Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3524 results about "Brass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure.

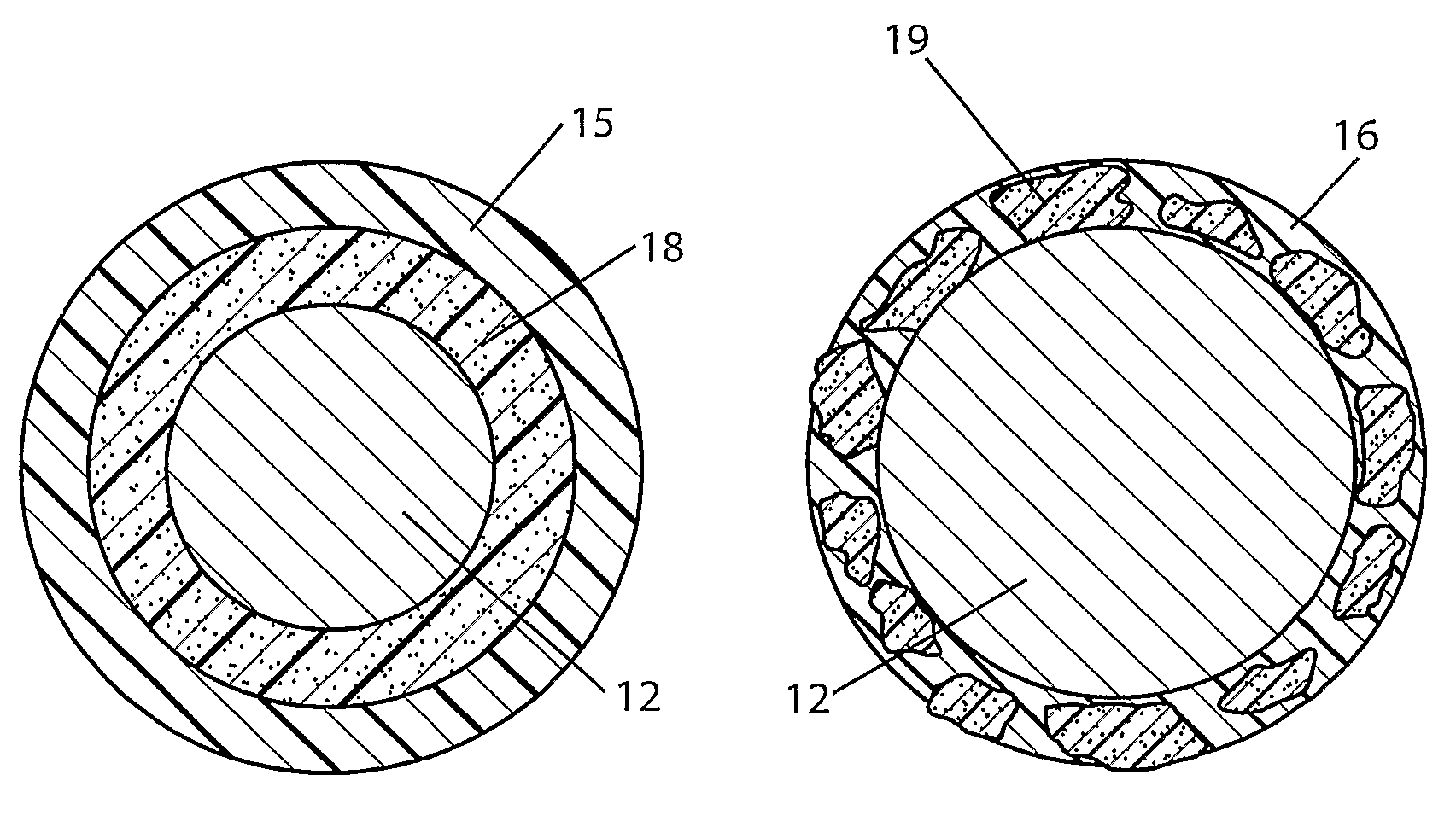

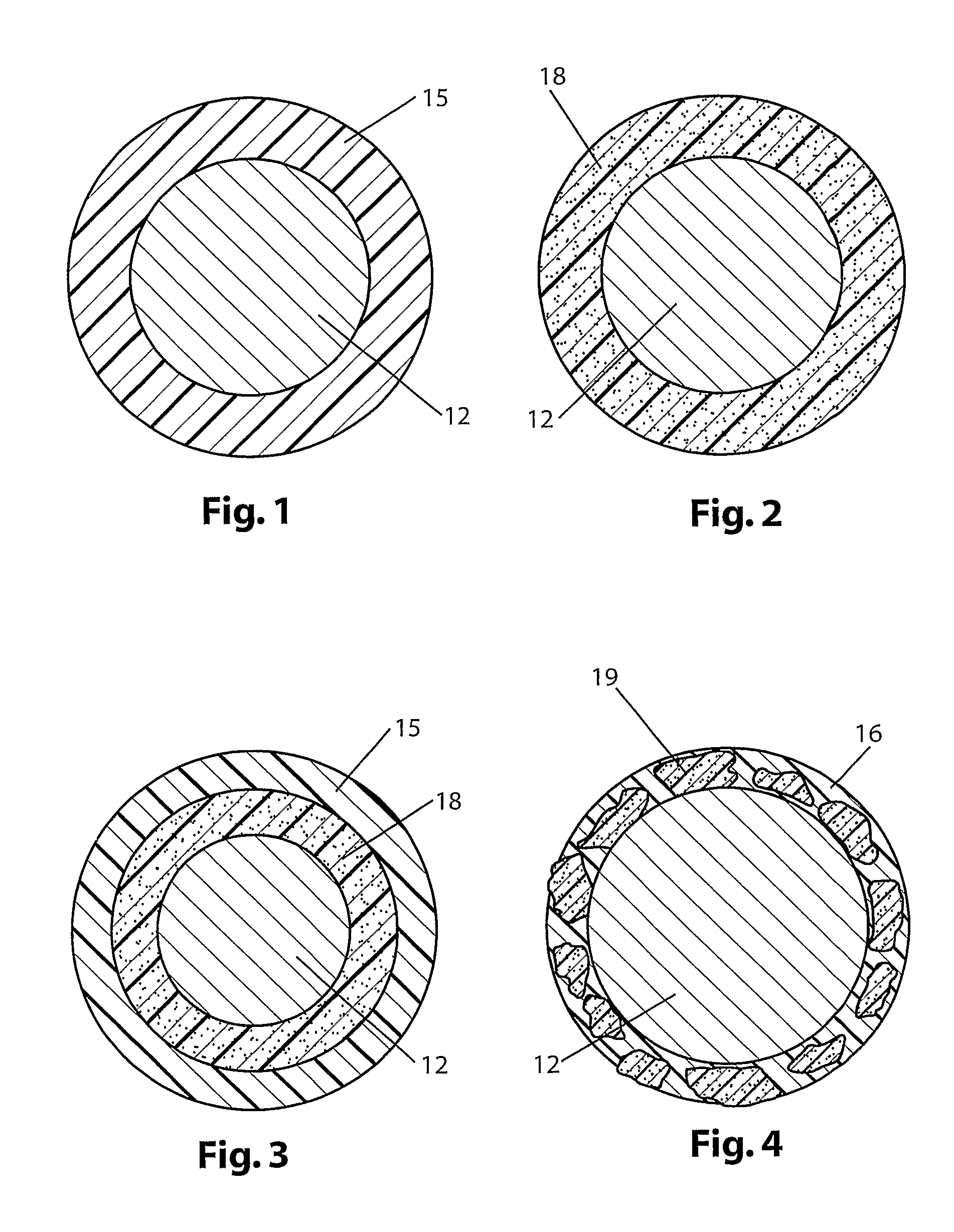

Ampoule with a thermally conductive coating

ActiveUS20080149031A1Improve temperature uniformityChemical vapor deposition coatingConductive coatingCompound (substance)

Embodiments of the invention provide an apparatus and a process for generating a chemical precursor used in a vapor deposition processing system. The apparatus includes a canister (e.g., ampoule) having a sidewall, a top, and a bottom encompassing an interior volume therein, inlet and outlet ports in fluid communication with the interior volume, and a thermally conductive coating disposed on or over the outside surface of the canister. The thermally conductive coating is more thermally conductive than the outside surface of the canister. The thermally conductive coating may contain aluminum, aluminum nitride, copper, brass, silver, titanium, silicon nitride, or alloys thereof. In some embodiments, an adhesion layer (e.g., titanium or tantalum) may be disposed between the outside surface of the canister and the thermally conductive coating. In other embodiments, the canister may contain a plurality of baffles or solid heat-transfer particles to help evenly heat a solid precursor therein.

Owner:APPLIED MATERIALS INC

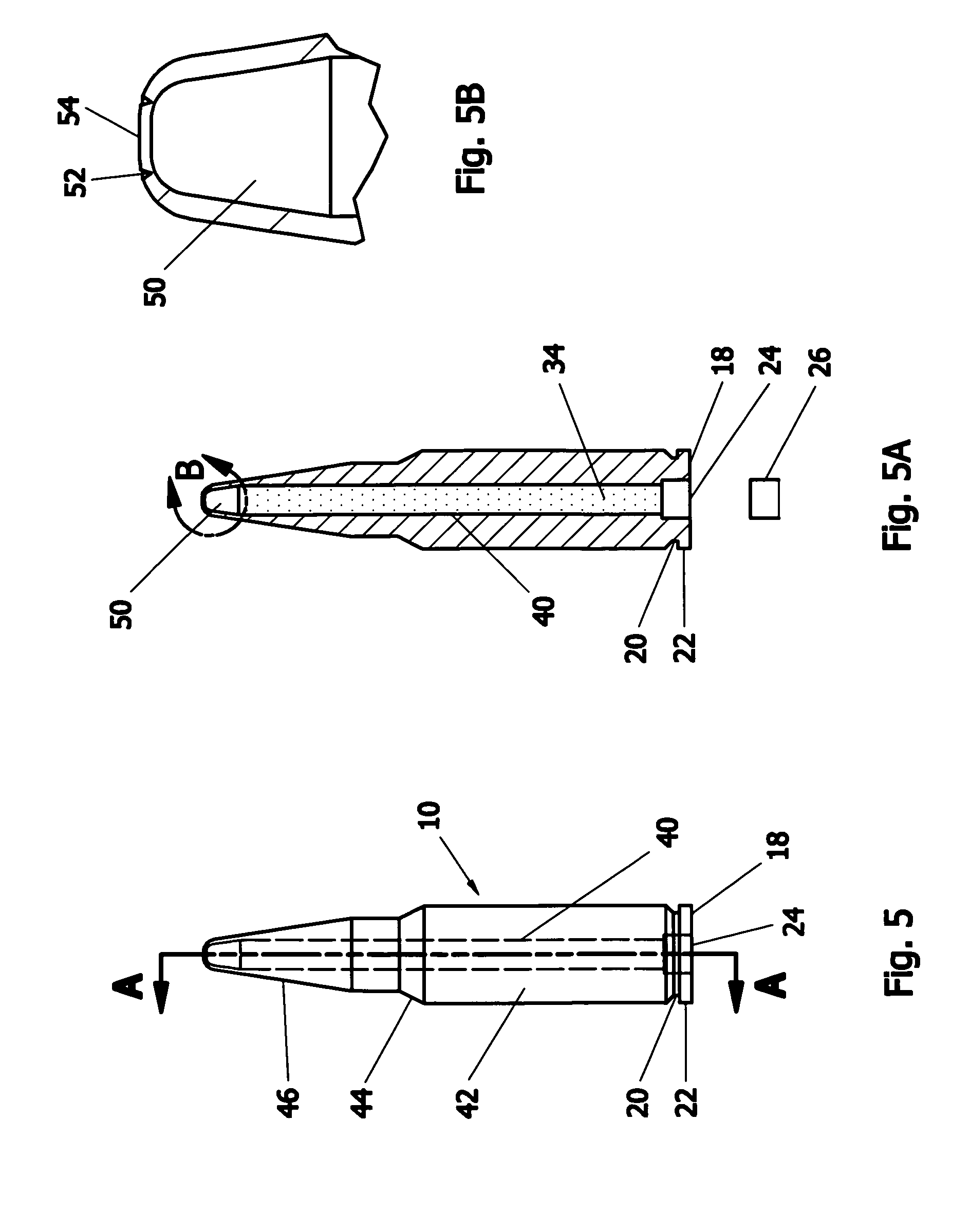

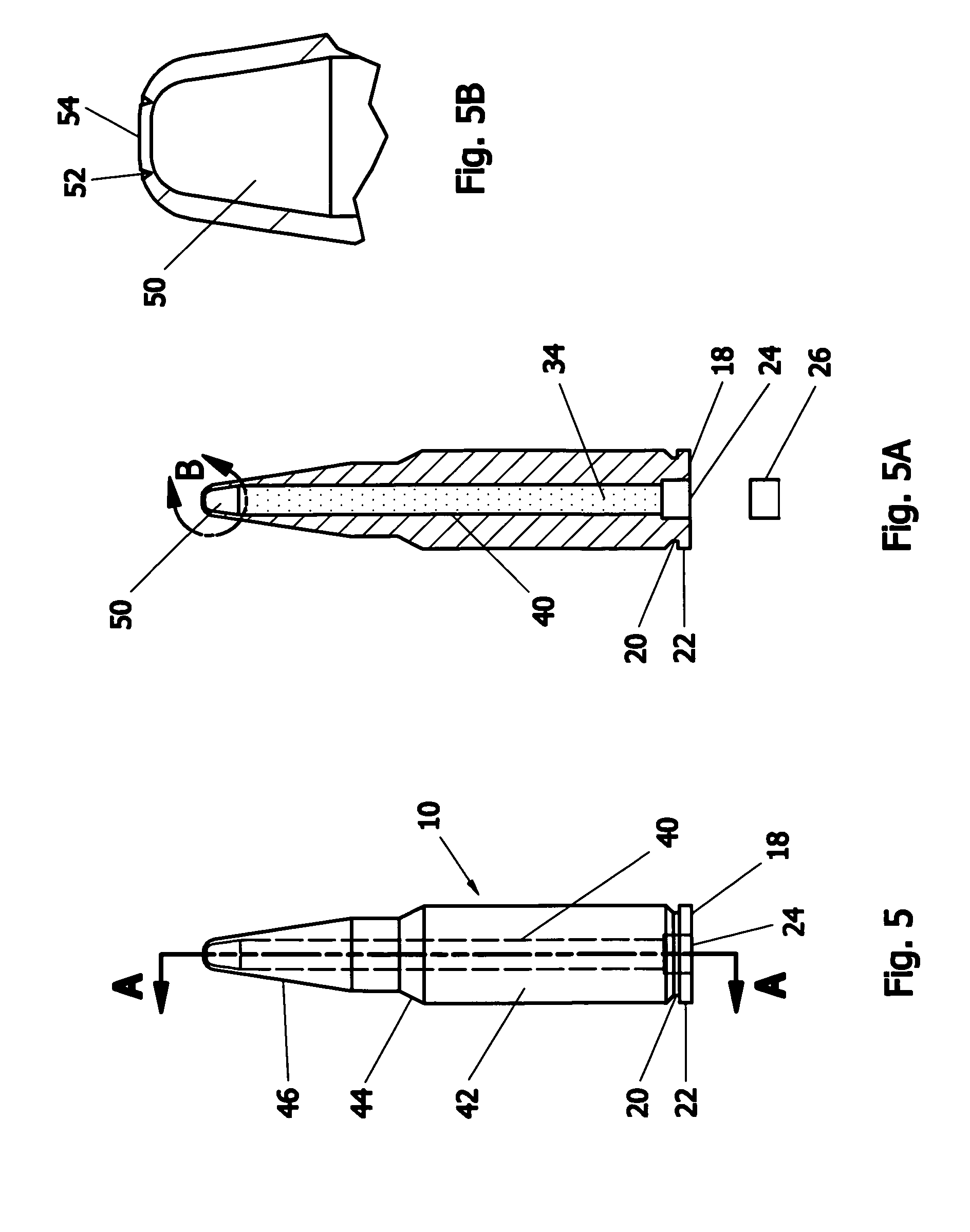

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

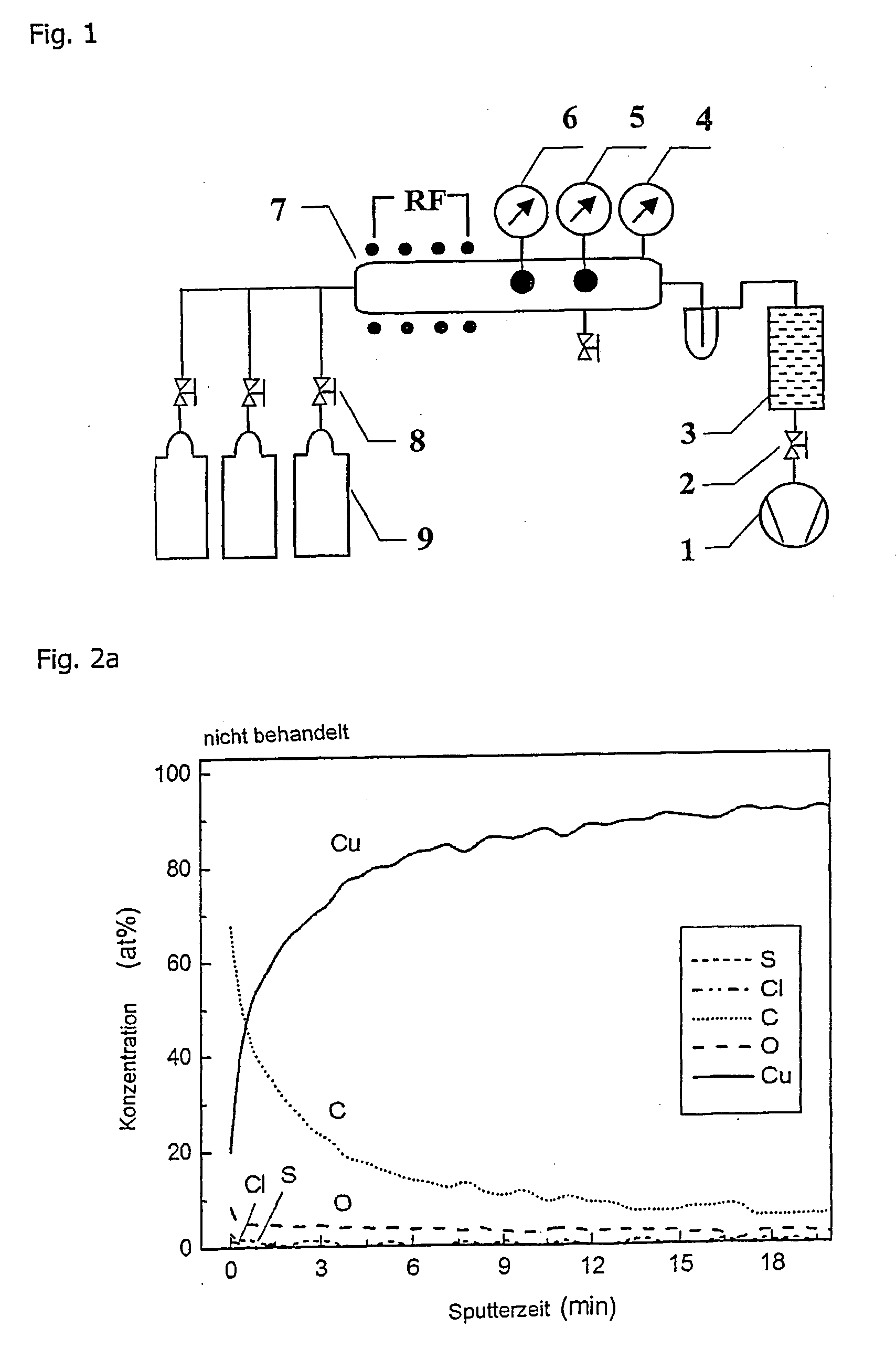

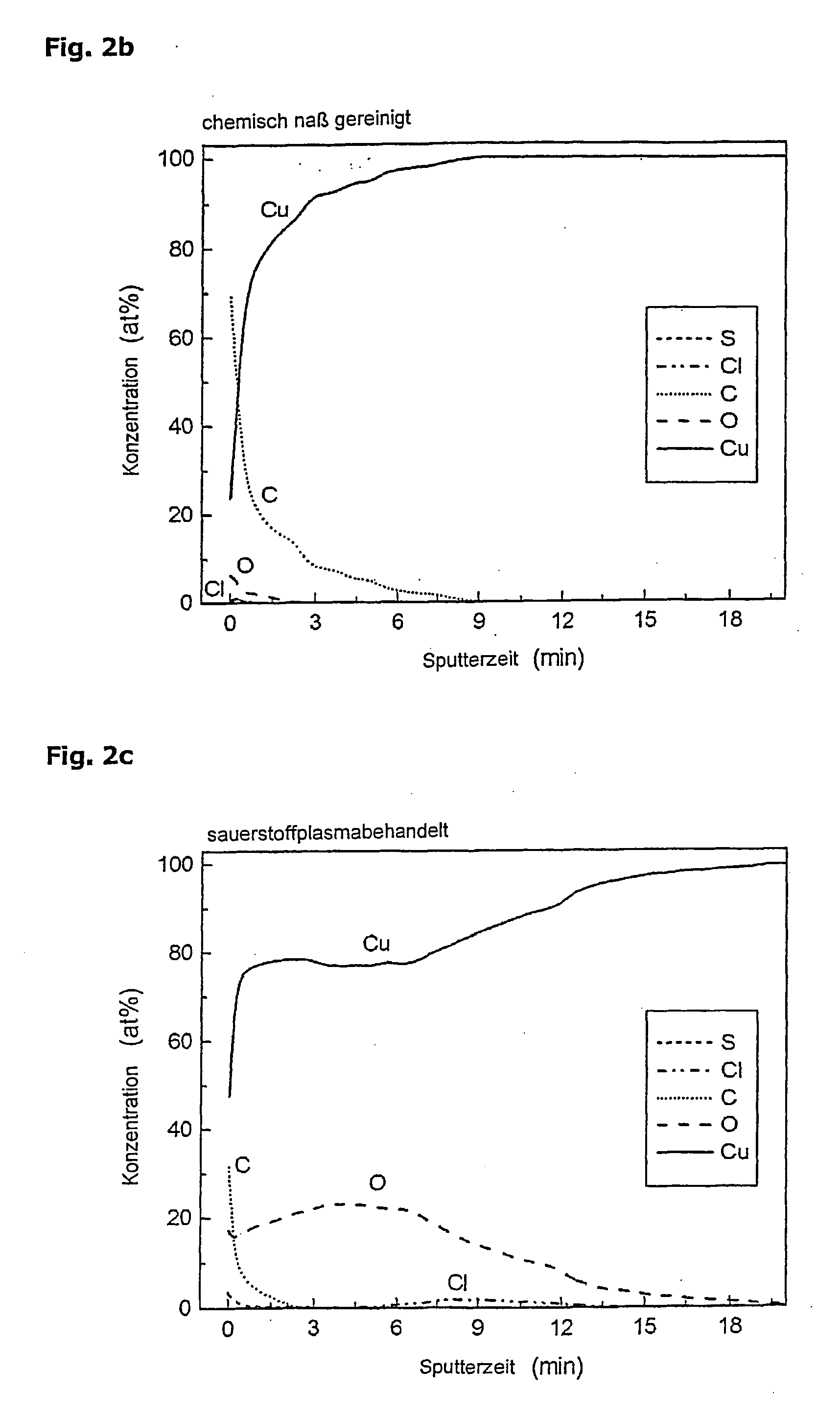

Plasma treatment for purifying copper or nickel

InactiveUS20060054184A1Reduce connection resistanceReduce impuritySoldering apparatusElectrostatic cleaningAlloyOxygen

A method for treating electronic components made of copper, nickel or alloys thereof or with materials such as brass or plated therewith and includes the steps of arranging the components in a treatment chamber, generating a vacuum in the treatment chamber, introducing oxygen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber, allowing the oxygen radicals to act on the components, generating a vacuum in the treatment chamber, introducing hydrogen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber and allowing the hydrogen radicals to act on the components.

