Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2775 results about "Nickel based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nickel-based alloy is an alloy whose main constituent is nickel. Nickel and nickel-based alloys are vitally important to industry because of their ability to withstand a variety of severe operating conditions involving corrosive environment, high temperatures, high stresses, and combinations thereof.

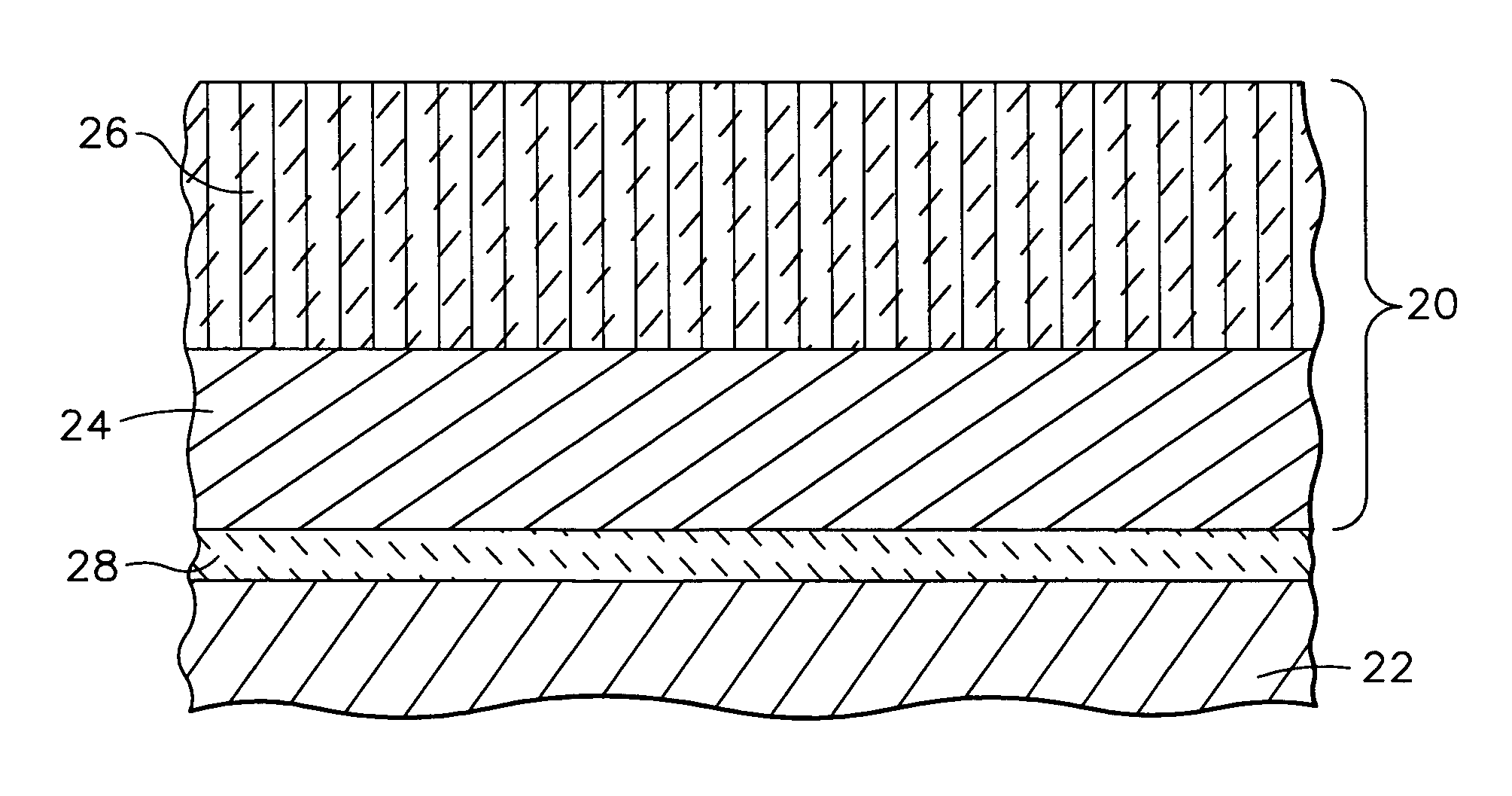

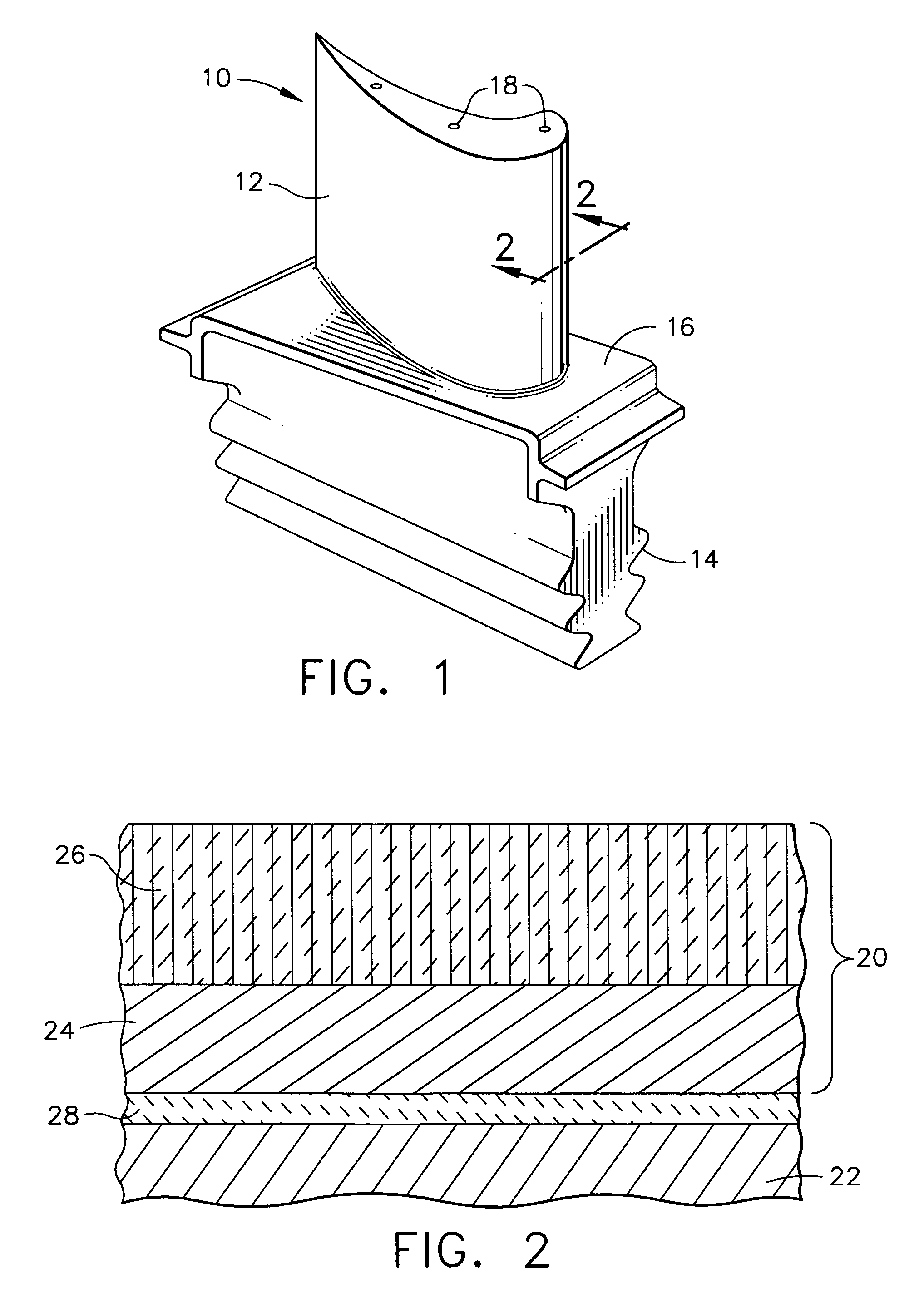

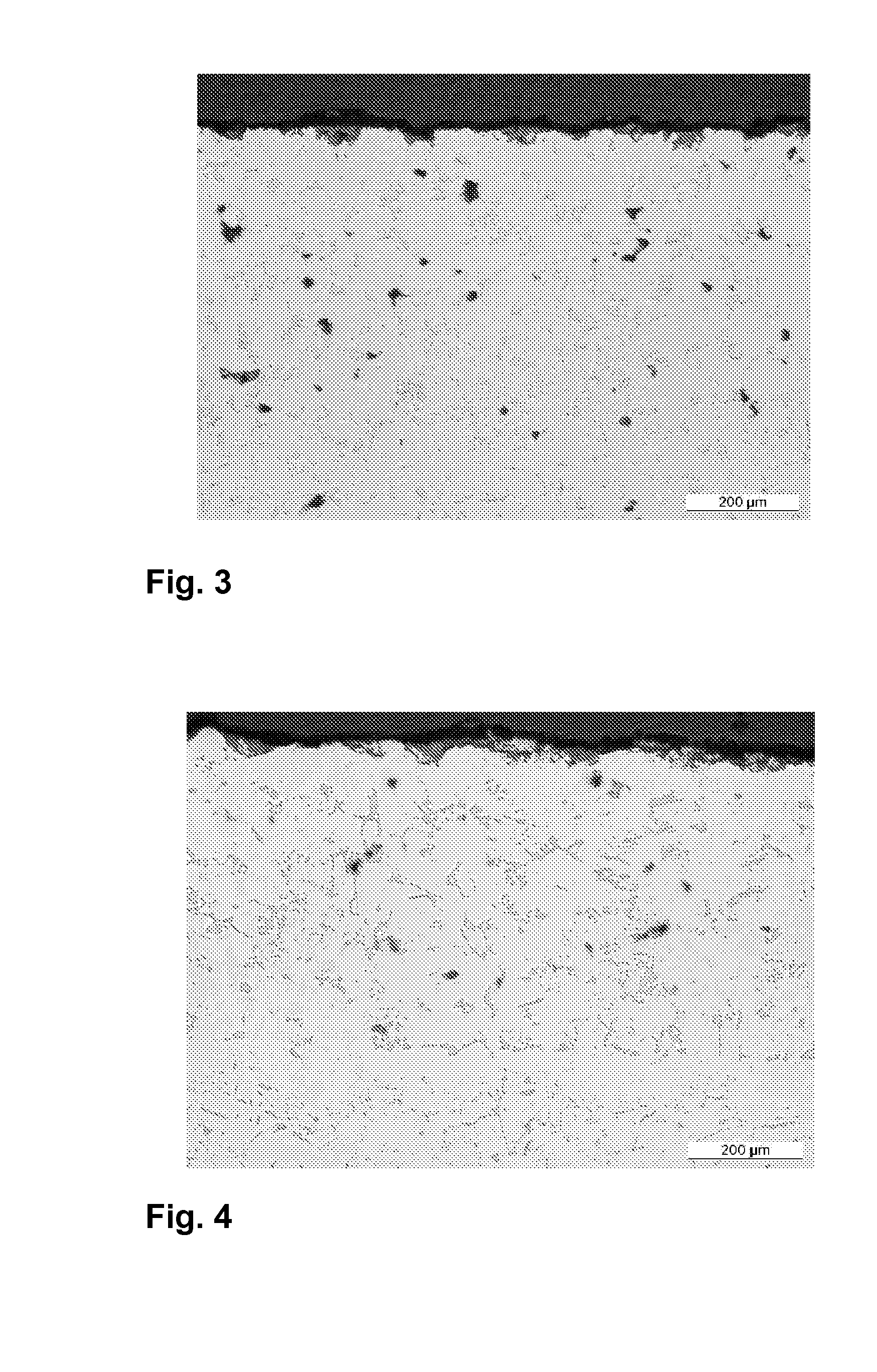

Metallic coating for single crystal alloys

InactiveUS20110256421A1Polycrystalline material growthMolten spray coatingSingle crystal superalloySingle crystal

A metallic coating for use in a high temperature application is created from a nickel base alloy containing from 5.0 to 10.5 wt % aluminum, from 4.0 to 15 wt % chromium, from 2.0 to 8.0 wt % tungsten, from 3.0 to 10 wt % tantalum, and the balance nickel. The metallic coating has particular utility in protecting single crystal superalloys used in high temperature applications such as turbine engine components.

Owner:UNITED TECH CORP

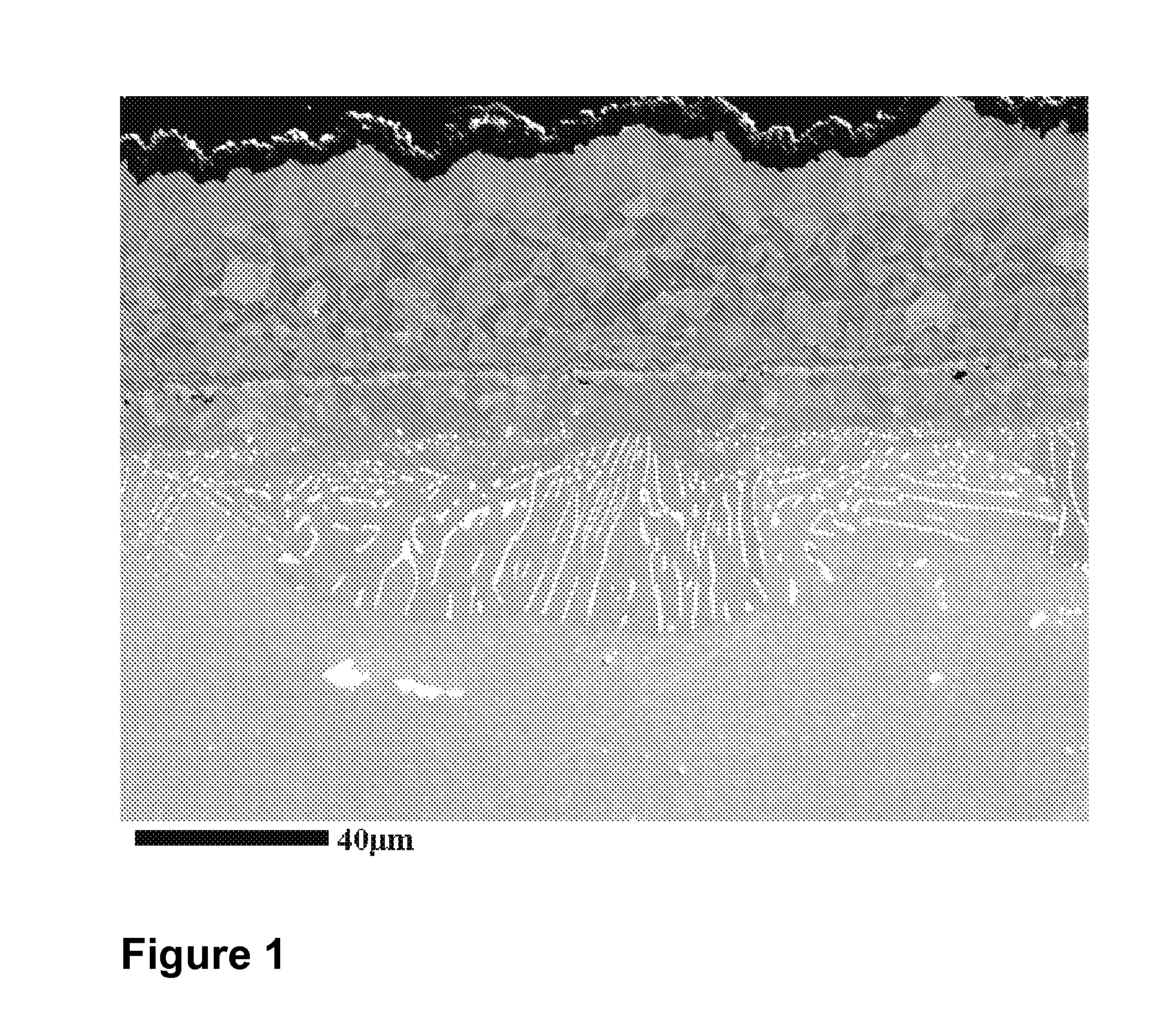

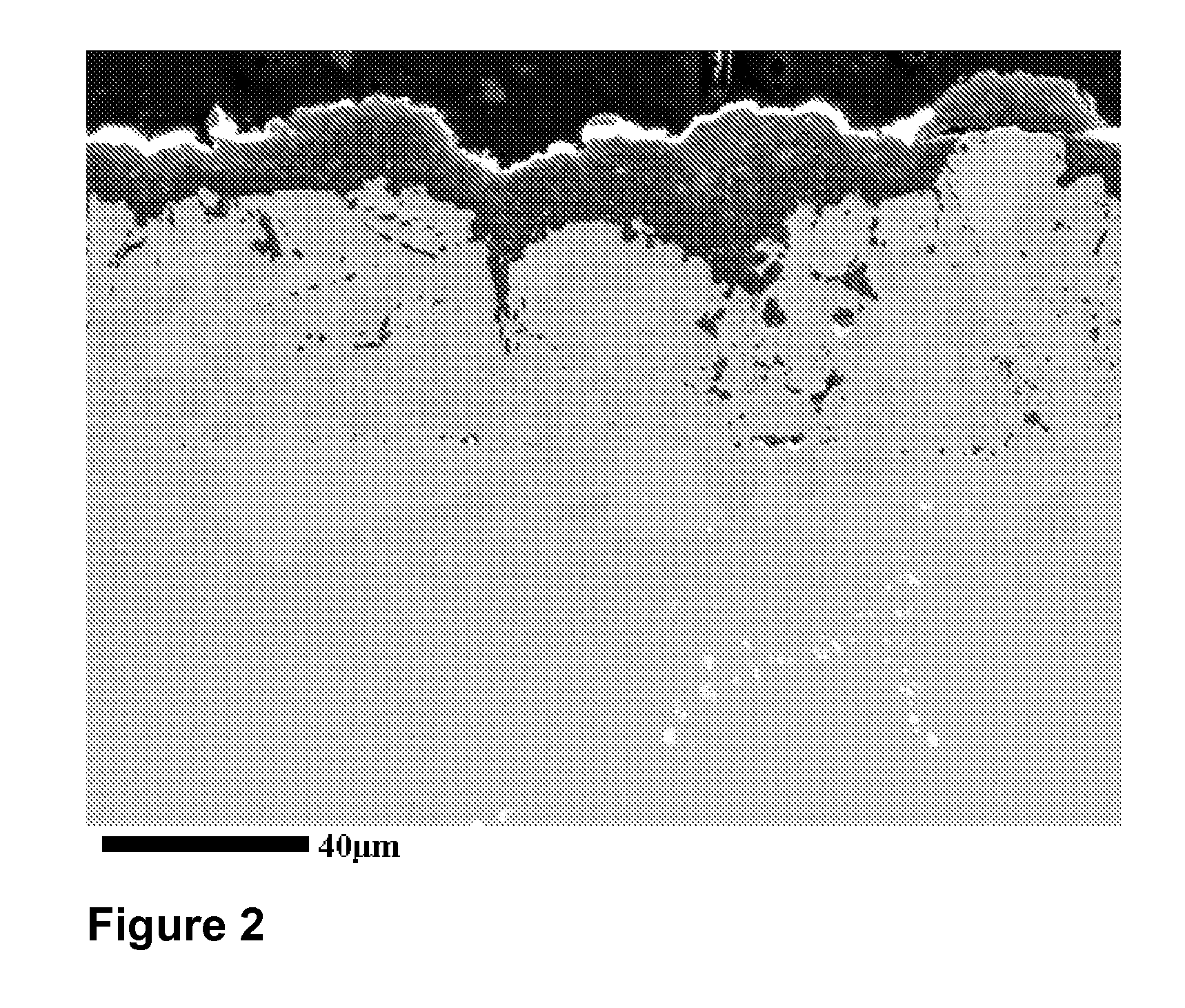

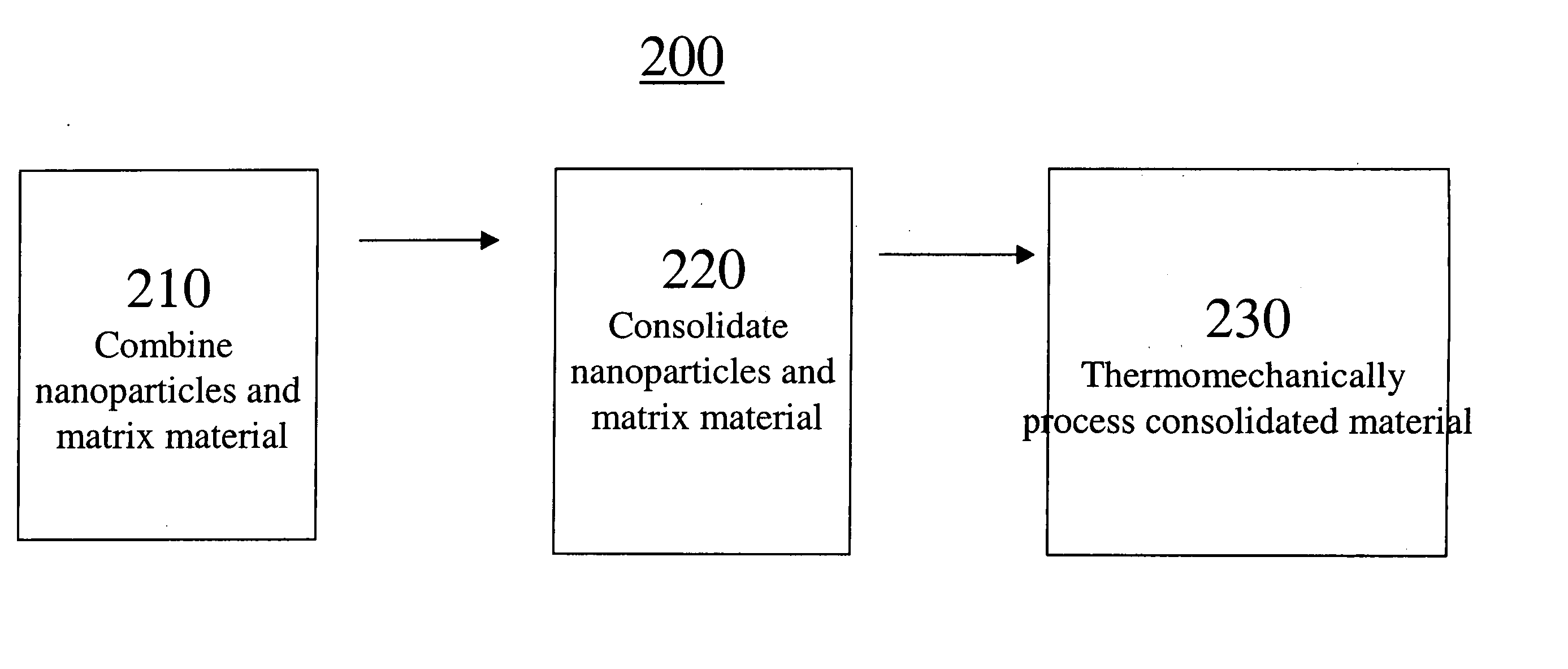

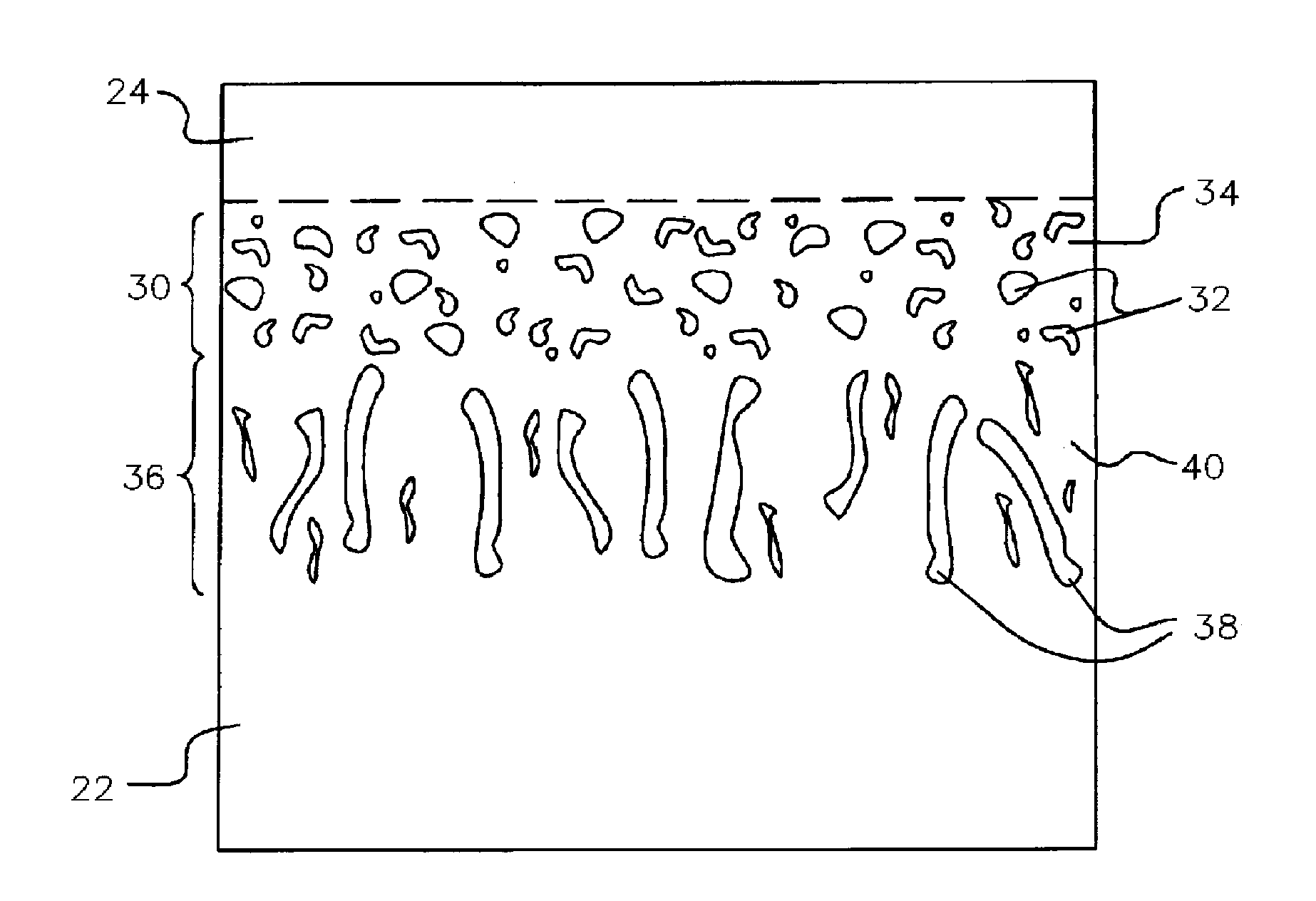

Metallic alloy nanocomposite for high-temperature structural components and methods of making

InactiveUS20050133121A1Increase volume fractionTransportation and packagingMetal-working apparatusNanocompositeAirplane

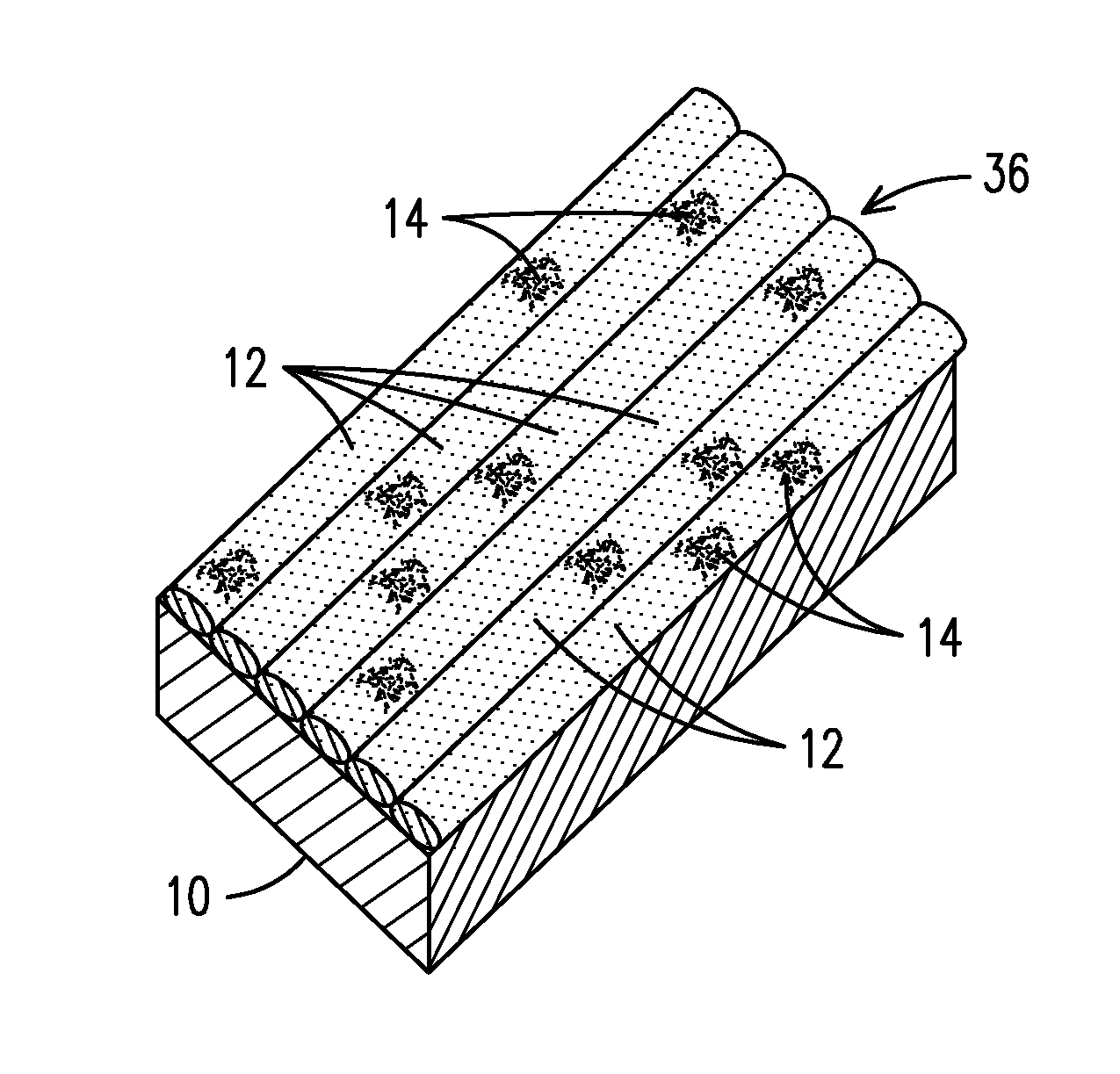

A nanocomposite comprising a plurality of nanoparticles dispersed in a metallic alloy matrix, and a structural component formed from such a nanocomposite. The metallic matrix comprises at least one of a nickel-based alloy and an iron-based alloy. The nanocomposite contains a higher volume fraction of nanoparticle dispersoids than those presently available. The structural component include those used in hot gas path assemblies, such as steam turbines, gas turbines, and aircraft turbine. A method of making such nanocomposites is also disclosed.

