Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Improve wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

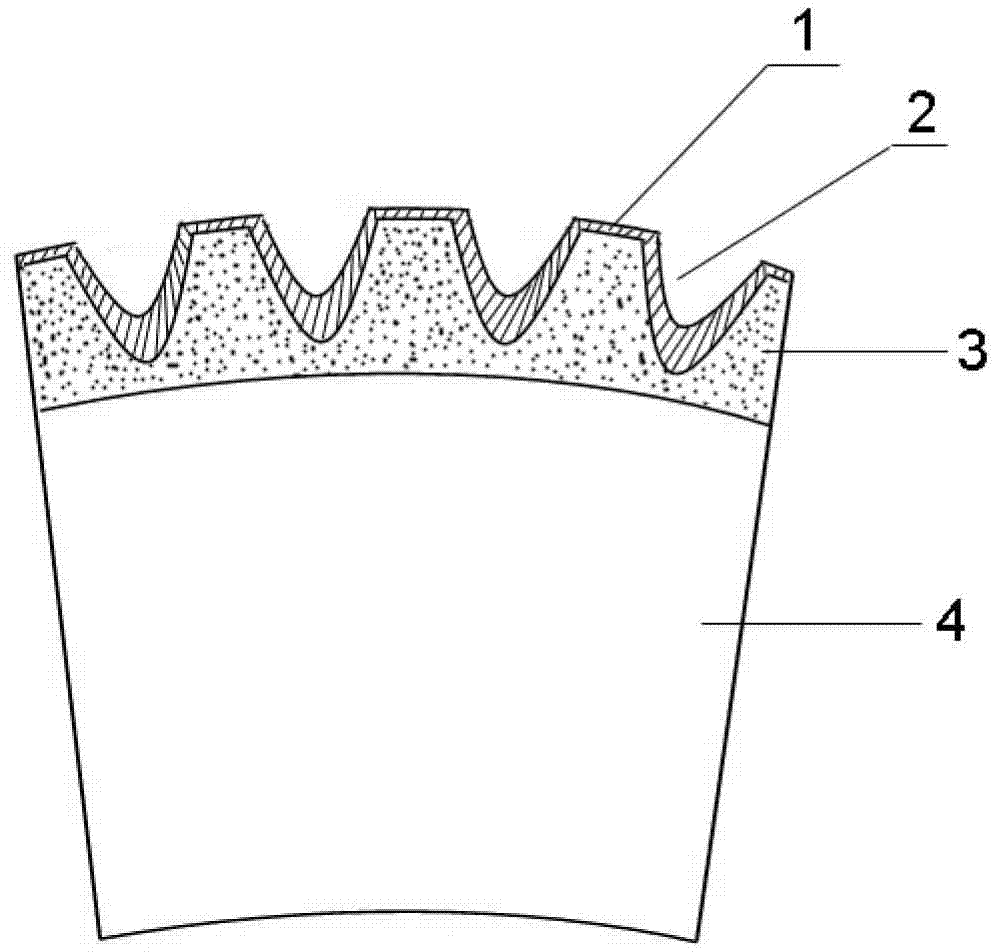

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

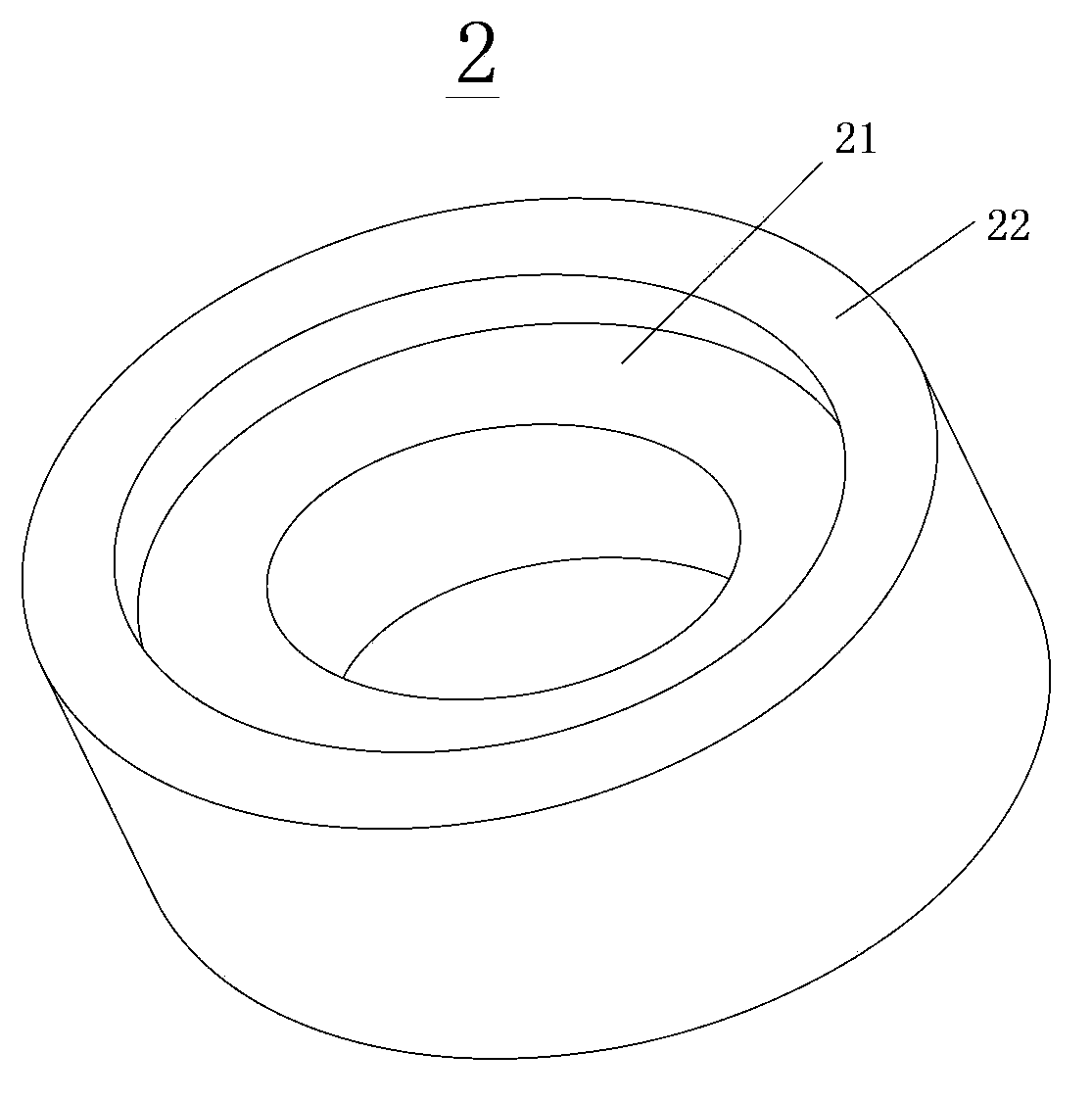

Rotary compressor and crank shaft piston assembly thereof

InactiveCN103511258AGuaranteed uptimeReduce noiseRotary piston pumpsRotary piston liquid enginesEllipseEngineering

The invention discloses a rotary compressor and a crank shaft piston assembly thereof. The crank shaft piston assembly comprises a crank shaft and a piston, wherein the crank shaft is provided with a driving part, the lower end surface of the driving part is a thrust surface to be supported on a subsidiary bearing of the rotary compressor, and a cross section of the driving part, which is orthogonal to the axial direction of the crank shaft, is of a centrosymmetric pattern relative to the central axis of the crank shaft; the piston is sleeved on the driving part, the cross section of the periphery surface of the piston, which is orthogonal to the axial direction of the crank shaft, is an ellipse, and the central axis of the piston is coincided with the central axis of the crank shaft. The crank shaft piston assembly provided by the invention does not have an exocentric structure, the operation is smooth and stable when the rotary compressor operates, the thrust surface is of a centrosymmetric structure, and therefore a dynamic oil film is uniformly formed on the thrust surface, the load of the thrust surface is uniformly distributed, and the performance of the rotary compressor is favorably improved. The invention also discloses the rotary compressor.

Owner:ANHUI MEIZHI PRECISION MFG

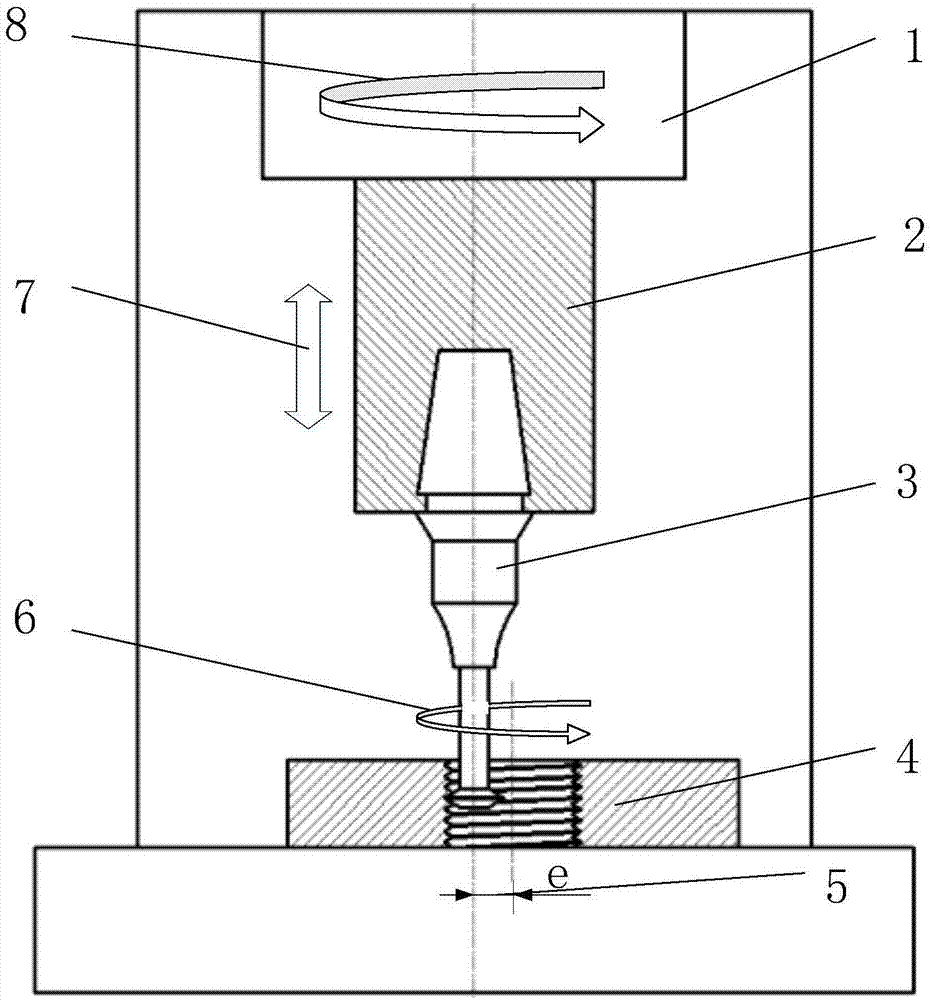

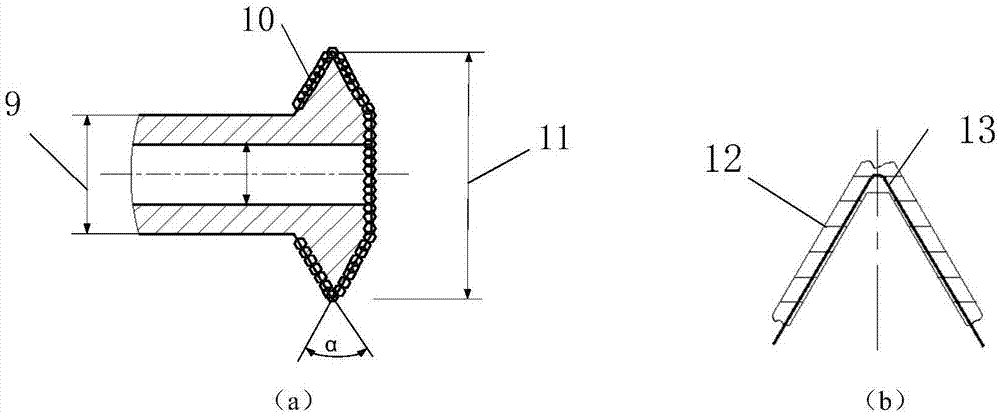

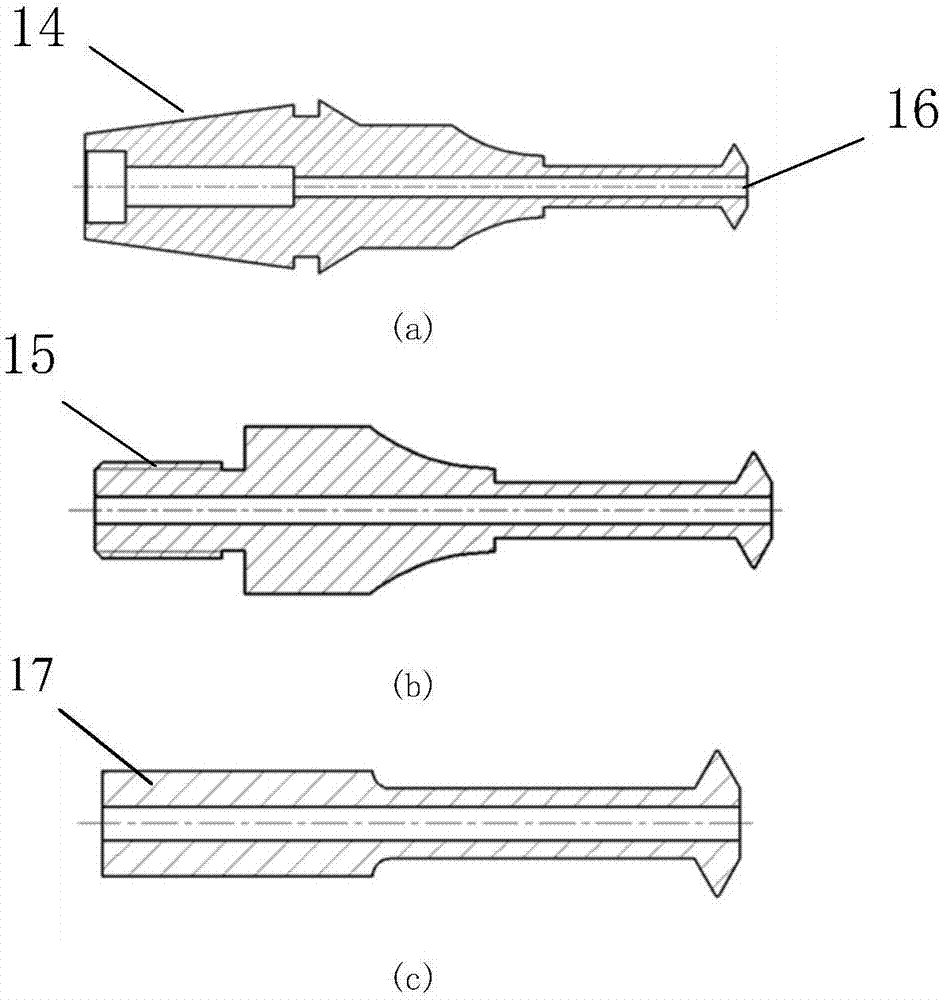

Ultrasonic vibration assisted spiral thread milling and grinding method

InactiveCN107442873AReduce cutting forceImprove use reliabilityThread cutting machinesUltrasonic vibrationCutting force

The invention provides an ultrasonic vibration assisted spiral thread milling and grinding method, and belongs to the technical field of machining and tools. A profiling grinding wheel tool is used in the method, and the tool is mounted on a spindle of an ultrasonic machine tool by an ultrasonic vibration hilt. In the method, the axis of the tool is parallel to the center of the axis of a threaded hole, and a spiral milling mode which is formed by compounding four movements including rotation of the grinding wheel tool, revelation of the profiling grinding wheel tool around the axis of the threaded hole, axial feeding of the profiling grinding wheel tool and axial vibration of the profiling grinding wheel tool along with the ultrasonic vibration hilt is adopted. By the method, a cutting force of hard and crisp materials difficult to machine in a thread machining process can be reduced effectively, the circumstance that a screw tap is broken in a tapping process due to insufficient strength to cause scrapping of parts is avoided, the thread machining quality and machining efficiency are improved, and abrasion of the tool is improved.

Owner:TSINGHUA UNIV

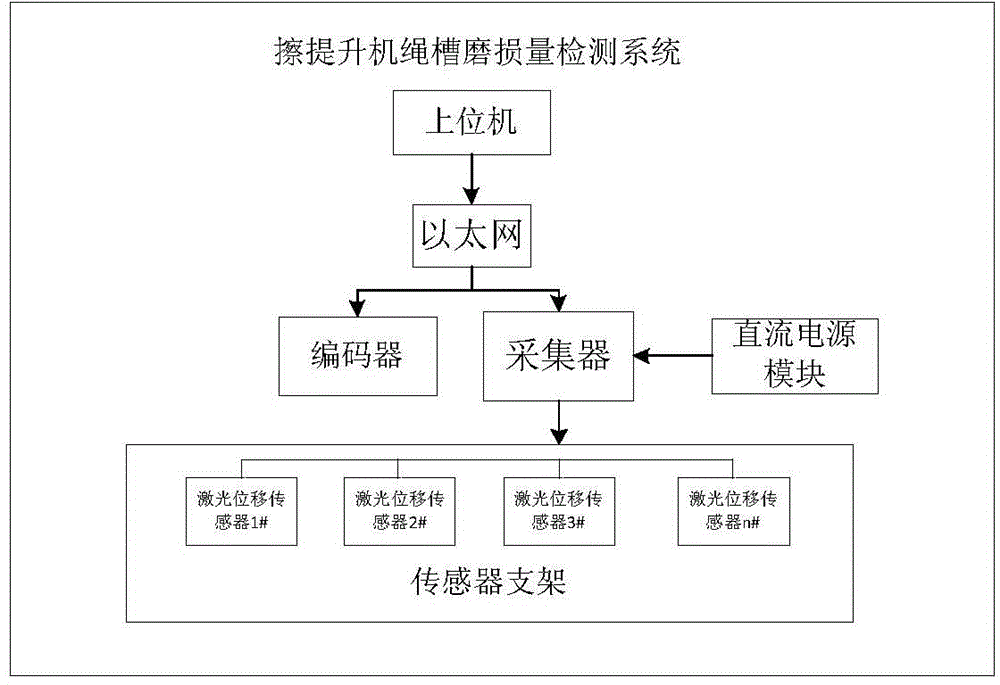

Detection system and detection method of friction elevator rope groove wear loss

InactiveCN104627762AReal-time online detectionReduce labor intensityElevatorsReal time analysisEngineering

The invention provides a detection system and a detection method of friction elevator rope groove wear loss, and belongs to the detection system and the detection method of the elevator rope groove wear loss. The system comprises an upper computer, a laser displacement sensor, a collector, a direct-current power source module and a sensor support. The laser displacement sensor is installed on the sensor support, and the output end of the laser displacement sensor is connected with the collector. An encoder is installed on a roller of an elevator, the output end of the encoder is connected with an Ethernet, and the output end of the collector is connected with the input end of the upper computer through an interface of the Ethernet. The upper computer achieves real-time analysis of the on-line detection of the friction elevator rope groove wear loss and determines the wear loss conditions of different positions according the encoder. The detection system and the detection method have the advantages that the real-time quick on-line detection of the wear loss of a friction liner can be achieved, the friction liner needing to be replaced can be positioned precisely in real time, the working intensity of workers is reduced, the service life of a steel wire rope is prolonged, and the problem that real-time monitoring of the wear loss of the friction line cannot be achieved in a project is solved.

