Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "No macro defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

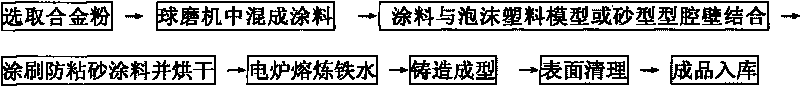

Method for preparing surface composite sinterer grate bars

InactiveCN101698230AImprove wear resistanceExcellent corrosion resistanceFoundry mouldsFurnace typesIron powderPolyvinyl alcohol

The invention relates to a method for preparing surface composite sinterer grate bars, and belongs to the field of metal matrix composites. The method comprises the following steps: adding aqueous solution of polyvinyl alcohol into SiC powder, alumina powder and chromium iron powder to prepare an alloy powder coating; coating the alloy powder coating on a working surface of a foam plastic model of the sinterer grate bars or on a wall of a cavity of a sand mould corresponding to the working surface; and smelting the melt of high-chromium iron or ferritic nodular cast iron in an electric furnace, and casting to prepare the surface composite sinterer grate bars. Tests show that an Al2O3+SiC reinforced particle surface composite layer and a cast iron matrix are in metallurgical bonding, and the composite layer is compact, has no macro defect, and has the thickness more than 5nm and the hardness HRC between 45 and 60.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

