Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3467results about "Reflecting/signal paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color effect compositions

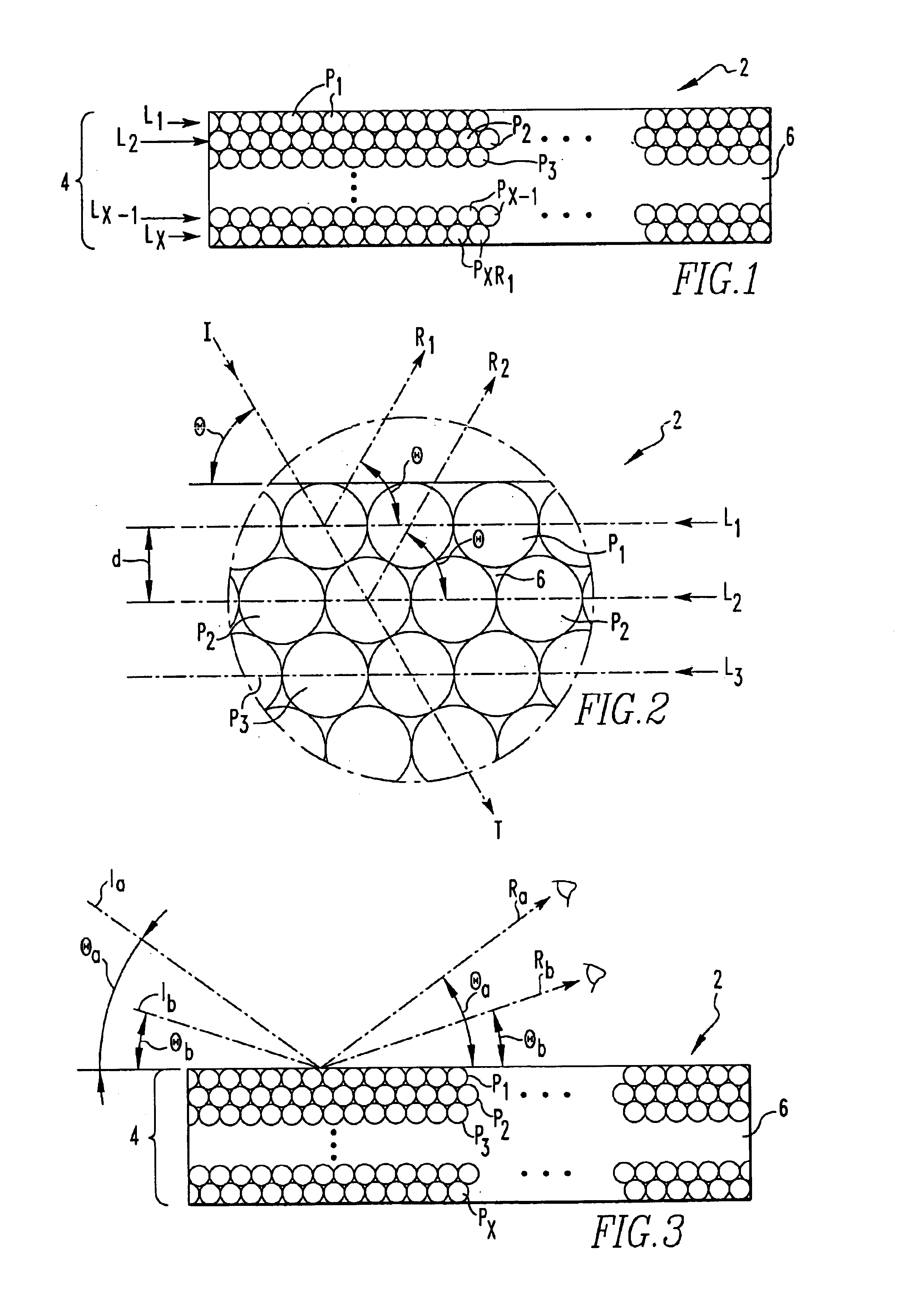

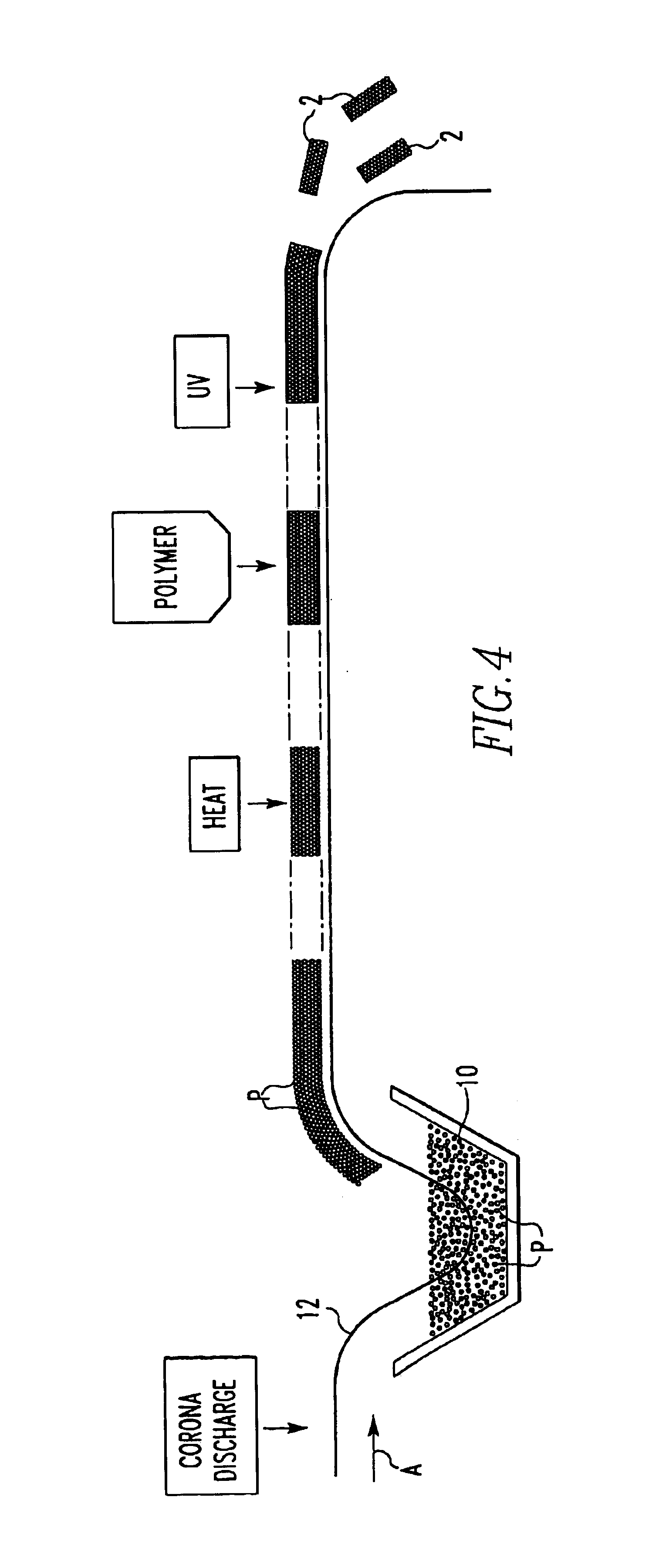

A coating composition comprising a resinous binder and a color effect colorant in particulate form. The colorant includes an ordered periodic array of particles held in a polymer wherein a difference in refractive index between the polymer and the particles is at least about 0.01. The colorant reflects visible light according to Bragg's law to yield a goniochromatic effect to the coating composition.

Owner:PPG IND OHIO INC

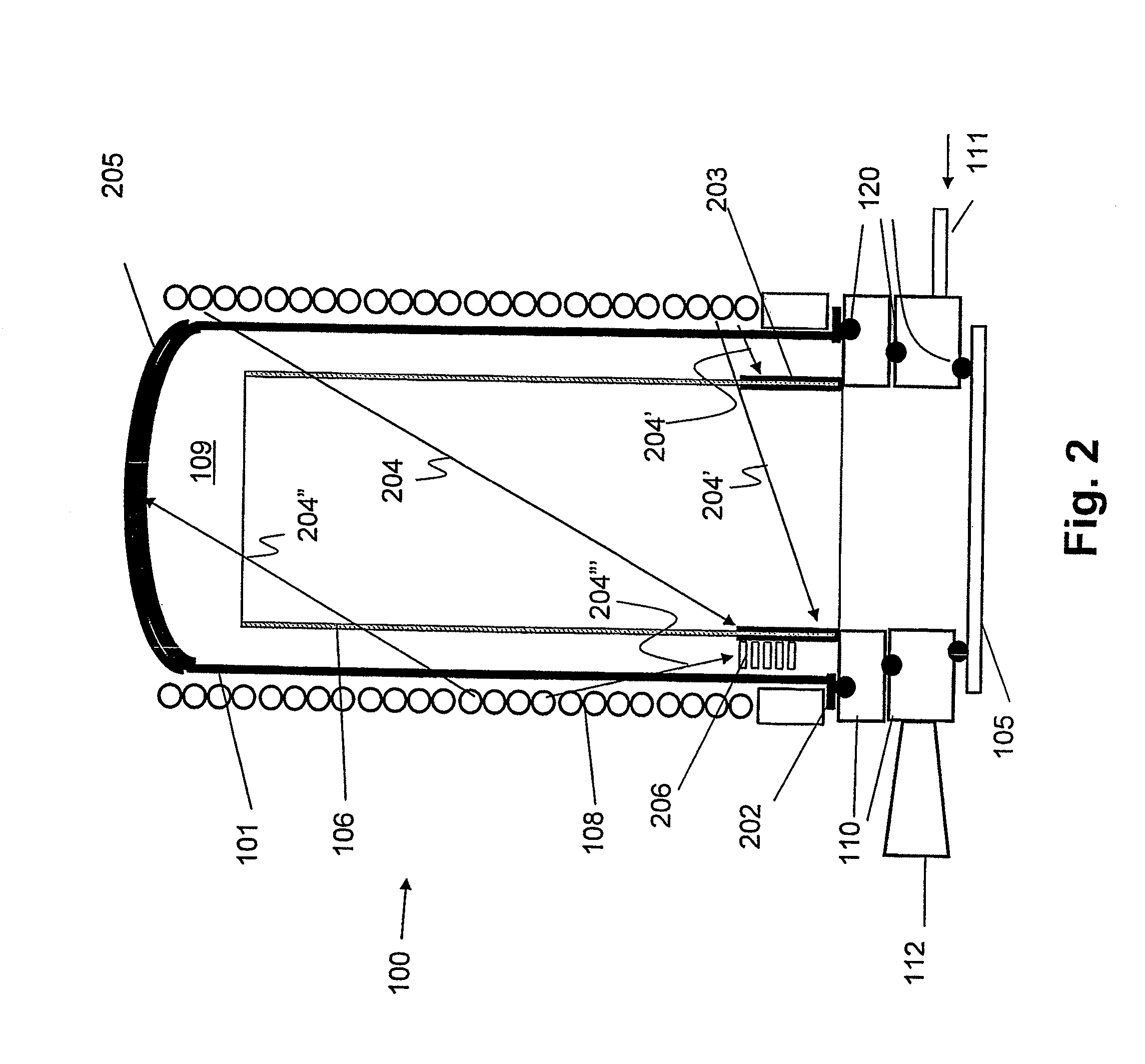

Semiconductor processing apparatus with improved thermal characteristics and method for providing the same

InactiveUS20090308315A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGaseous atmosphereEngineering

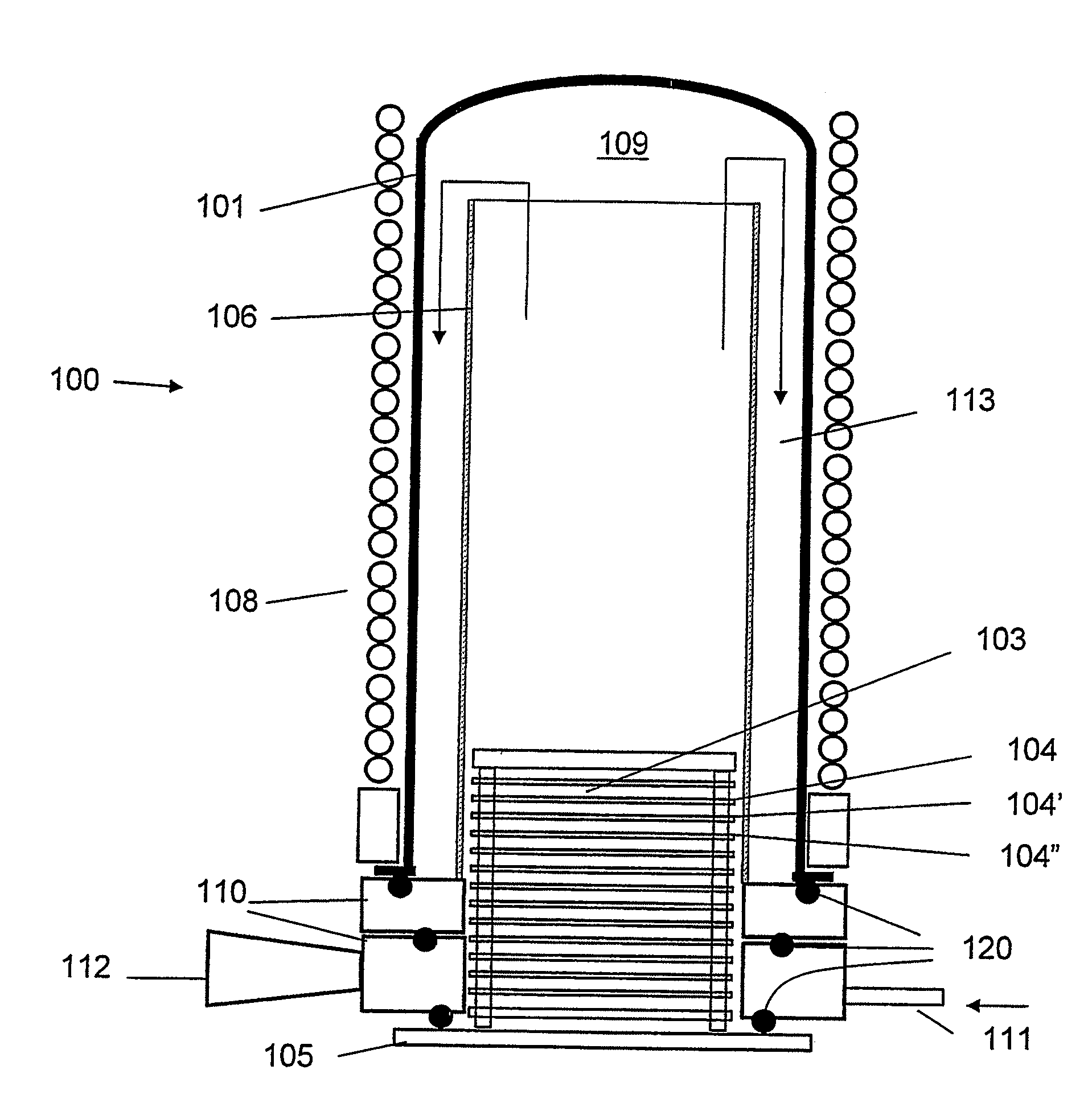

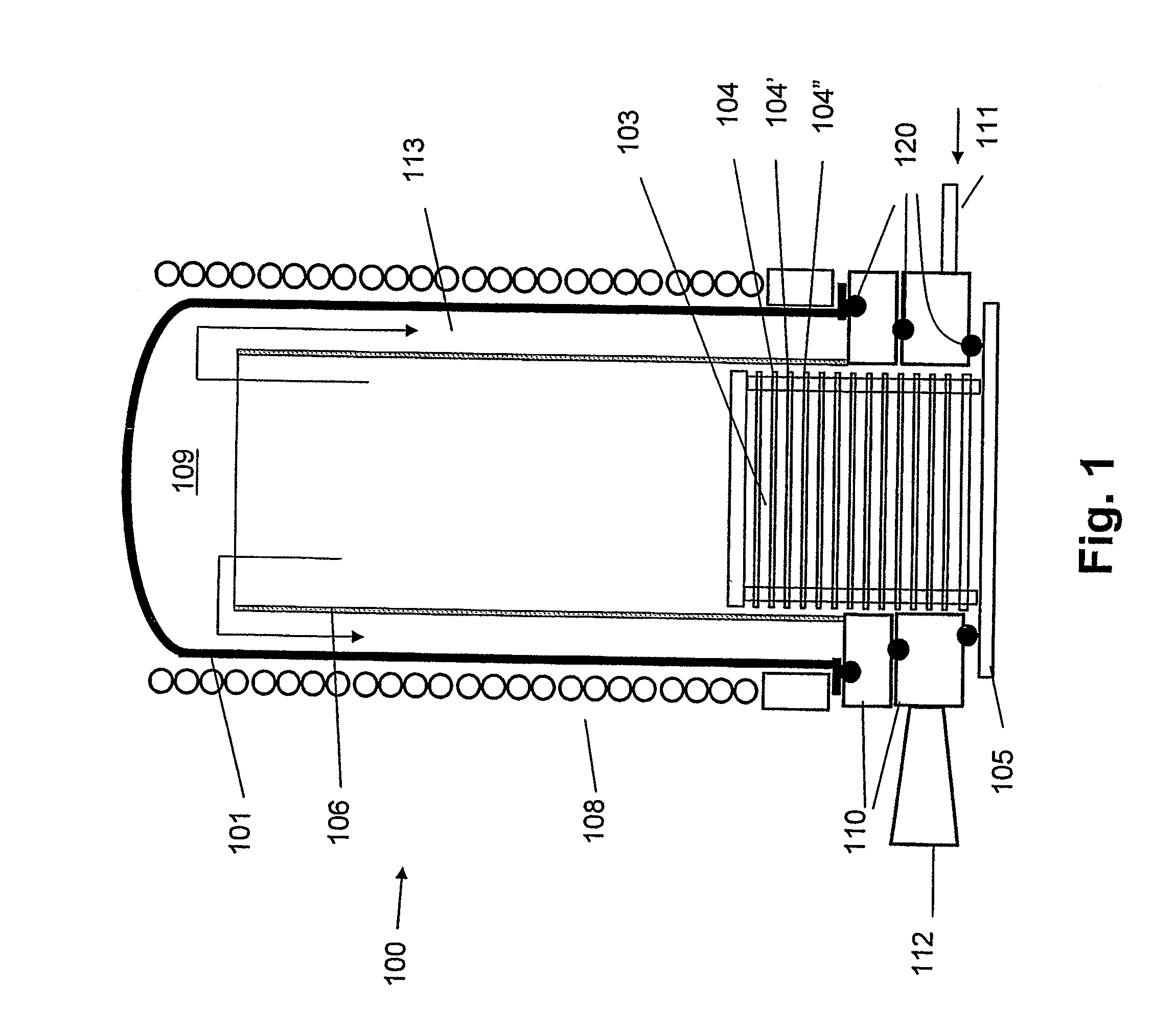

A semiconductor processing apparatus is disclosed, comprising a process chamber configured to contain a heated, gaseous atmosphere, the apparatus further comprising a number of mechanical parts, at least one of which parts is provided at least partly with a heat reflective, amorphous SiO2 powder coating. Also disclosed is a method for treating a component of a semiconductor processing apparatus, comprising at least partly providing a surface of the component with an amorphous SiO2 powder coating, and optionally sealing a surface of the applied coating.

