Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

306results about How to "Reduce pressure pulsation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

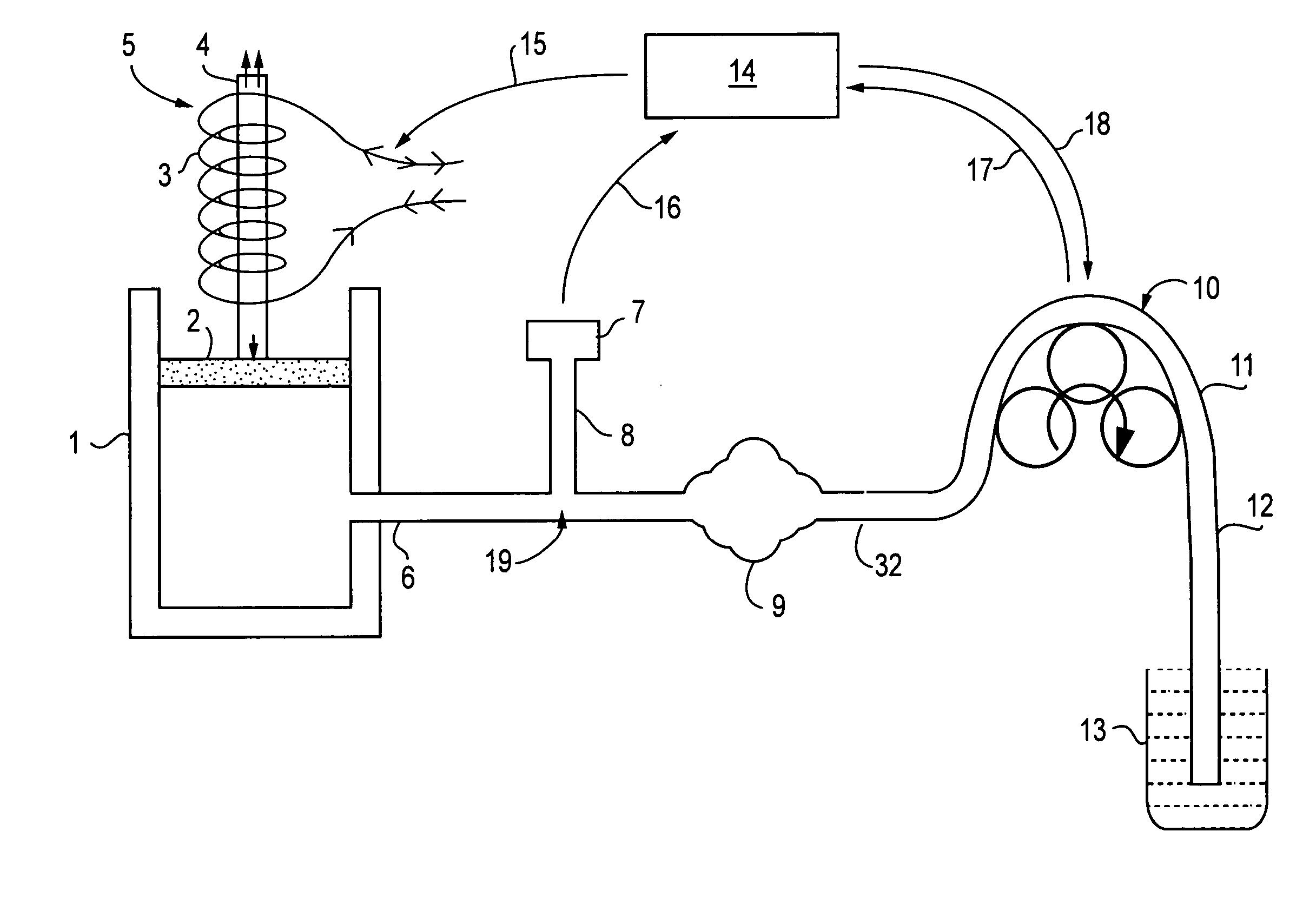

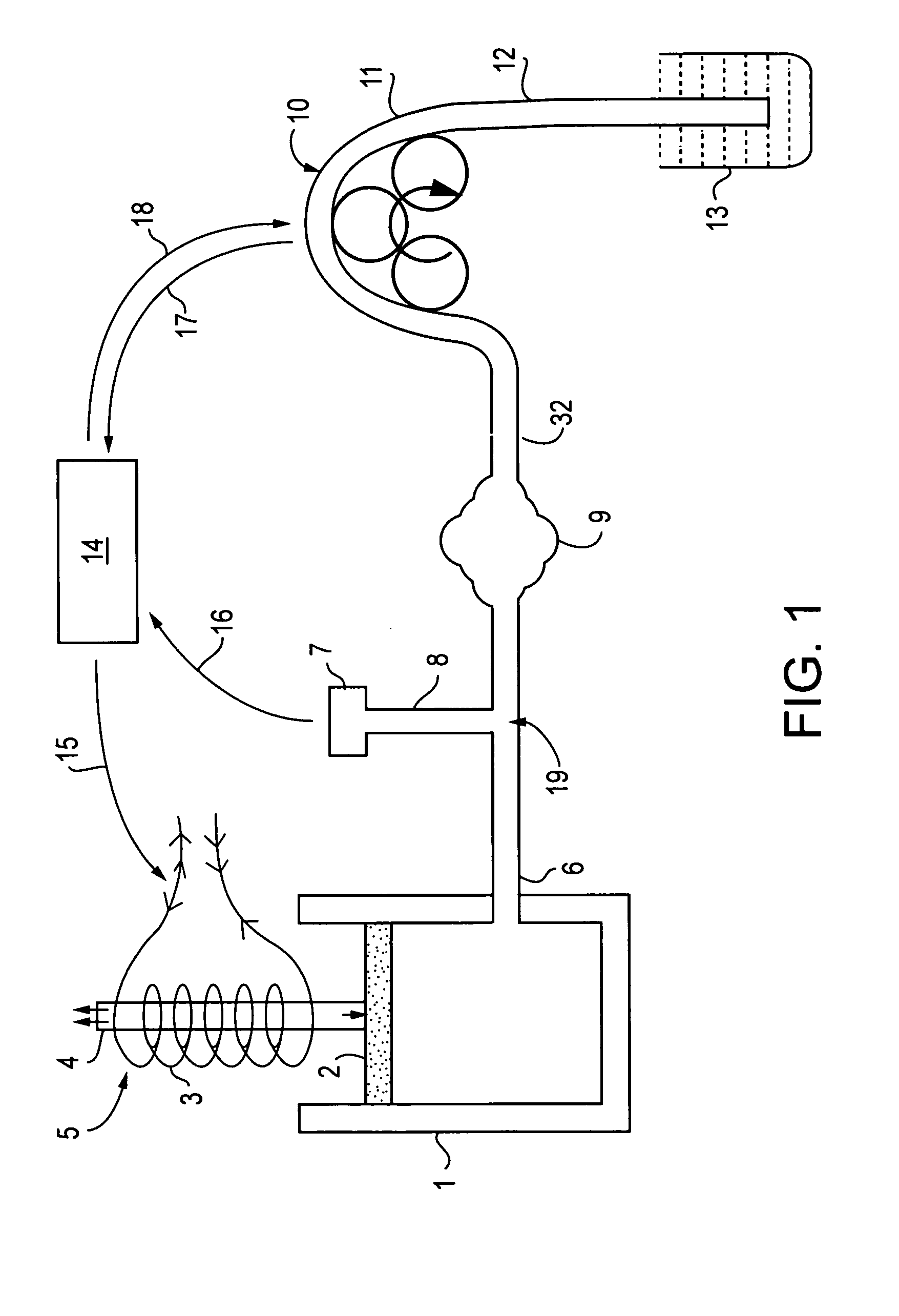

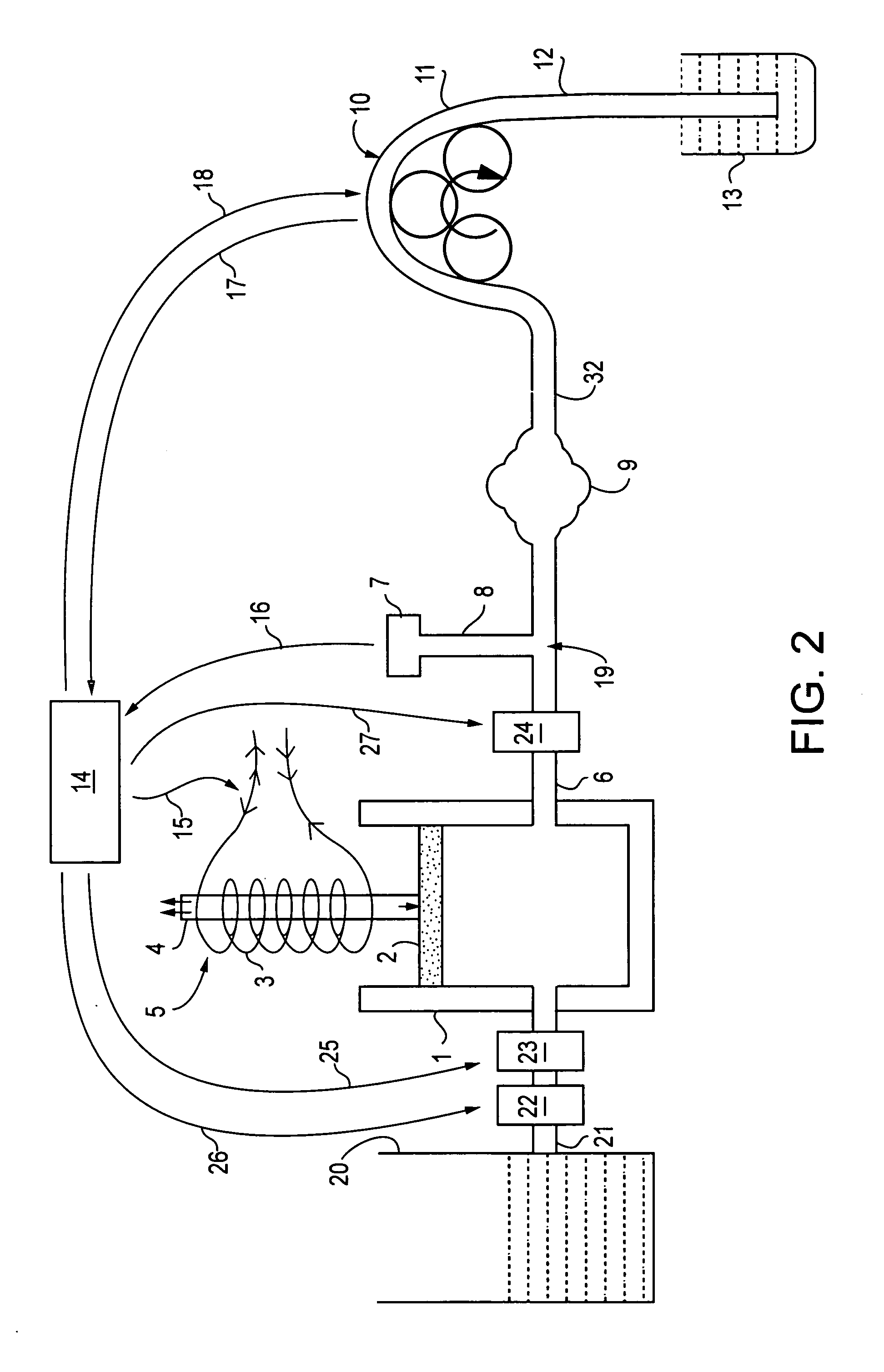

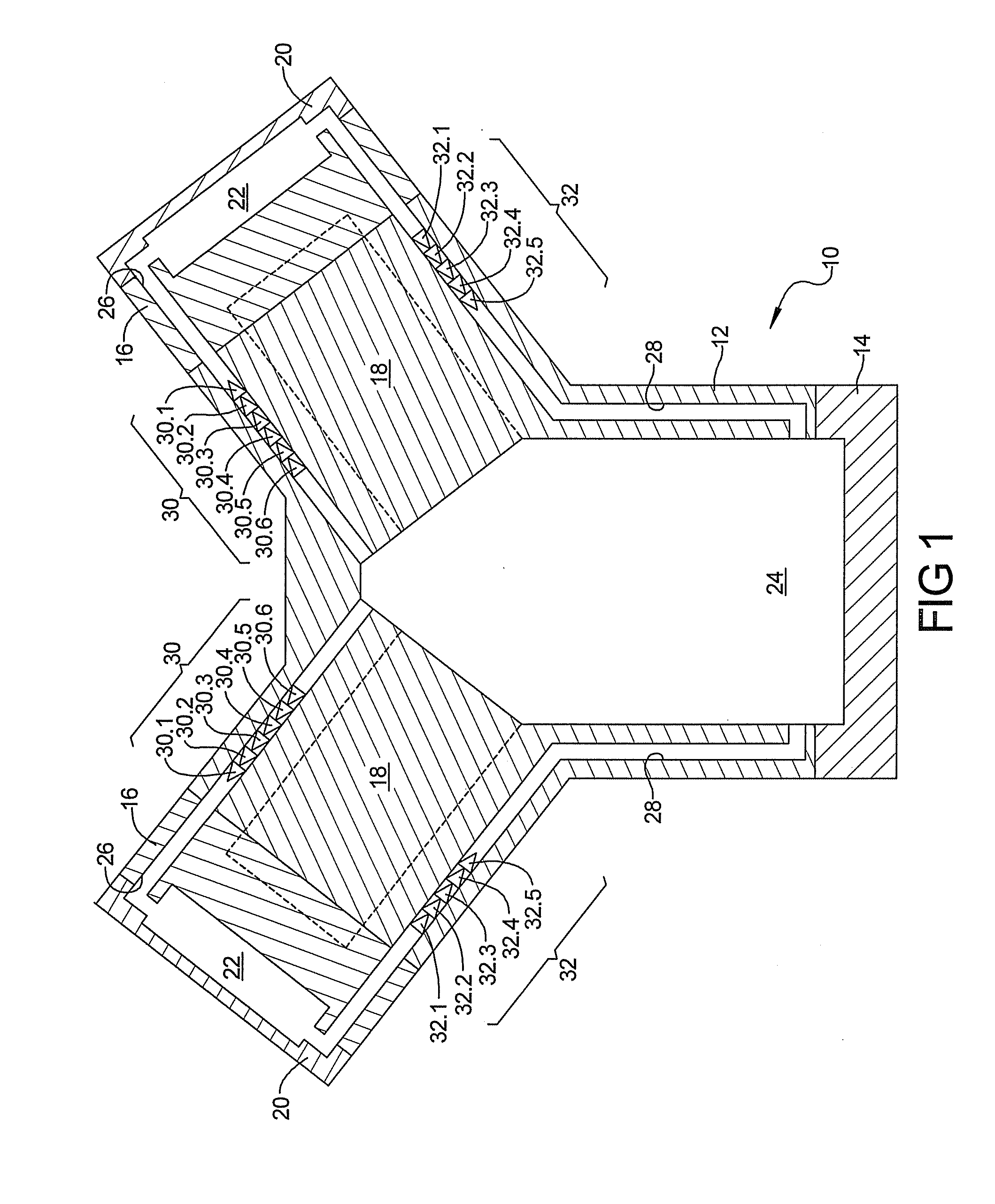

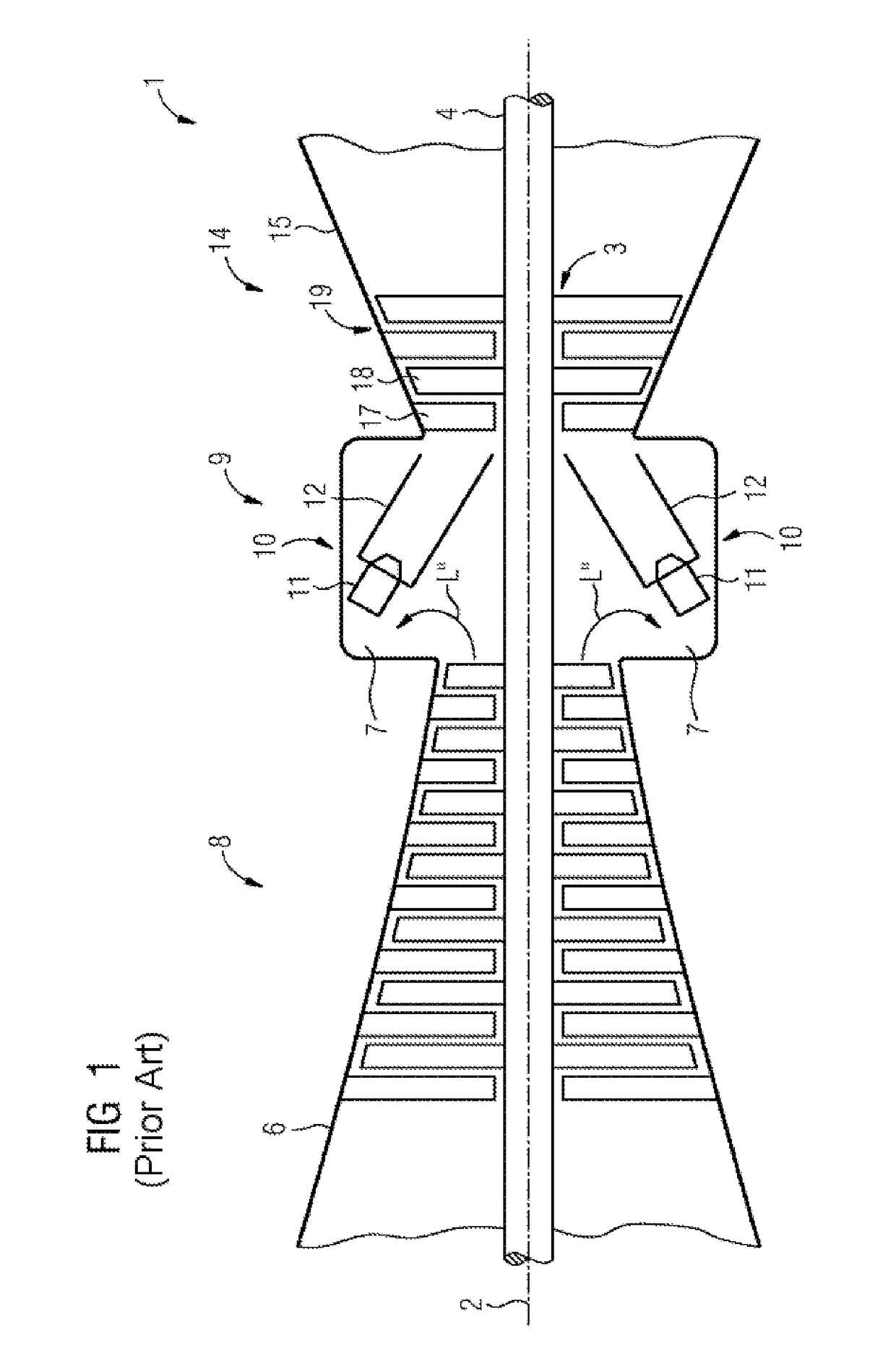

Electromagnetically controlled tissue cavity distending system

ActiveUS20060052666A1Accurate and reliable and simple mannerAltering valueJet injection syringesAutomatic syringesPeristaltic pumpEndoscopic Procedure

A system to minimize fluid turbulence inside a tissue cavity during endoscopic procedures. A body tissue cavity of a subject is distended by continuous flow irrigation using a solenoid operated pump on the inflow side and a positive displacement pump, such as a peristaltic pump, on the outflow side, such that the amplitude of the pressure pulsations created by the outflow positive displacement pump inside the said tissue cavity is substantially dampened to almost negligible levels. The present invention also provides a method for accurately determining the rate of fluid loss into the subject's body system during any endoscopic procedure without utilizing any deficit weight or fluid volume calculation, the same being accomplished by using two fluid flow rate sensors. The present invention also provides a system of creating and maintaining any desired pressure in a body tissue cavity for any desired cavity outflow rate.