Owner:GENERAL ELECTRIC CO

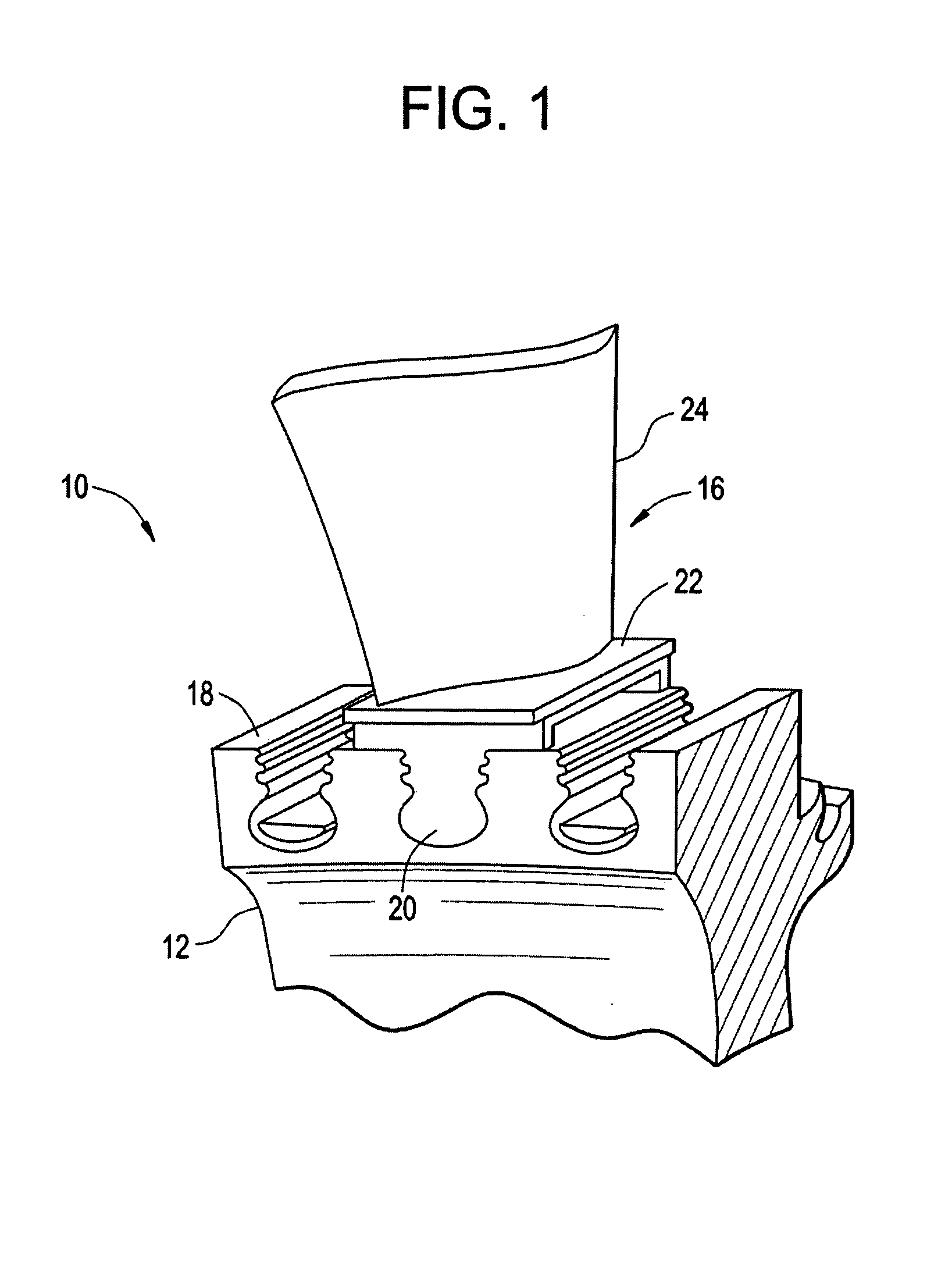

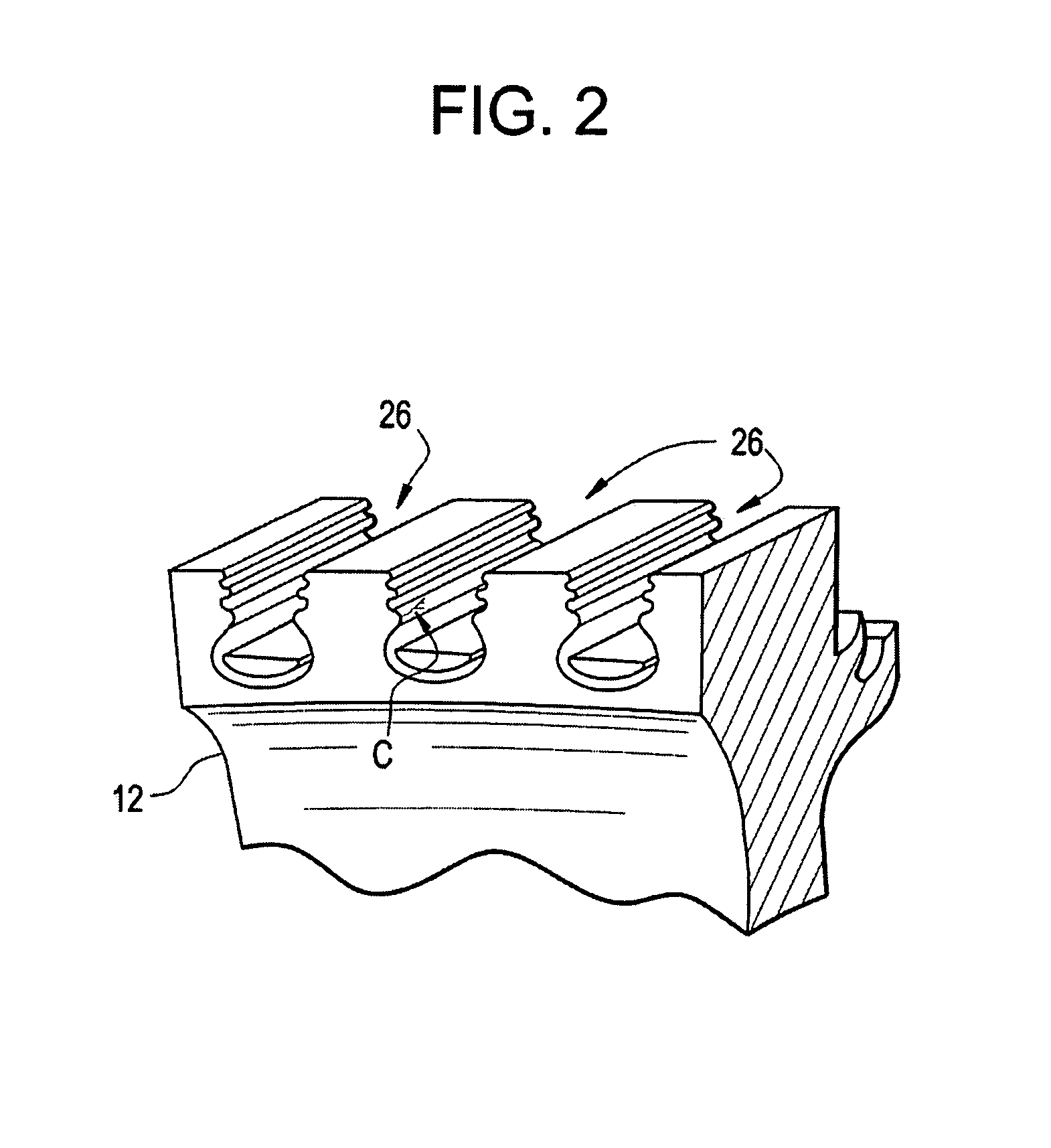

Superalloy Repair Welding Using Multiple Alloy Powders

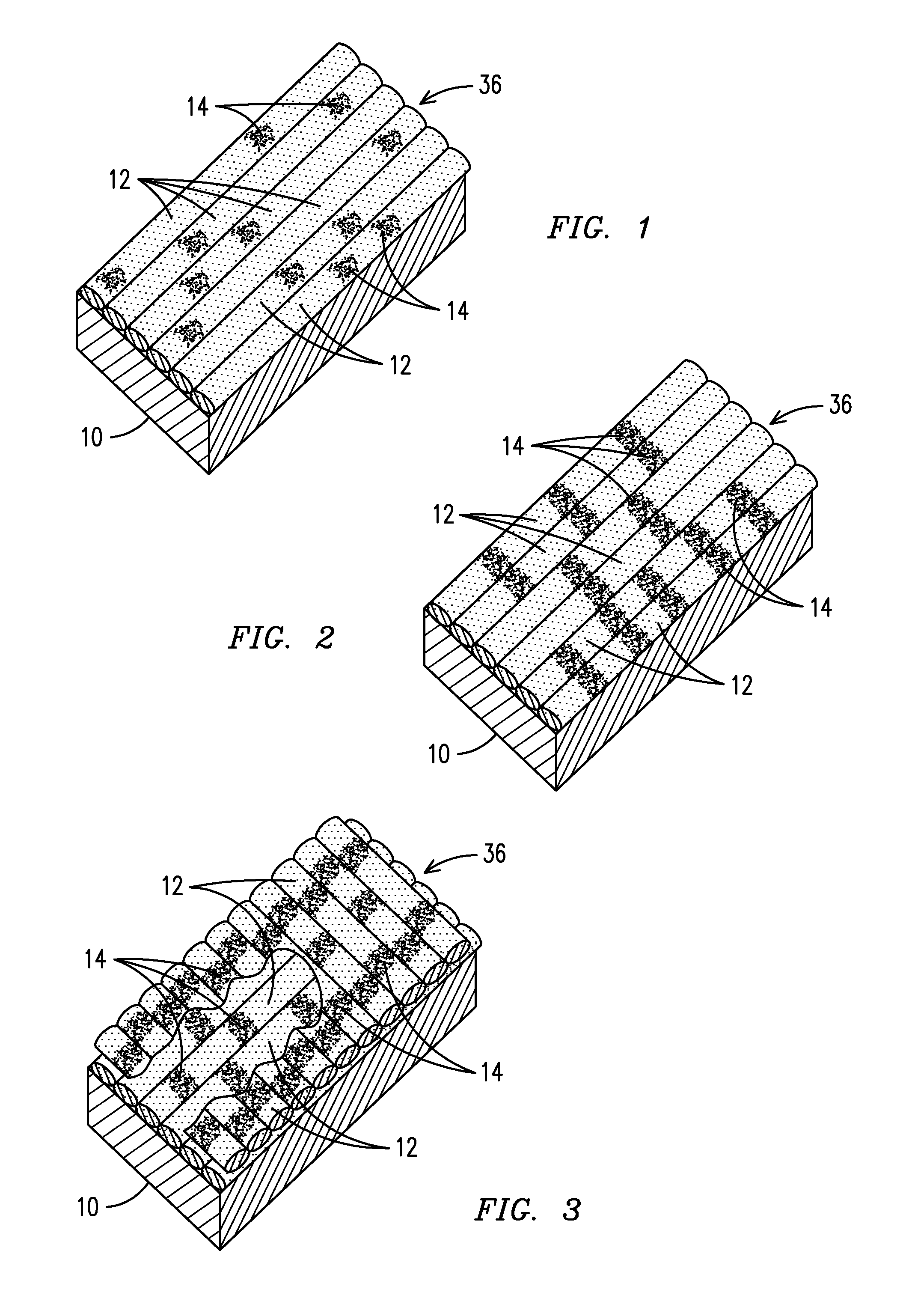

A method of welding a gas turbine engine substrate composed of a gamma prime precipitation strengthened nickel based superalloy, including the steps of: applying weld beads on the substrate to form a continuous layer the thickness of the weld beads; using a filler material made of a first material exhibiting comparable strength and ductility as the substrate, and a second material exhibiting greater ductility than the substrate; and creating crack propagation mitigating regions within the continuous layer by increasing the percentage of the second material in the crack propagation mitigating regions over the percentage of the second material in the remainder of the continuous layer.

Owner:SIEMENS ENERGY INC

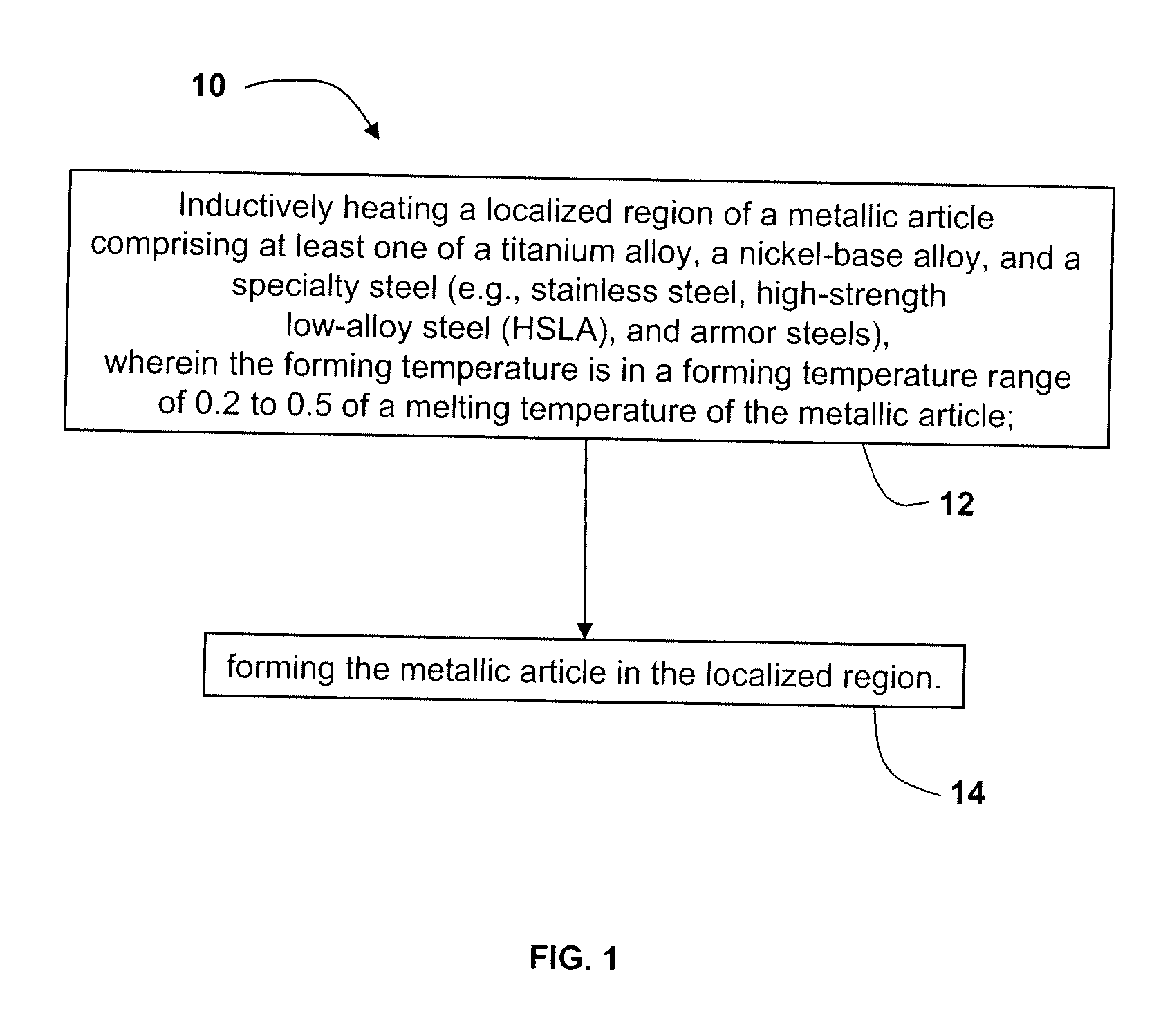

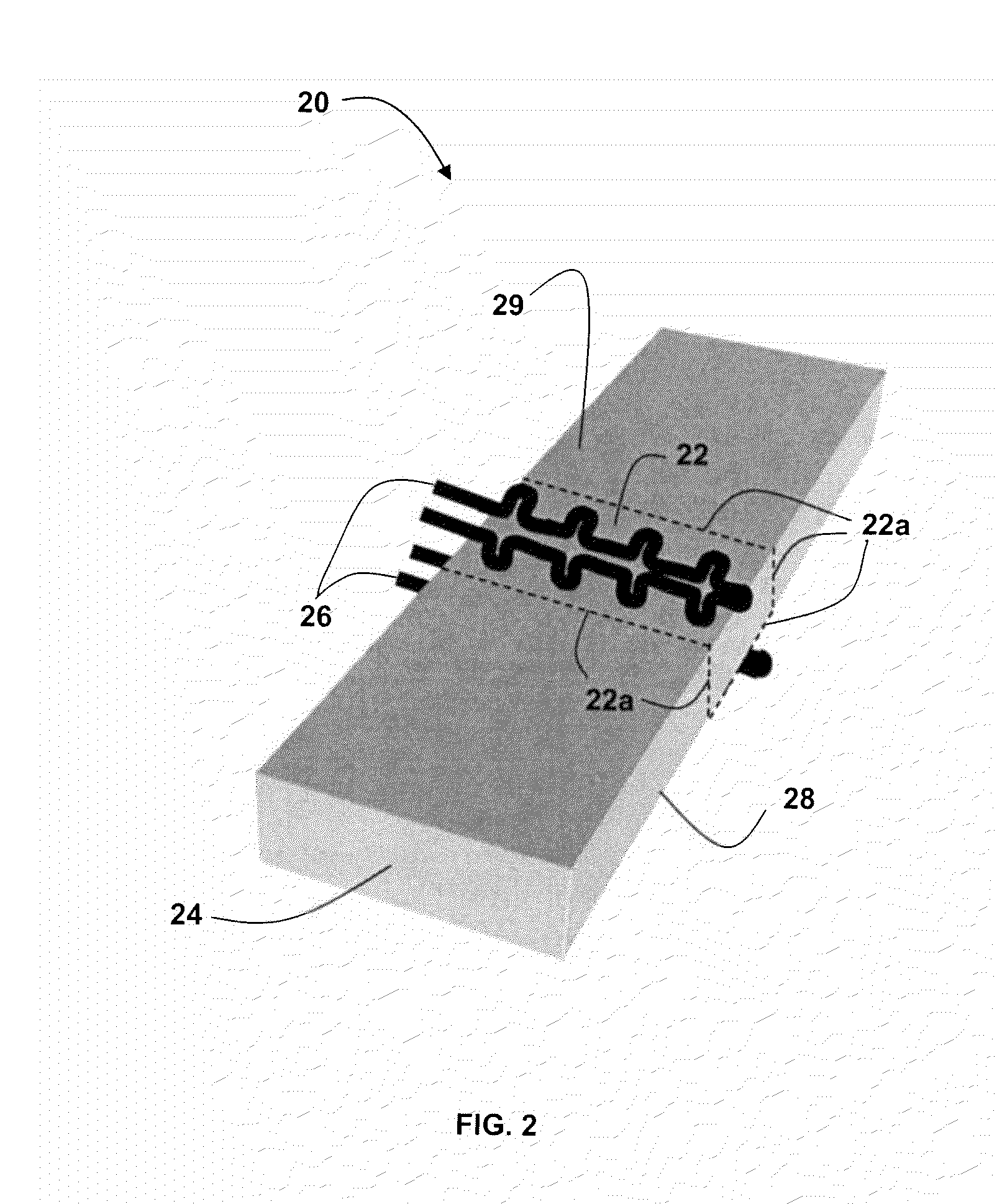

Elevated Temperature Forming Methods for Metallic Materials

A method of forming a metallic article includes directly and / or indirectly inductively heating a localized region of a metallic article to a forming temperature. The metallic article may comprise materials selected from titanium alloys, nickel-base alloys, and specialty steels, e.g., stainless steel, high-strength low-alloy steel, armor steel alloys, and the like. The forming temperature may be in a forming temperature range of 0.2 to 0.5 of a melting temperature of a metallic material comprising the article. The metallic article is formed in the localized region. Devices for indirectly and directly inductively heating a localized region of a metallic article are disclosed. Articles including metallic articles processed according to the methods and / or devices taught herein also are disclosed.