Owner:KOLEKTOR GRP D O O

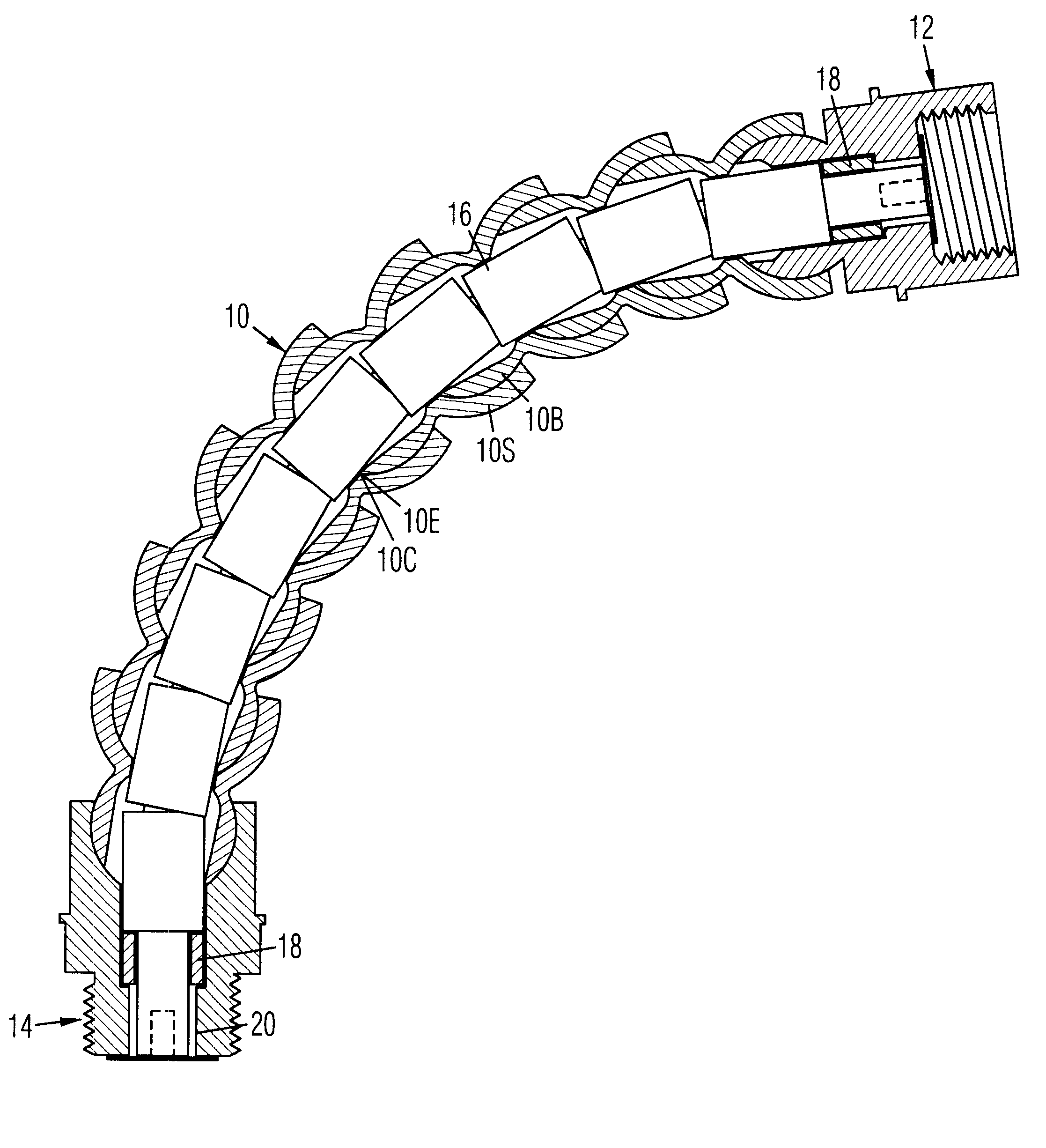

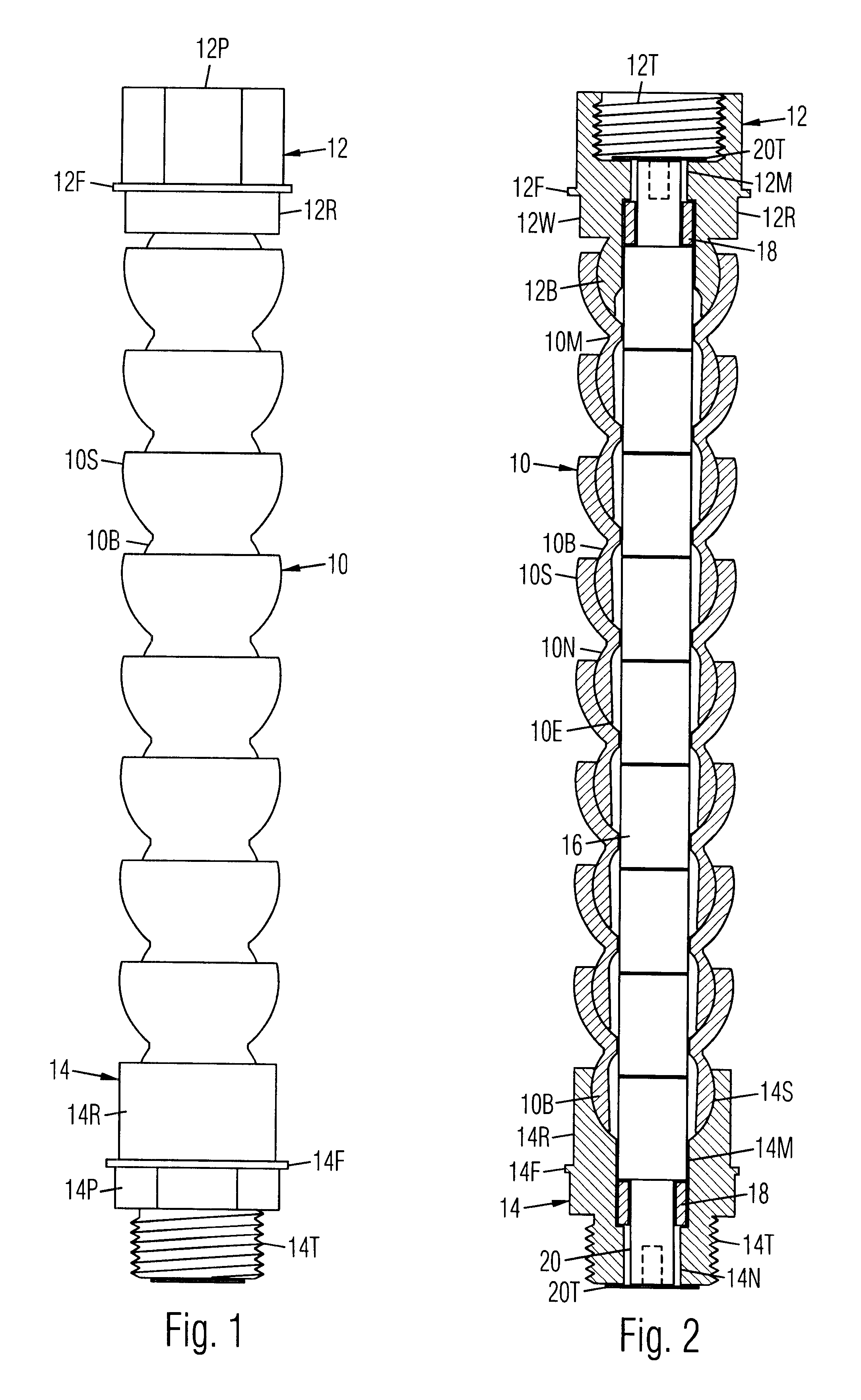

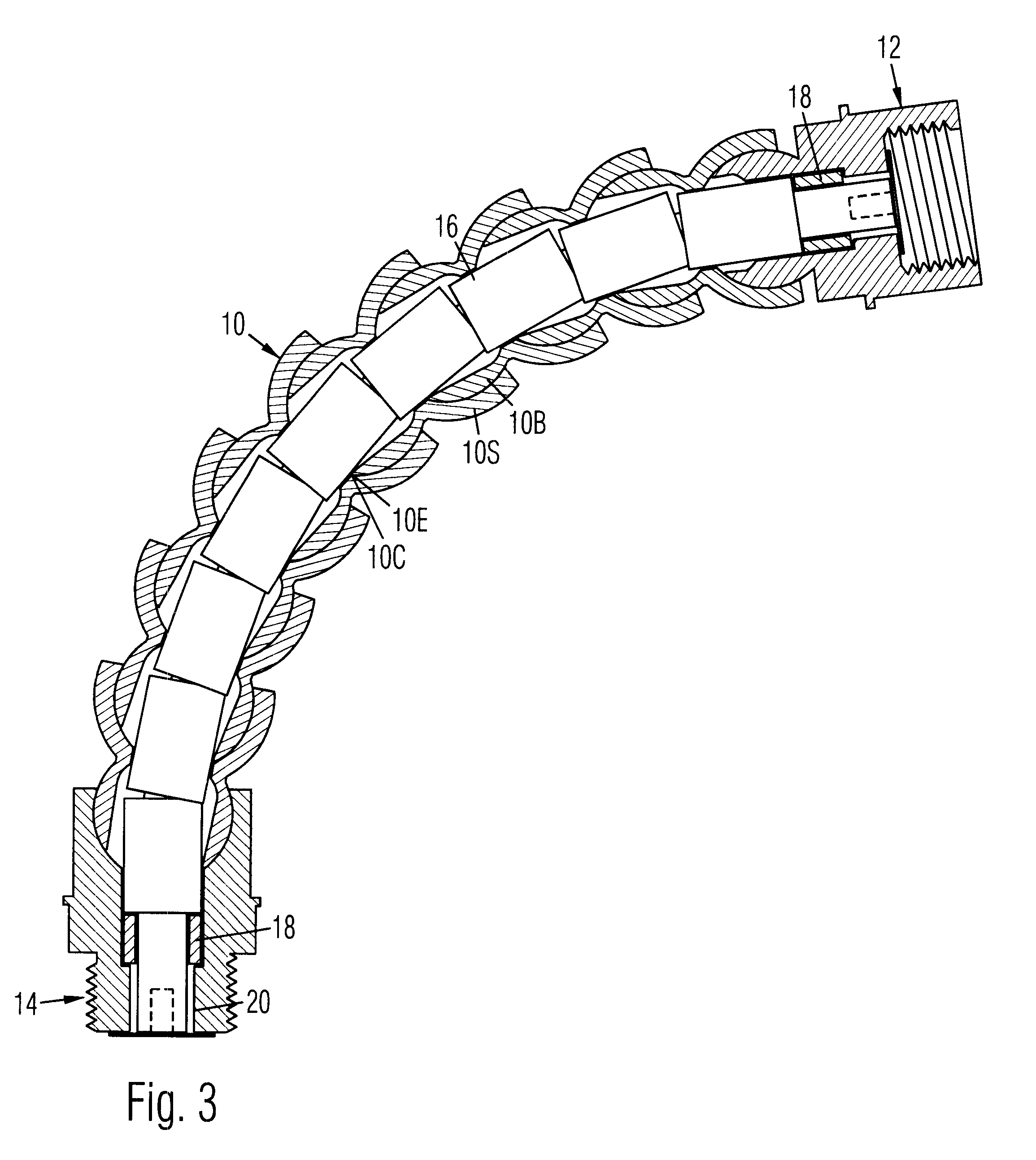

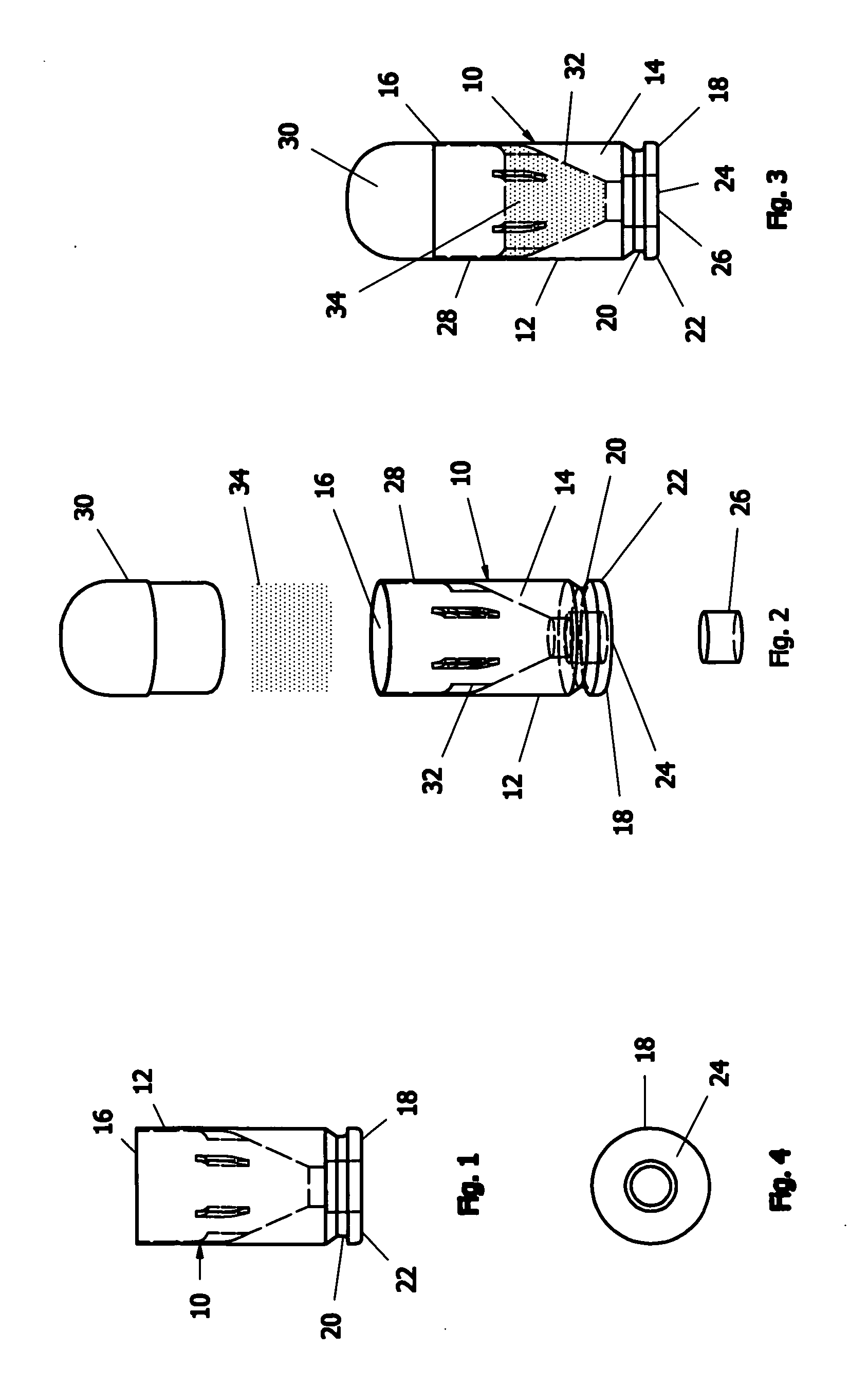

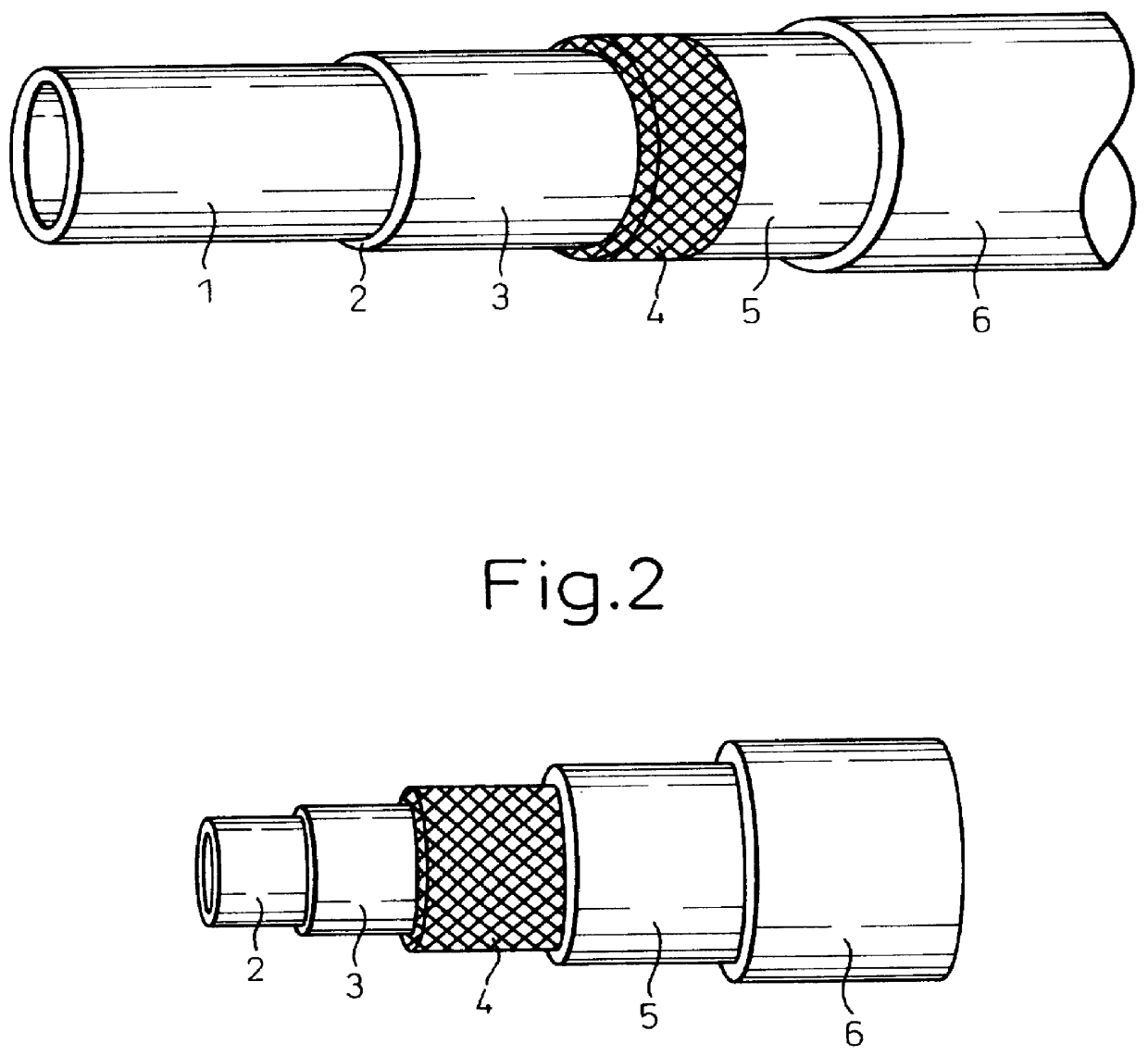

Flexible sectioned arm with internal overbending-prevention sleeves

A flexible, sectioned plastic arm for a showerhead comprises a series of interconnected ball-and-socket (B&S) sections (10) with a proximal (shower pipe) end piece (12) and a distal (showerhead) end piece (14). Each B&S section has a proximal (cup or socket) end (10S) and a distal (ball) end (10B). The proximal end piece has a proximal end with female threads which can be screwed onto a shower pipe and a ball-shaped distal end for snapping into the socket of the most proximal section of the shower arm. The distal end piece has a proximal end with a socket for snapping onto the most distal end section of the shower arm and a distal end with male threads (12T) which can be screwed onto the showerhead. The arm has a through hole containing a series or chain of cylindrical brass or other metal sections, tubes, or sleeves (16). These prevent the arm from being bent too far, thereby to keep the B&S from separating. The two end tubes abut a pair of respective resilient spacers (18) or springs (18S), which in turn abut shoulders in the end pieces to keep the series of tubes in place. Inside the series of tubes is a flexible plastic tube (20) for carrying the water without leakage. A T-shaped end fitting (20T) is attached to each end of the plastic tube. These end fittings hold the tube in the arm. The top arm of the T of the distal end fitting sits in the bottom of the female threaded end of the proximal end piece. The top arm of the T of the distal end fitting sits on the very end of the male threaded end of the distal end piece.

Owner:SHOWERTEK

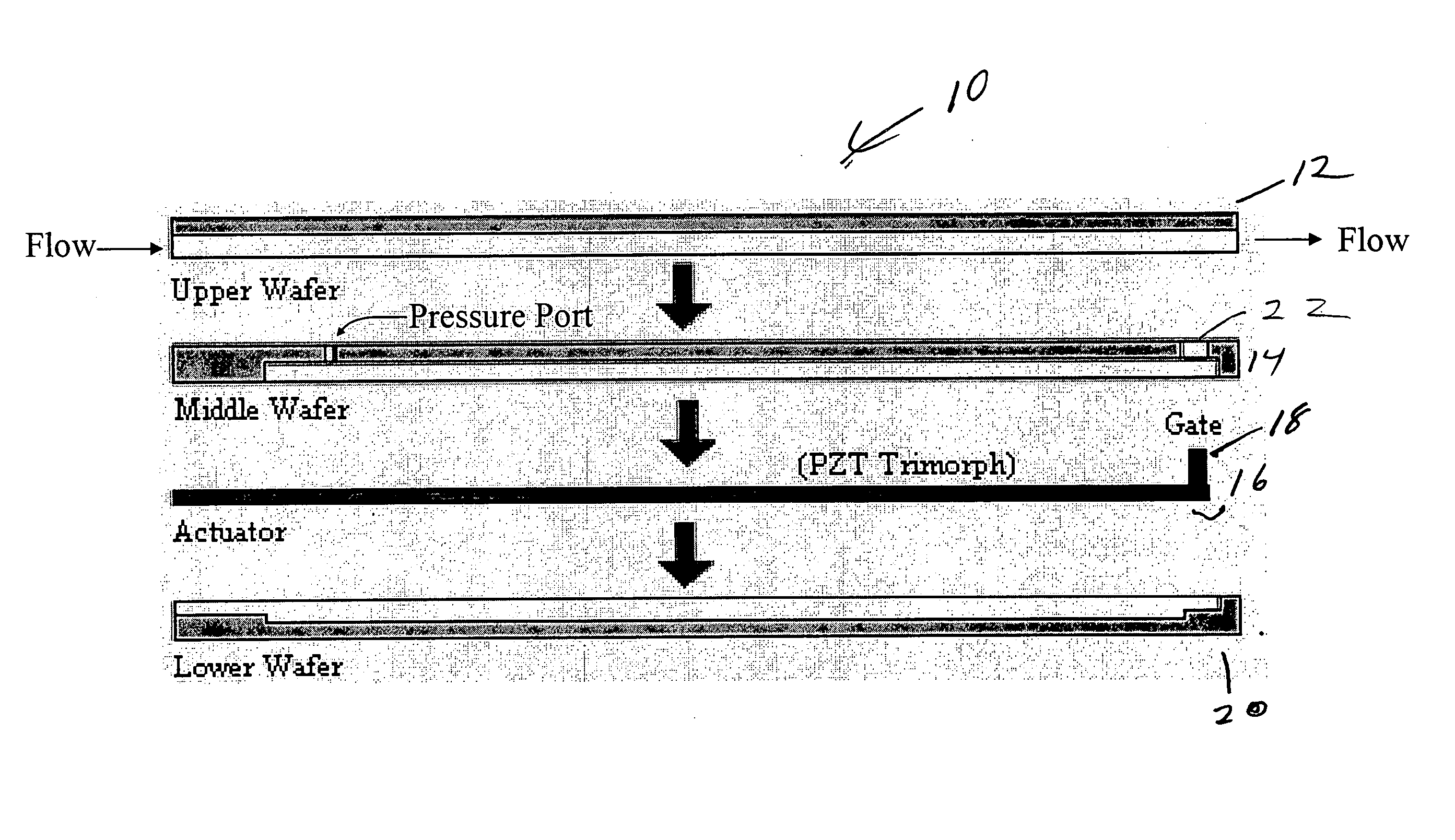

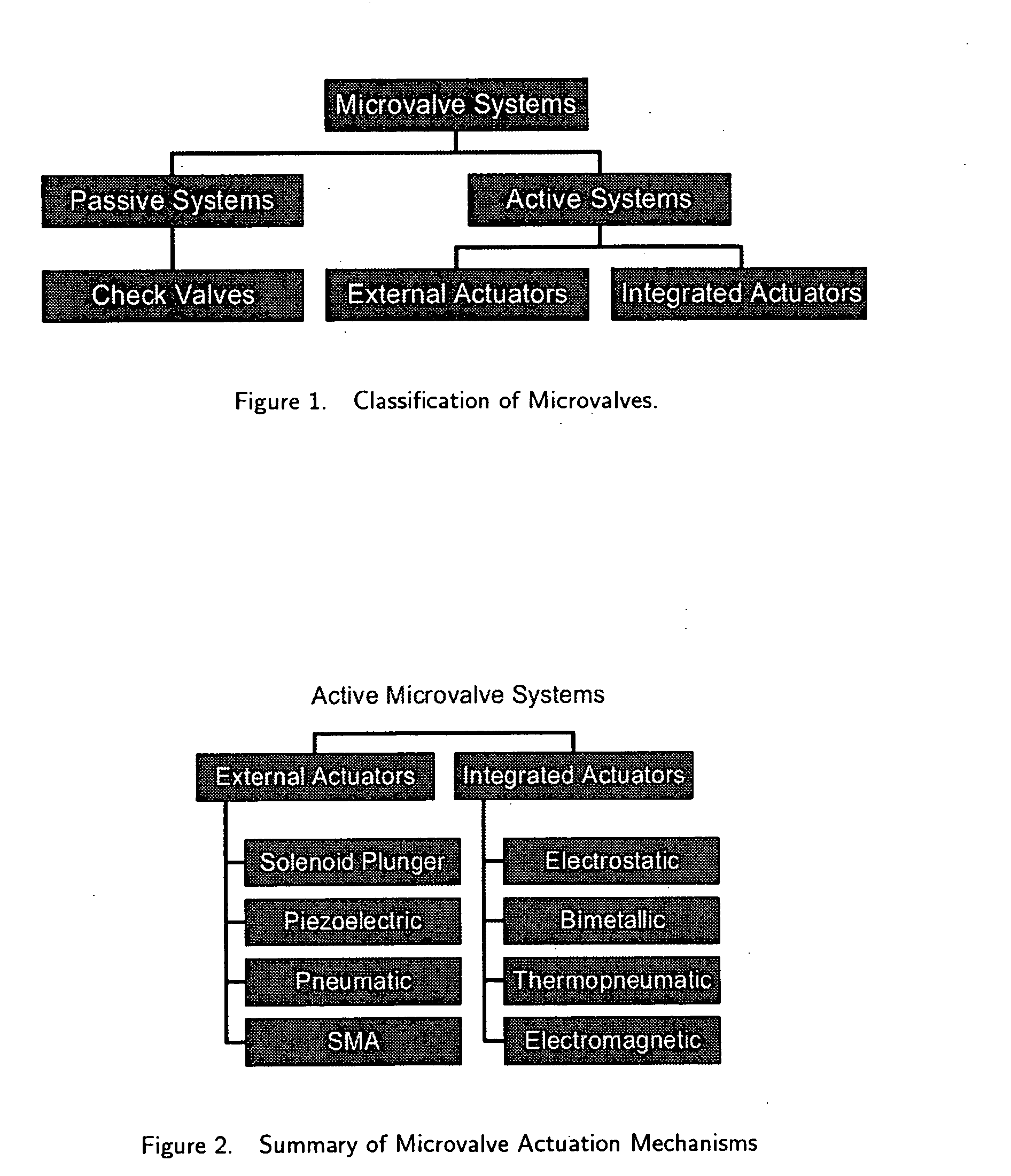

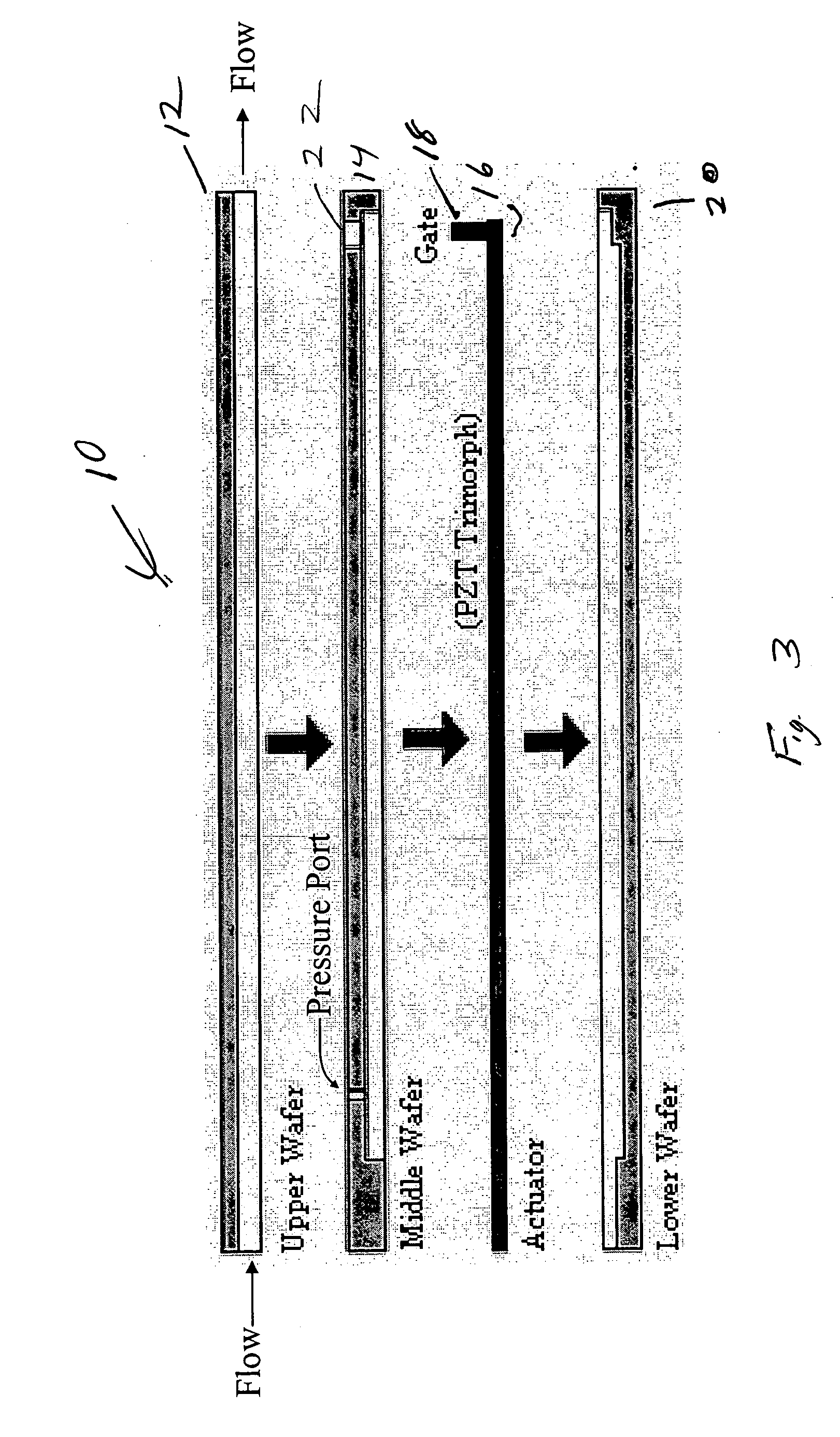

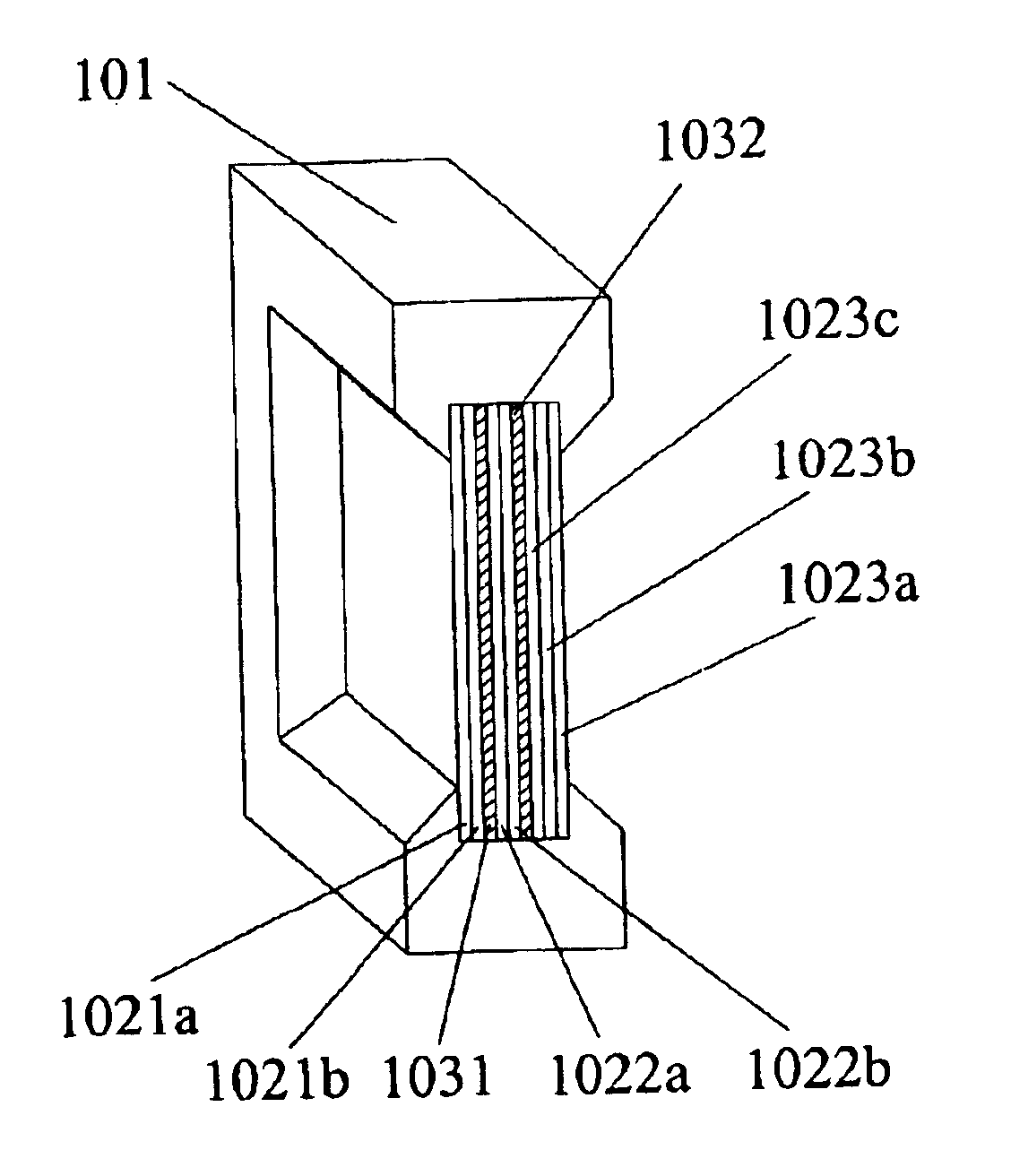

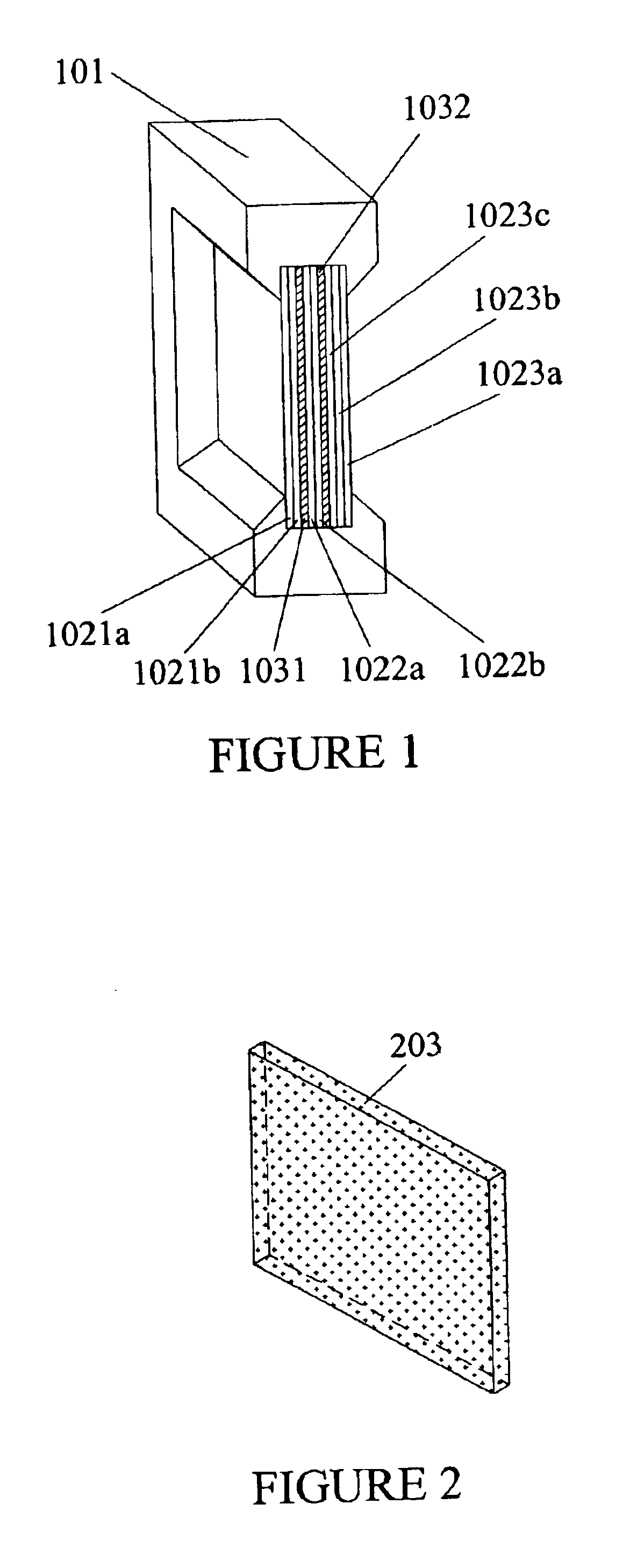

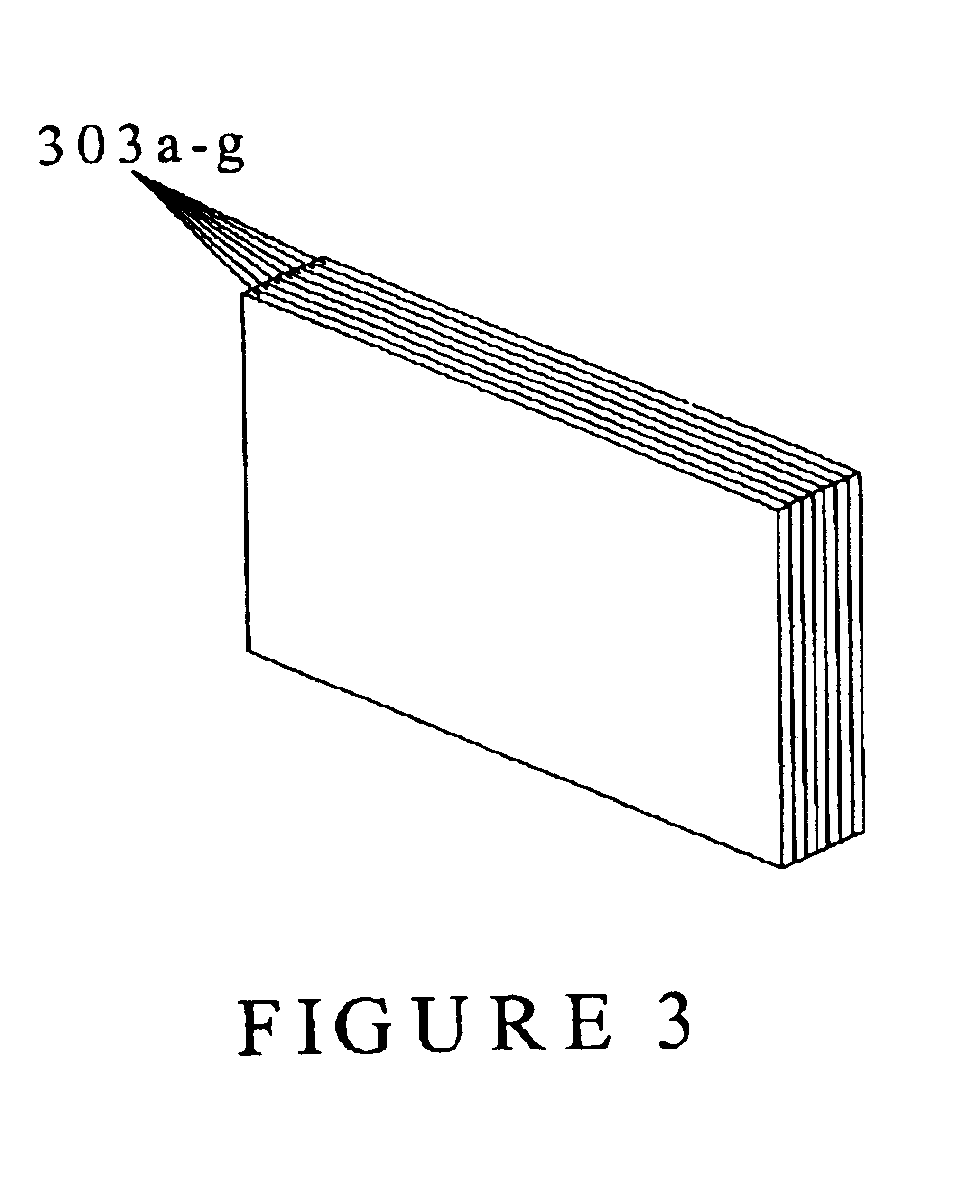

Piezoelectric axial flow microvalve

InactiveUS20040137300A1Operating means/releasing devices for valvesFinal product manufactureEpoxyPhotonics