Owner:KUMAR BV

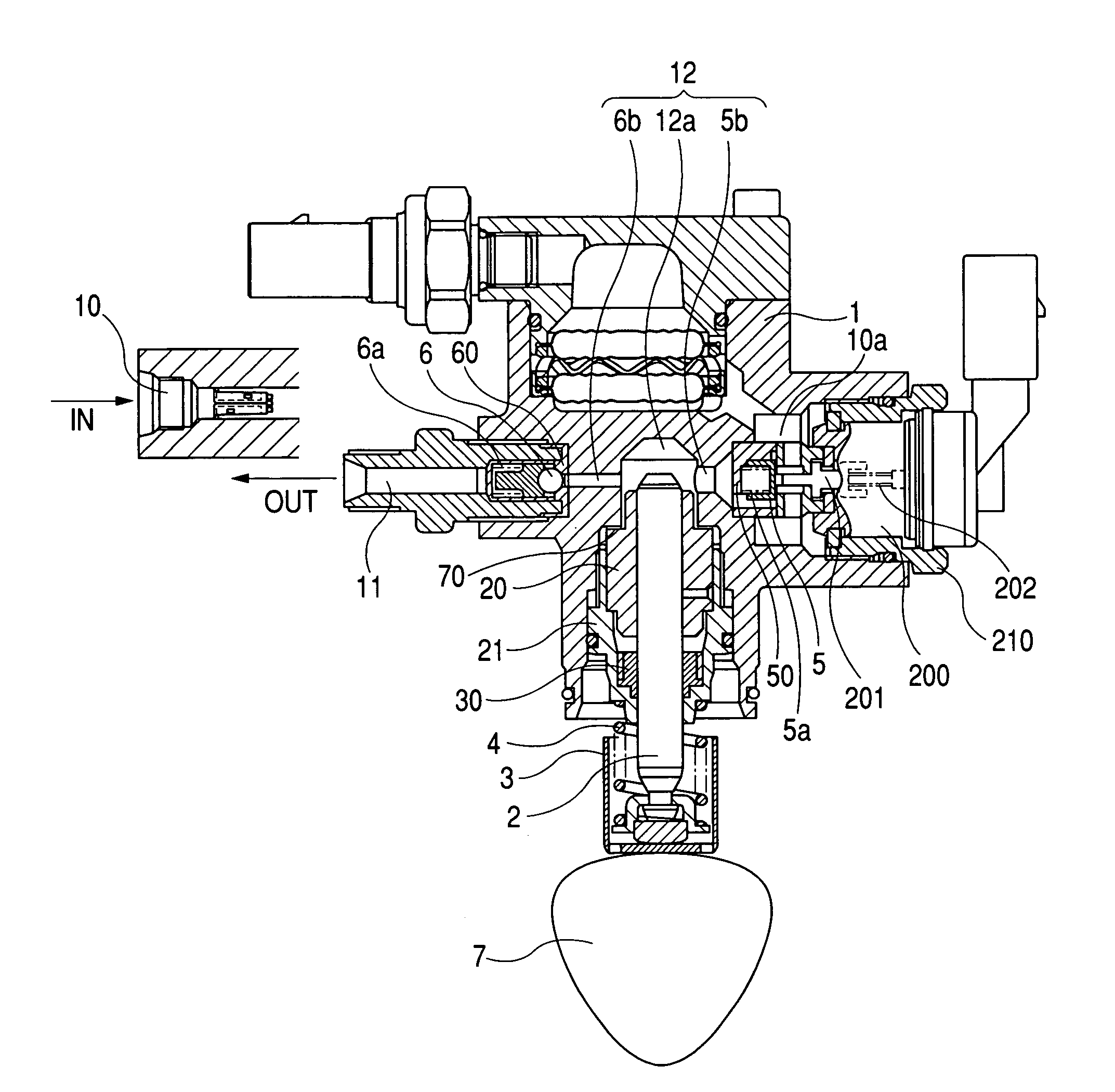

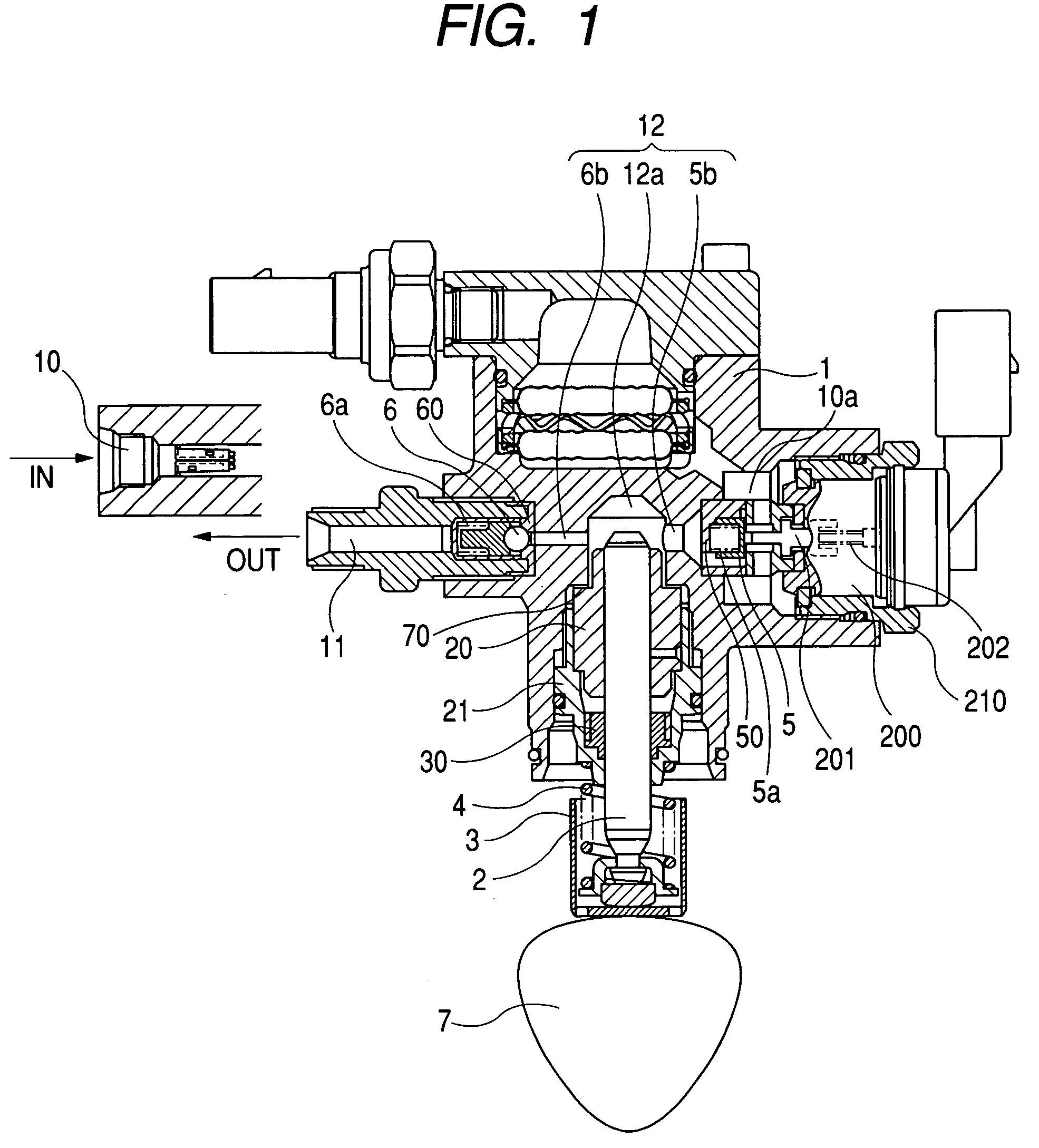

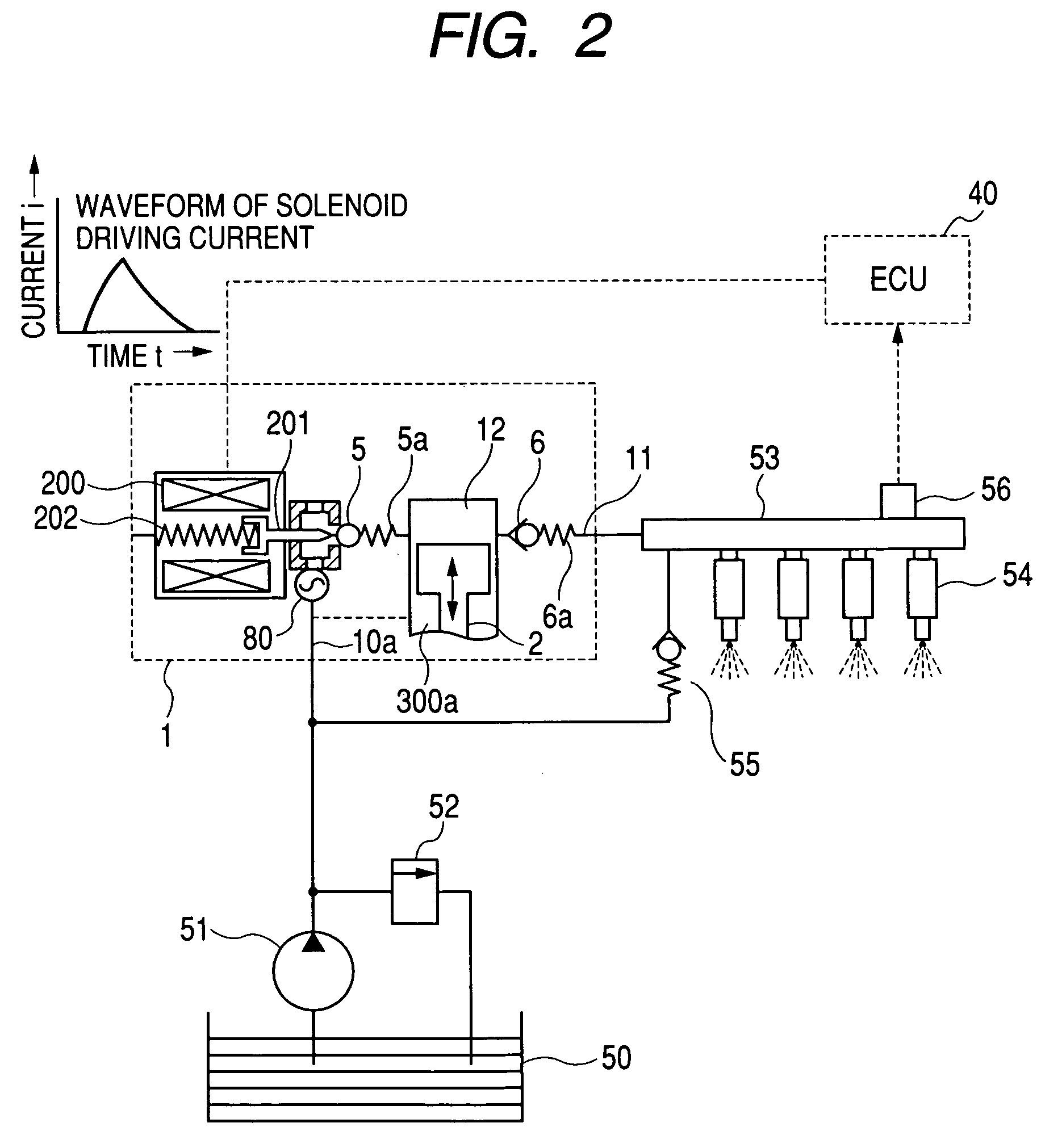

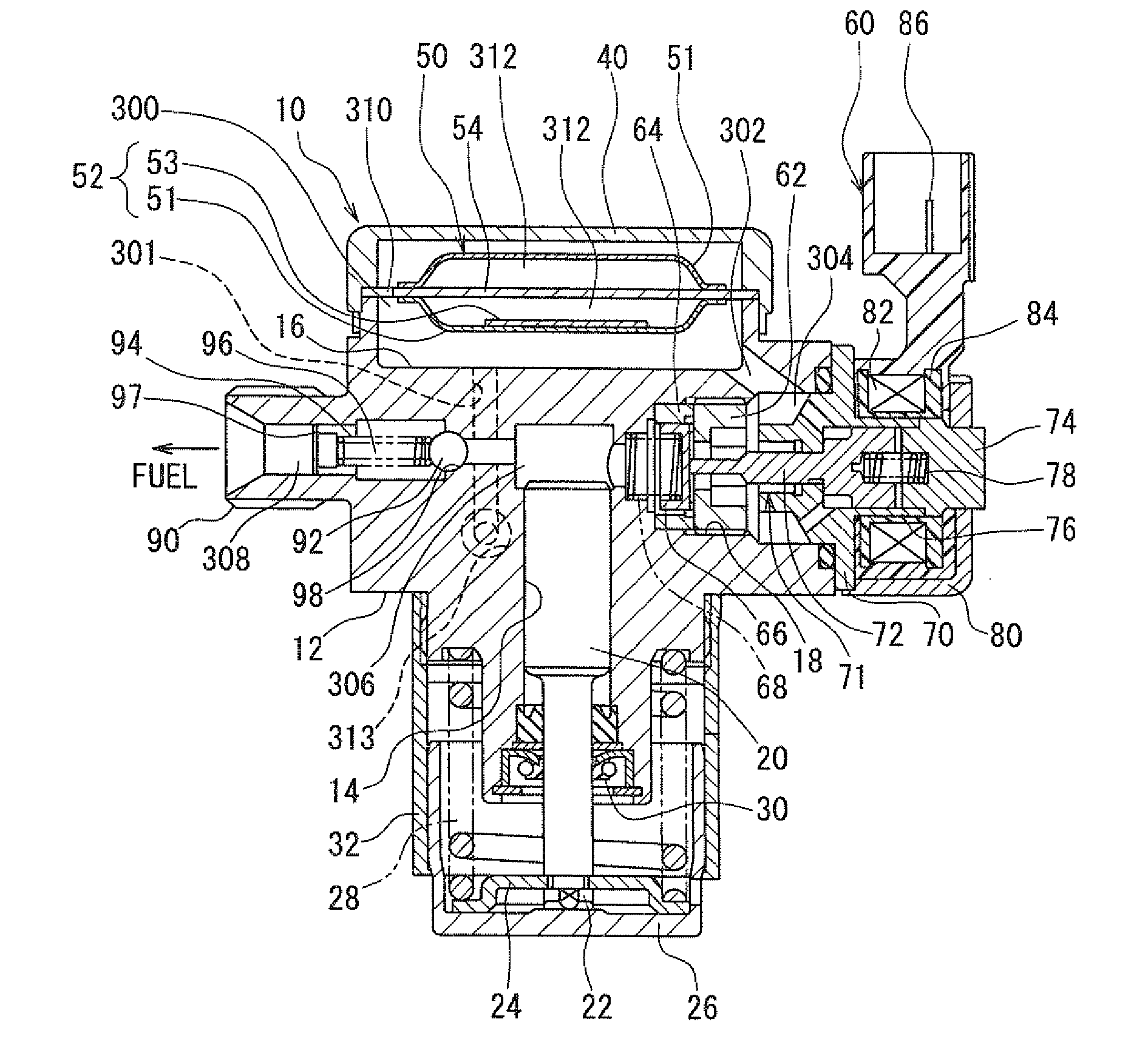

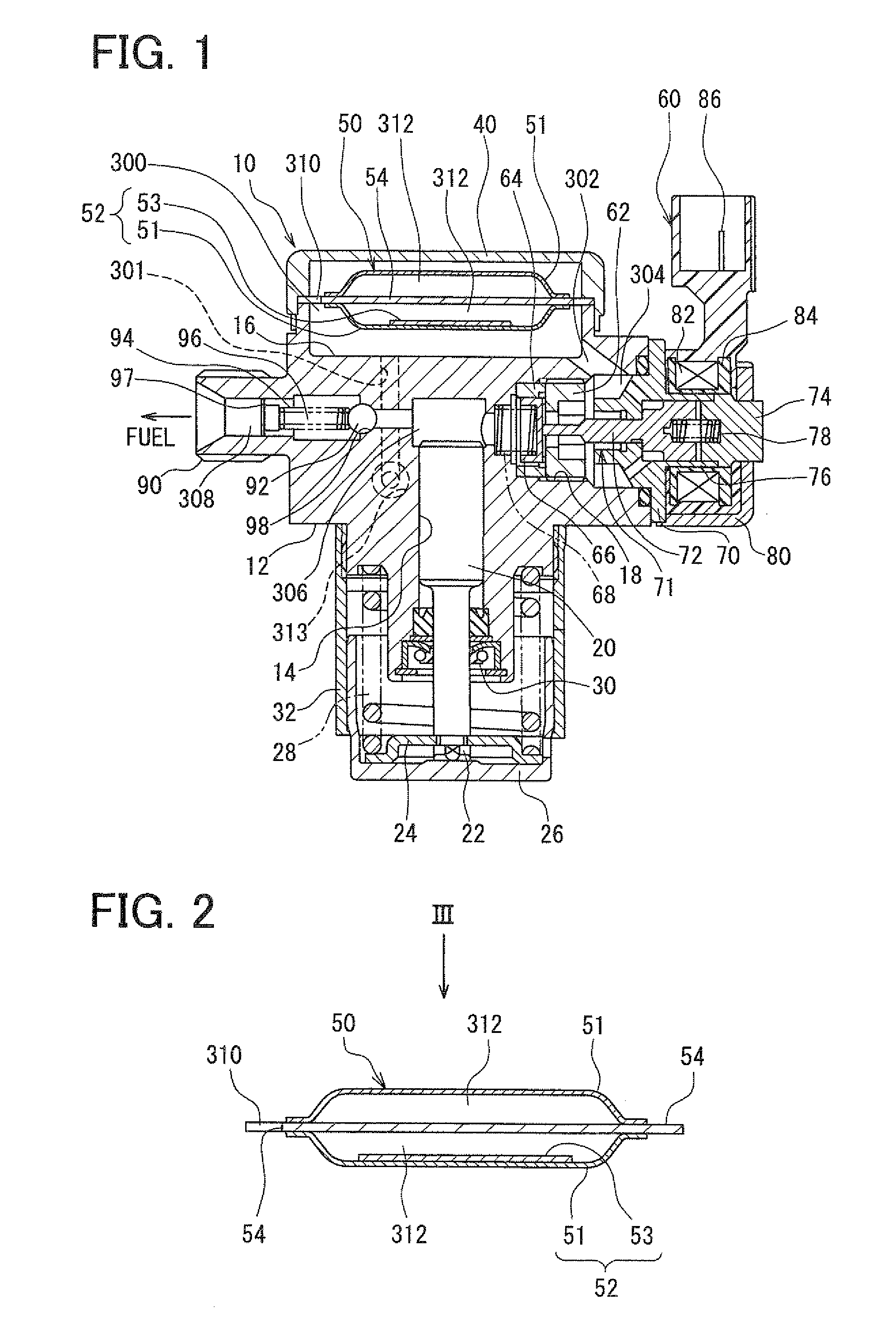

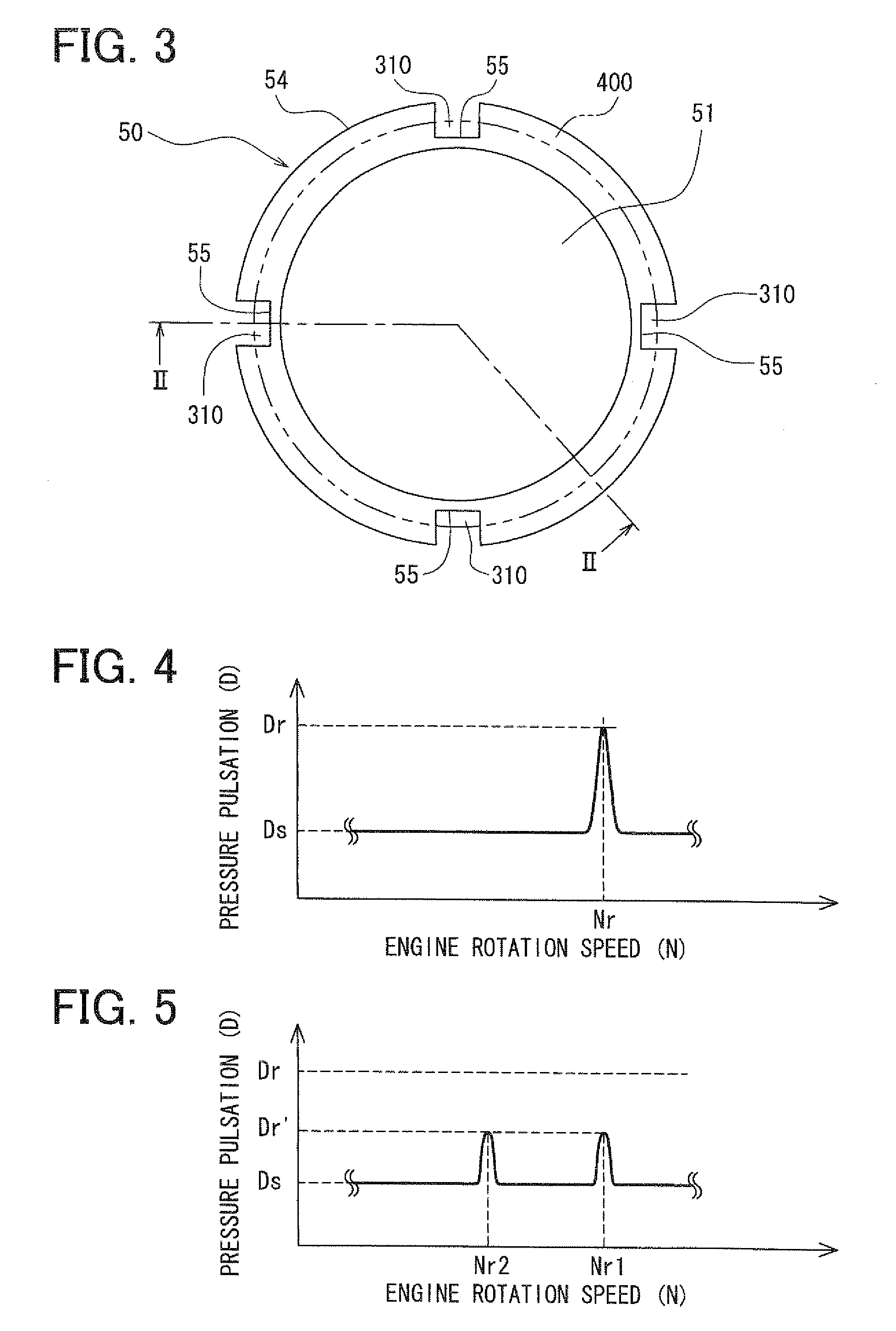

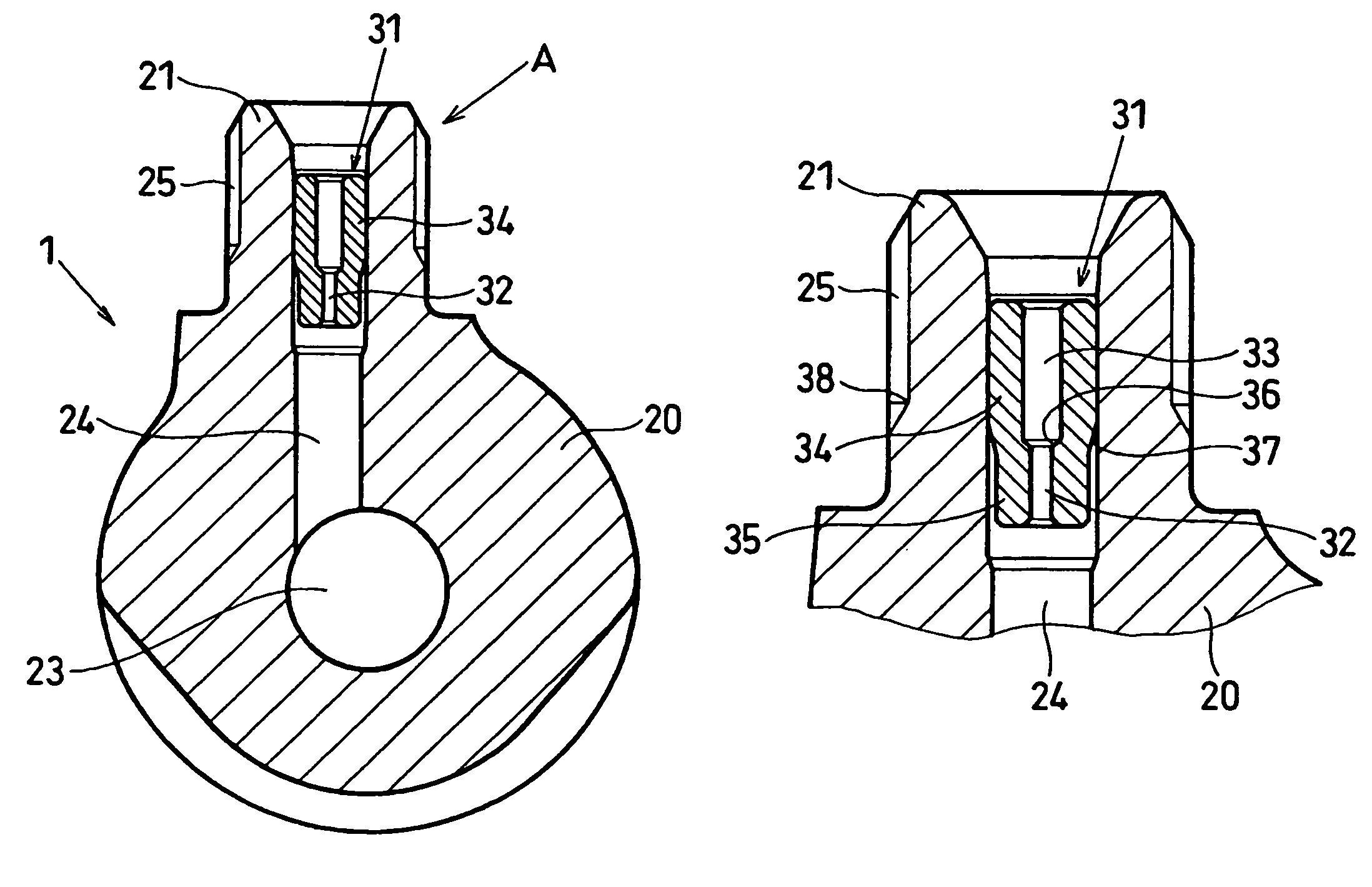

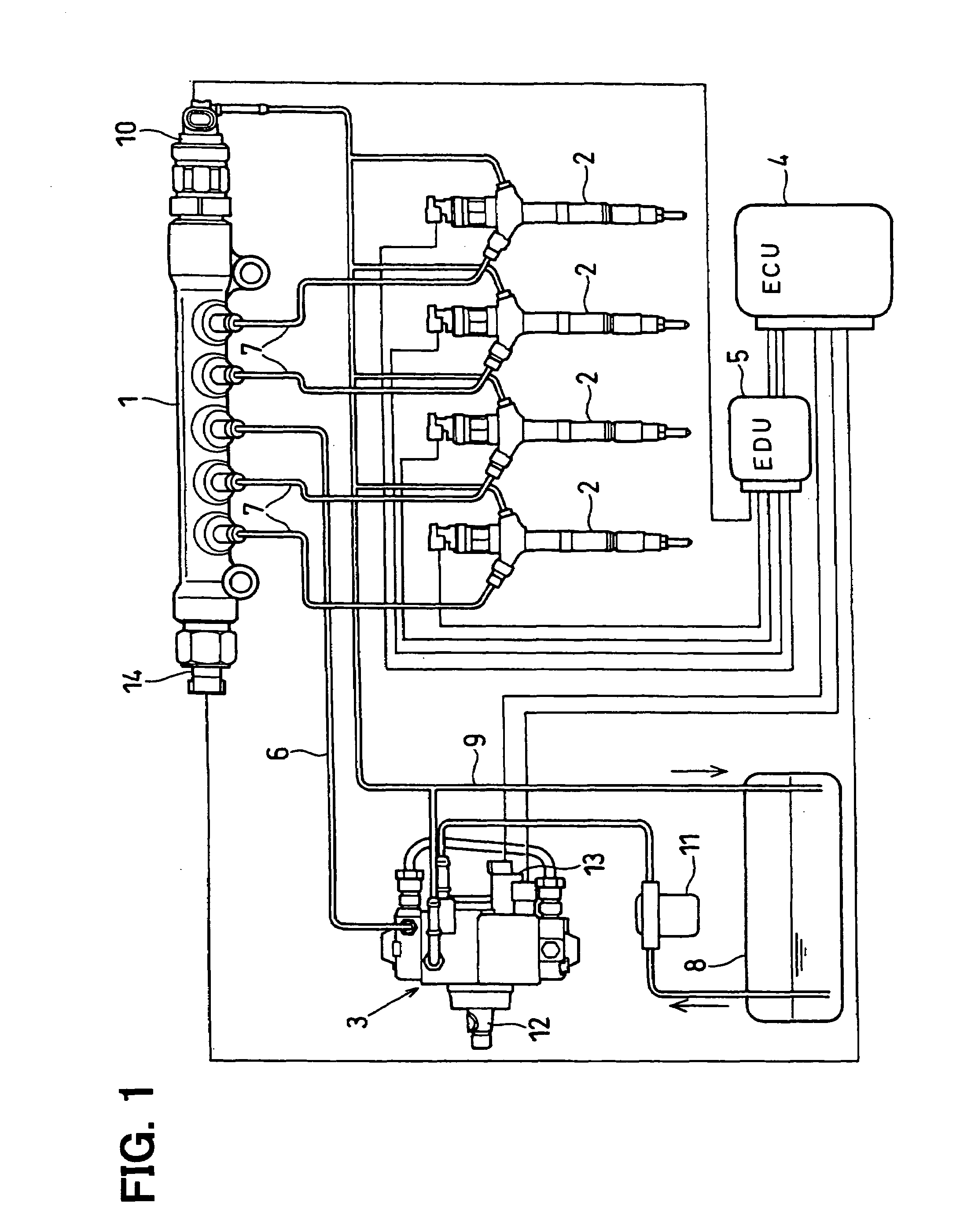

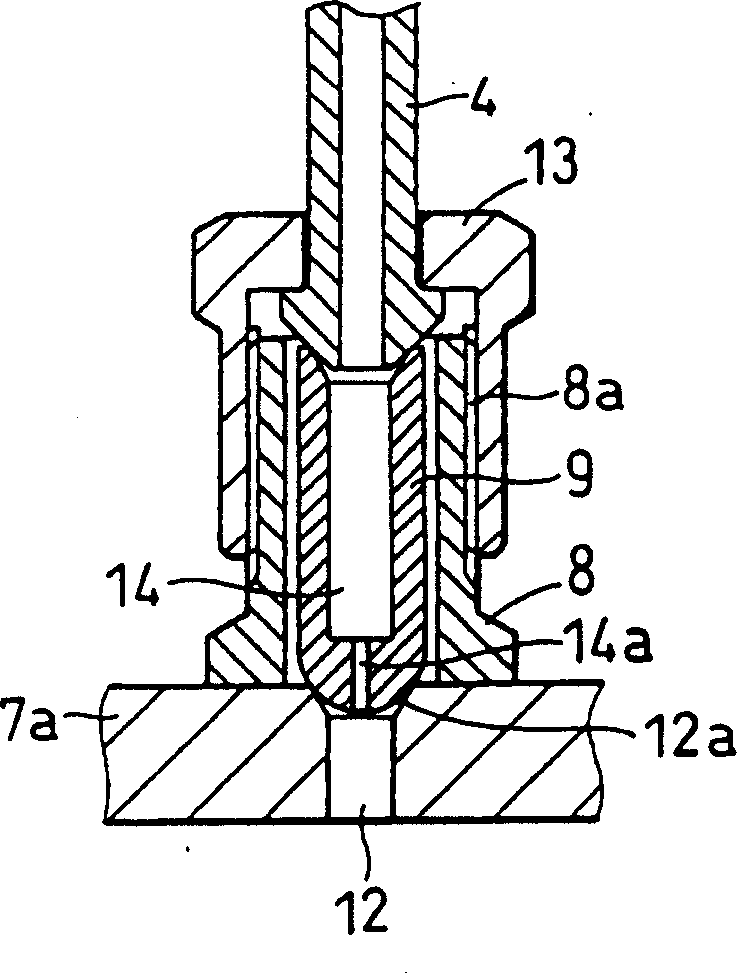

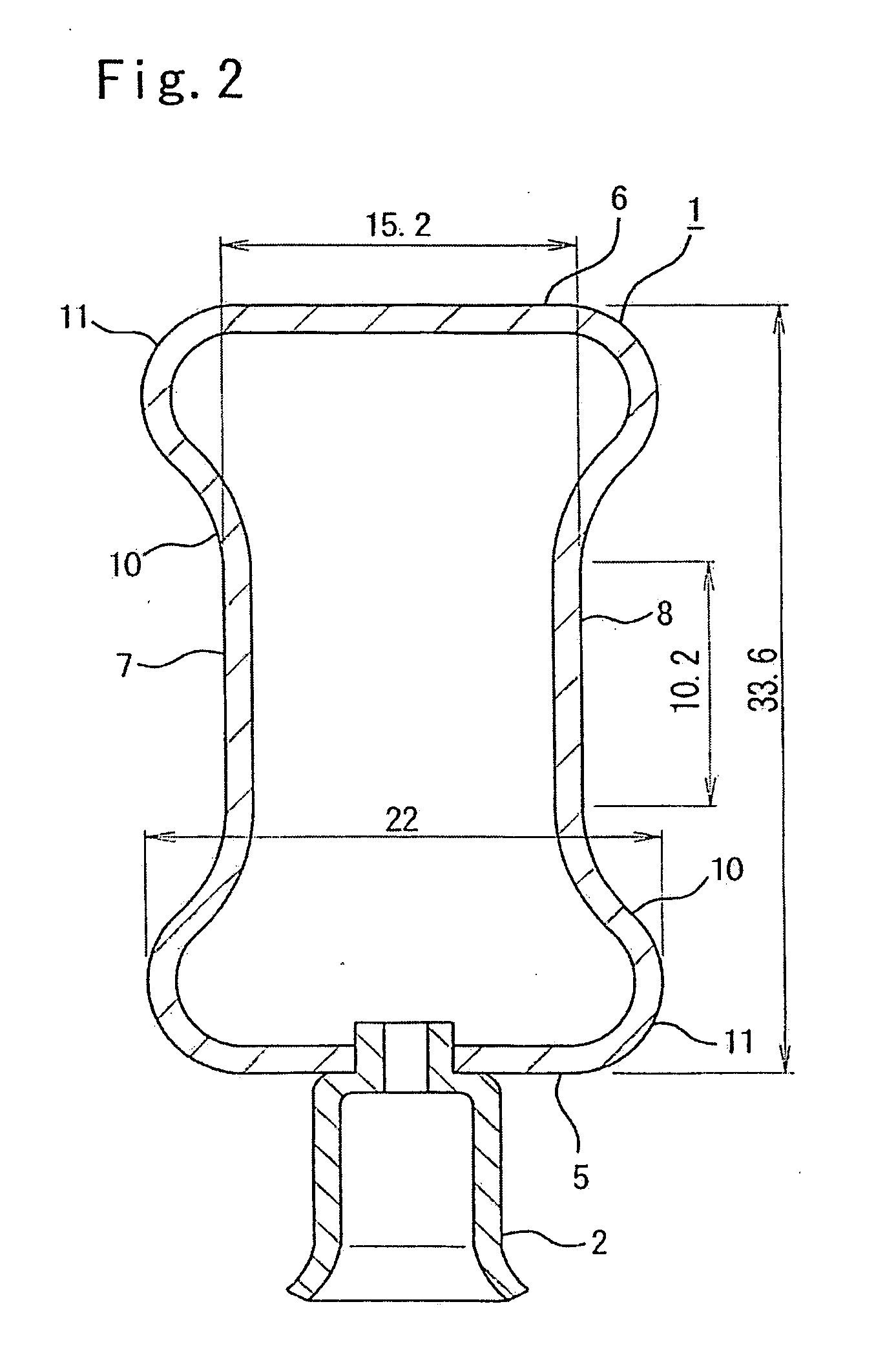

Damper mechanism and high pressure fuel pump

ActiveUS7124738B2Increase in sizeReduce pressure pulsationFuel injecting pumpsFuel injection with sensorsEngineeringHigh pressure

To obtain a small and high performance damper mechanism which reduces pressure pulsation in low pressure-side fuel in the high pressure fuel pump in a high pressure fuel supply system or a high pressure fuel pump provided with the small and high performance damper mechanism.Two metal diaphragms are welded together over the entire circumference to obtain a metal diaphragm assembly (also referred to as “double metal diaphragm damper”). The whole or part of the portion of the metal diaphragm assembly other than the weld (for example, the portion inside the weld) is clamped by a pressing member and thereby the assembly is secured in a housing enclosure. The housing enclosure may be formed integrally with the body of a high pressure pump.

Owner:HITACHI ASTEMO LTD

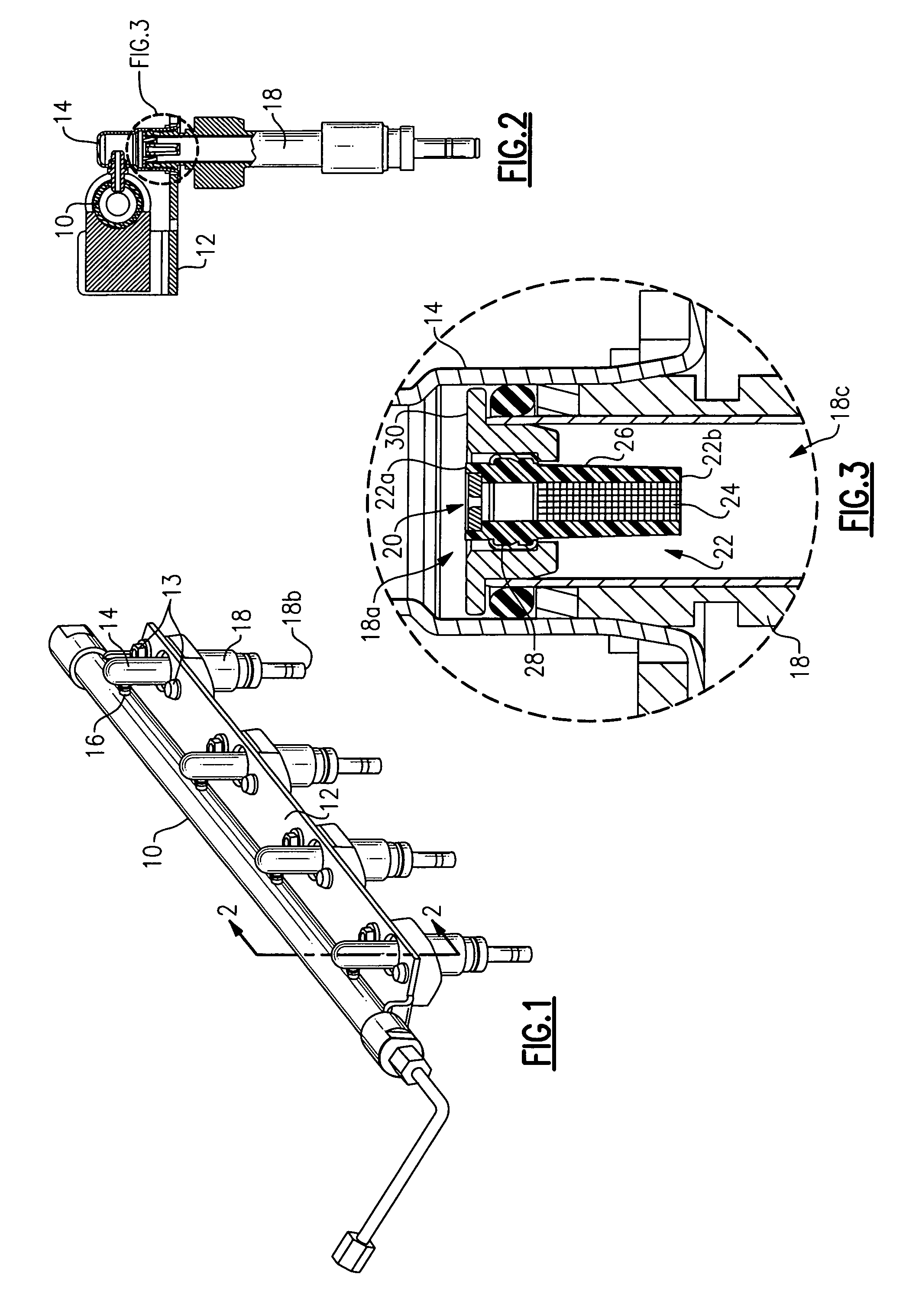

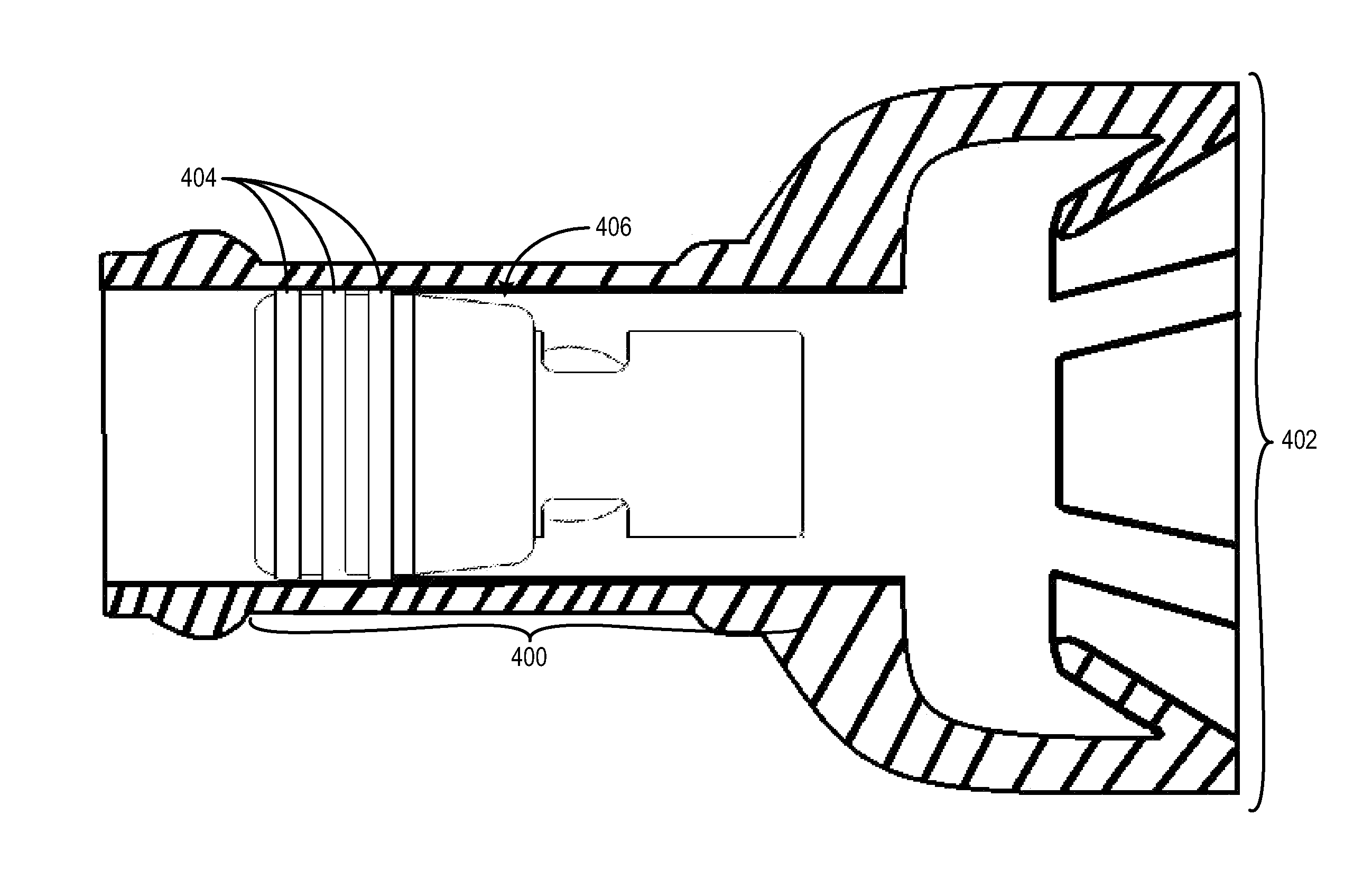

Injector fuel filter with built-in orifice for flow restriction

ActiveUS7617991B2Reduce pressure pulsationReduce or eliminate pressure pulsations through the fuel injectorSedimentation separationMachines/enginesFuel filterEngineering

Owner:DELPHI TECH IP LTD

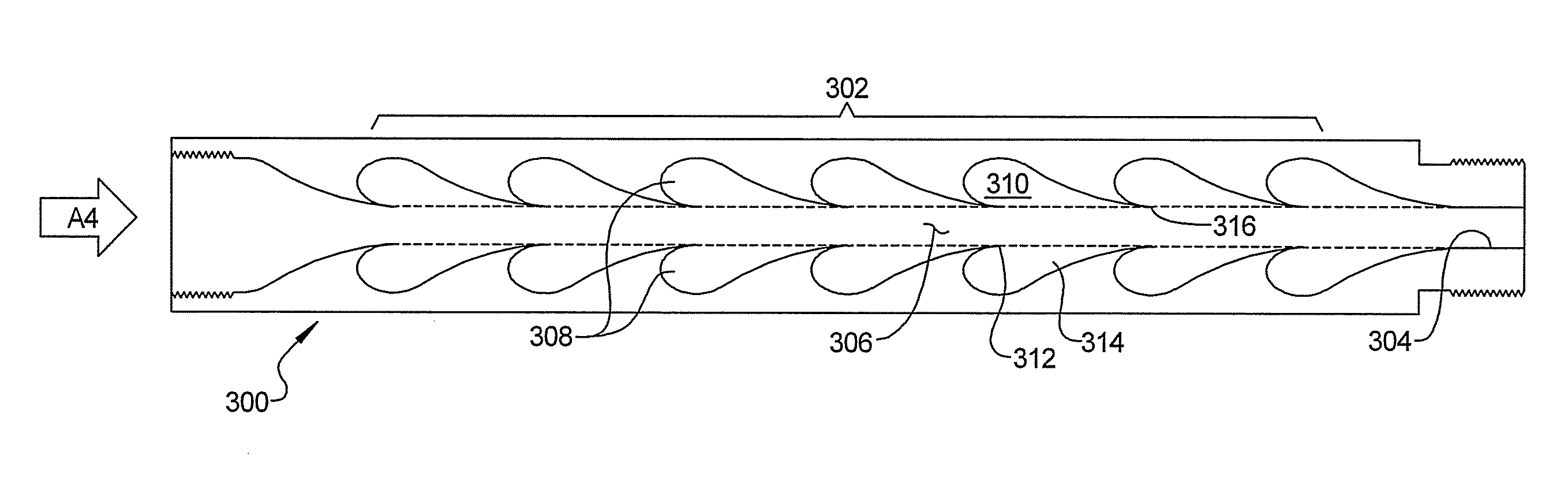

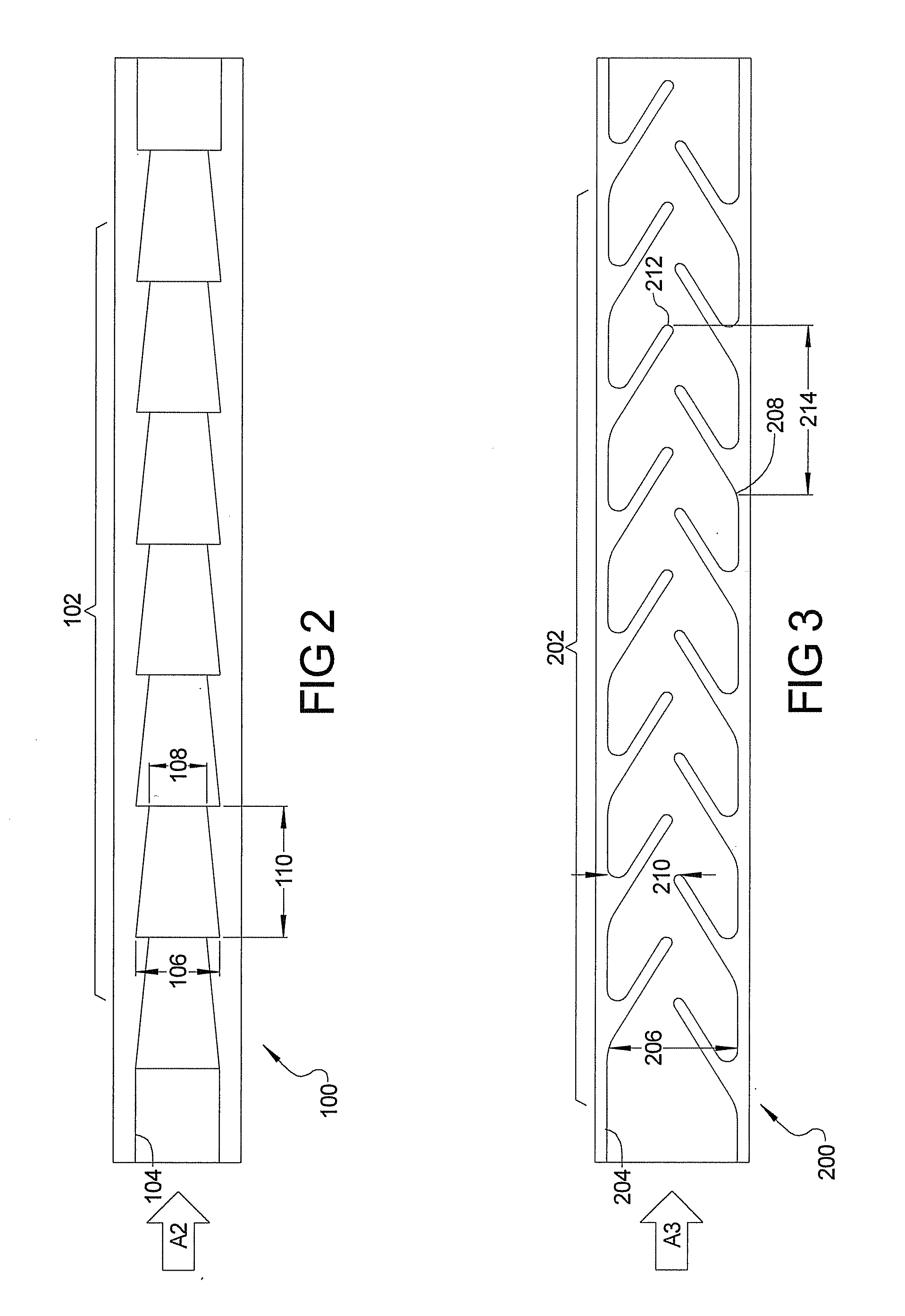

Engine Crankcase Breathing Passage With Flow Diode

InactiveUS20150059718A1Shorten speedStable flow patternCombustion enginesCrankcase ventillationBreatherCrankcase

An internal combustion engine is disclosed which includes an improved crankcase drain back system. A set of drain flow diodes are disposed in each of the drain lines to direct fluid flow in a direction from the head portion to the crankcase. Likewise, a set of breather flow diodes are disposed in the breather lines to direct fluid flow in a second direction from the cylinder portion to the head portion. The flow diodes include a series of stacked flow diode elements which allow flow in one direction, while resisting flow in the opposite direction.

