Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

255 results about "Arc stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

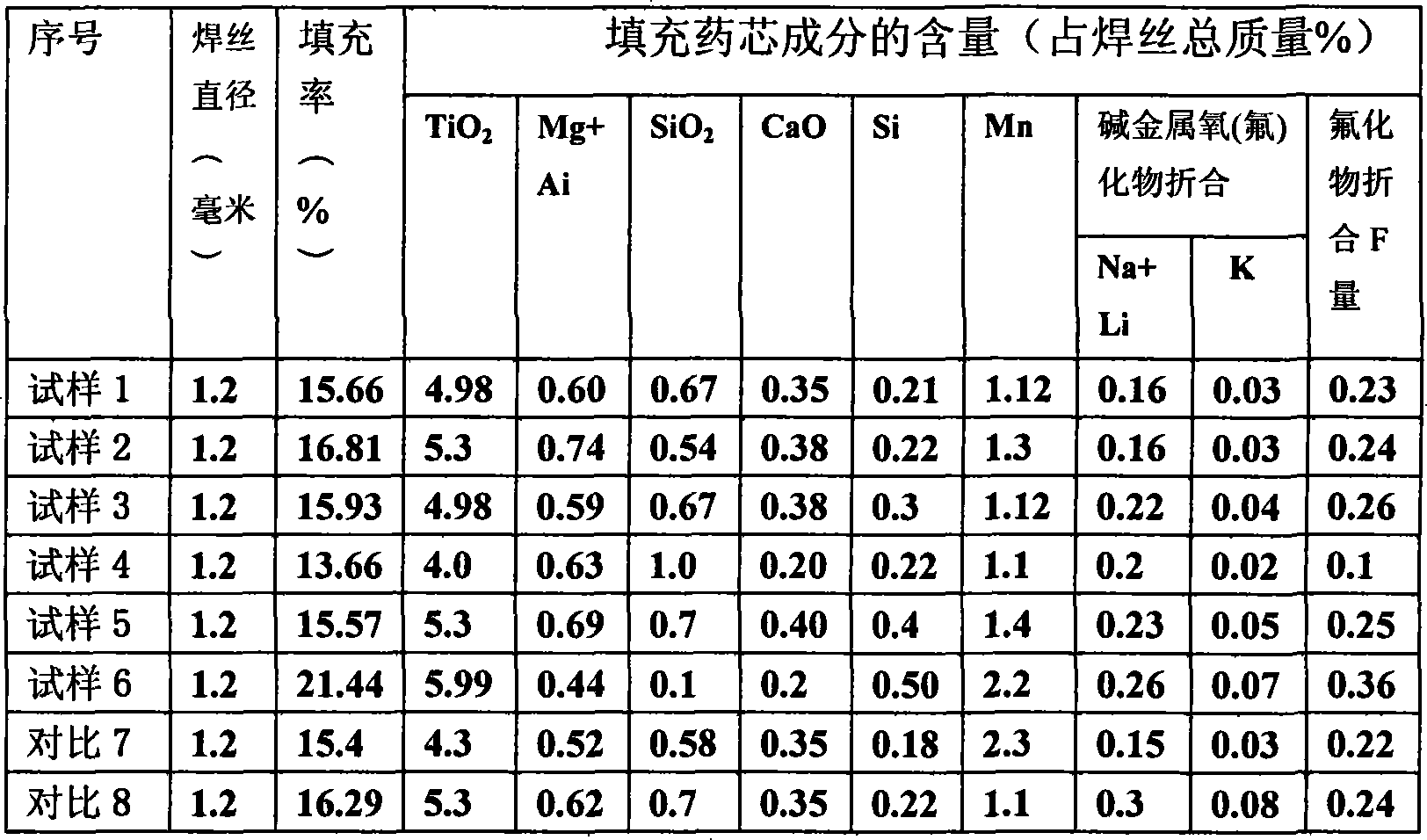

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

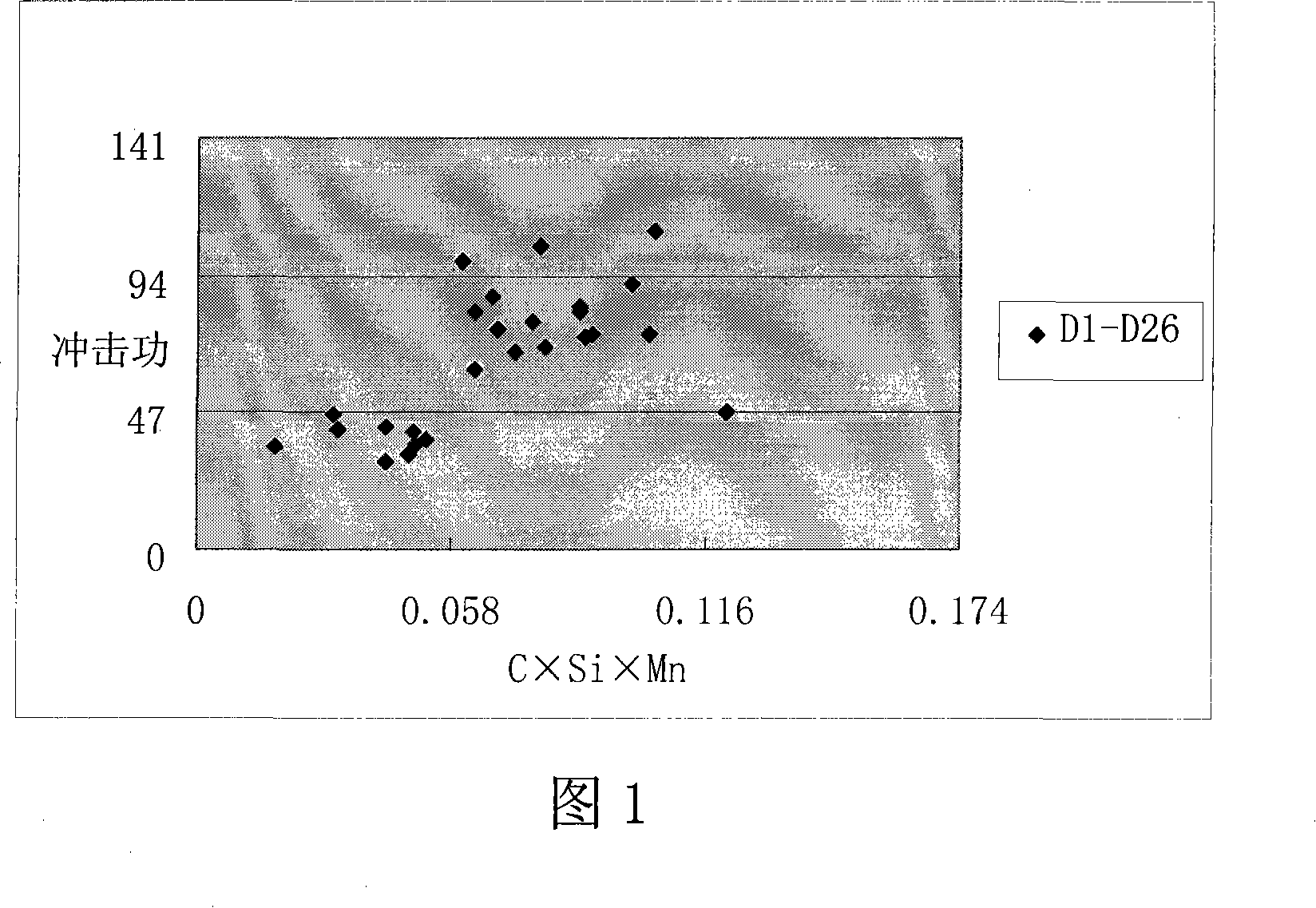

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

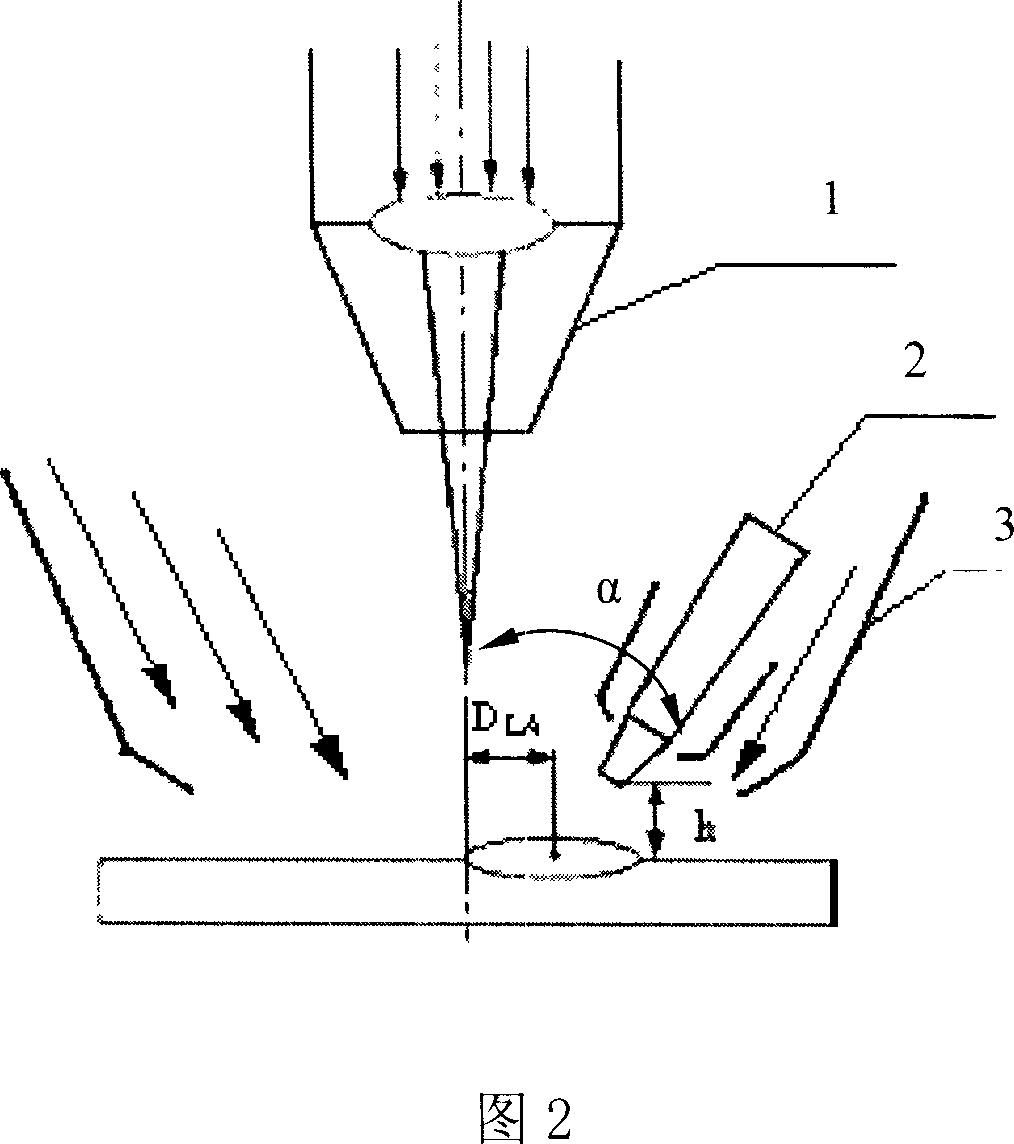

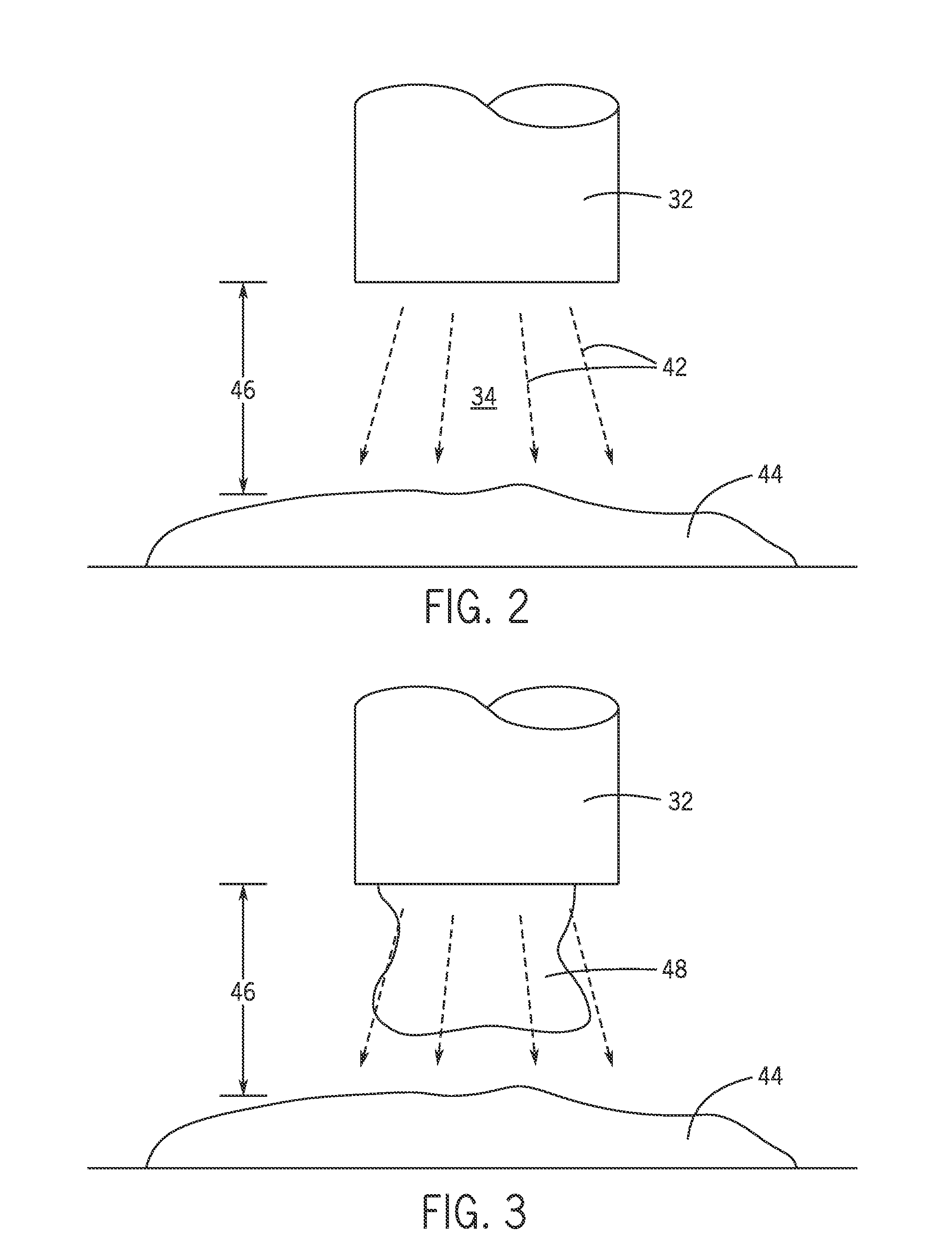

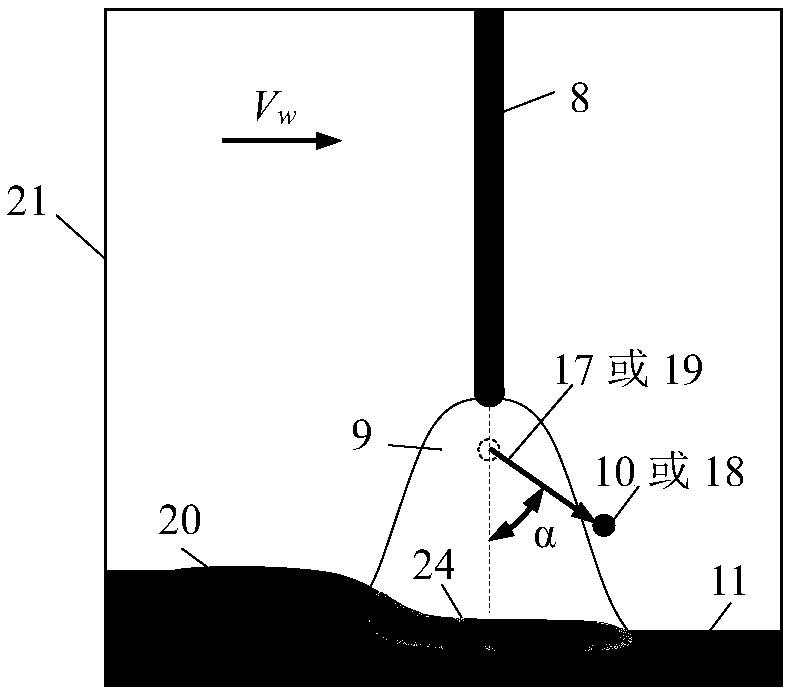

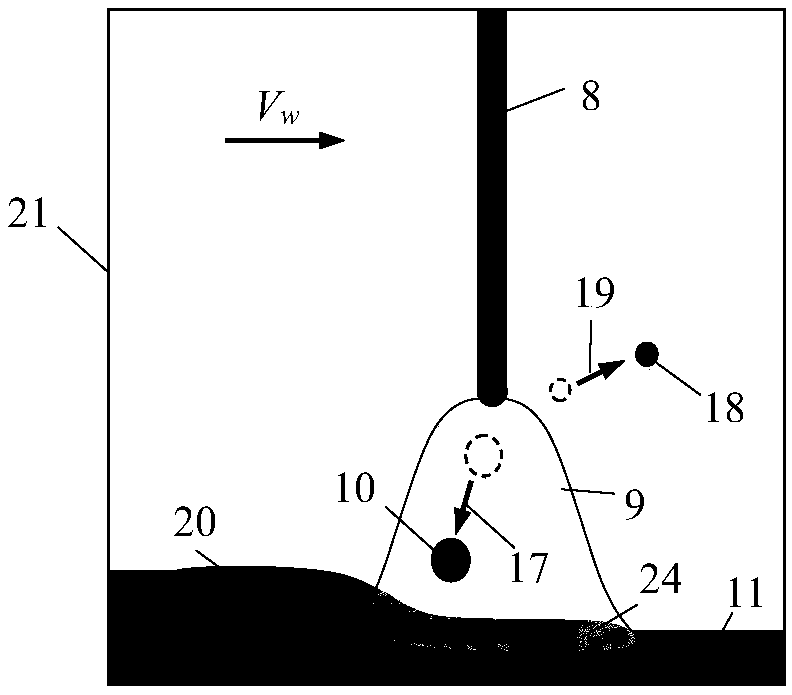

Method for welding with laser-cold metal transferred arc composite heat source

ActiveCN101811231ASolve the problem of poor spreadabilityImprove stabilityLaser beam welding apparatusArc stabilityAlloy

