Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1219 results about "Fuel filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fuel filter is a filter in the fuel line that screens out dirt and rust particles from the fuel, normally made into cartridges containing a filter paper. They are found in most internal combustion engines.

Fuel filter including slow release additive

This invention relates to a fuel filter for use with internal combustion engines. The fuel filter includes a fuel additive that can be released into fuel. The rate of release for the fuel can be controlled. In one form the fuel additive can be mixed with a matrix material and released at a substantially constant rate to maintain a uniform level of fuel additive in the fuel. Use of the present invention provides a fuel filter having an extended life span that is longer than fuel filters typically used with combustion engines.

Owner:DOBER CHEMICAL CORPORATION +1

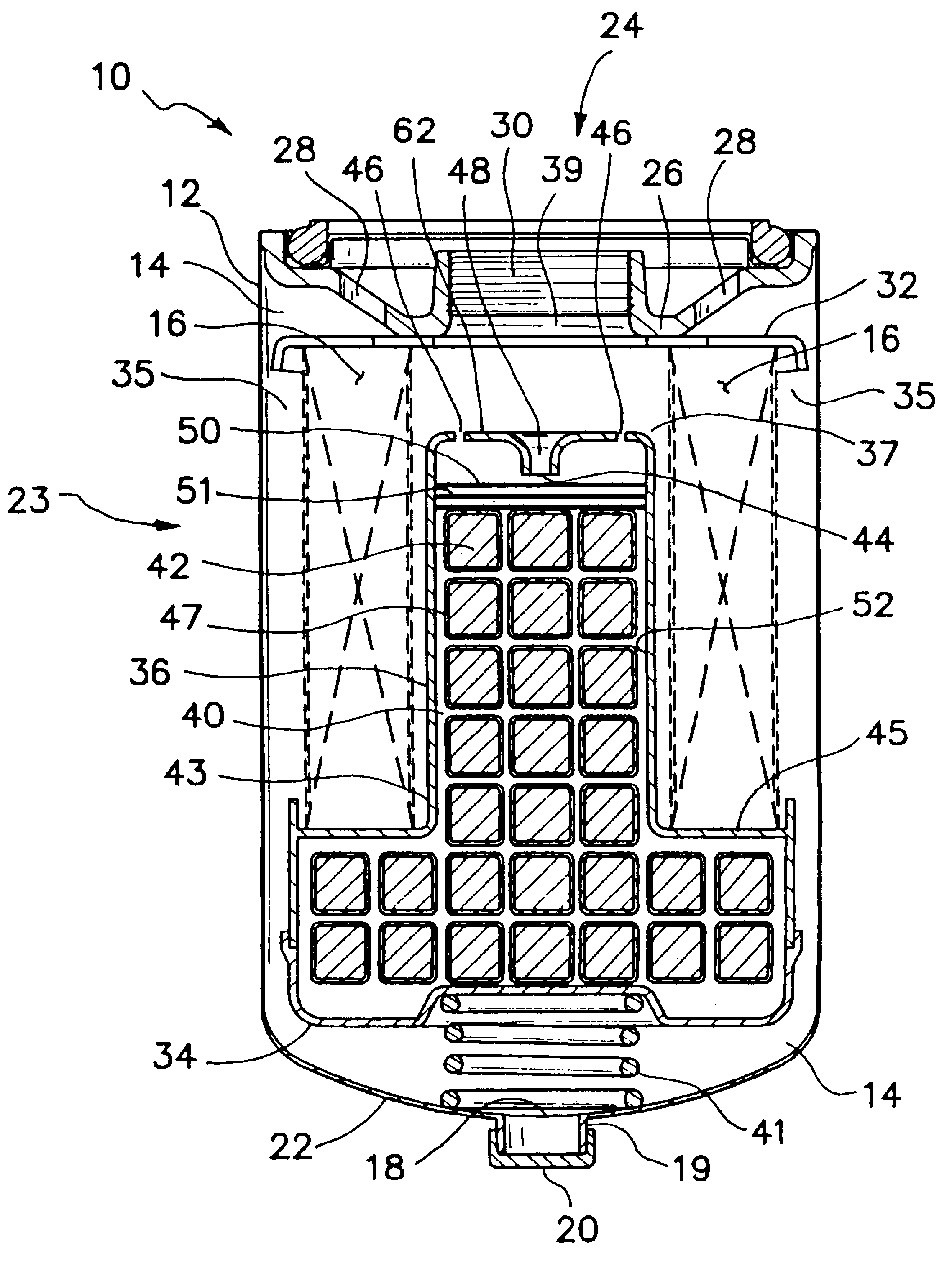

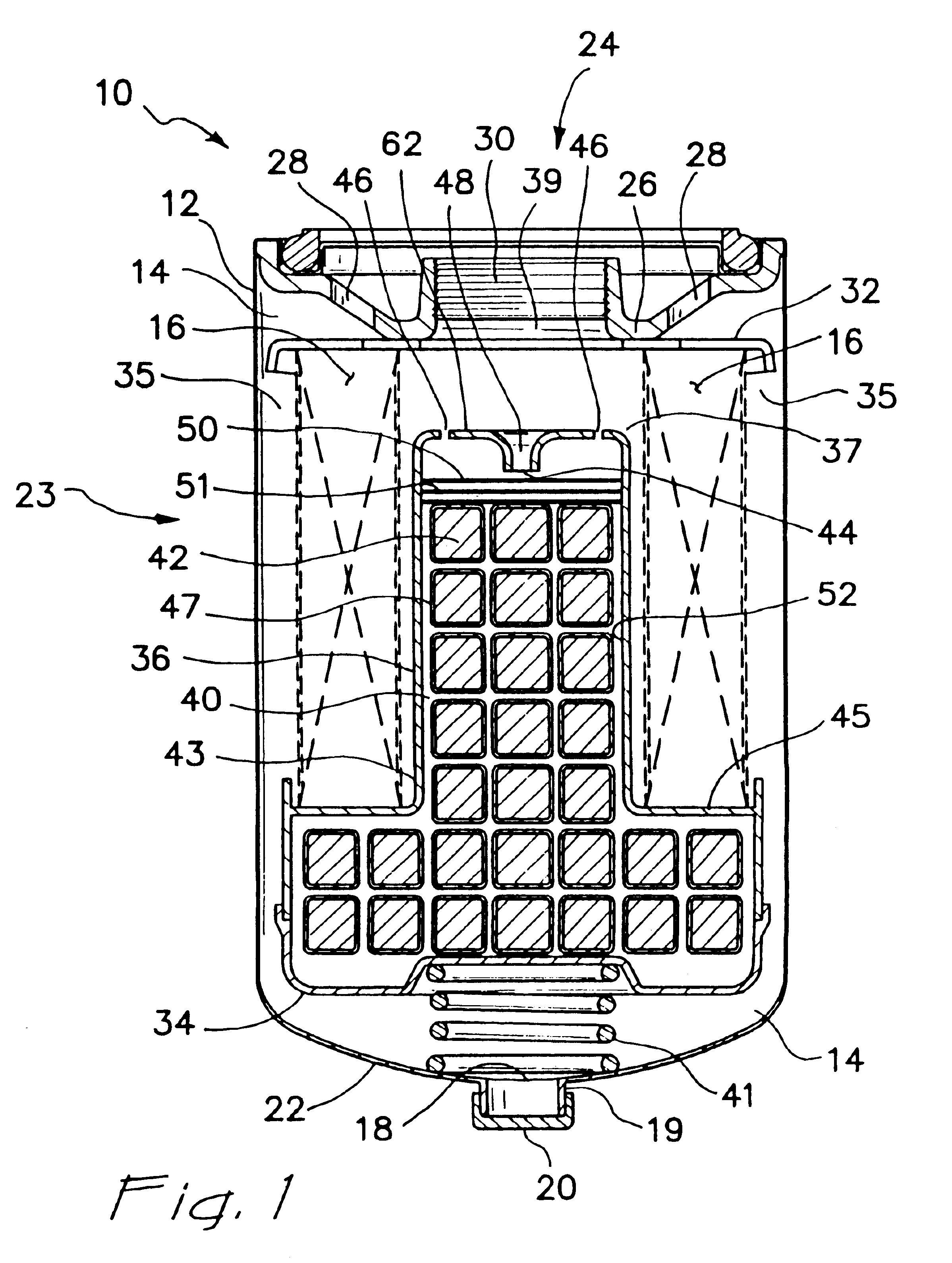

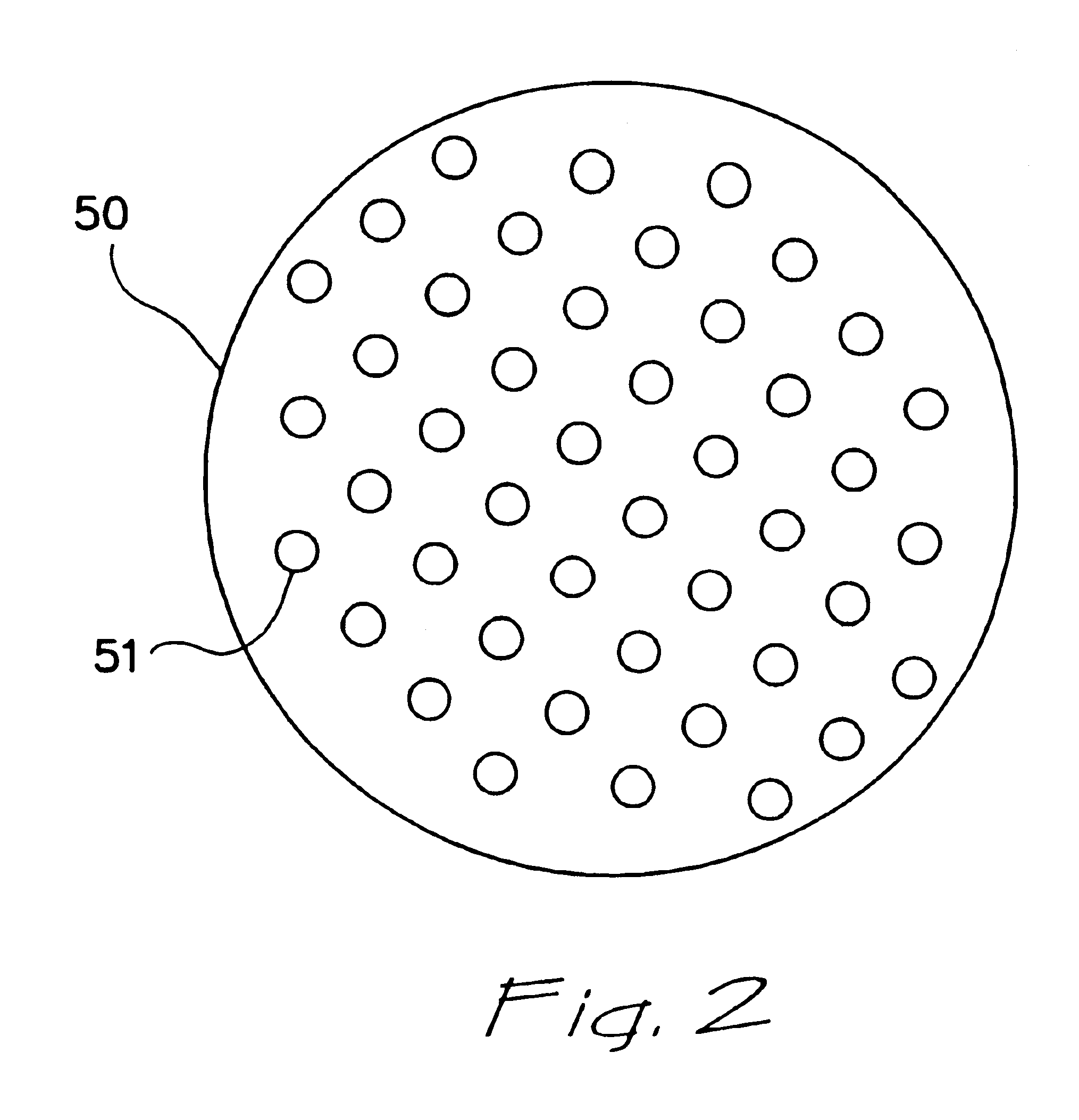

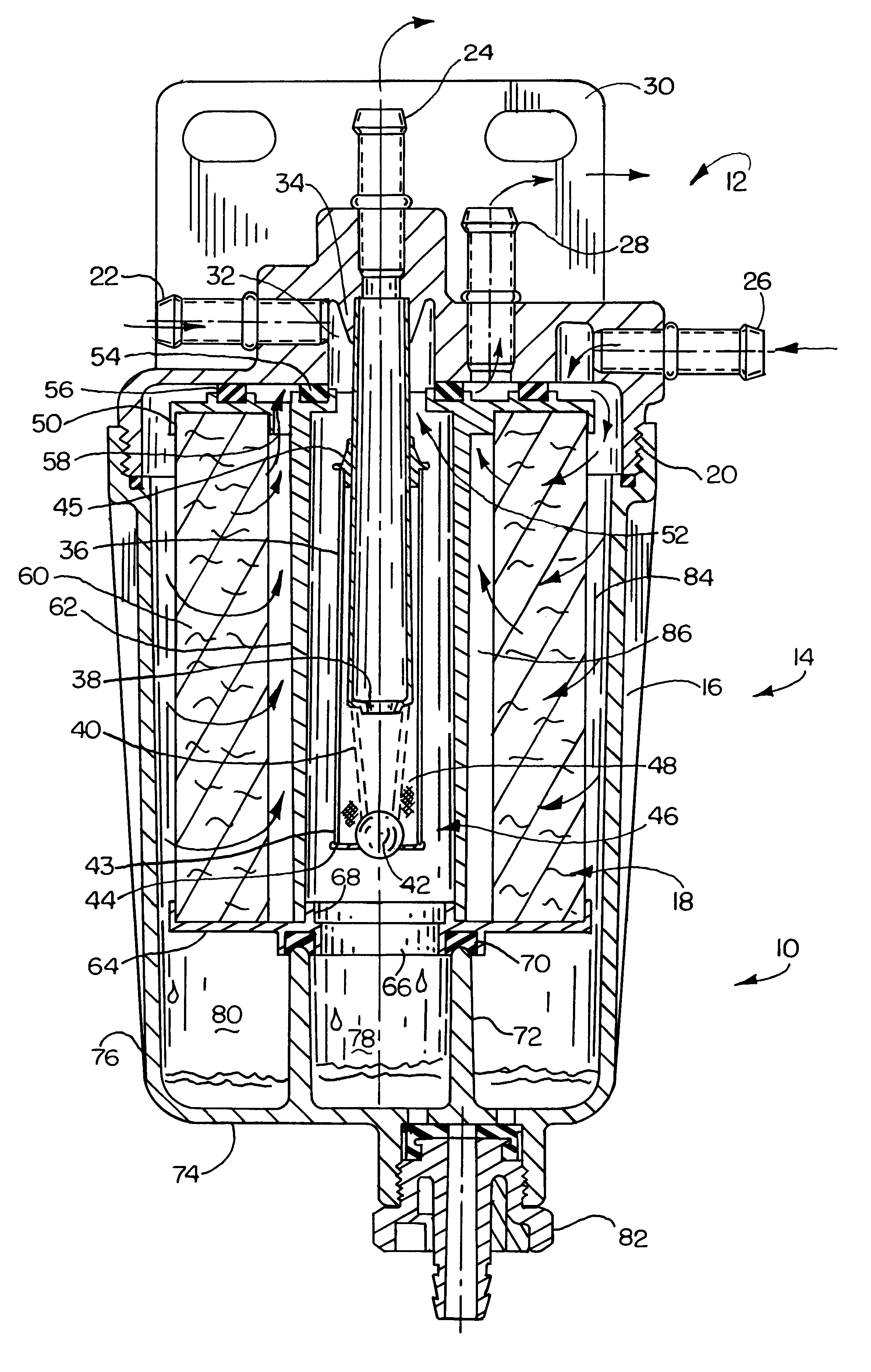

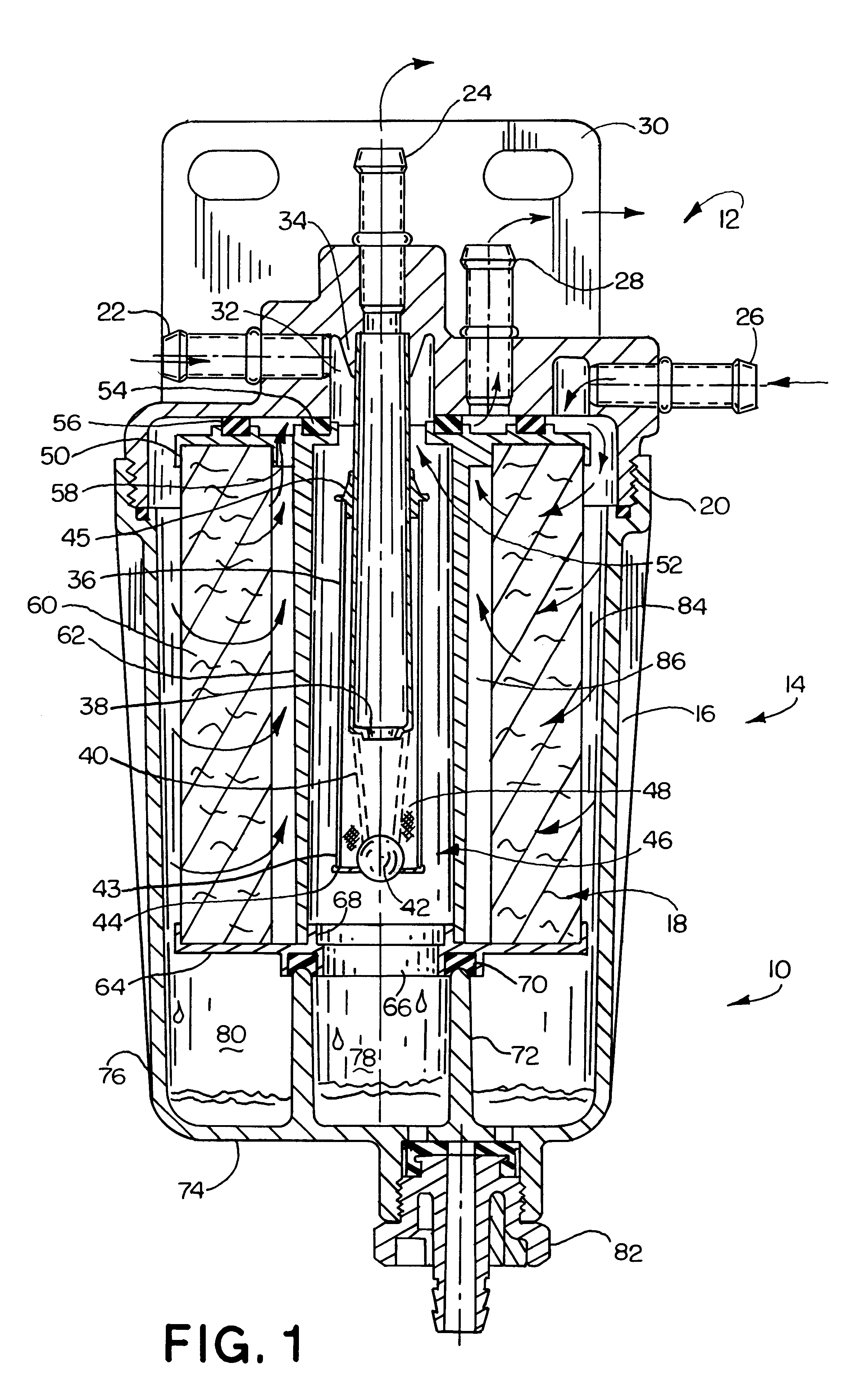

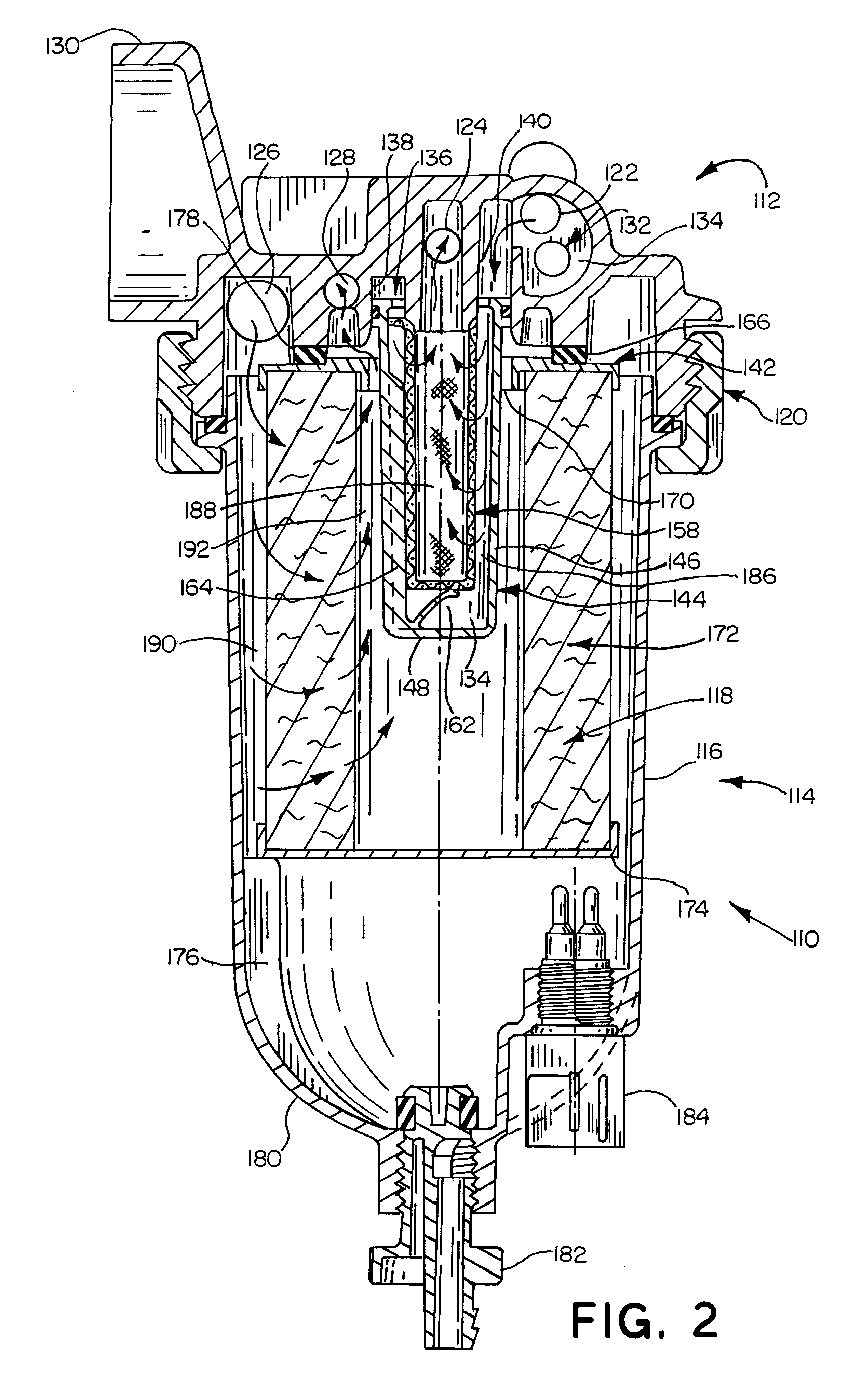

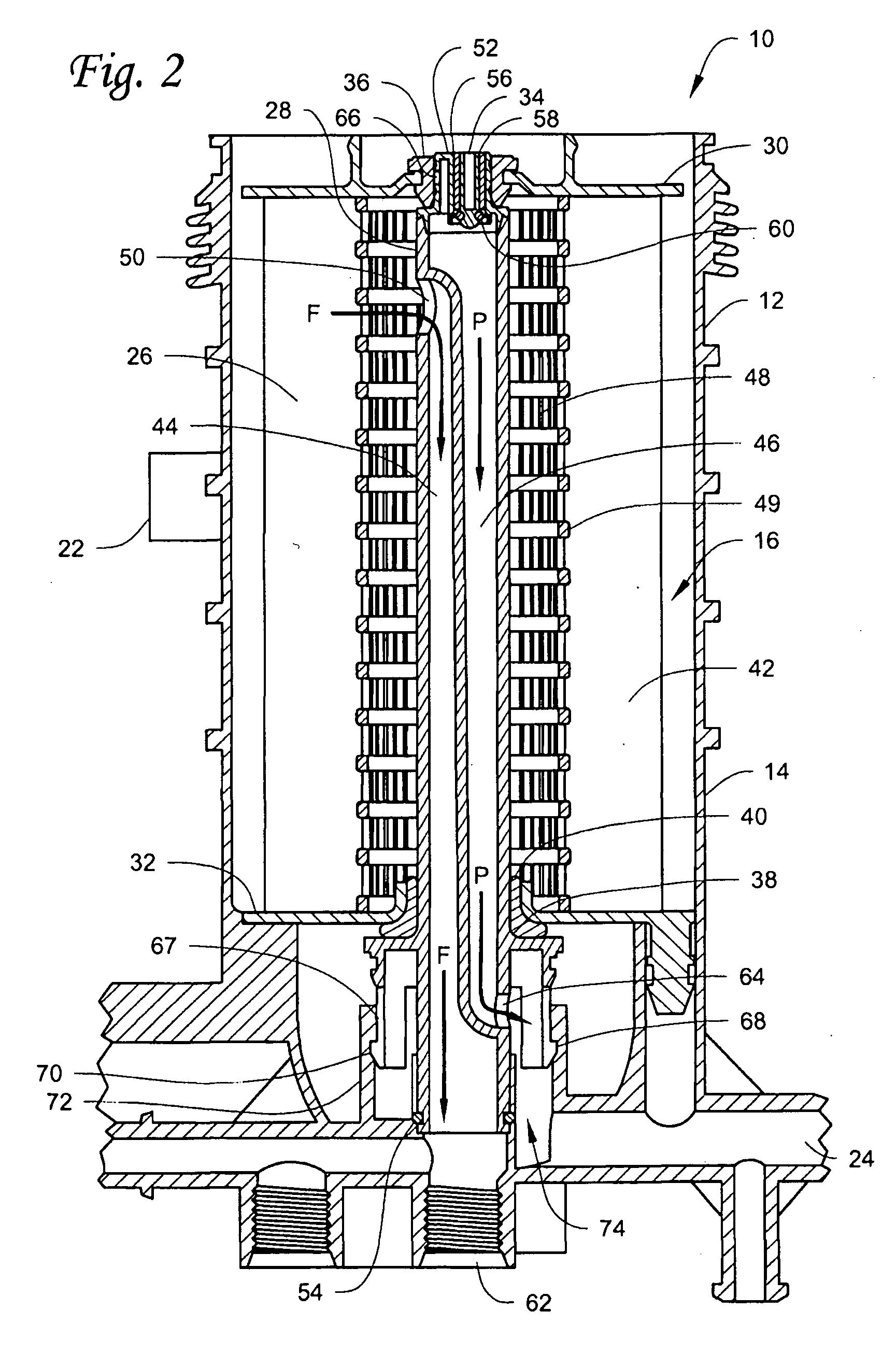

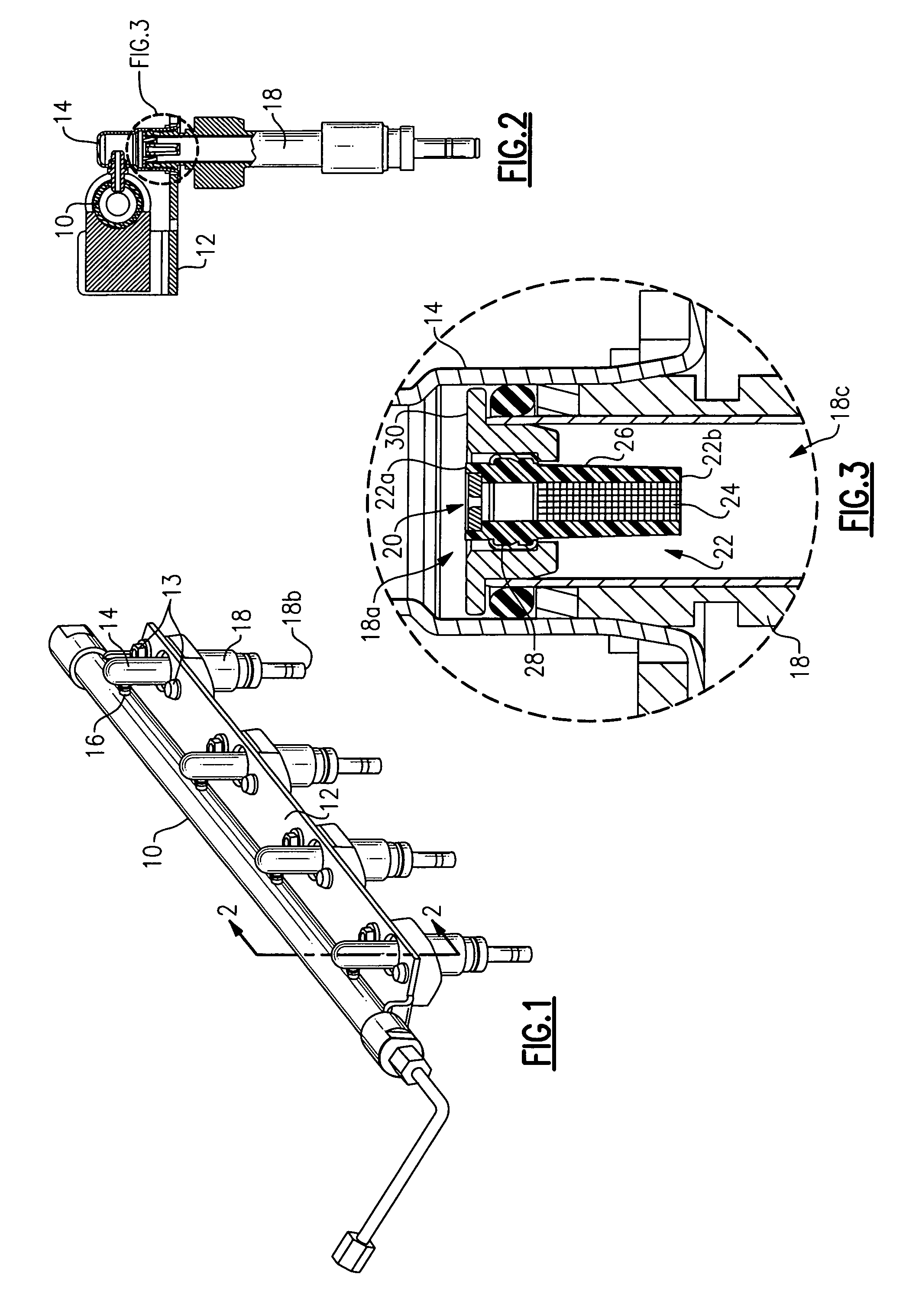

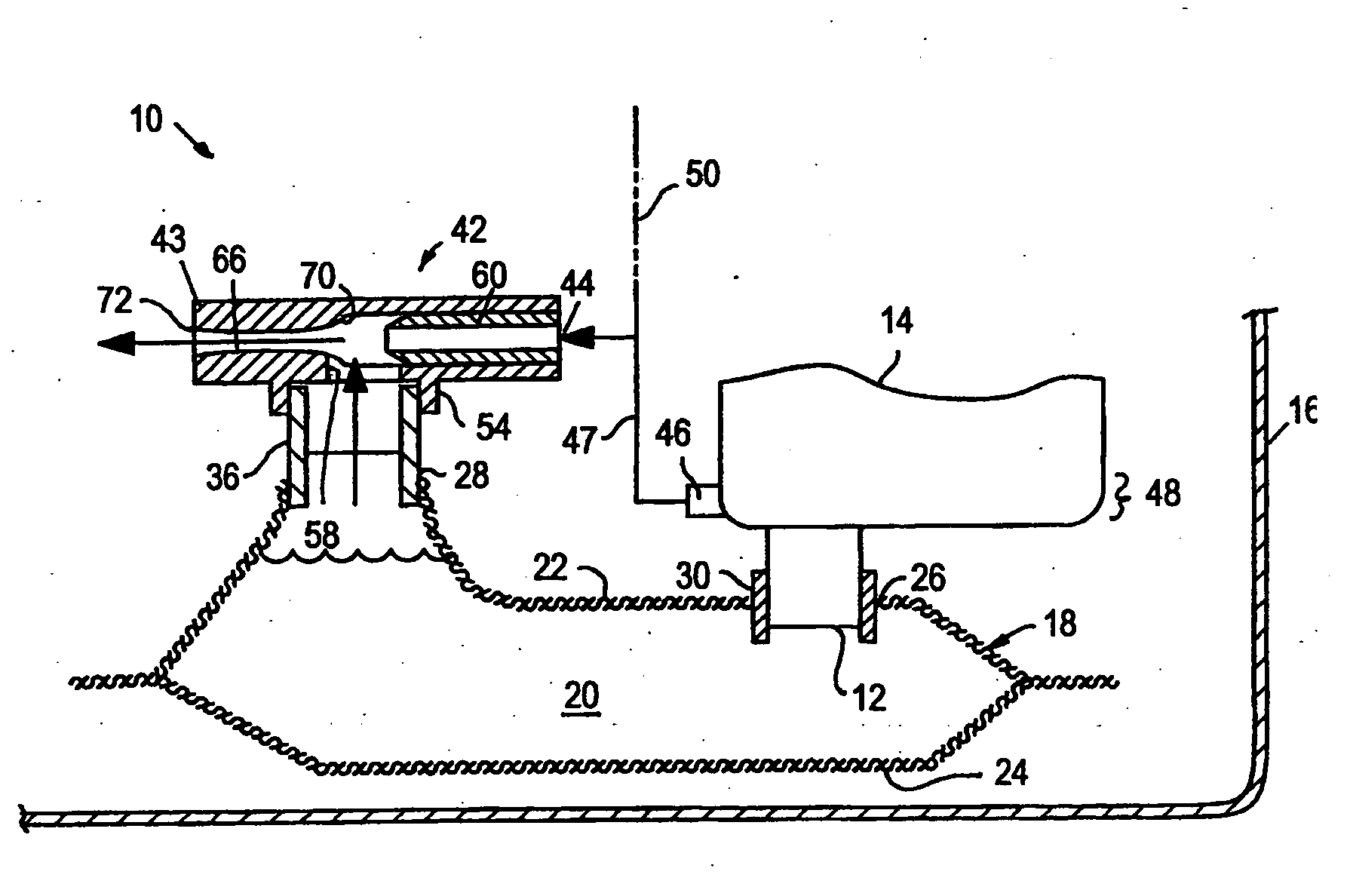

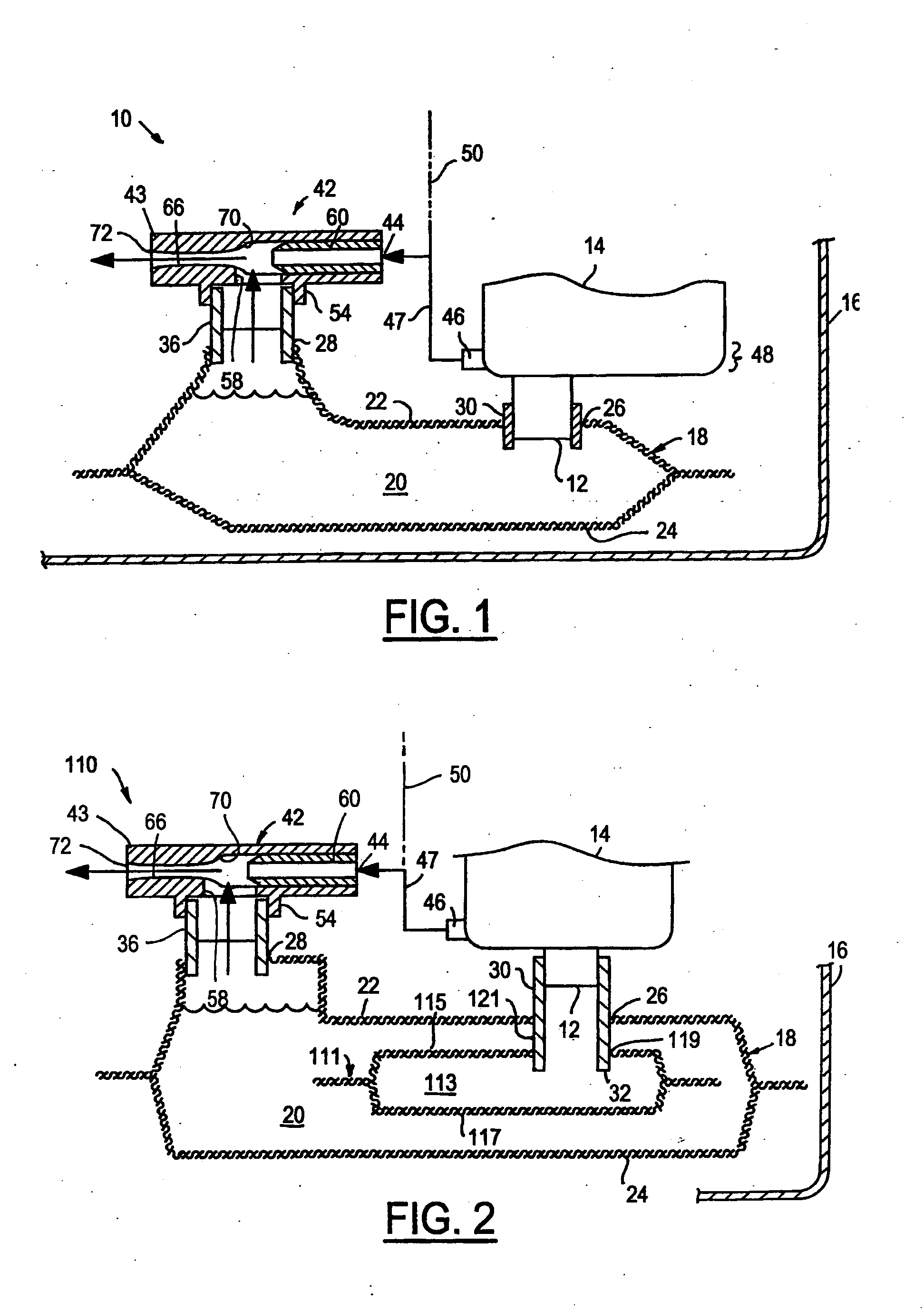

Double pass fuel filter assembly

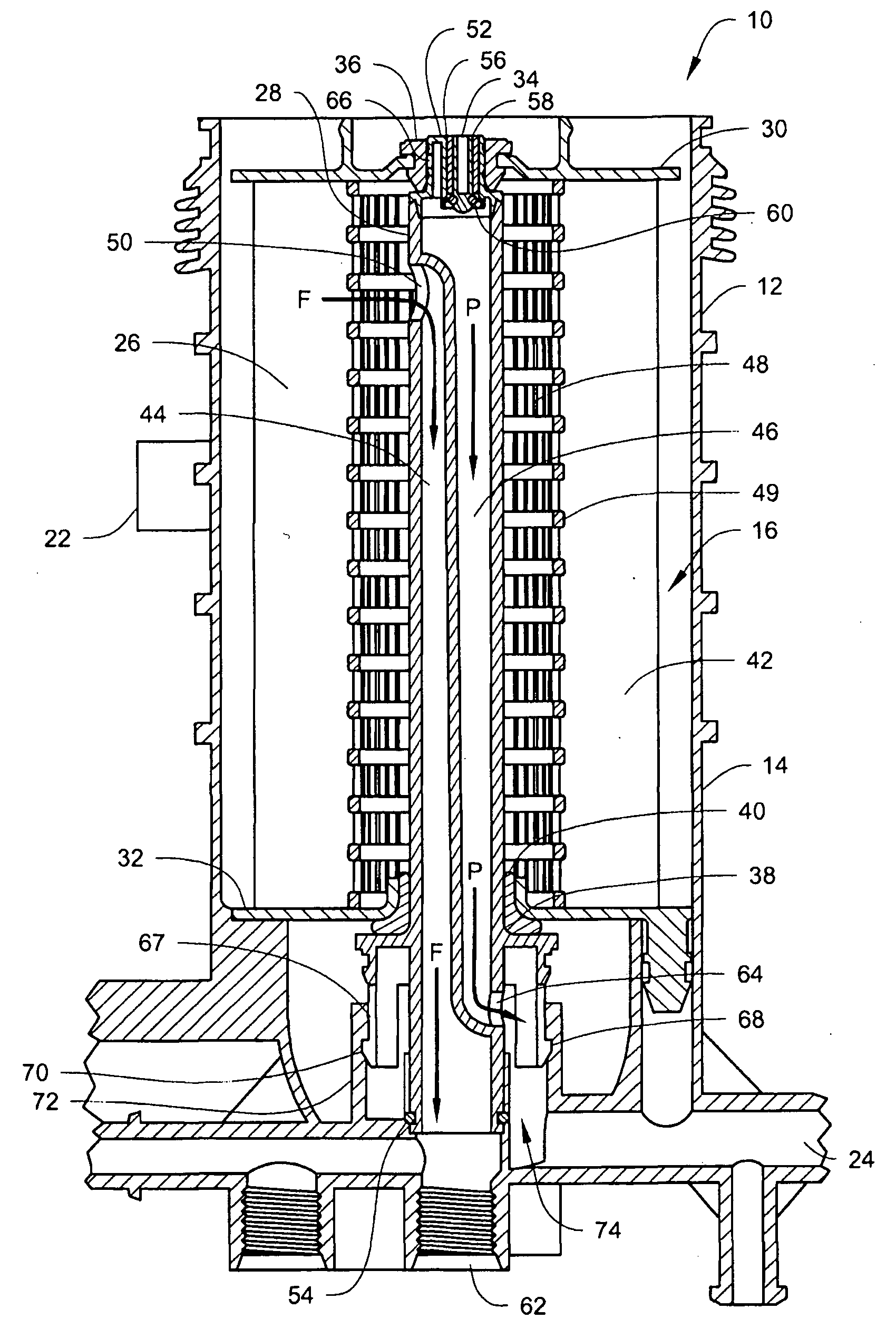

InactiveUS6248236B1Improve filtering effectMembrane filtersLoose filtering material filtersFilter mediaFuel filter

A fuel filter assembly (10) has a head portion (12) and an element portion (14) enclosing a replaceable cartridge (18). The assembly has a first inlet port (22) which accepts fuel from a tank (90) and filters it by passage through a screen (43) supported on a tube (36). The fuel that has been filtered by passage through the screen is delivered from the assembly through a first outlet port (24) for delivery to a lift pump (96). Fuel from the lift pump is returned to the fuel filter assembly through a second inlet port (26). The fuel is finely filtered by passage through a loop of filter media (60). Clean fuel is delivered from a second outlet port (28) to an engine (104). Contaminants separated from the fuel by passage through the screen and the media loop are collected in first-and second sump areas (78), (80) of the filter housing respectively. An alternative embodiment (110) includes a prefilter screen (158) integral with a replaceable cartridge (118).

Owner:PARKER INTANGIBLES LLC

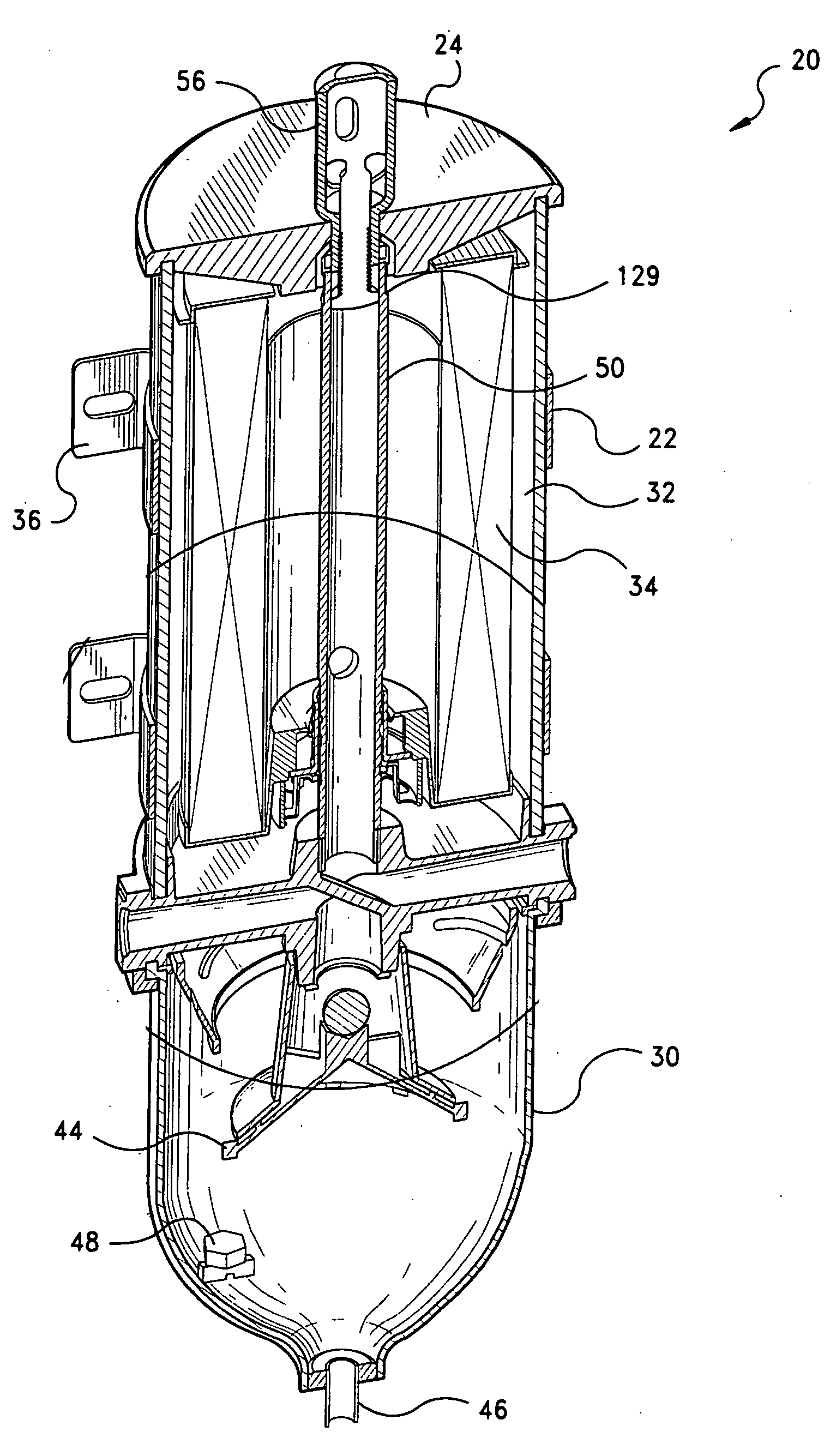

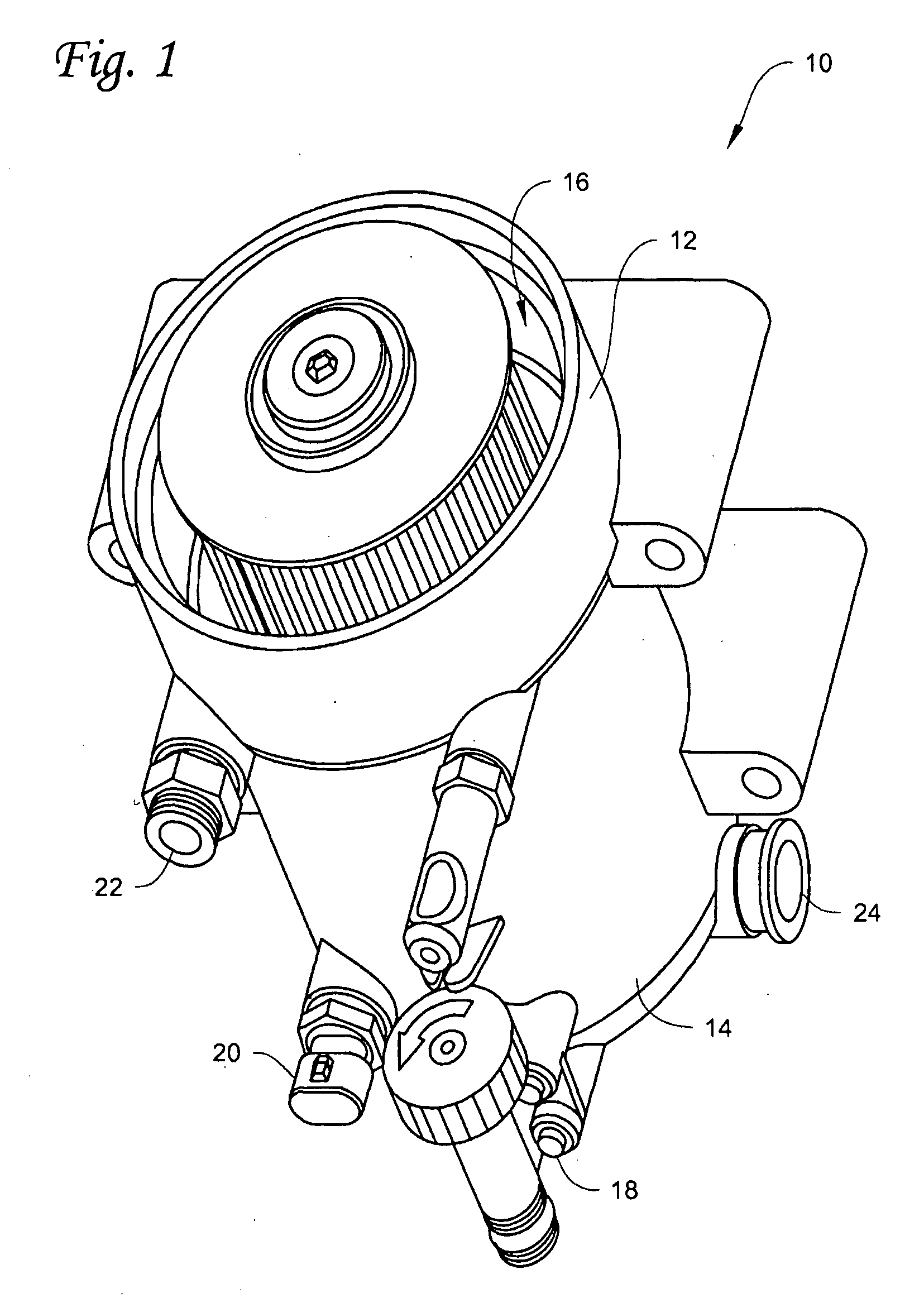

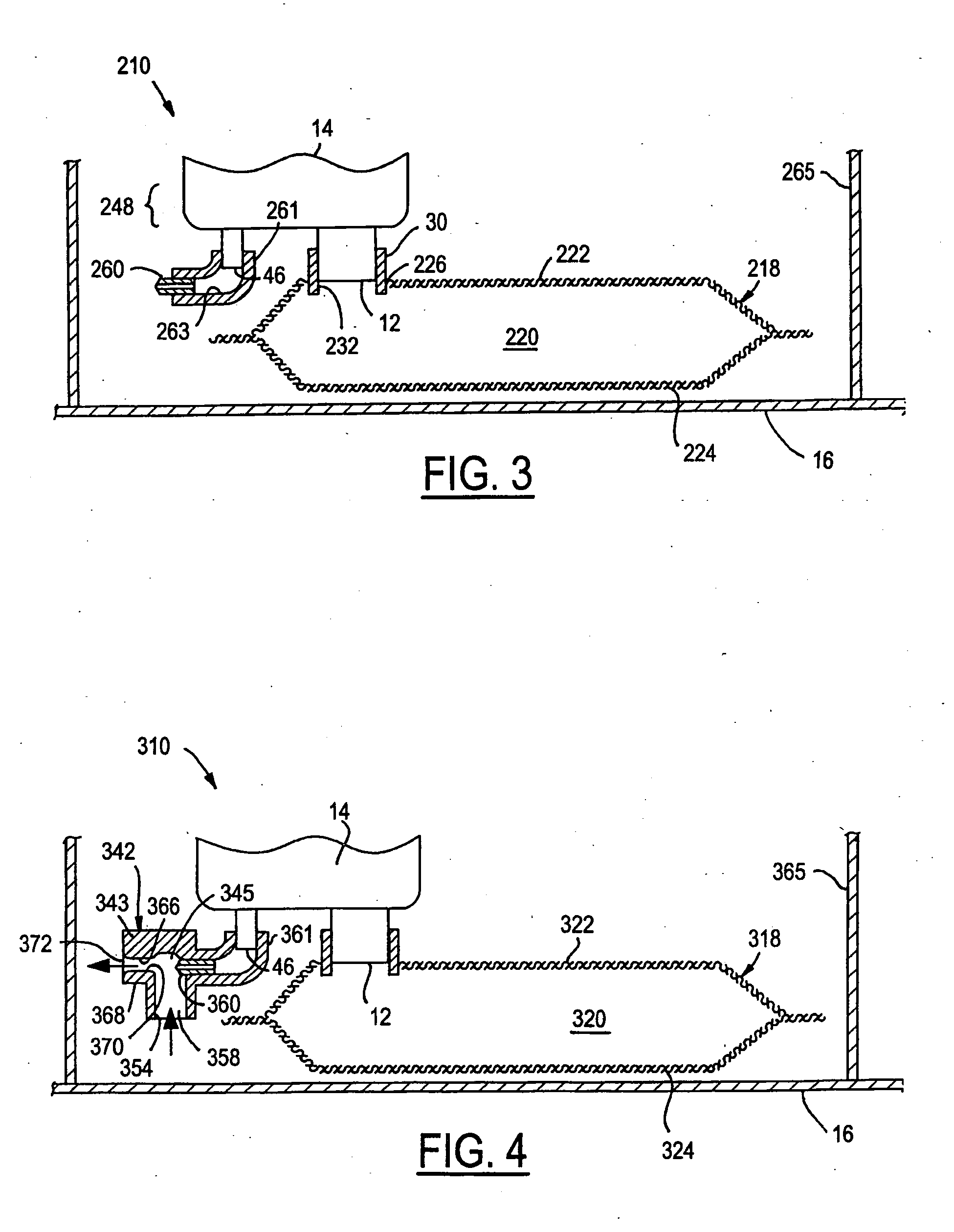

Fuel filter assembly with replaceable element

A fuel filter assembly includes a housing (12) with a removable element (24) mounted therein. The housing has an inlet port (14) in direct fluid communication with a chamber (18). The outlet port (16) is in direct fluid communication with a central standpipe (22). The standpipe has a flow element (42) movable therein for controlling the condition of flow openings (36) in the standpipe. The element includes projections (88) for engaging recesses (90) in a cover (28) to selectively latch the element and cover together. The cover further includes a cover projection (82) for supporting a projection (78) on end cap (60) of the filter element, which opens flow into the standpipe only when the element is installed. When the element is removed, the flow element prevents the introduction of contaminants into the standpipe.