This paper presents the fabrication and preliminary testing of a novel piezoelectric microvalve. Fabrication has three steps, which are the actuator fabrication, valve body fabrication and assembly of the microvalve. Fabricating an actuator involves cutting piezoelectric and brass beams, gluing the brass and piezoceramic beams into a trimorph sandwich structure, and curing them under pressure at elevated temperatures. Actuators are then wired either by using conductive epoxy or soldering. Valve body parts are constructed from single crystal silicon substrates using deep reactive ion etching (DRIE). DRIE is a subtractive process, whereby a mask is created on the surface of the stock, which will shield the parts that are not to be machined. Refinements in the actuator manufacturing process are made to increase the quality and decrease the fabrication time. Using a photonic probe, tip deflections of the actuators have been tested at various temperature and voltage levels. Currently, the valves are being assembled. Once assembled, multiple microvalves will undergo cold flow testing with air followed by extensive flow extensive flow testing at elevated temperatures with humidified hydrogen.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

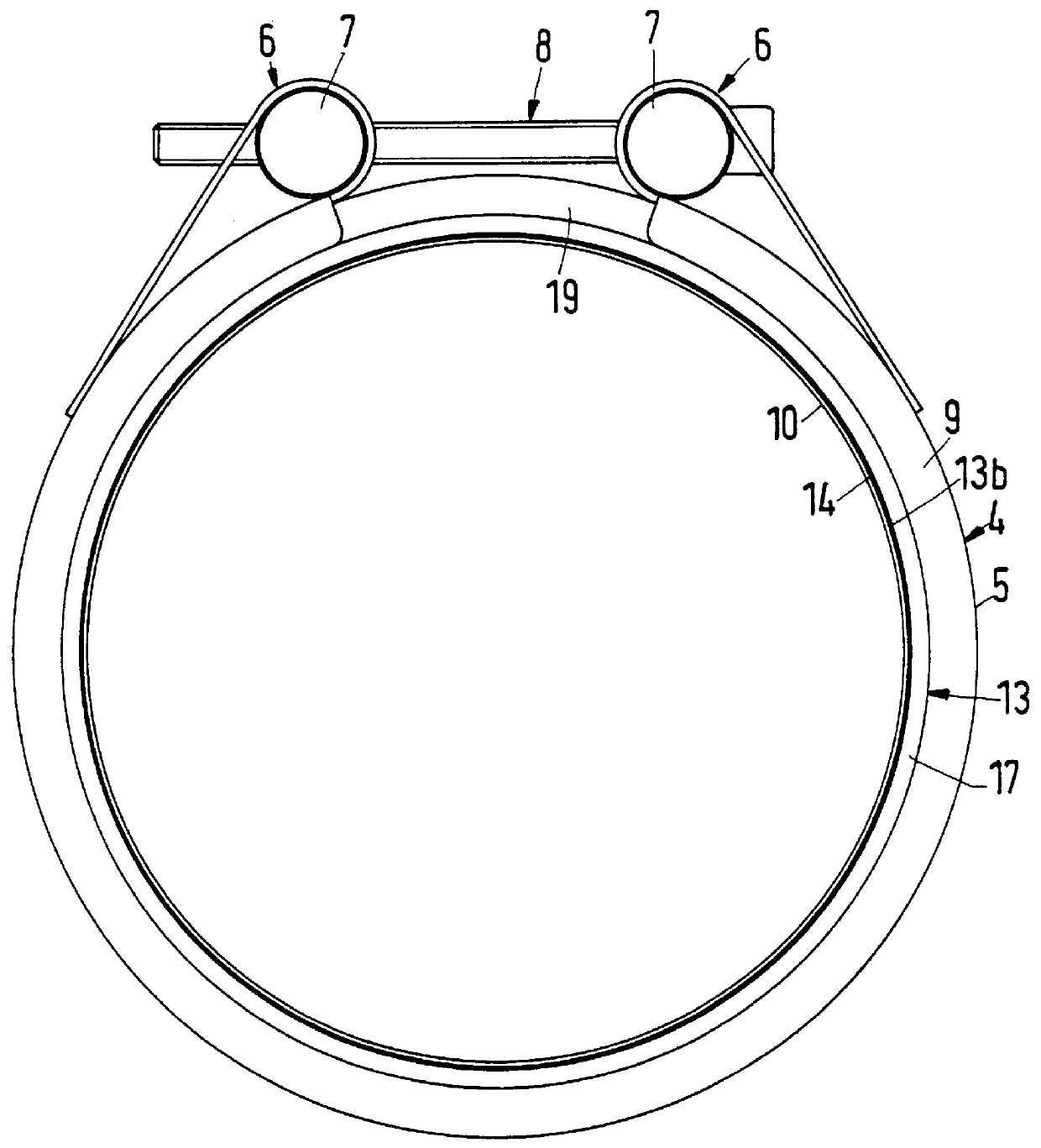

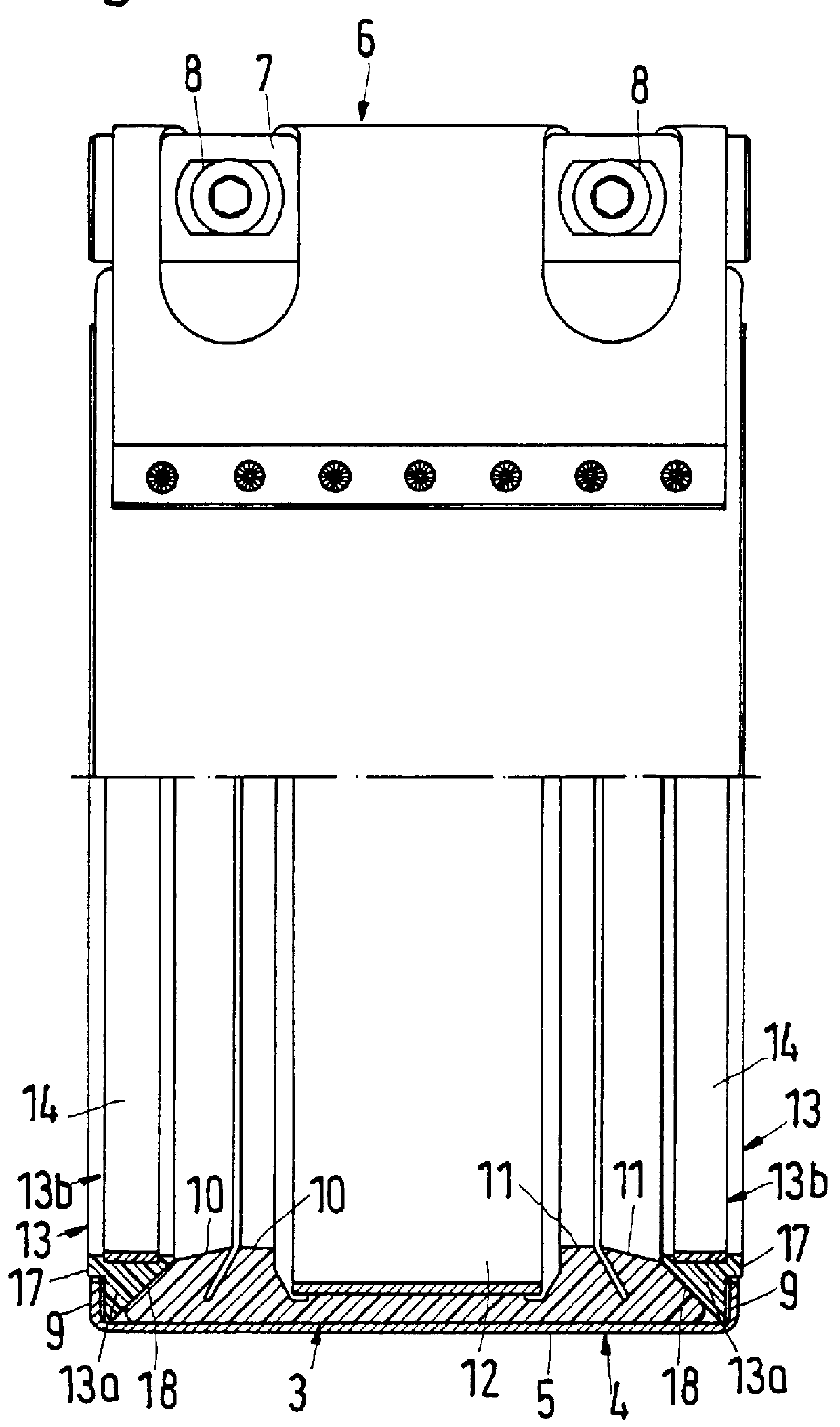

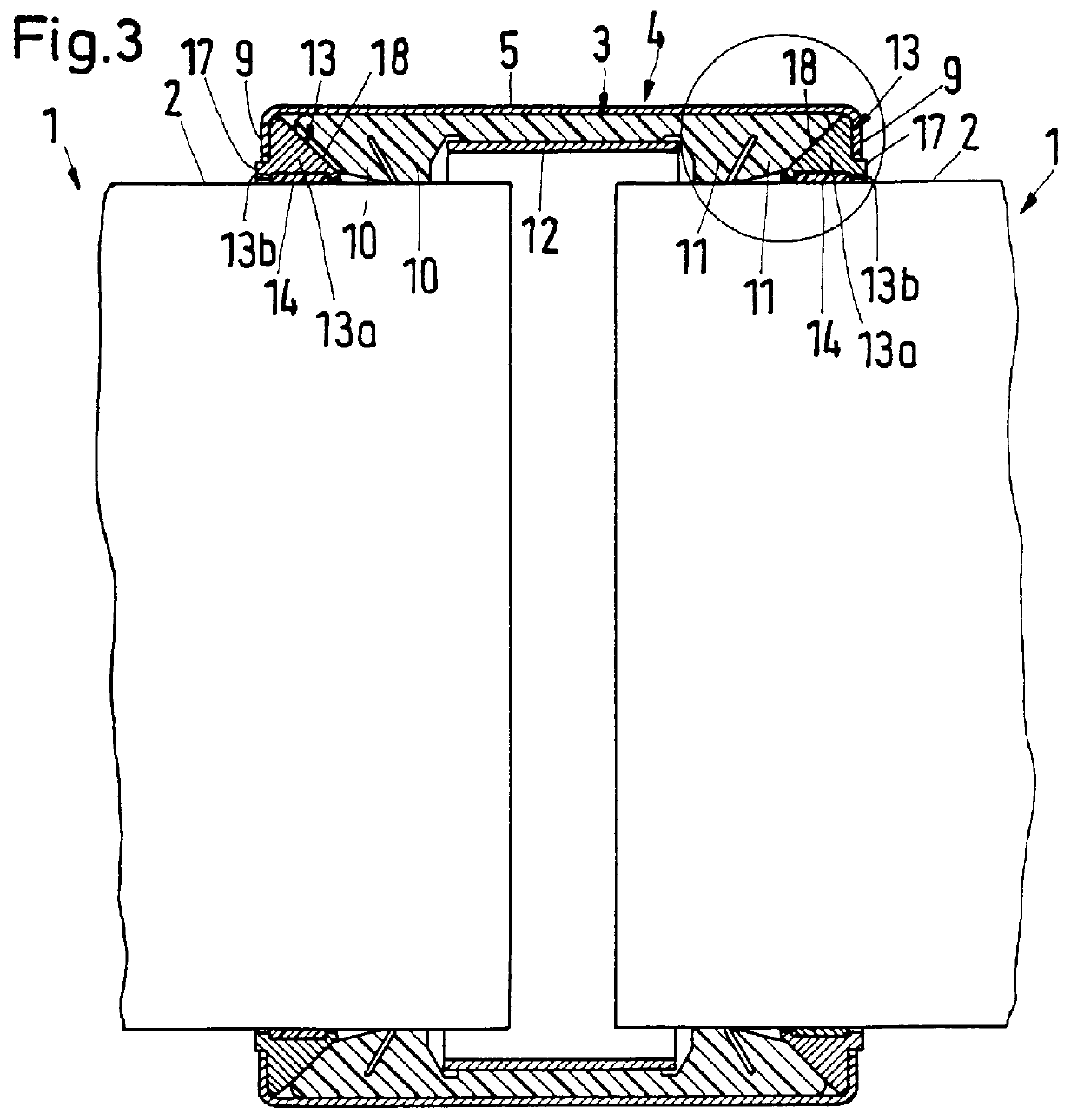

Pipe coupling

InactiveUS6070914AIncrease the cross-sectional areaHigh strengthSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

A pipe coupling for connecting pipes having unprofiled end sections includes an elastomeric sealing gasket for holding the unprofiled pipe end sections in a sealed manner. A clamping clip surrounds the sealing gasket. The clamping clip includes a clip strap having a first end and a second end. A first clamping jaw is formed at the first end. A second clamping jaw is formed at the second end. The clamping jaws are drawn together by a tensioning device. The clip strap has radially inwardly directed projecting flanges on each of its axial ends. A first C-shaped clamping ring and a second C-shaped clamping ring are each disposed between the sealing gasket and one of the flanges. Each of the C-shaped clamping rings are supported on a radially inner side of the clip strap. Each of the C-shaped clamping rings have projections projecting from its radially inner face and, when said clip strap is tensioned, the projections of the C-shaped rings engage in the pipe material. The clamping rings are substantially made of plastic and approximately fill the space between the sealing gasket and one of the flanges. The clamping rings may be formed as a single part or from two ring parts. If formed of two parts, the radially inner part may be made of a brass alloy. The projections may be formed as encircling ribs.

