Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

545results about How to "Increased strength and rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

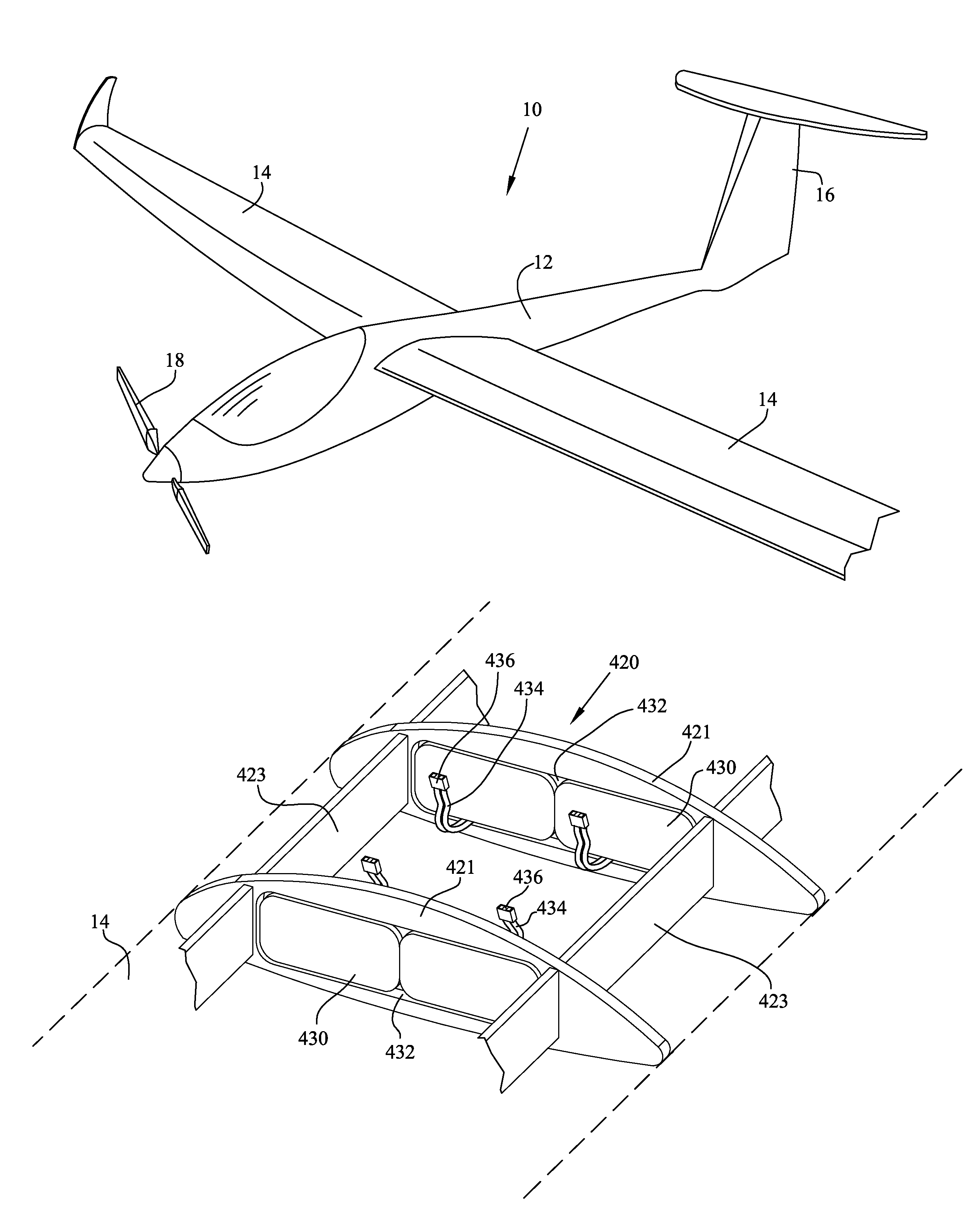

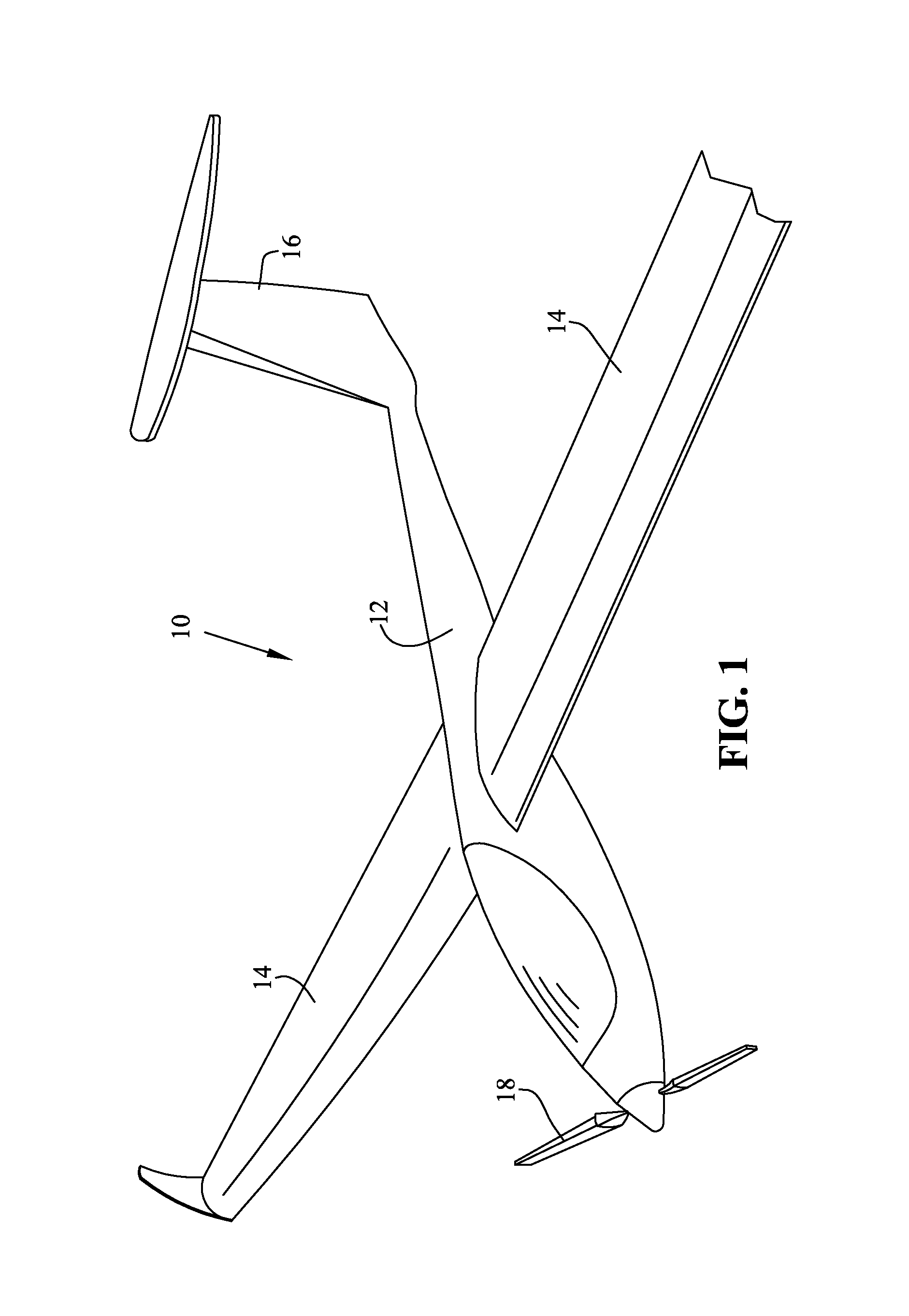

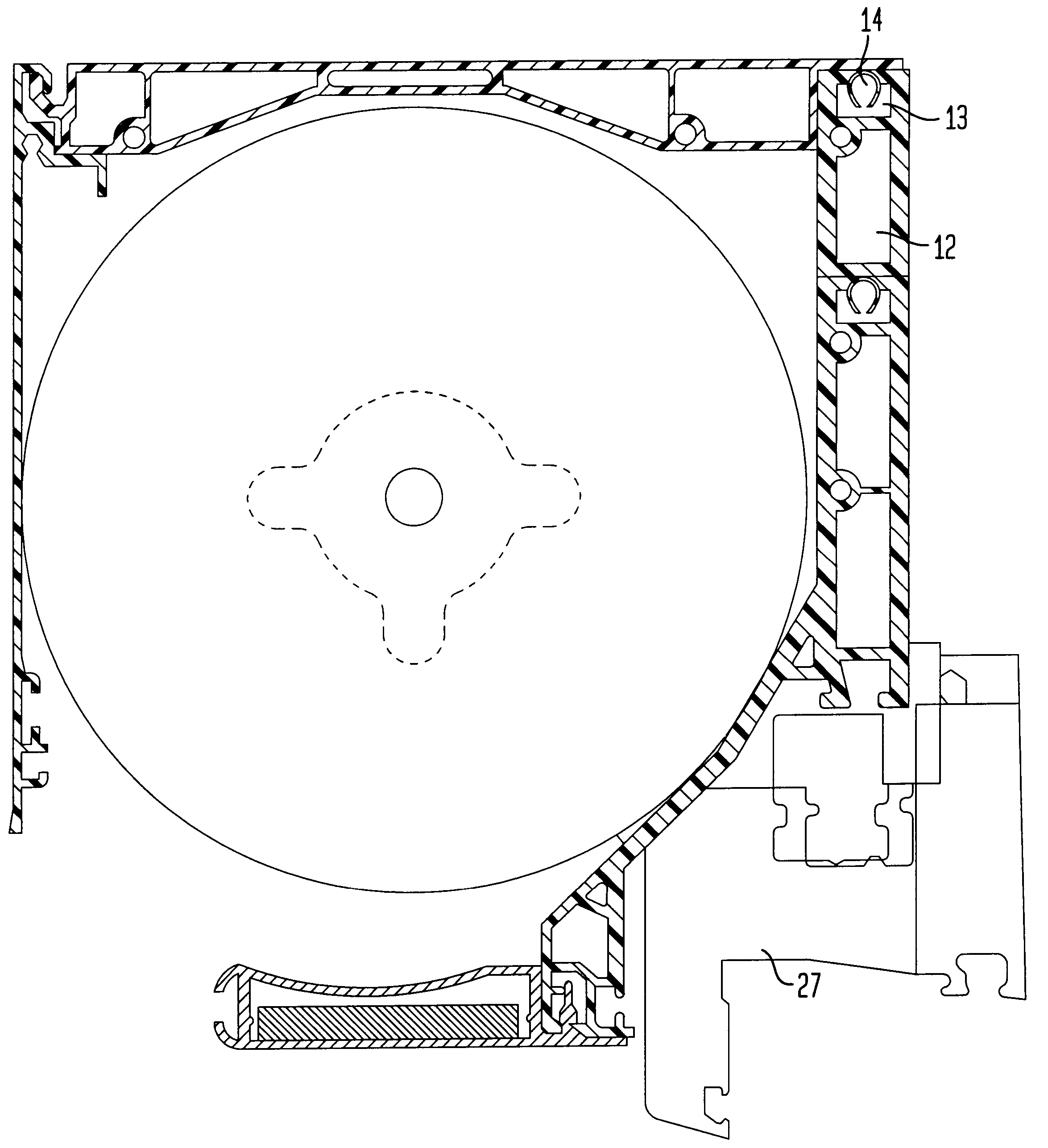

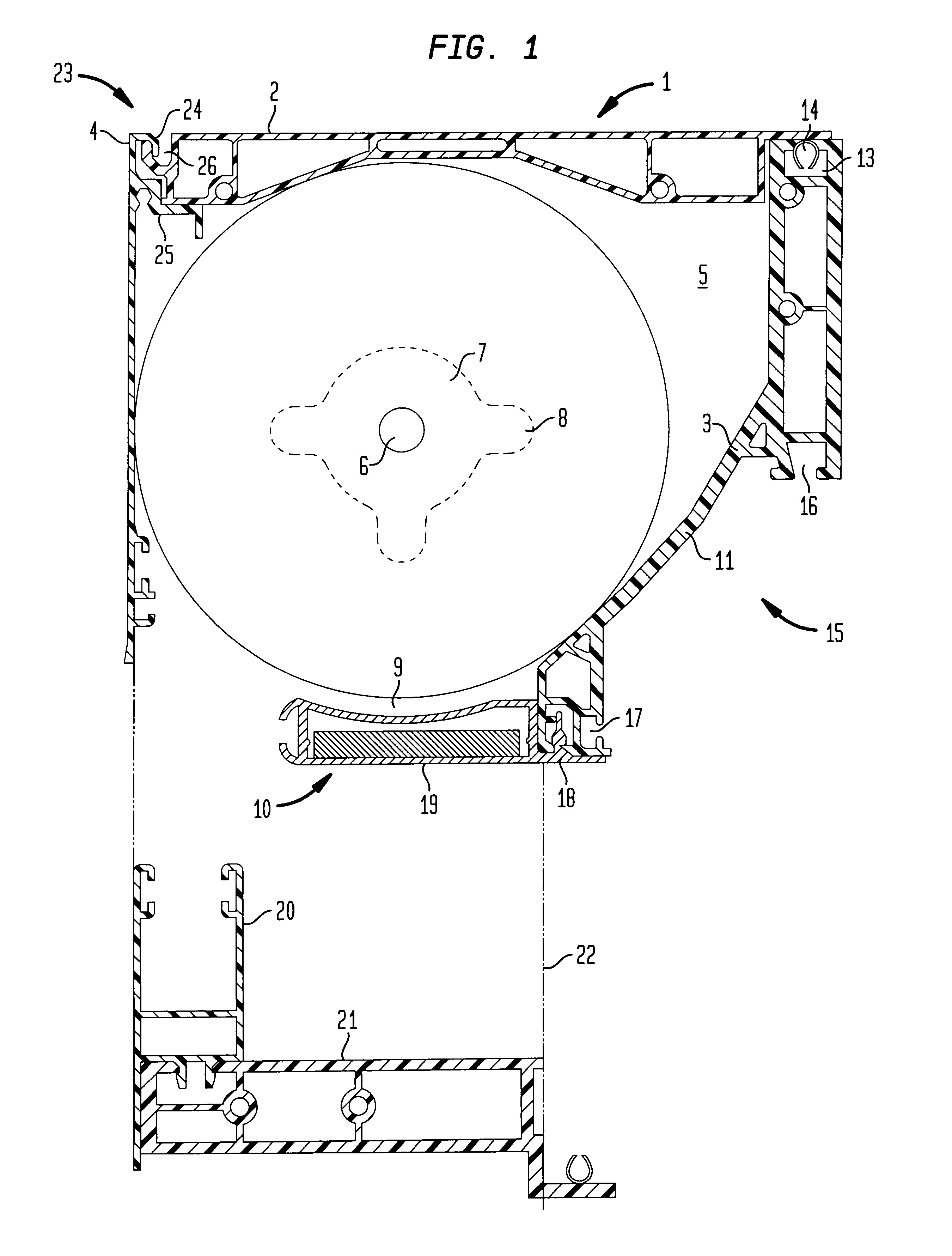

Battery-structure

InactiveUS8967529B1Improve rigidityIncreased strength and rigidityAircraft power plant componentsEfficient propulsion technologiesGlass fiberElectrical battery

A battery-structure that may be located at least partially in the wings of an aircraft. The battery-structure forms a portion of the structural support of the wings and includes a plurality of battery receiving compartments; and a plurality of batteries located in the battery-structure. The batteries are configured to fit snugly within the battery receiving compartments, thereby increasing the rigidity of the battery-structure and the wings. The structural constituent of the battery-structure may be made from a carbon or graphite reinforced composite material or from a fiberglass composite material. The battery-structure may include a top panel, a bottom panel, a pair of side panels, and a plurality of web members. The panels and the web members may define the battery receiving compartments. The batteries can be received snugly between the web members to reinforce the rigidity and / or strength of the battery-structure.

