Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3147results about How to "Good alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

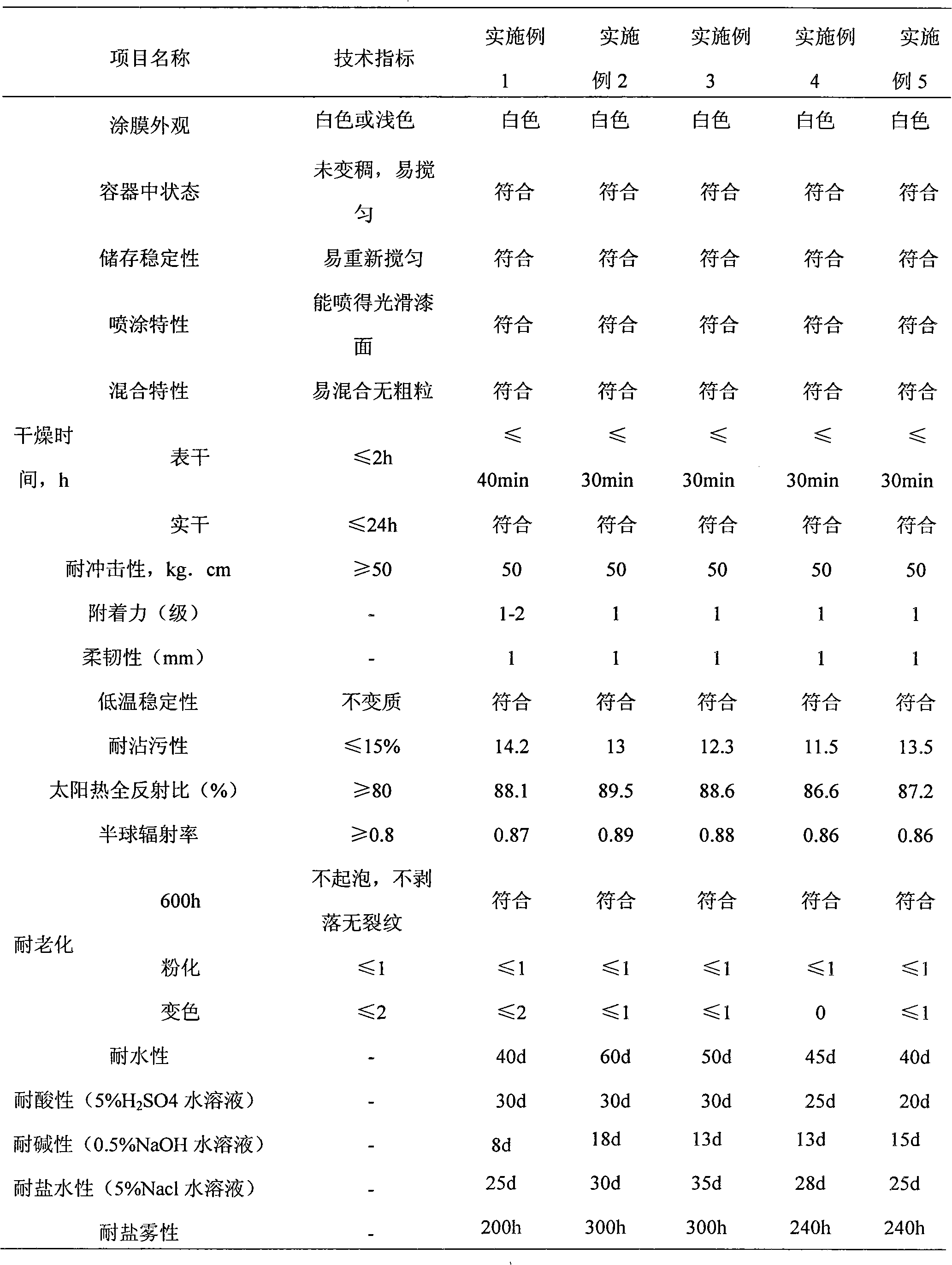

Nanometer compound water-based heat insulation anticorrosion paint used for metal and preparation method thereof

ActiveCN101665645AGood heat insulationImprove corrosion resistanceAnti-corrosive paintsReflecting/signal paintsWater basedAcrylic resin

The invention discloses a nanometer compound water-based heat insulation anticorrosion paint used for metal and a preparation method thereof. The raw materials of the paint consists of the following components: tap water, watercraft acrylic resin, rustproofing pigment, reflection pigment and filler, hollow micro-beads, watercraft nanometer size, anti-settling agent, wetting and dispersing agent A,wetting and dispersing agent B, film-forming assistant, defoaming agent, flatting agent, anti-flash rustproofing agent and thickening agent. Watercraft polyacrylic emulsion is styrene-crylic acid copolymerization emulsion, pure crylic acid polymerization emulsion or organic silicon-crylic acid copolymerization emulsion. The wetting and dispersing agent A is block macromolecule copolymer, multivalence carboxylate polymer and / or synthetic macromolecule copolymer, and the wetting and dispersing agent B is anion wetting agent and / or nonionic wetting agnet. The product contains no organic solvent,heavy metal and other harmful substances, is extremely excellent in environmental conservation, integrates the functions of anticorrosion and heat insulation as a whole and is simple and convenient for construction, safe in storage and stable in performance.

Owner:GUANGZHOU JOINTAS CHEM

Method for improving alkaline resistance of anode oxide film on surface of aluminum or aluminum alloy material

InactiveCN104233428AGood alkali resistanceImprove corrosion resistanceAnodisationOrganic acidSilanes

The invention discloses a method for improving the alkaline resistance of an anode oxide film on the surface of an aluminum or aluminum alloy material. The method comprises the following steps: performing polishing pretreatment on the aluminum or aluminum alloy material, performing anodic oxidation treatment in electrolytic liquid containing organic acid, inorganic acid and soluble oxysalt, performing closing treatment on an oxide film obtained after the anodic oxidation treatment, and forming a silane film layer on the surface of the aluminum or aluminum alloy material subjected to the closing treatment. The method for surface treatment of the aluminum or aluminum alloy material is easy to perform, economic, environment-friendly and capable of effectively improving the alkaline resistance of the anode oxide film on the surface of the aluminum or aluminum alloy material.

Owner:HUNAN UNIV

Modified epoxy resin adhesive and its preparation process

The invention relates to a modified epoxide resin adhesive agent and its preparation process to overcome the disadvantage such as brittleness and bad temperature resistance of common epoxide resin adhesive agents, which comprises: mixing the epoxide resin (component A) modified by polyurethane prepolymer and curing agent (component B) produced by author in the proportion of between 10:1 to 1:1 to prepare the curing system of fire resistant, good toughness and large reaction, wherein the polyurethane prepolymer is polysiloxane polyurethane prepolymer capped by isocyanate groups which are produced by the reaction of hydroxy-terminated polysiloxane and diisocyanate in a definite proportion, then using the said polyurethane prepolymer to modified treat epoxide resin. The said curing agent produced by author is made of diamine, imidazolinium compounds, silane coupling agents, mineral filler and catalyst. The said modified epoxide resin adhesive agent can be cured in room temperature and has the good characteristics of oil resistant, water resistant, acid and alkali resistant and resistance to organic solvent, also can adhere to the damp face, oil face, metal, plastic, ceramic, hard rubber and wood and so on.

Owner:李洁华

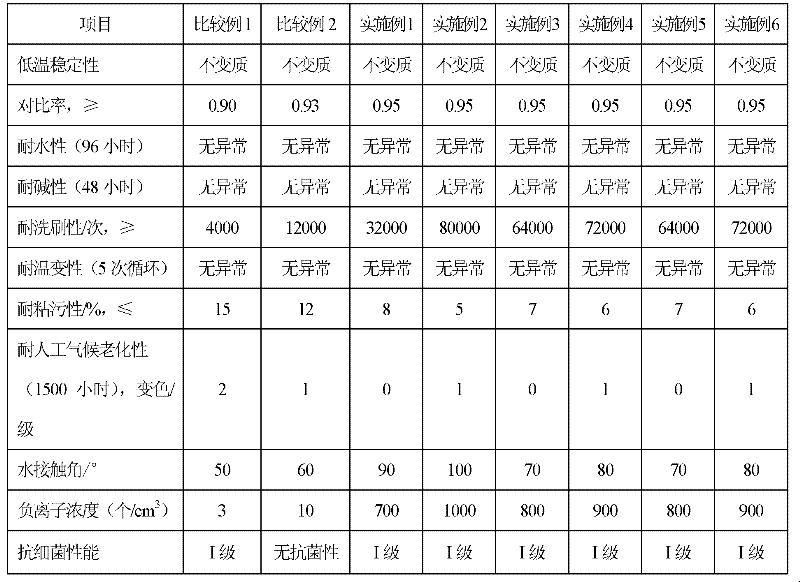

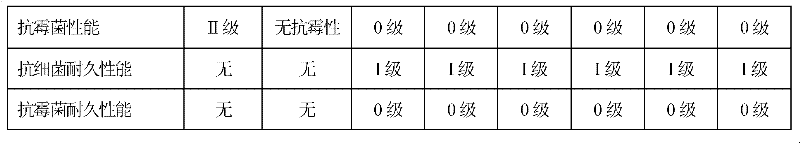

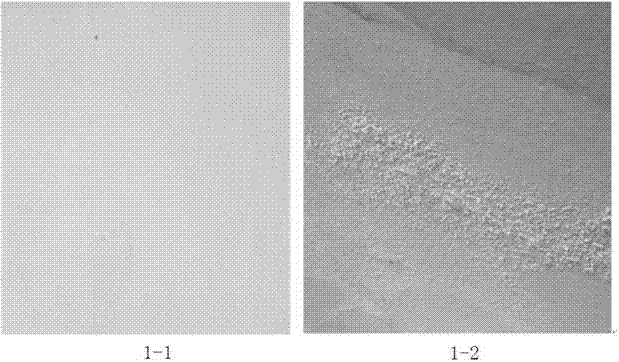

High-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and preparation method thereof

ActiveCN102417748AEasy to disperseStorage stableAntifouling/underwater paintsPaints with biocidesVolatile organic compoundEmulsion

The invention relates to a paint technology, an environment-friendly technology and an antibacterial mould-proof technology, in particular to high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and a preparation method thereof. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint comprises the following components in percentage by weight: 0.5 to 5 percent of wetting dispersant, 0.01 to 20 percent of inorganic composite nano antibacterial agent concentrated pulp, 0.5 to 10 percent of hydrophobing agent, 0.5 to 10 percent of anionic powder, 0.5 to 8 percent of film-forming aid, 0.1 to 2 percent of anti-settling agent, 0.8 to 10 percent of antifreezing agent, 0.1 to 3 percent of defoaming agent, 4 to 30 percent of pigment, 0 to 30 percent of filler, 15 to 45 percent of emulsion, 0.1 to 4 percent of thickening agent, 0.1 to 3 percent of flatting agent, 0 to 3 percent of pH regulator and 0.5 to 45 percent of water. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint is mainly prepared by adding the inorganic composite nano antibacterial agent into the basic materials, so that the paint has the coating characteristic of high performance, is low is cost, and has a function of purifying air, can eliminate harmful gas volatile organic compounds (VOC), formaldehyde and the like and also has a durable and high-efficiency antibacterial mould-proof function, so that the sterilizing rate within 6 hours reaches 100 percent and the mould-proof grade reaches the first grade. By the high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and the preparation method thereof, self-cleaning performance, hydrophobicity, scrubbing resistance, dirt resistance and weather resistance of the coating are improved; and the high-efficiency and durable antibacterial and mould-proof effect is achieved.

