Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2626 results about "Spring steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spring steel is a name given to a wide range of steels used in the manufacture of springs, prominently in automotive and industrial suspension applications. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant deflection or twisting.

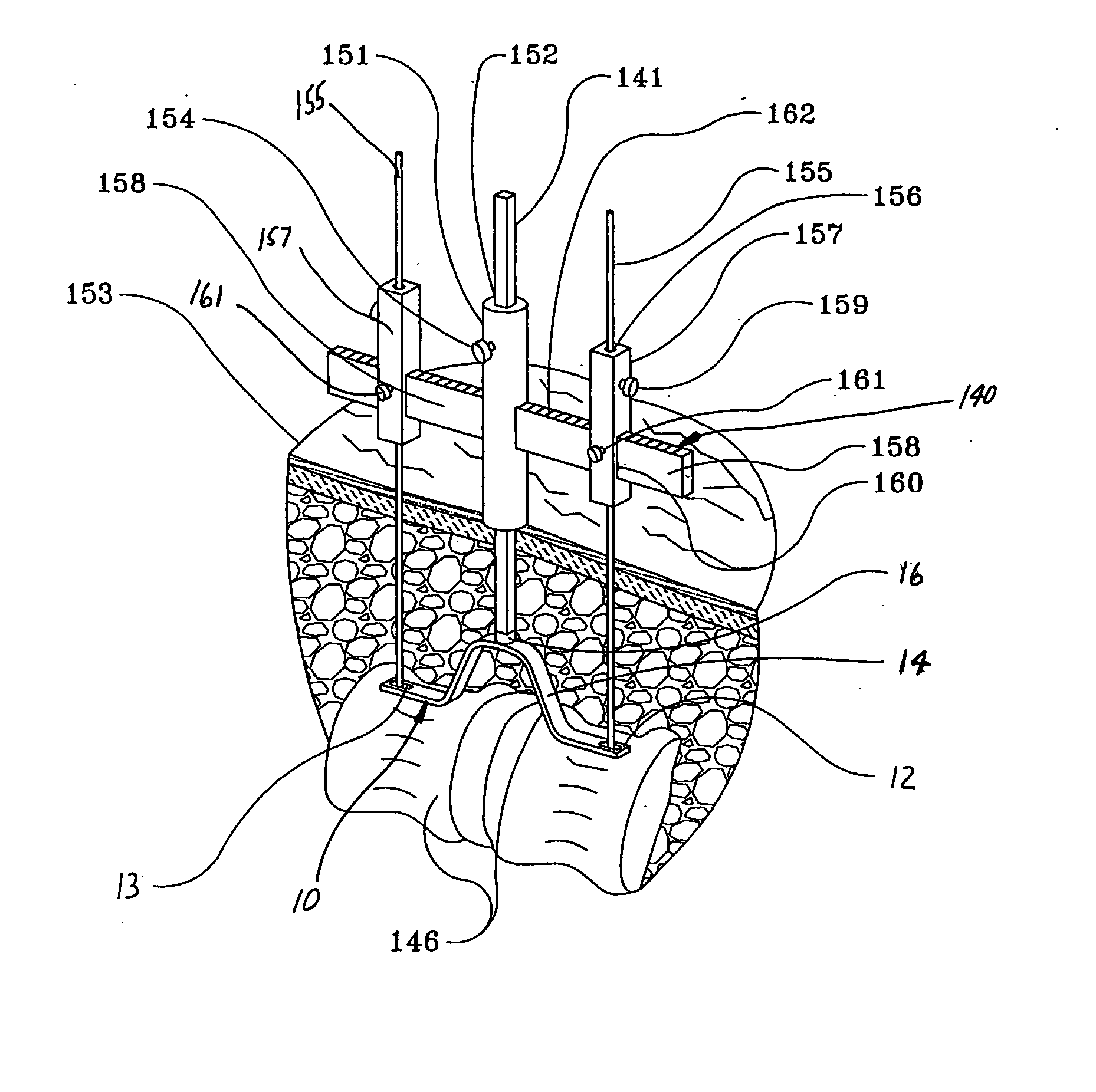

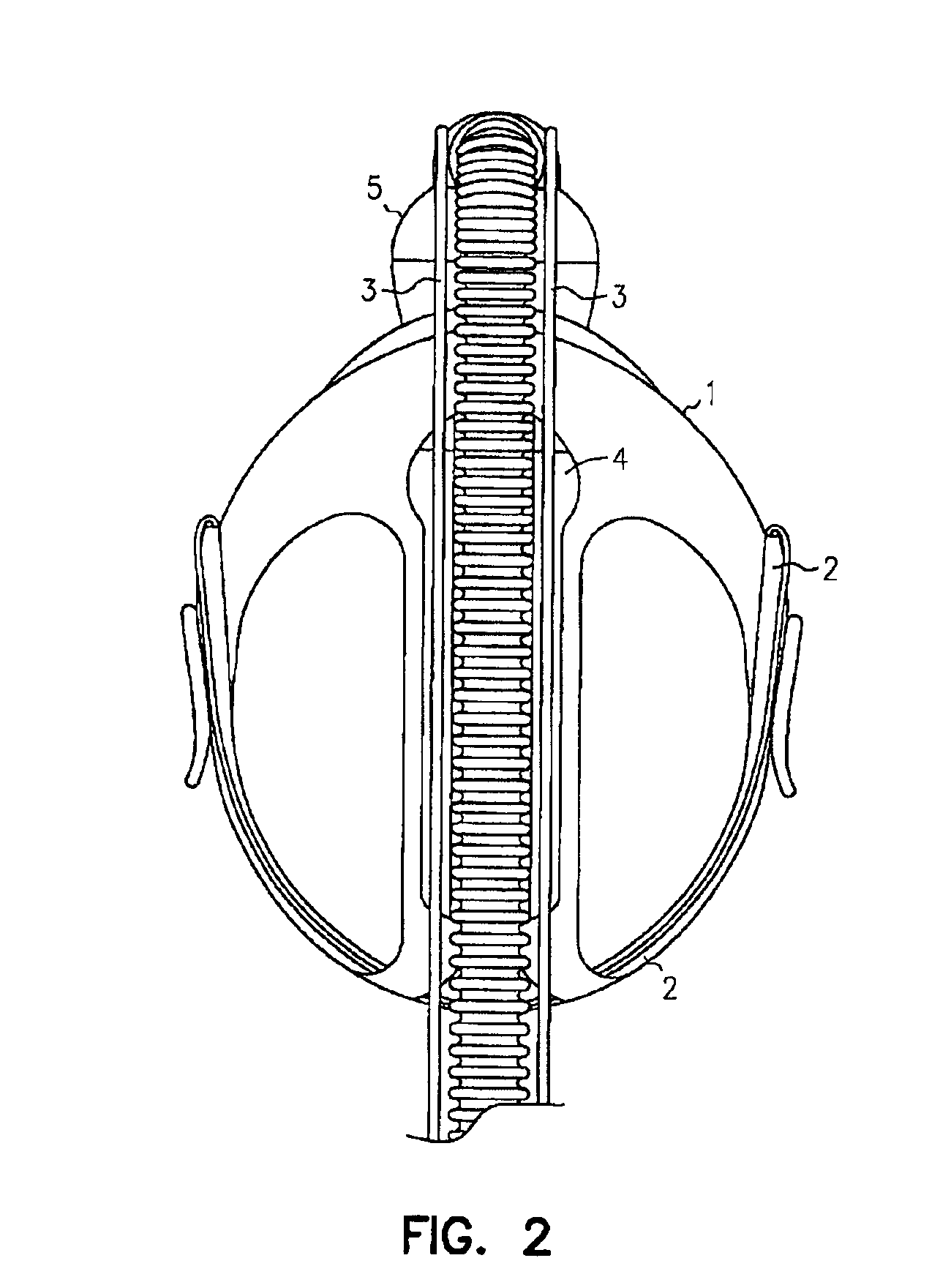

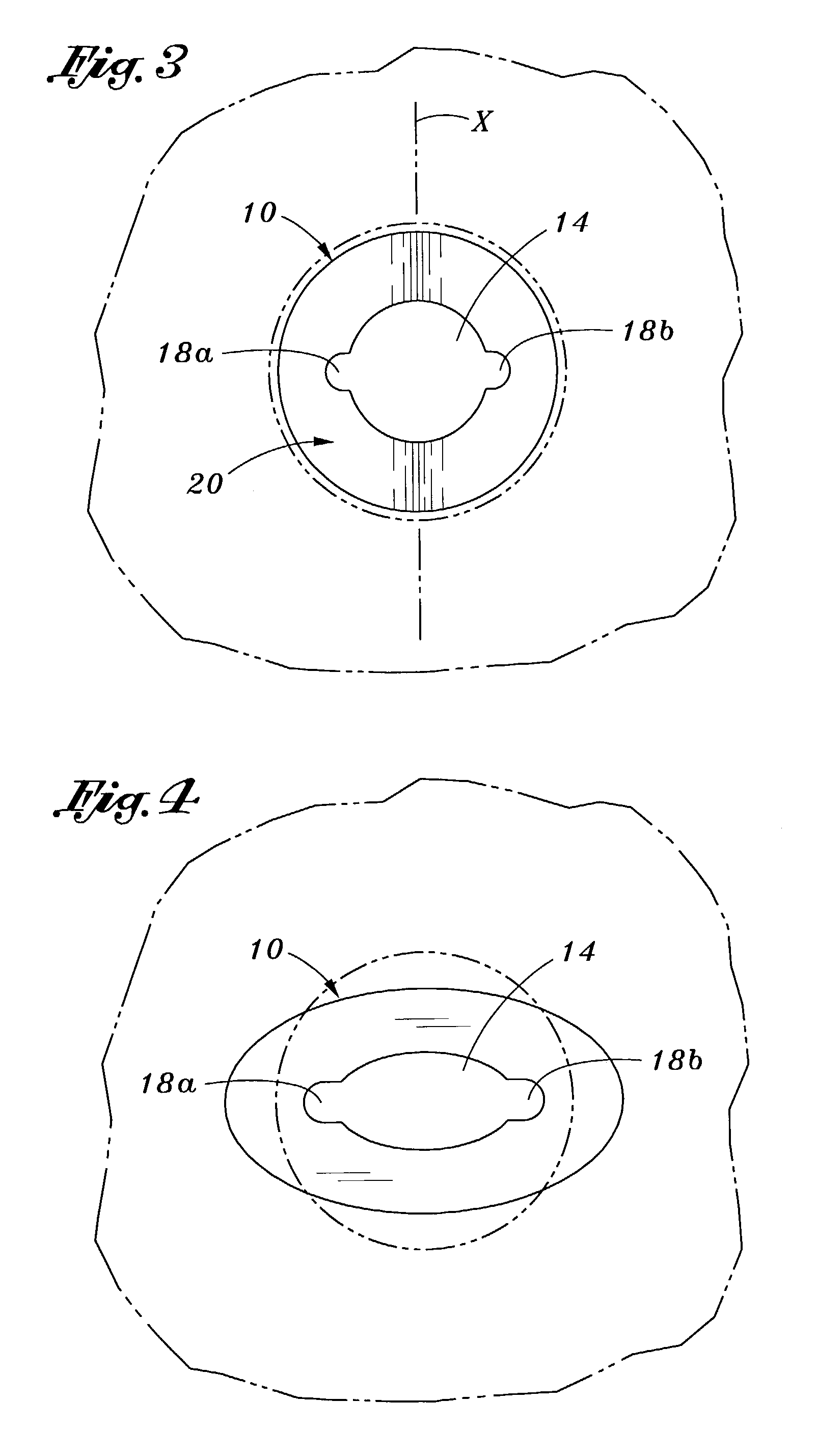

Artificial spinal joints and method of use

InactiveUS20050209694A1Preventing subluxationMaintain strengthInternal osteosythesisJoint implantsFiberCarbon fibers

An artificial spinal joint, consisting of a flexible or rigid member or a pair of moveably-joined, flexible or rigid segments, is formed into a spring-like shape, whose distal ends have feet with slots through which screws can be inserted to attach the artificial joint to vertebra whose facets (joints) are non-functional. The artificial spinal joint is able to prevent subluxation of the spine, while retaining the mobility of the spine and permitting angular deflection of the vertebra above and below a non-functional spinal joint. A jig is used to position tools and make passageways for screws to attach the artificial spinal joint to the vertebra or its pedicles or facets in a minimally invasive procedure. The rigid members or segments are bio-compatible and may be made of titanium, a titanium alloy, tantalum, medical grade stainless steel or carbon fibers in a matrix of a rigid, durable plastic. The flexible members or segments may be made of spring steel coated with a durable, bio-compatible material, small diameter carbon fibers in a flexible, durable plastic matrix, or a single shape or dual shape, superelastic memory metal. The feet, made of any of the rigid or flexible materials described above, may also be moveably attached to the proximal ends of the members or segments. Having the feet moveably attached to the segments facilitates insertion of the artificial spinal joint into the body by folding the feet parallel to the axis of the segments during insertion, and then unfolding the feet for attachment to the vertebra or its pedicles or facets. The artificial spinal joint may be inserted and attached to vertebra whose facets are non-functional in minimally invasive, moderately invasive or conventional surgical procedures.

