Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207results about How to "Improve metallographic structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087AEnsure billet qualitySimplify the traditional die forging processEngine componentsRheniumRare-earth element

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to 94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

Processing technology for rear axle drive bevel gear

ActiveCN103286533AImprove manufacturing precisionImprove bevel gear accuracyCarbon layerInternal pressure

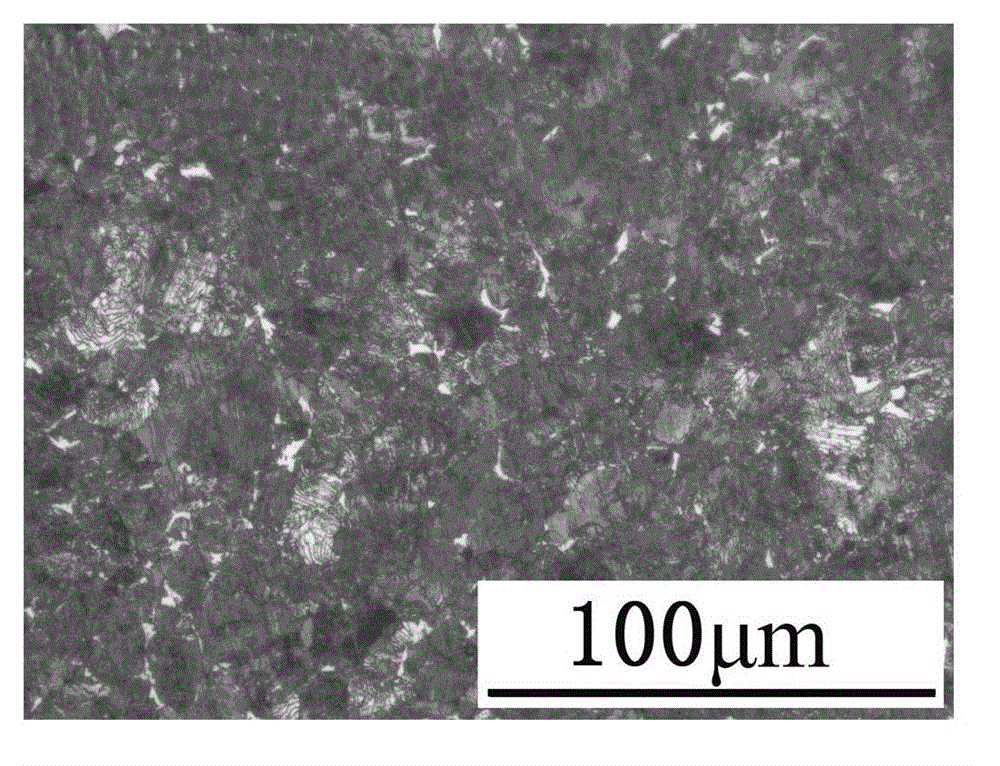

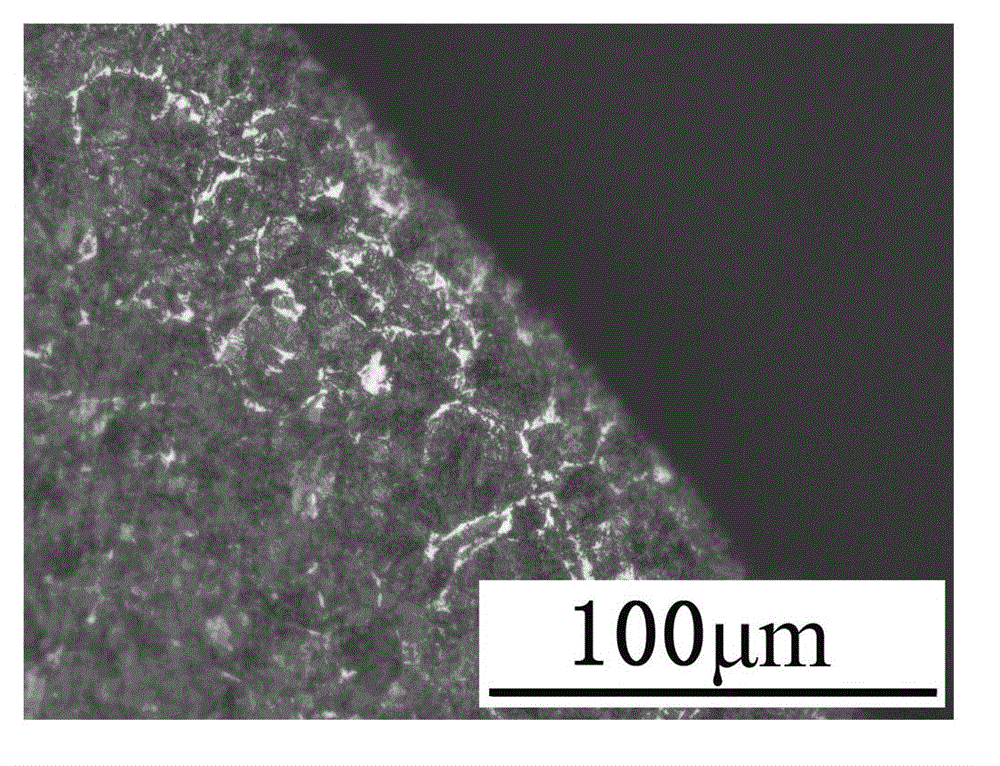

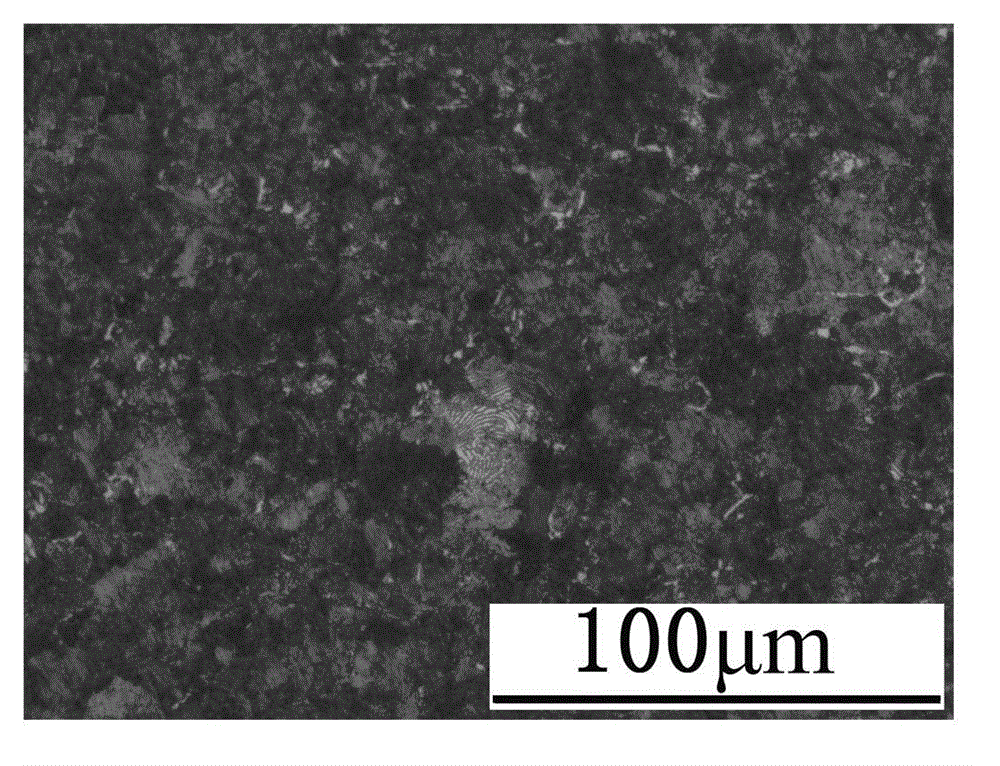

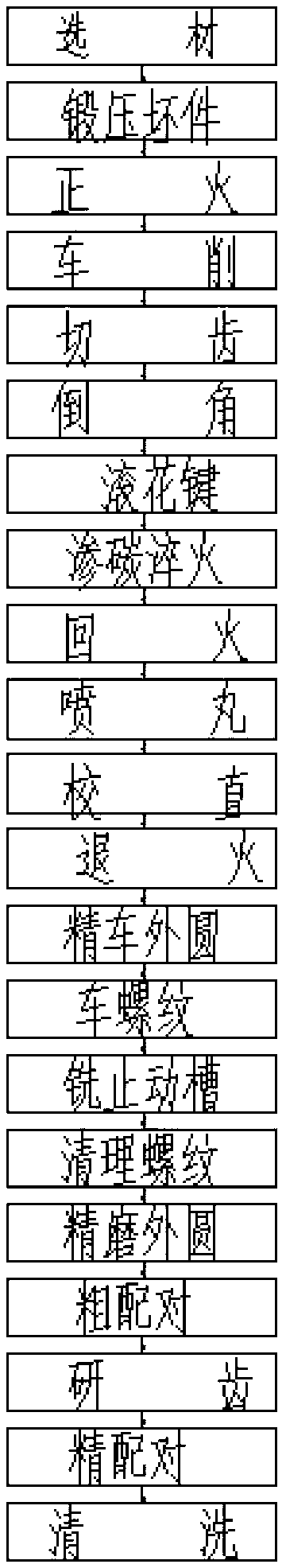

The invention discloses a processing technology for a rear axle drive bevel gear which is characterized by including steps of selecting raw materials, forging a blank, normalizing, turning, cutting a gear, chamfering, rolling a spline, carburizing and quenching, tempering, blasting shots, straightening, annealing, finely turning an outer circle, threading, milling a locking groove, cleaning a thread, finely grinding an outer circle, roughly matching, shaving the gear, finely matching and rinsing, and obtaining a finished product after rinsing the a workpiece. By the processing technology, machining precision of threads of the rear axle drive bevel gear is improved and reaches a grade of H6; quenching to harden the carbon layer is totally omitted through machining after heat treatment; hardness of a product surface and a core is reduced after annealing, internal pressure of the gear is eliminated, and a metallographic structure of the core of the gear is improved; the processing technology for the gear axle drive bevel gear is high in precision, and requirements of assembling is favorably achieved; service life of the gear axle drive bevel gear is prolonged.