Owner:广东腐蚀科学与技术创新研究院

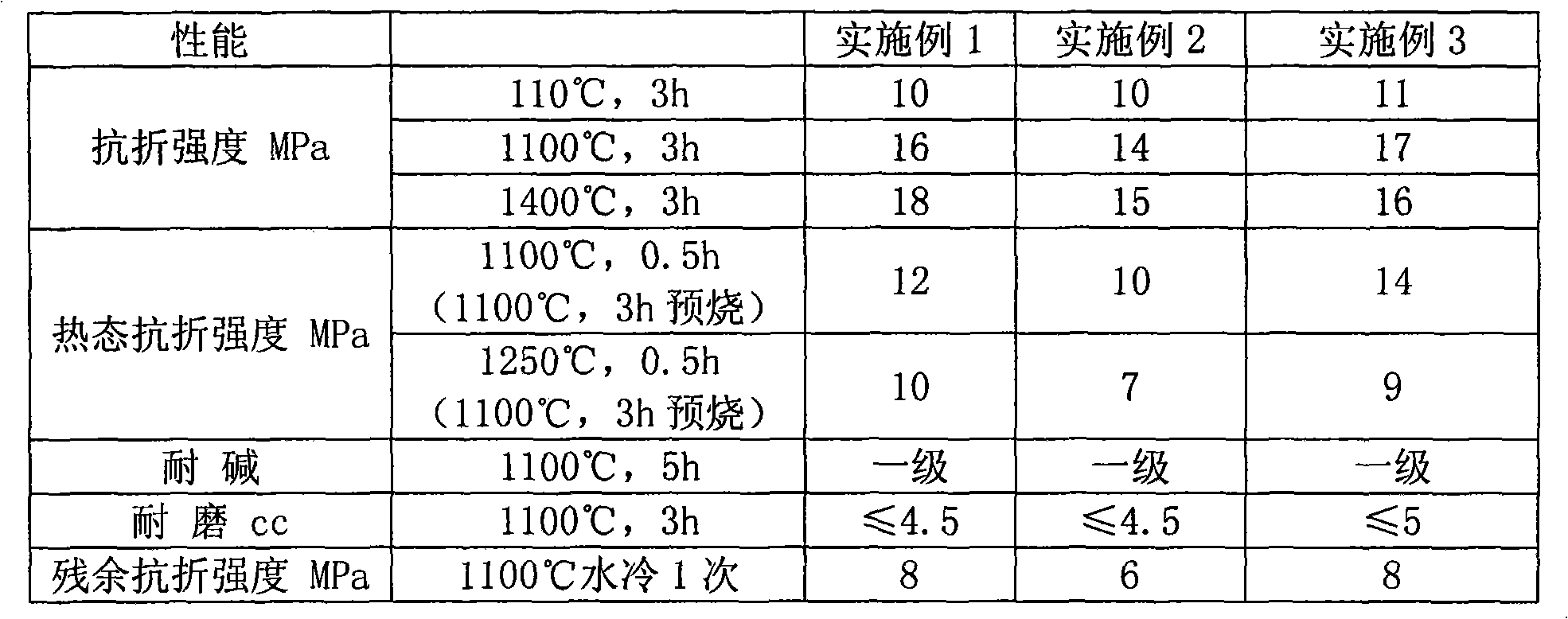

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Glass fibre reinforced nylon colorful heat insulation stripe for al-alloy door & window and method for preparing same

InactiveCN101307147ADifficult to disperseSolve easy discolorationDoors/windowsMasterbatchGlass fiber

The invention discloses a glass fiber reinforced nylon colored insulated strip used for an aluminum alloy door and window. The compositions by weight portion of the glass fiber reinforced nylon colored insulated strip are: 100 portions of nylon resin, 5 to 50 portions of glass fibers, 0 to 50 portions of inorganic filler, 5 to 25 portions of toughening agent, 0.3 to 5 portions of coupling agent, 0.3 to 5 portions of dispersing lubricant, 0.2 to 5 portions of antioxidant, 0.1 to 1 portion of light stabilizer, 0.1 to 1 portion of heat stabilizer and 2 to 10 portions of colored masterbatch. The invention also discloses a method for preparing the colored insulated strip. The glass fiber reinforced nylon colored insulated strip solves the problems that the masterbatch and the filler are difficult to disperse and nylon 66 is easy to change color during the processing procedure; the insulated strip products have various colors, superior performance and beautiful appearance; and the glass fiber reinforced nylon colored insulated strip realizes perfect matching with the window color, can achieve the beautility effect, meets and enlarges the demand of clients and the market, and is favorable for promotion, use and development of the glass fiber reinforced nylon 66 insulated strip.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

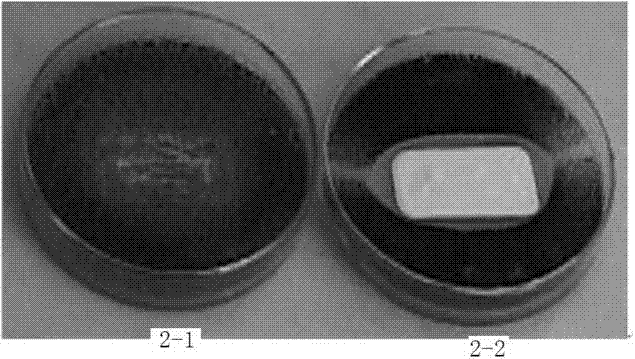

Nano-silica sol-modified outer wall paint and preparation method thereof

The invention discloses nano-silica sol-modified outer wall paint and a preparation method thereof. The nano-silica sol-modified outer wall paint comprises, by weight, 10-25% of nano-silica sol, 0.1-0.2% of a coupling agent, 0.2-2.0% of a neutralizer, 10-30% of an acrylic emulsion or a styrene-acrylic emulsion, 10-15% of a pigment, 10-20% of a filler, 0.2-0.4% of a dispersant, 0.2-0.4% of a wetting agent, 0.3-2.0% of a thickening agent, 0.2-0.4% of an antifoaming agent, 0.4-0.6% of a mildew-resistant antiseptic, 0.6-1.4% of an antifreezing agent, 0.4-1.2% of a film forming assistant and 20-30% of deionized water. The invention also provides the preparation method of the nano-silica sol-modified outer wall paint. The nano-silica sol-modified outer wall paint has good storage stability and can form a paint film which does not effloresce and fall off easily, has good permeability, does not mildew easily, and has excellent water resistance and alkali resistance.

Owner:CHANGSHA UNIVERSITY

Aqueous organic-inorganic composite coating and preparation method thereof

The invention discloses an aqueous organic-inorganic composite coating, comprising the base materials of water-soluble film-forming material, pigment, filler, additive and water. The aqueous organic-inorganic composite coating is specifically composed of the following component, by weight: 15-25 parts of potassium silicate, 10-20 parts of styrene-acrylic emulsion, 0.2-0.5 part of stabilizer, 0.2-0.5 part of dispersing agent, 0.3-0.6 part of defoaming agent, 0.2-0.5 part of film-forming additive, 0.2-0.5 part of antifreeze, 0.1-0.3 part of thickening agent, 14-20 parts of titanium dioxide, 15-25 parts of heavy calcium, 5-10 parts of talcum powder and 20-25 parts of water. The invention has the following advantages: high film hardness, no cracking, excellent weather fastness, lasting replenished film, no addition of preservatives, excellent environmental protection performance, long recoating period of film and resource saving. In addition, the product has minimal construction resistance, and is easy for painting, promotion and application. The aqueous organic-inorganic composite coating has wide application range, and can be applied to coating of basement, underground parking, inner wall and outer wall.

Owner:广东嘉宝莉科技材料有限公司

Surface treatment agent for metal, surface treatment method for metallic material, and surface-treated metallic material

InactiveCN101048476AImprove corrosion resistanceGood alkali resistancePolyurea/polyurethane coatingsMetallic material coating processesVanadium CompoundsEmulsion

An agent for treating metal surfaces which comprises an aqueous medium and, incorporated therein, (A) a cationic urethane resin which is water-soluble or in an aqueous emulsion form, (B) a cationic polycondensation product obtained from a phenol compound and an aldehyde, and (C) a zirconium compound and / or titanium compound. A coating film formed from the treating agent imparts excellent corrosion resistance and alkali resistance to a metallic material. When the proportion of the urethane resin (A) is equal to or higher than that of the polycondensation product (B), yellowing resistance can be also imparted. By incorporating a metal compound (D) containing a specific metal, excellent blacking resistance also can be imparted. Furthermore, by incorporating an acid ingredient (E) and a vanadium compound (F), a further improvement in performances can be attained.

Owner:NIHON PARKERIZING

Emulsified acrylic acid modified asphalt cement group waterproof coating material and method for producing the same

InactiveCN101220233AGood alkali resistanceAvoid demulsificationAntifouling/underwater paintsPaints with biocidesEmulsionAsphalt

The invention relates to an acrylic acid modified asphalt cement-based and water-proof coating and a preparation method. The emulsified acrylic acid modified asphalt cement-based and water-proof coating consists of component A and component B; wherein, the mixture ratio of the component A to the component B is from 1 : 0.5 to 1.5 (in weight); wherein, the raw materials of component A and the weight percentage thereof are respectively as follows: acrylic emulsion or amphetamine emulsion accounting for 40 to 70 percent, emulsified asphalt accounting for 10 to 50 percent, filler accounting for 8 to 20 percent, accessory ingredient accounting for 0.1 to 3 percent and water accounting for 1 to 19.0 percent; the raw materials of component B and the weight percentage thereof are as follows respectively: cement accounting for 70 to 100 percent and filler accounting for 0 to 30 percent. The acrylic acid modified asphalt cement-based and water-proof coating has the advantages of strong binding power with the base, high tensile strength, large unit extension, low cost and environment protection.

Owner:WUHAN YANGGUANG CONSTR NEW MATERIAL

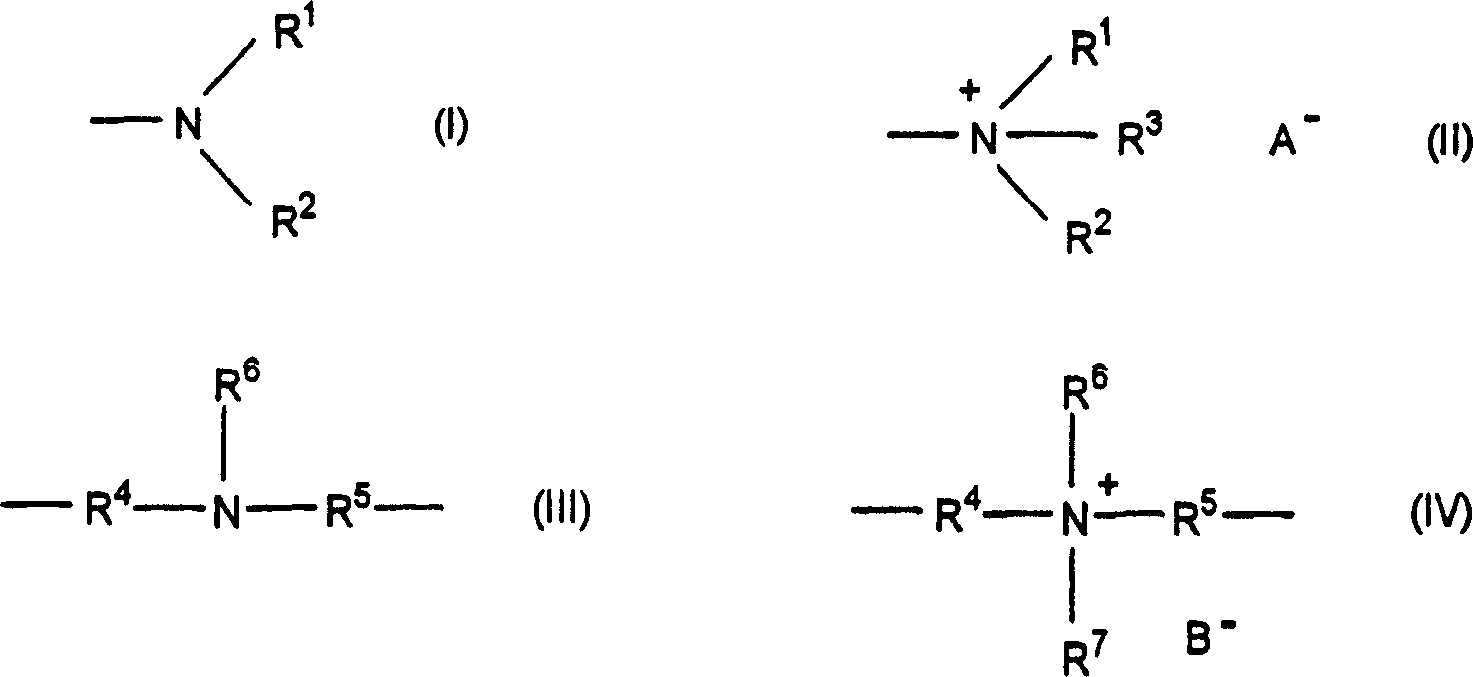

Alkali resistant glass compositions

ActiveUS7744689B2Good alkali resistanceReduce manufacturing costAlkali metal silicate coatingsInorganic adhesivesAlkali metalTitanium dioxide

An alkali resistant glass composition having improved durability to withstand highly alkali environments at elevated temperatures, such as curing of cementitious products in an autoclave, is conveniently formed from economical and abundant materials. The glass composition includes increased levels of calcium and iron, and relatively low levels of alkali metals, as compared to many other alkali resistant glass products, and comprises essentially of, by weight, >35% Si2O3, 1-25% CaO, 1-15% Fe2O3, 1-10% R2O, and an amount of Al2O3 such that the ratio of Si2O3:Al2O3 is greater than or equal to 1. Alkali resistance can be improved by forming a passivity layer on the surface of glass articles by treating the articles hydrothermally in a basic environment. Optionally zirconia and / or titania may be added to the composition to further improve alkali resistance.