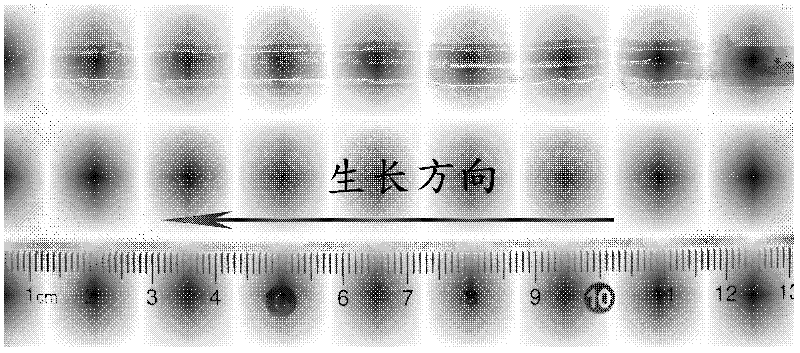

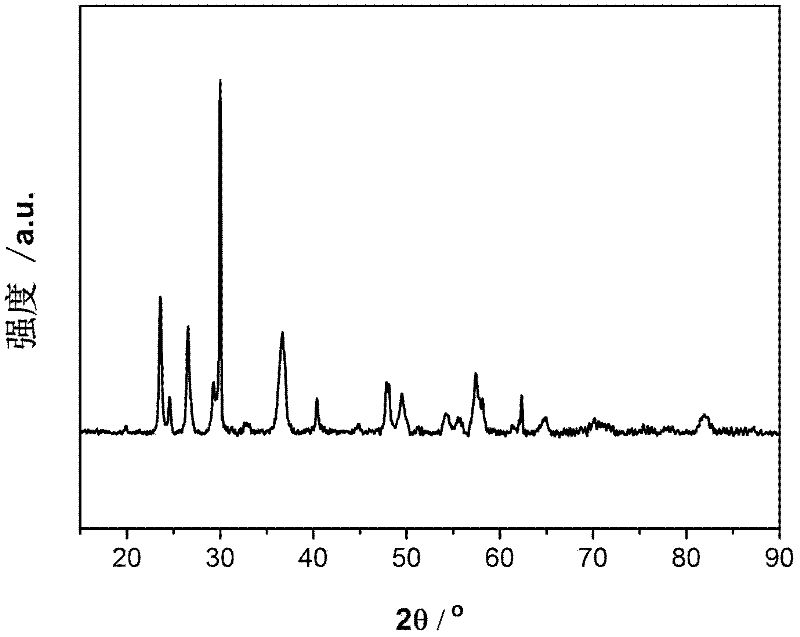

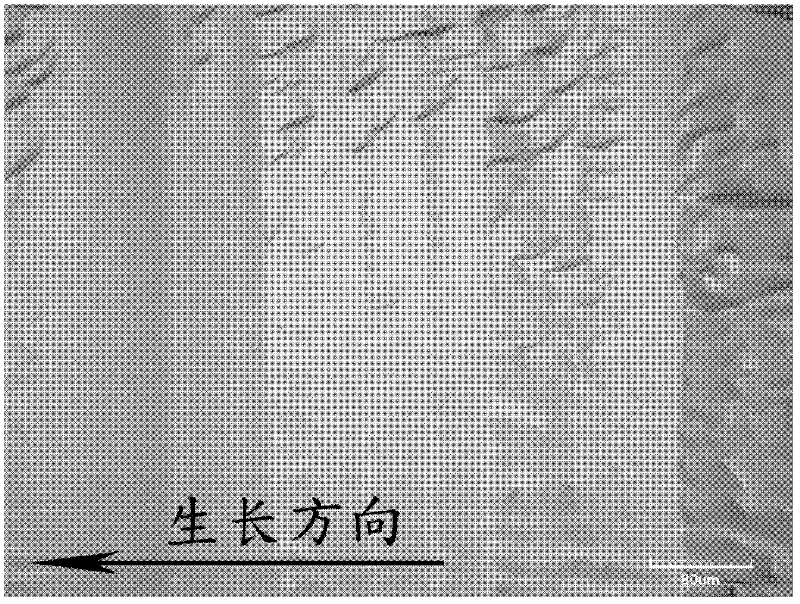

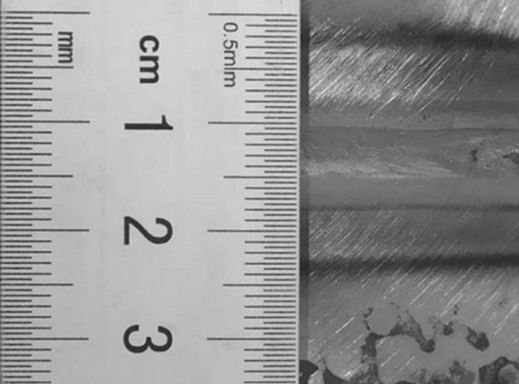

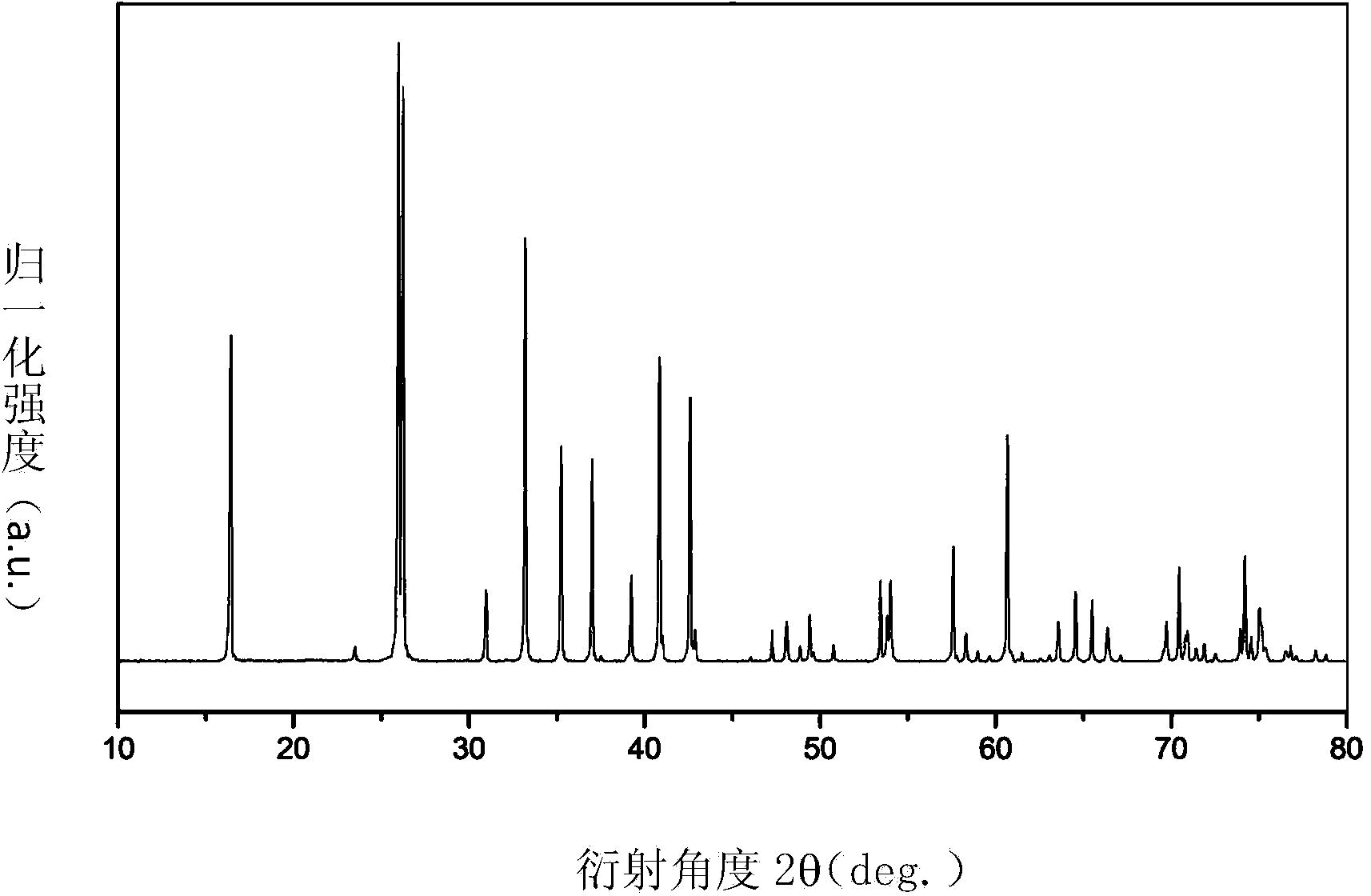

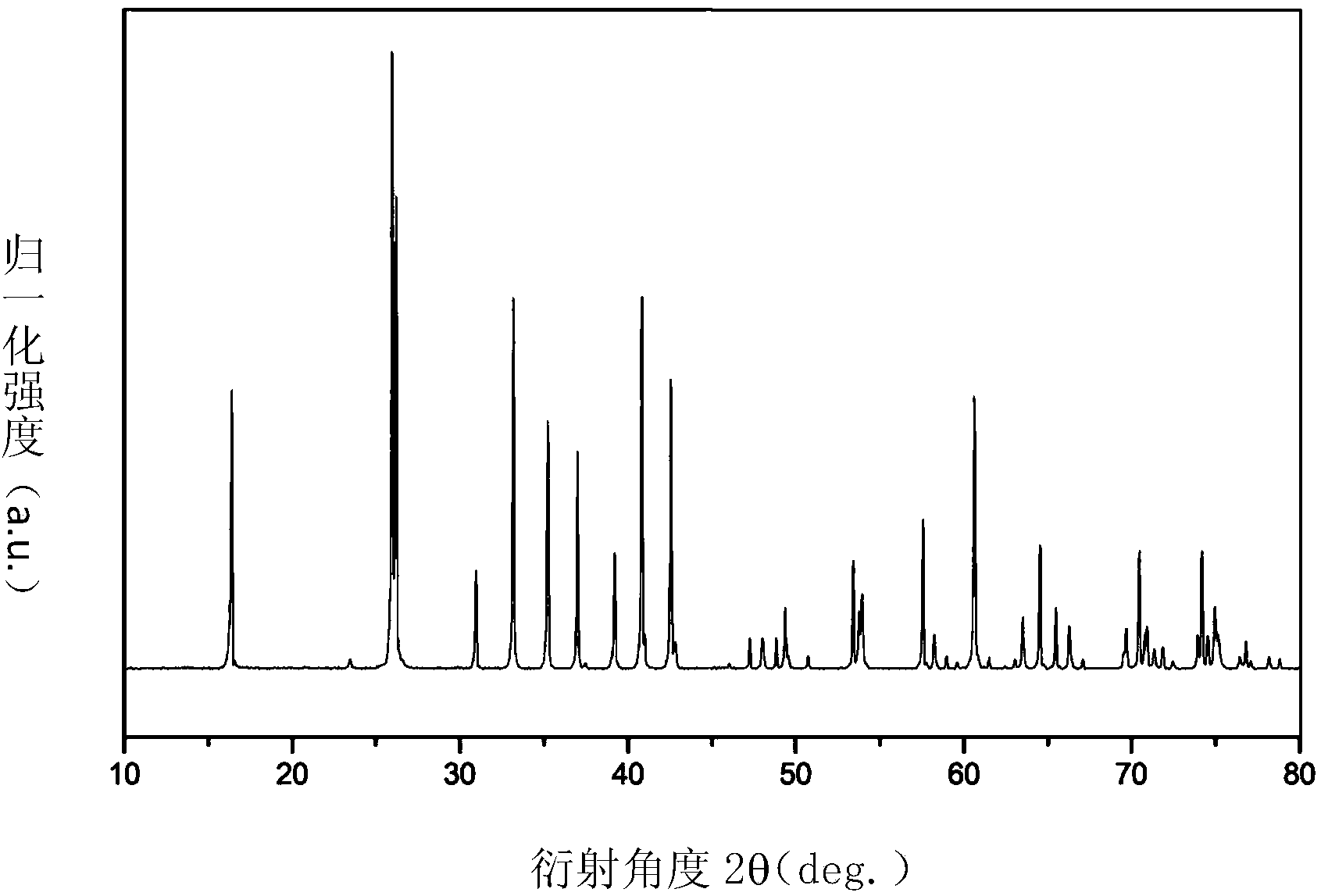

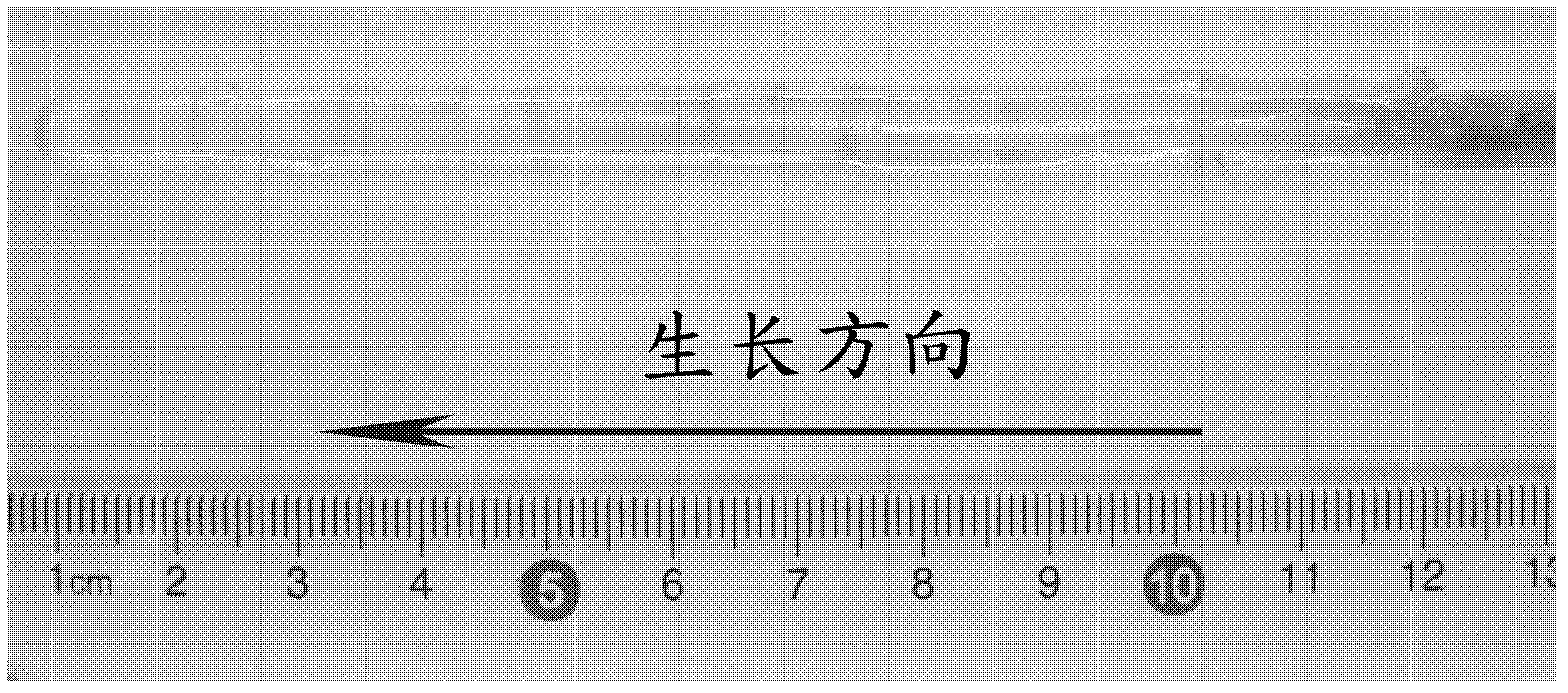

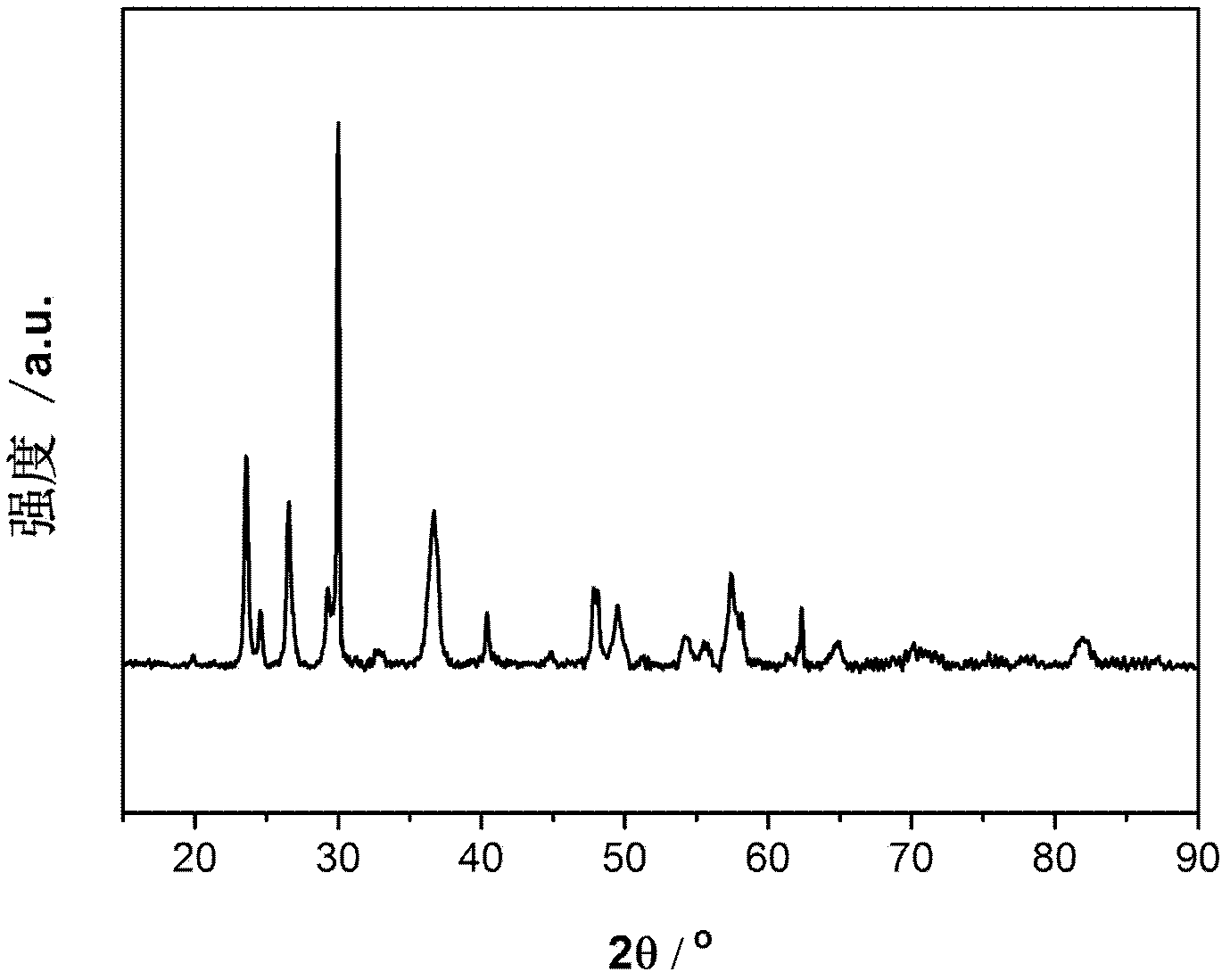

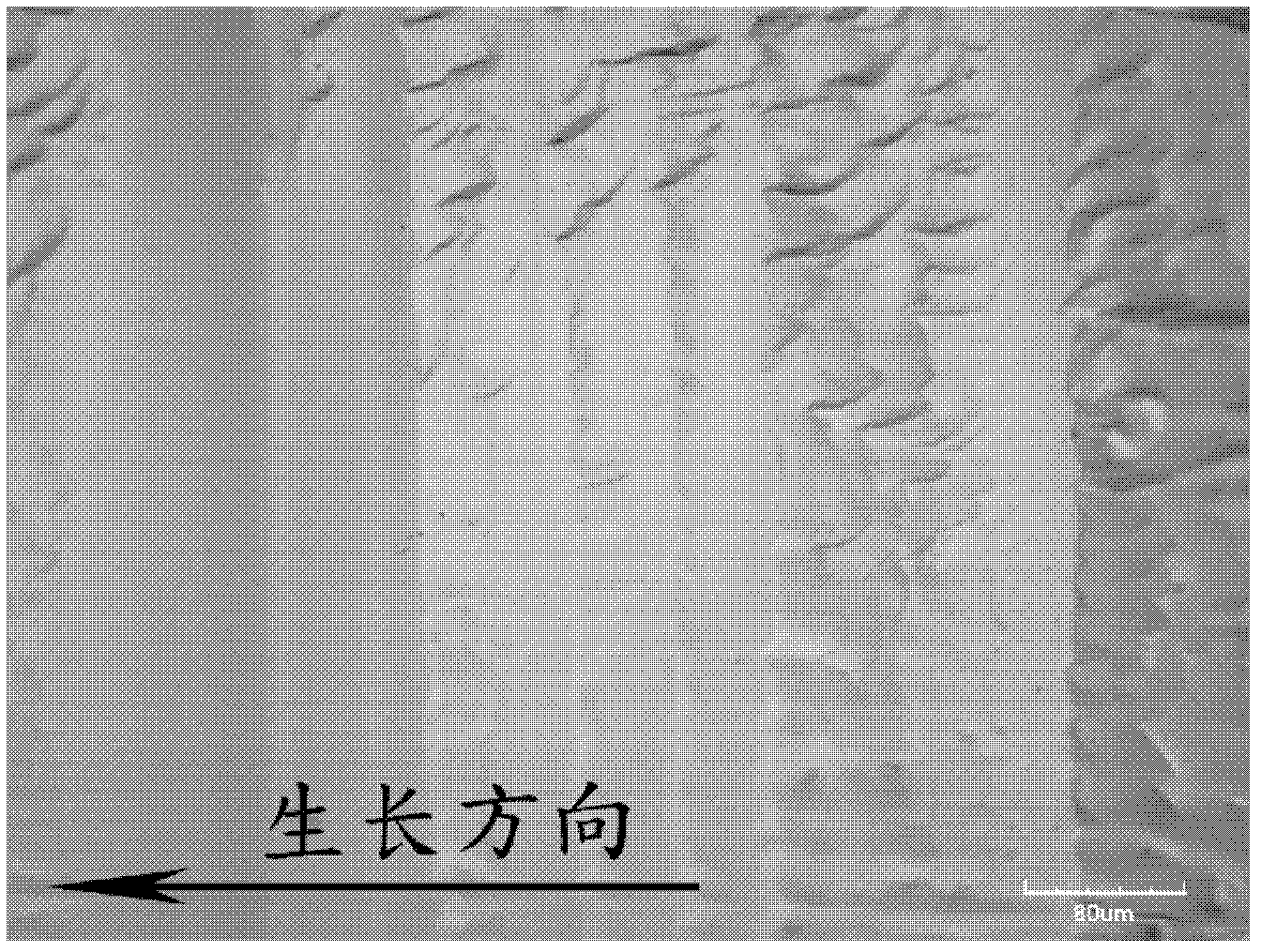

Method for growing large size Ta2O5 single crystal by using floating zone method

ActiveCN102312293AProcess advantagesNo macro defectsPolycrystalline material growthBy zone-melting liquidsRoom temperatureCrystal growth rate

The invention relates to a method for growing a large size Ta2O5 single crystal by using a floating zone method, and belongs to the field of crystal growth. The method comprises the following steps: carrying out ball milling and drying for a Ta2O5 powder material; placing the treated Ta2O5 powder material in a rubber tube, and carrying out isostatic pressing for the material to prepare a biscuit rod; carrying out sintering for the biscuit rod to obtain a polycrystalline rod; adopting the biscuit rod or the polycrystalline rod as the material rod, and adopting the polycrystalline or the Ta2O5 single crystal as the seed crystal, wherein the seed crystal and the material rod form a straight line in a vertical direction, and the contact point and a halogen lamp are at the same horizontal line; heating the material rod and the seed crystal until the material rod and the seed crystal are molten, wherein the heating rate is 30-60 DEG C per minute; adjusting the rotation speeds and the rotation directions of the material rod and the seed crystal, then carrying out inoculation; adopting the movement of a focusing lens or the up and down movement of the rod to enable the molten zone to be far away from the focusing point, enable the temperature of the molten zone to be decreased to realize the crystallization, wherein the crystal growth rate is 10-60 mm / h; cooling the grown crystal to the room temperature. With the method provided by the present invention, the growth period is short; the preparation efficiency is high; the Ta2O5 single crystal can be rapidly grown, wherein the grownTa2O5 single crystal has characteristics of size in centimeter magnitude, no macroscopic defect and high quality.

Owner:BEIJING UNIV OF TECH

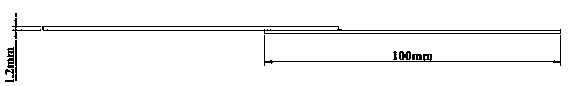

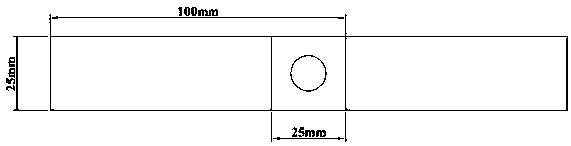

1800 MPa ultrahigh-strength thermoforming steel plate resistance spot welding technique

InactiveCN110548976AEasy to shapeNo macro defectsResistance electrode holdersSheet steelHigh intensity

The invention discloses an 1800 MPa ultrahigh-strength thermoforming steel plate resistance spot welding technique, and relates to a high-strength steel plate spot welding technique. According to the1800 MPa ultrahigh-strength thermoforming steel plate resistance spot welding technique, two ultrahigh-strength thermoforming steel plates are lapped together, and are clamped with a clamp; a resistance spot welding robot teaching panel is used; electrode positions are adjusted by designing a path, so that a welding part is located at the central spot of a lapping part; a welding command is addedon the teaching panel, and welding pressure is changed; after welding parameters are adjusted through a welding machine, one welding process is finished by inputting the welding command; and a resistance spot welding connector is formed. By adopting the technique, a manufacturing technique which can perfect ultrahigh-strength thermoforming steel plates can be provided, so that the ultrahigh-strength thermoforming steel plates can be strongly combined during manufacturing, and therefore comprehensive performance of products is obviously improved.

Owner:SHENYANG UNIV

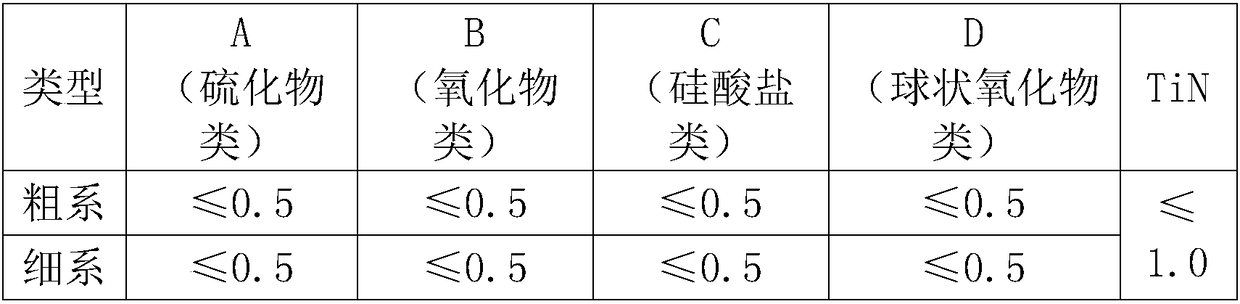

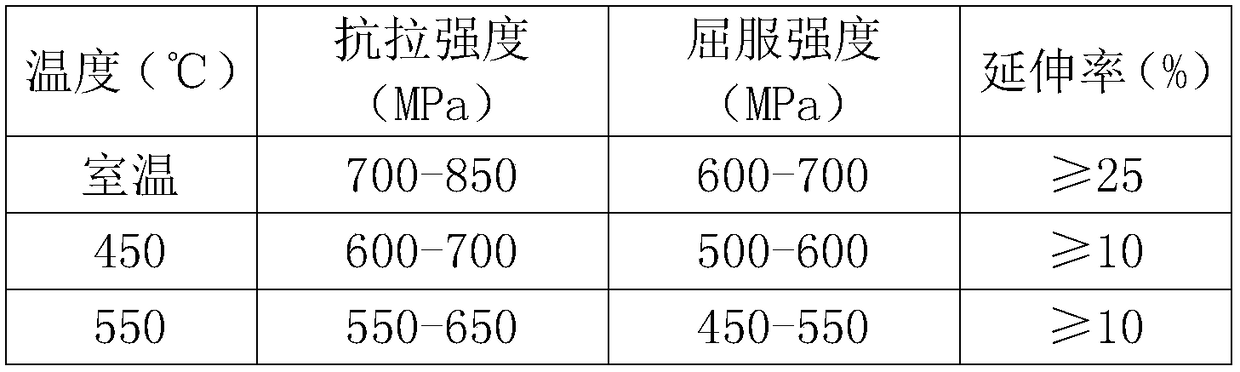

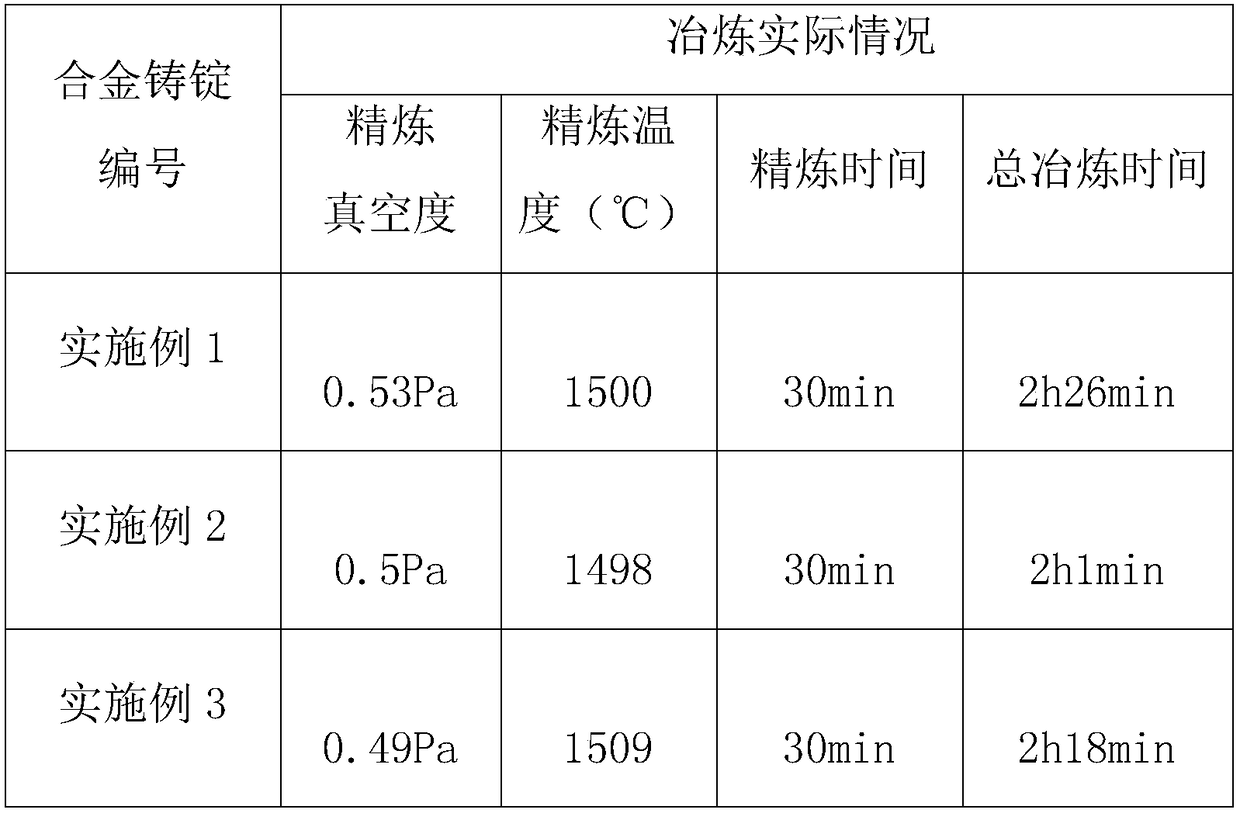

Austenitic stainless steel as well as preparation method thereof and application thereof

ActiveCN109355558AHigh room temperature and intermediate temperature tensile strengthGood plasticityAustenitic stainless steelLead bismuth

The invention discloses austenitic stainless steel as well as a preparation method thereof and application thereof. The austenitic stainless steel is prepared from the following components in percentage by mass: 0.04-0.08% of C, 16.5-20.0% of Cr, 14.5-16.5% of Ni, 1.0-3.0% of Si, 1.5-3.0% of Mn, 0.2-0.5% of Ti, 1.3-2.5% of Mo, 0.003-0.004% of B and the balance of iron. The austenitic stainless steel has a higher room temperature and medium-temperature tensile strength, is excellent in plasticity; alloy strength is improved after medium-temperature ageing treatment, plasticity is not obviouslyreduced, detrimental phase separation-out is avoided, and structure stability is good; and the austenitic stainless steel has excellent lead corrosion resistance and excellent lead-bismuth liquid-state metal corrosion resistance as well as excellent radiation resistance, and can meet material selection needs of lead-base fast reactor key parts better.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +4

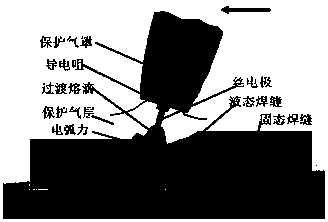

Laser-arc hybrid welding method for special aluminum alloy thin edge structure

ActiveCN103418919ASimple welding processImprove stabilityWelding apparatusStructural deformationAcid washing

The invention provides a laser-arc hybrid welding method for a special aluminum alloy thin edge structure. The method comprises the steps of (1) performing alkali washing on a structure to be welded by a NaOH solution to remove an oxidation film, performing acid washing on the structure to be welded by a HNO3 solution, then cleaning the structure to be welded by clean water, and drying the structure to be welded by compressed air; (2) welding the structure to be welded by adopting a laser guiding arc mode, wherein the welding speed is 1-3mm / min, the laser power is 500-2500W, the TIG arc current is 100-150A, the included angle between the TIG arc angle and the normal line is 35 degrees, the TIG arc height is 2-4mm, the laser arc heat source interval is 2-4mm, and the shielding gas is argon with the flow of 15-25L / min; and (3) cleaning the faces of the welding seams by using a steel brush. The stability in the welding process and the face quality of the welding seams are improved by adopting the laser-arc hybrid welding and optimized welding process, the assembly gap demand before welding is reduced and the structural deformation after welding is reduced.

Owner:CAPITAL AEROSPACE MACHINERY +1

Reactive powder concrete and preparing method and purpose thereof

The invention provides reactive powder concrete and preparing method and purpose thereof. The reactive powder concrete is prepared from 400-1000 parts of cement, 100-500 parts of modified superfines, 50-200 parts of modified steel fiber, 900-1300 parts of quartz sand, 100-220 parts of quartz powder, 10-30 parts of admixture, and 100-250 parts of water. According to characteristics of inorganic whisker which it has no macroscopic defect, its crystal intensity approximates theoretical value of intact crystal, and mechanical strength is equivalent to force of neighboring atoms, the invention, by adding whisker, improves RPC-related properties with compressive strength and rupture strength up to construction requirements; by modification of steel fiber, it improves wrapping of slurry on steel fiber, enhances fracture energy and strength increase of RPC product and reduces interface microcrack.

Owner:重庆天维绿色建筑技术开发有限公司

Laser welding process for dissimilar metal connecting material at tab part of lithium battery

PendingCN112439994AEasy to shapeLaser power is stableWelding/soldering/cutting articlesLaser beam welding apparatusSingle mode laserSurface cleaning

The invention relates to a laser welding process, and particular relates to a laser welding process for a dissimilar metal connecting material at a tab part of a lithium battery. The laser welding process comprises the following steps: adopted dissimilar metals are aluminum alloy and nickel-plated copper, the aluminum alloy is 6061 aluminum alloy, the mark of the nickel-plated copper is Ni6T2, a stitch welding mode is adopted for welding, and the welding process is carried out in a dust-free working chamber; before welding, the surface of an experimental material is cleaned firstly, and it isguaranteed that the surface of a plate is clean and free of pollution; then the plate is stacked on a workbench and fixed through a clamp, and the laser position is adjusted to be located at the center of a to-be-welded part; and laser welding parameters and the welding process are adjusted through a laser control system. According to the process, the welding problem of the series-parallel connection end of the tab in the production process of the 6061 aluminum alloy and the Ni6T2 is solved, stable laser power can be output by adopting the single-mode laser welding process, various welding process parameters are adjusted in the welding process, the process environment is improved, it is guaranteed that welding spots are well formed, macroscopic defects are avoided, and all performances meet the production and application standards.

Owner:SHANGHAI SKEQI AUTOMATION ENG CO LTD

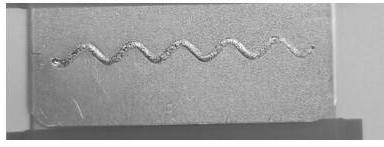

Laser welding process for welding nickel-plated copper with thickness of 200 microns by employing single-mode laser

PendingCN112439995AImprove process environmentWell formed weldLaser beam welding apparatusElectrical batteryShielding gas

The invention relates to a laser welding process, and particularly relates to a laser welding process for welding nickel-plated copper with the thickness of 200 microns by employing a single-mode laser. The laser welding process is characterized in that a welding clamp is a copper cup pressing mechanism and presses the periphery of a welding part of a test piece, and shielding gas is blown out inthe welding process to protect the welding part; an experimental material is placed on a workbench, a copper cup is controlled to move to the welding part through a PLC program and is pressed, and anair blowing instruction is given through a PLC in the welding process; the laser is the single-mode laser, a galvanometer head is adopted for welding, the defocusing amount is +2mm, and the laser power, the welding speed and the welding path are adjusted through a laser control system; and employed process parameters of the laser welding are as follows: the laser power is 900w-1200w, the welding speed is 170mm / s-240mm / s, the welding path is a hyperbola, and the defocusing amount is + 2mm. In the welding process, various welding process parameters are adjusted, the process environment is improved, it is guaranteed that welds are well formed, macroscopic defects are avoided, all performances meet the production and application standards, the welding problem generated when the nickel-plated copper is applied to the production of the positive electrode of the battery tab is solved, and the quality of the welding joints is guaranteed.

