Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1657results about How to "Weld firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

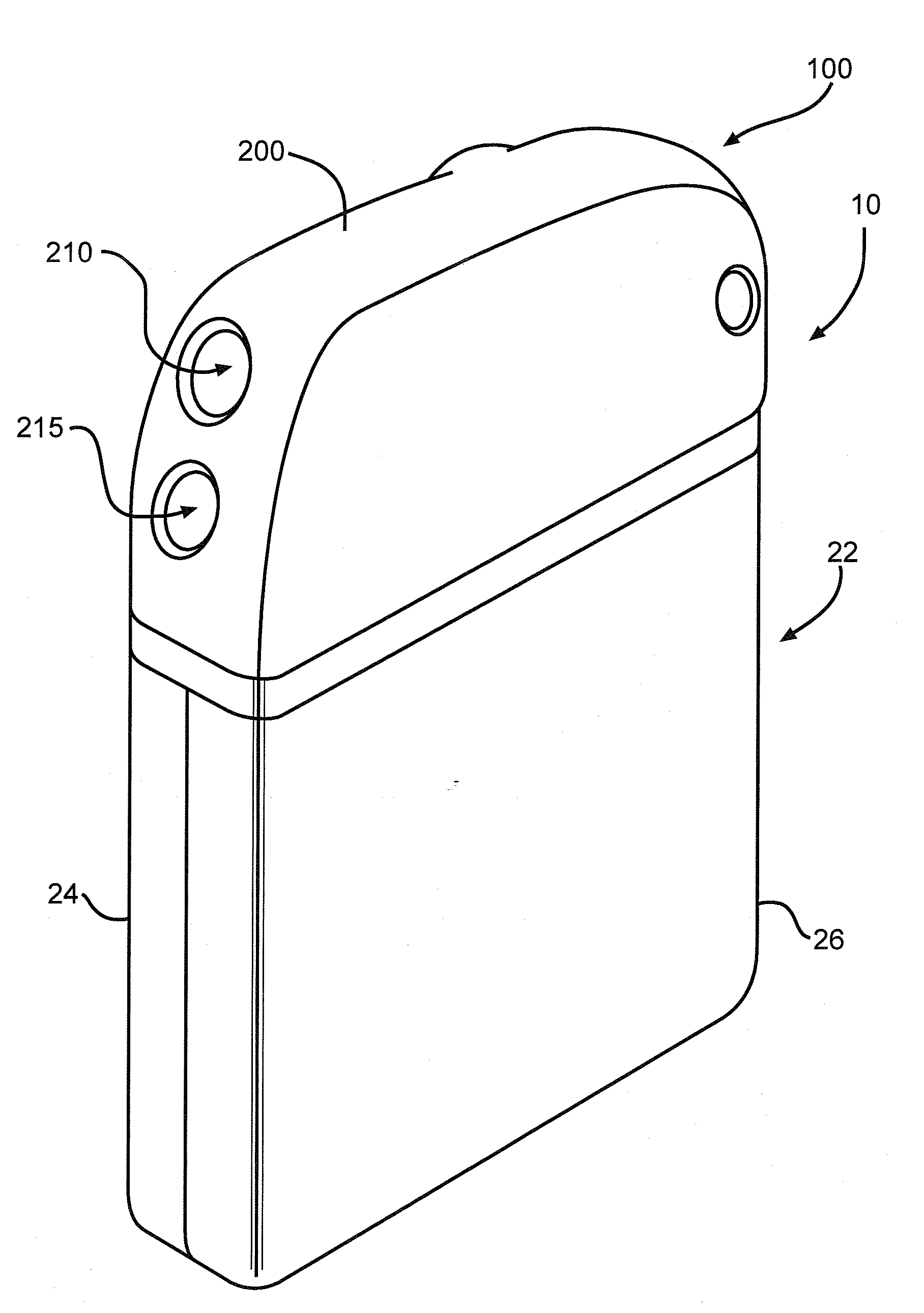

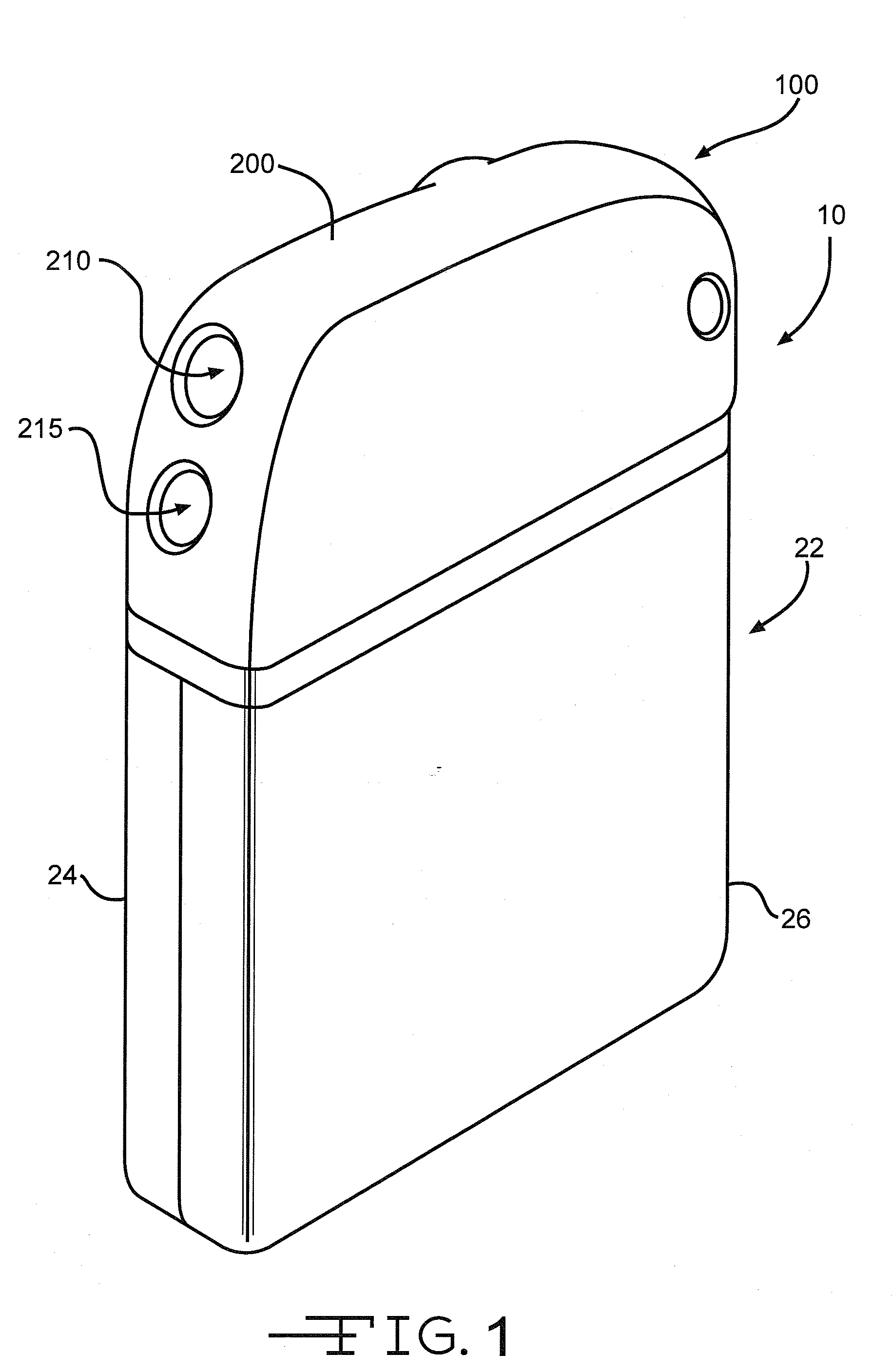

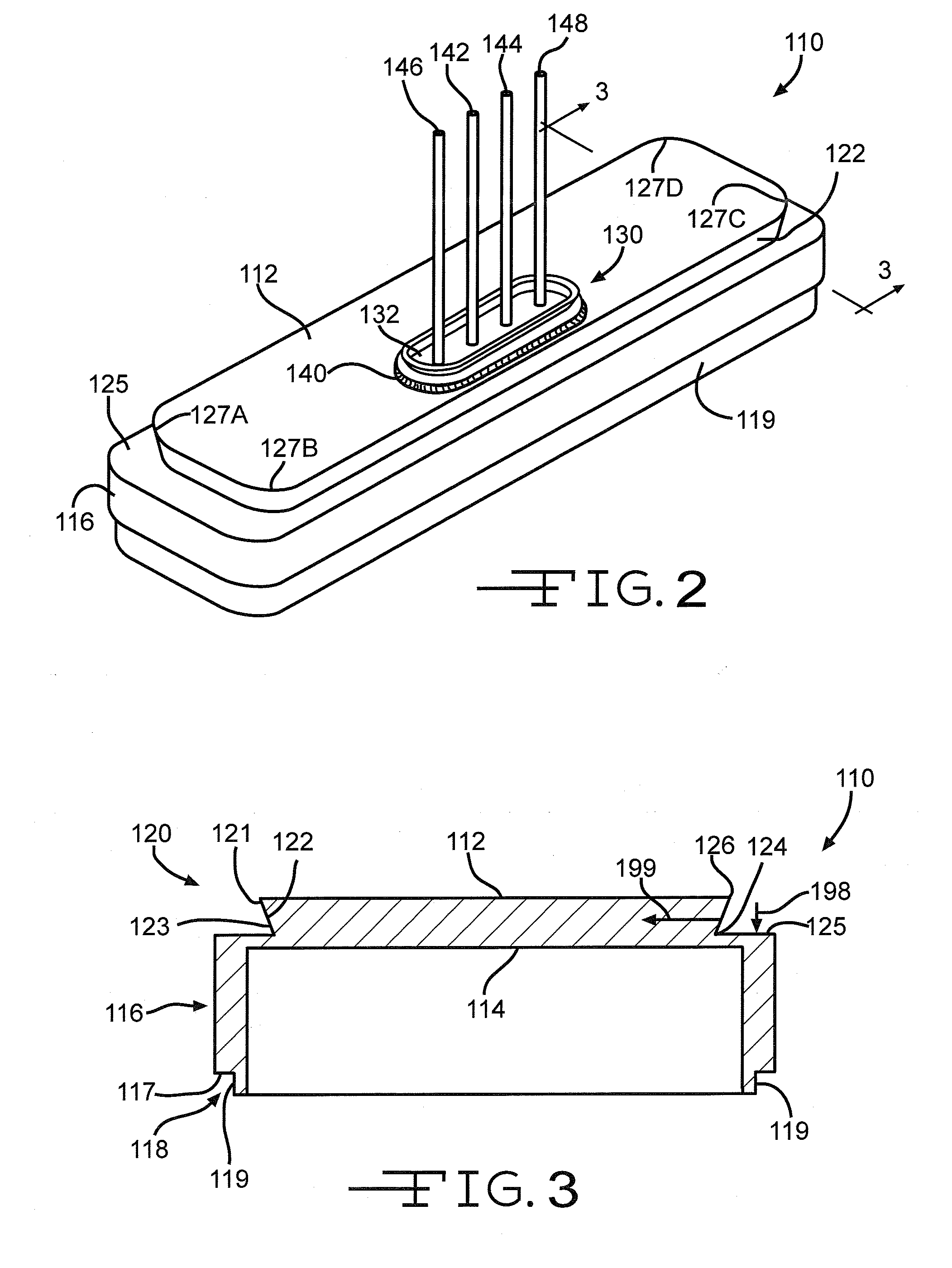

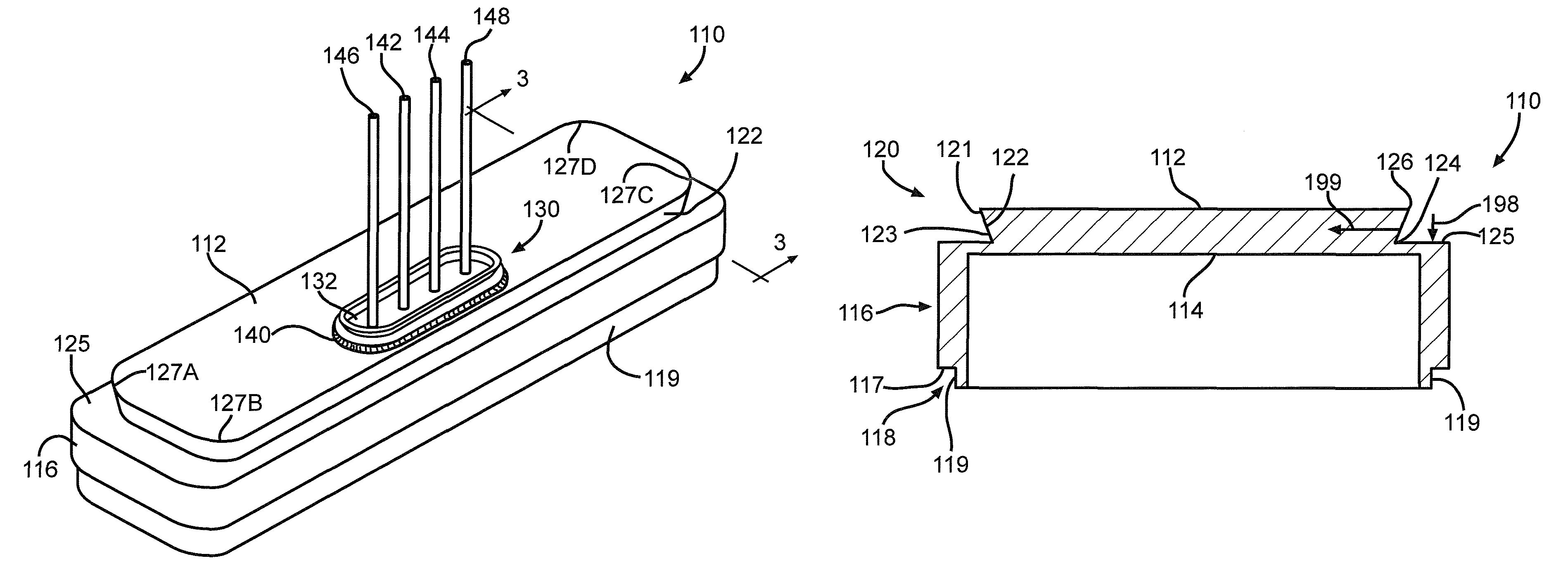

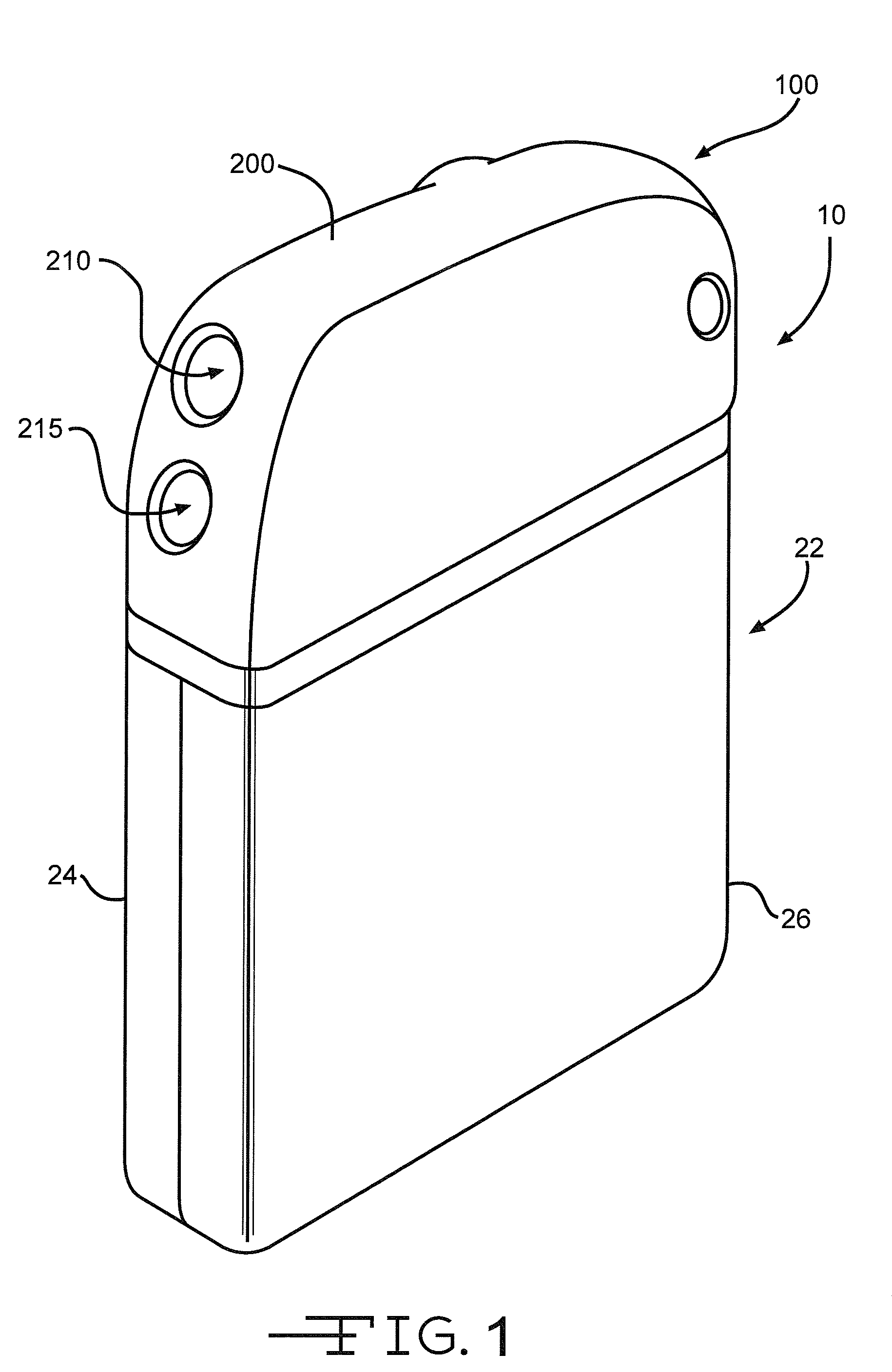

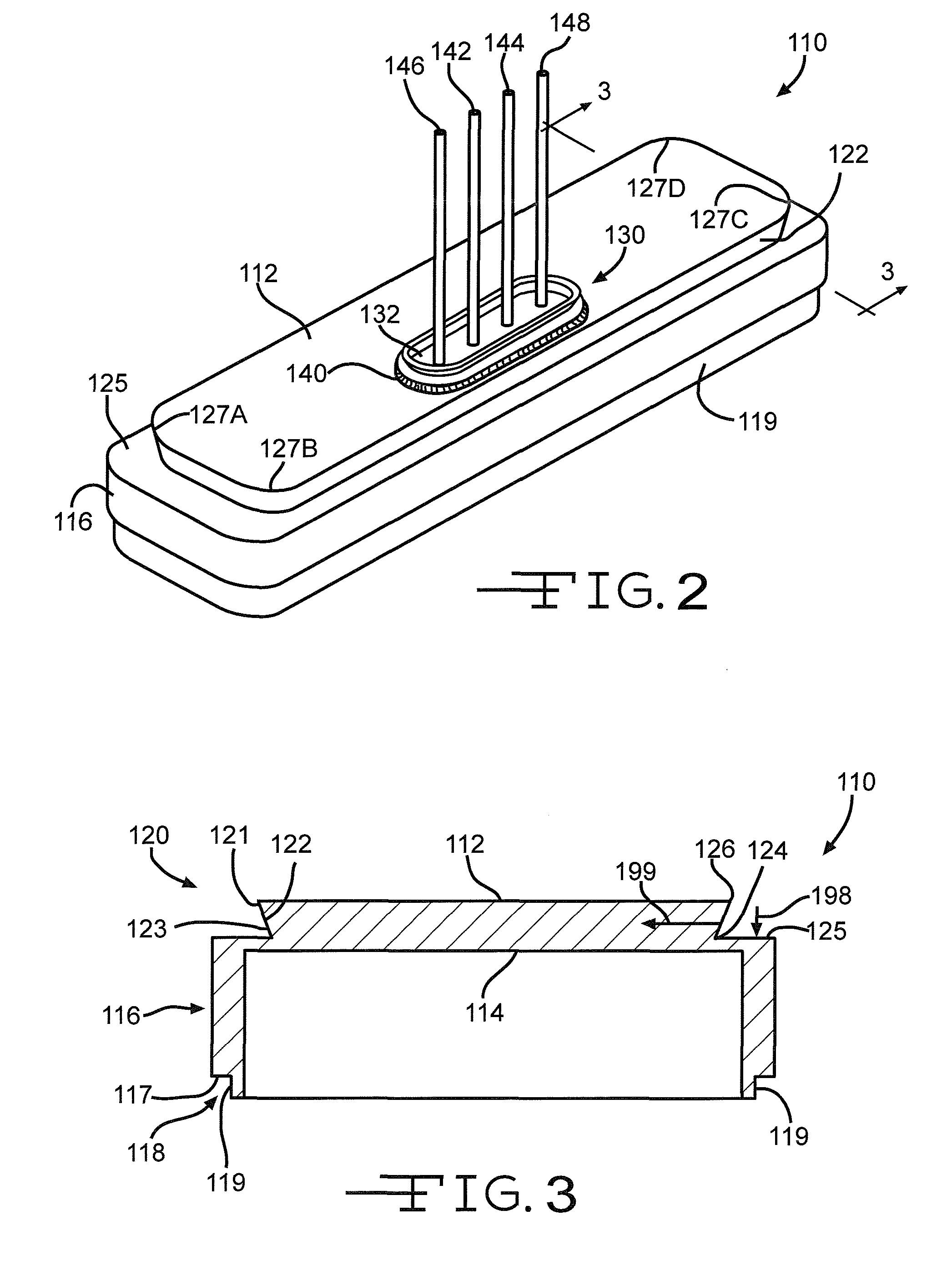

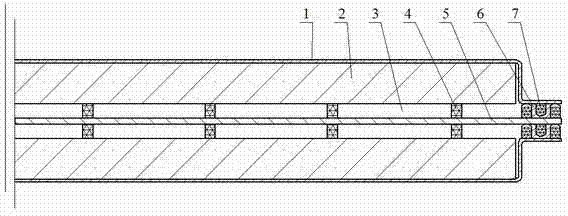

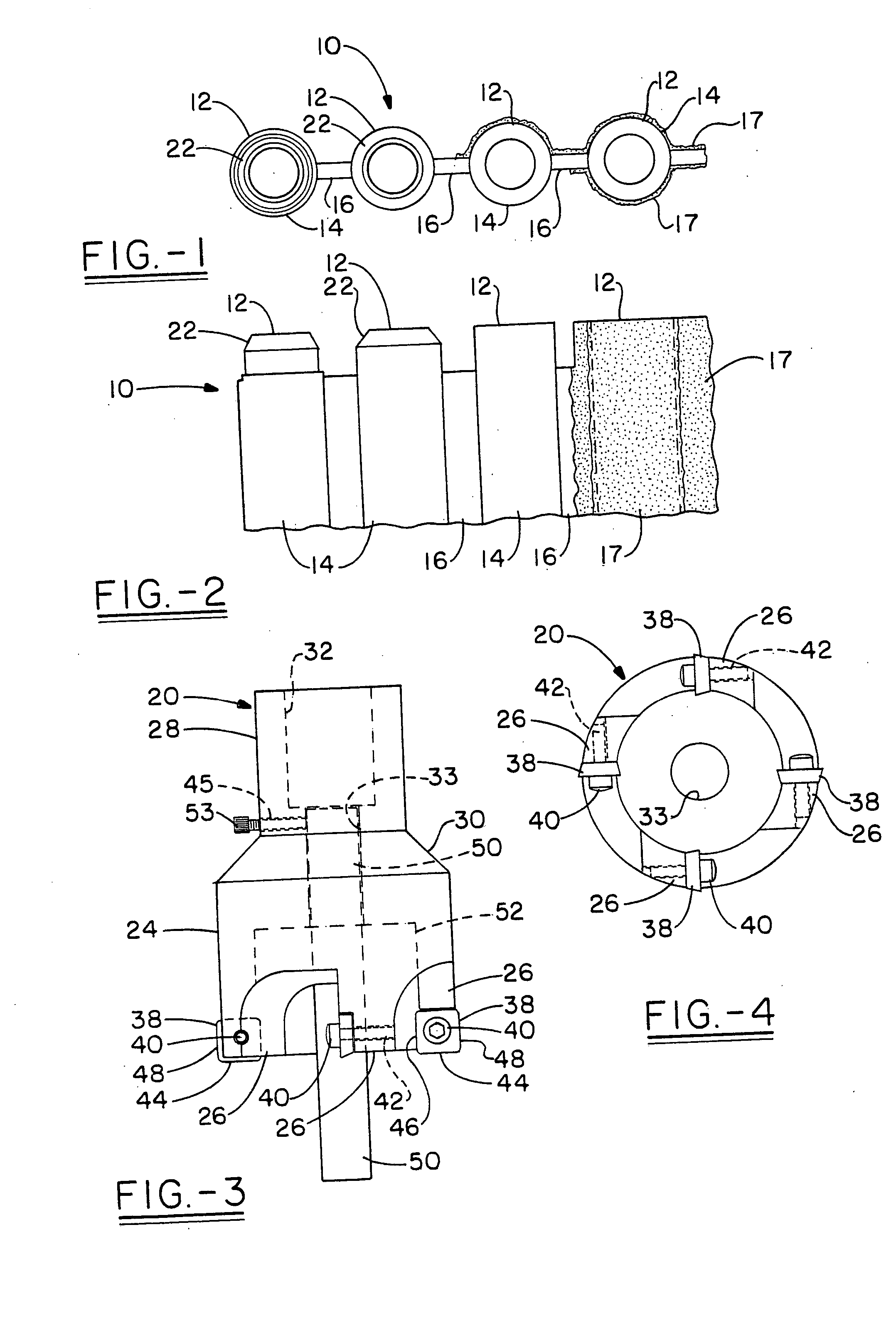

Header over-molded on a feedthrough assembly for an implantable device

A header assembly for connecting a conductor terminating at a body organ with an implantable medical device is described. The header assembly comprises a base plate, a feedthrough subassembly disposed in the base plate and comprising a ceramic-to-metal seal with first and second feedthrough wires passing through the ceramic-to-metal seal; a first electrically conductive terminal connected to a distal end of the first feedthrough wire and having a first lead opening sized to receive a first portion of a lead for the conductor; a second electrically conductive terminal connected to a distal end of the second feedthrough wire and having a second lead opening sized to receive a second portion of the lead for the conductor; a body of polymeric material molded in a two-part construction to encase the conductive terminals and their feedthrough wires except for a first bore communicating from outside the polymeric body to the first and second lead openings aligned in a first co-axial relationship. Preferably, the polymeric body comprises a first polymeric material such as Techothane® or Polysulfone® encasing the terminals except the bore and an epoxy as a second polymeric material molded over the first polymeric material.