Owner:JAMES HARDIE TECH LTD

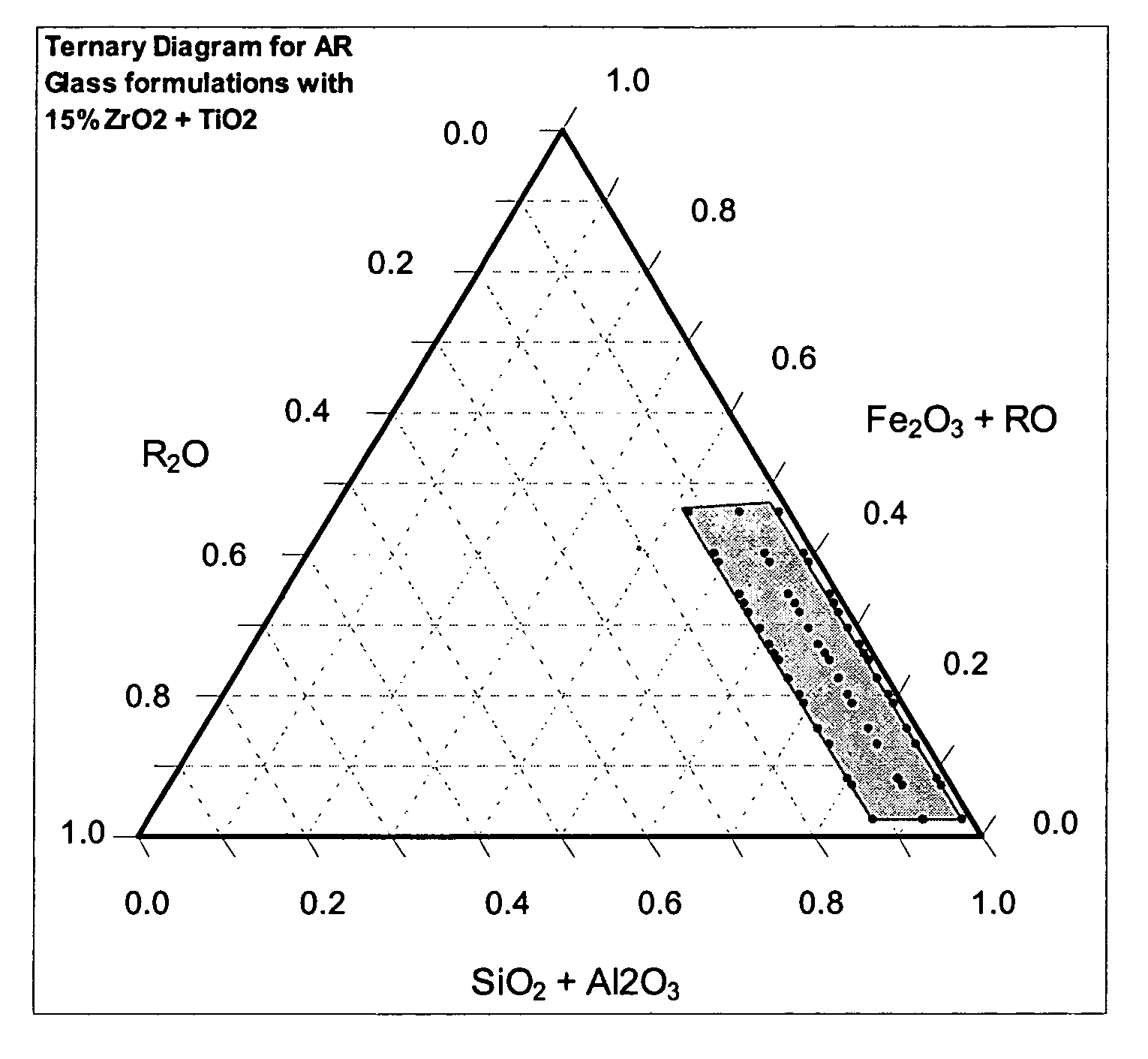

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Antireflective coating, coating composition, and antireflective coated article

InactiveUS20060078717A1Good alkali resistanceImproved resistance marGroup 4/14 element organic compoundsLayered productsSynthetic resinAqueous solution

An antireflective coating having improved alkali resistance is formed on a transparent substrate of synthetic resin as an outermost layer and has a three-dimensional crosslinked structure containing F and Si atoms. The crosslinked structure is composed of Si—O—Si and Si—C2H4—(CF2)n—C2H4—Si linkages wherein n is 4 or 6; the molar ratio of F atoms to Si atoms is from 8.0 to 10.0; and perfluoroalkyl groups account for 90 to 100 mol % of all monovalent organic substituent groups attached to silicon atoms. The antireflective coating can exhibit such alkali resistance that when a droplet of a 1 wt % NaOH aqueous solution is rested on the antireflective coating for 30 minutes and then wiped off, the appearance of the coating is kept unchanged from the initial appearance.

Owner:SHIN ETSU CHEM IND CO LTD

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

Antifouling flash insulator coating and preparation method thereof

ActiveCN101787244AGood electrical performanceImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesChemistryMoisture

The invention relates to a preparation method of antifouling flash insulator coating which is prepared by mixing fluorine-containing polysiloxane component A, linear hydroxyl-terminated polysiloxane component B, organic and inorganic silicon dioxide taken as reinforcing material component C, functional powder material component D, cross-linking agent E, catalyst component F and tackifier component G. The method prepares the single-component moisture curing antifouling flash insulator coating which is removed alcohol and oxime by adding fluorine-containing silicon material into the hydroxyl-terminated linear silicone and the reinforcing material, and has good electrical performance and aging resistance, better antifouling flash capability and excellent hydrophobicity and hydrophobicity migration performance.

Owner:TIANJIN DYLAN POWER TECH

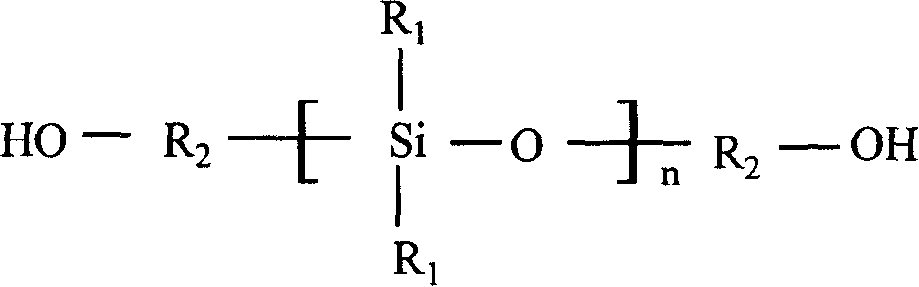

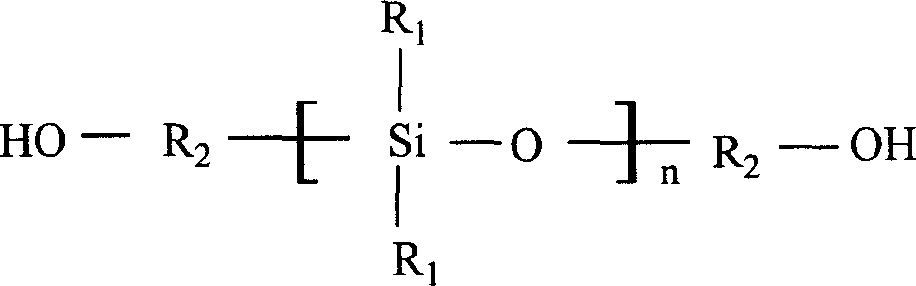

Preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and product thereof

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

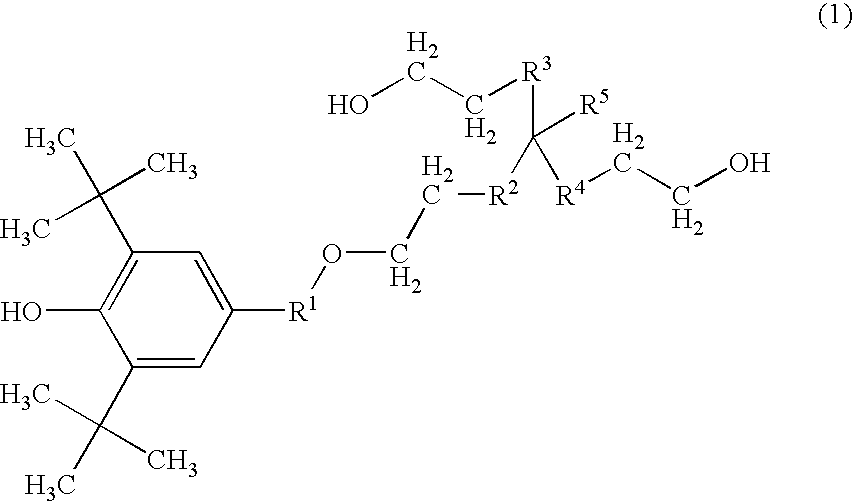

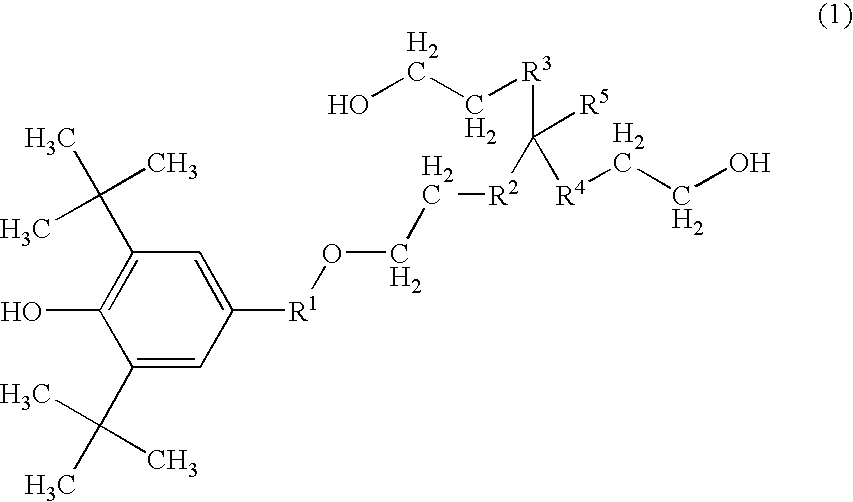

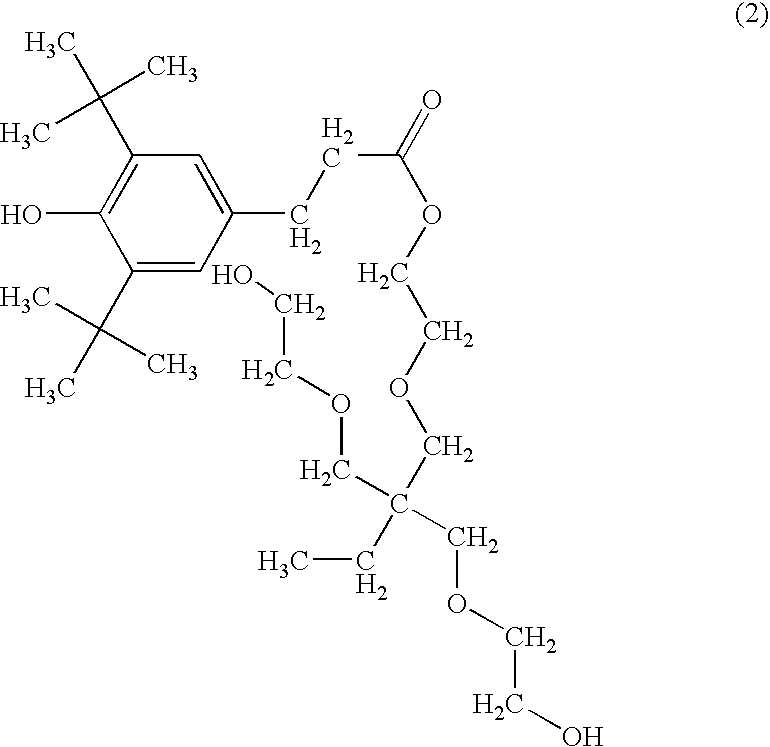

Resin with function of oxidation inhibition and emulsion thereof

InactiveUS7169844B2Good dispersionGood light fastnessPolyurea/polyurethane coatingsChemical inhibitorsEmulsionHydrogen

