Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3915 results about "Sump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sump (American English and some parts of Canada: oil pan) is a low space that collects often undesirable liquids such as water or chemicals. A sump can also be an infiltration basin used to manage surface runoff water and recharge underground aquifers. Sump can also refer to an area in a cave where an underground flow of water exits the cave into the earth.

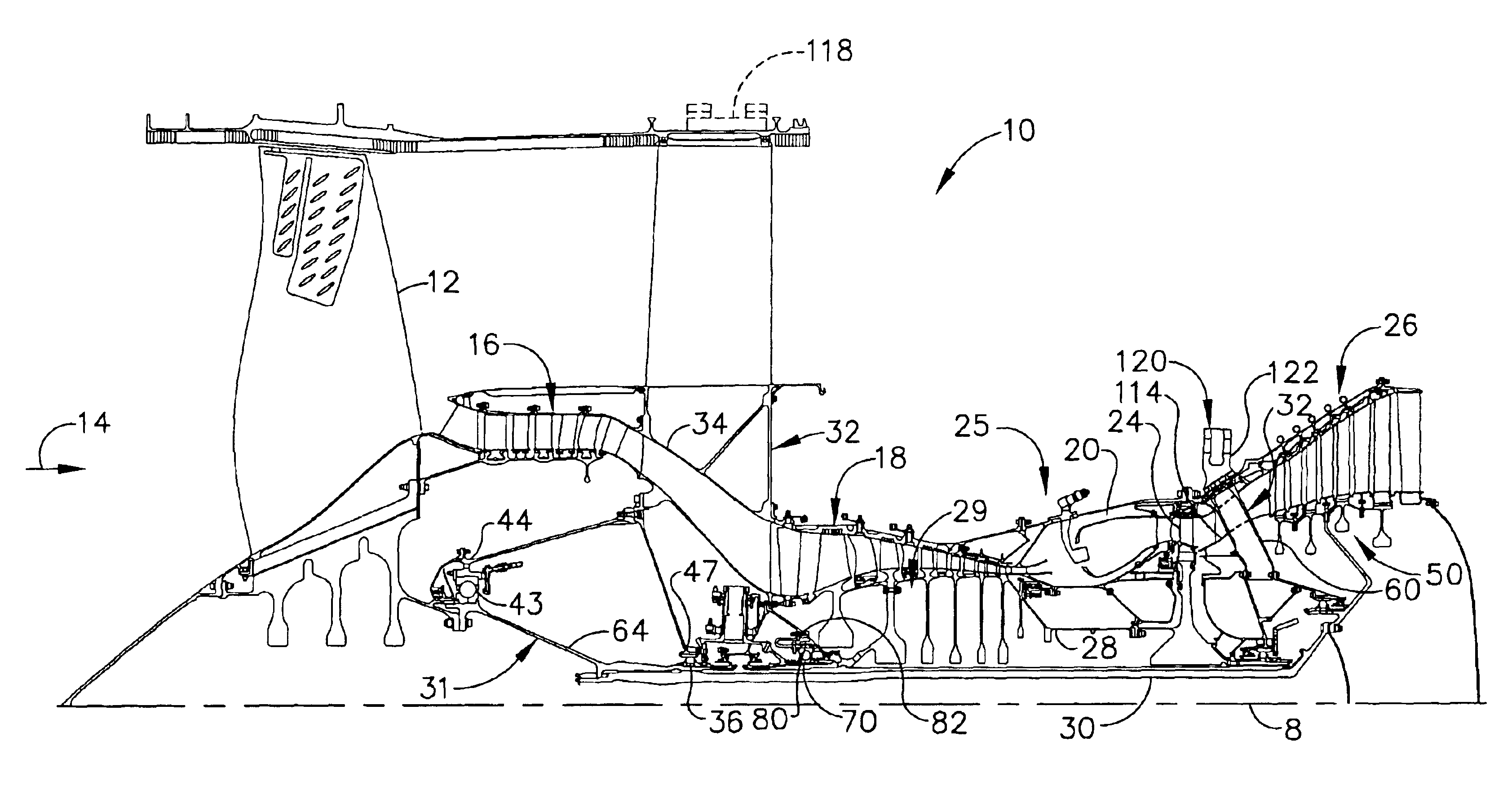

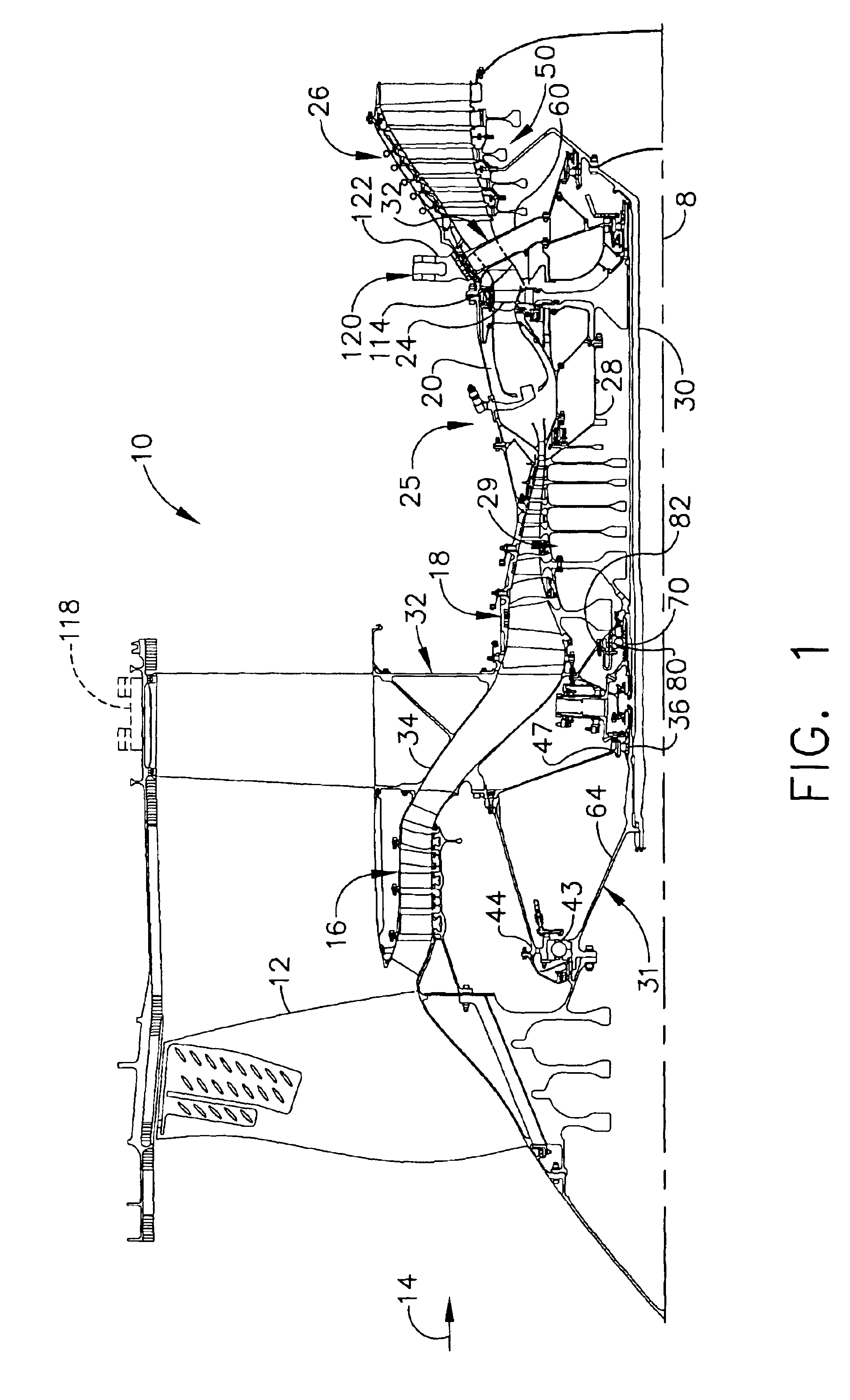

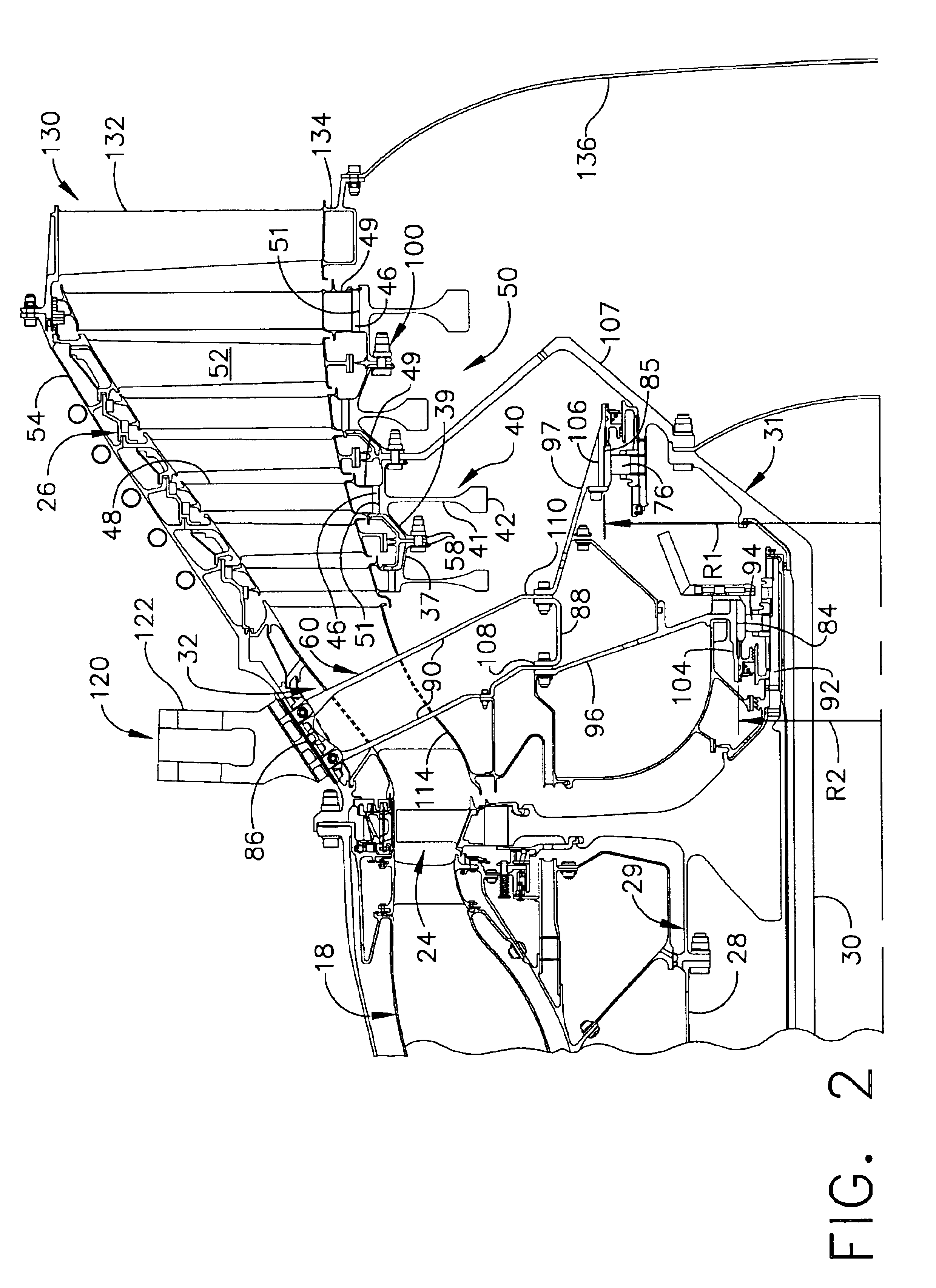

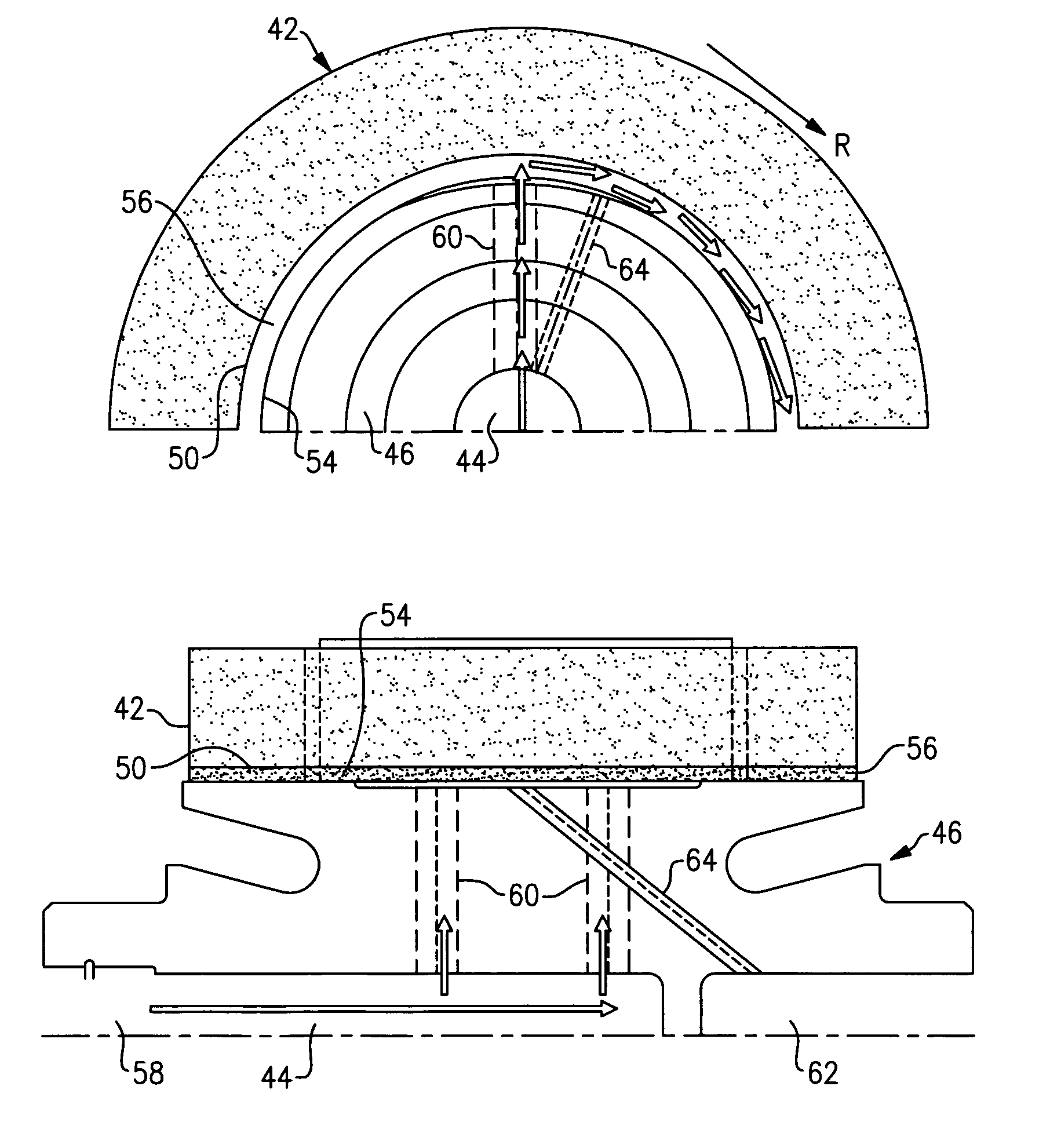

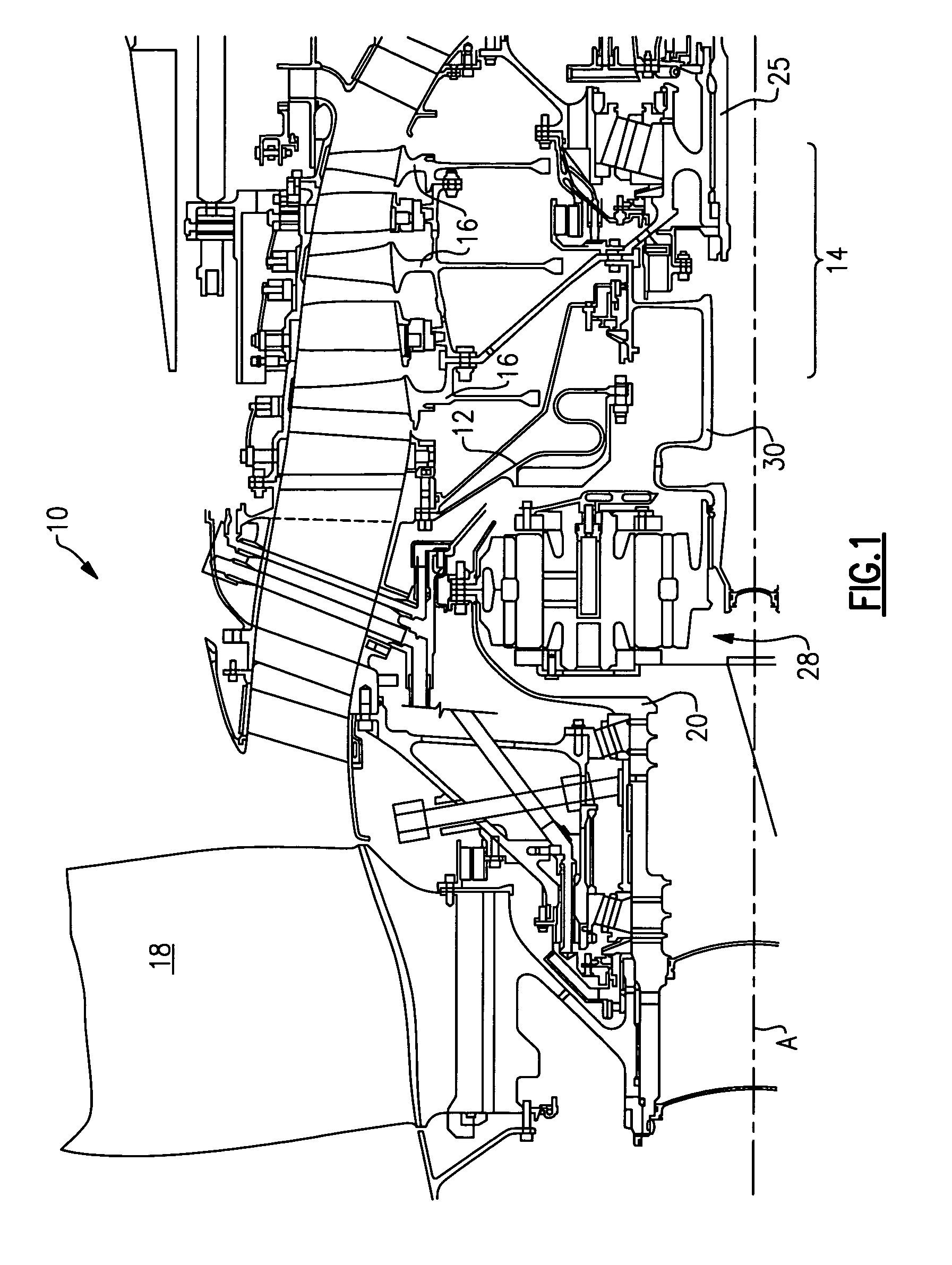

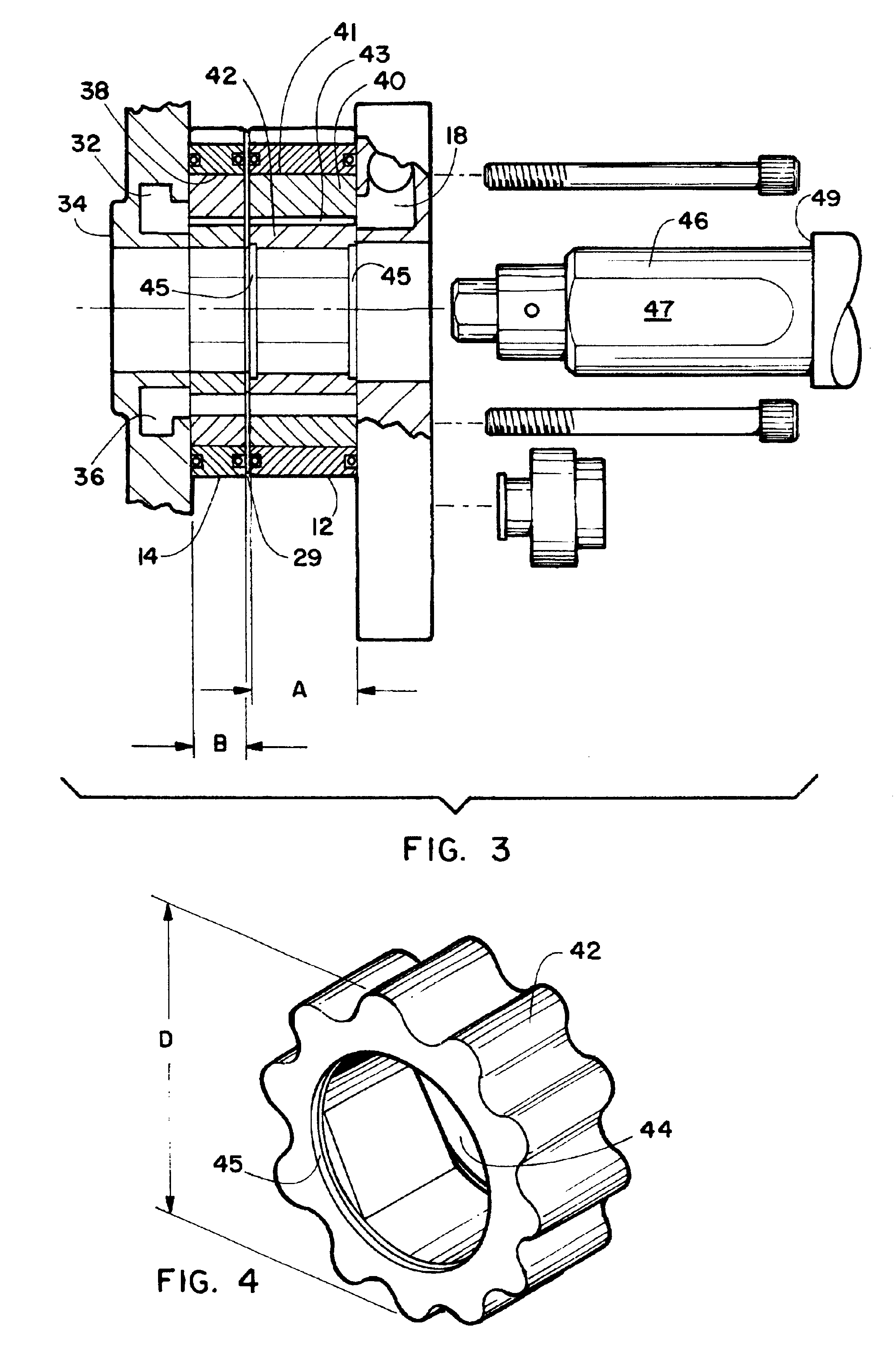

Aircraft engine with inter-turbine engine frame

An aircraft engine turbine frame includes a first structural ring, a second structural ring disposed co-axially with and radially spaced inwardly of the first structural ring about a centerline axis. A plurality of circumferentially spaced apart struts extend between the first and second structural rings. Forward and aft sump members having forward and aft central bores are fixedly joined to forward and aft portions of the turbine frame respectively. A frame connecting means for connecting the engine to an aircraft is disposed on the first structural ring. The frame connecting means may include a U-shaped clevis. The frame may be an inter-turbine frame axially located between first and second turbines of first and second rotors of a gas turbine engine assembly. An axial center of gravity of the second turbine passes though or very near a second turbine frame bearing supported by the aft sump member.

Owner:GENERAL ELECTRIC CO

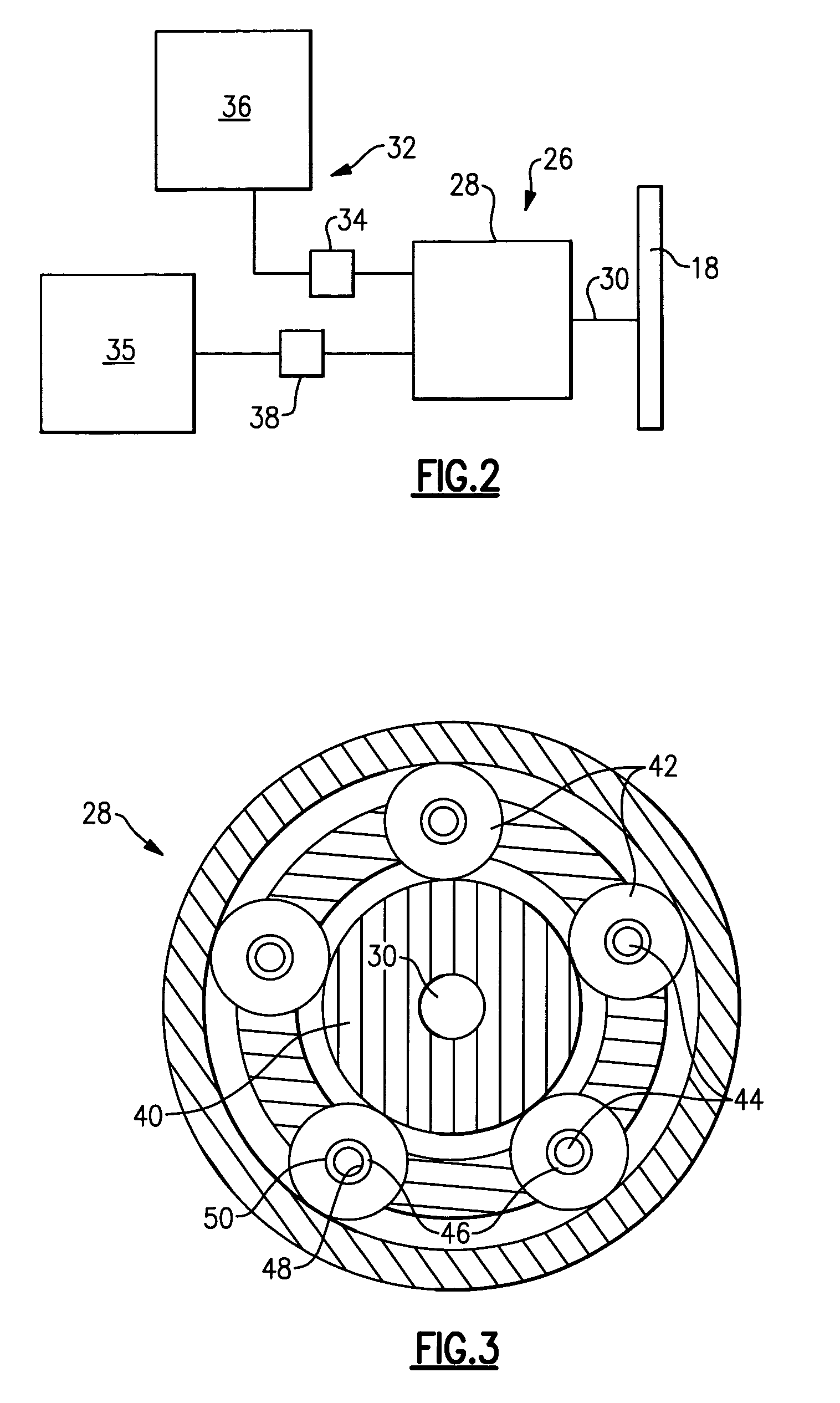

Lubrication of windmilling journal bearings

A support shaft provides lubrication to a journal bearing during windmilling operation of a gear set. A primary oil pump provides oil from an oil supply during driven operation of the fan, and a secondary oil pump provides oil from an internal sump during windmilling operation of the fan. During driven operation of the fan, oil is pumped with the primary oil pump through a primary oil flow path to an outer surface of the support shaft. During windmilling fan operation, oil is pumped from an internal sump with a secondary oil pump through the secondary oil flow path. The secondary oil flow path has a smaller flow capacity, and the secondary oil pump is a smaller capacity pump.

