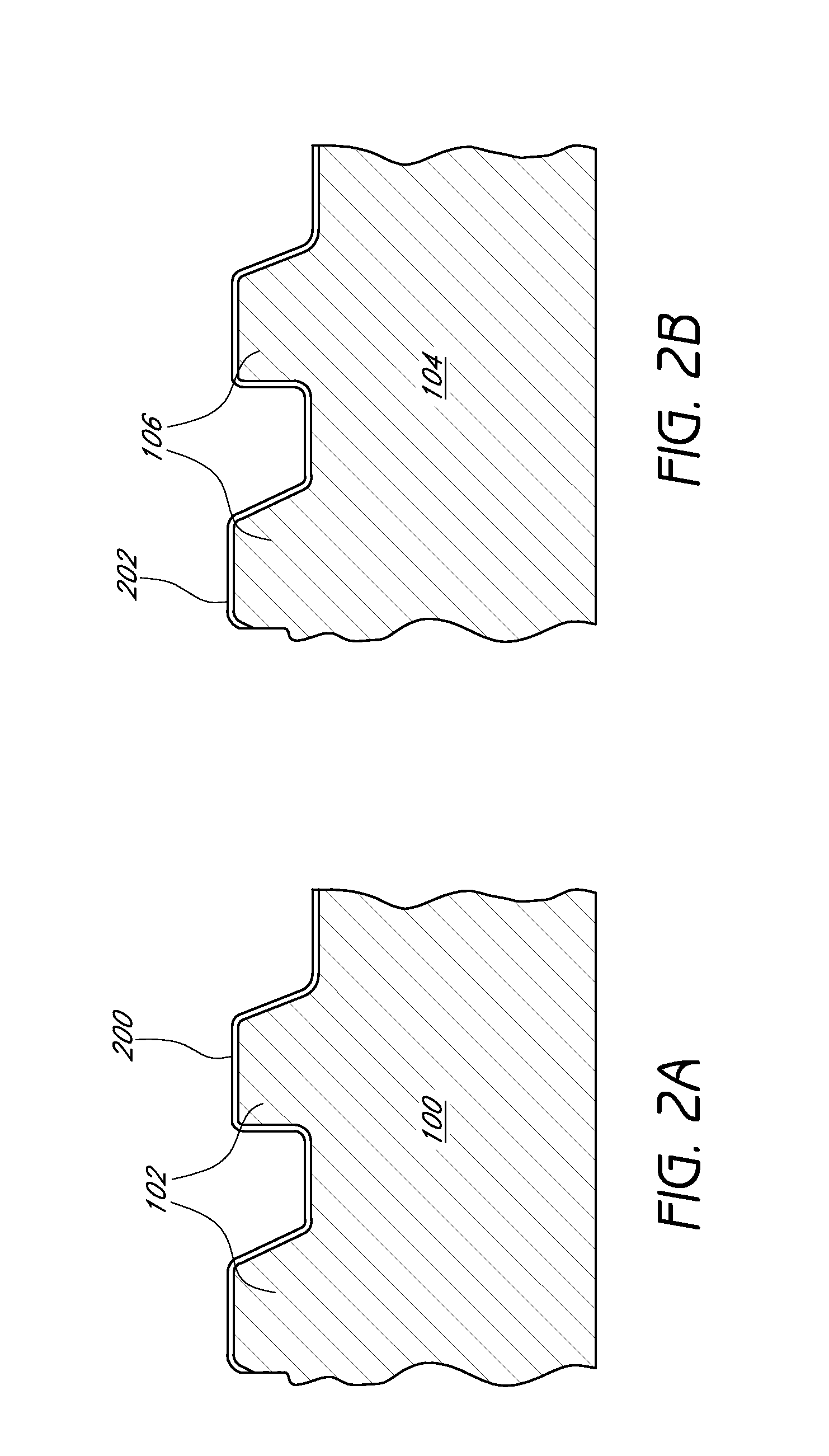

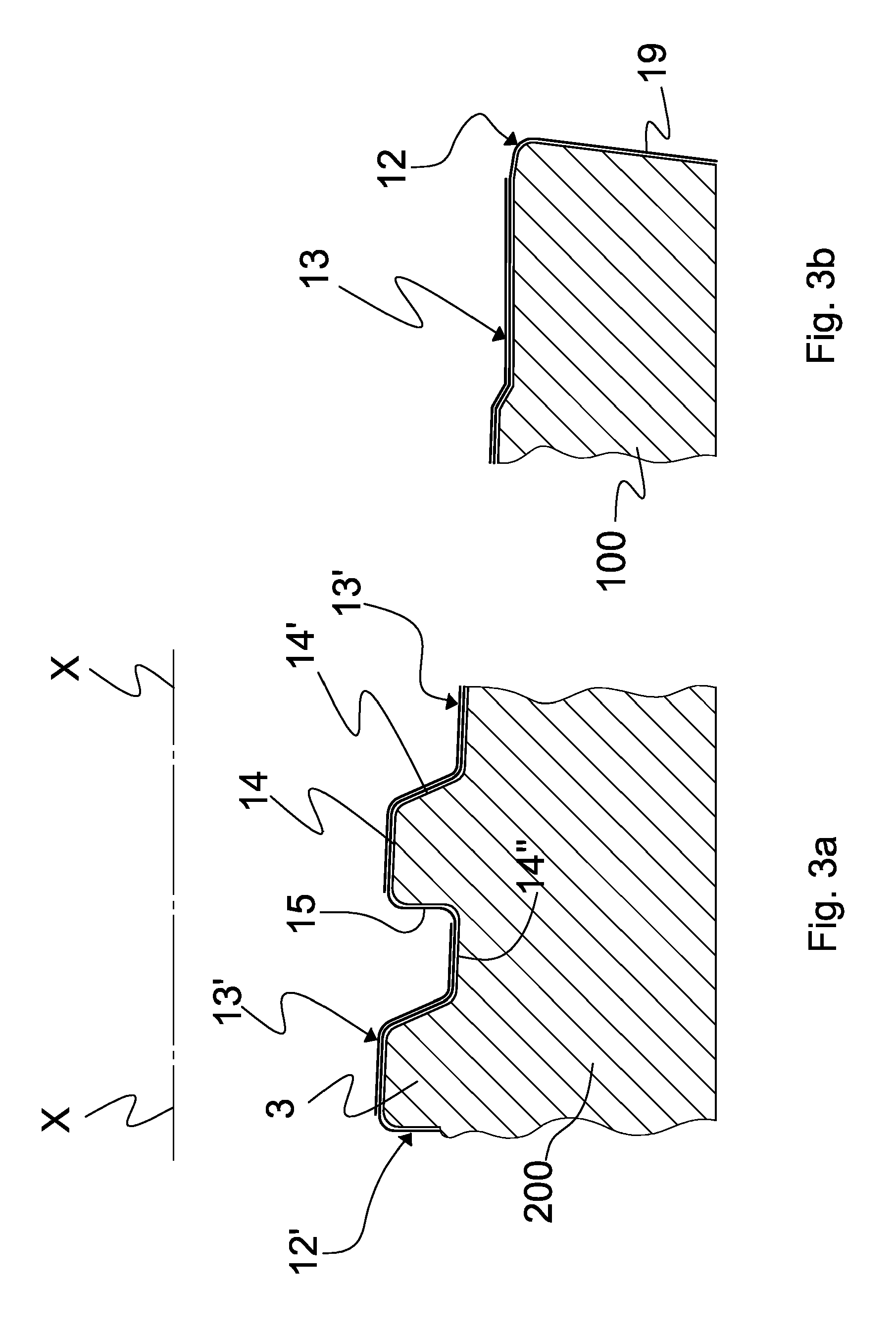

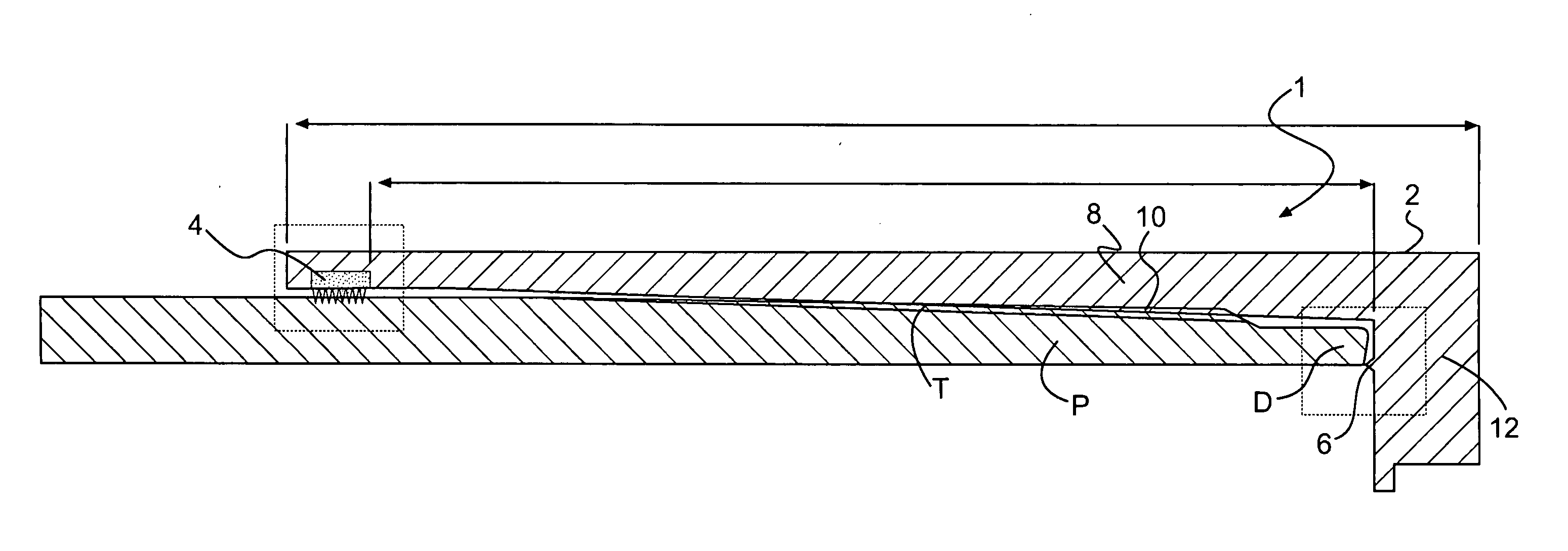

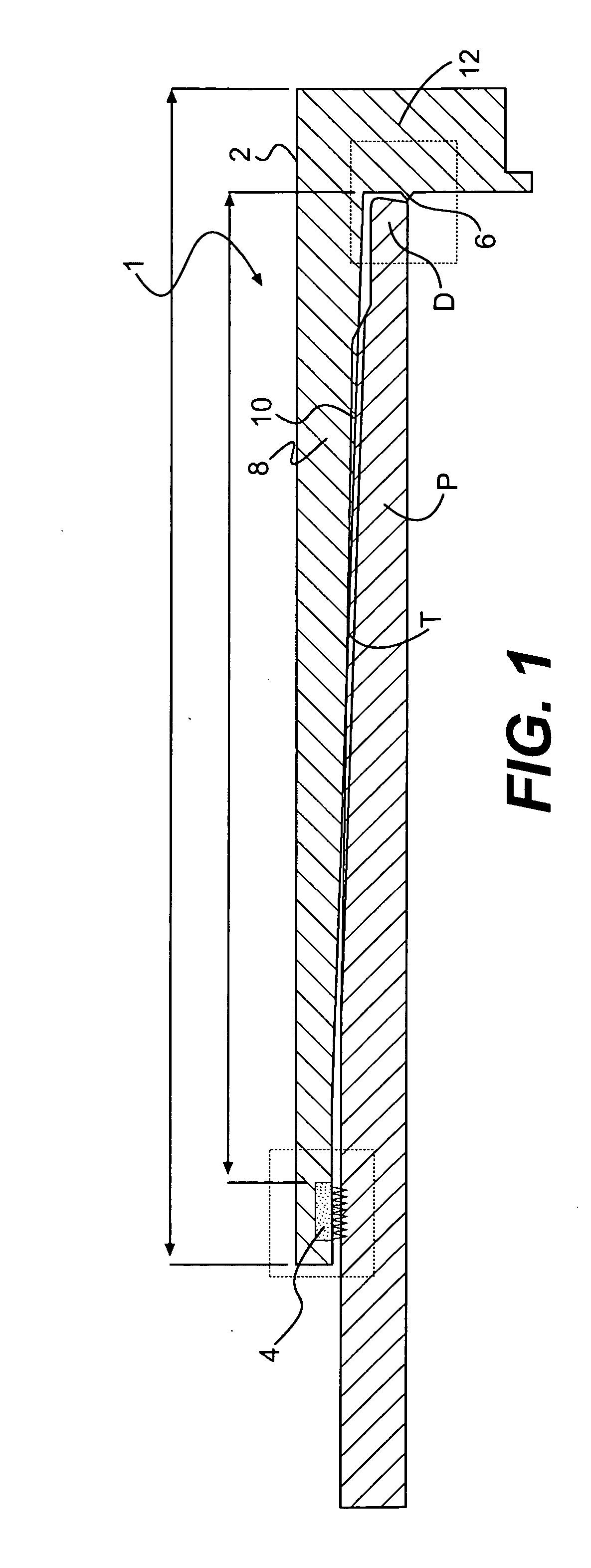

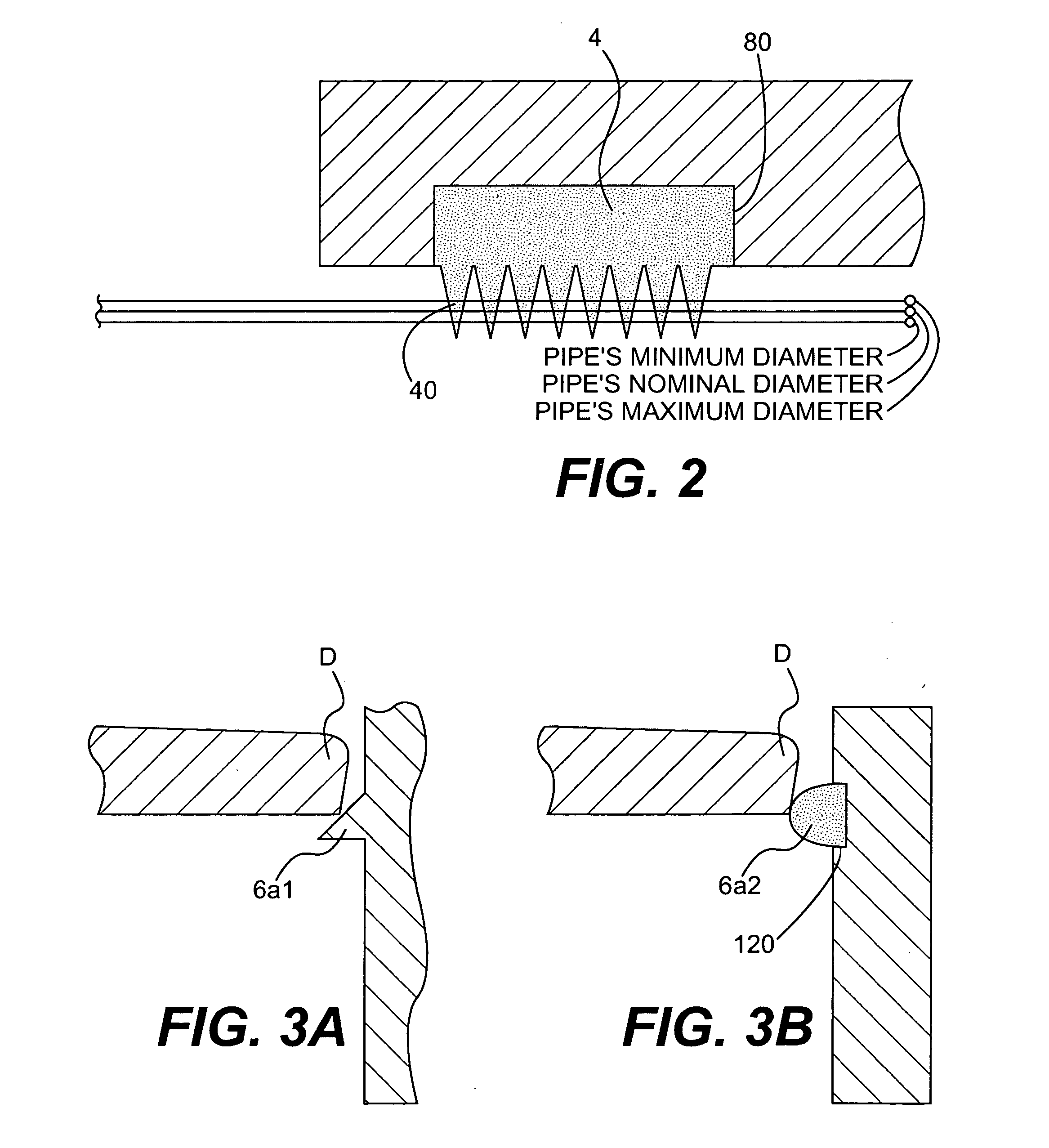

A threaded metallic joint has the thread surface of pin (100) and box (200) covered with a coating comprising a first layer (24) laid on the overall surface of the pin member (100), and a second layer (25) laid on part of the surfaces of either one of the pin or box members. In a first aspect, the coating comprises a first layer with high friction and anti-seize properties laid on the overall surface of the pin member (100), and a second layer (25) with low friction properties laid on specific parts of the surfaces of either one of the pin or box members. Preferably the specific surfaces are those which are in reciprocal radial contact during make-up until pin and box reach the point where shoulders (9, 10) abut. The second layer may contain polytetrafluoroethylene (PTFE). In a second aspect the first layer with a high friction and anti-seize properties laid on the overall surface of the box member (200).

Owner:TENARIS CONNECTIONS

Coating compositions, applications thereof, and methods of forming

InactiveUS20130167965A1Reduced growth rateReduced adhesion strengthMolten spray coatingSynthetic resin layered productsSurface layerLubricant

Disclosed herein is an article having a surface modified to alter its surface tension property and increase resistance to sand abrasion as characterized by a material volume loss of less than 75 mm3 according to ASTM G65-04 Procedure B. In one embodiment of the method, an intermediate layer is first deposited onto a substrate of the article. At least a substrate on the article is protected by a coating layer, which comprises: an intermediate layer adjacent to the substrate with a thickness of at least 2 mils containing a plurality of pores with a total pore volume of 5 to 50% within a depth of at least 2 mils; and a surface layer comprising a lubricant material deposited onto the intermediate layer. The lubricant material infiltrates at least a portion of the pores for the coating to have the desired surface tension depending on the application.