Owner:ATI PROPERTIES

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

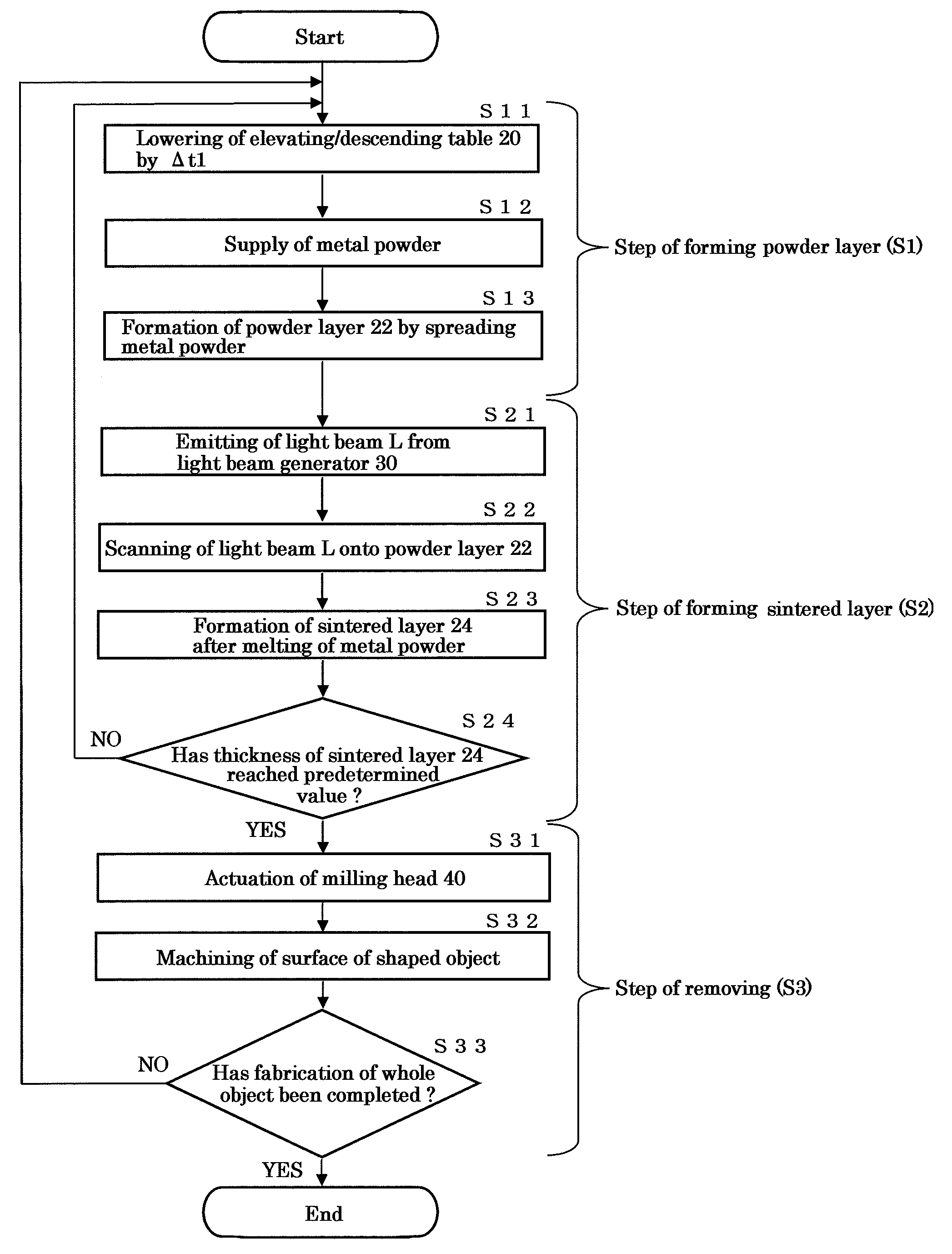

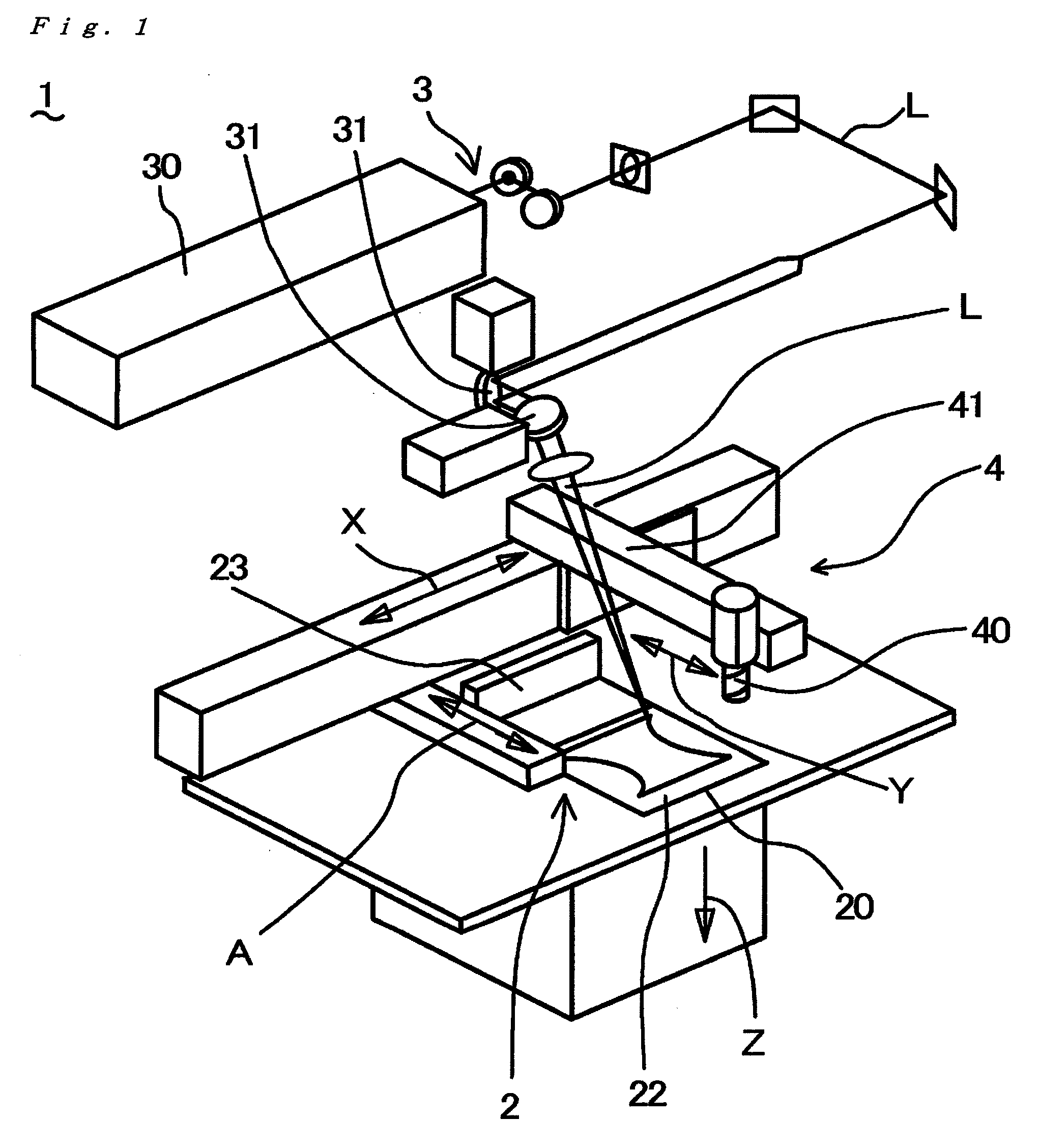

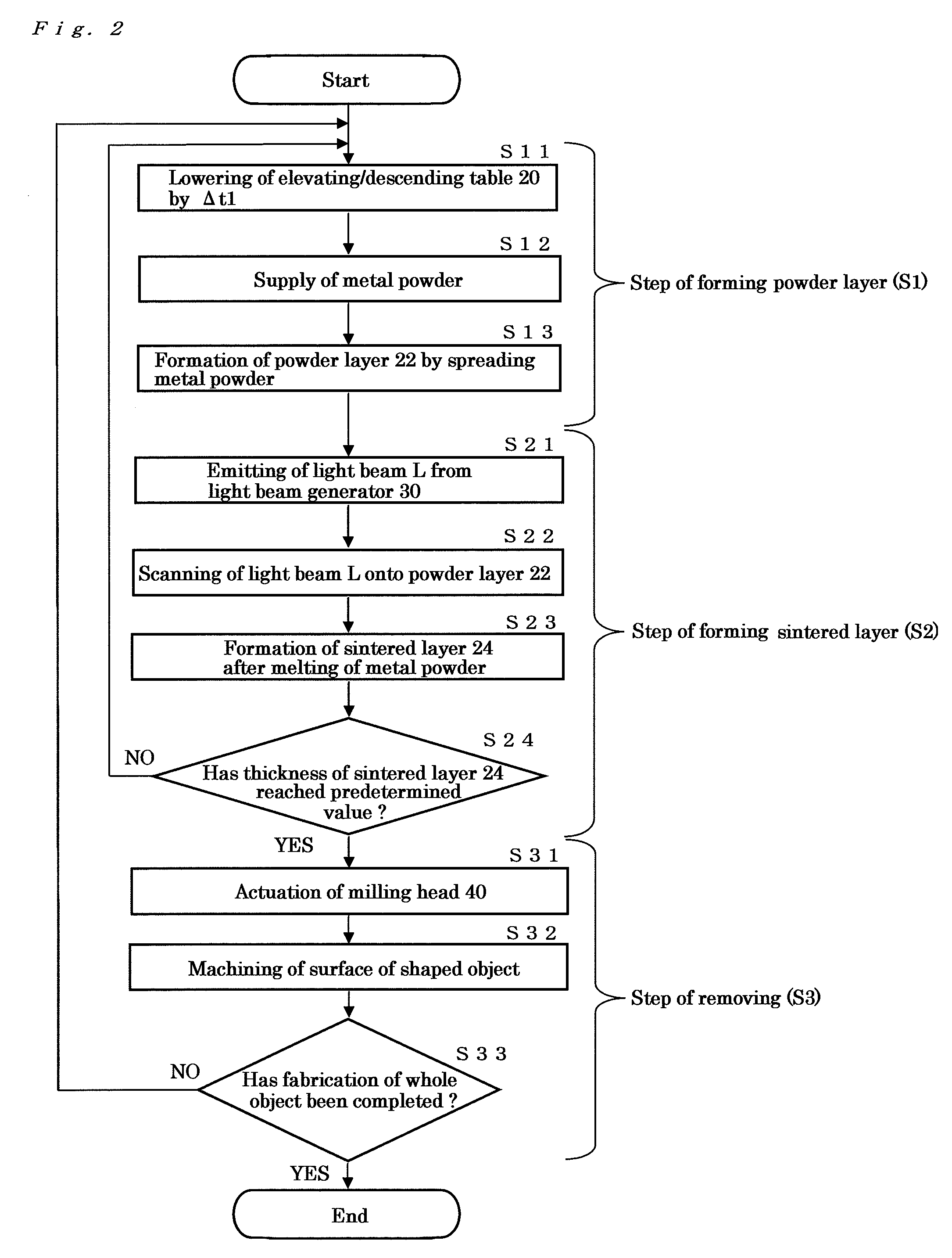

Metal powder for metal laser-sintering and metal laser-sintering process using the same

InactiveUS20110123383A1Reduce resistanceEliminate attachmentAdditive manufacturing apparatusTransportation and packagingAlloyGraphite

A metal powder for use in a metal laser-sintering wherein a three-dimensional shaped object is produced by irradiating a powder layer of the metal powder with a light beam to form a sintered layer and thereby laminating the sintered layers. The metal powder of the present invention is characterized in that it comprises an iron-based powder and at least one kind of powder selected from the group consisting of a nickel powder, a nickel-based alloy powder, a copper powder, a copper-based alloy powder and a graphite powder; and the iron-based powder has been annealed. In such metal powder, the iron-based powder is in a softened state due to the annealing treatment thereof. Accordingly, the use of the metal powder in a metal laser-sintering process makes it possible to reduce a machining resistance attributable to the residual metal powder adherent to the surface of the shaped object, which leads to an achievement of an extended lifetime of a machining tool.

Owner:PANASONIC CORP

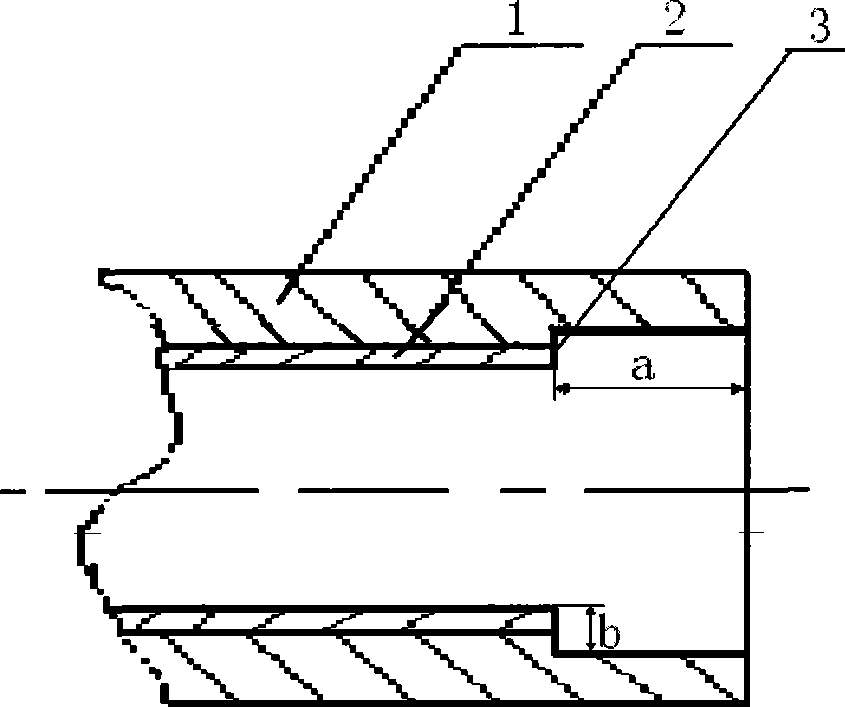

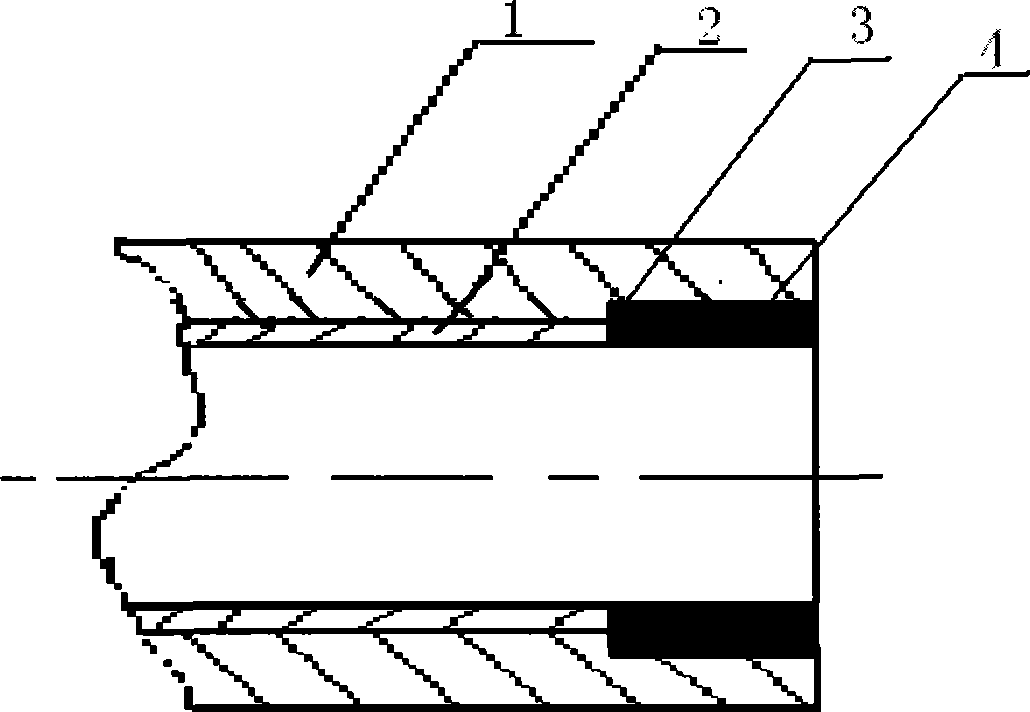

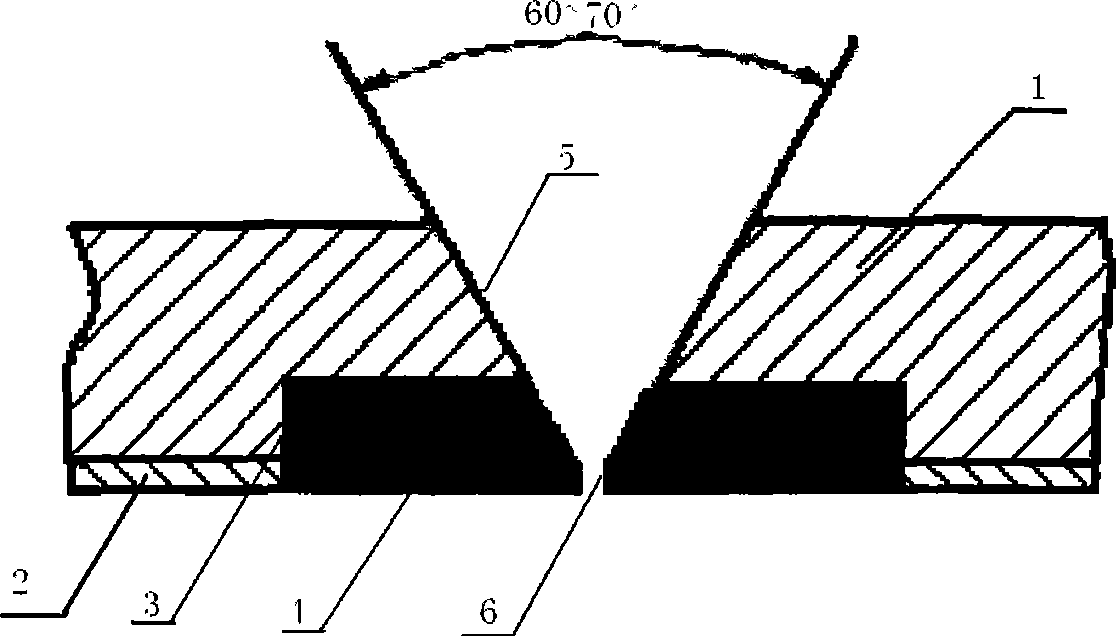

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

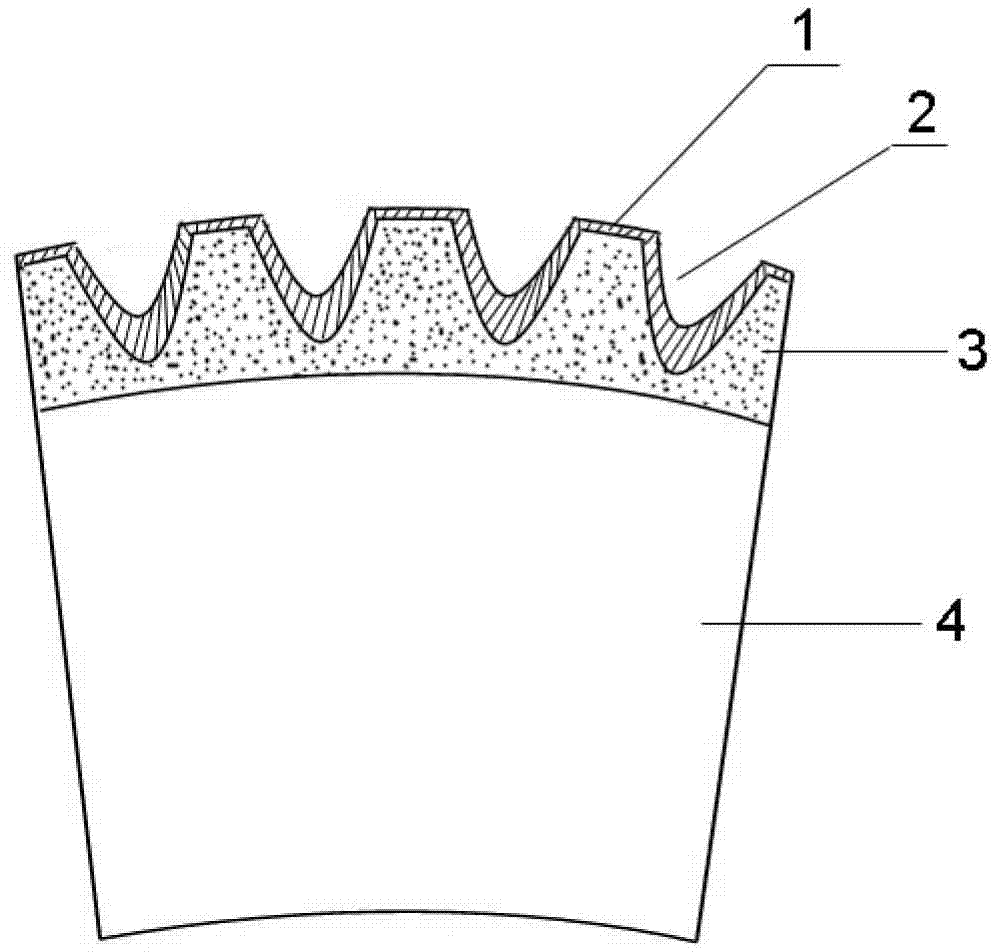

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

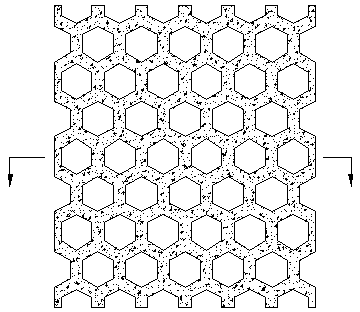

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

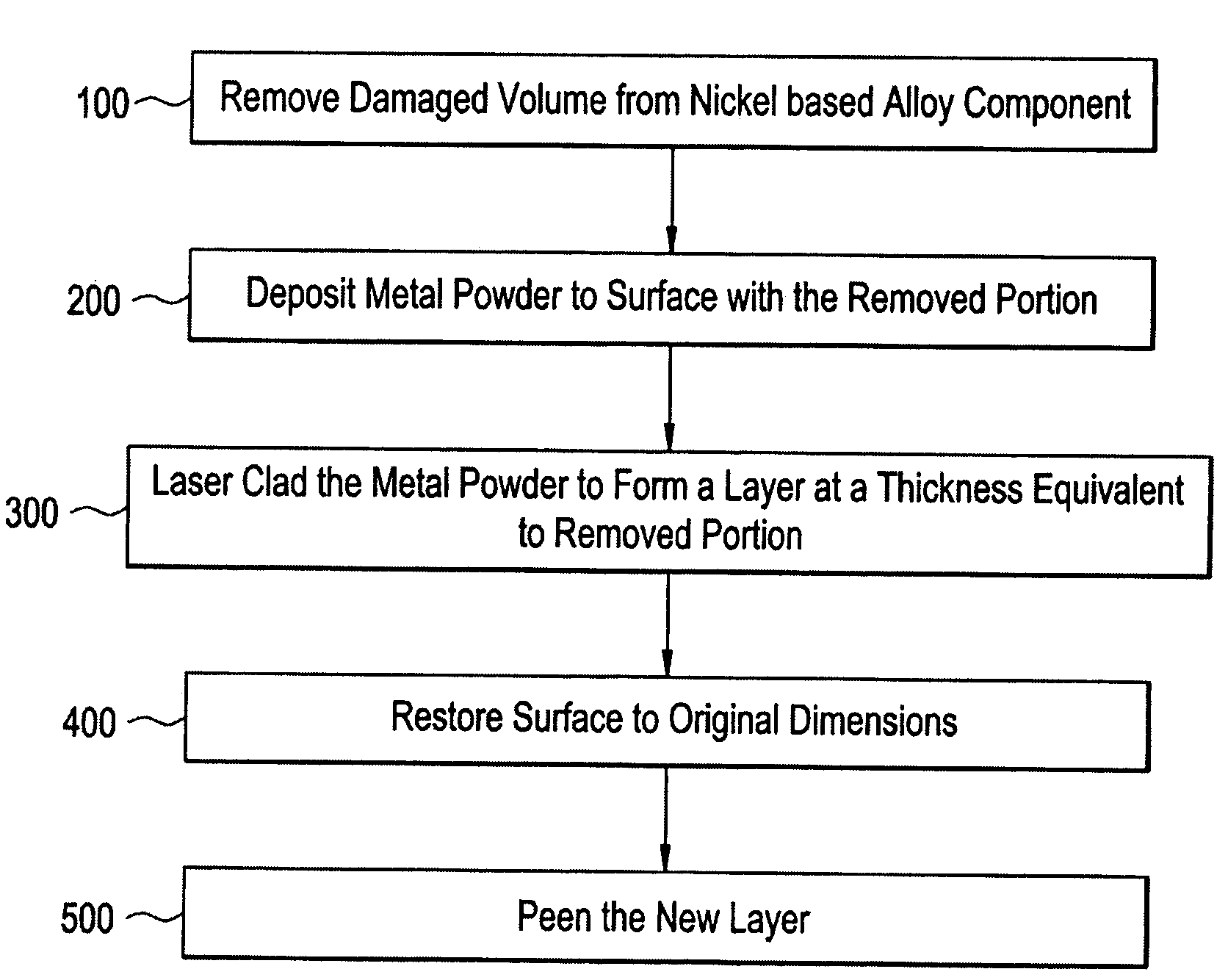

Method of Repairing Nickel-Based Alloy Articles

Methods for repairing nickel based alloy articles such as gas turbine rotors generally includes a removing a damaged portion of the articles and laser cladding a high temperature nickel based alloy powder thereto to form a solid layer. The process can be repeated until a desired thickness is obtained. Optionally, a peening process subsequent to laser cladding can be implemented to introduce compressive stress to the solid layer formed by laser cladding.

Owner:GENERAL ELECTRIC CO

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS20050158546A1High bulk densityGood rate characteristicsElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

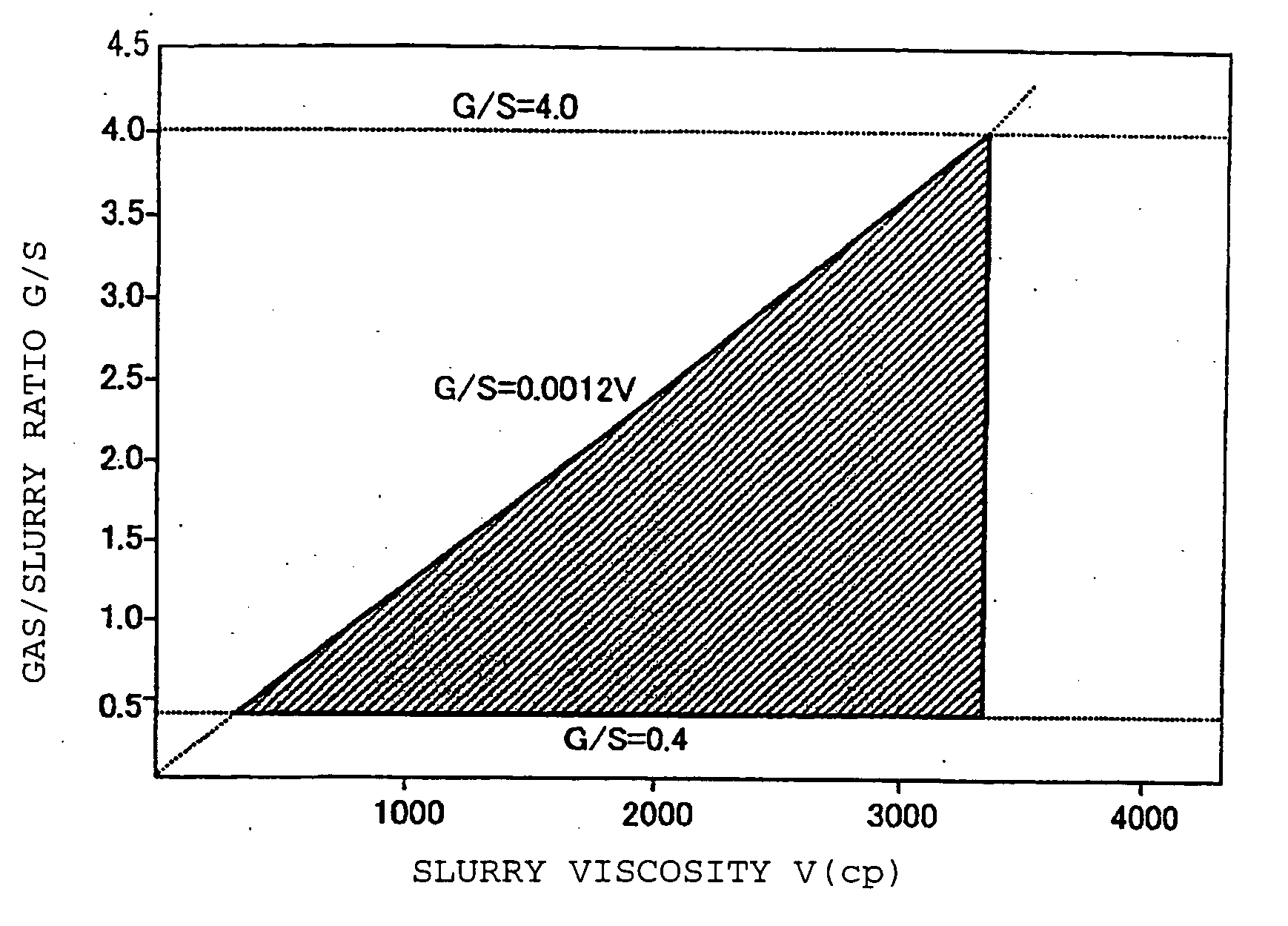

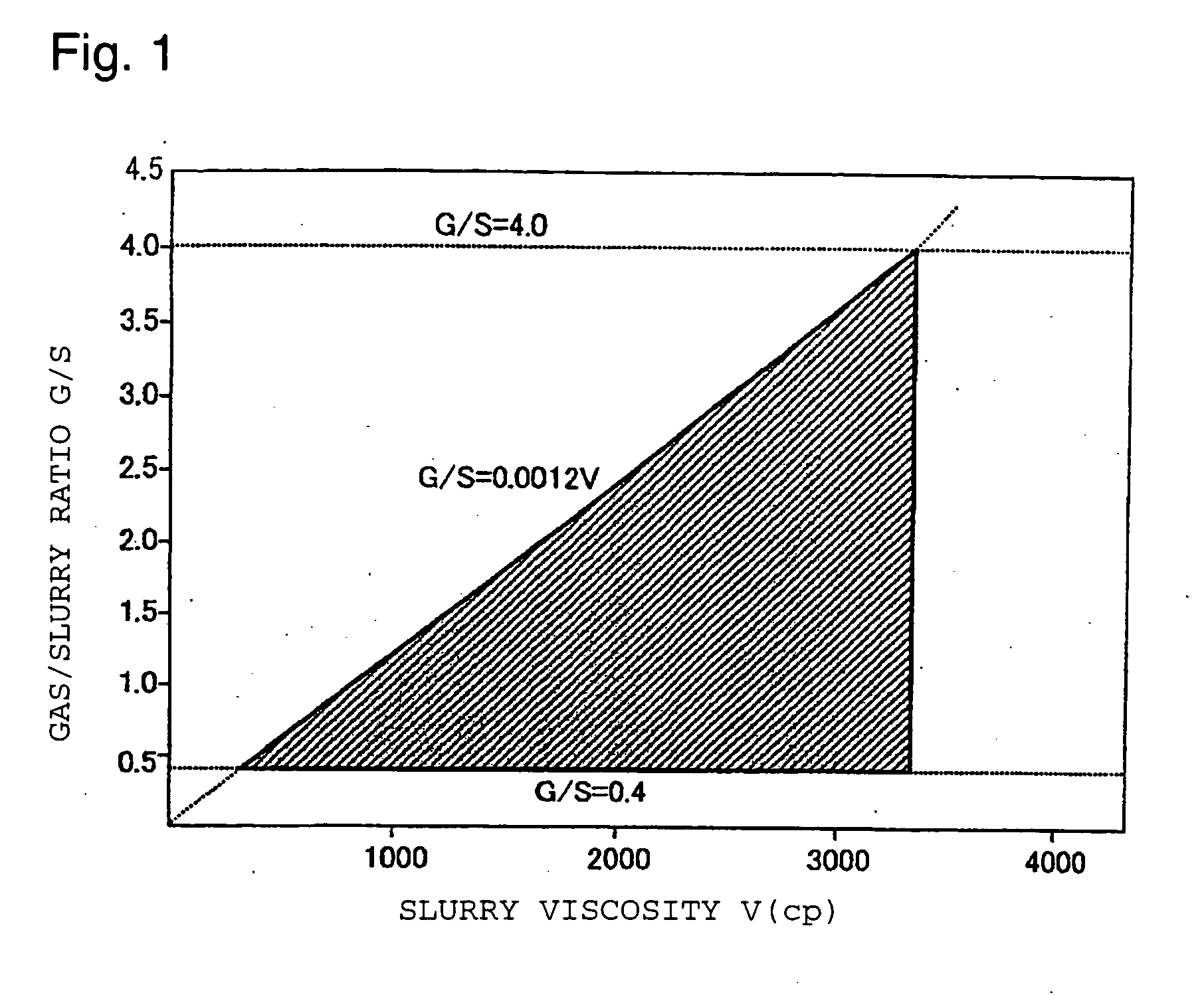

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

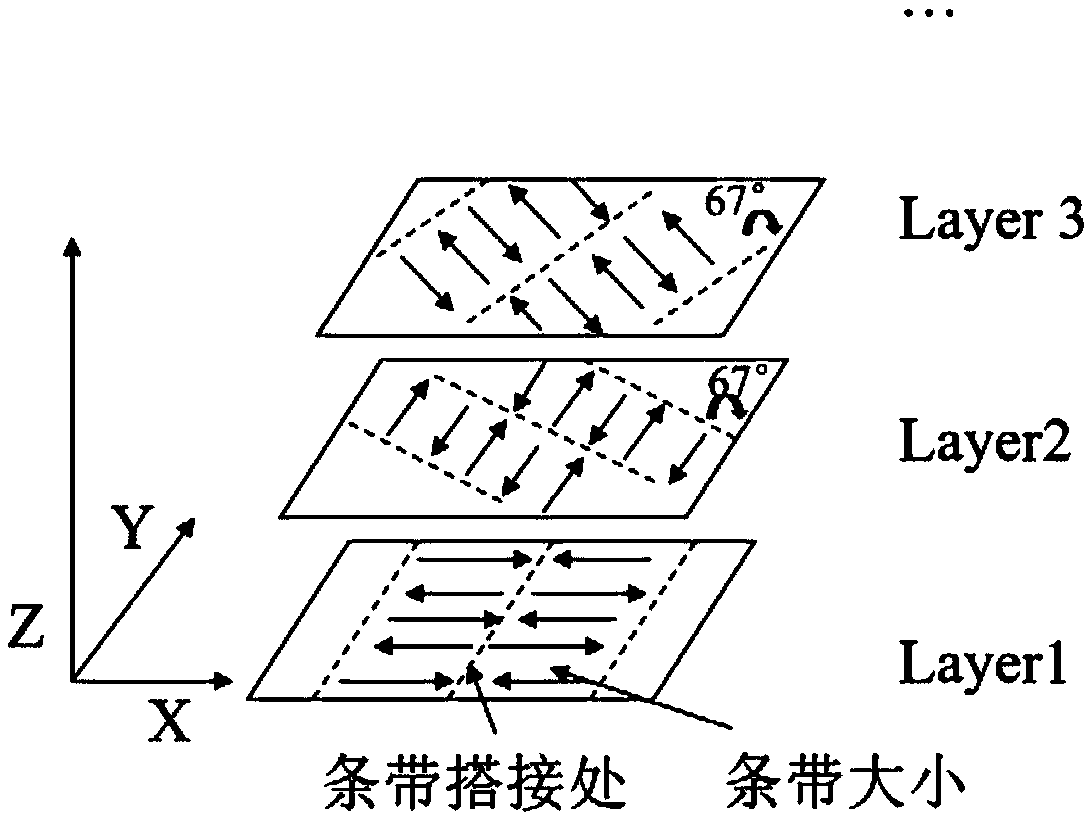

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

Powdery alloy processing material in site by movable laser smelt-coating process

A movable field processing alloy powder material for the laser melting is to reinforce the nickel-base alloy using the below elements: Cr, W, Mo, Al, Ti, Co; also it can be added with the Co, C, N, Nb, Cu, B, Si and the minim rare-earth metal which can be the Ce, Y and the Hf. The invention has the high hardness, the strength and the low melting point, high wearing resistance. It has improved the cracking resistance, moldability, the stability and the uniformity of the laser melting layer. So it can repair the high temperature alloy, the carbon steel, the structural steel and the stainless steel by the laser melting.

