Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7865 results about "Silica fume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

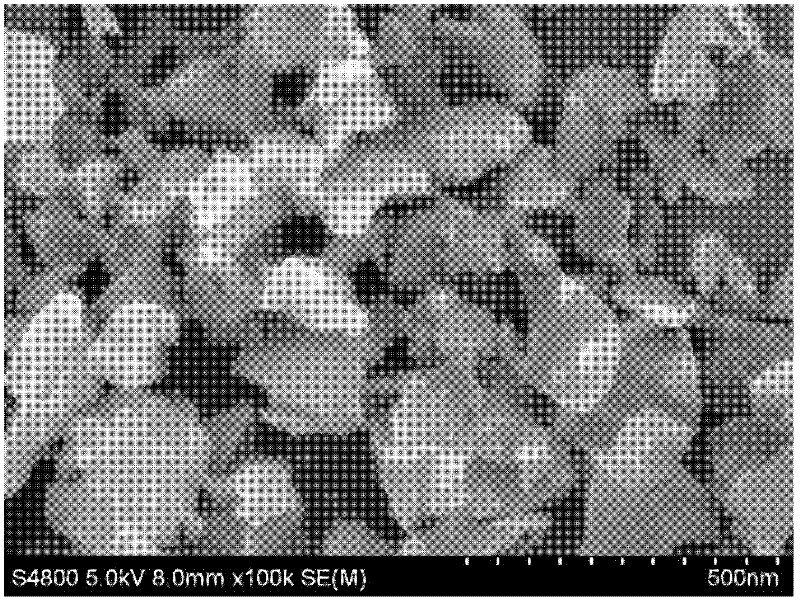

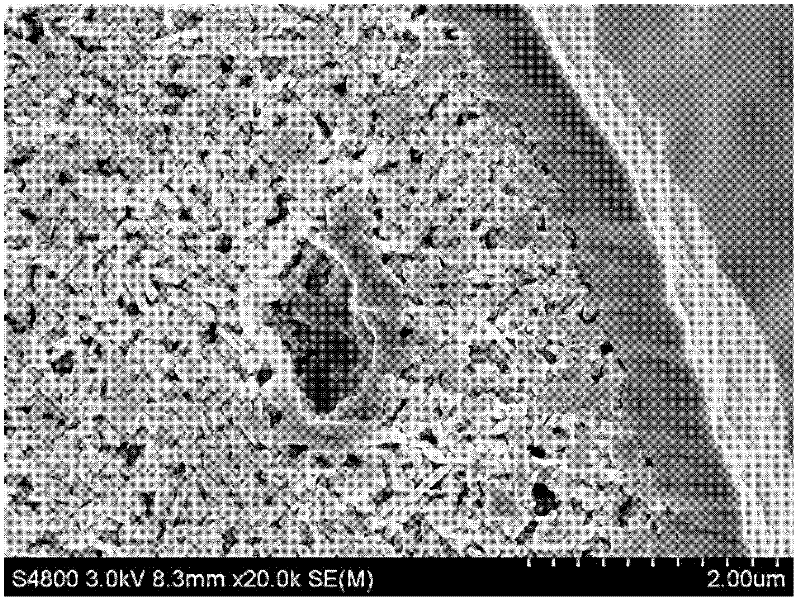

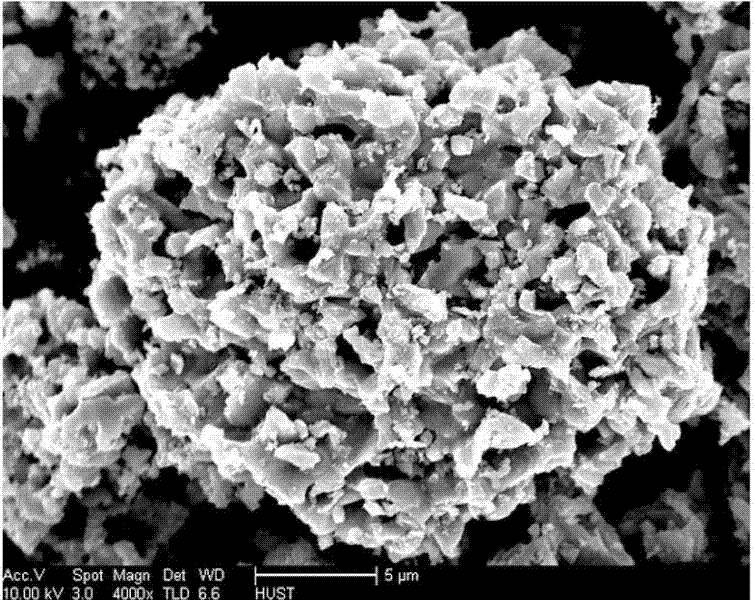

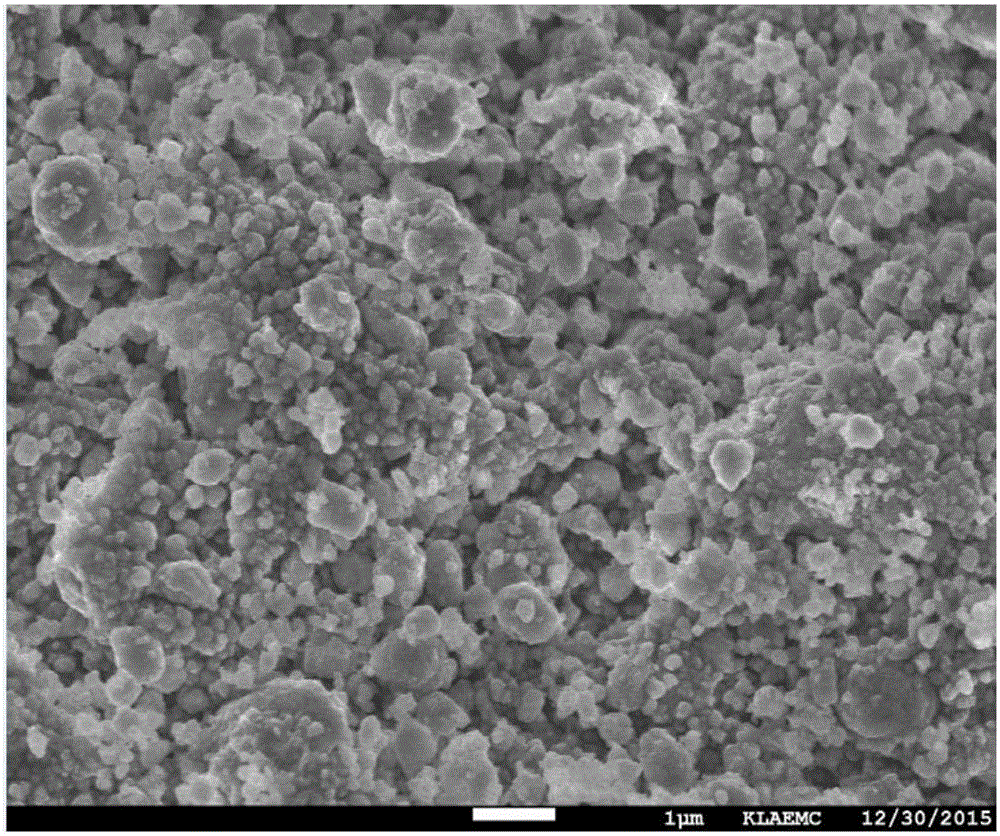

Silica fume, also known as microsilica, (CAS number 69012-64-2, EINECS number 273-761-1) is an amorphous (non-crystalline) polymorph of silicon dioxide, silica. It is an ultrafine powder collected as a by-product of the silicon and ferrosilicon alloy production and consists of spherical particles with an average particle diameter of 150 nm. The main field of application is as pozzolanic material for high performance concrete.

Porous silicon particulates for lithium batteries

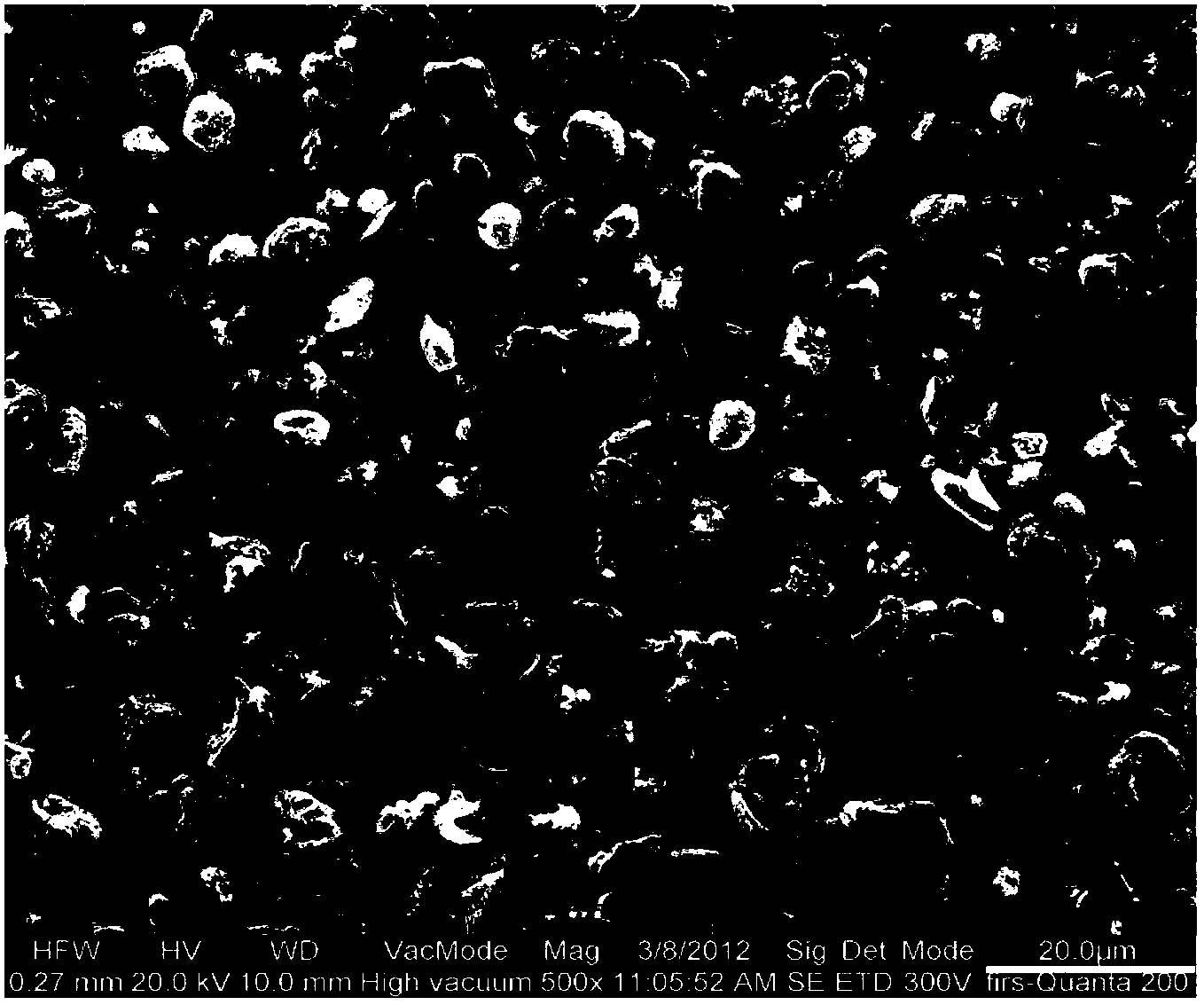

An anode structure for lithium batteries includes nanofeatured silicon particulates dispersed in a conductive network. The particulates are preferably made from metallurgical grade silicon powder via HF / HNO3 acid treatment, yielding crystallite sizes from about 1 to 20 nm and pore sizes from about 1 to 100 nm. Surfaces of the particles may be terminated with selected chemical species to further modify the anode performance characteristics. The conductive network is preferably a carbonaceous material or composite, but it may alternatively contain conductive ceramics such as TiN or B4C. The anode structure may further contain a current collector of copper or nickel mesh or foil.