Owner:SCOPERTA INC

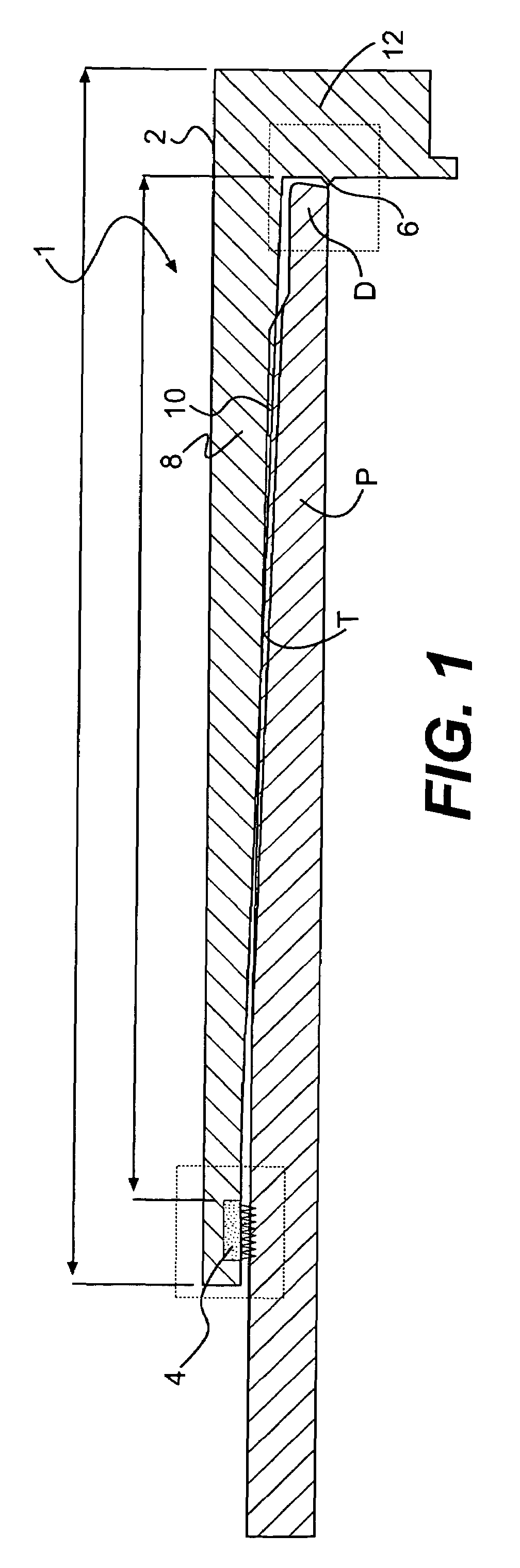

Thread protector for tubular members

A pipe thread protector includes a case, a first seal member, and a second seal member. The case is attachable to an end of a pipe to protect a threaded region of the pipe. The case has a cylindrical or frustoconical portion having threads over at least a portion of its length to engage the threaded region of the pipe, and an annular end portion configured to abut a distal end of the pipe. A first seal member is disposed at the cylindrical portion of the case, and a second seal member is disposed at the annular end portion of the case. At least one of the first and second seal members (i) is detachable from the case, and (ii) comprises a material different than a material of the case.

Owner:TENARIS CONNECTIONS

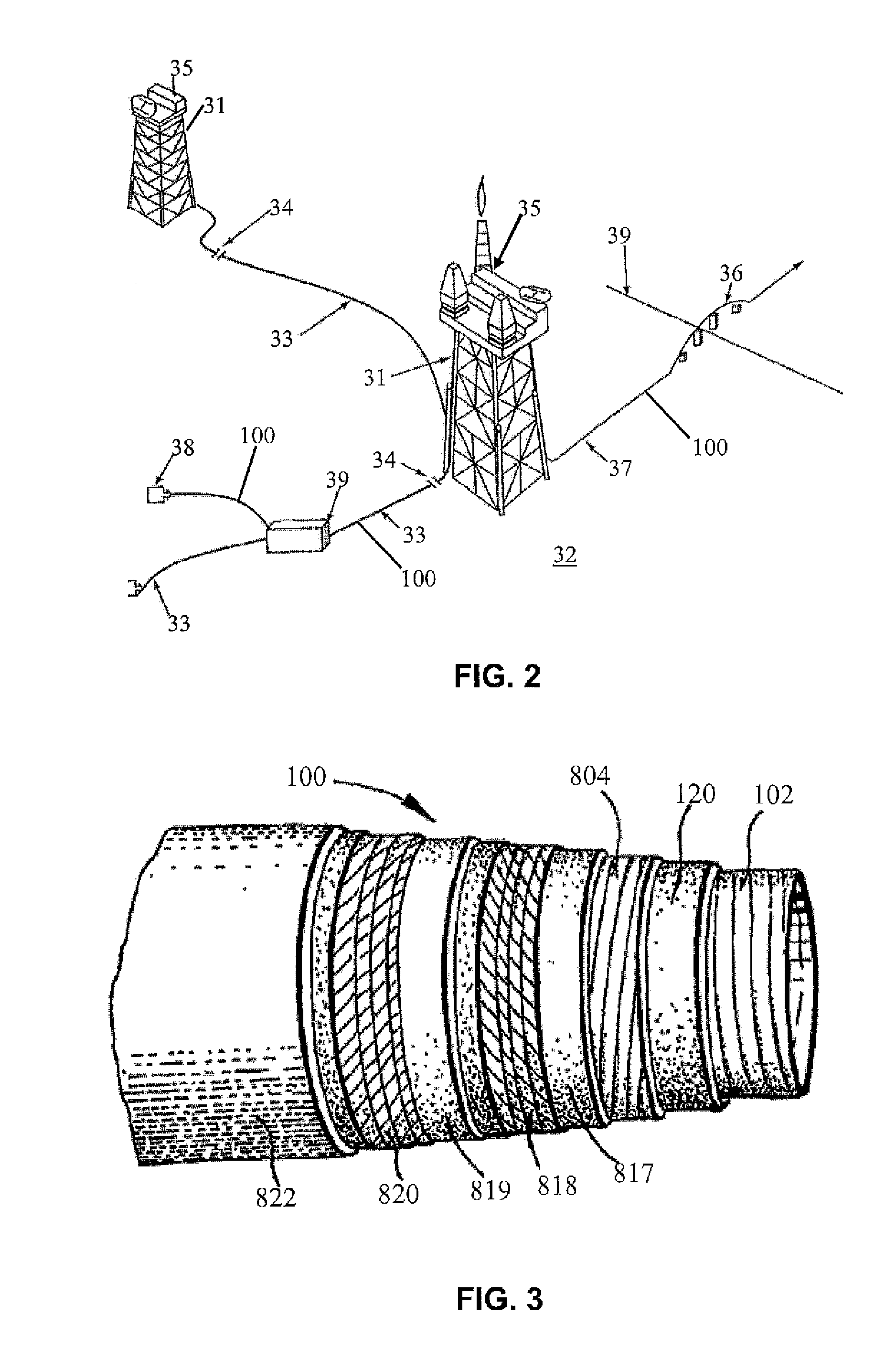

Structural Components for Oil, Gas, Exploration, Refining and Petrochemical Applications

A structural component for use in oil, gas, exploration, refining and petrochemical applications in the form of a pipe system is provided. The pipe system contains at least two pipe sections are that fusion bonded together, each pipe section comprises a plurality of layers, an inner layer in contact with the corrosive petroleum product comprising a thermoplastic material, a structural layer comprising a composite material, and an outer layer comprising a fire resistive material. In one embodiment, the pipe system meets level II fire endurance standard according to IMO A 18 / Res.753 fire testing protocol.