An emulsion of resin having a function of oxidation inhibition obtained by subjecting an antioxidant (A) having two or more alcoholic hydroxy groups, a polyol compounds (B) as an optical ingredient, a compound (C) having a carboxy group and an active-hydrogen group, and an organic polyisocyanate (D) to urethanation reaction in an organic solvent, neutralizing the resultant resin solution with a neutralizing agent (E), and then dispersing the solution in water. A resin having the function of oxidation inhibition is obtained from the emulsion.

Owner:DAICEL CHEM IND LTD

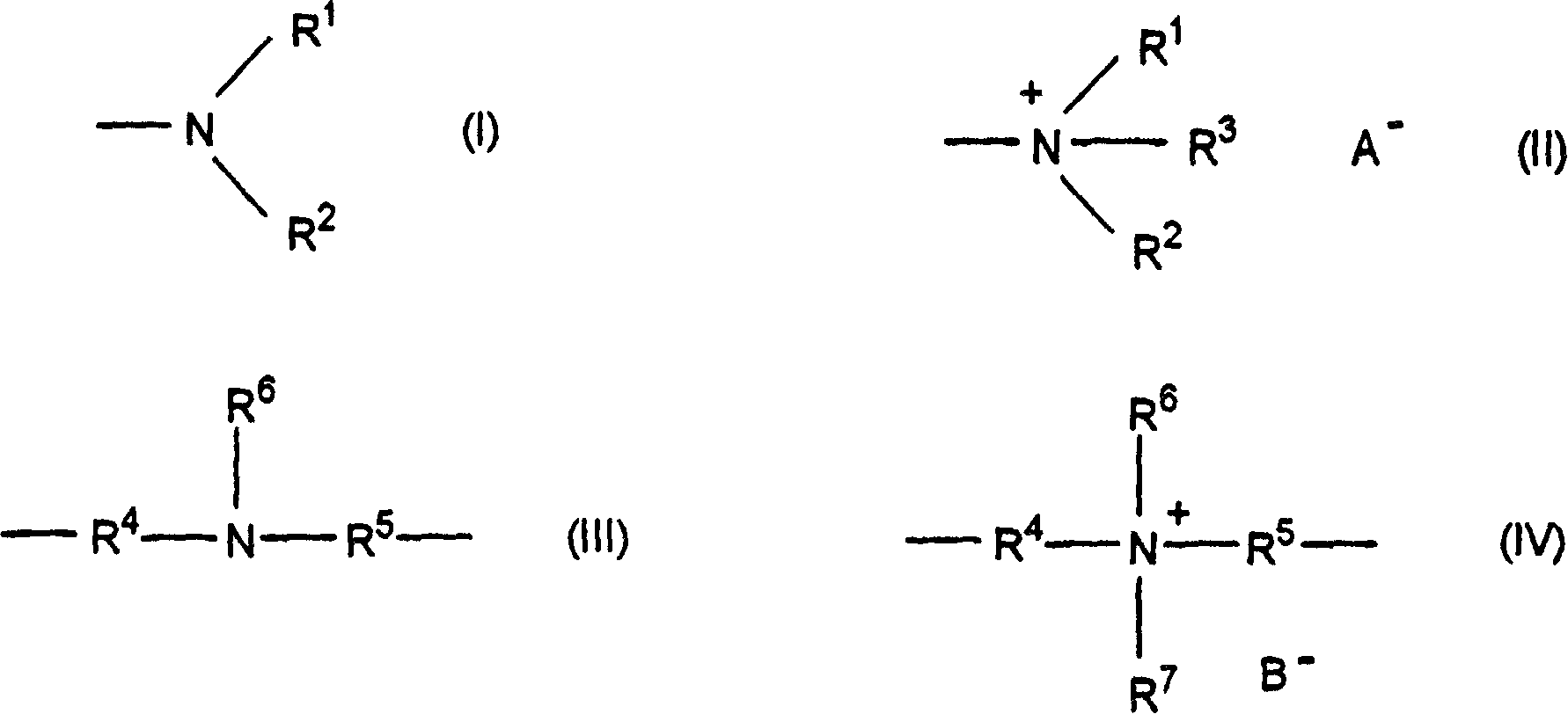

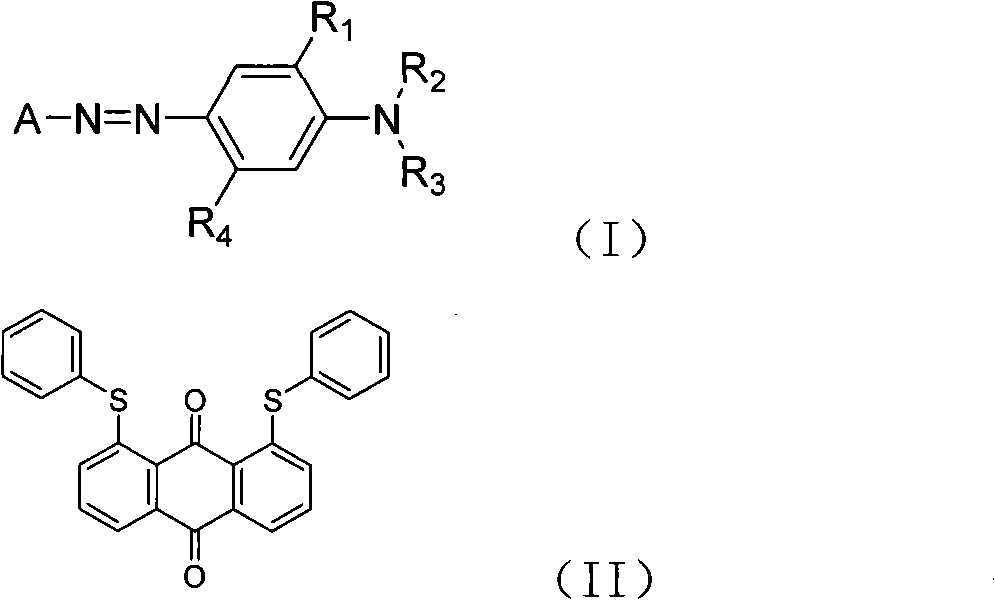

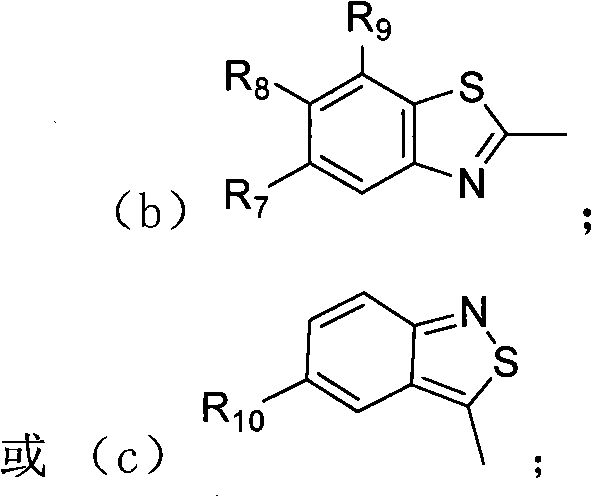

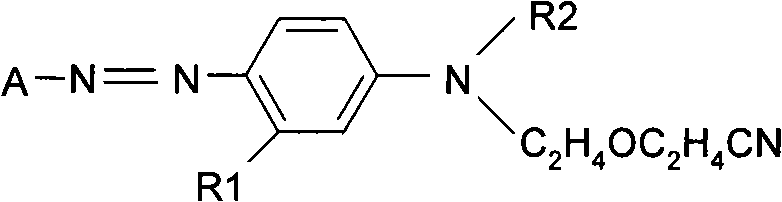

Azo dye composition and application thereof

ActiveCN101265369AChromatography is completeBright shadeOrganic dyesDyeing processAlkalinityDisperse dye

The invention relates to an azo dye compound and the application thereof. The compound is the combination of at least two dyes with A in the general formula (I) selected from any structure of (a), (b) or (c); any combination with A to be at least one from (a), at least one from (b) or at least one from (c); or the combination of at least one dye shown by the general formula (1) and at least one general disperse dye, or / and a dye as shown by the formula (2). Each substituent is shown as the claim of right. The compound can dye polyester and blended fabric thereof under the condition of strong alkalinity with pH more than or equal to 11 and less than or equal to 14; the alkalinity condition can effectively remove slurry and oil on the fabric, and overcomes the defect that decomposition products can be separated out in an acid bath, and cause dyeing defect. The cloth and the fabric adopting the azo dye compound are neat and have excellent styles. In addition, the polyester fiber and the blended fabric thereof can be pretreated with alkalinity and be dyed in a bath and at one step, thus improving the efficiency, and reducing the manufacturing cost and the waste water from dyeing.