Owner:SHANGHAI SKEQI AUTOMATION ENG CO LTD

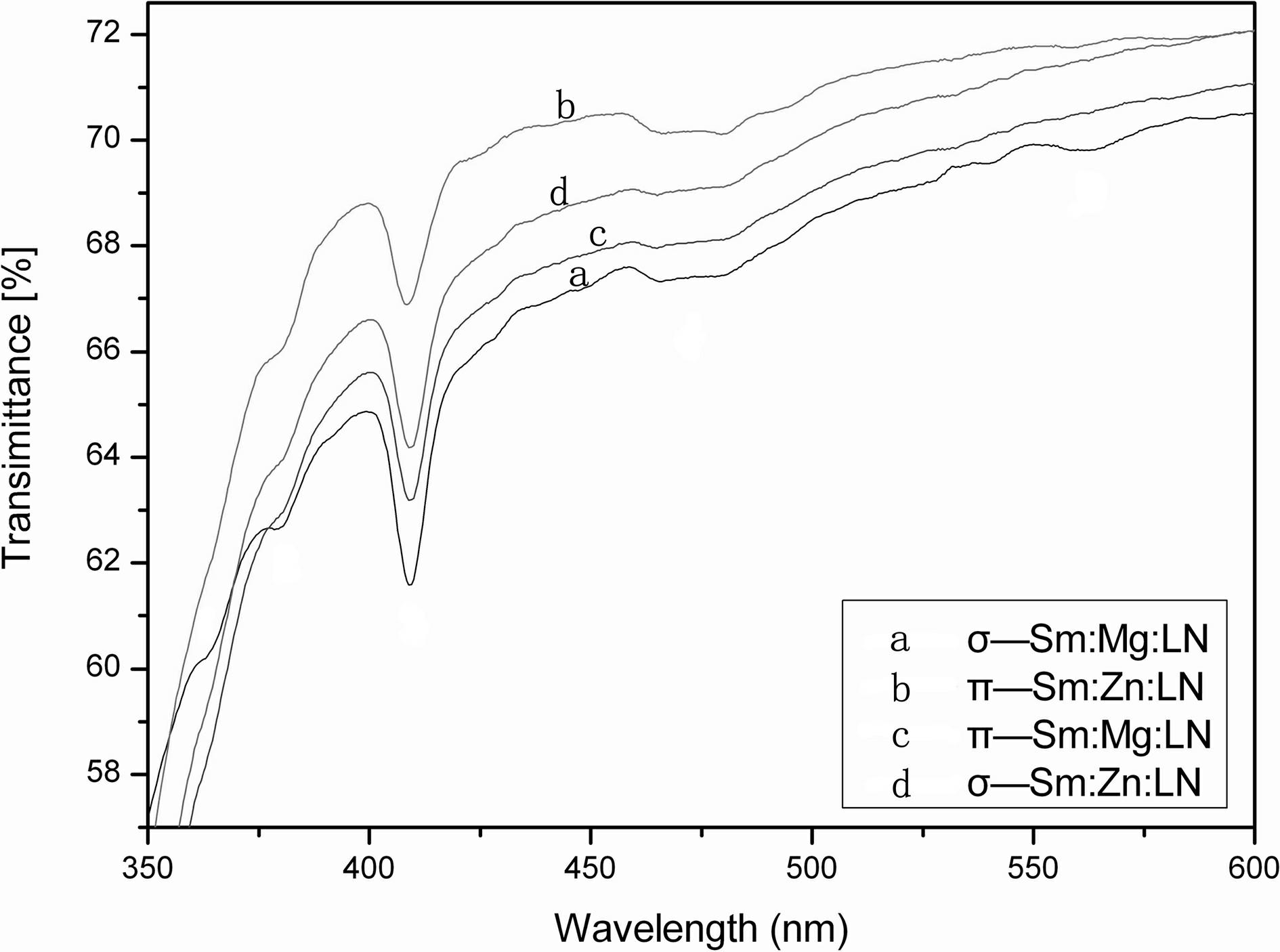

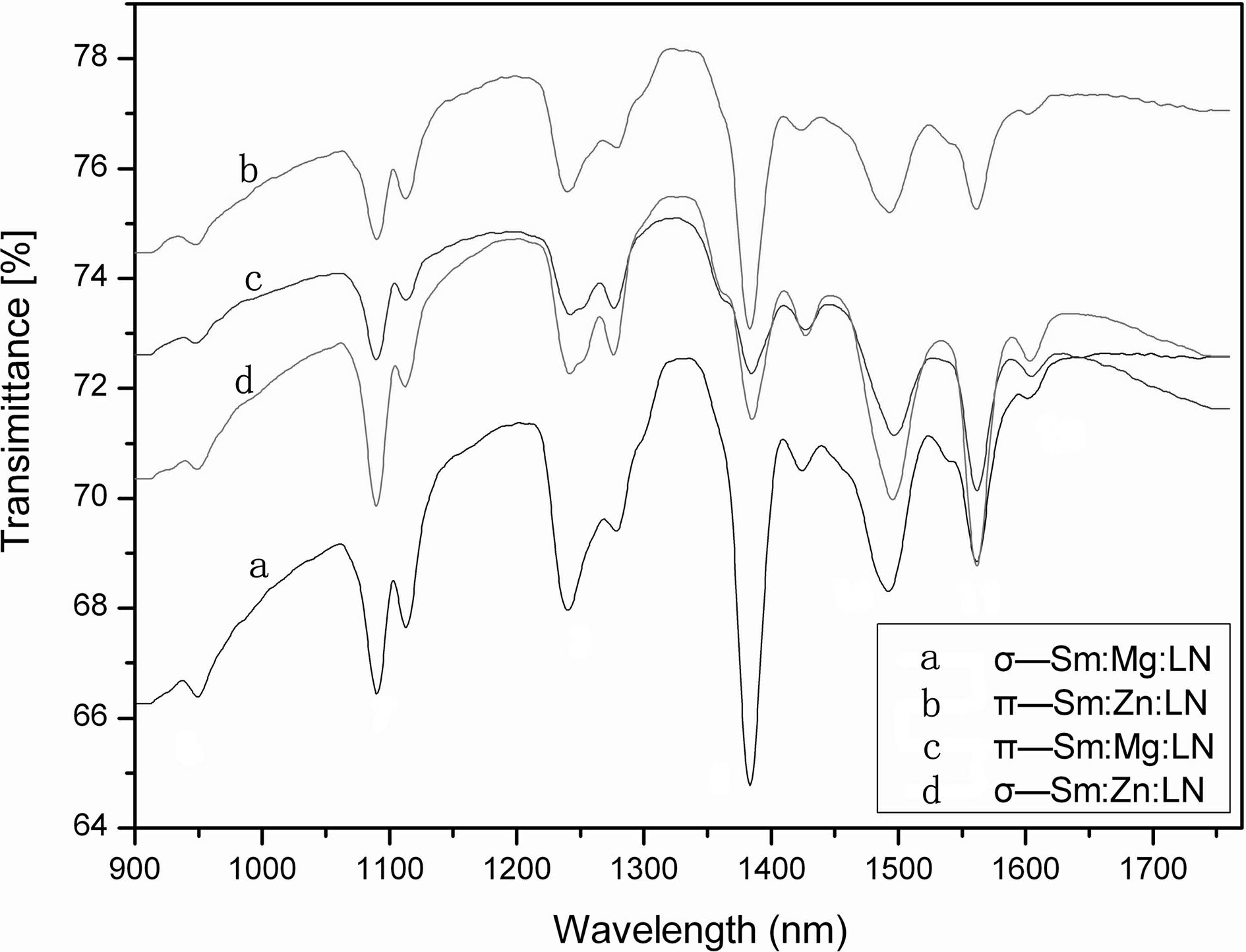

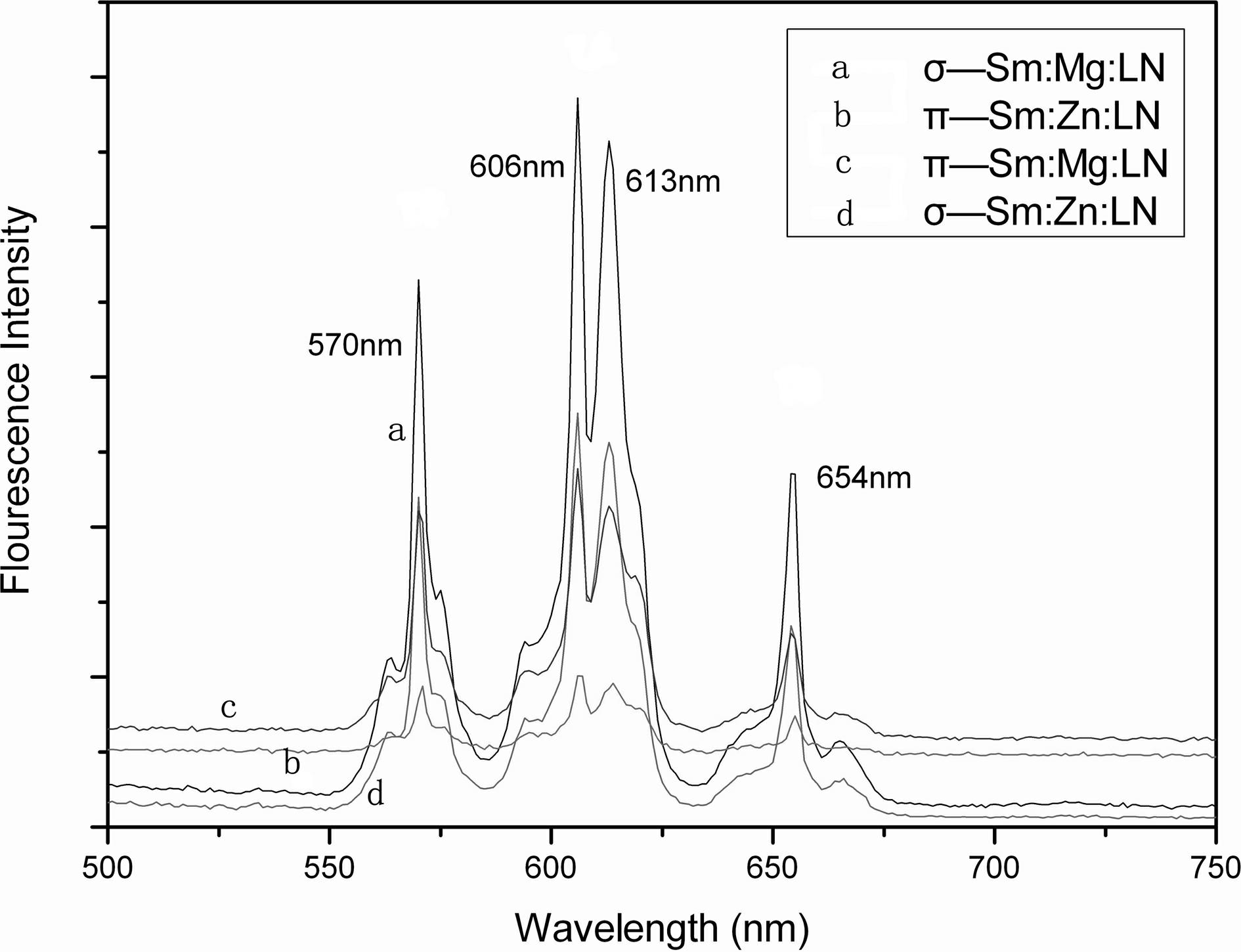

Double-doped lithium niobate crystal and preparation method thereof

InactiveCN102321918AHigh power outputShort wavelength outputPolycrystalline material growthBy pulling from meltIon distributionUltraviolet lights

The invention relates to the technical field of photoelectric crystals, and especially relates to a double-doped lithium niobate crystal which comprises SmxMy(Li0.946NbO3)100-x-y, wherein M is one of Mg and Zn; 0.15<=x<=0.3; when M is Mg, 5<=y<=8; when M is Zn, 6<=y<=7. In the double-doped lithium niobate crystal of the invention, rare earth ion samarium Sm adopts lithium niobate doped with photorefraction-resistant ion Mg or Zn as a substrate, not only has high photo damage resistance, but also realizes short-wavelength orange red light output; with the excitation of ultraviolet light, Sm realizes the output of orange red light of 606 nm and 613 nm within a visible light wave band directly in a down-conversion manner, realizes the high-power output of orange red visible light. The invention also relates to a preparation method of the double-doped lithium niobate crystal, and the prepared high-quality double-doped lithium niobate crystal has no macroscopic defect, no obvious growth striation, and uniform distribution of the doped ions.

Owner:SUN YAT SEN UNIV

1800MPa-grade ultrahigh-strength hot-formed steel plate resistance spot welding technology

InactiveCN113857636AEasy to shapeNo macro defectsResistance electrode holdersElectrical resistance and conductanceSpot welding

The invention discloses a 1800MPa-grade ultrahigh-strength hot-formed steel plate resistance spot welding technology, and relates to a high-strength steel plate spot welding technology. According to the technology, two pieces of ultrahigh-strength hot-formed steel are lapped together and clamped by a clamp, a resistance spot welding robot teaching panel is used, the position of a path adjusting electrode is set, a welding part is positioned at the central point of the lapped part, a welding instruction is added to the teaching panel, the welding pressure is changed, after welding parameters are adjusted through a welding machine, the welding instruction is input to complete the welding process once, and a resistance spot welding joint is formed. The manufacturing and processing technology capable of perfecting the ultrahigh-strength hot-formed steel plate is provided, and the ultrahigh-strength hot-formed steel plate can be favorably combined together in production and manufacturing, so that the comprehensive performance of the product is remarkably improved.