Owner:NORMA GERMANY GMBH

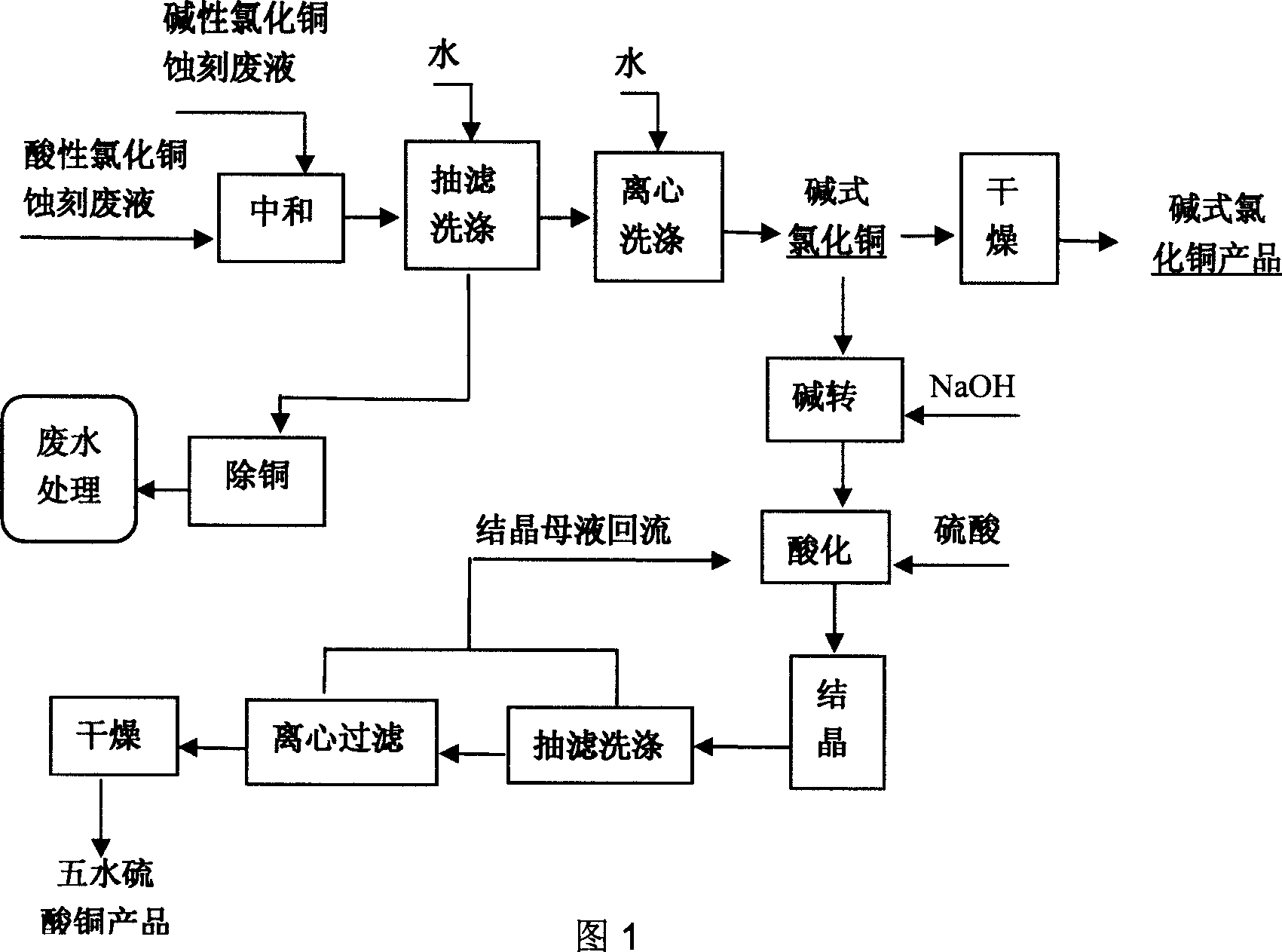

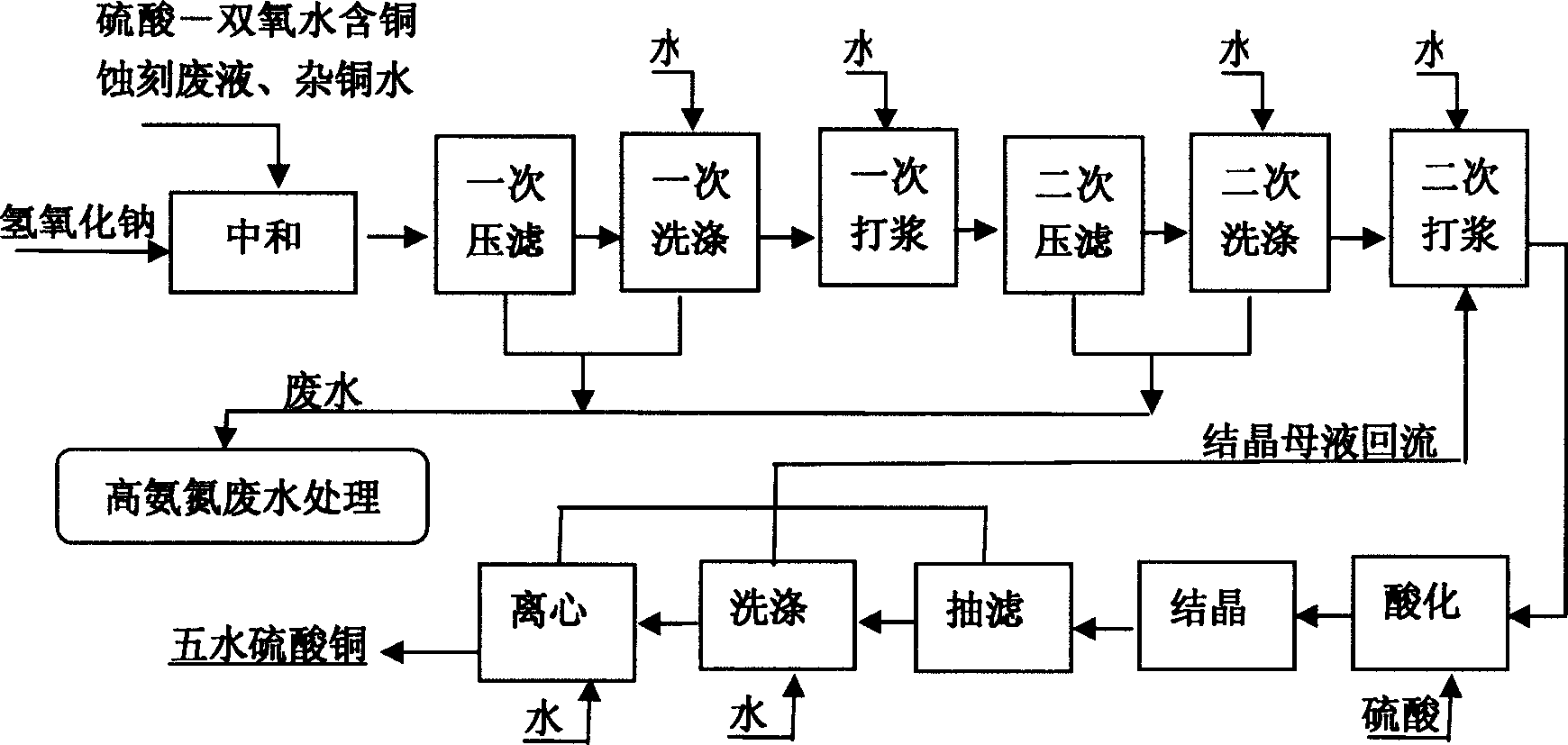

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

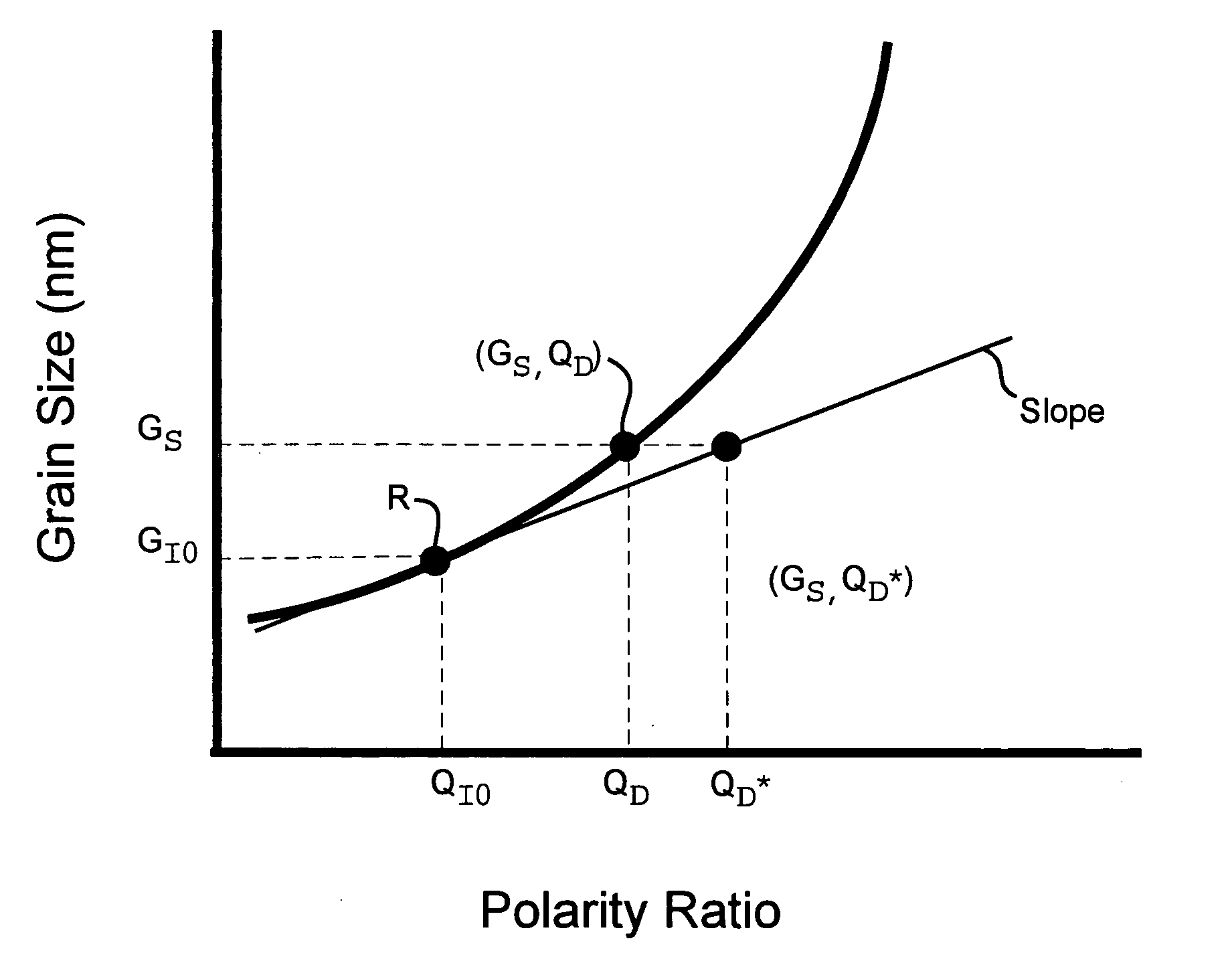

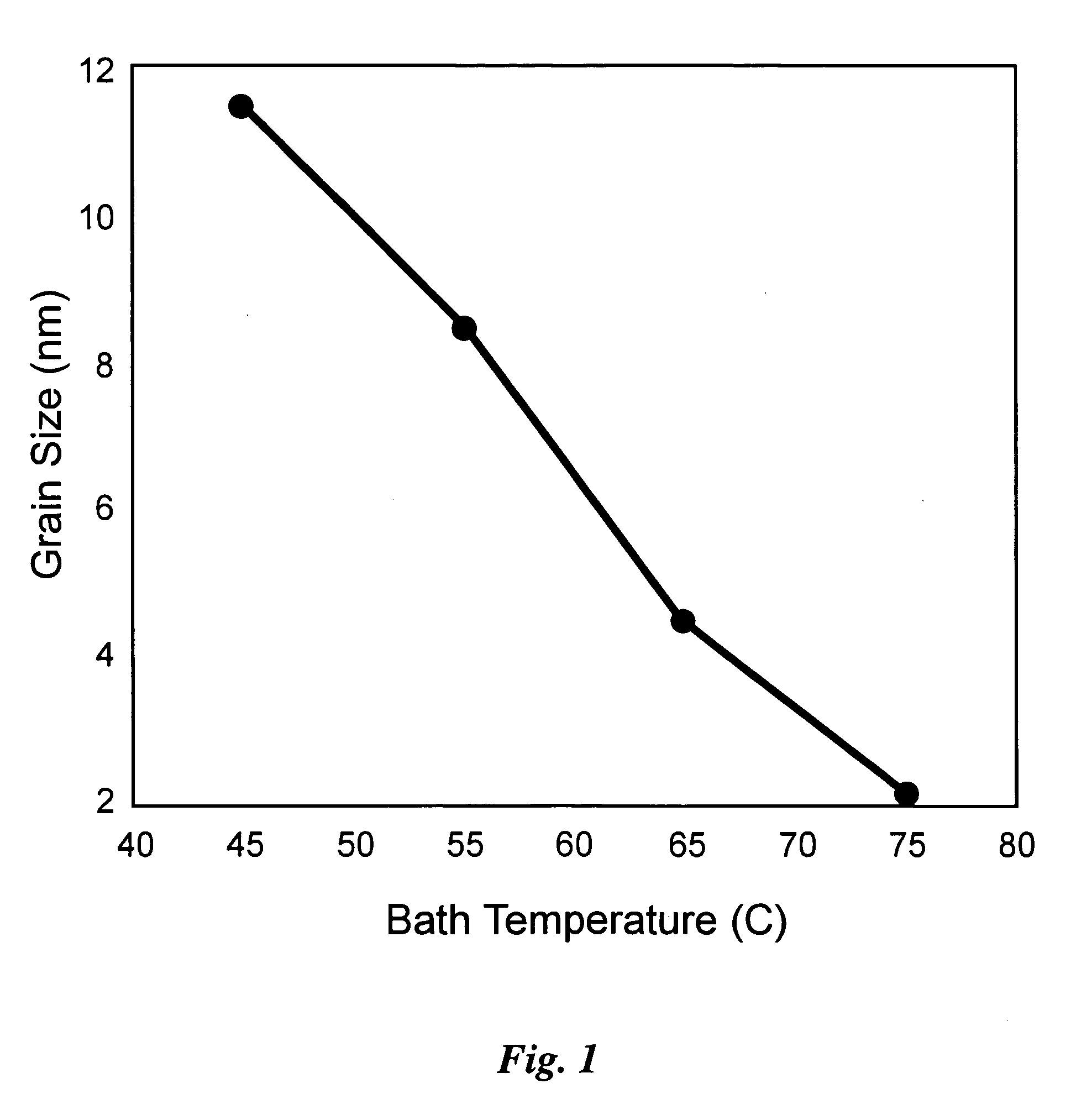

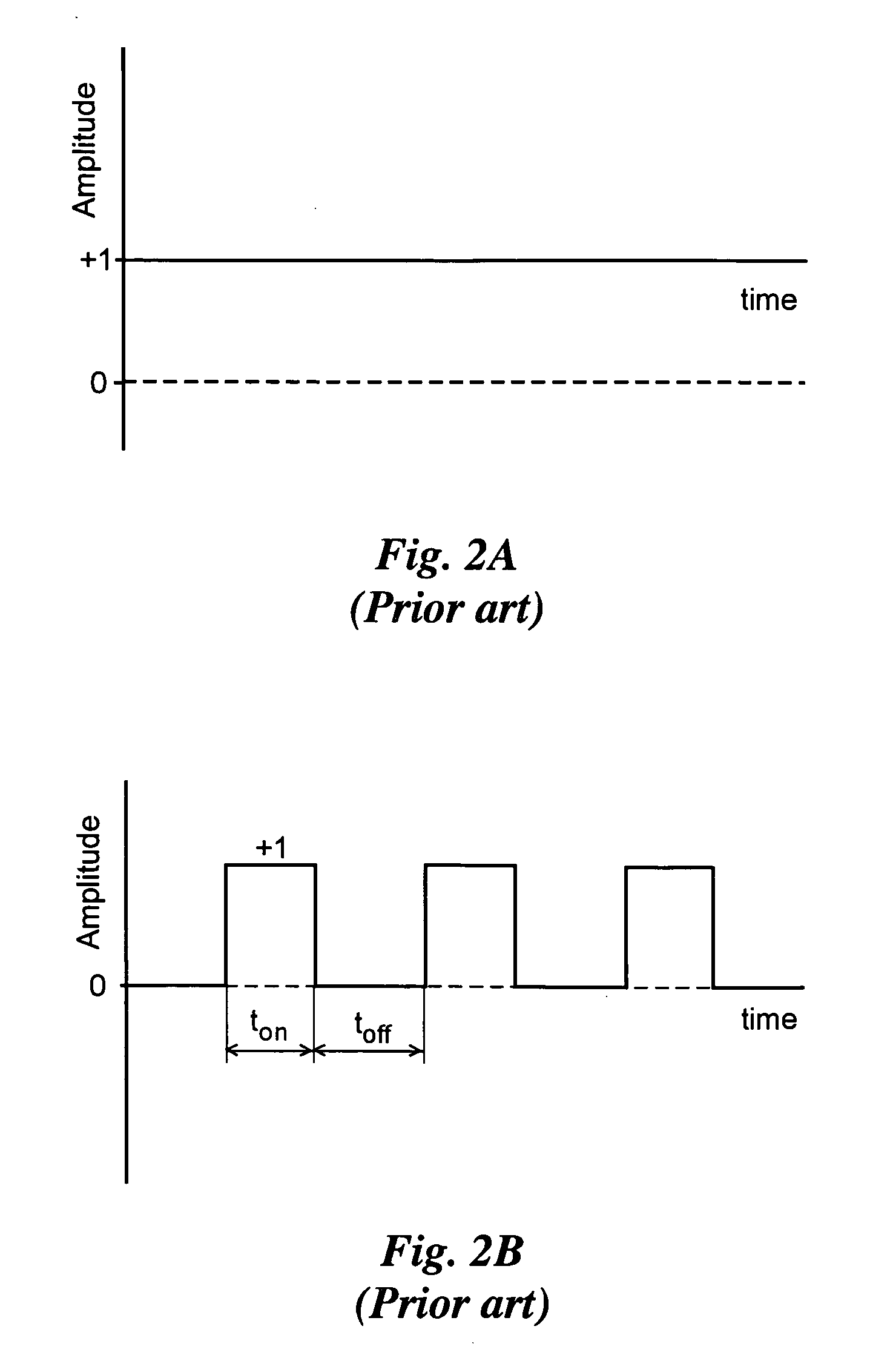

Method for producing alloy deposits and controlling the nanostructure thereof using negative current pulsing electro-deposition, and articles incorporating such deposits

Bipolar wave current, with both positive and negative current portions, is used to electrodeposit a nanocrystalline grain size deposit. Polarity Ratio is the ratio of the absolute value of the time integrated amplitude of negative polarity current and positive polarity current. Grain size can be precisely controlled in alloys of two or more chemical components, at least one of which is a metal, and at least one of which is most electro-active. Typically, although not always, the amount of the more electro-active material is preferentially lessened in the deposit during times of negative current. The deposit also exhibits superior macroscopic quality, being relatively crack and void free. Parameters of current density, duration of pulse portions, and composition of the bath are determined with reference to constitutive relations showing grain size as a function of deposit composition, and deposit composition as a function of Polarity Ratio, or, perhaps, a single relation showing grain size as a function of Polarity ratio. A specified grain size can be achieved by selecting a corresponding Polarity Ratio, based on these relations. Coatings can be in layers, each having an average grain size, which can vary layer to layer and also in a region in a graded fashion. Coatings can be chosen for environmental protection (corrosion, abrasion), decorative properties, and for the same uses as a hard chrome coating. A finished article may be built upon a substrate of electro-conductive plastic, or metal, including steels, aluminum, brass. The substrate may remain, or be removed.

Owner:MASSACHUSETTS INST OF TECH

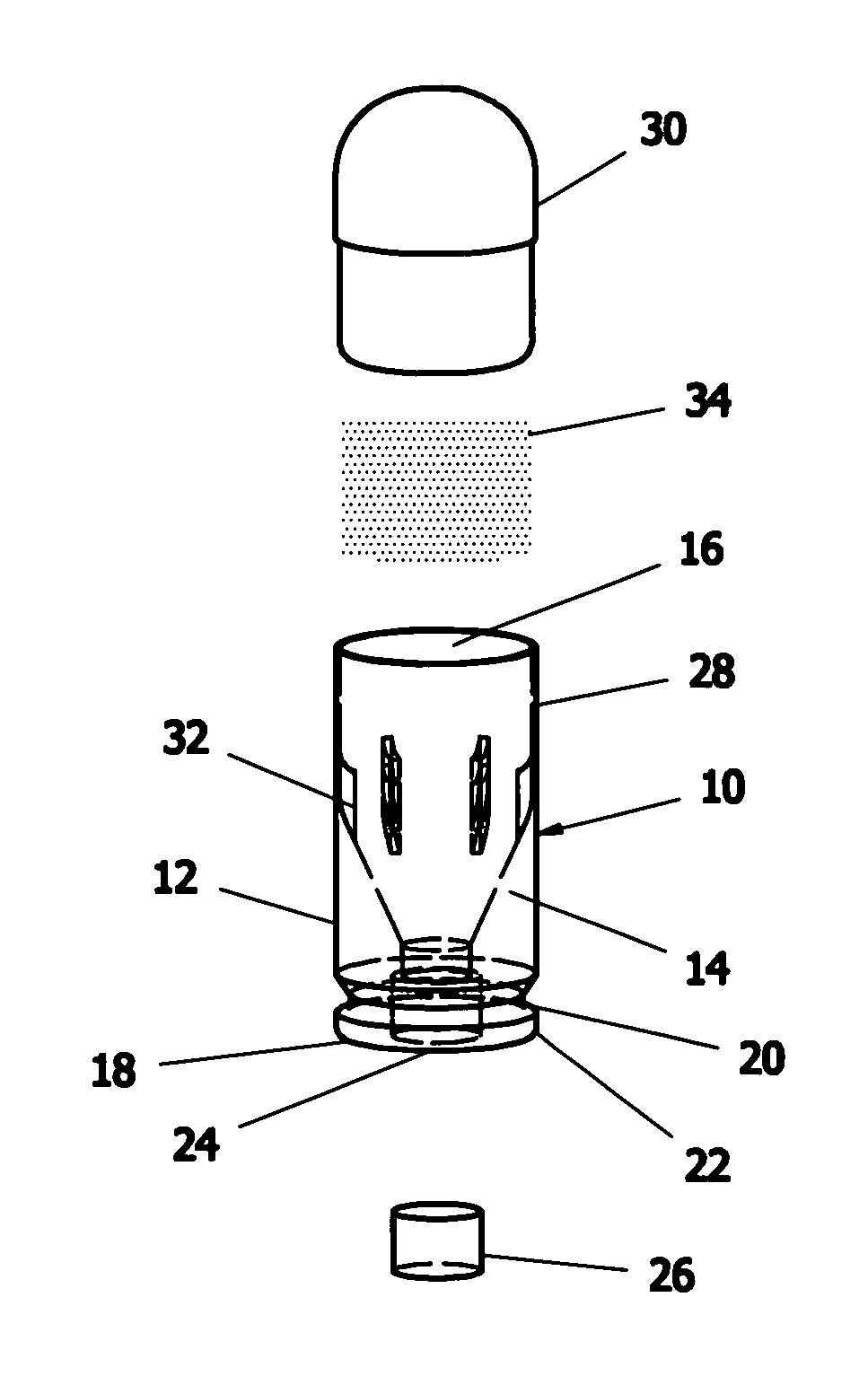

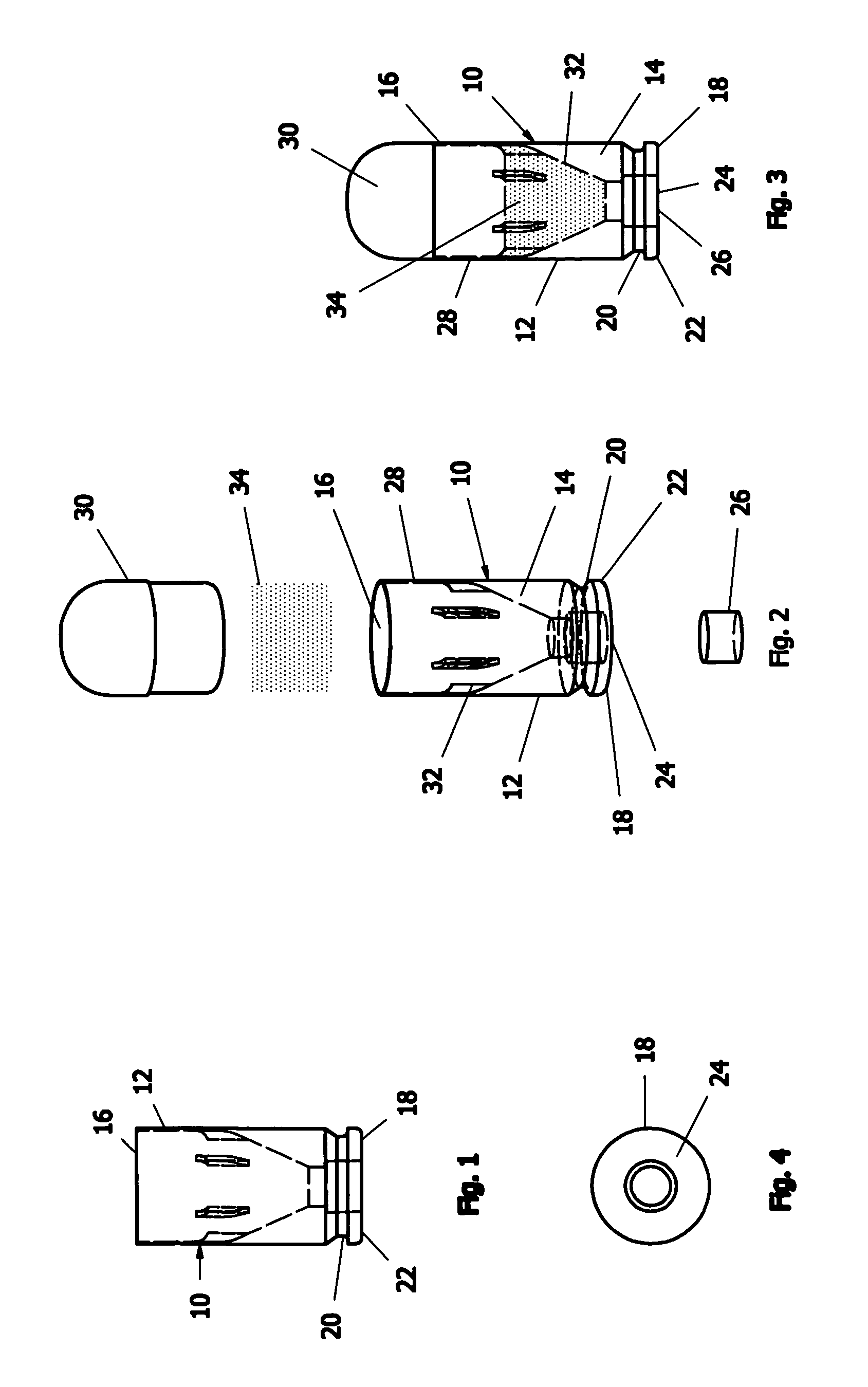

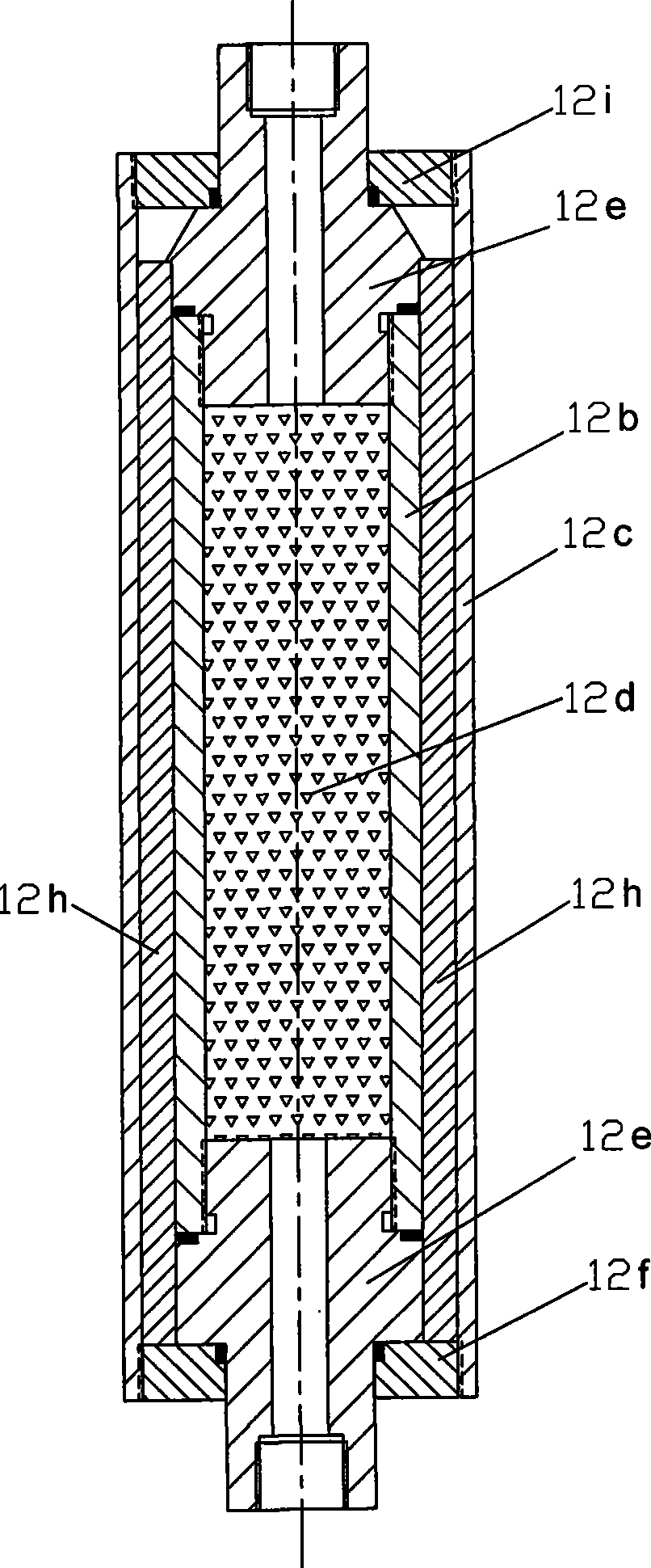

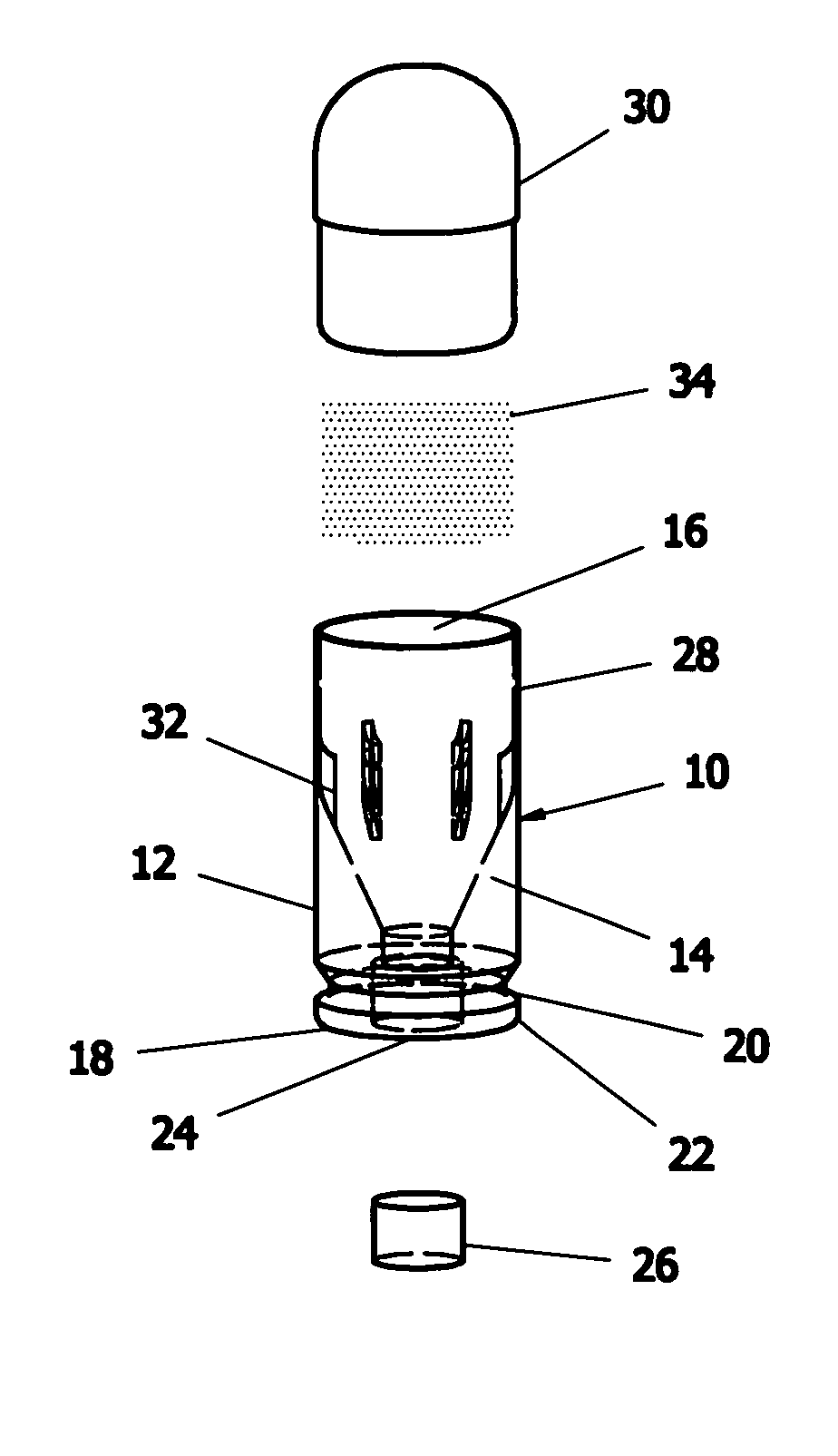

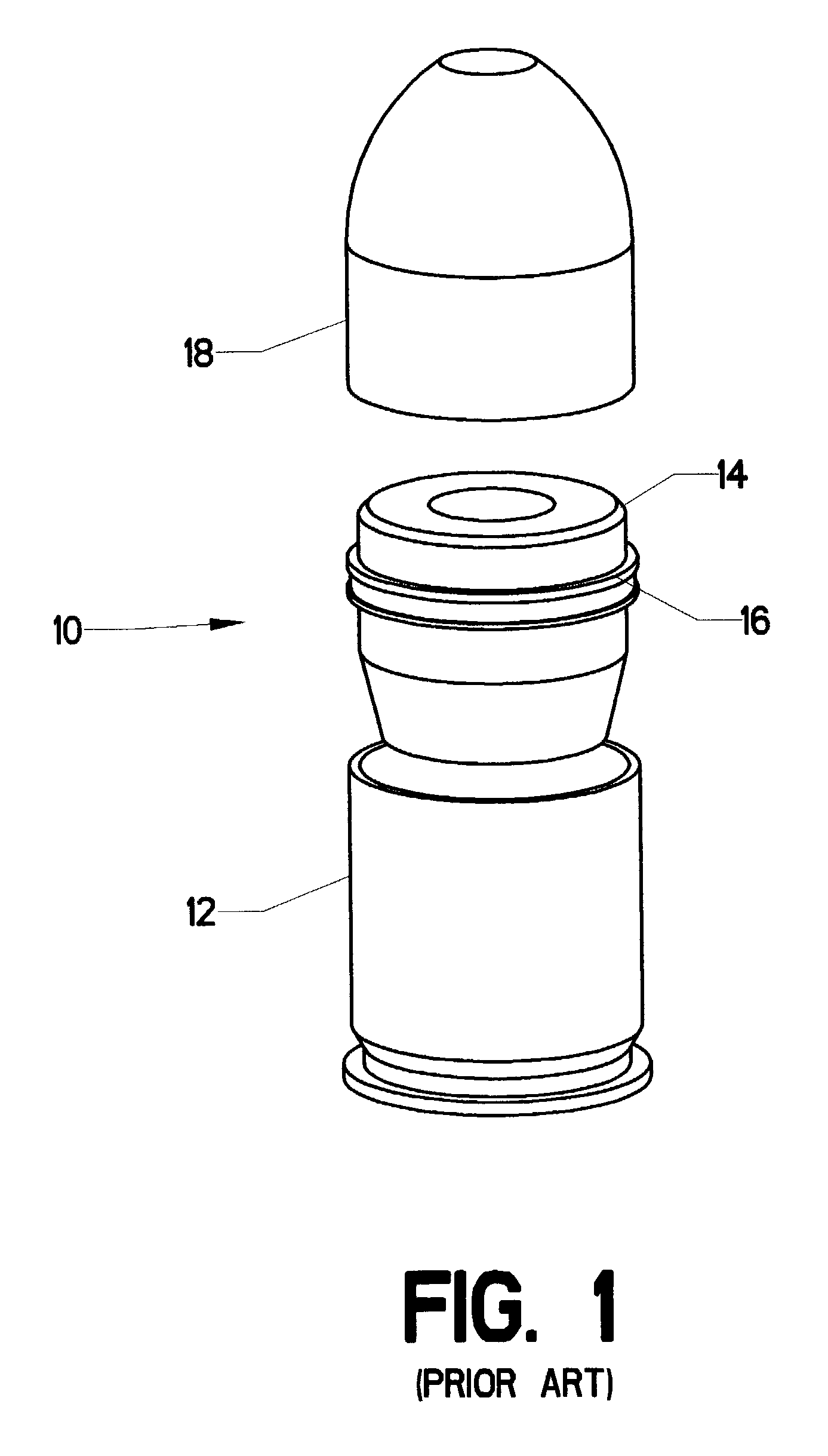

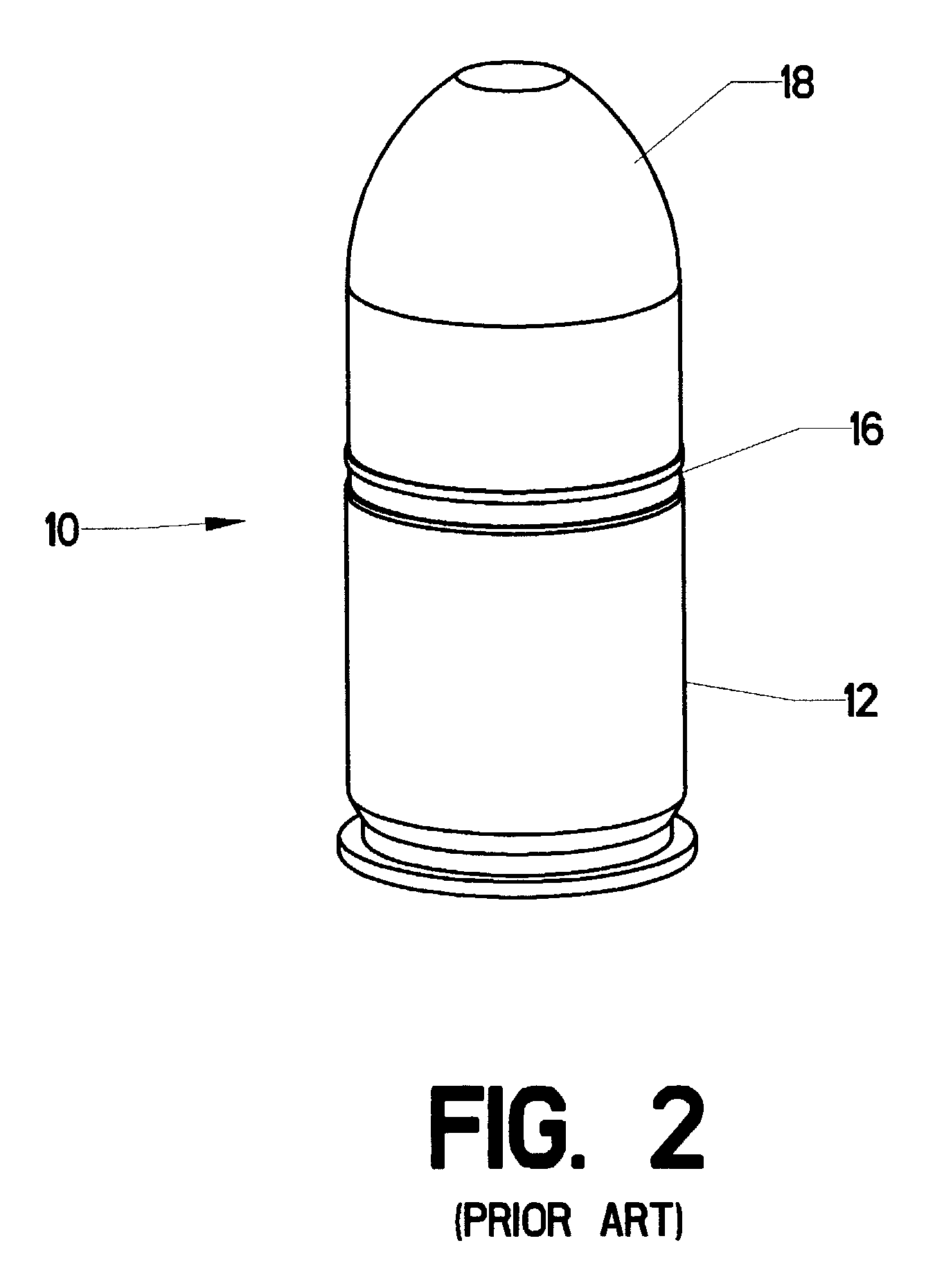

Plastic ammunition casing and method

Ammunition having an integrally formed, polymeric casing is provided. Plastic casings for ammunition may be made using injection molding processes for combat ammunition, target ammunition and blanks. The casings, in one embodiment, include a hollow tubular member with an open end and a closed end having an aperture for a primer cap. The base of the casing includes a conical shape within the tube that narrows toward the base. An annular groove and an annular rim are disposed about an outer periphery of the base. Plastic casings may be utilized for ammunition cartridges used in pistols, rifles and shotguns, and are lighter and less expensive to manufacture than traditional brass casings. Further, the polymeric casings may include any desired colorants to distinguish different calibers of ammunition by color, and the spent casings may be recyclable.

