Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2302 results about "Rotary compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

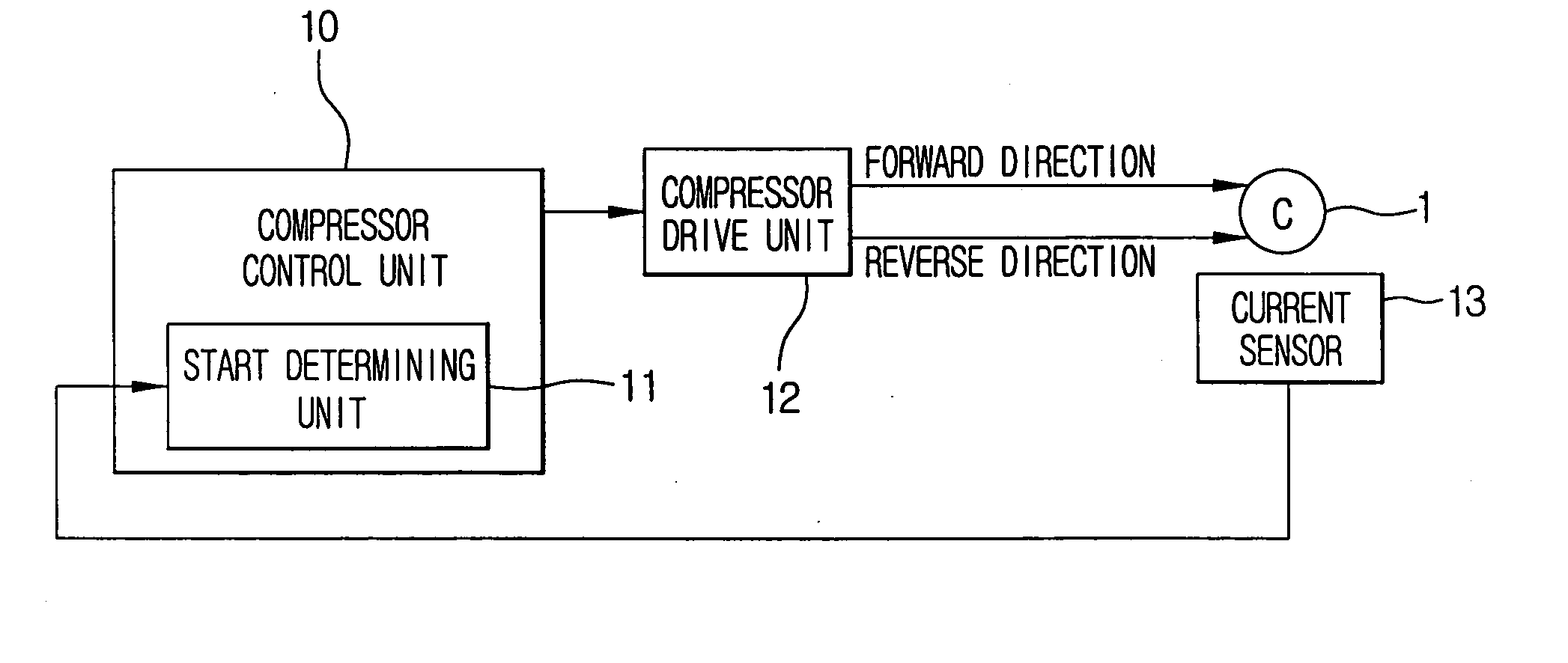

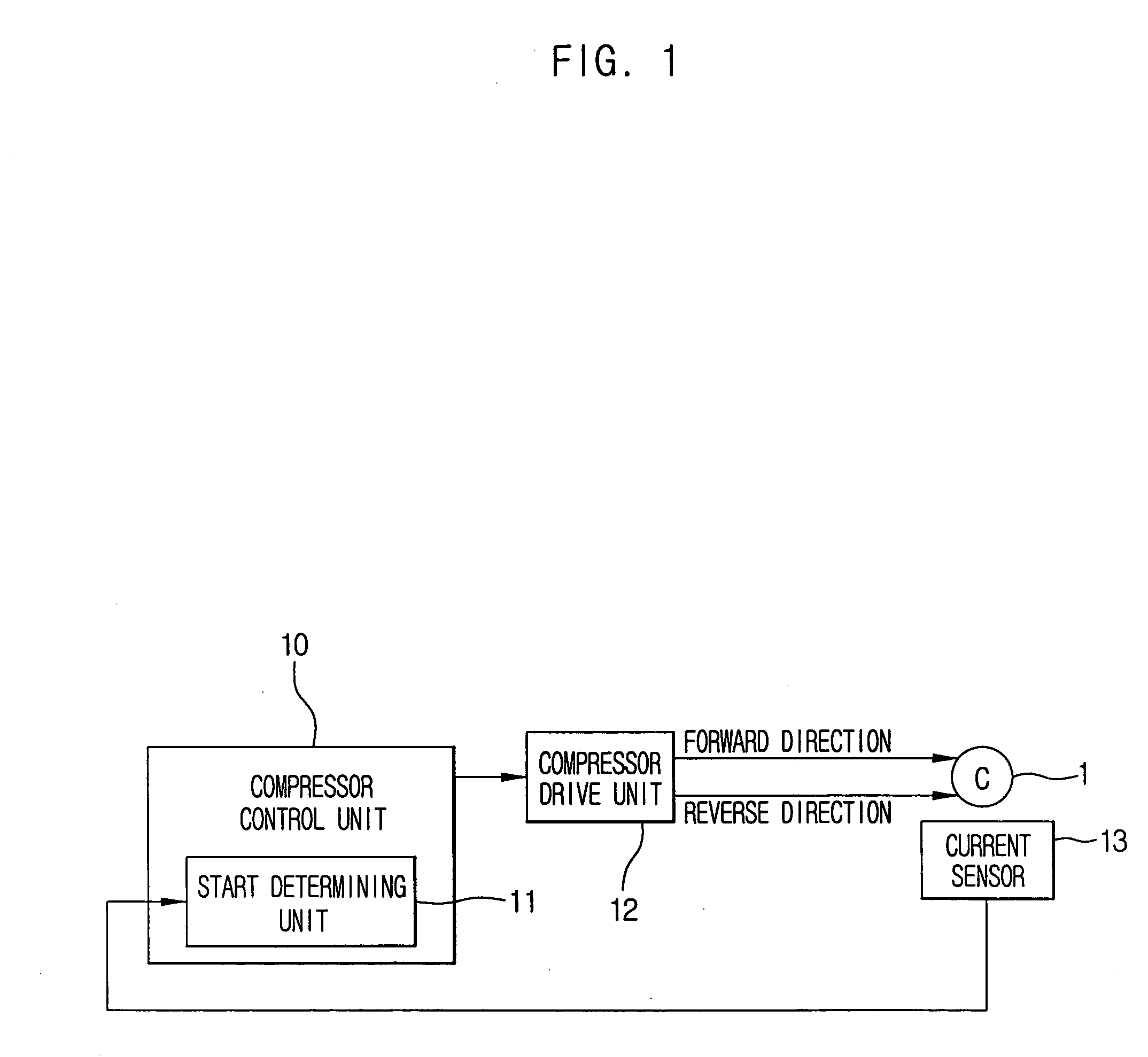

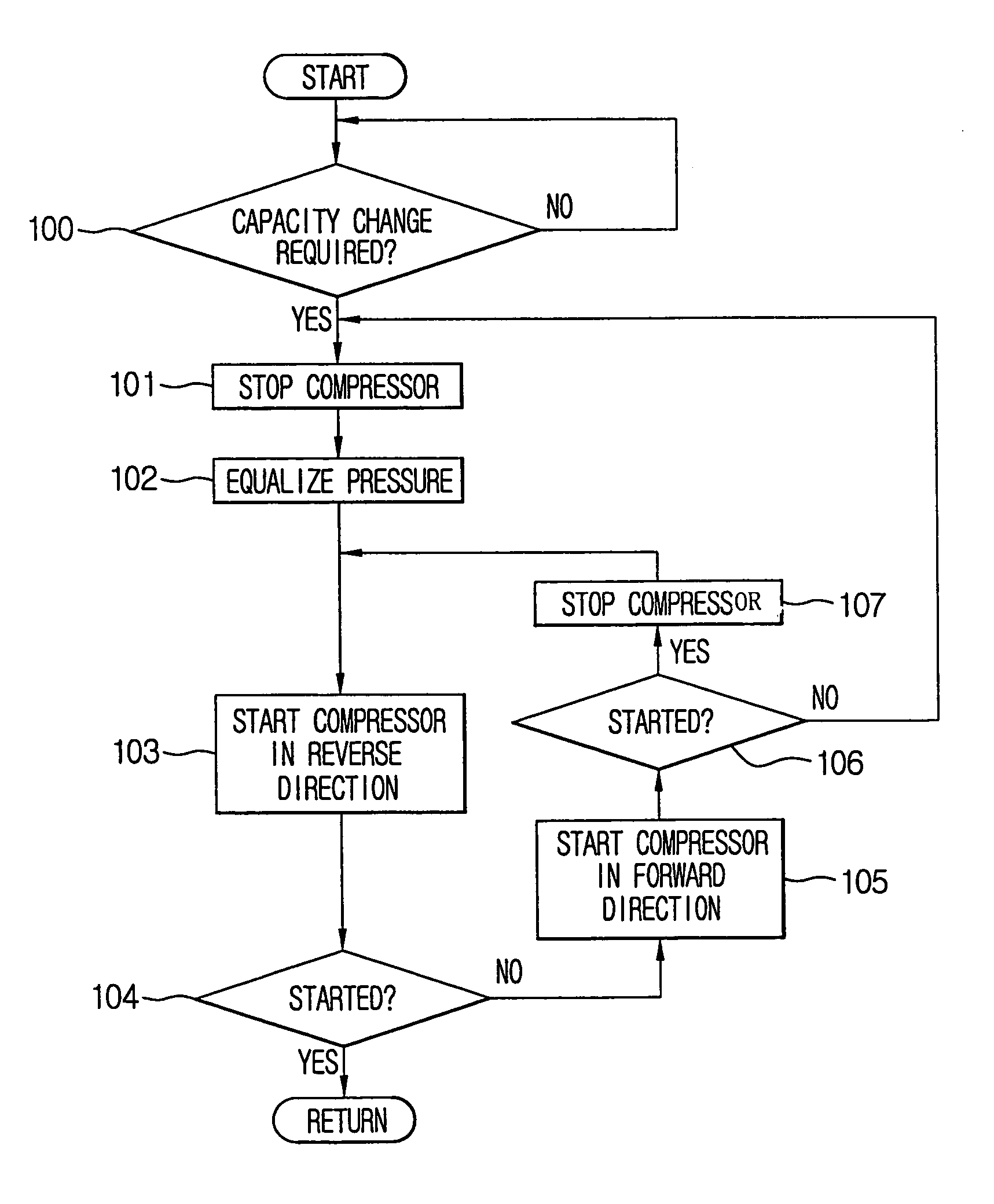

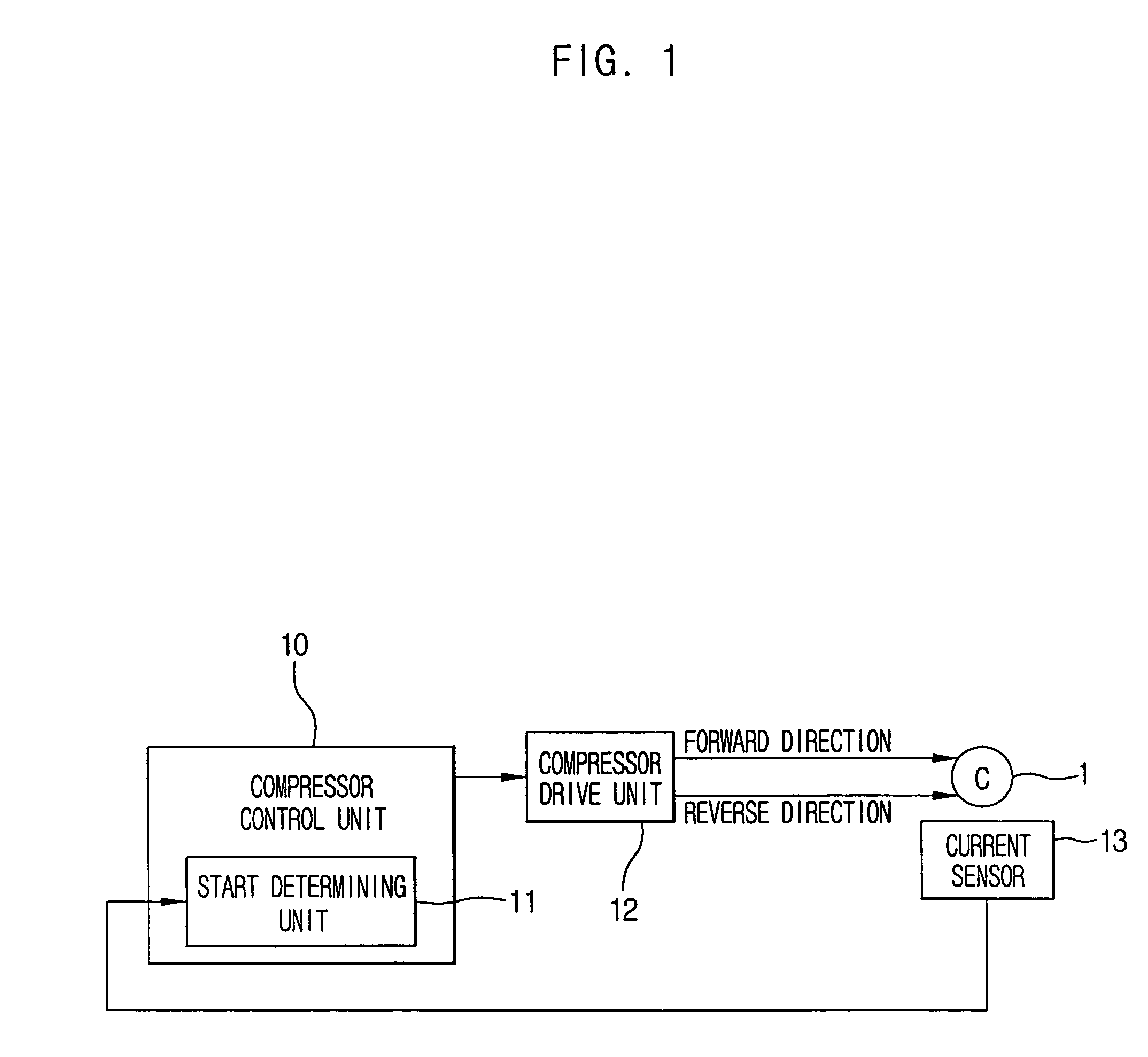

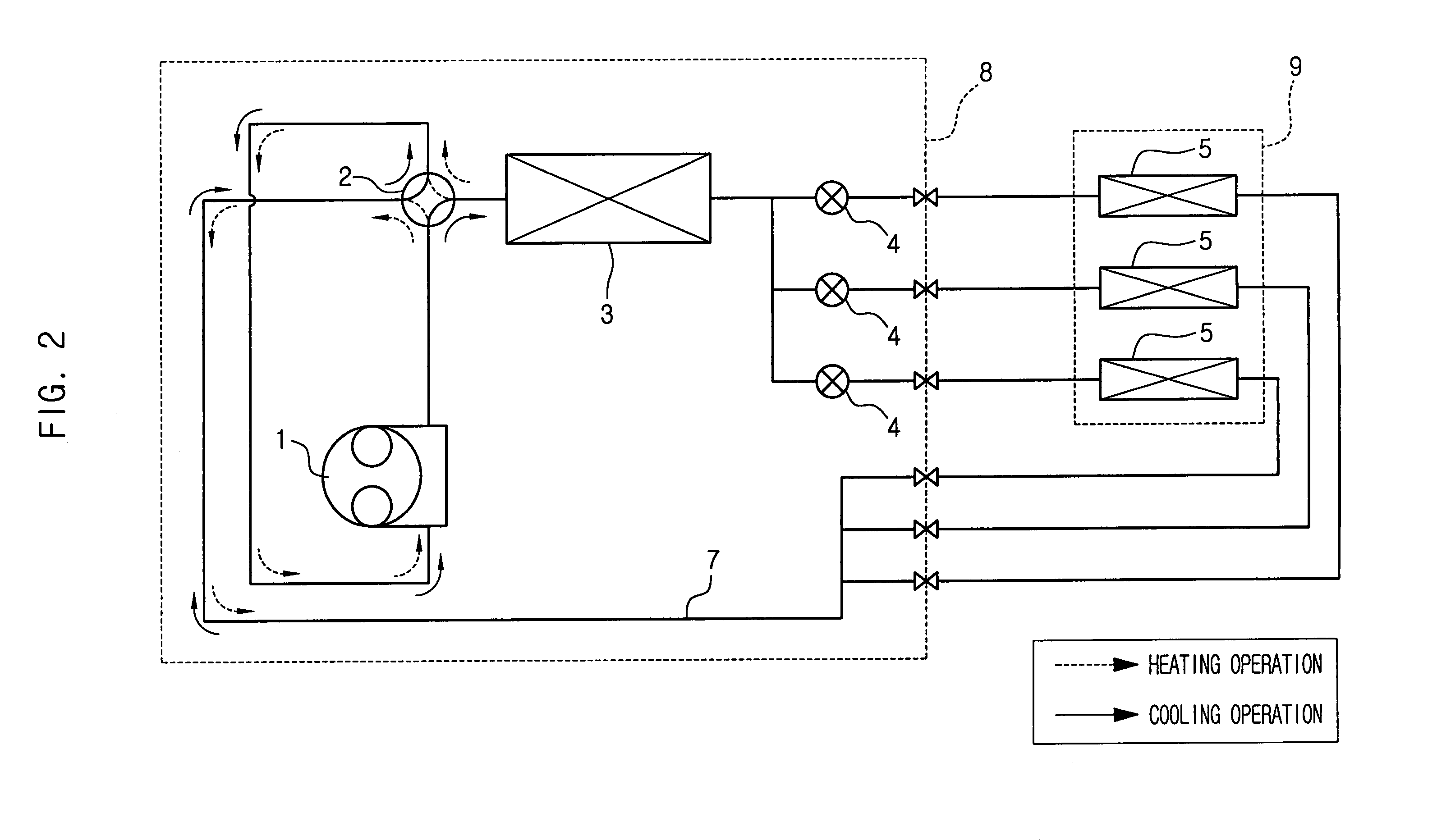

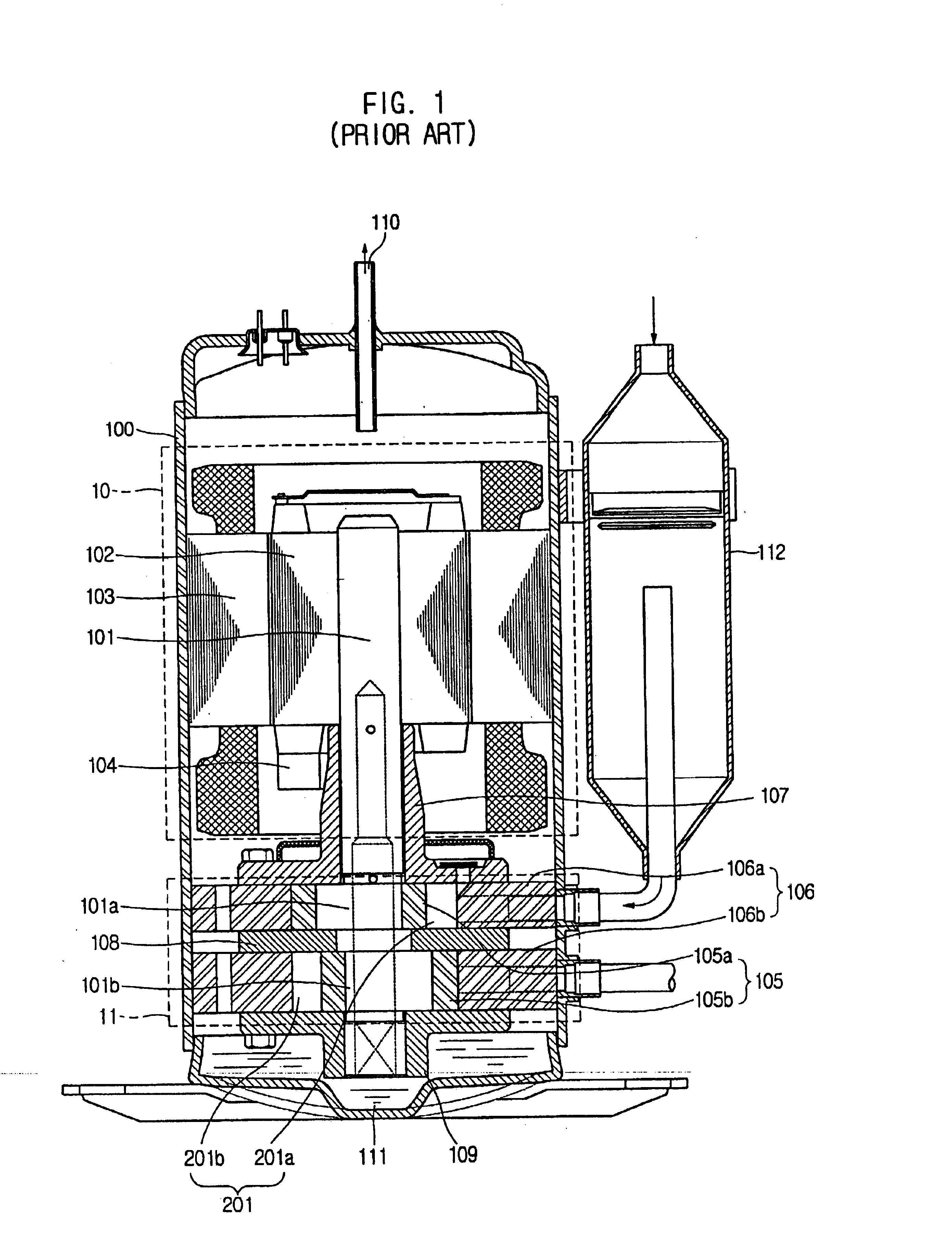

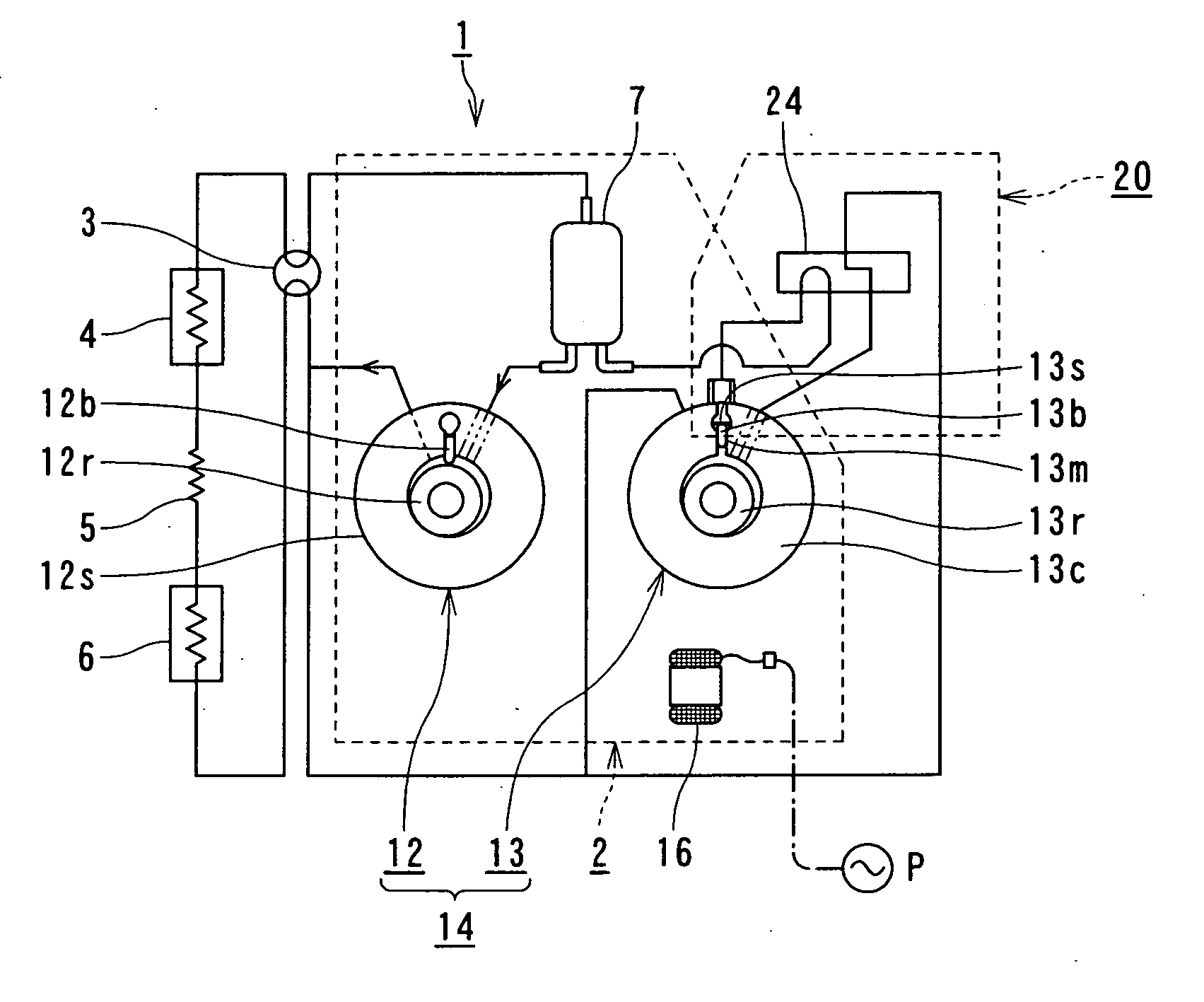

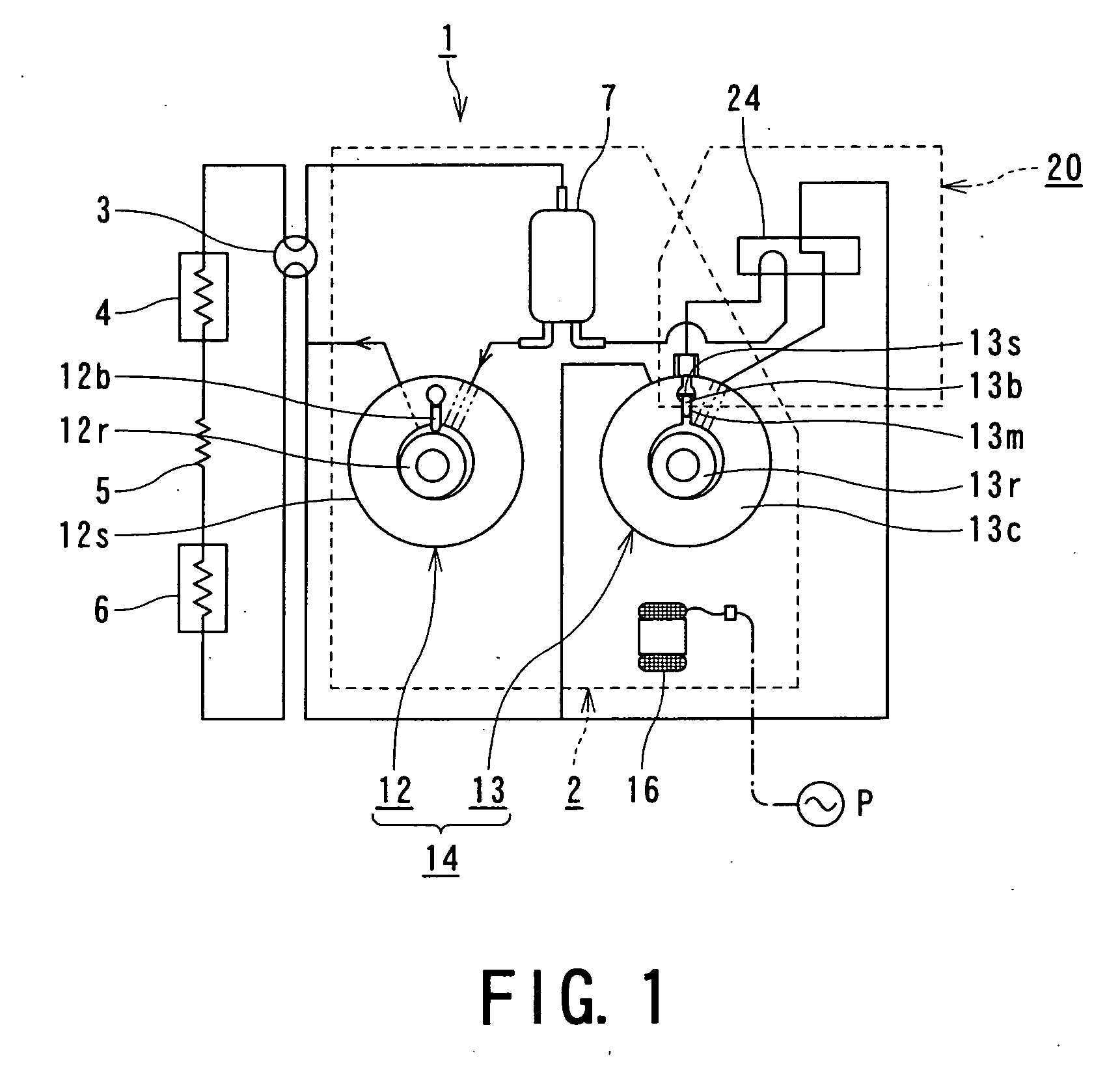

Air conditioner and method of controlling the same

InactiveUS20050050908A1Smooth startImprove startup reliabilityRotary/oscillating piston combinations for elastic fluidsSpace heating and ventilation safety systemsEngineeringControl theory

An air conditioner has a variable capacity rotary compressor, which allows the compressor to be smoothly re-started, thus increasing start reliability of the compressor. The air conditioner includes a compressor rotated in opposite directions. A drive unit rotates the compressor in a forward or reverse direction. A start determining unit determines whether the compressor has started to rotate in a forward direction or not. A control unit operates the drive unit so as to rotate the compressor in a direction opposite to the forward direction, and then re- start the compressor in the forward direction, when the compressor has failed to start. The air conditioner and a method of controlling the air conditioner allow the compressor to be smoothly and rapidly re-started even when the compressor has failed to re-start, thus increasing start reliability, and shortening a time required to re-start the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

Seal for a compressor and centrifugal compressor equipped with such a seal

A seal for a rotary compressor comprises a casing, at least one assembly having a rotating seal face ring which rotates as one with a sleeve intended to be mounted on a shaft of the compressor and of a stationary seal face ring mounted on the casing, the seal face rings being urged to press against one another via their rubbing face. The seal design further incorporates fluid circulation for heating leaks of compressible fluid conveyed by the compressor that occur between the seal face rings, this fluid circulation being formed in the casing and extending at least partially downstream of the seal face rings with respect to the direction of flow of the fluid stream.

Owner:THERMODYN

Rotary compressor having a discharge valve

InactiveUS7344367B2Improper seatingInsufficient compressionCheck valvesEqualizing valvesEngineeringMechanical engineering

A rotary compressor having a housing, a rotor positioned within the housing defining a compression chamber, the rotor rotatable about an axis of rotation, a discharge port in the rotor in fluid communication with the compression chamber, and a valve assembly mounted to the rotor to regulate the pressure of the fluid within the compression chamber. In one embodiment, the valve assembly is canted or obliquely aligned with respect to the axis of rotation of the rotor and a radial axis perpendicular to and intersecting the axis of rotation. Aligning the valve assembly in this way allows the displacement of the valve head of the valve assembly to be substantially collinear with forces acting on the valve head.

Owner:TECUMSEH PROD CO

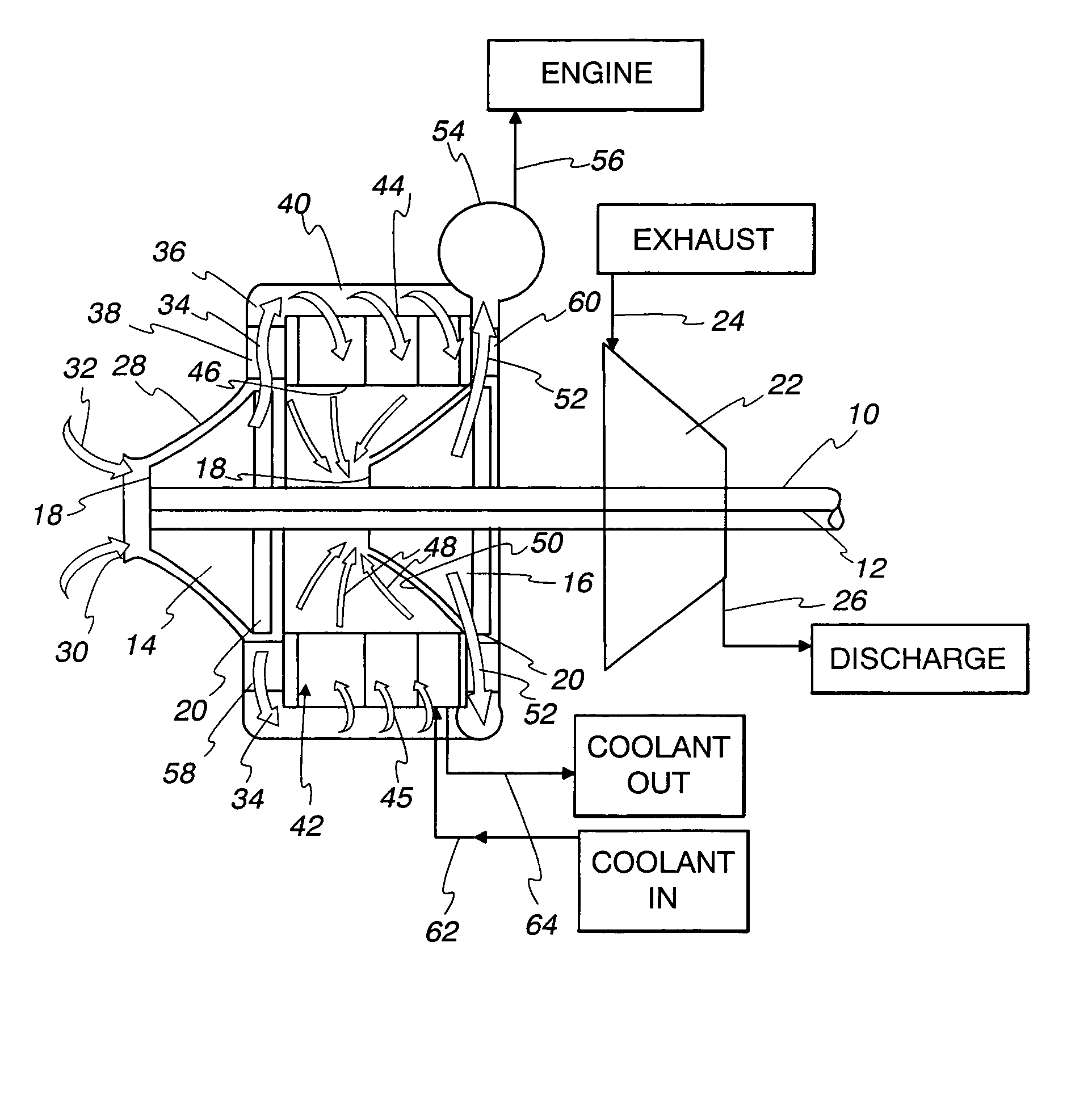

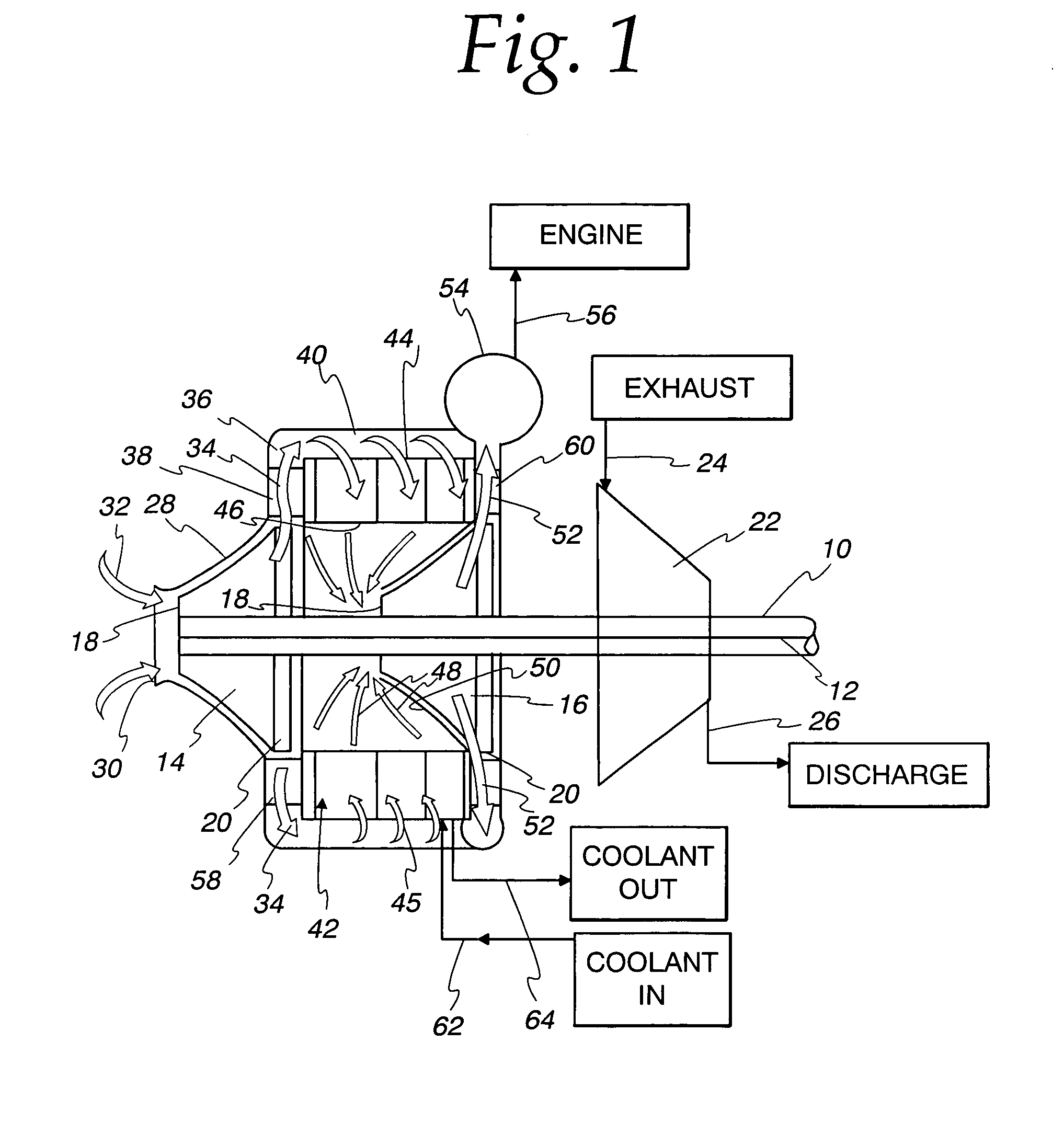

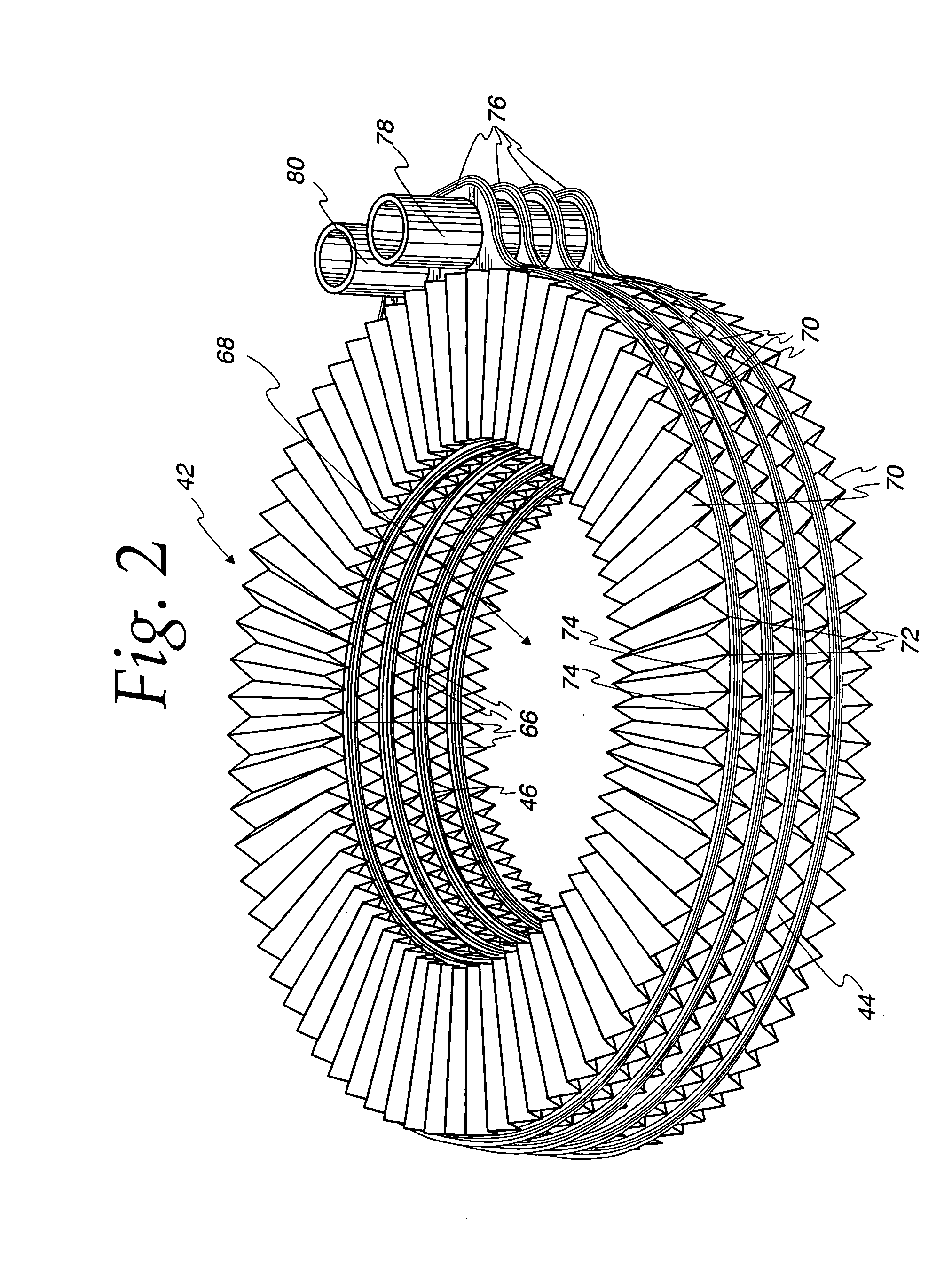

Formed disk plate heat exchanger

InactiveUS20050058535A1Obstruction in may takeInternal combustion piston enginesPump componentsImpellerPlate heat exchanger