Owner:ODYSSIAN TECH

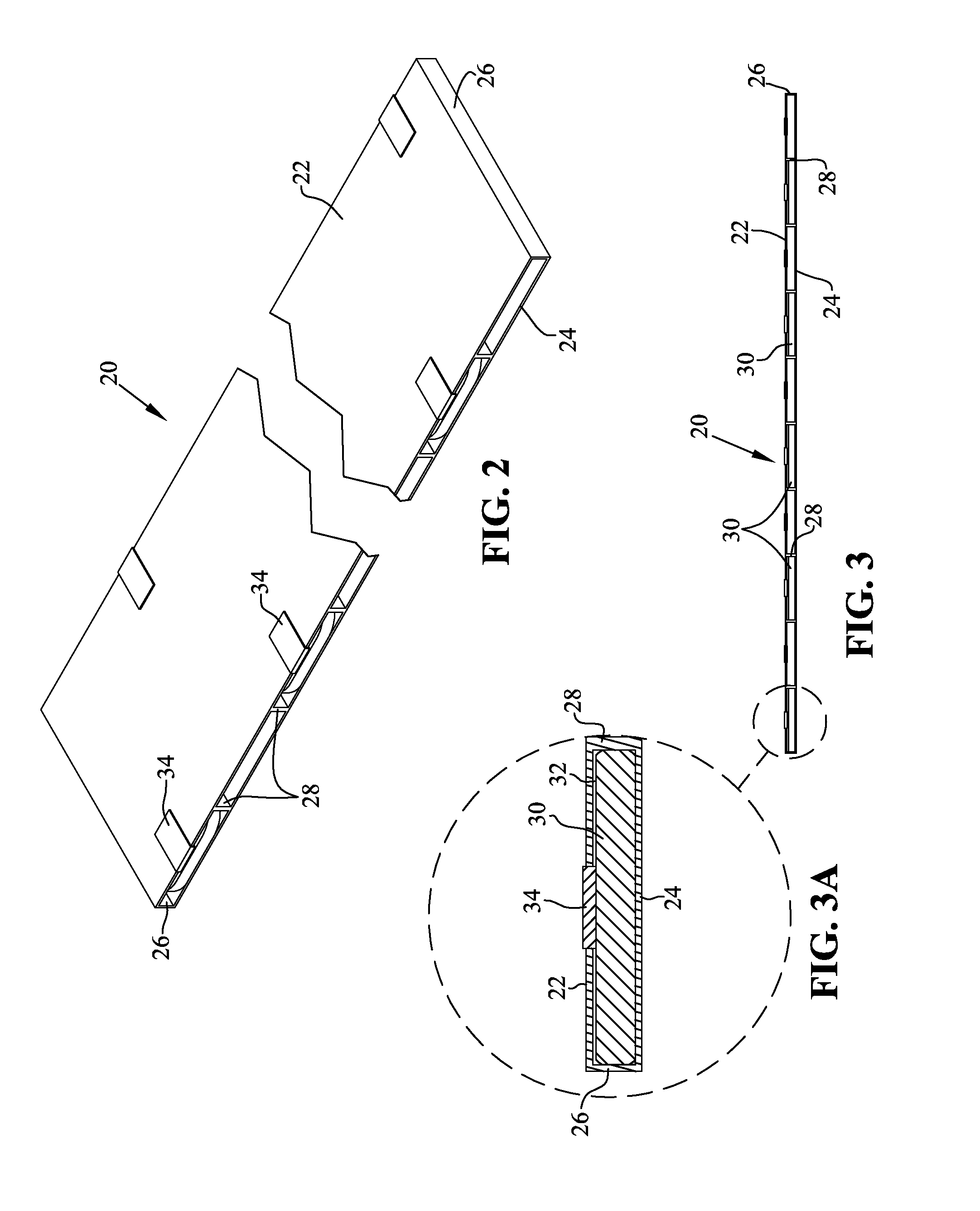

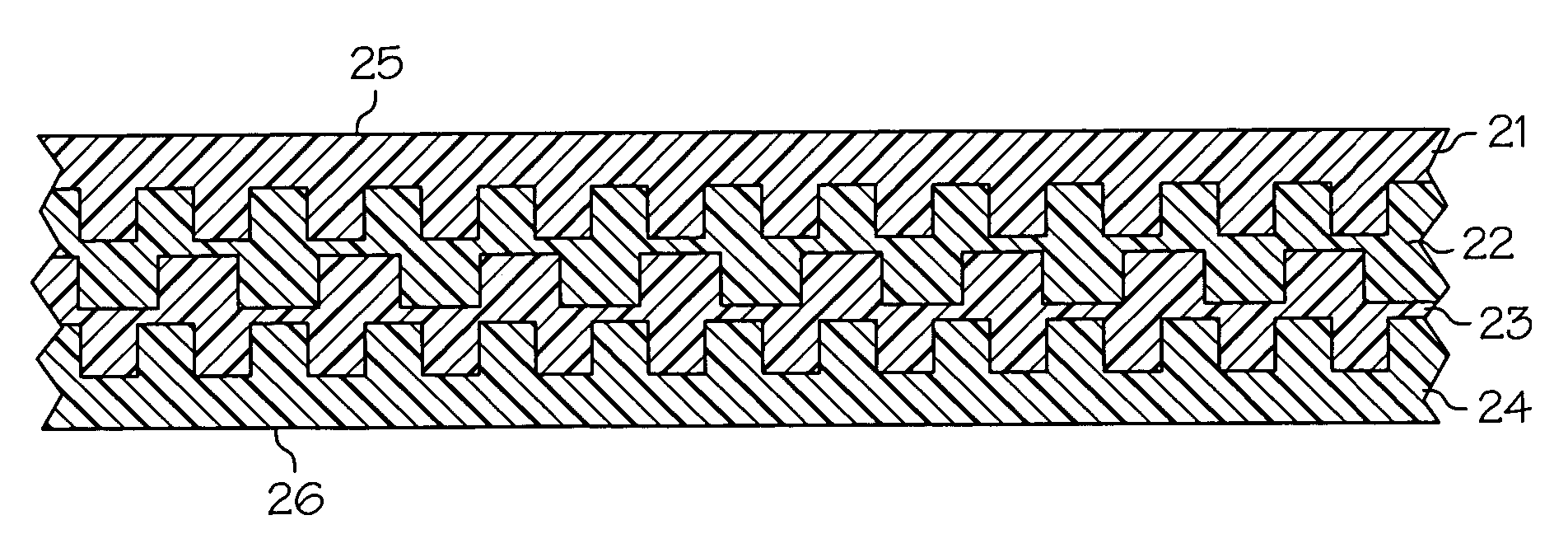

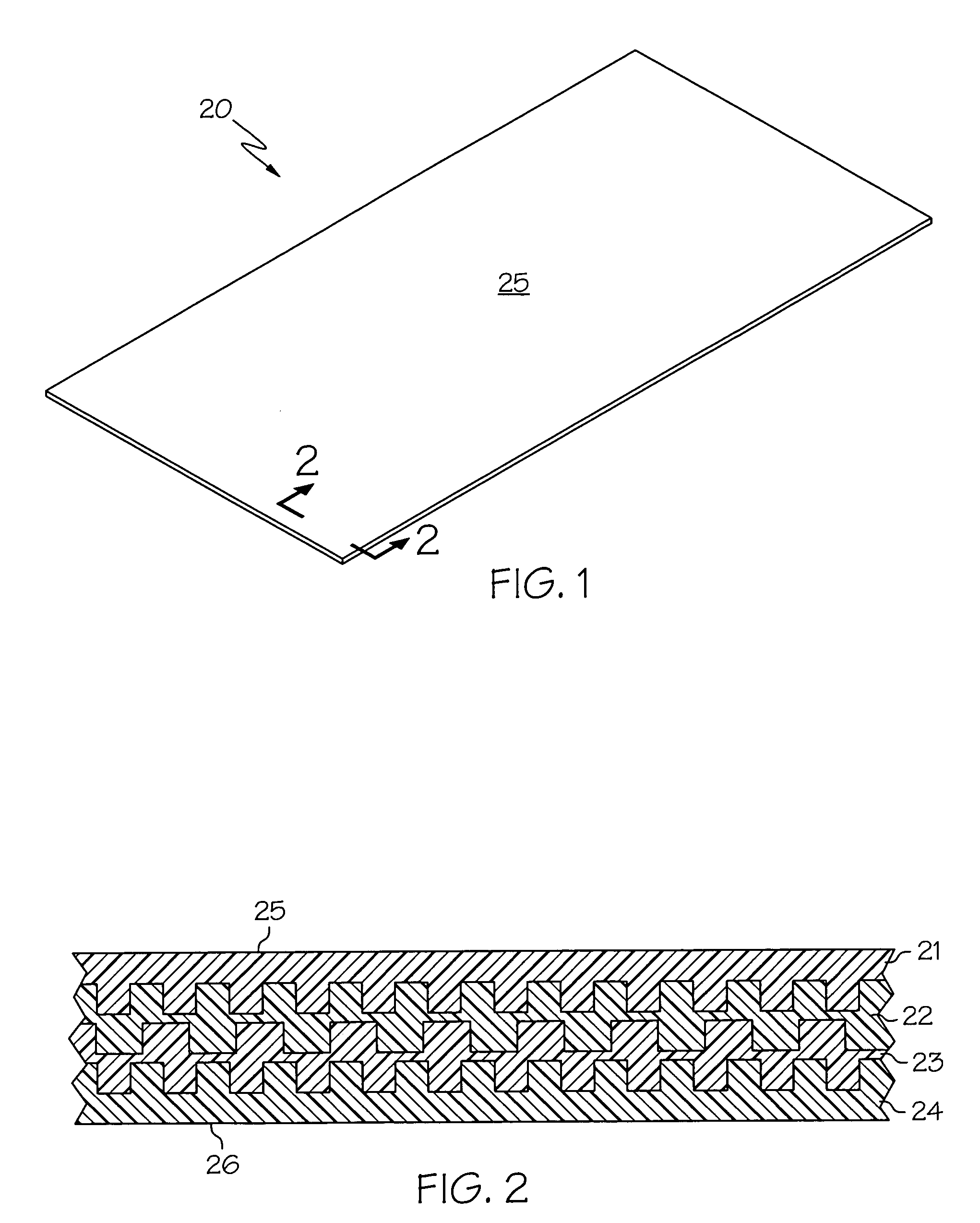

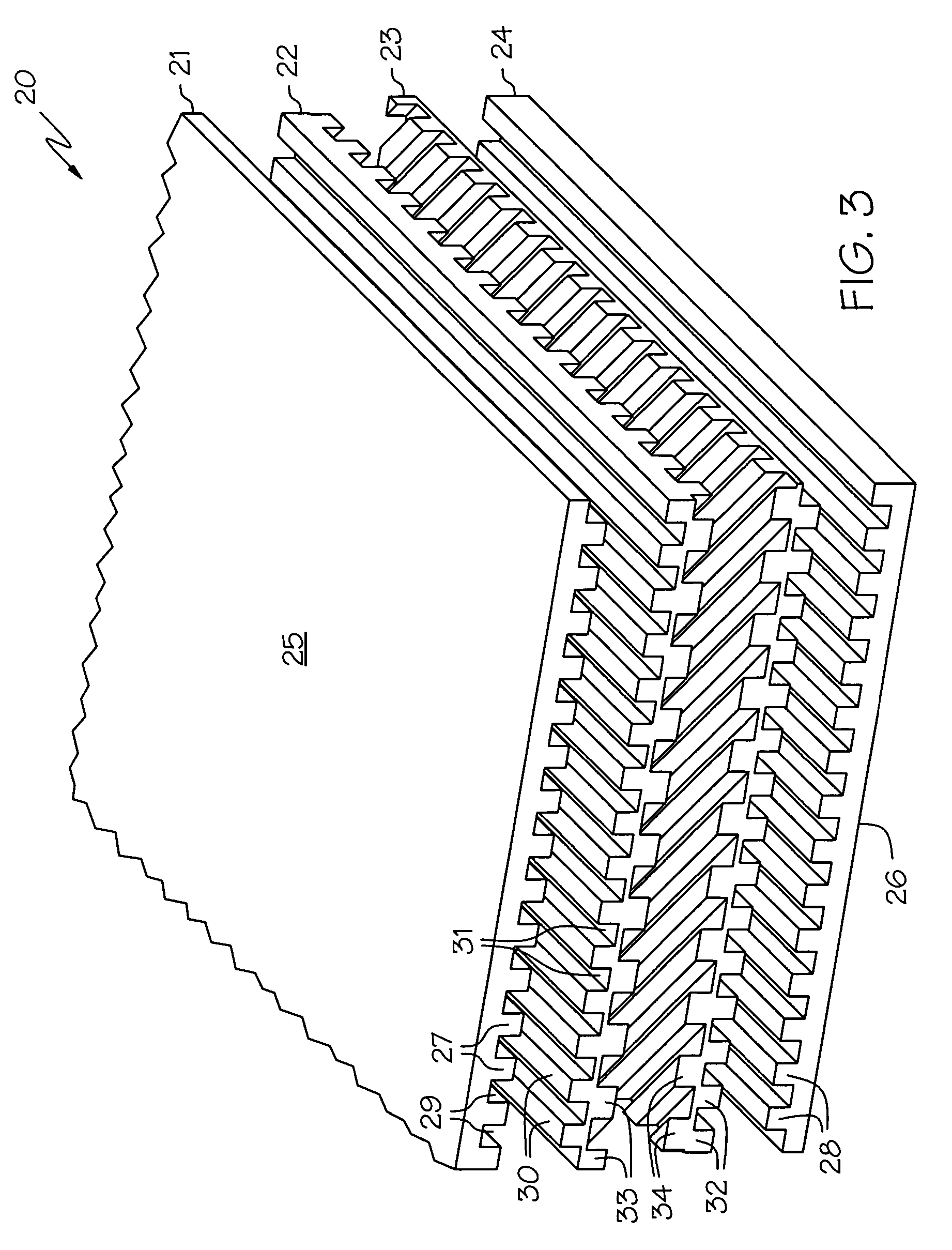

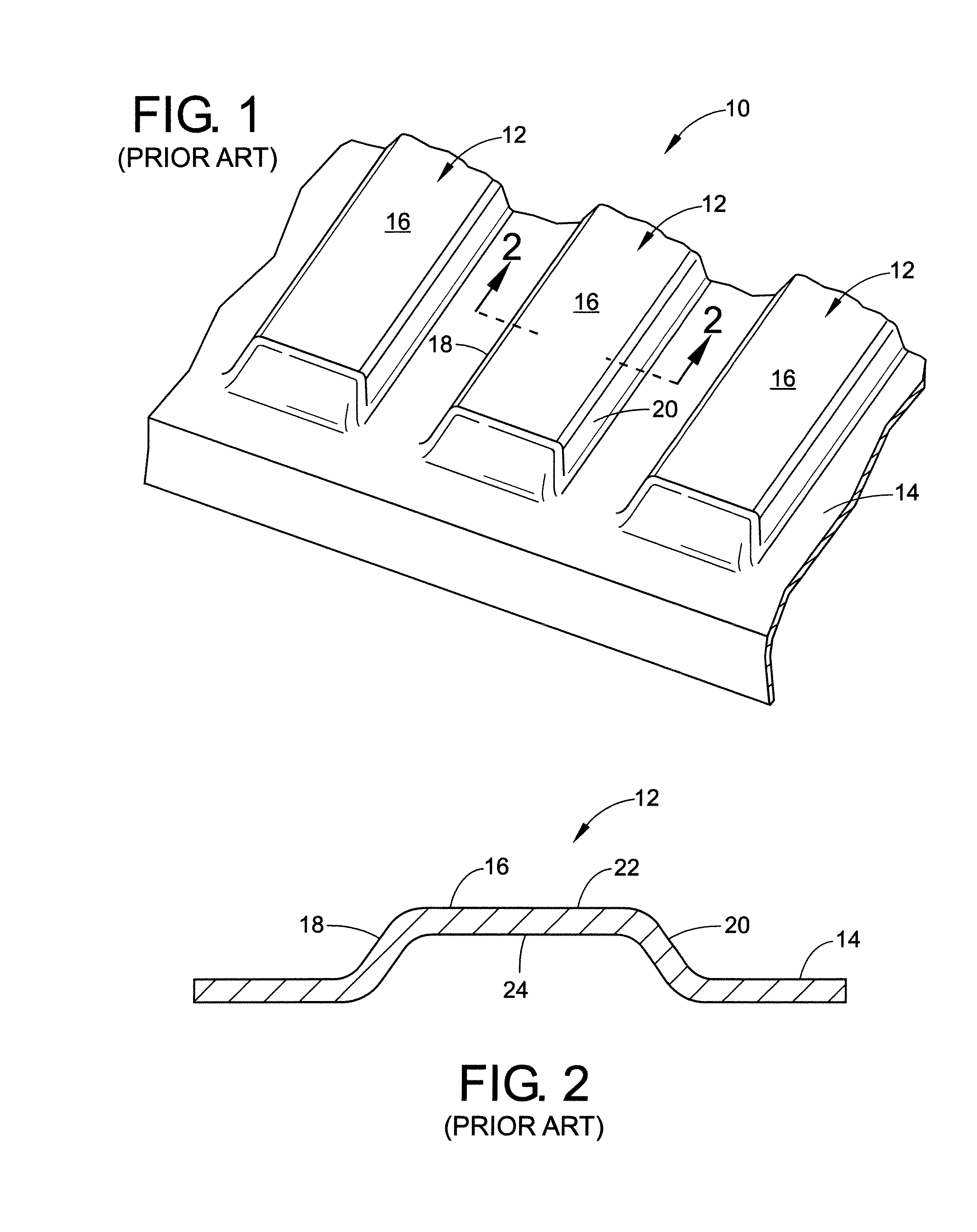

Composite articles formed from sheets having interconnecting ridges

ActiveUS7090911B2Increased strength and rigidityIncrease surface areaSynthetic resin layered productsLoad-supporting elementsManufactured formEngineering

A composite article of manufacture formed from at least three sheets of material laminated to one another. At least one surface of each of the sheets has a plurality of spaced-apart ridges which extend in a predetermined direction along the surface, and each of the pluralities of ridges is arranged so as to nest between a plurality of ridges on an adjacent sheet.

Owner:LASCELLES GARY

PC/ABS alloy modified engineering plastic dedicated for laptop casings and production method thereof

The invention discloses a PC / ABS alloy modified engineering plastic dedicated for laptop casings. The plastic comprises the following components in percentage by weight: 22% to 65% of polycarbonate, 1% to 10% of compatilizer, 22% to 65% of acrylonitrile-butadiene-styrene, 5% to 40% of mineral filling material, 0.3% to 1% of antioxidant, 3% to 20% of halogen-free fire retardant, 0.5% to 2% of dispersed lubricant, and 3% to 20% of flexibilizer. The invention also discloses a production method of the PC / ABS alloy modified engineering plastic dedicated for laptop casings. The PC / ABS alloy modified engineering plastic dedicated for laptop casings has the advantages of capability of being recycled and utilized, multi-choice of color and outer layer treatment, stable size, good heat radiation property, and high cost performance. The production method has the advantages of simple operation and suitability for mass production.

Owner:东莞市卡帝德塑化科技有限公司

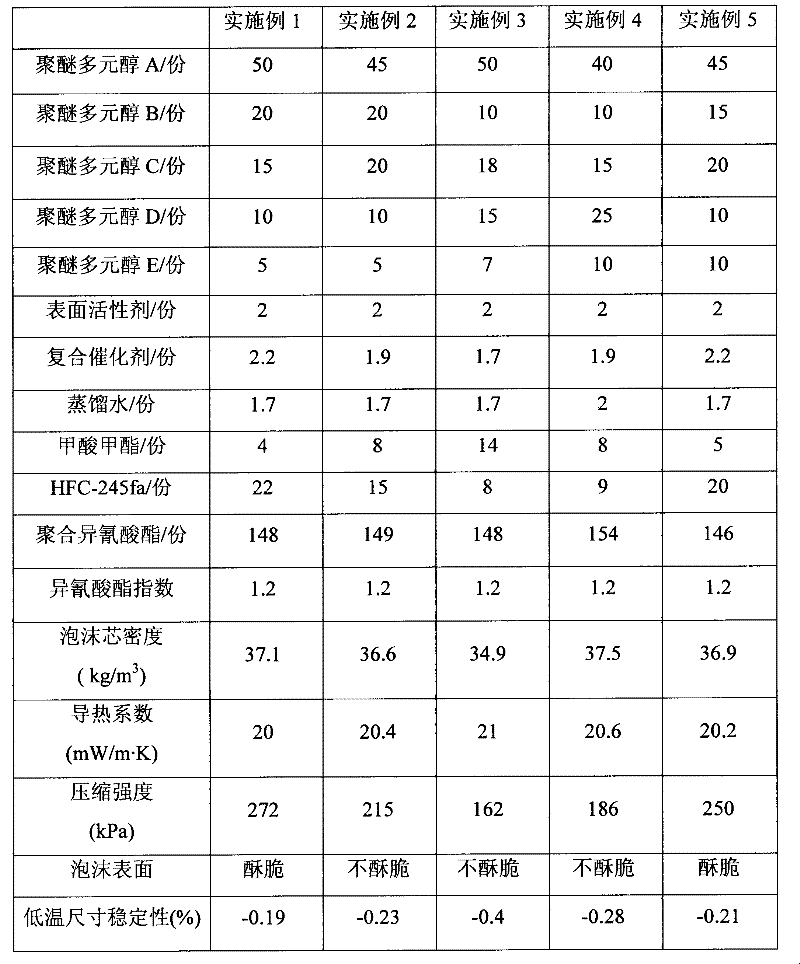

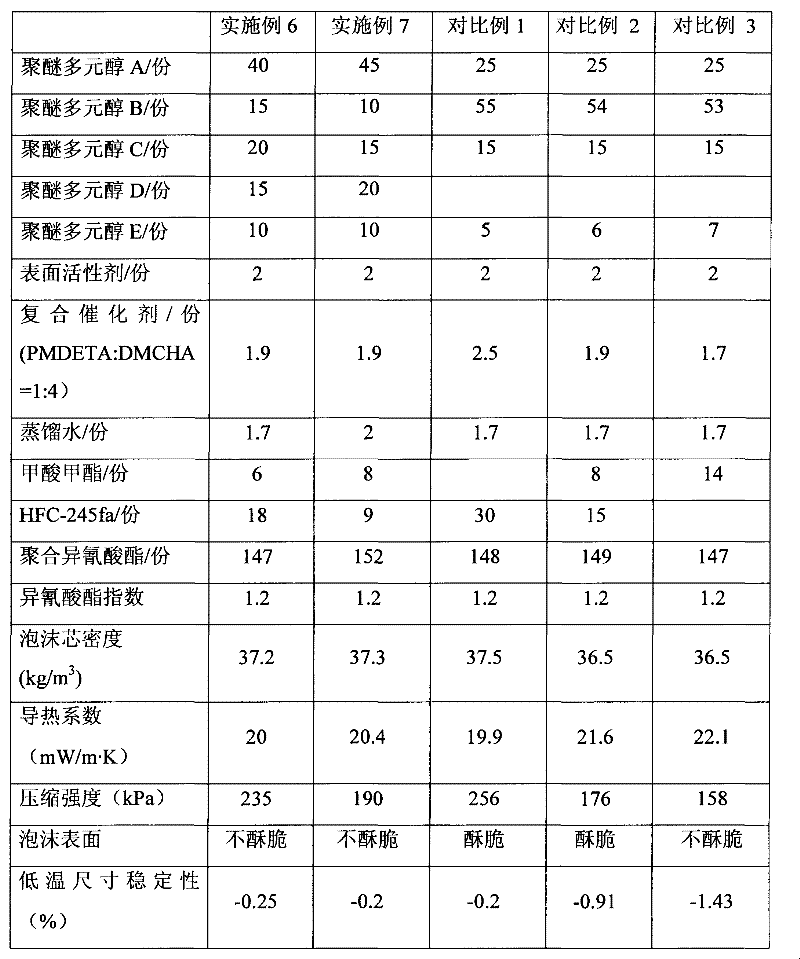

Polyurethane rigid foam and preparation method thereof

The invention discloses polyurethane rigid foam and a preparation method thereof, wherein foam plastic is prepared from the following raw materials by a high pressure foaming machine in parts by weight: 100 parts of combined polyether, 1.5-3 parts of surfactant, 1.5-3 parts of complex catalyst, 1-3 parts of water, 16-26 parts of mixed foaming agent and 140-170 parts of polymerized isocyanate, wherein the mixed foaming agent consists of methyl formate and 1,1,1,3,3-pentafluoropropane (HFC-245fa). The prepared polyurethane foam has low heat conductivity, good dimensional stability and proper cost.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