Owner:TRIMEDYNE

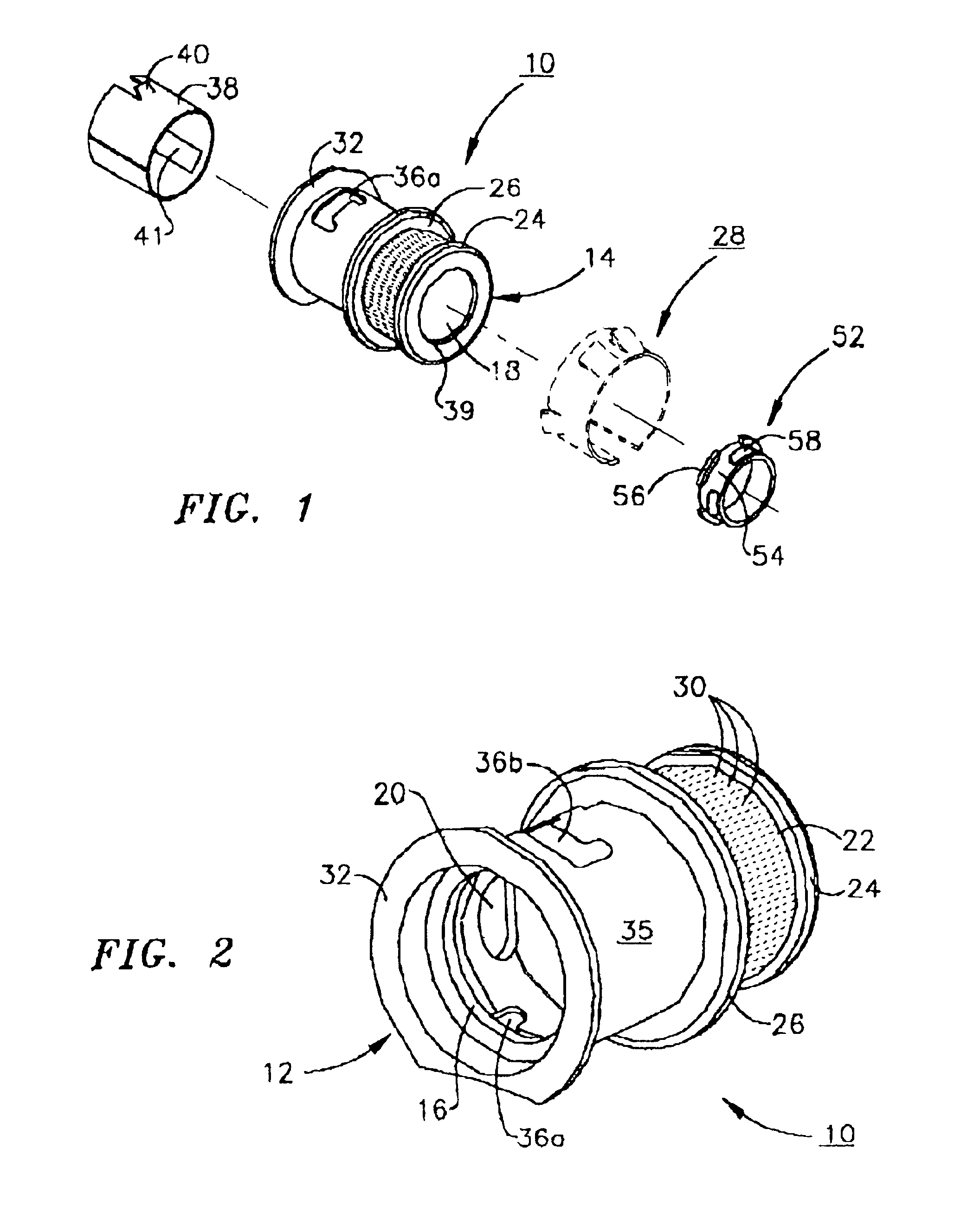

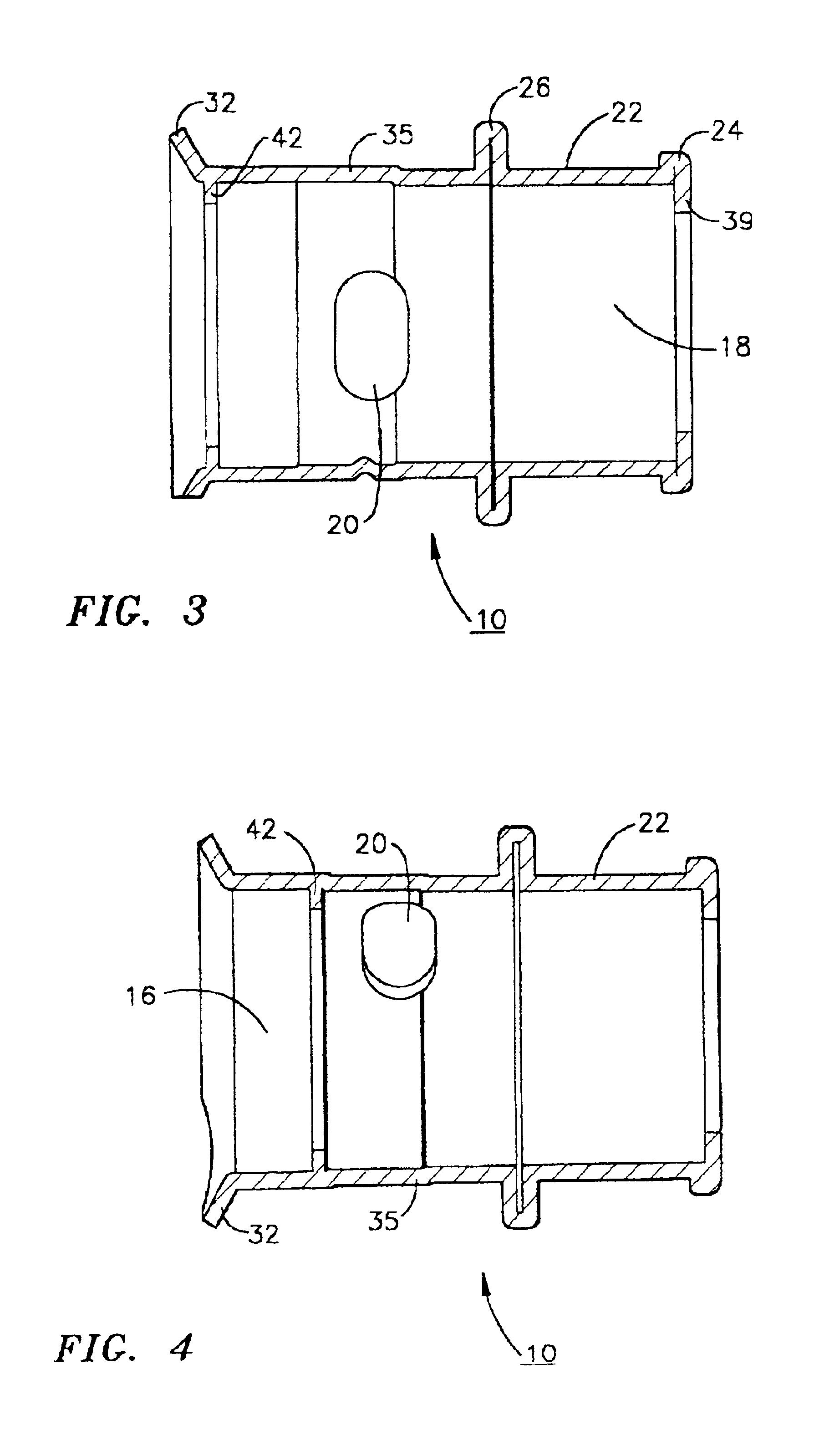

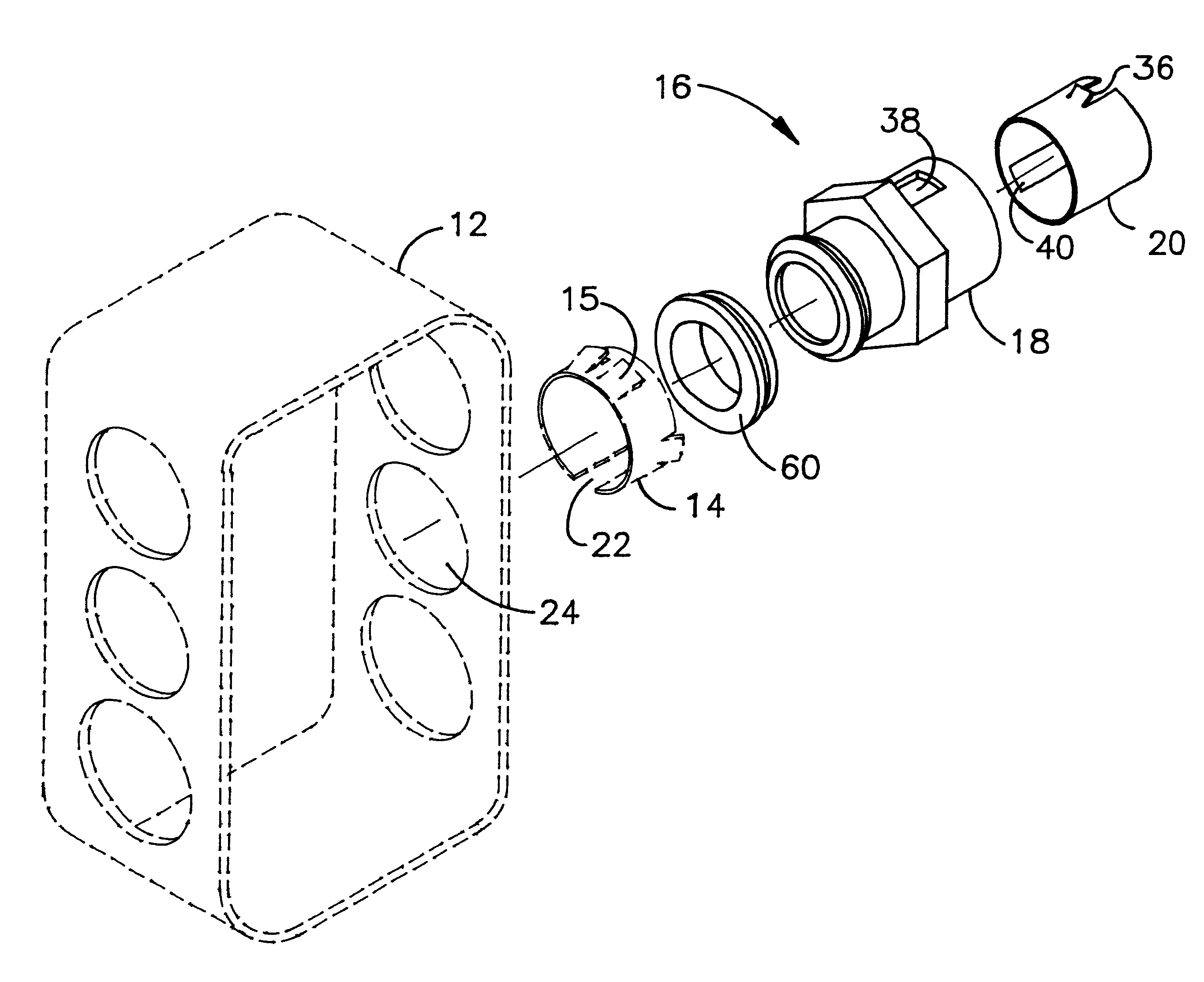

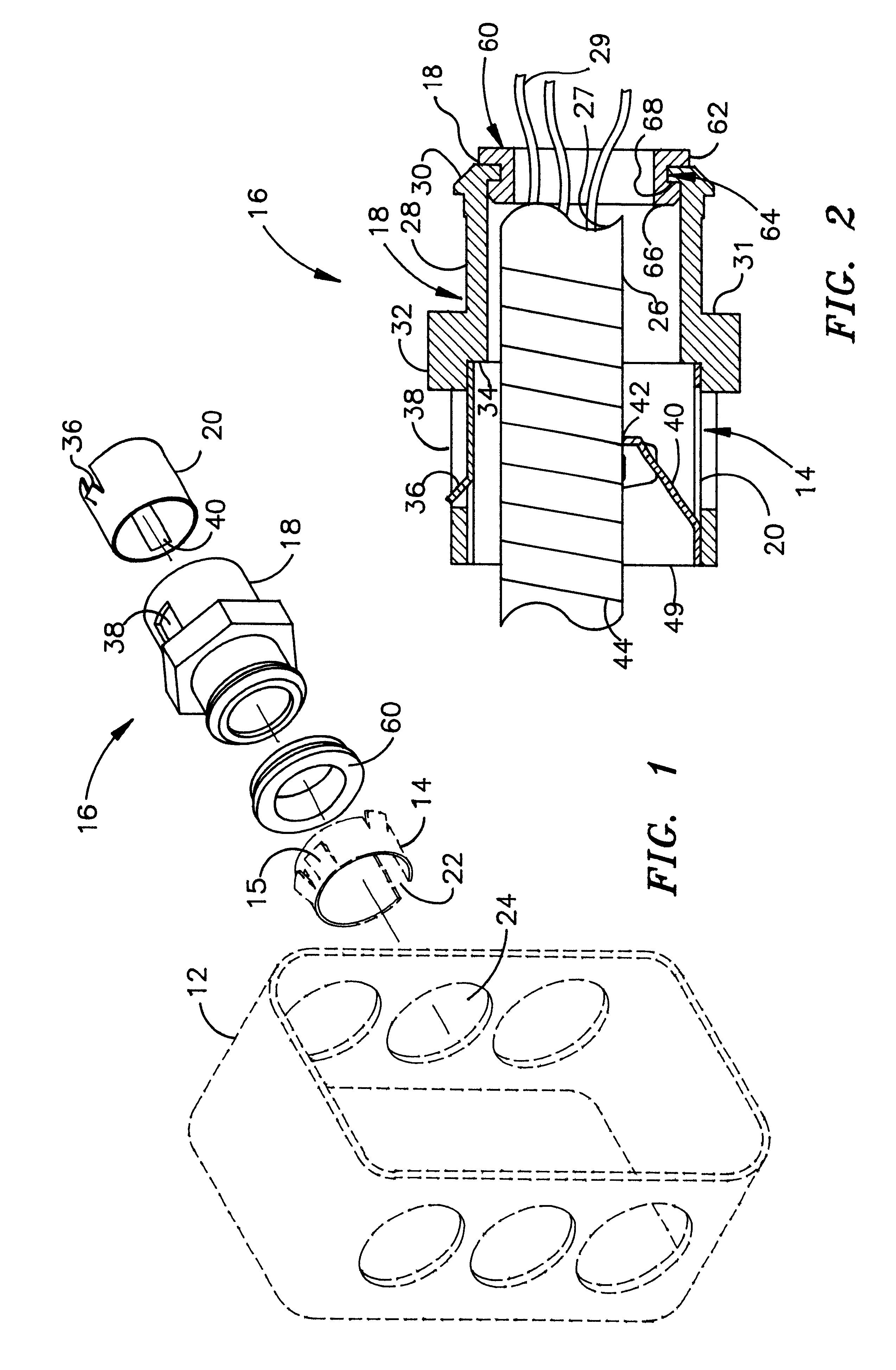

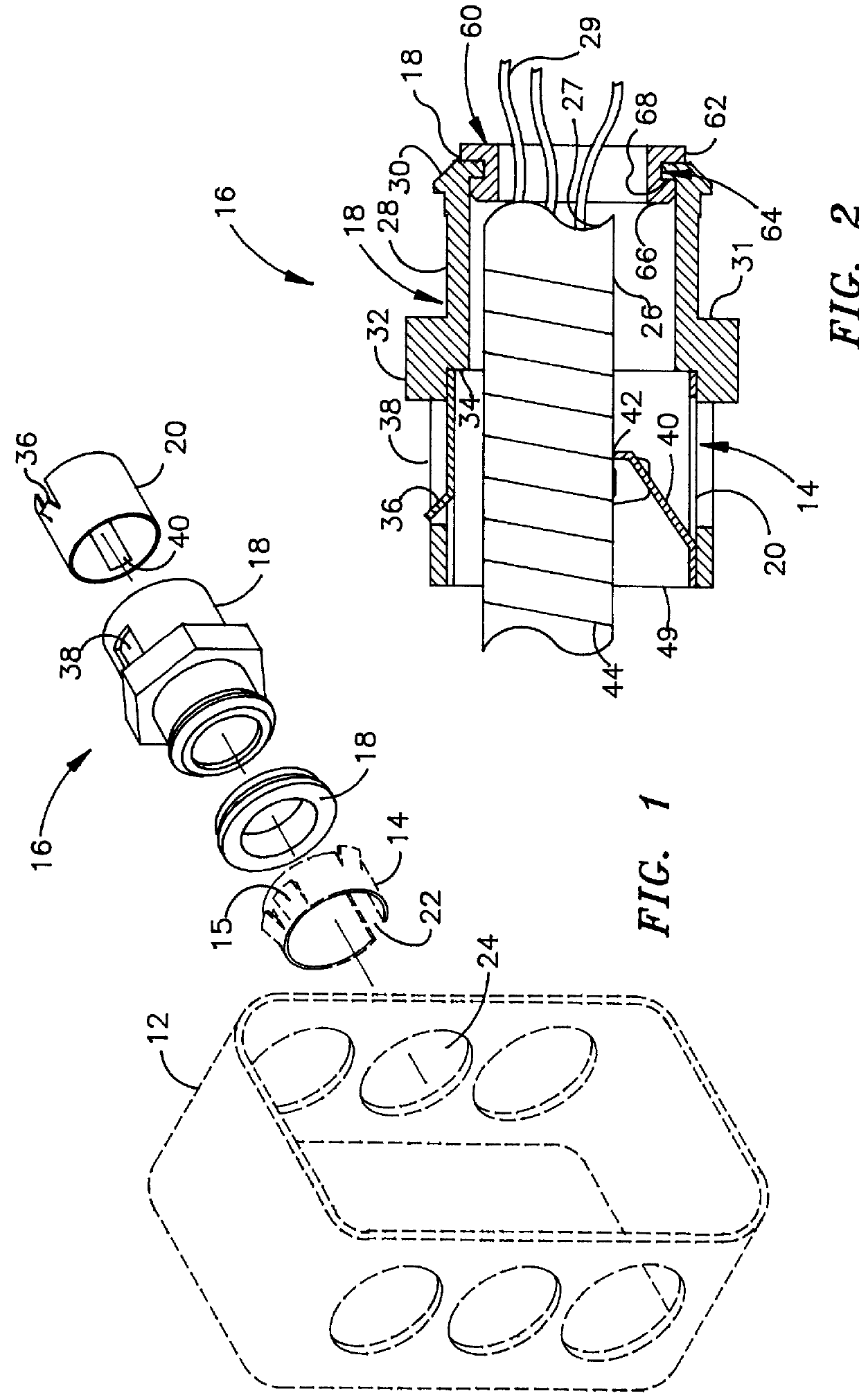

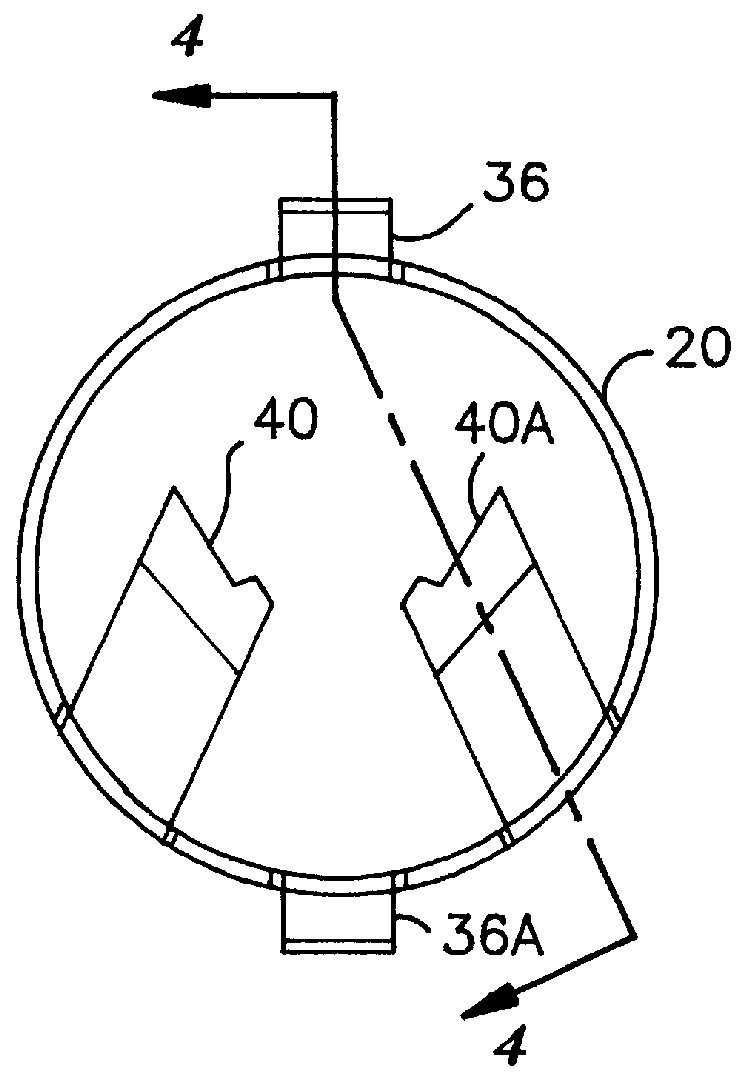

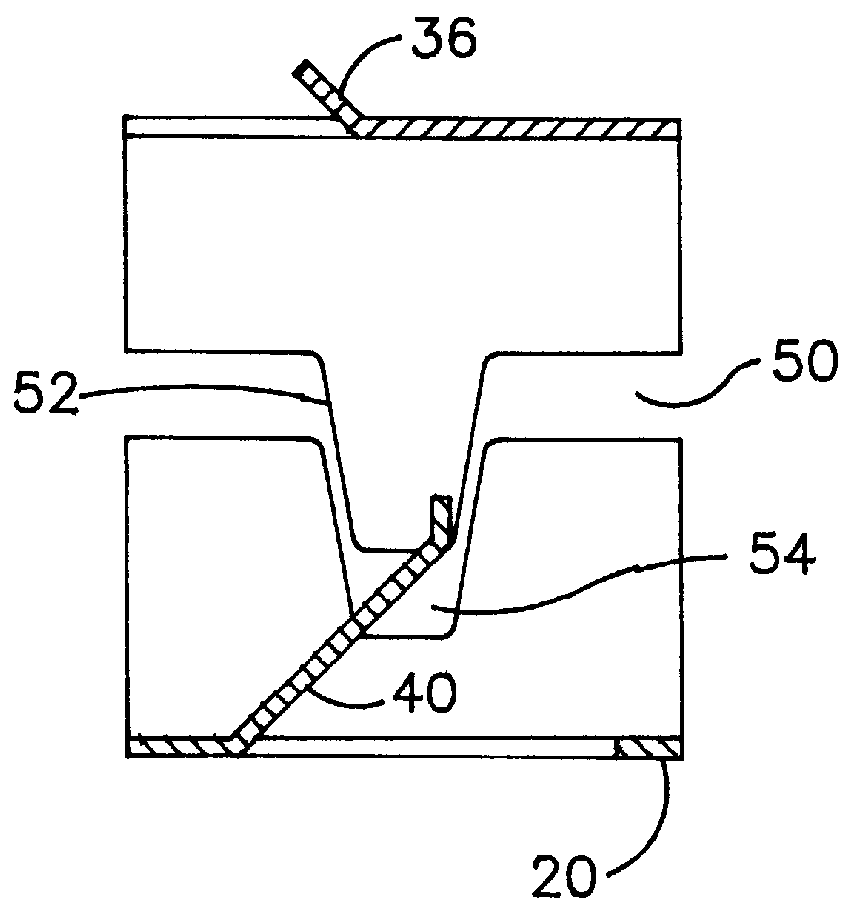

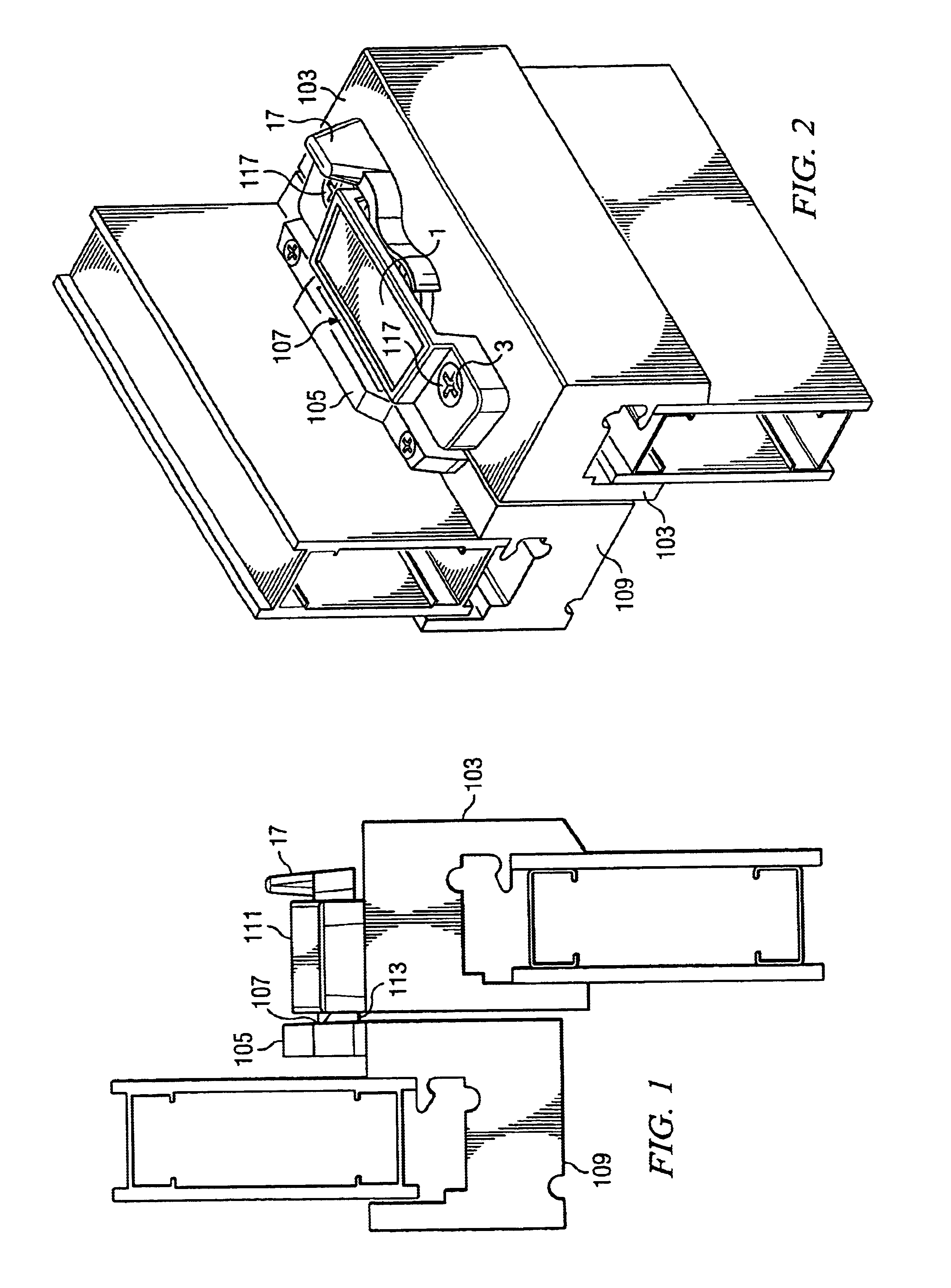

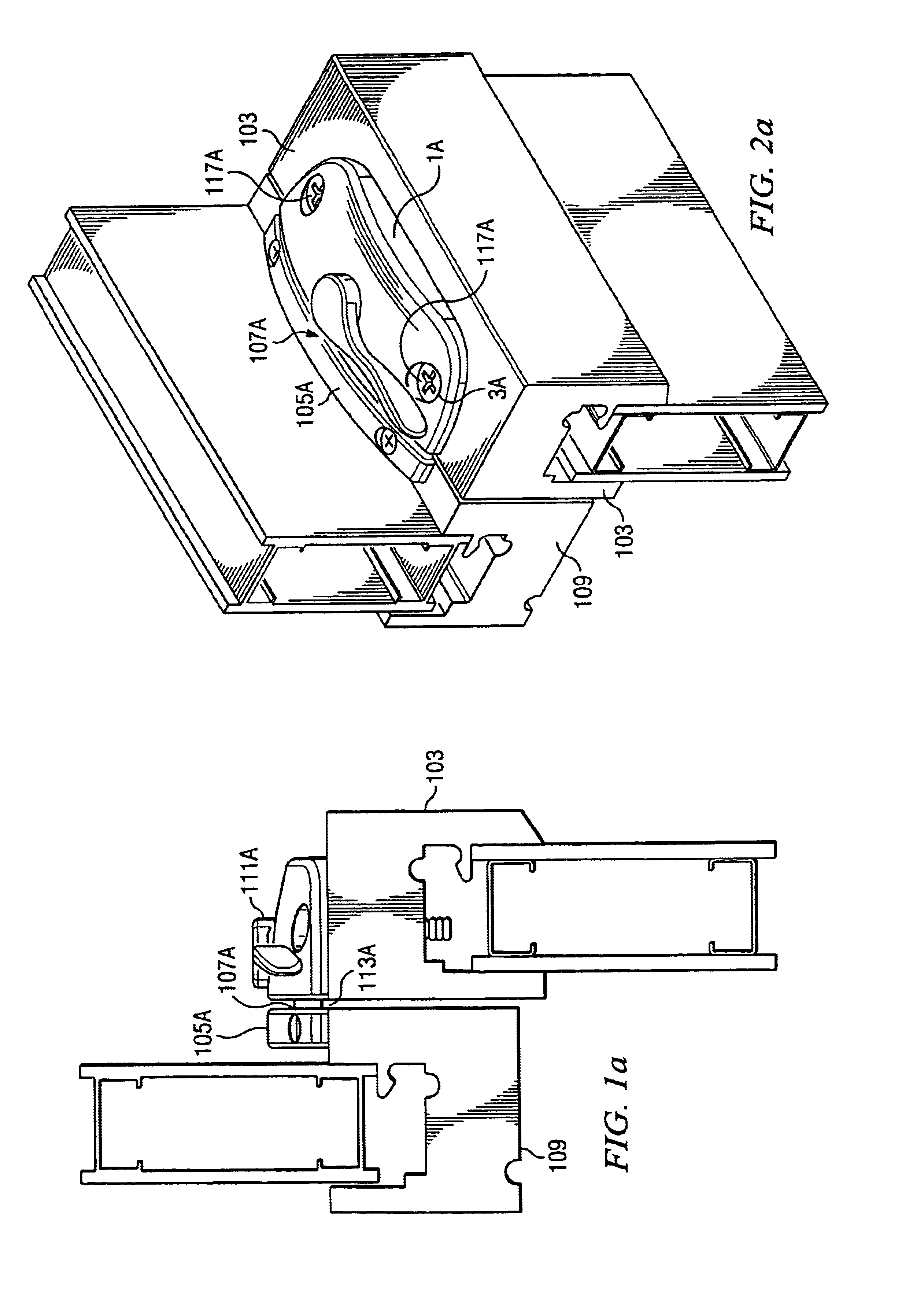

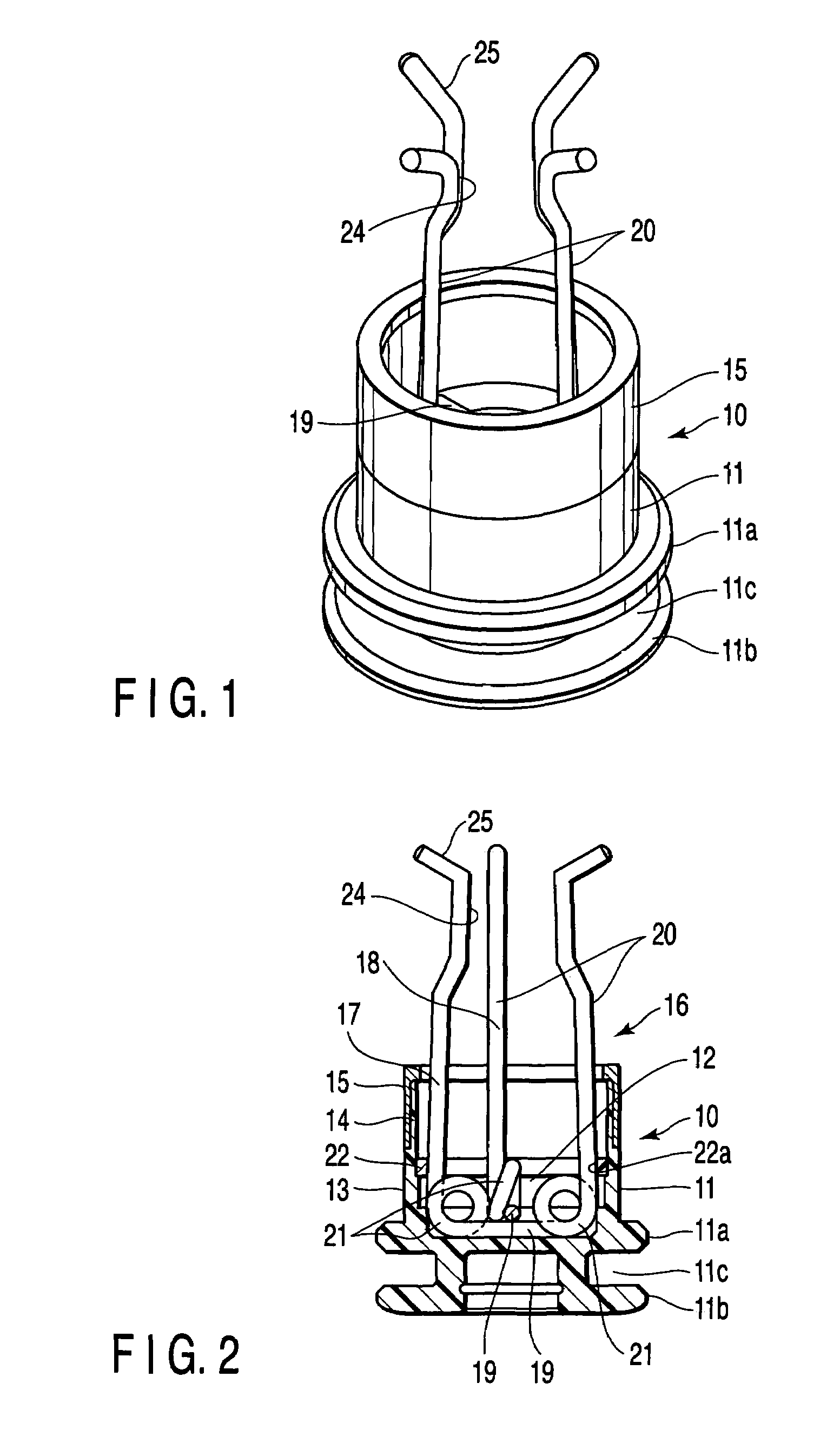

Electrical connector

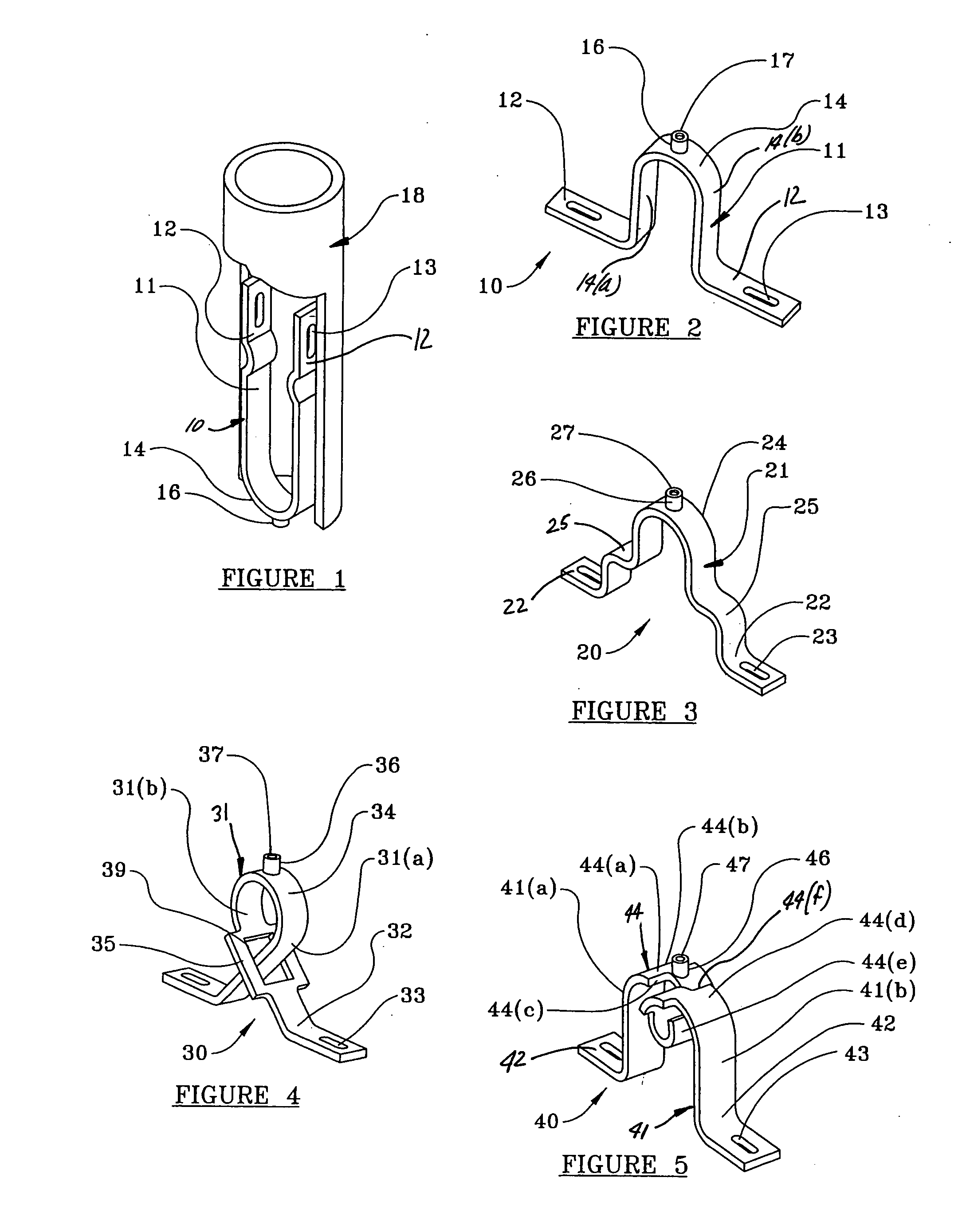

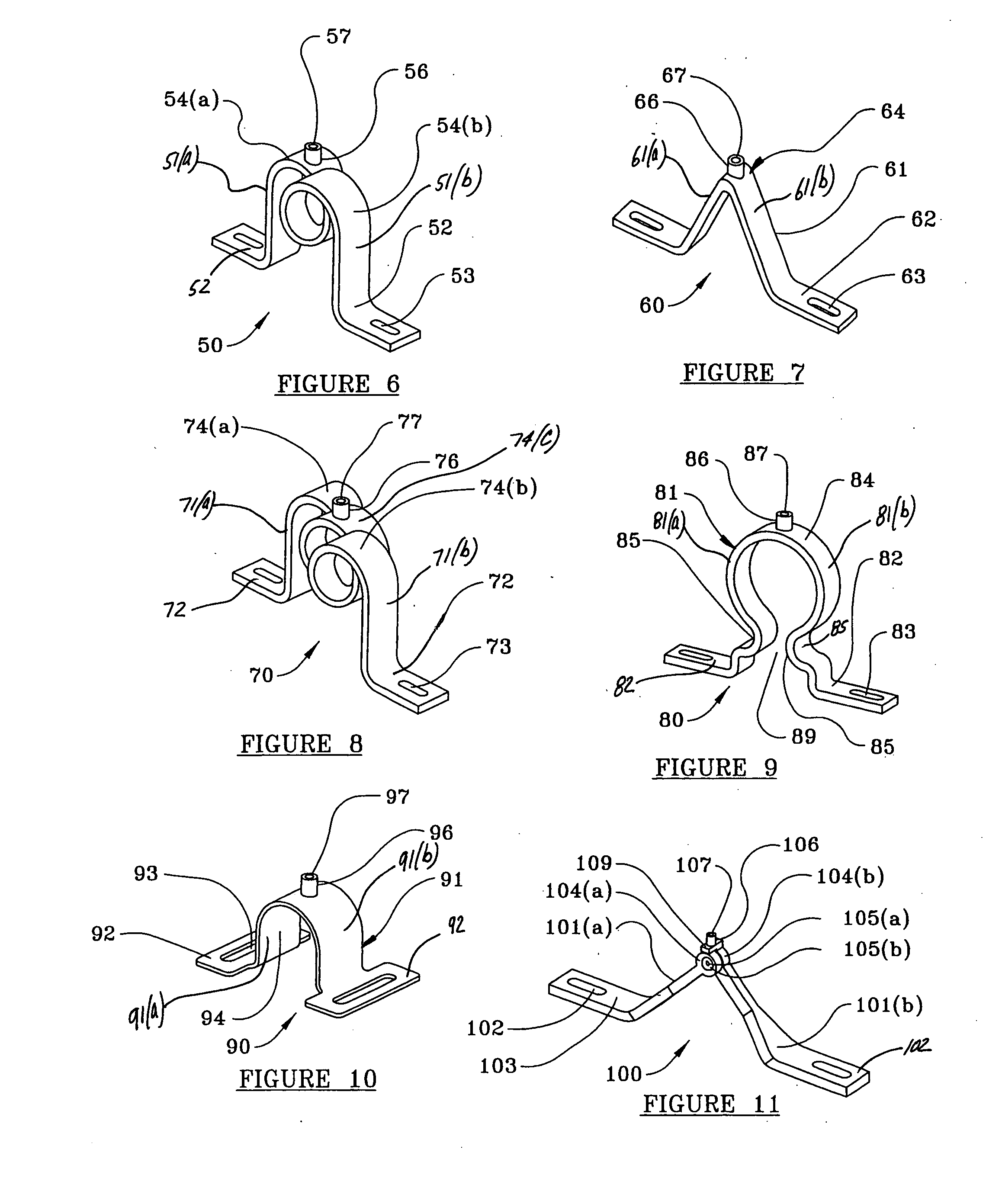

According to the present invention there is provided a snap in locking cable connector with a cylindrical housing having an entry end aperture and an exit end aperture. The entry end aperture can accept the snap-in spring steel adapter of U.S. Pat. No. 6,080,933 as well as the exit end peripheral spring steel locking ring described in this patent to provide a connector that allows rapid and simplified installation of armored cable into a junction or circuit box. The cylindrical housing includes an annular groove or ridge about the inner periphery thereof in the area of the entry end for retention of the spring steel adapter. An electrical cable connector of this type that relies upon frictional or interference fit for retention of the spring steel adapter is also described. Retention of the spring steel adapter with a screw, rivet or similar fastener is also described.