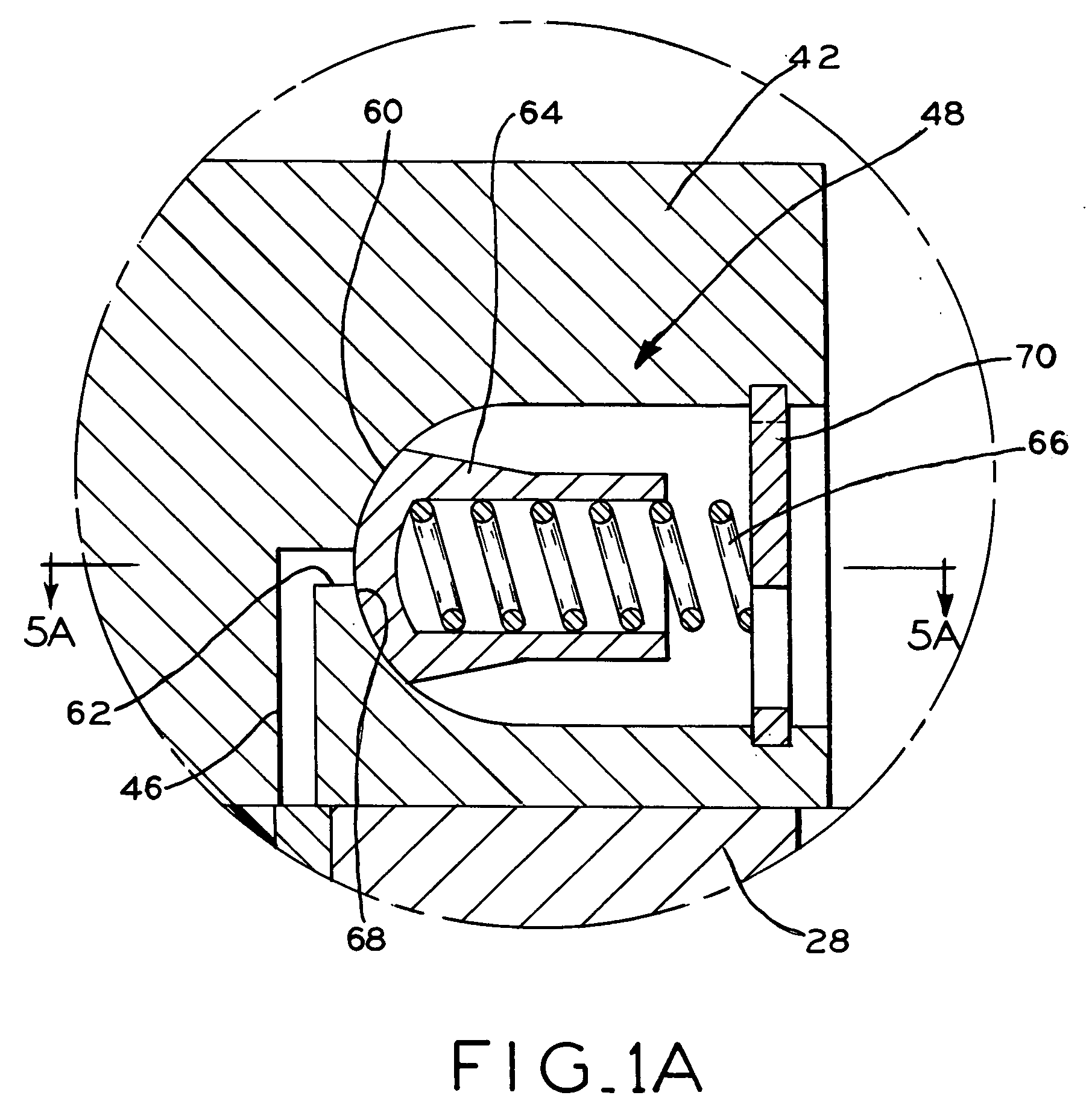

A compact rotary compressor unit within internal intercooling includes a rotary shaft (10) with at least one compressor wheel (14,16) mounted thereon for rotation therewith. The compressor wheel (14,16) has an inlet end (18) of relatively small diameter and a radial discharge end (20) of relatively large diameter. A nominally donut-shaped intercooling heat exchanger (42) is centered about the shaft (10) to receive compressed air from the compressor wheel and cool the same. Both the compressor wheel (14,16) and the heat exchanger (42) are confined in a housing (28).

Owner:MODINE MFG CO

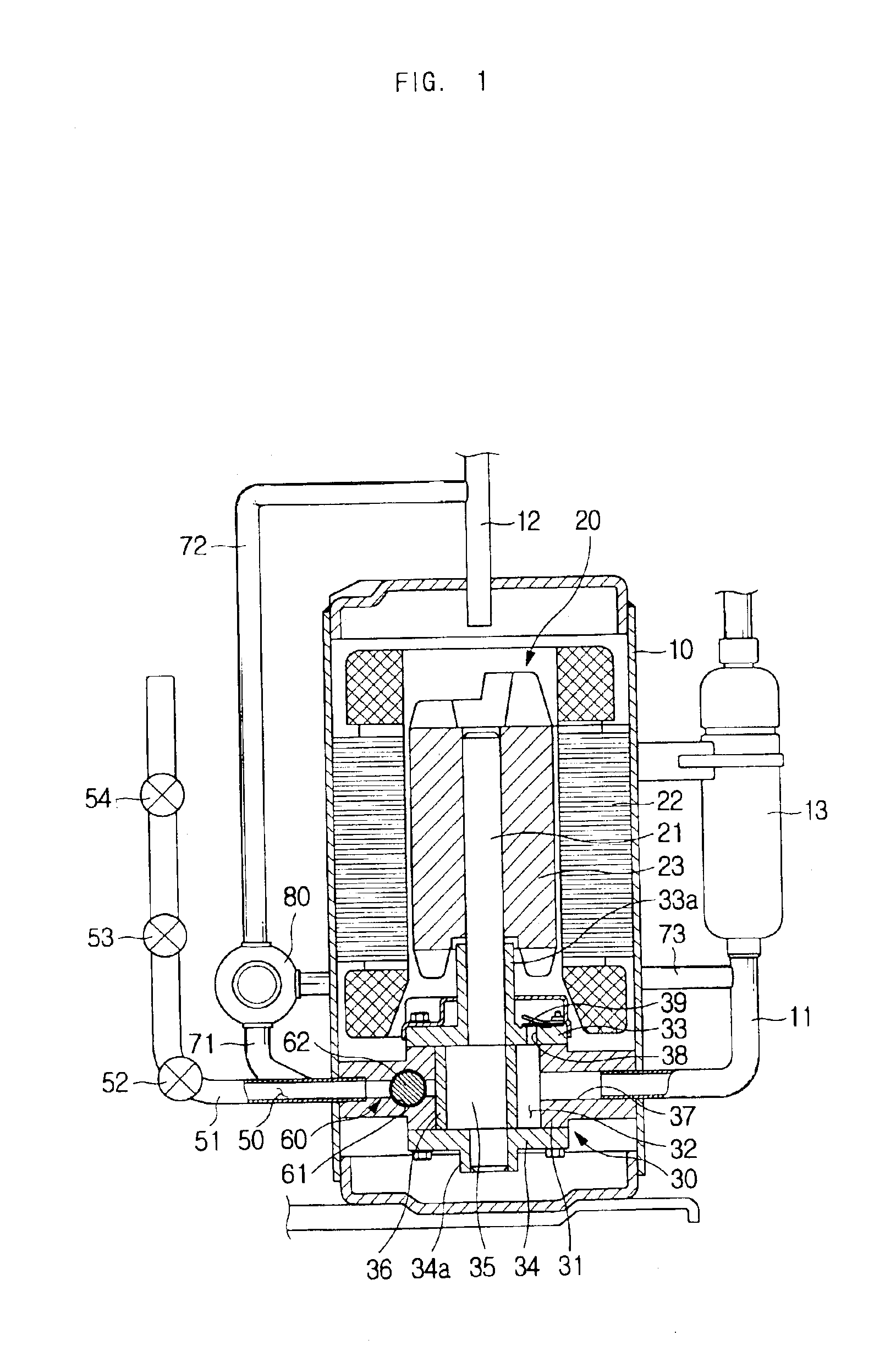

Air conditioner and method of controlling the same

InactiveUS7040107B2Smooth startImprove startup reliabilityRotary/oscillating piston combinations for elastic fluidsSpace heating and ventilation safety systemsCounter rotationVariable capacity

An air conditioner has a variable capacity rotary compressor, which allows the compressor to be smoothly re-started, thus increasing start reliability of the compressor. The air conditioner includes a compressor rotated in opposite directions. A drive unit rotates the compressor in a forward or reverse direction. A start determining unit determines whether the compressor has started to rotate in a forward direction or not. A control unit operates the drive unit so as to rotate the compressor in a direction opposite to the forward direction, and then re-start the compressor in the forward direction, when the compressor has failed to start. The air conditioner and a method of controlling the air conditioner allow the compressor to be smoothly and rapidly re-started even when the compressor has failed to re-start, thus increasing start reliability, and shortening a time required to re-start the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

Miniature rotary compressor, and methods related thereto

InactiveUS20060140791A1High densityImprove efficiencyProgramme controlCompressorMiniaturizationEngineering

Disclosed is a rolling piston rotary compressor for use with primary refrigerants that is miniaturized for portable and mobile applications for which size and weight are often crucial. The miniature rotary compressor comprises a compressor mechanism, a brushless DC motor and a casing. The compressor mechanism comprises, a cylinder, a shaft having an eccentric part, one or more bearings to support the shaft, a roller, a vane, an oil sump, openings for communicating with lubricant oil and refrigerant, and inlet and discharge ports. The compressor mechanism and the motor are housed in a hermetically sealed or semi-hermetically sealed casing. The configuration and design of the present invention allow the realization of an ultralight miniature compressor. The miniature rotary compressor provides a higher power density and comparable efficiency as compared to state-of-the-art refrigerant-based rotary compressors. Also disclosed are methods of manufacturing the miniature rotary compressor.

Owner:ASPEN COMPRESSOR

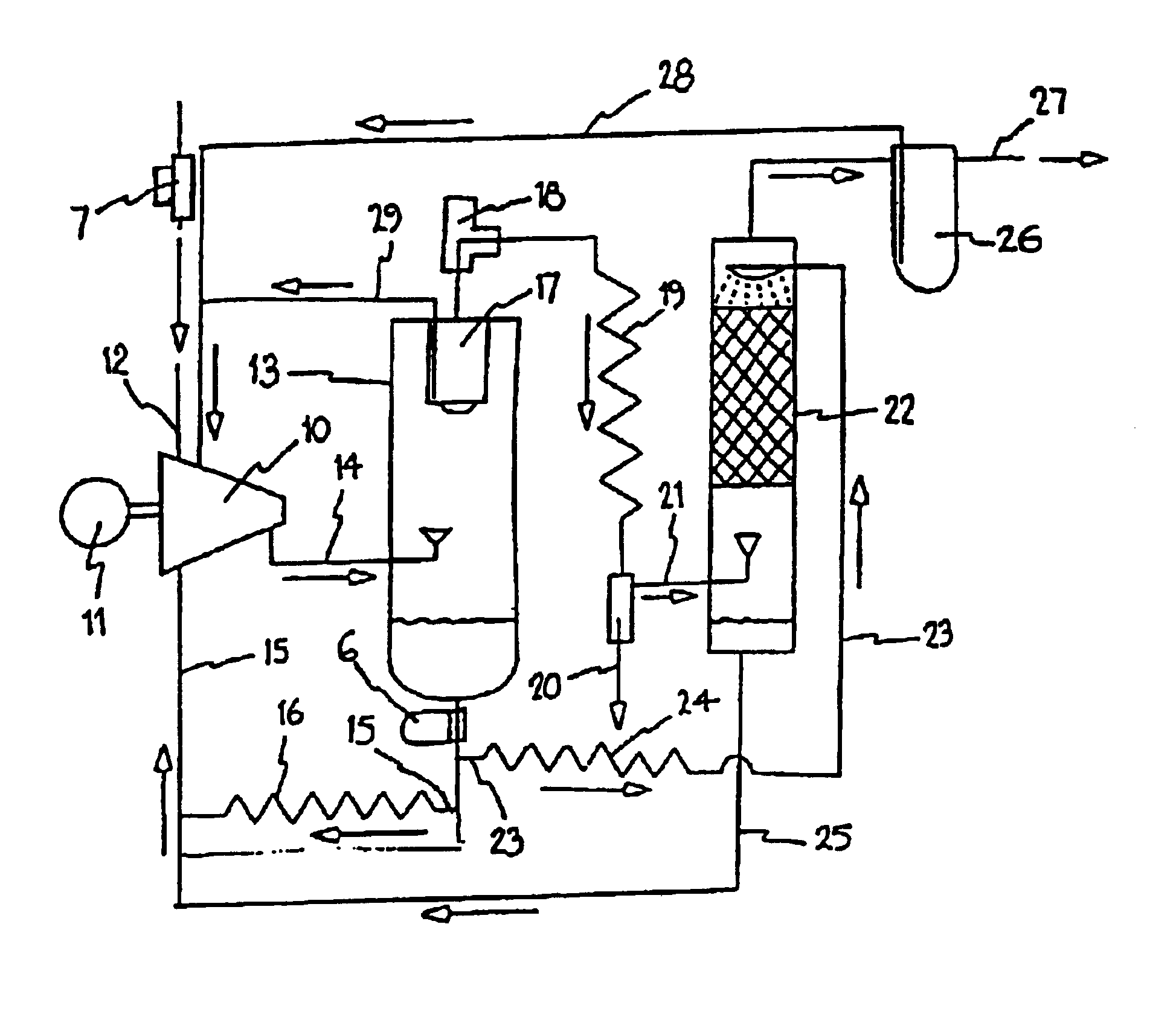

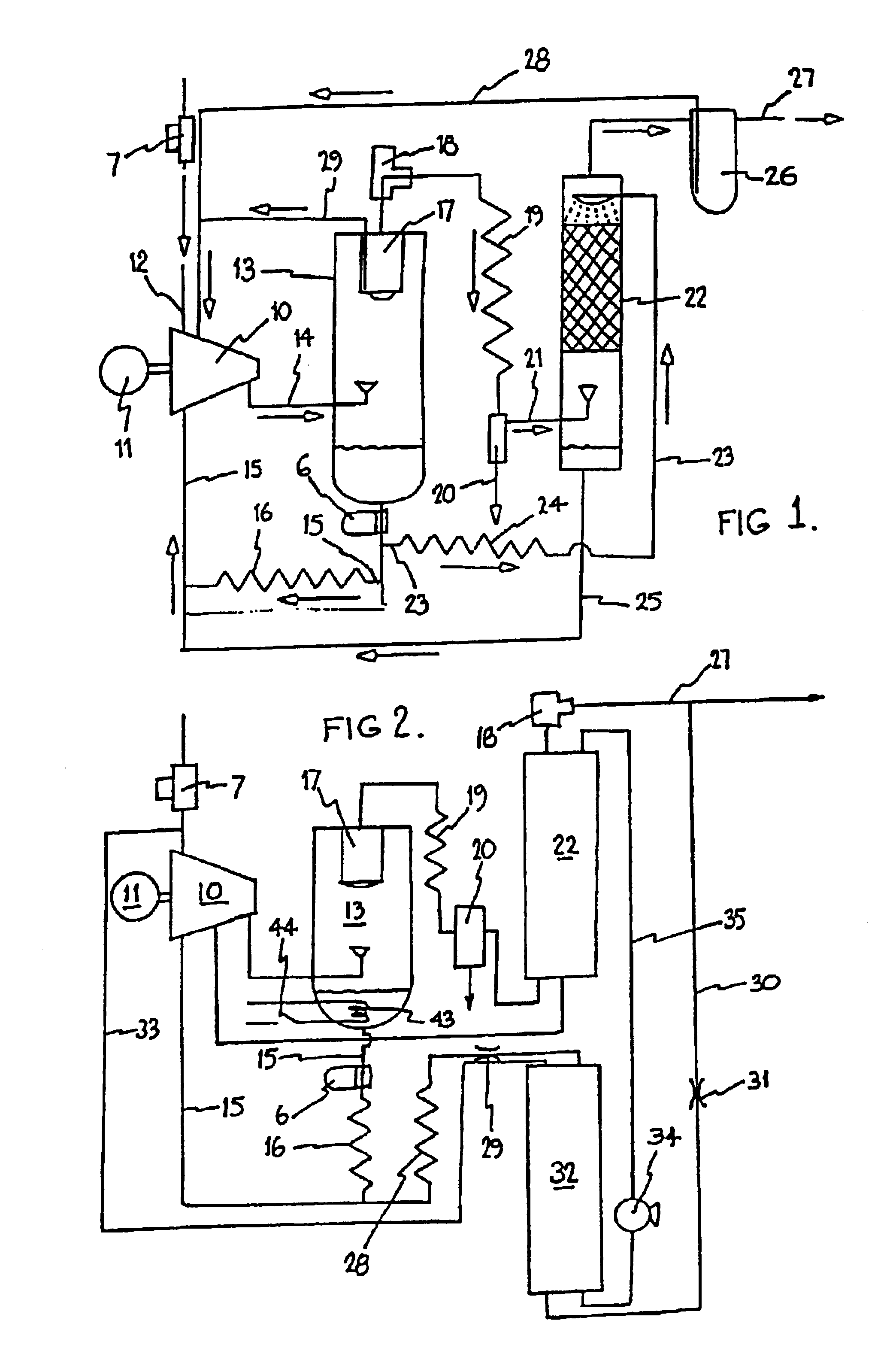

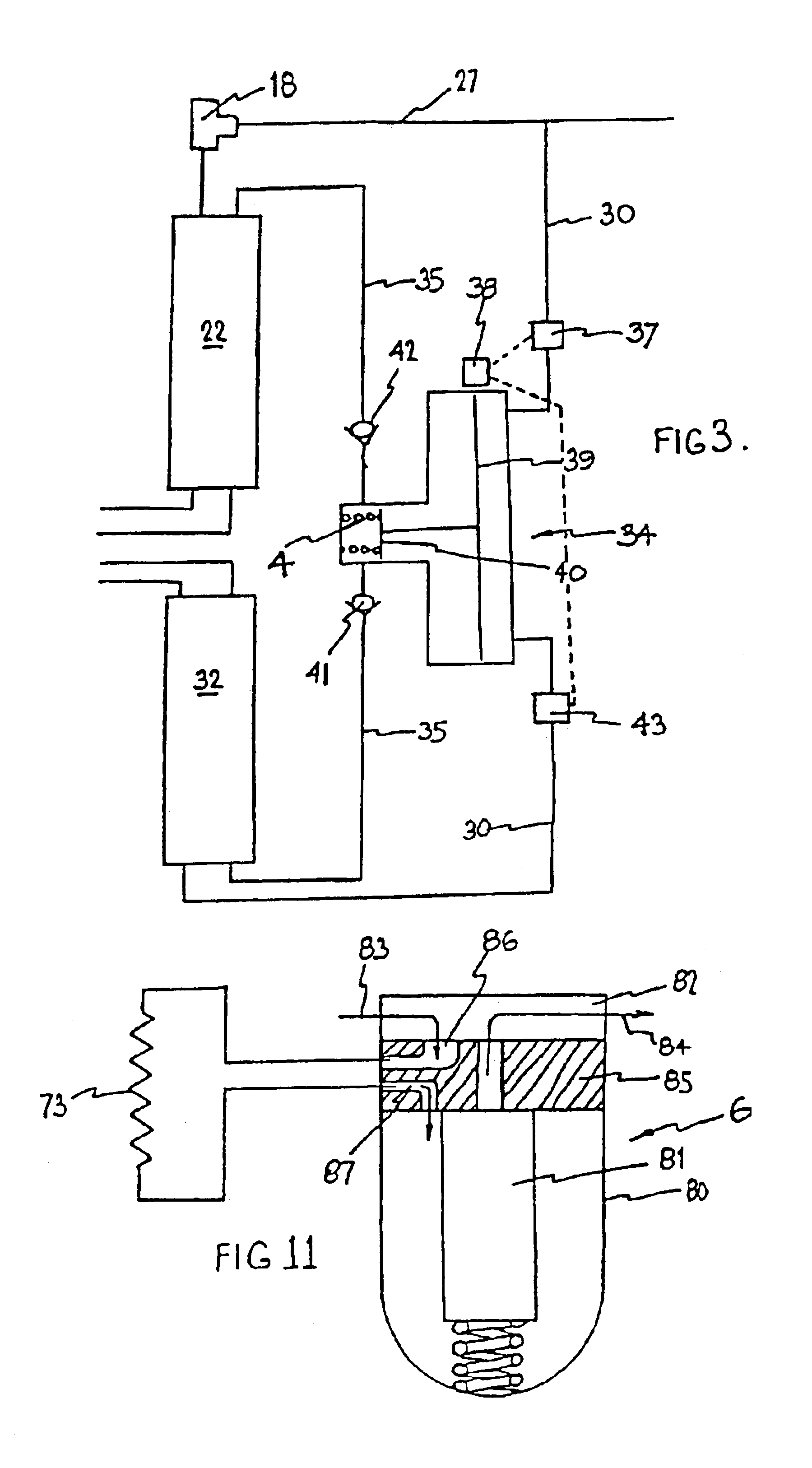

Integrated compressor drier apparatus

A rotary compressor system having a drive rotary compressor unit, a separator vessel (13) receiving compressed gas and entrained liquid from said compressor for collecting the liquid therein and for returning the liquid to a lower pressure zone of the compressor and a moisture absorber receiving compressed gas flow leaving a separation zone of the separator vessel and passing the compressed gas flow relative to a flow of said liquid such that moisture in the compressed gas flow is transferred to said liquid.

Owner:SULLAIR CORP

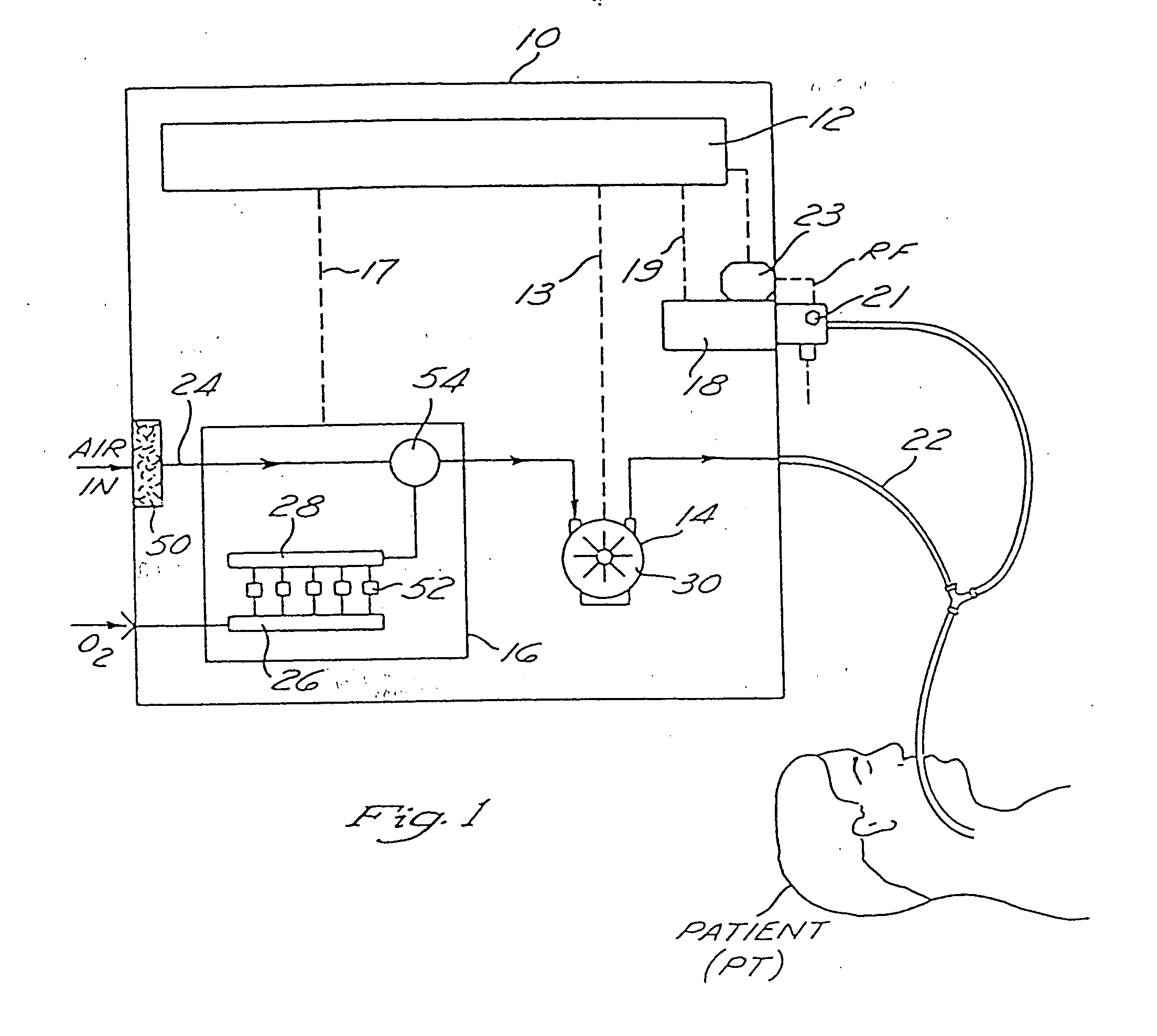

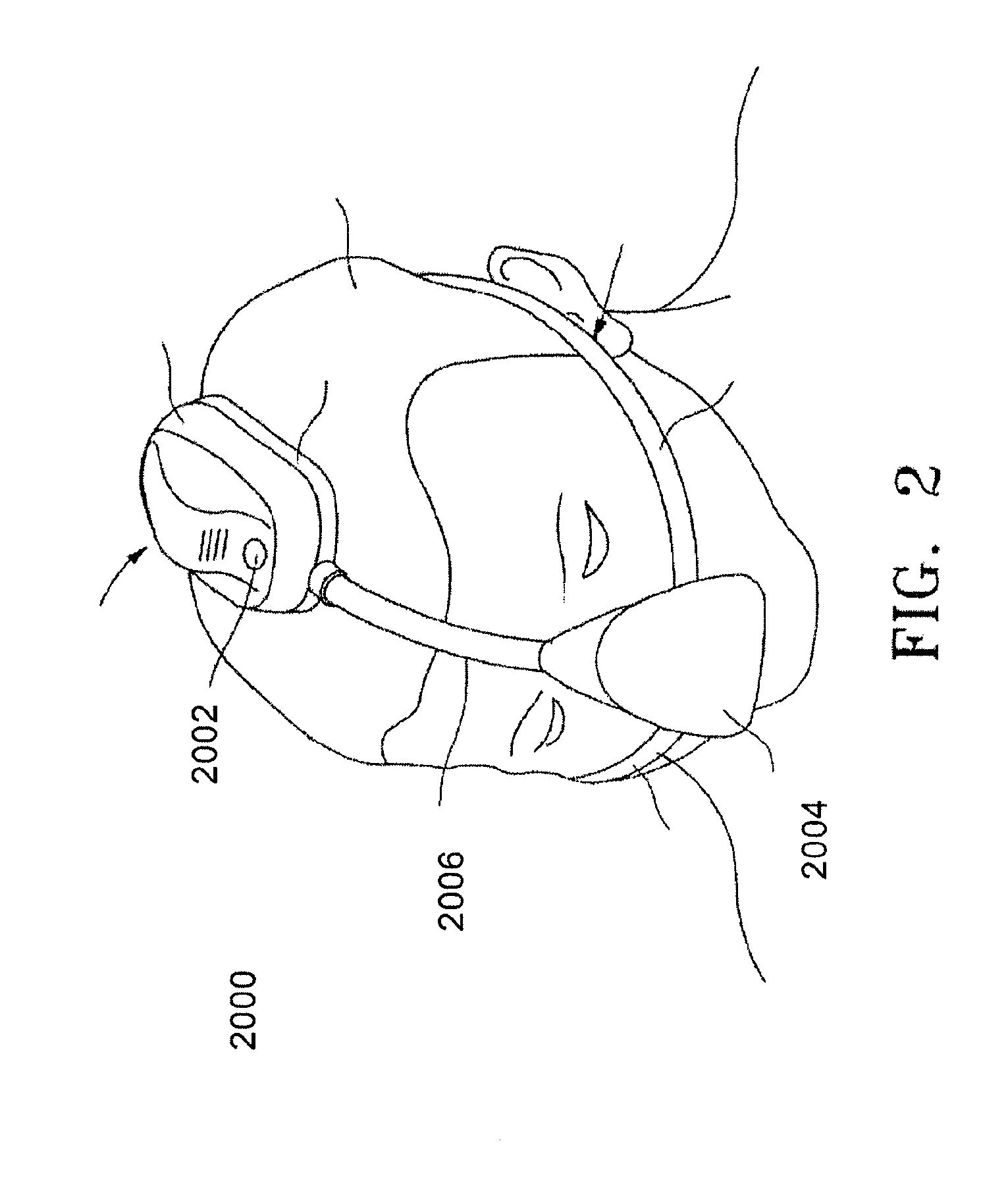

Portable drag compressor powered mechanical ventilator

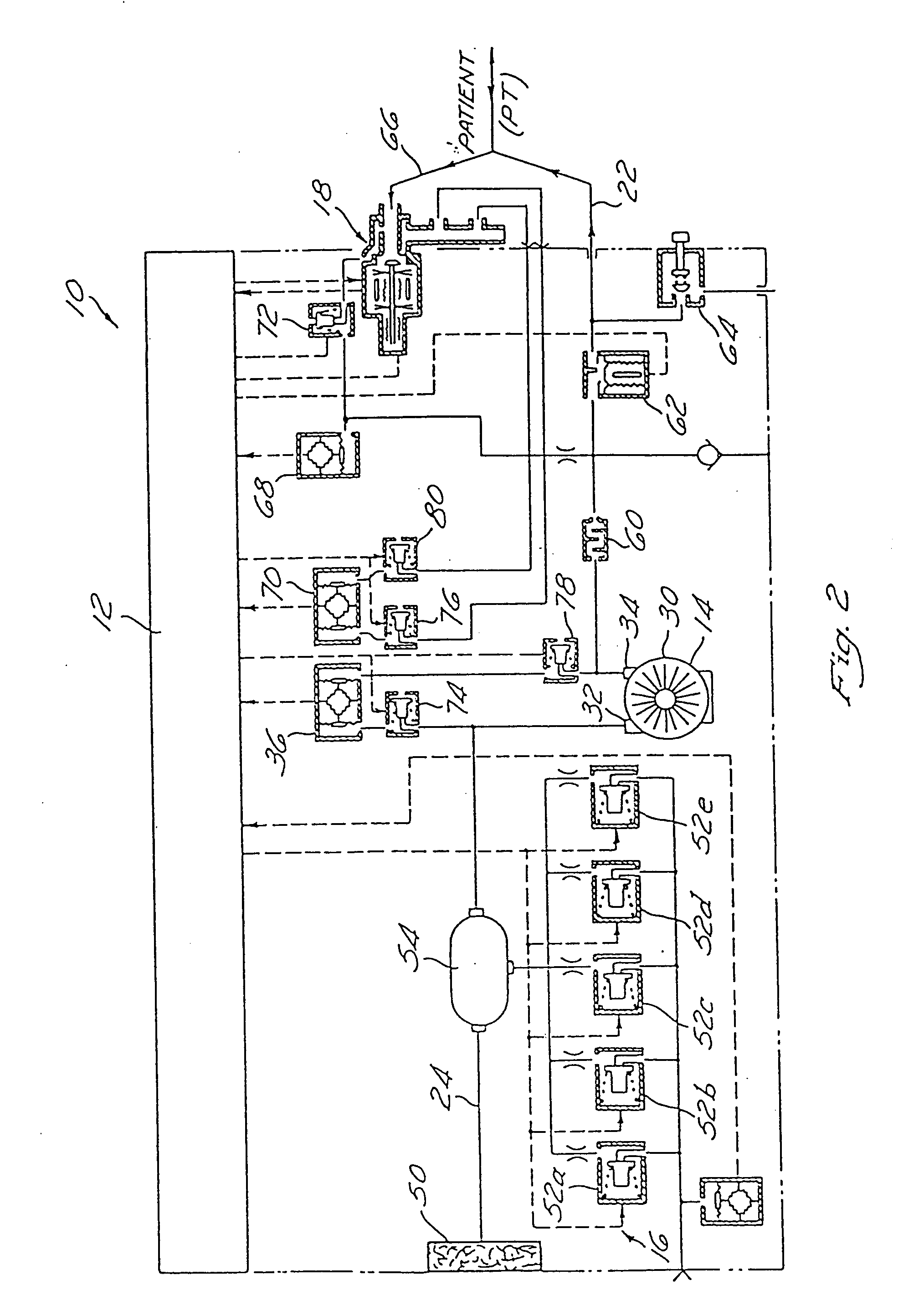

InactiveUS20050150494A1Accurate measurementMinimize inaccuracyRespiratorsOperating means/releasing devices for valvesSolenoid valveEngineering

A ventilator device and system comprising a rotating compressor, preferably a drag compressor, which, at the beginning of each inspiratory ventilation phase, is accelerated to a sufficient speed to deliver the desired inspiratory gas flow, and is subsequently stopped or decelerated to a basal flow level to permit the expiratory ventilation phase to occur. The ventilator device is small and light weight enough to be utilized in portable applications. The ventilator device is power efficient enough to operate for extended periods of time on internal or external batteries. Also provided is an oxygen blending apparatus which utilizes solenoid valves having specific orifice sizes for blending desired amounts of oxygen into the inspiratory gas flow. Also provided is an exhalation valve having an exhalation flow transducer which incorporates a radio frequency data base to provide an attendant controller with specific calibration information for the exhalation flow transducer.