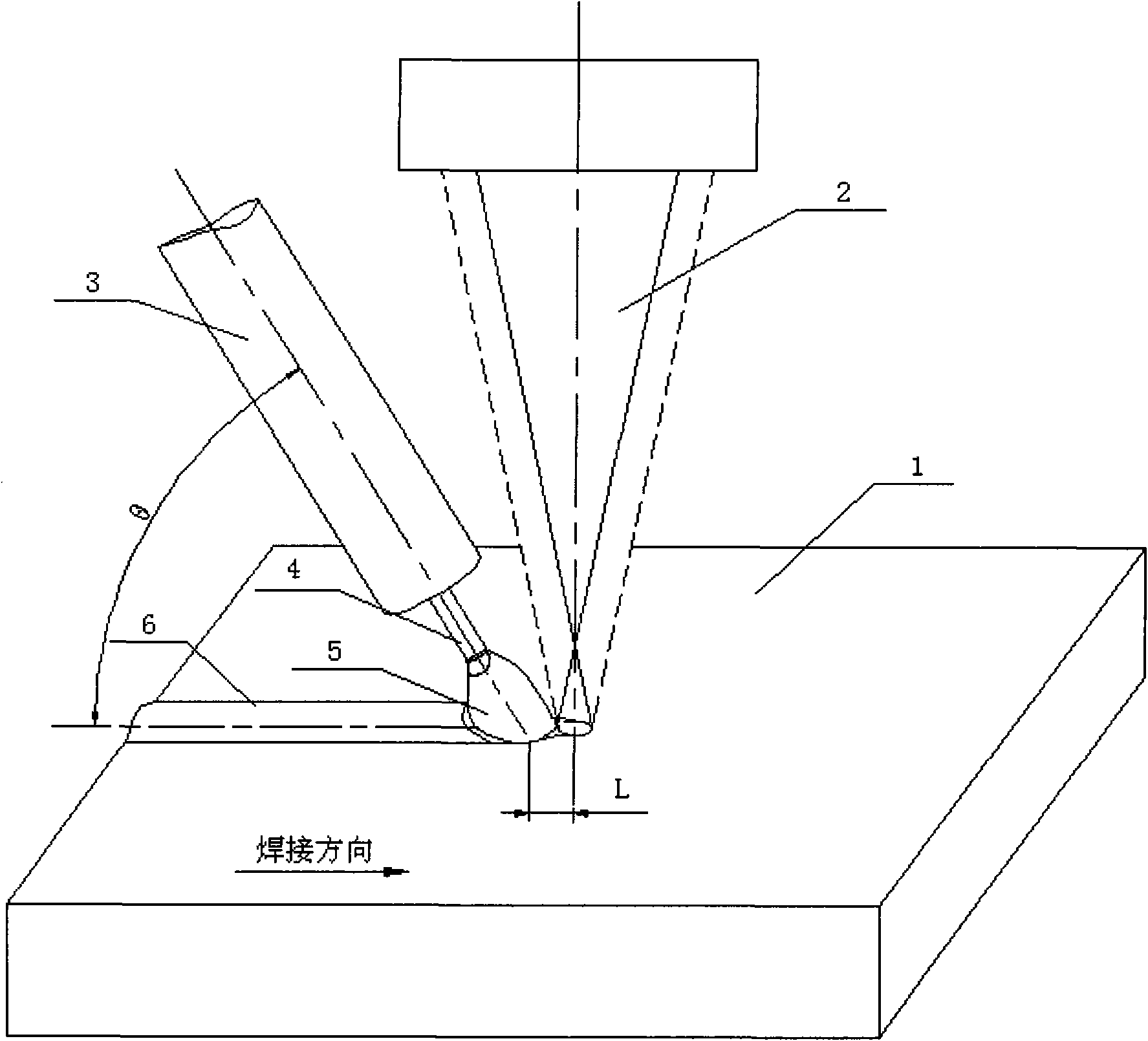

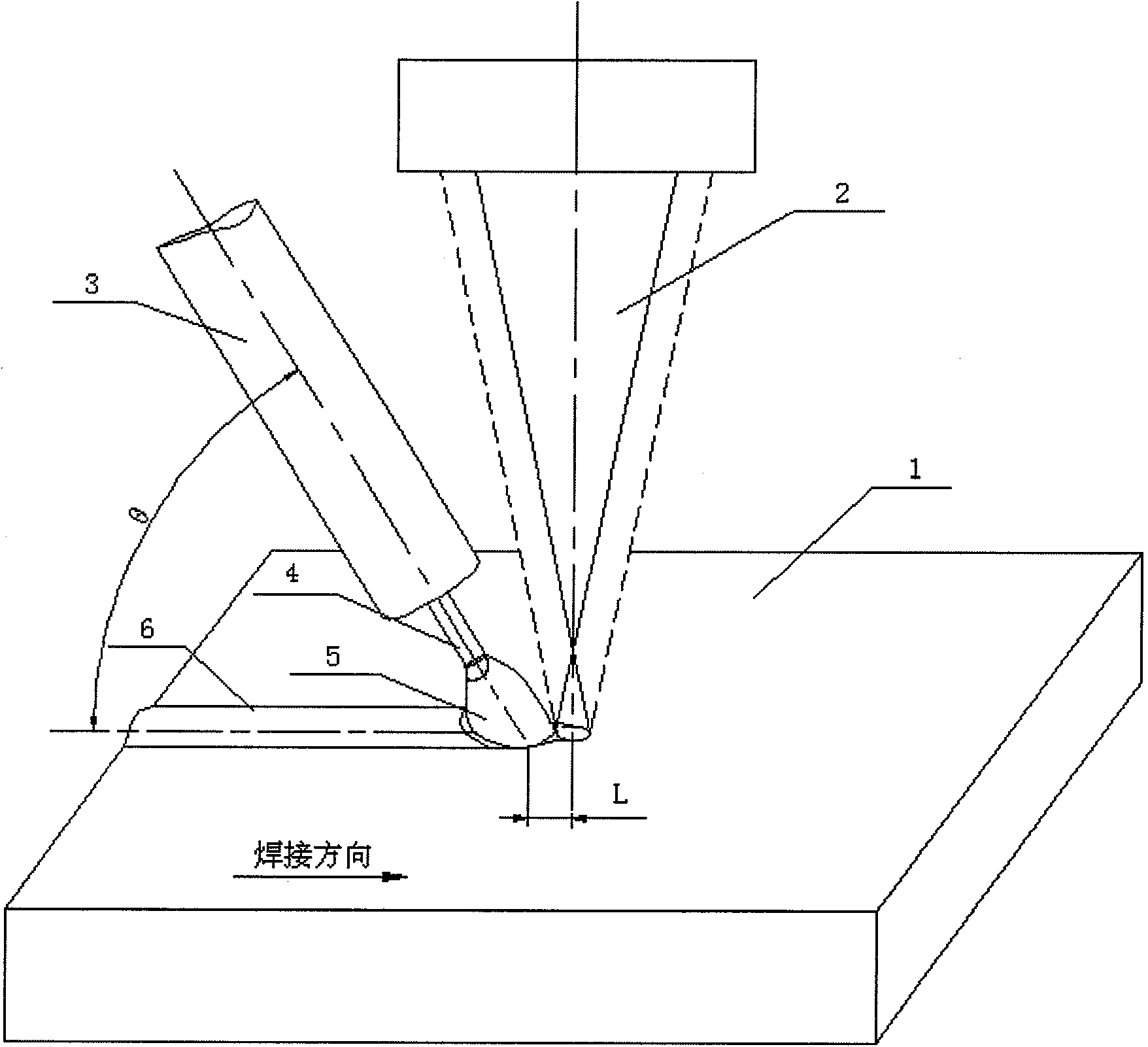

The invention provides a method for welding with a laser-cold metal transferred arc composite heat source, and belongs to the technical field of composite heat sources. The welding method solves the technical problems of low-quality welding lines and low arc stability of the pure Ar-protected cold metal transferred arc welding. The method comprises the following steps of: using pure Ar gas for protection during welding, and forming a novel composite heat source by using the cold metal transferred arc(5) and a laser beam (2) of which the power is more than or equal to 800, wherein the laser beam (2) is defocused, the diameter of a laser spot formed by the laser beam (2) on the surface of a workpiece (1) to be welded is 1 to 4mm, a spot of the cold metal transferred arc (5) can be arranged in front of or behind the spot of the laser beam (2), the central distance of the two spots is 0 to 8mm, and an included angle between a welding torch(3) of the cold metal transferred arc(5) and the horizontal plane is 45 and 75 degrees. The composite heat source is mainly used for welding plates and tubes made of stainless steel, high-strength steel and nickel-based alloy.

Owner:HARBIN WELDING INST LTD

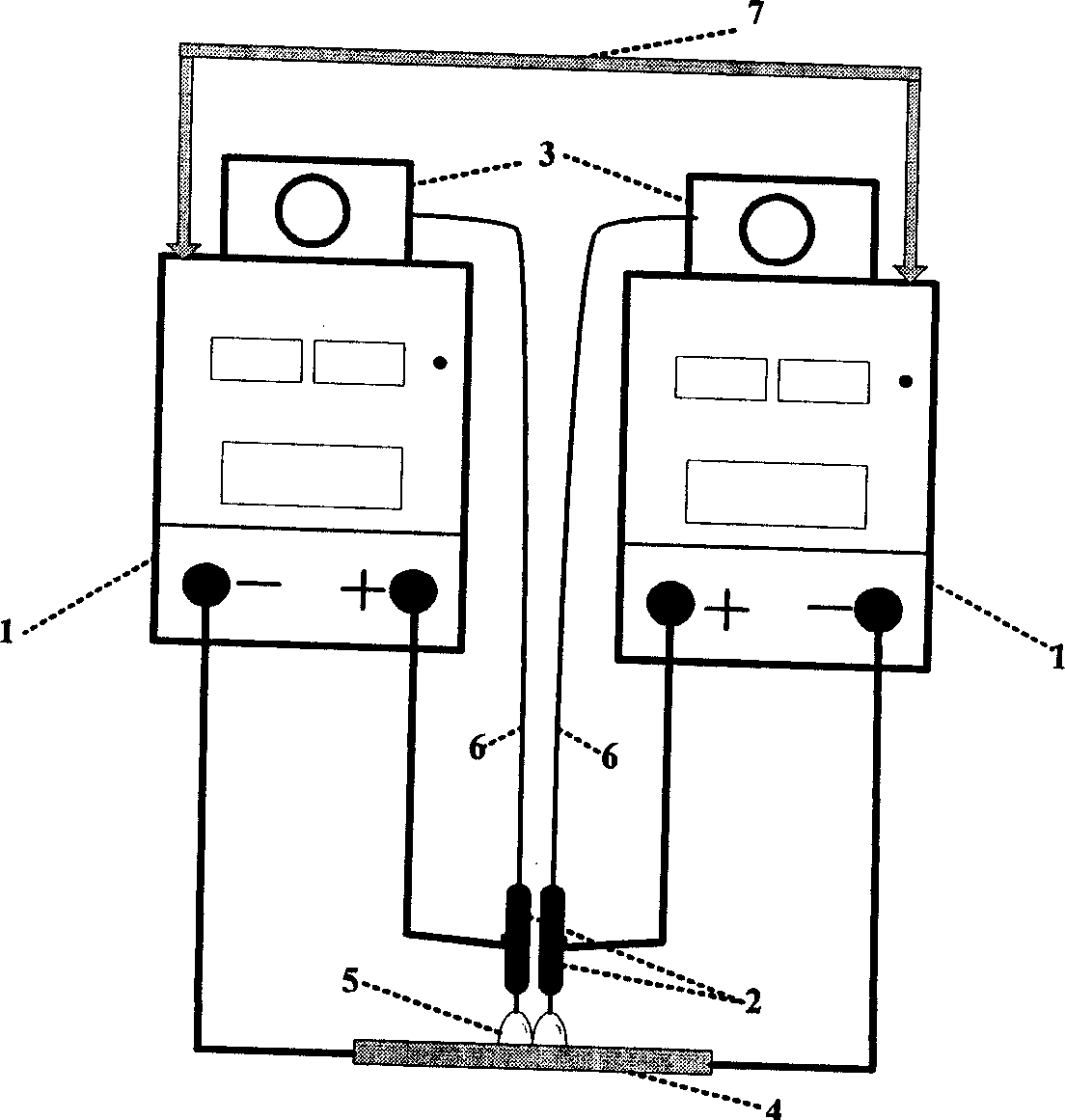

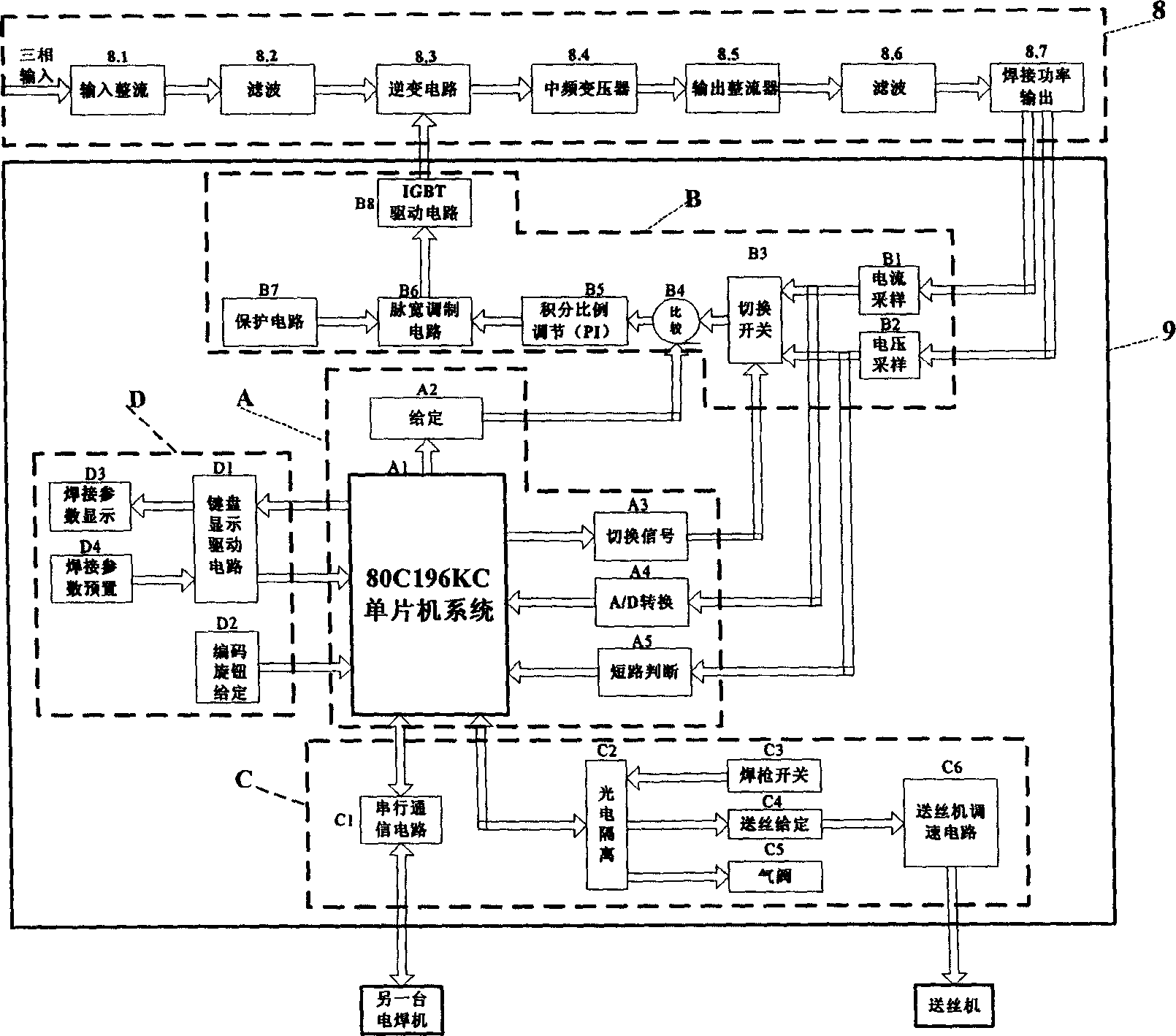

Welding control method of diplonema MAG and welding source

InactiveCN1695866AImprove stabilityControl the level of distractionArc welding apparatusConstant frequencyArc stability

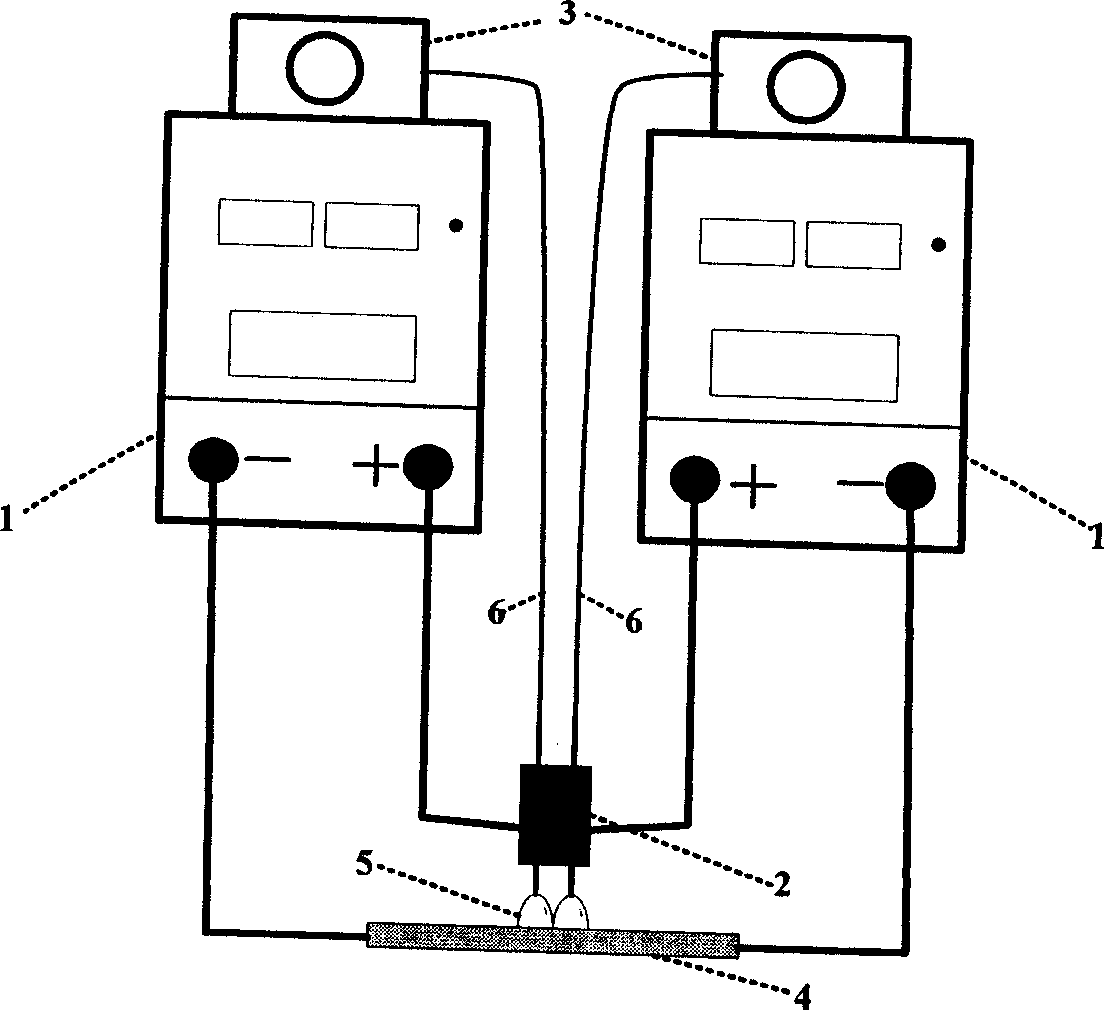

A dual-wire MAG welding control method features that the welding current feedback and voltage feedback are compared with the given signals in time shared mode, a control circuit is used to control welding, and during the welding two welders with constant frequency are used by keeping certain phase relation for high stability. Its welding power supply features that its controller uses a switching circuit consisting of current sampler, voltage sampler, switching switch, comparator, integral proportioner and amplifier connected to welding power output unit.