Owner:重庆市綦江区华丰变速箱有限公司

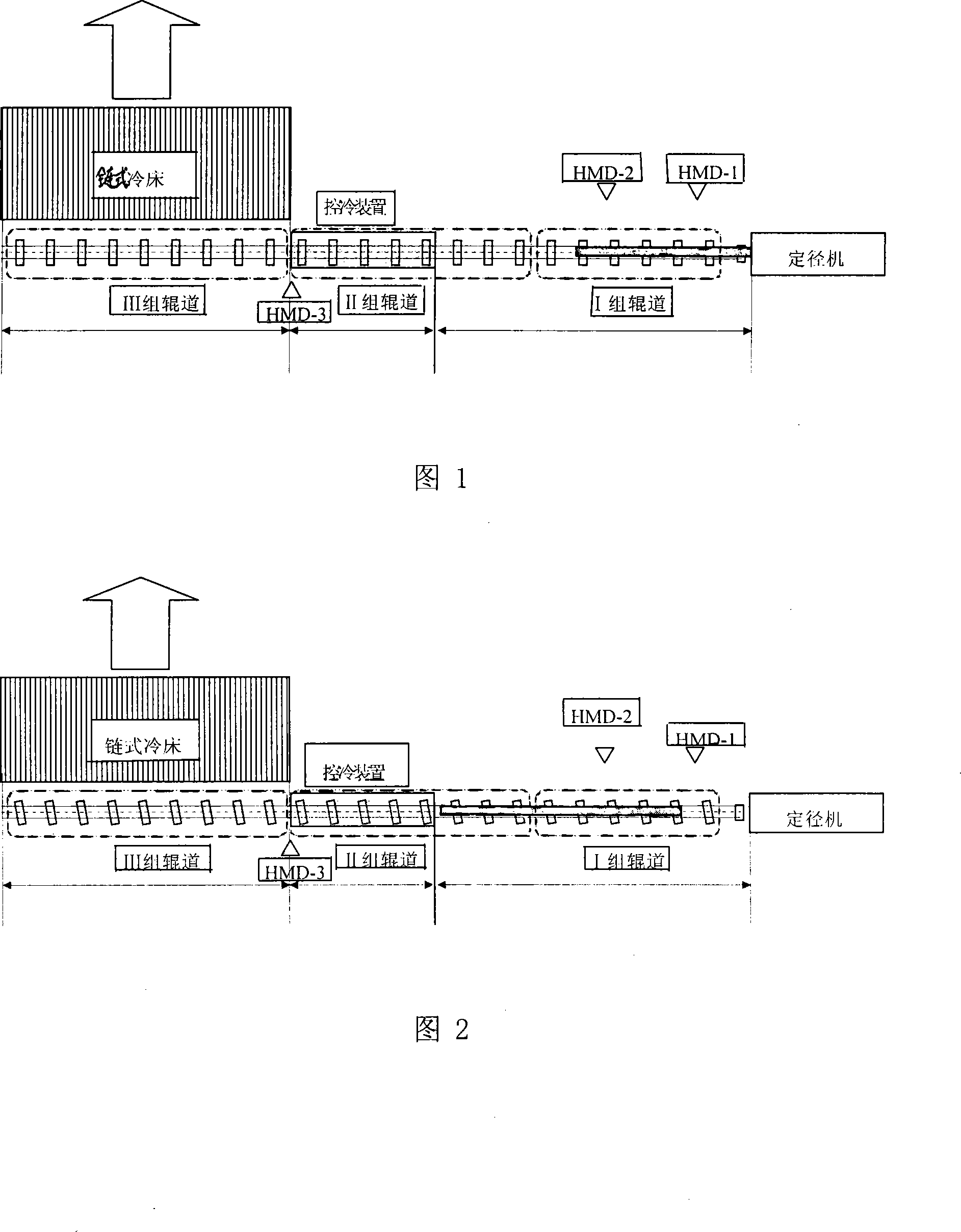

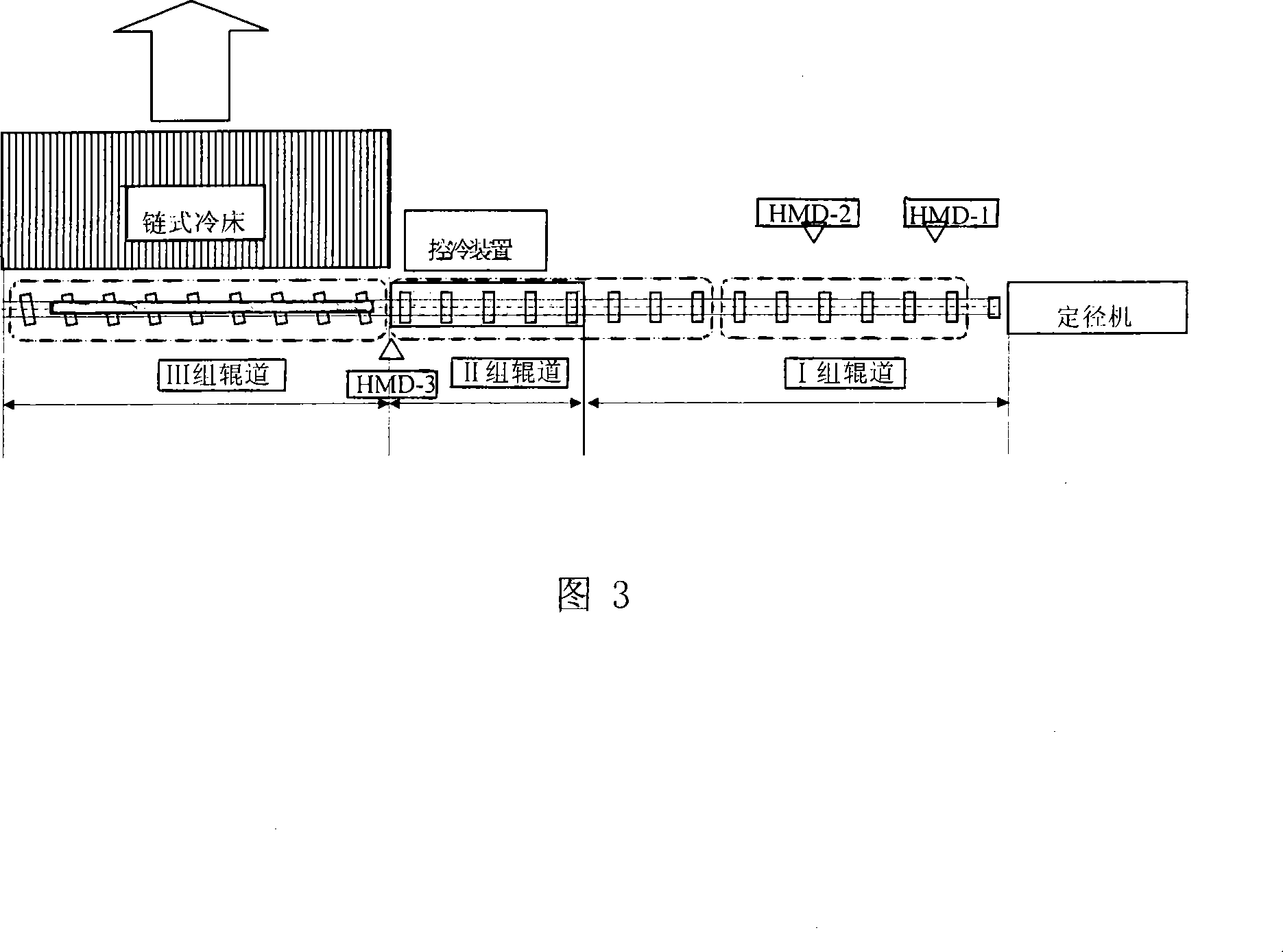

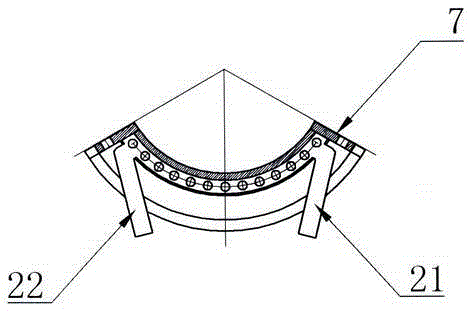

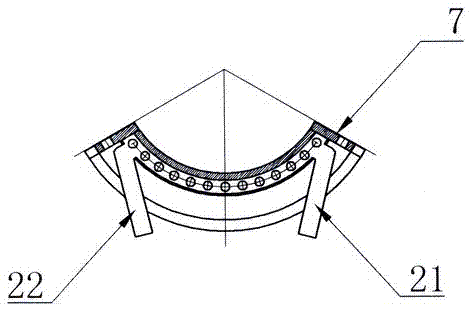

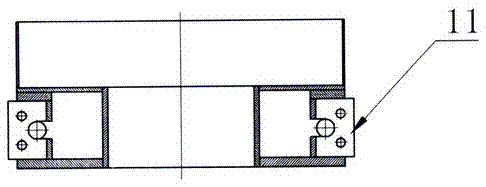

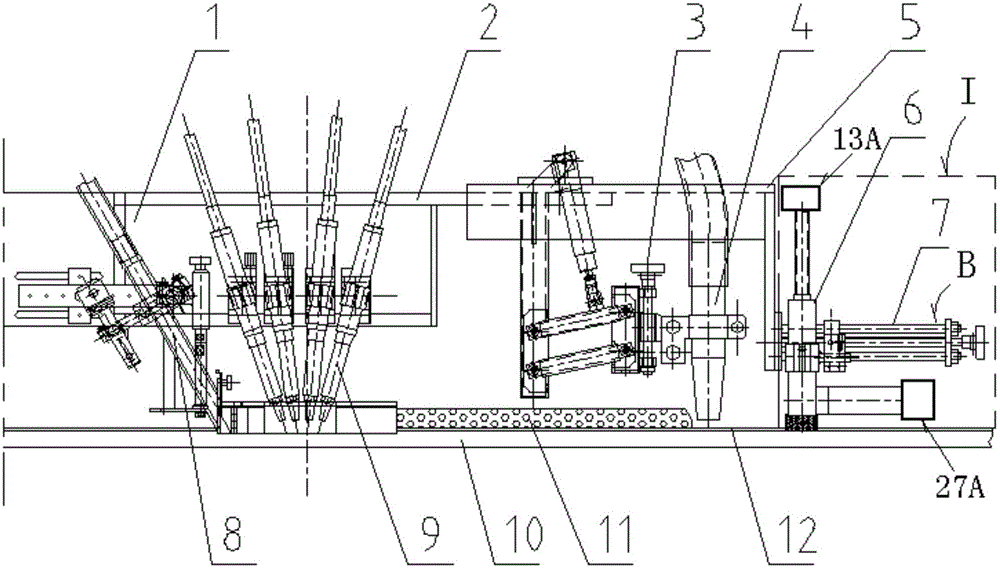

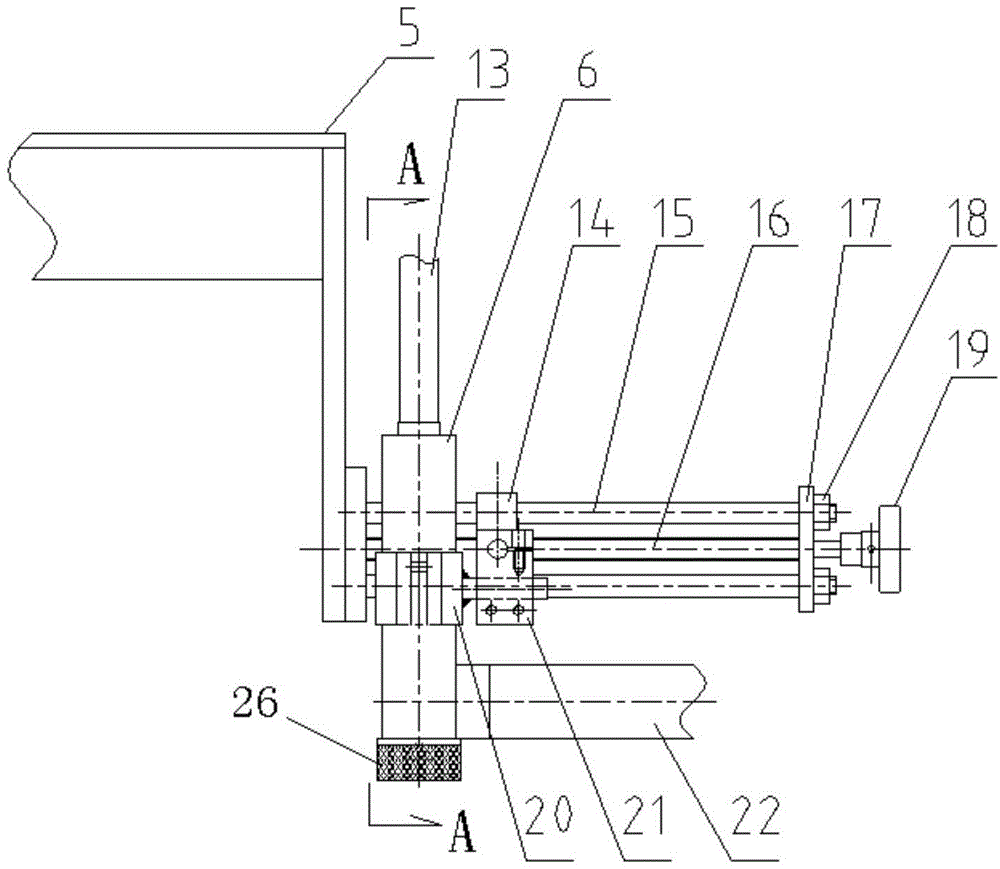

Technique of controlling and cooling hot-rolled seamless tube online

ActiveCN101157096AControl cooling effectImprove cooling effectTemperature control deviceMetal rolling arrangementsRoom temperatureChain type

The invention provides a method for the on line controlled cooling process of a hot rolling seamless steel pipe, the method is realized by a controlled cooling system, and the method comprises the steps that a blower fan and a water pump are started up; the controlled cooling device starts working; the rolled temperature of the seamless steel pipe which is rolled by a three-roller slight tension sizing mill is between 950 DEG C and 980 DEG C, when the tail of the seamless steel pipe is not completely rolled out from the end of the mill housing of the sizing mill, the rotation of the seamless steel pipe can not happen; when the tail of the seamless steel pipe completely breaks away from the end of the mill housing, and is detected by a thermometal detector, meanwhile a changeable angle roller way declines on the horizontal plane according to a set angle, to lead the seamless steel pipe to go forward in spiral way along the rolling direction by the own axis till the whole seamless steel pipe passes through completely; the cooling speed of the process requirement can be achieved finally; subsequently the seamless steel pipe enters into a chain-type cooling bed to implement the air cooling to the room temperature. The invention has the advantages that the controlled cooling process controls the cooling speed of the hot rolling seamless steel pipe after the rolling through the air-mist cooling, to meet the purpose of improving the metallographic structure and the comprehensive mechanical property of the seamless steel pipe.