Owner:WILSON GREATBATCH LTD

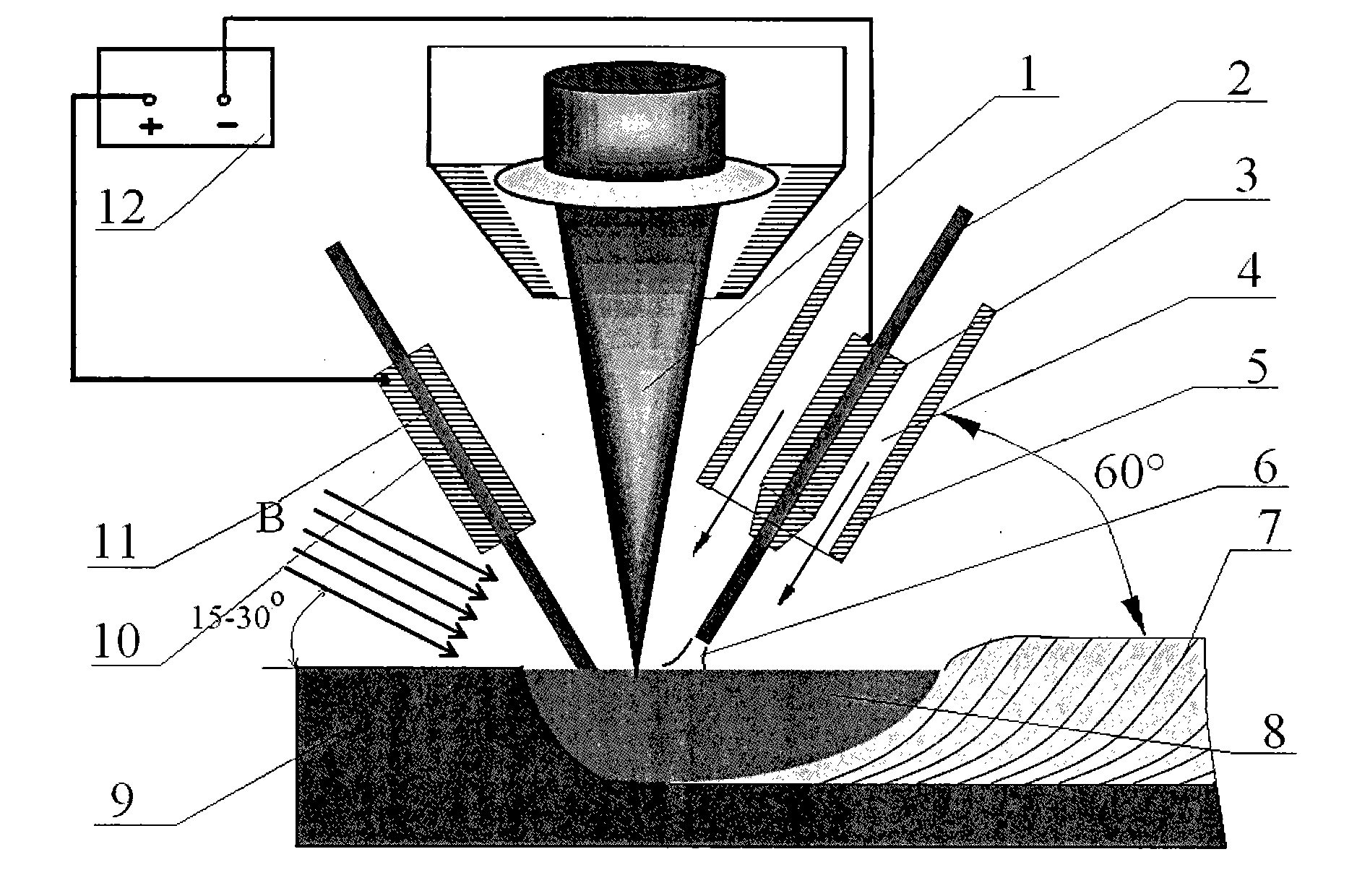

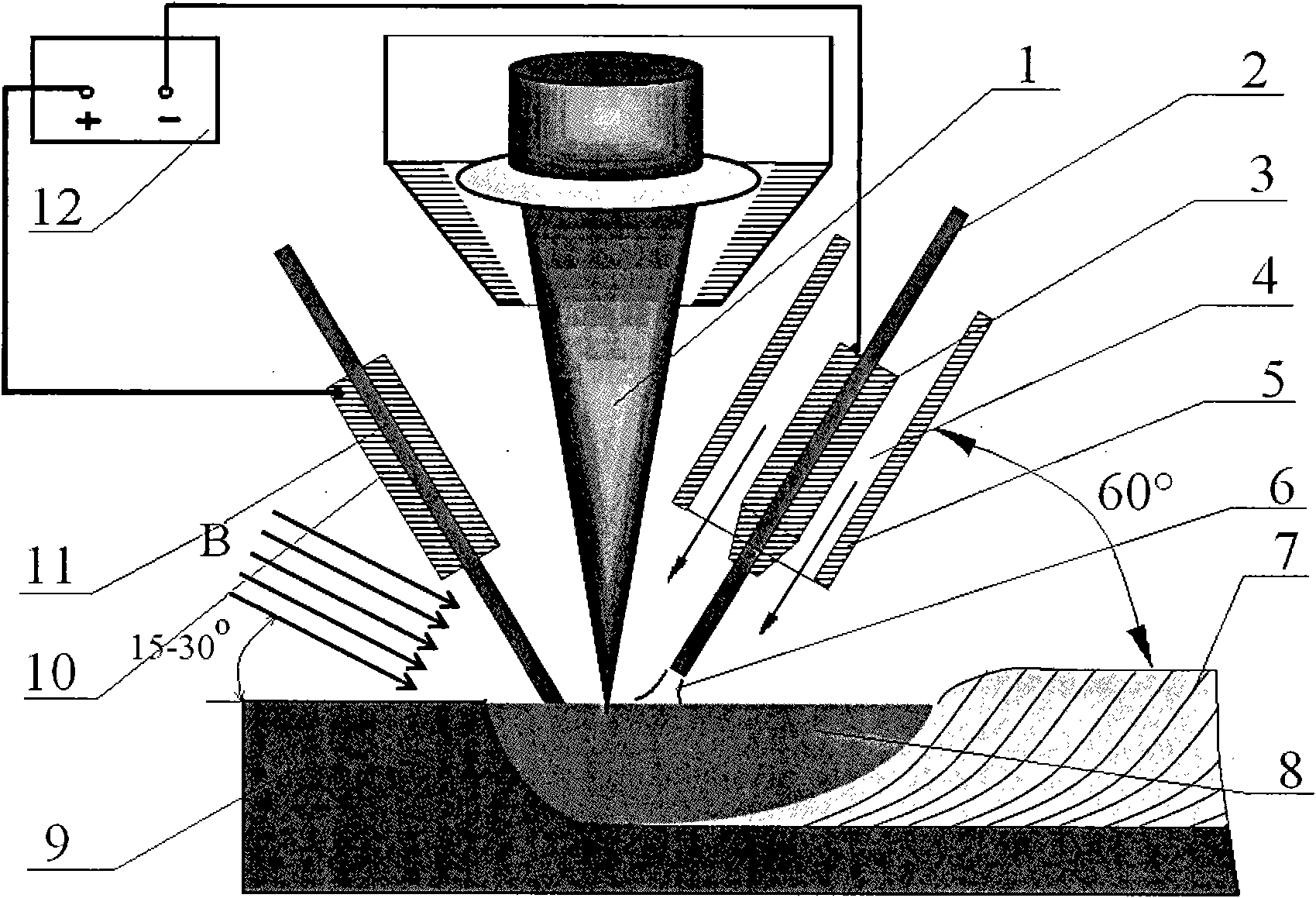

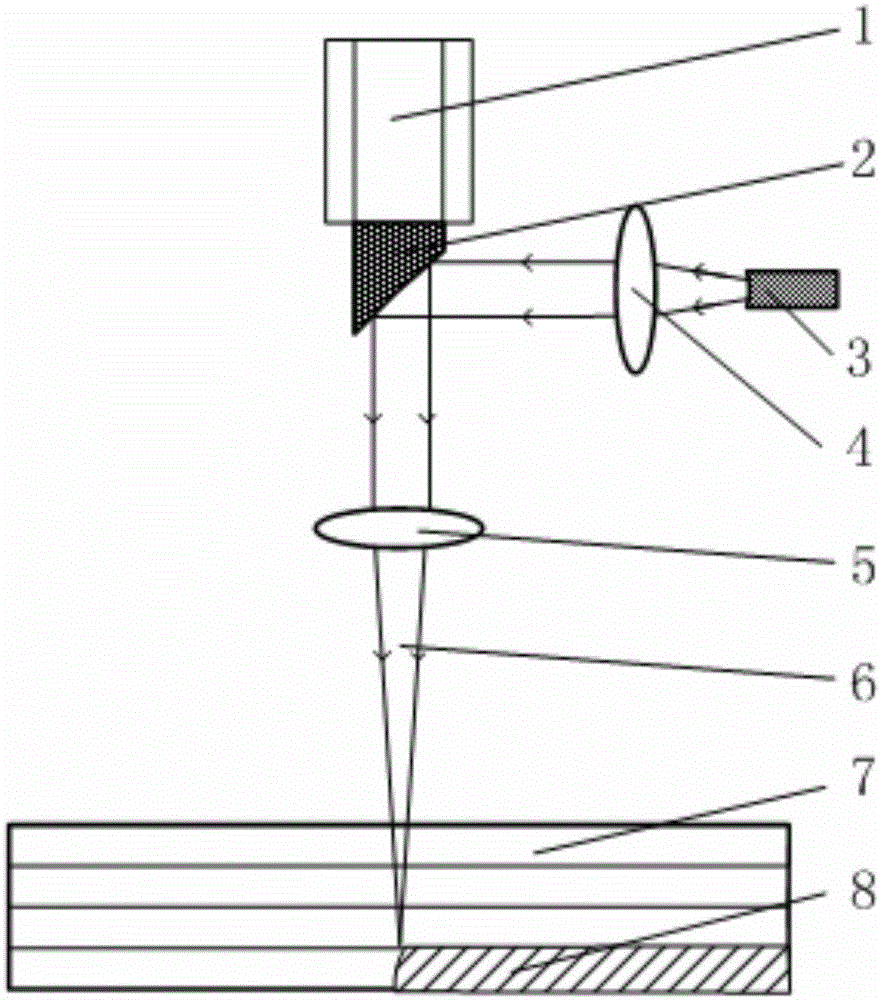

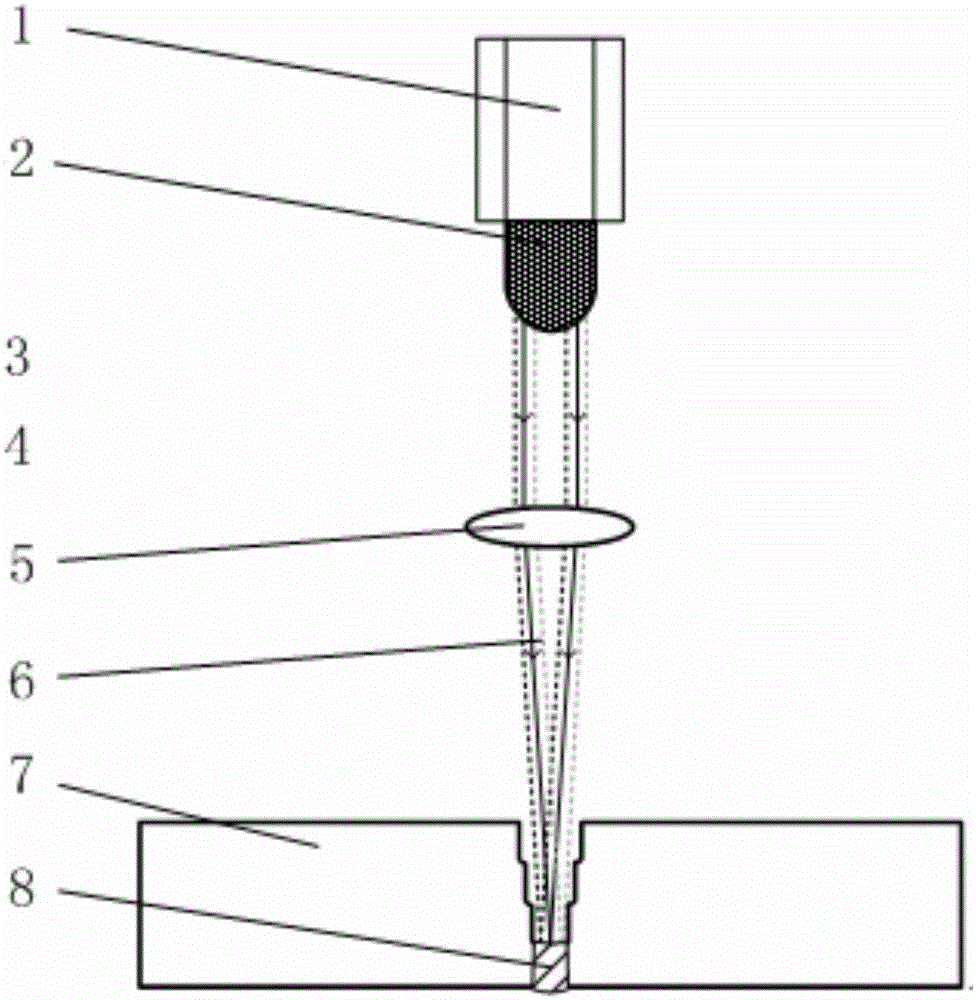

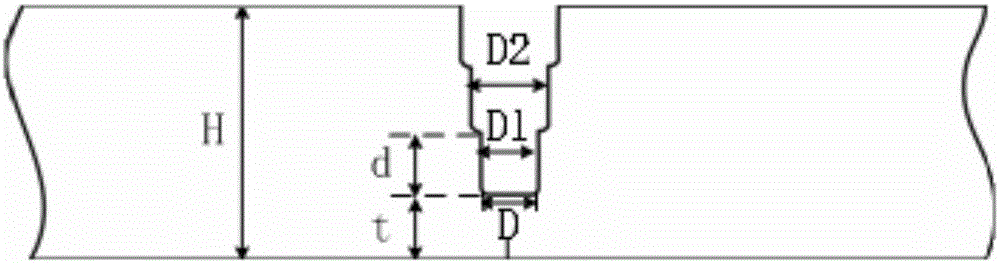

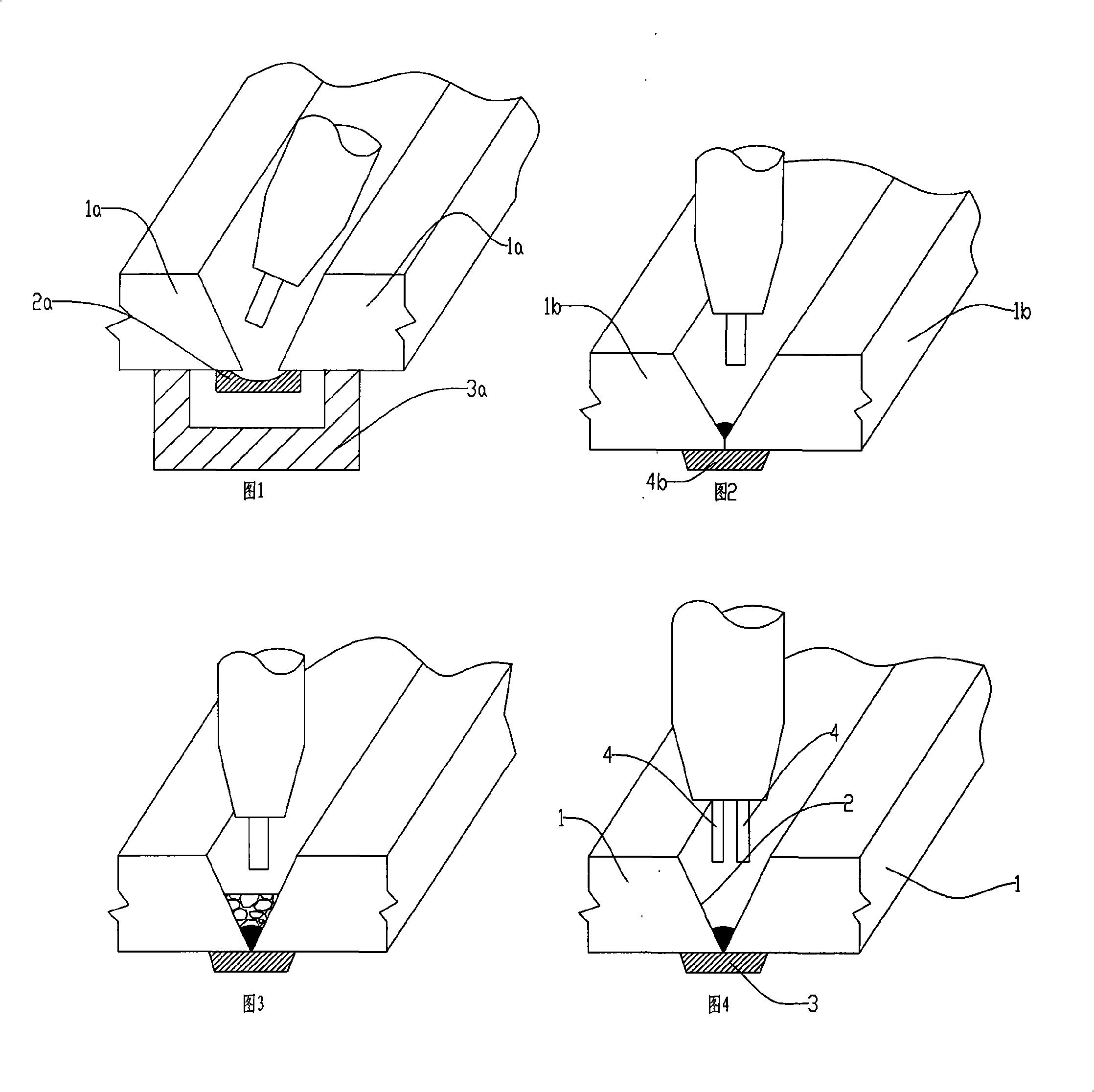

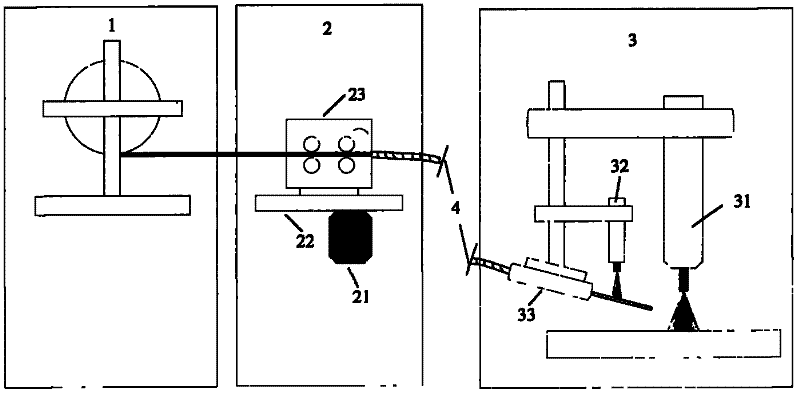

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

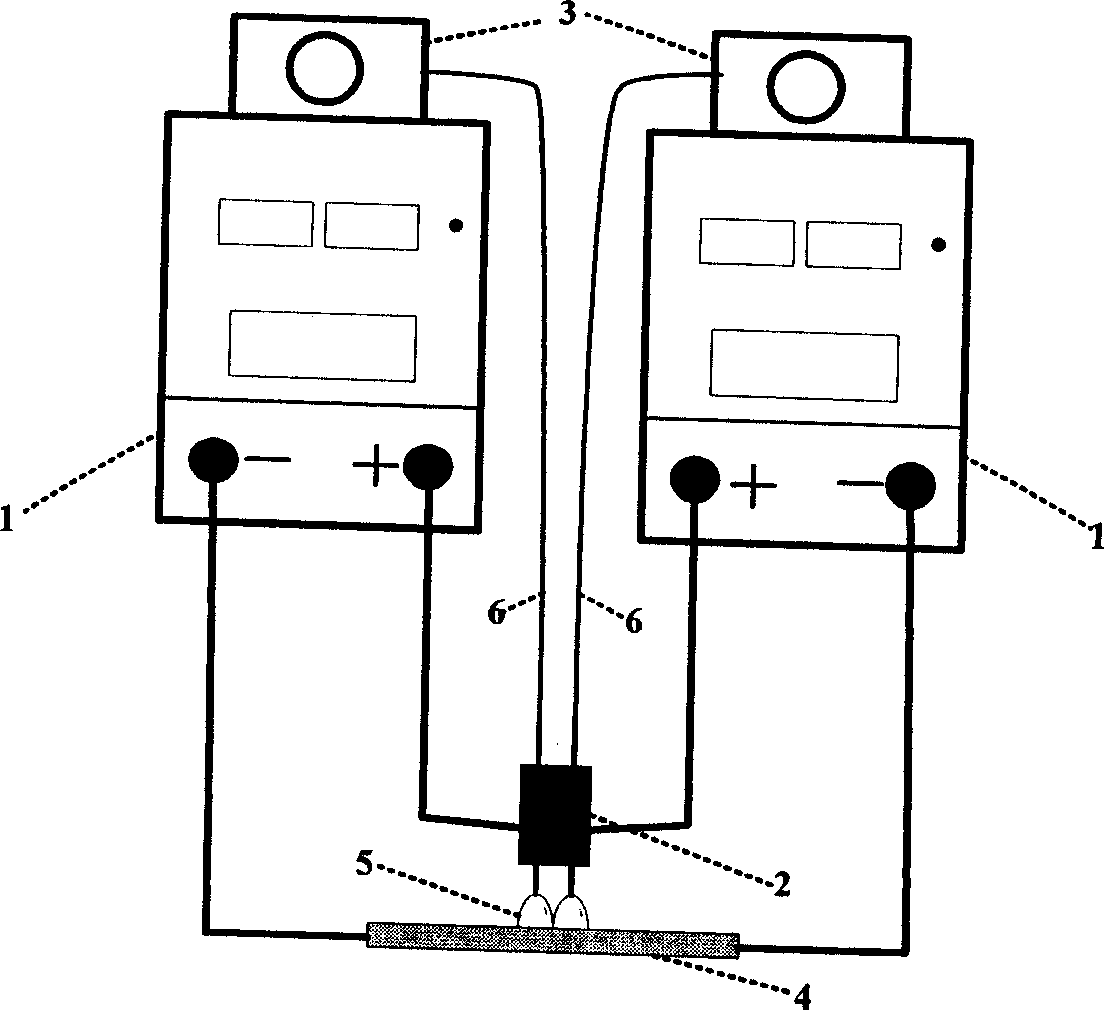

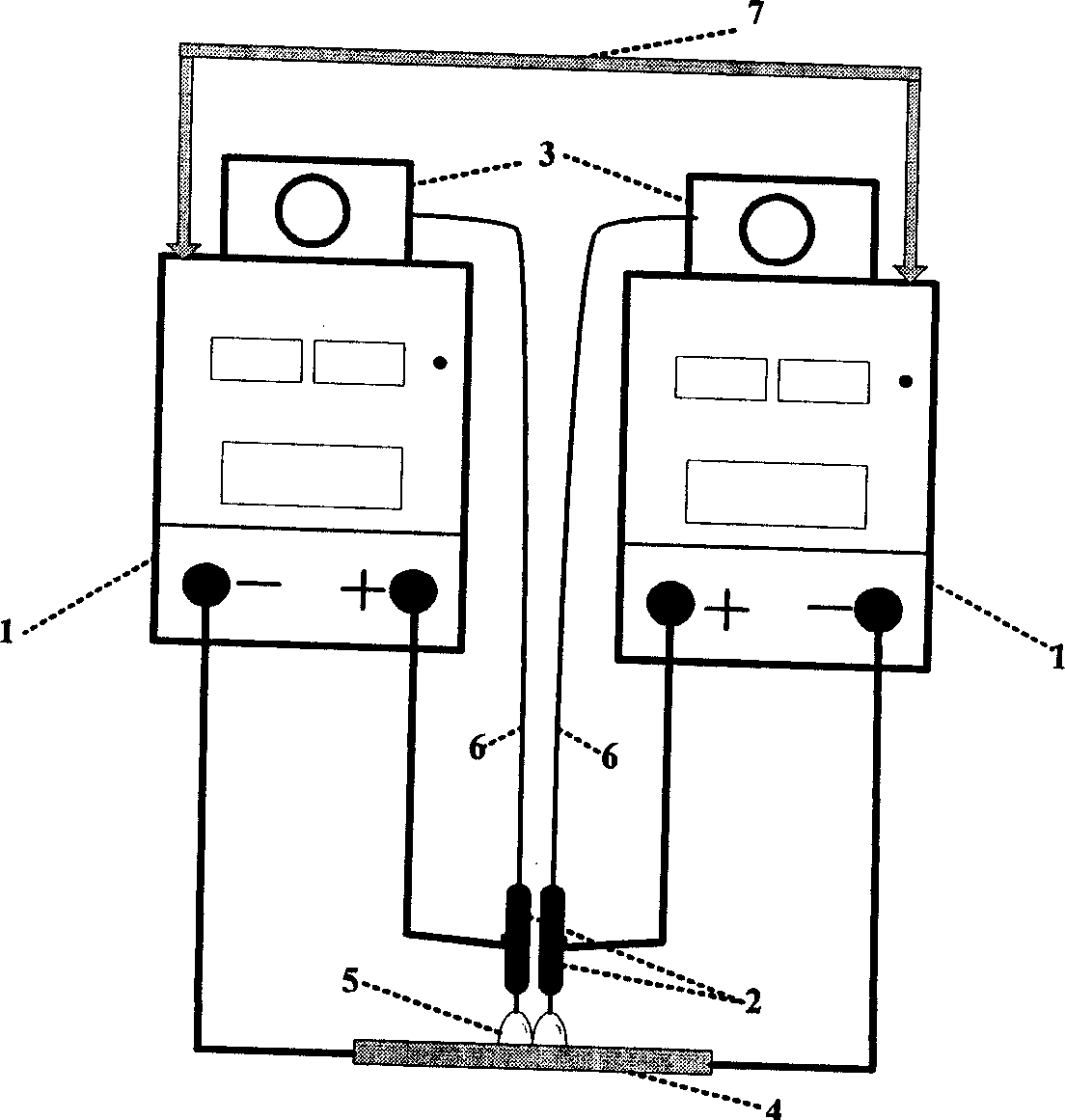

Welding control method of diplonema MAG and welding source

InactiveCN1695866AImprove stabilityControl the level of distractionArc welding apparatusConstant frequencyArc stability

A dual-wire MAG welding control method features that the welding current feedback and voltage feedback are compared with the given signals in time shared mode, a control circuit is used to control welding, and during the welding two welders with constant frequency are used by keeping certain phase relation for high stability. Its welding power supply features that its controller uses a switching circuit consisting of current sampler, voltage sampler, switching switch, comparator, integral proportioner and amplifier connected to welding power output unit.