Owner:GM GLOBAL TECH OPERATIONS LLC

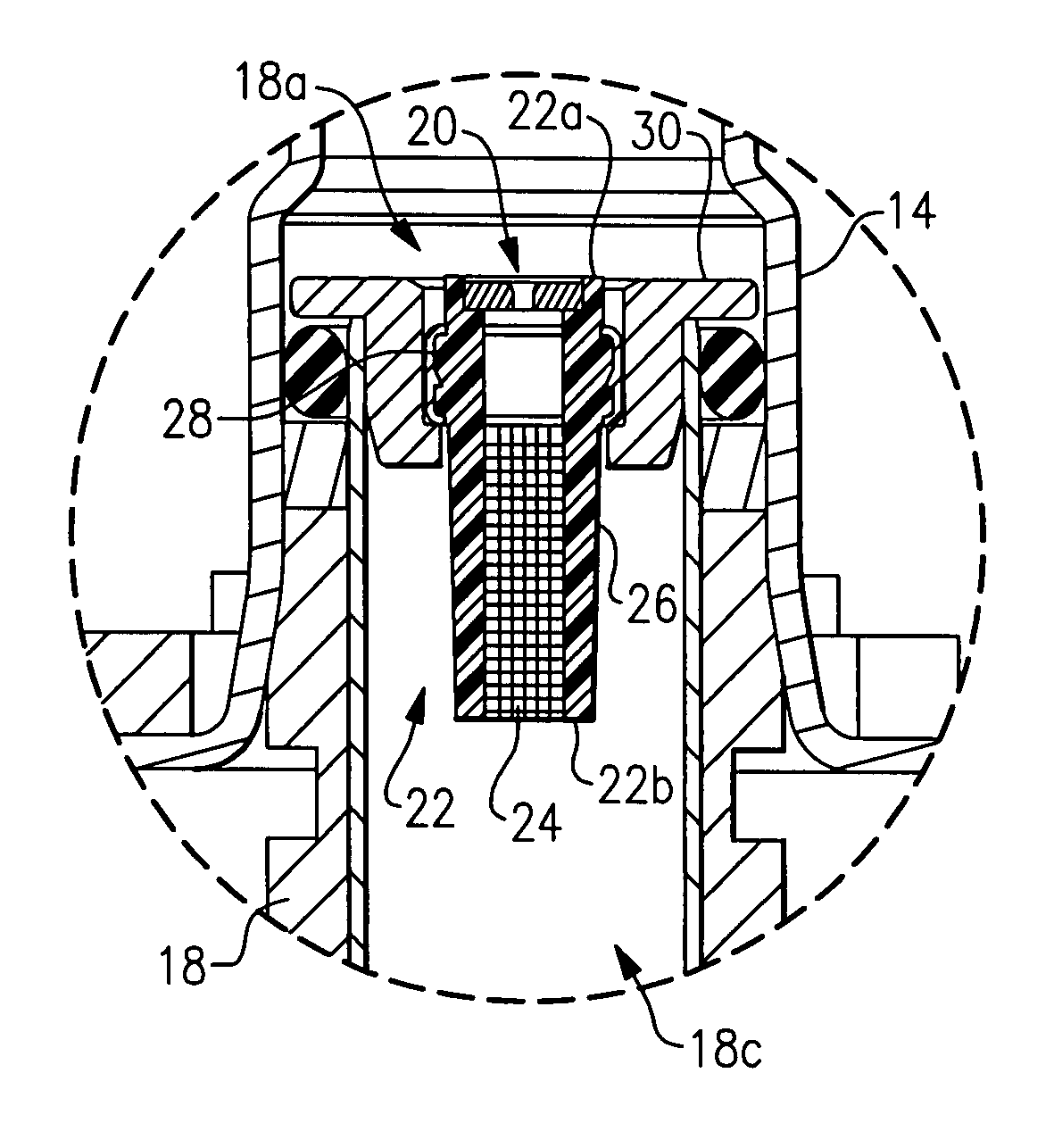

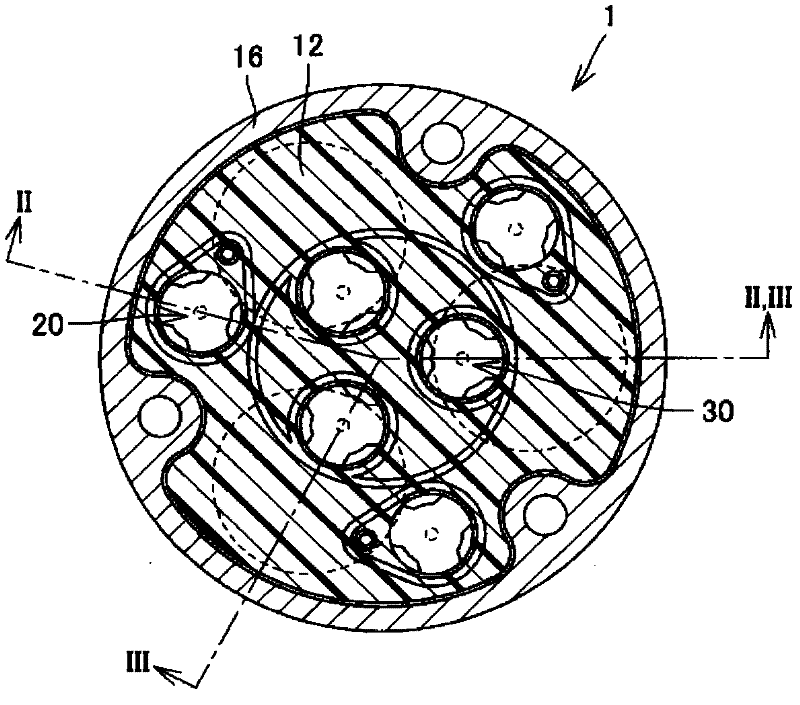

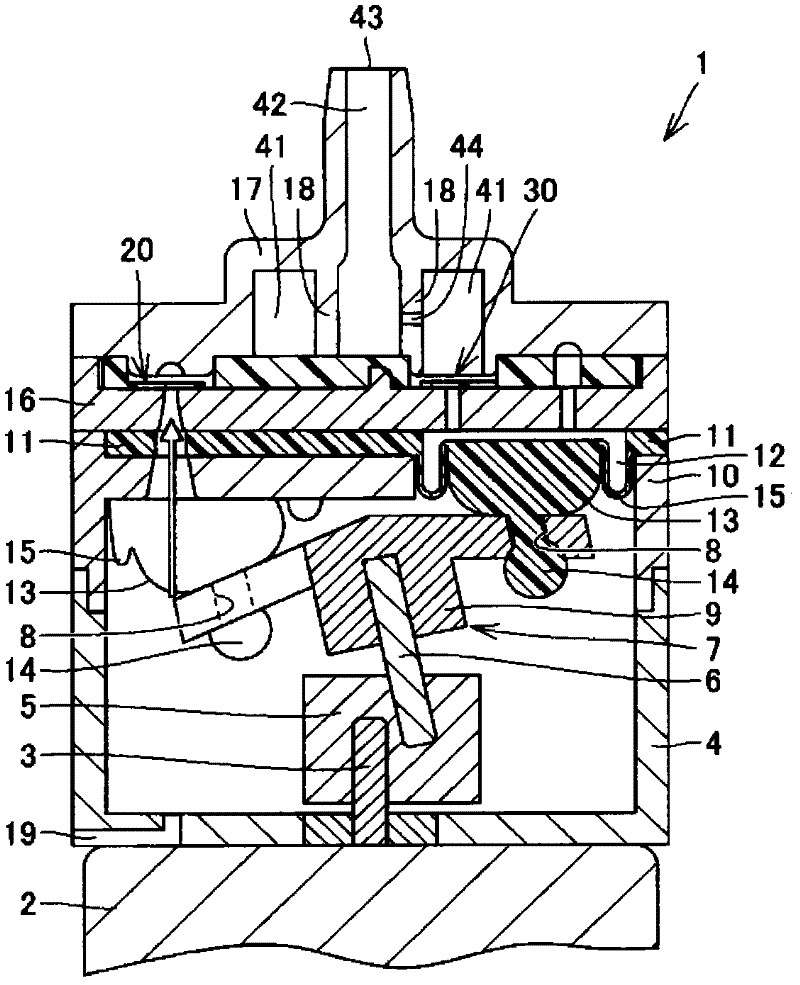

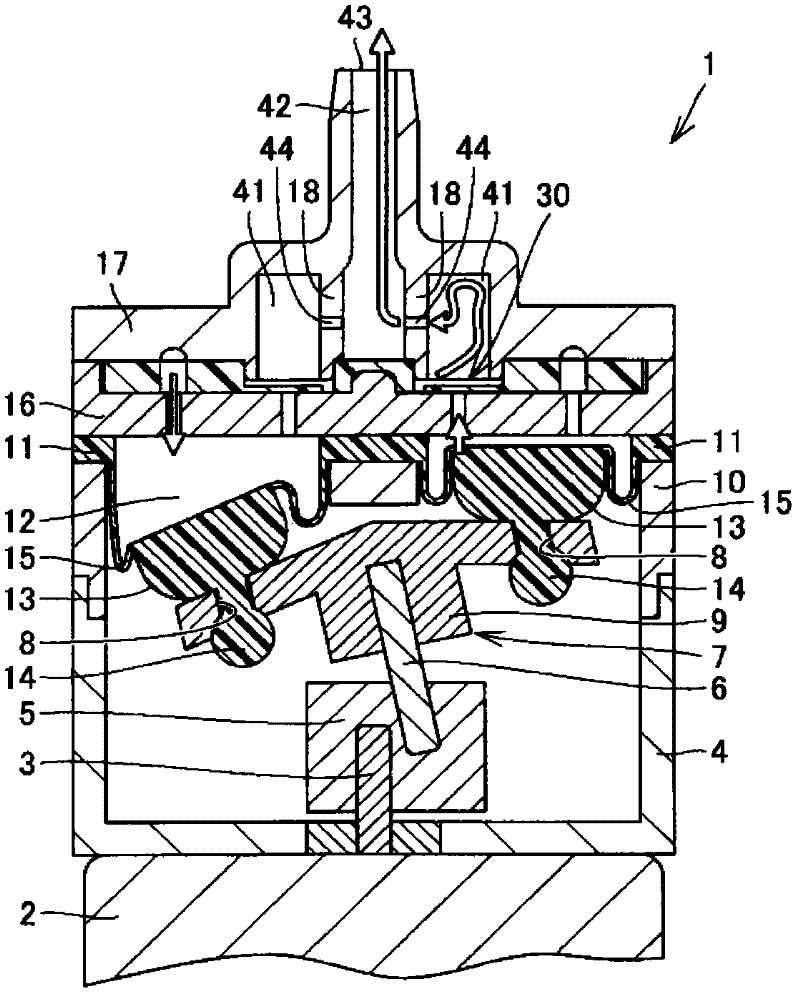

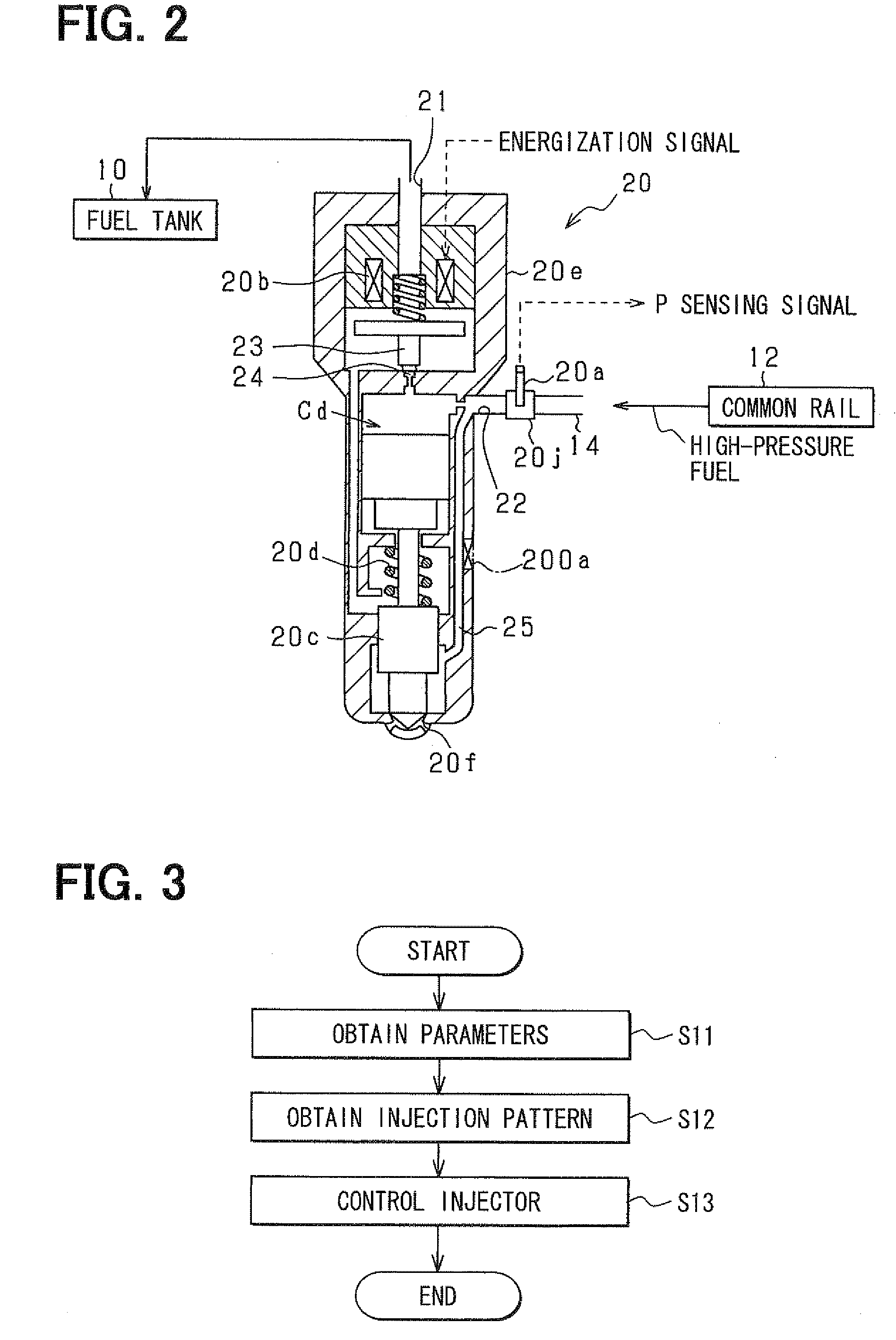

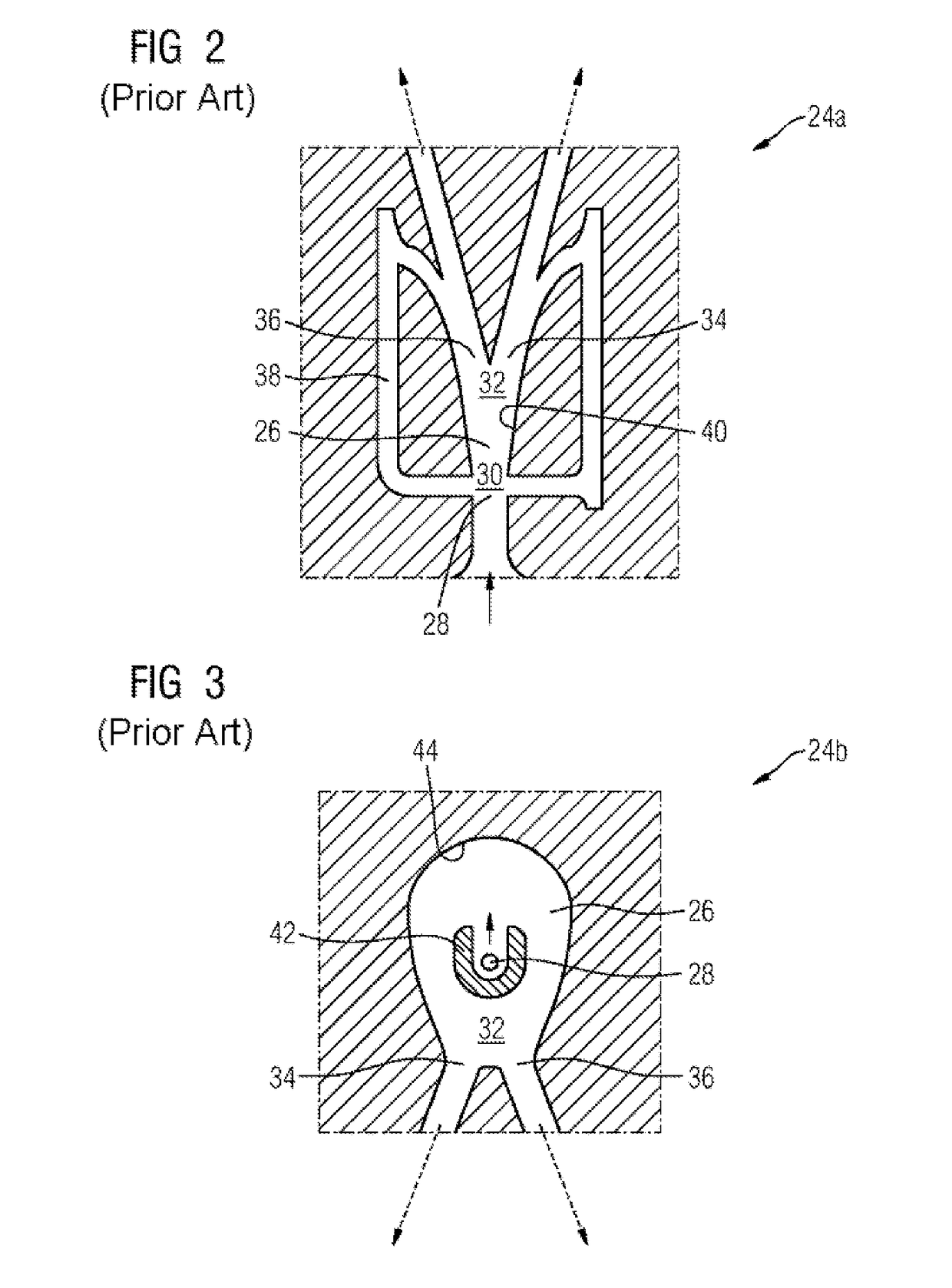

Fuel pump

ActiveUS20090185922A1Reduction effect of pressure pulsationIncrease production costFlexible member pumpsFuel injecting pumpsInterior spaceReciprocating motion

A fuel pump includes a housing having therein a suction passage and a pressurization chamber into which fuel from the suction passage flows, a plunger held in the housing to be reciprocable so as to pressurize the fuel flowing into the pressurization chamber, and a diaphragm device located in a suction chamber that is provided in the suction passage. The diaphragm device includes a pair of first and second diaphragms that are arranged to define an inner space therebetween and air-tightly sealed at its entire peripheries. A mass addition member may be attached to an inside surface of at least one of the first and second diaphragms, so that the first and second diaphragms with the mass addition member have different characteristic frequencies. Accordingly, pressure pulsation of the fuel in the suction chamber can be effectively reduced by the pulsation damper.

Owner:DENSO CORP

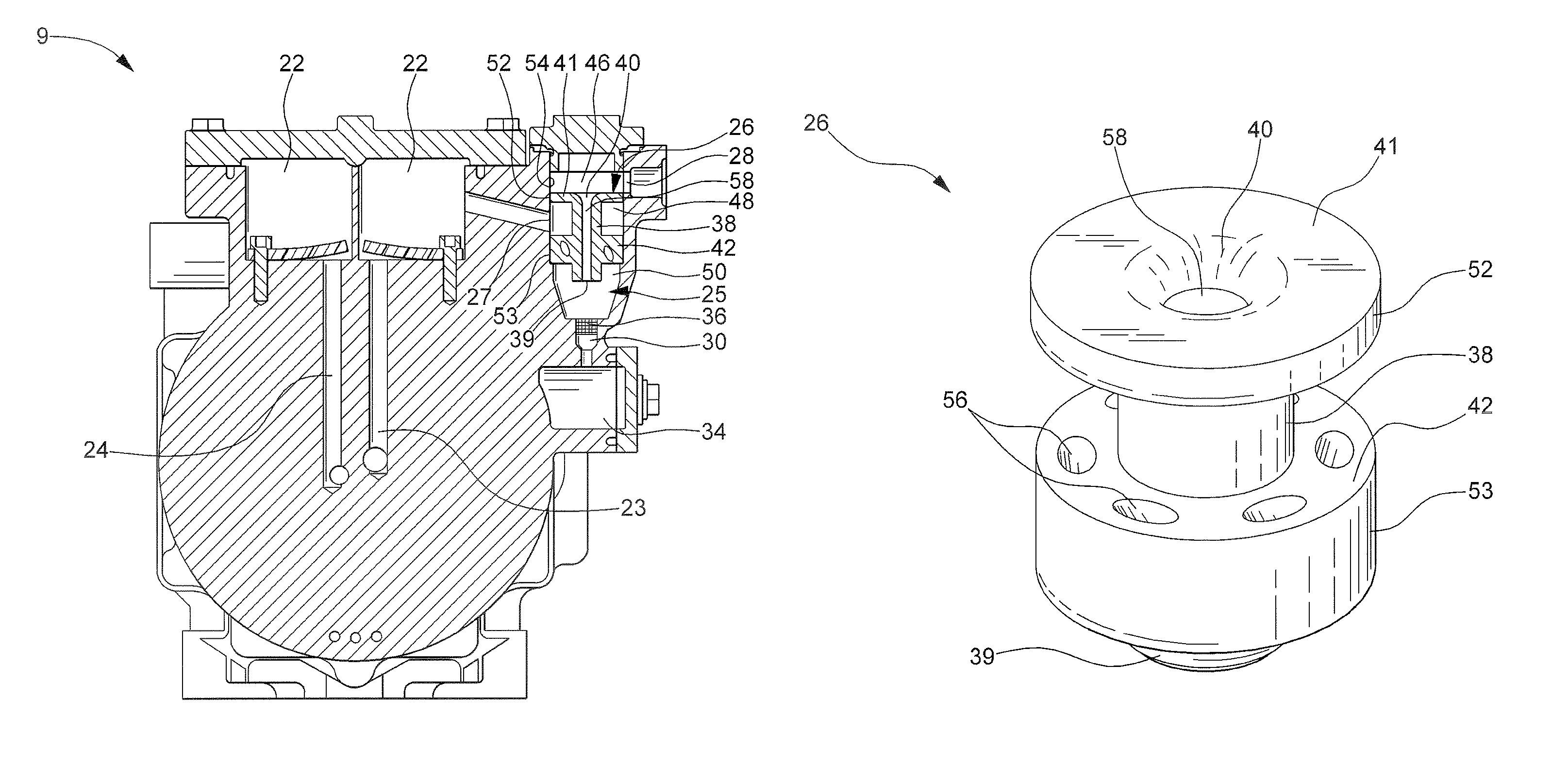

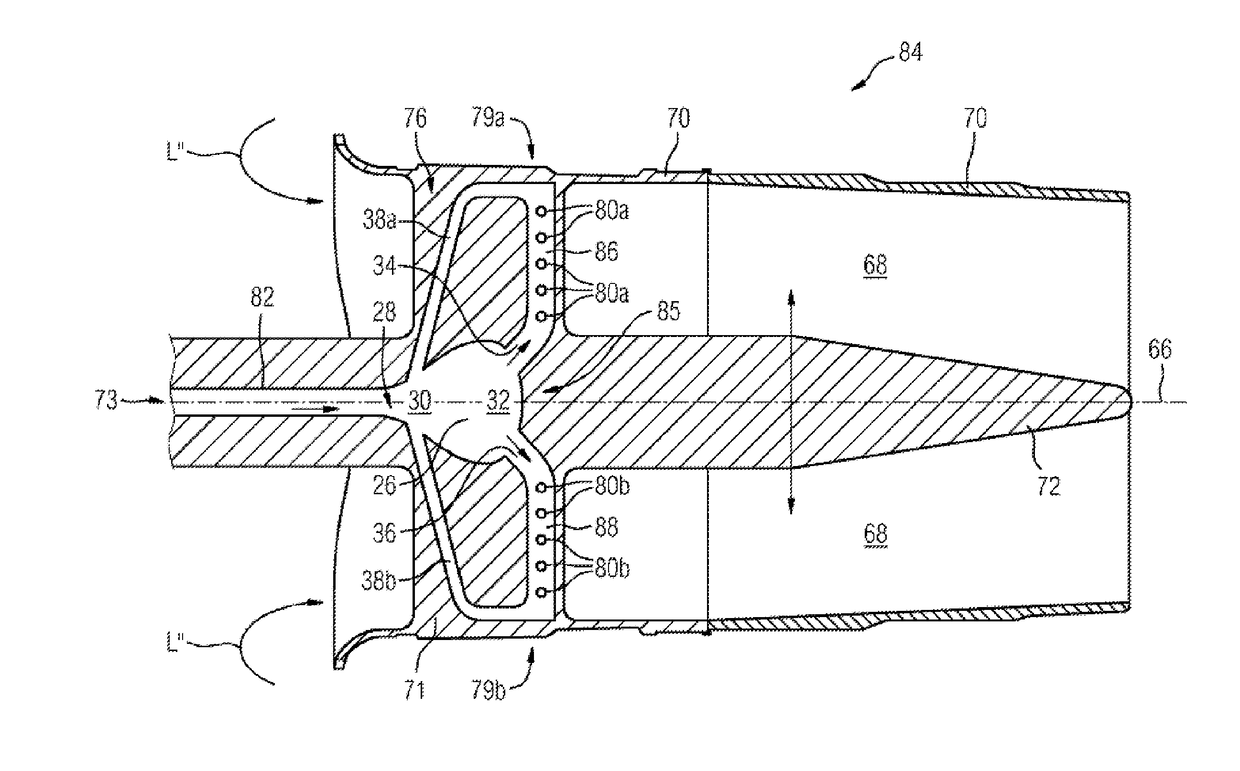

Fluid separator for a compressor

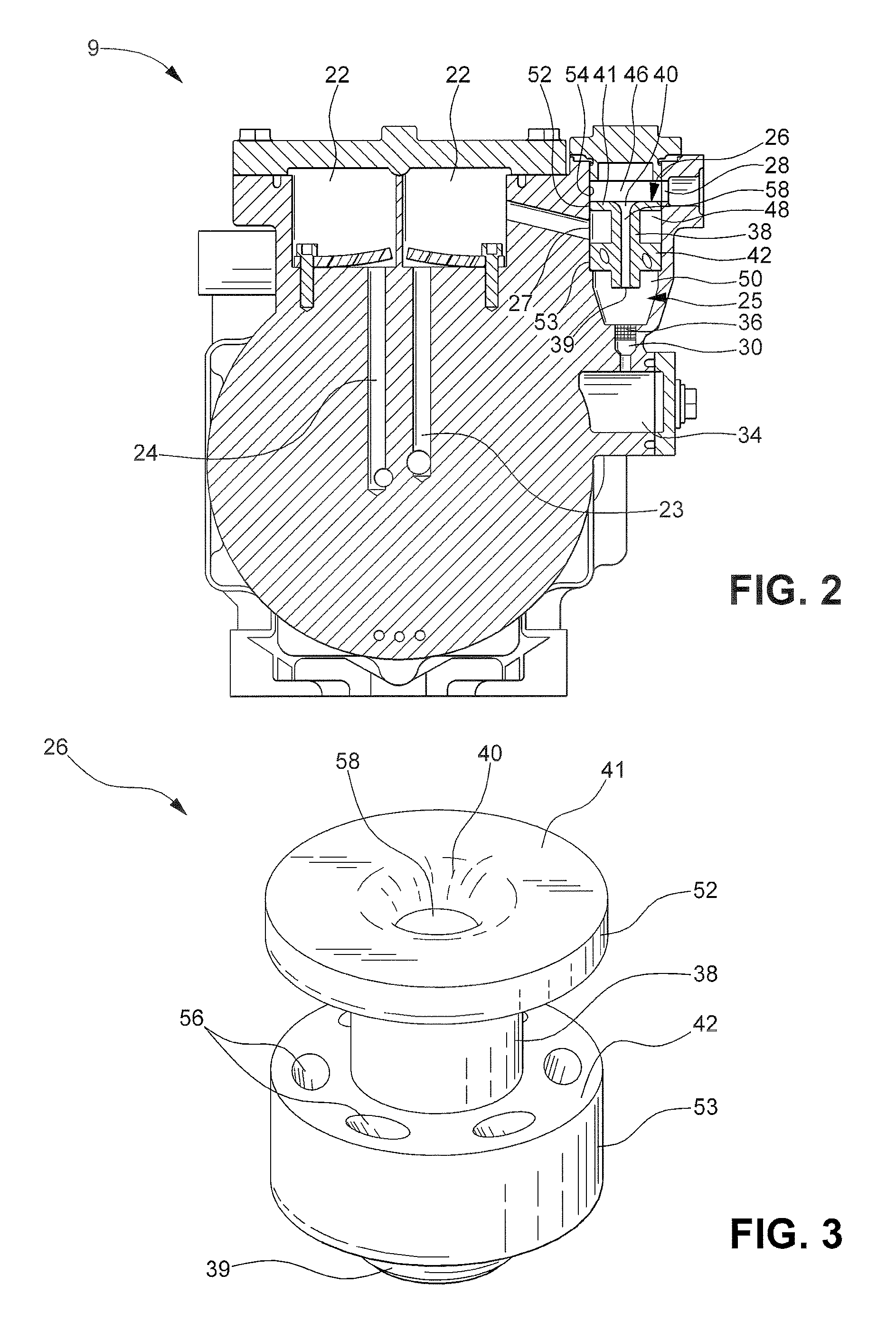

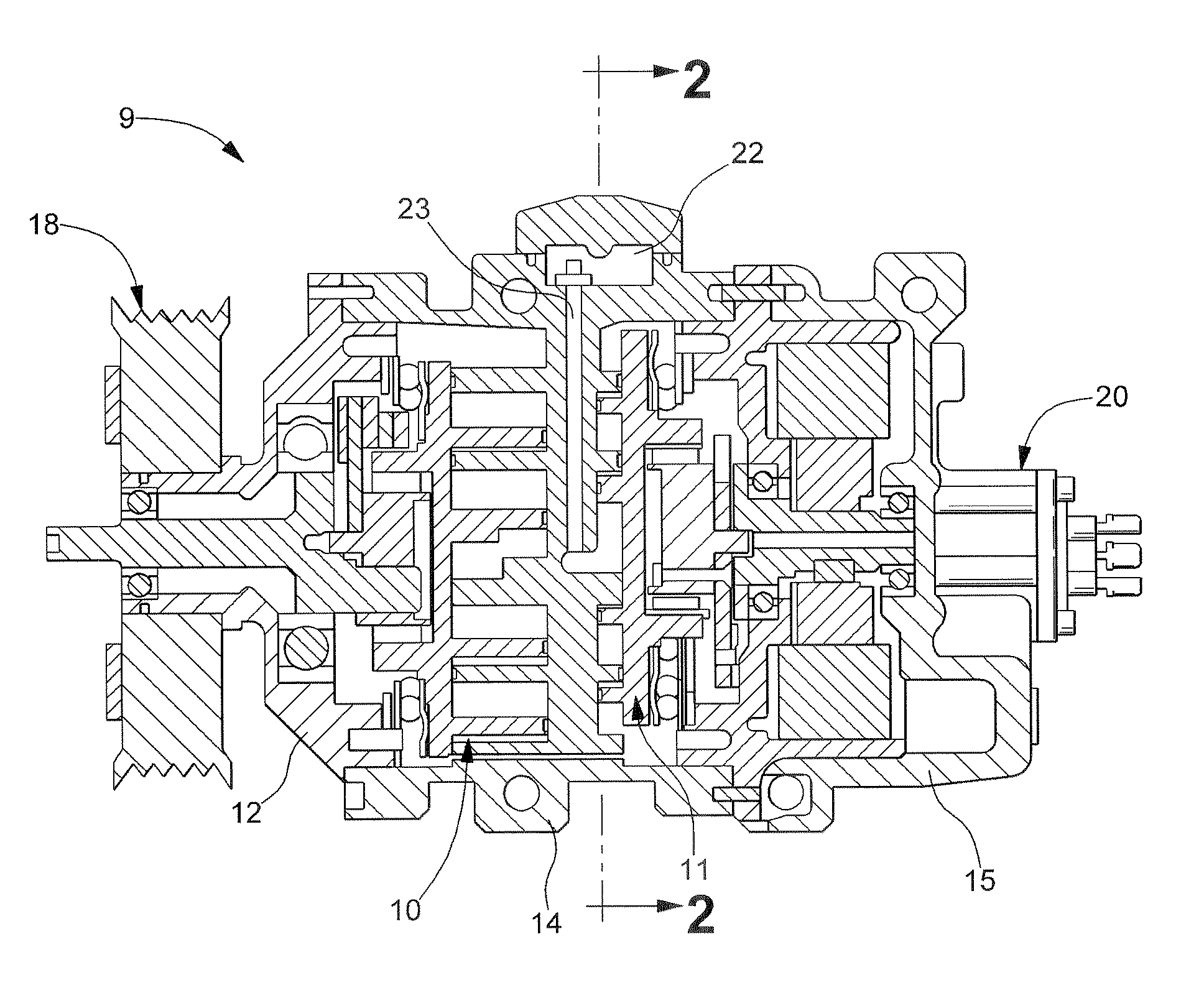

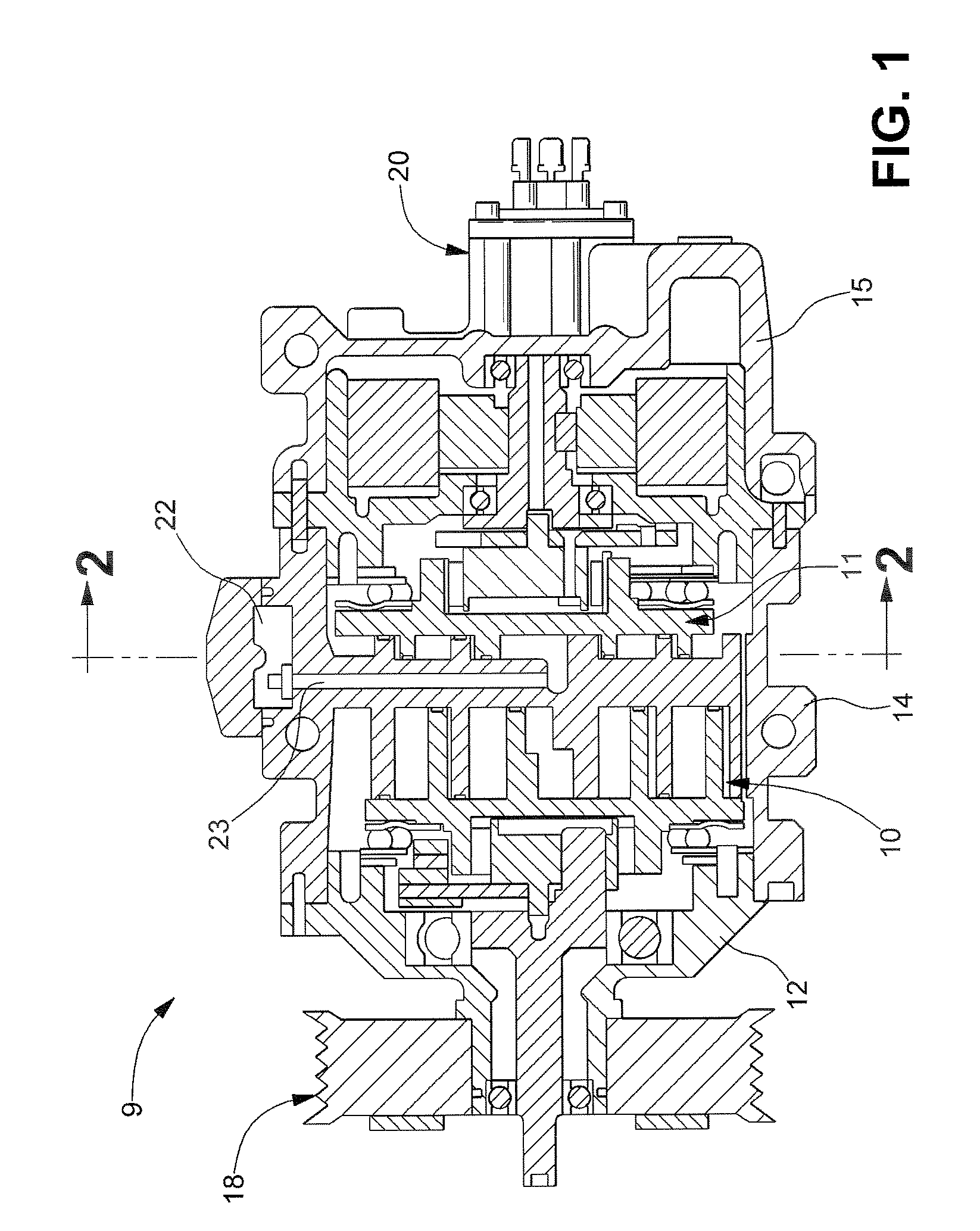

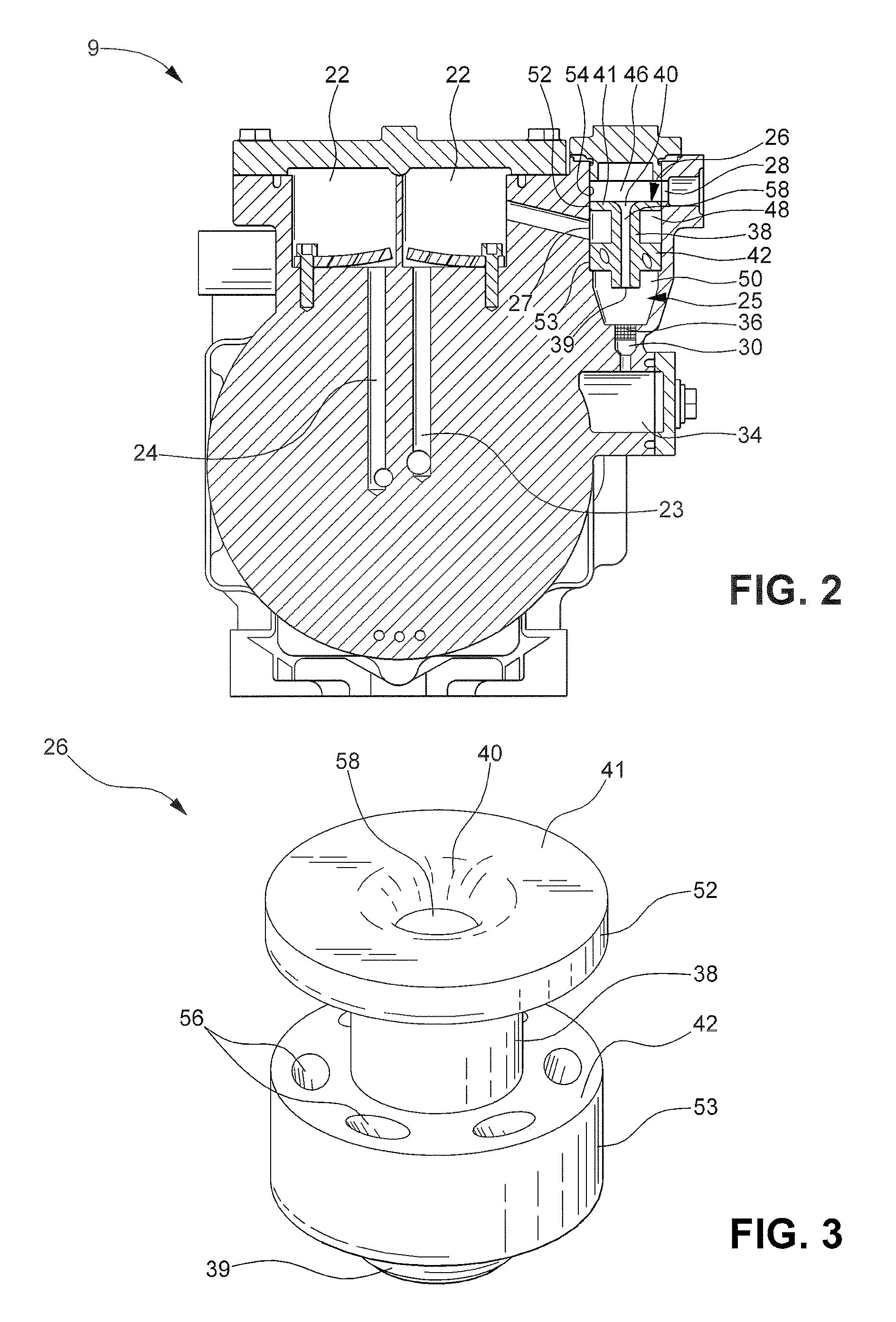

ActiveUS7708537B2Minimize complexityLow costRotary/oscillating piston combinations for elastic fluidsCombination devicesEngineeringShaft collar

A fluid separator for a compressor is disclosed including a hollow main body having an annular flange and an annular collar formed thereon, wherein the annular collar includes an annular array of apertures formed therein for separating a liquid from a fluid and attenuating pressure pulsations of the fluid.