Owner:TIANJIN STEEL PIPE MFG CO LTD

Method for producing accurate steel balls

InactiveCN101049665AHigh precisionImprove manufacturing precisionEdge grinding machinesPolishing machinesQuenchingSuperfine grinding

A technology for manufacturing precise steel balls includes such steps as providing the light-drawn steel wire, cold forging, shaping plus soft grinding, heat treating through heating, quenching and tempering in protective gas, cooling strengthening surface, hard grinding by abrasive ceramic disc, beautifying appearance by photoelectric eddy, ageing, cold treating, and superfine grinding.

Owner:SHANDONG DONGE STEEL BALL GRP

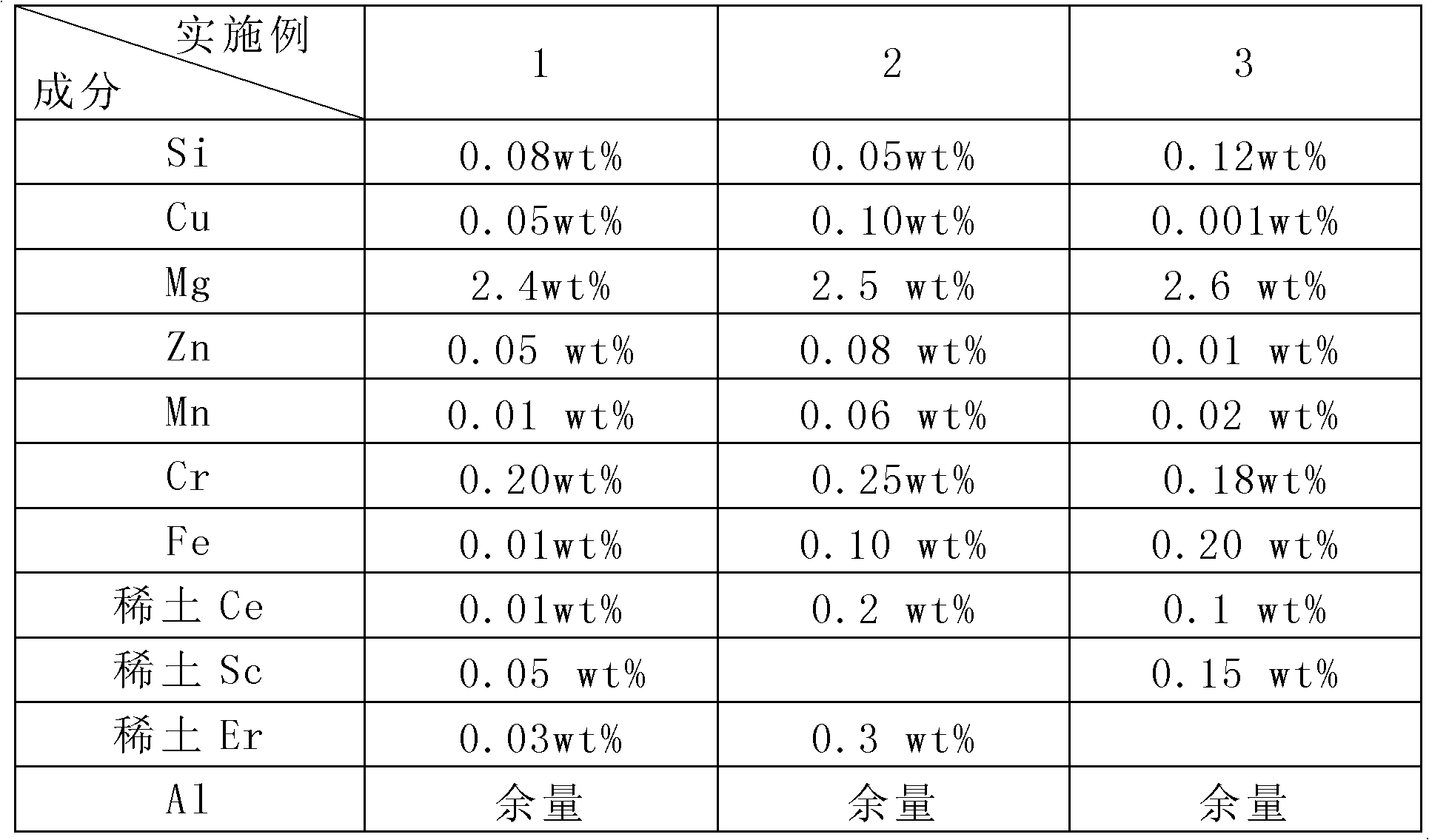

Aluminum alloy 5052 having high corrosion resistance and manufacturing method thereof

The invention provides an aluminum alloy 5052 having high corrosion resistance and a manufacturing method thereof, which belongs to the technical field of alloy materials and solves the problem of low corrosion resistance of the traditional aluminum alloy 5052 material. The aluminum alloy 5052 having high corrosion resistance comprises the following components in percentage by weight: no more than 0.20% of Si, no more than 0.20% of Cu, 2.4-2.6% of Mg, no more than 0.10% of Zn, no more than 0.10% of Mn, 0.18-0.30% of Cr, 0.01-0.40% of Fe, no more than 0.05% of single other element, no more than 0.15% of total other elements, 0.01-0.8% of rare earth elements and the balance of Al. The aluminum alloy 5052 having high corrosion resistance can improve the corrosion resistance and simultaneously maintain the stabilization of mechanical properties.

Owner:ZHEJIANG GKO ALUMINUM

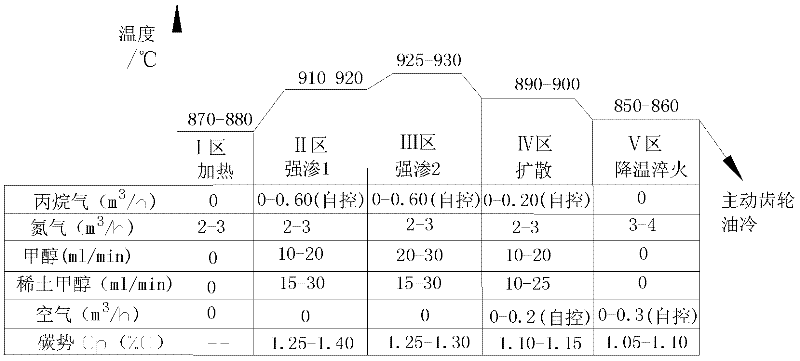

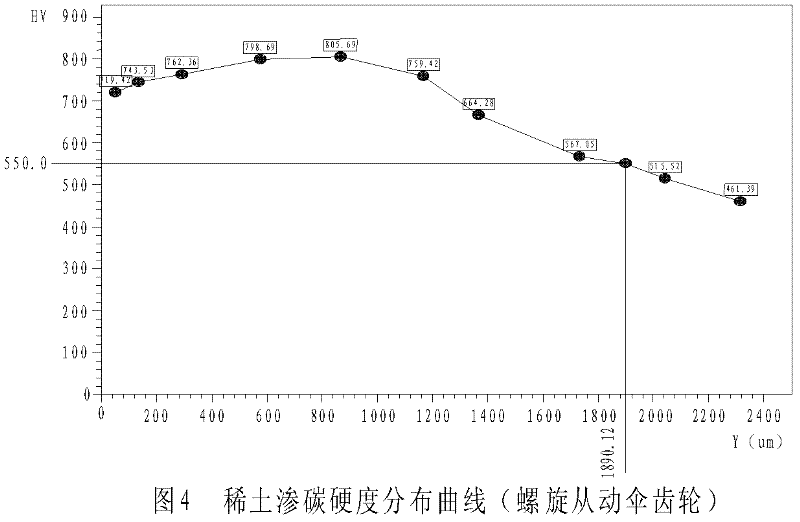

Heat treatment method of spiral bevel gear of cargo truck on double-row rare earth carburization equipment

ActiveCN102373400AEmission reductionIncrease carburizing speedSolid state diffusion coatingCarbon potentialRare earth

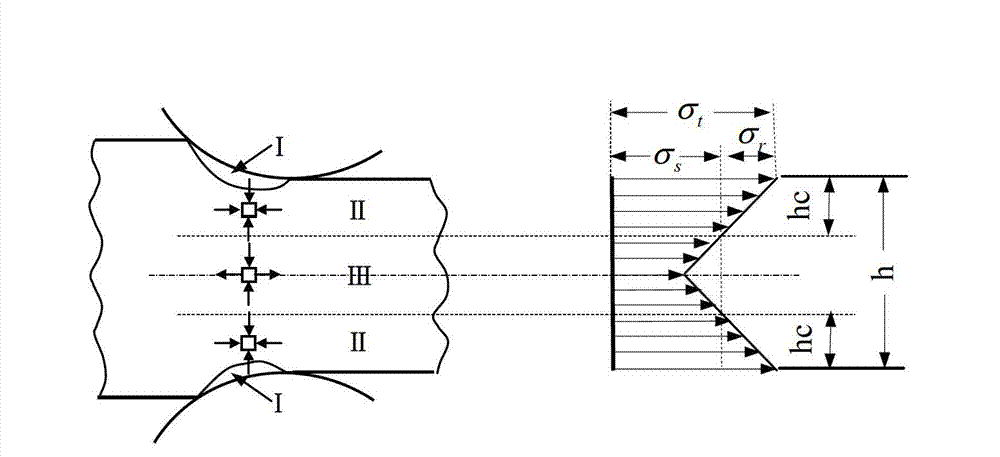

The invention provides a heat treatment method of a spiral bevel gear of a cargo truck on double-row rare earth carburization equipment, and relates to a carburization heat treatment technological process of the spiral bevel gear of the cargo truck. The invention solves the problems that energy consumption of carburization heat treatment is high, production cost of a product is high and carburization quenching and gear thermal distortion still exist in a carburization process. The method provided by the invention comprises the following steps of: taking a preheating zone as a strong leakage region 1 and taking a carburizing region as a strong leakage region 2, namely taking a region II and a region III as a carburizing speed main control region and taking a region IV and a region V as a metallographic structure main control region, carrying out temperature control in the regions I, II, III, IV and V, carrying out carbon potential control in the regions II, III, IV and V, and inputtingcarburizing medium propane gas, rare earth methanol penetrating agent, nitrogen, methanol and air into a furnace, thus the heat treatment method is realized. The metallographic structure and surface hardness of the spiral bevel gear subjected to the heat treatment method provided by the invention are all optimized, and heat treatment quality of the spiral bevel gear is improved; meanwhile, capacity is improved by 23%, heat treatment production cost is reduced by 18.9%, and pollution of exhaust emission to the environment is reduced.