Owner:SHENYANG DALU LASER TECH

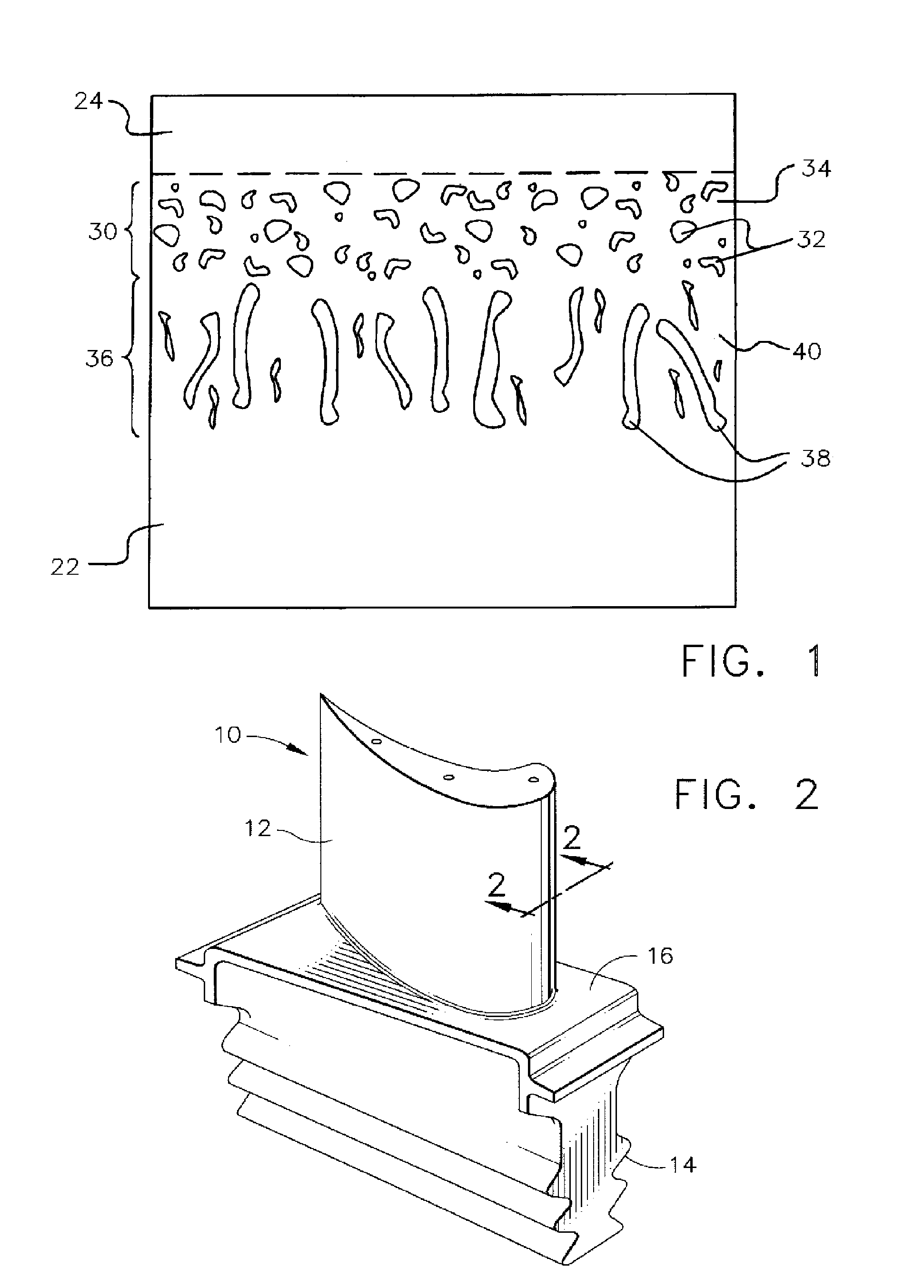

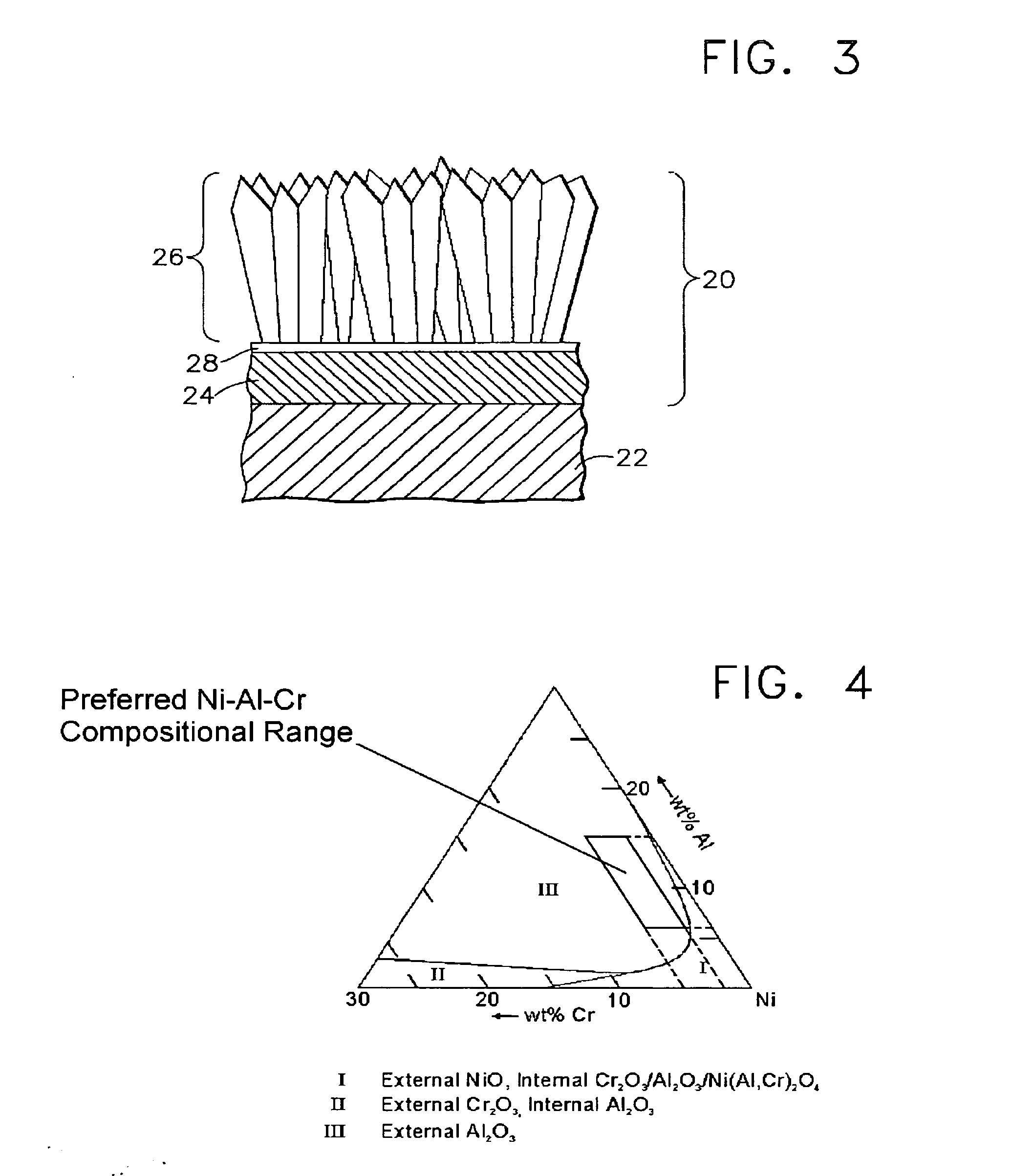

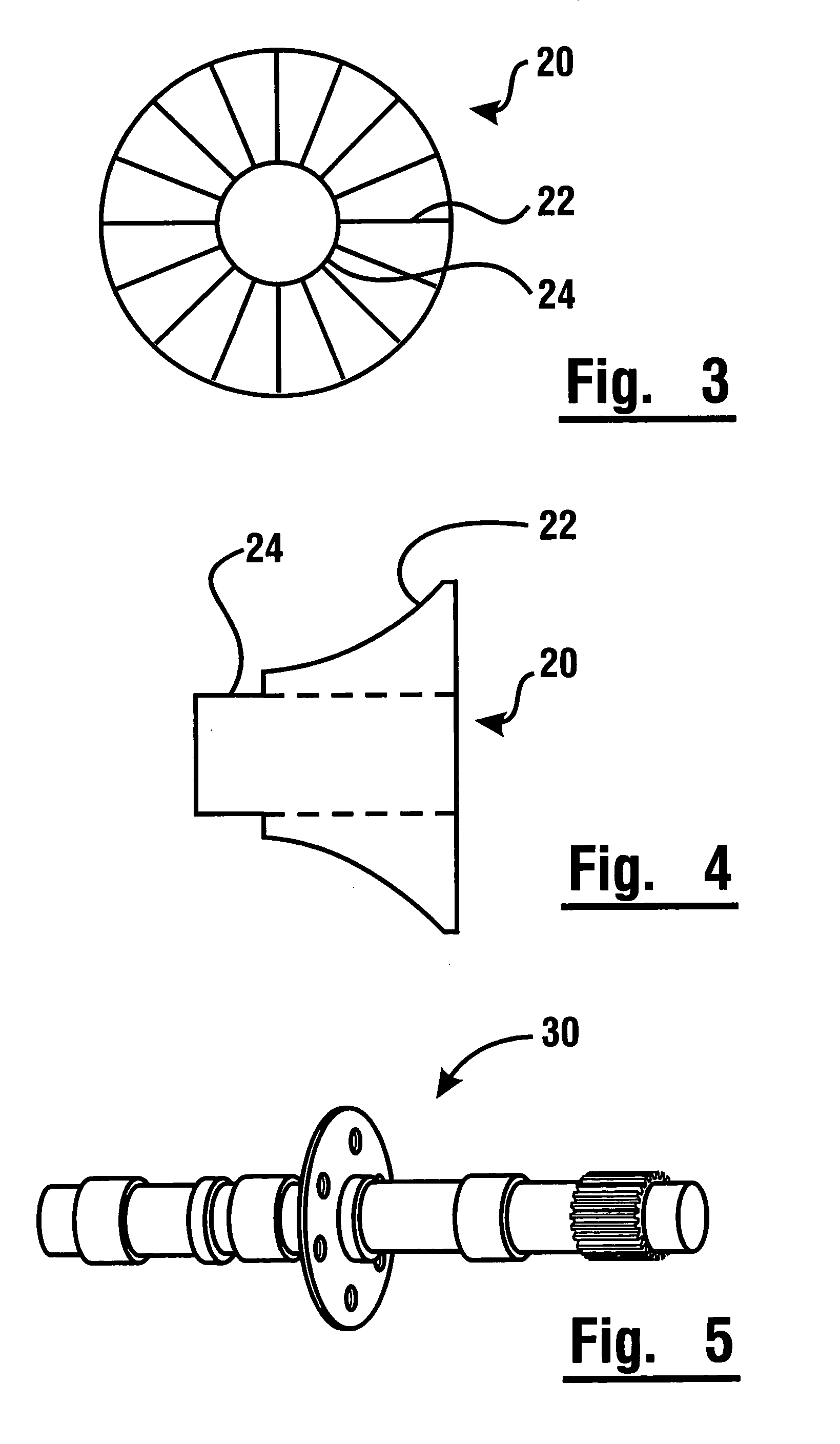

Superalloy article having a gamma-prime nickel aluminide coating

ActiveUS20060093851A1Reduce morbidityInhibited DiffusionPropellersRotary propellersReaction zoneBond coat

An article for use in hostile thermal environments, such as a component of a gas turbine engine. The article includes a nickel-base superalloy substrate that is prone to formation of a deleterious secondary reaction zone (SRZ), and an overlay coating having a predominantly gamma prime-phase nickel aluminide (Ni3Al) composition suitable for use as an environmental coating, including a bond coat for a thermal barrier coating. The coating comprises a chromium-containing nickel aluminide intermetallic overlay coating of predominantly the gamma prime phase, in which aluminum is present in the coating in an amount approximately equal to the aluminum content of the superalloy substrate so as to inhibit diffusion of aluminum from the overlay coating into the superalloy substrate.