Owner:TIEGS TERRY N

Construction products and method of making same

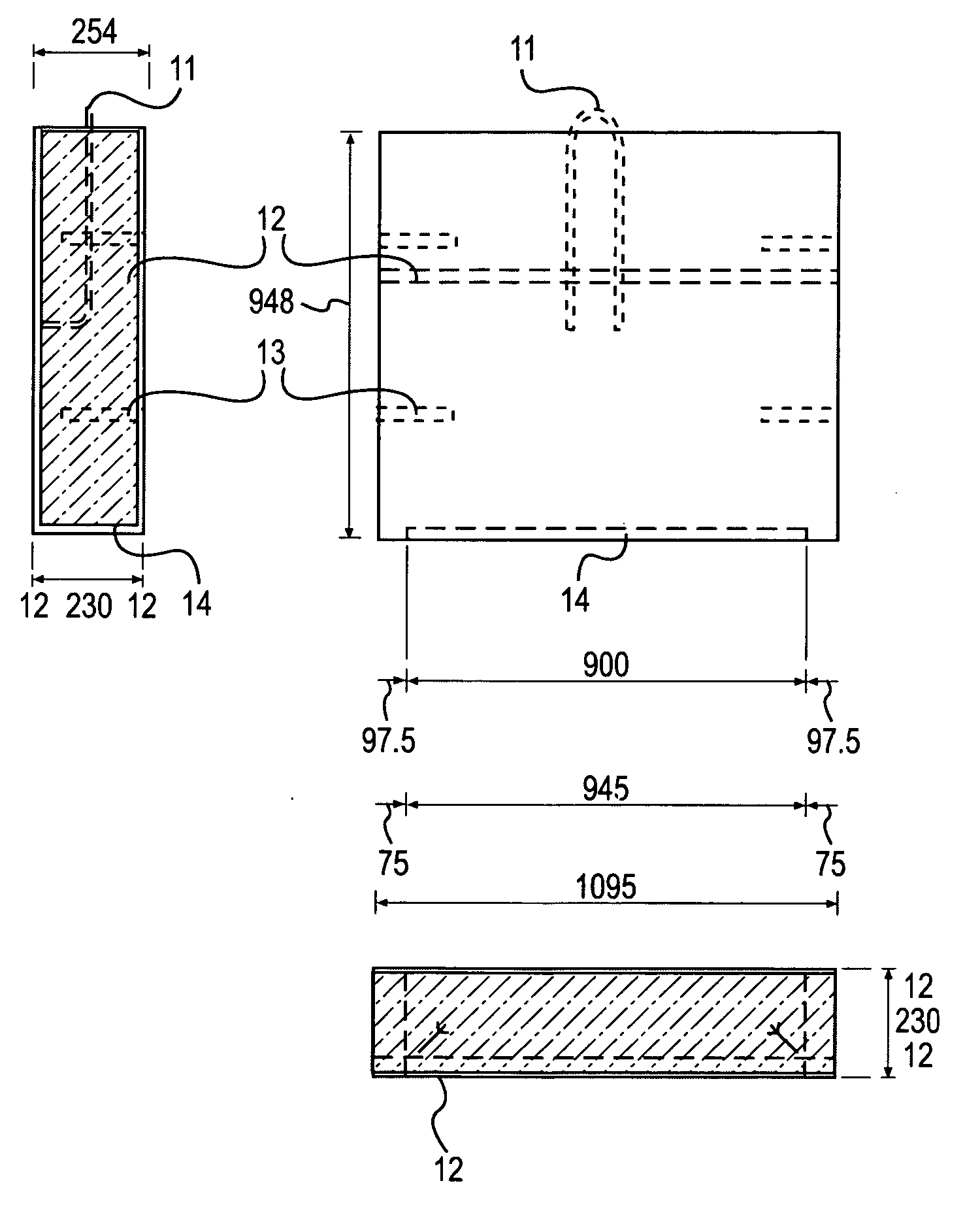

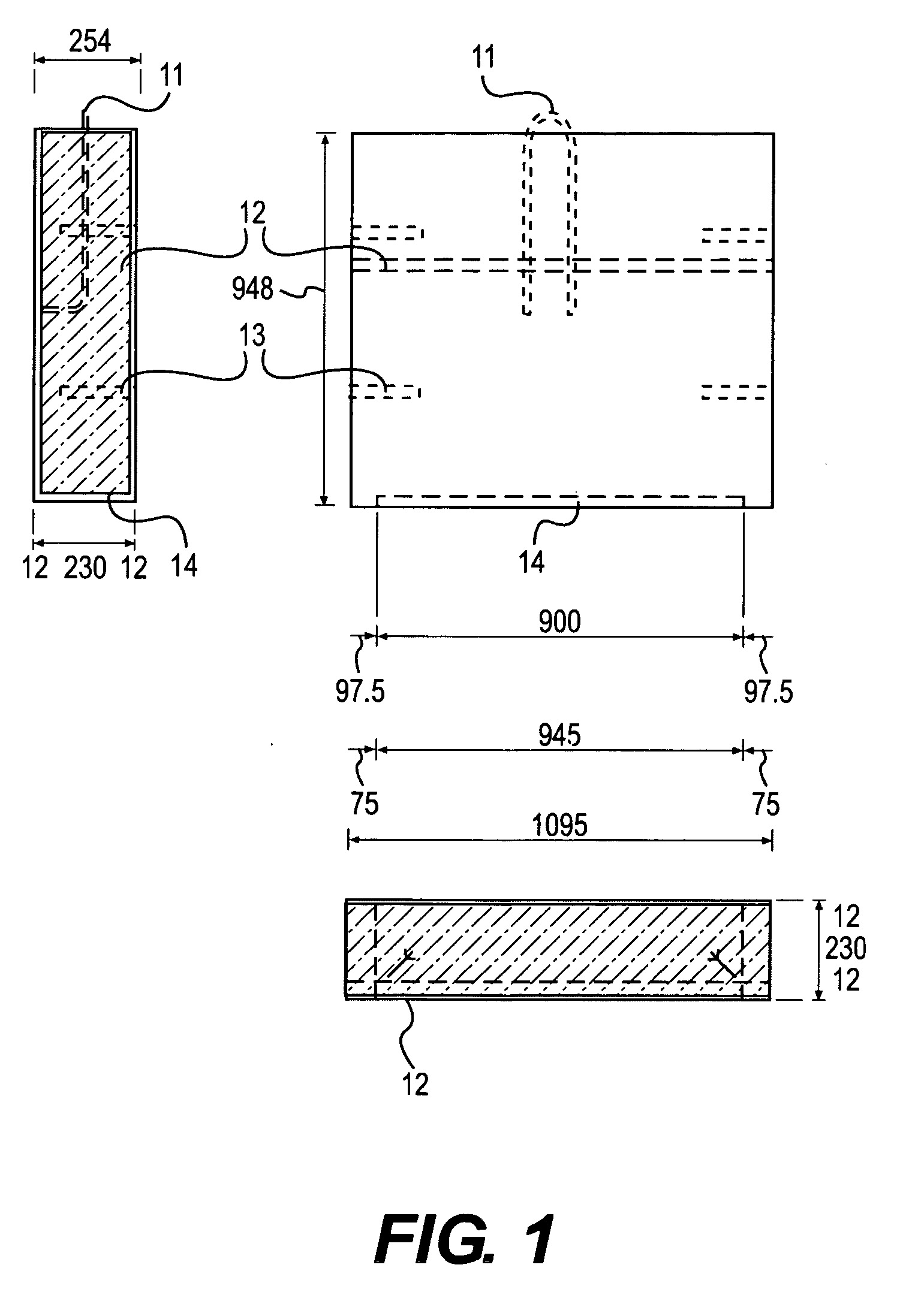

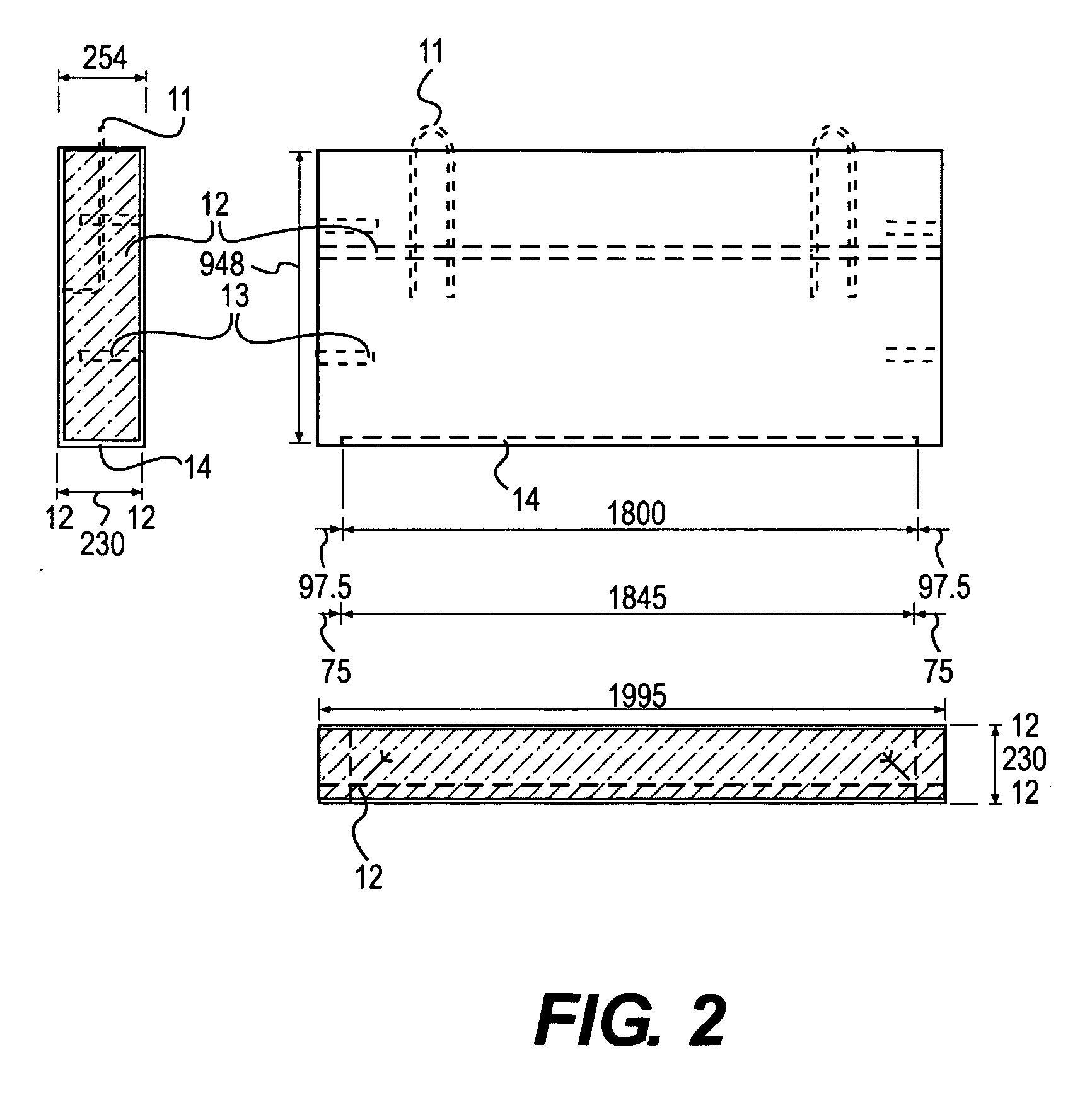

InactiveUS20070062143A1Eliminate needShorten construction timeSolid waste managementWallsBuilding productCement board

A highly durable and easy to use prefabricated construction product is disclosed having a cellular concrete component sandwiched between two cement boards, wherein the cellular concrete component comprises cement, fly ash, an activating agent and water, and the cement boards comprise cement, fly ash, an activating agent, sand, silica fume, a water reducer agent, a reinforcing fiber, and water.

Owner:NOUSHAD RAFIE LOTFI

Dental bleaching compositions containing sucralose

Dental bleaching compositions that include sucralose. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous such as a mixture of propylene glycol and silica fume. Anhydrous propylene glycol and / or anhydrous glycerin are especially useful in order to maintain the desired degree of hydration of the perborate being used. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

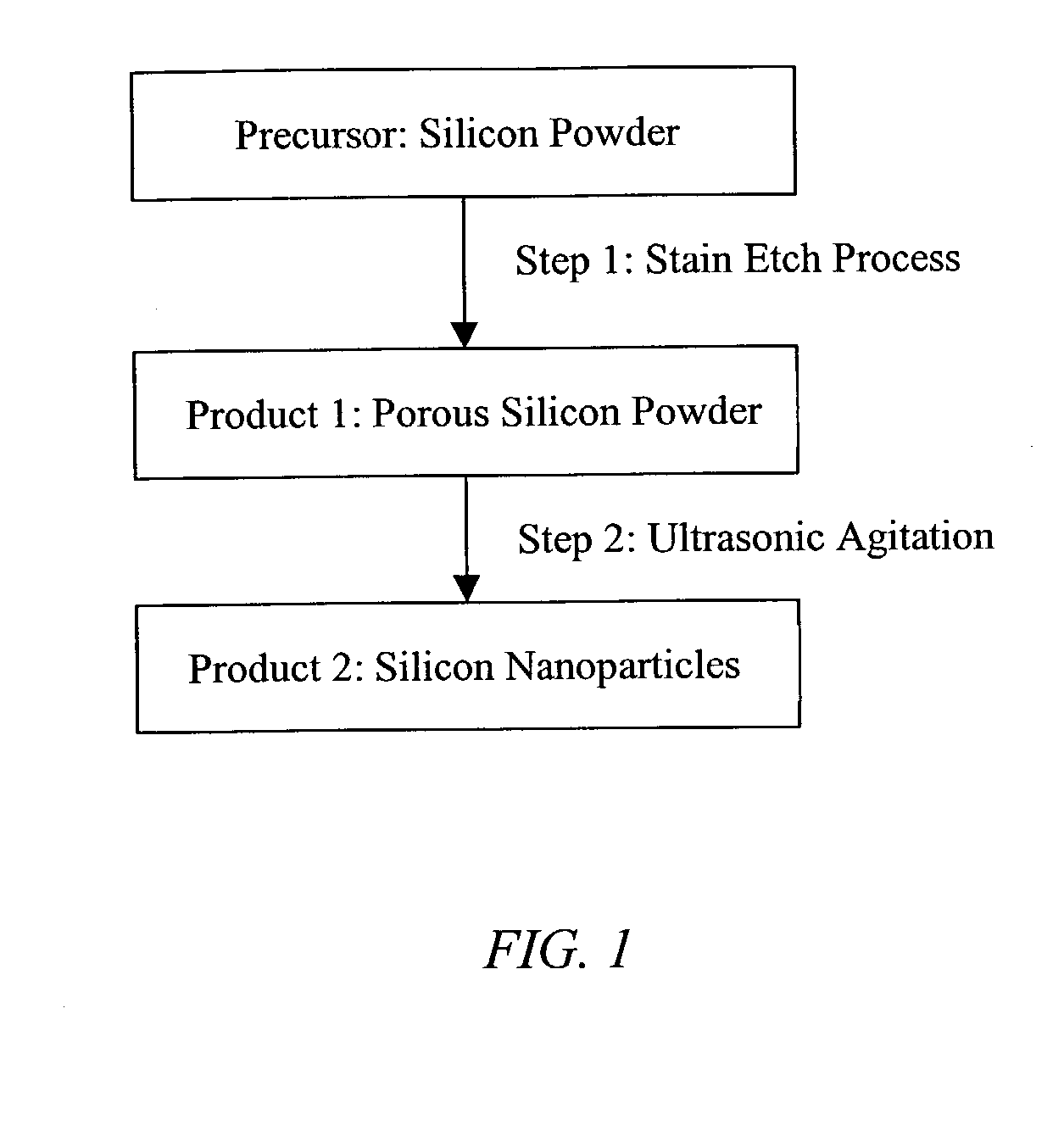

Method of producing silicon nanoparticles from stain-etched silicon powder

The present invention is for a porous silicon powder comprising silicon particles wherein the outermost layers of said particles are porous. The present invention is also directed to a method of making this porous silicon powder using a stain etch method. The present invention is also directed to a method of making silicon nanoparticles from the porous silicon powders using a process of ultrasonic agitation. The present invention also includes methods of processing these silicon nanoparticles for use in a variety of applications.