Owner:HANON SYST

Fluid separator for a compressor

ActiveUS20090173095A1Improve the noise reduction effectAvoid Insufficient SealingRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringAnnular array

A fluid separator for a compressor is disclosed including a hollow main body having an annular flange and an annular collar formed thereon, wherein the annular collar includes an annular array of apertures formed therein for separating a liquid from a fluid and attenuating pressure pulsations of the fluid.

Owner:HANON SYST

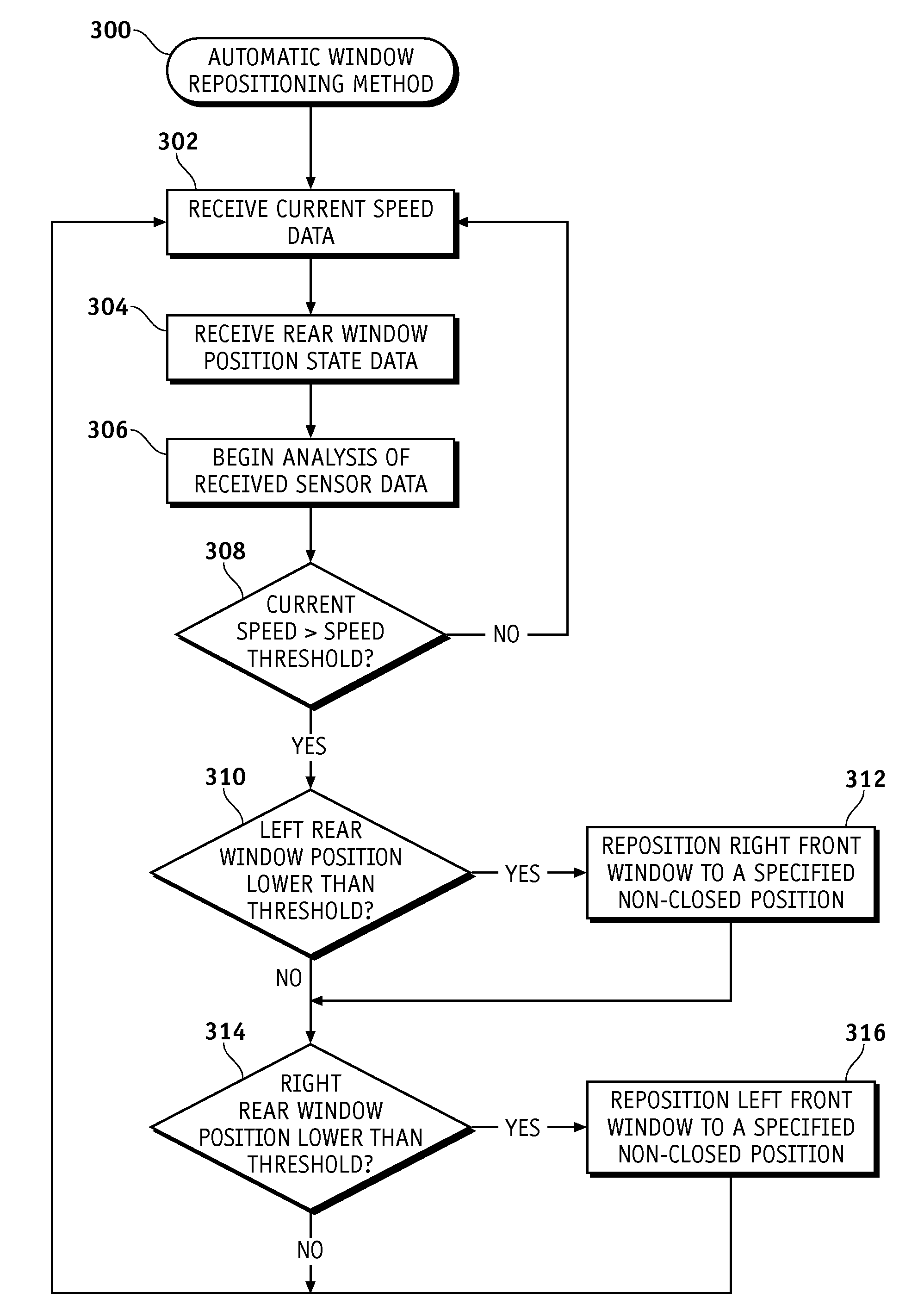

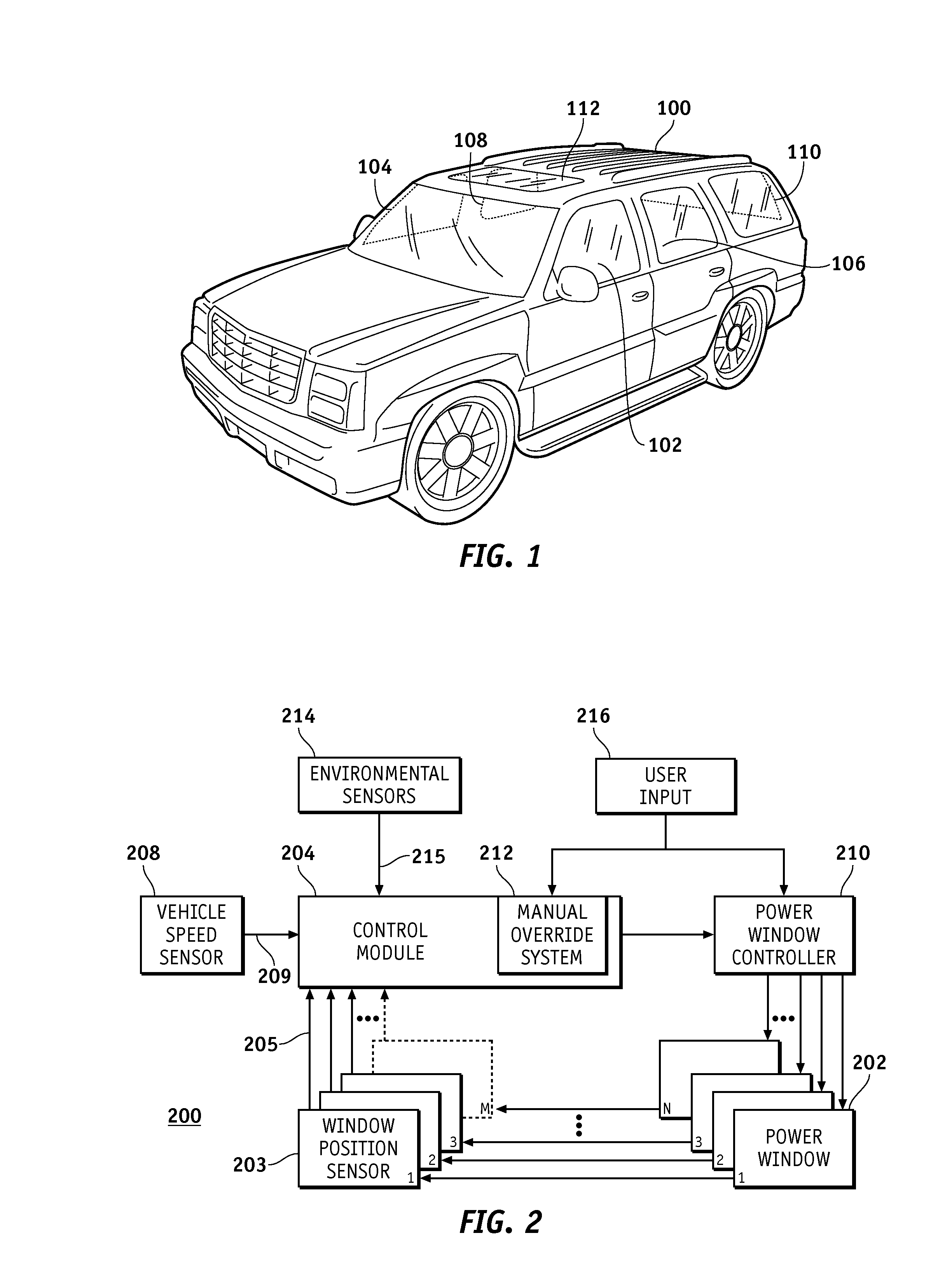

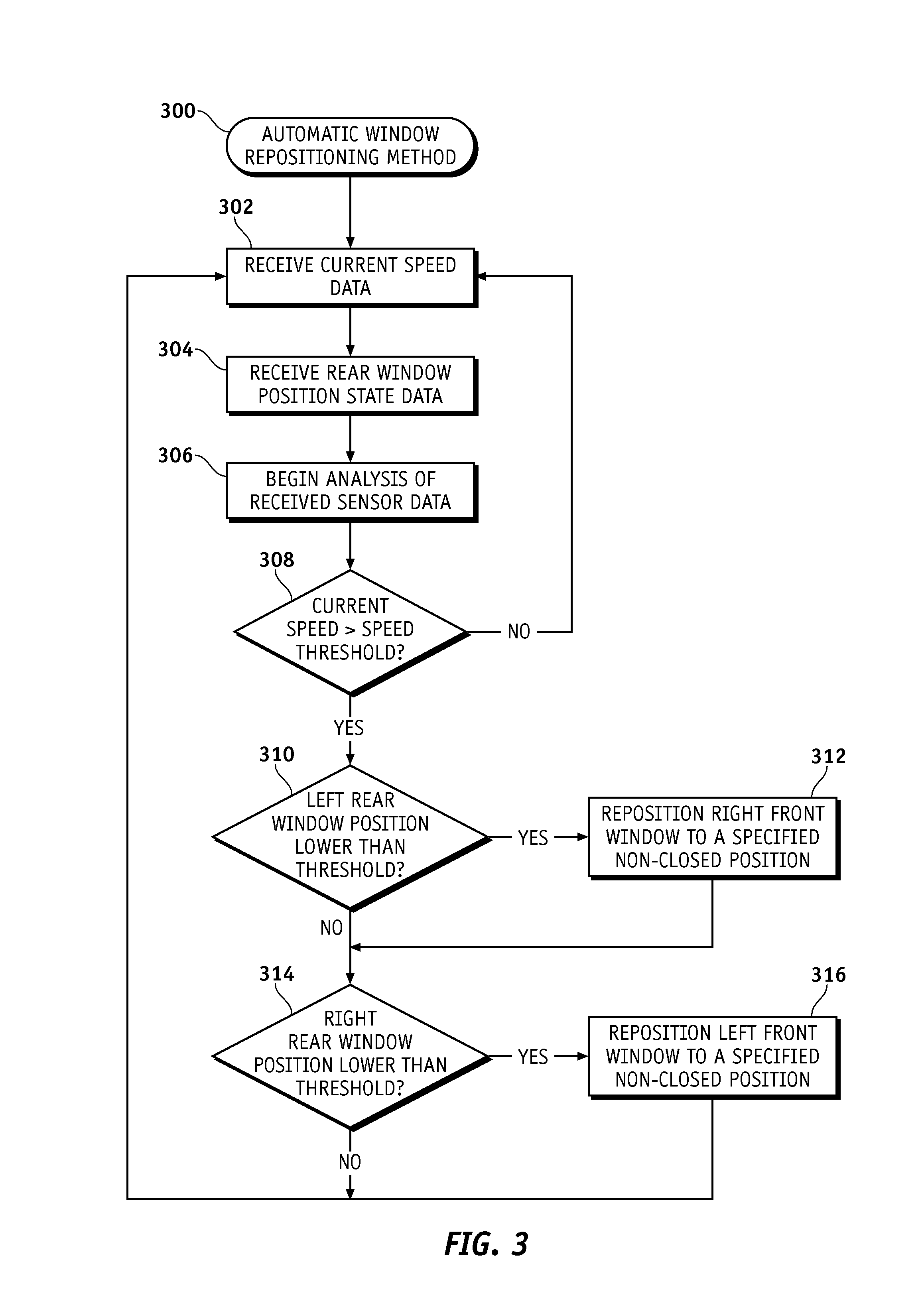

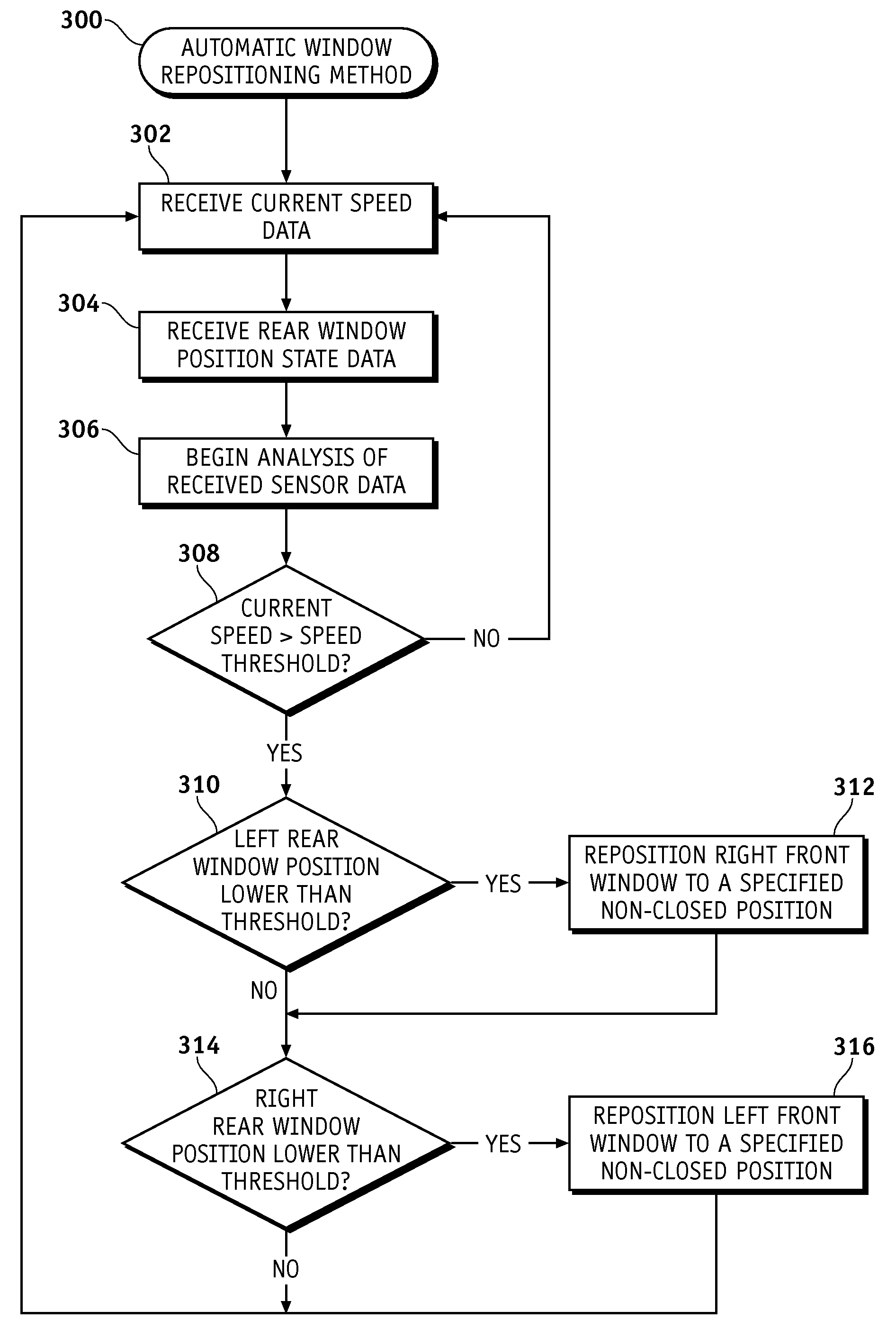

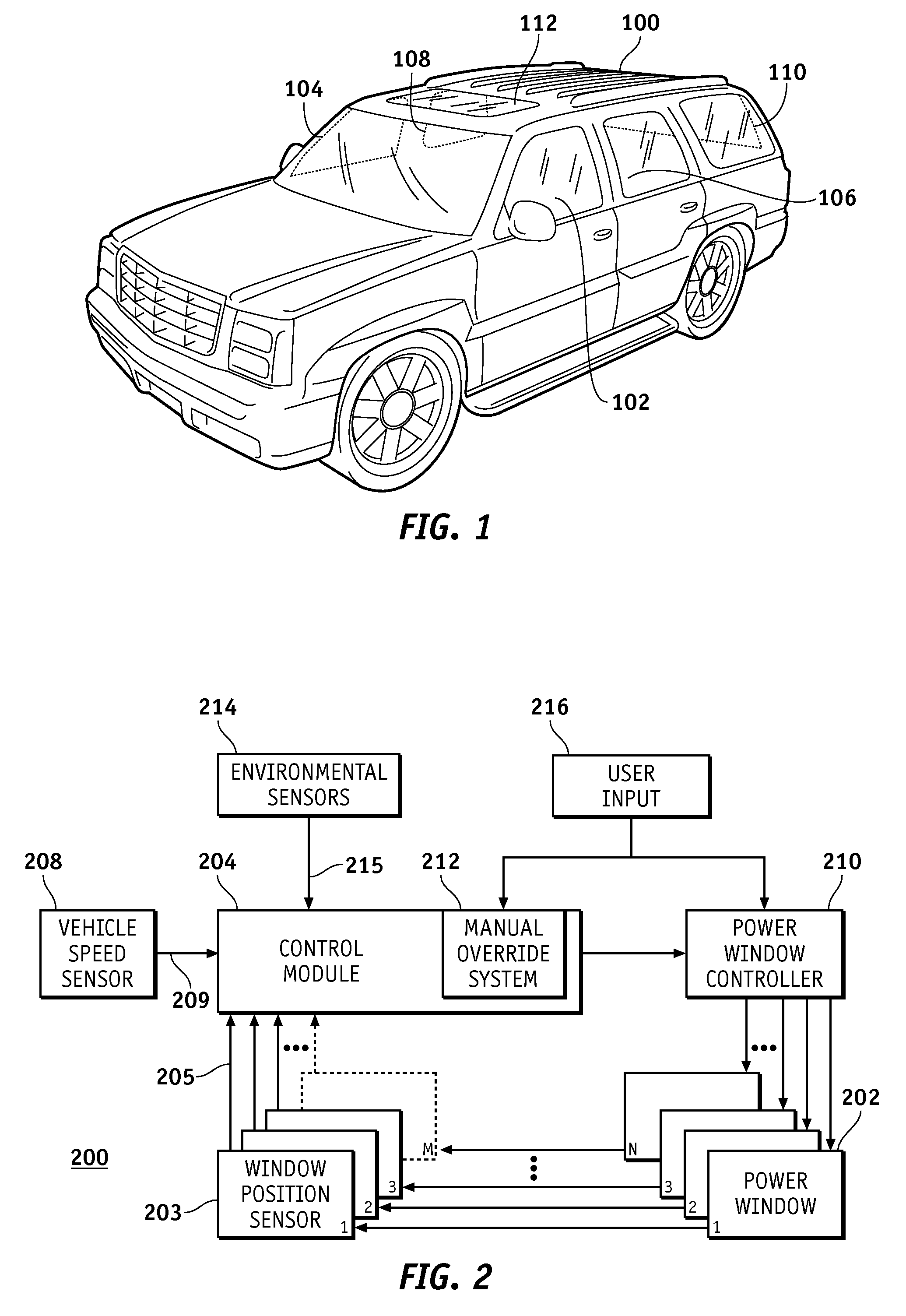

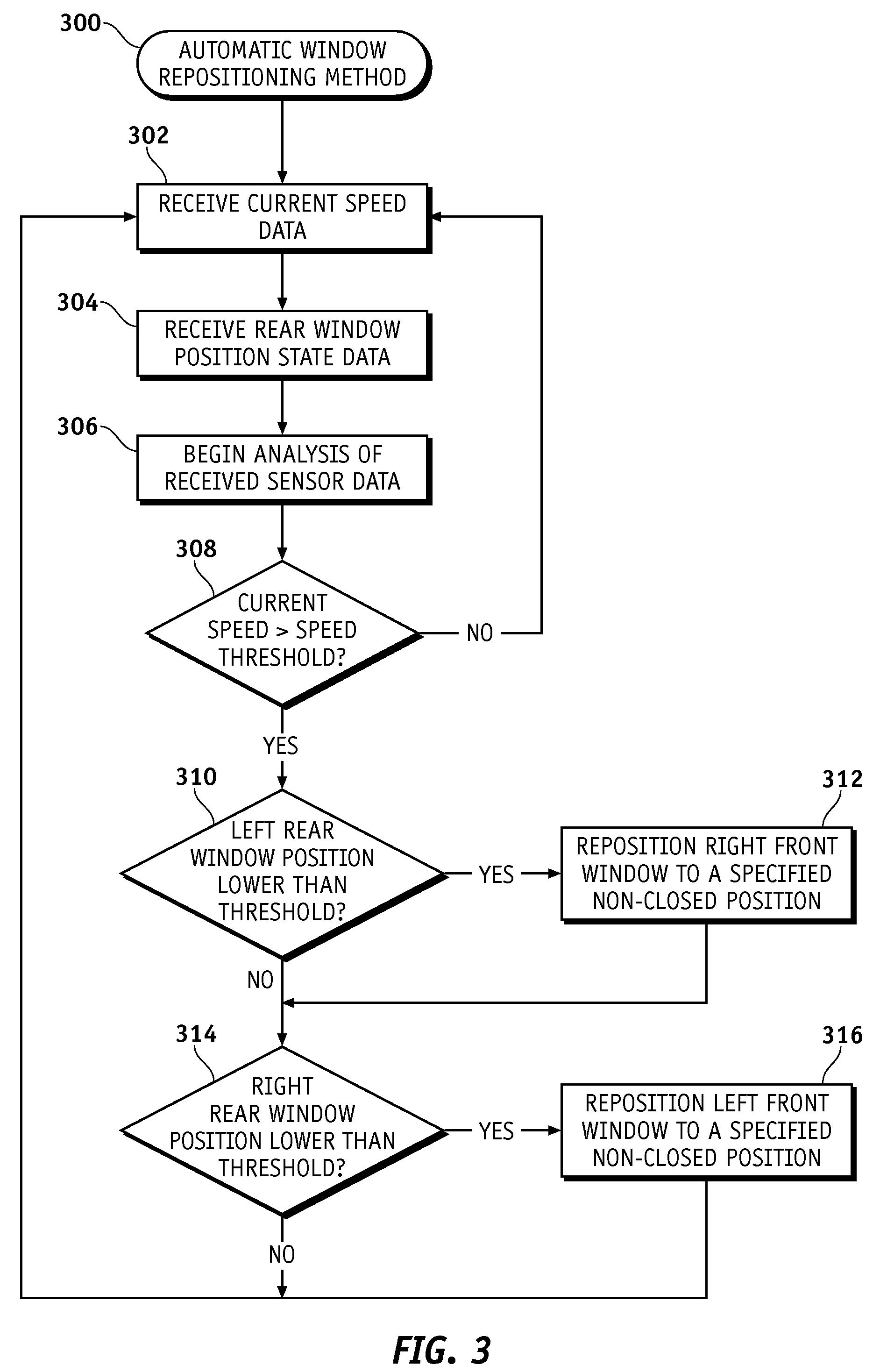

Automatic window repositioning to relieve vehicle passenger cabin wind pressure pulsation

InactiveUS20090069984A1Reduce vibration and noiseReduce intensityDC motor speed/torque controlDigital data processing detailsAutomotive engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