Owner:ARLINGTON INDS

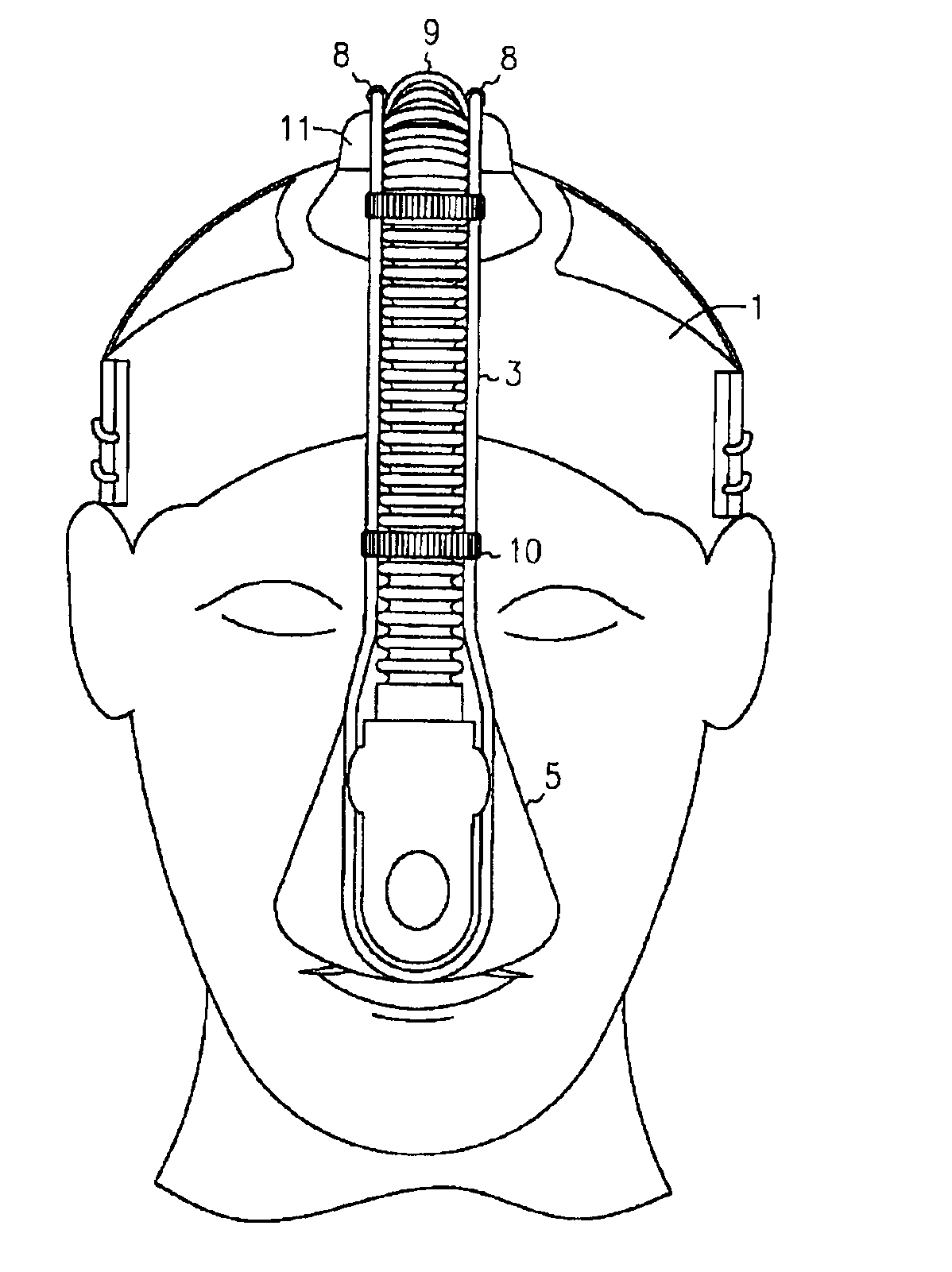

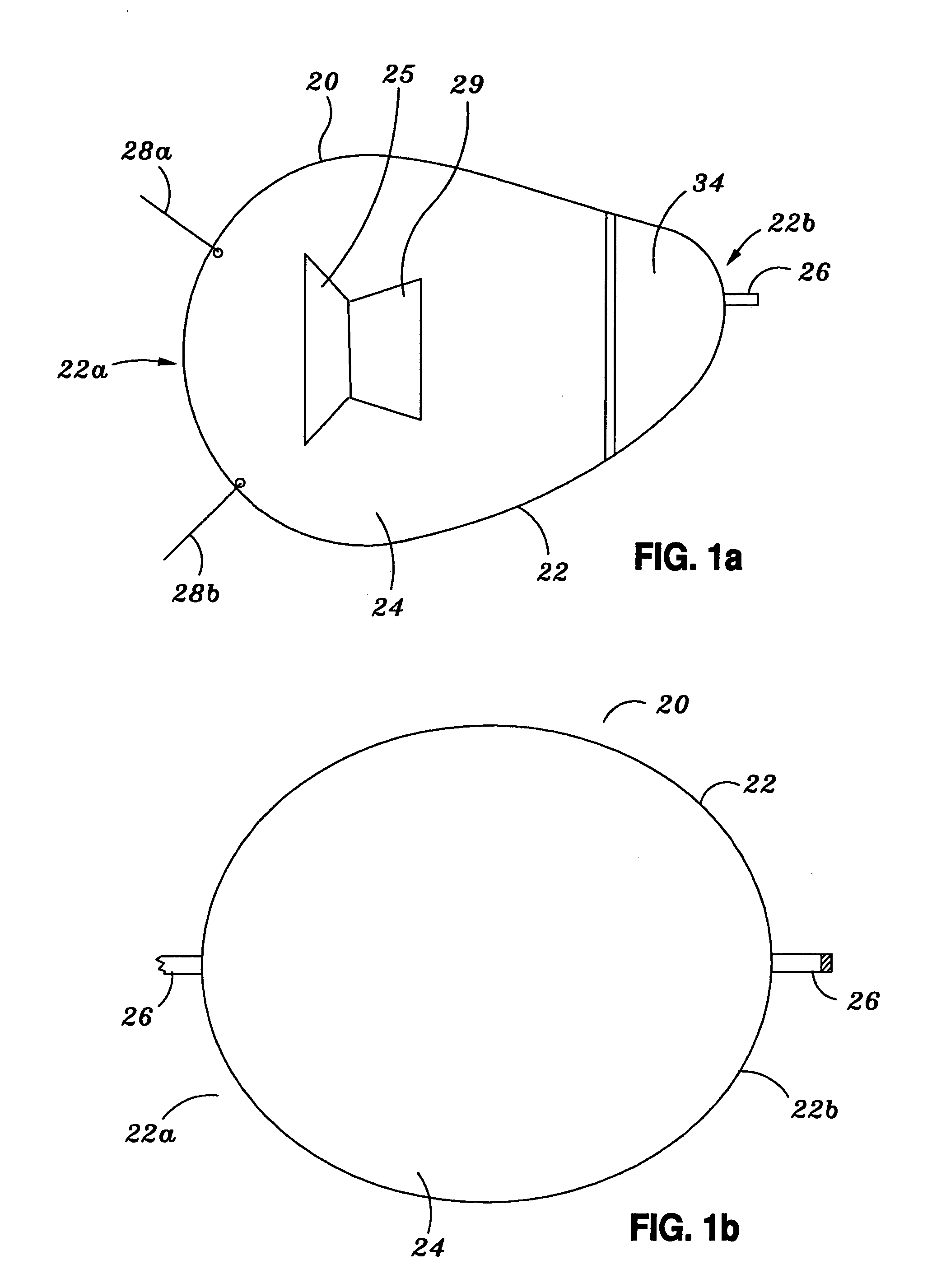

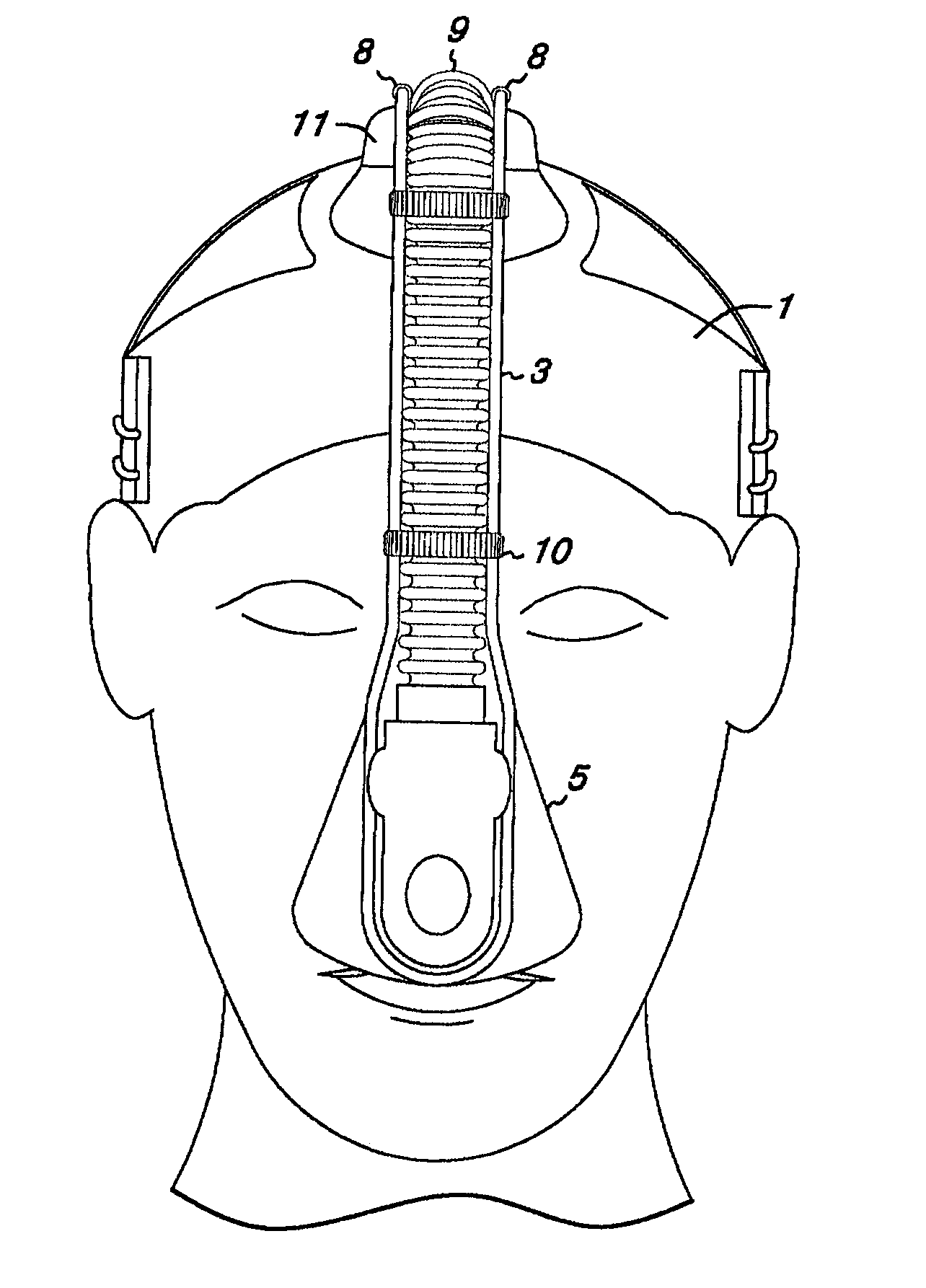

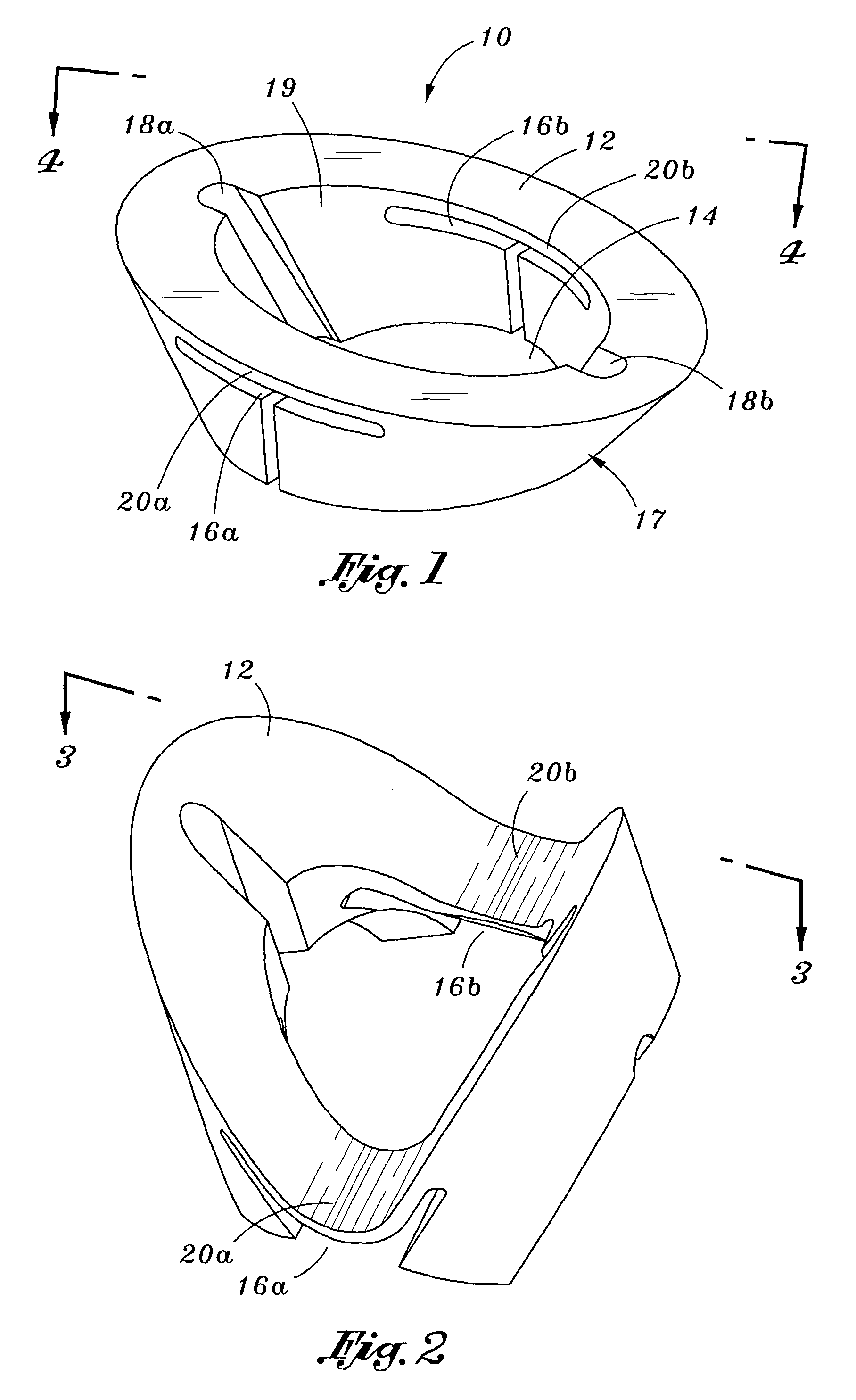

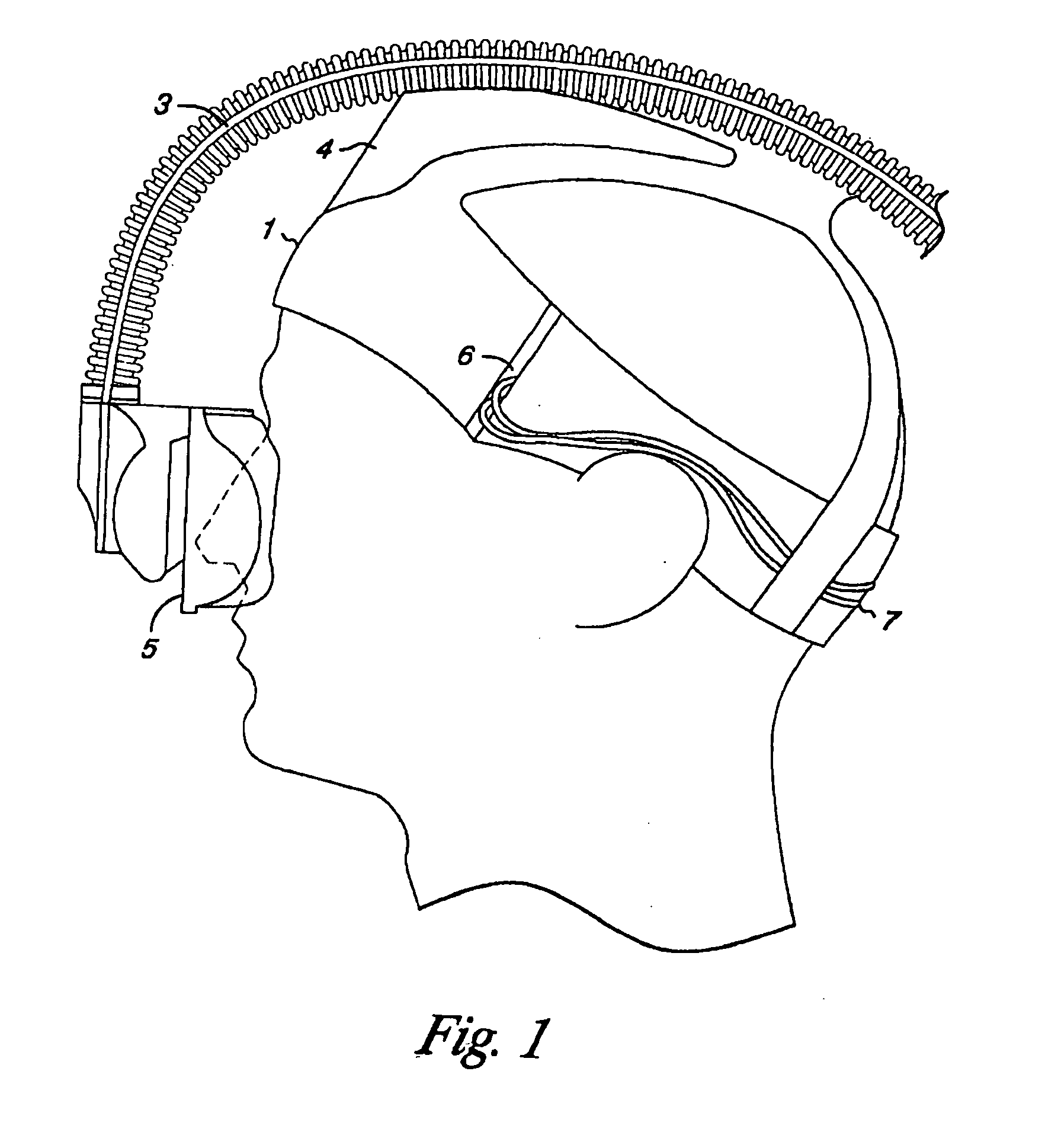

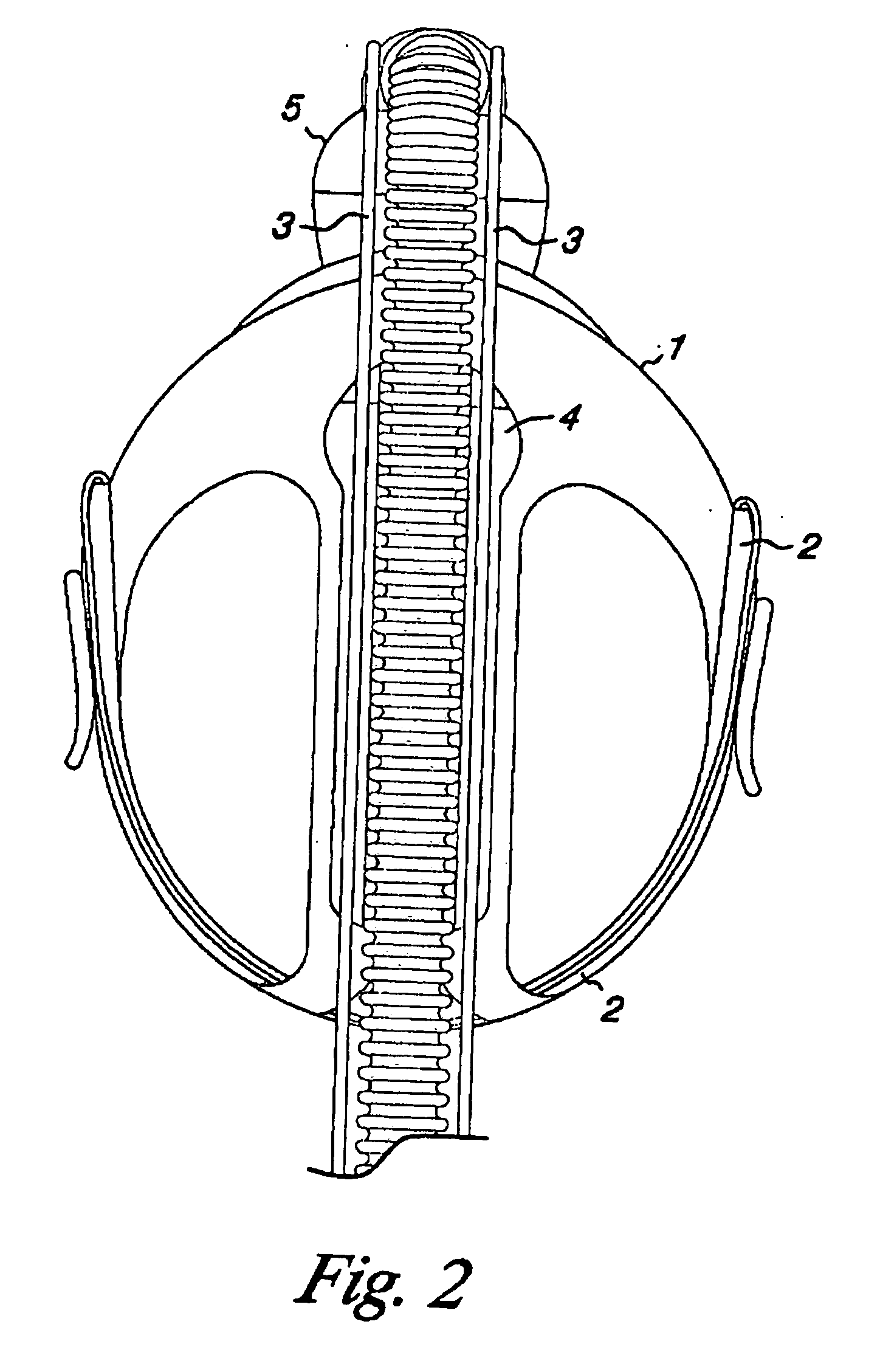

Face mask support

A face mask support for CPAP comprising a hemispheric cap with biasing means support at the medial line of the head. The circumferential edge of the cap extends from the high forehead to below the inion protrusion at the nape of the neck. A biasing means which is preferably of a length of spring steel is formed so as to extend from the biasing means support to form a loop around a face mask. The biasing means may be adjusted to accommodate facial configurations and to vary the pressure with which the face mask is apposed to the face. In an alternative embodiment, the support is open and is comprised of a circumferential band extending from the middle of the forehead to below the inion protrusion and a medial band extending along the medial line of the head and connecting to the circumferential band at the middle of the forehead and below the inion protrusion.

Owner:SOMNETICS INT INC

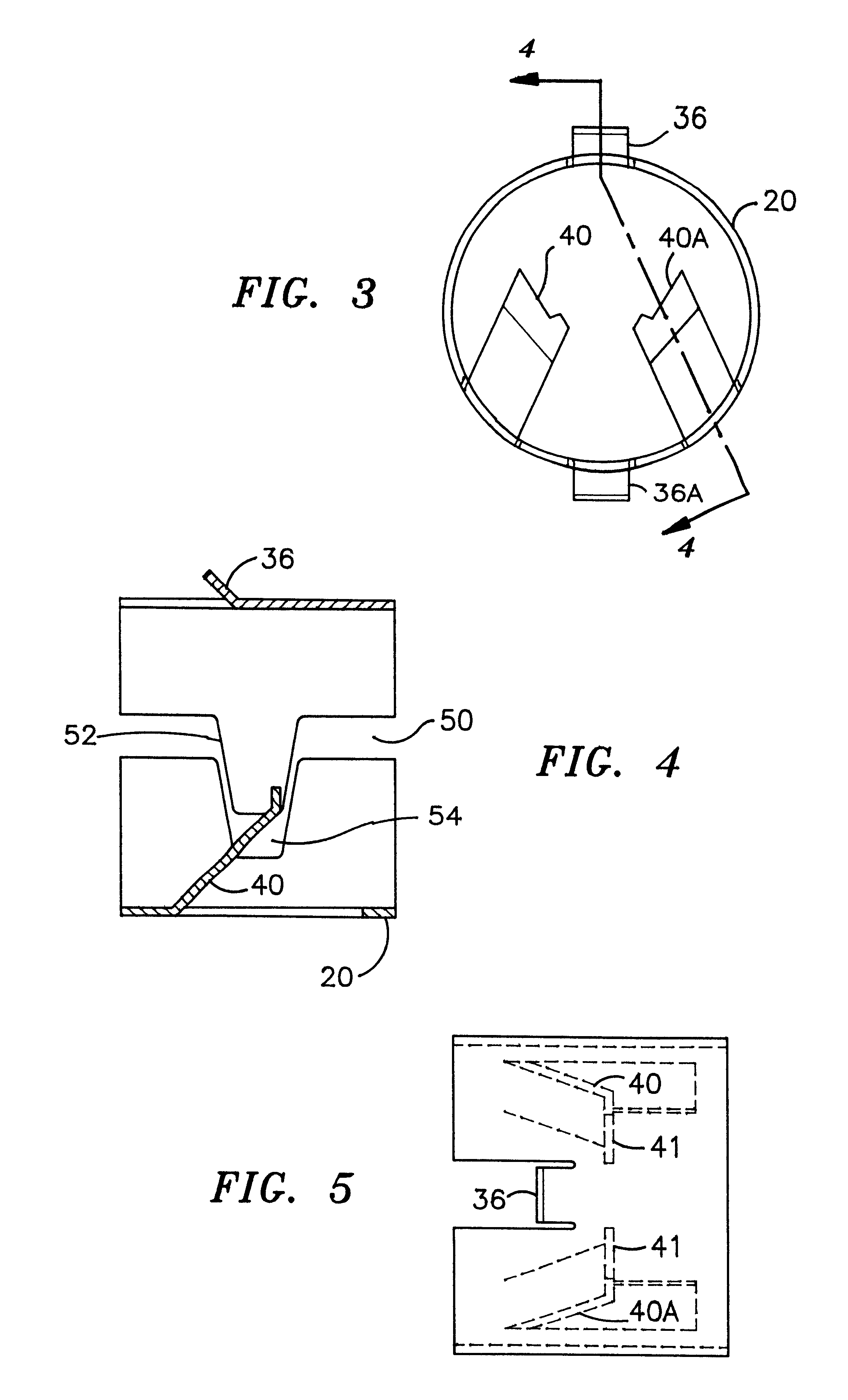

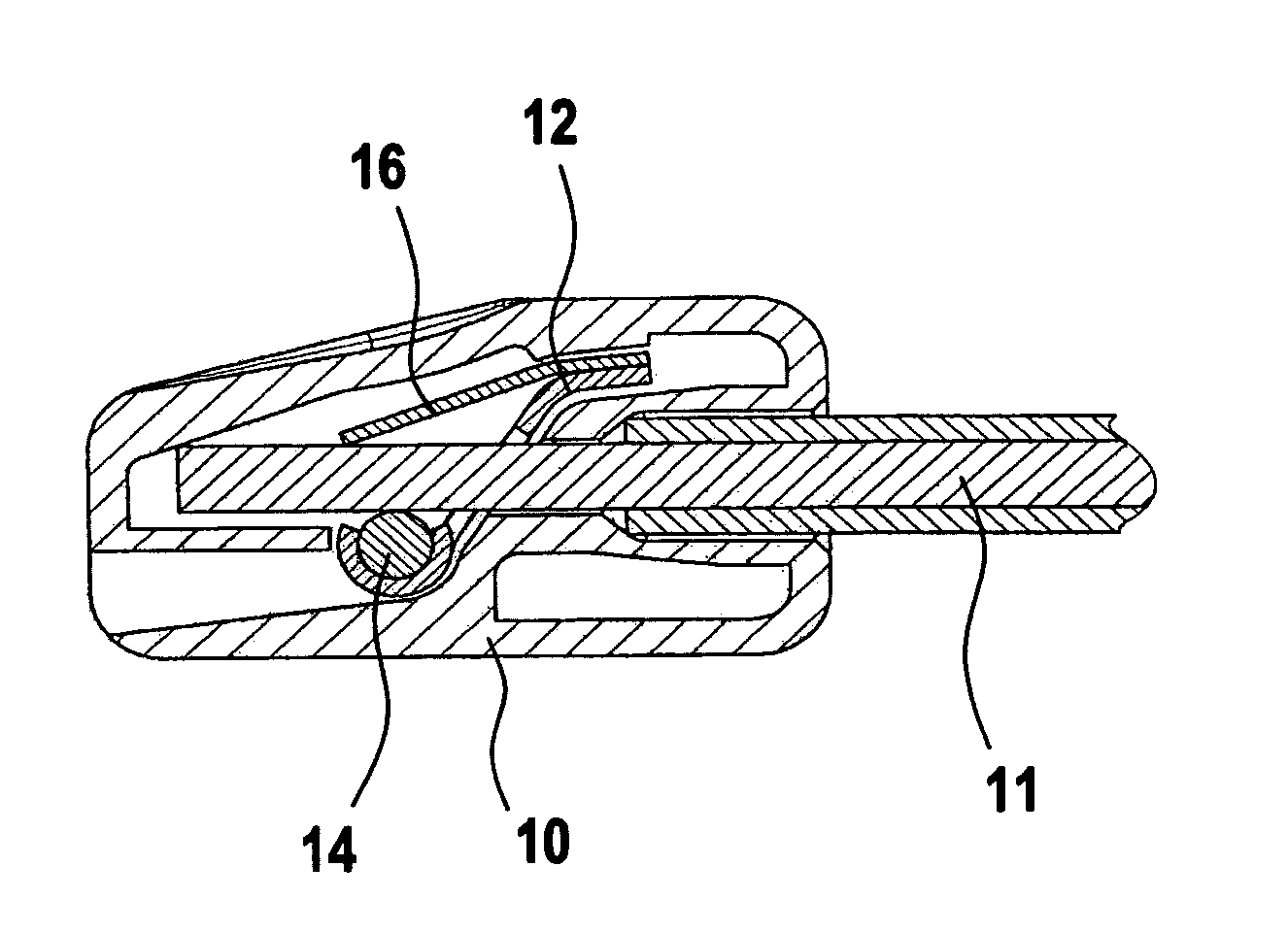

Snap in cable connector

InactiveUS6335488B1Easy to insertElectrically conductive connectionsPipesElectrical junctionDie casting

A snap in locking cable connector is composed of two mating pieces that snap together and provide a connector for armored or metal clad electrical conducts. One piece includes a die cast member including a smooth outer cylindrical section having an inner diameter that may accommodate a spring steel adaptor with flanges to hold the spring steel adaptor in place. The spring steel adaptor is used in conjunction with an electrical junction box to fix the location of the locking cable connector with respect to the junction box. Another piece includes a spring steel locking ring provided to receive an armored cable and lock into the die cast member. The spring steel locking ring has tangs allowing unidirectional insertion into the die cast member and restricting withdrawal motion from the die cast member. The spring steel locking ring also includes oppositely directed tangs to permit reception of the armored cable in one direction and restrict its movement in the reverse direction.

Owner:ARLINGTON INDS

Snap in cable connector

A snap in locking cable connector is composed of two mating pieces that snap together and provide a connector for armored or metal clad electrical conductors. One piece includes a member including a smooth outer cylindrical section having an inner diameter that may accommodate a spring steel adaptor with flanges to hold the spring steel adaptor in place. The spring steel adaptor is used in conjunction with an electrical junction box to fix the location of the locking cable connector with respect to the junction box. Another piece includes a spring steel locking ring provided to receive an armored cable and lock into the member. The spring steel locking ring has tangs allowing unidirectional insertion into the member and restricting withdrawal motion from the member. The spring steel locking ring also includes oppositely directed tangs to permit reception of the armored cable in one direction and restrict its movement in the reverse direction.

Owner:ARLINGTON INDS

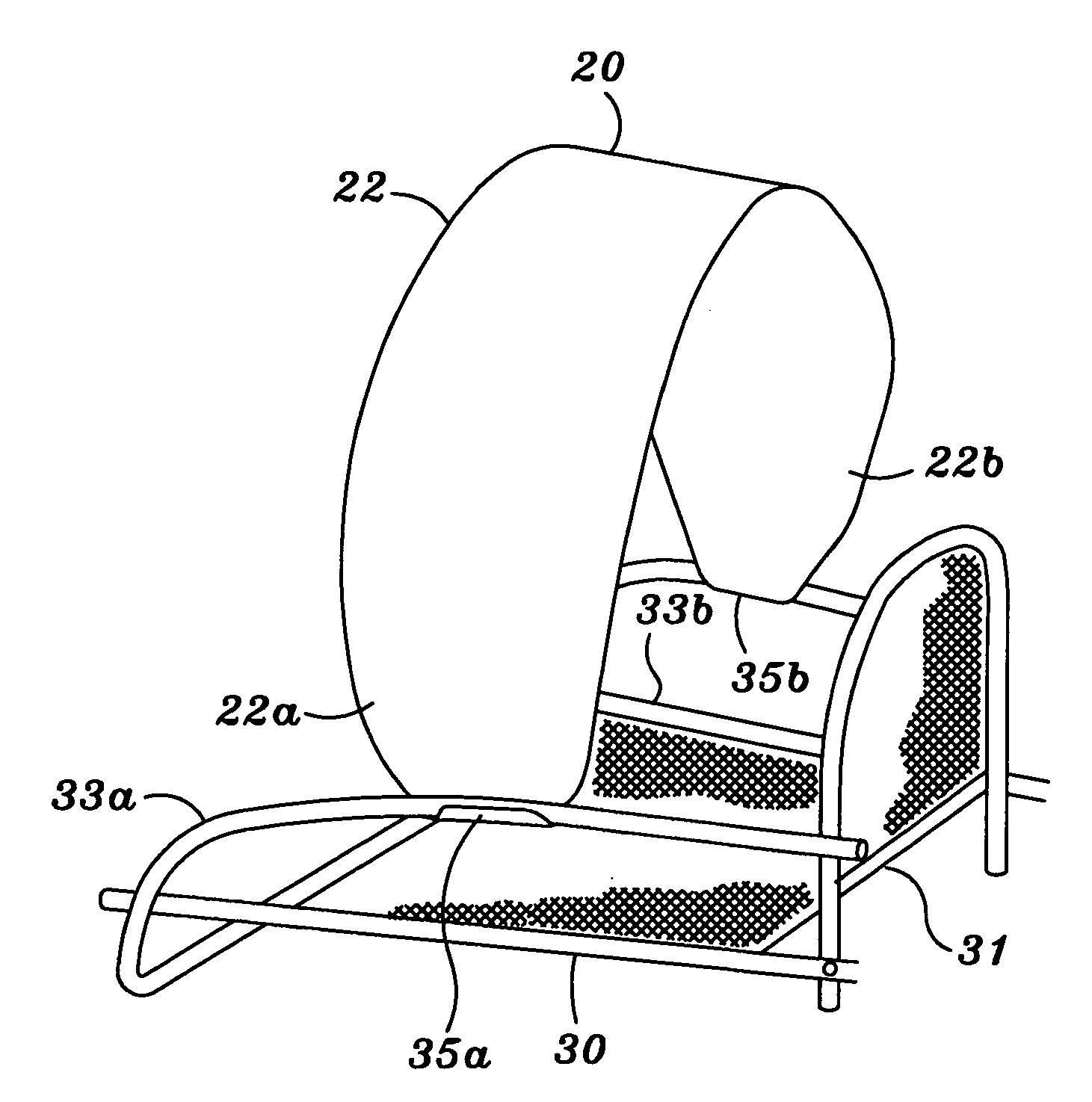

Collapsible sun shade for a chair

InactiveUS7048333B2Increased spring tensionProvide comfortTents/canopiesStoolsEngineeringSpring steel

A collapsible sun shade adapted to be used with a chair is disclosed. The shade is made of spring steel or equivalent material and is adapted to be affixed to cover the seat portion of a lounge chair. The shade is unfolded under the force of the compressed spring and attached to the chair to provide shade over the seat of the chair.

Owner:MARTINEZ ROBERT E

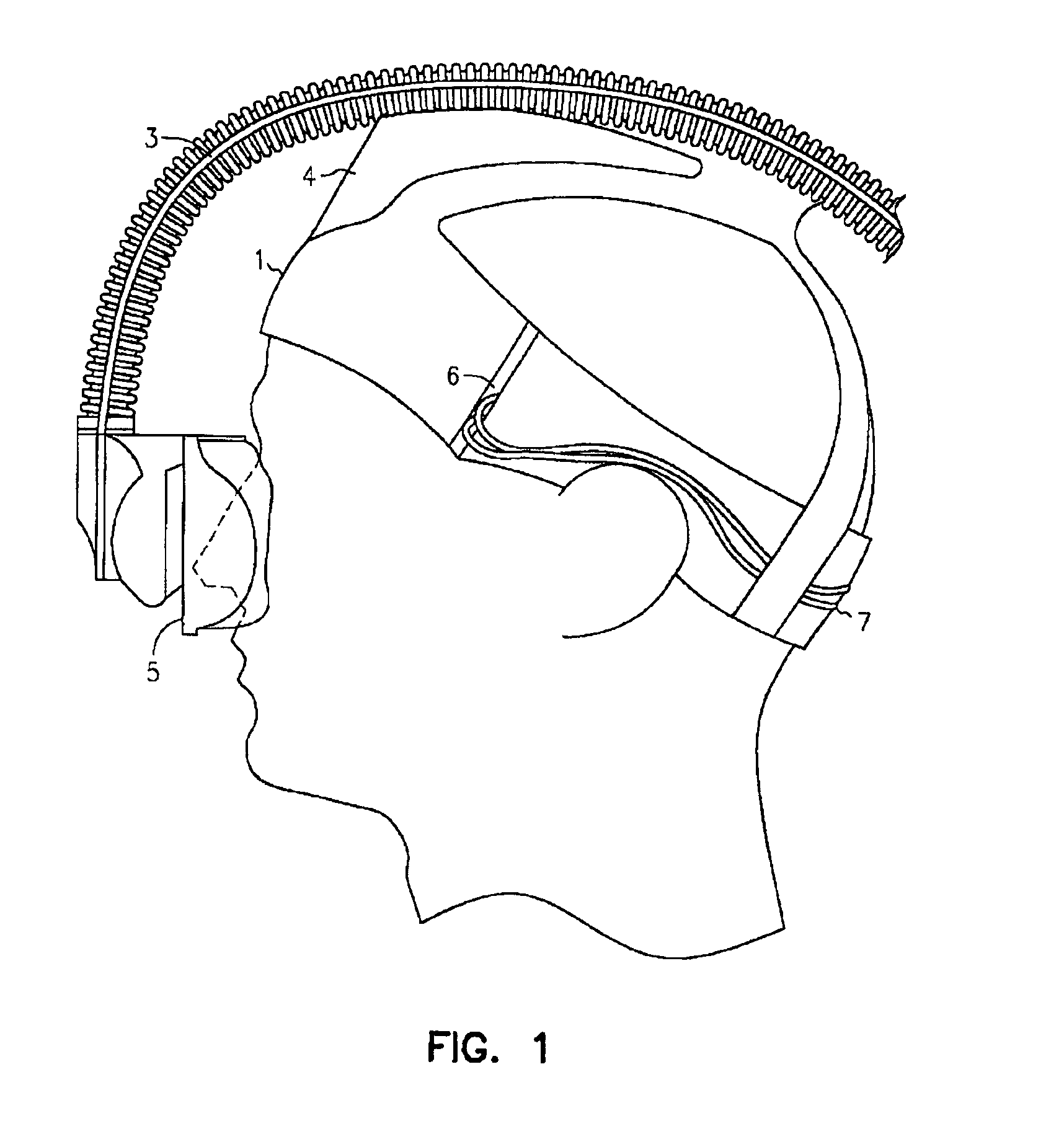

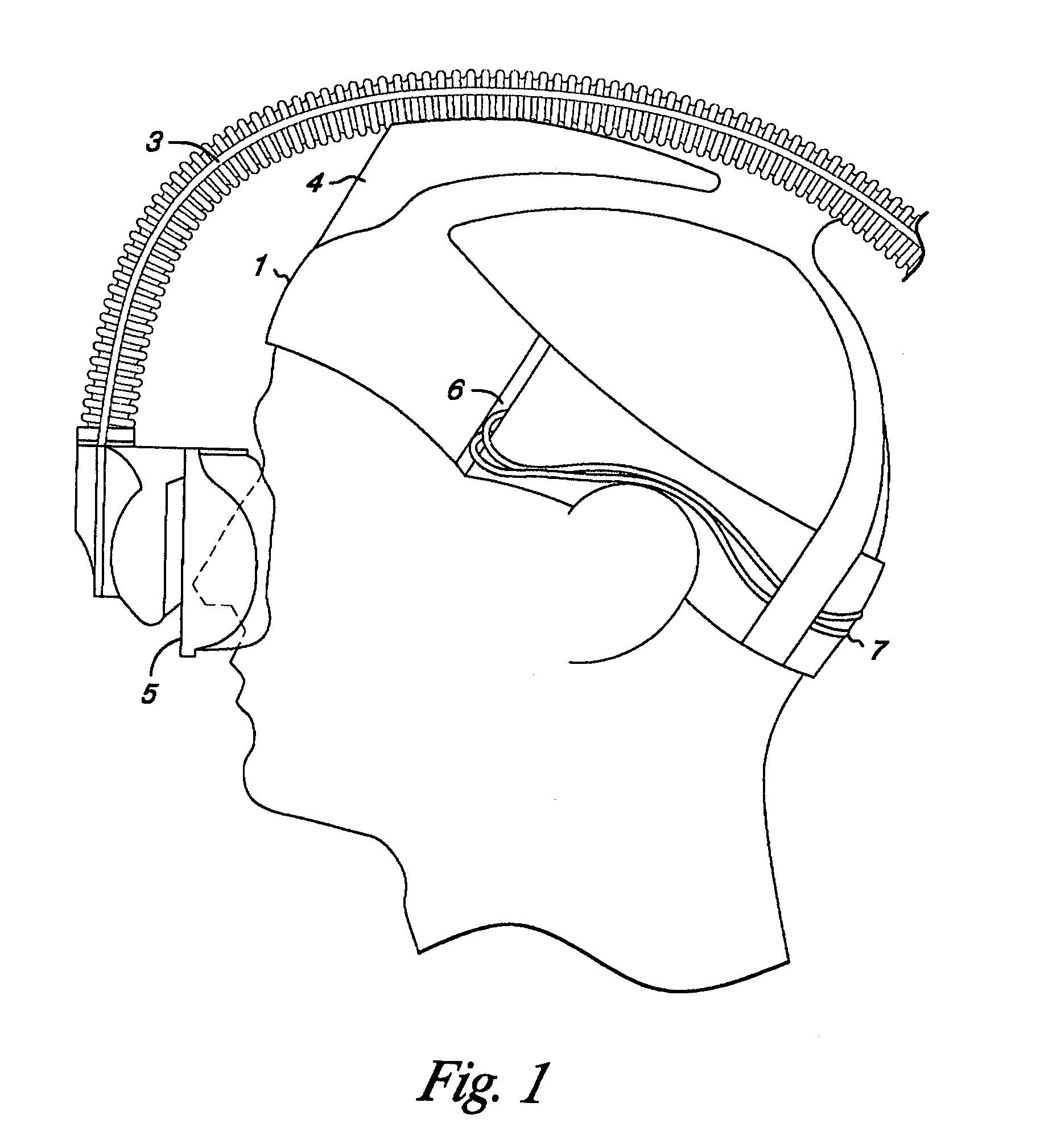

Face mask support

InactiveUS7089941B2Precise positioningTransmission of forceRespiratory masksBreathing masksNoseSpring steel

A face mask support for continuous positive airway pressure comprises a circumferential band with biasing means support at the crown of the head on the medial line of the head. The circumferential edge of the cap extends from just below the forehead of a patient to below the inion protrusion at the nape of the neck. A biasing means which is preferably of length of spring steel is formed so as to extend from the biasing means support hold a nasal or face mask apposed to the face of a patient. The circumferential band is stabilized by a band extending from the circumferential band at the region of the ear to the biasing means support.