Owner:BEIJING UNIV OF TECH

Microbeam tungsten argon arc welding method for magnesium alloy thin-walled tube

InactiveCN102554418AIncrease the difficultyLow yieldArc welding apparatusWelding/cutting media/materialsArc stabilityManganese

The invention relates to a microbeam tungsten argon arc welding method for a magnesium alloy thin-walled tube. A low-magnesium aluminum alloy welding wire is used as a filling material, and the thin-walled tube is welded by a microbeam tungsten argon arc welding process under inert gas shielding. The low-magnesium aluminum alloy welding wire comprise 9.5%-11.6% of Al (aluminum), 0.6%-1.75% of Zn (zinc), 0.15%-0.35% of Mn (manganese), 0.01%-0.05% of Cu (copper), 0.02%-0.05% of Si (silicon) and the balance Mg (magnesium) in mass percent. The microbeam tungsten argon arc welding method for the magnesium alloy thin-walled tube is high in welding efficiency and convenient and flexible in application, and can be used for obtaining a crack-free welding joint without magnesium-aluminum brittle compounds. Compared with a conventional tungsten argon arc welding method, the microbeam tungsten argon arc welding method has the advantages that arc stability of microbeam argon arc welding for the magnesium alloy thin-walled tube is obviously improved, the tensile strength of the welding joint is 30% higher than that of a conventional tungsten argon arc welding joint, the elongation of the welding joint is increased by 10%, and the use requirements of industrial production on magnesium alloy thin-walled tube welding component can be met.

Owner:SHANDONG UNIV

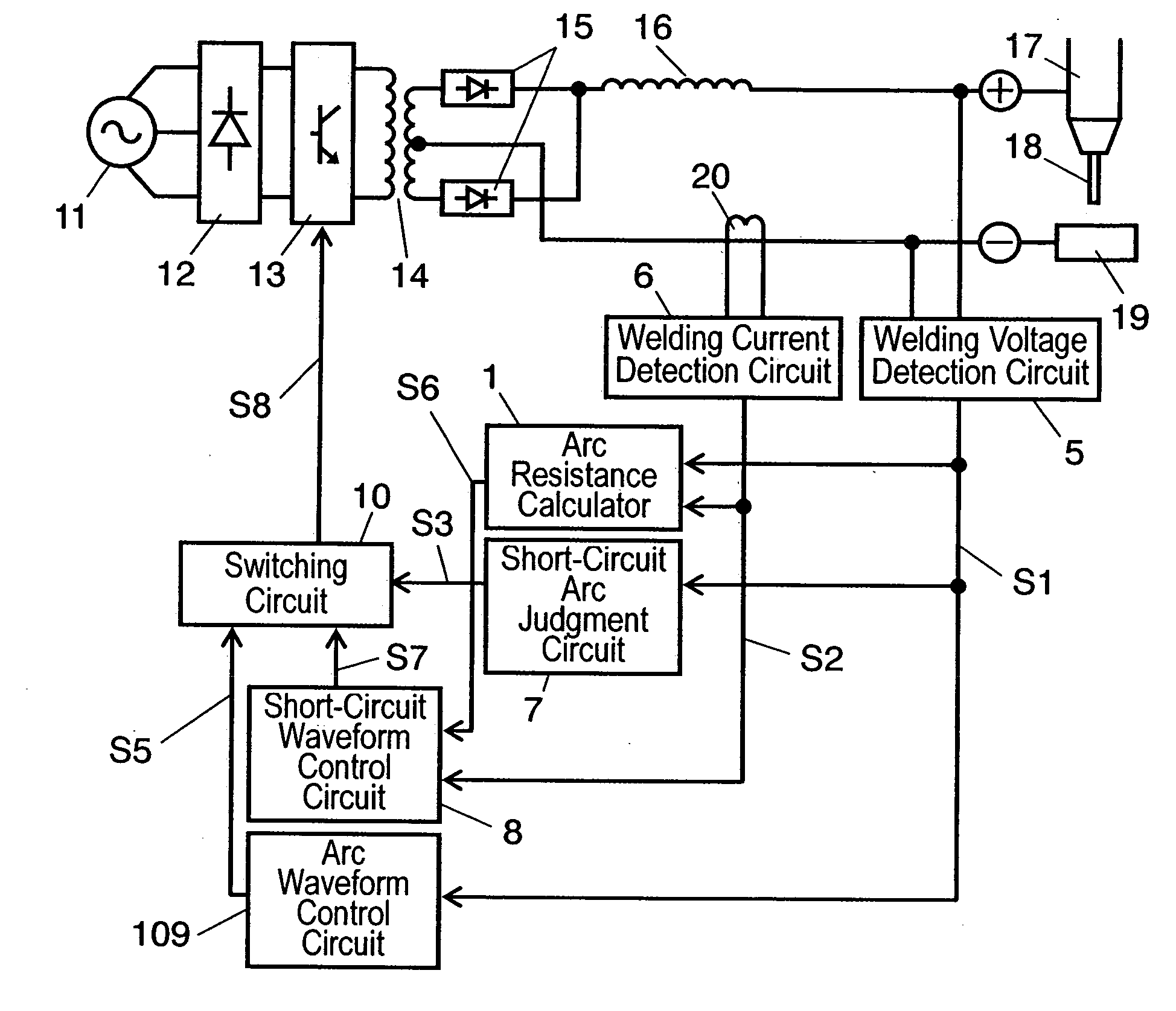

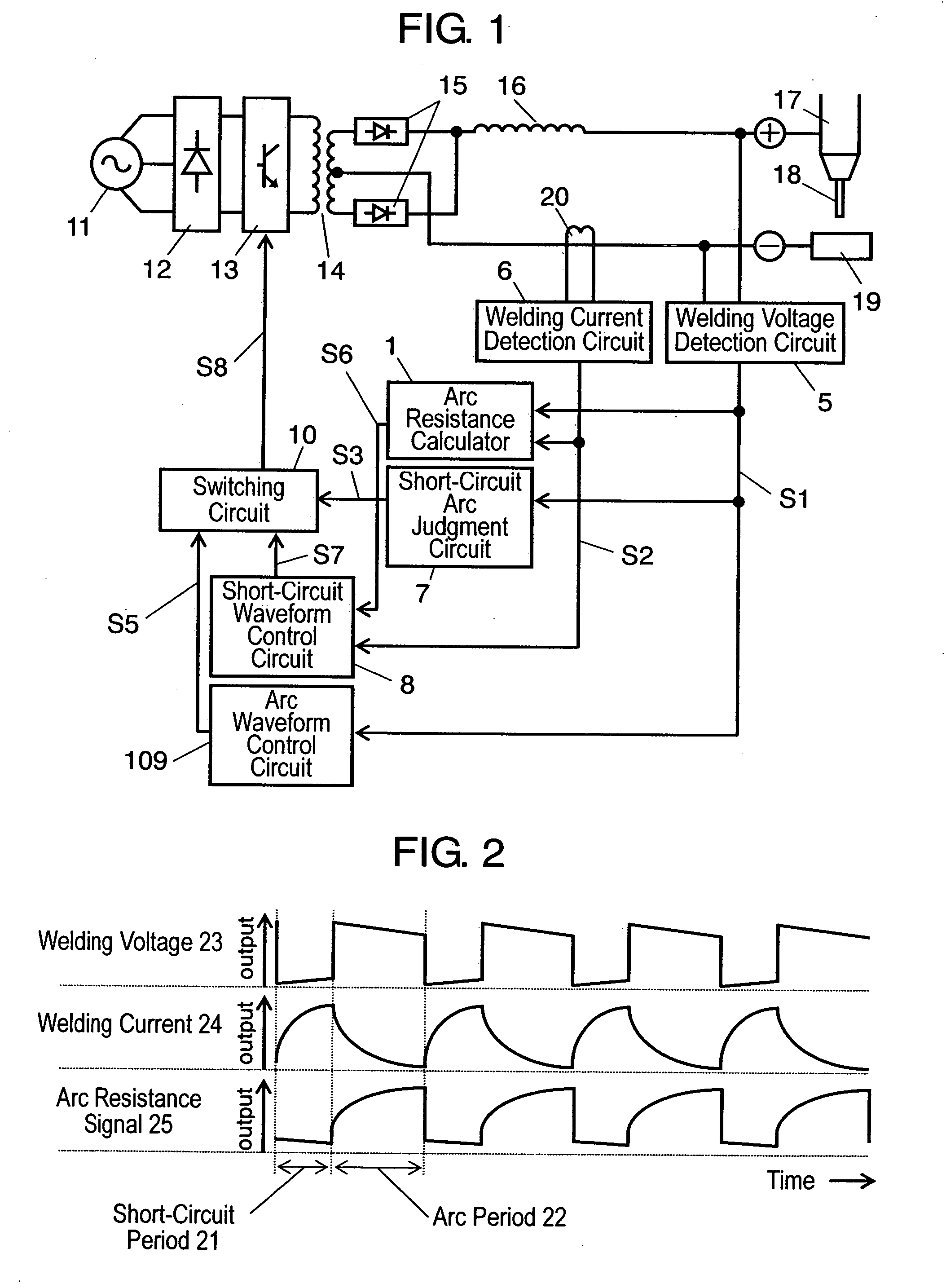

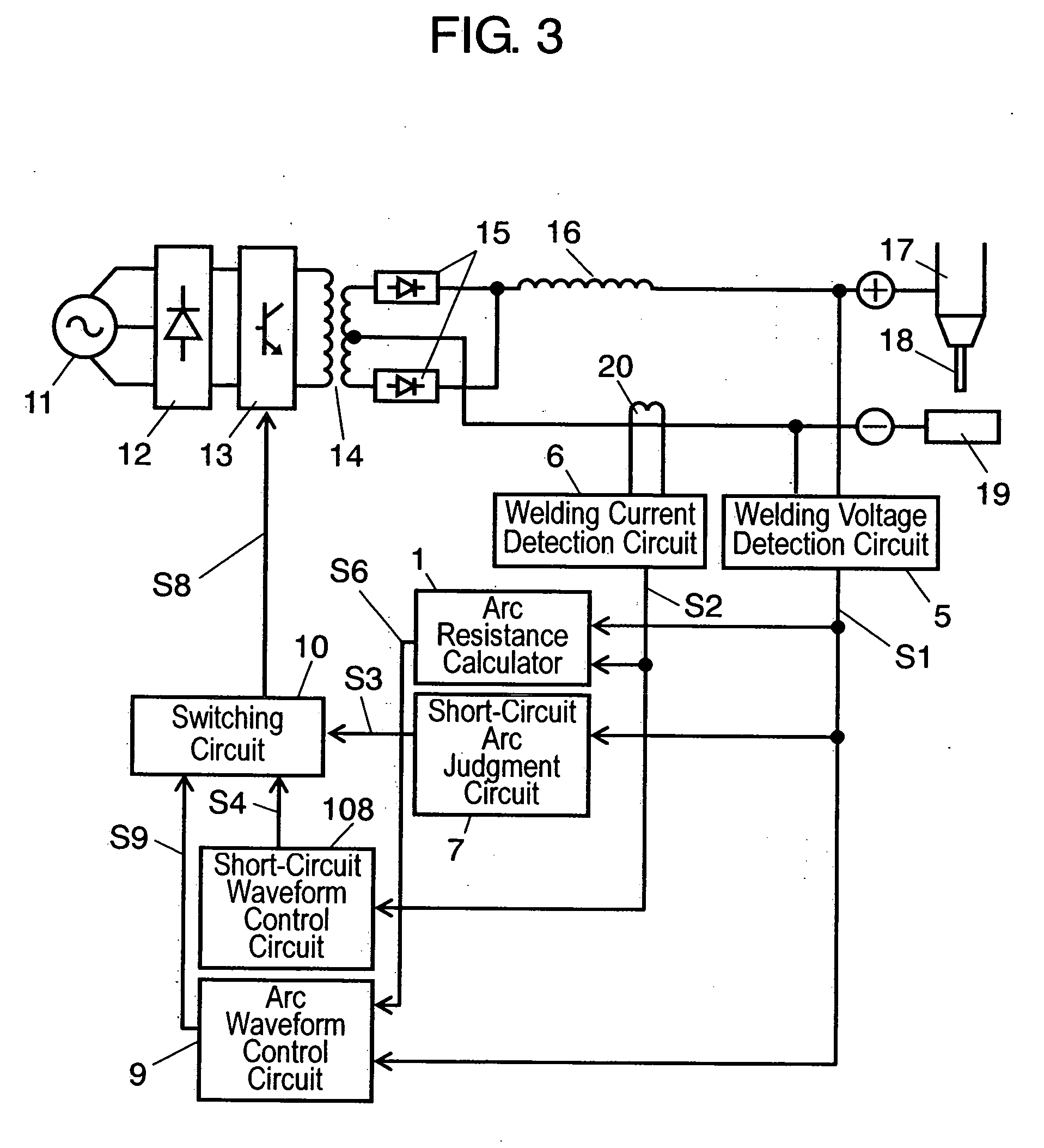

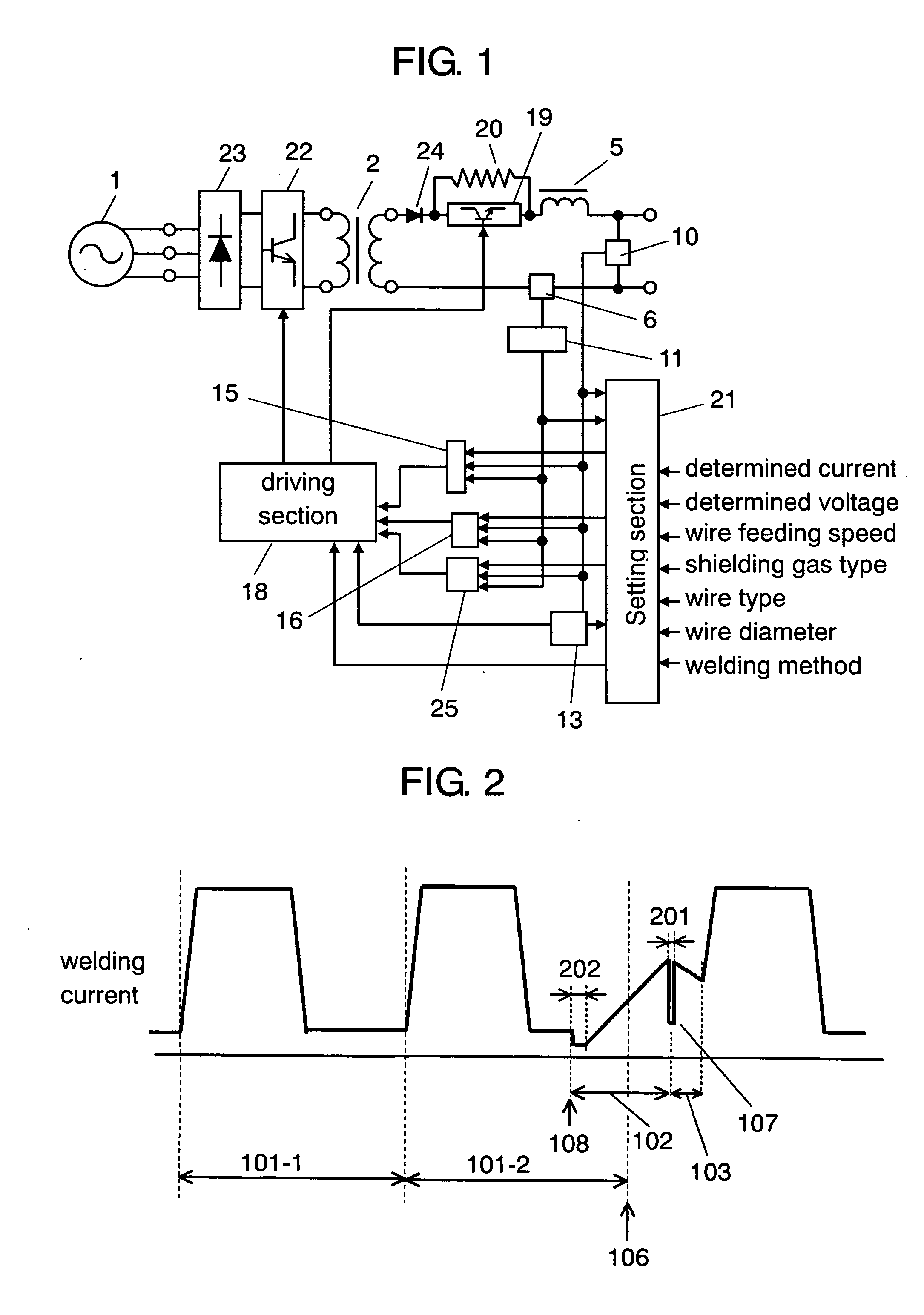

Consumable Electrode Type Arc Welding Machine

InactiveUS20080264916A1Dc-dc conversionElectrode supporting devicesElectrical resistance and conductanceArc stability

A consumable electrode arc-welding machine comprising an arc resistance calculating part that calculates an arc resistance from a welding current and a welding voltage to develop an arc resistance signal, wherein the welding current and welding voltage are controlled by a short-circuit waveform control signal and an arc waveform control signal that vary in accordance with the arc resistance signal. In this way, the spatter control and the arc stability can be achieved. During an arc period, if the arc resistance signal exhibits a level greater than a predetermined level for a predetermined period, a constant current control signal is developed to perform a constant current control of the welding current by use of a predetermined current value that is higher than the current value developed during the development of the arc waveform control signal, thereby preventing the arc from going off.