Owner:CHINA UNIV OF MINING & TECH

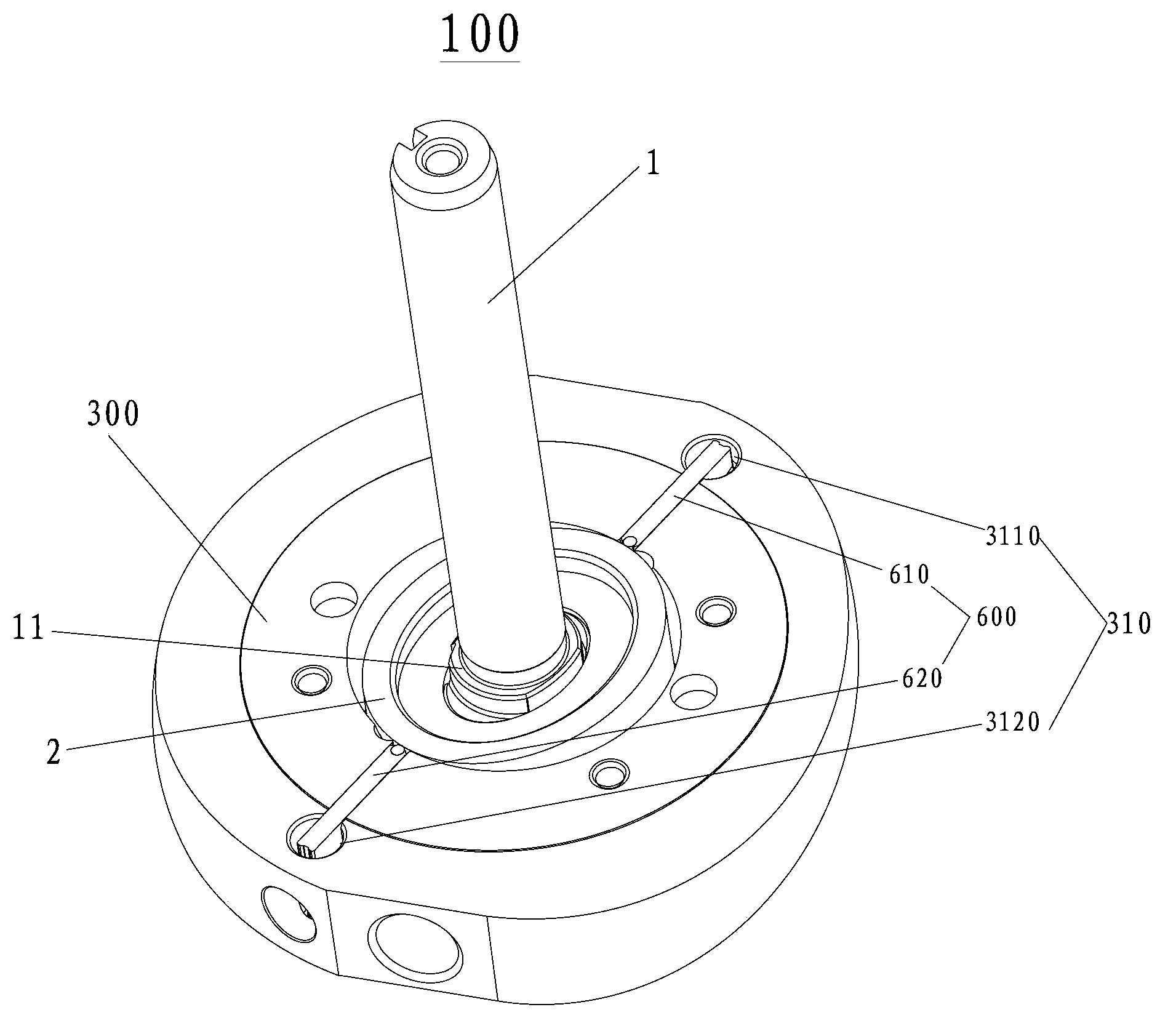

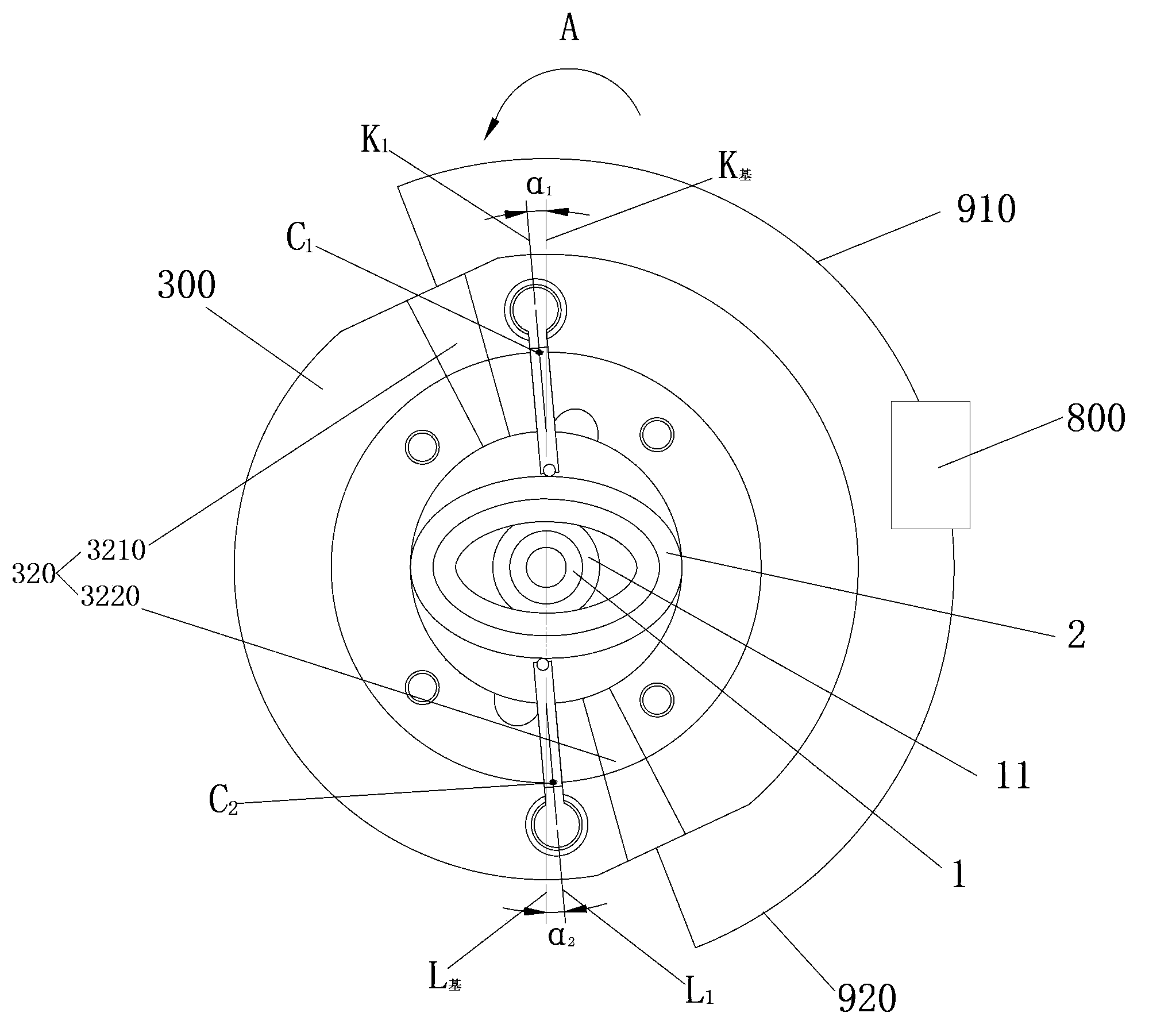

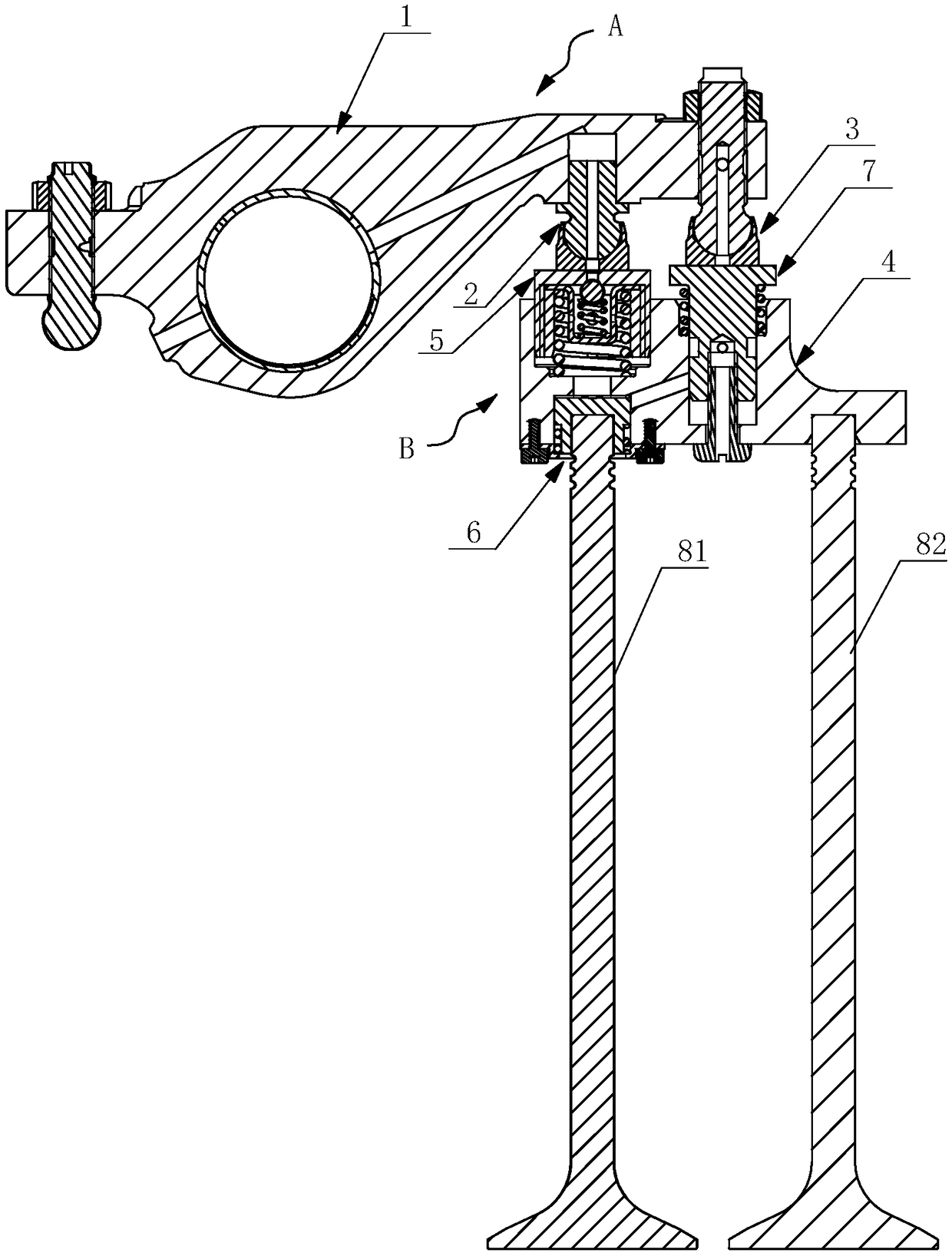

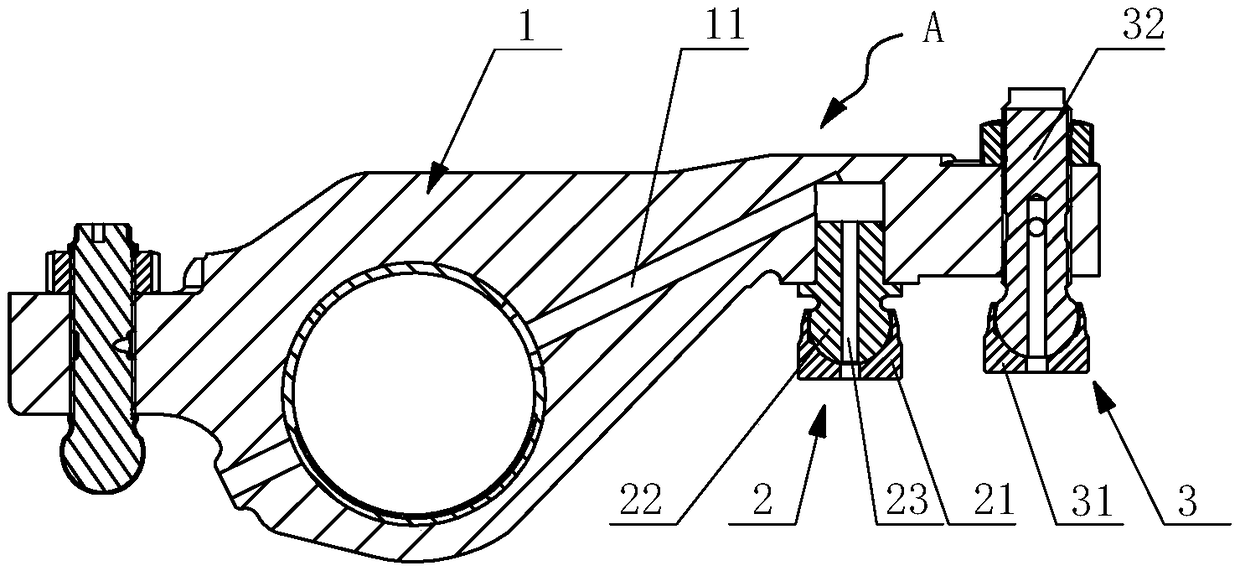

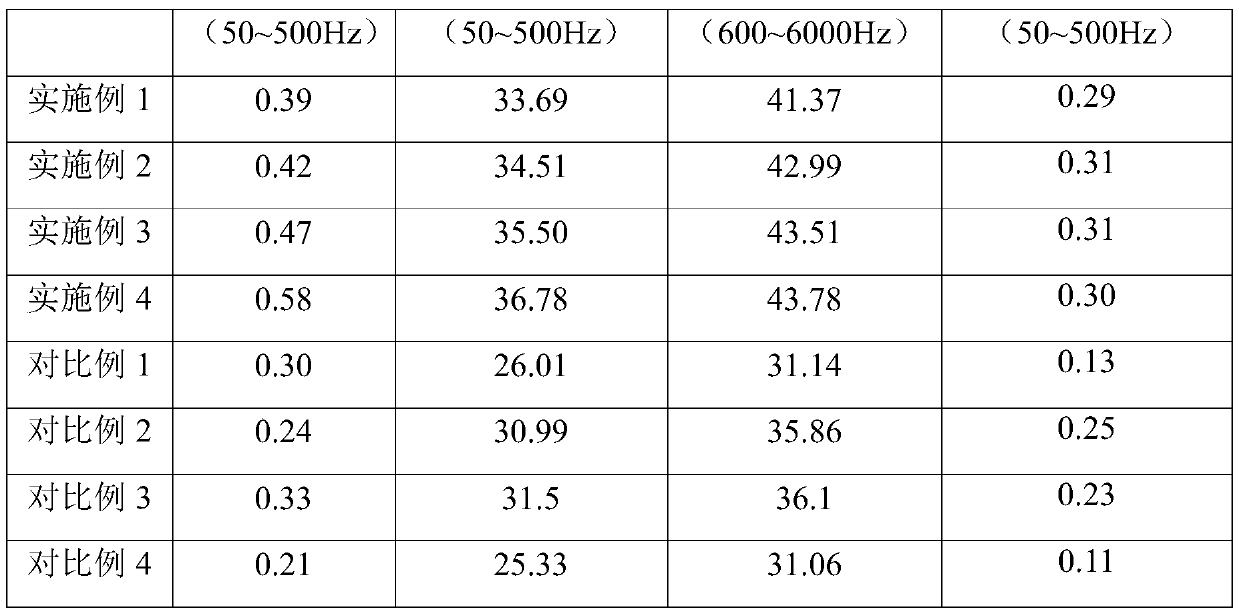

Sucker rod rope suspension apparatus

InactiveCN100999985AChange positional relationshipOvercome the defect of eccentric wearDrilling rodsFluid removalEngineeringClockwise

The sucker rod rotating rope hanger consists of a casing, a butterfly spring, a bearing, a bearer, a sucker rod seat, a ratchet wheel, a driving member, and other parts. Its operation principle is that during the sucker rod moves upwards, the increased sucker rod weight and the compressed spring make the driving member rotates clockwise while moving downwards; during the sucker rod moves downwards, the decreased sucker rod weight and the extending spring and the single direction rotating ratchet wheel make the driving member rotates counterclockwise idly; so that each motion period of the sucker rod makes the sucker rod under the action of the rope hanger rotate by some angle.

Owner:HENAN XINYU PETROLEUM MACHINERY MFG

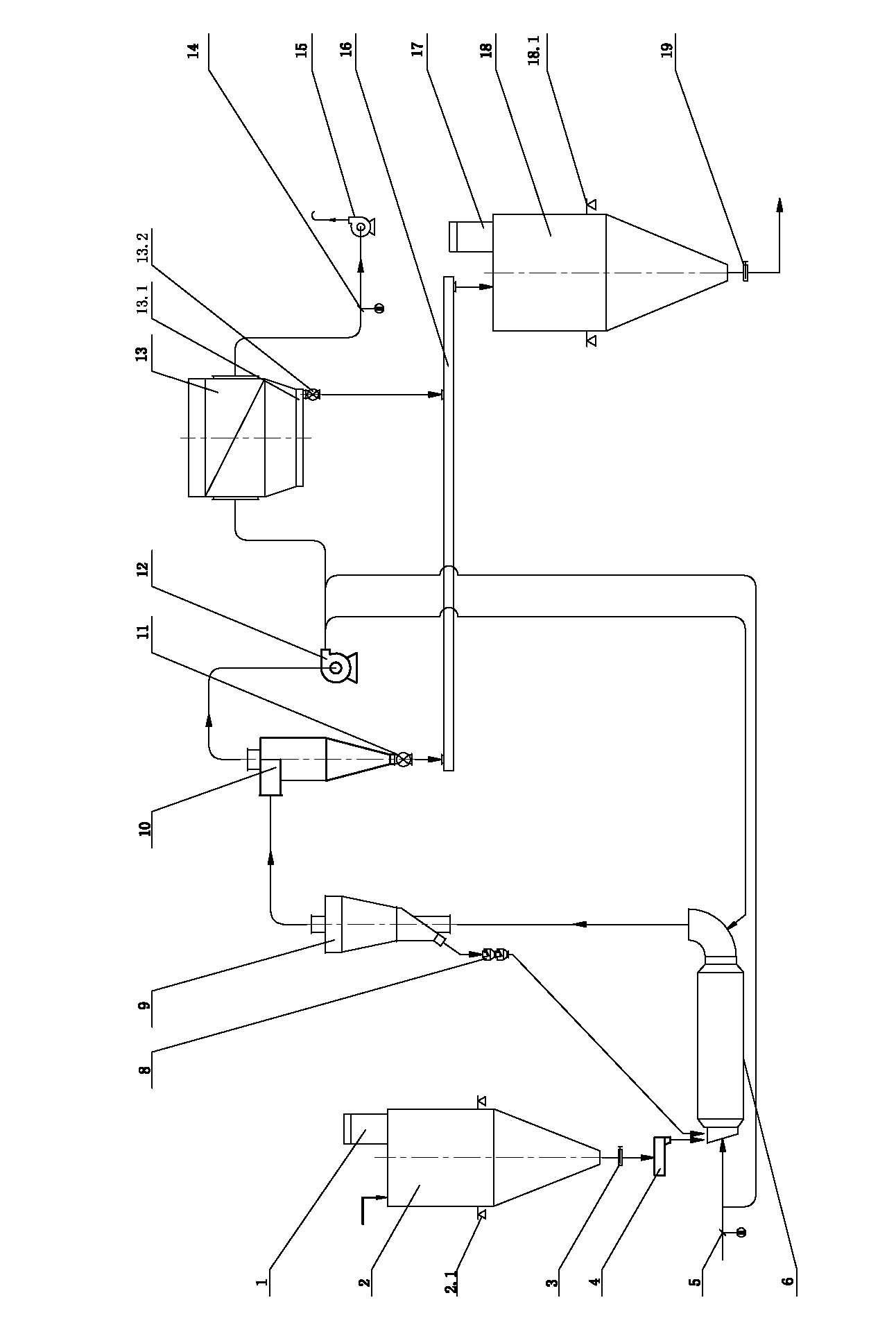

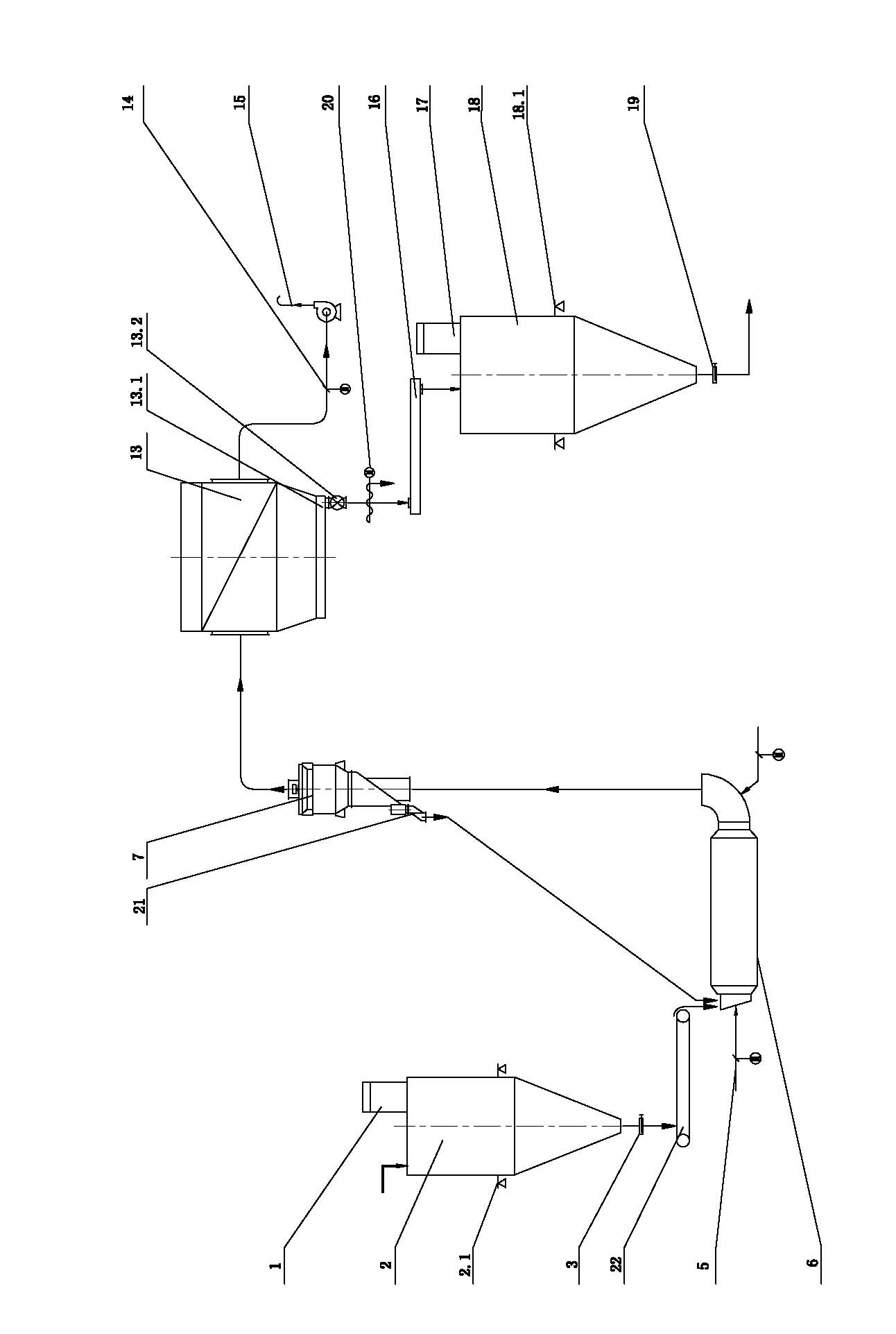

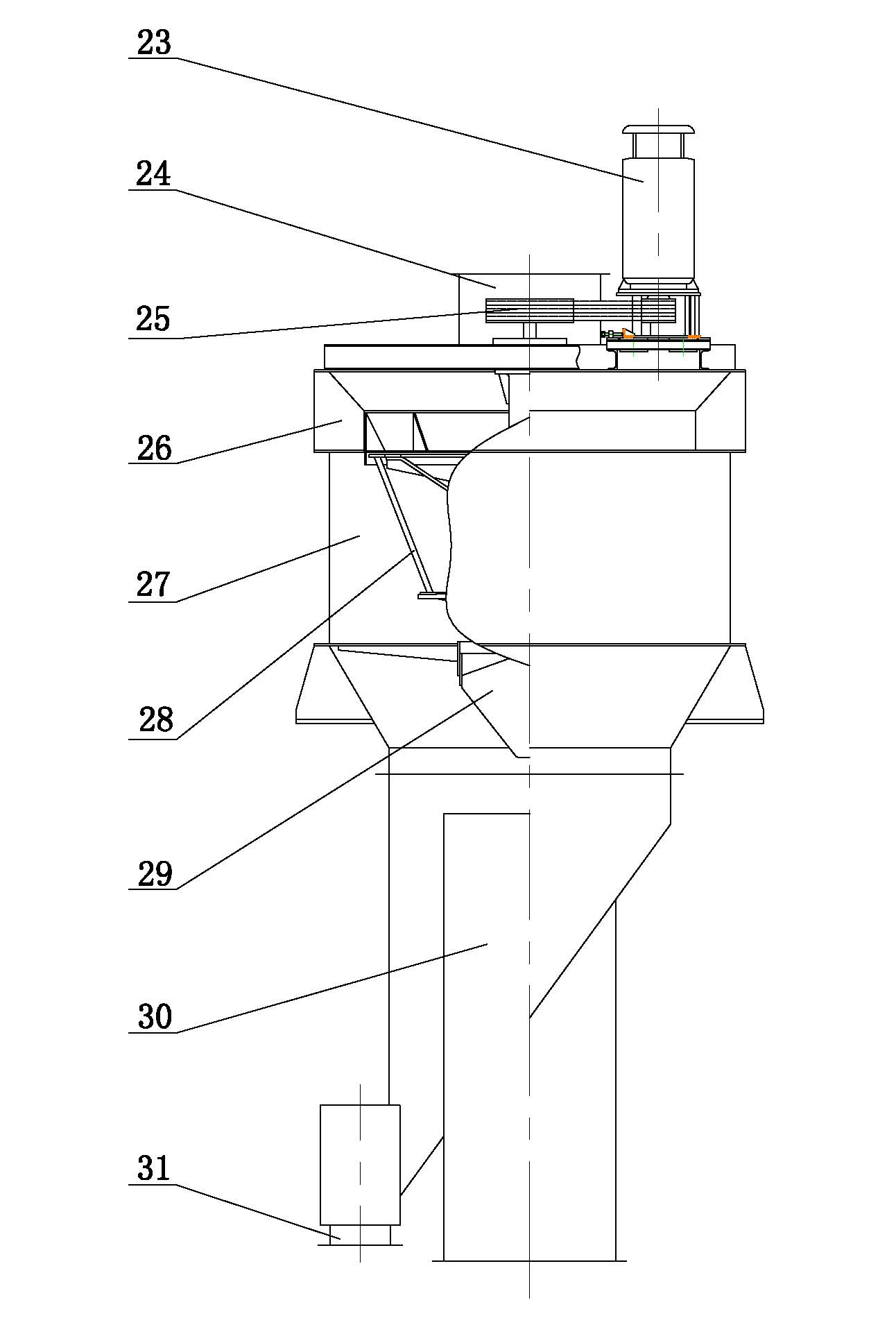

Process for preparing carbon forming powder

InactiveCN101972687AImprove dust carrying capacityReduce power consumptionGrain treatmentsProcess engineeringBall mill

The invention relates to a process for preparing carbon forming powder, in particular to a new process for preparing carbon forming powder by adopting an air swept type ball milling system. In the invention, equipment mainly comprises a raw material bin, an air swept type ball mill, a high-efficiency rotor type grader, a gas tank pulse bag type dust collector, a main exhaust fan and a finished powder bin. In the main work process of the invention, a raw material is fed and added to the air swept type ball mill through a feeder and is subjected to rough and fine powder grading through the high-efficiency rotor type grader, rough particles are returned to the ball mill for pulverizing once again, and fine particles enter the gas tank pulse bag type dust collector for collection. The invention has the technological performance advantages of high systemic force supply, low power consumption for unit product, high finished powder purity, and good uniformity and stability, and completely eliminates the phenomena of air leakage and ash flying in the traditional process because of the operation in a negative pressure state. The process is not only suitable for the optimization and technological improvement on the traditional process in the production process of the carbon forming powder, but also suitable for new projects of a carbon forming powder preparation system.