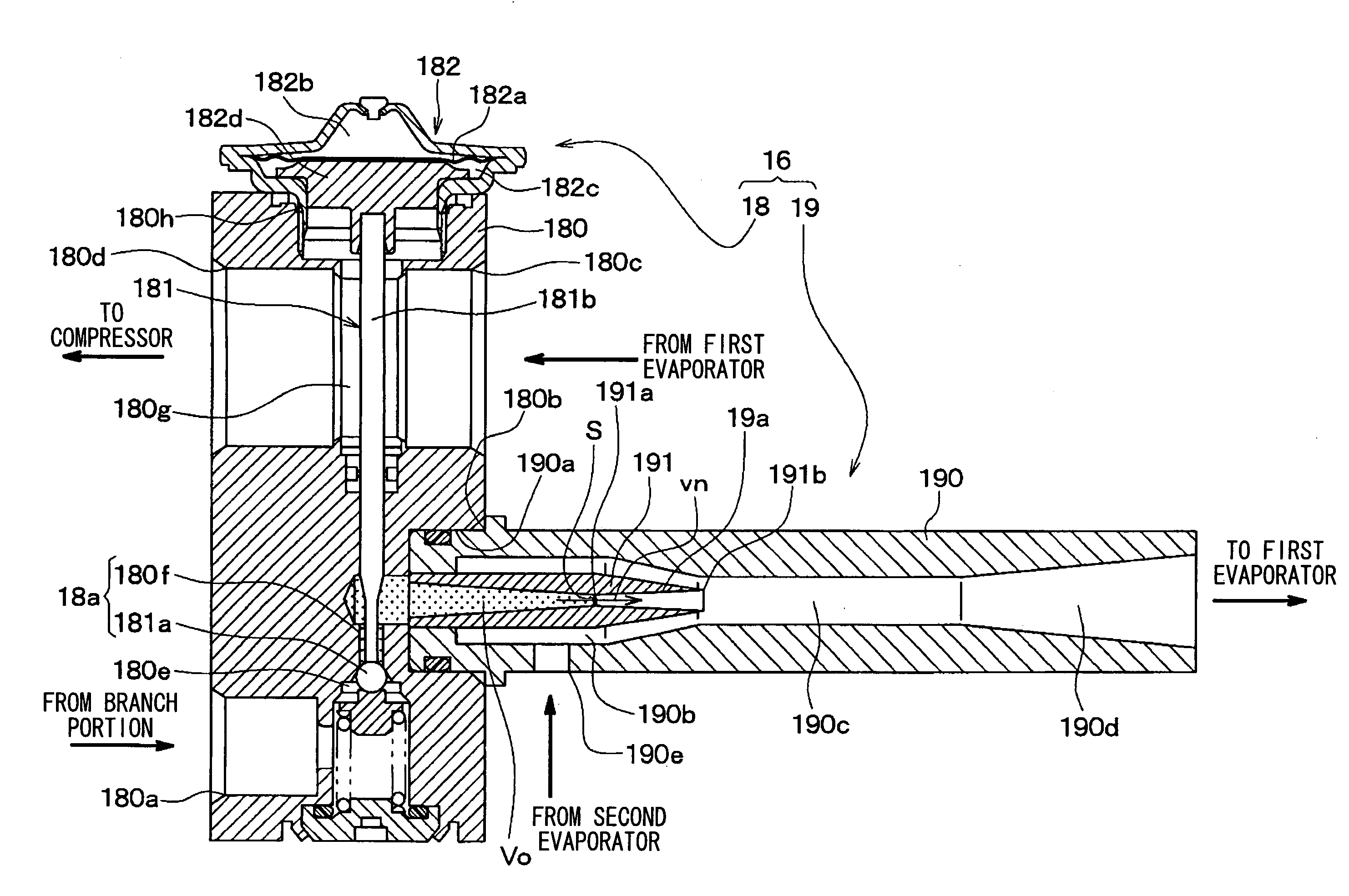

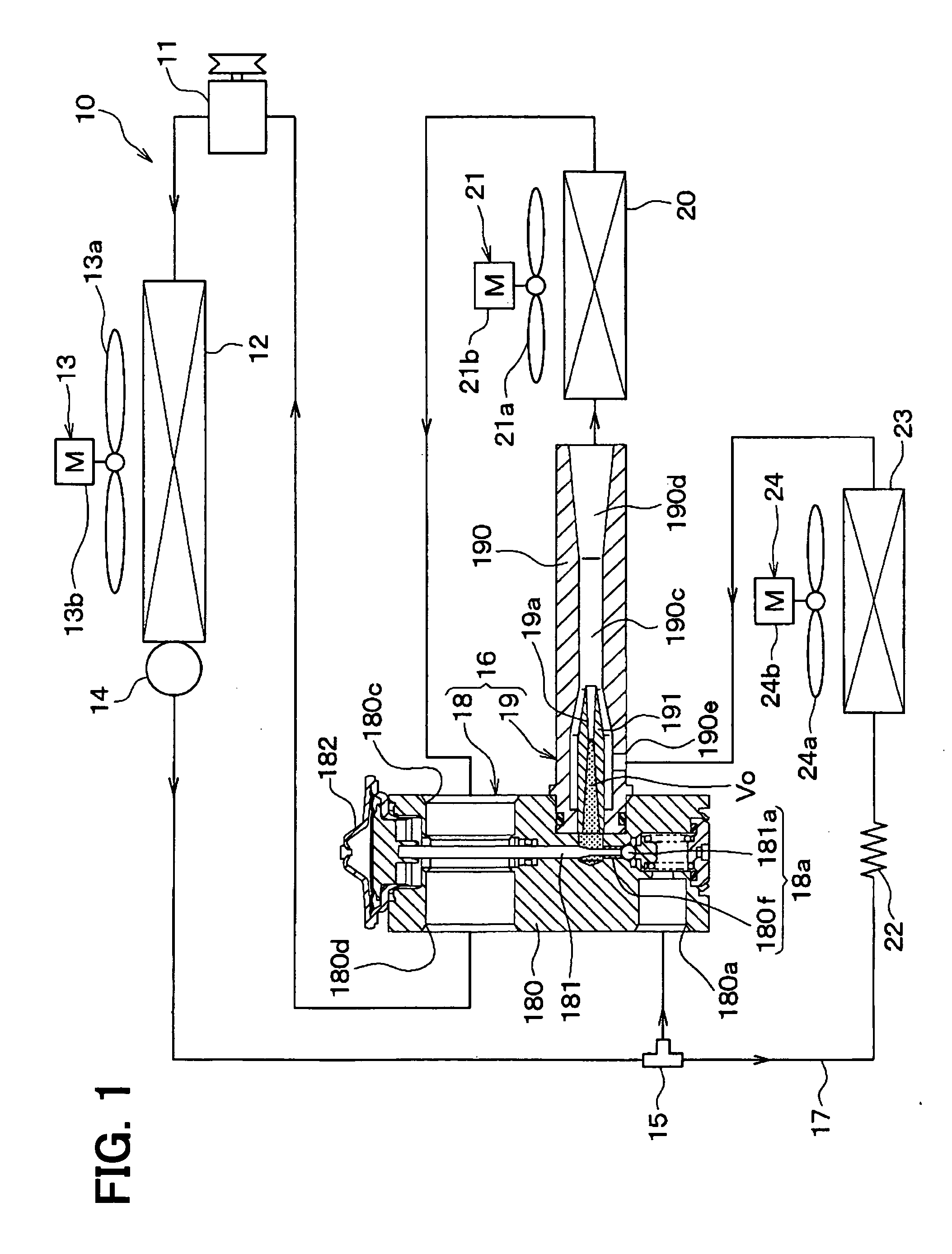

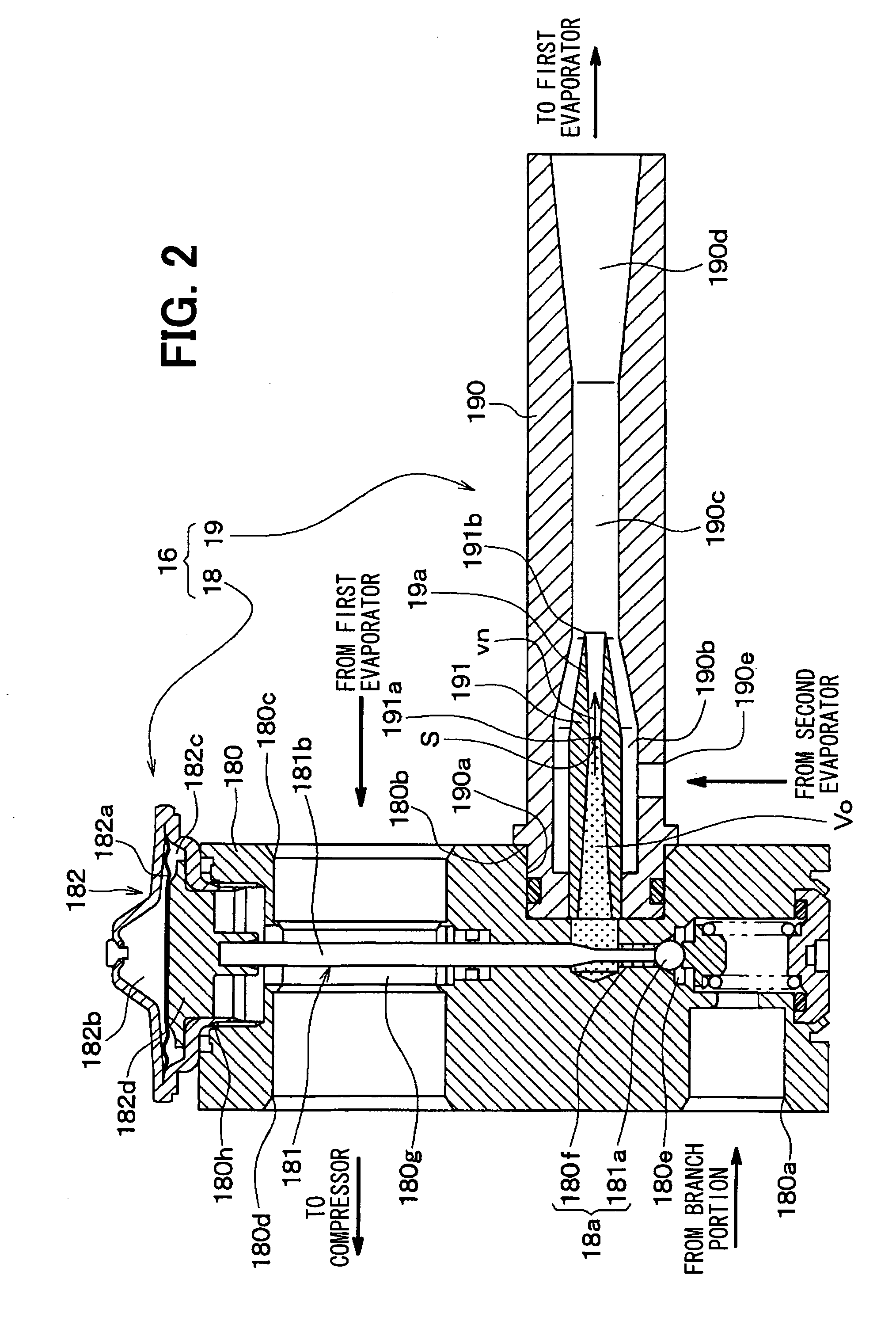

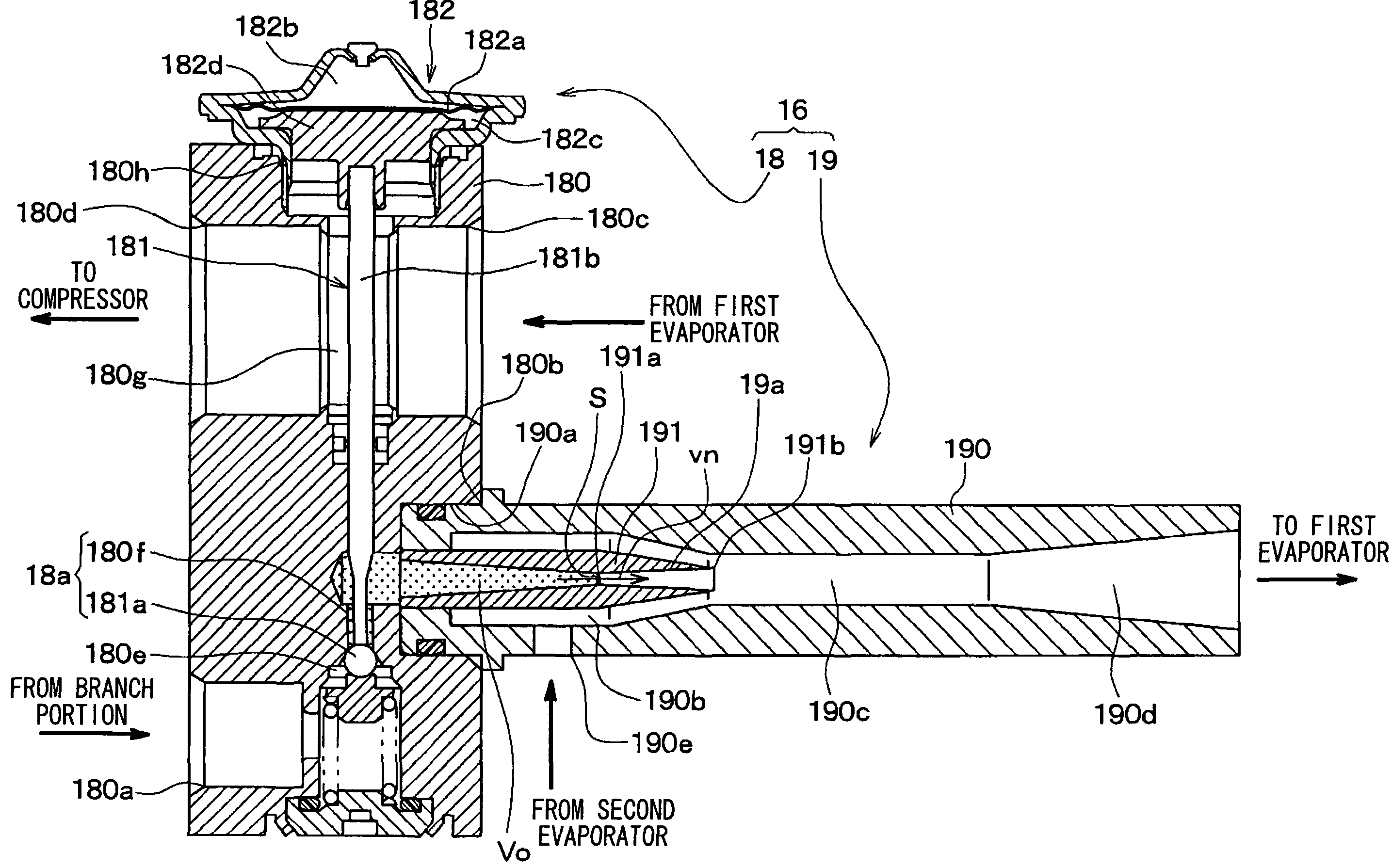

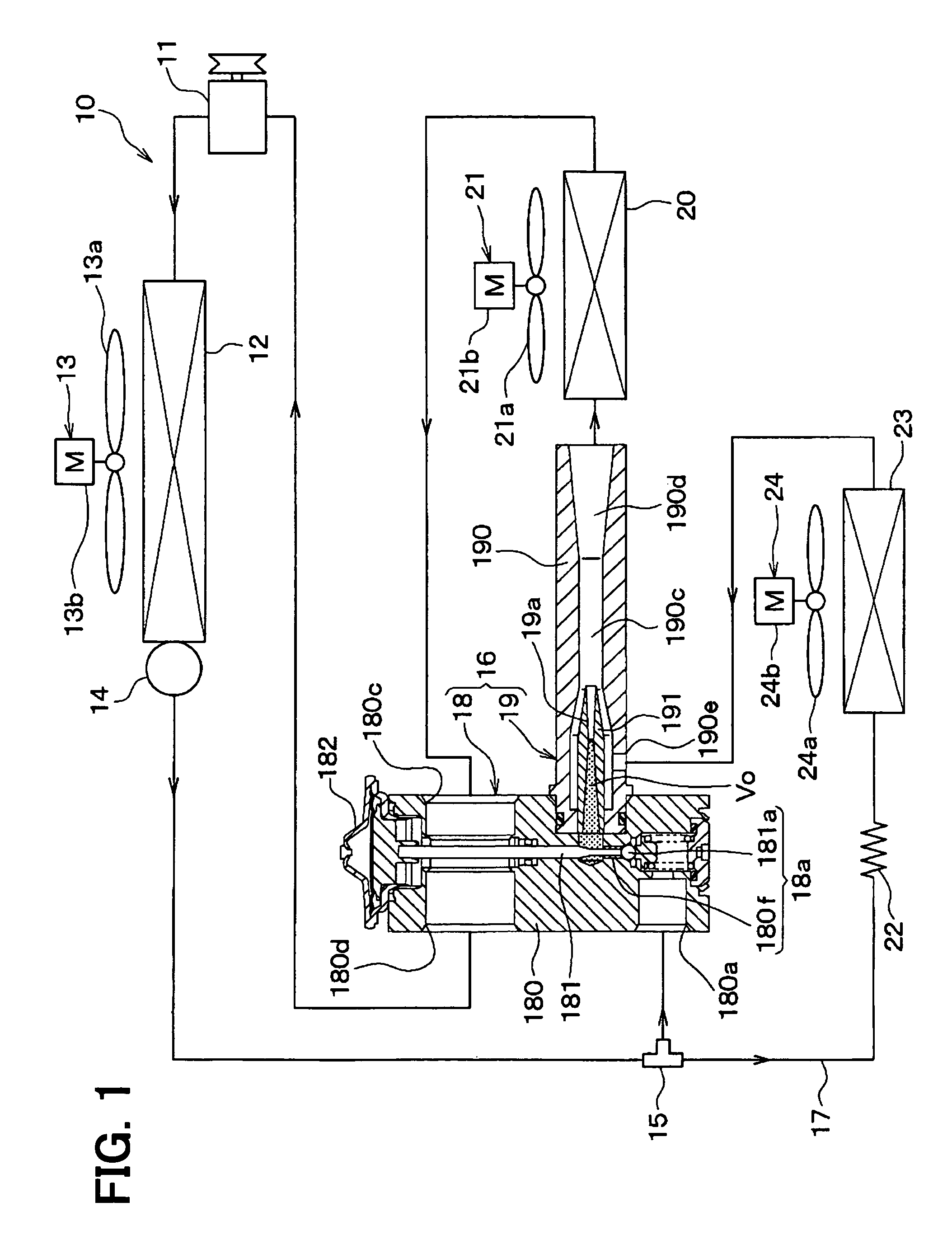

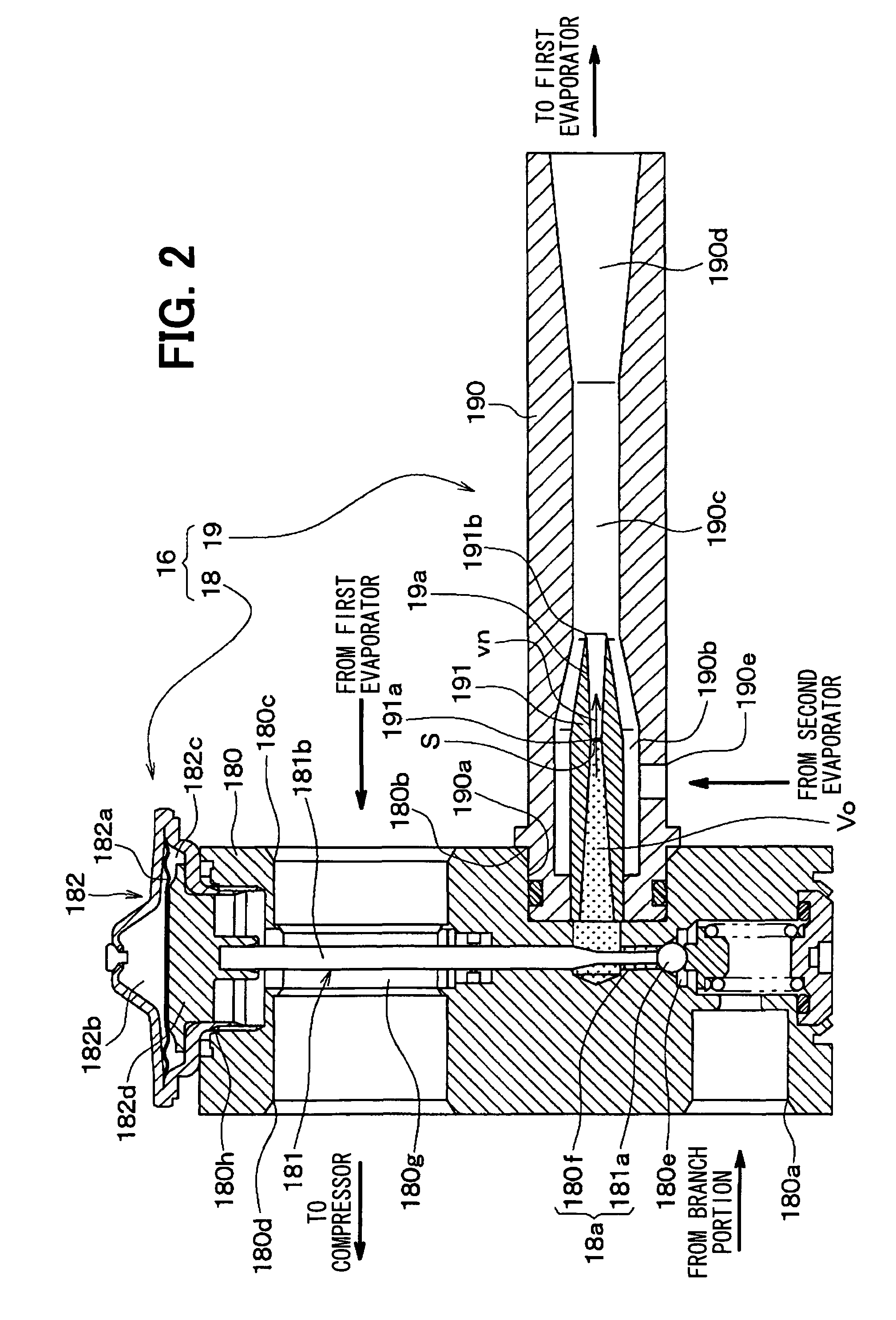

Two-stage decompression ejector and refrigeration cycle device

InactiveUS20090013704A1Avoid noiseReduce pressureCompression machines with non-reversible cycleJet pumpsEngineeringRefrigeration

A two-stage decompression ejector includes a variable throttle mechanism having a first throttle passage for decompressing a fluid and a valve body for changing a throttle passage area of the first throttle passage, a nozzle having therein a second throttle passage for further decompressing the fluid decompressed by the variable throttle mechanism, and a suction portion for drawing a fluid by a suction effect of a high-velocity jet fluid from the nozzle. The formula of 0.07≦Vo×S / vn≦0.7 is satisfied, in which Vo is an intermediate-pressure space volume (mm3) from an outlet of the variable throttle mechanism to an inlet of the second throttle passage, S is a throttle passage sectional area (mm2) of a minimum passage sectional area portion of the second throttle passage, and vn is a flow velocity (mm / s) of the fluid passing through the minimum passage sectional area portion.

Owner:DENSO CORP

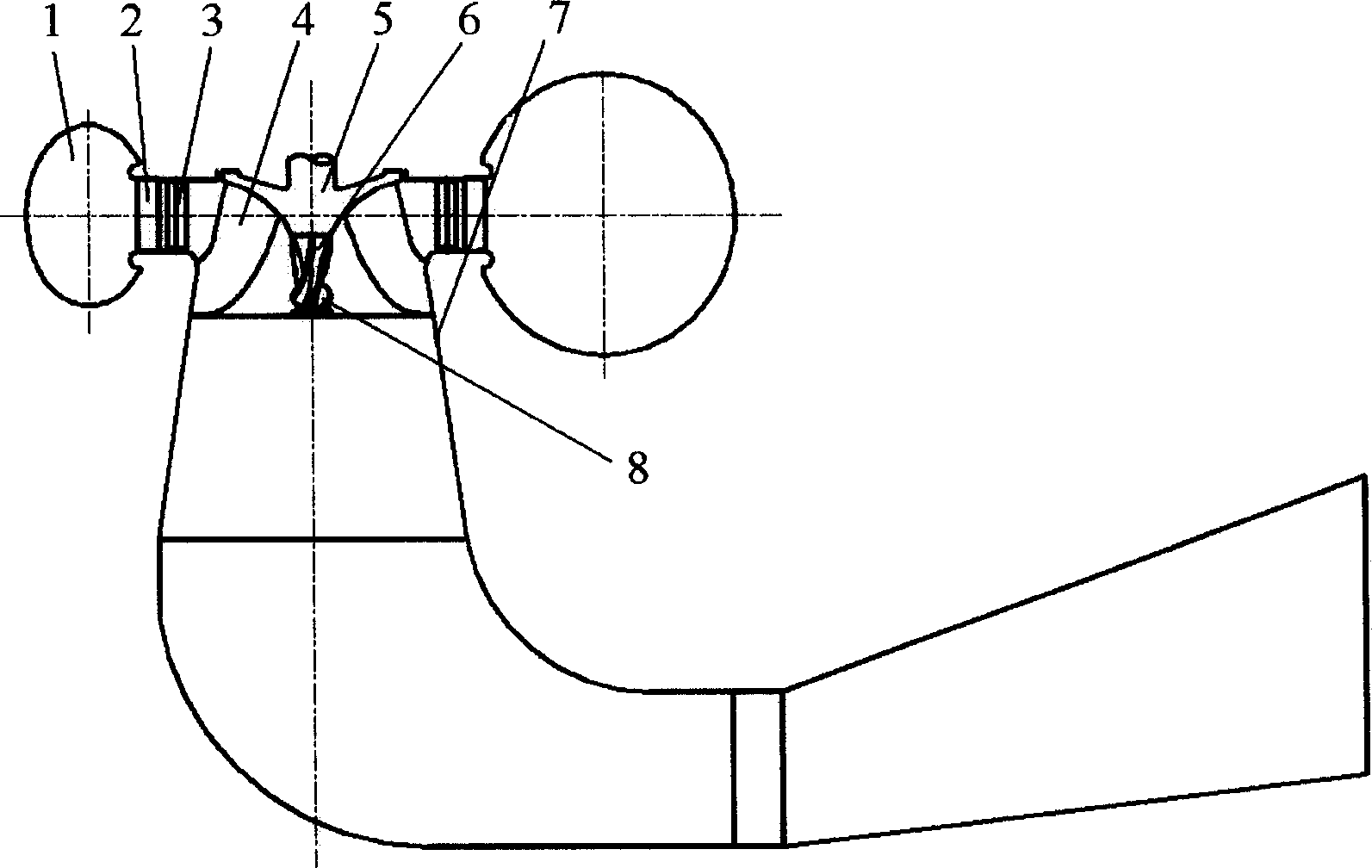

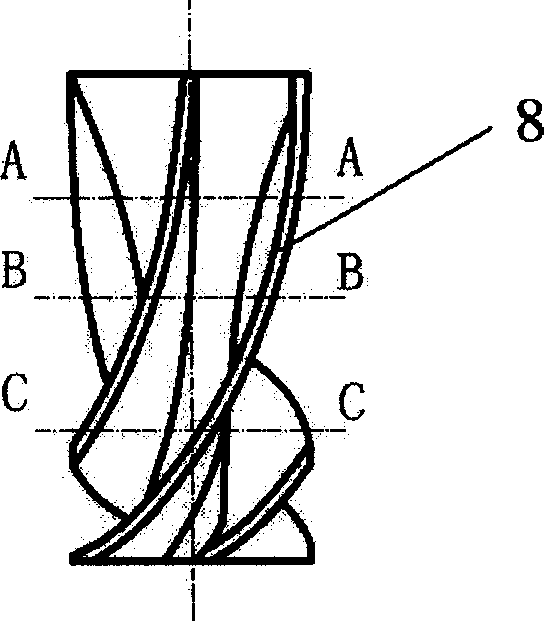

Mixed flow water turbine with an eddy suppressor

InactiveCN1702317ASimple structureEasy loading and unloadingHydro energy generationReaction enginesMixed flowSuppressor

This invention relates to a mixed flow turbine with eddy confinement device, characterized in that it sets an eddy confinement device applying axial-flow foliated structure between draft-tube and rotary wheel, and rotates with the wheel of the turbine; the inlet setting angles of axial-flow foliated and rotor blade are same; the blade wrap angle is 150~180 deg, and the length is 0.5-1.0 times of inlet diameter of the wheel. Said invention improves the flowing condition of wheel outlet, enhancing central current rate of draft-tube, decreasing pressure fluctuation of draft-tube, so it can improve operation stability of mixed flow turbine, meanwhile, it meets the stability requirement of both high volume behavior and small flow behavior.

Owner:TSINGHUA UNIV

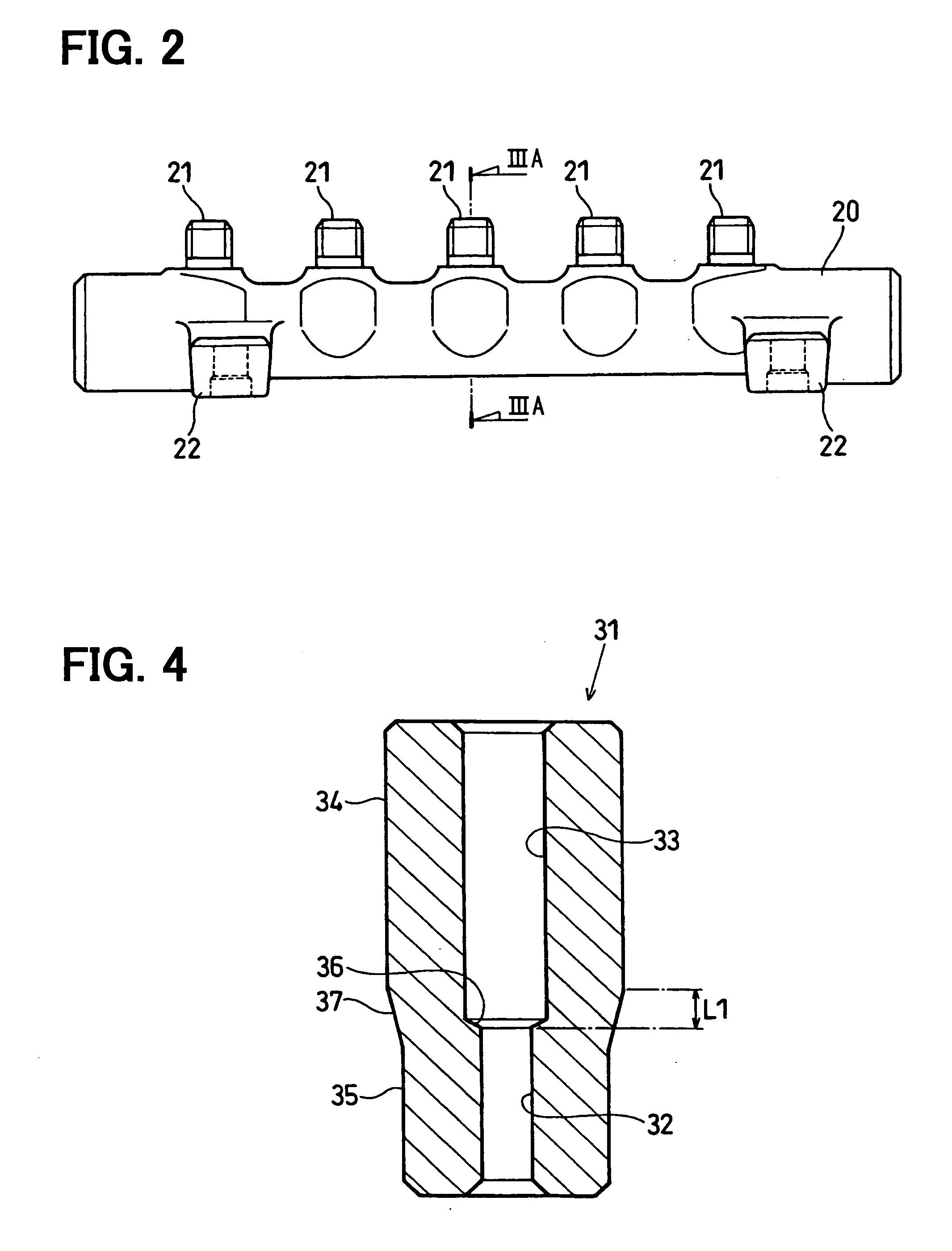

Common rail having orifice

ActiveUS7516734B2Avoid deformationReduce processLow pressure fuel injectionMachines/enginesCommon railEngineering

A bush incorporated in a common rail is formed with a smallest diameter orifice having a small inner diameter and an adjacent orifice having an inner diameter larger than that of the smallest diameter orifice on an inner peripheral face of the bush. A press-fitted portion, which is press-fitted into an inside-outside communication hole, and a non-press-fitted portion, which has a smaller outer diameter than the press-fitted portion, are formed on an outer peripheral face of the bush. The smallest diameter orifice and the press-fitted portion are deviated from each other in an axial direction of the bush to prevent an overlap in a radial direction of the bush. Thus, even if the bush is tightly press-fitted into the inside-outside communication hole, decrease of the inner diameter of the smallest diameter orifice can be averted.

Owner:DENSO CORP

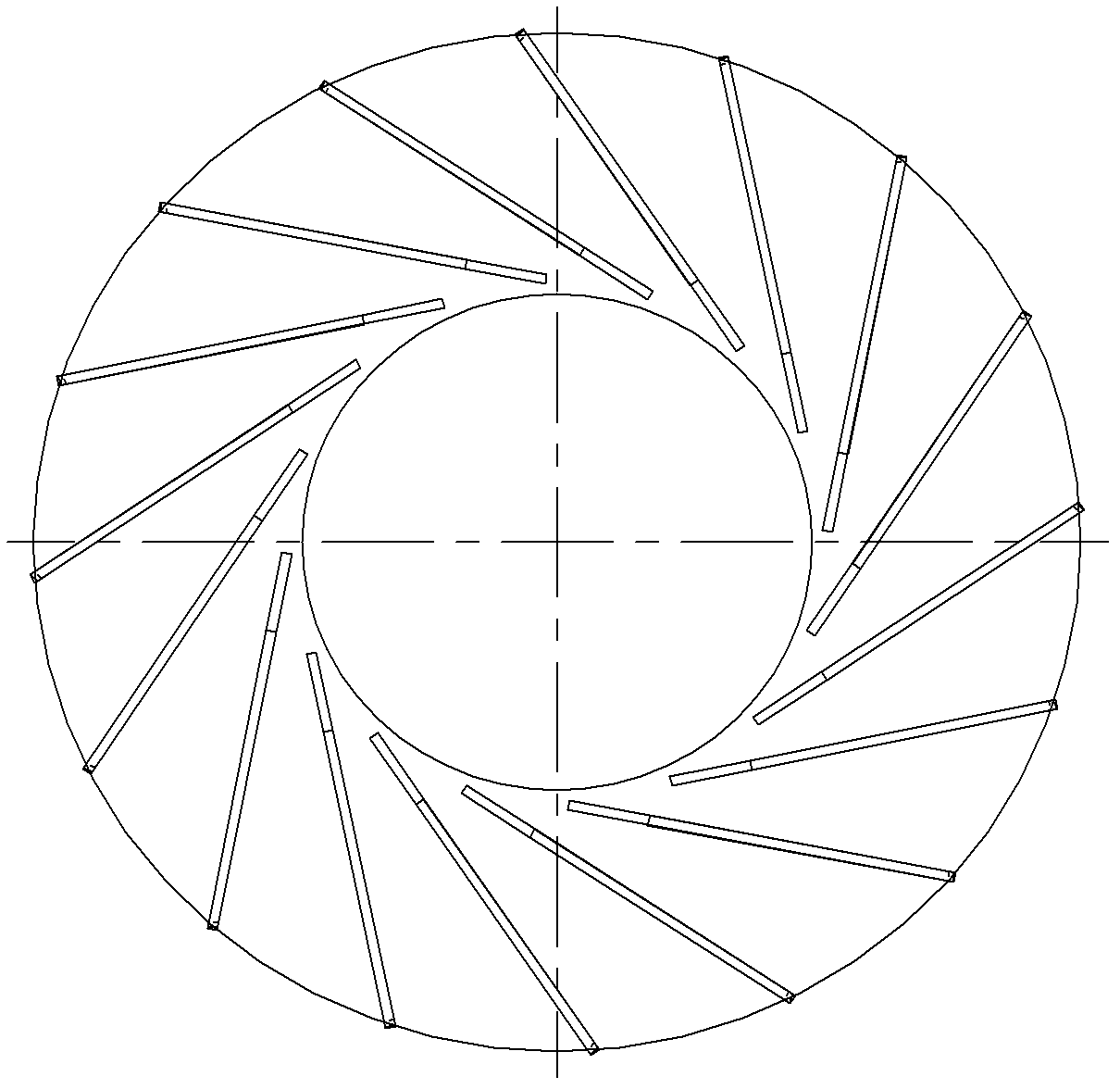

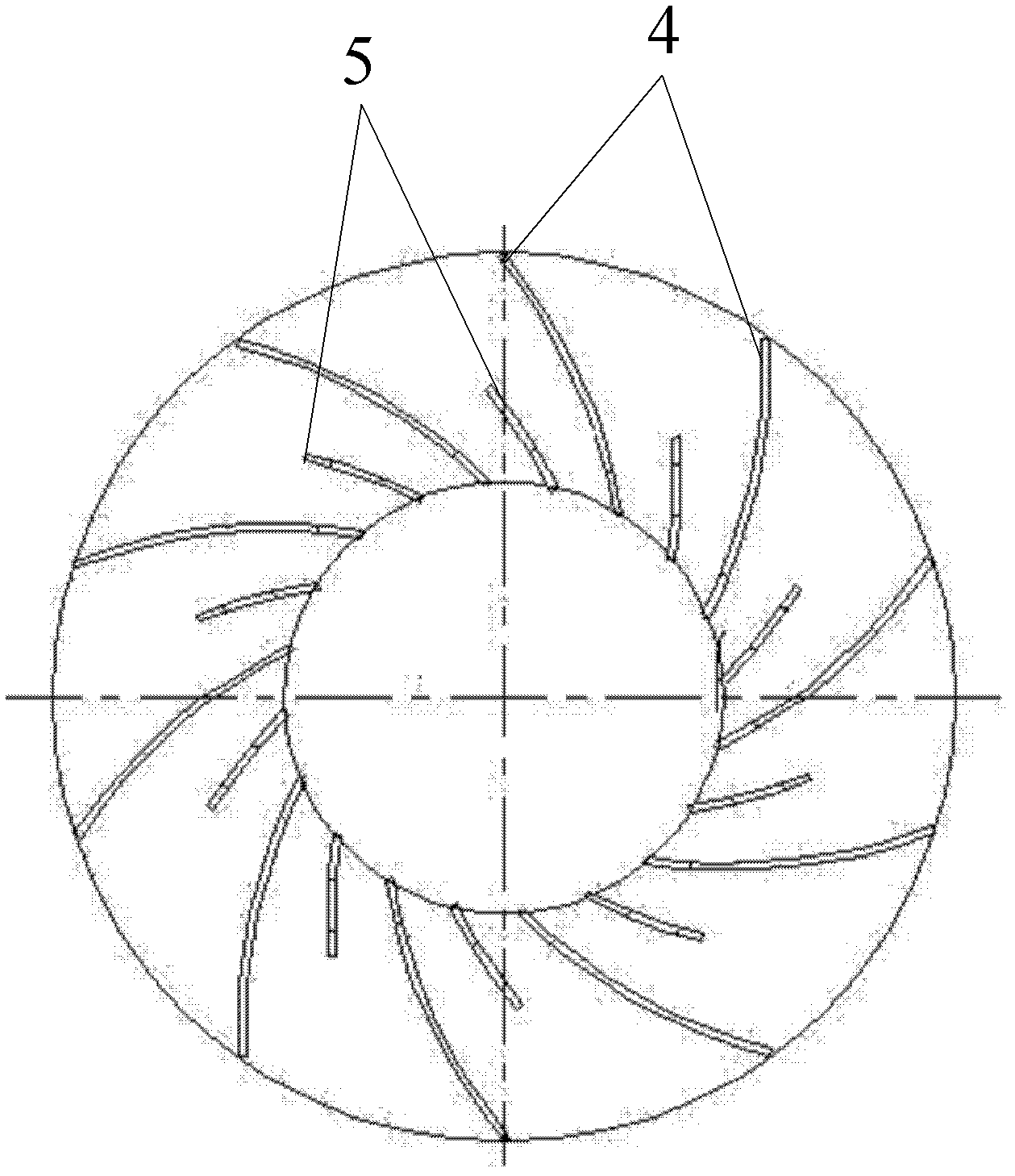

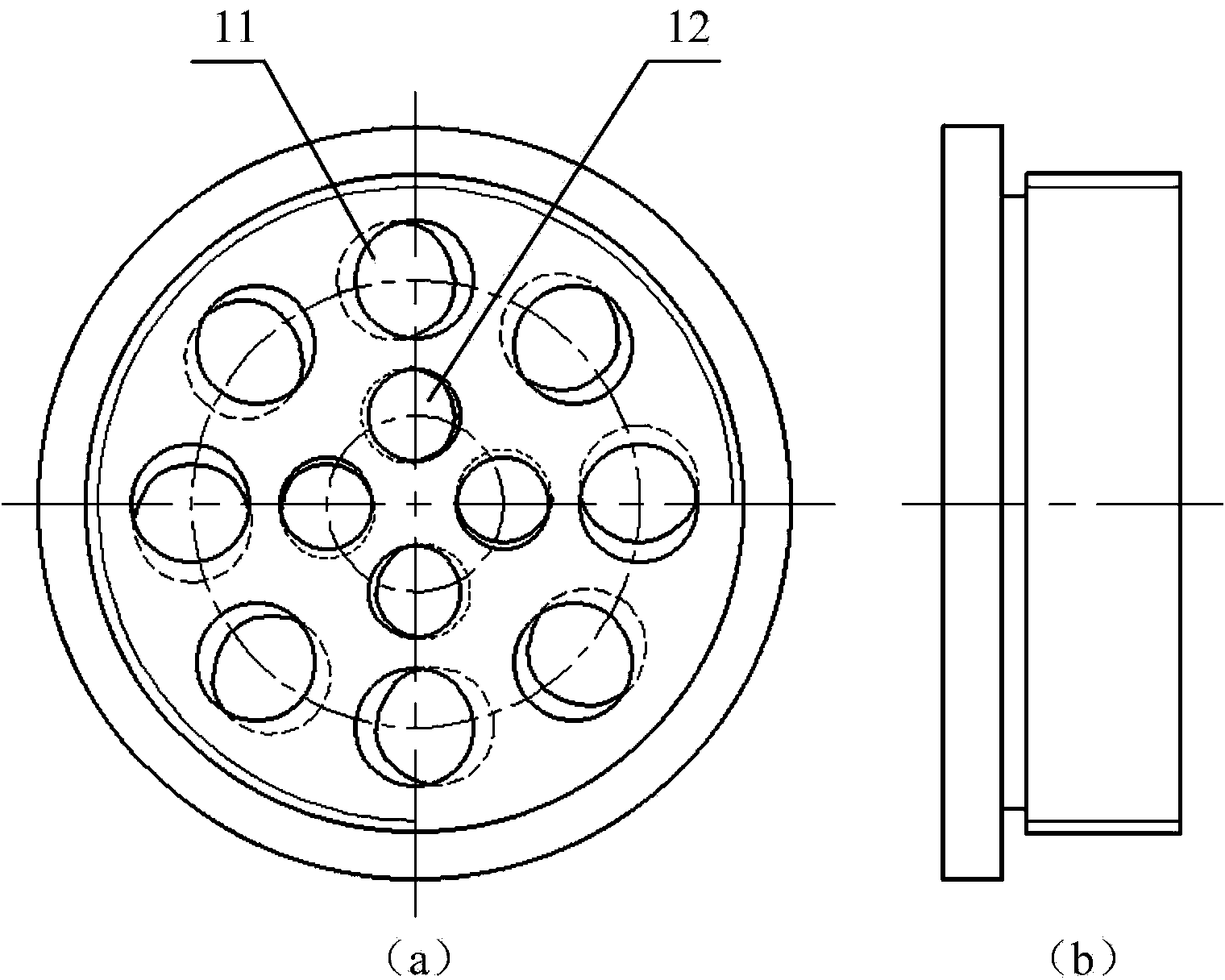

Centrifugal fan impeller and centrifugal fan

ActiveCN102518602AReduced pressure pulsation intensityReduce pressure pulsationPump componentsPumpsImpellerCentrifugal force