Owner:GENERAL ELECTRIC CO

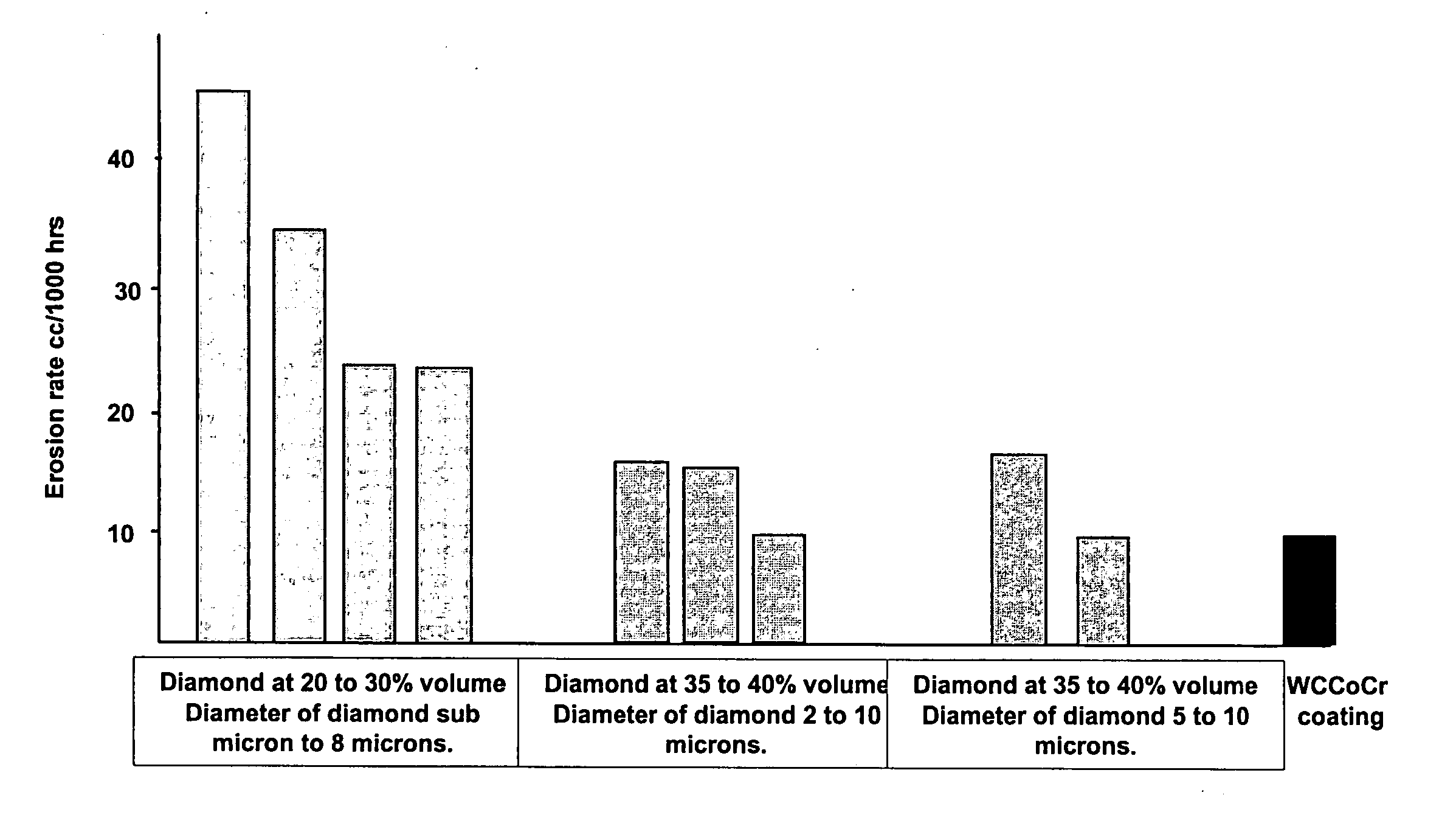

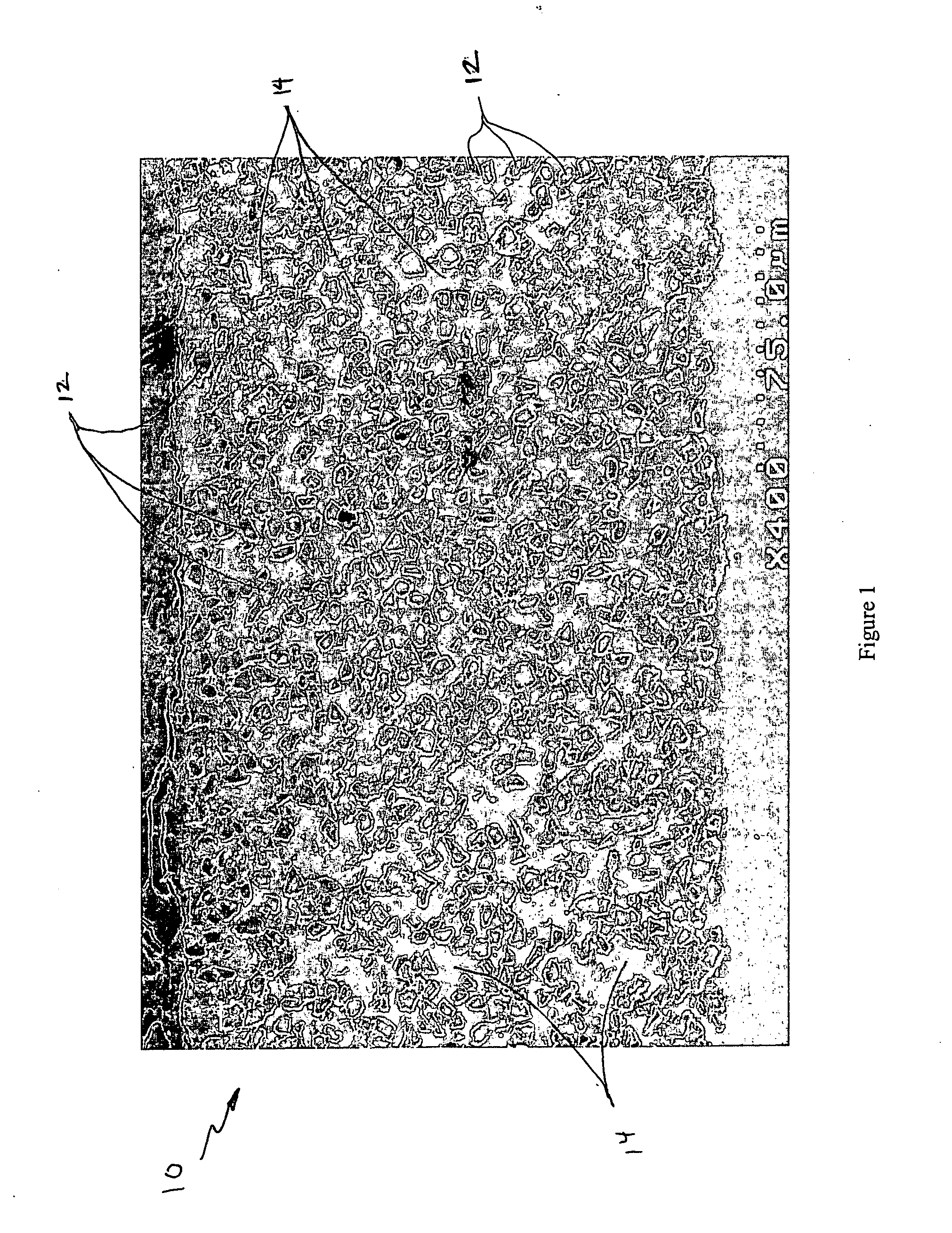

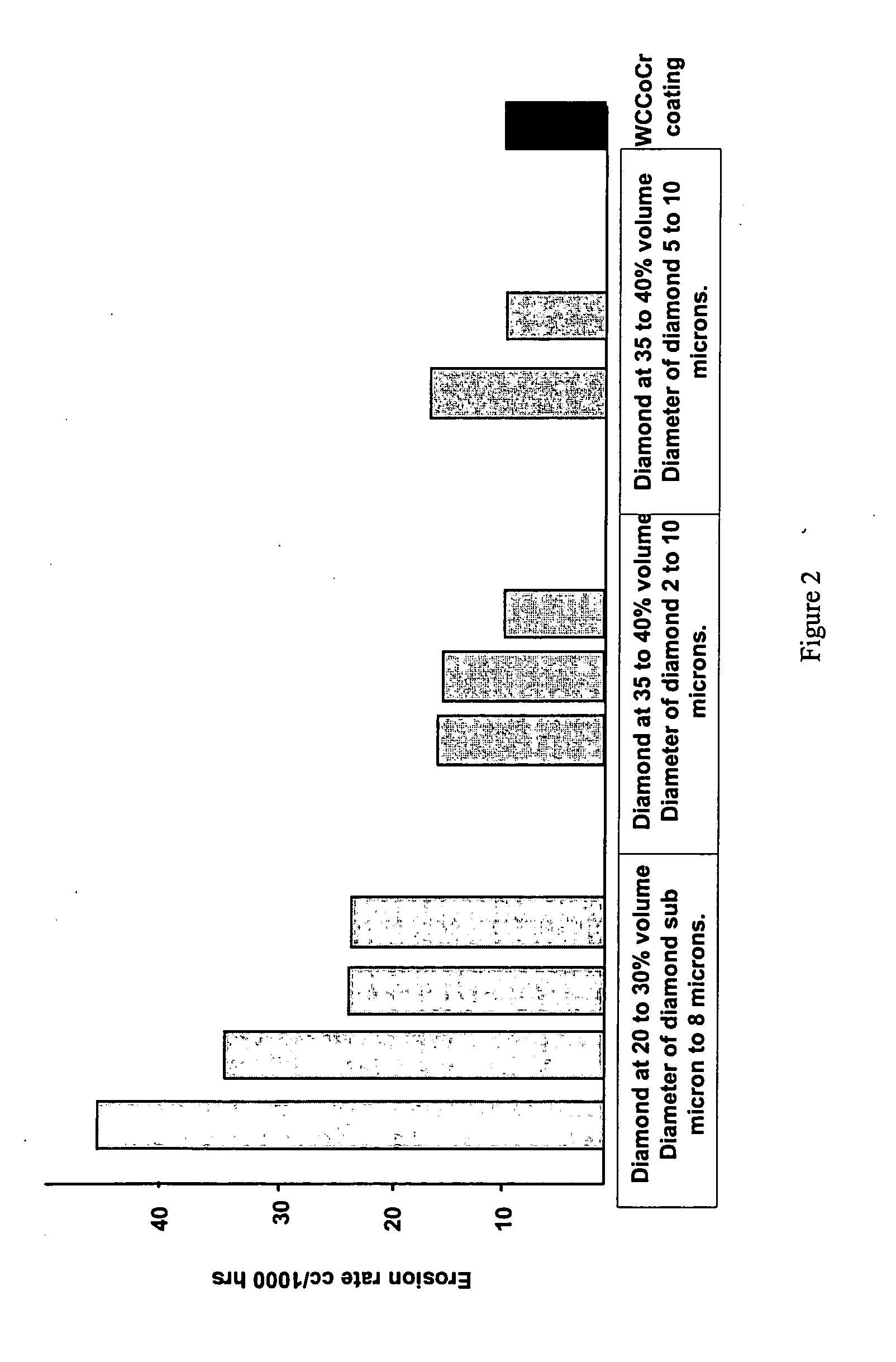

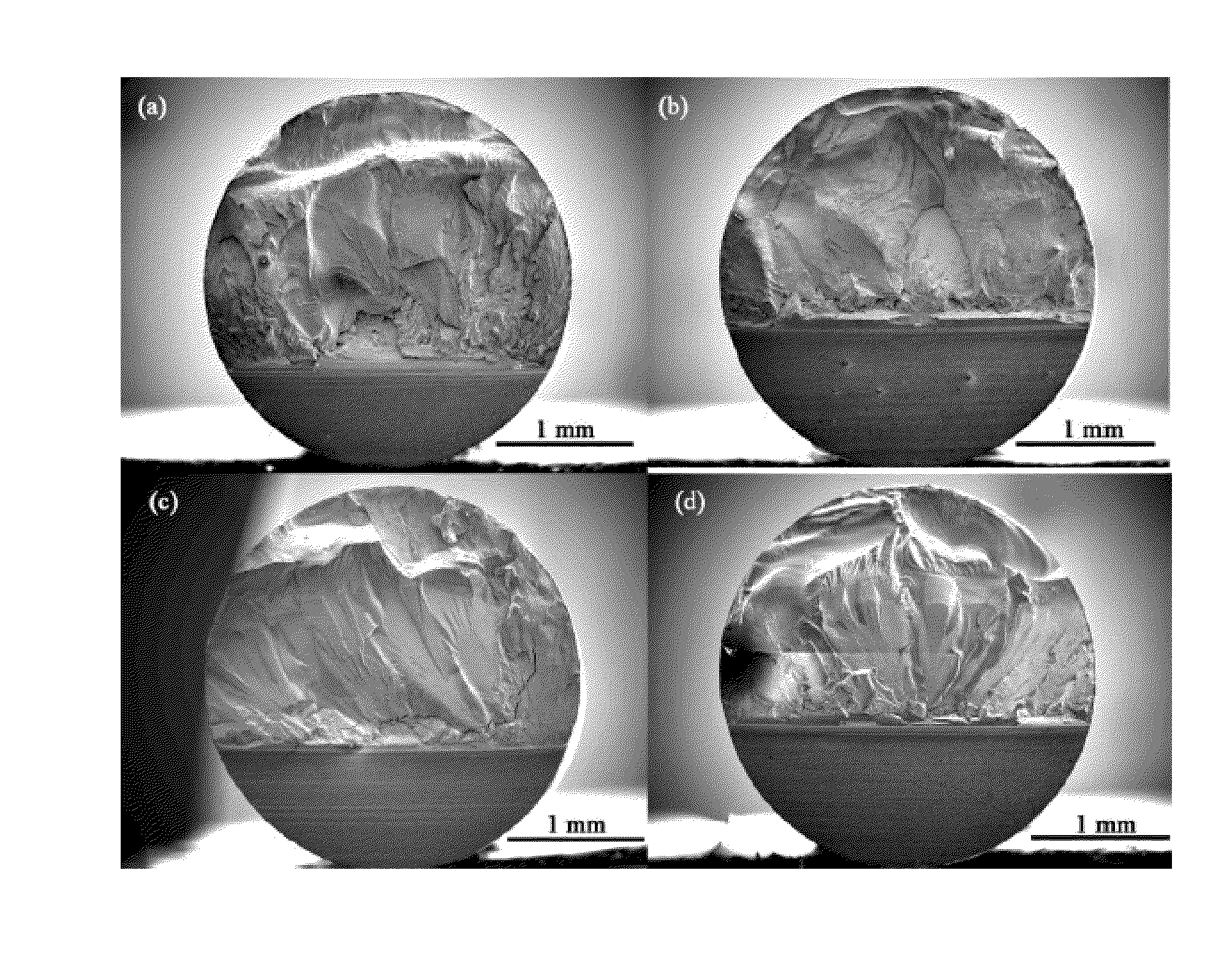

Erosion resistant coatings and methods thereof

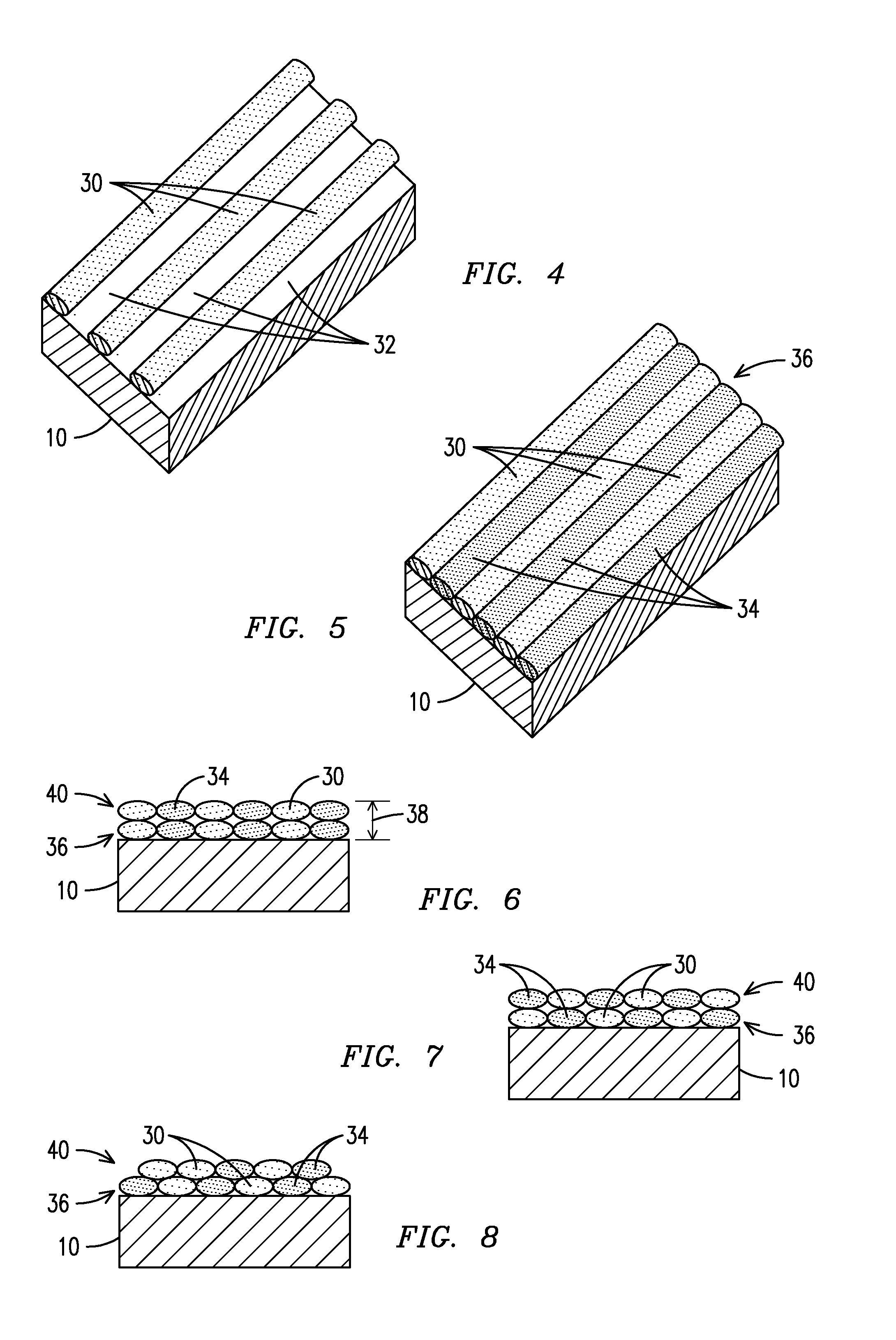

Erosion resistant coating compositions include hard particles in a metal matrix such as nickel-based, cobalt-based and iron-based matrices applied by a plating process for complex geometry or hard to access component surfaces or by thermal spray processes for line of sight applications. These materials and processes are especially suited for providing erosion resistance to hydroelectric turbine components.

Owner:GENERAL ELECTRIC CO

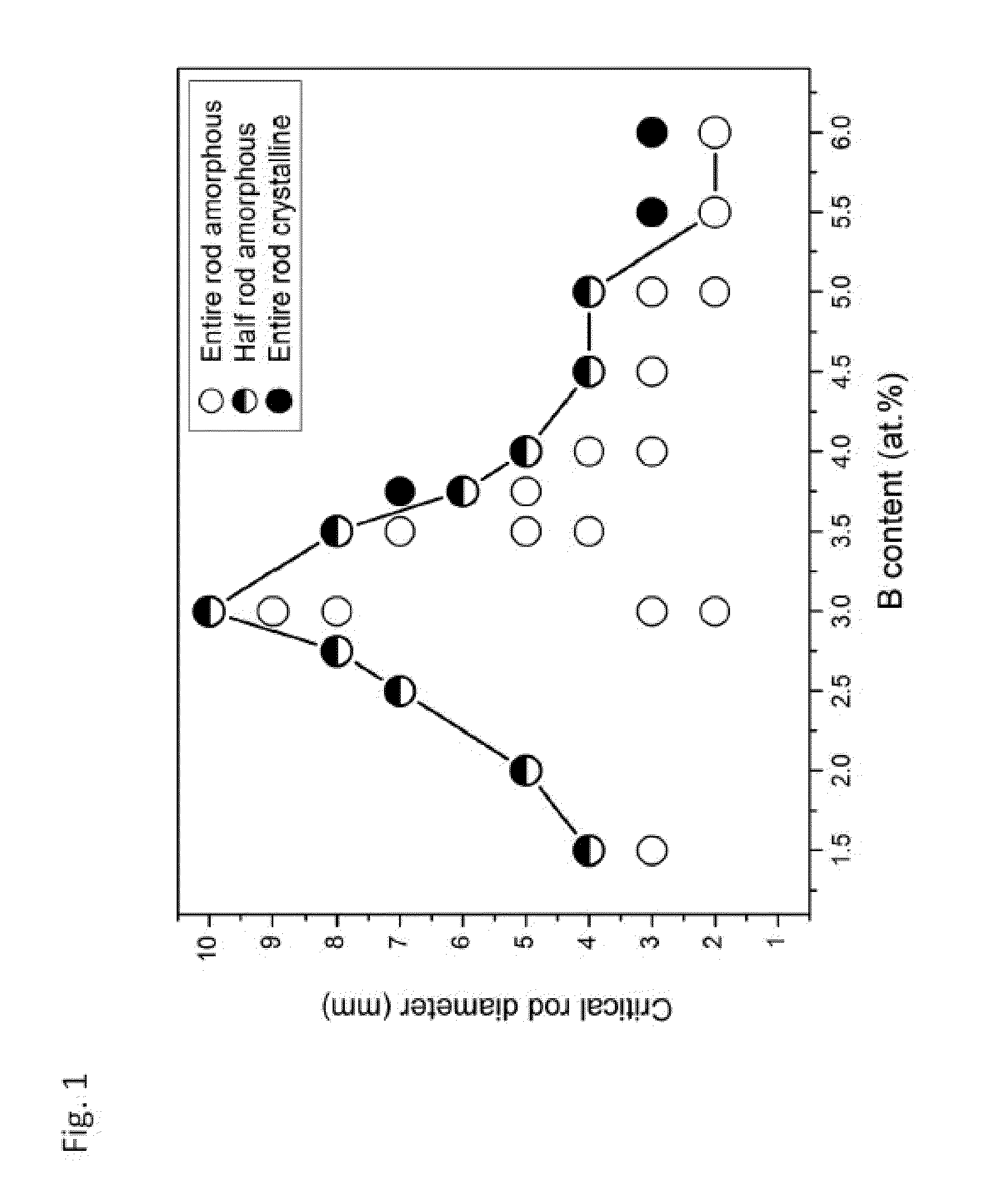

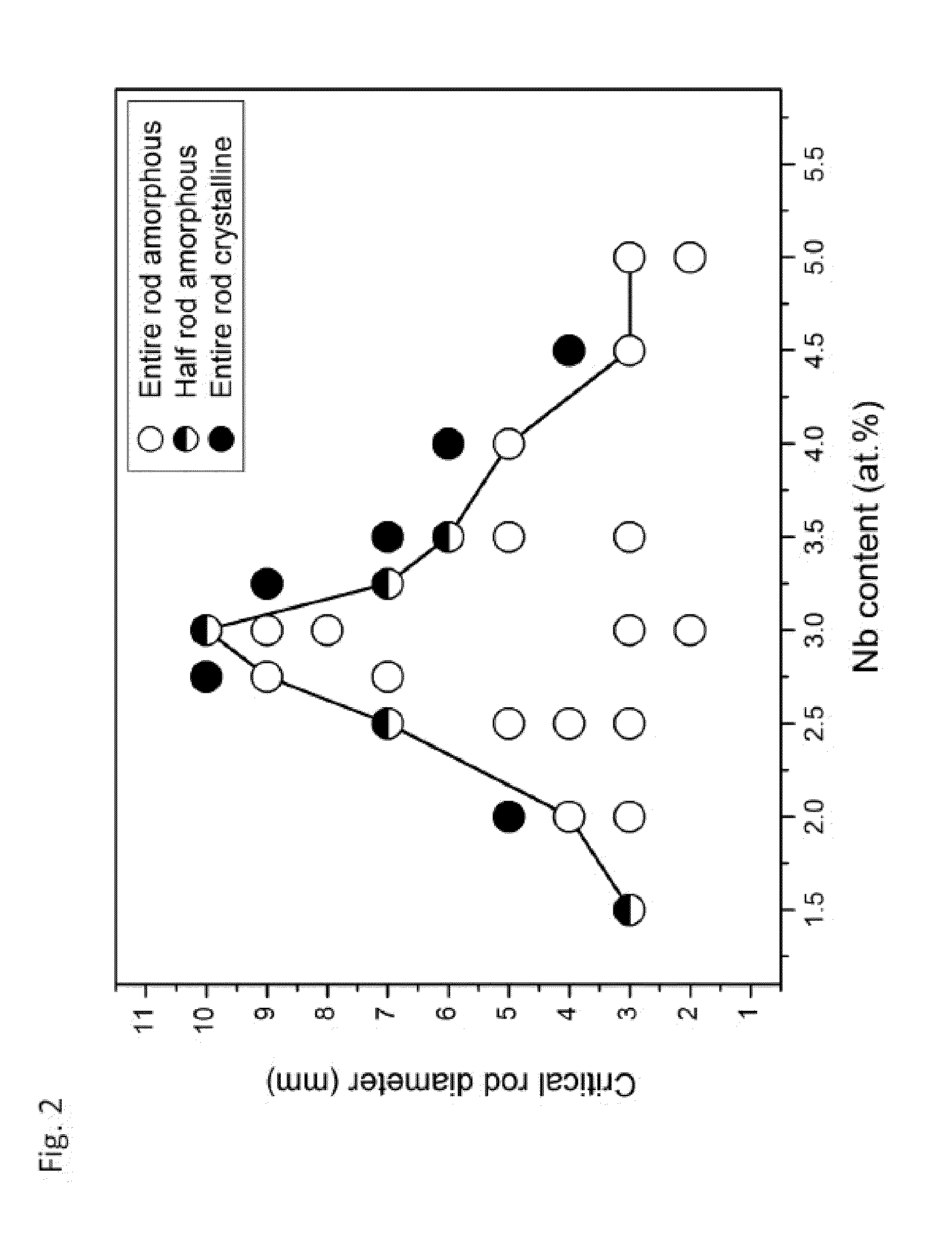

Bulk Nickel-Based Chromium and Phosphorous Bearing Metallic Glasses

Ni-based Cr- and P-bearing alloys that can from centimeter-thick amorphous articles are provided. Within the family of alloys, millimeter-thick bulk-glassy articles can undergo macroscopic plastic bending under load without fracturing catastrophically.

Owner:CALIFORNIA INST OF TECH

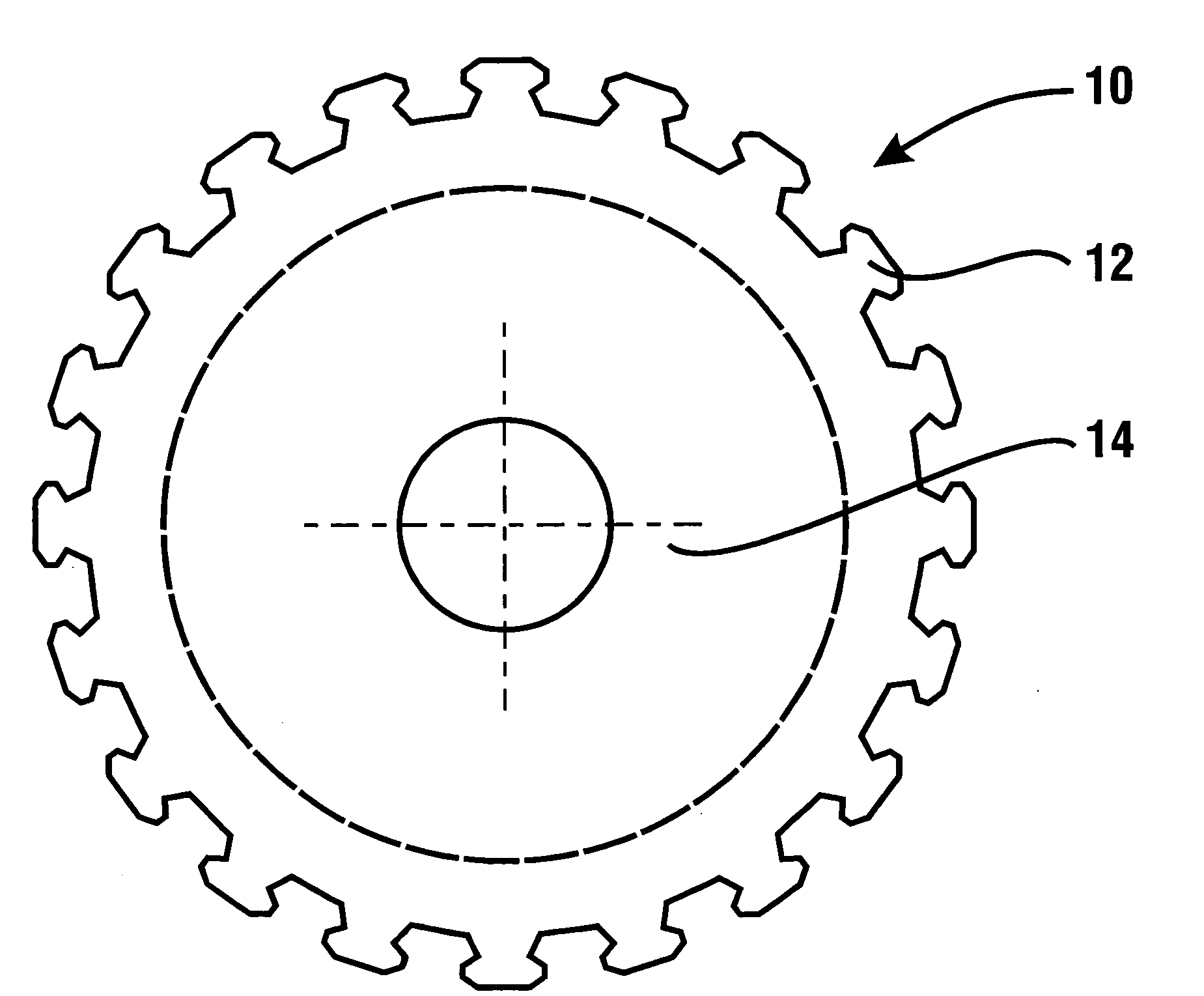

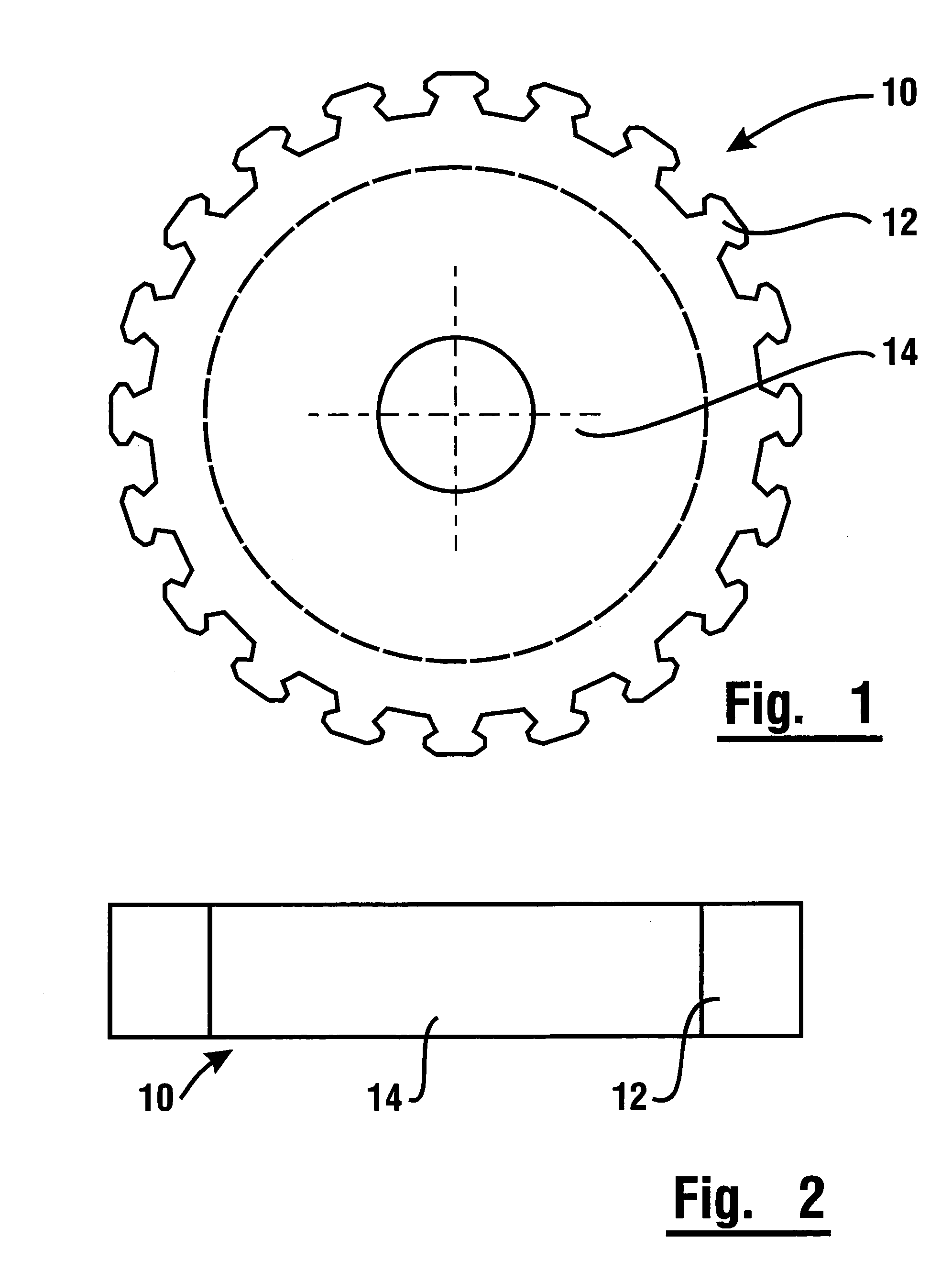

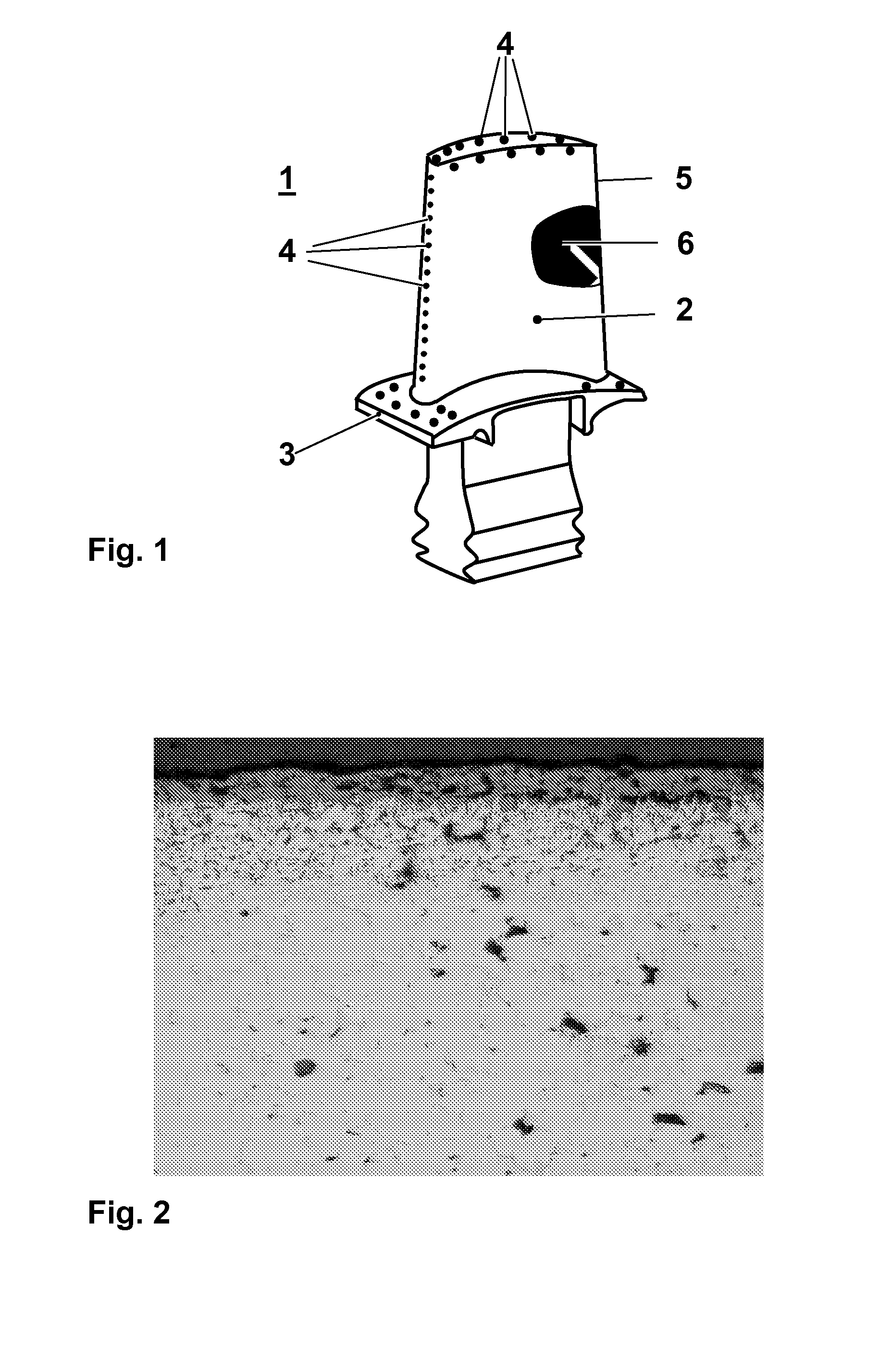

Nickel base superalloy turbine disk

InactiveUS6974508B1Favorable microstructuresImprove mechanical propertiesPropellersPump componentsImpellerRefractory

A low solvus, high refractory alloy having unusually versatile processing mechanical property capabilities for advanced disks and rotors in gas turbine engines. The nickel base superalloy has a composition consisting essentially of, in weight percent, 3.0–4.0 Al, 0.02–0.04 B, 0.02–0.05 C, 12.0–14.0 Cr, 19.0–22.0 Co, 2.0–3.5 Mo, greater than 1.0 to 2.1 Nb, 1.3 to 2.1 Ta, 3.0–4.0 Ti, 4.1 to 5.0 W, 0.03–0.06 Zr, and balance essentially Ni aid incidental impurities. The superalloy combines ease of processing with high temperature capabilities to be suitable for use in various turbine engine disk, impeller, and shaft applications. The Co and Cr levels of the superalloy can provide low solvus temperature for high processing versatility. The W, Mo, Ta, and Nb refractory element levels of the superalloy can provide sustained strength, creep, and dwell crack growth resistance at high temperatures.

Owner:NASA

Diffusion barrier and protective coating for turbine engine component and method for forming

A turbine engine component comprising a substrate made of a nickel-base or cobalt-base superalloy, a non-metallic oxide or nitride diffusion barrier layer overlying the substrate, and a protective coating overlying the barrier layer, the protective coating comprising at least one platinum group metal selected from the group consisting of platinum, palladium, rhodium, ruthenium and iridium. The diffusion barrier layer may be a deposited or thermally grown oxide material, especially aluminum oxide. The protective coating may be heat treated to increase homogeneity of the coating and adherence with the substrate. The component typically further comprises a ceramic thermal barrier coating overlying the protective coating. Also disclosed are methods for forming a protective coating system on the turbine engine component by forming the non-metallic oxide or nitride diffusion barrier layer on the substrate and then depositing the platinum group metal on top of the barrier layer.