Owner:SHENYANG UNIV

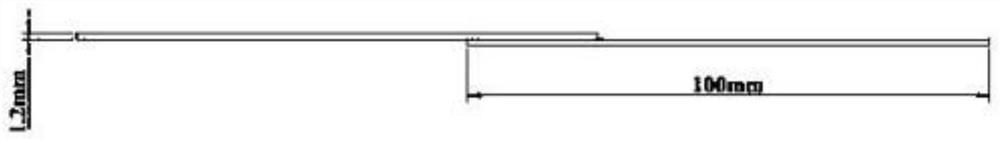

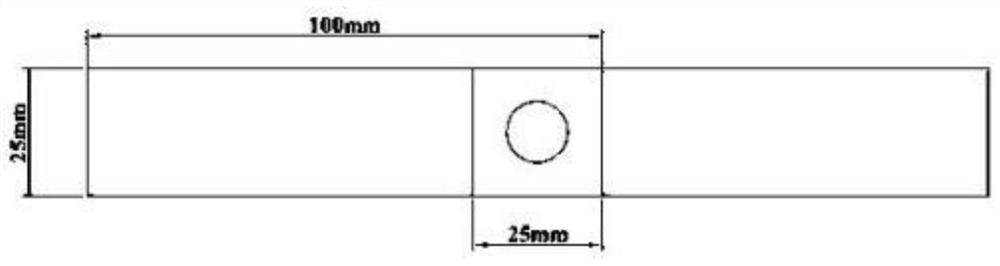

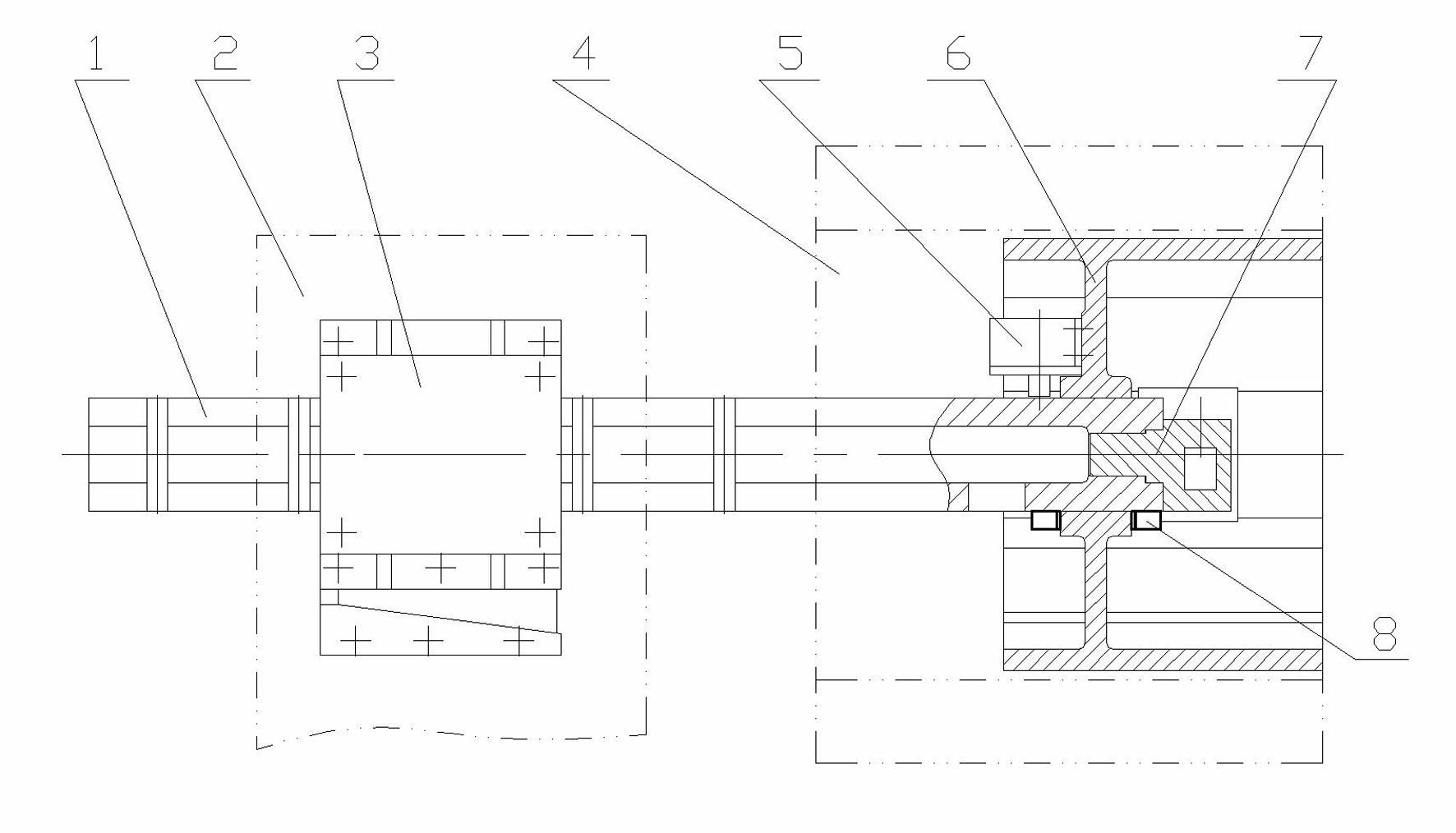

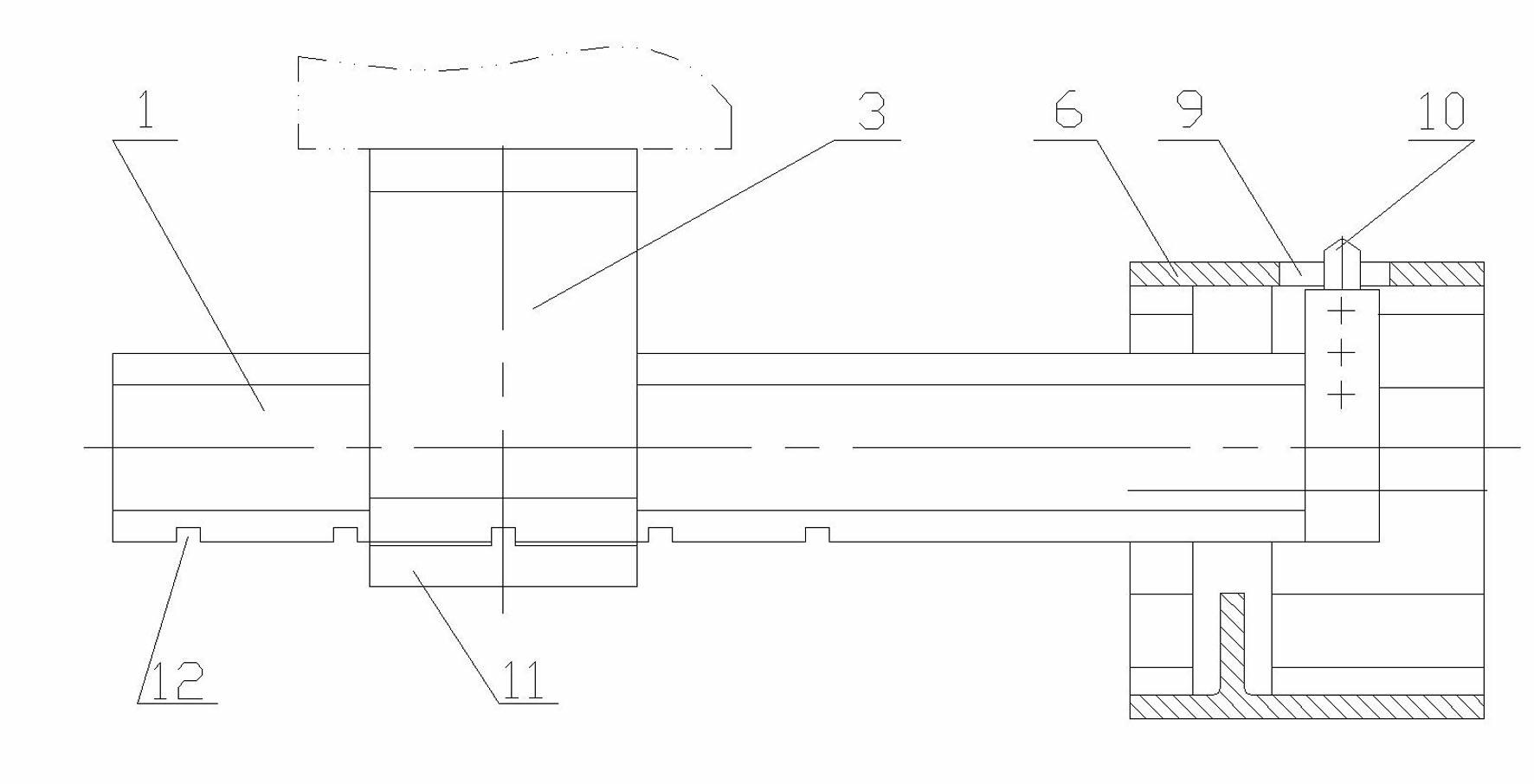

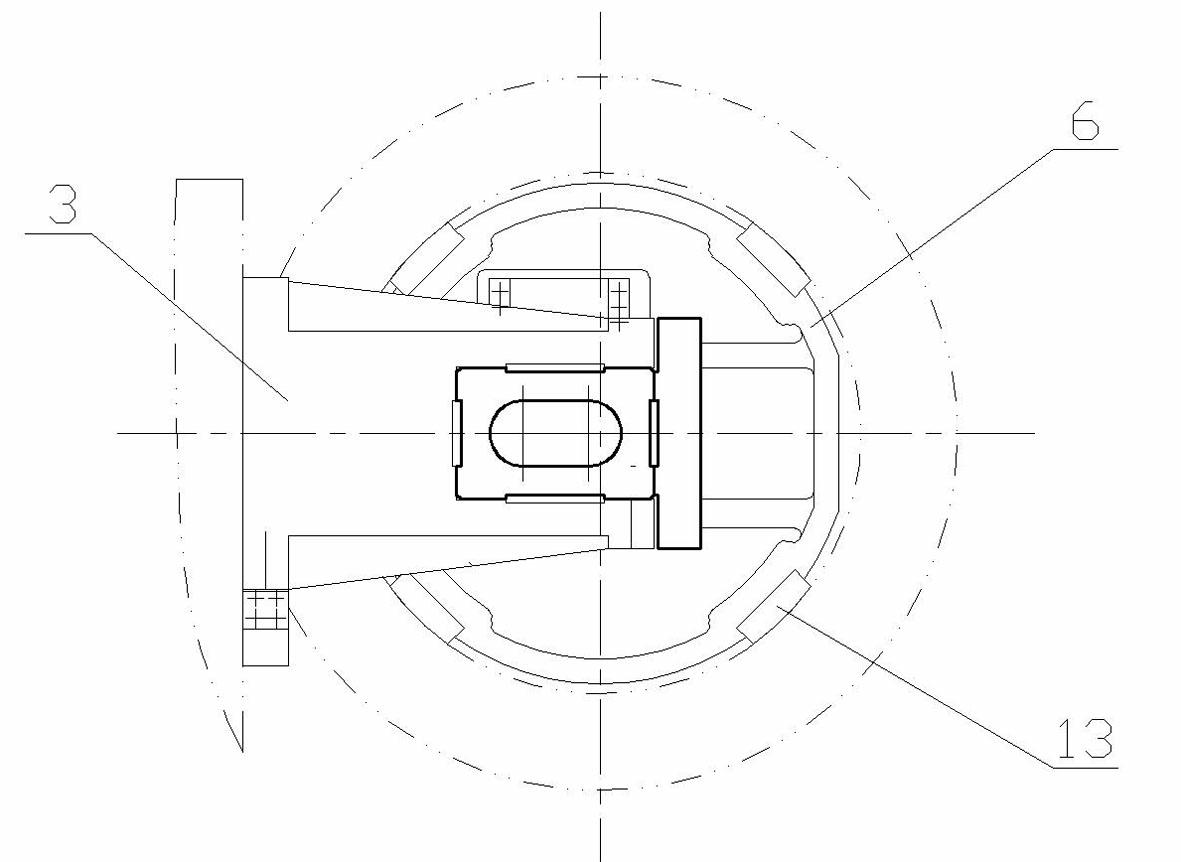

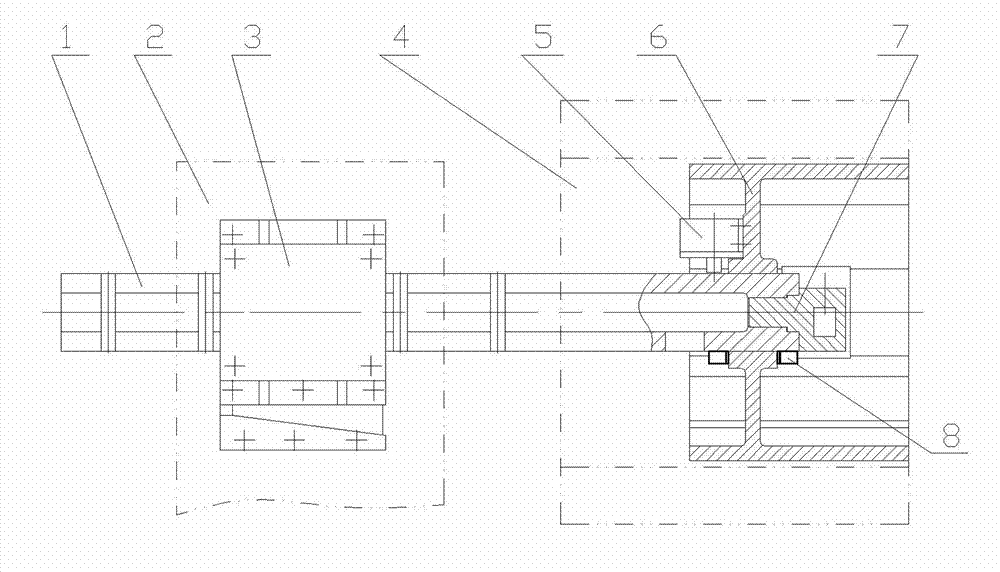

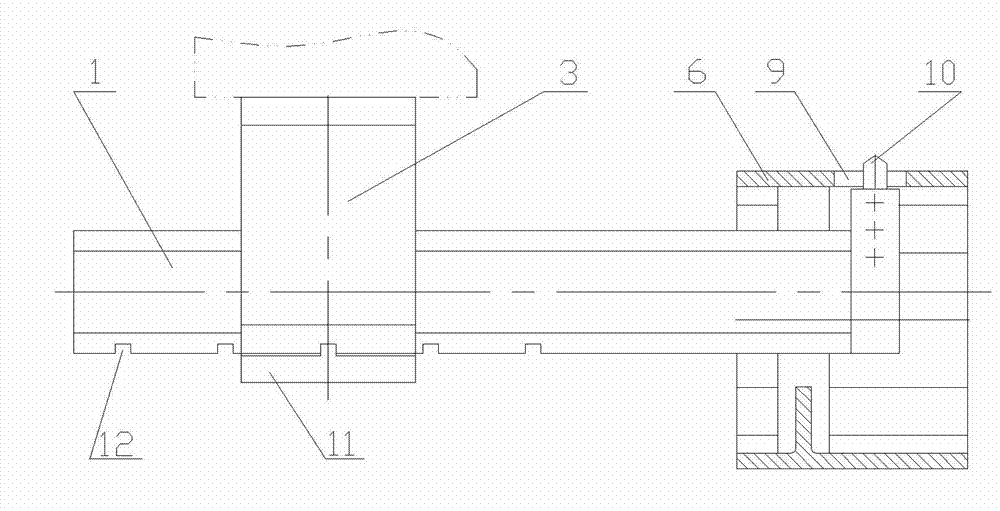

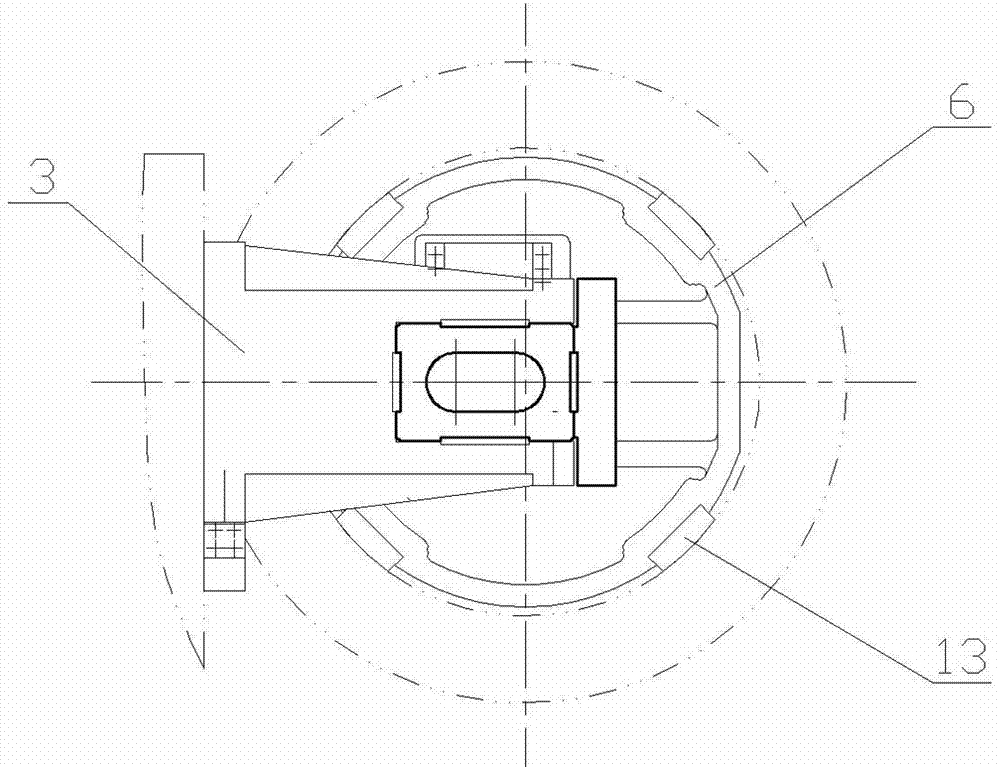

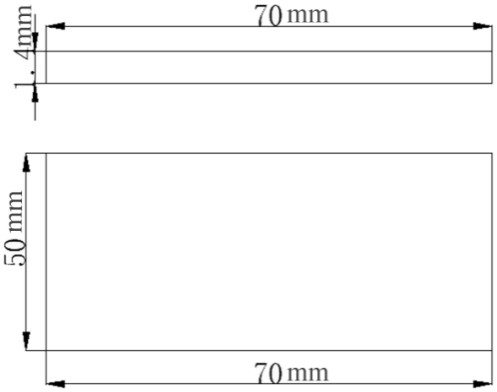

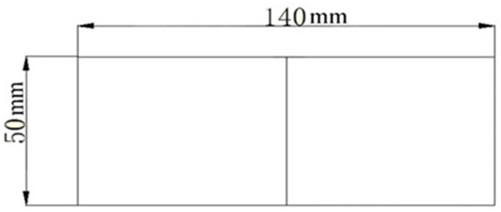

Large-lead nut turning device

ActiveCN102179572AImprove consistencyNo macro defectsThread cutting machinesMechanical engineeringEngineering

The invention discloses a large-lead nut turning device, which comprises a cutter base, a cutter bar, a lathe tool and a guide sleeve, wherein the cutter base comprises a connecting structure connected with a lathe cutter saddle; the cutter bar is fixedly arranged on the cutter base for extending into a prefabricated hole of the nut to be turned; the lathe tool is fixedly arranged on the part of the cutter bar for extending into the nut; and the guide sleeve is connected with the cutter bar for forming shaft fitting with the prefabricated hole of the nut to form auxiliary supporting. The large-lead nut turning device is high in processing precision and good in processing consistence.