Owner:CHEVROU USA INC

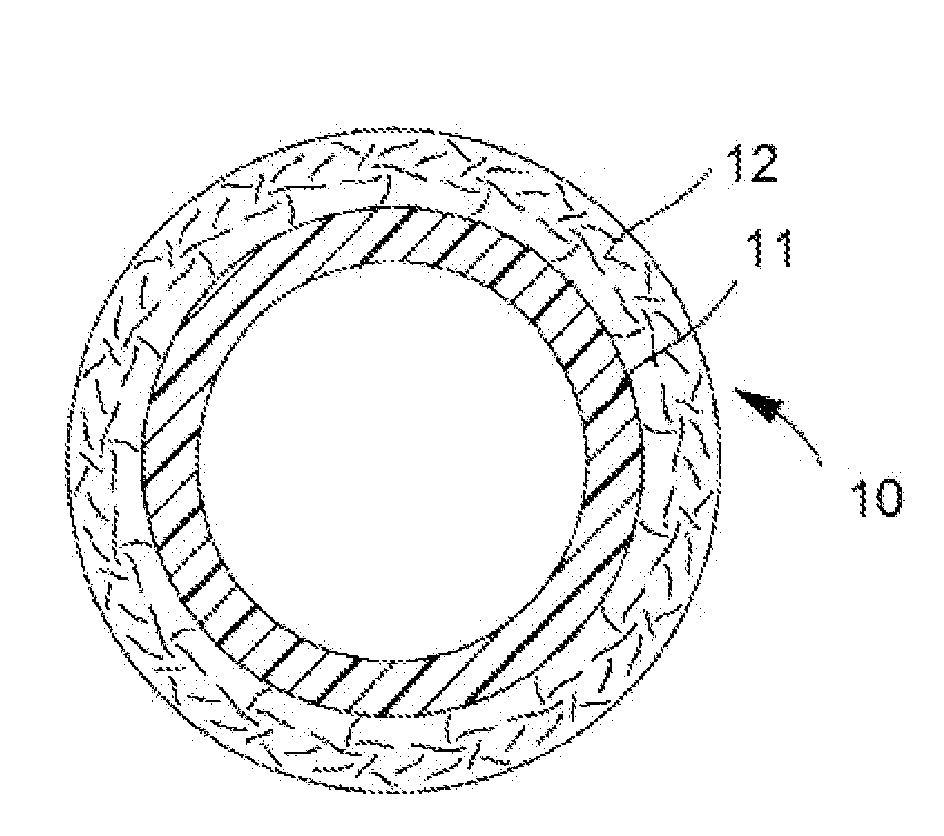

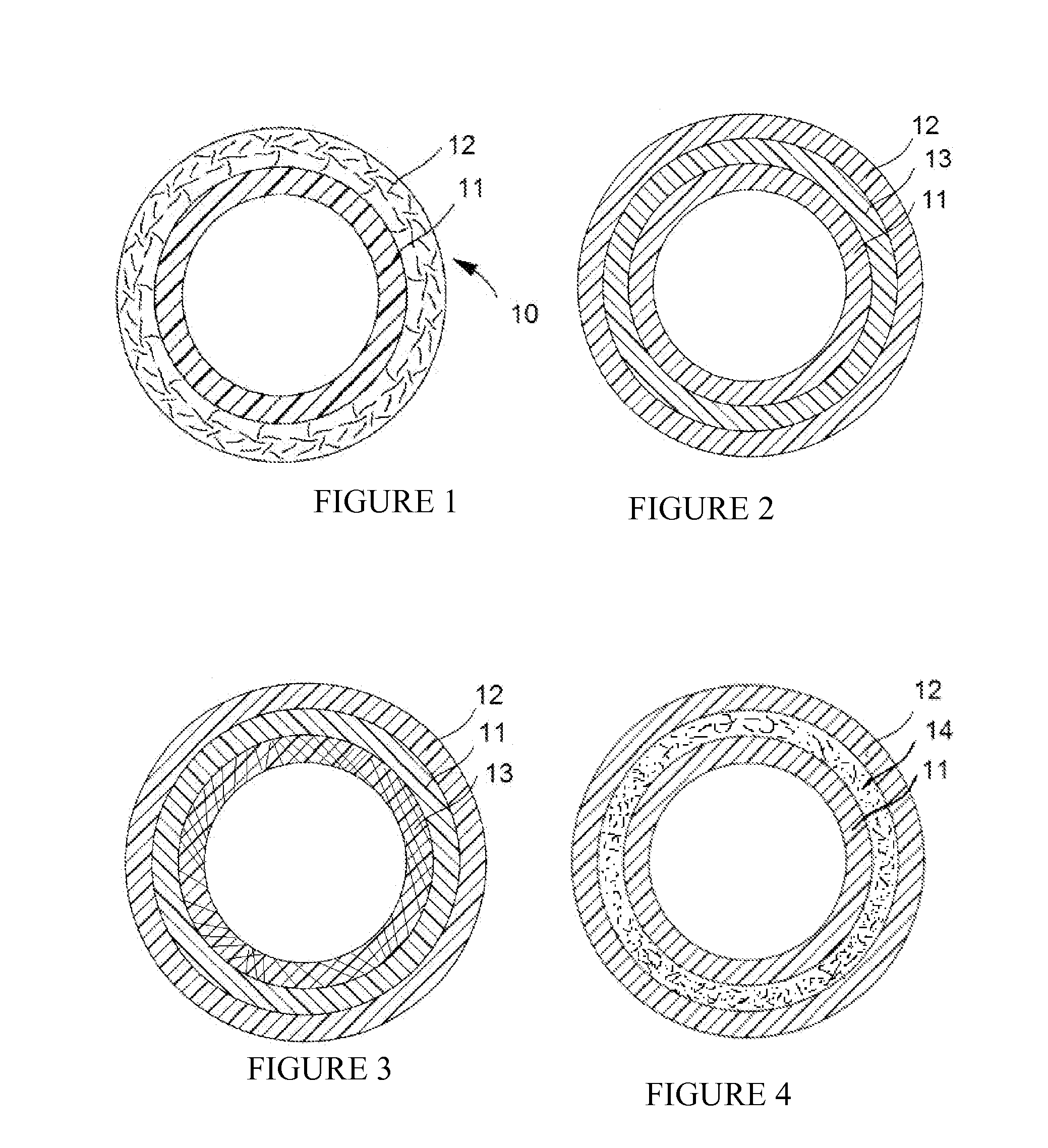

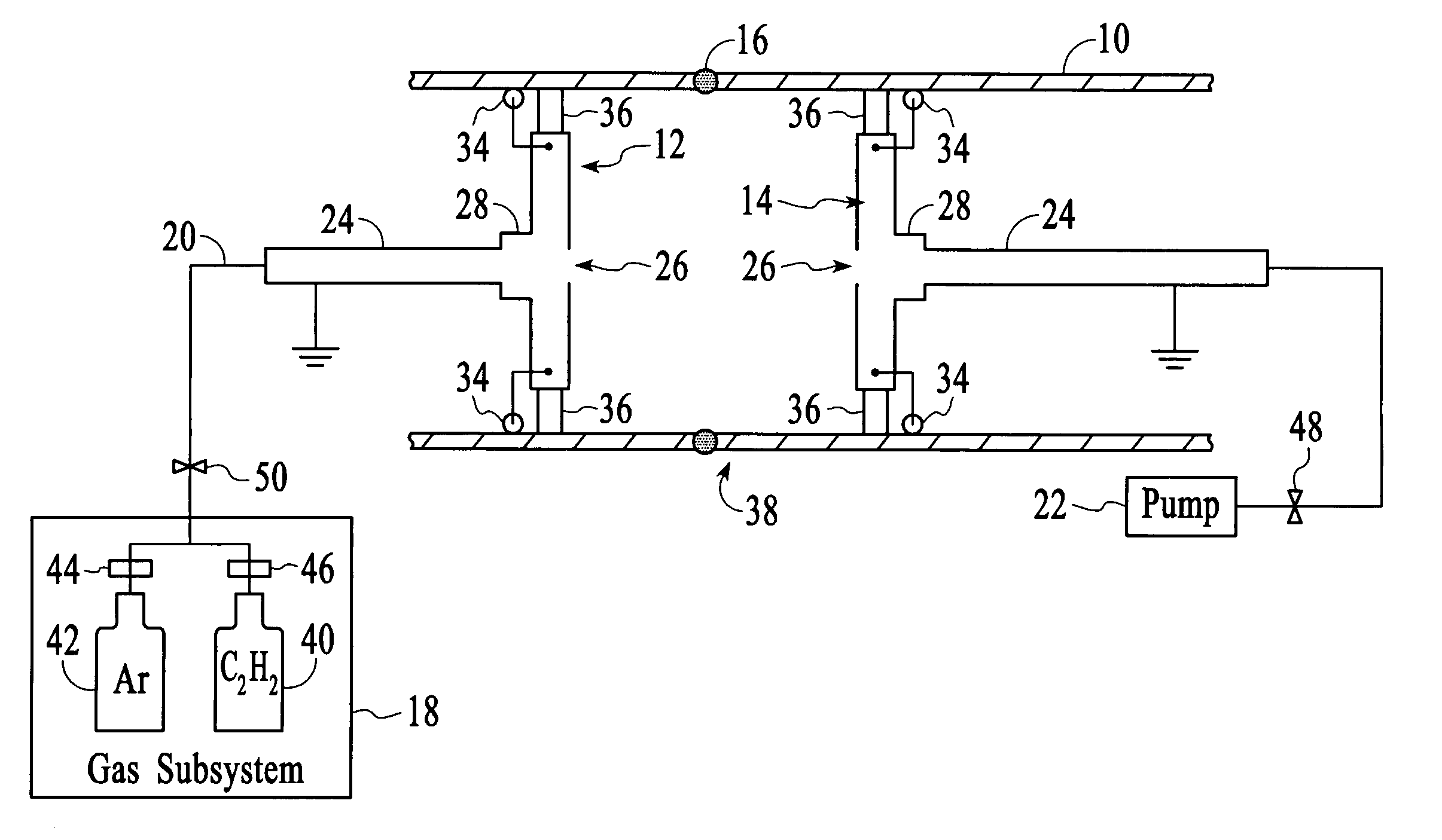

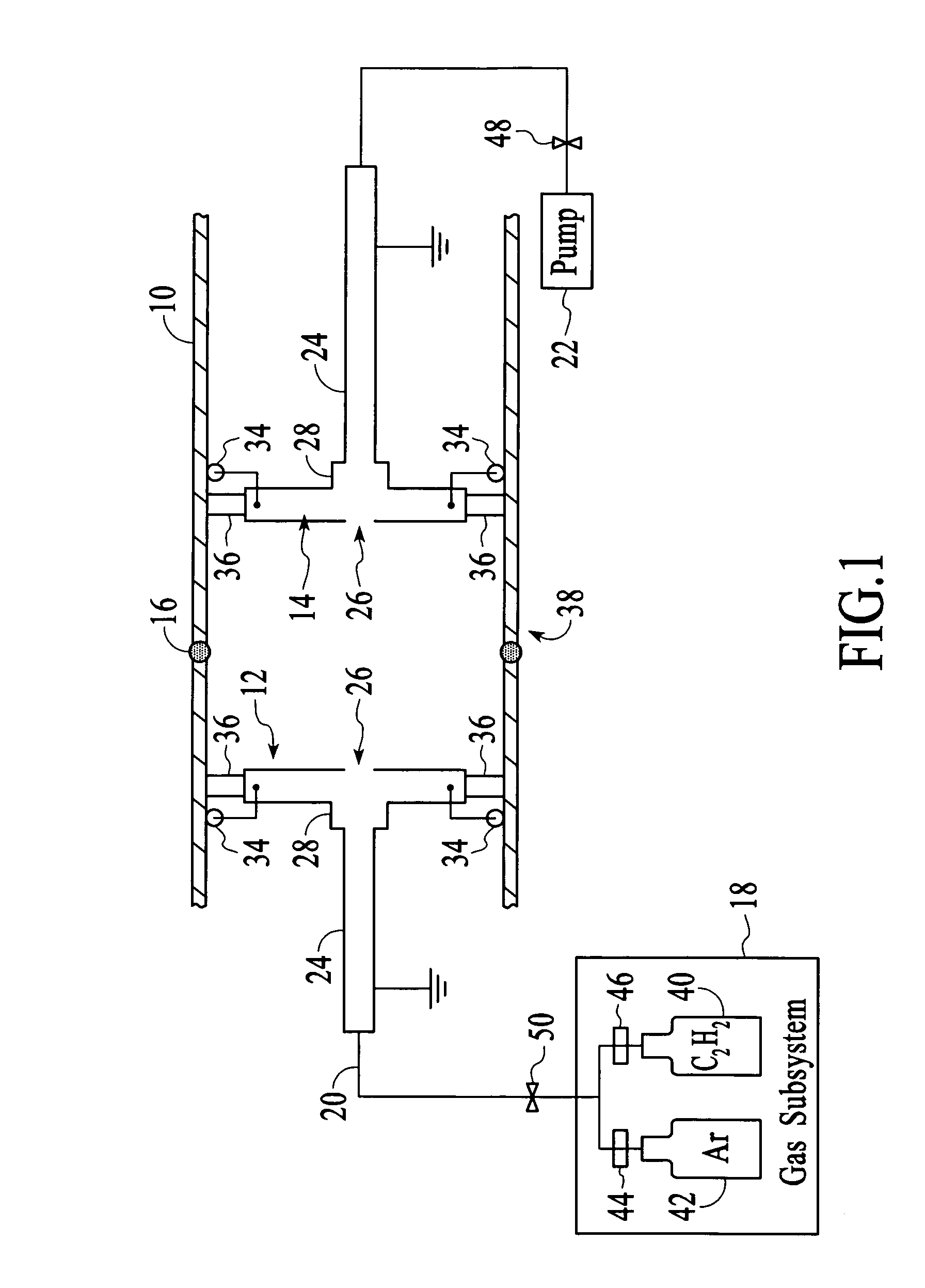

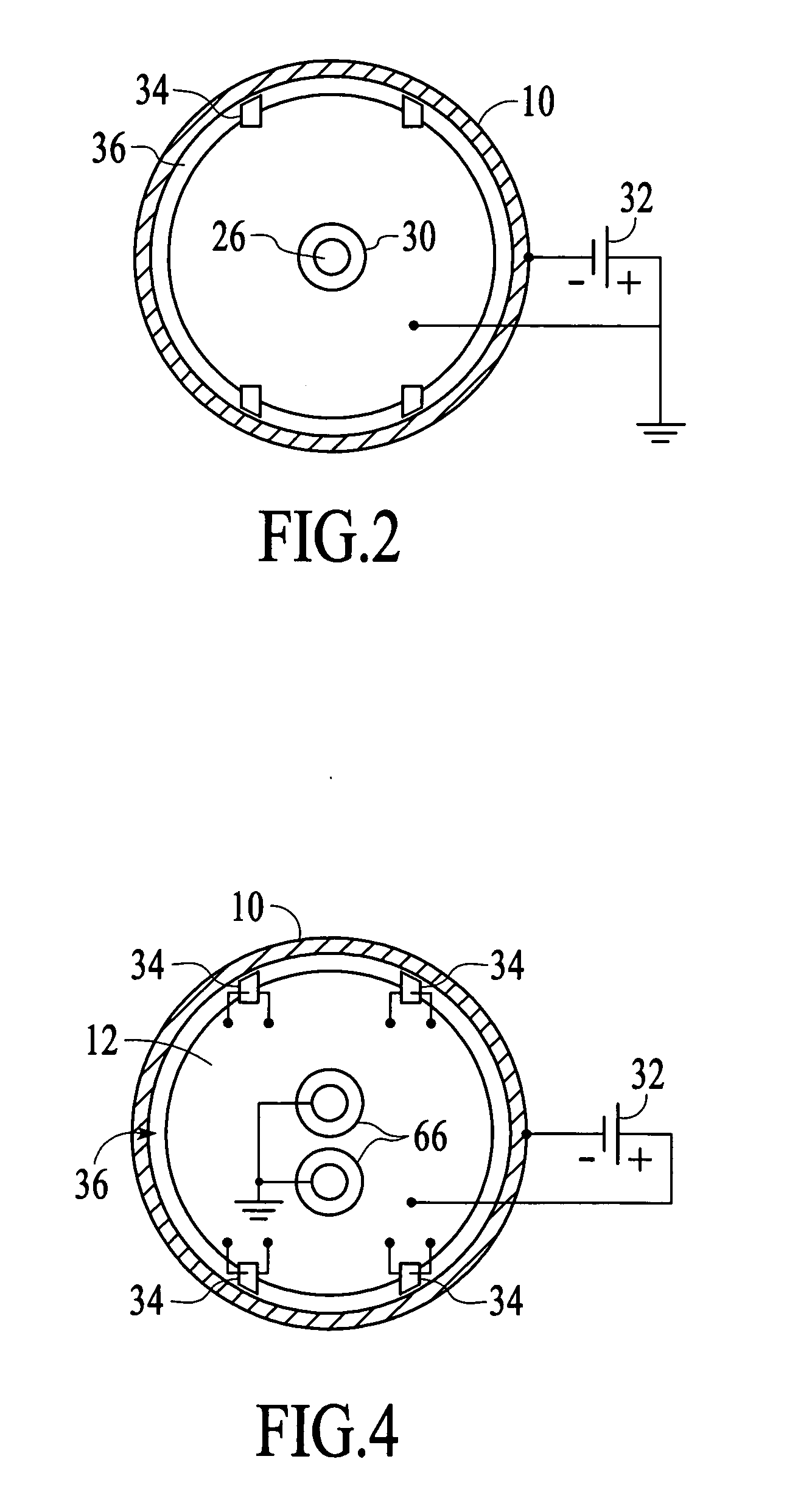

Method and system for coating sections of internal surfaces

ActiveUS7608151B2Low activation temperatureUniform coatingVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl systemEngineering

A method and system for coating the internal surfaces of a localized area or section of a workpiece is presented. Conductive structures are inserted into one or more openings of a workpiece to define the section to be coated. In some embodiments, a bias voltage is connected to a workpiece section, which functions as a cathode. A gas source and vacuum source are coupled to each conductive structure through a flow control system. The flow control system enables a first opening to function as a gas inlet and a second opening to function as a vacuum exhaust. Only the section encompassed by the conductive structures is coated. When the coating process is completed, a means for varying the conductive structures along the length is utilized to move onto the next section to be coated.

Owner:AGM CONTAINER CONTROLS

Styrenic insulation for pipe

ActiveUS20090159146A1Improve insulation effectReduce coating thicknessThermal insulationCorrosion preventionThermoplasticCompressive creep

Coatings for protecting and insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of up to 100° C. in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of thermal insulation comprising polystyrene or styrene-based thermoplastic, having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance.

Owner:SHAWCOR LTD

Lubricating coating composition suitable for lubrication of a threaded joint

InactiveUS6869111B2Good correlationImprove the immunityDrilling rodsPipe protection against corrosion/incrustationSulfonateMicrometer

A lubricating coating composition in which at least one basic lubricant selected from a basic sulfonate, a basic salicylate, and a basic phenate is dissolved in a volatile solvent is applied to the frictional surface of a box and a pin constituting a threaded joint for oil well pipes. The composition may further contain one or more of a thermoplastic resin powder, another lubricant, and an extreme pressure agent. The surface roughness of the frictional surfaces preferably has an Rmax in the range of 5-40 micrometers.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Nanocomposite coatings for threaded connections

Coating systems which provide corrosion resistance and, optionally, lubrication, for threaded connections are disclosed. The compositions comprise a first coating composition comprising polymer matrices of polyimides or epoxies which are modified with small amounts of a fluorine containing polymer. Also present in the coating compositions are corrosion inhibiting agents and inorganic particles having a mean diameter of between approximately 10 nm and 10 μm. Solid lubricants, which may include at least one of PTFE, HDPE, Graphite, and MoS2, are optionally added to provide the first coating with a low coefficient of friction. The coating systems may further comprise a second coating composition, comprising a solid lubricant dispersed within an epoxy resin and a solvent. The first and second coating compositions are deposited on at least a portion of at least one of the pin and box members of the threaded connections.