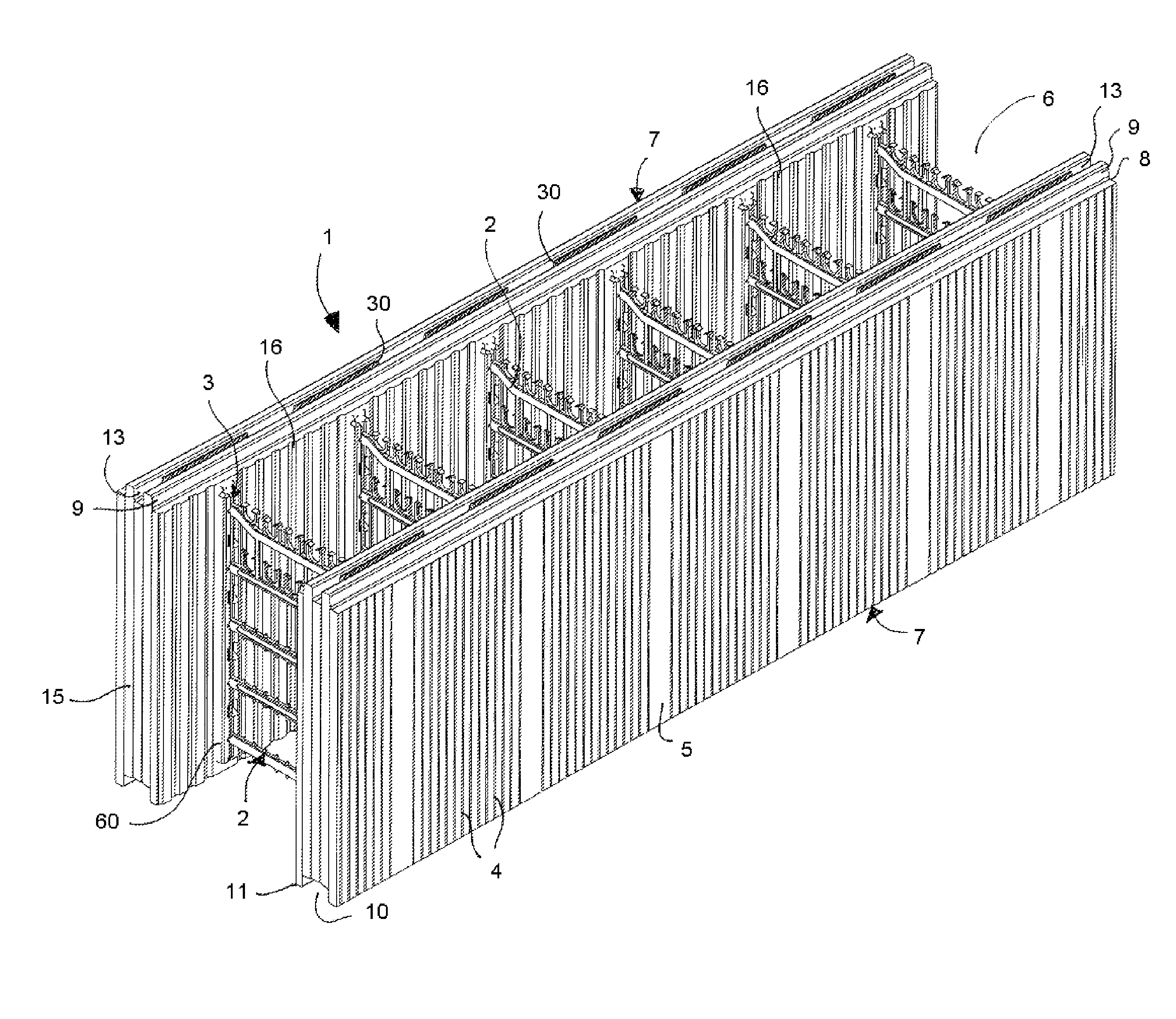

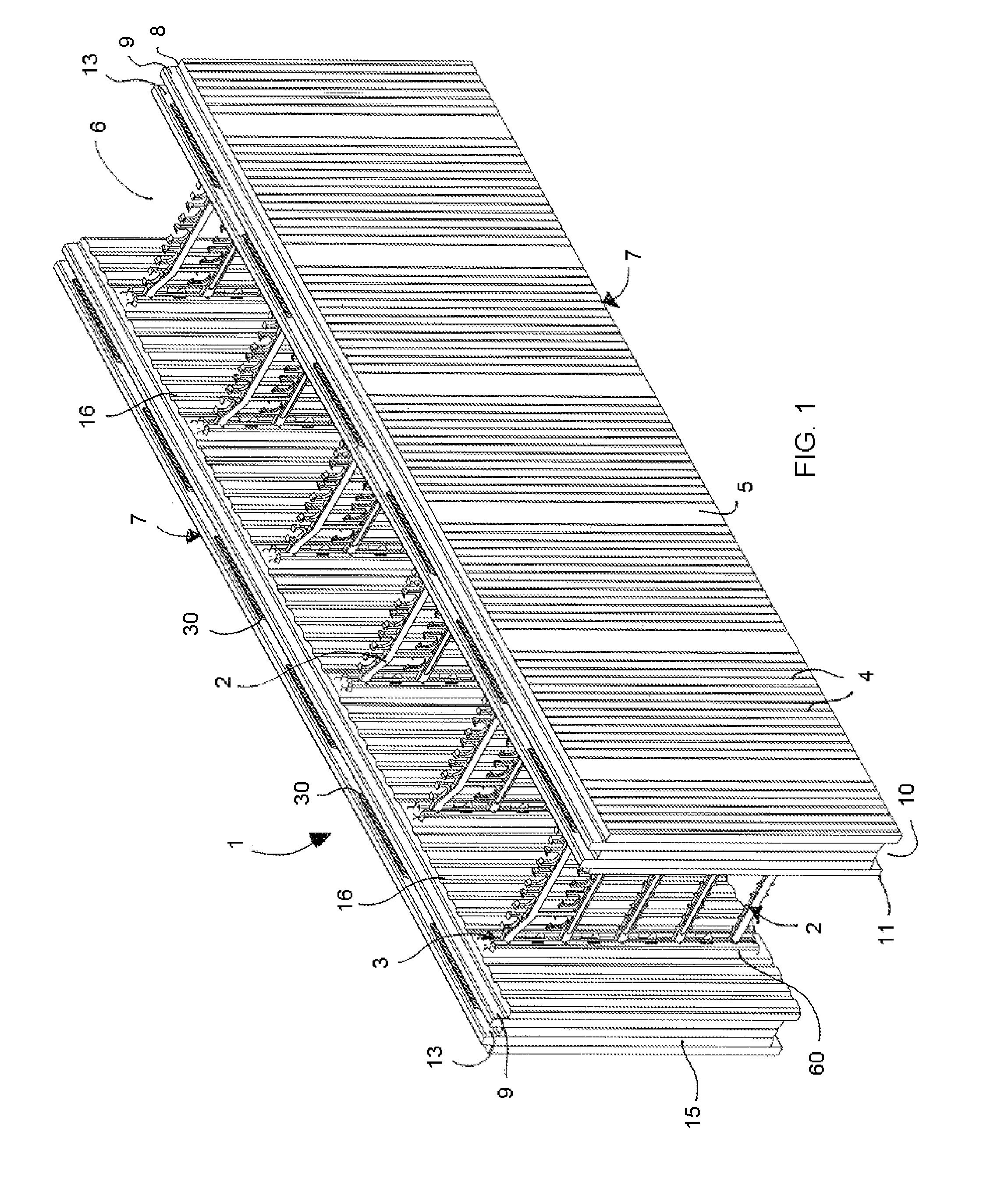

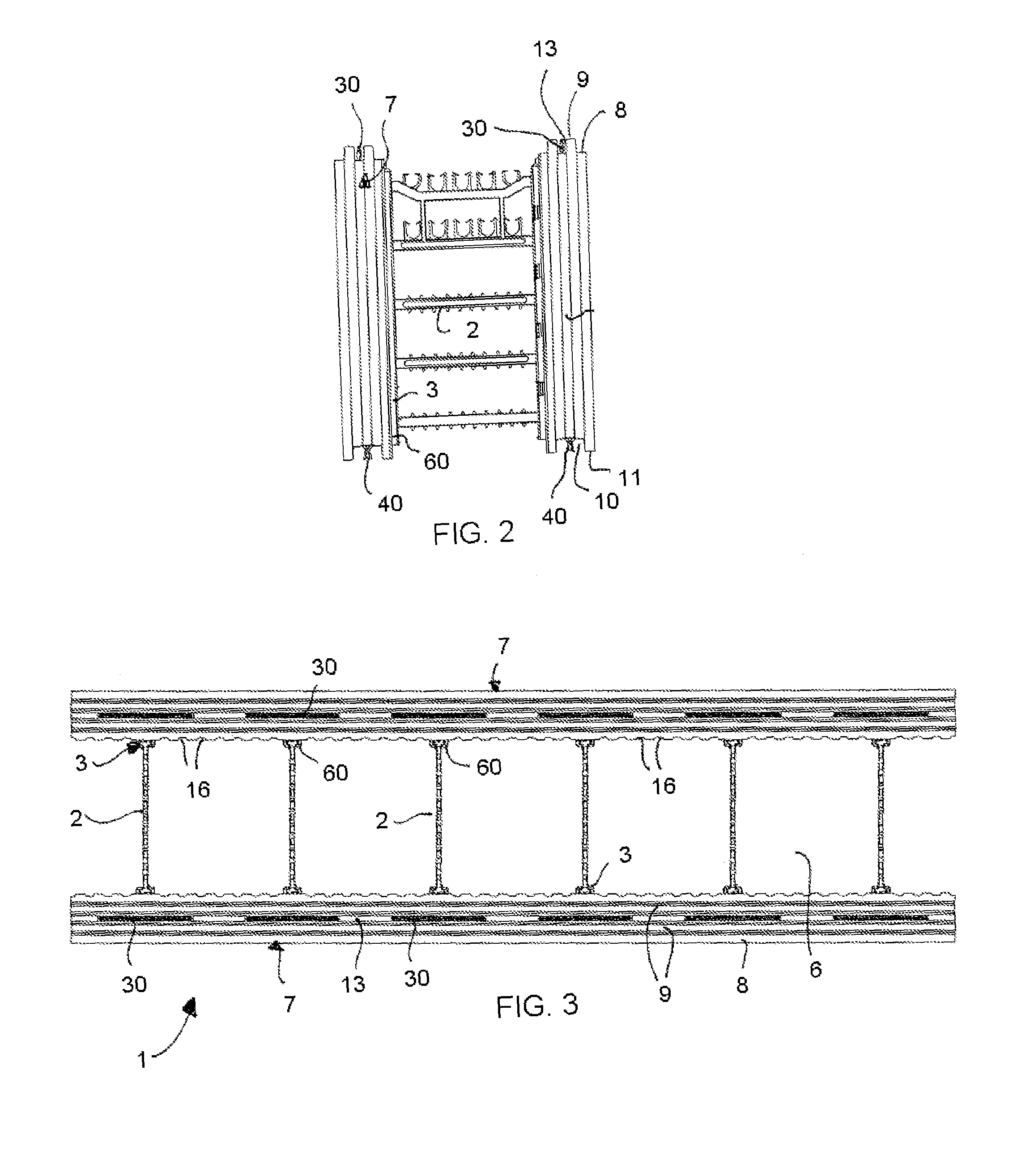

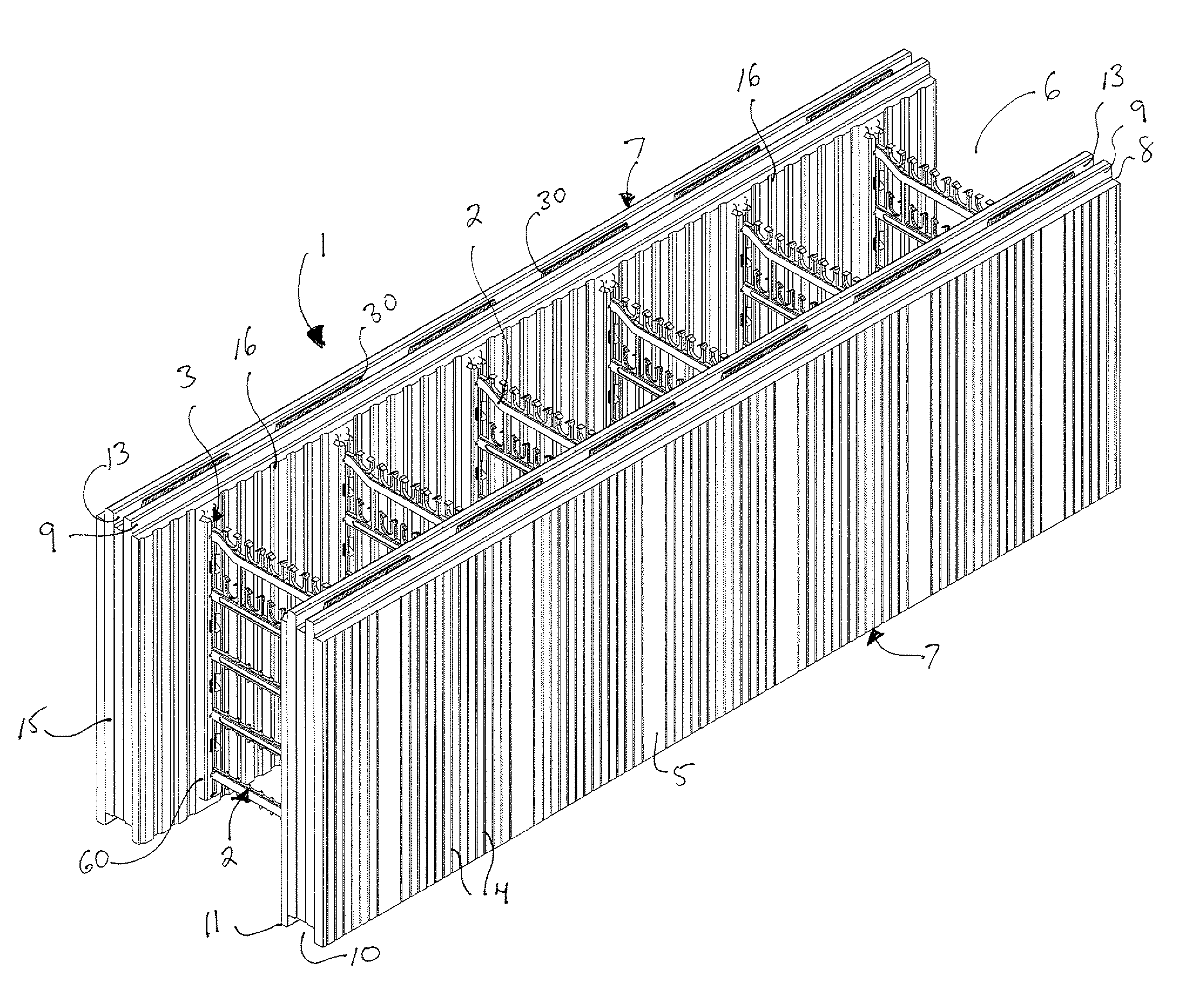

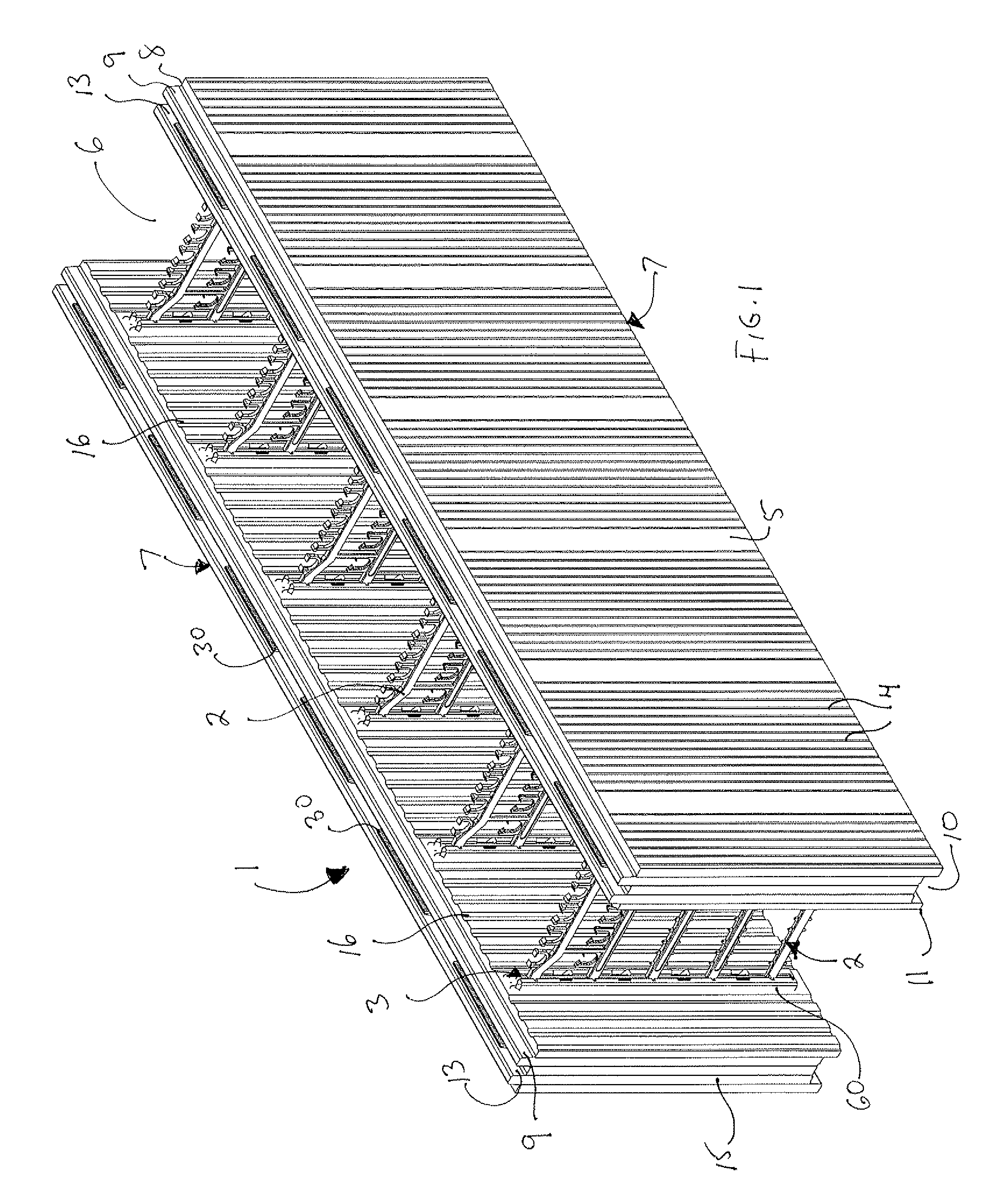

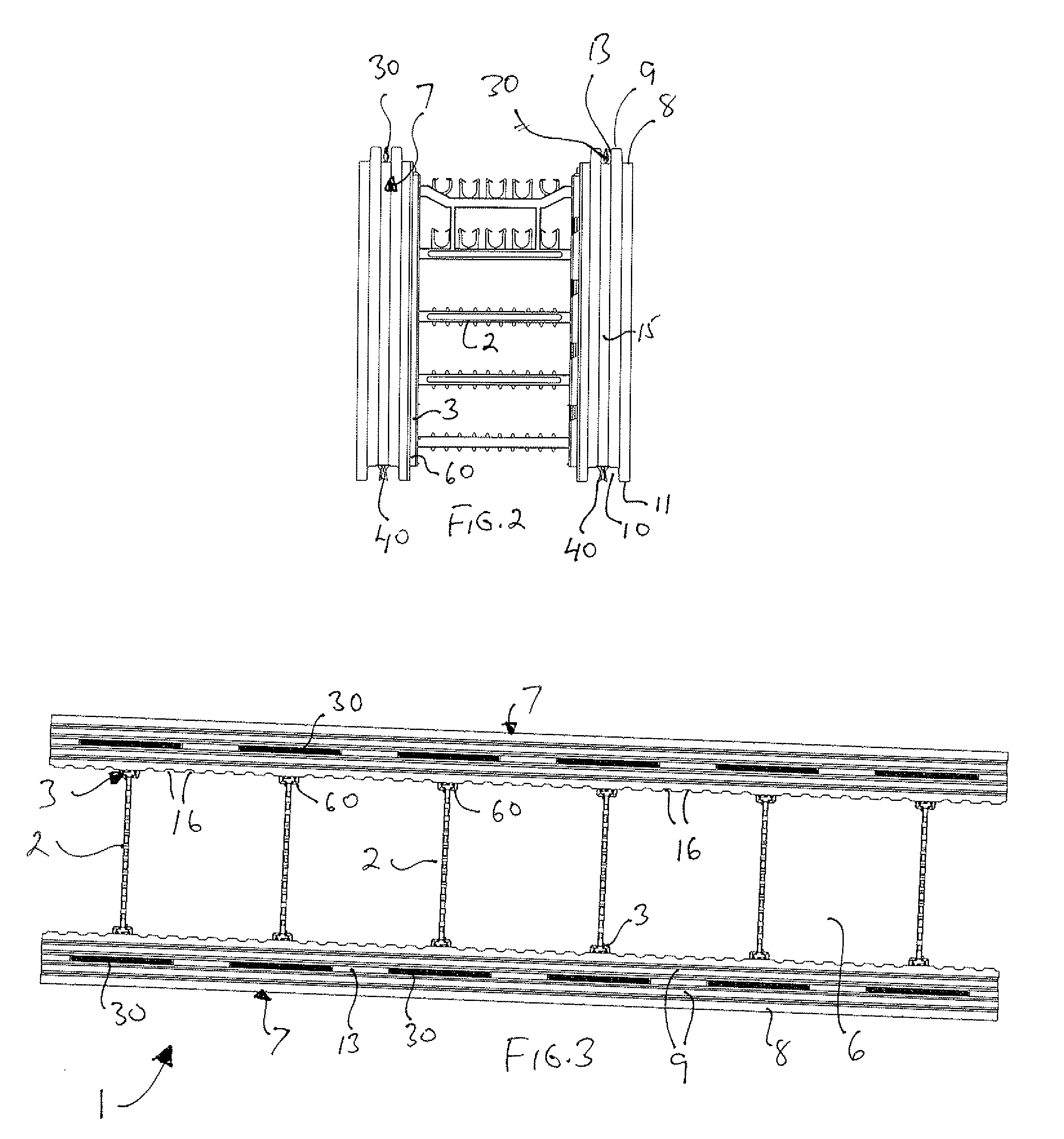

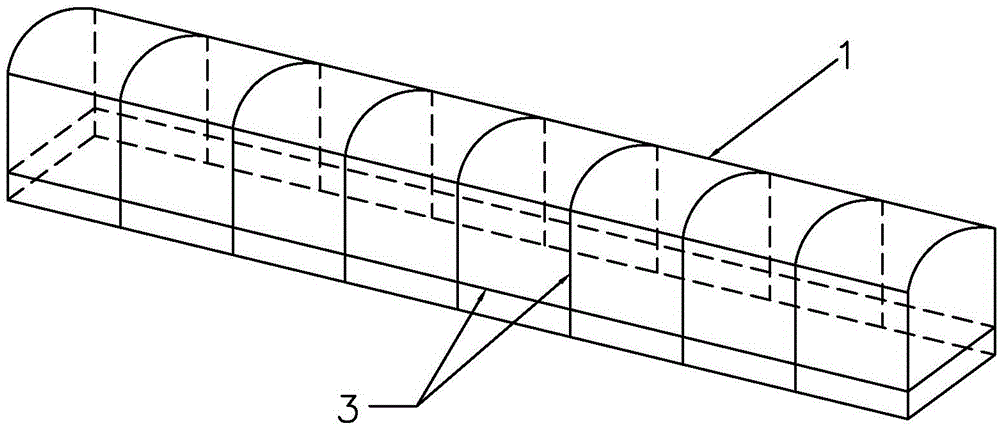

Insulated concrete form

There is described an apparatus for a concrete form for an insulated wall. The apparatus comprises first and second wall panels arranged in opposed spaced apart parallel relationship, each panel having an inner surface, an outer surface, an upper edge surface, a lower edge surface and end surfaces. A plurality of retainers are secured within each of said first and second panels at spaced apart intervals, each retainer including a connecting portion extending outwardly from the inner surface of each panel, and an anchoring portion. The anchoring portion includes a framework disposed within the panels, an upper connector extending upwardly from each panel's upper edge surface and a lower connector extending downwardly from each panel's lower edge surface. The upper and lower connectors are adapted to respectively engage the upper and lower connectors of the next vertically adjacent panel to securely attach the panels together. A plurality of cross webs extends between the first and second panels to tie them together, the cross webs being adapted for respective connection to the connecting portions of opposed retainers in the first and second panels.

Owner:ENCON ENVIRONMENTAL CONSTR SOLUTIONS

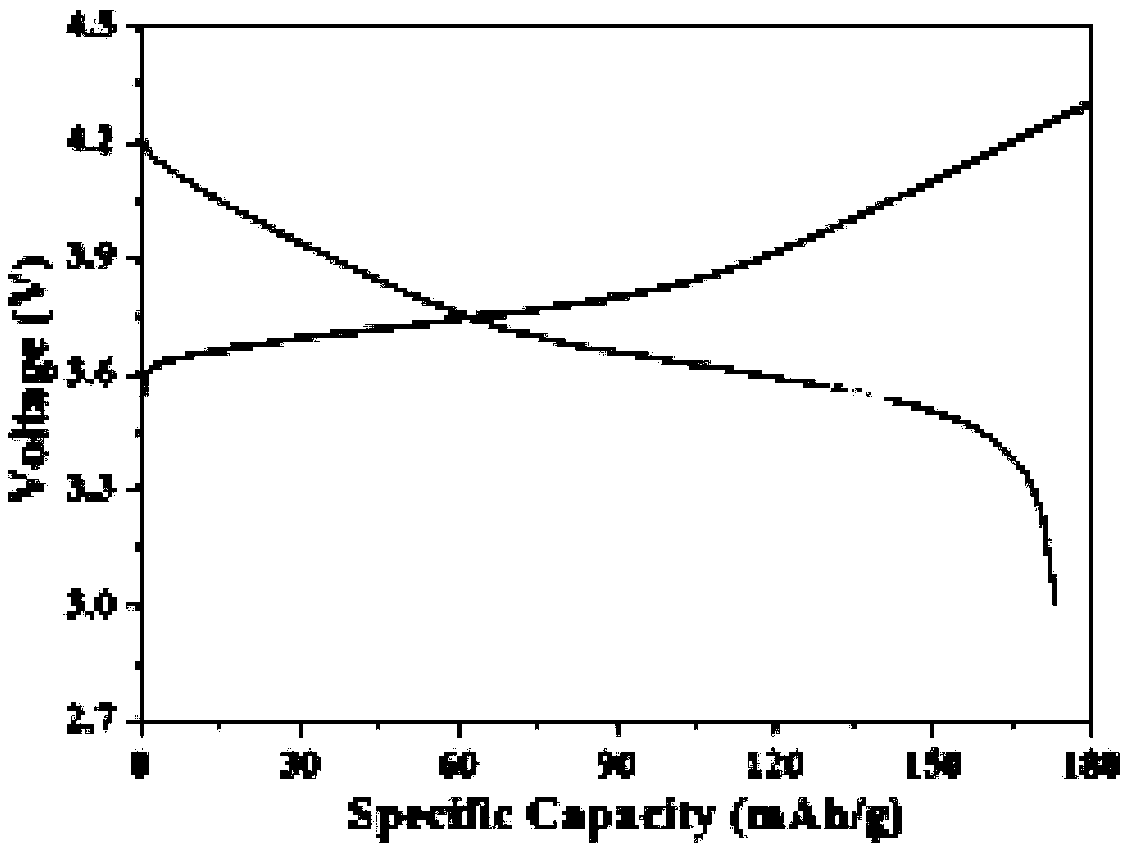

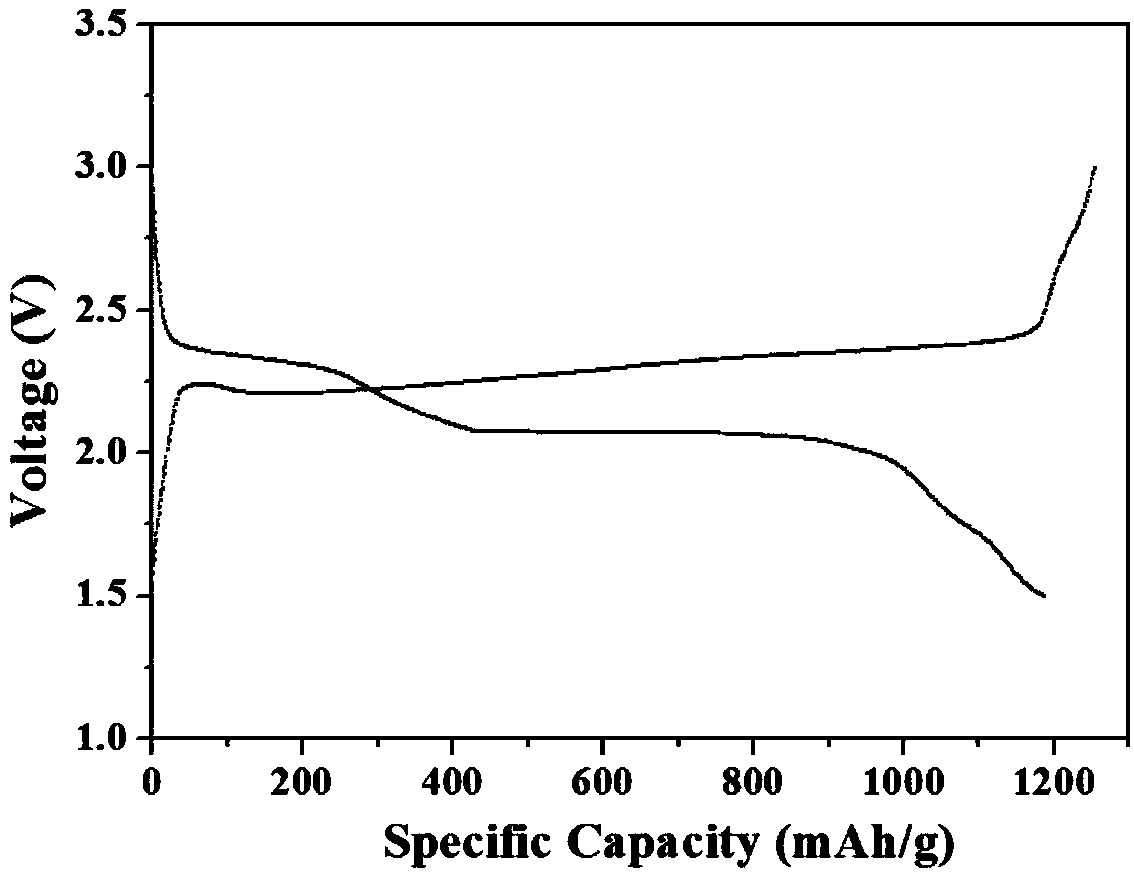

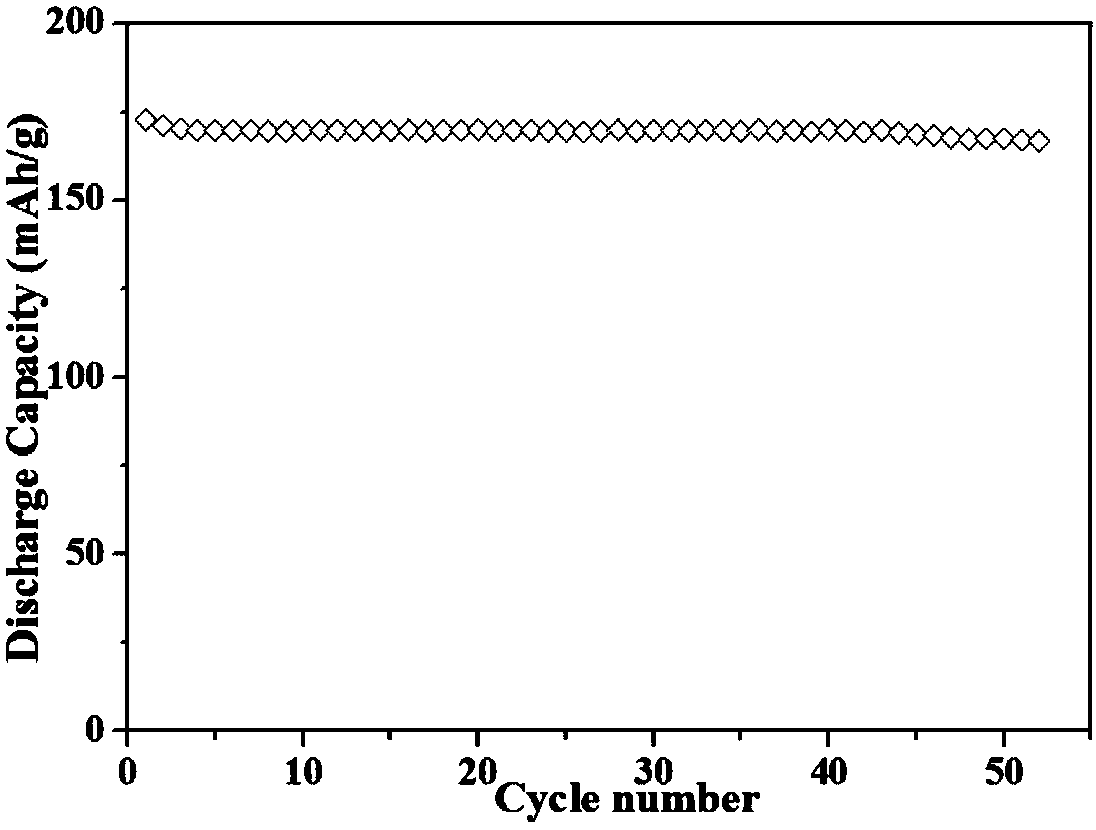

Organic-inorganic composite solid electrolyte, preparation method and application of electrolyte in solid lithium battery

ActiveCN108232293AFlexibleStretchableSolid electrolytesLi-accumulatorsSolid state electrolyteElectrical conductor

The invention discloses an organic-inorganic composite solid electrolyte. The solid electrolyte is characterized by being prepared from an acrylate material, lithium salt, a crosslinking agent, an initiator, a plasticizer, a fast ionic conductor and a porous rigid support material. The preparation method of the inorganic composite solid electrolyte is characterized by comprising steps as follows:mixing the acrylate material with the lithium salt to completely dissolve the lithium salt in acrylate; adding the crosslinking agent and the plasticizer to the mixed solution, and stirring the mixture evenly; adding the fast ionic conductor to the mixed solution, and performing ultrasonic treatment or stirring to disperse the conductor uniformly; adding the initiator to the mixed solution, and performing stirring uniformly; uniformly pouring the mixed solution on the porous rigid support material; performing heating initiation at 60-100 DEG C to enable the acrylate material to be copolymerized with the crosslinking agent to obtain the organic-inorganic composite solid electrolyte. The solid electrolyte has the advantages that the preparation method is simple, the production efficiency ishigh, and the assembled solid lithium battery has lower impedance and higher capacity.

Owner:QINGTAO KUNSHAN ENERGY DEV CO LTD

Shutter box for a window or door

InactiveUS6230782B1Integrally formedIncreased Strength and RigiditySunshadesShutters/ movable grillesMechanical engineeringOblique angle

A shutter box for a door having a leaf includes a top cover, and an angle section bar having an outward and upward leading wall portion and a substantially vertical portion extending to the top cover. The leading wall portion is connected directly to the vertical portion and forms an oblique angle therebetween. The shutter box is assembled utilizing exclusively engageable snaps and attachable to the door by engageable snaps, with the leading wall portion of the angle section bar arranged substantially parallel to an obliquely extending portion of the leaf of the door, when the door is in a closed state.

Owner:SCHUCO INT KG

Insulated concrete form

ActiveUS20070294970A1More disadvantageIncreased strength and rigidityConstruction materialStrutsEdge surfaceSurface plate

There is described an apparatus for a concrete form for an insulated wall. The apparatus comprises first and second wall panels arranged in opposed spaced apart parallel relationship, each panel having an inner surface, an outer surface, an upper edge surface, a lower edge surface and end surfaces. A plurality of retainers are secured within each of said first and second panels at spaced apart intervals, each retainer including a connecting portion extending outwardly from the inner surface of each panel, and an anchoring portion. The anchoring portion includes a framework disposed within the panels, an upper connector extending upwardly from each panel's upper edge surface and a lower connector extending downwardly from each panel's lower edge surface. The upper and lower connectors are adapted to respectively engage the upper and lower connectors of the next vertically adjacent panel to securely attach the panels together. A plurality of cross webs extends between the first and second panels to tie them together, the cross webs being adapted for respective connection to the connecting portions of opposed retainers in the first and second panels.

Owner:ENCON ENVIRONMENTAL CONSTR SOLUTIONS

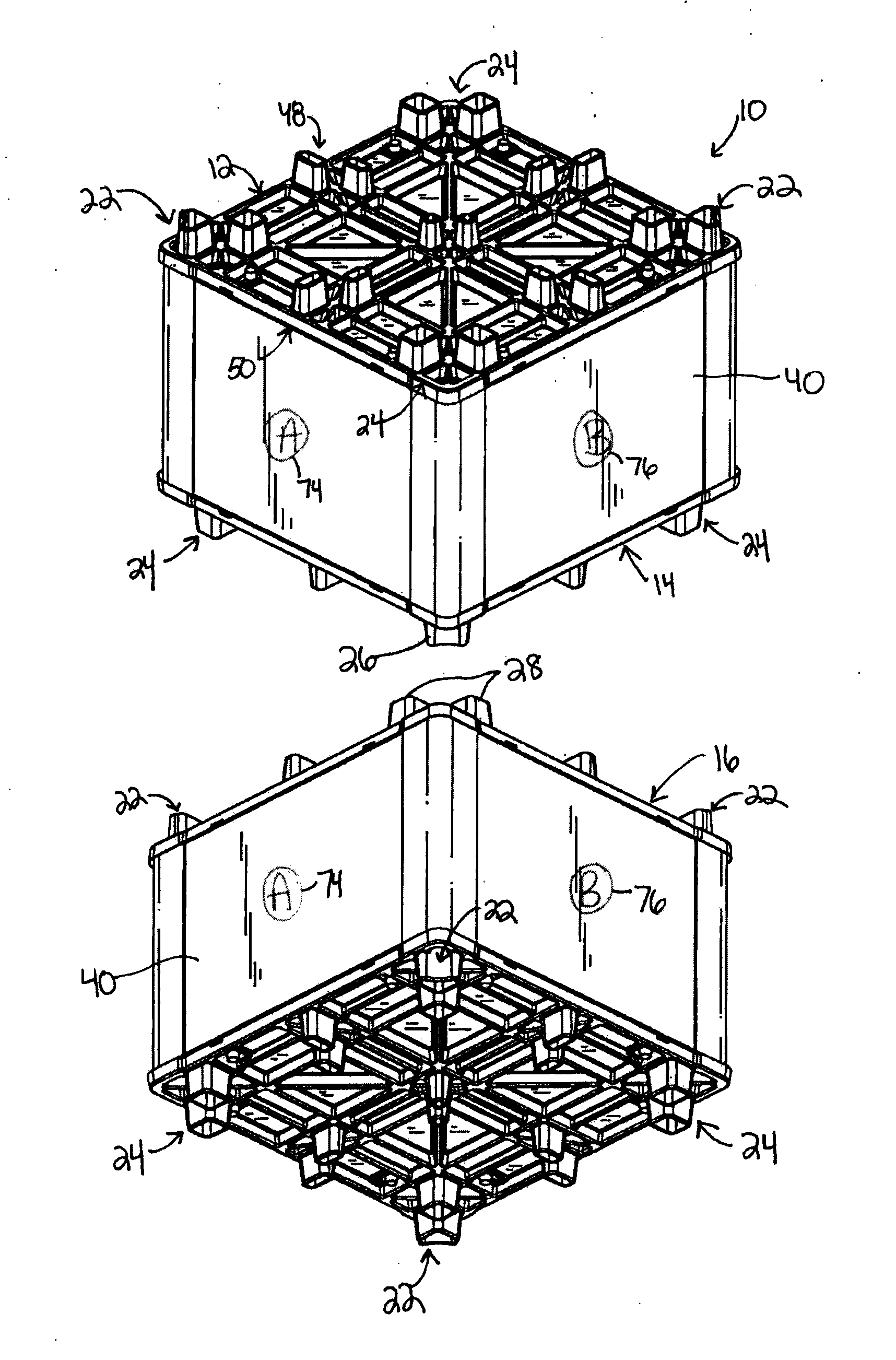

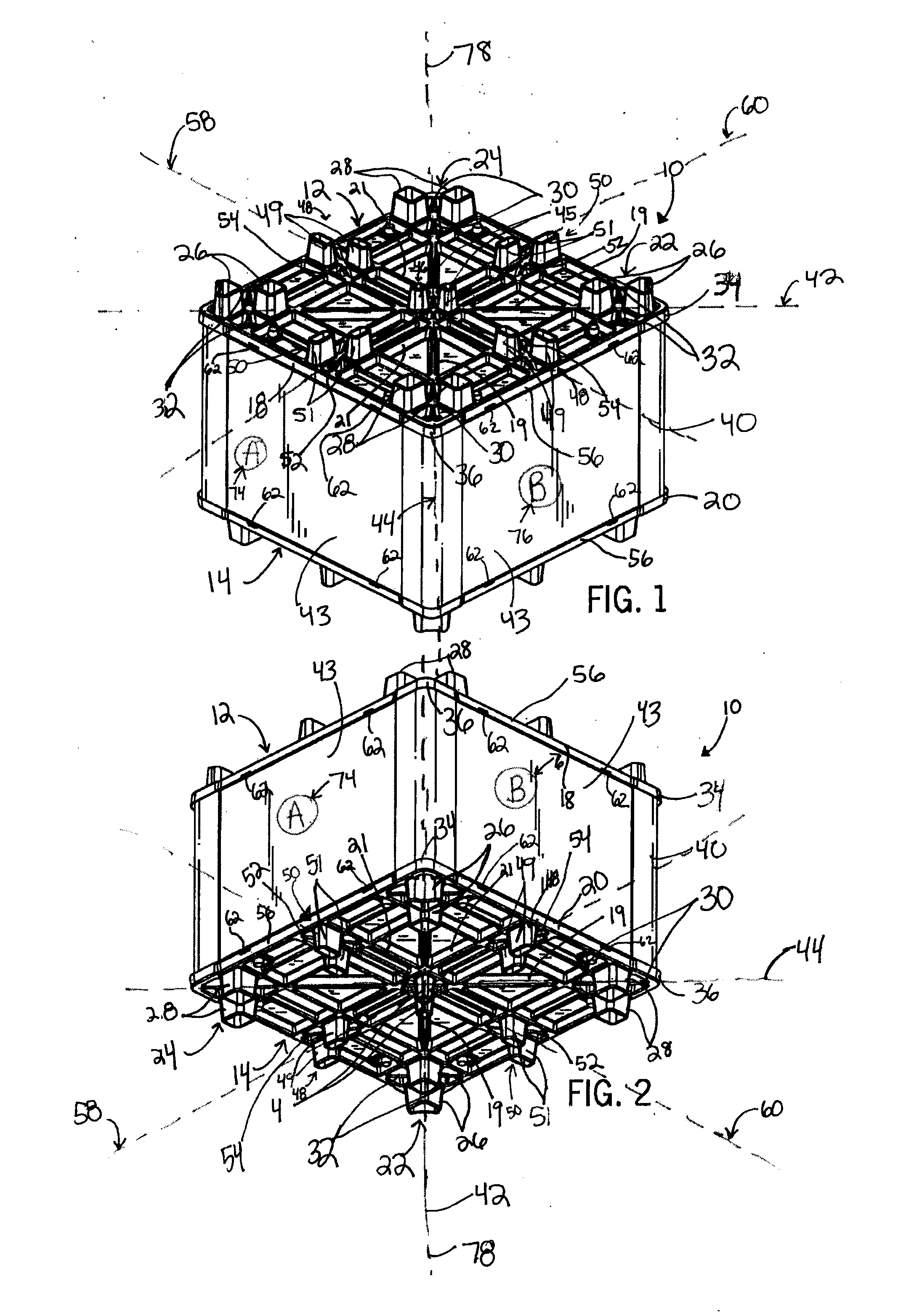

Nestable pallet and stackable sleeve pack

ActiveUS20150108037A1Reduce material costsImprove rigidityContainer decorationsLevel indicationsEngineeringPallet

A nestable pallet includes a first frame, at least one corner foot extending away from the frame, and at least one off-set corner foot extending away from the frame. The at least one corner foot being complementary with the at least one off-set corner foot, such that the pallet is nestable with a substantially identical pallet in a first nesting configuration and a second nesting configuration. In a preferred embodiment, the first frame includes a structural sheet fixed to the frame.