Owner:浙江昱泰染化科技有限公司

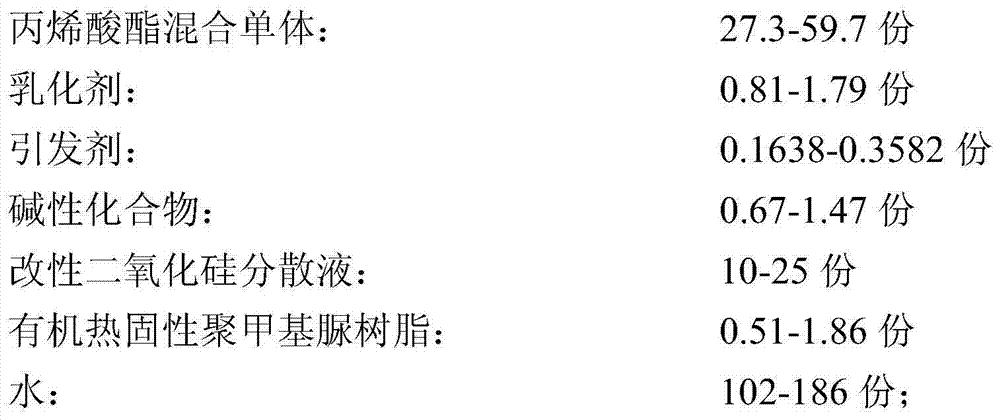

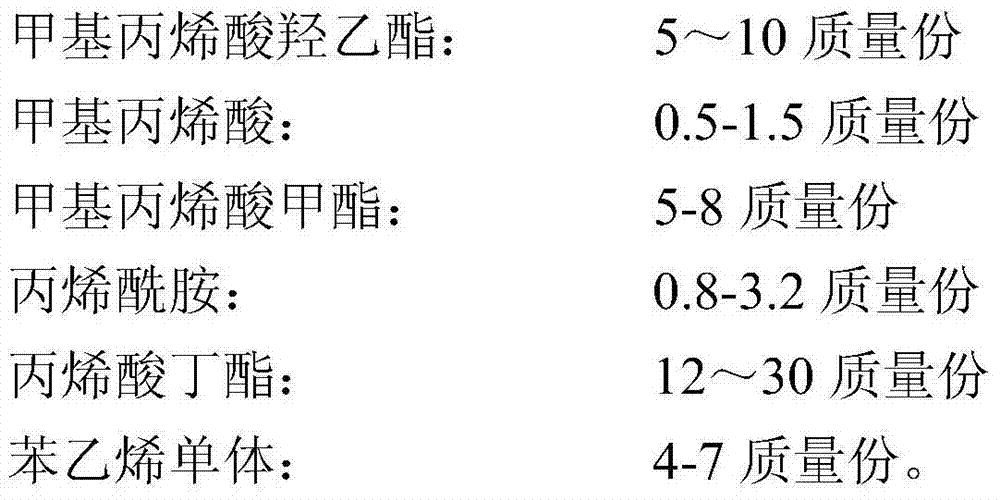

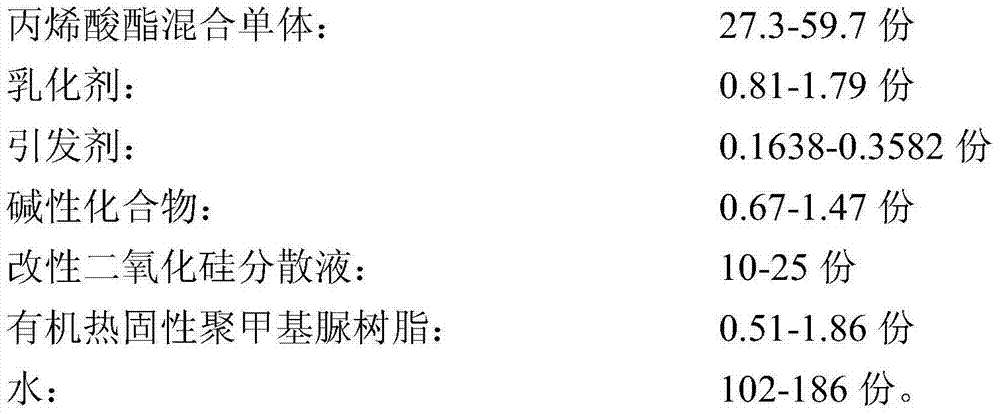

Aqueous multi-functional crylic acid extinction resin and preparation method thereof

The invention discloses an aqueous multi-functional crylic acid extinction resin and a preparation method thereof and belongs to the field of extinction type coatings. The preparation method of the aqueous multi-functional crylic acid extinction resin comprises the following steps: (1) preparing a crylic acid ester mixture monomer; (2) sufficiently mixing water, an emulsifier and a part of the crylic acid ester mixture monomer, heating to 70-90 DEG C, adding an initiator to react for 0.5-1 hour, dropwise adding the rest crylic acid ester mixture monomer within 3-5 hours, adding the rest initiator in different batches, performing heat preservation for 1-3 hours after the dropwise adding, cooling to 45 DEG C, sequentially adding modified silicon dioxide and an organic thermosetting polymethylurea resin with the particle size of 3.5mu m, uniformly stirring, cooling down and discharging so as to obtain the aqueous multi-functional crylic acid extinction resin. The aqueous multi-functional crylic acid extinction resin prepared by the preparation method disclosed by the invention is high in extinction efficiency, excellent in water resistance, acid resistance and alkali resistance, and good in abrasion resistance property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

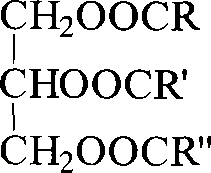

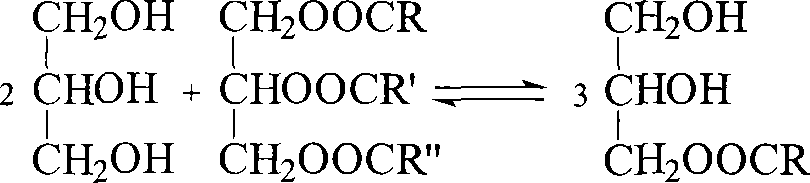

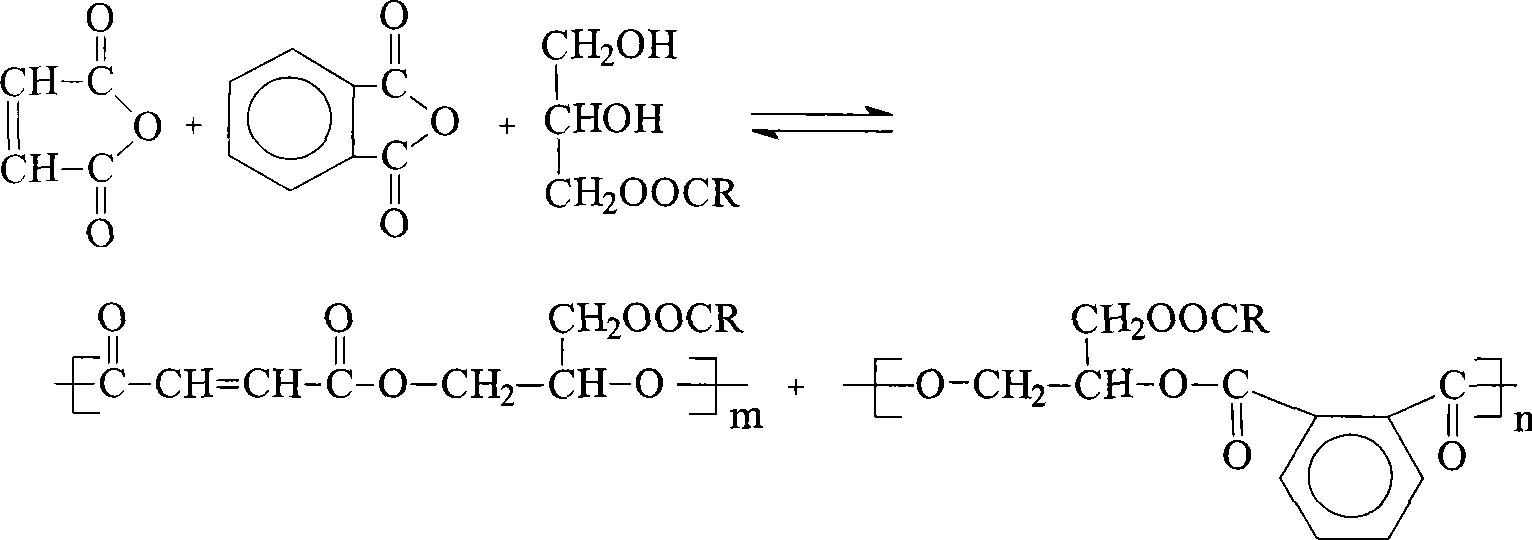

Method for synthesizing unsaturated polyester resin

The invention relates to a process for synthesizing unsaturated polyester resin with renewable vegetable fat, which comprises generating acid ester through conducting alcoholysis reaction for vegetable oil and organic polyatomic alcohol, using as modified dihydric alcohol and being leading to the typical synthesis formulation of unsaturated polyester resin, completely replacing conventional dihydric alcohol, using for synthesizing unsaturated polyester, and then mixing with cross-linking monomer. The resin which is synthesized has excellent hue, appropriate viscosity, excellent heat stability, favorable alkali resistivity, wonderful flexible property and low shrinking rate, which is suitable for various composite material shaping technology such as hand lay-up, winding and spraying and the like. Renewable raw material of vegetable oil with cheap price is applied in the synthesis process of the invention, and the stability of product is excellent.