Owner:TENARIS CONNECTIONS

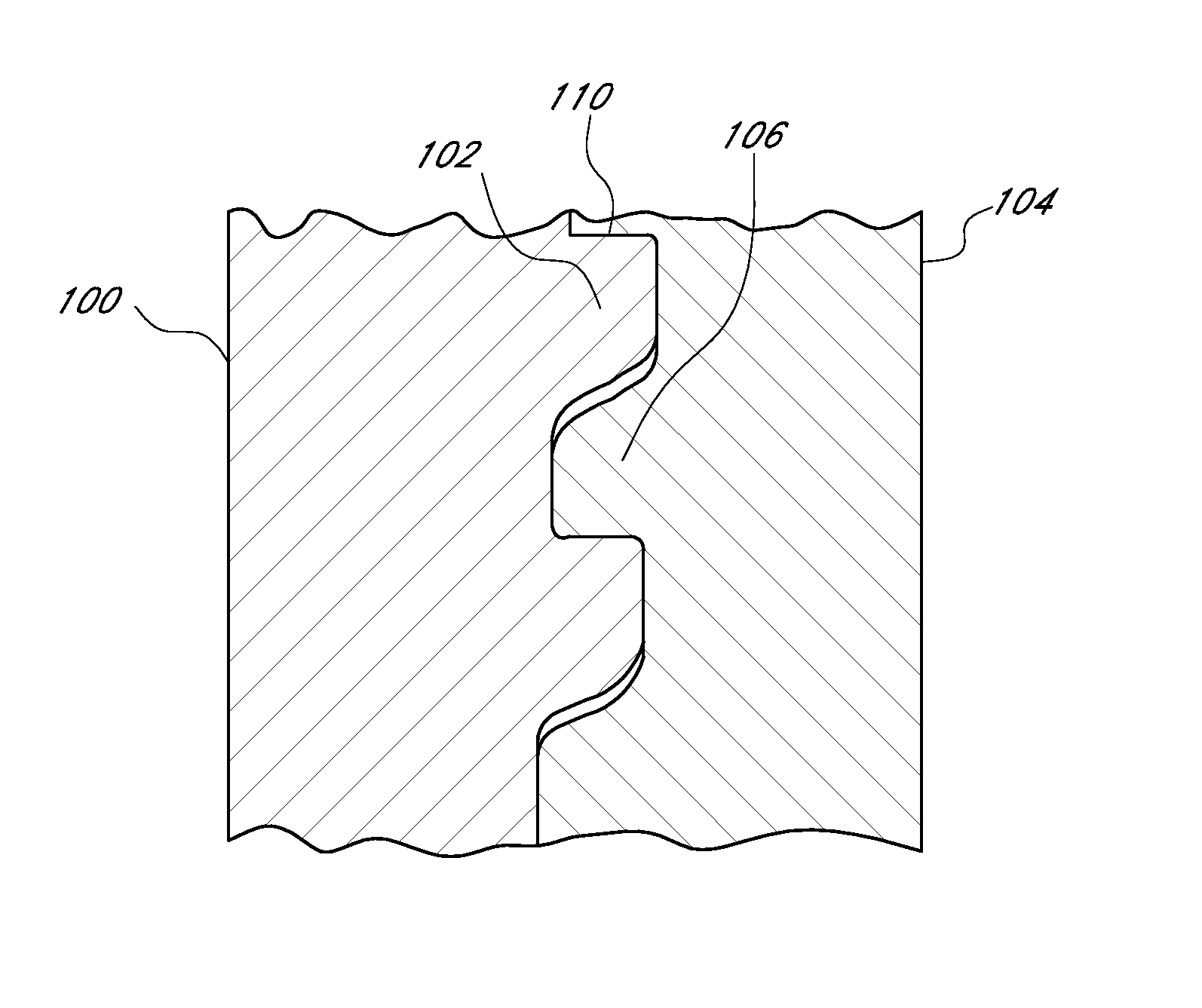

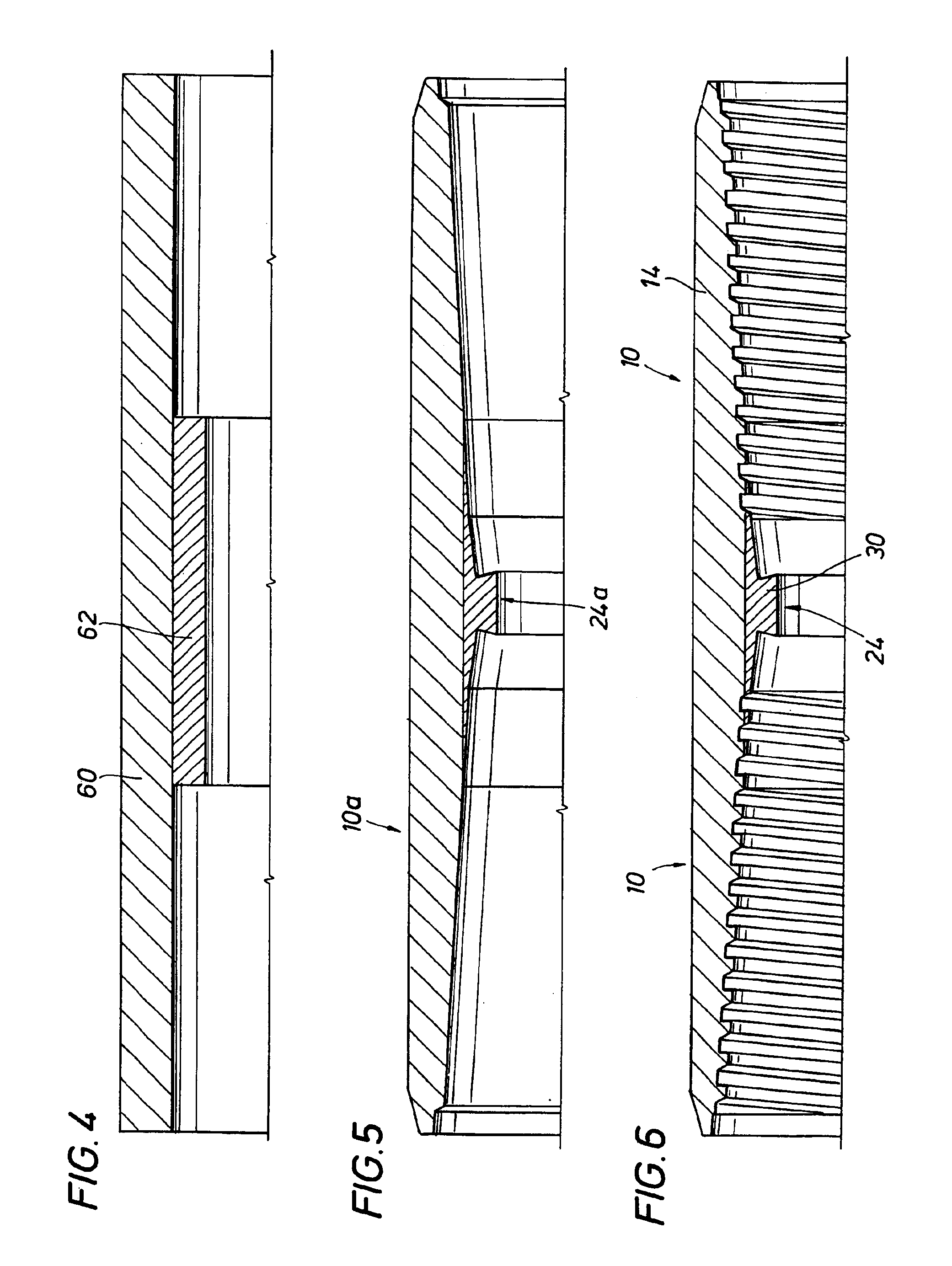

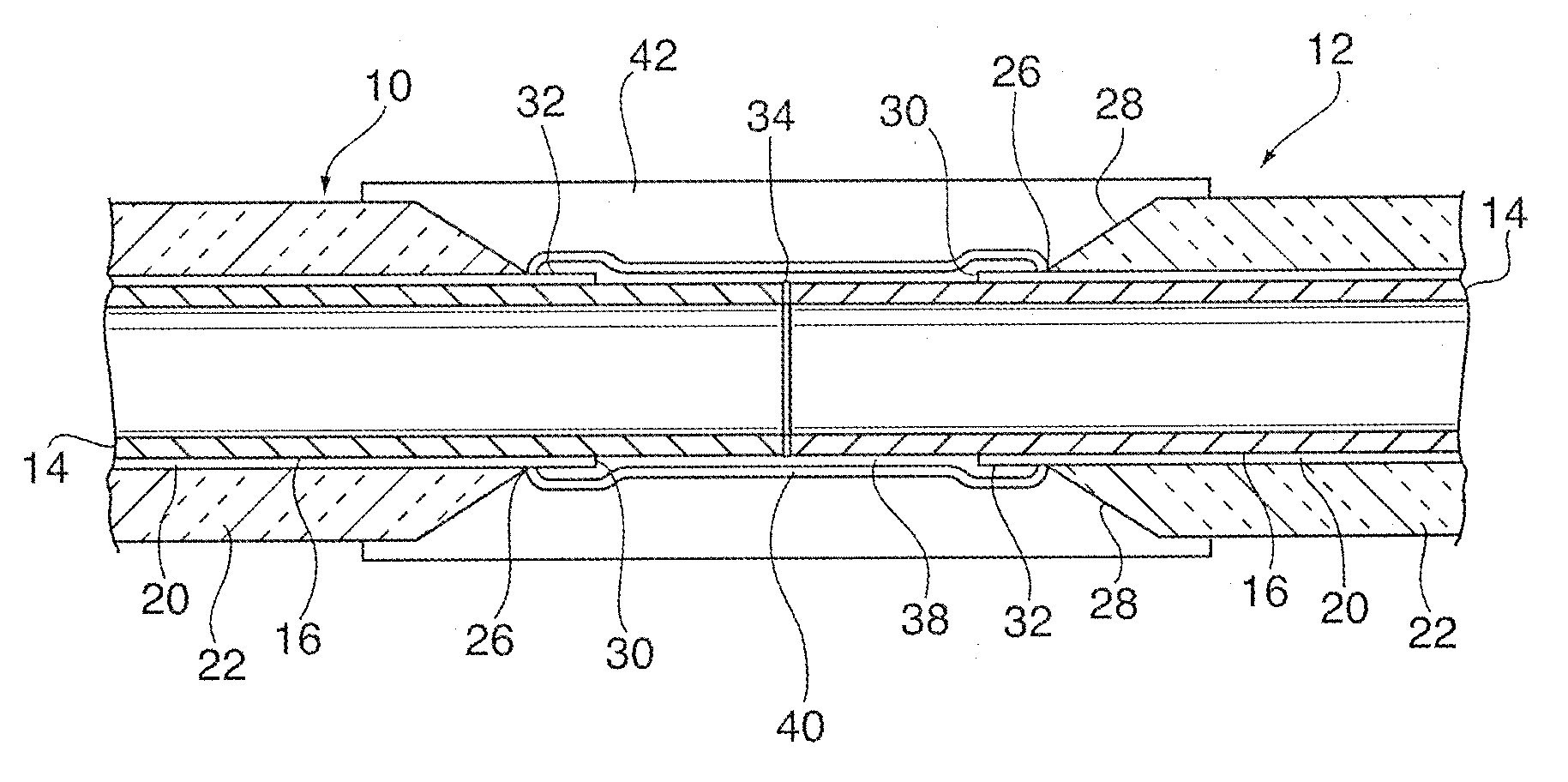

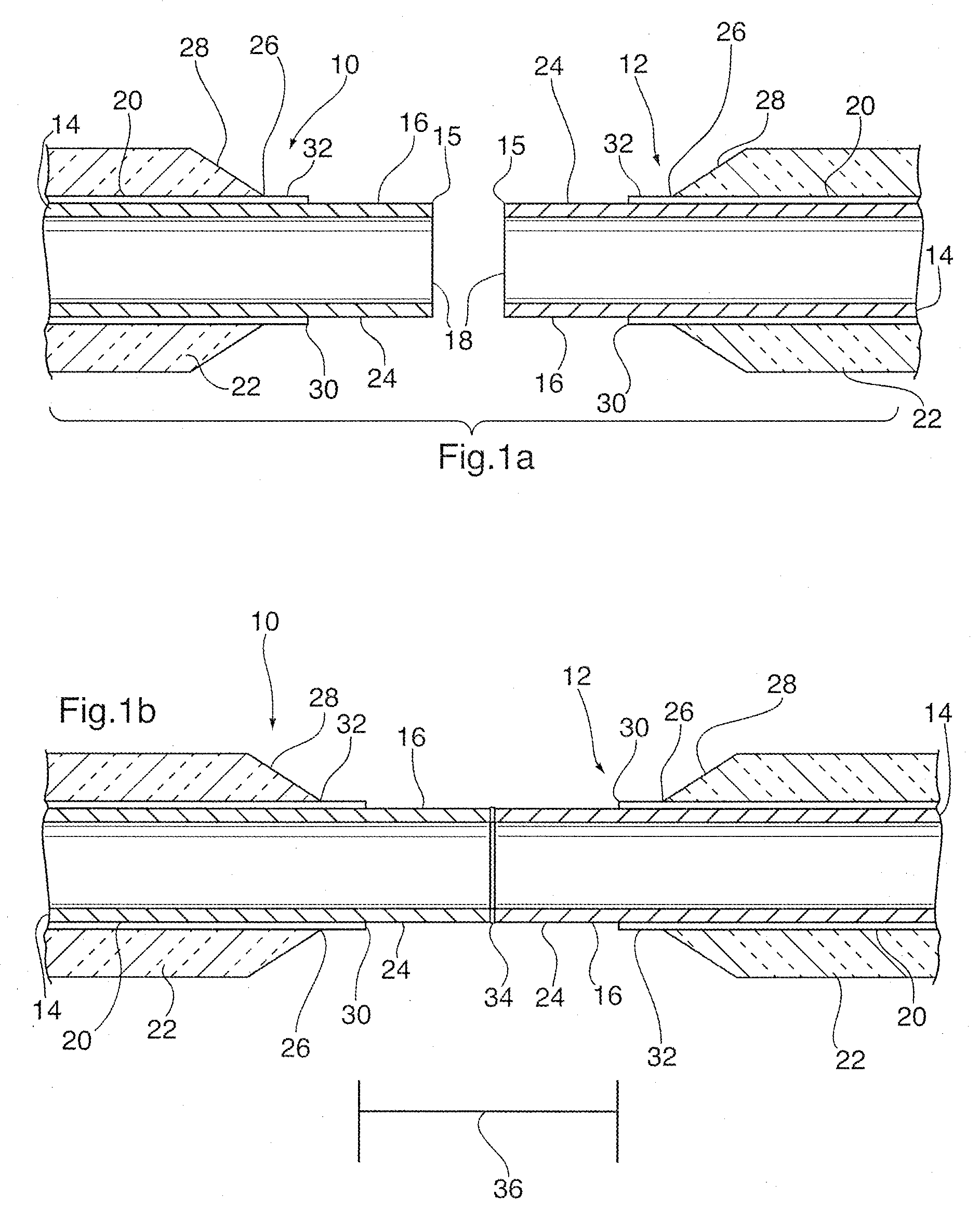

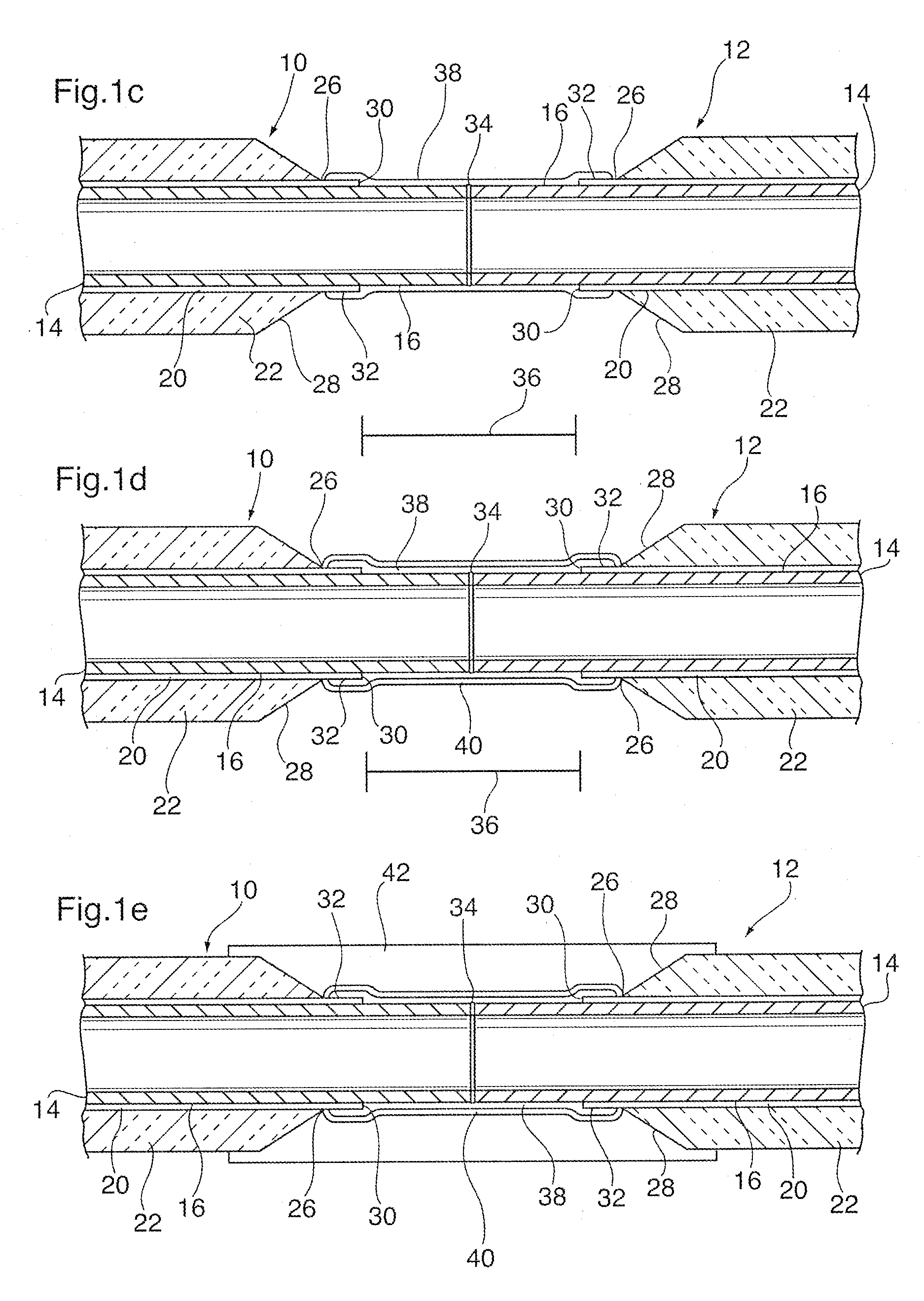

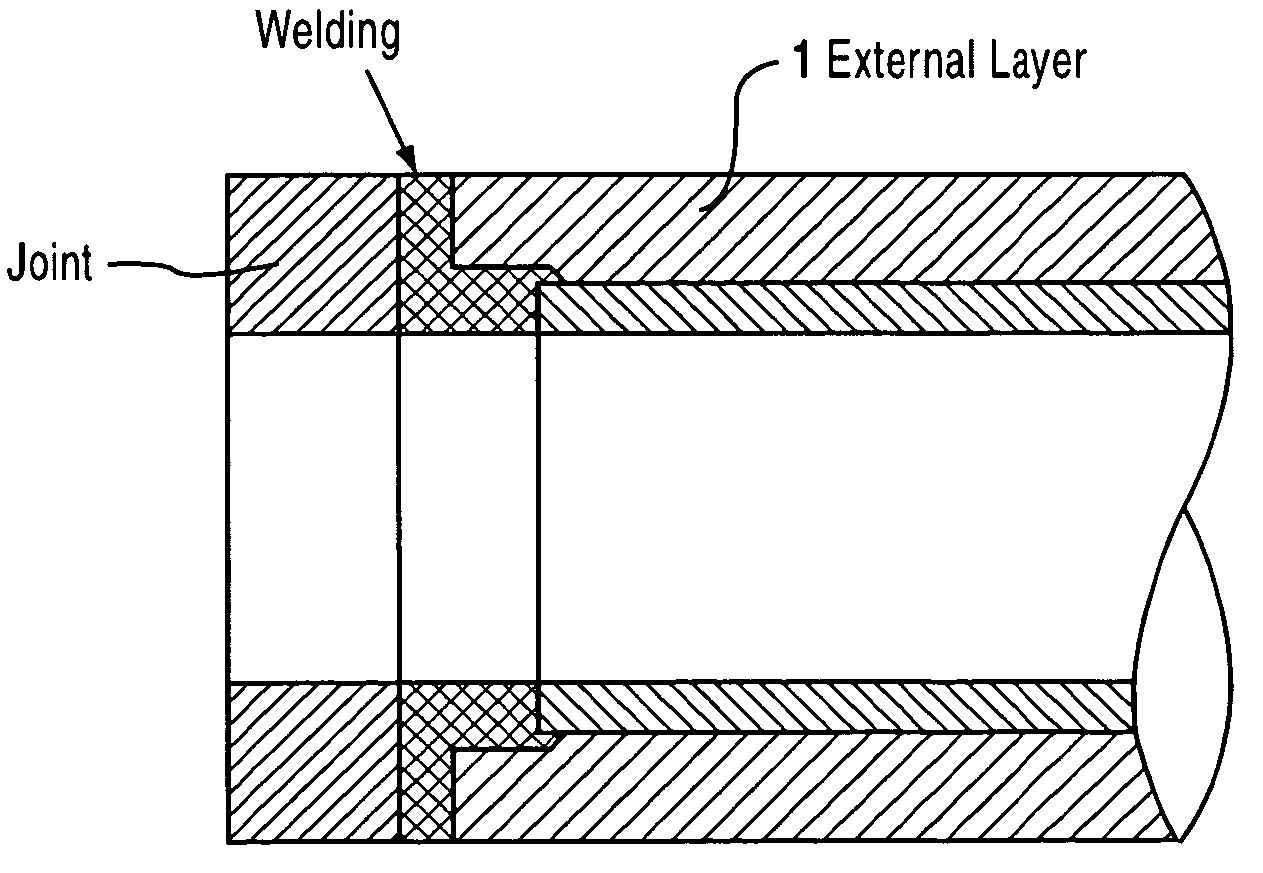

Threaded connection for internally clad pipe

A corrosion-resistant threaded connection including a first tubular member having an outer metal tube of corrosion-prone material and an inner metal lining of corrosion-resistant material, the first tubular member forming a first pin connection having a nose portion comprising a ring of corrosion-resistant material secured, e.g., welded, to the tube of corrosion-prone material, a radially outwardly facing, annularly extending thread-free first pin shoulder being formed on the corrosion-resistant ring, the first member including an externally threaded portion providing male threads, and a second tubular member comprising a metal coupling having a first end and a second end and forming a first box connection and a second box connection, respectively, the coupling including an internally disposed annularly extending metal section of corrosion-resistant material disposed intermediate the ends of the coupling, each of the box connections comprising a radially inwardly facing, annularly extending box shoulder formed on the section of corrosion-resistant material, each of the box connections further including a threaded female portion having threads complementary to the male threads, the pin and box shoulders being sized and configured such that when respective ones of the first pin connections are threadedly received in the first and second box connections, the pin and box shoulders are in metal-to-metal sealing engagement.

