Casting process of nodular cast iron planet carrier

A casting process, the technology of ductile iron, applied in the field of casting process of ductile iron planetary frame for gearbox, can solve the problems of low efficiency, high energy consumption, high process cost, etc., achieve efficiency improvement, increase yield rate, and facilitate feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

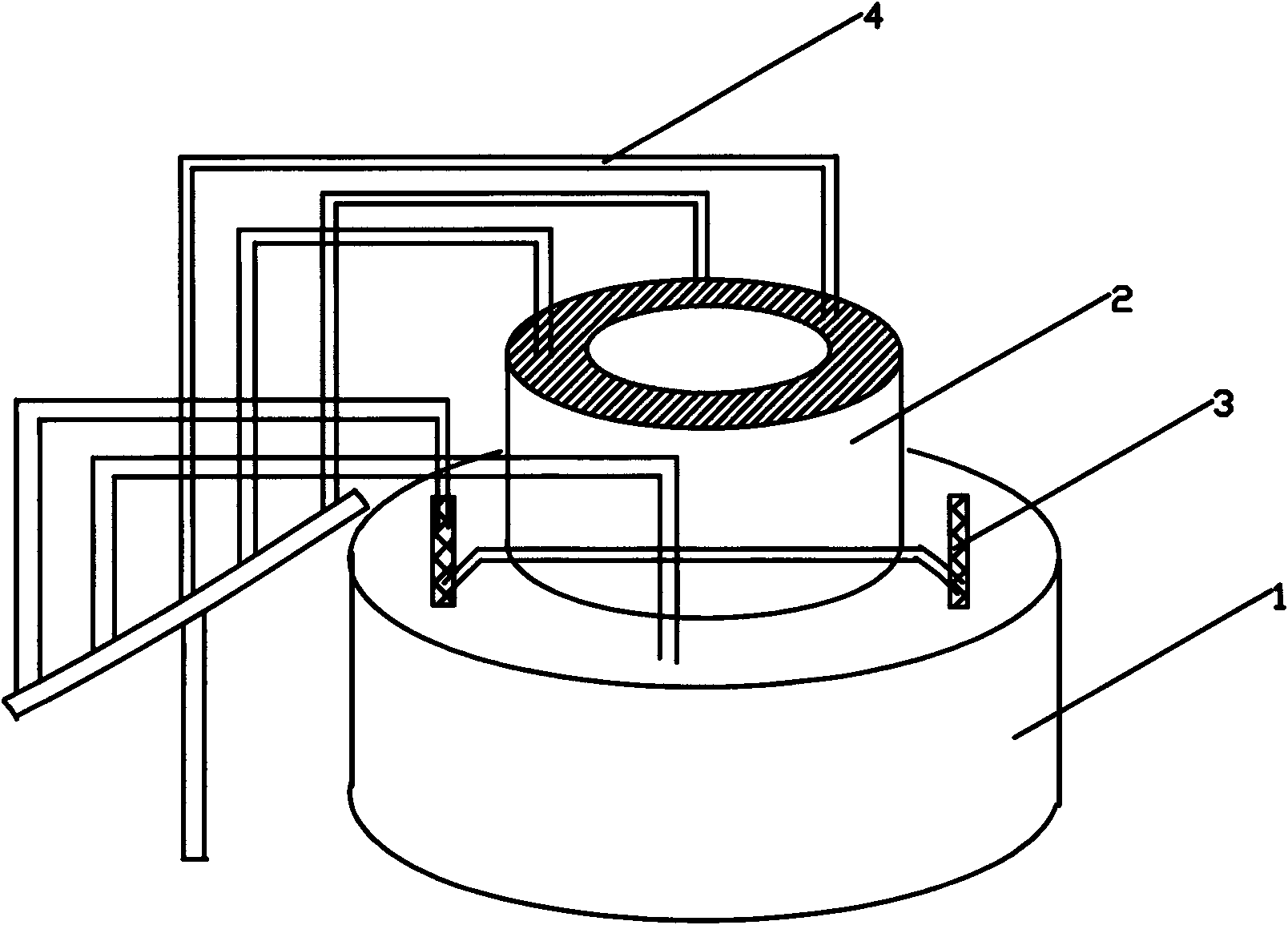

[0024] A casting process for a nodular cast iron planet carrier, including a molding process, molten iron smelting process, spheroidizing process, inoculation process, pouring process, normalizing process and stress relief annealing process, these processes are carried out according to common techniques in this field, and The step of the pouring process is improved as follows: in the pouring process, 4-10 stepped inrunners 4 are simultaneously poured on the top of the chassis 1 and the column 2 of the planet carrier.

[0025]In addition, the following improvements are made in other processes: in the molding process, cold irons are placed at the junction of the chassis 1 and the column 2 of the planet carrier and the two ends of the boss 3 on the chassis 1. In the molten iron smelting process, Sn element is added to the molten iron, and the added mass of the Sn element is 0.015-0.02% of the total mass of the molten iron. In the spheroidizing process, a pit-type treatment bag is...

Embodiment 2

[0027] The invention relates to a production process of a nodular cast iron planet carrier for a gear box. The process includes a molding process, a molten iron smelting process, a spheroidizing process, an inoculation process, a pouring process, a normalizing process, and a stress annealing process.

[0028] Molding process: Resin sand is used for molding. In terms of sand preparation, the ratio of sand, resin and curing agent is controlled at a ratio of 400:4:1, and the sand temperature is controlled at 30°C. When the mold is placed, place the cold iron on the thick-walled and sharply changing parts of the planetary frame and adopt the process of step-type pouring system. See the attachment for the placement of the cold iron and the design of the pouring system image 3 , When the mold is placed and the sand is placed, the sand flow rate should be large, and the speed should be controlled at 100Kg / 30s.

[0029] Smelting molten iron process: the raw materials used for smeltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com