Owner:NANJING UNIV OF TECH

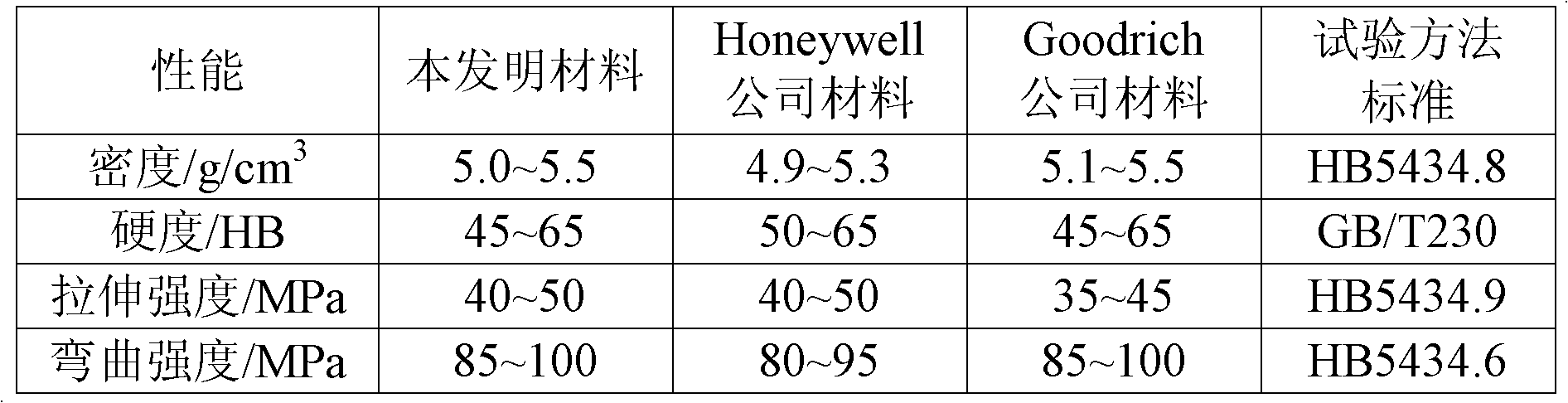

Friction material and process for manufacturing aircraft braking disc made from same

ActiveCN102604596AImprove heat resistanceImprove wear and tearOther chemical processesFriction liningAirplaneBoron nitride

The invention relates to a friction material which comprises the following components in percentage by weight: 62-72% of copper, 6-15% iron, 2-6% of aluminum, 3-8% of tin, 1-5% of nickel, 3-10% of cyanite (Al2O3.SiO2), 2-7% of boron nitride, 8-16% of graphite and 1-4% of molybdenum disulfide. The process for manufacturing an aircraft braking disc made from the friction material comprises the following steps: mixing a mixture of the friction material, pressing and moulding, preparing a steel back, and pressurizing and sintering the aircraft braking disc. Compared with the prior art, the mechanical performance, the physical performance, the friction and wear resistance, the use reliability and the service life of the aircraft braking disc made from the friction material reach or exceed those of the imported aircraft braking pair, and the aircraft braking disc made from the friction material can completely meet the use requirement of the Boeing 737 aircraft.

Owner:SHANTOU NORTHWEST AVIATION ARTICLES

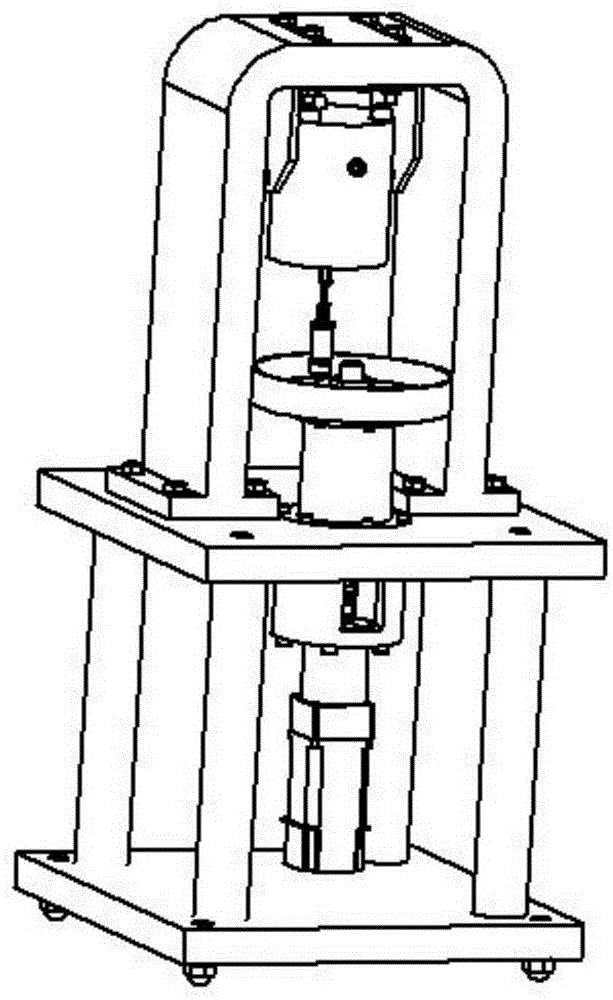

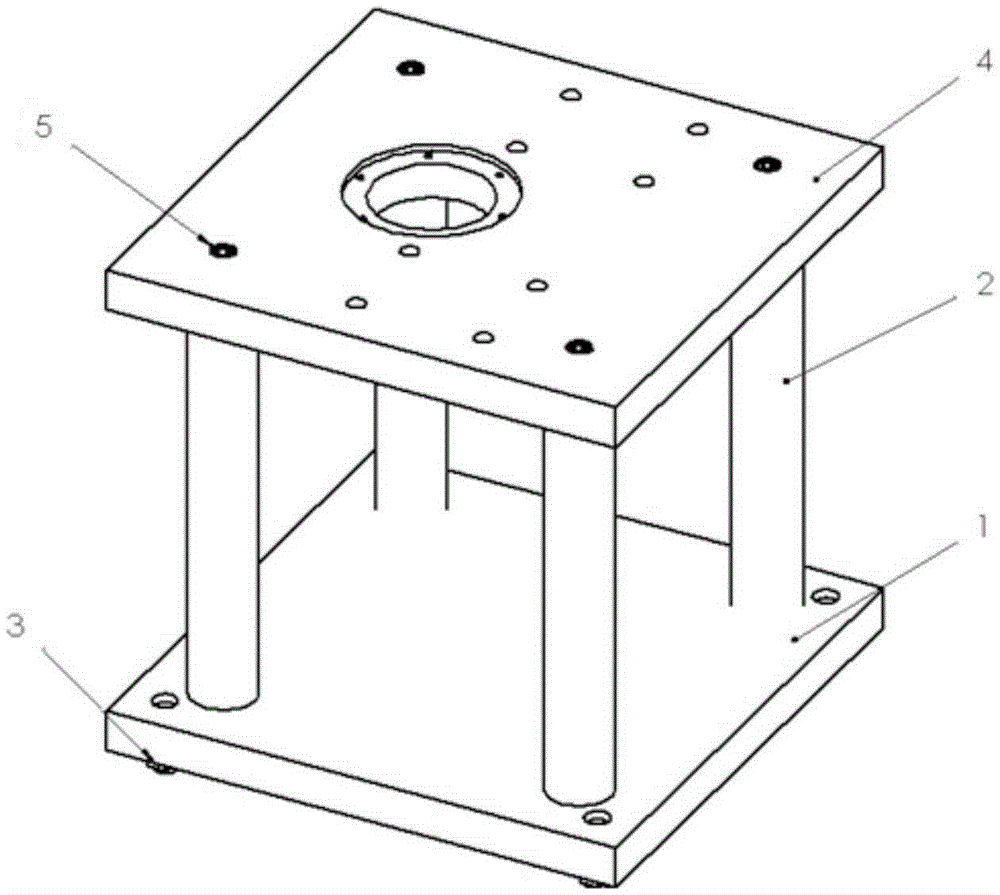

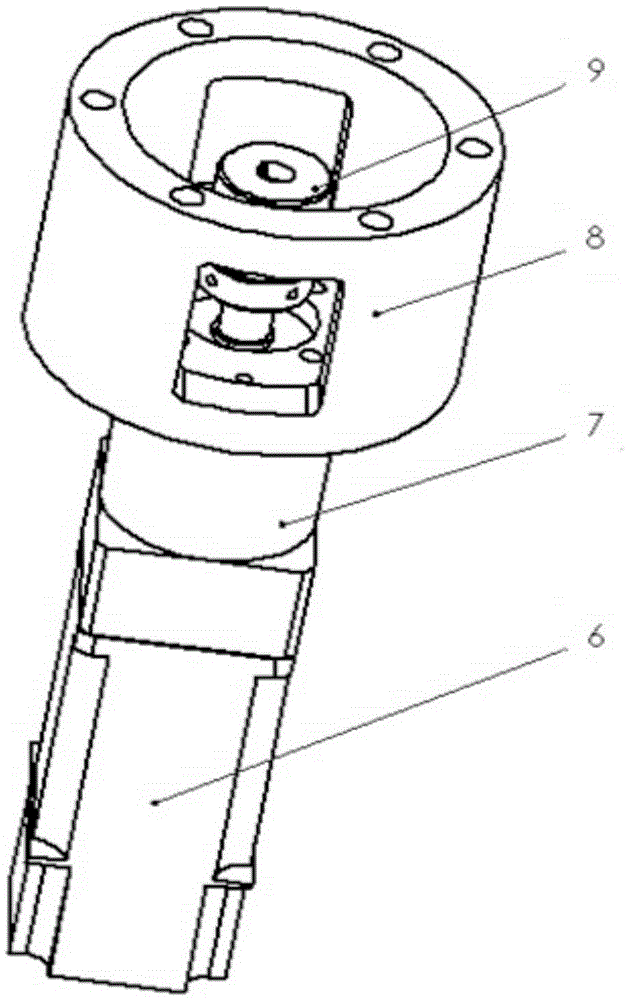

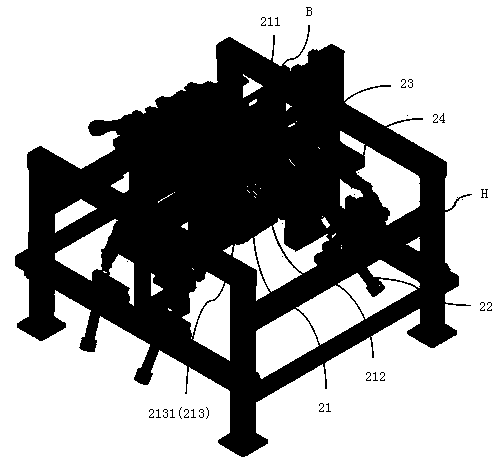

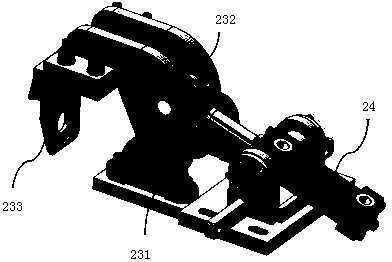

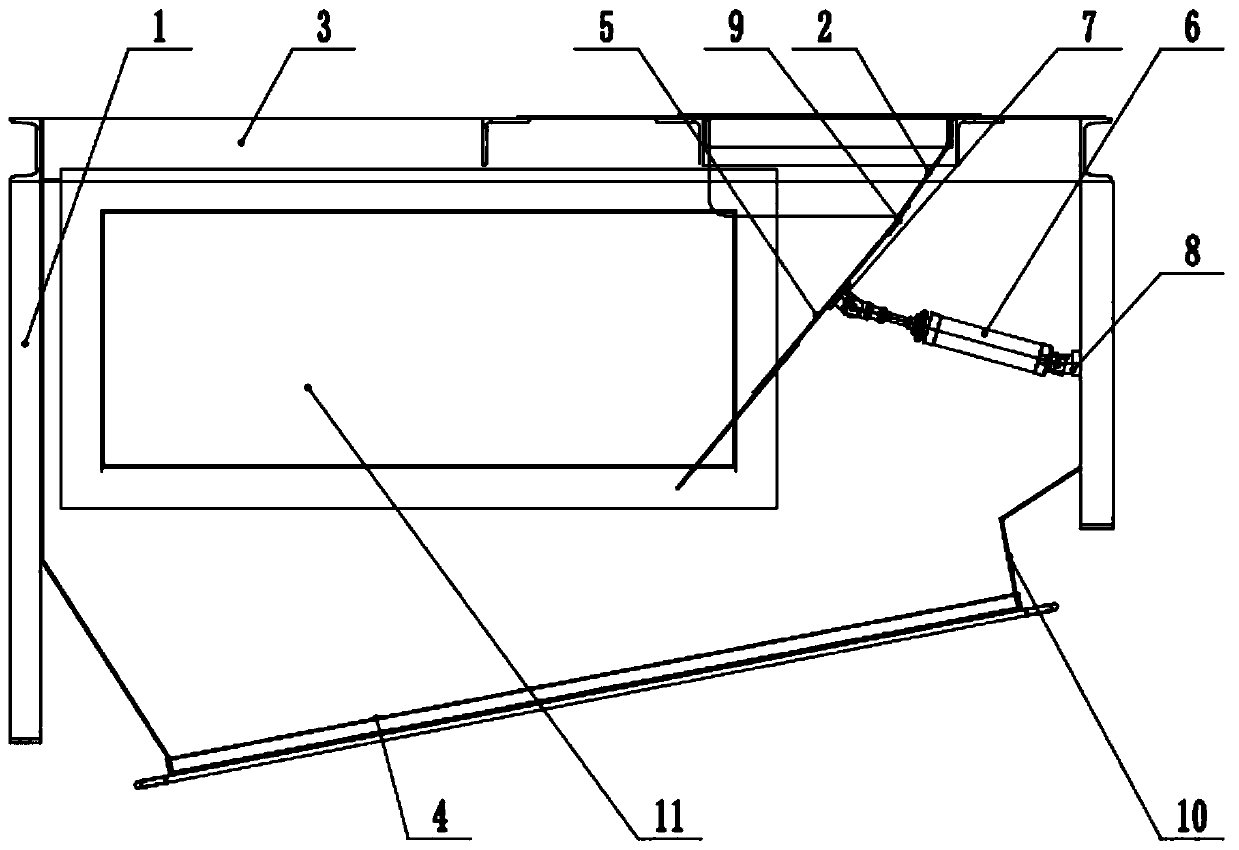

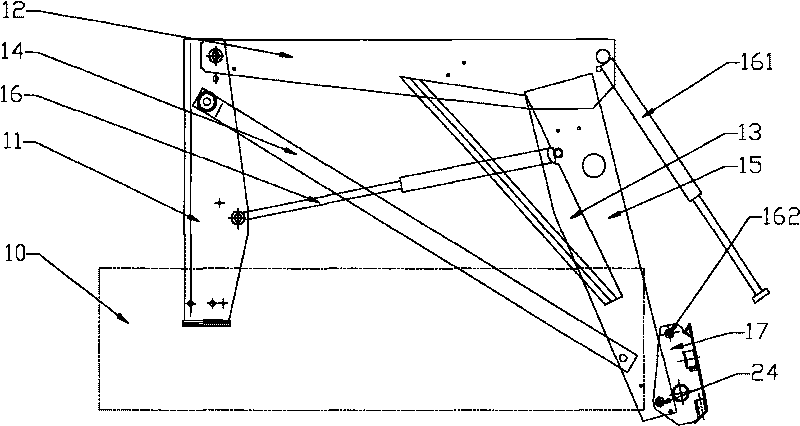

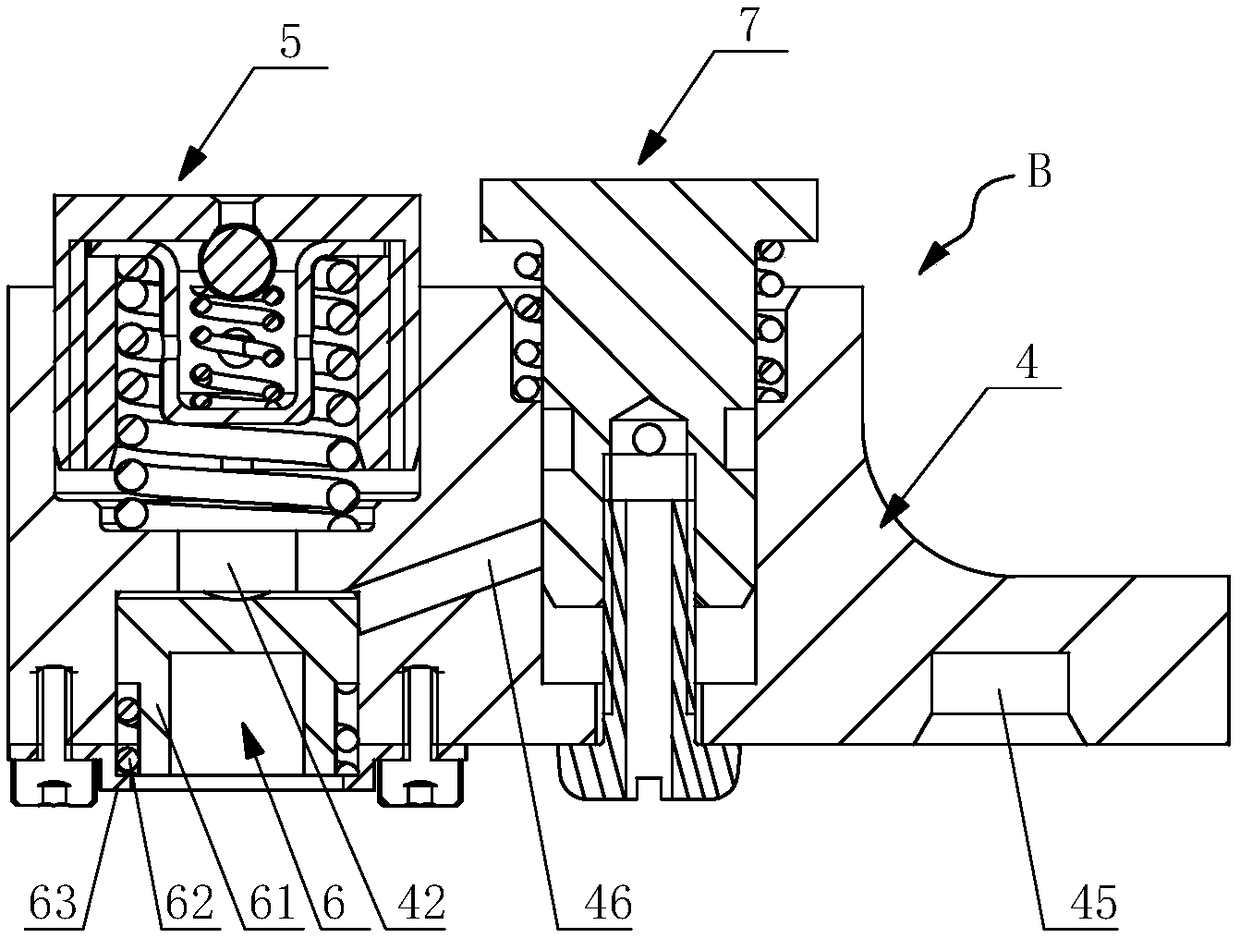

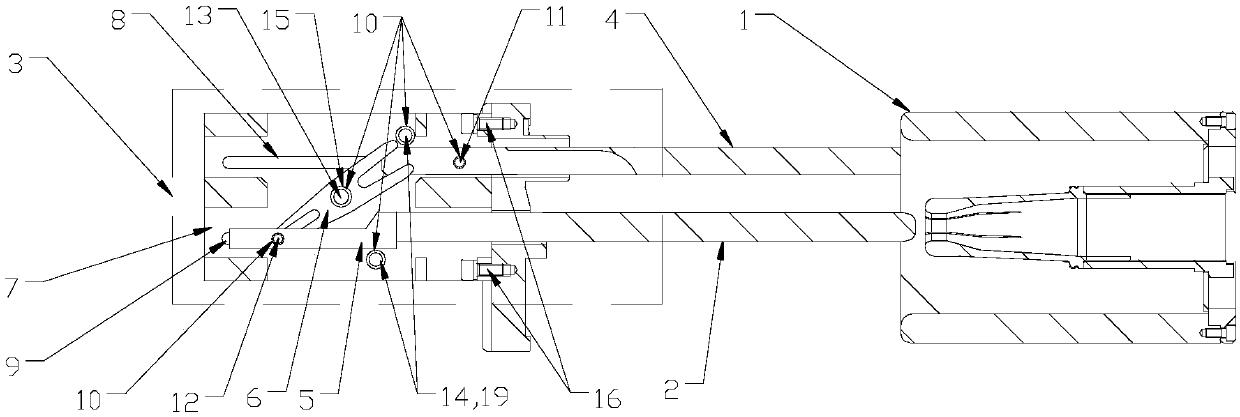

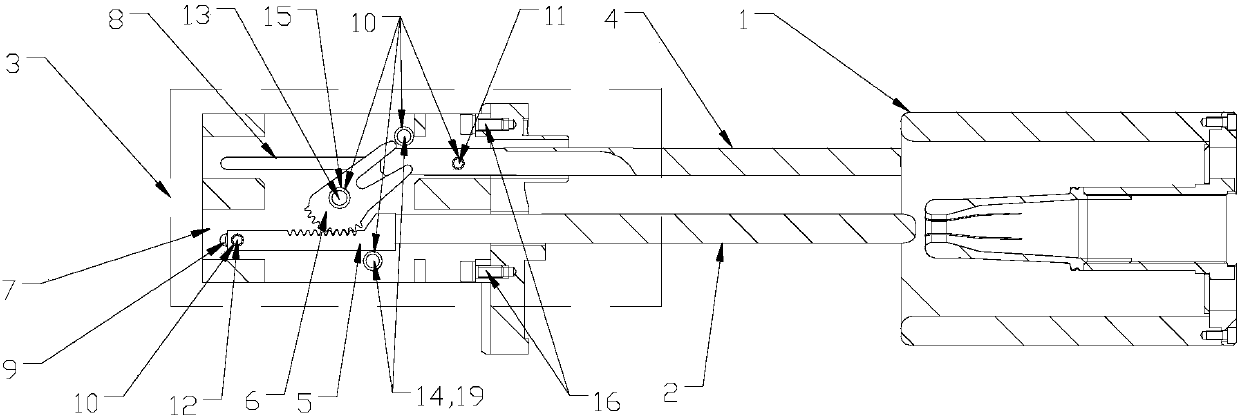

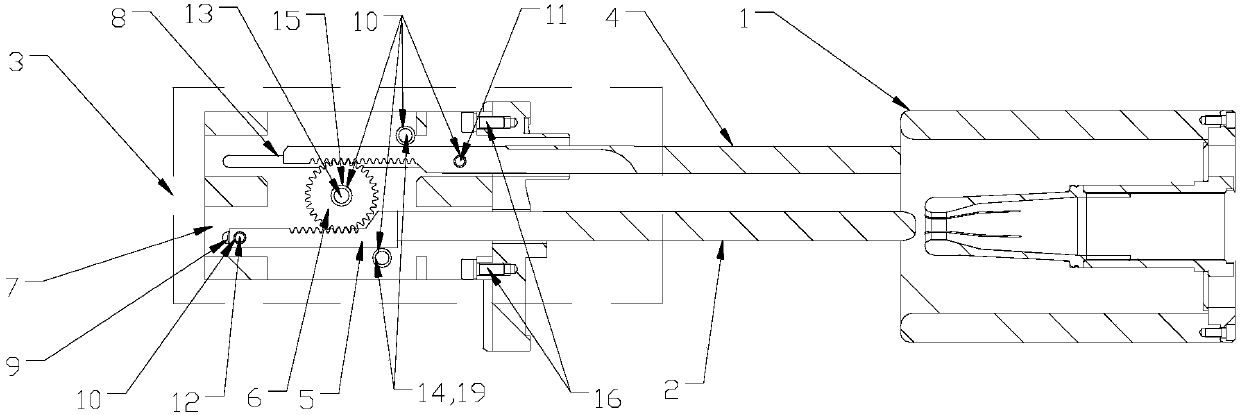

Small-load impact abrasion testing machine with tangential velocity

InactiveCN105300823AGood reproducibilityHigh degree of automationInvestigating abrasion/wear resistanceCouplingSoftware engineering