Owner:ASM INTERNATIONAL

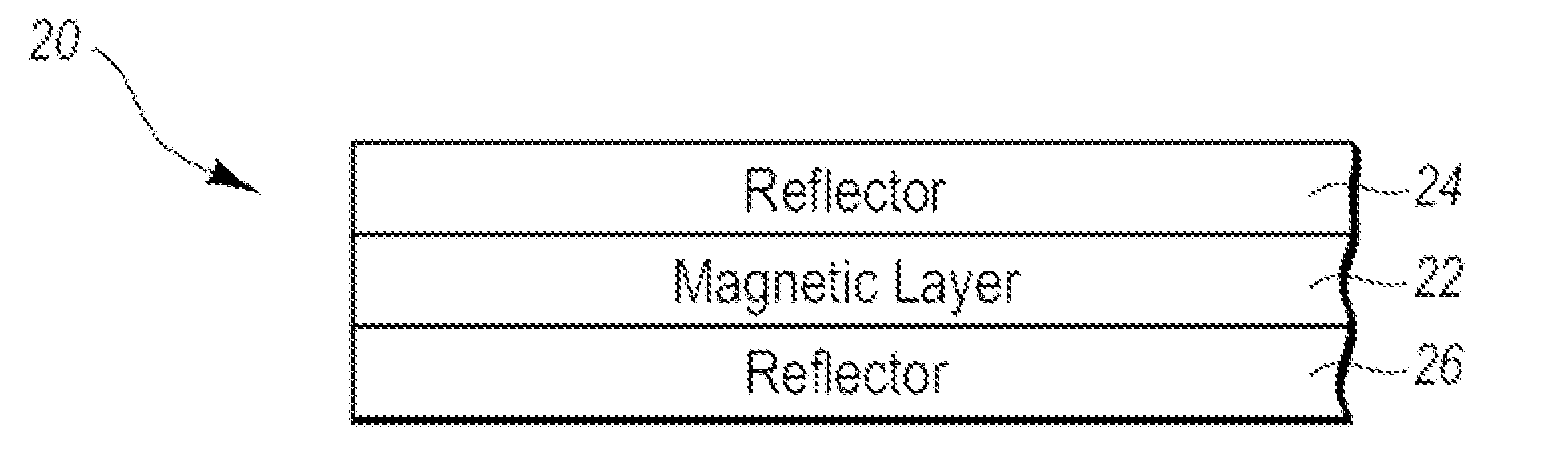

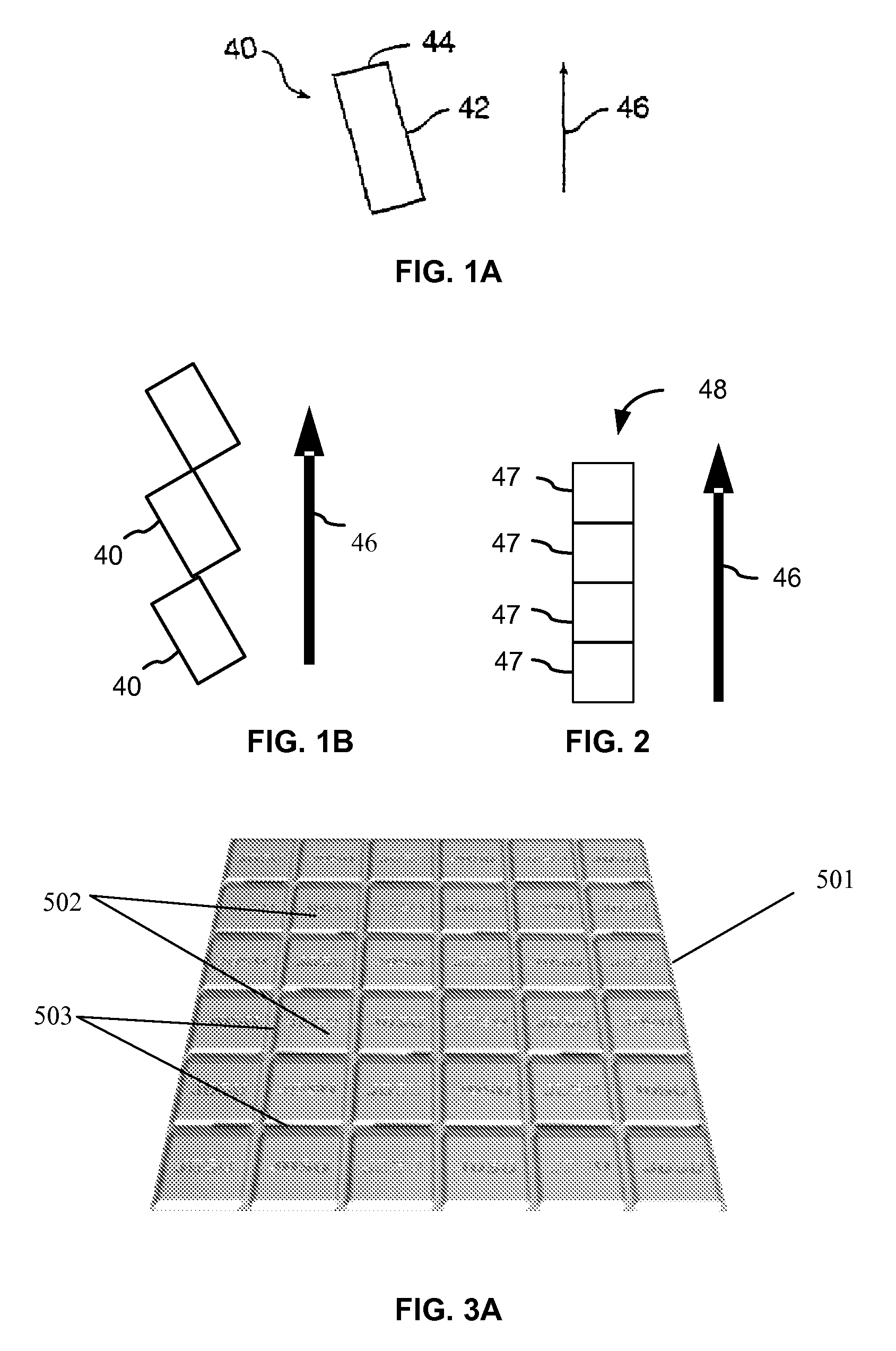

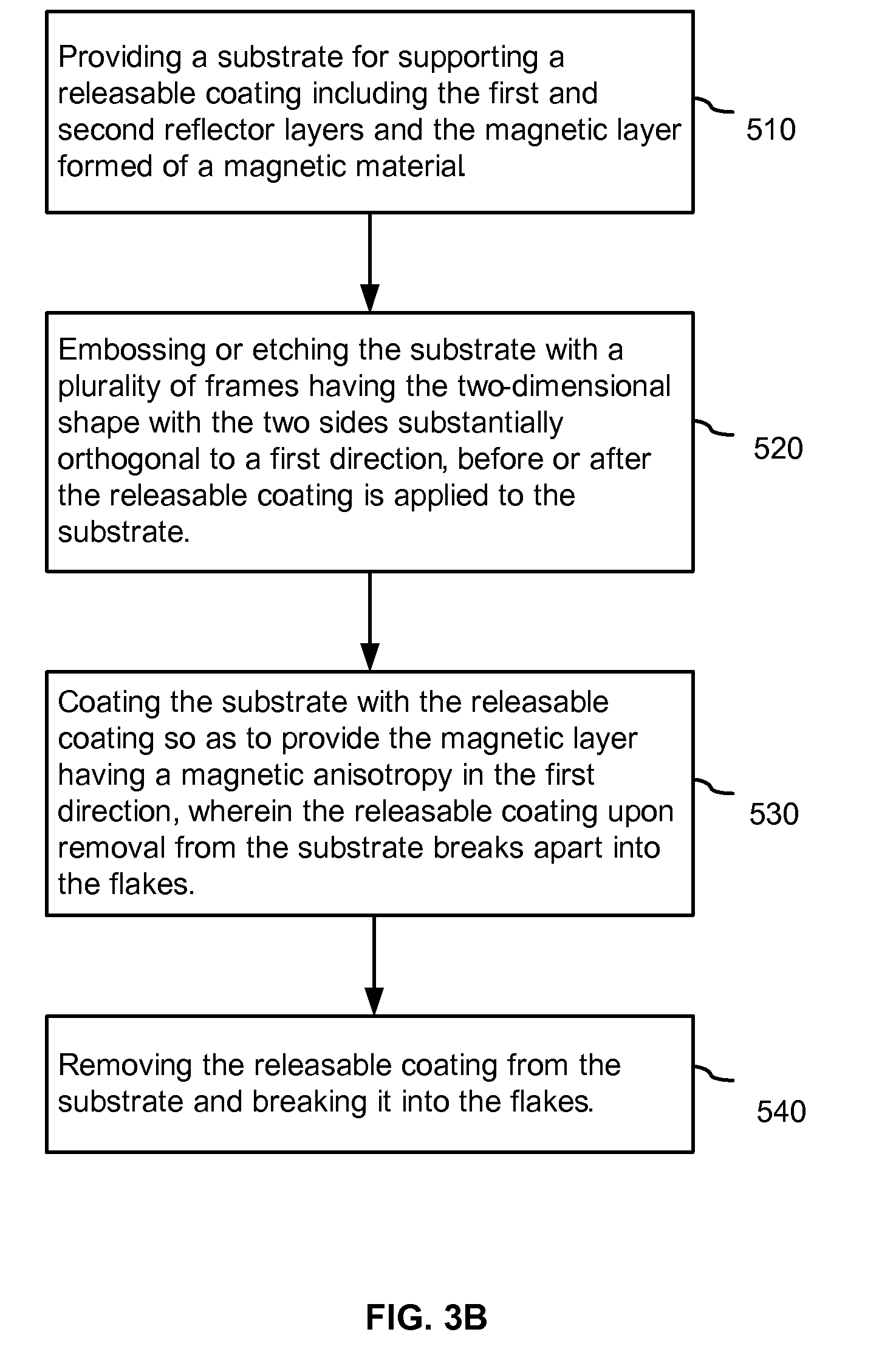

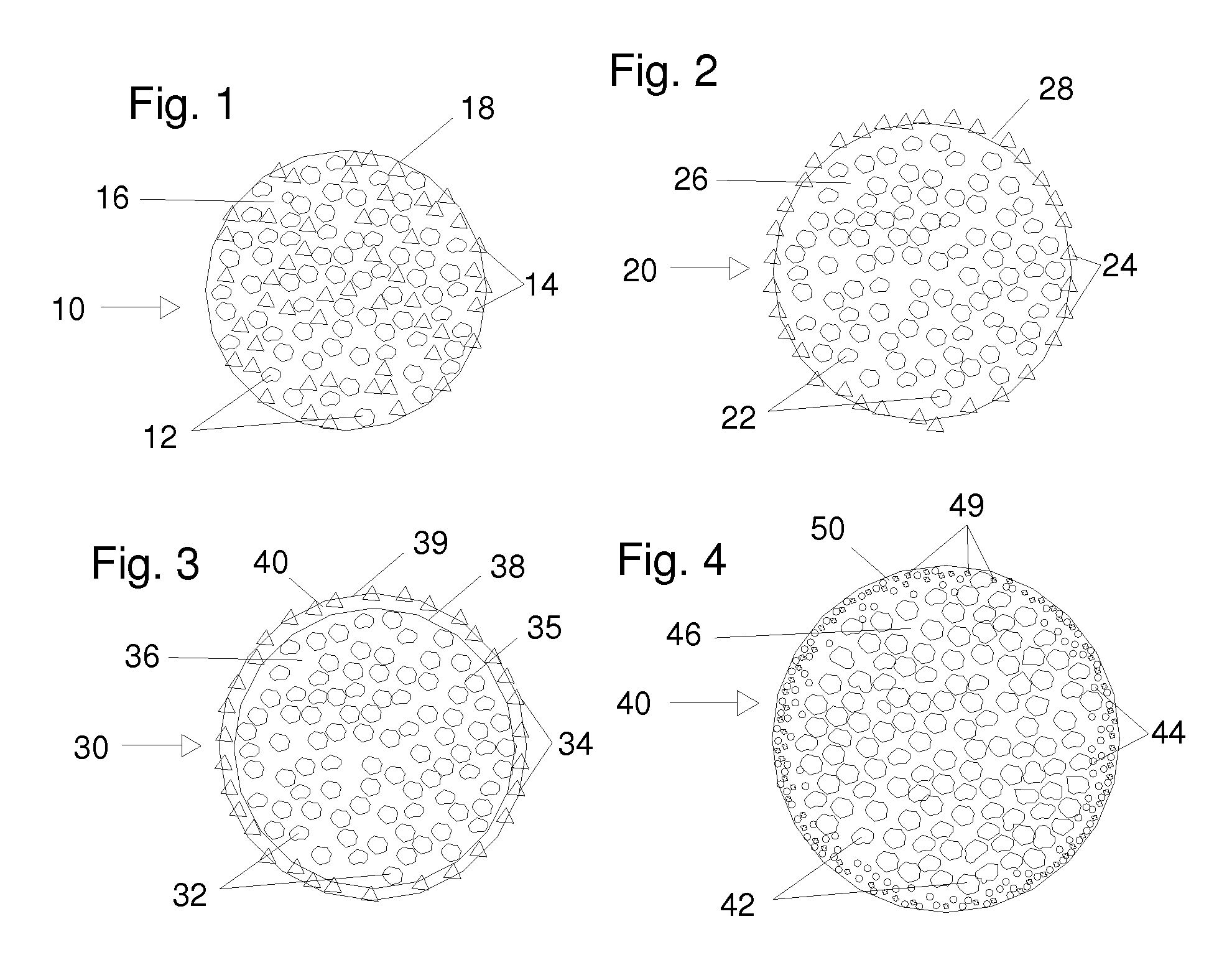

Anisotropic Magnetic Flakes

ActiveUS20090072185A1Cost effectiveMaterial nanotechnologyDecorative surface effectsHigh reflectivityMaterials science

The invention relates to anisotropic, reflective, magnetic flakes. In a liquid carrier and under influence of an external magnetic field, the flakes attract to one another side-by-side and form ribbons which provide higher reflectivity to a coating and may be used as a security feature for authentication of an object.