Owner:DON EVANS INC

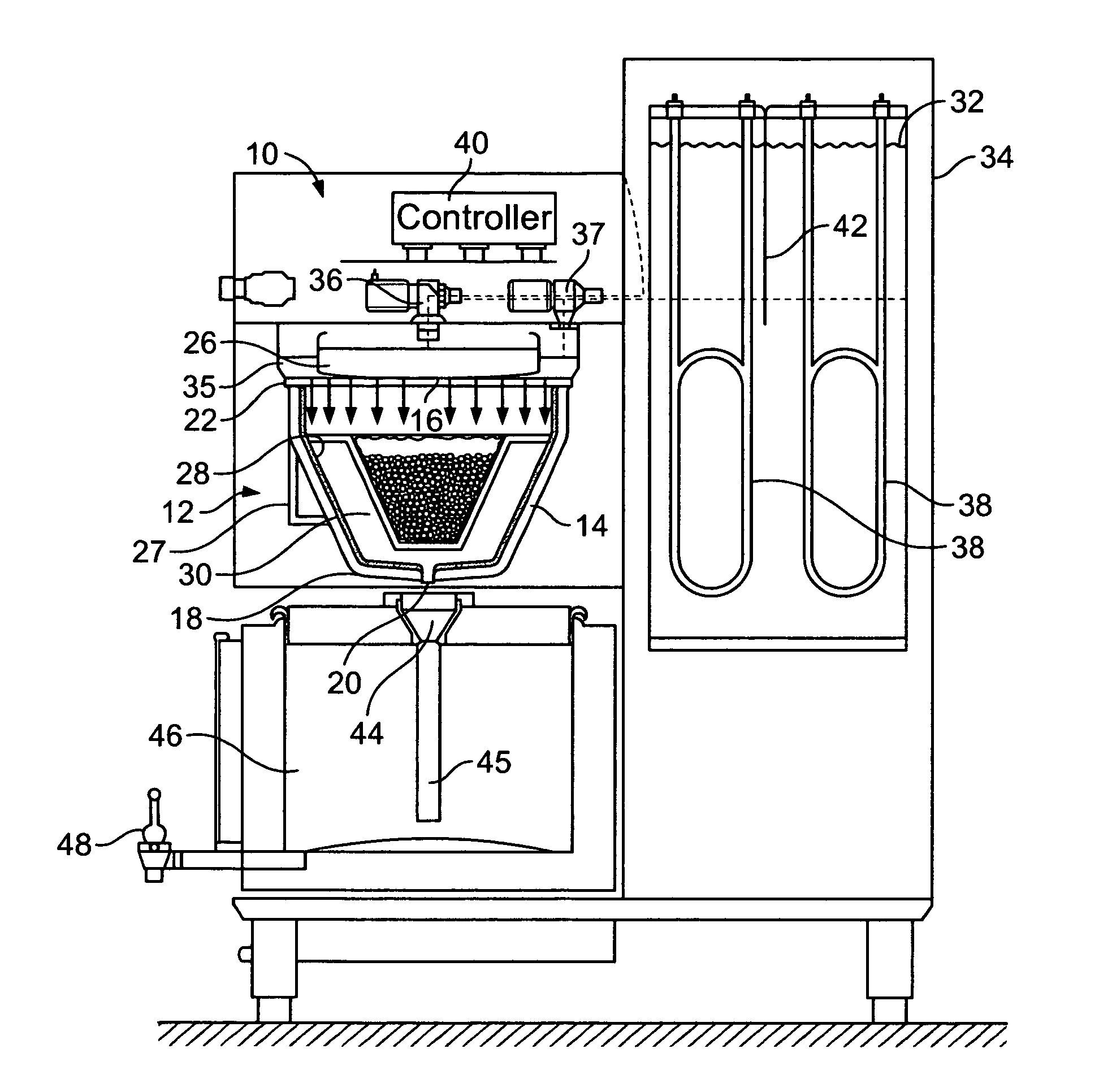

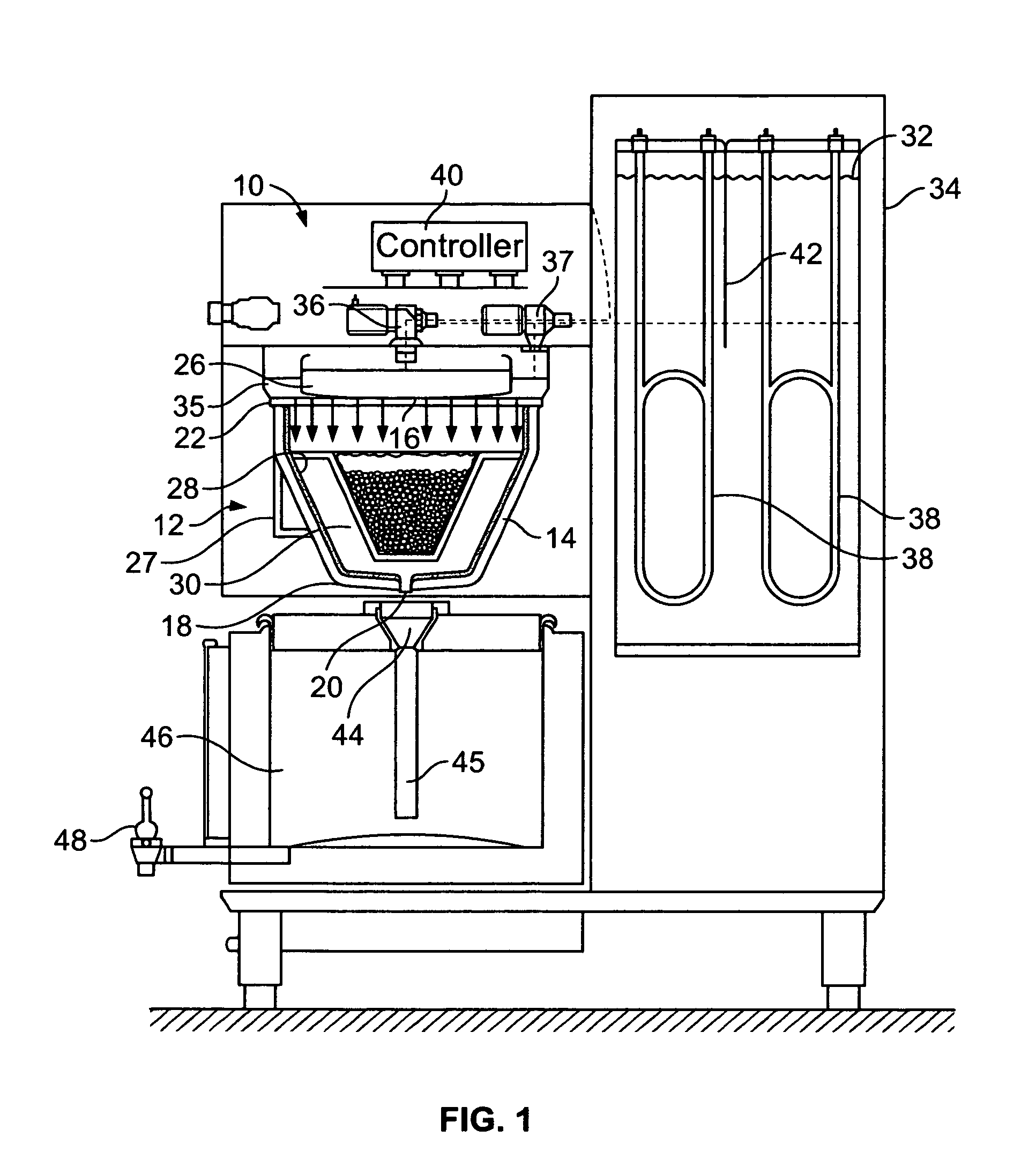

Beverage brewer with insulated brew basket assembly, insulated brew basket and method

ActiveUS7886655B1Reduce security risksReduce heat lossBeverage vesselsDomestic vesselsEngineeringMechanical engineering

An insulated brew basket assembly (12) having a metallic brew basket body (54) with an external surface covering non-metallic, insulating material (62) having a heat conductivity characteristic that is significantly less than that of the metal of the basket body (54), such as an insulating coating adhered to the inside, the outside or both the inside and the outside of the surrounding wall, an internal insulating liner fixedly or releasably attached to the surrounding wall at the inside or a releasably or permanently attached insulating jacket covering the outside of the surrounding side wall. The brew basket body may have a double-wall construction with an interior wall section (70) connected with an exterior wall section (72) in spaced relationship to define a gap (68), within which a non-metallic, insulating material, such as (a) a relative vacuum, (b) air at normal ambient air pressure, (c) an inert gas, (d) a foam insulation material and (e) a substantially solid plastic material, is protectively contained within the gap (68), is contained. The beverage is brewed in the insulated brew basket assembly (12) while being insulated to reduce heat loss and temperature loss of the beverage being passed to a dispenser (46) of a brewer.

Owner:FOOD EQUIP TECH

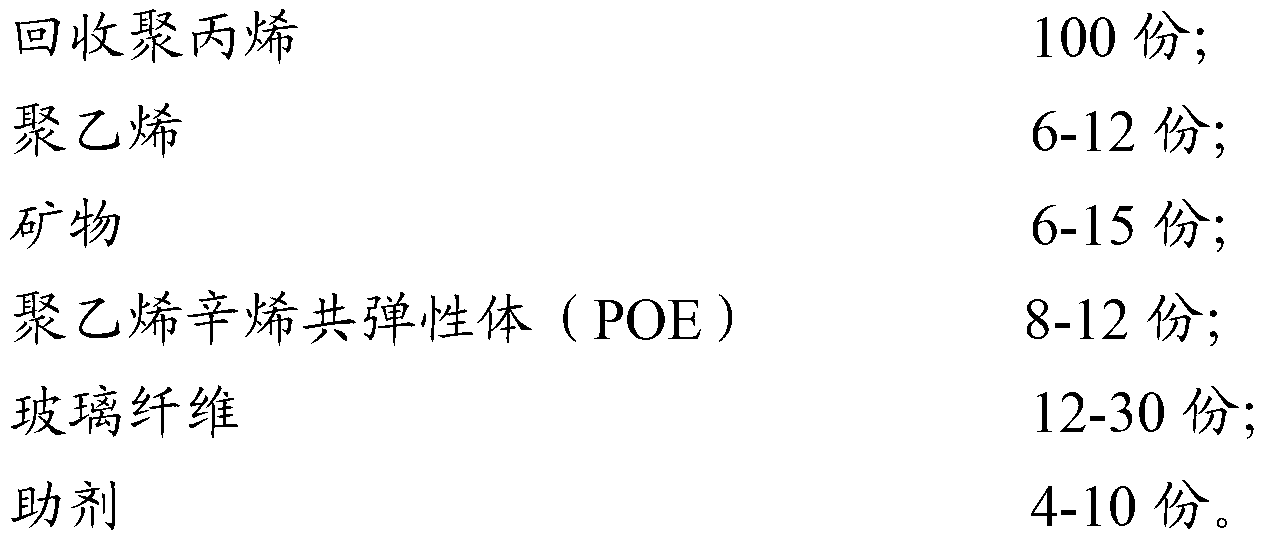

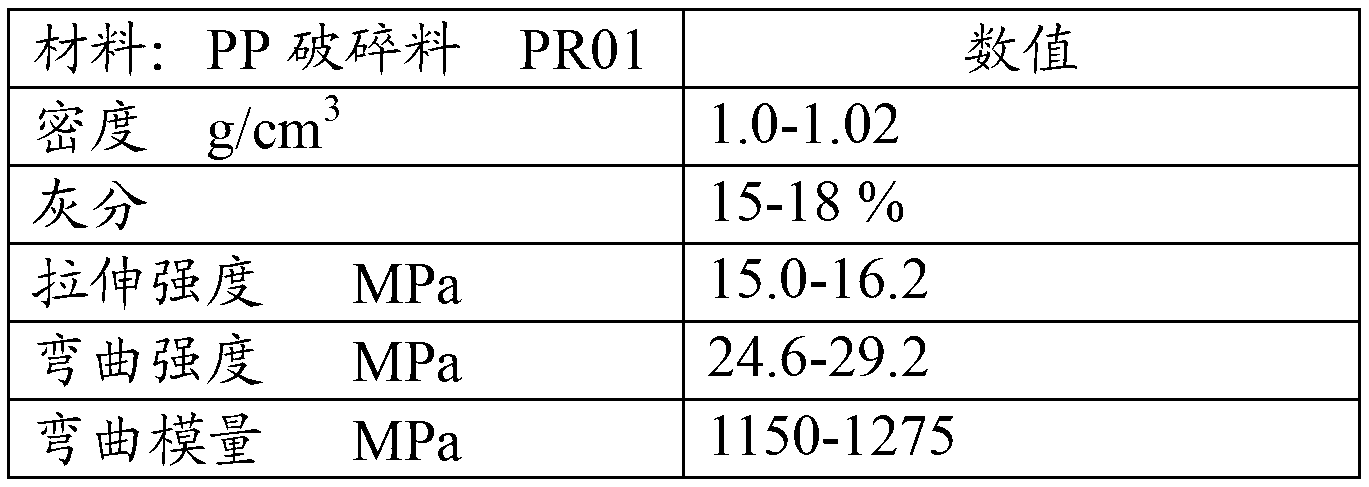

Modified composite material with recovered polypropylene as matrix and preparation method thereof

ActiveCN103254500AIncreased Strength and RigidityImprove abrasion and impact resistancePolypropyleneTwin screw extruder

The invention discloses a modified composite material with recovered polypropylene as a matrix. The composite material contains 100 parts of recovered polypropylene; 6-12 parts of polyethylene; 6-15 parts of a mineral; 8-12 parts of a polyethylene-octene elastomer; 12-30 parts of a glass fiber; and 4-10 parts of aids. The invention also discloses a preparation method of the modified composite material with recovered polypropylene as the matrix. The method includes: utilizing a single screw extruder to conduct fusion granulation on the recovered polypropylene, then mixing the coarse granulated polypropylene, the mineral, the polyethylene and the like, and adding the mixture into a twin-screw extruder through a main feeding port, adding the glass fiber through a side feeding port, and finally carrying out bracing granulation. In the invention, the synergism of the glass fiber and the mineral is utilized to modify the recovered polypropylene, thus improving strength and rigidity of the material, and also enhancing the wear resistance and impact resistance of the material. Also, employment of the recovered polypropylene as the main raw material achieves utilizability of resources.