Owner:PANASONIC CORP

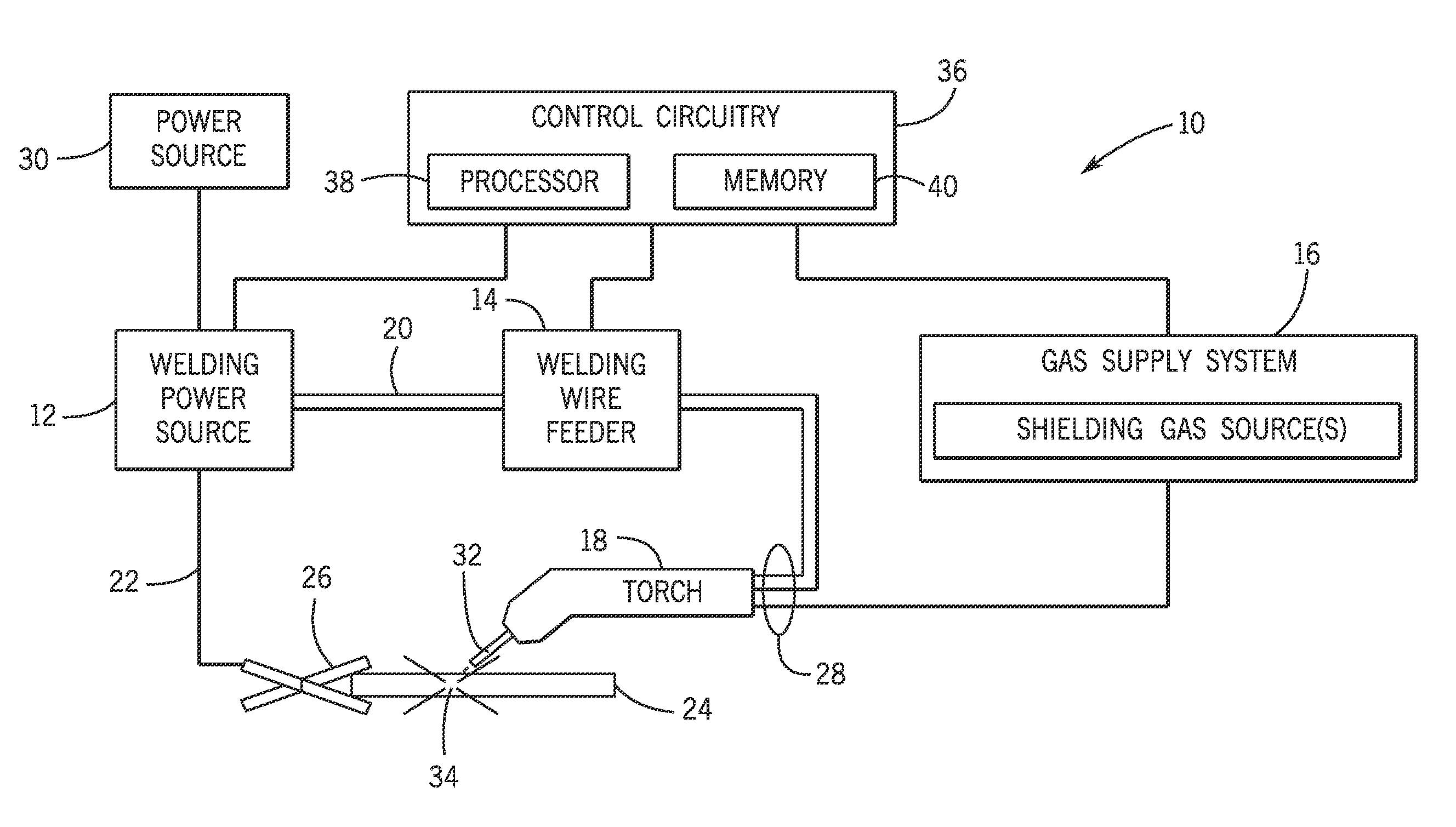

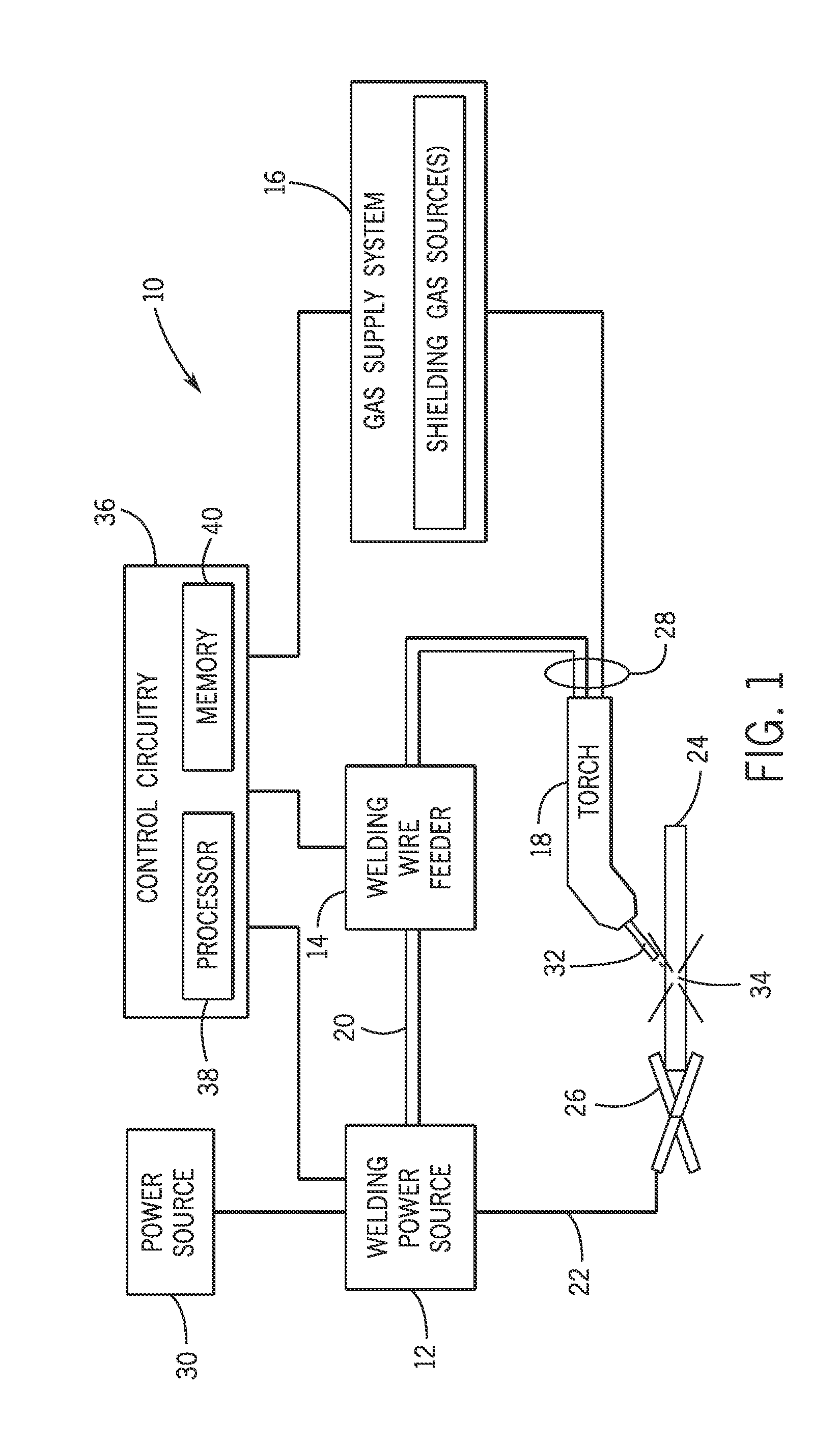

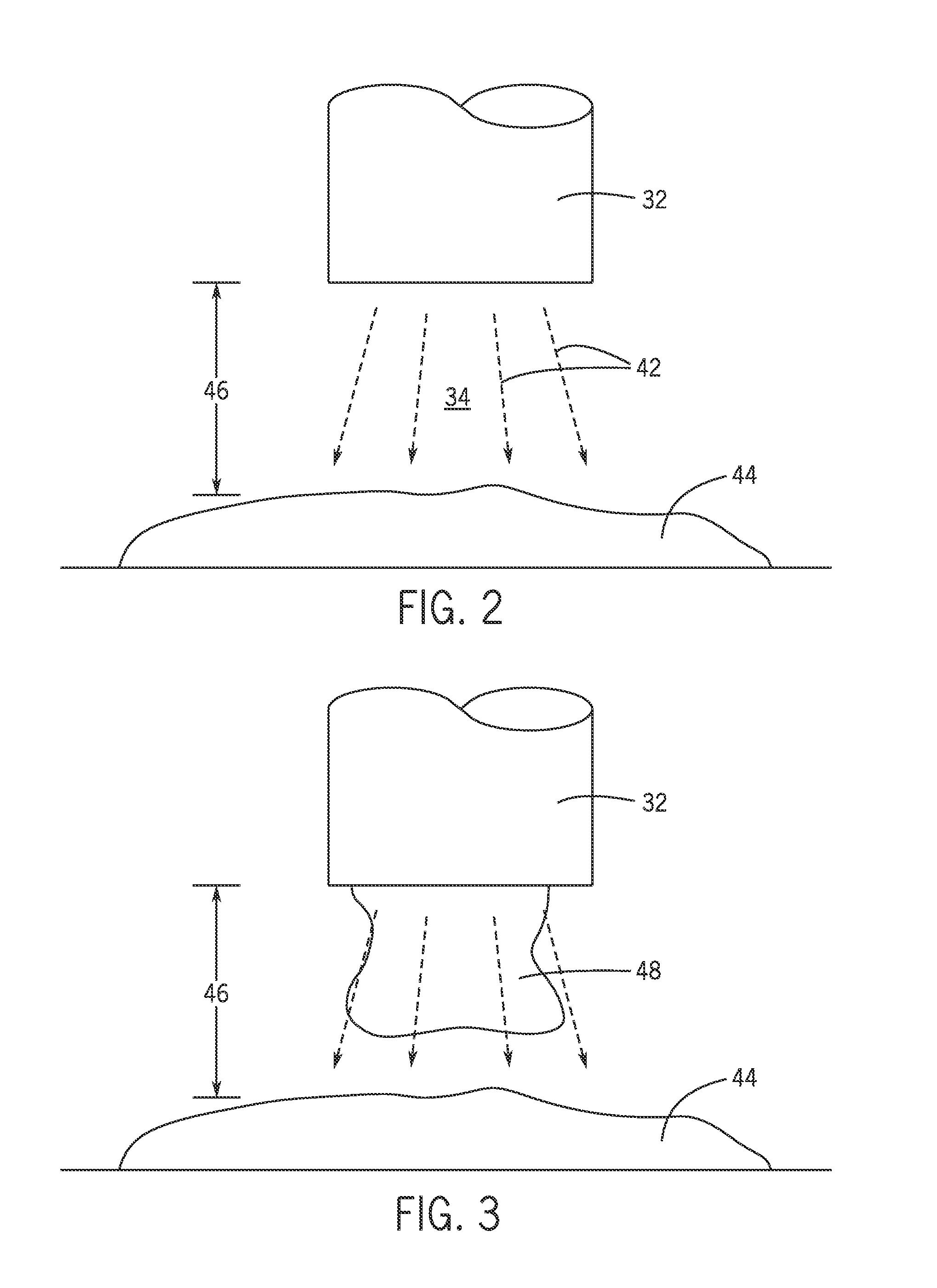

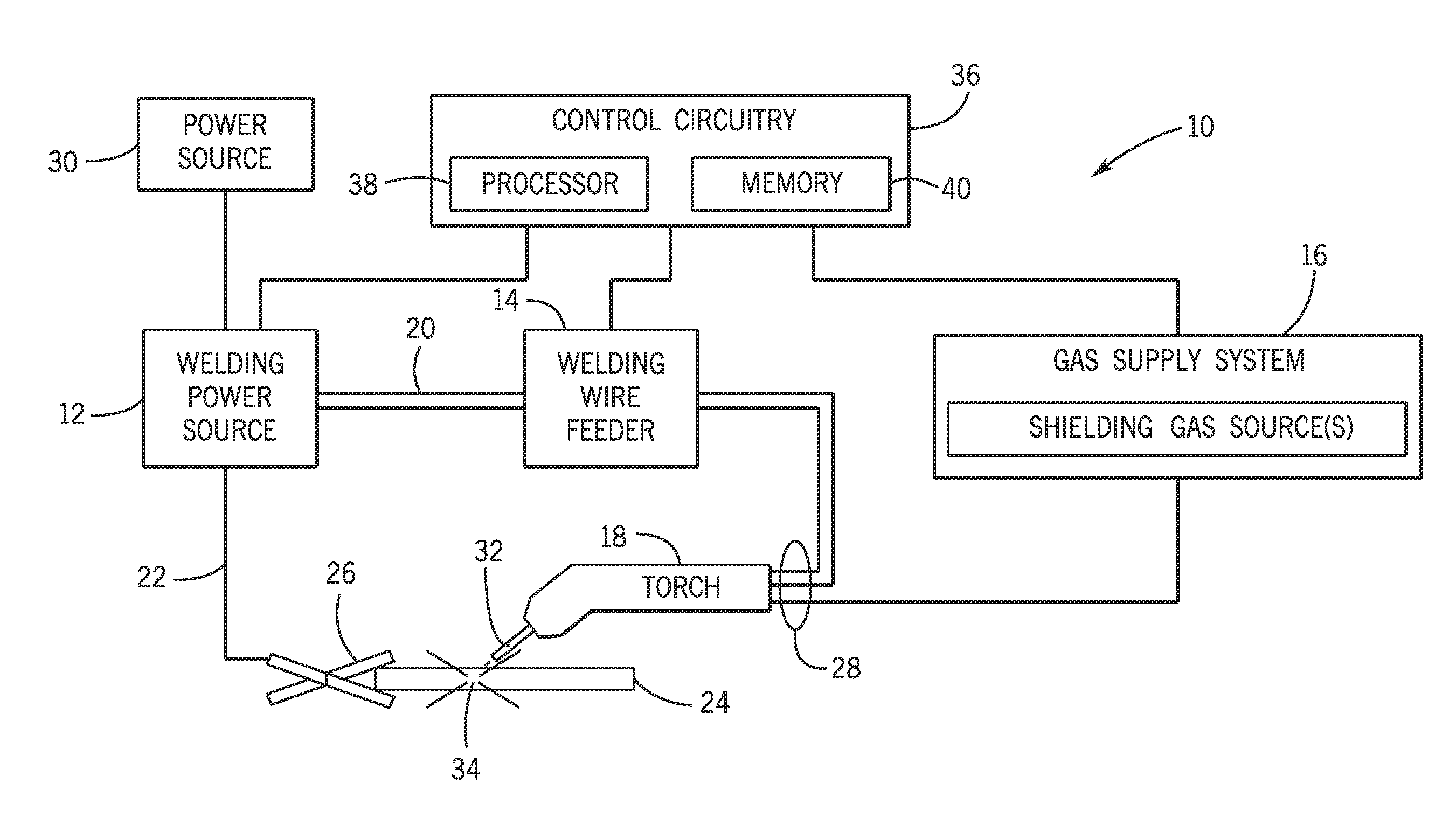

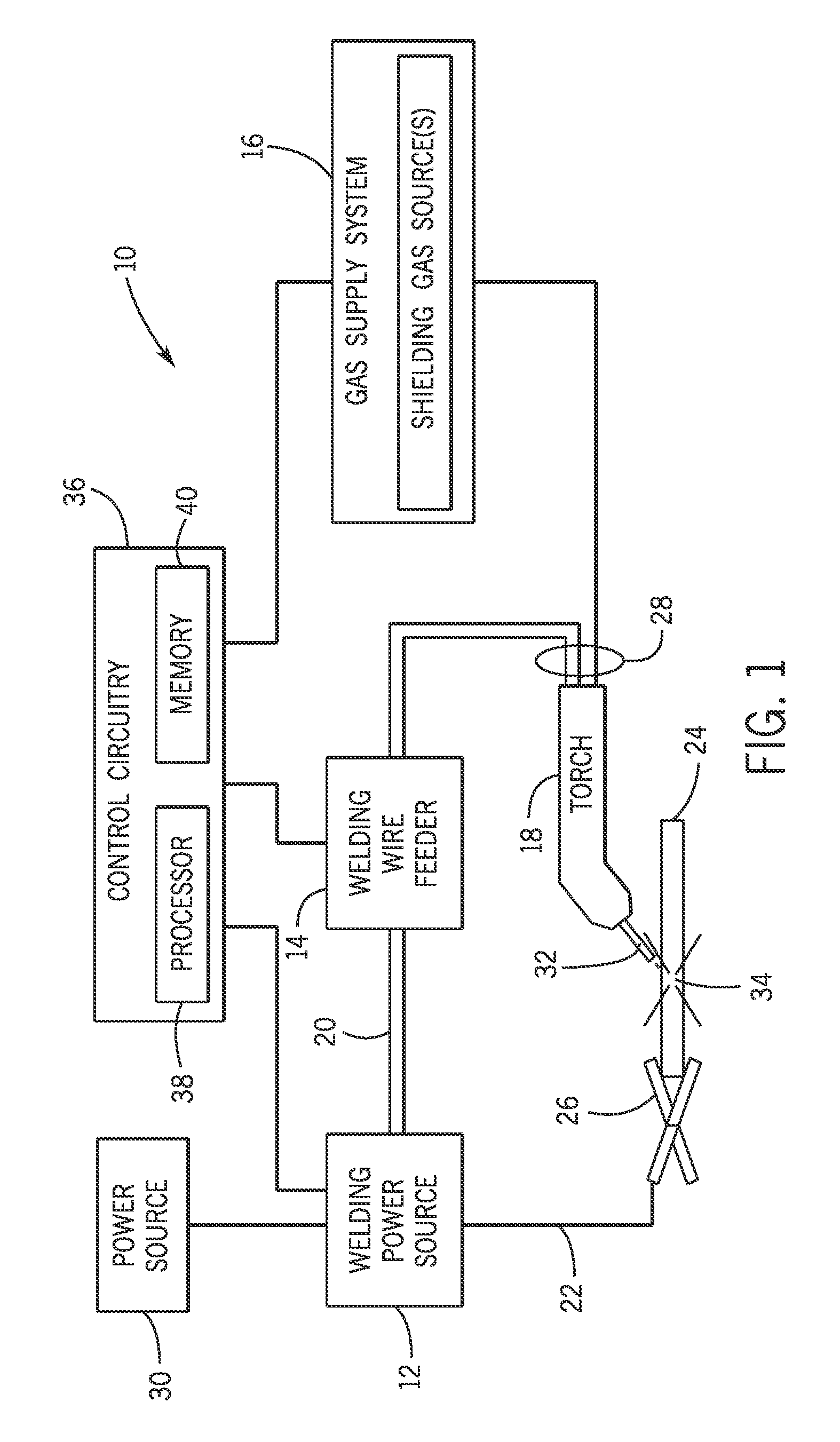

Electrode negative pulse welding system and method

A welding system includes a power source configured to generate power and deliver the power to a welding torch. The power is provided in accordance with an electrode negative pulse welding regime that includes a cyclic peak, followed by a stabilization phase, then a return to a background level. The stabilization phase has a generally parabolic current shape, and is performed in a current-closed loop manner until a transition point, where control becomes voltage-closed loop until the background level is reached. Resulting weld performance is improved, with a globular-like transfer mode, reduced shorts and enhanced arc stability.