Owner:BEIJING UNIV OF TECH

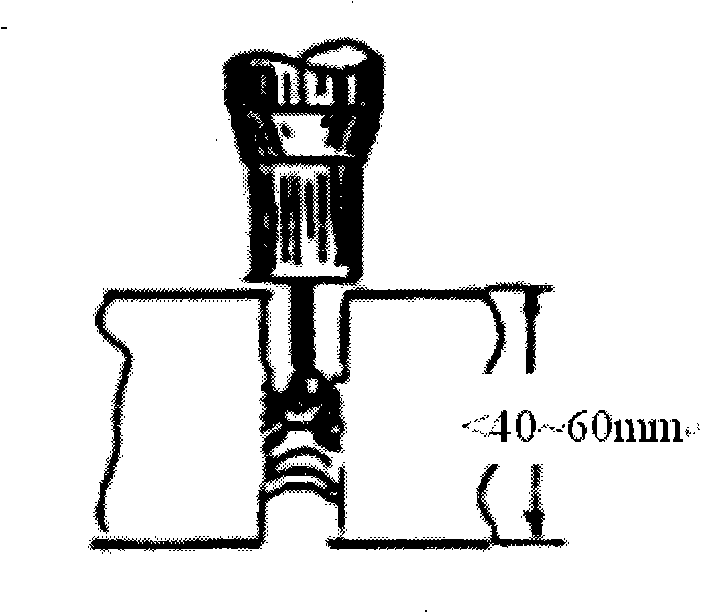

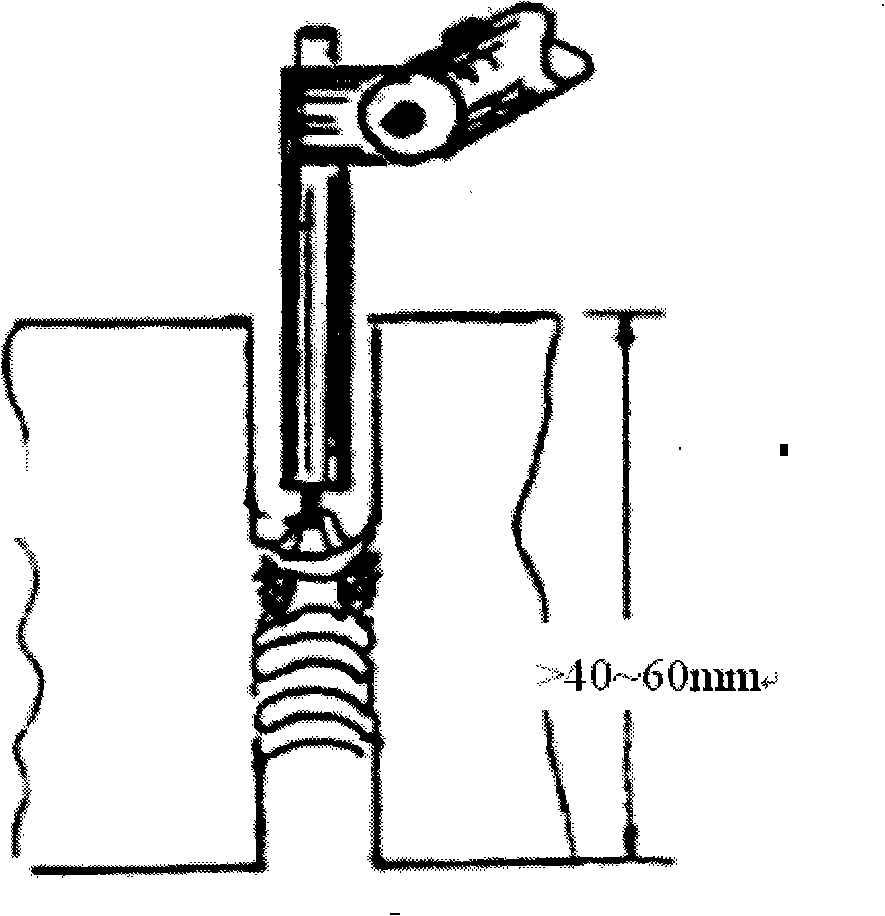

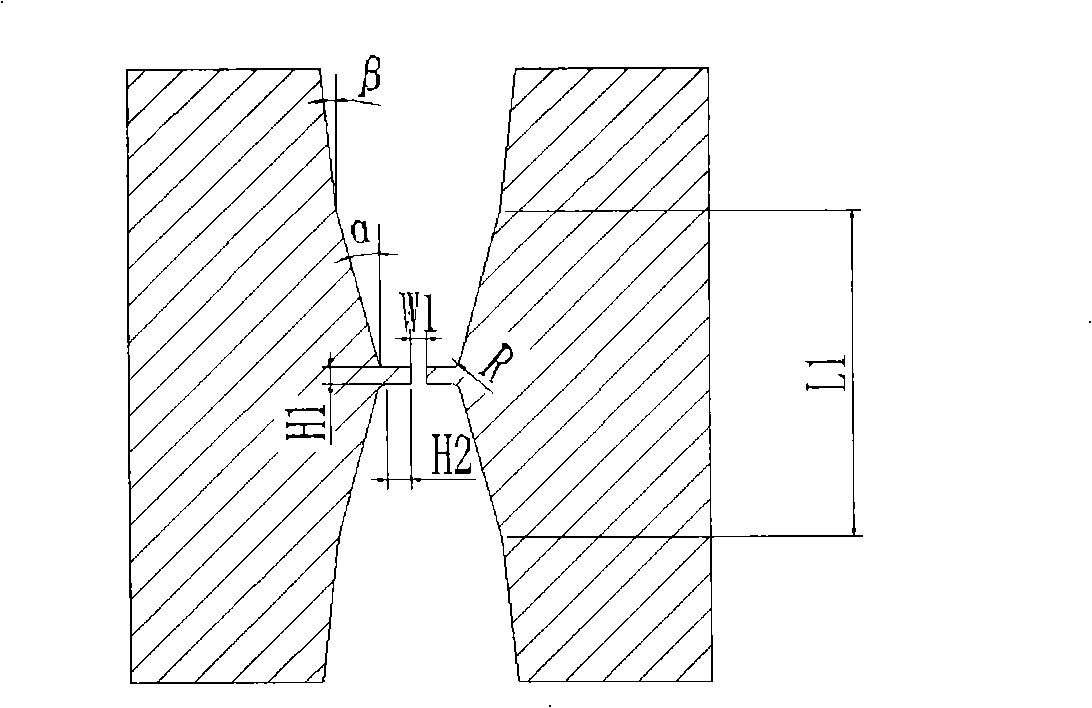

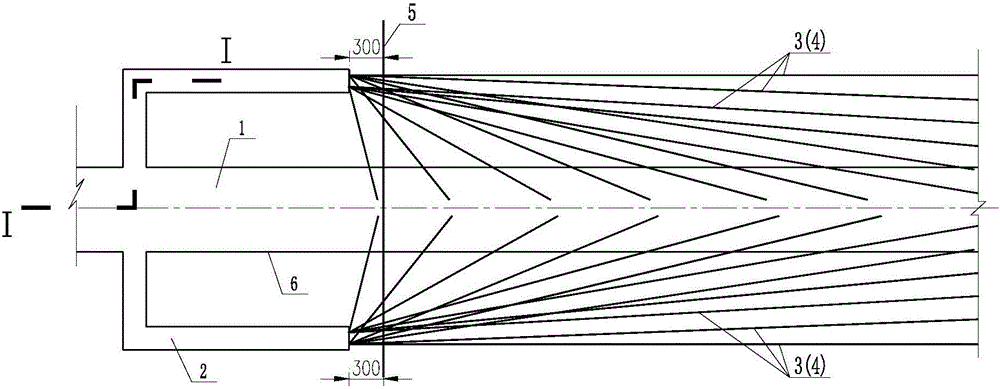

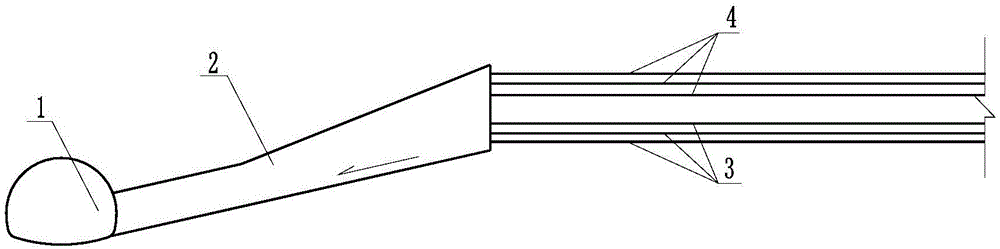

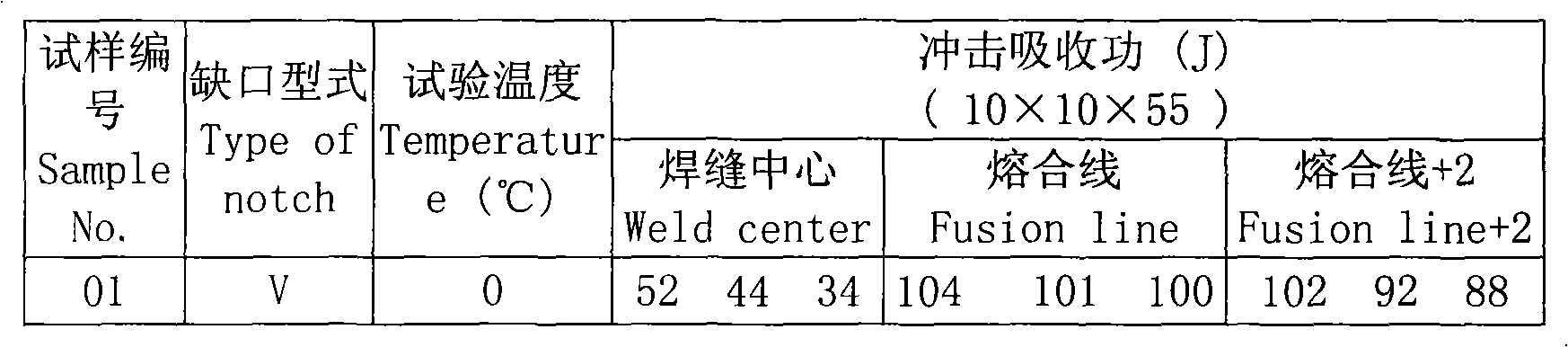

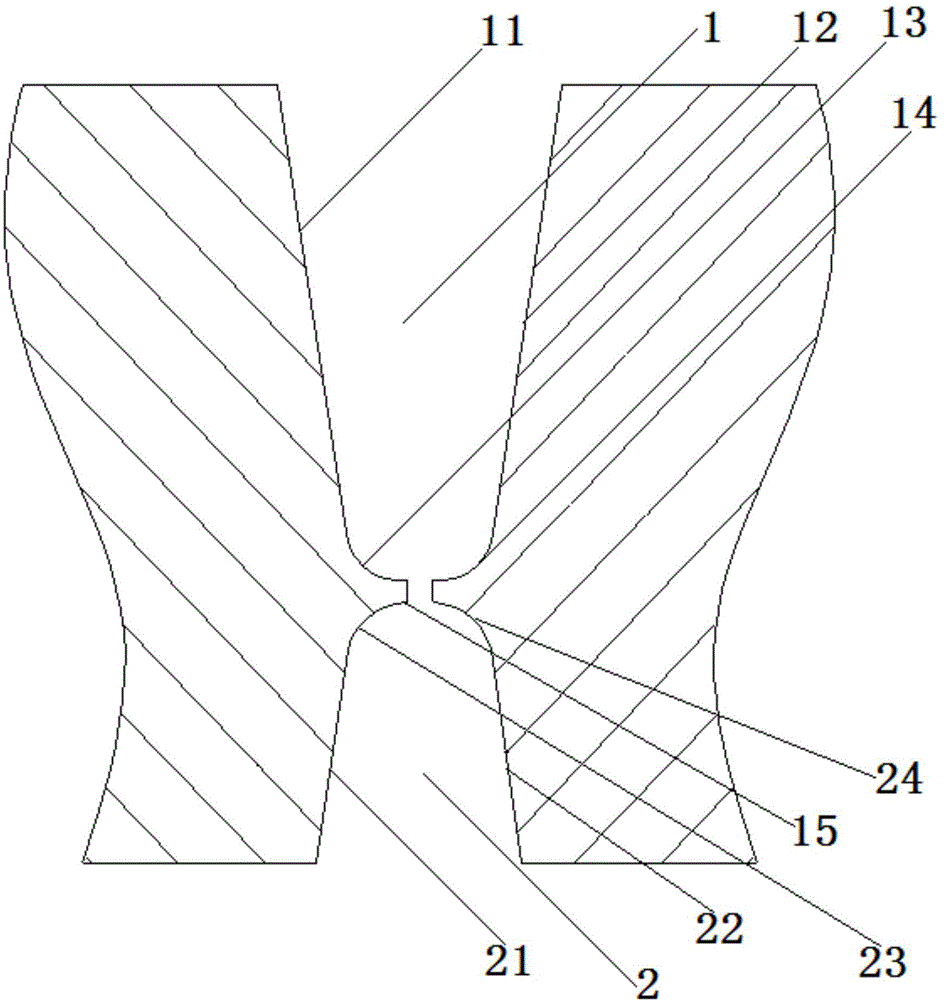

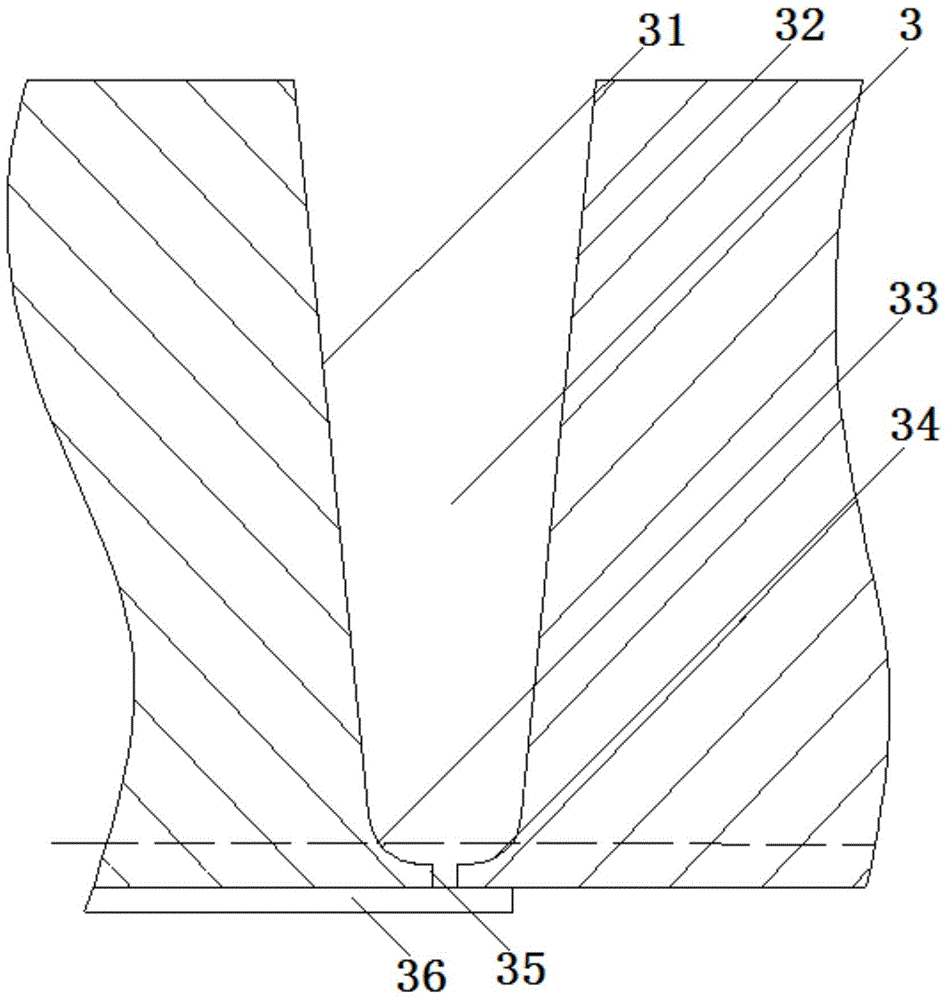

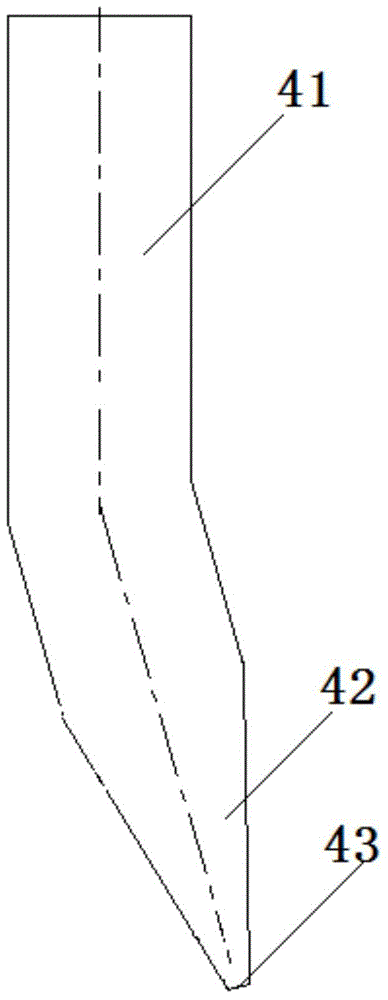

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

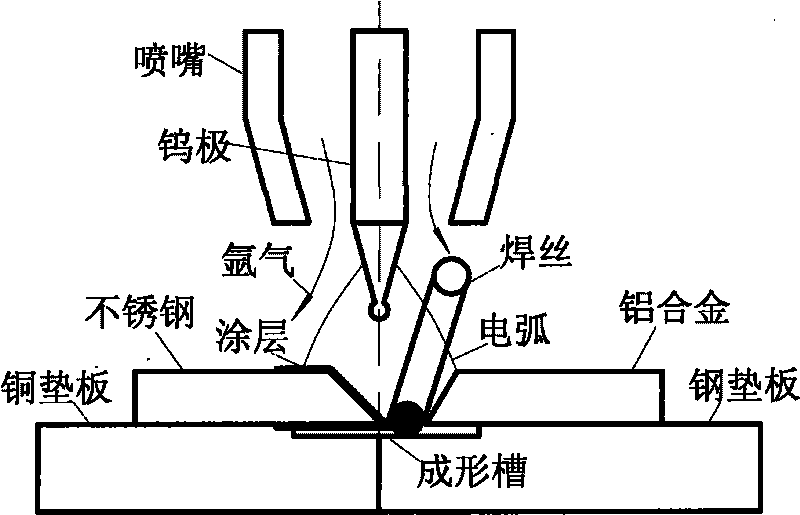

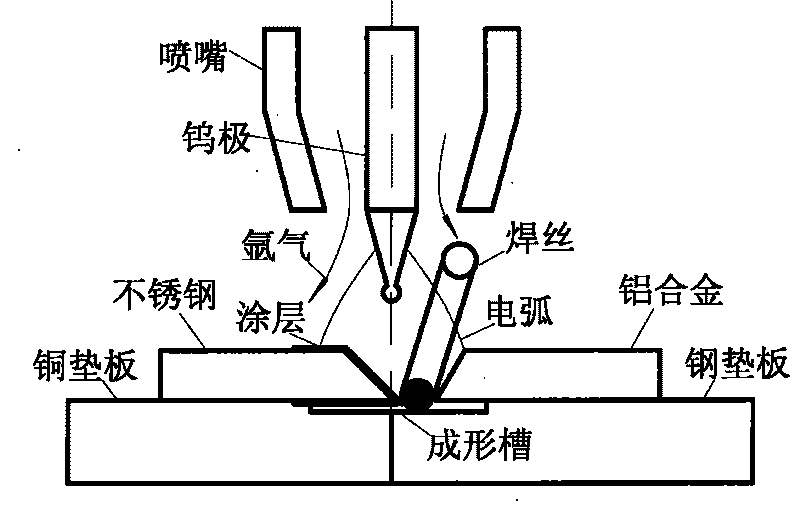

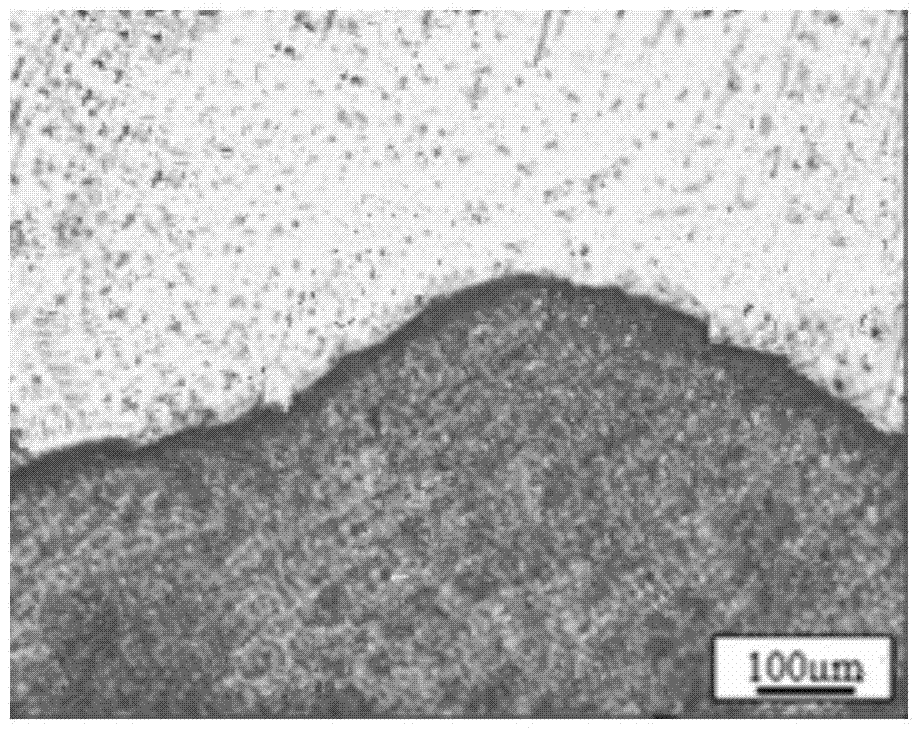

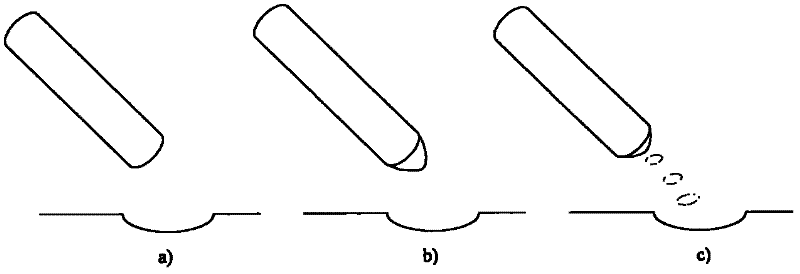

Assistant coating TIG fusing-brazing method suitable for aluminum/steel dissimilar alloy butting

InactiveCN101745709AImprove adhesionEasy to shapeSoldering apparatusWelding/soldering/cutting articlesSheet steelButt joint

The present invention provides an assistant coating TIG fusing-brazing method suitable for aluminum / steel dissimilar alloy butting. In the assistant coating TIG fusing-brazing method, a TIG electric arc is used as a heat source, and an assistant coating and joint groove design and a welding technology are used. In a welding process, electric arc heat firstly enables an assistant coating to fuse to form a liquid film at a steel groove surface; the TIG electric arc is covered on welding wires to directly heat the welding wires and a fused bath, while not to directly heat steel plates, so a fused phenomenon is avoided to be generated on steel surfaces; the welding wires are fused rapidly to moisten and spread rapidly on the steel groove surface under the function of the assistant coating; the welding wires are fed continuously to be fused to fill welding seams gradually; and meanwhile the electric arc walks rapidly, and brazing alloy spreading is stopped when the heat source is moved away. The welding process is stable, and butting joints of aluminum / steel dissimilar alloy TIG fusing-brazing with good formation are obtained.

Owner:HARBIN INST OF TECH

Process method for welding aluminum and aluminum alloy material by laser

InactiveCN101850472ASmall sizeEasy to closeGrinding machinesWelding/soldering/cutting articlesOrganic solventHigh energy

The invention relates to laser welding and discloses a process method for welding aluminum and aluminum alloy material by laser. The process method comprises steps of: (1) selecting an Nd:YAG laser with high beam quality and high energy density; (2) adopting double-beam laser to weld aluminum and aluminum alloy material, wherein the distance between the two beams is 0.6-1.0 mm, and the energy ratio of the two beams is larger than 1:1; (3) surface treatment of a material to be welded: removing greasy dirt and dust with an organic solvent and removing an oxidation film by mechanical cleaning and / or chemical cleaning; and (4) utilizing the two-beam laser to weld the aluminum and the aluminum alloy material. A needle body, a sleeve and a lead of the invention are manufactured into a whole; therefore, the invention solves adaptability of the laser welding to assembly precision, enhances the stability of welding process and improves welding line quality.

Owner:武汉楚天激光(集团)股份有限公司

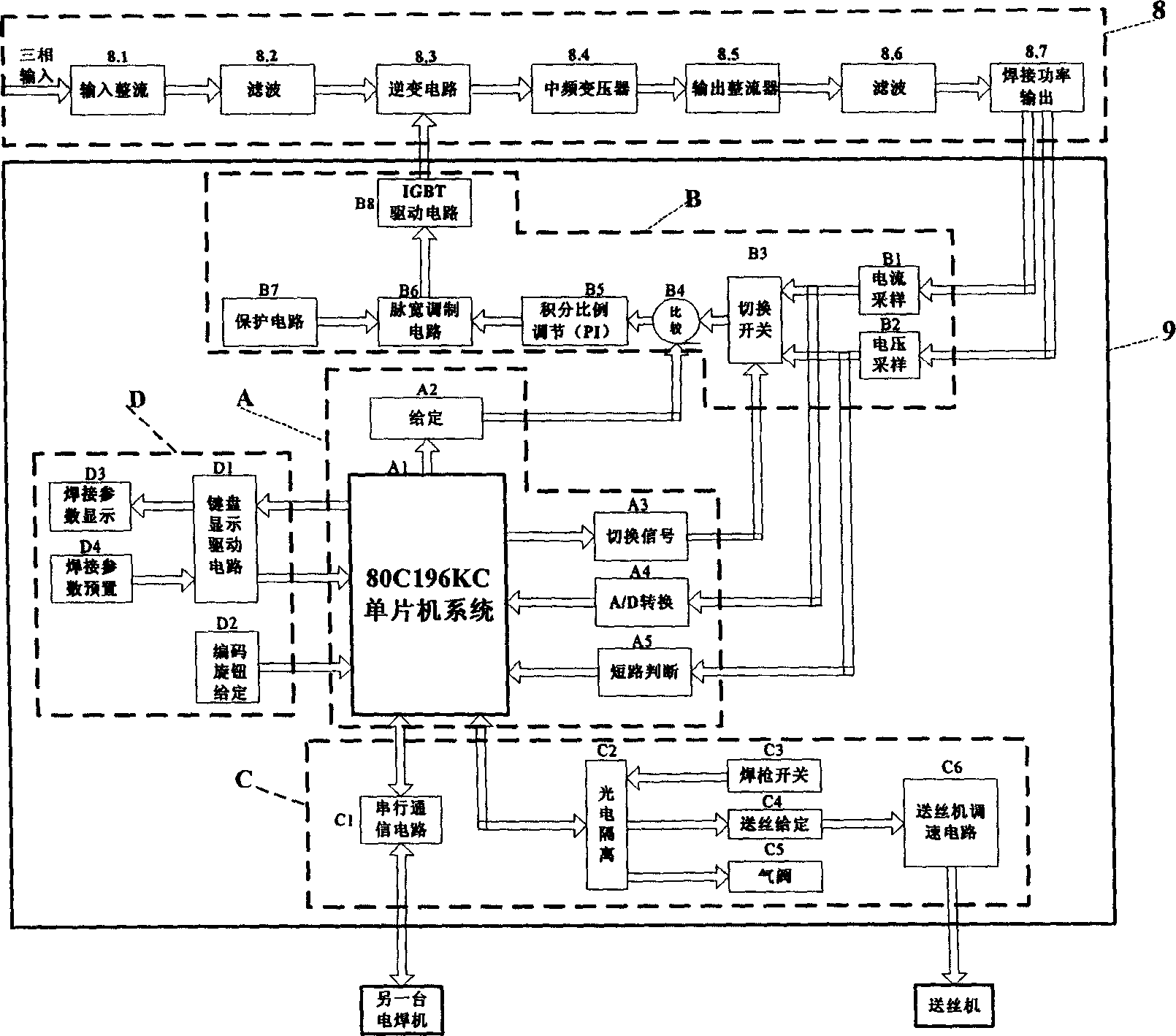

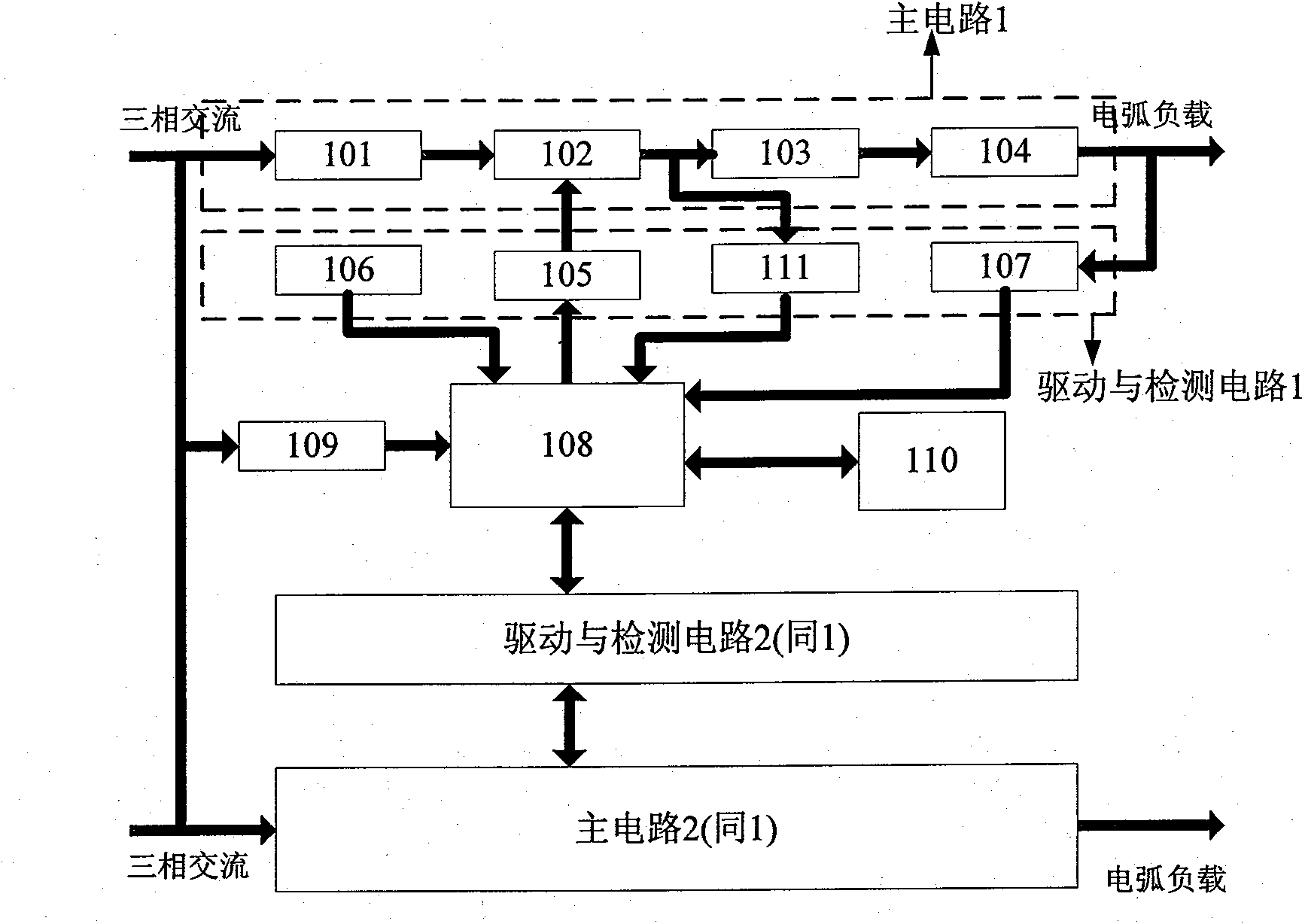

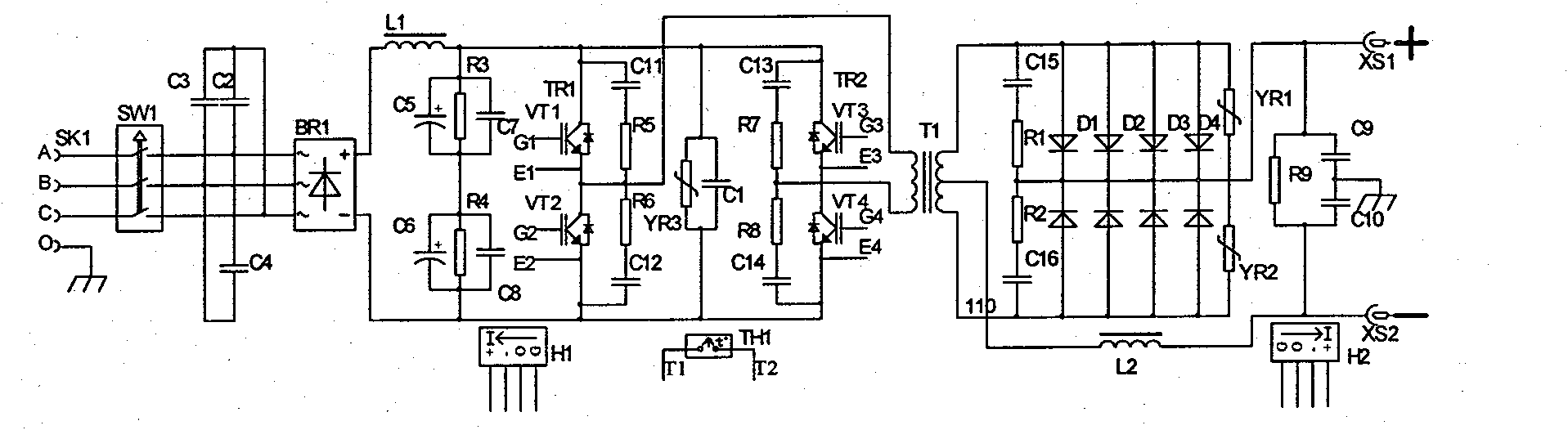

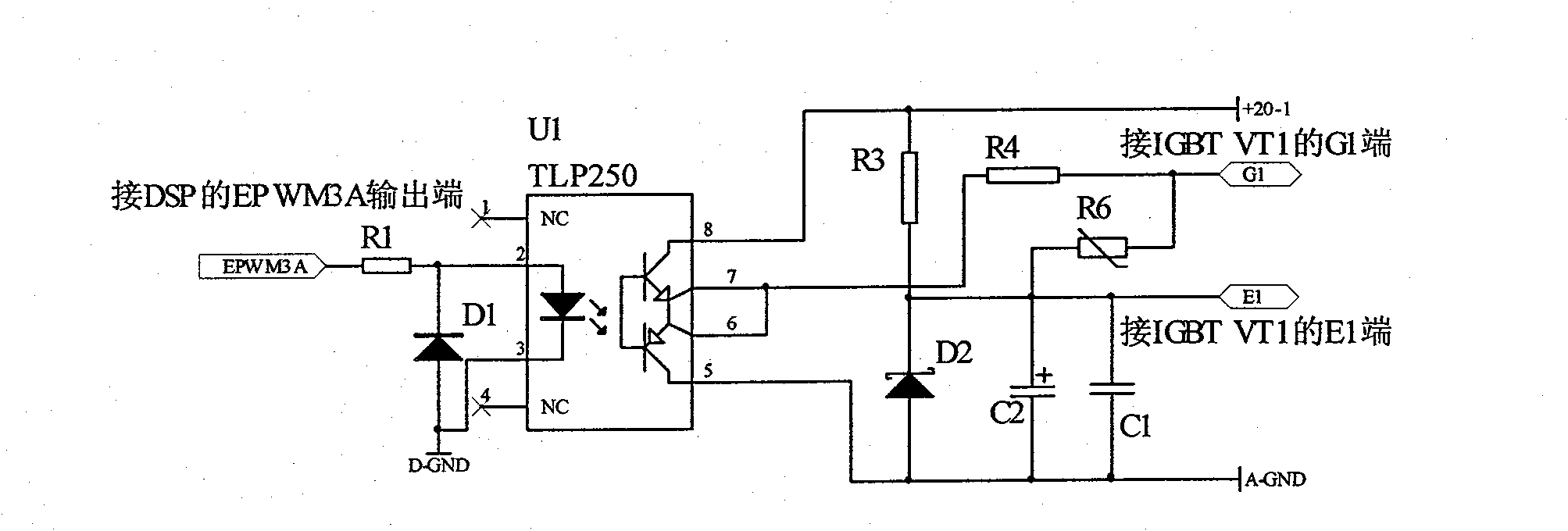

Aluminium alloy twin-wire dipulse welding method and welding power supply thereof

