Method for welding with laser-cold metal transferred arc composite heat source

A technology of cold metal transition and compound heat source, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high welding seam, unstable welding process, lack of fusion, etc. Welding quality and welding efficiency, effect of improving stability

Active Publication Date: 2010-08-25

HARBIN WELDING INST LTD

View PDF0 Cites 54 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the relatively low temperature of the molten pool in CMT arc welding, especially when welding medium and thick plate metal, the liquid weld metal has poor wettability on the base metal surface, poor spreadability, and high weld reinforcement. , prone to defects such as unfused or slag inclusions

In addition, when using CMT arc welding stainless steel, nickel-based alloy or high-strength steel protected by pure Ar, since there is no oxidizing gas in the shielding gas, the content of harmful impurity elements such as C and O in the weld metal can be reduced, thereby improving The metallurgical properties of the weld, but due to the lack of oxides in the molten pool, the cathode spots of the CMT arc are difficult to stabilize, and the cathode spots keep drifting during the welding process, which manifests as arc drifting, insufficient stiffness, unstable welding process, and negative impact on welding quality. have adverse effects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

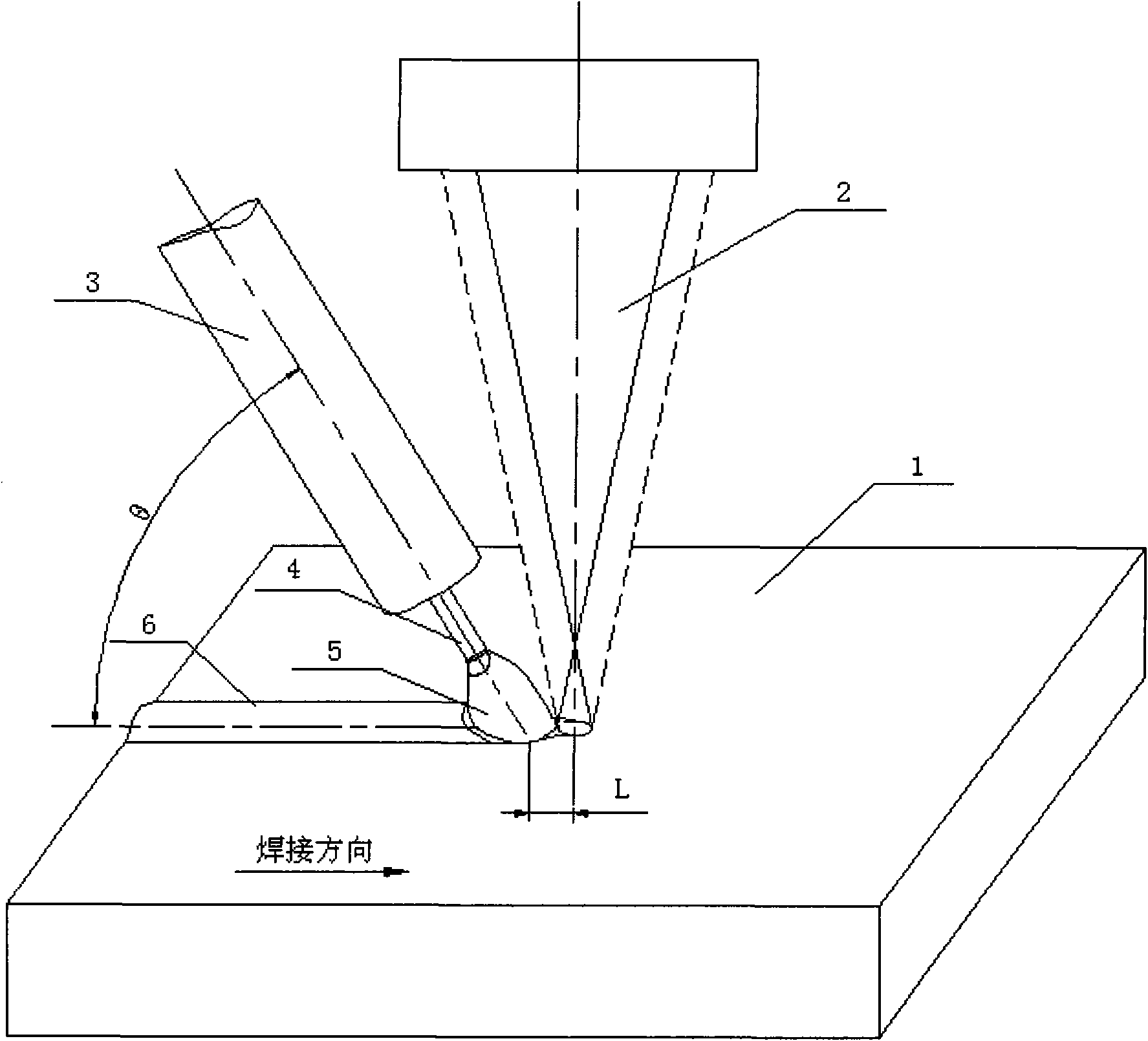

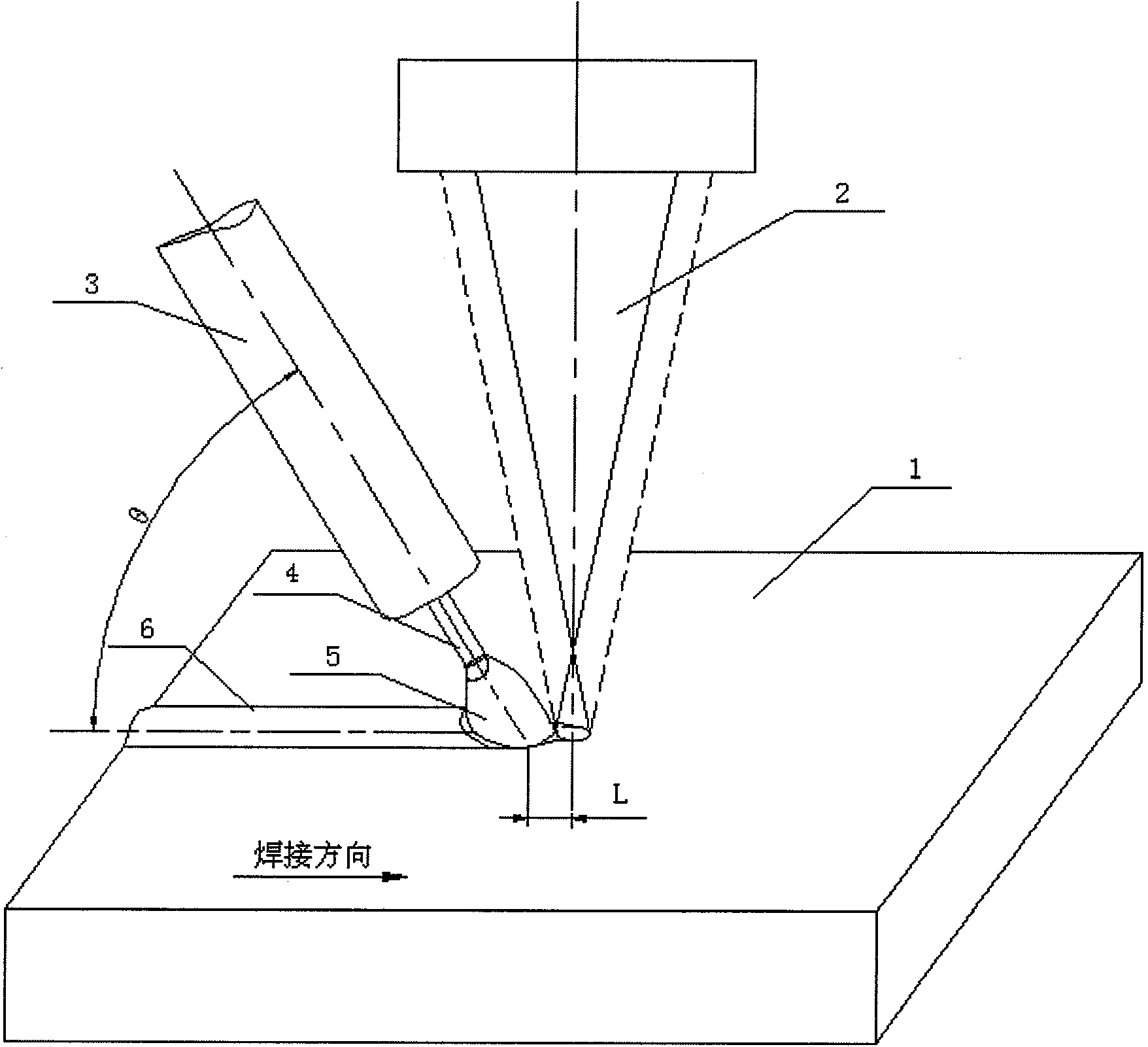

The invention provides a method for welding with a laser-cold metal transferred arc composite heat source, and belongs to the technical field of composite heat sources. The welding method solves the technical problems of low-quality welding lines and low arc stability of the pure Ar-protected cold metal transferred arc welding. The method comprises the following steps of: using pure Ar gas for protection