Owner:江苏大力士云石护理材料有限公司

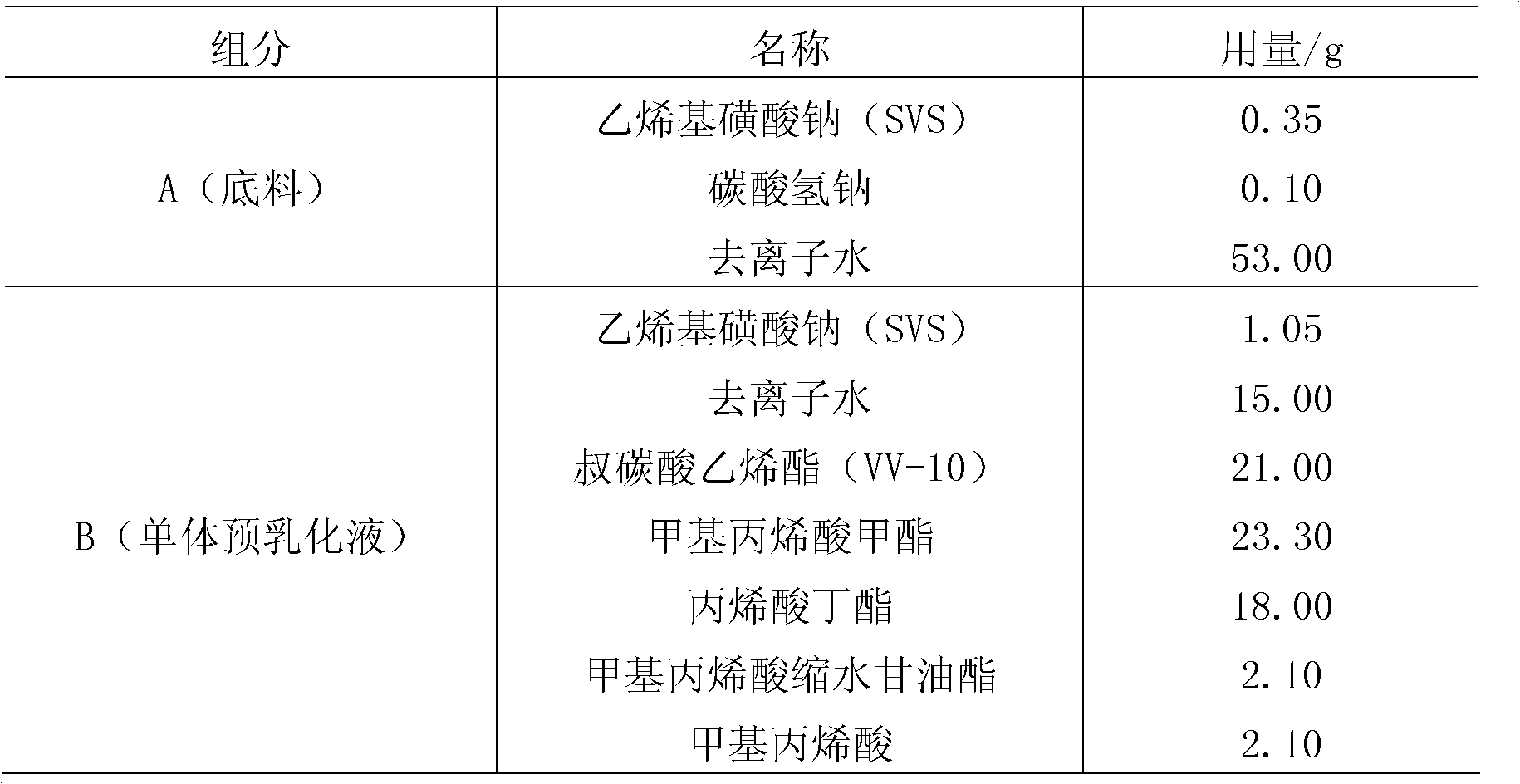

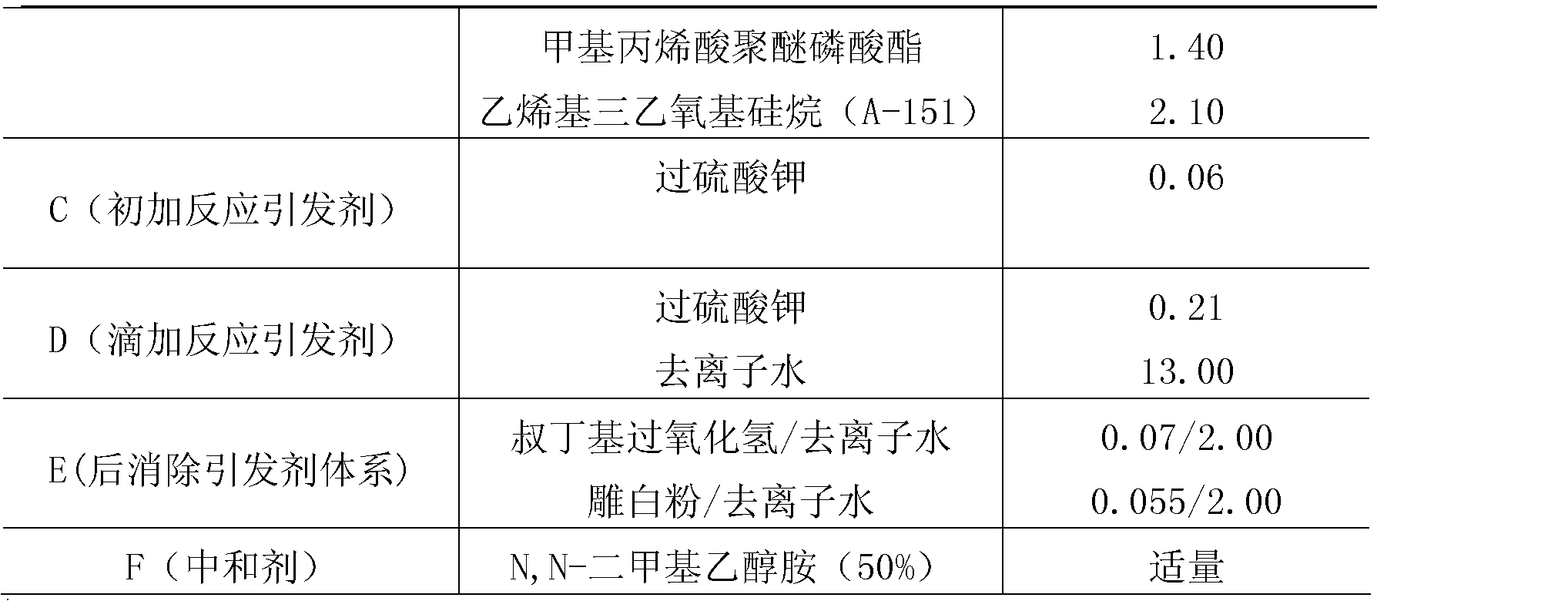

Preparation method for anti-rust soap-free acrylate emulsion

The invention relates to a preparation method for a base material of an anti-rust coating. The preparation method for an anti-rust soap-free acrylate emulsion is characterized in that a reactive emulsifier is selected, a polymeric monomer comprises (methyl) acrylic acid and an acrylic monomer thereof, a versatic acid vinyl monomer and a crosslinking monomer, a phosphate monomer is taken as a modified monomer, and the emulsion polymerization is carried out through semi-continue process under the action of an initiator, so that the soap-free anti-rust acrylate emulsion adopting water as dispersive medium is synthesized. The preparation method for the anti-rust soap-free acrylate emulsion can not only meet the requirement of environmental protection, but also enhance the rust resistance.

Owner:HUBEI EAST ST SPECIAL COATING TECH

Steel mill continuous annealing galvanized sheet chromium-free compound passivator and preparation method thereof

InactiveCN103834938AImprove corrosion resistanceExcellent coating adhesion performanceAnti-corrosive paintsMetallic material coating processesChromium freeEnvironmental resistance

The invention discloses a steel mill continuous annealing galvanized sheet chromium-free compound passivator which comprises the following raw materials in percentage by weight: 5-20 percent by weight of a main film-forming agent, 0.1-5 percent by weight of a coupling agent, 0.1-0.5 percent by weight of inorganic complex film-forming agent, 0.1-4 percent by weight of silicate, 0.1-0.4 percent of an emulsifying agent, 0.1-0.2 percent of a dispersing agent, 0.1-0.4 percent of a corrosion inhibitor, 0.1-0.3 percent of a protective colloid, 0.1-1 percent of a nanometer sealing agent, 0.1-0.4 percent of phosphate and the balance of water. The steel mill continuous annealing galvanized sheet chromium-free compound passivator disclosed by the invention is uniform in appearance, stabilizes a liquid, has an expiration date of above 90 days, is nontoxic and environment-friendly, and accords with the ROHS (Restriction Of Hazardous Substances) requirement. The steel mill continuous annealing galvanized sheet chromium-free compound passivator is simple in preparation process; a passivated film is uniform in appearance and has certain glossness. A galvanized sheet passivated by using the passivator has the advantages that the corrosion resistance is remarkably improved, the neutral salt mist SST (Sea Surface Temperature) resistant time reaches above 72 hours, the white rust area is less than 5 percent, the blackening resistance delta E is less than 5, the yellowing resistance delta E is less than 3, the alkaline resistance delta E is less than 3, the interlamination resistance R is less than 3 omega / cm, and the conductivity is less than 1 m Omega.

Owner:NORTHEASTERN UNIV

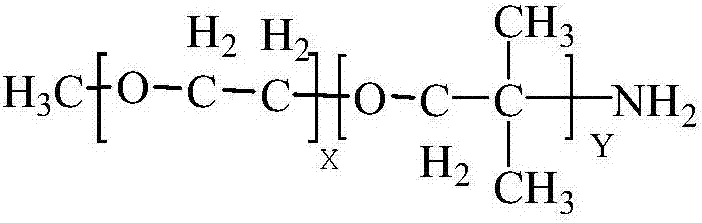

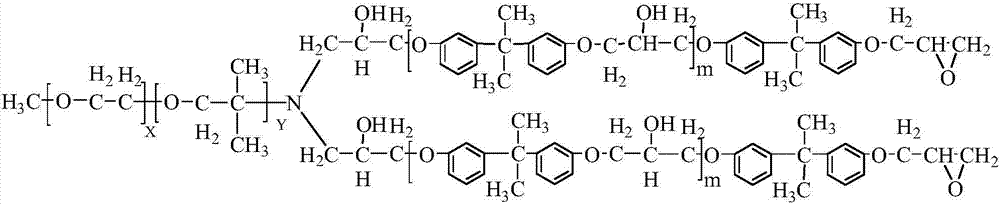

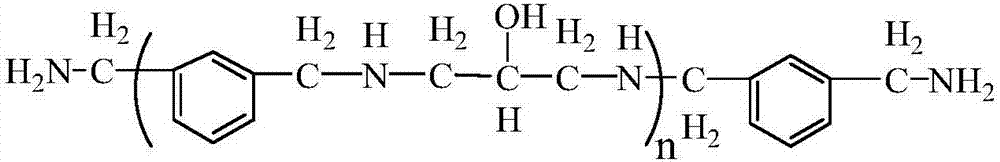

Nonionic waterborne epoxy resin emulsion, nonionic waterborne epoxy curing agent, preparation method of nonionic waterborne epoxy resin emulsion and nonionic waterborne epoxy curing agent and waterborne epoxy resin varnish

InactiveCN106987194AThe synthesis process is simpleMild conditionsEmulsion paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention discloses a nonionic waterborne epoxy resin emulsion, a nonionic waterborne epoxy curing agent, a preparation method of the nonionic waterborne epoxy resin emulsion and the nonionic waterborne epoxy curing agent and waterborne epoxy resin varnish. Polyether amine has reaction with epoxy resin to form a nonionic emulsifier, and then the nonionic waterborne epoxy resin emulsion is prepared through a phase inversion method; the nonionic waterborne epoxy curing agent matched with the nonionic waterborne epoxy resin emulsion during use is prepared; the prepared waterborne epoxy resin varnish comprises a component A and a component B, the component A is the nonionic waterborne epoxy resin emulsion and a defoaming agent, and the component B is the nonionic waterborne epoxy curing agent. The varnish film of the prepared waterborne epoxy resin varnish has comprehensive performance such as good water resistance, good acid resistance, good alkali resistance and high hardness.