InactiveCN101791733AImprove consistencyImprove dynamic response performanceArc welding apparatusSoft switchingWelding power supply

The invention discloses an aluminium alloy twin-wire dipulse welding method and a welding power supply thereof. The specific method is as follows: carrying out low frequency modulation on pulse wave shapes on the basis of high frequency to obtain periodically varied pulse bursts; and carrying out efficient and superior welding on aluminium alloy through the active phase match of two branches of the pulse bursts. The welding power supply comprises IGBT soft switching main circuits which are integrated into a whole, a DSP control circuit and a man-machine interactive system. The invention puts forward realizing dipulse aluminum alloy welding on a twin-wire welding machine for the first time, realizes all digital control, directly generates eight branches of PWM signals by utilizing a software module, controls the two main circuits, and reduces the control problems caused by communication; and simultaneously, the two main circuits are concentrated on the same welding machine so that the overall structure is much smaller than the master-slave mode welding machine, in addition methods such as instantaneous energy control and the like are adopted to realize the fine control of dipulse.

Owner:SOUTH CHINA UNIV OF TECH

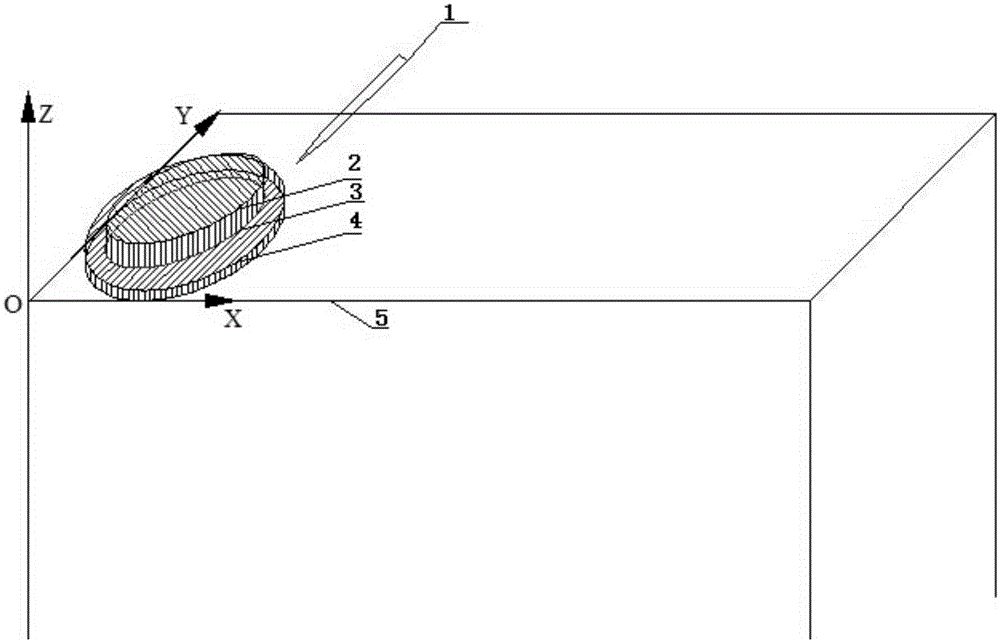

Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

InactiveCN105149786ASimplify the welding processPrecise control of single layer fill heightWelding/soldering/cutting articlesMetal working apparatusLaser processingThick plate

The invention belongs to the technical field of laser processing, and particularly relates to a narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials. The method aims at solving the problems that in the thick plate welding process, wire filling is difficult, and molten drop transition is not stable. According to the narrow-gap laser-scanning multi-layer self-melting welding method based on a prefabricated filling layer, a laser scanning welding technology and narrow-gap multi-layer filled welding are skillfully combined, therefore, a laser wire filling multi-layer welding mode for thick plate structure parts is converted into a laser self-melting multi-layer welding mode, and the single-layer filling height of a weld joint in a narrow-gap groove can be precisely controlled; due to the fact that the prefabricated filling layer can prevent the weld joint from shrinking, welding deformation can be further reduced, the thick plate welding process is greatly simplified, and the welding efficiency and the welding quality are improved. The method is suitable for narrow-gap laser welding of thin plates or thick plates of different thicknesses.

Owner:HARBIN INST OF TECH

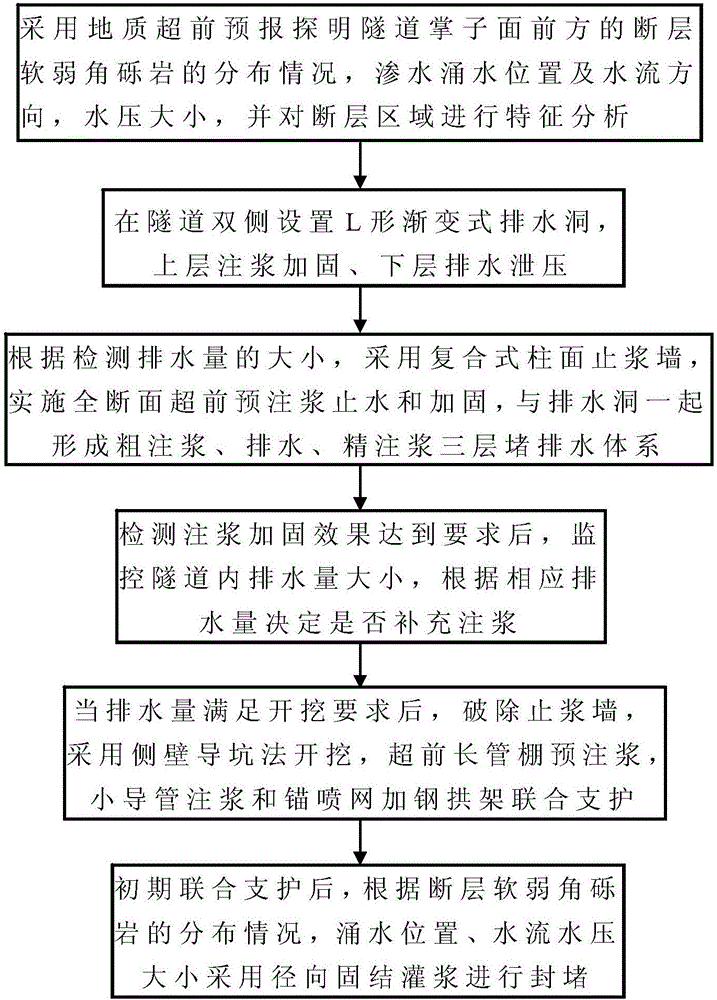

Construction method of high-tension water-rich extra-large-section weak breccia tunnel

The invention discloses a construction method of a high-tension water-rich extra-large-section weak breccia tunnel. The method includes the steps of exploring distribution of fault weak breccia in front of a tunnel face by an advanced geological forecast method; distributing L-shaped gradient drain holes in two inner sides of the tunnel, providing sector drain holes and grouting holes, and allowing upper grouting and lower drainage; providing a combined cylinder grout-stopping wall, and performing a full-face advanced chemical grouting consolidation; constructing an advanced long tube shed with a circumferential closed advanced tube shed guide wall having a foundation, distributing tapered quincunx examining drain holes to detect grouting effect, and finally excavating the tunnel. Through the use of the techniques such as three-layer stereoscopic grouting and drainage, and cement-water glass and epoxy resin sequential grouting, the problem that a high-tension water-rich surrounding rock area with loose weak breccia has ineffective grouting consolidation and non-obvious water plugging effect is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

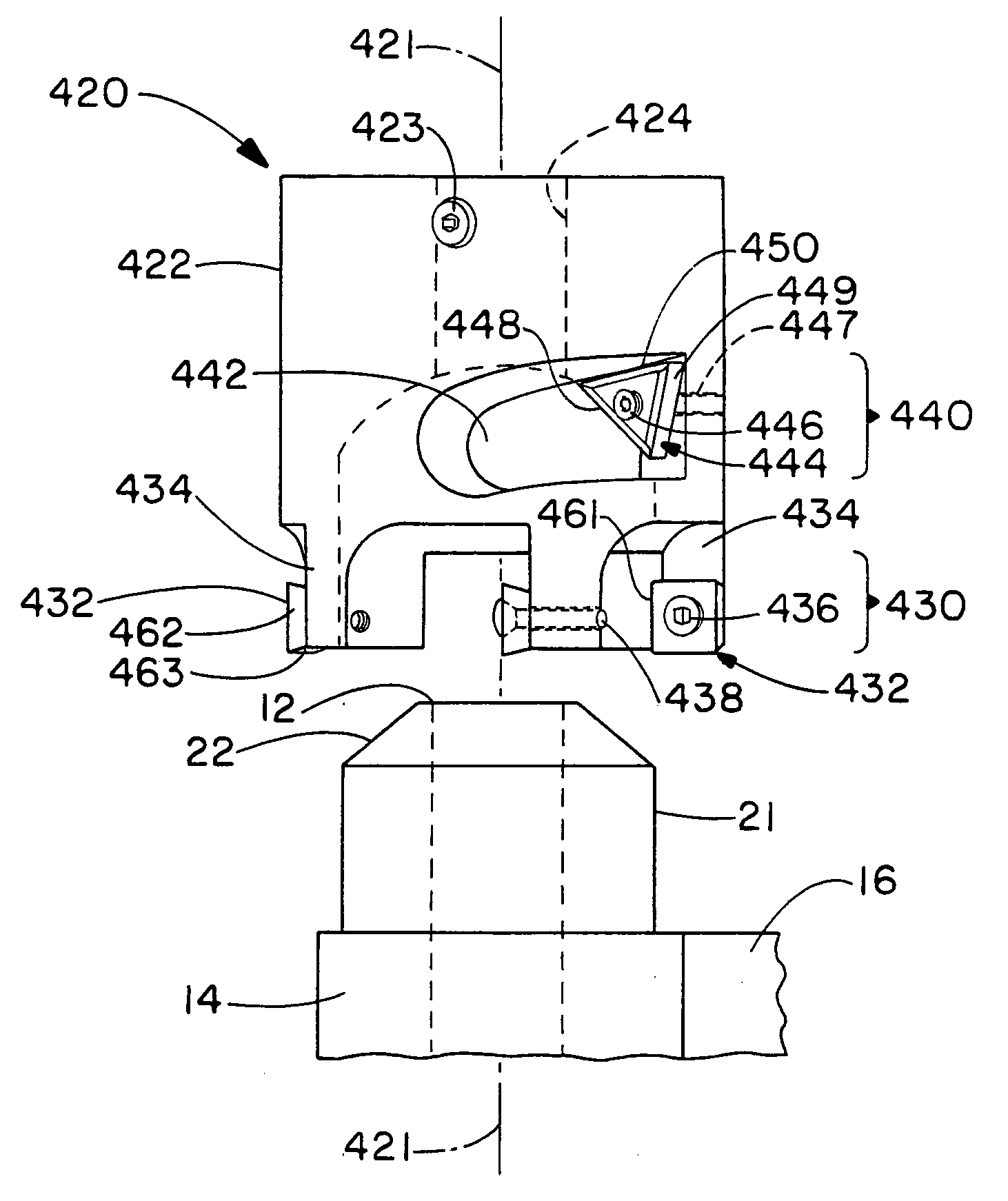

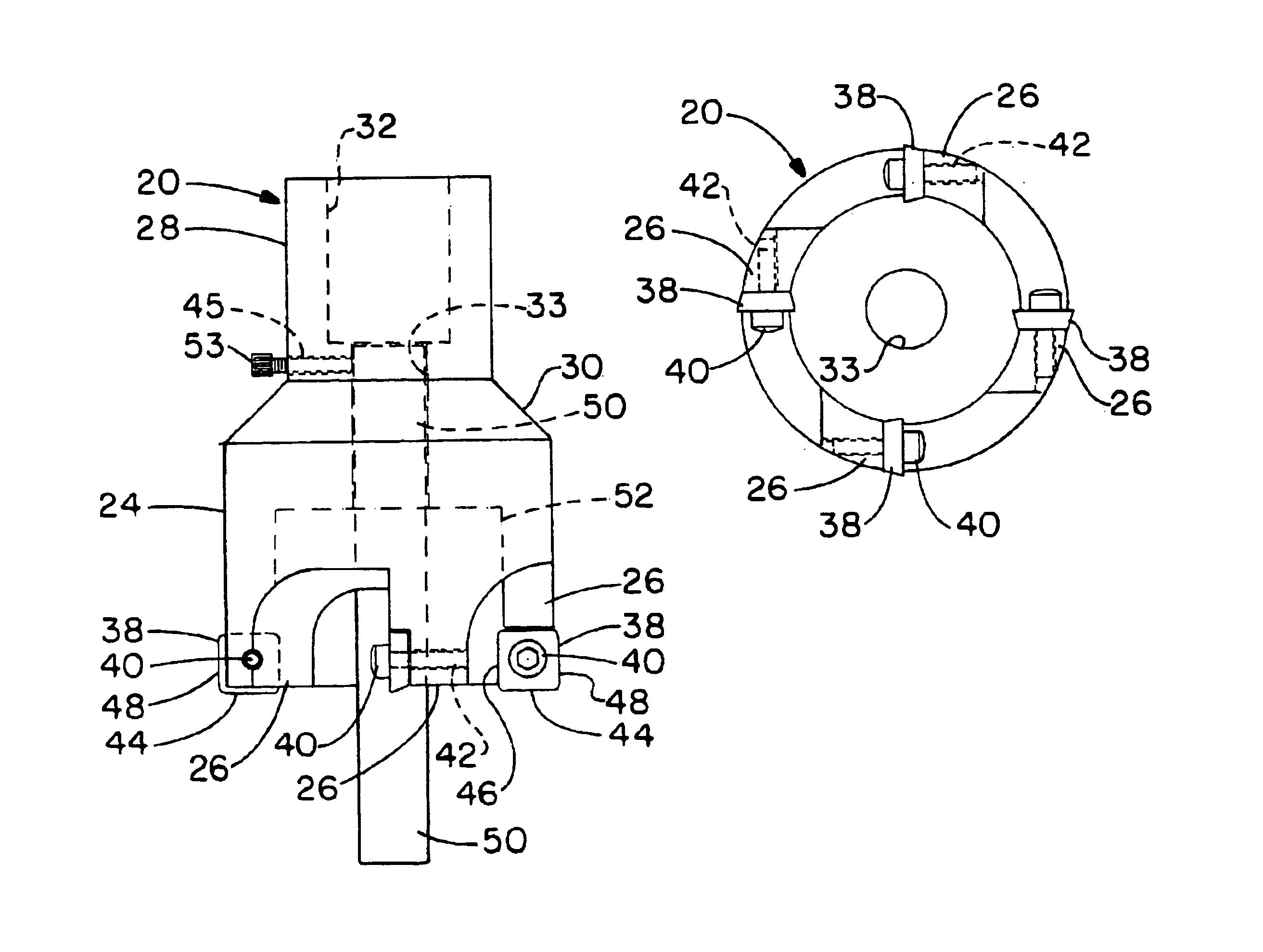

Header over-molded on a feedthrough assembly for an implantable device

A header assembly for connecting a conductor terminating at a body organ with an implantable medical device is described. The header assembly comprises a base plate, a feedthrough subassembly disposed in the base plate and comprising a ceramic-to-metal seal with first and second feedthrough wires passing through the ceramic-to-metal seal; a first electrically conductive terminal connected to a distal end of the first feedthrough wire and having a first lead opening sized to receive a first portion of a lead for the conductor; a second electrically conductive terminal connected to a distal end of the second feedthrough wire and having a second lead opening sized to receive a second portion of the lead for the conductor; a body of polymeric material molded in a two-part construction to encase the conductive terminals and their feedthrough wires except for a first bore communicating from outside the polymeric body to the first and second lead openings aligned in a first co-axial relationship. Preferably, the polymeric body comprises a first polymeric material such as Techothane® or Polysulfone® encasing the terminals except the bore and an epoxy as a second polymeric material molded over the first polymeric material.

Owner:WILSON GREATBATCH LTD

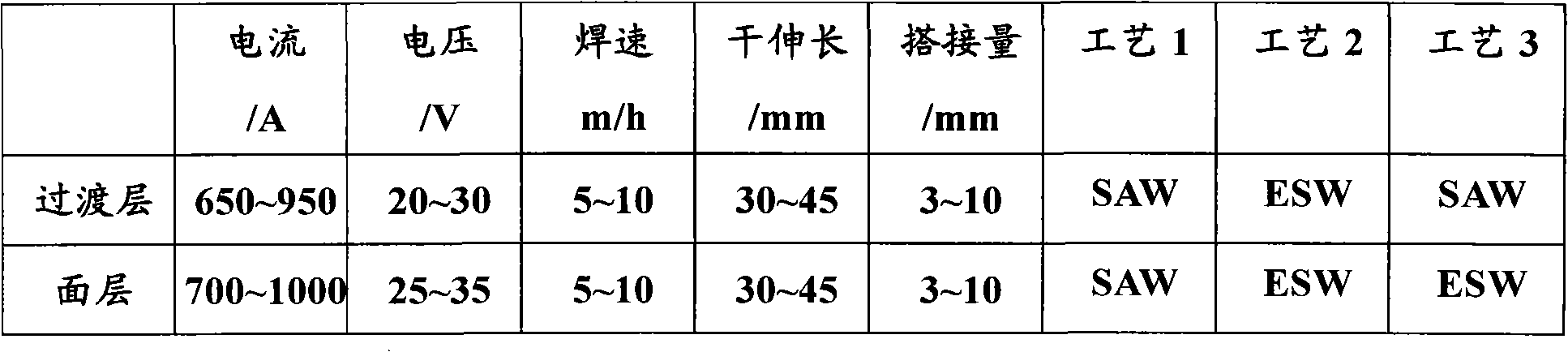

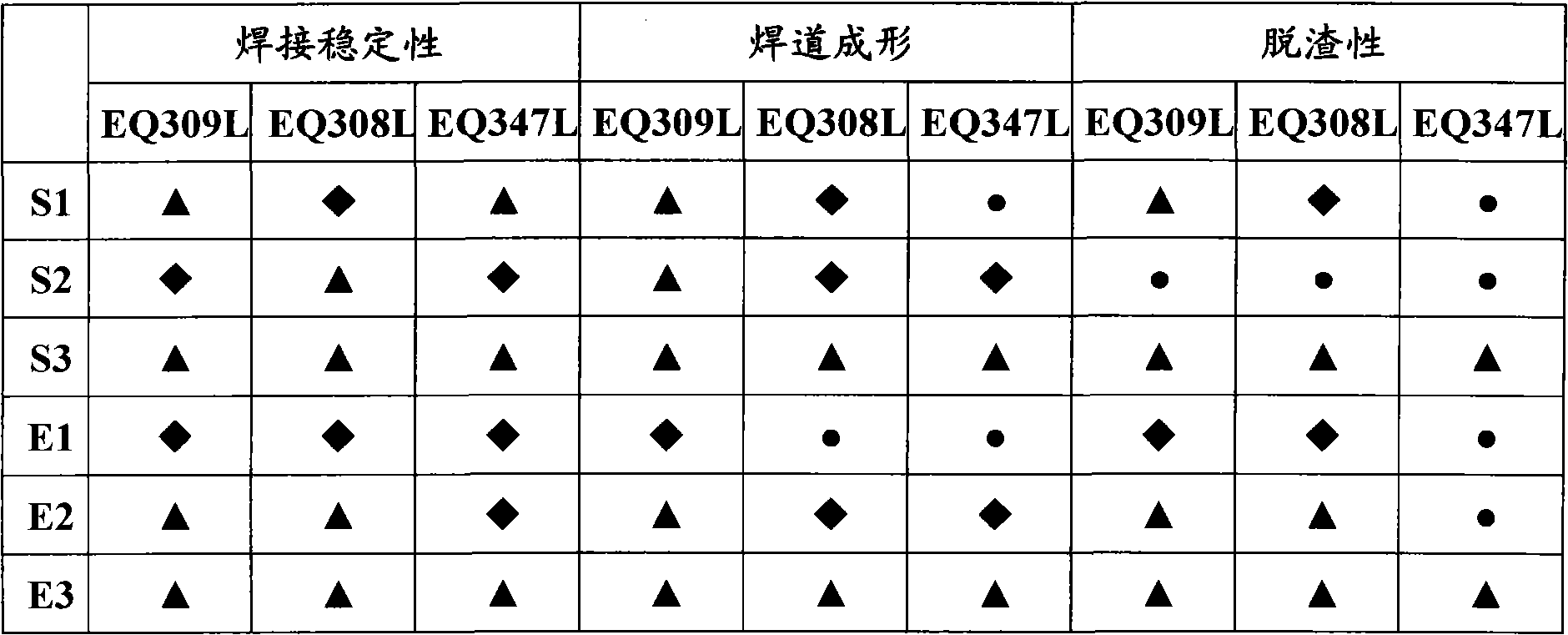

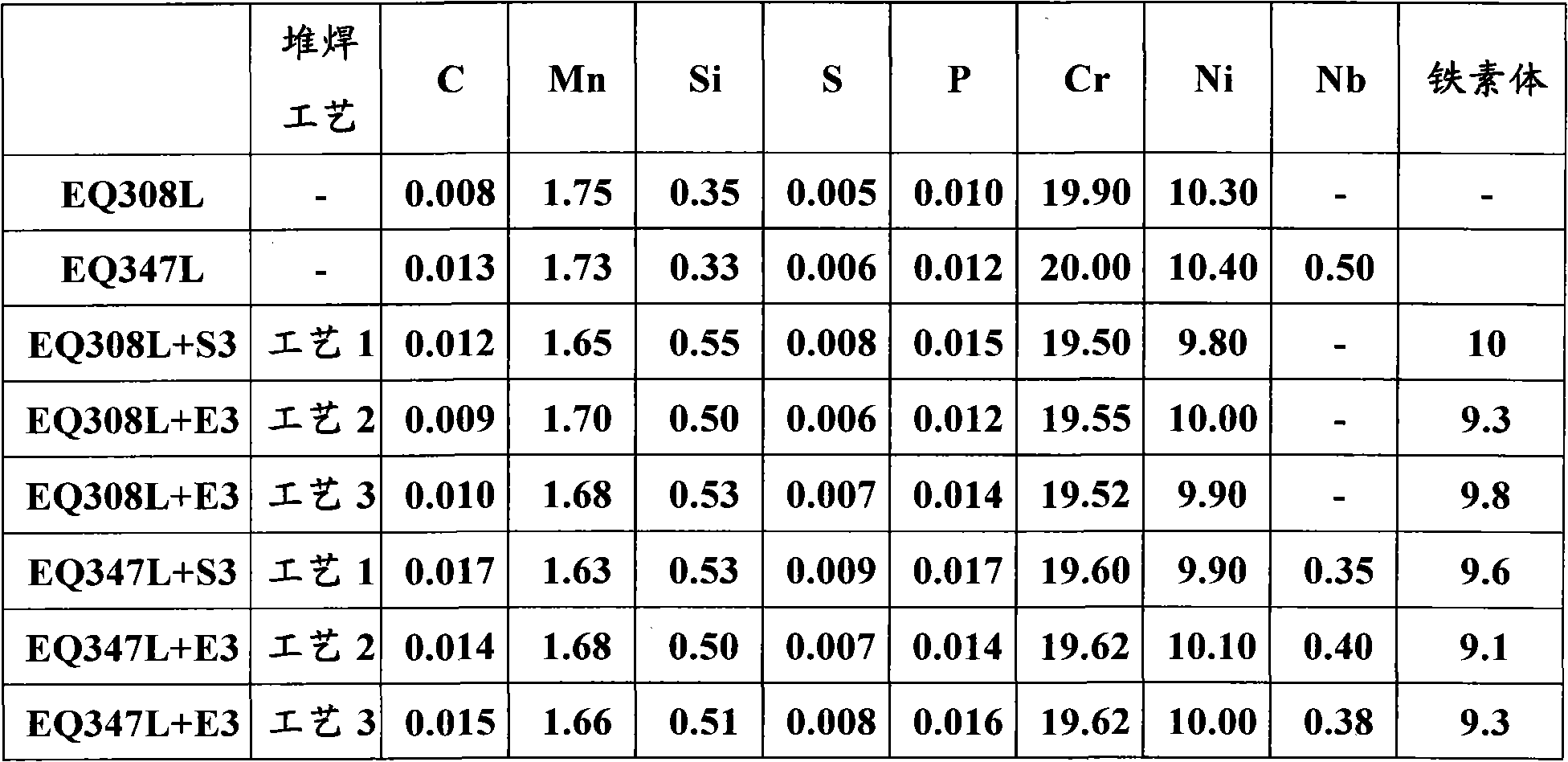

Sintered flux for stainless steel surfacing with band electrode

ActiveCN102581518AAdjustable viscosityWeld firmlyWelding/cutting media/materialsSoldering mediaRaw materialAlloy

The invention relates to a sintered flux for stainless steel surfacing with band electrode. One technical scheme of the sintered flux for stainless steel surfacing with band electrode includes that the sintered flux is formed by sintering the following components and the proportioned raw materials or materials, including 15-30 parts of CaF2, 20-50 parts of MgO, 1-10 parts of Al2O3, 15-30 parts of CaO, 25-50 parts of SiO2, and 1-5 parts of alloy powder. The another technical scheme includes that the sintered flux for stainless steel surfacing with band electrode comprises the following components and the proportioned raw materials or materials including 60-80 parts of CaF2,20-40 parts of Al2O3, 1-5 parts of CaO, 1-5 parts of SiO2, and 1-5 parts of alloy powder. The sintered flux has excellent performance and can meet the service requirements completely.