Owner:PARKER INTANGIBLES LLC

High efficiency fuel filter

InactiveUS20060277877A1Improve efficiencyImprove tear resistanceCombination devicesDispersed particle filtrationGlass fiberEpoxy

Provided is a composite fuel filter material which comprises (A) a support layer made of wet laid cellulose and / or synthetic fibers, (B) a barrier layer having wet laid glass fibers for providing increased efficiency to the filter material, (C) a thermosetting bonding agent dispersed through the composite and in an amount sufficient for bonding the composite into a strong, tear resistant and pleatable material, and (D) a water repellant agent dispersed in the composite for removing and coalescing water dispersed in a fuel to be filtered. In a preferred embodiment for a diesel fuel filter, the glass fibers have an average diameter of about 0.1 to 2.0 microns and the thermosetting bonding agent is an epoxy resin in the composite in an amount of between 1 and 5% by weight. A filter efficiency of at least 90% or even 99% can be achieved, along with a water removal of 90 to 99.9%. Preferably, the barrier layer has a small amount of synthetic fibers therein and an interface between the support layer and the barrier layer is mechanically interlocked.

Owner:LYDALL INC

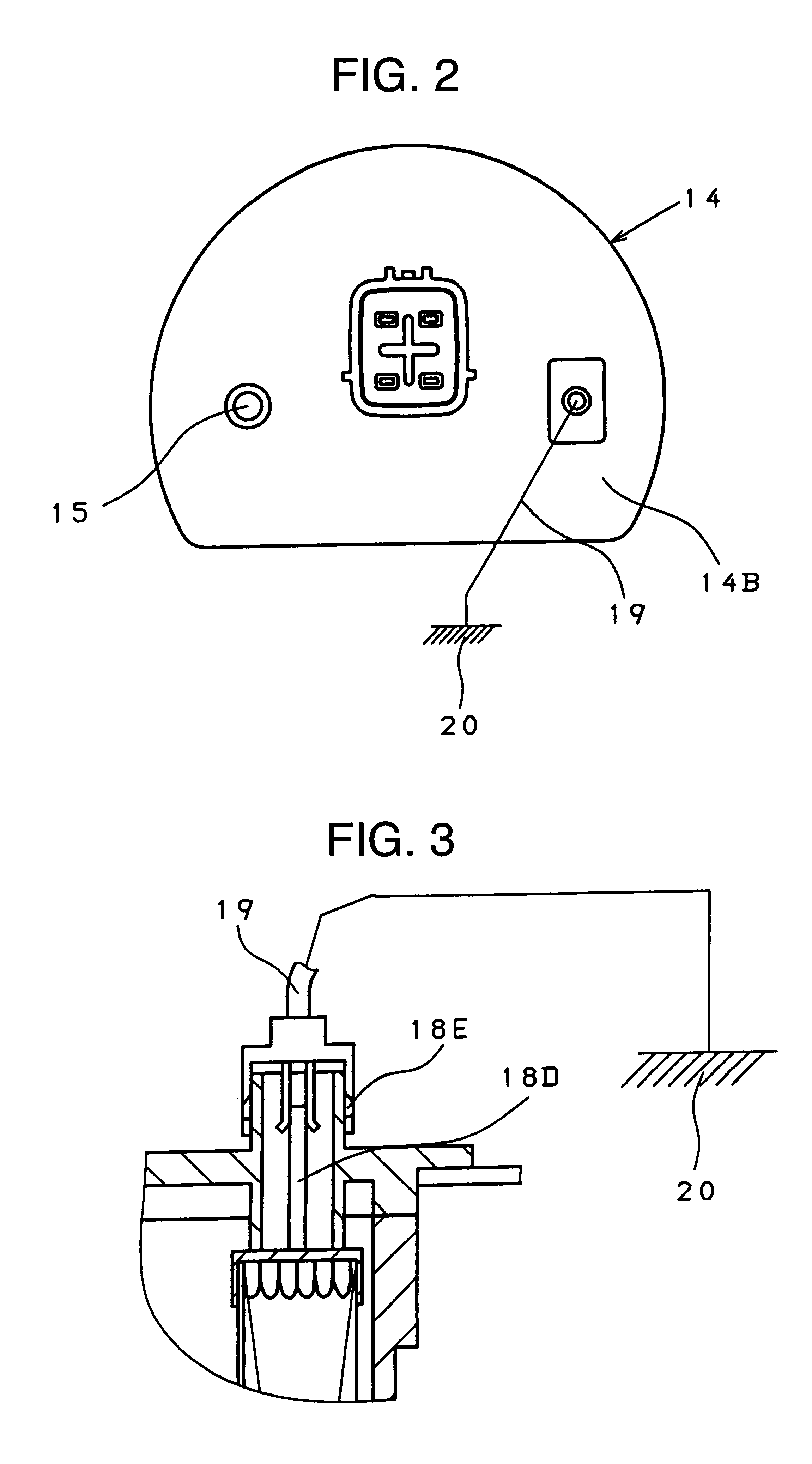

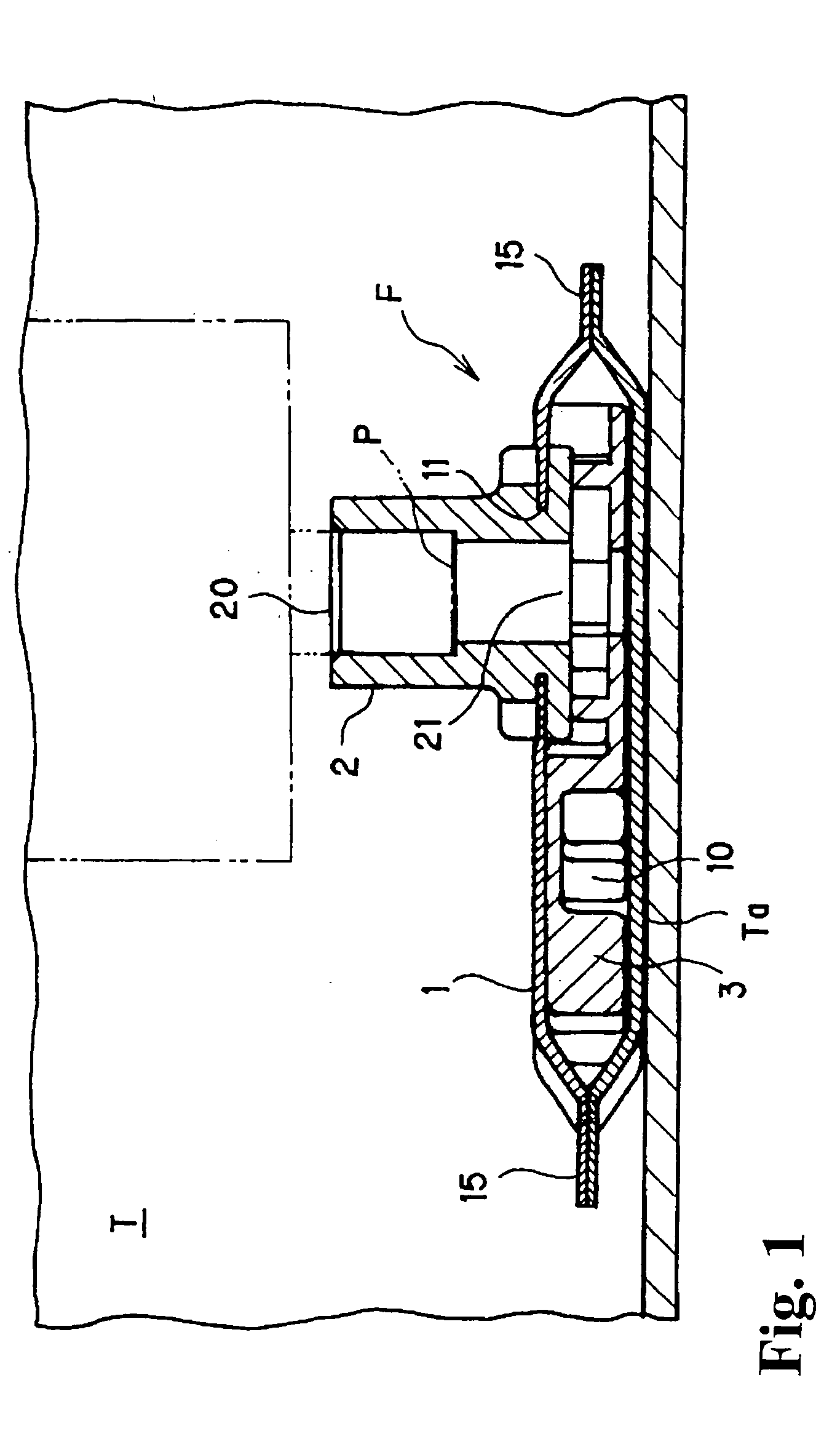

Electrostatic charge removing apparatus

An electrostatic charge removing apparatus in a fuel filter is capable of reliably removing electrostatic charge generated in a fuel filter and of reducing cost and weight of the fuel filter by escaping or discharging the electrostatic charge from parts of the fuel filter other than a case of the fuel filter. The fuel filter includes a filter portion that is connected to an outlet of a fuel pump disposed in a fuel tank and is clamped by end plates, a case housing the filter portion therein, wherein the end plates are formed of a conductive material, and a projection that penetrates a cap is formed on one end plate and is grounded.

Owner:KYOSAN DENKI KABUSHIKI KAISHA +1

Housing for environmentally friendly filter cartridge

InactiveUS7182864B2Reduced strengthDispersed particle filtrationMembrane filtersFilter systemFuel filter

A filter system in which a housing and an environmentally friendly filter cartridge are coordinated to provide ease of change of the filter cartridge and reliable operation. The cartridge contains no metal parts and is readily incinerateable. The housing is provided with a number of “universality” features including a changeable bottom which allows the housing to operate as a fuel filter, a lubrication filter, or a hydraulic filter in different applications. The housing and cartridge are configured to provide support for the plastic elements of the cartridge to prevent crushing of the filter under normal and abnormal filter operating conditions. A key system associated with the cartridge and the housing provides assurance that the correct filter is installed for a particular application.