An embodiment of the invention provides a centrifugal fan impeller and a centrifugal fan with the same. The centrifugal fan impeller comprises a hub, blades and an impeller cover, wherein the blades are mounted between the hub and the impeller cover and include backward long blades and short blades, the long blades are larger than the short blades in flow length, the long blades and the short blades are distributed alternately between the hub and the impeller cover, and the short blades are equal to the long blades in inlet diameter. A meridian channel molded line of the impeller cover is a smooth curved line from an inlet to an outlet of each of the long blade or short blade. Using the centrifugal impeller solves the problem of noise caused by an existing centrifugal fan impeller.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Structure for preventing backflow from entering air intake duct of air-breathing pulse detonation engine

InactiveCN103883428AImprove propulsion performanceReduce pressure pulsationRocket engine plantsFuel oilStreamflow

The invention discloses a structure for preventing backflow from entering an air intake duct of an air-breathing pulse detonation engine. The air intake duct of the engine is formed by an air intake housing and a rectification air intake cone. An annular passage is formed by a circular tube section and a cylinder. The rectification air intake cone is fixed to the cylinder. An adjustable inner plug is installed in the cylinder through threads. A diversion fin cylinder is arranged on the cylinder in a sleeved mode and fixed by the rectification air intake cone. The cylinder is fixed to the circular tube section through a fuel oil tube. Air enters a detonation chamber through the air intake duct and the annular passage, and fuel oil is axially sprayed into the detonation chamber through the fuel oil tube and mixed with the air. After ignition and detonation, the backflow enters an inner cavity of the cylinder against the incoming flow direction, enters the annular passage formed by the circular tube section and the cylinder through two rows annular slotted holes of the inner cavity, the backflow changes the direction and interacts with backflow passing by the cylinder under the diversion action of the diversion fin cylinder on airflow, the total pressure of the backflow is gradually reduced, the flow rate of the backflow entering the air inlet duct is reduced, and therefore the propulsion performance of the engine is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

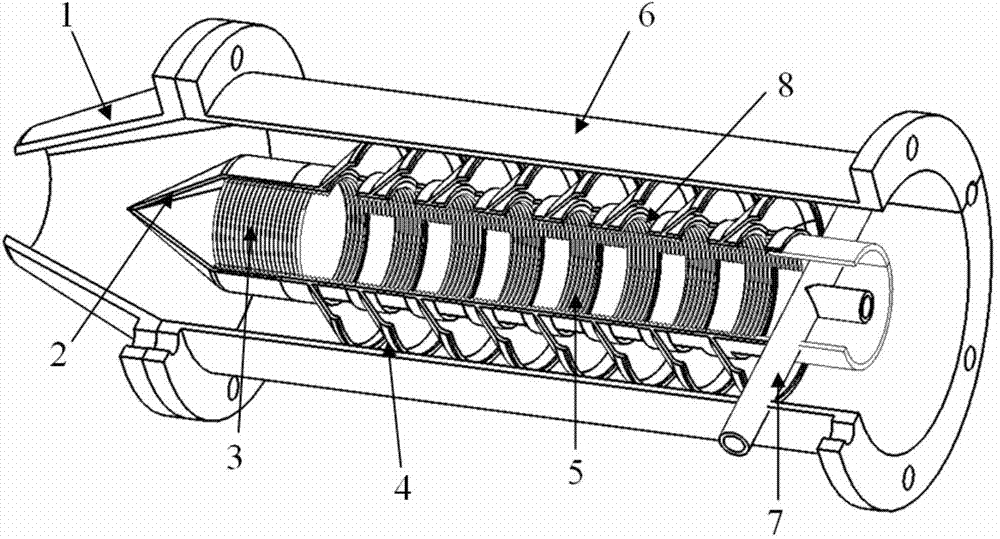

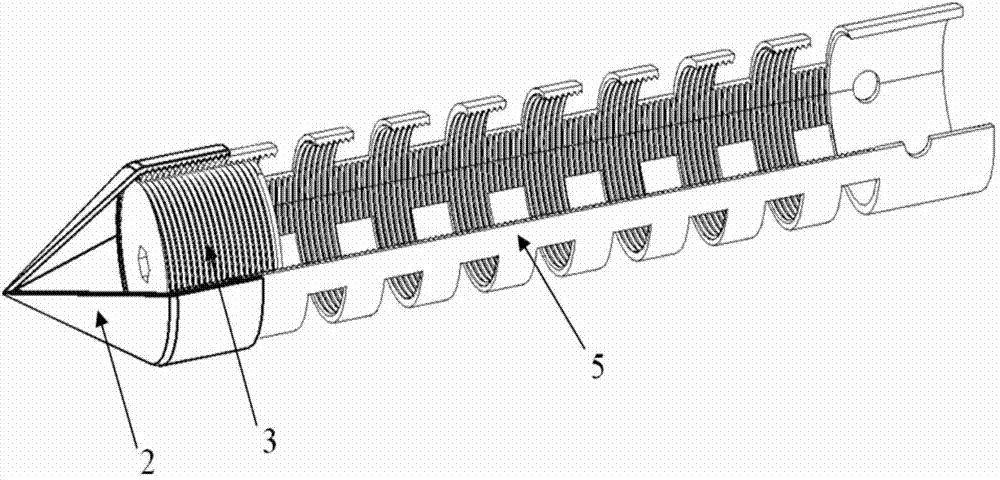

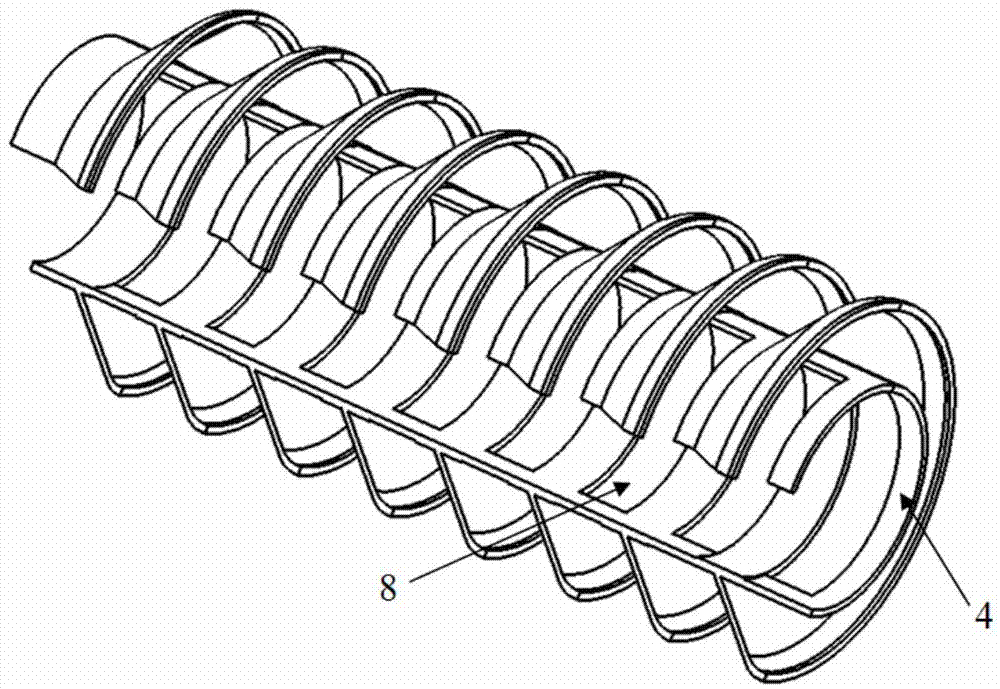

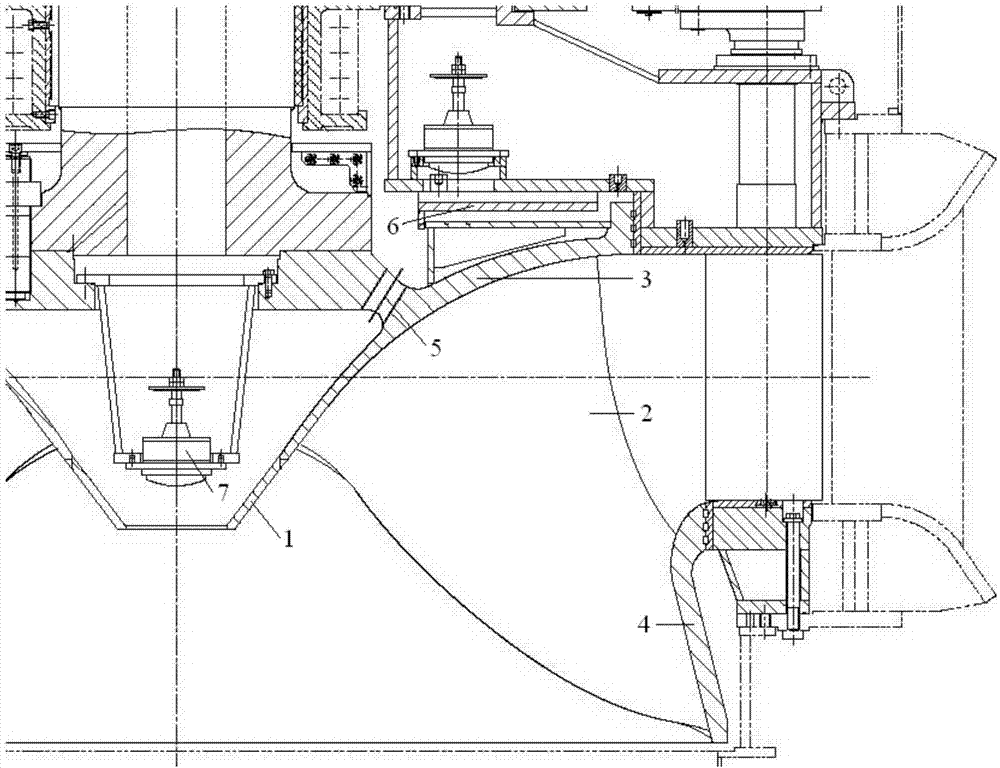

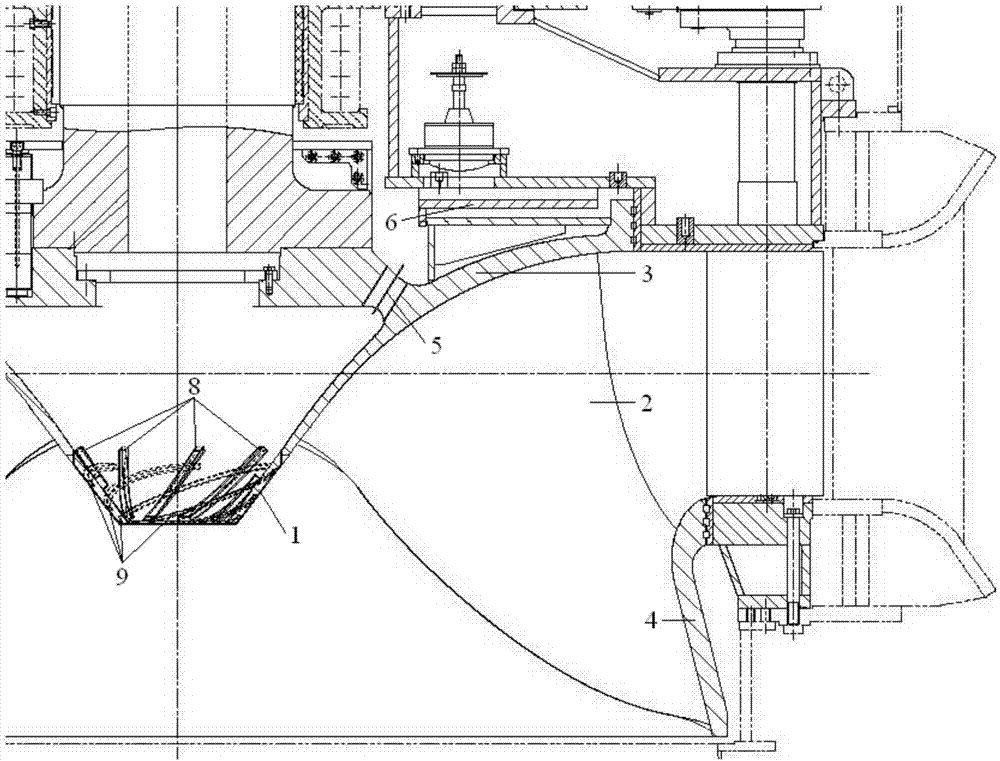

Pressure reduction and vibration damping runner cone device

InactiveCN104121137AImprove stressReduce axial water thrustHydro energy generationMachines/enginesMixed flowWater turbine

The invention relates to a pressure reduction and vibration damping runner cone device which comprises a runner cone (1) connected with a runner crown (3) of a rotary wheel, wherein a ribbed plate (8) is welded to the inner side of the runner cone (1), a spiral groove (9) is formed in the outer side of the runner cone (1), a water division plate (6) is arranged on a unit, and a drainage hole (5) is formed in the unit. When a mixed flow water turbine operates, the ribbed plate on the inner side of the runner cone pressurizes water flows drained out of the drainage hole, therefore, water drainage is increased, and axial hydraulic thrust of the unit is reduced; the spiral groove in the outer side of the runner cone drives the water flows close to the runner cone to rotate to smooth the water flows and perform water jet, pressure fluctuation of a draft tube is eliminated or weakened, and problems caused by hydraulic vibration are solved.

Owner:HARBIN ELECTRIC MASCH CO LTD

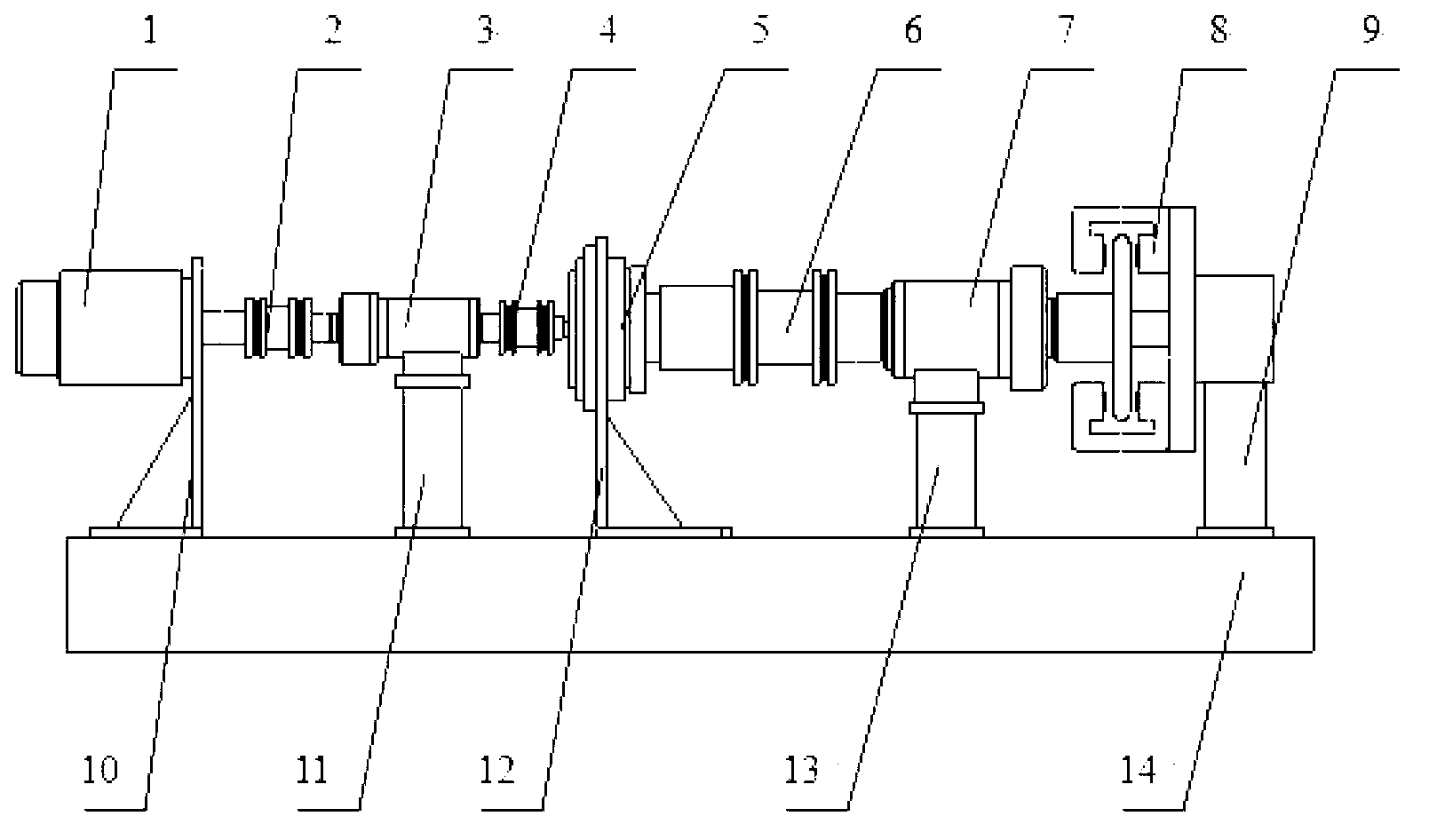

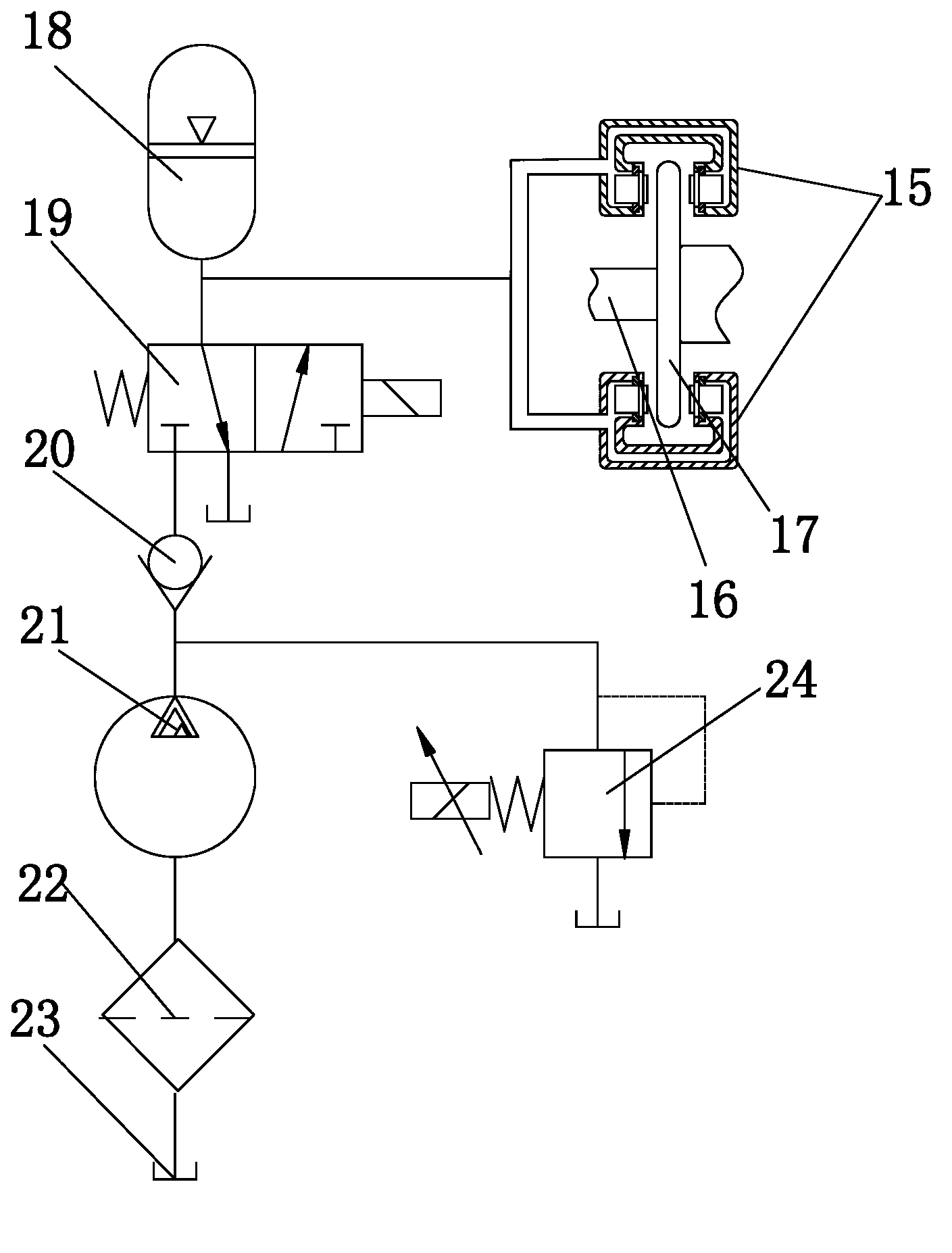

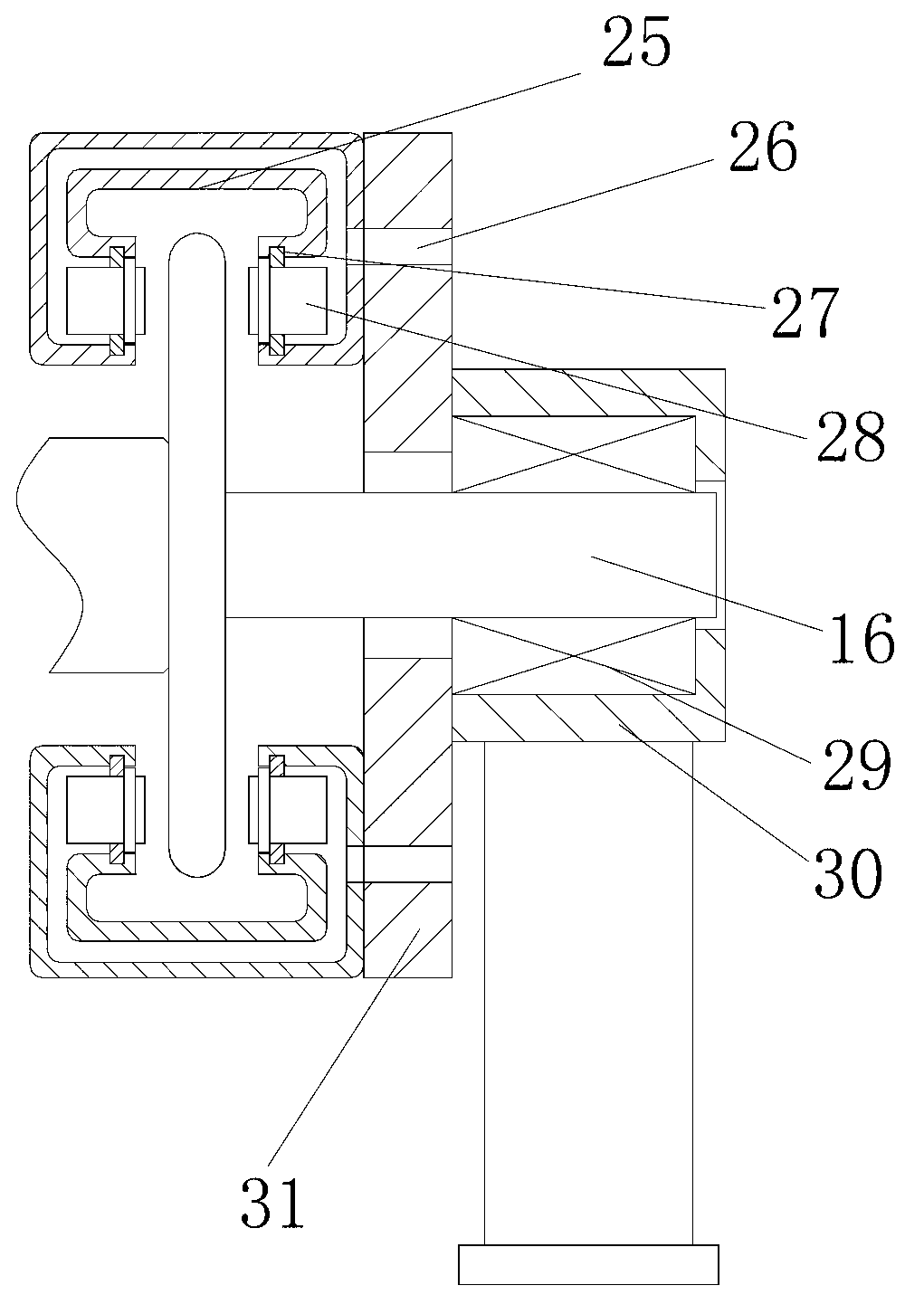

Electro-hydraulic loading device for reducer test

InactiveCN103175684ACompact structureLarge loading torqueMachine gearing/transmission testingServomotorsCouplingReduction drive

The invention discloses an electro-hydraulic loading device for a reducer test. The electro-hydraulic loading device comprises a base (14). A driving motor (1), a first coupler (2), a torque angle displacement sensor (3) of a reducer input end, a second coupler (4), the to-be-tested reducer (5), a third coupler (6), a torque angle displacement sensor (7) of a reducer output end and an electro-hydraulic loading mechanism (8) are kept horizontally coaxial and connected in sequence are arranged on the base (14). The electro-hydraulic loading mechanism (8) comprises a loading cylinder (15) which is provided with a spindle (16) with a brake disc (17). The loading cylinder (15) is sequentially connected with an energy accumulator (18), a switching valve (19), a check valve (20), a hydraulic pump (21), a filter (22) and an oil tank (23), and the check valve (20) is further connected with an overflow valve (24). The electro-hydraulic loading device for the reducer test is adaptable to the reducer test for a large torque efficient robot, also capable of testing a single reducer each time; and is stable in loading performance and convenient to use.

Owner:WENZHOU UNIVERSITY

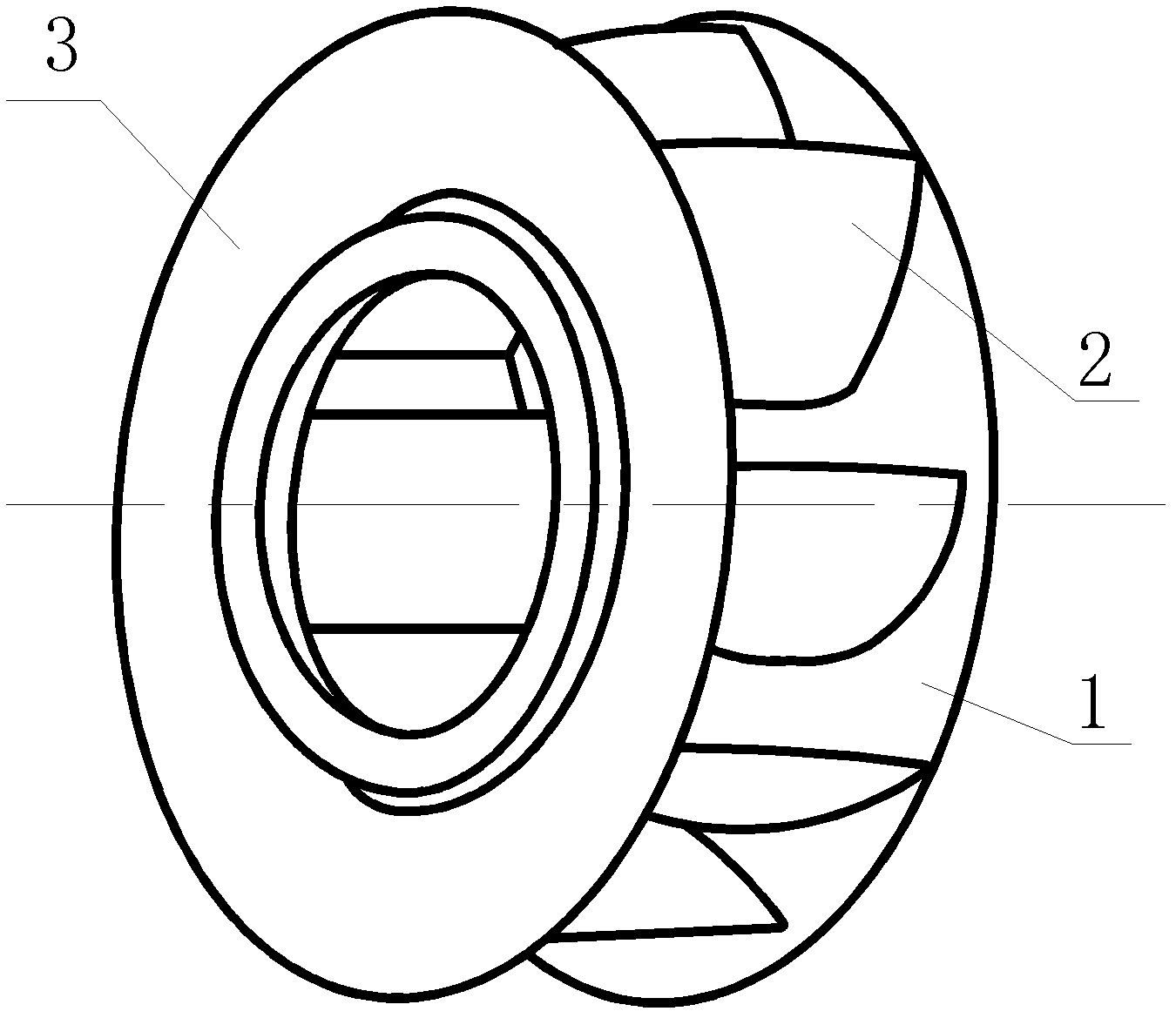

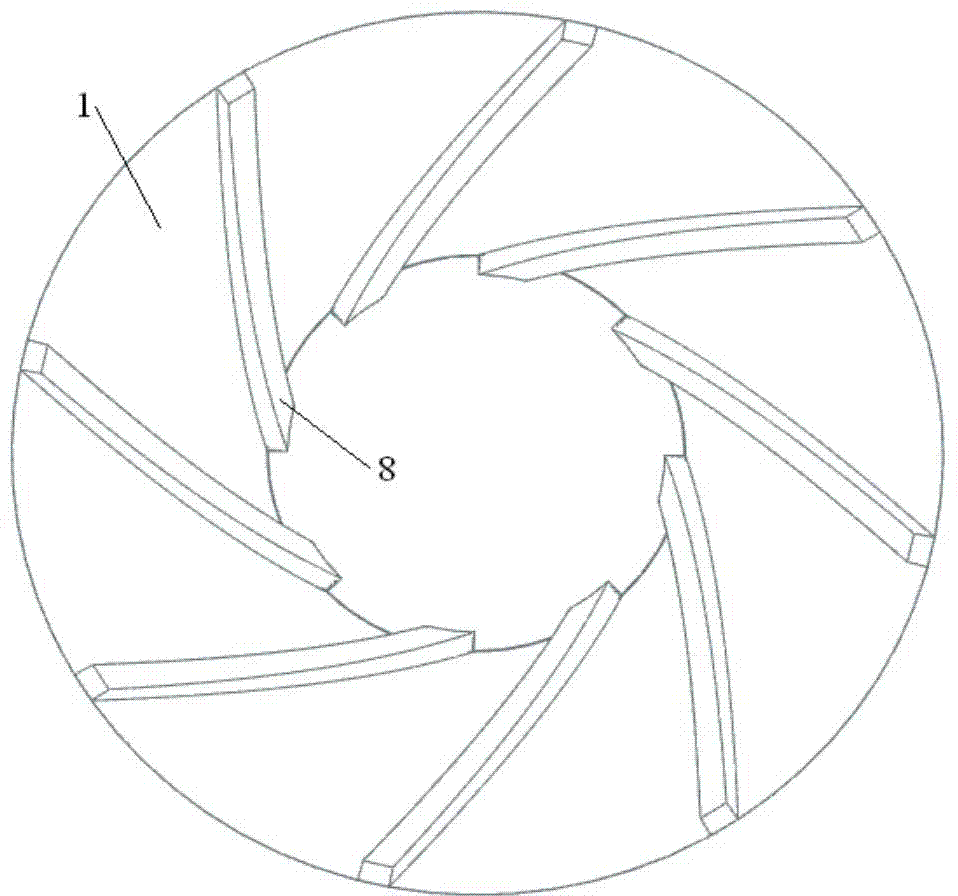

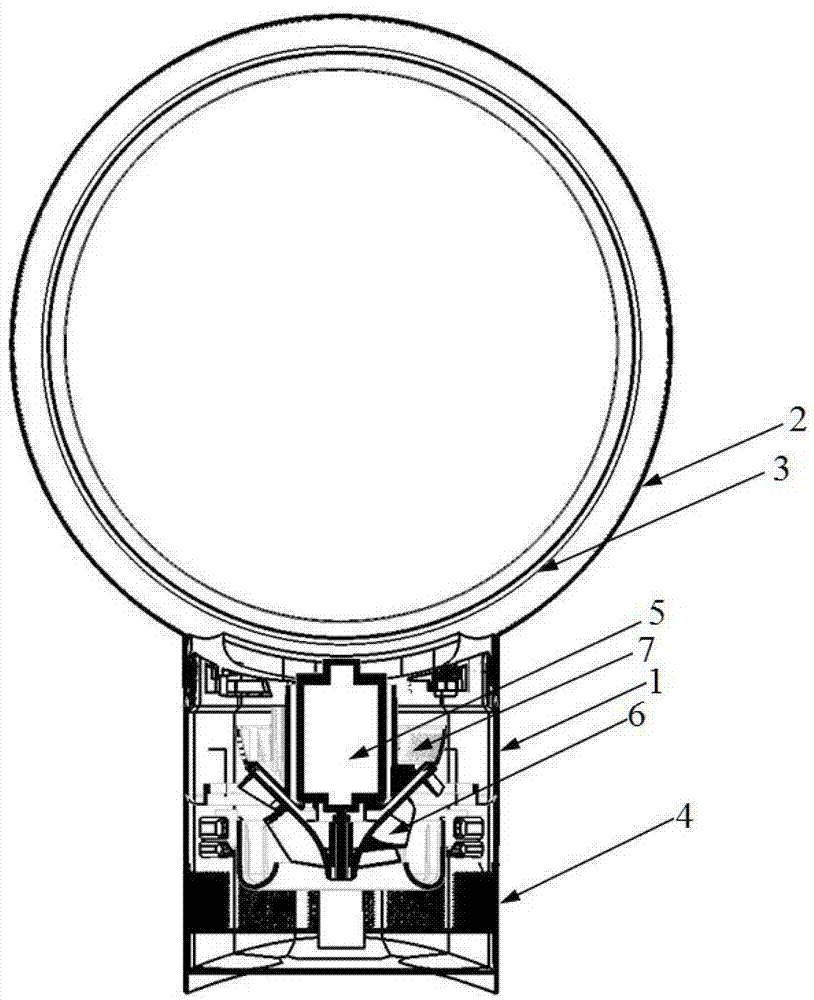

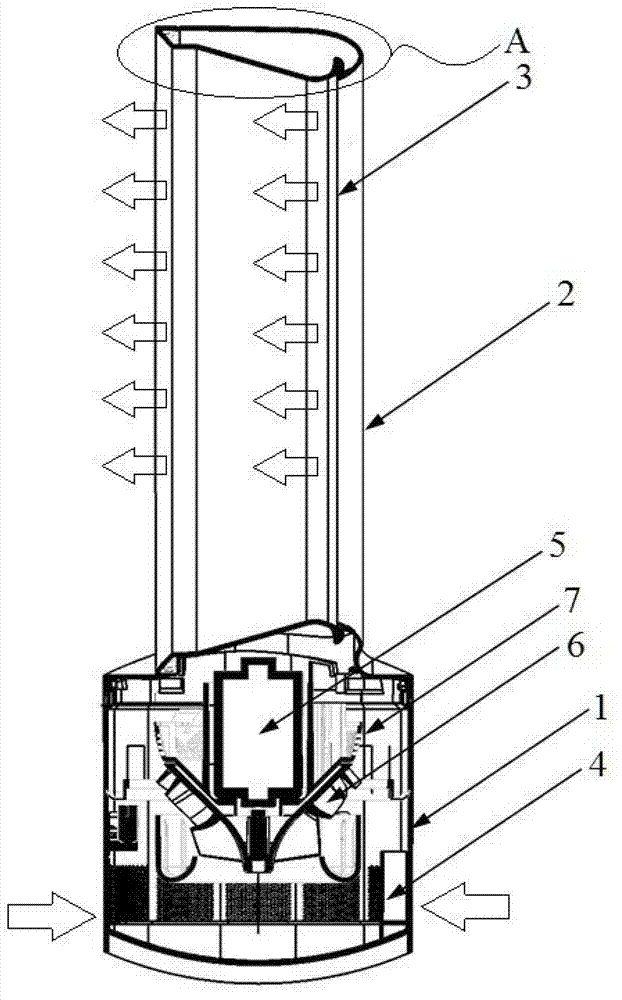

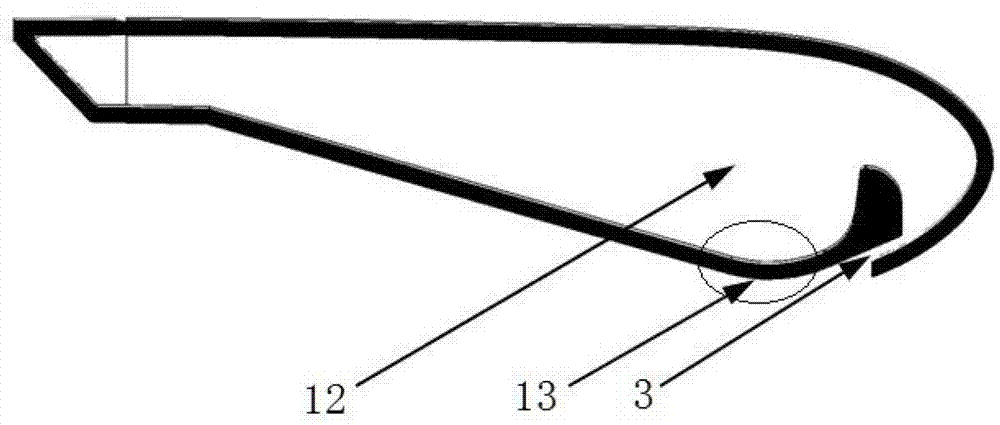

Bladeless fan turbine device with splitter blades

The invention discloses a bladeless fan turbine device with splitter blades. The bladeless fan turbine device with the splitter blades comprises a motor, a motor fixing device, a splitter blade turbine and an outer ring wall. A motor rotating shaft penetrates through the motor fixing device and is connected with the inner side of the inner ring wall of the splitter blade turbine. The inner side of the outer ring wall is sleeved on the splitter blade turbine. The splitter blade turbine comprises the inner ring wall, long blades and splitter blades, wherein the long blades are arranged in the peripheral direction of the inner ring wall, the splitter blades are located between every two adjacent long blades respectively and are distributed on the inner ring wall in the peripheral direction, the outlet diameters of the splitter blades equal those of the long blades, and the inlet diameters of the splitter blades differ from those of the long blades. The bladeless fan turbine device with the splitter blades is located in a bladeless fan base. Pressurizing ability and pressurizing efficiency of the bladeless fan turbine device with the splitter blades are effectively improved, service life of the bladeless fan turbine device with the splitter blades is prolonged, and therefore air-out amount of a bladeless fan is increased, operation stability is improved, noises of the bladeless fan are reduced, overall performance of the bladeless fan is improved, and the bladeless fan has the advantages of saving energy and protecting the environment.