Owner:GENERAL ELECTRIC CO +1

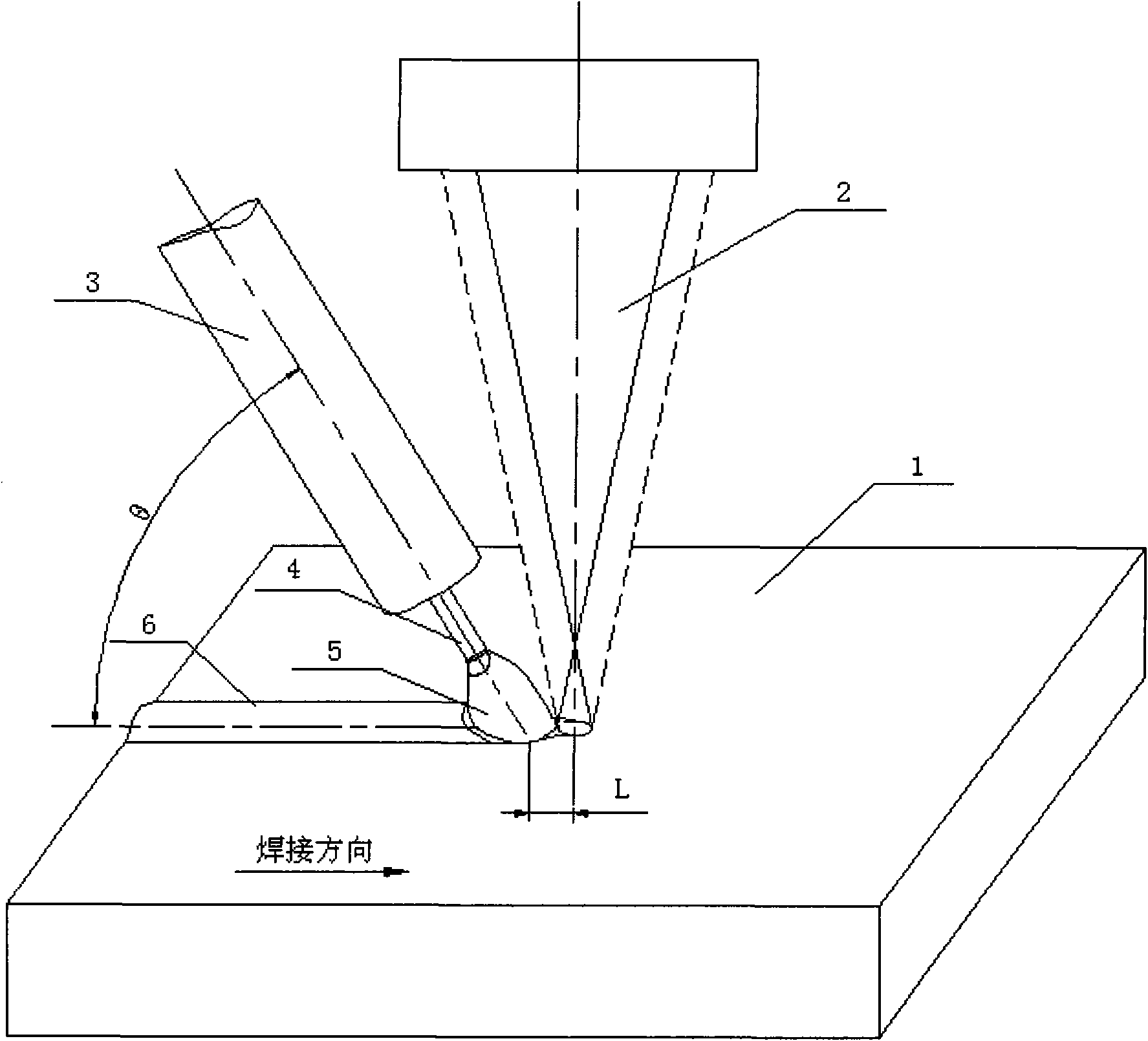

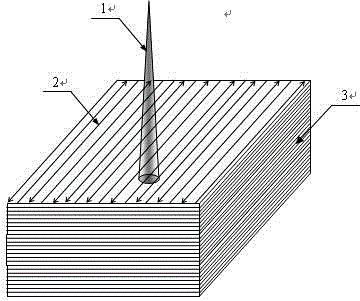

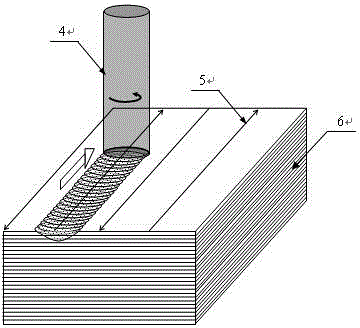

Method for welding with laser-cold metal transferred arc composite heat source

ActiveCN101811231ASolve the problem of poor spreadabilityImprove stabilityLaser beam welding apparatusArc stabilityAlloy

The invention provides a method for welding with a laser-cold metal transferred arc composite heat source, and belongs to the technical field of composite heat sources. The welding method solves the technical problems of low-quality welding lines and low arc stability of the pure Ar-protected cold metal transferred arc welding. The method comprises the following steps of: using pure Ar gas for protection during welding, and forming a novel composite heat source by using the cold metal transferred arc(5) and a laser beam (2) of which the power is more than or equal to 800, wherein the laser beam (2) is defocused, the diameter of a laser spot formed by the laser beam (2) on the surface of a workpiece (1) to be welded is 1 to 4mm, a spot of the cold metal transferred arc (5) can be arranged in front of or behind the spot of the laser beam (2), the central distance of the two spots is 0 to 8mm, and an included angle between a welding torch(3) of the cold metal transferred arc(5) and the horizontal plane is 45 and 75 degrees. The composite heat source is mainly used for welding plates and tubes made of stainless steel, high-strength steel and nickel-based alloy.

Owner:HARBIN WELDING INST LTD

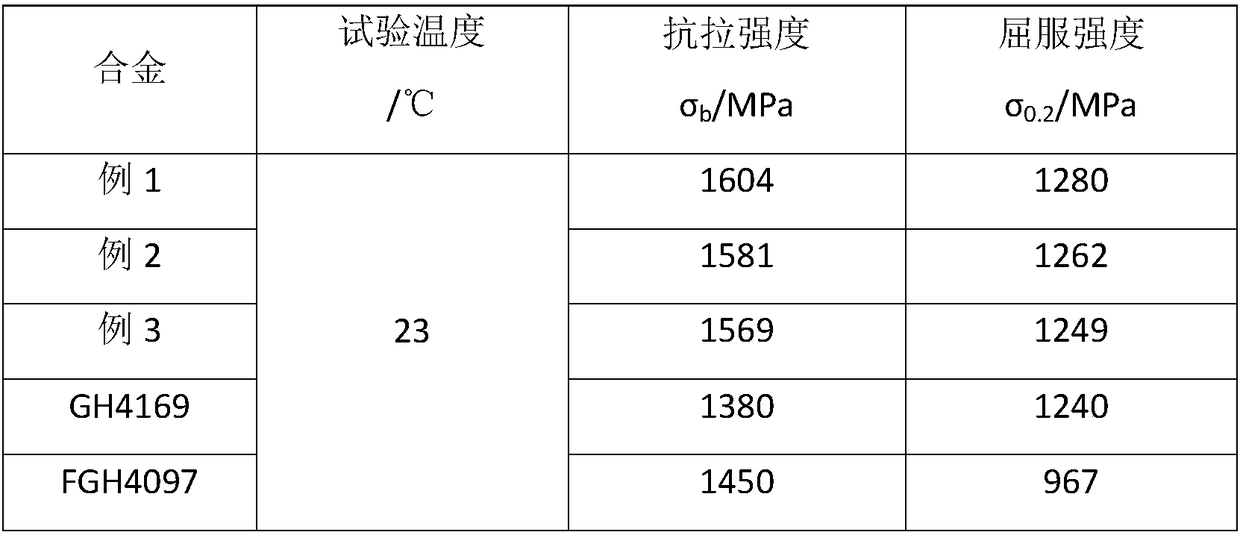

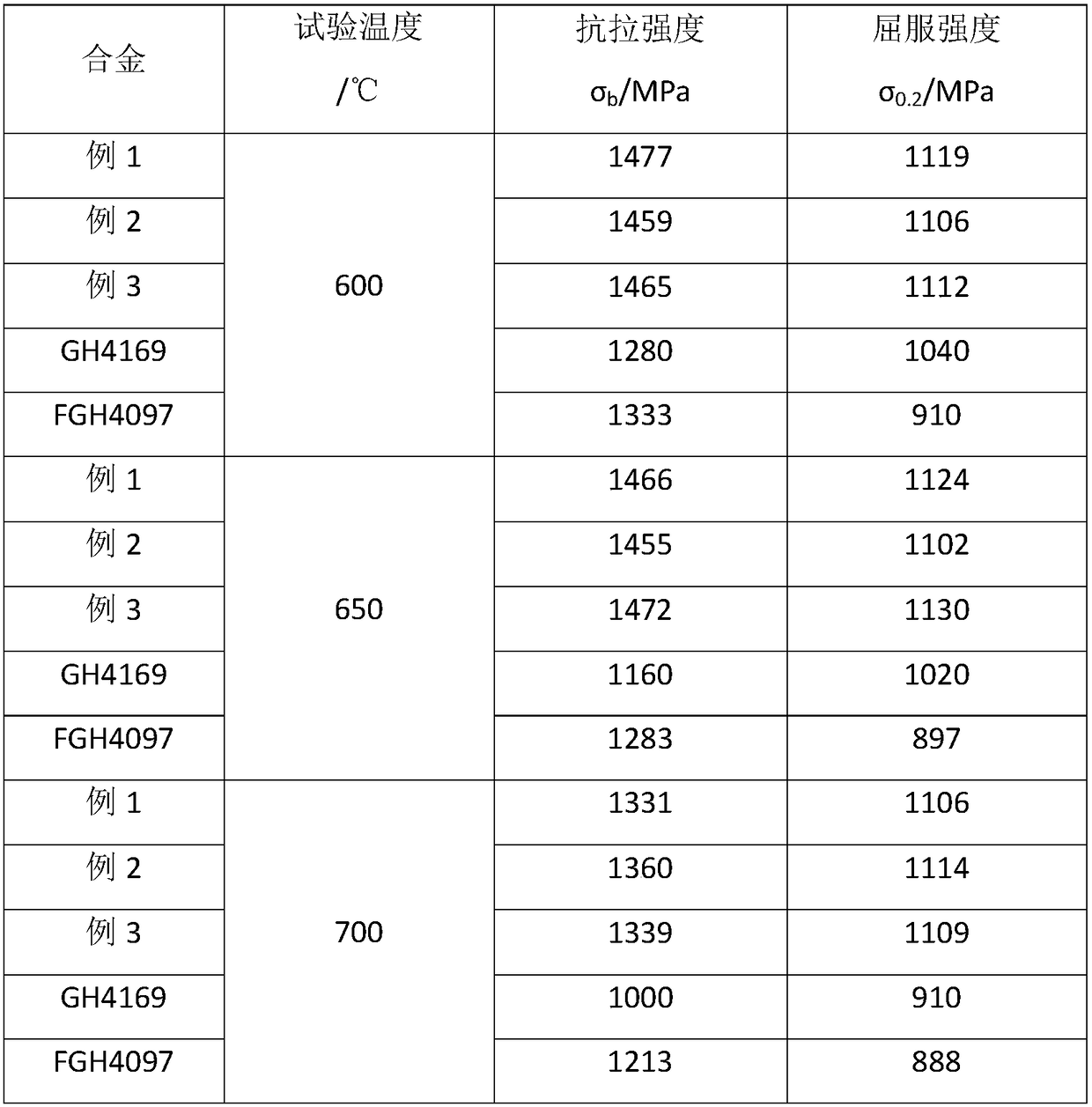

High-intensity nickel based wrought superalloy and preparation method thereof

ActiveCN108441705AHigh room temperature tensile strengthImprove heat strengthIncreasing energy efficiencyHigh intensityElectro-slag remelting

The invention belongs to the technical field of nickel based wrought superalloy, and particularly relates to a high-intensity nickel based wrought superalloy and a preparation method thereof. The high-intensity nickel based wrought superalloy comprises the following main elements in percentage by mass: 10.0-25.0% of Cr, 10.0-20.0% of Co, 0.1-6.0% of Mo, 0.1-6.0% of W, 0.1-6.0% of Al, 0.1-6.0% of Ti, 0.05-1.5% of Nb, 0.1-2.0% of Fe, 0.001-0.10% of C, 0.001-0.05% of B, 0.01-0.1% of Zr, 0.001-0.10% of Ce, 0.001-0.10% of Mg, 0.01%-0.5% of Hf, and the balance Ni and inevitable impurity elements. The preparation method comprises the steps of preparing a high-purity cast ingot by vacuum induction smelting, electroslag remelting and vacuum self-consumption remelting; performing high-temperature diffusion to uniformly anneal the cast ingot under the temperature ranging from 1170-1190 DEG C; heating the annealed cast ion to reach the temperature of 1130-1160 DEG C, maintaining the temperature for 2-4h; then forging the cast ingot into a bar as required through a quick forging press, and thermally processing a bar sample to obtain the alloy material meeting the design demand.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

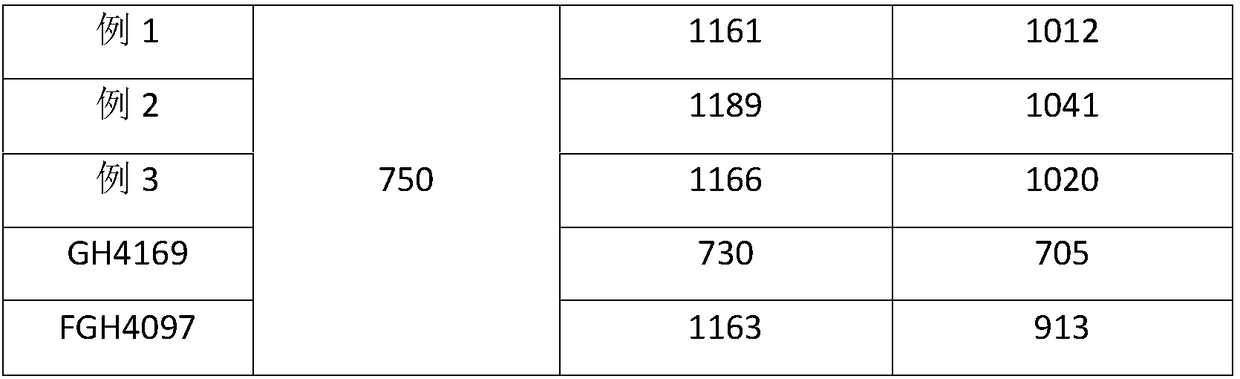

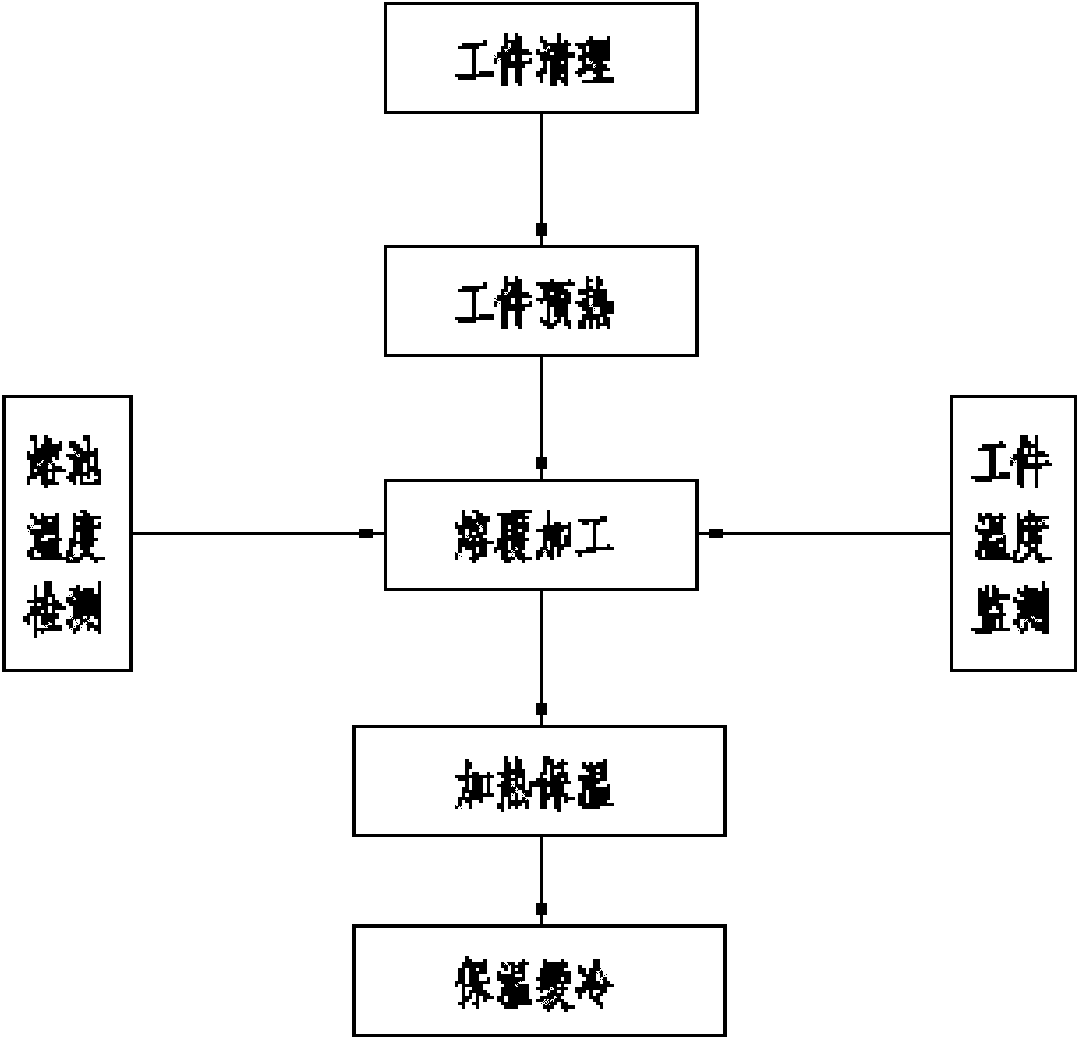

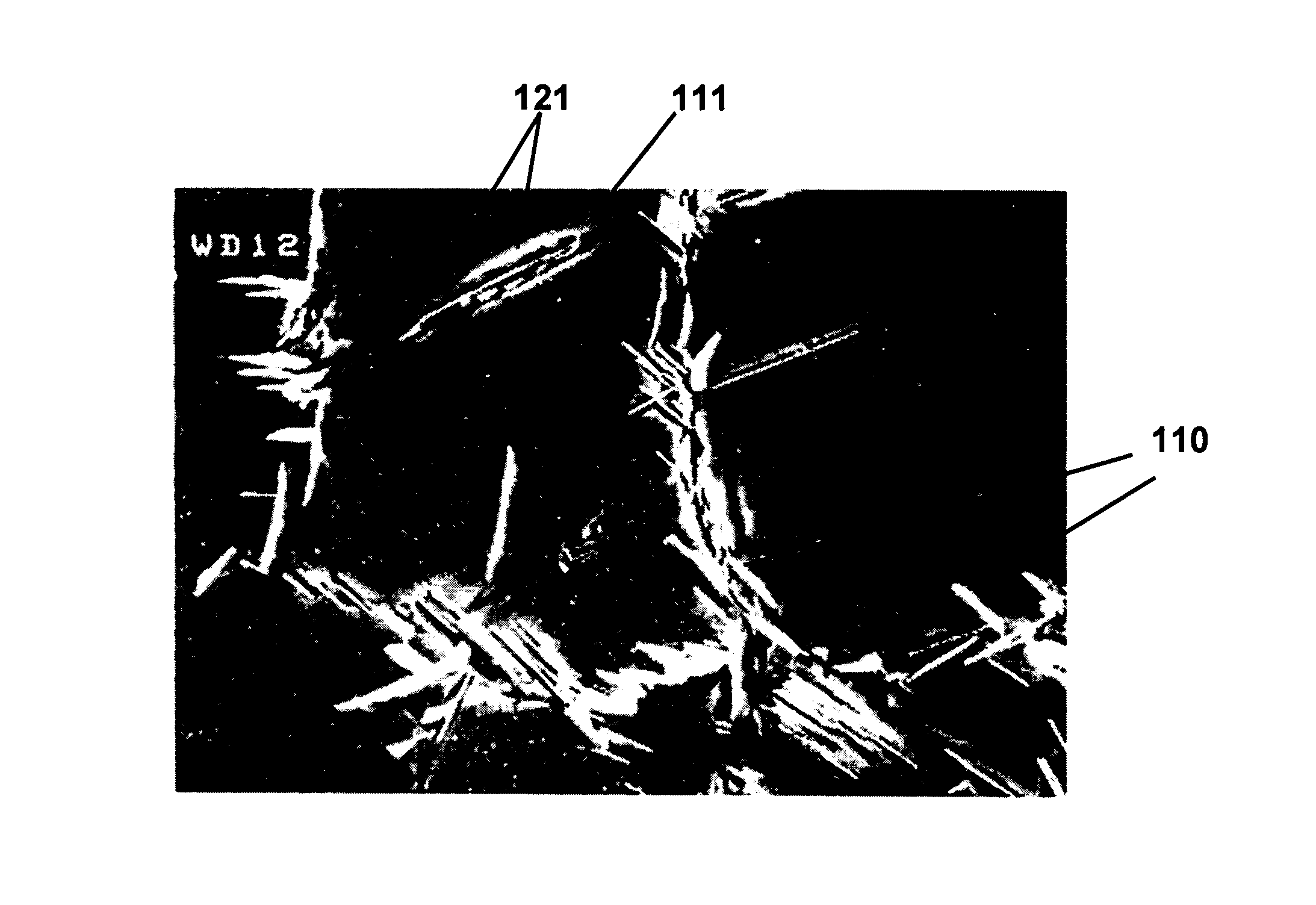

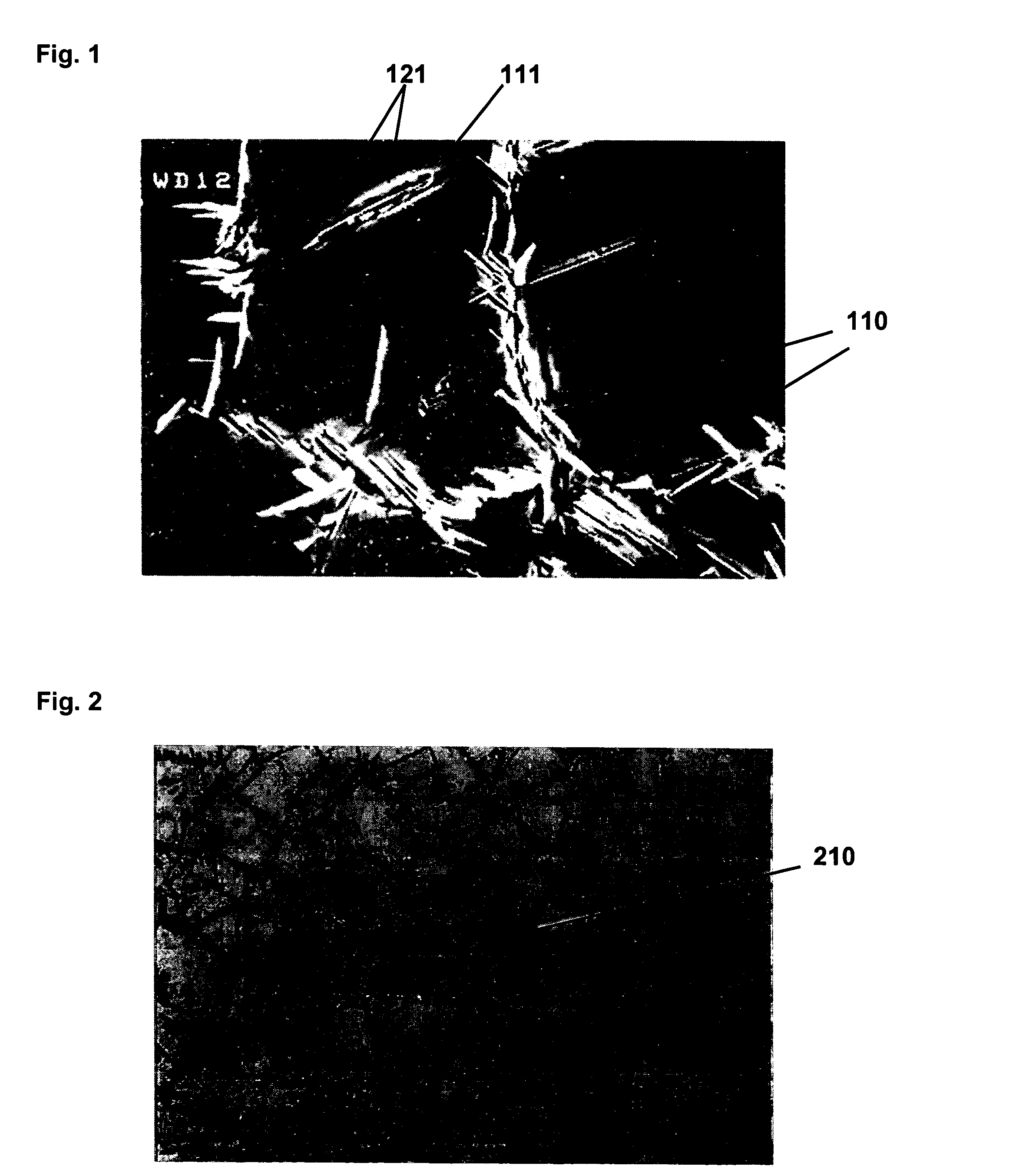

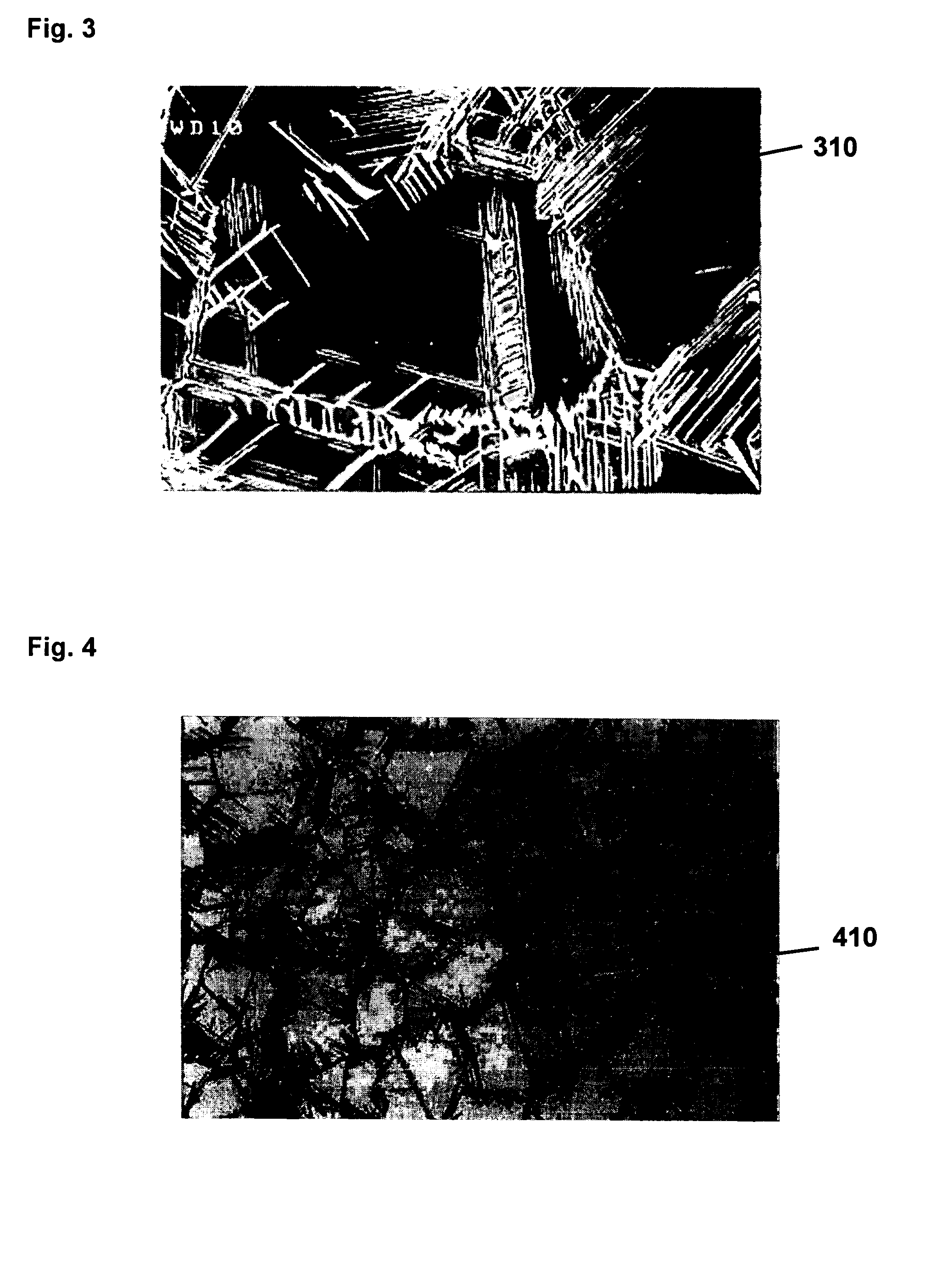

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294AImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

The invention belongs to the field of material surface engineering and more particularly relates to a method for carrying out cladding on a high-hardness wear-resistant anti-corrosion nickel-based alloy material on a metal substrate E in a large area by applying a laser cladding technology, solving the problem of cracks generated in the laser cladding process of the high-hardness wear-resistant nickel-based alloy, in particular the cladding defects, such as cracks with the thickness of more than 1mm, pores and the like during large-area cladding. According to the invention, the high-hardness nickel-based alloy powder material is cladded on the surface of the metal substrate in the large area to form a high-hardness wear-resistant anti-corrosion nickel-based alloy coating by applying the laser cladding technology and adopting a scientific and reasonable process method. According to the method disclosed by the invention, stability and consistency of laser cladding are foundationally ensured, defects, such as cracks, pores, impurities can be prevented from generating, heat affected regions of the substrate are reduced, dilution rate is reduced, the high-wear-resistance anticorrosion nickel-based alloy coating with firm metallurgical bonding and fine and compact grains is obtained and has the hardness reaching 58-63HRC, and the service life of the processed workpiece can be prolonged by more than 1-2 times.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

Preparation method of laser fusion covered nickel base nanometer WC/Co precoating layer

InactiveCN1786272AFlat surfaceEliminate cracksPretreated surfacesHeat inorganic powder coatingAlcoholNanotechnology

The invention relates to laser melting-covering nickel base nanometer WC / Co precoating manufacturing method. It includes the following steps: weighting lac absolute ethyl alcohol in proportion of 1:10-20; adding the lac into the absolute ethyl alcohol; weighting and mixing nickel base nanometer WC / Co powder and bonding agent in proportion of 1g: 0.1mL-0.25mL; fully stirring to form precoat agent; coating the precoat agent at the workpiece surface to form precoating; drying. The prepared nickel base nanometer WC / Co precoating is adopted laser melting-covering technique to form nickel base nanometer WC / Co composite coating.