Owner:BALDWIN FILTERS

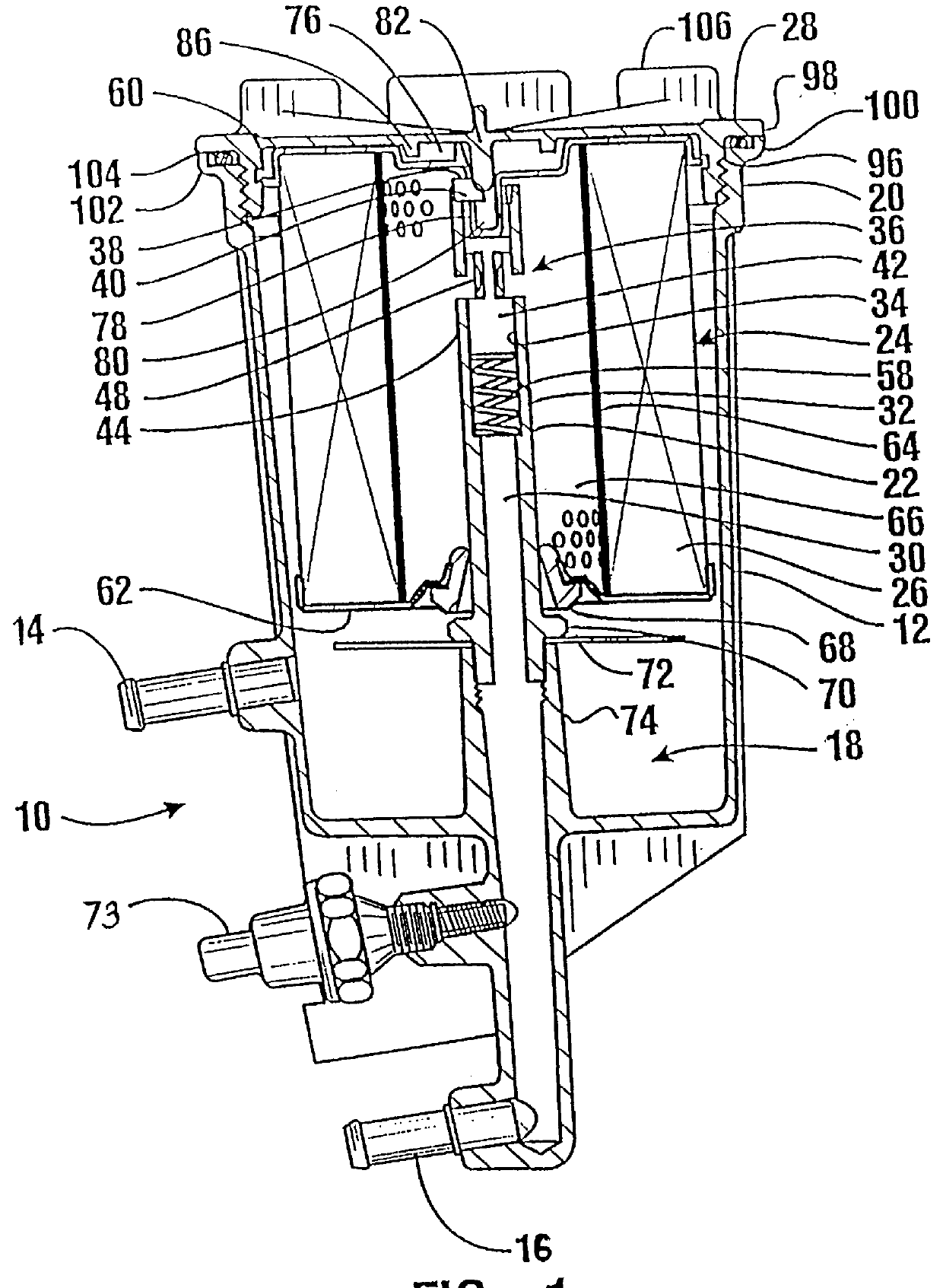

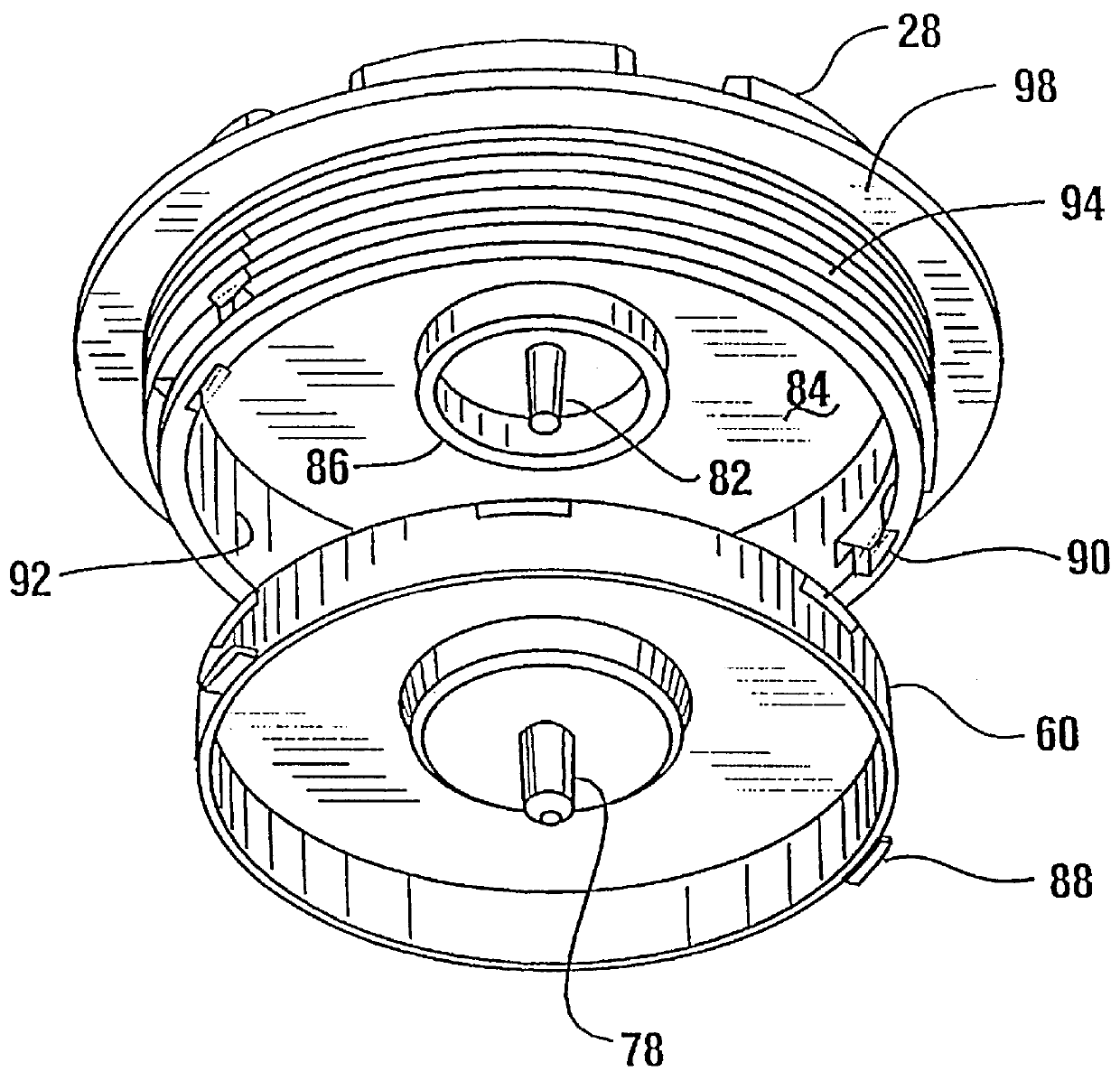

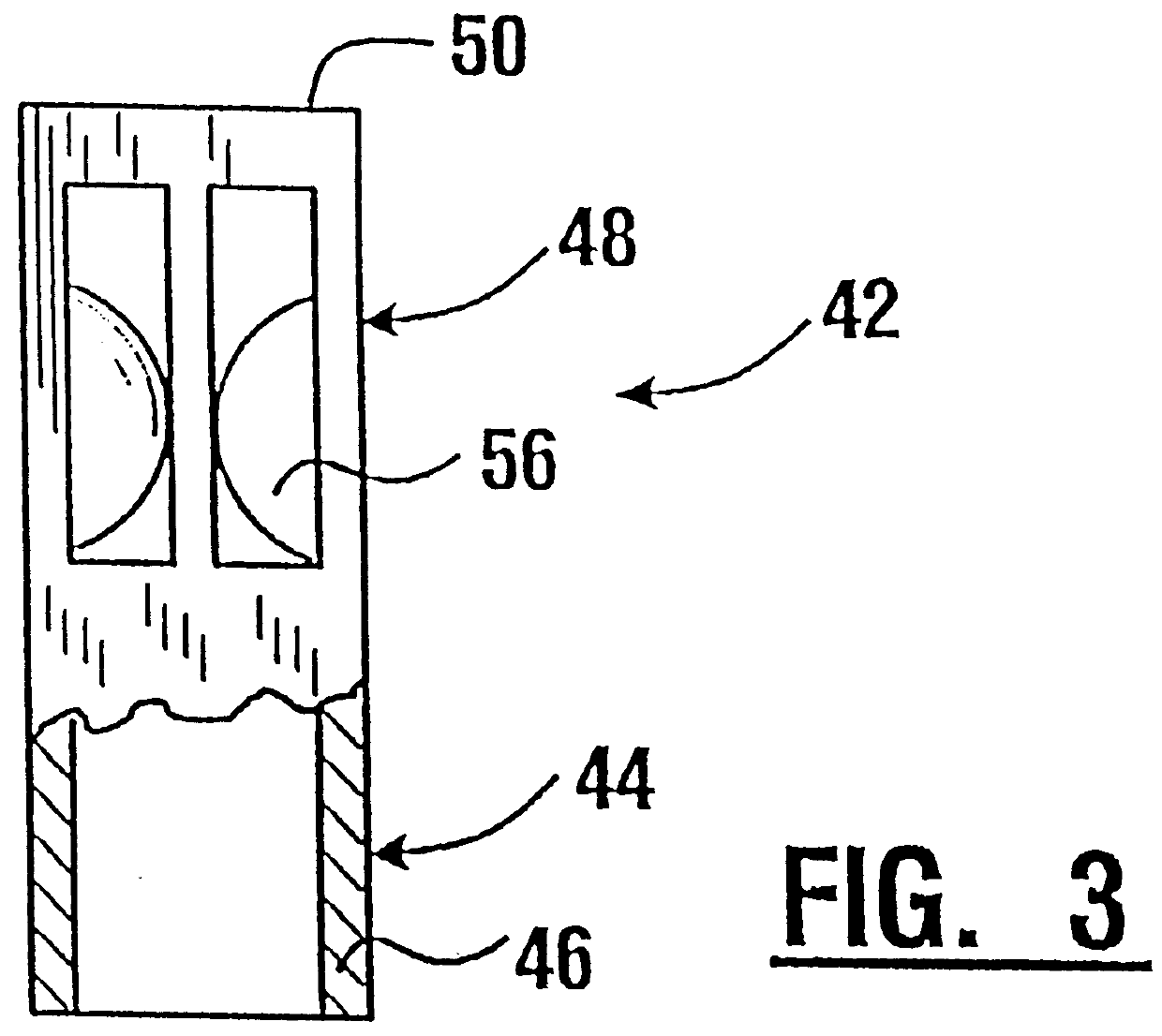

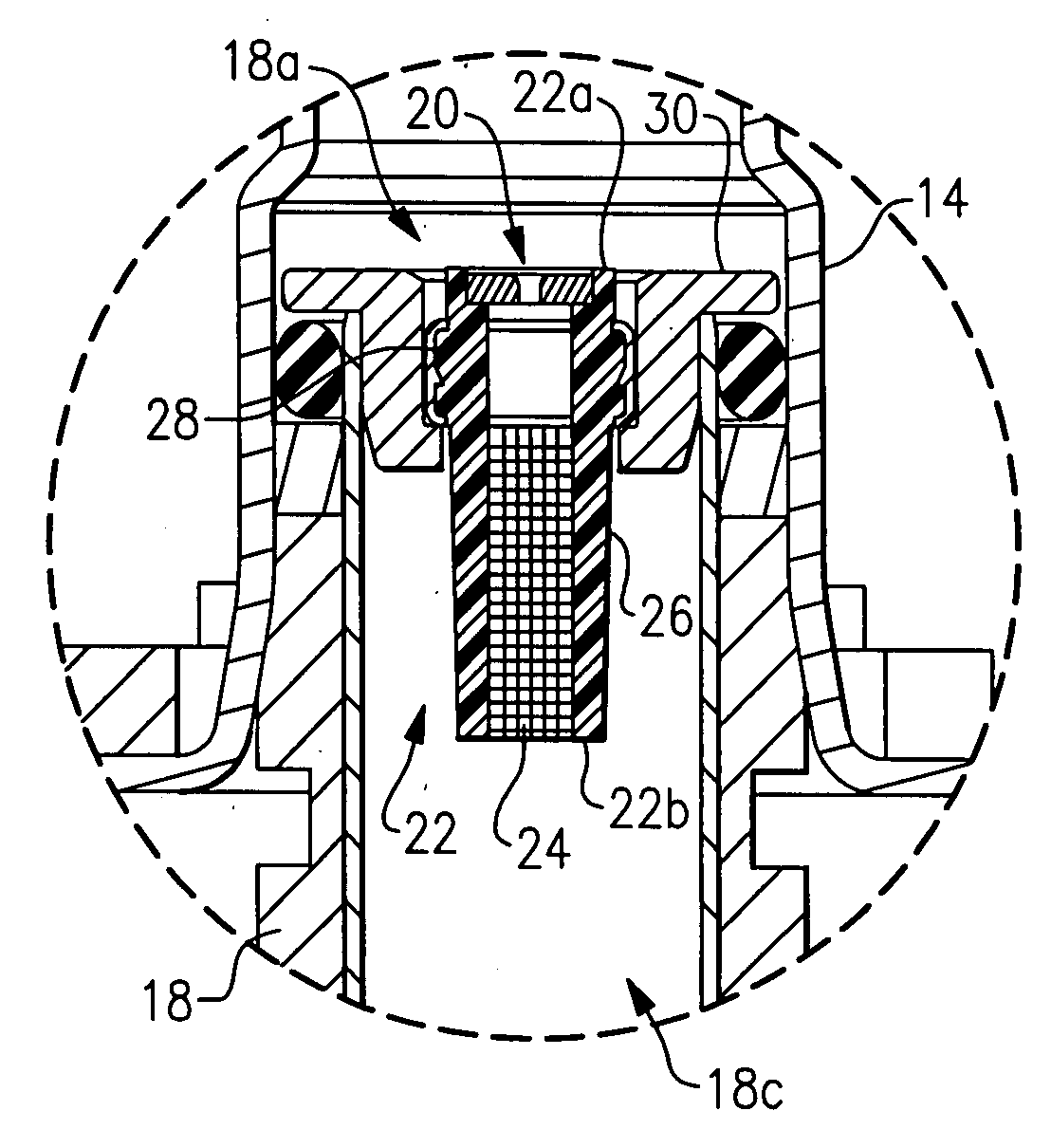

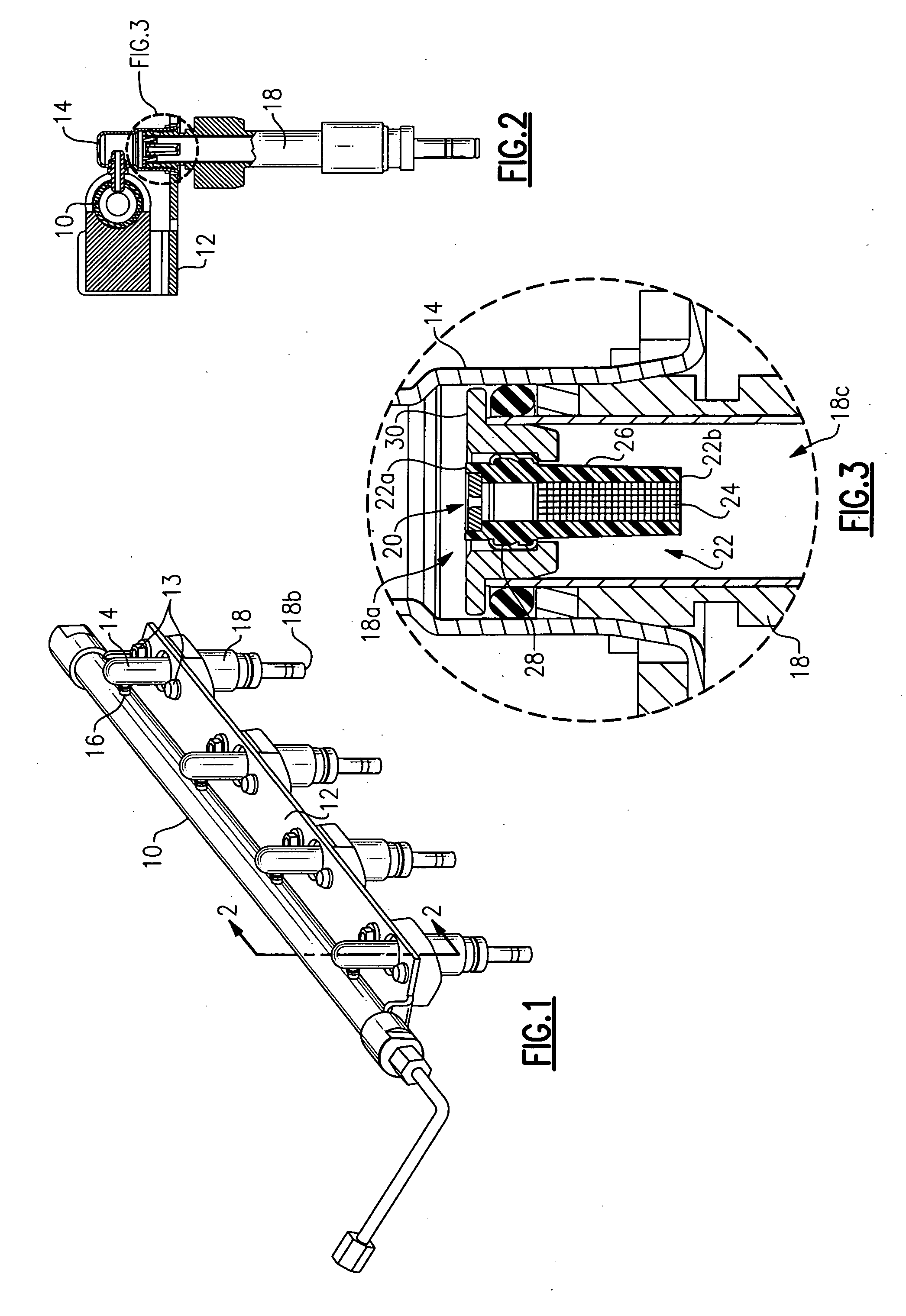

Keyed latch valve for fuel filter

InactiveUS20050000876A1Avoid passingEasy to assembleSettling tanks feed/dischargeMembrane filtersFuel filterVALVE PORT

A fuel filter includes mating housing portions defining an interior cavity. A pipe in the housing includes a central flow passage with an opening along the length of the pipe, and an exterior groove. A latch device with discrete fingers closely surrounds the pipe and is engageable with the groove to prevent the latch device (68) from moving axially along the pipe. The latch device has an annular sleeve, radially-outwardly spaced from the fingers. A moveable valve device surrounds the pipe and has a valve sleeve normally covering the opening in the pipe. An annular base on the sleeve includes radially projecting tabs defining a plurality of slots. A filter element is removeably located in the housing and has an end cap with a valve actuating portion. The valve actuating portion includes a cylindrical portion and an annular base projecting radially inward from the cylindrical portion. The valve actuating portion includes a plurality of thin, flat keys spaced around the annular base and projecting radially inward from the cylindrical portion and axially outward from the base. The keys have first portions which project through the slots in the valve device and engage the sleeve of the latch device to unlock the latch device from the pipe, and second portions which engage the base of the valve device and move the valve device to uncover the opening in the pipe, when the filter element is inserted into the housing.

Owner:PARKER INTANGIBLES LLC

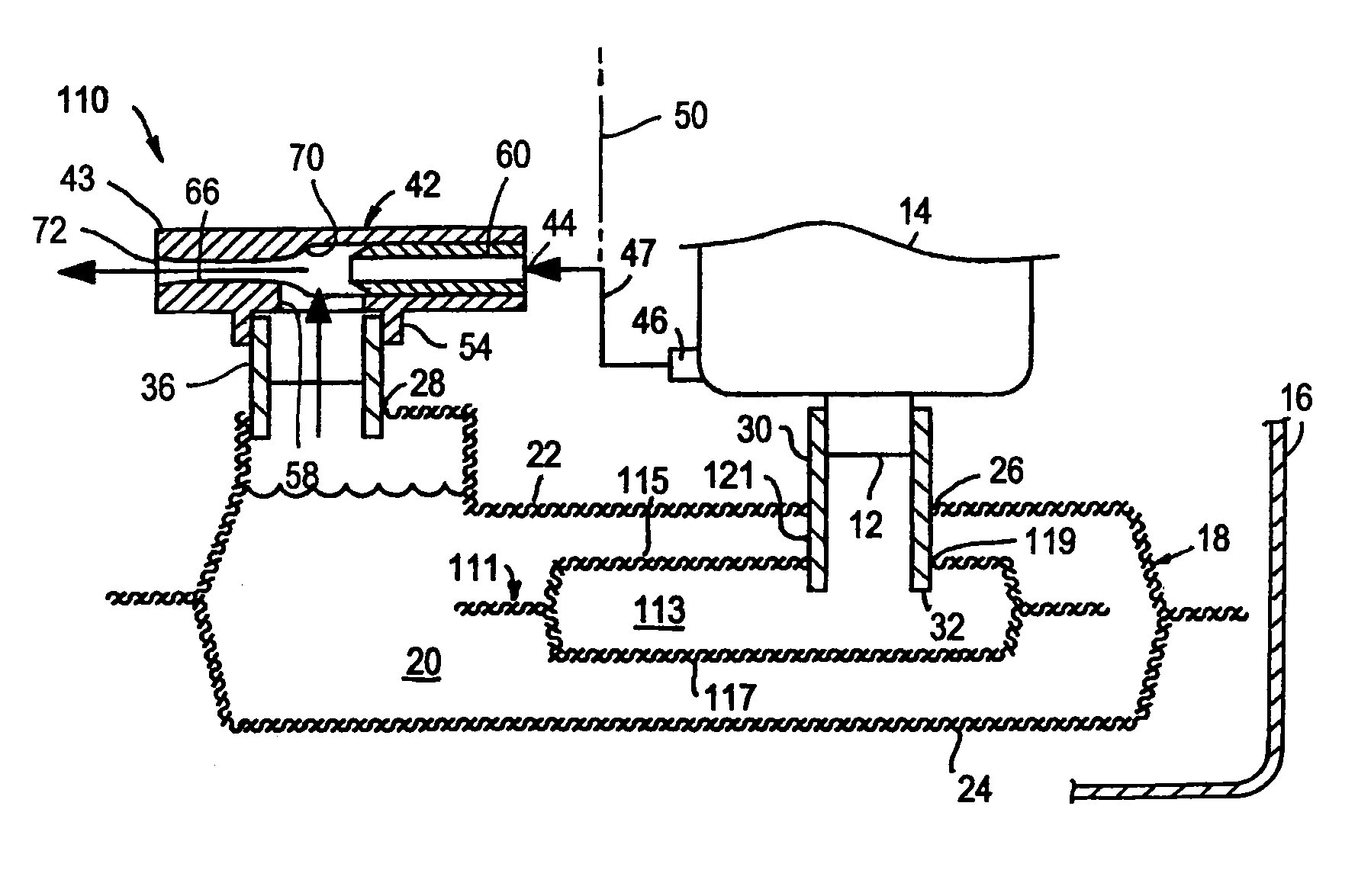

Method and apparatus for storing water separated from fuel

InactiveUS6893571B2Solve insufficient storage capacityEasy to disassembleInternal combustion piston enginesIon-exchanger regenerationFuel filterEngineering

An apparatus for storing water separated from fuels by a fuel filter is provided. The apparatus includes an absorber connected to a water accumulator of the fuel filter. The stored water may then be released again through heating or pressure using commercially available components and supplied to a further use.

Owner:MANN HUMMEL GMBH

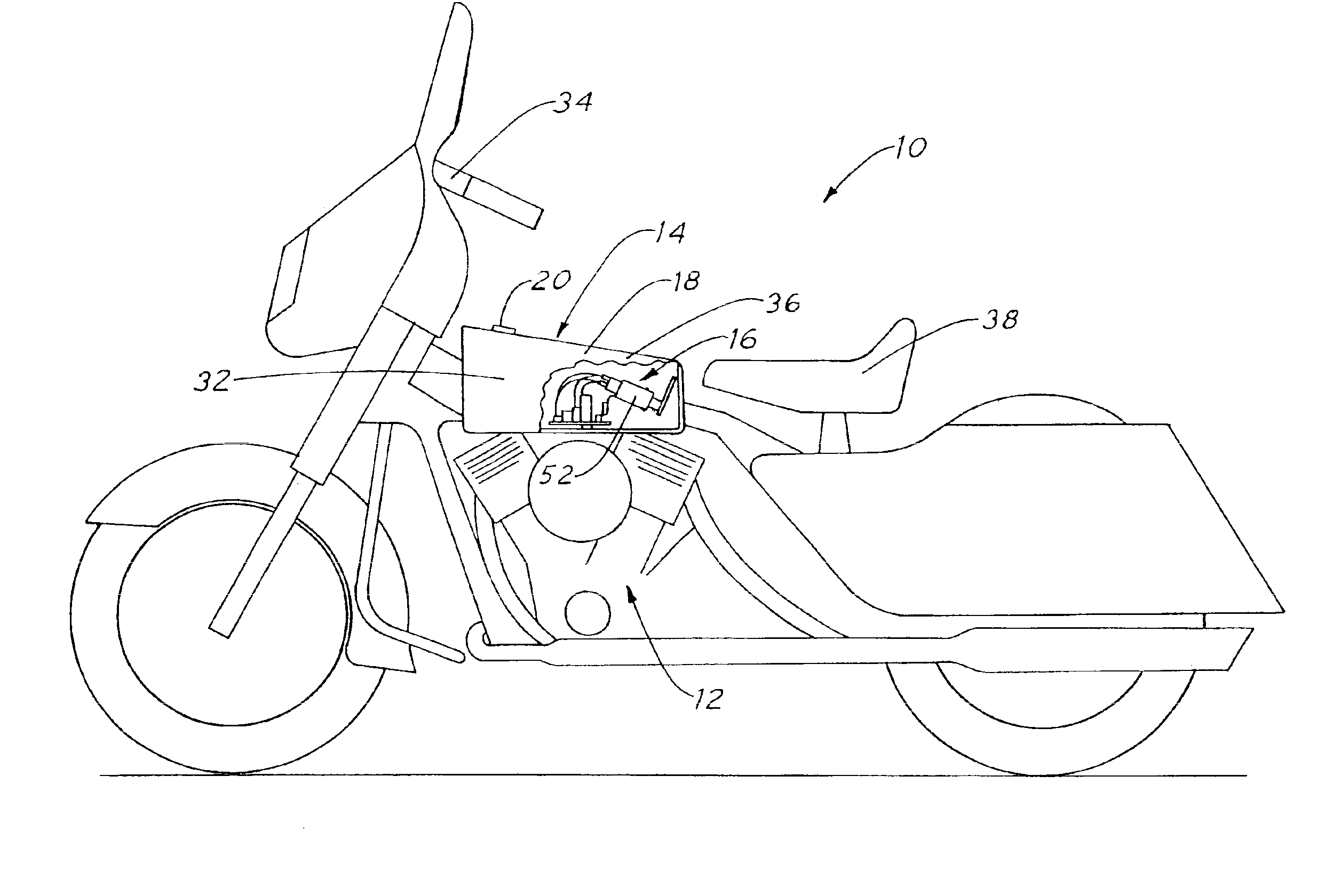

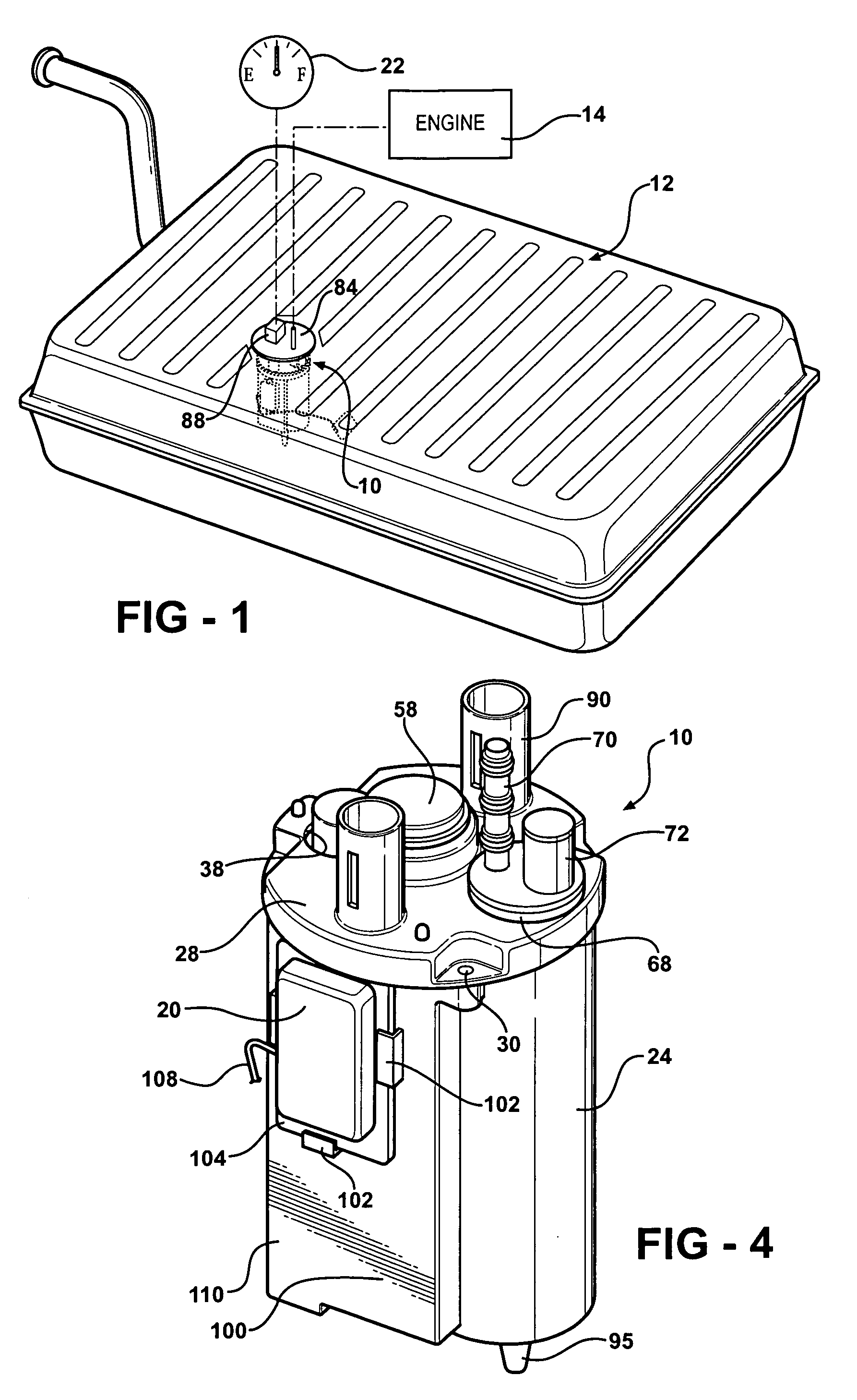

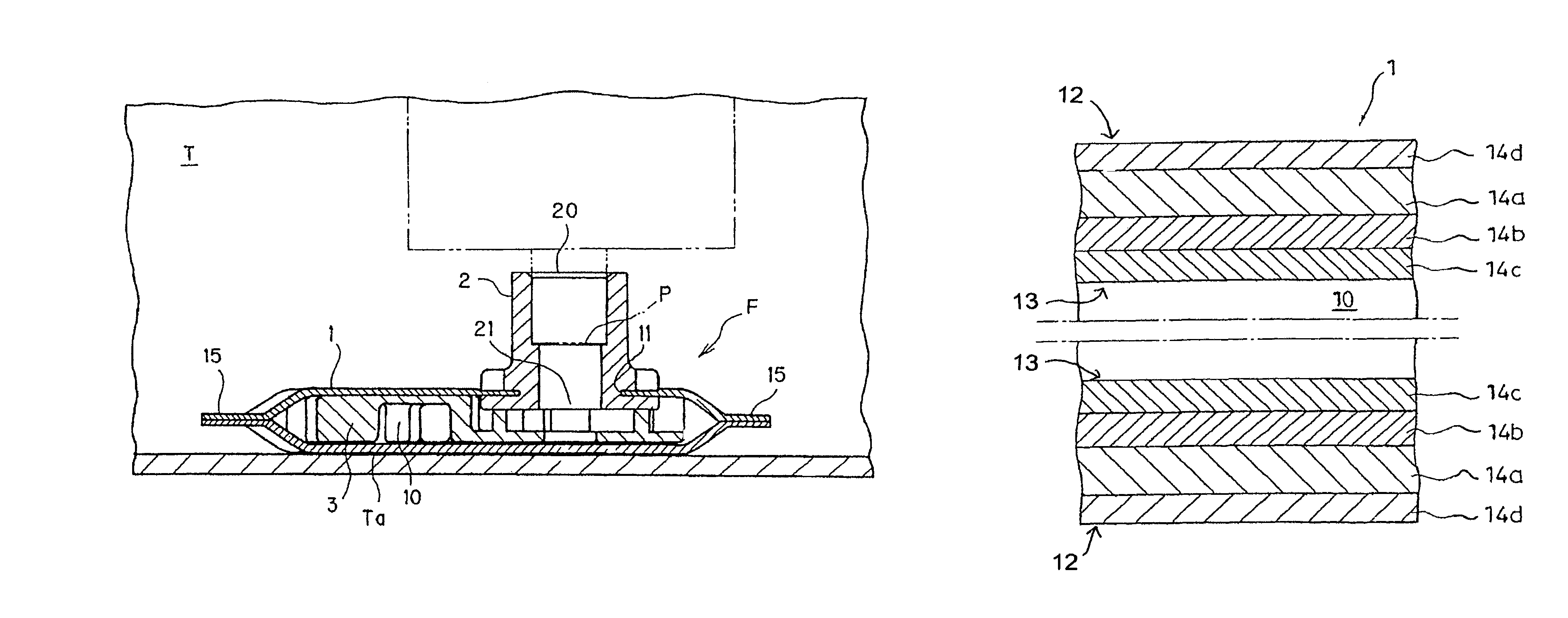

Fuel tank assembly

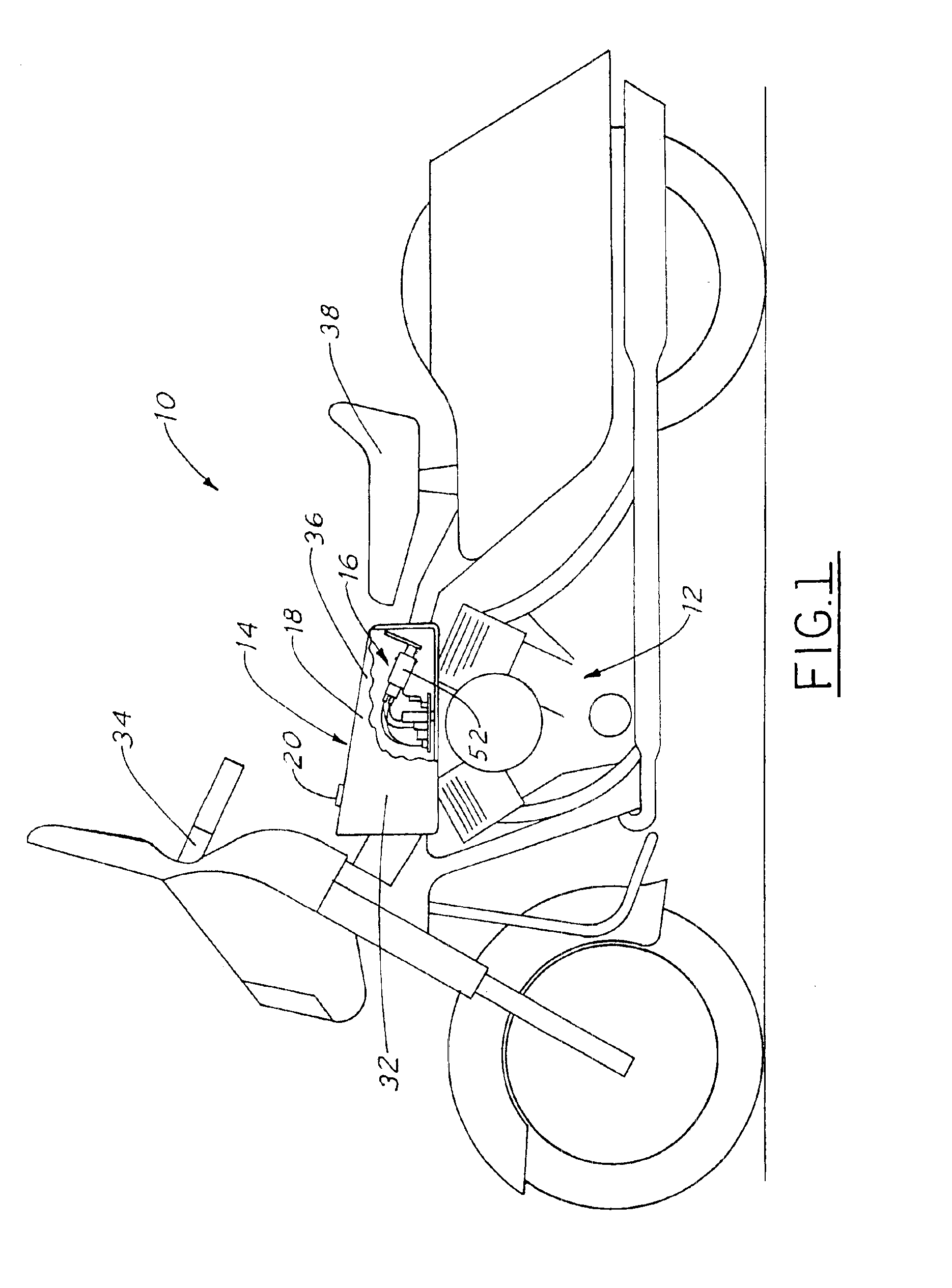

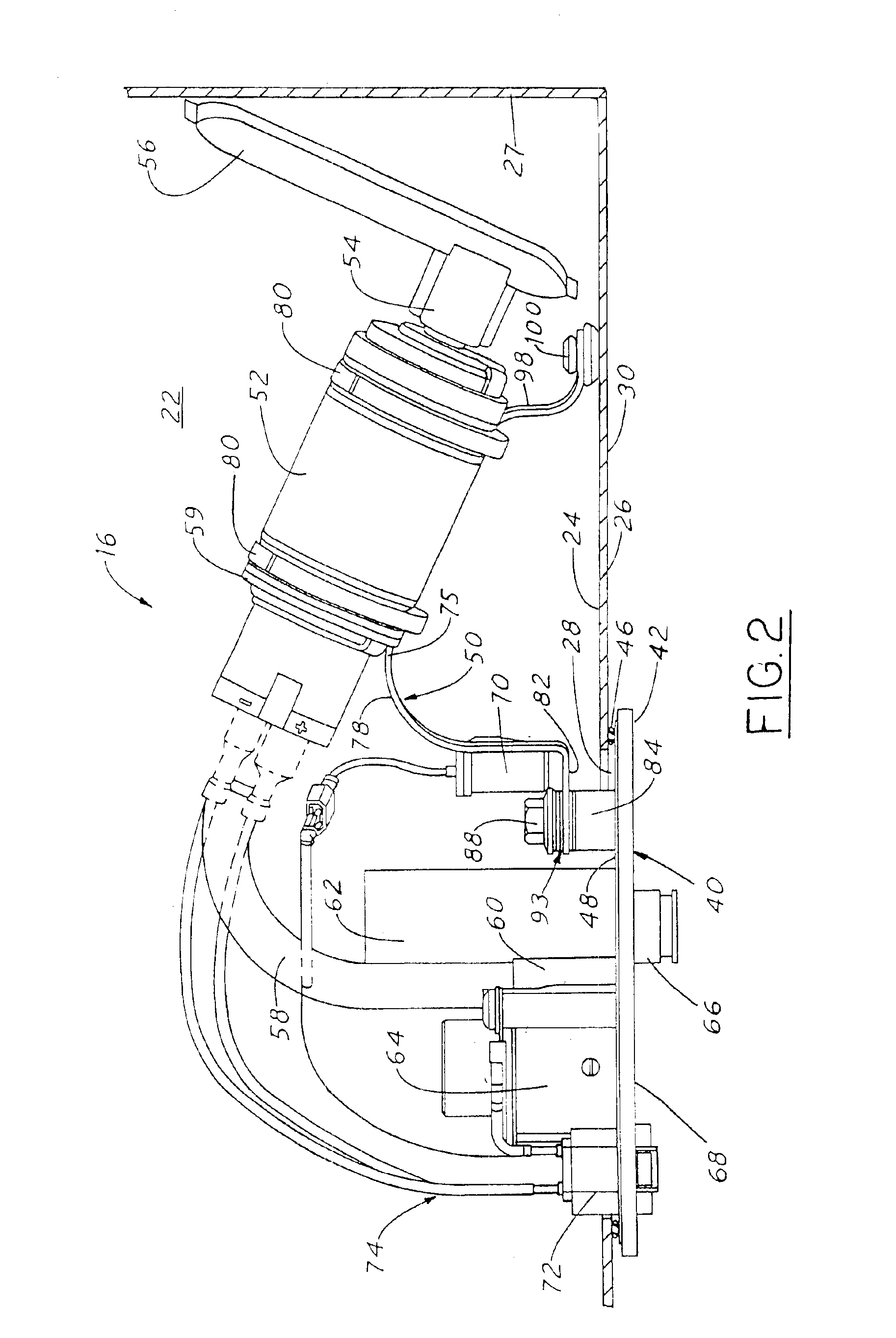

InactiveUS6907865B1Reduce connectionsExtended service lifeMachines/enginesLiquid fuel feedersLevel sensorFuel tank

A cosmetically attractive fuel tank assembly preferably for a motorcycle application has a fuel pump subassembly inserted into the fuel chamber of the tank through bottom access hole thus preserving the overall appearance of the tank itself. The flange of the fuel pump subassembly covers the bottom access hole and sealably months to a bottom wall of the fuel tank. Various fuel pump subassembly components, such as a fuel pressure regulator, an outlet fuel filter, an electrical connector and a fuel outlet mount directly to the flange along with a tripod like vibration absorbing bracket which supports the fuel pump and preferably a fuel level sensor. The bracket is flexible and resiliently contacts an internal surface of a bottom wall of the fuel tank via a resilient pad, and is threadably engaged to the flange and spaced therefrom by a vibration damping member.