Owner:BIRD PRODS

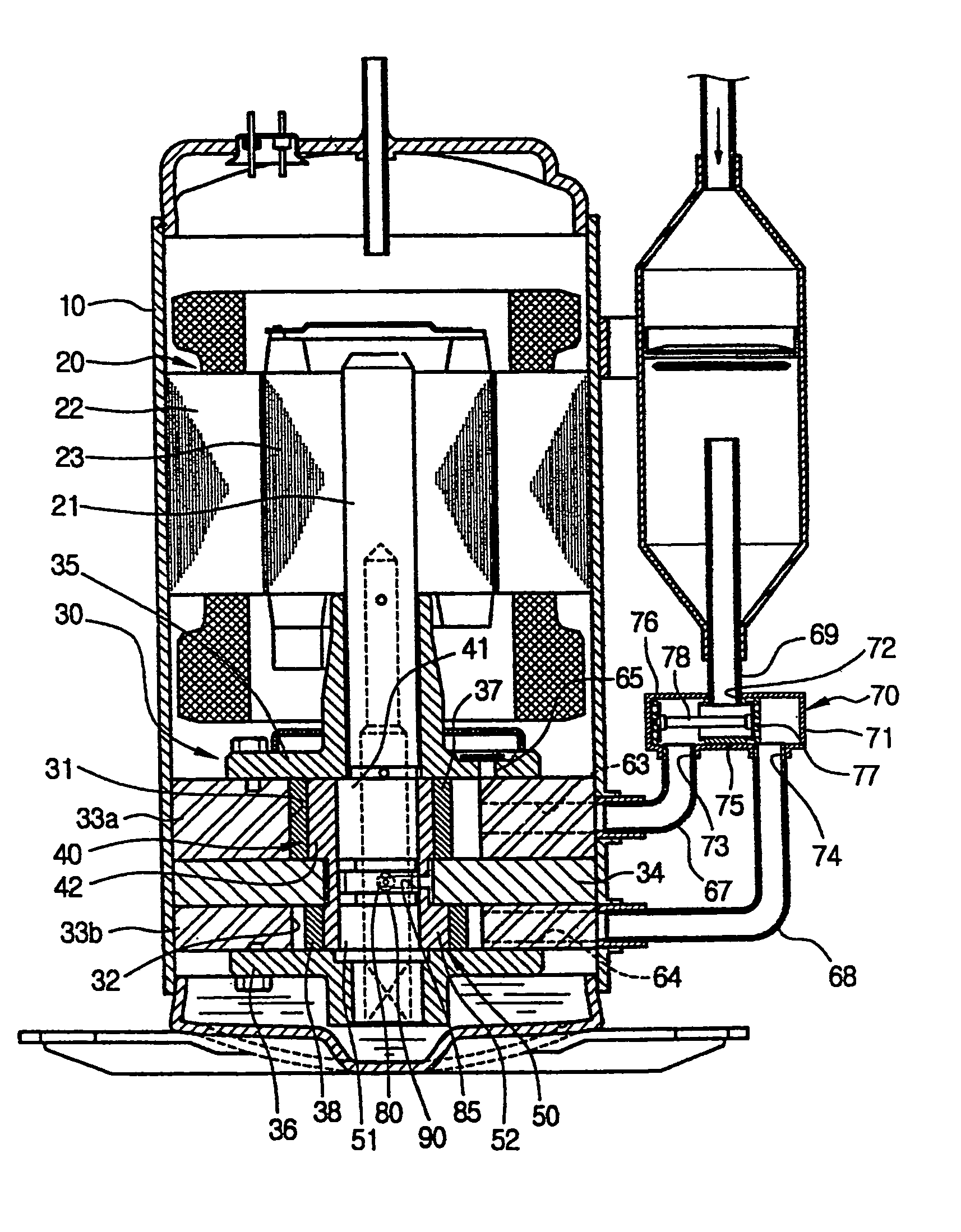

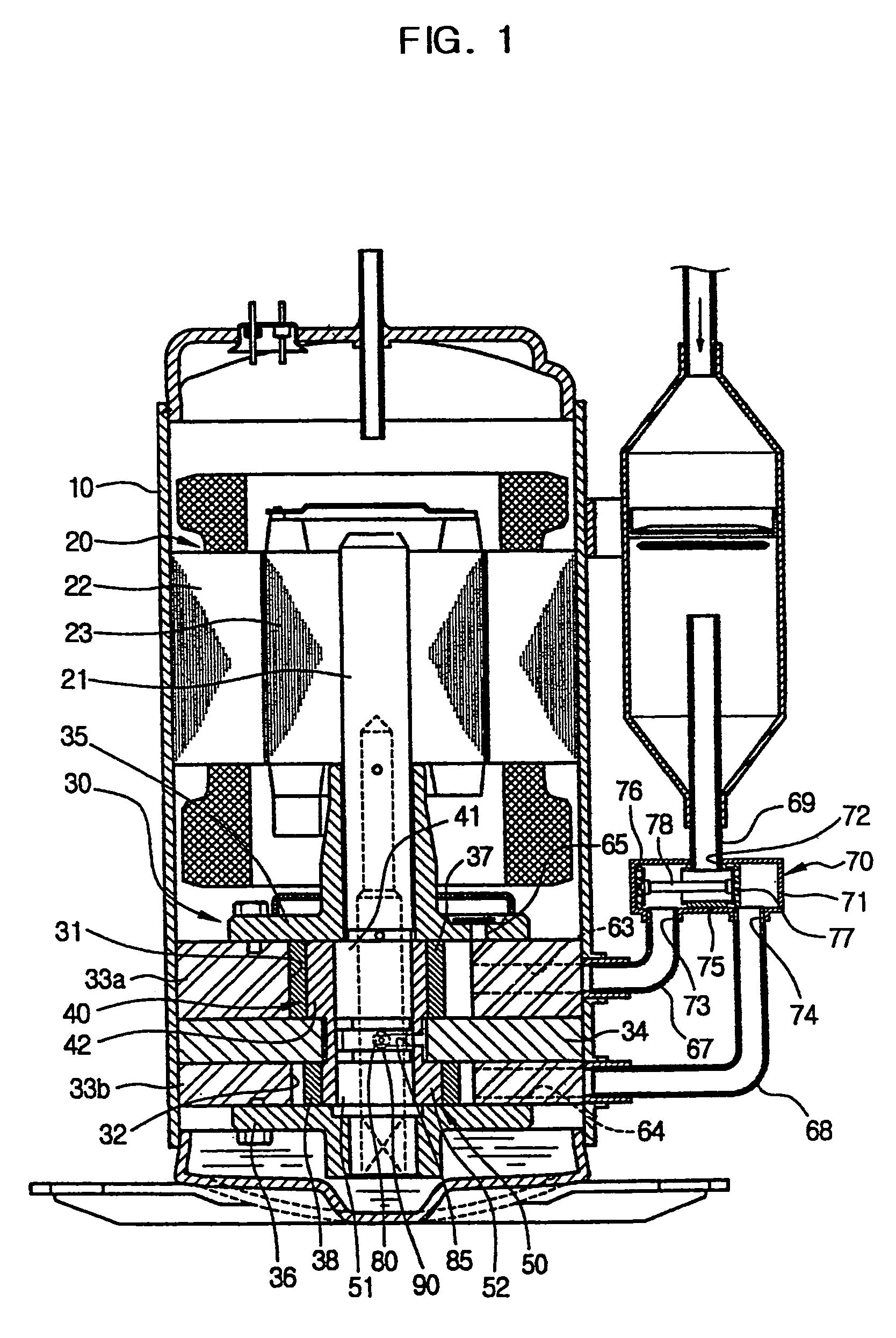

Rotary type compressor

InactiveUS7802972B2Reduce areaReduce intensityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

Owner:DAIKIN IND LTD

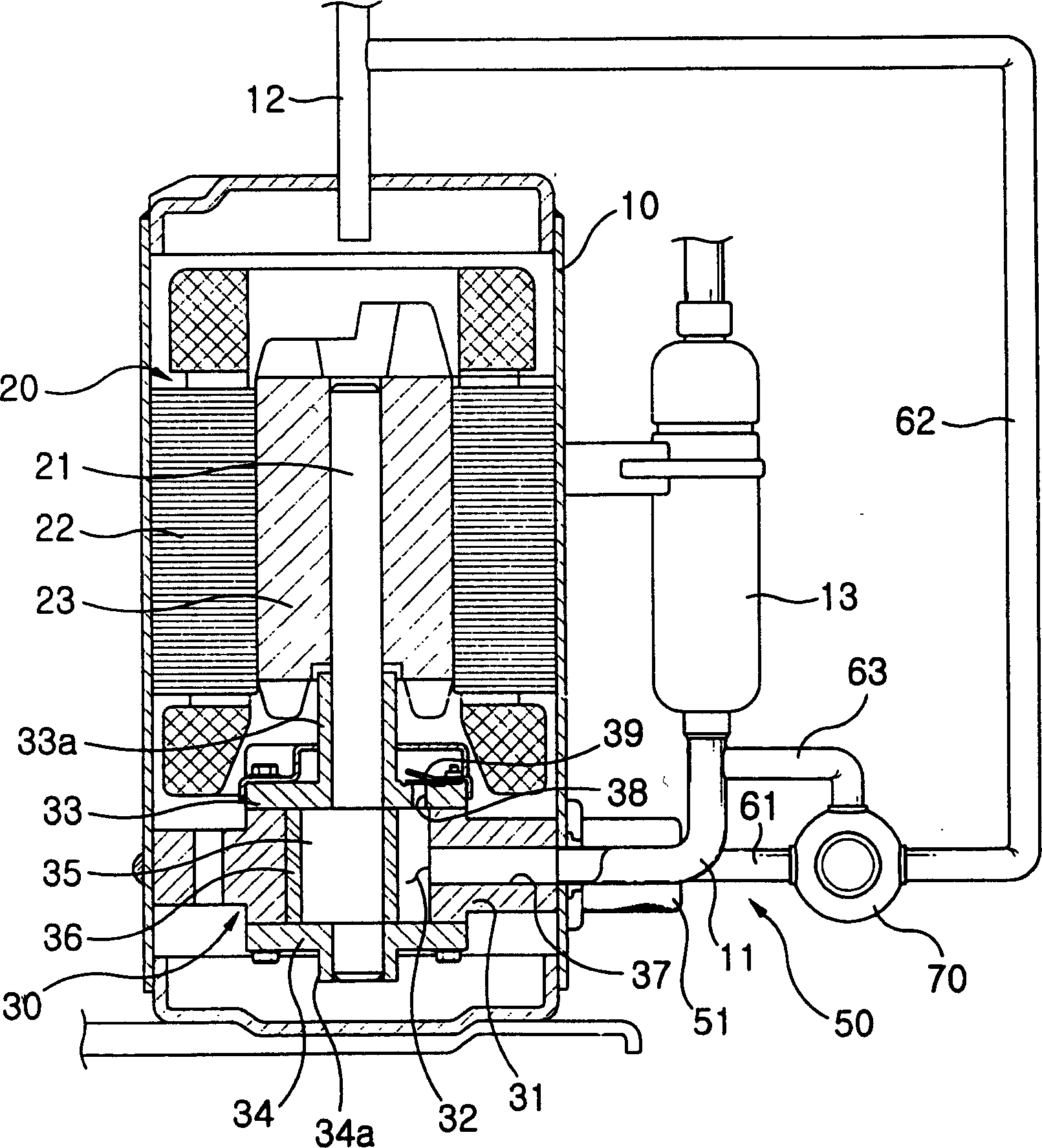

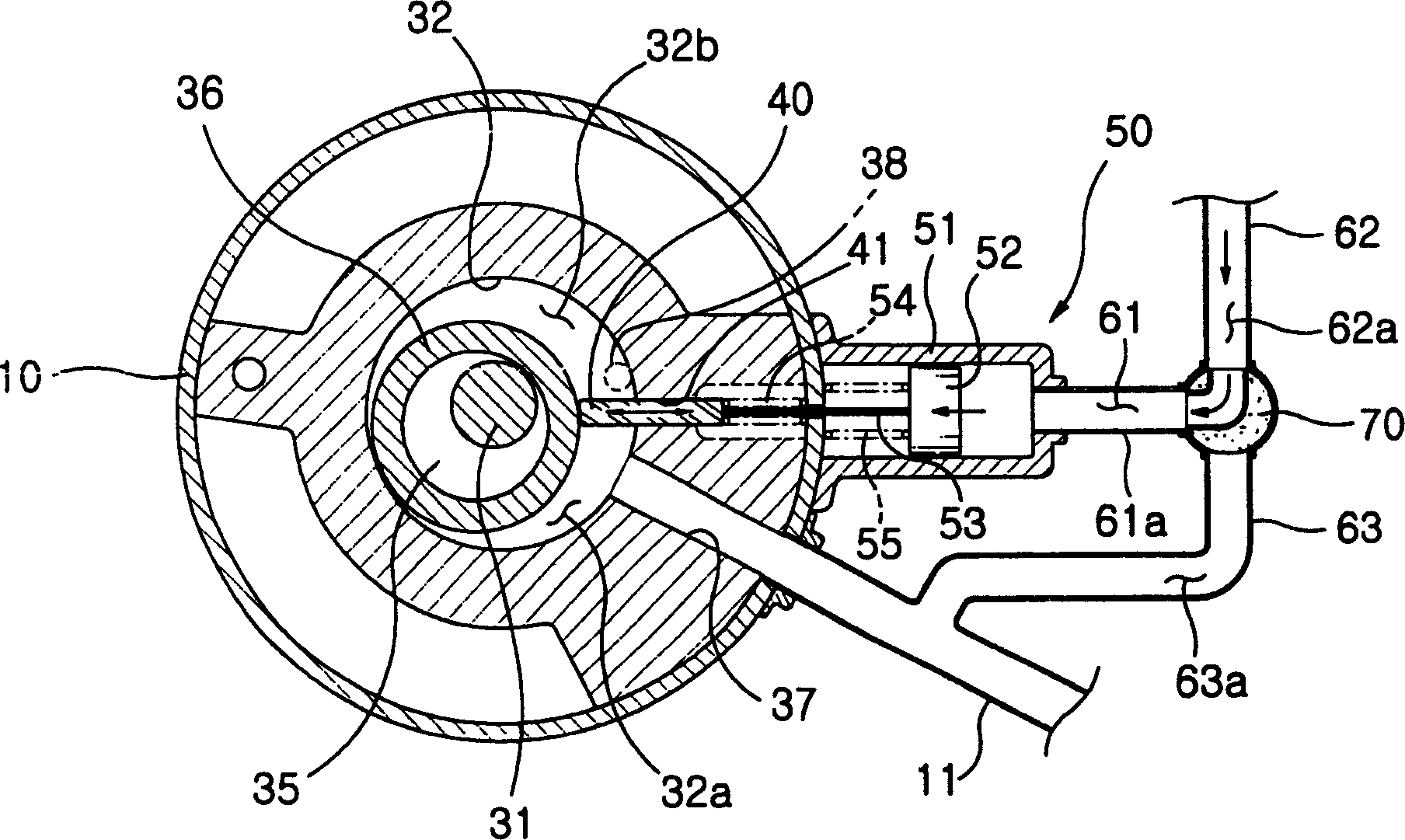

Rotary compressor

InactiveUS6860724B2Rotary/oscillating piston combinations for elastic fluidsOscillating piston enginesEngineeringRefrigerant

A rotary compressor having a plurality of compression chambers and adapted to vary a compression capacity according to a direction of rotation of roller pistons within the compression chambers. A rotating shaft provided with a plurality of eccentric parts drives the roller pistons to compress refrigerant in the compression chambers by eccentric rotations of the eccentric parts. A reversible motor selectively rotates the rotating shaft in opposite directions, and a clutch engages the roller pistons such that the roller pistons perform a compressing action or an idle action according to a rotating direction of the rotating shaft, thus varying the compression capacity of the compressor according to a rotating direction of the rotating shaft. Thus, the compression capacity may be varied without using an inverter circuit.