Owner:BEIJING JINWEI WELDING MATERIAL +1

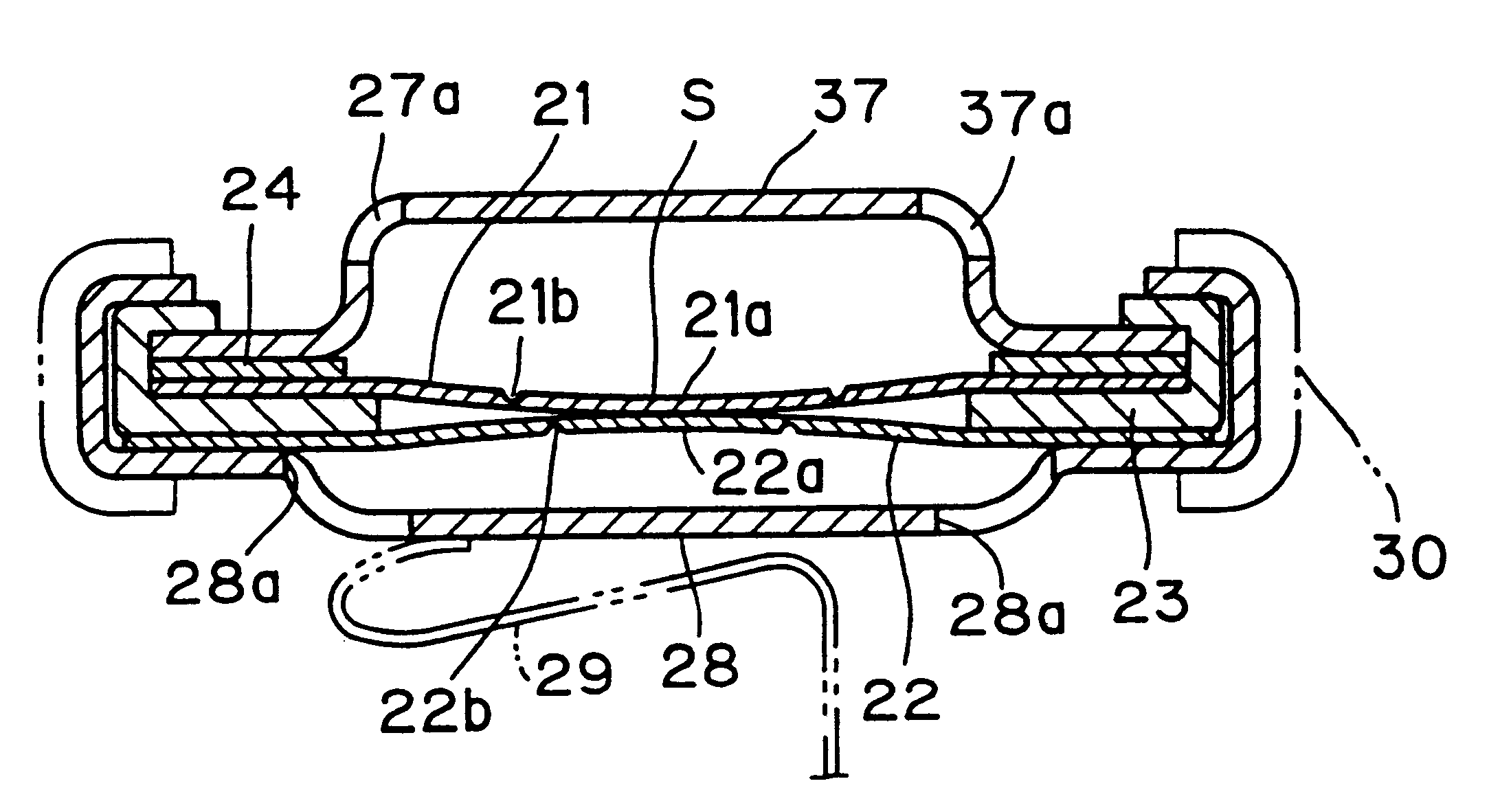

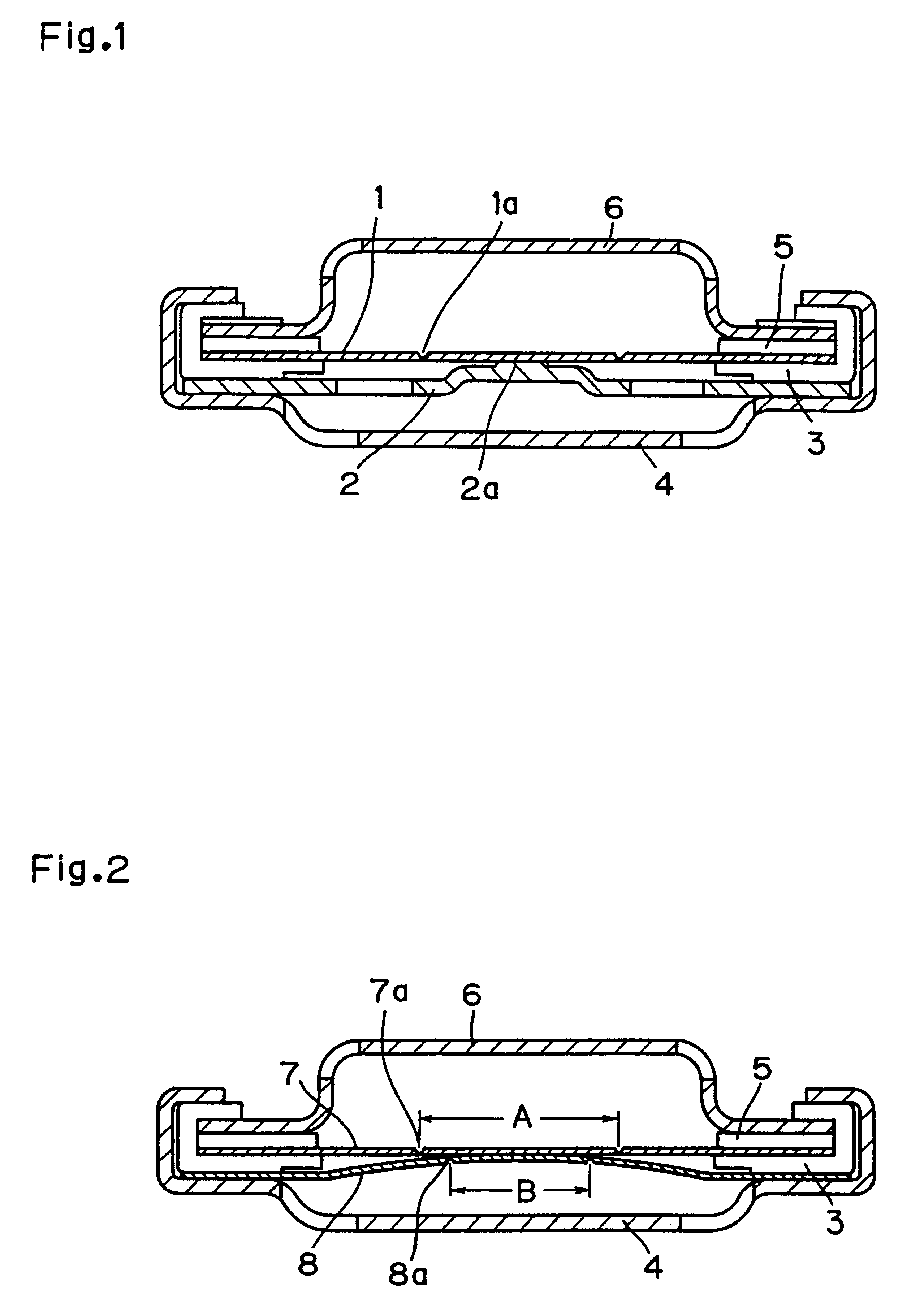

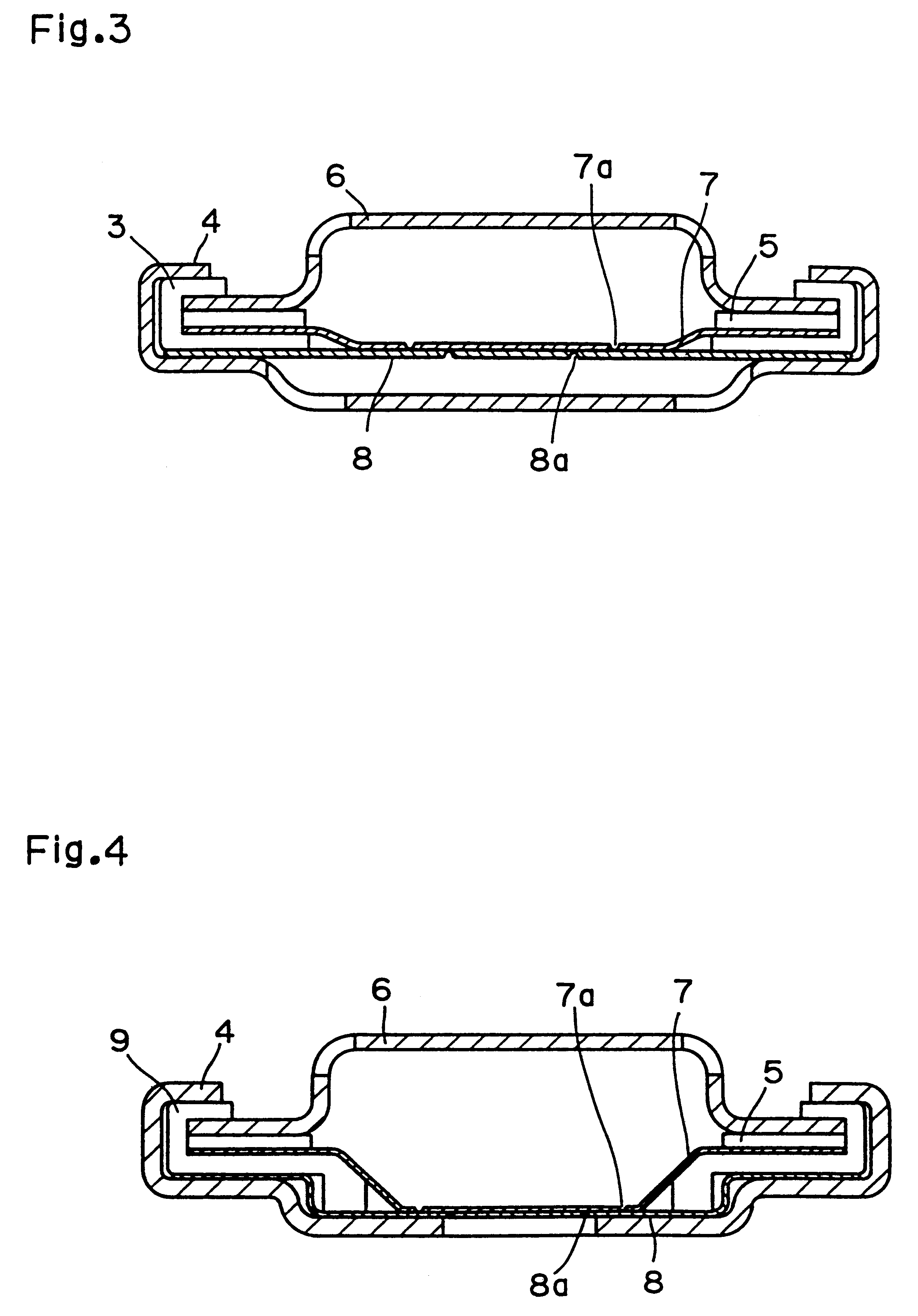

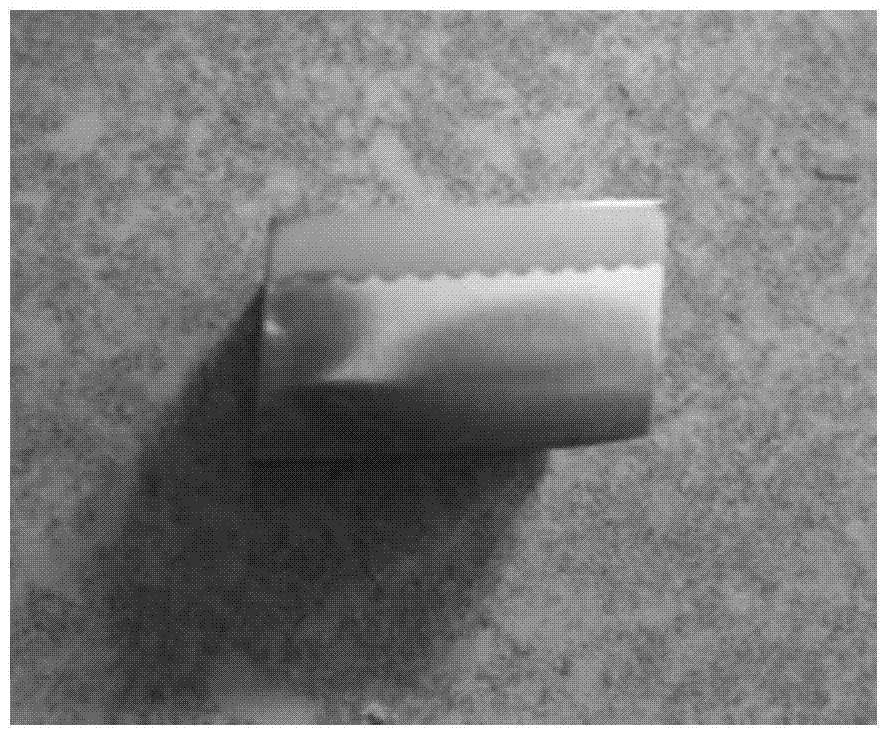

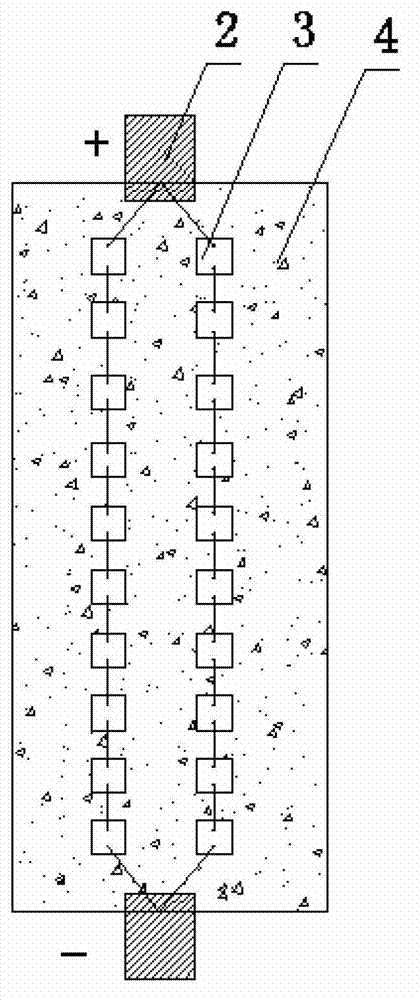

Explosion-proof seal plate for enclosed type cell and production method thereof

InactiveUS6242126B1Weld firmlyReliable exhaustCell component detailsElectrochemical responseMetallic foil

The present invention relates to an explosion-proof seal plate for a sealed cell and a production method thereof and aims at providing an explosion-proof seal plate and production method thereof, wherein problems of a risk of explosion of a cell due to an excessive pressure inside the cell caused by abnormal generation of a gas through a chemical reaction accompanying over charge or erroneous use of the cell or damaging of electronic equipment using the cell as the power source are solved, ignition and other accidents can be prevented with a high accuracy by reliably cutting off an electric current when the cell internal pressure increases, and the increase in the resistance due to permeation of an electrolyte can be limited. In order to accomplish this aim, the present invention provides a thin portion 7a having a breaking strength of 18-24 kg / cm2 in the central portion of an upper metallic foil 7 made of aluminum and a thin portion 8a having a breaking strength of 10-13 kg / cm2 in the central portion of a lower metallic foil 8 made of aluminum, wherein the diameter A of the thin portion 7a of the upper metallic foil and the diameter B of the thin portion 8a of the lower metallic foil 8 satisfy the relation AB. The two metallic foils are welded at the central portions with an insulating gasket interposed, and encased in a metallic case 4 made of aluminum having 4 vent holes, on top of which a temperature dependent resistor 5 and a metallic cap 6 having 4 vent holes are then placed. A seal plate is obtained by sealing the periphery of the metallic case 4, with which it is possible to prevent accidents such as ignition and explosion of a cell by reliably allowing internal gas to exhaust in the event of generation of a large volume of gas under an abnormal condition of a sealed cell.

Owner:PANASONIC CORP

Dissimilar metal welding joint and welding method thereof

InactiveCN103008875AHigh strengthNo pollution in the processWelding/soldering/cutting articlesWorkpiece edge portionsMaterials scienceFriction stir welding

The invention relates to a dissimilar metal welding joint and a welding method thereof, and belongs to the technical field of welding. The welding joint is formed by friction stir welding of AZ31 magnesium alloy and 7075 aluminum alloy by taking tin as an interface layer, and the thicknesses range of the AZ31 magnesium alloy and the 7075 aluminum alloy is from 5 mm to 20 mm; the welding method comprises the following steps: the 7075 aluminum alloy and the AZ31 magnesium alloy are placed on an advancing side and a retreating side respectively, and fixed in a butted manner, and a tin with thickness of 0.1-0.3 mm is arranged on the welding interface; the axle center of a mixing needle deviates 10-45 percent of the diameter of the mixing needle from the AZ31 magnesium alloy; and a stirring head is inclined at an angle of 2.5-3.5 degrees, the insertion speed of the stirring head is 15-20 mm / min, when the insertion depth of the stirring head is 97-99 percent of thickness of the magnesium or the aluminum alloy, the stirring head moves after being stopped for 1-3 seconds, when the rotational speed of the stirring head is 250-450 r / min, the welding speed is 50-80 mm / min, the stirring head is stopped for 2-6 seconds, and the draw speed of the stirring head is 15-30 mm / min. The welding joint has higher strength and better forming effect; the method is stable, and no environmental pollution is realized; and the pre-welding treatment is simple.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Explosive welding forming method of magnesium and aluminum alloy composite plates

InactiveCN103586574AImprove compactnessAdvancedMetal working apparatusNon-electric welding apparatusAlloy compositeFuel oil

The invention relates to an explosive welding forming method of magnesium and aluminum alloy composite plates. The explosive welding is performed according to the performance requirements of the magnesium and aluminum alloy composite plates, ammonium nitrate fuel oil mixture is adopted, and long-distance instantaneous explosive form is performed on a ground sand base. The welding method is high in forming speed, welding line is firm and is good in metallographic structure compactness, the combined rate is up to 99.5%, the interfacial shear strength is 120MPa, on the premise of strict operation, the welding process is safe and reliable, and the method is reliable and effective in magnesium and aluminum alloy composite plate production.

Owner:TAIYUAN UNIV OF TECH

Main plate opposing connection welding method

InactiveCN101342629AFast meltingImprove deposition efficiencyArc welding apparatusButt jointActive force

The invention discloses a butt-jointing and welding method of plates. The bases of the grooves of two plates which need to be welded are butt-jointed closely and are fixed in the groove through spot welding. A ceramic pad is stuck at the bottom of the butt-jointing place by an aluminum foil. Two parallel and separated thin welding wires are used to treat welding seam by submerged arc-welding. The butt-jointing and welding method effectively shunts the welding current to the two thin welding wires, not only improves the melting efficiency of the welding wire, but also avoids the excessive concentration of the active force of electric arc, not only has high welding efficiency, but also is easier to achieve a balance state to form the welding seam under the support of surface tension and the ceramic pad.

Owner:中船海洋与防务装备股份有限公司

Double-vacuum-layer metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746690AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationComposite plate

A double-vacuum-layer metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the core plates provide additional strength for the housing and ensure the smoothness of the housing under atmospheric pressure, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the core plate or the partition plate. A manufacturing method of the double-vacuum-layer metal vacuum composite plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

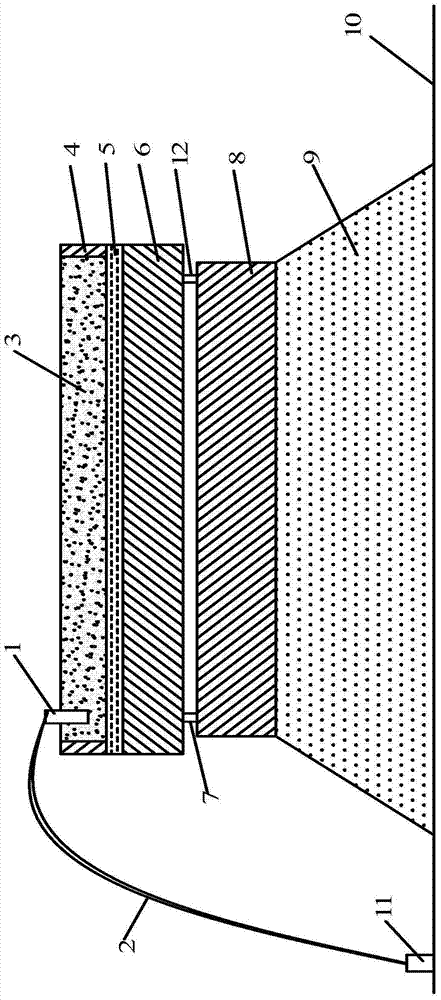

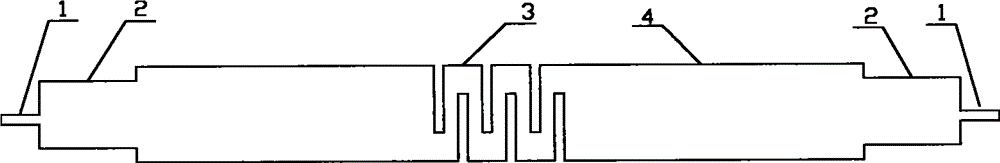

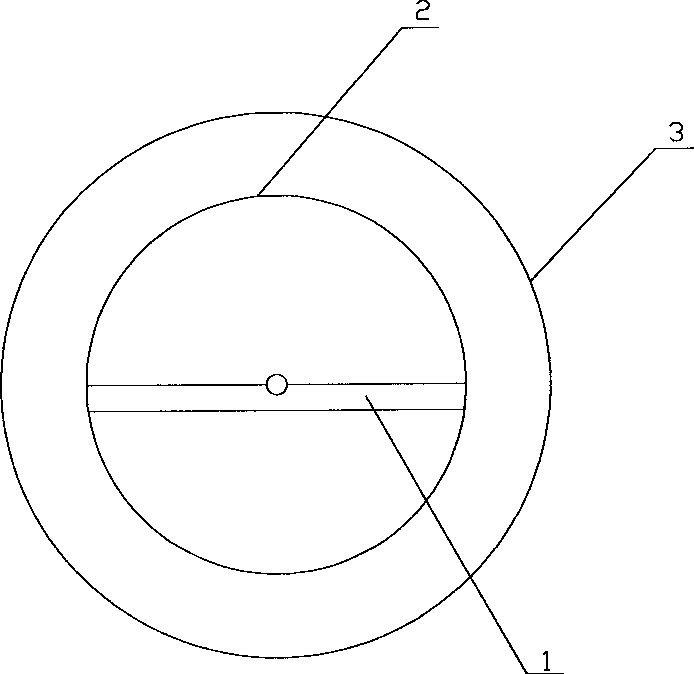

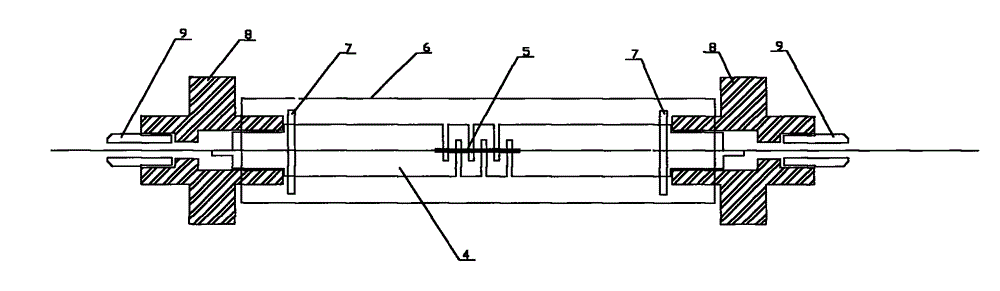

Fiber Bragg grating strain sensor

InactiveCN102865827AExtended service lifeFree from external corrosionUsing optical meansFiberGrating

The invention relates to a fiber Bragg grating strain sensor which comprises an elastic structure, an optical fiber grating, protective sleeves, sealing rings, fixed structures and sealing joints. The elastic structure comprises an elastic area with alternately spaced cavities, metal sheets and thread screws. The elastic area, the metal sheets and the thread screws are in an integral structure. The cavities forming the elastic area are vertical to the central axis of a cylinder, pass over the central axis of the cylinder and are distributed on the elastic structure in a staggered arrangement manner. Both ends of the elastic structure are in threaded connection with the fixed structures. The metal sheets are arranged in the fixed structures. The other ends of the fixed structures are in threaded connection with one ends of the sealing joints for fixing armored jackets. Both ends of the fiber Bragg grating passing through the central axis of the elastic structure are fixedly arranged on protruding metal sheets at both ends of the elastic structure by glass solder. The sealing rings arranged at the inner side of the thread screws of the fixed structures and the protective sleeves seal the elastic area. When the sensor is buried, the fixed structure is a flange structure. The fiber Bragg grating strain sensor provided by the invention has the advantages of large measuring range and simpleness in installation.

Owner:杭州珏光物联网科技有限公司

Cold metal transition welding method and device thereof

The invention aims at providing a cold metal transition welding method and a device thereof. The device consists of an MAG (Metal Active Gas) welding wire automatic feeding unit, a vibration wire feeding unit and an argon arc hot wire welding gun unit; the MAG welding wire automatic feeding unit is connected with the vibration wire feeding unit; the vibration wire feeding unit is connected with the argon arc hot wire welding gun unit through a hose; the argon arc hot wire welding gun unit comprises a straightener, an auxiliary arc welding gun and a main TIG (Tungsten Inert Gas) arc welding gun; and the auxiliary arc welding gun and the main TIG arc welding gun compose a heating source of the argon arc hot wire welding gun unit. The welding method comprises the following steps of: switching on a welding main circuit, and initiating a main TIG arc to heat a welding workpiece; and starting the MAG welding wire automatic feeding unit and a vibrating motor after the arcing of an auxiliary arc is stable. According to the cold metal transition welding method and the device thereof, the welding process is stable, the welding quality is even, the wire-feeding speed and the welding current are independently adjusted, the device is simple, and the cost is low. Based on the ordinary MAG welding wire feeding and arc wire-heating equipment, the vibration wire feeding unit is introduced, thewire heating manner is changed, thus, the cold metal transition welding is realized.