Owner:VAM USA +1

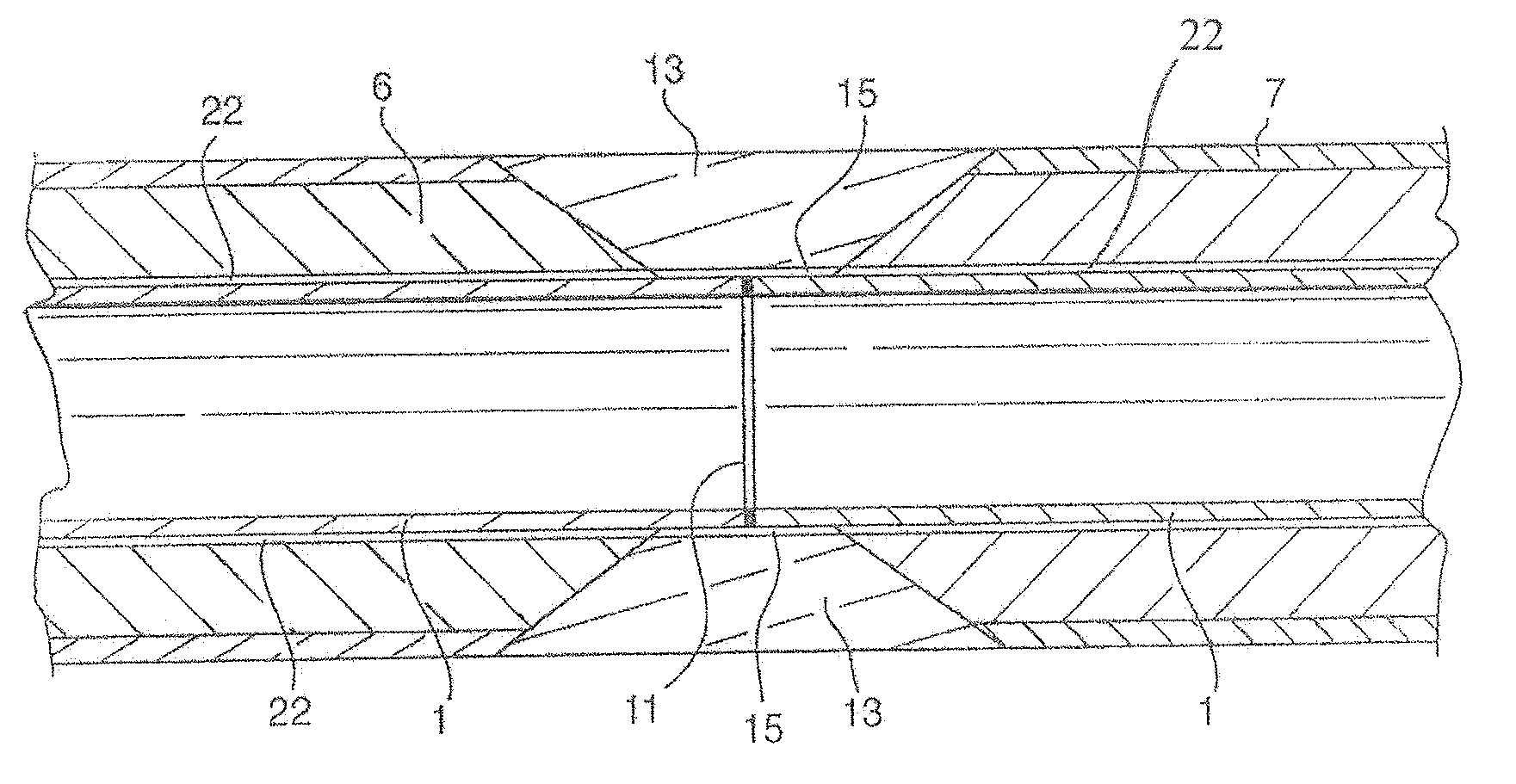

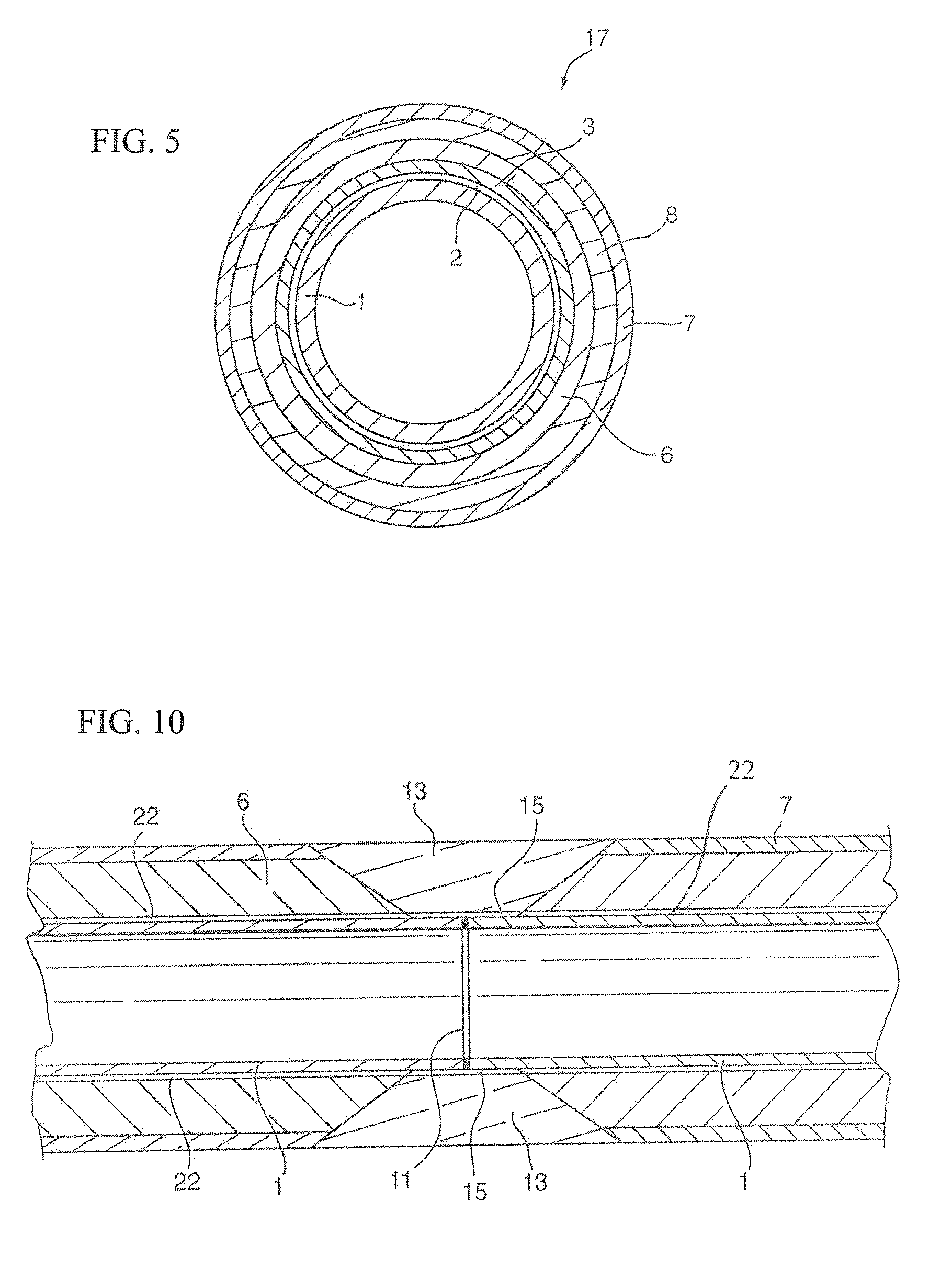

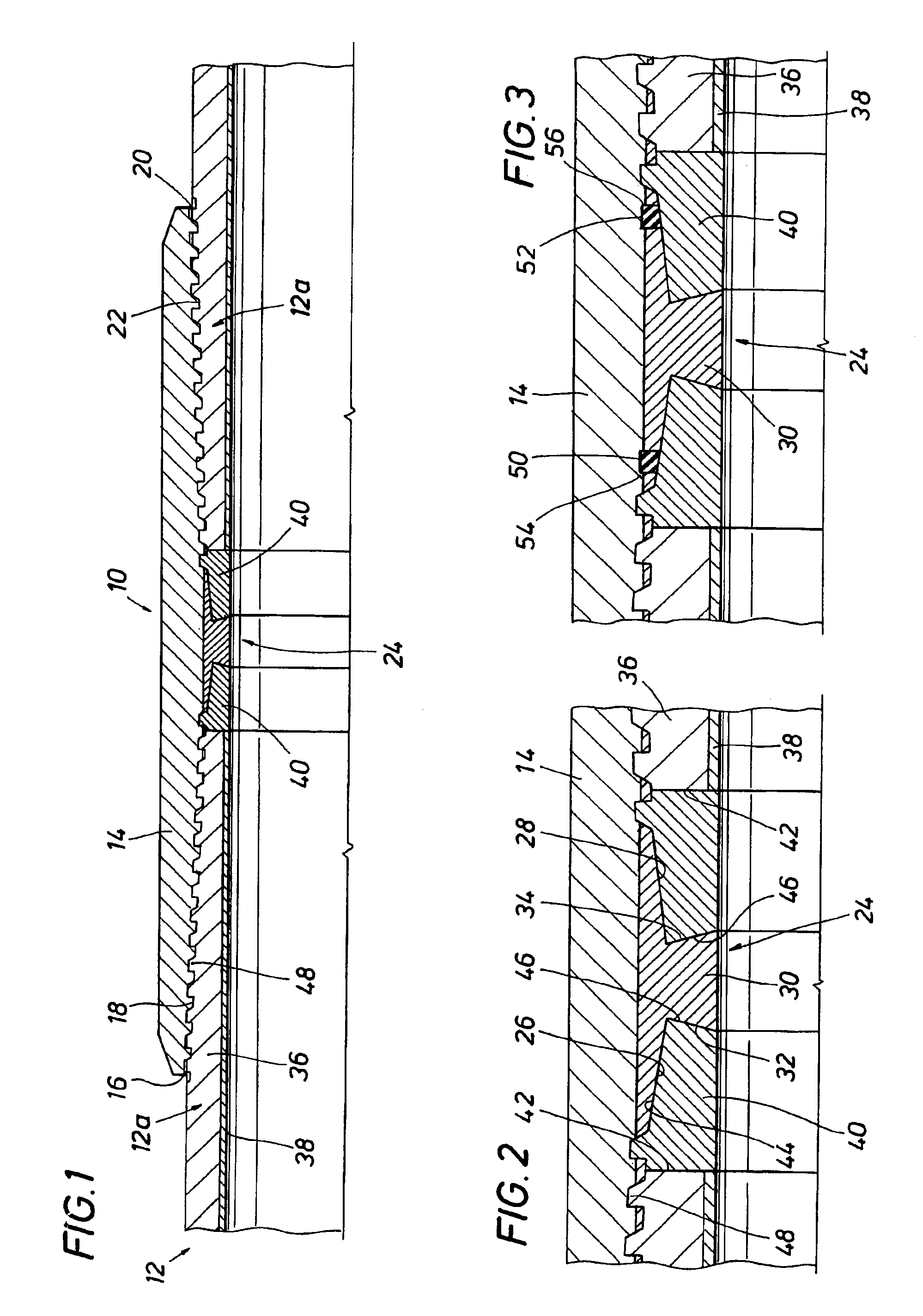

Low temperature method and system for forming field joints on undersea pipelines

A method for forming a field joints between sections of coated or insulated pipe which are to be welded together and incorporated into an undersea pipeline for carrying single or multi-phase fluids such as oil, gas and water. The method includes the application of a liquid epoxy layer which overlaps a lip of the factory-applied FBE coating protruding beyond a chamfered end of the factory-applied insulation layer, and which may be applied over the entire weld joint area. The liquid epoxy layer is partially cured by application of heat, and a layer of powdered adhesive is applied onto the partially cured liquid epoxy layer. The adhesive is subsequently sintered and activated by application of heat to its outer surface. The outer surfaces of the adhesive layer and the chamfers are then preheated and the thermal joint insulation is injection molded over the entire joint area. Throughout the entire method the temperature of the factory-applied FBE coating is maintained below its glass transition temperature so as to avoid weakening the bond between the FBE coating and the underlying steel pipe. The number and sequence of steps can be varied, depending at least partly on whether the liquid epoxy and adhesive layers are applied in a pipe coating facility or in the field.

Owner:SHAWCOR LTD

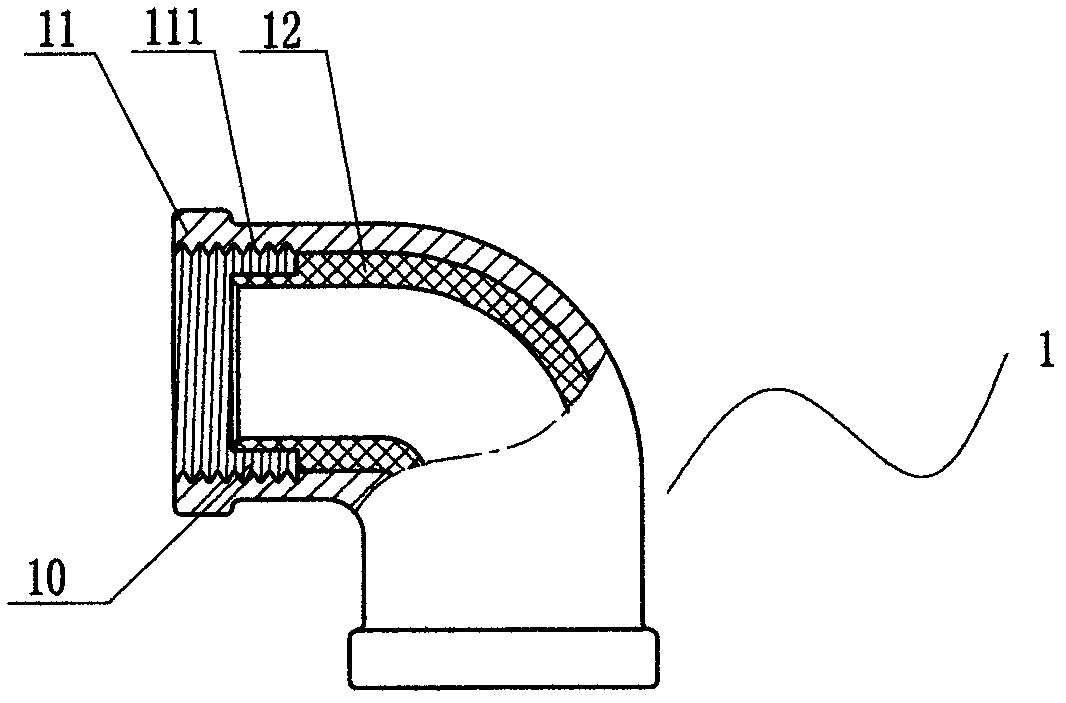

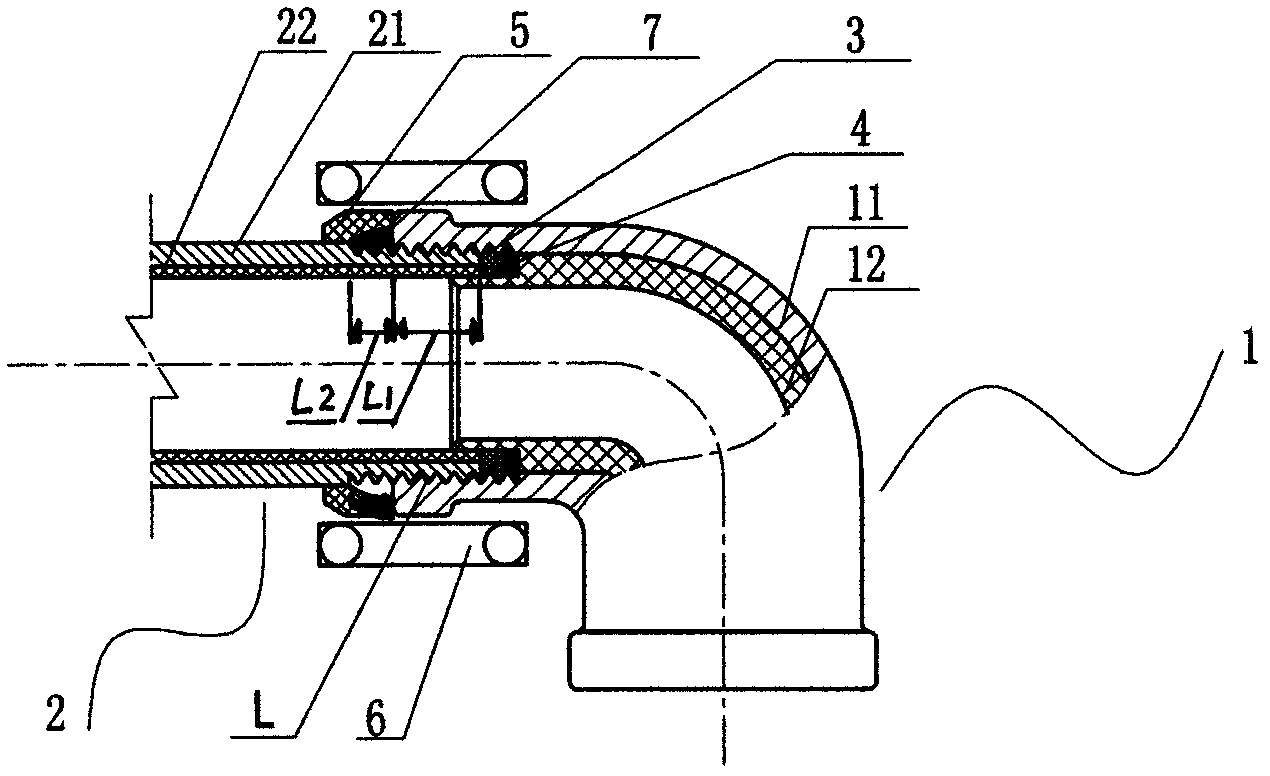

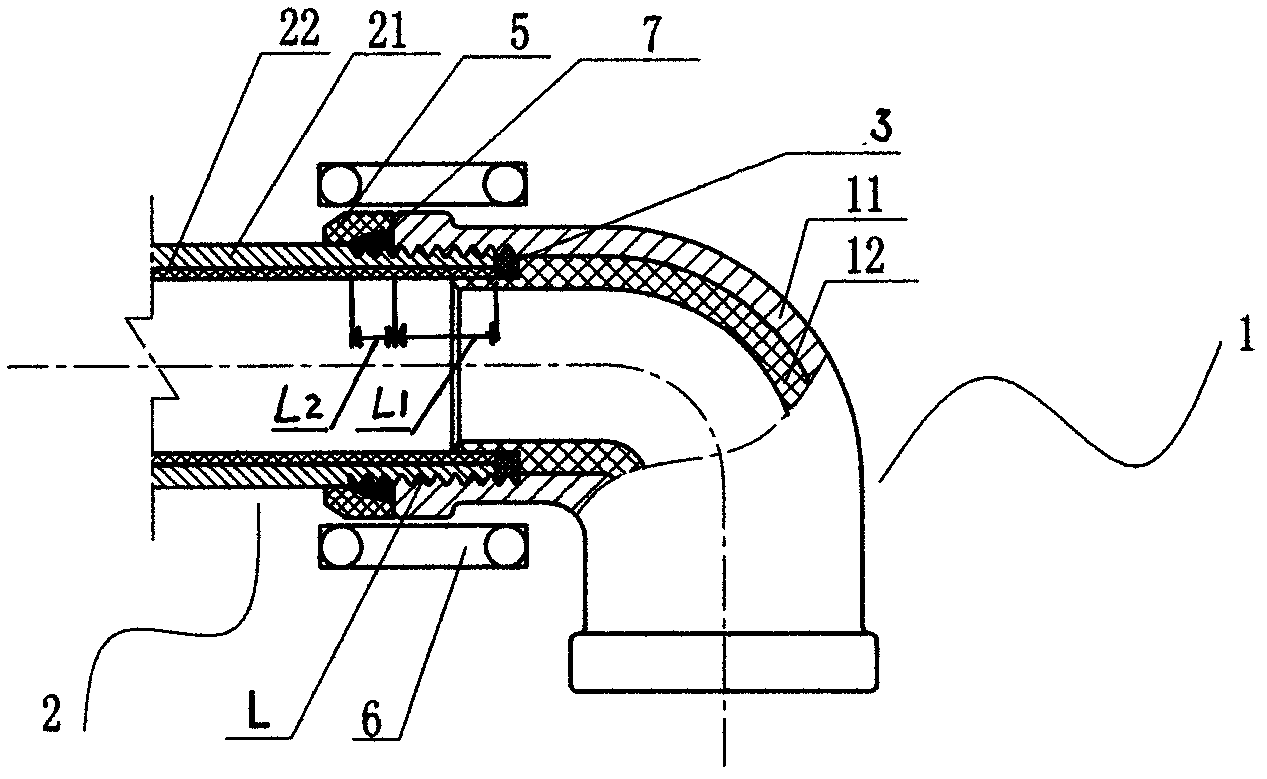

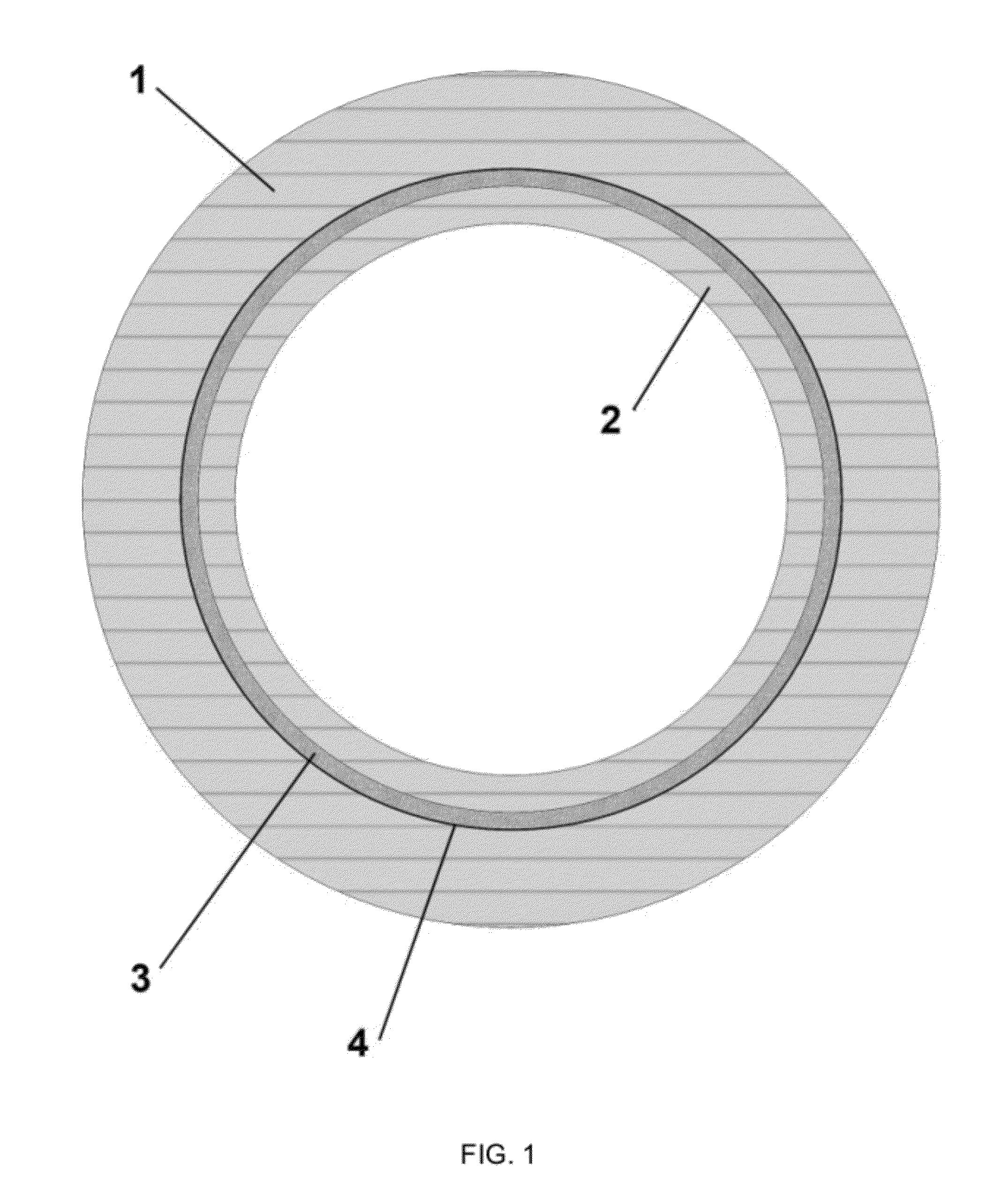

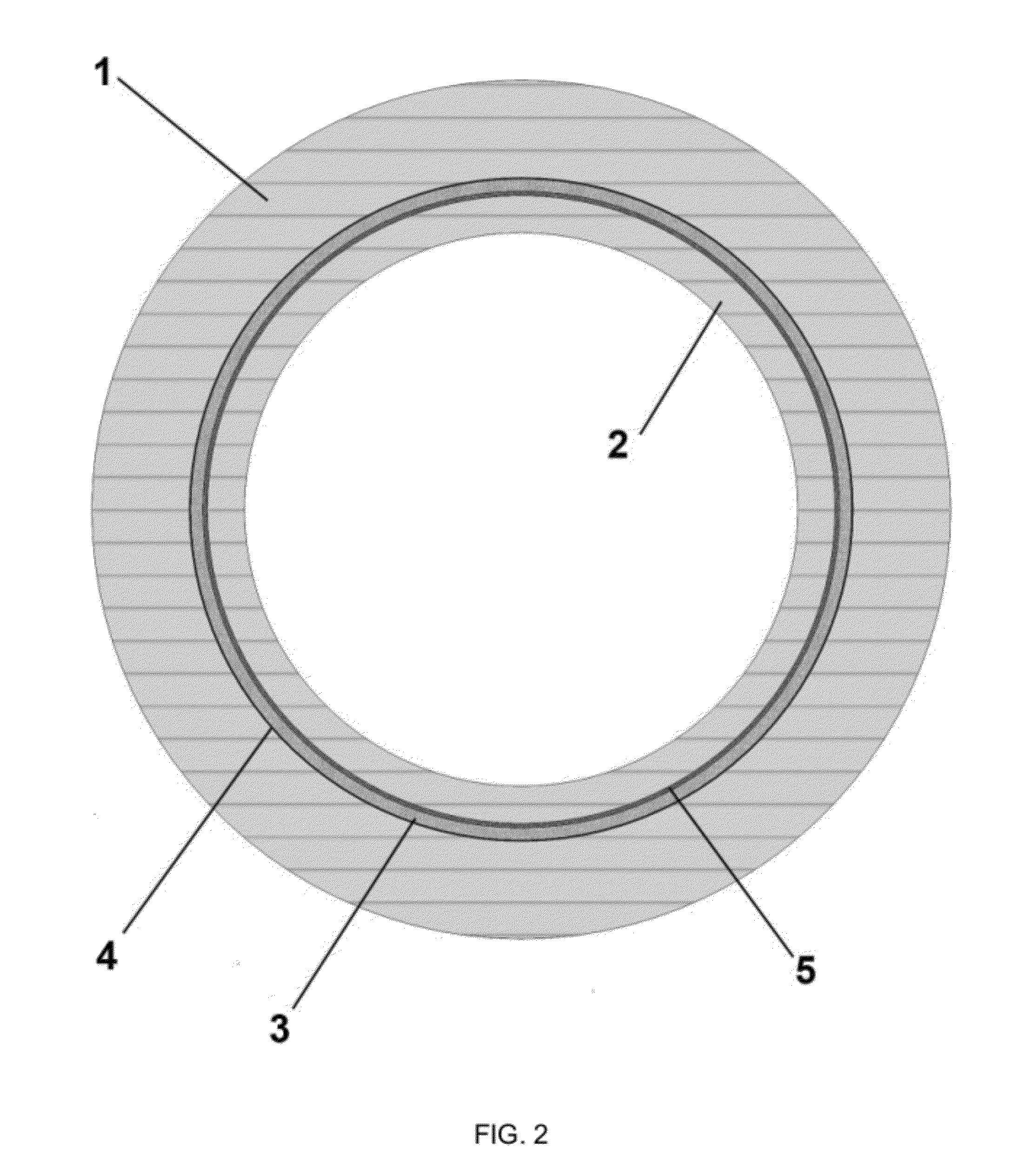

Full corrosion-resistant connection structure of steel lining plastic composite pipeline

InactiveCN102359697AReduce the chance of secondary pollutionEliminate interface rustCorrosion preventionPipe protection against corrosion/incrustationPipe fittingHot-melt adhesive

The invention discloses a full corrosion-resistant connection structure of a steel lining plastic composite pipeline, and belongs to the technical field of connection of the steel lining plastic composite pipeline. The structure comprises a corrosion-resistant ring sleeved on a non-meshing section of an external thread of a steel outer layer, a steel lining plastic composite pipe fitting consisting of a steel outer ring part and a plastic inner ring part, and a composite pipe consisting of the steel outer layer with the external thread, and a plastic inner layer, wherein the external thread consists of a meshing section and the non-meshing section; an annular cavity of which the inner wall is provided with an internal thread section is formed between the steel outer ring part and the plastic inner ring part; the pipe is in threaded connection with the pipe fitting; a solid hot melt adhesive is arranged in the annular cavity; when an alternating magnetic field is formed at the periphery of the joint of the pipe fitting and the pipe, the solid hot melt adhesive is in thread engagement with the steel outer ring part and in sealed connection with the end faces of the steel outer layer and the plastic inner layer; and the corrosion-resistant ring is in sealed connection with the non-meshing section of the pipe. After the scheme is adopted, the problem that the threads of the pipe and the pipe fitting are easily corroded and rusted is solved, and a full corrosion-resistant threaded connection effect is achieved.