Owner:SI DIAMOND TECH

Preparation method for fiber reinforced carbon-silicon carbide-zirconium carbide-based composite material

The invention discloses a preparation method for a fiber reinforced carbon-silicon carbide-zirconium carbide-based (C / C-SiC-ZrC) composite material. The preparation method comprises the following steps of: (a) evenly dispersing ZrC nanopowder in absolute ethyl alcohol; (b) mixing phenolic resin and ZrC dispersion liquid to form slurry; (c) immersing a two-dimensional carbon fiber sheet into the slurry for dipping and drying, then carrying out continuous superposition paving on the two-dimensional carbon fiber sheet, and carrying out curing and post-curing treatment to prepare a fiber-reinforced sintered body; (d) cracking the fiber-reinforced sintered body to obtain a porous C / C prefabricate; (e) placing silicon powder into a graphite crucible, burying the porous C / C prefabricate into the silicon powder, heating to 1,500-1,650 DEG C, and preserving heat for preset time so as to carry out liquid silicon permeation. The method can be used for improving the high-temperature oxidizing property and ablation property of the carbon fiber reinforced ceramic (C / C-SiC) composite material.

Owner:DALIAN UNIV OF TECH

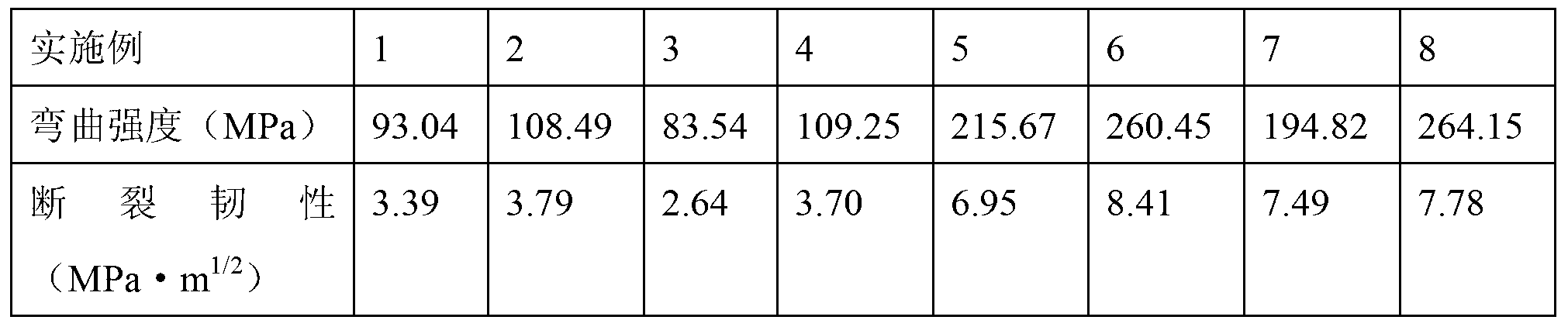

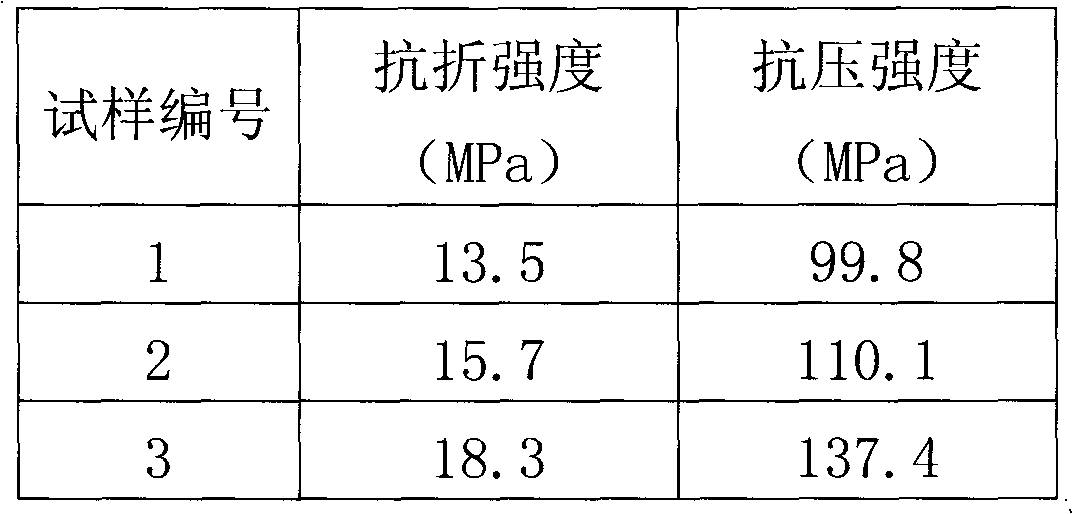

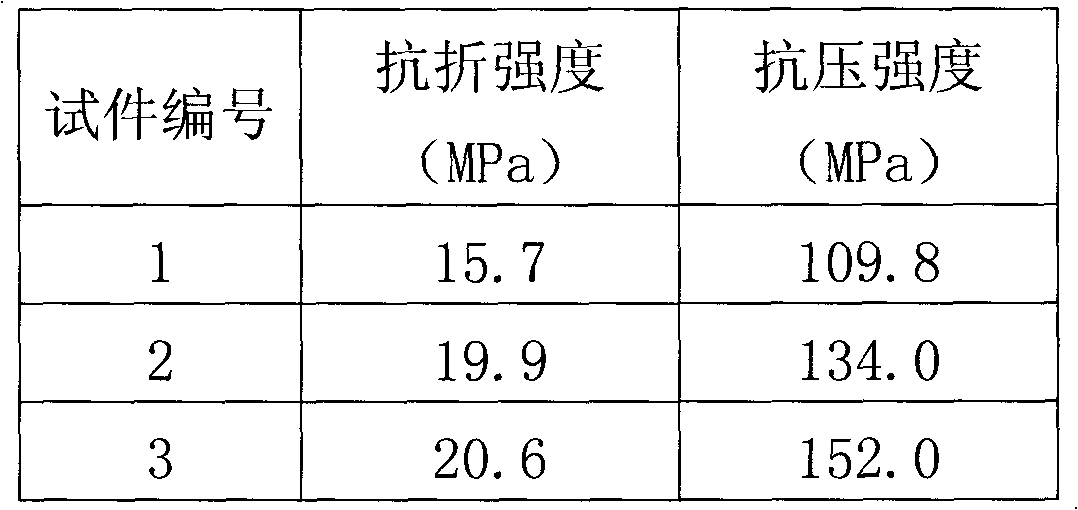

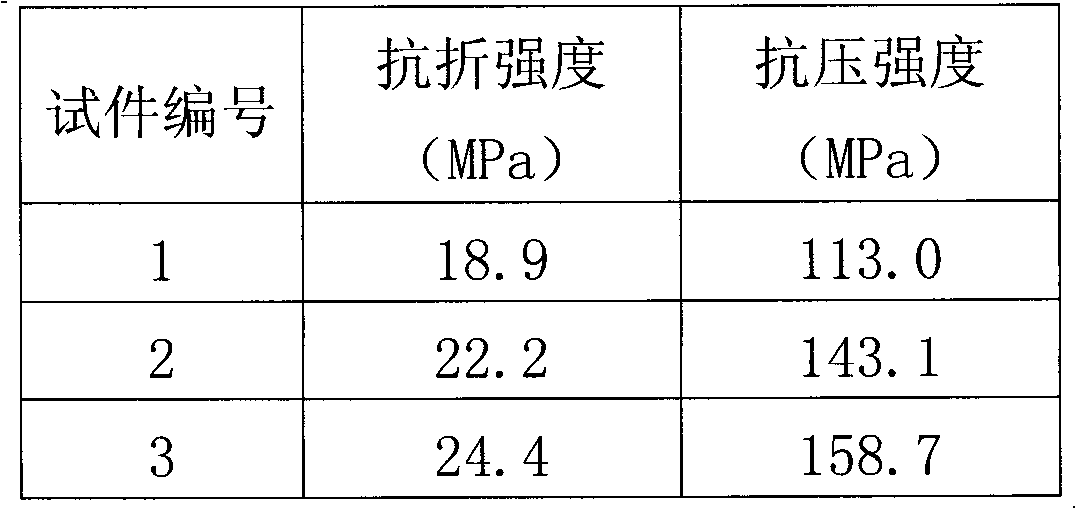

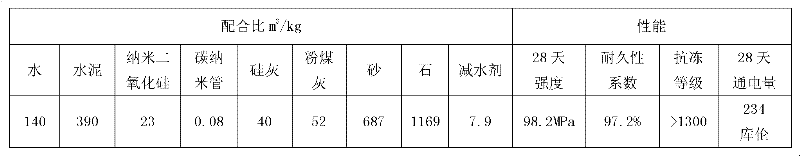

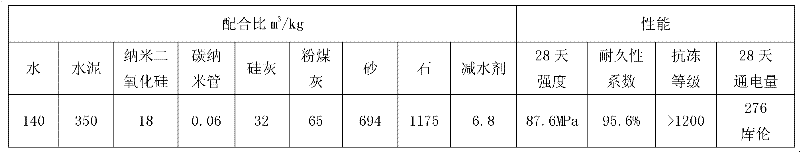

High-strength and high-toughness reactive powder concrete of carbon doped nano-tube and preparation method of high-strength and high-toughness reactive powder concrete

The invention provides high-strength and high-toughness reactive powder concrete of a carbon doped nano-tube. The high-strength and high-toughness reactive powder concrete is prepared by taking cement, a carbon nano-tube, silica fume, a water reducing agent, silica sand, coal ash, quartz powder, steel fiber and water as raw materials, wherein all the components in the mixture are calculated in parts by mass: 1000-1200 parts of cement, 250-350 parts of silica fume, 250-350 parts of slag powder, 40-50 parts of water reducing agent, 1200-1400 parts of silica sand, 180-230 parts of water, 190-230 parts of steel fiber, 180-250 parts of coal ash, 80-120 parts of quartz powder, 0.1-5 parts of carbon-nano-tube dispersing agent and 1-10 parts of carbon nano-tube powder. The invention also provides a preparation method of the high-strength and high-toughness reactive powder concrete. The reactive powder concrete obtained by the invention has the high compression strength of 250-300MPa and breaking strength of 45-60MPa, which are higher than the 200-level related performances of the traditional RPC (Reactive Powder Concrete). Meanwhile, the initial cracking strength of the reactive powder concrete material prepared by using the carbon nano-tube is greatly improved and is up to 10MPa in a direct stretching state, and the tensile strain corresponding to peak stress is up to more than 0.5%, so that the toughness and strength of the traditional RPC material are greatly improved.

Owner:浙江固邦新材料有限公司

Method for recycling silica powder and carborundum powder from cut waste mortar

The invention discloses an extracting method of high-purity silicon powder and carborundum powder from waste slurry of monocrystalline silicon cutting or grinding course, which comprises the following steps: separating solid from liquid for the waste slurry; using organic solvent to remove suspending agent and adhesive; doing gas float for solid sand; obtaining certain purity silicon powder; doing liquid float and gravity sorting for the silicon powder further; acidifying the silicon powder through acid; obtaining high-purity silicon powder; doing magnetic float for the composite powder of carborundum-metal through gravity; obtaining the pure carborundum powder. The invention can recycle high-purity silicon from waste slurry in the silicon bar cutting manufacturing course effectively, which changes waste into value with high receiving rate to solve the problem of resource shortage of high-purity silicon.

Owner:XI AN JIAOTONG UNIV

Method for preparing composite material of lithium ion battery cathode, and cathode and battery

ActiveCN101442124AGood lithium intercalation performanceHigh lithium intercalation abilityElectrode manufacturing processesActive material electrodesSlurrySolvent

The invention relates to a method for preparing a composite material for a cathode of a lithium ion battery, and the cathode and the battery which comprise the cathode material. The preparation method comprises: uniformly mixing silicon powder, graphite, pyrolytic carbon precursor and a solvent to prepare slurry, wherein the silicon powder comprises micro-silicon powder and nano-silicon powder, and the weight ratio of the micro-silicon powder and the nano-silicon powder is 2-20:1; and removing the solvent in the slurry, performing primary sintering under the protection of inert gas, performing primary ball grinding, performing secondary sintering under the protection of the inert gas, and performing secondary ball grinding, wherein the temperature of the secondary sintering is higher than that of the primary sintering. The battery made from the composite material for the cathode of the lithium ion battery obtained by the method has good cycling performance and charge and discharge capacity.