Owner:RTX CORP

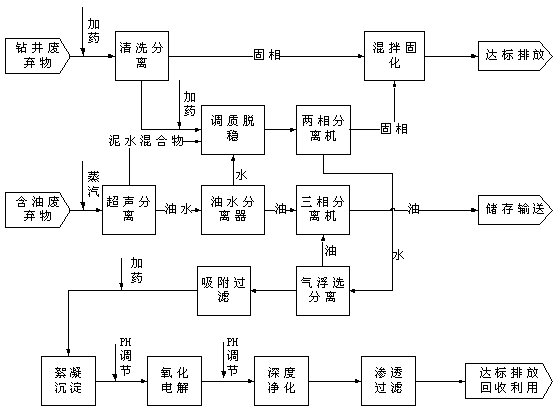

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

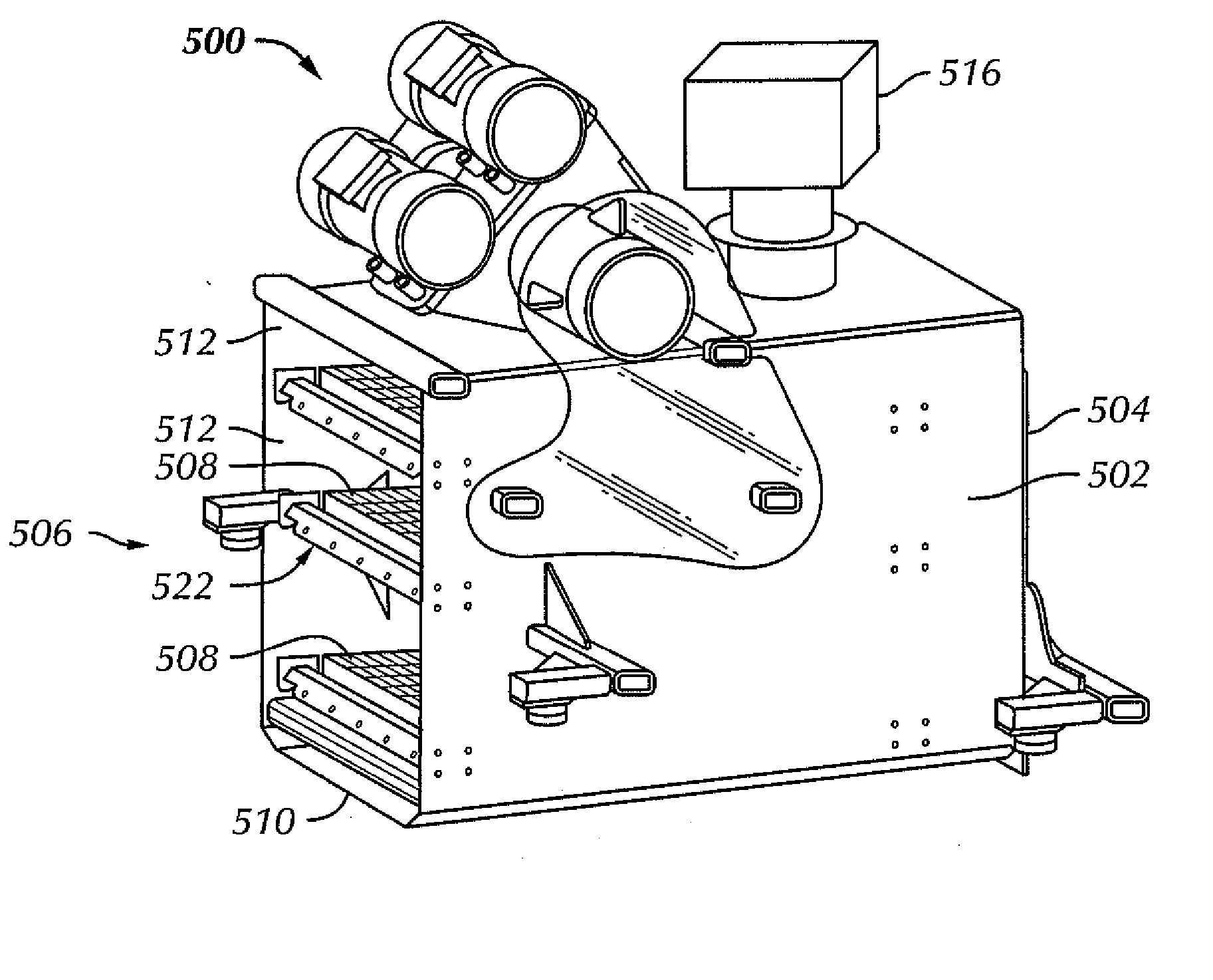

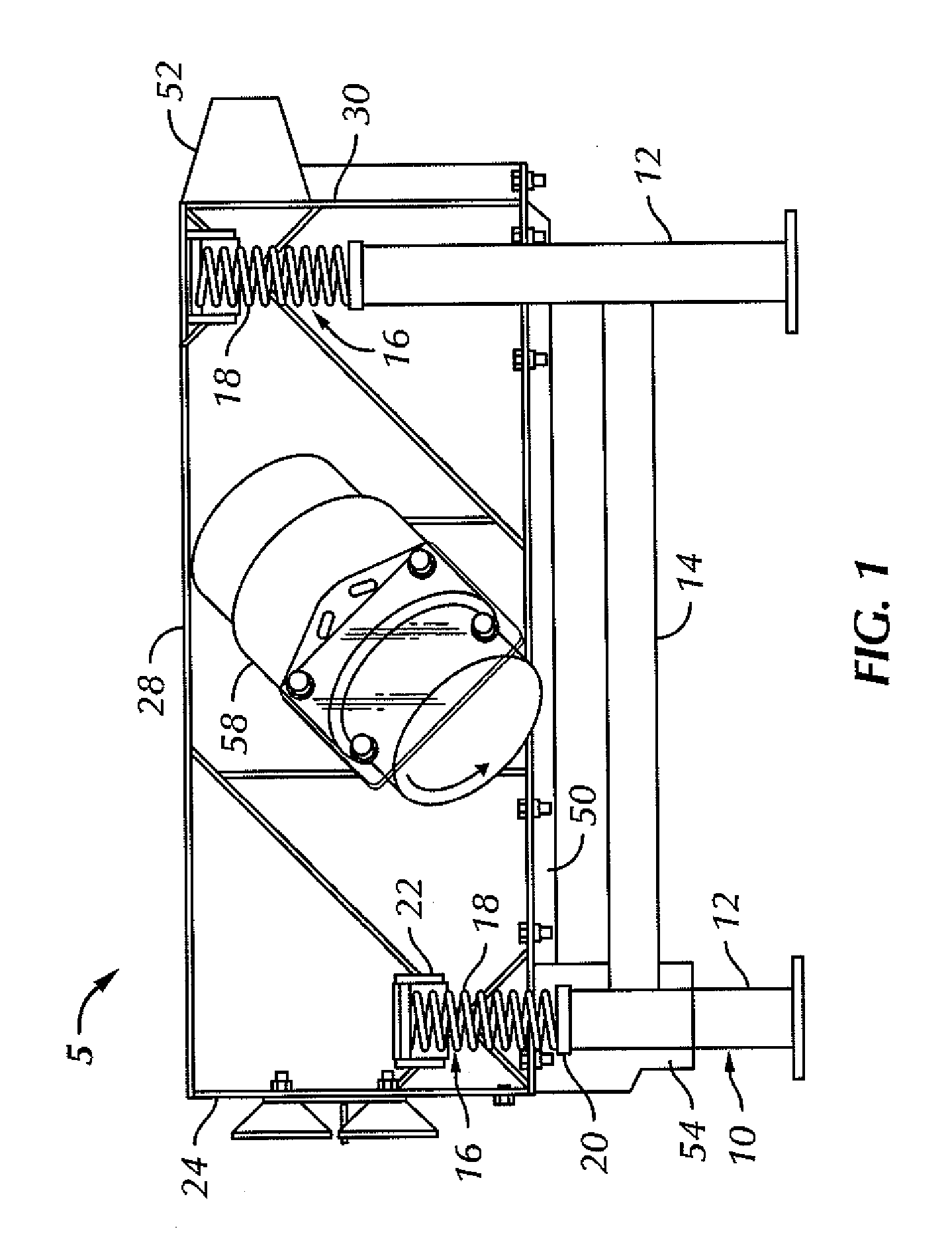

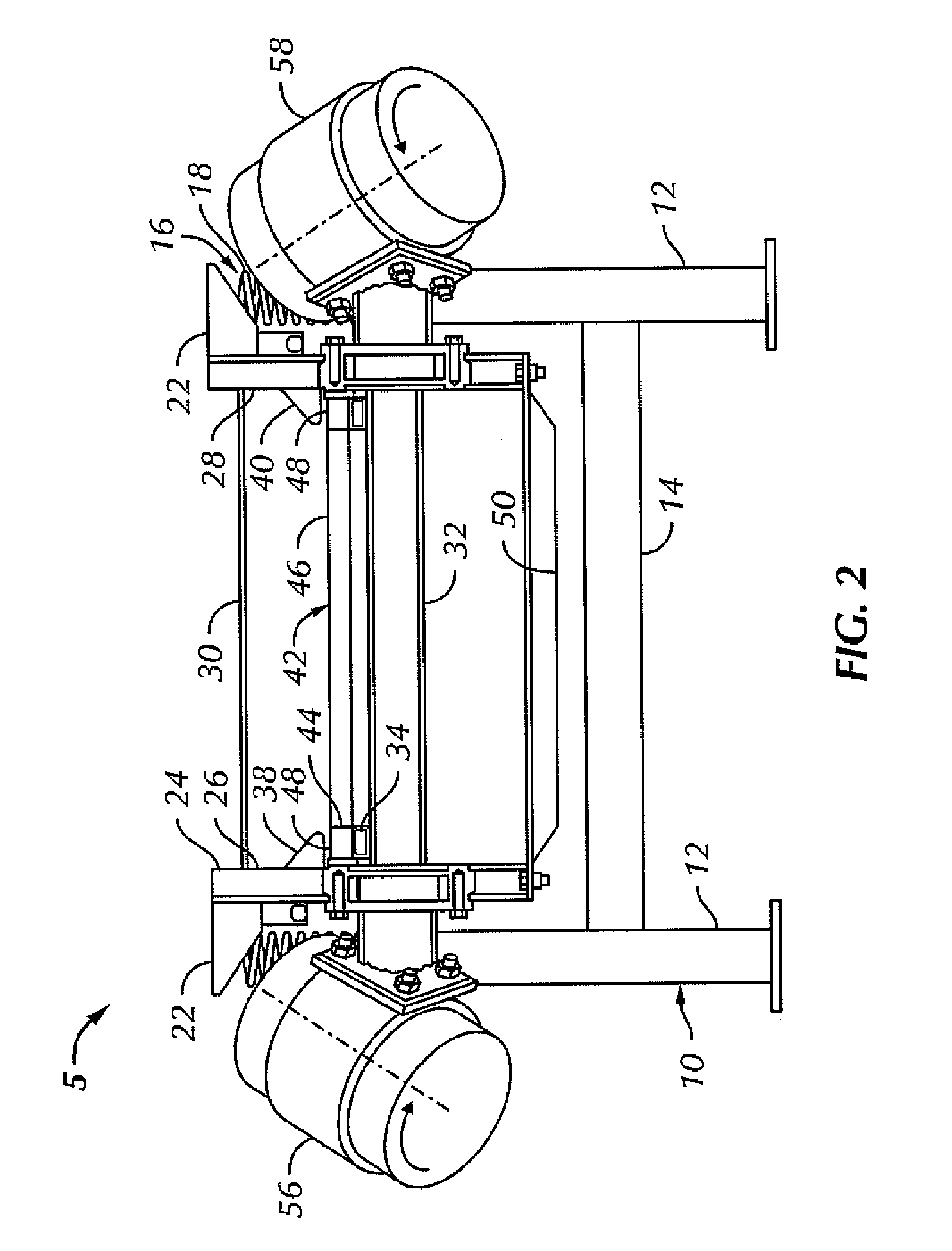

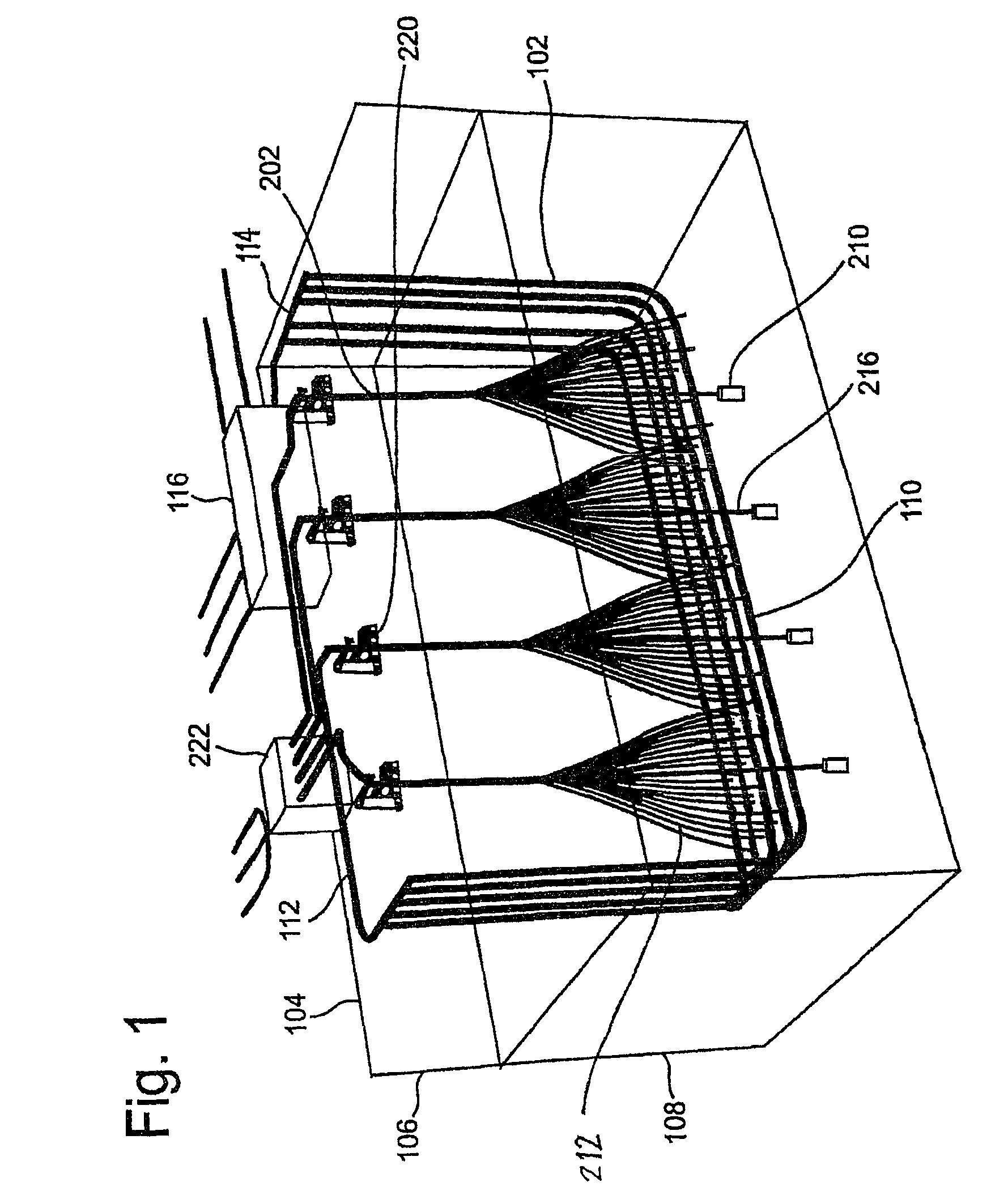

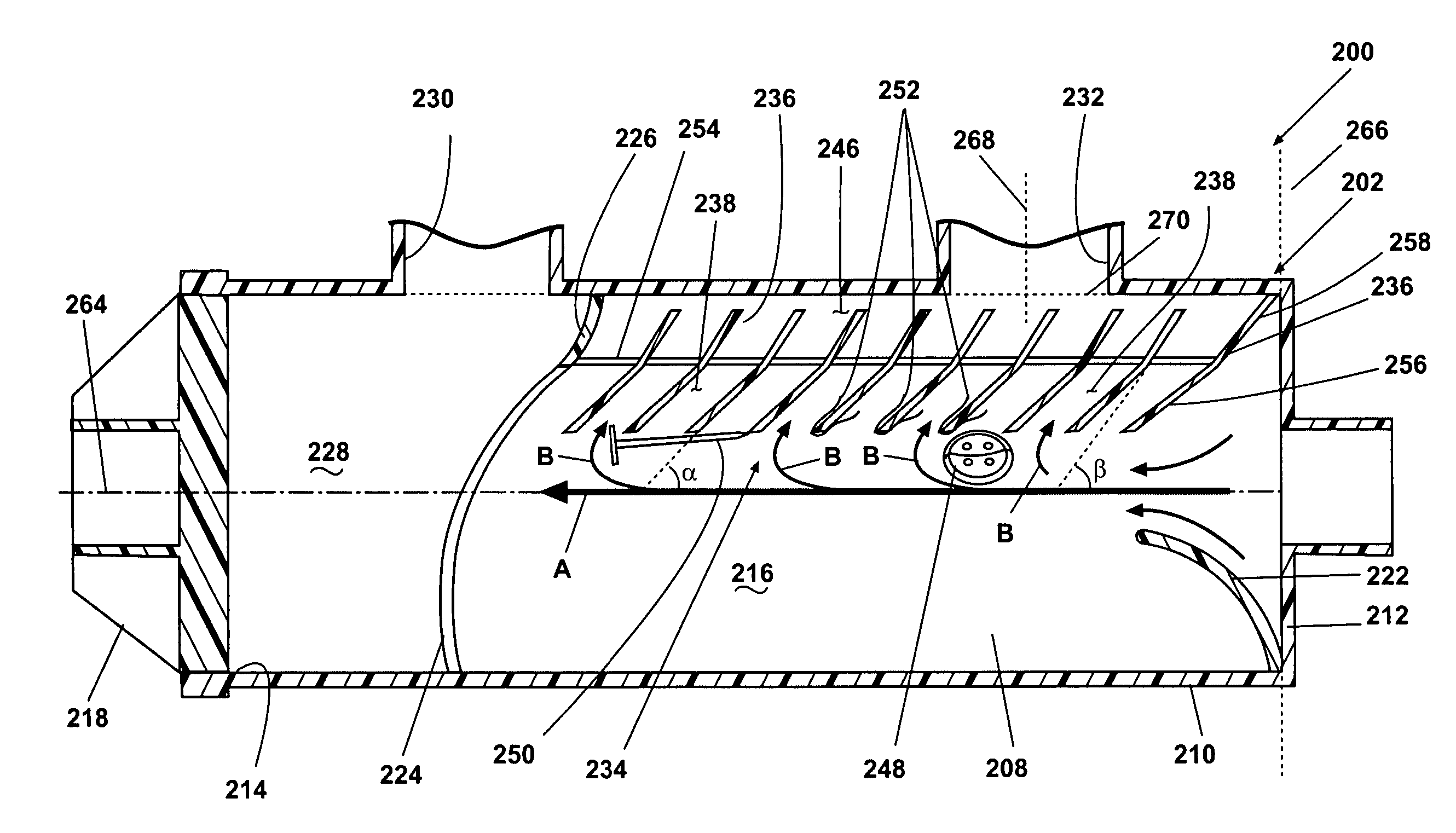

Shaker and degasser combination

A system for separating components of a slurry is disclosed, the system including a housing; a basket for holding at least one shaker screen, the basket movably mounted in the housing; at least one vibrator coupled to the basket; a sump disposed below the basket to collect at least a portion of the slurry passing through the at least one shaker screen; a pressure differential device fluidly connected to the sump for developing a pressure differential across the at least one shaker screen; and a toggling device for toggling the pressure differential across the screen. A system including a degassing chamber fluidly connected to a sump and a pressure differential device, wherein the degassing chamber is disposed between the sump and the pressure differential device, and a fluid conduit fluidly connected to the degassing chamber for recovering a degassed fluid is also disclosed.

Owner:MI

Method for removing oil from water coalescing in a polymer particle/fiber media

ActiveUS7297279B2Increase the liquid flow rateBig contactLiquid suspension thickening by filtrationSolid sorbent liquid separationFiberWater flow

Apparatus in fluid communication with a water leg portion of a hydrocarbon-contaminated water, e.g., a water leg portion of a produced water stream or an offshore drilling or production platform sump tank for conveying water, separated from oil, into contact with non-woven fiber / particulate polymer coalescing media-containing canisters such that the hydrocarbon droplets and other organic material droplets commingled with the sump tank or produced water will be coalesced by passage through the coalescing media. The canisters preferably are provided in a plurality of stacks in each vessel. Solids that do not pass through the canisters are accumulated at the bottom of the vessel and easily drained through a drain port. The water and hydrocarbons will pass through the coalescing media within the canisters and will be separated easily from each vessel, e.g., by gravity separation, sot that the water can be conveyed back to the ocean water without contamination.

Owner:AMCOL INTERNATIONAL CORPORATION

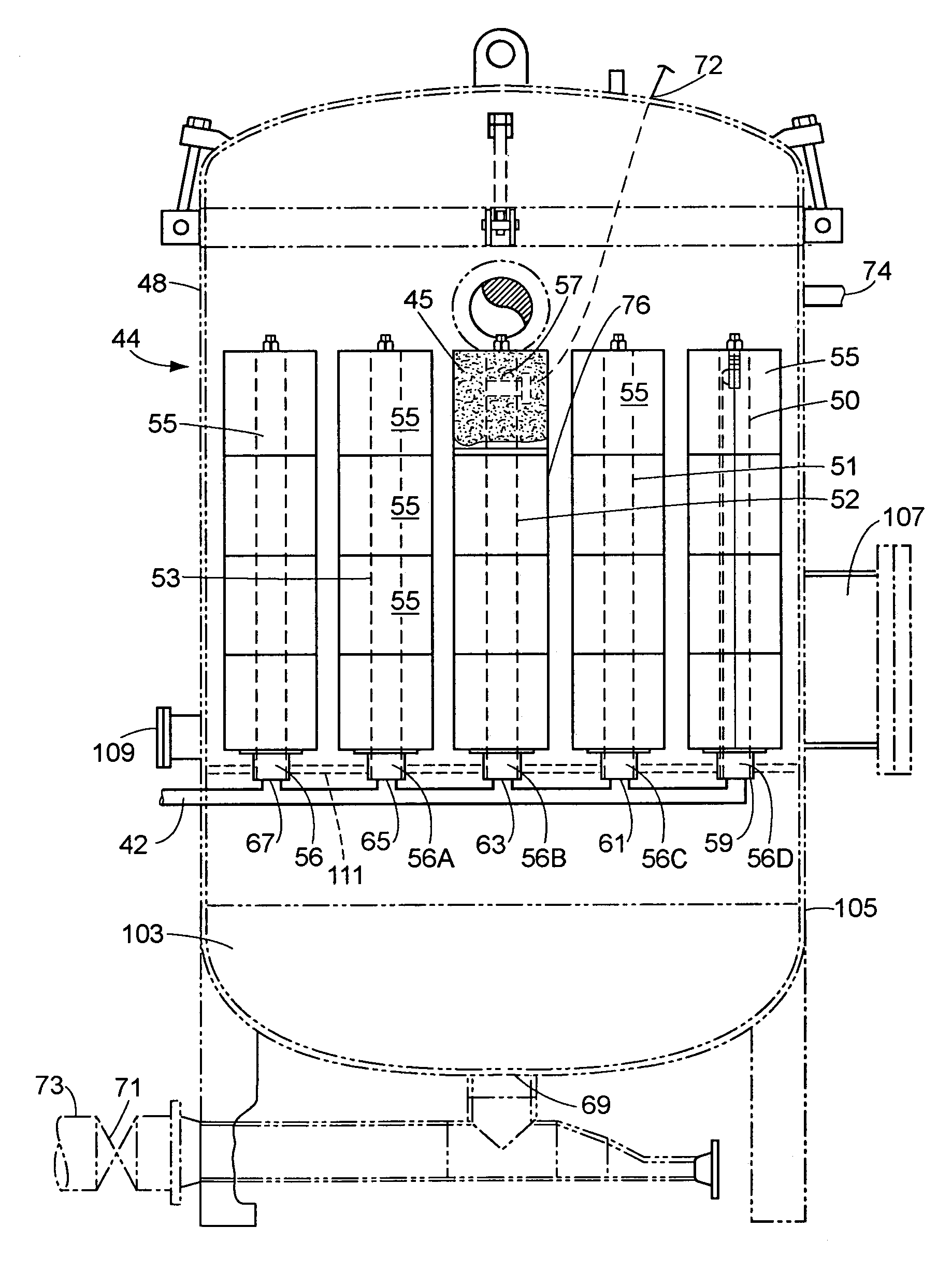

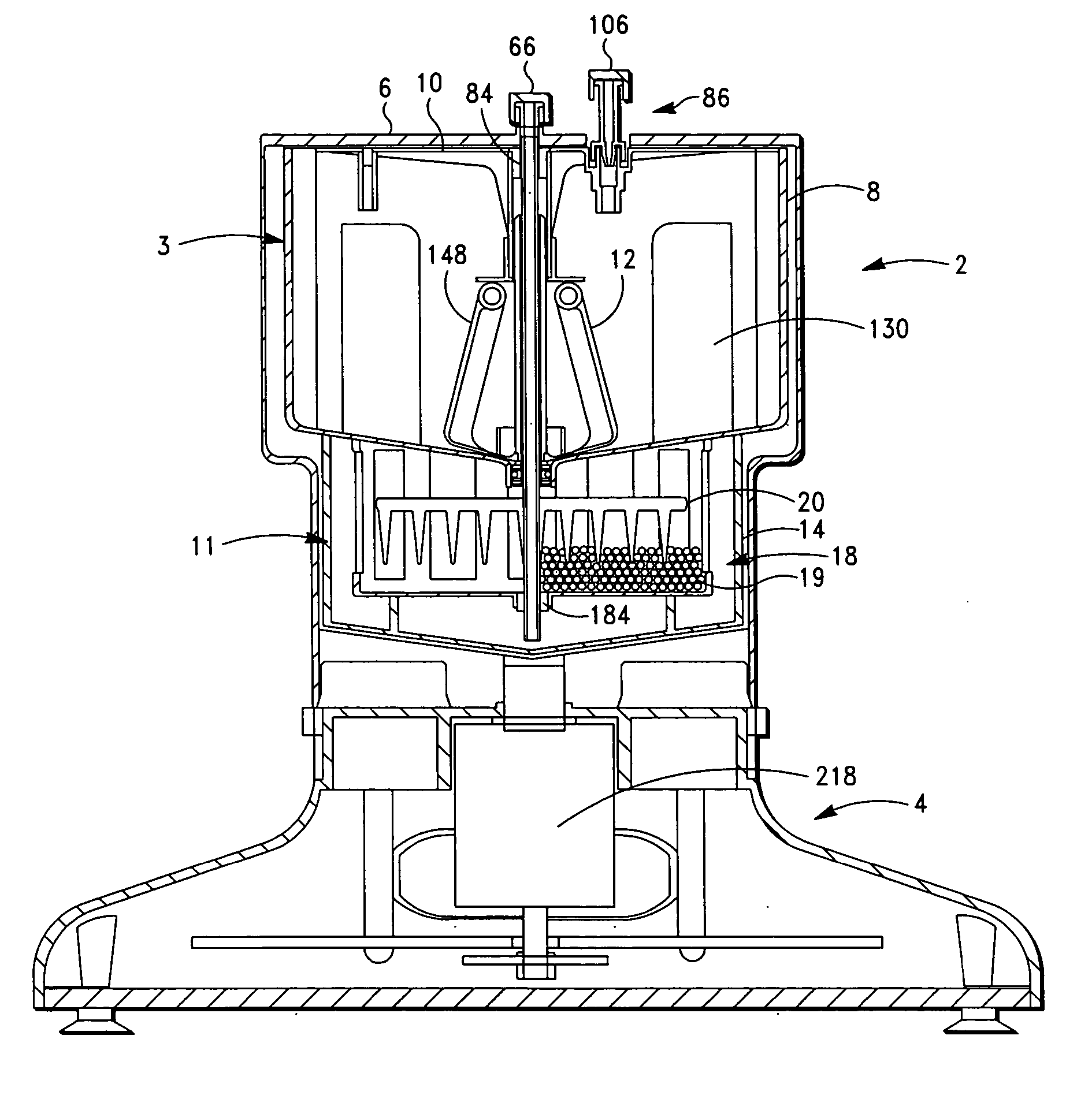

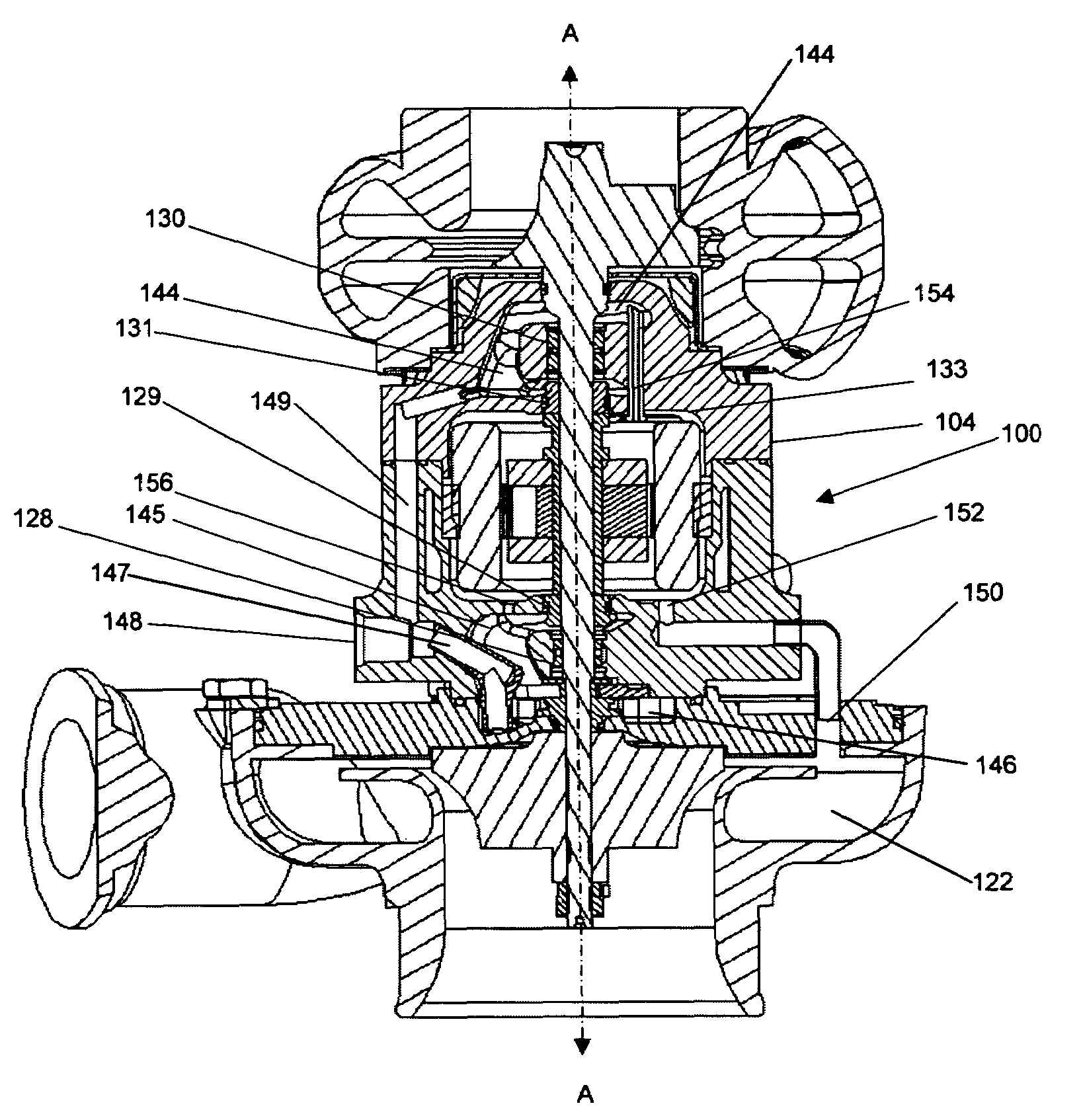

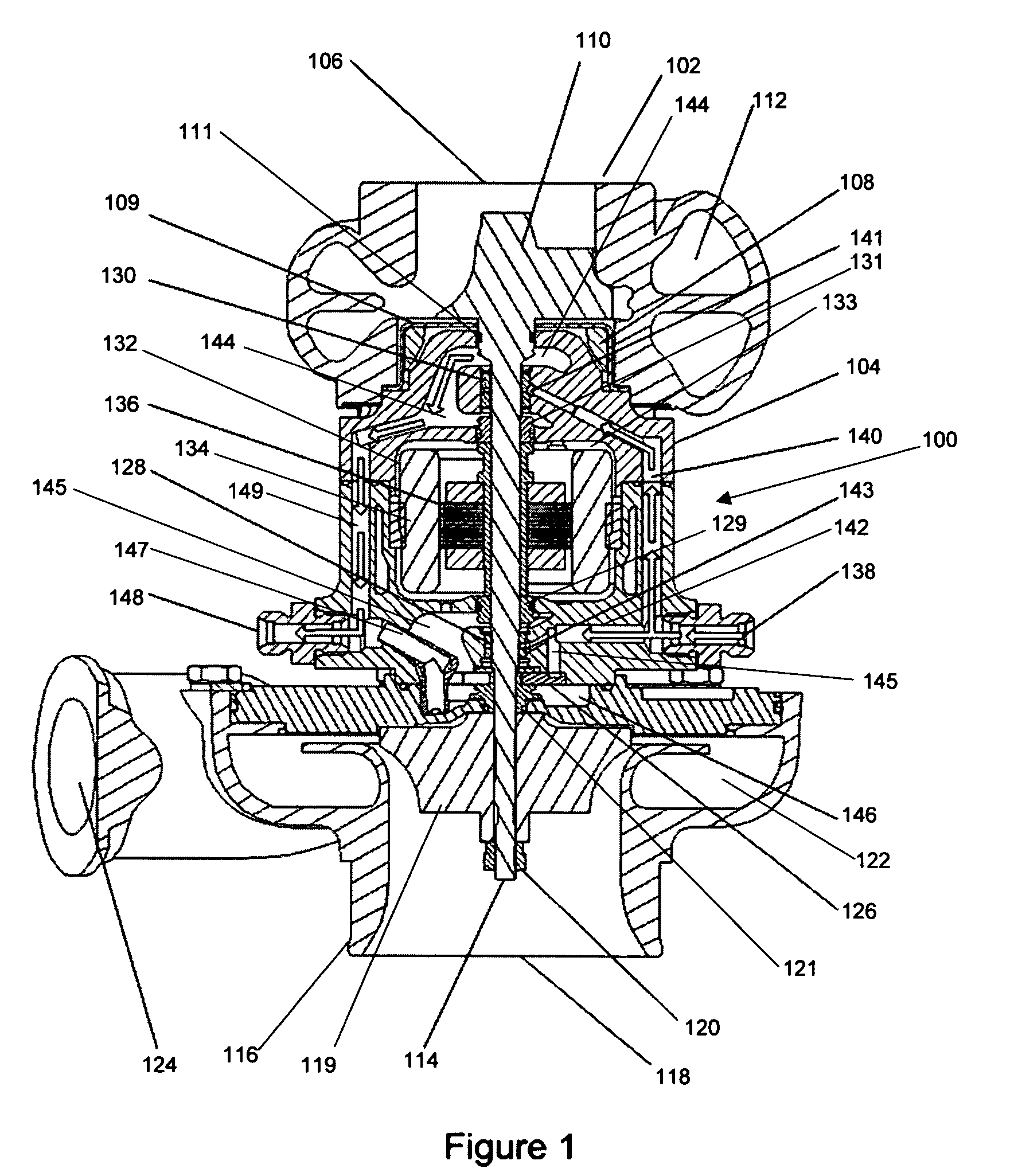

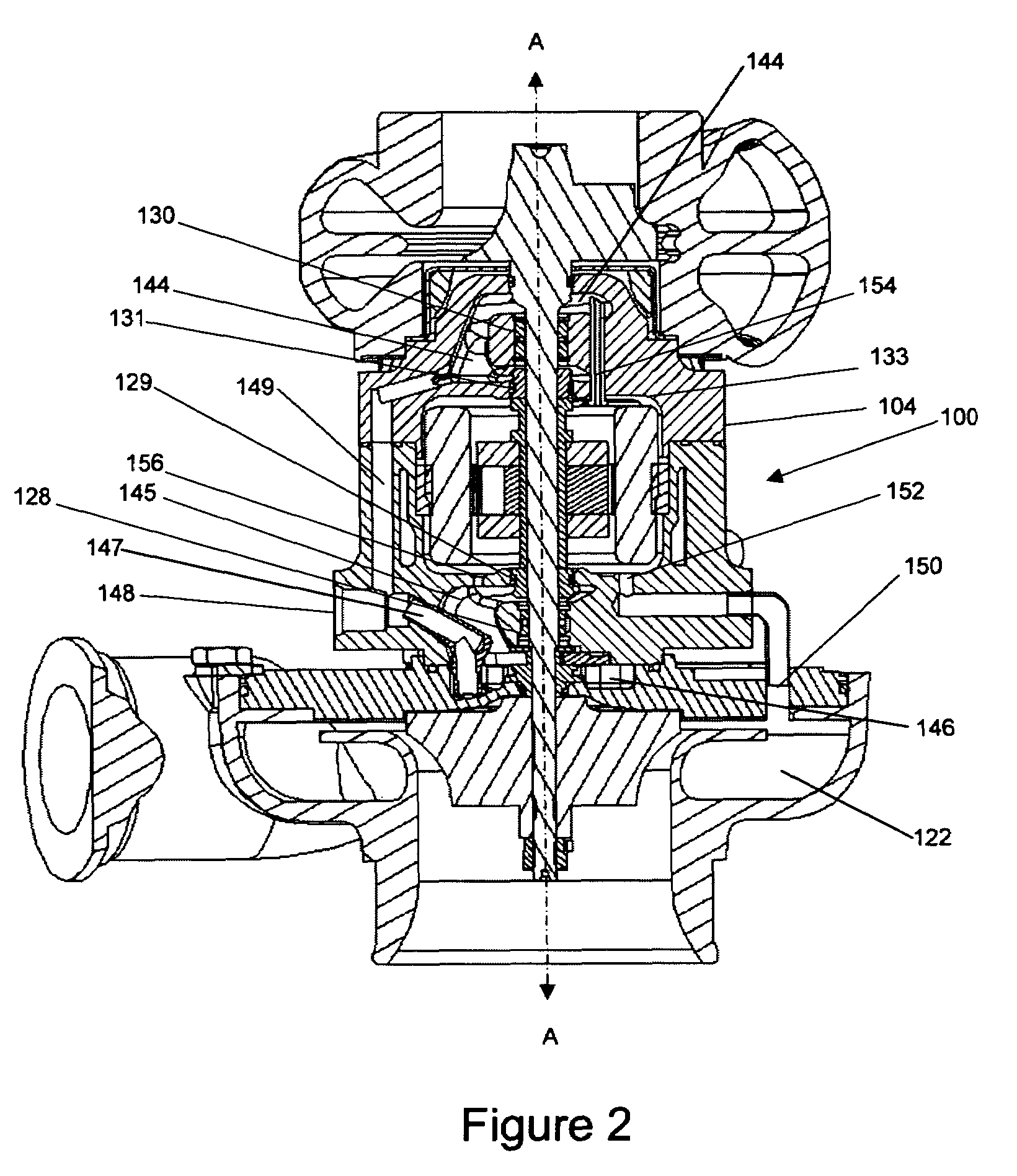

Apparatus and method for preparing platelet rich plasma and concentrates thereof

ActiveUS20060175244A1Increase in platelet levelAvoid assemblyRotary centrifugesMedical devicesRed blood cellEngineering

A PRP separator-concentrator comprising a housing, a separation assembly, and a concentration assembly. The concentration assembly has a concentration sump. An axially concentric rigid stationary outlet tube is secured to the housing and extends through the separation assembly to the sump. The separation assembly is attached to and positioned above the concentration assembly to form a combined separator-concentrator assemblage that is rotatable about the outlet tube. The separation assembly includes a separation chamber lined with a depth filter having pores and passageways that are sized to receive and entrap erythrocytes during centrifuging. The concentration chamber has a floor for supporting desiccated beads and a wall with at least one opening closed with a screen. The concentrator can have a distribution of upright screen supports, the upright screen supports having an inner surface and an outer surface, the cylindrical screen being supported on the outer surface of the upright screen supports. A stationary bead rake can be secured to the stationary tube and extend outward therefrom, the rake having distal ends that are spaced at a distance from the upright screen supports. The rake can comprise a longitudinal body, the center of which is secured to the rigid outlet tube. The separator-concentrator includes a valve assembly connecting the separation chamber and the concentration chamber. PRP concentrate is produced by contacting PRP with desiccated beads while the beads are stirred with a stationary rake, and rotating the concentration chamber at centrifugal speeds to separate PRP concentrate from the beads.