Owner:SOMNETICS INT INC

Sash lock

InactiveUS6871886B2Convenient preloadCost-effective and feasibleBuilding locksWing fastenersSash windowDetent

A sash lock apparatus which includes a keeper disposable on a first window sash and having a keeper aperture therein for lockingly receiving therein a selectively retractable element from a sash lock and the sash lock having the selectively retractable element disposable on a second window sash wherein the first and second window sashes are disposed for movement in a direction parallel to each other. The sash lock includes a rotatable lever having a tab extending therefrom and a spring slide deformable by rotation of the rotatable lever and movement of the tab against the spring slide for selectively causing a portion of the spring slide to enter and retract from the aperture to cause locking and unlocking of the first and second window sashes relative to each other. The spring slide includes a central aperture, the tab extending into the central aperture, rotation of the tab with the rotatable lever causing deformation of the spring slide and one of movement of the spring slide into or out of the keeper aperture. The housing has a shaft secured to the spring slide, the rotatable lever being rotatable about the shaft. The spring slide is preferably a spring steel slide. The apparatus may further include a member having member detents therein and secured to the shaft and rotatable member detents disposed on the rotatable member for entry into at least one selected member detent upon rotation of the rotatable member to one of an open or closed position.

Owner:HOWARD BERGER CO +1

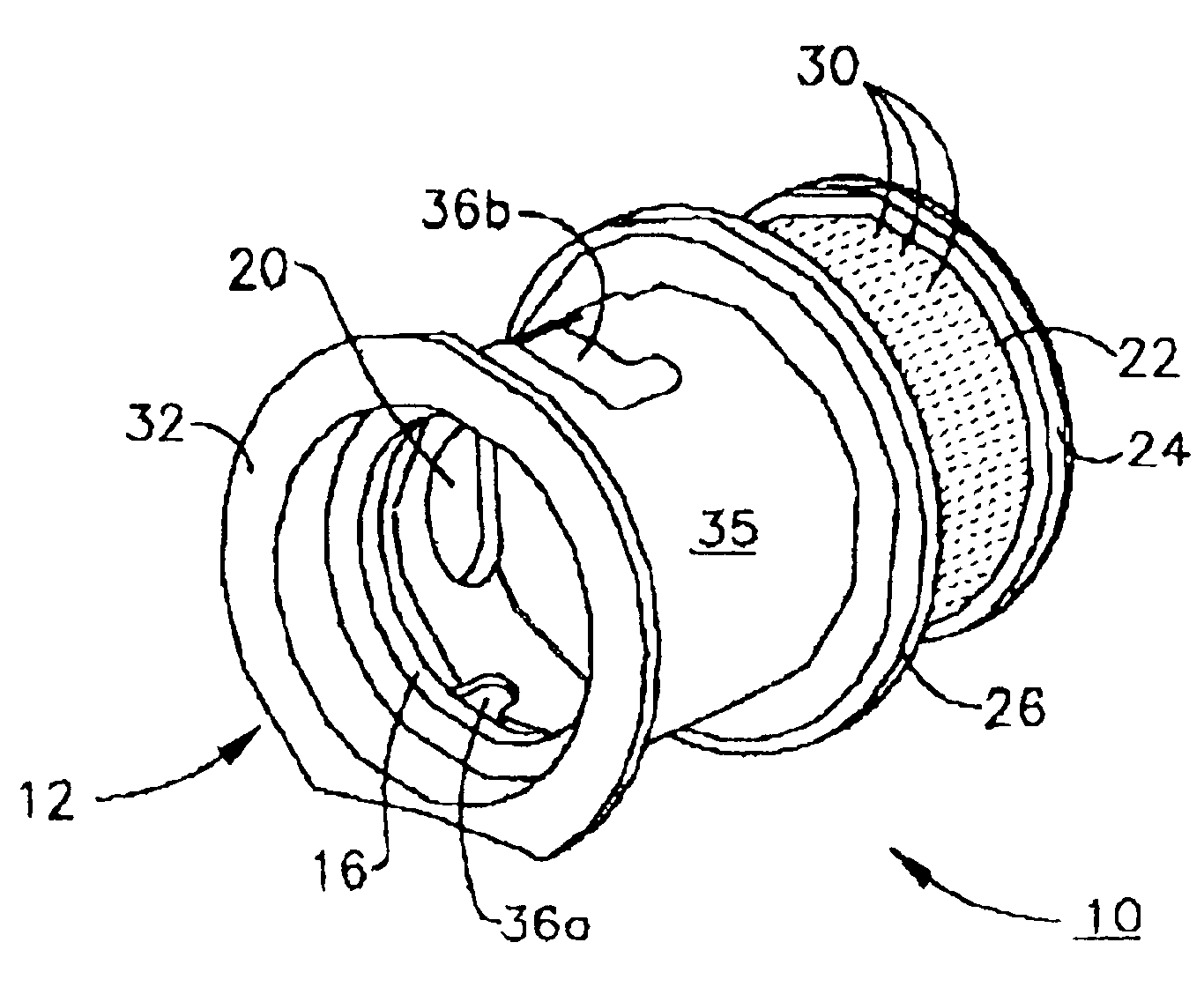

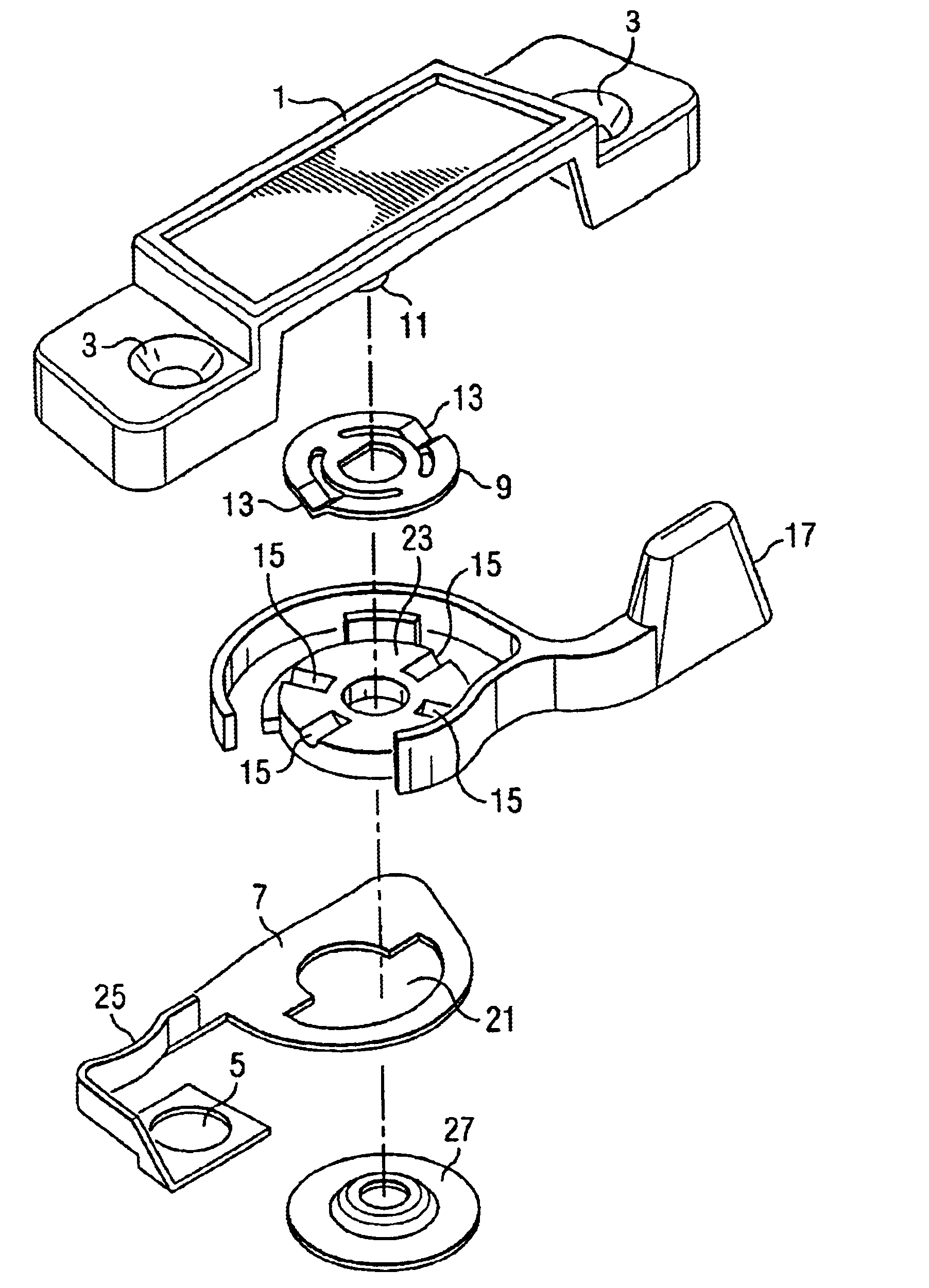

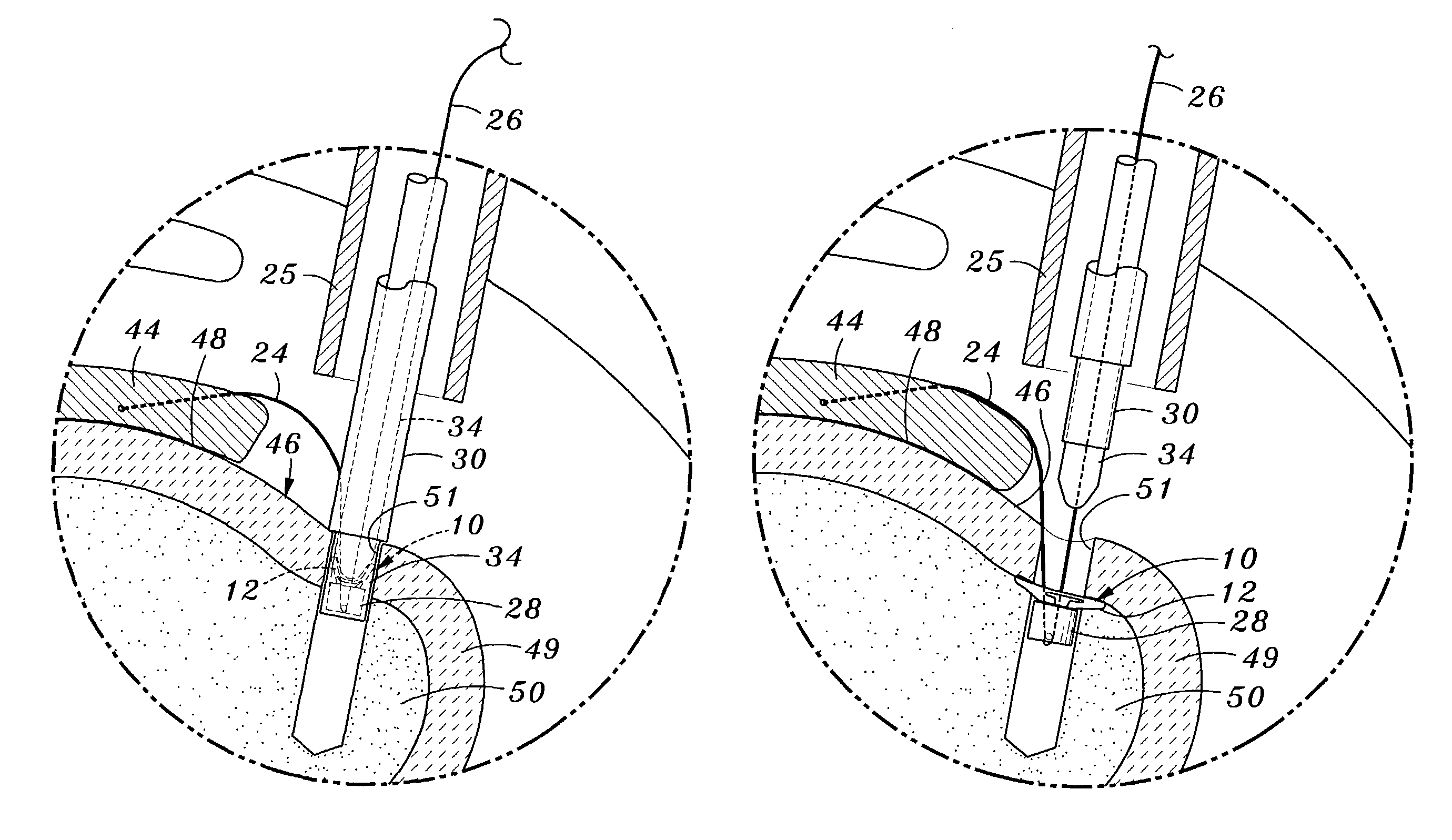

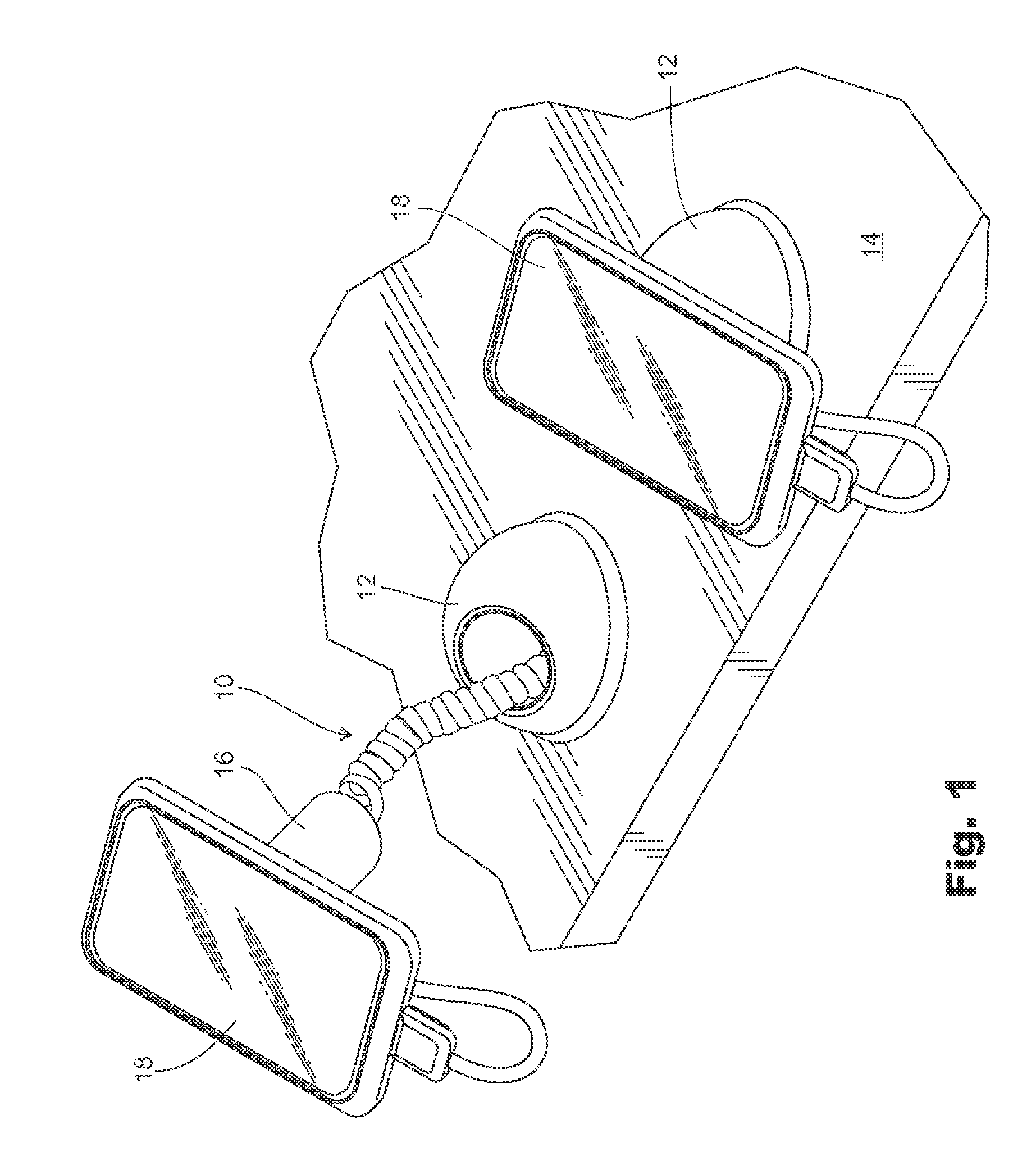

Method and apparatus for attaching connective tissues to bone using a cortical bone anchoring device

InactiveUS7674274B2Overcome disadvantagesNone provides advantagesSuture equipmentsBone implantBone CortexConnective tissue

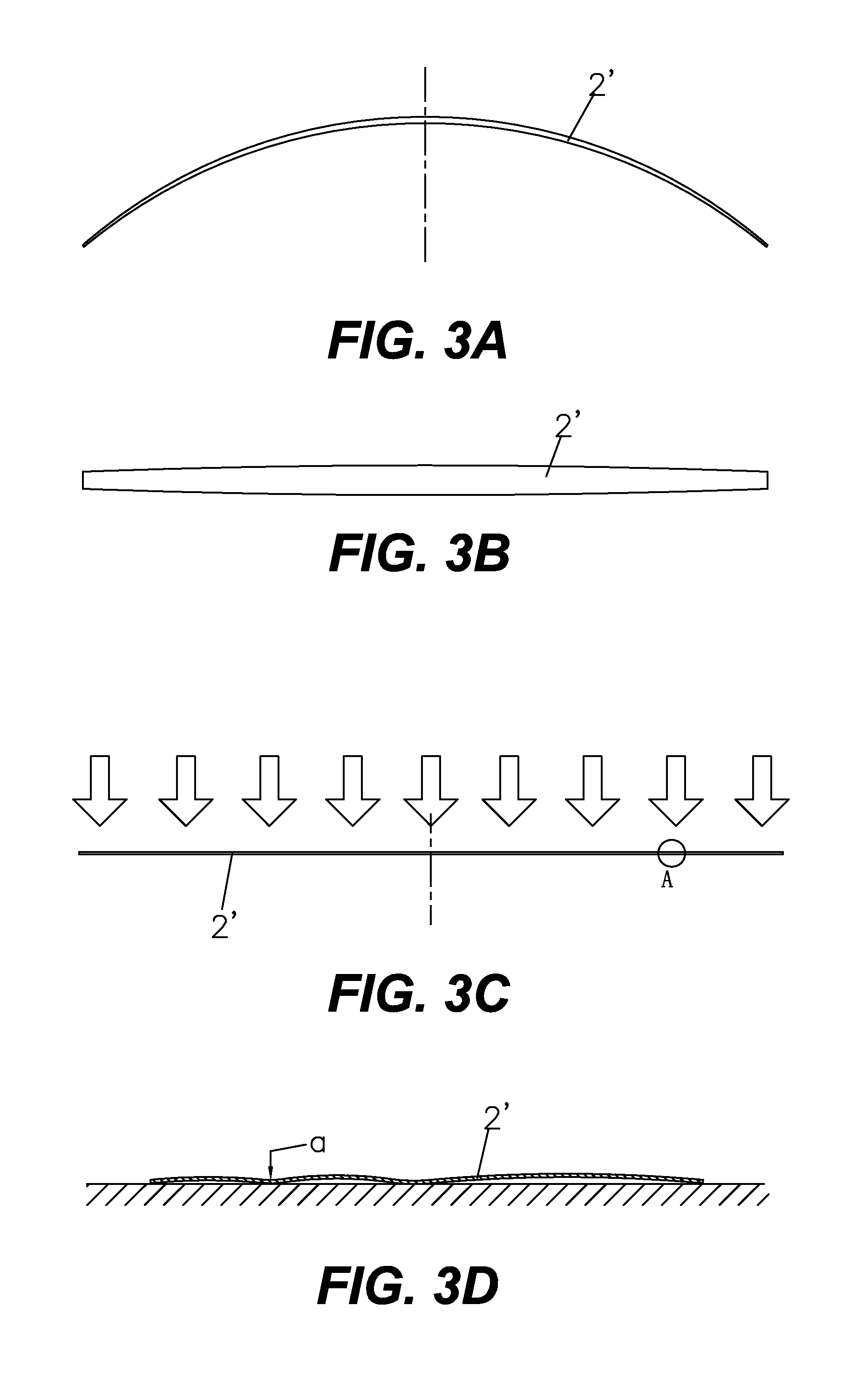

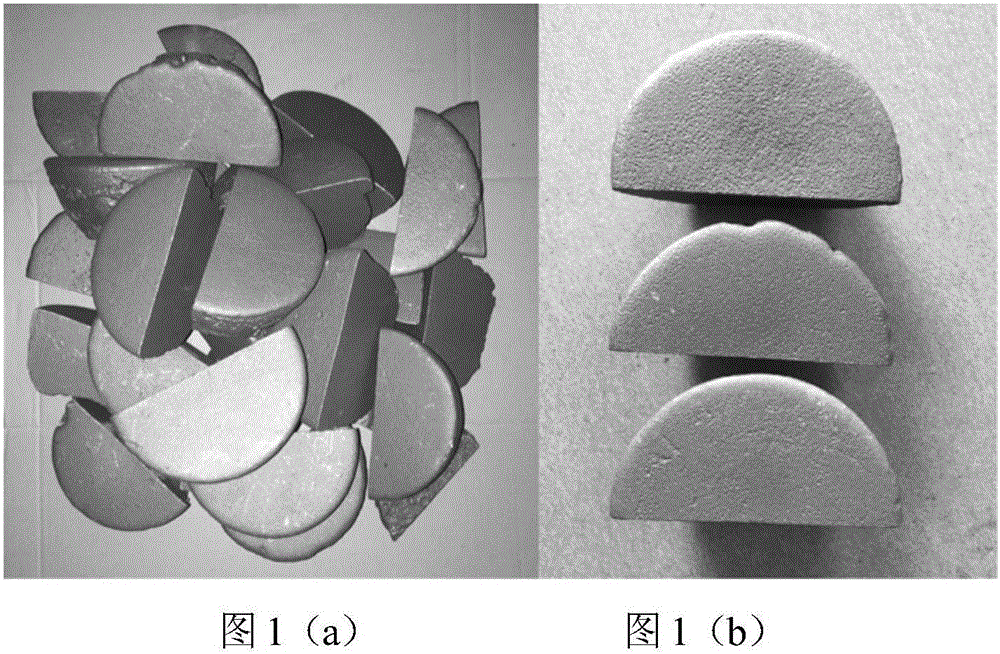

A bone anchor device for attaching connective tissue to bone comprises a disk adapted for insertion into a portion of bone to which the connective tissue is to be attached. The disk is movable between a bent orientation for presenting a smaller cross-section and an expanded orientation for presenting a larger cross-section. The bent orientation is utilized for inserting the disk through a small hole into a region of cancellous bone beneath the cortical bone layer, after which the disk is actuated to its expanded orientation so that it will be permanently anchored in the cancellous bone, as it will be too large to return proximally through the hole in the cortical bone layer. Two embodiments are disclosed. In a first embodiment, the disk is initially formed in the expanded orientation, of spring steel. In a second embodiment, the disk is initially formed in the bent orientation, and spring steel is not required.

Owner:ARTHROCARE

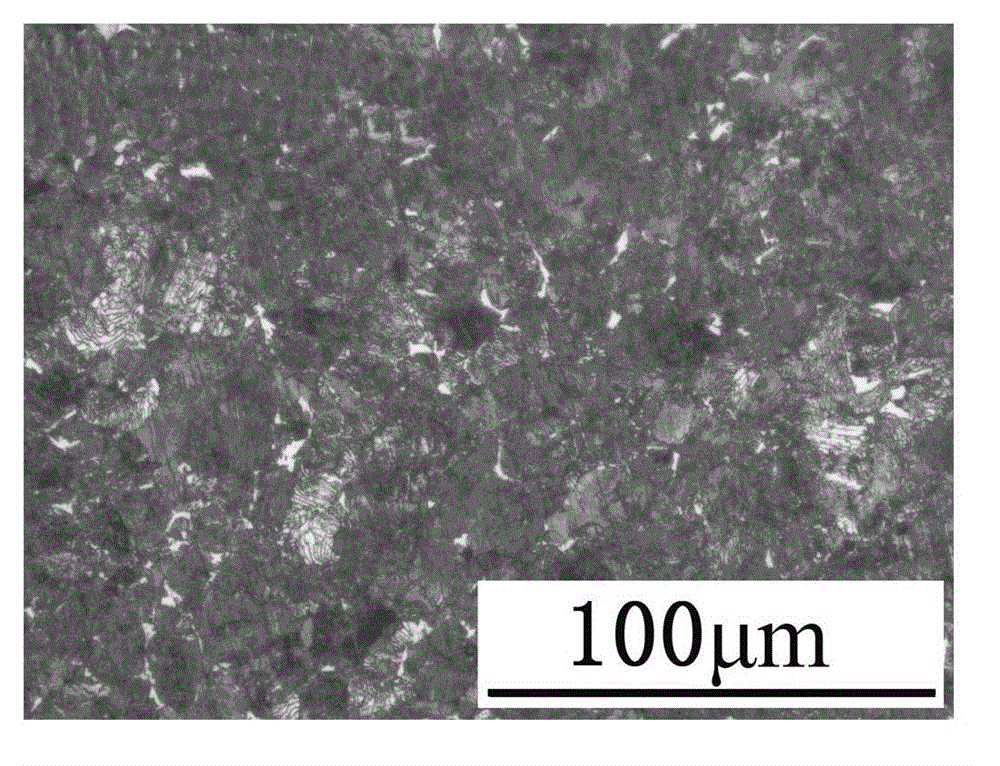

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

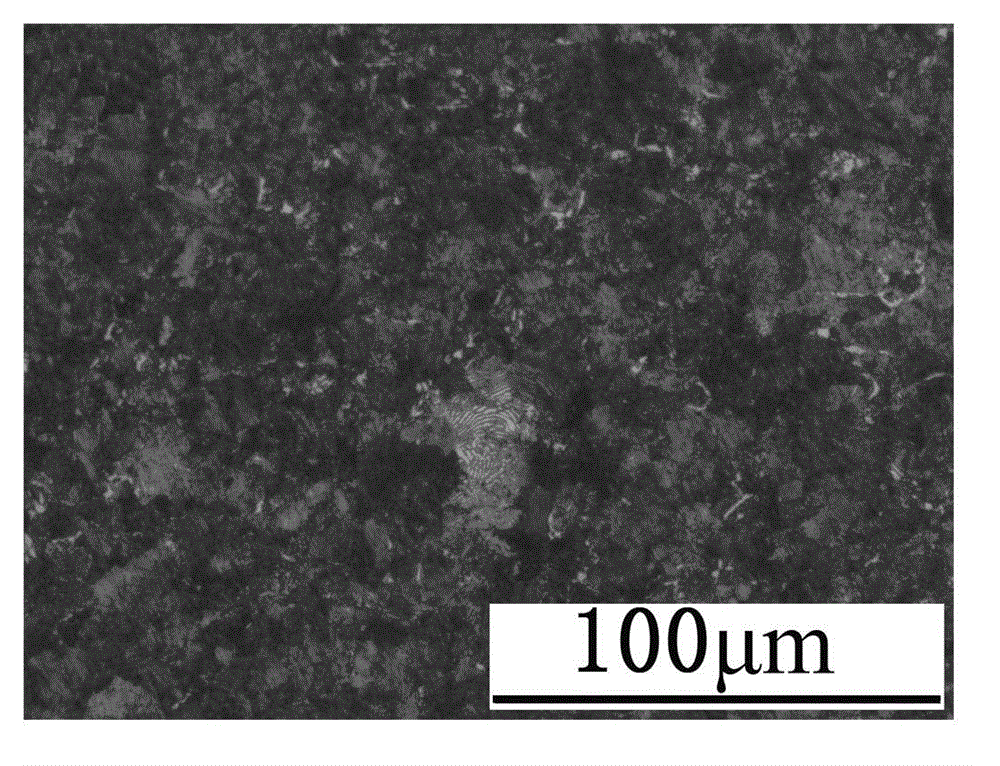

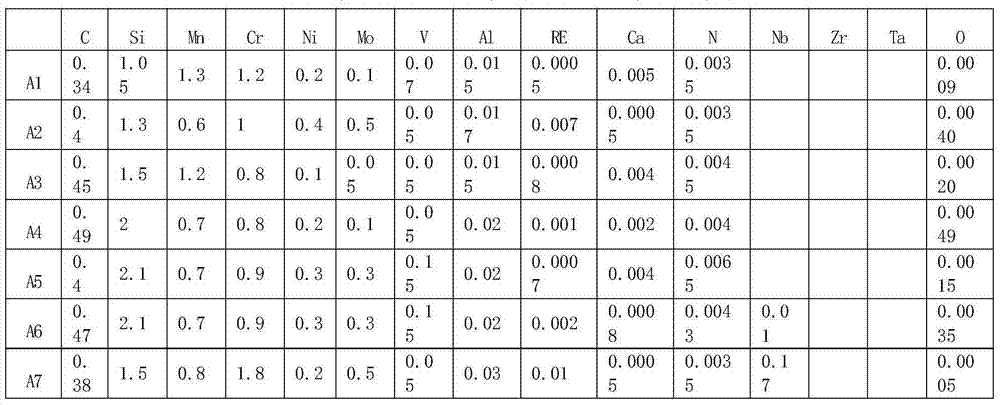

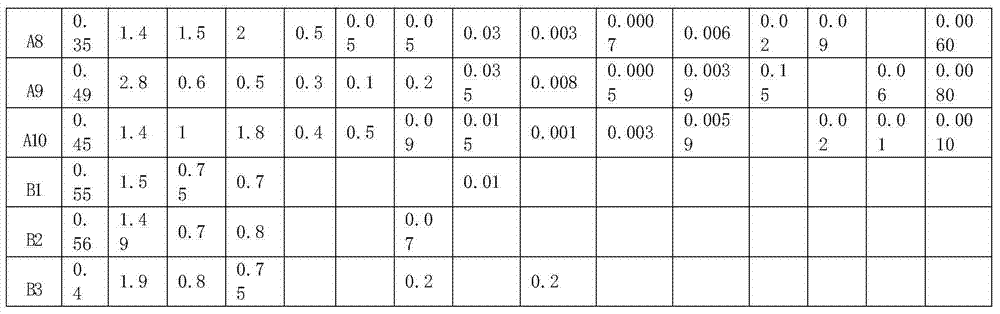

High-strength and high-toughness spring steel and manufacturing method thereof

ActiveCN103484781ASufficiently ductileSufficient resistance to elastic reductionChemical elementSpring steel

The invention discloses a high-strength and a high-toughness spring steel. The spring steel comprises the following chemical elements in percentage by mass: 0.34-0.49% of C, 1.00-2.80% of Si, 0.60-1.50% of Mn, 0.50-2.0% of Cr, 0.1-0.5% of Ni, 0.05-0.5% of Mo, 0.05-0.20% V, 0.0035-0.0065% of N, 0.0015-0.035% of Al, 0.0005-0.01 % of RE, 0.0005-0.005% of Ca, 0.005-0.0080% of O, and the balance of Fe and inevitable impurity wherein the following formulas are satisfied, Si+0.75*(Mn+Cr)+0.6*(Ni+Mo) is larger than or equal to 3.0%, Al / O is larger than or equal to 4.0, and RE+0.75*Ca is larger than or equal to 0.002%. Correspondingly, the invention further discloses a manufacturing method of the high-strength and high-toughness spring steel.