Owner:哈尔滨汇隆汽车箱桥有限公司 +3

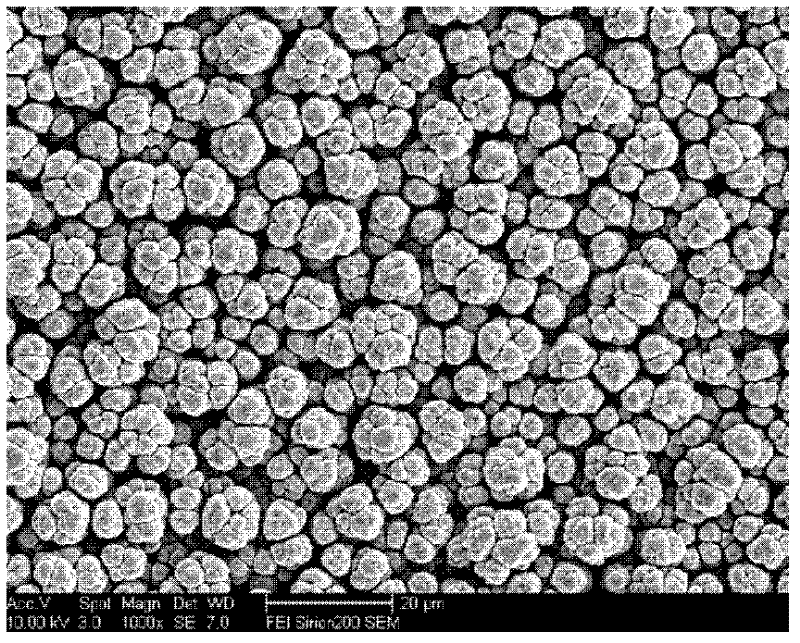

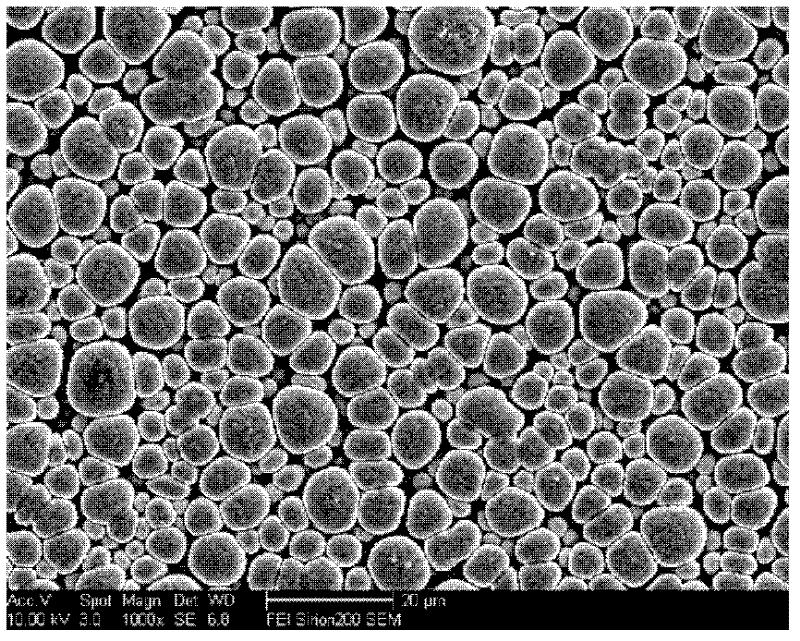

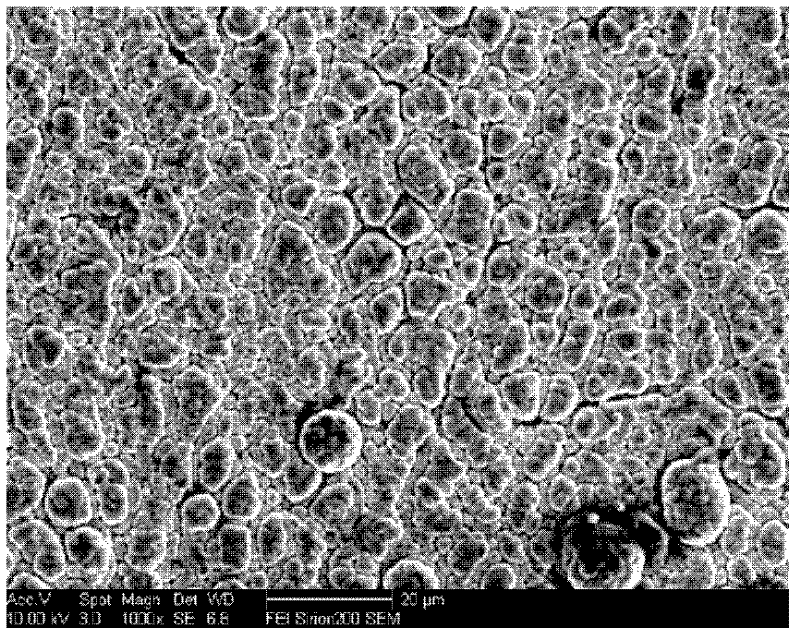

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

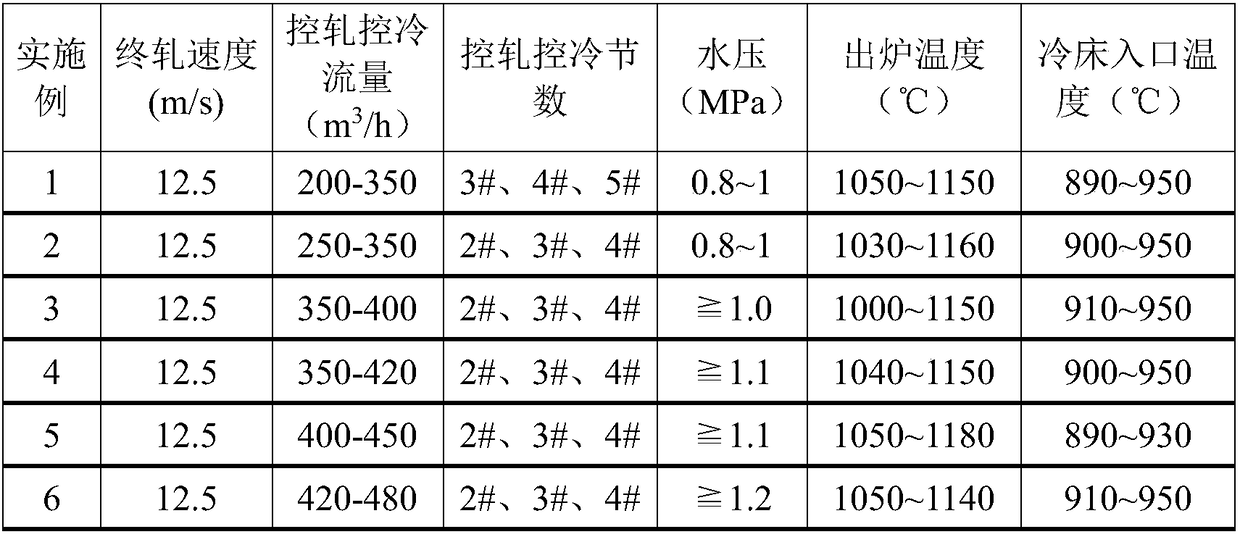

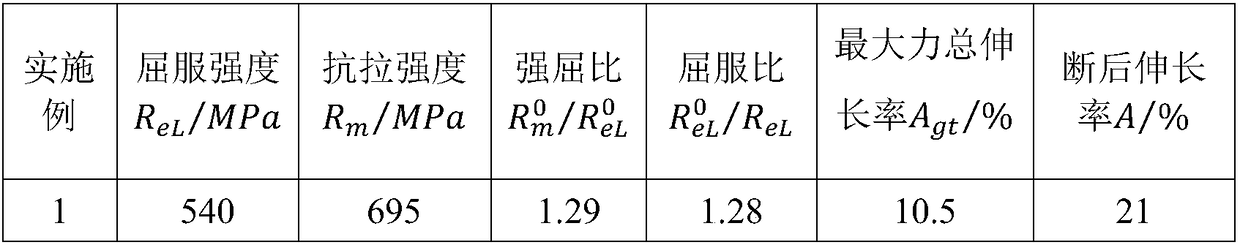

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

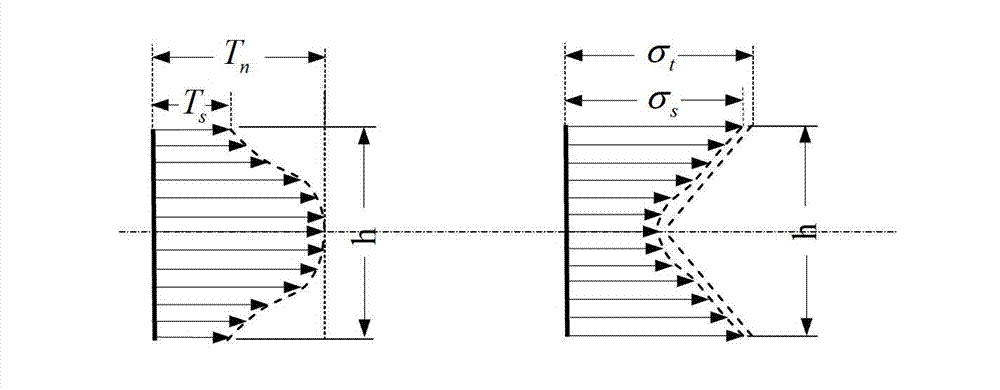

Manufacturing method of super-thick steel plate

ActiveCN103111464AReduced compression ratio requirementsLarge amount of deformationTemperature control deviceMetal rolling arrangementsThick plateIndustrial engineering

The invention discloses a manufacturing method of a super-thick steel plate (thickness is 60 millimeters) and belongs to the steel plate production field of metallurgical industry. The manufacturing method of the super-thick steel plate comprises the following steps: firstly, sending a plate blank which is heated to a certain temperature and removed an oxide scale to cooling space to conduct forced cooling, surface temperature cooling a phase transition temperature of the super-thick plate material above Ar 1, then by short time temperature returning, the surface temperature rising to the range between 780 DEG C and 880 DEG C, and sending the plate bland to a rolling mill to roll as soon as possible; when the surface temperature of the plate blank being higher than 880 DEG C, needing to conduct the forced cooling again, and then conducting the subsequent rolling. A cooling-temperature returning-rolling process can be repeated for many times if needed till rolling to the needed thickness of the super-thick steel plate. The manufacturing method of a super-thick steel plate can increase dependent variable of the central area by increasing temperature difference between a surface layer and the central area and has the advantages of being beneficial to refining central organization and improving impact toughness, beneficial to removing center porosity of the super-thick plate, and capable of reducing double strand shape on lateral sides of the super-thick plates. The manufacturing method of a super-thick steel plate further has the advantages of being saving in investment, and flexible to operate.

Owner:UNIV OF SCI & TECH BEIJING

Water-soluble quenching medium

InactiveCN1465722AImprove quenching qualityImprove metallographic structureQuenching agentsQuenchingCarbon steel

The present invention relates to a water-soluble quenching medium. It is formed from proper quantity of polyether high-molecular mixture, surfactant, inorganist salt, sterilizing agent, inorganic alkali and water, and when it is concentration is 4-6%, it can be used for integrally quenching carbon steel, and when its concentration is 8-12%, it can be used for high-frequency quenching carbon steel, and it has the advantages of low use concentration, long service life and stable quenching quality.

Owner:FAW GROUP

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

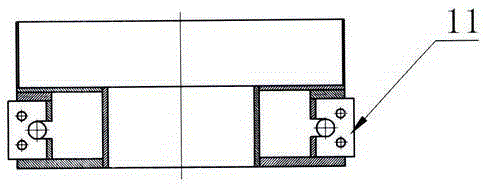

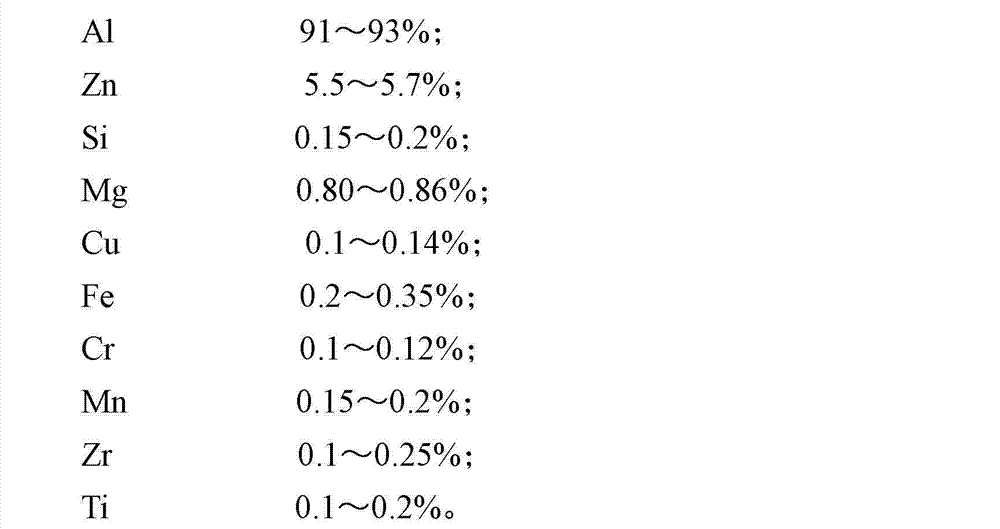

Aluminum profile and heating processing technology thereof

An aluminum profile is annular and is prepared by components in percentage by weight: 91-93% of Al, 5.5-5.7% of Zn, 0.15-0.2% of Si, 0.80-0.86% of Mg, 0.1-0.14% of Cu, 0.2-0.35% of Fe, 0.1-0.12% of Cr, 0.15-0.2% of Mn, 0.1-0.25% of Zr and 0.1-0.2% of Ti. A heating processing technology comprises following steps of: (1) smelting and casting raw material aluminum ingots, enabling a casting speed to be 85-95mm / min, enabling a pouring temperature to be 715-730 DEG C, and enabling cooling water pressure to be 0.04-0.08MPa; (2) extruding, enabling an extruding temperature to be 440-460DEG C, and enabling an extruding speed to be 3-6M / min; (3) conducting stretcher strengthening, and enabling strengthening deformation quantity to be 0.5%-1.5%; (4) conducting aging furnace heating, enabling a furnace temperature of an aging furnace at a first section of aging to be 100 DEG C, enabling heat preservation time to be 3h, enabling the furnace temperature of the aging furnace at a second section of aging to be 160 DEG C, and enabling heat preservation time to be 5h; and (5) testing and packaging. The aluminum profile mainly solves the problem that the aluminum profile in the prior art is not high in strength, poor in breakage toughness and poor in fatigue performance.