Owner:WALBRO ENGINE MANAGEMENT

Standpipe with integrated regulator valve

An apparatus, system, and method for bypassing a fuel filter pressure regulation valve which includes a bypass window and bypass passage. The bypass passage window is positioned in the top of a standpipe of a filter. The filter includes a filter cartridge with top and bottom end plates. The top end plate of the filter cartridge has a hole to receive a standpipe. The top end plate also has a sealing gasket to seal the bypass passage window when the proper filter cartridge is in place. This arrangement exposes the regulator valve to the fuel and / or air at the top of the filter housing when the proper filter cartridge is in place. Pressure in the housing opens the valve, allowing air and / or fuel to be vented through the bypass passage and back to the fuel tank.

Owner:CUMMINS FILTRATION IP INC

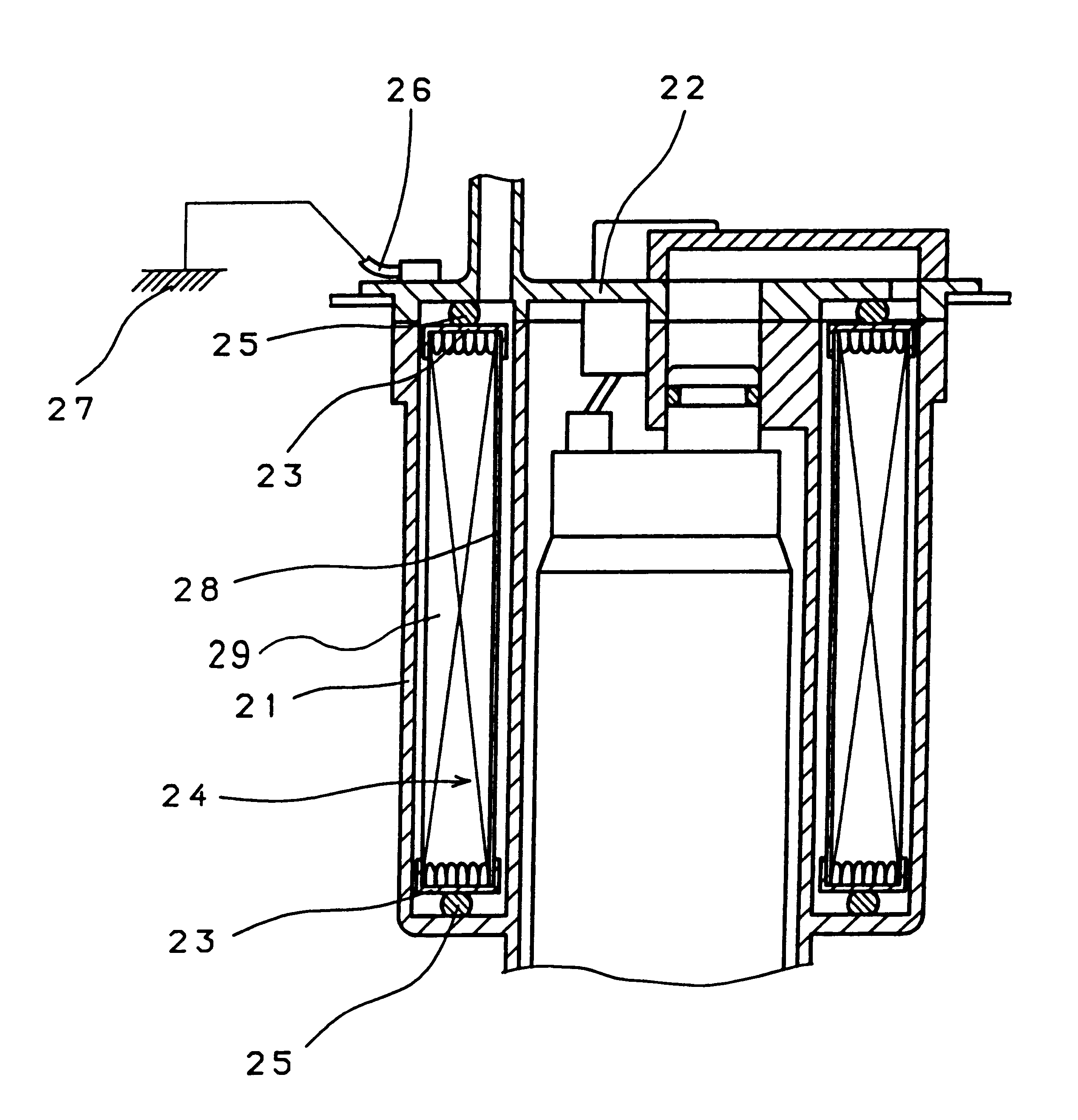

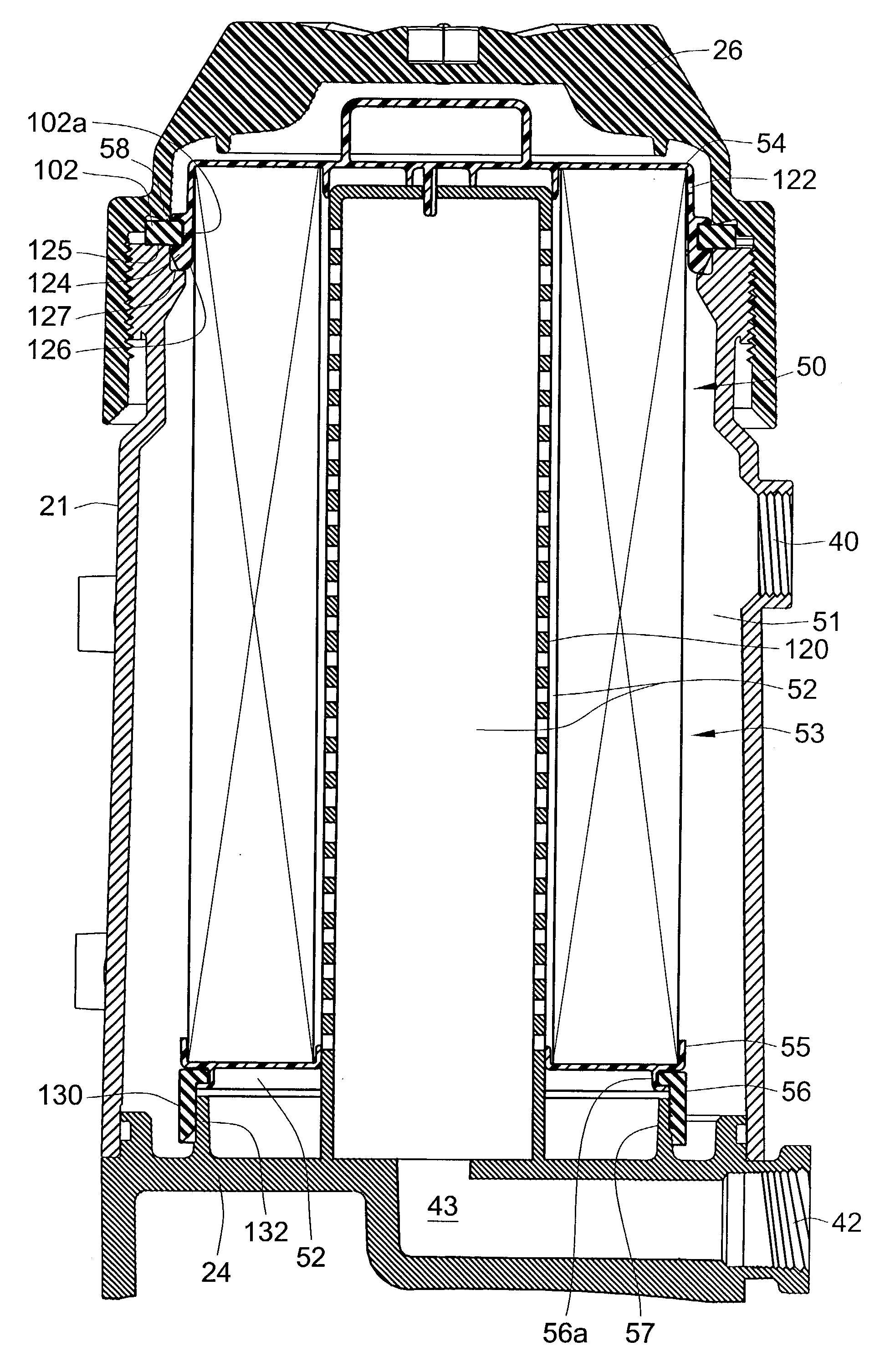

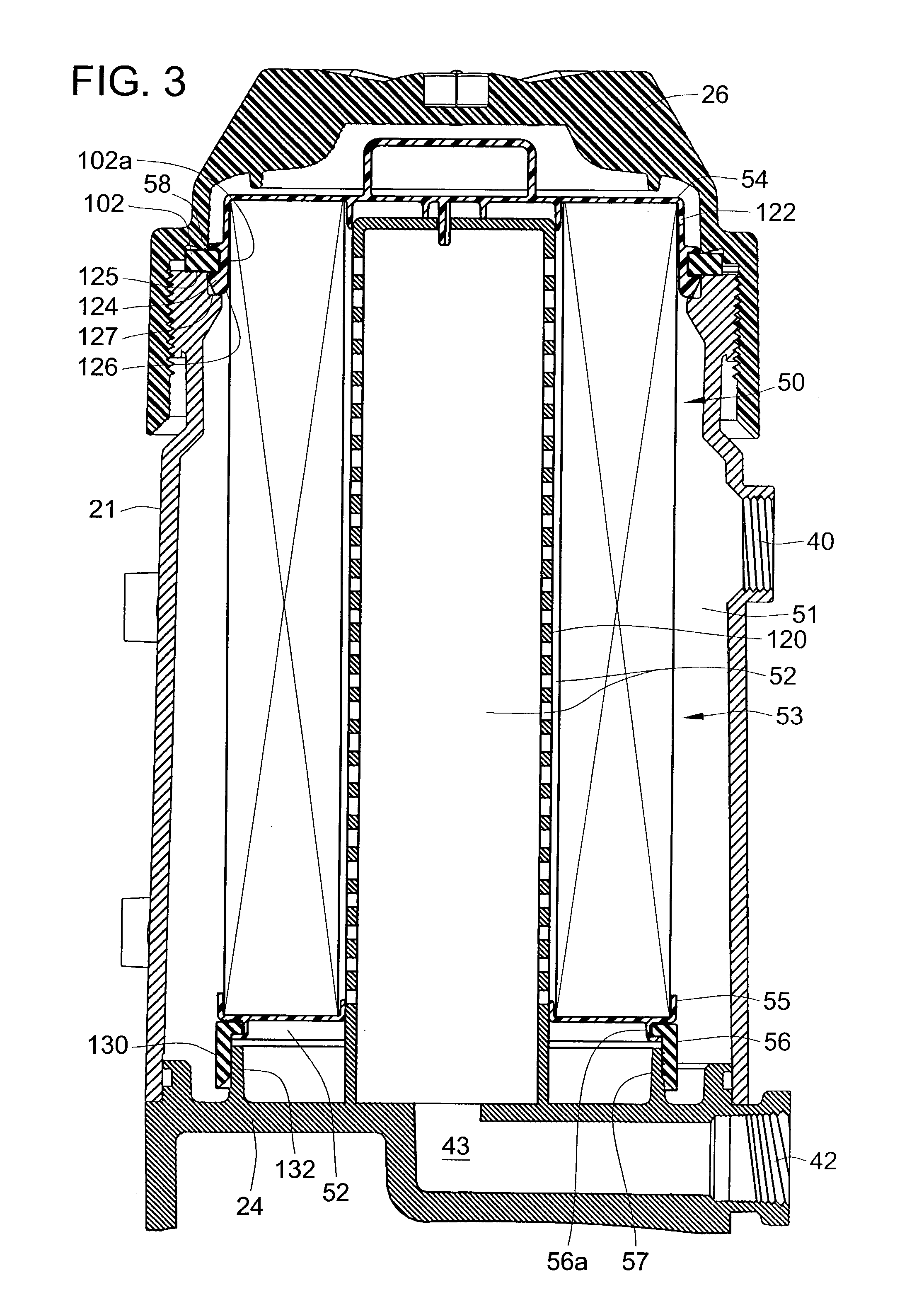

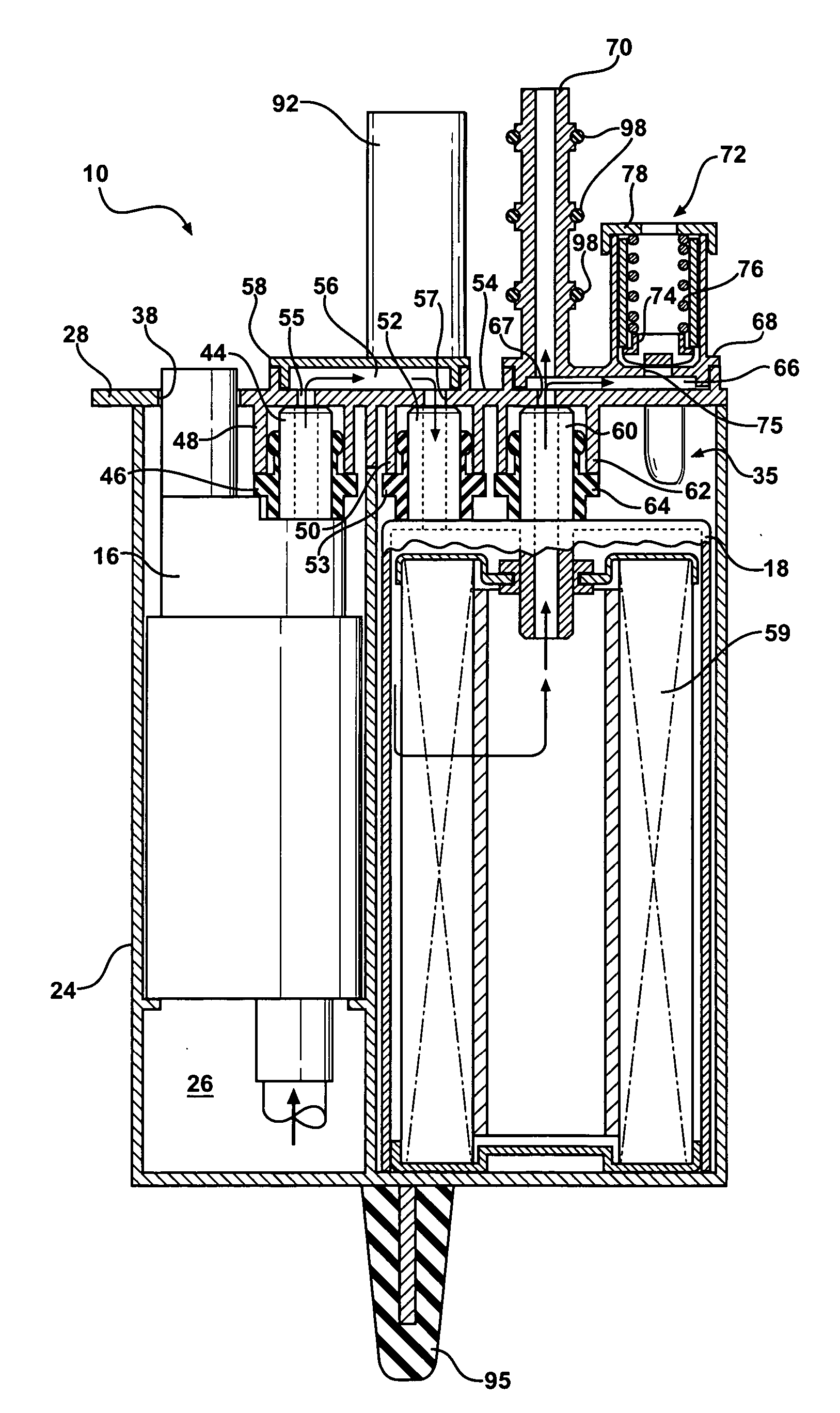

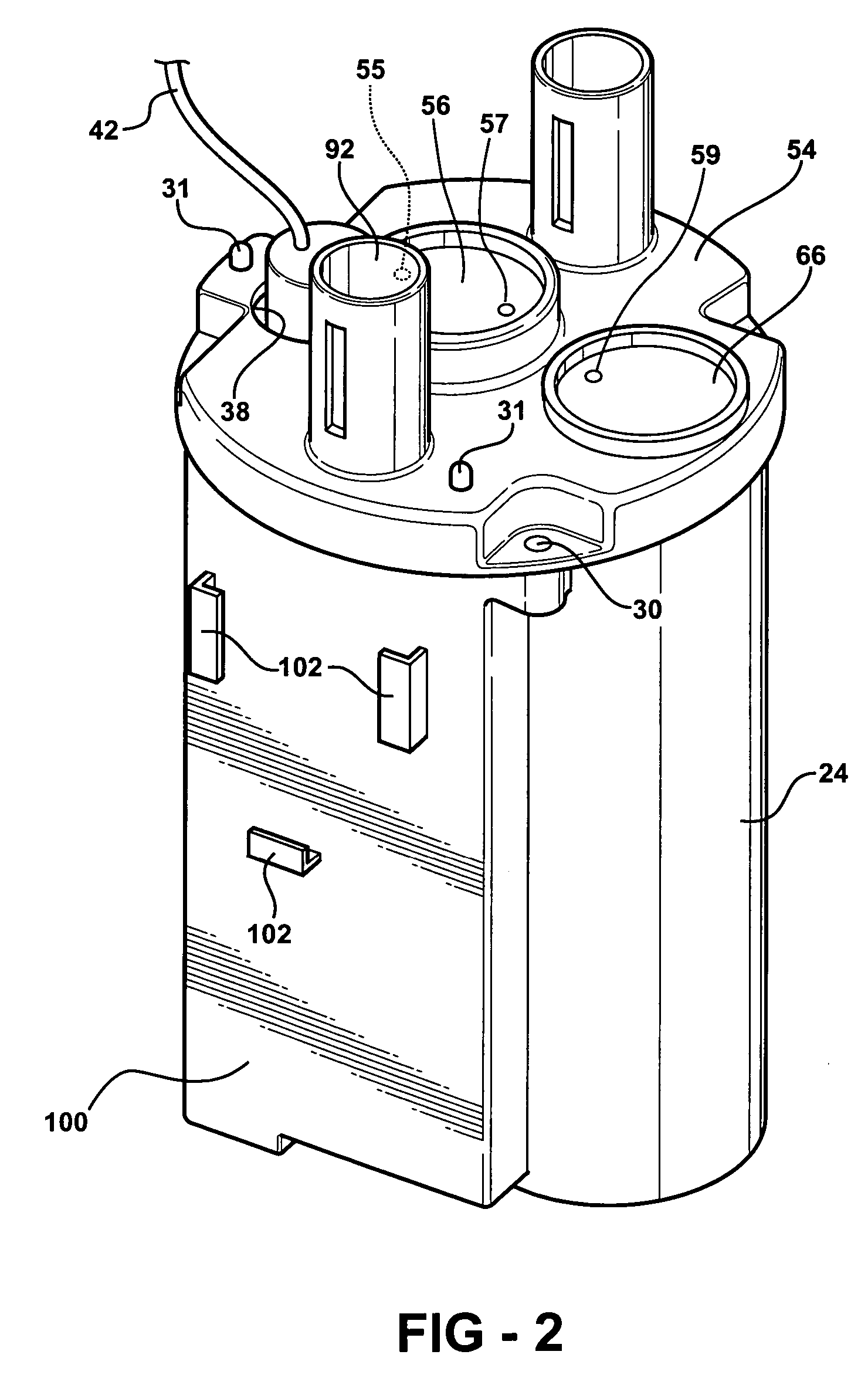

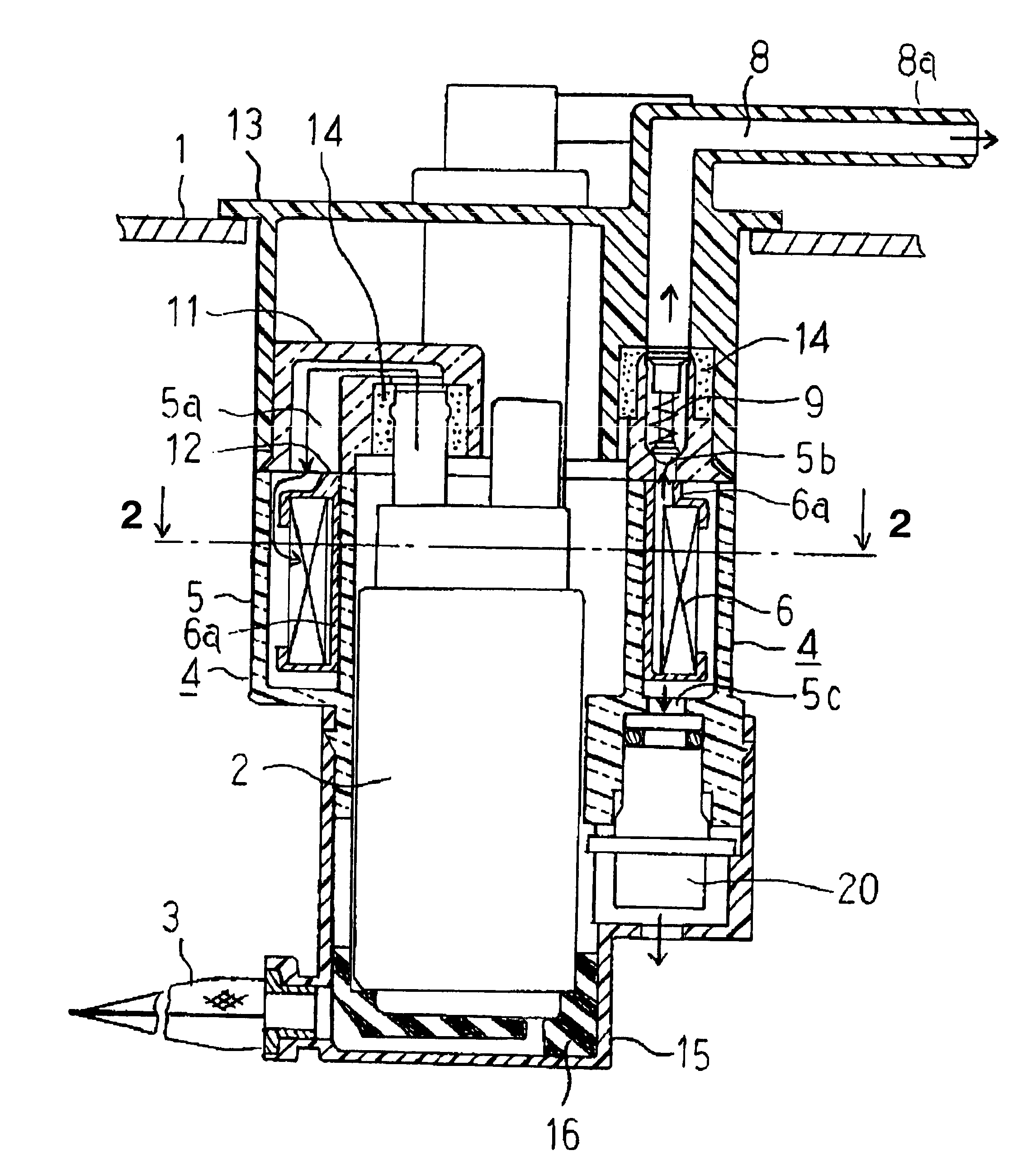

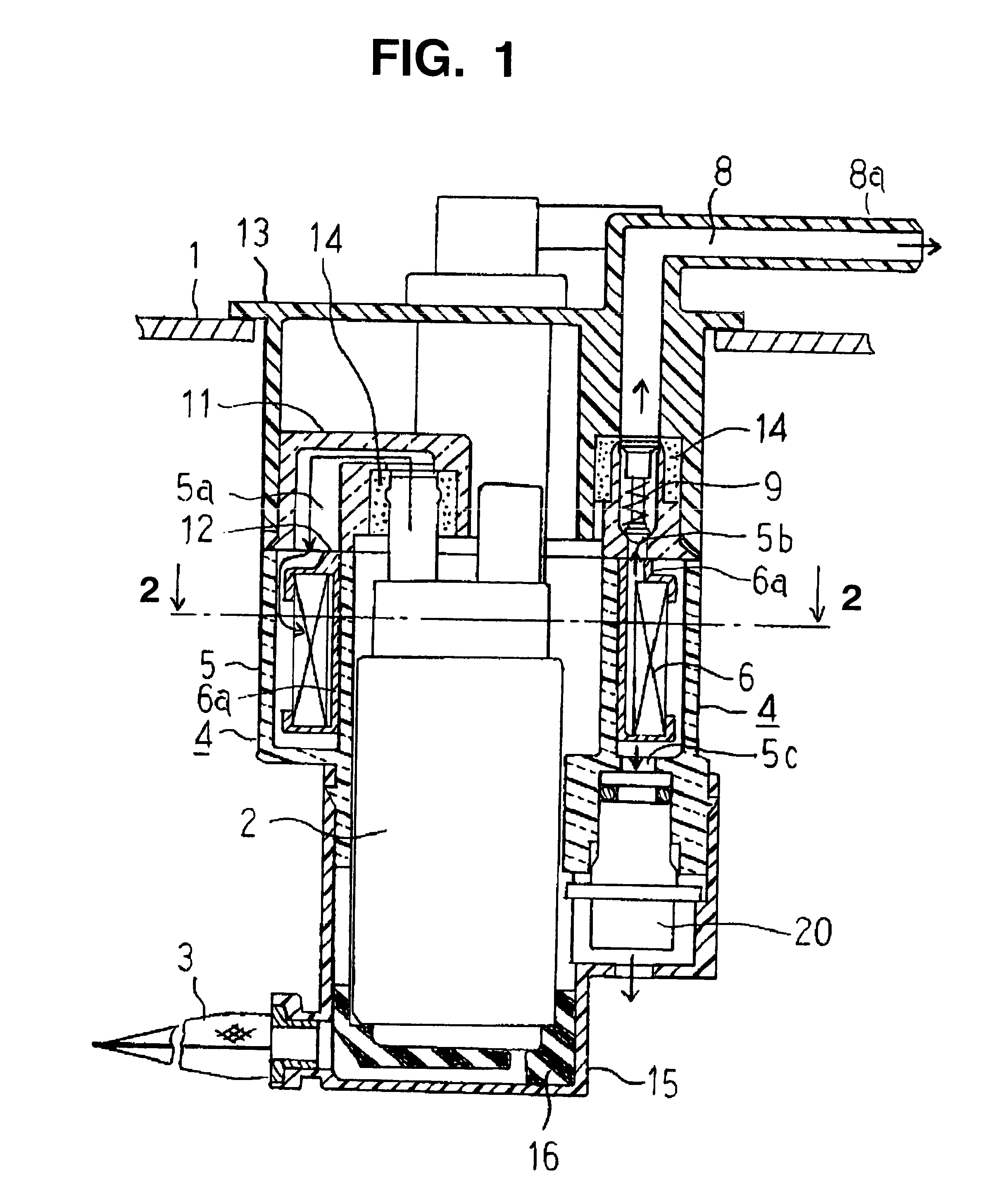

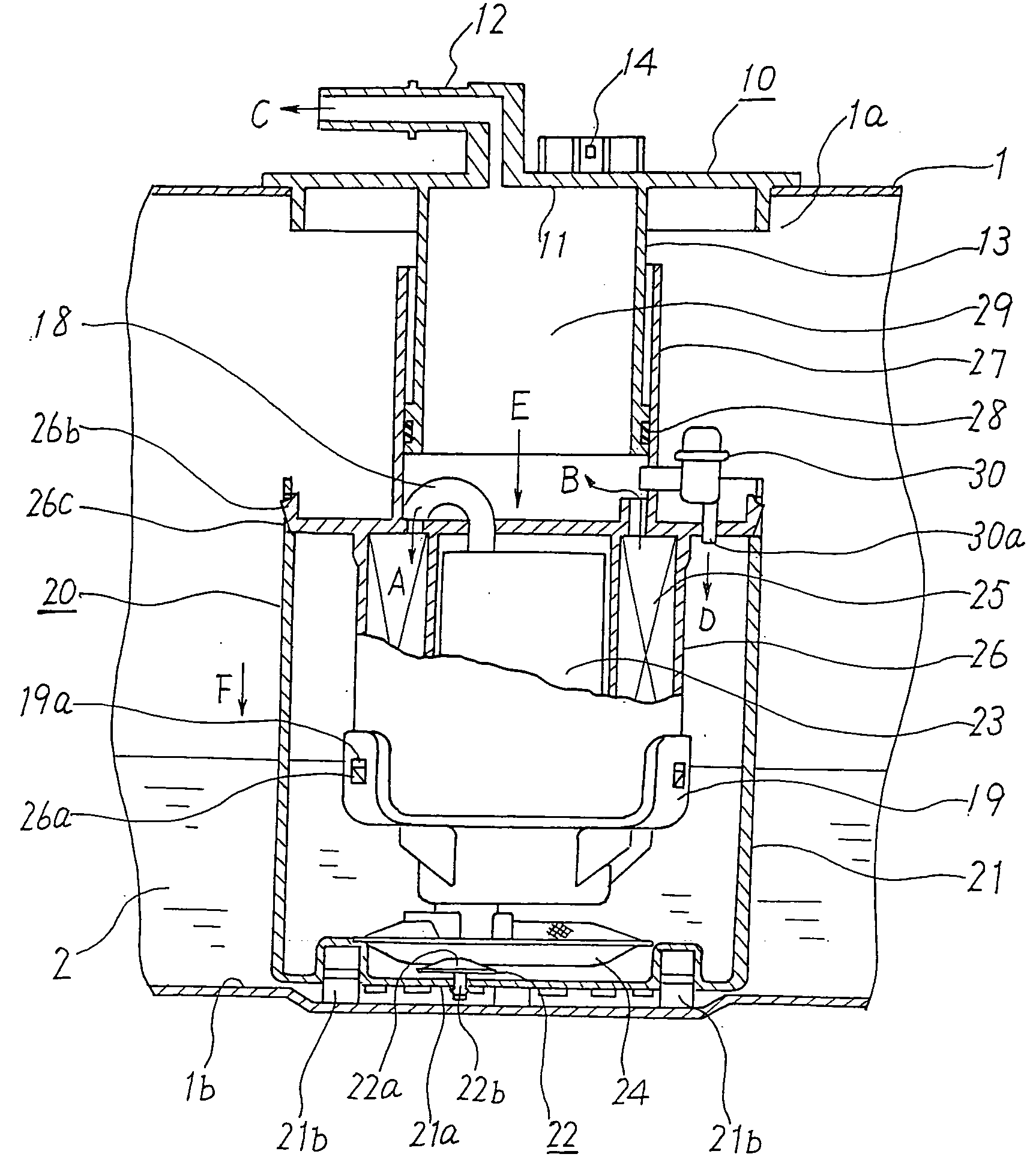

In-tank fuel module

A fuel module includes a fuel pump having a fuel inlet and fuel outlet. The module also includes a fuel filter having a filter inlet and a filter outlet. The module has a housing with a body that defines a cavity. The fuel pump and fuel filter are arranged in the cavity. The housing includes a removable end cap that at least partially encloses the cavity in an installed position and provides access to the cavity in a service position. Fastening elements such as threaded fasteners secure the removable end cap to the body in the installed position. Seals are arranged between the fuel pump and fuel filter and the end cap when in the installed position. The end cap also includes caps secured to a surface of the end cap to provide fluid passages where necessary. When the fuel pump or fuel filter requires replacement, the threaded fasteners and end cap are removed from the body, and the fuel pump and / or fuel filter may be detached from the end cap.