The invention provides a small-load impact abrasion testing machine with a tangential velocity. The small-load impact abrasion testing machine comprises a substrate, a motion system, a test piece installation system and an impacting device, wherein the substrate is provided with an upper table top 4 and a lower bottom plate 1; the upper table top 4 is provided with an installation hole; the motion system is arranged between the upper table top 4 and the lower bottom plate 1 and is fixedly connected with the upper table top 4 through a fixing device; the motion system is provided with a coupler 9 and is connected with the test piece installation system 6 through the coupler 9; the test piece installation system comprises a main shaft 16 and a disk test piece 11 installed above the main shaft 16. The testing machine is suitable for a small-load impact abrasion test, the abrasion experiment of an impact working condition of the tangential velocity can be realized through the arrangement of the impact device, the motion system and the test piece installation system, and the small-load impact abrasion testing machine has the advantages of high automation degree, stable working load, good lasting work capability, high precision and good test data reproducibility.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

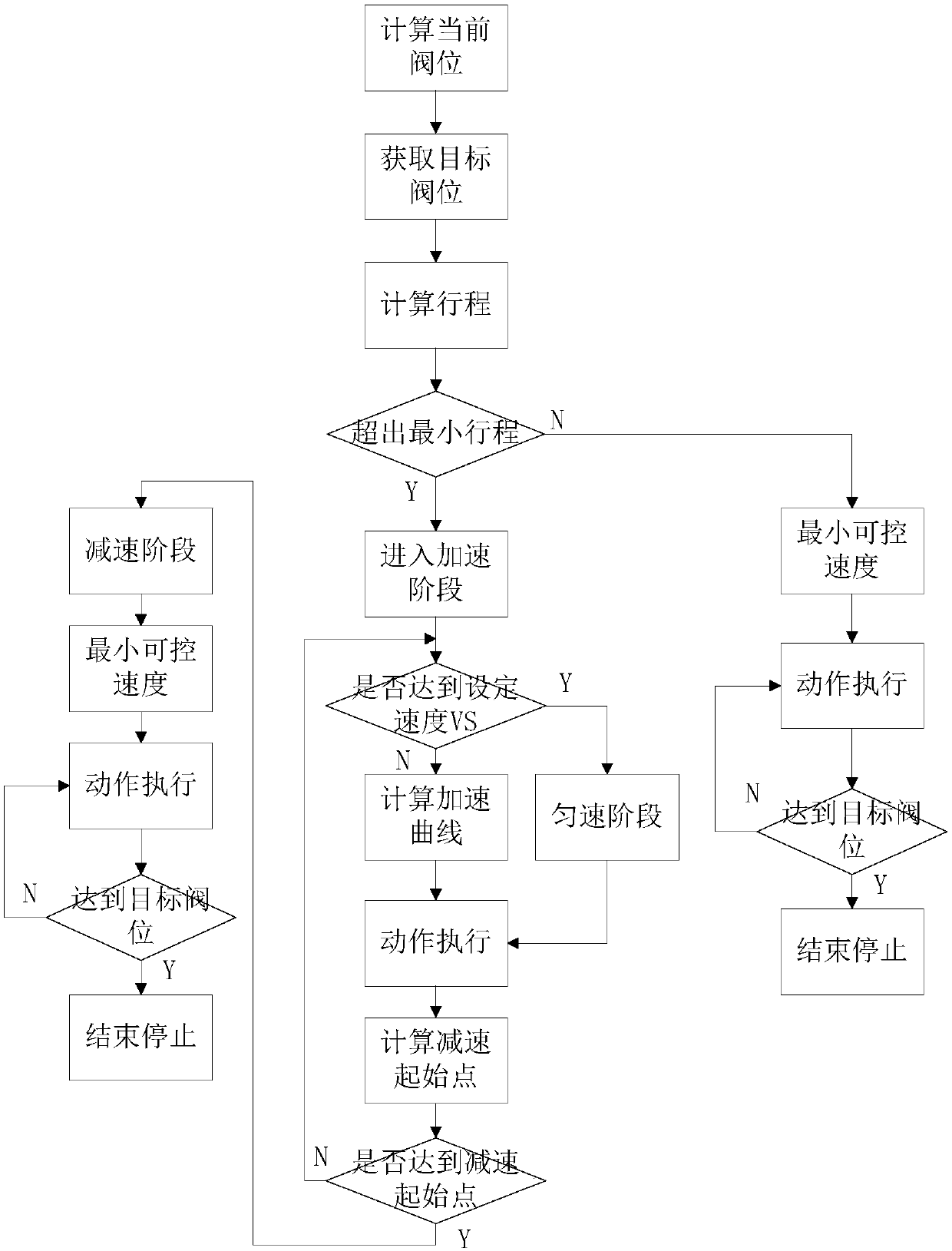

High-precision valve control method

ActiveCN108227756AHigh precisionReduce shockOperating means/releasing devices for valvesElectric motor controlMechanical impactEngineering

The invention discloses a high-precision valve control method. The method comprises the following steps of 1, setting system parameters; 2, judging a current valve location value of a valve; 3, according to a target valve location value, calculating a motion stroke at this time; 4, judging the motion stroke at this time; 5, planning a speed curve, wherein according to the motion stroke at this time, the speed curve is planned, and is divided into an acceleration phase, a uniform speed phage and a deceleration phase; 6, controlling the rotational speed according to the speed curve planed in step 5. By means of the high-precision valve control method, the motion control precision of an executor is improved, the running speed can be flexibly adjusted, mechanical shock brought in running is lowered, the material wearing condition of a transmission structure is improved, and the service life of products is prolonged.

Owner:NANJING SCIYON AUTOMATION GRP

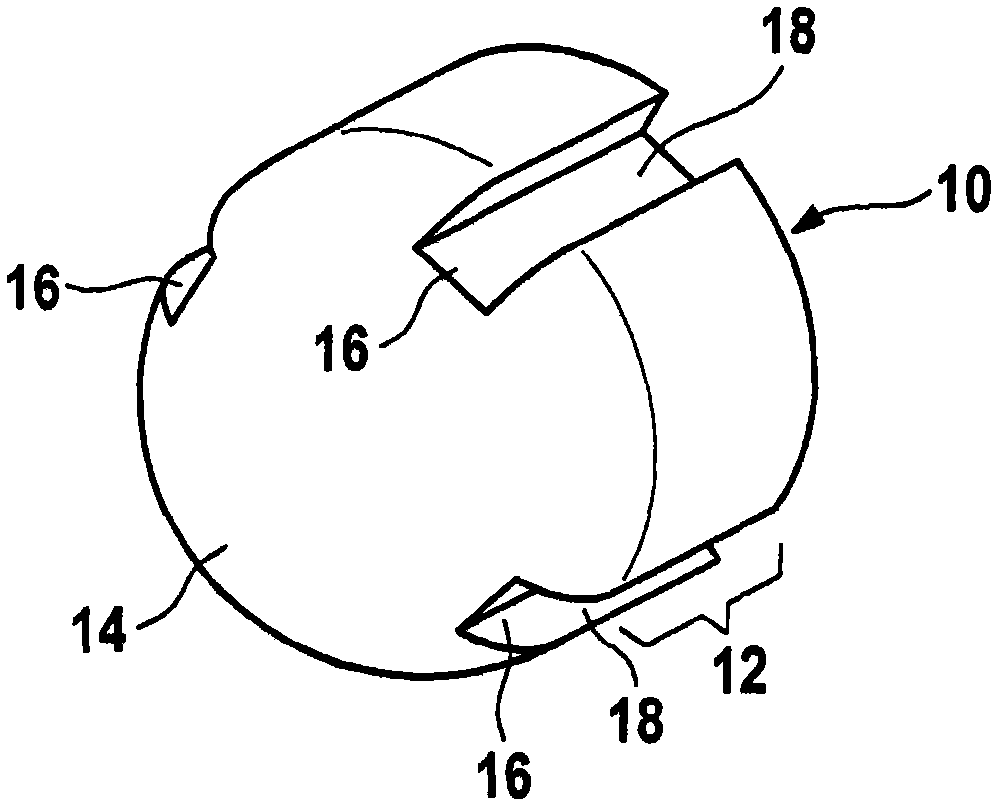

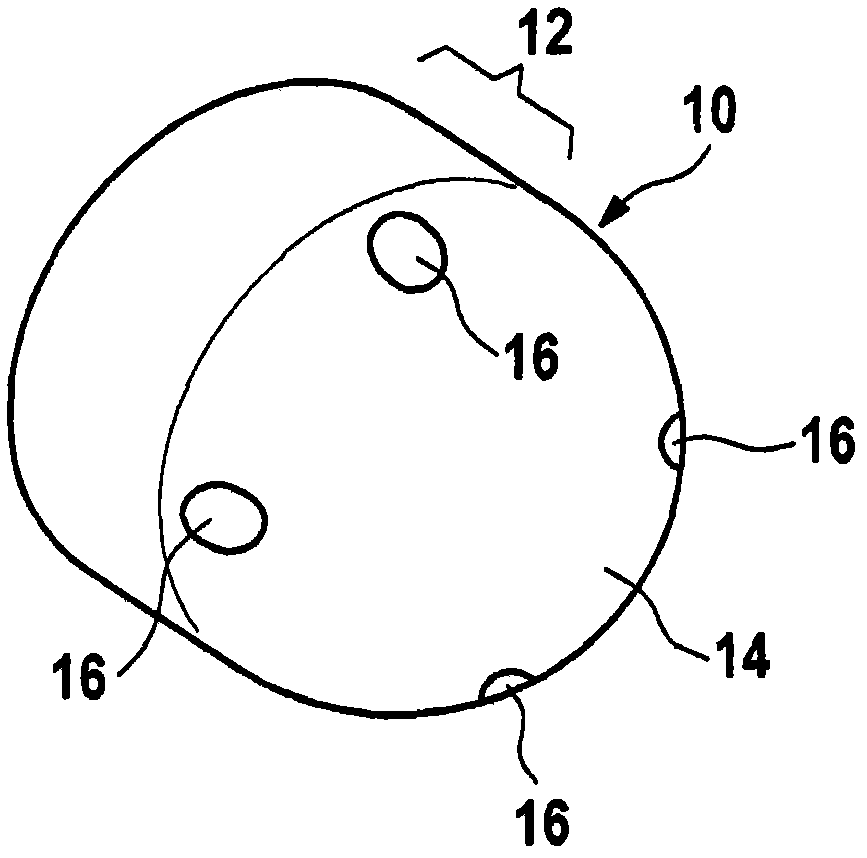

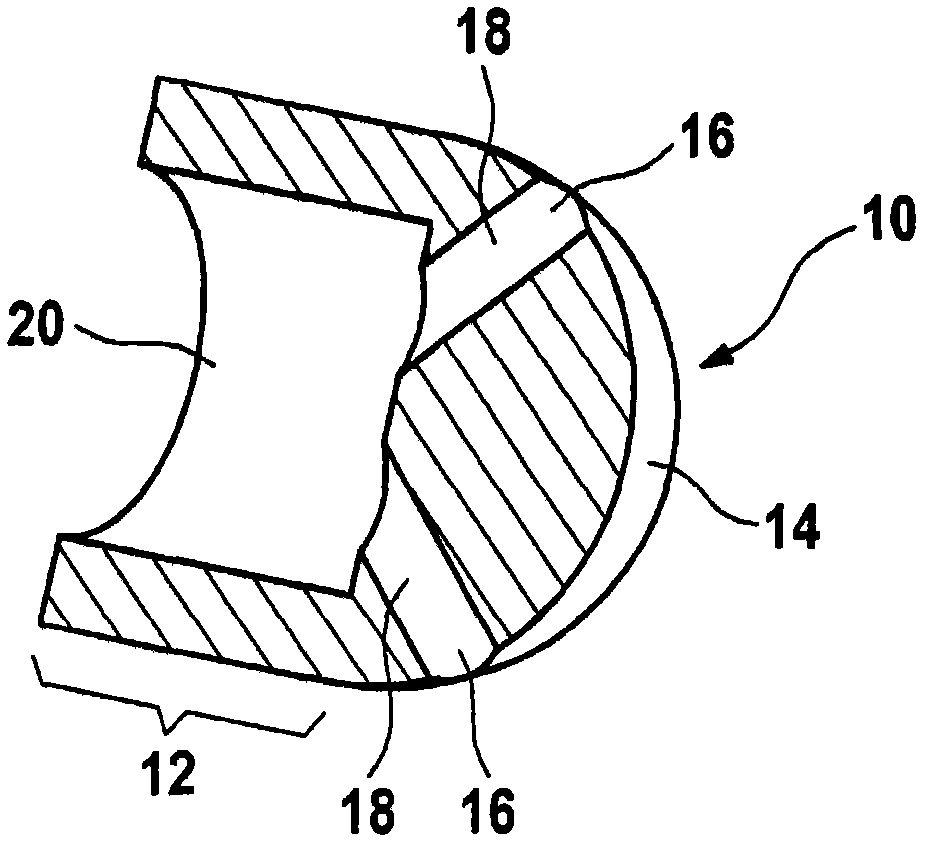

Valve with valve closure body

InactiveCN102072146AReduce manufacturing costEasy to integrateOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringValve seat

The invention relates to a valve for a piston pump, wherein the valve (22) comprises a valve closure body (10) and a valve seat (26) disposed longitudinally facing to the valve closure body (10); the valve closure body (10) comprises a cylindrical guide section (12) and a hemispheric sealing section (14) longitudinally facing to the cylindrical guide section (10) and facing to the valve seat (26); the sealing section is used for selectively closing and opening a hole (30) enclosed by the valve seat (26); according to the invention, the sealing section (14) comprises at least one channel opening (16) which is located out of the hole (30) enclosed by the valve seat (26) under the state that the valve (22) is closed, and extended into a channel (18) in the valve closure body (10) substantially extending along a flow direction.

Owner:ROBERT BOSCH GMBH

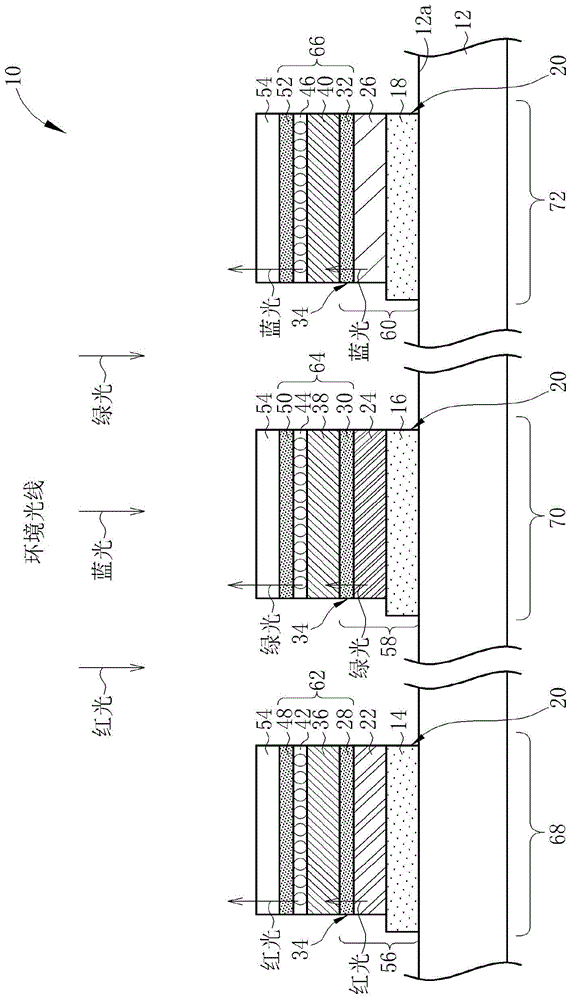

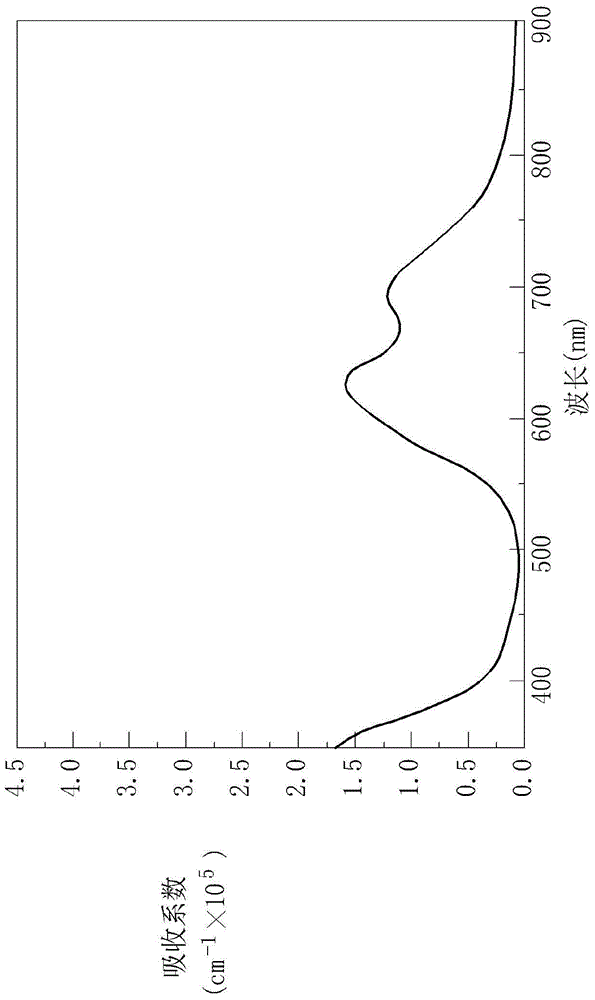

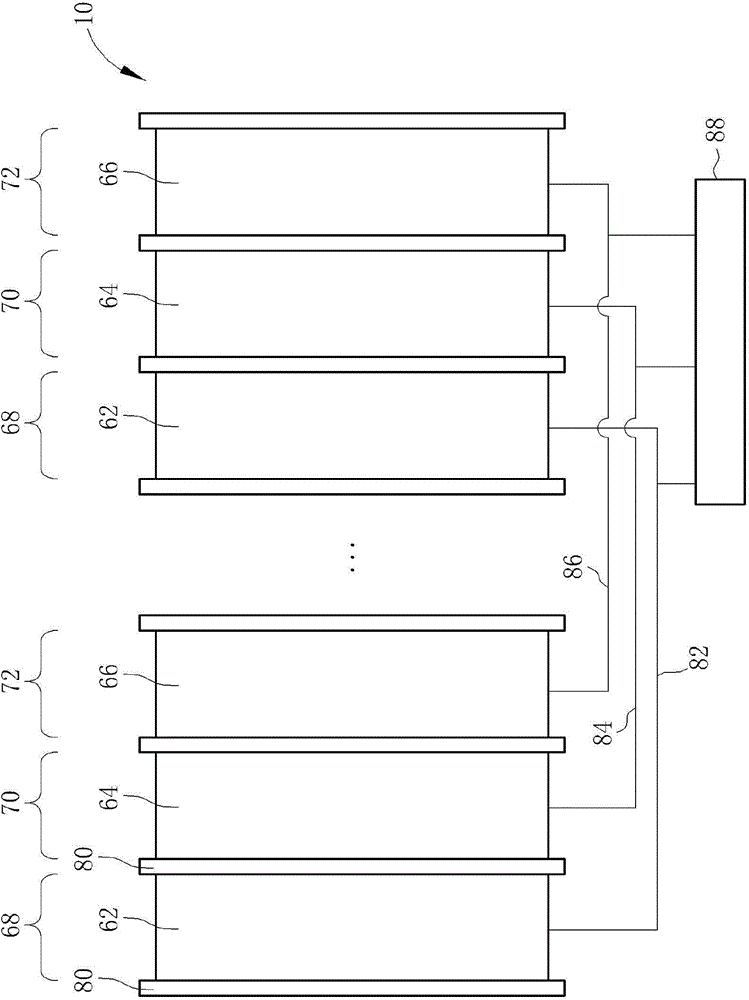

Organic luminescent display with solar cell

InactiveCN104576679AWill not significantly affect the light brightnessImprove wear and tearSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellLight energy

The invention discloses an organic luminescent display with a solar cell. The organic luminescent display comprises a substrate, at least one organic luminescent unit, and at least one solar cell unit. The organic solar unit is arranged on one side of the substrate and comprises a first electrode layer, an organic luminescent material layer, and a second electrode layer. The organic luminescent material layer is arranged between the first electrode layer and the second electrode layer. The first electrode layer is arranged between the organic luminescent material layer and the substrate. The solar cell unit is arranged on one side of the substrate and comprises a third electrode layer and an organic solar cell material layer. The organic solar cell material layer is arranged between the second electrode layer and the third electrode layer. The provided organic solar cell unit can provide a similar effect of a color light filter, can directly absorb the lights in the organic luminescent display and external lights, is capable of converting the light energy into electric energy, and improves the situation of energy loss.