Owner:SAMSUNG ELECTRONICS CO LTD

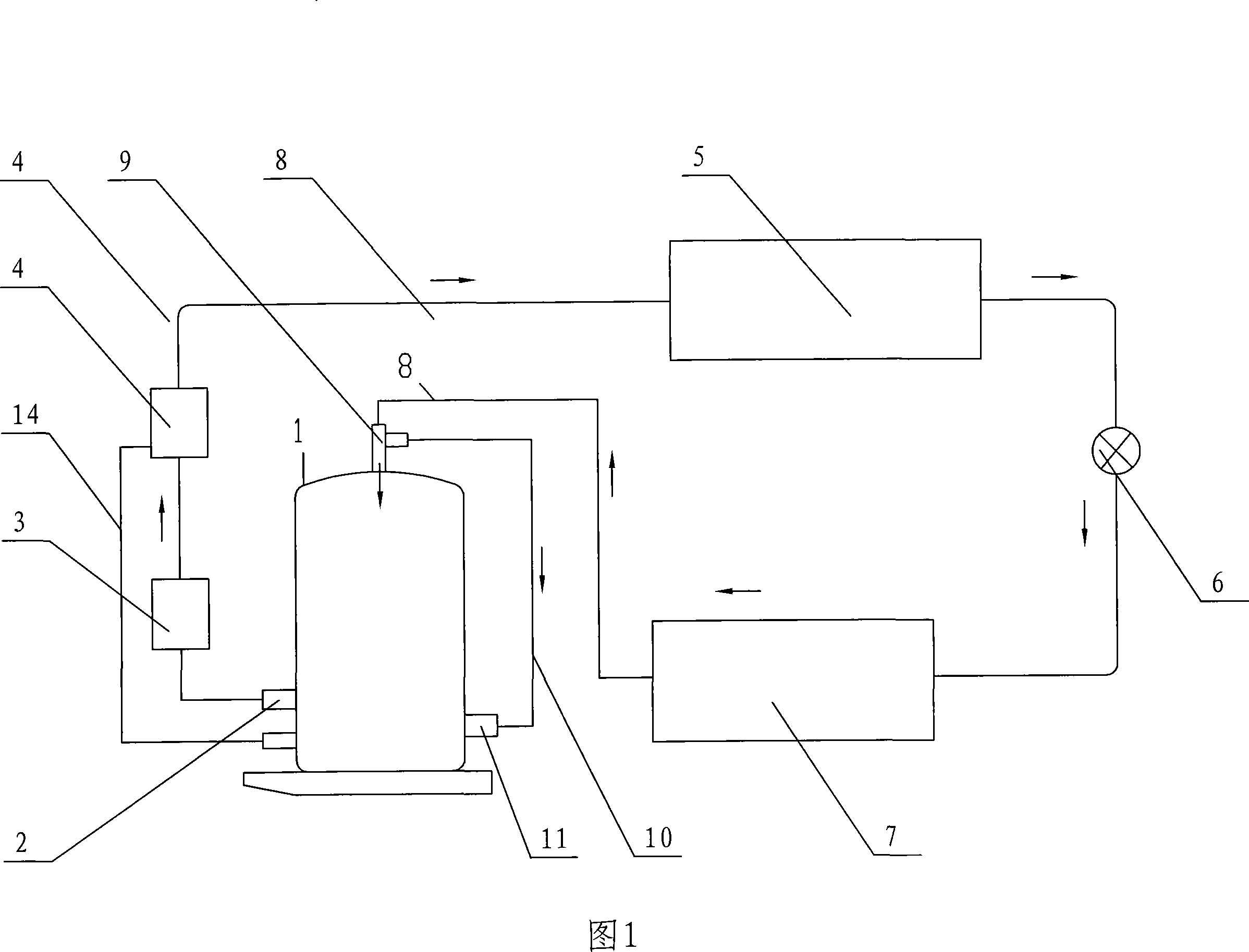

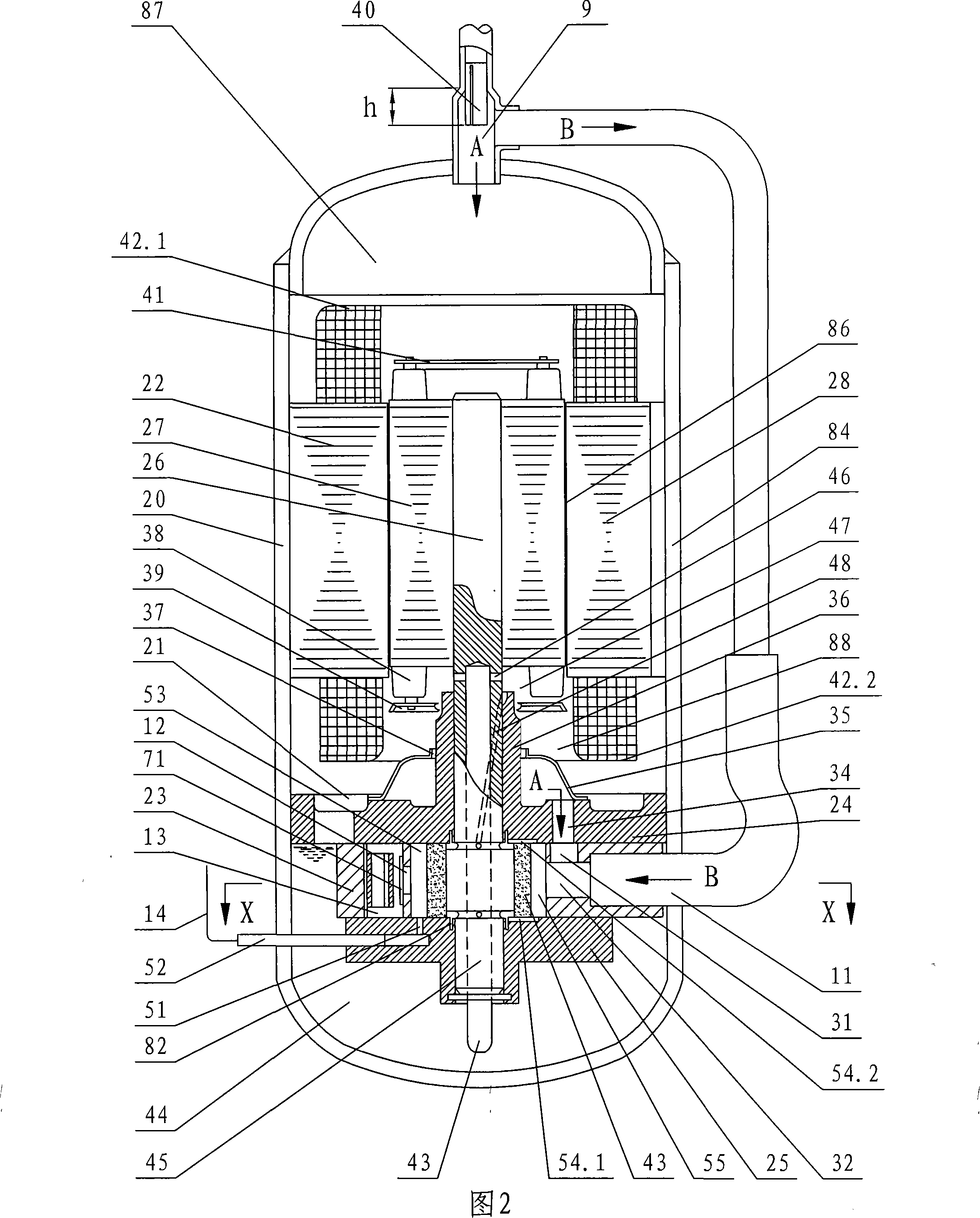

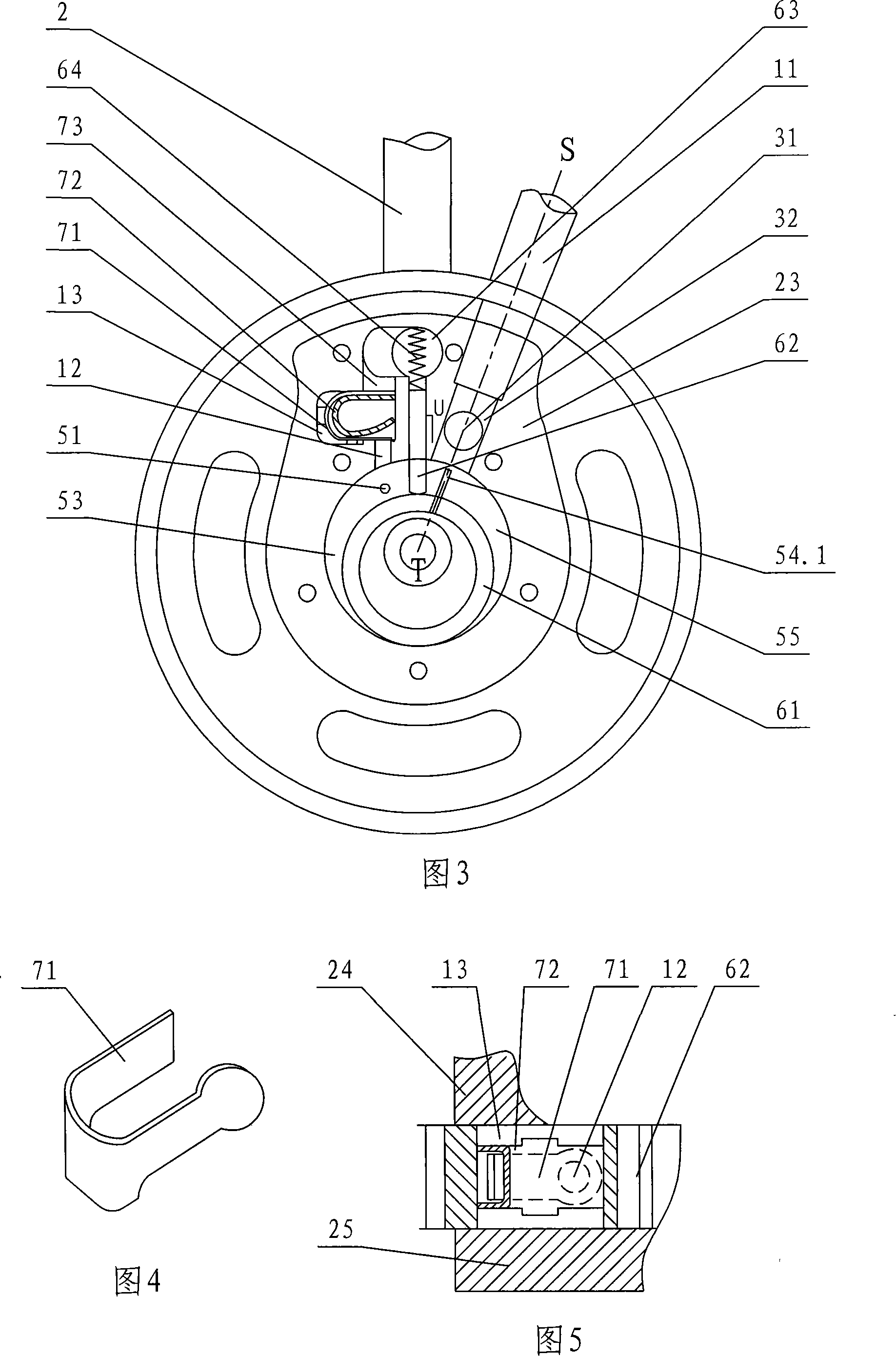

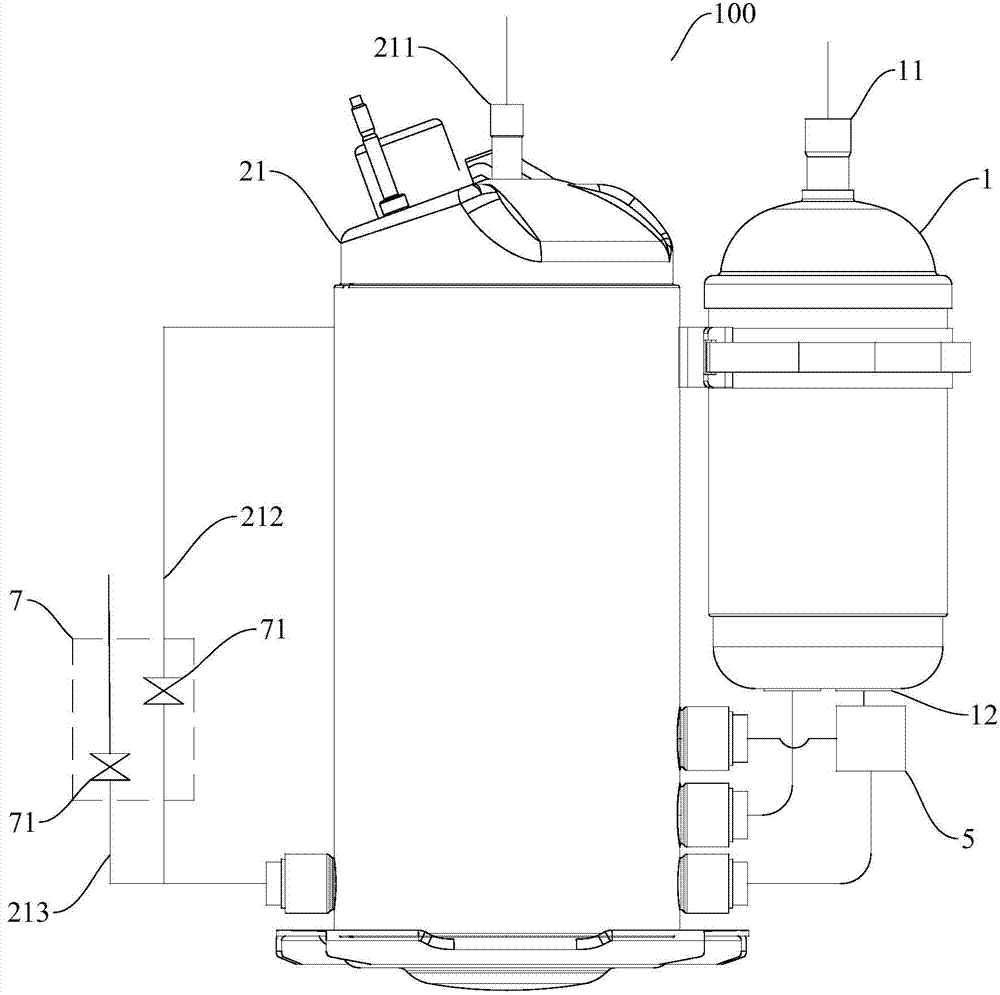

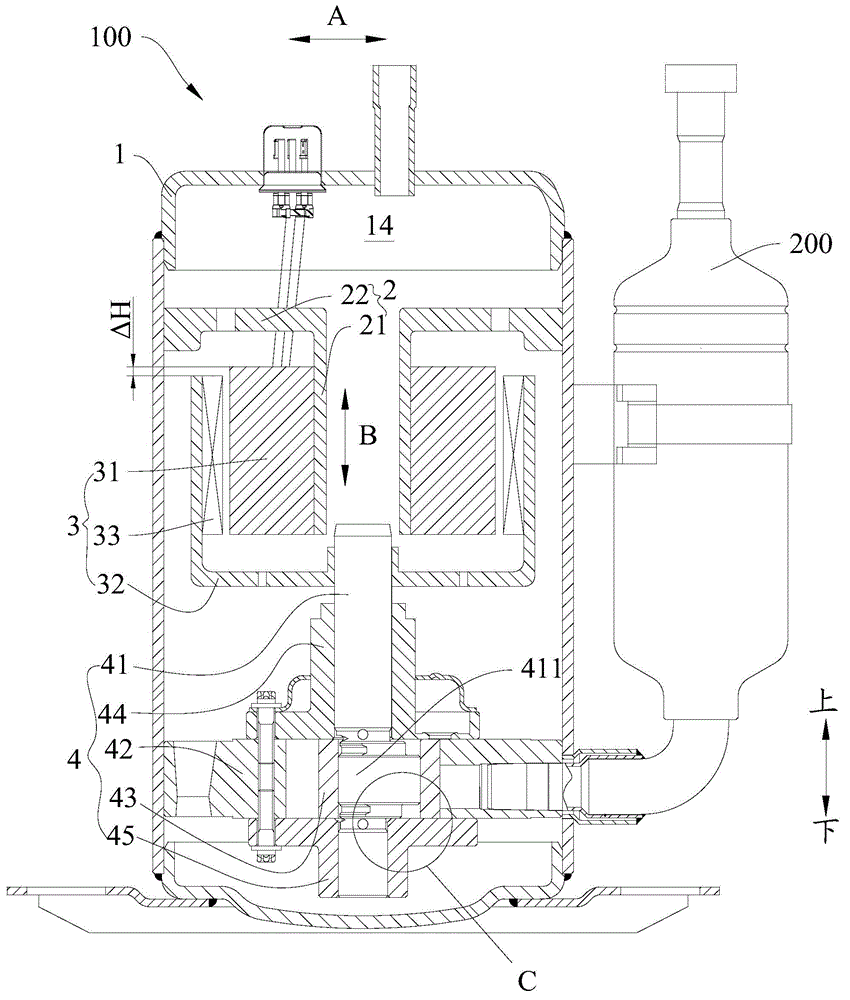

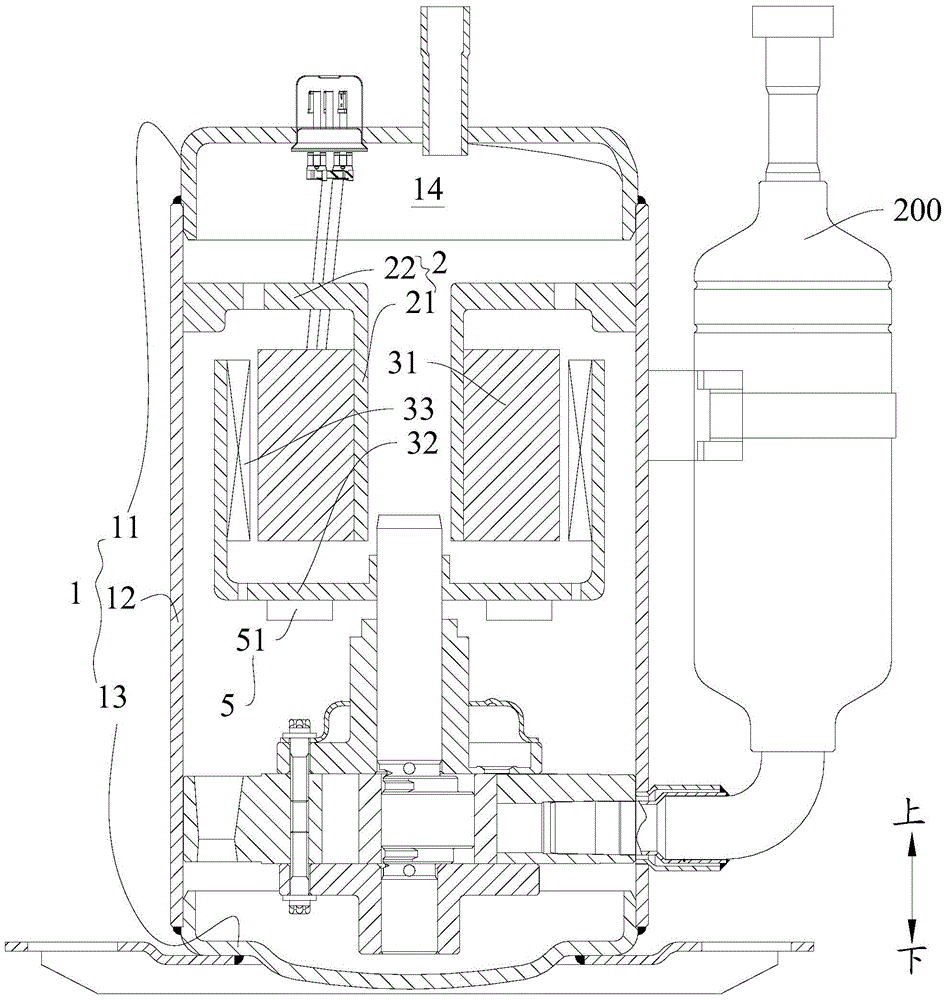

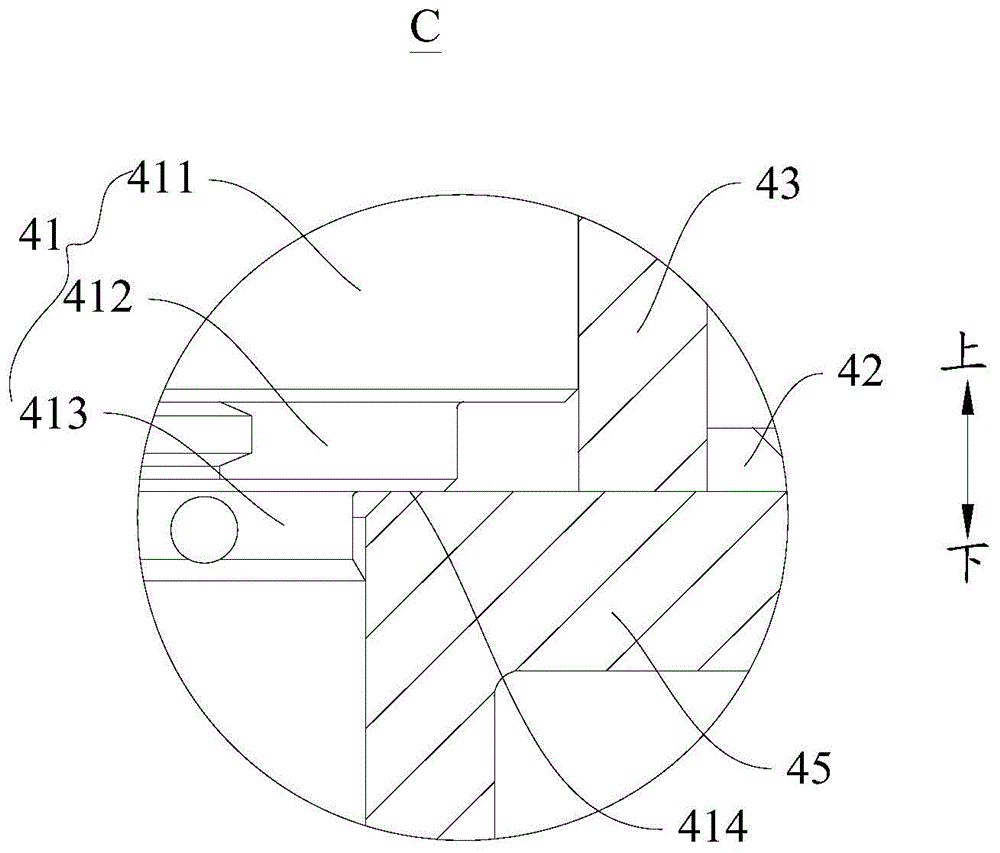

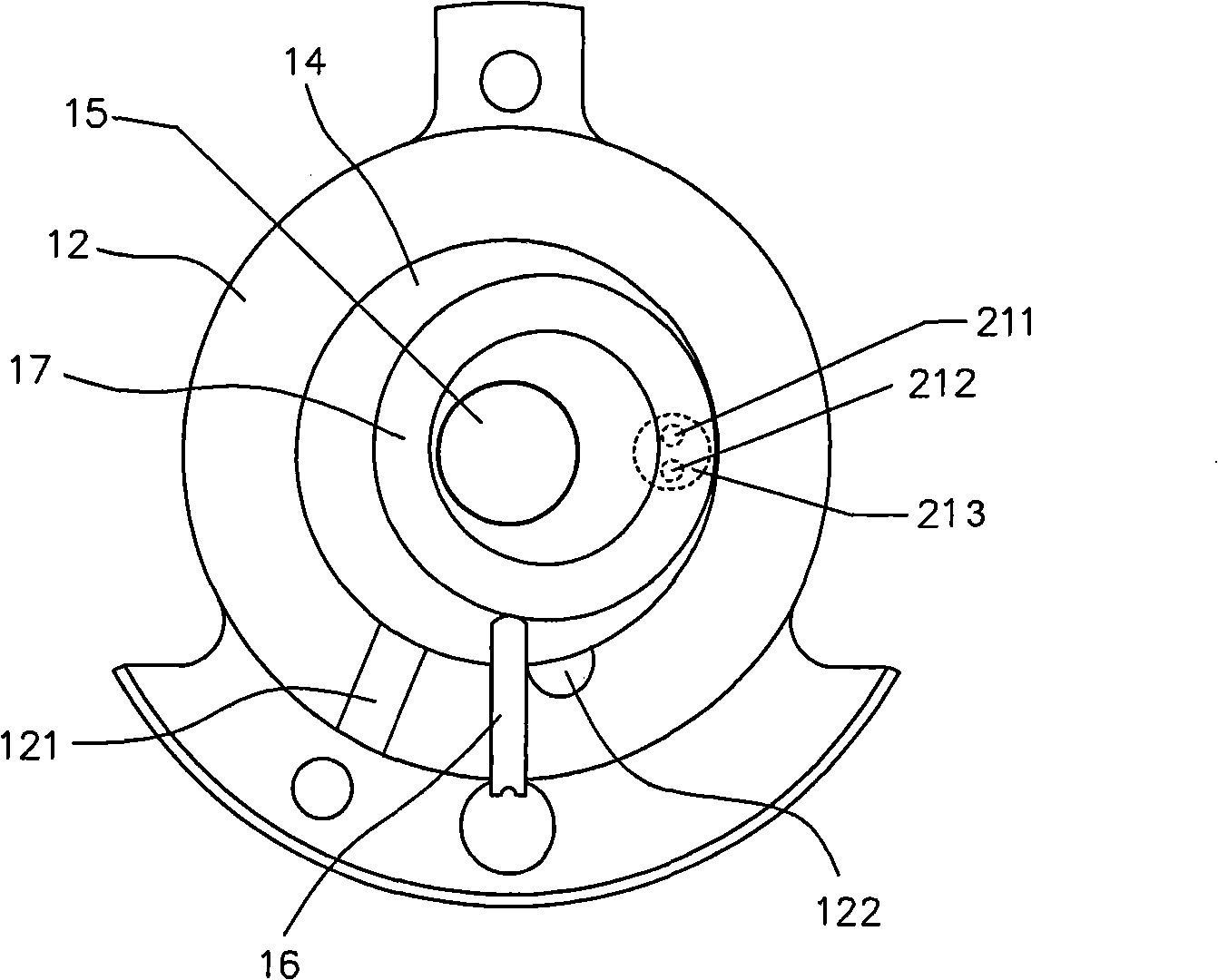

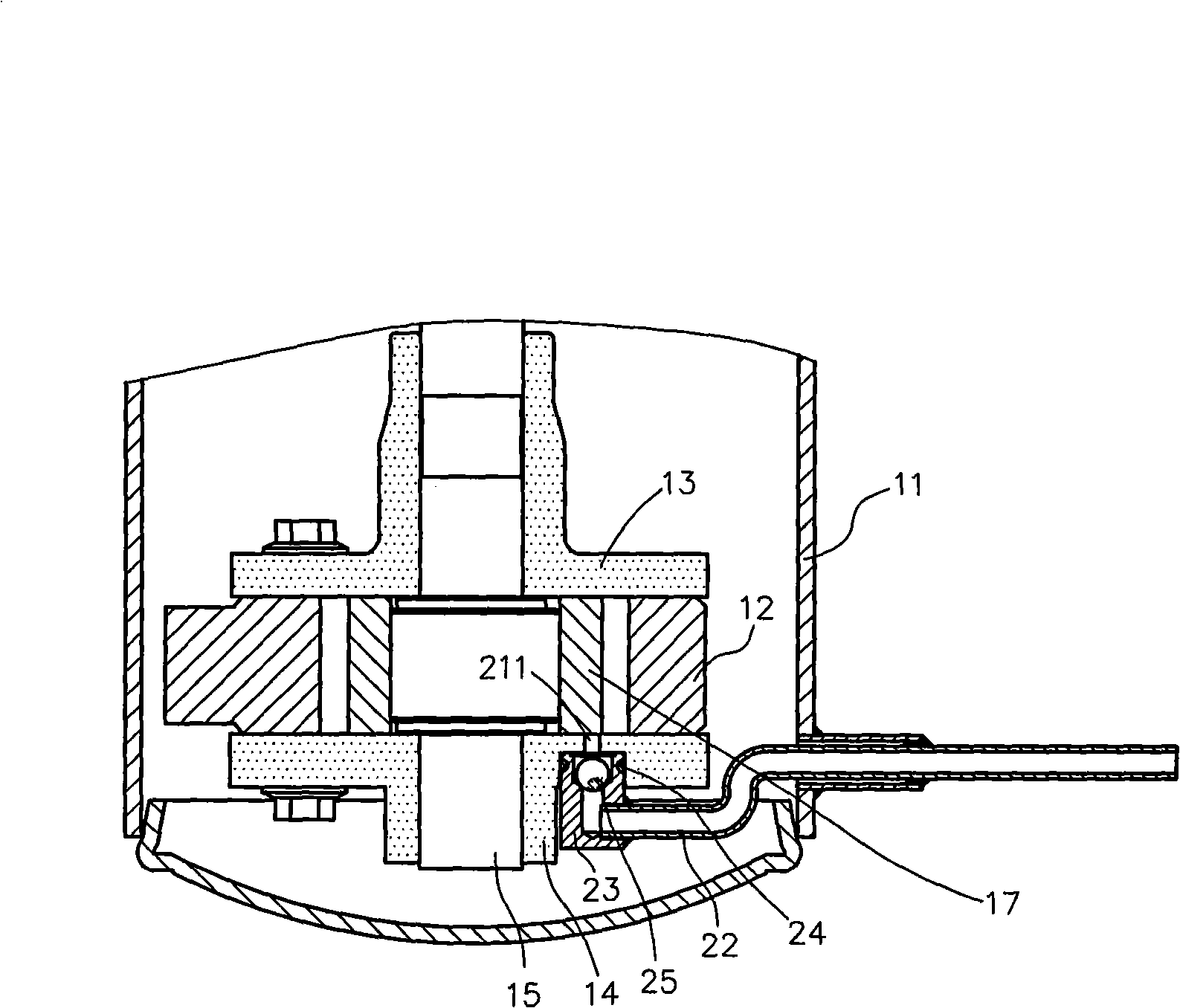

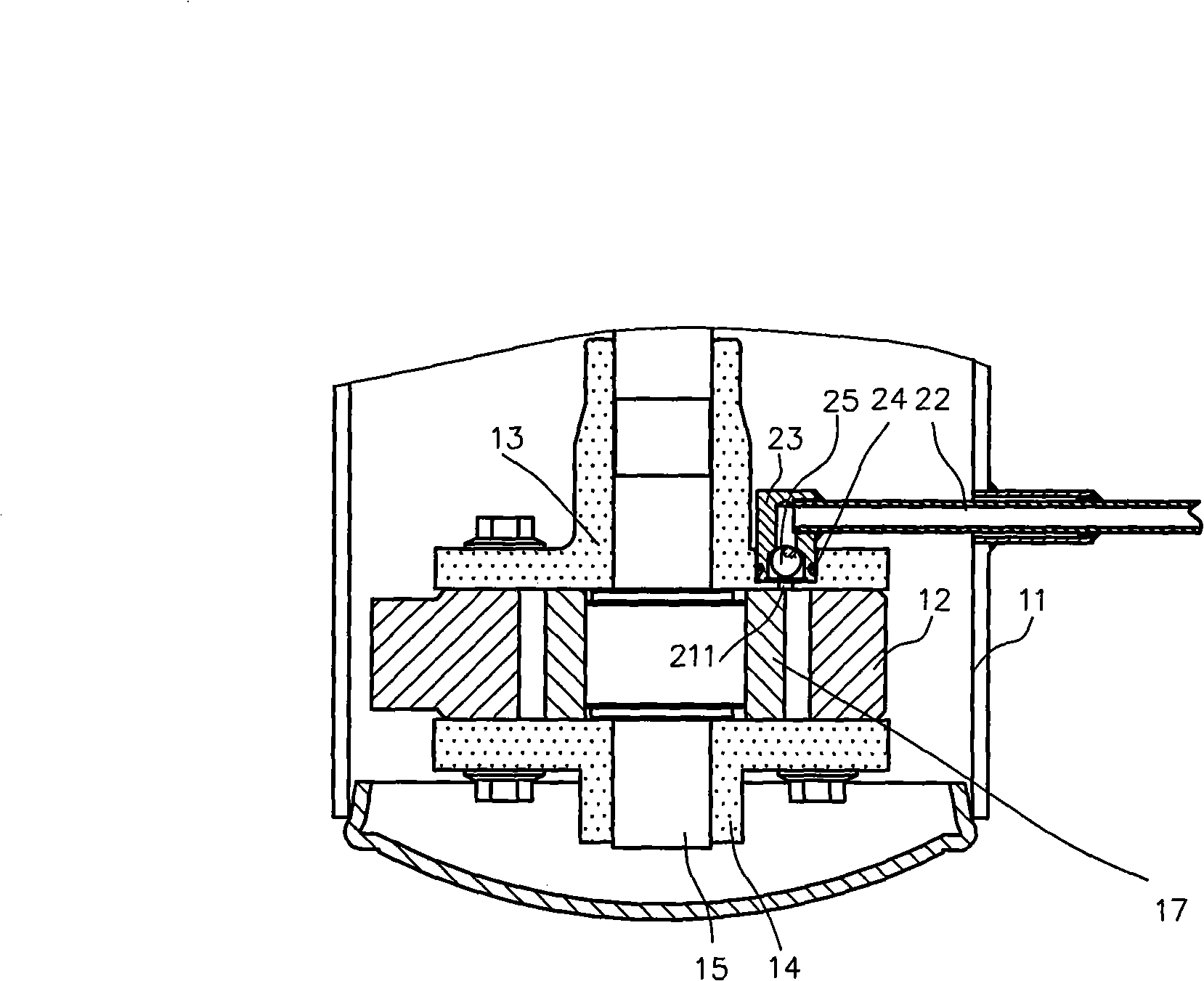

Rotation-type compressor with housing low pressure, control mode of coolant and oil return and applications thereof

ActiveCN101158352AProduction cost advantageEasy to useCompression machines with non-reversible cycleRotary piston pumpsControl mannerEngineering

A shell low-pressure rotary compressor and a control type and application for refrigerant and oil return of the compressor comprise a compression component and a motor component arranged in the shell. The compression component comprises one and more cylinders, pistons arranged in the cylinders, sliding pieces arranged in sliding piece trough of the cylinder, an eccentric crankshaft driving the piston and an upper bearing and a lower bearing supporting the eccentric crankshaft; the motor component comprises a motor rotor, and a motor stator; the shell is provided with a refrigerant diffluence device which is arranged on top or side surface of the shell; the refrigerant diffluence device comprises a diffluence pipe which is internally provided with a spring pipe which adjusts the diffluence rate. An air suction muffler is arranged between the motor component and the compression component; a radial spacing is arranged between the air suction muffler and a main bearing, and / or the motor rotor or the eccentric crankshaft or the upper bearing which is provided with a round plate. The invention has the advantages of high safety degree, low manufacture cost, smart operation, good lubrication performance, little oil consumption, high compression efficiency, and long service life.

Owner:GUANGDONG MEIZHI COMPRESSOR

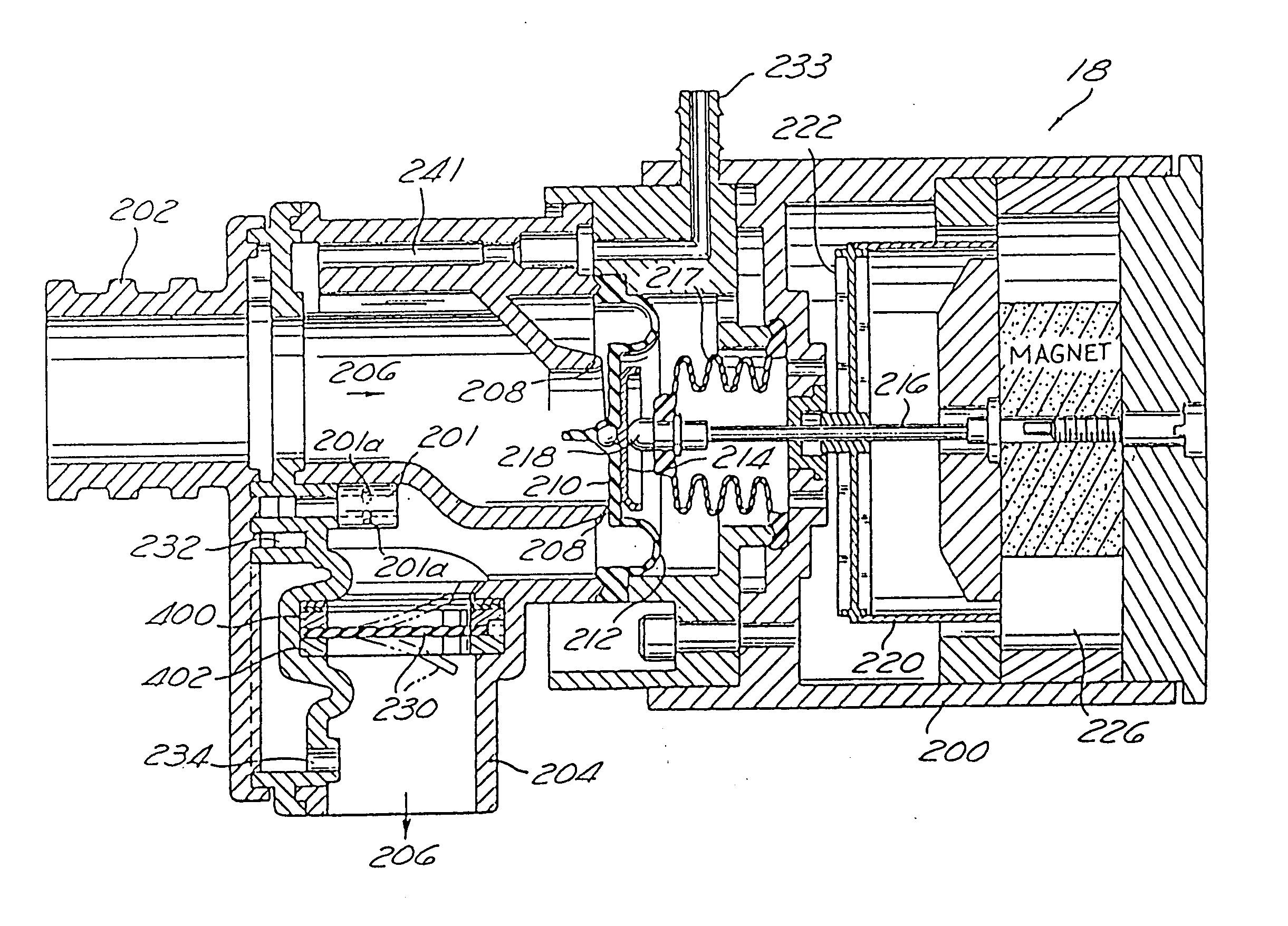

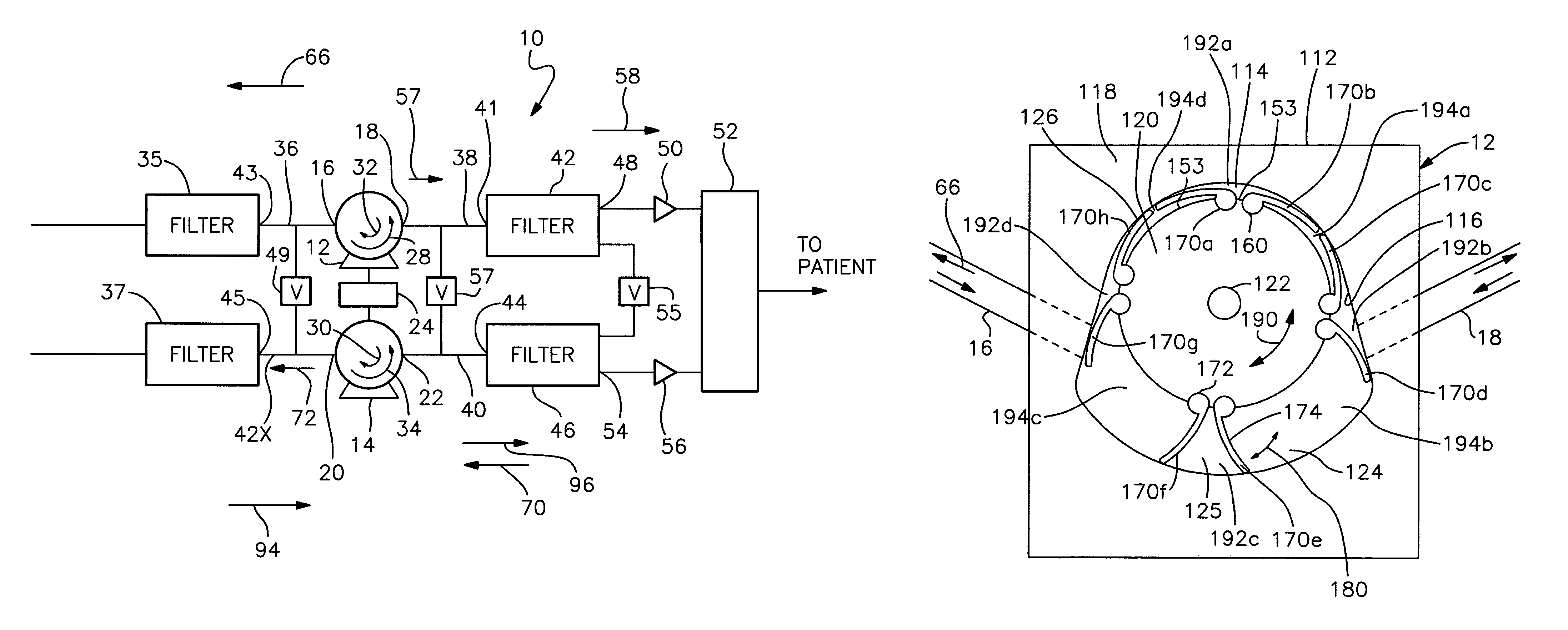

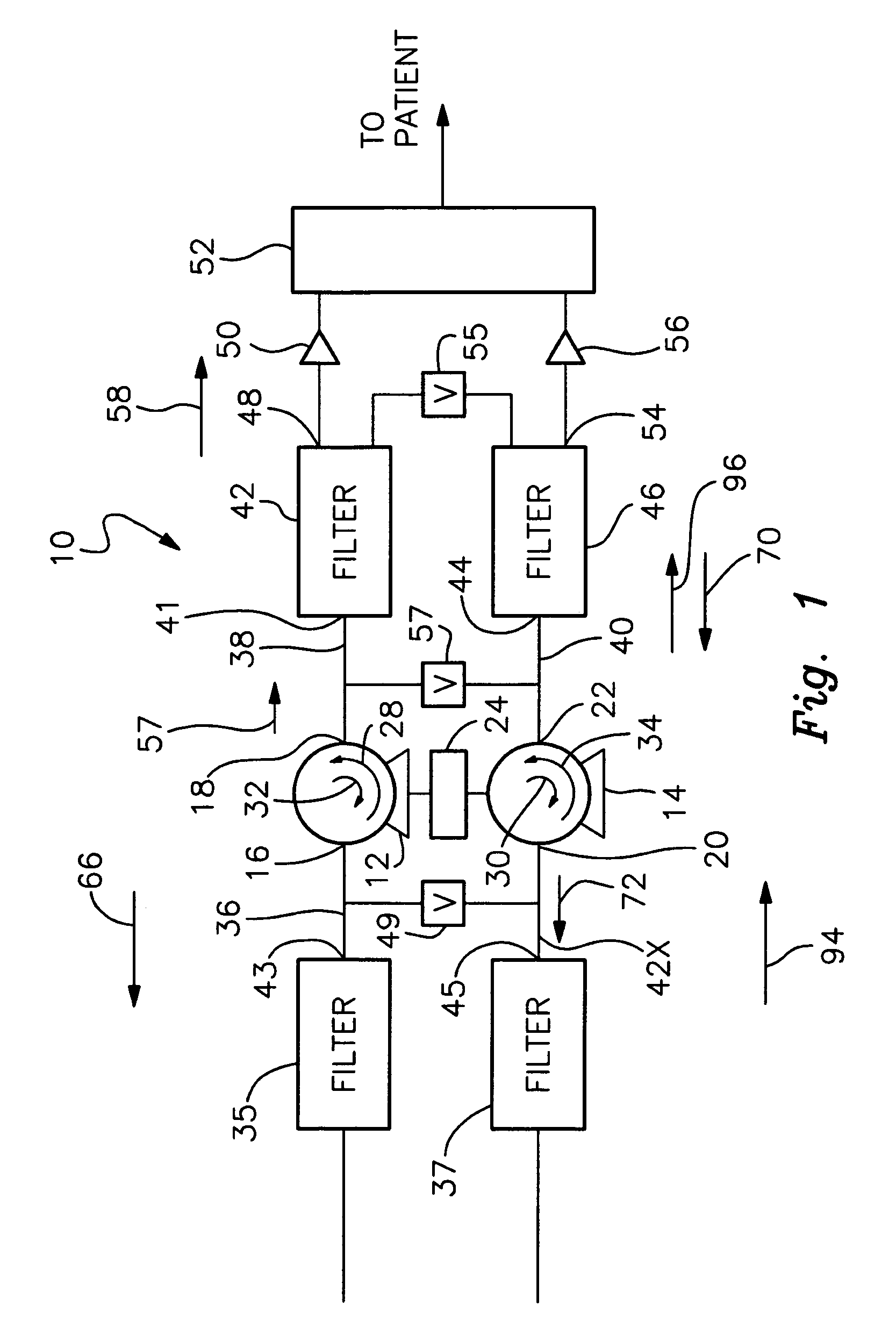

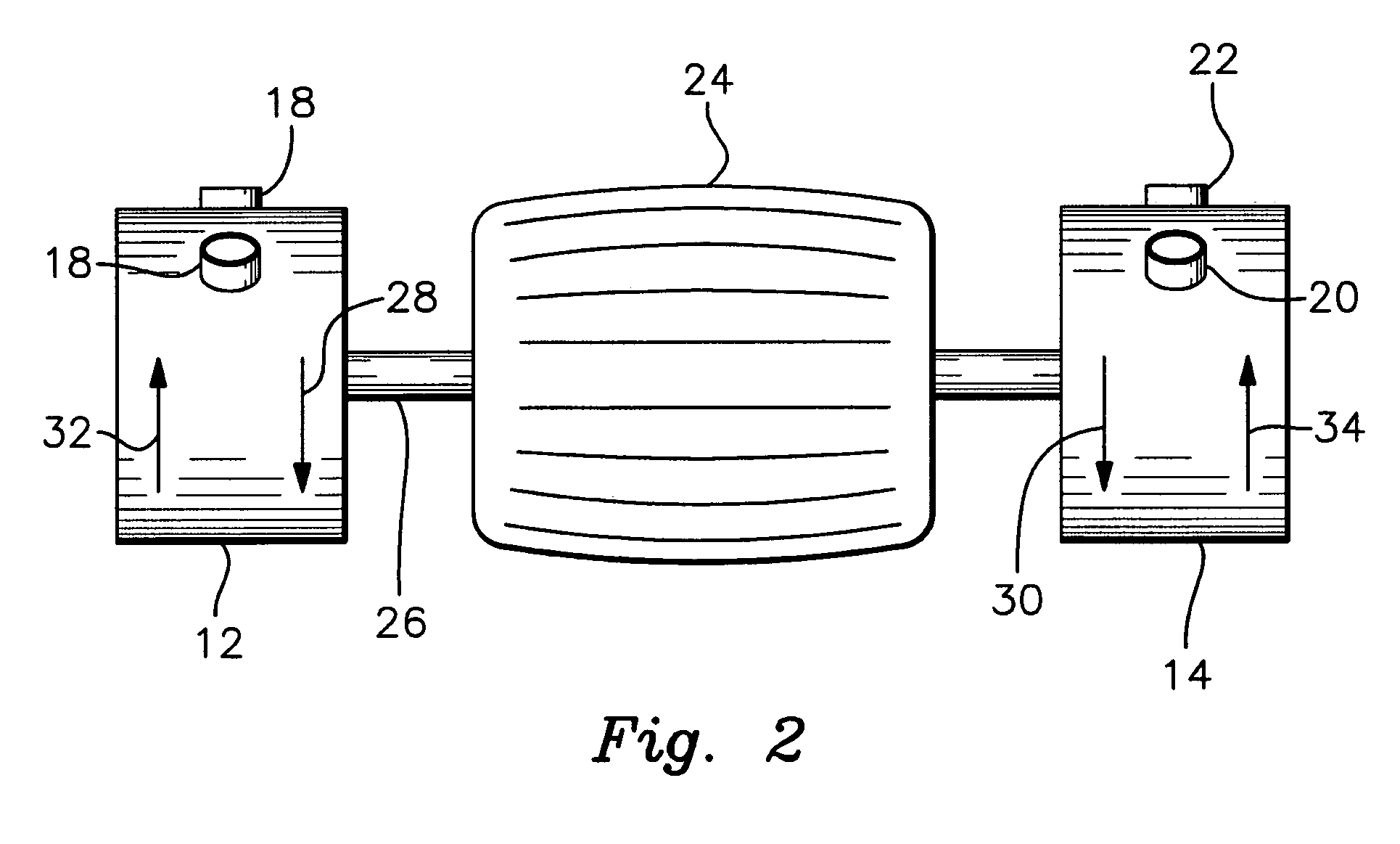

Valve-free oxygen concentrator featuring reversible compressors

InactiveUS7114932B1Enhance purging of nitrogenReduce deliveryRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringPear shaped

A pivoting vane rotary compressor includes a housing having a generally pear-shaped chamber. A rotor mounted within the chamber defines a main and constricted chamber regions. Reversible intake and exhaust ports alternately introduce air into and exhaust air from the chamber. The rotor carries pivotable vanes and a motor drives the rotor alternately in opposing first and second directions to open the vanes and define compartments that transmit the air through the chamber between the ports. Air introduced through one of the ports is compressed and discharged through the other port. A concentrator employs a pair of these compressors as well as associated filters and crossover valves.

Owner:BASSINE STUART

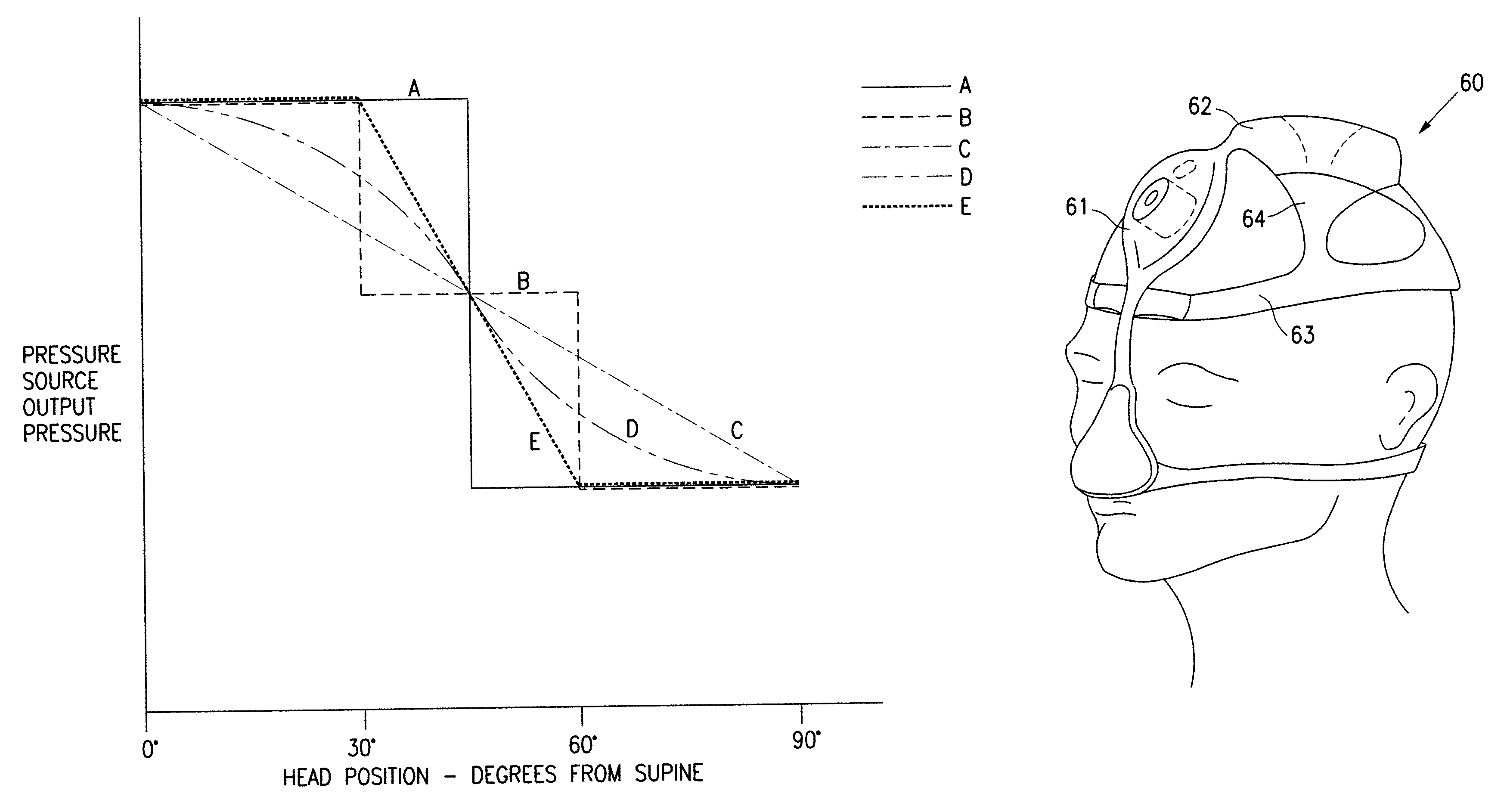

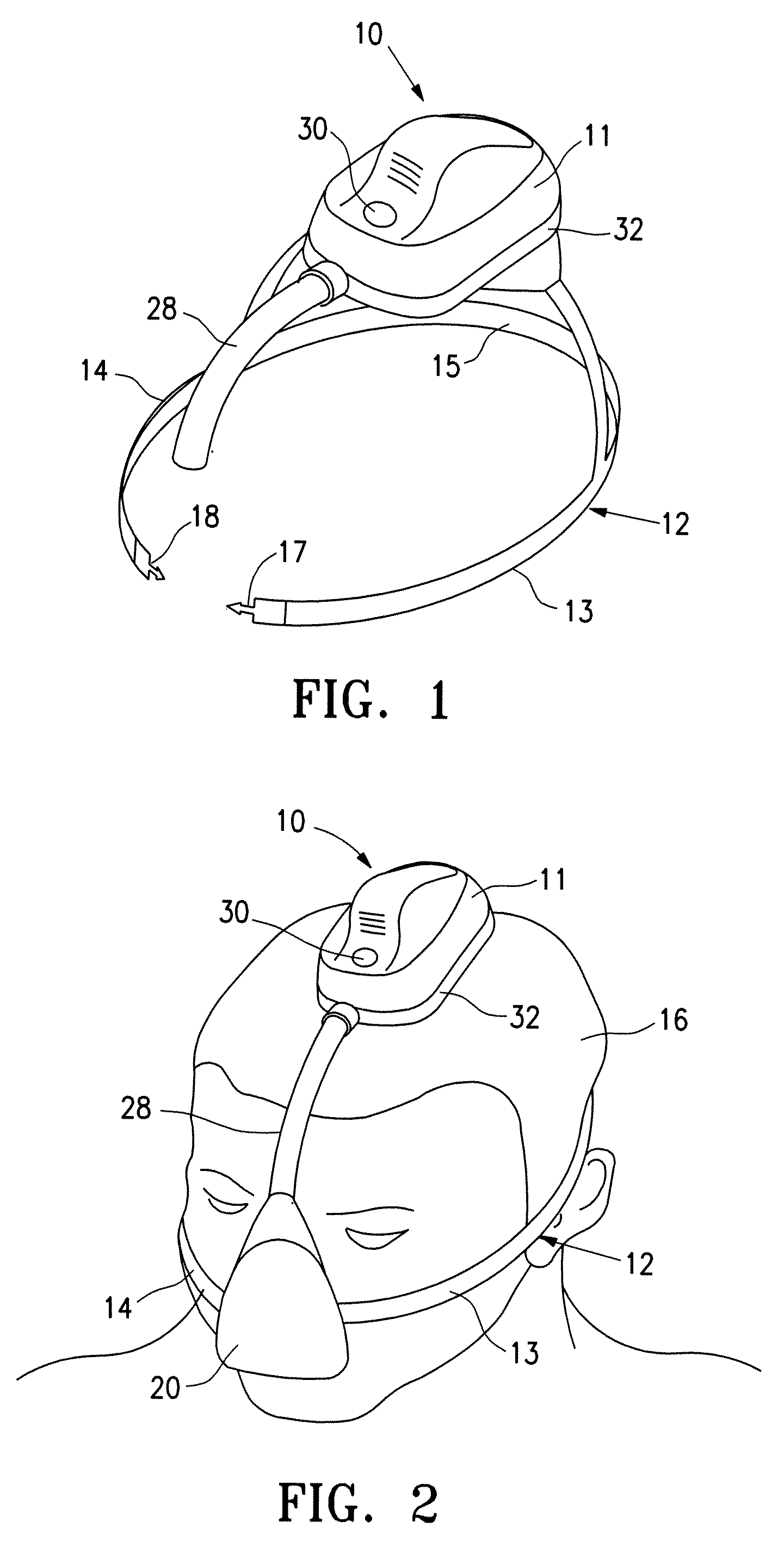

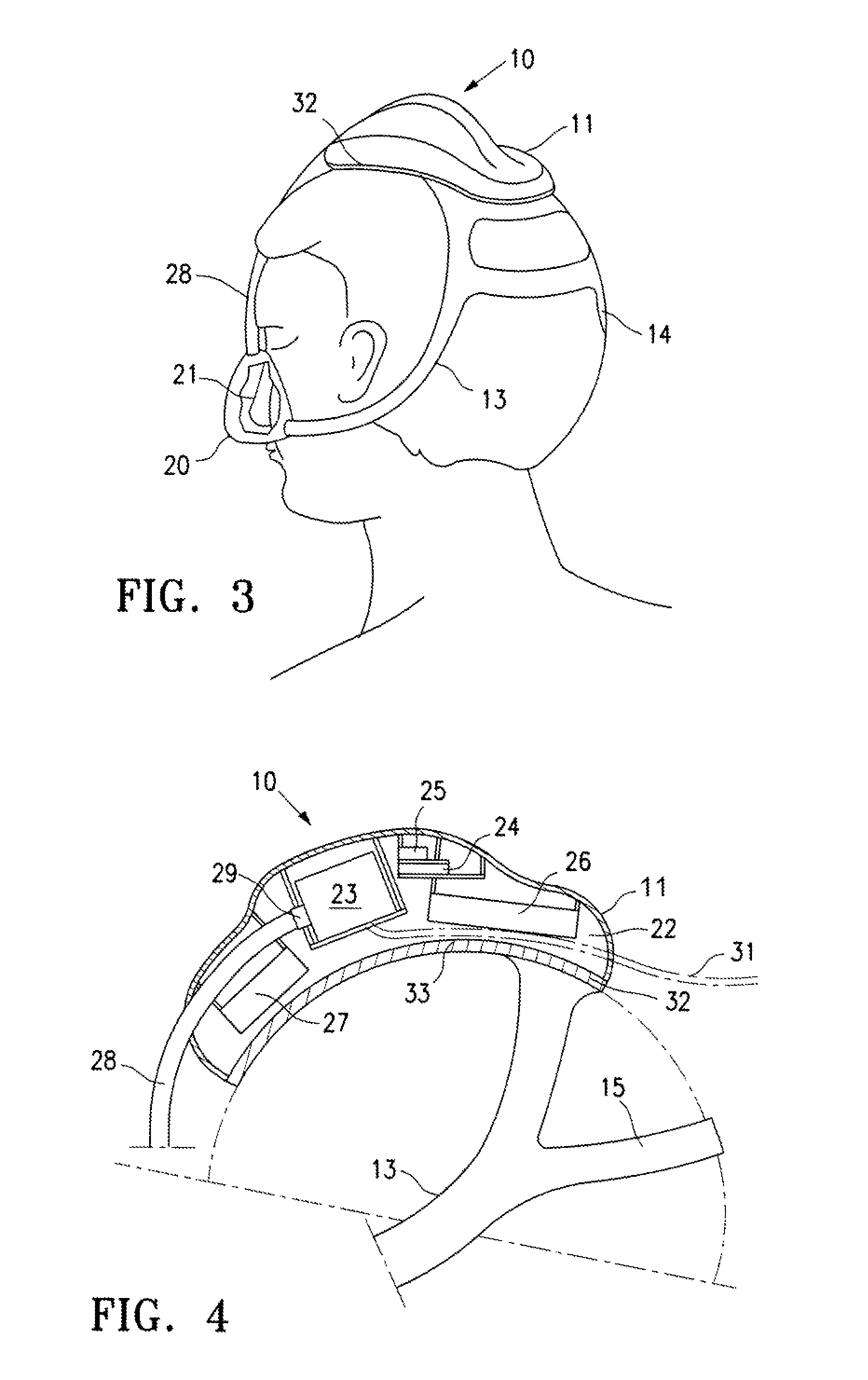

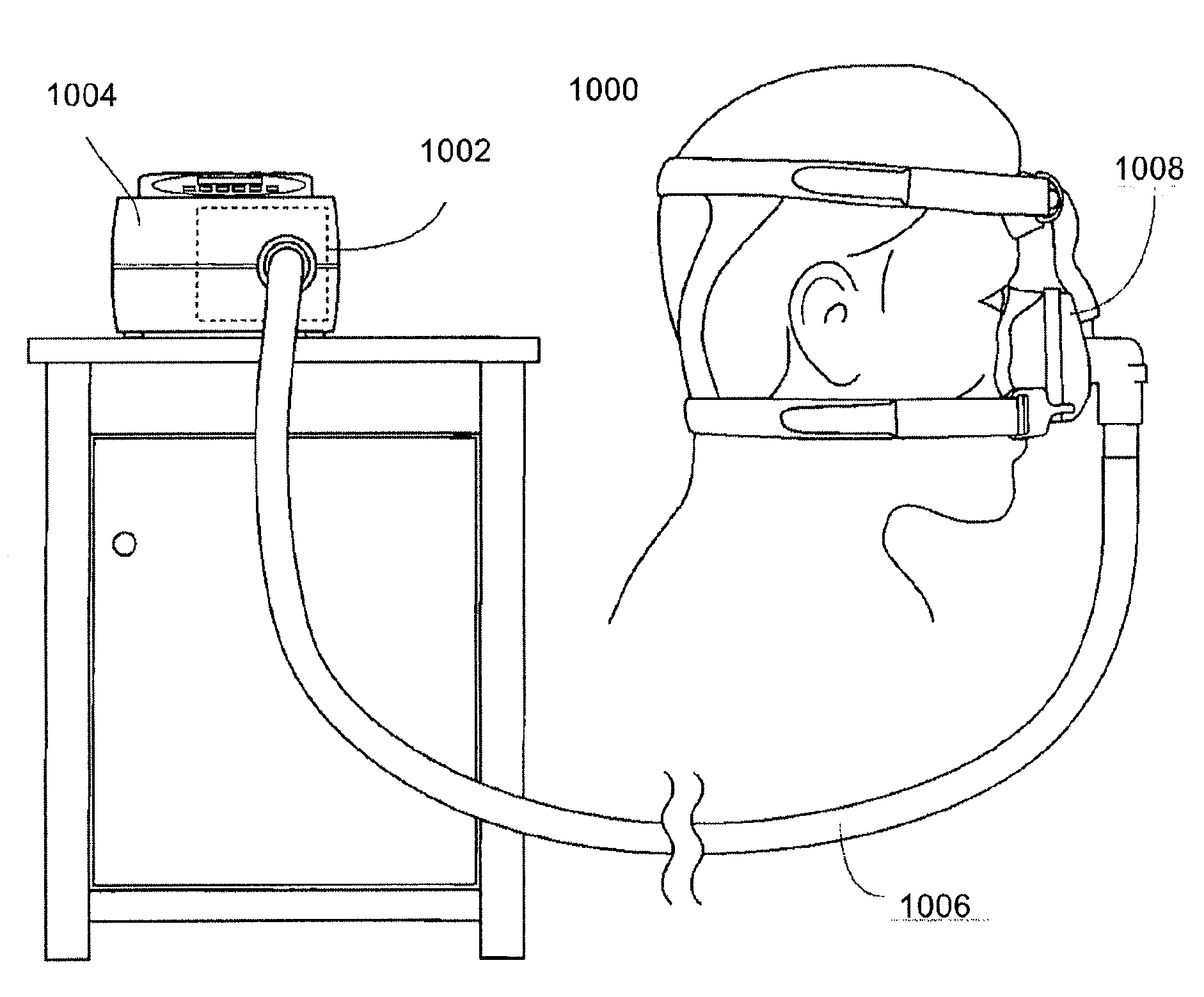

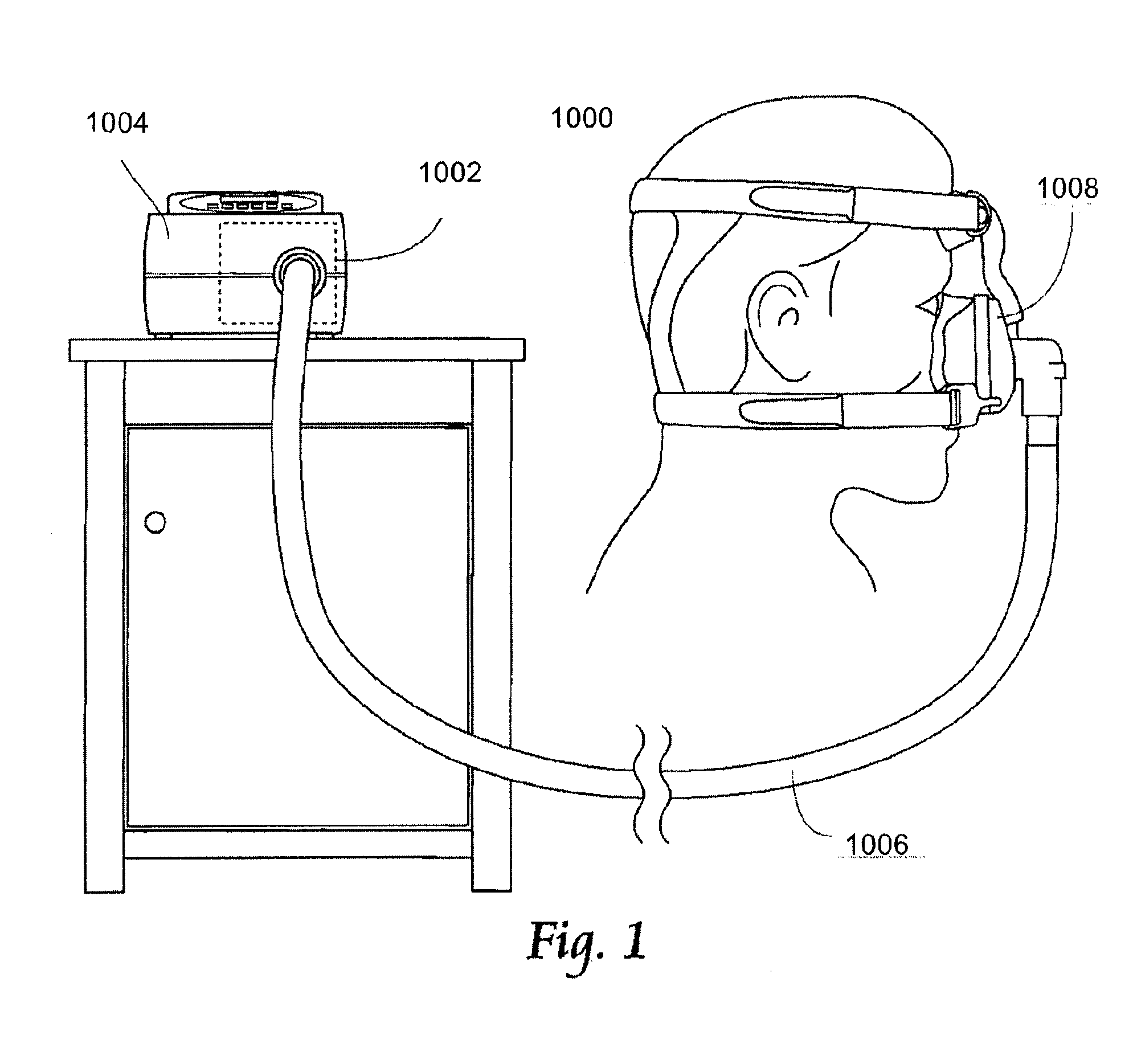

Positive airway pressure system with head position control

ActiveUS8327846B2Control pressureImprove patient comfortRespiratorsOperating means/releasing devices for valvesPositive airway pressureAccelerometer

The invention is directed to a positive airway pressure (PAP) system with a head mounted harness assembly with a housing and a head position sensor located within or secured to the housing that detects the position of a patient's head, and communicates this head position information to a controller of the system which may be disposed within the housing having the position sensor or a second housing. The controller varies the output pressure of the pressure source, e.g. a rotary compressor, based, at least in part, on the head position information provided by the head position sensor. In a preferred embodiment, the position sensor is an accelerometer.