Owner:TRIVETTE ROGER BLAINE

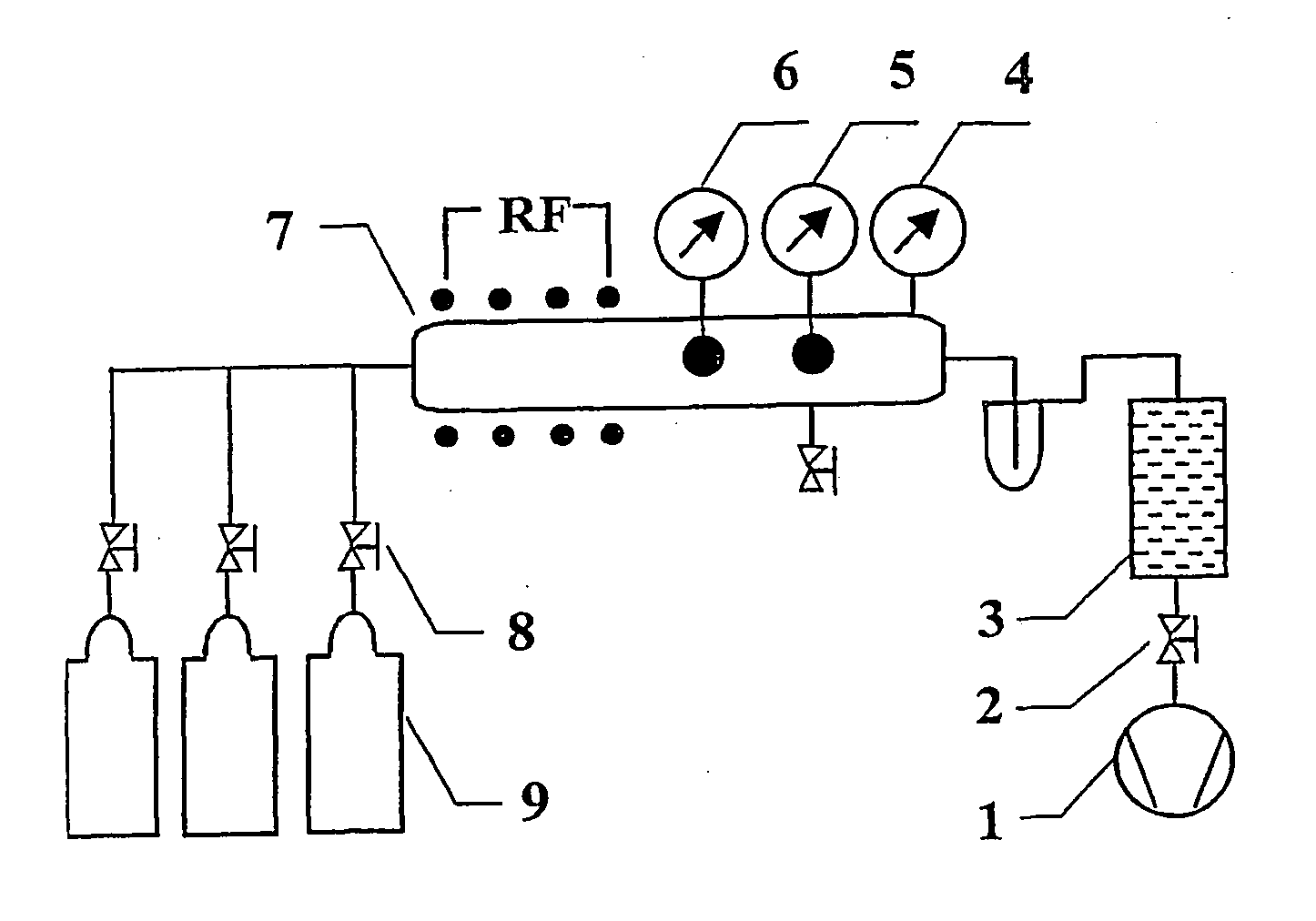

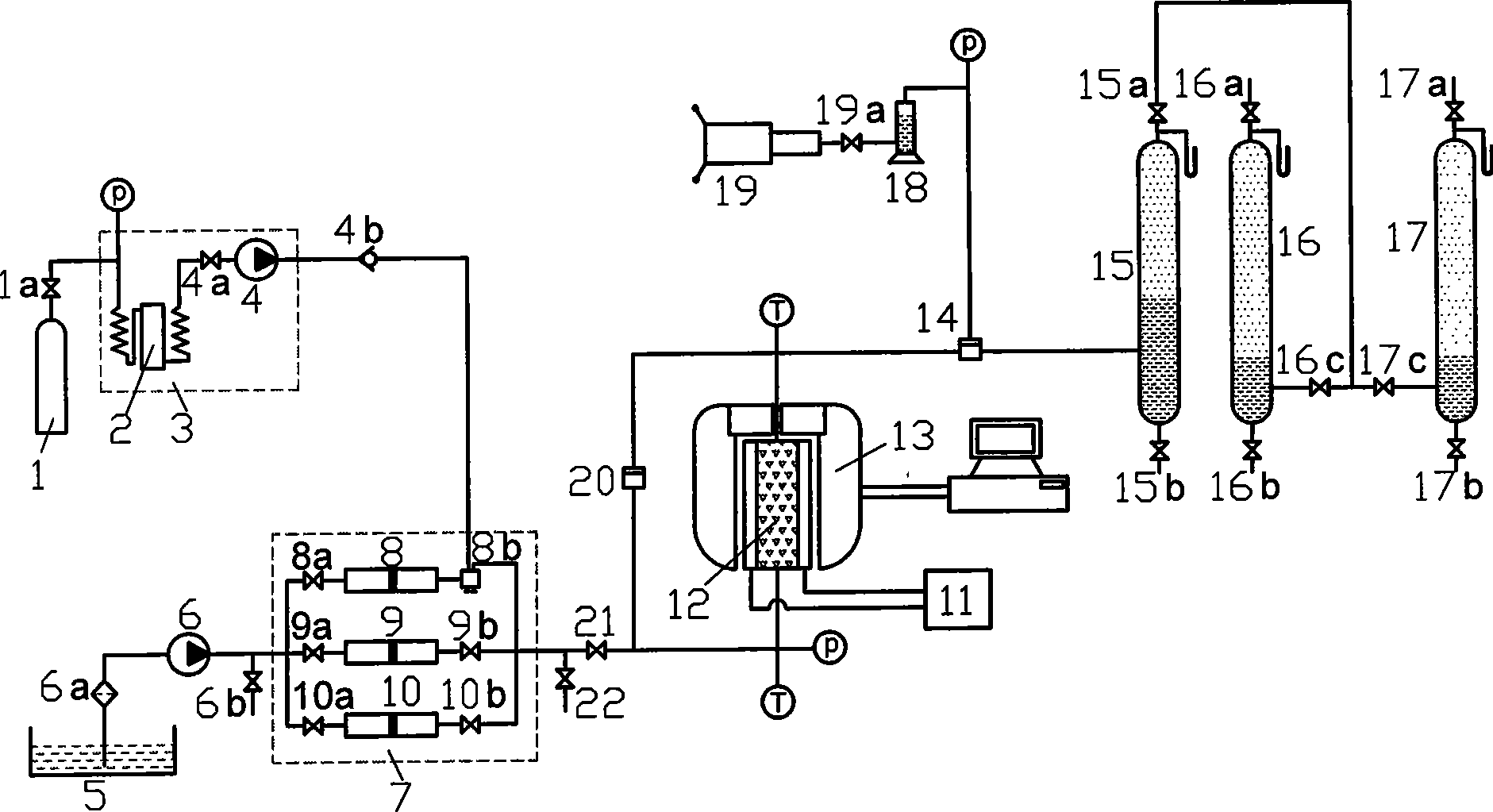

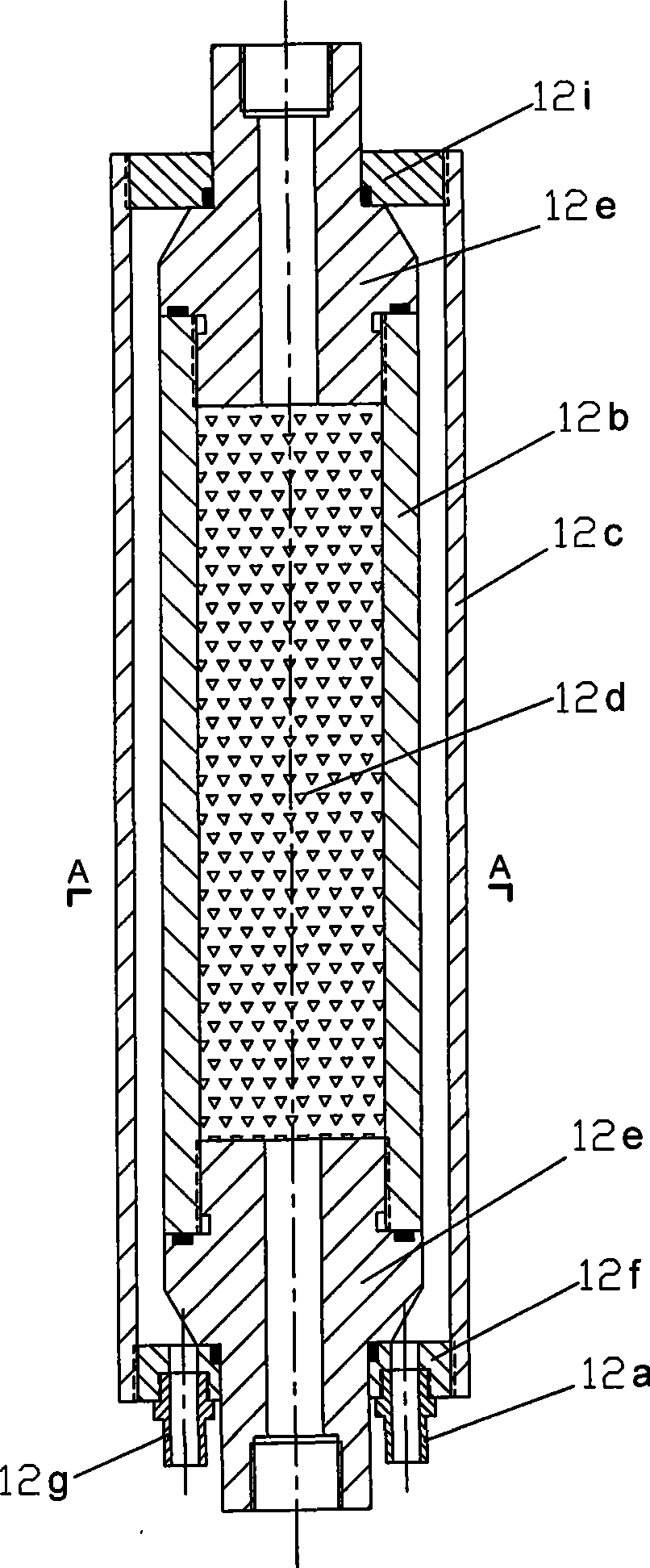

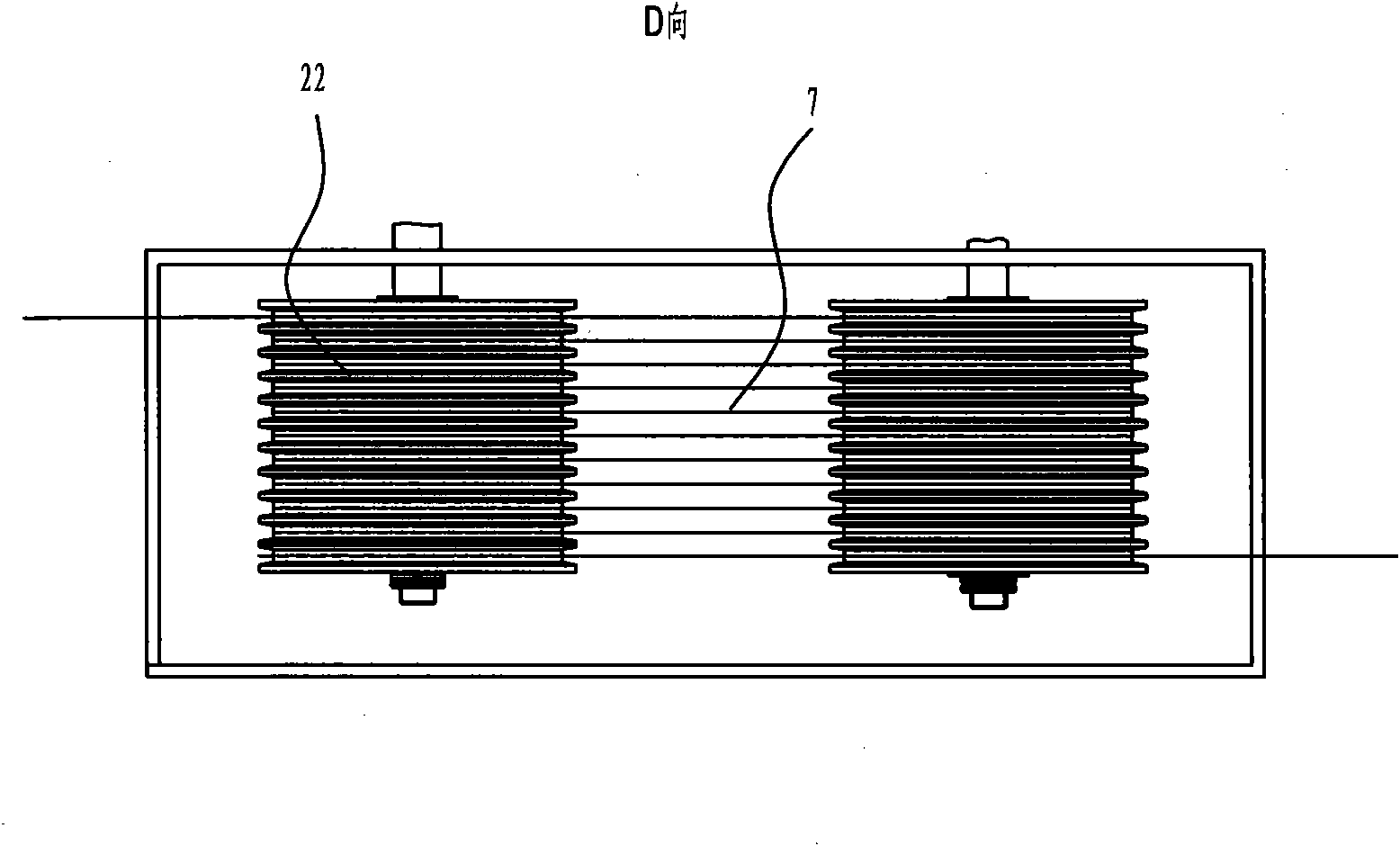

Carbon dioxide oil-displacing nmr imaging detection device

InactiveCN101458218AEasy to meet high pressure strength requirementsCompact designWater resource assessmentAnalysis using nuclear magnetic resonancePorous mediumImage detection

A carbon dioxide drive nuclear magnetic resonance imaging detection device belongs to the technical field of petroleum engineering and technology. The detection device comprises: a simulation core device which is arranged in a nuclear magnetic resonance imaging device; an injection system which sequentially injects formation water, crude oil and supercritical carbon oxide into the simulation core device; a measurement and control system which is employed to control pressure and temperature of the whole system; the nuclear magnetic resonance imaging device which is employed to detect and perform quantitative analysis on an image to be tested to obtain voidage and permeability of a porous medium, and saturation seepage parameters of the supercritical carbon oxide, the formation water and the crude oil; and an output measuring system which is employed to measure volumes of the carbon dioxide gas, the formation water and the crude oil. The detection device has a design pressure of 0-40MPa and design temperature of 0-180 DEG C, and can simulate experimental studies of different displacement schemes of the supercritical CO2 under a complex petroleum reservoir condition; the simulation core device is made of a brass material, which produces no magnetism, satisfies requirements for high pressure and strength, has a compact structure, can be recycled, is conveniently operated, simple and applicable in an experimentation.

Owner:DALIAN UNIV OF TECH

Plastic ammunition casing and method

InactiveUS20100275804A1Ammunition projectilesShotgun ammunitionShotgun pelletInjection molding process

Ammunition having an integrally formed, polymeric casing is provided. Plastic casings for ammunition may be made using injection molding processes for combat ammunition, target ammunition and blanks. The casings, in one embodiment, include a hollow tubular member with an open end and a closed end having an aperture for a primer cap. The base of the casing includes a conical shape within the tube that narrows toward the base. An annular groove and an annular rim are disposed about an outer periphery of the base. Plastic casings may be utilized for ammunition cartridges used in pistols, rifles and shotguns, and are lighter and less expensive to manufacture than traditional brass casings. Further, the polymeric casings may include any desired colorants to distinguish different calibers of ammunition by color, and the spent casings may be recyclable.

Owner:TRIVETTE ROGER BLAINE

Leadless easy cutted brass ally material and its manufacturing method

An easily cutted lead-free brass alloy is prepared from Cu (60-62 wt.%), Bi (0.5-2.2), Al (0.01-0.1), Sn (0.5-1.6), P (0.04-0.15) and Zn (rest) through heat treating at 460-600 deg.C for 30 min-4 hr, and slow cooling at speed lower than 70 deg.C / hr.

Owner:SAN ETSU METALS

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

Copper-based alloy excellent in dezincing resistance

A copper-based alloy excellent in dezincing resistance comprises, in percentage by weight, Cu: 57-69%, Sn: 0.3-3%, Si: 0.02-1.5%, Bi: 0.5-3%, and Pb: not more than 0.2%, where the ratio of Si / Sn expressed in weight percentage is in the range of 0.05-1 and apparent zinc content as defined by the following formula is in the range of more than 39-50 wt. %, and the balance of unavoidable impurities: Apparent Zn content=[(Zn %+2.0xSn %+10.0xSi %) / (Cu %+Zn %+2.0xSn %+10.0xSi %)]x100. Despite the fact that contains no added environment-unfriendly Pb, the alloy exhibits enhanced cuttability, together with excellent forgeability, dezincing resistance and hot forgeability.

Owner:DOWA METALTECH CO LTD

Electromagnetic radiation attenuating and scattering member with improved thermal stability

ActiveUS6912049B2Improve thermal stabilityLower requirementPhotometry using reference valueDiffusing elementsInvarSpectralon

The present invention provides a thermally stable reference member comprising, at least one radiation attenuating element and at least one radiation scattering element. The radiation attenuating element comprising at least one aperture for transmission of radiation therethrough. The attenuating and scattering elements placed in series so that radiation transmitted through the reference member passes through each of the attenuating and scattering elements. The attenuating and scattering elements of the reference member may further comprise a thermally stable mount to hold the elements in a selected position relative to each other, and in relation to an instrument, or the elements may be bonded together. The radiation attenuating element may be comprised of a material selected from the group consisting of INVAR, tungsten, brass, and a material substantially non-transparent for incident radiation, and the radiation scattering element may be comprised of a radiation scattering material selected from the group consisting of opalescent glass, SPECTRALON, PTFE, ZERODUR, fused silica, quartz, sapphire, diamond, and a transparent material with essentially low thermal expansion.

Owner:TYCO HEALTHCARE GRP LP

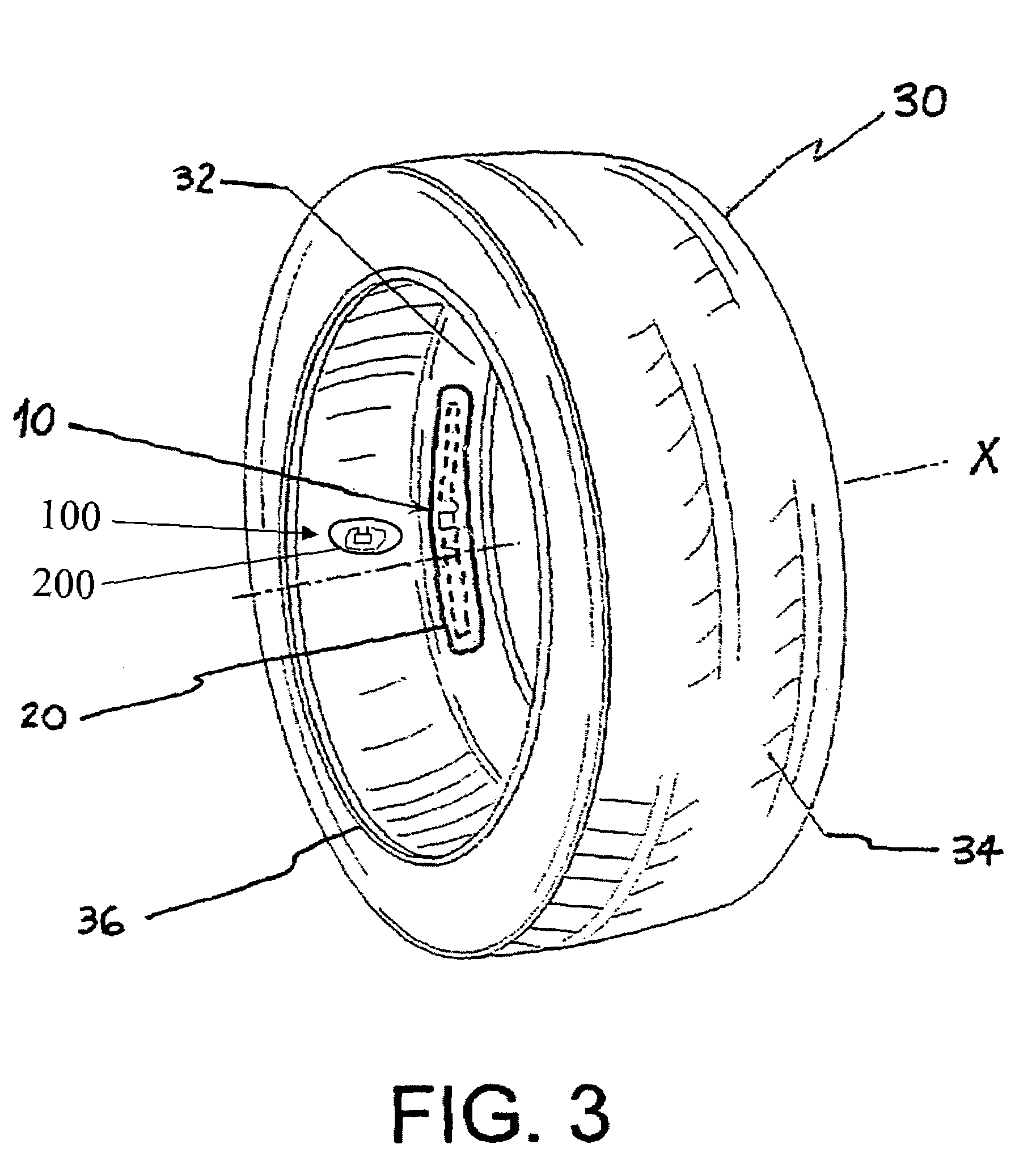

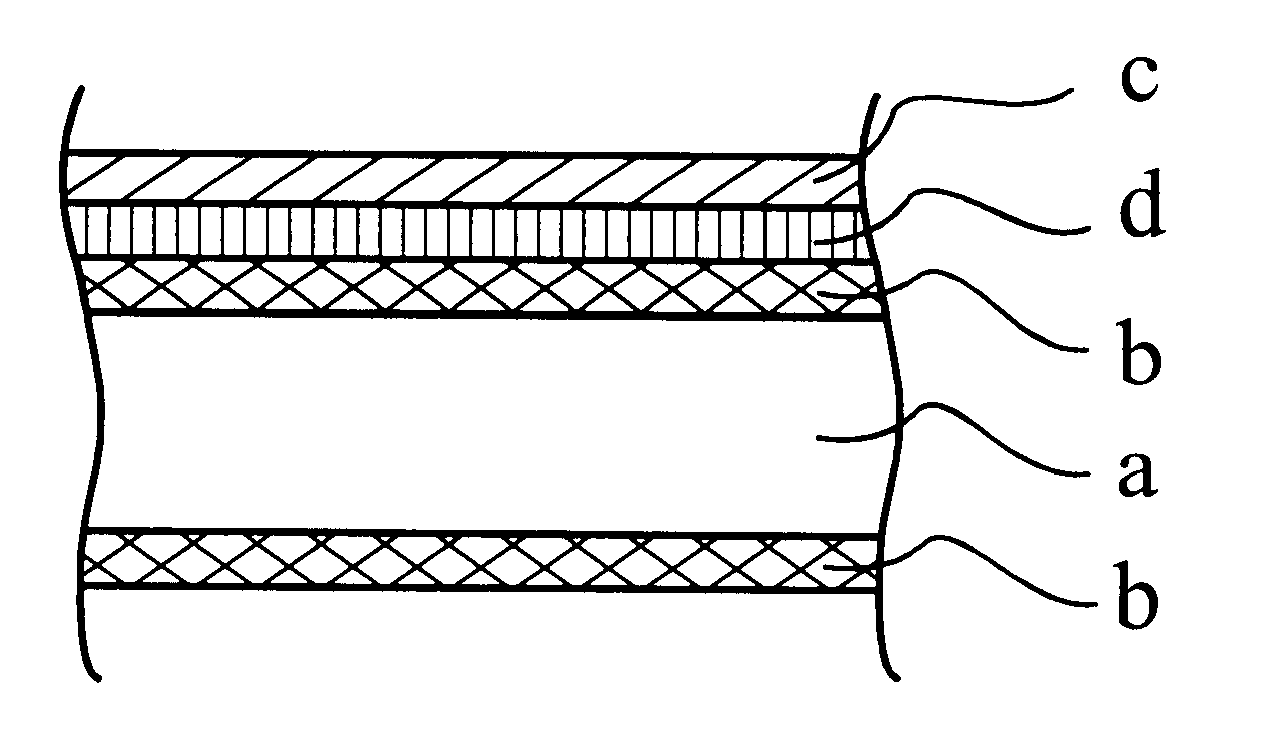

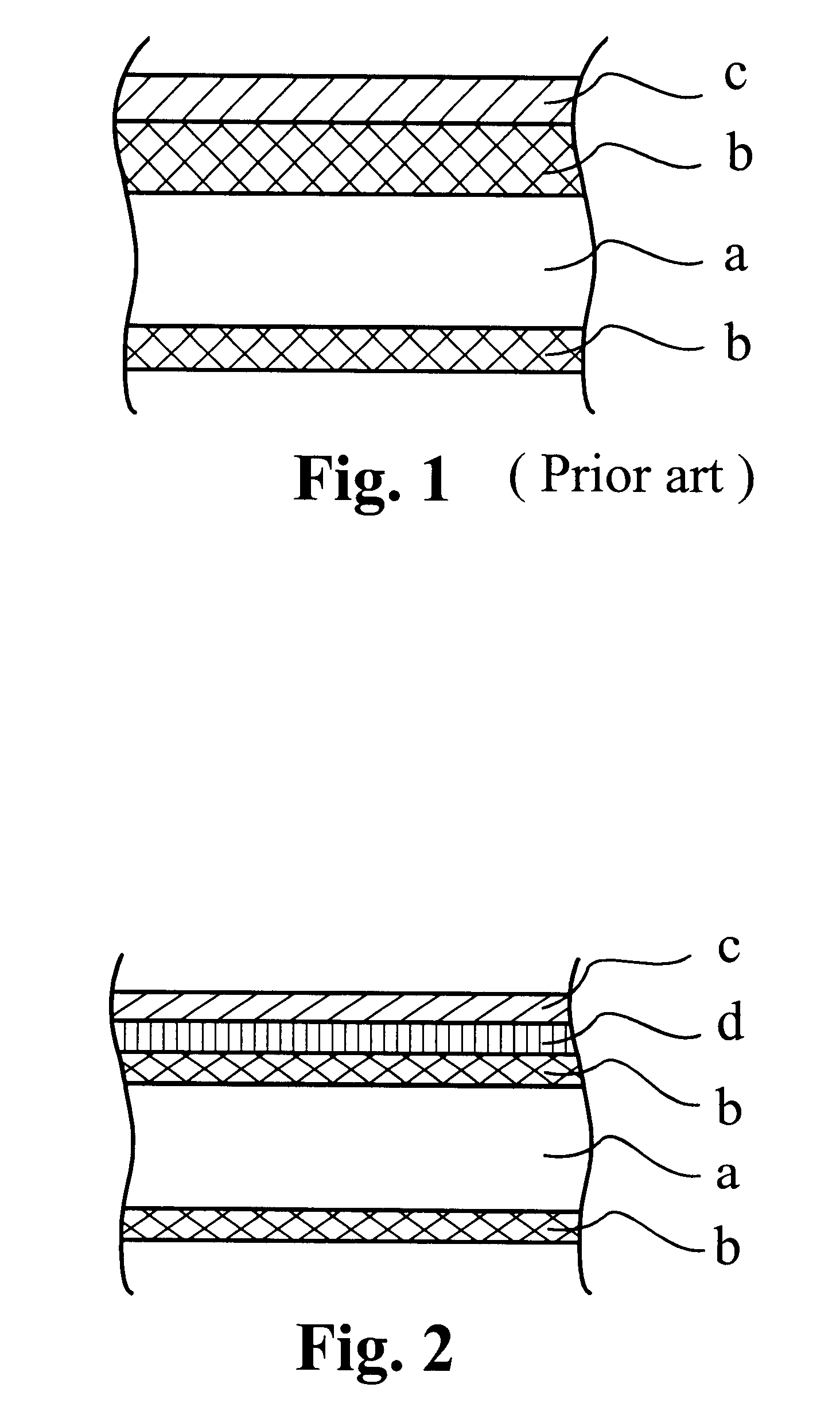

Thermoplastic elastomer composition, hose comprising thermoplastic elastomer composition and process of production thereof

InactiveUS6166143AImprove compatibilitySolve the lack of flexibilityClosuresClosure using stoppersThermoplasticCross-link

PCT No. PCT / JP97 / 03987 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20068 PCT Pub. Date May 14, 1998A thermoplastic elastomer composition containing a component (A) (thermoplastic polyolefin resin), component (B) (epoxy-group-containing ethylene acrylic ester copolymer rubber), and component (C) (acid-modified polyolefin resin) comprising a continuous phase of the component (A) in which the component (B) is dispersed as a dispersed phase and is cross-linked by a peroxide; a thermoplastic elastomer composition comprising a continuous phase of a thermoplastic polyolefin resin (A) and a dispersed phase of an epoxy-group-containing ethylene-acrylic ester copolymer rubber component (B) and acrylonitrile butadiene rubber component (C), which is dynamically cross-linked; and a hose having an inner tube, at least one reinforcing layer, and an outer cover, wherein the inner tube and the outer cover contain a thermoplastic elastomer composition comprised of a thermoplastic resin in which is blended an at least partially cross-linked elastomer component, the reinforcing layer is a brass-plated wire, and the reinforcing layer and inner tube and the reinforcing layer and outer cover have between them a maleic-acid-modified polyolefin thermoplastic resin.