Owner:SOUTH CHINA UNIV OF TECH

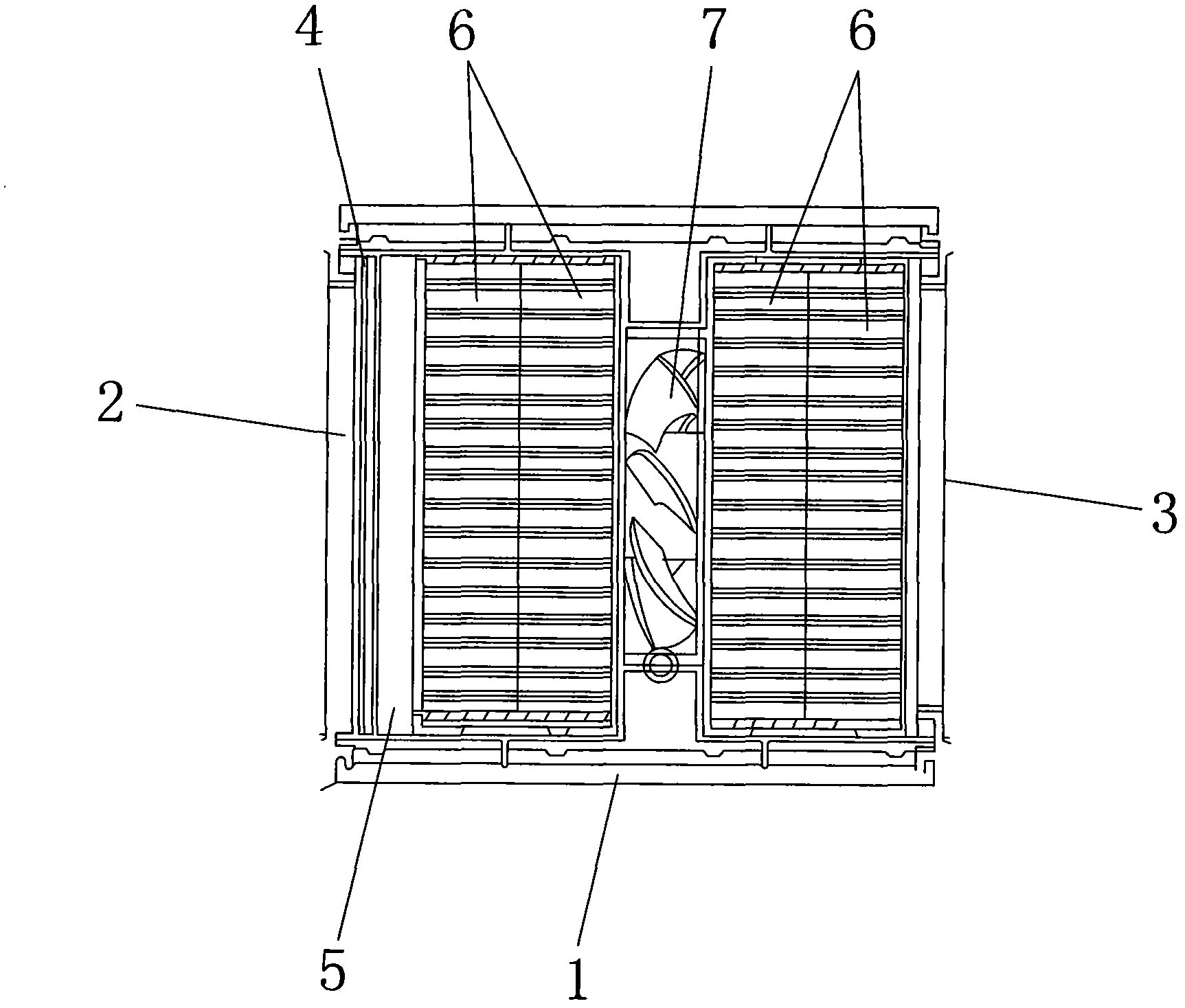

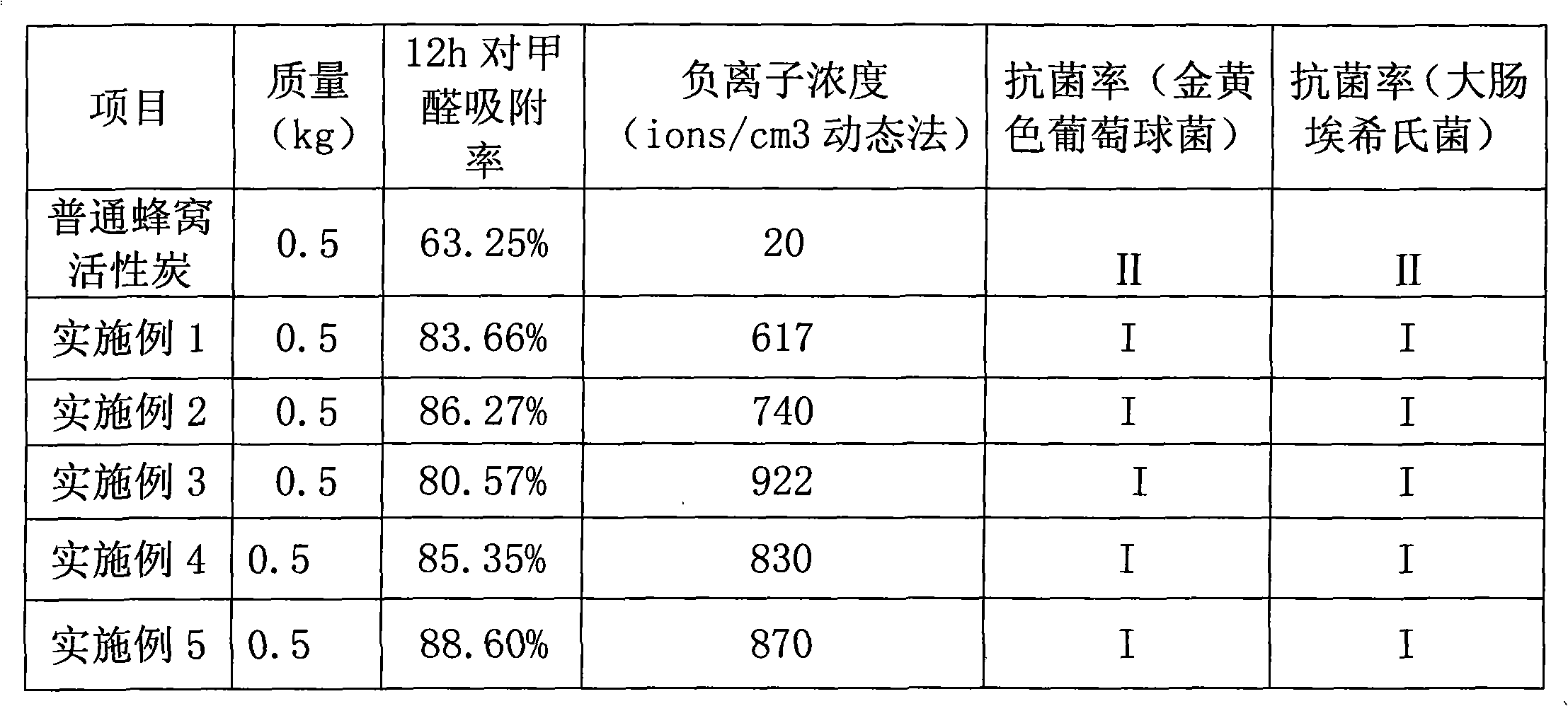

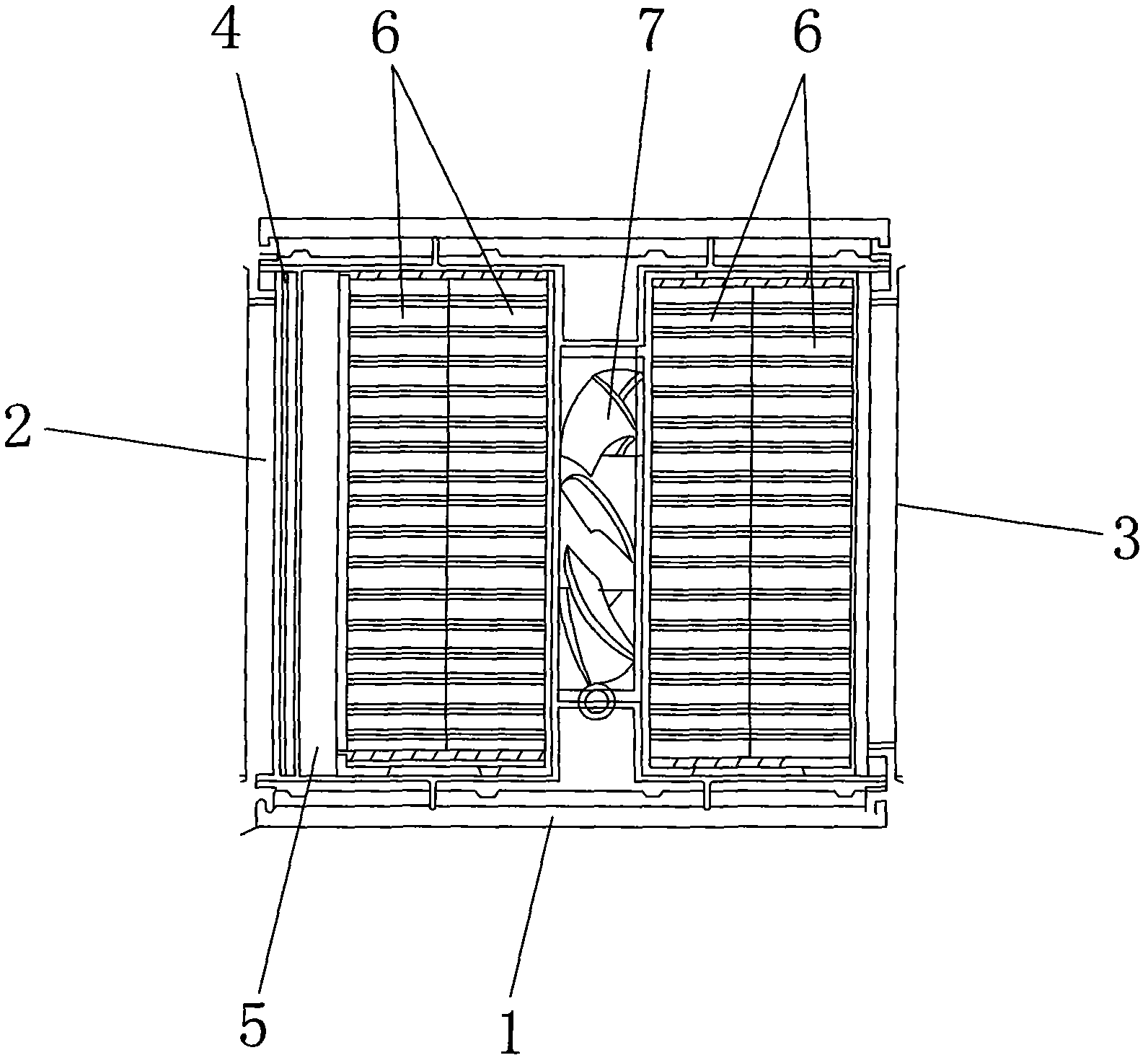

Honeycomb activated carbon, preparation method thereof, and air purifier prepared from honeycomb activated carbon

ActiveCN102489250AImprove adsorption capacityHigh strengthBiocideOther chemical processesParticulatesHEPA

The invention provides honeycomb activated carbon with a good purification function. The honeycomb activated carbon is characterized by consisting of the following components in percentage by weight: 50 to 75 percent of activated carbon, 20 to 40 percent of silicate, 3 to 15 percent of negative ion powder, and 1 to 5 percent of nano TiO2 powder. The activated carbon is prepared by the steps of mixing, ball-milling, filter-pressing and drying, pugging, performing extrusion molding, drying and calcining. An air purifier which is prepared from the activated carbon comprises a shell; two ends of the shell are provided with an air inlet and an air outlet; the air purifier is characterized in that: three plane filter plates, namely primary filter cotton, a high-efficiency particulate air (HEPA) high-efficiency filter element, and a cellular activated carbon sieve are sequentially arranged in the shell from the air inlet to the air outlet; and the three plane filter plates are parallel to the planes of the air inlet and the air outlet; and a fan is fixed on a support arranged in the shell, and a rotation shaft of the fan is vertical to the plane filter plates.