Owner:ZHEJIANG SCI-TECH UNIV

Automatic window repositioning to relieve vehicle passenger cabin wind pressure pulsation

InactiveUS7877180B2Reduce vibration and noiseReduce intensityDC motor speed/torque controlDigital data processing detailsEngineeringAutomotive engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

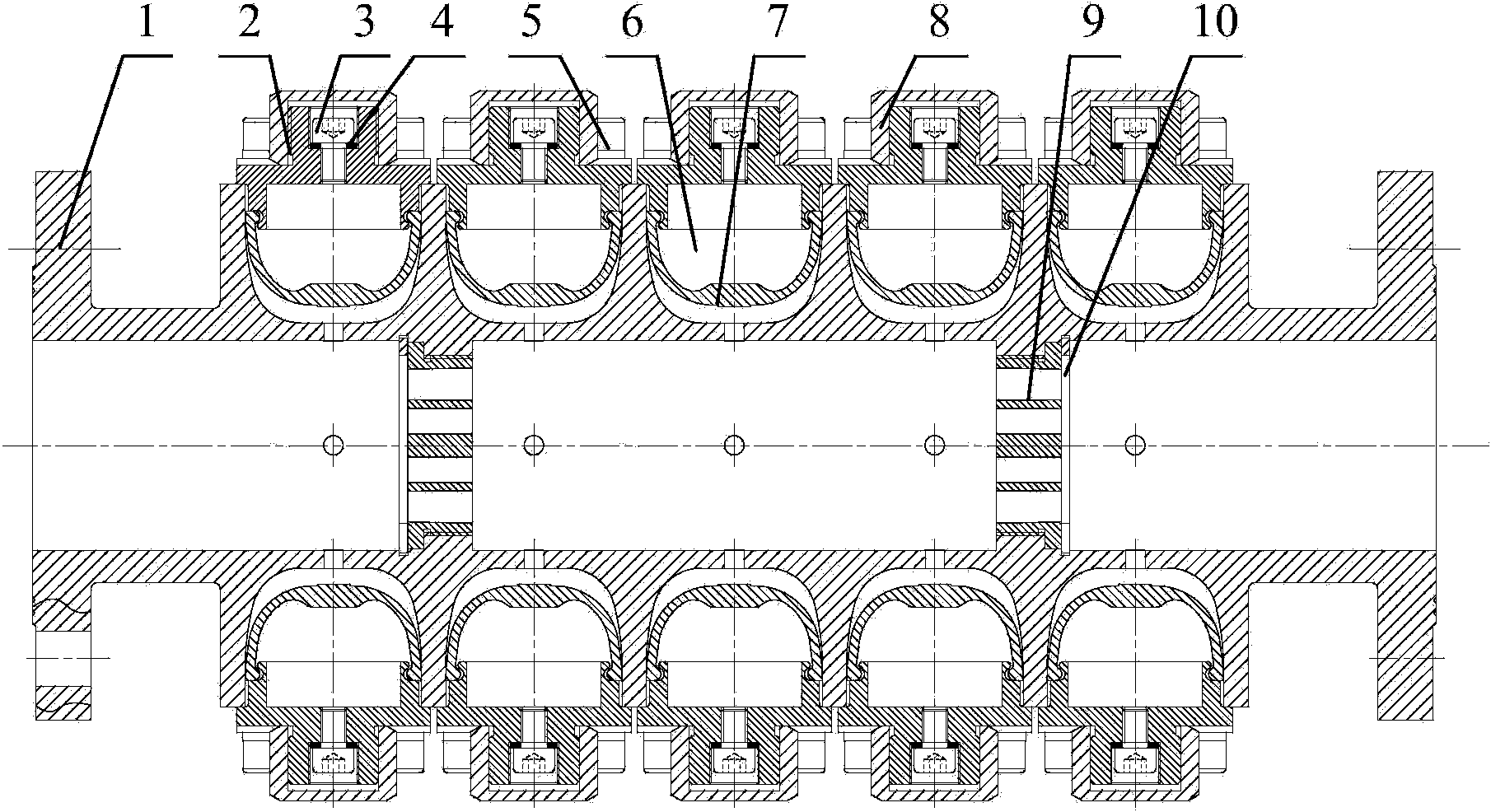

Broad-frequency pressure-variable pressure pulsation attenuator

ActiveCN103758798AReduce pressure pulsationSuitable for pressure applicationsFluid dynamicsVena contracta diameterUltrasound attenuation

The invention discloses a broad-frequency pressure-variable pressure pulsation attenuator which comprises a shell, end caps, elastic diaphragms and orifice plates. The two ends of the shell are used for being connected with a water inlet pipe and a water outlet pipe respectively, the side wall of the outer portion of the shell is evenly provided with multiple cavities in the axial direction and the circumferential direction, each cavity is divided into an upper cavity body and a lower cavity body through one elastic diaphragm in the corresponding cavity, the upper end of each upper cavity body compresses the corresponding elastic diaphragm through the corresponding end cap so as to seal the corresponding cavity, the upper cavity bodies serve as gas pressure cavities, the lower cavity bodies serve as energy storage cavities, and energy storage device holes are machined in the side wall of the shell so that the energy storage cavities can be communicated with the inside of the shell; the inside of the shell is axially provided with multiple round orifice plates provided with inclined through holes, the orifice plates are located between two axially adjacent energy storage device holes, and the surfaces of the orifice plates are axially perpendicular to the shell. A diaphragm device energy storage set is effectively combined with an orifice plate pulsation attenuator, so that attenuation can be carried out on pressure pulsation of different frequencies and pressures, broad-frequency pressure-variable pressure pulsation attenuation can be achieved, and the attenuator is suitable for various pressure application occasions.

Owner:HUAZHONG UNIV OF SCI & TECH

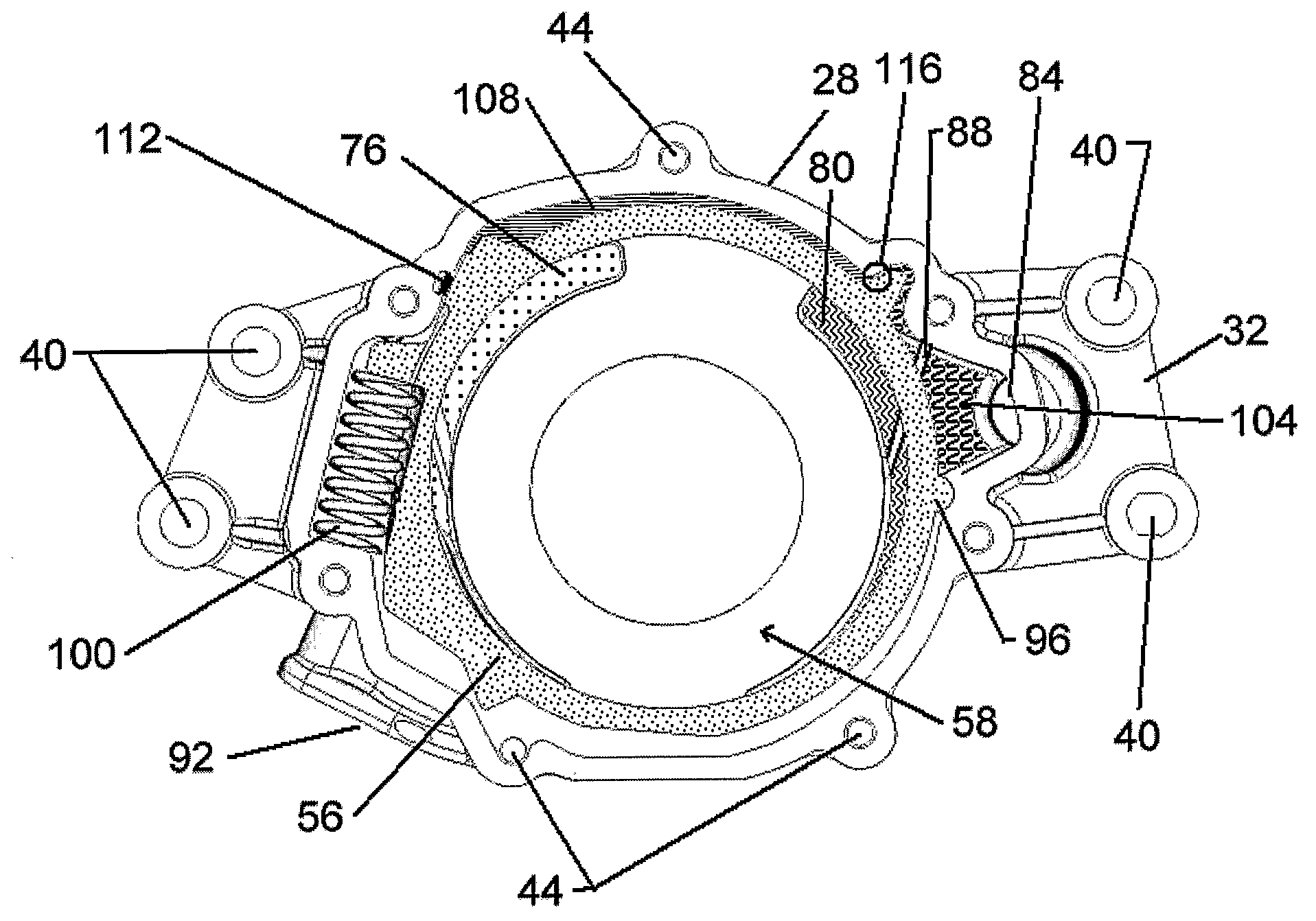

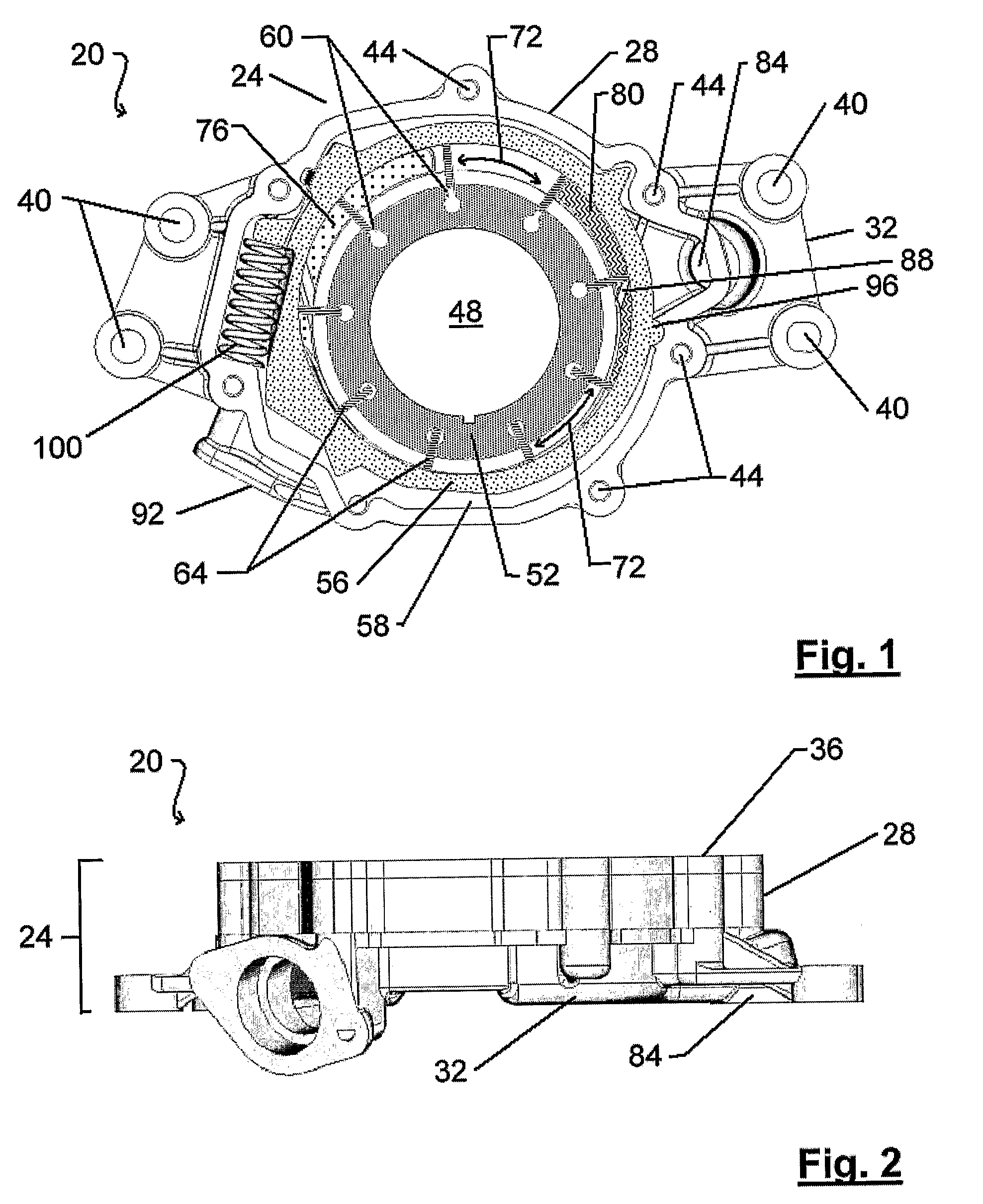

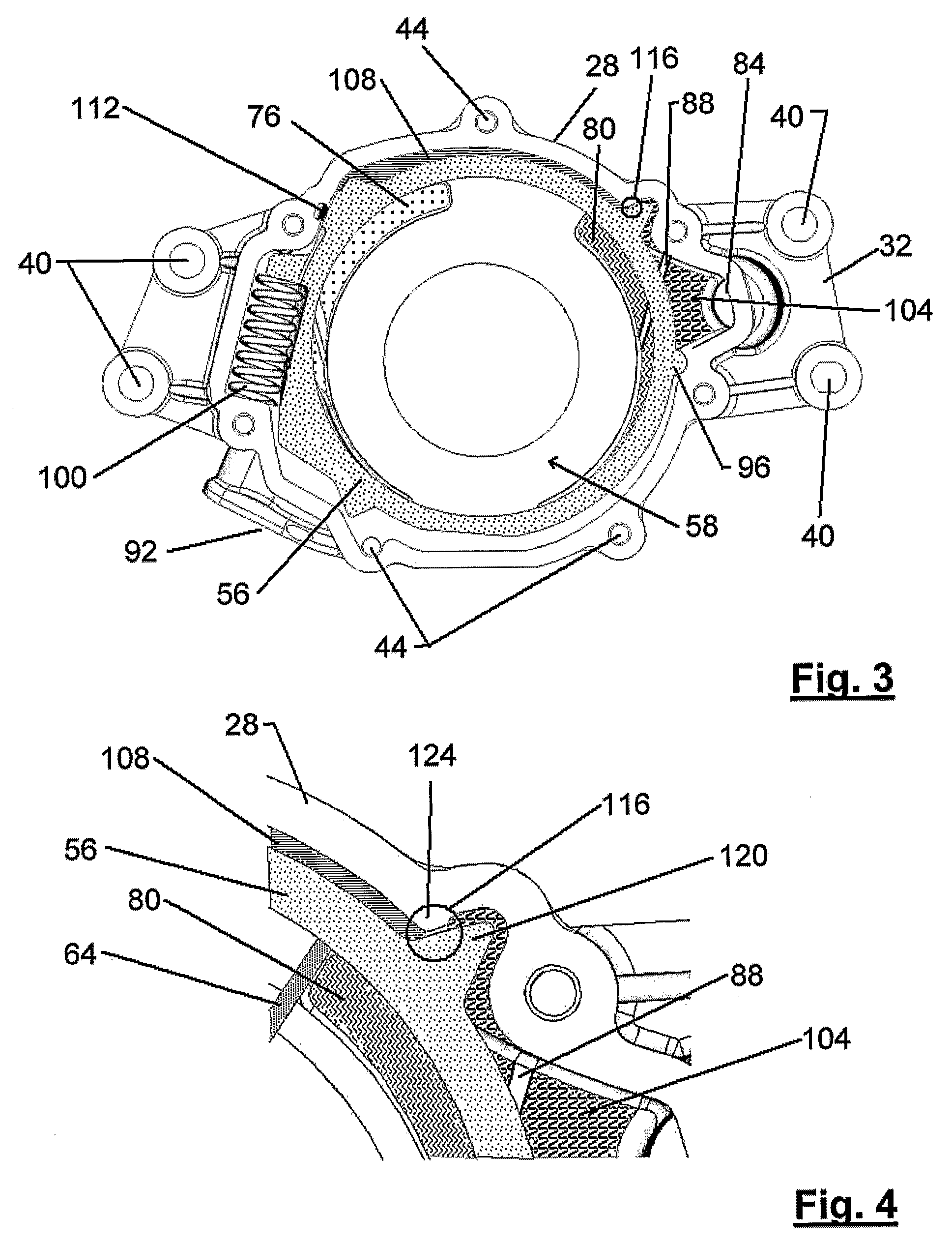

Vane pump using line pressure to directly regulate displacement

InactiveUS7798790B2Increased initial cross-sectional flow areaReduce pulsationOscillating piston enginesRotary piston pumpsCavitationWorking fluid

A variable displacement vane pump includes at least two regulation chambers to provide a regulating force to the cam ring to counter the force applied to the cam ring by a regulating spring and reduce pulsation in the output working fluid from the pump. A first regulation chamber is part of the pump outlet and is in fluid communication with the outlet port of the pump via a passage which allows the pump to be fabricated from a diecast process or the like. A second regulation chamber is connected to the first chamber via an orifice which reduces the pressure of working fluid supplied from the first chamber to the second. The pump outlet need not overlie the pump outlet. Further, a pump with an inlet port with a relatively large initial cross-sectional flow area inhibits cavitation of the working fluid when the pump is operated at higher operating speeds.

Owner:TESMA INT INC

Diaphragm pumps and sphygmomanometers

ActiveCN102292549AReduce noiseReduce pressure pulsationFlexible member pumpsEvaluation of blood vesselsDiaphragm pumpPump chamber

Owner:OMRON HEALTHCARE CO LTD

Two-stage decompression ejector and refrigeration cycle device

InactiveUS7823400B2Reduce pressureIncrease pressureCompression machines with non-reversible cycleJet pumpsEngineeringRefrigeration

A two-stage decompression ejector includes a variable throttle mechanism having a first throttle passage for decompressing a fluid and a valve body for changing a throttle passage area of the first throttle passage, a nozzle having therein a second throttle passage for further decompressing the fluid decompressed by the variable throttle mechanism, and a suction portion for drawing a fluid by a suction effect of a high-velocity jet fluid from the nozzle. The formula of 0.07≦Vo×S / vn≦0.7 is satisfied, in which Vo is an intermediate-pressure space volume (mm3) from an outlet of the variable throttle mechanism to an inlet of the second throttle passage, S is a throttle passage sectional area (mm2) of a minimum passage sectional area portion of the second throttle passage, and vn is a flow velocity (mm / s) of the fluid passing through the minimum passage sectional area portion.

Owner:DENSO CORP

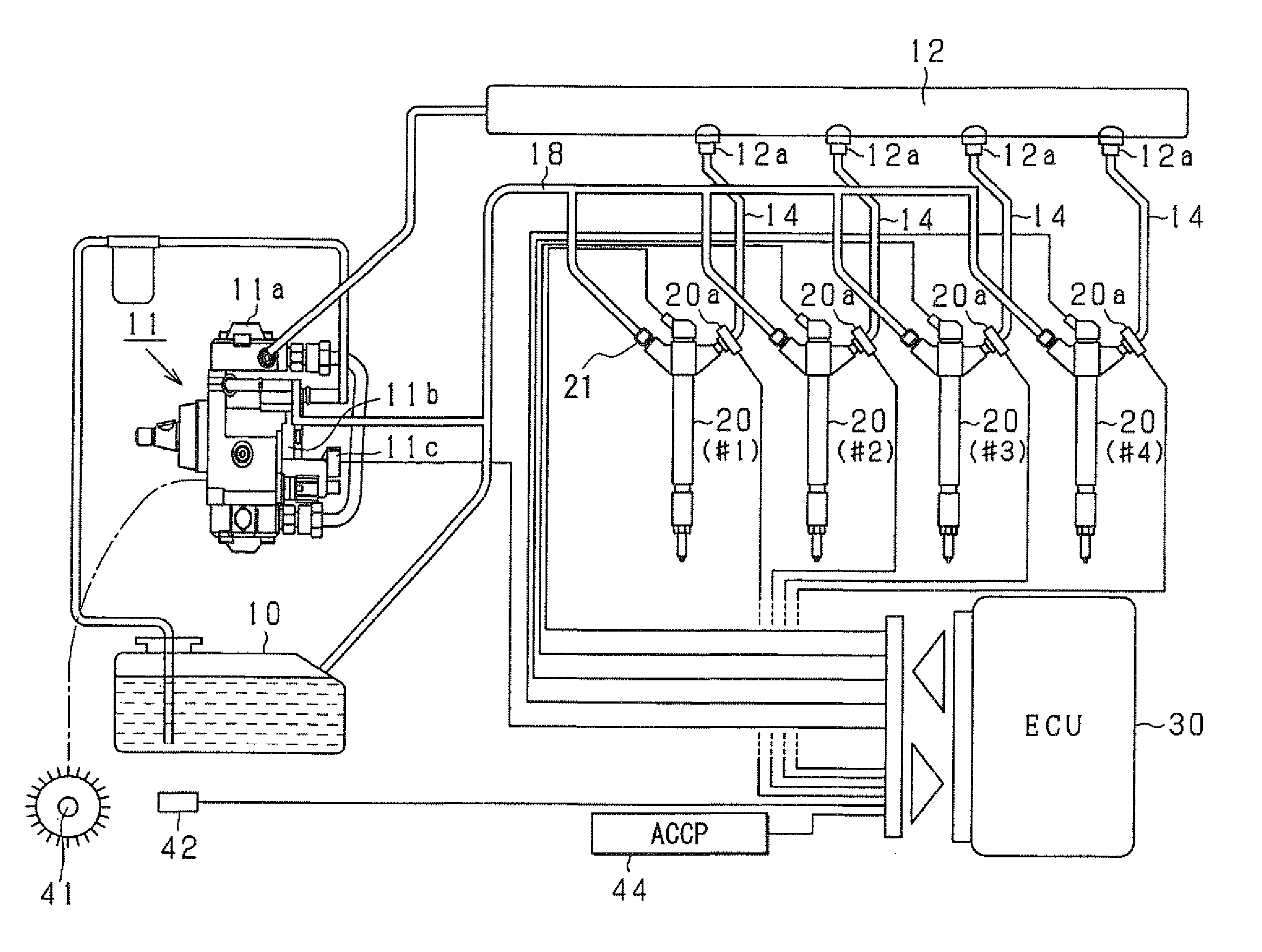

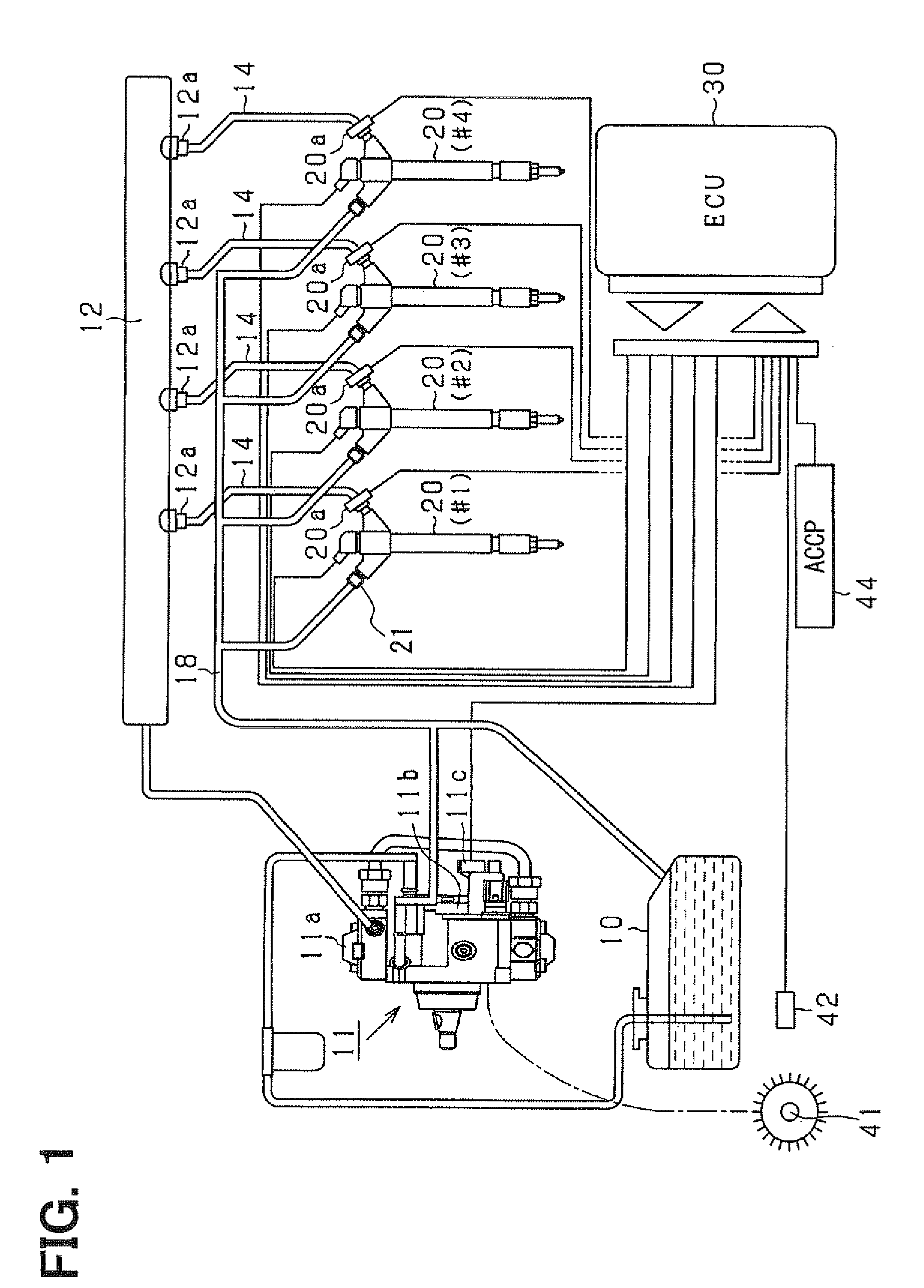

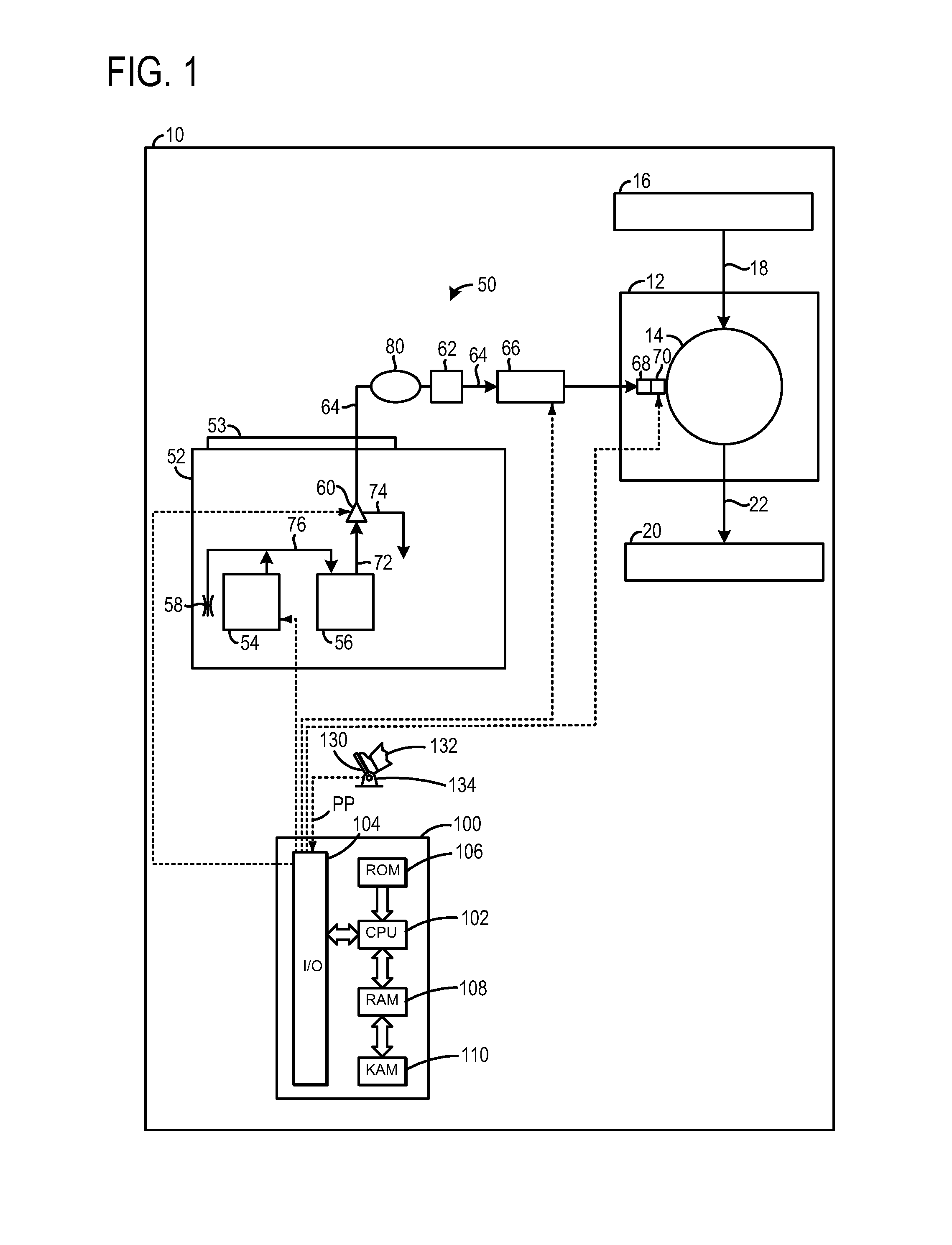

Exhaust gas recirculation distribution variation sensing device

InactiveUS20090107227A1Simple fixed structureReduce pressure pulsationInternal-combustion engine testingElectrical controlInjectorExhaust fumes

An exhaust gas recirculation distribution variation sensing device has a torque sensing section that senses instantaneous torque caused with combustion of fuel injected from an injector for each cylinder, an injection quantity sensing section that senses an actual injection quantity of the injected fuel for each cylinder and an exhaust gas recirculation distribution variation calculating section that calculates an exhaust gas recirculation distribution variation as a distribution variation of recirculated exhaust gas to respective cylinders based on a variation in the torque sensing value of the torque sensing section among the cylinders (i.e., a torque variation) and a variation in the injection quantity sensing value of the injection quantity sensing section among the cylinders (i.e., an injection quantity variation).