Owner:HUAHUI CONSTR GROUP

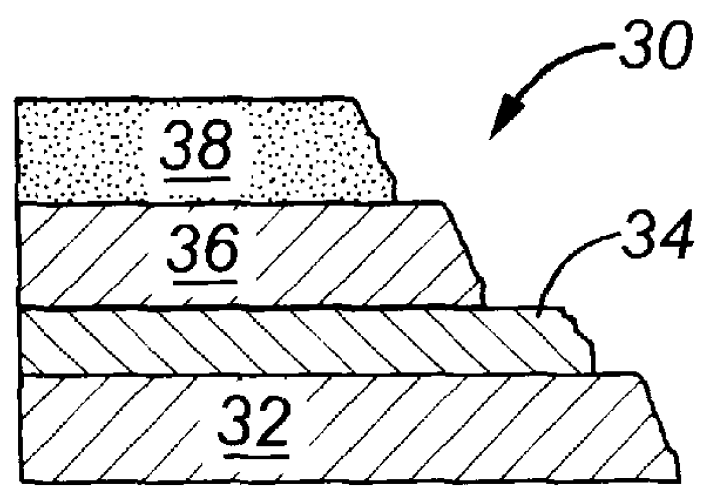

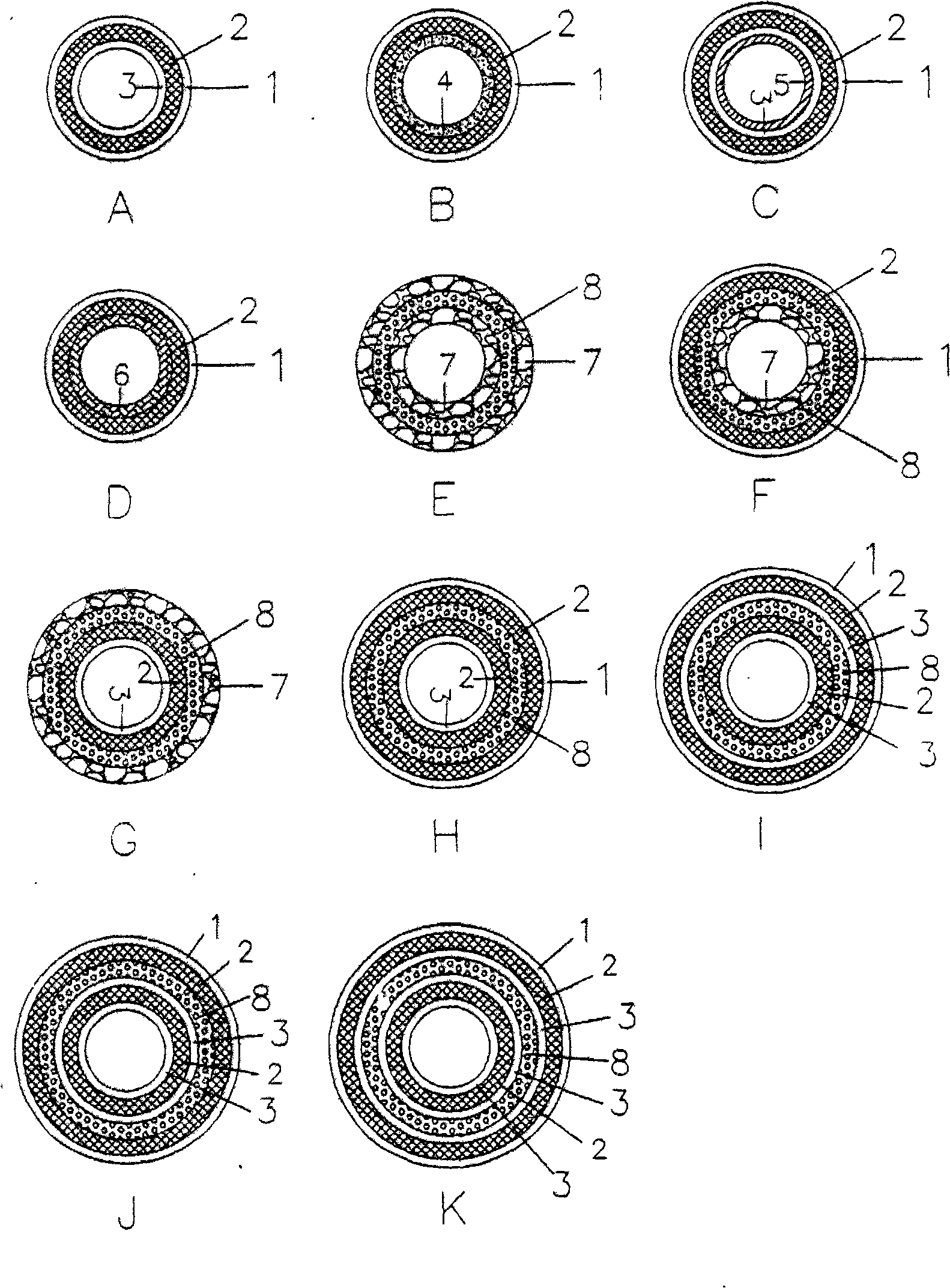

Multilayered structure and multifunction pipeline and connecting device

The invention relates to a multilayered structure and multifunction pipeline and a connecting device, solving the disadvantages of poor corrosion resistance, poor crushing resistance, poor heat-insulating property, no shapely appearance, high production cost, single structure, and the like of the existing pipelines. The pipeline comprises a corrosion resistance layer, a crushing resistance layer, a heat-insulating layer and a bacteria resistance layer, and can be of the types of single corrosion resistance and crushing resistance, bacteria resistance, corrosion resistance and crushing resistance and heat-insulating, corrosion resistance and crushing resistance. The invention has the advantages of favorable corrosion resistance, high crushing resistance, favorable heat-insulating property, bacteria resistance, simple installation and connection, reduced production and installation cost, diversified structural type of pipeline and connecting device, and the like. The pipeline can be used for drinking water supply projects, drainage engineering, oil transportation, corrosive liquid transportation, high temperature liquid and gas transportation, etc.

Owner:韦鸿雁

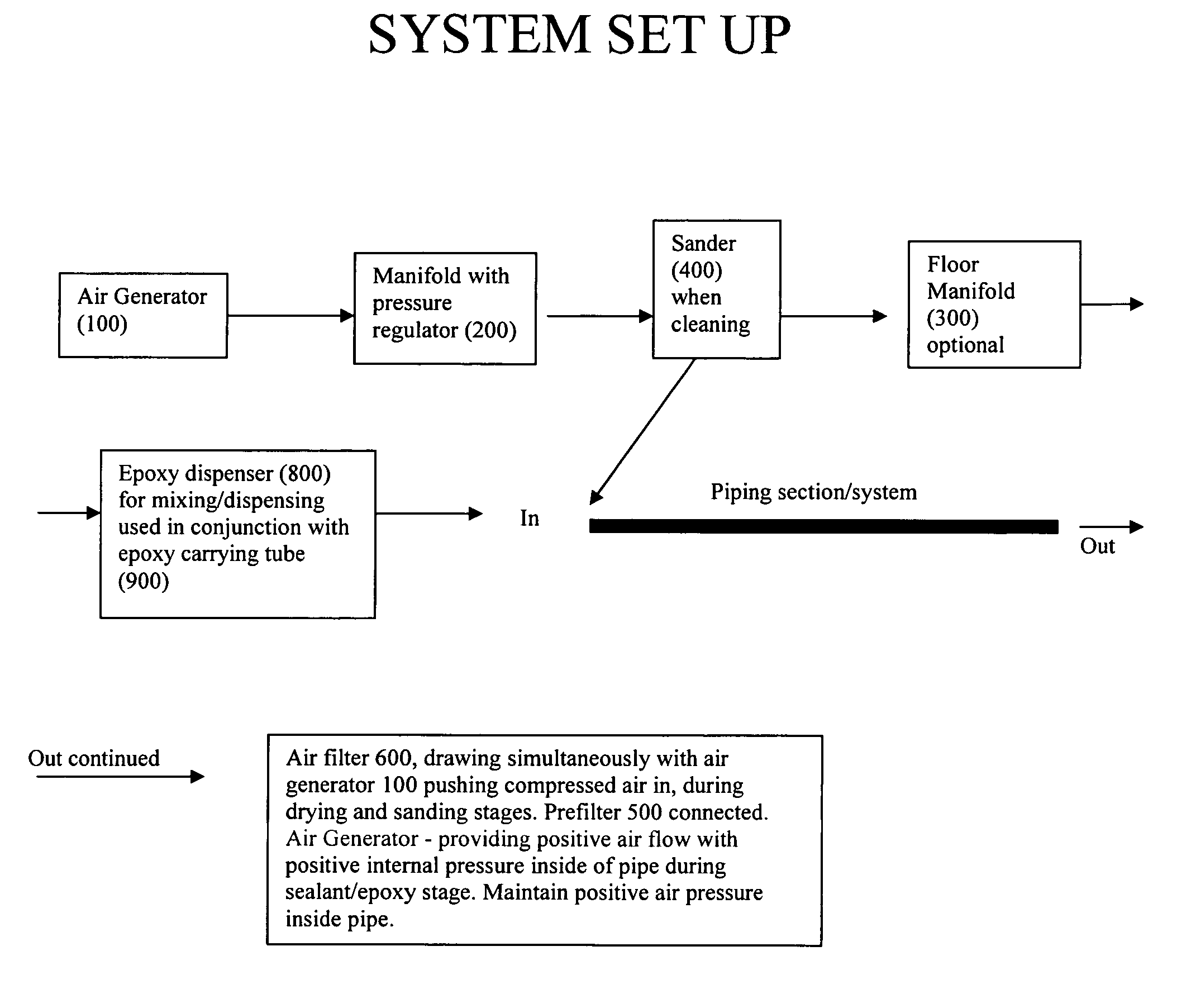

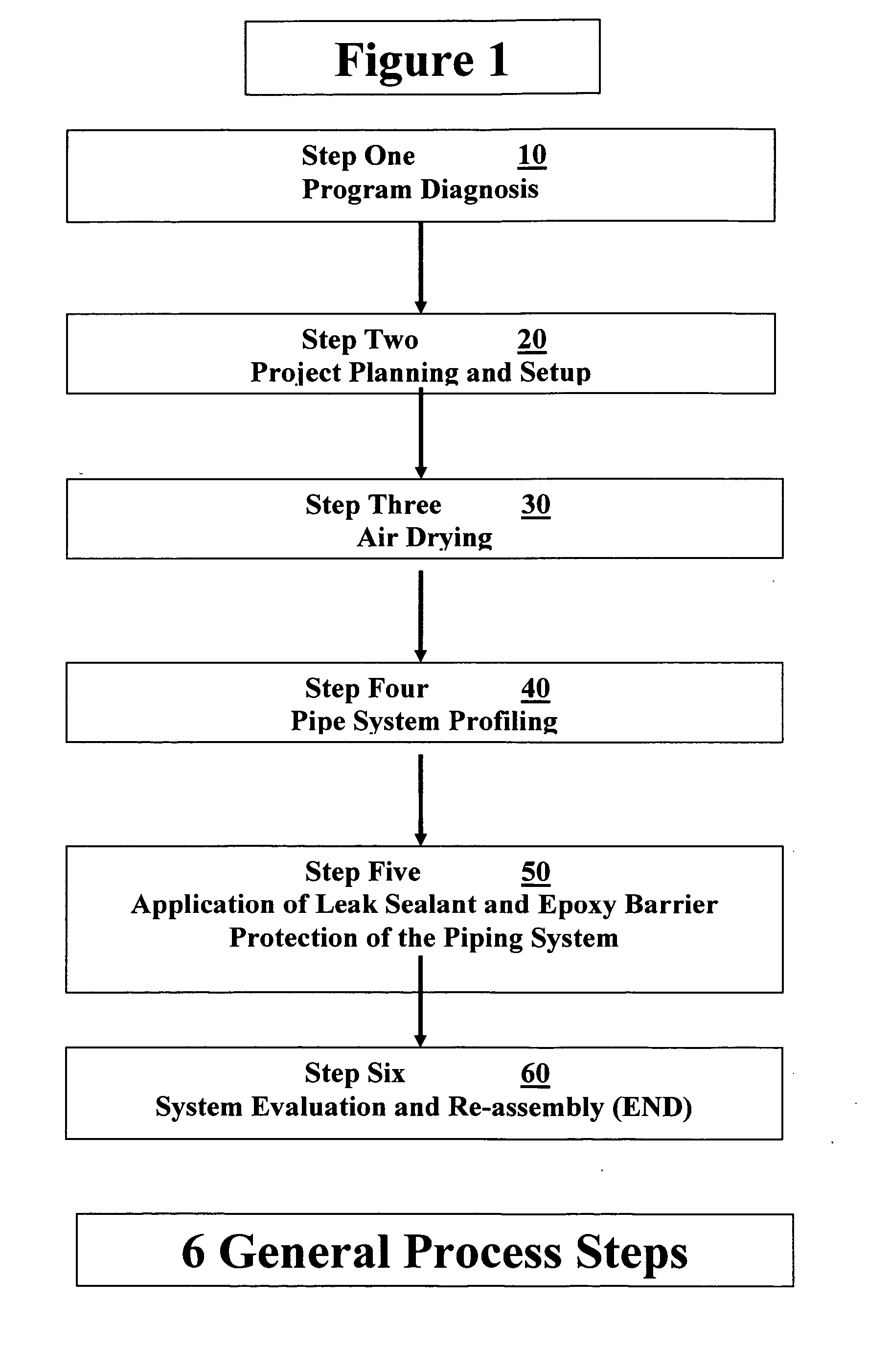

Methods and systems for coating and sealing inside piping systems

Methods and systems for cleaning, coating and sealing leaks in existing pipes, in a single operation. A piping system can be cleaned in one pass by dry particulates forced and pulled by air throughout the piping system by a generator and a vacuum. Pipes can be protected from water corrosion, erosion and electrolysis, extending the life of pipes such as copper, steel, lead, brass, cast iron piping and composite materials. Coatings can be applied to pipes having diameters up to approximately 6″. Leak sealants of at least approximately 4 mils thick can cover insides of pipes, and can include novel mixtures of fillers and epoxy materials, and viscosity levels. A positive pressure can be maintained within the pipes during applications. Piping systems can be returned to service within approximately 96 hours.

Owner:PIPE RESTORATION TECH

Hardfacing alloy, methods and products

InactiveUS7569286B2Increase resistanceReduce coefficient of frictionDrill bitsDrilling rodsBorideCasing wear