Owner:ILLINOIS TOOL WORKS INC

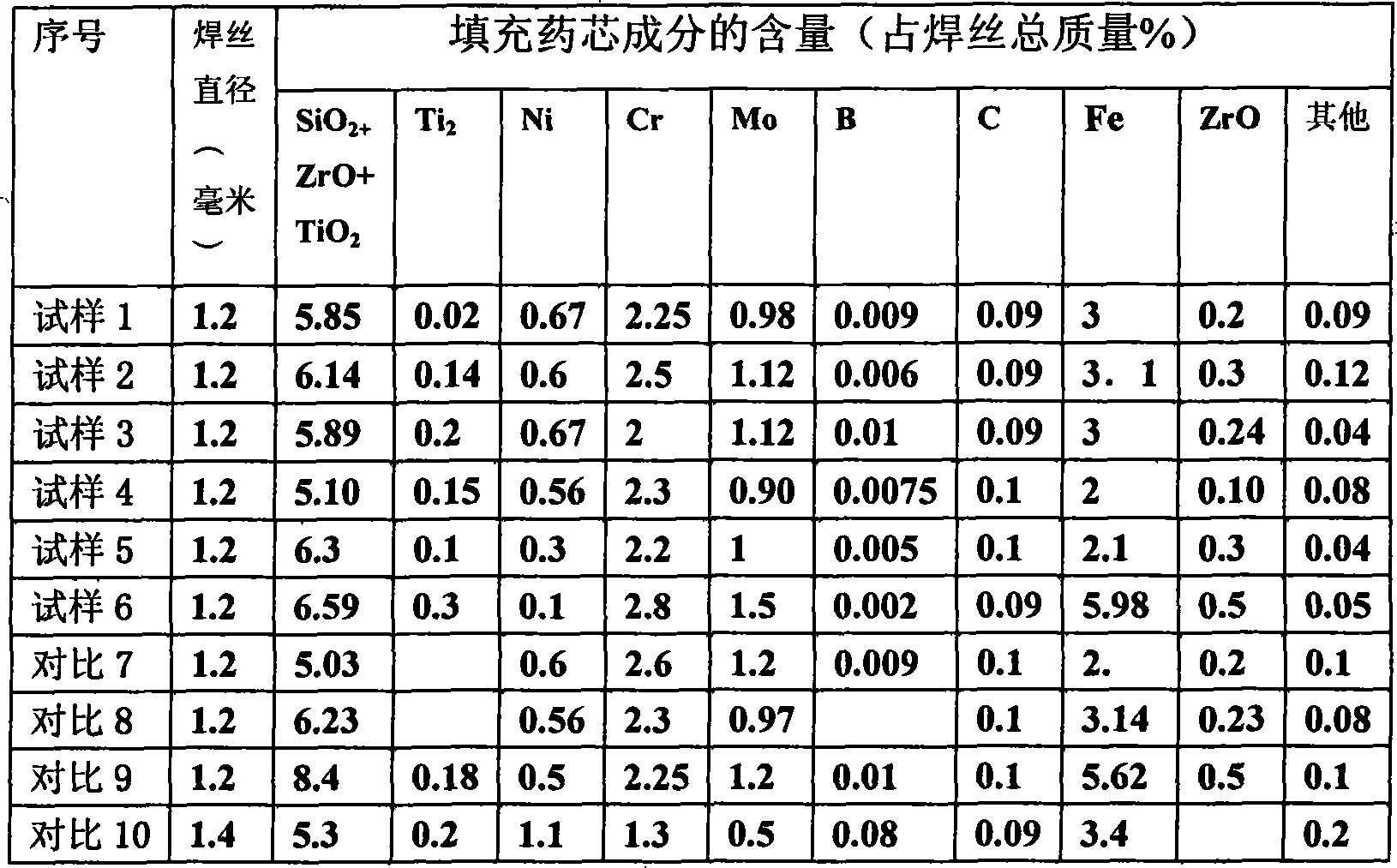

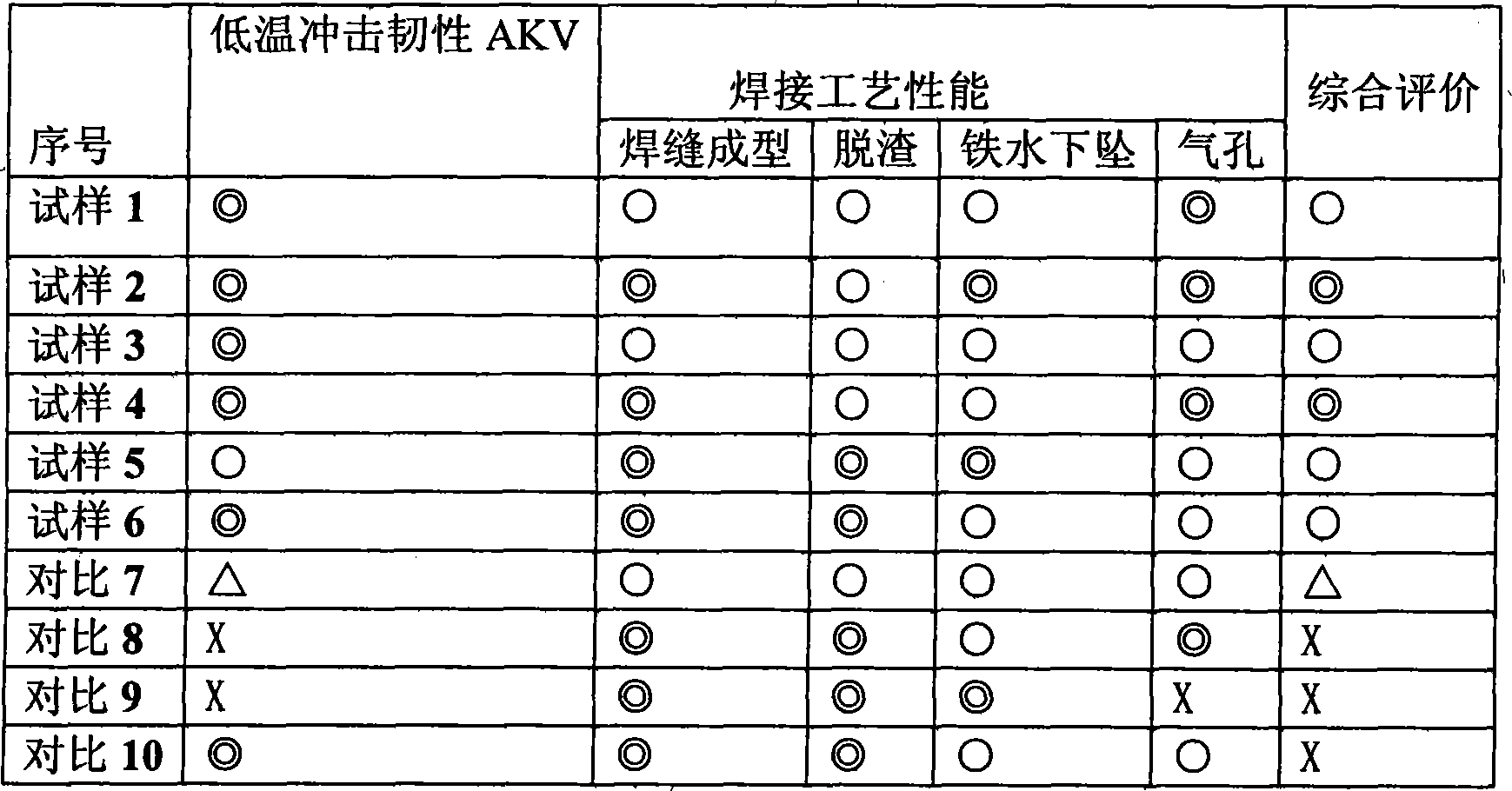

Low-temperature steel flux-cored wire

InactiveCN101450426AExcellent Oxygen Content Diffusion Hydrogen ContentOxygen Diffusion Good Hydrogen ContentWelding/cutting media/materialsSoldering mediaArc stabilitySlag

The invention discloses a low-temperature steel flux cored wire. Flux core of the flux cored wire comprises the following raw materials by weight percentage: 28 to 33 percent of rutile, 1 to 3 percent of aedelforsite, 14 to 18 percent of silicon-manganese alloy, 16 to 21 percent of ferrous powder, 2 to 4 percent of nickel powder, 1 to 2 percent of cryolite, 5 to 7 percent of feldspar, 1.5 to 2.5 percent of ferrotitanium, 0.5 to 1 percent of ferroboron, 5 to 6 percent of mid-carbon ferromanganese, 2.5 to 4 percent of magnesite, 4 to 6 percent of quartz and 1.5 to 3.5 percent of fluorite. Compared with the similar product of the prior art, the flux cored wire belongs to the meta-acid slag series, and has the advantages of good electric arc stability, less splash, easy slag removal, good low-temperature impact ductility, good low-temperature crack resisting performance, high efficiency and low cost.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Pulse arc welding control method and pulse arc welding device

ActiveUS8049140B2Reduce the amount presentEasy maintenanceArc welding apparatusArc stabilityPulse waveform