Owner:SHANDONG PRECION GROUP

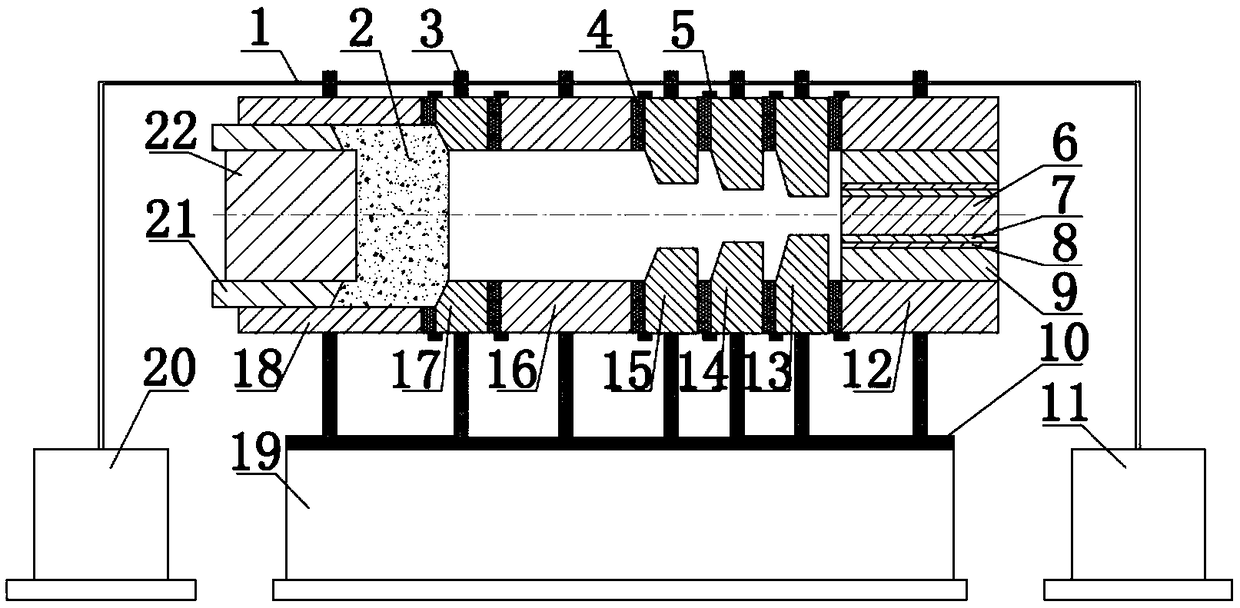

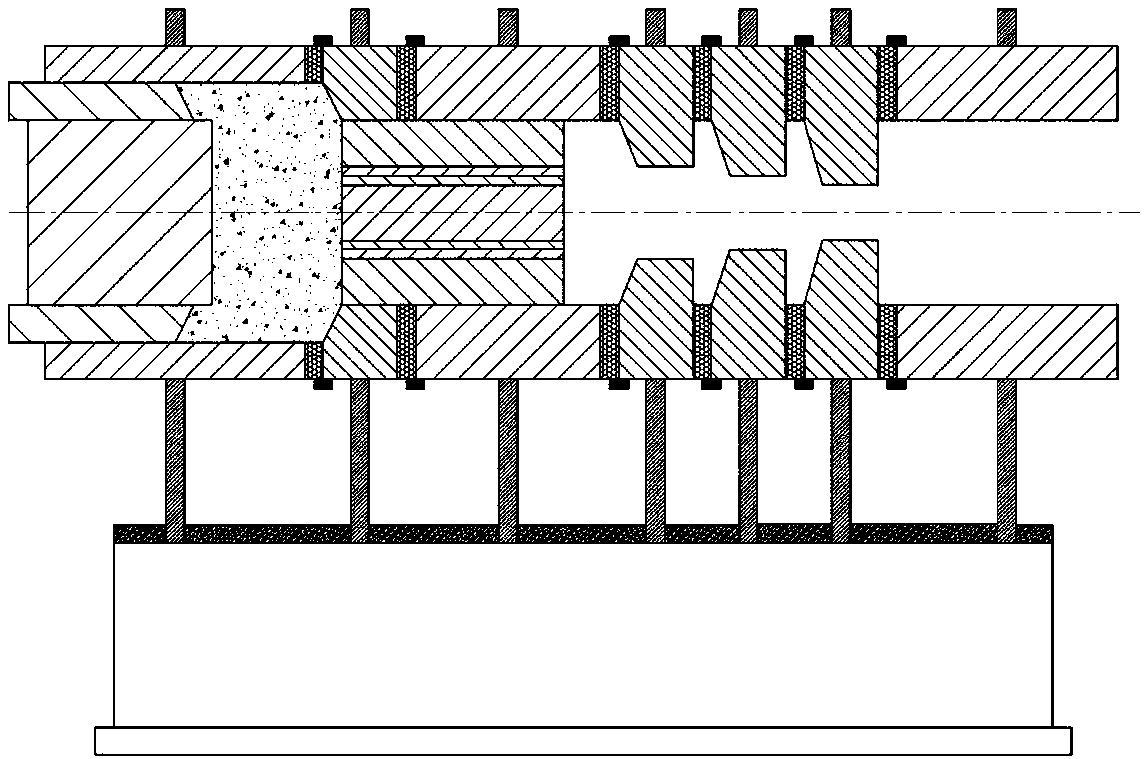

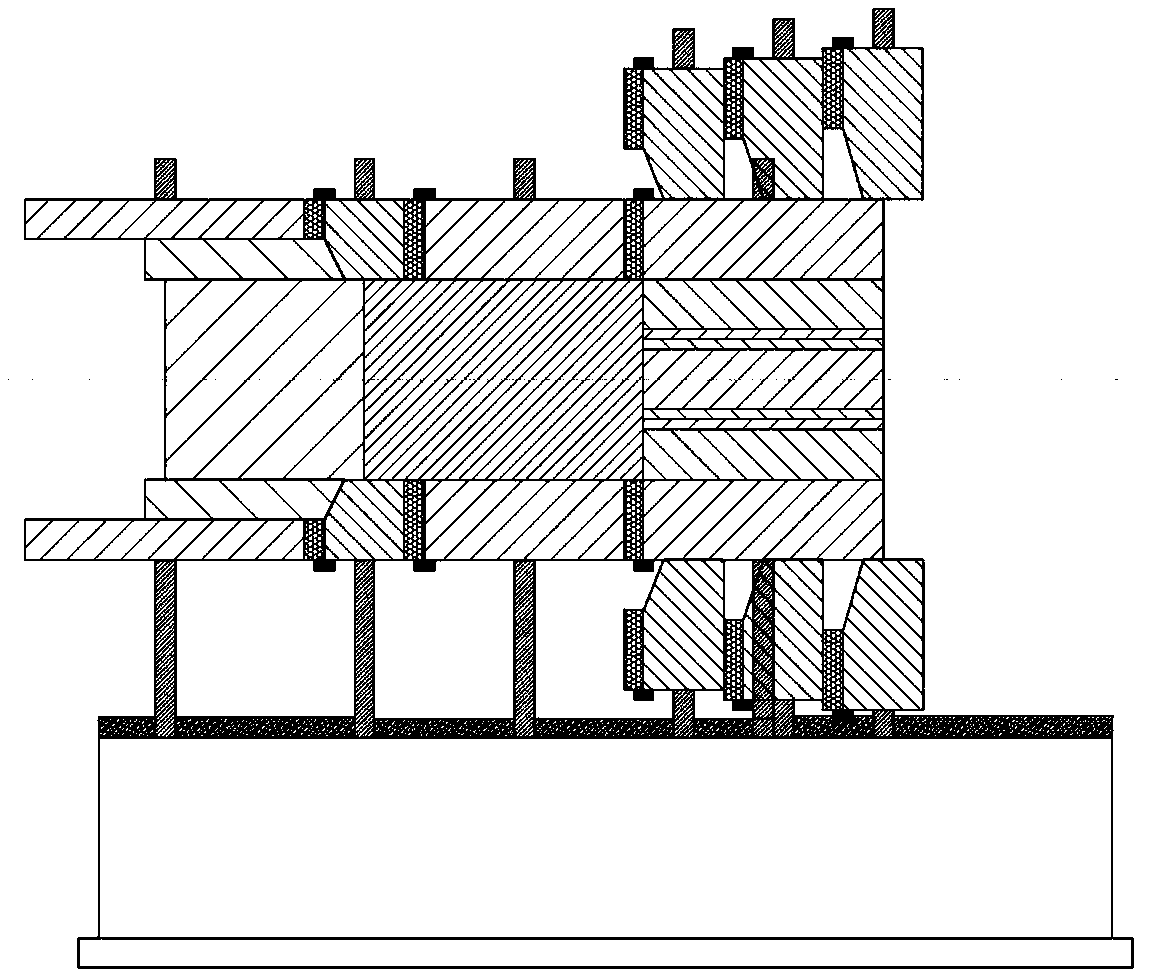

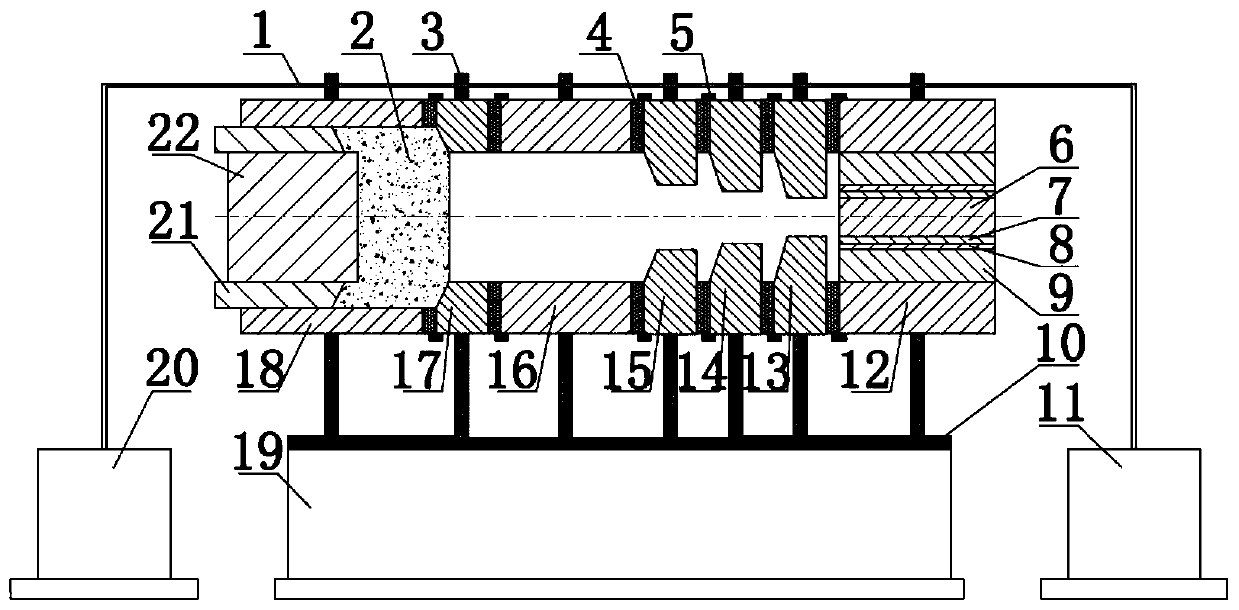

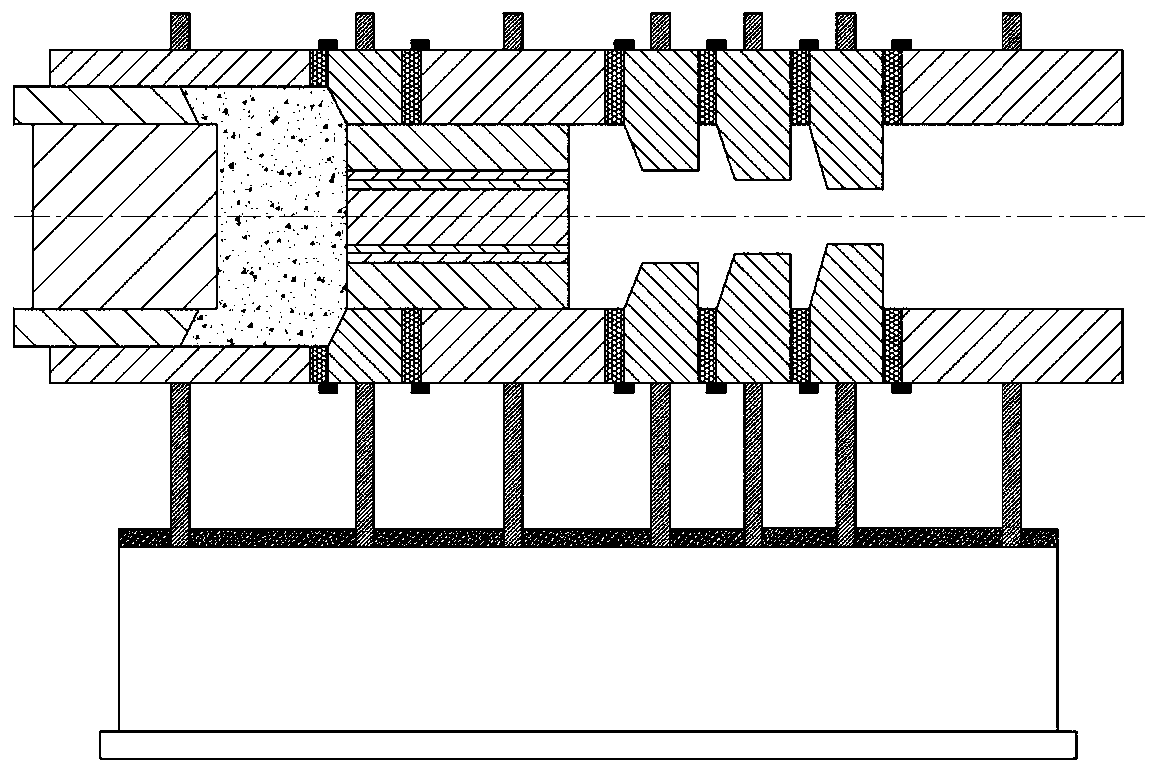

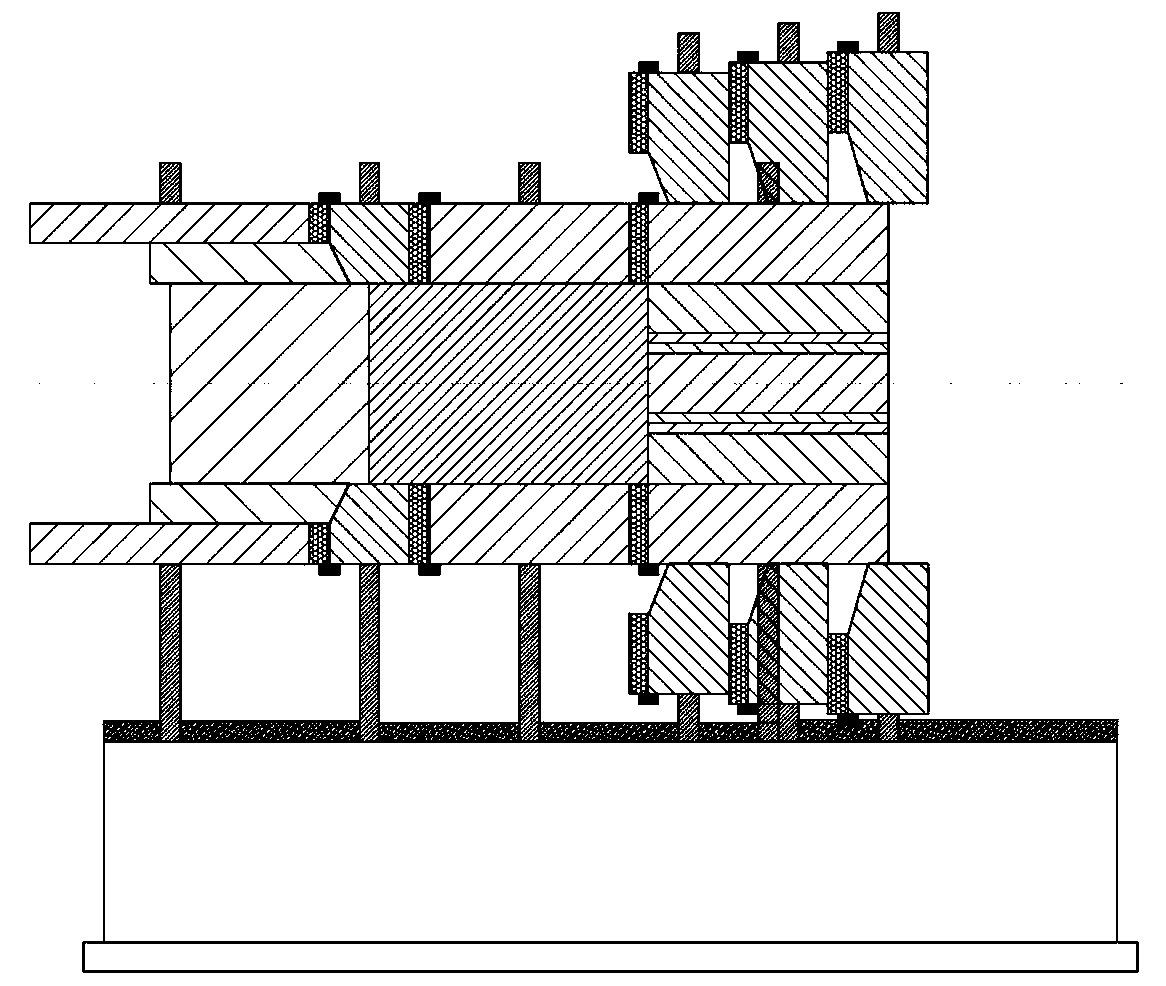

Stage heating and extrusion controlling device for powder superalloy members and using method

The invention relates to a stage heating and extrusion controlling device for powder superalloy members and a using method. According to the using method, with the help of the deformation temperatureand pressure of stage change, the low-temperature and low-pressure curing and high-temperature and high-pressure controlling of powder materials at a time are realized. The method comprises the stepsthat firstly, powder is preliminarily cured under the conditions of lower temperature (no more than 700 DEG C) and lower pressure (no more than 500 MPa); then, the superalloy powder is completely densified by increasing the temperature (no more than 1000 DEG C) and combining plastic deformation parameters such as low extrusion ratio (no more than 2:1) and deformation speed, and a powder superalloyingot with certain deformation is obtained; and a microstructure with the grain size being 7-13 levels can be obtained by further increasing the temperature (no more than 1100 DEG C) and combining plastic deformation parameters such as larger extrusion ratio ((4:1)-(9:1)) and deformation speed. The integration of solidification-control of the powder superalloy members is achieved, the technological process is simplified, the development cycle is shortened, the material utilization rate is improved, and the manufacturing cost of the members is reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