Owner:LIAONING SUPOR SHOWER EQUIP

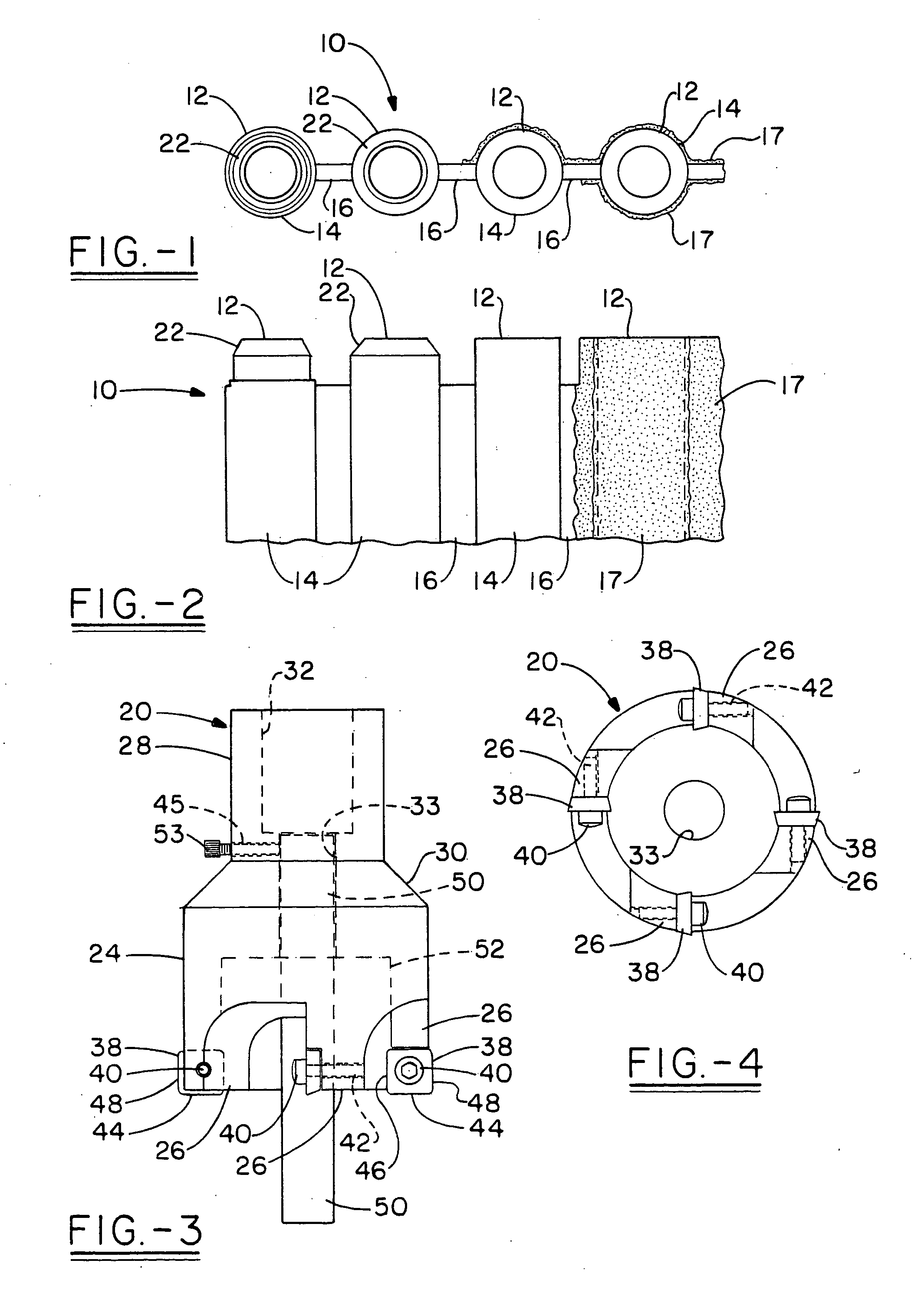

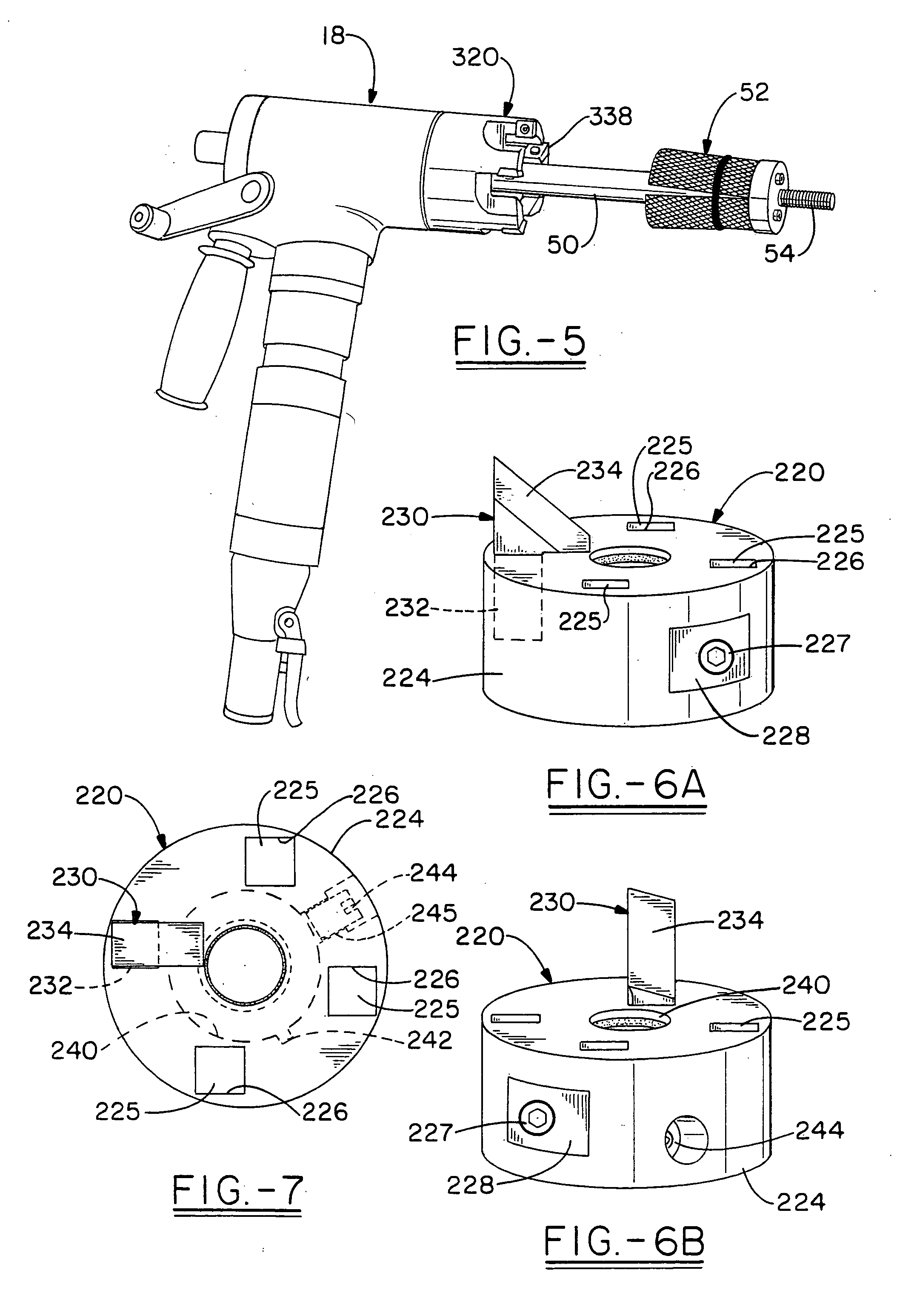

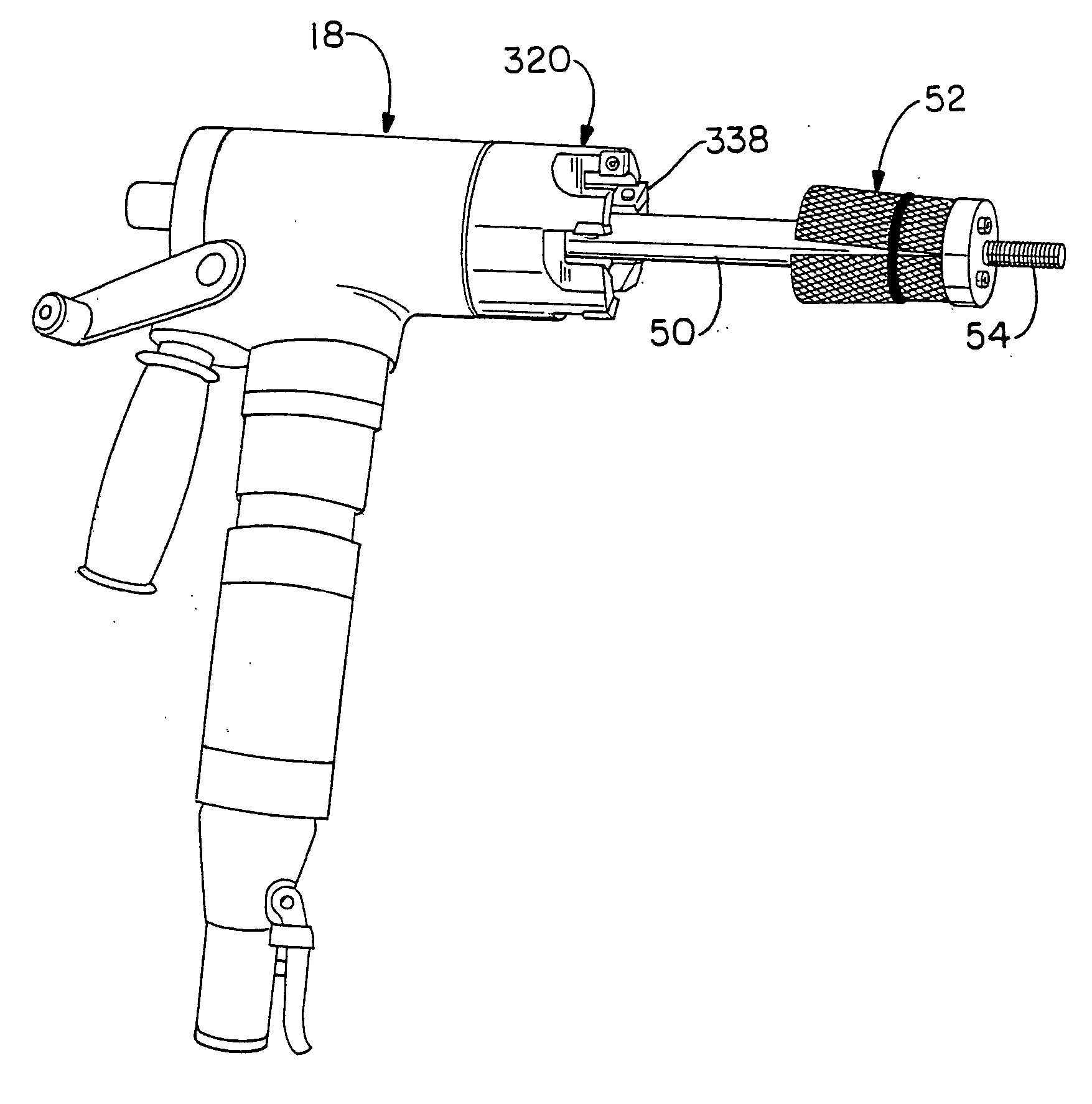

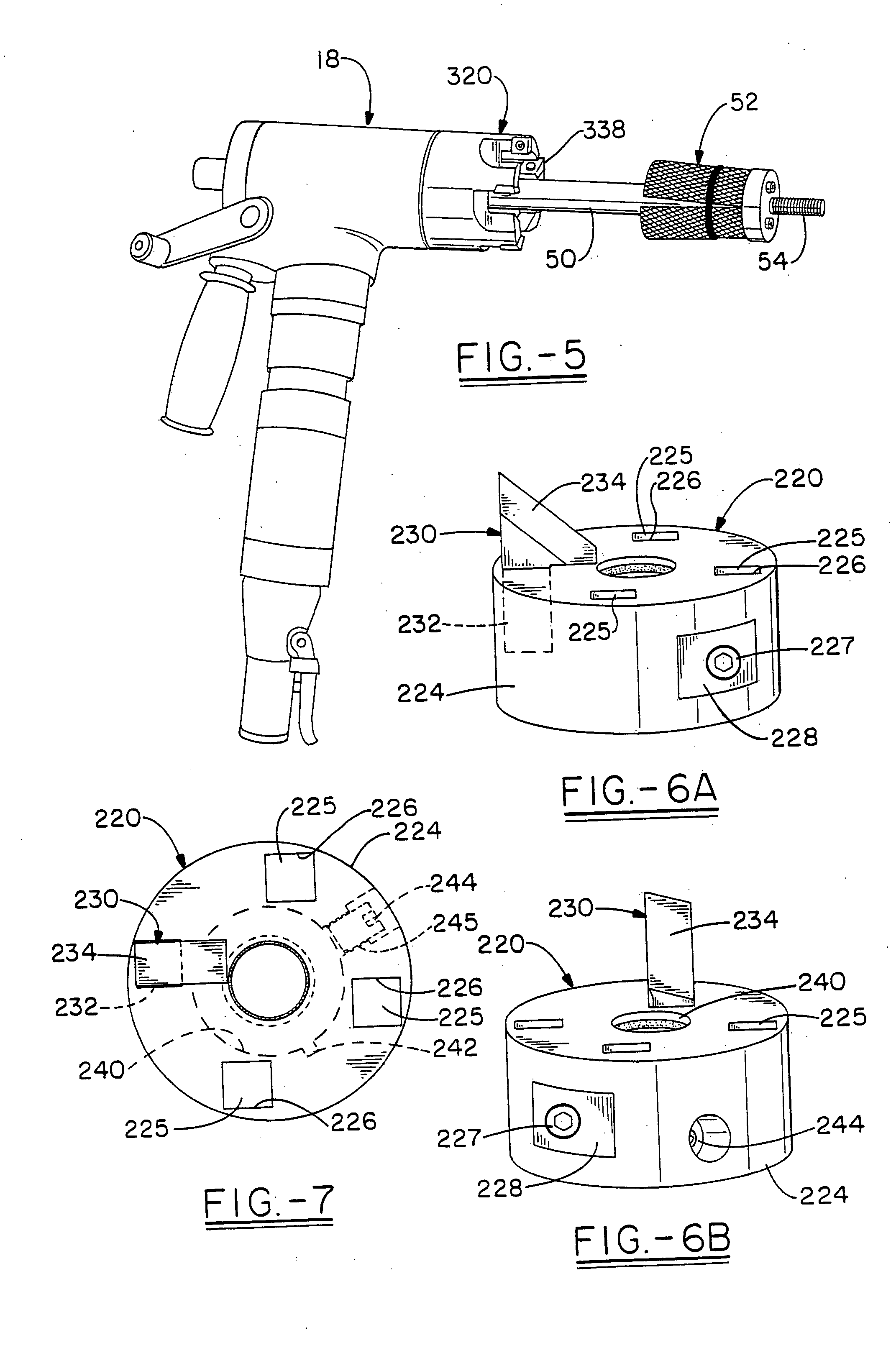

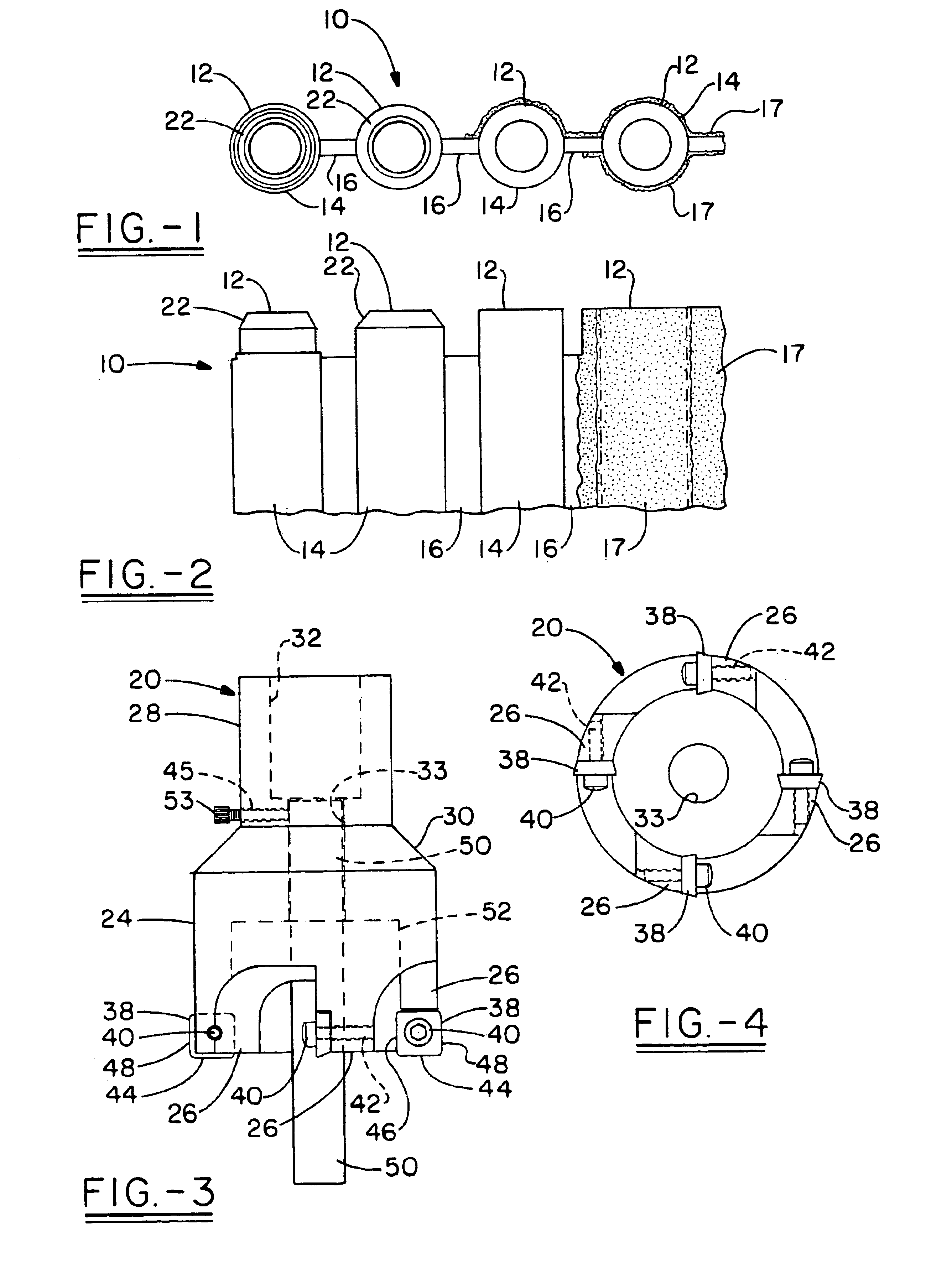

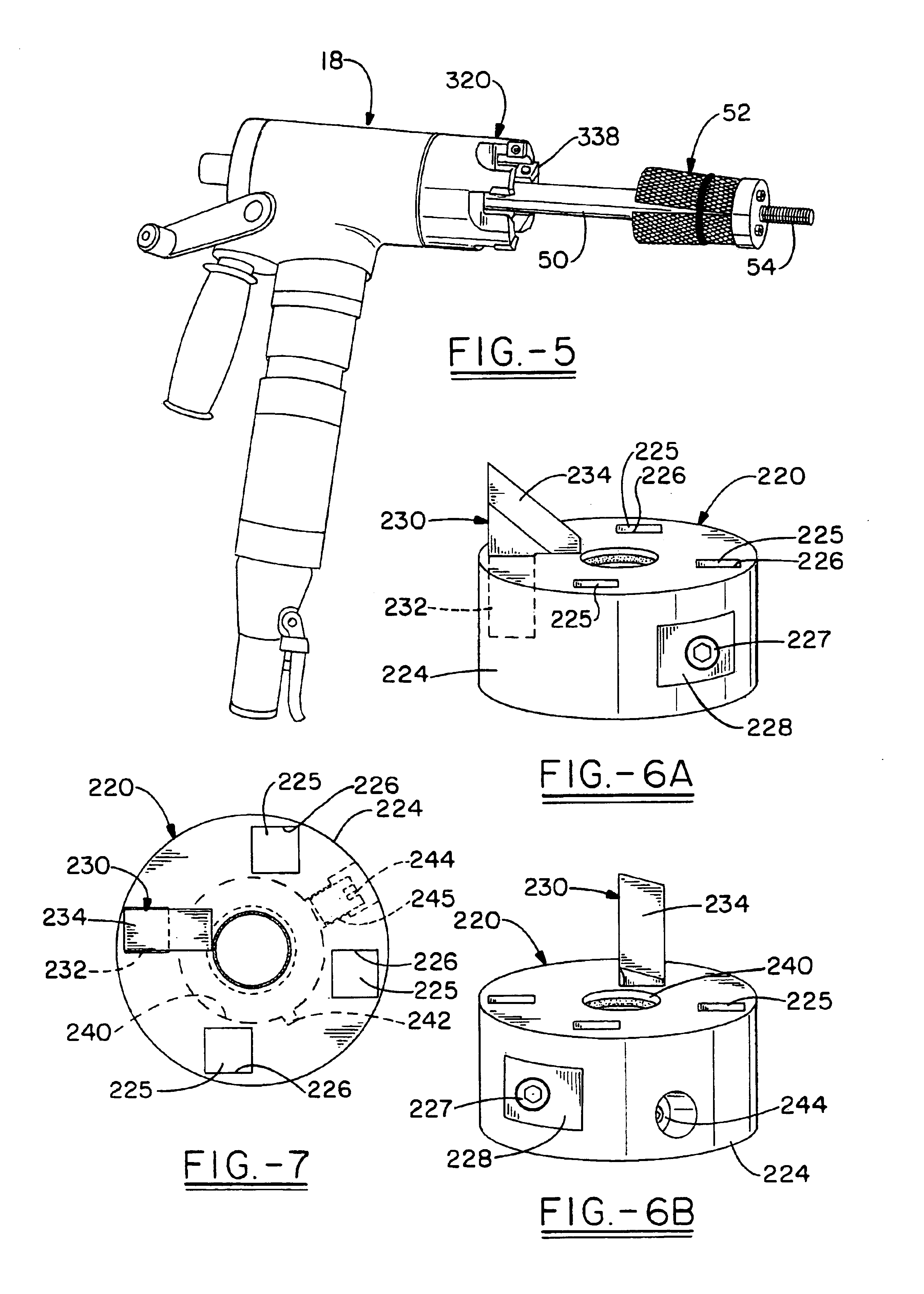

Tube milling head

ActiveUS20050053432A1Improve relationshipSave downtimeMilling cuttersWorkpiecesEngineeringKnife blades