Owner:张家港市金邦铝业股份有限公司

Method for making hammer stem for forging equipment

ActiveCN1962177ALarge amount of deformationImprove mechanical propertiesForging hammersFurnace typesElectricityThermal insulation

The invention relates to a method for producing hammer rod in forge device, wherein it comprises selecting material, forging, thermal treatment, rough treatment, defect detection, adjusting material, and fine treatment. The invention uses steel block, rolling material or forge material refined from steel pack or slag fusion technique. The invention uses gradient heating, multistage thermal insulation to heat, and uses hydraulic machine to forge, and it has defect detection after rough treatment to select different adjustments, therefore, the final metal phase and mechanical property can reach best. The invention can improve the service life of hammer rod, while the average hammer times can reach 300 thousand.

Owner:CHONGQING CHANGZHENG HEAVY IND

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

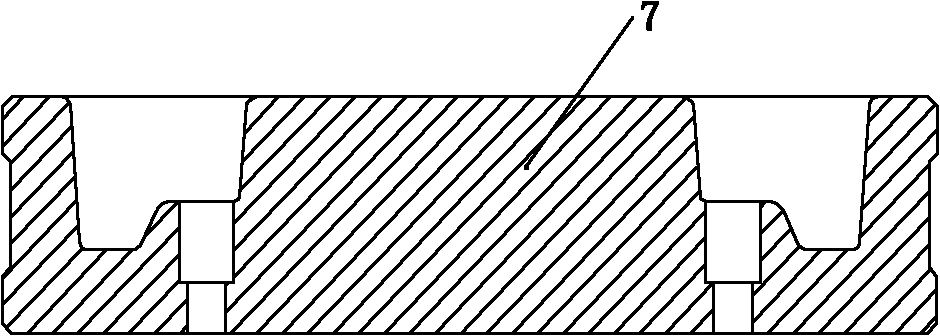

Centrifugally-cast burr cylinder sleeve and preparation method thereof

The invention discloses a centrifugally-cast burr cylinder sleeve and a preparation method thereof, and belongs to the field of cylinder sleeves. The centrifugally-cast burr cylinder sleeve comprises,by weight, 2.8%-3.7% of carbon, 0.03%-0.08% of sulfur, 1.7%-2.8% of silicon, more than zero and no more than 0.5% of phosphorus, 0.5%-1.0% of manganese, more than zero and no more than 0.4% of chromium, 0.1%-0.6% of copper, and the balance iron. A-type graphite is no less than 80% in the metallographic phase of the cylinder sleeve, the length of the A-type graphite is at 4-7 grades, the matrix structure is fine lamellar pearlite, ferrite is no more than 3%, the amount of carbide and iron phosphide eutectic is no more than 5%, and the carbide and the iron phosphide eutectic are in discontinuous network distribution or even distribution. Customer requirements to mechanical performance can be met, the condition of pull of the inwall of a pipe mould is reduced obviously, the life of the mouldis prolonged greatly, and the processing performance of the cylinder sleeve is better.

Owner:ZYNP GRP

Manufacturing technique and device for improved bainite nodular cast iron composite roller provided with forged steel roller neck

The invention discloses a manufacturing technique and device for an improved bainite nodular cast iron composite roller provided with a forged steel roller neck. The improved bainite nodular cast iron composite roller provided with the forged steel roller neck is prepared from, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% f Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0-0.05% of P, 0-0.30% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE, and the balance Fe and inevitable trace elements. According to the manufacturing technique and device for the improved bainite nodular cast iron composite roller provided with the forged steel roller neck, yttrium-based rare earth is used for nodularization, Ba, Ca and silicon iron are used for combined inoculation, Nb, Ti, V, B and Sb are added for modification treatment, and thus the mechanical property of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved; integral in-mold heating and casting of a core rod are conducted through an induction heater, and a water-cooling crystallizer is used for formation; the interface of a composite layer can be controlled dynamically, the technique is simple, power consumption is low, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Thermal treatment method of cam shaft

ActiveCN102925655AImprove wear resistanceImprove fatigue strengthFurnace typesIncreasing energy efficiencyHardnessCam

The invention discloses a thermal treatment method of a cam shaft, which solves the problem of non-uniform heating temperature and temperature gradient on a cam profile. The quenching comprises the following steps of: a, preheating: sheathing an induction coil of an induction heating device outside a cam, placing a shielding plate between a cam lifting part and the induction coil, and preheating for 33-45 seconds under the conditions with voltage of 340-480V and current of 160-230A; b, stopping heating, removing the shielding plate, and 5-8 seconds later, continuously heating for 8-14 seconds under the conditions with voltage of 410-500V and current of 200-250A; and c, cooling: cooling the cam with a quenching medium. Through the invention, the quenching hardness range of the produced cam shaft is reduced by 3.5HRC from that of common surface quenching, the depth range of a hardening layer is reduced by 3.7mm, the metallographic structure is obviously improved, and quenching cracks are avoided; and moreover, the wear resistance and fatigue strength of the cam shaft are obviously improved, and the service life of the cam shaft is obviously prolonged.

Owner:CHONGQING YUEJIN MACHINERY

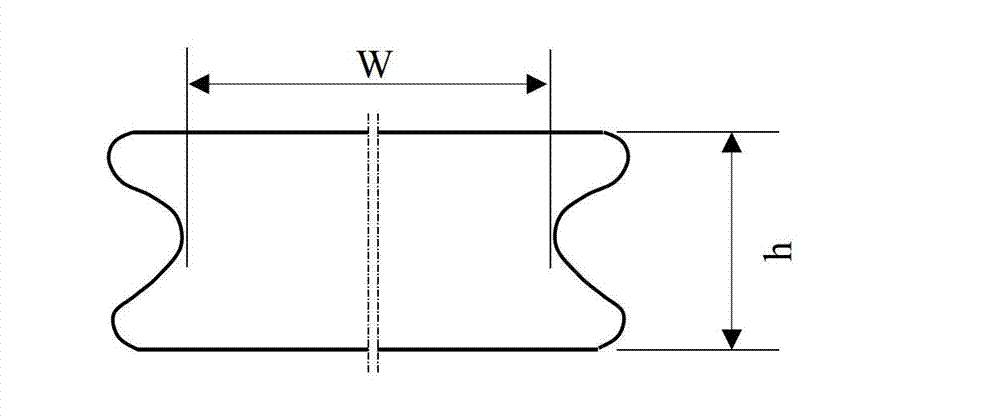

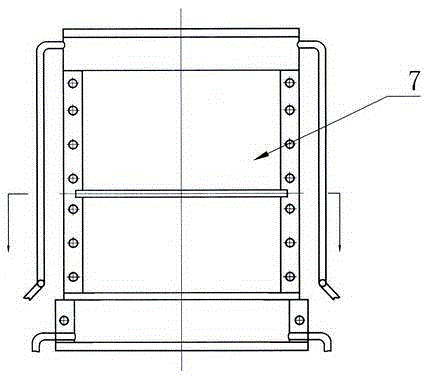

Welding method and device for welding with accelerated cooling

InactiveCN106141474AImprove embrittlement and softening problemsImprove metallographic structureWelding accessoriesHeat-affected zoneCooling effect

The invention discloses a welding method and device for welding with accelerated cooling and belongs to the field of welding and manufacturing. The method disclosed by the invention is characterized in that accelerated cooling for welding seams and a heat affected zone or a local zone of parent metal in the welding process is realized, and the aims of improving the welding seams and metallographic structures in the heat affected zone, refining grains and improving the problems of embrittlement and softening in the heat affected zone are achieved on the premise of not influencing the welding speed. The device is arranged on a machine head of a welding machine and synchronously moves along with the machine head of the welding machine, and comprises a driving connection part, a clamping and adjusting part, a spray head, a medium transporting part and an adsorbing part. By means of the structure, a proper accelerated cooling effect for high-temperature welding seams and metal in the heat affected zone in the welding process is realized, and the aims of improving the welding seams and the metallographic structures in the heat affected zone, refining the grains and improving the problems of embrittlement and softening in the heat affected zone are achieved on the premise of not influencing the welding speed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

High-silicon aluminum alloy swash plate die-forging process and die

InactiveCN101628312AIncrease profitImprove mechanical propertiesForging/hammering/pressing machinesWheelsSiliconHeating temperature

The invention discloses a high-silicon aluminum alloy swash plate die-forging process, which realizes plastic forming of die forgings by a small flashing open type forging die. The die-forging process comprises the following steps: extruding a bar material, blanking, heating, die-forging plastic forming and post treatment, wherein the heating temperature of a blank is 500+ / -5 DEG C, and the preheating temperature of a concave die is 200+ / -5 DEG C; the small flashing die-forging process directly forges the heated aluminum alloy bar material to form swash plate die forgings with small flashing; the die is the small flashing open type forging die and consists of an upper convex die, a lower convex die and an extrusion cylinder; the concave die adopts a detachable structure; during ejecting, the die forgings are directly ejected from the lower convex die; the upper convex die is provided with annular even gaps of which height is 3 millimeters and thickness is 0.5 millimeter, namely flashing grooves; and the gradient of all surface withdrawing die contacted with the extrusion cylinder is less than or equal to 5 degrees. The process flow is reasonable, the process parameter and performance are stable, the die has a simple structure, the manufacture, assembly and use are convenient, and the work is reliable.

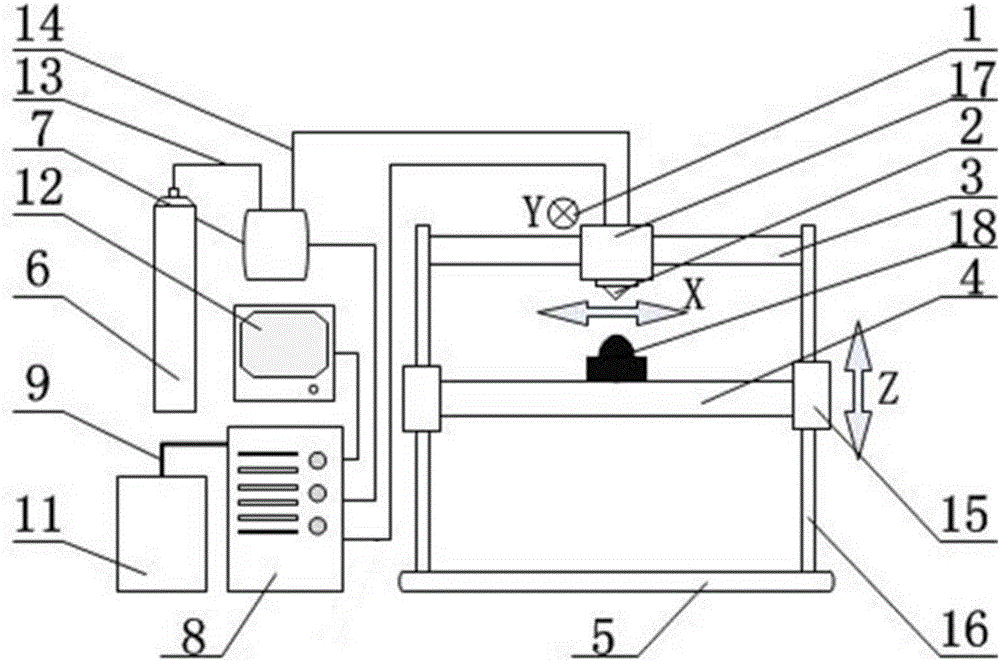

Equipment and method for 3D printing of architectural ornaments

ActiveCN105799172ABroaden the thinking spaceLow heat inputAdditive manufacturing apparatusSprayerControl system