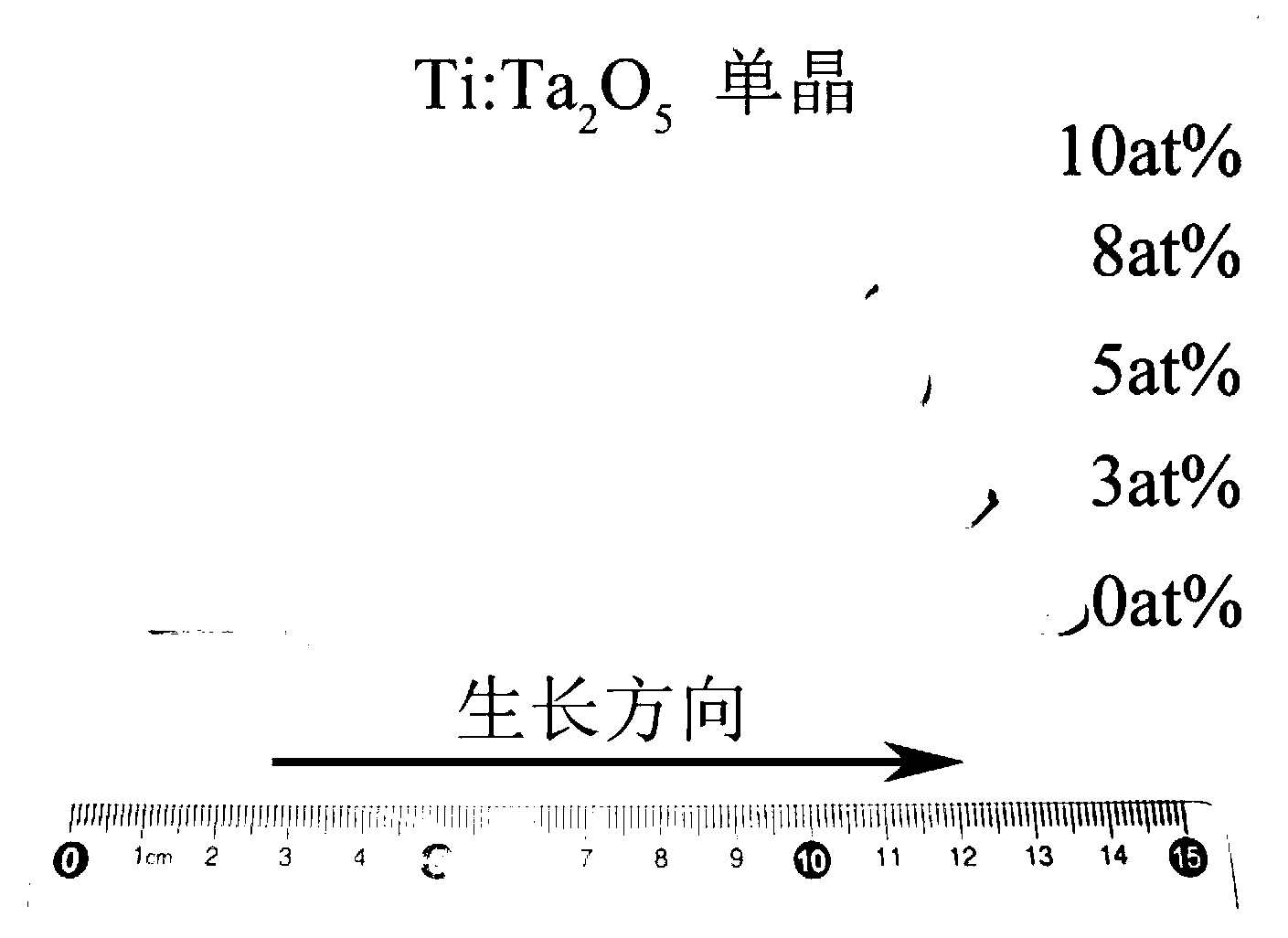

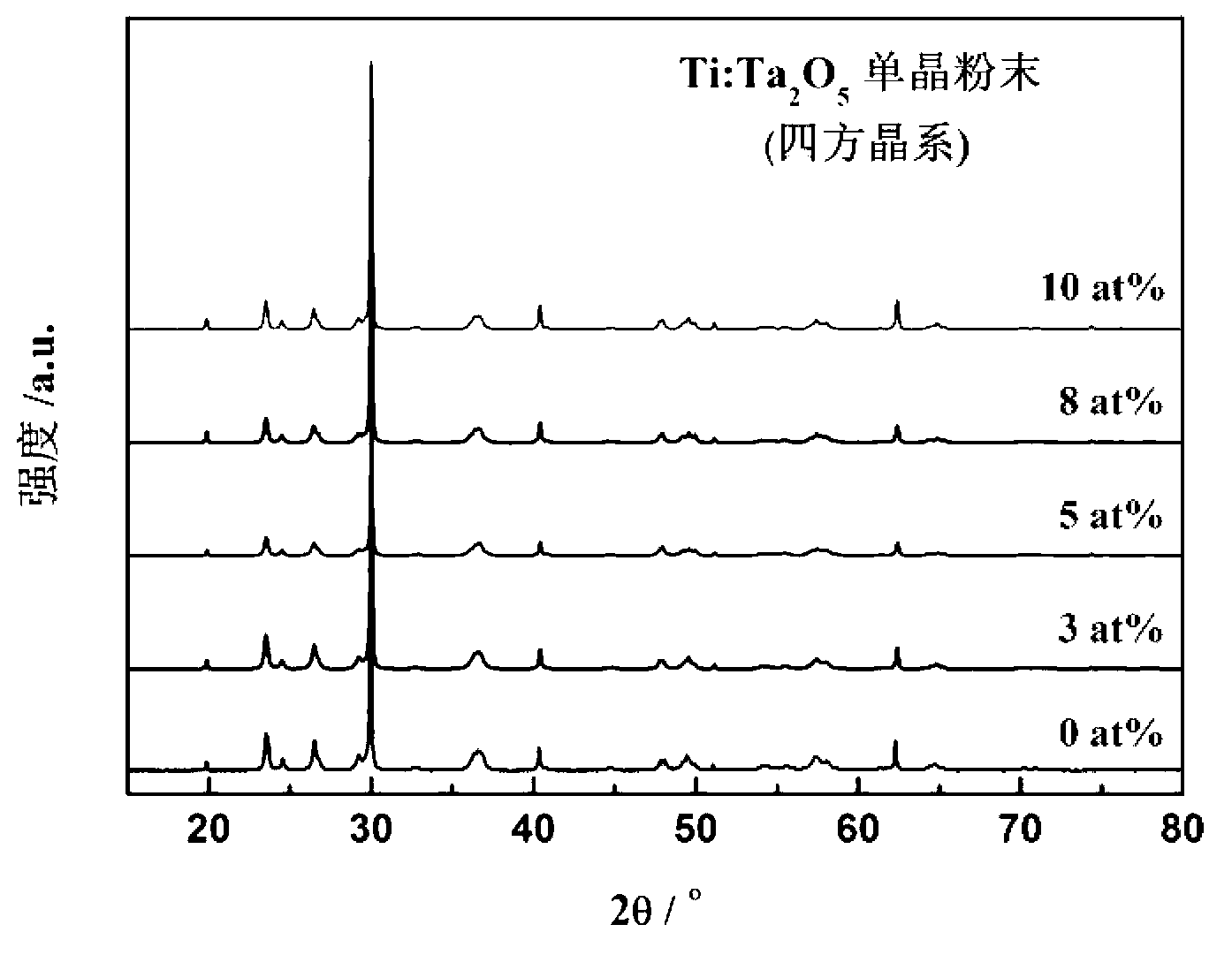

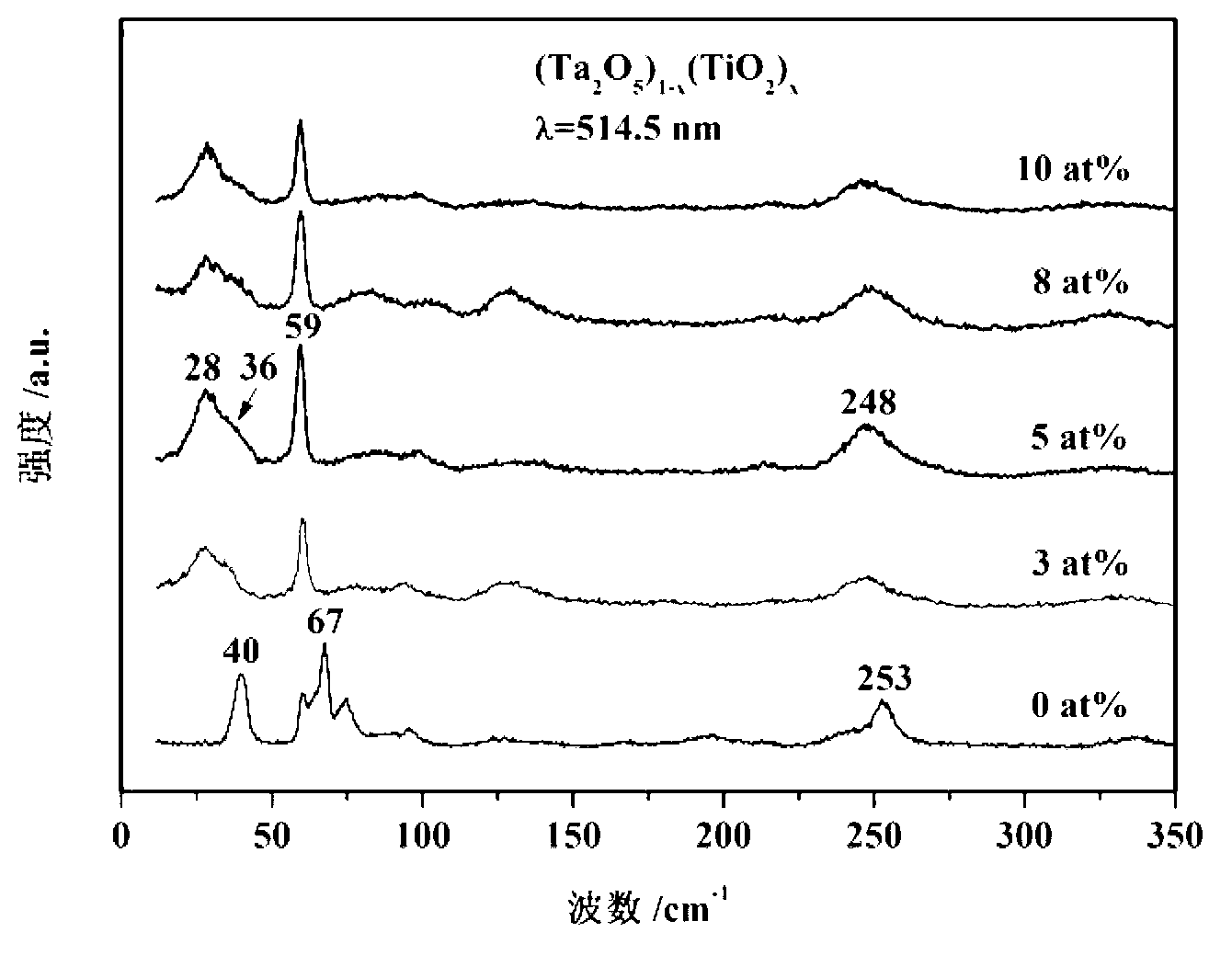

Method for crucible-free rapid growth of centimeter magnitude Ti:Ta2O5 crystals

ActiveCN102912438ANo macro defectsReduce energy consumptionPolycrystalline material growthBy zone-melting liquidsCrucibleRoom temperature

A method for crucible-free rapid growth of centimeter magnitude Ti:Ta2O5 crystals belongs to the field of Ti:Ta2O5 crystal growth. Mixing, ball-milling and burning are carried out on TiO2 and Ta2O5 powder to press rob-shaped polycrystalline rods; the polycrystalline rods respectively serve as charge rods and seed crystals to be installed in a single crystal furnace, a heating rate is set, crystal growth is carried out, cooling time is set, the crystals after growing are cooled to a room temperature. The method is a crucible-free growth technique which can rapidly grow centimeter magnitudes, is free of macroscopic defect and has high-quality Ti:Ta2O5 crystals.

Owner:BEIJING UNIV OF TECH

Method for growing zinc bismuth borate monocrystal through zone melting method

InactiveCN103966669ANo macro defectsReduce energy consumptionPolycrystalline material growthBy zone-melting liquidsNonlinear optical crystalZone melting

The invention relates to a method for growing a zinc bismuth borate monocrystal through a zone melting method, which comprises the following steps: synthesizing a powder pure phase through a solid phase method, and growing the crystal through a zone melting device. The zinc bismuth borate Bi2ZnB2O7 nonlinear optical crystal grown through the zone melting method has the advantages that the crystal is short in growing period, easy to grow and high in efficiency; the grown crystal has high optical quality, has no macroscopic imperfection, is high in purity and is uniformly doped; the crystal can be grown without using a platinum crucible and without being subjected to environmental influence and the like. The Bi2ZnB2O7 crystal obtained through the method can be used in nonlinear optical devices such as frequency multiplication generators, upper or lower frequency converters, optical parametric oscillators and the like; and the method provided by the invention provides a new way for preparation of a large-sized Bi2ZnB2O7 nonlinear optical crystal.

Owner:XINJIANG UYGUR AUTONOMOUS REGION PROD QUALITY SUPERVISION & INSPECTION RES INST

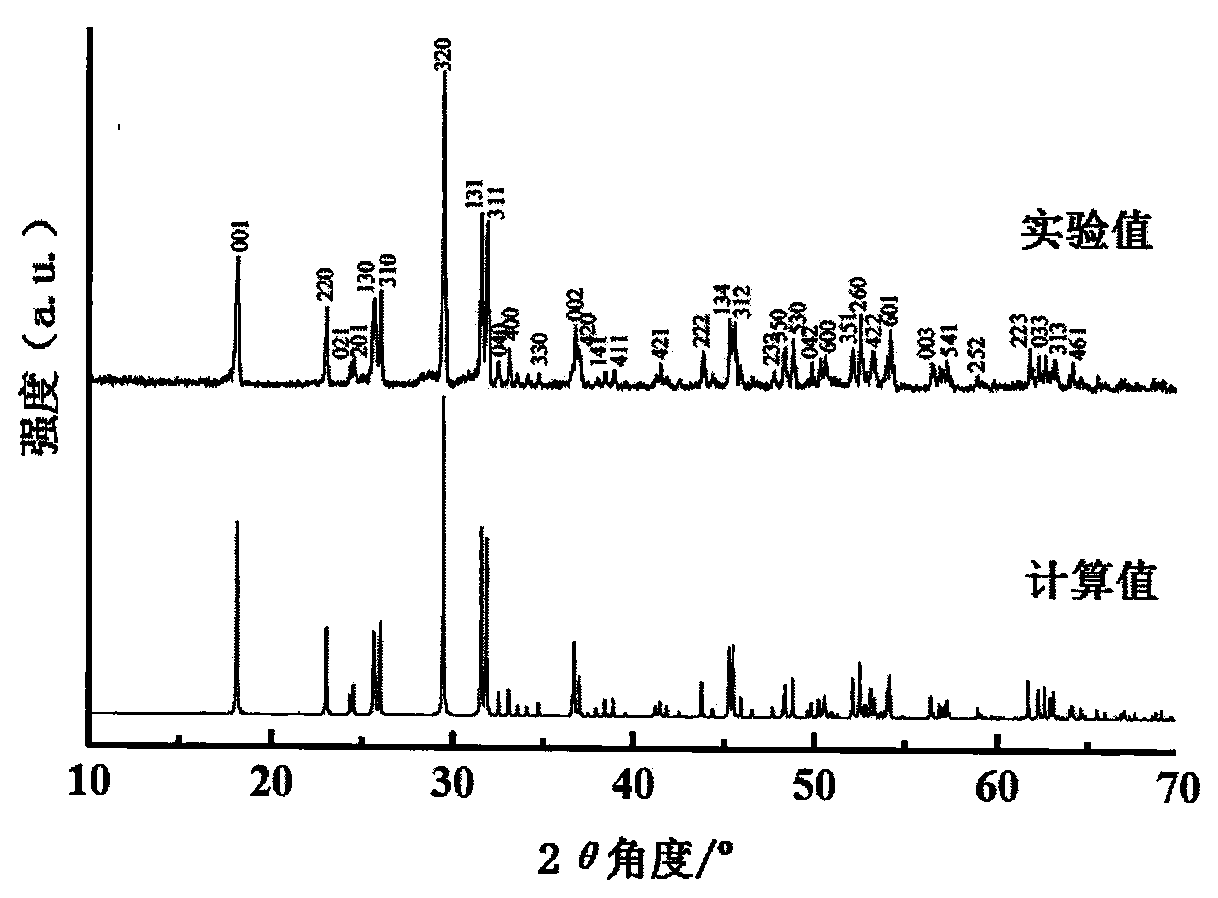

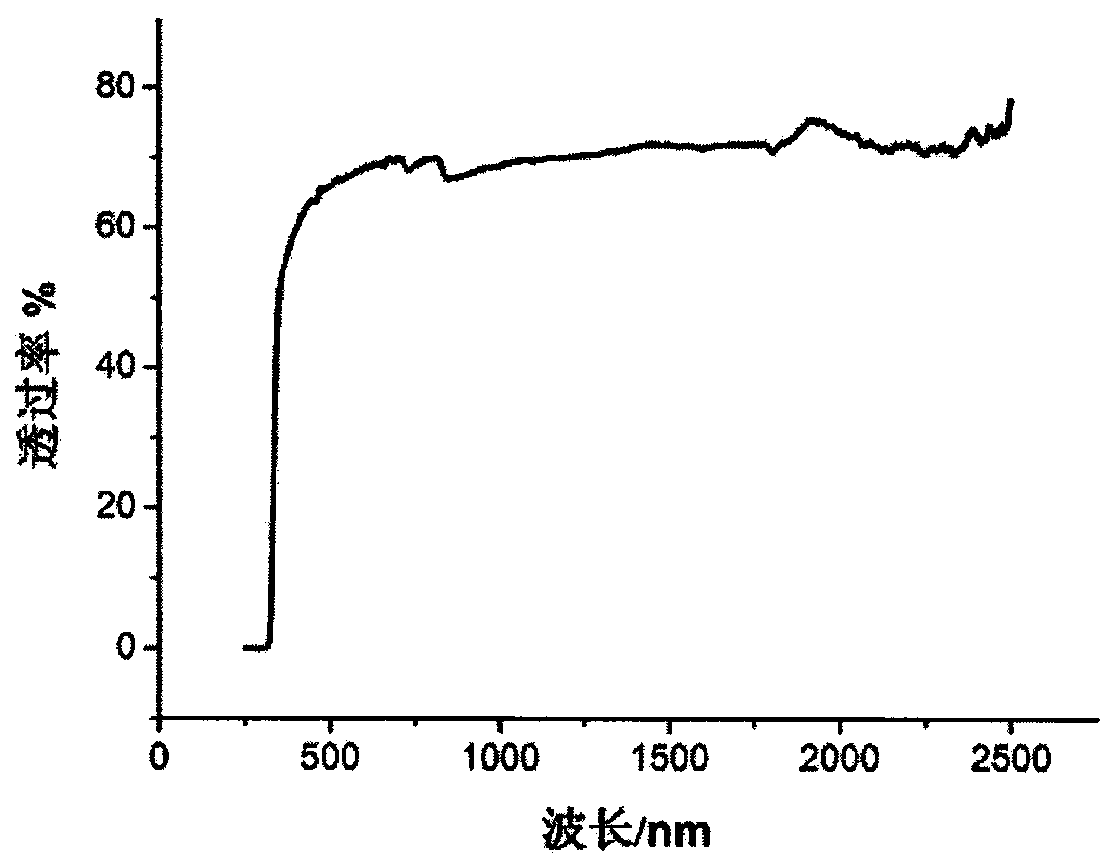

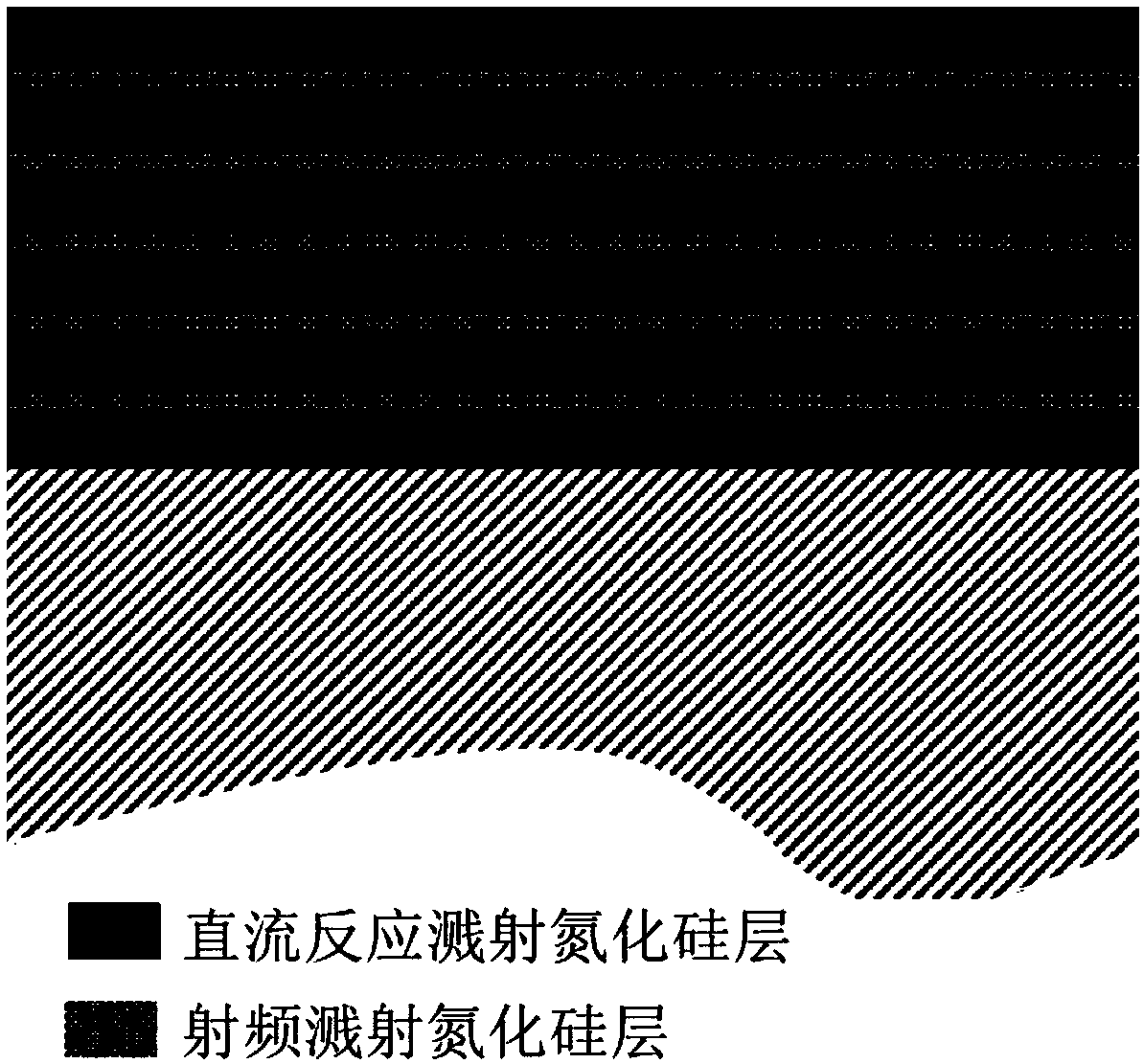

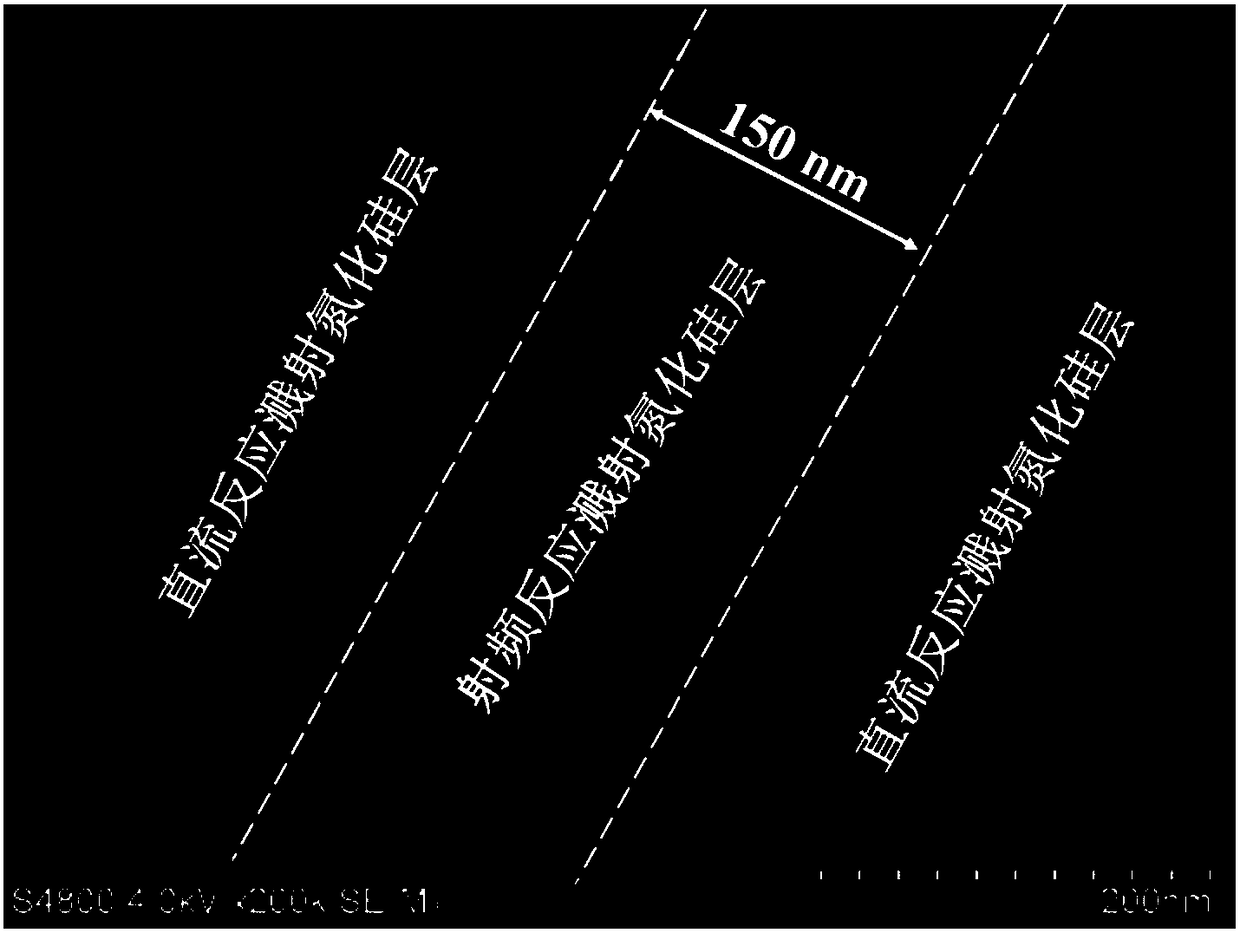

Nano multilayered silicon nitride ceramic coating and preparation method and application thereof

ActiveCN108265272AImprove bindingImprove toughnessVacuum evaporation coatingSputtering coatingElectrolysisCeramic coating

The invention discloses a nano multilayered silicon nitride ceramic coating and a preparation method and application thereof. The coating comprises a multilayered structure which is formed by direct-current reaction sputtering silicon nitride layers and radiofrequency sputtering silicon nitride layers which are alternately overlapped. The preparation method of the coating comprises the following step: depositing on a base material by taking a monocrystalline silicon target and / or a silicon nitride target as a cathode and taking inert gas and nitrogen as working gas and by a direct-current reaction sputtering technology and a radiofrequency sputtering technology to form the nano multilayered silicon nitride ceramic coating. The nano multilayered silicon nitride ceramic coating comprises direct-current reaction sputtering silicon nitride layers and radiofrequency sputtering silicon nitride layers which are alternately stacked. The nano multilayered silicon nitride ceramic coating is combined to a porous ceramic base material and the like well, has the advantages of compact structure, controlled thickness, high hardness, low internal stress, zero macroscopic defects and the like, andcan be applied to multiple fields of precise filtering and separation of various media, high-temperature wave transmitting / wave absorbing, electrolysis diaphragms and the like.