Owner:BIOMET BIOLOGICS +1

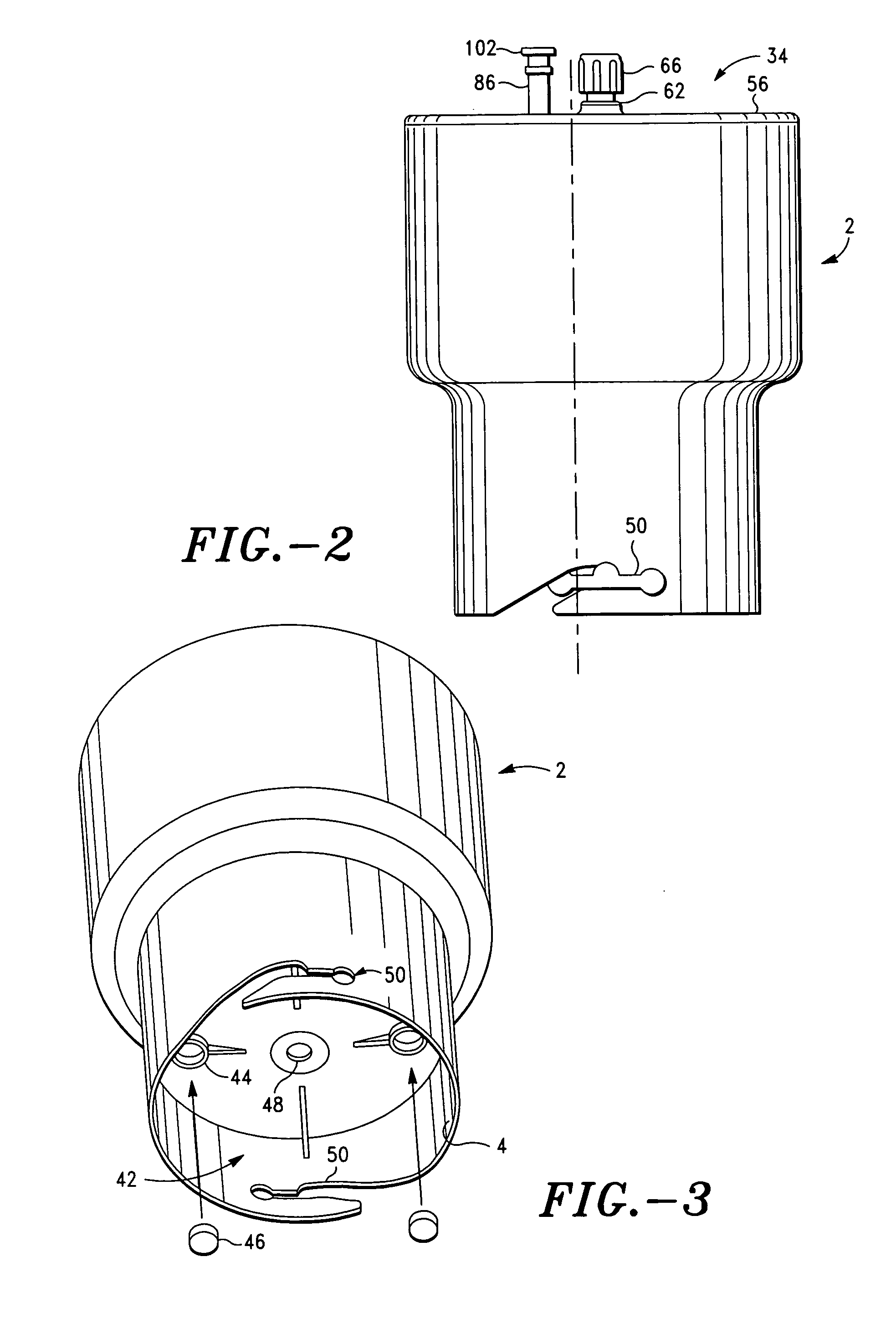

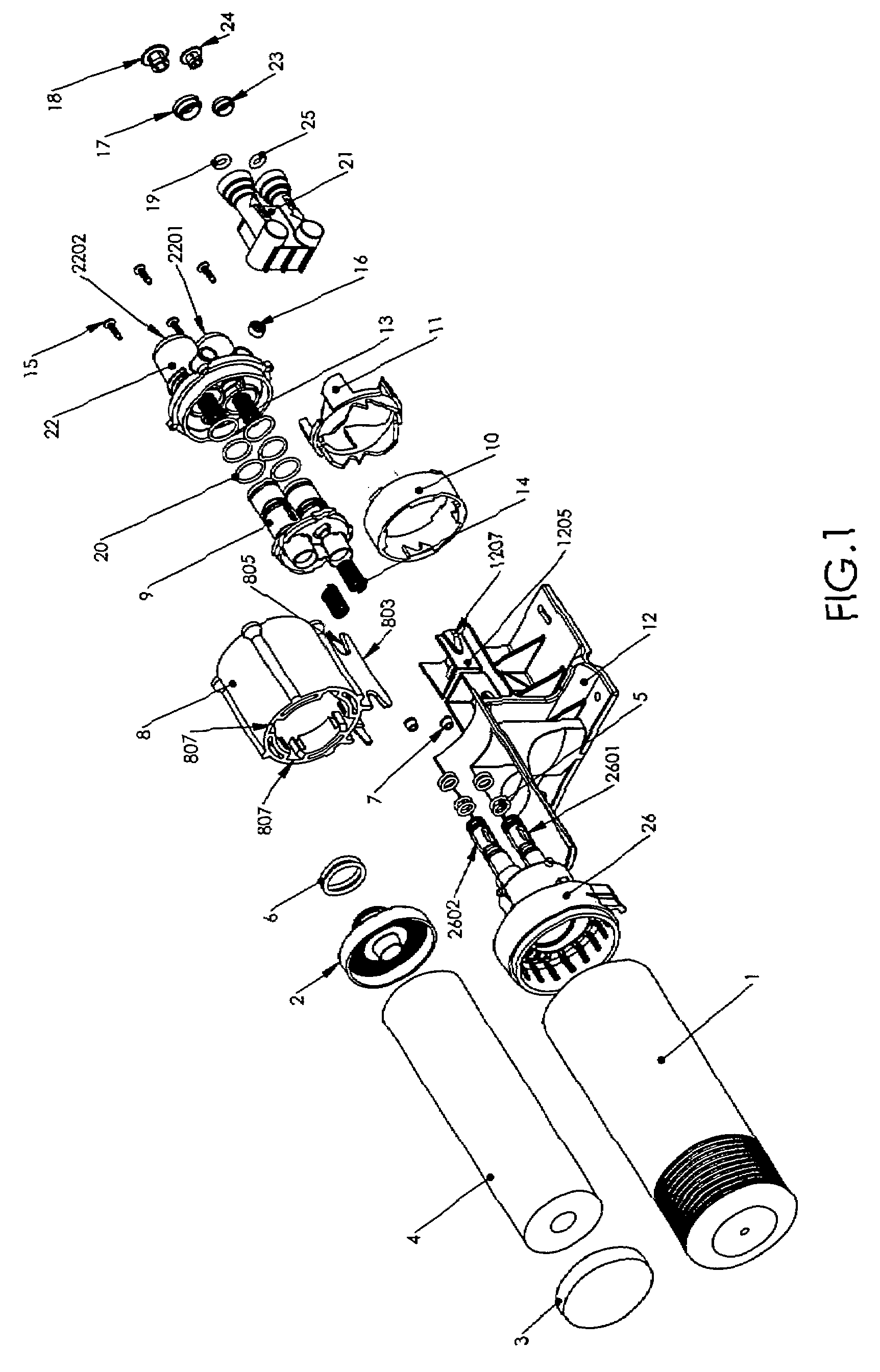

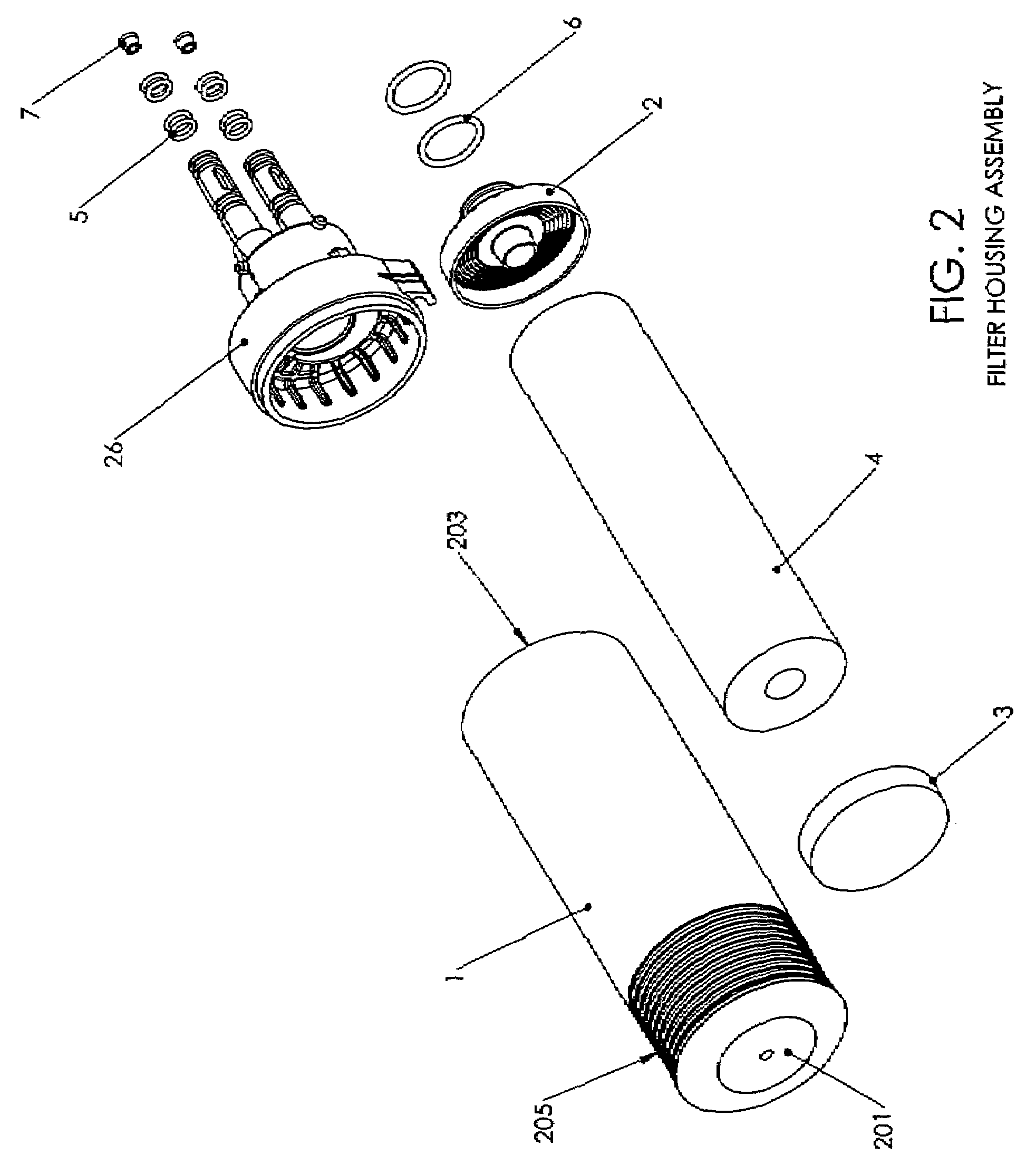

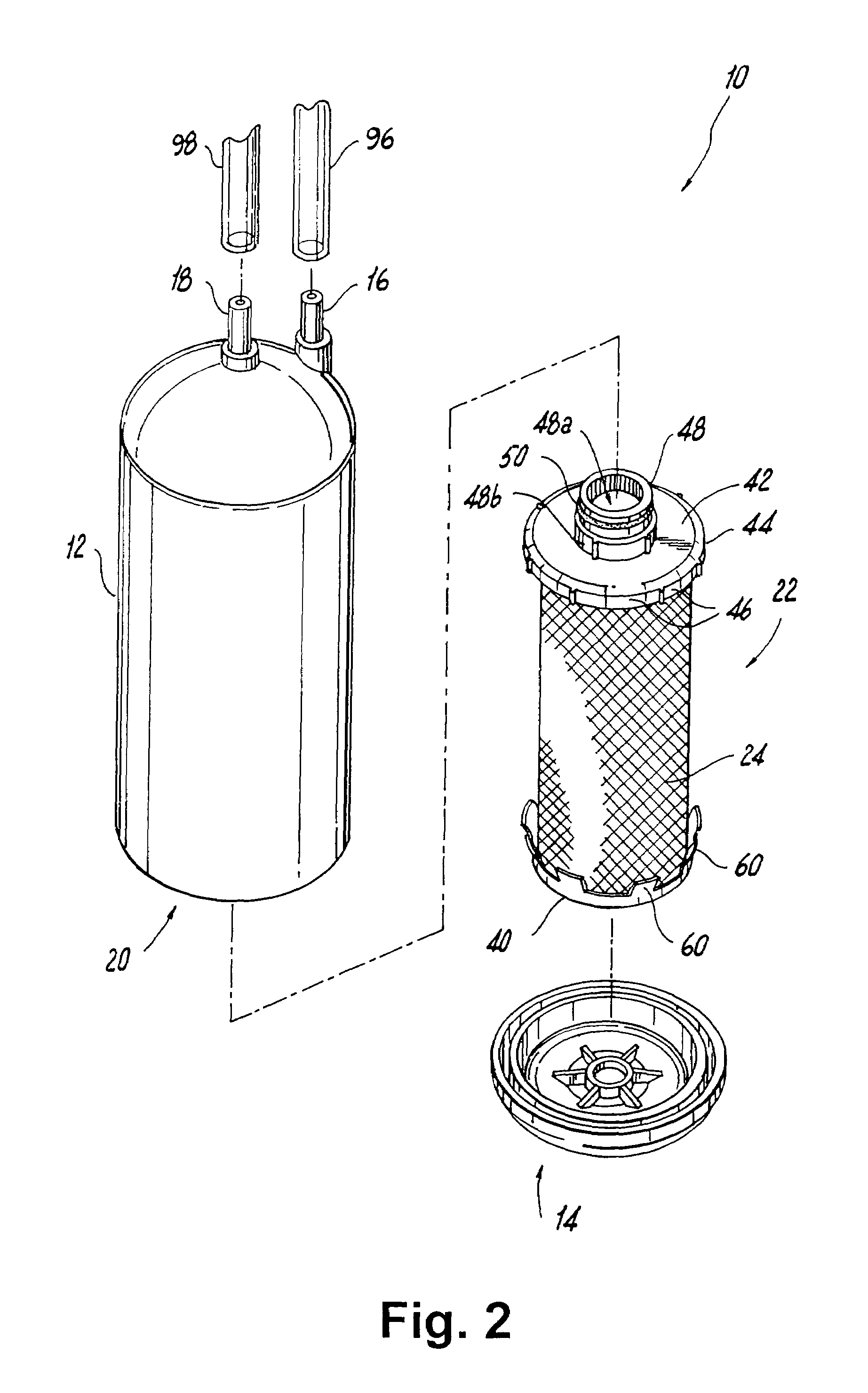

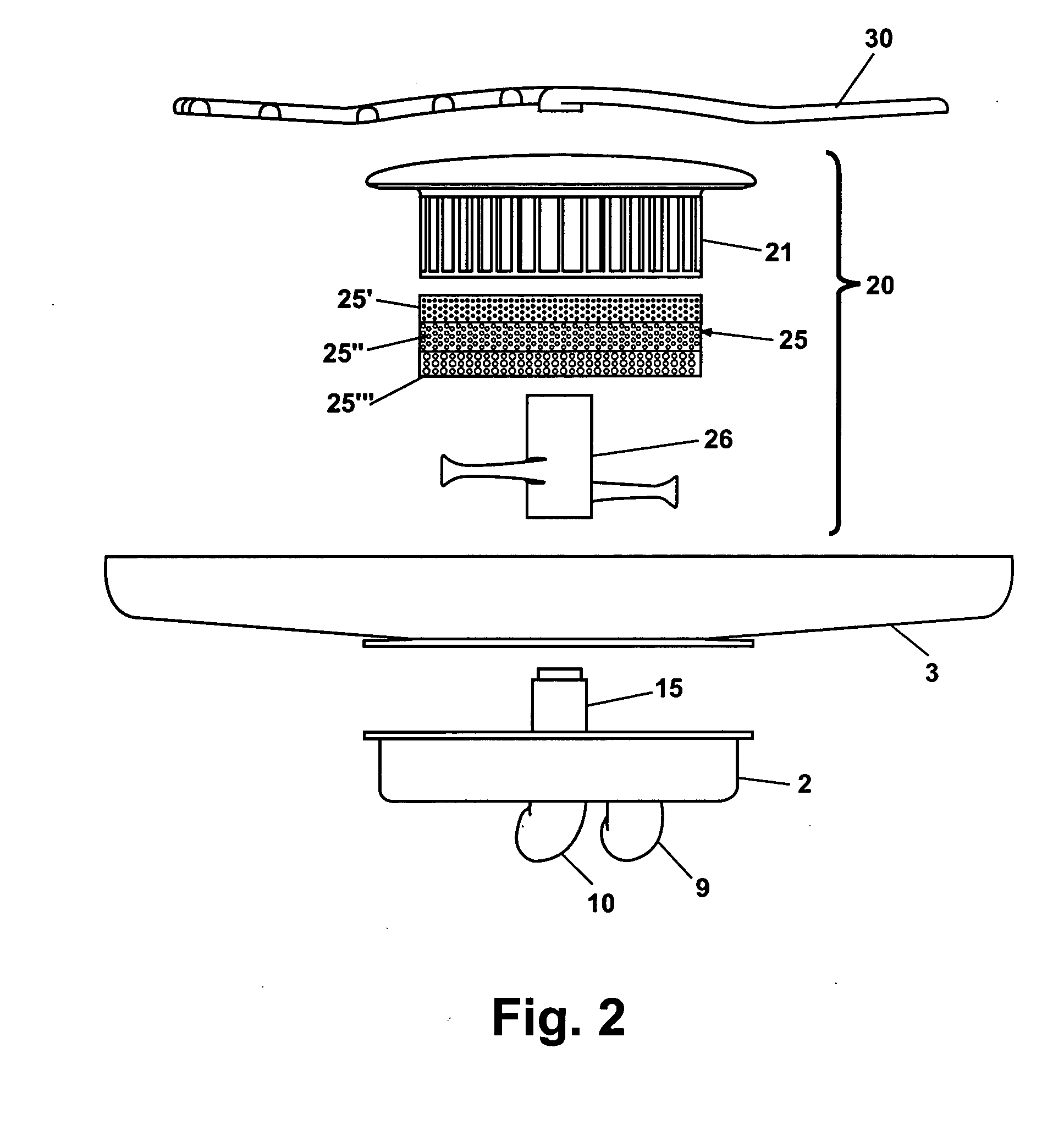

Filter housing apparatus with roatating filter replacement mechanism

InactiveUS20080047889A1Easy to disassembleSimple replacement and removalDomestic cooling apparatusSettling tanks feed/dischargeFilter mediaFluid filtration

A filter assembly for fluid filtration having a push-activated lock and release mechanism. The filter housing has a sump for enclosing the filter media, a filter head, and at least one standoff protruding outwards for use in securing the filter head to a filter manifold. The filter manifold supports the filter housing with a filter locator. A filter guide having a rotator actuating mechanism secures and holds the filter head in place when the filter head is axially inserted. The rotator actuating mechanism has tabs and slots that rotate upon a transverse axial force from the standoff and from tabs on an internal shutoff. The internal shutoff has an inlet extension and an outlet extension with apertures for fluid ingress and egress. The internal shutoff tabs slidably contact and align the rotator actuating mechanism to secure and remove the filter head.

Owner:KX TECH LLC (DW US)

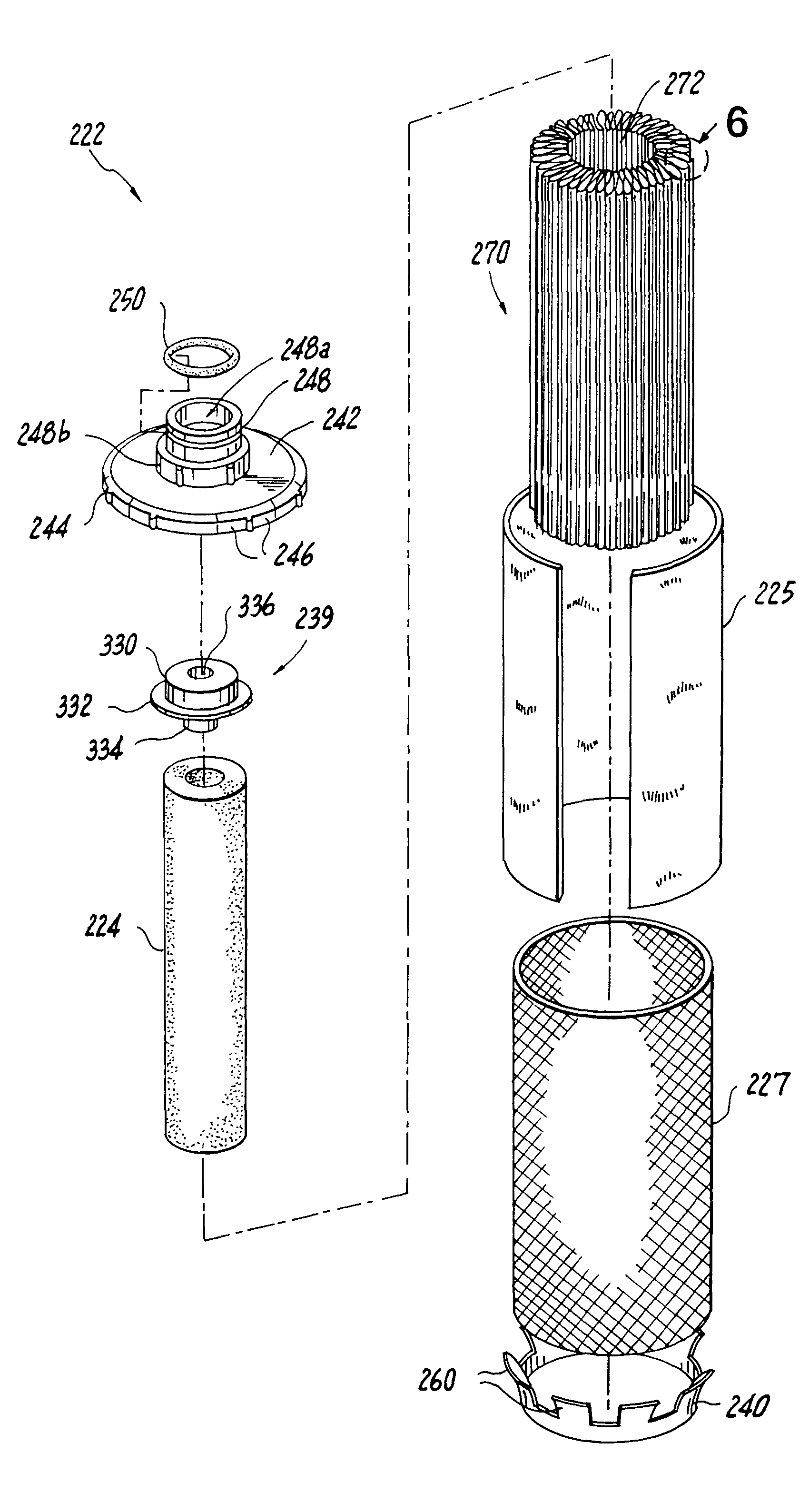

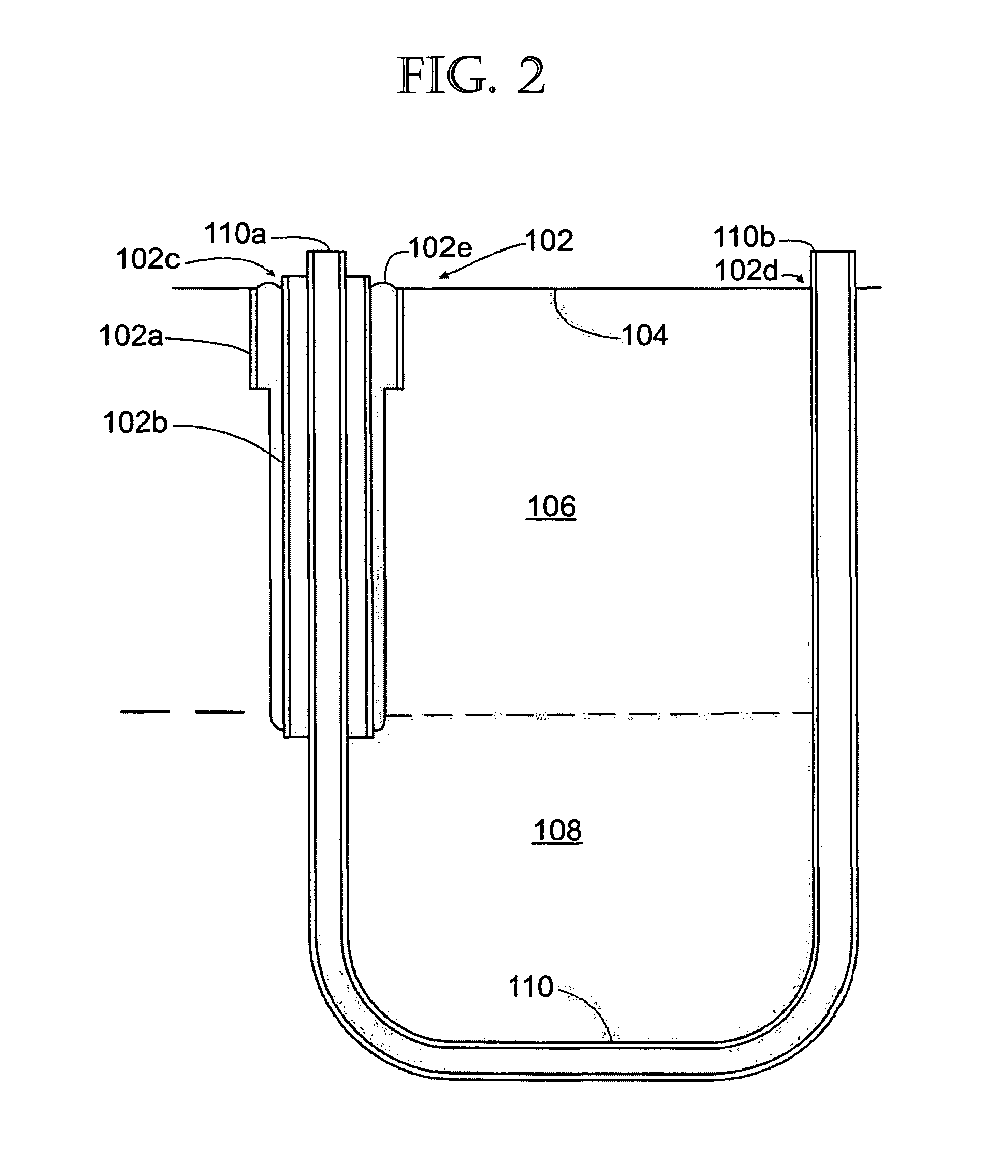

Encapsulated filter cartridge

InactiveUS7081201B2Easy to disconnectIncreased ease of manufacturingUltrafiltrationTreatment involving filtrationFiberEngineering

An encapsulated filter cartridge is disclosed, which includes a filter assembly including a carbon block filter element and a microporous filter element. The filter cartridge has a permanently sealed sump defining an interior chamber configured to accommodate the filter assembly, the sump having an inlet for permitting unfiltered fluid to enter the interior chamber for communicating with the radially outer surface of the filter assembly and an outlet for permitting filtered fluid to exit the interior chamber from the axial portion of the filter assembly. The microporous filter element of the filter assembly may include a hollow fiber subassembly housed within the axial cavity of the carbon block element, said fiber subassembly including a plurality of hollow microporous fibers, or a pleated filter element surrounding the radially outer surface of the carbon block element.

Owner:3M INNOVATIVE PROPERTIES CO

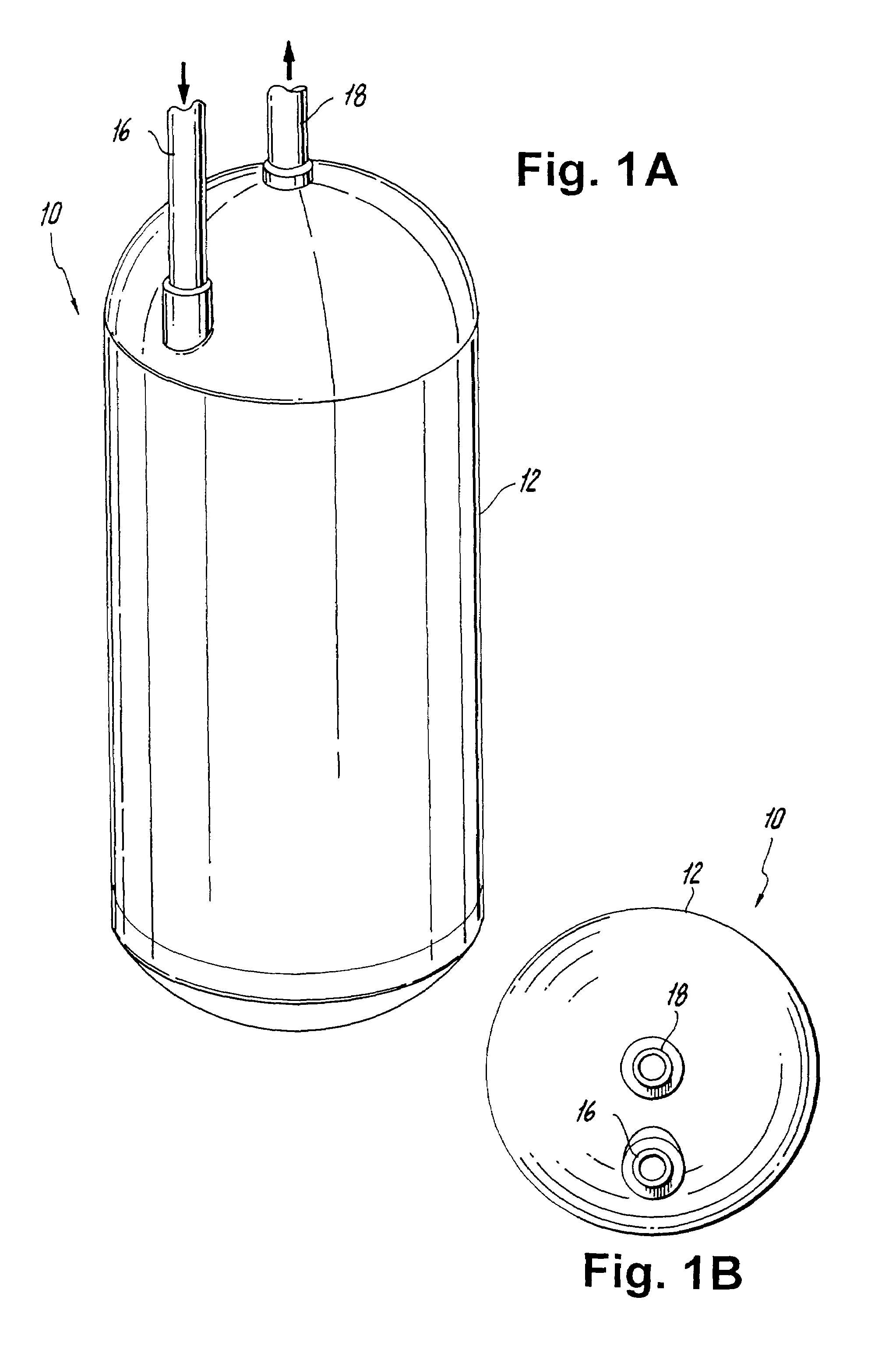

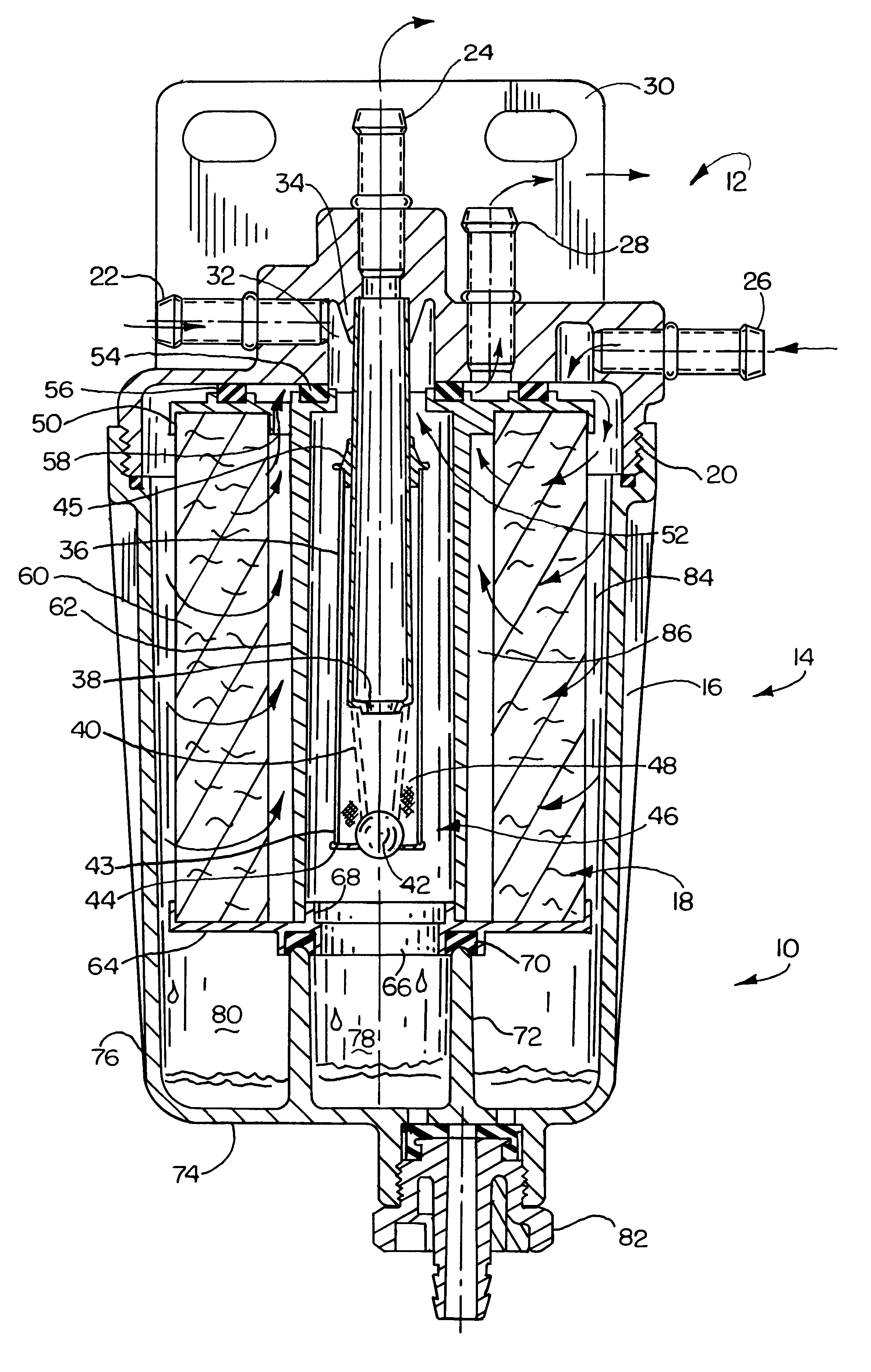

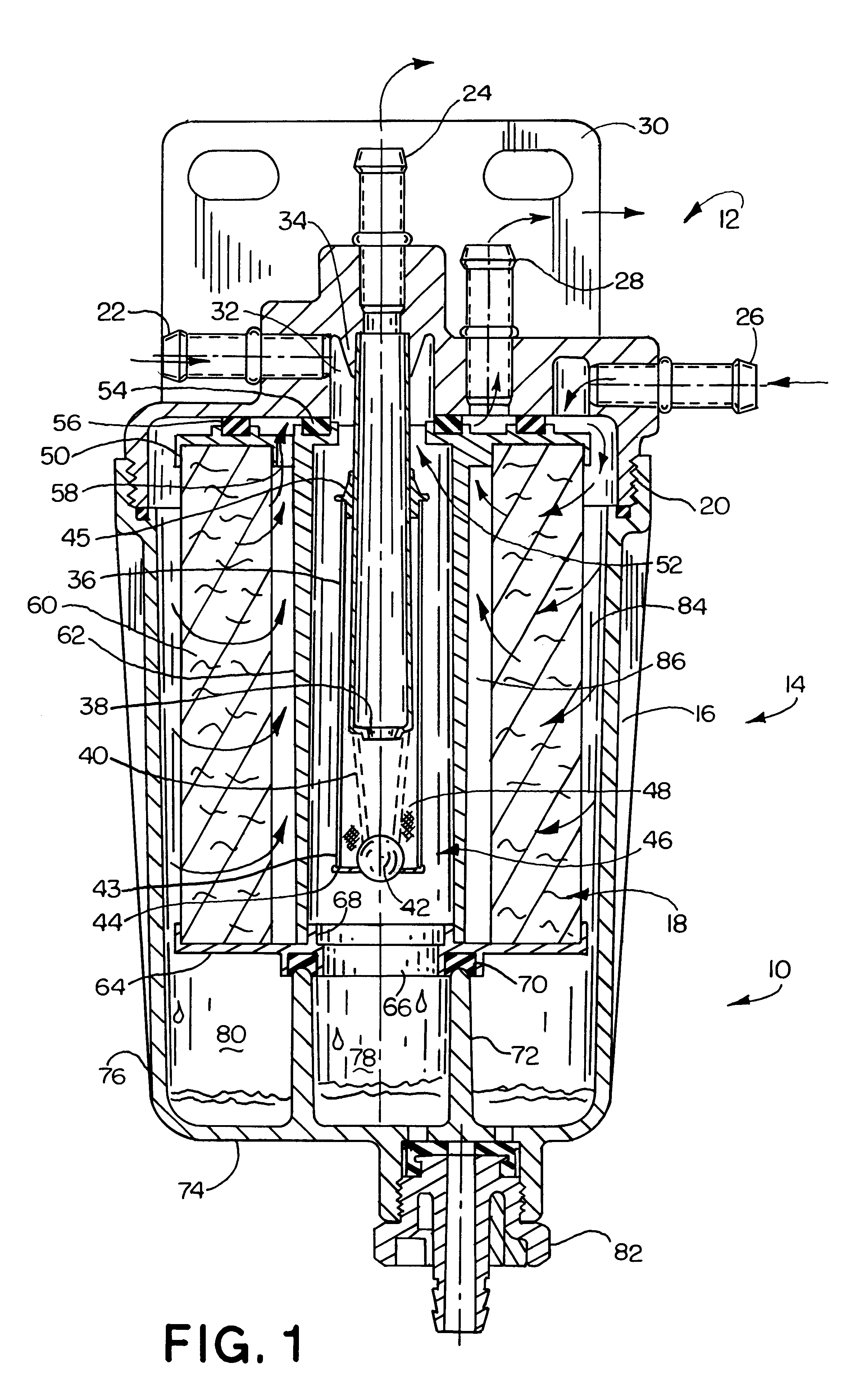

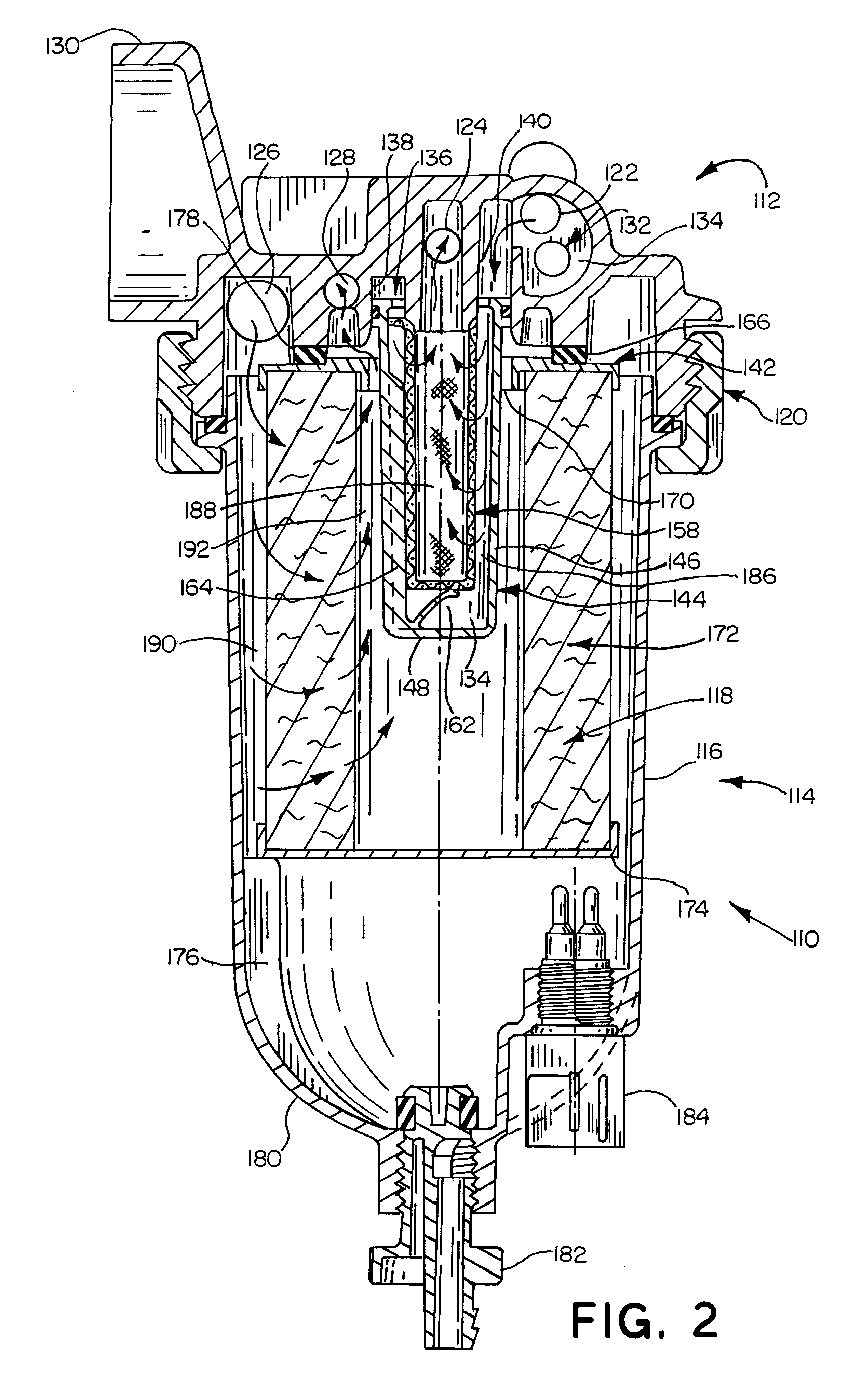

Double pass fuel filter assembly

InactiveUS6248236B1Improve filtering effectMembrane filtersLoose filtering material filtersFilter mediaFuel filter

A fuel filter assembly (10) has a head portion (12) and an element portion (14) enclosing a replaceable cartridge (18). The assembly has a first inlet port (22) which accepts fuel from a tank (90) and filters it by passage through a screen (43) supported on a tube (36). The fuel that has been filtered by passage through the screen is delivered from the assembly through a first outlet port (24) for delivery to a lift pump (96). Fuel from the lift pump is returned to the fuel filter assembly through a second inlet port (26). The fuel is finely filtered by passage through a loop of filter media (60). Clean fuel is delivered from a second outlet port (28) to an engine (104). Contaminants separated from the fuel by passage through the screen and the media loop are collected in first-and second sump areas (78), (80) of the filter housing respectively. An alternative embodiment (110) includes a prefilter screen (158) integral with a replaceable cartridge (118).