Owner:RESMED INC

Position control devices and methods for use with positive airway pressure systems

ActiveUS20150367092A1Precise positioningImprove patient comfortOperating means/releasing devices for valvesRespiratory masksPositive airway pressureEngineering

Described here are positive airway pressure (PAP) systems and methods with various mechanisms for altering the air pressure based in part on the head position of the user. This can be achieved actively or passively. Passively, pressure is altered when head position is altered, as gravity acts to open or close venting elements. Actively, head position information can then be communicated to a controller of the system which may be disposed within the housing having the position sensor or within a separate housing. The controller varies the output pressure of the pressure source, e.g. a rotary compressor, based, at least in part, on the head position information provided.

Owner:RESMED INC

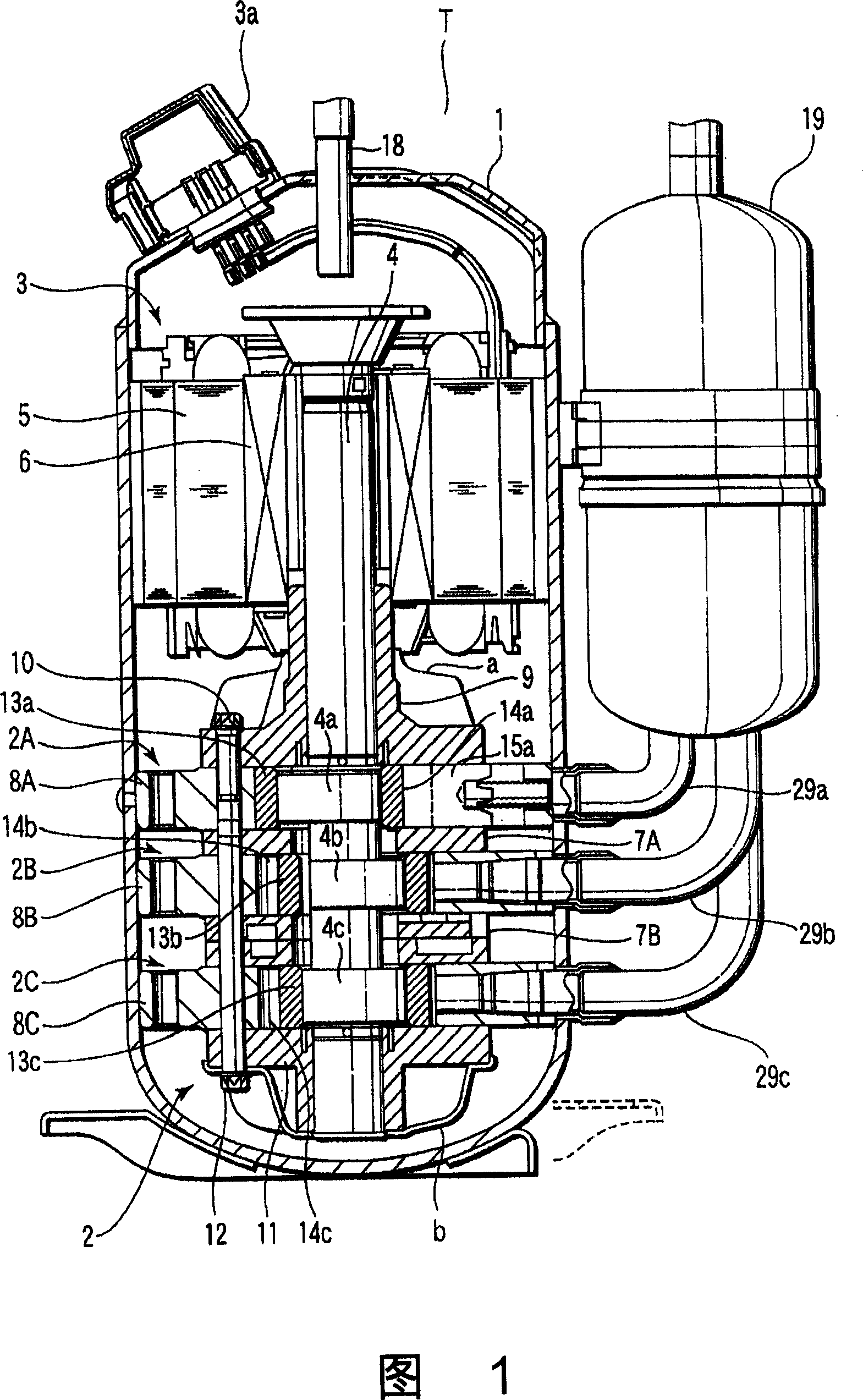

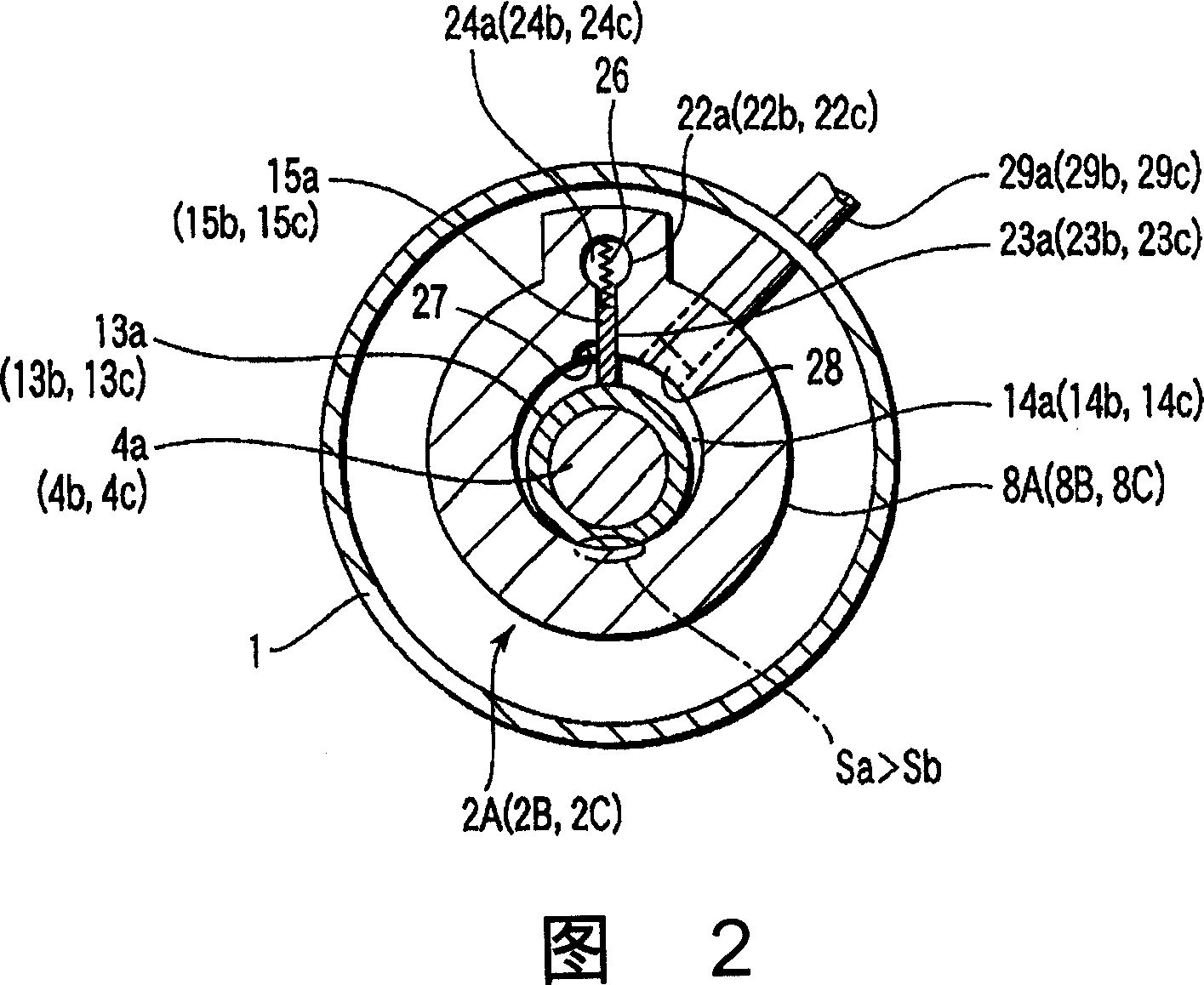

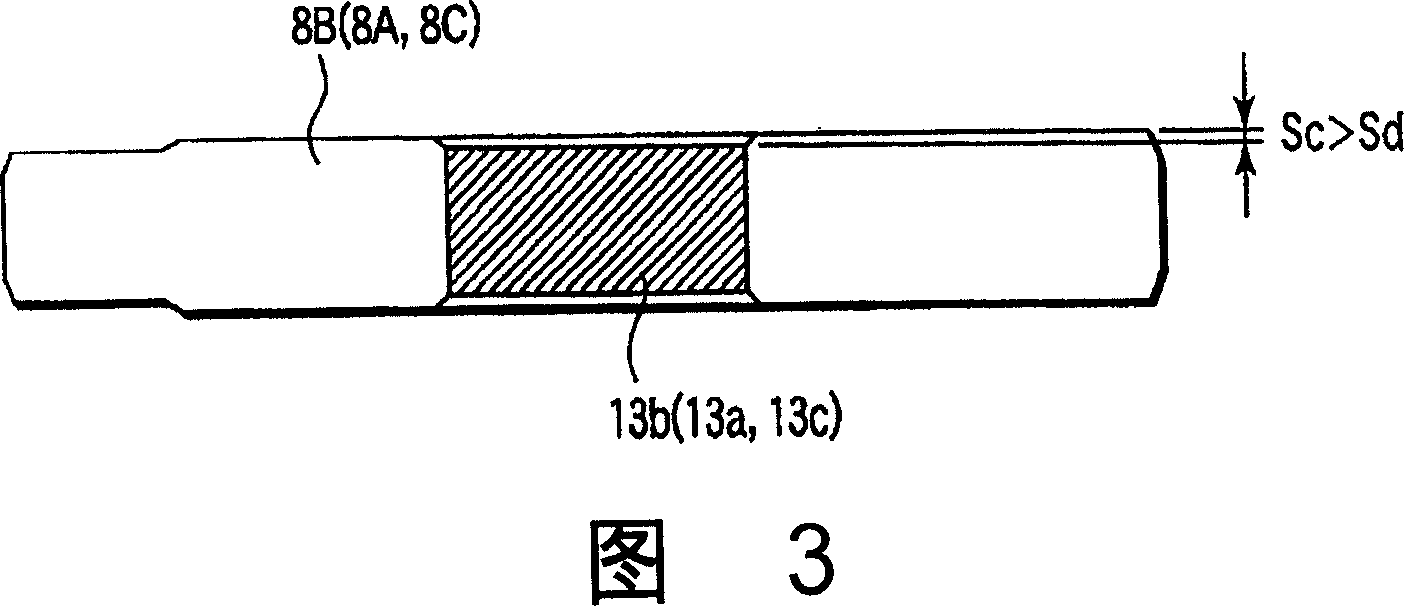

Multi-cylinder rotary compressor

InactiveCN1950611AReduced OscillationImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsMachines/enginesEngineeringElectric motor

A multi-cylinder rotary compressor is constructed by receiving in a sealed chamber (1) a rotating shaft (4), an electric motor section (3), and first to third compression mechanism sections (2A-2C). The rotating shaft (4) is rotatably supported by bearings (9, 11). The compression mechanism sections (2A-2C) respectively have cylinder chambers (14a-14c) in which eccentric sections (4a-4c) and eccentric rollers (13a-13c) provided on the rotating shaft are received, cylinders (8A-8C) having the cylinders chambers, and blades (15a-15c) of which each head edge is in contact with the peripheral surface of the eccentric roller to partition the cylinder chamber into two. At least one of the two clearances, out of clearances in sliding sections of the compression mechanism sections, of the second compression mechanism section not in contact with the bearings is set greater than the clearances in the first and third compression mechanism sections in contact with the bearings. Run-out of the rotating shaft involved in its rotation can be reduced to improve compression efficiency.

Owner:TOSHIBA CARRIER CORP

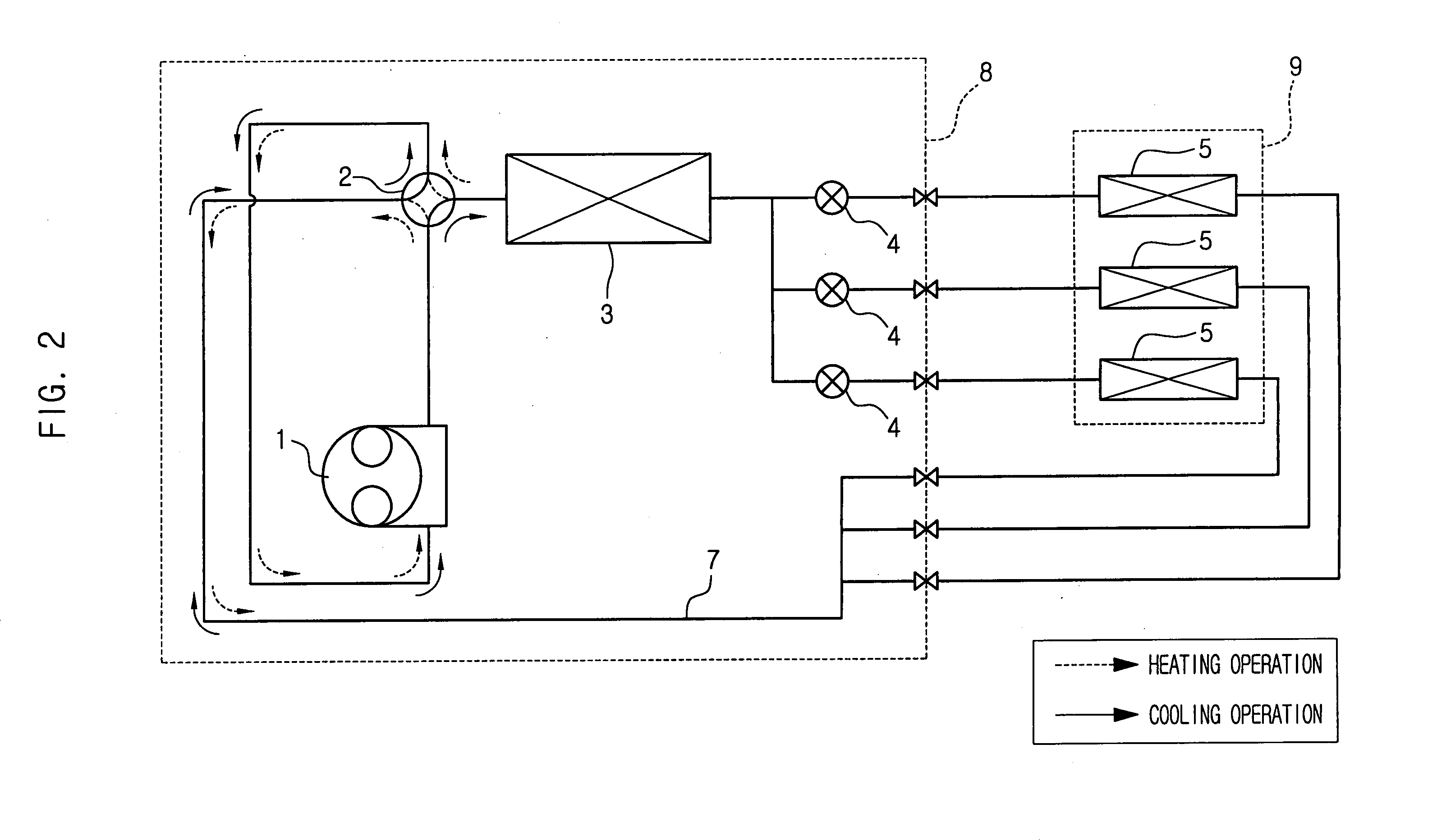

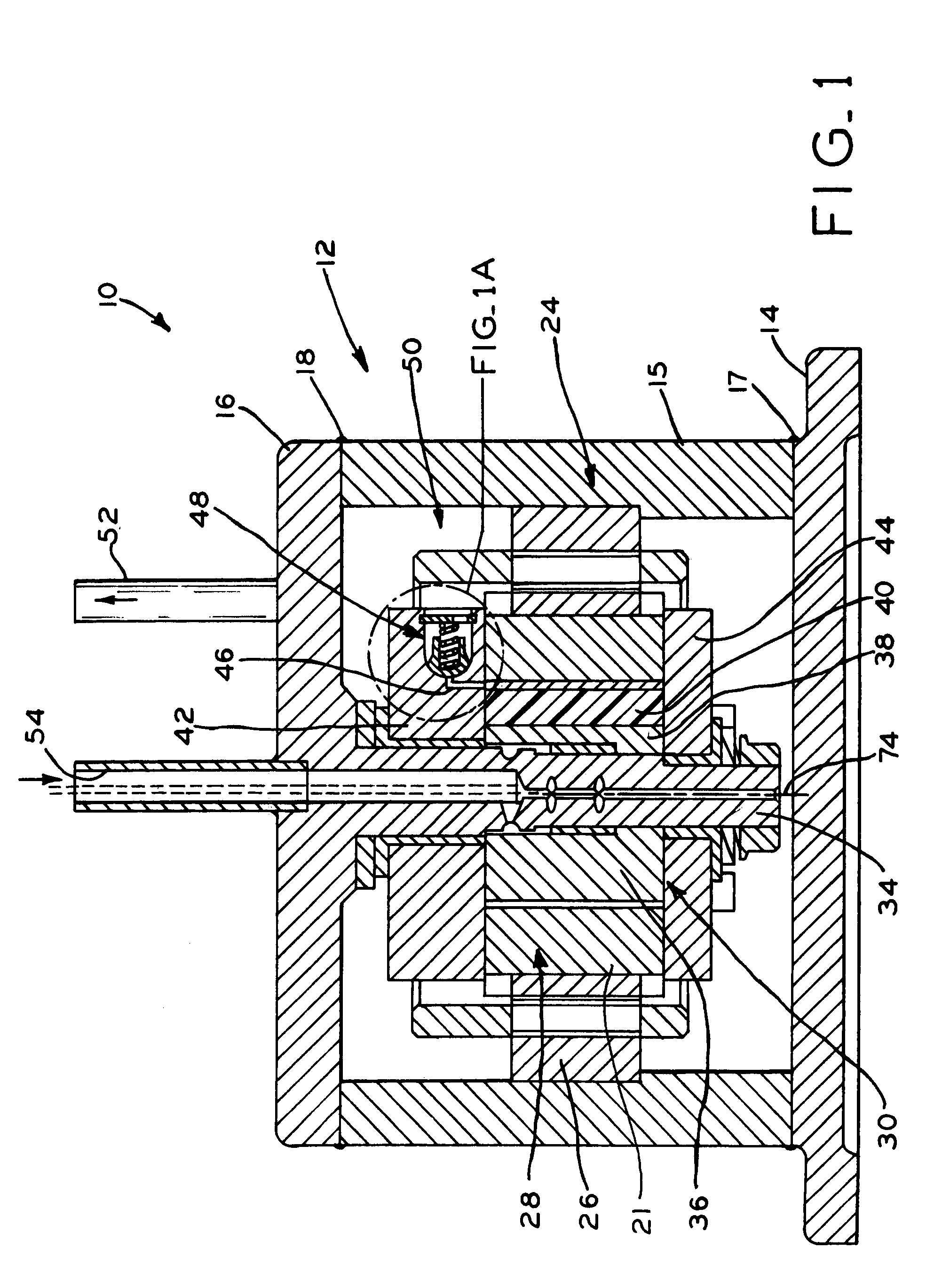

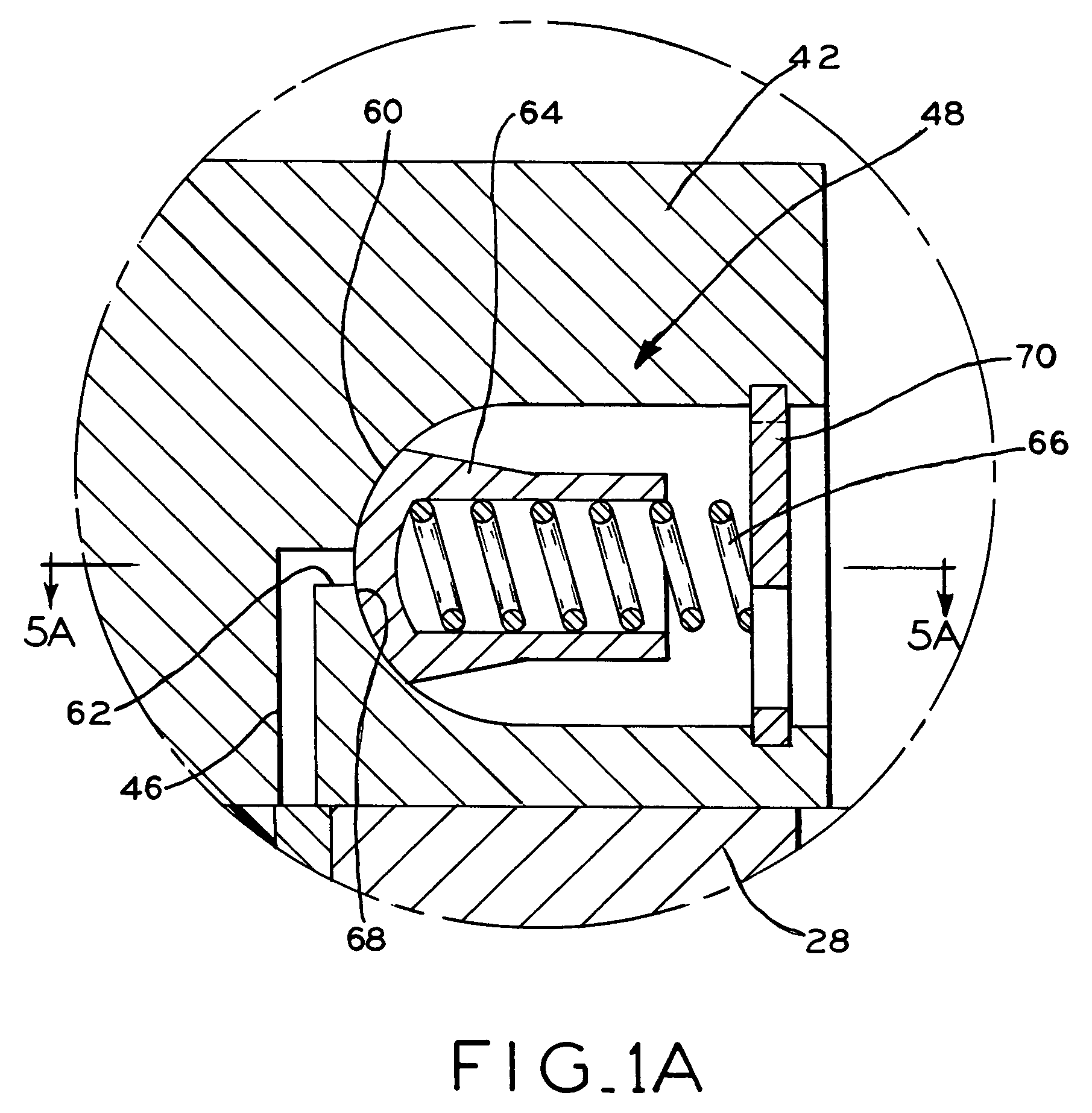

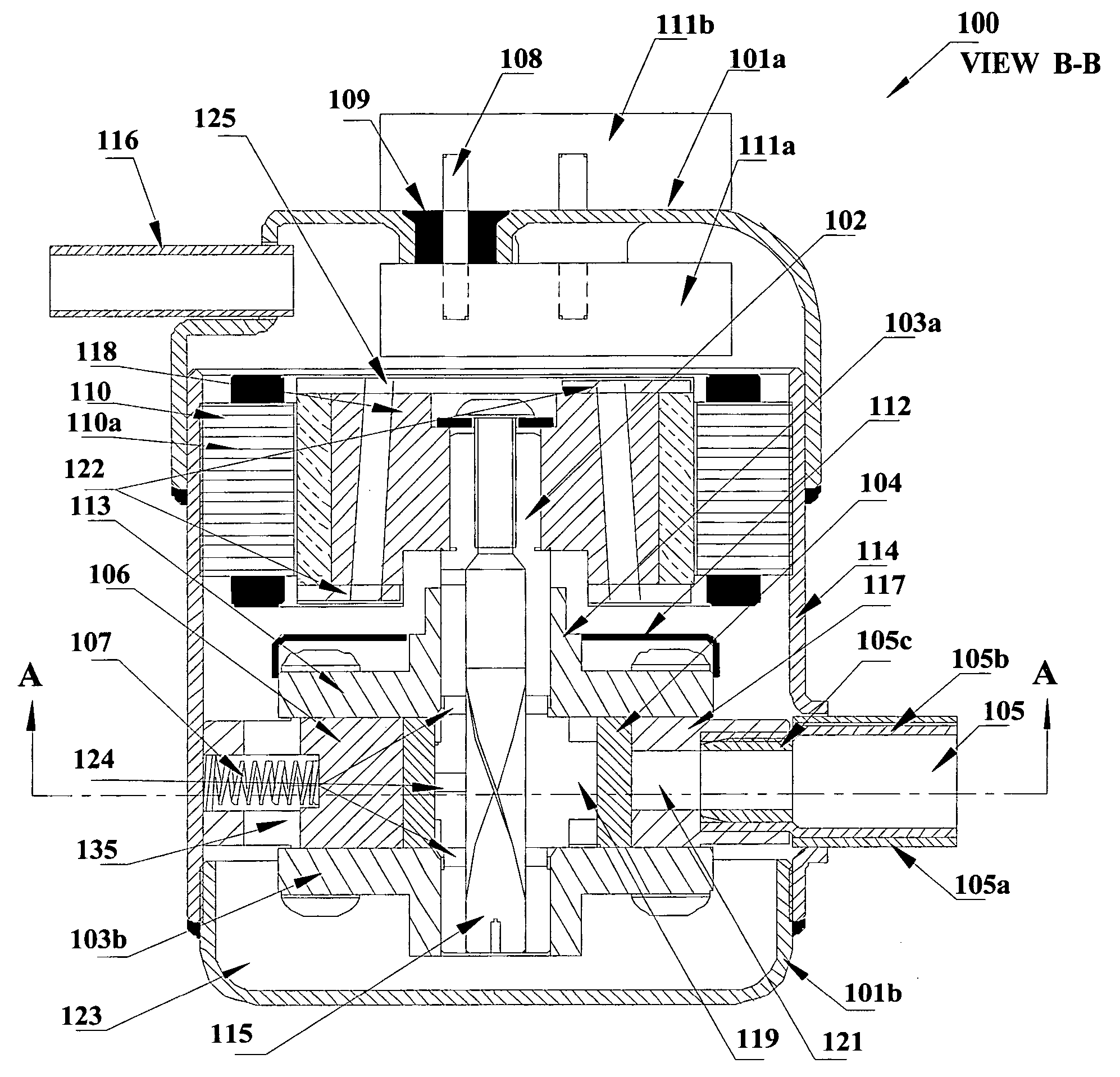

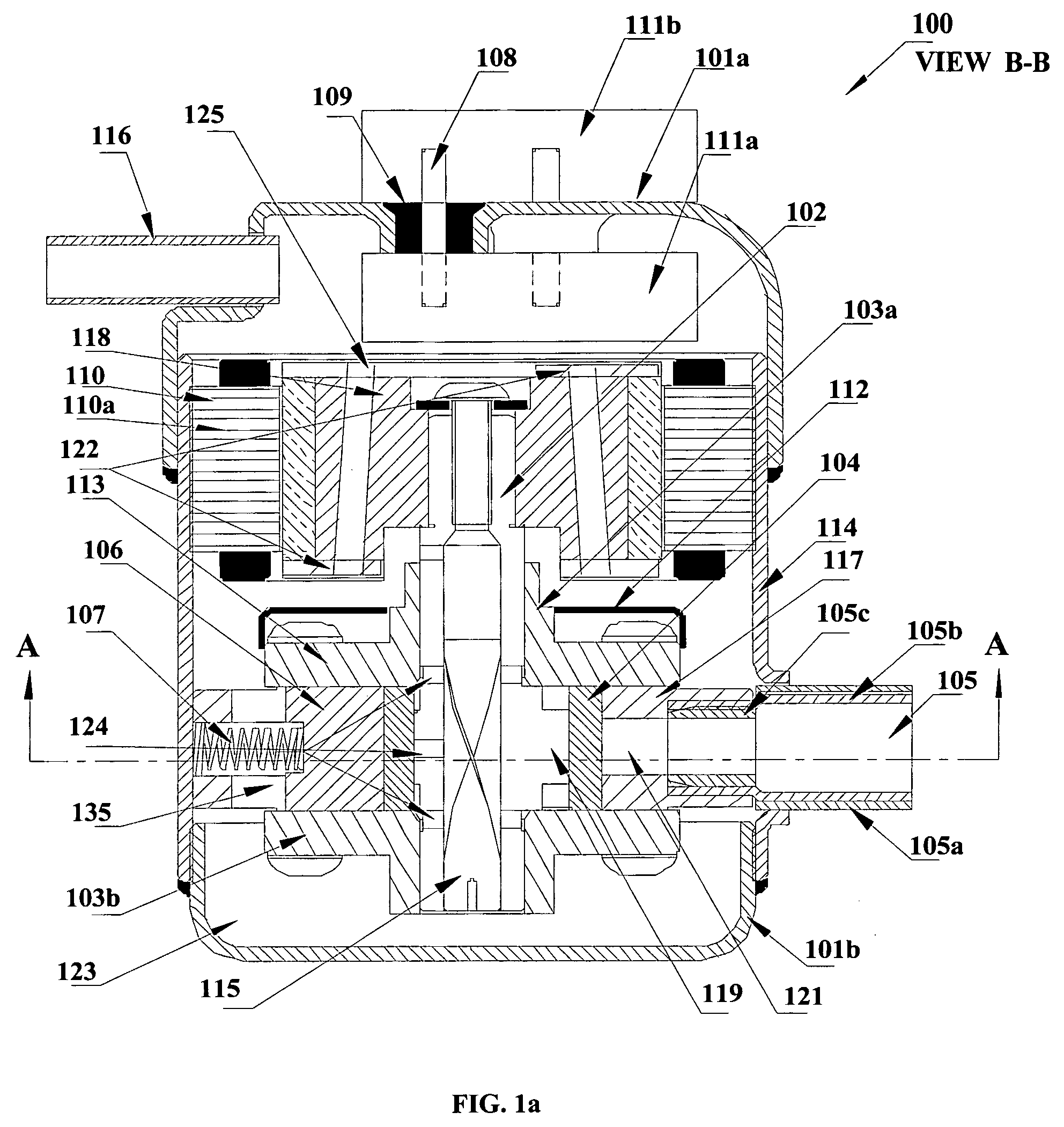

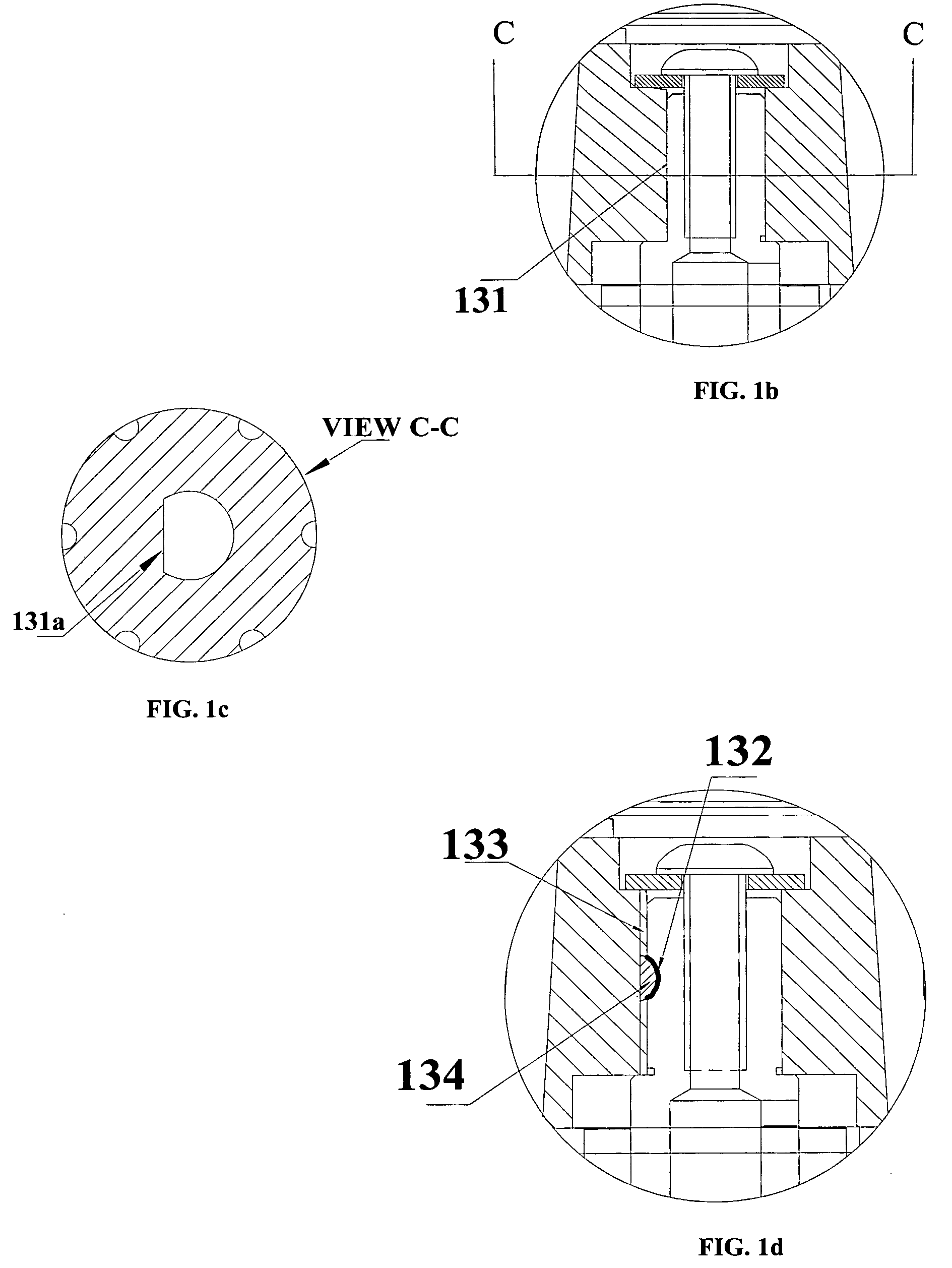

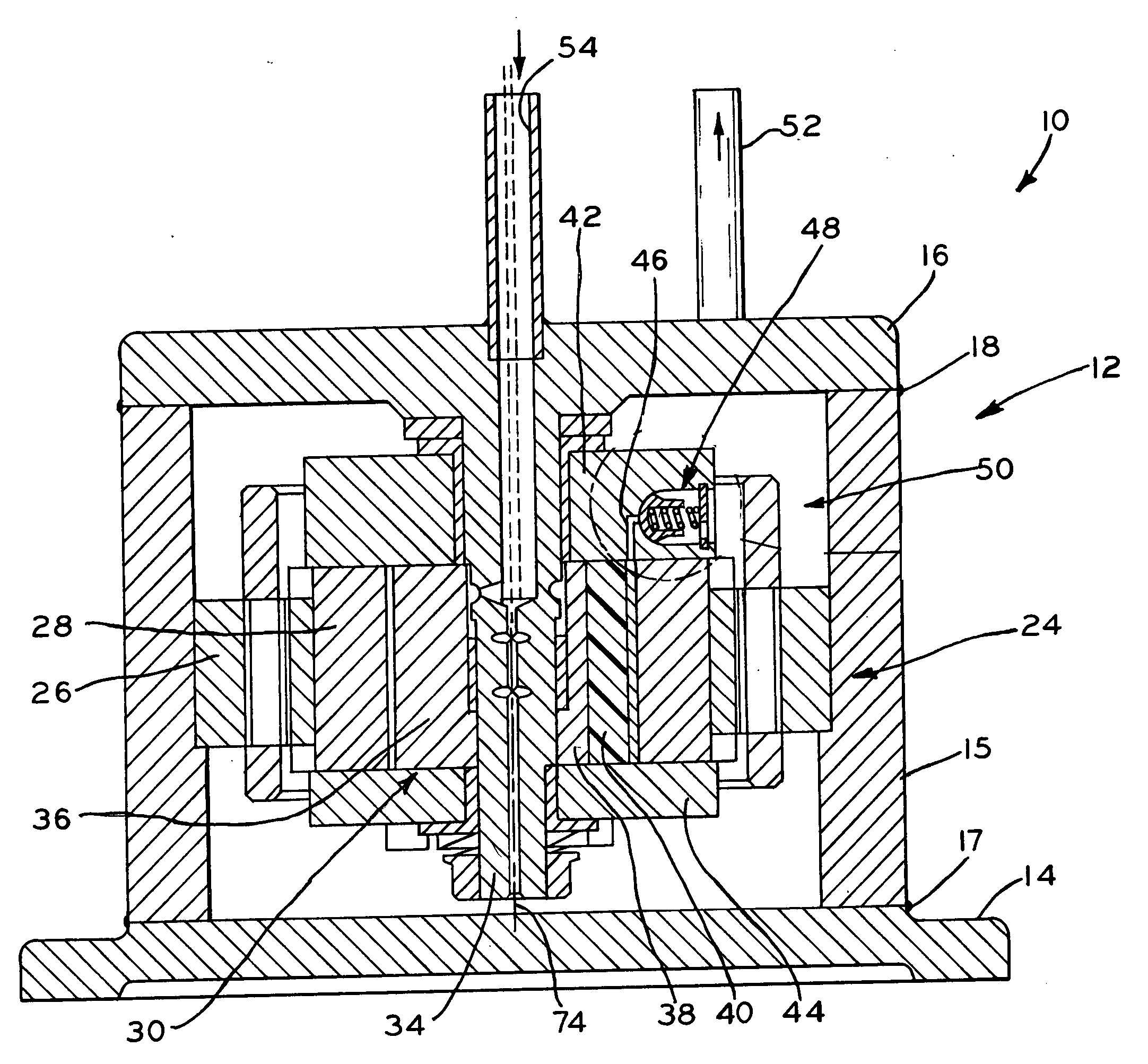

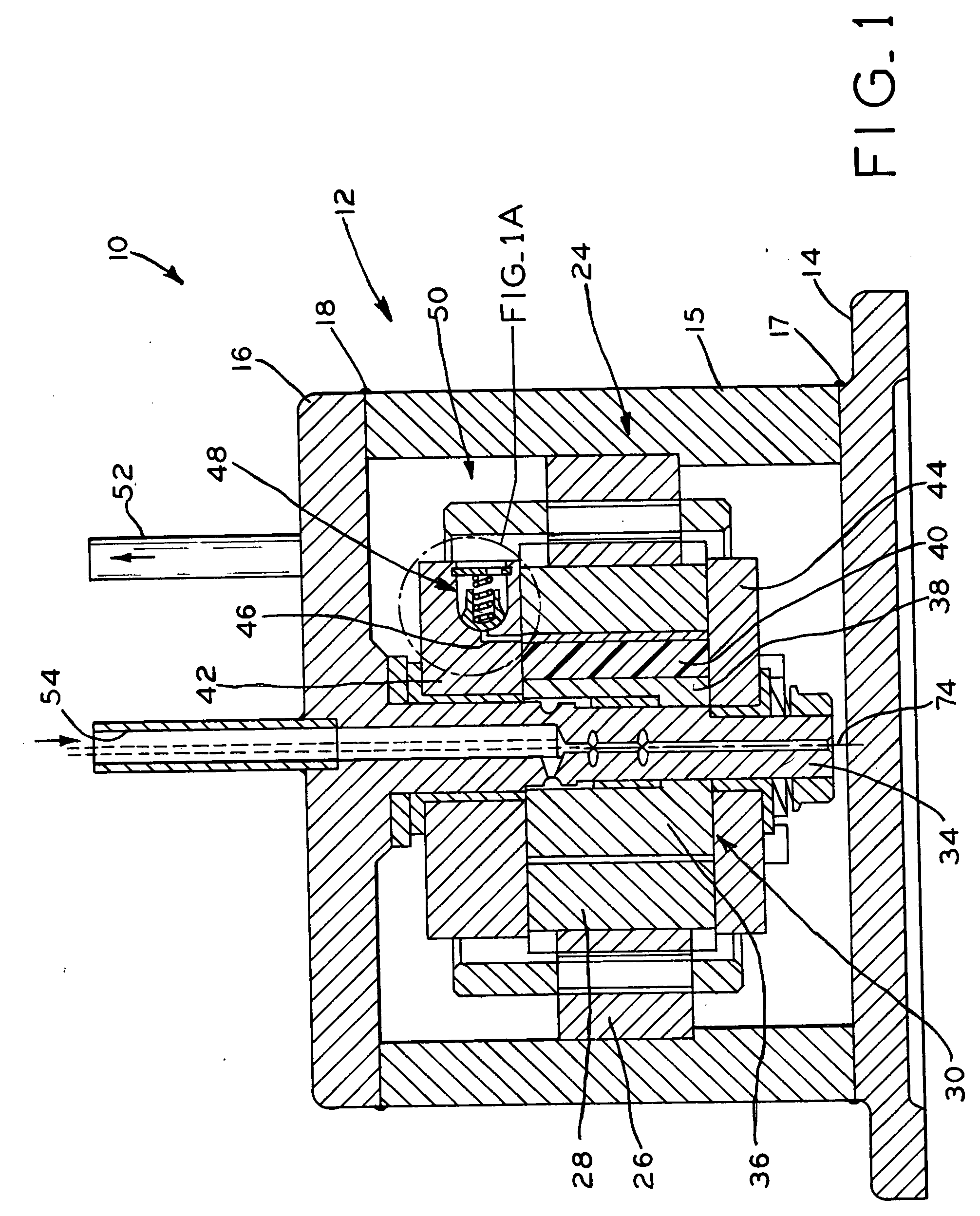

Rotary compressor having a discharge valve

InactiveUS20060159570A1Improper seatingInsufficient compressionCheck valvesEqualizing valvesEngineeringVALVE PORT

A rotary compressor having a housing, a rotor positioned within the housing defining a compression chamber, the rotor rotatable about an axis of rotation, a discharge port in the rotor in fluid communication with the compression chamber, and a valve assembly mounted to the rotor to regulate the pressure of the fluid within the compression chamber. In one. embodiment, the valve assembly is canted or obliquely aligned with respect to the axis of rotation of the rotor and a radial axis perpendicular to and intersecting the axis of rotation. Aligning the valve assembly in this way allows the displacement of the valve head of the valve assembly to be substantially collinear with forces acting on the valve head.