Owner:PANASONIC CORP

Pulse arc welding control method and pulse arc welding device

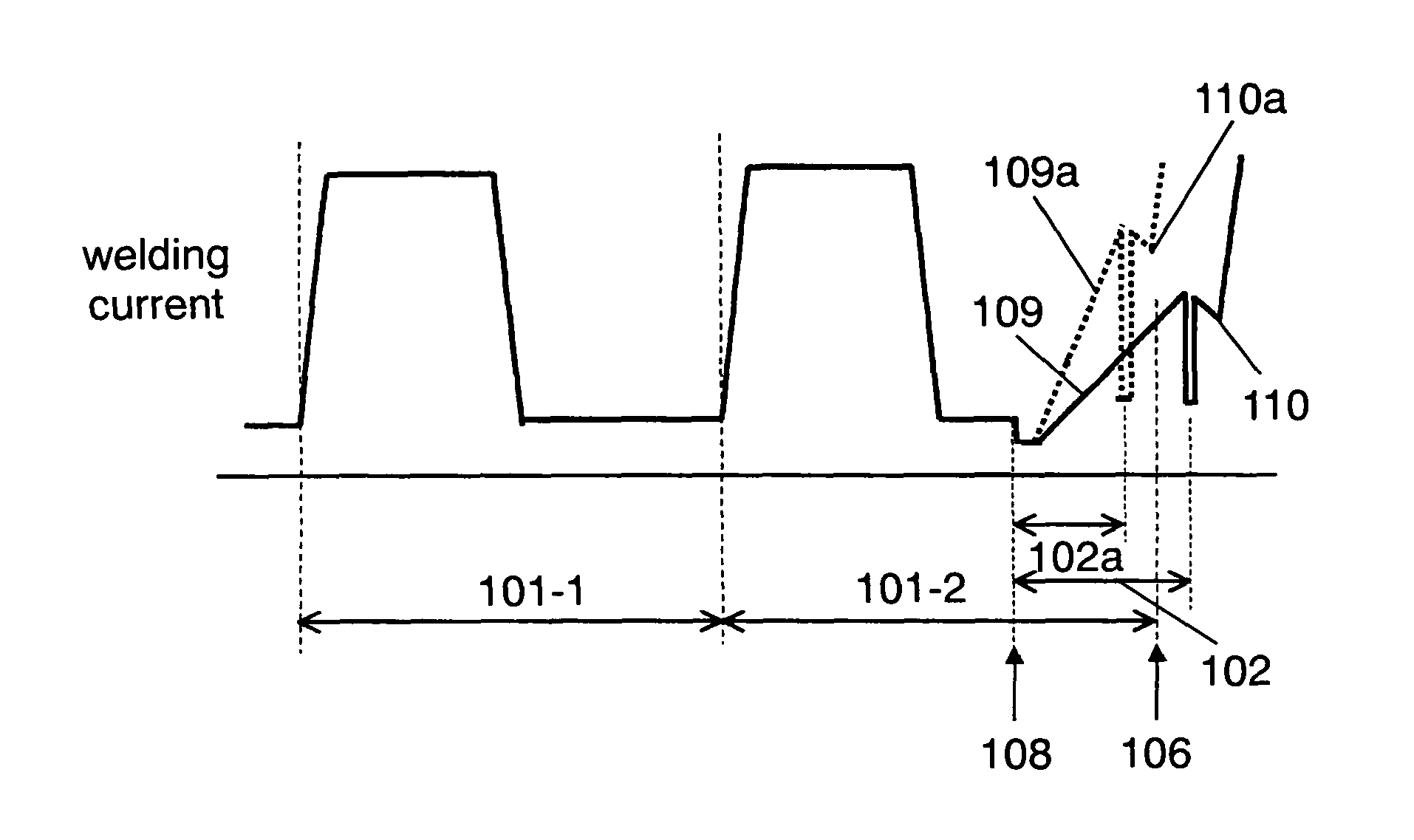

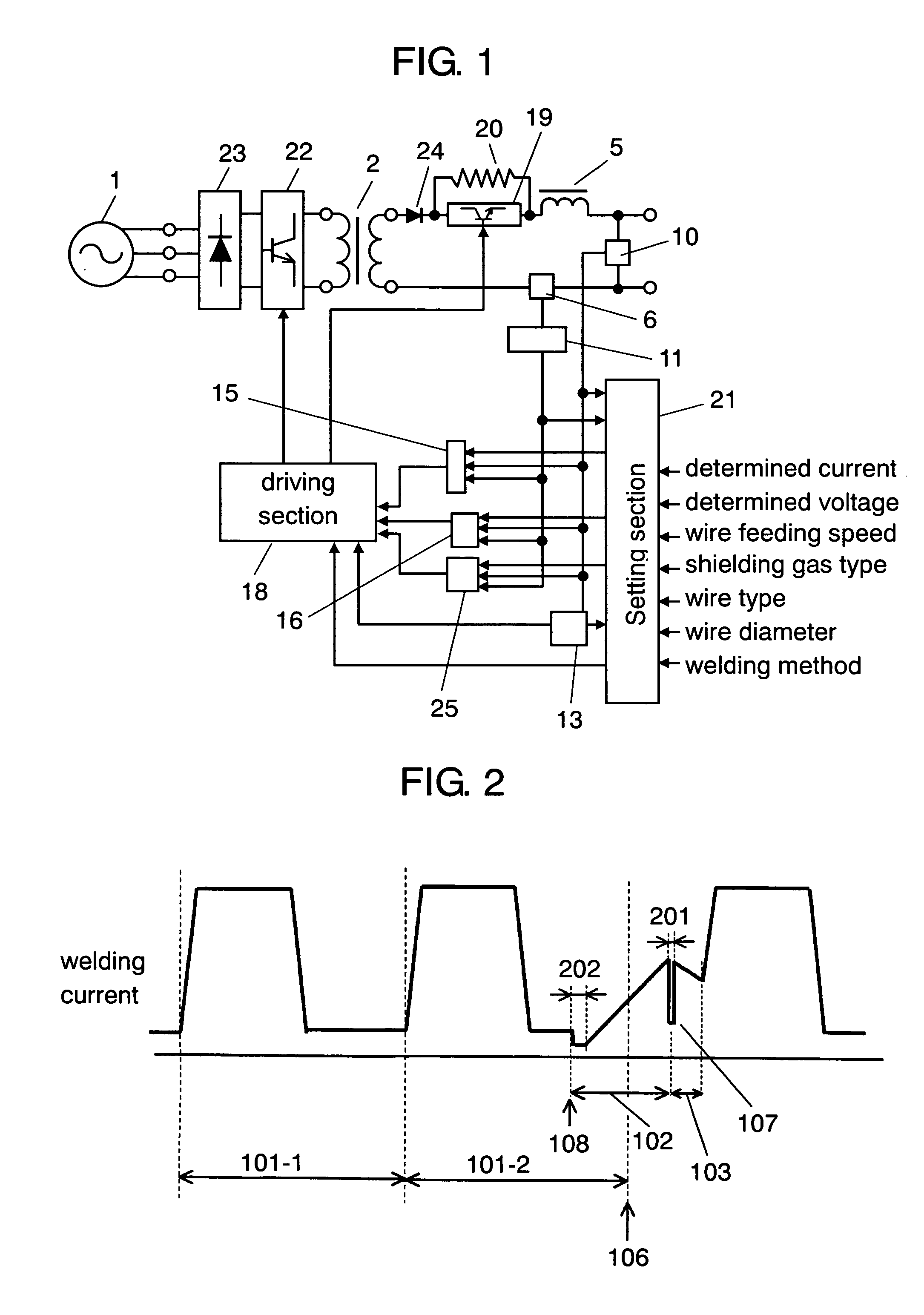

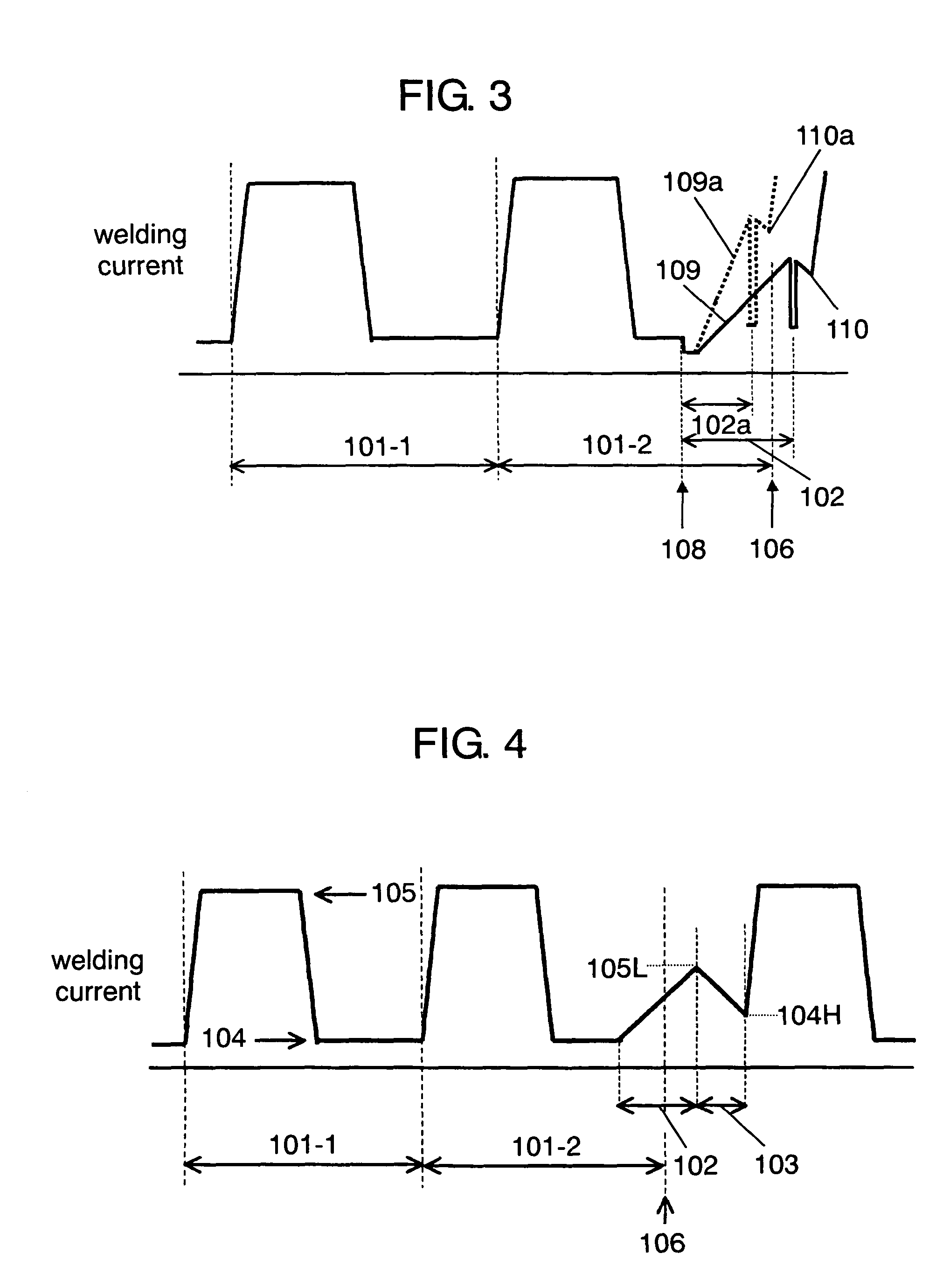

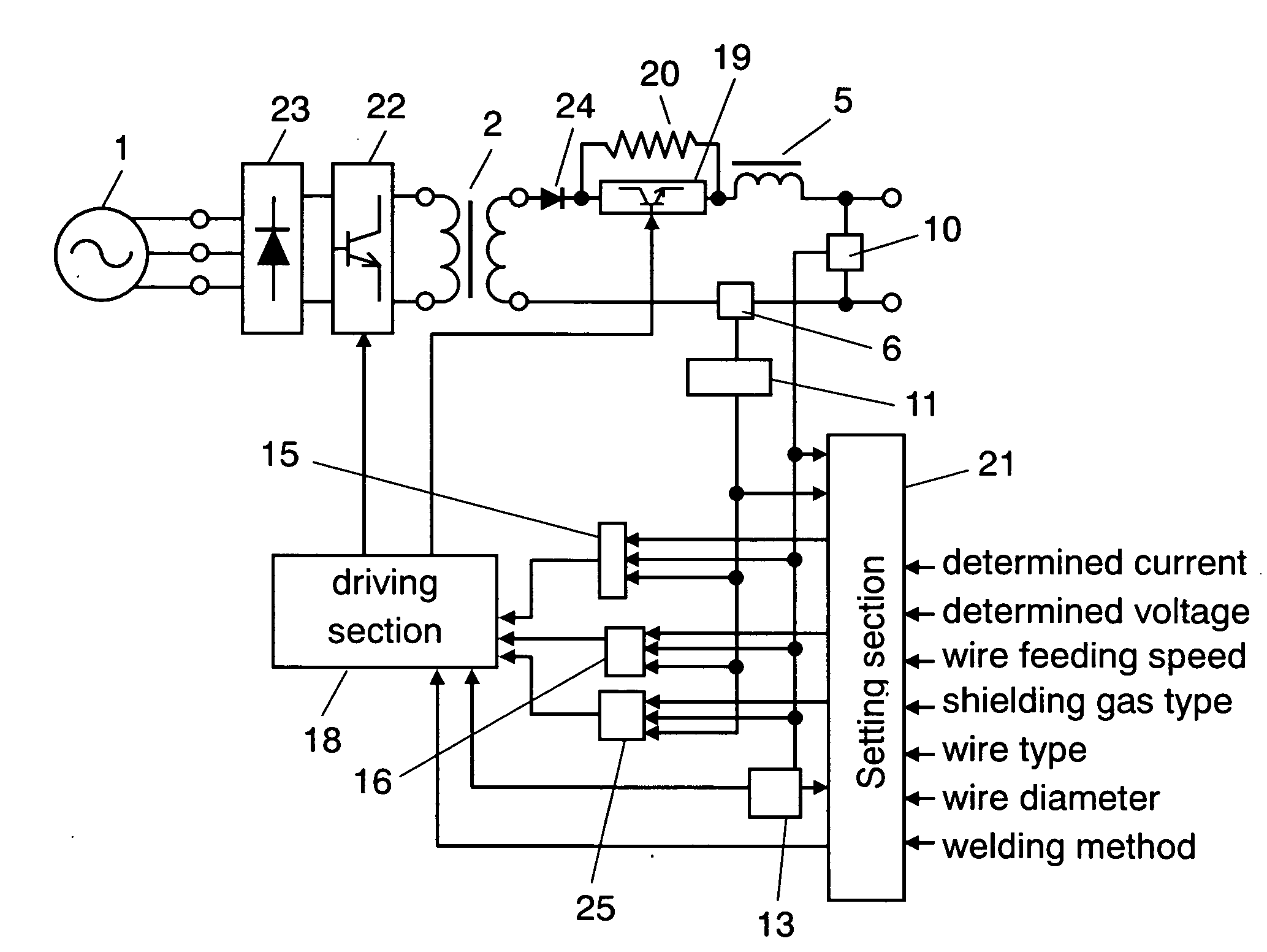

ActiveUS20090152252A1Shortens short-circuit durationImproved arc stabilityArc welding apparatusArc stabilityVoltage

Disclosed here is a pulse welding control method and a pulse arc welding device capable of improving arc stability, and decreasing the amount of spatters. The structure contains arc short-circuit judging section (13) for judging a welding state; setting section (21) for defining parameters used for a short-circuit period and an arc period; secondary control section (25); and driving section (18). Secondary control section (25) sharply decreases welding current on detecting a moment when the tip of a wire has a neck just before recovery from the short circuit, according to at least any one of outputs from a welding current value detector, a welding voltage value detector, and the setting section. Driving section (18) selects from outputs of a pulse-waveform circuit section and a dip-waveform circuit section according to the signal from the setting section and the output from the arc short-circuit section, and outputs the selected data to a switching element.

Owner:PANASONIC CORP

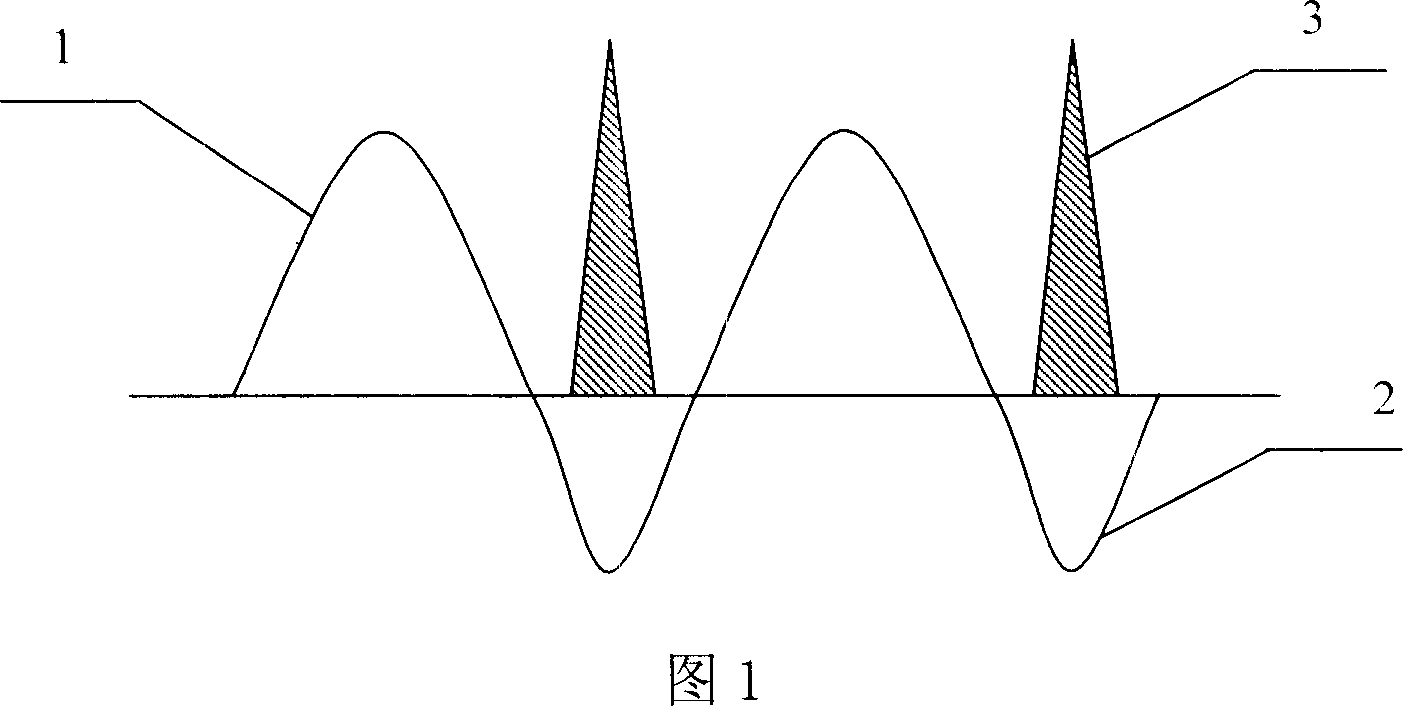

Laser-electric arc composite processing method

InactiveCN1943959AReduce lossImproved Surface FormingArc welding apparatusLaser beam welding apparatusArc stabilityLight beam

The present invention is material processing composite heat source method, and has the technological scheme that during processing with composite laser-electric arc heat source, the output laser power pulse and the AC arc are controlled with the trigger signal of sync pulse for cooperative output, that is, the peak power of the laser pulse emerges always in the negative half wave region of the AC arc. The present invention includes coaxial or paraxial laser and arc; non-consumable electrode arc with gas protection, consumable electrode arc with gas protection or plasma arc; and solid YAG laser, CO2 laser or semiconductor laser. The present invention has positive effects of reduced laser energy consumption, the best utilization of laser energy, enhanced AC arc discharge in the negative half wave region, less influence of processing parameters and environment factors on the processing stability, raised arc stability, etc.

Owner:DALIAN UNIV OF TECH

Chromium-molybdenum-seel flux welding wire for gas shielded arc welding

InactiveCN101244496AImprove impact toughnessHigh strengthWelding/cutting media/materialsSoldering mediaCrack resistanceArc stability

The invention discloses a Cr-Mo steel flux-cored wire applying to gas shielded welding. The content proportion of the core wire accounting for the weight of the welding wire is as following: TiO2: 4 to 6%, Si: 0.2 to 0.5%, Mn: 1 to 2.2%, SiO2: 0.1 to 1%, ZrO2: 0.1 to 0.5%, Cr: 2 to 2.8%, Mo: 0.9 to 1.5%, Ni: 0 to 5%, B: 0.002 to 0.01%, Ti: 0.02 to 0.3%, Fe: 2 to 6%, Al+Mg: 0.4 to 0.75%, K, Na and Li: 0.1 to 0.35 which is converted from K, Na and Li alkali oxide and / or fluoride, wherein k: 0.02 to 0.07%, Na / Li / Na+Li: 0.08 to 0.3%, F: 0.1 to 0.35% converted from fluoride. The proportion of S, P, Sn and Bi is less than 0.035% in the carbon steel and the core wire powders. The welding wire has the advantages that: the intensity and heat-resistant of the weld joint can be insured, at same time, the invention still has good low-temperature impact toughness and global welding performance; the stability of the electric arc and the welding operation processing property are both good; the weld joint is smooth; the weld joint metal is of good low-temperature impact toughness and crack resistance; the invention is suitable for welding heat-resistant steel such as the 2.25-Cr-1-Mo steel.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Electrode negative pulse welding system and method

A welding system includes a power source configured to generate power and deliver the power to a welding torch. The power is provided in accordance with an electrode negative pulse welding regime that includes a cyclic peak, followed by a stabilization phase, then a return to a background level. The stabilization phase has a generally parabolic current shape, and is performed in a current-closed loop manner until a transition point. Resulting weld performance is improved, with a globular-like transfer mode, reduced shorts and enhanced arc stability.

Owner:ILLINOIS TOOL WORKS INC

Carbon steel cored solder wire for gas-shielded arc welding

InactiveCN1775452AImprove performanceExcellent all-position welding performanceWelding/cutting media/materialsSoldering mediaMischmetalArc stability

The present invention relates to a carbon steel flux-cored welding wire for gas shielded are welding. Its flux composition contains (by wt%) TiO2 4-6.5, Si 0.3-0.8, Mn 1.5-3.1, SiO2 0.1-0.8, ZrO2 0.1-0.5, Fe 2-7, Al+Mg 0.5-1.2, alkali metal oxide (fluoride) (reduced K,Na,Li) content 0.1-0.35, F (conversion value) 0.05-0.2 and oxide or fluoride of alkali earth metal 0.005-0.2.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

High-hardness self-protecting flux-cored welding wire for overlaying repair of continuous casting roller

InactiveCN104690451AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsArc stabilityHigh carbon

The invention discloses a high-hardness flux-cored welding wire for overlaying repair of a continuous casting roller, and belongs to the technical field of welding in material processing engineering. An H08A cold-rolled steel strip is adopted as an outer cover, a flux core comprises the following components in percentage by weight: 20-40% of TiO2, 5-15% of high-carbon ferrochrome, 12-30% of low-carbon ferrochrome, 0.5-5% of Mn-Si alloy, 0.5-5% of Al-Mg alloy, 5-15% of Ni, 0.5-2.5% of fluoride, 5-15% of Mo, 0.5-2.5% of V, 2-10% of Cr, 0.5-5% of Al2O3 and the balance of iron powder. The filling rate of the traditional Chinese medicine core of the flux-cored welding wire is 20-35%. The welding wire has the advantages that the flux-cored welding wire adopts a self-protecting overlaying manner, and shielding gas and welding flux are not needed in the overlaying repair process of the continuous casting roller, so that the repair cost can be greatly reduced, the manual labor intensity is lowered, and the production efficiency is improved; the welding wire has good arc stability, excellent abrasion-proof property and excellent thermal fatigue resistant property, and the service life of the continuous casting roller is effectively prolonged.

Owner:SHOUGANG CORPORATION

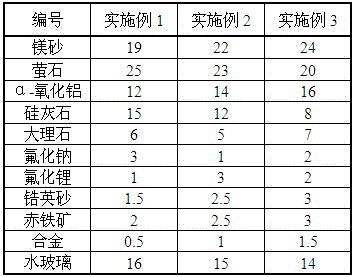

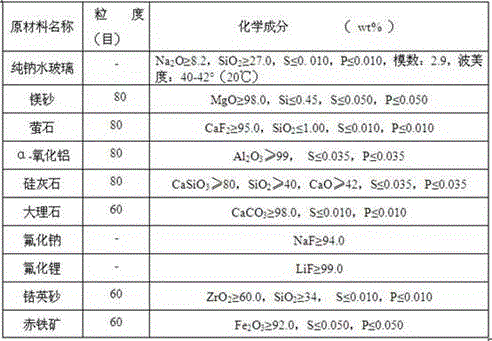

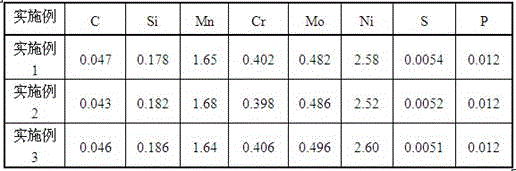

Sintered flux for welding of high-strength steel for ocean engineering and preparation method of sintered flux

ActiveCN106271218AGood workmanshipArc stabilizationWelding/cutting media/materialsSoldering mediaProcess specificationHydrogen

The invention discloses sintered flux for welding of high-strength steel for ocean engineering and a preparation method of the sintered flux. The sintered flux belongs to fluoride-basic type sintered flux and is prepared from components in parts by weight as follows: 19-24 parts of MgO, 20-25 parts of CaF2, 12-16 parts of Al2O3, 4-8 parts of SiO2, 8-10 parts of CaO, 2-4 parts of BaO, 1-3 parts of NaF, 1-3 parts of LiF, 1-2 parts of ZrO2, 2-3 parts of Fe2O3, 0.5-1.5 parts of an alloy and 14-16 parts of water glass. The sintered flux has good manufacturability, has arc stability under broader process specification, can meet requirements for welding of E550 steel plates with yield strength higher than 550 MPa and E690 steel plates with yield strength higher than 690 MPa and has lower diffusible hydrogen, slag removal is easy, and welding bead forming is attractive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

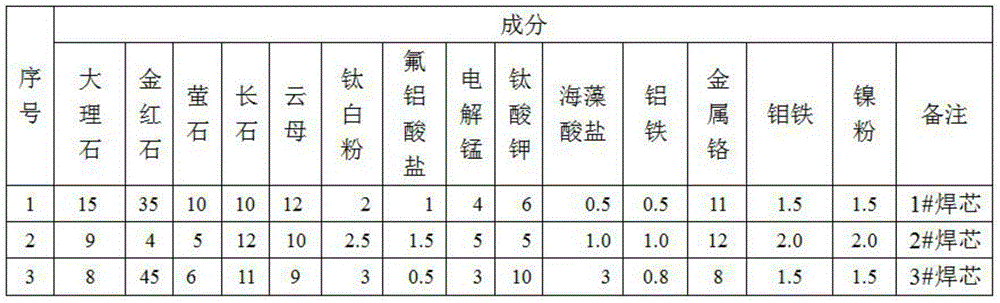

Double-phase stainless steel electric welding bar

InactiveCN101817123AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaArc stabilityElectrolysis

The invention discloses a double-phase stainless steel electric welding bar, and relates to the stainless steel electric welding field of electric arc welding. The invention provides a novel titanium-calcium type double-phase stainless steel electric welding bar, which has good welding performance such as little splash, low cost, good slag removal performance and the like. The electric welding bar is characterized in that: according to the coating formula, the electric welding bar comprises the following components in part by weight: 35 to 38 parts of rutile, 8 to 10 parts of natural mica, 1 to 2 parts of potassium titanate, 5 to 7 parts of marble, 10 to 12 parts of iron powder, 1 to 2 parts of bentonite, 2 to 3 parts of electrolytic manganese, 3 to 5 parts of fluorite, 1 to 2 parts of potassium feldspar, 1 to 2 parts of sodium alginate, 2 to 3 parts of chromium nitride, 20 to 24 parts of chromium metal, 8 to 10 parts of ferromolybdenum, 2 to 4 parts of magnesite, 2 to 4 parts of nickel powder and 1 part of Teflon. The welding process performance of the stainless steel welding bar is improved, and particularly the application range of the stainless steel welding bar is enlarged during welding, so the double-phase stainless steel electric welding bar has good welding performance such as good electric arc stability, little splash, low cost, good slag removal performance and the like.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Stainless steel welding rod of new dregs series

InactiveCN1958213AReduce slag viscosityImprove conductivityWelding/cutting media/materialsSoldering mediaArc stabilitySlag

A welding stainless steel electrode with improved slag detachability and welding quality is composed of a core and a coated flux layer prepared proportionally from rutile, feldspar, marble, fluorite, wollastonite, megnesite, titaniunm oxide powder, hematite, aluminum fluoride, mice, barium carbonate, Cr, Ni, sodium carbonate, electrolytic manganese and ferrotitanium.