Owner:PARKER INTANGIBLES LLC

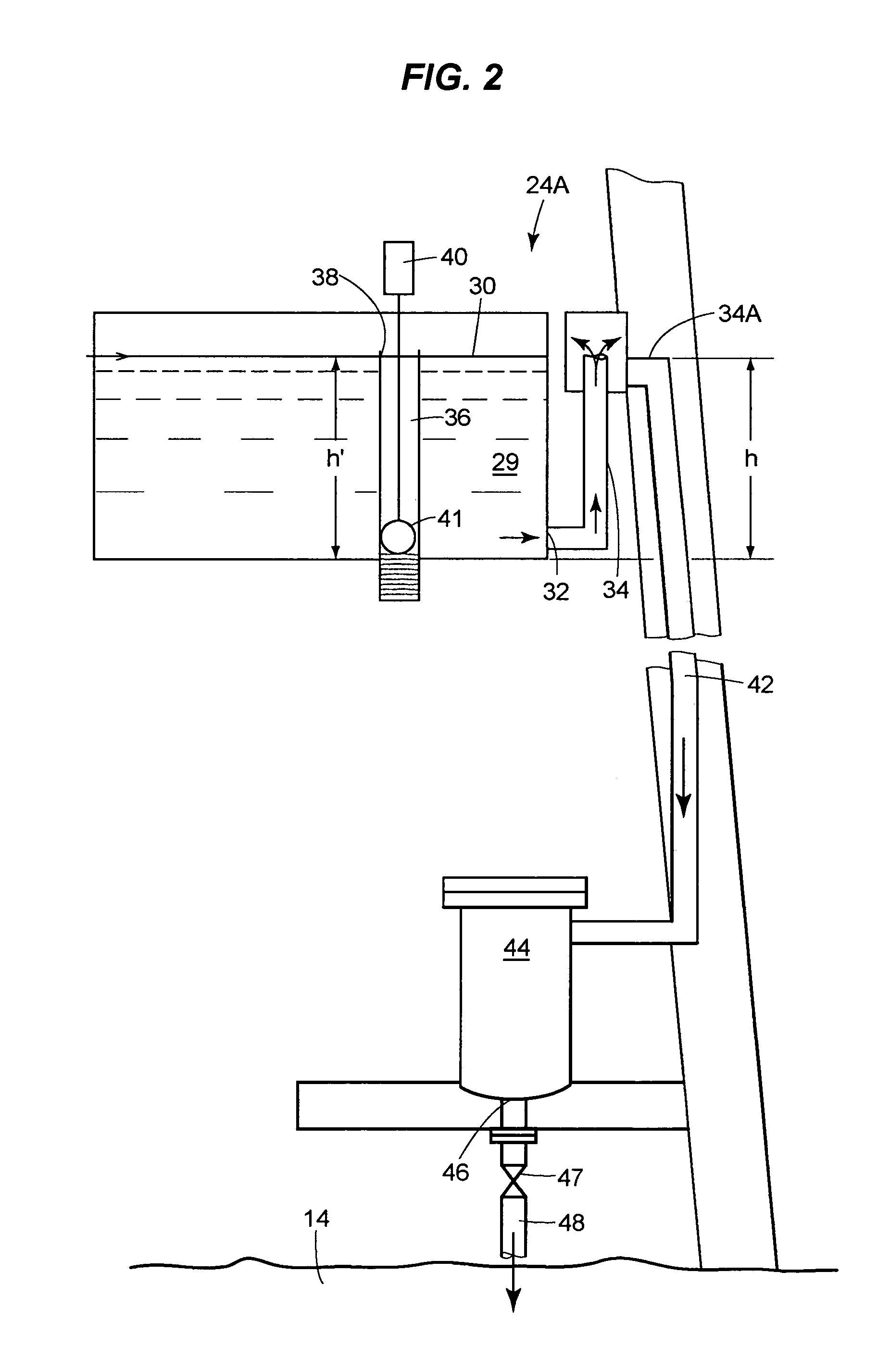

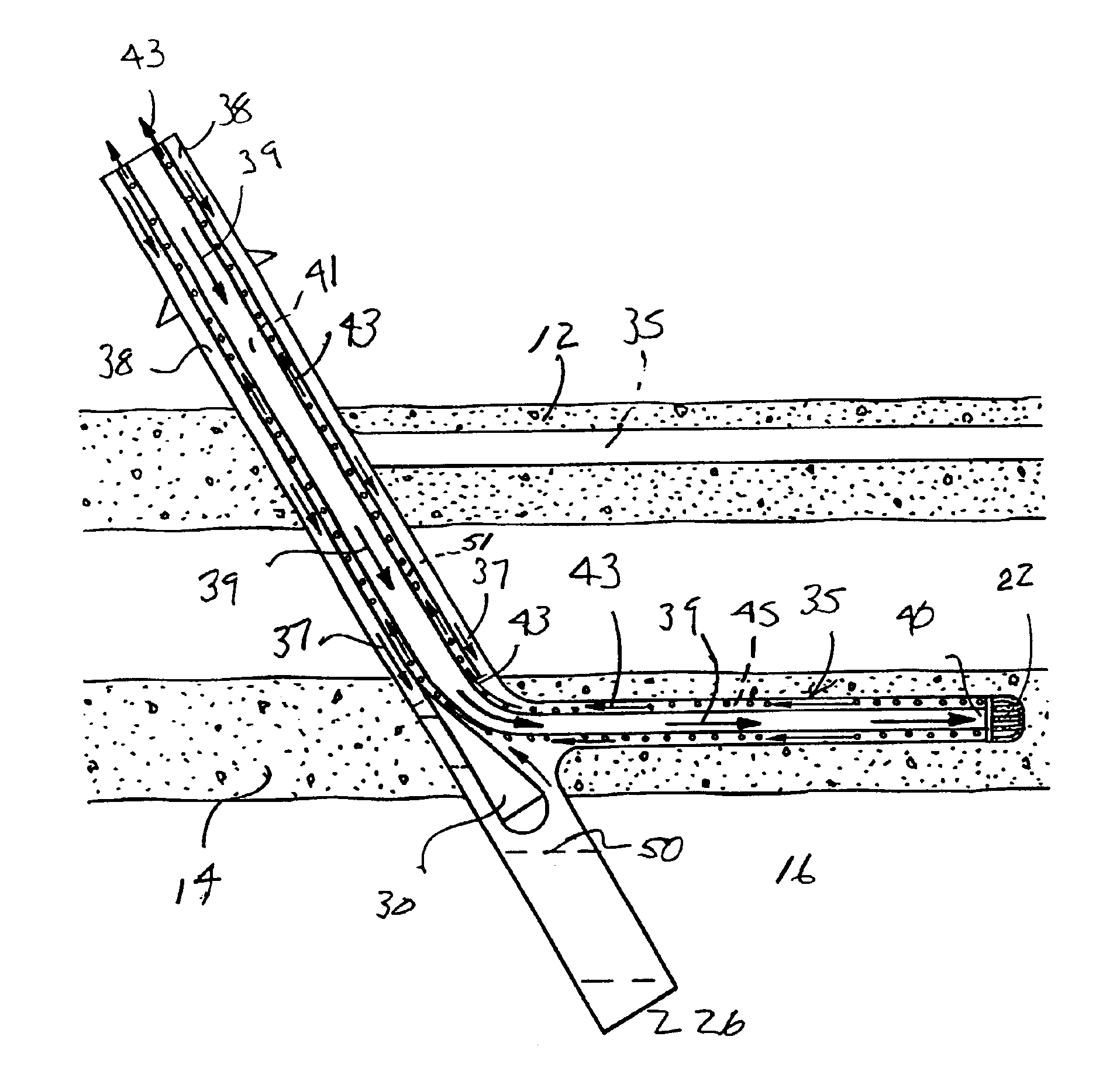

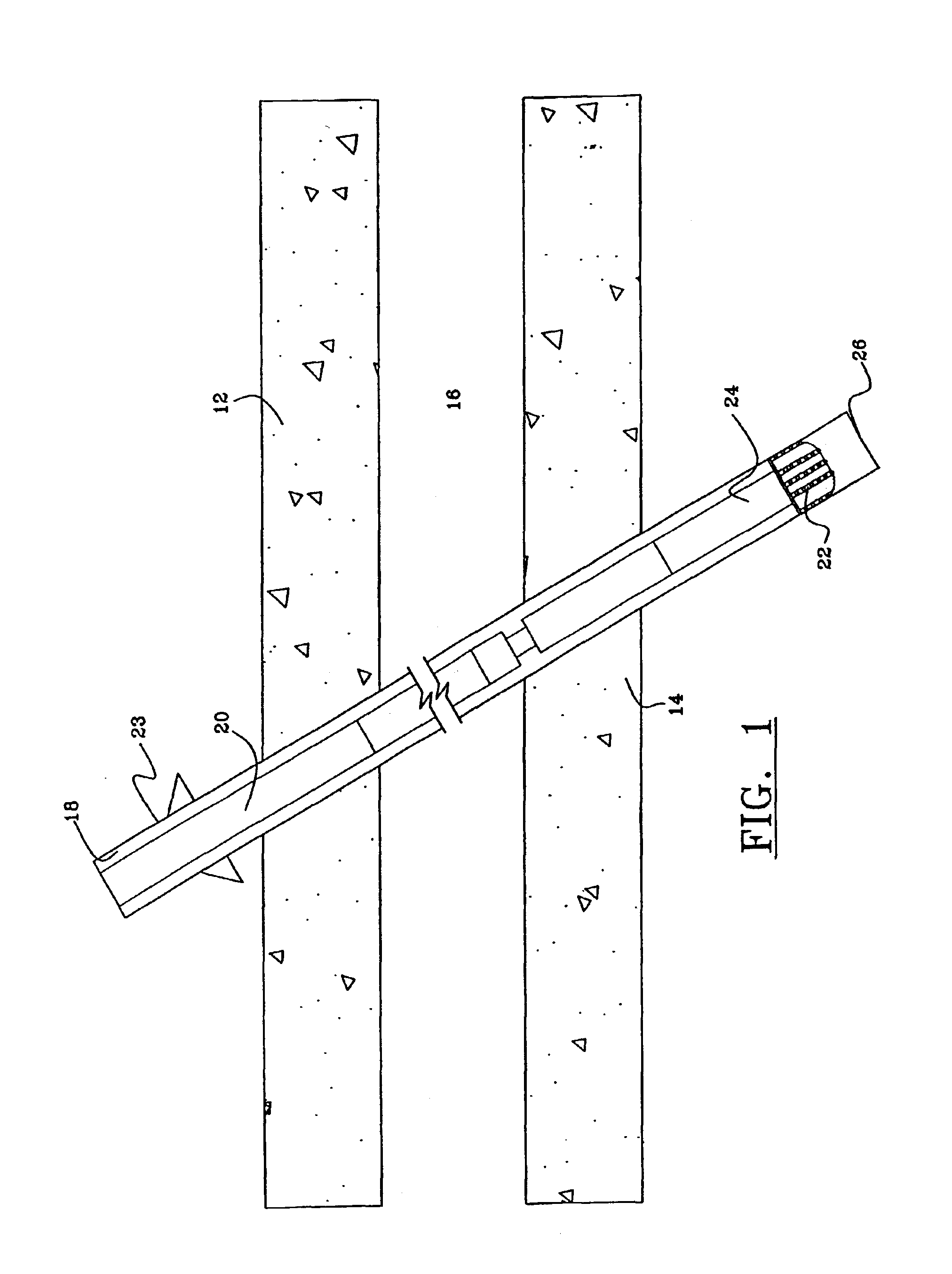

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

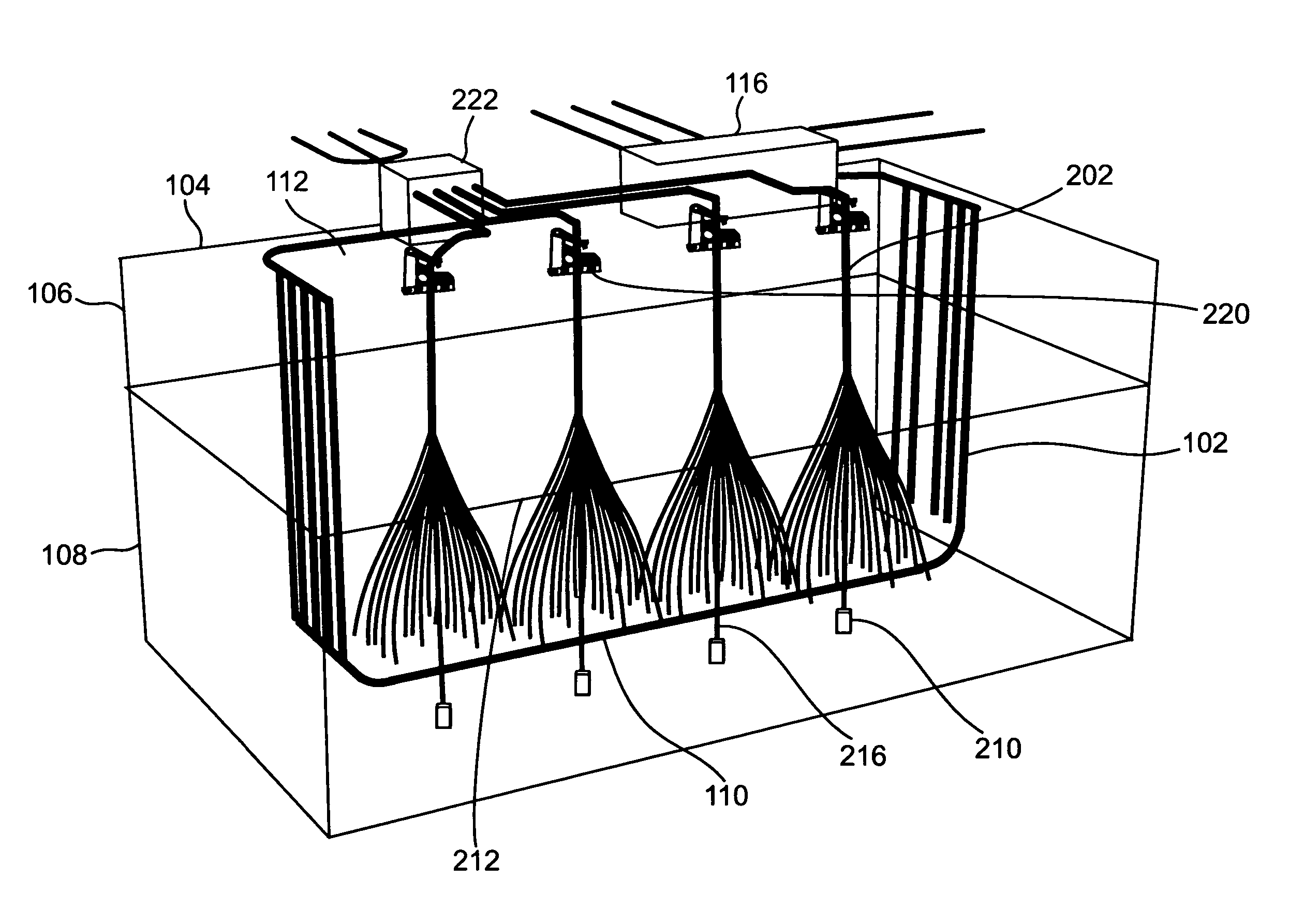

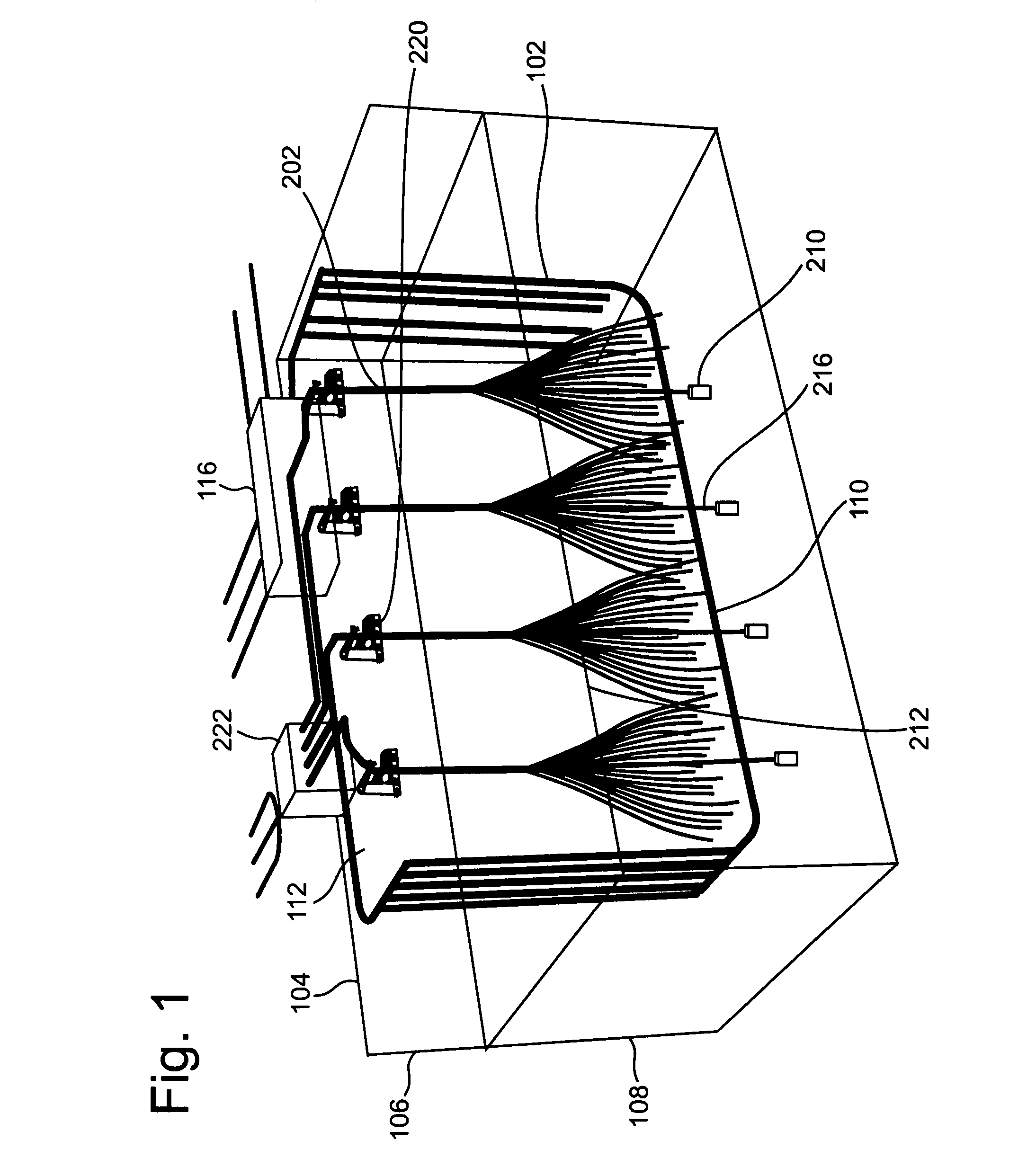

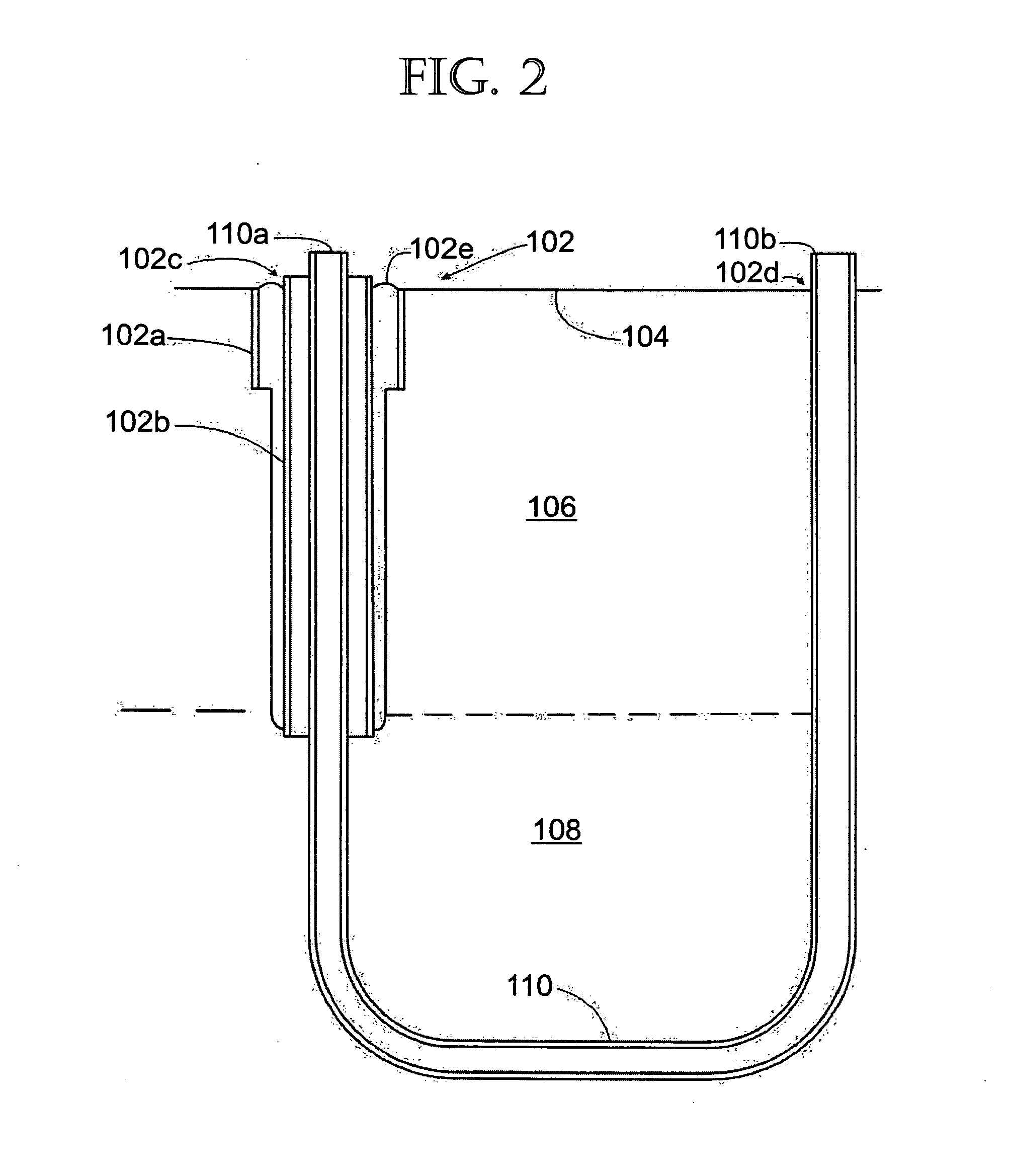

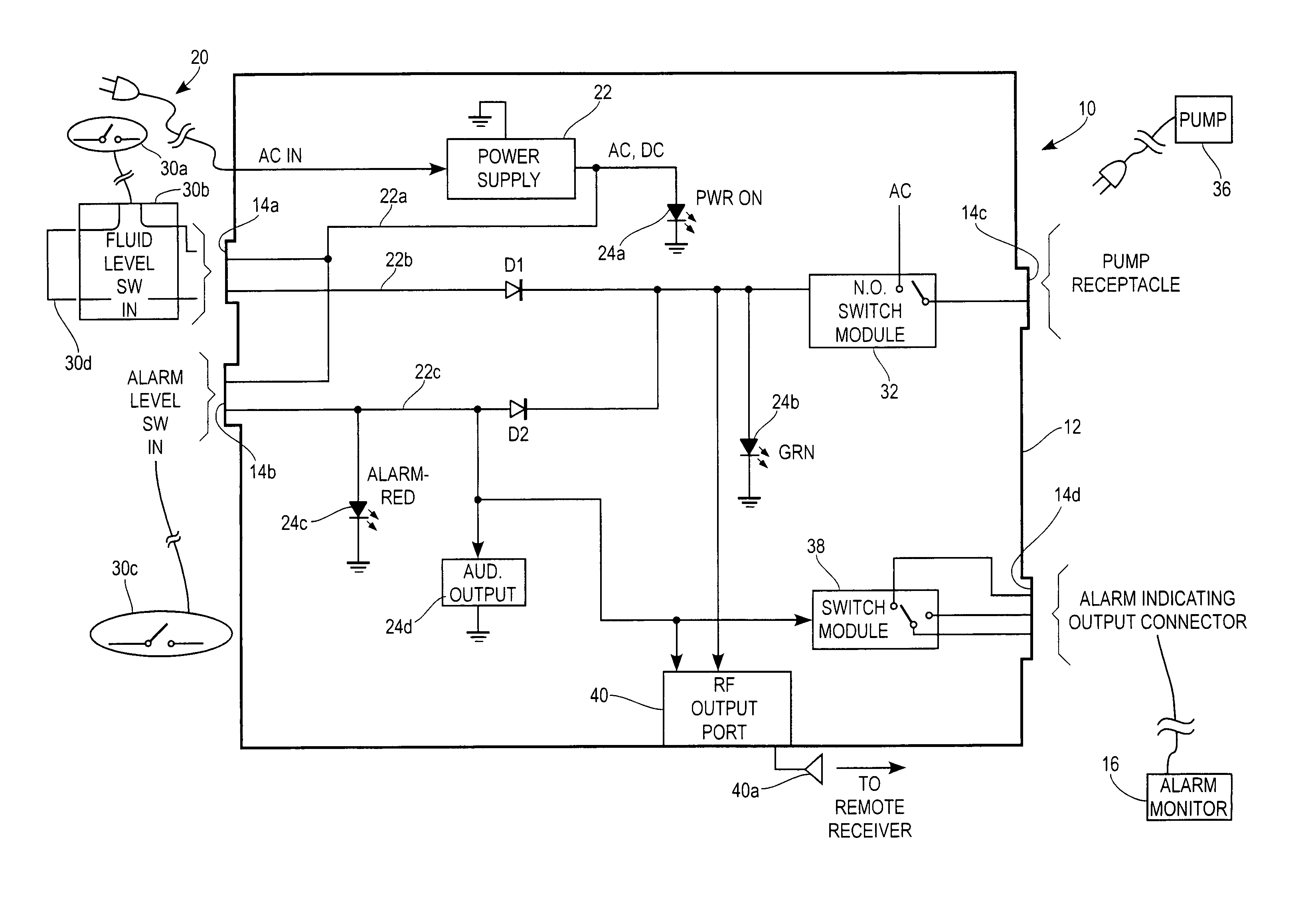

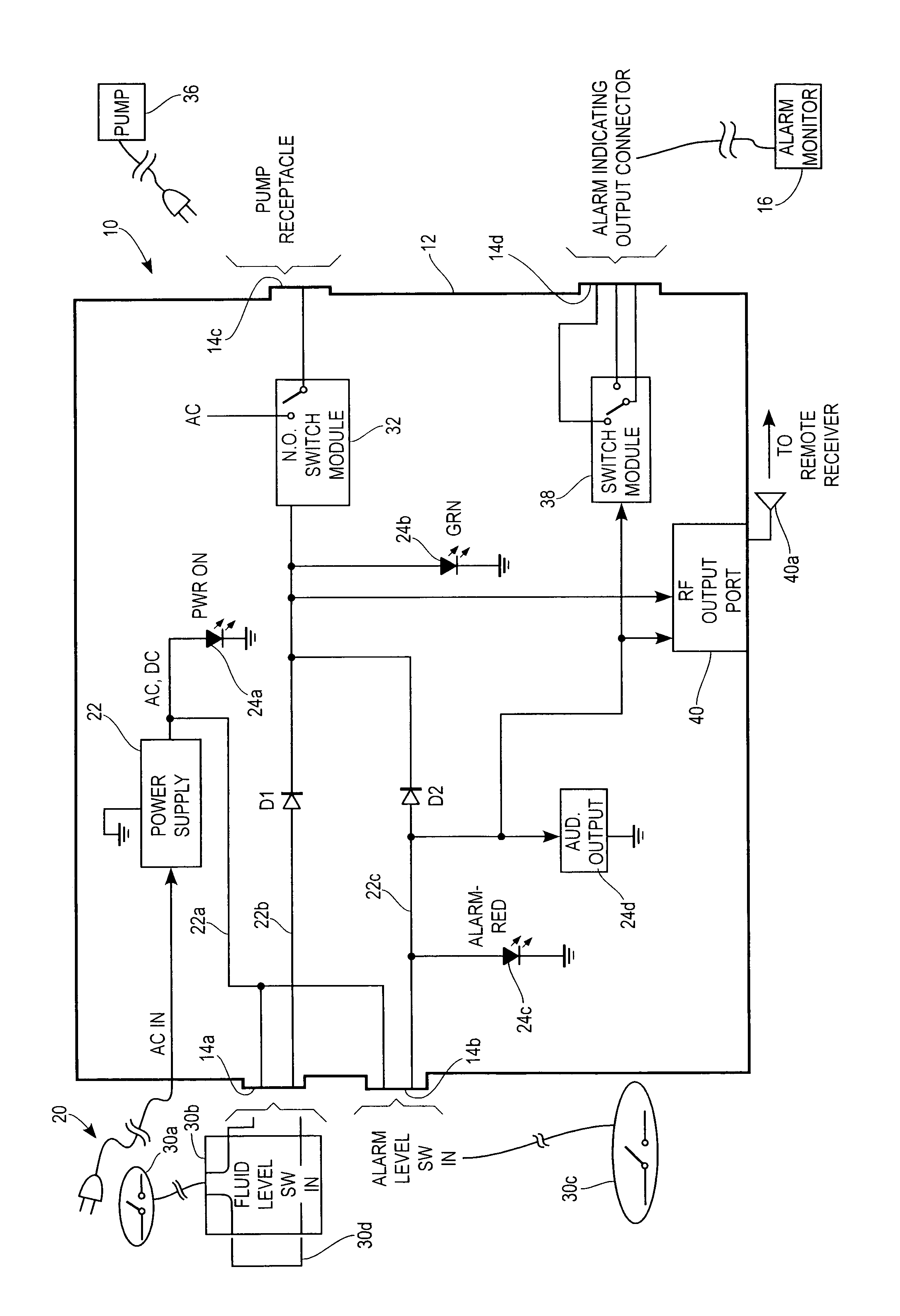

Pump connector system

A single pump control unit can be coupled to first and second float switches and a pump for purposes of removing fluid from a region such as a sump. A supplemental set of contacts can be provided to couple an alarm indicating signal to a remote alarm. An alarm state can also be transmitted wirelessly.

Owner:METROPOLITAN IND

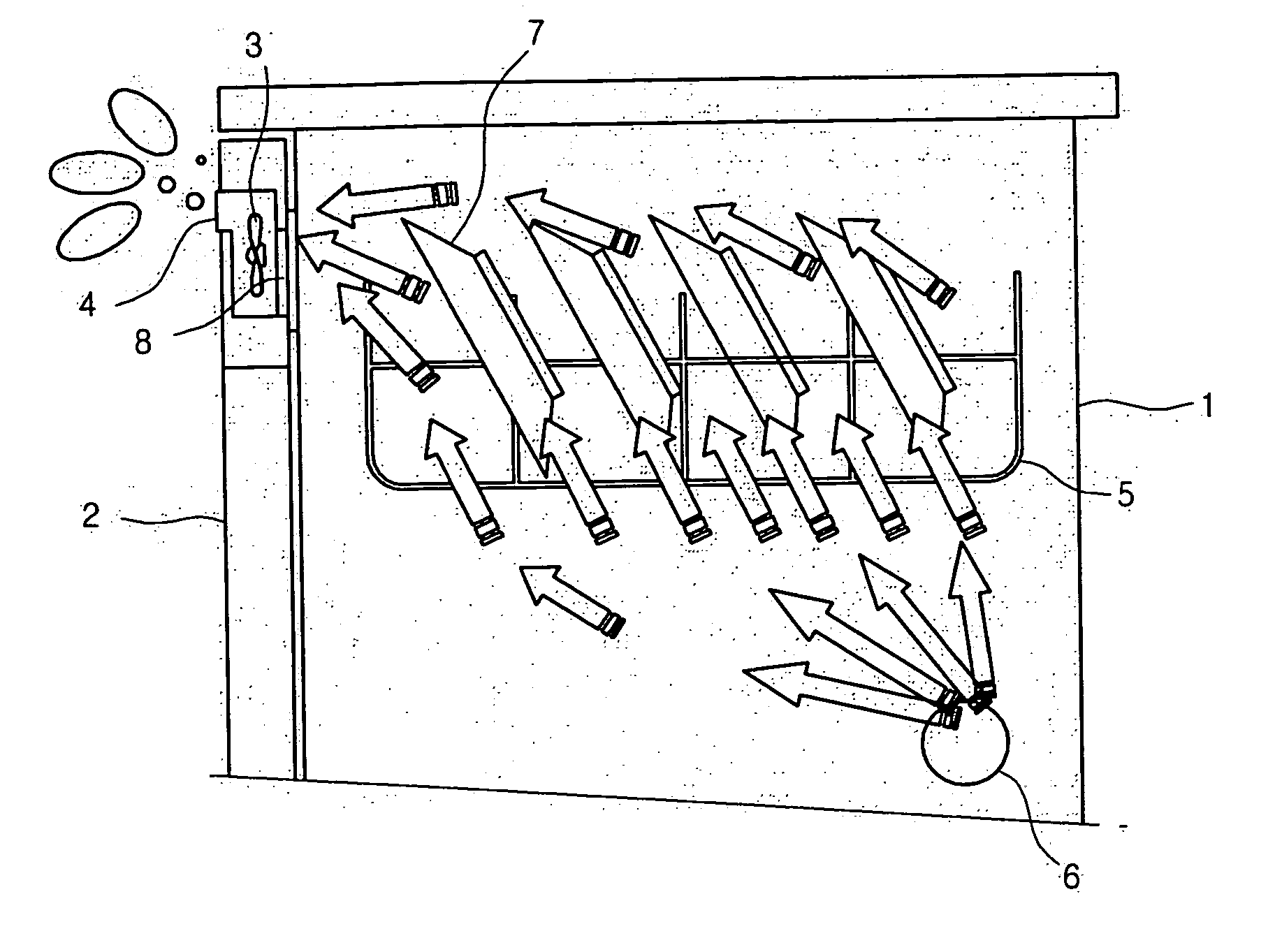

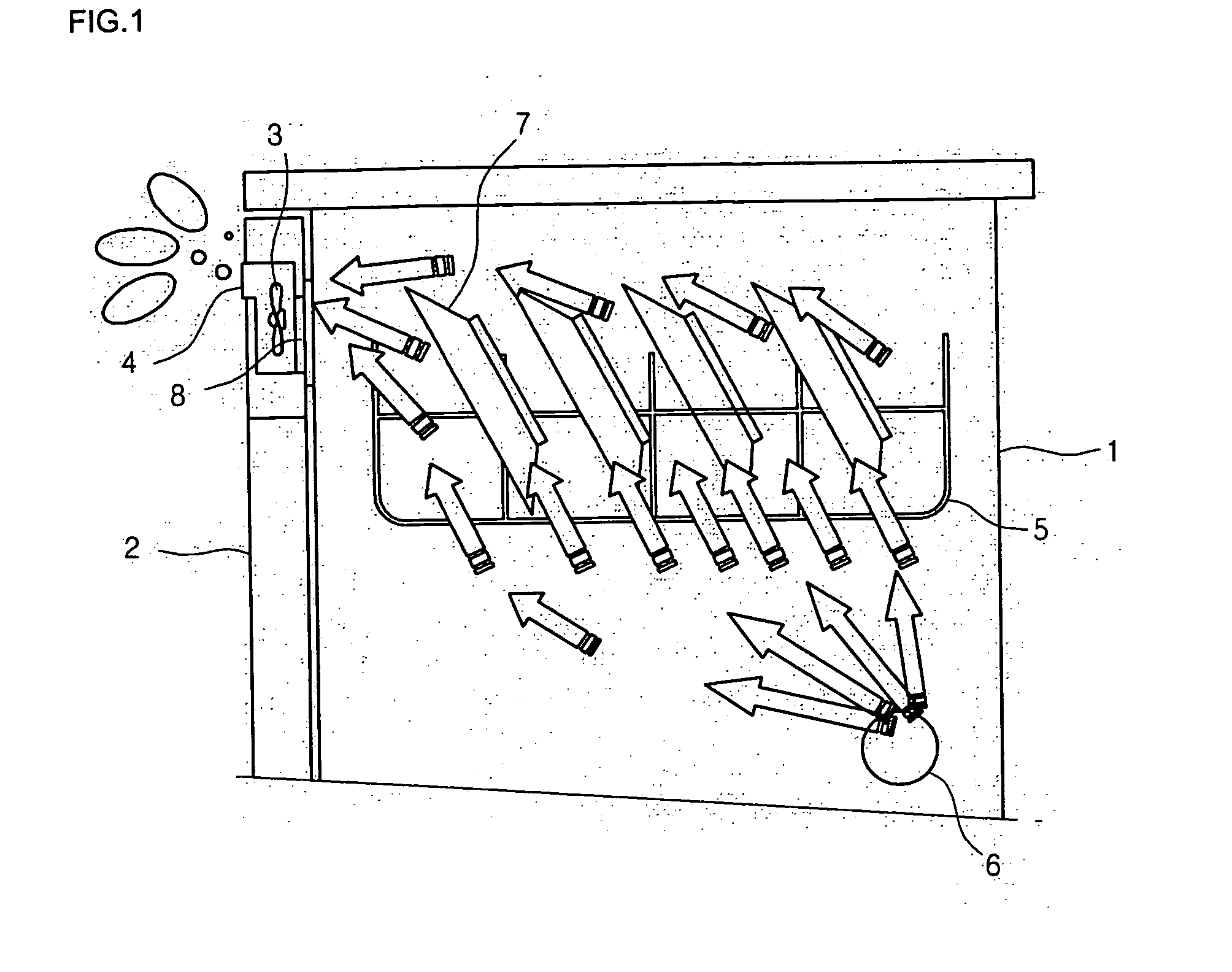

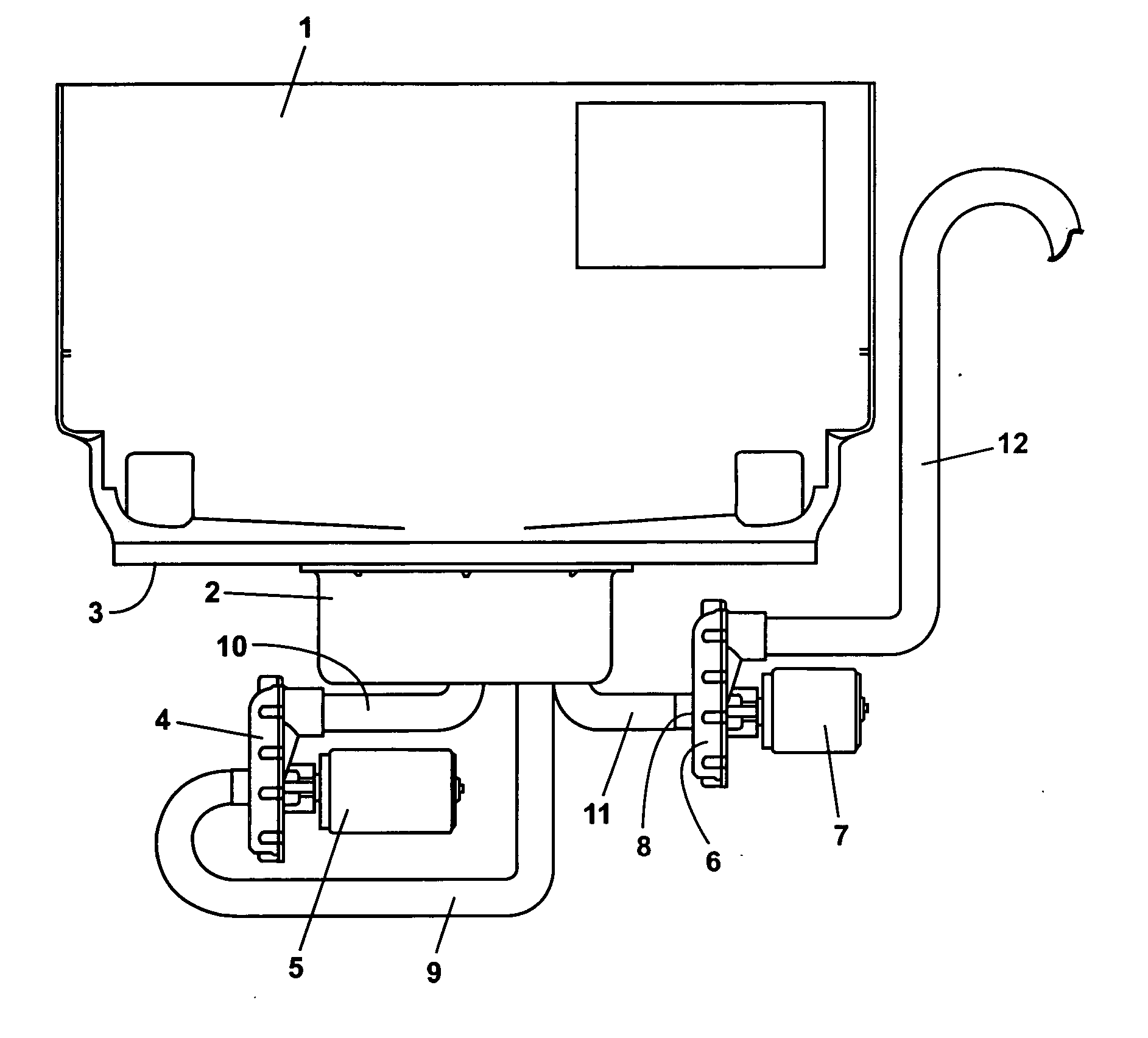

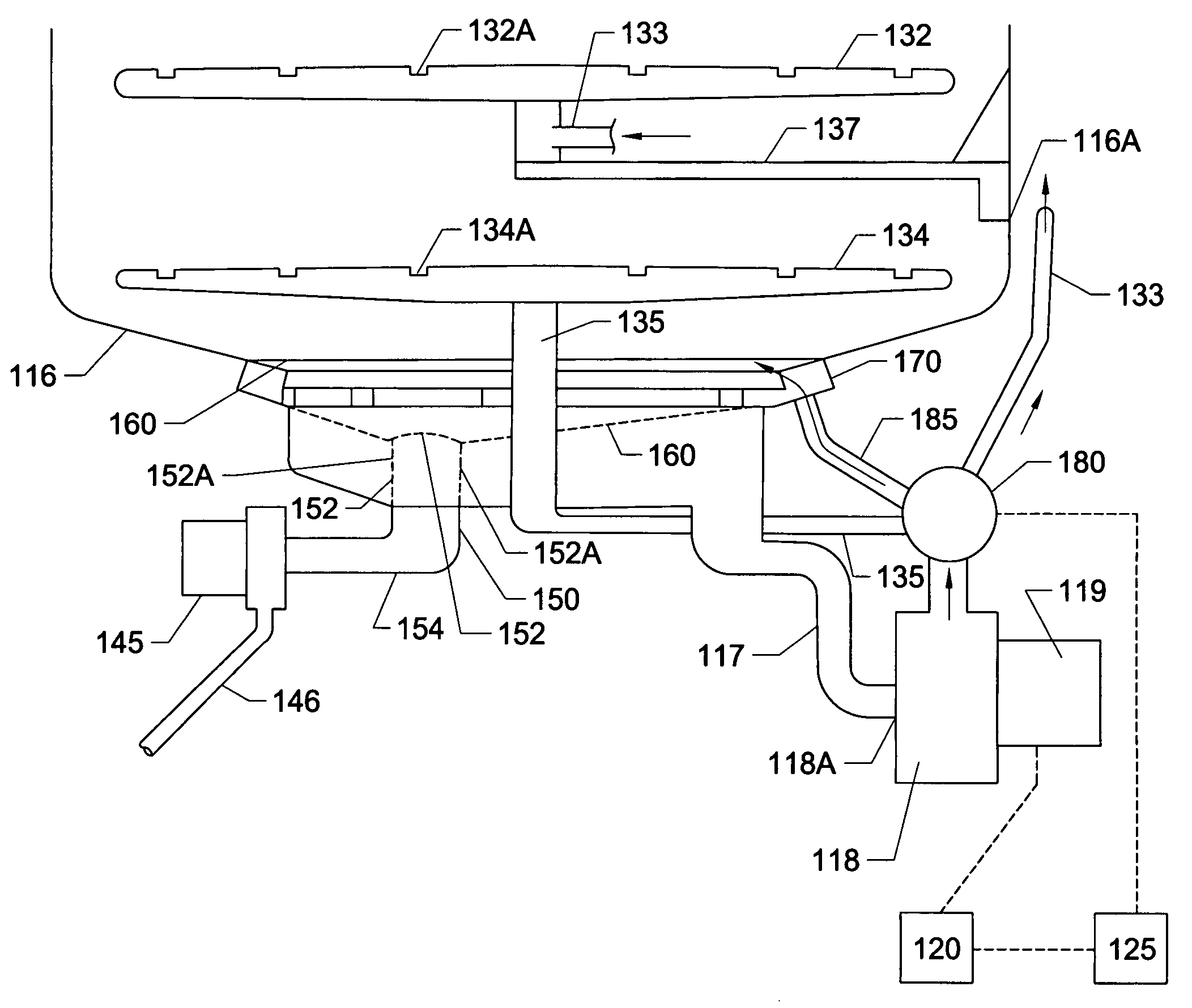

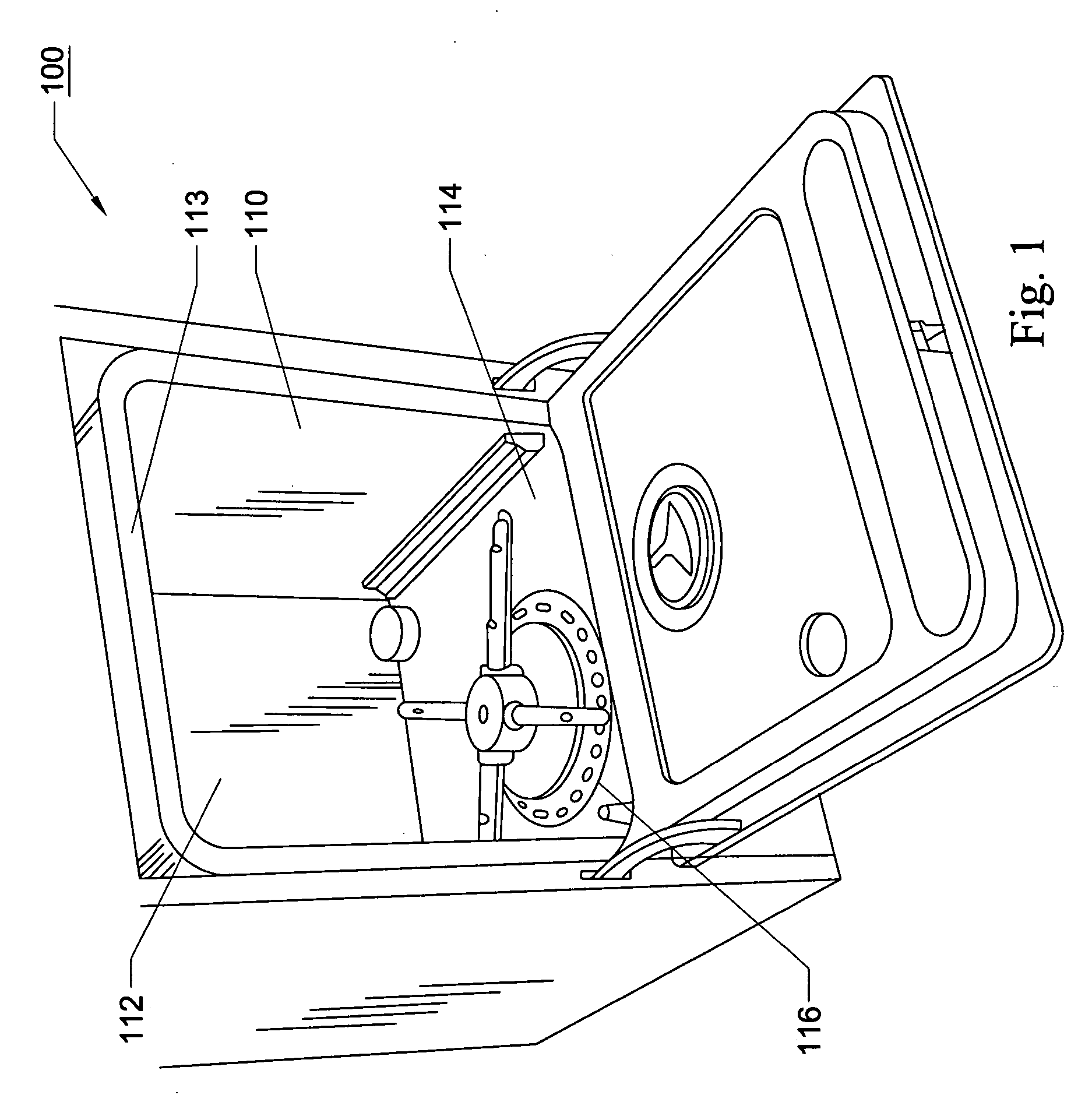

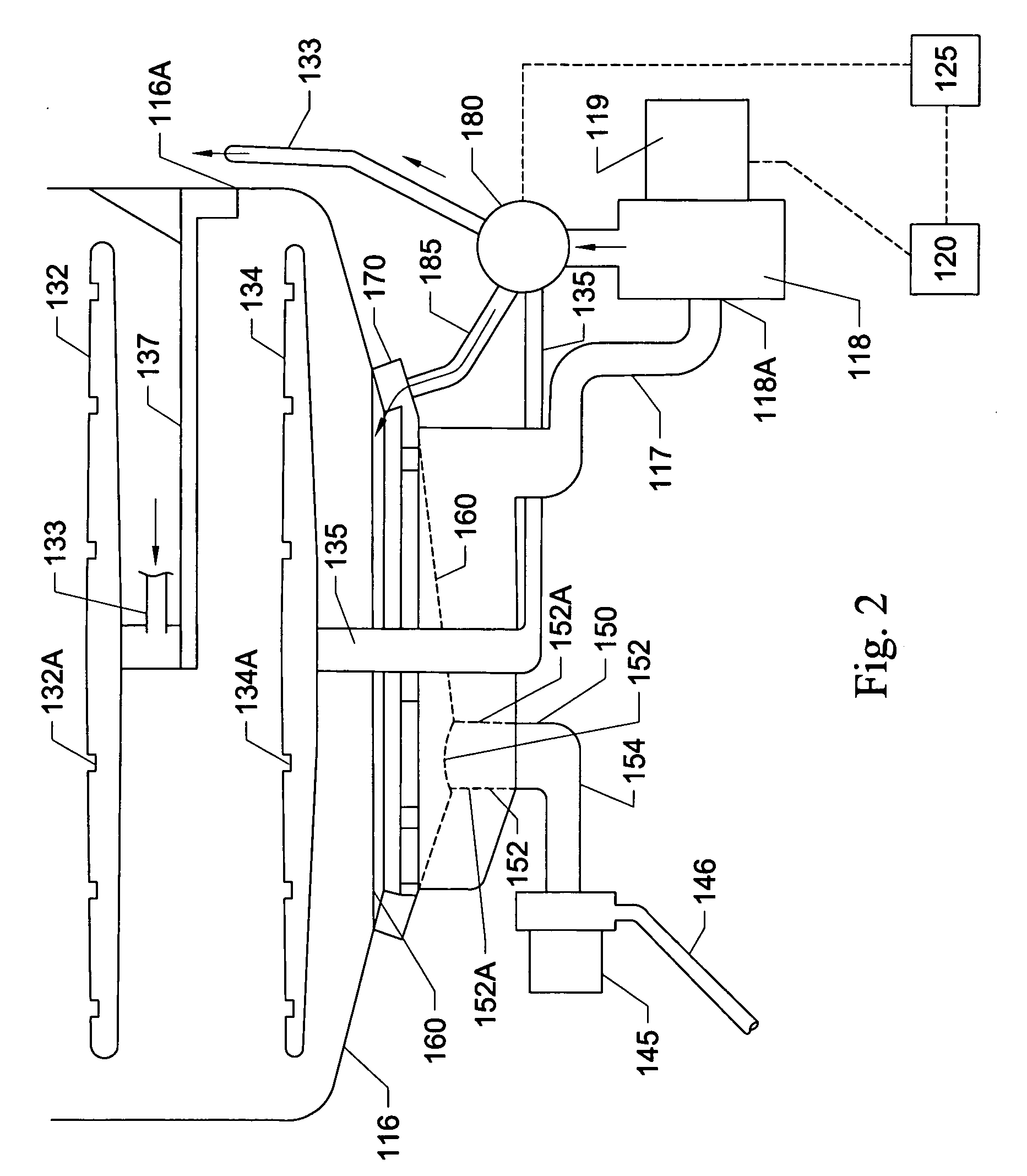

Dishwasher and method of controlling the same

InactiveUS20070006898A1Increase humidityShorten the timeTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionDrive motorControl theory

A dishwasher includes a drying fan formed on a side of the door to suck wet-vapor existing in a tub, a fan driving motor for rotating the drying fan, a sump formed on a bottom of the tube to reserve washing water, a drain motor for draining the washing water out of the sump, and a control unit for controlling the fan driving motor as well as the drain motor. The control unit controls the operation of the drain motor while the fan driving motor operates.

