3D printing cement-based material used for underwater construction and preparation method thereof

A cement-based material, 3D printing technology, used in additive processing, sustainable waste treatment, solid waste management, etc., can solve problems such as collapse and poor dispersion resistance, and achieve small plastic deformation, good crack resistance, and adhesion. Good junction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

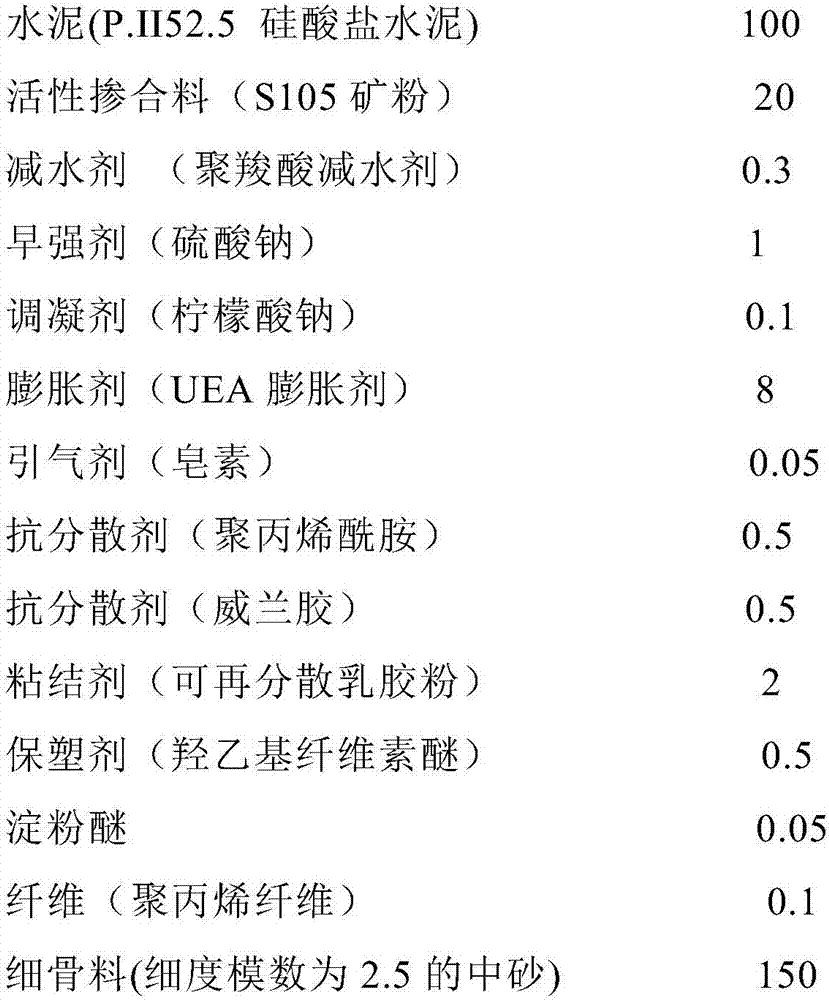

Embodiment 1

[0035]

[0036] Preparation method: Weigh various raw materials according to the formula, and add cement (P.II52.5 Portland cement), active admixture (ultra-fine slag powder), and water reducer (polycarboxylic acid water reducer) in the mixer. ), early strength agent (sodium sulfate), coagulant (sodium citrate), expansion agent (UEA expansion agent), air-entraining agent (saponin), anti-dispersant (polyacrylamide, welan gum), adhesive Mixing agent (re-dispersible latex powder), plasticizer (hydroxyethyl cellulose ether), starch ether, and fiber (polypropylene fiber) thoroughly to obtain a powdery gelling material, which is packaged to form a product.

[0037] During the on-site construction, weigh the fine aggregate (medium sand with a fineness modulus of 2.5) into a special mixer and mix it with the powdery cementitious material. According to the 1000kg mixture, add 120kg of water and mix it evenly to produce printed concrete The mixture can be printed and constructed. The mate...

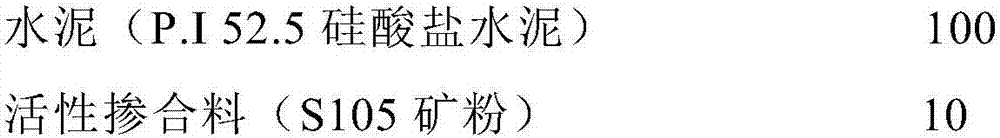

Embodiment 2

[0039]

[0040]

[0041] Preparation method: Weigh various raw materials according to the formula, and add cement (PI 52.5 Portland cement), active admixtures (slag powder, silica fume), water reducing agent (amino water reducing agent), and early strength in the mixer. Agent (calcium formate), expansion agent (ZY concrete expansion agent), air-entraining agent (sodium lauryl sulfate), anti-dispersant (Welan gum), binder (re-dispersible latex powder), plastic preservative (Hydroxypropyl methyl cellulose ether), starch ether, and fiber (polypropylene fiber) are thoroughly stirred and packaged to form a product.

[0042] During on-site construction, weigh the fine aggregate (10-60 mesh quartz sand) into a special mixer and mix it evenly with the powdery cementitious material. Add 130kg of water to 1000kg of the mixture and mix evenly to prepare a printed concrete mixture. , You can print and construct. The material properties are shown in Table 1.

Embodiment 3

[0044]

[0045]

[0046] Preparation method: Weigh various raw materials according to the formula, add cement (P.II52.5R Portland cement), active admixtures (ultrafine slag powder, silica fume), and water reducer (polycarboxylic acid Water reducing agent), early strength agent (sodium aluminate), expansion agent (UEA expansion agent), air-entraining agent (saponin), binder (re-dispersible latex powder), anti-dispersant (polyacrylamide), The plasticizer (hydroxyethyl cellulose), starch ether, and fiber (polypropylene fiber) are fully stirred evenly to obtain a powdered gelling material, which is packaged to form a product.

[0047] During on-site construction, weigh the fine aggregate (medium sand with a fineness modulus of 2.5) into a special mixer and mix it with the powdery cementitious material evenly, add 110kg of water to 1000kg of the mixture and mix it evenly to produce printed concrete The mixture can be printed and constructed. The material properties are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com