Owner:HARBIN UNIV OF SCI & TECH

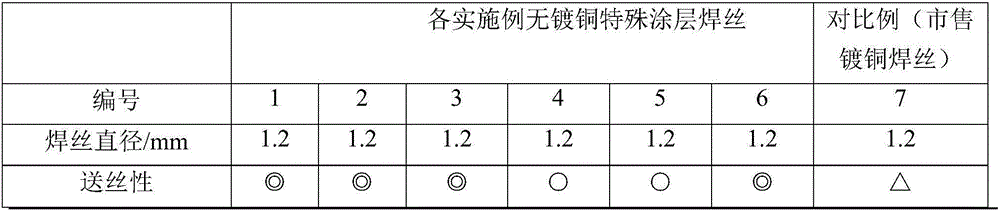

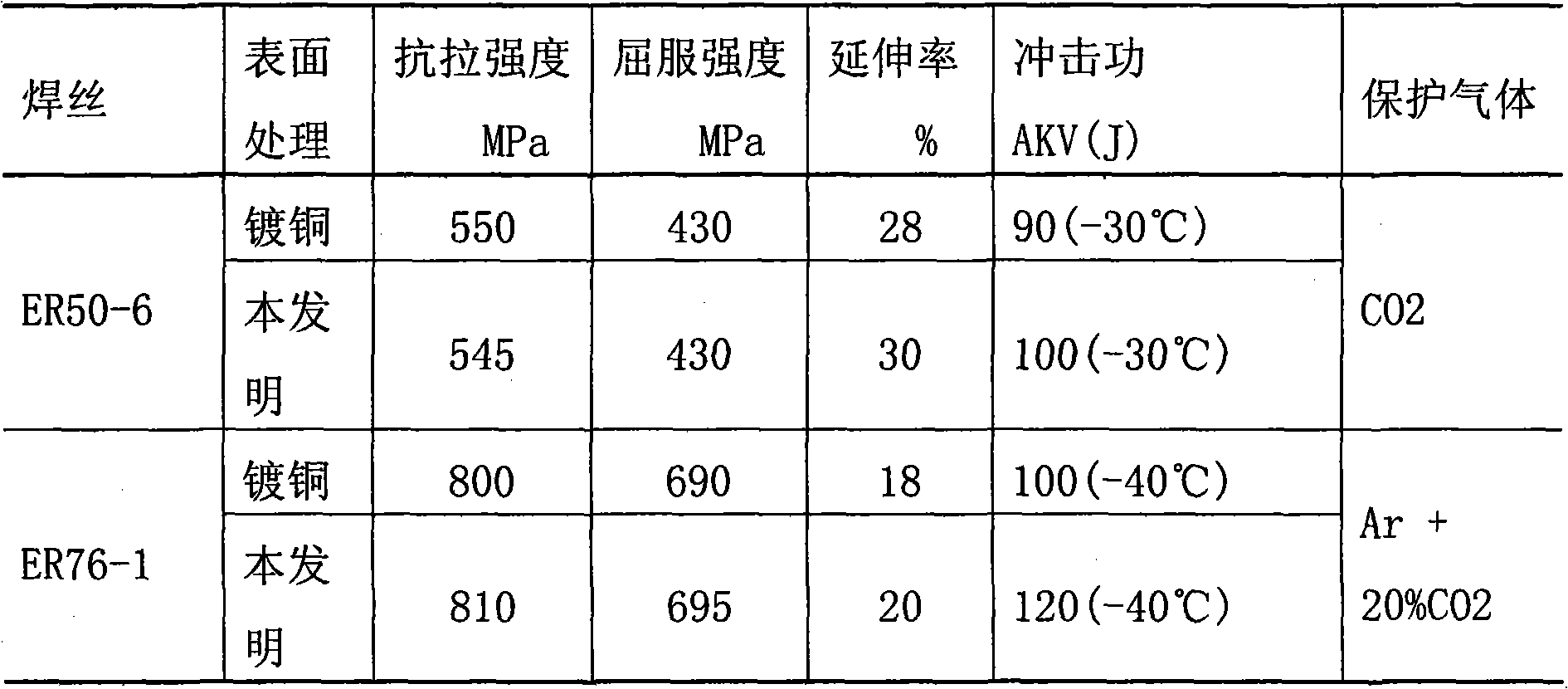

Nanometer lubricating oil used for special coating welding wire not plated with copper and preparation method of nanometer lubricating oil

ActiveCN106541224AImprove anti-wear and anti-friction performanceImproved arc stabilityWelding/cutting media/materialsSoldering mediaArc stabilityCopper plating

The invention discloses nanometer lubricating oil used for a special coating welding wire not plated with copper and a preparation method of the nanometer lubricating oil and relates to the technical field of chemical engineering. The nanometer lubricating oil is prepared from 55-75% of palm oil, 3-16% of polytetrafluoroethylene, 4-20% of carbon black, 2-7% of graphene, 2.5-7.5% of MoS2, 0.3-5% of nanometer CuO and 0.2-1.6% of nanometer TiO2. The preparation method includes the following steps that the basic oil in the above weight percentage is added into a reaction kettle and is stirred for 1 h at the constant temperature of 75-90 DEG C, and heating stops; and the polytetrafluoroethylene, the carbon black, the MoS2, the nanometer CuO, the nanometer TiO2 and the graphene in the above mass percentage are thrown into the reaction kettle, heating is performed at the pressure intensity of 0.4-1.7 Mpa till the temperature of 50-75 DEG C is achieved, a reaction is performed for 1 h, and then only homogenizing and degassing are needed. The nanometer lubricating oil is coated on the surface of the special coating welding wire not plated with copper and guarantees good wire feeding performance, rust resistant performance and electric arc stability of the special coating welding wire not plated with copper.

Owner:BEIJING UNIV OF TECH

Method for producing large-sized zirconium ingot with the specification Phi of more than 600mm

The invention relates to a method for producing large-sized zirconium ingot with the specification Phi of more than 600mm, and the technical characteristics lie in that a consumable electrode with relatively uniform components is prepared by adopting dosing, mixing and vacuum plasma arc electrode assembly and welding technology, and vacuum consumable electric arc melting is carried out for at least twice by adopting technology of 'speed reducing melting' and 'component uniformity controlling' and the like under the conditions that the melting speed control parameter is 10-40kg / min and the arc stability control is carried out with the magnetic induction of 10-50 Gauss and the stable arc current alternate control time of 1-60 seconds. Compared with the prior art, the invention has the advantages that the large-sized zirconium ingot produced by the invention has uniform and stable chemical components and excellent ingot surface quality, is better than small ingot melted by vacuum consumable electric arc, and has the advantages of high yield, high production efficiency and being easy for producing large zirconium material and the like; and the invention is applicable to producing ingots for large zirconium material.

Owner:BAOJI TITANIUM IND CO LTD

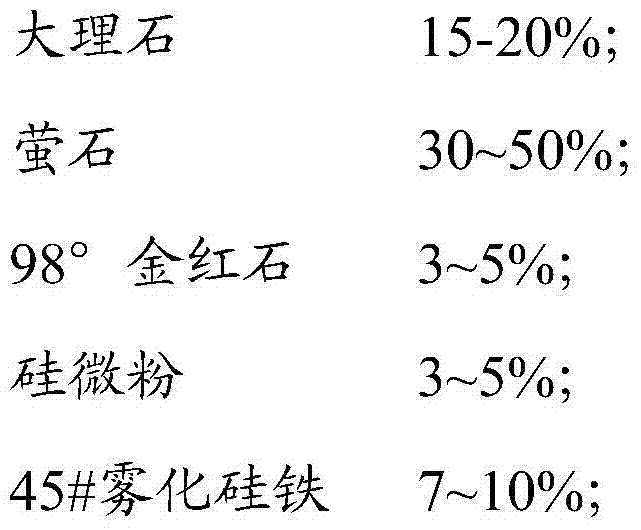

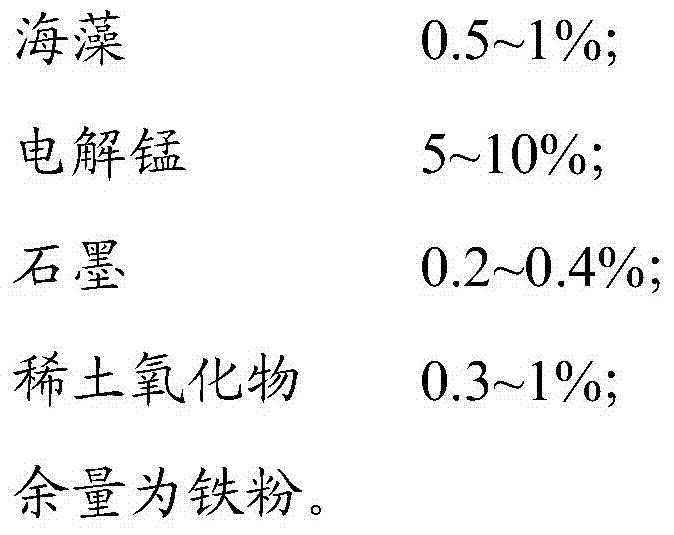

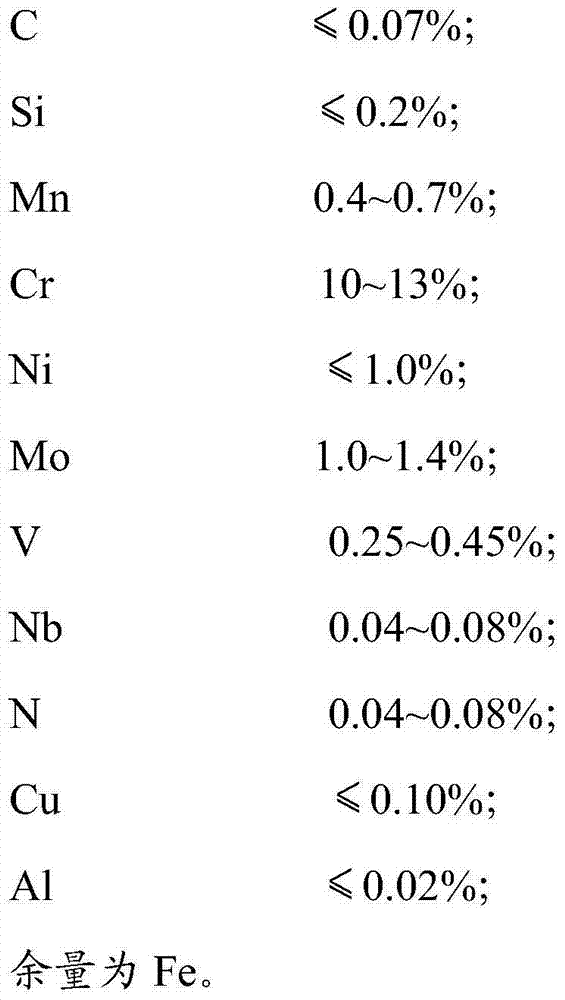

Low hydrogen type super-critical ferrite heat resistant steel electrode

ActiveCN104117788AImprove craftsmanshipLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaCrack resistanceElectrolysis

The invention belongs to the technical field of welding materials, and provides a low hydrogen type super-critical ferrite heat resistant steel electrode. A coating comprises, by weight, 15-20% of marble, 30-50% part of fluorite, 3-5% of rutile with purity being 98 percent, 3-5% of silica powder, 7-10% of 45# pulverization silicon iron, 0.5-1% of seaweed, 5-10% of electrolytic manganese, 0.2-0.4% of graphite, 0.3-1% of rare earth oxide, and the balance iron powder. According to the low hydrogen type super-critical ferrite heat resistant steel electrode, the ratio of the marble and the fluorite in the steel electrode coating is about 1: 2, the diffusible hydrogen content of a weld joint is reduced, the technical performance of the steel electrode is improved, the core wire component is microalloyed, the core wire tradition alloy component is adopted, the good mechanical performance is obtained, and the experience shows that the steel electrode is good in electric arc stability, impact toughness and crack resistance, good in welding technology and suitable for full-position welding of T / P91 steel, and the diffusible hydrogen reaches the ultralow hydrogen level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Self protection flux core welding wire of pipe line steel full position

InactiveCN1943965AImprove smoothnessReduce nitrogen and hydrogenWelding/cutting media/materialsSoldering mediaArc stabilityLine tubing

The self-protecting welding wire with flux core for pipeline steel has welding wire comprising BaF2, SrF2 and / or CaF2 7-12 wt%, LiF 0.8-3.0 wt%, CaO 0.2-0.8 wt%, SiO2 0.1-0.4 wt%, Al 1.2-2.0 wt%, Mg 1.2-2.0 wt%, Mn 0.6-1.2 wt%, Ni 0.6-1.2 wt%, C 0.05- 0.10 wt%, Zr 0.05-0.3 wt%, B 0.002-0.012 wt%, and Fe for the rest; and flux core accounting for 18-25 wt%. It contains water in 0.010-0.120 wt%, and has reduced current fluctuation and raised welding performance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Gas protecting welding wire with nano-coating

ActiveCN101407004AArc stabilizationExcellent anti-rustWelding/cutting media/materialsSoldering mediaArc stabilityCopper plating

The invention relates to the welding field, in particular to a gas protection welding wire with nano coating. The gas protection welding wire with nano coating is characterized in that the surface of the welding wire is provided with a coating, and the coating comprises the following components in weight percentage: 0.05 to 0.18 percent of potassium tetraborate, 0.15 to 0.80 percent of calcium stearate, and the balance of titanium dioxide; and the thickness of the coating is between 100 and 300nm. Due to the adoption of the technical proposal, the defects that the weld spatter of the copper coated welding wire is big, the surface of the welding is easy for pitting corrosion, the copper element which is transitional to the welding seam possibly lowers the performance of the welding seam, and the content of the poisonous substance copper element is high are completely overcome, so that with the technical proposal of the invention, the gas protection welding wire which has the advantages of arc stability, small weld spatter, good rust proof performance, easy wire feed and good toughness of the welding seam.

Owner:上海斯米克焊材有限公司

Preparation process for anti-oxidation copper-based bonding wires

ActiveCN102324392AHigh hardnessIncrease anti-oxidation functionSemiconductor/solid-state device detailsSolid-state devicesArc stabilityHardness

The invention provides anti-oxidation copper-based bonding wires, which comprise copper serving as a base material, wherein trace metal elements such as Pt, Ce and Pd are added into the copper to form a master alloy base material; the master alloy base material is made into thin wires, and a gold layer is plated on the surfaces of the thin wires to form the bonding wires; and the purities of the copper and gold are more than 99.99 percent. The invention also provides a preparation process for the bonding wires. The preparation process comprises the steps of master alloy melting, drawing, cleaning, gold plating, annealing, winding, packaging and the like. The copper-based bonding wires have the advantages of copper bonding wires and gold bonding wires, have the characteristics of high oxidation resistance and electrical conductivity and low arc stability, have higher hardness compared with a single copper material, and have the advantages of low price and the like; moreover, the copper-based bonding wires are simple and convenient to package, can be stored for a long time at normal temperature, and can meet the requirement on electronic packaging high-end development.