Owner:BYD CO LTD

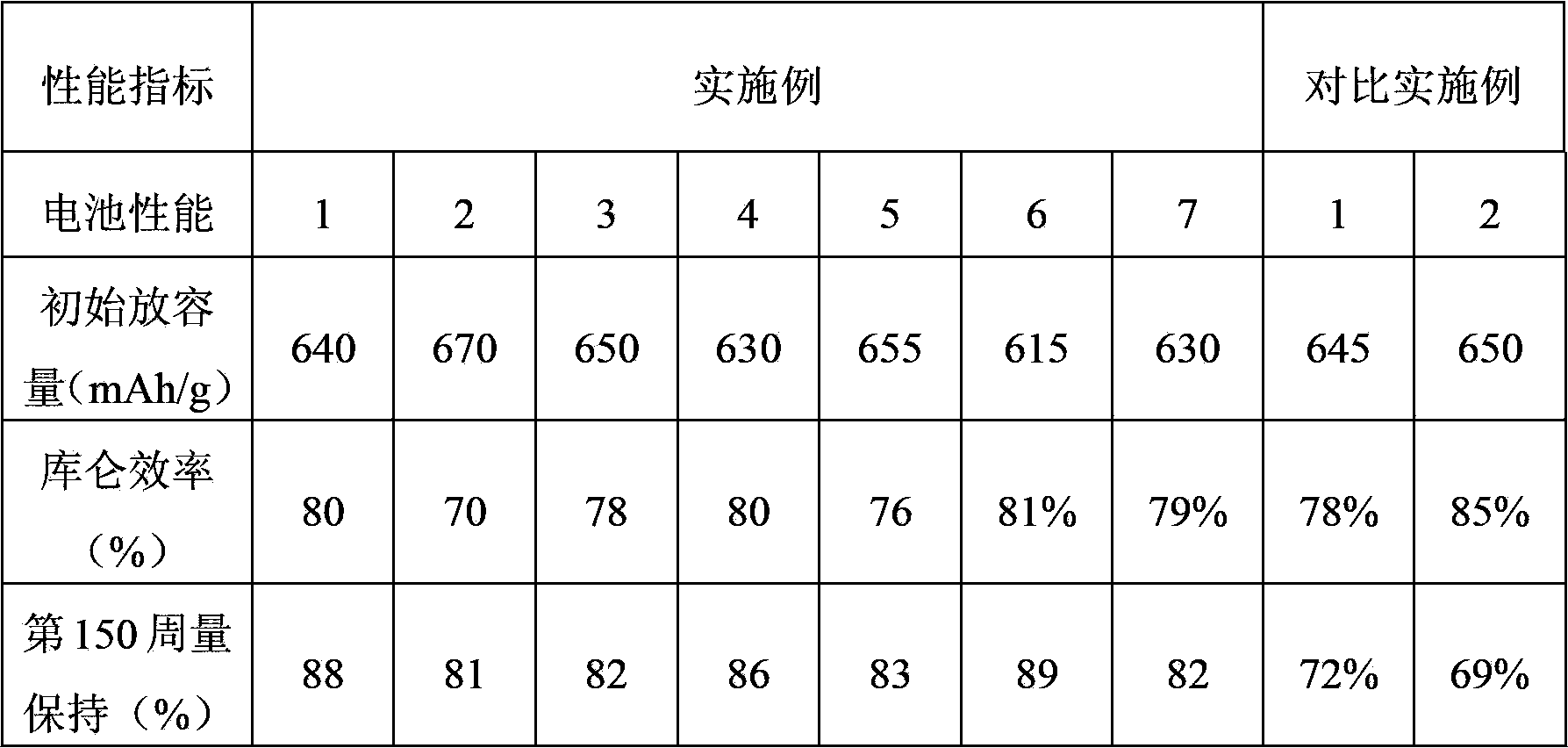

Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

ActiveCN102394287AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesFiberCarbon composites

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation method thereof, and solves the technological problem of improving the charge and discharge cycling stability of the electrode material. The silicon-carbon negative electrode material is prepared by mixing a silicon-carbon composite material and a natural graphite material, wherein the weight of the silicon-carbon composite material is 7-20% and the silicon-carbon composite material is prepared by depositing carbon nanotube and / or carbon nanofiber on the surface of nanometer silica fume and / or embedding into the nanometer silica fume to form core, the surface of which is covered with 3-15wt% of a carbon layer. The preparation method provided by the invention comprises steps of: precursor silicon powder preparation; chemical vapor deposition; liquid-coating roasting; crushing; and mixing. In comparison with the prior art, the reversible specific capacity of the silicon-carbon composite negative electrode material is greater than 500mAh / g; the coulombic efficiency for a first cycle is greater than 80%; the capacity conservation rate of cycling for 50 weeks is greater than 95%. The preparation method is simple, is easy to operate, requires low cost and is suitable for a high-volume negative electrode material of lithium ion batteries used for various portable devices.

Owner:BTR NEW MATERIAL GRP CO LTD

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

Crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and preparation method

ActiveCN106699026AStrong adaptability to high alkaline environmentAdaptableOn/in inorganic carrierWater reducerMechanical property

The invention discloses crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and a preparation method. The crack self-remediation regenerated concrete comprises components, namely, expanded perlite carried with urease production microorganisms, cement, stone, sand, silica fume, water, urea, calcium chloride, a urease production microorganism suspension and a water reducing agent. The urease production microorganisms are adopted as a concrete crack remediation agent, urease can be generated through metabolism through the urease production microorganisms, and the urea can be decomposed into NH4<+> and CO3<2+>, and furthermore the calcium carbonate can be mineralized and deposited to remedy cracks. In the preparation process, a part of the crack remediation agent is directly mixed with the concrete, then cracks and holes in regenerated crude aggregate self and weak adhesion areas between regenerated aggregate and a new cement stone base can be remedied, and thus the mechanical property of the regenerated concrete can be improved; meanwhile, the other part of the crack remediation agent is firstly adsorbed into an expanded perlite carrier and is further mixed into the concrete, then the crack self-remediation property of the regenerated concrete in the service period can be improved, and thus the anti-penetrability performance and the durability of the regenerated concrete can be improved.

Owner:TAIYUAN UNIV OF TECH

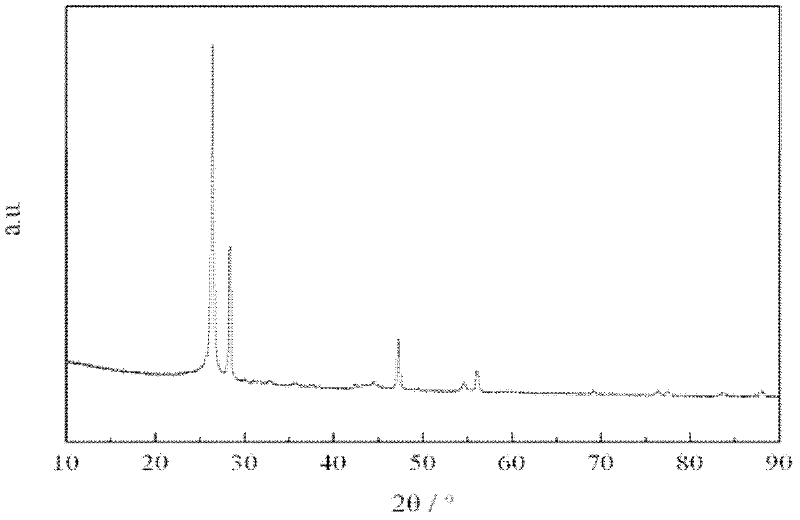

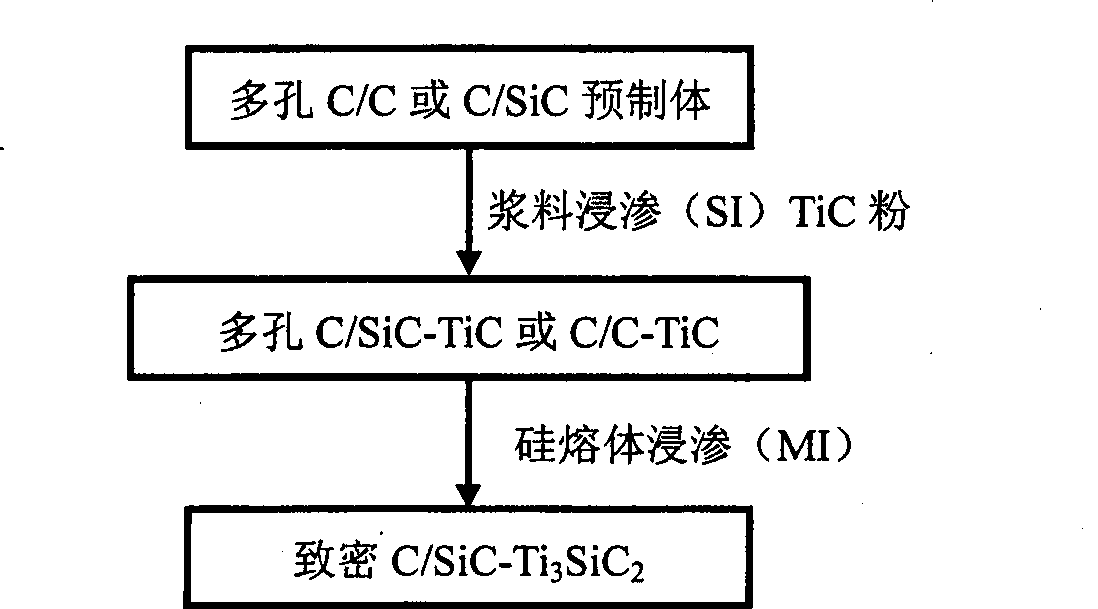

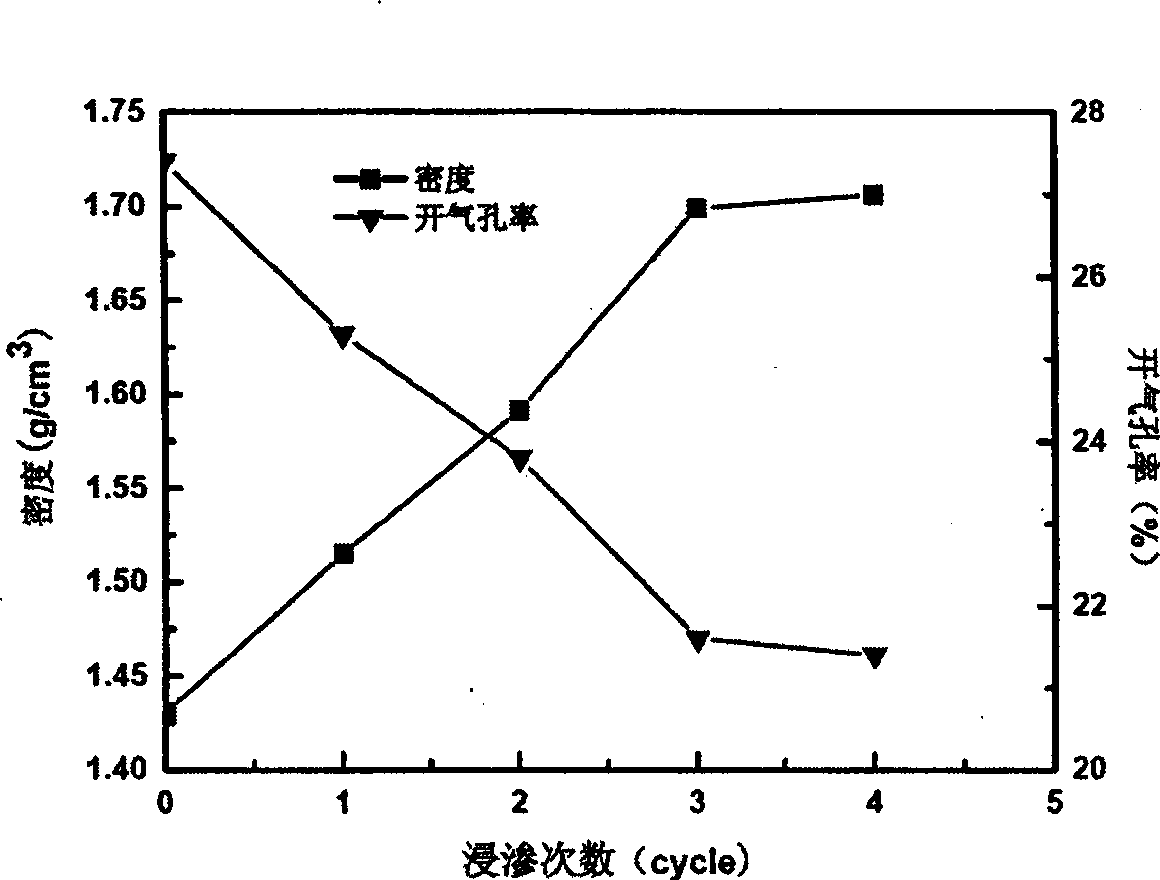

Process for producing composite material of Ti3SiC2 modified C/SiC

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low density cements for use in cementing operations

A cement mix suitable for blocking or plugging an abandoned pipeline or back filling a mine shaft, tunnel or excavations contains Portland cement or a cement blend of two components selected from Portland cement, fly ash, pozzolan, slag, silica fume and gypsum; diatomaceous earth; zeolite and an inorganic salt accelerator. The cement mix may further contain an alkali metasilicate and / or alkali silicate. A cementitious slurry, formulated from the cement mix, may have a density less than or equal to 1500 kg / m3, and exhibits good compressive strength.