Owner:SHANGHAI UNIV OF ENG SCI

Braze Alloy And The Use Of Said Braze Alloy

InactiveUS20080017694A1Improve oxidation resistanceImprove the immunityCooking-vessel materialsTurbinesBraze alloyCobalt

The invention relates to an oxidation and corrosion resistant braze alloy consisting of (wt.-%) 10-15% Cr, 4.5-6% Al, 0.17-0.3% Y, 8-12% Co, 0-4% W, 2.5-5% Ta, 2.0-3.5% B with Cr+Al>15%, Cr / Al≦3 and Al+Ta>7.5%, remainder Nickel and unavoidable impurities and to the use of this alloy for brazing onto a Nickel based or a Cobalt based superalloy article. The braze alloy can either be used in pure form as a paste or a foil or as a blend in a blend braze paste, in a braze tape or in a pre-sintered braze sheet.

Owner:ALSTOM TECH LTD

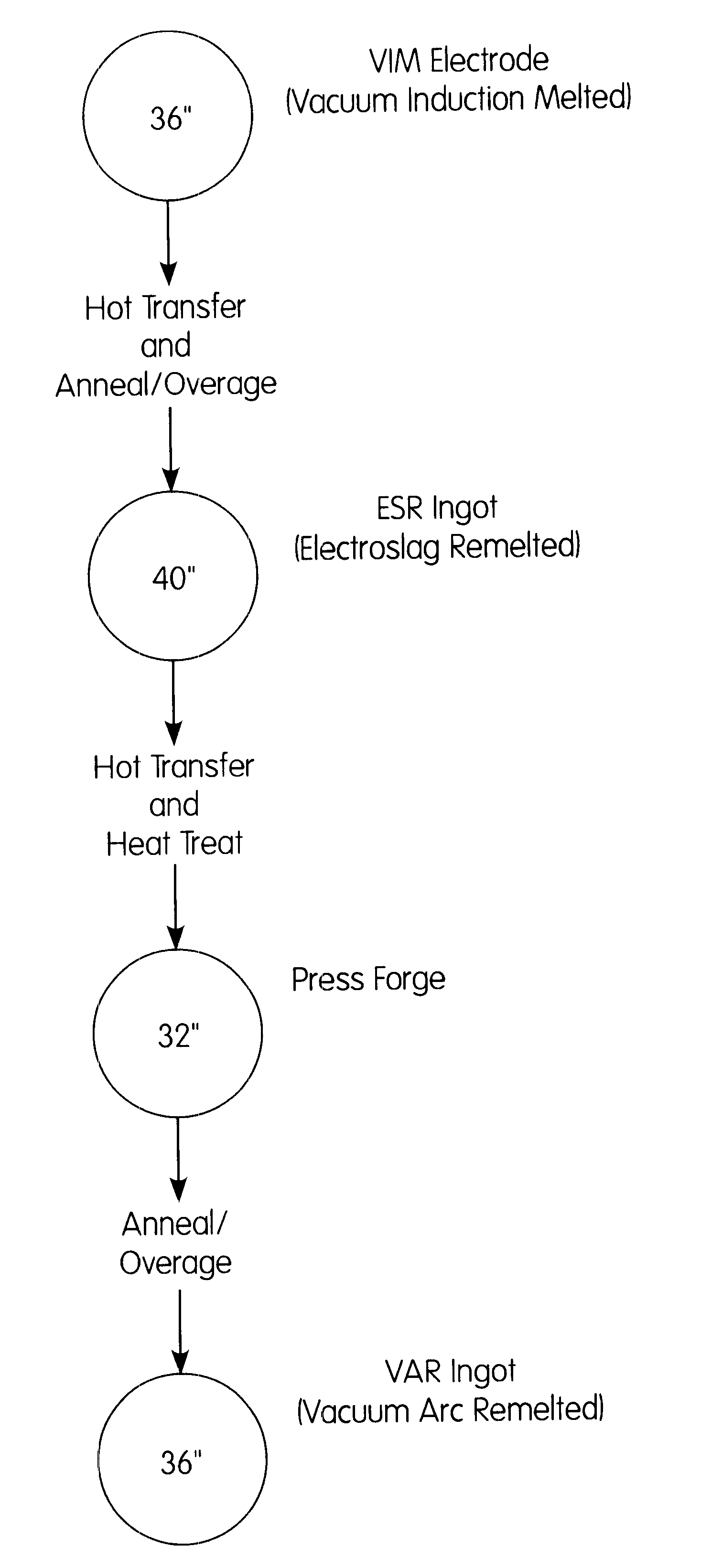

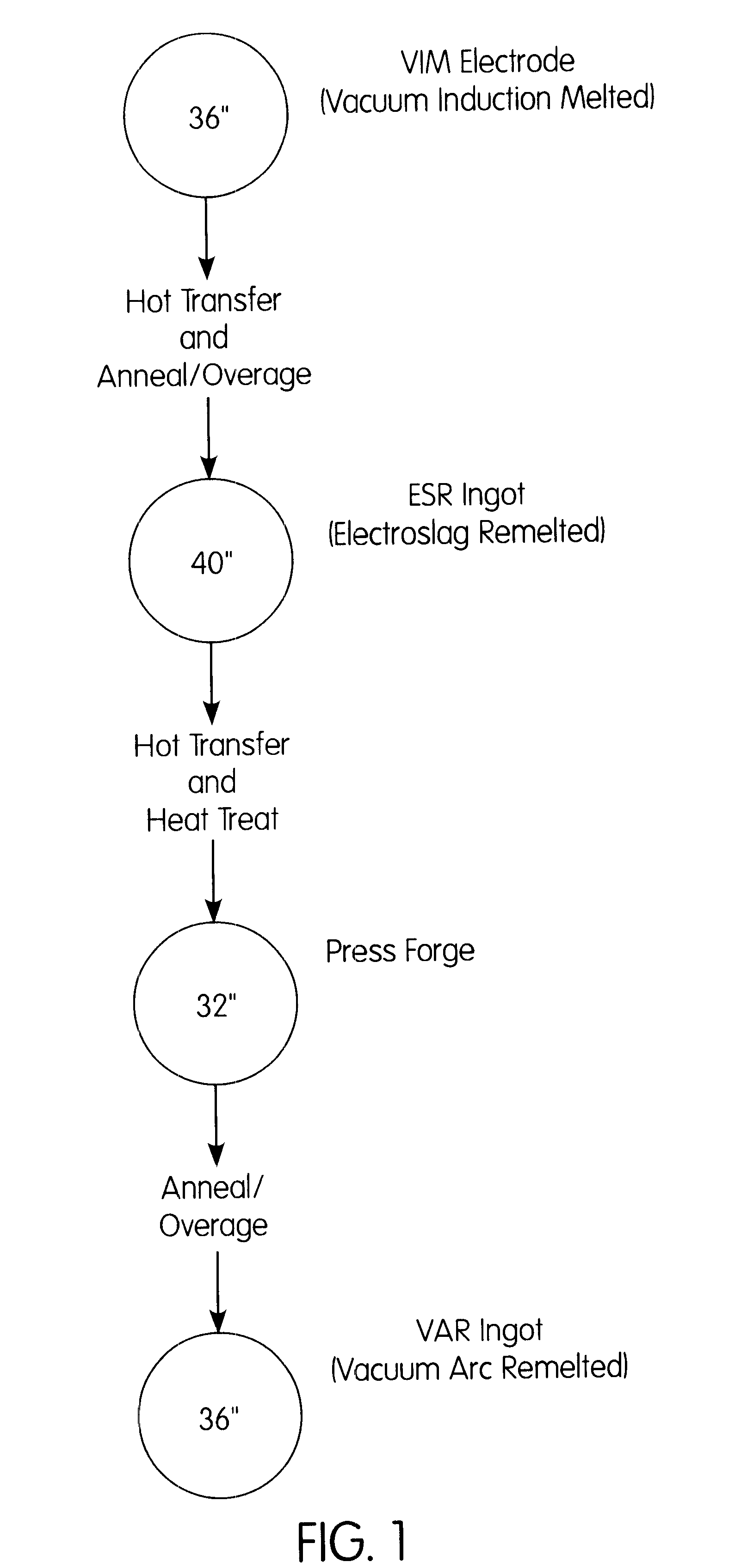

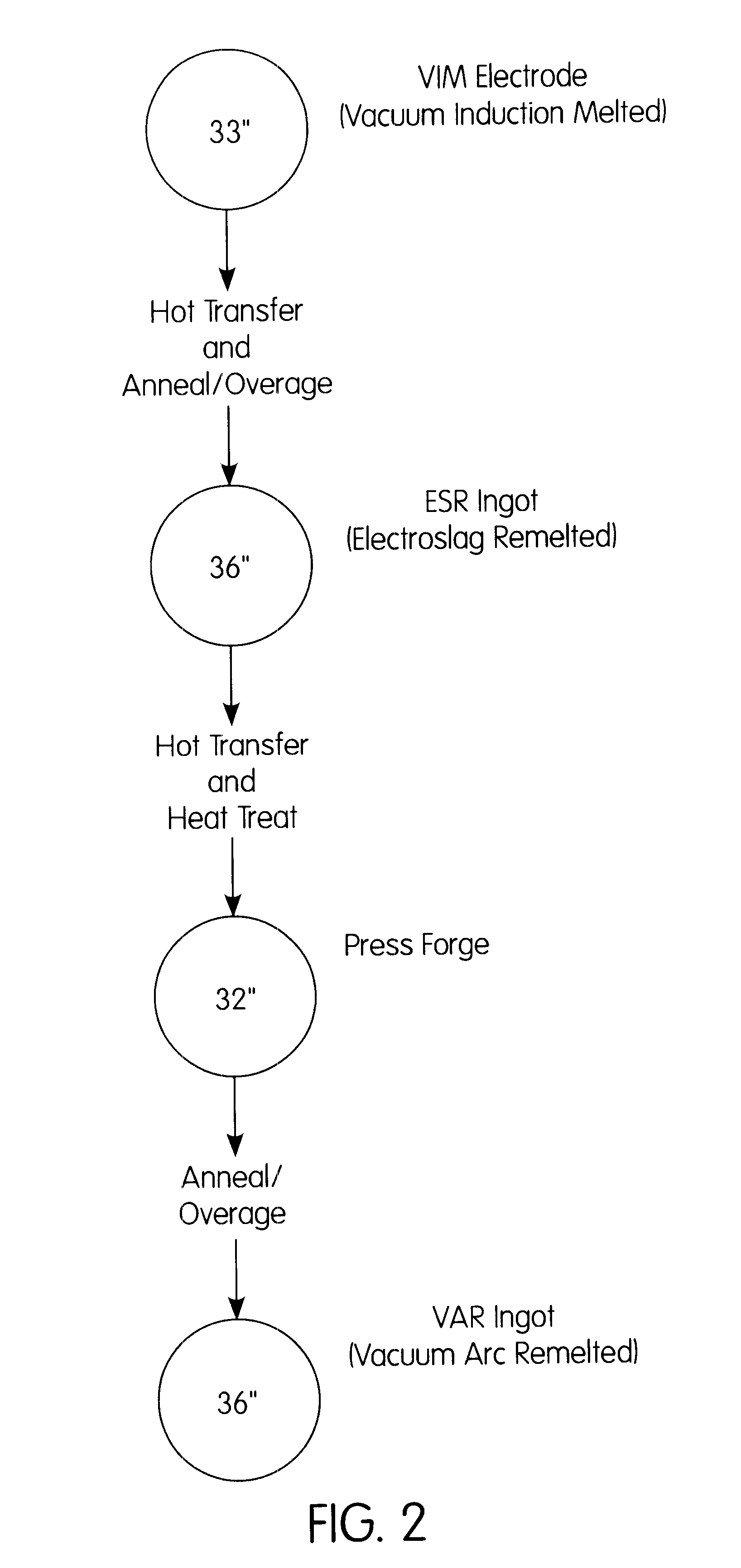

Method for producing large diameter ingots of nickel base alloys

InactiveUS6416564B1Inhibit thermal stressLarge caliberWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remeelted at a melt rate of at least 8 lbs / min (3.63 kg / mm.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

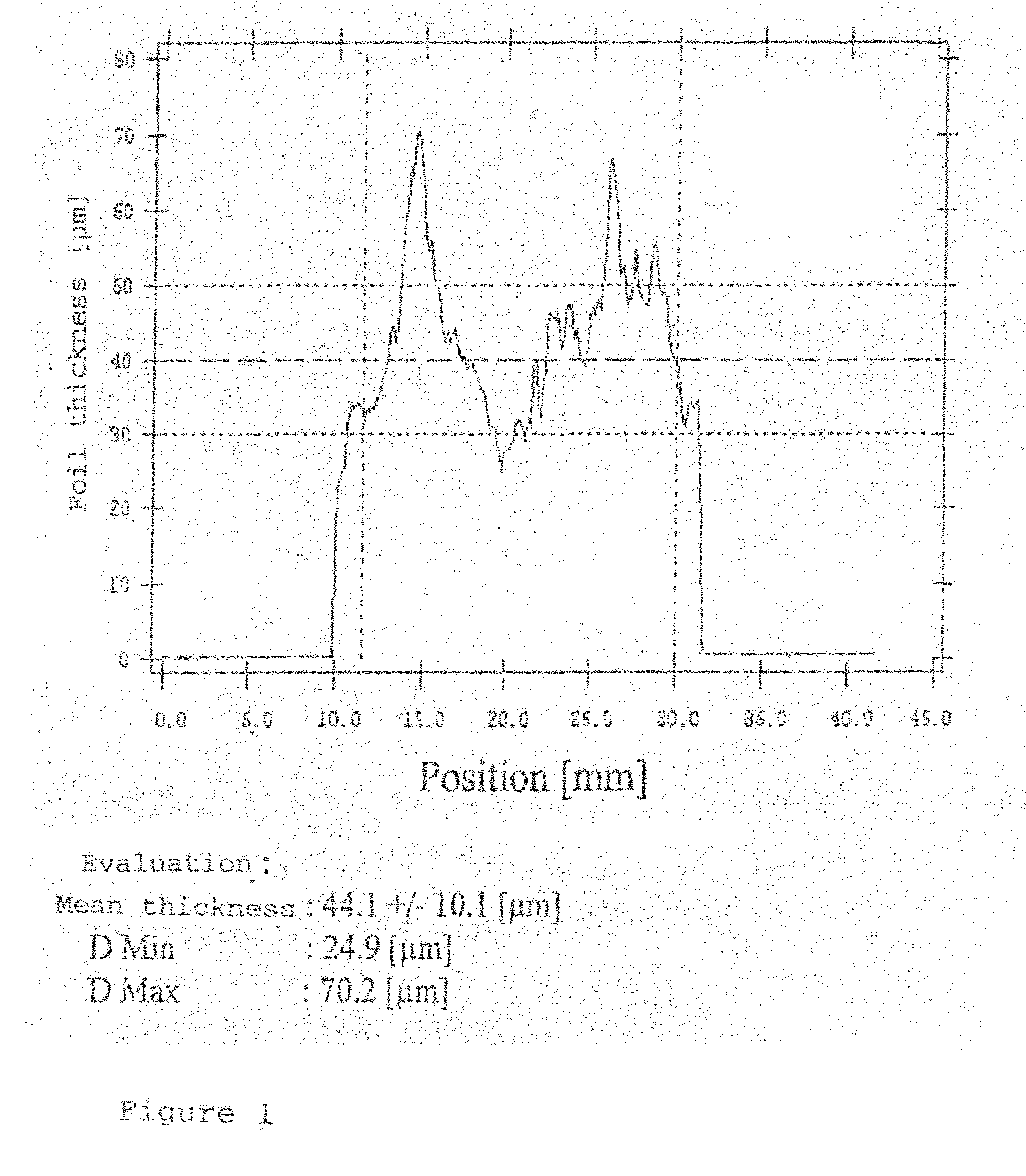

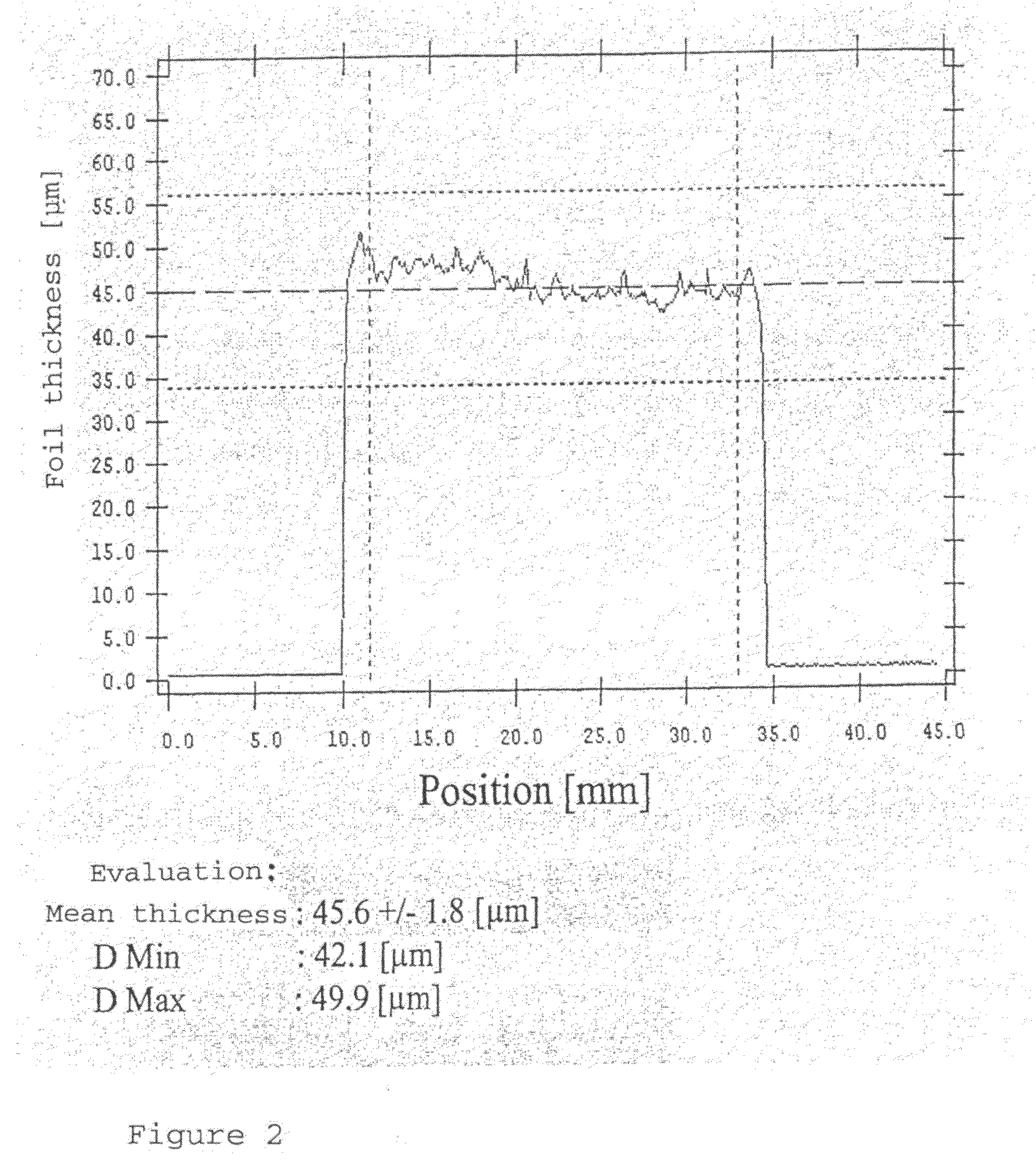

Nickel-based brazing foil and process for brazing

ActiveUS20090110955A1Low costImprove joint reliabilityNon-fuel substance addition to fuelExhaust gas recirculationImpurityMaterials science

Disclosed is an amorphous, ductile brazing foil with a composition consisting essentially of NirestCraBbPcSid with 2 atomic percent ≦a≦30 atomic percent; 0.5 atomic percent ≦b≦14 atomic percent; 2 atomic percent ≦c≦20 atomic percent; 0 atomic percent ≦d≦14 atomic percent; incidental impurities ≦0.5 atomic percent; rest Ni, where c>b>c / 15 and 10 atomic percent ≦b+c+d≦25 atomic percent. Also disclosed is amorphous, ductile Ni-based brazing foil having a composition consisting essentially of NirestCraBbPcSidCeXfYg wherein a, b, c, d, e, f, and g are numbers such that 2 atomic percent ≦a≦30 atomic percent; 0.5 atomic percent ≦b≦14 atomic percent; 2 atomic percent ≦c≦20 atomic percent; 0 atomic percent ≦d≦14 atomic percent; 0 atomic percent ≦e≦5 atomic percent; 0 atomic percent ≦f≦5 atomic percent; 0 atomic percent ≦g≦20 atomic percent; wherein incidental impurities are present, if at all, in amounts ≦0.5 atomic percent; wherein rest indicates that the balance of the composition is Ni; wherein c>b>c / 15; wherein 10 atomic percent ≦b+c+d≦25 atomic percent, wherein X is one or more of the elements Mo, Nb, Ta, W and Cu; and wherein Y is one or both of the elements Fe and Co. Also disclosed are methods for making and using these brazing foils, and brazed objects produced therefrom.

Owner:VACUUMSCHMELZE GMBH & CO KG

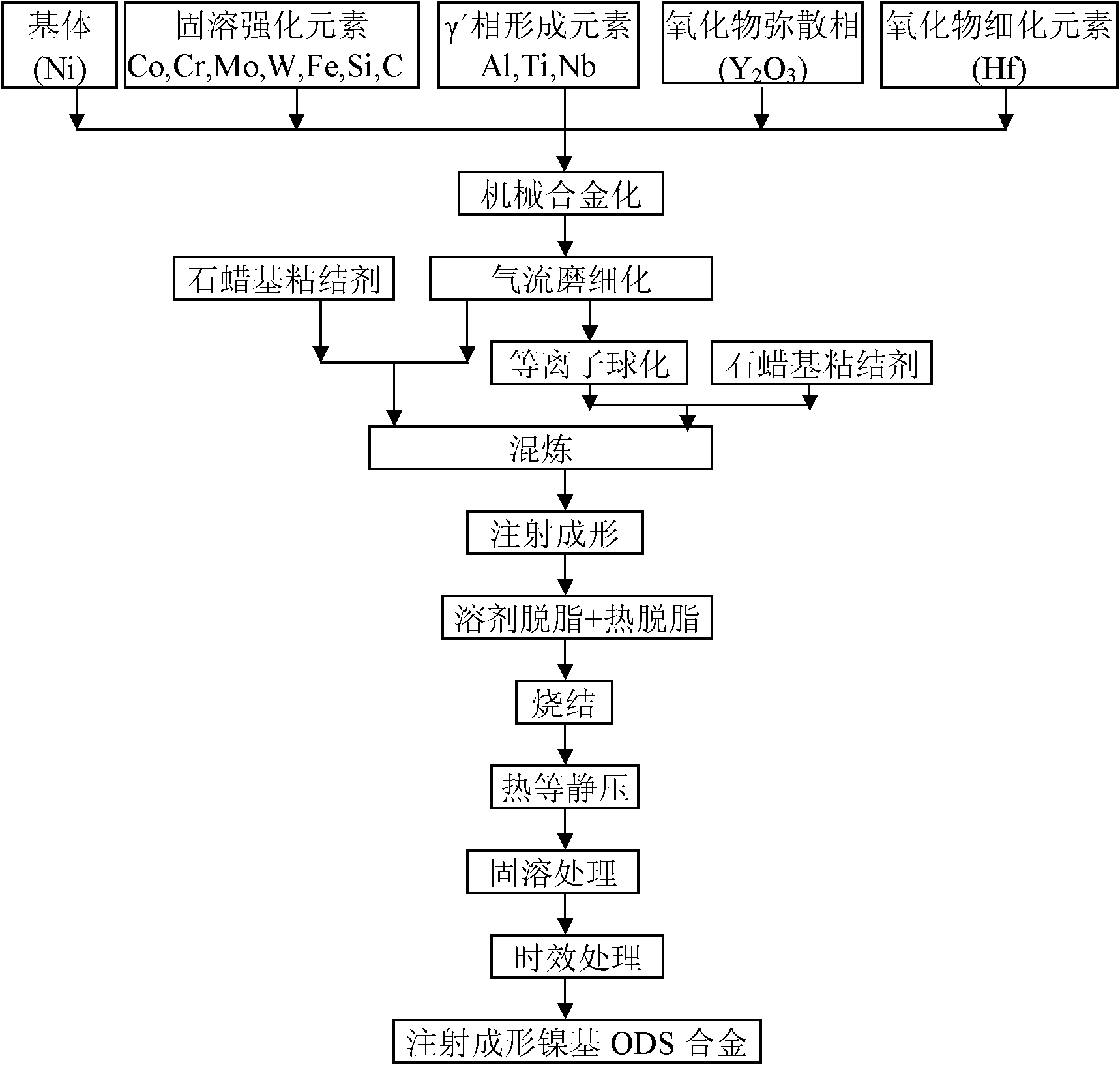

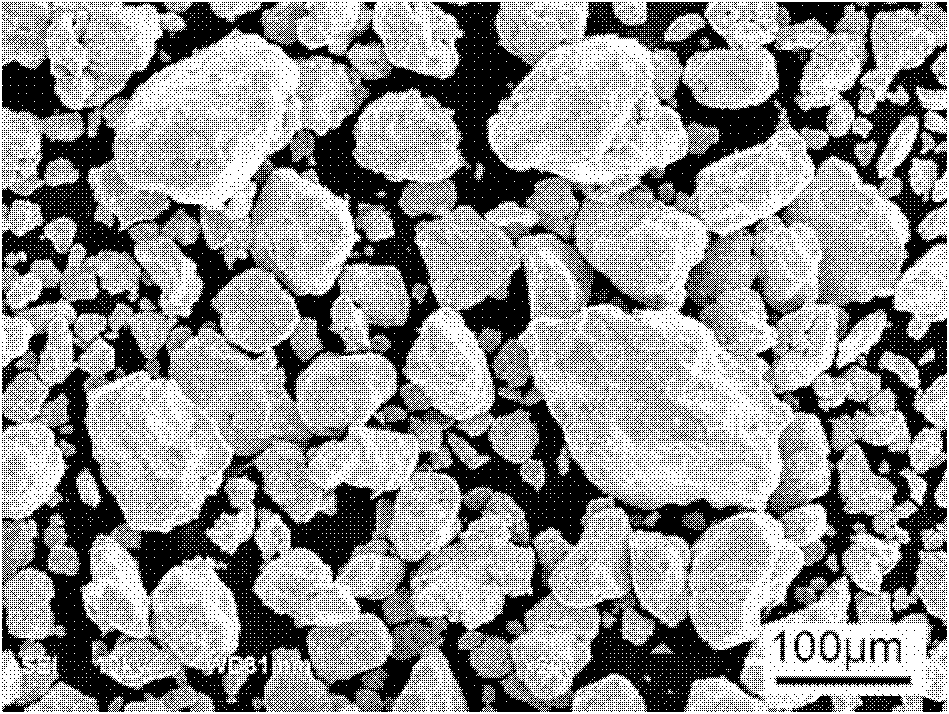

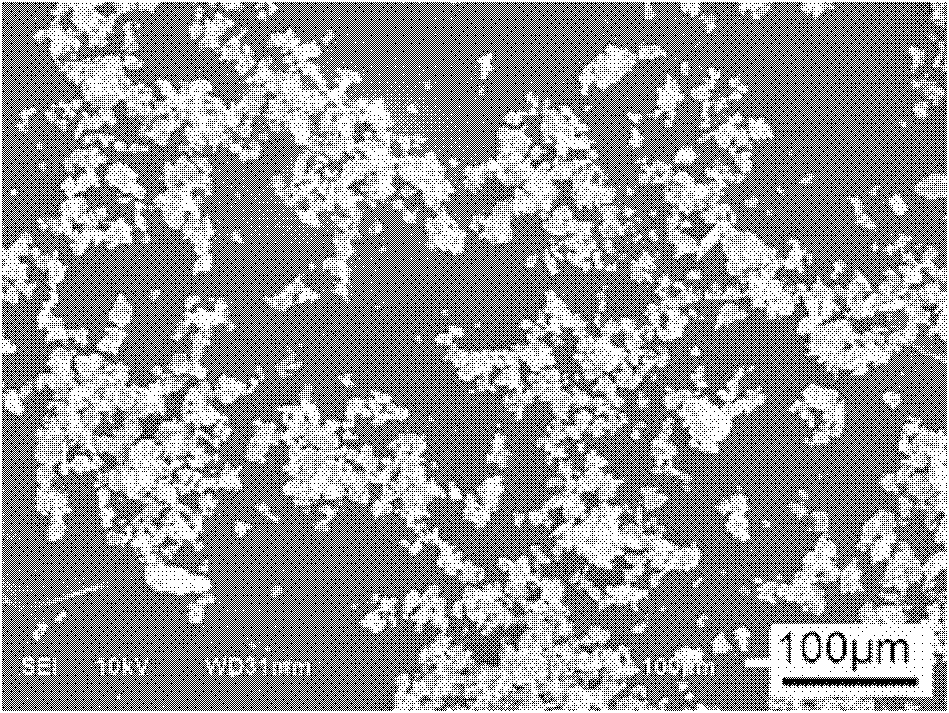

Method for preparing injection-molding nickel-base ODS (oxide dispersion strengthened) alloy

The invention provides a method for preparing a nickel-base ODS (oxide dispersion strengthened) alloy by injection molding, belonging to the technical field of injection molding of powder. The method comprises the following steps: carrying out high-energy ball milling on the raw material powder so that Y2O3 particles are uniformly dispersed in a nickel substrate, refining mechanical alloy powder by jet milling, and carrying out plasma nodularization on the powder which is refined by jet milling; evenly mixing and smelting the powder, which is refined by jet milling and plasma nodularization, and adhesive to obtain a uniform feed material; and carrying out injection molding, two-step degreasing and sintering on the feed material to obtain a sintered blank of which the density is 93-96%, carrying out hot isostatic compaction on the sintered blank so that the sintered blank is completely compact, and finally, carrying solution heat treatment and aging heat treatment to obtain the injection-molding nickel-base ODS alloy. The nickel-base ODS alloy can be prepared into high-precision parts in complex shapes, thereby solving the problem of difficulty in molding of nickel-base ODS alloy. The gamma' phase and the oxide strengthening mechanism are combined to greatly enhance the high-temperature mechanical properties of the nickel-base ODS alloy.