Owner:PUROLATOR ADVANCED FILTRATION

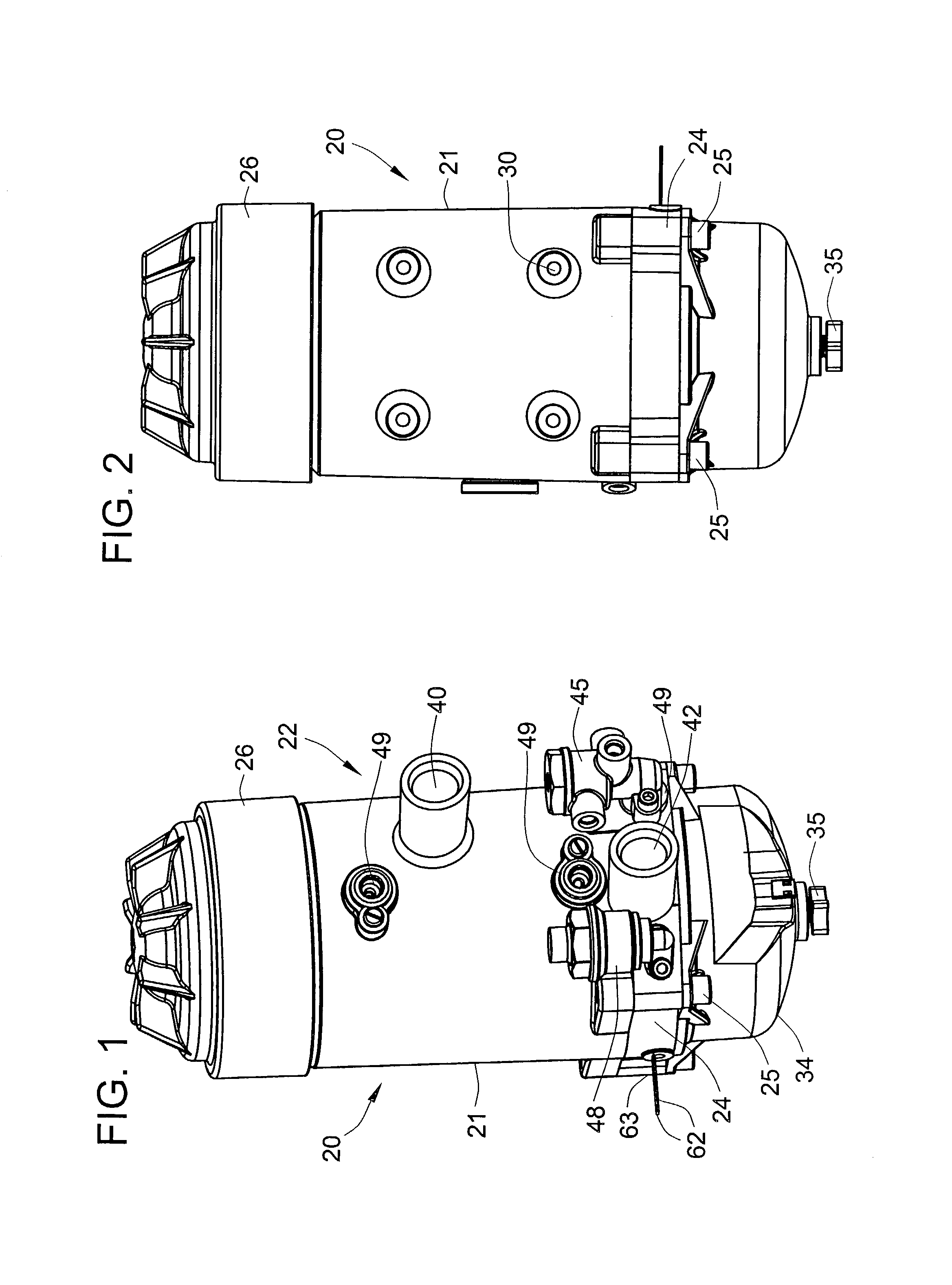

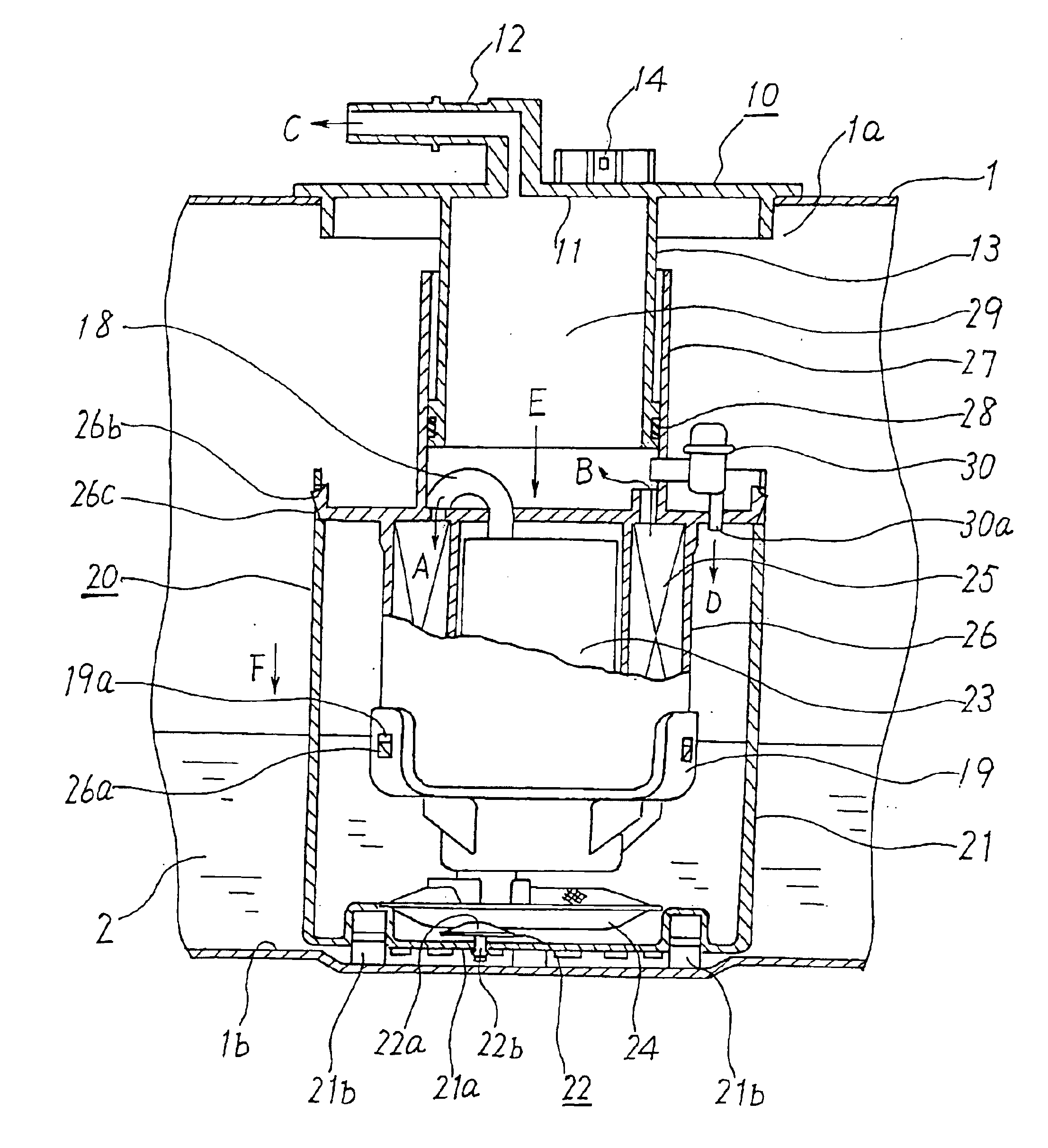

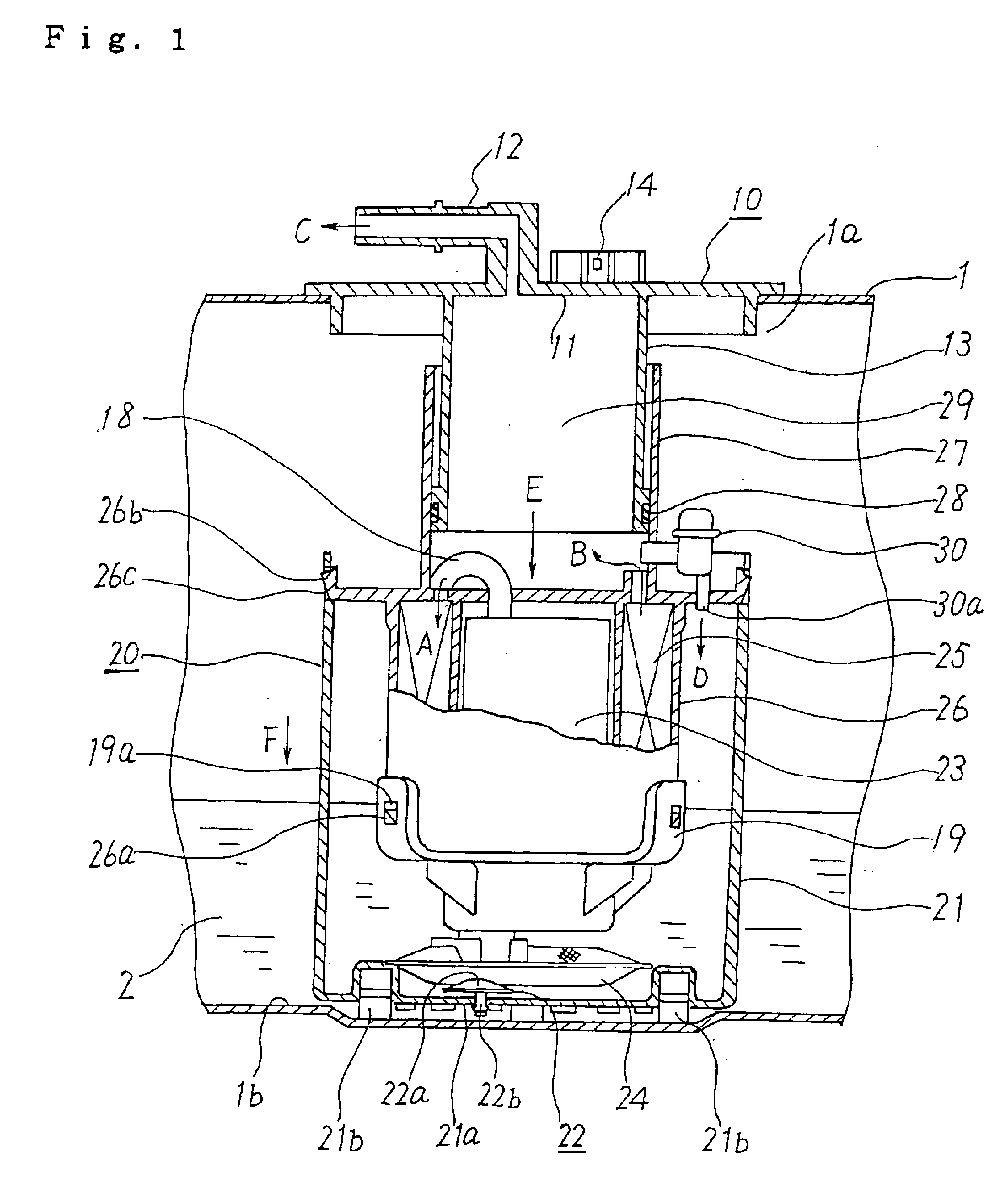

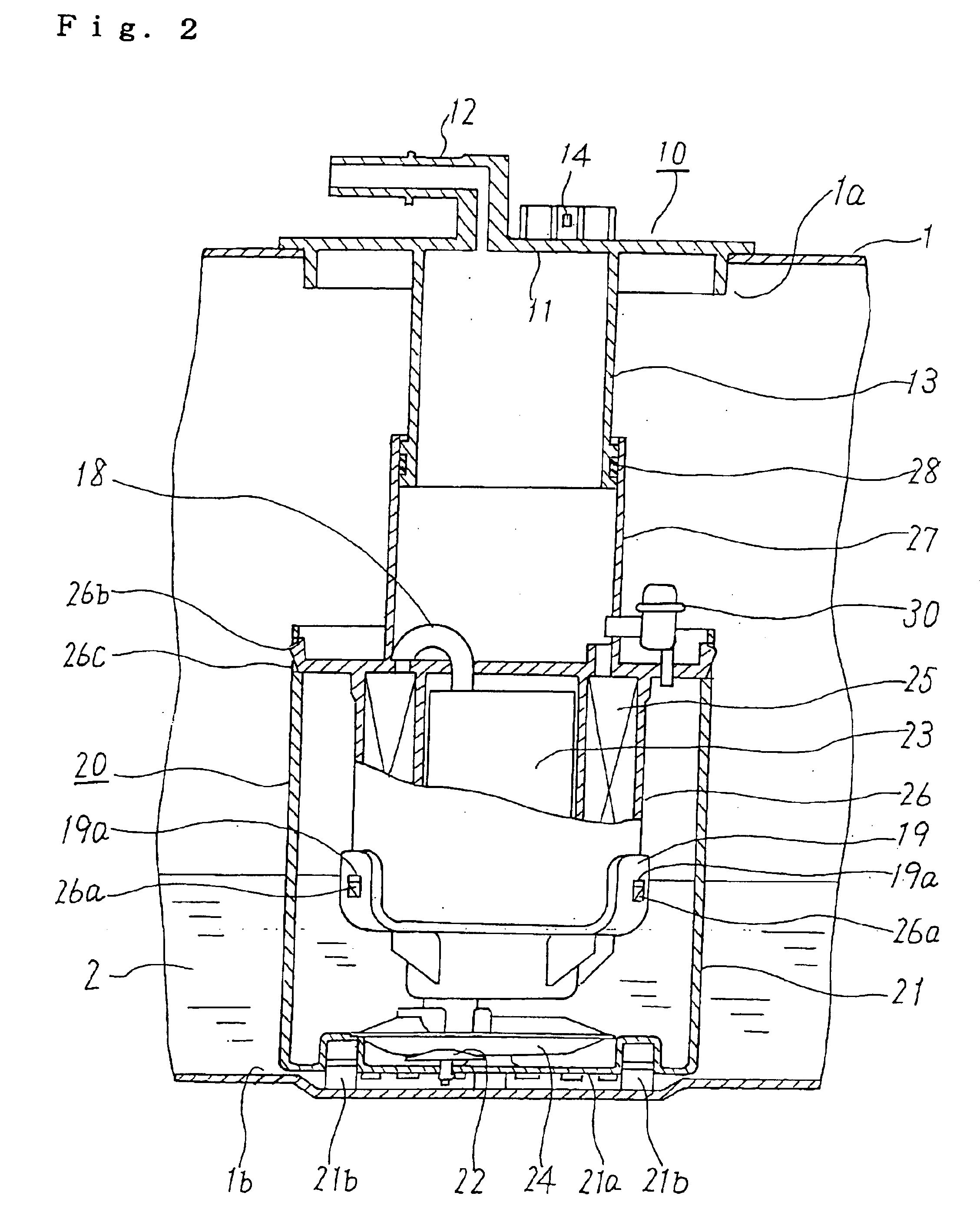

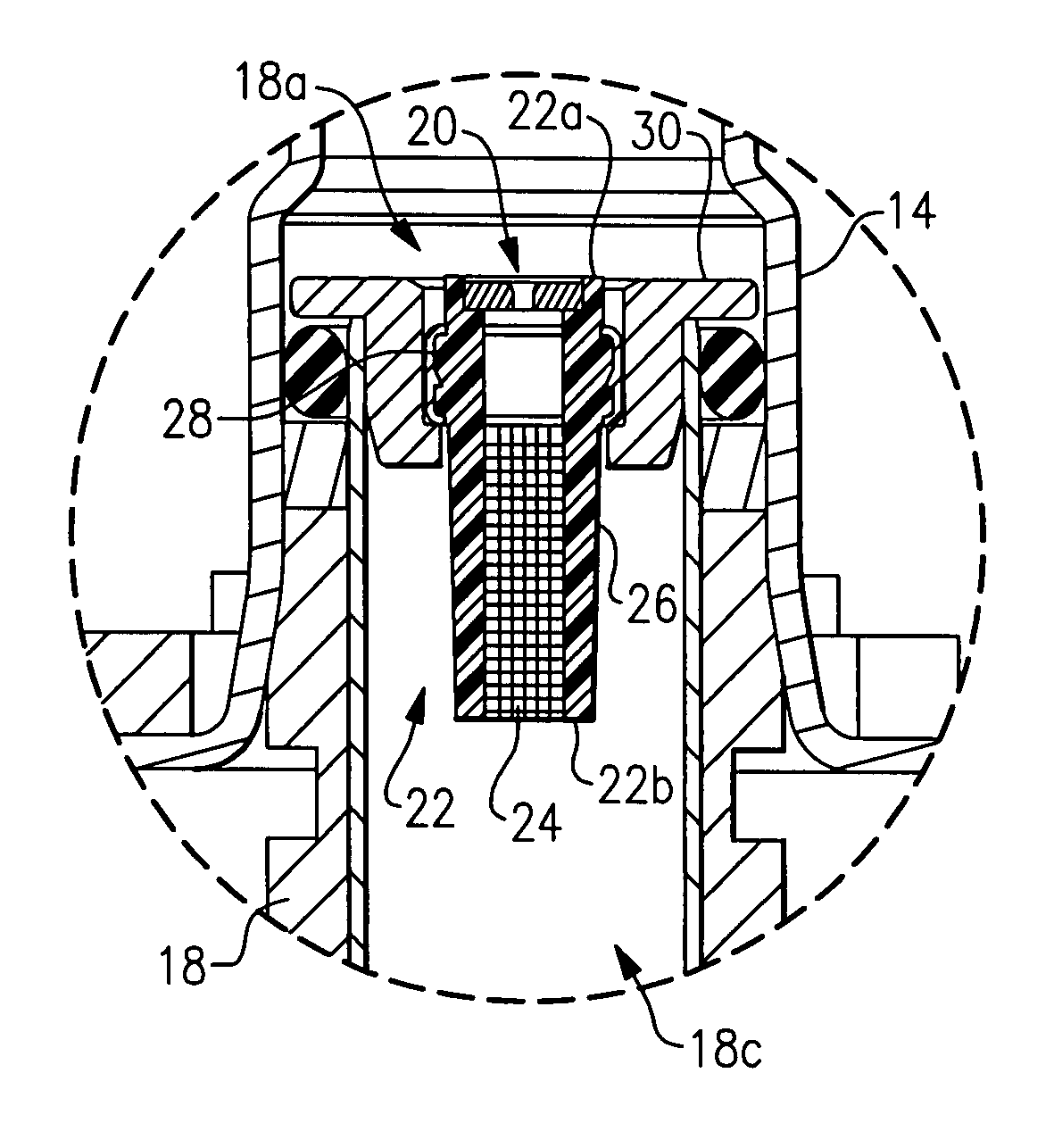

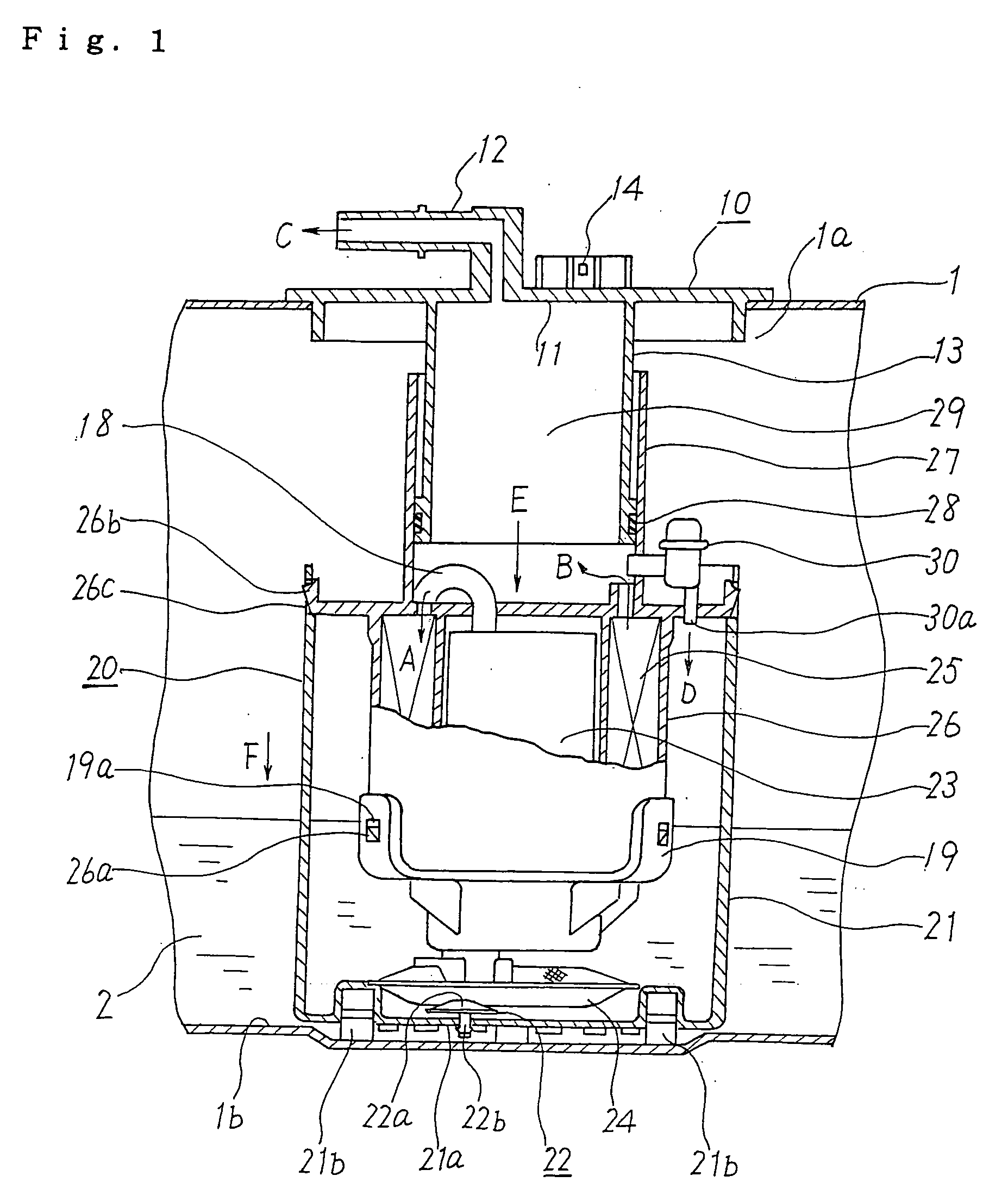

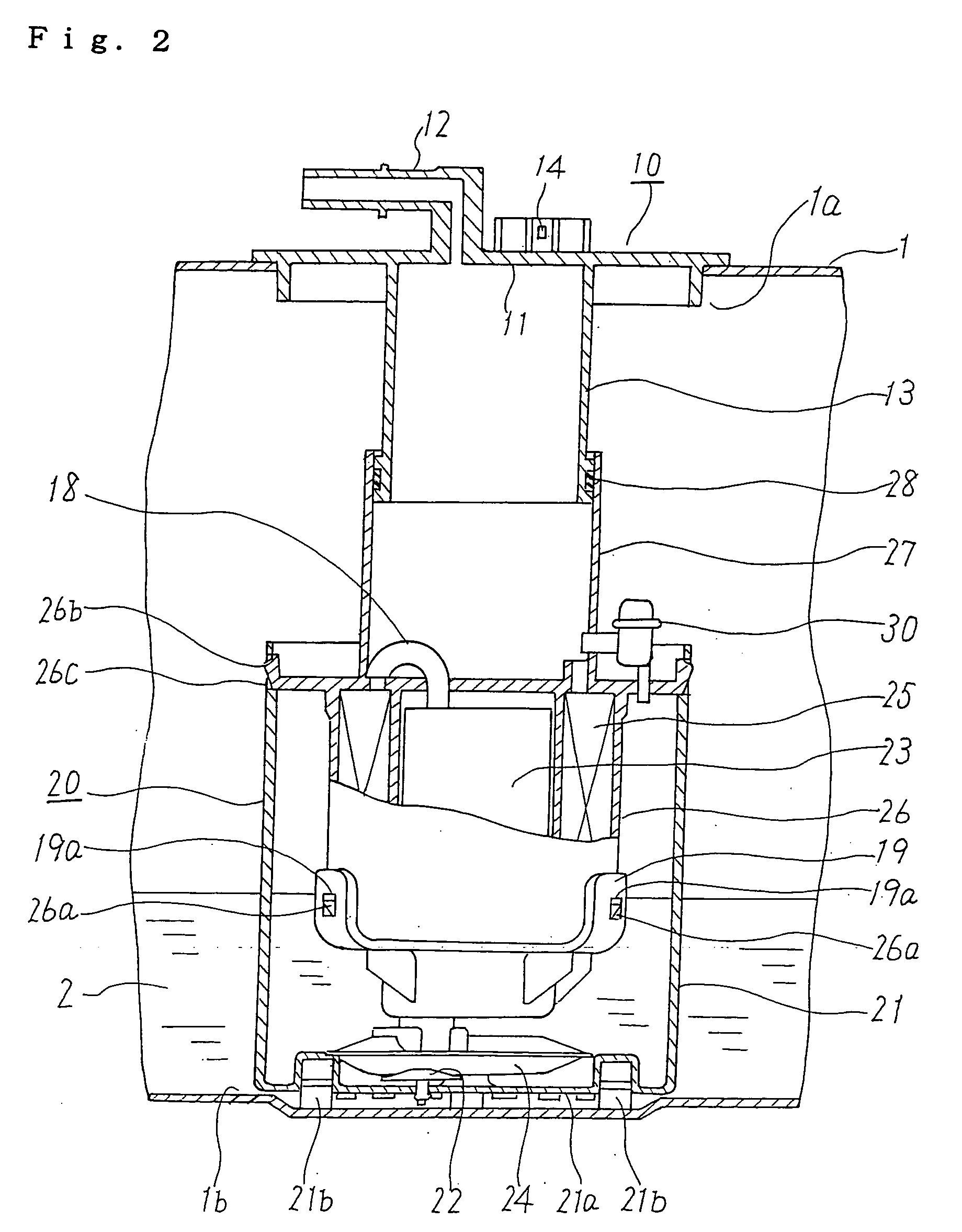

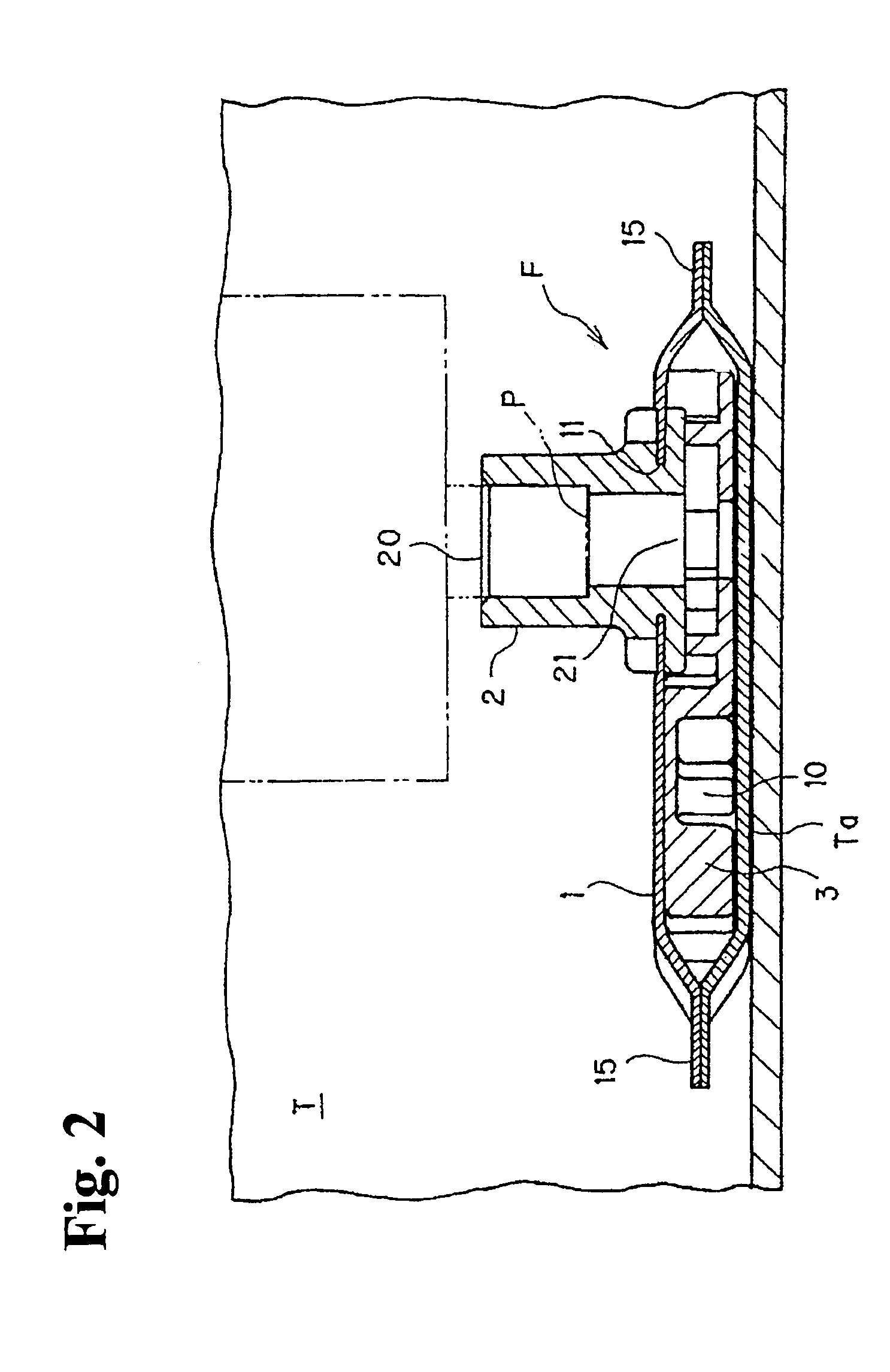

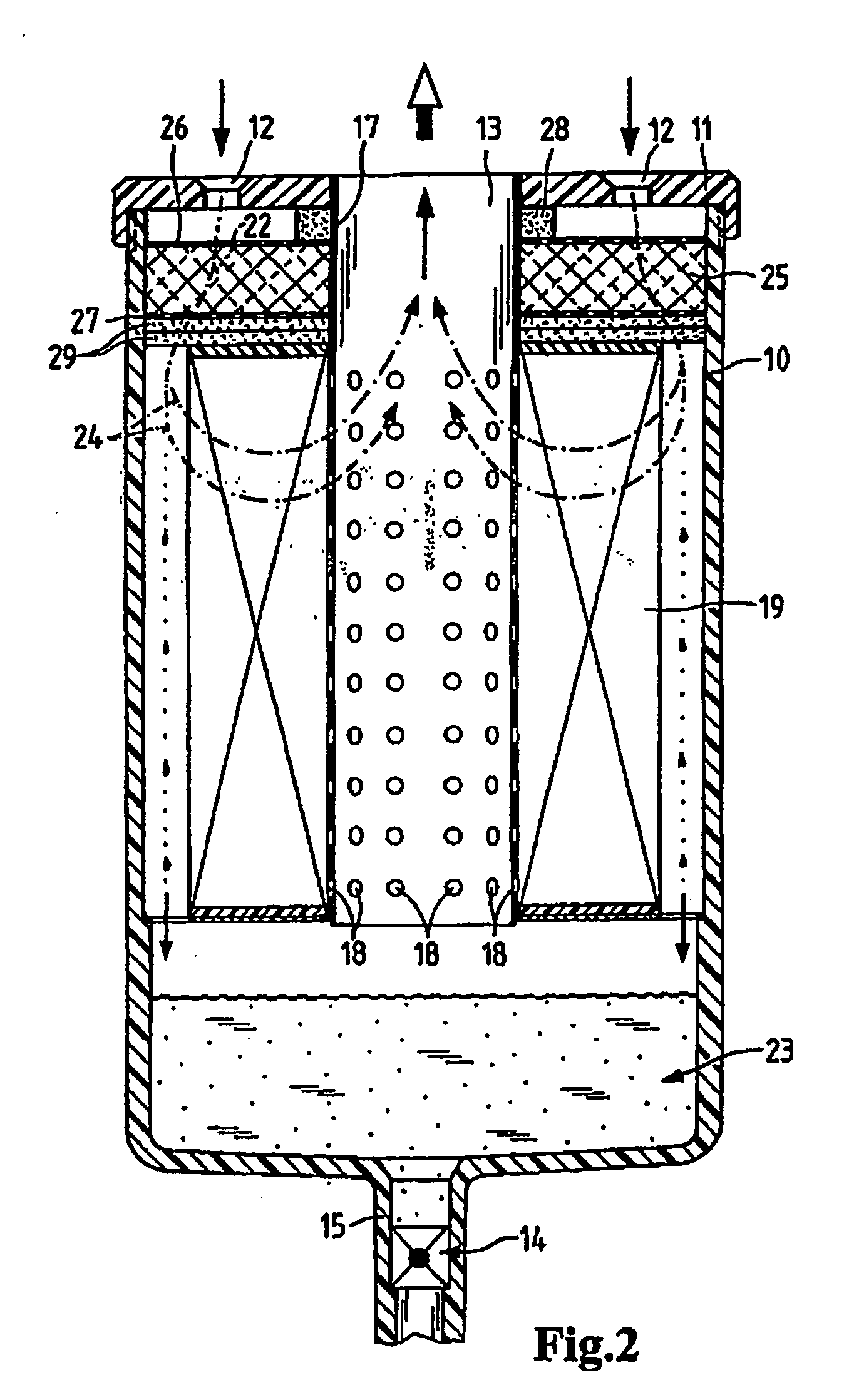

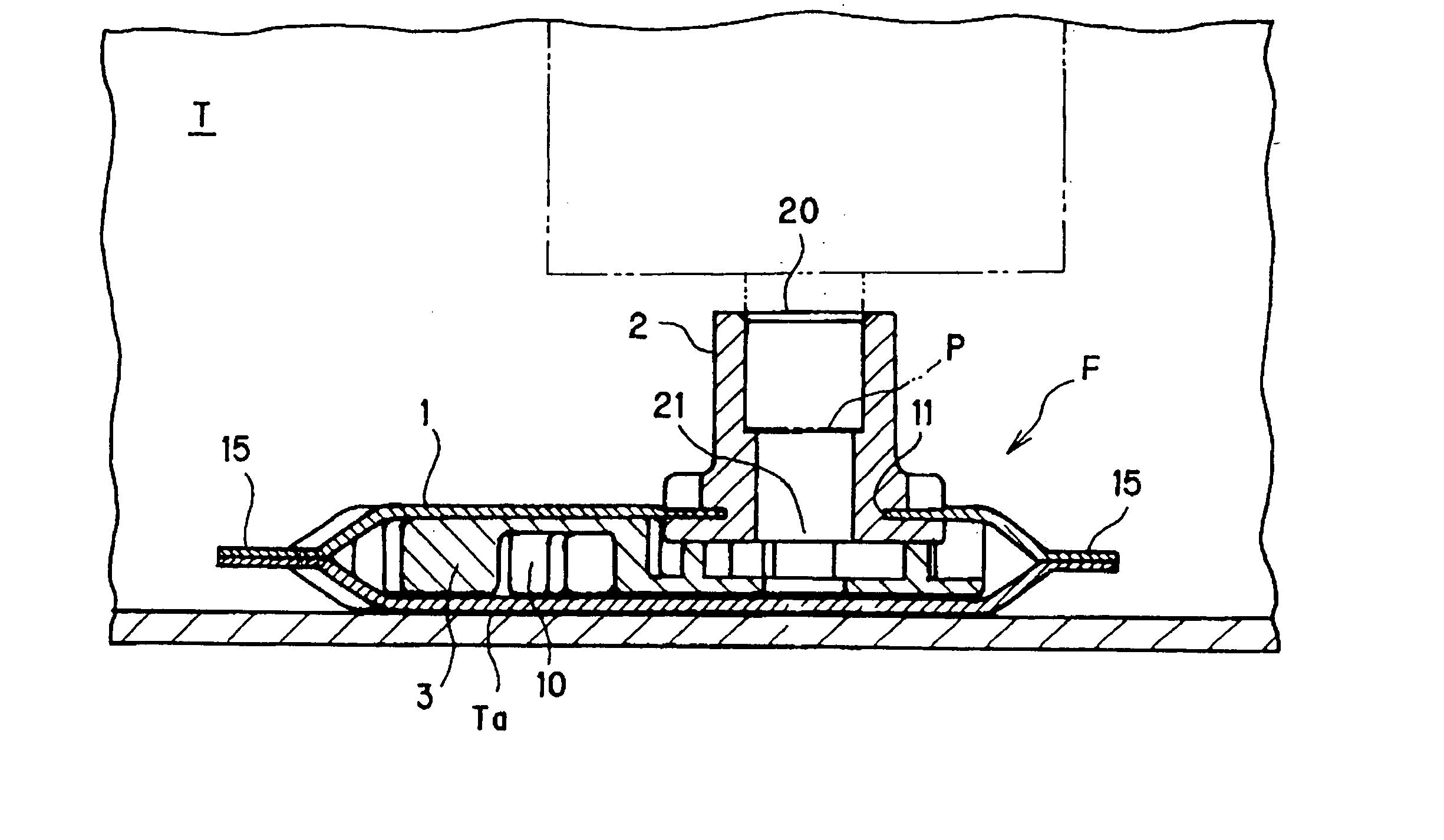

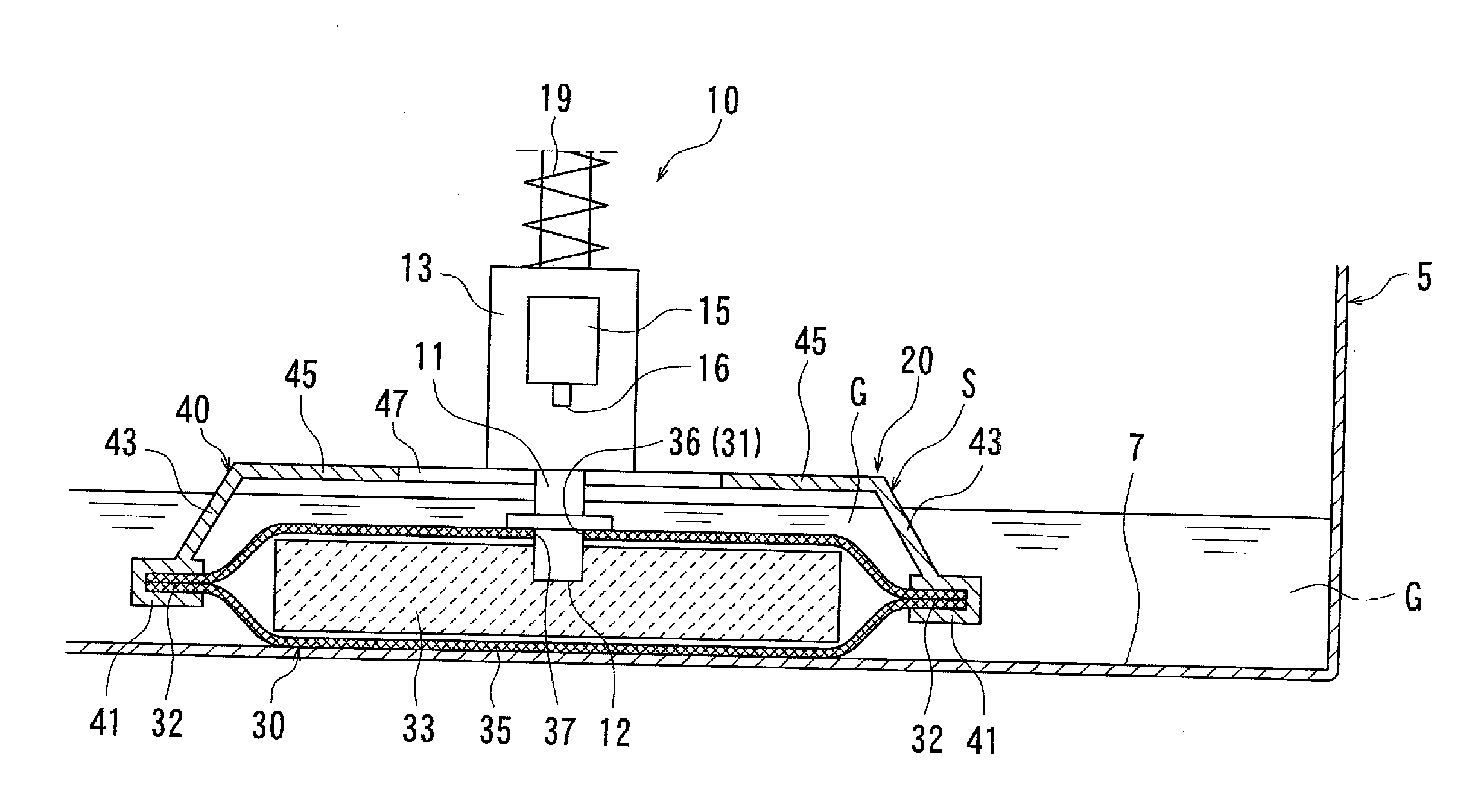

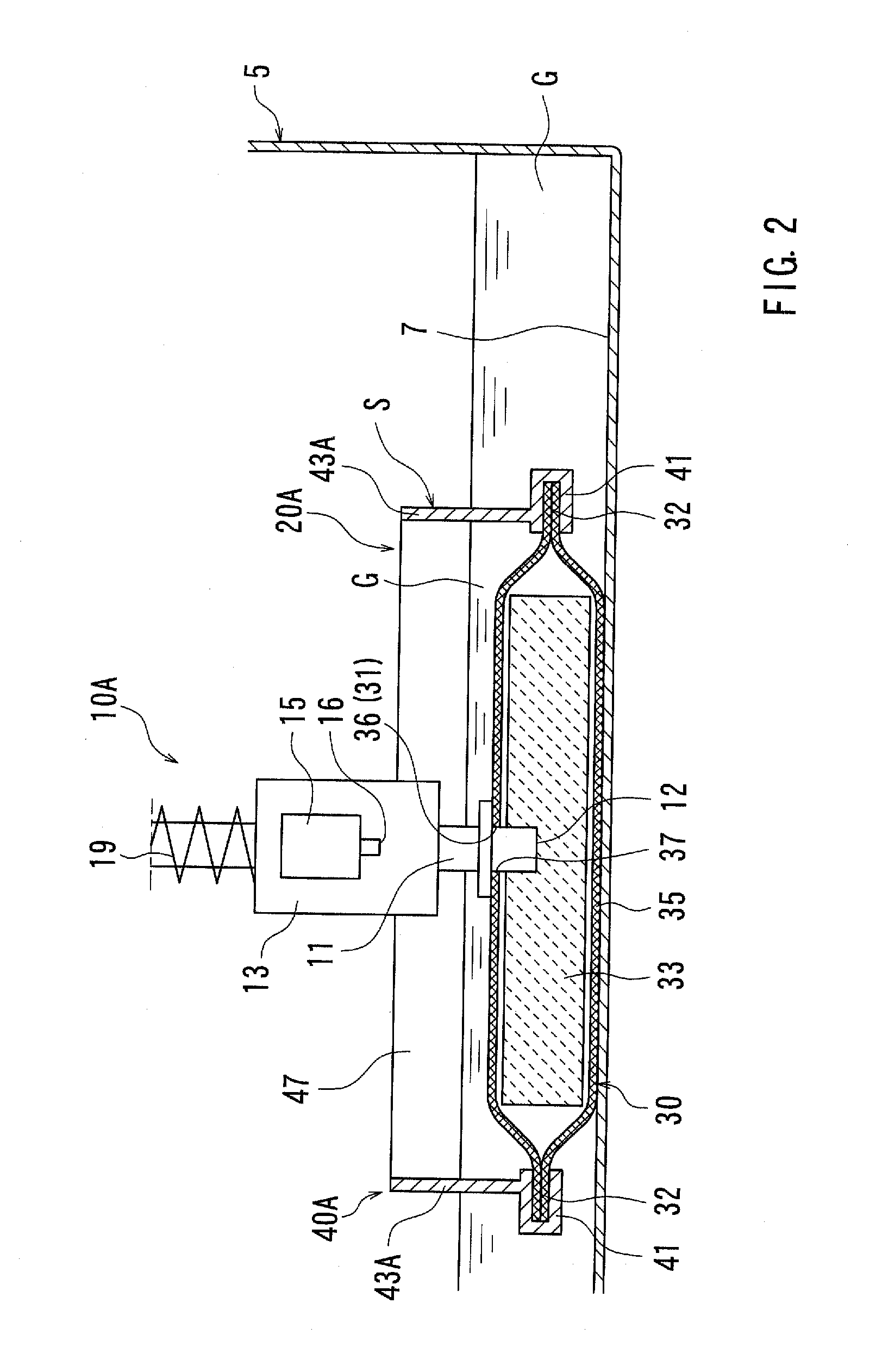

Fuel supply apparatus

InactiveUS6923164B1Easy constructionImprove the ease of assemblyMachines/enginesLiquid fuel feedersFuel tankFuel filter

A fuel supply apparatus capable of following the positional variations of the bottom side of a fuel tank through a simple construction and improved in terms of ease of assembly in the fuel tank. The apparatus includes a fuel pump body in which a filter-integrated pump in which a fuel pump and a fuel filter are integrally formed is integrally accommodated in a fuel reservoir having a bottom capable of coming into abutment with a bottom side of the fuel tank, and causes the fuel pump body to travel to follow the variations of the bottom side of the fuel tank so as to be placed in abutment with the bottom side of the fuel tank, by means of an urging force generated on the basis of the pressure of the fuel inside the fuel pump body.

Owner:MITSUBISHI ELECTRIC CORP

Injector fuel filter with built-in orifice for flow restriction

ActiveUS7617991B2Reduce pressure pulsationReduce or eliminate pressure pulsations through the fuel injectorSedimentation separationMachines/enginesFuel filterEngineering

Owner:DELPHI TECH IP LTD

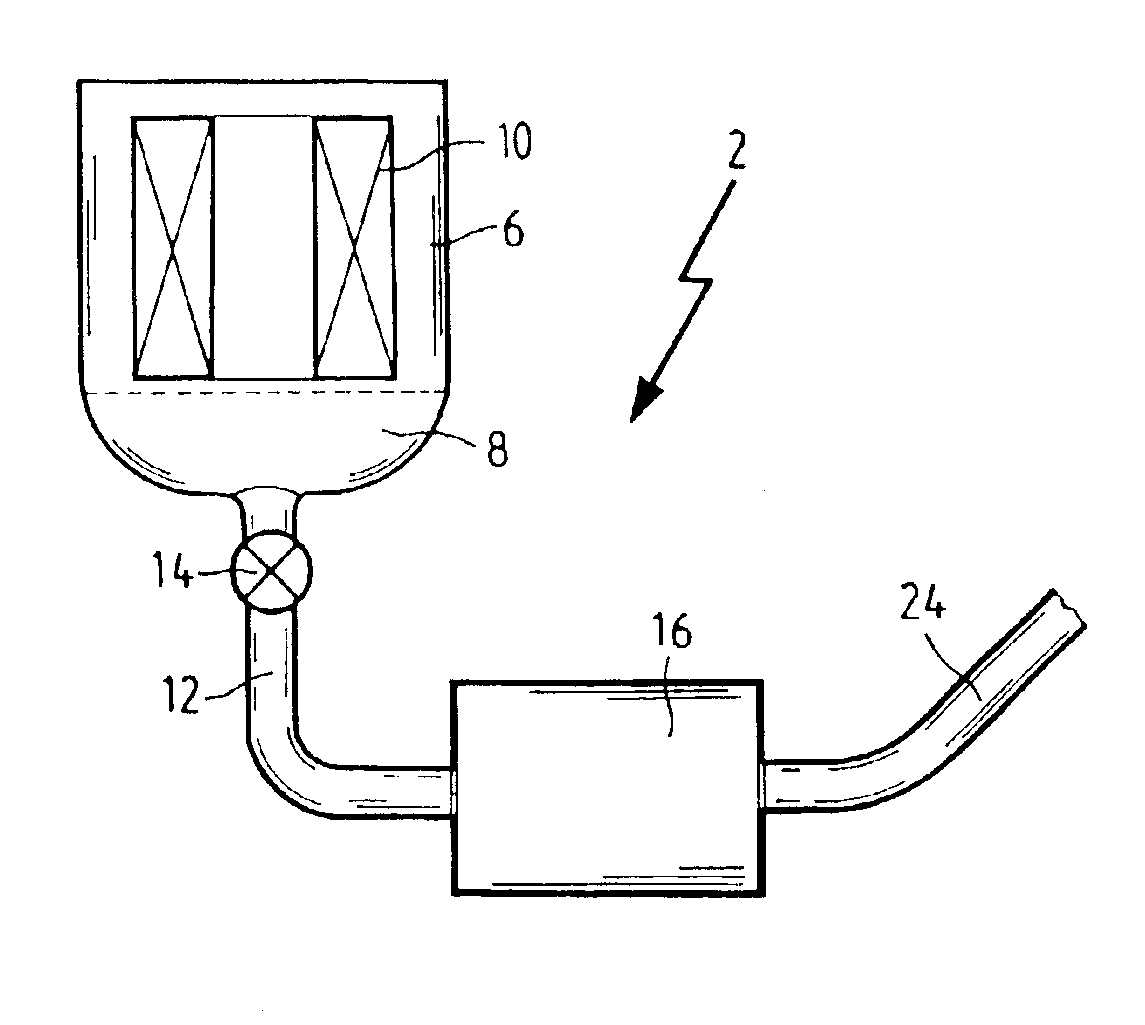

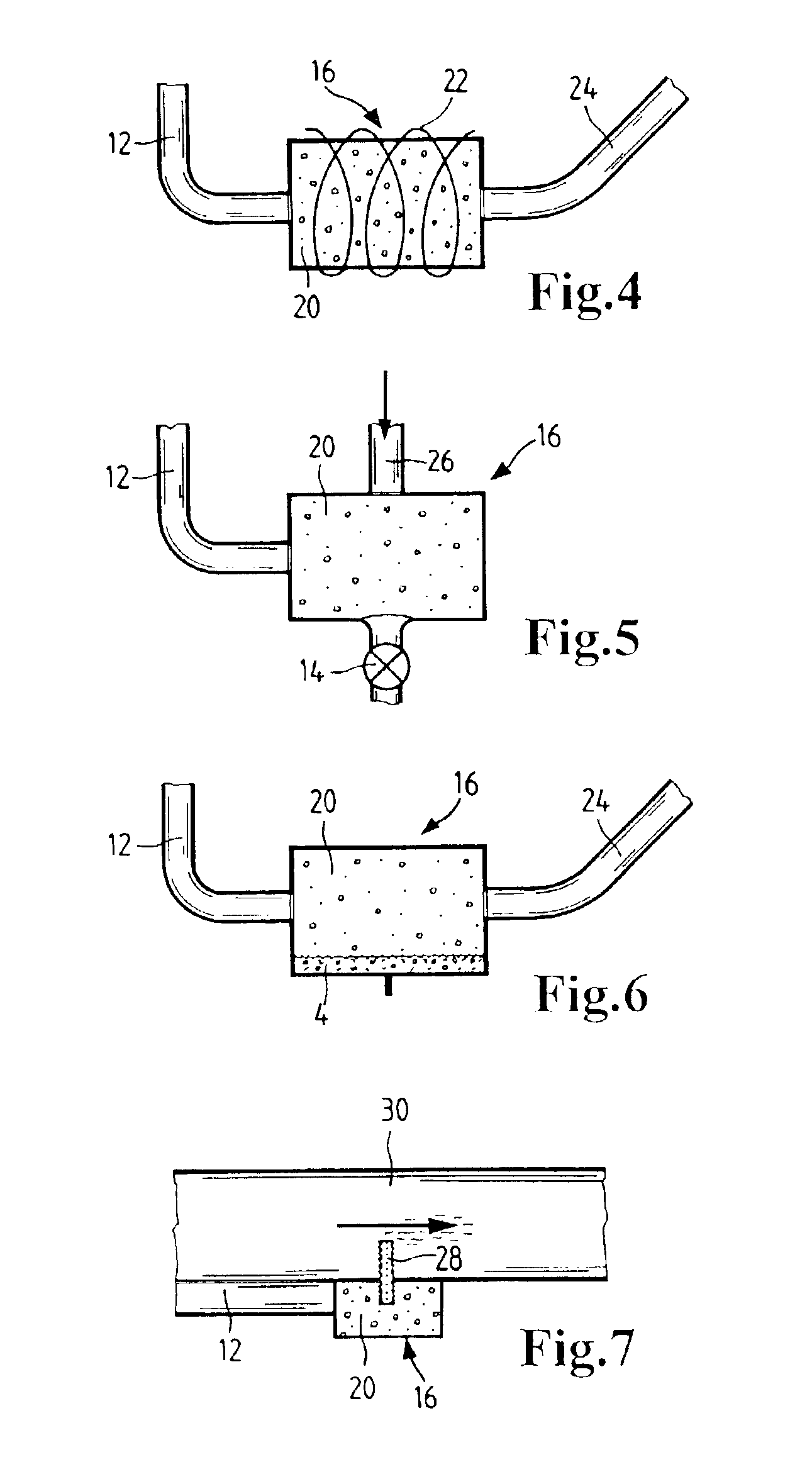

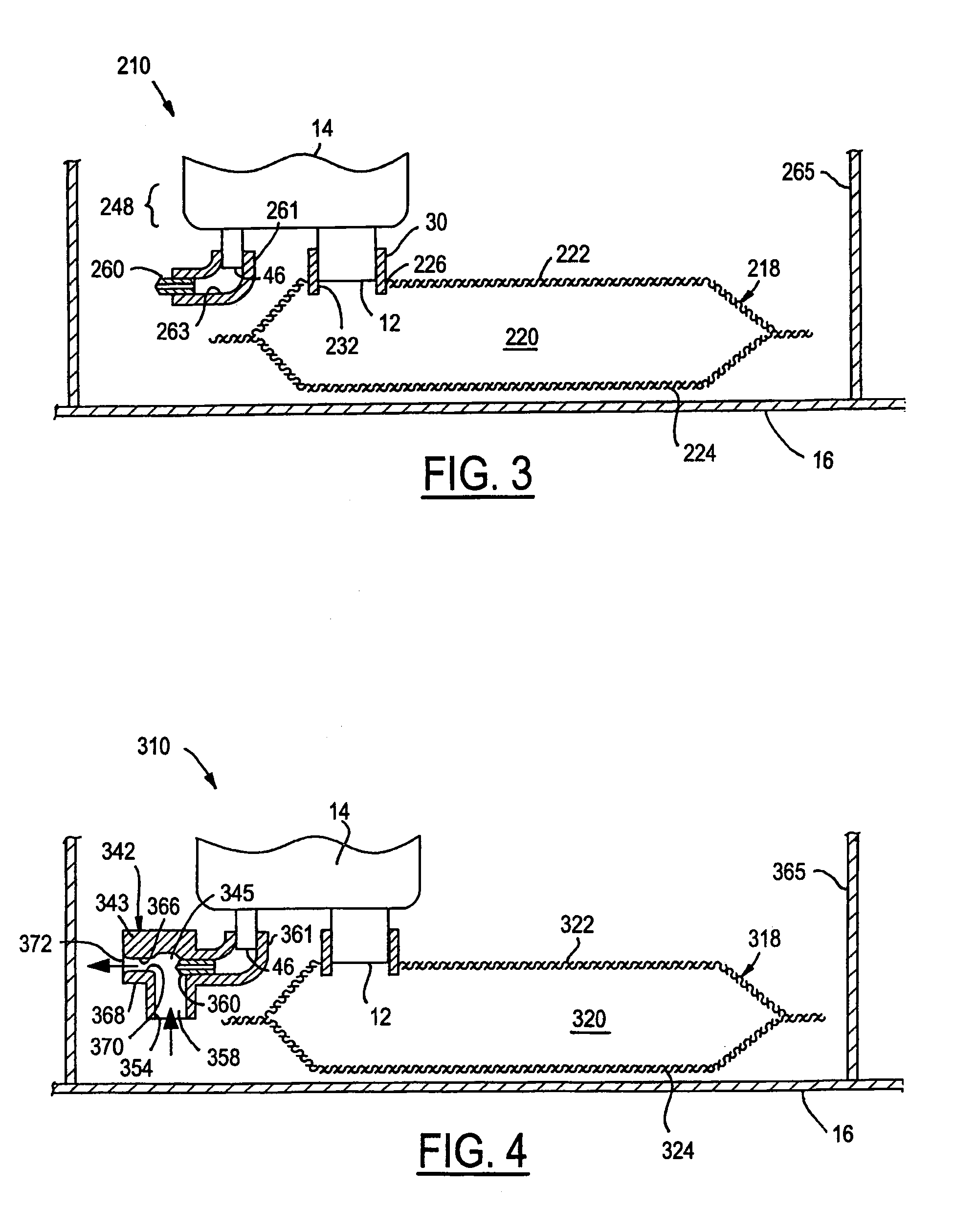

Fuel filter arrangement

ActiveUS7182869B2Improving the running efficiency of an engineEliminating flowCombination devicesJet pumpsFuel filterLiquid fuel

A fuel filter and vapor separator arrangement having at least one layer of liquid fuel permeable material defining at least one substantially enclosed cavity. The permeable material has at least one opening to provide fluid communication of liquid fuel within the cavity with an inlet of a high pressure fuel pump outside the cavity. A jet pump and / or fuel vapor vent is arranged relative to the cavity to facilitate the elimination of fuel vapor flowing to the high pressure fuel pump.

Owner:TI GRP AUTOMOTIVE SYST LLC

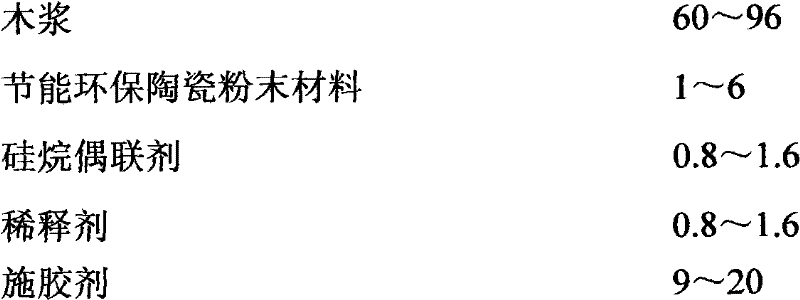

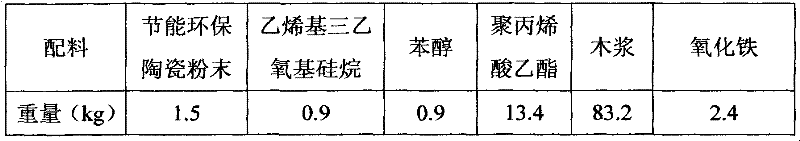

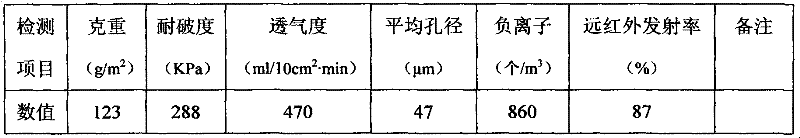

Filter paper of energy-saving and environment-friendly filter and making method thereof

ActiveCN102199903AHigh filtration precisionHigh burst resistanceInorganic fibres/flakesFiltration separationAir filterFuel filter

The invention relates to filter paper of an energy-saving and environment-friendly filter and a making method thereof. The filter paper is made from an energy-saving and environment-friendly ceramic powder material, a silane coupling agent, a dilute, a sizing agent and wood pulp. The filter paper can be made into an air filter and a fuel filter so as to improve the power performance by 6-12%, save the fuel by 2-5% and reduce pollutants in discharged tail gas by 16-47%.

Owner:北京联飞翔科技股份有限公司

In-tank fuel supply apparatus