Owner:BAOSHAN IRON & STEEL CO LTD

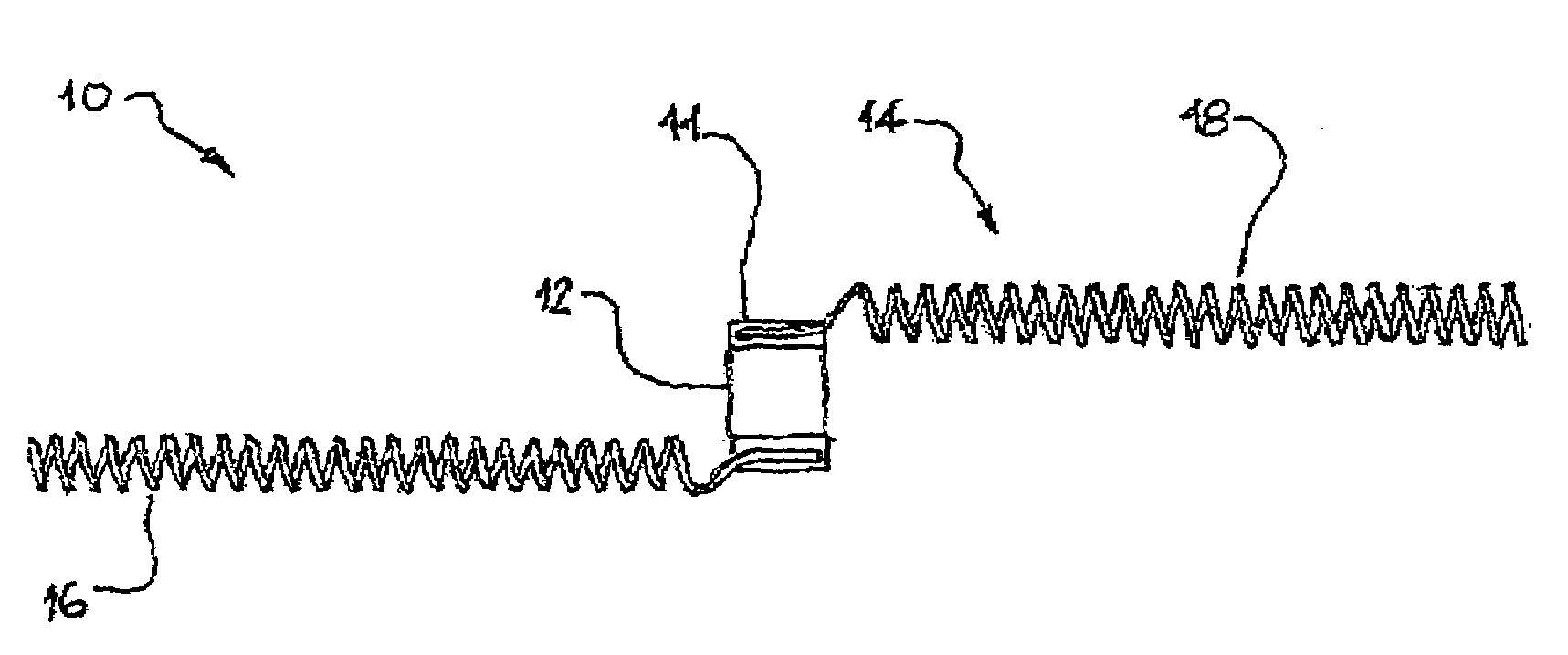

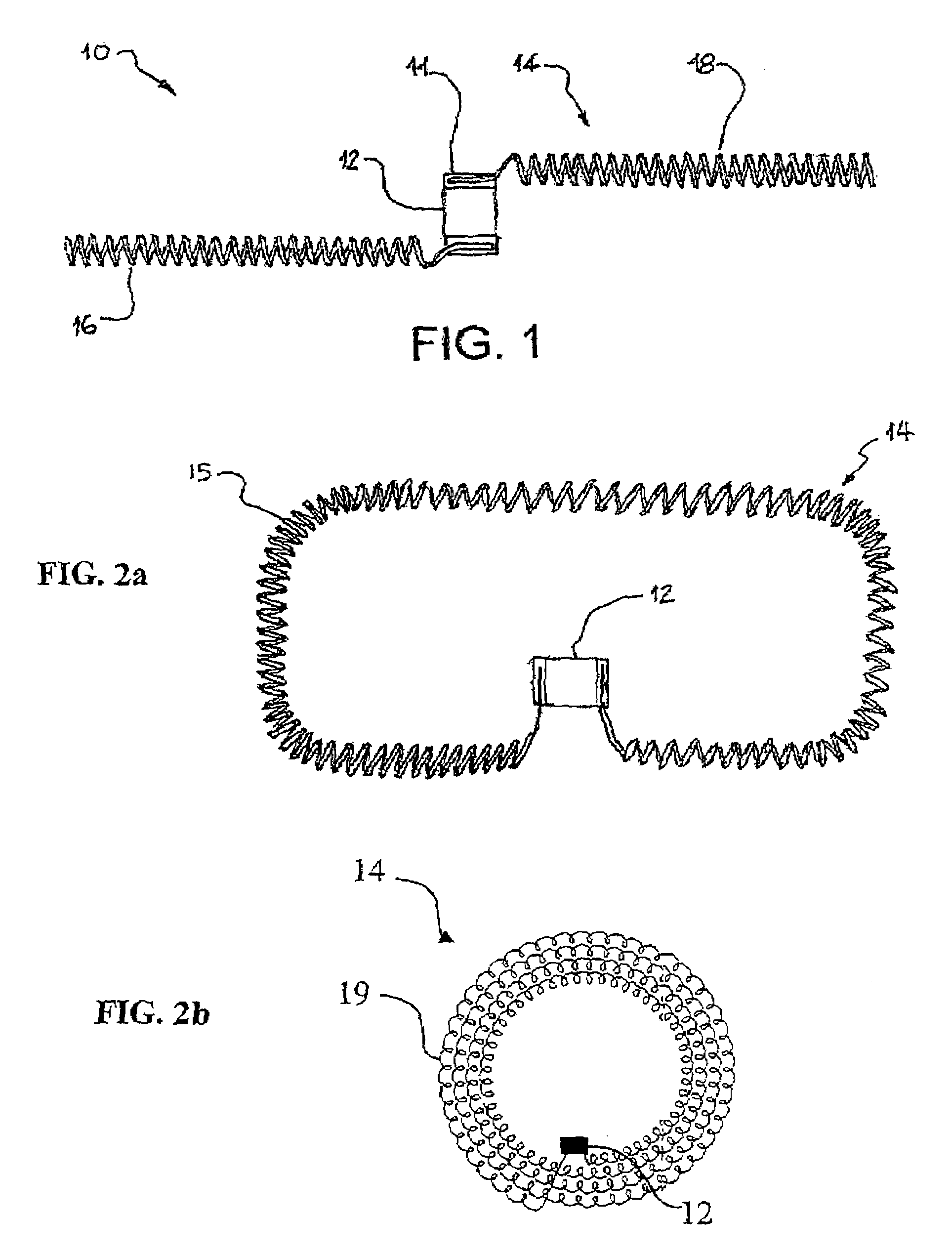

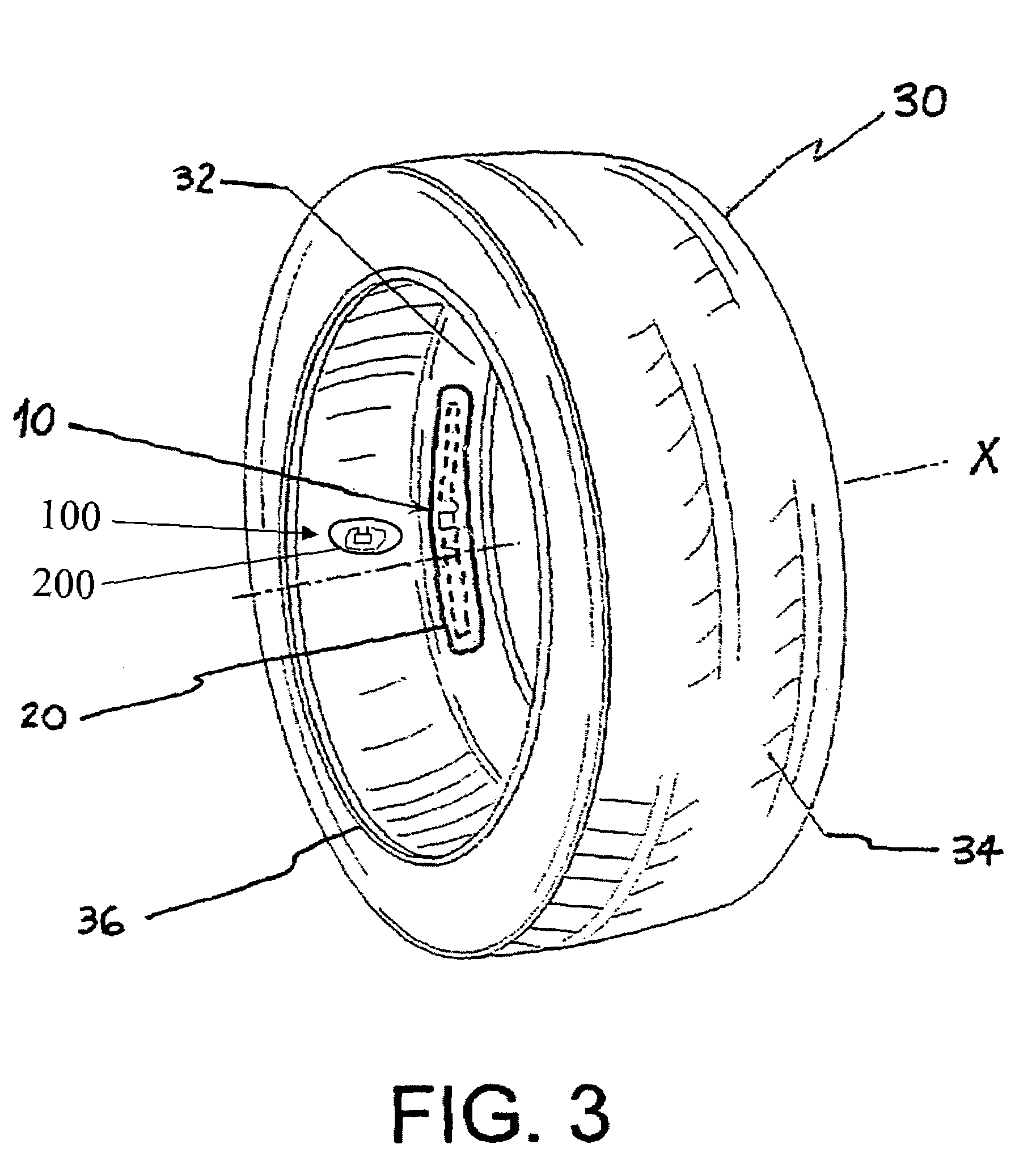

Electronic device for a tire having an extensible antenna

ActiveUS7102499B2Low frequency communicationAvoid problemsAntenna supports/mountingsTyresElectronic communicationEngineering

An electronic communication device for a tire includes a radio device and an antenna intended to be attached to or embedded in a tire, the antenna being spirally or helically shaped to absorb tensile and bending stress applied by the tire. The antenna body may be a wire formed of spring steel, brass or zinc coated spring steel, or spring brass. A coating of insulating material coats the radio device and antenna for mounting on or in, and operation in, a tire structure.

Owner:MICHELIN RECH & TECH SA

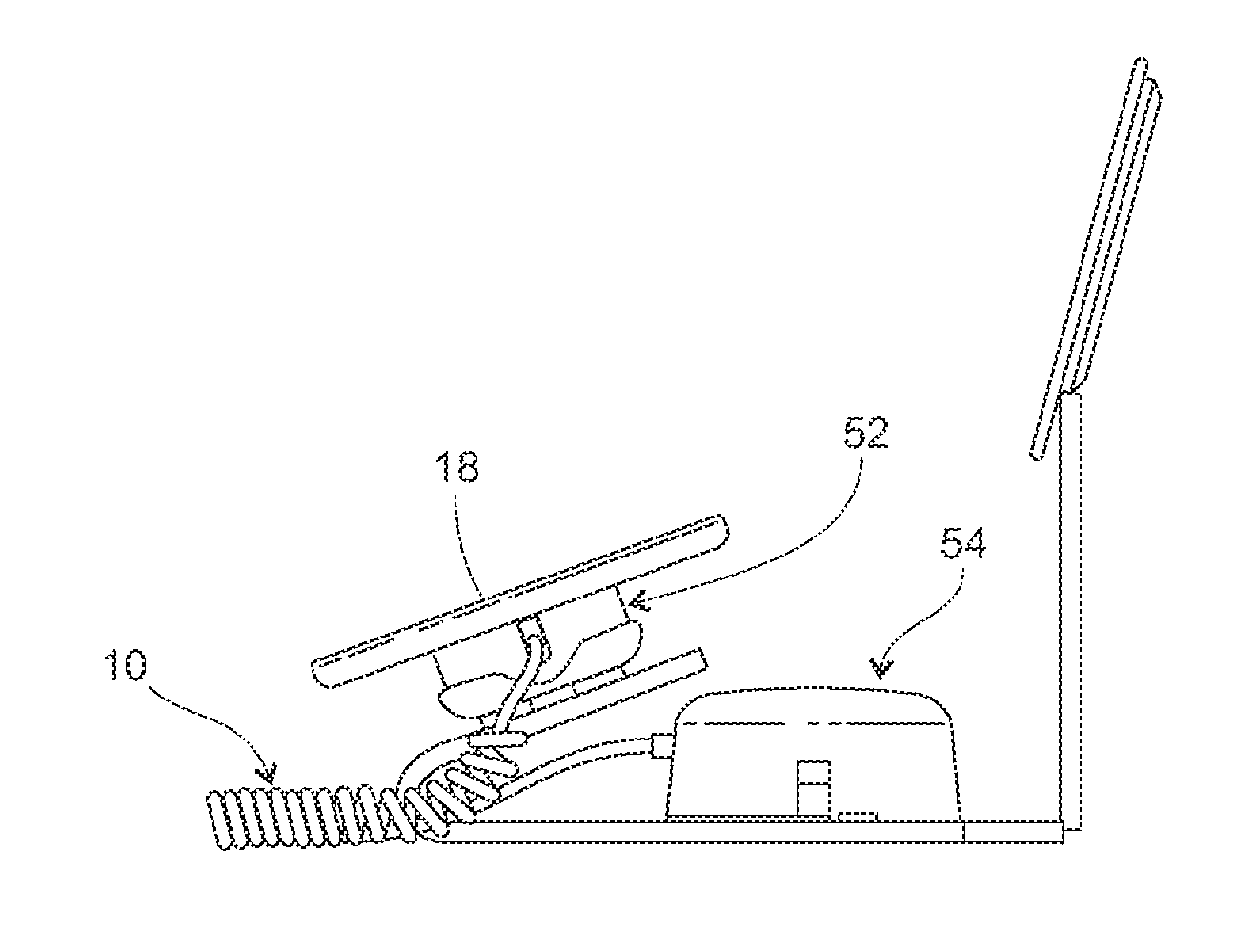

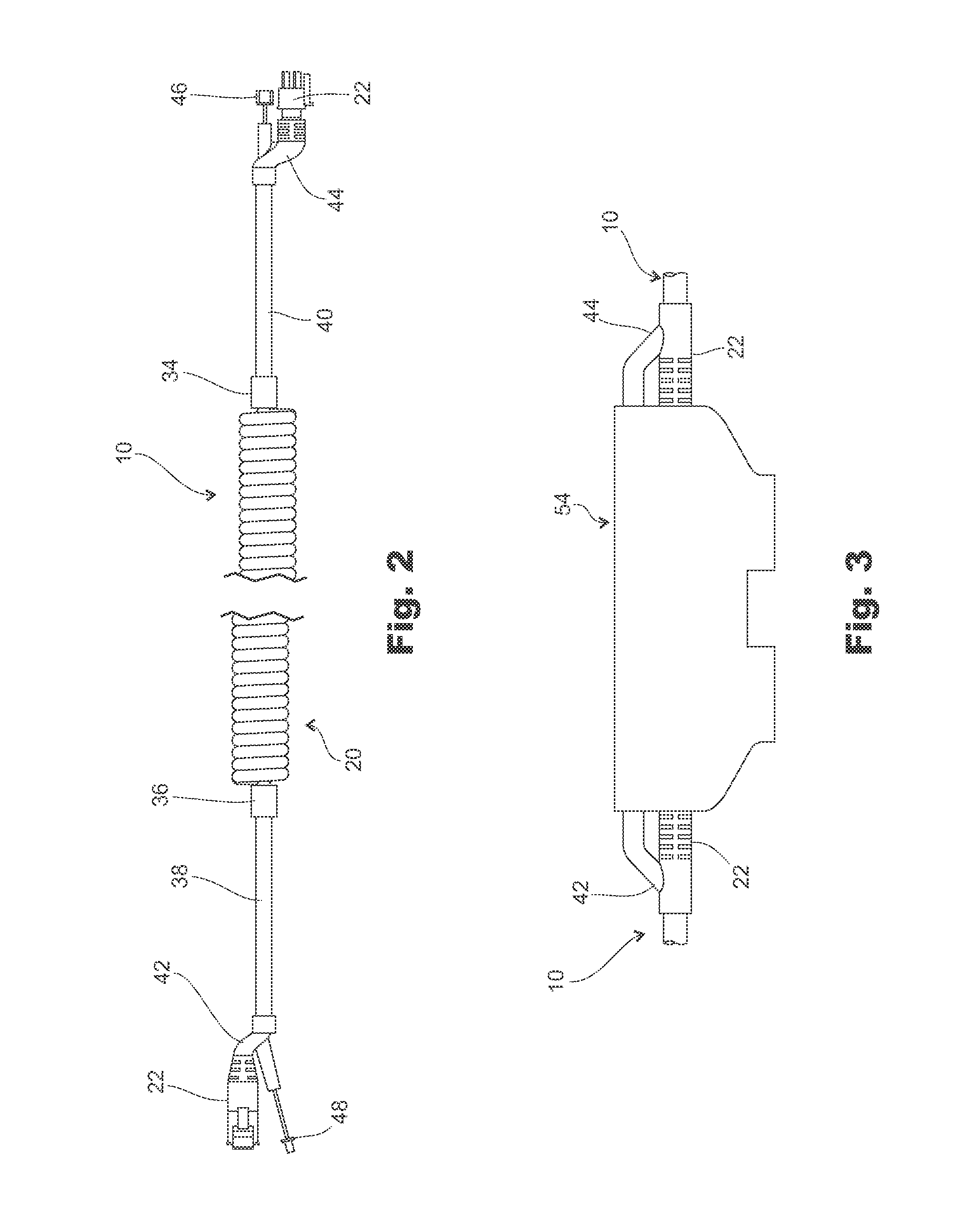

Security/Tether Cable

ActiveUS20130161054A1Avoid insufficient thicknessIncrease the difficultyExtensible conductorsBurglar alarmElectrical conductorPhysical Barrier

A power / security cord for use in a retail display includes the combination of at least one spring steel strand and at least one conductor coiled into the shape of a “curly-Q” cord. The steel strand provides a physical barrier against cutting the cord. The conductor provides wiring for power.

Owner:MOBILE TECH

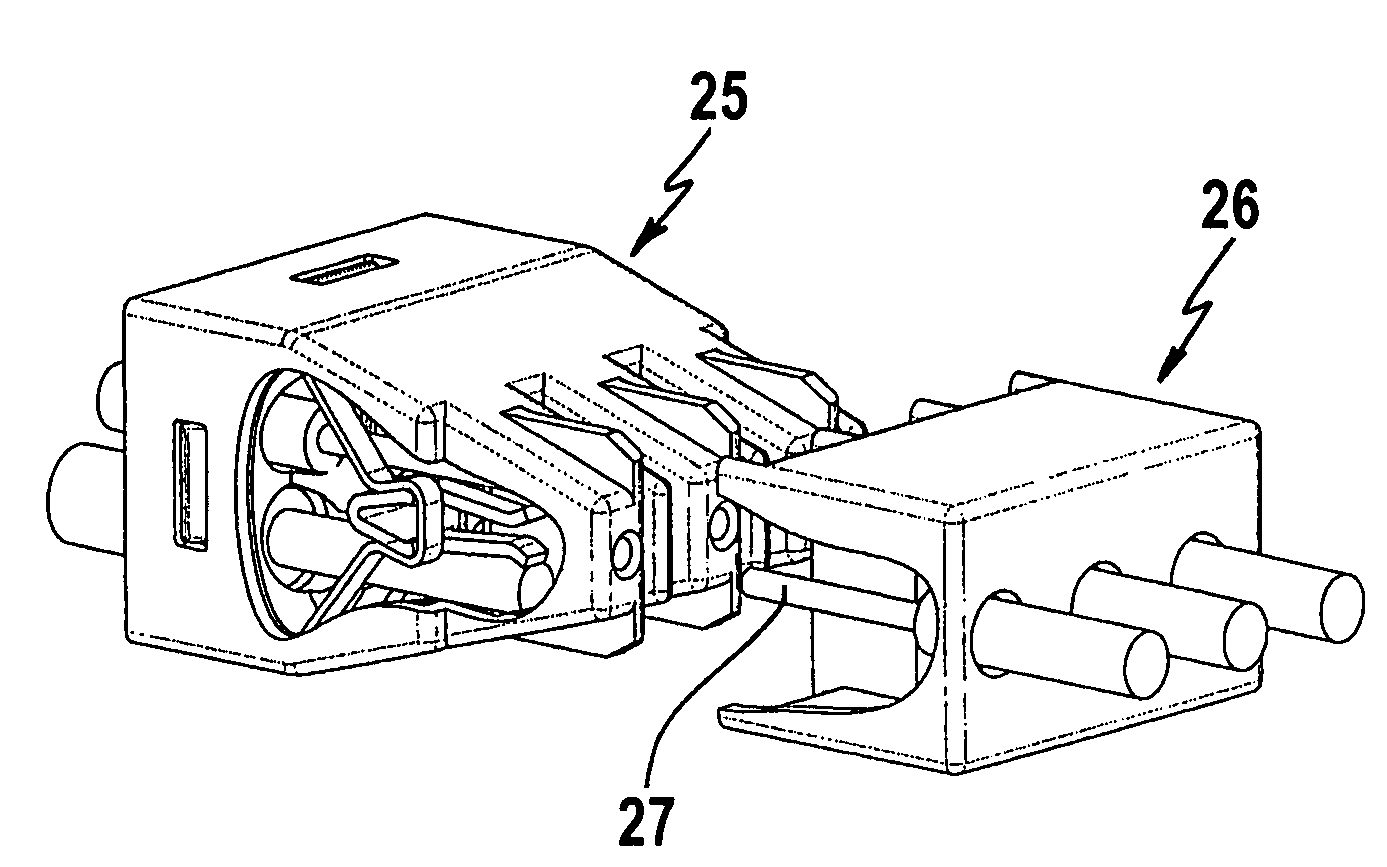

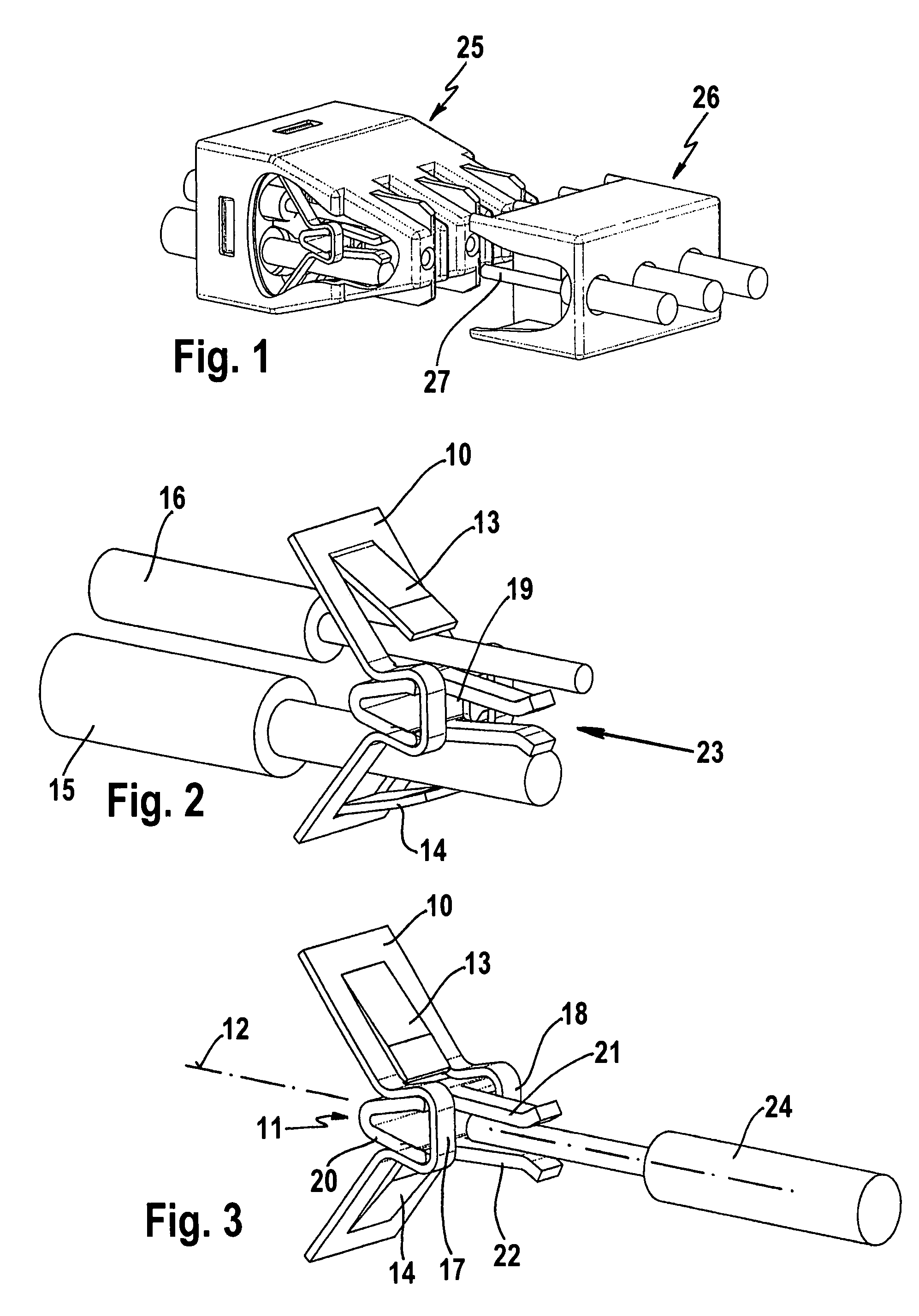

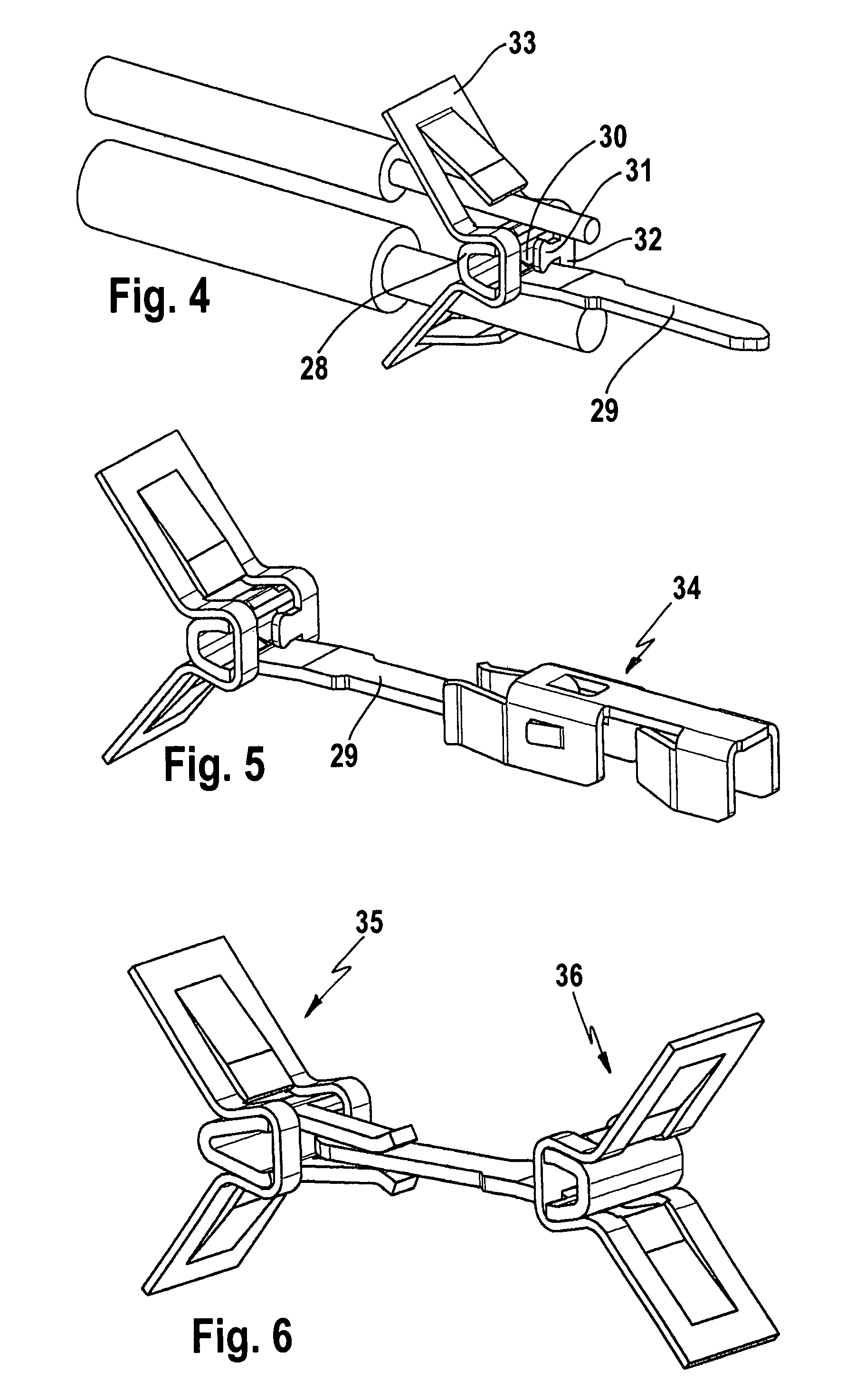

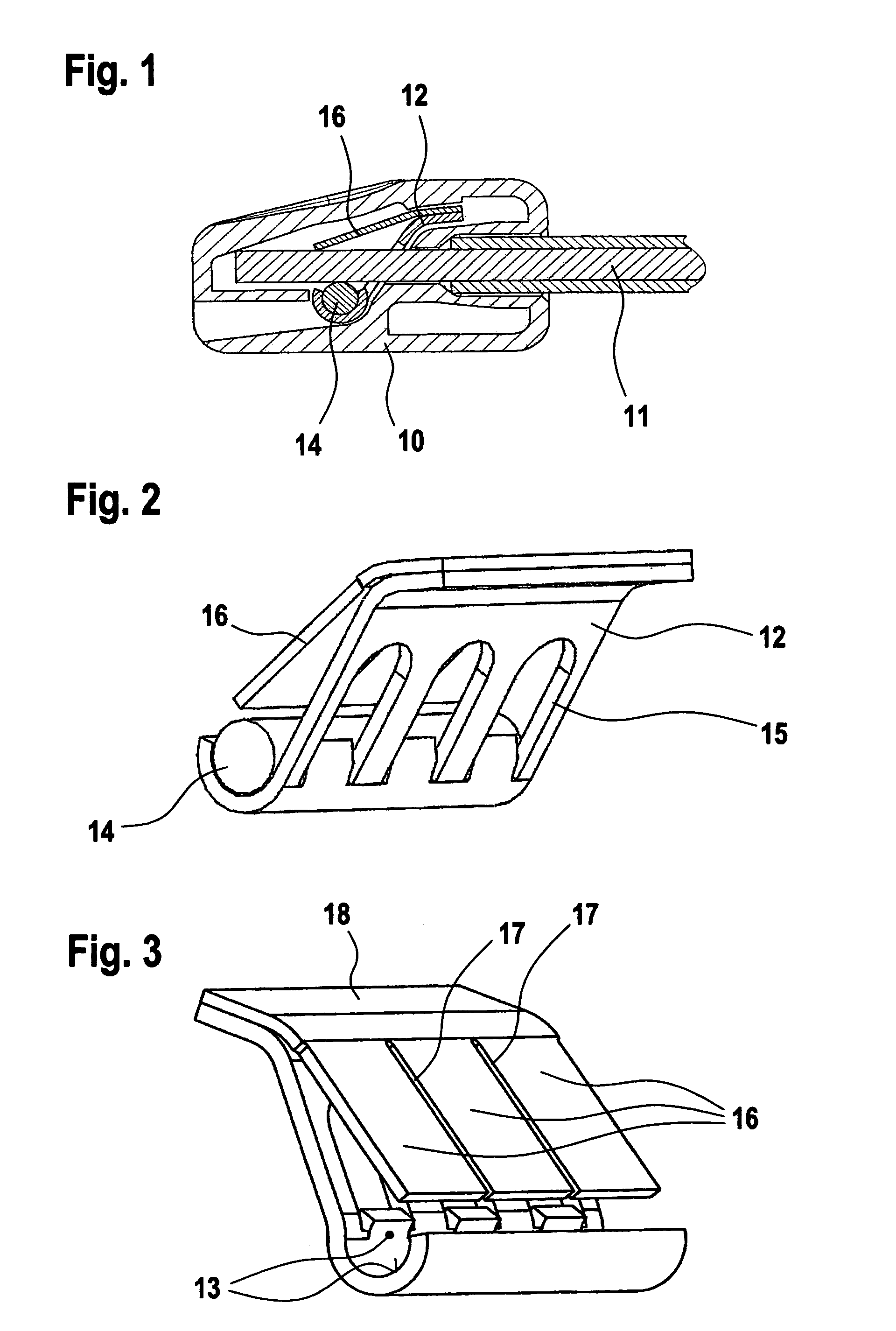

Electrical clamp connector and connecting terminal

InactiveUS7384319B2Contact member manufacturingCoupling contact membersElectrical conductorEngineering

The invention relates to an electrical clamp connector and connecting terminal that, per pole, has at least two conductor terminal connections oriented in the same direction and an additional connecting contact on the opposite-lying side, which serves for connecting a countercontact external to the terminal. It is proposed for such a terminal to use the especially small-construction design features of a terminal that is produced from a single piece of spring steel sheet and a busbar rod, and to combine these with the new features that the busbar rod has one or two cross projections, which project through the free opening in the spring steel sheet and form the additional connecting contact, which, for example, may be constructed in the form of a socket contact or in the form of a plug-in contact.