Owner:BAKER HUGHES INC

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

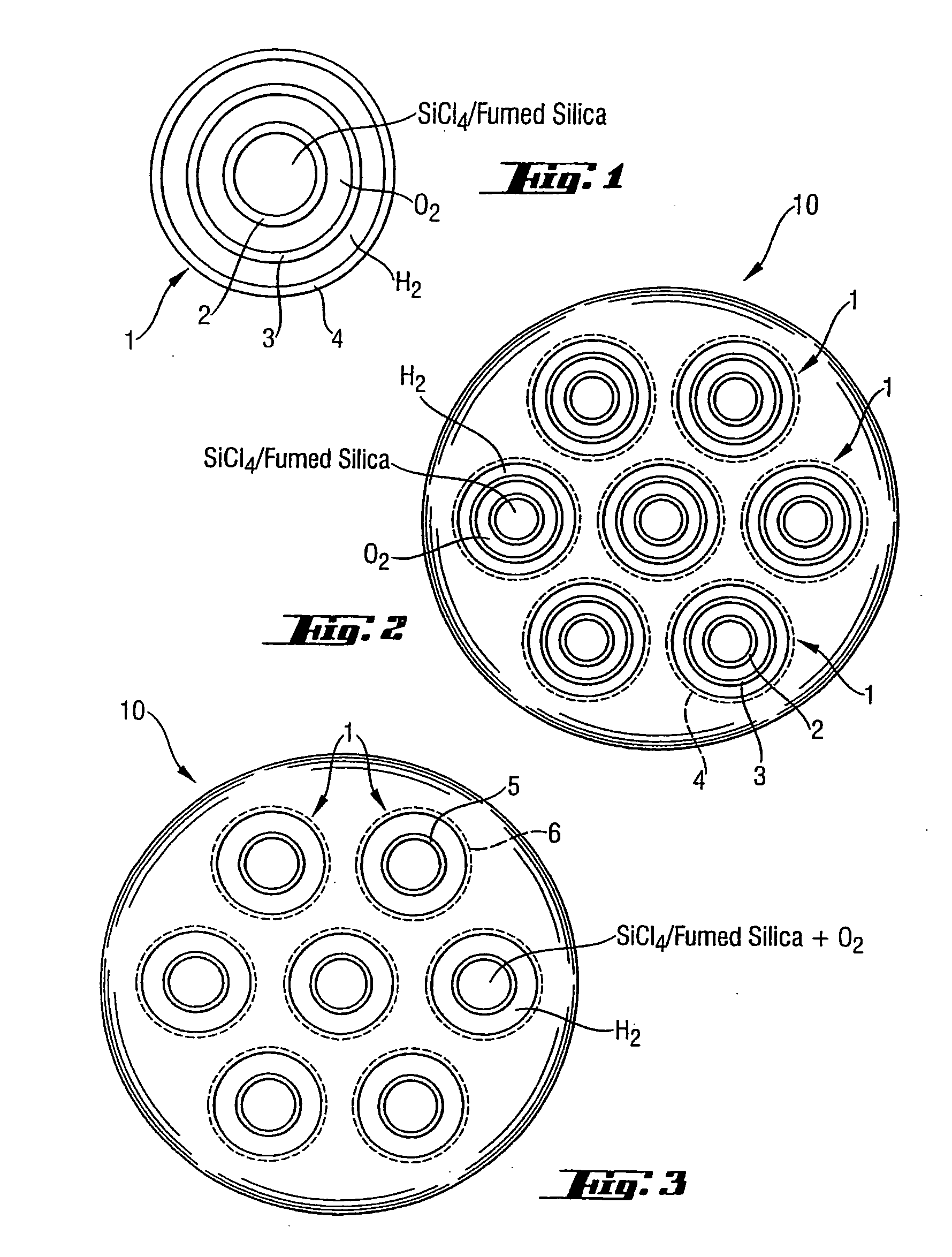

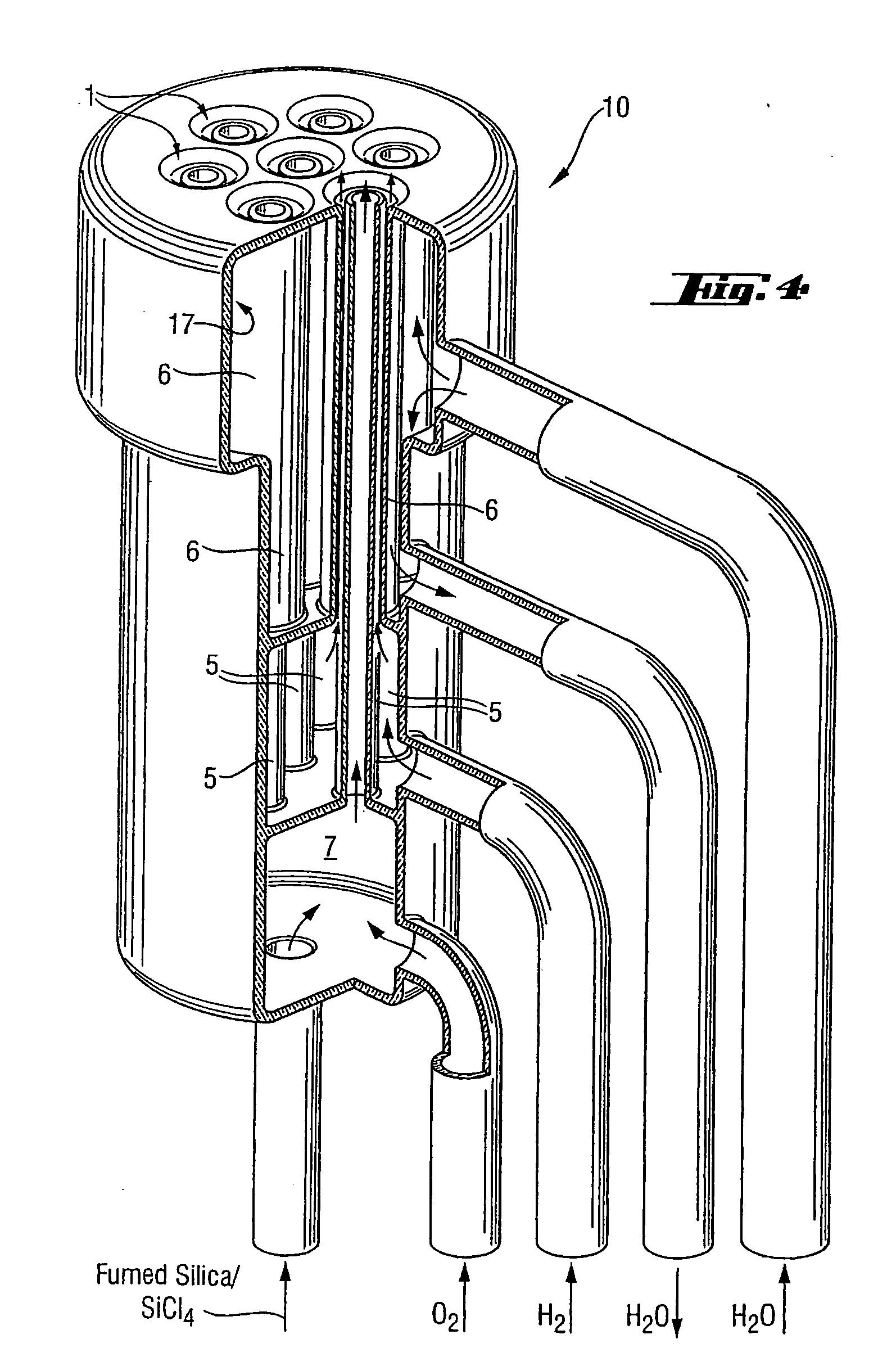

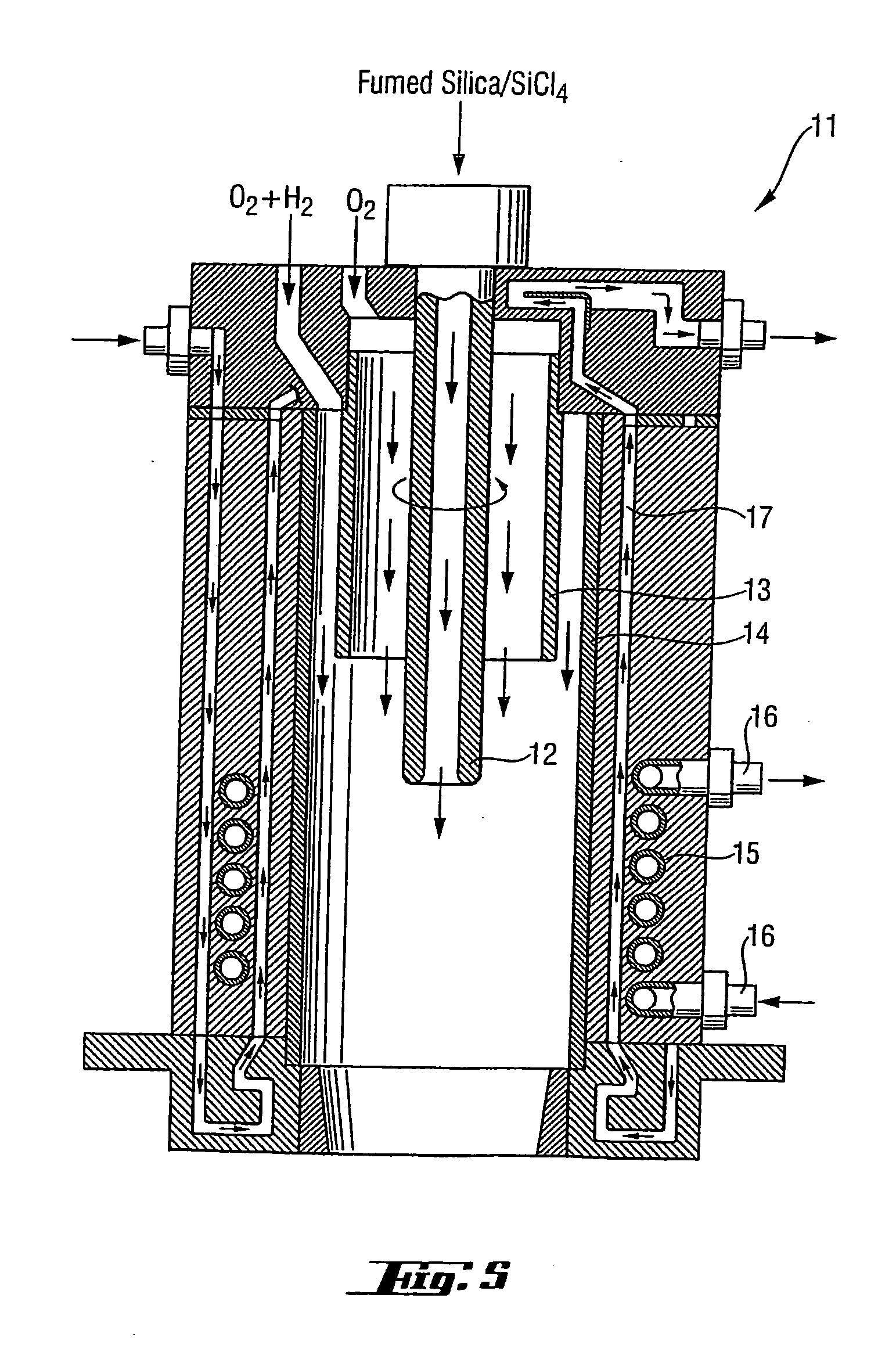

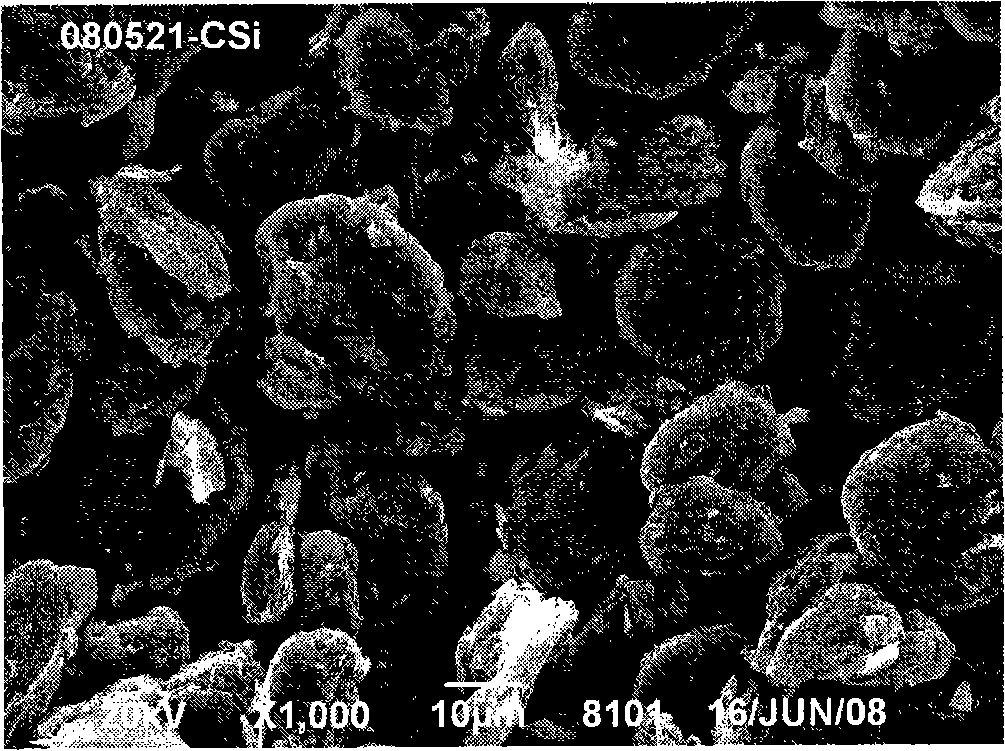

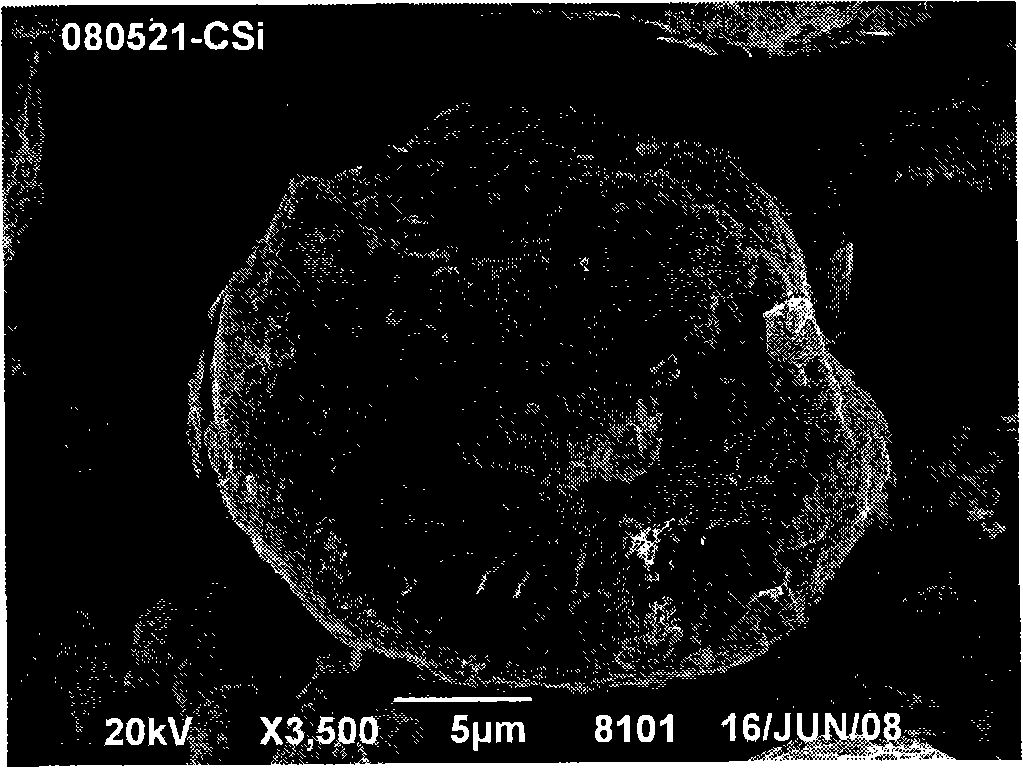

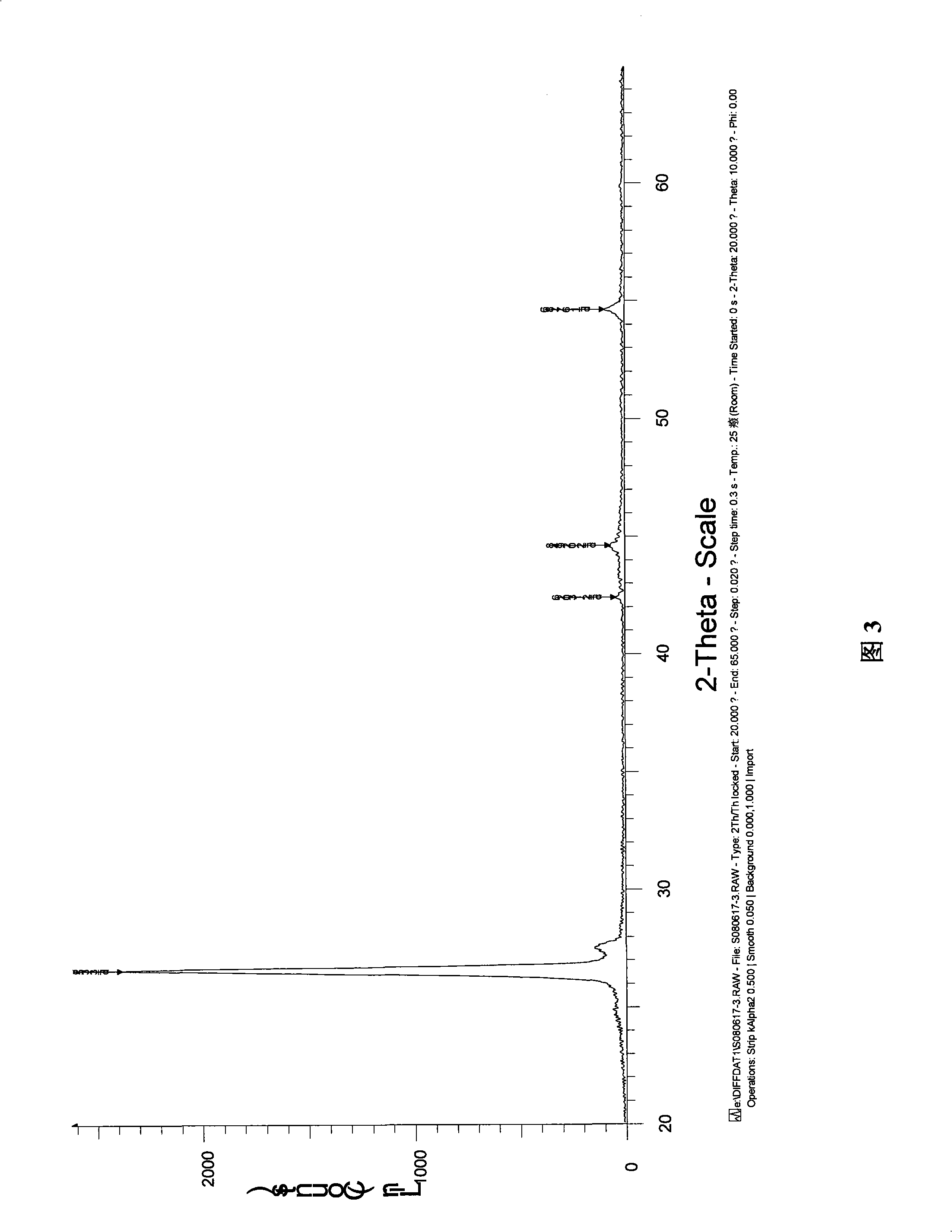

High-purity silica powder, and process and apparatus for producing it

Use of a flame hydrolysis apparatus for preparing fumed silica particles or a plasma torch apparatus for sintering fumed silica particles to fused silica particles is capable of producing highly pure silica with non-silicon metal impurities less than 500 pb, when at least an inner nozzle is constructed of a silicon-containing material having a low level of non-silicon metal impurities. Preferably, all surfaces in the respective apparatus which contact silica are of similar construction. The silica contains a low level of impurities as produced, without requiring further purification.

Owner:WACKER CHEM GMBH

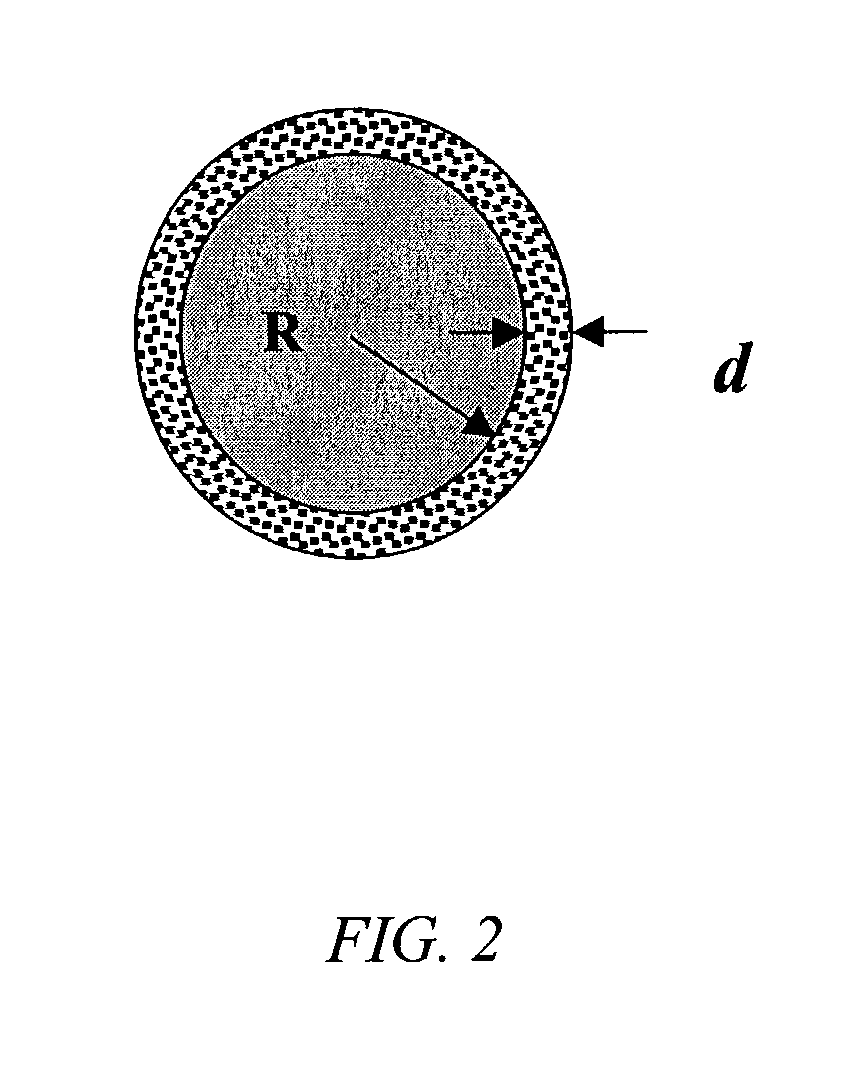

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

High performance cement-base self-leveling mortar

The invention discloses a high performance cement-base self-leveling mortar. The mortar is characterized by comprising cement, an auxiliary gel material, fine aggregate, a filling material, an additive, and water; wherein the cement is common silicate cement and sulphoaluminate-silicate cement, the auxiliary gel material comprises mineral slag, fly ash, silica fume, and gypsum, and the ratio of common silicate cement to sulphoaluminate-silicate cement to gypsum is equal to 1:0.2-0.6:0.1-0.4. The mortar has a self-leveling function without vibration, so the surface flatness is very high. The curing speed of the mortar is very quick, and after two hours, the strength of the mortar can meet the requirements of subsequent construction. Moreover the mortar has the advantages of low contraction rate, good volume stability, good surface wear resistance, and high compression strength.

Owner:广东省建筑工程监理有限公司

Technological process for preparing active powder concrete by using iron tailing