The invention discloses equipment and a method for 3D printing of architectural ornaments. The equipment mainly comprises Y-axis guide rails, an X-axis guide rail, Z-axis guide rails, a movable forming platform, a wire feeder, a CMT power source system, a CMT sprayer, a water-cooling machine, a protective gas device, a central control system and the like, and the movable forming platform is arranged on the Z-axis guide rails. By means of connection, combination and control of the Z-axis guide rails, the Y-axis guide rails, the X-axis guide rail and other parts, accuracy in the Y direction, X direction and Z direction is achieved, objects in any shape can be rapidly formed, structures which cannot be obtained through traditional manufacturing methods can be perfectly printed, creativity of designers is freed, unrestrained imagination of the designers is met, and the aesthetic property and the grade of architectural ornament parts are improved. Compared with the mode adopting a laser, the CMT system is adopted by the equipment, the heat input amount is lower, a heat affected zone is smaller, deformation is smaller, the forming precision is higher, and the size error is smaller. Compared with traditional preparation processes for the architectural ornament parts, the cost is greatly reduced, and the precision is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

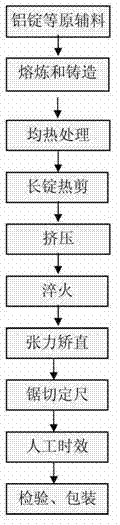

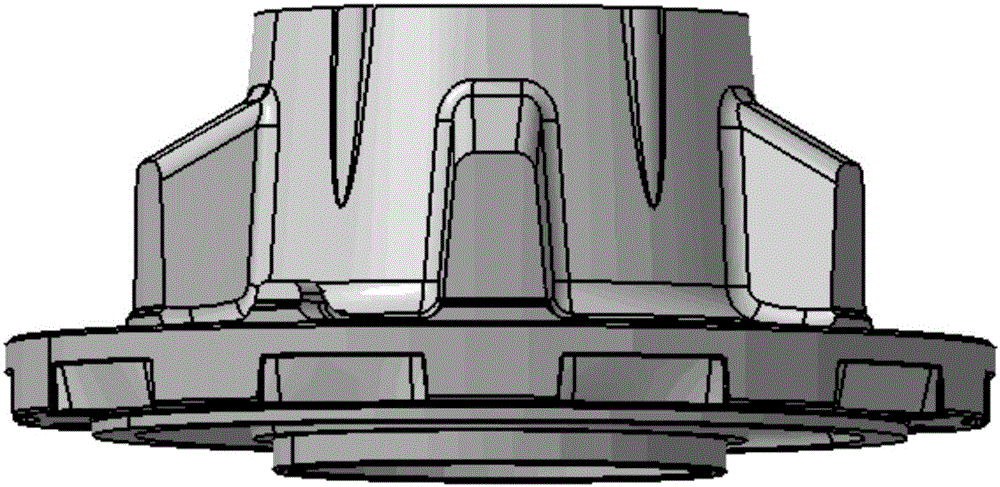

Liquid forging technology method for 6061 material commercial vehicle aluminum alloy shaft head

ActiveCN106319305AImprove metallographic structureEliminate shrinkageRare-earth elementSurface finishing

The invention discloses a liquid forging technology method for a 6061 material commercial vehicle aluminum alloy shaft head. The method mainly comprises the following steps of alloy component optimizing, smelting, melt purifying, liquid forging forming, demolding, trimming, hole tapping, heat treatment enhancing, machining and surface treatment. Firstly, components of elements in a 6061 alloy are optimized, a proper number of rare earth elements Gd and Sm and a proper number of elements Hf are added in a matched manner, and the vehicle shaft head is prepared through combination of the liquid forging technology; and through optimization of the chemical components of the alloy and the melt purifying technology, the metallographical structure of the alloy is improved, and shrinkage, loosening, air holes, cracks and other inner defects of products are greatly removed. The appearance quality of the shaft head product is obviously improved, the inner defects are obviously reduced, the production efficiency is high, the process is short, the technology cost is low, energy is saved, environment pollution is little, and economic benefits and social benefits are obvious.

Owner:辽宁忠相铝业有限公司

Method for co-depositing Al-Mn alloy plating layer in ionic liquid system

The invention relates to an electroplating method, in particular to a method for co-depositing an Al-Mn alloy plating layer in an ionic liquid system. The method has the characteristics in that: a metal material is taken as a cathode and a pure aluminum material with the purity of more than 99 wt% is taken as an anode; a mixture of MnSO4, R3(SO4)3 and Al2O3 is added into an electrolytic cell, themixture is fused with [EMIM]HSO4 ionic liquid, and then the fused mixture is used as an electrolyte to carry out electrolysis. The method provided by the invention has the advantages that: the [EMIM]HSO4 ionic liquid is adopted as the electrolyte so that aluminum ions and manganese ions are electrolyzed and co-deposited on a cathode material to generate a uniform and dense Al-Mn alloy plating layer; the heat energy needed by generating the plating layer is low (the step of plating can be carried out at a temperature of 100 DEG C), the oxidization loss of an alloy metal is small, a zero-pollution emission is realized and the production cost is low, so that the method accords with a development tendency of the modern industrial production.

Owner:淄博鸿润新材料有限公司

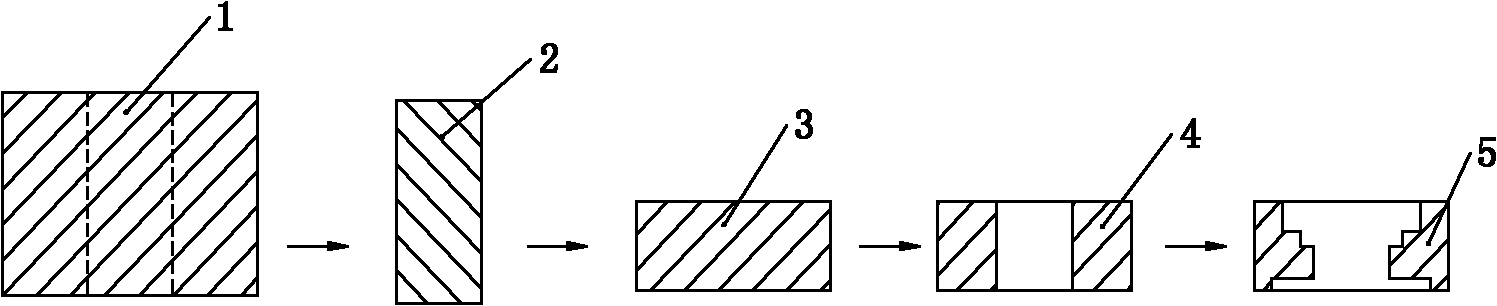

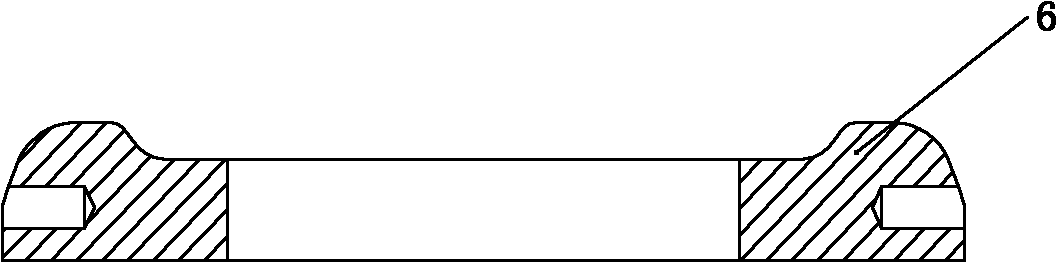

Gear blank production technology method with hammer forging and die forging combined

ActiveCN103157760AImprove metallographic structureAchieve mechanical propertiesWheelsIngotMechanical property

The invention discloses a gear blank production technology method with hammer forging and die forging combined. The method comprises the steps that a) an electroslag ingot is manufactured; b) blank materials before forging are prepared; c) the blank materials are heated; d) first cogging is carried out; e) second cogging is carried out; f) an annular blank is heated; g) die forging is carried out; h) a gear is subjected to quenched-tempered heat treatment; i) gear blanks are sampled and tested; j) qualified gear blanks by testing are subjected to rough machining, and end products are formed. The gear blanks are produced in a mode that hammer forging and die forging are combined, forging tolerance allowance is small, materials are saved, mechanical performance of produced gear blank end products is high, and service life is long.