Owner:WAGO VERW GMBH

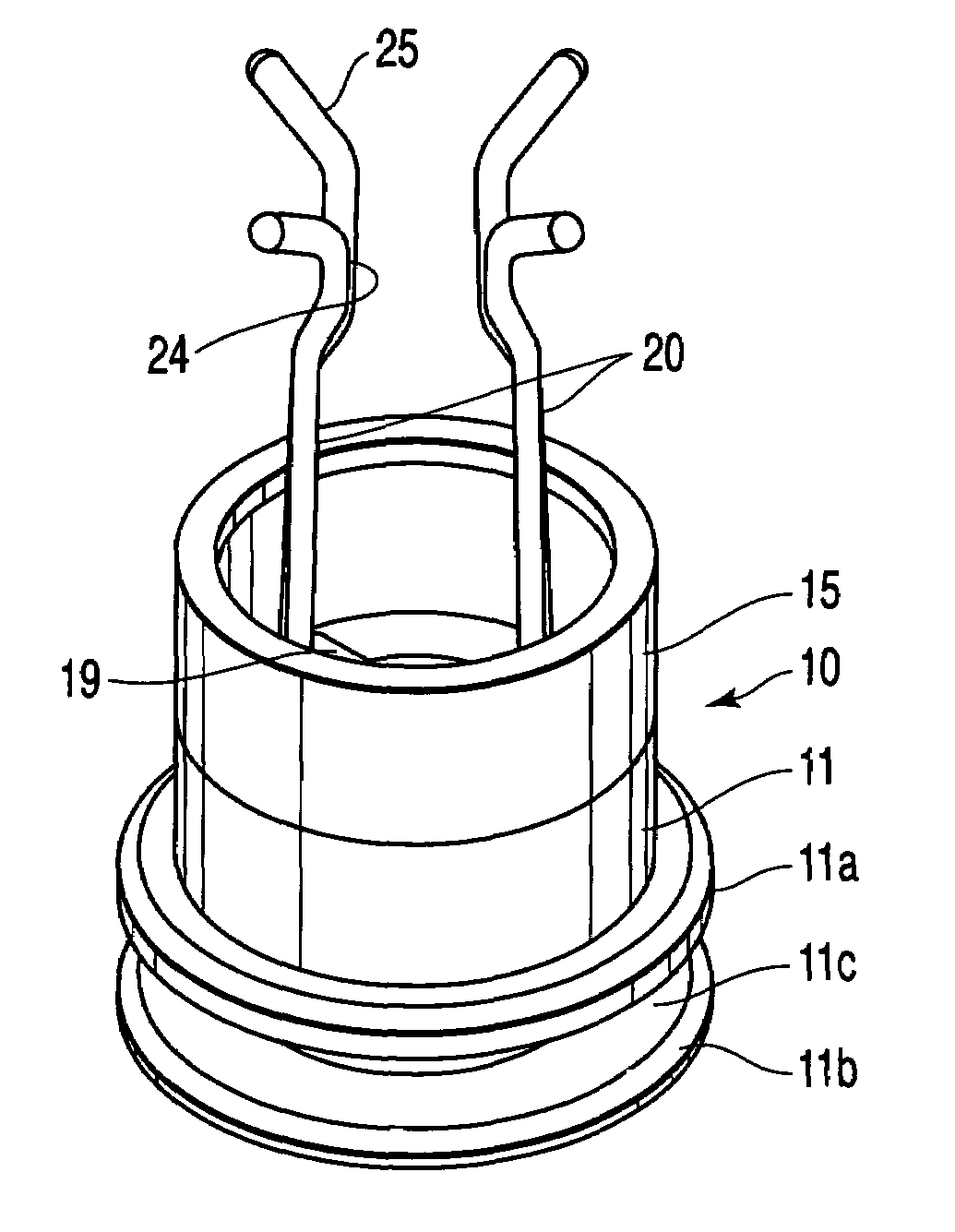

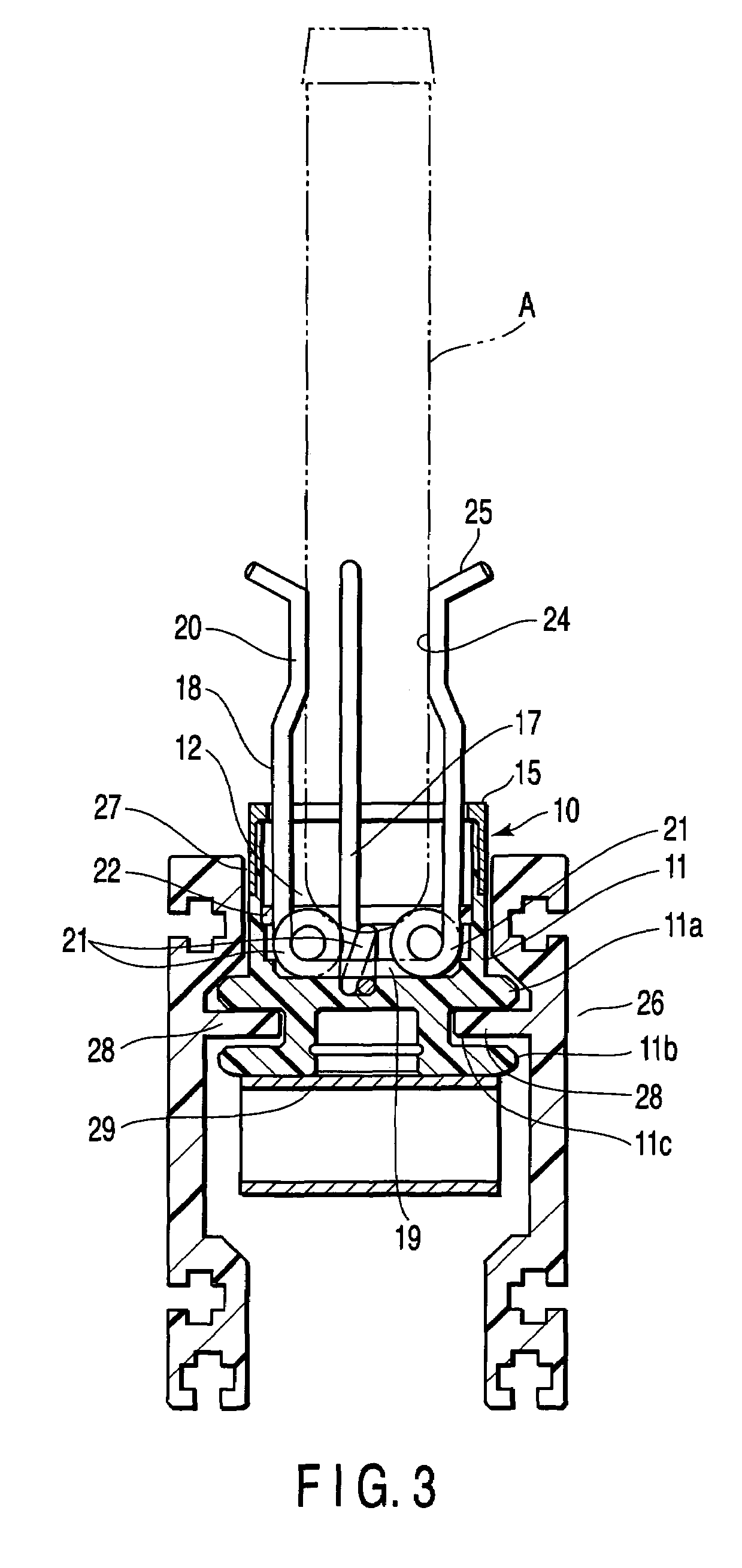

Test tube holder

ActiveUS7485264B2Simple structureEasy to assembleContainer/bottle contructionShow shelvesEngineeringSpring steel

A test tube holder includes a main body and an adapter. The main body includes a cylindrical hollow portion for accommodating a test tube. The adapter is provided in the cylindrical hollow portion to hold the test tube. The adapter includes bottom portions, holding portions and loop portions, which are U-shaped as a whole. The bottom portions are located to cross the center axis of the cylindrical hollow portion. The loop portions are provided at the ends of the bottom portions, and coiled at least one. The holding portions are continuous with the loop portions and the bottom portions. The bottom portions of first and second spring steel wires are provided in the cylindrical hollow portion to intersect with each other. The holding portions of the first and second spring steel wires are projected upwards from the cylindrical hollow portion.

Owner:IDS CO LTD

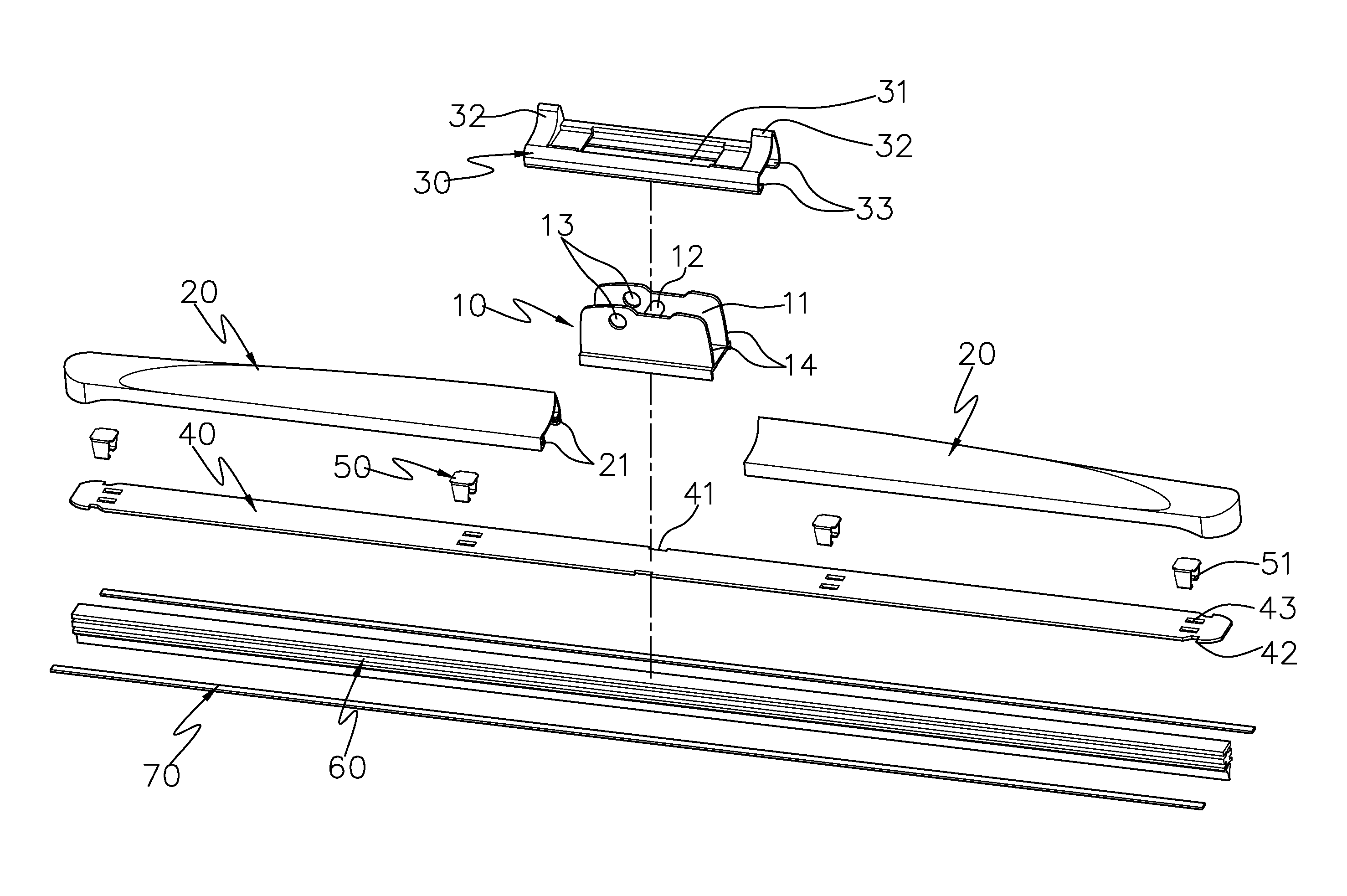

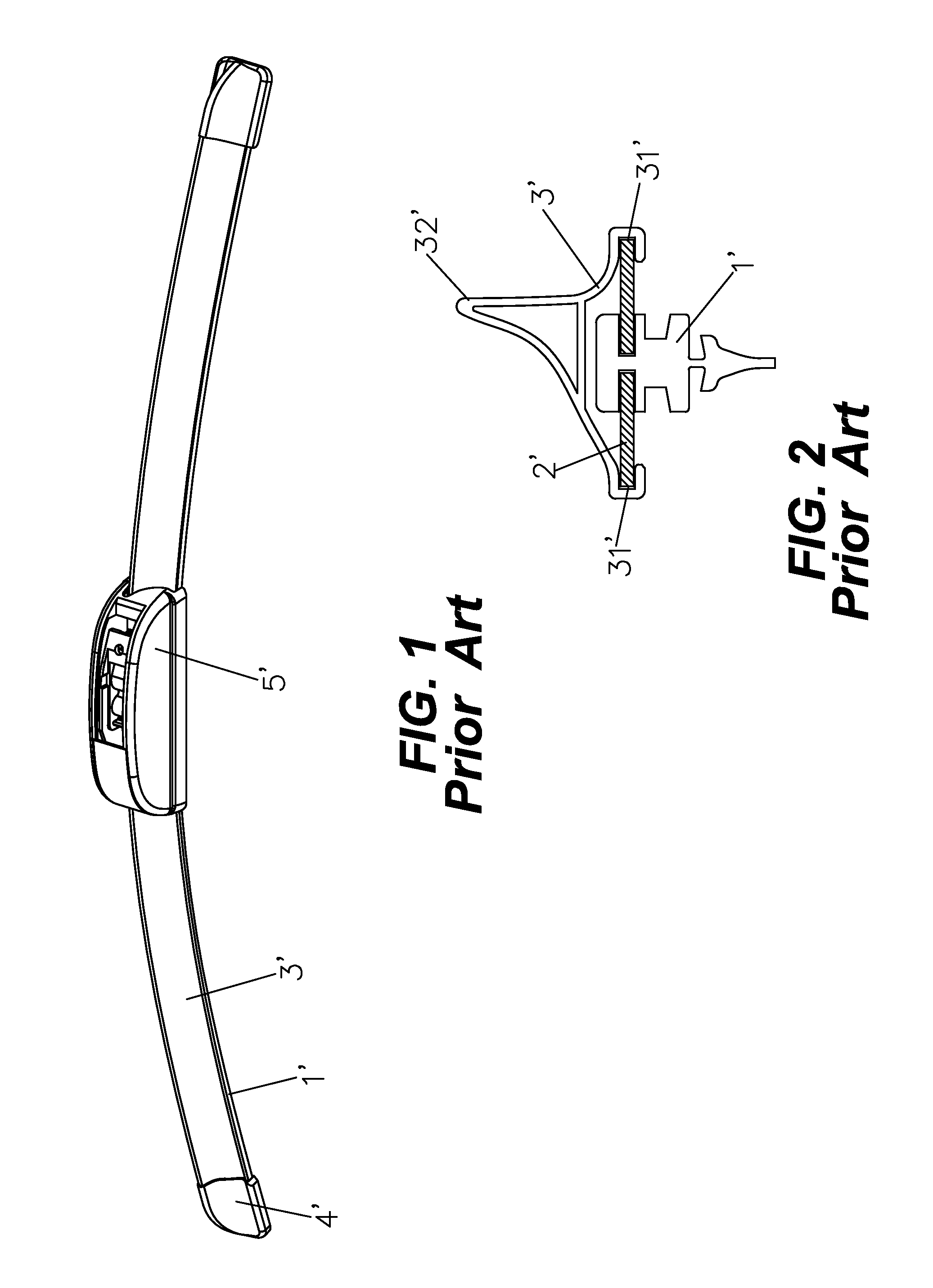

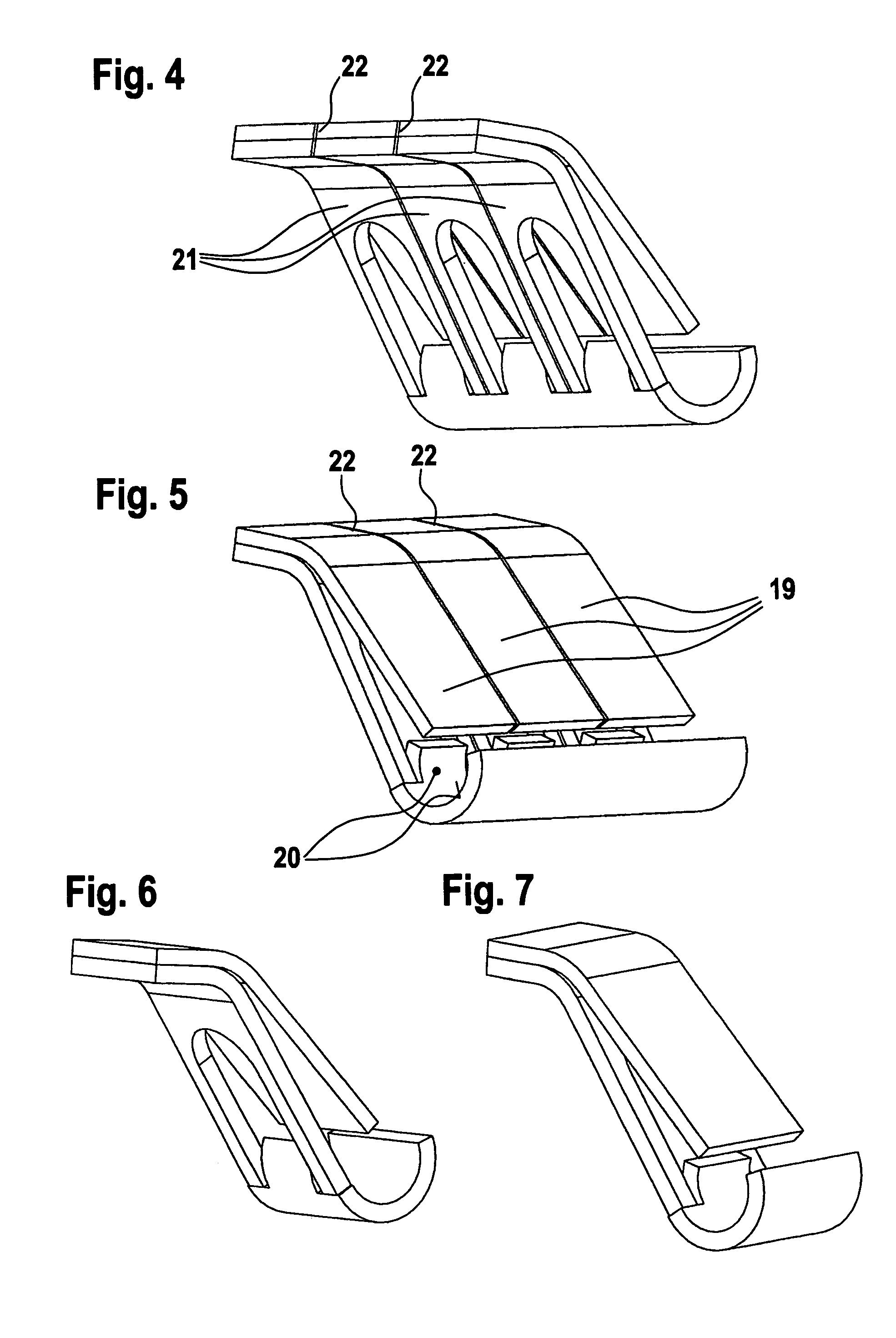

Boneless wiper blade

The prevent invention discloses a boneless wiper blade, which mainly consists of a pivot socket, two end ferrules, spring steel sheet and rubber strip, wherein the spring steel sheet is used to support and fix the rubber strip, and the pivot socket, on which the connecting adaptors are installed to connect with wiper arms, is mounted on the center of the spring steel sheet and the rubber strip, with end ferrules mounted at both ends of them. The upper part of the wind-pressure sheathes featuring specially curved surface is designed to prevent the wiper blade from lifting off from the surface of the windshield at highway speeds. The said spring steel sheet is so parabolically designed that the rubber strip can firmly and closely contact the various windshield glasses. Both connecting structures between the connecting adaptor and the pivot socket, and the pivot socket and the spring steel sheet and rubber strip are removable, it is same with the connecting structure between end ferrule and spring steel sheet and rubber strip. In this way, it is easy to assemble, dismount and replace them, and even facilitate use of them. The wiper blade has strong compatibility in that the pivot socket can be mounted with various kinds of connecting adaptors to be compatible with multiple wiper arm configurations.

Owner:XIAMEN METO AUTO PARTS

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

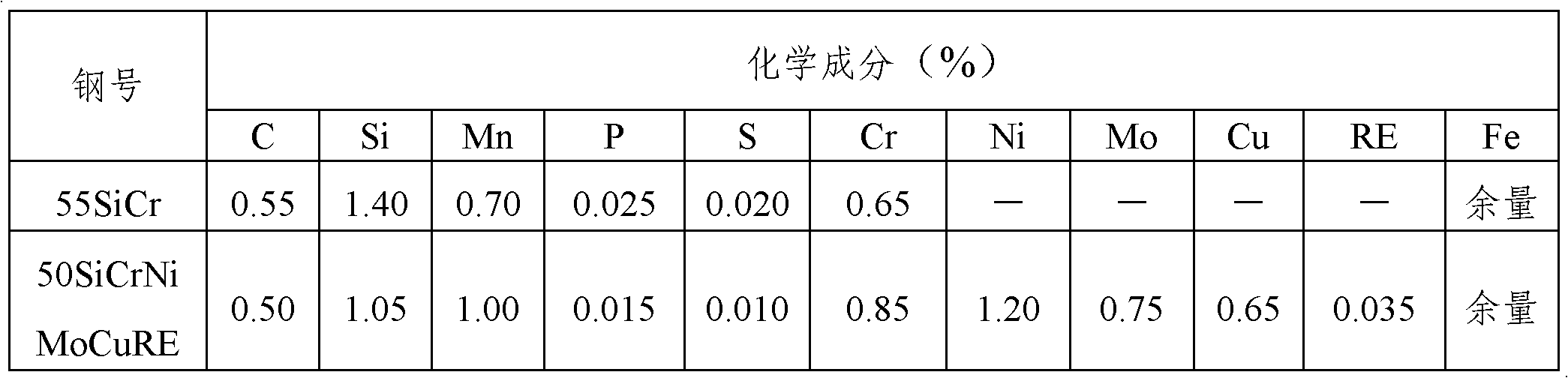

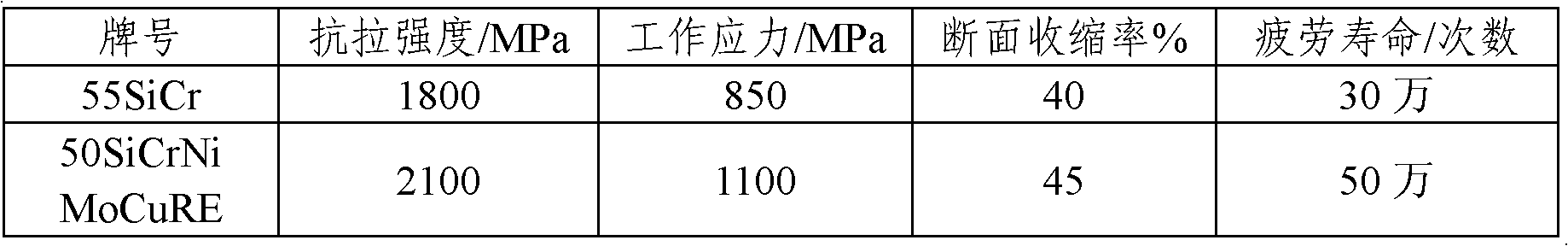

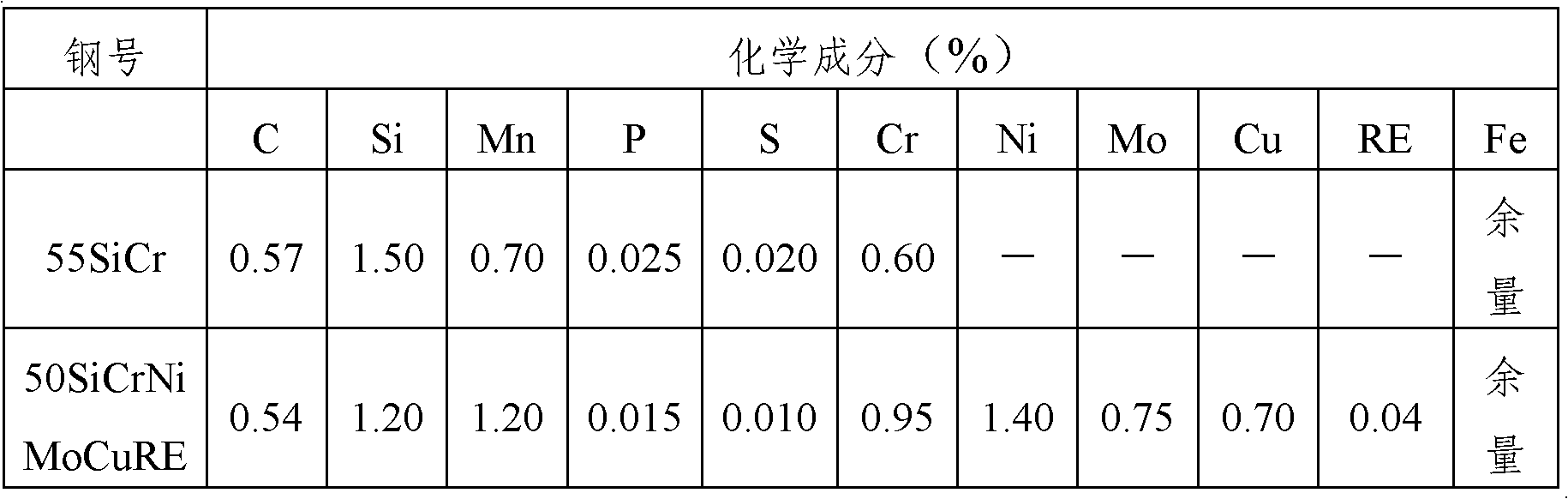

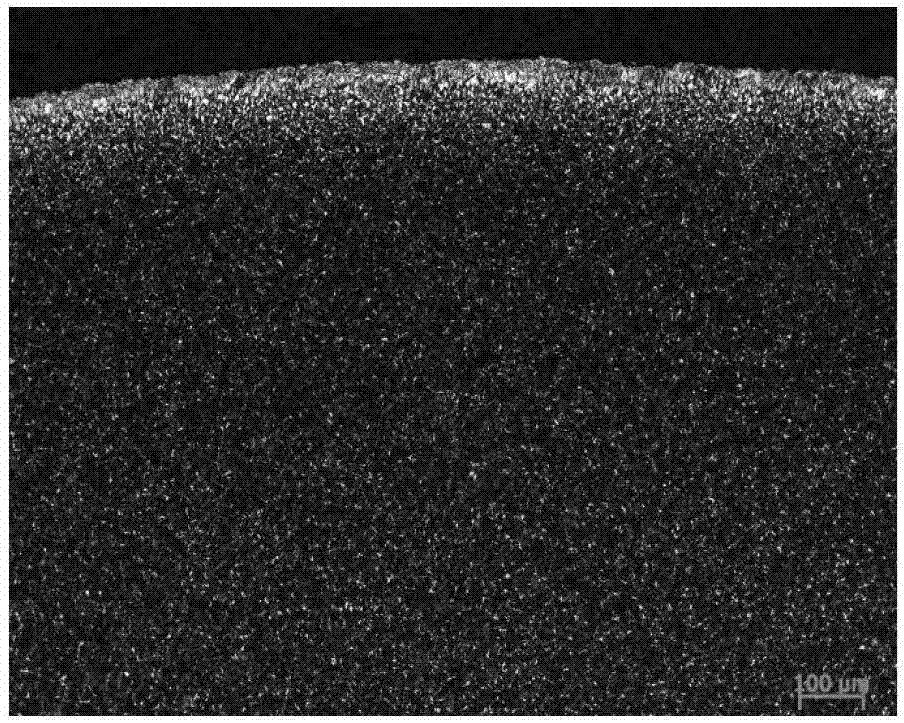

Spring steel used for automobile suspension as well as preparation method and application thereof

ActiveCN102634735AHigh tensile strengthIncrease work stressProcess efficiency improvementChemical compositionSpring steel

The invention provides a spring steel used for an automobile suspension. the spring steel comprises the following ingredients in percentage by weight: 0.46-0.56% of C, 0.90-1.20% of Si, 0.80-1.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.70-1.0% of Cr, 0.90-1.50% of Ni, 0.60-0.90% of Mo, 0.50-0.80% of Cu, 0.02-0.07% of RE and the balance of Fe and inevitable impurities. The invention also provides a preparation method for the spring steel and a method for preparing a spring steel wire by using the spring steel. According to the invention, the chemical components of the spring steel are reasonably designed, and the smelting rolling and steel wire preparation method and the auxiliary material adding method and proportion are improved. Compared with the existing 55SiCr steel, the tensile strength of the spring steel disclosed by the invention is improved by 400MPa, the working stress is improved by 200MPa, and the fatigue life is improved by 200 thousand times.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