A technological process for preparing active powder concrete by using iron tailing is characterized by performing screening and mechanical-chemical activation to iron tailing, using partial iron tailing after screening as fine aggregate of the active powder concrete, using activated tailing as component of the active powder concrete, and preparing the active powder concrete. The invention substitutes partial cement, quartz powder and silica fume with mechanically-activated iron tailing and fly ash or slag, and quartz sand or river sand with screened iron tailing fine aggregate, and prepares high-strength active powder concrete under standard curing or high-temperature high-pressure curing condition; and compared with conventional method, the invention reduces raw material cost, improves iron tailing comprehensive utilization rate, reduces natural resource consumption amount, and promotes development of ecological environment protection and circular economy promotion.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

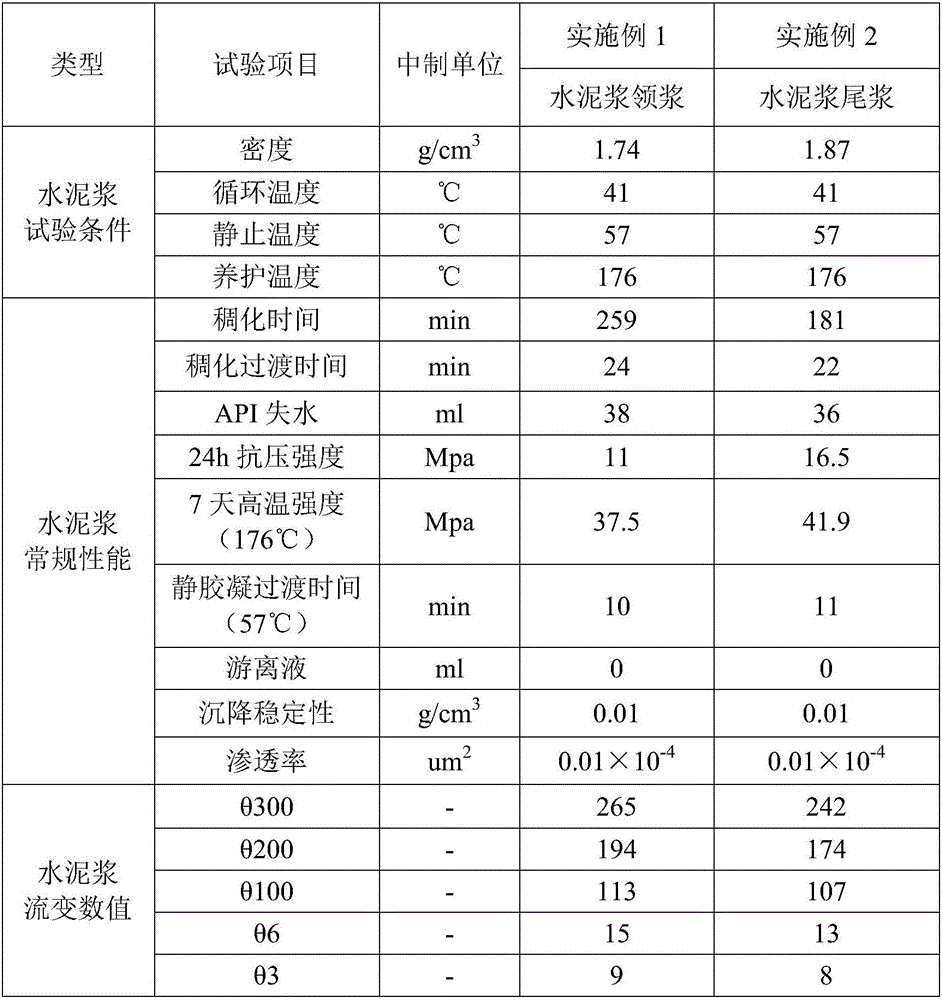

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Production method of vacuum insulation wall thermal insulation board by using expanded vitrified microspheres

ActiveCN102296714ALow thermal conductivityImprove insulation effectMixing operation control apparatusClimate change adaptationThermal insulationMetallurgy

The invention discloses a production method for producing a heat insulation board for a vacuum heat insulation wall body by utilizing small expanded and vitrified balls, and the method comprises the following steps: putting the small expanded and vitrified balls, glass fiber, silica fume, bentonite and a getter into a stirring kettle, adding a wetting agent and a bonding agent, and stirring for forming a paste-like material; uniformly spreading the well stirred paste-like material on a micro-wave baking line according to the required thickness for baking, and further cutting into blocks when the water content in the board is below 1%; further placing the board which is cut into the blocks on a vacuum machine assembly line and vacuum pumping till the vacuum degree is below 200Pa; and cutting and packaging the heat insulation board for the vacuum heat insulation wall body. By applying the method provided by the invention for production, the process is simple, the emission of three wastes can be avoided, the produced heat insulation board for the vacuum heat insulation wall body is easy to construct, the fireproof property can be realized, the heat insulation board for the vacuum heat insulation wall body can play great roles in heat preservation and heat insulation, the combustion performance is grade A, the weight is light, the weather-resistant time is long, and the service life can be above 30 years.