Owner:WINTEK CORP

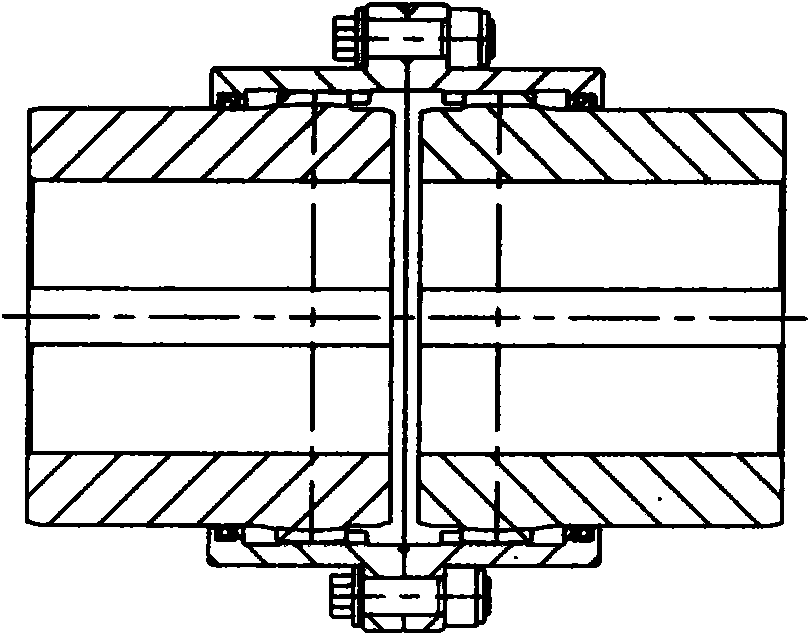

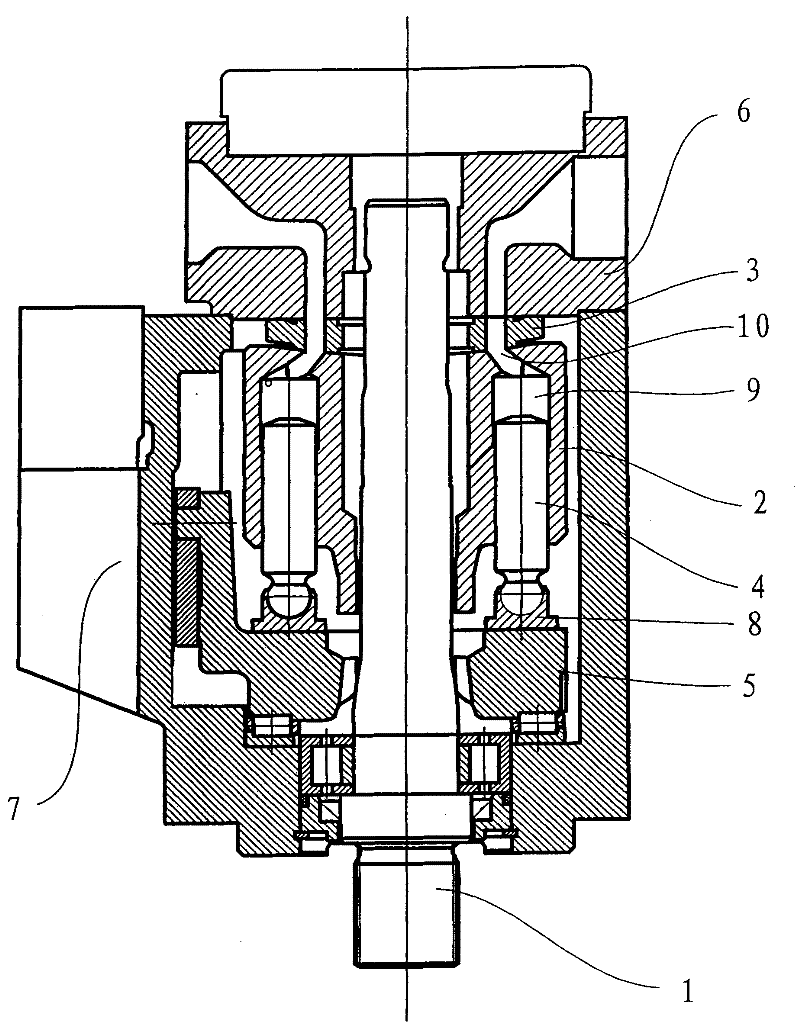

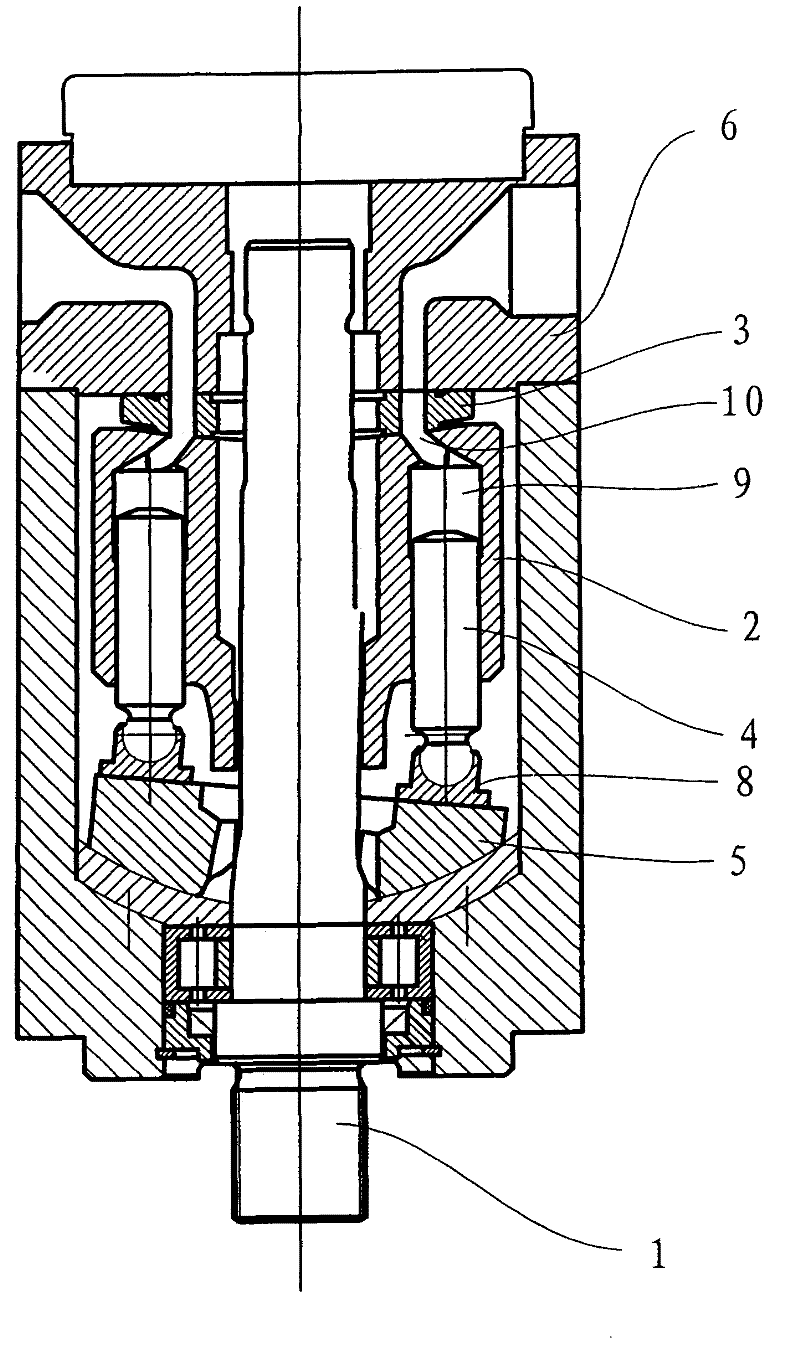

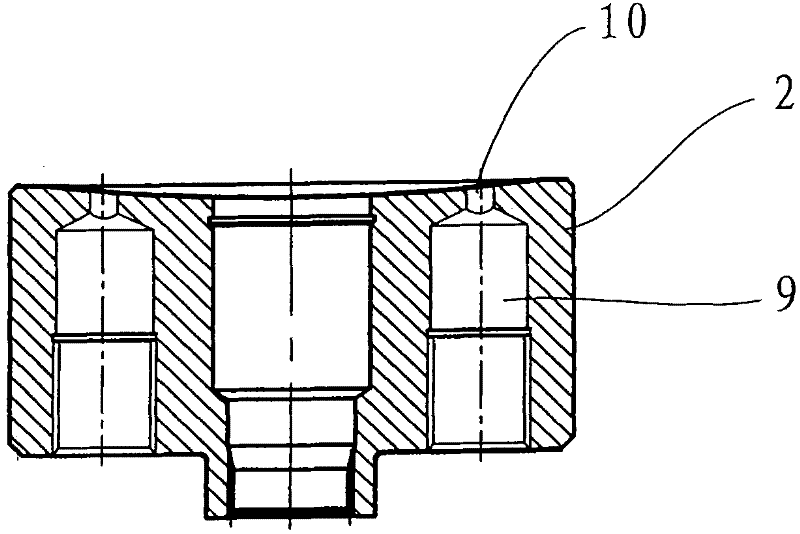

Short rzeppa synchronous universal coupling

InactiveCN101639098AGreat angular compensationEliminate shear forceYielding couplingShortest distanceSteel ball

The invention provides a short rzeppa synchronous universal coupling, which is mainly used for the power transmission with short distance, small inclination angle and high rotating speed in the metallurgical, heavy-duty, mining, lifting, transportation machinery and other industries. The coupling consists of two all-sealed rzeppa universal joints which mesh with each other through two outer ringsprovided with teeth on the end surfaces and are fastened through a bolt, wherein an inner hole of an inner ring is a spline or keyway hole and is matched with corresponding shaft extension to achive the transmission of a driving / driven end; a steel ball is arranged between the inner ring and the outer rings; the steel ball is arranged in a window of a cage; the cage is embedded between the inner ring and the outer rings; a link bolt does not bear shear force formed by torque transmission ; and torque is transmitted to the driven end through an inner-ring channel of the driving end, the steel ball and an outer-ring channel. The coupling has the advantages of constant-speed transmission, smooth operation, compact structure, high bearing capacity, great angular compensation (generally up to 5degrees), strong adaptability to field work, convenient installation and adjustment, improvement on internal friction and wear, longer life span and capability of effectively preventing vibration from causing bolts to loosen.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

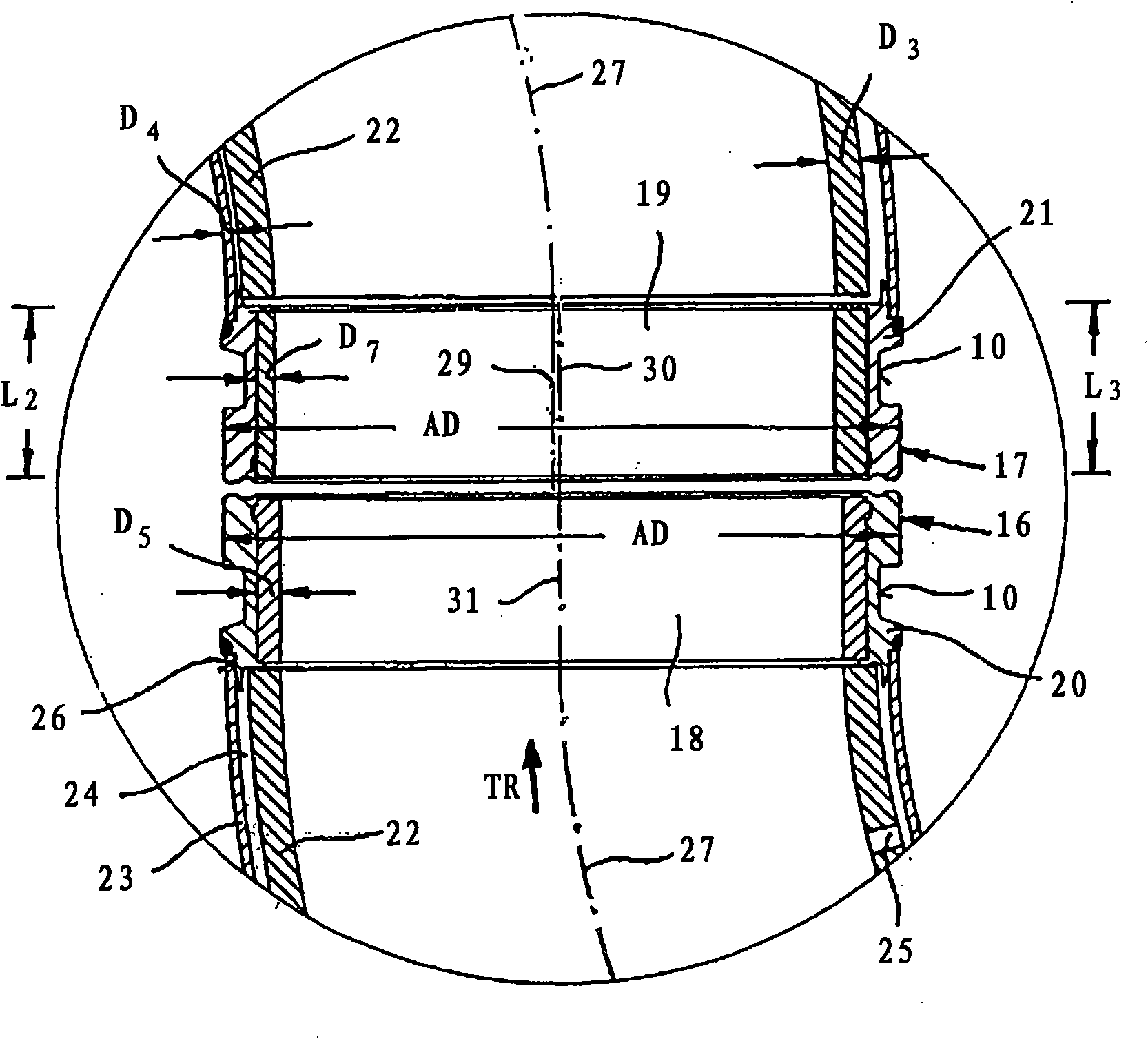

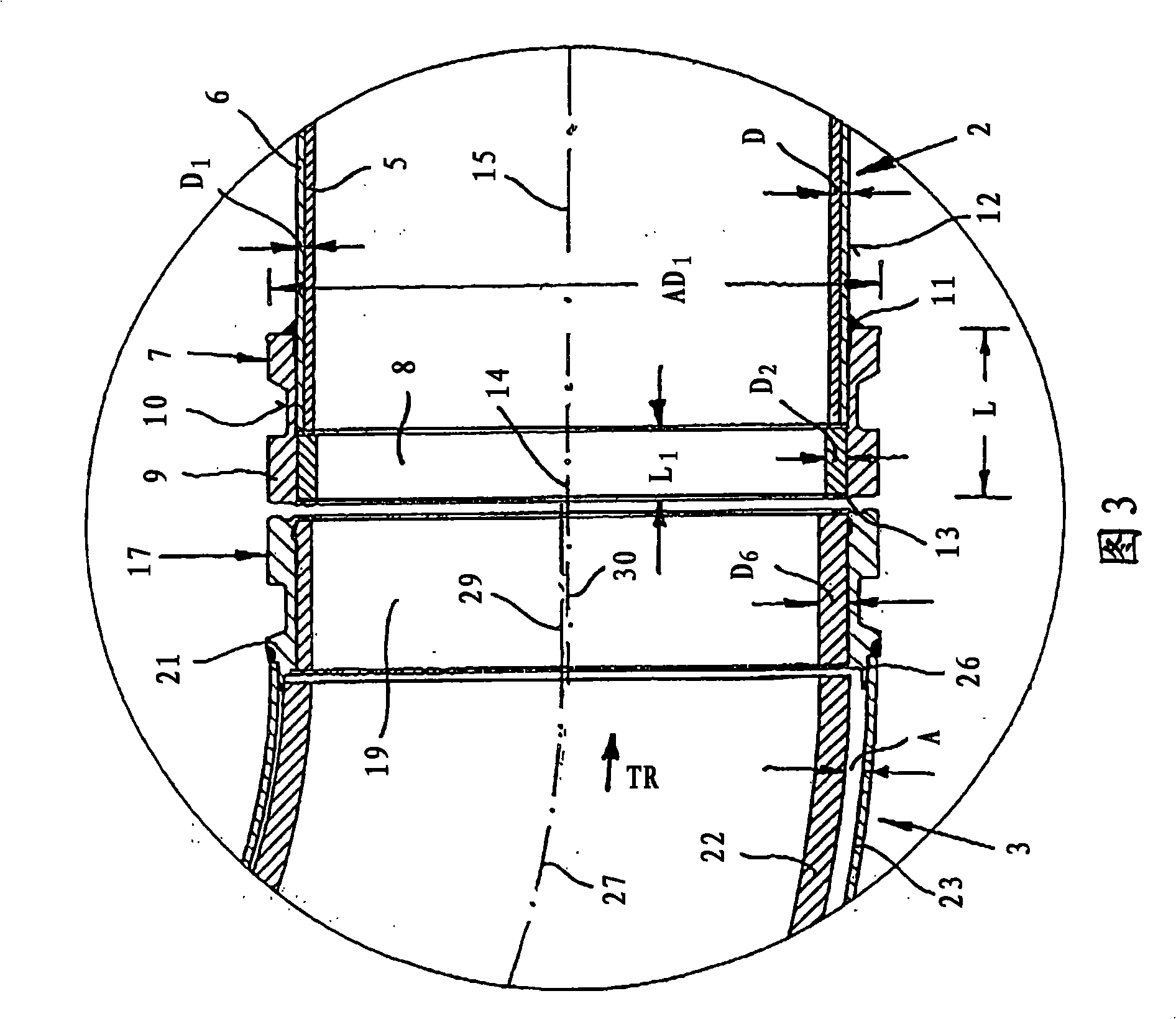

Axial plunger pump with double rows of cylinder holes and cylinder bodies

InactiveCN102192119AWidely used valueReduce variable swing anglePositive displacement pump componentsPositive-displacement liquid enginesSEMI-CIRCLECylinder block

The invention relates to an axial plunger pump, and in particular relates to an axial plunger pump with double rows of cylinder holes and cylinder bodies. The plunger pump comprises a driving main shaft, a cylinder body, a fluid distributor, a plunger, a swinging tray and an upper cover, wherein the cylinder bodies are provided with a plurality of cylinder holes; the fluid distributor is provided with two semi-circle fluid distribution holes; the plunger pump is characterized in that the plurality of cylinder holes in the cylinder bodies are divided into two rows; the numbers of the two rows of cylinder holes are equal, and are alternatively distributed on two circumferences with the same radius centering on the axis of the driving main shaft; the bottom part of each cylinder hole is provided with waist-shaped through holes which are communicated with the fluid distribution holes on the fluid distributor; and the waist-shaped through holes are all distributed on the circumferences with the same radius centering on the axis of the driving main shaft. Through the application of the cylinder bodies of the two rows plunger holes, the fluid pulsation can be reduced effectively, the stability of the pump operation can be improved, so that the aim of vibration and noise reduction is achieved; by adopting the cylinder bodies of the two rows of plunger holes, under the condition of increasing discharging amount without changing the integral structure of the pump, the integral structure is more compact; and the increase of the flow rate also enables the working range of the pump to be increased greatly.

Owner:BEIJING HUADE HYDRAULIC INDAL GROUP

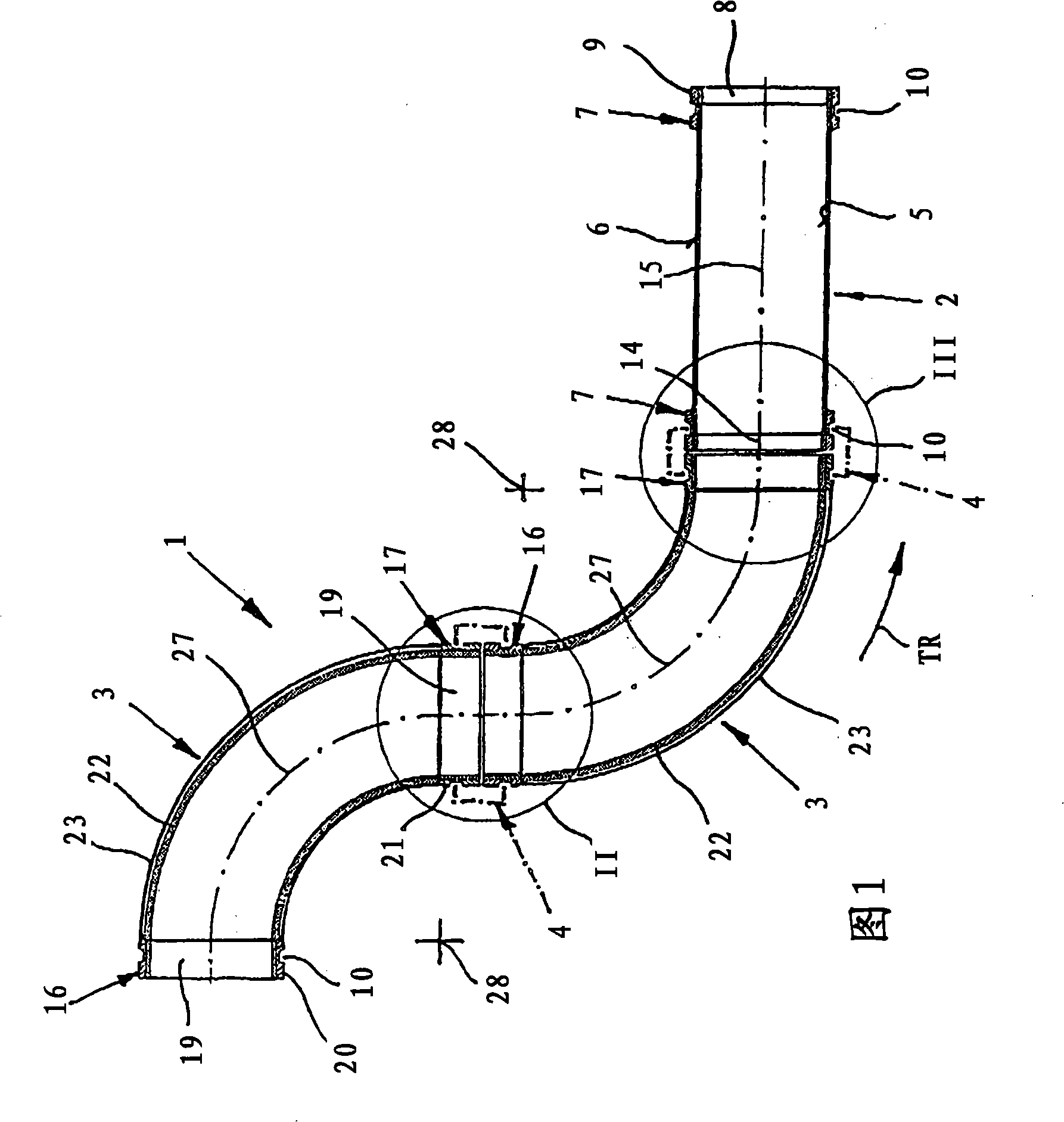

Pipeline for the hydraulic or pneumatic transport of solids

InactiveCN101331075AExtend your lifeUniform wall thicknessBulk conveyorsBuilding material handlingPipingRevolute joint

A piping (1) comprises straight pipe sections (2) and curved pipe bends (3) having each an inner pipe (5; 22), an outer pipe (6; 23) and end, double-layered coupling flanges (7; 16, 17) composed of inner wear rings (8; 18, 19) and outer annular collars (9; 20, 21) with coupling grooves (10). Pipe sections (2) and / or pipe bends (3) which follow one another in sections are detachably coupled by split couplings (4) that act as revolute joints and pipe connectors. The wear rings (19) in the coupling flanges (17) of the pipe bends (3) at the outlet end of the piping have different wall thicknesses about their circumferences, while the wear rings (18) in the coupling flanges (16) at the inlet end of the piping and in the coupling flanges (7) of the pipe sections (2) have a uniform wall thickness about their circumference.; The wall thickness of the wear rings (19) in the coupling flanges (17) of the pipe bends (3) at the outlet end of the piping is greater in the circumferential sections further away from the curvature mid-points (28) of the pipe bends (3) than in the circumferential sections closer to the curvature mid-points (28).