A fuel supply apparatus for installation in a fuel tank includes a fuel pump, a housing, and a filter element disposed in the housing and having an upstream side communicating with the discharge port of the fuel pump. A check valve communicates with a downstream side of the fuel filter, and a pressure regulator communicates with the upstream side of the filter element. A sedimentation flow path may be provided for removing sediment from fuel discharged from the pressure regulator. The sedimentation flow path may be substantially cylindrical vortex spaces between fins disposed on the inner periphery of the pump holder and has blind holes at the bottom for trapping the sediments.

Owner:MITSUBISHI ELECTRIC CORP

Injector fuel filter with built-in orifice for flow restriction

ActiveUS20070227984A1Reduce pressure pulsationReduce or eliminate pressure pulsations through the fuel injectorSedimentation separationMachines/enginesEngineeringFuel filter

Owner:DELPHI TECH IP LTD

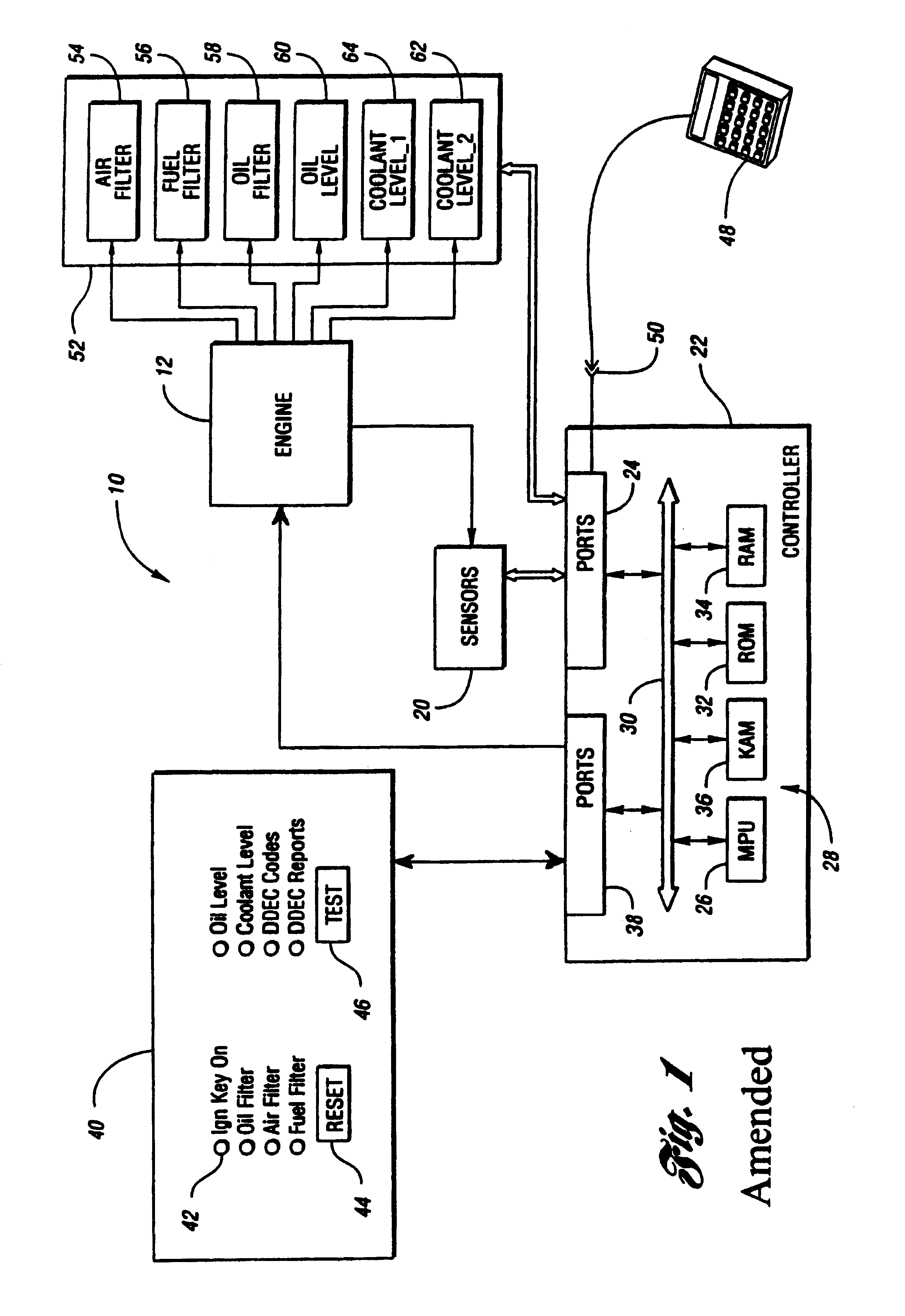

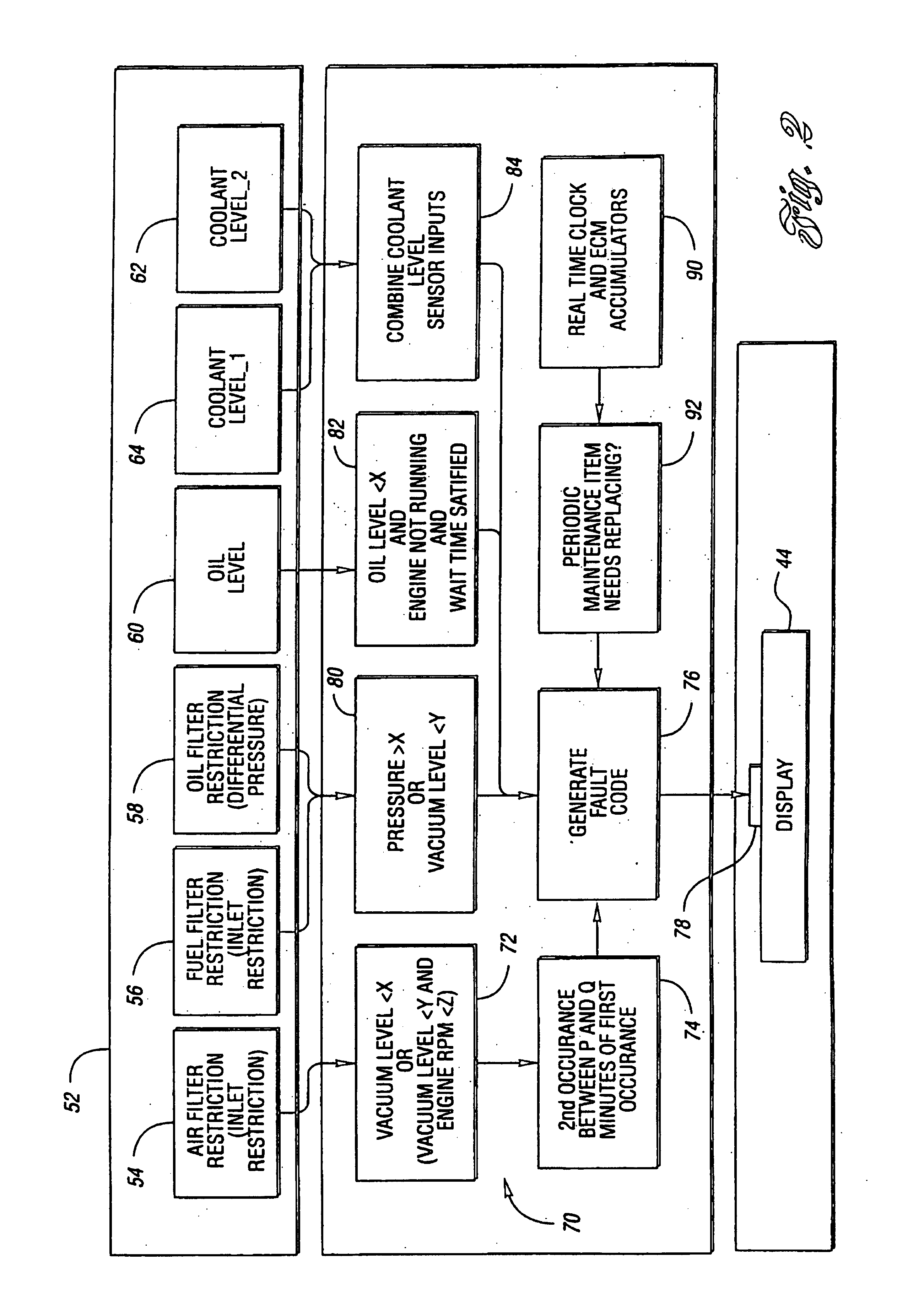

Maintenance alert system for heavy-duty trucks

A real-time maintenance alert system and method for use in a heavy-duty truck having an engine controller with memory are provided. The system includes a sensor operative to indicate an engine condition from the group consisting of: oil filter restriction, air filter restriction, fuel filter restriction, oil level, and coolant reserve tank fluid level. Control logic at the engine controller processes the sensor signal to determine a real-time fault condition, when appropriate.

Owner:DETROIT DIESEL CORP

Fuel filter arrangement

ActiveUS20060076287A1Improve filtering effectImprove performanceCombination devicesJet pumpsEngineeringLiquid fuel

A fuel filter and vapor separator arrangement having at least one layer of liquid fuel permeable material defining at least one substantially enclosed cavity. The permeable material has at least one opening to provide fluid communication of liquid fuel within the cavity with an inlet of a high pressure fuel pump outside the cavity. A jet pump and / or fuel vapor vent is arranged relative to the cavity to facilitate the elimination of fuel vapor flowing to the high pressure fuel pump.

Owner:TI GRP AUTOMOTIVE SYST LLC

Fuel supply apparatus

InactiveUS20050155583A1Easy constructionImprove the ease of assemblyMachines/enginesLiquid fuel feedersFuel tankEngineering

A fuel supply apparatus capable of following the positional variations of the bottom side of a fuel tank through a simple construction and improved in terms of ease of assembly in the fuel tank. The apparatus includes a fuel pump body in which a filter-integrated pump in which a fuel pump and a fuel filter are integrally formed is integrally accommodated in a fuel reservoir having a bottom capable of coming into abutment with a bottom side of the fuel tank, and causes the fuel pump body to travel to follow the variations of the bottom side of the fuel tank so as to be placed in abutment with the bottom side of the fuel tank, by means of an urging force generated on the basis of the pressure of the fuel inside the fuel pump body.

Owner:MITSUBISHI ELECTRIC CORP

Fuel filter

ActiveUS8173013B2High filtration precisionLow priceWater/sewage treatmentMembrane filtersFuel tankFuel filter

Disclosed is a fuel filter in which is disposed in a fuel suction port of a fuel tank or in a fuel line and used to filter the fuel. At least one of filter materials constituting the fuel filter is made into a multifunctional filter material having a function of trapping dust of different particle diameters in stages, by differing the diameter of the pores in the filter material from the primary side to the secondary side of the filter material so that the size of the pores decreases toward the secondary side.