Owner:韶关市中机重工有限责任公司

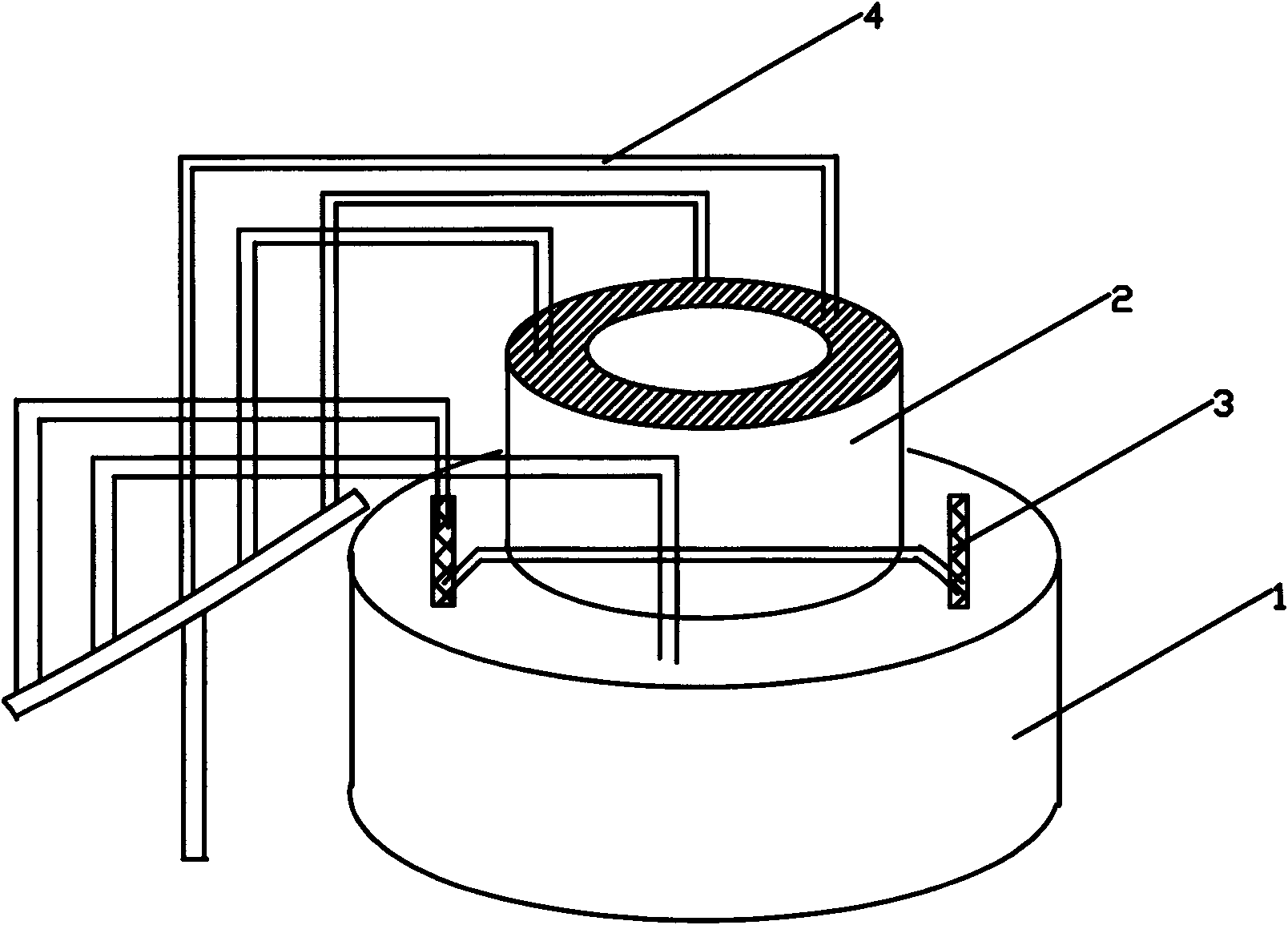

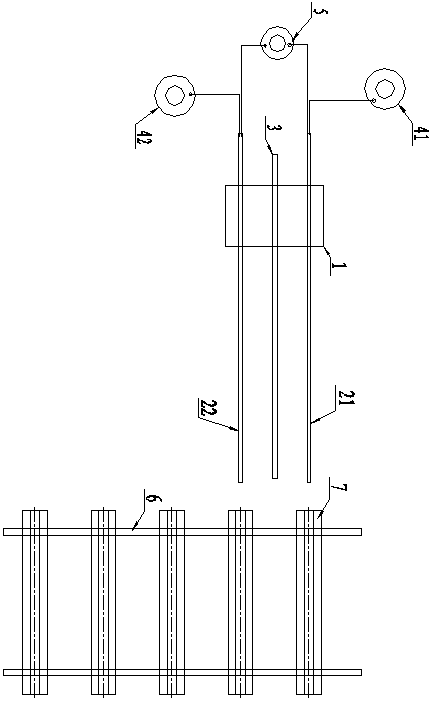

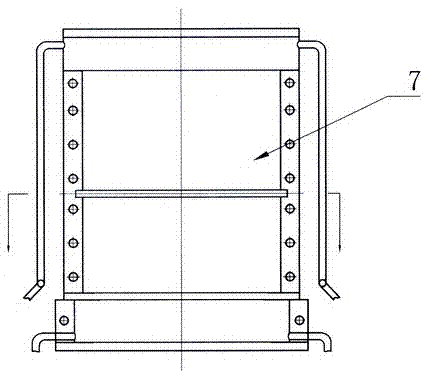

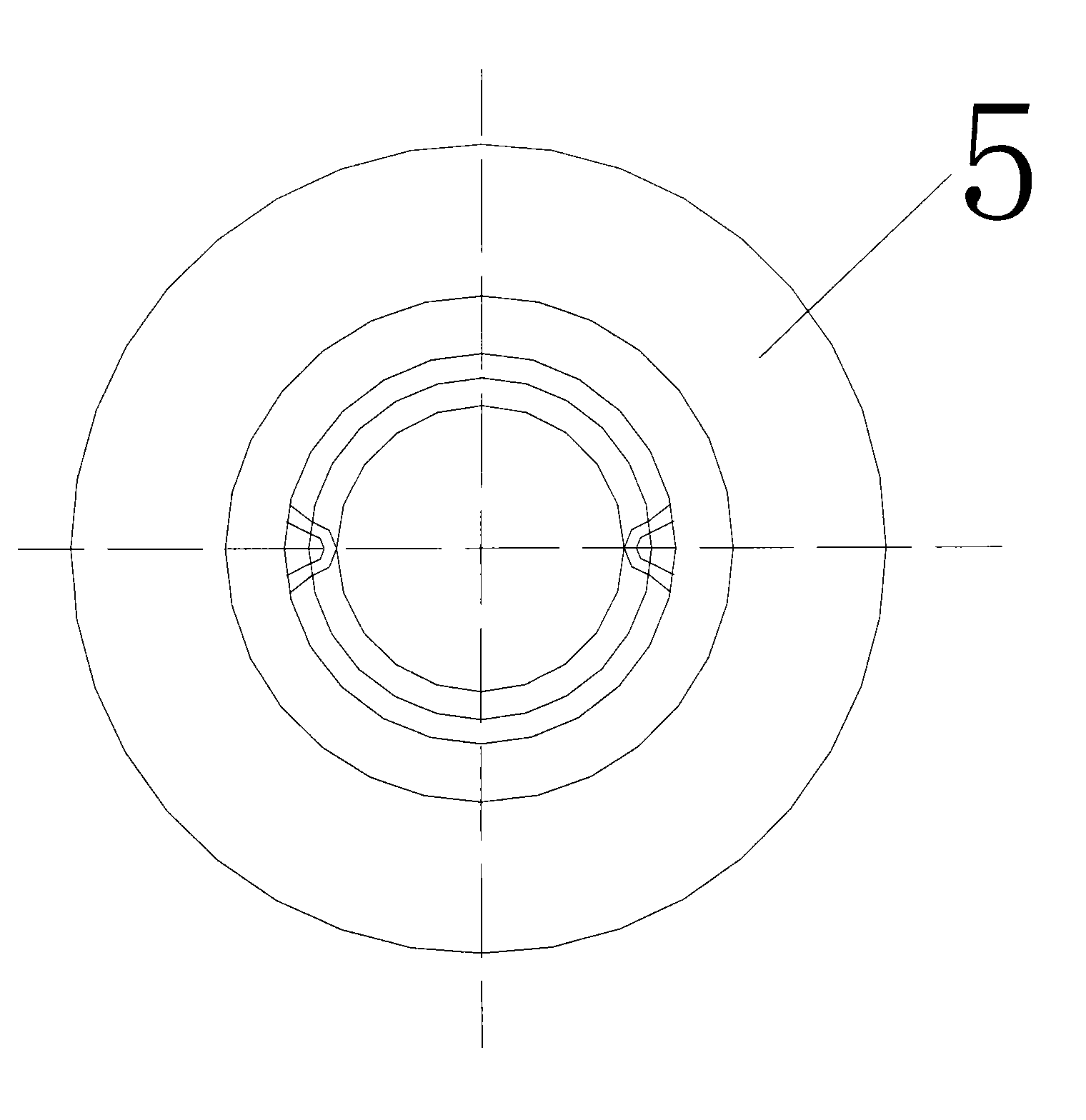

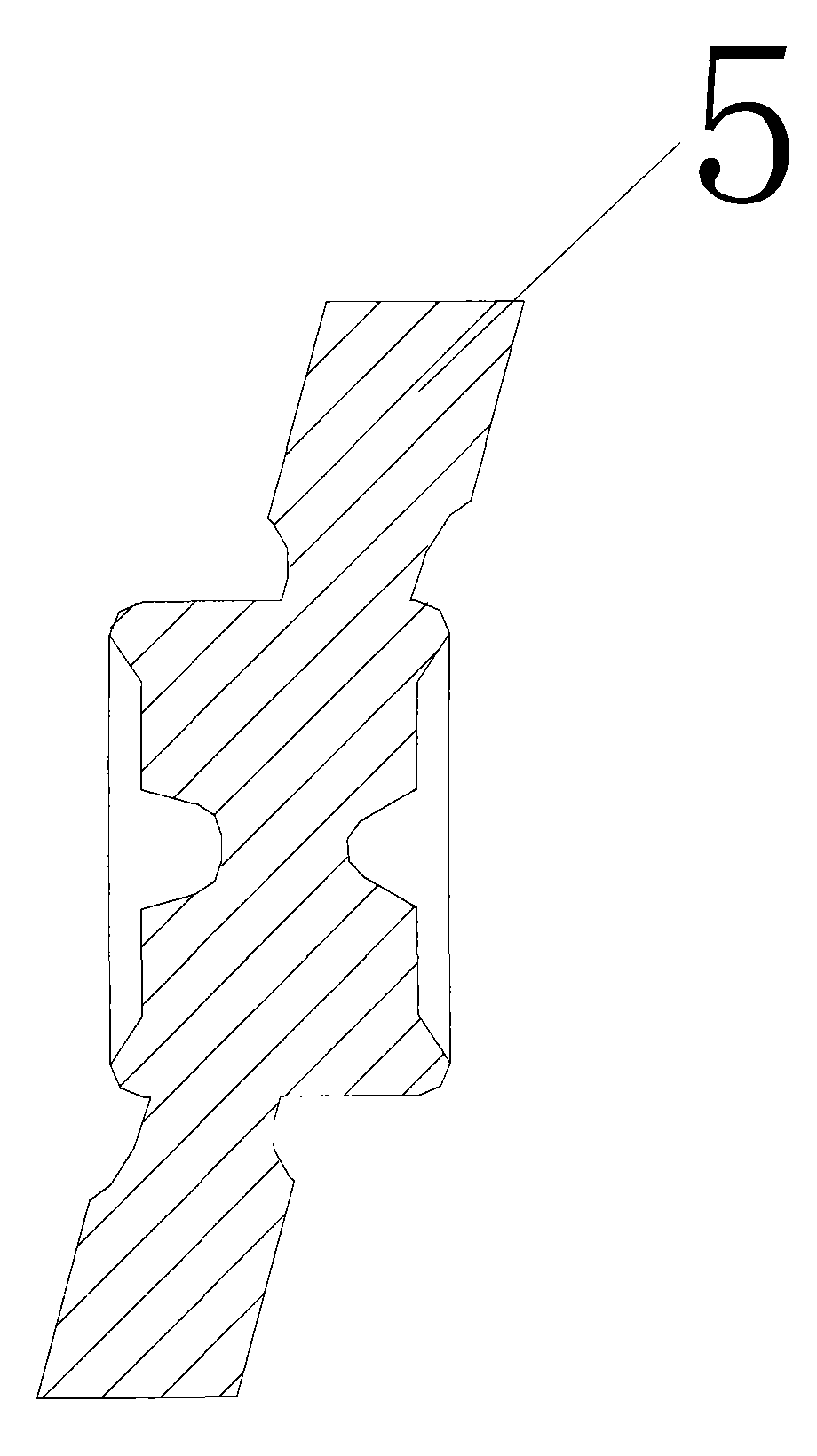

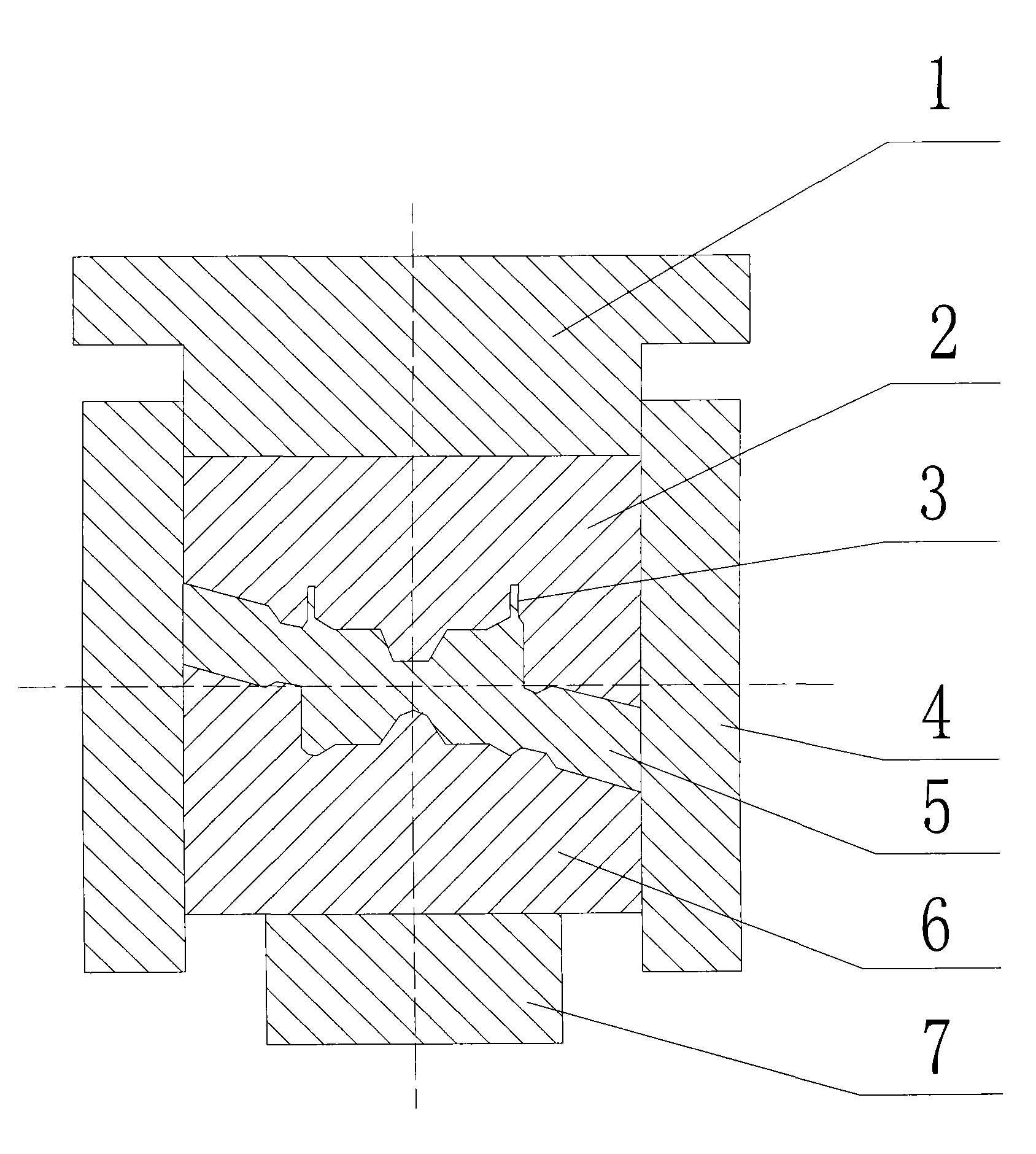

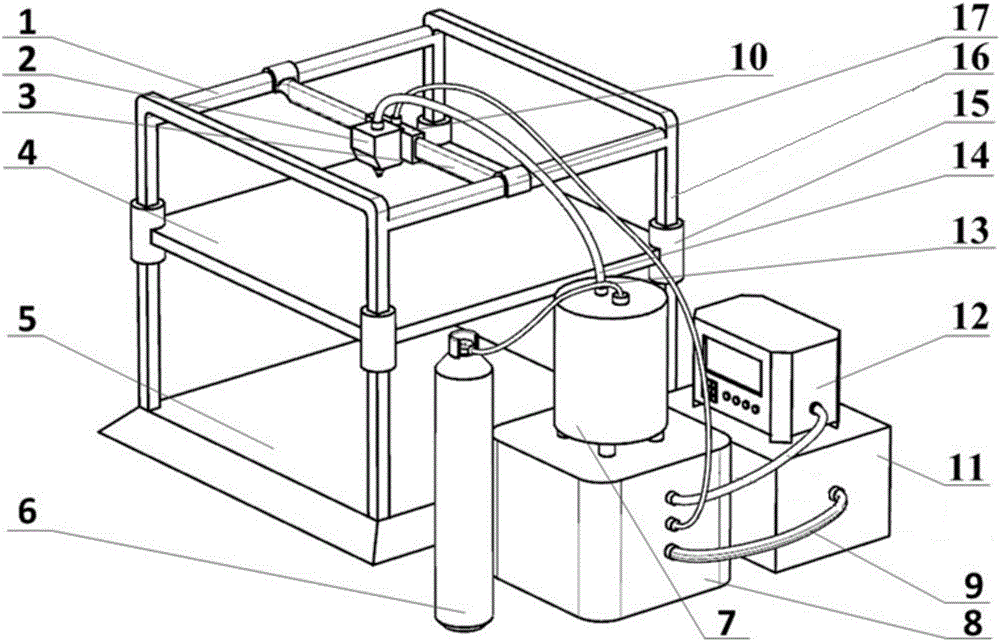

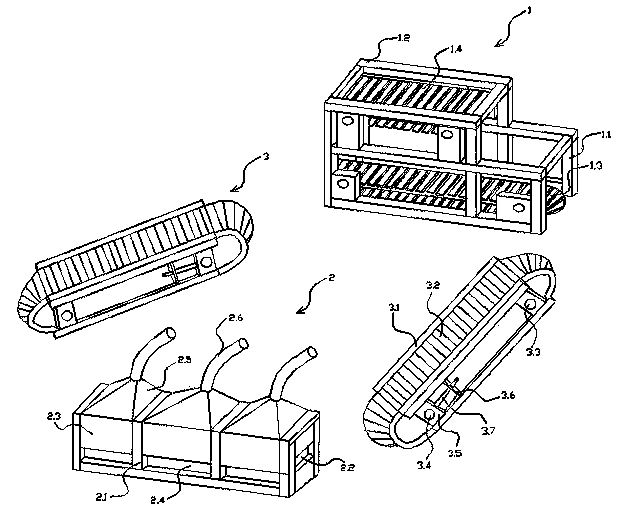

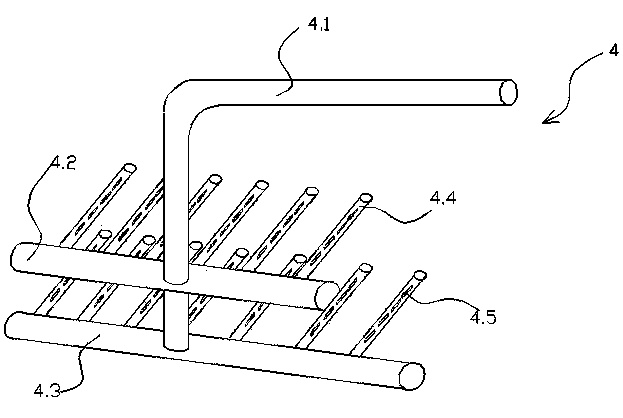

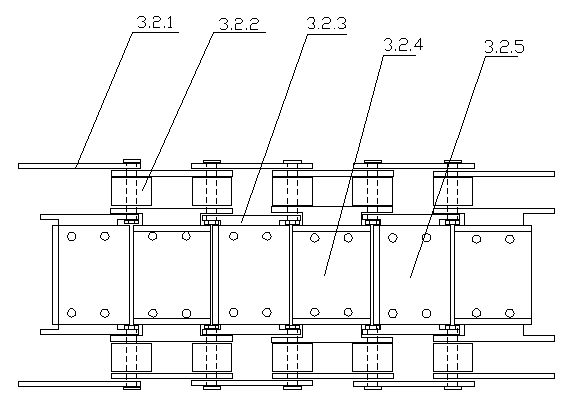

Compound steel ball tempering process by using waste heat

ActiveCN103966414AImprove metallographic structureReduce hardness lossFurnace typesHeat treatment furnacesMetallurgySteel ball

The invention relates to a compound steel ball tempering process by using waste heat, which comprises the following steps: 1, primary tempering; 2, air cooling; 3, secondary tempering. Devices adopted in the above steps comprise a double-layer tempering device (1), a steel ball severe-convection cooling device (2), high-temperature-resistant steel ball lifting conveyors (3) and a waste heat pipe system (4). The compound steel ball tempering process by using the waste heat, provided by the invention, is low in energy consumption and good in tempering effect.

Owner:JIANGYIN HUAZHENG METAL TECH

Camshaft specialized inoculant

The invention discloses a camshaft specialized inoculant. The formula of the inoculant comprises: by weight, 5% of barium alloy, 4.5% of strontium alloy, 6.5% of rare earth ferrosilicon, 81.5% of ferrosilicon and 3.5% of silicozirconium. As elements of strontium, barium, zirconium, rare earth and the like are added into a traditional inoculant and contents of the above elements are adjusted in the invention, problems such as chilling tendency, graphite form, microstructure, hardness, wear resistance, processability and the like existing in camshaft products of the prior art are solved. Through long-term use of verification, the inoculant provided by the invention can be used to obviously refine microstructure of a camshaft, improve graphite form, make hardness of a camshaft uniform, increase wear resistance and reduce quality problems caused by processing. The inoculant has a wide application prospect in the industry.

Owner:成都宏源铸造材料有限公司

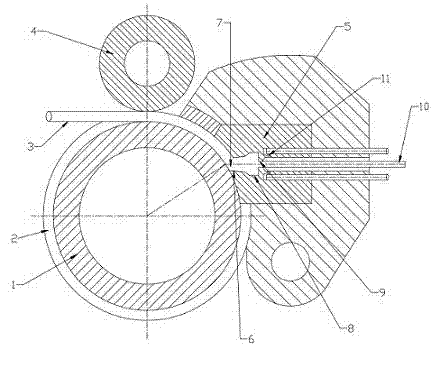

Continuously extruding method and extruding device of non-radial feeding

The invention discloses a continuously extruding method of non-radial feeding, comprising the steps of a, depressing the blank by a compaction wheel and enabling the blank to enter into an extruding tool due to the friction force generated by rotating the groove of an extruding wheel and the blank; b, enabling the blank to enter into the feed port of an extruding tool after the blank advances to a stop block, wherein the center line of the feed port of the extruding frock is at the chord direction of the extruding wheel; c, extruding the product from the die and fast cooling the product through a jet cooling device by arranging a metal molding cavity at the tail end of the feed port of the extruding tool and arranging a die at the tail end of the metal molding cavity. Different from the continuous channel corner extrusion, in the whole working process of which the geometrical shape of the blank basically remains the same, the continuously extruding method and extruding device of non-radial feeding disclosed by the invention aim at obtaining high-performance materials of fine grain tissue finally by shear deformation.