Owner:YOKOHAMA RUBBER CO LTD

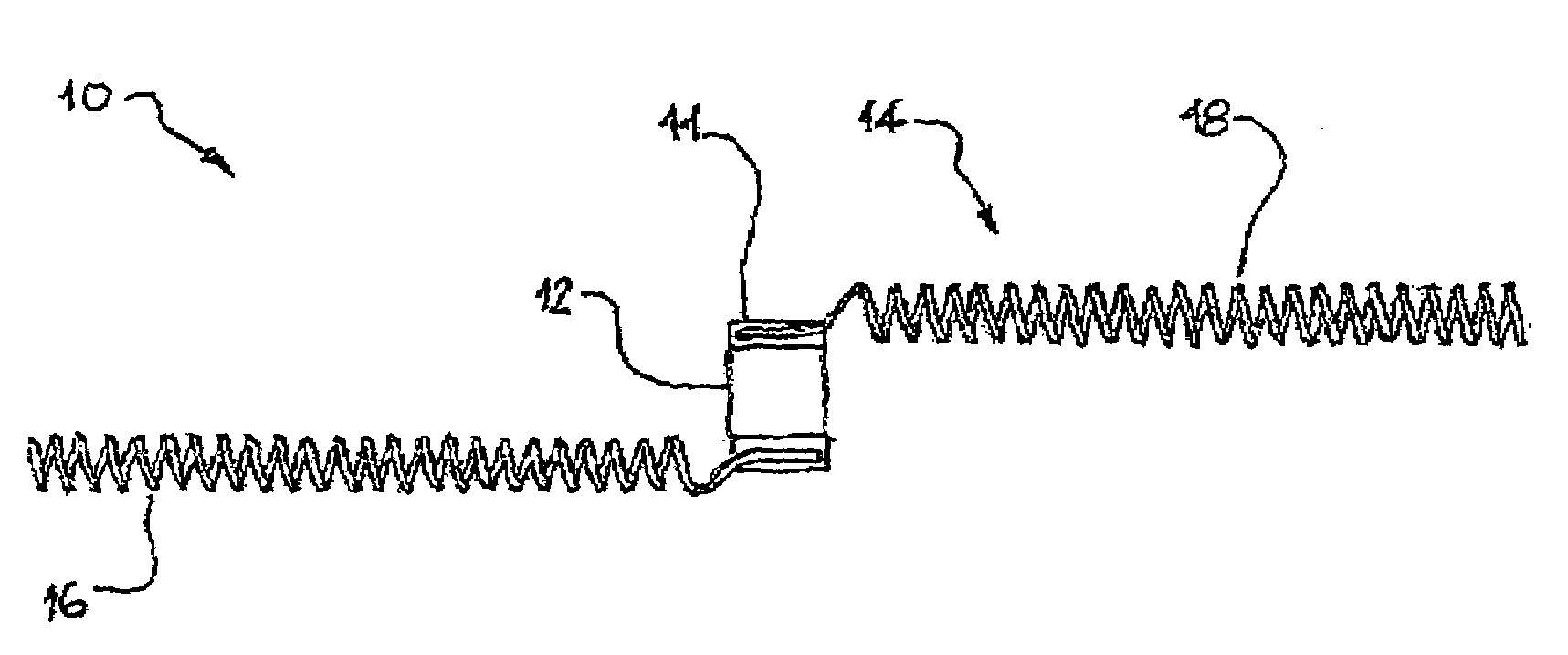

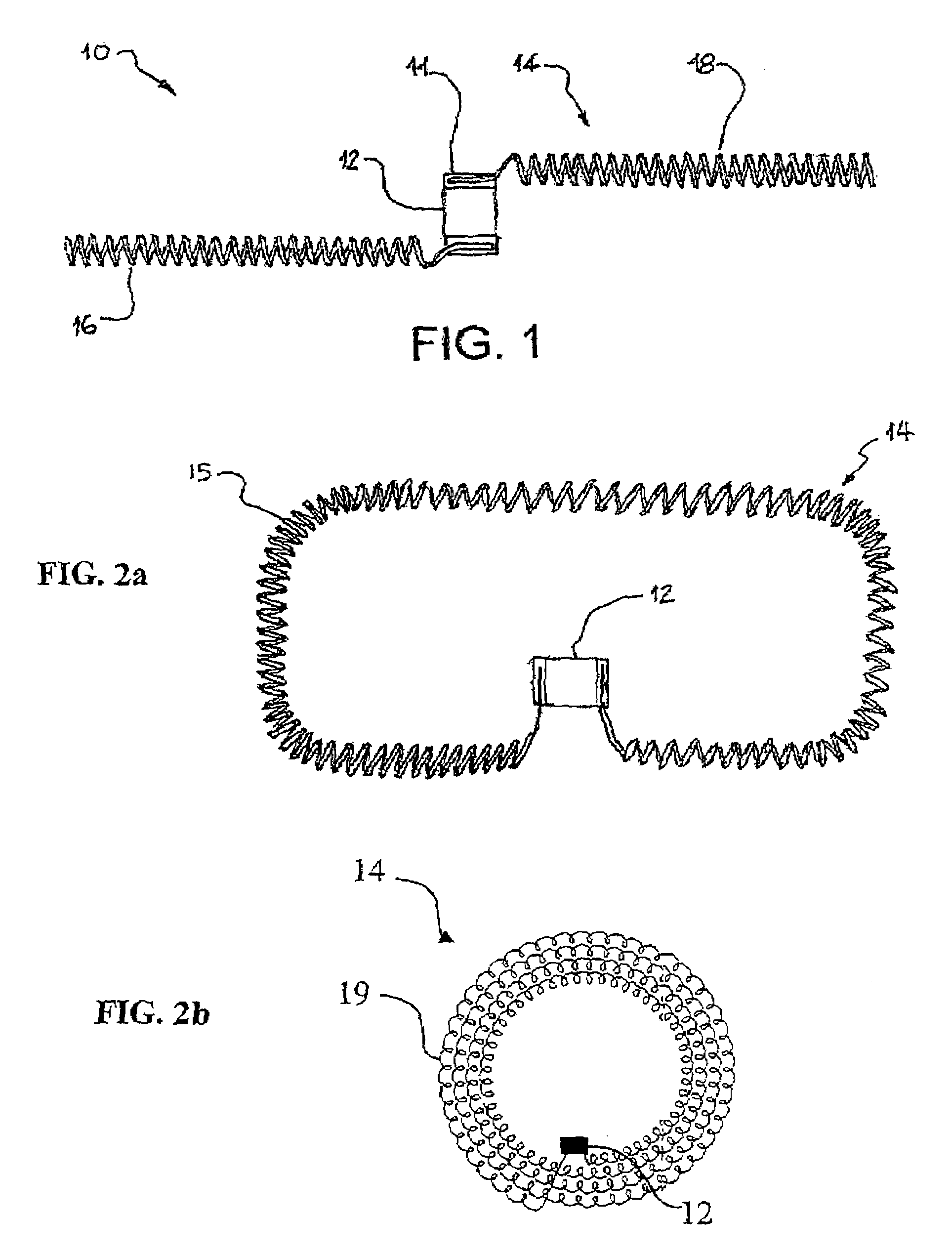

Electronic device for a tire having an extensible antenna

ActiveUS7102499B2Low frequency communicationAvoid problemsAntenna supports/mountingsTyresElectronic communicationEngineering

An electronic communication device for a tire includes a radio device and an antenna intended to be attached to or embedded in a tire, the antenna being spirally or helically shaped to absorb tensile and bending stress applied by the tire. The antenna body may be a wire formed of spring steel, brass or zinc coated spring steel, or spring brass. A coating of insulating material coats the radio device and antenna for mounting on or in, and operation in, a tire structure.

Owner:MICHELIN RECH & TECH SA

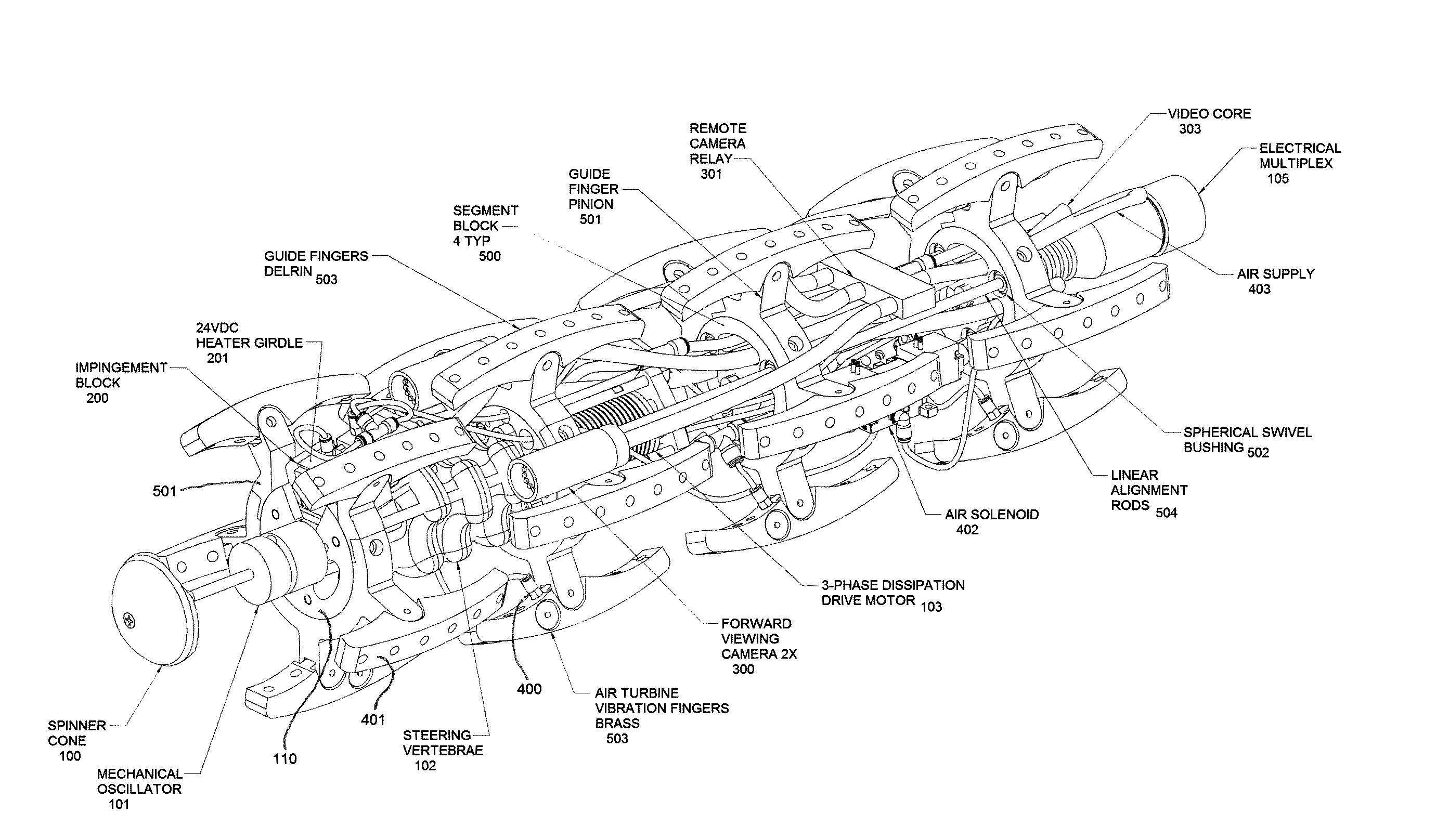

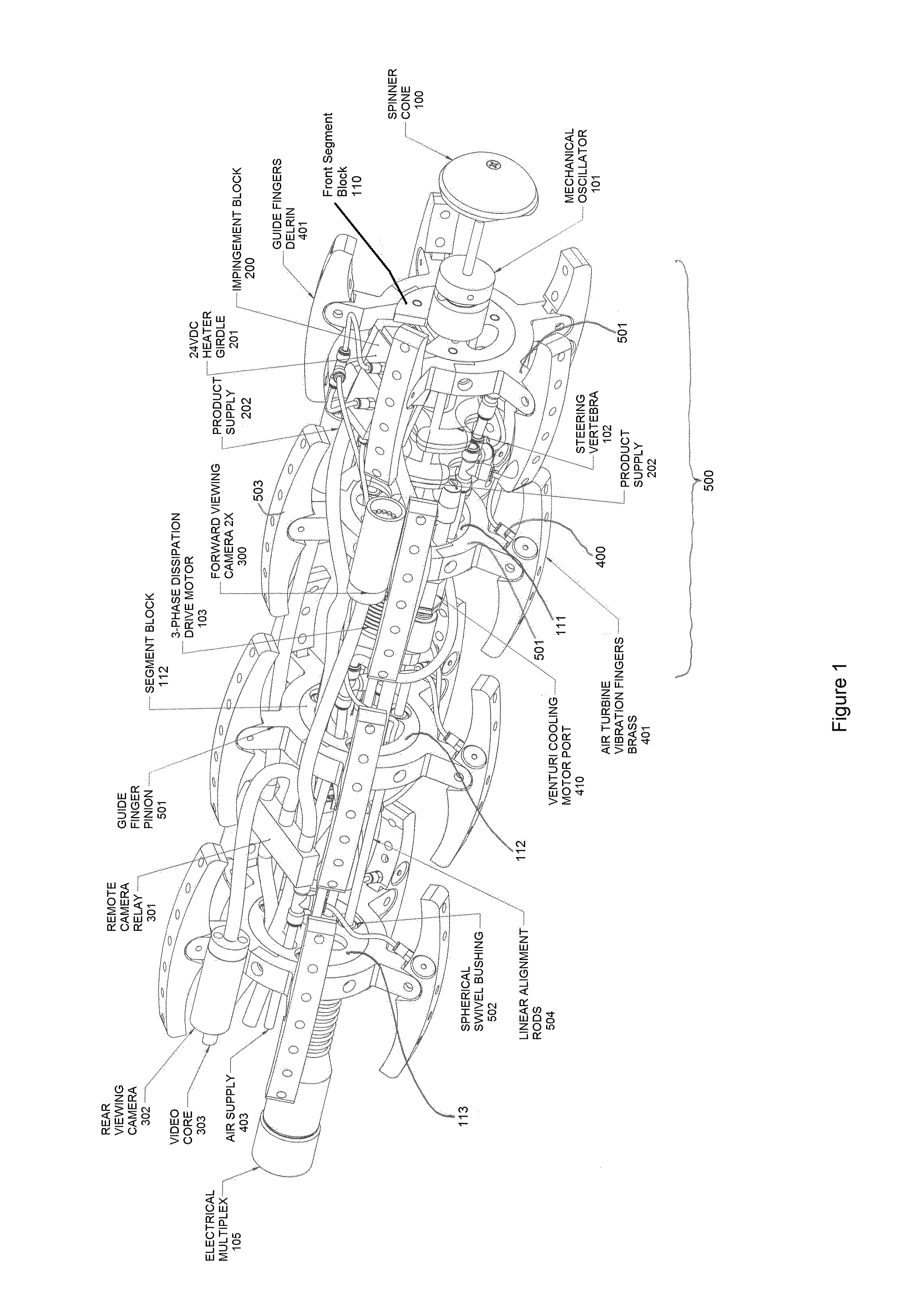

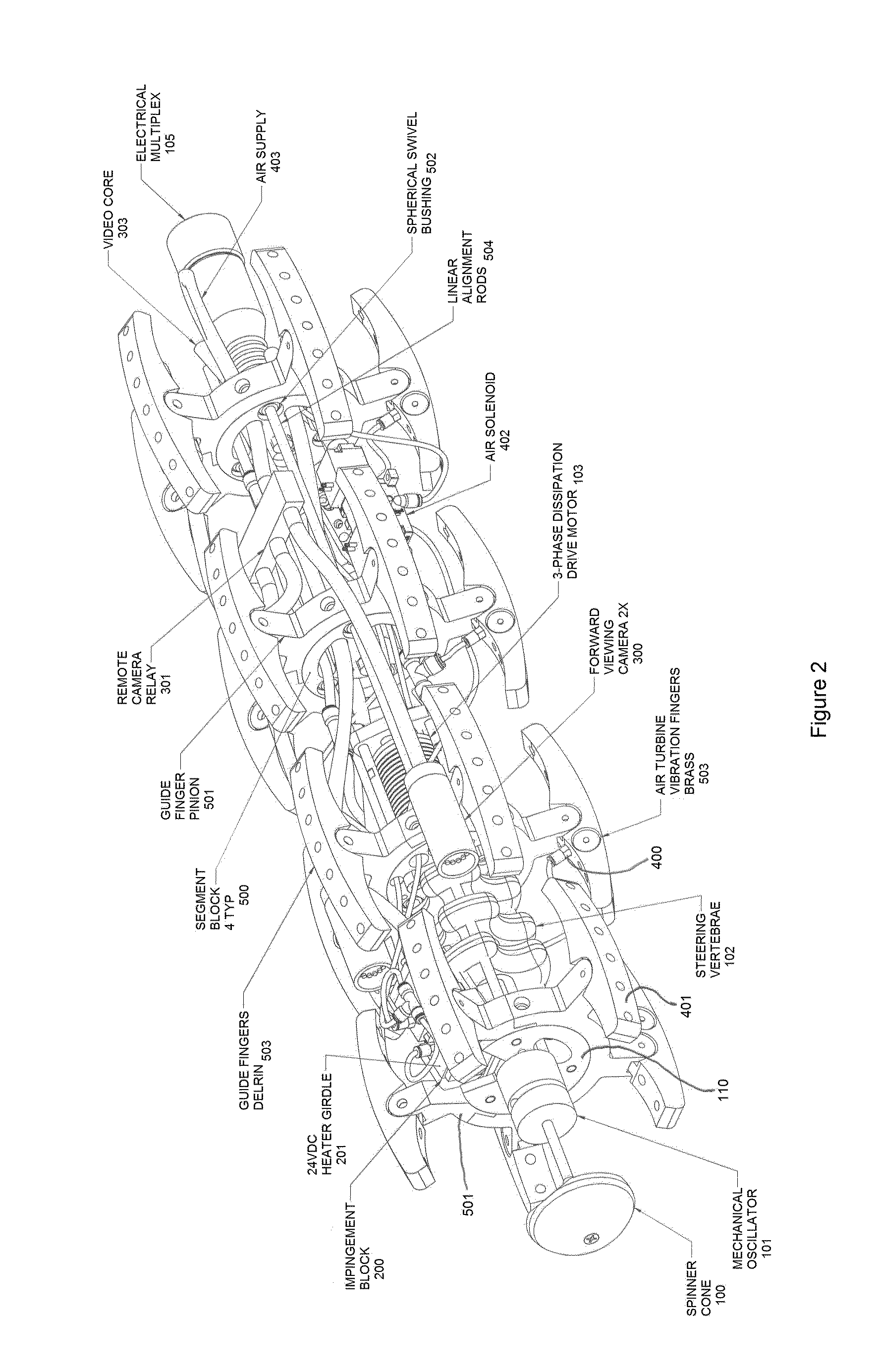

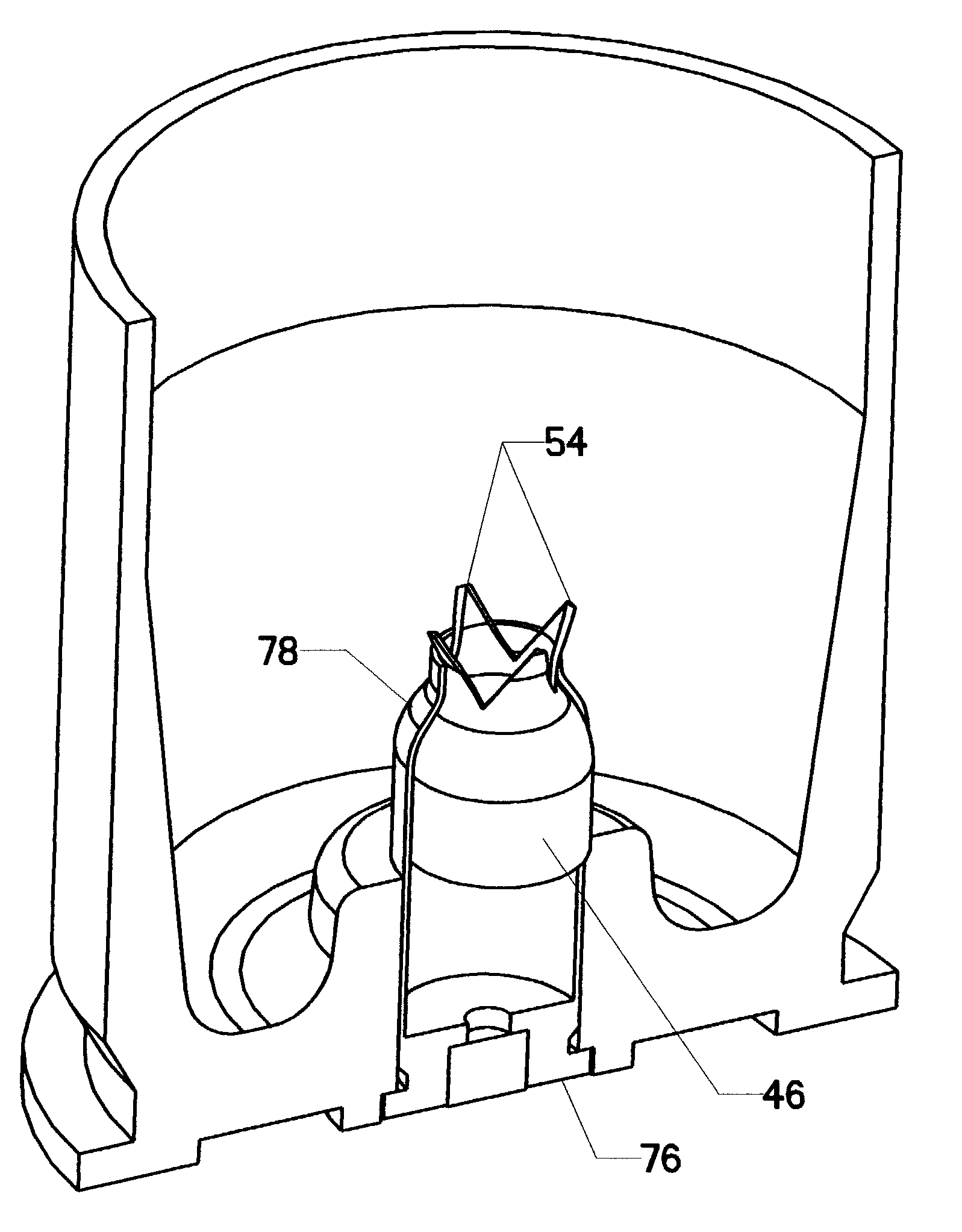

Multi-segmented apparatus for lining pipe with multiple convoluted bends and varied orientations with a structural membrane

ActiveUS8402911B1Rapid responseFast curingRailway tunnelsRailway componentsTeleoperated robotEngineering plastic

The invention provides an improved method and robotic apparatus for applying a structural membrane lining in conduits. The remotely controlled robot comprises a series of segment blocks maintained in alignment by flexible linear rods supported in spherical swivel bushings. The rods allow for articulation as the robot negotiates bends. Segment blocks include radial guide finger pinions and guide fingers for concentric positioning. Fingers are of engineered plastics and brass to provide ballast weight for perpendicular alignment and contain high frequency air turbine vibrators. Steering vertebrae are included to maintain concentricity of the lining dissipation cup through bends. Also included are electric servo motors controlling cables and take up wheels controlling the angle of the segment blocks.

