Stage heating and extrusion controlling device for powder superalloy members and using method

A high-temperature alloy and step-by-step heating technology, which is applied in the field of thermal processing, can solve the problems of long preparation cycle, complex process, and narrow processing window, and achieve the effects of improving material utilization, simplifying process flow, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

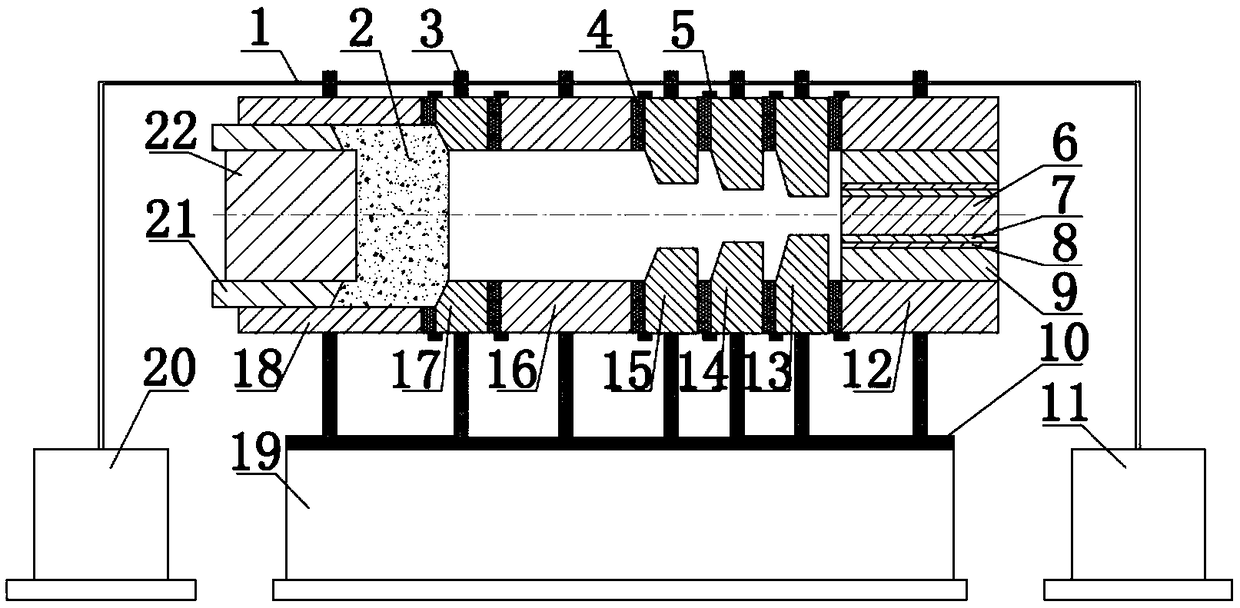

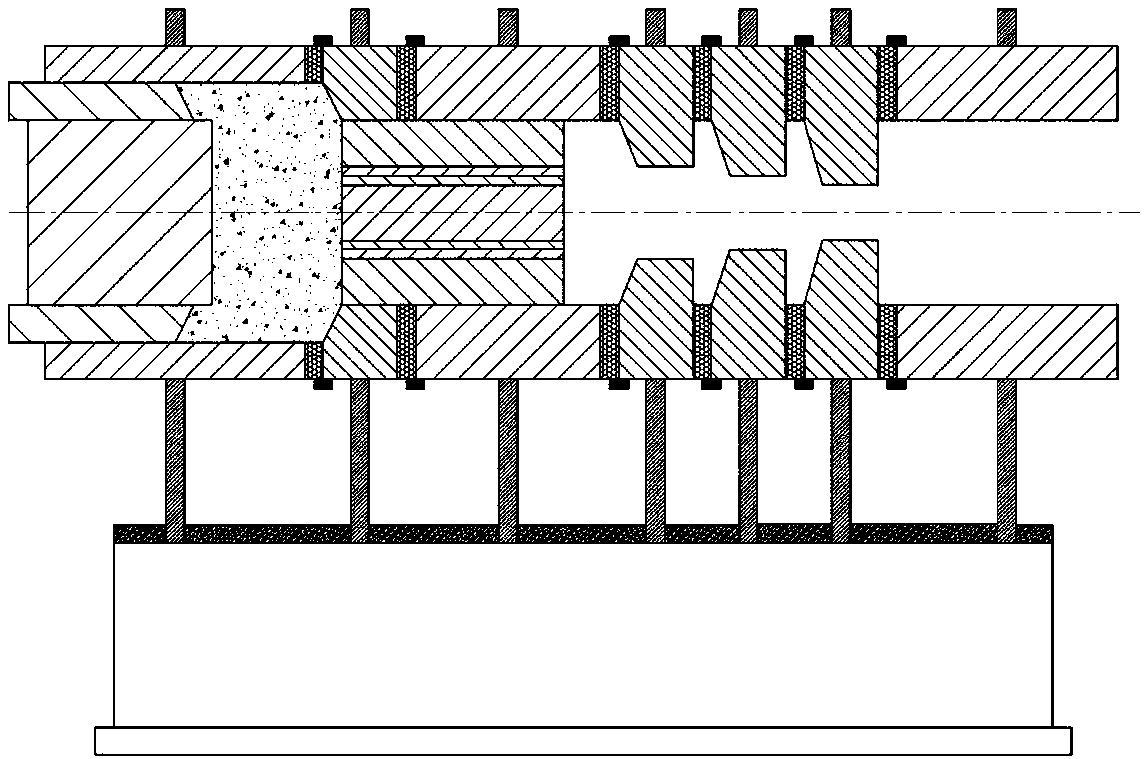

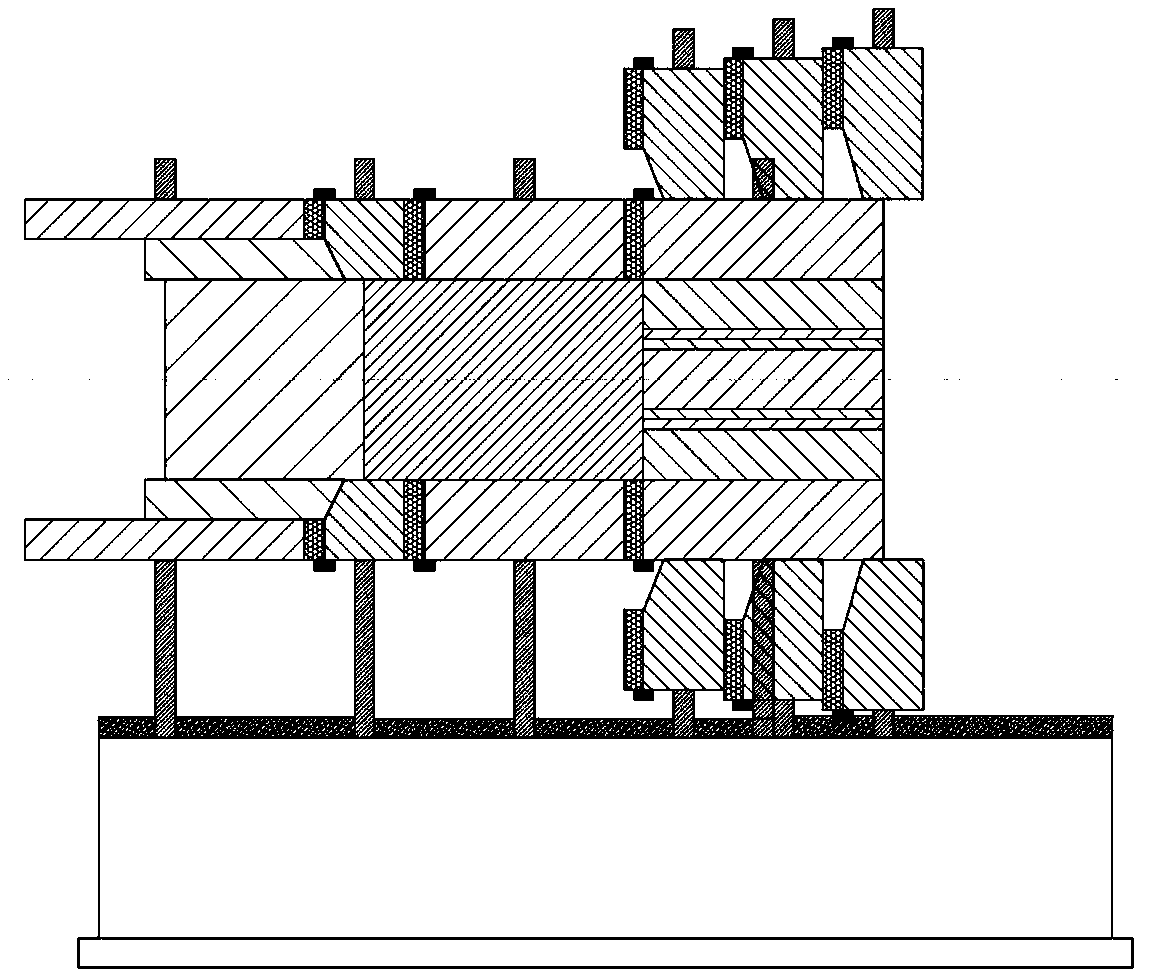

[0043] See attached figure 1 As shown, the extrusion die includes a curing cavity and a forming cavity. The two parts are connected together and placed coaxially and horizontally. The curing cavity includes an annular upper mold cavity 18 and an upper pressure ring 21. The upper pressure ring 21 is sleeved on the upper In the mold cavity 18 and for transition fit, a columnar upper pressure head 22 is installed in the central hole of the upper pressure ring 21 and for transition fit, an annular primary extrusion die 17 is connected to the rear end of the upper die cavity 18;

[0044] The rear end of the first-stage extrusion die 17 is a forming cavity, and the connection structure of the forming cavity from front to back is an annular middle die cavity 16, a second-stage extrusion die 15, a third-stage extrusion die 14, and a fourth-stage extrusion die....

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com