Owner:CGN JUNER NEW MATERIALS +1

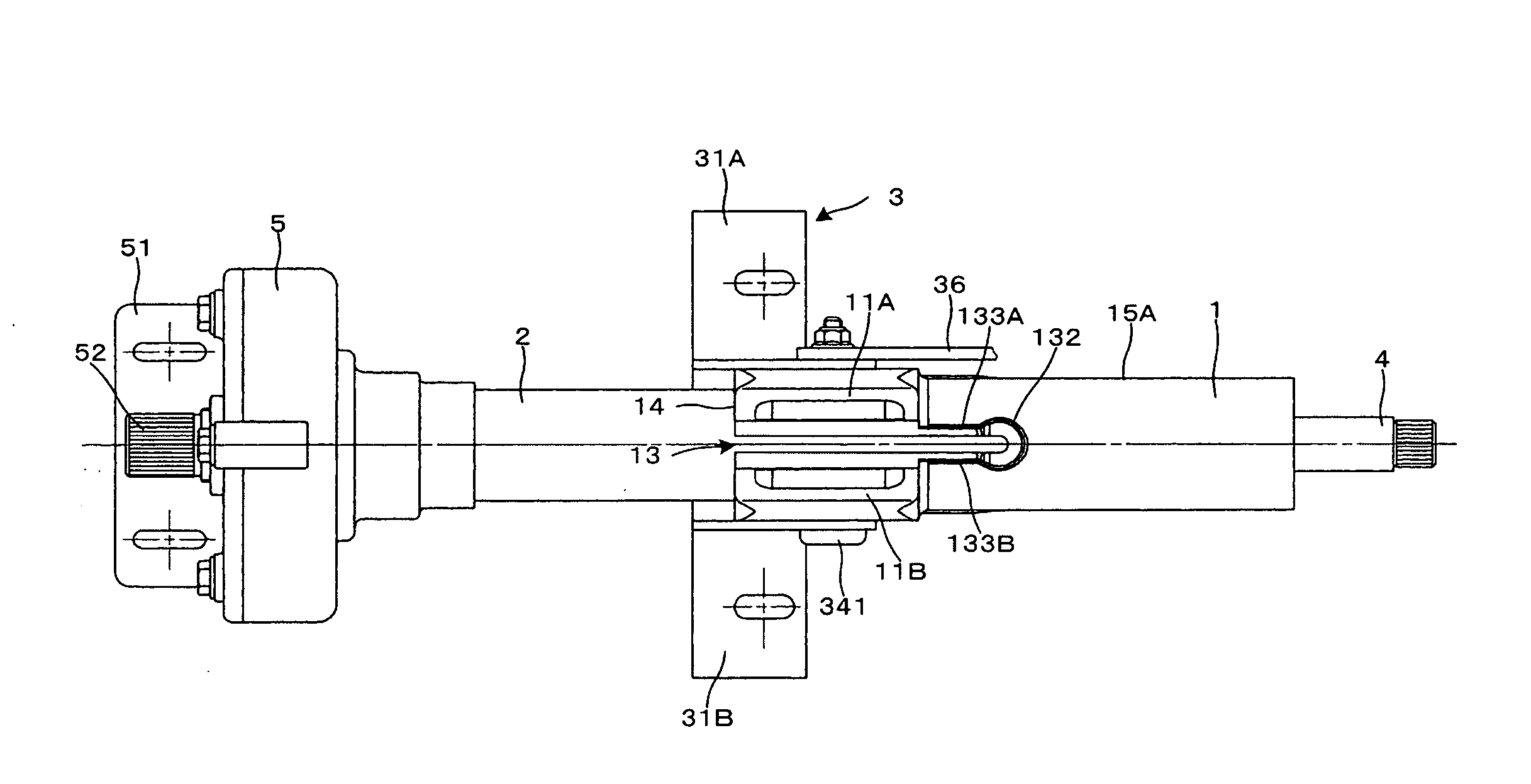

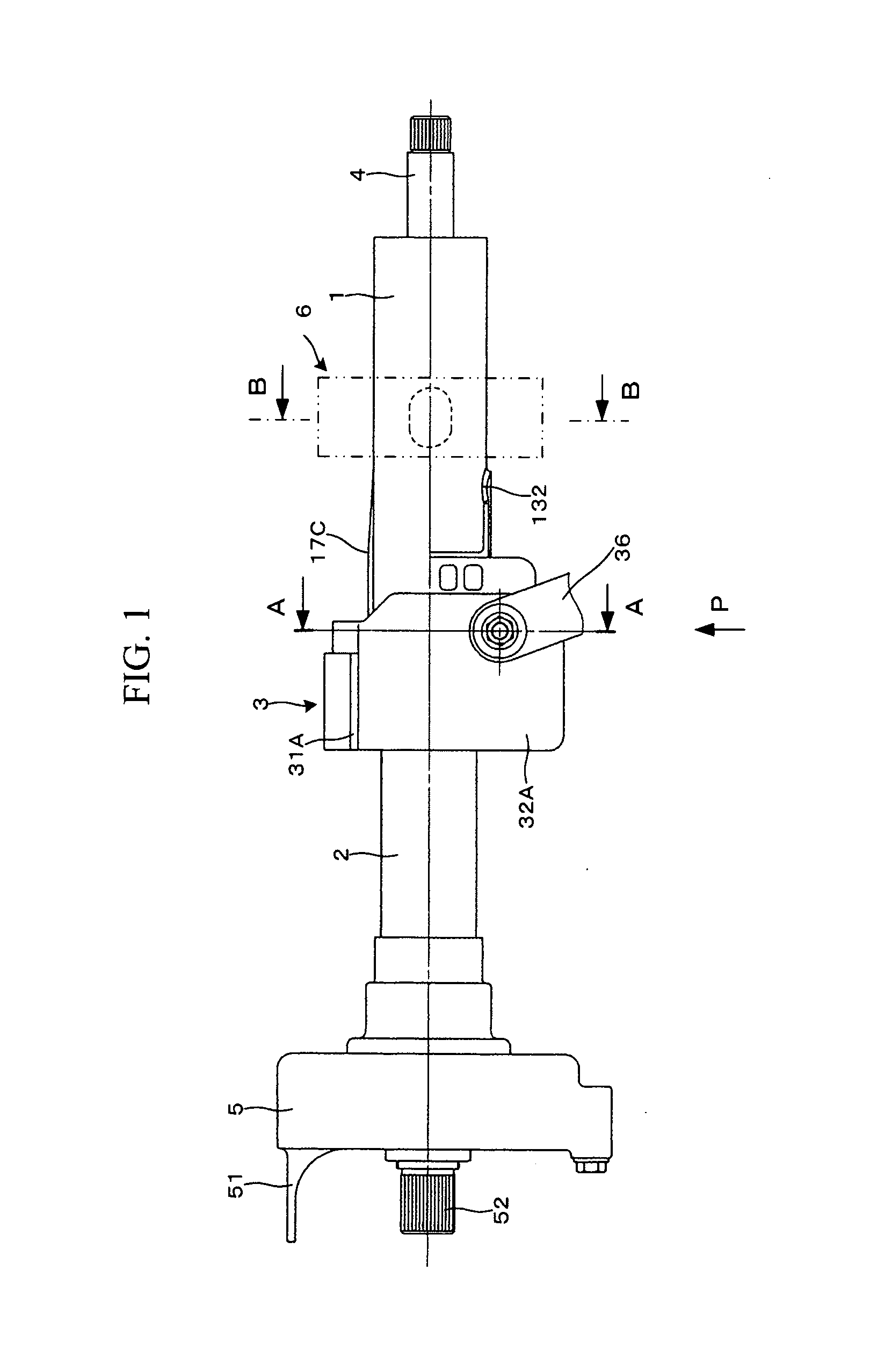

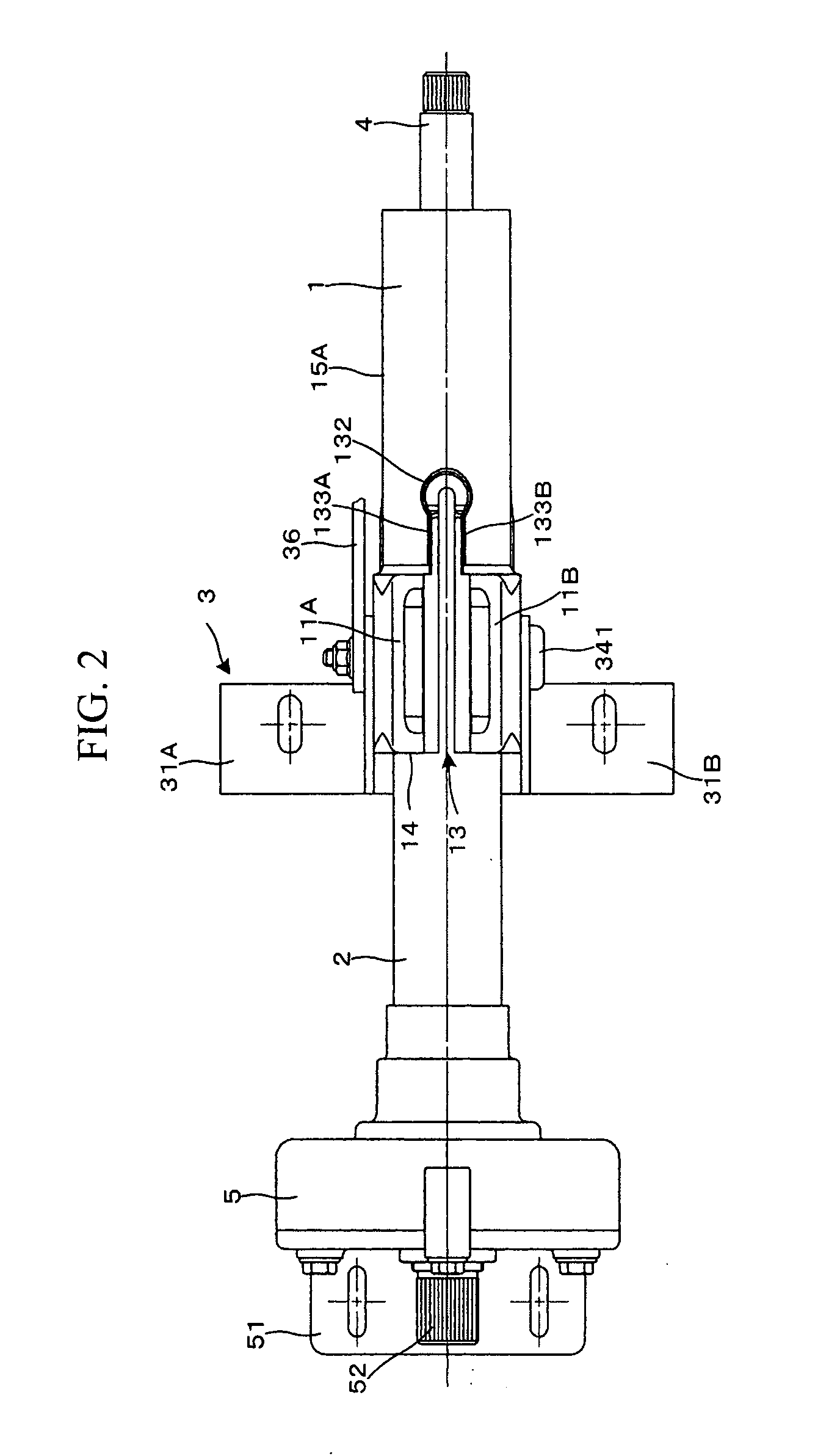

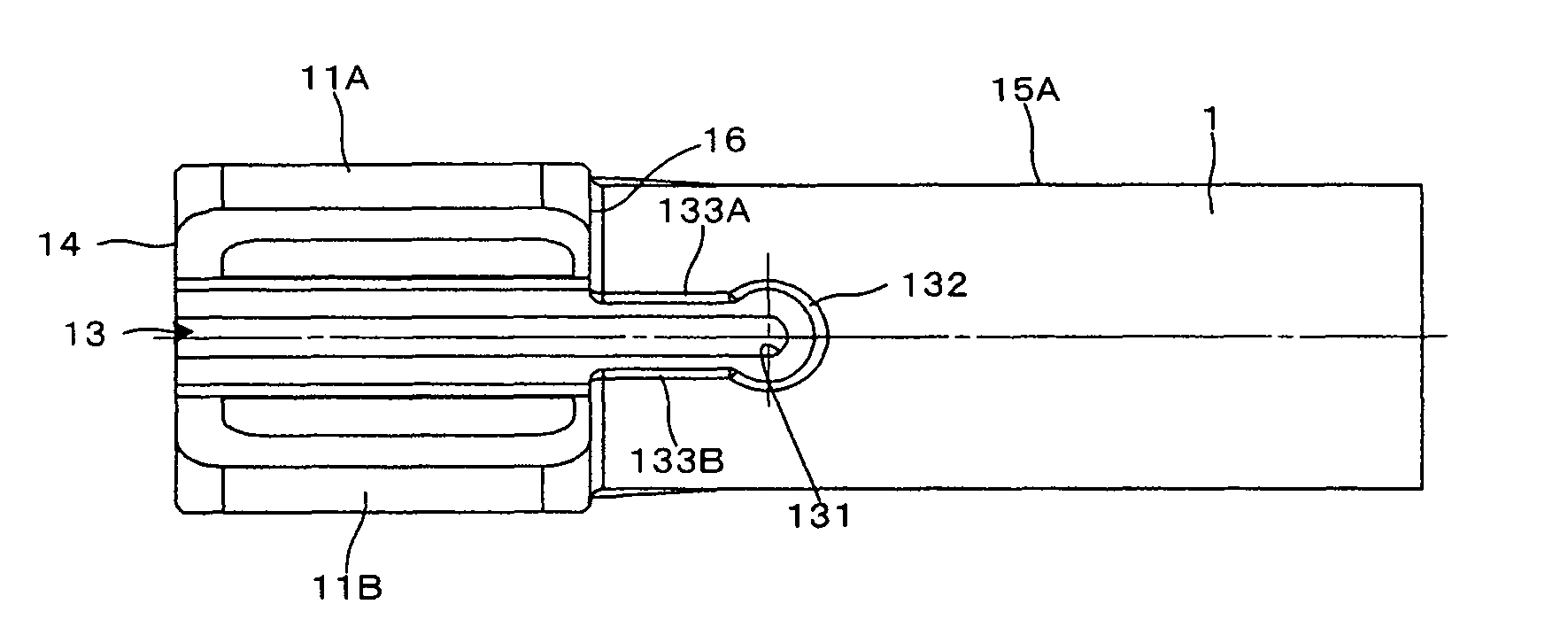

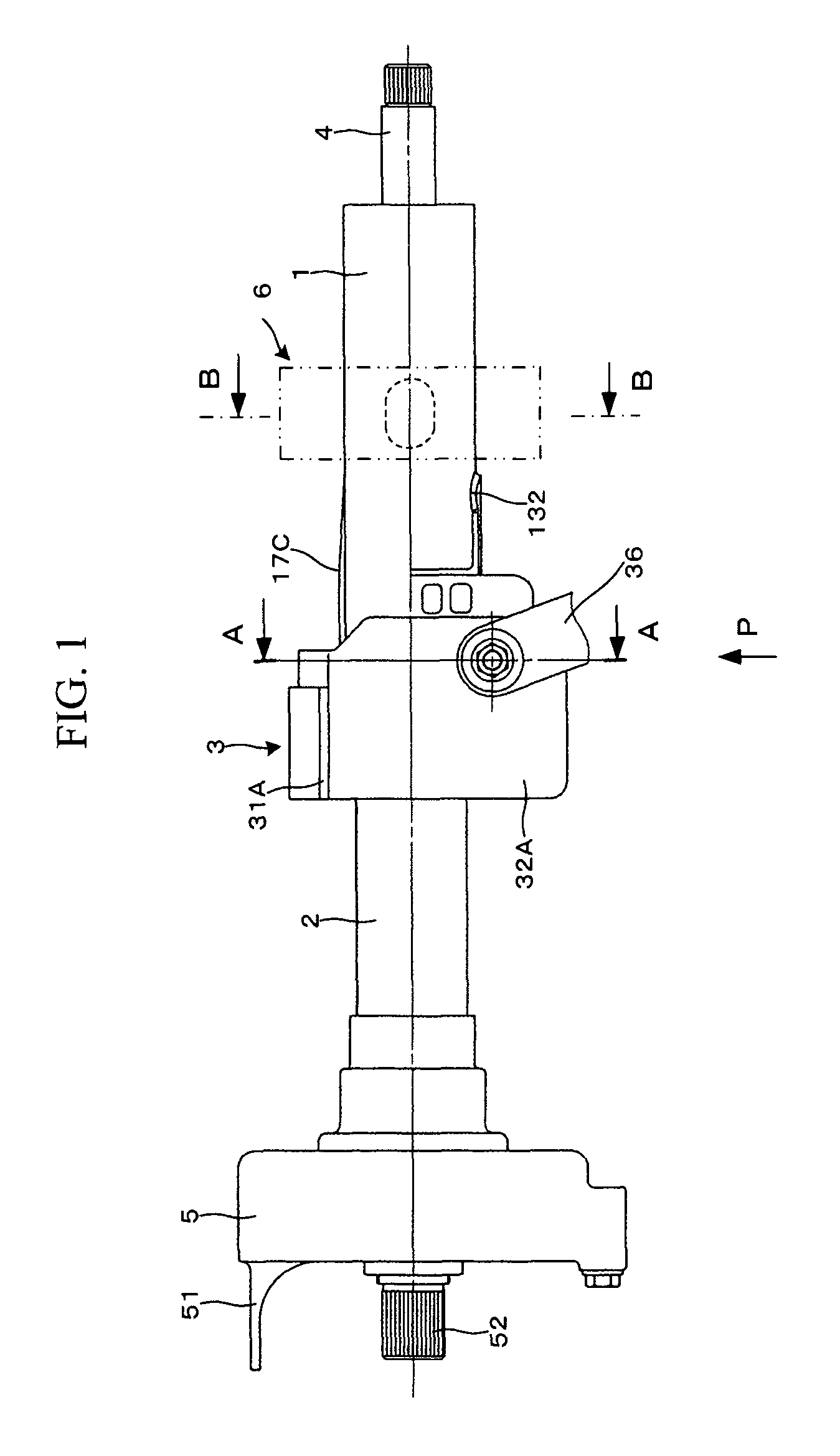

Steering column device

A steering column device where an inner column can be reliably clamped and sufficient rigidity and strength of an outer column can be achieved. A semi-circular arc rib (132) is formed on the peripheral edge of a closed end section (131) of a slit (13). The rib (132) is substantially semi-circular are-shaped and projects outward from an outer peripheral surface (15A) of an outer column (1). Further, linear ribs (133A, 133B) extend linearly toward the vehicle body front side so as to be continuous from the vehicle body front side of the semi-circular arc rib (132). The semi-circular arc rib (132) and the linear ribs (133A, 133B) reinforce the peripheral edge of the slit (13) of the outer column (1) whose rigidity and strength are impaired. Thus the rigidity and strength of the outer column (1) are improved.

Owner:NSK LTD

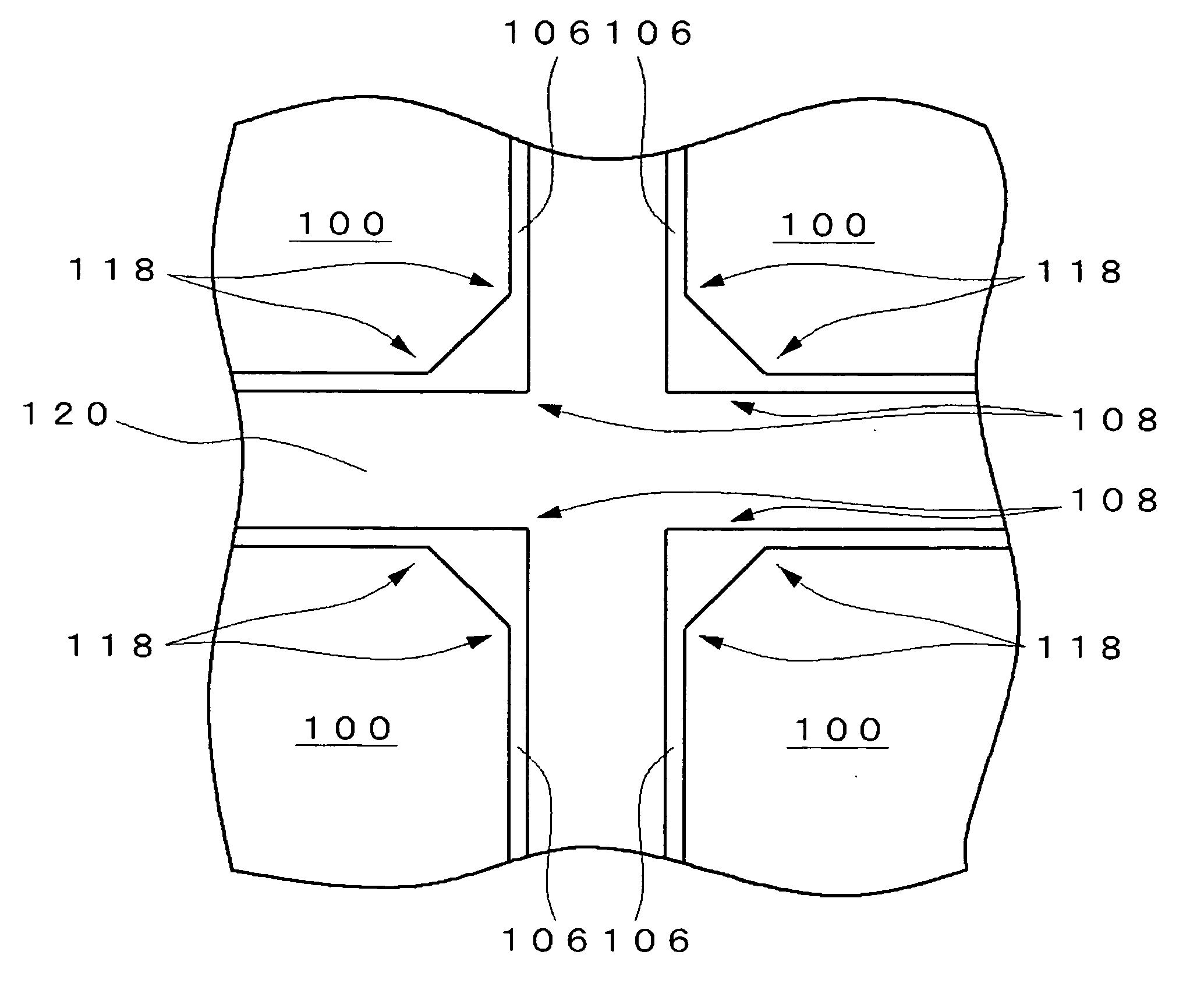

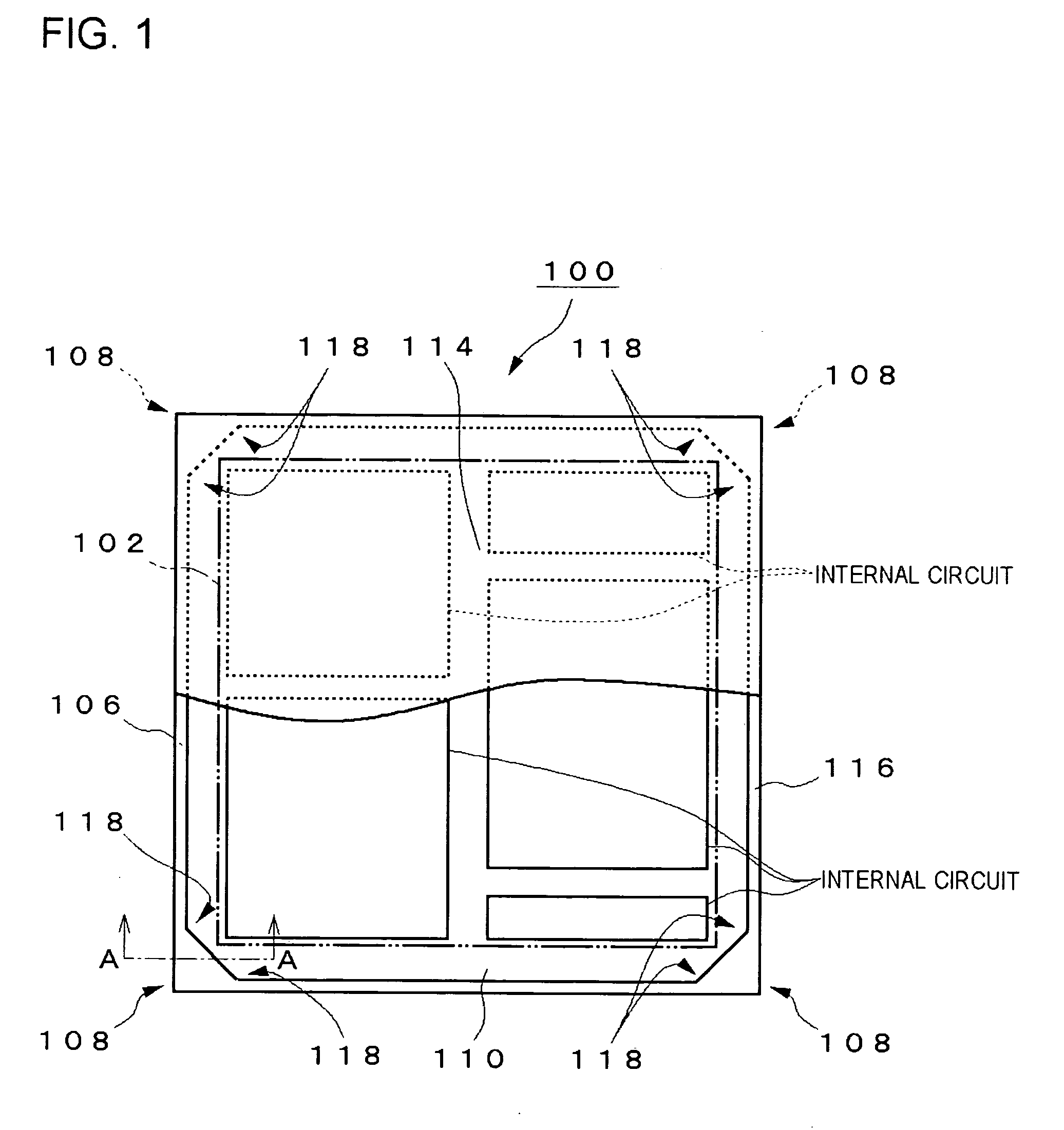

Semiconductor device

InactiveUS20060163720A1Improve rigidityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device is provided with a sealing ring 106 made of a metal which surrounds an integrated circuit part 102 and which is formed on a substrate 104 along an outer perimeter of the rectangular device. At least one corner part 108 of the sealing ring is formed to have a larger width than other parts of the sealing ring 106, so as to increase the rigidity and the strength of the corner part of the sealing ring 106. Thus, the strength of the corner part of the sealing ring is improved. Also, even if the corner part of the sealing ring is lost, the penetration of moisture into the integrated circuit side is inhibited.

Owner:NEC ELECTRONICS CORP

Alkaline battery separator and alkaline primery battery

ActiveCN101128948AGood alkali resistanceImprove compactnessCell component detailsDry cellsPolymer scienceOrganic solvent

An alkaline battery separator comprising an alkali-resistance synthetic fiber, a fibrillated organic solvent-spun cellulose fiber having a Canadian standard freeness value of 10 to 280 ml, and a mercerized pulp having a Canadian standard freeness value of not less than 550 ml is prepared. In the separator, the proportion of the alkali-resistance synthetic fiber, the proportion of the fibrillated organic solvent-spun cellulose fiber, and the proportion of the mercerized pulp relative to the total amount of the separator are respectively 25 to 62% by mass, 5 to 25% by mass, and 33 to 50% by mass, provided that the total amount of the separator is 100% by mass. The alkali-resistance synthetic fiber may comprise a polyvinyl alcohol-series fiber having an average fiber fineness of not more than 1 dtex. The alkaline battery separator may further comprise a polyvinyl alcohol-series binder in a proportion of 3 to 20% by mass relative to the total amount of the separator. The alkaline battery separator of the present invention may have a shrinkage by the of not more than 3.5% after immersing in an aqueous solution of potassium hydroxide having a concentration of 40% by mass at 80°C for 24 hours and a stiffness strength of not less than 2 N.

Owner:KURARAY CO LTD

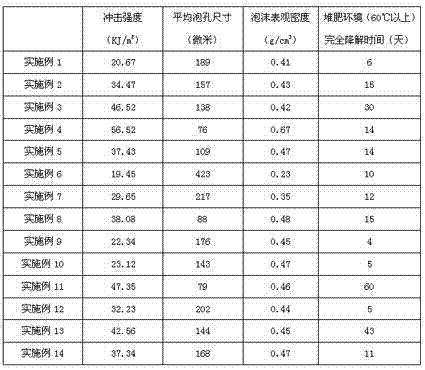

Blended foam material based on polycaprolactone (PCL) and modified polylactic acid (PLA) and preparation method thereof

The invention discloses a blended foam material based on PLC and modified PLA and a preparation method thereof, and belongs to the foam material field. The foam material comprises, by weight, 60-90 parts of PLA, 1-25 parts of PCL, 2-10 parts of reinforcing agents, 1-3 parts of nanometer nucleating agents, 4 parts of foaming agents, 0.1-1 part of a blowing promoter, 1-3 parts of environment-friendly flame retardants and 0.5-1 part of a surfactant. According to the foam material and the preparation method thereof, composite foamed plastics with good mechanical properties and superior surface quality can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

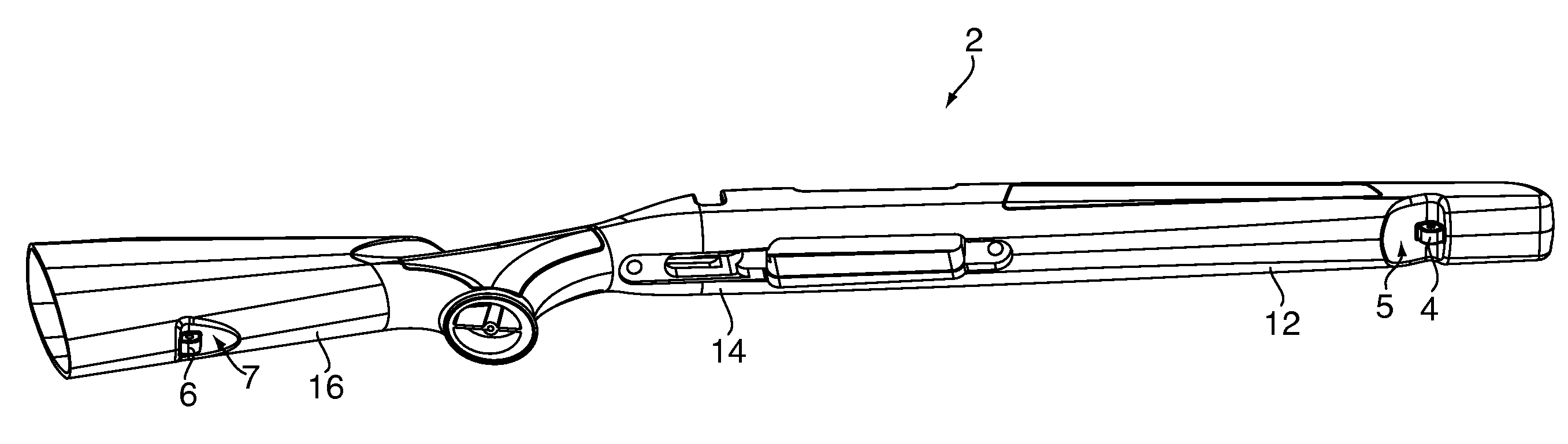

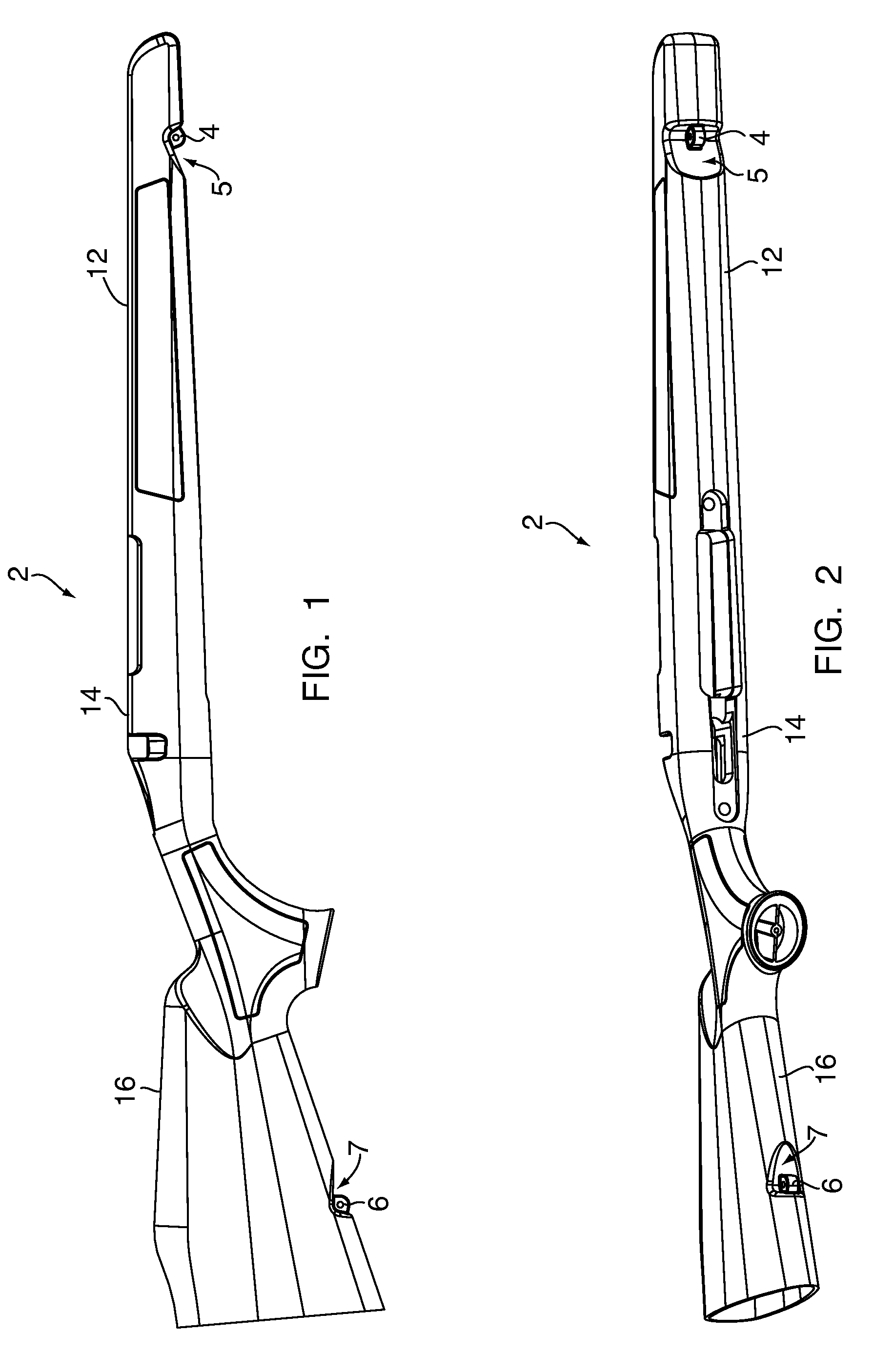

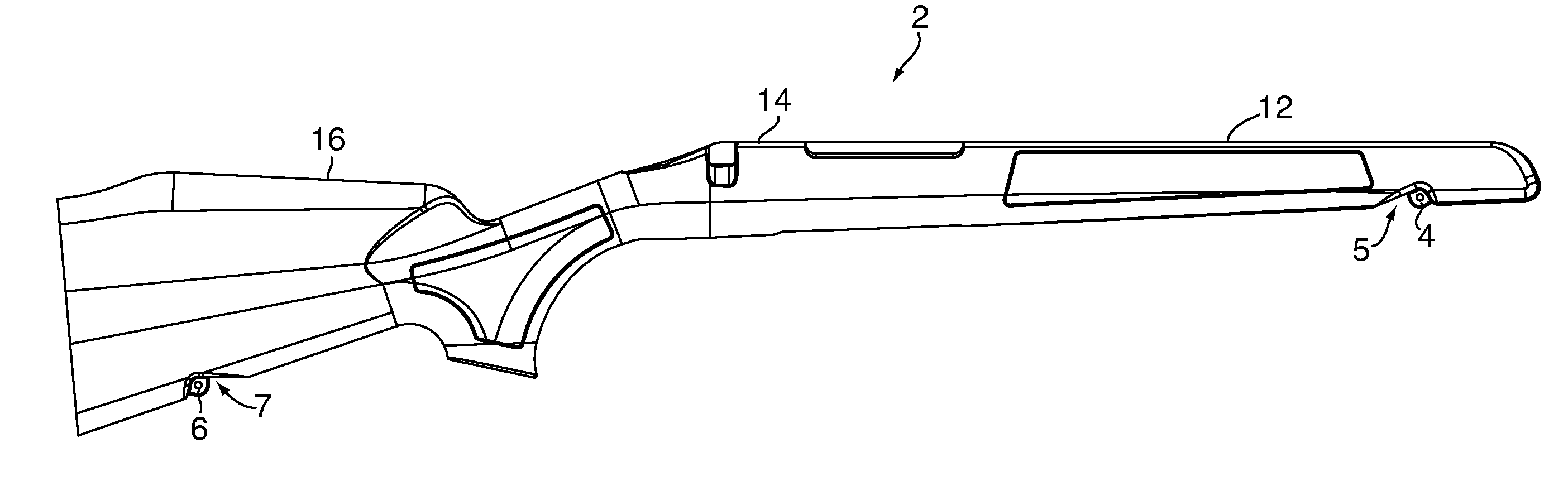

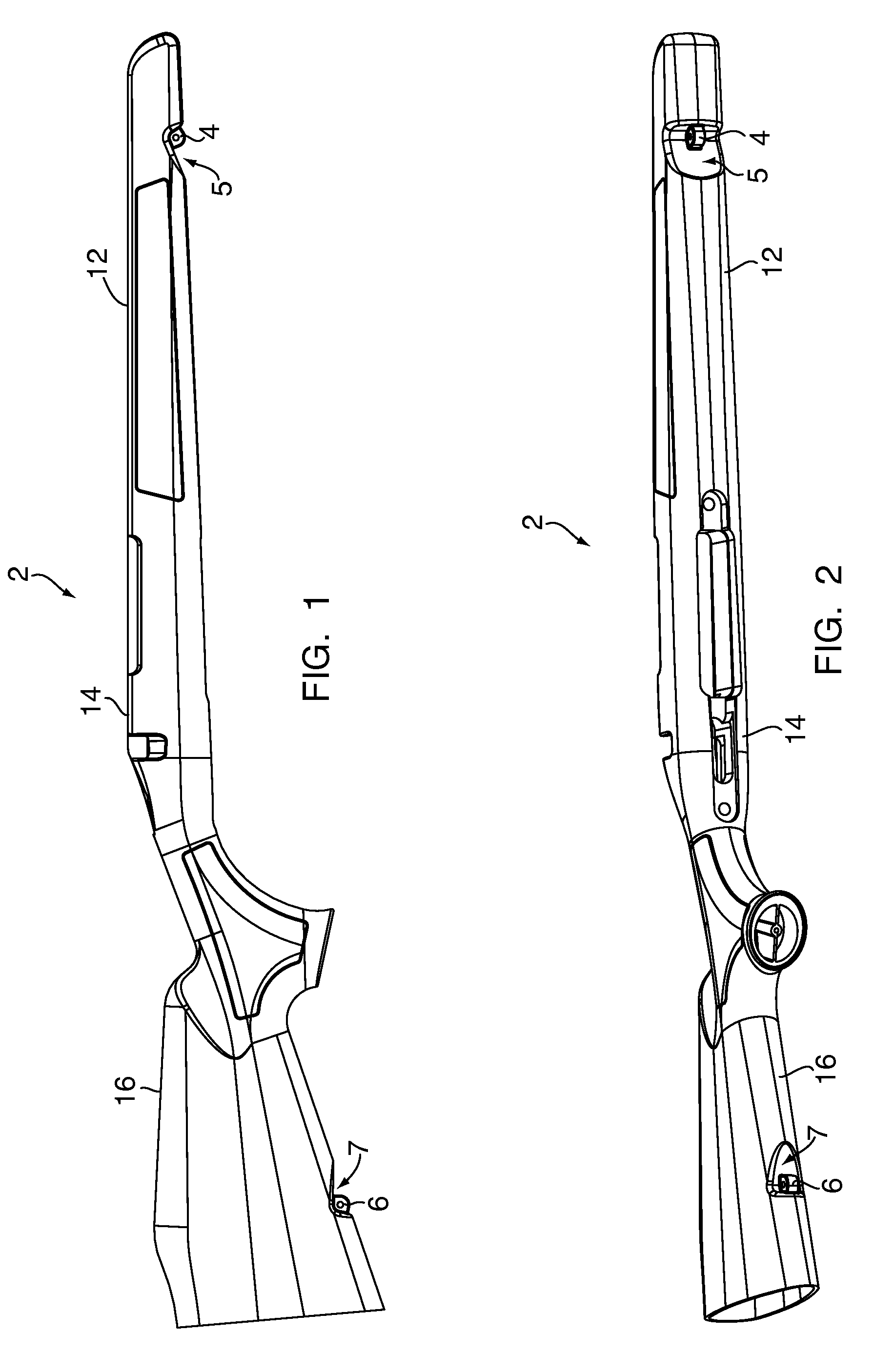

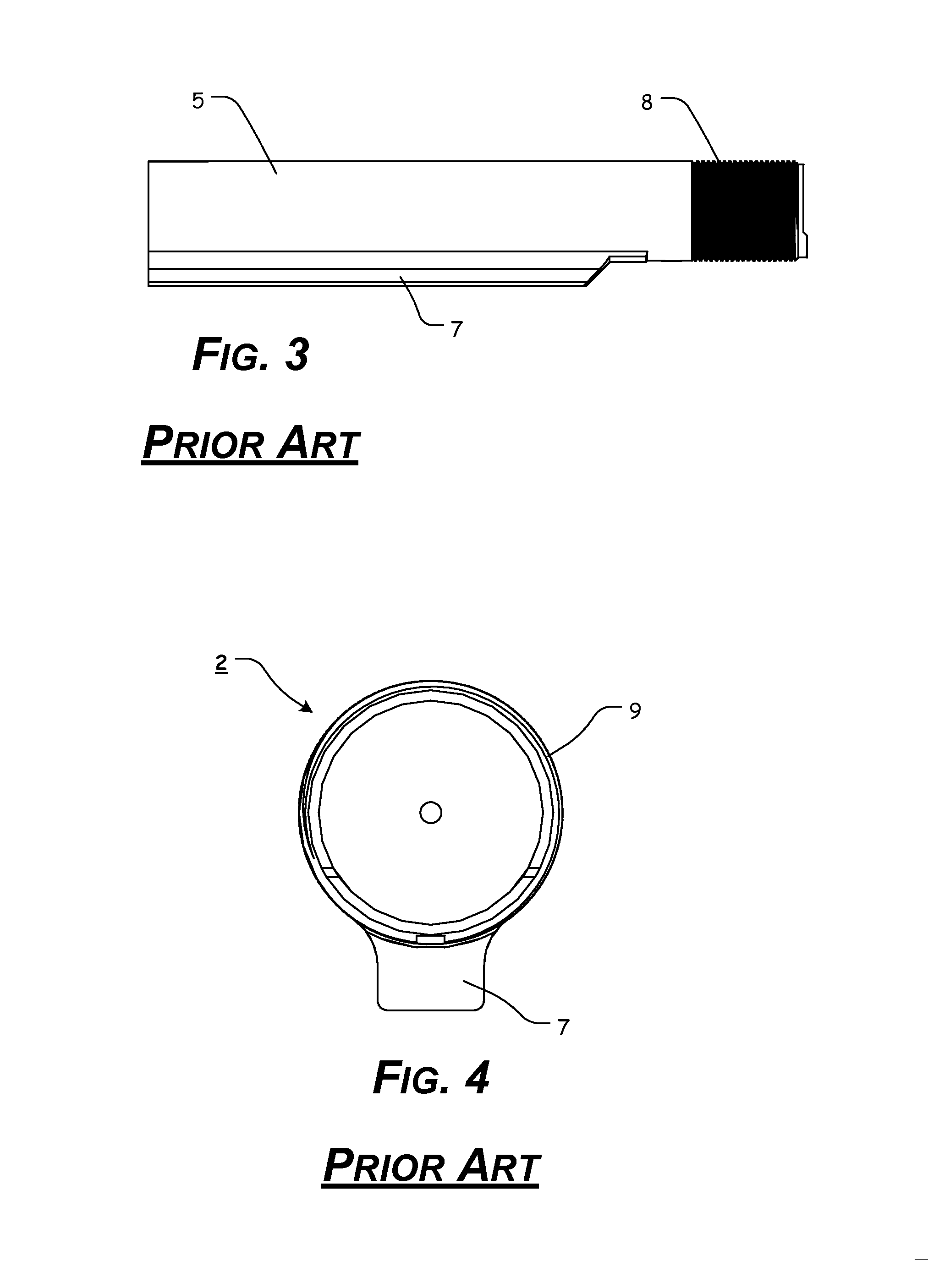

Molded rifle stock

InactiveUS20080244951A1High strengthImprove rigidityBreech mechanismsButtsEngineeringUltimate tensile strength

A molded firearm stock is disclosed. The stock includes a molded front sling lug and a molded rear sling lug. Both sling lugs are integrally molded to the stock and accommodate the fastening of a sling. The stock also includes a cavity with an open end that is open to a butt-plate of the stock. The cavity is integrally molded to the stock and is sized to accommodate a recoil-reducing device. The stock has a bed portion with a forward section, and a plurality of crossbeams are in the forward section to provide increased strength and rigidity.