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

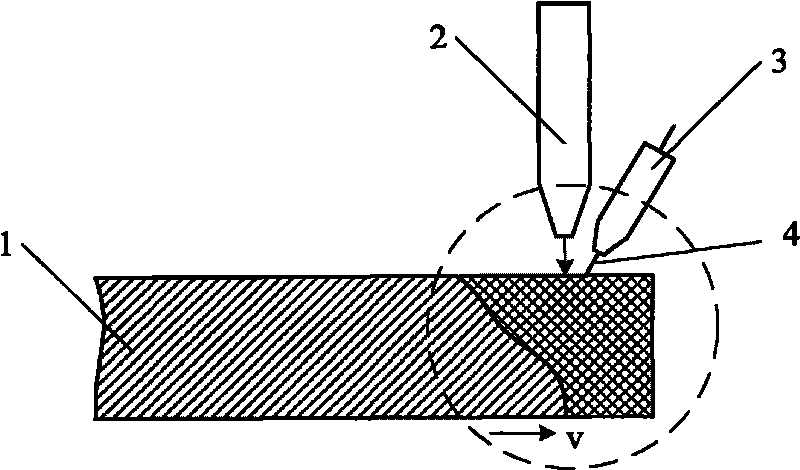

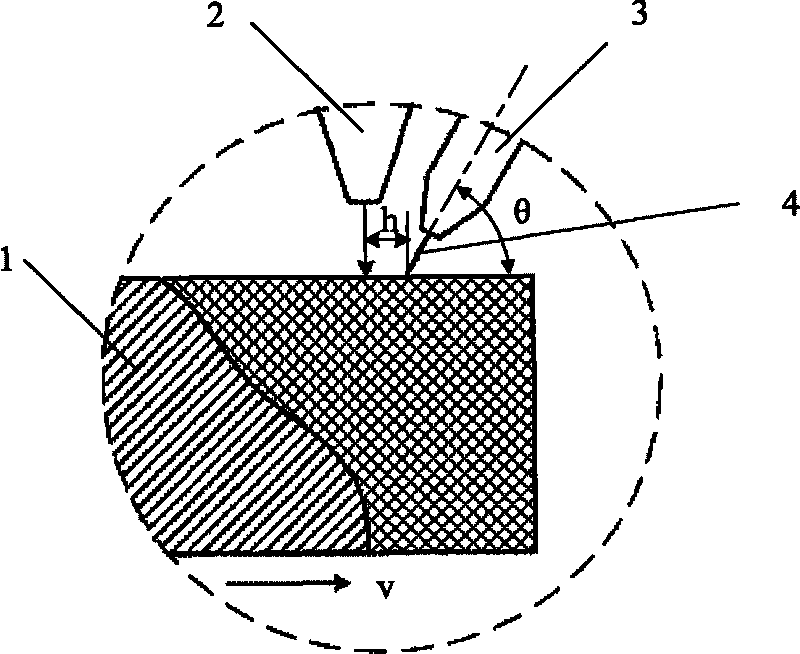

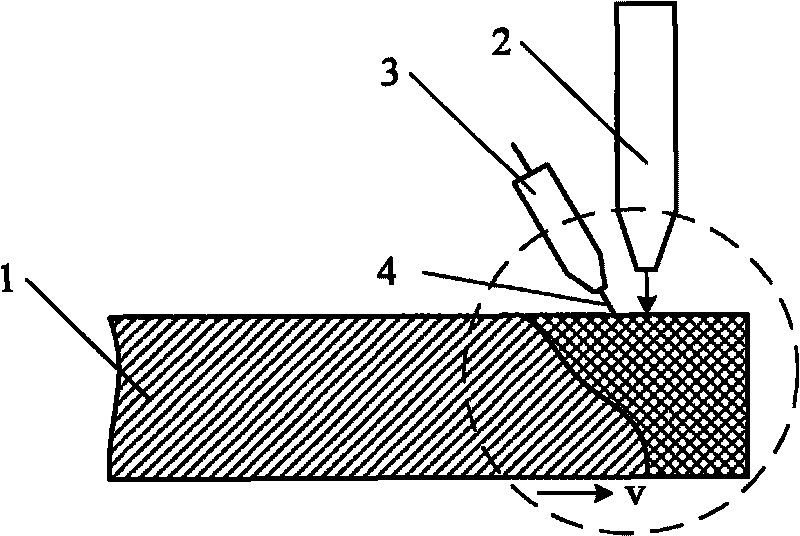

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

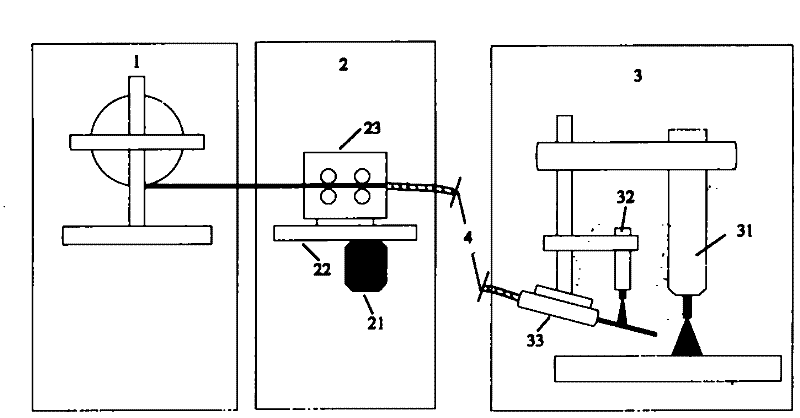

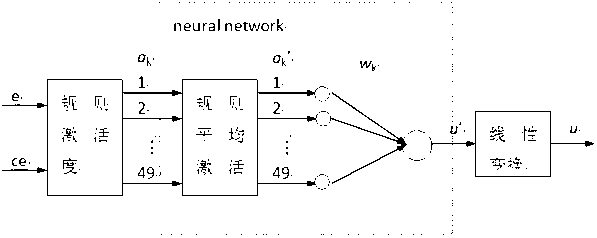

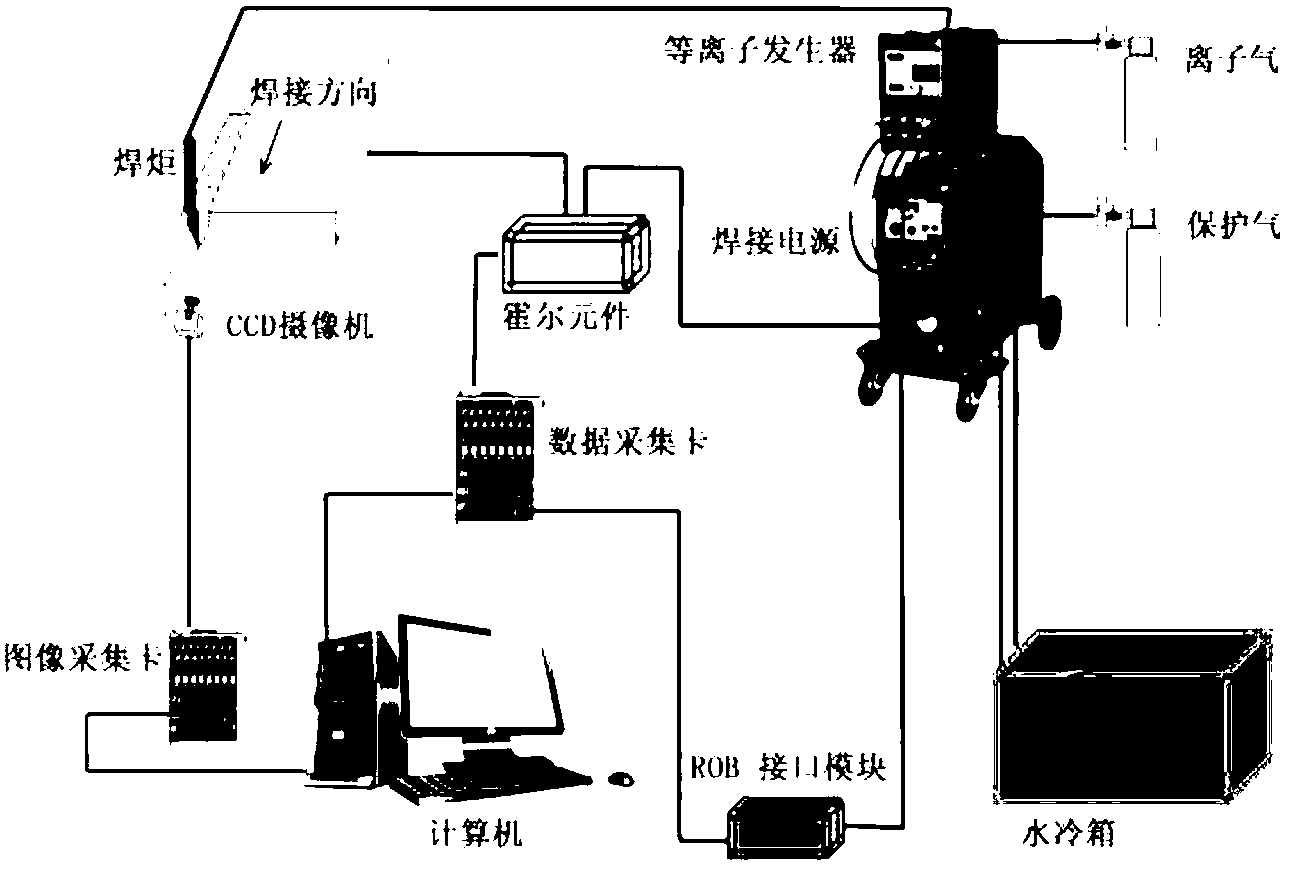

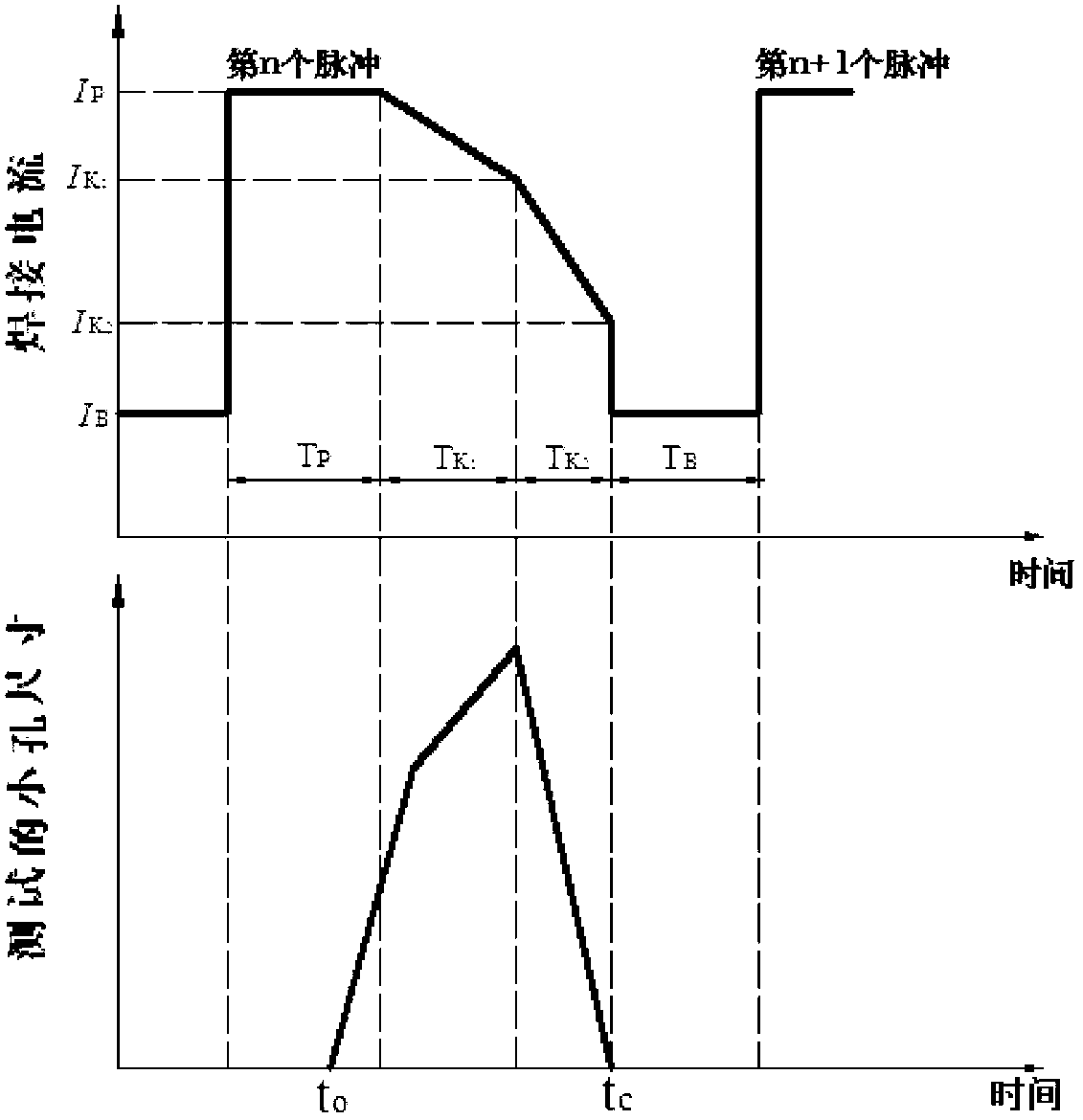

Controlled perforation plasma-arc welding system and process on basis of back small-hole visual inspection

InactiveCN103264216AState transitions are smoothHigh sensitivityPlasma welding apparatusVision sensorVisual perception

The invention discloses a controlled perforation plasma-arc welding system on the basis of back small-hole visual inspection. The controlled perforation plasma-arc welding system comprises a welding machine system, an electric parameter acquisition system, a visual sensor system and a regulation and control system. The invention further discloses a controlled perforation plasma-arc welding process on the basis of the back small-hole visual inspection. The controlled perforation plasma-arc welding process includes the following steps: (1) starting: selecting appropriate current waveform parameters according to texture and plate thickness of materials to be perforated; and (2) starting welding after the parameters are selected and set, acquiring current waveforms and back small-hole images in real time, transmitting the information to a computer, calculating the size of a small hole, and calculating deviation of the size of the small hole and a set value until welding is finished. The controlled perforation plasma-arc welding system and process on the basis of the back small-hole visual inspection enables a one-pulse and one-hole welding mode to be expanded from welding of stainless steel sheets with thickness less than 4mm to welding of middle thickness plates with 8mm thickness, guarantees perforation of workpieces, enables the size of the small hole to be maintained at a value nearby a predetermined value, and effectively prevents a furnace hearth from collapsing and being burnt through.

Owner:SHANDONG UNIV

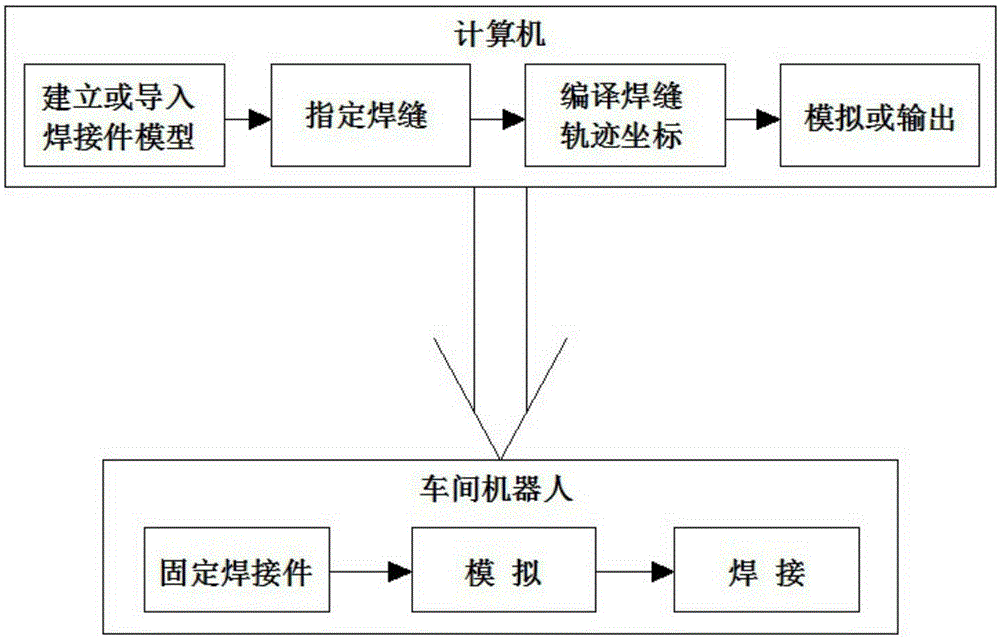

3D printing welding method using multi-degree-of-freedom robot

InactiveCN105171742AAvoid Poor Weld Quality SituationsLow costProgramme-controlled manipulatorArc welding apparatusGraphicsImaging processing

The invention discloses a 3D printing welding method using a multi-degree-of-freedom robot. A computer and a workshop welding robot are included, and the computer controls a welding arm of the workshop welding robot; by means of the novel 3D printing technology, a welding part 3D model is built in the computer, and then a welding line required to be welded in the model is assigned, the computer will extract welding line trajectory coordinates, and the trajectory coordinates are compiled into execution stage robot language commands which are output to the workshop welding robot; and after simulation is free of errors, 3D printing welding is achieved. Through the method, the condition that according to a modern automatic welding robot, due to problems of welding line tracing, image processing and the like, the welding quality is poor is avoided, welding is stable, operation is convenient, a large number of sensors are not needed, and the cost is low.

Owner:NANJING UNIV OF TECH +1

Method for tube end preparation and milling head therefore

InactiveUS20050053440A1Improve relationshipSave downtimeThread cutting toolsTransportation and packagingEngineeringMetal

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

Tube milling head

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

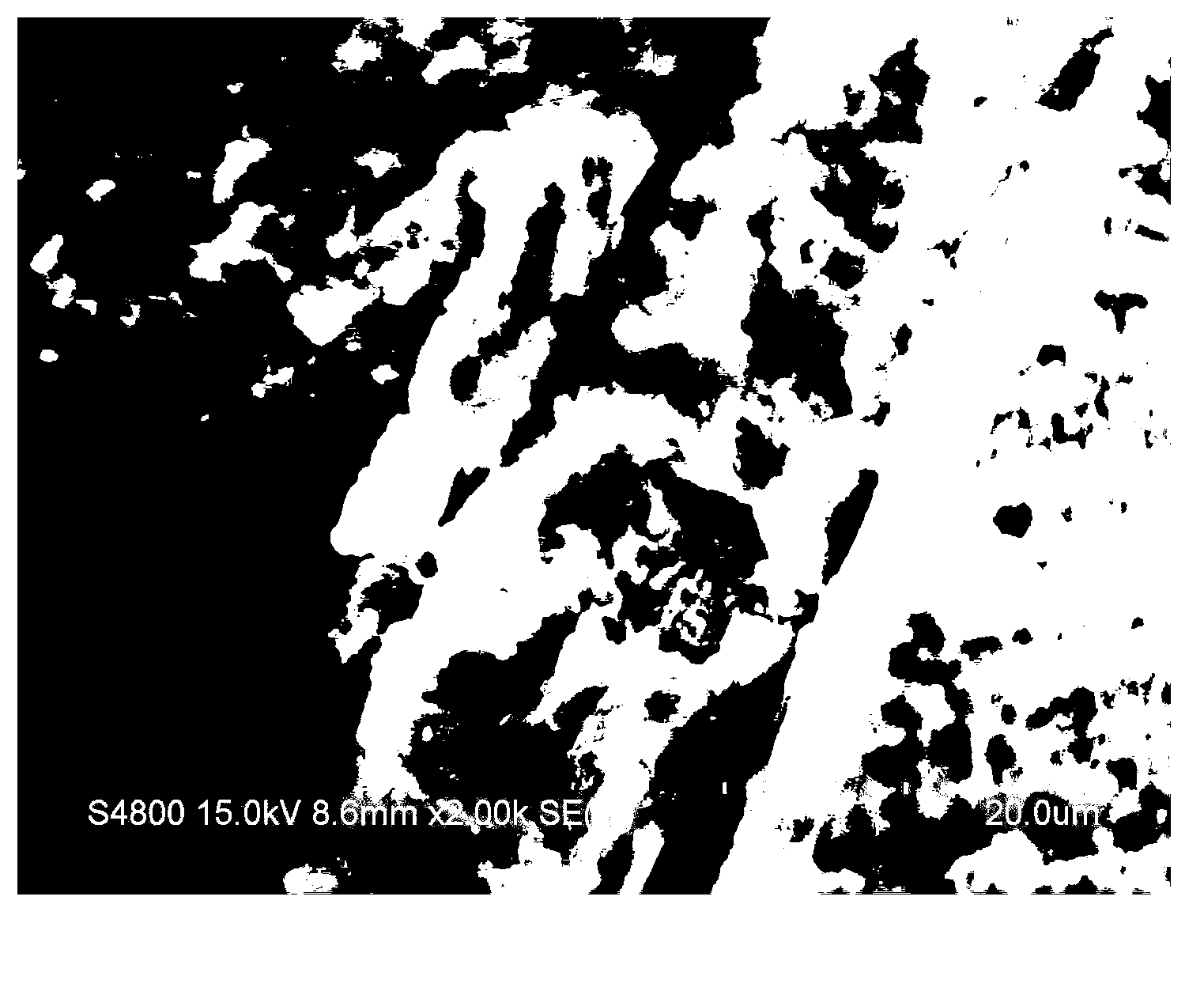

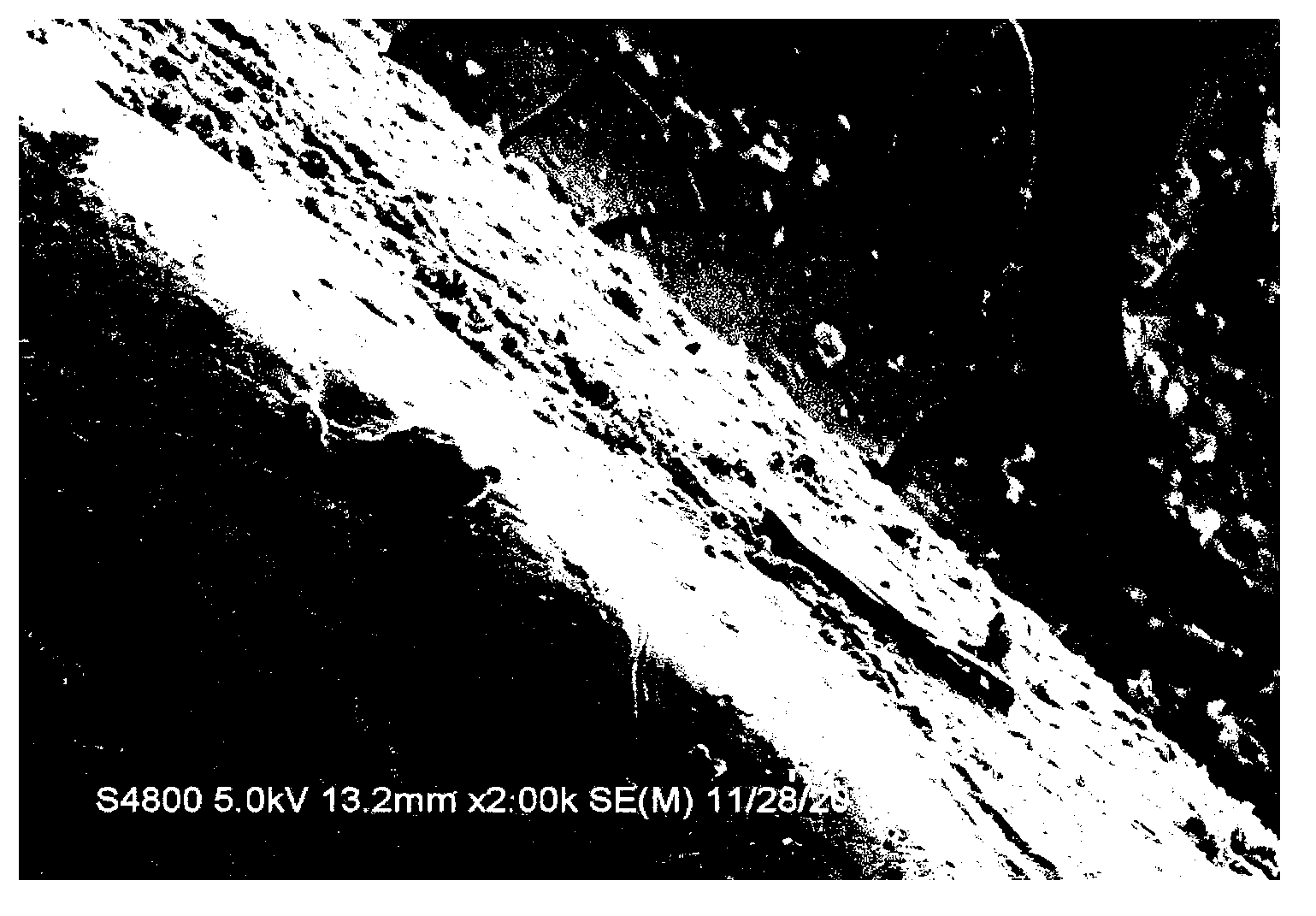

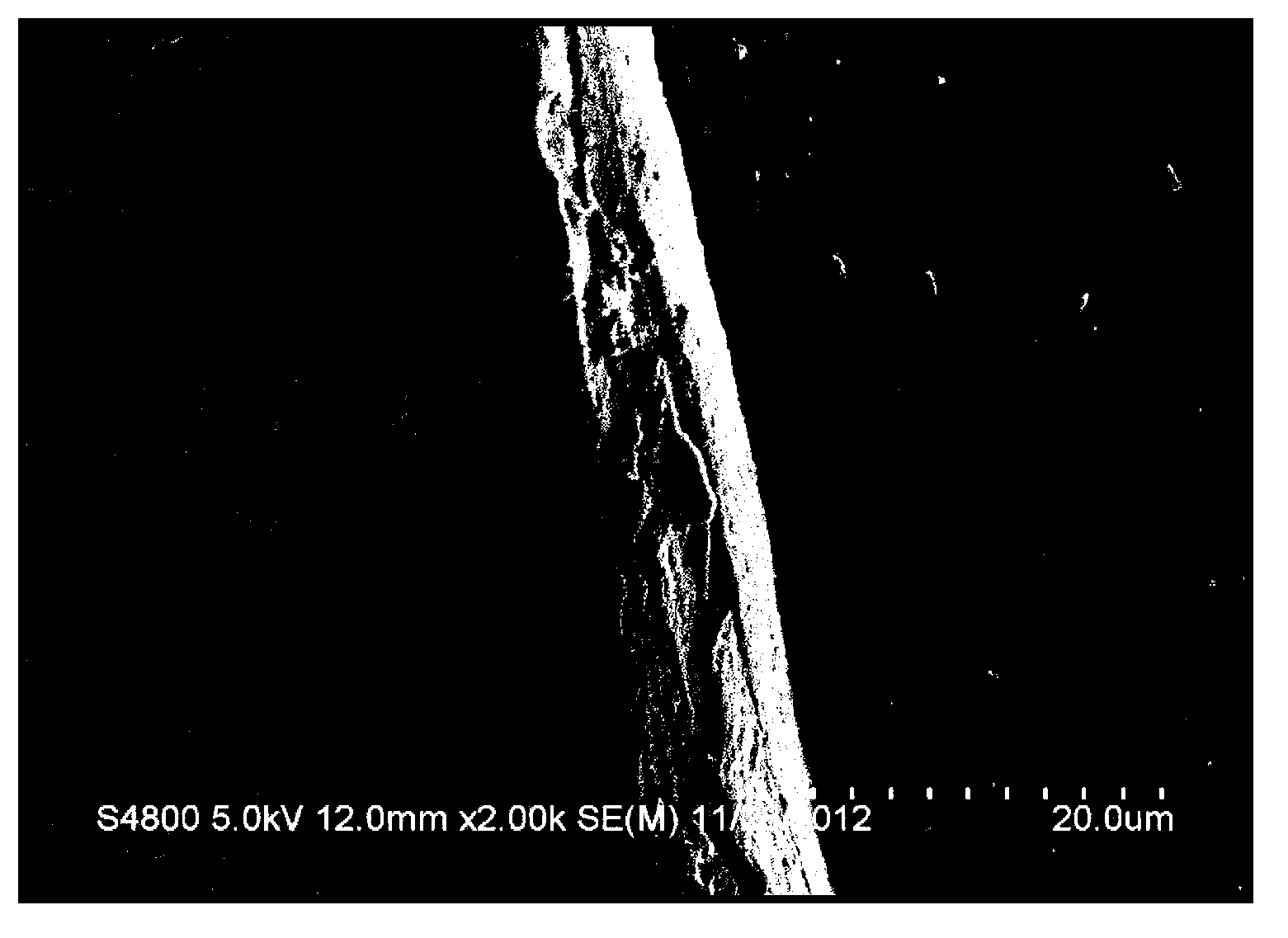

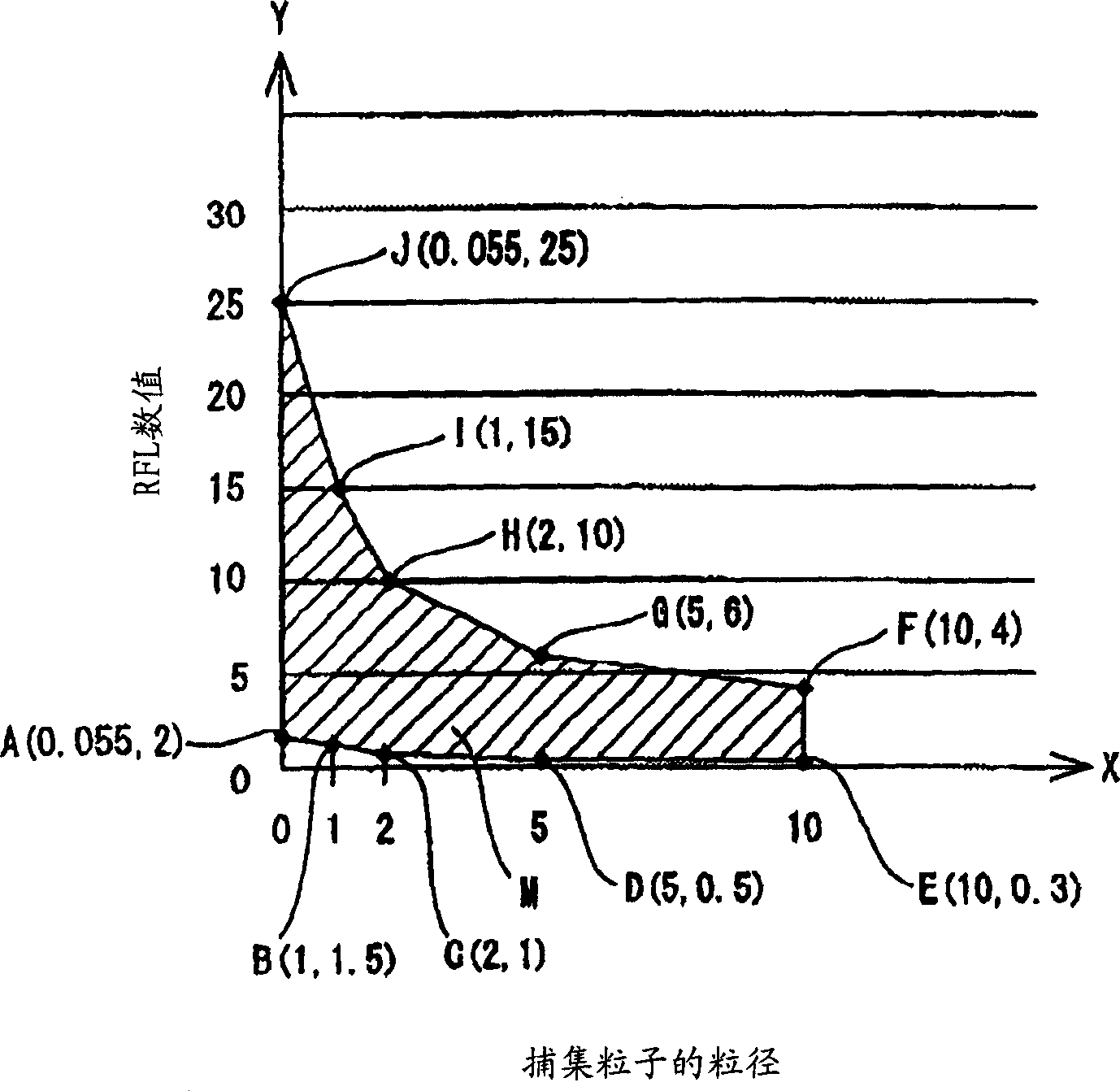

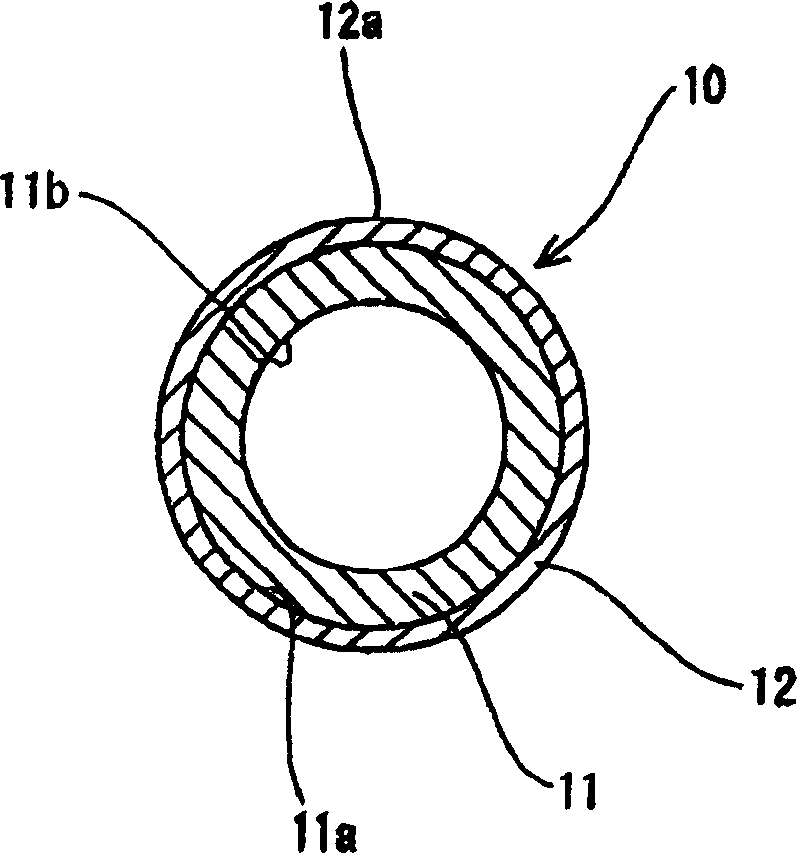

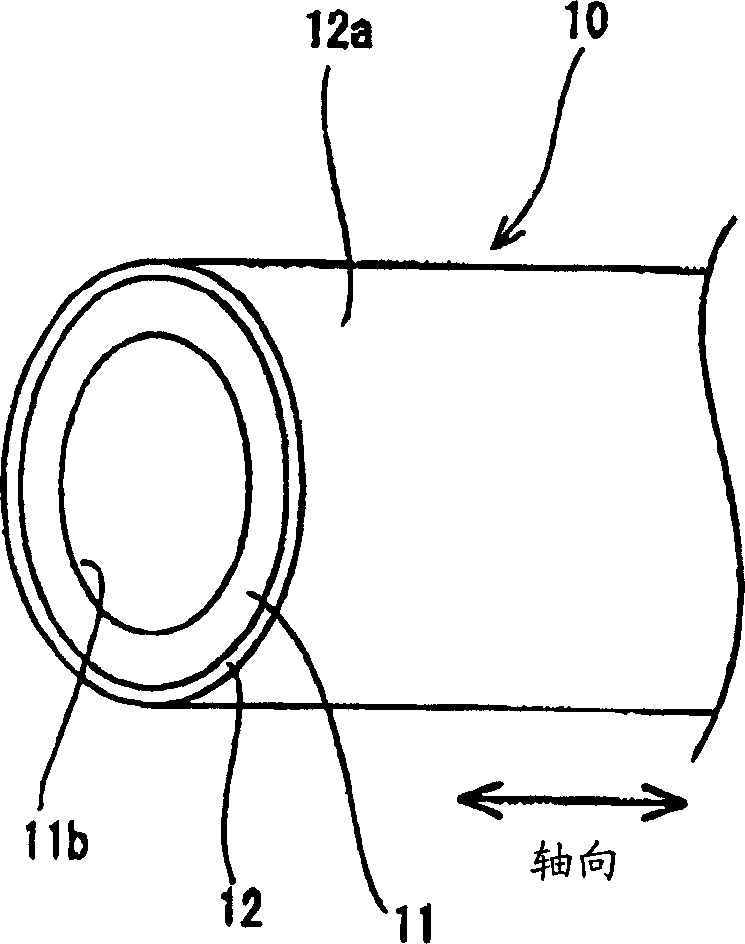

Porous multi-layer hollow fiber, filtering moudle and method for producing porous multi-layer hollow fiber

InactiveCN1507939AAvoid enteringNo cloggingSemi-permeable membranesThin material handlingFiberParticle trapping

A porous multilayered hollow fiber for outer side pressed filtration is made of a multilayer comprising a supporting layer constituted of the thickness of an expanded porous polytetrafluoroethylene tube, and a filtration layer provided on the outer surface of the supporting layer, wherein pores surrounded by fibrous frameworks in the filtration layer are smaller than those of the supporting layer, and the mean of the maximum fibril length (L) of the fibrous frameworks surrounding each pore in the outer surface of the filtration layer is designed to be small such that (X) and (Y) fall within the range on the XY plane, where (X) is a particle diameter of particles captured when the particle trapping ratio is equal to or more than 90% in the case where the filtration is done under an elevated pressure of 0.1 MPa, and (Y) is a value designated as RFL obtained by dividing (L) by (X). Thus, the degradation of flow rate due to the elapse of time can be prevented, since solid particles to be separated do not enter into pores, and dogging and blockade of the pores do not occur even in the case of filtering a solution of high turbidity. As a result, it is possible to recover filtration property easily by performing back-wash reverse filtration and to maintain excellent filtration property for a long time.