Owner:ESSER WERKE

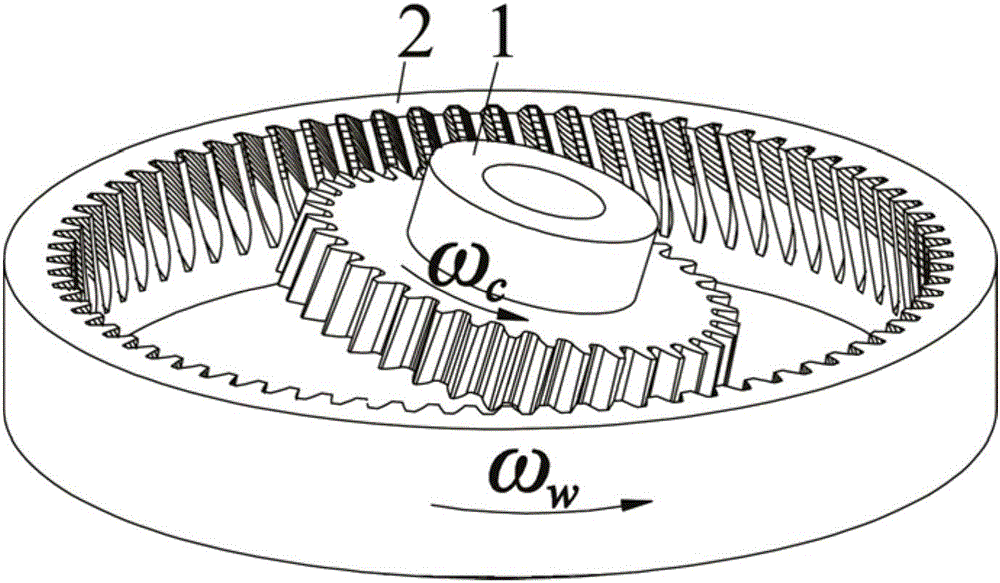

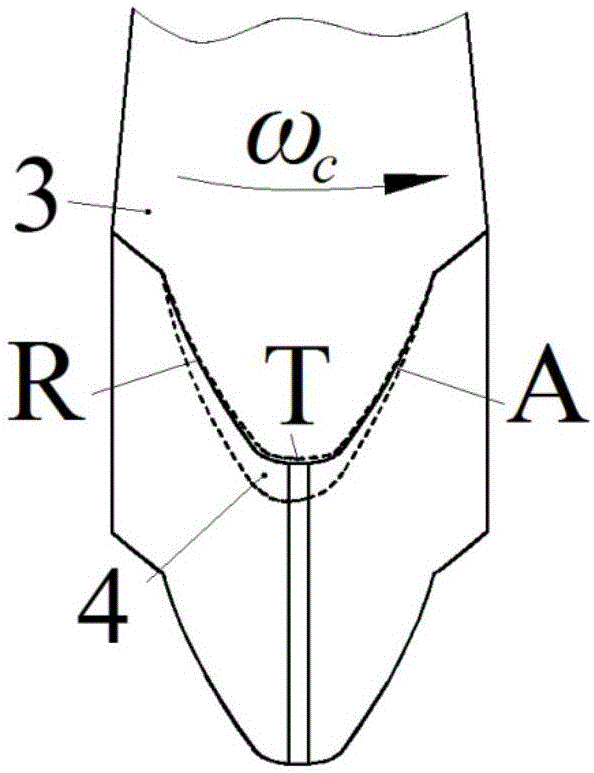

Skiving cutter feeding method realizing singe-edge cutter relieving radical cutter feeding

ActiveCN106271874AExtend your lifeImprove wear and tearAutomatic control devicesFeeding apparatusGear wheelEngineering

The invention discloses a skiving cutter feeding method realizing singe-edge cutter relieving radical cutter feeding. The cutter feeding method belongs to the improvement on a tooth profile-following radical cutter feeding method. In several former times of cutter feeding of a cutter, when the cutter completes radical cutter feeding once, a workpiece does not rotate for a peripheral compensation rotating angle theta i and a cutter avoiding angle phi i; during the cutter feeding of the cutter in a next time, a cutting-out side cutter edge of the cutter is staggered for a gap with a processed tooth surface of a workpiece; the extrusion friction between the cutting-out side cutting edge and the tooth surface of the workpiece is avoided; the last one or several last radical cutter feeding of the cutter is for finish machining; single-edge cutter relieving by the workpiece is avoided, so that the processing precision of the tooth surface of the workpiece is ensured. When the multi-time radical cutter feeding is needed for gear mechining, the skiving cutter feeding method realizing single-edge cutter relieving radical cutter feeding can prolong the service life of the cutter through being compared with the tooth profile-following radical cutter feeding method.

Owner:XI AN JIAOTONG UNIV

Non-ironing process for epoxy resin

InactiveCN104975509ASoft touchImprove wear and tearFibre treatmentLiquid/gas/vapor removalEpoxyEngineering

The invention provides a non-ironing process capable of searching formaldehyde content and improving fabric strength aiming at shortcomings of the prior art. A fabric is put into a finishing working solution to be padded for two times and then is put into a tentering dryer to be subjected to tentering drying. Compared with the prior art, according to the invention, hydrophilic silicone softener is adopted to change the problem that the hand feeling of a fabric treated by adopting epoxy resin is hard, and the finished fabric is soft in hand feeling. The finishing effect of the fabric after non-ironing finishing can reach a good effect, namely, the flatness reaches more than or equal to 3.5, the formaldehyde content is zero, furthermore, the strength is improved by more than or equal to 20%, the situation that clothes is worn due to forcible damage is improved, and the life of the clothes is prolonged.

Owner:SHANGHAI YUFENG SCI & TECH

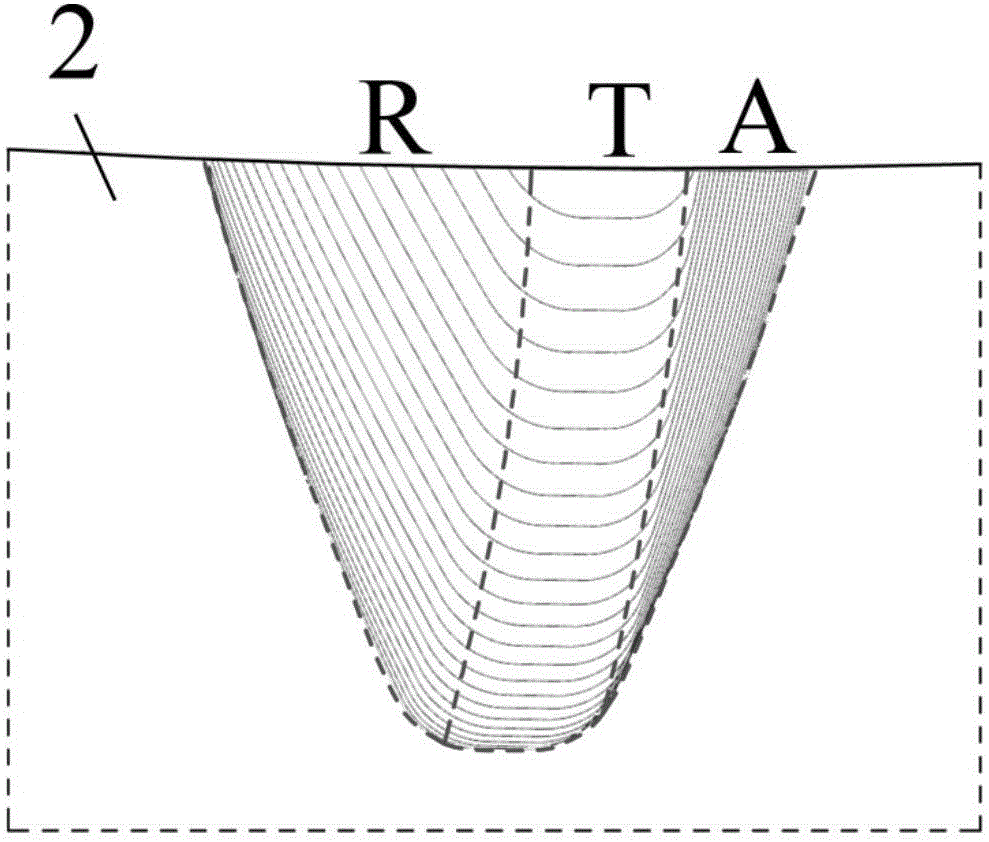

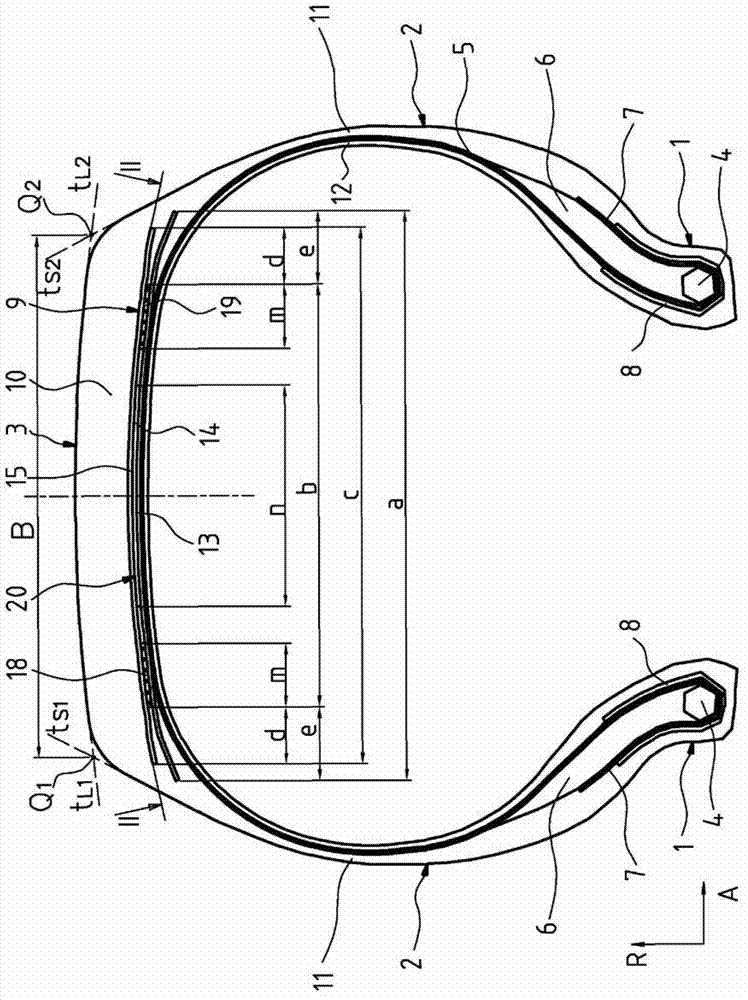

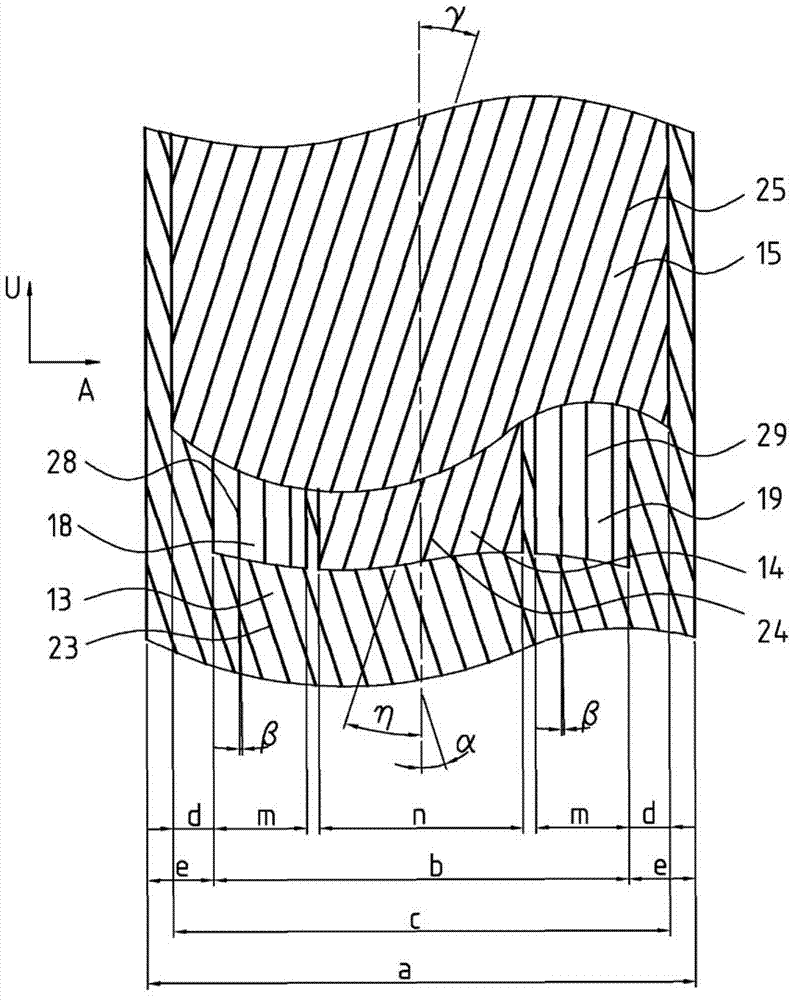

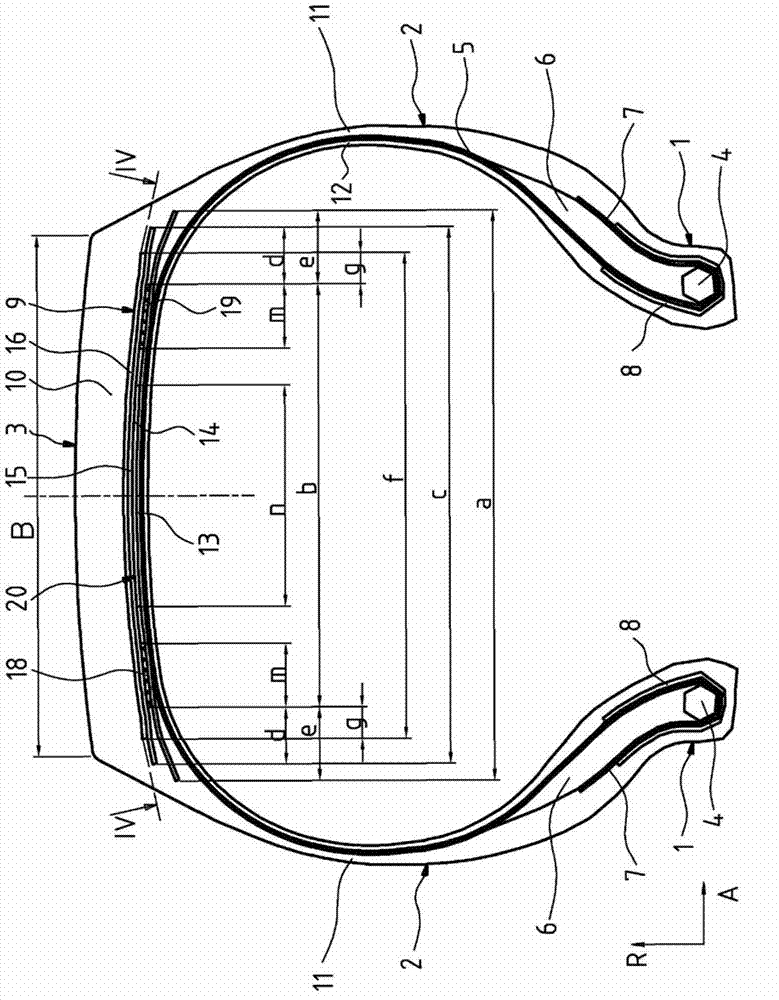

Pneumatic vehicle tyre

InactiveCN102858557AHigh Circumferential ReinforcementIncreased durabilityHeavy duty tyresHeavy duty vehicleEngineeringCommercial vehicle

A pneumatic vehicle tyre for commercial vehicles, comprising a carcass (5), a breaker belt (9) and a profiled tread rubber (10), wherein the breaker belt (9) is formed by at least three belt plies (13, 14, 15), of which the radially inner ply (13) and the radially outer ply (15) are formed as working plies with parallel steel reinforcing elements (23, 25) embedded in rubber, wherein the reinforcing elements (23, 25) of the working plies (13, 15) have opposed axial directions of inclination and an angle in relation to the circumferential direction of 10 DEG -45 DEG , and wherein the belt ply (14) arranged between the two working plies (13, 15) is divided in the axial direction and is formed by two axial outer peripheral ply portions (18, 19) and one central ply portion (14) arranged axially between said peripheral portions, wherein the two peripheral ply portions (18, 19); are formed as zero degree plies with reinforcing elements (28, 29), which include an angle in relation to the circumferential direction U of 0 DEG -5 DEG , and the central ply portion (14) is formed with reinforcing elements (24) which include an angle in relation to the circumferential direction U of 5 DEG -90 DEG.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

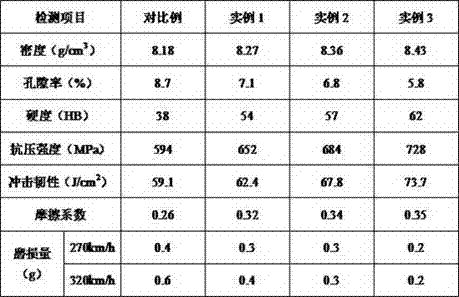

Preparation method for high-speed rail brake powder metallurgy copper base friction material

InactiveCN107326248AImprove frictional stabilityReduce wearMolybdenum oxides/hydroxidesCopper nitrateHydrolysis

The invention discloses a method for preparing a high-speed rail brake powder metallurgy copper-based friction material, which belongs to the technical field of friction material preparation. The present invention oxidizes and modifies molybdenum trioxide by mixing potassium permanganate solution and glacial acetic acid, crystallizes it to form a rod-shaped structure, and disperses it in deionized water, and loads the copper hydroxide colloid formed by the hydrolysis of copper nitrate on the rod-shaped structure. The surface of molybdenum trioxide is mixed with flake graphite, atomized copper powder, iron powder, etc. by ball milling and sintered at high temperature to form a sintered material, which is crushed, milled and sieved to prepare a copper-based friction material. Molybdenum trioxide in rod-shaped composite particles The high-temperature stability performance of the copper-based friction material is effectively enhanced, and at the same time, the rod-shaped structure effectively enhances the friction force and improves the wear loss during its braking wear, and has broad application prospects.

Owner:常州市宝平不绣钢制品有限公司

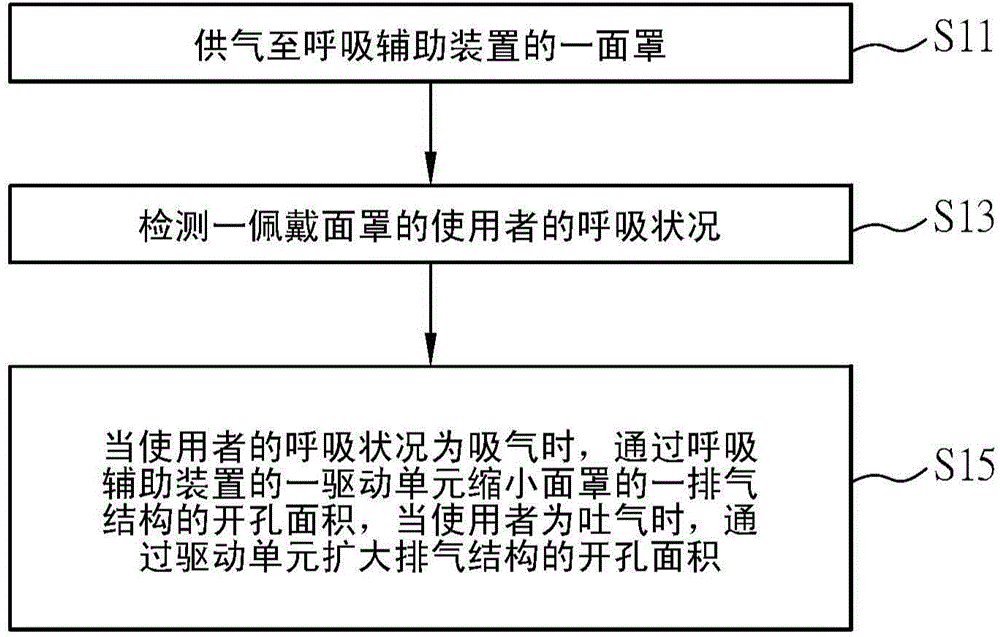

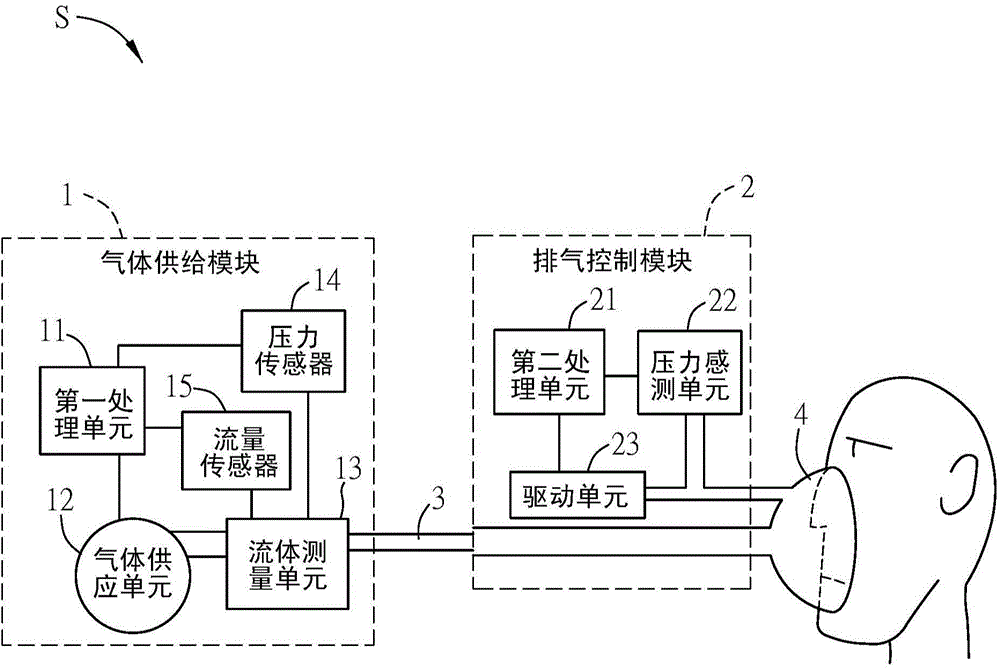

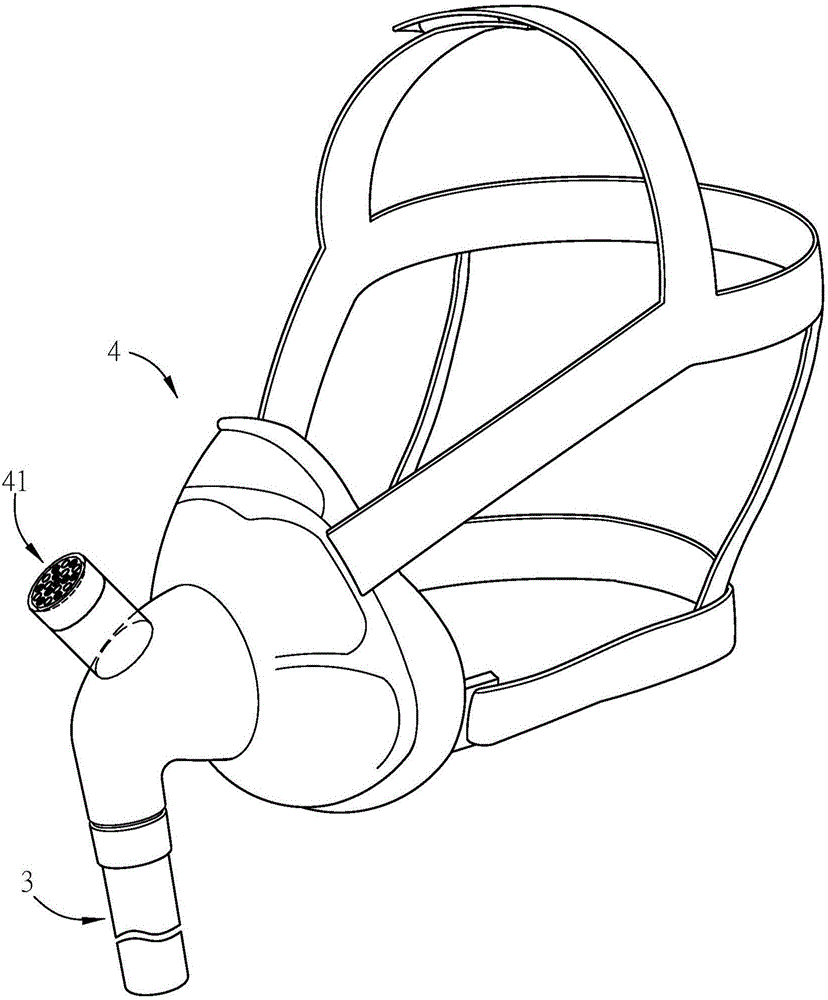

Exhaust control method and breathing auxiliary apparatus applying same

The invention discloses an exhaust control method. The exhaust control method comprises following steps: supplying air to one surface cover of the breathing auxiliary apparatus; detecting the breathing state of a user wearing the surface cover; and decreasing an opening area of an exhaust structure of the surface cover through a driving unit of the breathing auxiliary apparatus when the user inhales and increasing the opening area of the exhaust structure through the driving unit when the user exhales. The invention further provides other exhaust control methods and a breathing auxiliary apparatus. The exhaust control method and the breathing auxiliary apparatus applying the same helpeffectively decrease noise caused by rapid speed change of a host.