Owner:LG ELECTRONICS INC

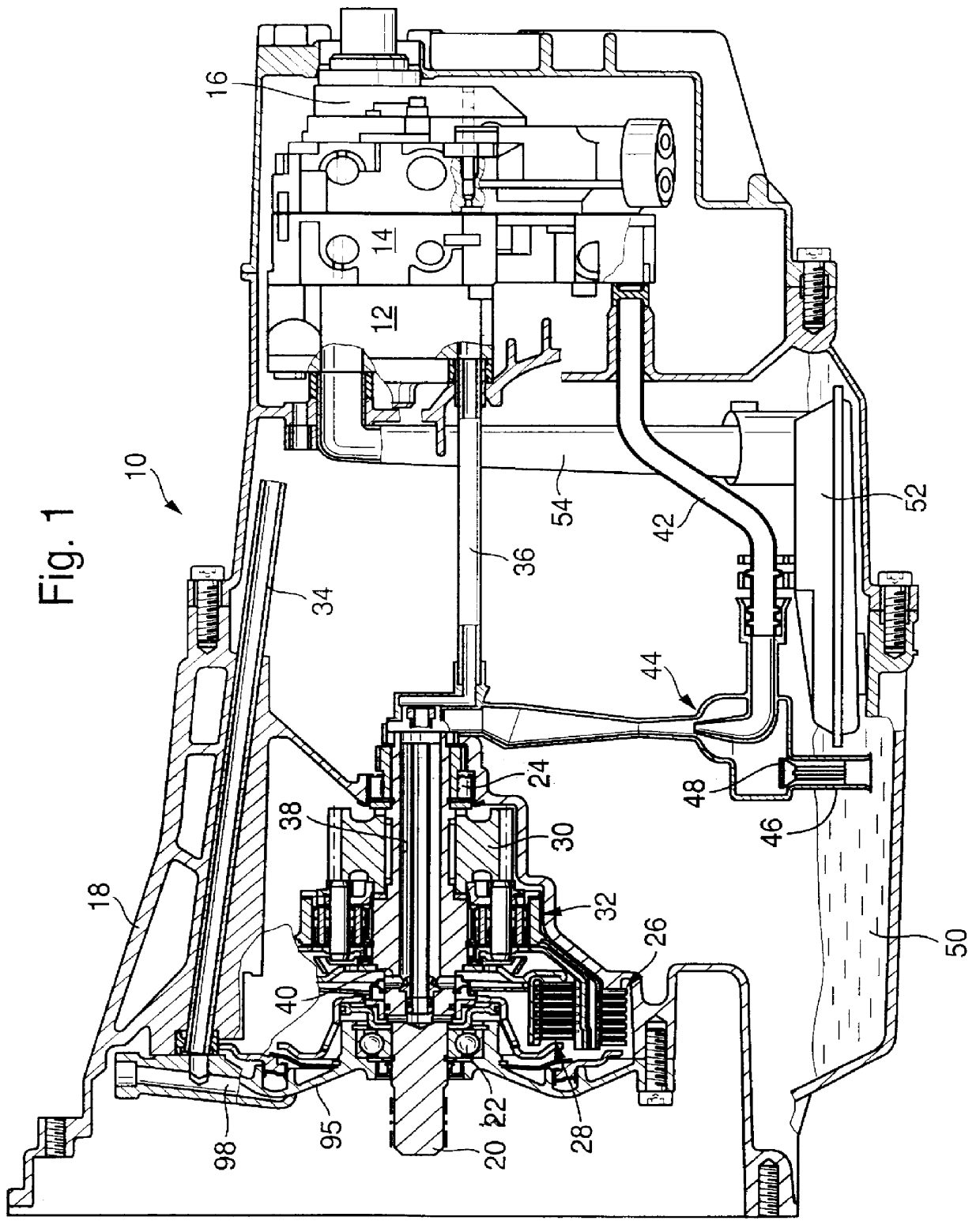

Engine lubrication system

ActiveUS6941922B2Small sizeLubrication of auxillariesLubricant conduit arrangementsLine tubingEngineering

A lubrication system for an engine including a sump for lubricant, a main pump operable to pump lubricant to first lubrication positions within the engine, and an auxiliary lubricant pump also operable to pump lubricant to second lubrication positions within the engine and wherein the auxiliary pump is an electrically driven pump which is controlled by a system controller the output of the auxiliary pump being controlled according to engine operating conditions, the main pump in use, pumping lubricant to the first lubrication positions within the engine along a main lubricant feed line, and the auxiliary pump when operated pumping lubricant to the second lubrication positions within the engine along an auxiliary feed line, and wherein the main and auxiliary feed lines, are connected via a communication passage which includes a closeable communication valve, the communication valve when closed preventing the flow of lubricant from the auxiliary feed line to the first lubrication positions, and when open permitting the flow of lubricant from the auxiliary feed line to the first lubrication positions.

Owner:PIERBURG PUMP TECH UK

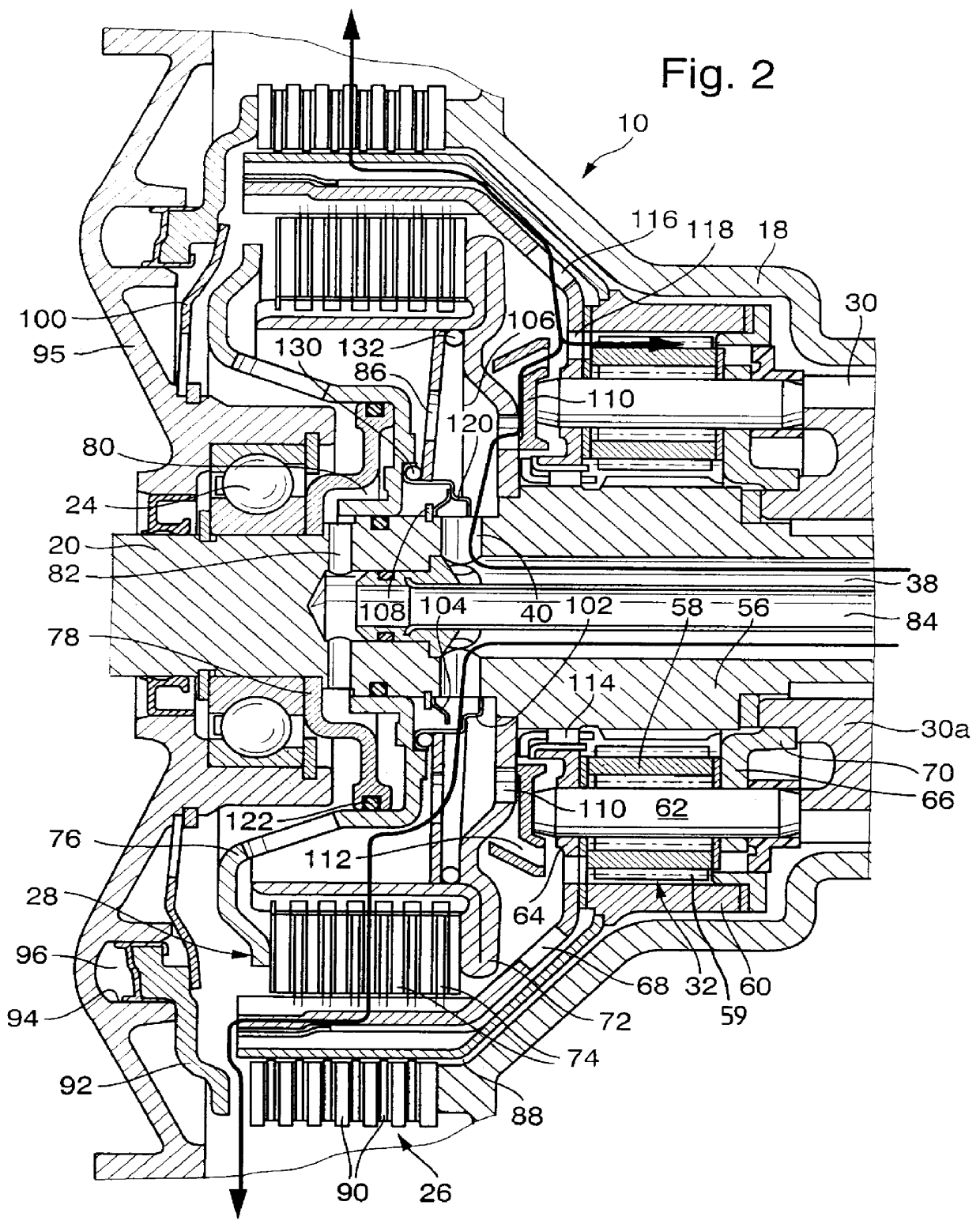

Apparatus for cooling clutches on a transmission shaft

InactiveUS6059682AExtended service lifeSimple and inexpensive and compactFluid actuated clutchesGear lubrication/coolingMobile vehicleDrive shaft

A change-speed transmission in the power train of a motor vehicle has a planetary gearing and coaxial radially inner and outer disc clutches, namely a direct clutch and a reverse clutch. At least that clutch which is engaged (i.e., in use) is cooled by a lubricant for the planetary gearing, and the flow of coolant to the clutches is regulated by the axially movable pressure plate of one of the clutches. A jet pump conveys lubricant from the sump in the transmission case into an axially extending channel of the input shaft of the transmission, and such channel forms part of a system of passages which supply coolant at least to that clutch which is then in use to transmit torque from the input shaft to an output element of the transmission.

Owner:LUK GETRIEBE SYST +1

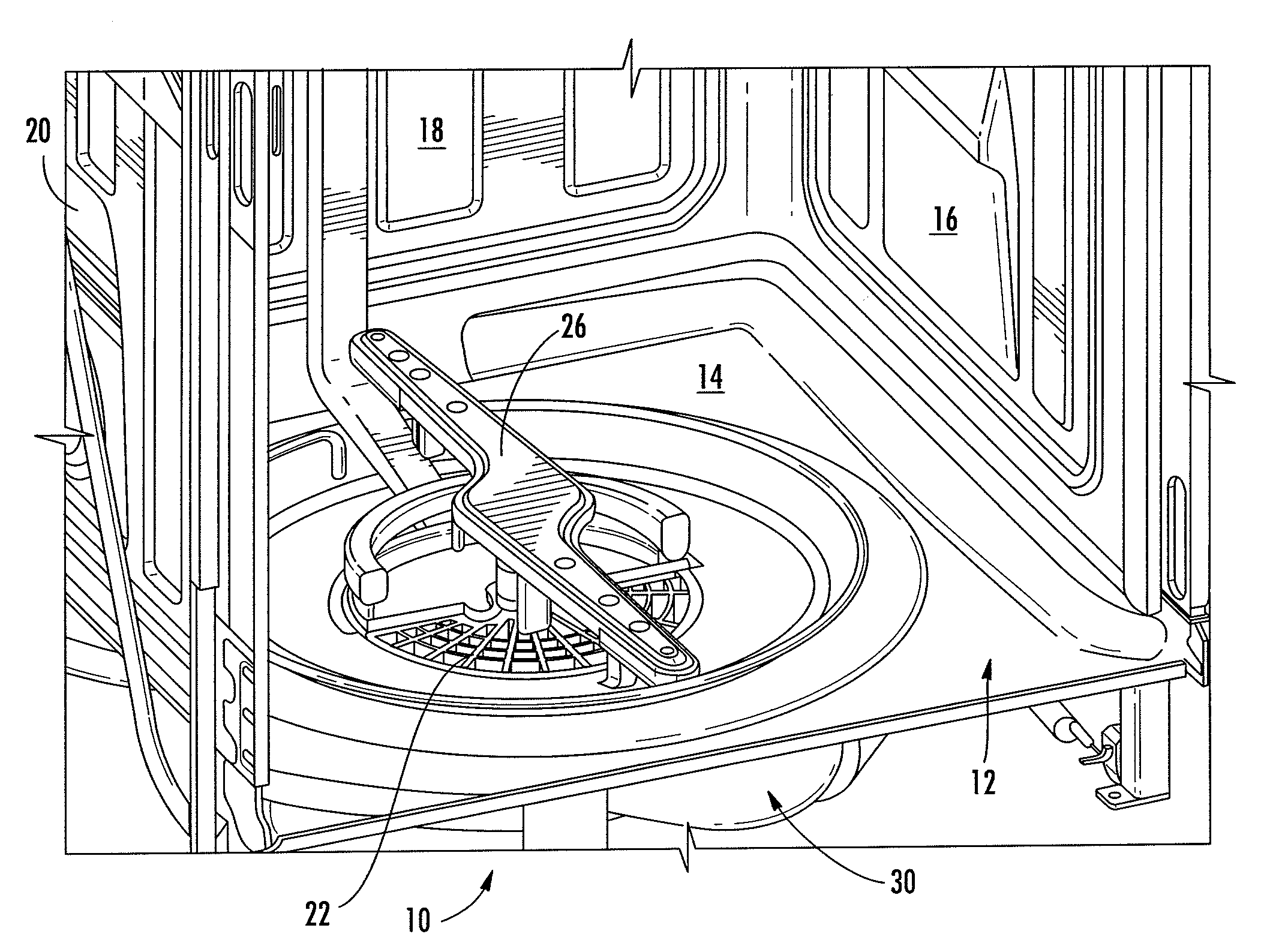

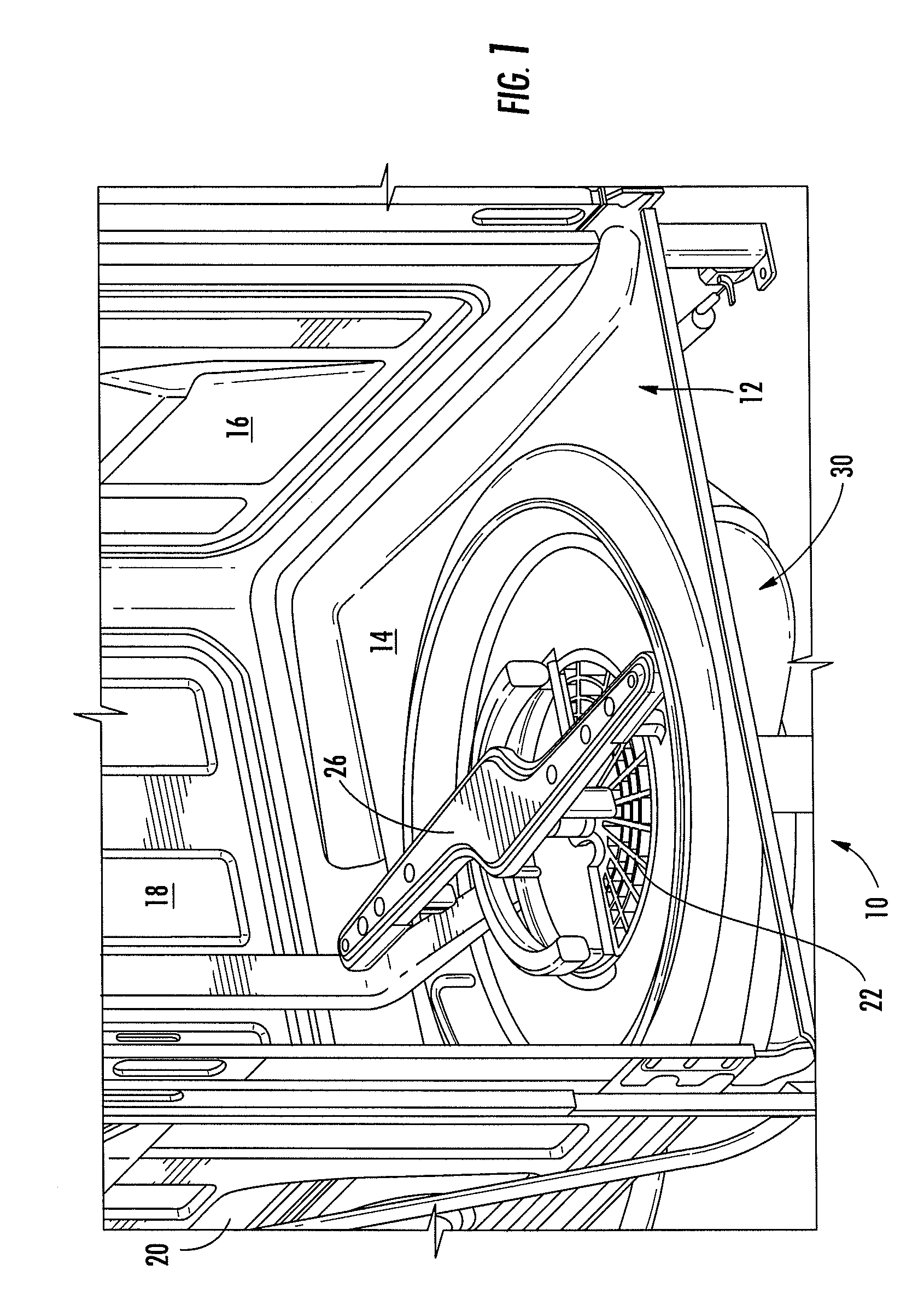

Dishwasher filter system

A filter system for dishwasher with a sump having inlets leading to a wash pump and a drain pump in the bottom wall. The filter assembly includes a vertical filter retainer an overlying perforate hood, a multiple porosity filter element carried on the filter retainer and a back wash sprayer rotatably mounted inside the filter retainer with at least one backwash nozzle directed toward the filter assembly. The inlet leading to the wash pump is positioned inside the filter element and the inlet to the drain pump is located outside the filter element. The filter element has openings that vary in size from the top to the bottom of the filter element. The filter element openings can be arranged in bands of different porosity openings including fine, medium and coarse porosity openings. The perforate hood can have coarse porosity openings.

Owner:WHIRLPOOL CORP

Primary filter cleaning system for a dishwasher

InactiveUS20060237049A1Easy to moveHollow article cleaningElectrostatic cleaningWash waterSpray nozzle

A dishwasher incorporates a primary filter cleaning system for removing food debris from circulated wash water. The dishwasher having a sump formed in the bottom and a wash pump having an inlet in communication with the sump. A collection chamber is formed through the bottom of the sump and a filter is situated over the top of the sump. The filter has an opening for depositing debris in the collection chamber. A stationary manifold is situated about the upper periphery of the sump and is aligned with the discharge of the pump. The manifold has multiple spaced spray nozzles, with each of the nozzles being aligned for spray contact with the filter. When water is pumped from the sump to the manifold, the water is sprayed across the filter to remove any food debris on the filter. The debris is then swept into the collection chamber.

Owner:VIKING RANGE

Dishwasher filter system

A filter system for dishwasher with a sump having inlets leading to a wash pump and a drain pump in the bottom wall. The filter assembly includes a vertical filter retainer an overlying perforate hood, a multiple porosity filter element carried on the filter retainer and a back wash sprayer rotatably mounted inside the filter retainer with at least one backwash nozzle directed toward the filter assembly. The inlet leading to the wash pump is positioned inside the filter element and the inlet to the drain pump is located outside the filter element. The filter element has openings that vary in size from the top to the bottom of the filter element. The filter element openings can be arranged in bands of different porosity openings including fine, medium and coarse porosity openings. The perforate hood can have coarse porosity openings.