during welding, and forming a novel composite heat source by using the cold metal transferred arc(5) and a laser beam (2) of which the power is more than or equal to 800, wherein the laser beam (2) is defocused, the diameter of a laser spot formed by the laser beam (2) on the surface of a workpiece (1) to be welded is 1 to 4mm, a spot of the cold metal transferred arc (5) can be arranged in front of or behind the spot of the laser beam (2), the central distance of the two spots is 0 to 8mm, and an included angle between a welding torch(3) of the cold metal transferred arc(5) and the horizontal plane is 45 and 75 degrees. The composite heat source is mainly used for welding plates and tubes made of stainless steel, high-strength steel and nickel-based alloy.

Description

A laser-cold metal transition arc composite heat source welding method Technical field A laser-cold metal transition arc composite heat source welding method proposed by the present invention belongs to the technical field of composite heat source welding, and in particular relates to the fact that the composite heat source welding method can improve the spreadability of a single cold metal transition arc weld and can replace non-melting electrodes Inert gas shielded welding (TIG welding) welding stainless steel, high-strength steel, nickel-based alloys. Background technique CMT (Cold Metal Transfer) is a new welding technology gradually developed and matured by Fornis Company on the basis of research on thin plate welding, non-spatter transfer technology and connection technology of aluminum and steel dissimilar metals. Cold metal transition technology (hereinafter referred to as CMT) digitally coordinates the wire feeding and droplet transfer process. The completion of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K28/02B23K26/348

Inventor 林尚扬杜兵雷振王旭友王威卜大川穆瑞骥徐孝福滕彬于洪军

Owner HARBIN WELDING INST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com