Owner:TECUMSEH PROD CO

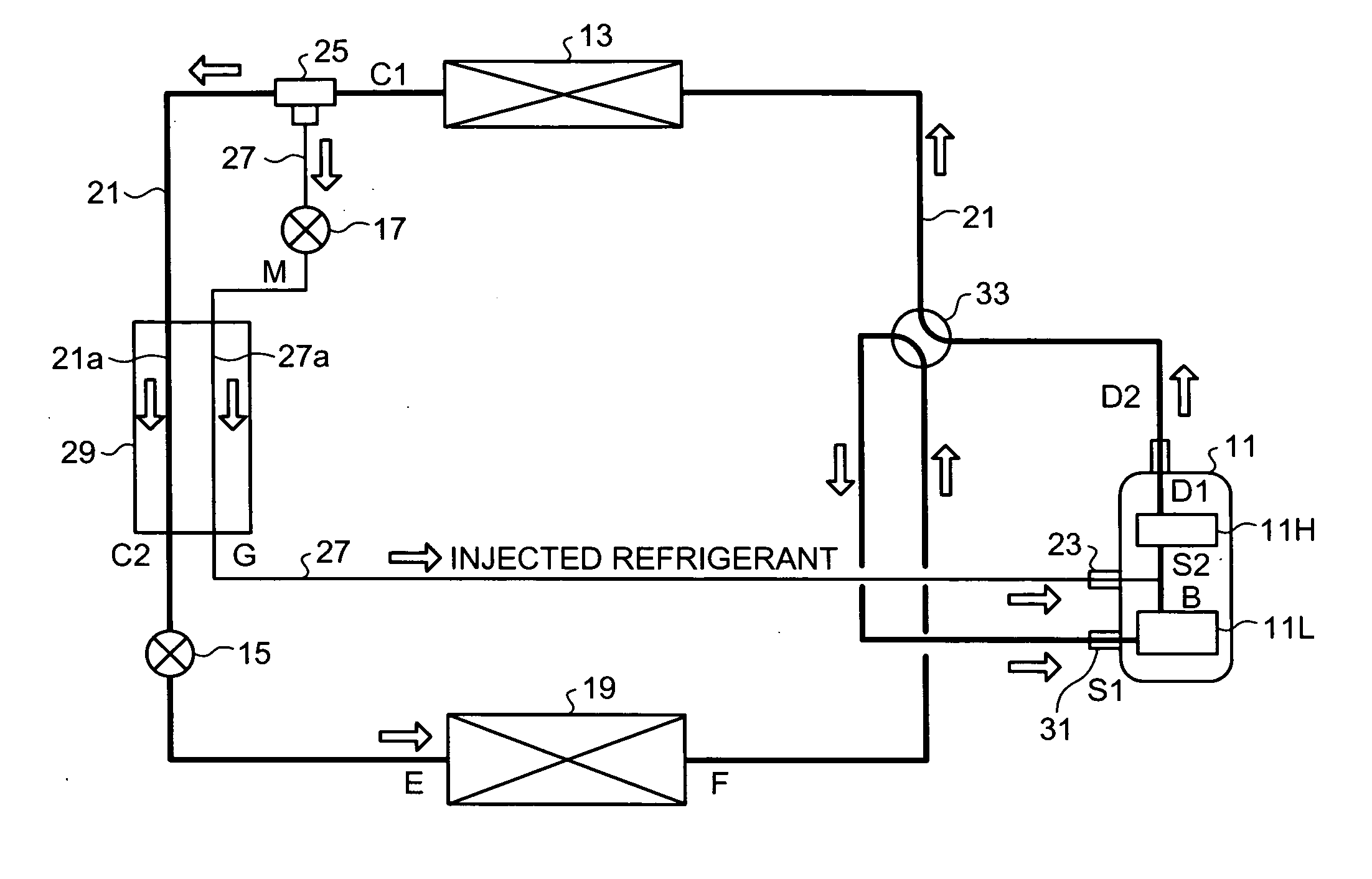

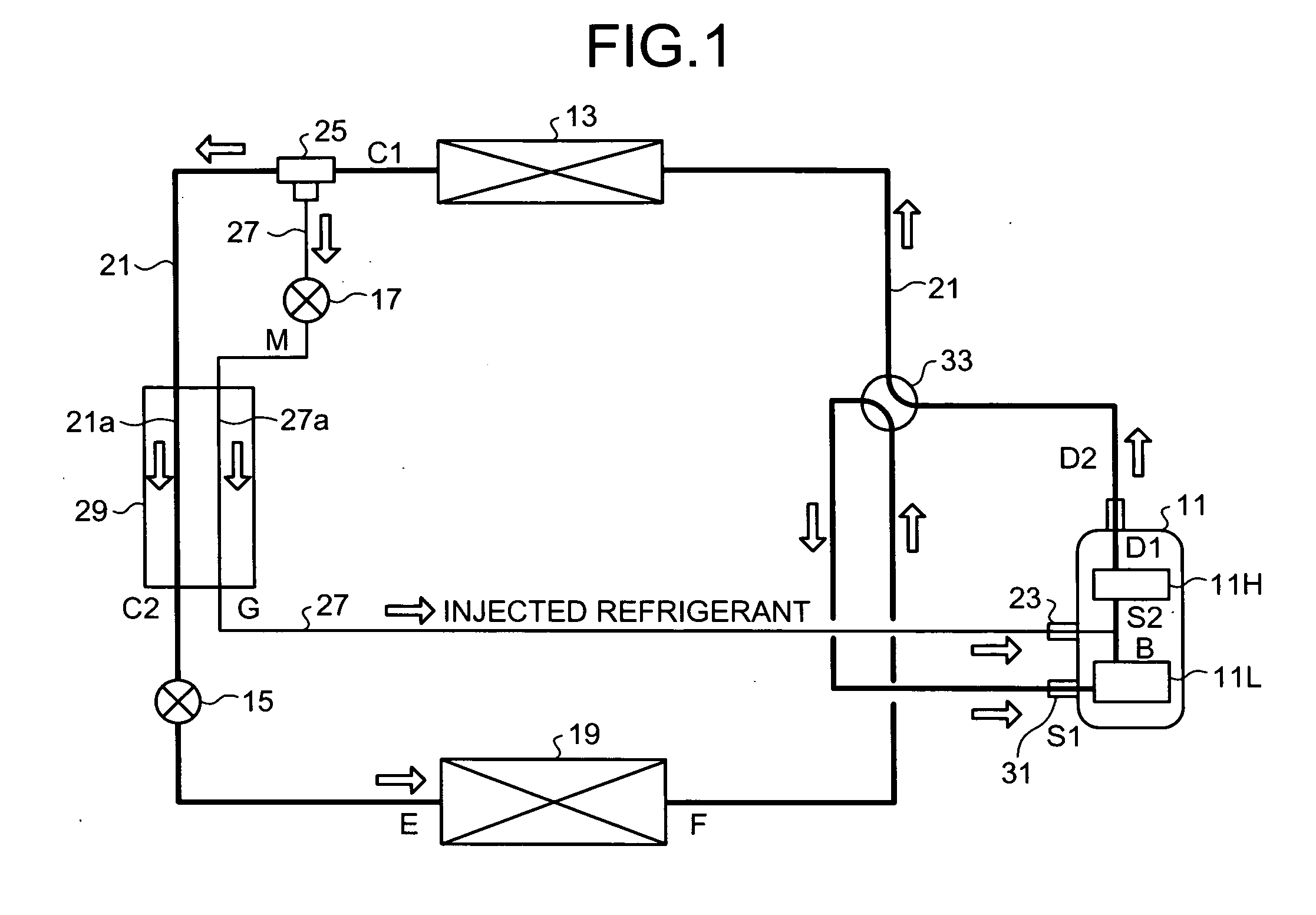

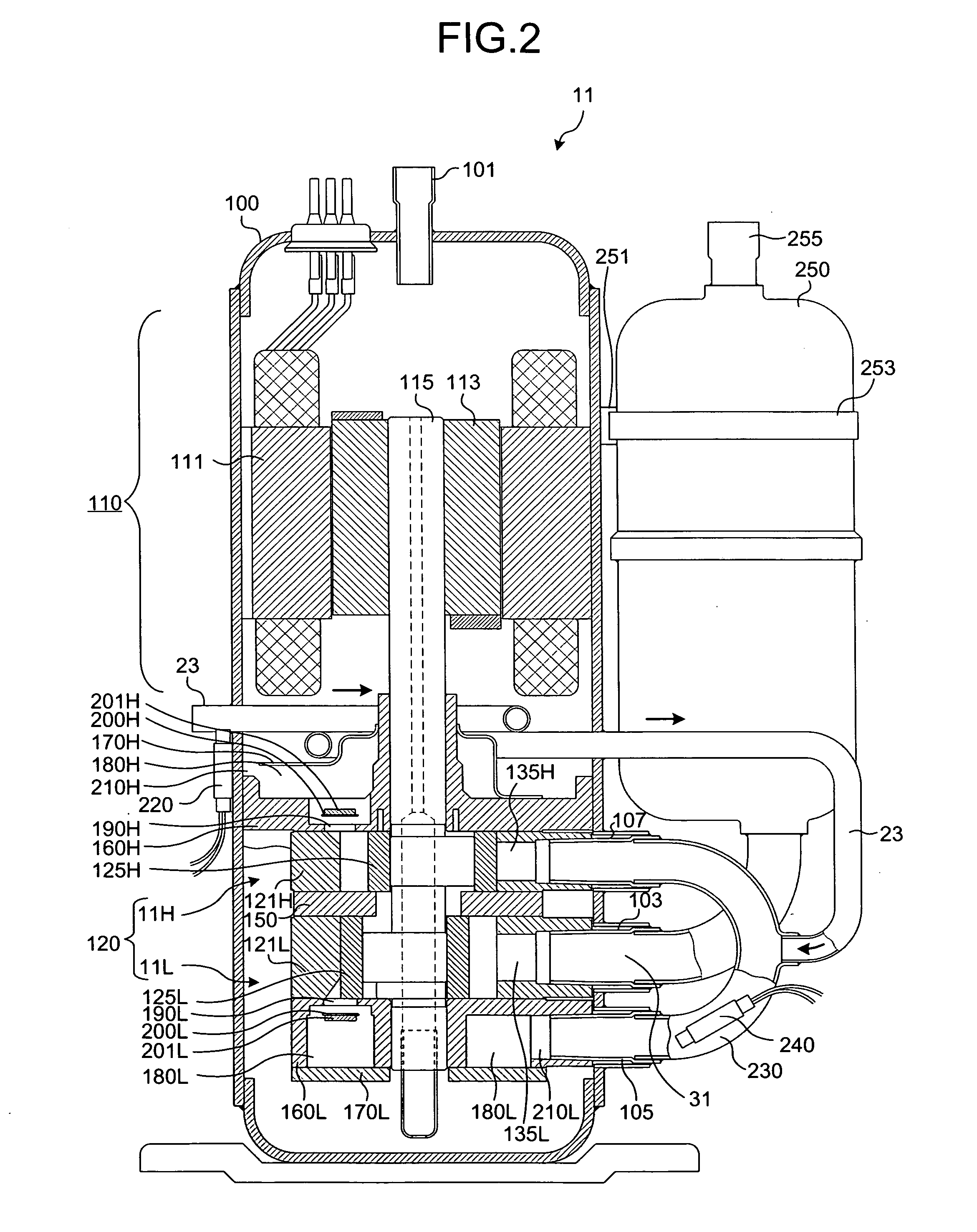

Injectible two-staged rotary compressor and heat pump system

InactiveUS20080236184A1Solve problemsReduce the amount of solutionRotary/oscillating piston combinations for elastic fluidsHeat pumpsInterior spaceEngineering

In an injectable two-staged rotary compressor, a second suction pipe includes a heat-exchange promoting unit that promotes heat exchange between intermediary-pressure injected refrigerant and internal space or an external surface of a sealed container. The heat being exchanged by the intermediary-pressure injected refrigerant absorbing heat.

Owner:FUJITSU GENERAL LTD

Air conditioning system and rotating compressor component thereof

ActiveCN104728109AImprove energy efficiencyAvoid overcompressionRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringSlip sheet

The invention discloses an air conditioning system and a rotating compressor component thereof, wherein the rotating compressor component comprises a liquid accumulator and a rotating compressor, the liquid accumulator is provided with an air outlet; the rotating compressor comprises a compressing mechanism which comprises a main bearing, an air cylinder component and a supplementary bearing, the air cylinder component comprises two air cylinders, a baffle plate and two slip sheets, each air cylinder is provided with a compression chamber, a first air entry and a slip sheet groove, and the compression chamber comprises an intake chamber and an exhaust chamber, the compressing mechanism is provided with a jet chamber, the exhaust chamber, of one of the two air cylinders, is connected with the jet chamber which is provided with a second air entry and an exhaust port, the second air entry is used for introducing a medium-pressure refrigerant and a high-pressure refrigerant, the first air entry, of one of the two air cylinders, is connected with the air outlet, the first air entry, of the other air cylinder, is connected with the air outlet or the exhaust port. According to the rotating compressor component thereof disclosed by the invention, the energy efficiency of a rotating compressor component is improved.

Owner:ANHUI MEIZHI PRECISION MFG +1

Horizontal two stage rotary compressor

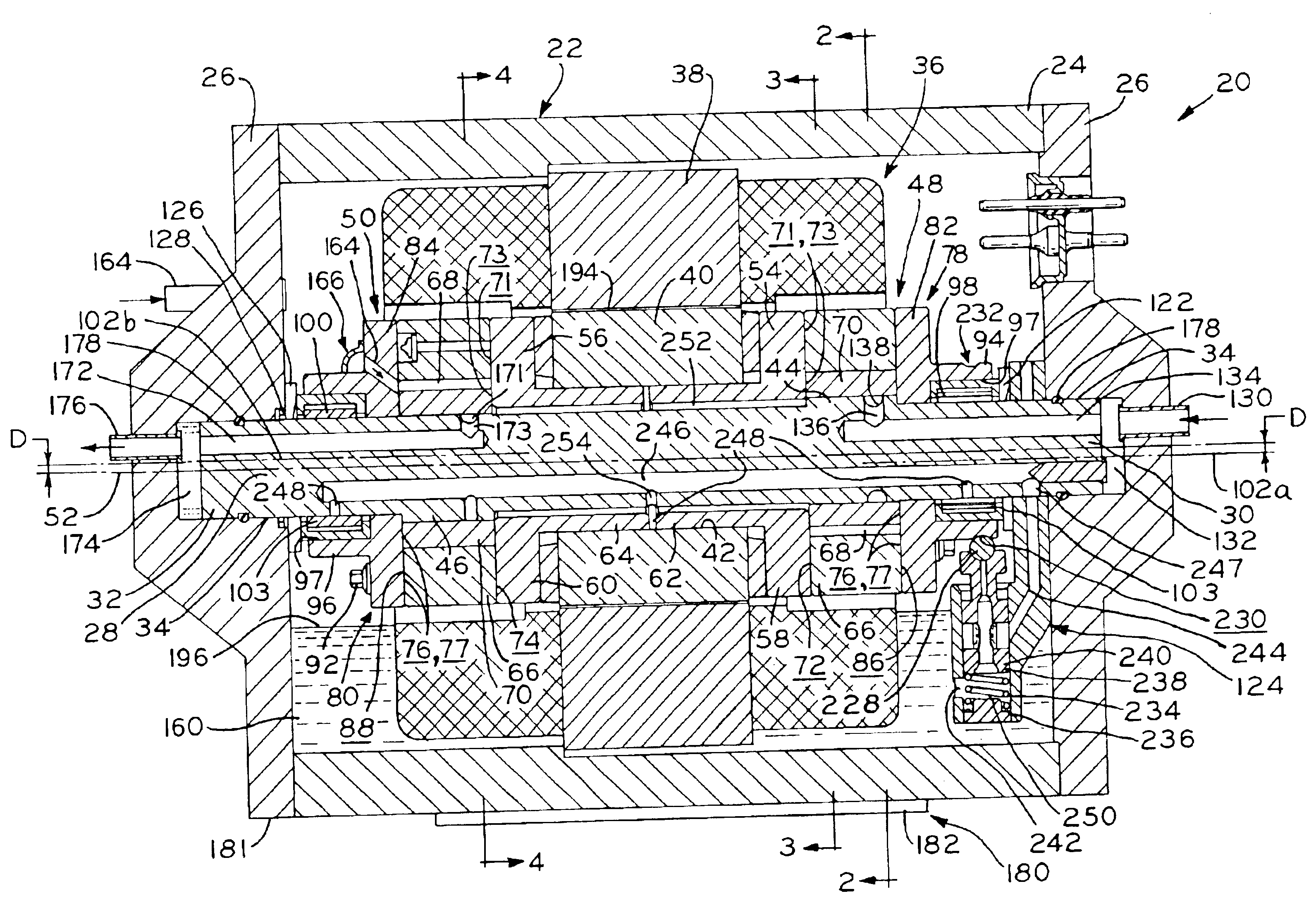

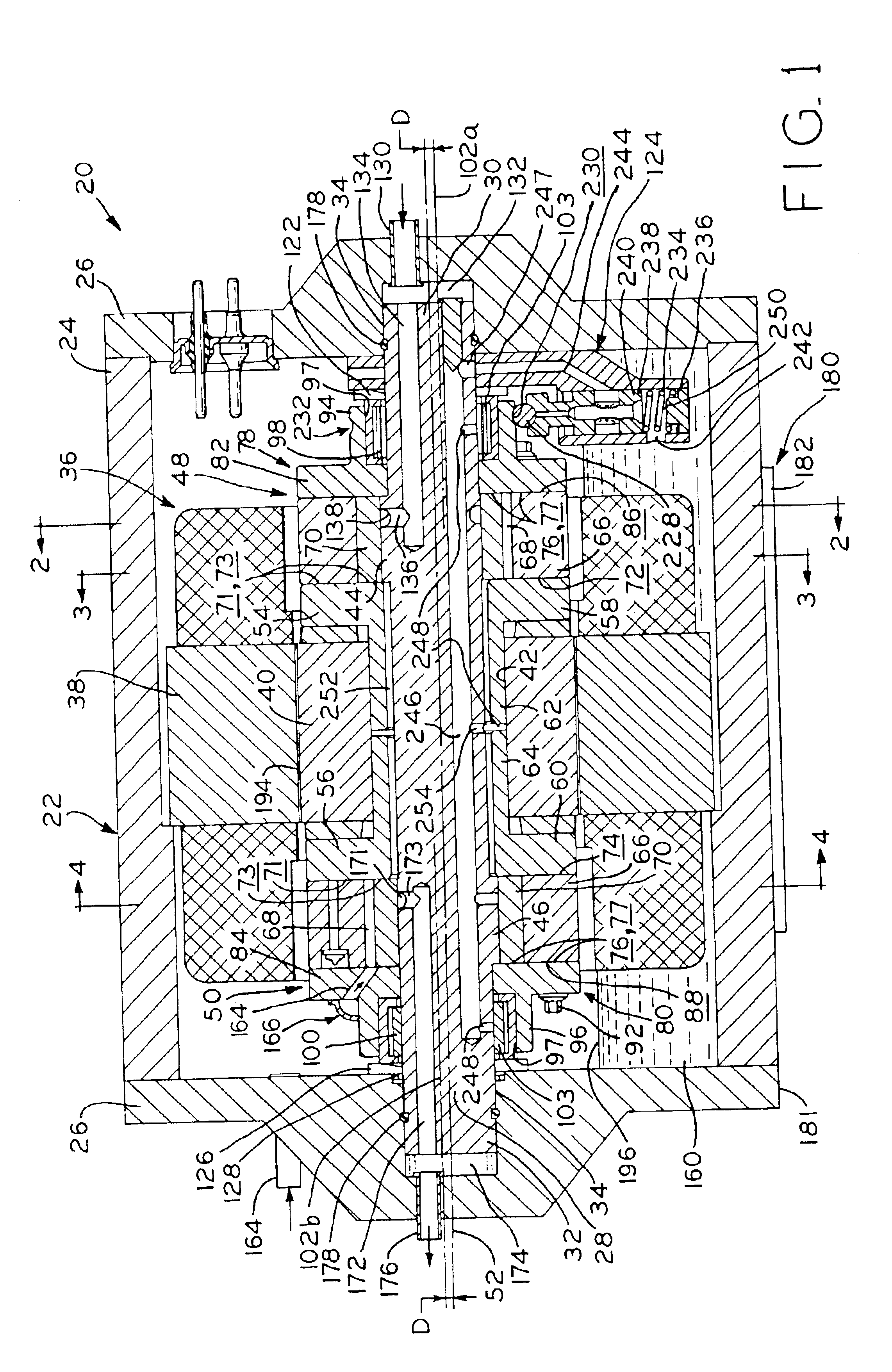

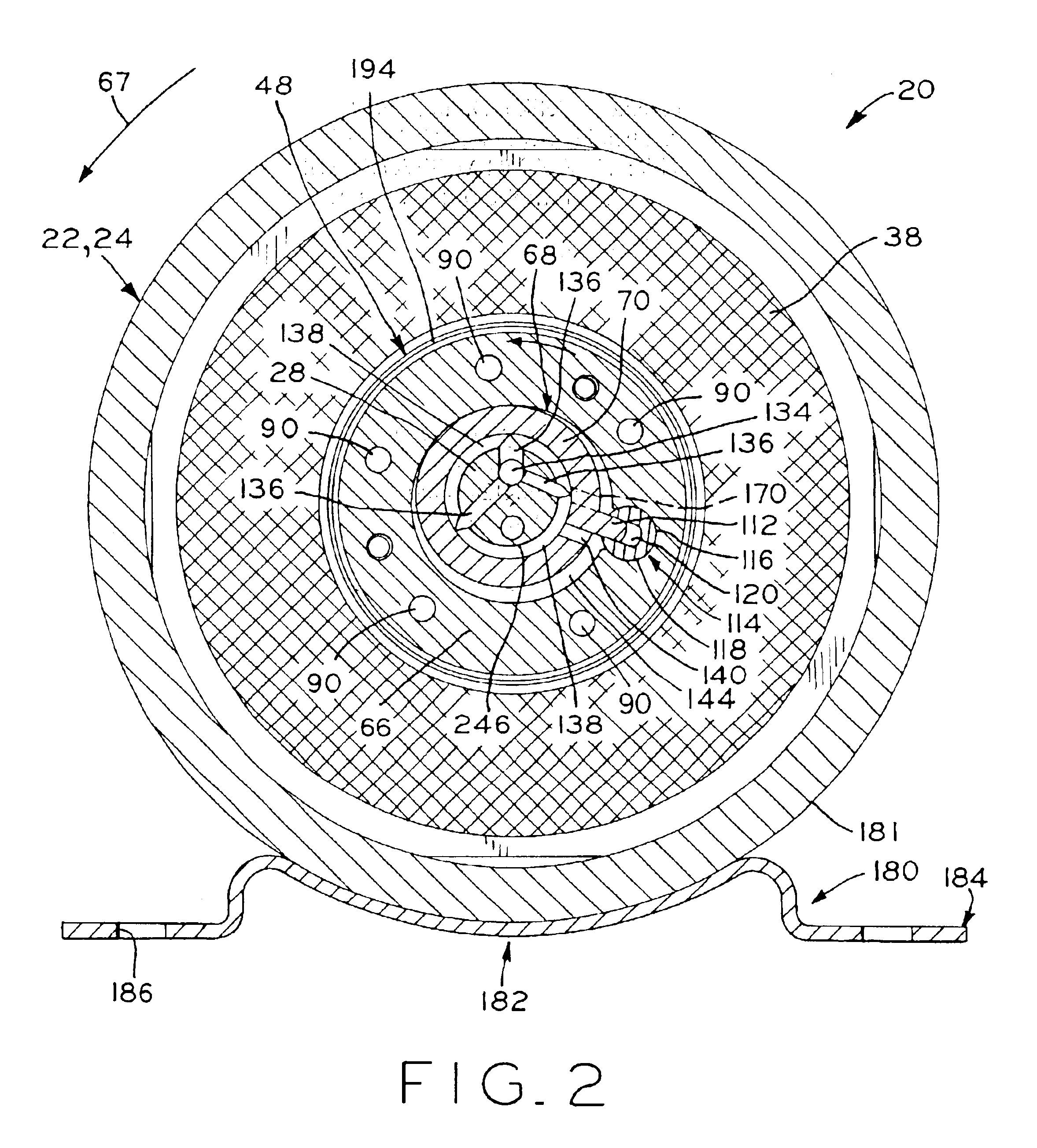

InactiveUS6929455B2Reduce loadEliminate needRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringSump

A hermetic two stage rotary compressor having a housing with a stationary shaft fixedly mounted in the housing. A motor having a rotor and a stator is mounted in the housing with the rotor being rotatably mounted on the shaft. A pair of compression mechanisms are rotatably mounted on the shaft with one compression mechanism being located adjacent a first end of the rotor, and one compression mechanism being located adjacent a second end of the rotor. The compression mechanisms are operatively associated with the rotor such that rotation of the rotor drives the compression mechanisms. A fluid flow path is defined in the compressor including a plurality of longitudinal bores formed in the stationary shaft. A mounting assembly is attached to the housing so as to mount the compressor in either a substantially horizontal or vertical orientation. The pump is positioned so as to be at least partially immersed in an oil sump in the housing when the compressor in either orientation.

Owner:TECUMSEH PROD CO

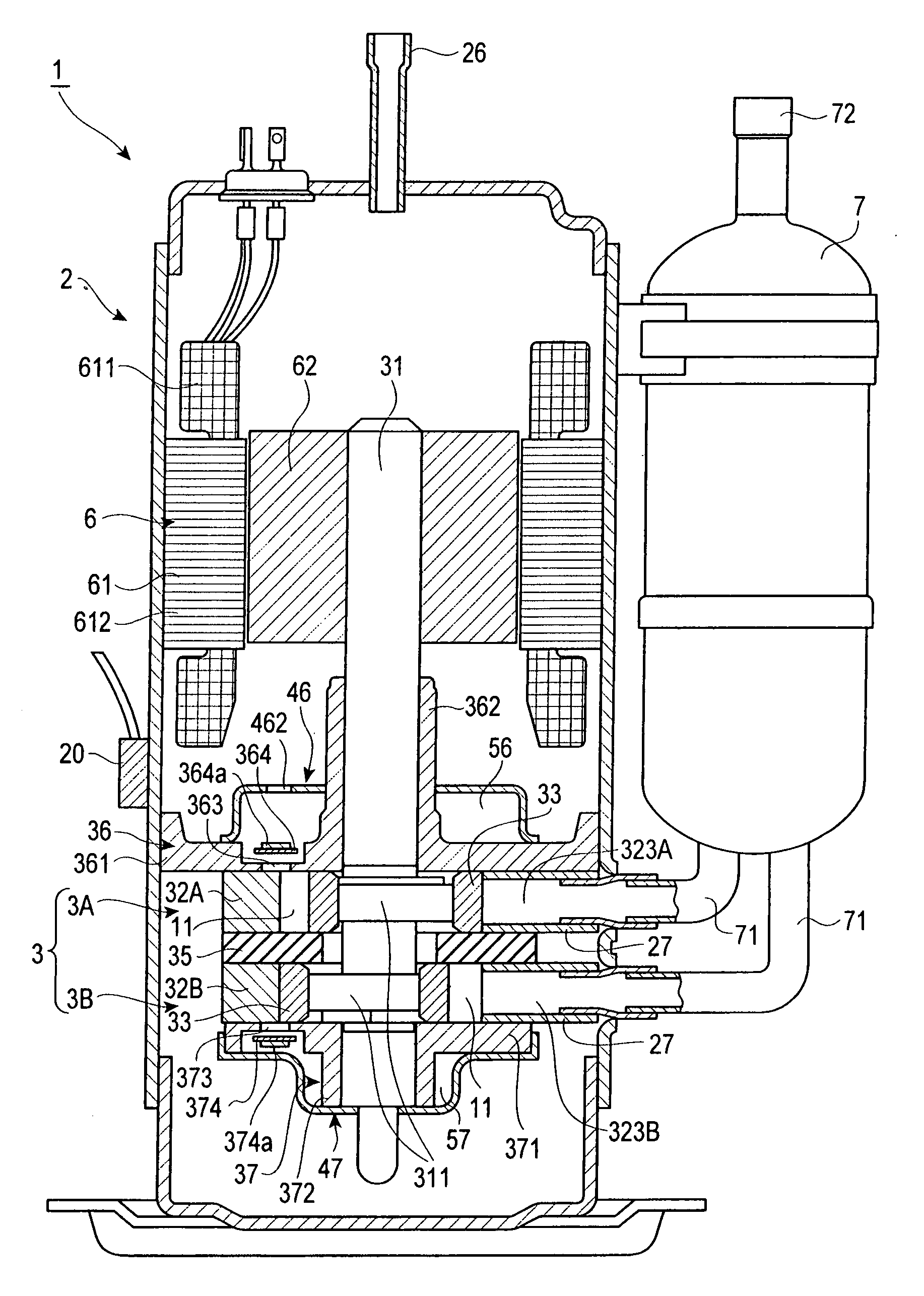

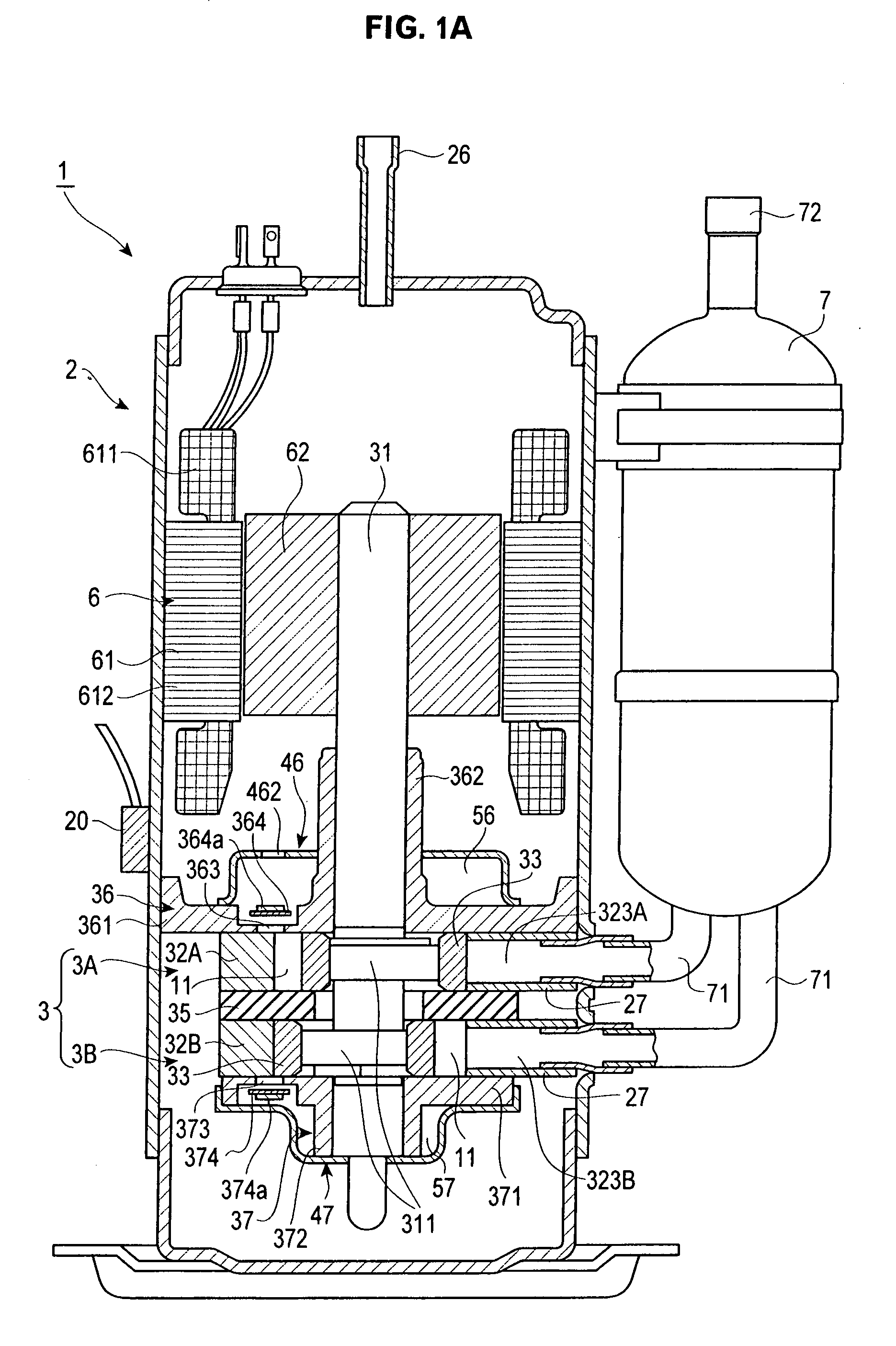

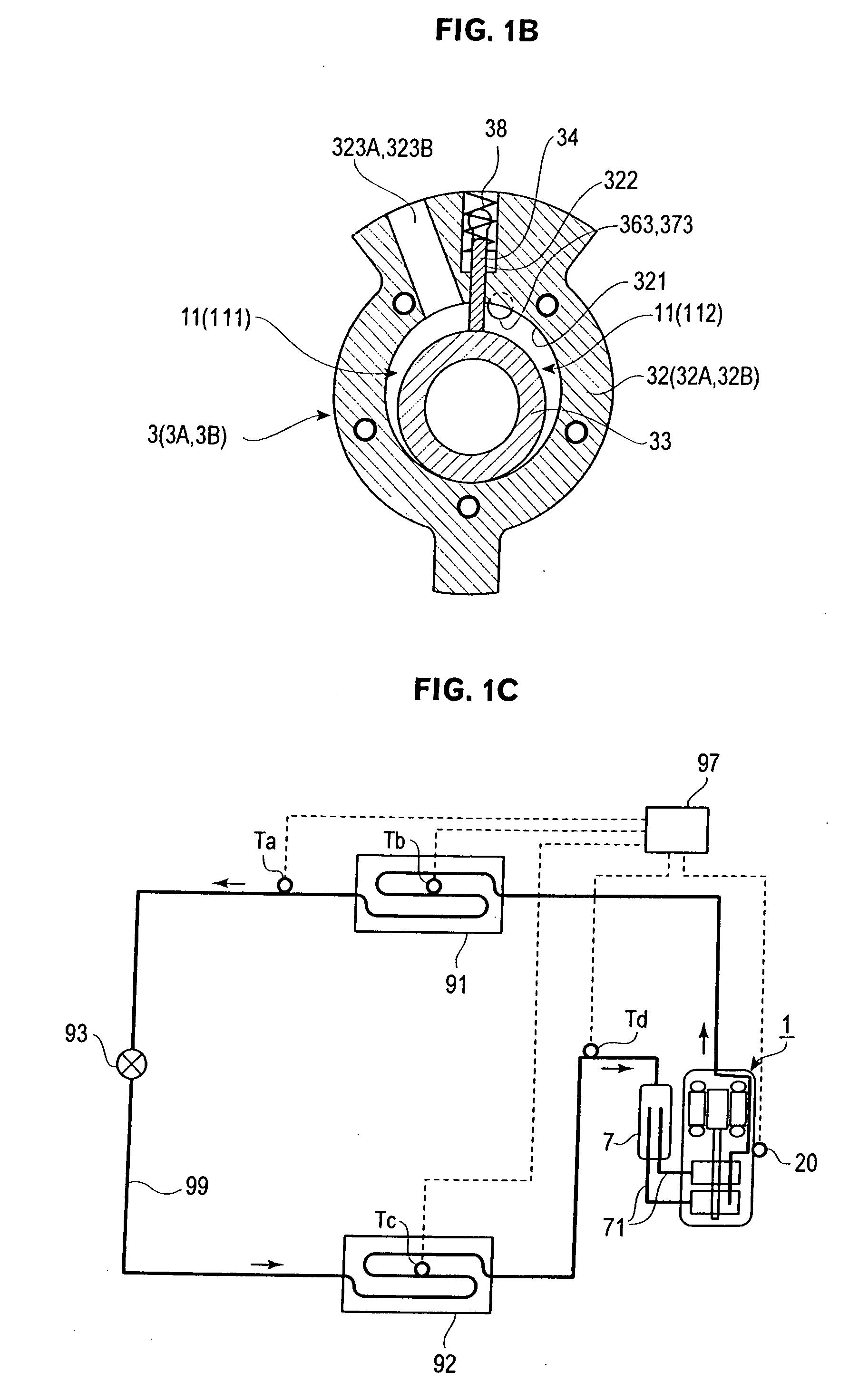

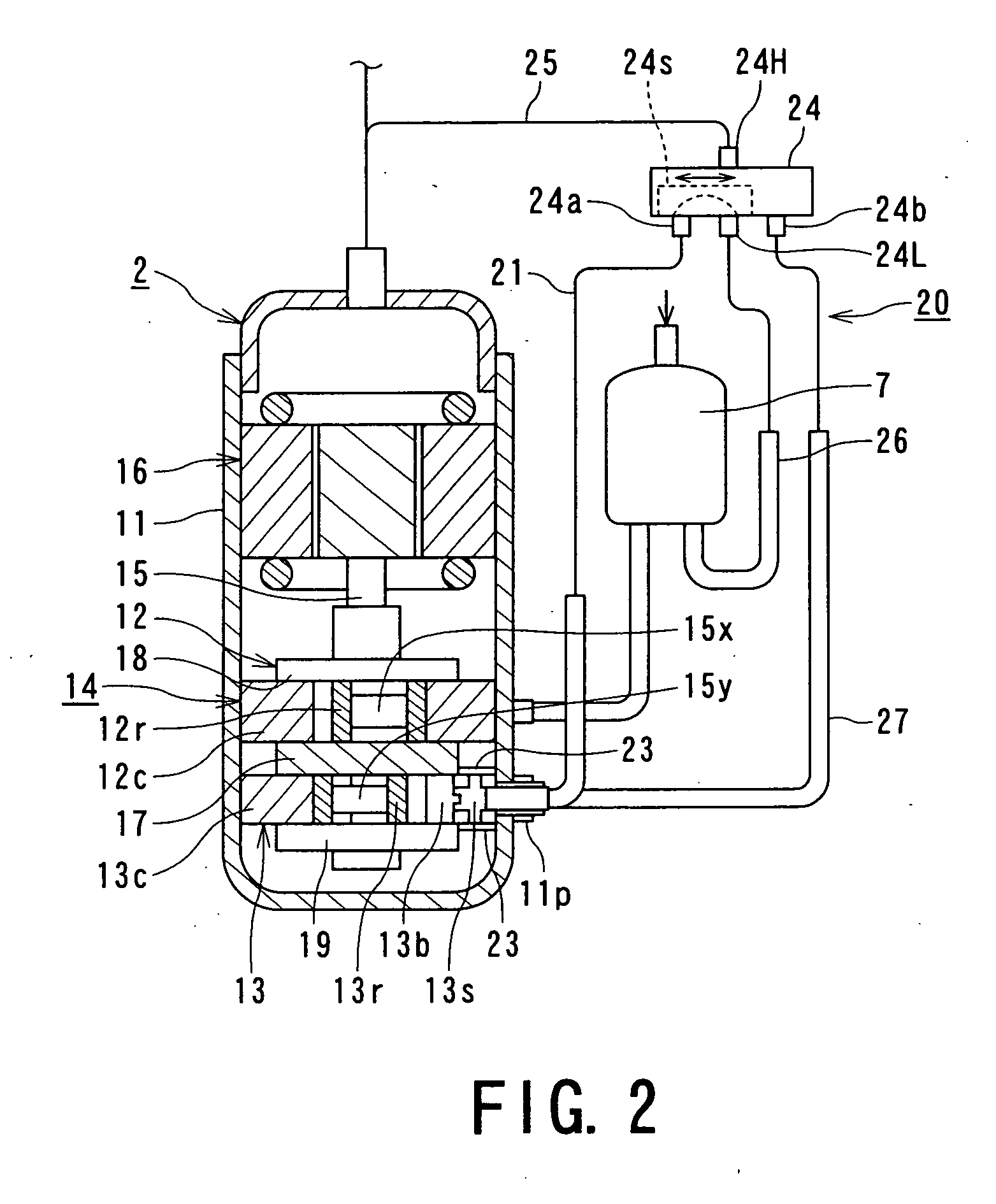

Rotary compressor and heat pump system

InactiveUS20080078191A1Low costImproves inventionRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleEngineeringRefrigerant

A problem to be solved by the present invention is that the temperature of a refrigerant discharged from a compression section can be detected more exactly without being influenced by variable factors existing around the compression section. In a rotary compressor 1 having a motor 6 and a compression section 3 provided in a closed container 2, and also having a discharge pipe 26 provided in an upper part of the closed container 2 to discharge a refrigerant compressed by the compression section 3 to the outside of the closed container 2, a refrigerant discharge part 462 for discharging the refrigerant compressed by the compression section 3 toward the inner peripheral surface of the closed container 2 is provided, and a discharge temperature sensor 20 for detecting the discharge temperature of compressed refrigerant is arranged in a portion opposed to the refrigerant discharge part 462 on the outer peripheral surface side of the closed container 2.