Owner:WHIRLPOOL CORP

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

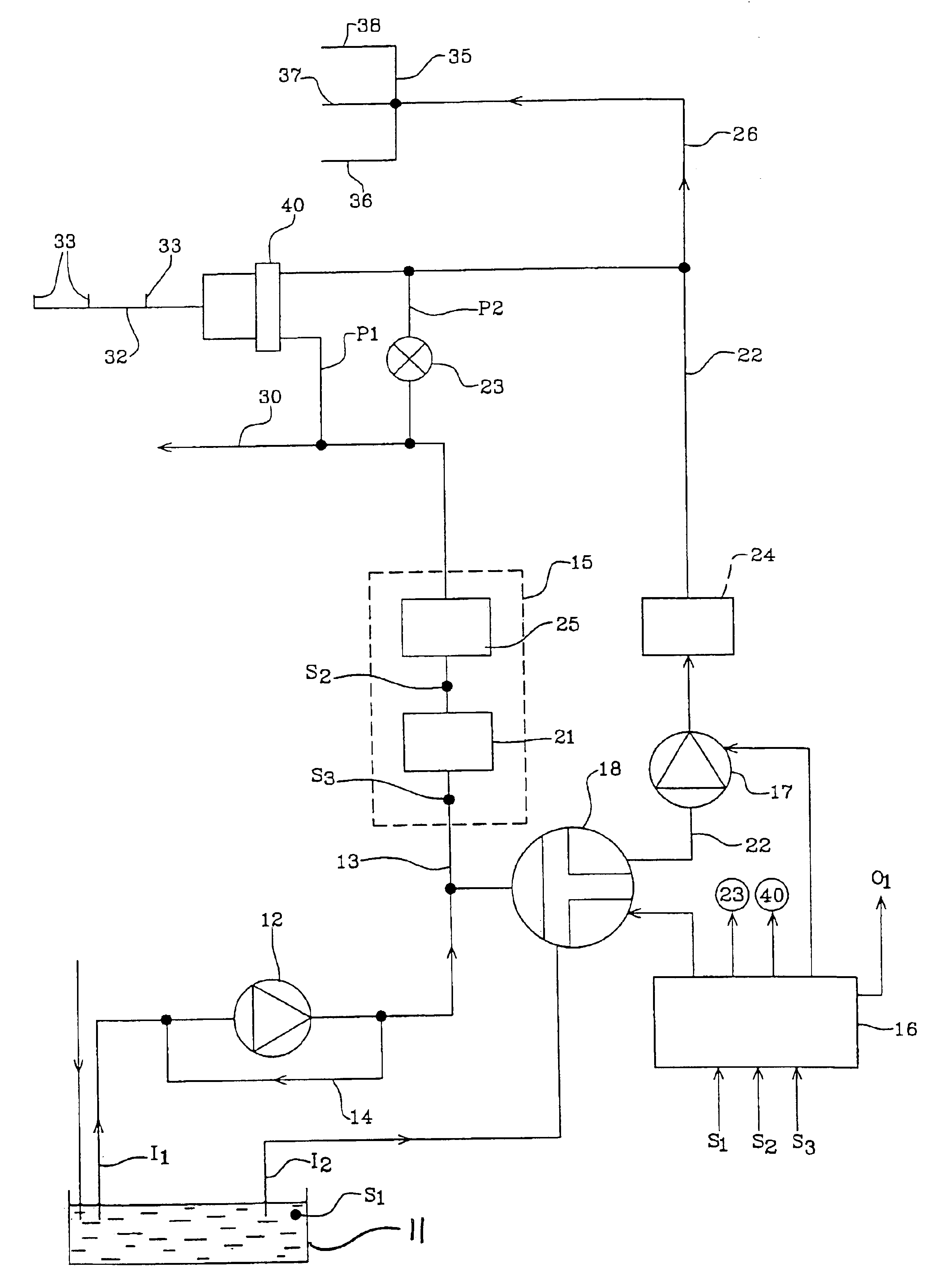

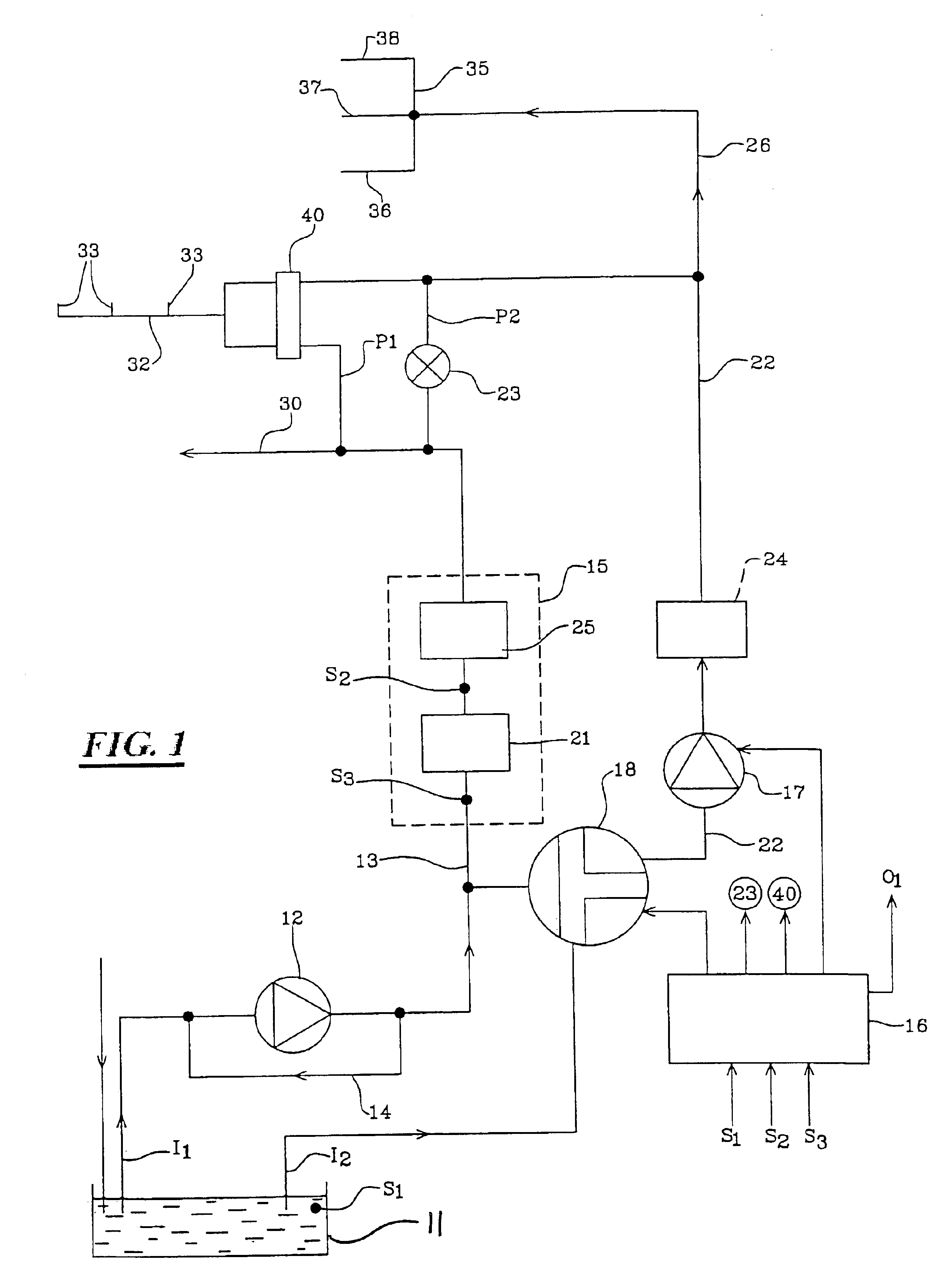

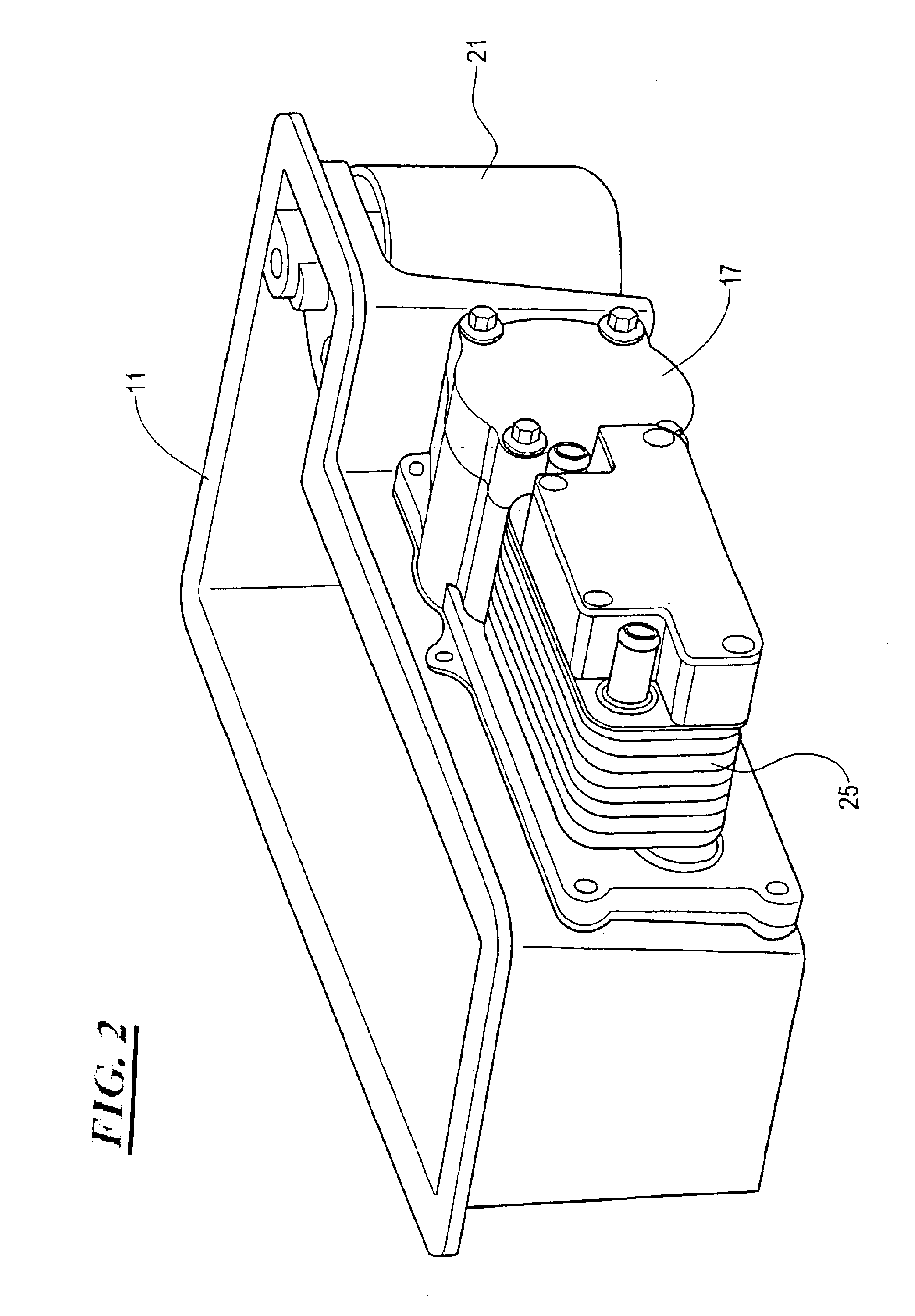

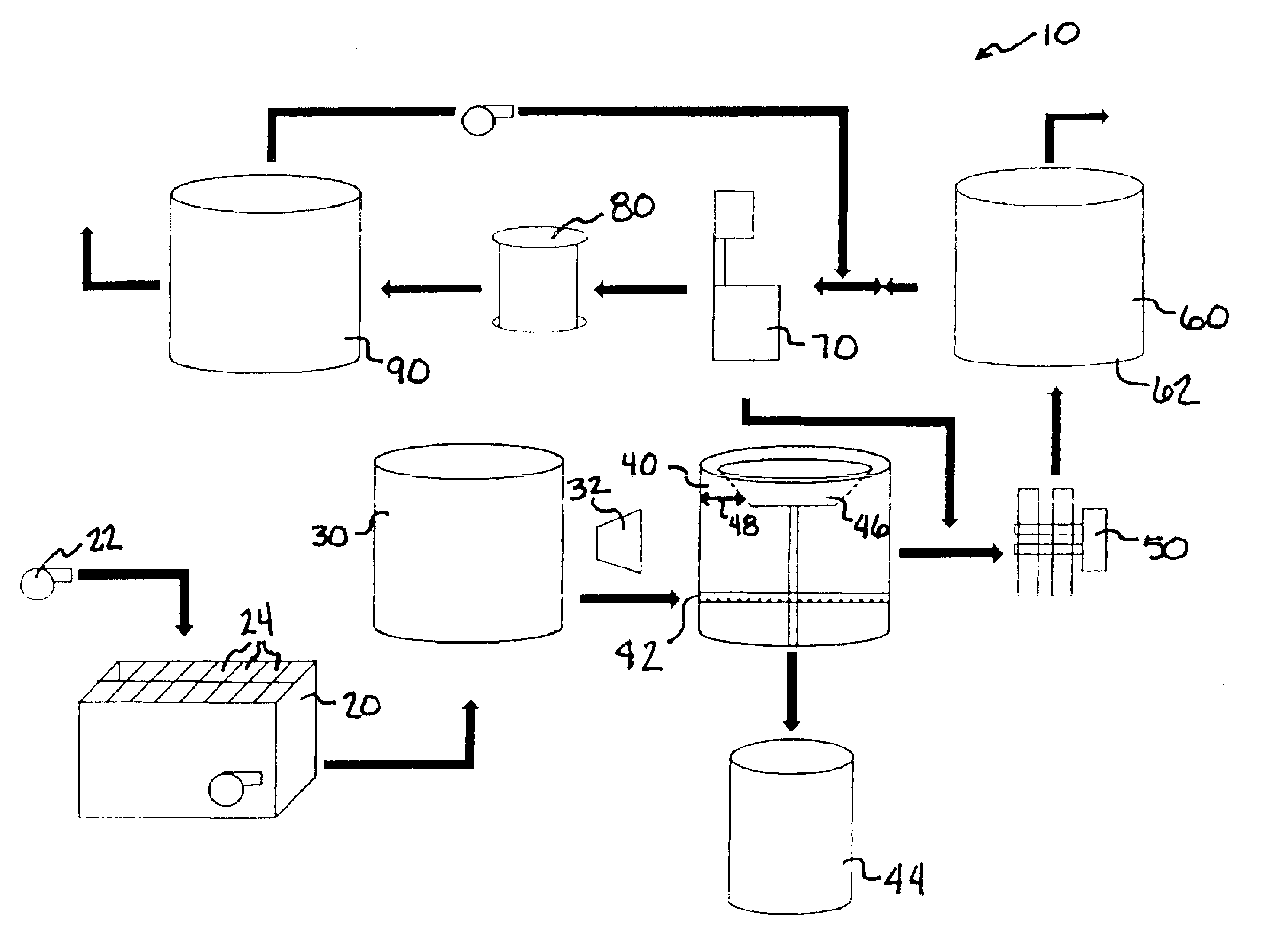

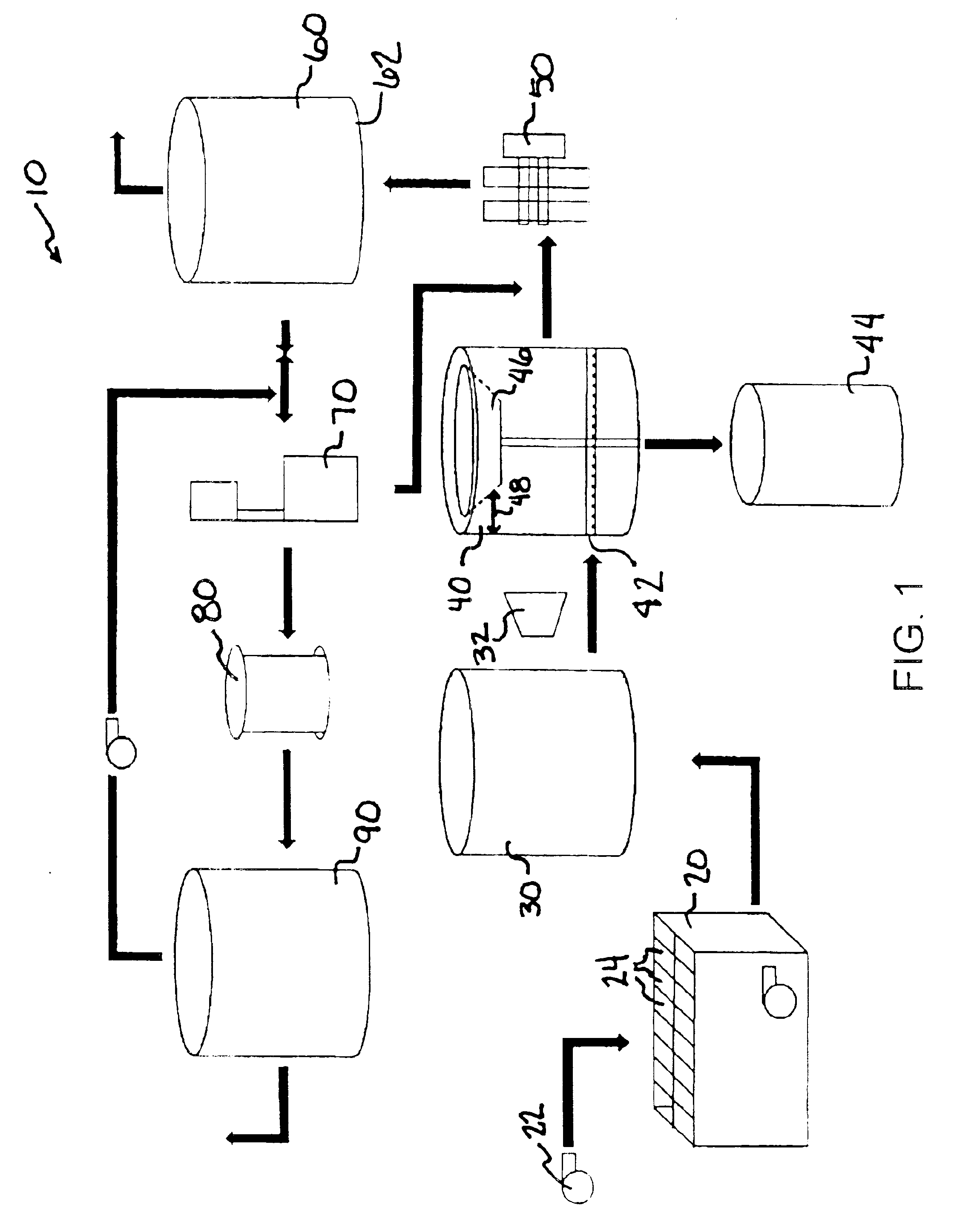

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

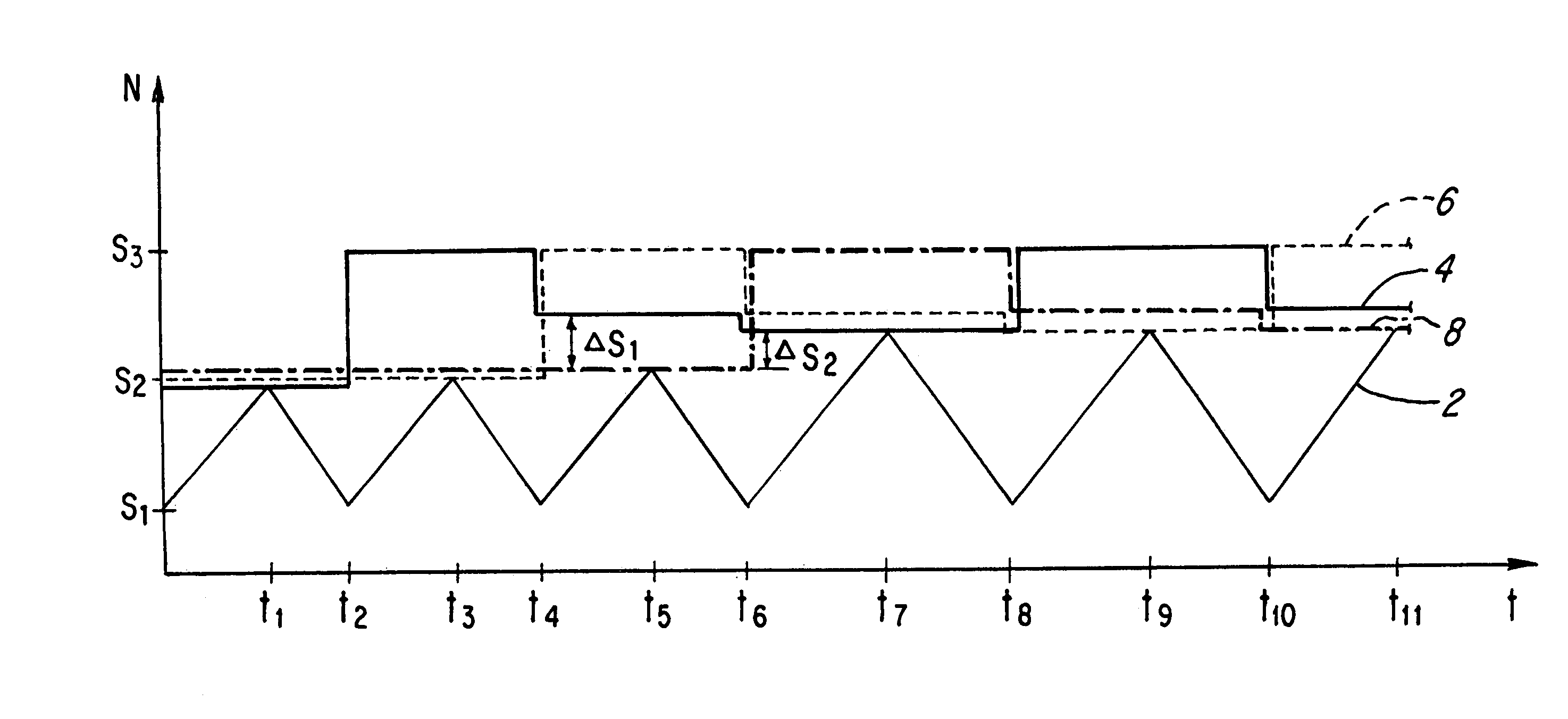

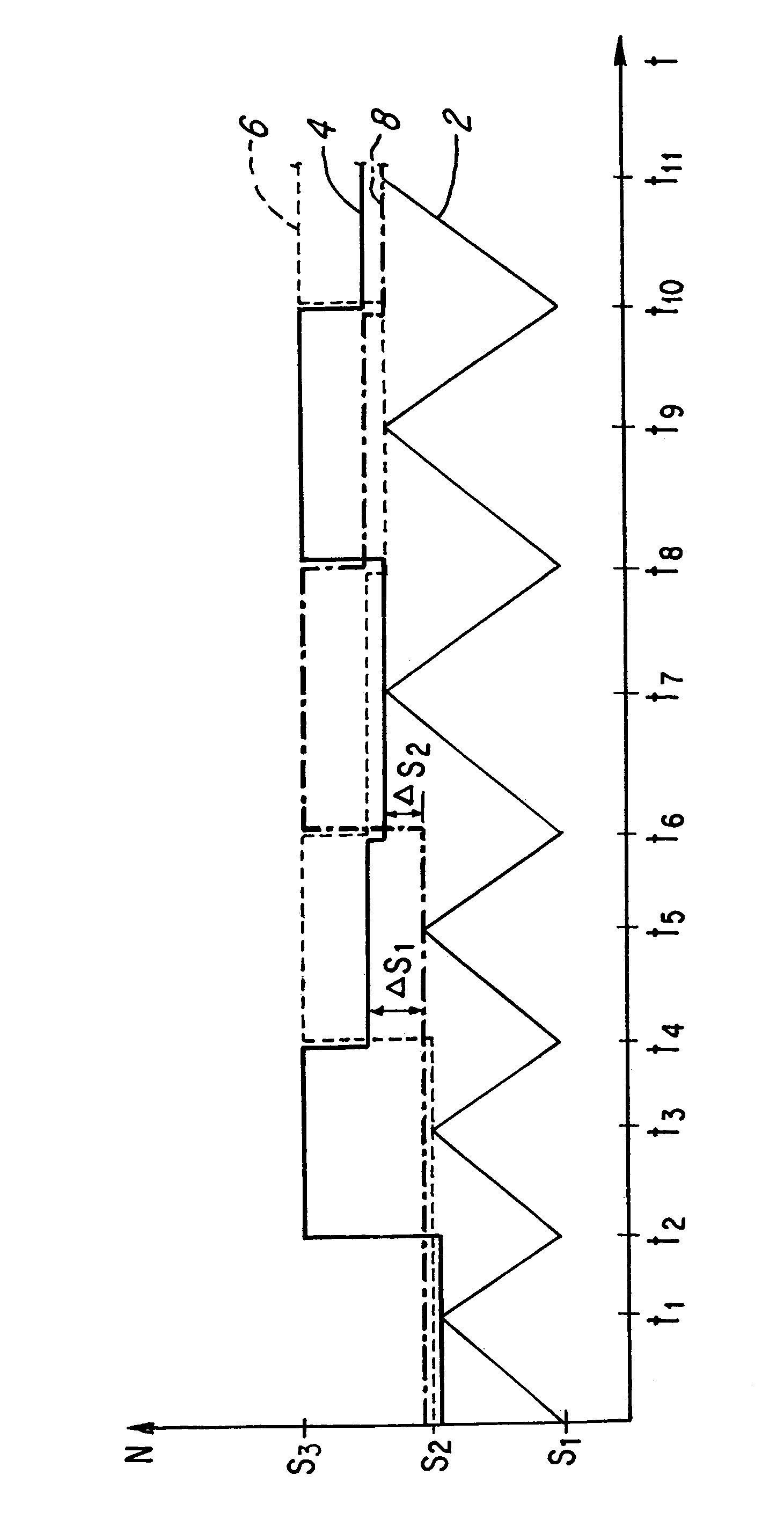

Method for controlling several pumps

ActiveUS7195462B2Easy to controlEasy to assembleFlexible member pumpsPump controlBiochemical engineeringSump

The invention relates to a method for controlling several pumps in a pump sump, with which each pump comprises a switch which switches on the pump and each pump after its running is first blocked and depending on the running of the further pumps in the pump sump is released again. The invention further relates to a pump for carrying out this method.

Owner:GRUNDFOS

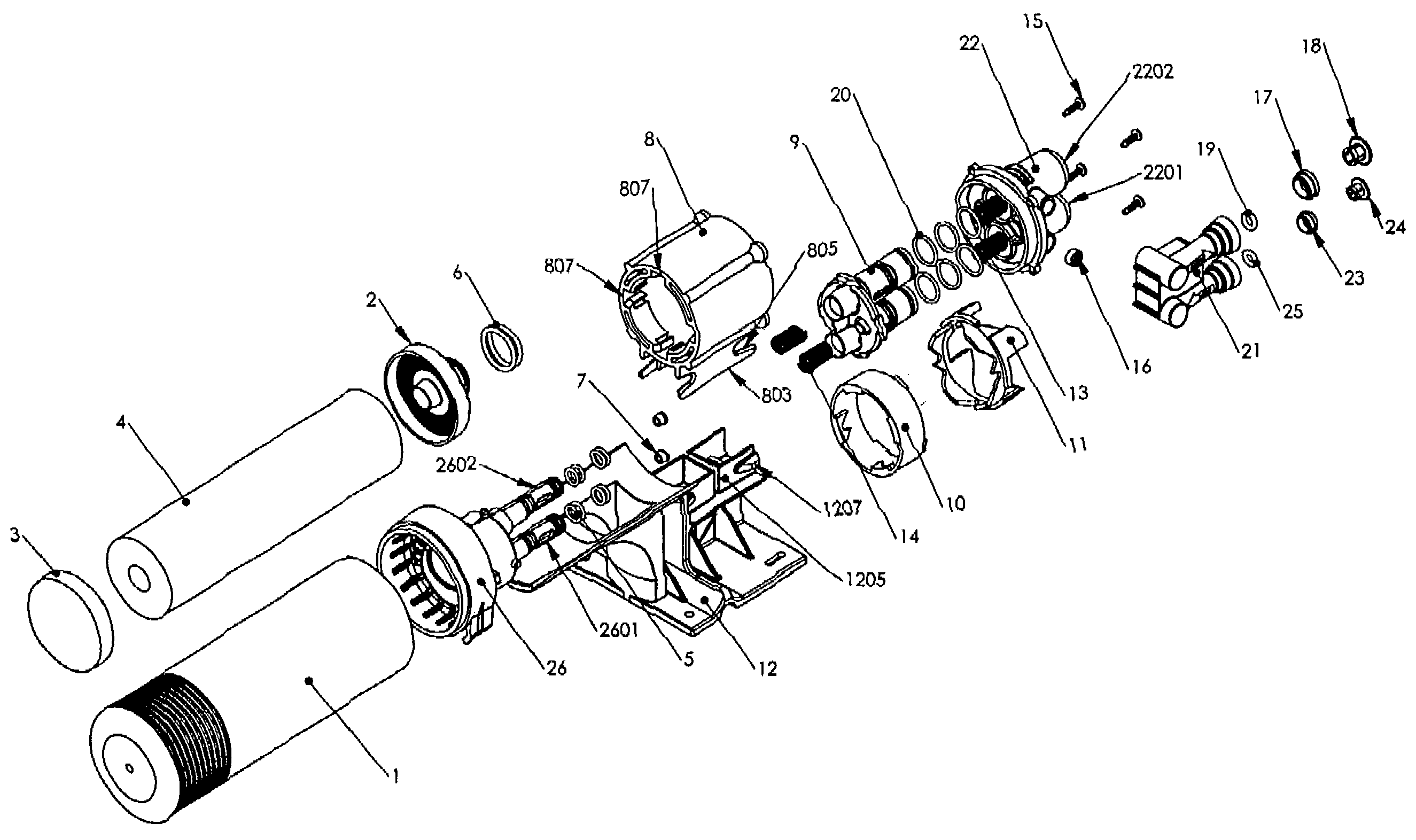

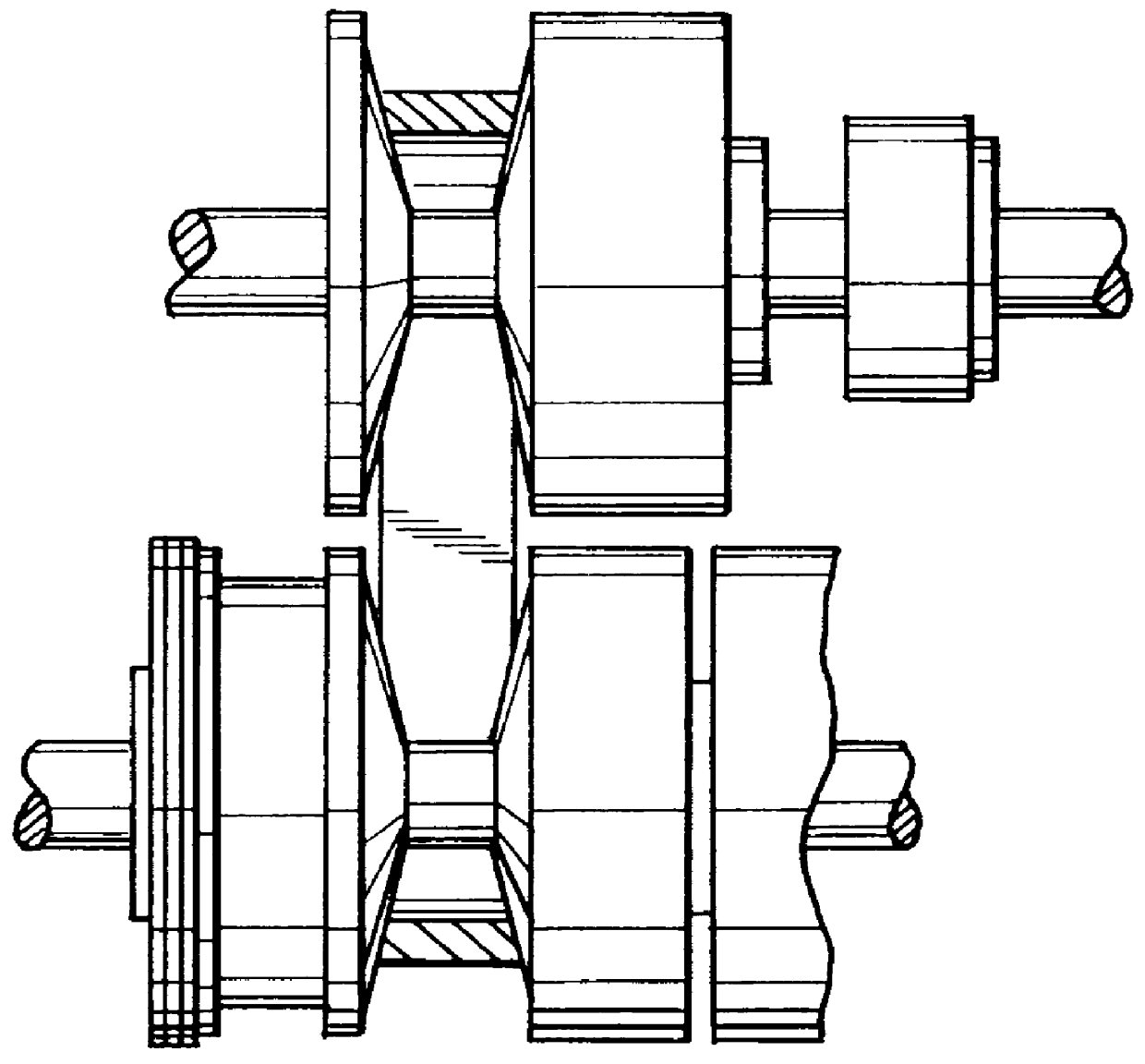

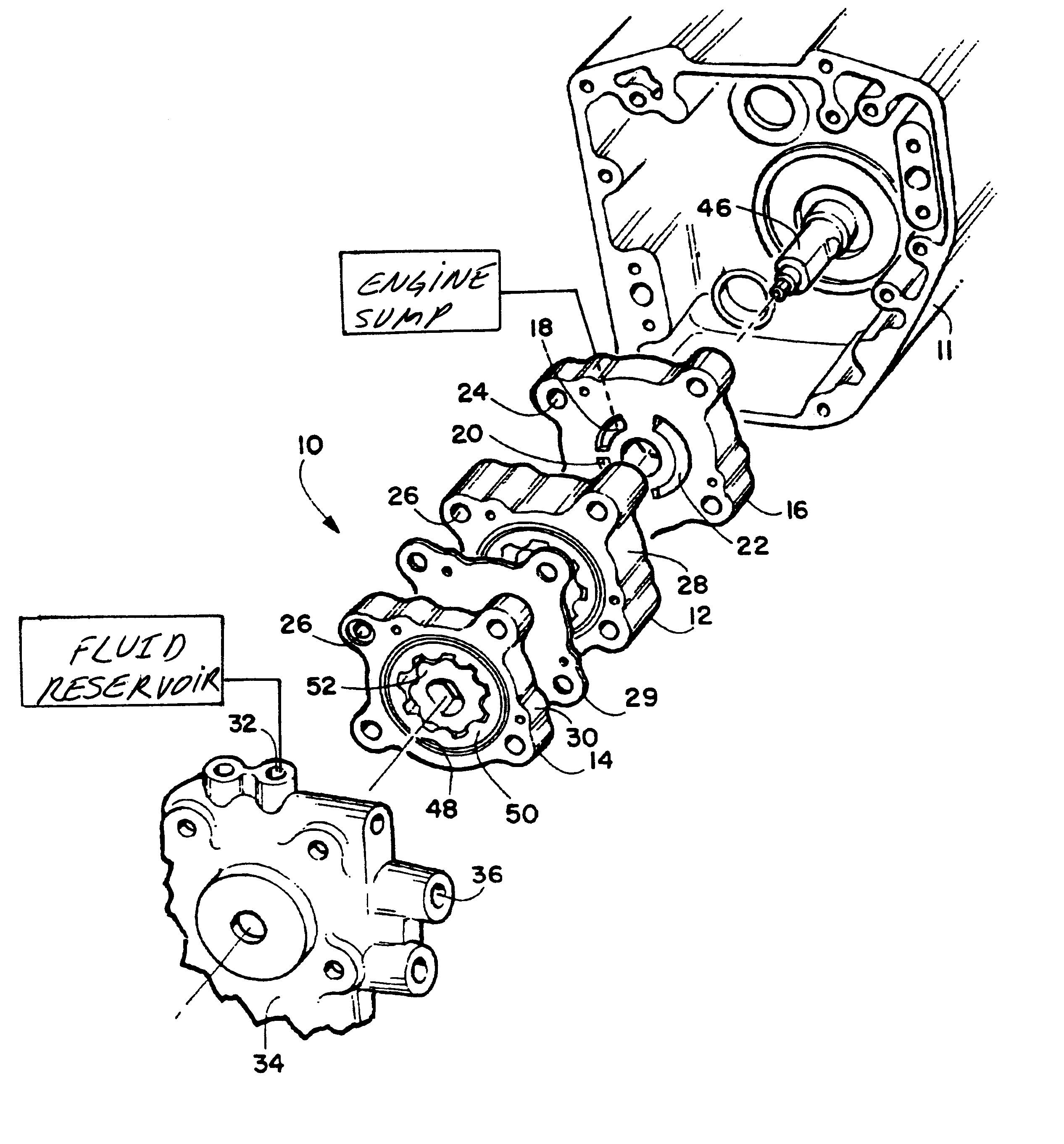

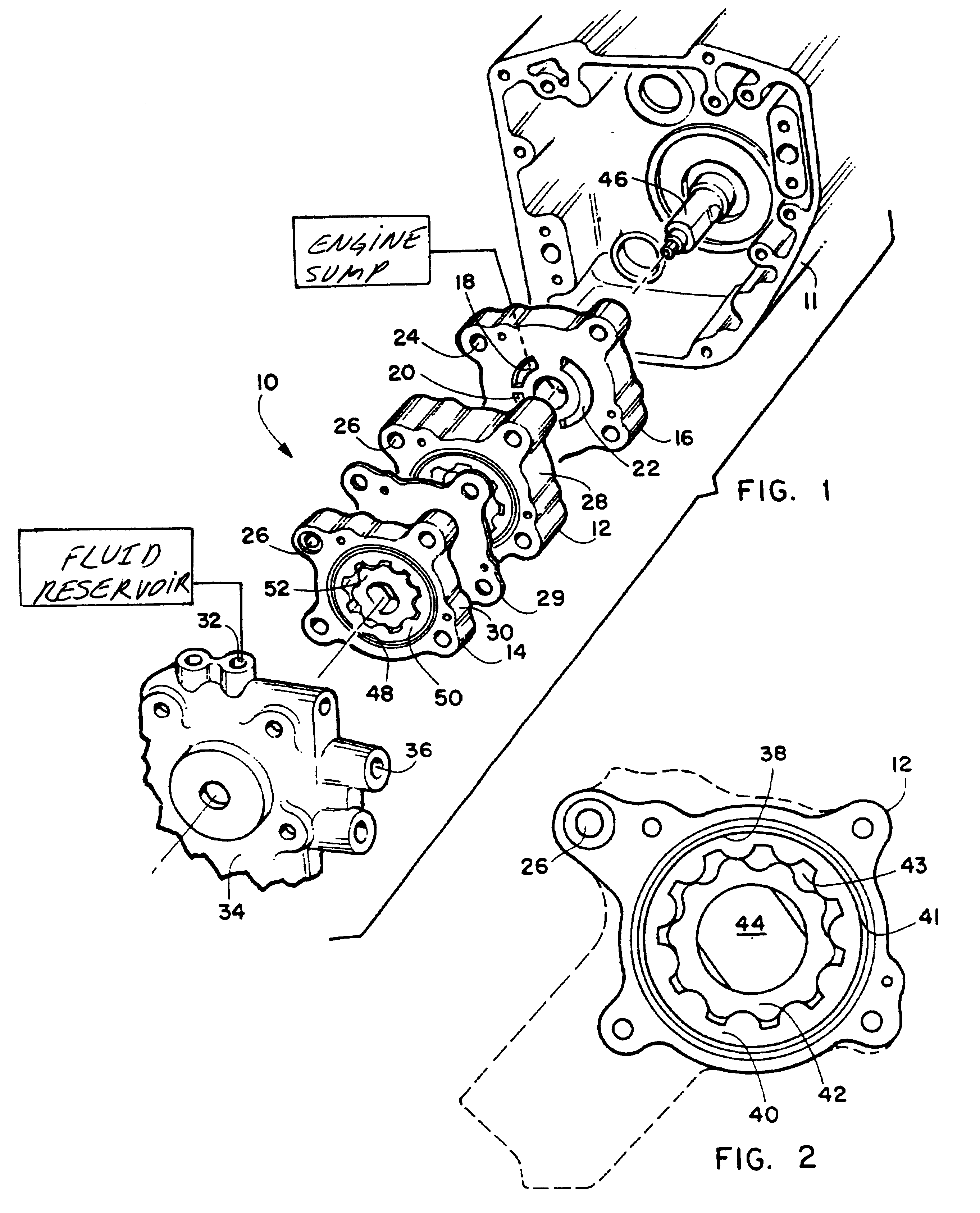

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

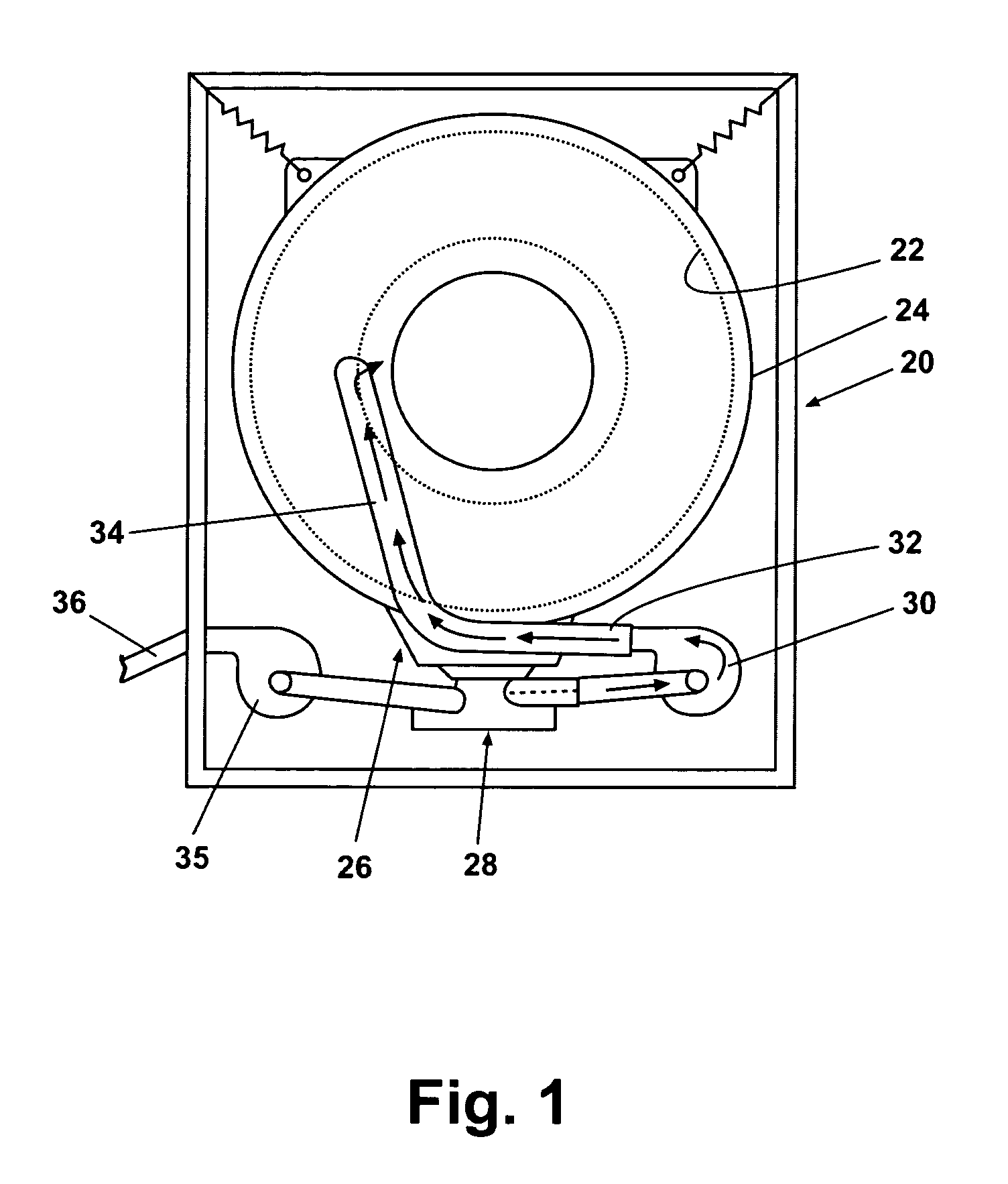

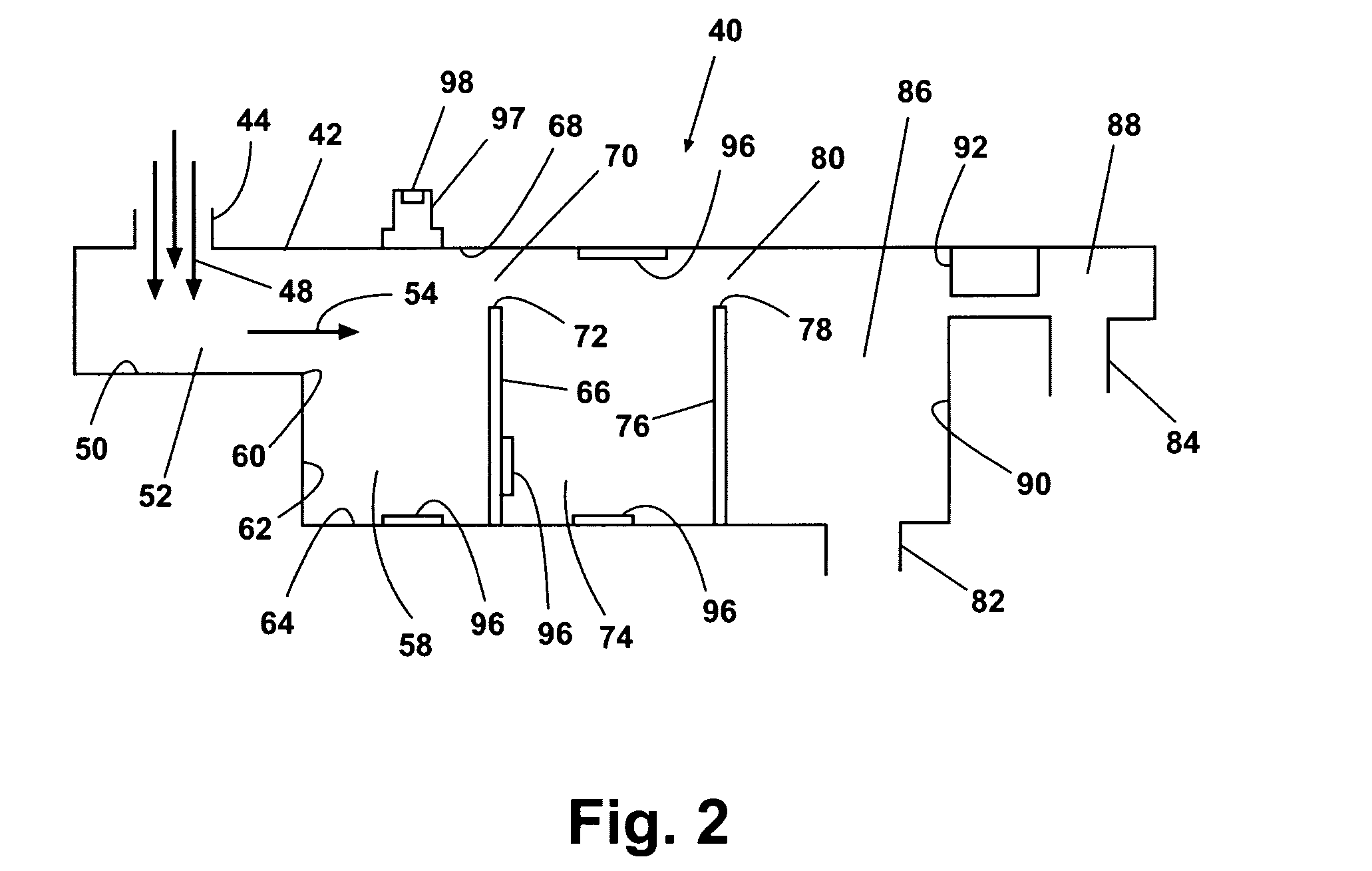

Remote sump with film heater and auto purge

An automatic washer comprises a remote sump fluidly connected to a drain pump and a recirculation pump, and a separator comprising an array of regularly-spaced fins oriented upstream of the recirculation pump for intercepting foreign objects in wash liquid. The remote sump also comprises a wash liquid heater. The separator is automatically purged when the drain pump is operated.

Owner:WHIRLPOOL CORP

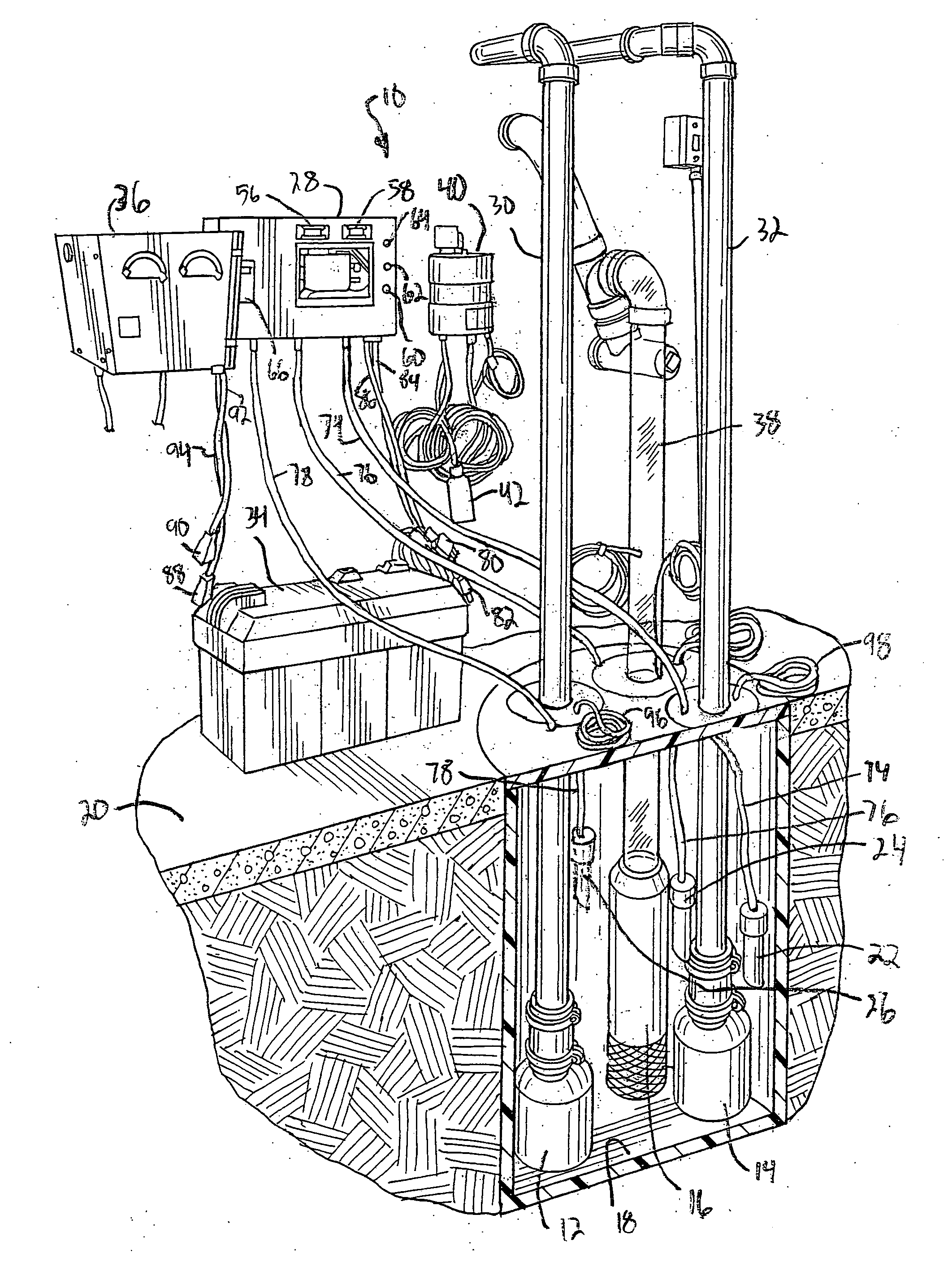

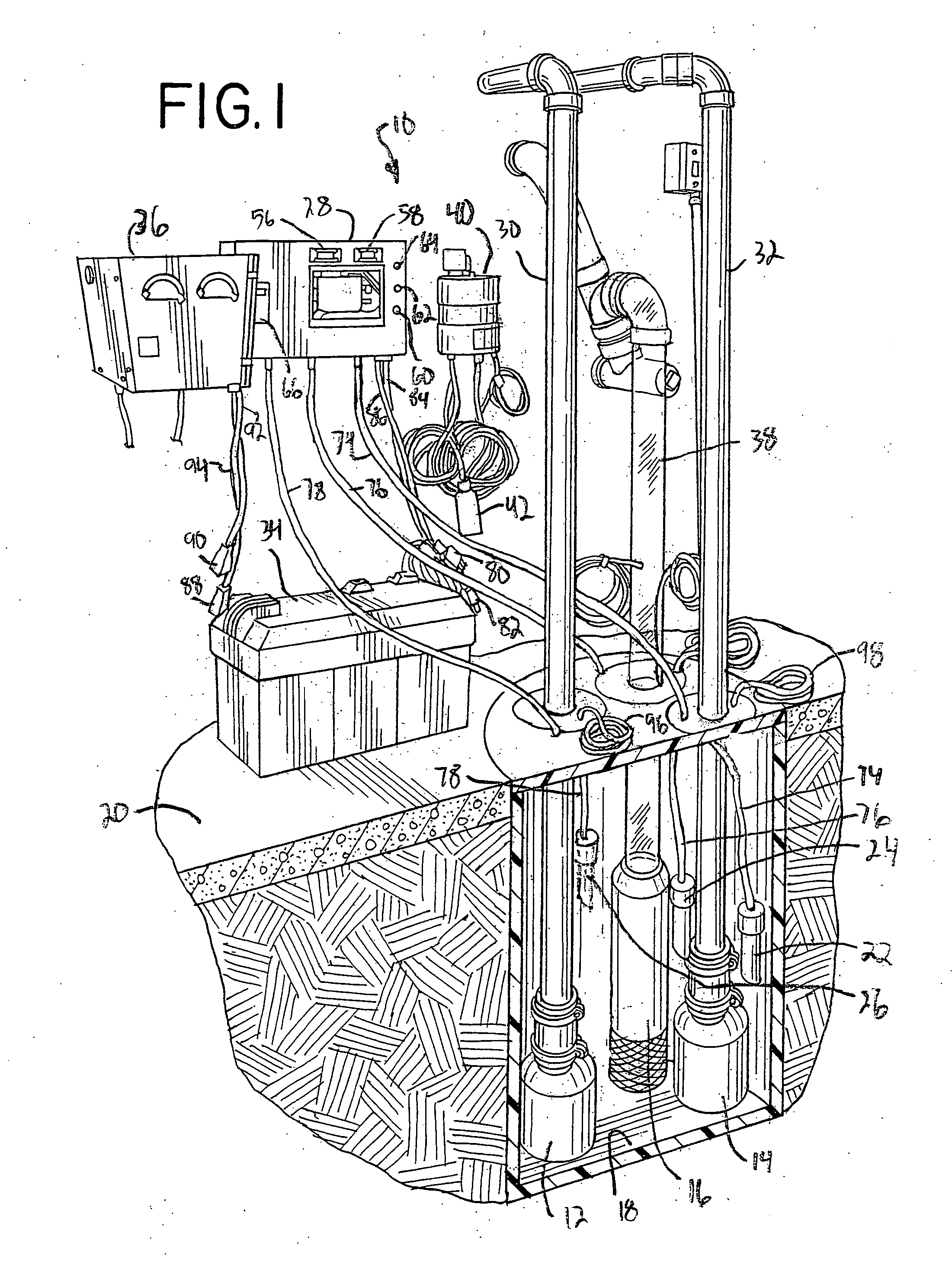

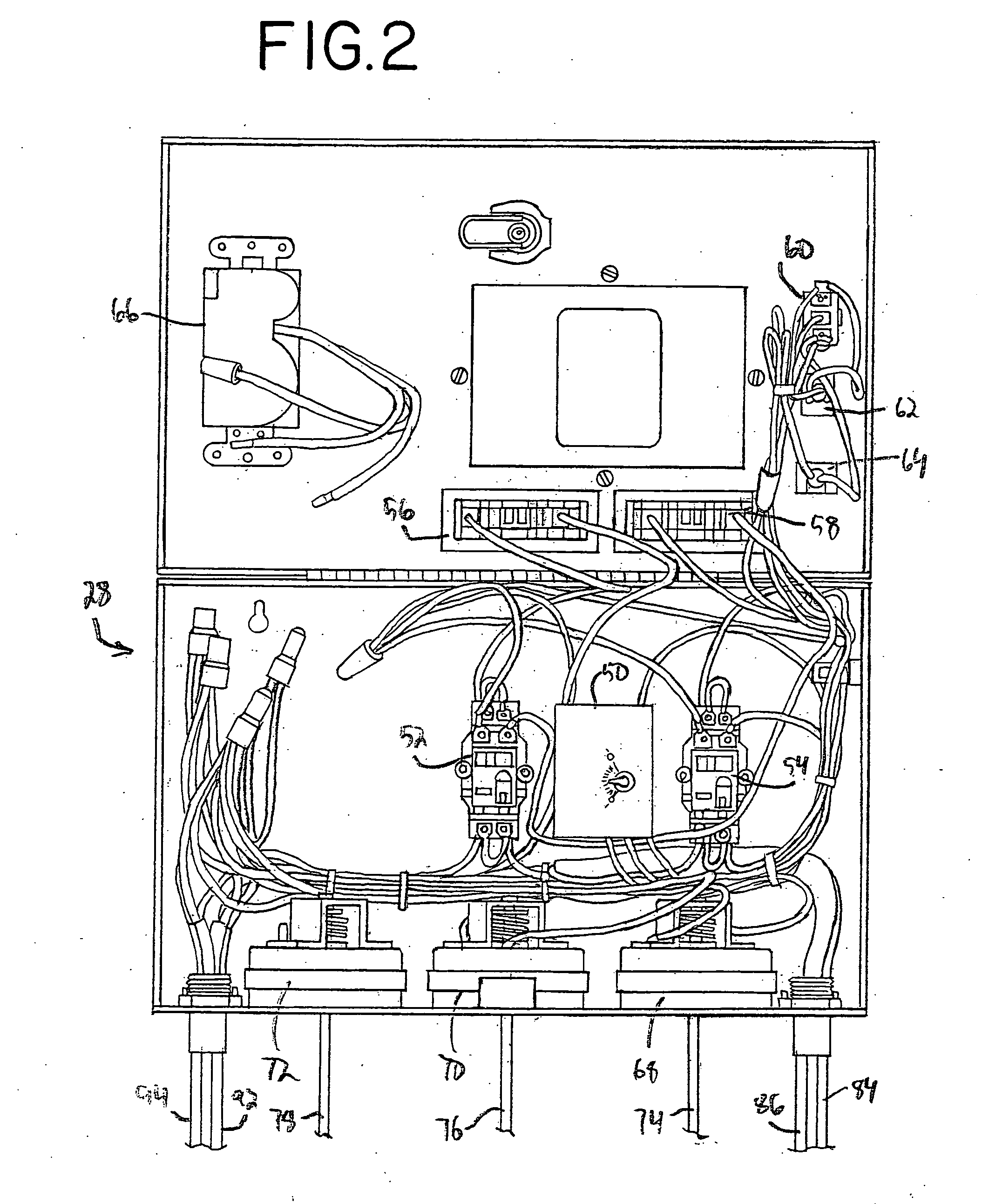

Basement flood control system

A basement flood control system for use in a structure having a basement floor located below ground level and having a sump pit or other collection basin for gathering subterranean water. The system has two primary pump units operated with line current, a battery-operated back-up pump unit, and a sensor arrangement for sensing water level in the collection basin. A controller is connected to the sensor arrangement and the pump units for variously activating the pump units singly or in any combination responsive to the water level detected by the sensor arrangement.