Owner:SMITH & WESSON

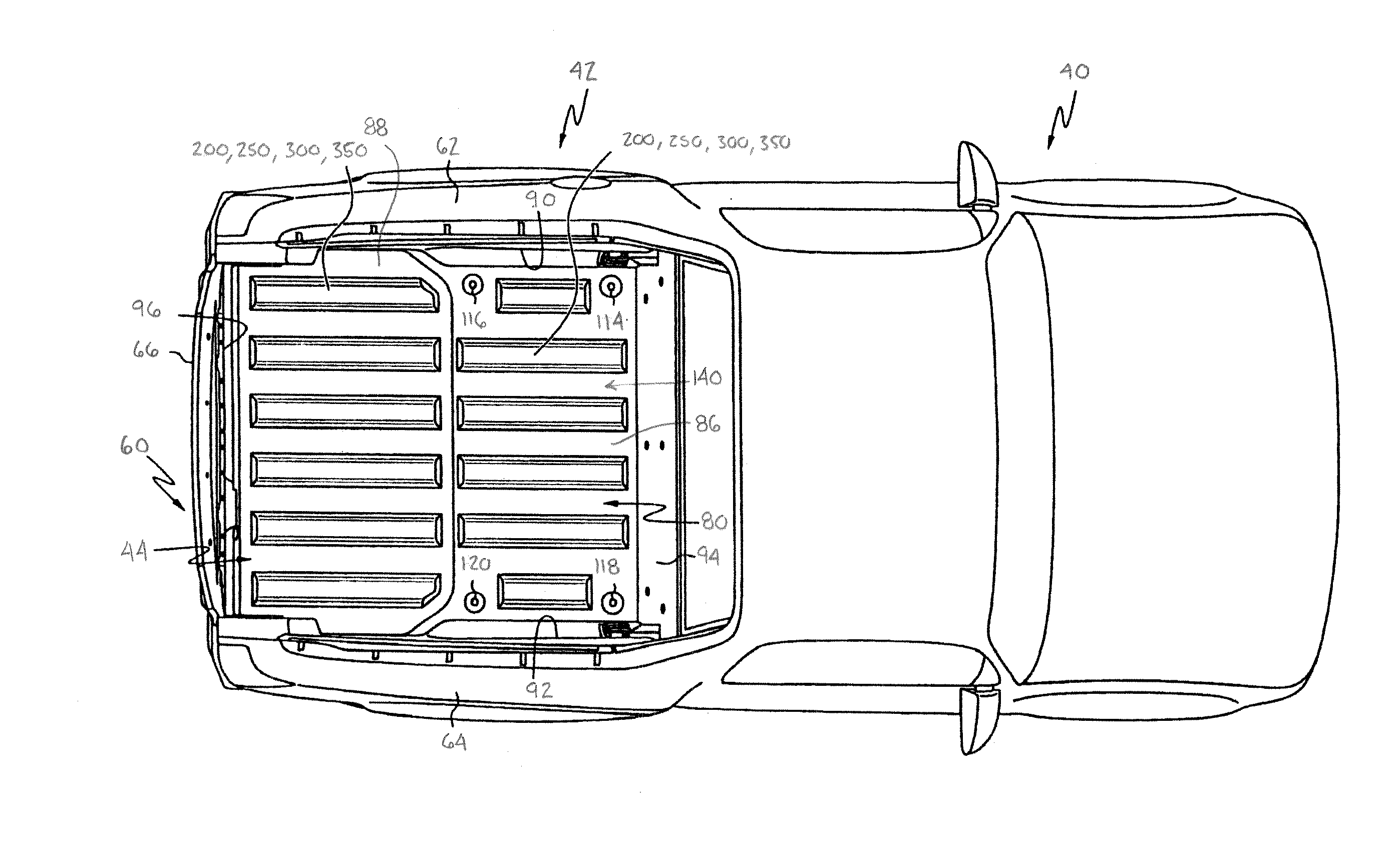

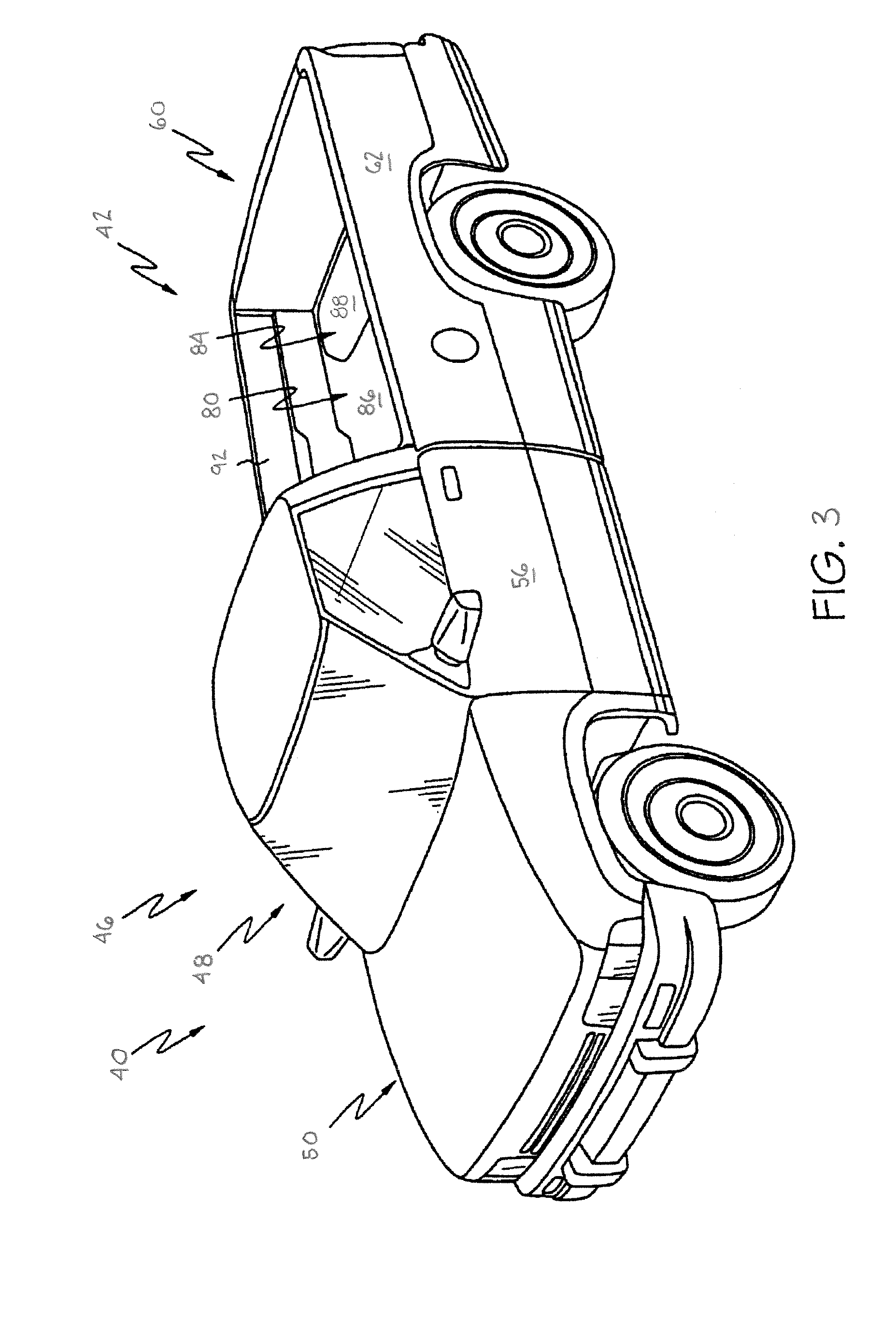

Bed corrugation for vehicle load-carrying bed

ActiveUS20110031778A1Increased strength and rigidityIncreasing the thicknessSupplementary fittingsMonocoque constructionsWear resistantEngineering

A cargo protecting system for a vehicle having a load-carrying bed comprises a support structure and a bed floor fixedly supported by the support structure. The support structure forms at least a portion of a frame of a vehicle. The bed floor includes a support surface having a plurality of longitudinal extending, spaced apart raised ridges for directly supporting cargo. Each ridge has elevated and angled parts and an upper part. The upper part of each ridge has an increased thickness compared to the other parts and a raised section for increased strength and rigidity of the ridge. Each ridge includes a wear resistant surface having a first texture disposed substantially over the entire ridge and a second texture disposed over the upper part of the ridge. The second texture is disposed at least partially over the first texture.

Owner:HONDA MOTOR CO LTD

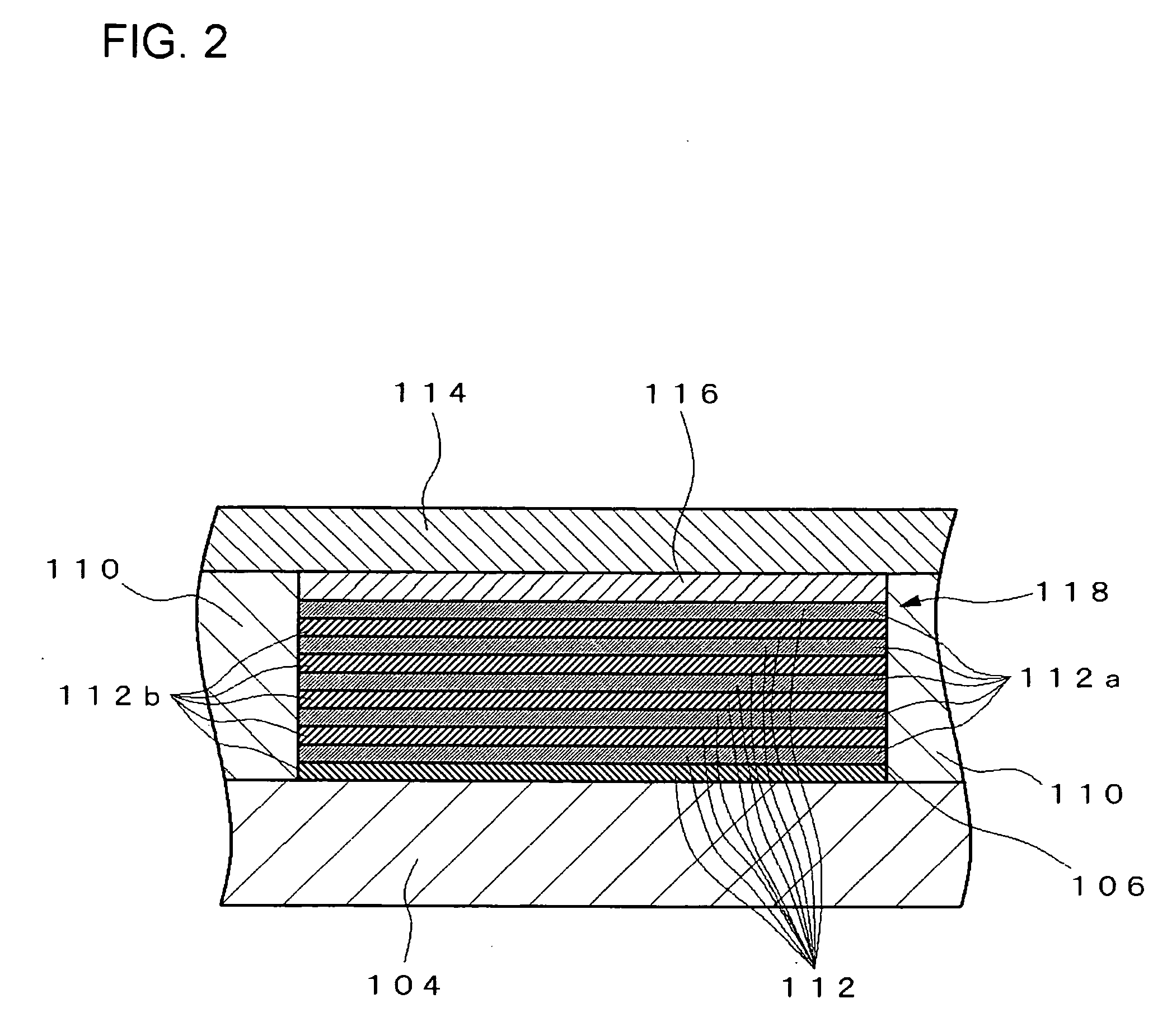

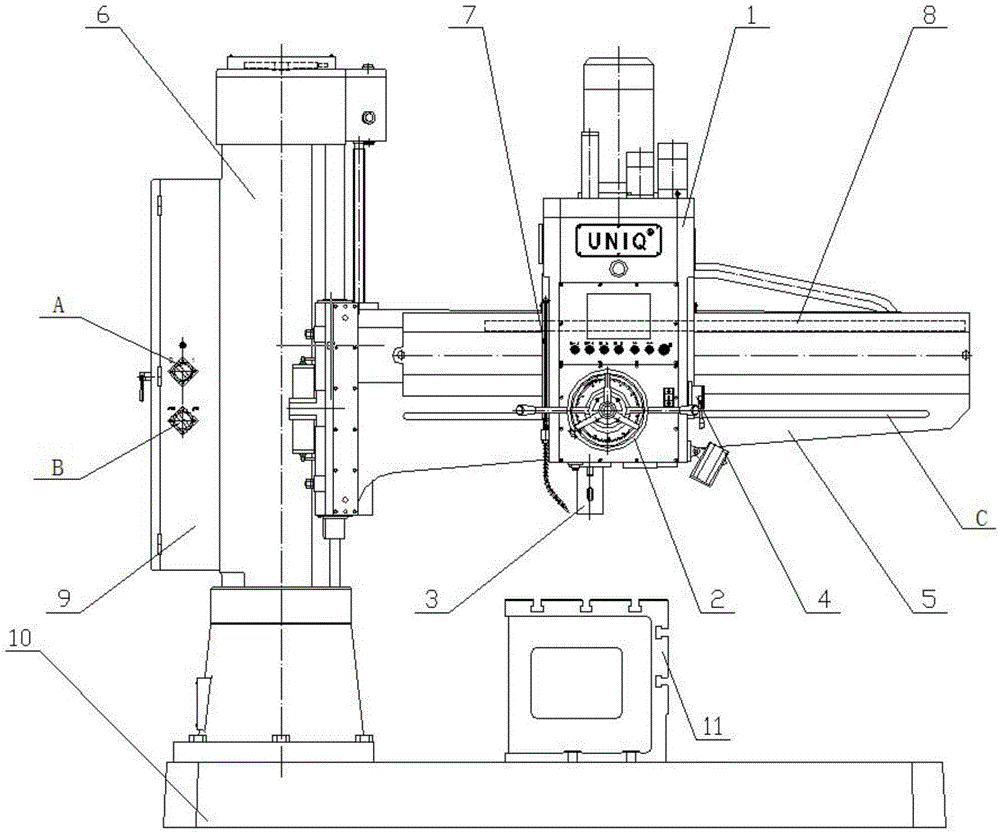

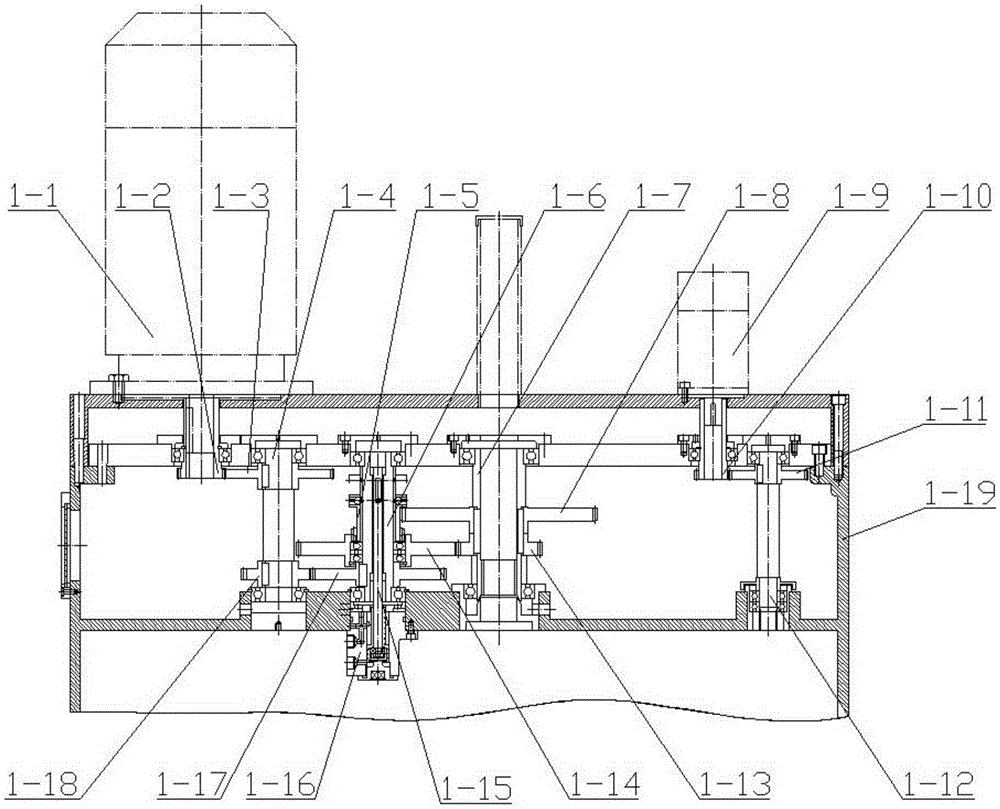

Numerical display type radial drilling machine

ActiveCN105252035AHigh guiding precisionEasy to fixMeasurement/indication equipmentsFeeding apparatusGraphicsBalancing machine

The invention provides a numerical display type radial drilling machine, comprising a spindle speed regulating and spindle feeding speed regulating system, a spindle feeding mechanism, a spindle and balance mechanism, a spindle positive / negative rotation and variable-speed control mechanism, a rocker arm and clamping mechanism, an upright and rocker arm lifting mechanism, a hydraulic and cooling system, a testing system, a numerical display control system and the like; the upright and rocker arm lifting mechanism is mounted on a base; the rocker arm and clamping mechanism is mounted on the upright and rocker arm lifting mechanism; the numerical display control system is mounted on the upright and rocker arm lifting mechanism; the spindle speed regulating and spindle feeding speed regulating system is mounted on the rocker arm and clamping mechanism; the spindle feeding mechanism, the spindle and balance mechanism, the spindle positive / negative rotation and variable-speed control mechanism, and the hydraulic and cooling system are mounted on the spindle speed regulating and spindle feeding speed regulating system. According to the numerical display type radial drilling machine, stepless speed changing of a spindle can be realized without shutdown; graphic and numerical display can be realized at working positions; a die wall clamping device of a guide rail and a spindle limiting structure are sensitive and reliable; in short, the numerical display type radial drilling machine is applicable to machining industries.

Owner:SHENYANG JINGHONG NUMERICAL CONTROL EQUIP CO LTD

Molded rifle stock

InactiveUS7716864B2Increased strength and rigidityBreech mechanismsButtsEngineeringUltimate tensile strength

A molded firearm stock is disclosed. The stock includes a molded front sling lug and a molded rear sling lug. Both sling lugs are integrally molded to the stock and accommodate the fastening of a sling. The stock also includes a cavity with an open end that is open to a butt-plate of the stock. The cavity is integrally molded to the stock and is sized to accommodate a recoil-reducing device. The stock has a bed portion with a forward section, and a plurality of crossbeams are in the forward section to provide increased strength and rigidity.