Owner:UNIV OF SCI & TECH BEIJING

Metal laser melting additive manufacturing method

ActiveCN104404509AEliminate cracksSpheroidization EliminationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMetallic materials

The invention discloses a metal laser melting additive manufacturing method. After each layer is machined by utilizing the laser additive manufacturing method, a single-layer laser photocoagulation area is modified by utilizing a selective friction stir welding, photocoagulation cracks are eliminated and nanocrystalline is formed. Each additive-manufactured layer is subjected to laser melting and friction stir welding and multiple layers are machined by the method repeatedly, so that nanocrystalline complex metal components with high strength and ductility and no cracks are manufactured. The laser melting additive manufacturing method provided by the invention comprises a selective laser melting technique based on powder bed formation and a laser engineering near-net forming technique based on laser coaxial powder feeding, wherein the involved metal materials comprise an aluminum base, a copper base, a titanium base, an iron base, a nickel base and a cobalt base; the selective friction stir welding can eliminate cracks, balling and holes generated during laser additive manufacturing and improves the formation quality; the selective friction stir welding can crush network carbides in a laser photocoagulation structure, so that the crushed network carbides are distributed in a dispersion manner, and the structure is regulated to be the nanocrystalline.

Owner:CENT SOUTH UNIV

Nickel-base alloys and methods of heat treating nickel-base alloys

Embodiments of the present invention relate to nickel-base alloys, and in particular 718-type nickel-base alloys, having a desired microstructure that is predominantly strengthened by γ′-phase precipitates and comprises an amount of at least one grain boundary precipitate. Other embodiments of the present invention relate to methods of heat treating nickel-base alloys, and in particular 718-type nickel-base alloys, to develop a desired microstructure that can impart thermally stable mechanical properties. Articles of manufacture using the nickel-base alloys and methods of heat treating nickel-base alloys according to embodiments of the present invention are also disclosed.

Owner:ATI PROPERTIES

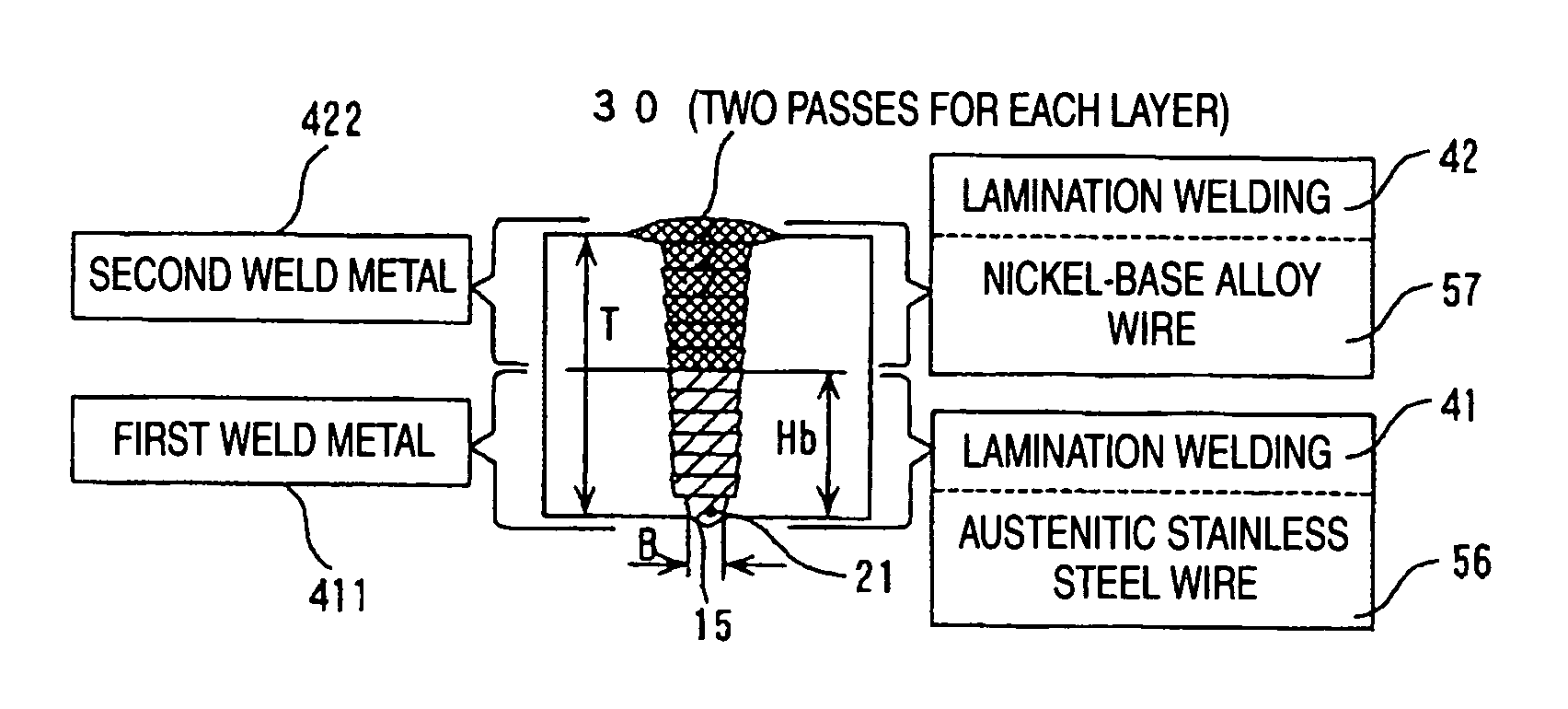

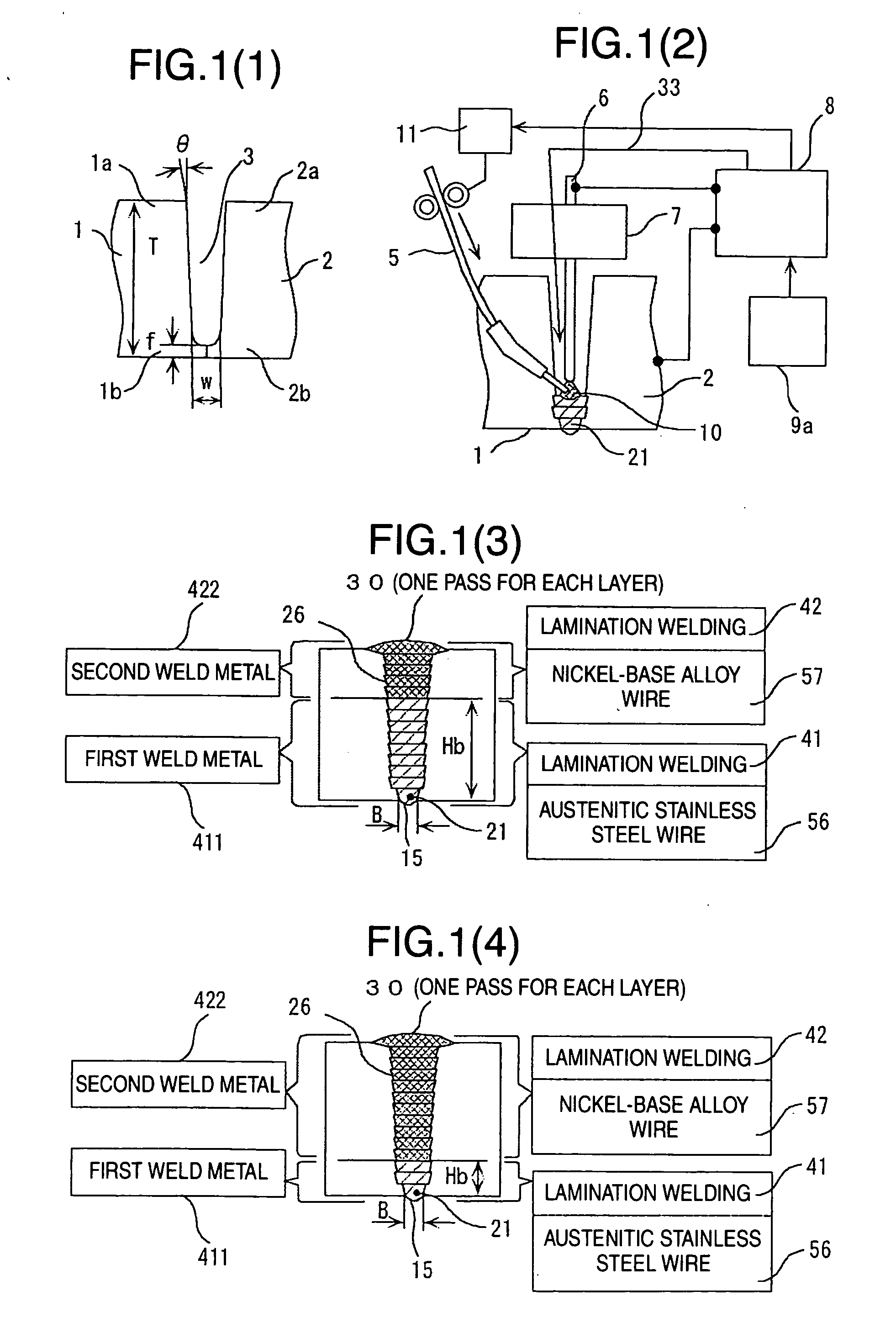

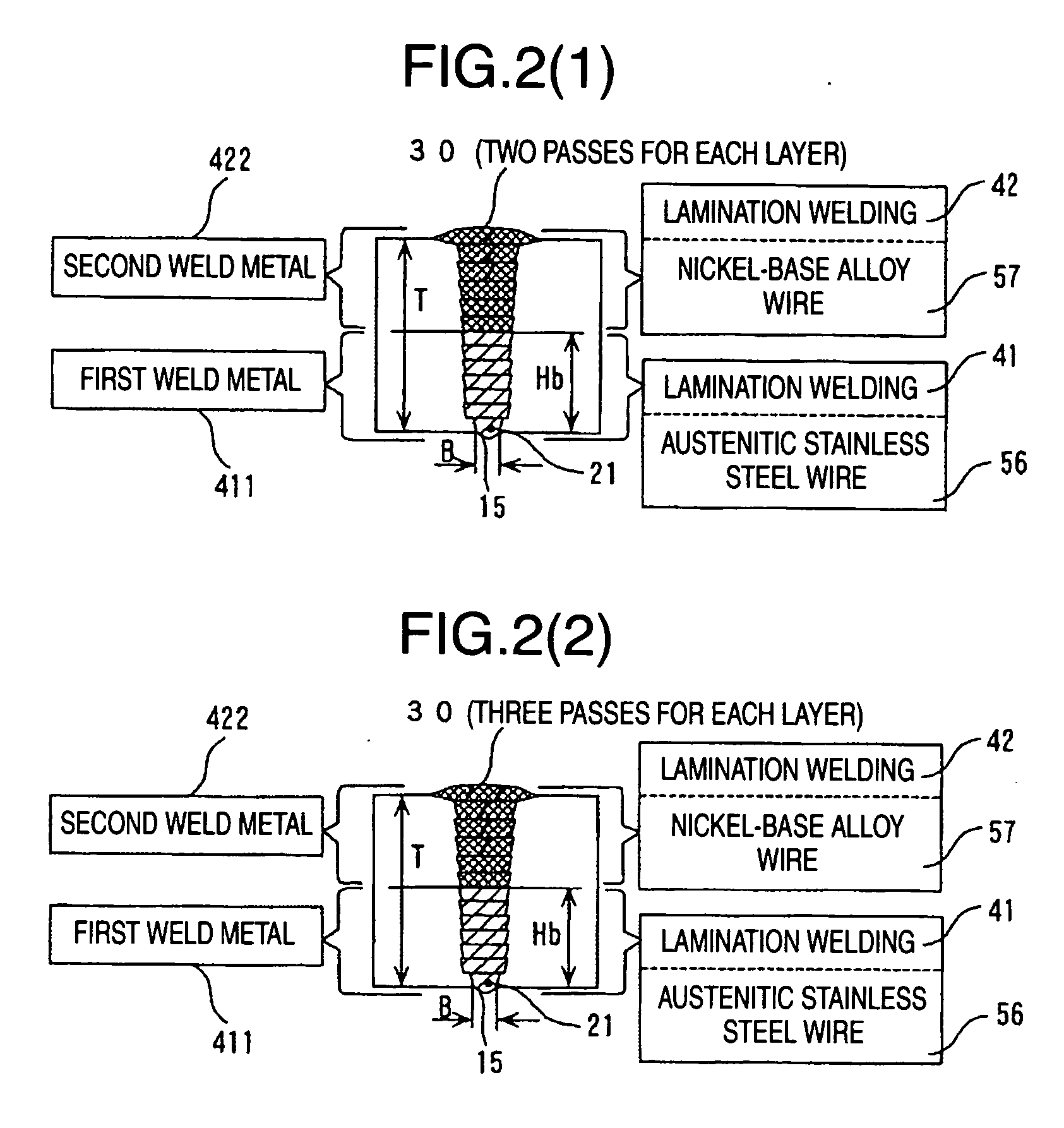

Welding process for stainless steel piping

InactiveUS20060201915A1Suppresses stress corrosion crackingReduce residual stressArc welding apparatusWelding/soldering/cutting articlesAlloyAustenite

The present invention has an object to reduce residual stress in a tensile direction of a weld on the inner side in contact with reactor water of austenitic stainless steel piping, and to change the residual stress into compressive stress, to reduce stress corrosive cracking. The present invention provides a welding process for stainless steel piping of laminating two types of welding wire made of different materials in a groove of austenitic stainless steel piping, including at least one of a first layer penetration welding step of performing a predetermined back bead width on the back side of the groove bottom and a tack welding step, a first lamination welding step of lamination welding of austenitic stainless steel wire from the bottom to the top of the groove, and a second lamination welding step of lamination welding of nickel-base alloy wire to a final layer at the top of the groove.

Owner:HITACHI LTD

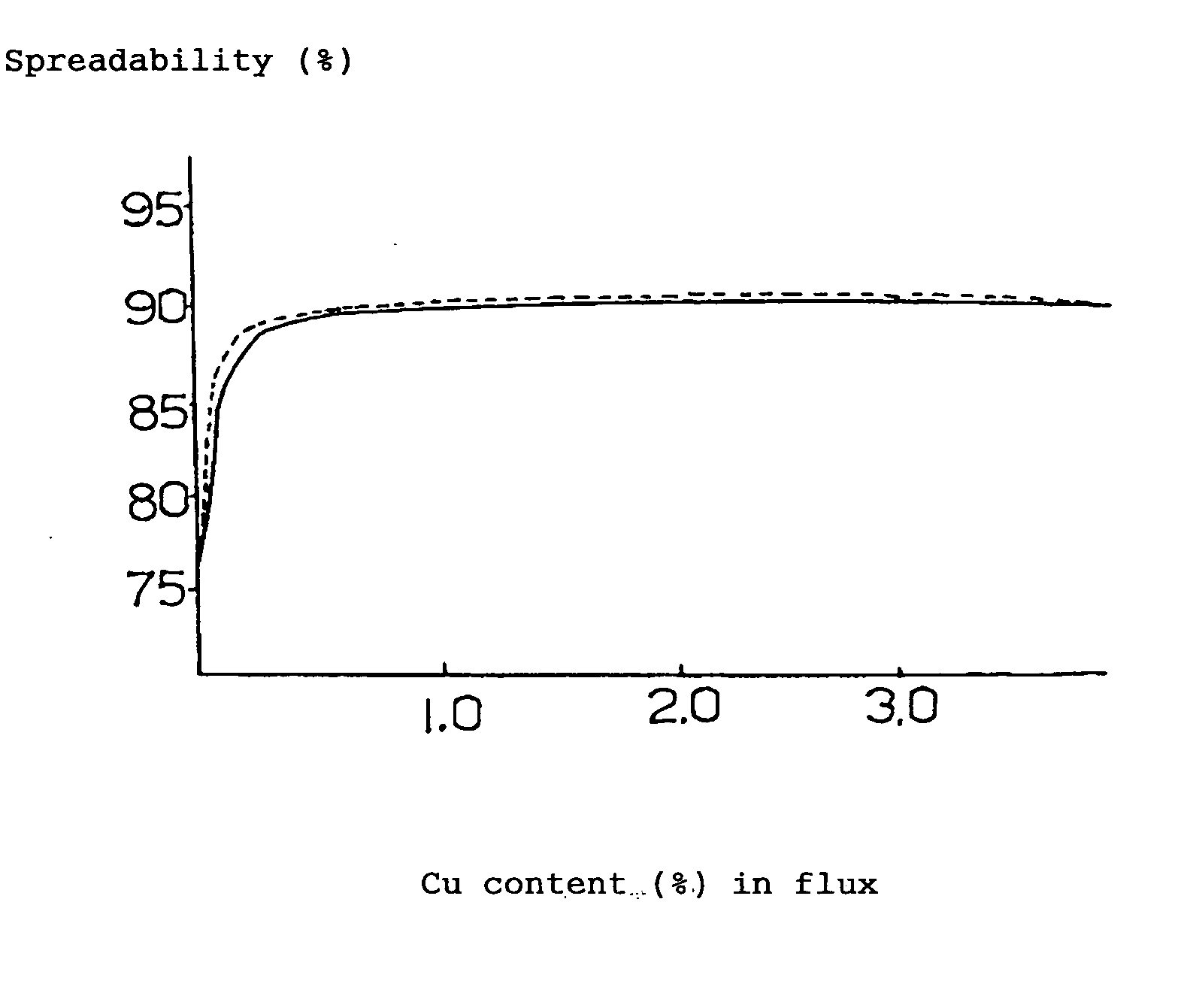

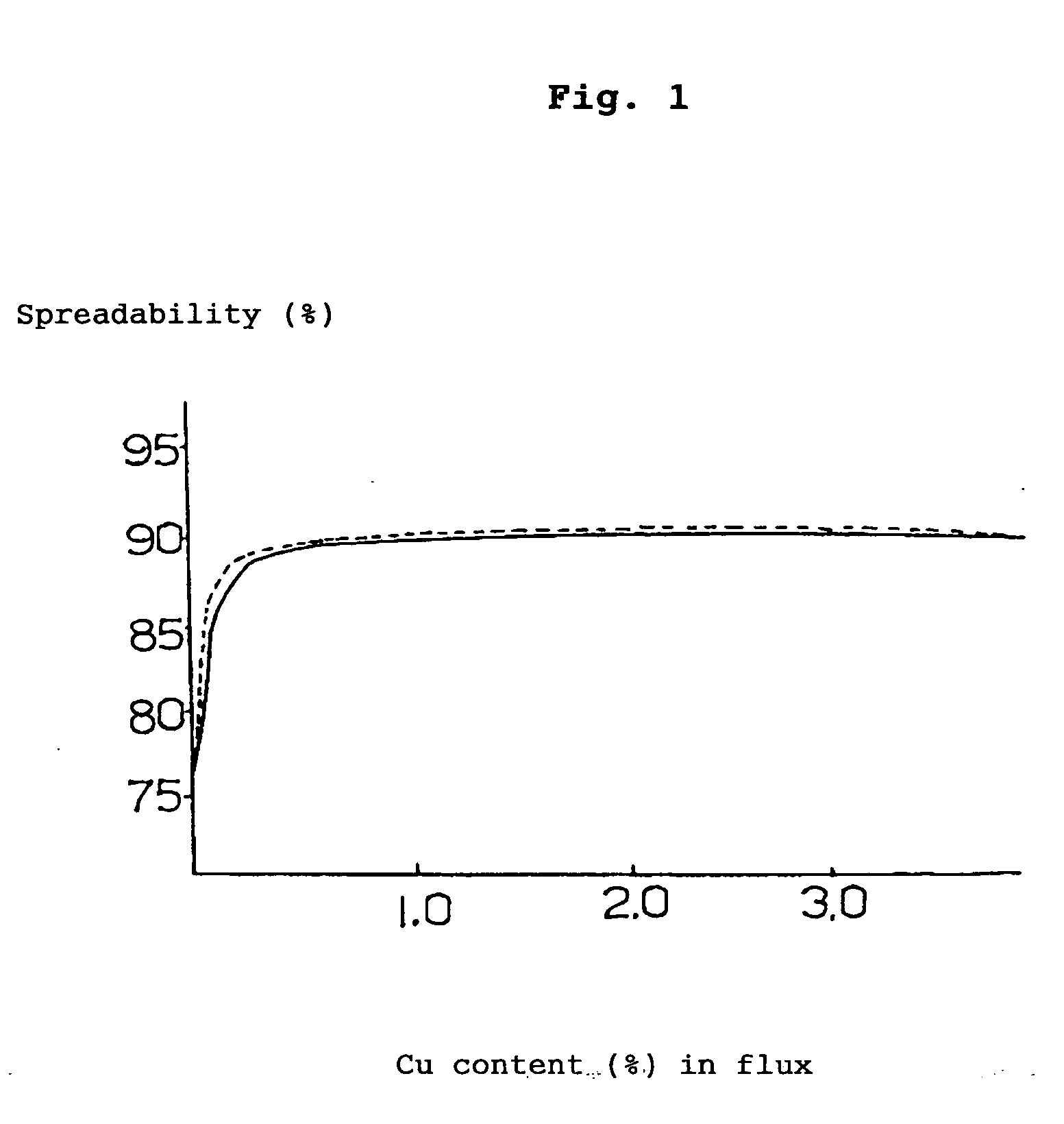

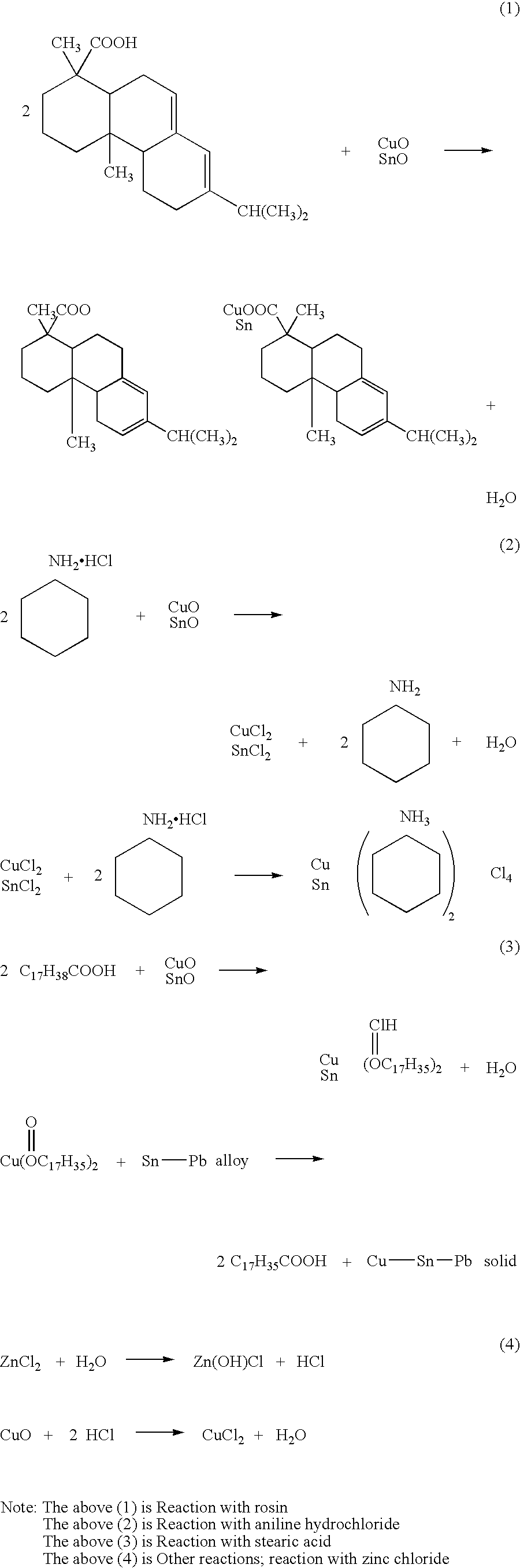

Preflux, flux, solder paste and method of manufacturing lead-free soldered body

InactiveUS20050217757A1Improve stabilityReduce contentPrinted circuit assemblingWelding/cutting media/materialsThioketoneKetone

There is closed a flux which is designed to be used in a soldering using a lead-free and zinc-free solder containing tin as a major component and not containing lead, the soldering being adapted to be applied to a surface portion which is constituted by a copper-based metal and / or a nickel-based metal (excluding the case where the surface portion is constituted by electroless nickel plating), wherein the flux contains at least one kind of material selected from the group consisting of a copper-based metal, a nickel-based metal, an inorganic salt of copper-based metal and / or a nickel-based metal, an inorganic complex of copper-based metal and / or a nickel-based metal, and an organic complex of copper-based metal and / or a nickel-based metal (a metal complex of an organic compound where atoms of N, O and S in amine (excluding nitrogen-containing hetrocyclic compounds), imine (excluding nitrogen-containing hetrocyclic compounds), oxime, ketone, alkoxy and thioketone are coordinated with a metal). There is also closed a method of manufacturing a lead-free soldered body wherein this flux is employed.

Owner:ESE IND S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com