Owner:宁波海强装备科技有限公司

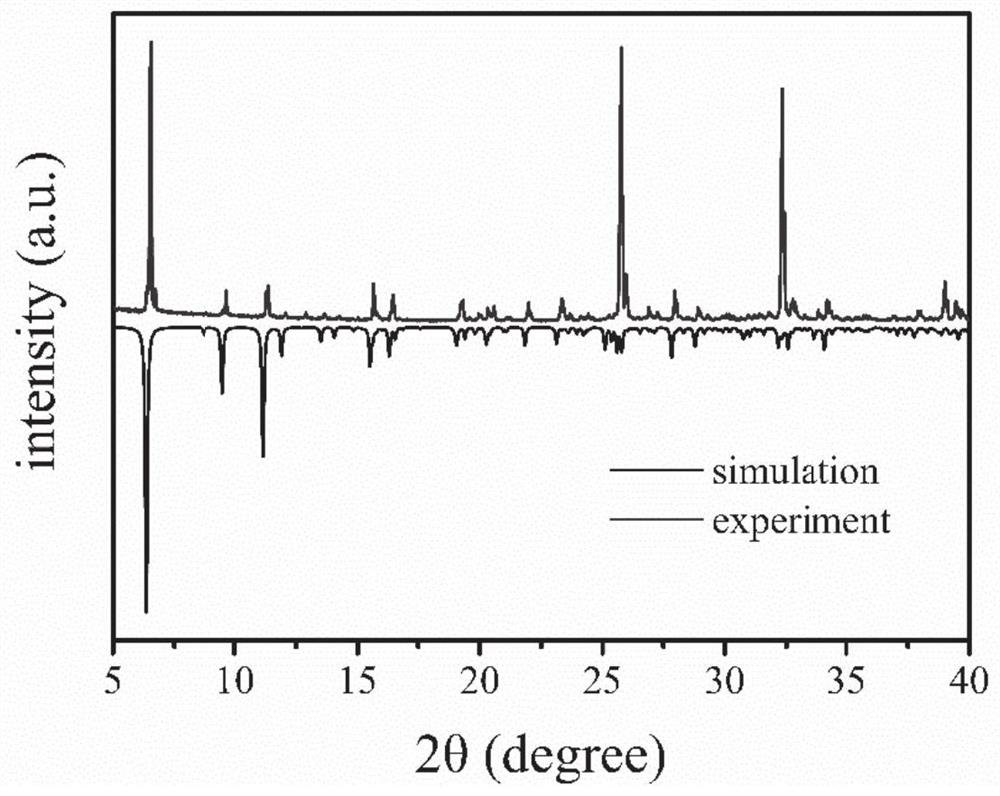

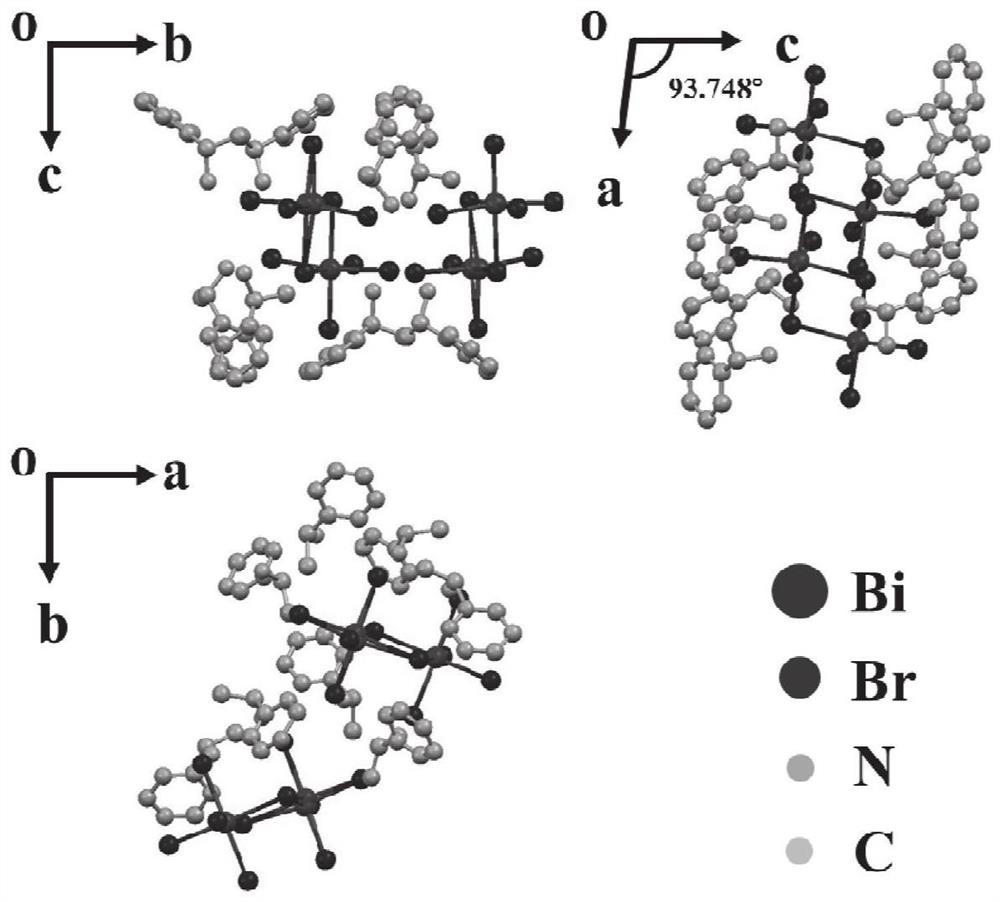

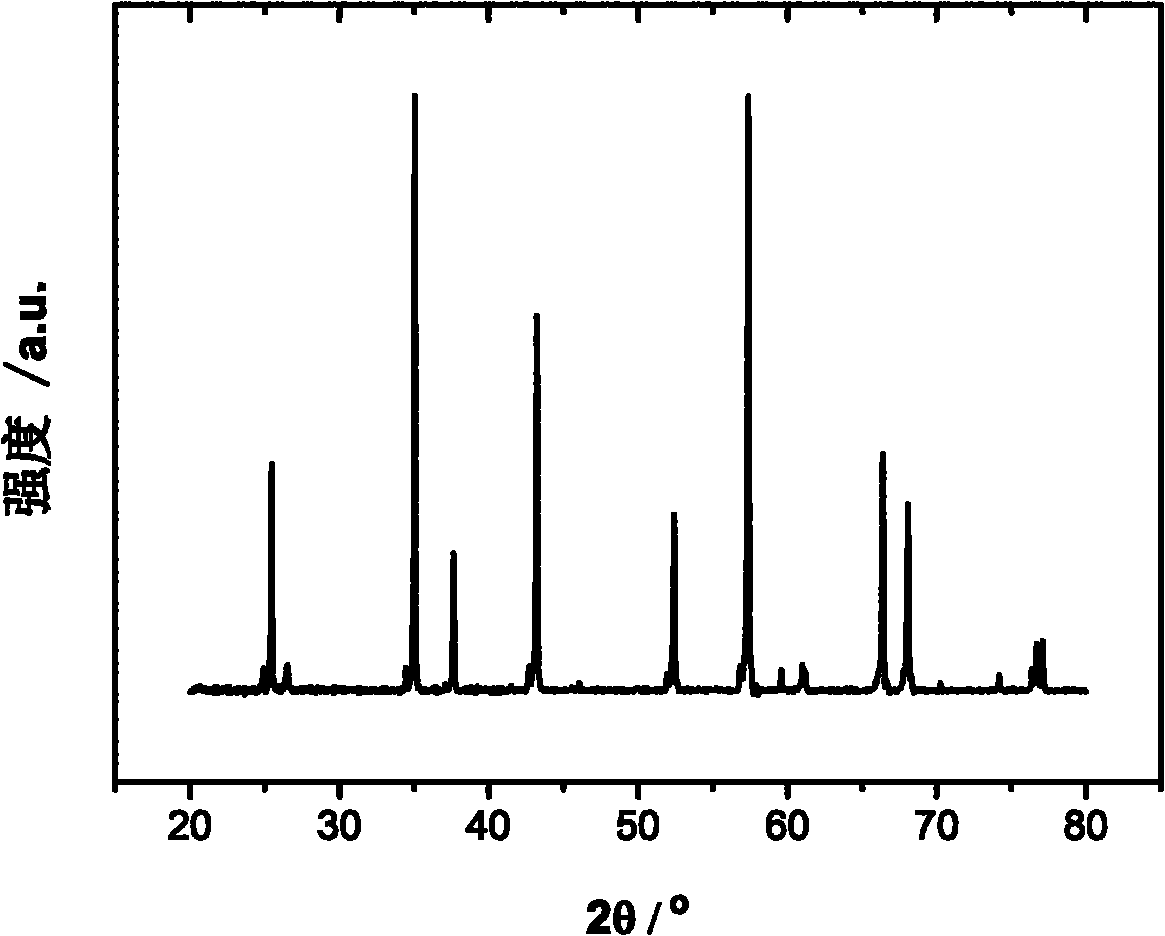

Preparation method and application of organic-inorganic hybrid lead-free piezoelectric crystal

ActiveCN114108069ALow costGood crystallization performancePolycrystalline material growthFrom normal temperature solutionsElectricityOxide

The invention relates to a preparation method of an organic-inorganic hybrid lead-free piezoelectric crystal, which comprises the following steps: uniformly mixing bismuth oxide, hydrobromic acid and R (+)-alpha-methylbenzylamine, heating in a drying oven, and cooling twice to obtain the organic-inorganic hybrid lead-free piezoelectric crystal. Compared with a pure organic piezoelectric material, the piezoelectric property is improved. Bismuth atoms are adopted to replace lead atoms to serve as central atoms, preparation of the lead-free material is achieved, and the method is more environmentally friendly.

Owner:SHANDONG UNIV

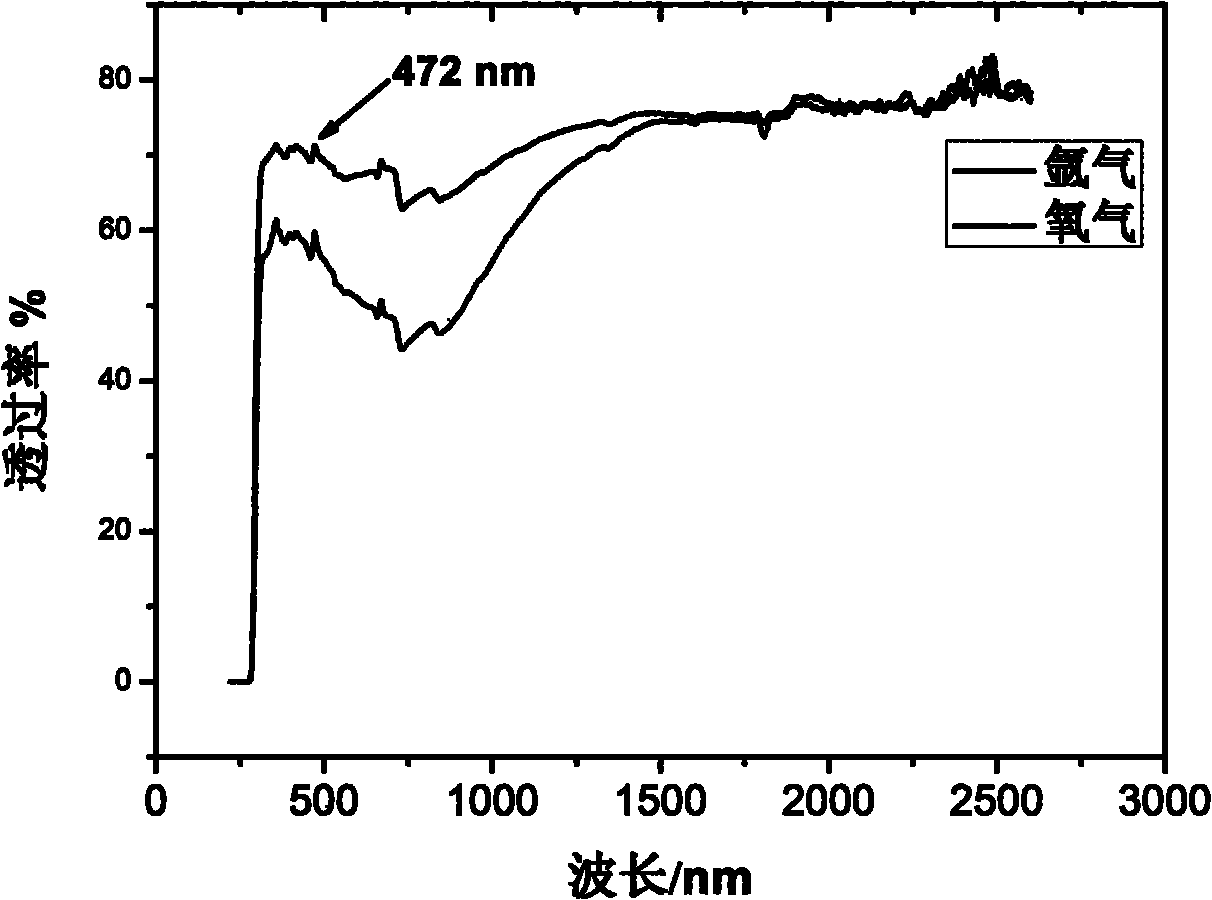

Crucibleless growth method of sapphire crystals in different atmospheres

InactiveCN102115911AUniform colorImprove crystal qualityPolycrystalline material growthUnder a protective fluidCrystallographyCrucible

The invention discloses a crucibleless growth method of sapphire crystals in different atmospheres, and belongs to the field of sapphire crystal growth. The method comprises the following steps: a polycrystalline rod is prepared by using high-purity raw materials of Al2O3, FeTiO3 and Fe2O3; the polycrystalline rod is put into a crystal growth furnace, and is sleeved by a quartz tube; oxygen gas or argon gas is led to the quartz tube, and a gas valve is closed when the pressure reaches a certain value; the temperature rises for 0.5 to 1 hour until the material rod and seed crystals are melted; a crystal growth speed is set for crystal growth; the grown crystals are cooled to reach the room temperature; and the gas valve is opened, and the gas is released to the normal atmospheric pressure. The sapphire crystals grown through the method have large sizes, evener color and better quality, and avoid macroscopic defects.

Owner:BEIJING UNIV OF TECH

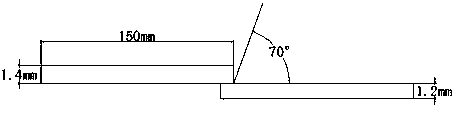

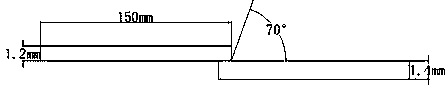

Unequal-thickness heterogeneous dual-phase steel cold metal transition welding technology

PendingCN109807439AGood mechanical propertiesSimple process conditionsArc welding apparatusWeld seamEngineering

The invention discloses an unequal-thickness heterogeneous dual-phase steel cold metal transition welding technology, and relates to a metal welding technology. The technology comprises the followingsteps that the surfaces of to-be-machined plates are processed through acetone under the clean experimental environment, and it is ensured that the surfaces of the to-be-machined plates are free of oil contamination and impurities; the unequal-thickness heterogeneous dual-phase steel plates are placed on a testbed in an overlap joint mode; a welding mode is set through a control panel of a CMT welding machine, after the welding mode is determined, a welding gun is put on an automatic trolley fixture and subjected to position and angle adjusting, and after it is determined that the to-be-weldedparts of the test pieces are consistent with the welding gun in moving direction, welding is conducted; and welding is carried out through a left welding method. According to the unequal-thickness heterogeneous dual-phase steel cold metal transition welding technology, by adopting cold metal transition welding, in the welding process, various welding technology parameters are adjusted, the technology condition is improved, and it is ensured that welded seams are good in form, uniform, smooth and free of macroscopic defects. Especially, through the technology, welding heat input is effectivelydecreased, the cost is reduced, and connectors good in mechanical property can be obtained.

Owner:SHENYANG UNIV

Preparation method of special wear resistant plastic ramming mass for pure low-temperature cogeneration technology

The invention discloses a preparation method of a special wear resistant plastic ramming mass for a pure low-temperature cogeneration technology. The method comprises the following steps of: (1) blending raw materials, wherein the raw materials comprise a ramming mass matrix, high-carbon asphalt powder, a surface treating agent and a composite binder, and the ramming mass matrix comprises emery, spheroidal graphite powder, Al2O3 powder, SiO2 micro powder, blue crystal powder and chromium mineral powder; (2) carrying out first-layer mixing on the components in the ramming mass matrix except the Al2O3 powder and the SiO2 micro powder with the high-carbon asphalt powder, then adding the SiO2 micro powder and silicon-aluminum oxide powder which are treated by using the surface treating agent to carry out second-layer mixing, and next, adding the composite binder to carry out a third-layer mixing; and (3) carrying out toughening treatment on the ramming mass by adopting a metal hexsteel, and then carrying out the toughening treatment by blending with steel fibers in the ramming mass. The ramming mass prepared by using the method has wear resistance, long service life and high heat utilization ratio.