Owner:VIAVI SOLUTIONS INC

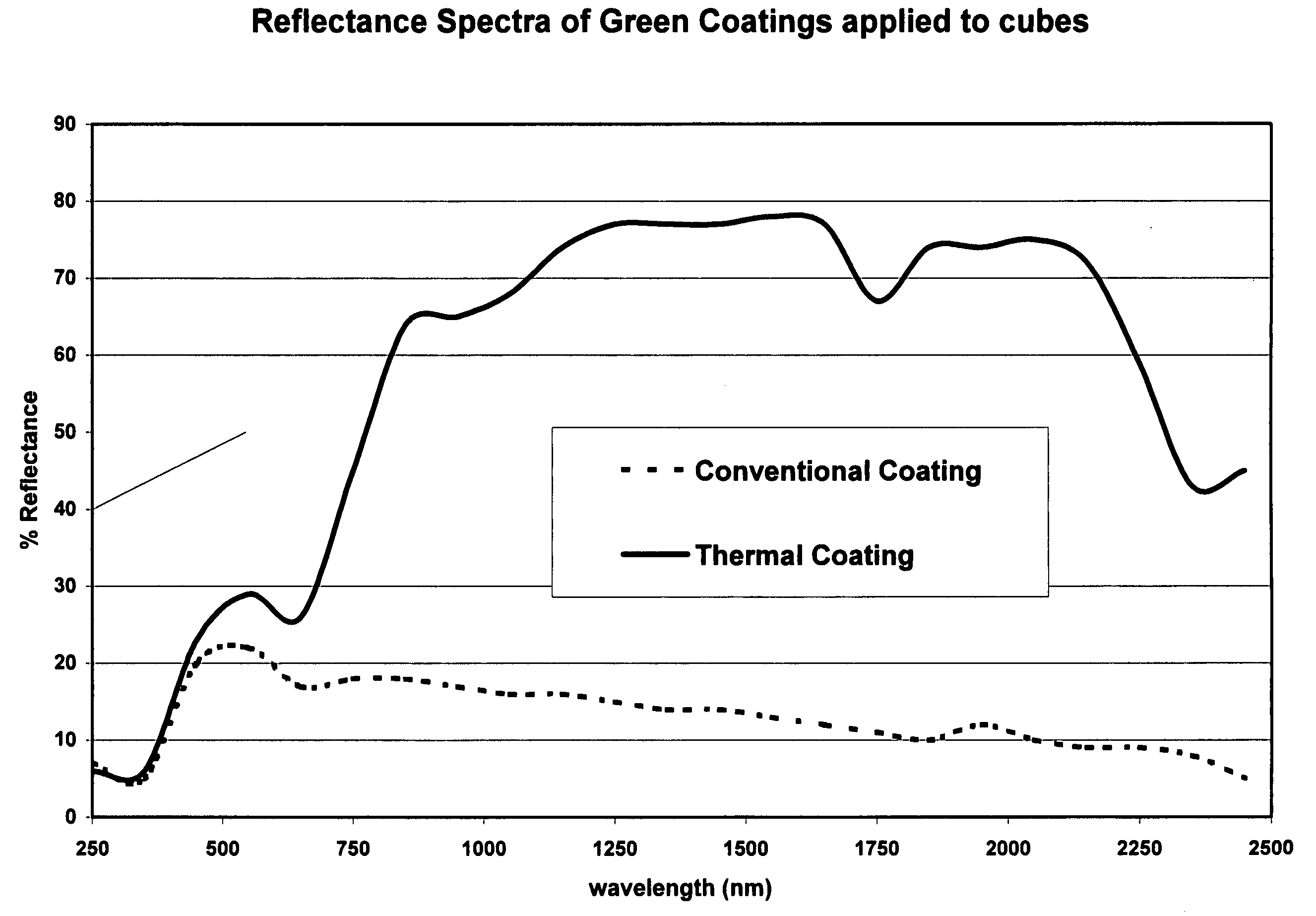

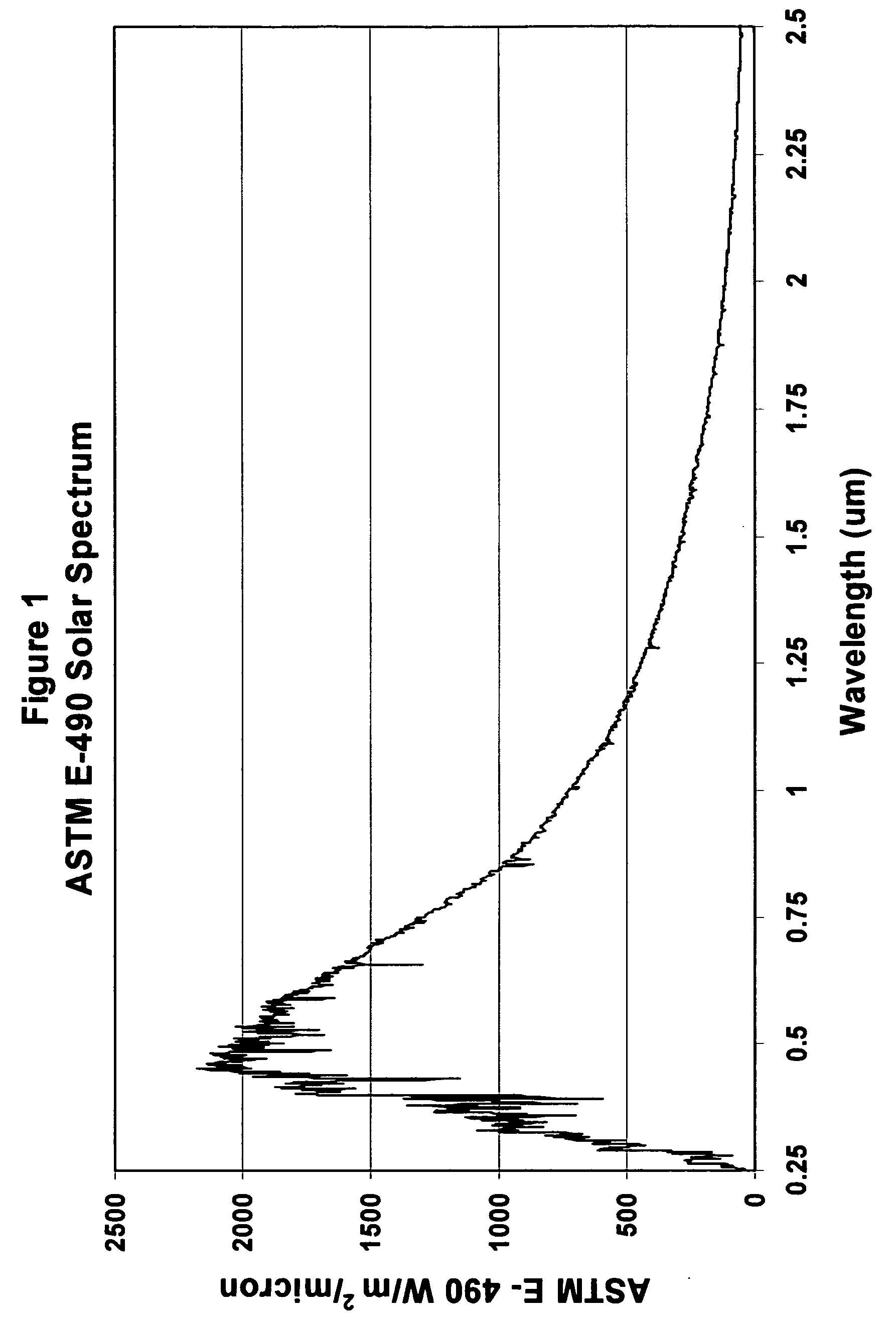

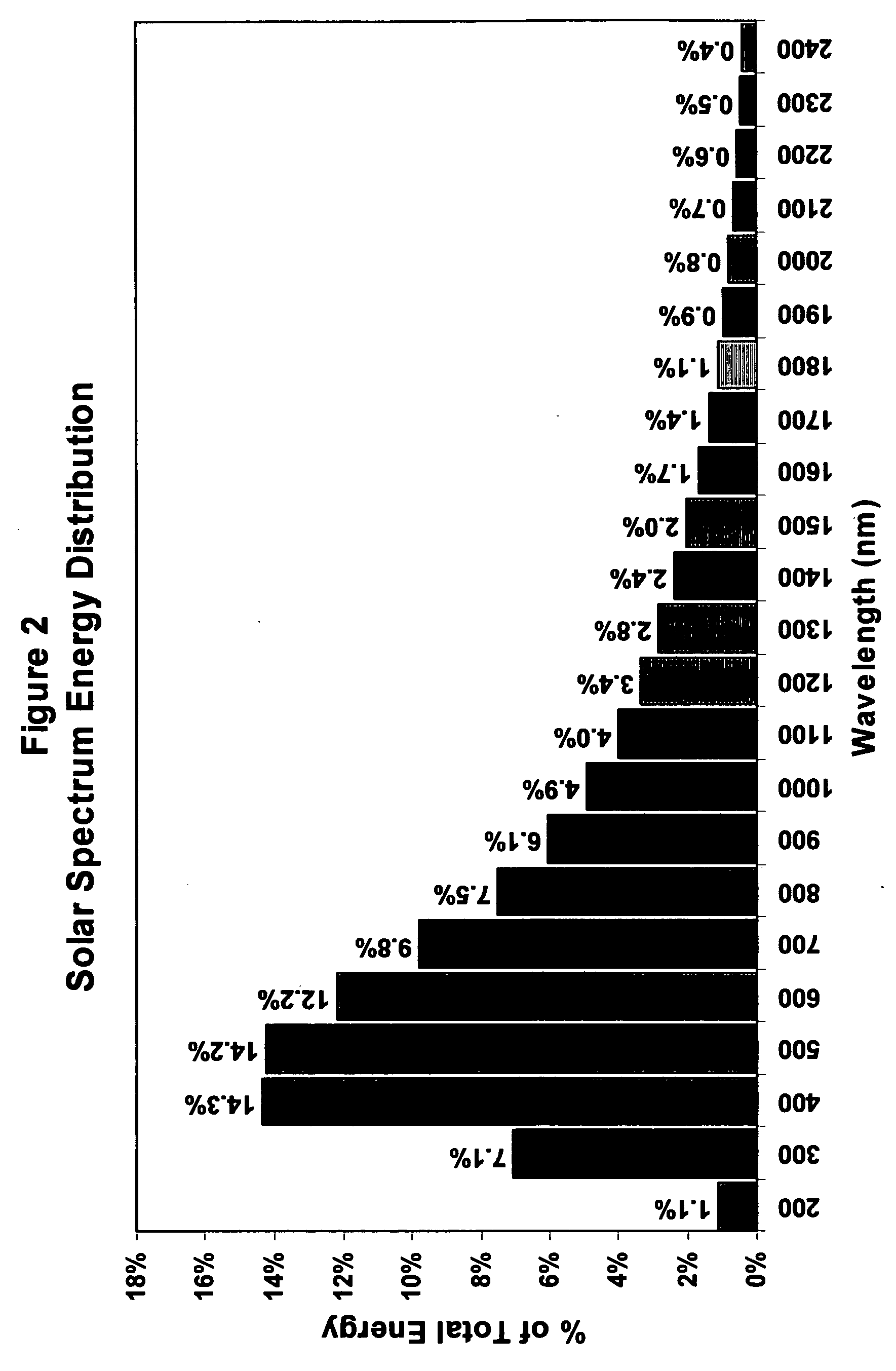

Composition of a thermaly insulating coating system

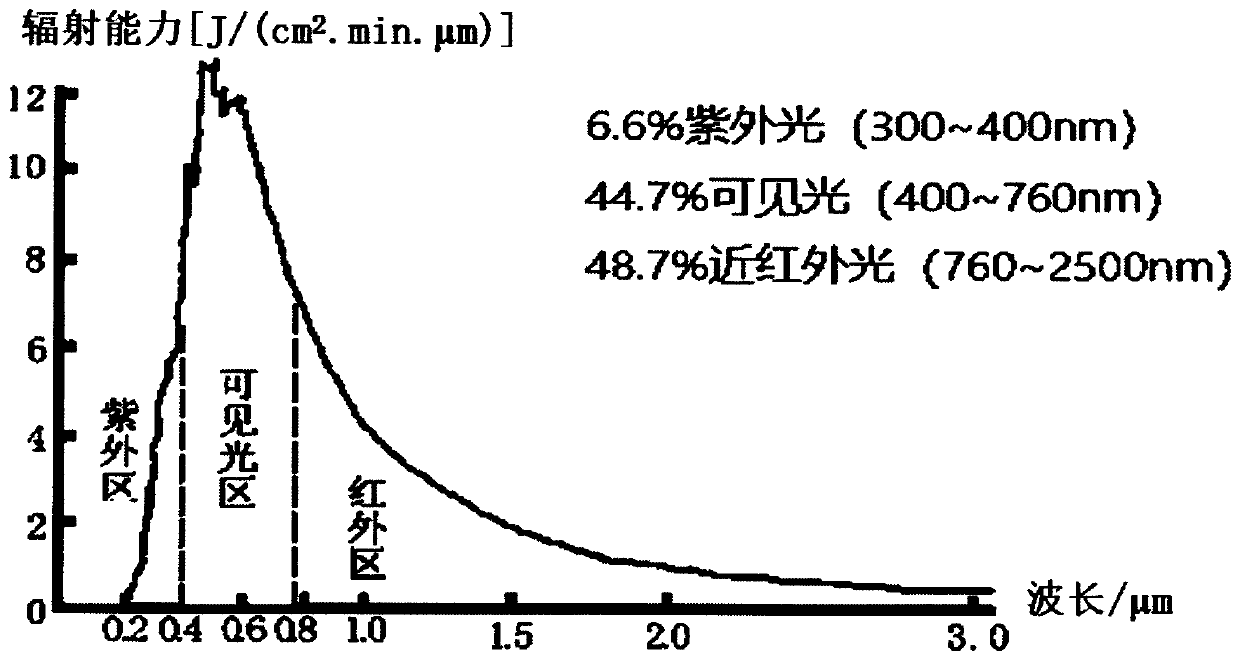

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

Nanometer compound water-based heat insulation anticorrosion paint used for metal and preparation method thereof

ActiveCN101665645AGood heat insulationImprove corrosion resistanceAnti-corrosive paintsReflecting/signal paintsWater basedAcrylic resin

The invention discloses a nanometer compound water-based heat insulation anticorrosion paint used for metal and a preparation method thereof. The raw materials of the paint consists of the following components: tap water, watercraft acrylic resin, rustproofing pigment, reflection pigment and filler, hollow micro-beads, watercraft nanometer size, anti-settling agent, wetting and dispersing agent A,wetting and dispersing agent B, film-forming assistant, defoaming agent, flatting agent, anti-flash rustproofing agent and thickening agent. Watercraft polyacrylic emulsion is styrene-crylic acid copolymerization emulsion, pure crylic acid polymerization emulsion or organic silicon-crylic acid copolymerization emulsion. The wetting and dispersing agent A is block macromolecule copolymer, multivalence carboxylate polymer and / or synthetic macromolecule copolymer, and the wetting and dispersing agent B is anion wetting agent and / or nonionic wetting agnet. The product contains no organic solvent,heavy metal and other harmful substances, is extremely excellent in environmental conservation, integrates the functions of anticorrosion and heat insulation as a whole and is simple and convenient for construction, safe in storage and stable in performance.

Owner:GUANGZHOU JOINTAS CHEM

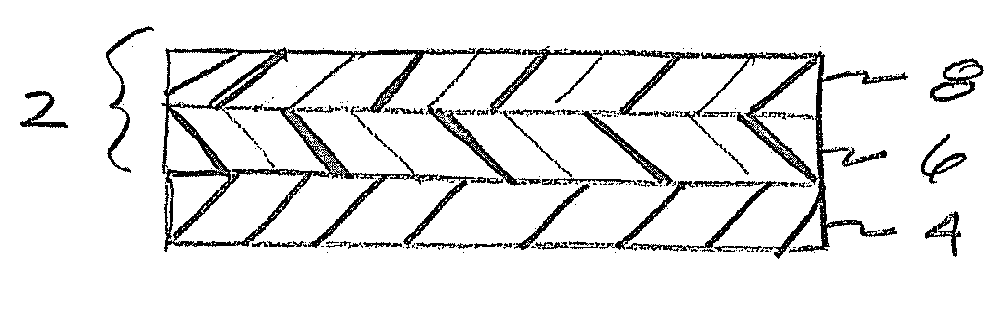

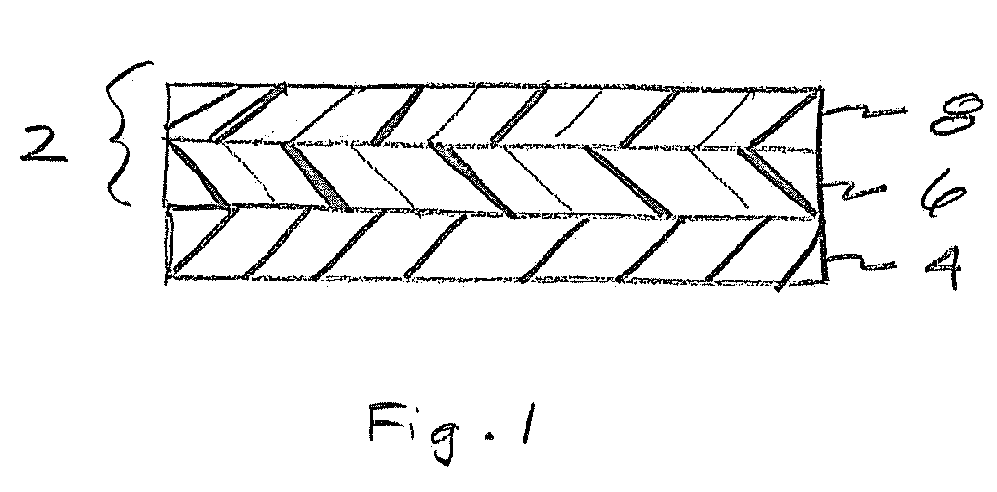

Coating system exhibiting cool dark color

A layered coating composition for use in producing a cool dark coating composition. The coating system includes an IR reflecting layer, having IR-reflective pigments in a resinous binder. A radiation absorbing layer is coated onto the IR reflecting layer. The radiation absorbing layer includes nano-sized pigments dispersed in a resinous binder.