Owner:大连康丰科技有限公司

Manufacturing method for aluminum alloy air cylinder cover

InactiveCN107338387AHigh hardnessImprove wear resistanceTransportation and packagingMetal-working apparatusRare-earth elementNanoparticle

The invention discloses a manufacturing method for an aluminum alloy air cylinder cover. The manufacturing method includes the following steps that raw materials are weighed according to weight parts, then the above materials are mixed, are stirred for 10 min to 15 min under the temperature of 40 DEG C to 50 DEG C and are then loaded into a die to be pressed into a blank; then the blank is put into a sintering furnace to be sintered under the nitrogen atmosphere shield; and finally, the pressed blank is sent into a steam treatment furnace, steam is led into the furnace for 60 min to 90 min under the condition that the temperature in the furnace ranges from 200 DEG C to 300 DEG C, and then the pressed blank is obtained through air cooling. The aluminum alloy air cylinder manufactured through the method is high in hardness and good in wear resistance, rare earth elements and nano particles are matched, the metallographic phase structure is improved, the tissue is compact, the microstructure is good, pores are very few, and the structure rigidity and hardness, the fatigue resistance and the tensile strength are good.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

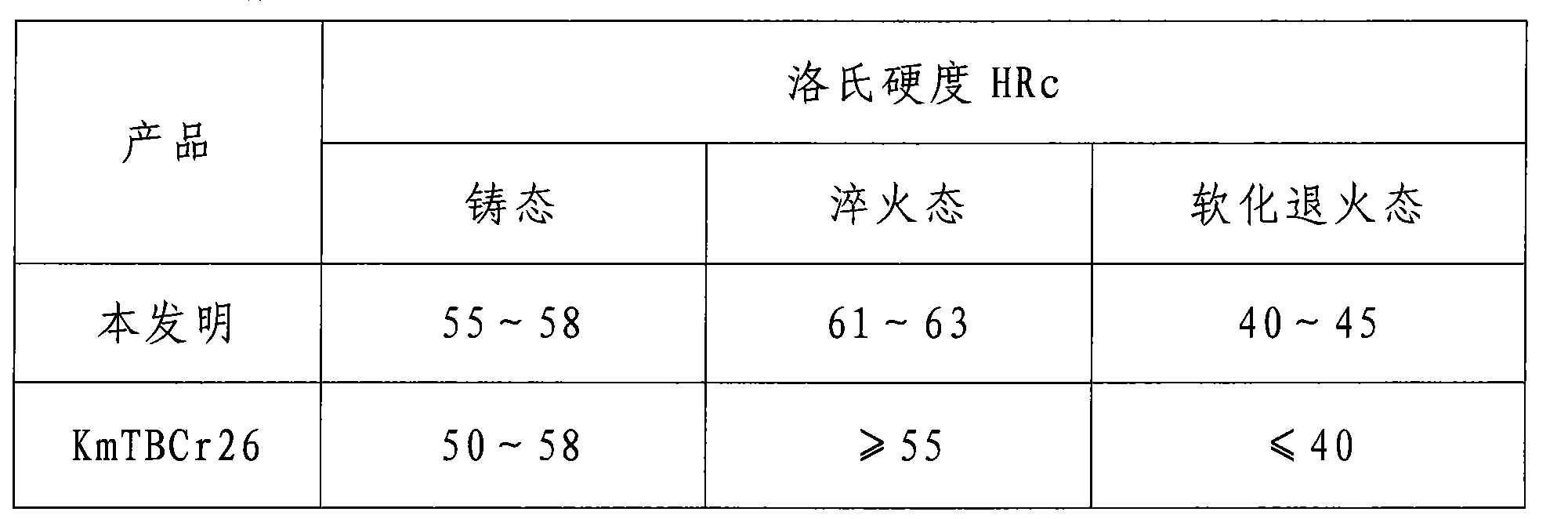

Wear resistant cast iron

InactiveCN101440454AImprove hardness and wear resistanceImprove metallographic structureWear resistantCast iron

The invention discloses a cast iron material with higher hardness, corrosion resistance, high-temperature oxidation resistance and abrasion endurance of an abrasive material with larger impact load. The cast iron material consists of the following compositions by weight percentage: 2.8 percent of C, 0.2 to 1.0 percent of Si, 0.5 to 1.0 percent of Mn, less than or equal to 0.06 percent of S, less than or equal to 0.1 percent of P, 21 to 23 percent of Cr, 0 to 1.5 percent of Ni, 1.0 to 1.5 percent of Mo, and the balance being Fe and unavoidable impurities. The cast iron material has the advantages of improving hardness and other comprehensive performances of the material, and being helpful for prolonging the service life of a finished product manufactured by the cast iron material.

Owner:蔡柏林

Metal plate asynchronous rolling method

InactiveCN101524707ASimple methodImprove metallographic structureMetal rolling arrangementsRoll speed control deviceMetalCrystal

The invention discloses a metal plate asynchronous rolling method which adopts a rolling pair roller for rolling, and an upper rolling roller and a lower rolling roller of the rolling pair roller adopt different linear velocity when rolling metal plates. The invention has simple method, and rolled products have good metallurgical structure, fine and uniform crystal grains, strong intensity, favorable tightness and good quality.

Owner:江苏包罗铜材集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com