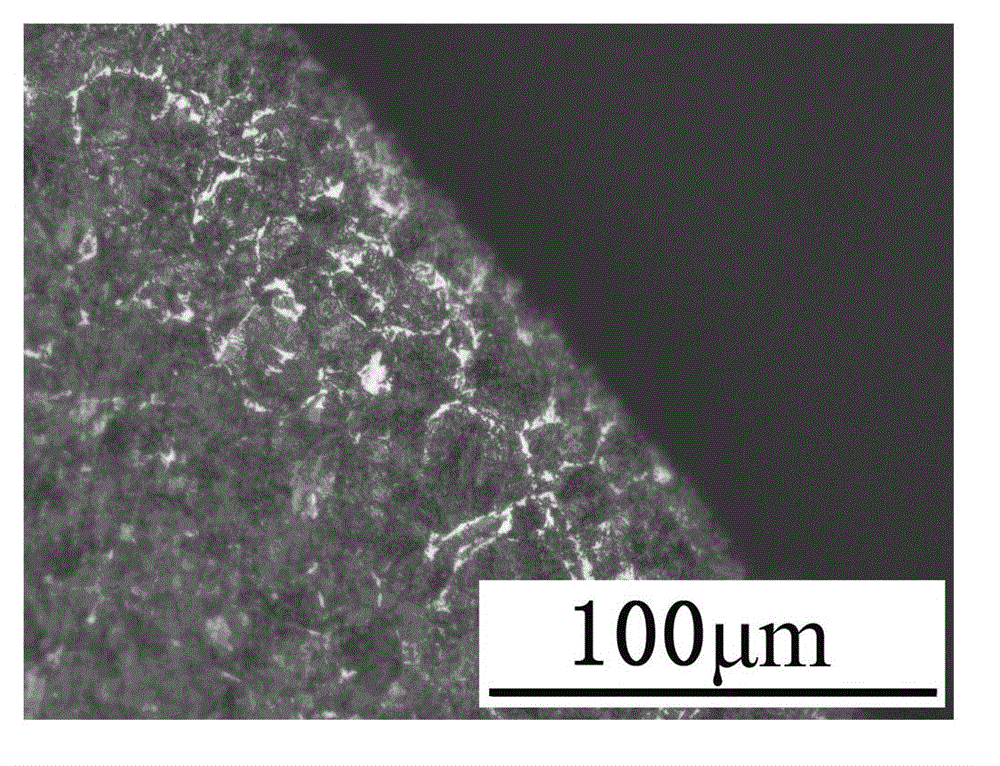

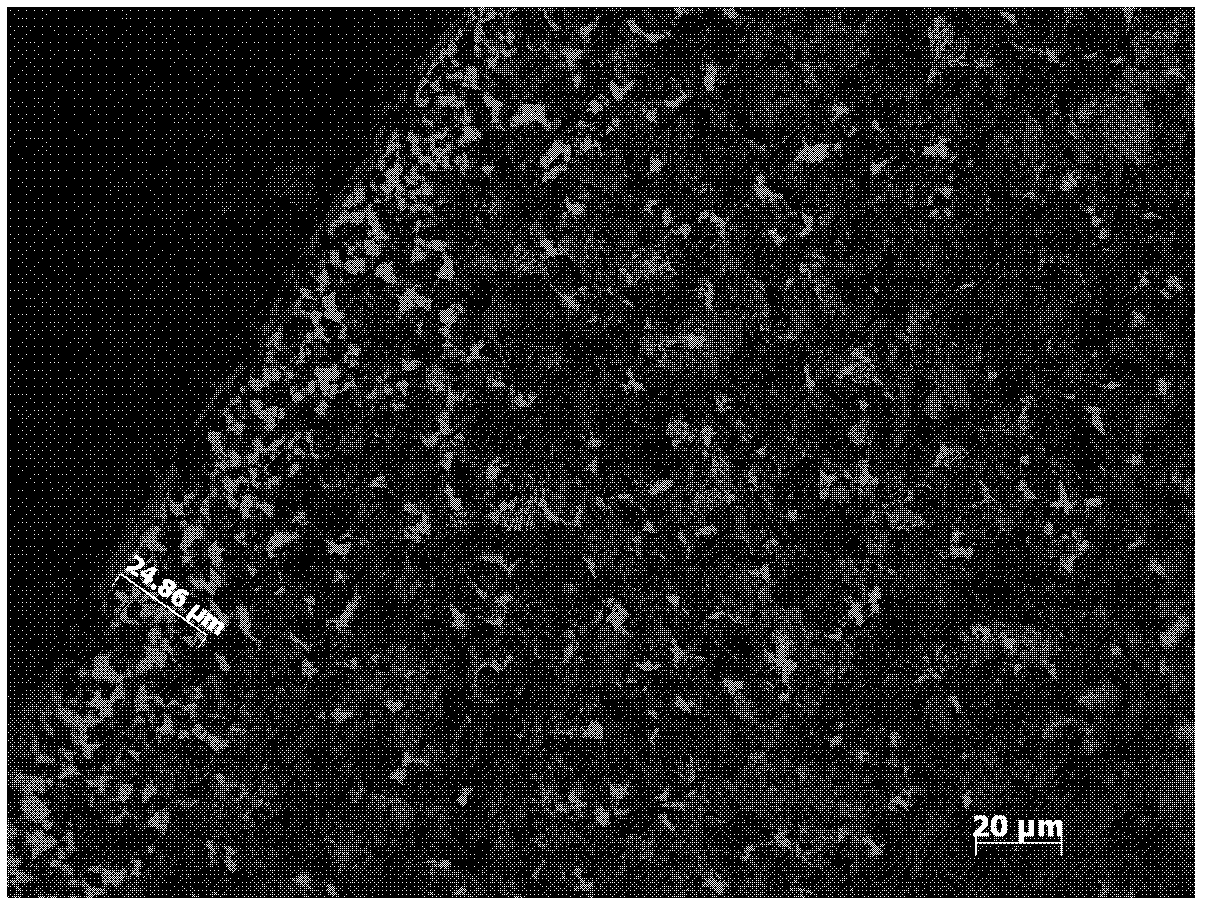

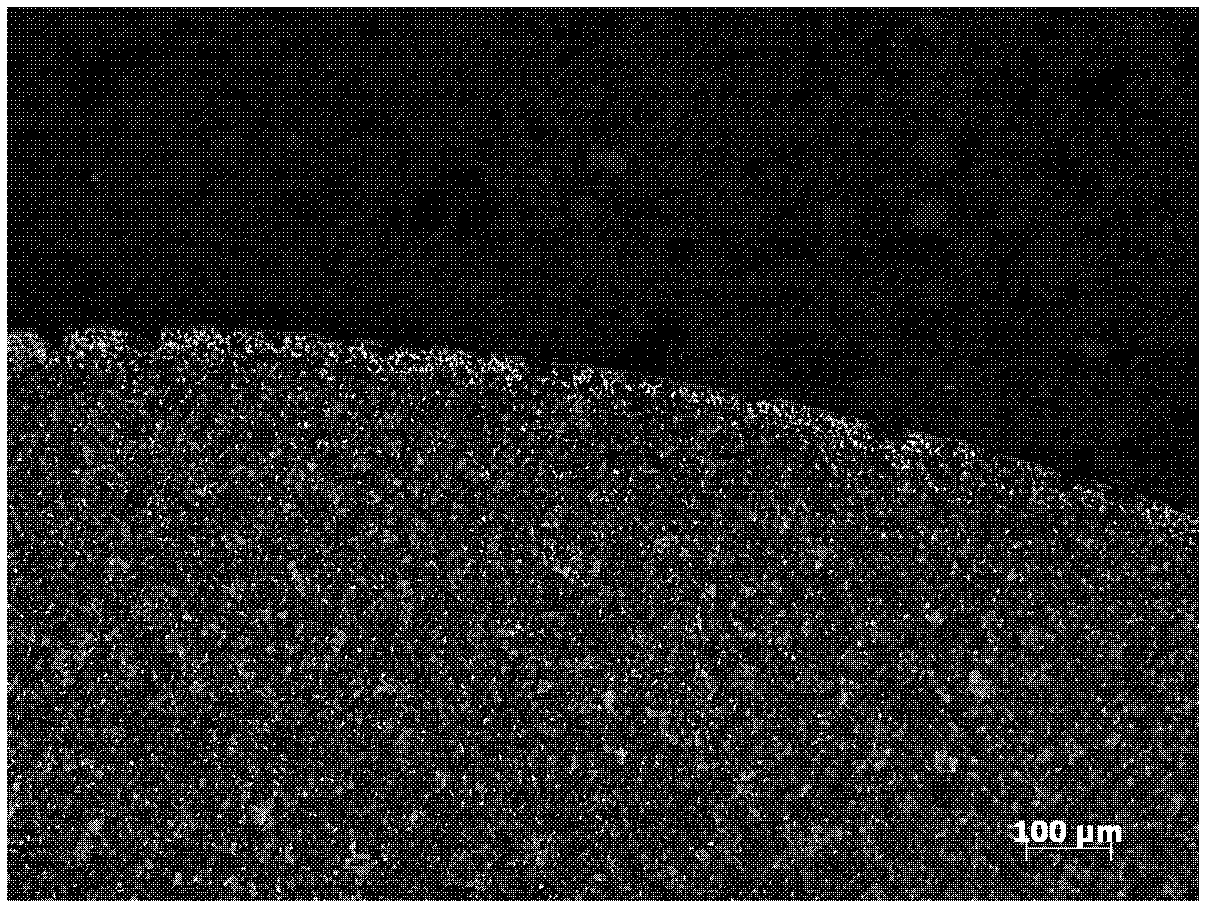

Control method for surface decarburization and ferrite distribution of steel disc bar of spring

ActiveCN103045935AReduce manufacturing costReduce intensityManufacturing convertersWire rodSpring steel

The invention relates to a control method for surface decarburization and ferrite distribution of a steel disc bar of a spring. The method comprises the steps of raw material preparation,smelting in a converter, LF (Ladle Furnace), VD (Vacuum Degassing) treatment, continuously casting, flaw detection and coping, heating, rolling, spinning, wind cooling by stelmor, intensively coiling, detecting and putting in a storeroom, rolling wire rods to be 8-18 mm in diameter, ensuring that the tensile strength (ob) is 950-1100MPa and the percentage reduction of area (Z) is 30-50 percent after aging treatment, and organizationally adding a small amount of dispersedly distributed into sorbite. Compare with other processes, the strength is decreased to a certain extent, the reduction of area is improved to a certain extent, the variation range of the strength and reduction of area is smaller, the performance is more stable, pulling and reeding operation is facilitated, the production cost of spring steel is lowered, and the service life of the spring steel is prolonged.

Owner:TIANJIN IRON & STEEL GRP

High strength spring steel having excellent hydrogen embrittlement resistance

InactiveUS20060169367A1High strengthLow priceFurnace typesOhmic-resistance heatingAustenite grainHigh intensity

The present invention provides a high strength steel used for spring steel that has excellent hydrogen embrittlement resistance. The high strength steel which spring steel having excellent hydrogen embrittlement resistance comprises 0.20 to 0.60% of C, 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, higher than 0% and not higher than 1.5% of Al, 0.15% or less P, 0.02% or less S, and balance of iron and inevitable impurities and the structure includes: 1% or more residual austenite; 80% or more in total of bainitic ferrite and martensite; and 10% or less (may be 0%) in total content of ferrite and pearlite in the proportion of area to the entire structure, and also the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher and the steel tensile strength is 1860 MPa or higher.

Owner:KOBE STEEL LTD +1

Face mask support

InactiveUS20060231102A1Precise positioningTransmission of forceChemical protectionHeat protectionSpring steelForehead

A face mask support for continuous positive airway pressure comprises a circumferential band with biasing means support at the crown of the head on the medial line of the head. The circumferential edge of the cap extends from just below the forehead of a patient to below the inion protrusion at the nape of the neck. A biasing means which is preferably of length of spring steel is formed so as to extend from the biasing means support hold a nasal or face mask apposed to the face of a patient. The circumferential band is stabilized by a band extending from the circumferential band at the region of the ear to the biasing means support.

Owner:SOMNETICS INT INC

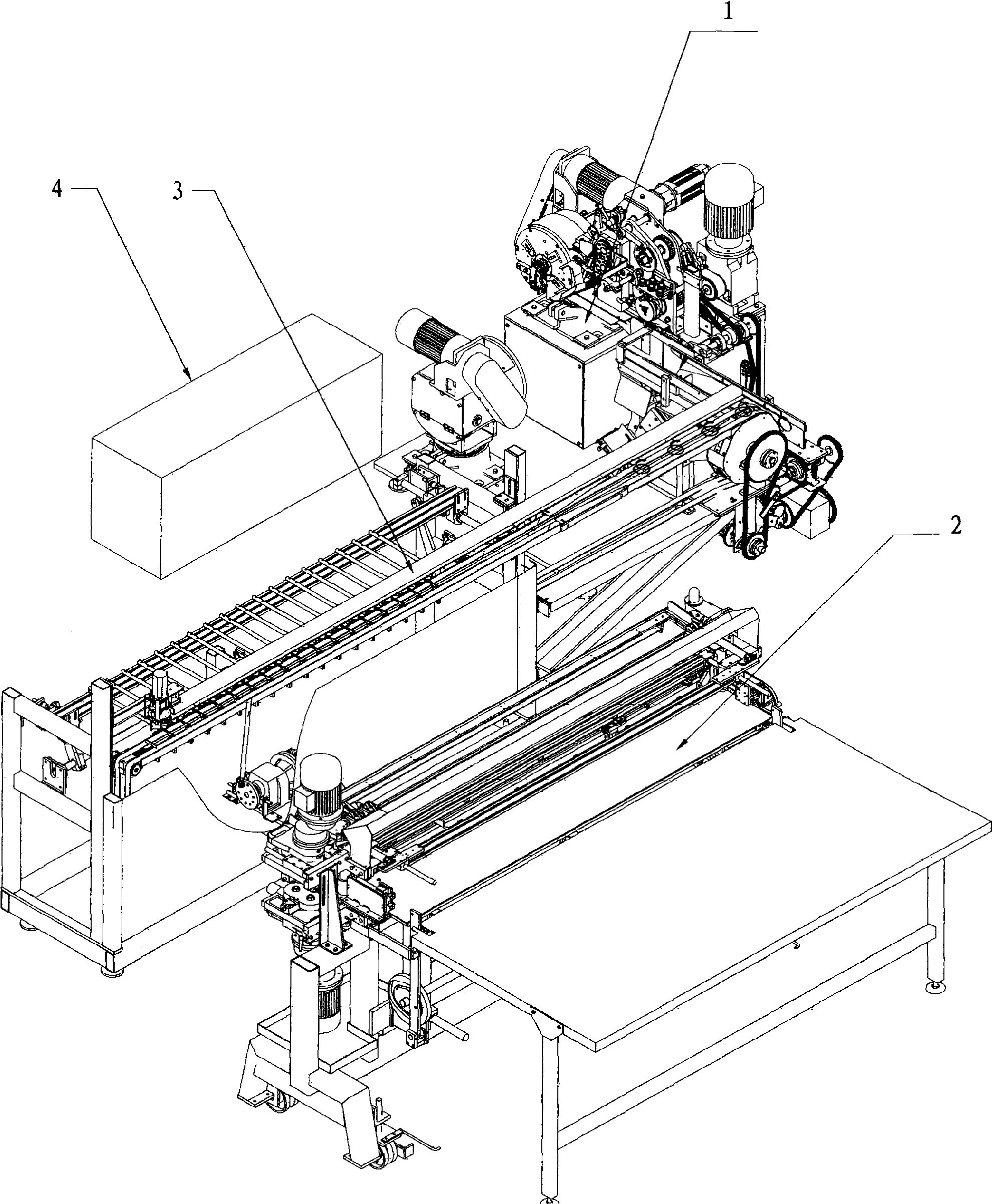

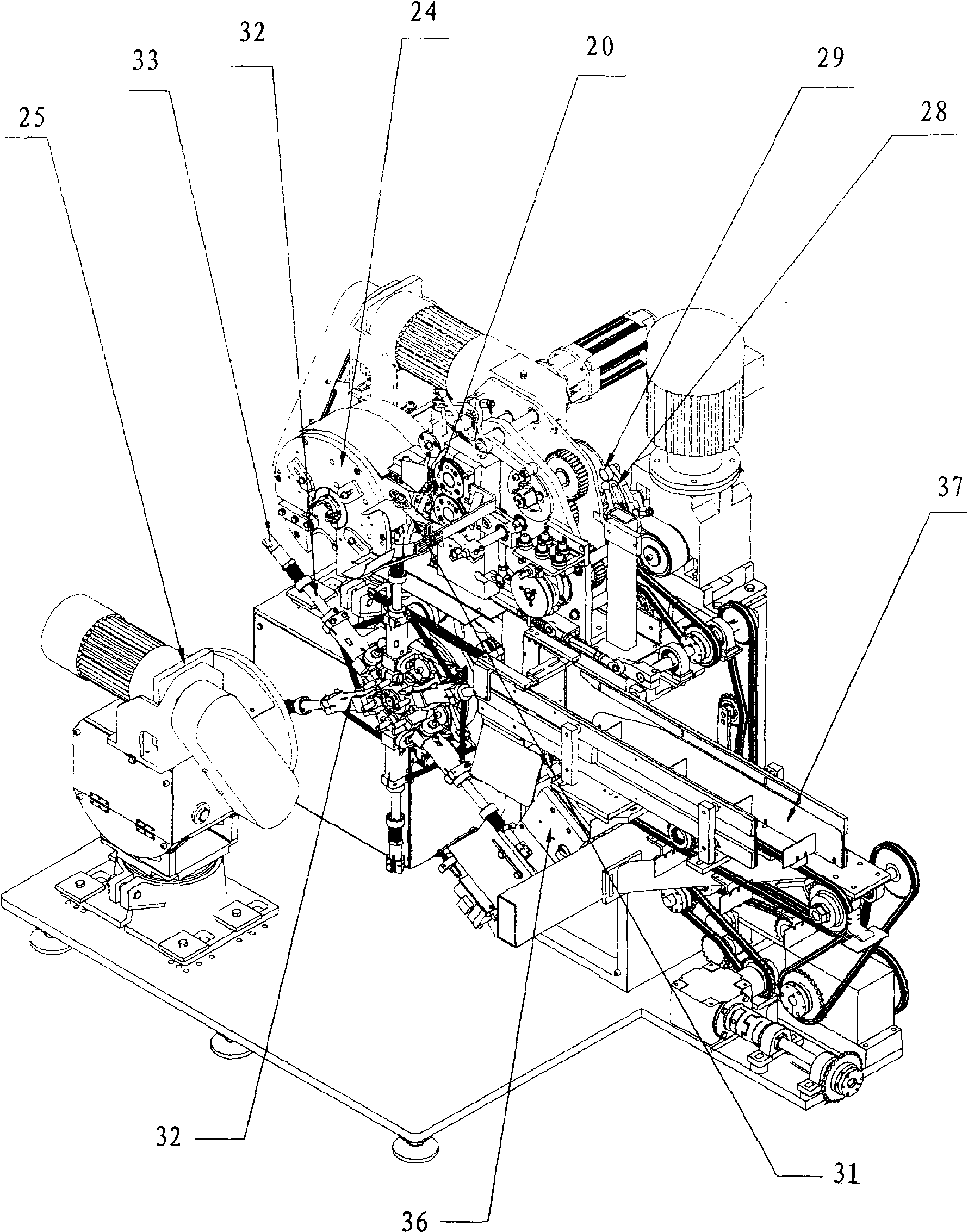

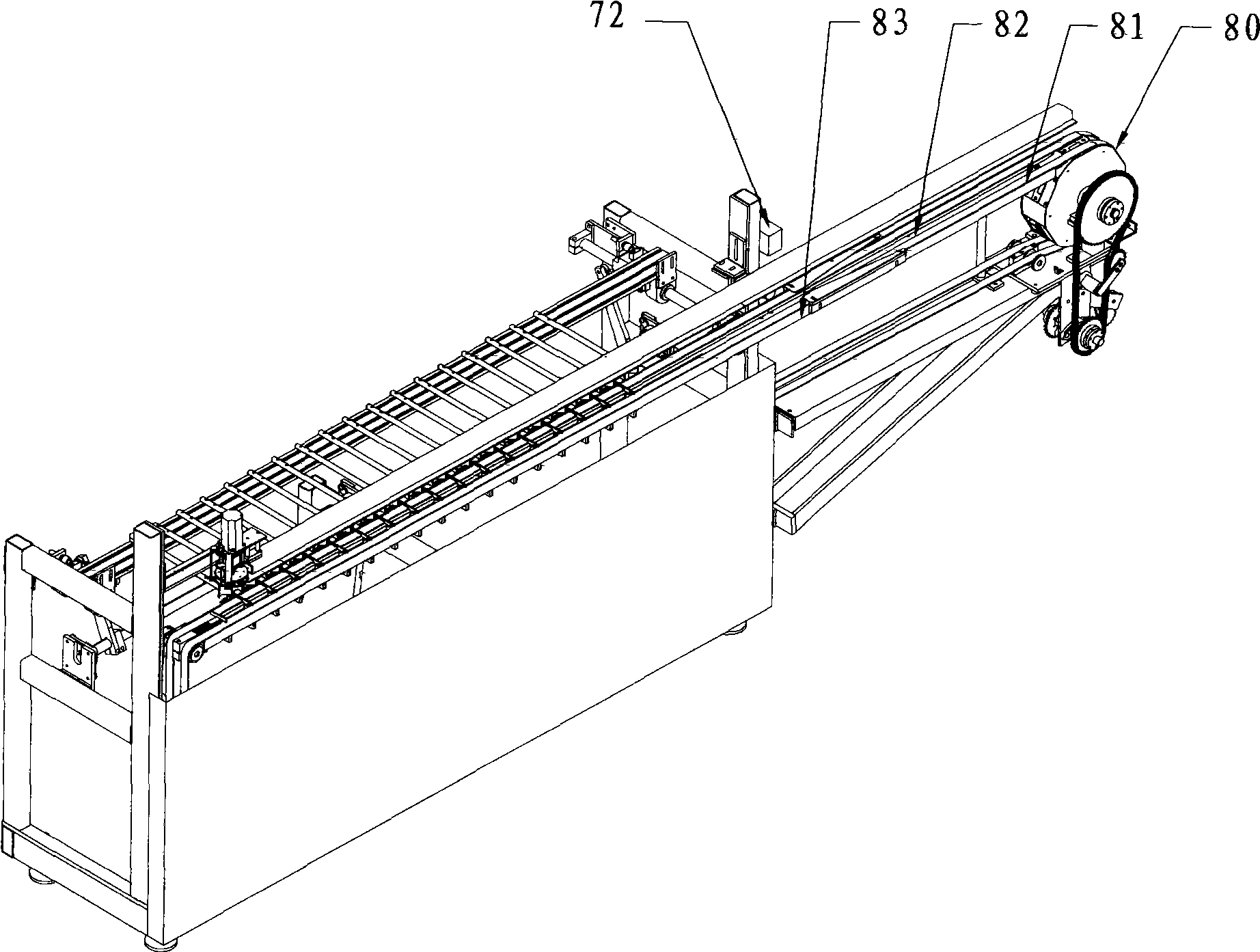

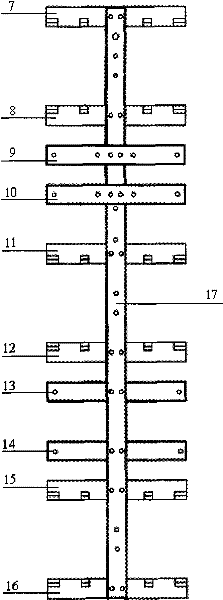

Method and device for fully automatically producing bed core

InactiveCN101530889AEasy to sendConvenient ArrangementConveyorsMetal-working apparatusMachine controlEngineering

The invention discloses a method for fully automatically producing a bed core, which comprises: step 1, coiling steel wires into springs, and outputting the springs at equal intervals; step 2, adjusting the springs to upright conveying, then positioning the springs, arraying the springs into groups, and then automatically pushing the springs to a string spring position; and step 3, stringing the springs into the bed core by string spring steel wires. The invention also discloses a device for fully automatically producing the bed core, which comprises an automatic spring coiling machine, an automatic string spring assembling machine, an automatic feeding machine and a complete machine control device. The automatic spring coiling machine is provided with a step output mechanism. The automatic feeding machine is provided with a turnover mechanism, a transmission mechanism and a positioning push mechanism. The turnover mechanism is connected with the step output mechanism and simultaneously connected with the transmission mechanism. The positioning push mechanism comprises a position sensor, a plurality of positioning plates and a plurality of push plates. The automatic string spring assembling machine is placed on the transmission mechanism of the automatic feeding machine in parallel. The complete machine control device is connected with the position sensor. The method and the device can achieve full automatic production from the steel wires to the bed core, and have high efficiency.

Owner:叶超英

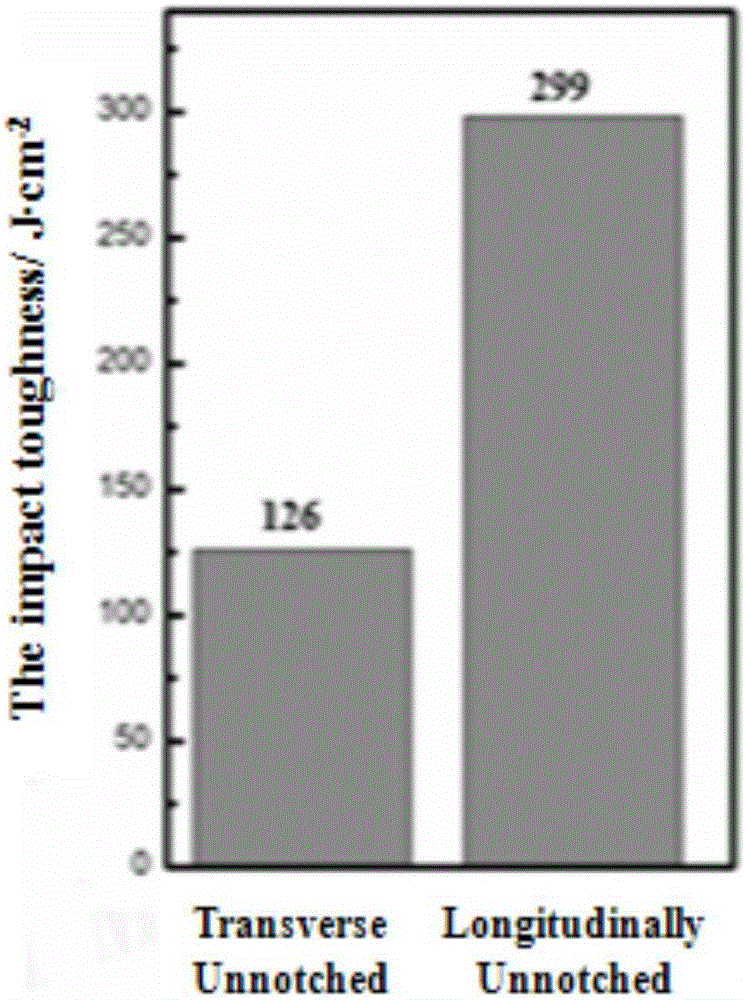

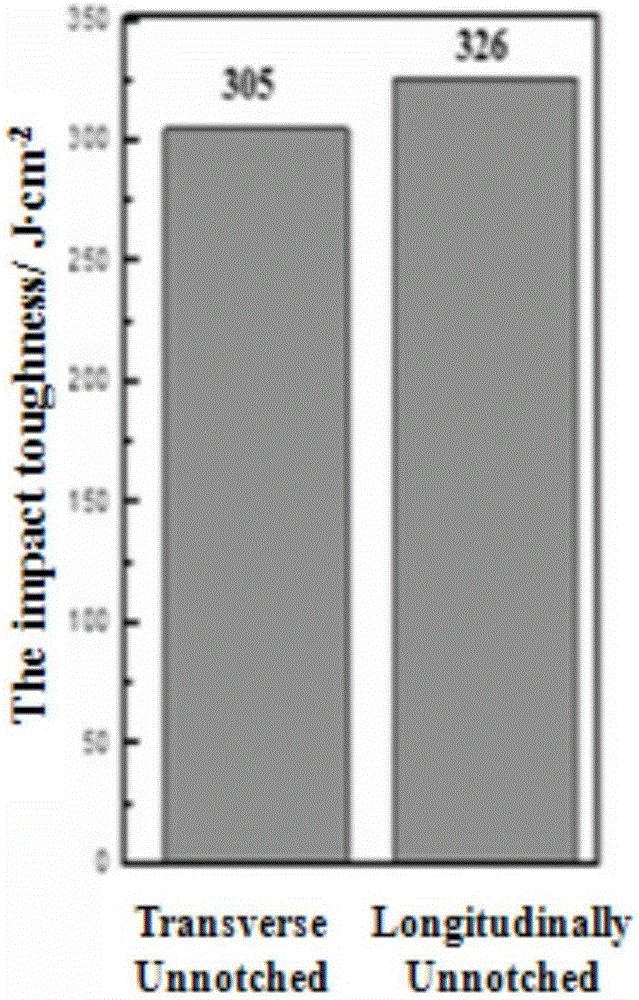

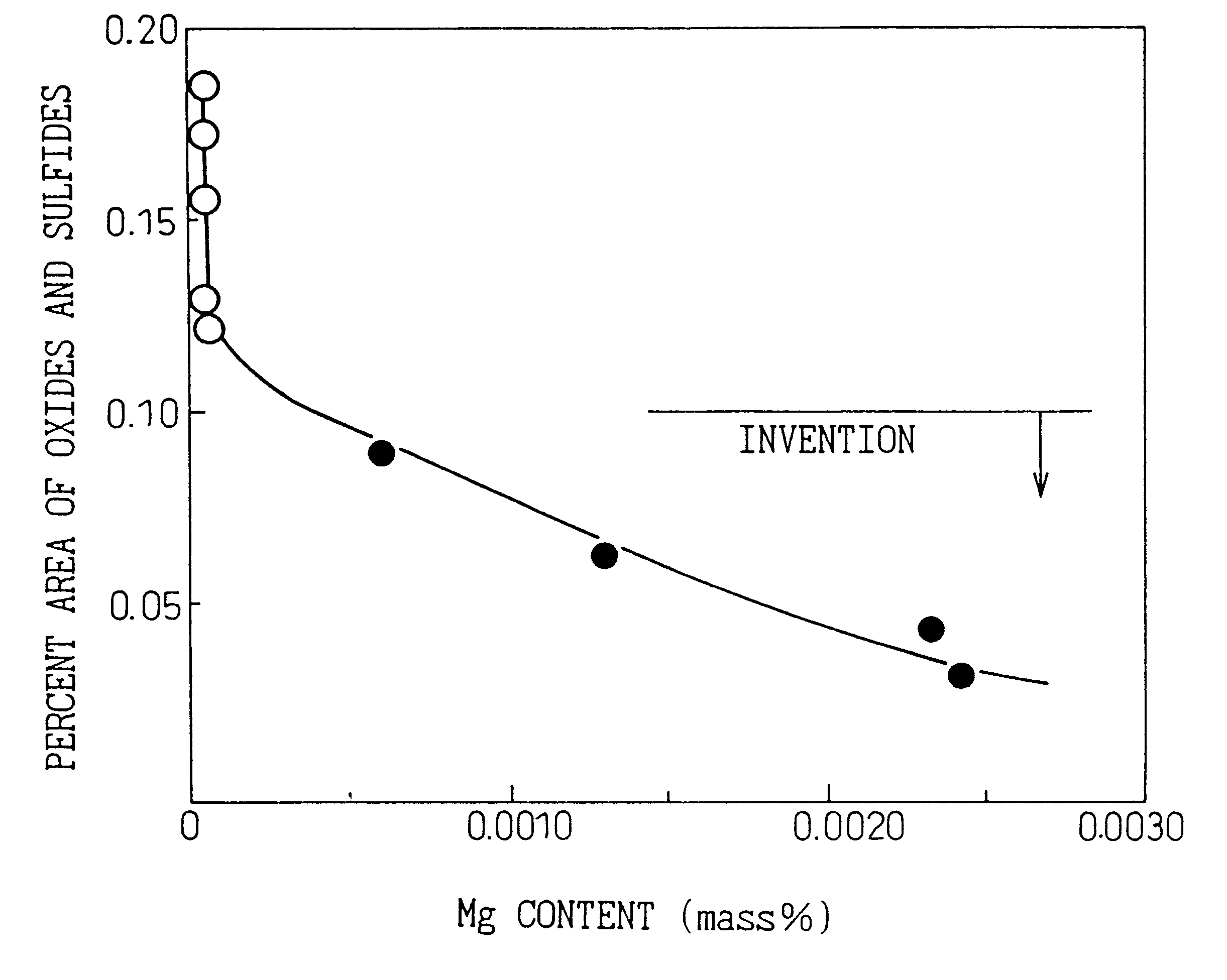

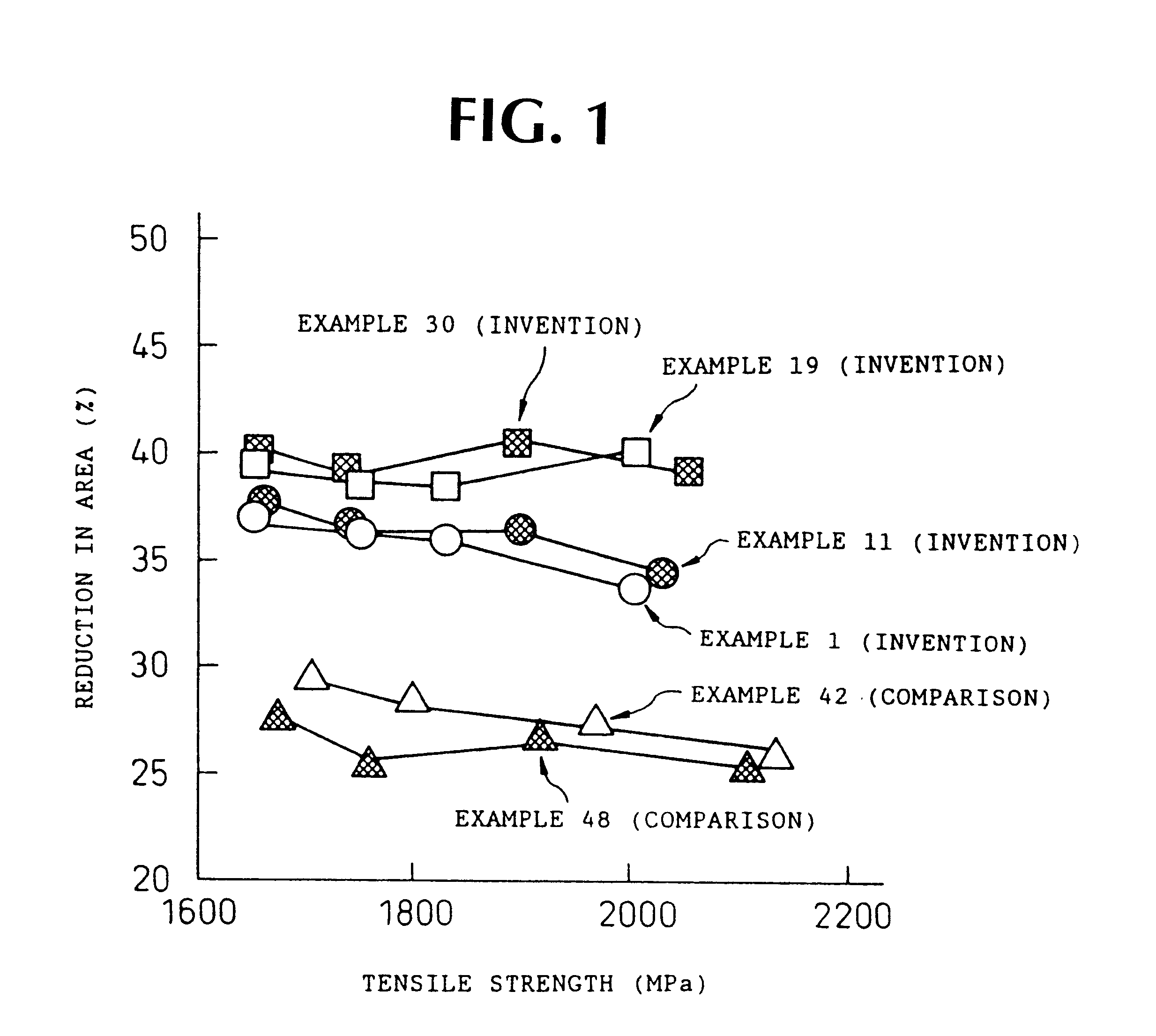

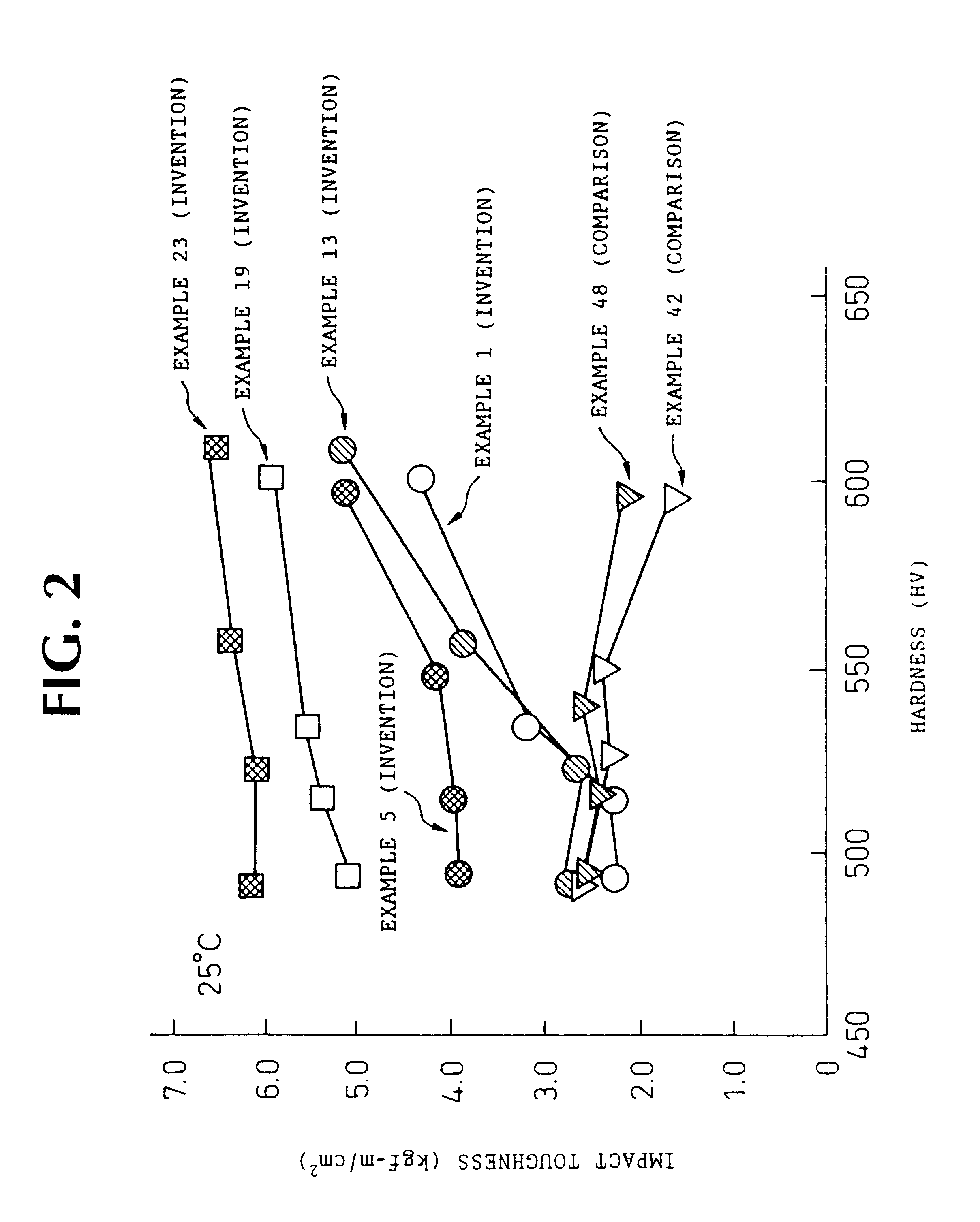

High toughness spring steel

InactiveUS6406565B1Solve the lack of ductilityAvoid lack of toughnessFurnace typesHeat treatment furnacesSulfideSpring steel

The present invention provides a spring steel showing a sufficient reduction in area and an impact toughness while the steel has a high strength, in particular a tensile strength as high as at least 1,500 Mpa. A high toughness spring steel according to the present invention comprises, based on mass, 0.45 to 0.85% of C, 0.9 to 2.5% of Si, 0.1 to 1.2% of Mn, 0.1 to 2.0% of Cr, 0.005 to 0.07% of Ti, 0.001 to 0.007% of N, the Ti content being greater than four times the N content in terms of percent by mass, 0.0005 to 0.0060% B, at least one of 0.0005 to 0.01% Mg, 0.0005 to 0.01% La, and 0.0005 to 0.01% Ce, P and S with restrictive contents of less than 0.020% and less than 0.020%, respectively, and the balance of Fe and unavoidable impurities, and selectively contains V, Nb, Ni, Mo and Cu. The percent area of oxides and sulfides is not more than 0.1%.