Owner:DELTA ELECTRONICS INC

Plate peeling machine group

PendingCN108588765AStripping AidImprove surface qualityElectrolysis componentsElectrolysisBrush device

The invention belongs to the technical field of electrolysis smelting, and discloses a plate peeling machine group. The machine group comprises a plate peeling system used for peeling sedimentation plates off, an electrode plate inputting system used for delivering electrolyzed cathode plates to the plate peeling system, and a conductive bar cleaning and brushing system used for cleaning and brushing the peeled cathode plates so that the cathode plates can enter the next electrolysis circulation; the electrode plate inputting system comprises a washing chamber and a push plate range expandingdevice used for expanding the range between the electrode plates to be put into the washing chamber; the plate peeling system comprises a swing arm type plate peeling device entering from the part above the sedimentation plates to peel the sedimentation plates off from the cathode plates and an auxiliary separation device entering from the two sides of the sedimentation plates to assist separation; the conductive bar cleaning and brushing system comprises a conductive bar cleaning and brushing device used for cleaning conductive bars of the cathode plates. According to the machine group, by the arrangement of the plate peeling system, the scratching of the surfaces of the cathode plates can be prevented to reduce the peeling difficulty of the sedimentation plates, by the arrangement of theconductive bar cleaning and brushing system, the conductive bars can be timely cleaned to reduce the resistance of the cathode plates and improve the electrolysis efficiency of a workshop, by the arrangement of the electrode plate inputting system, the electrode plates can be thoroughly cleaned, and finally the sedimentation plates with high quality can be obtained.

Owner:株洲优瑞科有色装备有限公司

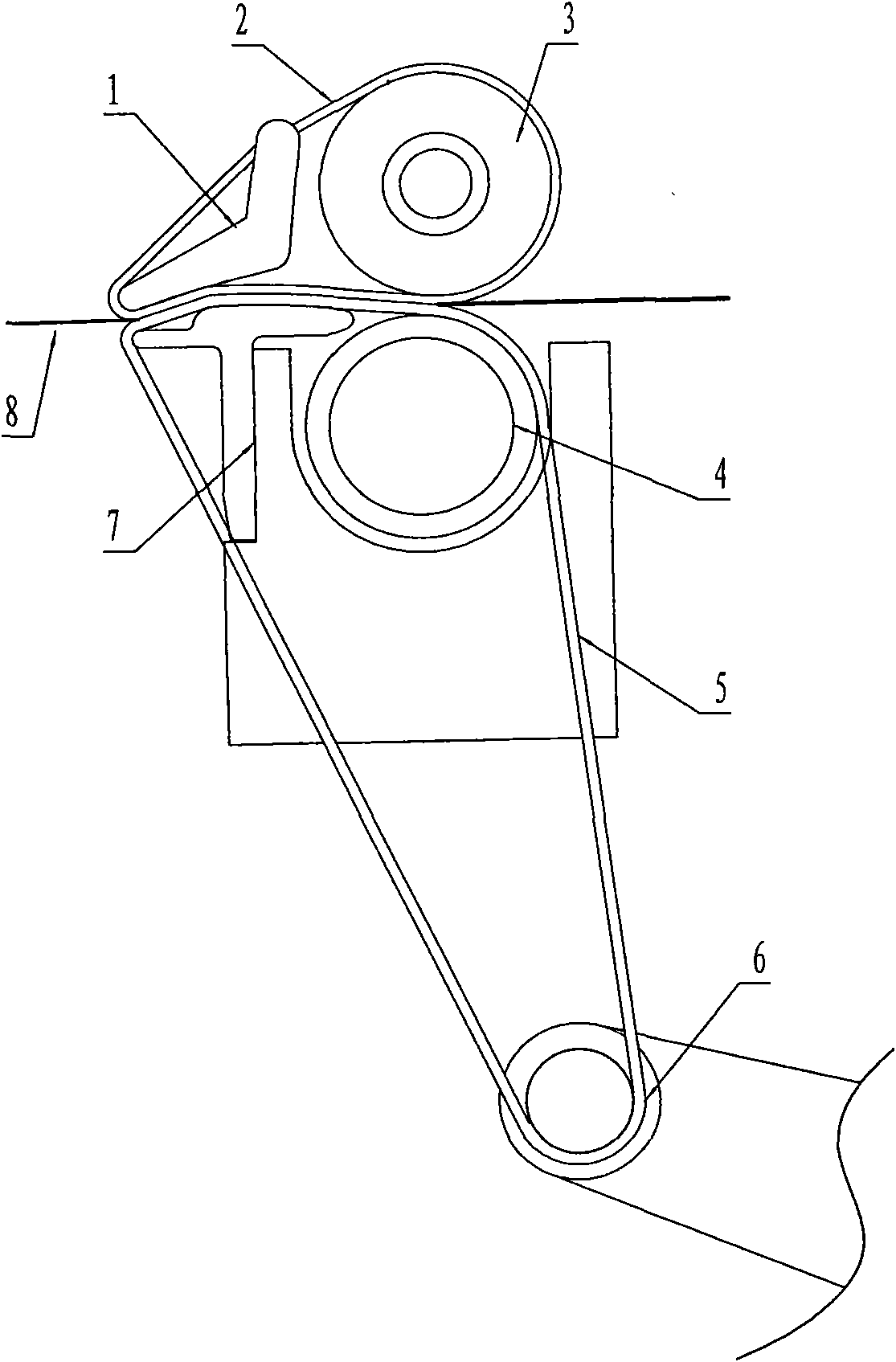

Spinning machine drafting component capable of improving yarn quality

InactiveCN101805947AReduce friction for serious problemsReduce shift point distribution rangeDrafting machinesFiberYarn

A spinning machine drafting component capable of improving yarn quality is used for solving the problem of easy slipping or easy wear of the drafting components. The technical scheme is as follows: the drafting component comprises a top pin, a middle top roller, a top apron surrounding the top pin and the middle top roller, a middle bottom roller, a bottom pin, a tension frame and a bottom apron surrounding the middle bottom roller, the bottom pin and the tension frame; the middle parts of the internal surfaces of the improved top apron and bottom apron are flat and smooth surfaces and the two sides of the improved top apron and bottom apron are pattern surfaces which are symmetrically arranged. The drafting component is designed to utilize flat and smooth surface contact in the fiber strand movement area, thus being conductive to reducing serious friction of the front jaw of the top pin, and to utilize patterns at the two sides, thus solving the problem of easy slipping due to small friction of flat and smooth surface contact between the aprons and the rollers. The drafting component is stable in transmission, greatly reduces slipping, has remarkably increased friction on the same contact area, improves the stability of operation in the main drafting area, is conductive to giving full play to the advantages of fiber control by the aprons and elastic floating jaws, further ensures the uniformity of the yarns and improves the yarn quality.

Owner:张晓方

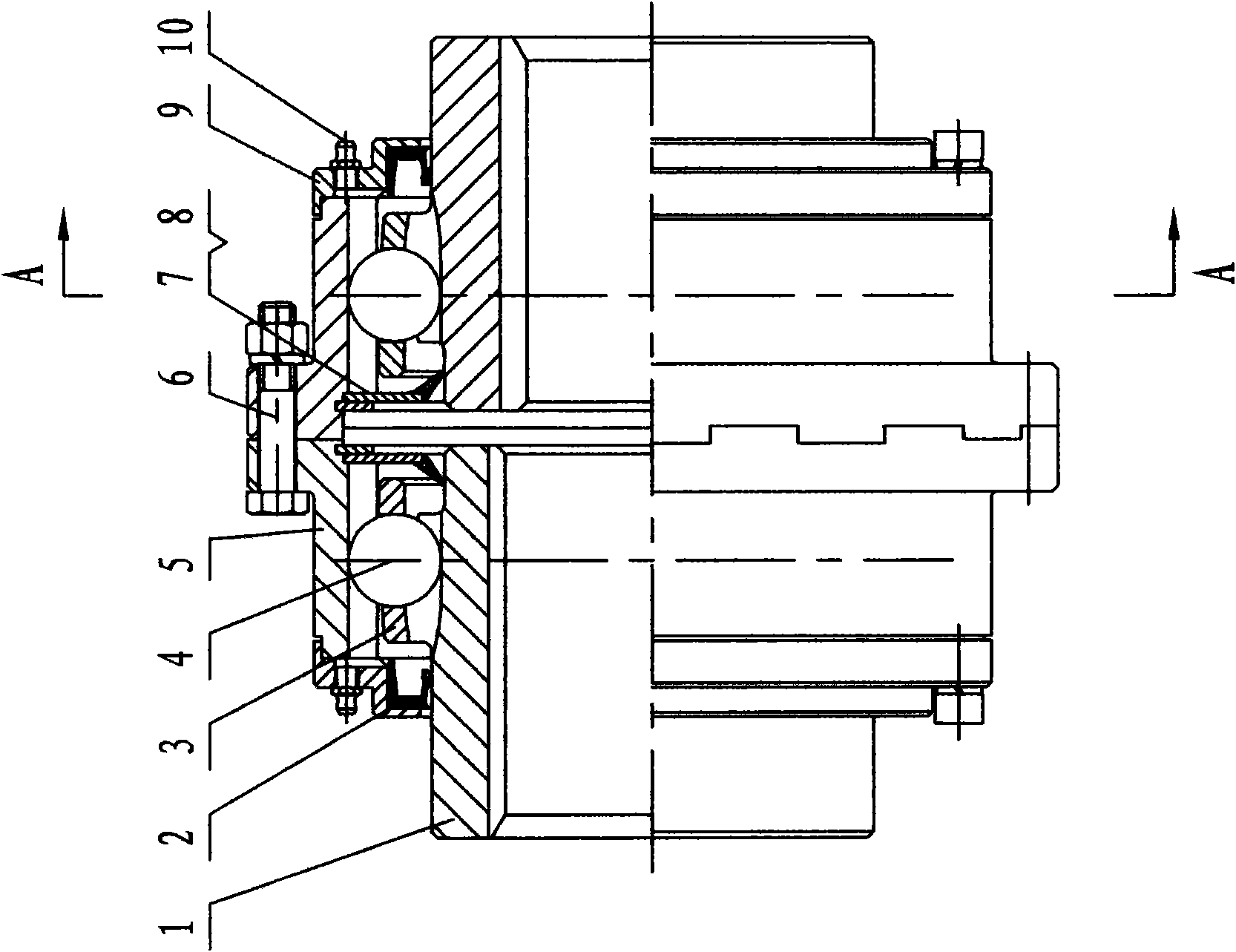

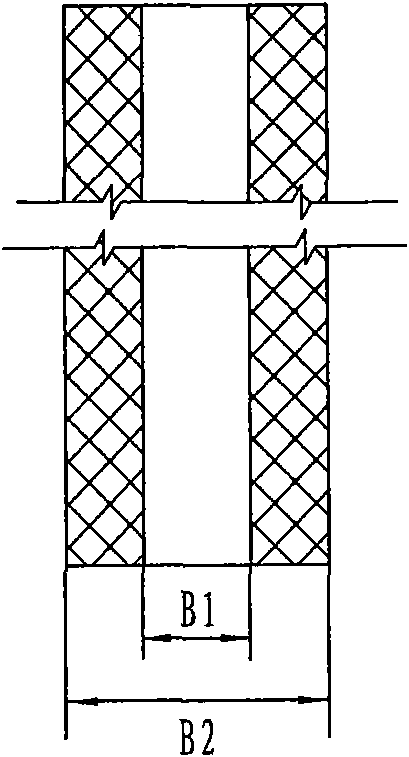

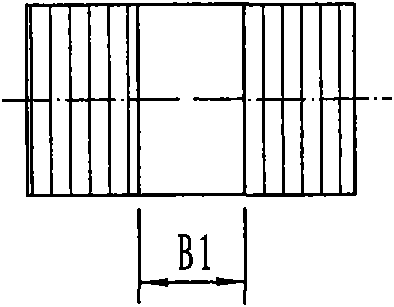

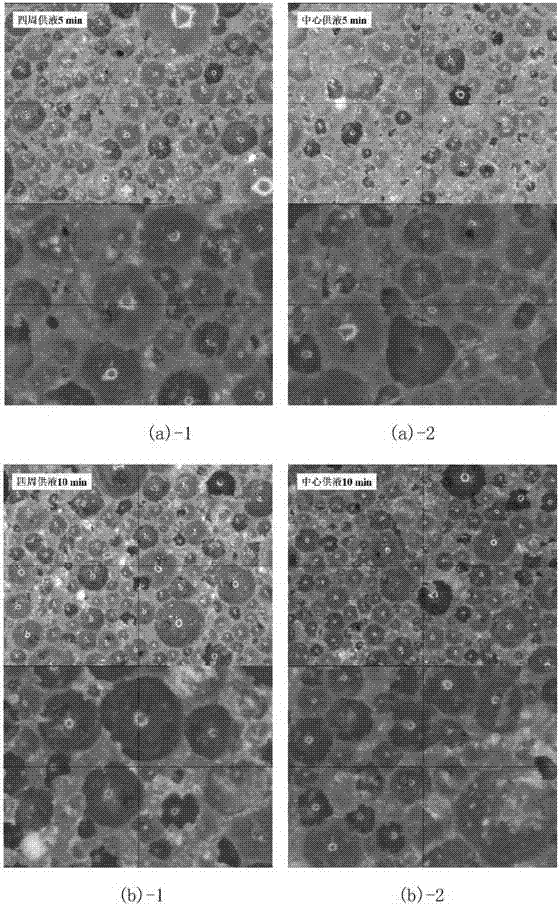

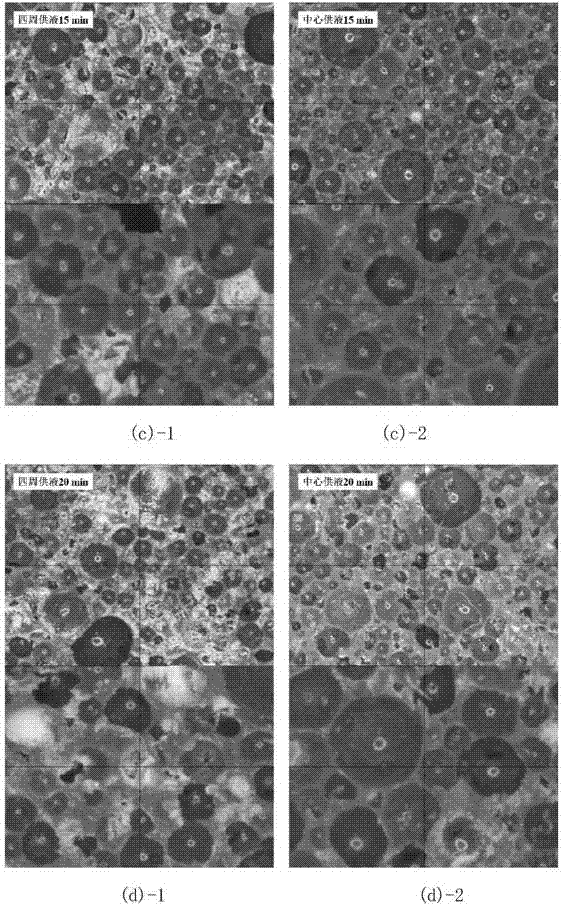

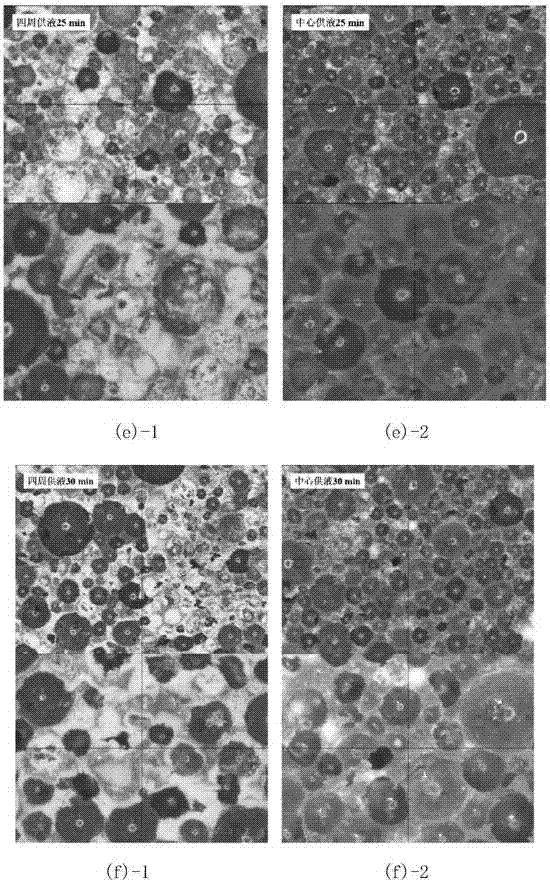

Center liquid supply small grinding head polishing tool

InactiveCN107344329ASufficient supplyExcellent surface wearPolishing machinesGrinding headsCouplingEngineering

The invention discloses a center liquid supply small grinding head polishing tool. The polishing tool comprises a flexible polishing pad, a sponge sandwich layer, a polishing disc, a connecting rod, a hose, a flexible coupling and an electric main shaft. The polishing tool has the following effects: the peripheral liquid supply is improved to the center liquid supply; sufficient polishing liquid is supplied to the center area; the polishing liquid takes away a lot of machining heat and chips from the machining area; and the surface wear condition of the flexible polishing pad is obviously better than that of a traditional small grinding head polishing tool. The wear resistance of the flexible polishing pad can be improved; the service life of the flexible polishing pad is prolonged by more than four times; the replacement frequency of the flexible polishing pad is reduced; and the production cost is reduced. The polishing liquid is supplied from the center of a tool to the periphery; and compared with the peripheral liquid supply, the abrasive grain supply in the whole machining area is more sufficient and uniform, and the updating speed of abrasive grains is more stable, so that the wear condition of the flexible polishing pad is greatly improved. The center liquid supply small grinding head polishing tool is more stable in material removing efficiency in whole machining period, and is higher in surface shape control capacity.

Owner:TIANJIN UNIV

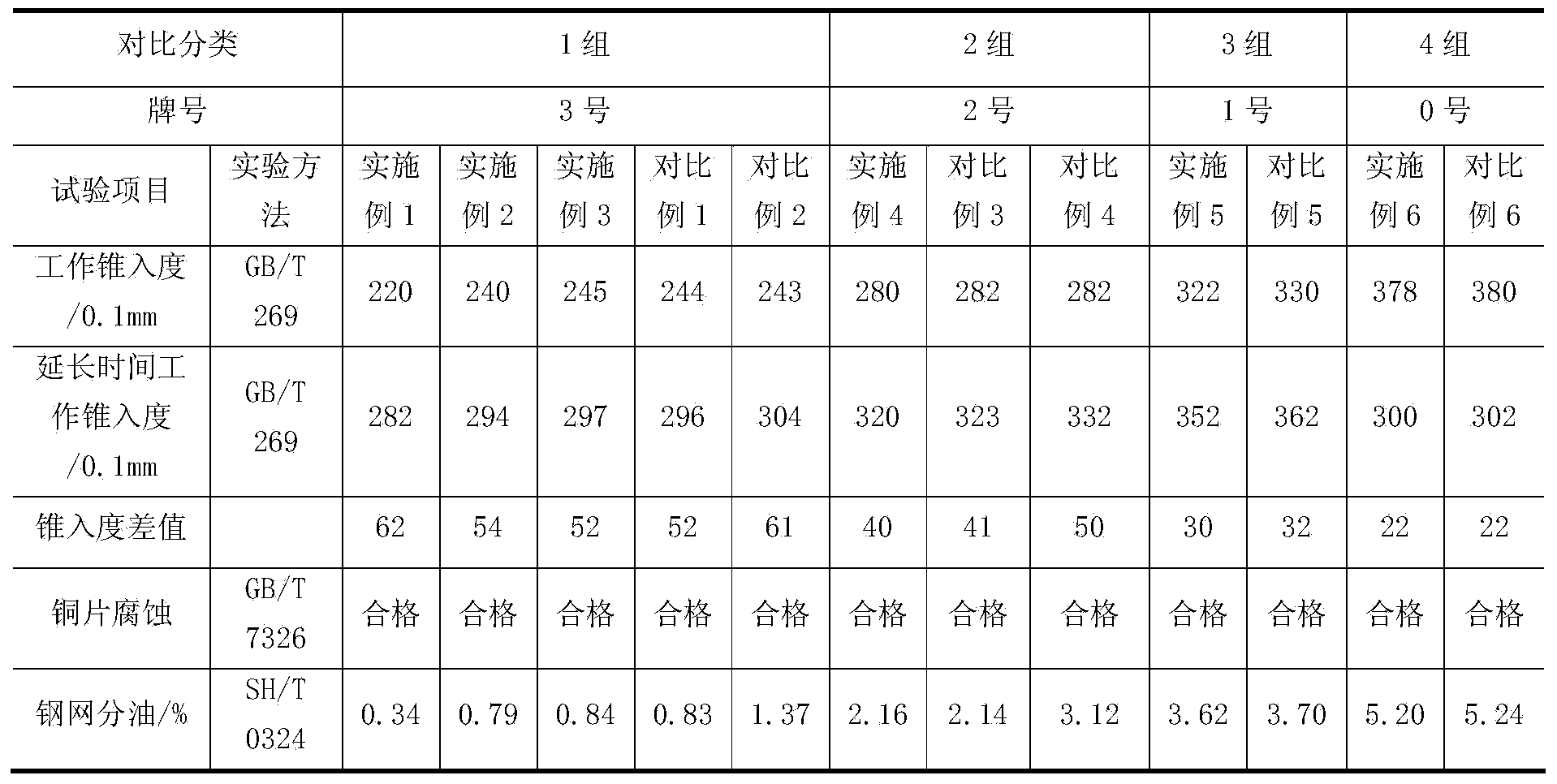

Lithium-based lubricating grease composition and preparation method for same

InactiveCN103525503AImprove structural stabilityIncrease frictionBase-materialsLithium 12-hydroxystearateLithium stearate

The invention provides a lithium-based lubricating grease composition and a preparation method for the lithium-based lubricating grease composition. The lithium-based lubricating grease is prepared by saponifying special high-acid value mineral base oil. The preparation method comprises the following steps of putting the high-acid value mineral base oil into a kettle, adding 12-lithium hydroxyl-stearate soap and lithium stearate soap, and performing stirring and heating; when temperature rises to 210 to 220 DEG C, keeping the temperature, and performing stirring for 1 to 5 minutes; putting ordinary mineral base oil into the kettle, quickly cooling the materials, and adding an additive when the temperature reaches 140 to 150 DEG C; uniformly stirring the materials, and discharging the materials from the kettle; grinding the materials to obtain a finished product by using a three-roller grinding machine. According to the lubricating grease composition, conventional base oil resources in China are reasonably utilized instead of a naphthenic acid raw material, so that the production cost of the lubricating grease is remarkably lowered; the lubricating grease has high mechanical stability, colloid stability and lubricating performance, and the friction and abrasion conditions of mechanical equipment during operation can also be effectively improved; the produced lubricating grease can be used for lubricating automobiles, construction machinery and other mechanical equipment.