Owner:PPG IND OHIO INC

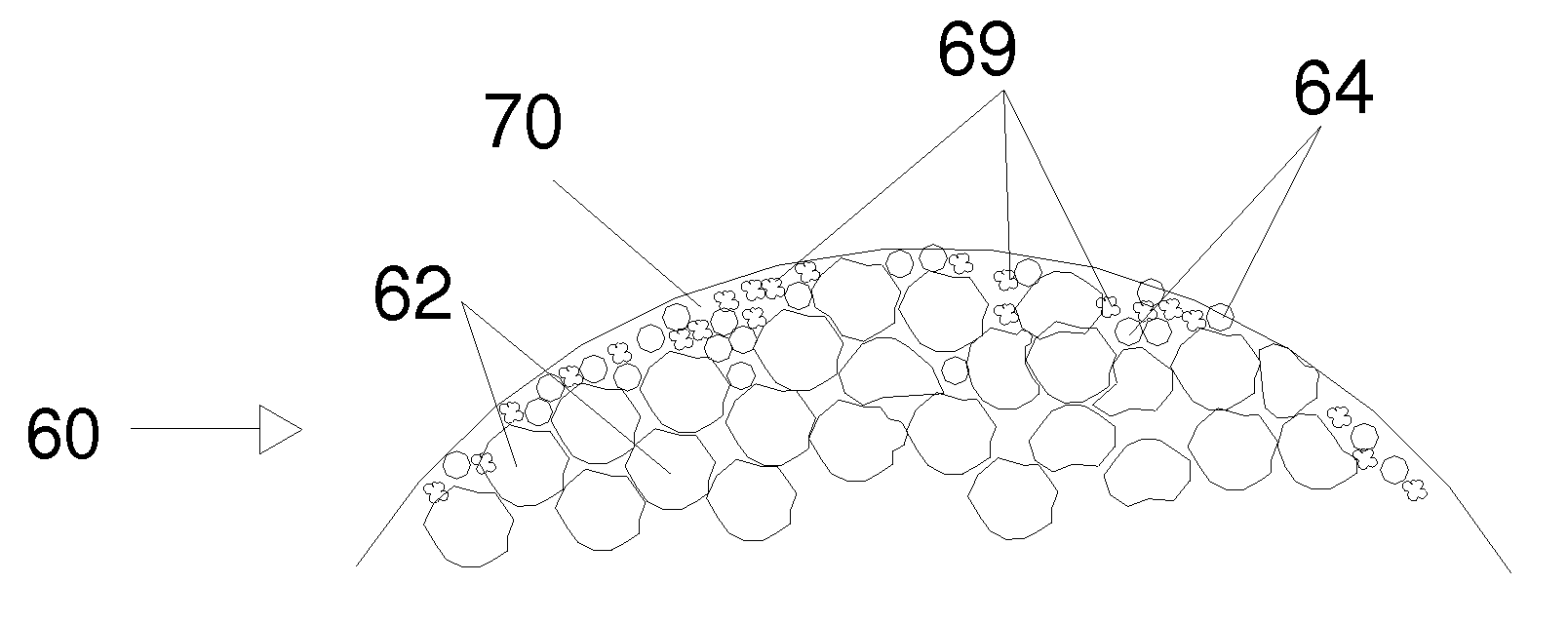

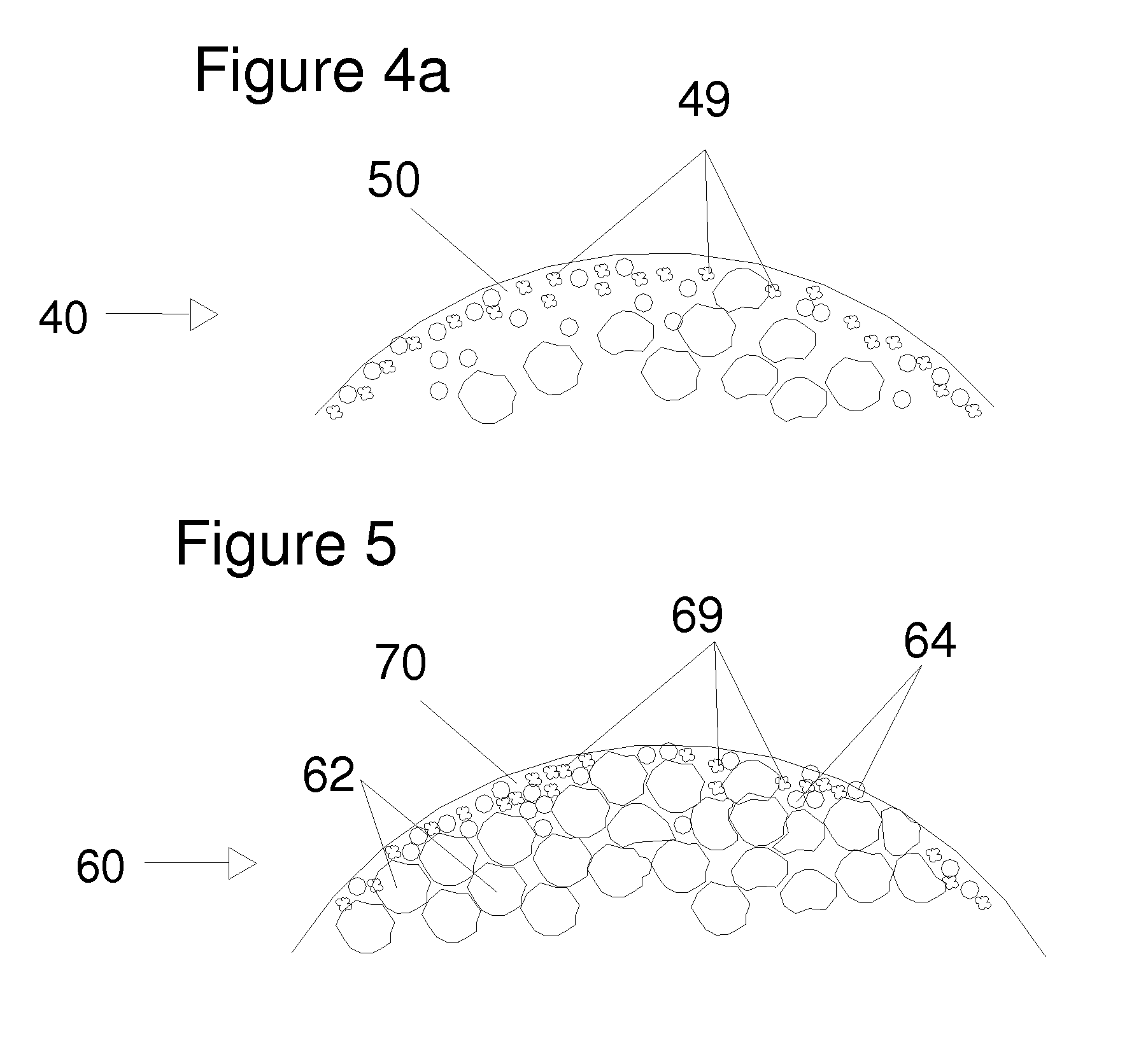

Roofing granules with high solar reflectance, roofing products with high solar reflectance, and processes for preparing same

InactiveUS20100203336A1Improve solar reflectivityRoof improvementWood working apparatusMineral particlesOptoelectronics

Solar reflective roofing granules include a binder and inert mineral particles, with solar reflective particles dispersed in the binder. An agglomeration process preferentially disposes the solar reflective particles at a desired depth within or beneath the surface of the granules.

Owner:CERTAINTEED CORP

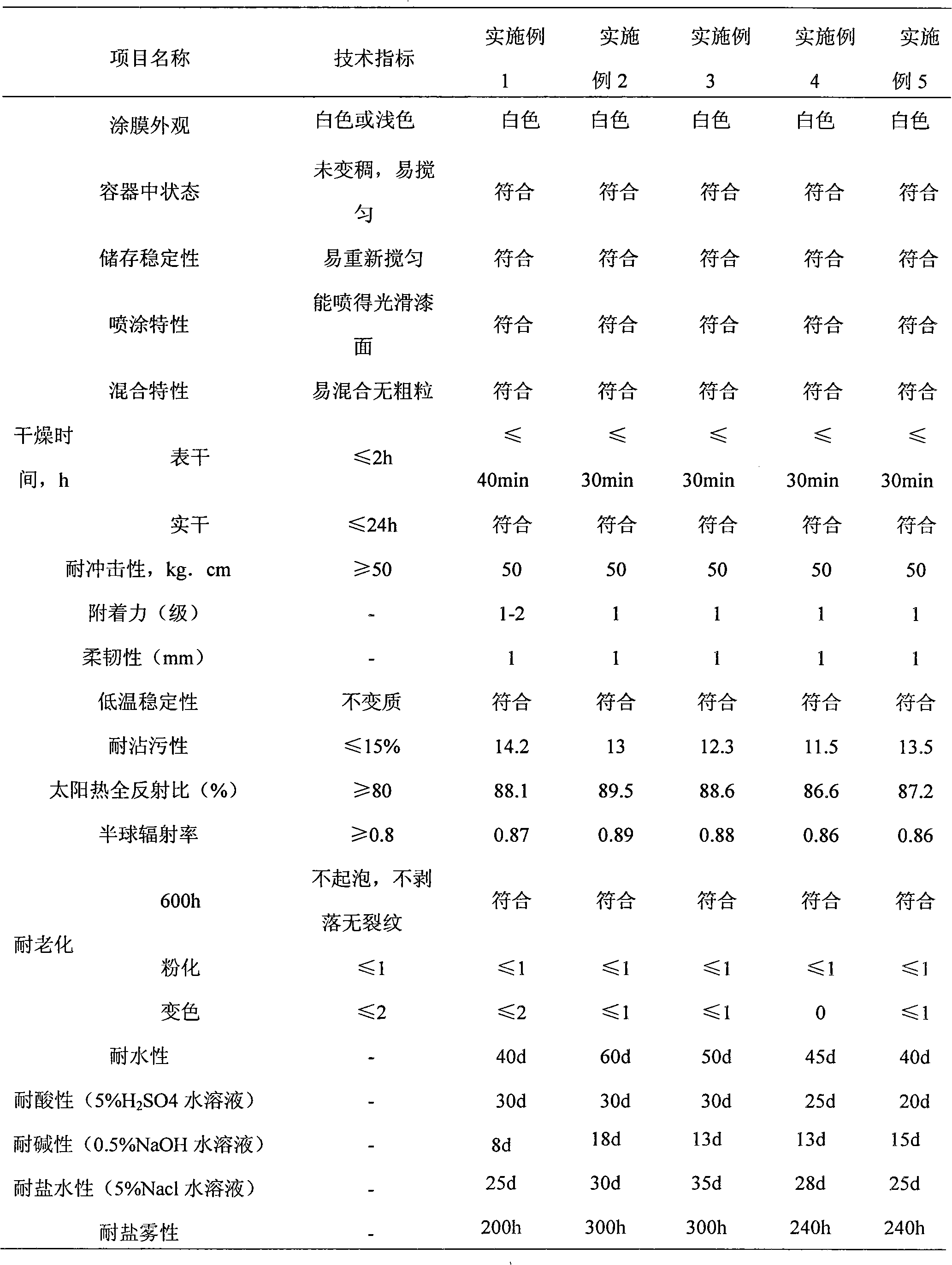

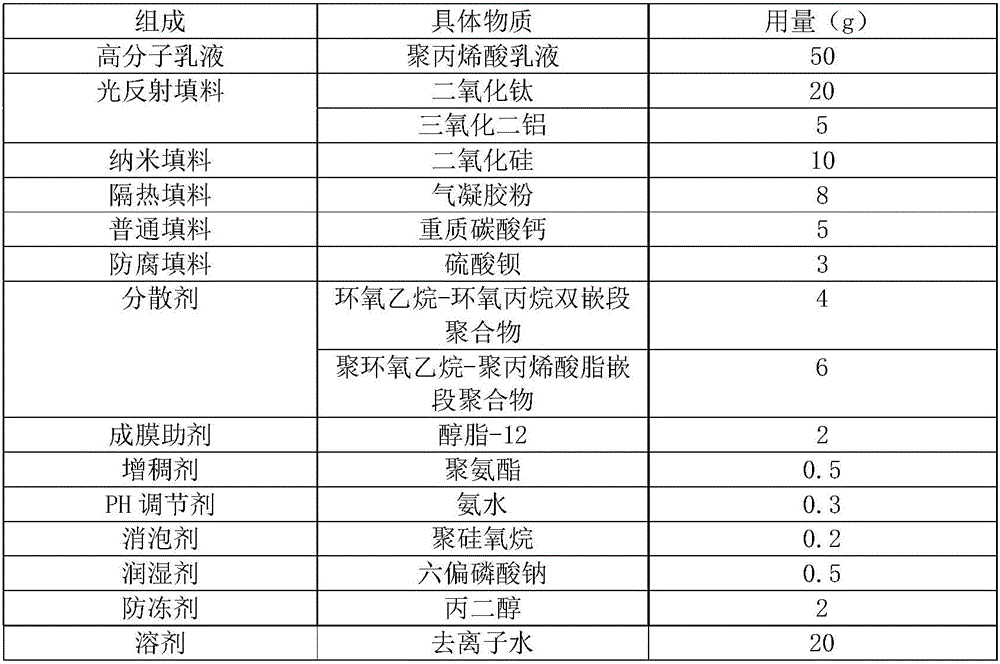

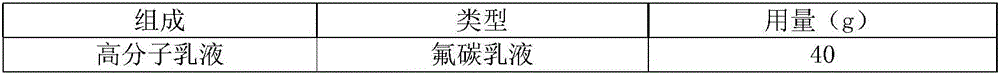

Water-based light reflex industrial insulation coating and preparation method thereof

ActiveCN106752526AGood compatibilityImprove thermal insulation performanceAnti-corrosive paintsReflecting/signal paintsWater basedDefoaming Agents

The invention relates to an industrial coating, in particular to a water-based industrial insulation coating with light reflection, heat insulation and corrosion protection effects and a preparation method thereof. The coating is prepared from the following components in percentage by weight: 25 percent to 50 percent of polymer emulsion, 5 percent to 30 percent of light reflective filler, 1 percent to 5 percent of nanofiller, 5 percent to 10 percent of heat-insulating filler, 5 percent to 10 percent of anti-corrosion filler, 5 percent to 8 percent of normal filler, 0 percent to 10 percent of curing agent, 1 percent to 5 percent of dispersing agent, 0.1 percent to 4 percent of coalescing agent, 0.1 percent to 2 percent of thickening agent, 0 percent to 1 percent of defoaming agent, 0.01 percent to 0.5 percent of PH (Potential Of Hydrogen) regulator, 0.1 percent to 2 percent of wetting agent, 0.5 percent to 1 percent of antifreezing agent, and the balance of deionized water. The coating provided by the invention has the effects on light reflection, heat insulation and corrosion protection at the same time, can be applied in the fields of storage tanks, pipelines, outdoor equipment, containers and the like, has the characteristics of safety, nontoxicity, environmental protection and pollution free, and has favorable weather fastness, stain resistance, salt fog resistance and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