Owner:蒋美芳

A kind of active powder concrete and its preparation method and application

The invention provides reactive powder concrete and preparing method and purpose thereof. The reactive powder concrete is prepared from 400-1000 parts of cement, 100-500 parts of modified superfines, 50-200 parts of modified steel fiber, 900-1300 parts of quartz sand, 100-220 parts of quartz powder, 10-30 parts of admixture, and 100-250 parts of water. According to characteristics of inorganic whisker which it has no macroscopic defect, its crystal intensity approximates theoretical value of intact crystal, and mechanical strength is equivalent to force of neighboring atoms, the invention, by adding whisker, improves RPC-related properties with compressive strength and rupture strength up to construction requirements; by modification of steel fiber, it improves wrapping of slurry on steel fiber, enhances fracture energy and strength increase of RPC product and reduces interface microcrack.

Owner:重庆天维绿色建筑技术开发有限公司

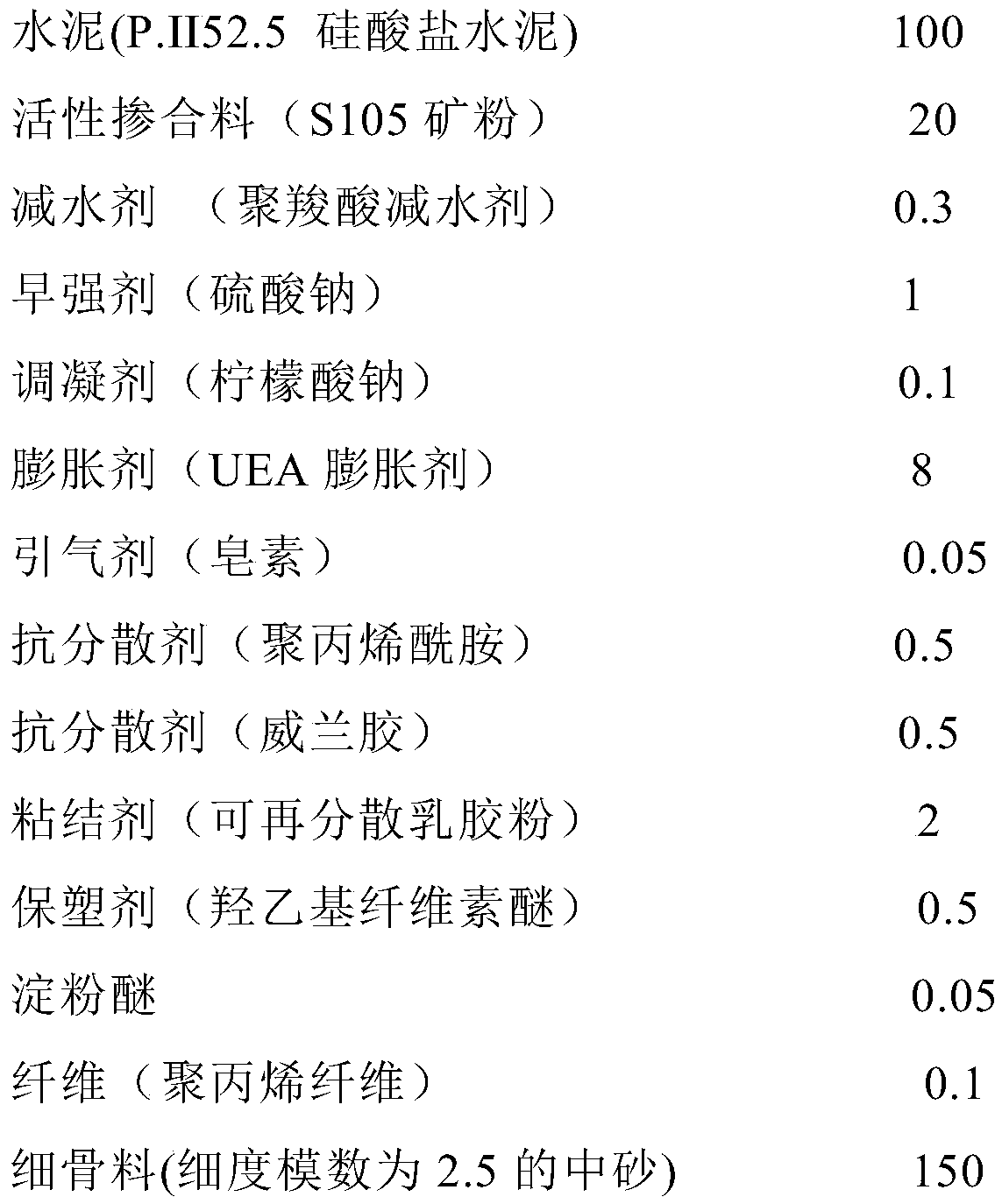

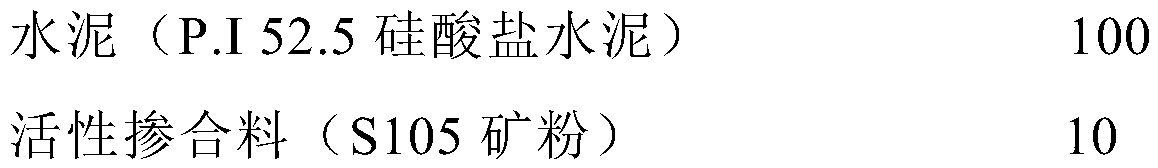

A 3D printing cement-based material for underwater construction and its preparation method

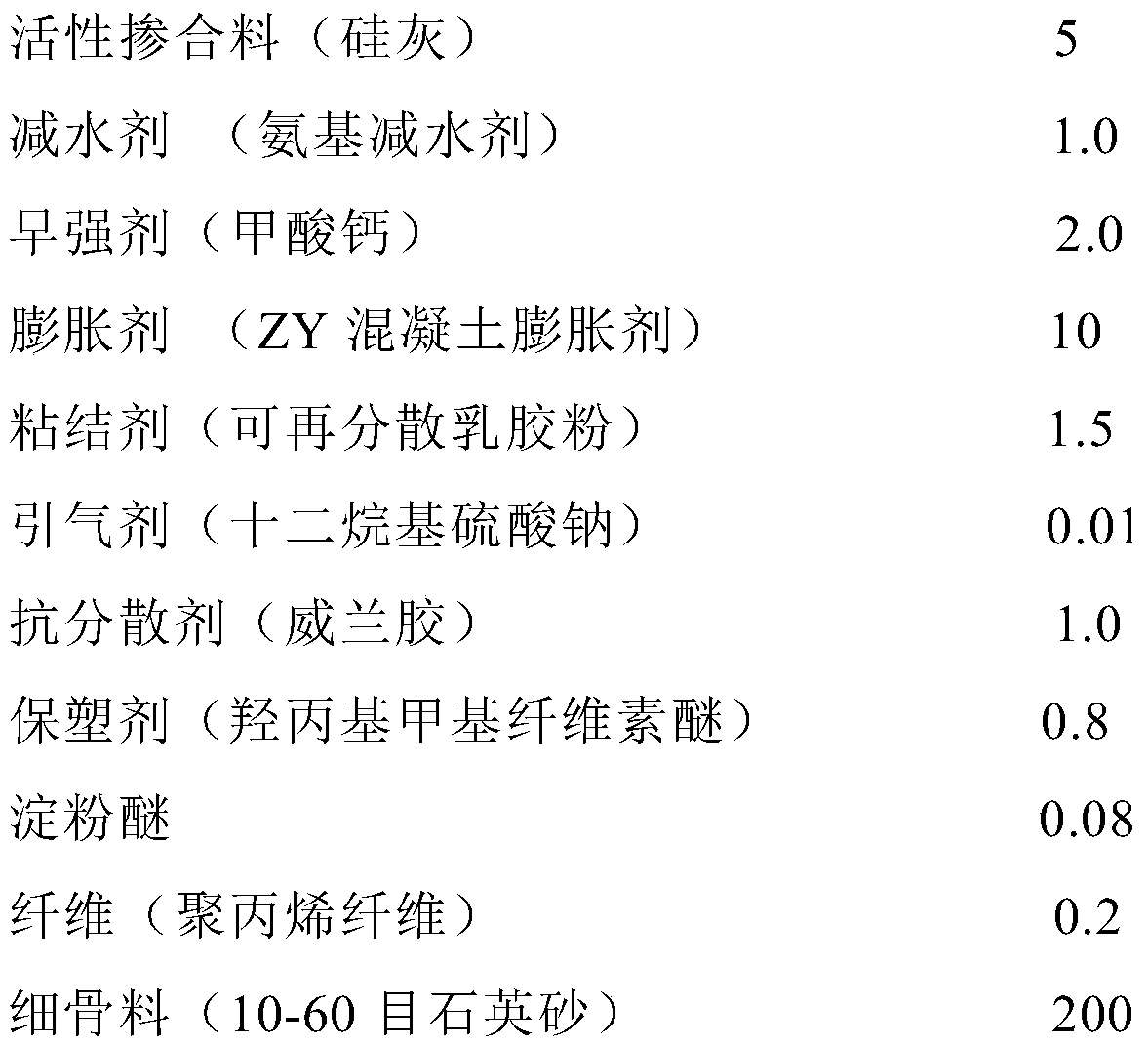

ActiveCN107311561BImprove water retentionGood dispersionAdditive manufacturing apparatusSolid waste managementFiberMechanical property

The invention relates to a 3D printing cement-based material used for underwater construction and a preparation method of the 3D printing cement-based material. The 3D printing cement-based material is prepared from the following components and raw materials by weight: 100 parts of cement, 0-60 parts of mineral powder, 0-30 parts of fly ash, 0-20 parts of silica fume, 0.1-3 parts of a water reducing agent, 0.1-5 parts of an anti-dispersion agent, 0.2-5 parts of a binder, 0.005-0.5 part of an air entraining agent, 0.01-25 parts of a plastic retaining agent, 0-0.5 part of starch ether, 0.01-0.5 part of a thickening time control agent, 0.1-10 parts of an expanding agent, 0.1-10 parts of an early strength agent, 0.01-0.5 part of fiber, 50-300 parts of fine aggregate, and 0-400 parts of coarse aggregate. Compared with the prior art, the 3D printing cement-based material, when used in the underwater printing construction, has the excellent advantages of constructability, dispersion resistance and durability and has an excellent bulk property in water, a printed building does not collapse, and the mechanical property is excellent.

Owner:TONGJI UNIV

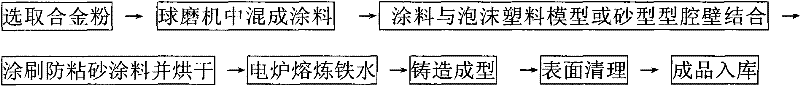

Preparation method of surface composite sintering machine grate bar

InactiveCN101698230BImprove antioxidant capacityExtended service lifeFoundry mouldsFurnace typesPolyvinyl alcoholComposite substrate

The invention relates to a method for preparing surface composite sintering machine grate bars, and belongs to the field of metal matrix composite materials. The present invention comprises SiC powder, aluminum oxide powder, ferrochrome powder, adds polyvinyl alcohol aqueous solution and is mixed with alloy powder coating, then it is coated on the working surface of sintering machine grate bar foam plastic model or the mold cavity of sand mold is corresponding to on the molded wall of the work surface. The high chromium cast iron or ferritic nodular cast iron melt is smelted in an electric furnace and cast, so as to prepare the surface composite sintering machine grate. After testing: the surface composite layer containing Al 2O 3+SiC reinforced particles is metallurgically bonded to the cast iron matrix, and the composite layer is dense without obvious macro defects, with a thickness of more than 5mm and a hardness of HRC45-60.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Large-lead nut turning device

ActiveCN102179572BImprove consistencyNo macro defectsThread cutting machinesStructural engineeringIndustrial engineering

The invention discloses a large-lead nut turning device, which comprises a cutter base, a cutter bar, a lathe tool and a guide sleeve, wherein the cutter base comprises a connecting structure connected with a lathe cutter saddle; the cutter bar is fixedly arranged on the cutter base for extending into a prefabricated hole of the nut to be turned; the lathe tool is fixedly arranged on the part of the cutter bar for extending into the nut; and the guide sleeve is connected with the cutter bar for forming shaft fitting with the prefabricated hole of the nut to form auxiliary supporting. The large-lead nut turning device is high in processing precision and good in processing consistence.

Owner:SHANDONG PRECION GROUP

A kind of argon arc welding process of 1800mpa ultra-high strength hot forming steel plate

ActiveCN112935481BWell formed weldNo macro defectsElectrode supporting devicesWelding accessoriesForeign matterUltimate tensile strength

A argon arc welding process for 1800MPa ultra-high-strength hot-formed steel sheets. The method is to butt together two ultra-high-strength hot-formed steels with clean surfaces and no foreign matter, and tighten them with clamps to ensure that the plates will not be displaced during the welding process. . Set the path program of the welding robot so that the welding torch moves along the weld. Adjust the relevant parameters of the argon arc welding machine to weld the plate. The invention provides a manufacturing and processing technology capable of perfecting the ultra-high-strength hot-formed steel sheet. Using the invention, the ultra-high-strength hot-formed steel sheet can be advantageously combined in production, thereby significantly improving the comprehensive performance of the product.

Owner:SHENYANG UNIV

Method for growing mullite crystals through floating-zone method

InactiveCN103806103ANo macro defectsQuality improvementPolycrystalline material growthBy zone-melting liquidsMulliteRoom temperature

The invention discloses a method for growing mullite crystals through a floating-zone method, belonging to the field of crystal growth. The method comprises the following steps: dosing Al2O3 and SiO2 powder according to a stoichiometric ratio; ball-milling, drying, screening, pre-sintering and re-screening the dosed mixture; pressing the powder into rod-shaped material rods; sintering the prepared material rods in a muffle furnace, thereby obtaining dense and uniform polycrystalline rods; putting the polycrystalline rods into a floating zone furnace, raising the temperature at a rate of 50-100 DEG C per minute until the material rods and seed crystals are molten, butting, setting the crystal growth speed at 2-10mm / h after the melting zone is stabilized within 3-5 minutes, and starting crystal growth; setting the cooling parameters and cooling to room temperature after the growth is ended. The mullite crystals without macro defects are growth at the first time by using the floating-zone method, the crystal forming quality is high, and the growth speed is high.

Owner:BEIJING UNIV OF TECH

Laser-arc hybrid welding method for dissimilar aluminum alloy thin edge structure

ActiveCN103418919BSimple welding processImprove stabilityLaser beam welding apparatusStructural deformationShielding gas

The invention provides a laser-arc hybrid welding method for a special aluminum alloy thin edge structure. The method comprises the steps of (1) performing alkali washing on a structure to be welded by a NaOH solution to remove an oxidation film, performing acid washing on the structure to be welded by a HNO3 solution, then cleaning the structure to be welded by clean water, and drying the structure to be welded by compressed air; (2) welding the structure to be welded by adopting a laser guiding arc mode, wherein the welding speed is 1-3mm / min, the laser power is 500-2500W, the TIG arc current is 100-150A, the included angle between the TIG arc angle and the normal line is 35 degrees, the TIG arc height is 2-4mm, the laser arc heat source interval is 2-4mm, and the shielding gas is argon with the flow of 15-25L / min; and (3) cleaning the faces of the welding seams by using a steel brush. The stability in the welding process and the face quality of the welding seams are improved by adopting the laser-arc hybrid welding and optimized welding process, the assembly gap demand before welding is reduced and the structural deformation after welding is reduced.

Owner:CAPITAL AEROSPACE MACHINERY +1

Method for growing large size Ta2O5 single crystal by using floating zone method

ActiveCN102312293BProcess advantagesNo macro defectsPolycrystalline material growthBy zone-melting liquidsRoom temperatureCrystal growth rate

The invention relates to a method for growing a large size Ta2O5 single crystal by using a floating zone method, and belongs to the field of crystal growth. The method comprises the following steps: carrying out ball milling and drying for a Ta2O5 powder material; placing the treated Ta2O5 powder material in a rubber tube, and carrying out isostatic pressing for the material to prepare a biscuit rod; carrying out sintering for the biscuit rod to obtain a polycrystalline rod; adopting the biscuit rod or the polycrystalline rod as the material rod, and adopting the polycrystalline or the Ta2O5 single crystal as the seed crystal, wherein the seed crystal and the material rod form a straight line in a vertical direction, and the contact point and a halogen lamp are at the same horizontal line; heating the material rod and the seed crystal until the material rod and the seed crystal are molten, wherein the heating rate is 30-60 DEG C per minute; adjusting the rotation speeds and the rotation directions of the material rod and the seed crystal, then carrying out inoculation; adopting the movement of a focusing lens or the up and down movement of the rod to enable the molten zone to be far away from the focusing point, enable the temperature of the molten zone to be decreased to realize the crystallization, wherein the crystal growth rate is 10-60 mm / h; cooling the grown crystal to the room temperature. With the method provided by the present invention, the growth period is short; the preparation efficiency is high; the Ta2O5 single crystal can be rapidly grown, wherein the grownTa2O5 single crystal has characteristics of size in centimeter magnitude, no macroscopic defect and high quality.

Owner:BEIJING UNIV OF TECH

A powder superalloy component stage heating extrusion control device and its use method

ActiveCN108994299BImprove overall utilizationRealize the integration of solidification and controlDeformation velocitySuperalloy

The invention relates to a stage heating and extrusion controlling device for powder superalloy members and a using method. According to the using method, with the help of the deformation temperatureand pressure of stage change, the low-temperature and low-pressure curing and high-temperature and high-pressure controlling of powder materials at a time are realized. The method comprises the stepsthat firstly, powder is preliminarily cured under the conditions of lower temperature (no more than 700 DEG C) and lower pressure (no more than 500 MPa); then, the superalloy powder is completely densified by increasing the temperature (no more than 1000 DEG C) and combining plastic deformation parameters such as low extrusion ratio (no more than 2:1) and deformation speed, and a powder superalloyingot with certain deformation is obtained; and a microstructure with the grain size being 7-13 levels can be obtained by further increasing the temperature (no more than 1100 DEG C) and combining plastic deformation parameters such as larger extrusion ratio ((4:1)-(9:1)) and deformation speed. The integration of solidification-control of the powder superalloy members is achieved, the technological process is simplified, the development cycle is shortened, the material utilization rate is improved, and the manufacturing cost of the members is reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Welding process of aluminum alloy network cabinet

ActiveCN104907676BThe appearance of the weld seam is beautifulWeld firmlyArc welding apparatusWelding/soldering/cutting articlesUltimate tensile strengthWelding deformation

The invention discloses a welding technology for an aluminum alloy network cabinet, and belongs to the technical field of welding. The welding technology includes the steps of 1, material preparing, 2, pre-welding cleaning, 3, pre-welding preheating, 4, welding work, 5, post-welding cleaning and the like. A welding wire comprises, by mass, 7% of Mg, 0.5% of Mn, 0.54% of Ti, 0.7% of Zn, 0.8% of Cr, 0.6% of Zr, 2% of Sc, 0.4% of Fe, 0.45% of Si, 0.74% of Li, 1% of B and the balance Al. Weld joints, processed with the welding technology, of the network cabinet are attractive in appearance, the welding process is stable, and no macro defect exists on the surfaces of the weld joints; as the material components of the welding wire are optimized, the welding wire has the excellent welding technological performance, and a welded connector is high in strength and good in corrosion resistance; as the welding technology is optimized, surface defects are avoided, and welding deformation is reduced; the welding efficiency is high, and the welding speed is higher than 1 mm / min.

Owner:昆山力盟机械工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com