Owner:SMITH & WESSON INC

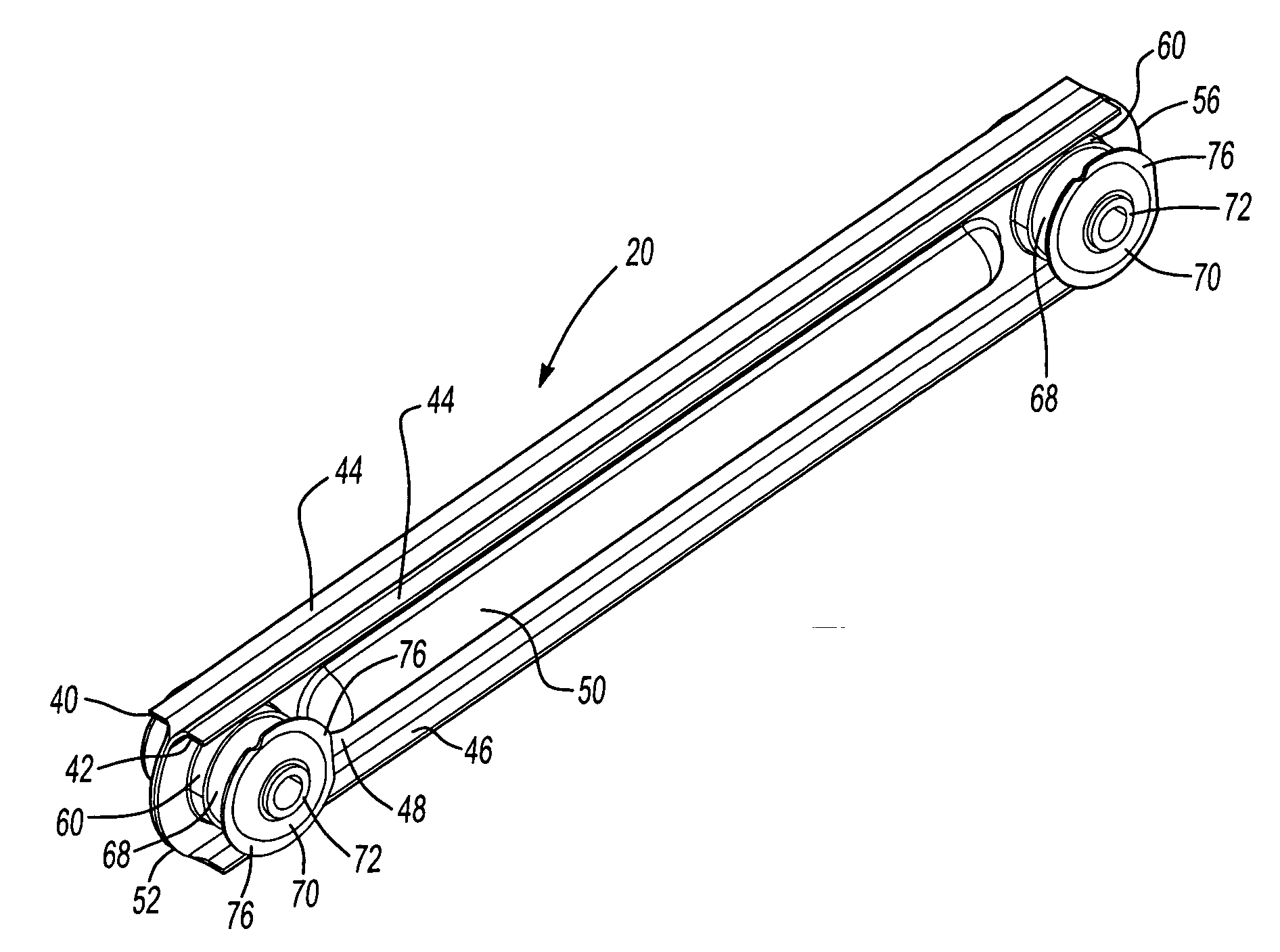

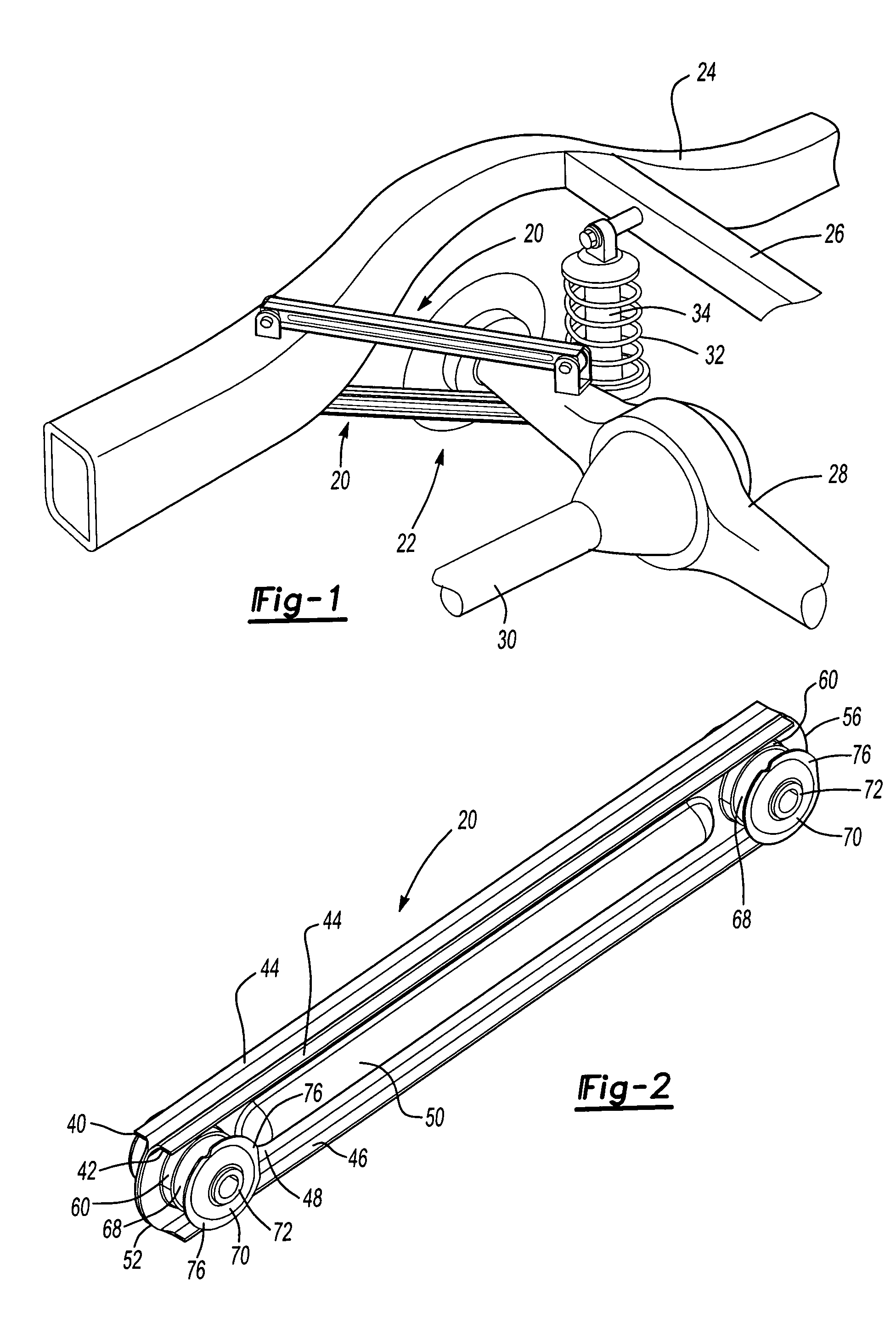

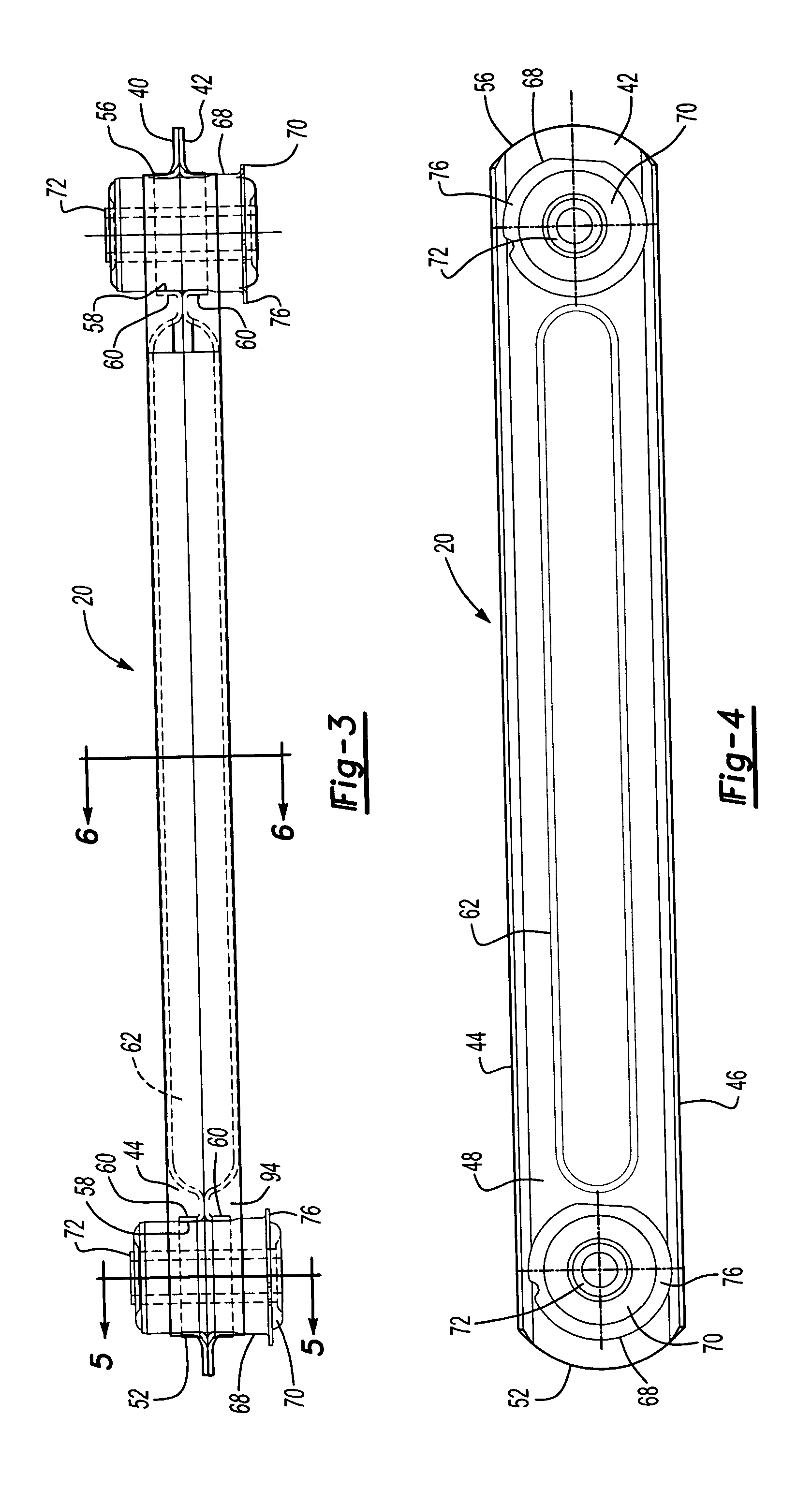

Control arm for a vehicle suspension and method of making same

InactiveUS20050258613A1Improve rigidityHigh strengthRigid suspensionsInterconnection systemsControl armEngineering

A control arm for use with a vehicle suspension having first and second elongated channel sections. Each of the channel sections including an upper flange portion, a lower flange portion and a web portion combined to form a substantially C-shaped cross-section. The web portion further having an indentation or recess extending longitudinally along the length of the respective channel sections, the indentation or recess creating a protrusion or rib member in the web portion and acts as a strengthening member providing additional rigidity to the first and second elongated channel sections. The channel sections are placed adjacent and connected at the respective web portions. An isolator, such as a compressible or flexible member is secured to the respective first and second ends of the connected first and second channel sections.

Owner:SKD AUTOMOTIVE GRP

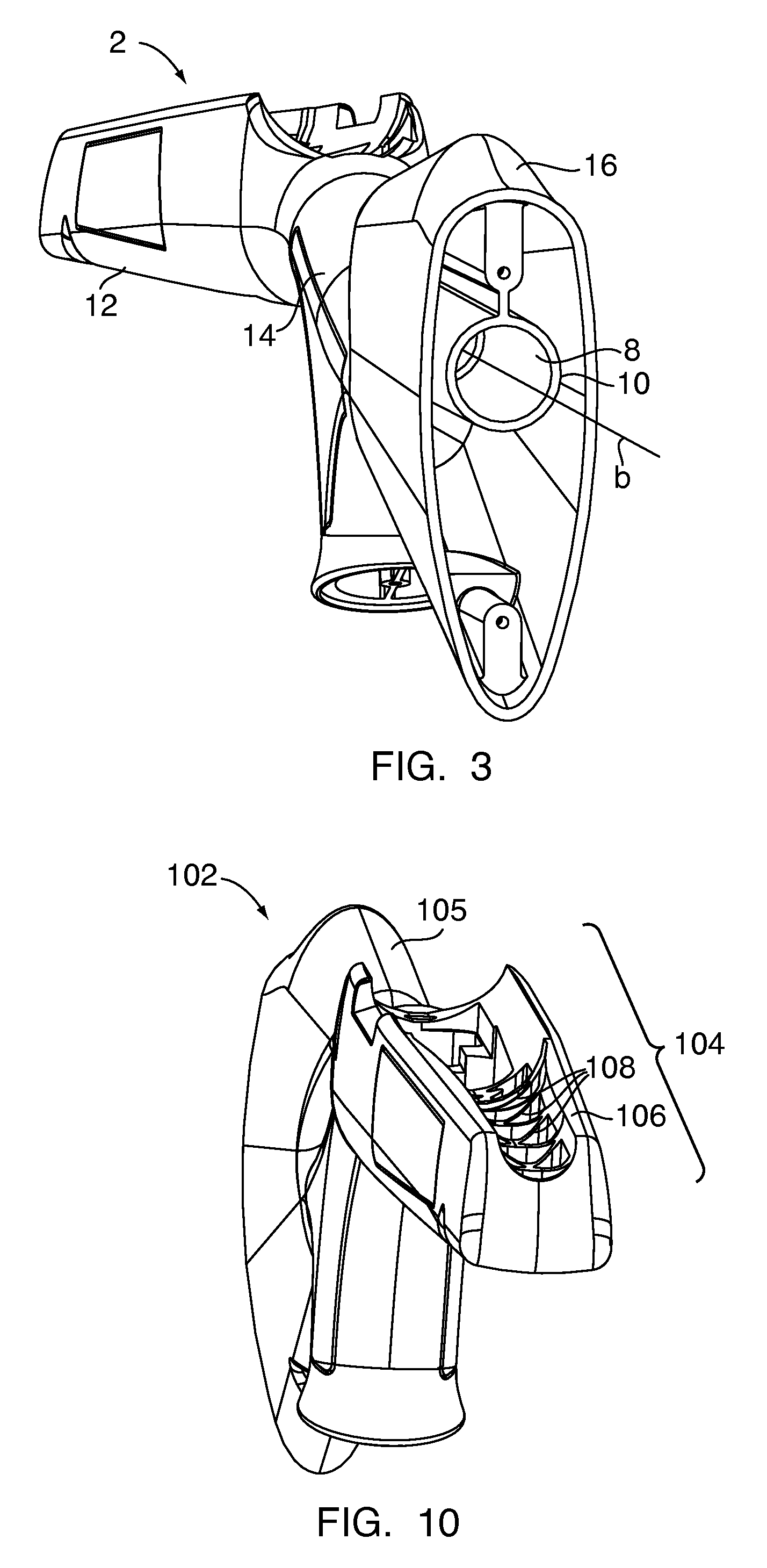

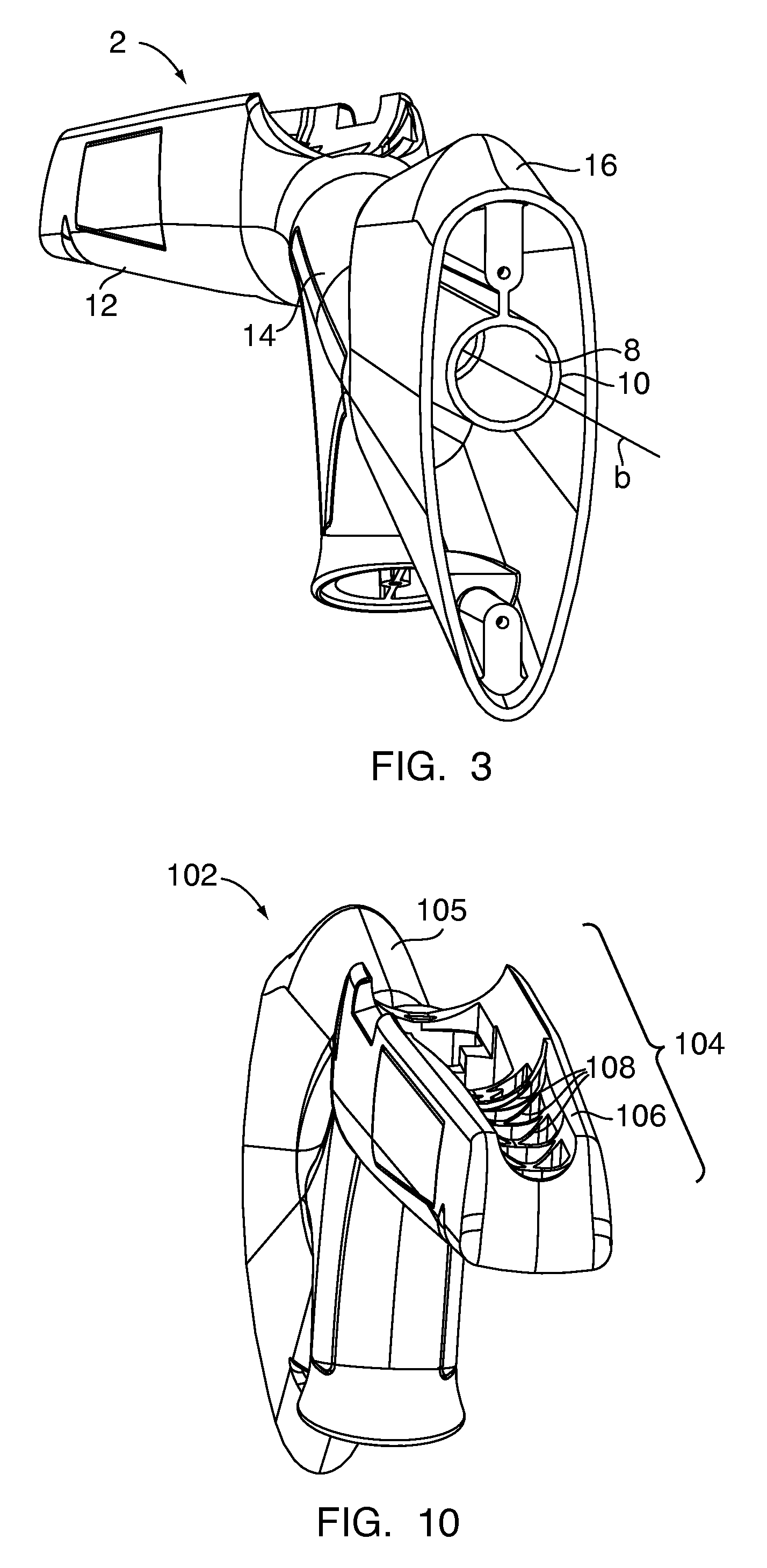

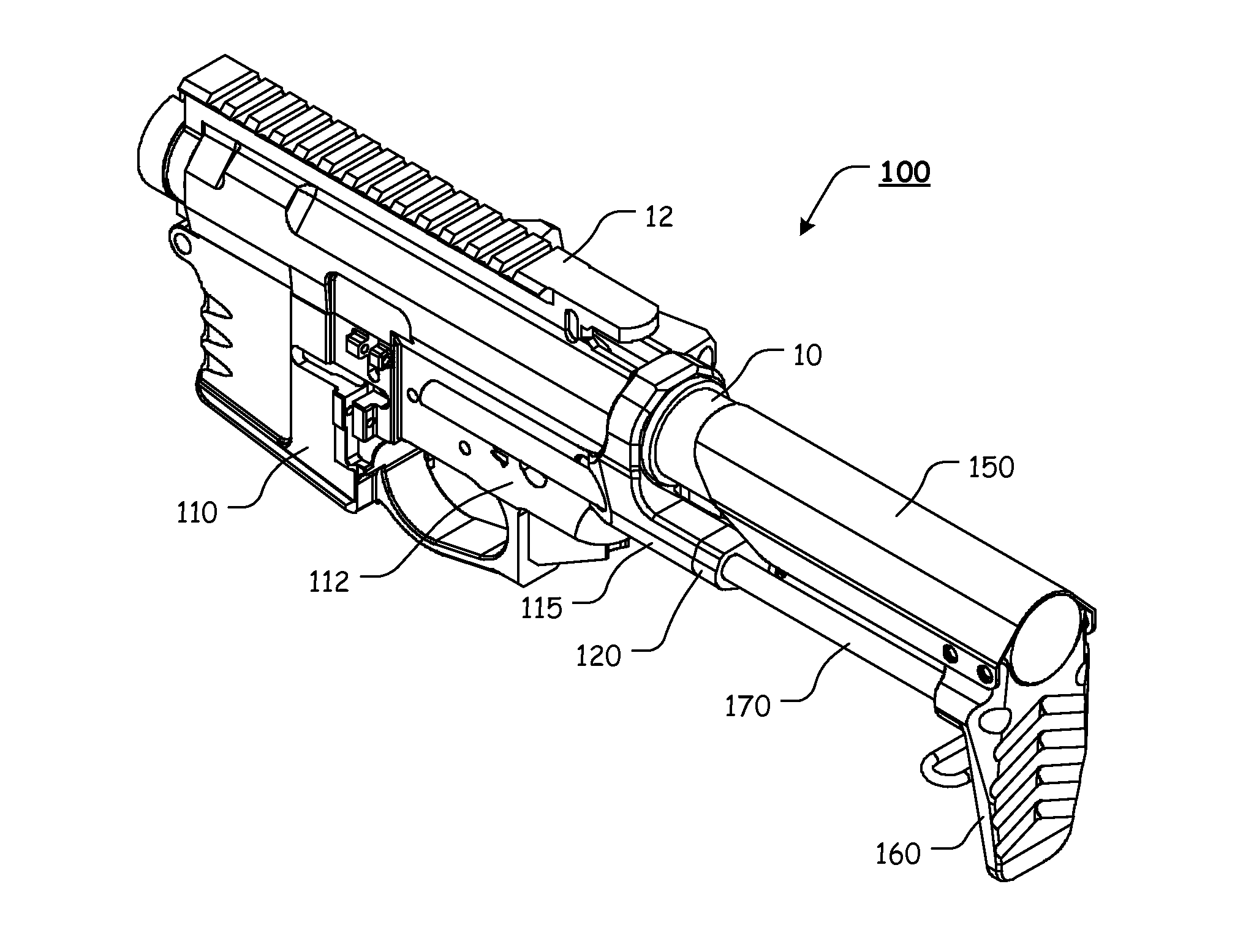

Receiver and Collapsible Buttstock for a Firearm

ActiveUS20160258713A1Increased strength and rigidityEasily manipulateBreech mechanismsButtsCHEEK DIMPLESEngineering

A receiver having an integral stock connector component that extends along the receiver; two extension rod / rail apertures formed through the integral stock connector component, wherein each extension rod / rail aperture is formed so as to slidably receive an extension rod / rail extending from a buttstock, such that each extension rod / rail is slidably movable within one of the extension rod / rail apertures; wherein each extension rod / rail comprises a rod channel and two or more rod dimples / detents formed along the rod channel; and a latch that is movable between an engaged position and a disengaged position, wherein when the latch is in the engaged position, a protrusion portion urges latch elements into the rod / rail apertures a distance that seats the latch elements into the rod dimples / detents, and wherein when the latch is in the disengaged position, the protrusion portion allows the latch elements to retract from the rod dimples / detents and into the rod channels.

Owner:HUANG GEORGE +1

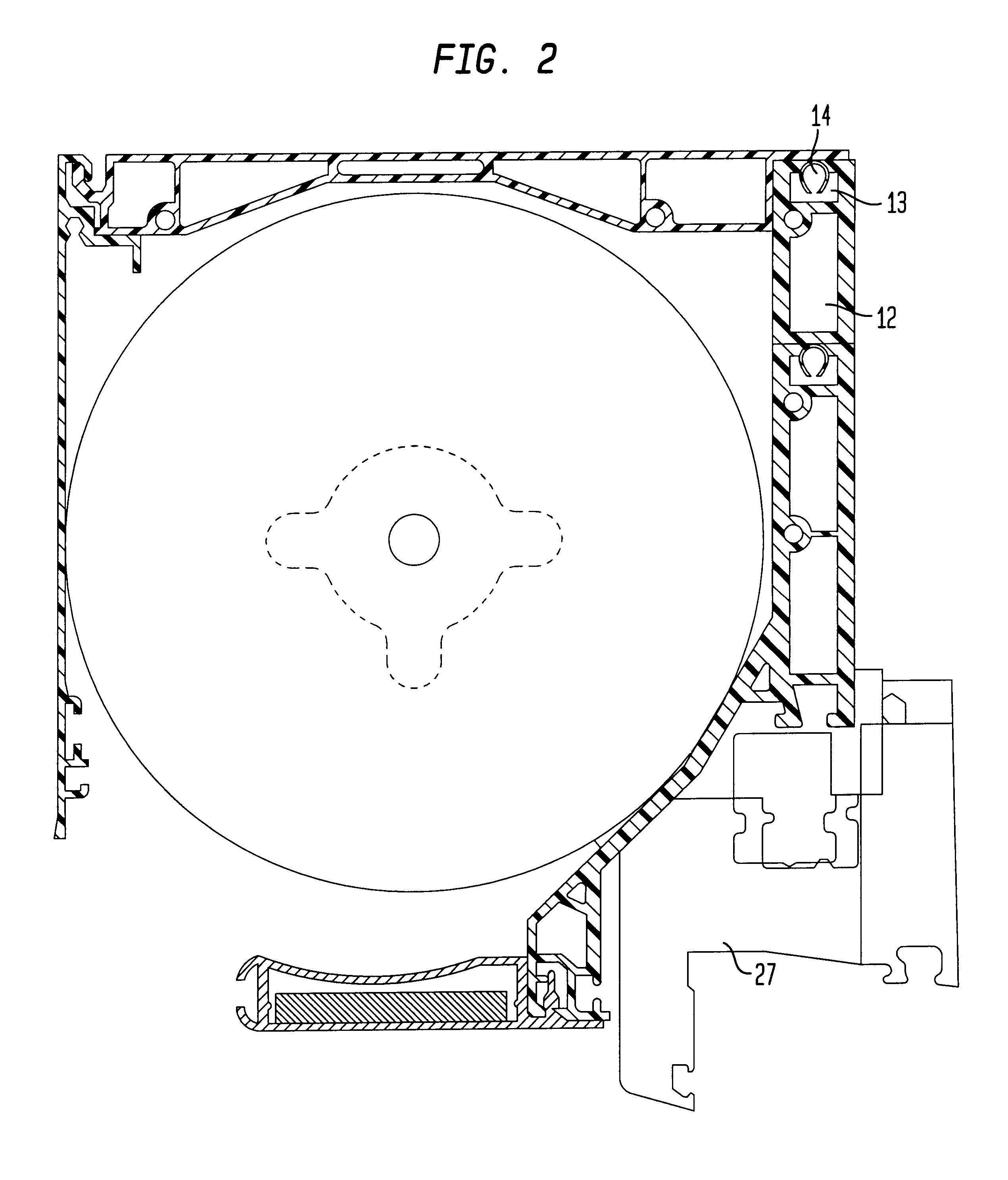

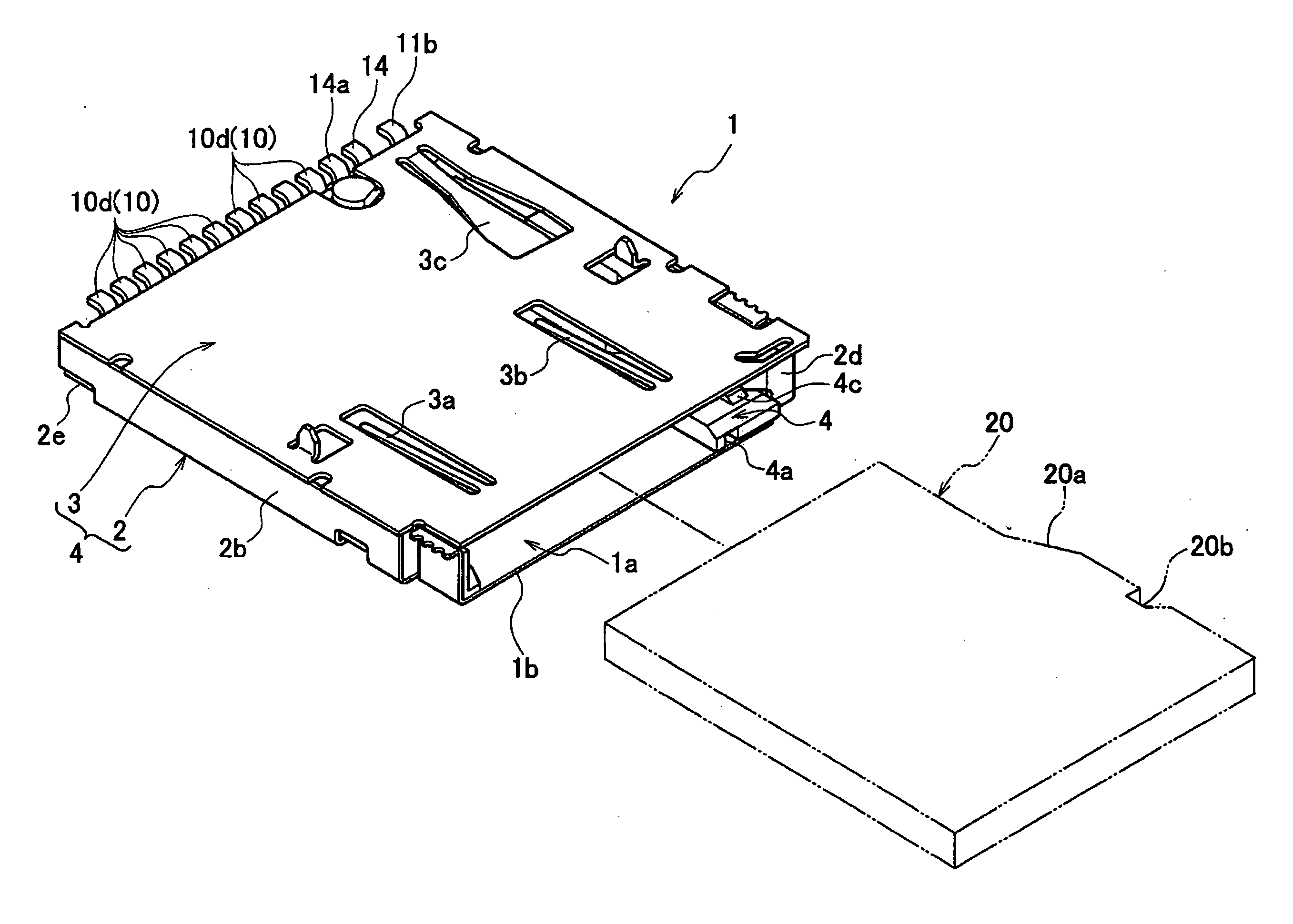

Memory card socket structure

InactiveUS20070072464A1Increased strength and rigidityReduce in quantityEngagement/disengagement of coupling partsConveying record carriersCoil springEngineering

A memory card socket structure includes a card compartment for allowing a memory card to be inserted thereinto or taken out therefrom, a contact block disposed at a rear side of the card compartment, a slider moved back and forth between a position near the opening side and a position near the rear side in the card compartment along with an insertion and extraction of the memory card, a coil spring for pressing the slider toward the opening side of the card compartment, and a spring guide fixed at the contact block and elongated toward the opening side of the card compartment to be inserted through the coil spring. The spring guide includes a base end portion provided with a connection portion to be adjoined to the circuit board.