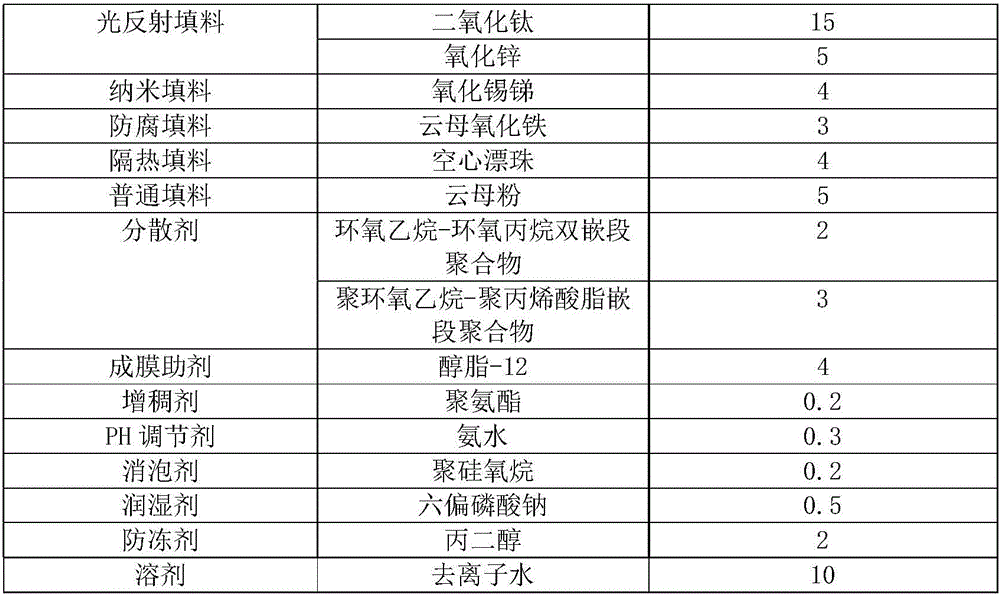

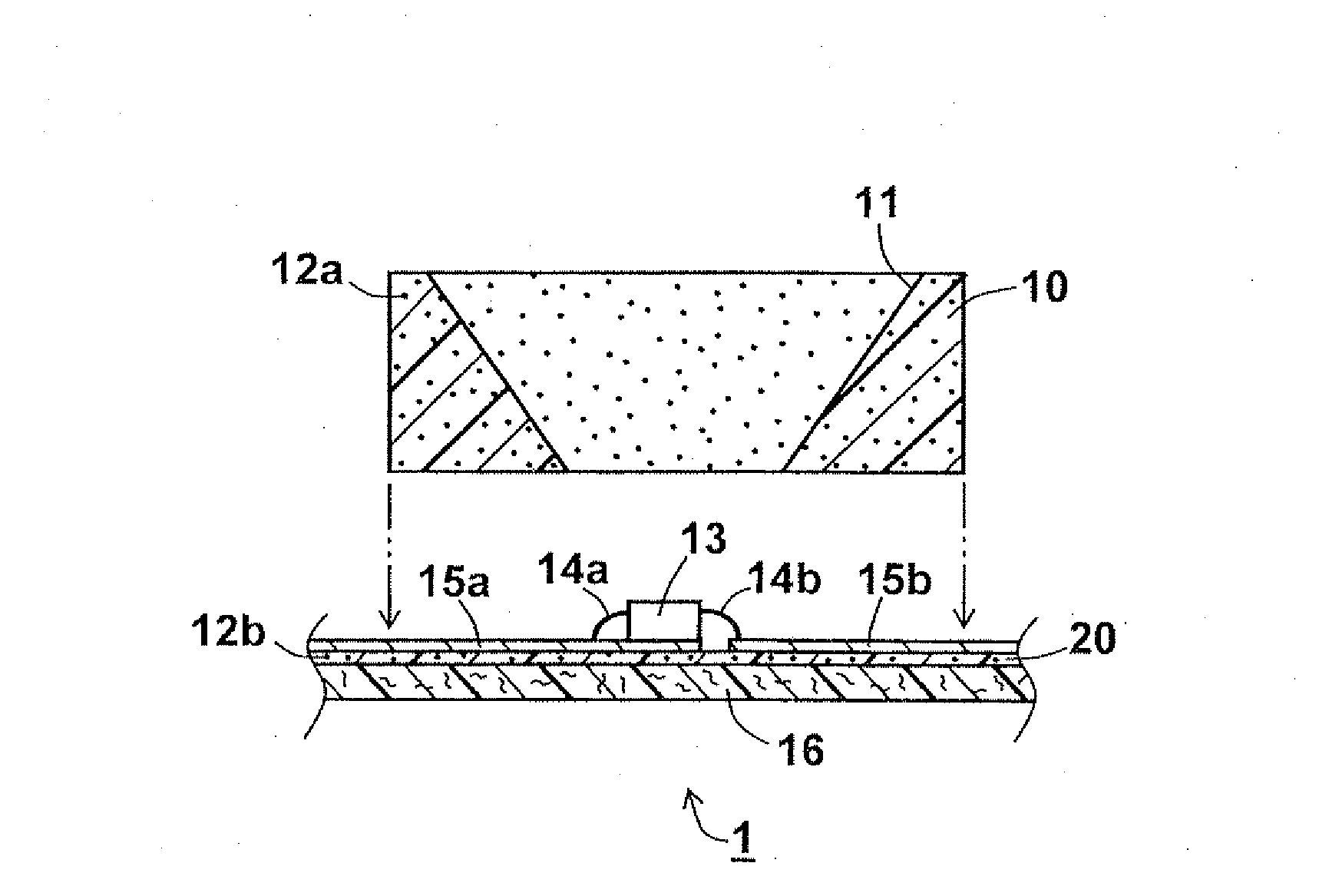

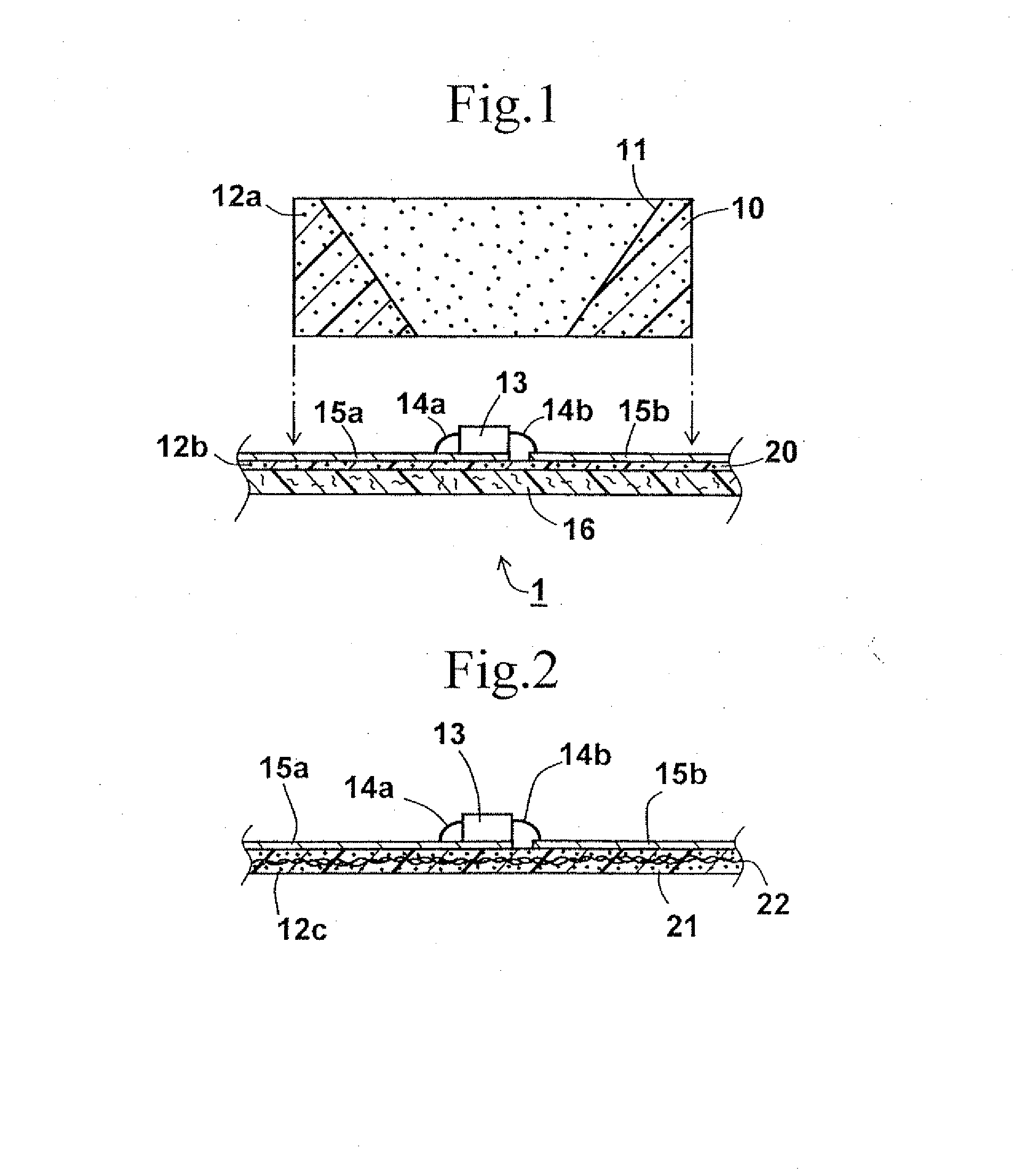

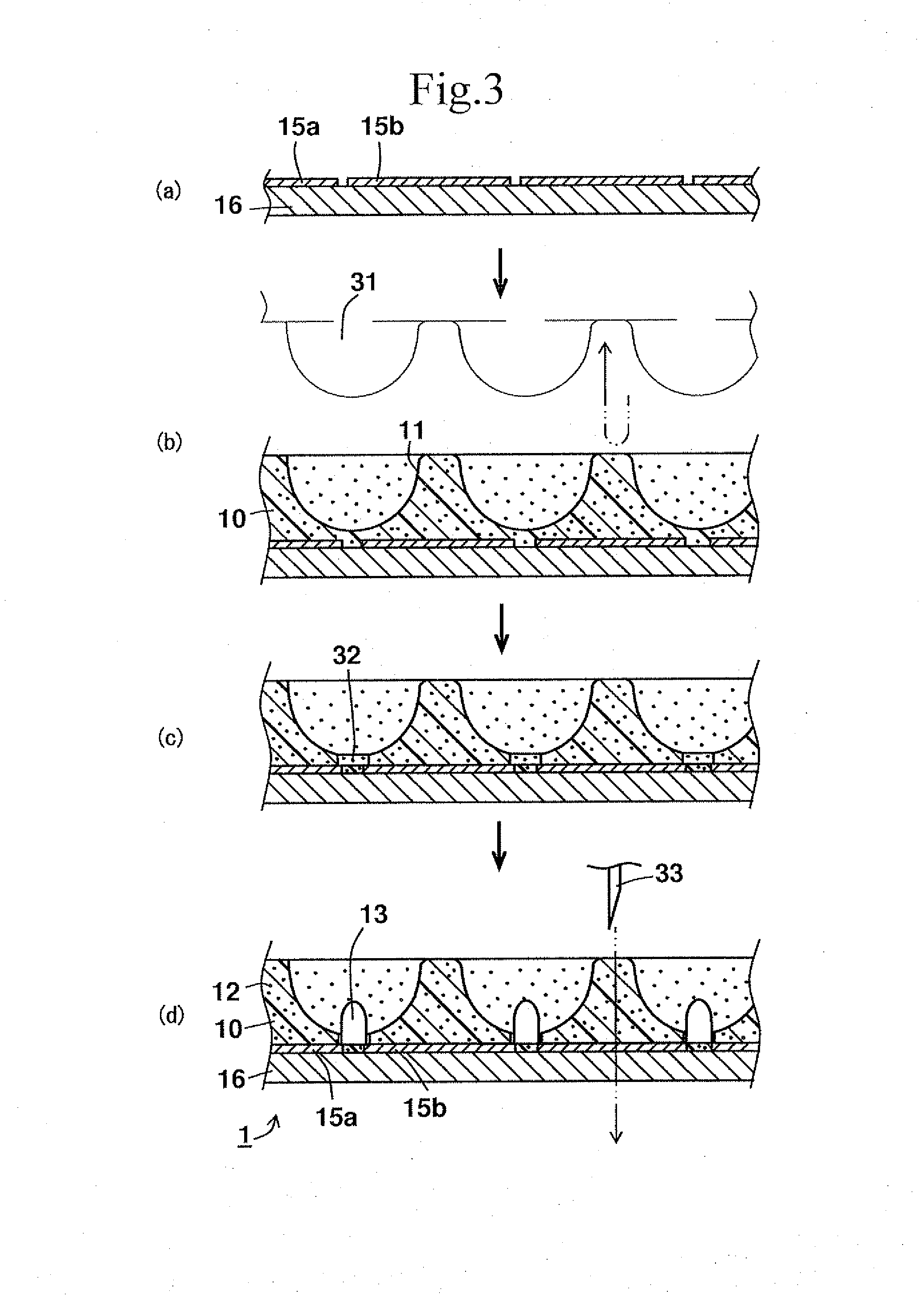

Silicone resin reflective substrate, manufacturing method for same, and base material composition used in reflective substrate

ActiveUS20130011617A1Low viscosityImprove adhesionDiffusing elementsSolid-state devicesCross-linkInfra-red color

A versatile silicone resin reflective substrate which exhibits high reflectance of high luminance light from an LED light source over a wide wavelength from short wavelengths of approximately 340-500 nm, which include wavelengths from 380-400 nm near lower limit of the visible region, to longer wavelength in the infra-red region. The silicone resin reflective substrate has a reflective layer which contains a white inorganic filler powder dispersed in a three-dimensional cross linked silicone resin, the inorganic filler powder having a high reflective index than the silicone resin. The reflective layer is formed on a support body as a film, a solid, or a sheet. The silicone resin reflective substrate can be easily formed as a wiring substrate, a packaging case or the like, and can be manufactured at low cost and a high rate of production.

Owner:ASAHI RUBBER

Infrared reflective wall paint

ActiveUS7157112B2Reduce energy consumptionReduce absorptionLiquid surface applicatorsElectrostatic spraying apparatusInfraredLacquer

Owner:TEXTURED COATINGS OF AMERICA

Dew resistant coatings

The present invention relates to dew resistant coatings and articles having the dew resistant coating adhered thereto. The dew resistant coatings comprise elongate silica particles. These coating are useful on articles or surfaces used in outdoor applications and articles and surfaces used in moist indoor environments.

Owner:AVERY DENNISON CORP

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

Coating material compositions

InactiveCN101353546AEffective adhesionImprove corrosion resistanceCosmetic preparationsLiquid surface applicatorsPolyesterAdditive ingredient

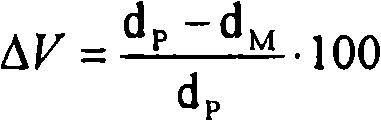

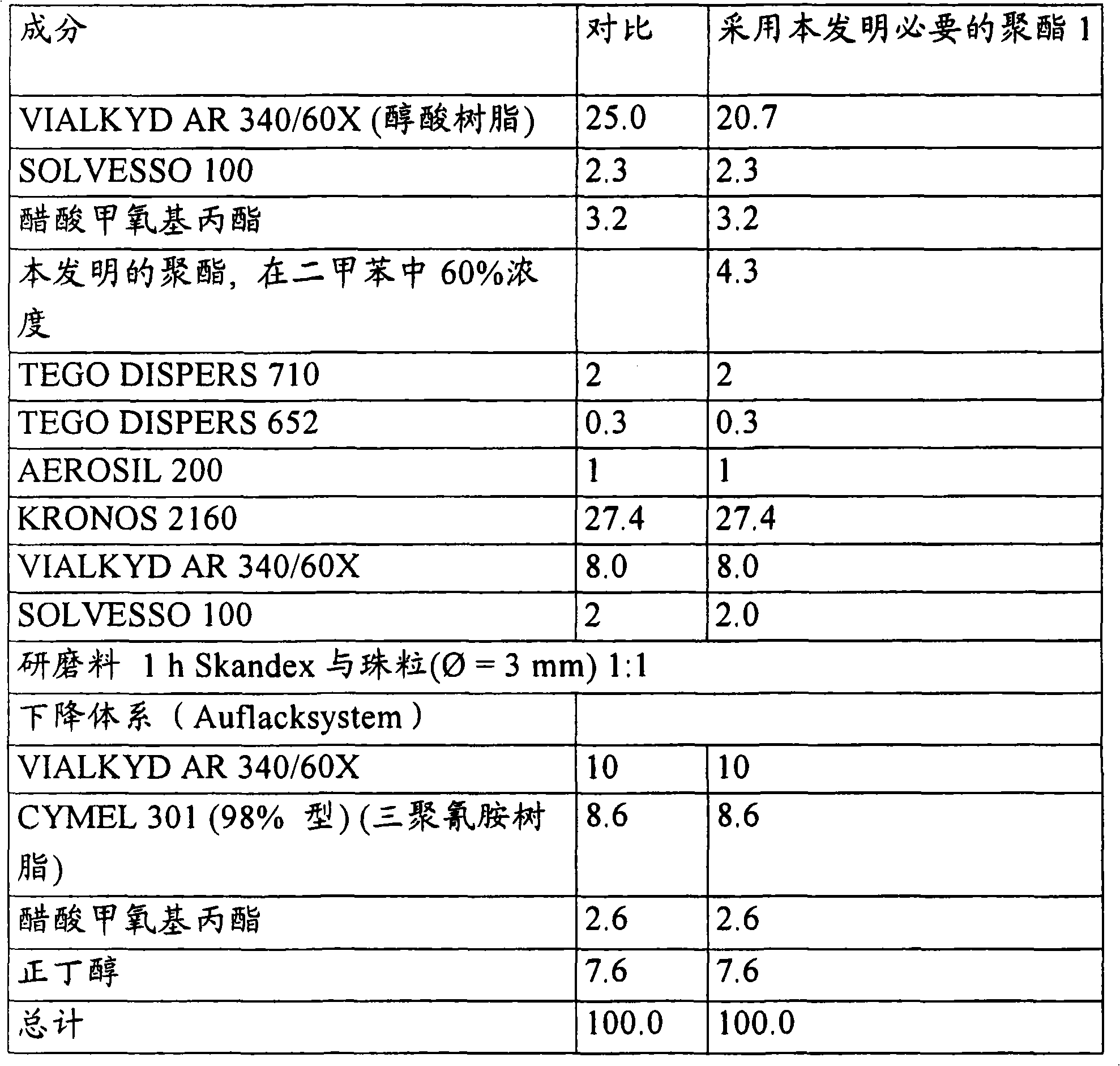

The invention relates to coating material compositions for, for example, metallic, mineral substrates or for substrates of wood, paper and plastics, which comprise yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde, as a result of which the adhesion of these coating material compositions is improved even under critical ambient conditions, and to a preparation process and use of said compositions. More specifically, the invention relates to coating material compositions, substantially including 1, yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde; 2, at least one other adhesive; 3, at least one accessory ingredient and / or additive; 4, at least one colorant and / or stuffing. The yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters are composed by the following components: I. acid components, made up of A) at least one alpha, beta-unsaturated dicarboxilic acid, and B) at least one linear and / or branch fatty group and / or alicyclic and / or aromatic bifunctional and / or polyfunctional carboxyl acid, which is not provided with alpha, beta-unsaturated part; II. alcohol components, made up of C) bis(hydroxymethyl)tricyclo compounds and D) at least one bifunctional and / or polyfunctional alcohol, wherein, based on the polyesters, the content of benzene is lower than 10mg / kg and the content of formaldehyde is lower than 10mg / kg, the molecular weight distribution polydispersity of the polyesters is 1.3-4.5, the content of tricyclodecane(mono- / di-)aldehyde in the bis(hydroxymethyl)tricyclo compound C) is lower than 2 weight percent; mono(hydroxymethyl)tricyclo [5.2.1.0<2,6>] decane in the compound C) is lower than 10 weight percent, and the content of chromium, nickel, copper, cadmium and plumbum in the compound C) is lower than 2mg / kg.