Owner:NIEDERMEYER KARL

Turbocharger

InactiveUS7360361B2Elimination of gravitational effectHigh trafficInternal combustion piston enginesEngine manufactureTurbochargerInduction motor

An electrically controlled turbocharger having a substantially vertically oriented shaft interconnecting a turbine and a compressor. The vertical orientation serves to eliminate the effects of gravity on the rotating components. Placing the turbine vertically above the motor and compressor and provides additional cooling through convection of heat produced by hot exhaust gas flowing through the turbine. A lubricating system utilizes scavenged air from the compressor to draw lubricating oil through internal passages of the motor housing to maintain a desirable oil sump level, ventilate the auxiliary induction motor, and provide pressure to the oil seals of the motor cavity.

Owner:ADVANCED PROPULSION TECH

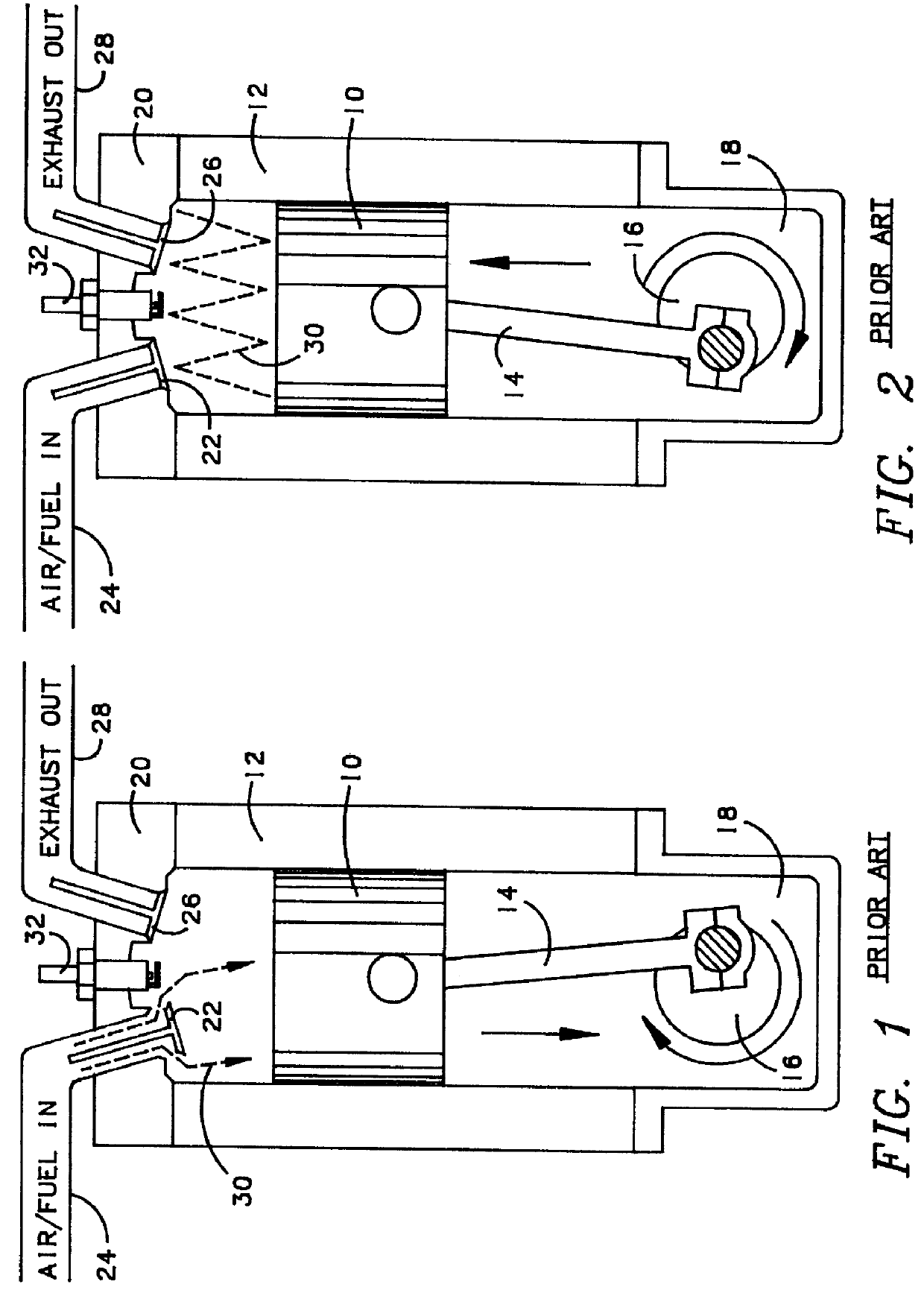

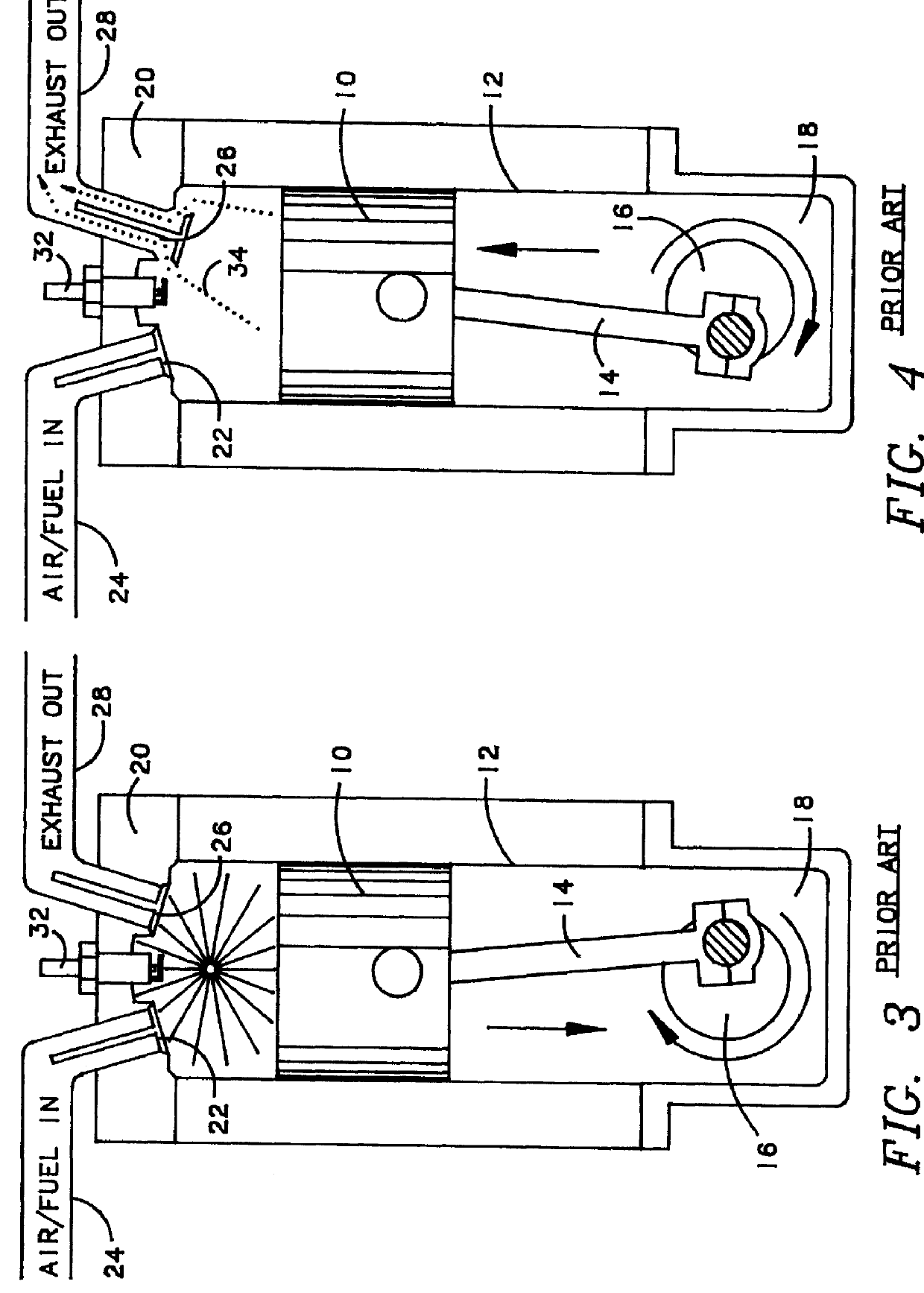

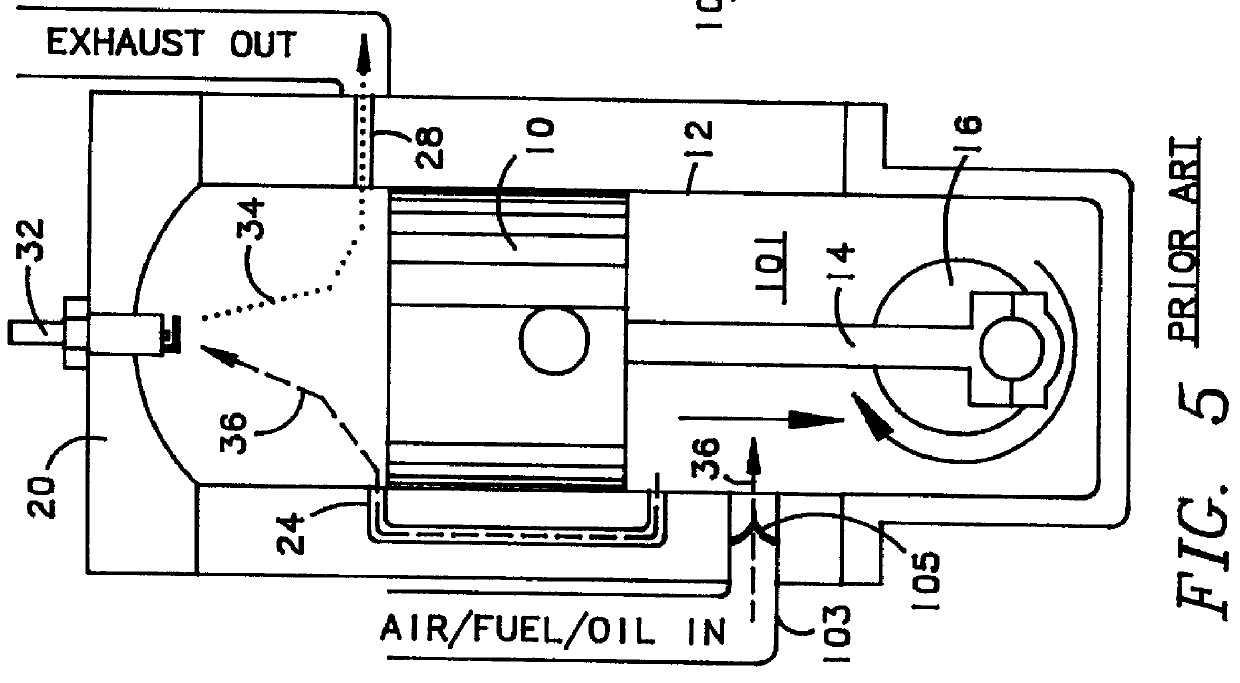

High efficiency low-pollution engine

InactiveUS6026568AEliminate needCasingsInternal combustion piston enginesExternal combustion engineCylinder head

An internal combustion engine of either two-cycle or four-cycle construction including a block having at least one cylinder bore therein having sidewalls carrying a liner of a structural fiber reinforced ceramic matrix composite material disposed in sealed fiber reinforced sliding relationship within the cylinder bore, and a cylinder head sealing atop end of the cylinder bore to form a closed combustion chamber in combination with the piston. The cylinder head also has the structural fiber reinforced ceramic matrix composite material disposed on an inner surface thereof facing the combustion chamber. The preferred engine is a two-cycle engine having an externally scavenged intake system and an oil sump lubricating system thereby eliminating the need to separately mix or inject lubricating oil. Higher operating temperatures and closer tolerances allow higher fuel efficiency and less pollutant production. A preferred structural fiber reinforced ceramic matrix composite material and the method of making same is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

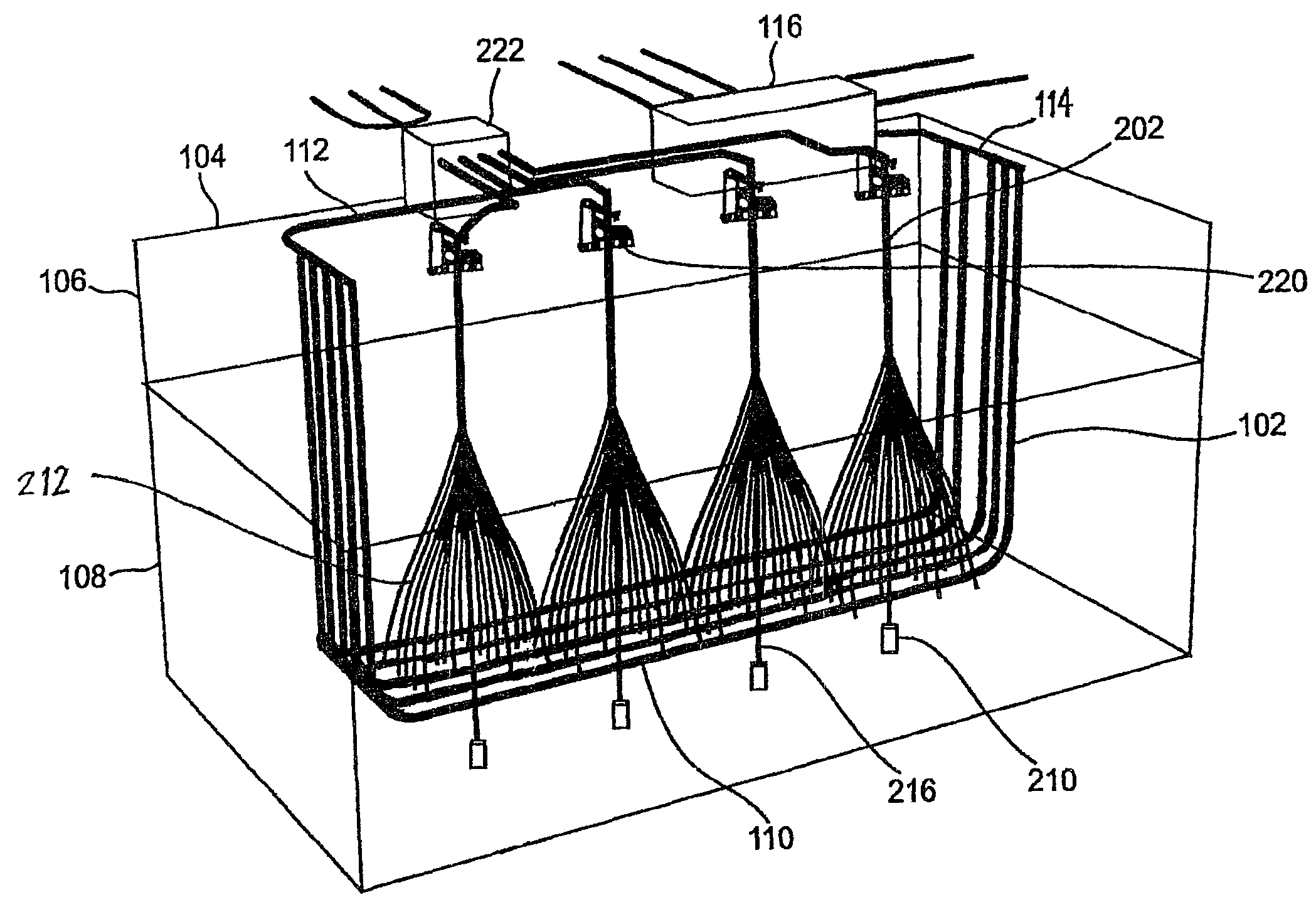

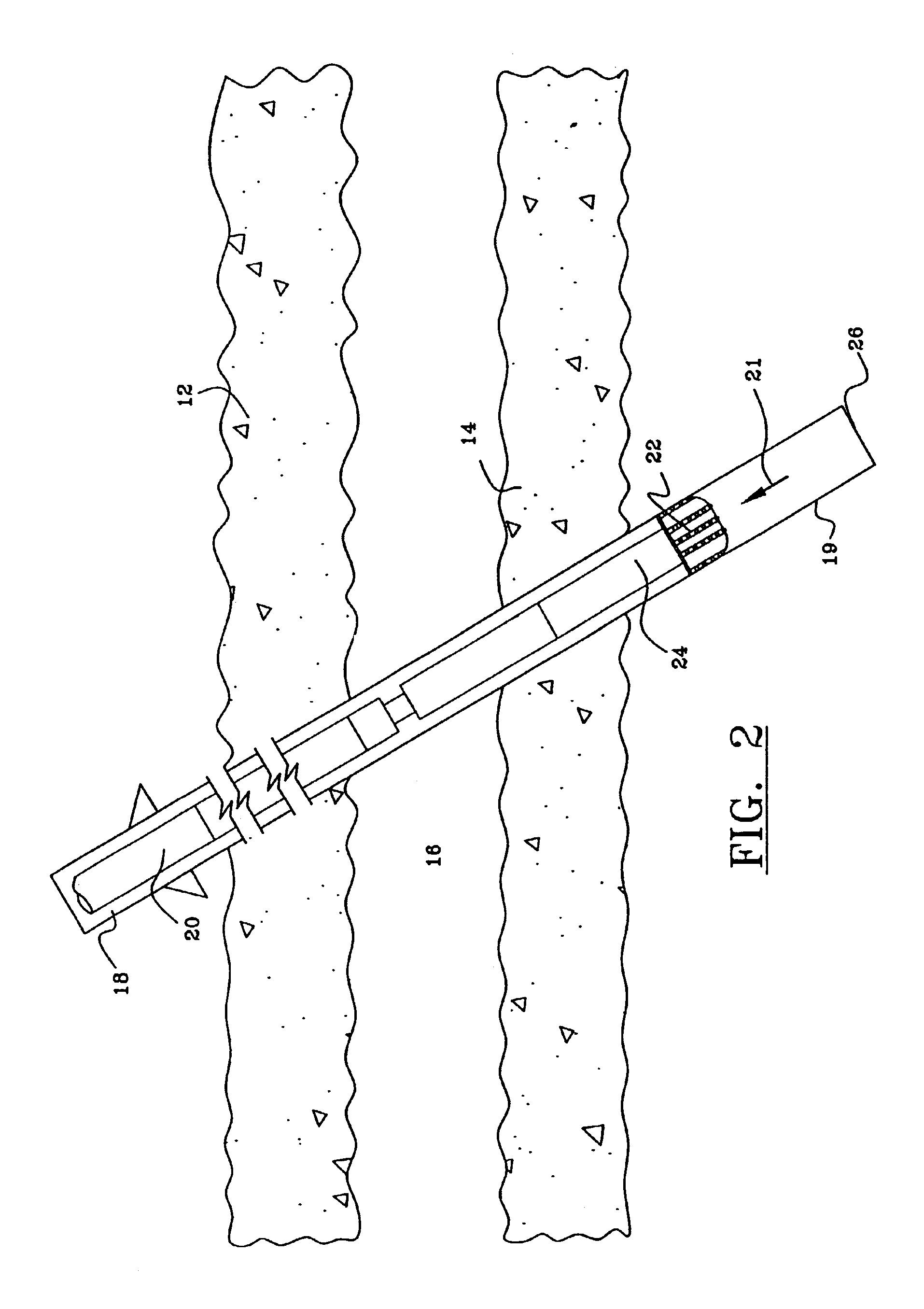

Multi seam coal bed/methane dewatering and depressurizing production system

InactiveUS6923275B2Minimal environmental impactEliminate infrastructure long-term maintenance and environmental impactFluid removalDirectional drillingWell drillingProduct gas

A process for underbalanced drilling into multiple coal and shale formations, and dewatering the drilled formations, which includes drilling a first borehole through several coal seams to a certain depth, defined as a cased borehole; lowering an upstock on the end of a carrier string to the depth of the upper coal seam; lowering a drill string in the carrier string, and angling off of the upstock, to drill a lateral or horizontal borehole within the coal seam; repeating the process for the second coal seam; setting a packer in place above the first coal seam in the annulus between the cased borehole and the carrier string; forming perforations in the wall of the carrier string below the packer; retrieving the upstock from the carrier string; lowering an electrical submersible pump to the bottom of the principal borehole, defined as a sump portion of the borehole; collecting methane gas from the two coal seams through the annulus between the second drill string and the carrier string to the surface; pumping water from the sump portion to the surface within the annulus of the second drill string, while gas within the annulus between the carrier string and the outer casing enters the plurality of perforations in the carrier string to be carried up to the surface.

Owner:GARDES ROBERT

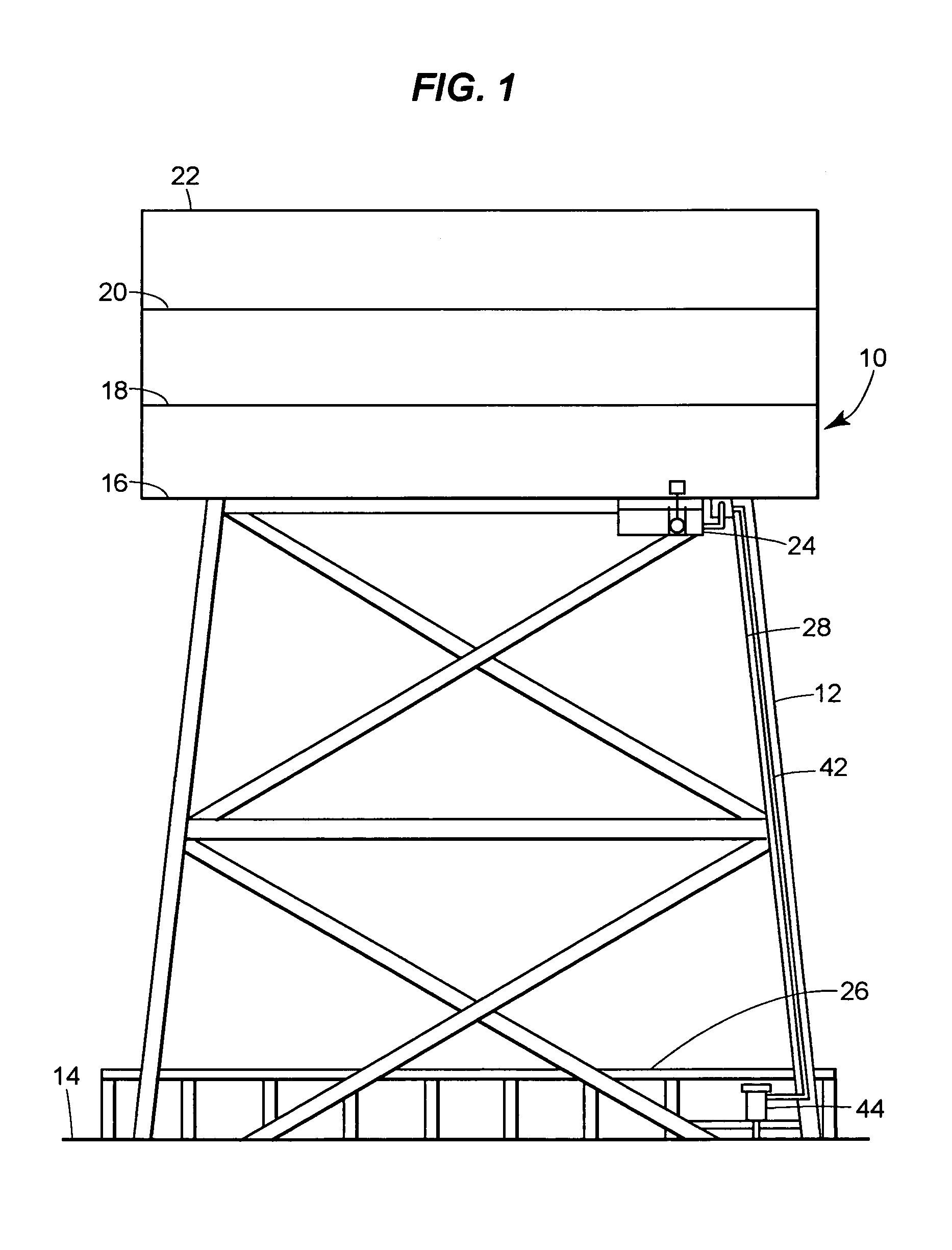

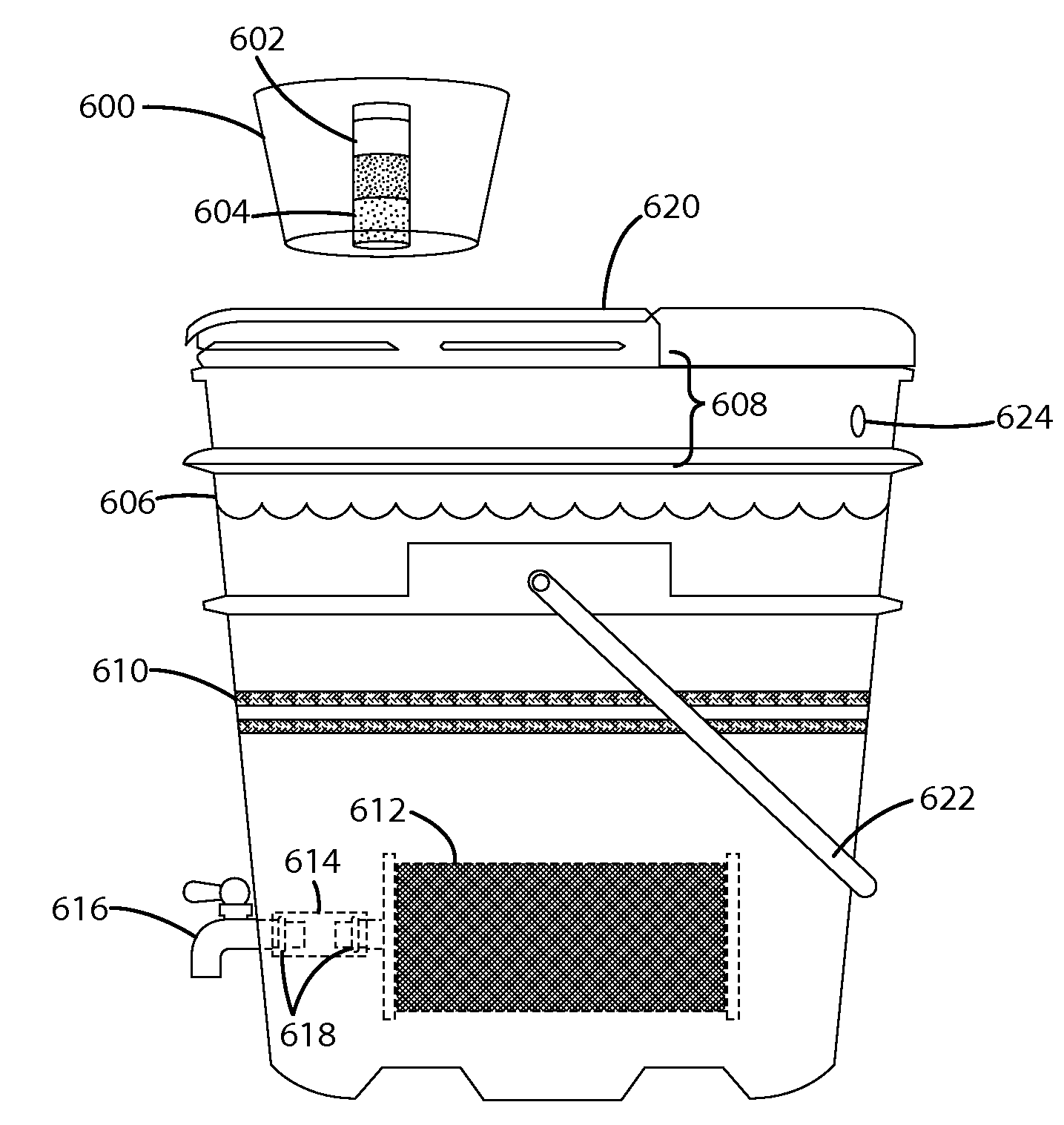

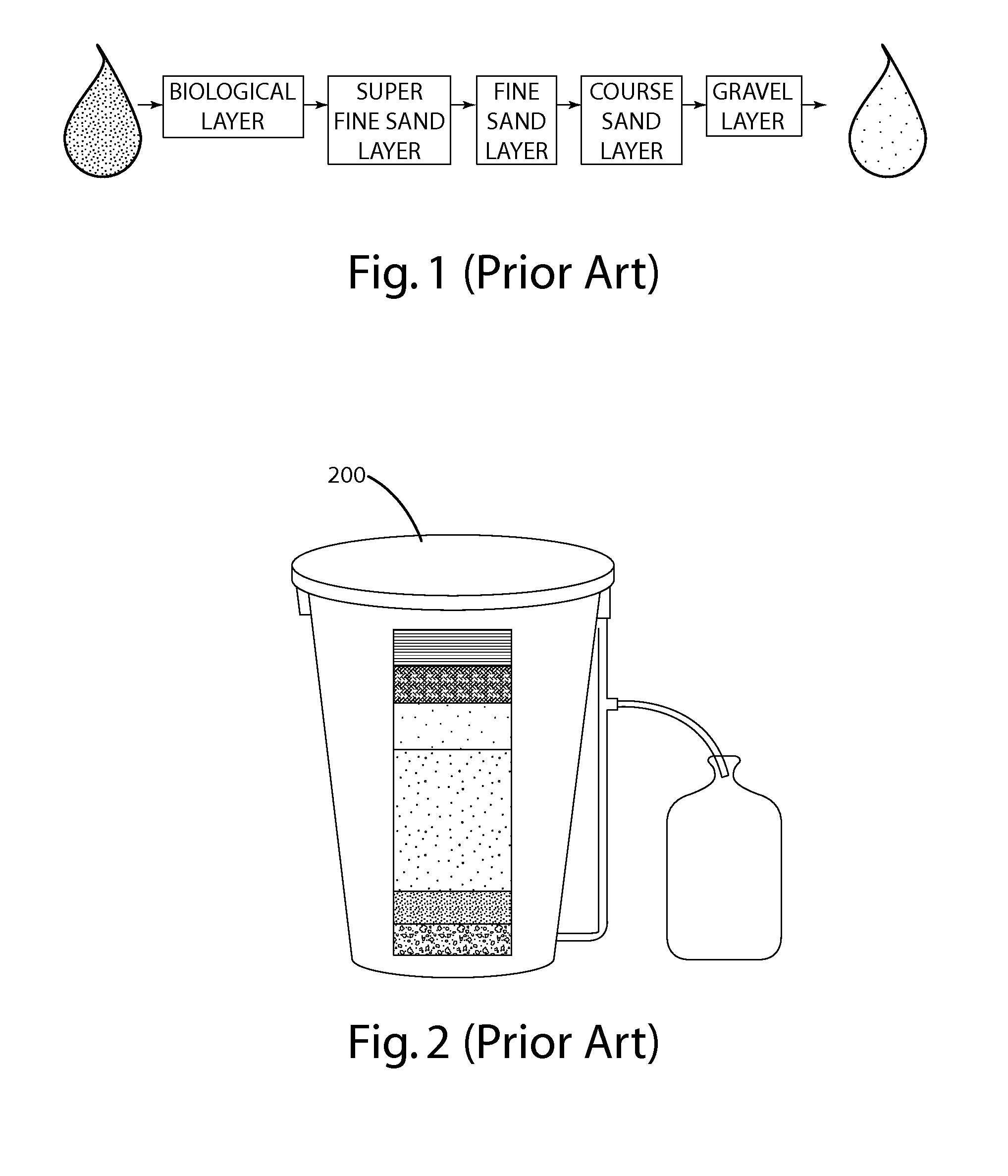

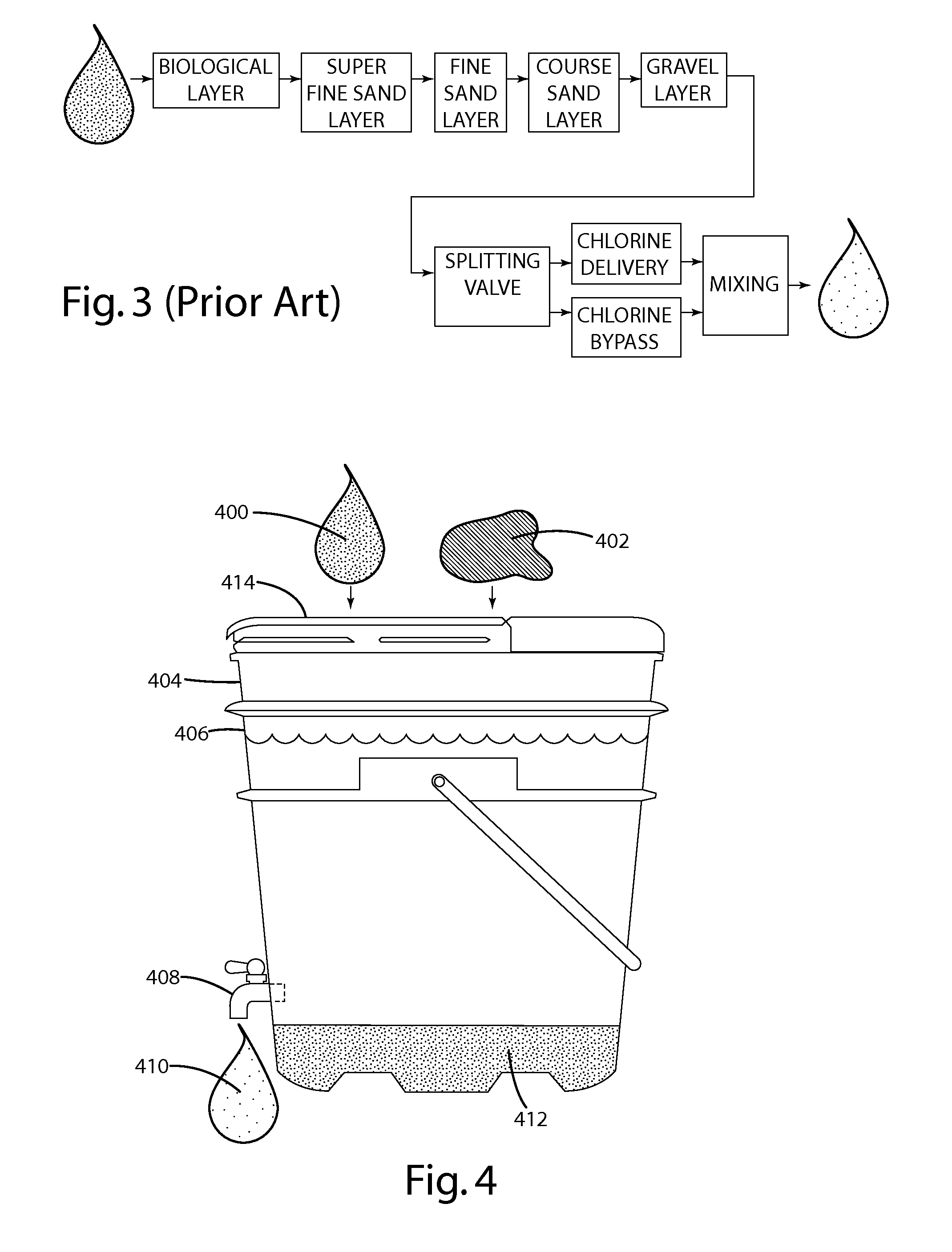

Gravity feed water treatment system

ActiveUS20110303589A1Increase flow rateHigh flow rateTreatment using aerobic processesTreatment involving filtrationFlocculationSiphon

A portable water treatment system includes at least one sub-system to treat water including a flocculation system, a chlorination system, and a bio-sand filter system. The water treatment system may include multiple sub-systems for treating water that feed into one another. The sand filter system may include a mini bio-sand filter, a foam filter, or a pressed block filter. The flocculation system may include a tank bottom that urges settling particles toward a sump and a ladle that removes settled particles. A manual pump or siphon may be included in the water treatment system.