Owner:NIFCO INC

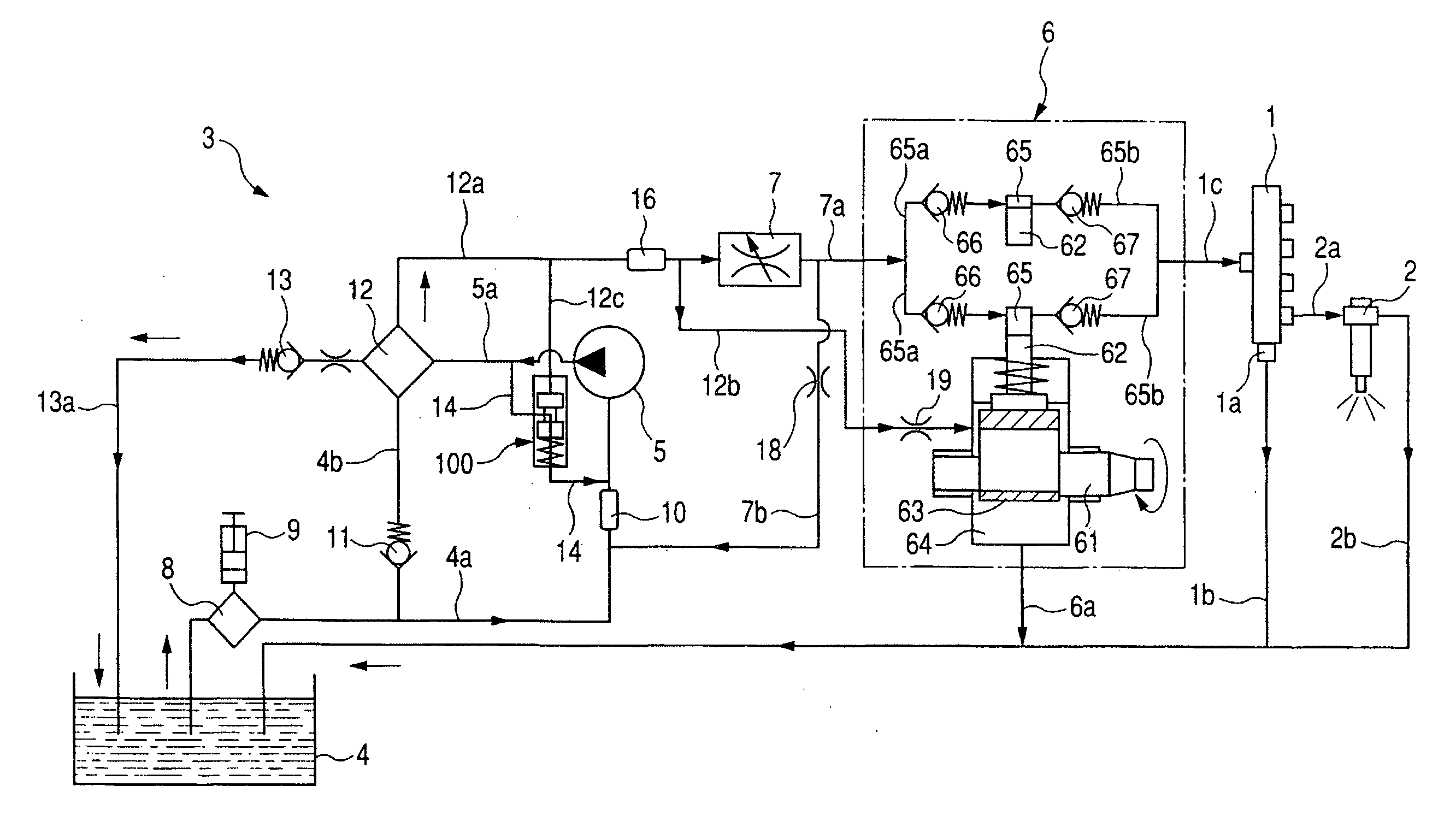

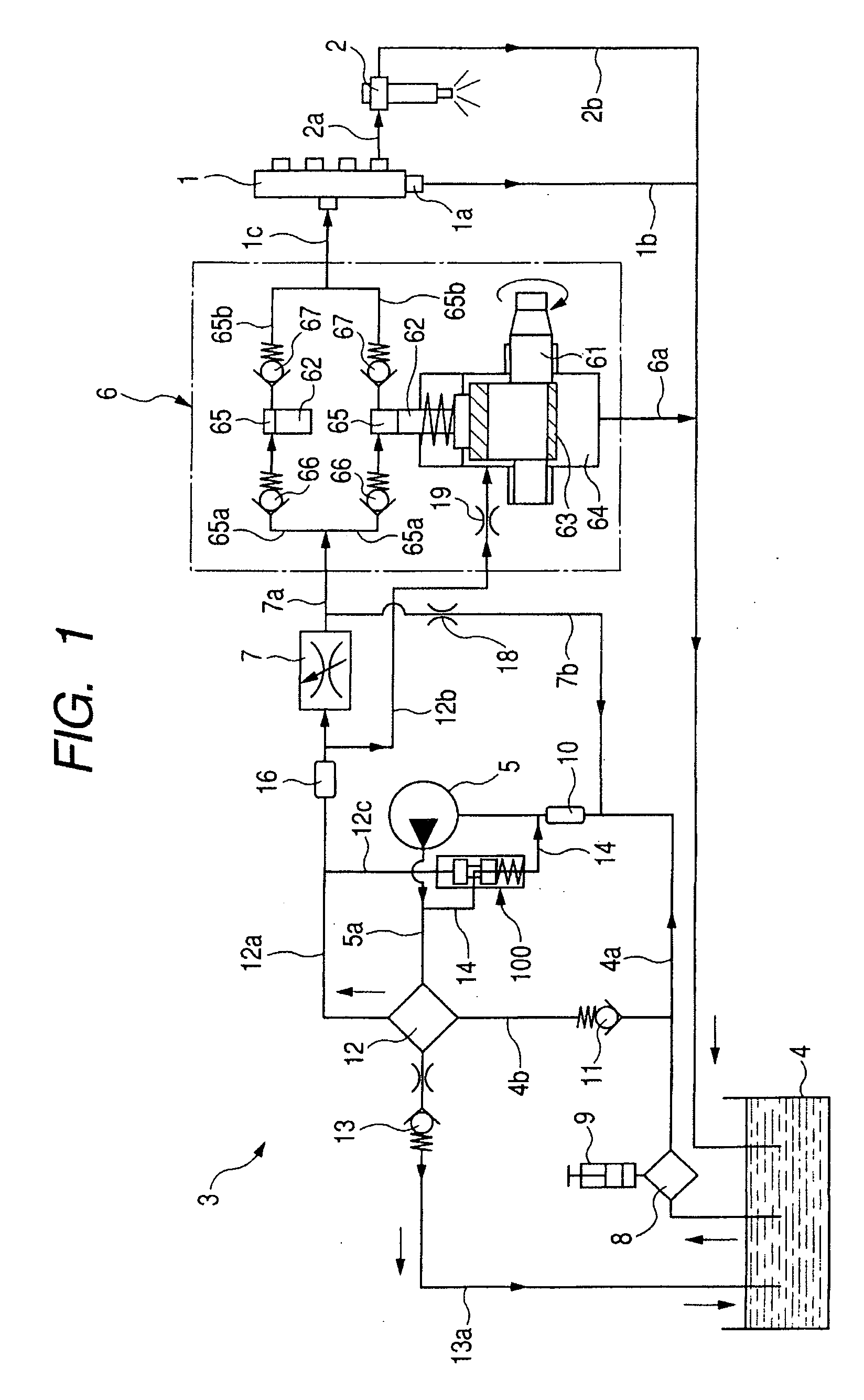

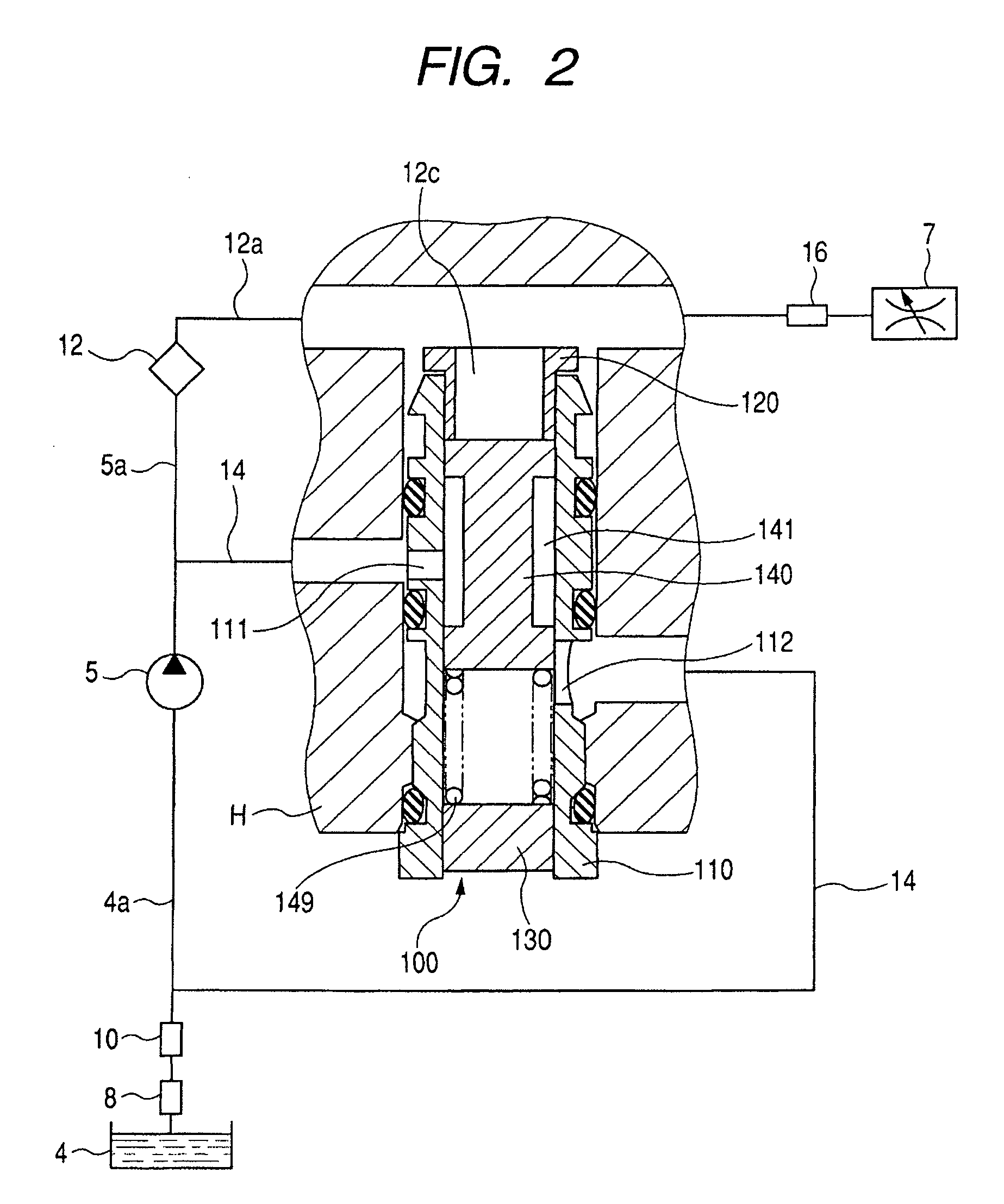

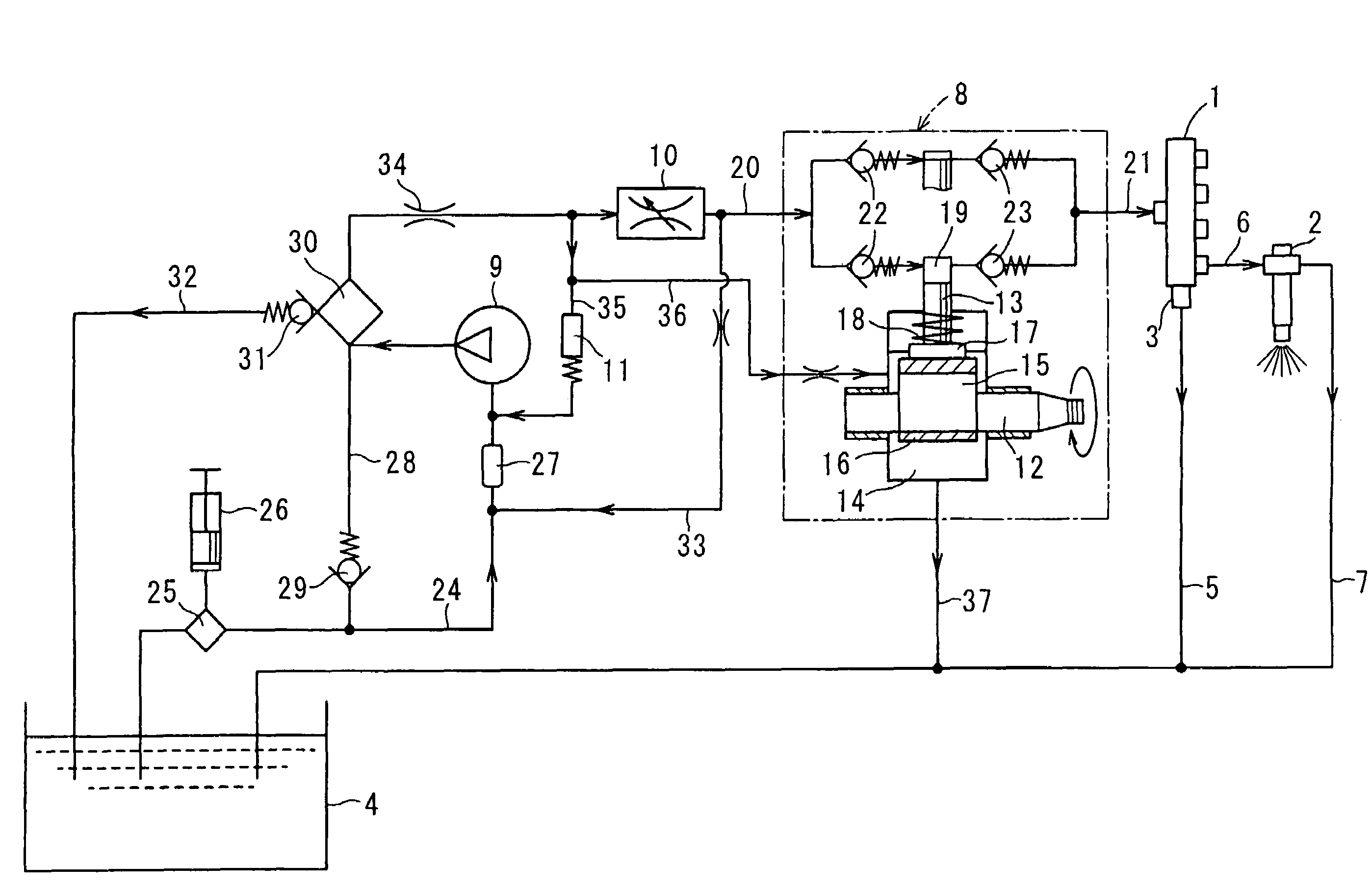

Fuel supply system having fuel filter installed downstream of feed pump

ActiveUS20090145402A1Simple structureEnsure mountabilityLow pressure fuel injectionMachines/enginesSystems designFuel tank

A fuel supply system for an accumulator fuel injection system designed to inject fuel, as stored in an accumulator, into an internal combustion engine through a fuel injector The fuel supply system includes a feed pump working to pump the fuel out of a fuel tank and a fuel filter disposed between the feed pump and a high-pressure pump working to deliver the fuel to the accumulator. The fuel supply system also includes a return path and a control valve. When the pressure of the fuel between the fuel filter and the flow rate control valve exceeds a first set pressure, the control valve opens the return path to return the fuel from downstream to upstream of the feed pump to keep the pressure of fuel supplied to the flow rate control valve below the first set pressure, thereby controlling the flow rate of the fuel passing through the fuel filter.

Owner:DENSO CORP

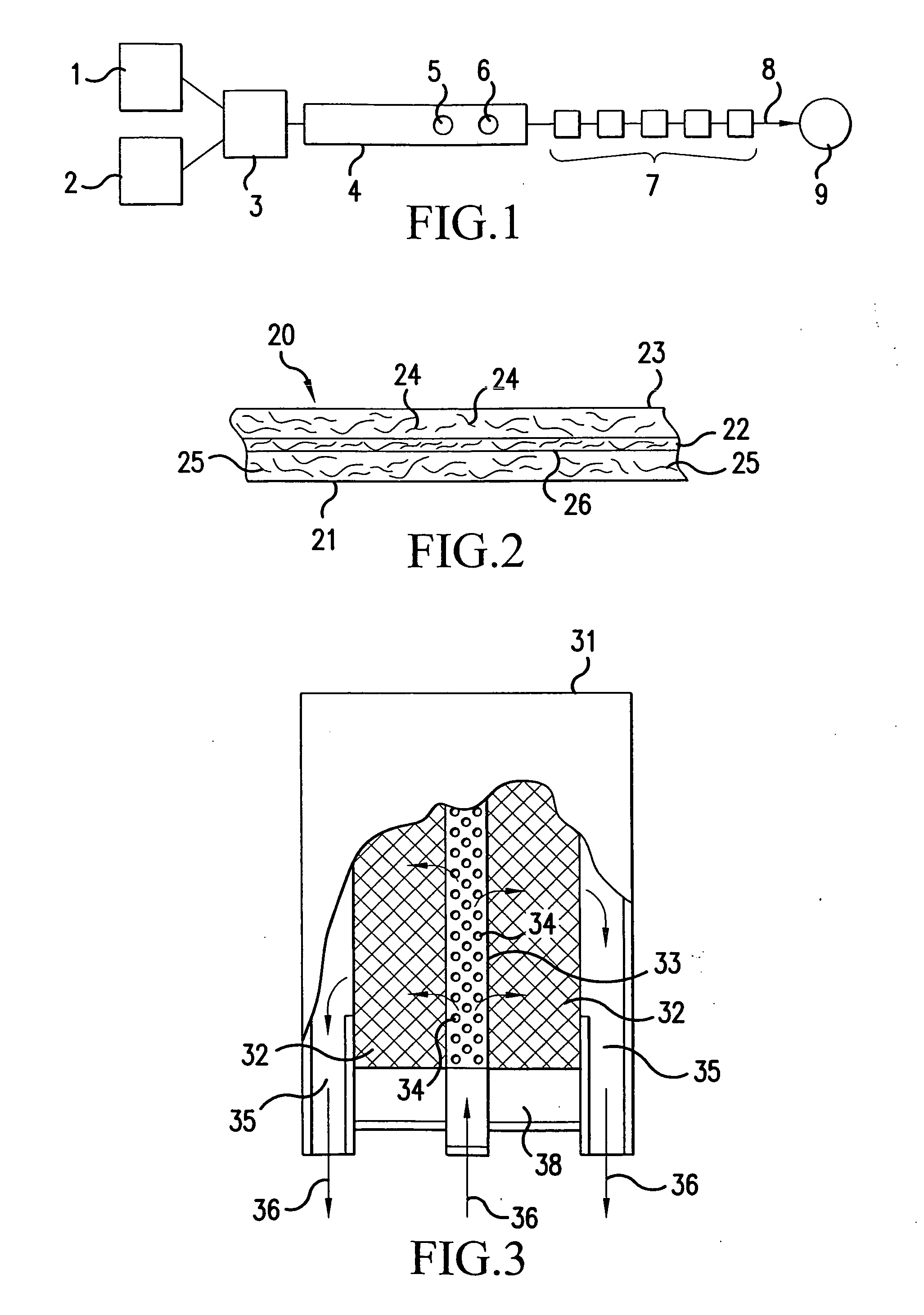

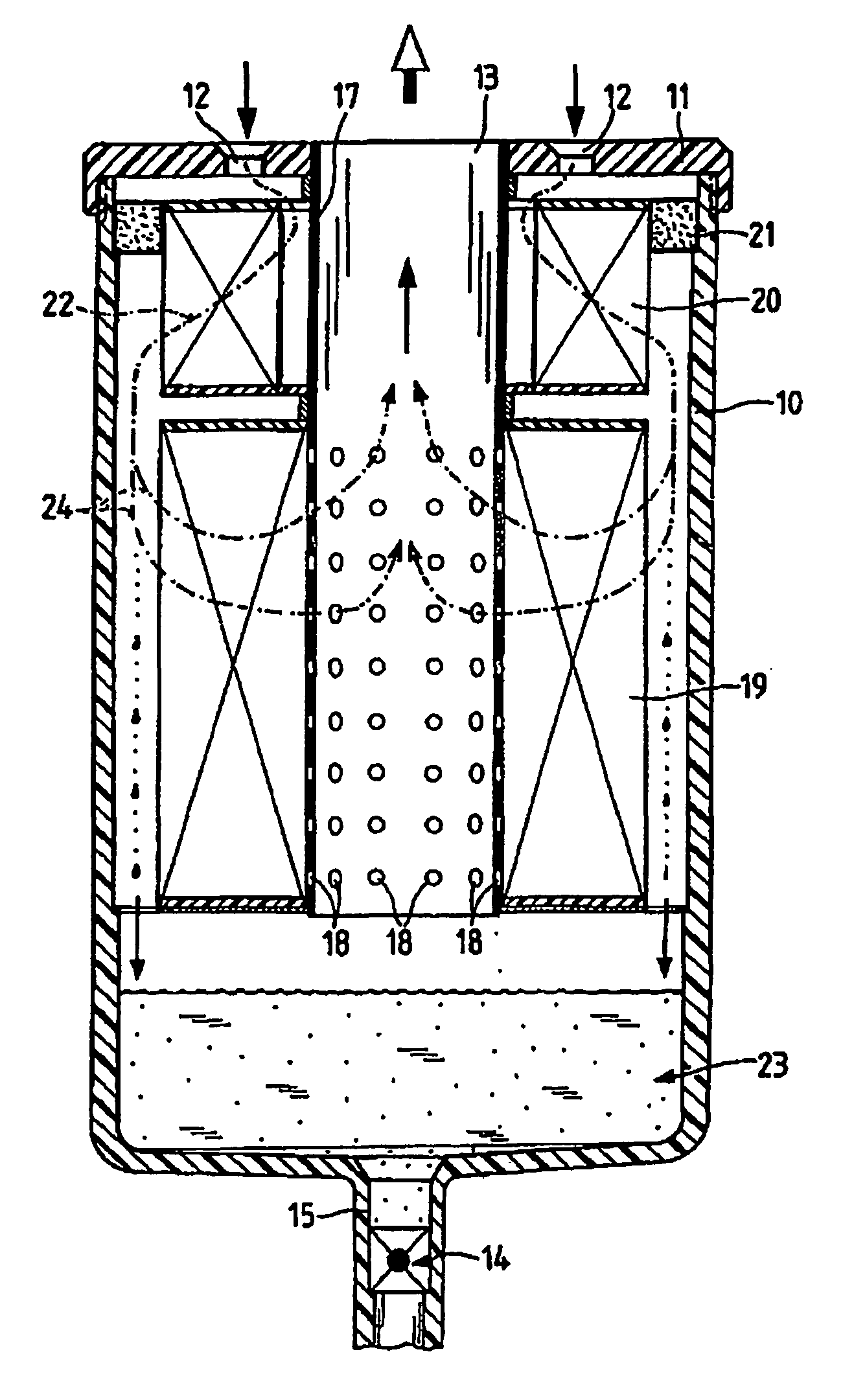

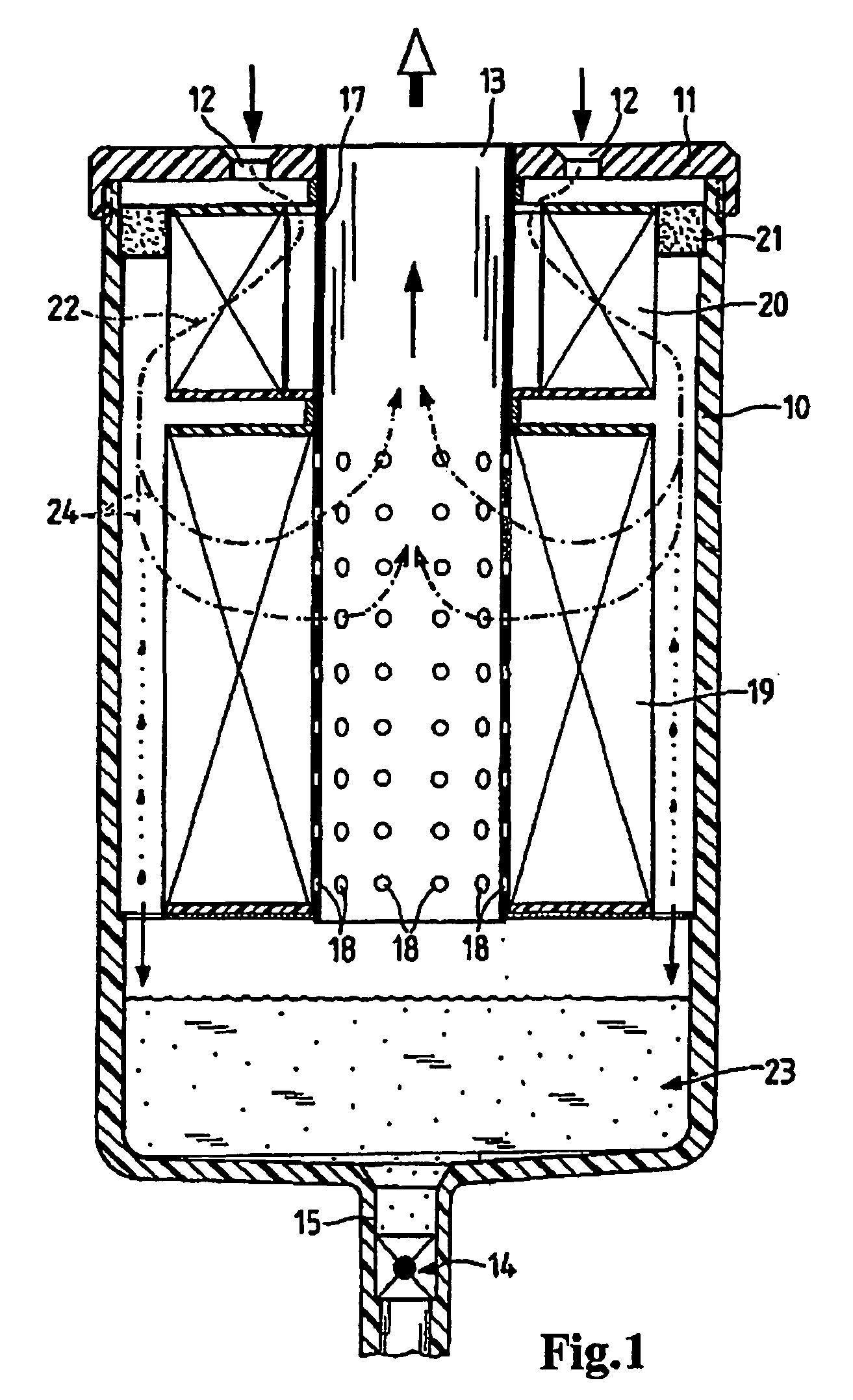

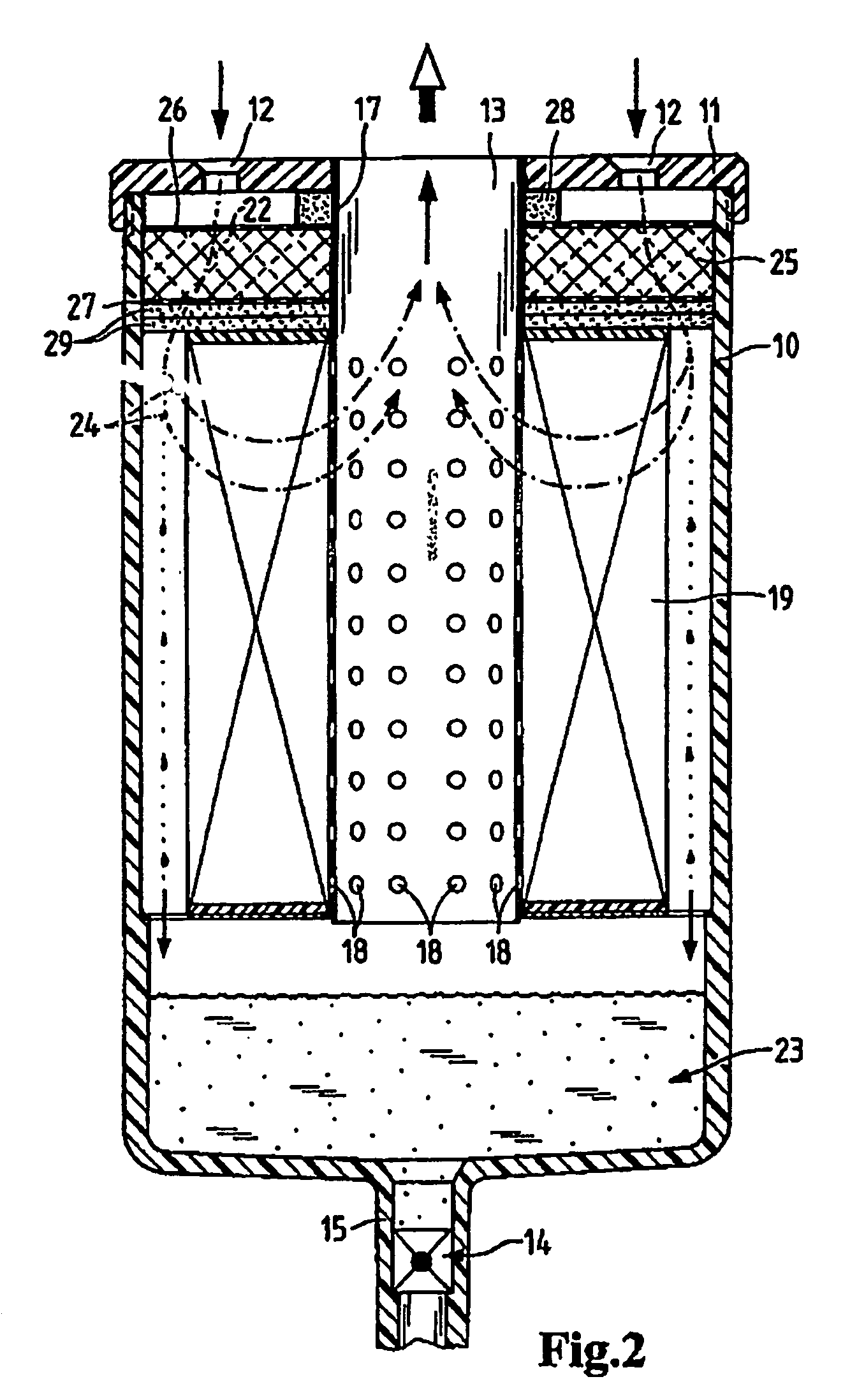

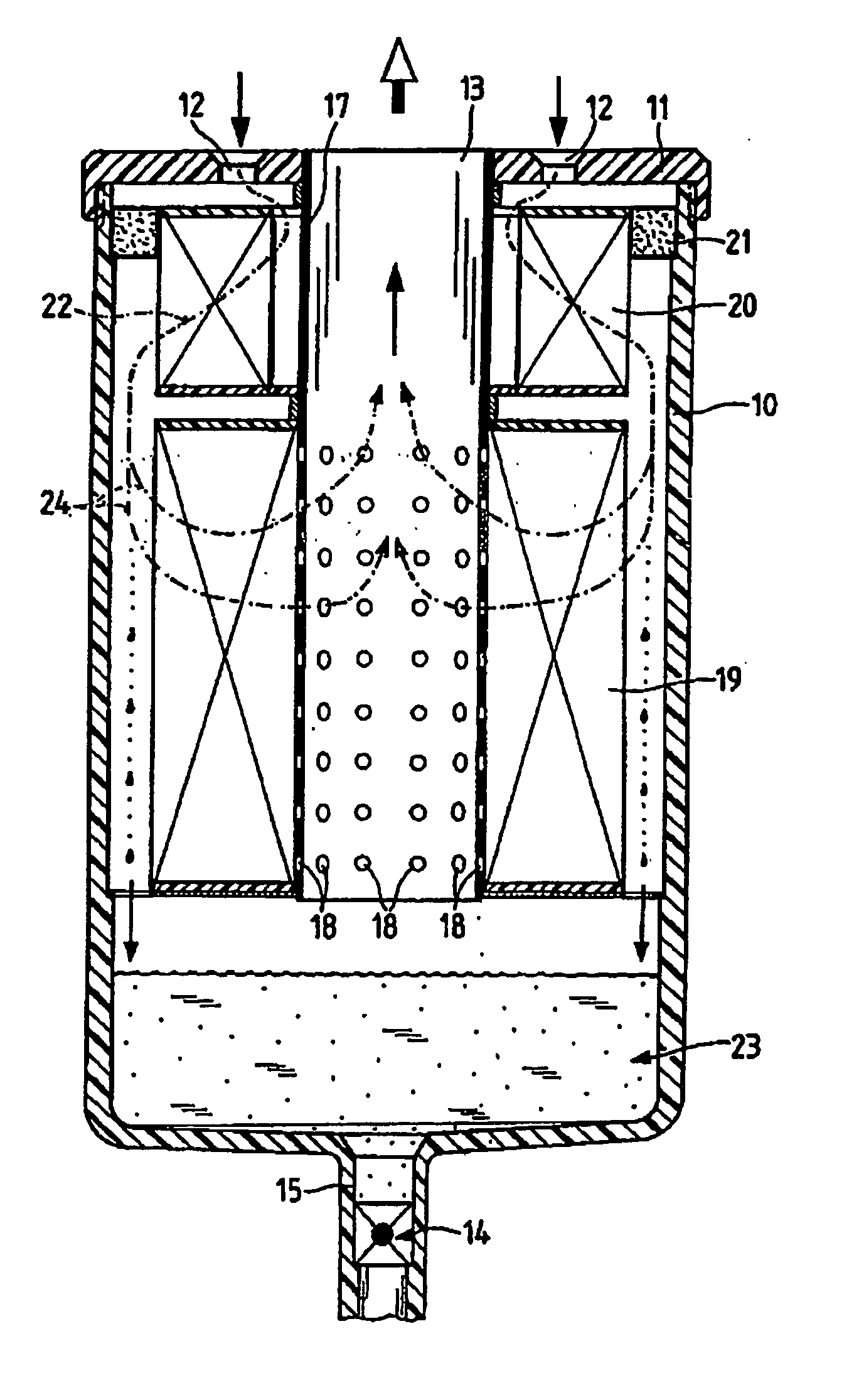

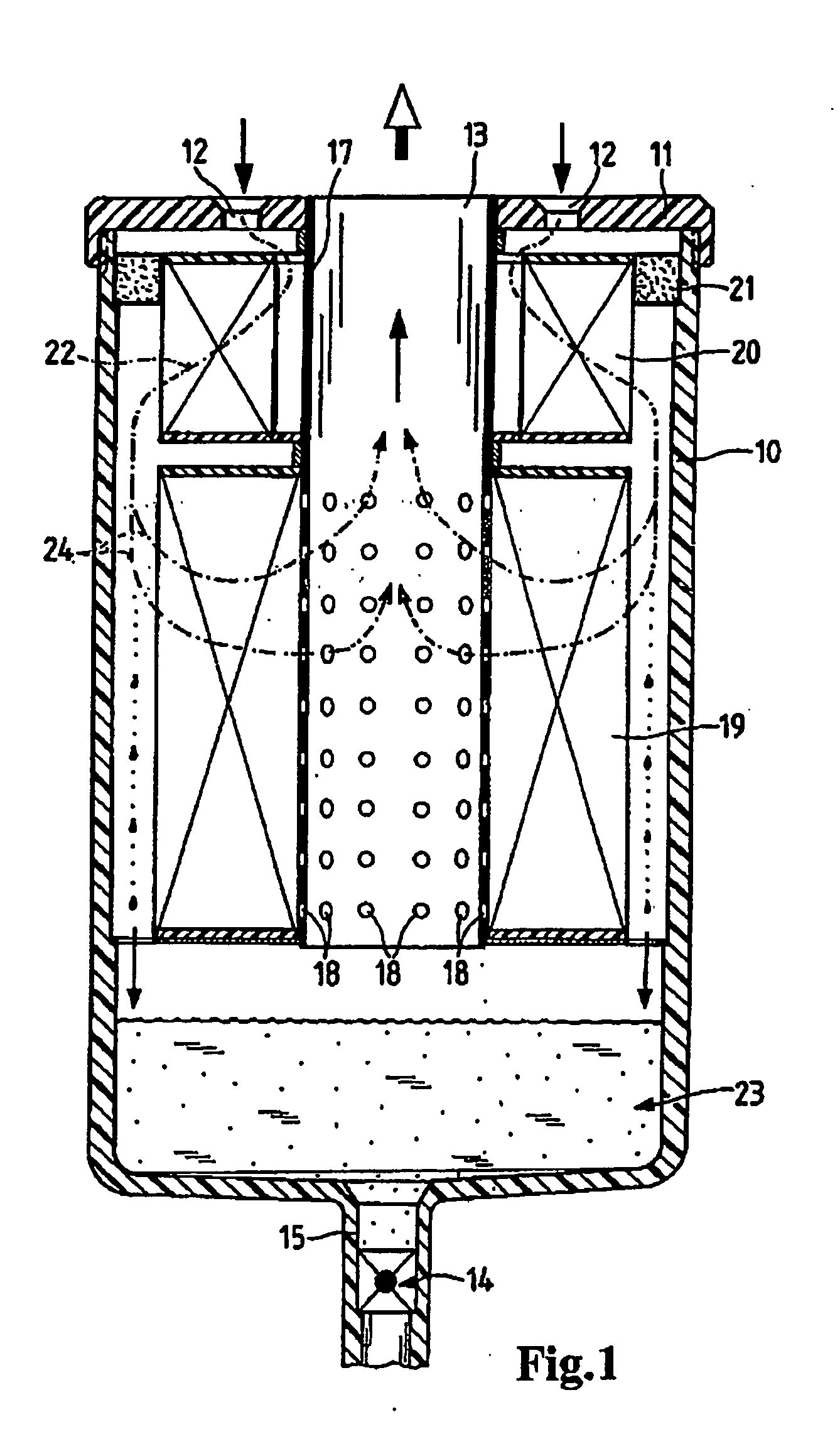

Fuel filter system

ActiveUS7938963B2Efficient separationAvoid disadvantagesSeparation devicesSedimentation separationFilter systemFuel filter

A fuel filter system, particularly a diesel filter, including a housing, a particle filter arranged in the housing, and a coalescer element mounted on the particle filter. Fuel passes successively through the serially connected coalescer and particle filter. The coalescer element improves the separation of any water contained in the fuel to be filtered, while exhibiting no or no significant fuel-filtering properties.