Owner:EVONIK DEGUSSA GMBH

Waterborne external thermal insulation coating and preparation method thereof

InactiveCN102329545AImprove waterproof and anti-corrosion performanceEasy constructionPolyurea/polyurethane coatingsReflecting/signal paintsThermal insulationDefoaming Agents

The invention provides a waterborne external thermal insulation coating. The coating consists of the following components in part by weight: 25 to 50 parts of functional filler, 30 to 50 parts of emulsion, 20 to 35 parts of filler, 8 to 20 parts of film-forming aid, 1 to 3 parts of wetting dispersant, 1 to 2 parts of propylene glycol, 1 to 2 parts of defoaming agent, 0.5 to 1.5 parts of mildew preventive, 1 to 5 parts of thickening agent and 10 to 20 parts of water. The invention is characterized in that: the coating is safe and environment-friendly, has excellent waterproof and anticorrosive properties, high thermal resistance and reflectivity, excellent thermal insulation property, and good weather resistance, is convenient to construct, and can be well adhered to various base materials, and the density of a dry film is low; an extremely thin hollow cavity layer is formed after the coating is coated on the surface of a base material and then is dried, so that an effective thermal barrier is formed; functional filler particles have large heated cathodes, low coefficient of thermal conductivity, and high heat reflectivity; the consumption of energy sources is remarkably reduced; the coating can reflect, refract and scatter thermal radiation and stop heat conduction; and the energy is saved.

Owner:QINGDAO AIR NEW MATERIALS

Heat insulation coating capable of reflecting solar heat rays

InactiveCN101121858AImprove reflection efficiencyIncrease thermal resistanceFireproof paintsPolyurea/polyurethane coatingsPolymer resinThermal radiation

A heat-insulating coating for reflecting solar heat rays, which is composed of two parts: a primer and a top-coat. 10-50%, adhesive polymer resin 10-70%; the percentage of solid matter in the top coating is: surface coating reflective heat ray composite material 5-40%, heat reflective material 10-50%, adhesive Polymer resin 10-70%. The coating of the present invention is mainly used as the exterior surface coating of buildings, automobiles, trains, pipelines, storage tanks, etc. When the thickness of the dry coating film is 0.3-0.5mm, the total reflectance to heat rays can reach 85-90%, which can effectively prevent Thermal radiation from the sun.

Owner:马承银

Low-carbon energy-saving coating

InactiveCN103788849APlay the effect of thermal insulationThe Call to Realize Low Carbon and Energy ConservationPolyurea/polyurethane coatingsEpoxy resin coatingsEmissivityRadiation rays

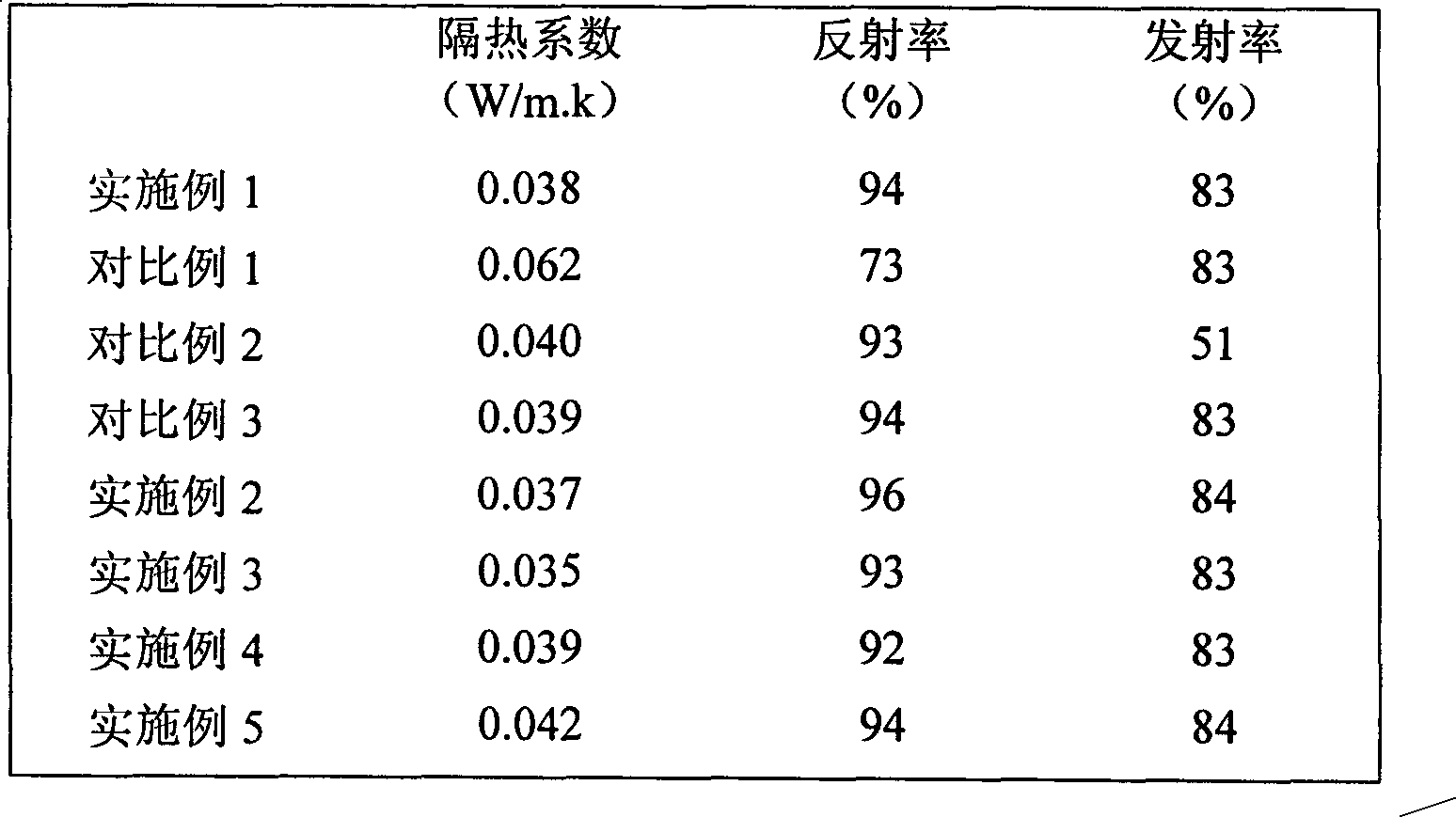

The invention discloses a low-carbon energy-saving coating, and concretely relates to a coating for the reflection, heat insulation and emission of solar radiation and other heat radiation rays. The coating is composed of a hollow silica material with the surface coated with a nano-material, a heat ray reflection characteristic material, self made infrared emission powder, a functional filler and an aqueous resin liquid. The coating has a heat insulation coefficient of 0.01-0.5W / m.k, a reflectivity to heat rays of above 90%, and a heat emissivity of above 80%.

Owner:SHENZHEN RUNWU TECH CO LTD

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

Water-based weather-proof stain-proof thermal reflective insulation coating and preparation method thereof

InactiveCN104250498ALow costInhibitionAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses a water-based weather-proof stain-proof thermal reflective insulation coating which comprises the following components in percentage by mass: 30%-50% of film forming emulsion, 10%-20% of heat reflection pigment, 6%-15% of hollow microspheres, 5%-10% of fillers, 3%-8% of a water repellent agent, 4%-8% of an assistant and the balance of de-ionized water. By introducing the industrial water repellent agent, the coating is excellent in weather resistance, stain resistance and adhesion on basic materials, and then the reflective insulation property is kept for a long time. The invention further provides a preparation method of the coating; the preparation method comprises the following steps: stirring, uniformly mixing, filtering, and packaging. According to the preparation method, the damage on the hollow microsphere structures can be reduced to the maximum extent, and the coating is guaranteed to be good in heat insulation property; in addition, the coating is low in VOC (volatile organic compound) content and environment-friendly, and the preparation process is simple and easy for large-scale industrialized production.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Aqueous emulsion type electromagnetic wave shielded coating and preparation process thereof

InactiveCN1450137AGood performance in physical environmentNo sheddingPolyurea/polyurethane coatingsEpoxy resin coatingsAdjuvantEmulsion

The composition of water emulsion electromagnetic wave shielding paint is composed of (by weight portion) 20-60 portions of water soluble film-forming resin, 20-60 portions of conducting filler, 30-100 portions of pure clean water, 1-5 portions of thickening agent and 1-5 portions of film-forming adjuvant, and its preparation process includes the following steps: (1) drying conducting filler, controlling temp. at 50-80 deg.C until the conducting filler is become into powder; (2). mixing the dried conducting filler together with film-forming adjuvant, film-forming resin and pure clean water orclean running water and grinding by using grinding machine; and (3) adding thickening agent and regulating the paint to make it have a certain viscosity.

Owner:SICHUAN UNIV

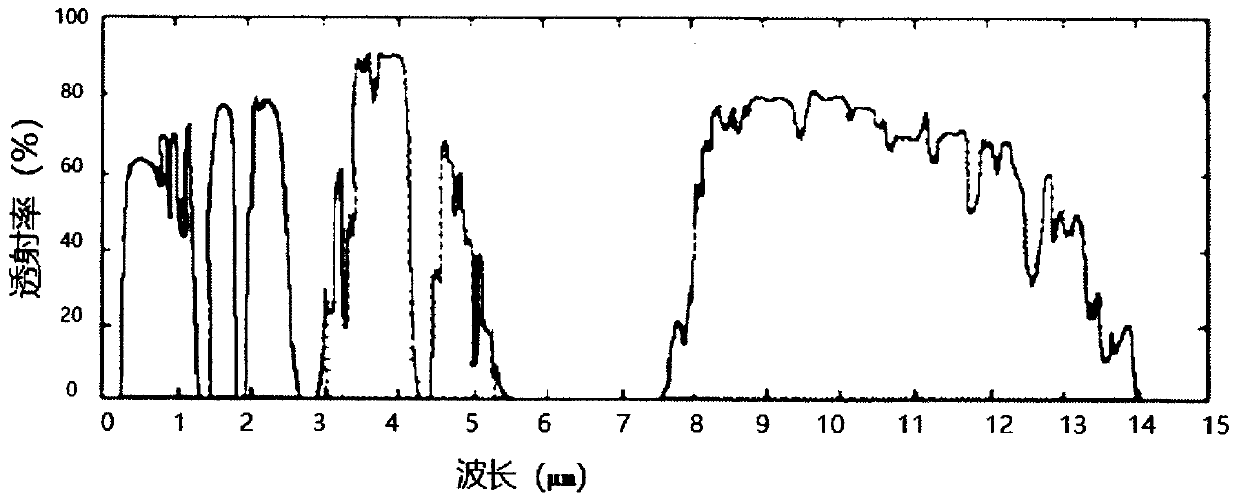

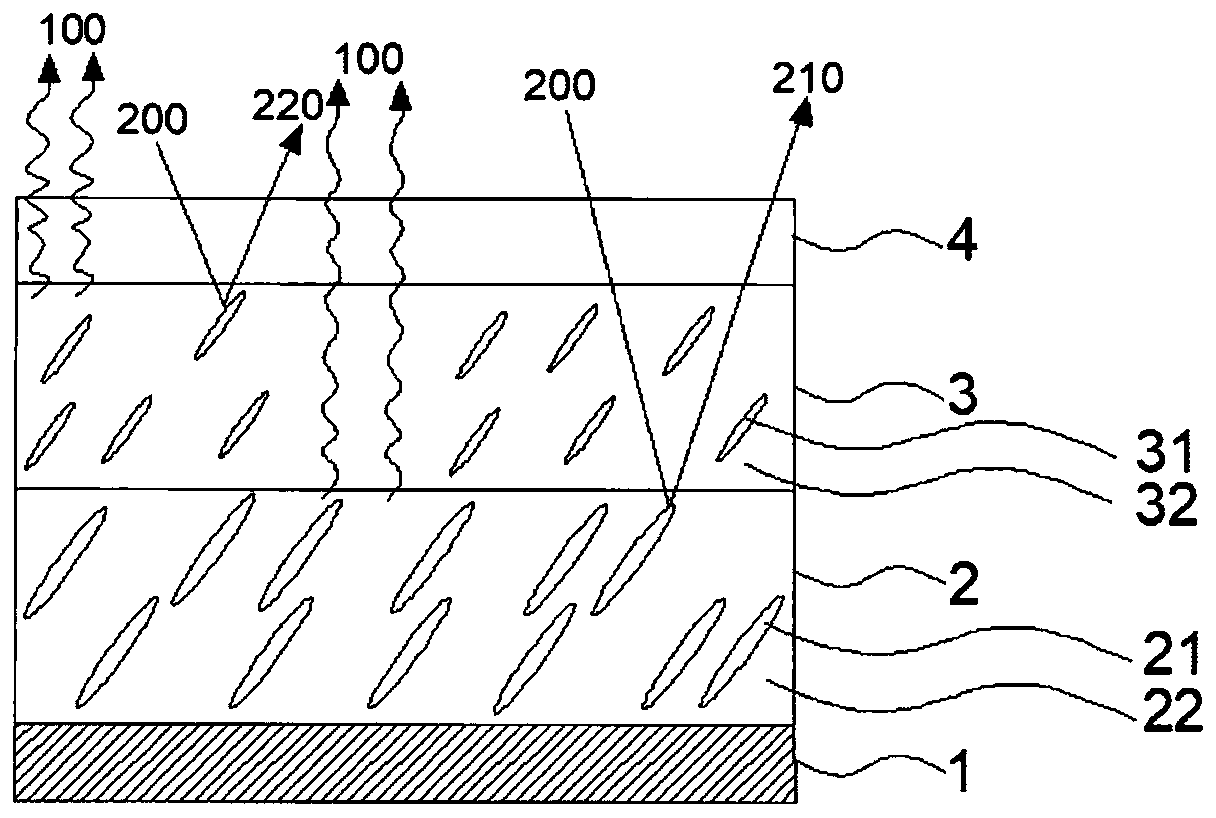

Selective radiation refrigeration coating and composite material and application method thereof

PendingCN110317521AHigh mechanical strengthGood weather resistanceLuminescent paintsBuild-up roofsUltraviolet lightsReflectivity

The invention discloses a selective radiation refrigeration coating and a composite material and application method thereof. The selective radiation refrigeration coating comprises a radiation refrigeration function layer with special structure particle filler. The radiation refrigeration function layer is used for reflecting ultraviolet light and / or visible light and / or near infrared light in sunlight and emitting heat through an atmosphere window in an infrared radiation mode, the radiation refrigeration function layer comprises a rodlike structure particle filler and radiation refrigerationfunction layer resin, and the particle filler is distributed in the radiation refrigeration function layer resin. According to the coating, the reflectivity for solar spectrum energy is larger than or equal to 80%, the reflectivity of the atmosphere window is larger than or equal to 80%, and the radiation refrigeration power being 100 W / m<2> or above can be supplied under the normal temperature.The coating is high in mechanical strength and good in weather resistance and has the quite high practical value.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD +1

Composition of insulating mold coating in use for glass, and preparation method

InactiveCN101050065ACurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyFatty alcohol

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

Preparation method of heat-reflecting insulation coating

InactiveCN101665648AHigh visible light transmittanceEffective shieldingReflecting/signal paintsWater bathsEmulsion

The invention relates to a preparation method of a heat-reflecting insulation coating, which is characterized by comprising the following steps of: 1) preparation of heat-reflecting nano-powder slurry; 2) preparation of insulation powder slurry; 3) preparation of heat-reflecting insulation coating: adding silicone-modified acrylic emulsion or styrene-acrylic emulsion, a defoamer, a thickener and afilm-forming auxiliary agent to the heat-reflecting nano-powder slurry, later adjusting the pH to 6.5-7. 0, and stirring for 2-3h, so as to obtain the heat-reflecting emulsion; and then treating theinsulation powder slurry for 1-2h at the temperature of 85-90 DEG C under water bath, which is then added to the heat-reflecting emulsion and stirred for 3h, and finally obtaining the heat-reflectinginsulation coating. The preparation method of the heat-reflecting insulation coating has the advantages of simple preparation process, higher visible light transmittance rate and infrared reflection for the coating, transparent and uniform coating, good adhesion and washing resistance, and outstanding ultraviolet aging resistance, and can be widely used on the exterior walls and the outdoor sunshade fabrics for heat insulating and cooling.