Owner:潍坊三强集团有限公司

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

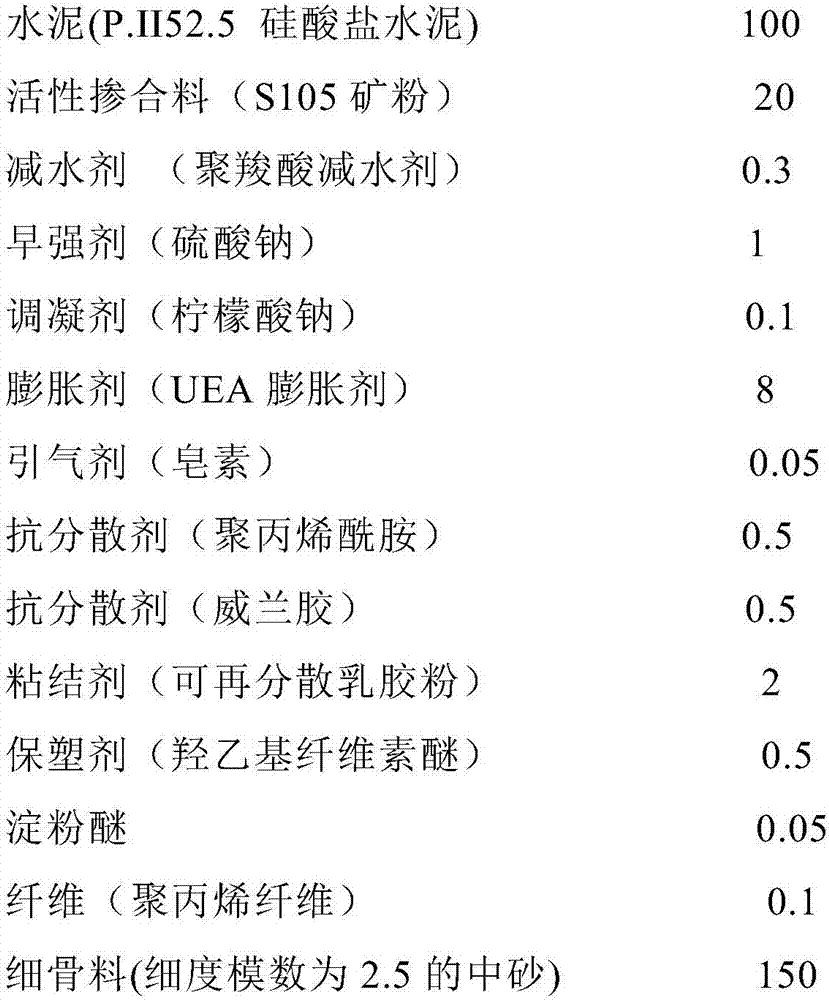

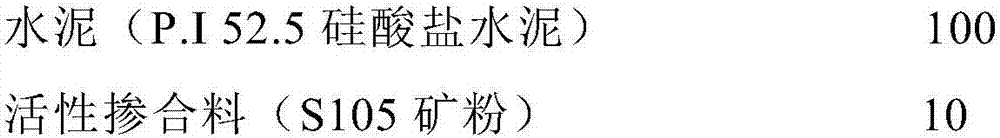

3D printing cement-based material used for underwater construction and preparation method thereof

ActiveCN107311561AImprove water retentionGood dispersionAdditive manufacturing apparatusSolid waste managementFiberMechanical property

The invention relates to a 3D printing cement-based material used for underwater construction and a preparation method of the 3D printing cement-based material. The 3D printing cement-based material is prepared from the following components and raw materials by weight: 100 parts of cement, 0-60 parts of mineral powder, 0-30 parts of fly ash, 0-20 parts of silica fume, 0.1-3 parts of a water reducing agent, 0.1-5 parts of an anti-dispersion agent, 0.2-5 parts of a binder, 0.005-0.5 part of an air entraining agent, 0.01-25 parts of a plastic retaining agent, 0-0.5 part of starch ether, 0.01-0.5 part of a thickening time control agent, 0.1-10 parts of an expanding agent, 0.1-10 parts of an early strength agent, 0.01-0.5 part of fiber, 50-300 parts of fine aggregate, and 0-400 parts of coarse aggregate. Compared with the prior art, the 3D printing cement-based material, when used in the underwater printing construction, has the excellent advantages of constructability, dispersion resistance and durability and has an excellent bulk property in water, a printed building does not collapse, and the mechanical property is excellent.

Owner:TONGJI UNIV

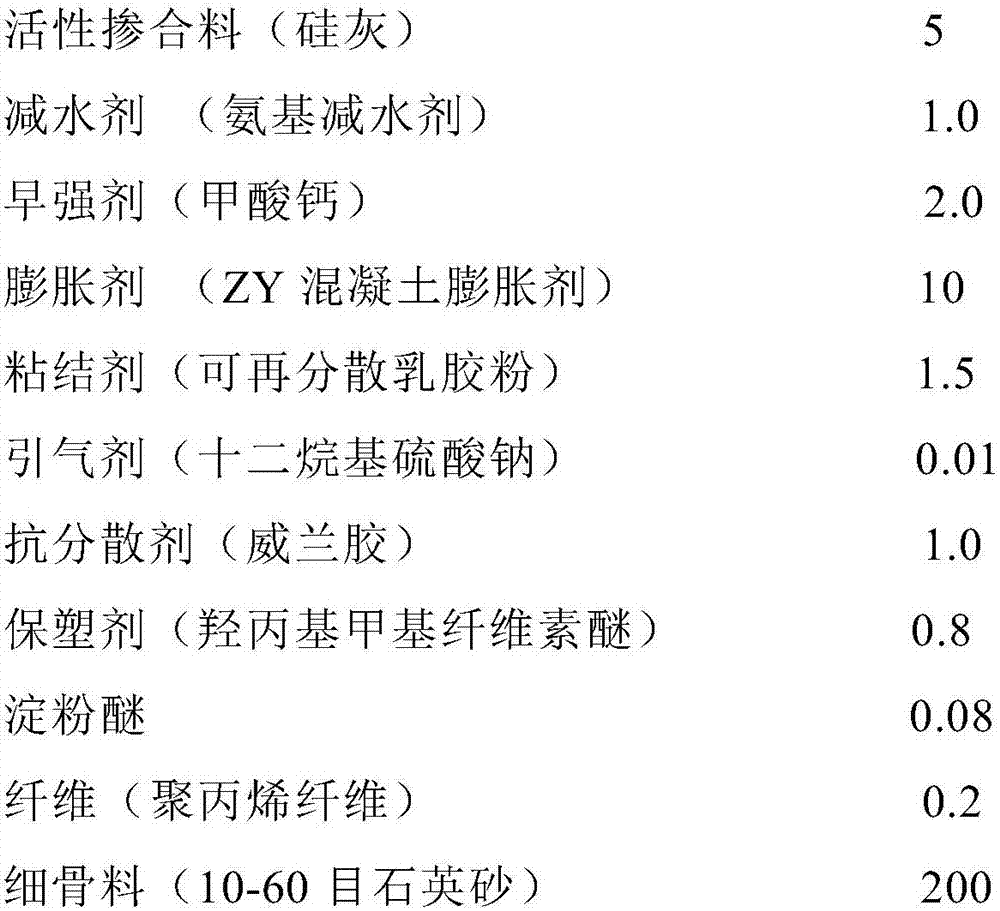

Nano-material composite concrete with super high performance

InactiveCN102199021AImprove mechanical propertiesIncreased durabilitySolid waste managementCarbon nanotubeAmmonium bromide

The invention relates to a preparation technology for concrete with super high performance, and belongs to the field of concrete technology in civil engineering. The invention is characterized in that: 1 m<3> of concrete contains 380 to 420 kg of cement, 680 to 740 kg of fine aggregate, 1120 to 1190 kg of coarse aggregate, 130 to 160 kg of water, 50 to 75 kg of fly ash, 25 to 64 kg of silica fume, 6.1 to 10.4 kg of a high performance water reducer, 0.05 to 0.25 kg of multi-walled carbon nanotubes and 15 to 25 kg of nanometer silica. The preparation technology is to carry out mechanical stirring for 180 to 240 seconds. The carbon nanotubes are added in the form of dispersion liquid, and a dispersant is cetyl trimethyl ammonium bromide (C16TAB), wherein the dispersion liquid is prepared according to the following portion MWNRs : C16TAB : water = 0.48 g : 4.1 g : 40 ml. The invention enables the super high performance concrete to have an enhanced mechanical property and lasting quality, a drastically increased service life, and capacity of being used in projects where requirements for the performance of concrete are high, for example, large-scale cross-sea bridges, super high buildings, and the like. The invention has a high utility value.