Owner:广东佳博电子科技有限公司

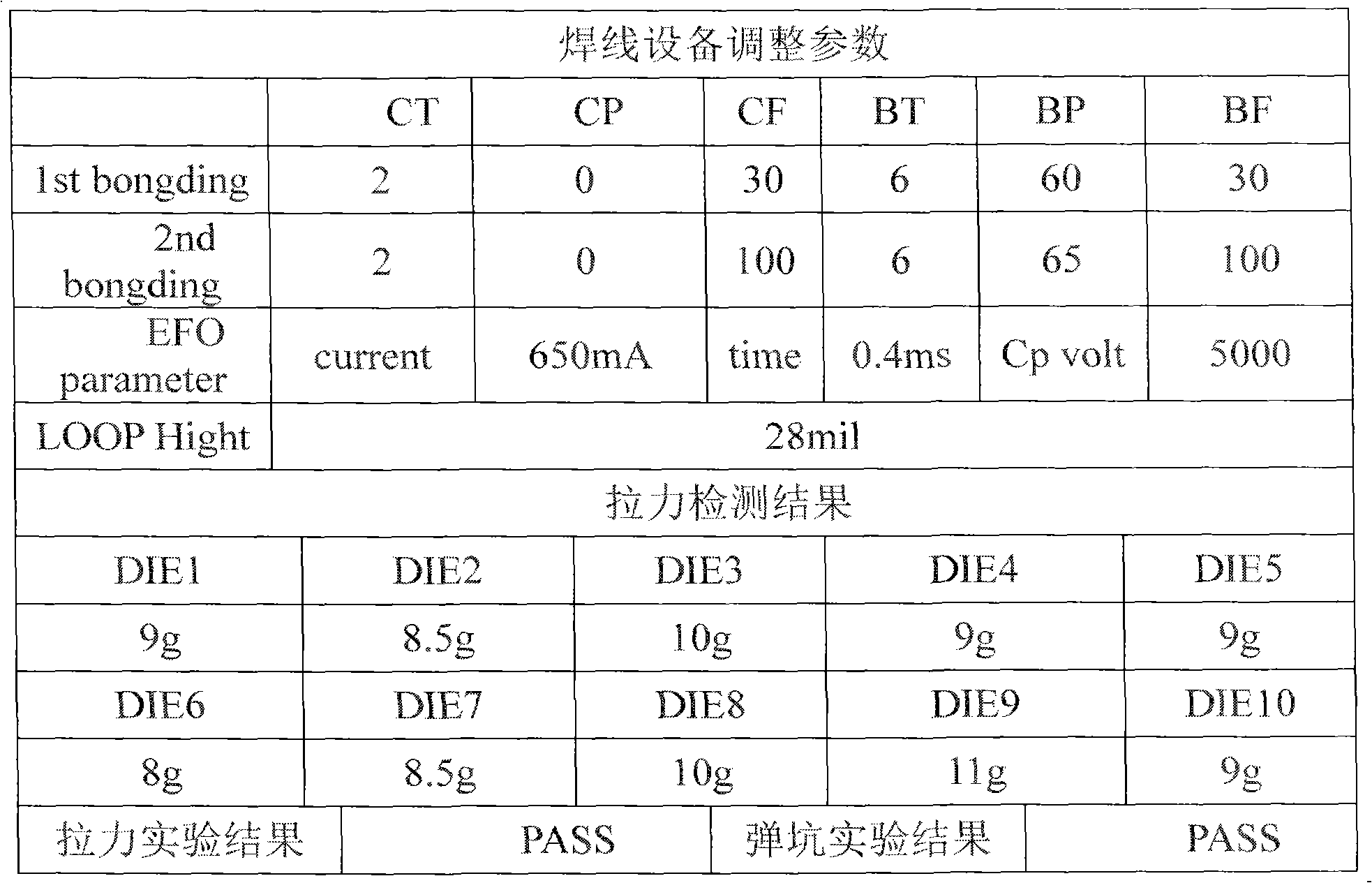

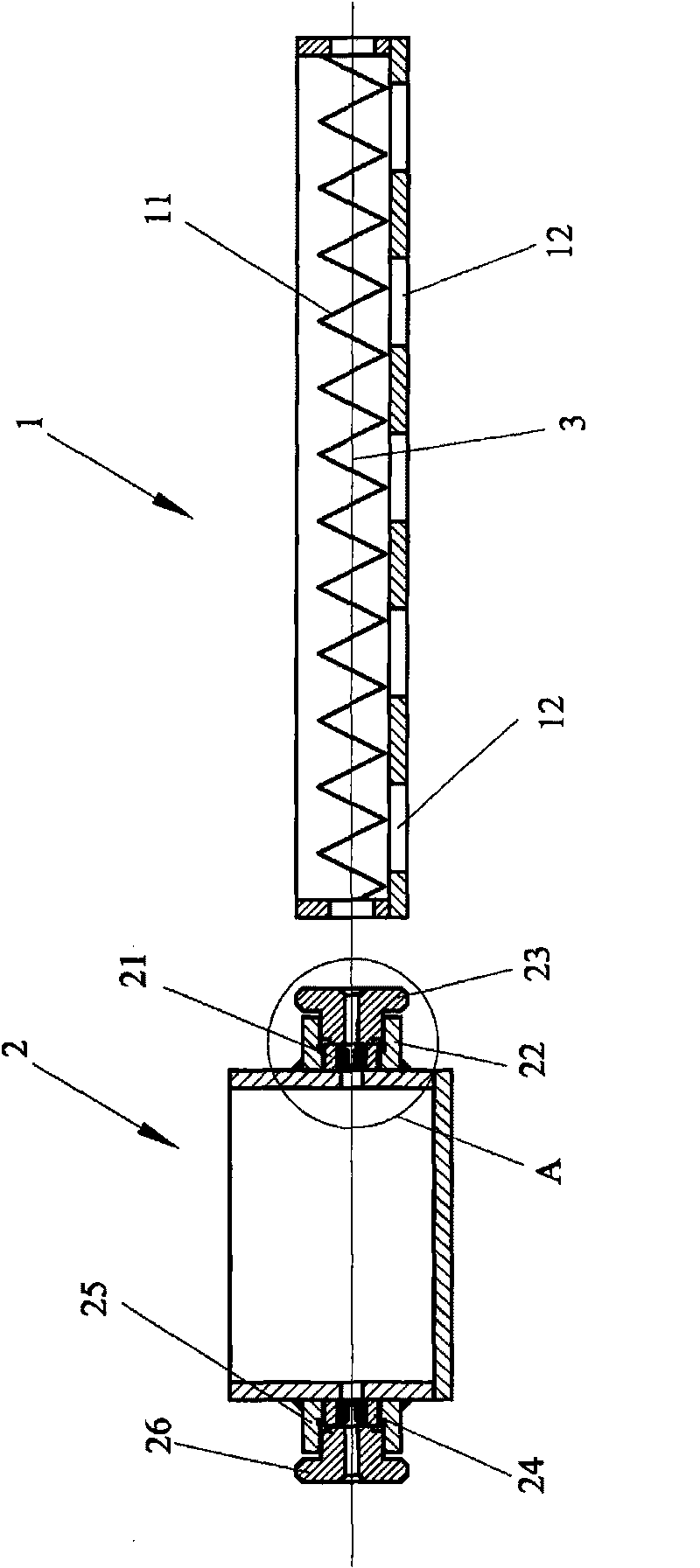

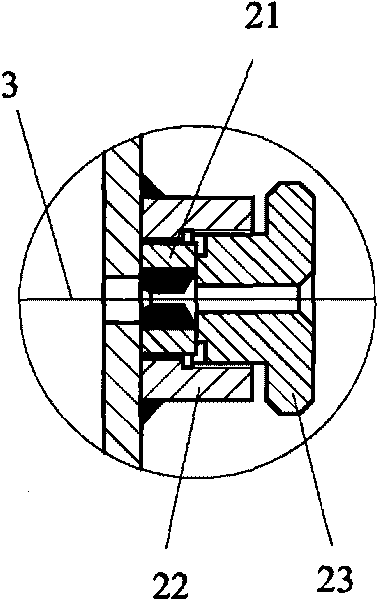

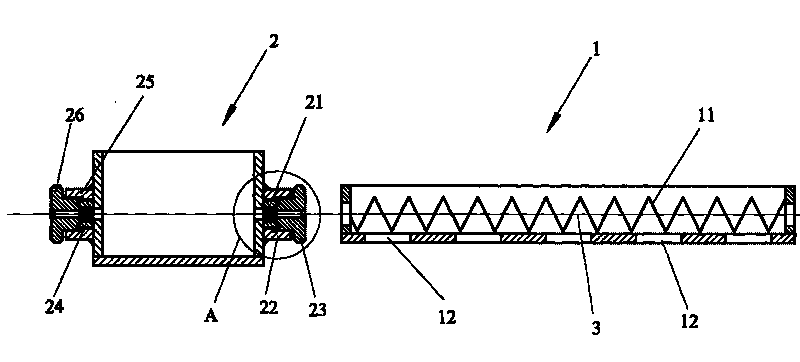

Device and method for evaluating welding process performance of gas-shielded welding wire

ActiveCN109530955AEvaluation of welding processabilityHelp advance engineering applicationsArc welding apparatusArc stabilityMolten bath

The invention discloses a device and a method for evaluating the welding process performance of a gas-shielded welding wire. The device comprises a high-speed camera, an optical filter system, an auxiliary light source, an air-shielded welding system, an arc voltage and welding current sensor, a signal synchronization recorder, a computer and the like; the method comprises the following steps thatthe high-speed camera and the signal synchronization recorder are adopted to synchronously acquire a welding image, arc voltage and welding current in the welding process of the gas-shielded weldingwire to be detected, signal processing is carried out through a computer, the standard deviation of the arc voltage and the welding current, the globular transfer mode, the size and frequency, the welding spattering form and the generation frequency are detected, and meanwhile, the wettability angle and the symmetry degree of a weld joint section after welding are measured, and the arc stability of the gas-shielded welding wire, the globular transfer behavior and the molten bath fluidity are detected, and finally, the welding process performance of the gas-shielded welding wire is evaluated according to the three indexes. The method is wide in application range, high in accuracy, low in implementation cost and good in reliability.

Owner:JIANGSU UNIV OF SCI & TECH

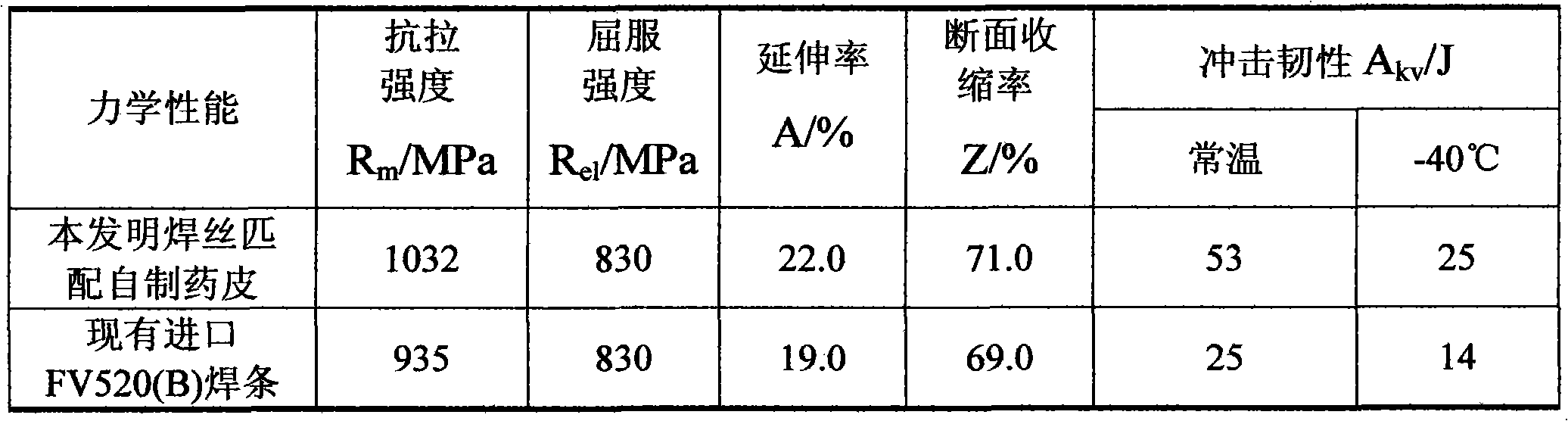

Low-hydrogen basic electrode for manual metal arc welding of FV520 (B) stainless steel

ActiveCN101913034AThe smelting process is stableEasy to implementArc welding apparatusWelding/cutting media/materialsArc stabilitySlag

The invention discloses a low-hydrogen basic electrode for manual metal arc welding of FV520 (B) stainless steel, which comprises a core and a coating. The core comprises the following components in percentage by weight: 0.030%-0.080% of C, 0.30%-1.0% of Si, 0.70%-1.50% of Mn, 4.80%-6.00% of Ni, 1.00%-1.80% of Mo, 13.00%-13.80% of Cr, 0.10%-0.25% of Ti, 0.10%-0.50% of Nb, 0.60%-1.50% of Cu, 0.002%-0.006% of B, 0.10%-0.30% of Re, less then 0.005% of S, less than 0.005% of P and the balance of Fe. The low-hydrogen basic electrode has the advantages of high arc stability, good molten bath fluidity, fine spatter particles, easy deslagging after welding, uniform slag coverage and controlled diffusible hydrogen content in deposited metal.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

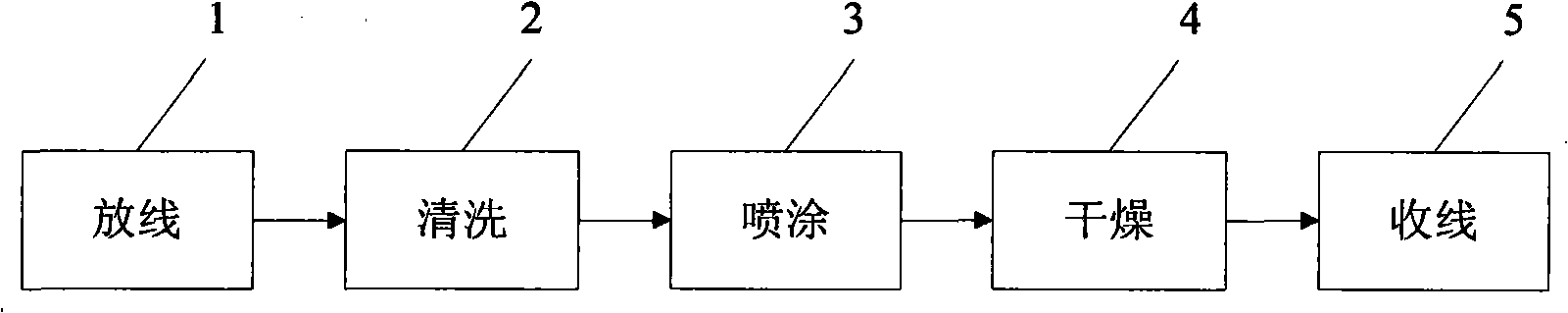

Method and device for processing surface of flux-cored welding wire during drawing flux-cored welding wire

InactiveCN101708570AGood surface treatmentImproved arc stabilityWelding/cutting media/materialsSoldering mediaArc stabilitySurface cleaning

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Stainless steel welding rod used for 904 L steel welding

ActiveCN105537801AHigh purityImprove performanceWelding/cutting media/materialsWelding/soldering/cutting articlesElectrolysisCrack resistance

The invention discloses a stainless steel welding rod used for 904 L steel welding. The stainless steel welding rod comprises a welding core and a titanium-calcium type coating covering the outside of the welding core. The welding core comprises, by weight, 0%-0.02% of C, 1.50%-2.50% of Mn, 0%-0.30% of Si, 24.0%-26.0% of Ni and the like. The coating comprises, by weight, 30%-45% of rutile powder, 8%-15% of marble powder, 3%-10% of fluorite powder, 8%-12% of feldspar, 9%-12% of mica, 1.5%-3% of titanium dioxide, 0.5%-1.5% of fluoroaluminate, 3%-5% of electrolytic manganese and the like. According to the stainless steel welding rod used for 904 L steel welding, the electric arc stability and the liquidity of a molten pool are good, and slag shells of molten slag are uniformly covered; deslagging is easy; a formed welding seam is flat, and the welding seam crack resistance is good; the purity of the chemical composition of postwelding deposited metal is high, and the performance is superior.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Aluminum alloy band for jalousie and manufacturing method thereof

ActiveCN101144133AImprove the distribution patternSimple structureLight protection screensBase framesArc stabilityRare earth

The present invention discloses an aluminum alloy strip steel rolled stock used for a window blind and the production method thereof. The present invention is characterized in that the strip steel rolled stock includes the components and the weight mixing proportions of the material that iron is 0.26-0.34 percent, silicon is 0.05-0.15 percent, copper is 0.005-0.04 percent, manganese is 0.005-0.04 percent, chromium is 0.21-0.28 percent, magnesium is 2.20-2.48 percent, titanium is 0.025-0.045 percent, rare earth metal is 0.10-0.20 percent, and the residual is aluminum; the production method of the aluminum alloy strip used for the window blind comprises smelting, casting, head cutting and surface milling, homogenization annealing, hot rolling, intermediate annealing, cold rolling, intermediate annealing, cold rolling, draw bending and straightening, stabilizing treatment, and vertical cutting and strip separating. Compared with the prior art, the present invention has the remarkable advantages that the surface quality is good, the size accuracy is high, the shape of strip steel rolled stock is smooth, and the tensile strength, the product forming performance, and the arc stability better conform to the demand to the window blind.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

Method for pulsed argon arc welding of titanium alloy and pure aluminum

InactiveCN102615403ANo crackNot low tensile strengthArc welding apparatusWelding/cutting media/materialsArc stabilityTitanium alloy

The invention discloses a method for pulsed argon arc welding of a titanium alloy and pure aluminum. The method comprises the following steps of: polishing a silicon-aluminum alloy filling welding wire by using a piece of fine sand paper before welding; and before the pulsed argon arc welding, polishing a chamfer angle at a joint on one side of the titanium alloy, scraping a joint on one side of the pure aluminum, and butting flat plates of the titanium alloy and the pure aluminum. The welding parameters of the pulsed argon arc welding are that: the background current is 40 to 60 A, the pulse current is 38 to 80 A, the pulse duration is 5 to 10 s, the pulse frequency is 35 to 65 Hz, the welding voltage is 8 to 16 V, the argon flow is 6 to 18 L / min, the distance between a welding gun nozzle and a workpiece is 8 to 12 mm, and the included angle between a welding gun tungsten electrode and the workpiece is 70 to 85 degrees. The welding gun is cooled after welding, and the cooling mode is preferred to be water cooling mode. According to the method for pulsed argon arc welding of the titanium alloy and the pure aluminum, the arc stability is obviously improved, the tensile strength of a welding joint is not lower than the tensile strength of a pure aluminum parent metal, and the operating requirements on titanium alloy and aluminum welding components in production can be met.

Owner:SHANDONG UNIV

Flux-cored wire of low-temperature steel

InactiveCN101850484ASimple welding processImproved arc stabilityWelding/cutting media/materialsSoldering mediaArc stabilityCrack resistance

The invention discloses a flux-cored wire of low-temperature steel. Powder of the flux-cored wire comprises the following chemical components in percentage by weight: 33-35 percent of titanium dioxide, 4-8 percent of silicon dioxide, 10-13 percent of silicon manganese alloy, 10-12 percent of nickel powder, 3-5 percent of ferrotitanium and 14-18 percent of medium carbon ferromanganese. The invention has the advantages of slant acidity slag system, favorable electric arc stability, little splash, easy deslagging, favorable low-temperature impact toughness, favorable low-temperature crack resistance, high efficiency and lower cost.

Owner:NANTONG CHENXI WELDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com