Owner:WUHAN UNIV OF TECH

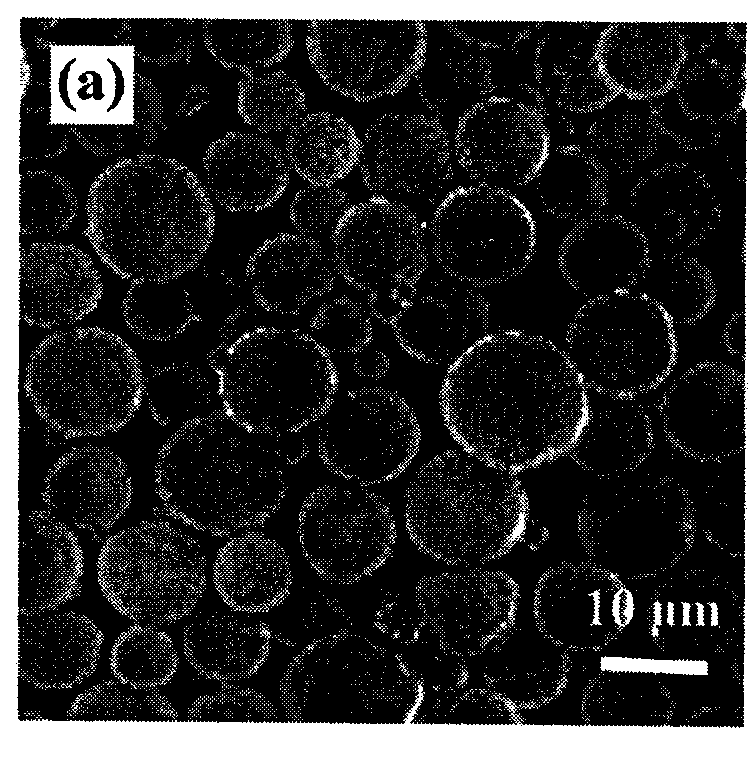

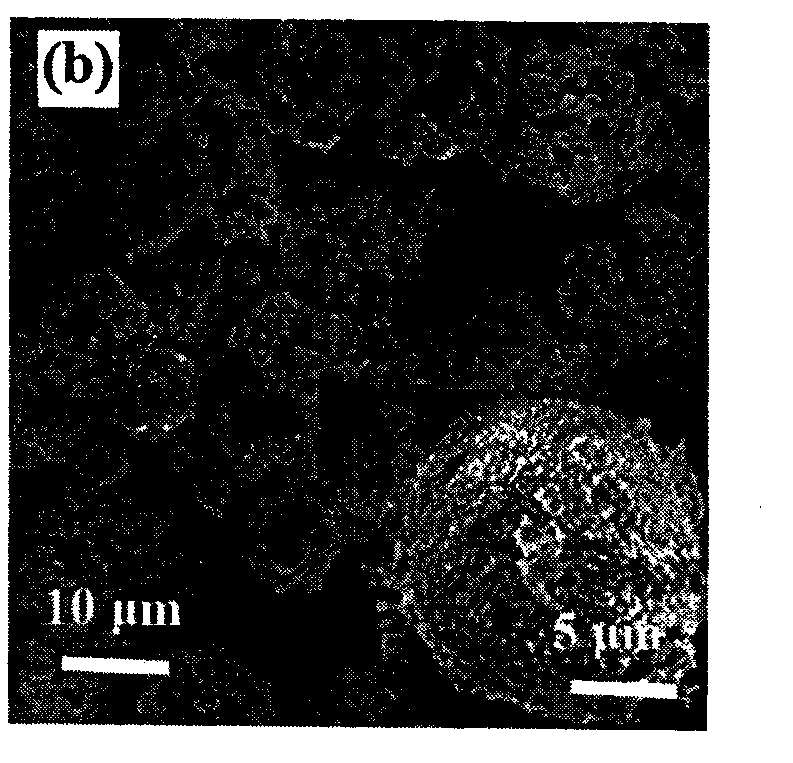

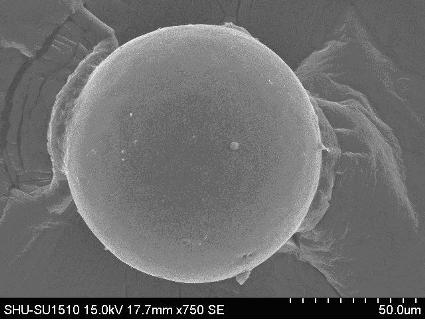

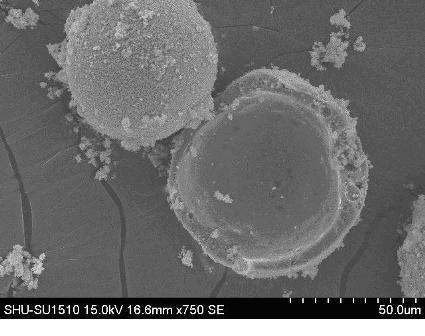

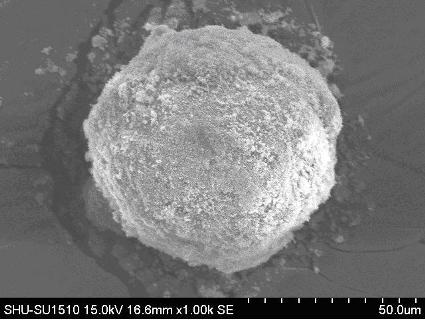

Method for preparing hollow glass microsphere coating titanium dioxide

InactiveCN102002263AEasy to depositExtended service lifePigment treatment with organosilicon compoundsReflecting/signal paintsFiltrationDistilled water

The invention discloses a method for preparing titanium dioxide for coating surfaces of hollow glass microspheres. The method comprises: washing the hollow glass microspheres with alkali liquor to remove impurities and etching to improve activity; performing surface activation and modification by using a silane coupling agent; mixing the activated hollow glass microspheres and distilled water in a mass ratio of 1:10; fully stirring at 40 to 90 DEG C; in the stirring process, dripping solution of titanium sulfate at a constant speed with in 2 to 6 hours according to a mass ratio of the hollow glass microspheres to the titanium sulfate of 1:0.8-1:1.6; slowly adding alkali liquor, keeping the pH value of the reaction system between 5 and 7, and stirring first at a speed of 400r / min for the first 1 / 5 of reaction time and then at a speed of 100 to 300r / min for the rest 4 / 5 of reaction time; and after the reaction is finished, standing, performing suction filtration, washing with distilled water, drying and calcining. The hollow glass microspheres coated with the titanium dioxide can serve as filler for reflective and thermal-insulation coating. Compared with common hollow glass microspheres, the hollow glass microspheres can be used for preparing and synthesizing high-performance coating combining various thermal-insulation mechanisms.

Owner:SHANGHAI UNIV

Reflective heat-insulation coating and preparation method thereof

ActiveCN101565581AGood weather resistanceLower thermal equilibrium temperatureReflecting/signal paintsMicrosphereHeat balance

The embodiment of the invention provides a reflective heat-insulation coating and a preparation method thereof. The reflective heat-insulation coating comprises the following raw materials of aqueous pure crylic acid resin, aqueous elastic resin, titanium dioxide, ceramic hollow microspheres, infrared powder, a flame retardant, water, an organic dispersant, a film-forming additive, an antifreeze, a thickener, an anti-foaming agent, a wetting agent, a preservative and a pH value regulator. The coating is a single-component aqueous coating, has no toxicity and good weatherability; extremely fine hollow microsheres are closely arranged by multi-stage in the coating to form a vacuum layer so as to have extremely strong reflection and obstruction function to the solar radiation heat and can effectively reduce the radiation heat transfer and convection heat transfer, thus reducing the heat balance temperature on the surface of the article. The reflective heat-insulation coating leads the building space and the facility container to be warm in winter and cool in summer, reduces the heat island effect and energy consumption of the air conditioner, has obvious energy-saving effect, and reduces the surface temperature by 20 DEG C to a maximum extent and reduces the internal temperature by 5-10 DEG C compared to the normal coating.

Owner:厦门富思特新材料科技有限公司

Building coating with heat insulation function and preparation method thereof

InactiveCN106118307AGood thermo-optic comprehensive performanceWith thermal insulation functionReflecting/signal paintsBuilding energyMetallurgy

The invention provides a building coating with a heat insulation function and a preparation method thereof. The building coating with the heat insulation function is divided into an internal wall coating and an external wall coating, wherein each of the internal wall coating and the external wall coating is composed of a basic carrier for film forming of the coating, a heat insulating material, a heat reflecting material, a heat radiating material, filler, an assistant and water. The preparation method comprises the following steps: preparation of heat insulating material slurry, preparation of function material slurry, grinding of slurry, and paint mixing. The film forming thickness of the building coating is 0.2-0.3mm, so that the building coating belongs to a thin building energy-saving coating; the internal and external wall building coatings have higher heat conducting resistance and lower convection heat transfer, so that the building coating has different heat radiating effects under different temperature environments in different seasons and has the heat insulation function; the building coating is high in safety and long in service life; and the preparation method is simple and is suitable for industrial production.

Owner:马承银

Heat resistant and fire retardant materials and methods for preparing same

InactiveUS8172938B2Increased durabilityHigh strengthFireproof paintsSolid waste managementWater basedFluoropolymer

A silica cement blend having an insulating, fire retarding and high temperature characteristic capable of withstanding temperatures ranging from ambient to greater than 40000 F without degradation of the concrete structure. In addition to its high temperature capabilities the blend can be produced as ultra light weight to heavy weight concrete. The silica based mixture when added to cementitious materials such as Portland cement, Class C Fly Ash, silica fume and other cementitious materials. Presented also are methods for reducing fire damage by coating interior / exterior walls, ceiling, and roofs of a building with a water based latex coating containing a fire retardant material and low heat conductivity silicas. Methods for painting internal / external walls, ceilings, and roof are also presented. This coating retains thermal blocking properties comprised of processed, expanded and / or finely milled, pyrogenic silicas and micro spheres in combination of but not limited to, one, two or more component water based polymer / copolymer latex binders and a water born fluoropolymer emulsion. The combined properties of these elements create a coating similar to paint with a high level of thermatic resistance which slows the composition break-down from fire, extreme temperatures, and restricts the thermal conductivity which helps to preserve the integrity of the substructure or underlying materials. The properties of this coating reduce or slow the potential of catastrophic fire by retarding flashover and protecting the under structure; which in turn assist fire fighters and rescue personnel by helping to retard the potential of a catastrophic fire.