Owner:QUEST INSPAR

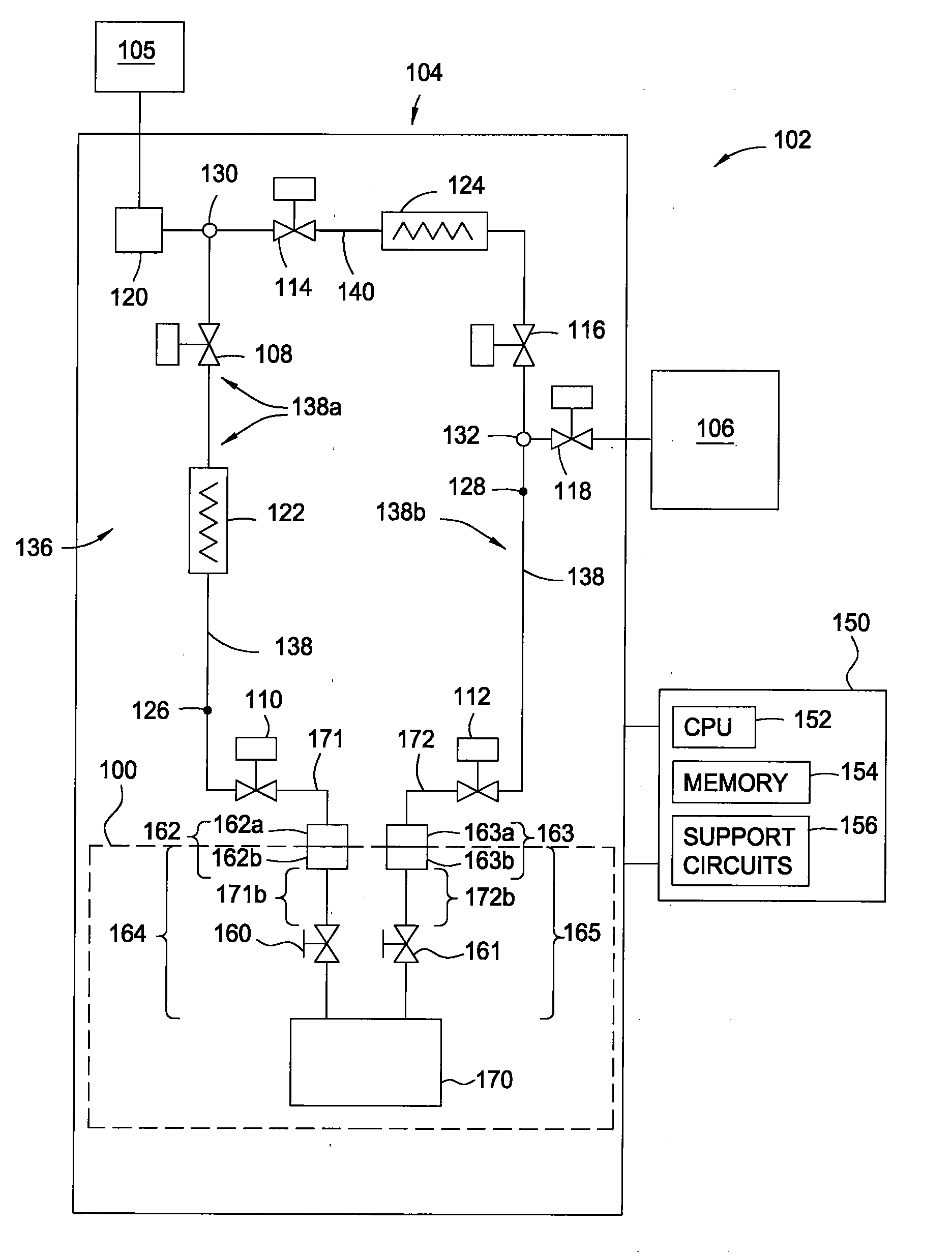

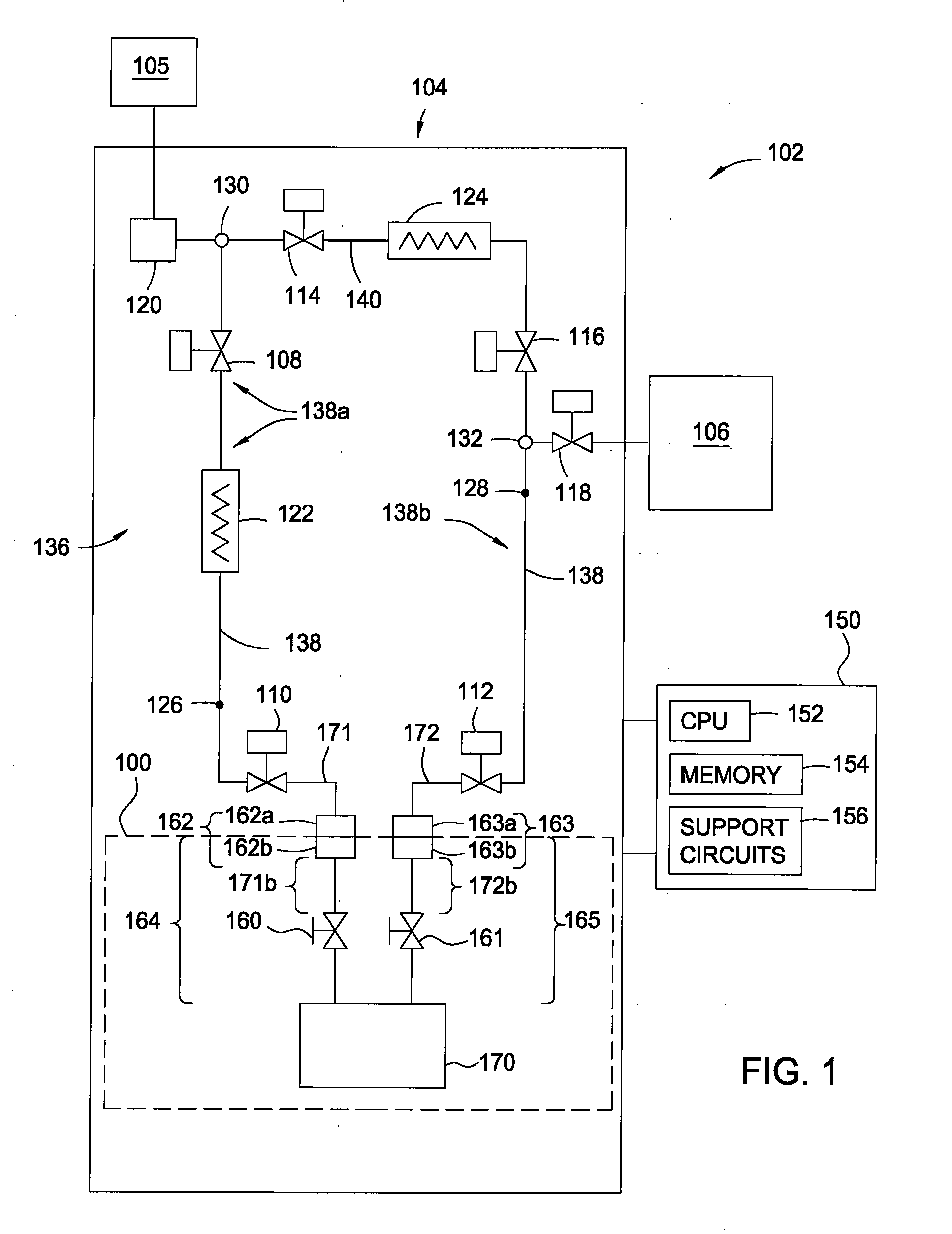

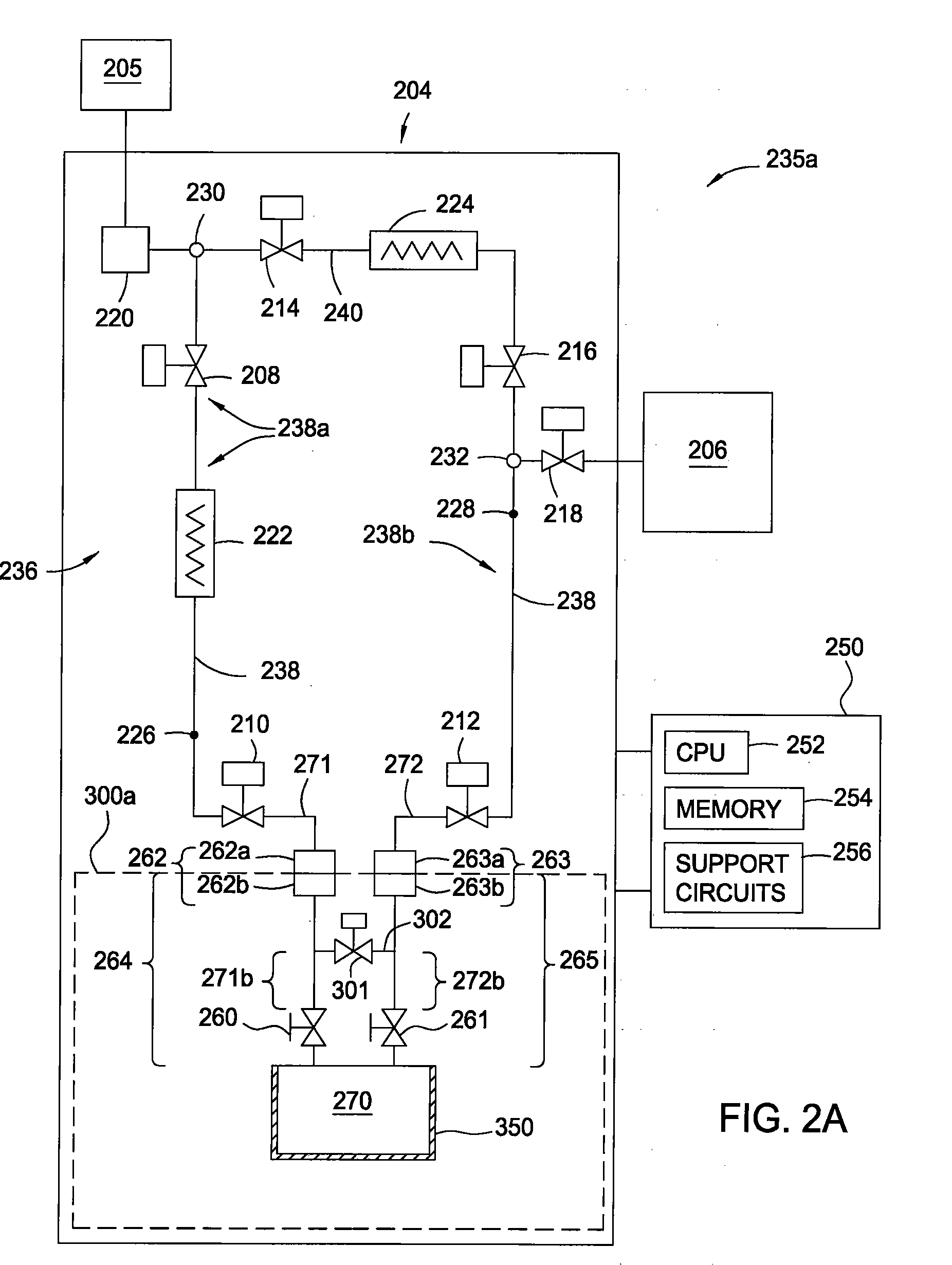

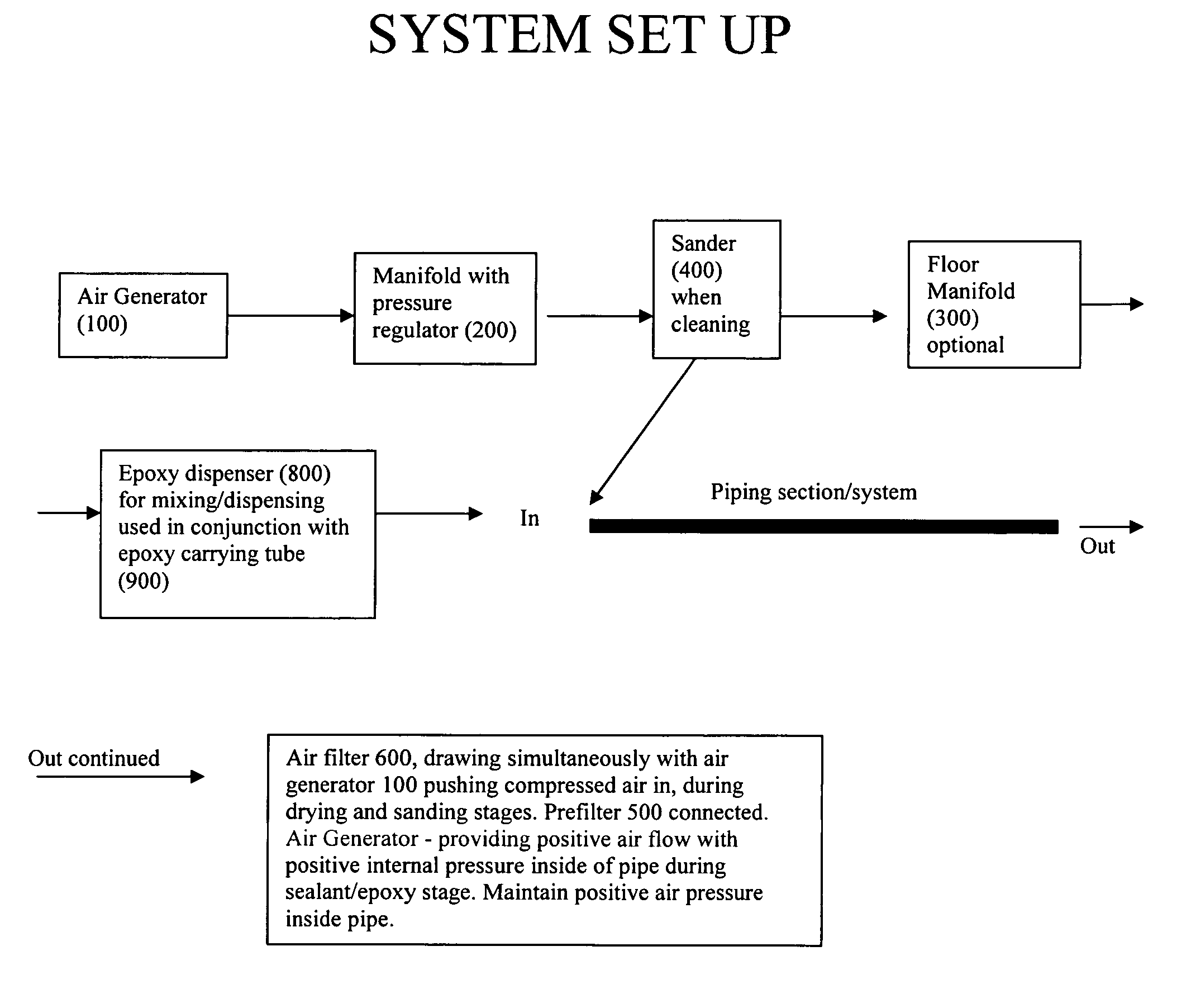

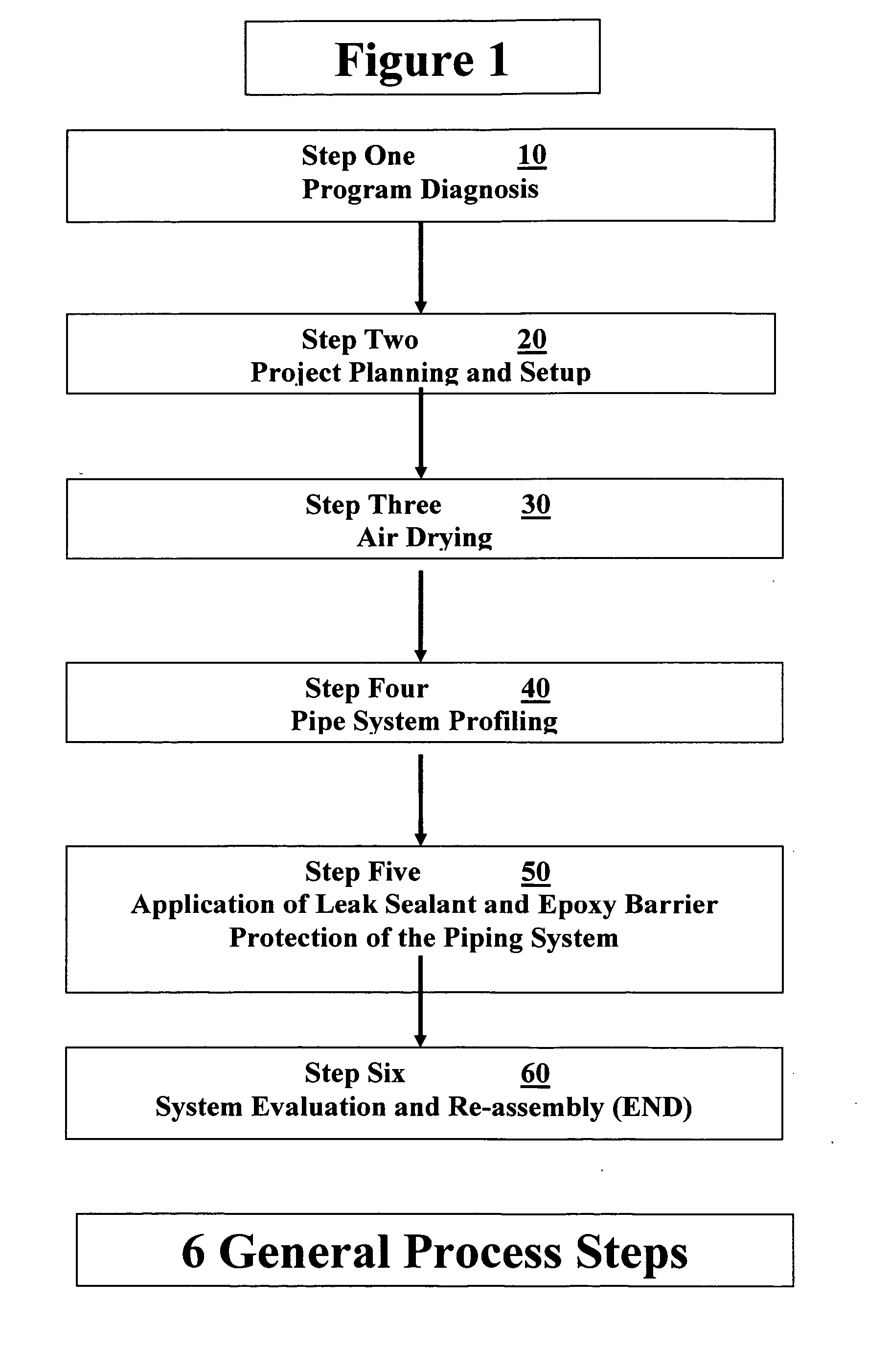

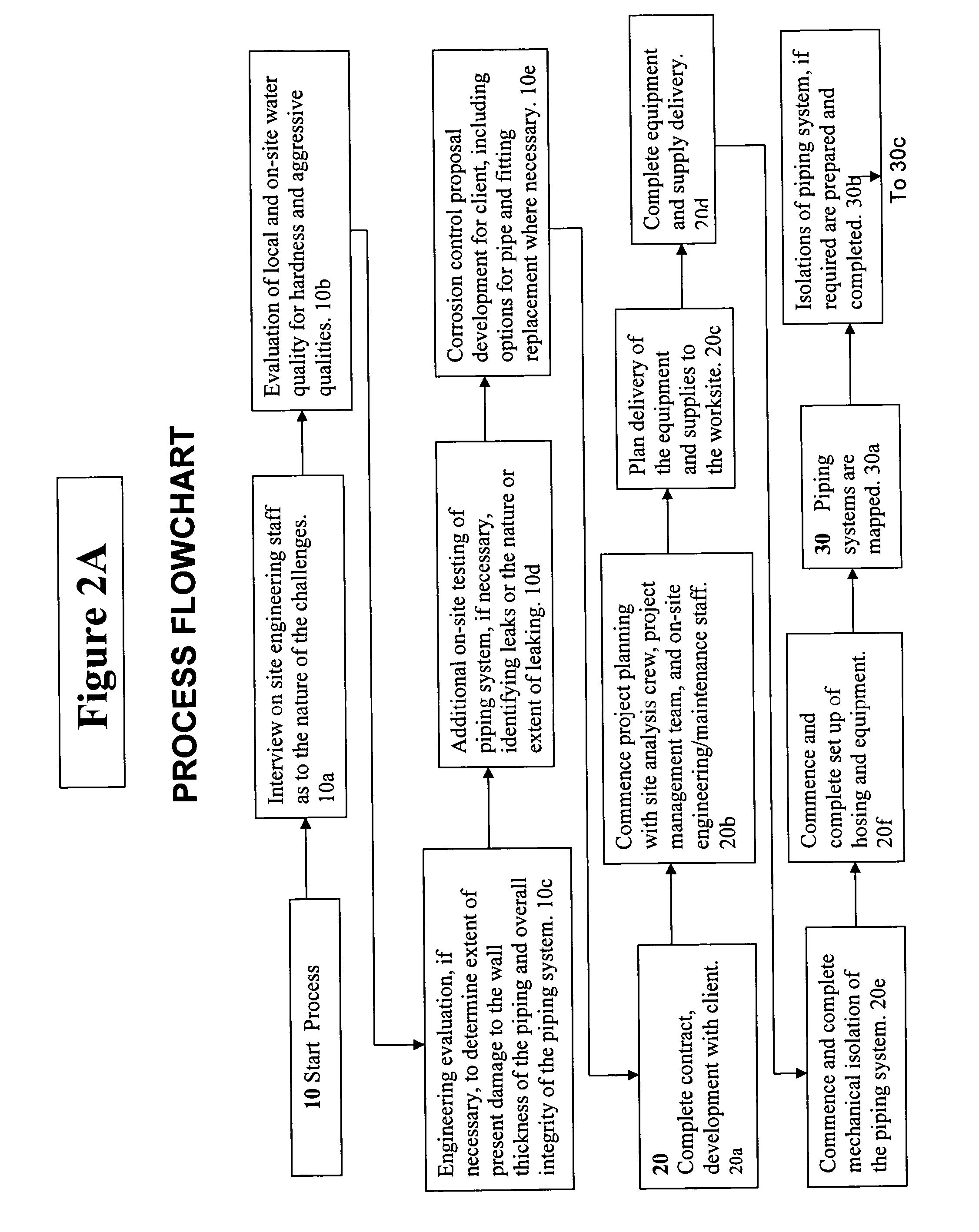

Methods and systems for coating and sealing inside piping systems

Methods and systems for cleaning, coating and sealing leaks in existing pipes, in a single operation. A piping system can be cleaned in one pass by dry particulates forced and pulled by air throughout the piping system by a generator and a vacuum. Pipes can be protected from water corrosion, erosion and electrolysis, extending the life of pipes such as copper, steel, lead, brass, cast iron piping and composite materials. Coatings can be applied to pipes having diameters up to approximately 6″. Leak sealants of at least approximately 4 mils thick can cover insides of pipes, and can include novel mixtures of fillers and epoxy materials, and viscosity levels. A positive pressure can be maintained within the pipes during applications. Piping systems can be returned to service within approximately 96 hours.

Owner:PIPE RESTORATION TECH

Chemical deplating solution and deplating method suitable for removing tin-nickel coating on surface of brass

InactiveCN101775601AImprove the status quo of low dissolution rateImprove work efficiencyWater bathsTin

The invention discloses a deplating solution and a deplating method thereof for tin-nickel coating (commonly called plated scrap) on the surface of brass. The deplating solution comprises oxidizer, accelerator, complexing agent and inhibitor, and the deplating solution is prepared by adding water to the reagents, stirring, dissolving, then putting in a water bath and slowly heating. The oxidizer adopts 65-68% nitric acid, the accelerator adopts 36-38% hydrochloric acid, the complexing agent adopts citric acid and the inhibitor adopts benzotriazole. After being deplated by the deplating solution of the invention, the surface of the brass is bright, the color of the substrate is basically unchanged, and the brass has no pinholes and small corrosion amount.

Owner:HEFEI UNIV OF TECH

Controlled fluid energy delivery burst cartridge

A modified gas delivery cartridge. A conventional straight-sided brass cartridge case is primed and then filled with solid propellant. A burst cup is then inserted in the case mouth. The burst cup is embossed with a cross or other shape to promote predictable rupture. Once the burst cup is in place, the upper edges of the cartridge case are rolled over the burst cup. In operation, the propellant is ignited to produce pressure within the sealed case. This pressure builds steadily until the embossed cross in the burst cup ruptures. The propellant gases are then vented in a metered fashion through the ruptured burst cup. However, the burst cup is retained by the case so that no solid object escapes the high pressure cartridge. In addition, by carefully designing the shape of the burst cup and the components surrounding it, it is possible to create an efficient expansion nozzle to better meter the propellant gases.

Owner:MARTIN ELECTRONICS

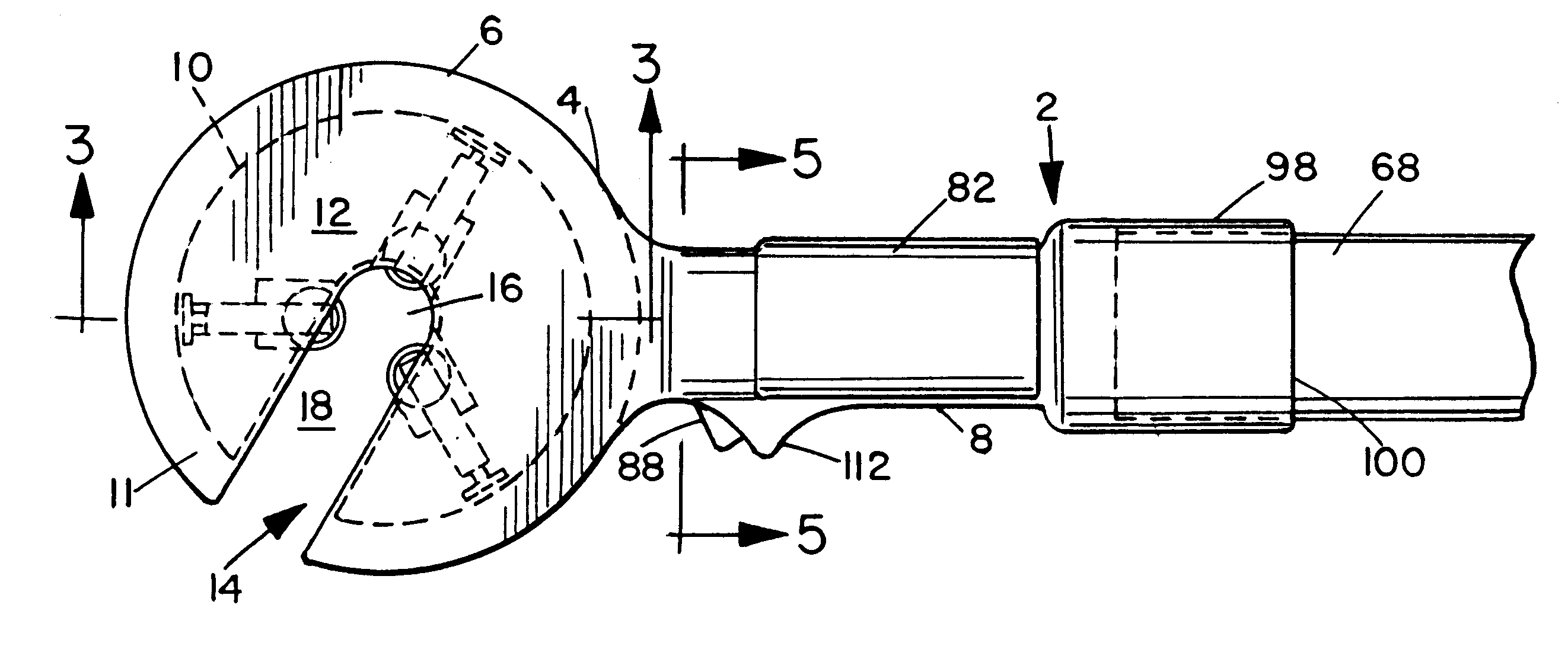

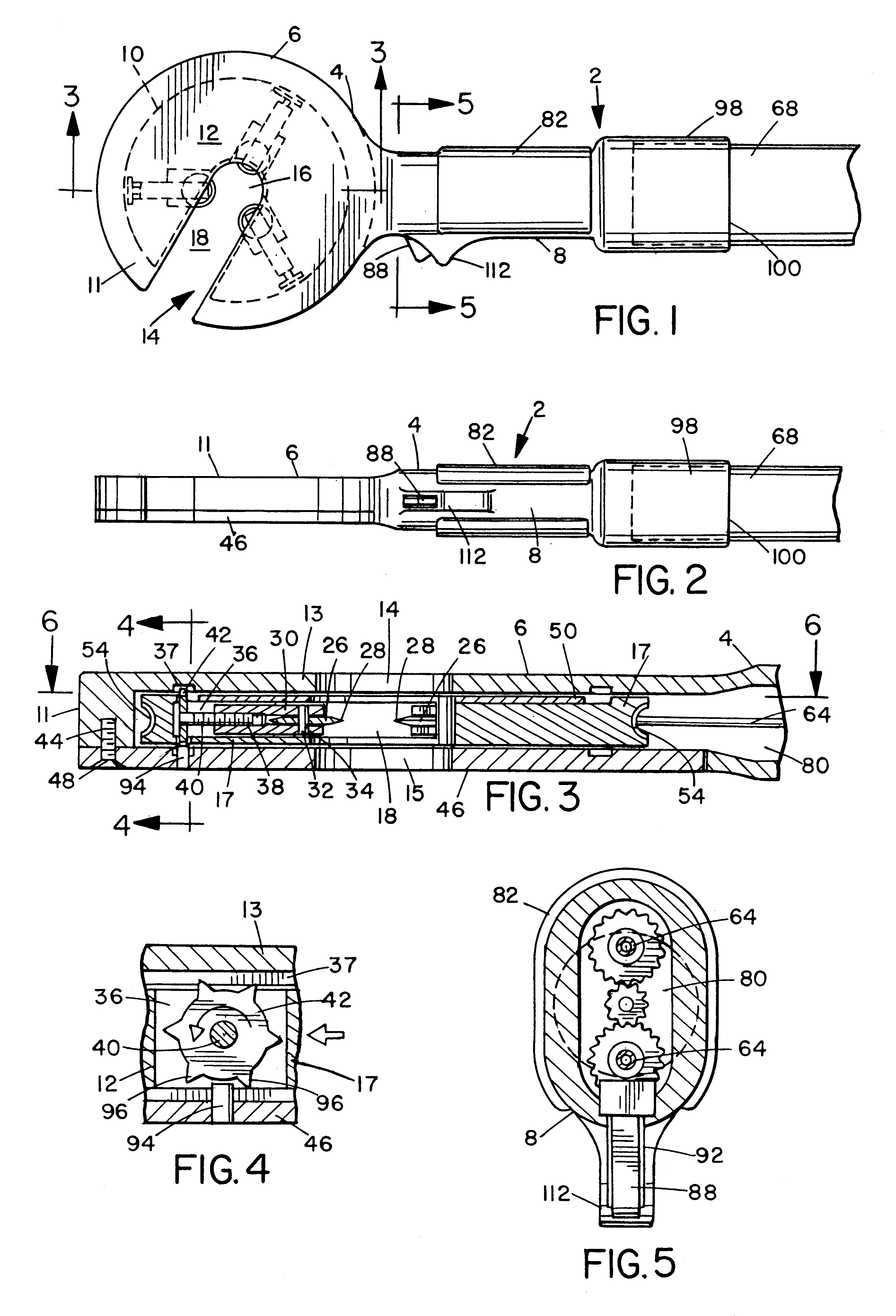

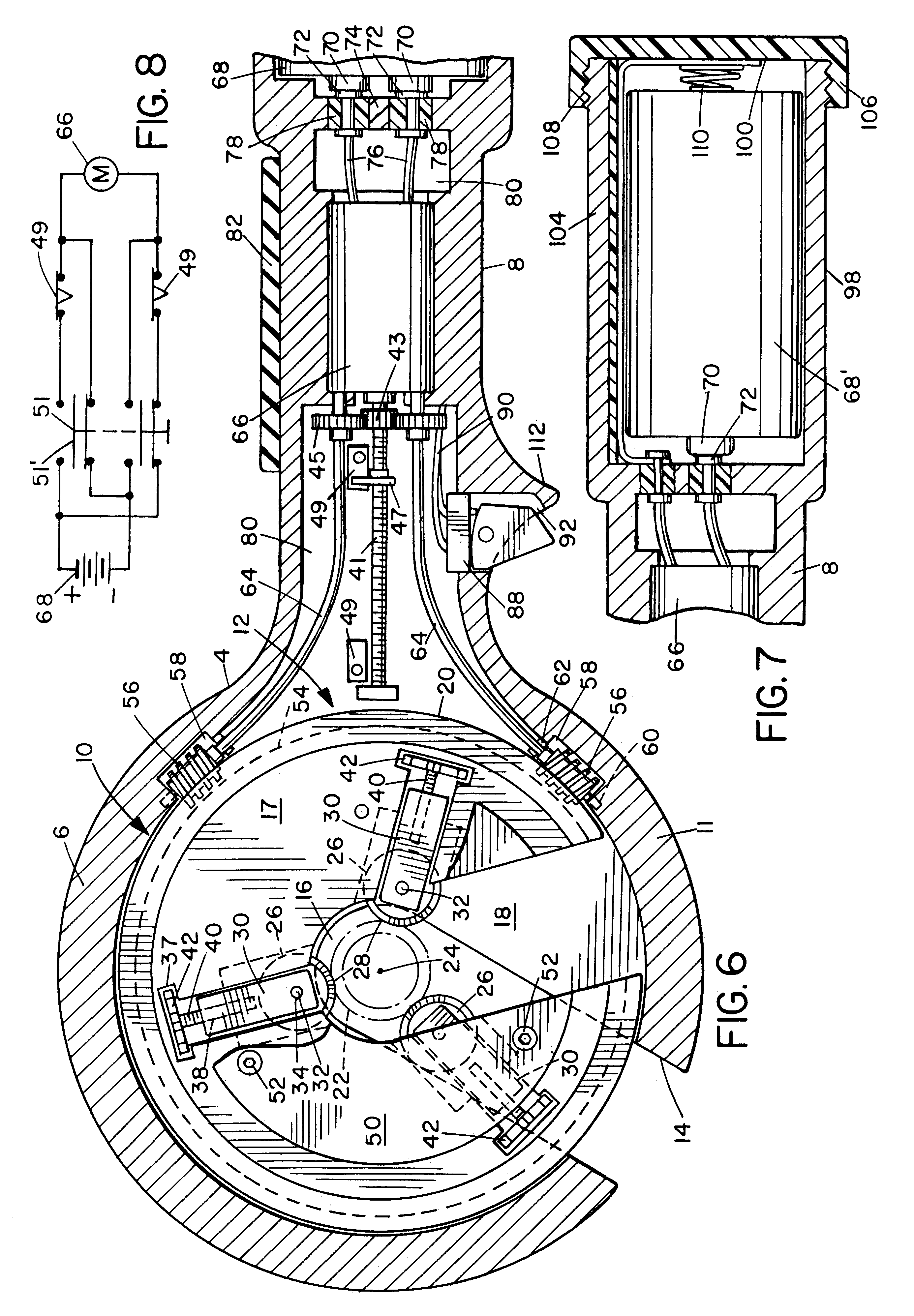

Power-driven hand-held tubing cutter

A motor driven, hand-held tubing cutter is disclosed, which can be held stationary by a worker while cutting the tubing, and does not require that the tubing be held in a vise or other clamping tool. The device is reversible, and upon completion of the cut, the device can be reset automatically to its initial position to receive a subsequent length of tubing for cutting. The tool has a motor-rotated cutting head into which the tubing to be cut is inserted, one or more cutting blades which are urged into cutting contact with the tubing wall by the motor-driven rotation of the head in cooperation with indexing bosses, and, once the tubing is cut through, reversal of the driving motors causes the blades to be retracted into the head, resetting the tool for further cutting. The tool may be used to cut any cuttable metal or plastic tubings, including tubing of aluminum, brass, copper, steel, ABS, PVC, polycarbonate, phenolic, etc.

Owner:WRATE LEONARD A

Method of manufacturing an assembly of brazed dissimilar metal components

InactiveUS6503640B2Improve abilitiesHigh strengthBuilding componentsElectron beam welding apparatusTitanium coatingSS - Stainless steel

Owner:DANA CANADA CORP

Continuous pickling and wiredrawing process of brass wire

ActiveCN101961736AImprove surface qualityReduce labor intensityDrawing diesCompression injuryProduction line

The invention relates to a continuous pickling and wiredrawing process of a brass wire, which is characterized in that: after being drawn out of a wire releasing disc, a brass wire blank is subjected to continuous processes of pickling, neutralizing, brushing, cleaning and wiredrawing. A continuous producing mode is used for connecting the pickling process and the drawing process of the brass wire together, namely that after an annealed brass wire blank is arranged on a wire releasing frame by one end of a production line, a finished product of the fine-drawn brass wire can be generated from the other end, therefore, the continuous producing mode has few processing and flowing processes and stops scrapes and compression injuries in the flowing process; pickled products are wiredrawn in a shorter period to ensure better brightness and consistency of product appearance and obviously increase the surface quality of the finished product of the brass wire; the processing process has high automation degree, reduces labor intensity of staffs and increases production efficiency; when the brass wire is in the pickling process, an oxide layer on the surface of the brass wire only needs to be loosened; and therefore, when the brass wire is pickled, nitric acid does not need to be added, the usage amount of acid liquor is greatly reduced, and the production cost is reduced.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Environment friendly free-cutting leadless copper alloy material and processing technology

ActiveCN101386931ARealize the purpose of lead-free environmental protectionEliminate intermediate annealing processRare-earth elementManganese

The invention relates to an environment-friendly free cutting copper alloy material. The compositions of the environment-friendly free cutting copper alloy material are 30 to 45 percent of zinc, 0.05 to 2.0 percent of aluminum, less than or equal to 1.0 percent of iron, less than or equal to 0.5 percent of boron, less than or equal to 0.5 percent of titanium, less than or equal to 0.3 percent of one element or more than one element in a rare earth element RE system, less than or equal to 0.01 percent of plumbum, less than or equal to 0.1 percent of stibium, less than or equal to 0.3 percent of unavoidable impurities and the balance being copper; and 0.05 to 1.6 percent of phosphor or 0.05 to 3.0 percent of silicon or 0.1 to 3.0 percent of magnesium or 0.05 to 3.0 percent of silicon and 0.05 to 0.5 percent of tin or 0.05 to 3.0 percent of silicon, 0.05 to 0.5 percent of tin and 0.05 to 0.5 percent of manganese are added into the compositions for mixture, and the mixture is cast into blanks after mixture. The lengthening and drawing coefficient is controlled to between 1.05 and 2.6, and the annealing temperature is controlled to between 300 and 400 DEG C. The copper alloy has the cutting performance of leaded brass, simplifies the processing technique, saves the step of intermediate annealing, and reduces the processing cost.