Owner:MATSUSHITA ELECTRIC WORKS LTD

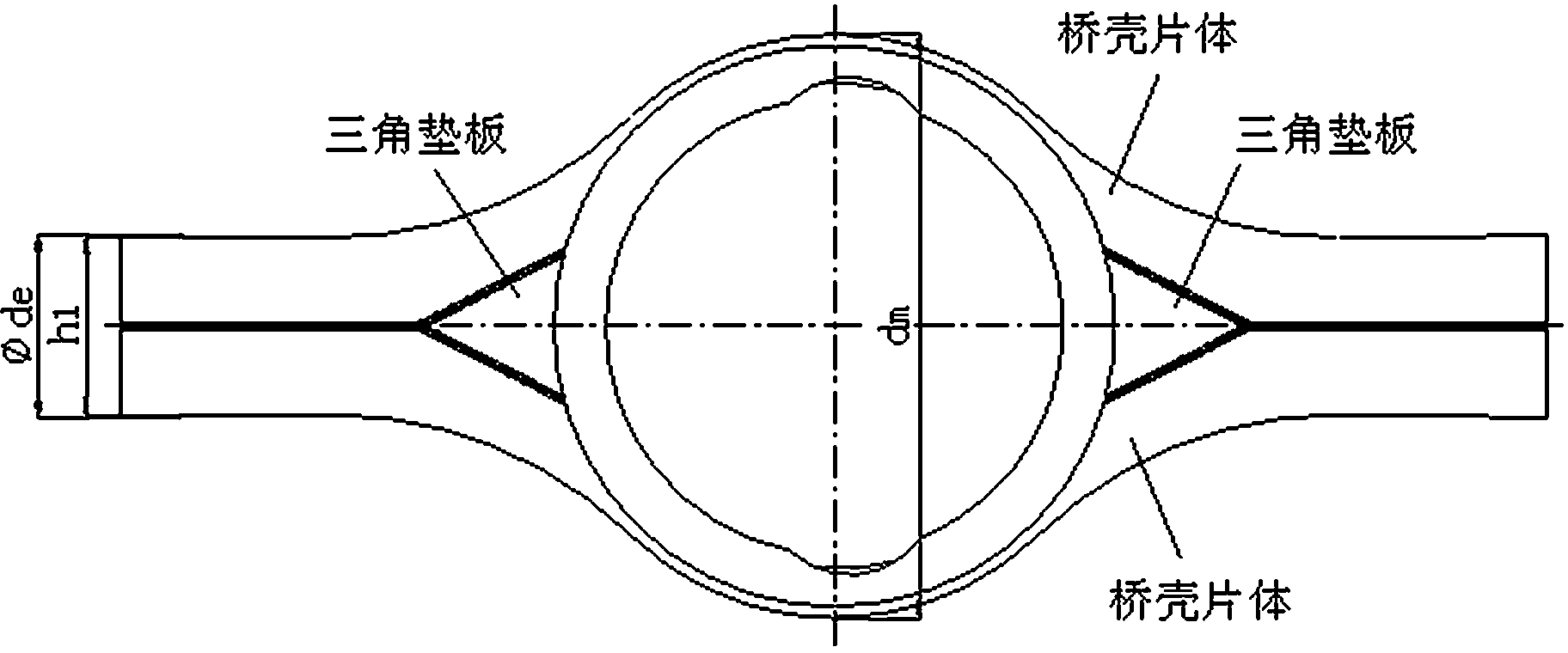

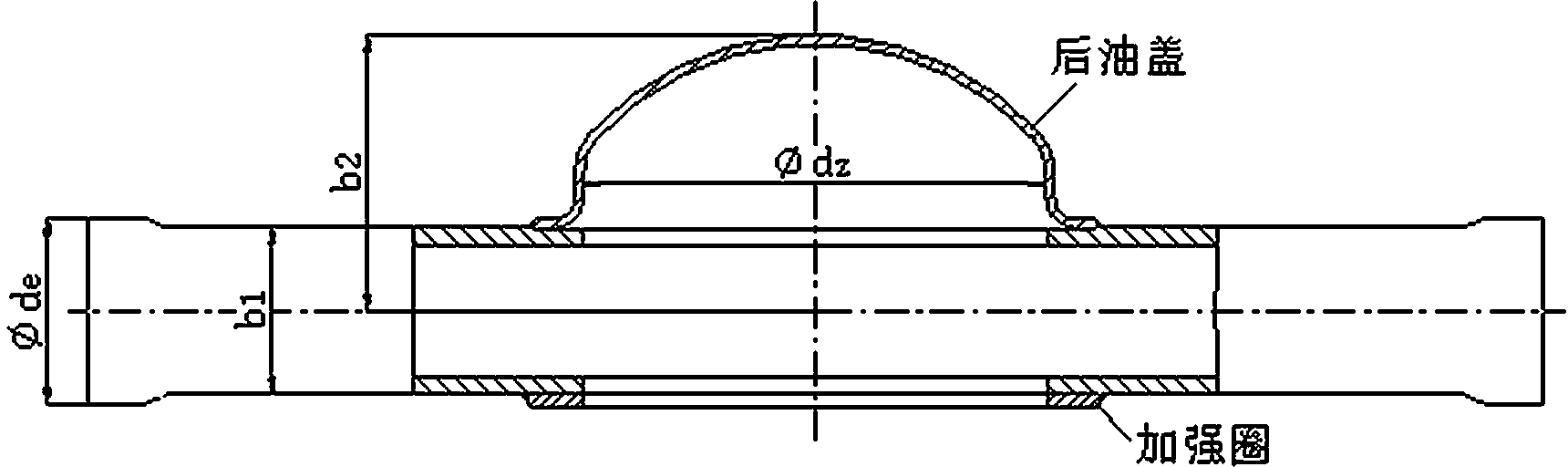

Integral forming method of weldless axle housing of heavy truck

ActiveCN103252404AReasonable distribution of wall thicknessIncreased strength and rigidityHousing FirstTruck

The invention discloses an integral forming method of a weldless axle housing of a heavy truck. According to the method, reversed central spindle necking is carried out on two sides of the axle housing first, then hydro-bugling is carried out on the middle of the axle housing to obtain a bulging tube blank with sizes of two sides of the axis different, and then necking is carried out on two ends of the axle housing to obtain a preformed tube blank; ends of the preformed tube blank are sealed by a left pressure head and a right pressure head of a die and liquid is filled in the axle housing on a four-way hydraulic machine, integral press-forming is carried out on the preformed tube blank from the upper side, the lower side, the front side and the back side through an upper module, a lower module, a front module and a back module to obtain an axle housing tube fitting, a hemispherical rear oil cap is arranged on the rear side of an axle package part, and the front side of the axle package part is a plane; a round hole is punched in the front side of the axle package, the rear oil cap is reshaped with a stamping die, and then an axle housing workpiece is obtained. The heavy truck axle housing manufactured with the method is weldless, high in strength and rigidity, high in shape accuracy, good in wall thickness distribution, and low in manufacturing cost. Compared with a traditional hydro-bugling technique, the method has the advantages that liquid pressure needed in a manufacturing process is reduced by more than 60% and the tonnage of forming equipment is reduced by more than 50%.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

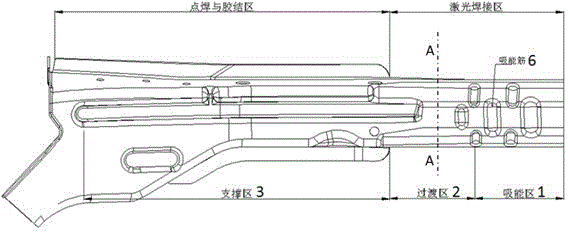

Continuous variable cross-section car front longitudinal beam and preparation method thereof

ActiveCN103600773AHigh impact energy absorption performanceIncreased Strength and RigidityUnderstructuresEnergy absorbingEngineering

The invention provides a car front longitudinal beam structure and a preparation method thereof. The front longitudinal beam is of a hollow type cavity structure which is formed by connecting an inner plate with an outer plate along a longitudinal extension direction, and comprises an energy absorption region located at the front part of the front longitudinal beam, a support region located at the rear part of the front longitudinal beam and a transition region for connecting the energy absorption region with the support region, wherein a plate material in the energy absorption region is thinner than a plate material in the support region, and the plate material in the transition region is continuously and uniformly transitioned from the energy absorption region to the support region. The inner plate and the outer plate are connected through the adoption of a technology of combining laser welding, spot welding and cementation, so that the front longitudinal beam preparation technology is simple; the transition region of the inner and outer plates is continuously and smoothly connected with the relatively thin energy absorption region and the relatively thick support region, so that difference of front and back performances of the front longitudinal beam is realized, light weight and relatively high collision and energy absorption effects are guaranteed; energy absorbing ribs are arranged uniformly on each surface of the inner and outer plates, so that the car front longitudinal beam structure further improves collision energy absorption and is conductive to further improving car safety performance.

Owner:CHERY AUTOMOBILE CO LTD

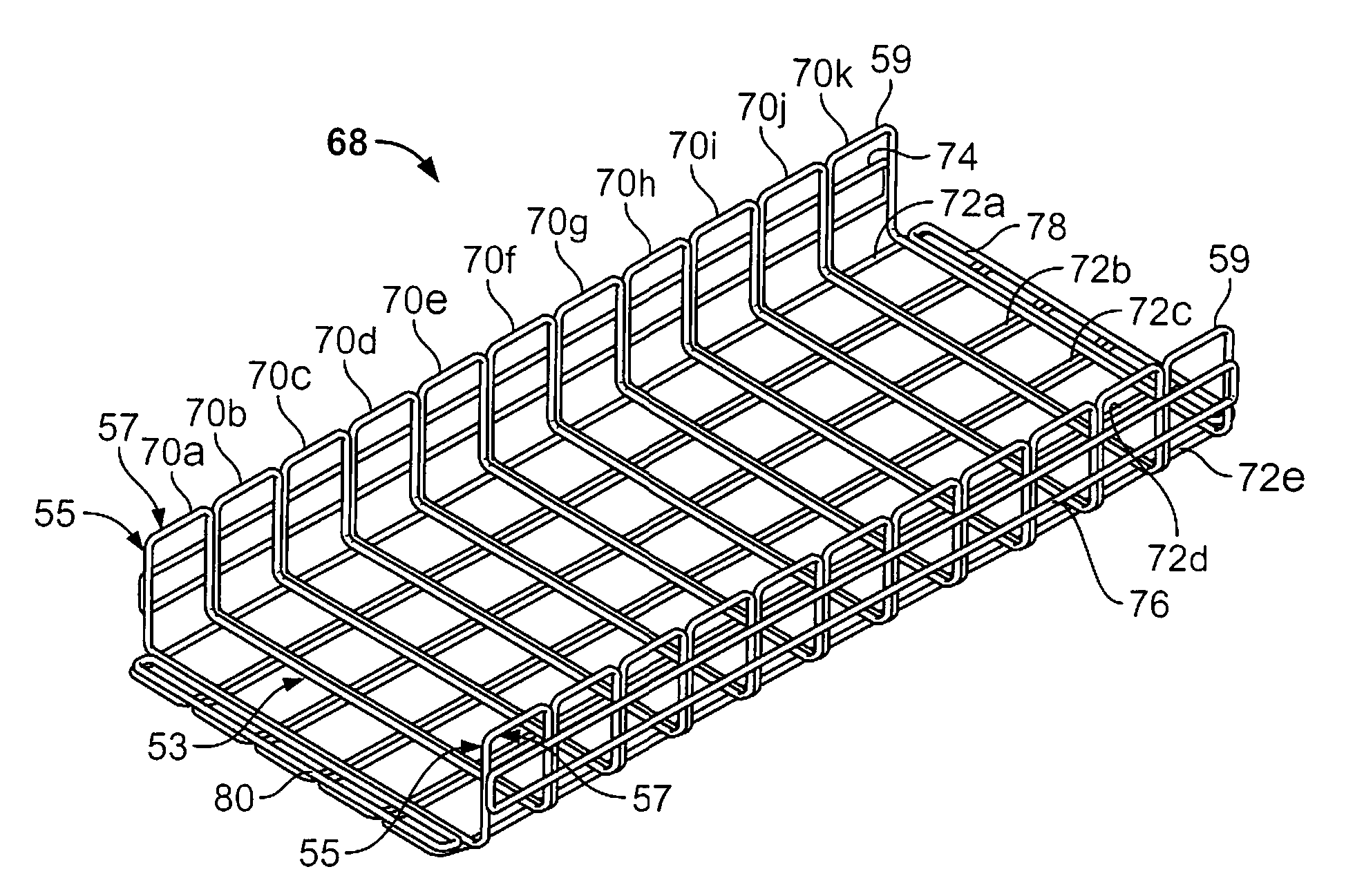

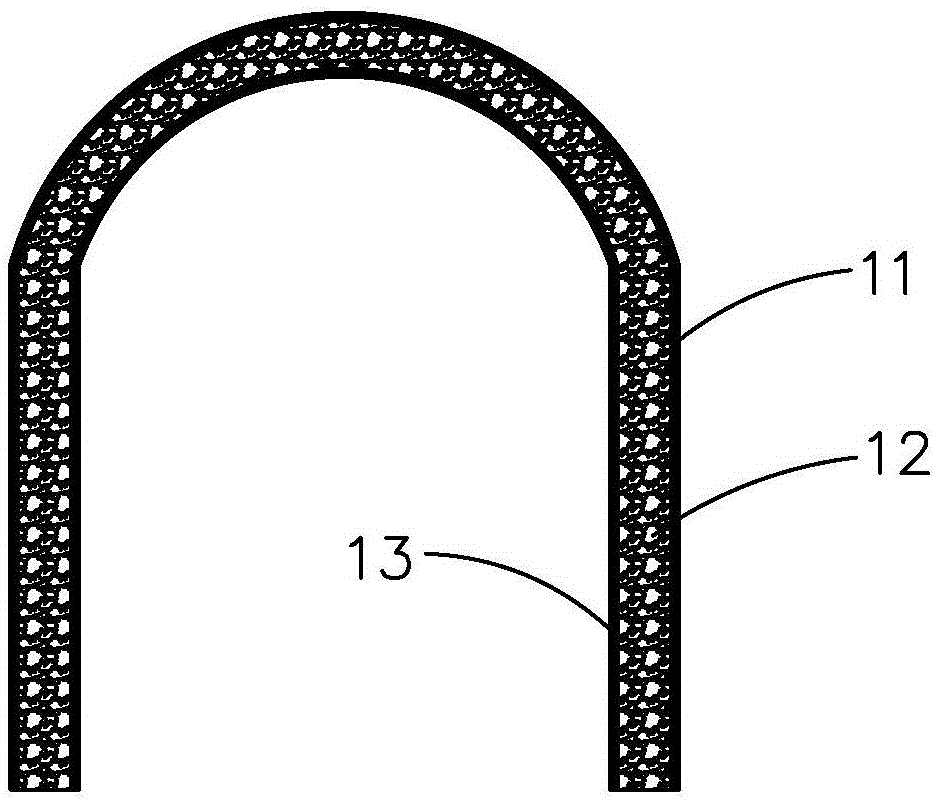

Wire basket pathway system

InactiveUS20090008512A1Increased strength and rigidityFacilitates reroutingInsulated cablesStands/trestlesWire frameEngineering

A wire basket for supporting cables includes a plurality of wire frames connected together in a side-by-side manner in forming a generally flat bottom and first and second opposed upraised end portions so as to form a generally U-shaped frame. Each wire frame is formed of a single closed section of wire comprising at least one radial bend positioned at opposite ends of the wire frame. The wire frame may also include an extended mounting member attached to the frame such that a distal end of the mounting member is generally aligned with and extends beyond the bottom portion.

Owner:PANDUIT

Steering column device

ActiveUS8505407B2Increased strength and rigidityHigh strengthSteering columnsSteering columnEngineering

Owner:NSK LTD

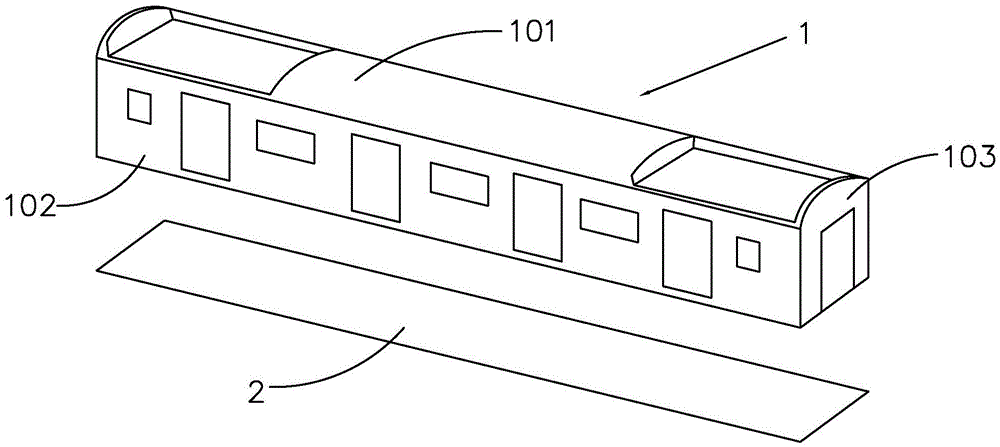

Carbon fiber composite vehicle body and manufacturing method thereof

ActiveCN105128876AWith sound and heat insulationIncreased Strength and RigidityAxle-box lubricationRailway bodiesCarbon fiber compositeMaterials science

The invention discloses a carbon fiber composite vehicle body. The carbon fiber composite vehicle body comprises bodywork and a bottom plate, the bottom plate is connected with the bottom of the bodywork, the bodywork is manufactured through integral forming, the bodywork comprises an outer skin, a sandwich layer and an inner skin which are sequentially arranged from outside to inside, reinforcing ribs are bonded on the inner skin, and the carbon fiber composite vehicle body has the advantages of being high in rigidity and strength, light in mass, soundproof and heat resistant. The carbon fiber composite vehicle body is formed by connecting the bodywork which is manufactured through integral forming with the bottom plate, connecting structures of the vehicle body can be greatly reduced, the rigidity and the strength of the vehicle body are improved, and the safety of the vehicle body is facilitated. The invention further discloses a manufacturing method of the carbon fiber composite vehicle body, the degree of production integration is high, and the method has important meanings on reducing the manufacturing cost and improving the rigidity and the strength of the vehicle body.

Owner:SOUTHWEST JIAOTONG UNIV

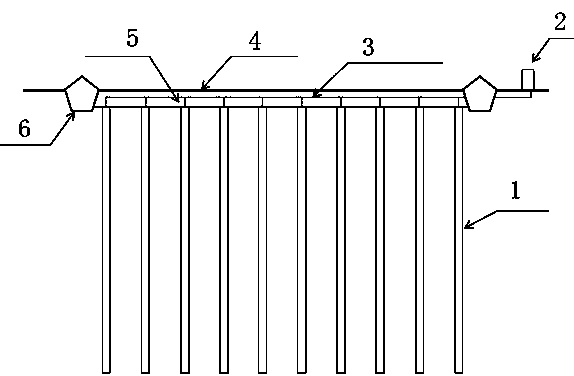

Foundation treatment method adopting water penetration pile in combination with vacuum preloading

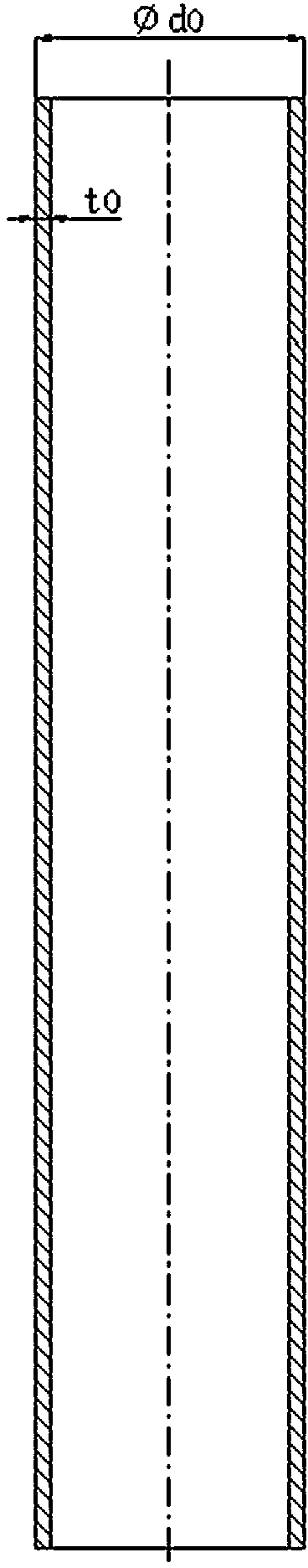

ActiveCN103628468AAccelerates soil consolidation and settlementIncreased Strength and RigiditySoil preservationPile capStructural engineering

The invention discloses a foundation treatment method adopting a water penetration pile in combination with vacuum preloading. The foundation treatment method comprises the following steps: (1) fabricating the water penetration pile, wherein a pile body of the water penetration pile is a hollow tubular pile and provided with a pile cap; (2) blocking a treatment area of a foundation, forming a zone with a plurality of adjacent single blocks, carrying out synchronous construction on all the blocks during vacuum preloading, and carrying out a flow process between the zones; (3) driving the prefabricated water penetration pile in the foundation in a preloading zone, and fully spreading a sand cushion in a preloading area; (4) laying a vacuum pipe network; (5) paving a sealing film on the surface of the flattened sand cushion for a plurality of times; (6) digging out a seal trench in the periphery of an reinforcement zone, and vertically inserting the edge of the sealing film into weak soil along the inner wall of the seal trench and paving the film at the bottom of the trench flatly; and (7) carrying out vacuumizing and tightening the pile cap. As the water penetration pile is high in rigidity and strength, and good in water penetration performance, the pore water pressure and the settlement respectively accumulated in the foundation treatment process are low, and correspondingly, the post-construction settlement of the foundation is reduced; the bearing strength of the foundation is also improved.

Owner:SHANDONG UNIV

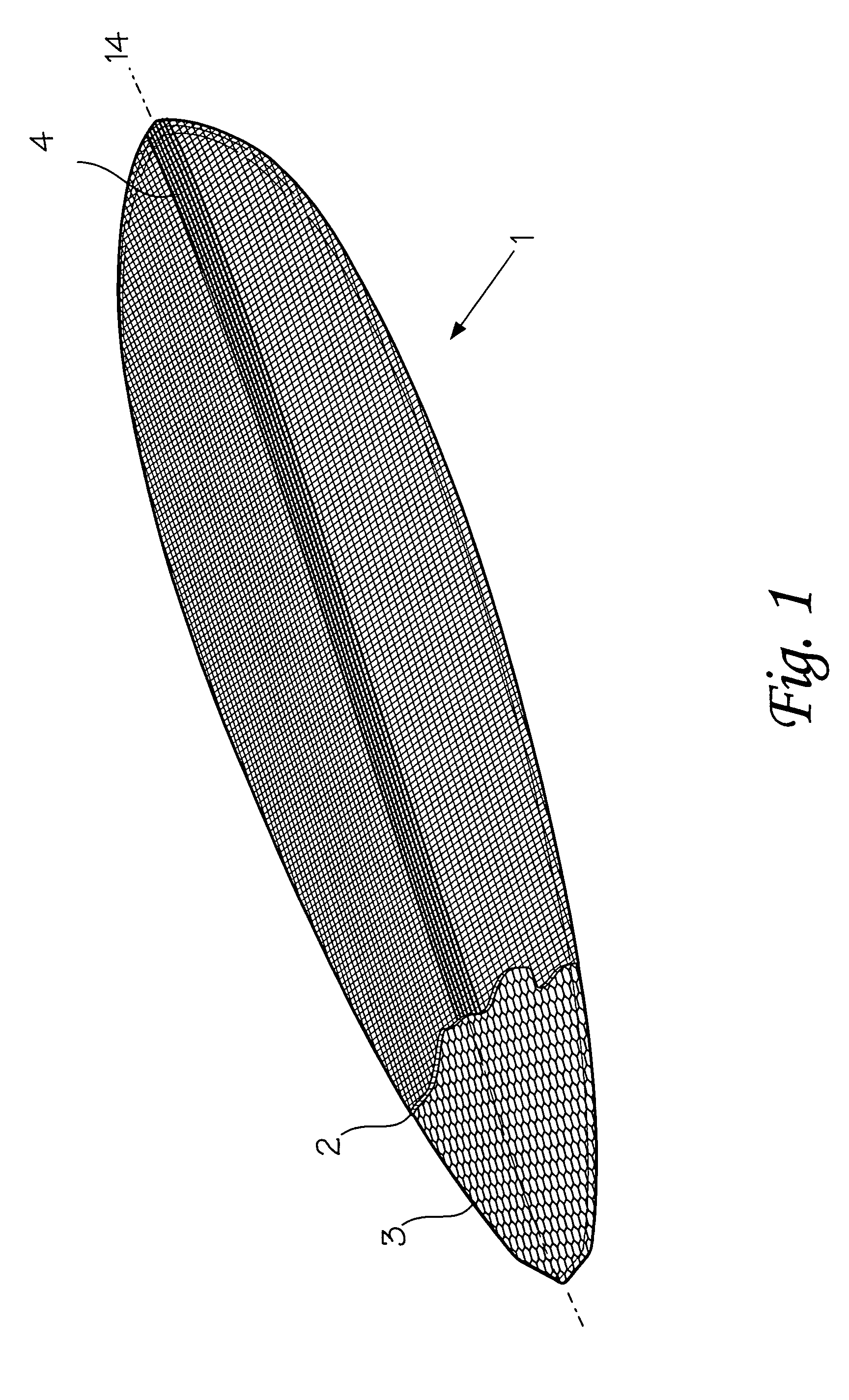

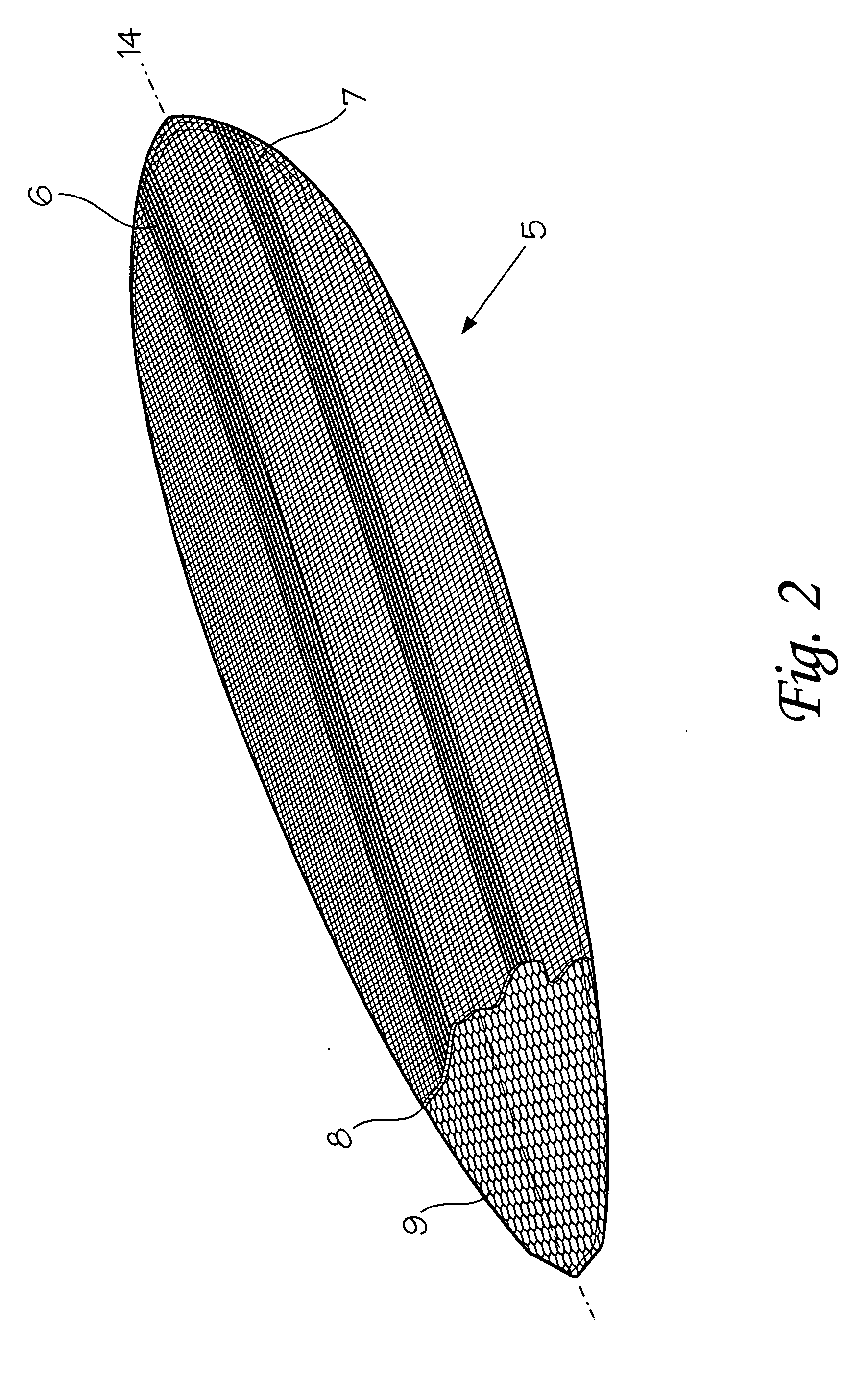

Surfboard having a skin of reinforced fabric

InactiveUS20070218787A1Increased strength and rigidityImprove rigidityWater sport boardsWaterborne vesselsWater SportQuartz fiber

A fiberglass covered recreational board for surfing and other water sports having increased strength and rigidity provided by a longitudinal, central band or bands of higher strength glass fibers such as S Glass and S-2 Glass, or by aramid fibers, or by quartz fibers that are woven into the fiberglass cover as warp threads.

Owner:JPS COMPOSITE MATERIALS

PPS (polyphenylene sulfite)/LCP (liquid crystal polymer) composite material and preparation method thereof

The invention discloses a PPS (polyphenylene sulfite) / LCP (liquid crystal polymer) composite material and a preparation method thereof. The method comprises the following raw materials in parts by weight: polyphenylene sulfide, a liquid crystal polymer, a compatilizer, a filling and reinforcing agent, a lubricating agent and other aids. The preparation method comprises the following steps of: (a) respectively drying polyphenylene sulfide resin and the liquid crystal polymer; (b) uniformly mixing the filling and reinforcing agent, the lubricating agent and other aids; (c) mixing the raw materials processed in the steps (a) and (b) at a high speed, then adding the compatilizer and uniformly mixing; and (d) melting and extruding the mixed raw materials in the step (c) by using a double-screw extruder and granulating. The invention provides the PPS / LCP composite material having high strength and rigidity and also provides the preparation method of the PPS / LCP composite material with simple preparation process, low cost and good economic benefits.

Owner:SHENZHEN KEJU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com