Owner:DALIAN UNIV OF TECH

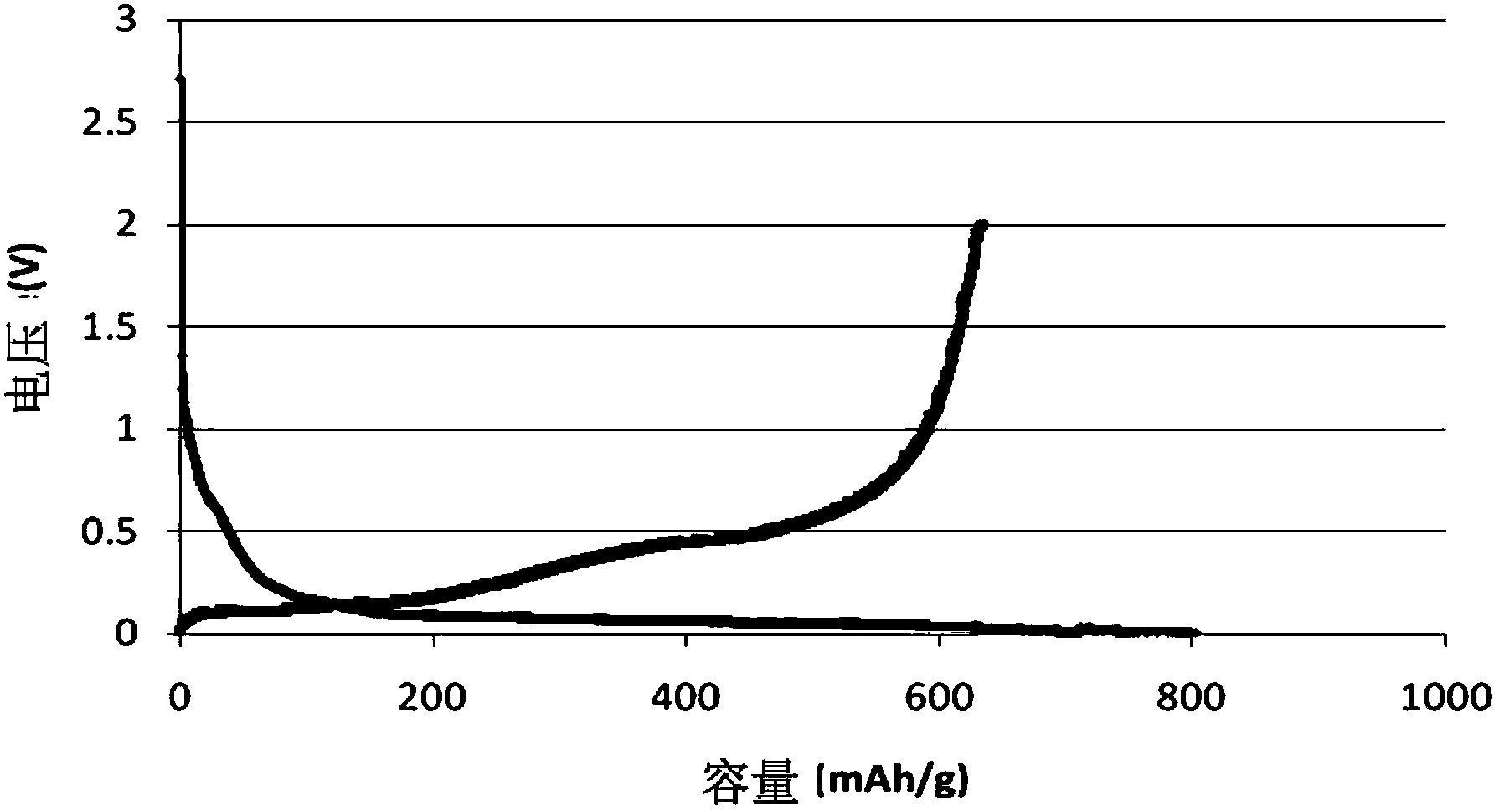

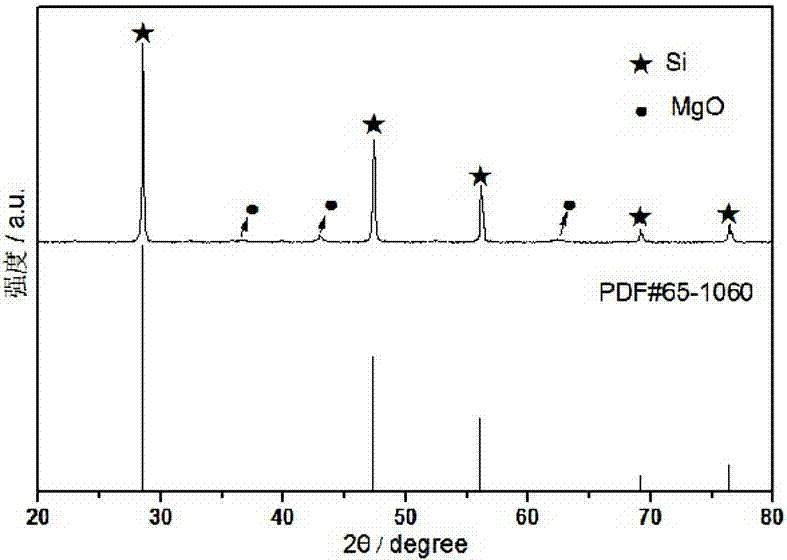

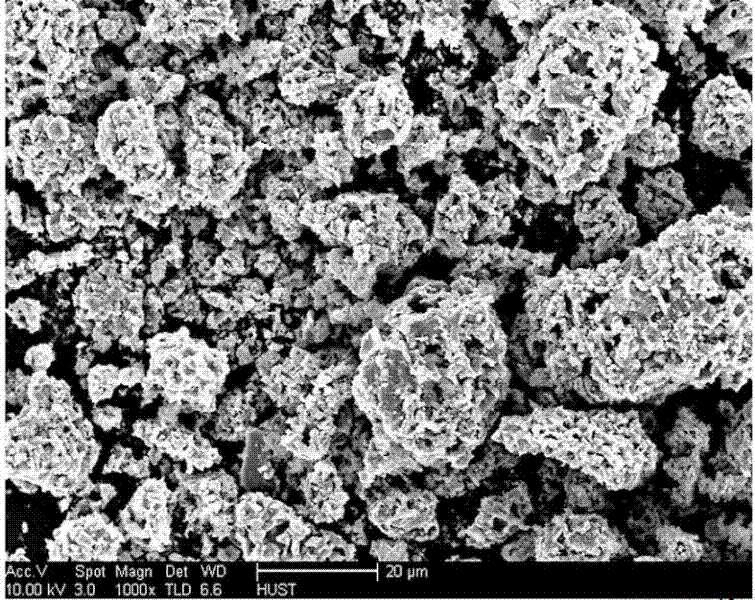

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

ActiveCN102237519AAvoid pollutionHigh specific capacityCell electrodesSodium-ion batterySilicon particle

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

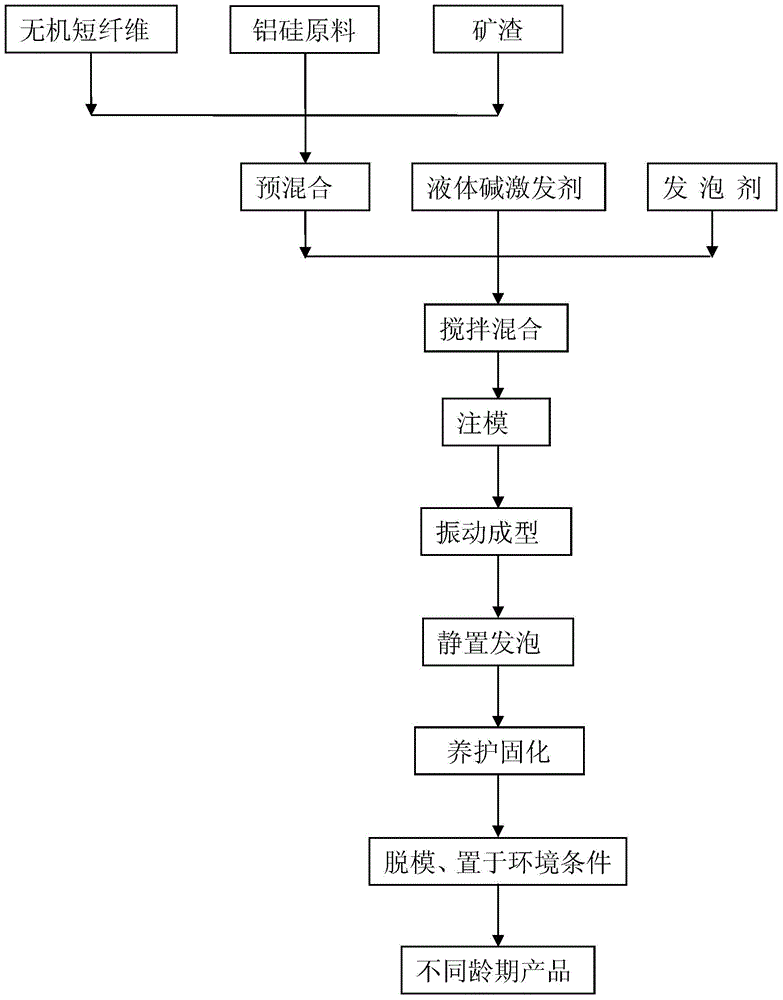

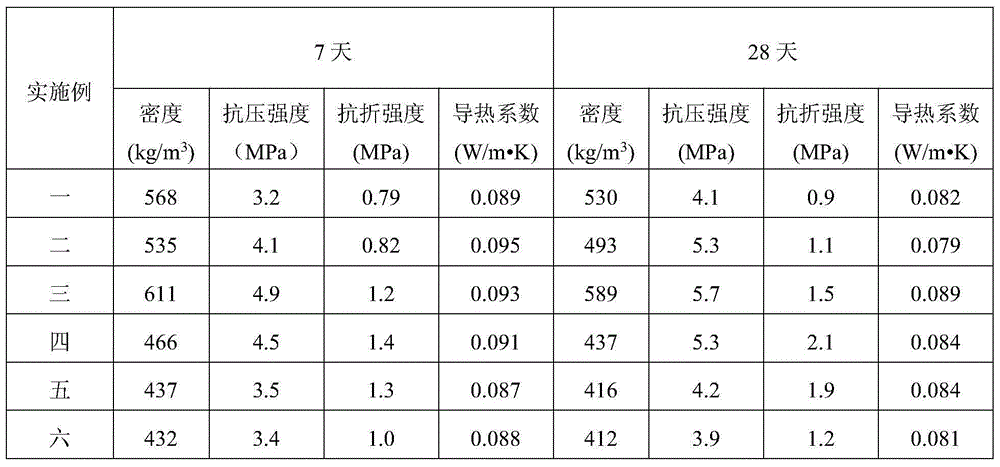

Fibre reinforced coal ash based geopolymer foam material and preparation method thereof

InactiveCN103601524ARealize high value utilizationReduce pollutionCement productionCeramicwarePolymer scienceSlag

The invention discloses a fibre reinforced coal ash based geopolymer foam material and a preparation method thereof. The fibre reinforced coal ash based geopolymer foam material disclosed by the invention comprises the following components in percentage by weight: 50-70% of aluminium silicon raw material, 5-15% of slag, 3-8% of inorganic fibre, 15-30% of liquid alkaline exciting agent, 0.2-2% of foaming agent, and 2.5-3.5% of foam stabilizer. The preparation method disclosed by the invention comprises the step of also adding the foam stabilizer while adding the foaming agent by adopting the liquid alkaline exciting agent by taking the inorganic fibre as the reinforcing agent, the slag as the Ca adjusting agent and other solid raw materials (such as coal ash, metakaolin and silica fume) as powder for providing aluminium silicon. The light foam material prepared by the invention has the characteristics of being high in intensity, small in size change rate, low in water absorption and the like in the event of having same volume weight and heat conductivity of the similar materials, and is applied to various applications.

Owner:TIANJIN UNIV

Recovery processing method of silicon slice cut waste mortar

The invention relates to a recovery processing method of silicon slice cut waste mortar, comprising the following steps: (1) separating solid-liquid components in the silicon slice cut waste mortar; (2) further recovering the remained cutting liquid component in a solid; (3) separating silicon powder and silicon carbide through water flow flotation; (4) recovering the silicon powder; (5) recovering the silicon carbide; (6) coarsely filtering, finely filtering, decoloring, vacuum distilling and dehydrating the recovered cutting liquid, and adding component with corresponding amount for secondary filter. The method can get various recovered products, such as silicon carbide micro powder, cutting liquid and silicon powder, has high recovery rate and recovery profit and can save the cost of the mortar by at least 40 percent; meanwhile, the invention effectively solves the problem of possible secondary pollution caused by single recovery; the cutting function of recovered and treated silicon carbide micro powder is recovered again, thereby changing waste into wealth, realizing the resource reutilization in true sense, and promoting the development of recycling economy; and the method basically realizes the zero emission of waste liquid by reutilizing the treated waste water after combining a sewage treatment process, thereby being beneficial to environment protection.

Owner:HENAN XINDAXIN SCI & TECH

Ultrahigh-toughness concrete and preparation method thereof

ActiveCN104556881AImprove toughnessHigh-efficiency water reducer reduces water-cement ratio and improves toughnessSolid waste managementFiberSlag

The invention discloses an ultrahigh-toughness concrete and a preparation method thereof. The ultrahigh-toughness concrete mainly comprises cement, silica fume, mineral slag, fly ash, quartz powder, quartz sand, steel fiber, nano calcium carbonate, water and a water reducing agent. The weight ratio of the silica fume to the cement is (10-20):100; the weight ratio of the mineral slag to the cement is (1-20):100; the weight ratio of the fly ash to the cement is (5-20):100; the weight ratio of the quartz powder to the cement is (30-38):100; the weight ratio of the quartz sand to the cement is (80-150):100; the steel fiber accounts for 2.0-4 vol% of the concrete; the weight ratio of the calcium carbonate to the cement is (0.1-5):100; the water-binder ratio is 0.16-0.22; and the weight ratio of the water reducing agent to the cement is (0.5-4):100. The concrete has the advantages of high strength, high toughness and favorable workability; the slump is greater than or equal to 180mm; and the concrete is pumpable and can be cast in place.

Owner:GUANGDONG GUANSHENG CIVIL ENG TECH

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

Thermal-insulation loading recycled concrete

The invention relates to a concrete commonly used in building materials, and especially relates to a thermal-insulation loading recycled concrete. A technical problem to be solved is to provide a recycled concrete which is an integration of thermal insulation, loading, quake resisting, and energy saving and emission reduction. A technical scheme adopted is characterized in that a weight ratio (kg / m<3>) of a composite lightweight aggregate admixture: cement: recycled fine aggregate: sand: recycled coarse aggregate: cobblestone: ceramsite: coal ash: water: additives is (5-250):(200-800):(20-500):(5-800):(30-600):(5-1400):(50-800):(10-600):(50-500):(0.1-200); the composite lightweight aggregate admixture is a mixture of glazed hollow beads and an aerogel, and the weight part ratio of the glazed hollow beads to the aerogel is 1:(0.7-1.5); and the additives comprise the following components, by weight, 10-150 parts of silica fume, 4-40 parts of an air entraining agent, 5-30 parts of a foaming agent, 3-30 parts of a water reducing agent, 1-30 parts of a polypropylene fiber, and 10-150 parts of waste slag. The technical scheme is used for making the recycled concrete.

Owner:TAIYUAN UNIV OF TECH

Preparation method for carbon-coated silicon negative electrode material for lithium ion battery

InactiveCN105958036ALow costAlleviate volume changesCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention provides a preparation method for a carbon-coated silicon negative electrode material for a lithium ion battery. The negative electrode material for the lithium ion battery with excellent performance is obtained from silicon powder by two times of carbon coating; the preparation method comprises the following steps of carrying out liquid phase dispersion on the silicon powder, then carrying out dispersion on the silicon powder, the first carbon coating layer and a dispersing agent; removing the solvent, and carrying out high-temperature carbonization treatment on the obtained solid material to obtain primary carbon-coated silicon negative electrode material; preparing a dispersion solution of a second carbon-coated material, dispersing the primary carbon-coated silicon material to the dispersion solution of the second carbon-coated material, and then removing the solvent and carrying out secondary roasting to obtain the secondary carbon-coated silicon negative electrode material. According to the preparation method, the raw materials are low in cost and easily available; the ratio of silicon to carbon can be optionally regulated and controlled; and the preparation method is simple in equipment, easy to implement the technological process, and suitable for scale production.

Owner:天津普兰能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com