Owner:中铝洛阳铜加工有限公司

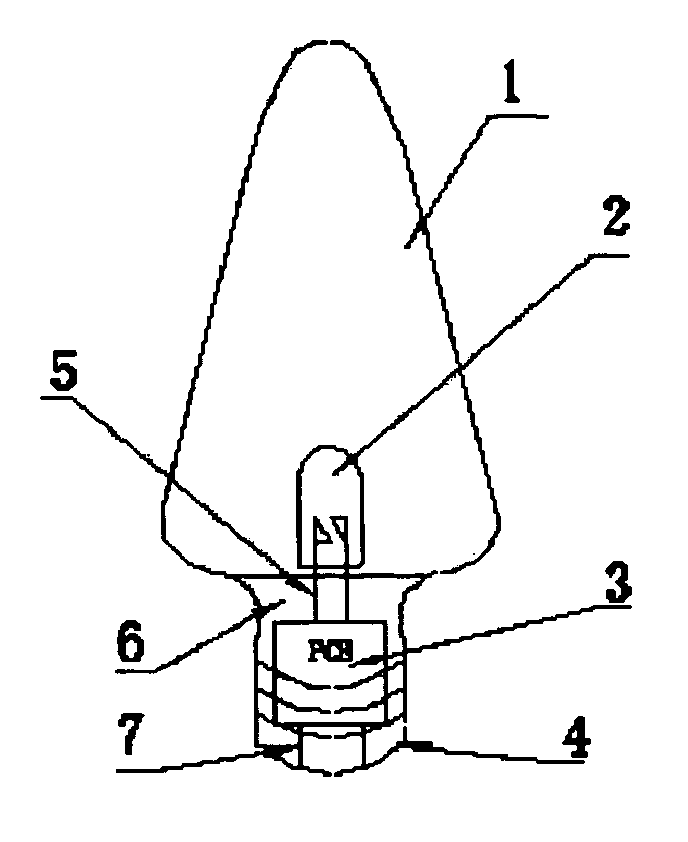

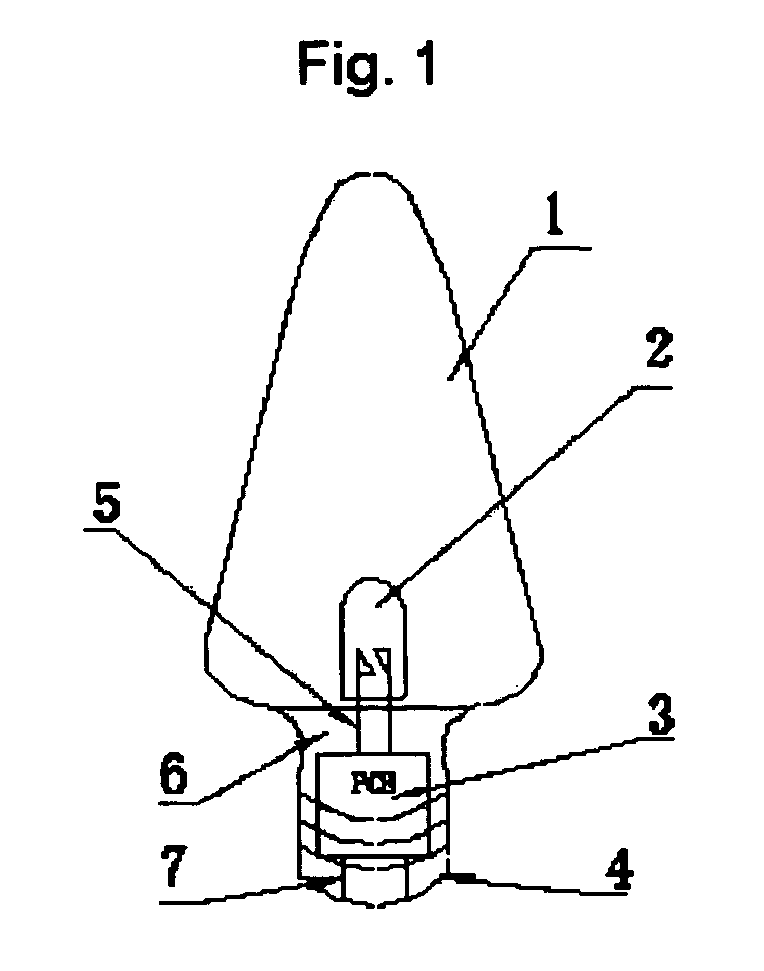

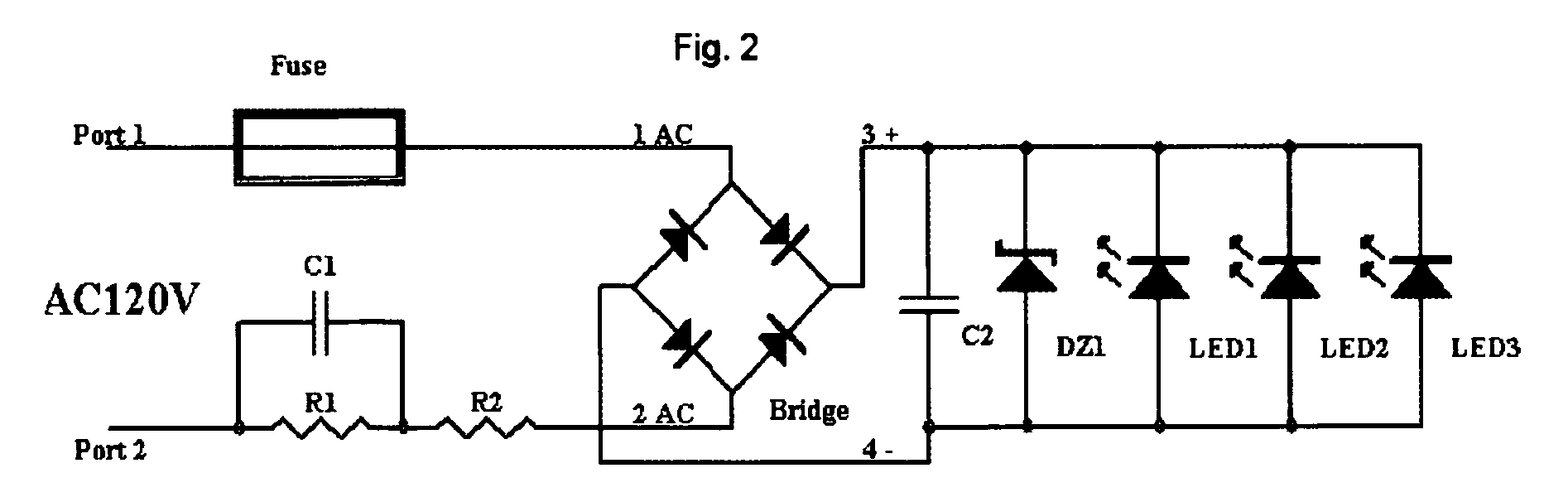

C7, C9 LED bulb and embedded PCB circuit board

The invention presents a new design of C7 or C9 type LED bulb and its embedded PCB electronic circuit board structure, comprising a lamp cover, LEDs, a PCB circuit board and a base. The bulb houses one or multiple number of LEDs. The LEDs are soldered on the PCB board that is embedded inside of the base. The PCB board power input ports connect to the brass base or are directly wired to outside the base. The base and the lamp cover may be attached together by means of bonding (thermal, sonic or solvent), friction interference fit, adhesive or simply by screwing the lamp cover into the threaded base. The PCB board, utilizing a bridge design, allows the LED bulb to be directly powered by 110-120V AC voltage power sources. The simple bulb design significantly reduces the weight of the entire product and power consumption.

Owner:YU JING JING

EDM wire

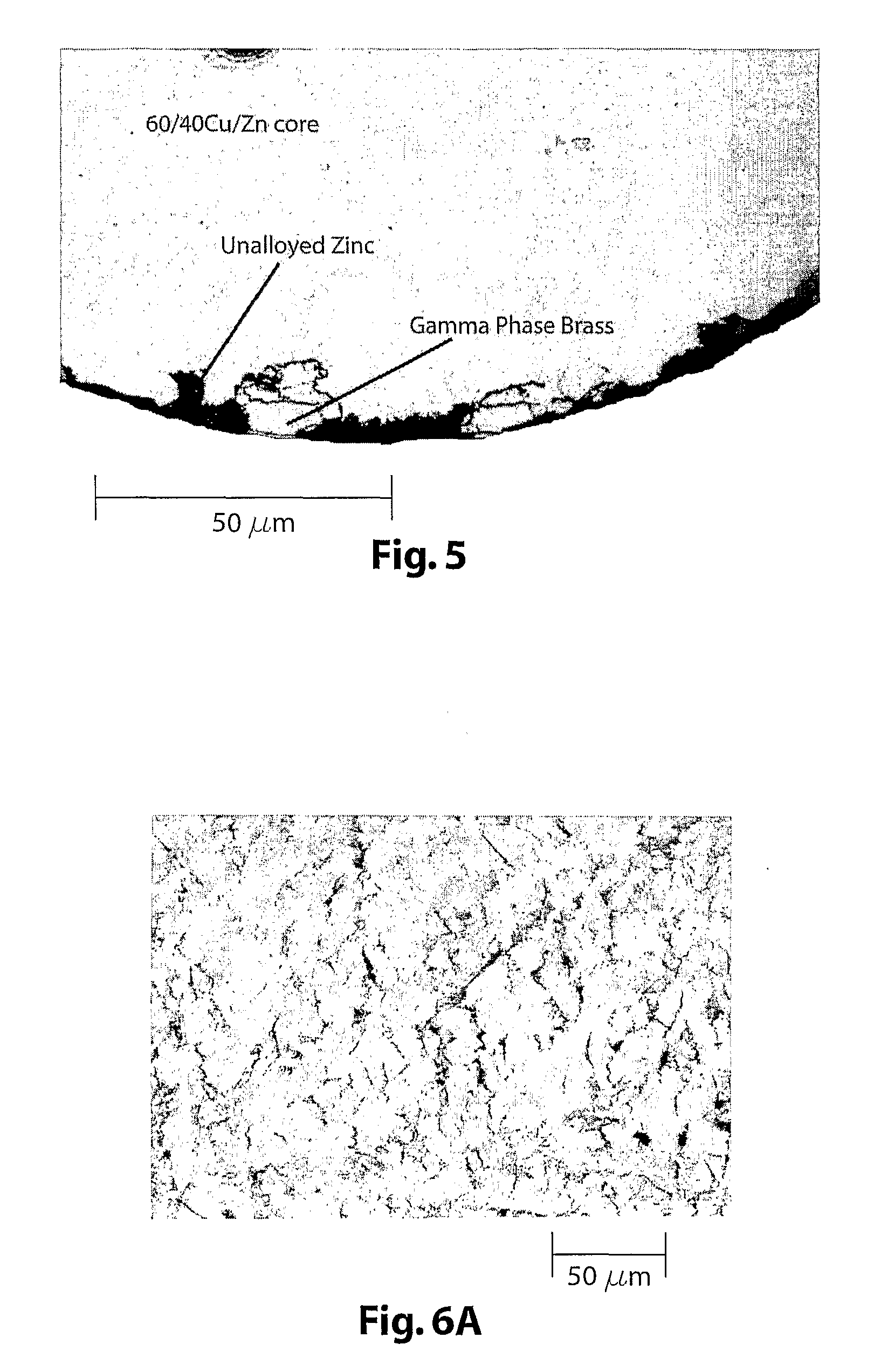

An EDM wire having an outer coating of gamma phase brass with an overlayer of continuous unalloyed zinc or ductile epsilon phase brass entrapping the gamma phase and a process for manufacturing the EDM wire is provided. A second process for synthesizing a ductile epsilon phase brass coating on the aforementioned and other substrates is also provided. The first process includes coating a copper bearing metallic core with zinc. The zinc coating is then converted to gamma phase brass via a diffusion anneal and subsequently re-coated with zinc prior to being cold drawn to its finish diameter.

Owner:THERMOCOMPACT

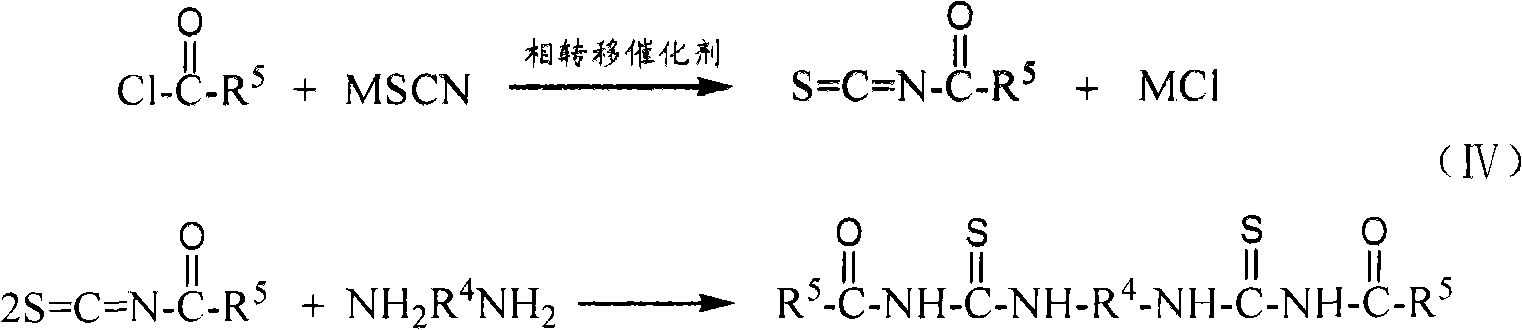

Sulphide ore floation collector and use method of diacyl bis-thiourea and preparation method thereof

InactiveCN101337206AEasy to makeEfficient flotation separationOrganic chemistryFlotationMagmaThiourea

The invention discloses the application processes and the preparation methods of a sulphide ore flotation collector as well as a diacyl bis-thiourea. The invention relates to a novel collector used for high efficiently recycling valuable sulfide minerals from metal sulphide ores; the compositions of the sulphide ore flotation collector include diacyl bis-thiourea surface active agents; the diacyl bis-thiourea compound is shown in the constitutional formula (1) or (2). The collector has strong collecting ability to copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and has good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc., thereby realizing the high efficient flotation separation of the copper sulphide minerals and ferric sulfide minerals when the pH value of ore magma is below 11, reducing the used amount of lime, and improving the comprehensive recovery of copper sulphide ores.

Owner:CENT SOUTH UNIV

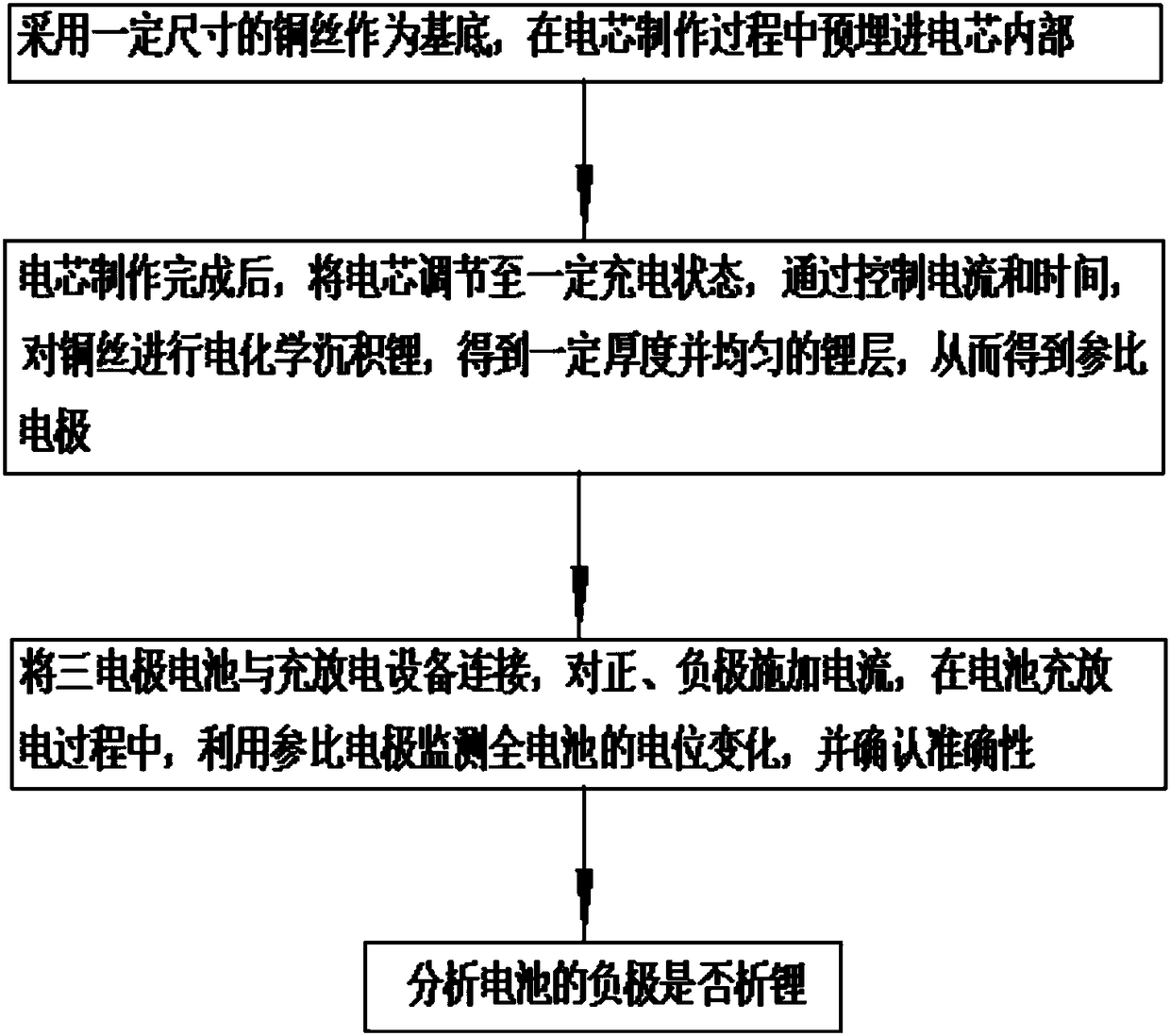

Experiment method for monitoring cathode lithium precipitation via use of reference electrode

InactiveCN108427077AIncrease credibilityFinal product manufactureElectrical testingElectrical batteryCharge discharge

The invention discloses an experiment method for monitoring cathode lithium precipitation via use of a reference electrode. The method comprises the following steps: a brass wire of a certain dimension is used as a substrate and is pre-embedded in an electrical core during electrical core making processes, the electrical core is adjusted to a certain charging state after the electrical core makingprocesses are finished, the brass wire is subjected to electrochemical deposition of lithium, a uniform lithium layer of a certain thickness is obtained, and therefore the reference electrode is obtained; a three electrode battery is connected with charge-discharge equipment, a current is applied to an anode and a cathode, electric potential change of a whole battery is monitored via user of thereference electrode during battery charging and discharging processes, and accuracy is confirmed; at last whether lithium precipitation occurs in the cathode of the battery is analyzed. The beneficialeffects of the method are that the electric potential change of all electrodes in the battery can be monitored via use of the reference electrodes through an electrochemical method, and breakdown points of cathode lithium precipitation can be determined; compared with a conventional disassembling observation method, the method disclosed in the invention is advantaged by simplicity, convenience, high credibility and high practicality.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

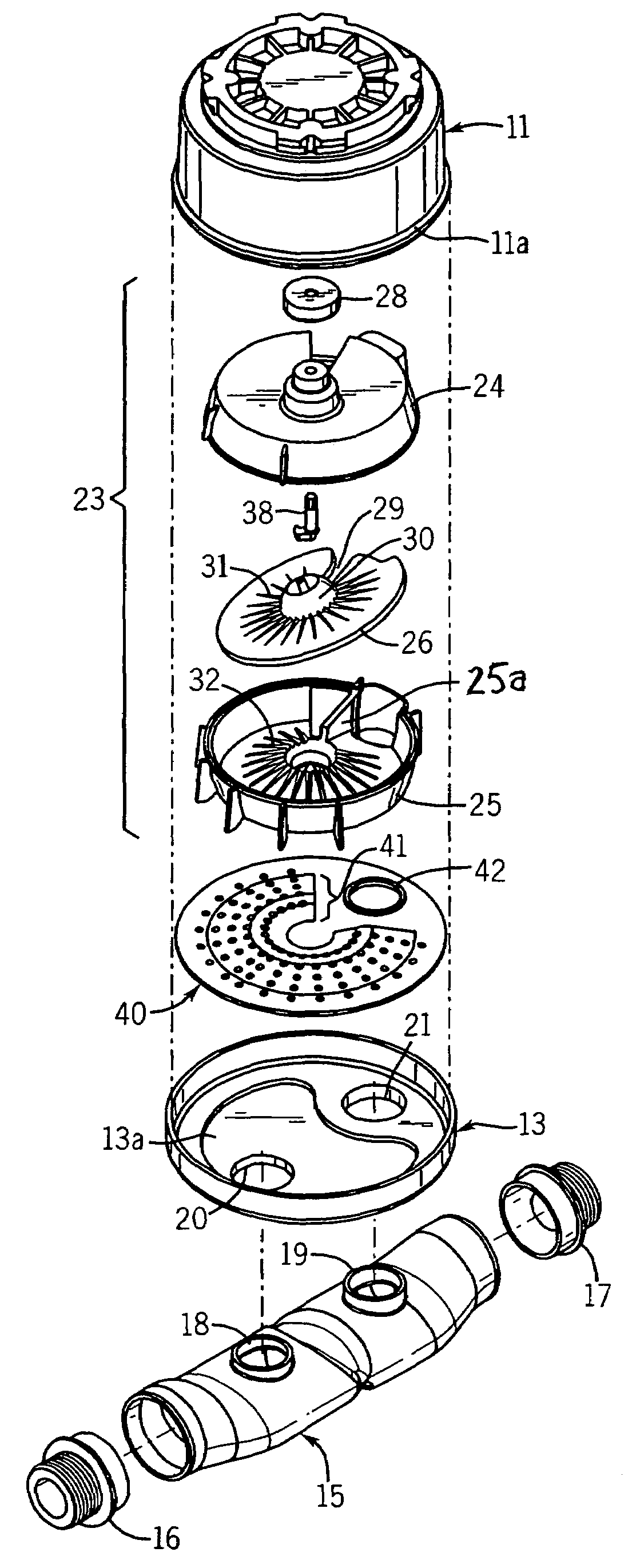

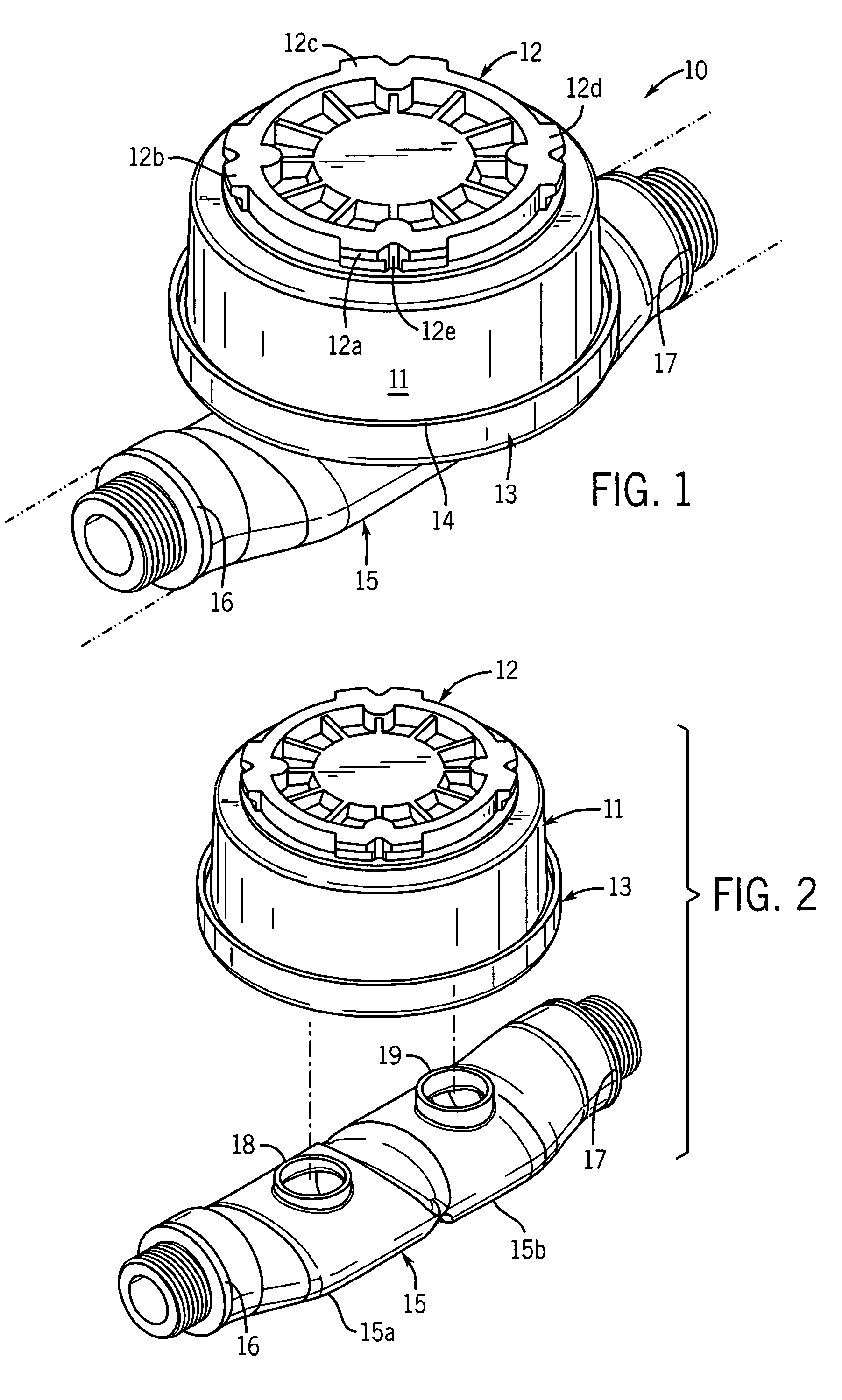

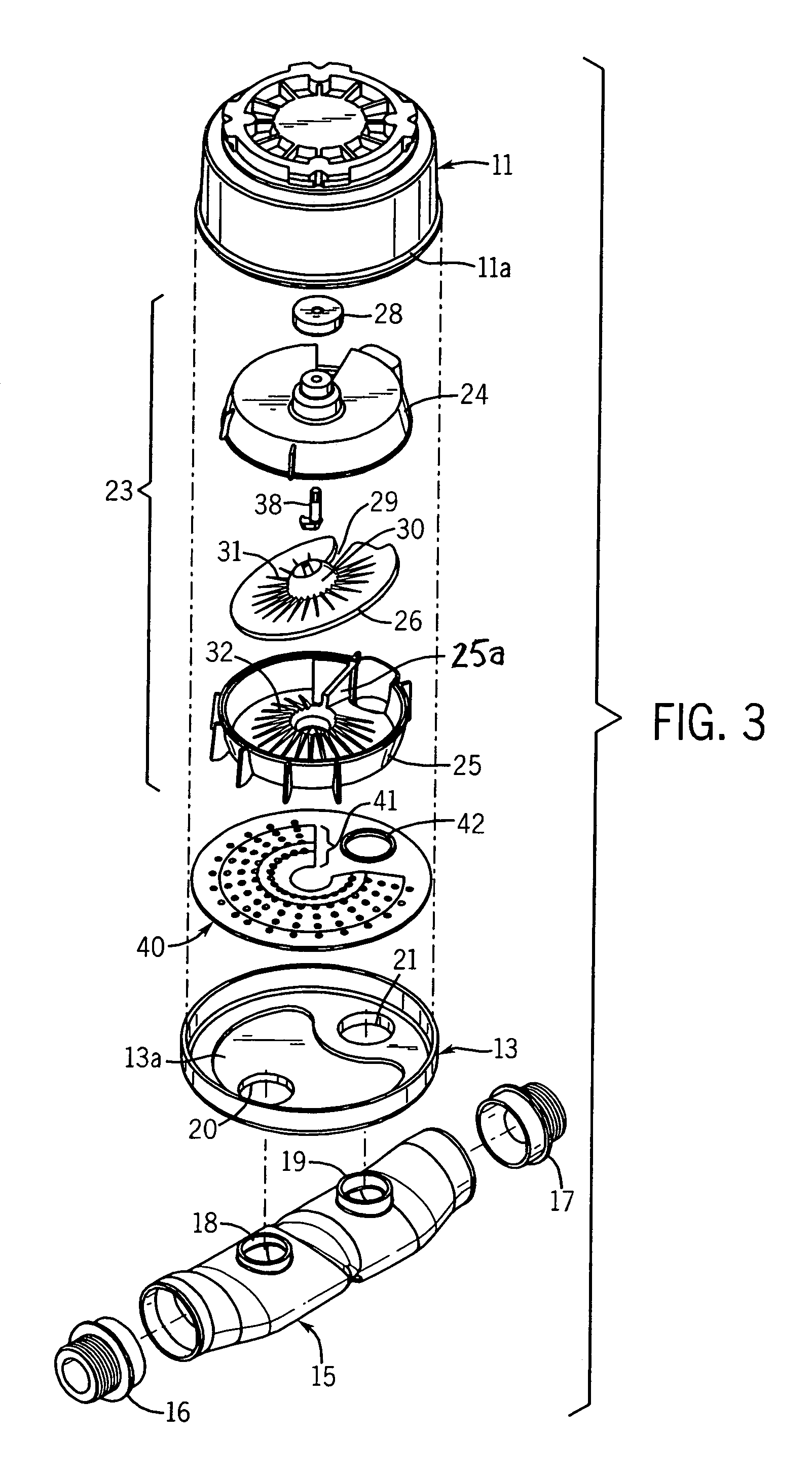

Meter housing assembly and method of assembly

ActiveUS7143645B2Reduce manufacturing costVolume/mass flow by mechanical effectsVolume meteringFoundryLine tubing

A water meter housing assembly (10) comprises a cylindrical, plastic housing body (11), a non-cast housing bottom (13) of hydroformable or stamped brass, a single-piece strainer and sealing member (40) that is disposed in the housing bottom (13) and portions of non-cast hydroformable or stamped brass tubing (15) with spud ends (16, 17) for connection in a water supply line. The brass consists essentially of lead-free material. The assembly (10) is designed to provide a lower cost alternative to foundry cast meter housings. The assembly (10) also provides advantages in a method of vertical assembly that saves manufacturing cost.

Owner:BAKER MARK +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com