Owner:湖南文象炭基环保材料股份有限公司

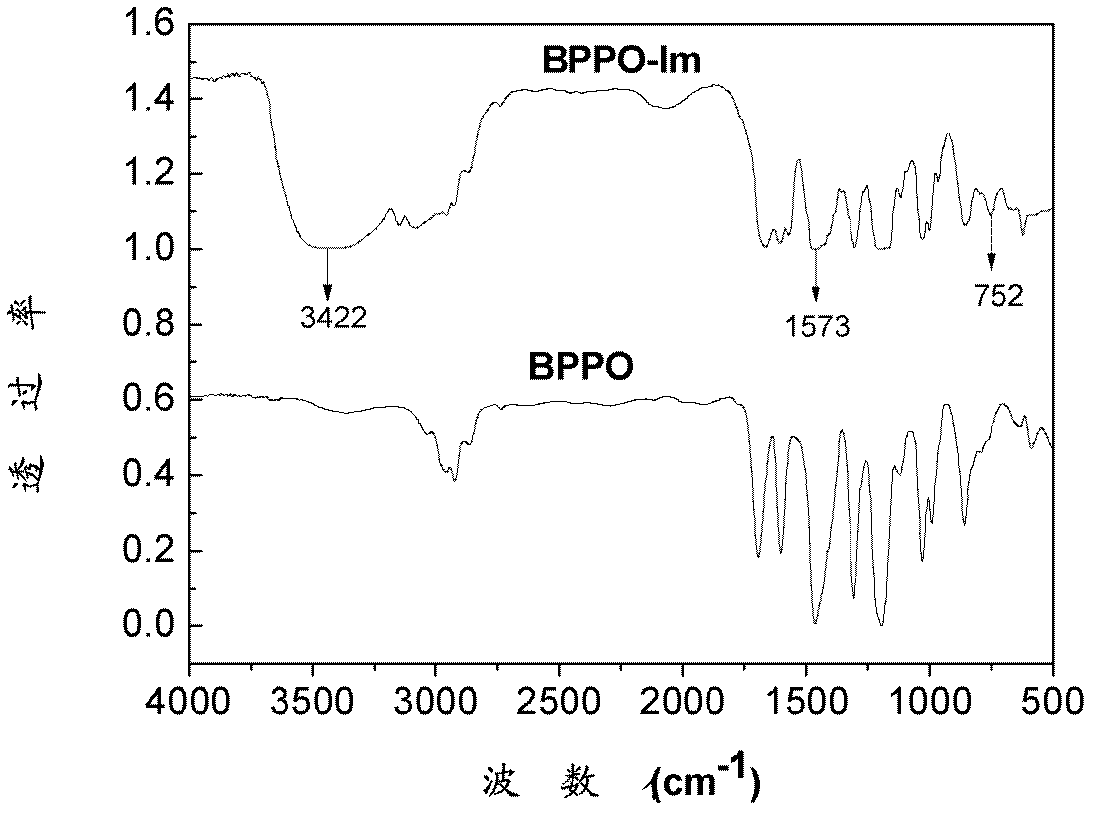

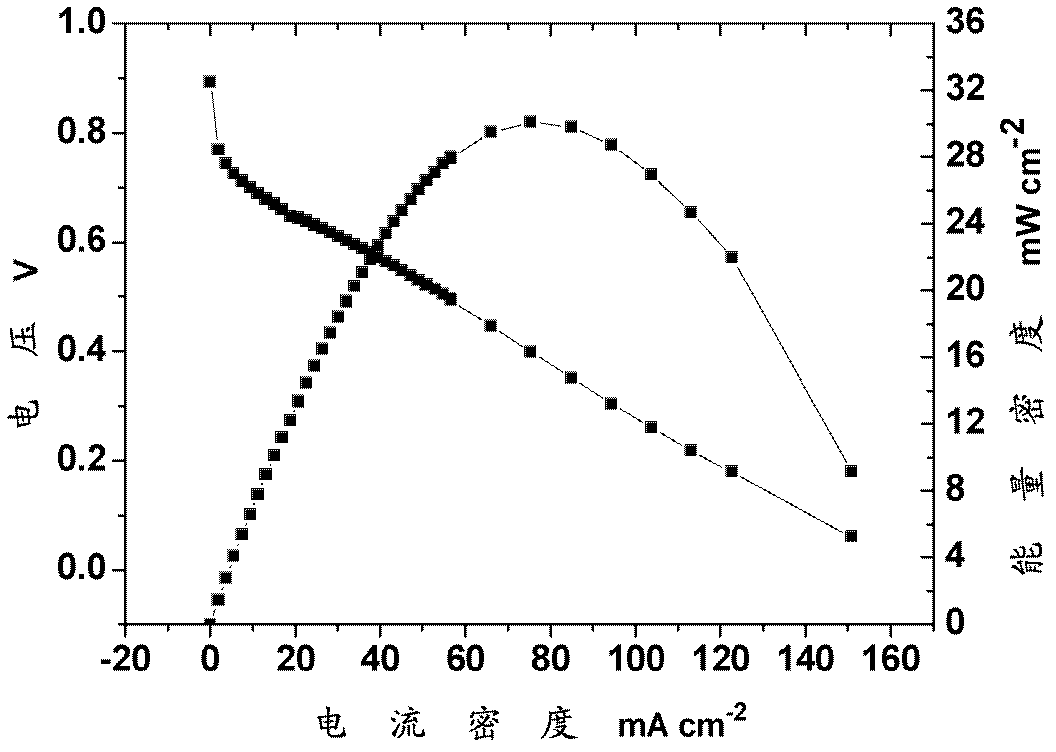

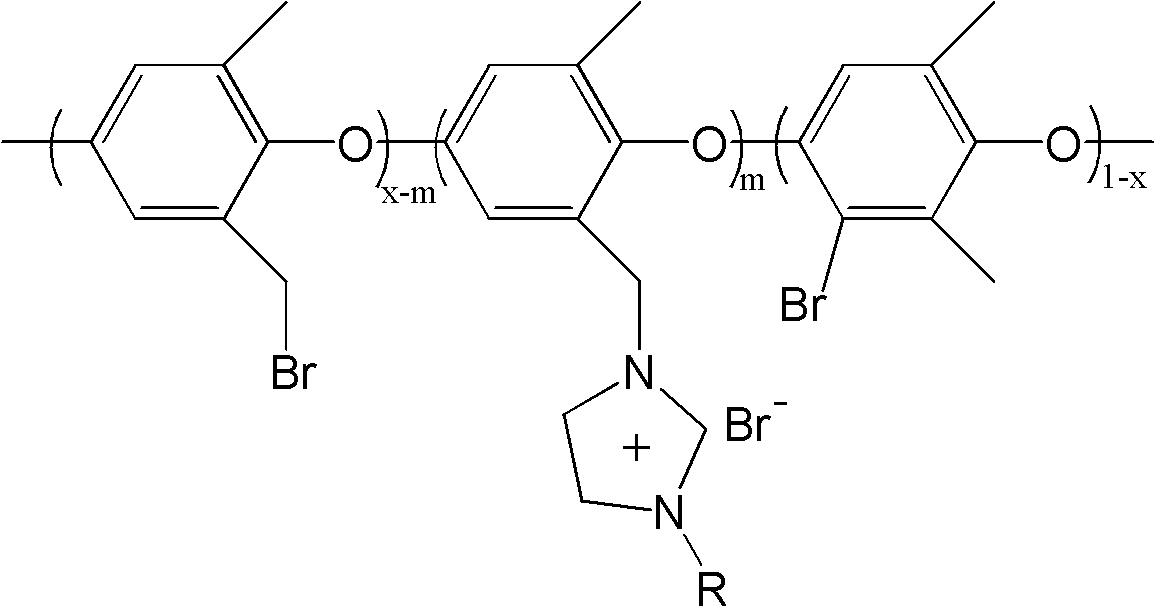

Anion-exchange film, preparation method thereof and fuel cell

ActiveCN103372381AOH-high conductivityGood thermal stabilitySemi-permeable membranesAnion exchangersIon-exchange membranesChemistry

The invention provides an anion-exchange film, a preparation method of the anion-exchange film and a fuel cell. The anion-exchange film comprises imidazole functionalized brominated polyphenylene oxide with the structure shown in the specification. The preparation technology of the film is simple, the obtained imidazole functionalized brominated polyphenylene oxide has excellent film properties, such as high anion-exchange film OH-conductivity, good heat stability and good alkaline resistance, and the performance of the film can be adjusted and controlled by simply changing the adding amount of N-substitution imidazole micromolecules.

Owner:UNIV OF SCI & TECH OF CHINA

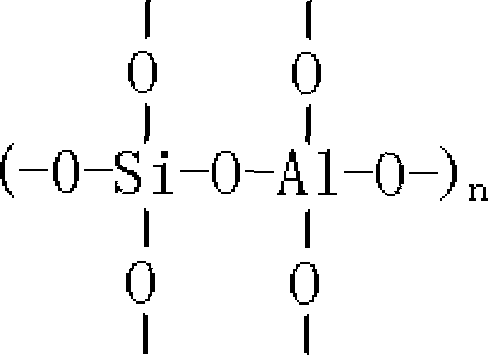

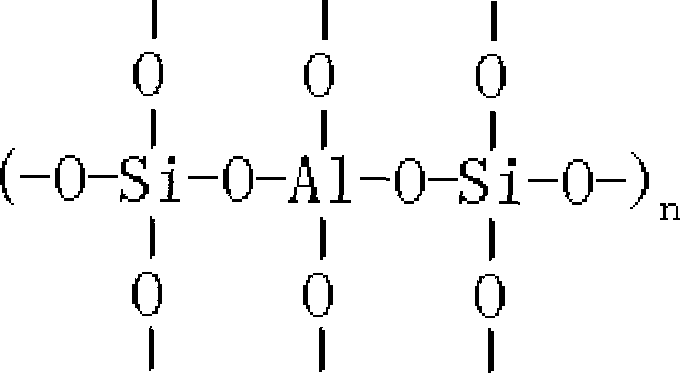

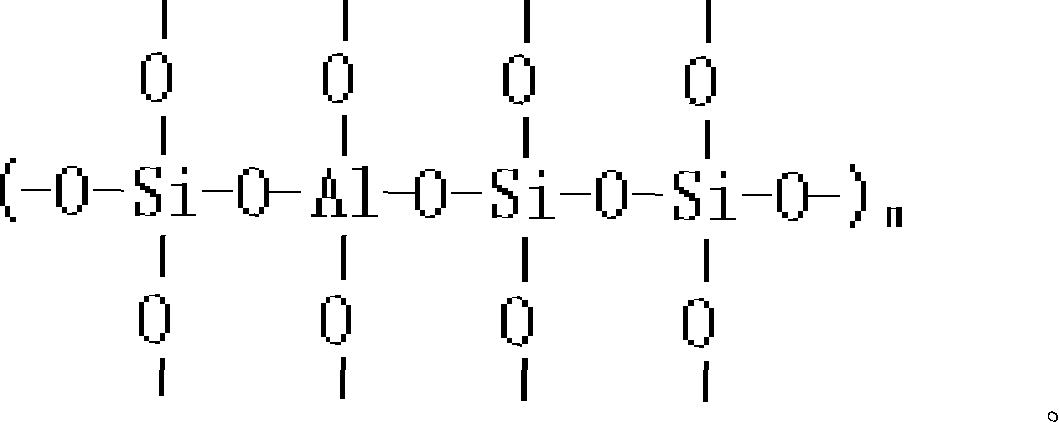

Polymer coating composite and preparation method thereof

InactiveCN101045832ALow costEasy to use on siteSolid waste managementCement productionPolymer scienceOxygen

This invention relates to a dope combination. The film coating it formed is amorphous gelatinous substance, base unit is three-dimensional network formed by connection of silicon - oxygen tetrahedron and aluminium - oxygen tetrahedron. end product takes electrovalent bond and covalent bond as main, vander waas bond as complement, possess linkage structure of organic heavy polymer, and double property of inorganic polymer and organic polymer. The unique performance supple the insufficiency of organic high molecular polymer. It possesses favorable performance of acid-proof, alkali-proof, impervious, antifreeze, seawater resistance and high temperature resistance.

Owner:袁景华 +1

Alkali resistant glass compositions

ActiveUS20060240967A1Good alkali resistanceReduce manufacturing costAlkali metal silicate coatingsInorganic adhesivesAlkali metalTitanium dioxide

An alkali resistant glass composition having improved durability to withstand highly alkali environments at elevated temperatures, such as curing of cementitious products in an autoclave, is conveniently formed from economical and abundant materials. The glass composition includes increased levels of calcium and iron, and relatively low levels of alkali metals, as compared to many other alkali resistant glass products, and comprises essentially of, by weight, >35% Si2O3, 1-25% CaO, 1-15% Fe2O3, 1-10% R2O, and an amount of Al2O3 such that the ratio of Si2O3:Al2O3 is greater than or equal to 1. Alkali resistance can be improved by forming a passivity layer on the surface of glass articles by treating the articles hydrothermally in a basic environment. Optionally zirconia and / or titania may be added to the composition to further improve alkali resistance.

Owner:JAMES HARDIE TECH LTD

Preparation method of cable fire-proof sealing filling

InactiveCN101037583AImprove fire resistanceImprove air tightnessOther chemical processesInsulated cablesAluminium hydroxideSlurry

The relates to a fireproof seal filler for ship cable transfixion channel and opening and preparing method thereof, which belongs to flame-proof sealing material technique field. Components and weight percent of raw materials employed by the invention are that: kaolin of 10-20%, talcum powder of 5-10 % and silicon micro-powder of 30-50% are used as base-material; aluminum hydroxide of 10-20%, hydrated zinc borate of 5-10% and magnesium hydroxide of 10-20% are used as flame retardant; wherein proportion of the base-material and the flame retardant is 1:1-2.3:1; in addition, coagulants of calcium sulfate, calcium chloride, magnesium chloride and sodium carbonate are added, weight percents of the four coagulants are separately 20-40% based on total weight of the base-material and the flame retardant as 100%. Firstly the coagulant is mixed with water to prepare serum, when actually using, the serum is added in mixed powder material of the base-material and the flame retardant, and the pasty fireproof seal filler is obtained by sufficiently stirring of highly effective stirring machine.

Owner:SHANGHAI UNIV

Surface treating agent with excellent alkali resistance and solvent resistance and for zinc coated steel plate

ActiveCN1887449AEasy to handleGood alkali resistancePretreated surfacesAnti-corrosive paintsTectorial membraneSolvent

The present invention relates to surface treating agent for zinc coated steel plate, and is especially one kind of surface treating agent with excellent alkali resistance and solvent resistance for zinc coated steel plate. The surface treating agent is water solution, which consists of fluoric acid with 4 or more fluorine atoms and at least one of Ti, Zr and Si atome in 0.1-5.0 wt%; phsosphorus containing compounding 0.01-0.5 wt%; one or more organic silicon coupling agent with amino group containing at least one active hydrogen atom 10-20 wt%, one or more organic silane coupling agent with at least one epoxy group 25-50 wt%; at least one kind of cationic or non-ionic water soluble polyurethane resin 30-60 wt% and vanadium compound 0.1-1.0 wt%. It is used in forming protecting film with excellent performance on the surface of zinc coated steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com