Owner:MANN HUMMEL GMBH

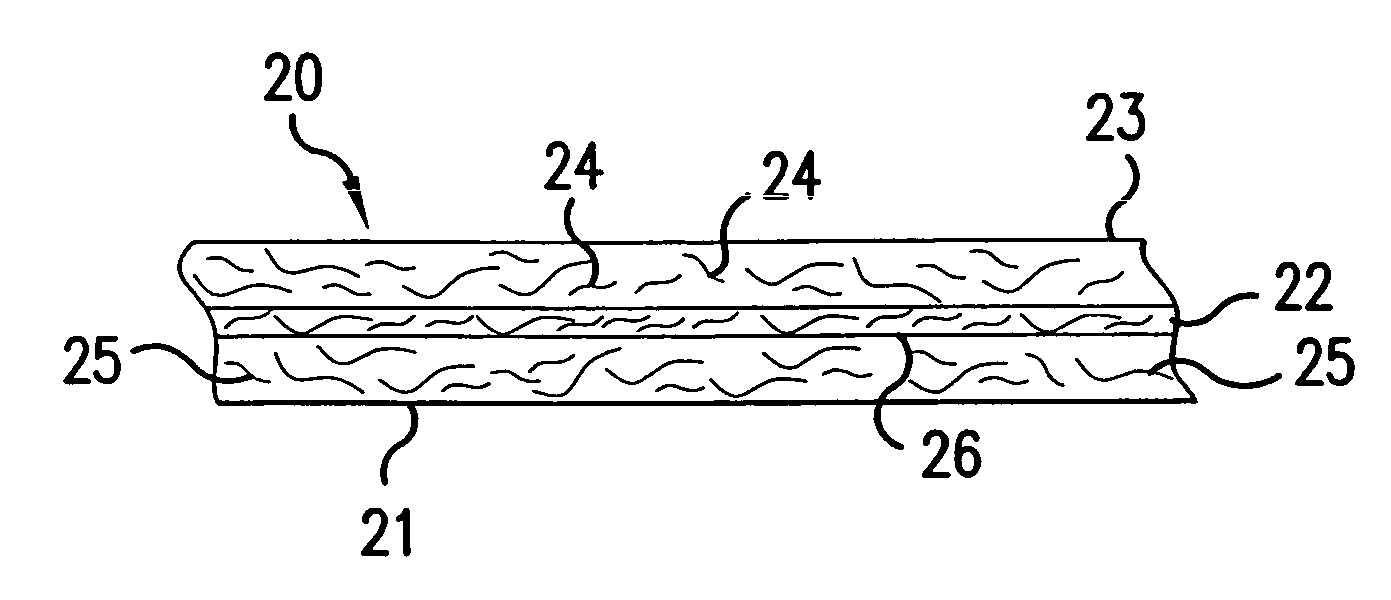

Fuel filter

Disclosed herein is an engine fuel filter containing a filter medium of a filtering mass of a nanoweb preferably situated between two scrims. The scrims can be nonwoven webs and the filtering mass is located in an enclosure so as to be crossed by the fuel in its path inside the filter. The nanoweb has a basis weight between about 1.5 gsm and about 40 gsm, and can be in face-to-face and fluid contact with either or both of the upstream and downstream scrims. The nanoweb does not contain glass.

Owner:EI DU PONT DE NEMOURS & CO

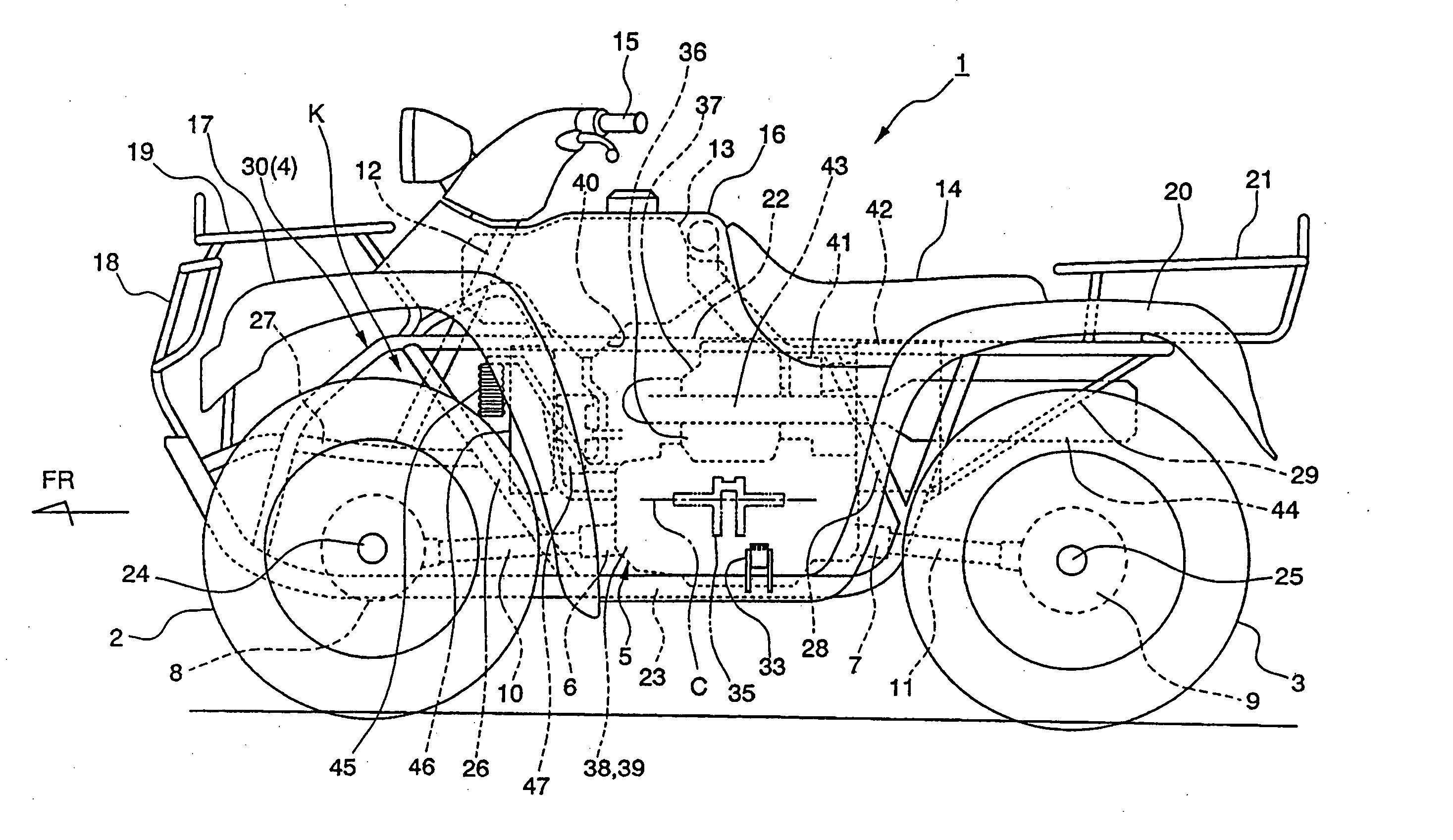

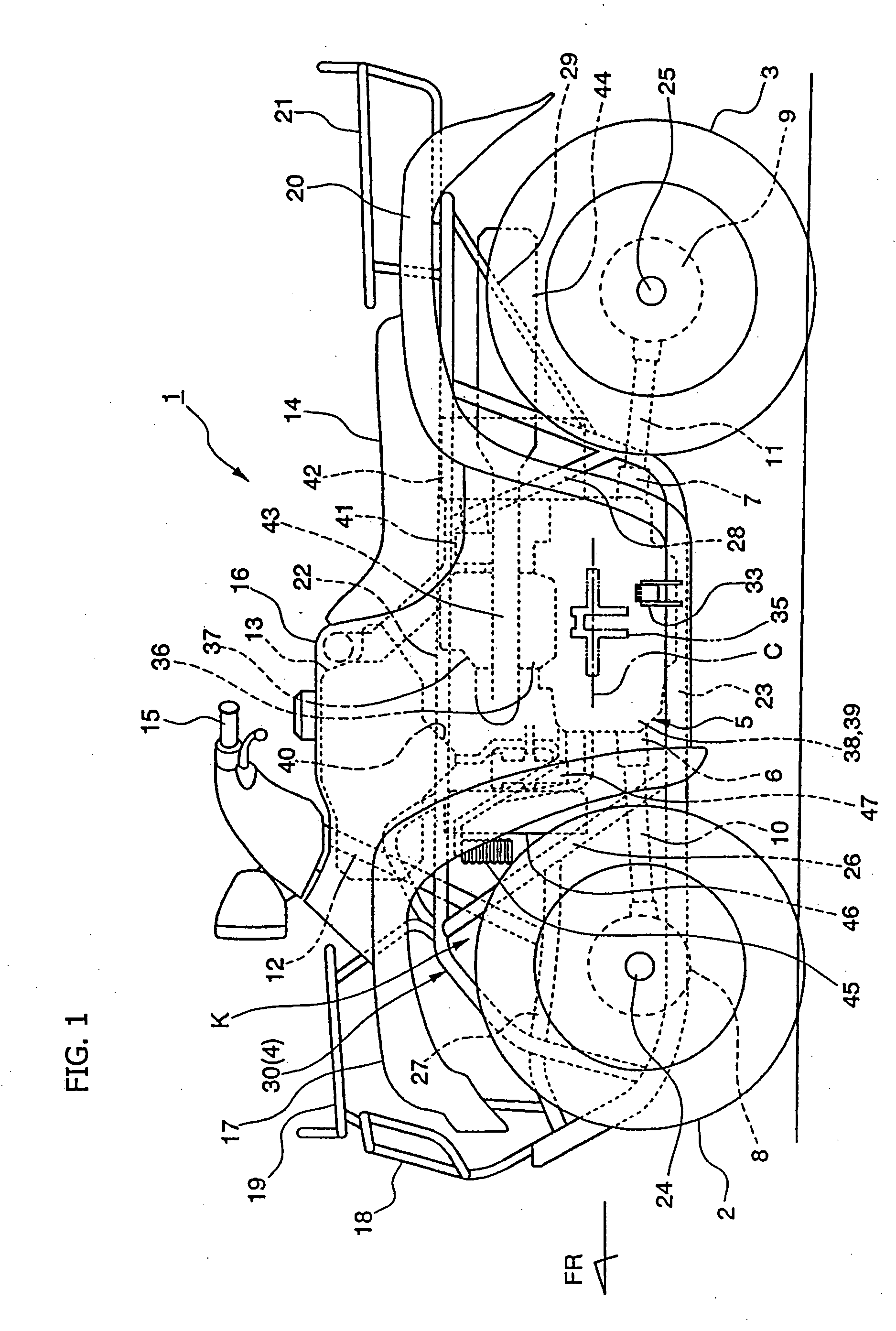

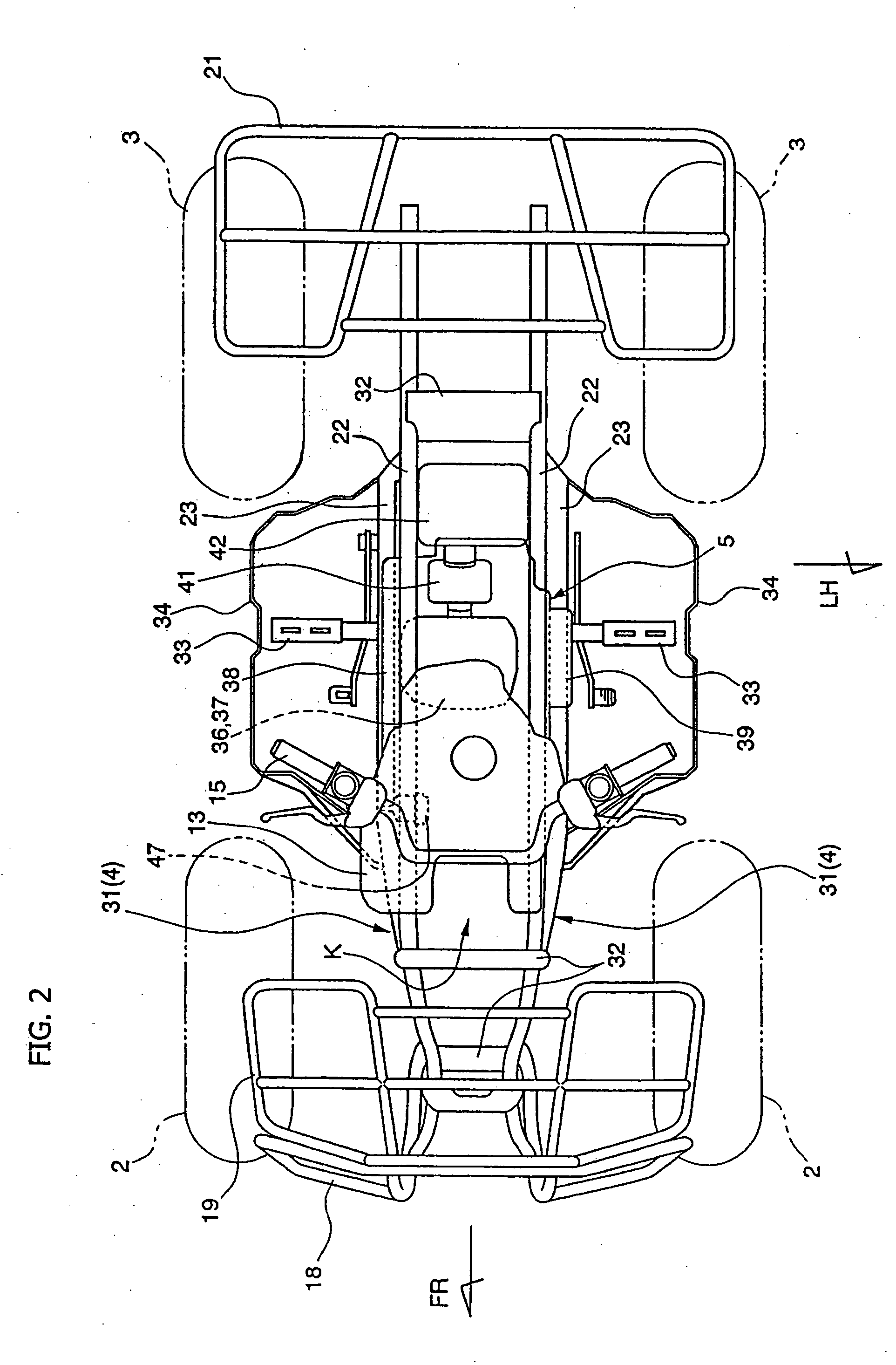

Fuel injection system and related structure for a four-wheeled saddle-type vehicle

InactiveUS20050150706A1Less likely to draw mudLess likely to dustElectric propulsion mountingGas pressure propulsion mountingTerrainCylinder head

A saddle riding type four-wheeled vehicle, suitable for rough terrain running, includes an engine having an electronically controlled fuel injection system. The vehicle also includes a throttle body disposed in back of a cylinder head of the engine. This configuration substantially protects the engine from drawing in mud, dust, and the like, and also eliminates the need for a protector of a throttle body. The fuel pump unit of the fuel injection system integrates the fuel pump, the fuel filter, and the pressure regulator into a single housing, to simplify the fuel piping required to connect different parts of the fuel supply system, as compared with conventional structures. This facilitates procedures of removing and installing the fuel tank and the fuel pump unit. The feature also reduces pumping loss of the fuel pump as well as parts cost.

Owner:HONDA MOTOR CO LTD

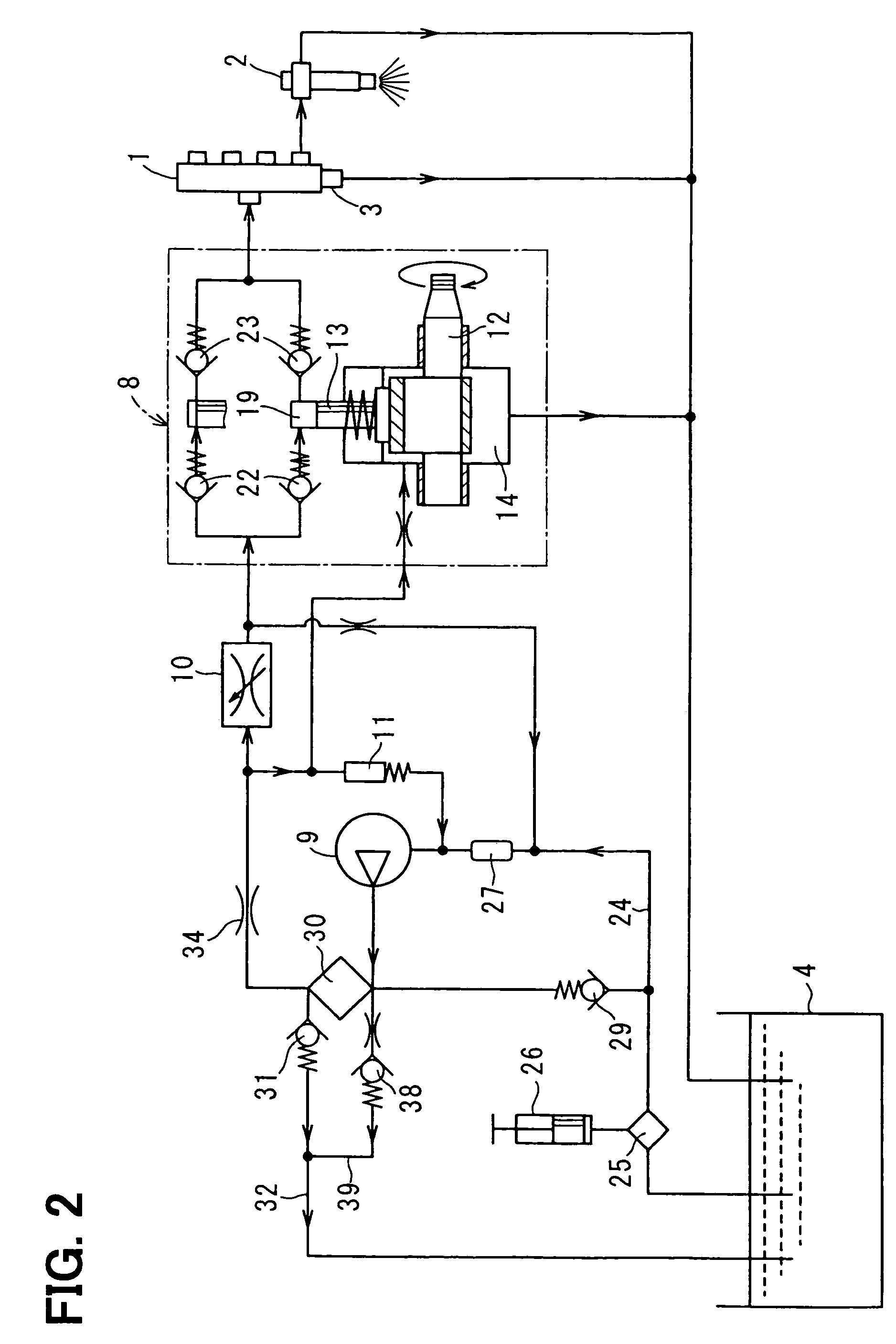

Fuel supply device

ActiveUS7343901B2Small sizeIncrease in sizeLow pressure fuel injectionMachines/enginesPositive pressureFuel filter

A fuel filter is located downstream of a feed pump to filter fuel discharged from the feed pump. An orifice is located between the fuel filter and a suction quantity control valve to restrict a flow rate of the fuel passing through the fuel filter. A positive pressure of the feed pump is applied to the fuel filter, and a passing pressure at the fuel filter increases. Even if viscosity of the fuel increases and the fuel becomes wax-like at low temperature, clogging of the fuel filter or an insufficient flow rate can be inhibited. The orifice restricts the flow rate of the fuel passing through the fuel filter. Accordingly, an increase in size of the fuel filter can be prevented even if the fuel filter is located downstream of the feed pump.

Owner:DENSO CORP

Fuel filter system

ActiveUS20060006109A1Improves separation of waterEfficient separationSeparation devicesSedimentation separationEngineeringFuel filter

A fuel filter system, particularly a diesel filter, including a housing, a particle filter arranged in the housing, and a coalescer element mounted on the particle filter. Fuel passes successively through the serially connected coalescer and particle filter. The coalescer element improves the separation of any water contained in the fuel to be filtered, while exhibiting no or no significant fuel-filtering properties.

Owner:MANN HUMMEL GMBH

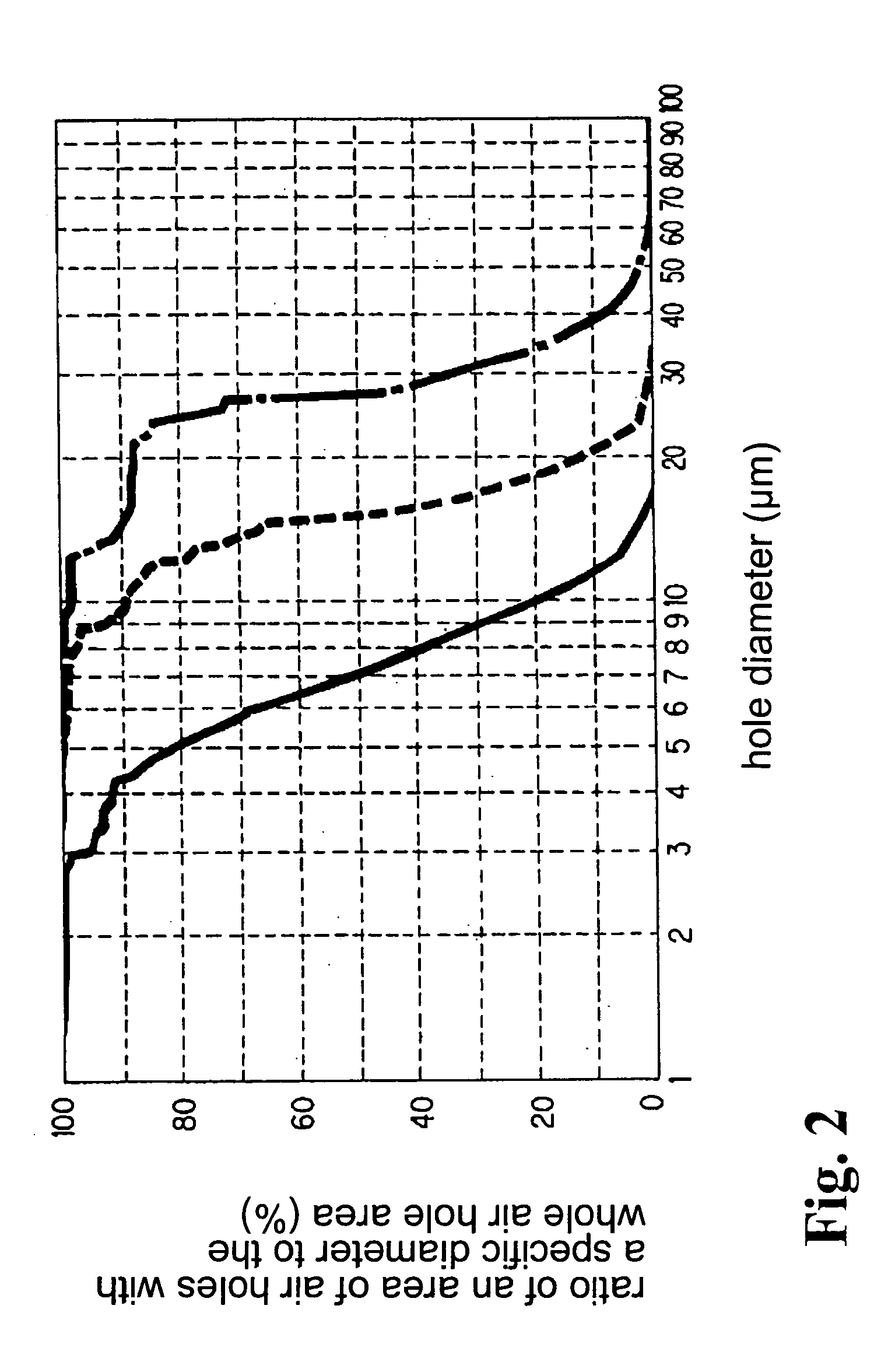

Fuel filter device

InactiveUS20050023201A1Easy to integrateEliminate cloggingWater/sewage treatmentMachines/enginesFuel filterEngineering

A filter member includes at least two non-woven layers, wherein one non-woven layer has air holes with an average diameter different from those of the other non-woven layer. Among the non-woven layers, the non-woven layer located on an inner side of the filter member has the air holes with the average diameter smaller than those of the non-woven layers located on an outer side of the non-woven layer. Also, the non-woven layers are formed with a melt blown method, so that the filtering slope becomes gentle. In the fuel filter device, it is possible to reduce clogging of the filter member as little as possible while improving the filtering accuracy of the filter member.

Owner:NIFCO INC

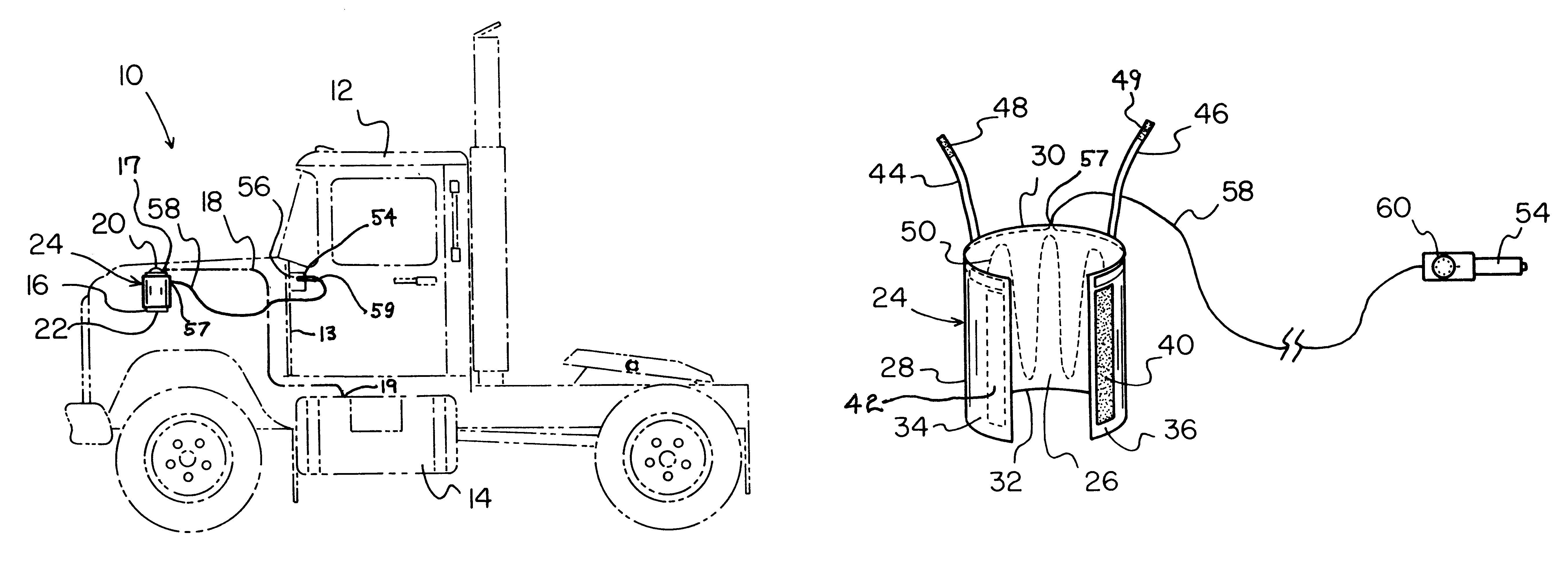

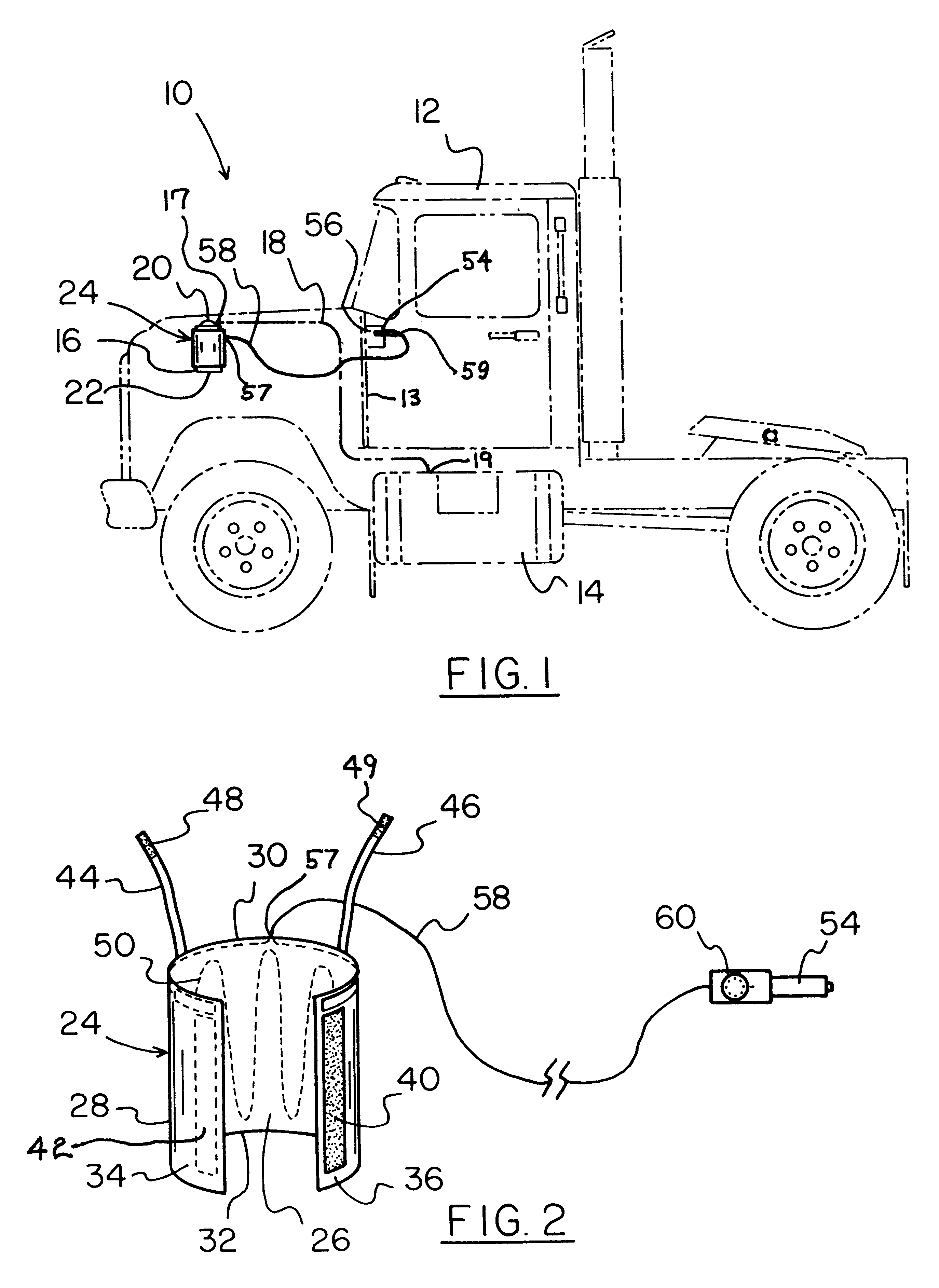

Thermal filter blanket

An electric blanket that can be wrapped around the fuel filter and powered by the automotive vehicle battery by means of a cigarette lighter adapter.

Owner:WHITE JAY P +1

Fuel filter

InactiveUS20110192786A1Easy and inexpensive to manufactureReduce the number of partsMachines/enginesCartridge filtersFuel tankEngineering

A fuel filter for filtering engine fuel received in a fuel tank when the engine fuel is fed to an engine may include a filter member that is received in the fuel tank and is capable of being connected to a fuel inlet port through which the engine fuel is drawn, and a wall member that is connected to a circumferential periphery of the filter member to form a container member. The wall member and the filter member are respectively arranged and constructed to function as a side portion and a bottom portion of the container member. The filter member is capable of being disposed in the fuel tank so as to draw the engine fuel received in the fuel tank through a side thereof that faces the bottom wall of the fuel tank.

Owner:AISAN IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com