Owner:CHINA PETROLEUM & CHEM CORP

Feeding adjusting device for screening machine

PendingCN110252652AAdjust position angleAdjust the incident angleSievingScreeningMechanical engineeringEngineering

The invention discloses a feeding adjusting device for a screening machine. The feeding adjusting device comprises a rack, and a feeding port fixing slot, a feeding port adjustable slot and a blanking port formed in the rack. The feeding port fixing slot is hinged to the feeding port adjustable slot, the feeding port adjustable slot is connected to a driving device, the driving device can drive the feeding port adjustable slot to rotate, the feeding port fixing slot and the feeding port adjustable slot are formed in the top of the blanking port, the feeding port fixing slot is formed obliquely toward the direction of the blanking port, the blanking port can be connected to a feed inlet of the screening machine, and a material is conveyed to a screen surface of the screening machine. By arranging the feeding port adjustable slot, a blanking position of the material is adjusted. The feeding port fixing slot is formed obliquely toward the direction of the blanking port, so that the material slides under the action of gravity. The feeding port fixing slot is hinged to the feeding port adjustable slot, and the driving device changes a projection position of the end, far away from the feeding port fixing slot, of the feeding port adjustable slot in the blanking port by driving the feeding port adjustable slot to rotate, so that a purpose of adjusting the material blanking position is achieved.

Owner:BCEG RESOURCES RECYCLING CO LTD

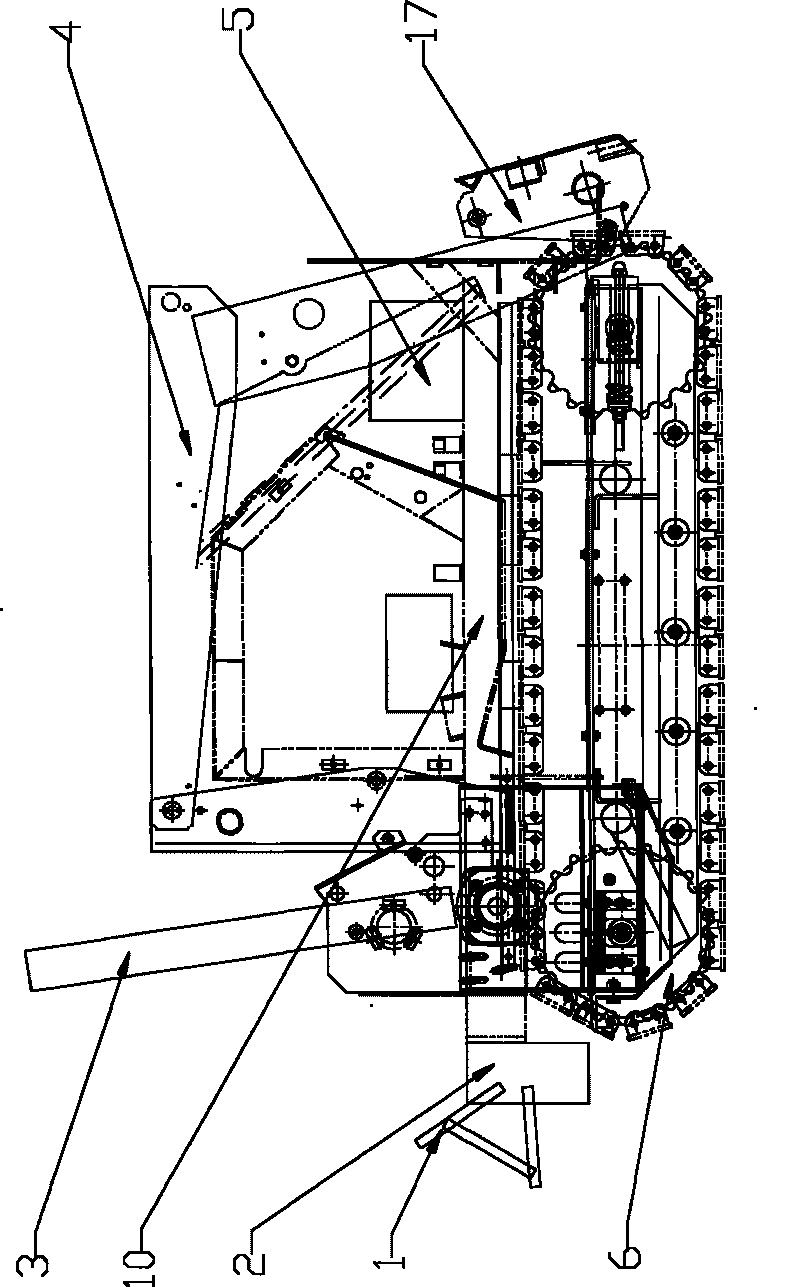

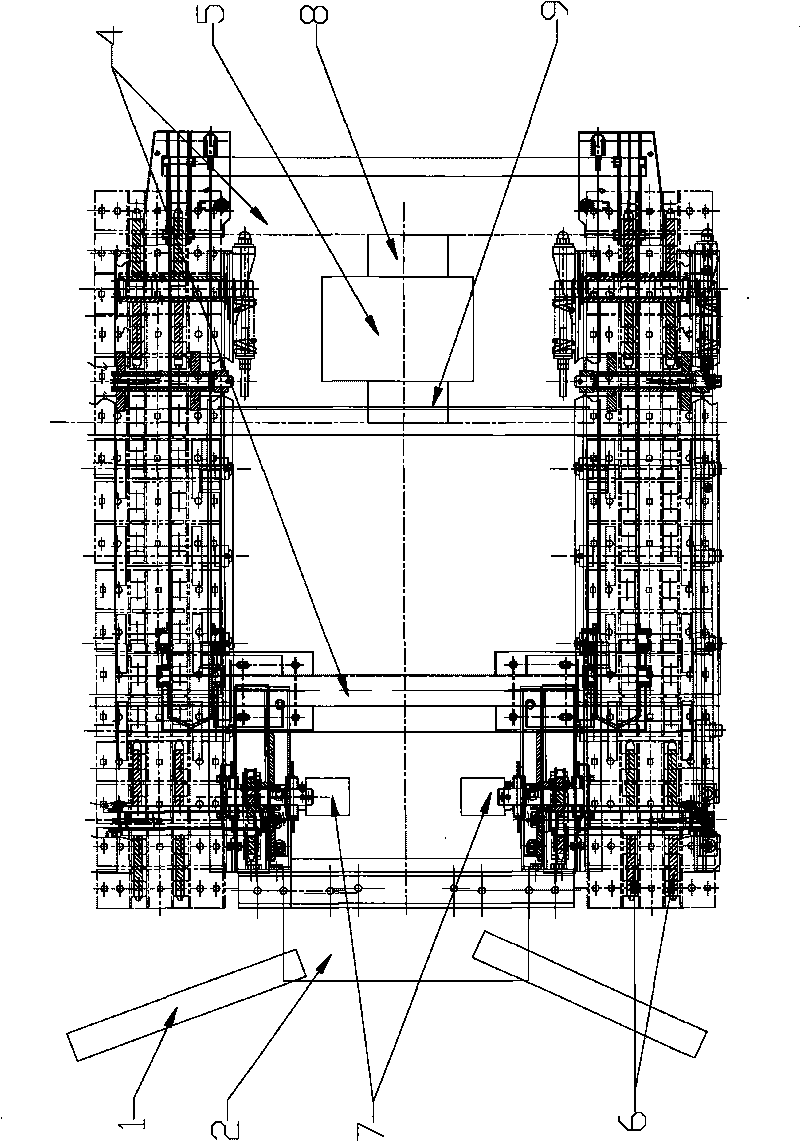

Multifunctional workover rig

InactiveCN101715660AReduce weightGuaranteed stiffnessAgricultural undercarriagesForest industryHydraulic pump

The invention discloses a multifunctional workover rig, which comprises a framework, a power system, a crawler traveling mechanism and an operating system, wherein the power system comprises an engine, a hydraulic oil pump and a hydraulic control system which are used for providing working pressures for hydraulic motors of the operating system and the crawler traveling mechanism respectively; the operating system comprises a multifunctional power arm (4), a fast-assembling connecting mechanism assembly (17), a power output device (2) and a three-point hydraulic suspension assembly (1); the fast-assembling connecting mechanism assembly (17) is arranged at the front end of the multifunctional power arm (4); and most components of the multifunctional workover rig are made by bending and welding steel plates. The multifunctional workover rig has a compact and small structure without a cast part, a forged piece or a stamped part. Besides performing engineer operation and dozens of operations such as bulldozing, loading, excavating, snow shoveling, forest industry and the like, the multifunctional workover rig can finish the operations of plowing, harrowing, sowing, harvesting, electric power generation, water pumping and the like due to the three-point hydraulic suspension assembly and the power output shaft.

Owner:天津市三佳动力机械制造有限公司

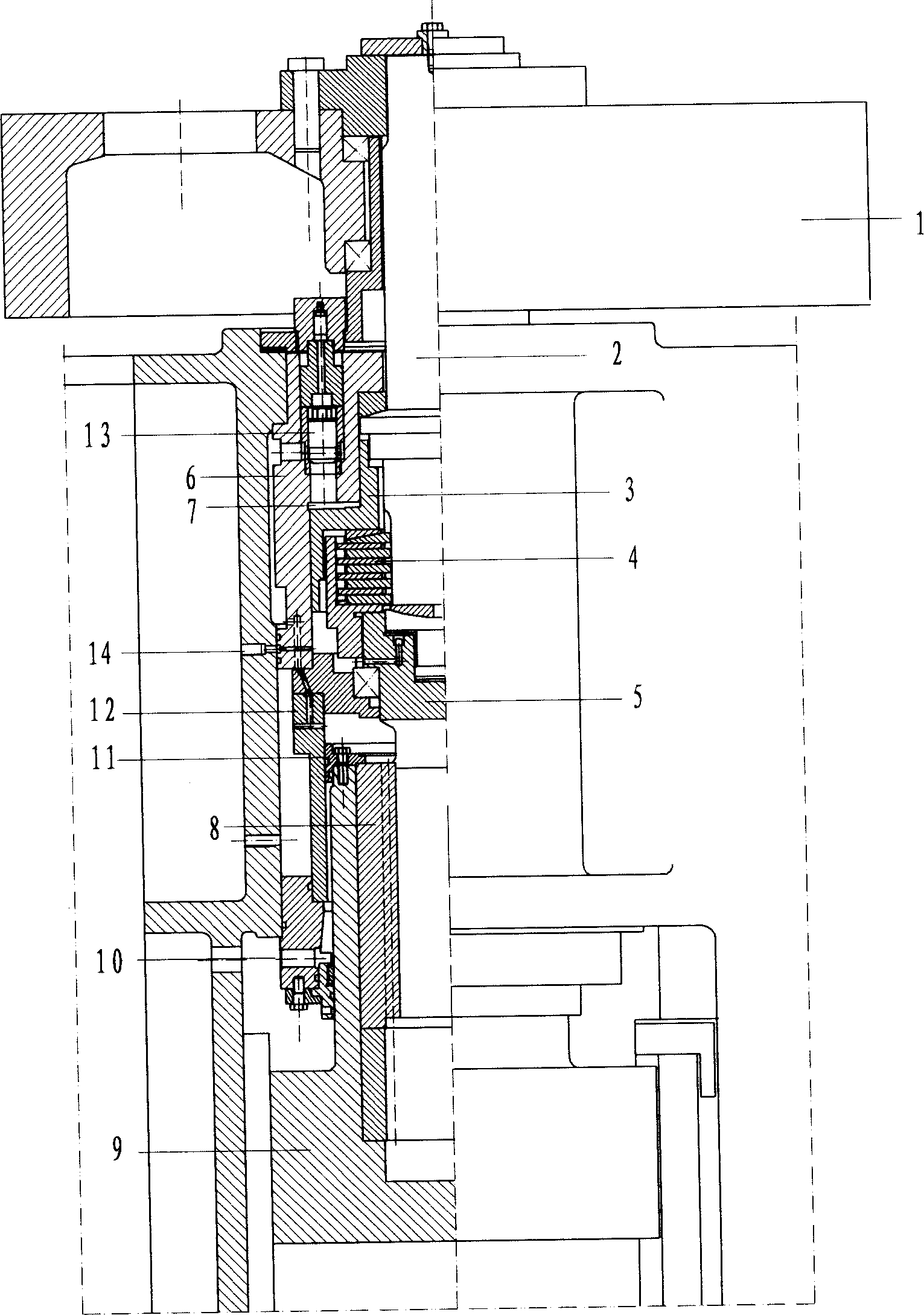

Air valve bridge assembly, in-cylinder brake system and engine

ActiveCN109356683AImprove wear and tearImprove reliabilityValve arrangementsMachines/enginesEngineeringRocker arm

The invention discloses an engine, an in-cylinder brake system and an air valve bridge assembly. The air valve bridge assembly comprises a main piston mounting hole and a brake piston mounting hole, wherein the main piston mounting hole is formed in the inner side end of an air valve bridge body; the brake piston mounting hole is formed below the main piston mounting hole and communicates with themain piston mounting hole; an oil unloading assembly mounting hole is formed in the outer side end; an air valve bridge oil duct communicating the piston mounting hole with the oil unloading assemblymounting hole is formed in the air valve bridge body; a main piston assembly is mounted in the main piston mounting hole; a brake piston assembly is mounted in the brake piston mounting hole; an oilunloading assembly is mounted in the oil unloading assembly mounting hole; the in-cylinder brake system comprises an exhausting rocker arm assembly and an air valve bridge assembly; and a ball pin assembly keeping contact with the main piston assembly and an adjusting screw assembly keeping contact with the oil unloading assembly are arranged on the air valve side of the rocker arm body of the exhausting rocker arm assembly. The load transmitted to a push rod side by the in-cylinder brake system is greatly reduced, so that separation of the rocker arm and the air valve bridge is prevented, thefailure that a rocker arm elephant foot overturns and is knocked to be damaged is avoided, and the reliability is greatly improved.

Owner:WEICHAI POWER CO LTD

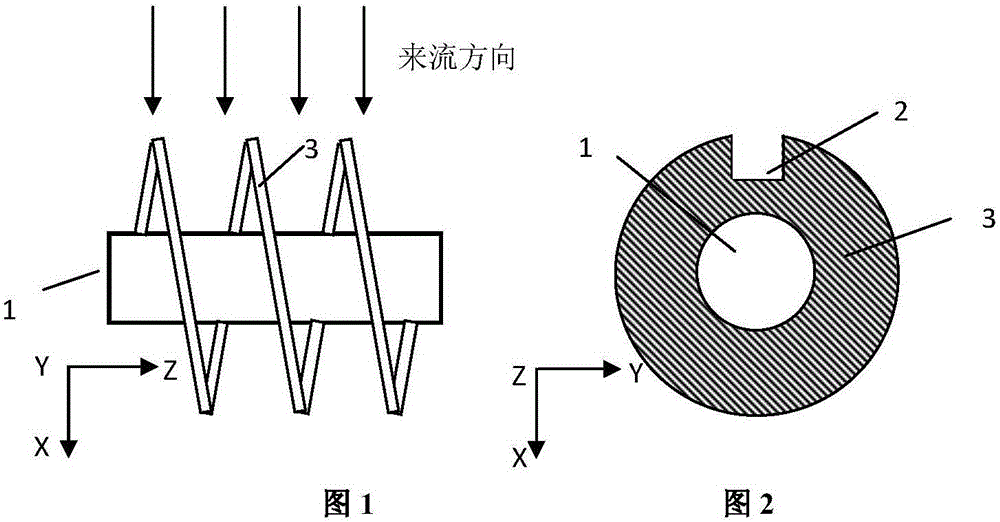

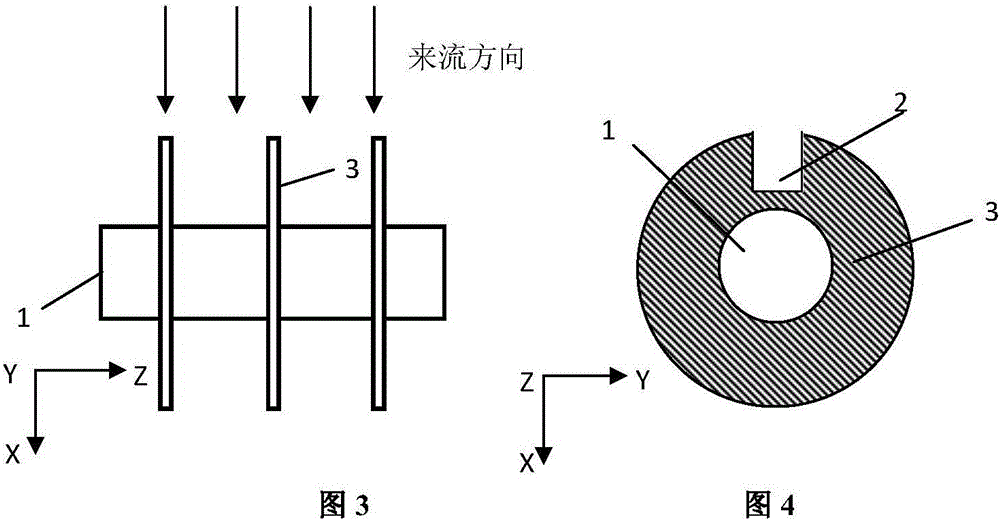

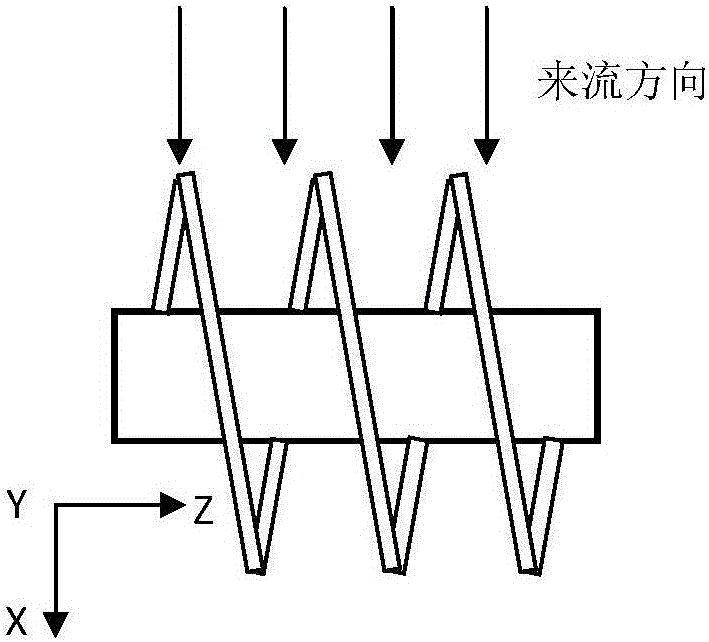

Abrasion resistance finned tube and heat exchanger

InactiveCN105021080AGuaranteed heat transfer efficiencyImprove the flow fieldTubular elementsThermodynamicsEngineering

The invention discloses an abrasion resistance finned tube and a heat exchanger. The abrasion resistance finned tube comprises a base tube and fins arranged on the outer surface of the base tube. The abrasion resistance finned tube is characterized in that a drainage groove with an opening at the upper end is formed in the incident flow surfaces of the fins, and the height of the drainage groove is 1 / 2 to 4 / 5 of the height of the fins; and the width of the drainage groove is 1 / 6-1 / 4 of the diameter of the base tube; and the fins are parallel fins or spiral fins arranged at internals. Compared with the prior art, according to the abrasion resistance finned tube, the groove is formed in the incident flow surfaces of the fins on spiral or circular finned tubes, the influence on the extension surface area of the finned tubes is not large, and the advantage of large heat exchange areas of the finned tubes is retained. Through the adjustment of the height and the width of the drainage groove, the abrasion condition of traditional spiral finned tubes or circular finned tubes is effectively improved, and the abrasion resistance property is superior to that of H type finned tubes. Meanwhile, since the fins of the abrasion resistance finned tube are in a circular arc shape, the advantage of the abrasion resistance property of the fins is more obvious than the advantage of the H type finned tubes

Owner:SOUTHEAST UNIV +1

Arc extinguishing chamber for high-voltage circuit breaker

ActiveCN107658175AControl motion overshootGuaranteed stabilityHigh-tension/heavy-dress switchesAir-break switchesPush pullRelative motion

The invention provides an arc extinguishing chamber for a high-voltage circuit breaker. The arc extinguishing chamber comprises a motion reversing mechanism, a driving side contact and a driven side contact, wherein the driving side contact and the driven side contact are arranged on the motion reversing mechanism separately and move oppositely; the motion reversing mechanism comprises a driving side push-pull rod connected with the driving side contact, a driven side push-pull rod connected to the driven side contact, a reversing device and an integrally molded guide rail; two motion channelsfor opposite motion of the driving side push-pull rod and the driven side push-pull rod are arranged in the guide rail; the guide rail is provided with a driving side push-pull rod sliding rail and adriven side push-pull rod sliding rail; the driving side push-pull rod and the driven side push-pull rod are arranged in the corresponding sliding rails through shaft pins in a sliding manner; a limiter is arranged at one side of the driving side push-pull rod sliding rail and / or the driven side push-pull rod sliding rail for limiting and auxiliary guiding of the driving side push-pull rod and the driven side push-pull rod. A double-acting arc extinguishing principle is adopted by the arc extinguishing chamber, so that the arc extinguishing chamber is simple in structure, reasonable in design, simple in operation and reliable in working, the stability is greatly improved and the mechanical life is greatly prolonged.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

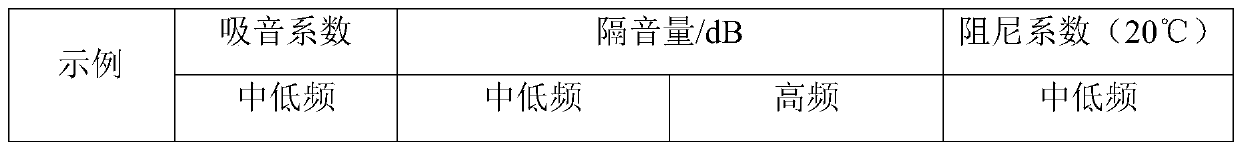

High-performance sound-absorbing damping soft porcelain decorative material and preparation method thereof

InactiveCN111187032AMeet the durabilityImprove mechanical propertiesCovering/liningsNoiseInorganic pigments

The invention discloses a high-performance sound-absorbing damping soft porcelain decorative material and a preparation method thereof, and belongs to the field of novel building decorative materials.The high-performance sound-absorbing damping soft porcelain decorative material sequentially comprises a soft porcelain decoration surface layer, a sound-absorbing layer and a sound-insulating damping layer, wherein the soft porcelain decoration surface layer comprises the following components in parts by weight: 10-25 parts of silicone acrylic emulsion, 30-60 parts of quartz sand, 10-30 parts ofcement, 5-15 parts of a flame retardant, 0.5-2 parts of an inorganic pigment, 0.5-2 parts of a silane coupling agent and 10-25 parts of water, and the sound-absorbing layer and the sound-insulating damping layer respectively contain a sound-absorbing material and a sound-insulating material. According to the invention, the soft porcelain decoration surface layer is good in hydrophobicity and stain resistance, the sound-absorbing layer and the sound-insulating damping layer are obvious in noise reduction effect of, the decoration surface layer, the sound-absorbing layer and the sound-insulating damping layer are connected into a whole through slurry materials, and the prepared high-performance sound-absorbing damping soft porcelain decorative material has good flexibility and tensile resistance, has obvious sound-absorbing and noise-reducing effects, relieves the current noise pollution pressure in China, improves the living environment of people, and is an excellent building decorative material.

Owner:万卓(武汉)新材料有限公司

High energy screw press

The present invention is a quick pressure-relieving high-energy screw press for implementing die forging and finish forging process instead of friction press and hot die forging press. Said invented screw press is formed from machine body, motor, pulley, freewheel, screw rod, nut, slide block return system, clutch and its compression system, pressure-relieving system, hydraulic system and circuit system. The pressure-relieving system adopts electromagnetic hydraulic sensor, and the oil pressure in the compression cylinder can be increased with the increment of processing force, and when the oil pressure is reached to the electromagnetic current set value, the electromagnetic hydraulic sensor can act, and can utilize pilot valve and main valve to implement quick pressure relief, the lower cavity of piston is filled with low pressure oil with 0.2 MPa, and between the piston and friction disk and between driving shaft and screw rod the spherical pads are mounted.

Owner:夏天赳 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com