Owner:FUJITSU GENERAL LTD

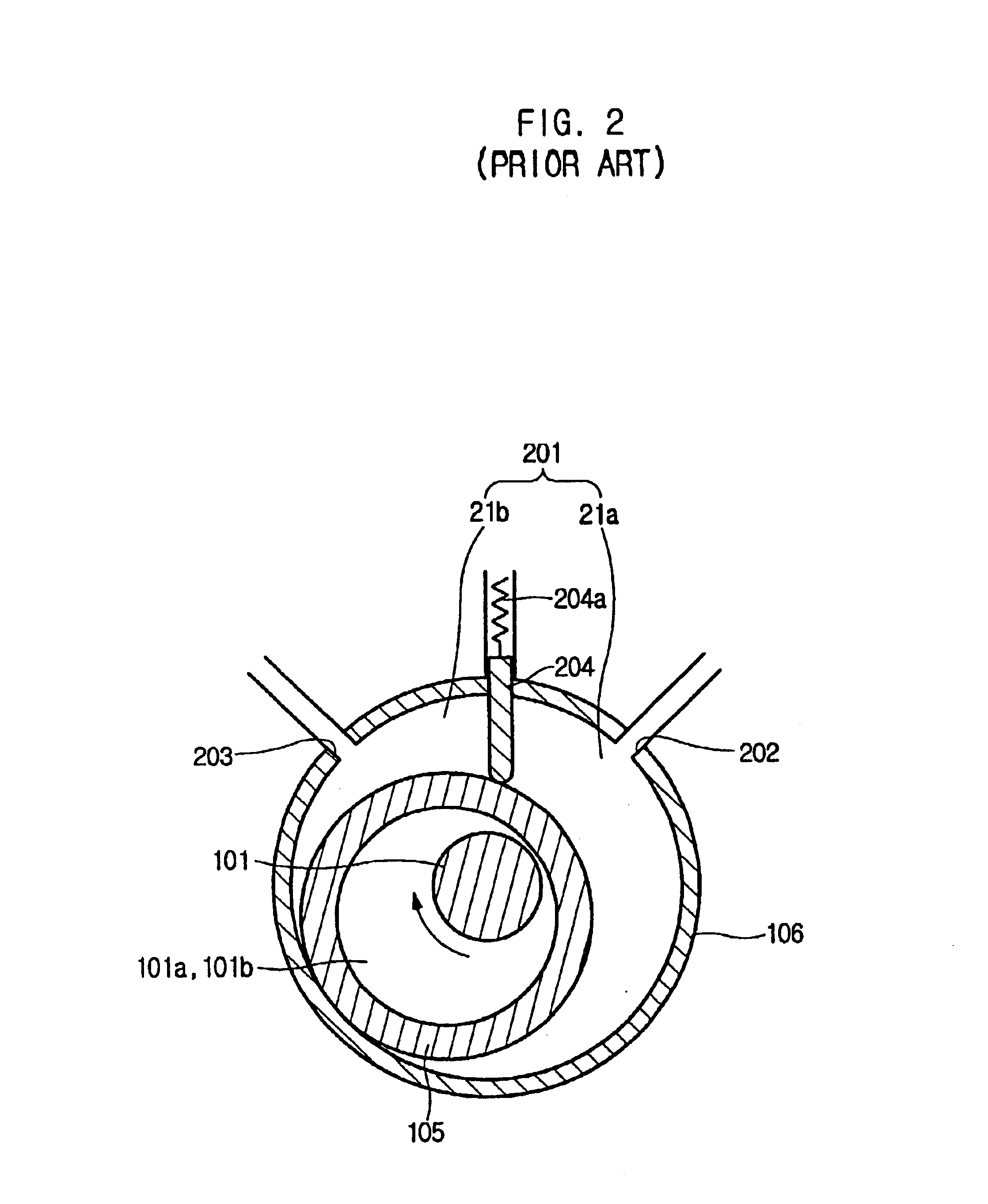

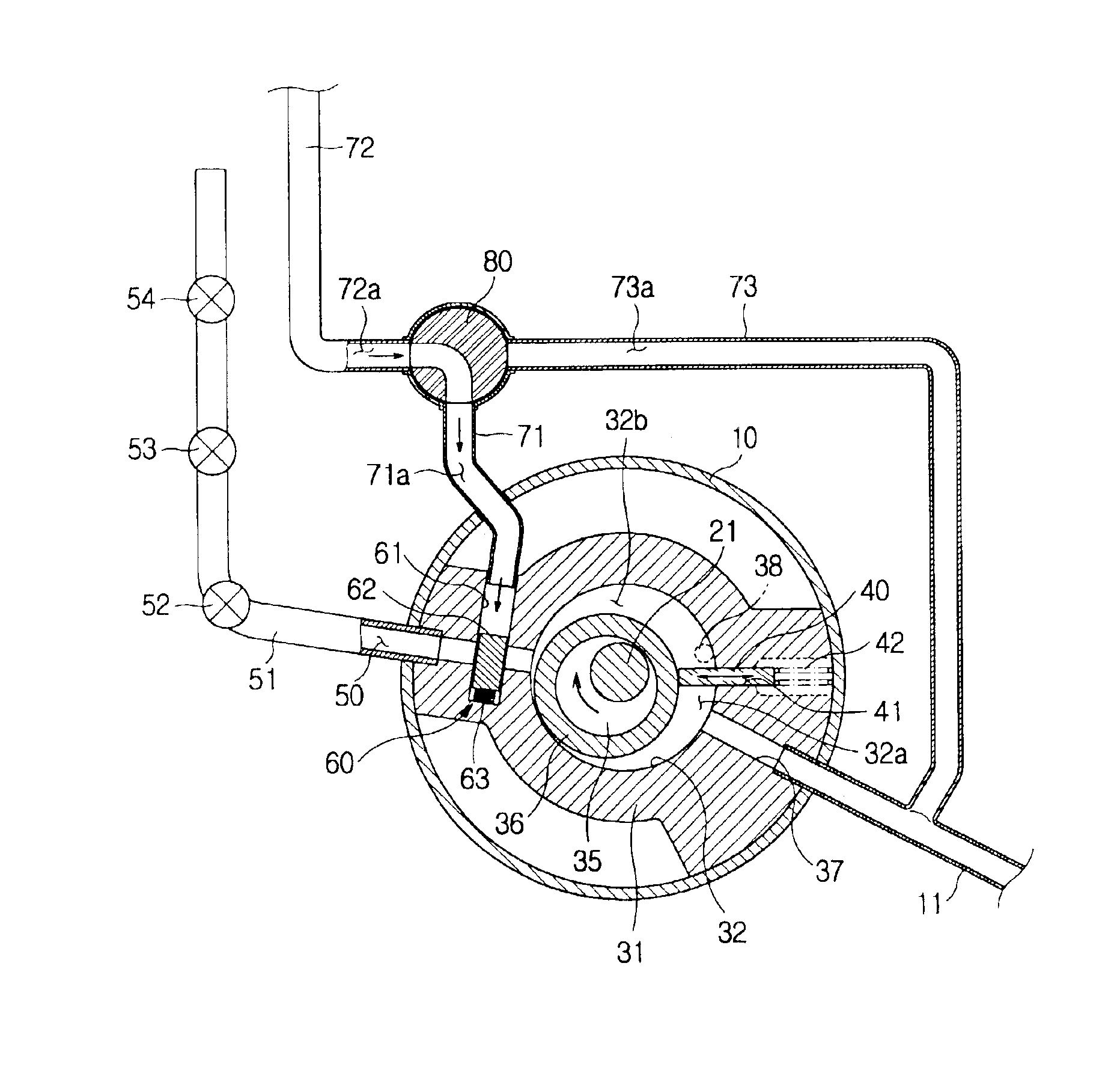

Variable capacity rotary compressor

InactiveCN1467379ASimple structureEasy to produceRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigerant

A variable capacity rotary compressor includes a housing having a cylindrical compressing chamber defined therein, a rotating shaft having an eccentric body part which rotates in the compressing chamber, a ring piston fitted over the eccentric body part of the rotating shaft so as to have the ring piston rotate while being in contact with an inner surface of the compressing chamber, a vane mounted in the housing so as to have the vane advance or retract in a radial direction of the compressing chamber in accordance with a rotation of the ring piston, and a control unit which is connected to the vane and moves in opposite directions in response to pressures of a refrigerant inlet and a refrigerant outlet of the compressor, so as to control a moving range of the vane. Accordingly, a simpler construction of the compressor is achieved and a refrigerant compressing capacity is easily controlled.

Owner:SAMSUNG ELECTRONICS CO LTD

Refrigeration cycle system

InactiveUS20070154329A1No deterioration in system performanceAvoid noiseRotary/oscillating piston combinations for elastic fluidsPump controlInterior spaceLow load

A refrigeration cycle system is provided with a two-cylinder type rotary compressor having one compression mechanism which includes a switching mechanism for switching a back surface side of a blade between a low pressure mode and a high pressure mode and controlling the inner space of the cylinder chamber to the high pressure upon switching at the low pressure mode. In a high load state, a normal operation is performed by switching the pressure of the back surface side of the blade of the one compression mechanism at the high pressure mode. In a low load state, an uncompressed operation is performed by switching the pressure of the back surface side of the blade of the one compression mechanism at the low pressure mode and by controlling the inner space of the cylinder chamber to the high pressure to move the blade away from the roller. This makes it possible to provide the refrigeration cycle system which generates no noise and causes no damage to the blade, thus allowing the uncompressed operation to be continuously performed.

Owner:TOSHIBA CARRIER CORP

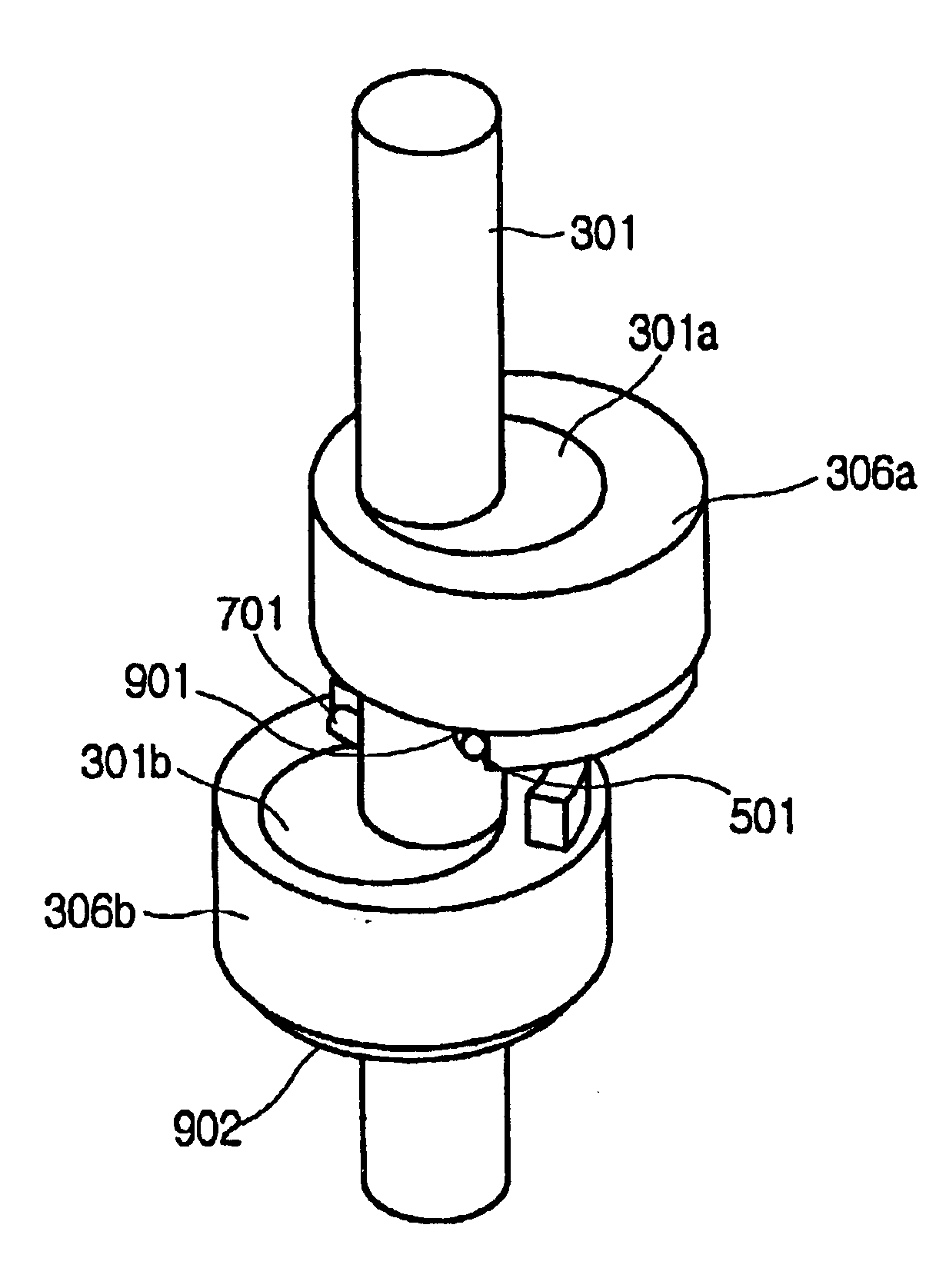

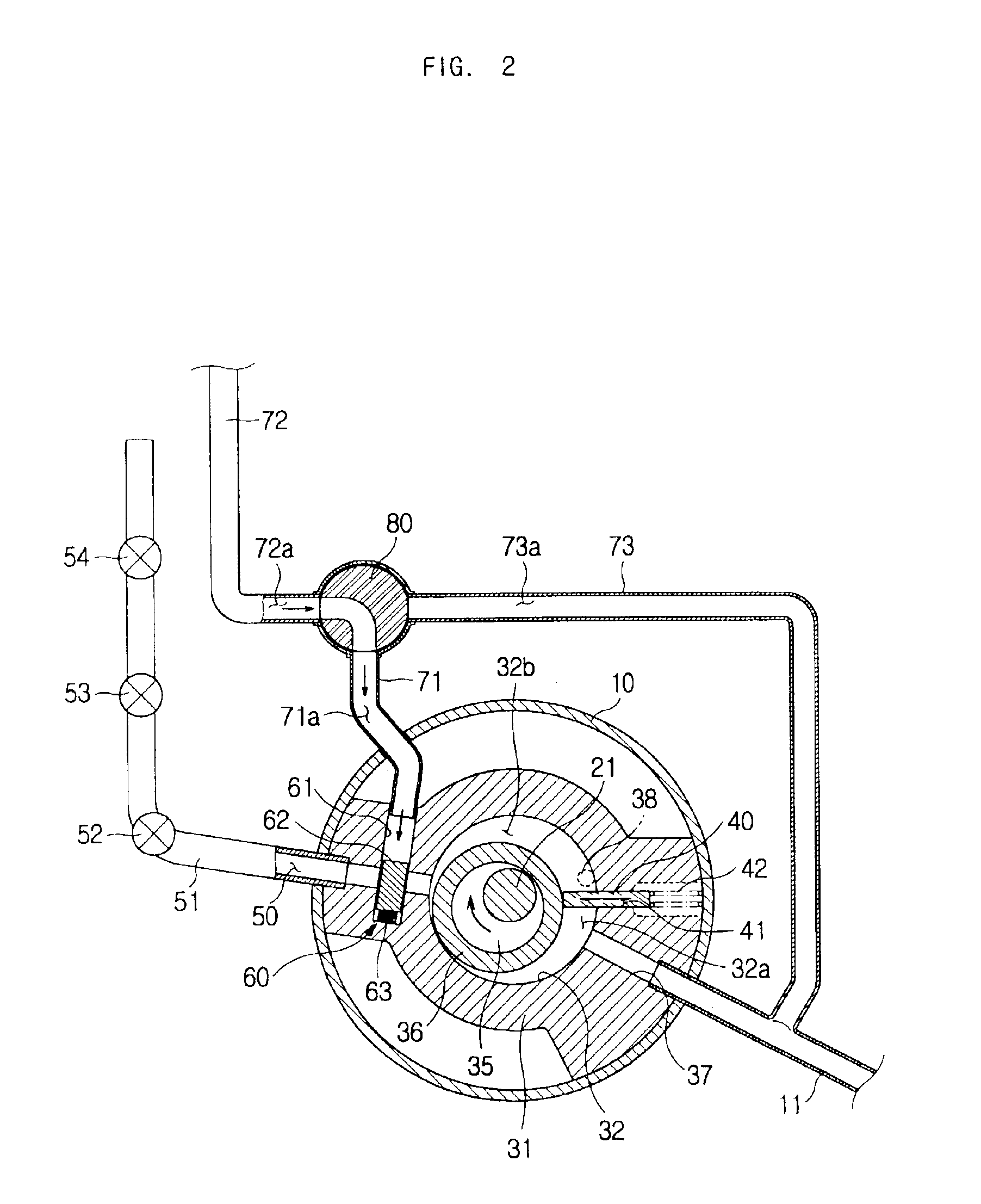

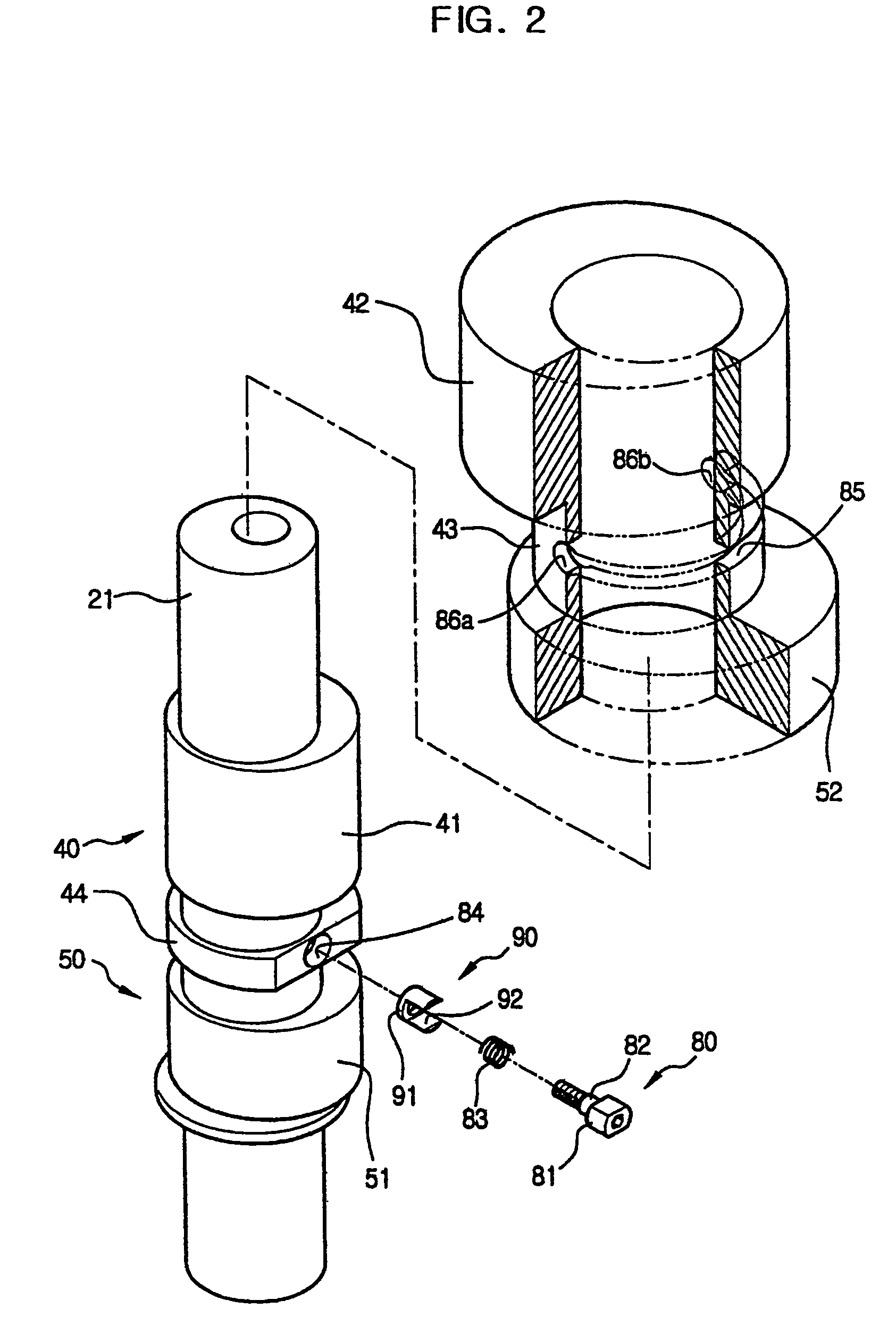

Variable capacity rotary compressor

InactiveUS6932588B2Easy to changeEasily varies compression capacityEngine of arcuate-engagement typeOscillating piston enginesReciprocating motionRefrigerant

A variable capacity rotary compressor includes a housing defining a cylindrical compression chamber therein and having an inlet port and an outlet port communicating with the compression chamber. A rotating shaft is provided with an eccentric part to rotate in the compression chamber. A ring piston is rotatably fitted over the eccentric part such that an outer surface of the ring piston is in contact with an inner surface of the compression chamber. A vane is installed in the housing so as to be in contact with the outer surface of the ring piston and radially reciprocates, and partitions the compression chamber into an intake part and a discharging part. A re-expansion space communicates with the compression chamber, and receives refrigerant therein. A control unit opens or closes an inlet of the re-expansion space to vary a capacity of the rotary compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

Variable capacity rotary compressor

InactiveUS7104764B2Avoid noiseIncreased durabilityEngine of arcuate-engagement typeRotary piston pumpsRotational axisReciprocating motion

A variable capacity rotary compressor is designed to prevent eccentric bushes from slipping during a compression operation, thus preventing noise from being generated and increasing durability. The compressor includes a housing to define two compression chambers having different capacities therein. A rotating shaft is rotated in the compression chambers. Two eccentric cams are mounted to the rotating shaft. Two eccentric bushes are rotatably fitted over the eccentric cams. Two rollers are rotatably fitted over the eccentric bushes. Two vanes are installed in the compression chambers to be reciprocated in a radial direction of the rotating shaft. A cylindrical connecting part integrally connects the eccentric bushes to each other, with a locking slot being provided around the connecting part. A locking pin is mounted to the rotating shaft to project from the rotating shaft, and is locked by either of opposite ends of the locking slot, according to a rotating direction of the rotating shaft, thus making one of the eccentric bushes eccentric from the rotating shaft while making a remaining one of the eccentric bushes be released from eccentricity from the rotating shaft. A restraining unit outwardly moves from the rotating shaft by a centrifugal force when the rotating shaft is rotated, to restrain the connecting part.