Owner:NIPPON STEEL CORP

Clamp terminal for connecting electrical conductors

InactiveUS7150646B2Small structure sizeShorten the lengthOne pole connectionsContact members penetrating/cutting insulation/cable strandsFoot regionElectrical conductor

Owner:WAGO VERW GMBH

Spring steel and preparation method thereof

InactiveCN101671792AImprove fatigueOvercome the disadvantage of low fatigue strengthSpring steelQuenching

The invention discloses spring steel. Based on the total weigh of the spring steel, the spring steel comprises 0.56 to 0.64 weight percent of C, 1.6 to 2 weight percent of Si, 0.6 to 0.9 weight percent of Mn, 0 to 0.015 weight percent of Ti, 0.0055 to 0.03 weight percent of S, 0.01 to 0.02 weight percent of Als and the balance of Fe and inevitable impurities, wherein the weight ratio of the S to the Als is 0.55 to 3; and the Als is acid soluble aluminum. The invention also provides a preparation method of the spring steel, which comprises: subjecting the raw material of the spring steel to primarily smelting, refining, cold forming, rolling, quenching and tempering, wherein the composition of the raw material of the spring steel ensures the composition of the spring steel obtained is the same as the composition of the spring steel of the invention. The spring steel is high in fatigue resistance. The production method is simple and reduces cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

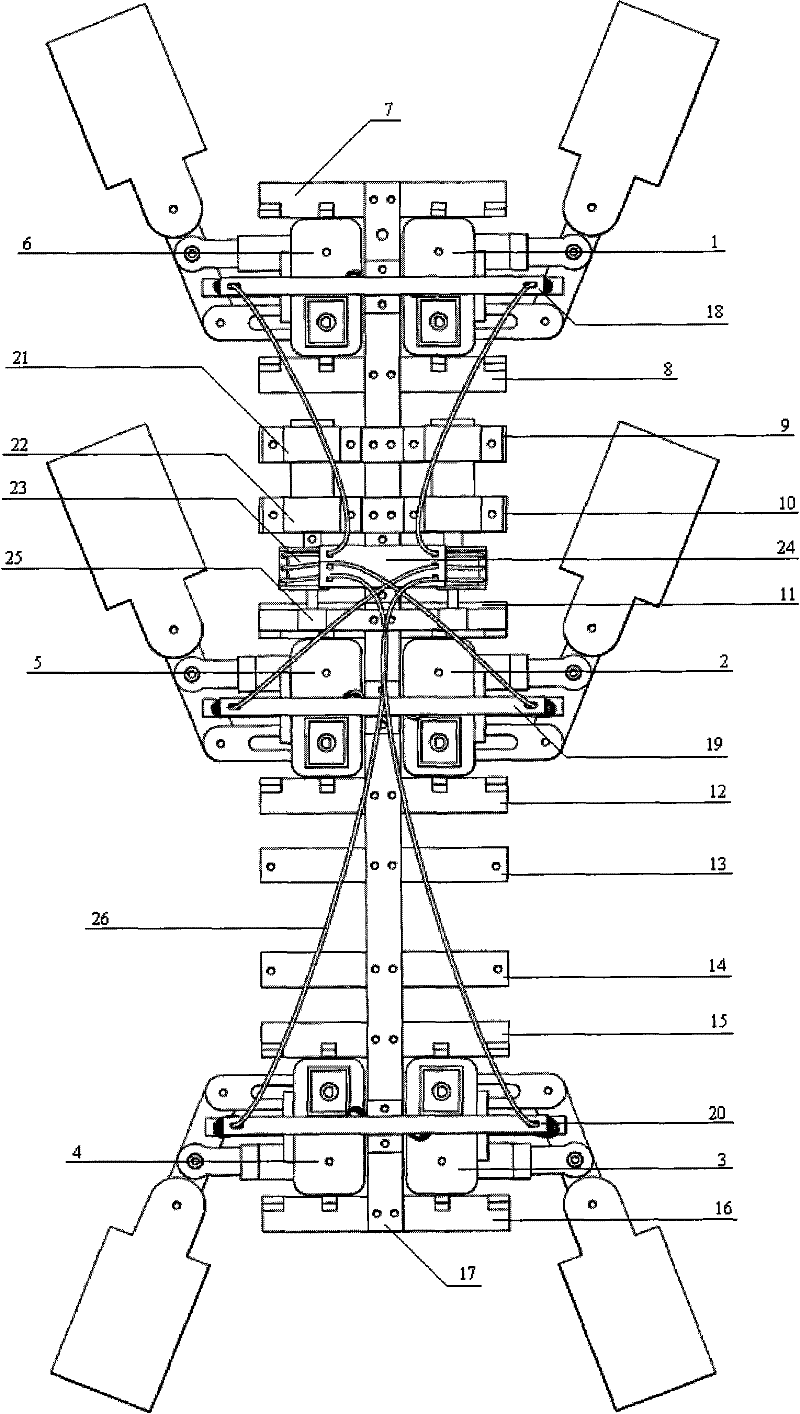

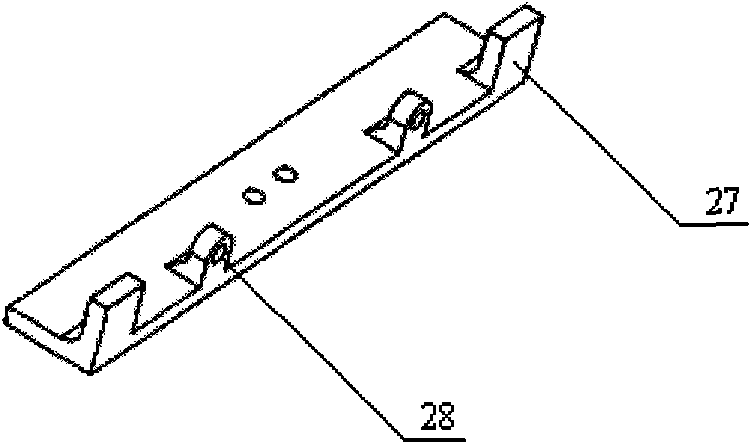

Hexapodous biomimetic wet-sucking wall-climbing robot

The invention relates to a hexapodous biomimetic wet-sucking wall-climbing robot, which belongs to the technical field of bionics. The robot comprises a body framework, biomimetic podites, motors, a driving circuit, a pre-compression structure, a cam structure and a pull rope structure, wherein all the components are installed on the body framework. The body framework comprises a support and a crossbeam which is installed in the groove of the body framework; each biomimetic podite comprises a base seat, a femur, a tibia, a spring steel sheet and a flexible structure, one end of the femur and the flexible structure is connected with the base seat, the other end thereof is connected with the tibia, and the spring steel sheet is installed on the tibia; the driving circuit performs joint control to the motors, the motors are vertically installed in the motor grooves and horizontally installed on the crossbeam; the pre-compression structure comprises a podite support and a T-shaped femur extension support which are connected through a spring; the cam structure comprises a cam and a cam fixing support, one end of the cam is fixed on the motor shafts, and the other end is connected with the cam fixing support; the pull rope structure comprises a pull rope support, pull ropes and brake lines, and the pull ropes are connected with the biomimetic podites through the pull rope support. The hexapodous biomimetic wet-sucking wall-climbing robot has the advantages of simple structure, part modularization and standardization, convenient processing and assembly, hollow structure, light overall weight, multi-motor driving, easy gait planning, and easy realization of stable and reliable operation of the hexapodous wall-climbing robot.

Owner:TONGJI UNIV

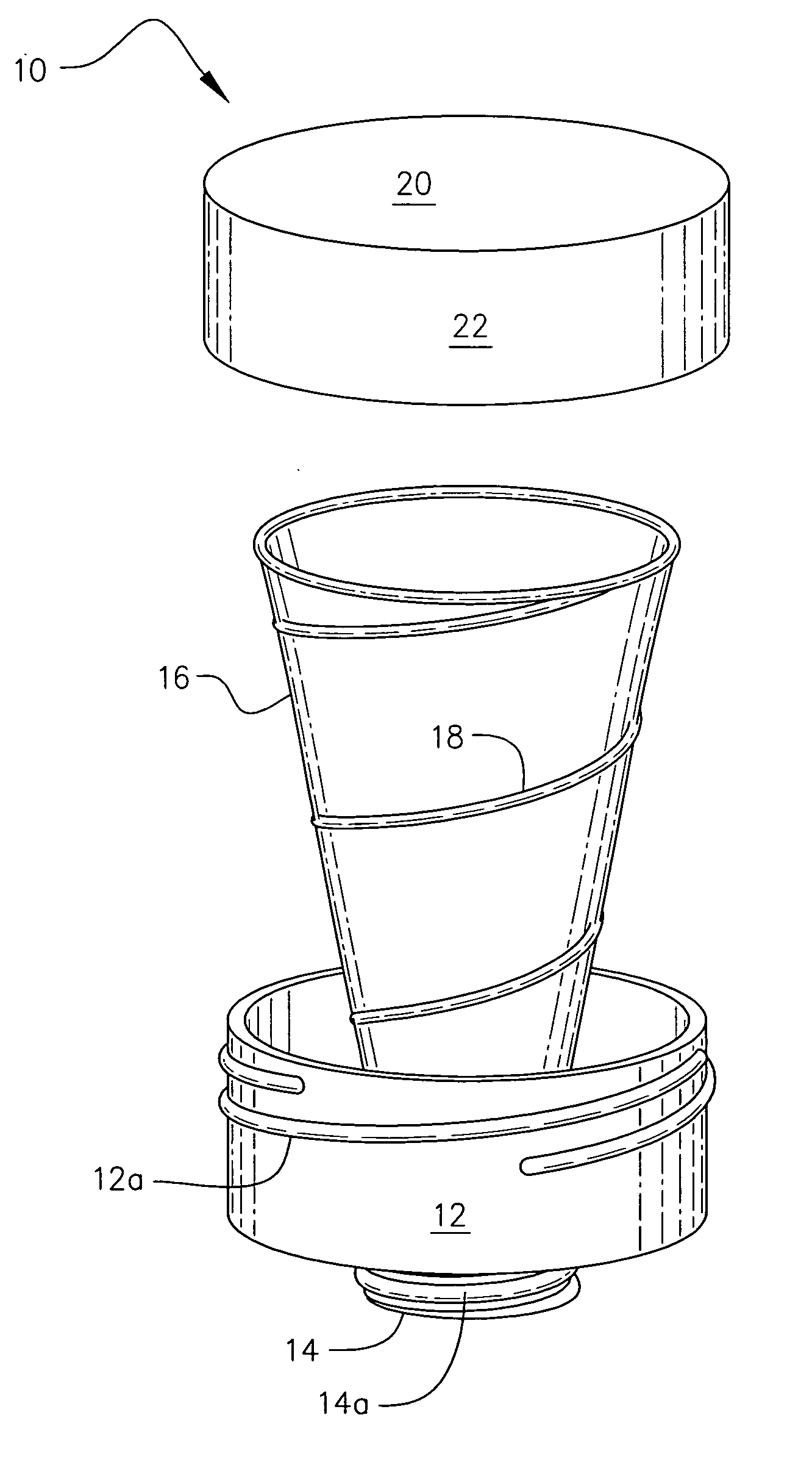

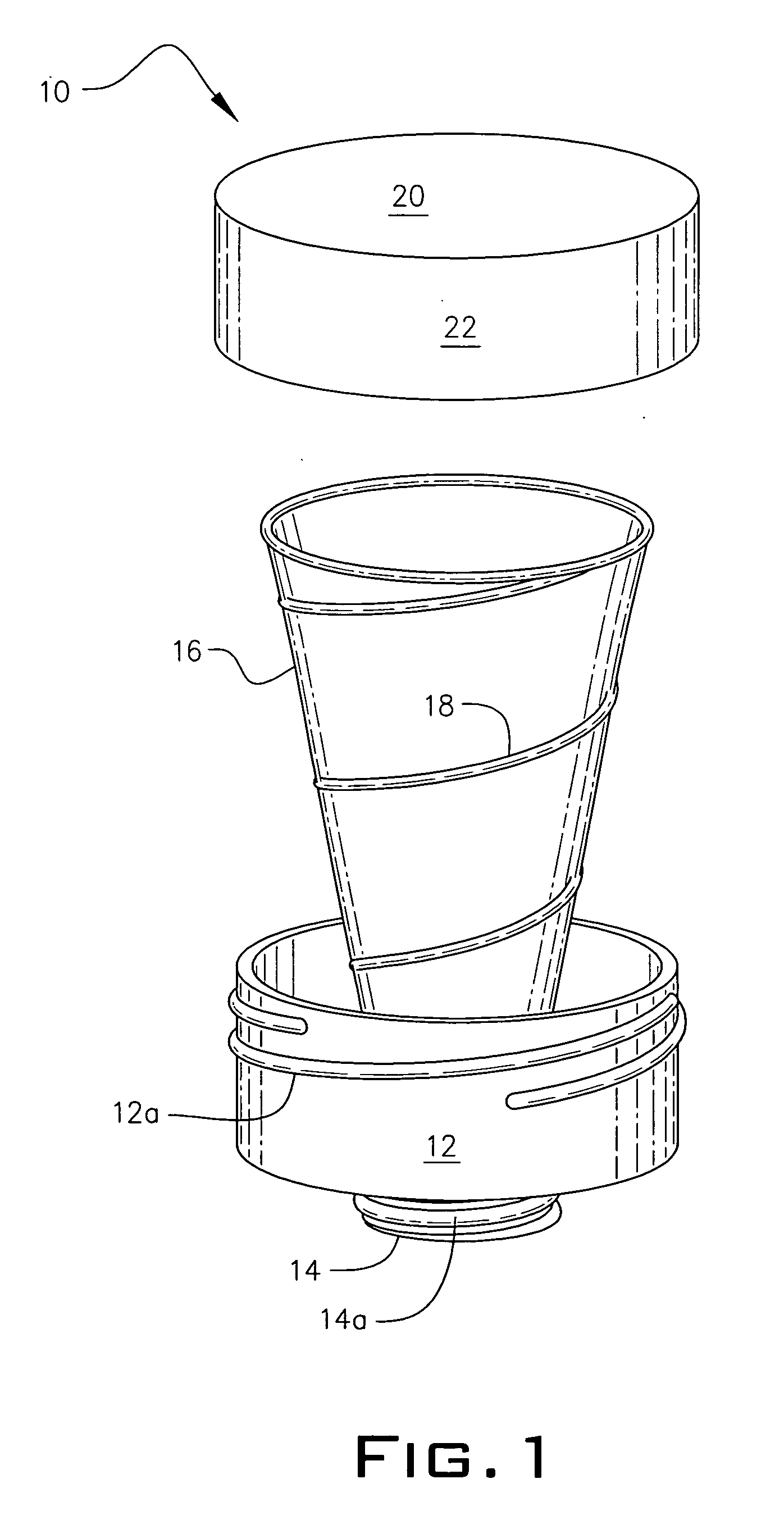

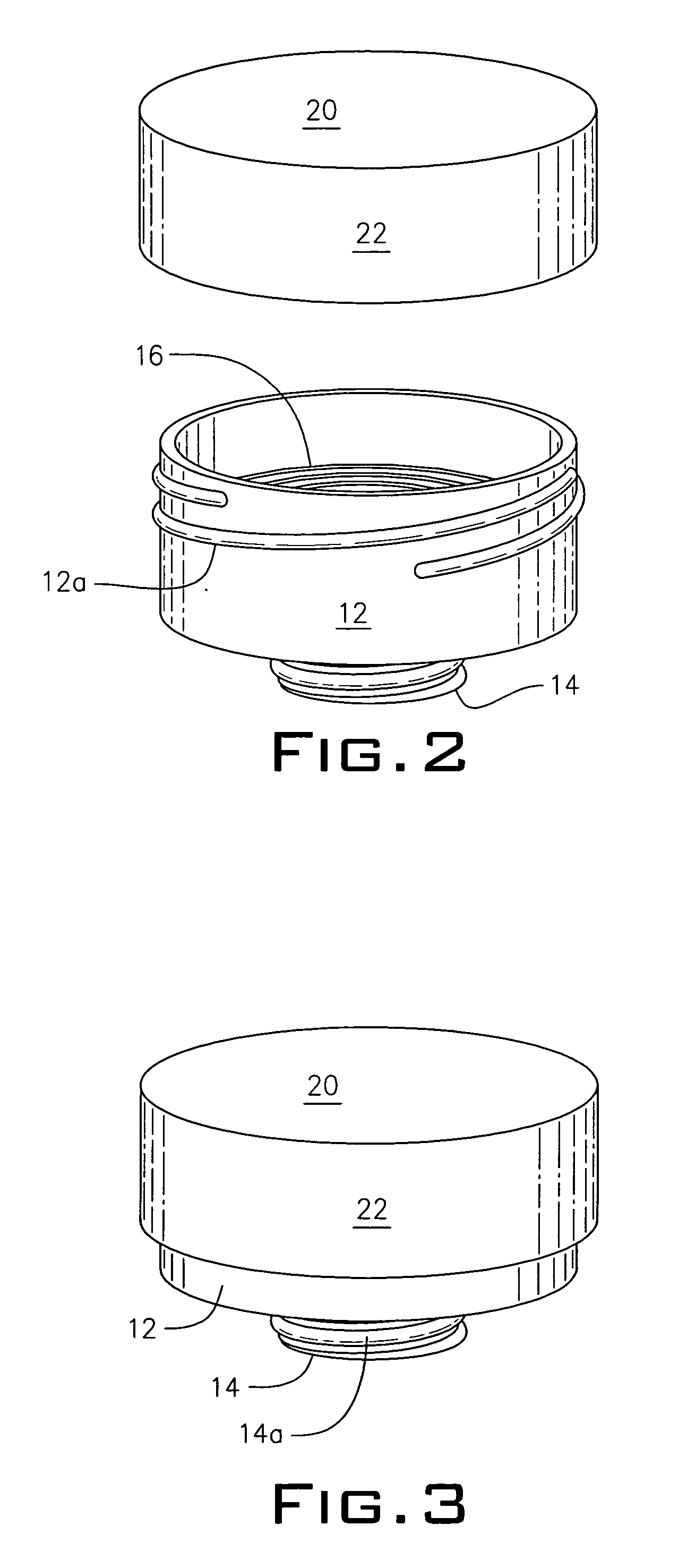

Self-deploying funnel

A funnel assembly includes a collapsible funnel mounted to a base. The funnel is formed by consecutive windings of spring steel wire. Each winding has a reduced diameter so that the windings collectively form a funnel having a conical shape and an inherent bias. The funnel is confined into a relatively small storage space and the funnel is compressed when a cap releasably engages the base. Upon disengaging the cap from the base, the bias unloads and fully deploys the funnel. A downspout depends from the base and engages the fill spout of an oil crankcase so that the funnel assembly is mounted to the fill spout. A user therefore does not hold the funnel assembly while pouring oil from a can into the deployed funnel. By holding the base in one hand and the cap in the other, a user may deploy the funnel and return it to storage without touching the funnel.

Owner:RINALDI MARK

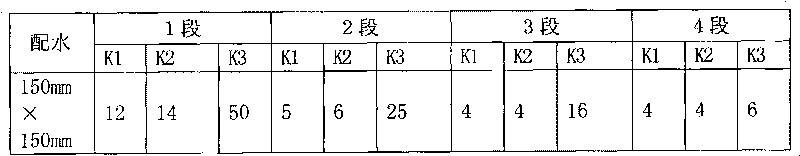

Method for controlling surface decarburization of spring steel wires

The invention belongs to the technical field of spring steel production, in particular to a method for controlling the surface decarburization of spring steel wires. The steel comprises the chemical components by weight percentage that continuous casting billets comprise the chemical components by mass percent as follows: C accounts for 0.51 to 0.59 percent, Mn accounts for 0.50 to 0.80 percent, Si accounts for 1.20 to 1.60 percent, Cr accounts for 0.5 to 0.8 percent, Ni is less or equals to 0.35 percent, Cu is less or equals to 0.25 percent, and Fe and inevitable impurities in balancing amount. The method adopts the manufacturing technology that the continuous casting billets of 150 mm multiplied by 150 mm are adopted, the first zone furnace temperature of a heating furnace is controlled to range from 900 to 960 DEG C, the second zone furnace temperature of the heating furnace is controlled to range from 990 to 1050 DEG C, the soaking zone furnace temperature of the heating furnace is controlled to range from 1050 to 1100 DEG C, in-furnace time ranges from 90 to 150 minutes, the soaking zone air-fuel ratio is controlled to be about 0.8, the spinning temperature is controlled to be about 820 DEG C, and quick cooling is performed at the cooling speed of 10 DEG C / s after spinning so as to reach about 660 DEG C. Fully decarburized layers cannot be formed on the surfaces of 55SiCr spring steel wires that are produced by utilizing the technology of the method, and the thickness of a partly decarburized layer is less than 30 micrometers.

Owner:NANJING IRON & STEEL CO LTD

55Si2MnVNbN spring steel and production process thereof

InactiveCN101717893AHigh strengthHigh tensile strengthTemperature control deviceMetal rolling arrangementsWorking environmentSpring steel

The invention relates to spring steel and a production process thereof, in particular to 55Si2MnVNbN spring steel and a production process thereof. The 55Si2MnVNbN spring steel comprises the following components in percentage by weight: 0.52 to 0.60 percent of C, 1.60 to 1.90 percent of Si, 0.60 to 0.80 percent of Mn, 0.15 to 0.35 percent of Cr, 0.06 to 0.12 percent of V, 0.015 to 0.025 percent of Nb, 0.80 to 1.50 percent of N, less than or equal to 0.0035 of P, less than or equal to 0.0035 percent of S and the balance of Fe and inevitable impurities. The process comprises electric furnace electrosmelting, LF refining, VD furnace vacuum degassing, continuous casting and rolling. The spring steel can meet the requirements of springs on various severe working environments, high strength and long service life and has high tensile strength, high delayed fracture resistance, high corrosion resistance, high fatigue resistance and high elasticity attenuation resistance.

Owner:NANJING IRON & STEEL CO LTD

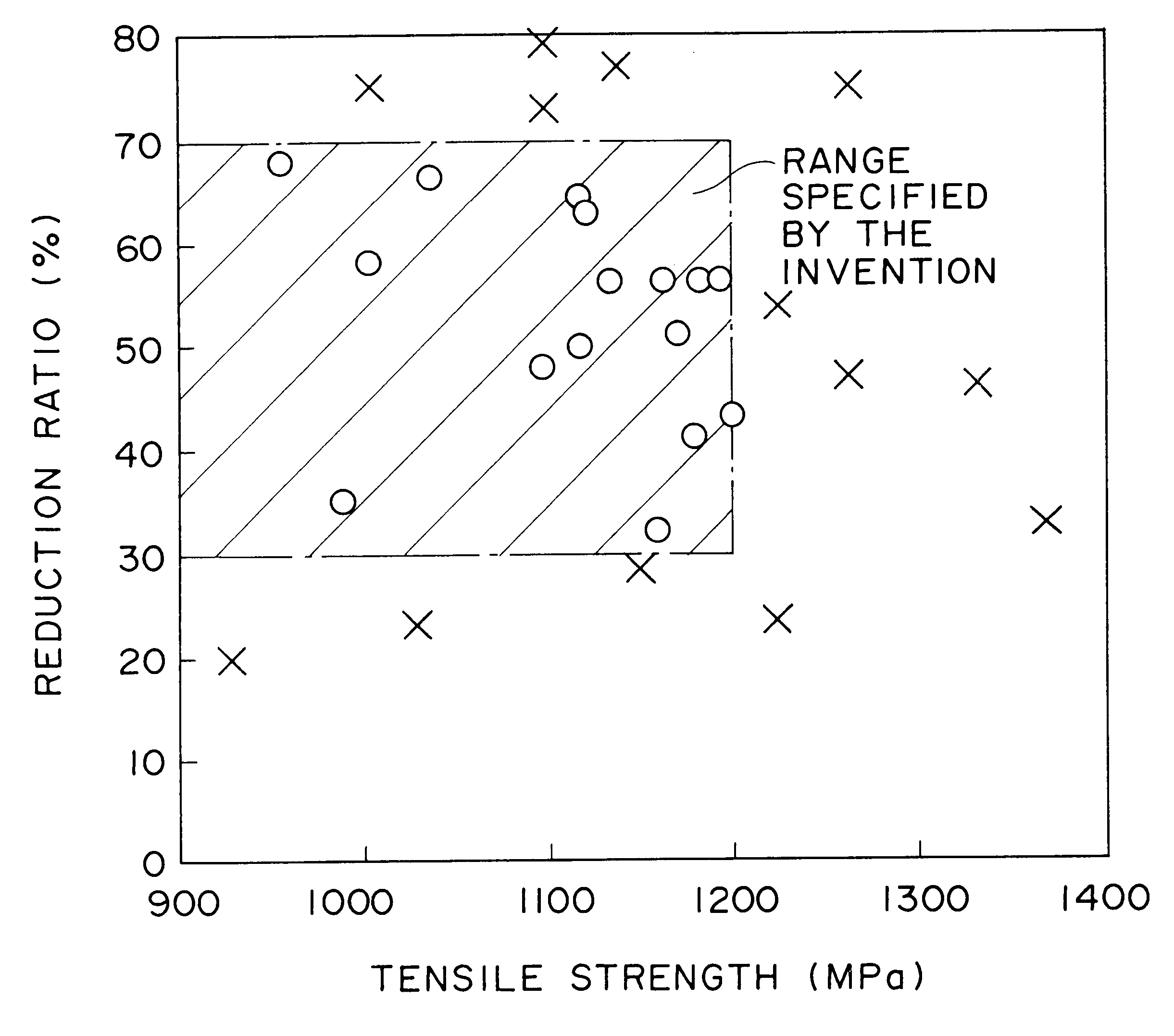

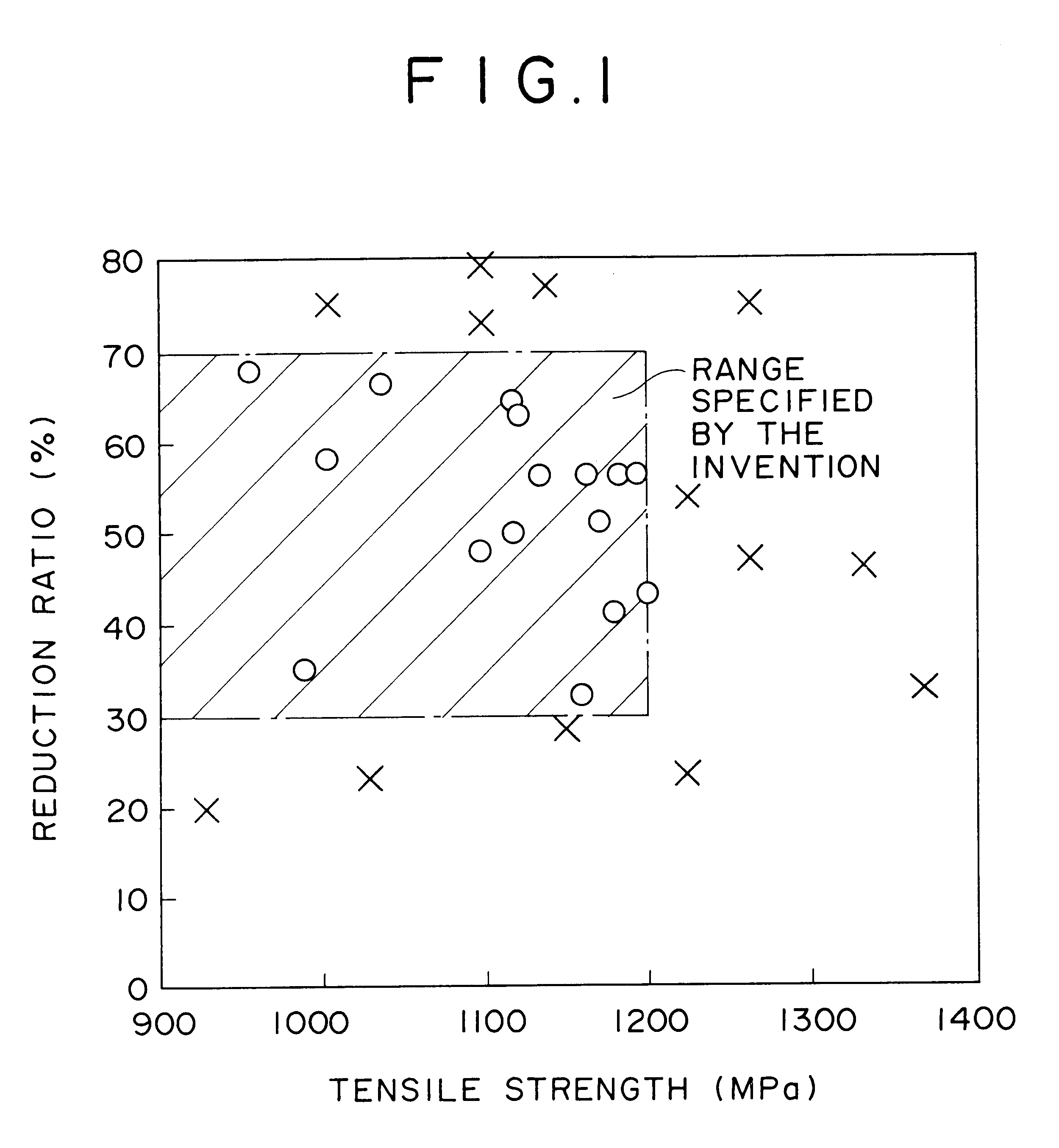

Spring steel superior in workability

A spring steel which is superior in both shaving properties and green drawing properties, which are important in spring production. A process for making the spring steel into wire rods for good springs. A rolled spring steel superior in workability characterized in that it has the following mechanical properties.Tensile strength<=1200 MPa30%<=reduction of area<=70%A process for producing a steel wire rod for springs from said spring steel, said process comprising drawing, shaving, and oil tempering, which are carried out sequentially, said drawing being optionally followed by prescribed treatment.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com