Owner:SUMITOMO ELECTRIC IND LTD

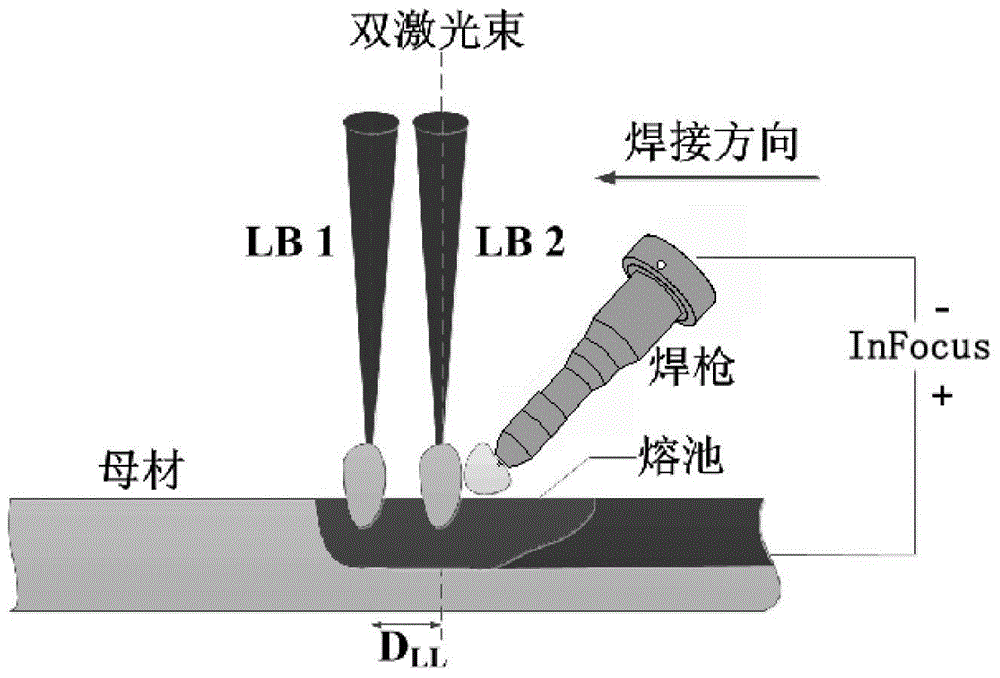

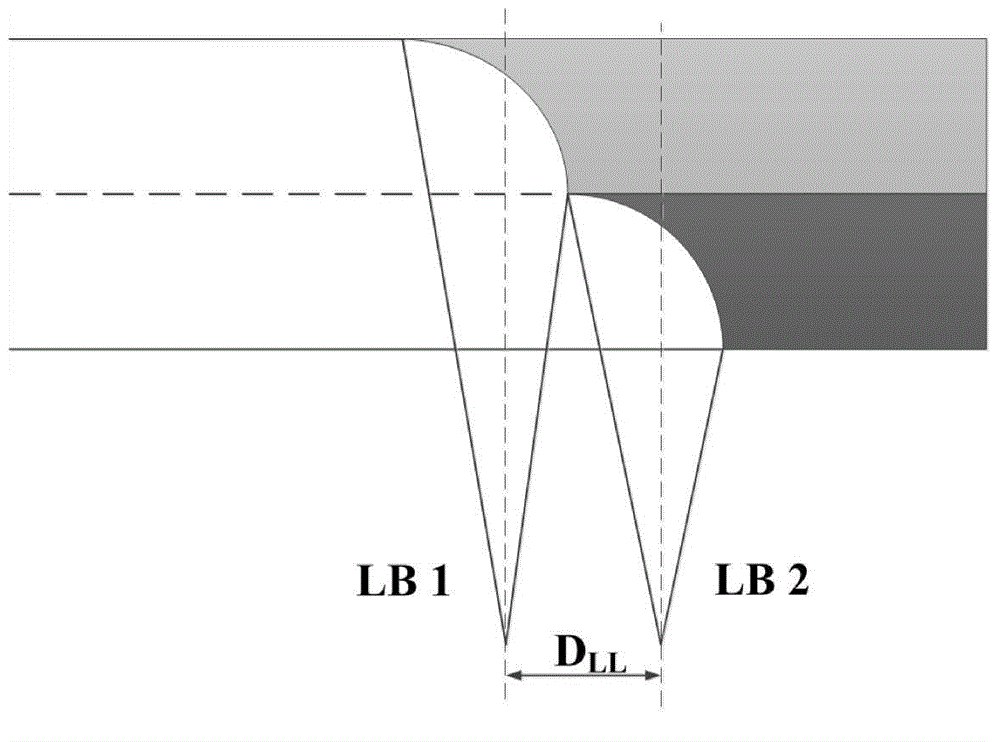

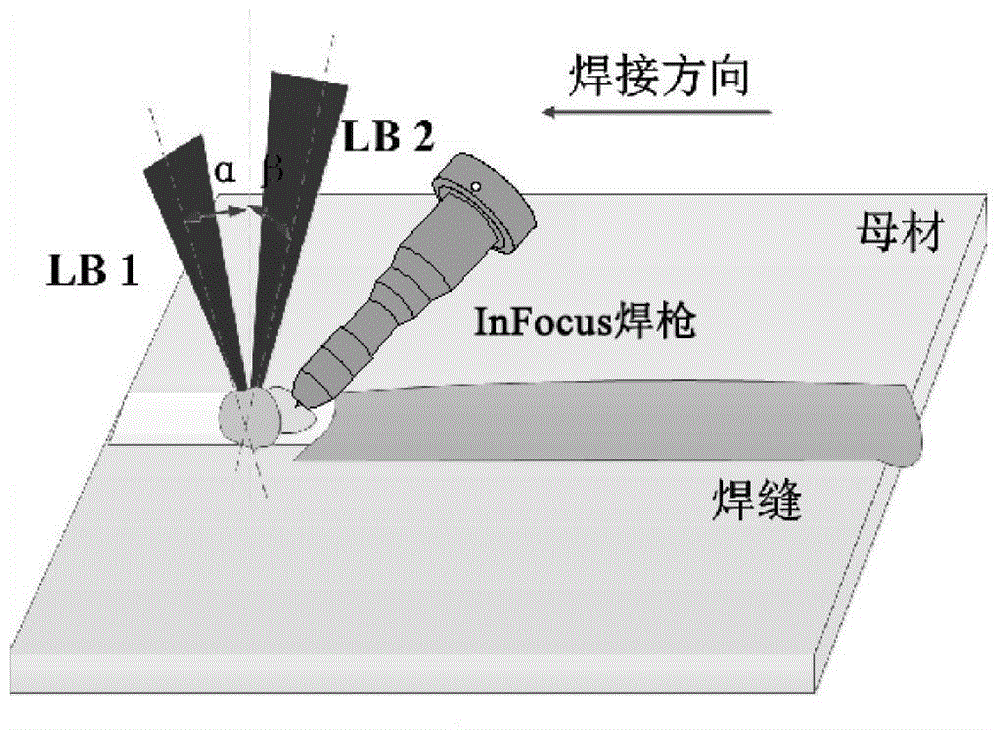

Bifocus laser and InFocus arc hybrid welding method

InactiveCN104985327AImprove energy utilizationIncrease weld penetrationLaser beam welding apparatusElectric arcEngineering

The invention discloses a bifocus laser and InFocus arc hybrid welding method, and relates to a welding method. The method includes the steps that (1) a to-be-welded workpiece is polished or washed; (2) the spot diameter is set to range from 0.1 mm to 0.5 mm, and the defocusing amount ranges from -3 mm to +3 mm; (3) welding parameters are set, wherein the arc current ranges from 50 A to 900 A, an included angle formed between a welding gun and the vertical direction ranges from 25 degrees to 55 degrees, the welding speed ranges from 100 mm / min to 1000 mm / min, the wire feeding speed ranges from 100 mm / min to 600 mm / min, the protection gas is inert gas, and the flow of the protection gas ranges from 15 L / min to 30 L / min; and (4) a switch is started, and laser-InFocus arc welding is carried out. According to bifocus lasers and InFocus, as the InFocus arc fusion depth is larger, and a key hole can be formed through welding, when a medium-thickness plate is welded, the lasers can directly act on the bottom of the key hole generated by the InFocus arc, and the fusion depth is continuously increased.

Owner:HARBIN INST OF TECH

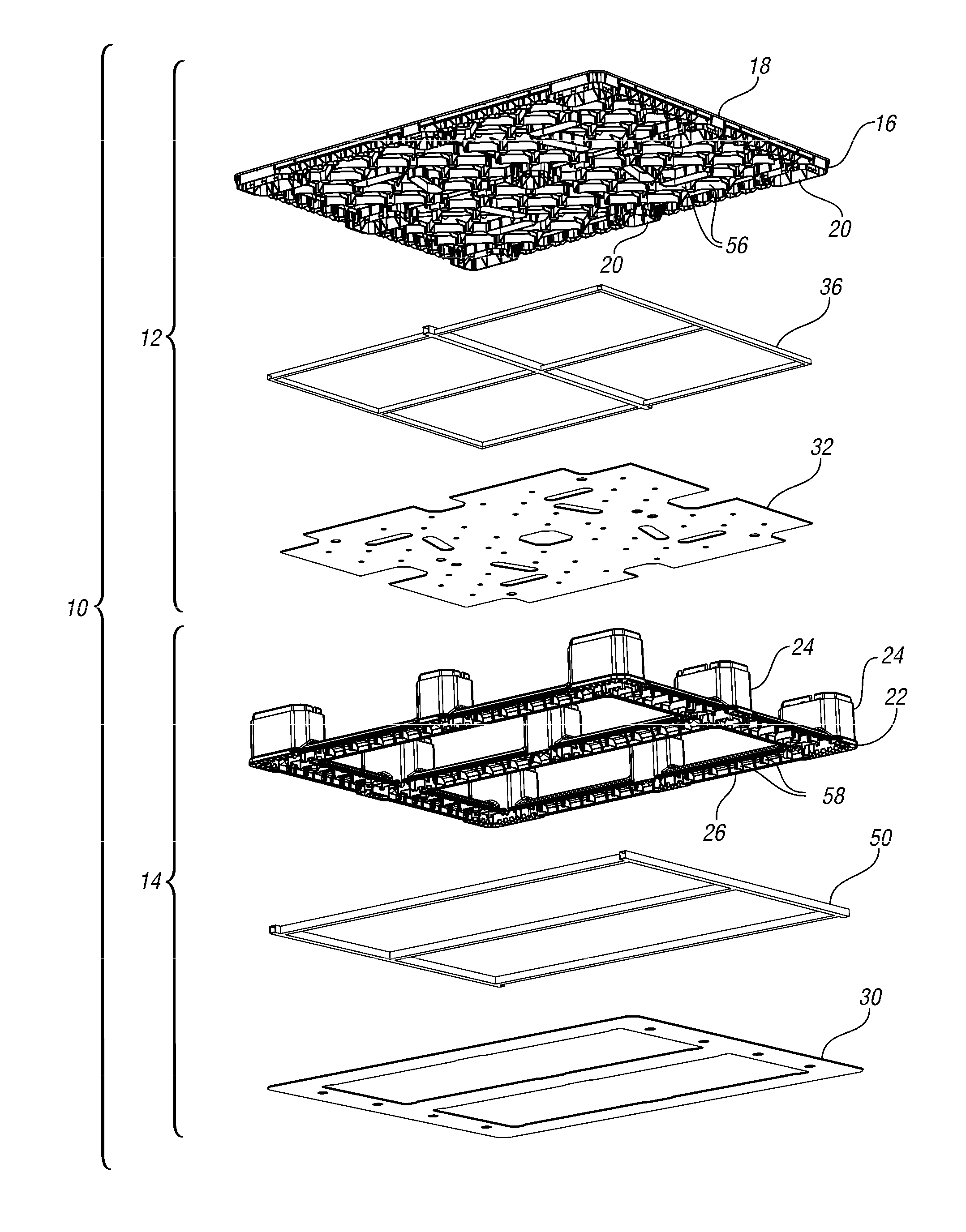

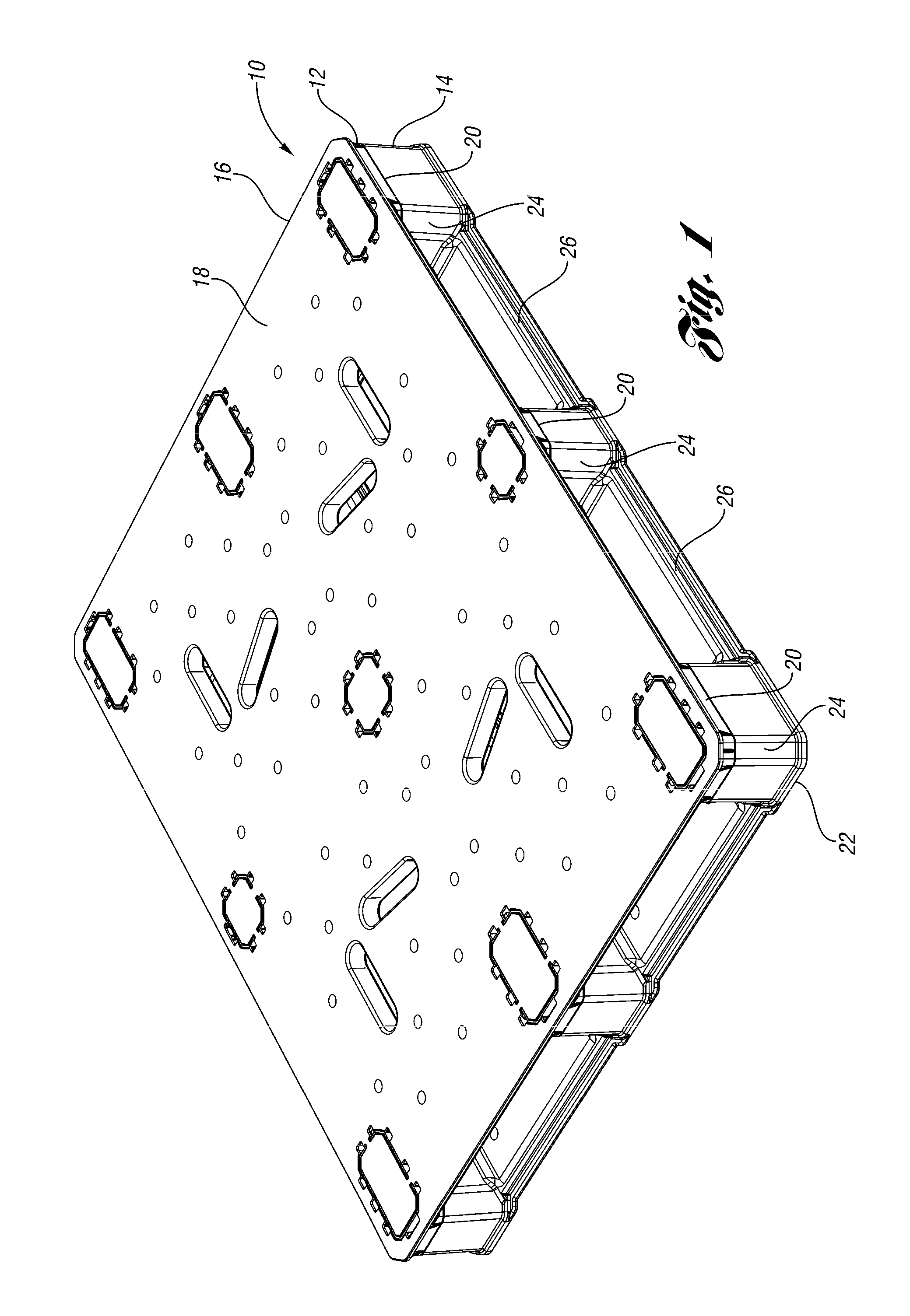

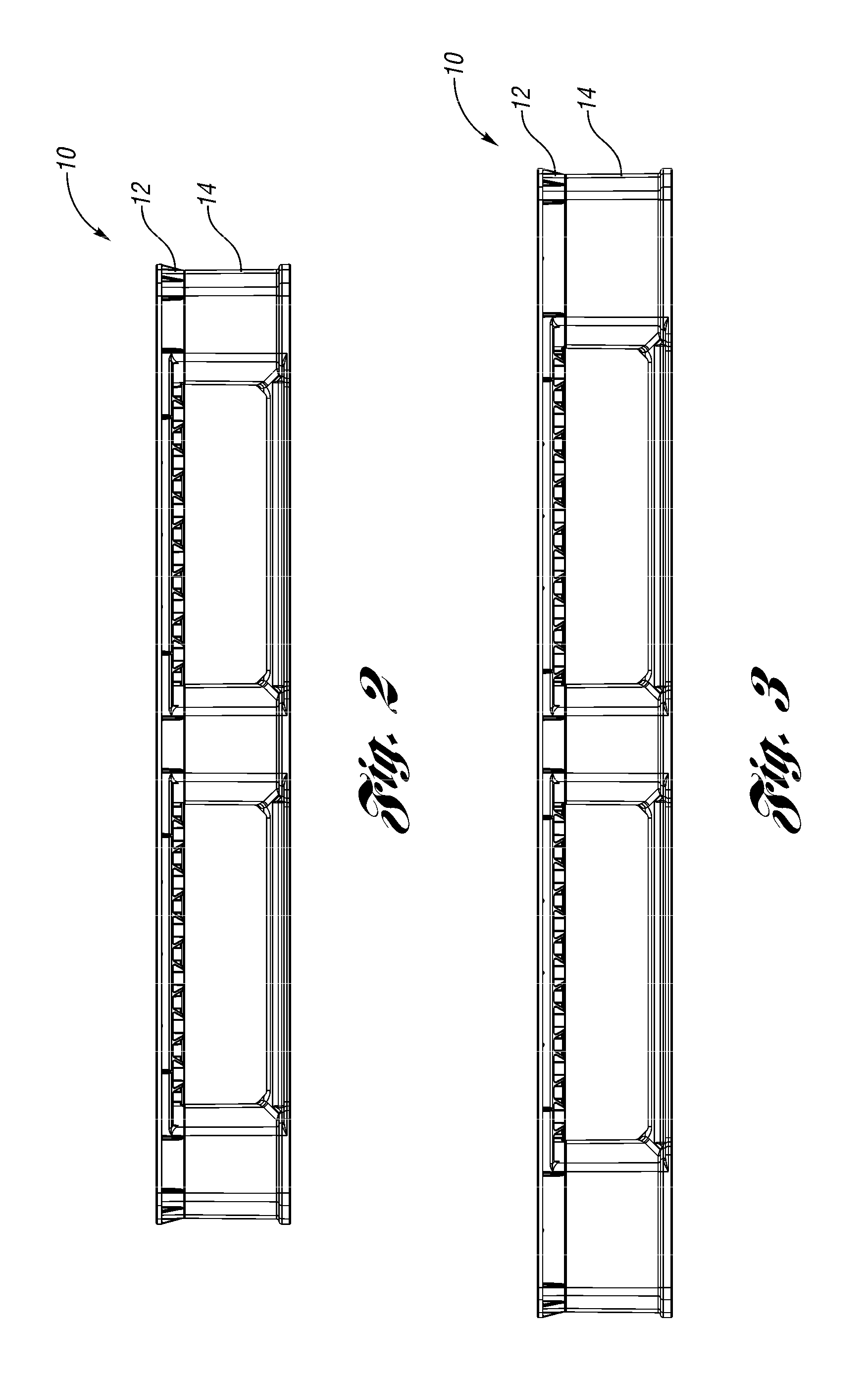

Pallet assembly

ActiveUS9452864B2Improve flame retardant performanceImprove performanceRigid containersEngineeringFire retardant

Owner:REHRIG PACIFIC CO INC

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

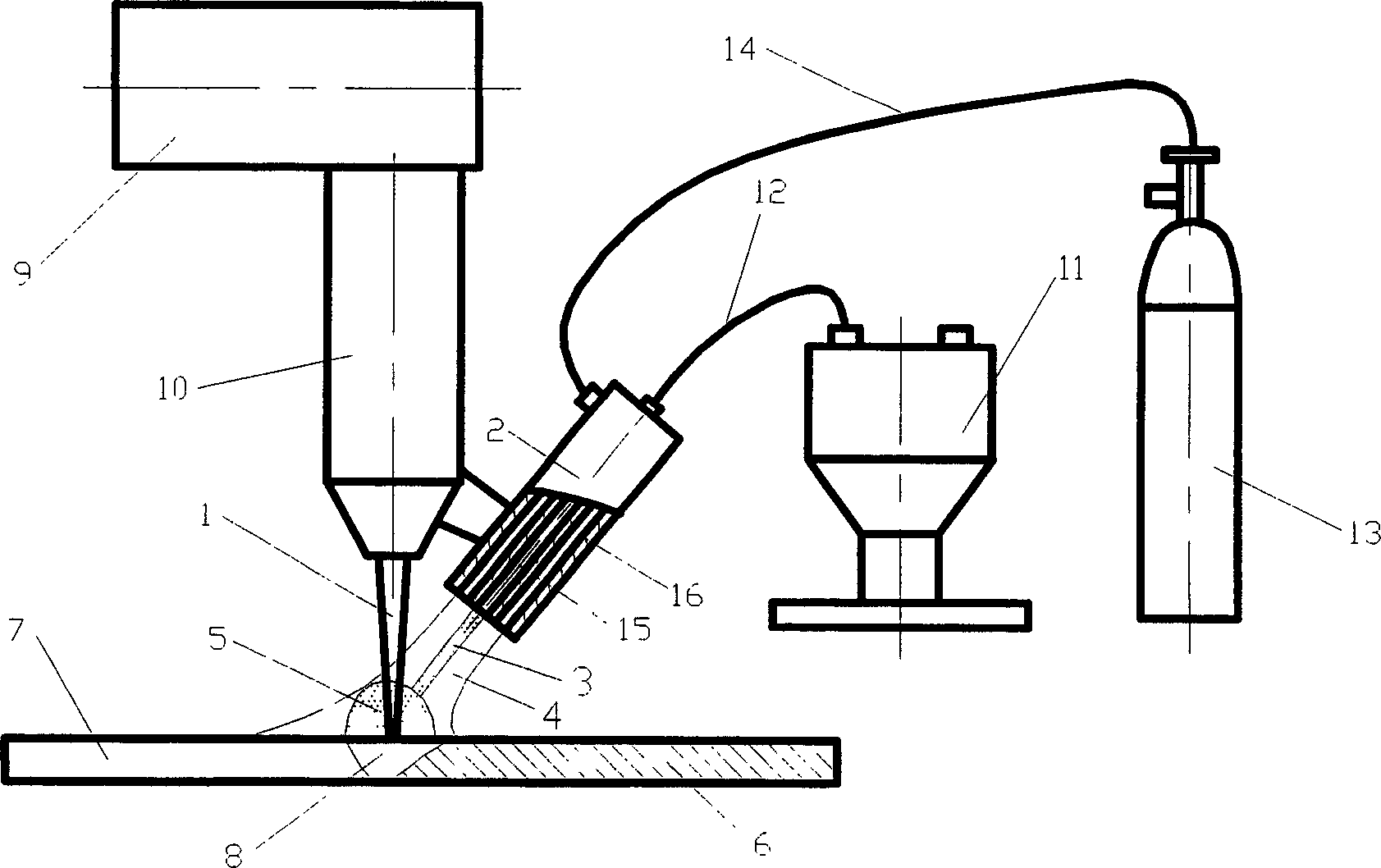

Aluminium alloy laser welding method by powder reinforced absorption

InactiveCN1586786APromote absorptionReduce output powerMetallic material coating processesLaser beam welding apparatusLaser power densityLaser beam quality

The present invention relates to powder absorption reinforced aluminum alloy laser welding method in laser material processing field. Into one common laser welding apparatus, one powder feeder is increased and has its powder feeding nozzle fixed to the laser welding head in the angle of 25-75 deg to the surface of workpiece. The present invention features that the fed aluminum or aluminum alloy powder of size 2-300 micron in the feeding speed of 1-20 g / min; and the laser power density of 0.15-3.5 MW / sq cm for CO2 laser welding and 0.1-1.8 MW / sq cm for YAG laser. Owing to the great specific surface area and small size effect of the powder, the metal or alloy powder under the action of the laser beam is gasified to form plasma, and this reinforces the absorption of the aluminum alloy material to laser, realizes the high efficiency laser welding at low power density of aluminum alloy material and reduces the requirement in laser power and laser beam quality for welding aluminum alloy.

Owner:BEIJING UNIV OF TECH

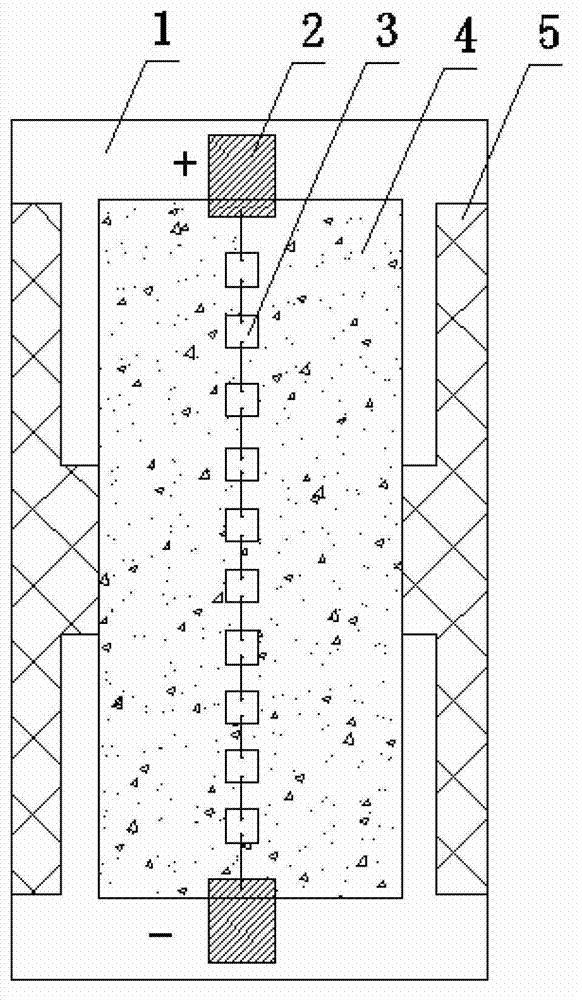

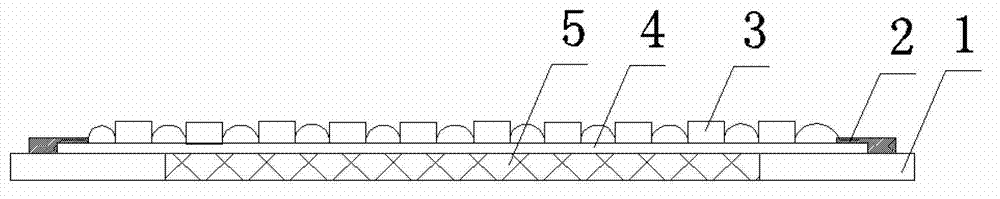

Flexible light-emitting diode (LED) lamp band and manufacturing method thereof

InactiveCN102788284AGood flexibilityImprove cooling effectPoint-like light sourceElectric circuit arrangementsOn boardEngineering

The invention discloses a flexible light-emitting diode (LED) lamp band and a manufacturing method thereof. The lamp band is formed by arranging a plurality of LED light source modules. The flexible LED lamp band is characterized in that each LED light source module comprises an upper copper sheet, a lower copper sheet and an insulation sheet, wherein the upper copper sheet and the lower copper sheet are isolated; the insulation sheet is connected between the upper copper sheet and the lower copper sheet; heat conduction layers are respectively coated on the upper surface of the copper sheet and the upper surface of the insulation sheet; at least one string of LED chips is mounted on each heat conduction layer; the corresponding upper copper sheet and the corresponding lower copper sheet are respectively provided with an electrode soldering point; and the LED chips are connected in series between each upper electrode soldering point and each lower electrode soldering point. The manufacturing method comprises the following six steps of cutting, etching, packing, coating, mounting and wiring. The invention has the obvious effects that the lamp band is good in connectivity; chip on board (COB)-packaged LED light source modules are high in stability and convenient in assembly. The single LED light source module can be mounted or multiple LED light source modules can be combined; and large-scale mass production manufacturing can be realized. The flexible LED lamp band not only can be applied to corn lamps but also can be used for manufacturing various traditional lamps and also can be well utilized on street lamp light source modules or tunnel lamp light source modules.

Owner:重庆楚商光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com