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD

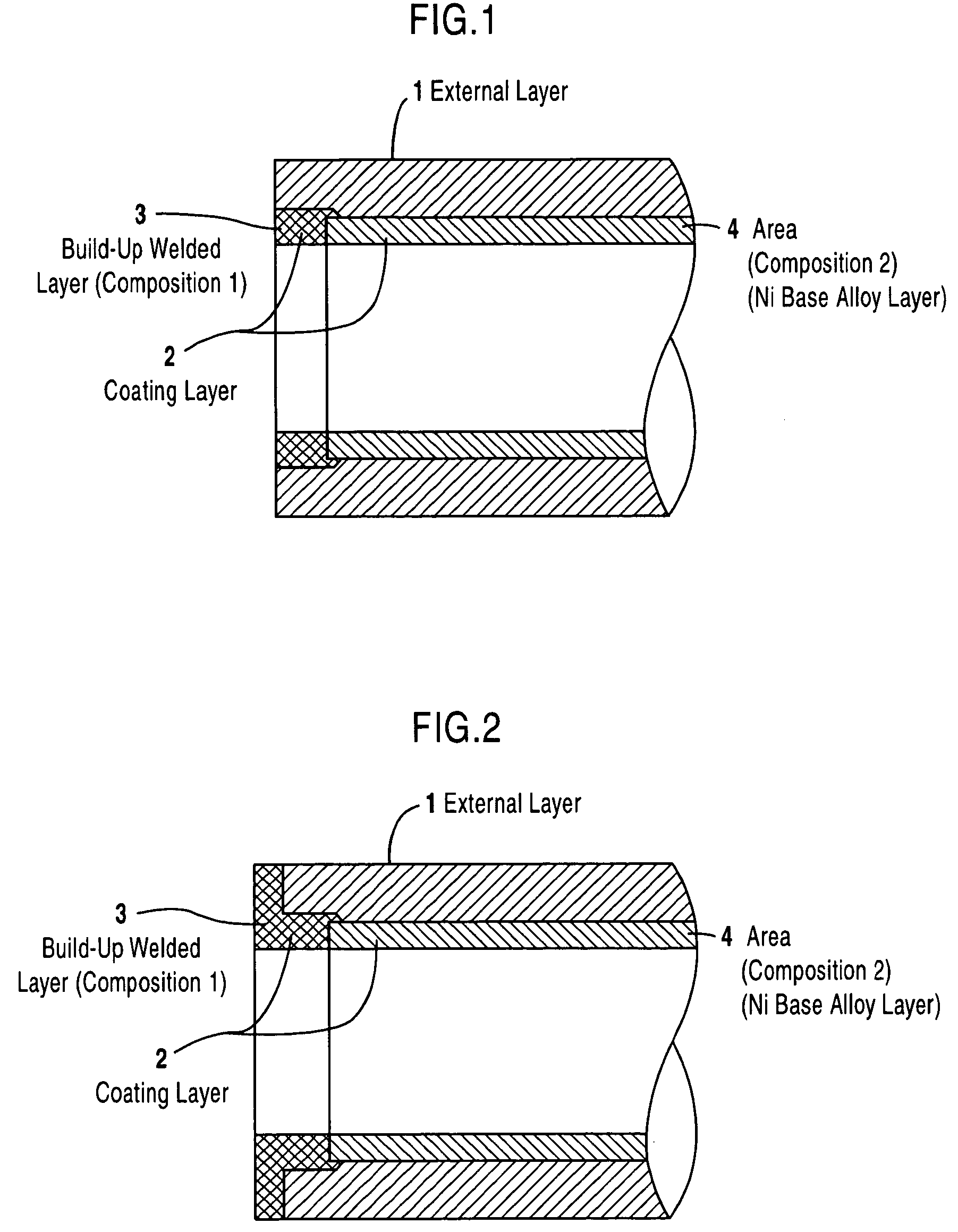

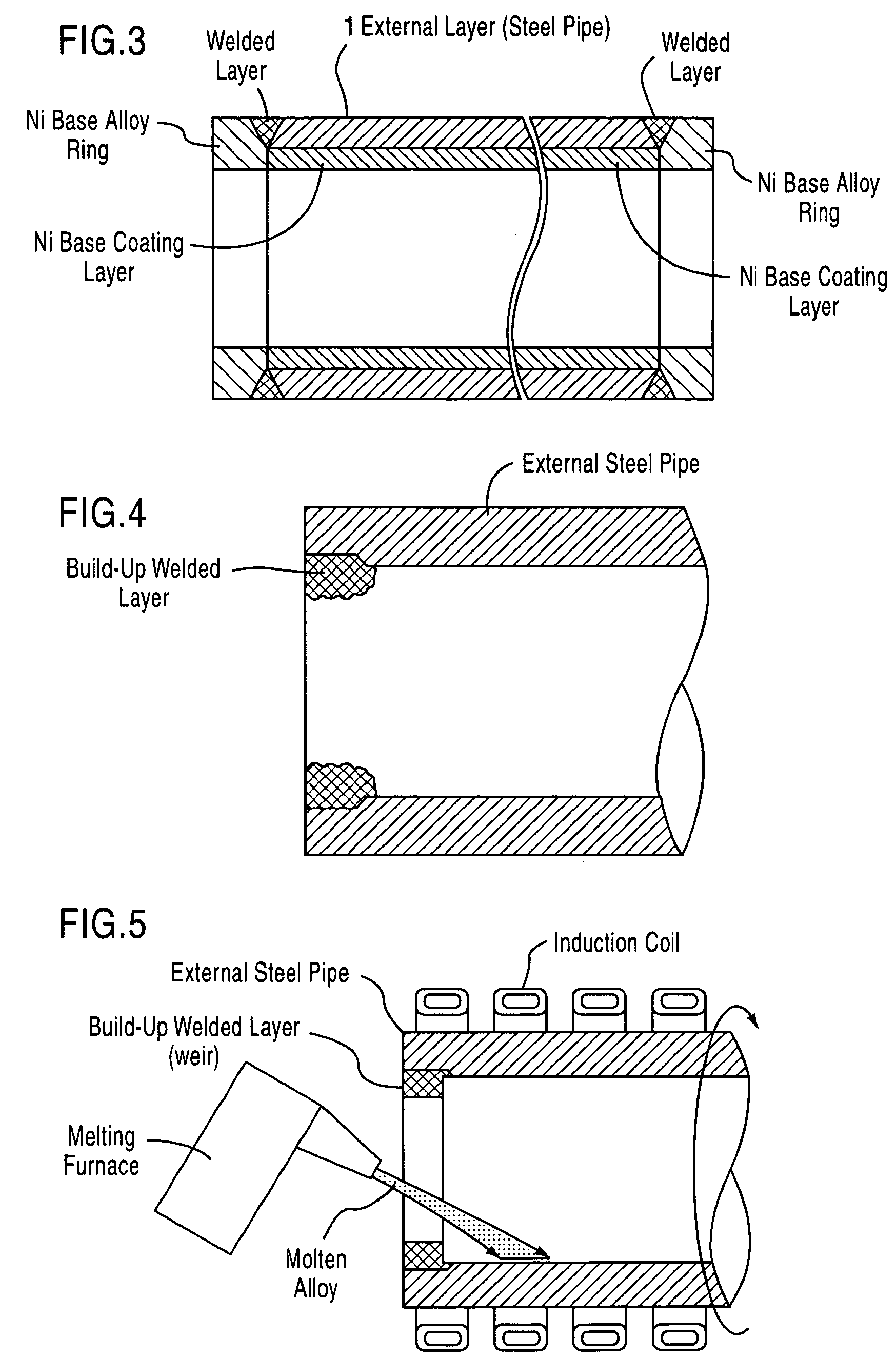

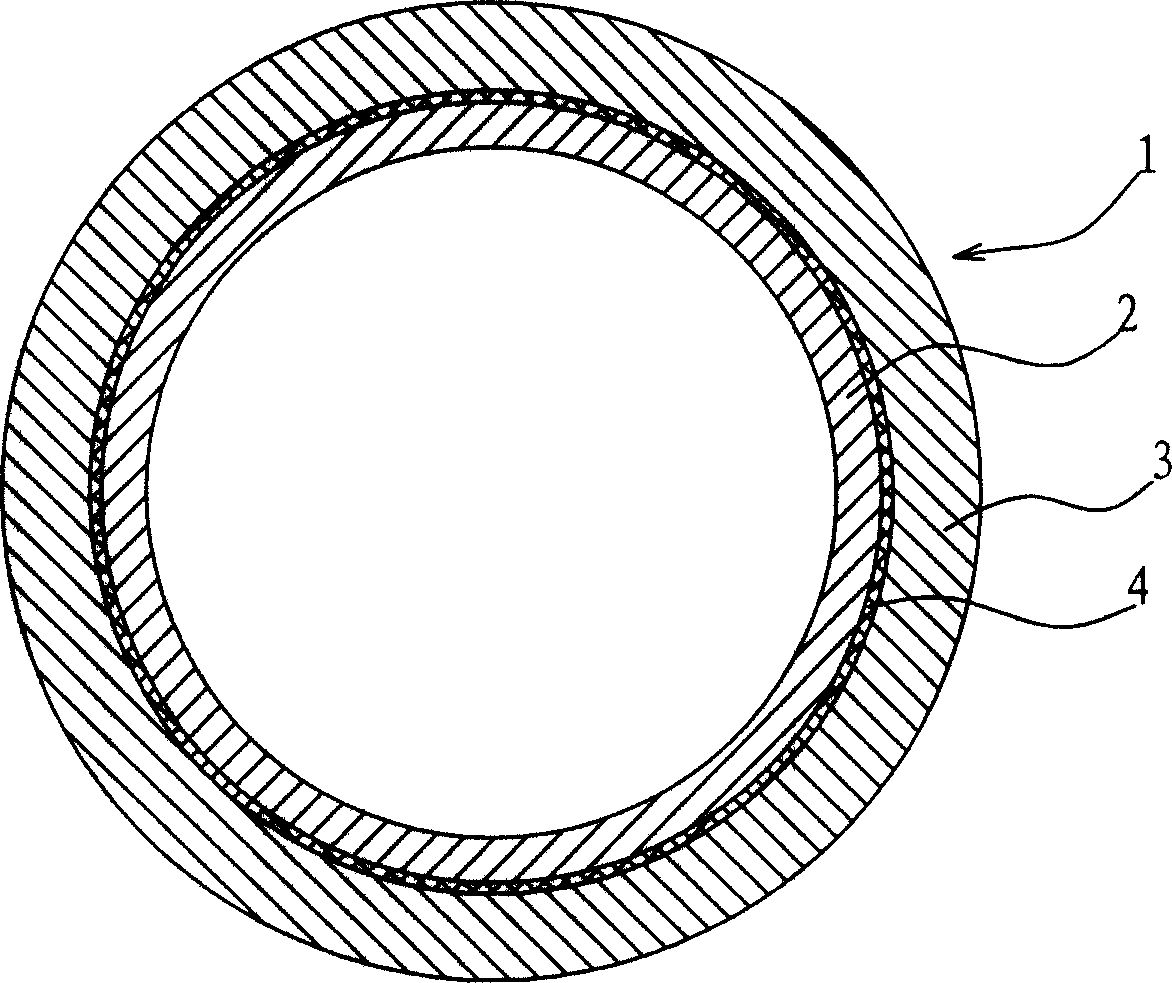

Clad pipe

InactiveUS20050166987A1Improve corrosion resistanceEasy to weldEnvelopes/bags making machineryMolten spray coatingMetallurgyAlloy

A clad pipe includes an external layer and a coating layer made of Ni base anticorrosion alloy. Both end portion areas of the coating layer are formed by a build-up welded layer (Ni base alloy of composition 1) on the inner surface of the external layer. Other areas are formed by a Ni base alloy layer (Ni base alloy of composition 2) fusion-bonded to the build-up welded layers and the inner surface of the pipe, a solidus-curve temperature of the Ni base alloy layer being 1300° C. or below and lower than a solidus-curve temperature of the Ni base alloy formed by build-up welding by 150° C. or more. Composition 1 and composition 2 are adjusted so that, in the same environment, corrosion resistance of the Ni base alloy of composition 1 is equivalent to or superior to that of the Ni base alloy of composition 2.

Owner:DAI ICHI HIGH FREQUENCY

Method for manufacturing copper aluminium composite tubing and copper aluminium tubing produced thereby

The invention relates to a copper-aluminum compound tube material and relative producing method, belonging to the technique of metallic compound tube material production. Said invention comprises a copper inner layer and an aluminum outer layer. It is characterized in that: at the connection of copper and aluminum layers, said inner and outer layers are dispersed to each other to form a connecting layer to combine them. The producing method comprises; using planet rolling tube has single-rail sectional contraction rate on the compound tube is 50-95%; the outlet rolling speed is 5-30m / min; and the single-rail rolling is processed when the temperature of distortion section reaches 200-600Deg. C. The inventive method can combine two layers, with fewer processes, high efficiency, large batch and lower cost. And the product has better mechanical and thermal exchange properties, without defects in following process. It can be used to replace copper and alloy tube, to reduce producing cost.

Owner:JIANGSU XINGRONG HI TECH

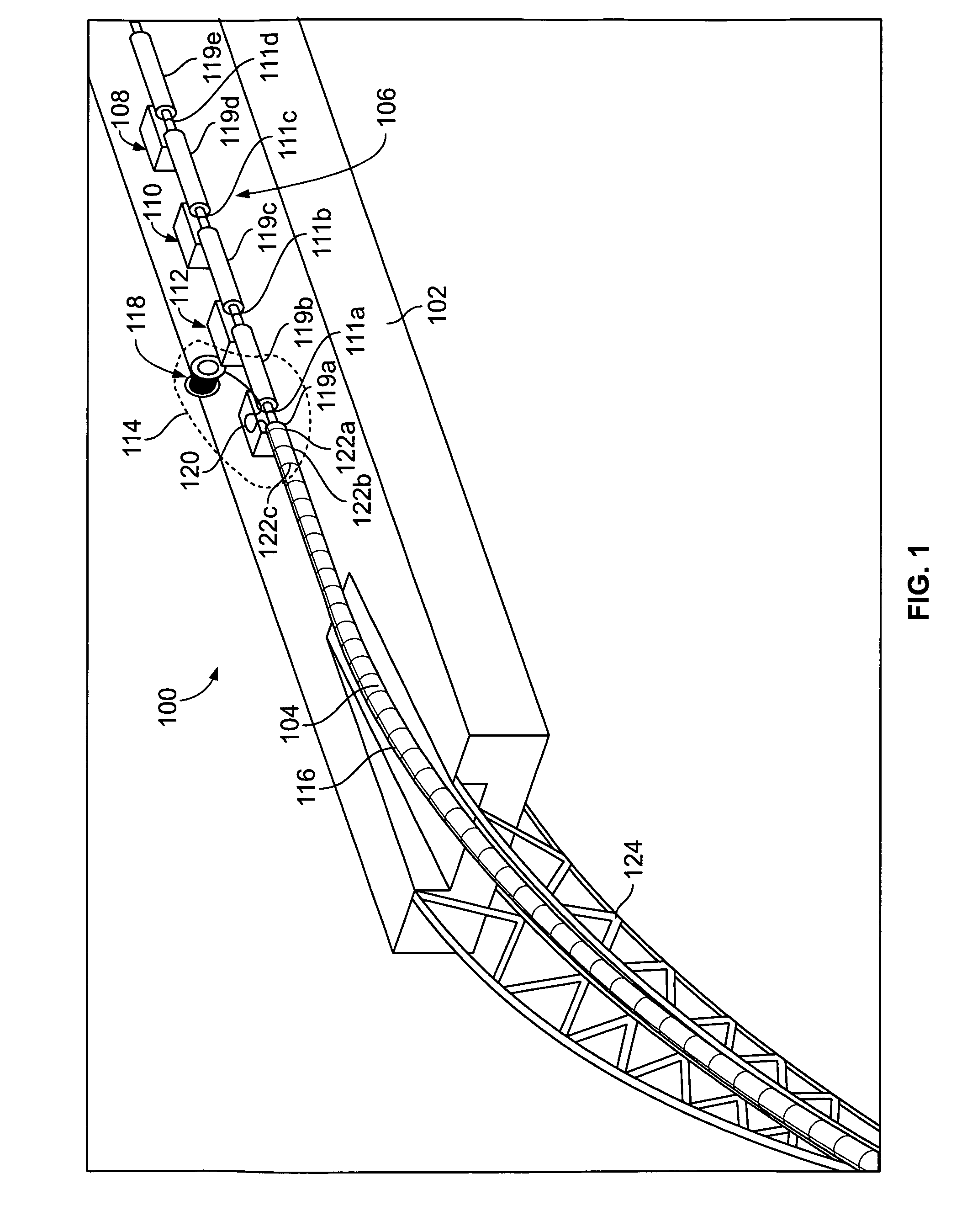

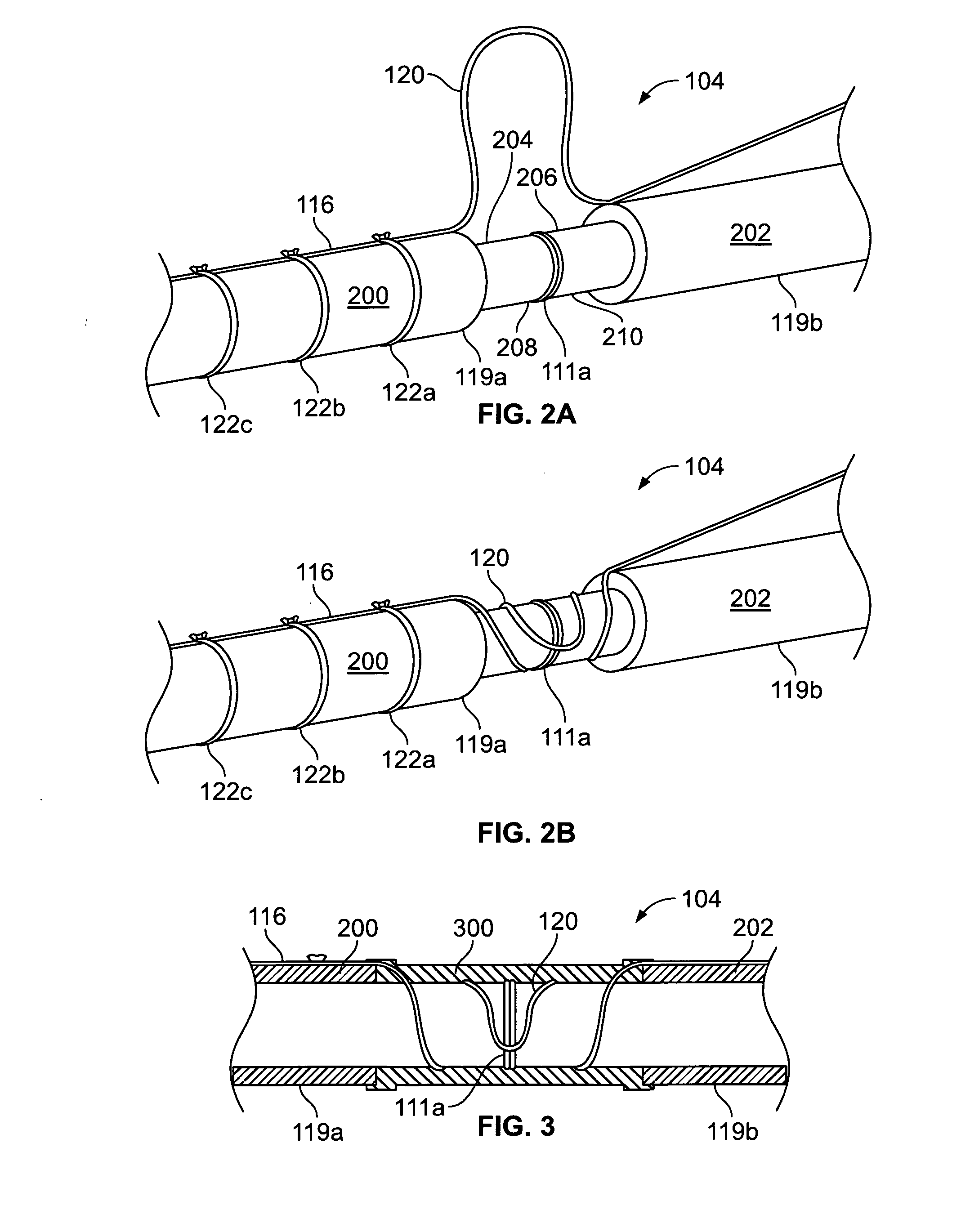

Pipeline with Integrated Fiber Optic Cable

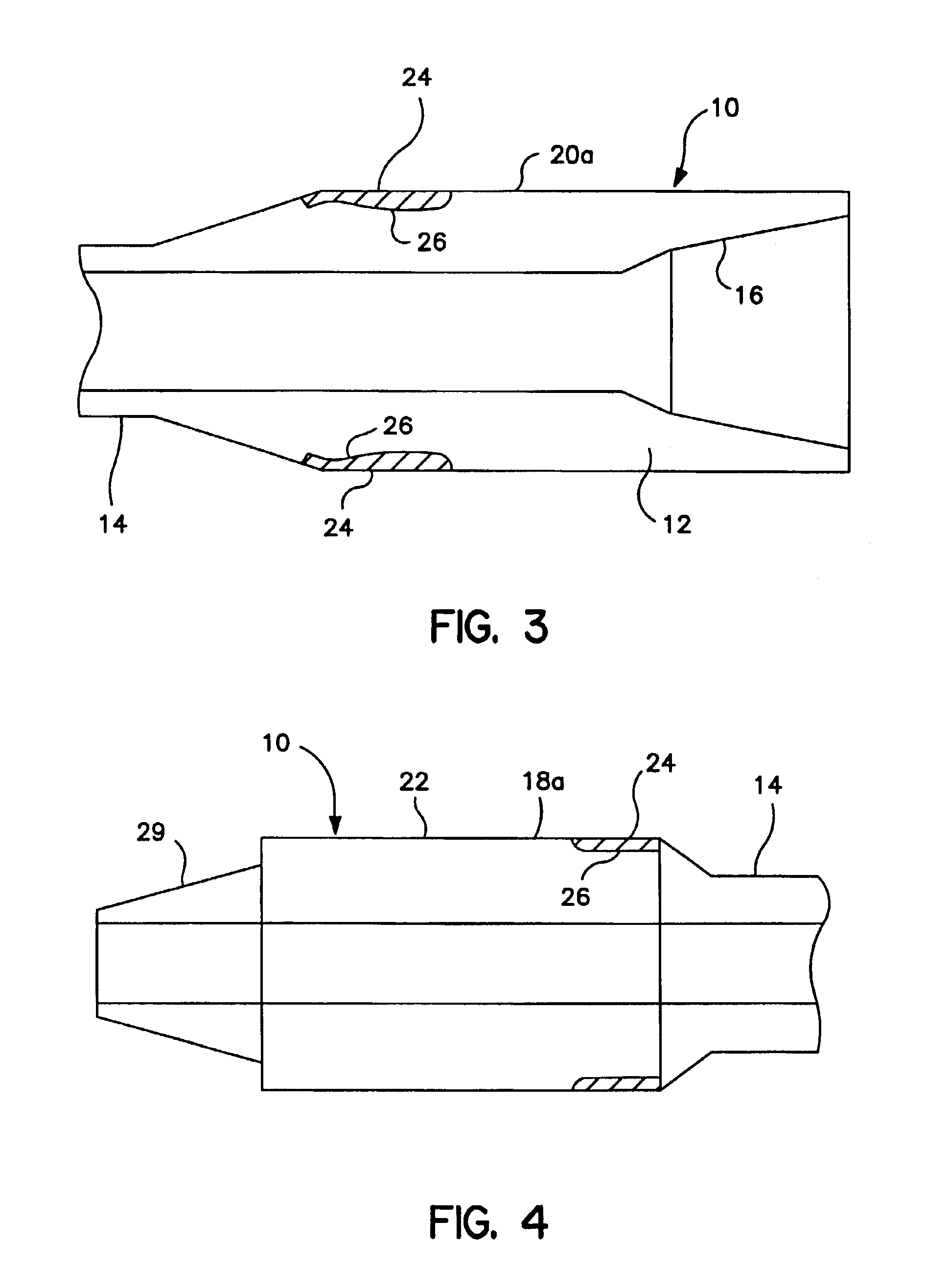

Apparatus and methods for integrating a fiber optic cable (116) with a pipeline (104) are described. An example pipeline having an integrated fiber optic cable includes a plurality of pipe sections (119a, 119b), where each of the pipe sections has a thermally insulating outer layer (200, 202) and ends not covered by the outer layer. The ends of each of the pipe sections are welded to respective ends of other pipe sections to form field joints (111a) at the welded ends. The pipeline also includes a fiber optic cable, where first portions (120) of the fiber optic cable are in contact with some of the pipe sections at some of the field joints and where second portions of the fiber optic cable between the first portions are fixed to the outer layer. A coating is applied to cover each of the first portions of the fiber optic cable to integrate the fiber optic cable with the pipeline.