Owner:ACCESS BUSINESS GRP INT LLC

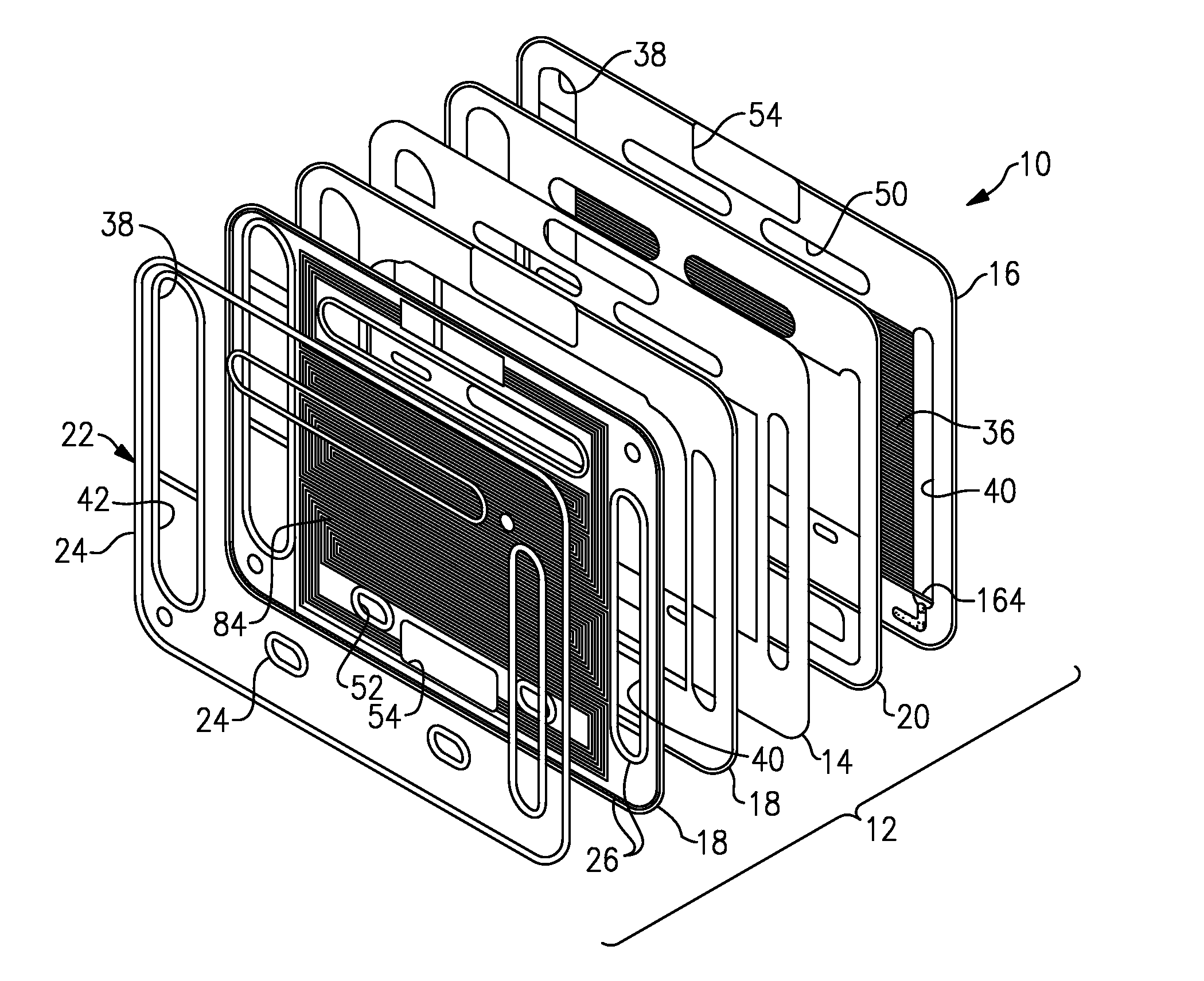

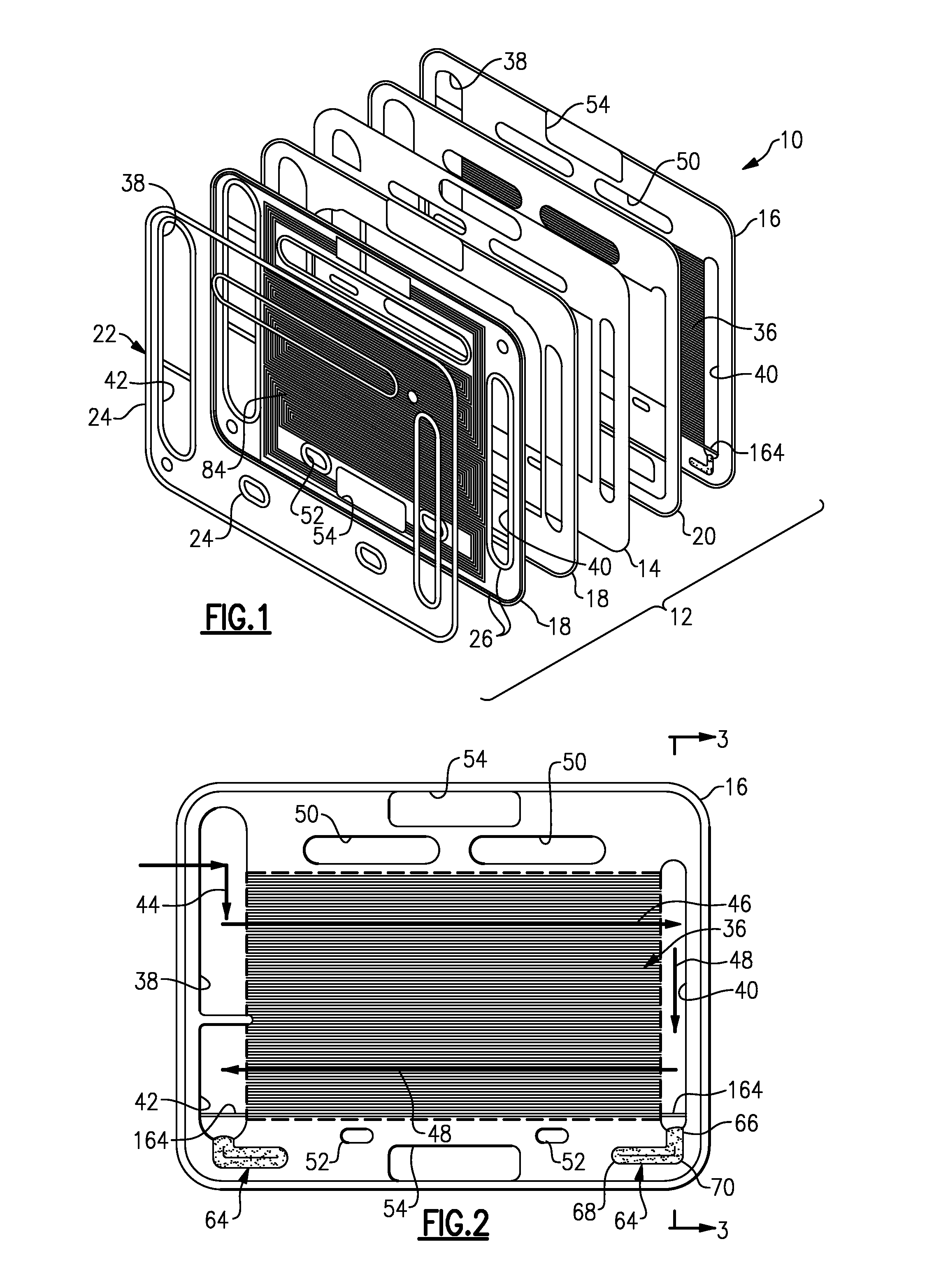

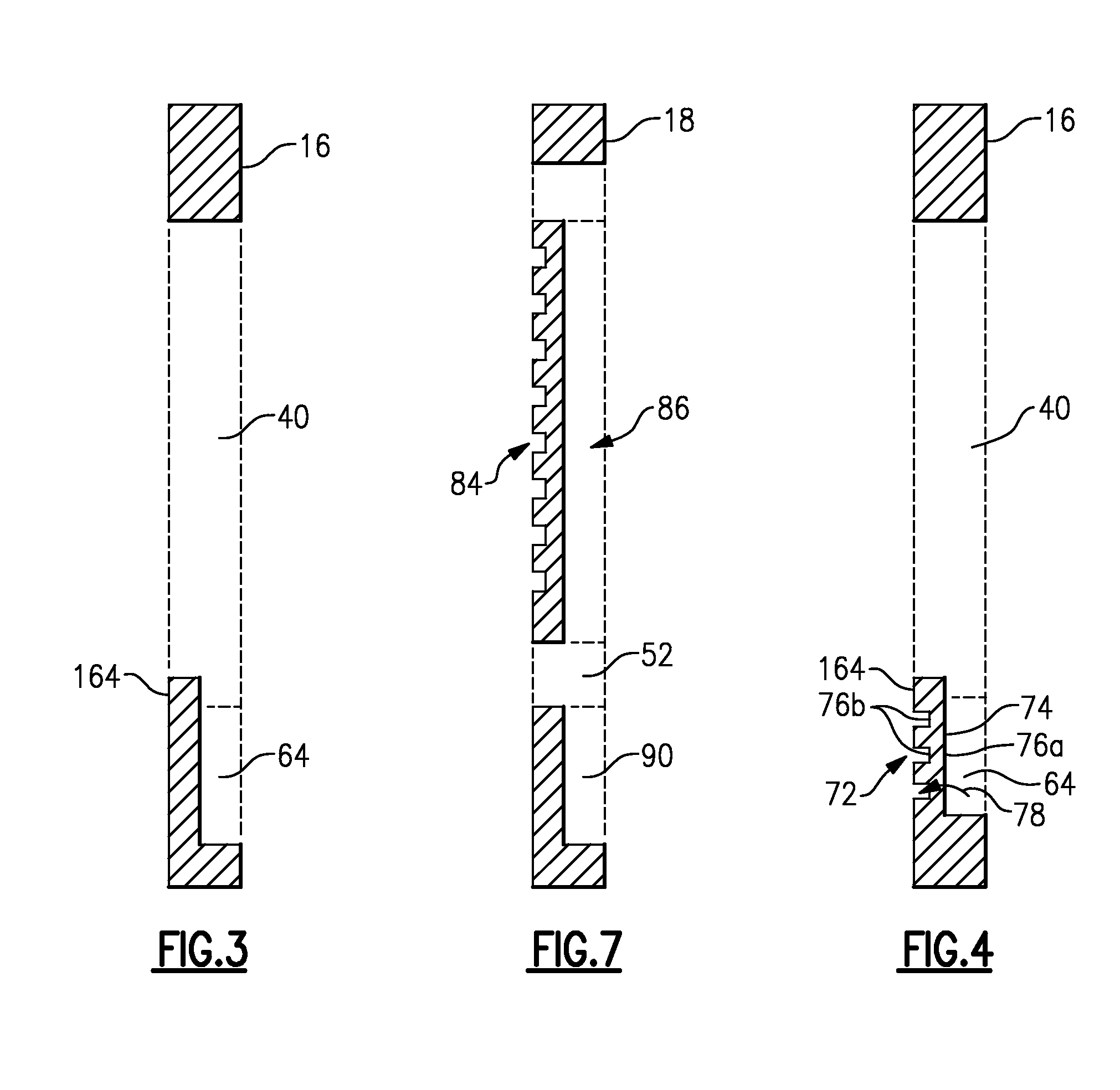

Fuel cell and bipolar plate having manifold sump

InactiveUS20110020722A1Facilitating reduction of water blockageFuel cell auxillariesFuel cellsElectrical and Electronics engineering

Owner:AUDI AG

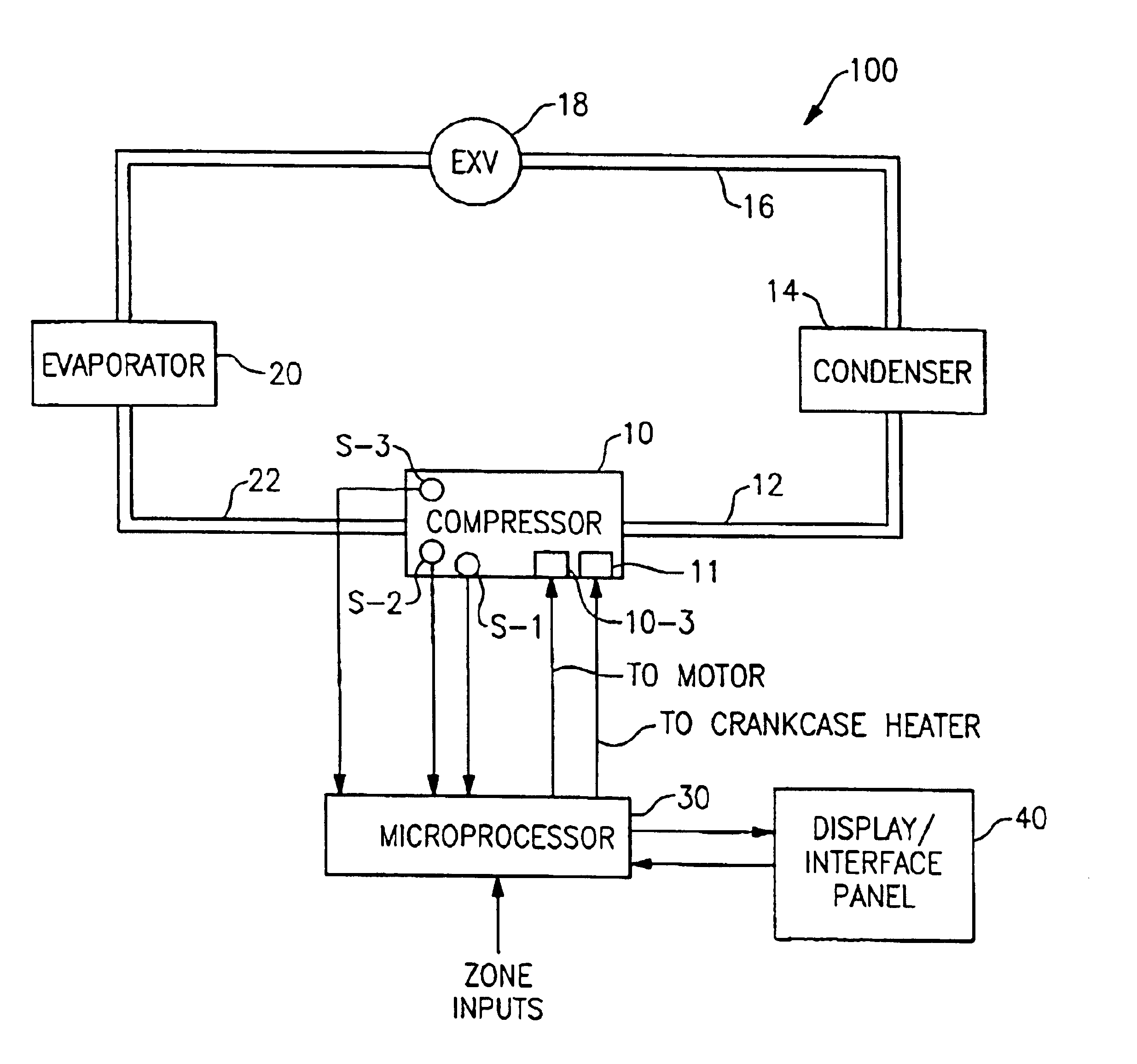

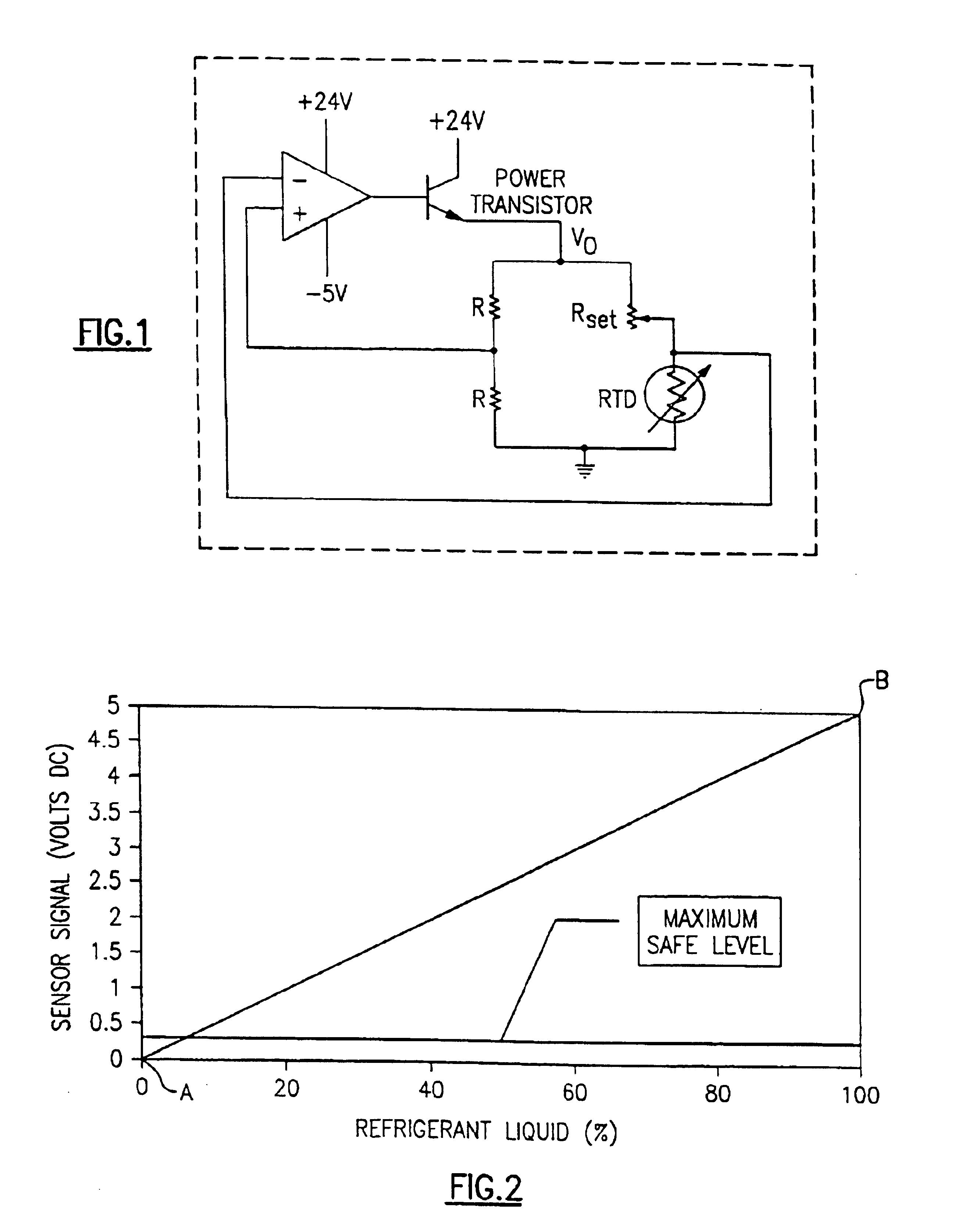

Compressor protection from liquid hazards

InactiveUS6886354B2Minimize liquid hazardMinimize liquid hazardsCompressorPositive displacement pump componentsEngineeringRefrigerant

Two liquid levels are sensed in the oil sump of a compressor to determine if sufficient oil and excess refrigerant are present prior to starting the compressor and appropriate steps taken, if necessary. At start-up, and during operation, the presence or flow of liquid refrigerant in the suction of the compressor is sensed and appropriate steps taken, if necessary.

Owner:CARRIER CORP

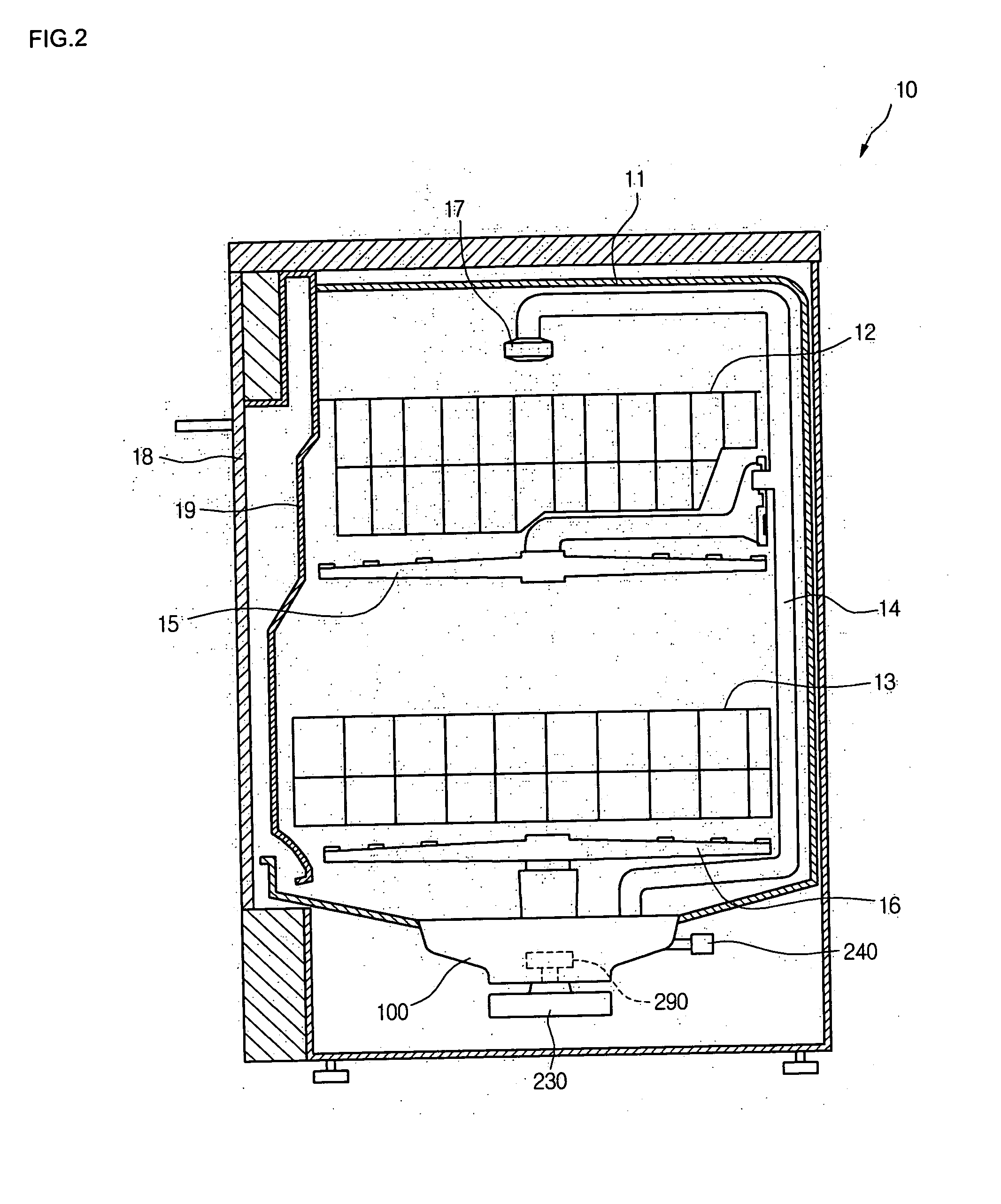

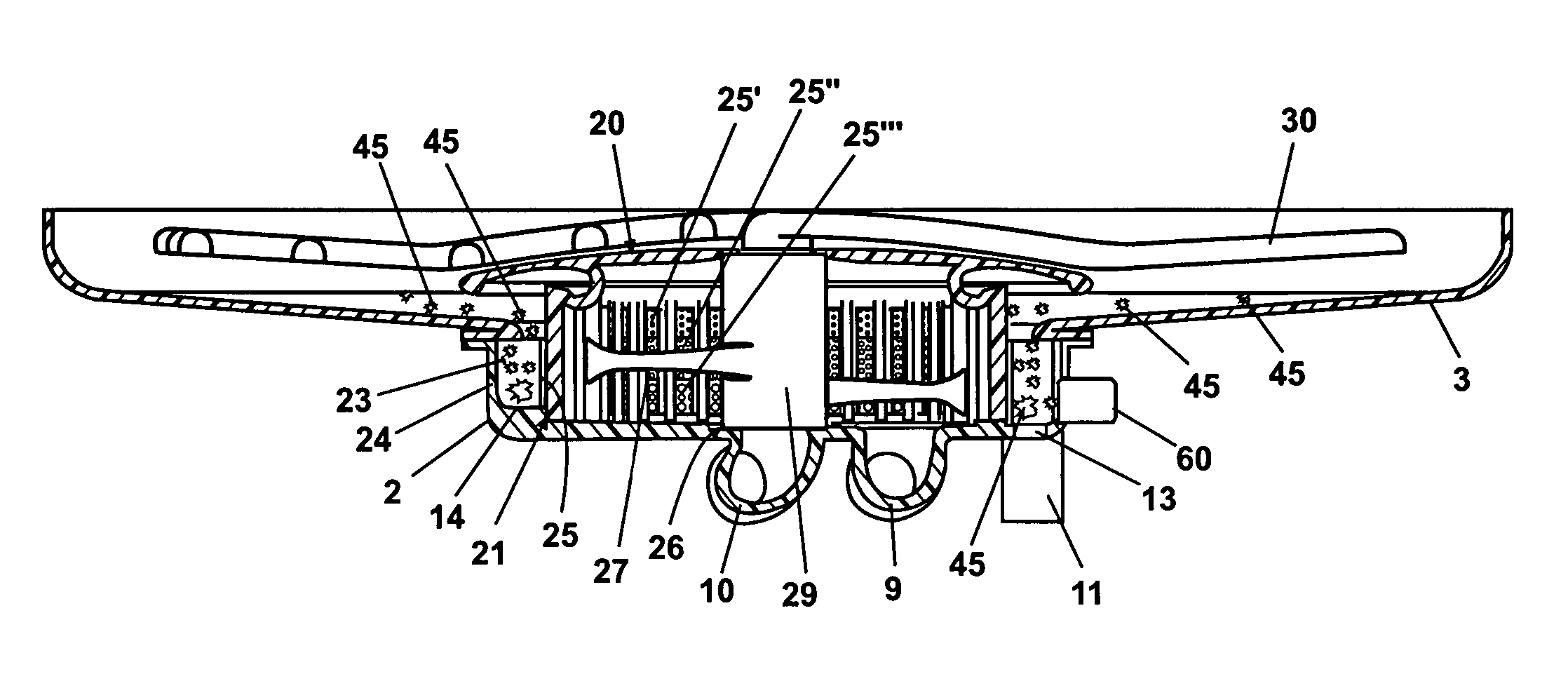

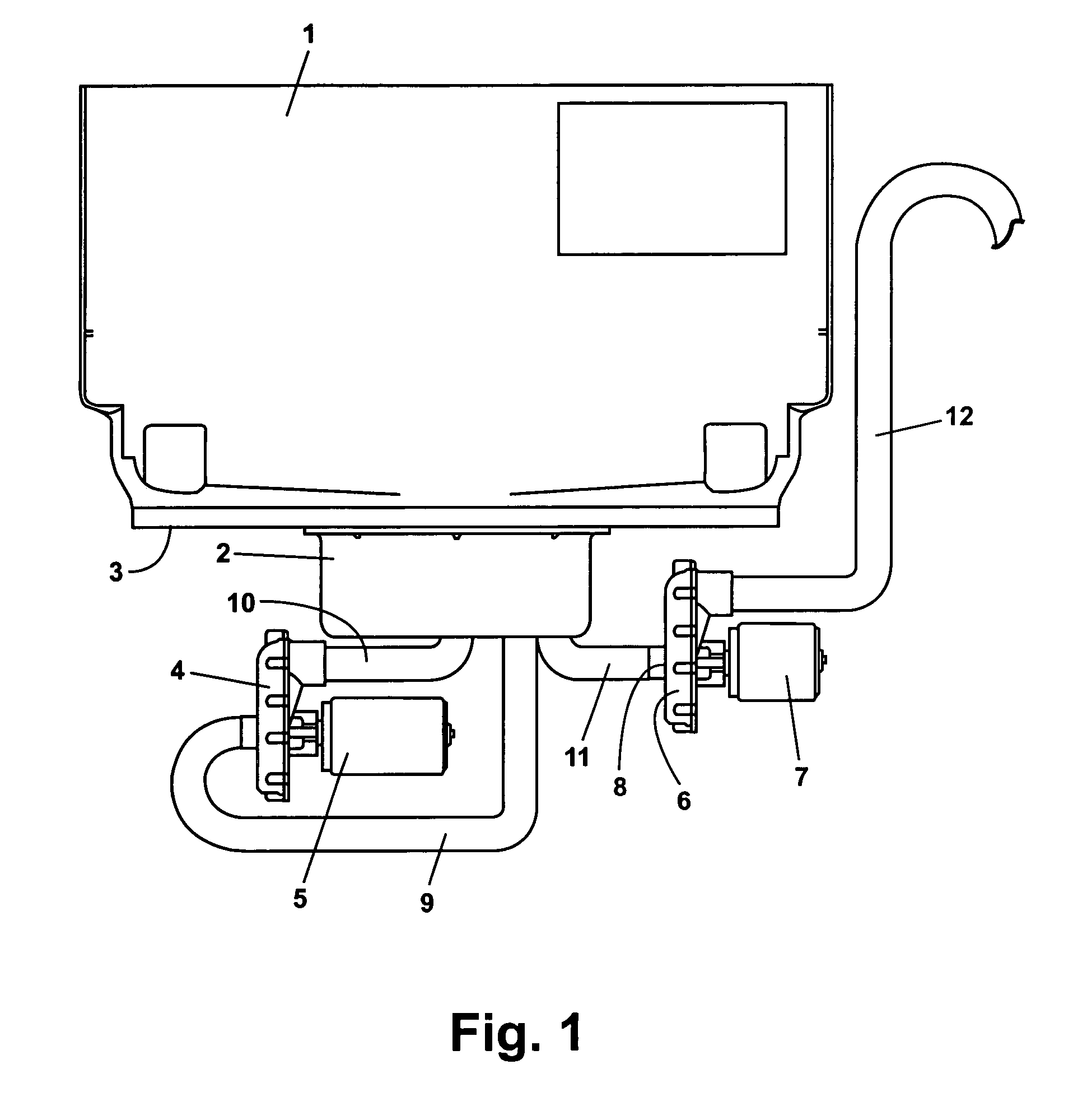

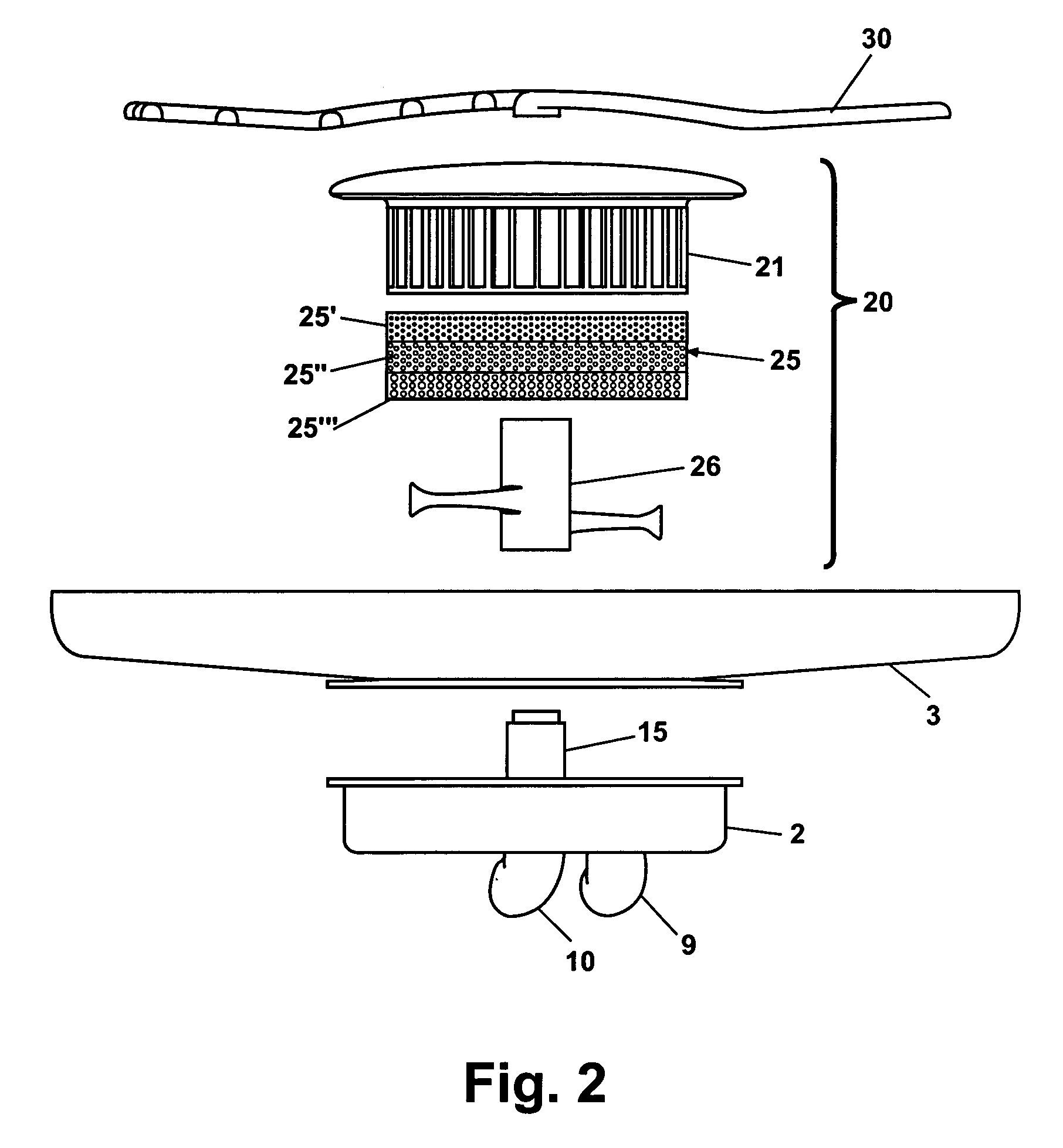

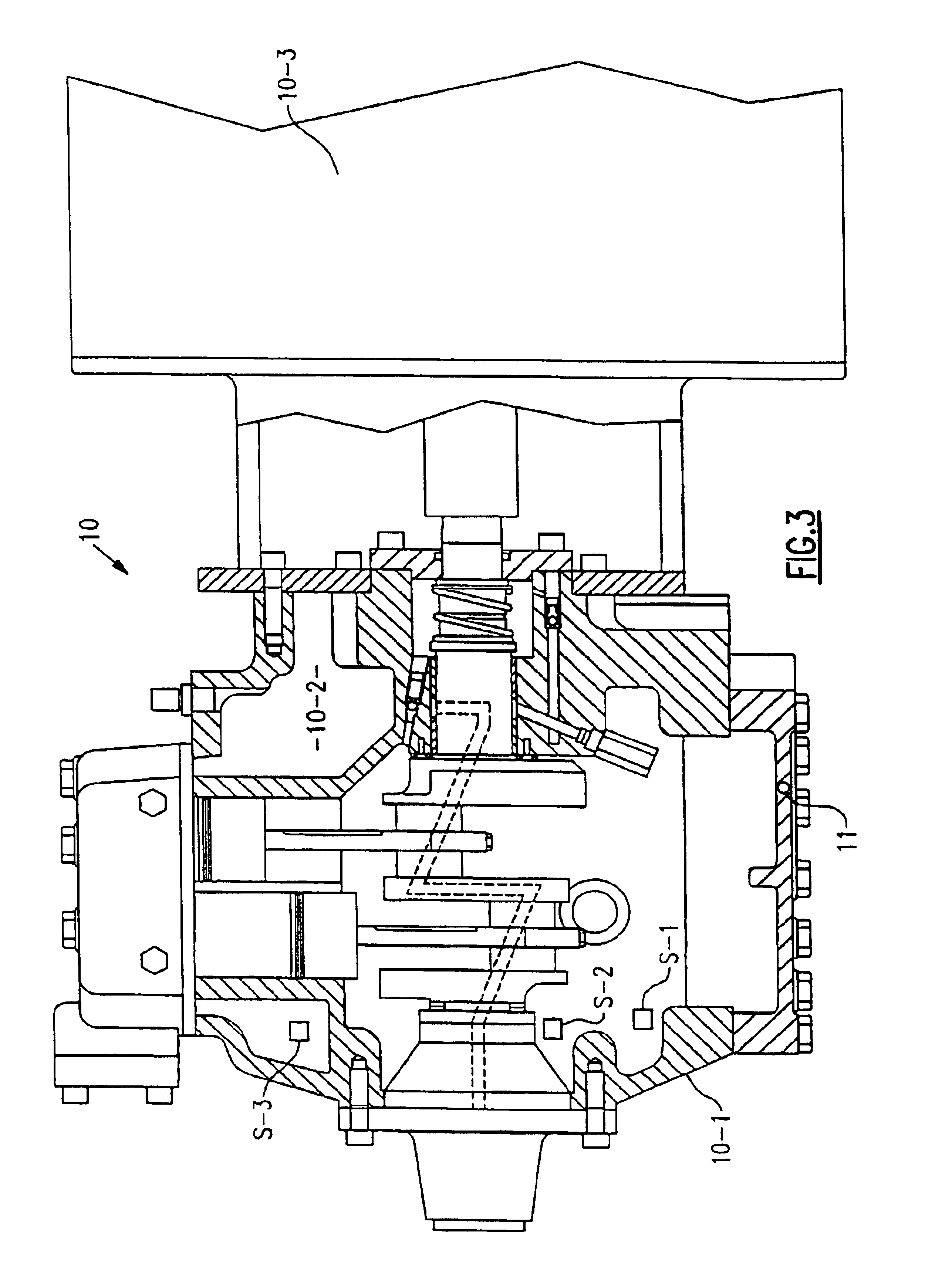

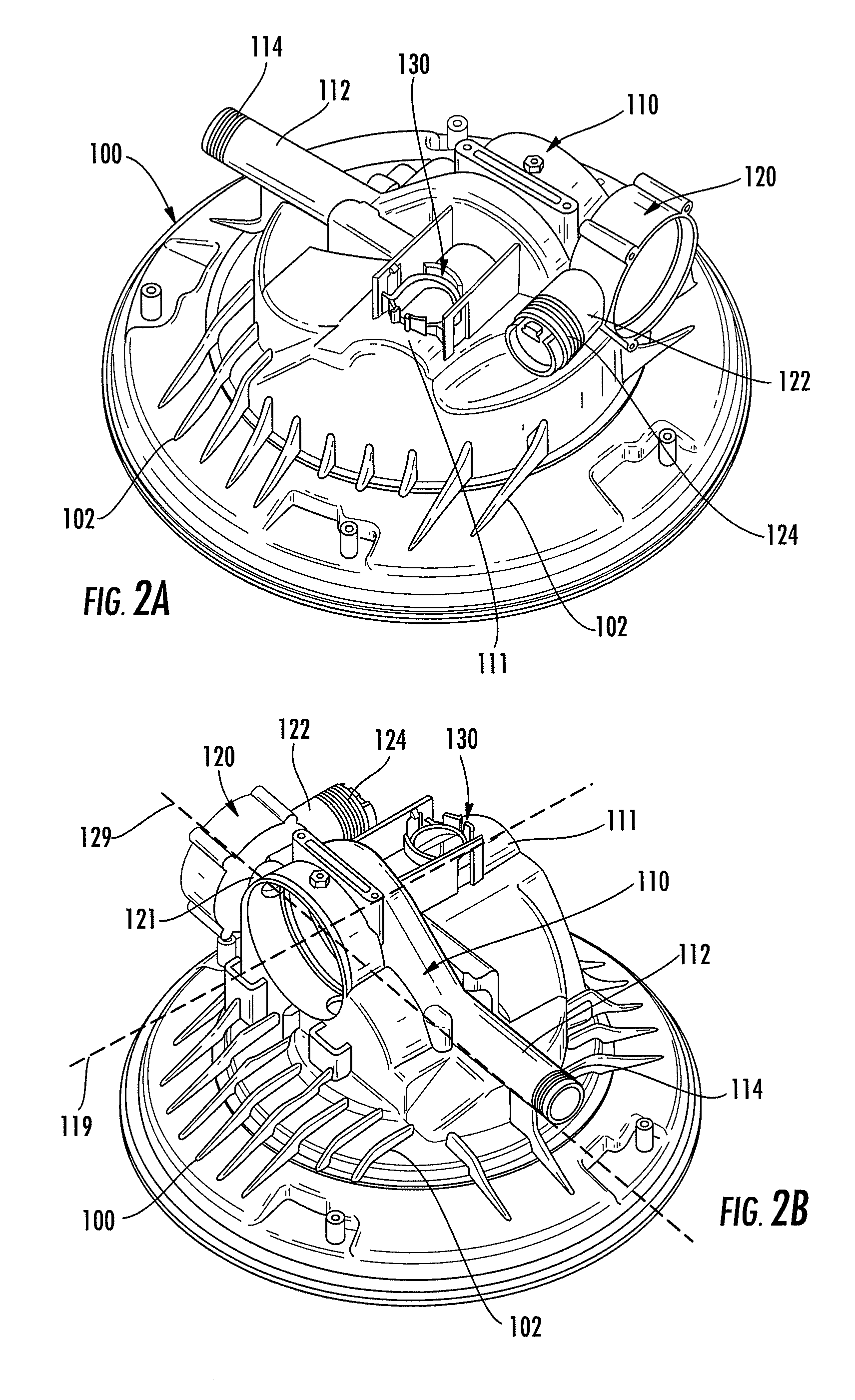

Sump assembly for a dishwasher, and associated method

ActiveUS20100012159A1Tableware washing/rinsing machine detailsElectrostatic cleaningHorizontal axisEngineering

A sump assembly for a dishwasher and associated method are provided. The sump assembly comprises an integrally-formed sump member defining a circulation pump volute receptacle and a drain pump volute receptacle. The circulation pump volute receptacle and the drain pump volute receptacle are adapted to receive respective pump and motor assemblies. Each of the volute receptacles is configured to receive the respective pump and motor assembly along a respective horizontal axis defined thereby. The drain pump volute receptacle includes a washing fluid input in direct communication with the circulation pump volute receptacle for receiving the washing fluid therefrom.

Owner:ELECTROLUX HOME PROD CORP NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com