Owner:SPECIALTY CONCRETE DESIGN

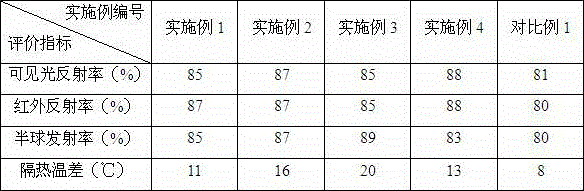

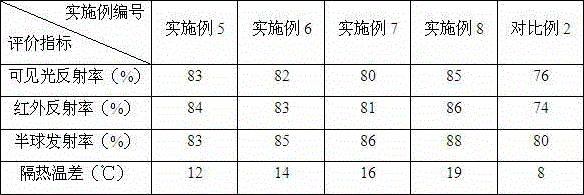

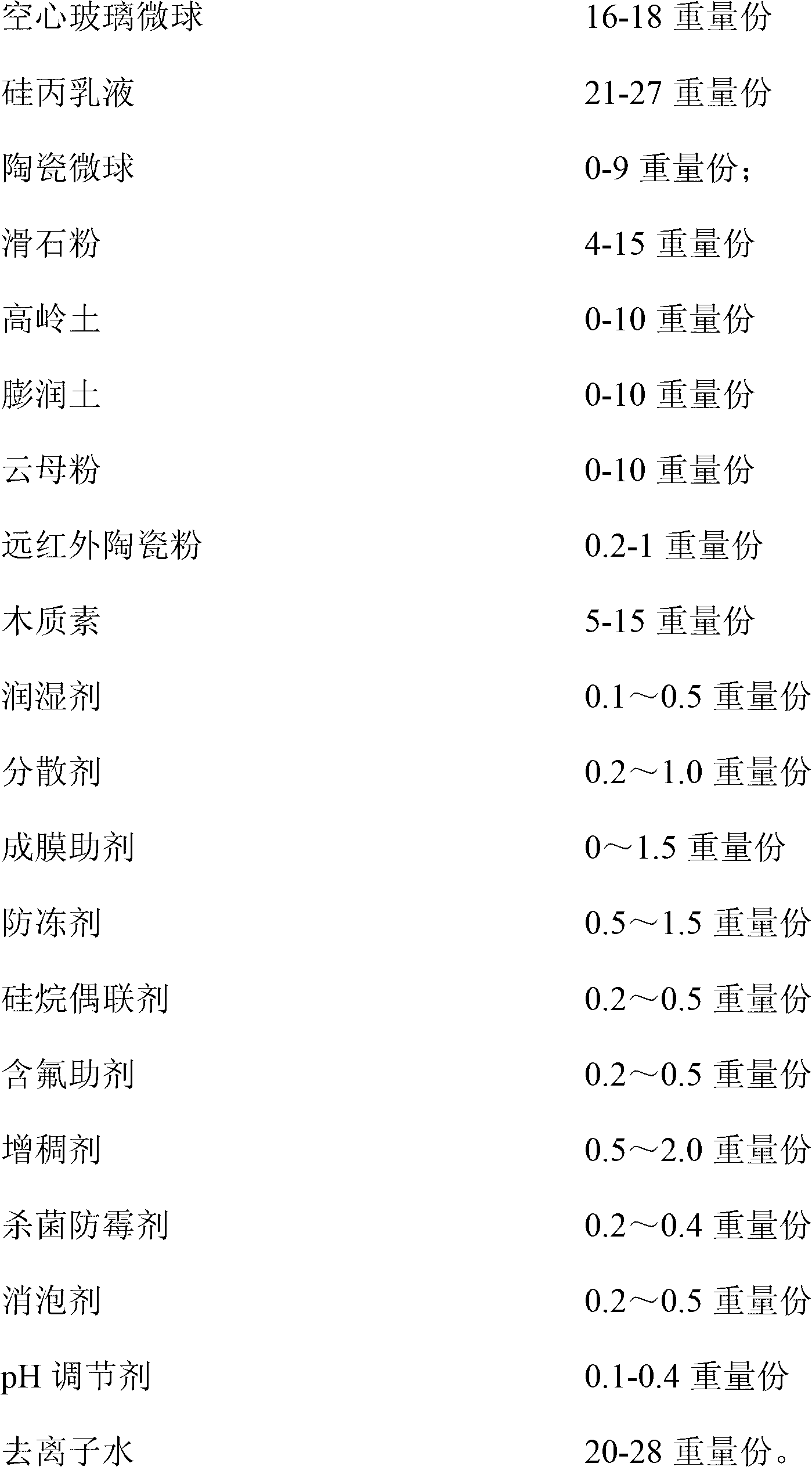

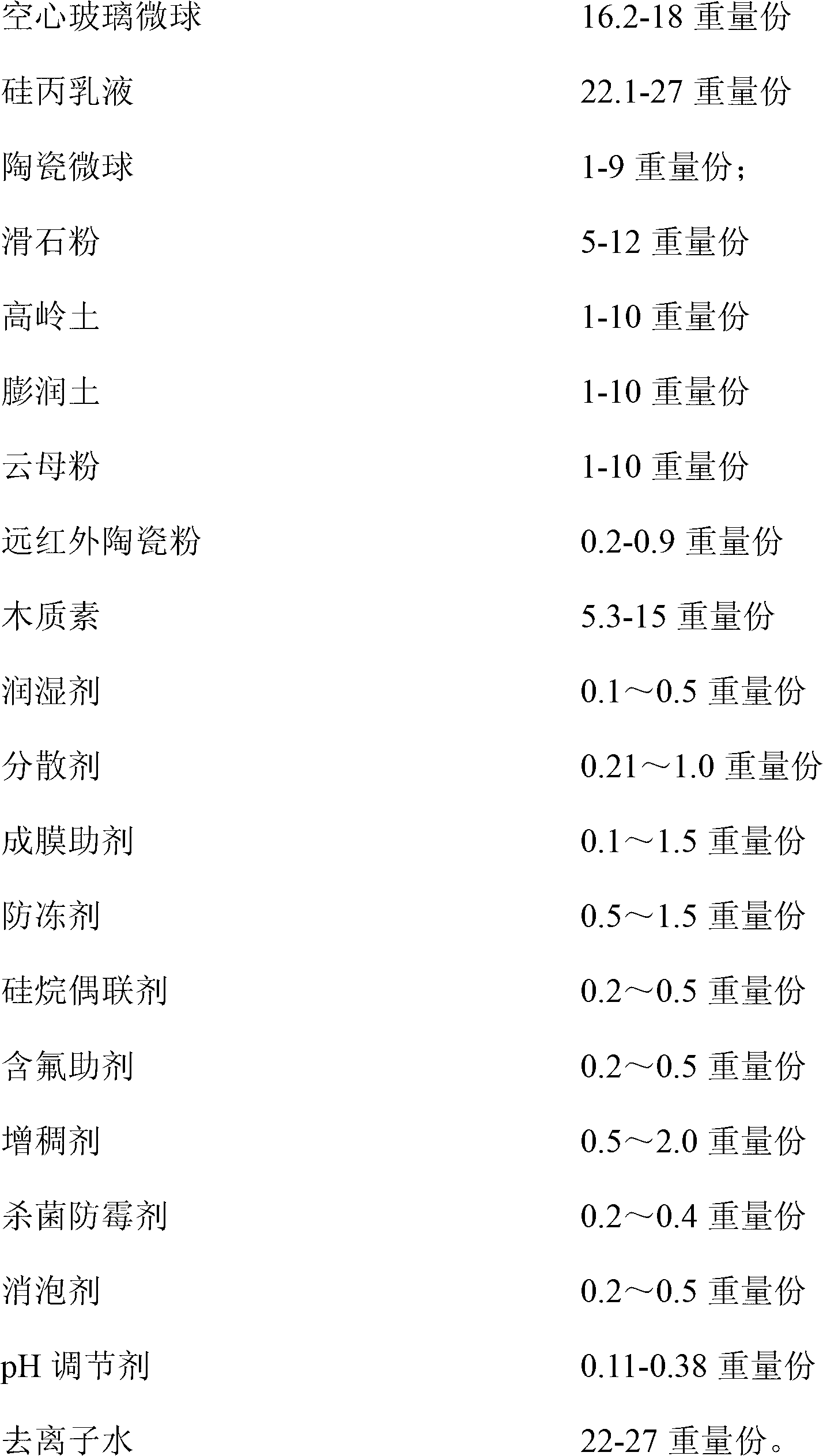

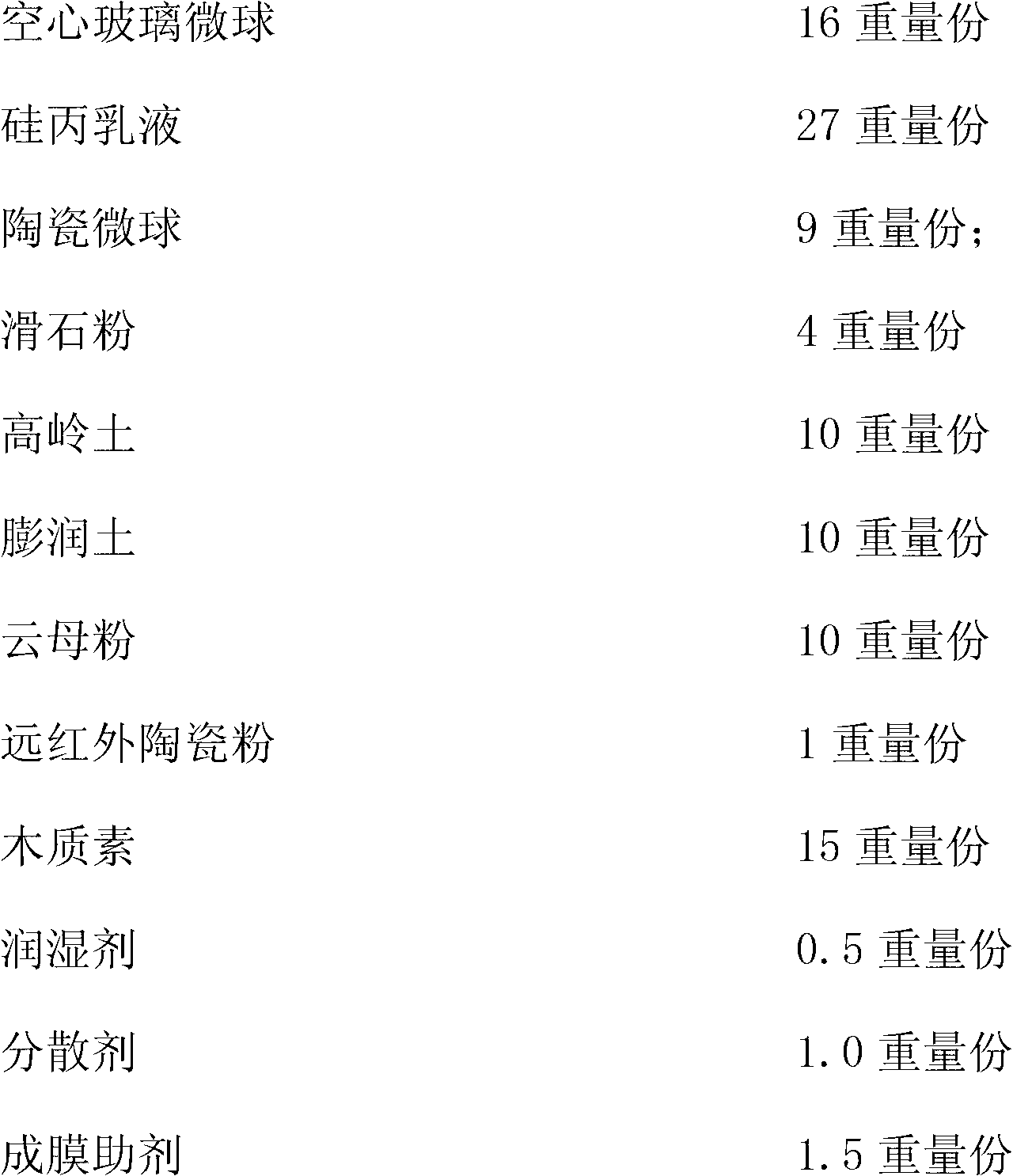

Waterproof thermal insulation coating composition and preparation method thereof

InactiveCN102702904AStir wellHigh solar reflectanceAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

The invention relates to a waterproof thermal insulation coating composition, which comprises an aggregates, a substrate, an auxiliary filling and an assistant, and is characterized in that the aggregates are hollow glass microspheres, and the substrate is silicone acrylic emulsion; in the thermal insulation coating composition, 6-18 parts by mass of hollow glass microspheres and 21-27 parts by mass of silicone acrylic emulsion are provided. According to the invention, the silicon acrylic emulsion is selected, so that the thermal insulation coating has excellent thermal insulation property, and good waterproof and antifouling performance, and the waterproof and antifouling performance is more excellent for fluorine-containing silicone acrylic emulsion.

Owner:TIANCHANG JULONG TRAVEL PAINT

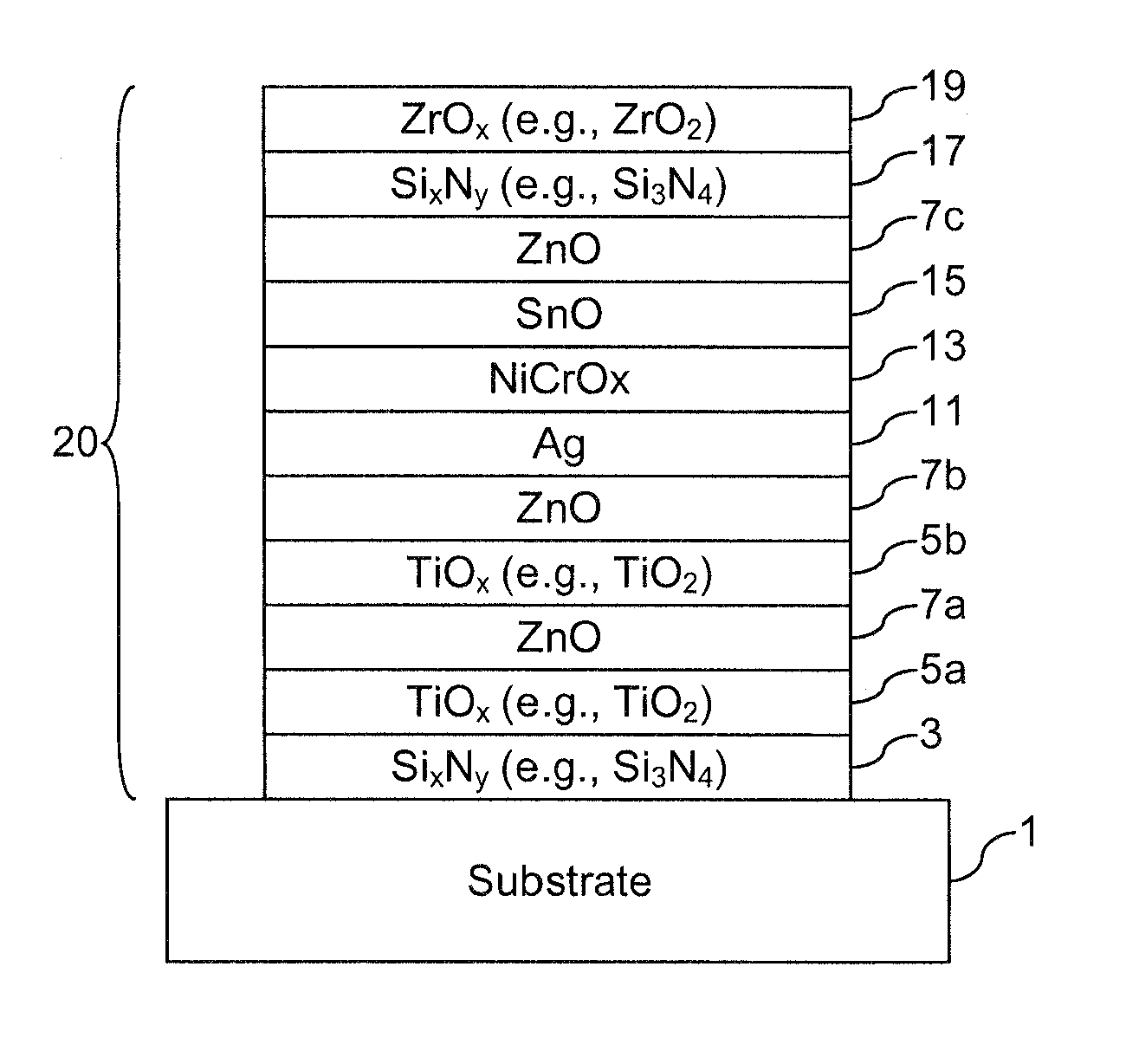

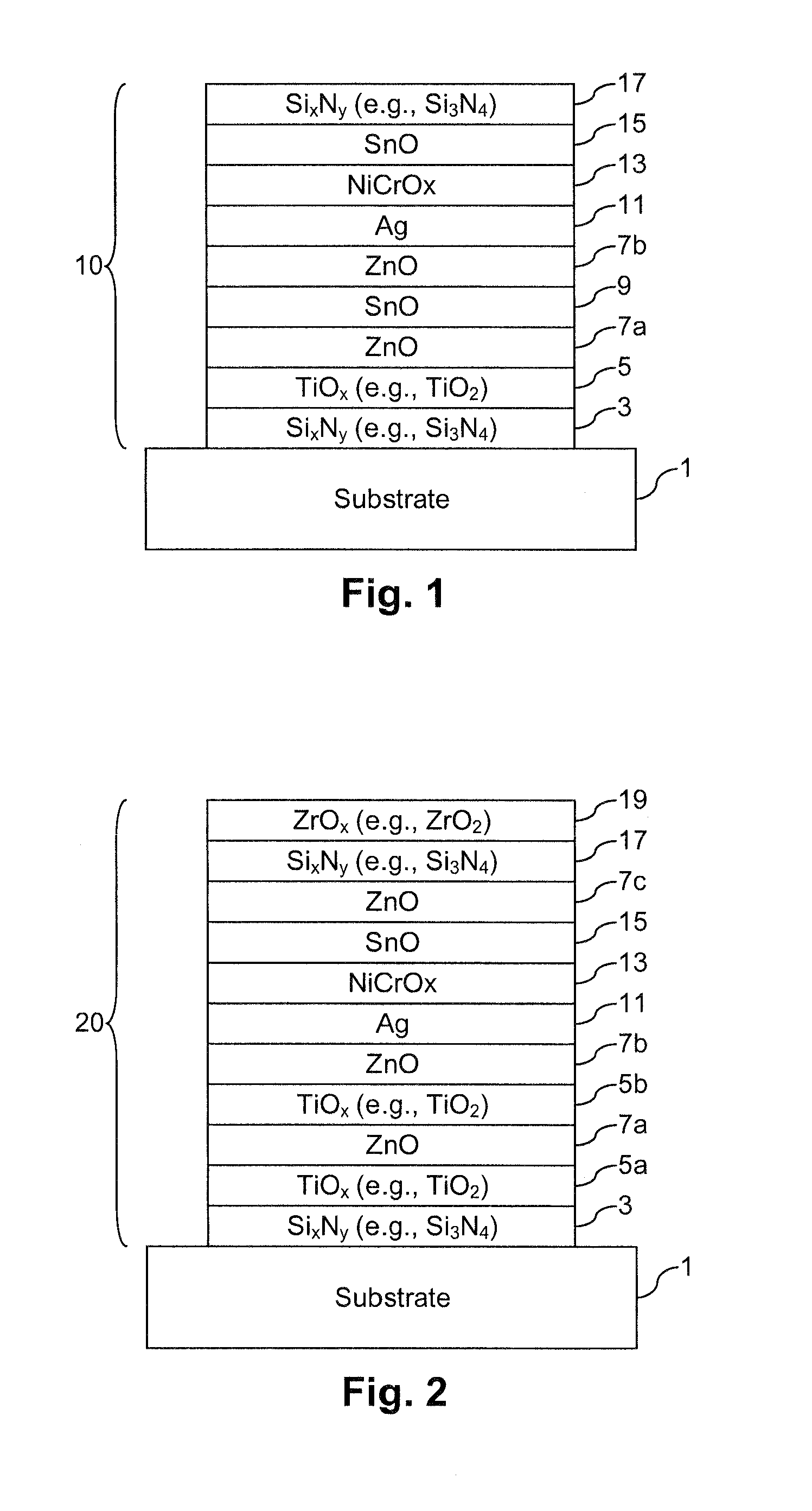

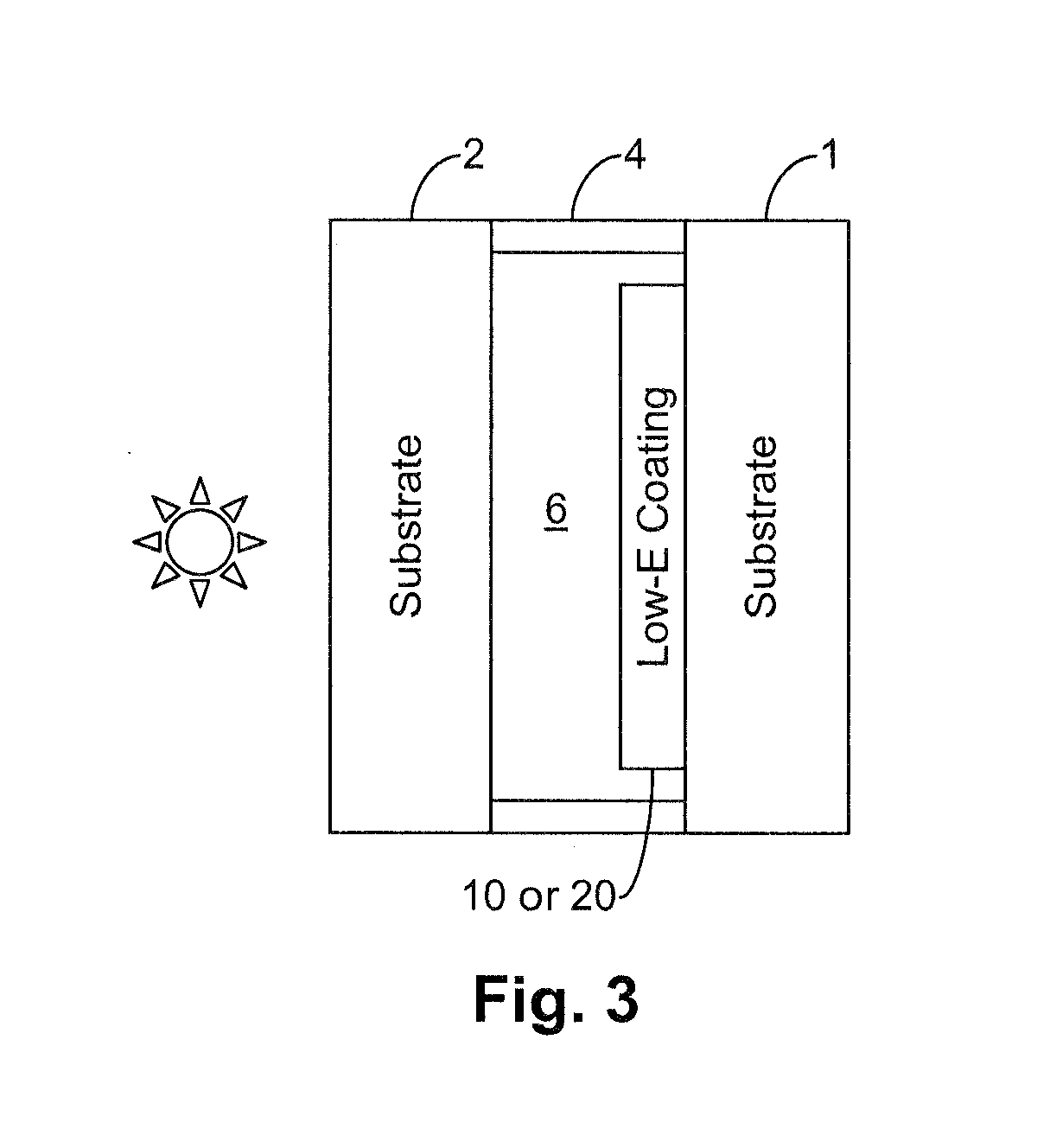

Coated article with low-e coating having barrier layer system(s) including multiple dielectric layers, and/or methods of making the same

InactiveUS20130164464A1Reduce generationGood choiceVacuum evaporation coatingSputtering coatingInsulated glazingThermal stability

Certain example embodiments of this invention relate to coated articles with low-E coatings having one or more barrier layer systems including multiple dielectric layers, and / or methods of making the same. In certain example embodiments, providing barrier layer systems that each include three or more adjacent dielectric layers advantageously increases layer quality, mechanical durability, corrosion resistance, and / or thermal stability, e.g., by virtue of the increased number of interfaces. These barrier layer systems may be provided above and / or below an infrared (IR) reflecting layer in the low-E coating in different embodiments. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, vehicle windows, other types of windows, or in any other suitable application.

Owner:GUARDIAN EURO S A R L

Double-coated hollow glass microbead heat-insulated coating and preparation method thereof

InactiveCN102391754AGood heat insulationEnvironmental protection and energy savingReflecting/signal paintsCelluloseMeth-

The invention discloses double-coated hollow glass microbead heat-insulated coating and a preparation method thereof. The double-coated hollow glass microbead heat-insulated coating is prepared from the following raw materials in percentage by weight: 20 to 30 percent of organic silicon modified styreneacrylic emulsion, 9 to 13 percent of double-coated hollow glass microbead, 8 to 12 percent of titanium dioxide rutile, 5 to 8 percent of talcum powder, 17 to 23 percent of heavy calcium, 1.5 to 2 percent of glycol, 0.13 to 0.2 percent of hydroxymethyl cellulose, 0.6 to 1 percent of dispersing agent, 0.35 to 0.45 percent of defoaming agent, 0.15 to 0.19 percent of wetting agent, 0.08 to 0.13 percent of multifunctional aid, 1.0 to 1.5 percent of film-forming aid and the balance of water. Reflective heat-insulated coating is prepared by performing pretreatment on hollow glass microbeads by a double-coated method, selecting silicone / acrylic emulsion as a base material, using the pretreated hollow glass microbeads, the titanium dioxide rutile, the talcum powder, the heavy calcium and the like as pigment fillers and adding a certain amount of fillers. The coating can improve reflectivity and weather resistance, and has the beneficial effects of environmental friendliness, energy conservation, simple production process, good dispersing effect, low cost, stable performance and long service life.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com