Owner:SCHLUMBERGER TECH CORP

Pipe Section Having Bonded Composite Barrier Layer

InactiveUS20130269819A1Pipe protection against corrosion/incrustationCoatingsMetallic materialsMetal

Pipe sections and methods for forming pipe sections are disclosed. A pipe section includes a hollow body formed from a metal material, the hollow body having an inner surface and an outer surface, the inner surface defining an interior. The pipe section further includes a barrier layer surrounding and bonded to the hollow body, the barrier layer having an inner surface and an outer surface. The barrier layer is formed from a continuous fiber reinforced thermoplastic material. Such pipe sections may be lightweight and flexible while exhibiting improved strength characteristics.

Owner:TICONA LLC

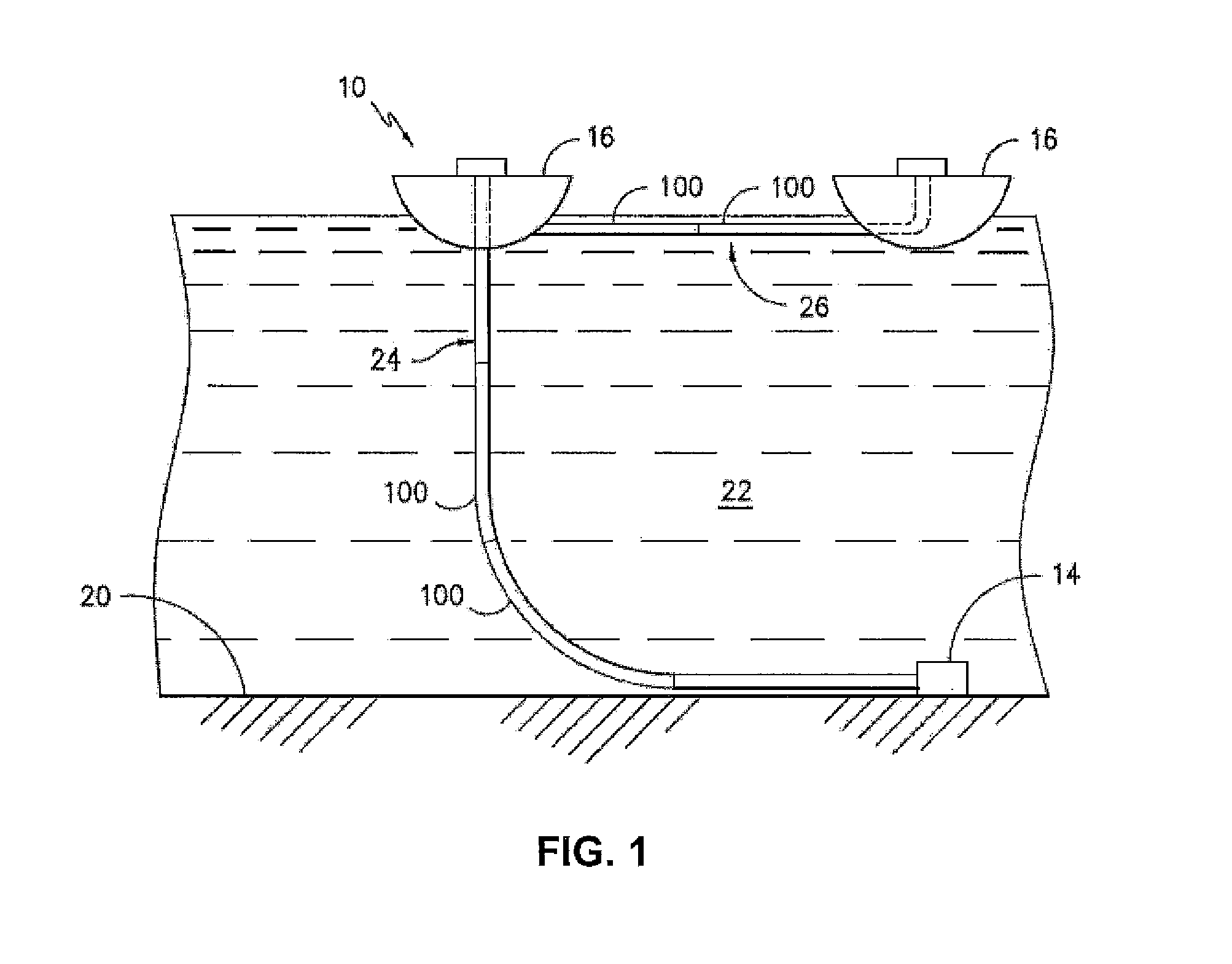

Pig and Method for Applying Prophylactic Surface Treatments

InactiveUS20090098289A1Decreased interruption and interferenceReducing and eliminating effectivenessEfficient propulsion technologiesCorrosion preventionFluid transportTransport system

The invention relates to method for forming at least one metal oxide on one or more interior surfaces of closed or partially closed fluid transport or processing systems. The method involves applying at least one metal compound to the interior surfaces to be treated using, for example, one or more traveling applicators, commonly known as “pigs.” Then, the at least one metal compound is converted to at least one metal oxide, such as by heating the surfaces. In some embodiments, the at least one metal oxide provides a protective metal oxide coating adhered to those surfaces. Embodiments of the present invention can be performed in situ on existing fluid processing or transport systems.

Owner:C 3 INTL

Construction and Manufacturing of Long Tubes with Embedded Corrosion- and Wear-Resistant Coatings Applied Directly to the Interior Surfaces

InactiveUS20120160361A1Cost-effective and highly-productive manufactureEnvelopes/bags making machinerySoldering apparatusSolid structureWear resistant

Owner:FISCHER GEORG +1

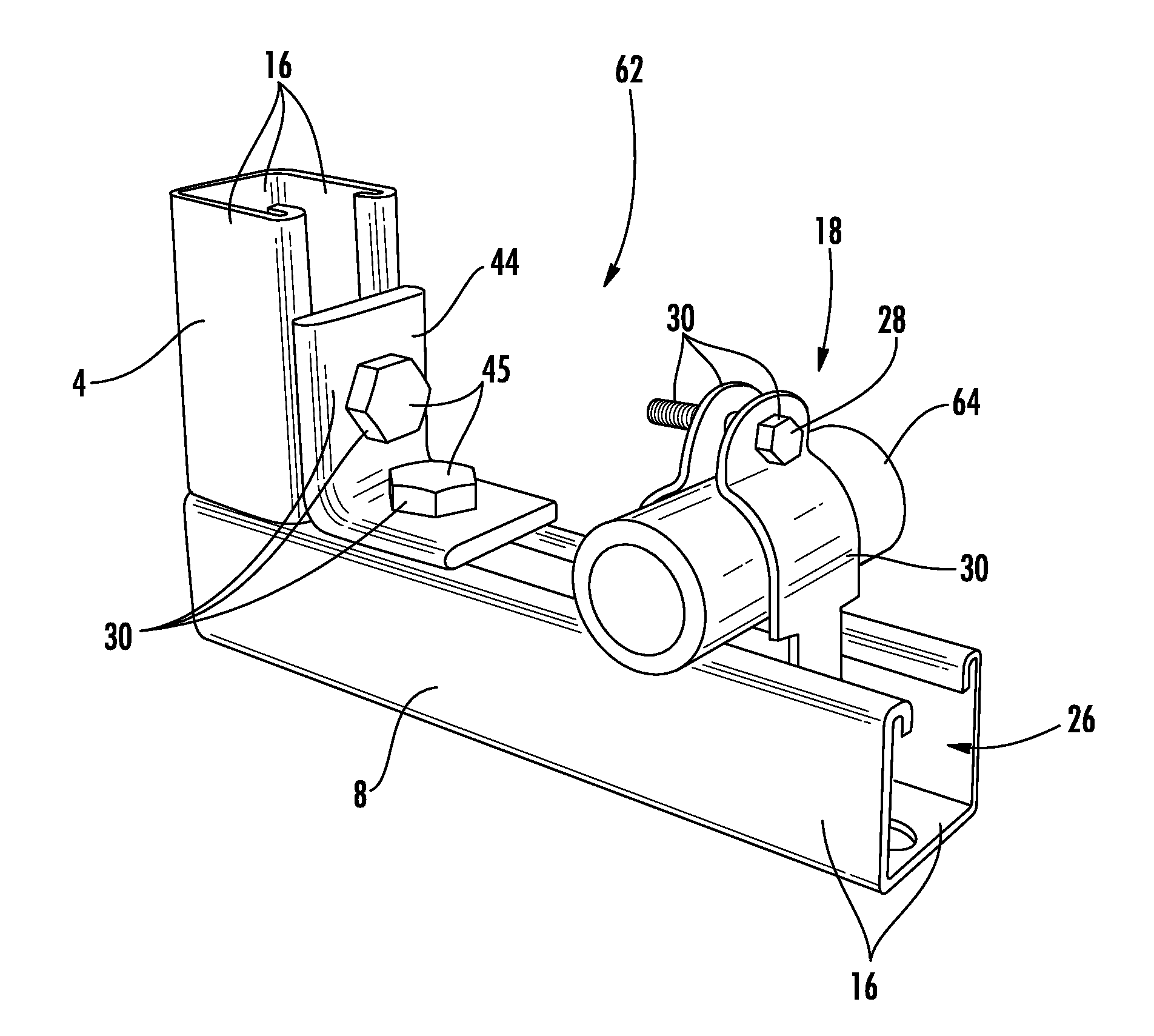

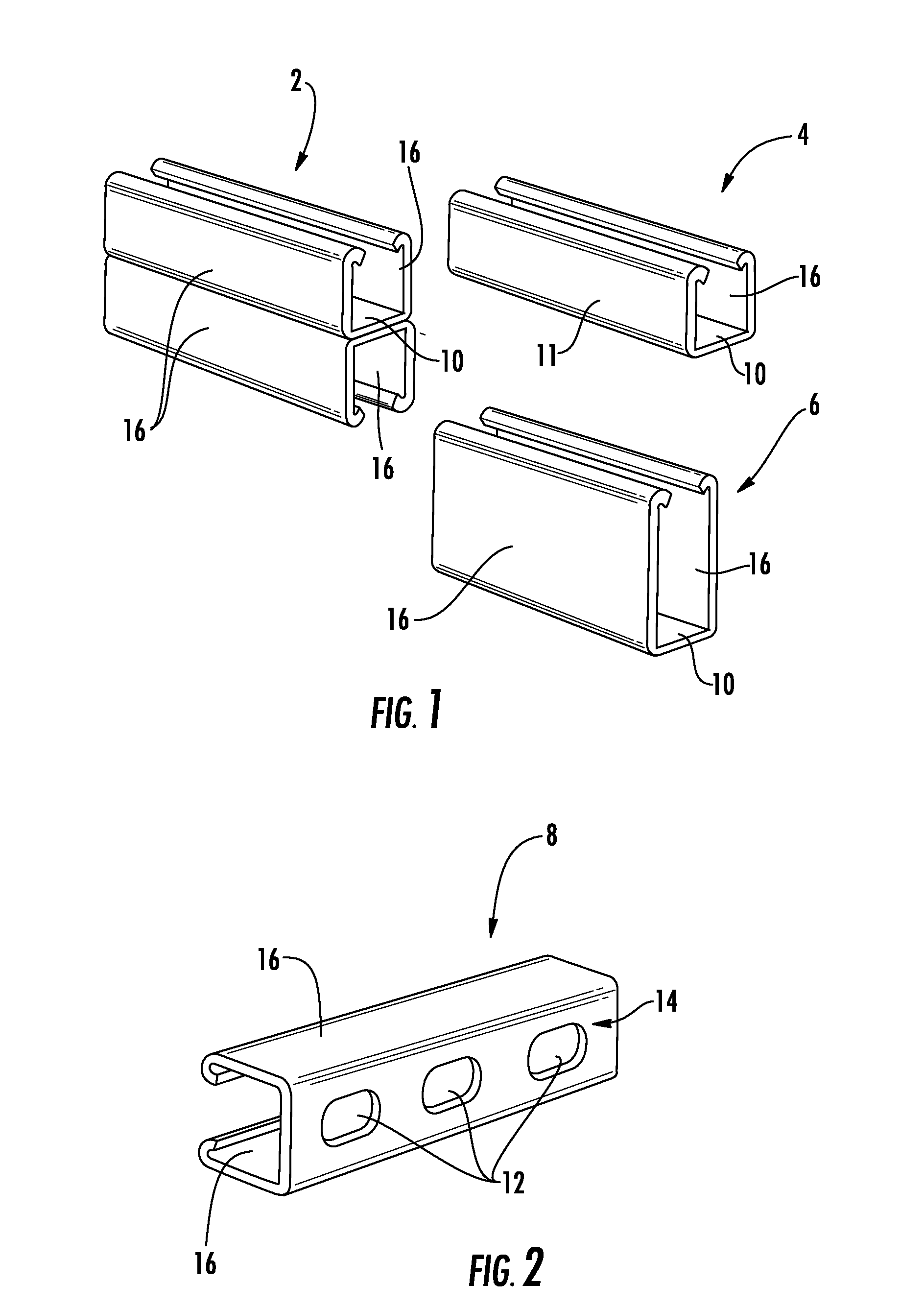

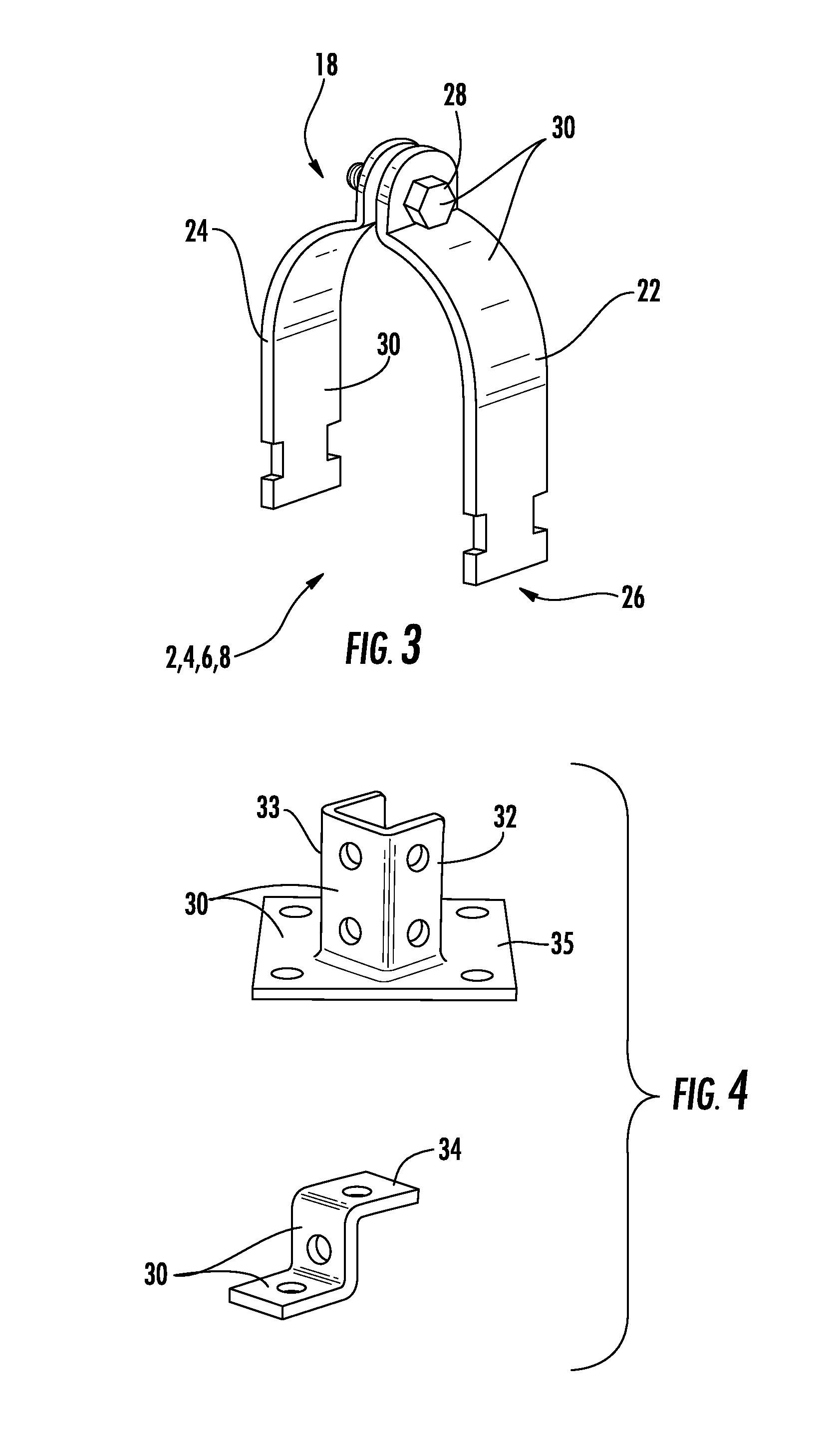

Enhanced corrosion resistant channels, fittings and fasteners

A corrosion resistant support system includes a first channel member having a first corrosion resistant coating. The first corrosion resistant coating is a zinc-aluminum-magnesium coating. A fitting is engageable with said channel member and a first mechanical fastener to couple the fitting to the channel member, the fitting and the first mechanical fastener having a second corrosion resistant coating. The second corrosion resistant coating is a thermal diffusion galvanized coating or a zinc-aluminum-magnesium coating. The first channel member and the first mechanical fastener may also have a third corrosion resistant coating disposed over the first and second corrosion resistant coatings, respectively. The third corrosion resistant coating can be a Perma-Green™ coating, a powder coating, an electrocoating (E-coat or Electrophoretic deposition coating), a paint coating, an epoxy coating, a polyvinyl chloride (PVC) coating, a trivalent chromium coating, a hexavalent chromium coating, a zinc coating, and / or a copper coating.

Owner:UNISTRUT INT CORP

Balanced Composition Hardfacing Alloy

An iron based hardfacing alloy with an undiluted (all weld material) alloy composition is substantially balanced in order to achieve an hypo-eutectic primary austenitic with secondary martensitic solidification mode. The alloy enables the deposition of substantially crack-free single layers of hardfacing onto industrial components without any post weld treatment. The hardfacing alloy is capable of withstanding abrasion of silicious earth particles when applied to industrial products, such as tool joints, stabilizers and casing and other tubulars used in oil and gas well drilling, and other industrial products.

Owner:ATT TECH LTD

Thread protector for tubular members

A pipe thread protector includes a case, a first seal member, and a second seal member. The case is attachable to an end of a pipe to protect a threaded region of the pipe. The case has a cylindrical or frustoconical portion having threads over at least a portion of its length to engage the threaded region of the pipe, and an annular end portion configured to abut a distal end of the pipe. A first seal member is disposed at the cylindrical portion of the case, and a second seal member is disposed at the annular end portion of the case. At least one of the first and second seal members (i) is detachable from the case, and (ii) comprises a material different than a material of the case.

Owner:TENARIS CONNECTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com