Owner:SAMSUNG ELECTRONICS CO LTD

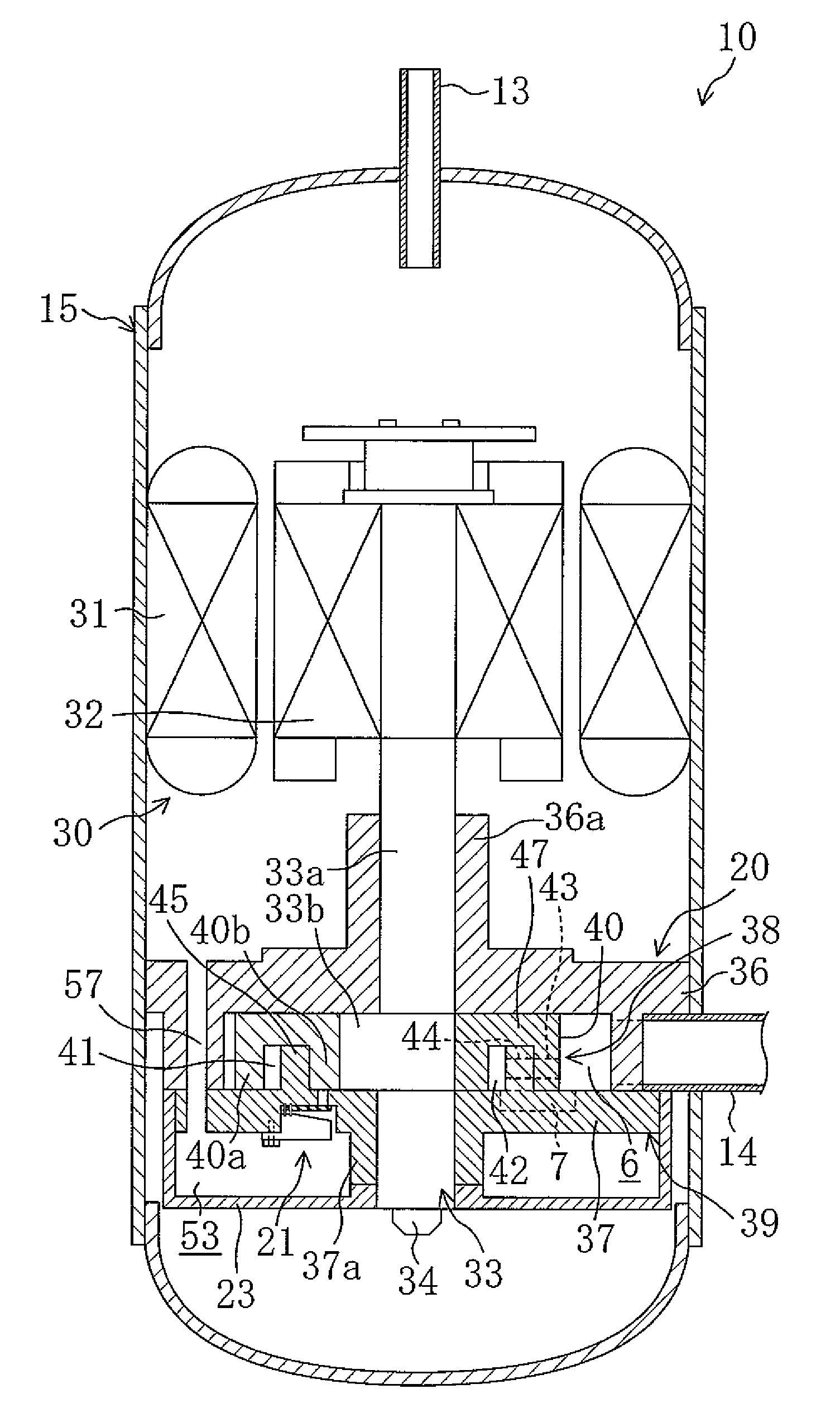

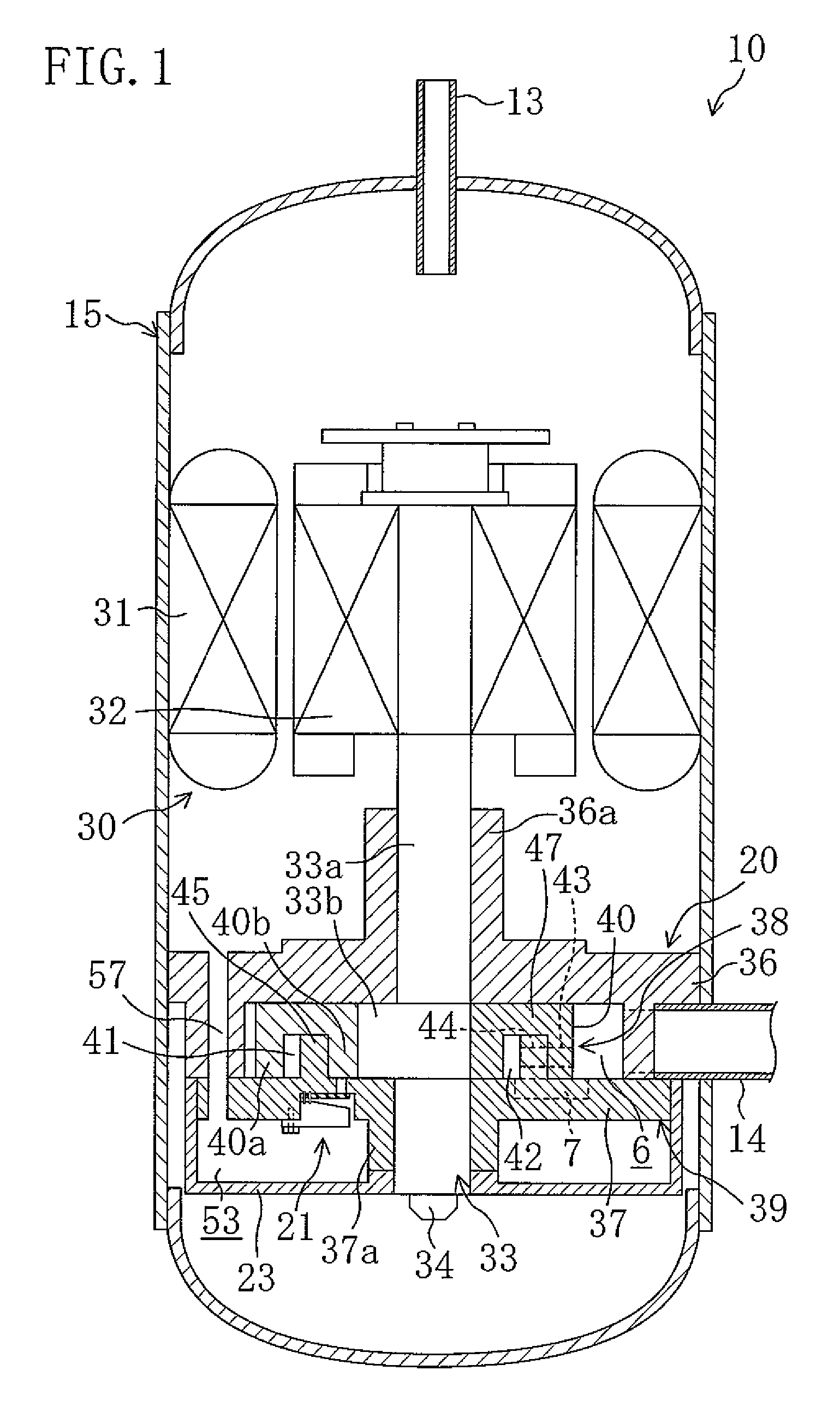

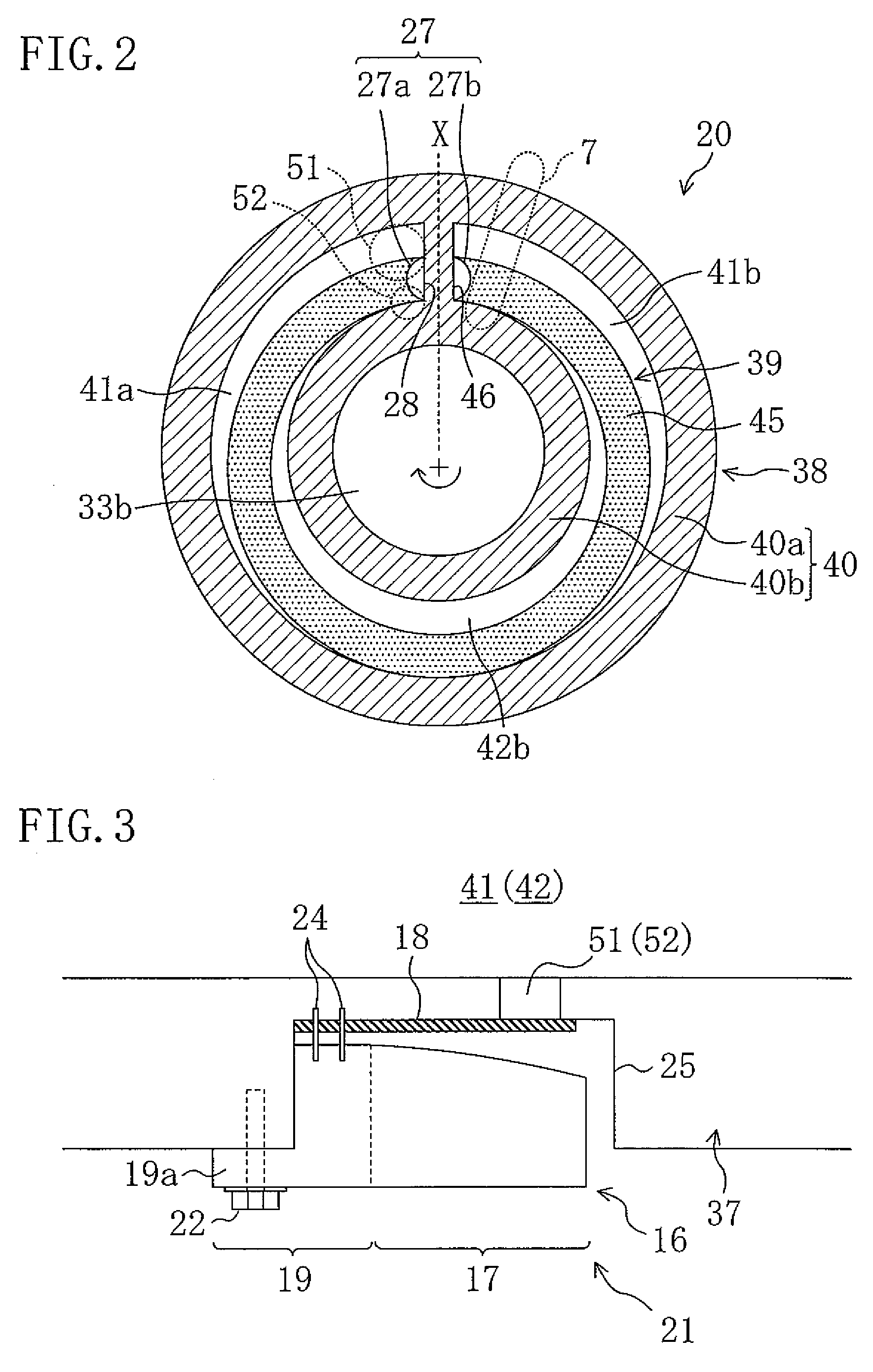

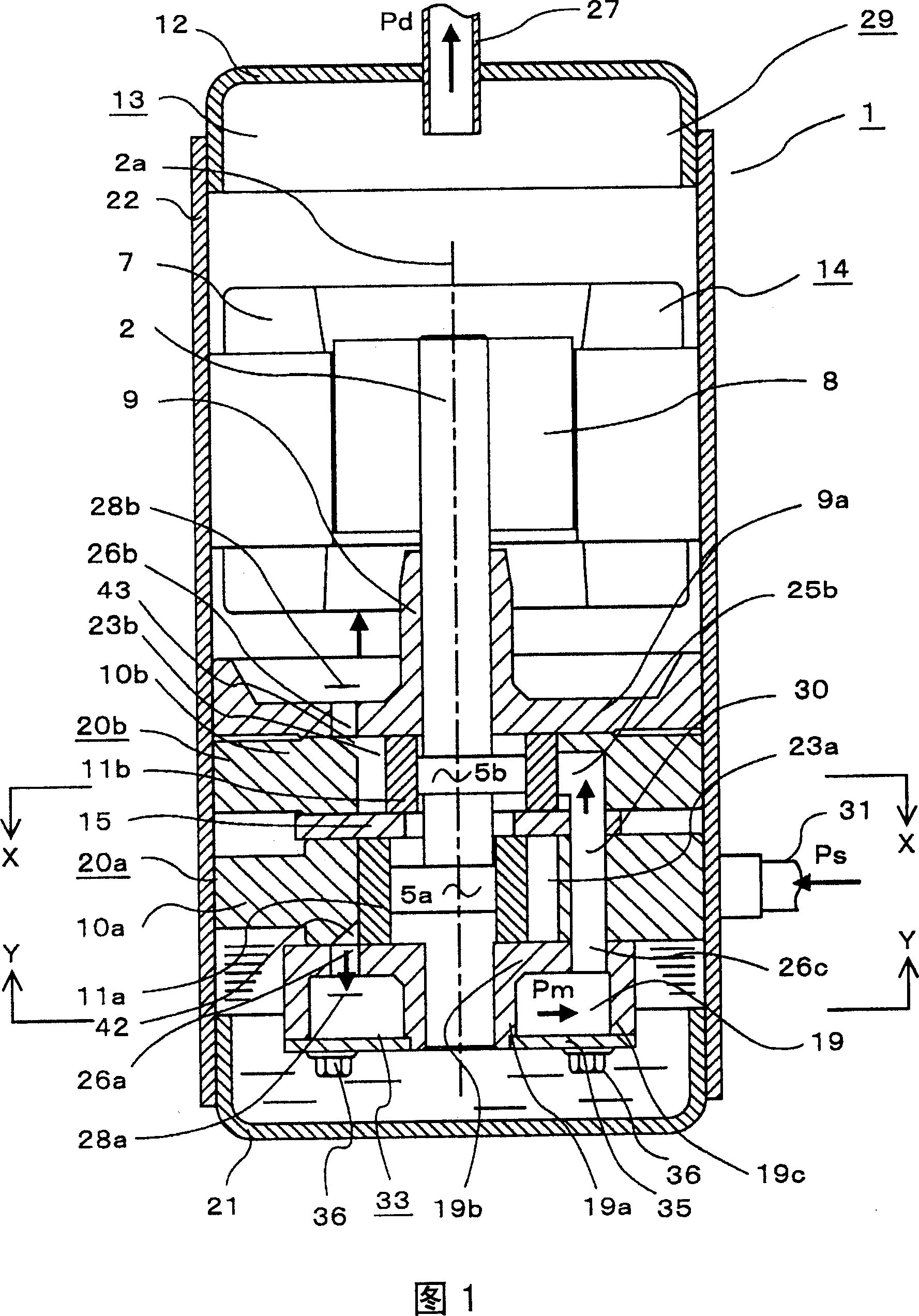

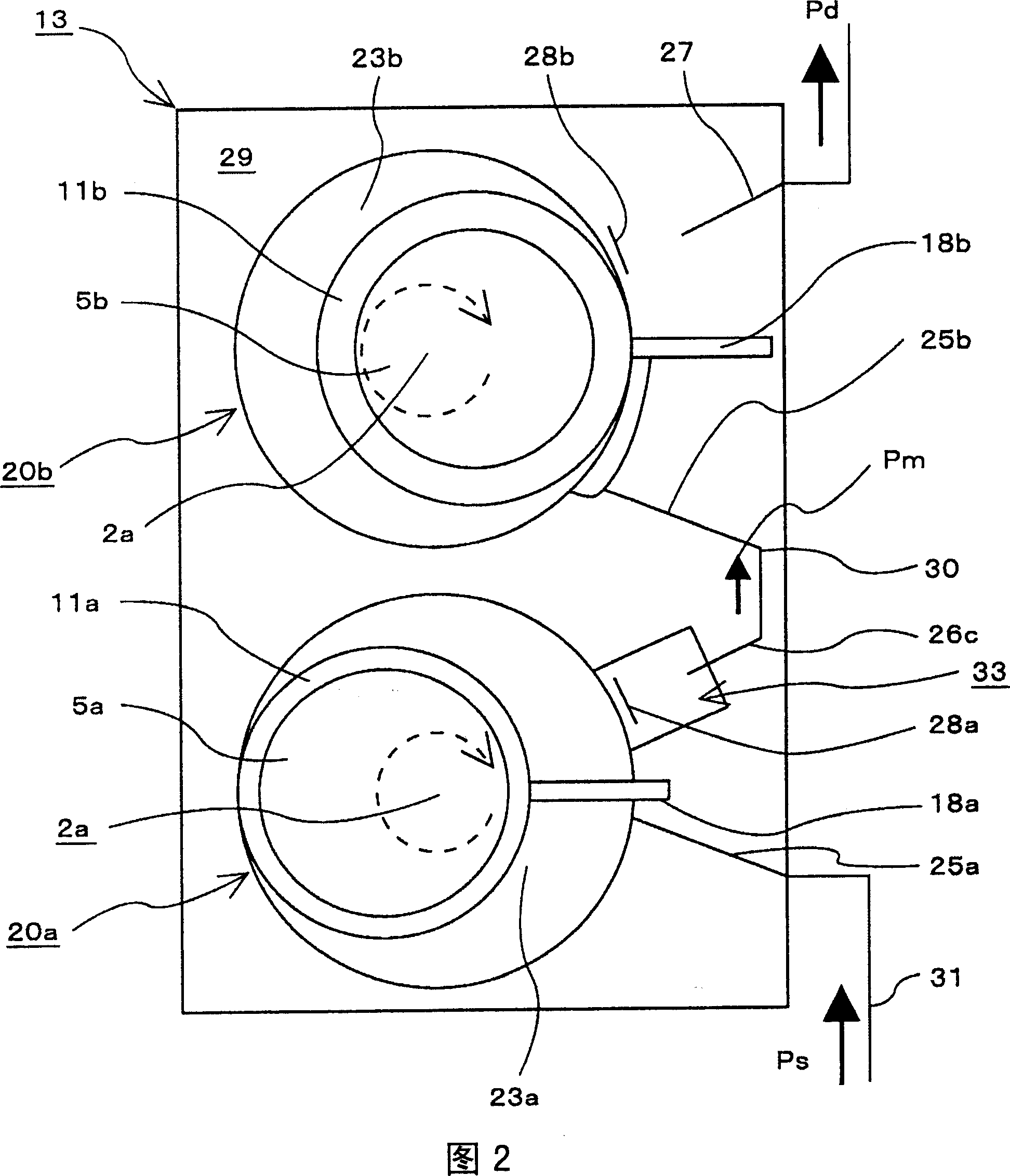

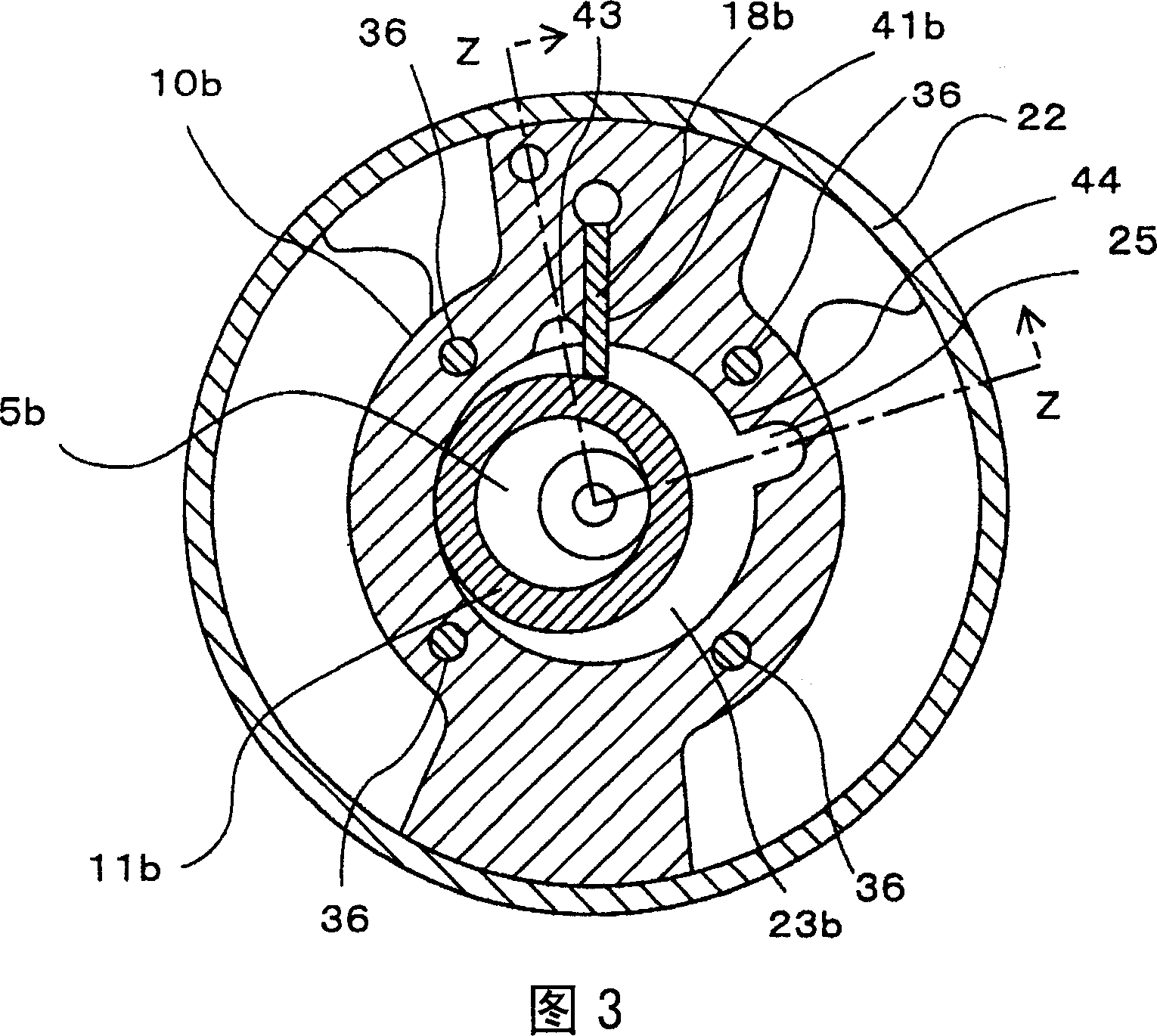

Hermetic two-stage rotary compressor

InactiveCN1959116ALow costShorten the middle connecting pathRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringMechanical engineering

Disclosed is a hermetic two-stage rotary compressor in which a low stage compression element is connected with a high stage compression element with a simple structure to largely reduce a cost while shortening an intermediate communication passage. The hermetic two-stage rotary compressor 1 has the low stage compression element 20a and high stage compression element 20b driven by a crankshaft 2. The crankshaft has a low-stage eccentric part 5a, and a high-stage eccentric part 5b different in phase by 180 degrees from the low-stage eccentric part 5a. A low-stage end plate 19b, a low-stage cylinder 10a, a partition plate 15, a high-stage cylinder 10b, and a high-stage end plate 9a are integrally fastened through bolts 36, with a state where they are stacked in this order and plane angle positions of a vane groove of the low-stage cylinder and a vane groove of the high-stage cylinder are the same. An intermediate discharge space 33 in which gas of intermediate pressure is discharged communicates with a suction port 25 of a high-stage compression chamber 23b through the intermediate communication passage 30 passing through the low-stage end plate, low-stage cylinder, partition plate, and high-stage cylinder.

Owner:HITACHI APPLIANCES INC

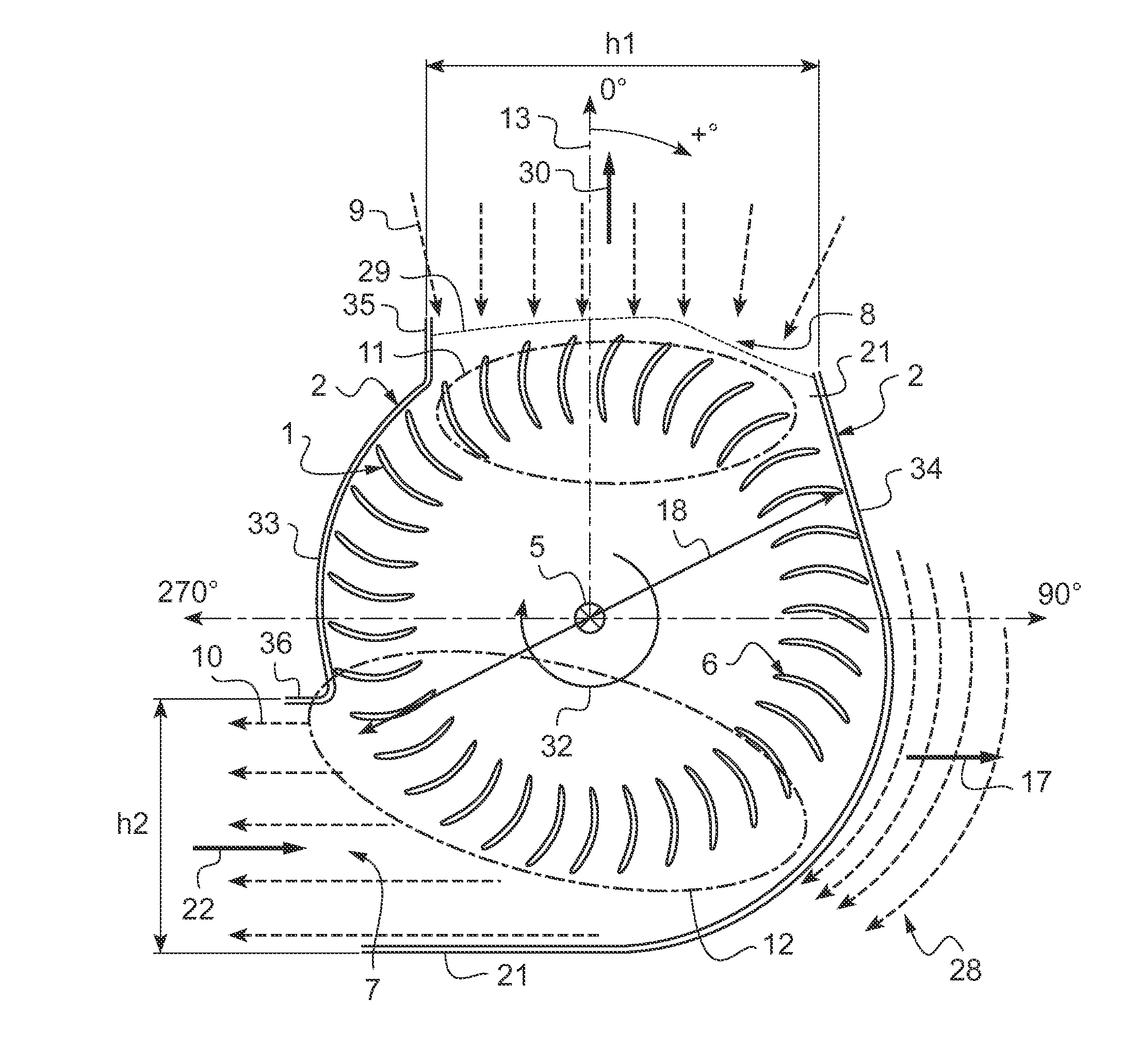

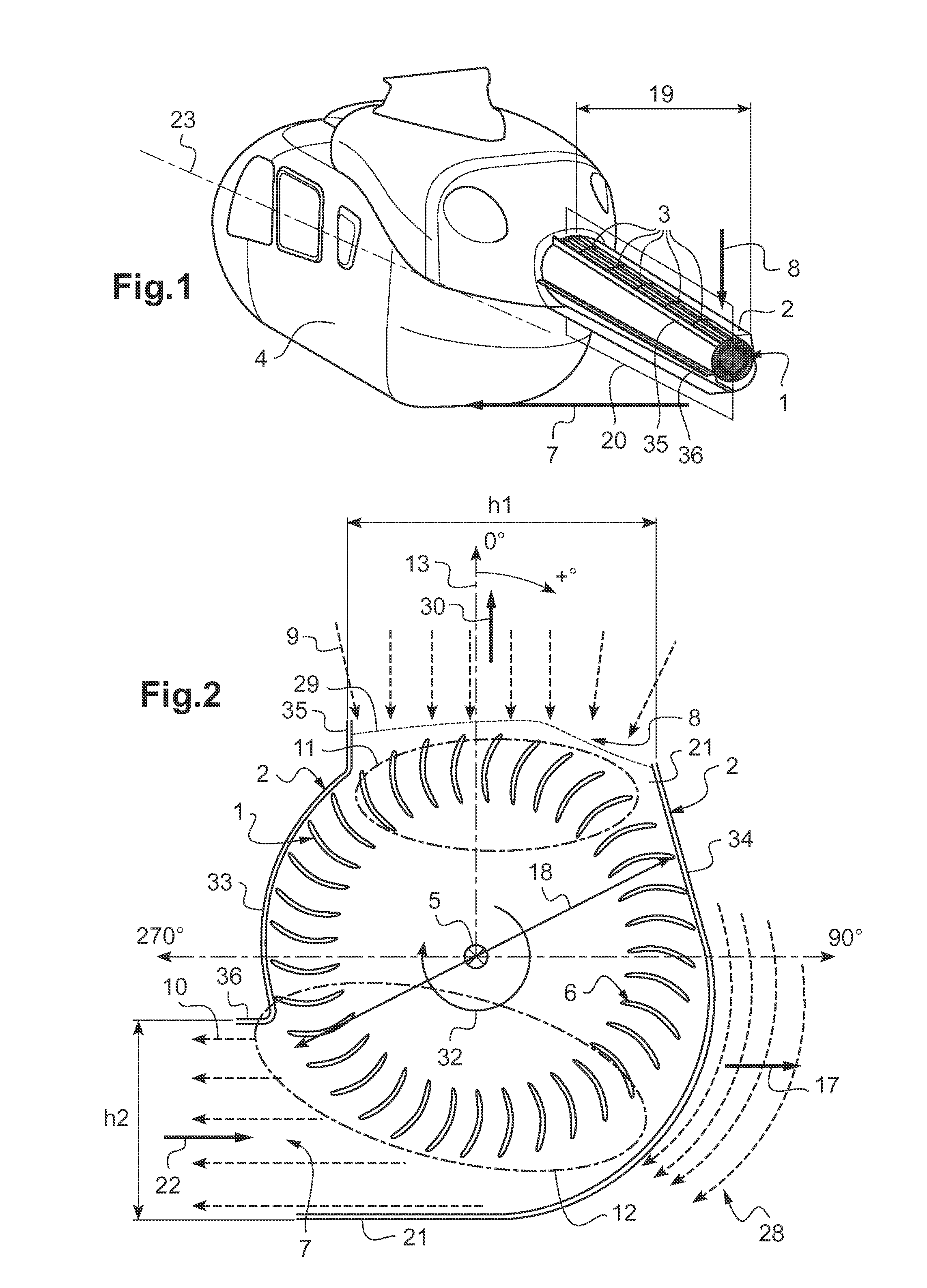

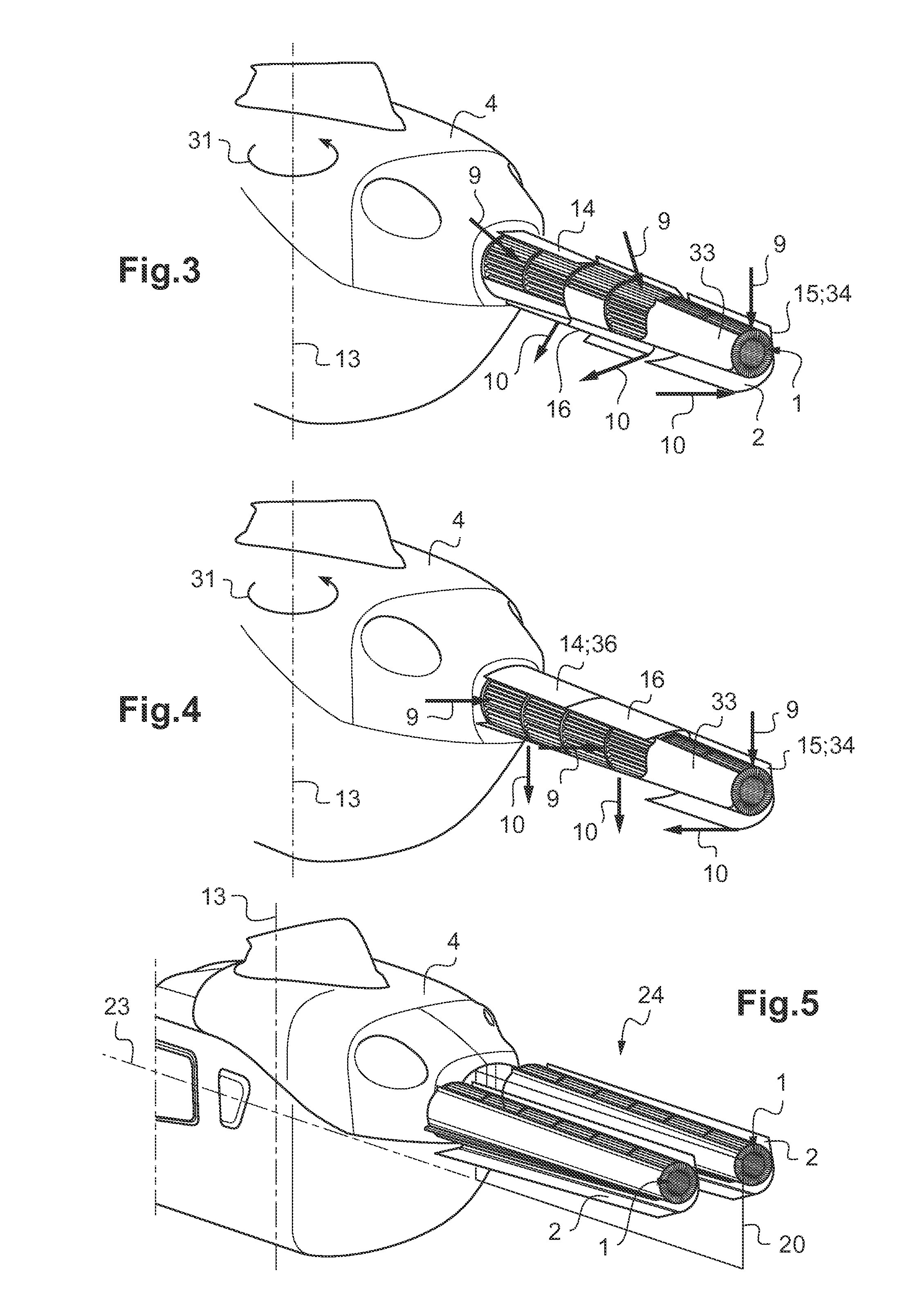

Helicopter with cross-flow fan

A helicopter with a fuselage (4), at least one engine, a roll axis, at least one main rotor, and at least one housing (2) mounted to said fuselage (4). An air inlet (8) and an air outlet (7) are provided along at least a part of a circumference of the at least one housing (2), said air inlet (8) and said air outlet (7) being formed by angularly offset and separate gaps between an inside segment (33) and an outside segment (34) essentially extending respectively longitudinally in direction of said roll axis. At least one rotatable compressor (1) with a plurality of airfoil blades (6) is provided radial inside said at least one housing (2) between said air inlet (8) and said air outlet (7), said at least one rotatable compressor (1) being drivable by said at least one engine about a fan axis (5) and each chord of said airfoil blades (6) is essentially radial oriented with regard to said fan axis (5).

Owner:AIRBUS HELICOPTERS DEUT GMBH

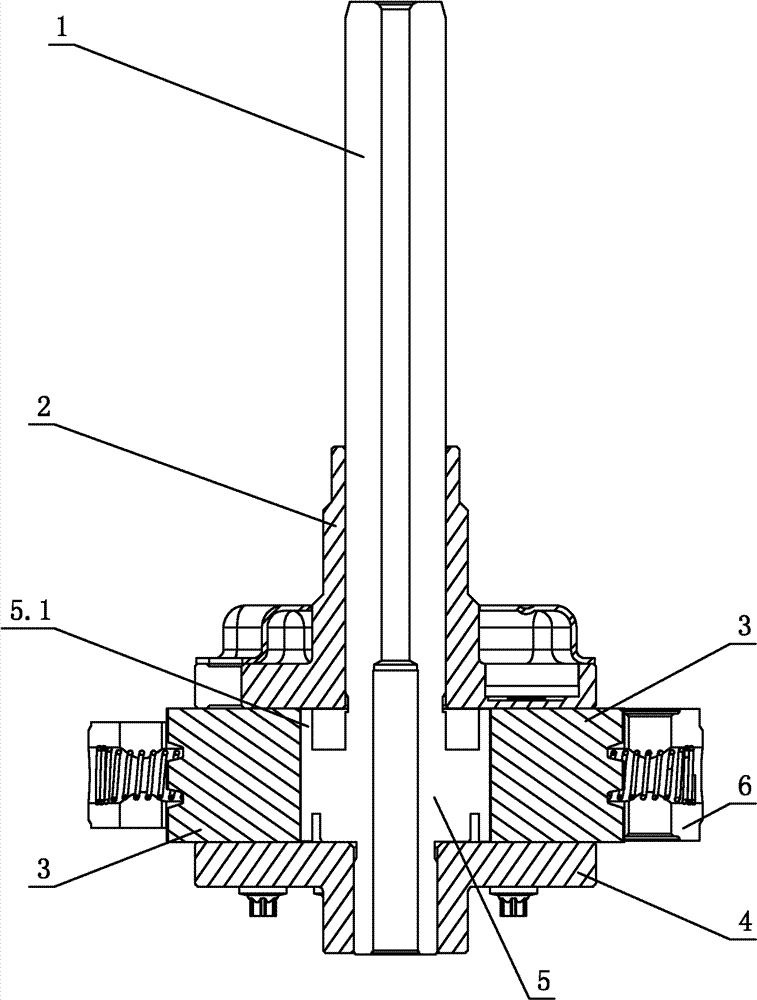

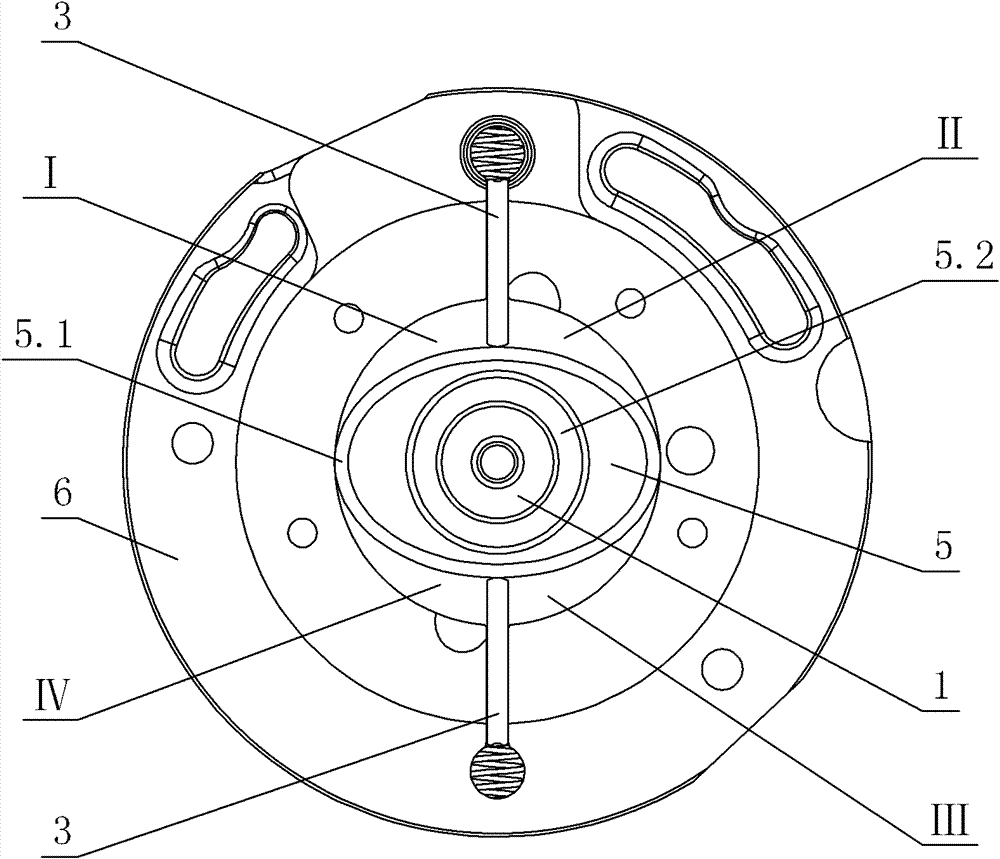

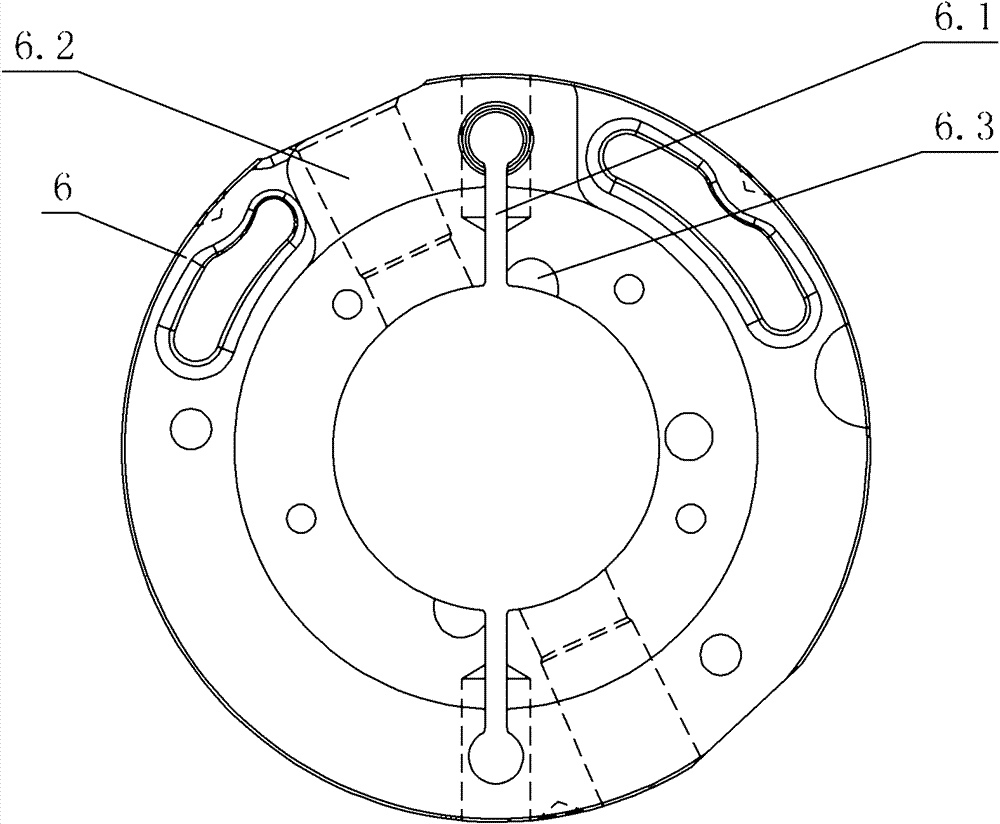

Rotary compressor

InactiveCN102788019AAchieve isolationReduce vibrationRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention relates to a rotary compressor, which comprises a motor assembly and a pump assembly, wherein the motor assembly and the pump assembly are arranged inside a housing, and the motor assembly is arranged above the pump assembly. The motor assembly comprises a stator and a rotor. The pump assembly comprises a cylinder, an elliptical piston arranged inside the cylinder, slide sheets arranged inside cylinder slide sheet grooves, a rotation shaft for driving the elliptical piston to rotate, a main bearing and a sub-bearing, wherein the main bearing and the sub-bearing are arranged on an upper side and a lower side of the cylinder. A center line of the elliptical piston and a center line of the cylinder cavity are overlapped. The two slide sheet grooves are arranged, each slide sheet groove is provided with the slide sheet, and one end of the slide sheet contacts the outer periphery of the elliptical piston. During compressor operation, the end portion of the slide sheet is tightly close to the outer periphery of the elliptical piston. The rotary compressor of the present invention has characteristics of simple and reasonable structure, smooth and reliable operation, and low vibration noise.

Owner:GUANGDONG MEIZHI COMPRESSOR

External rotor rotary compressor

ActiveCN105317678AReduce mechanical wear and tearIncrease power consumptionRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsCompression deviceStator coil

The invention discloses an external rotor rotary compressor comprising: a shell body, a stator support, a stator, a rotor and a compression device. A chamber is formed in the shell body; the stator support is fixed in the chamber; the stator is fixed on the stator support; a stator coil is winded on the stator; the rotor is rotatably disposed on exterior of the stator in a sleeving manner; a magnet is embedded in the inner side, which is towards the stator, of the rotor; an upper end surface of the magnet is lower than the upper end surface of the stator; the compression device is arranged in the shell body; and the upper end of a crank shaft of the compression device is connected to the rotor. According to the external rotor rotary compressor in the embodiment, the upper end surface of the magnet of the rotor is lower than the upper end surface of the stator so that an axial electromagnetic force generated to the rotor is upward when the external rotor rotary compressor works, so that the axial force applied to the crank shaft by the rotor is reduced and further mechanical loss of the external rotor rotary compressor is reduced. The external rotor rotary compressor is improved in power consumption and is improved in reliability and performance.

Owner:GUANGDONG MEIZHI COMPRESSOR

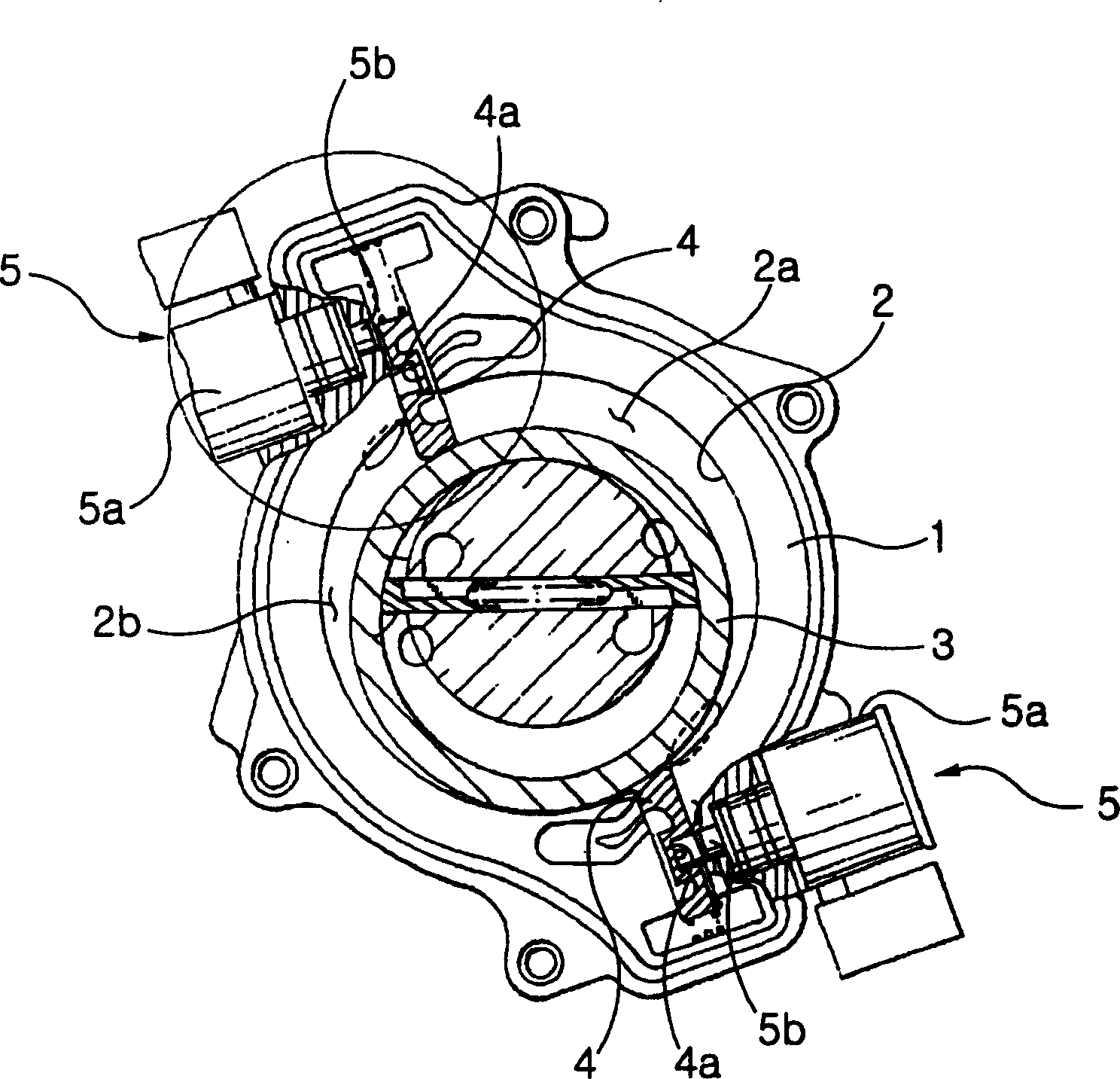

Rotary compressor

InactiveUS6077058AReduce total powerImprove compressor efficiencyEngine of arcuate-engagement typeOscillating piston enginesDrive shaftEngineering

PCT No. PCT / JP96 / 02658 Sec. 371 Date Dec. 31, 1997 Sec. 102(e) Date Dec. 31, 1997 PCT Filed Sep. 13, 1996 PCT Pub. No. WO97 / 12148 PCT Pub. Date Apr. 3, 1997When a driving shaft rotates, a piston (9) revolves around the driving shaft in a cylinder room (6a) with supported by a swing bush (32) as a supporting point through a blade (31). Discharge ports (22) are formed in a front head (7) and a rear head (8) respectively and are disposed to be located in the proximity of the blade (31) and to communicate with a high pressure room. A semicircular portion of the discharge port (22) overlaps with the swing bush (32) and the cylinder (6). A pair of upper and lower cut parts (41) are each formed by cutting away an outer peripheral edge of the swing bush (32) and an inner peripheral edge of the cylinder (6) which are overlapped with the discharge port (22).

Owner:DAIKIN IND LTD

Rotary compressor with air injection enthalpy-increasing function

InactiveCN101294568ASimple structureRaise the suction temperatureRotary piston pumpsRotary piston liquid enginesEngineeringInjection air

The invention relates to a rotary compressor with enthalpy-gaining function. An upper bearing or a lower bearing of the rotary compressor is provided with one or more gas orifices; the gas orifices are matched with a pipeline so as to allow an air cylinder of the compressor to communicates with the external part of the compressor through the gas orifices; the gas orifices are provided with a one-way valve for allowing external fluid to enter the air cylinder through the pipeline and the gas orifices and preventing the fluid in the air cylinder from discharging from the gas orifices and the pipeline. The rotary compressor of the invention improves the structure of conventional rotary compressor by enabling a gaseous refrigerant to be injected into the compressor air cylinder through the pipeline, thus increasing the suction temperature of the rotary compressor, improving the compression efficiency and saving energy.

Owner:GREE ELECTRIC APPLIANCES INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com