Owner:DENSO CORP

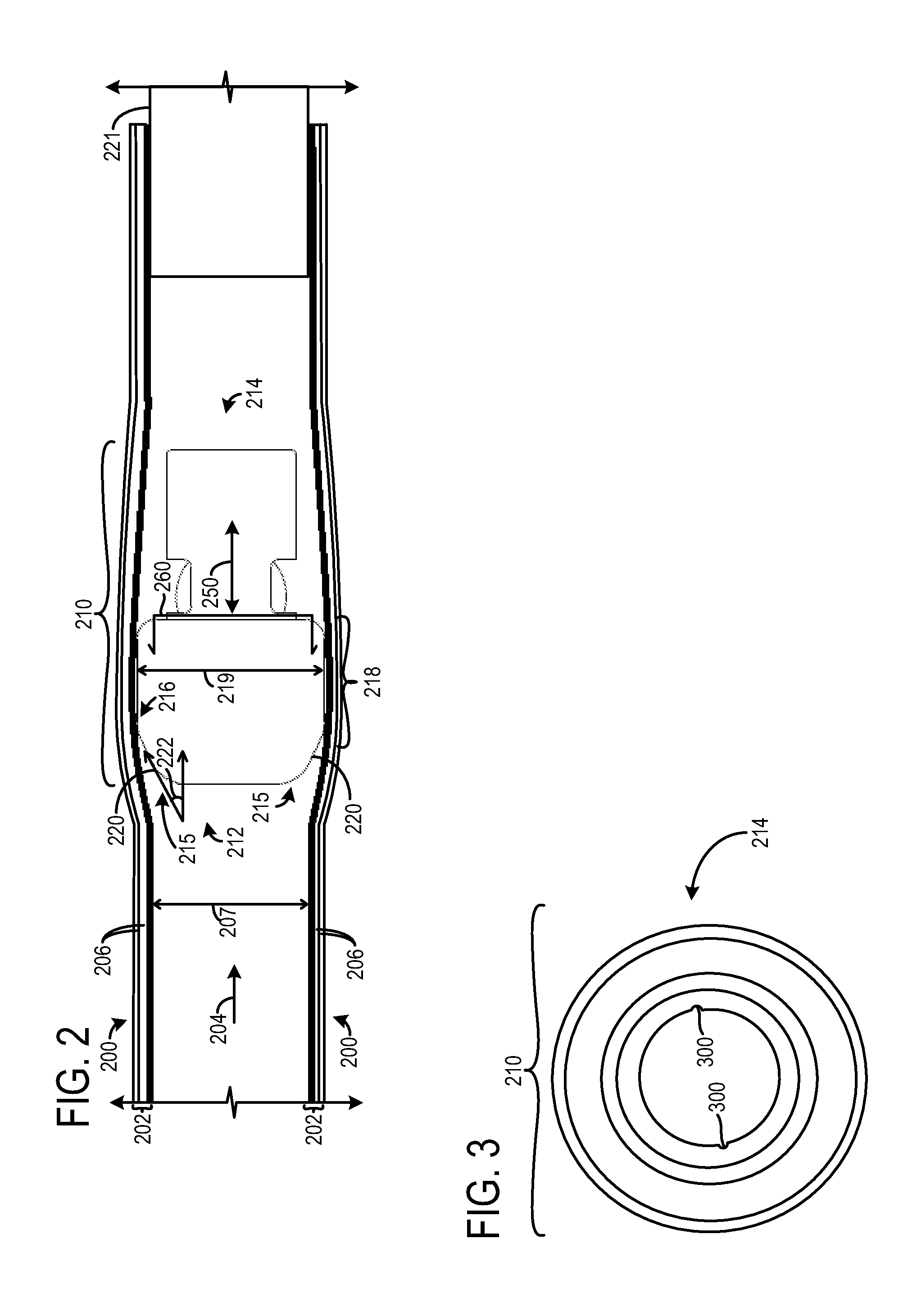

Fuel delivery system including integrated check valve

ActiveUS20150068491A1Reduce fuel consumptionNegatively affectedValve members for absorbing fluid energyCombustion enginesNoise, vibration, and harshnessEngineering

A fuel delivery system is provided to reduce the pressure pulsations and noise vibration and harshness of direct injection systems. The fuel delivery system includes an elastic fuel line positioned between a first fuel pump and a second fuel pump and a check valve positioned in the elastic fuel line near the inlet of the high pressure pump, the check valve including an external housing having a peripheral surface with a greater diameter than an unstretched inner diameter of the elastic fuel line.

Owner:FORD GLOBAL TECH LLC

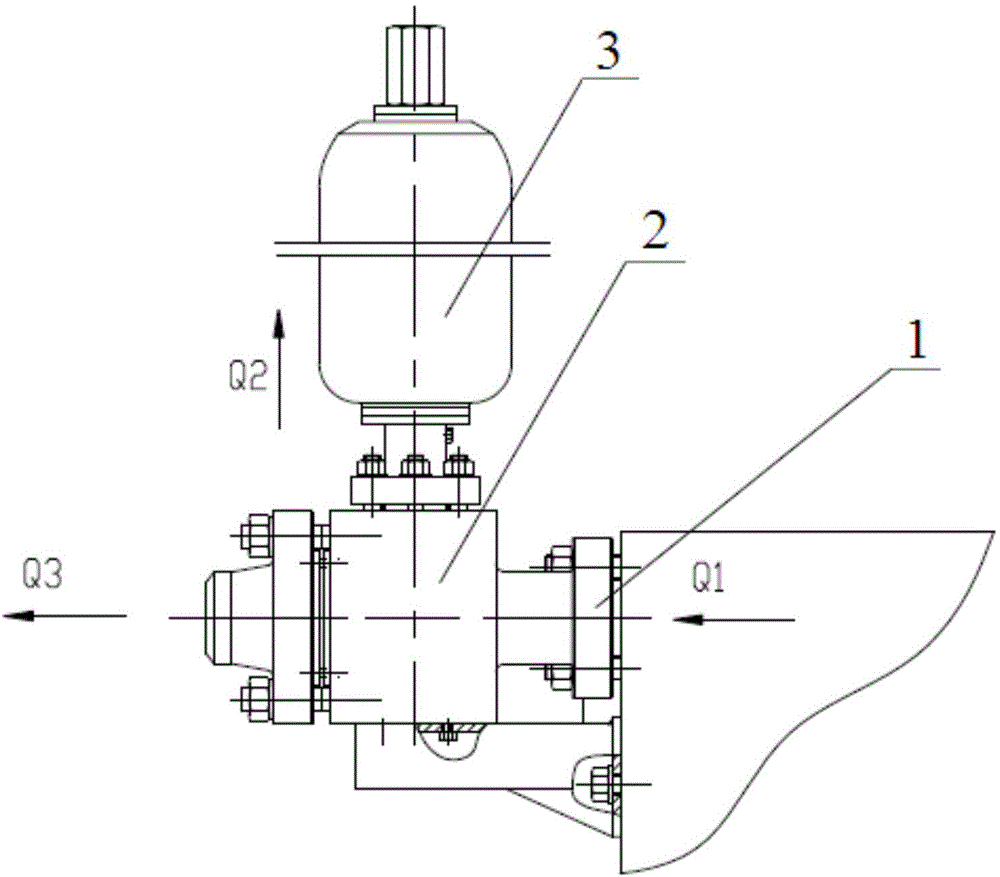

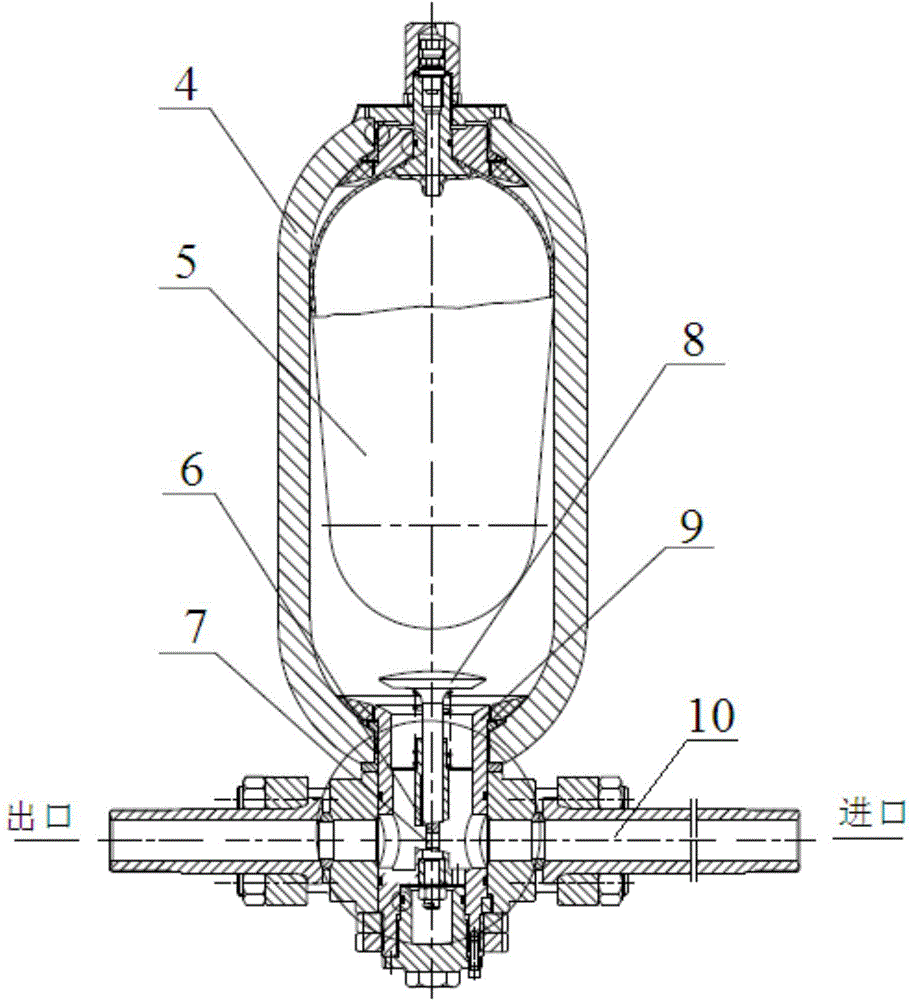

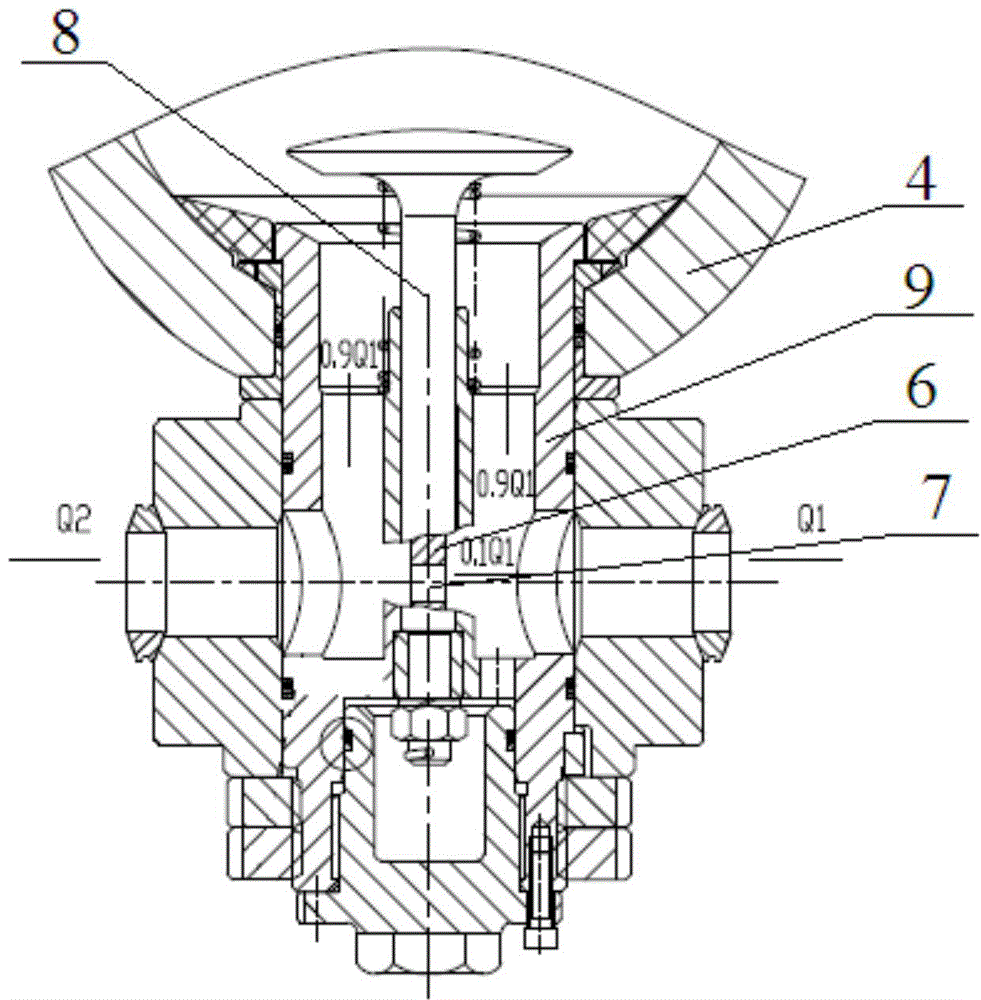

Low-pulsation series capsule type buffer

InactiveCN104373741ALow outlet pressure pulsation rateGood voltage stabilizationPipe elementsWater flowBiomedical engineering

The invention relates to a low-pulsation series capsule type buffer. The low-pulsation series capsule type buffer can be connected to an outlet pipeline of a hydrostatic test pump when a pressure test is conducted on a loop system. The buffer comprises a shell, a valve body, a capsule and a fungus type valve, wherein one end of the shell is sealed, the valve body is arranged at the other end of the shell, the valve body is communicated with the outline pipeline of the hydrostatic test pump, the capsule is arranged in the shell, a valve rod of the fungus type valve is arranged in the valve body, a valve cap is located in the shell, a partition board is connected to the lower end of the valve rod of the fungus type valve, the interior of the valve body is separated by the partition board in the water flow direction of the outlet pipeline, and a damping hole is formed in the partition board; fluid comes up against the partition board after entering the valve body, a small part of the fluid directly flows out from the damping hole, and the other most part of the fluid rushes to the capsule along a gap between one side of the fungus type valve and the valve body under the blockage of the partition board, then flows back into the valve body along a gap between the other side of the fungus type valve and the valve body after a part of energy is absorbed by the capsule, and finally flows out. Compared with the prior art, the low-pulsation series capsule type buffer has the advantages that the pressure stabilizing effect and the damping effect are good, and the structure is simple.

Owner:SHANGHAI DALONG MACHINE FACTORY CO LTD

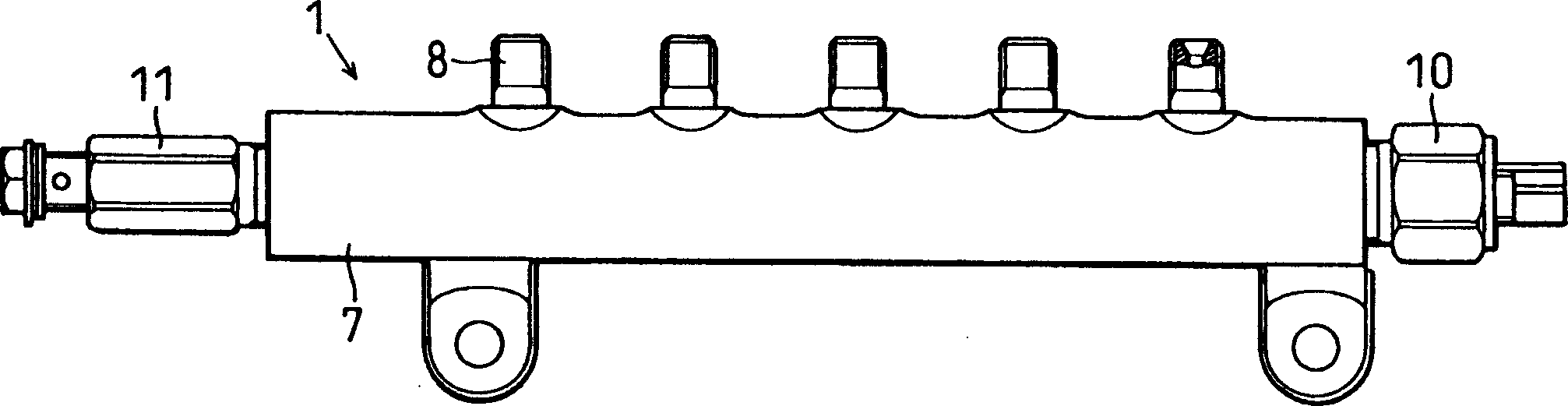

High-pressure fuel pressure accumulator

InactiveCN1517544AMade preciselyReduce pressure pulsationMachines/enginesSpecial fuel injection apparatusCommon railEngineering

A common rail has an accumulation pipe in which high pressure fuel is accumulated, a pipe joint to which a high pressure pipe is connected and an orifice member housed inside the pipe joint. The orifice member is provided with a conduit through which a fuel port formed in the accumulation pipe communicates with the high pressure pipe. The conduit is provided at an end thereof with an orifice. The orifice serves to reduce pressure pulsation generated by fuel injection of an injector so that fuel pressure in the common rail is stable. Since the orifice is formed in the orifice member housed in the pipe joint, the orifice is easily and accurately manufactured at a lower cost, compared to an orifice formed in the accumulation pipe. It is easy to standardize the manufacture of plural models of common rails whose orifice diameters are different.

Owner:DENSO CORP

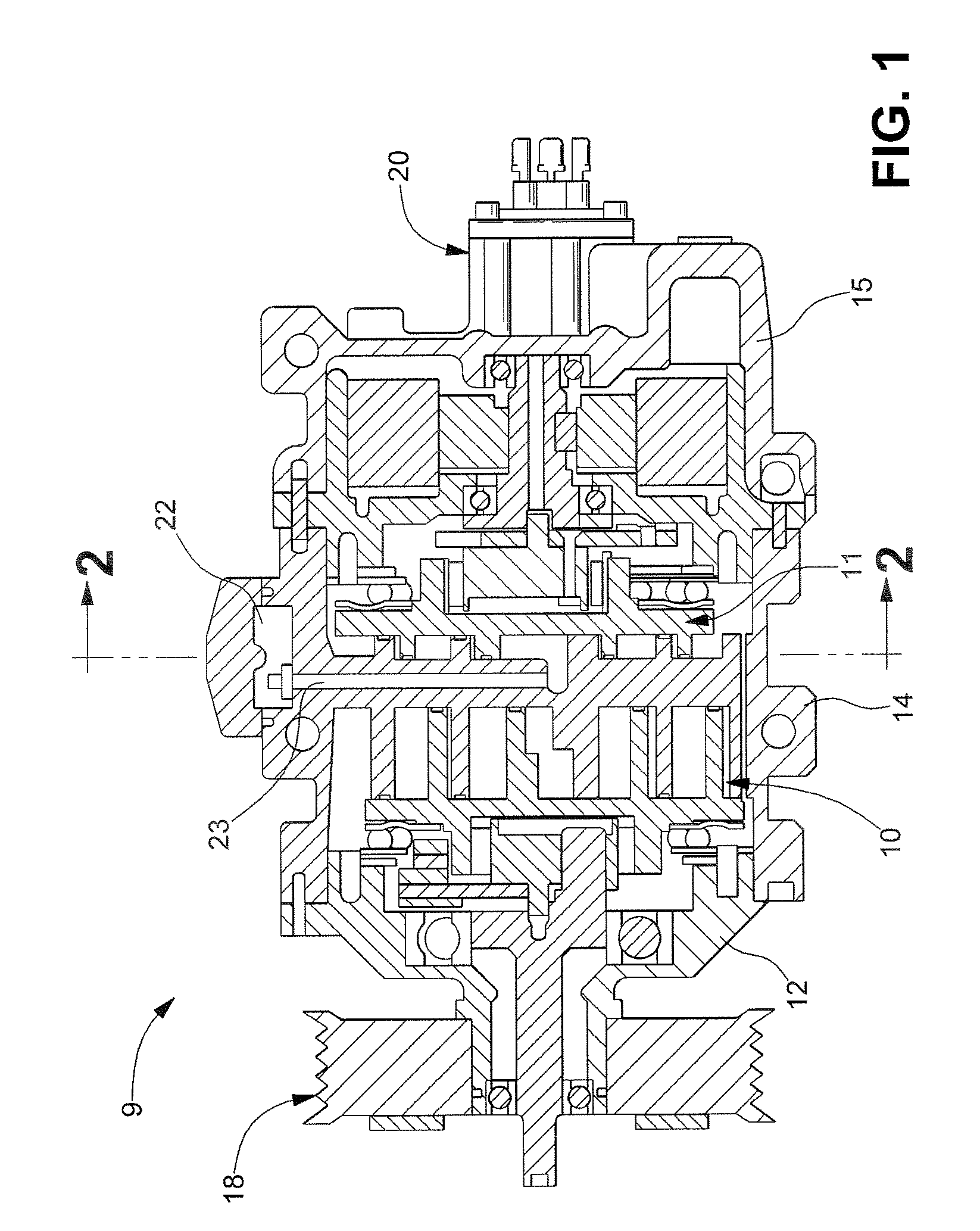

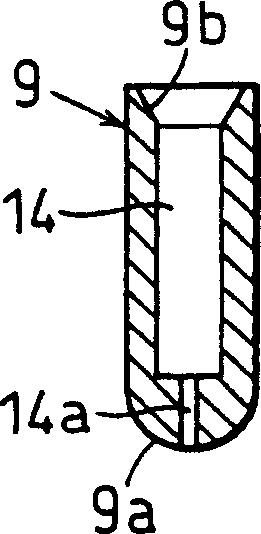

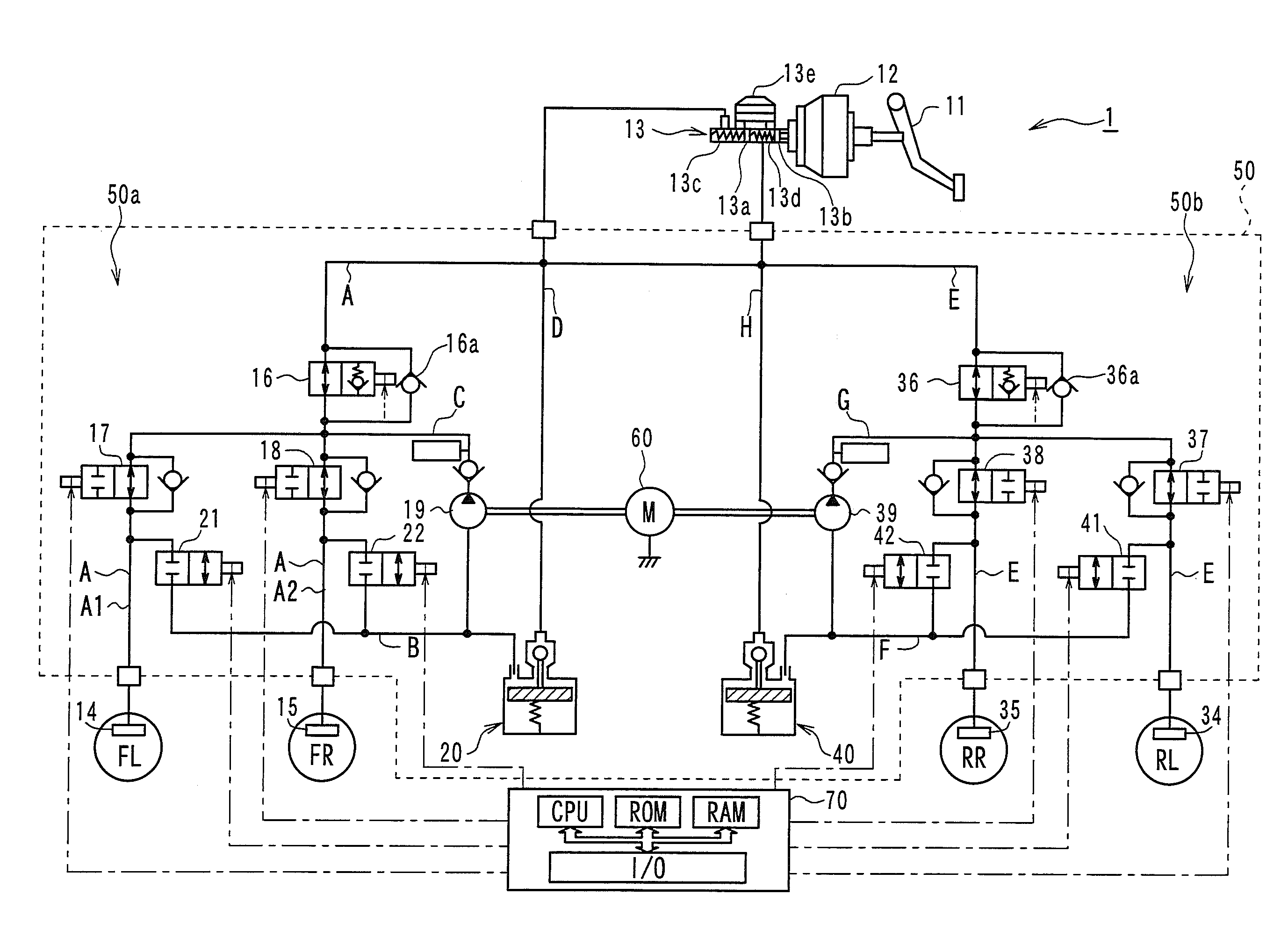

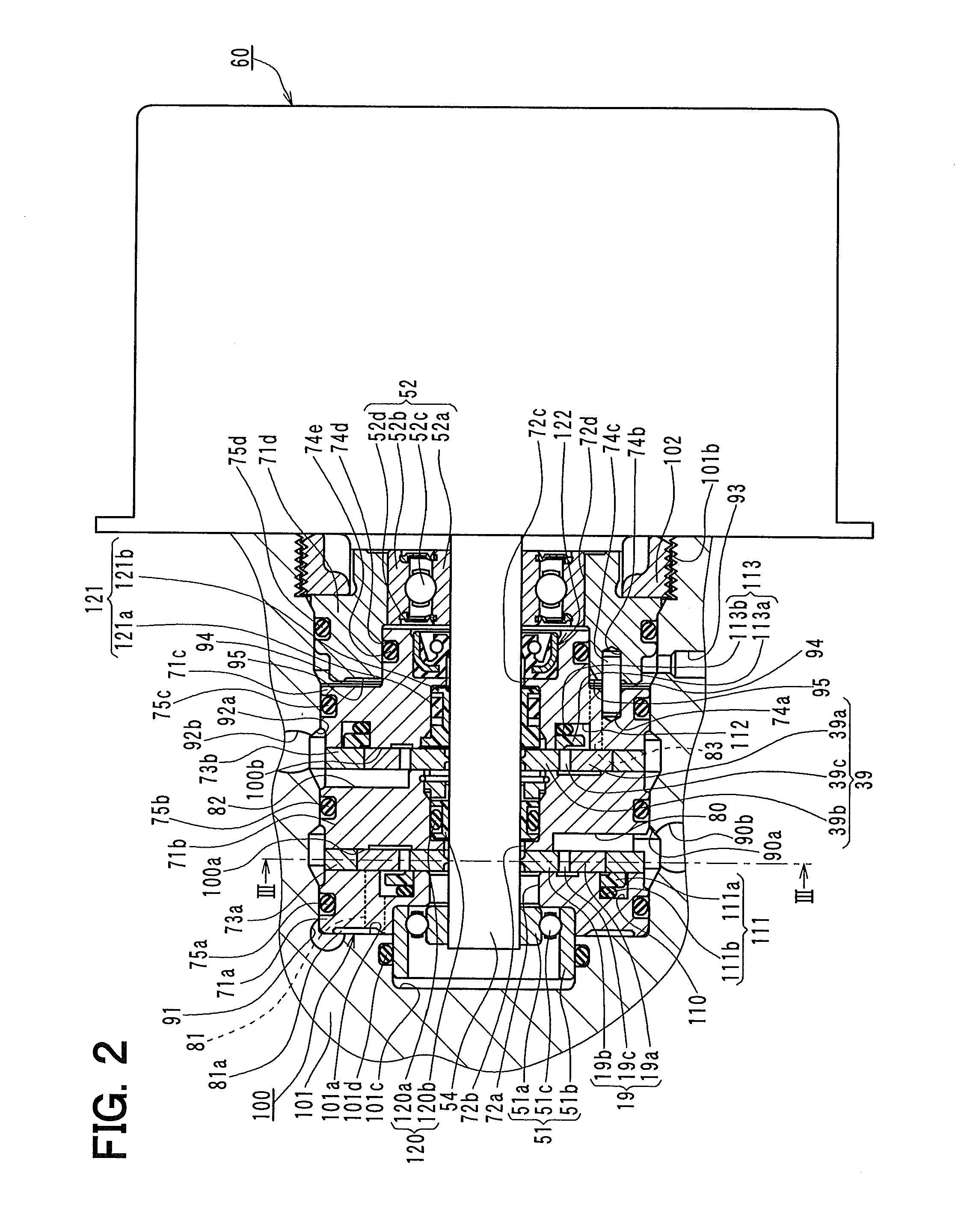

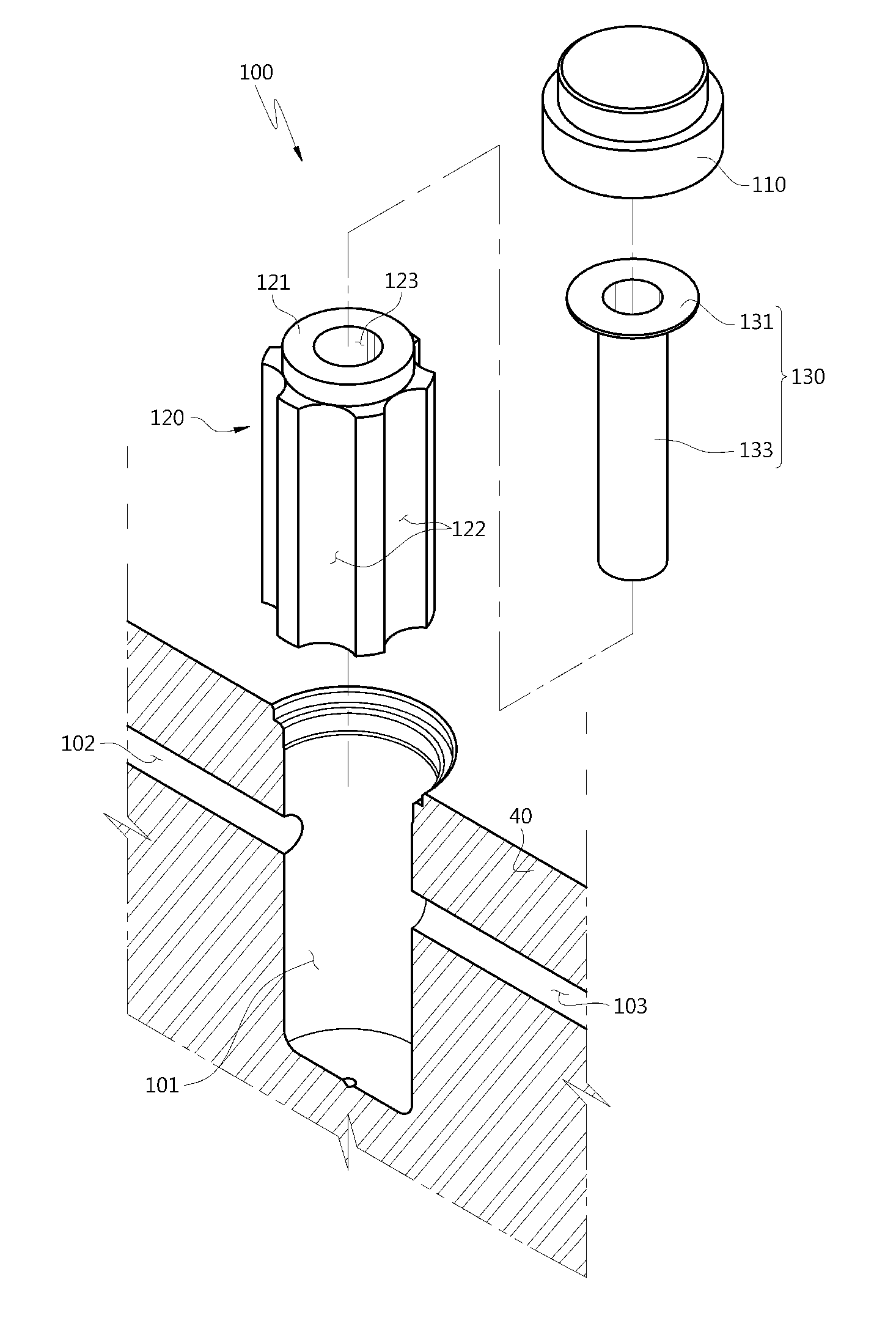

Rotary pump device and vehicle brake control system

ActiveUS20110116939A1Small rigidityIncreased durabilityPositive displacement pump componentsRotary piston pumpsWorking fluidRotary pump

A first and a second rotary pumps are provided in a first pump casing of a pump body, which is inserted into a cylindrical recessed portion of a housing 101. A first outlet port is opened at a first space formed between a bottom surface of the cylindrical recessed portion and an axial forward end surface of the first pump casing, so that discharge pressure of working fluid of the first pump is supplied to the first space. A second outlet port is opened at a second space formed between an axial backward end surface of the first pump casing and an axial forward end surface of a second pump casing, so that discharge pressure of working fluid of the second pump is supplied to the second space.

Owner:ADVICS CO LTD

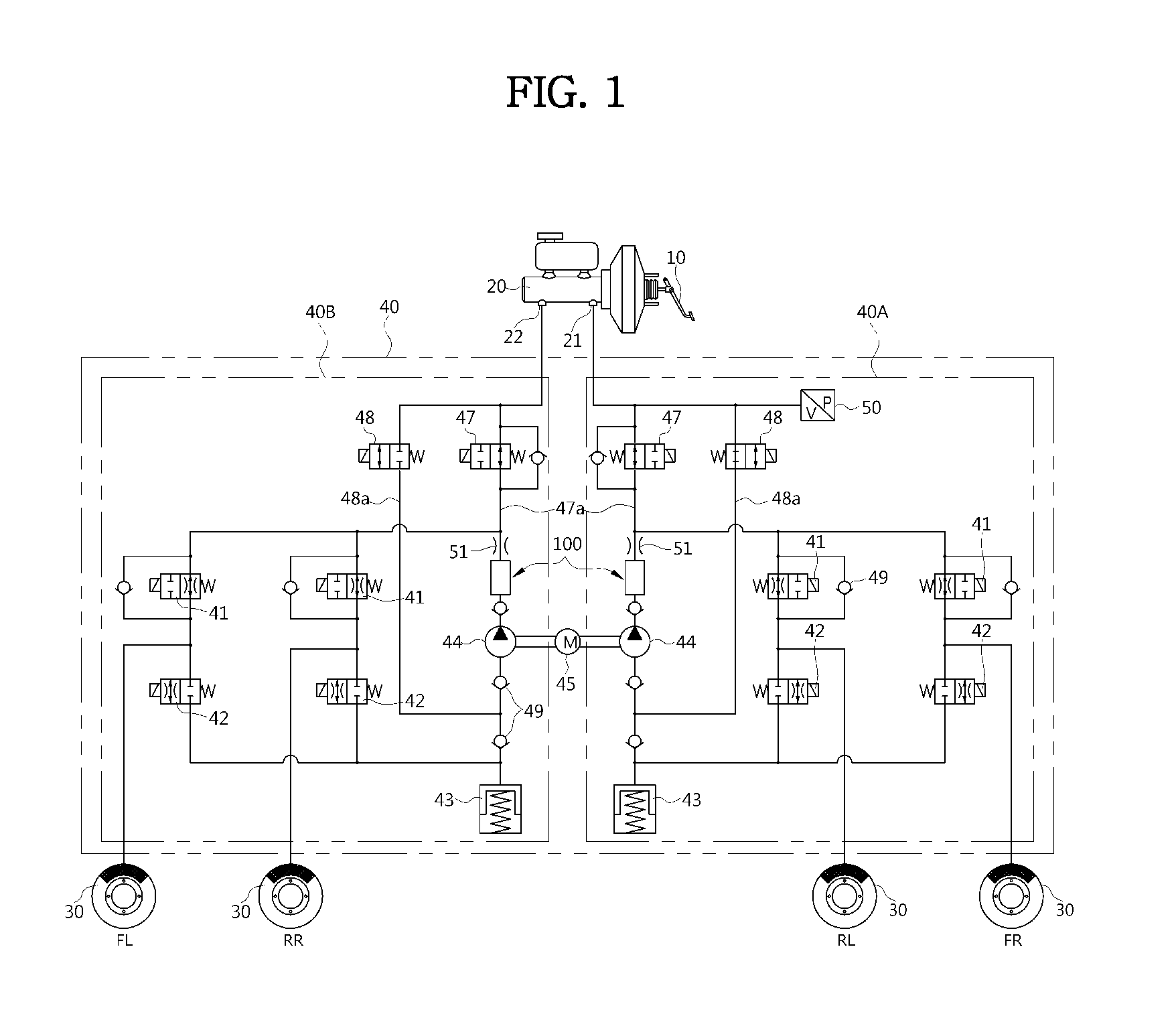

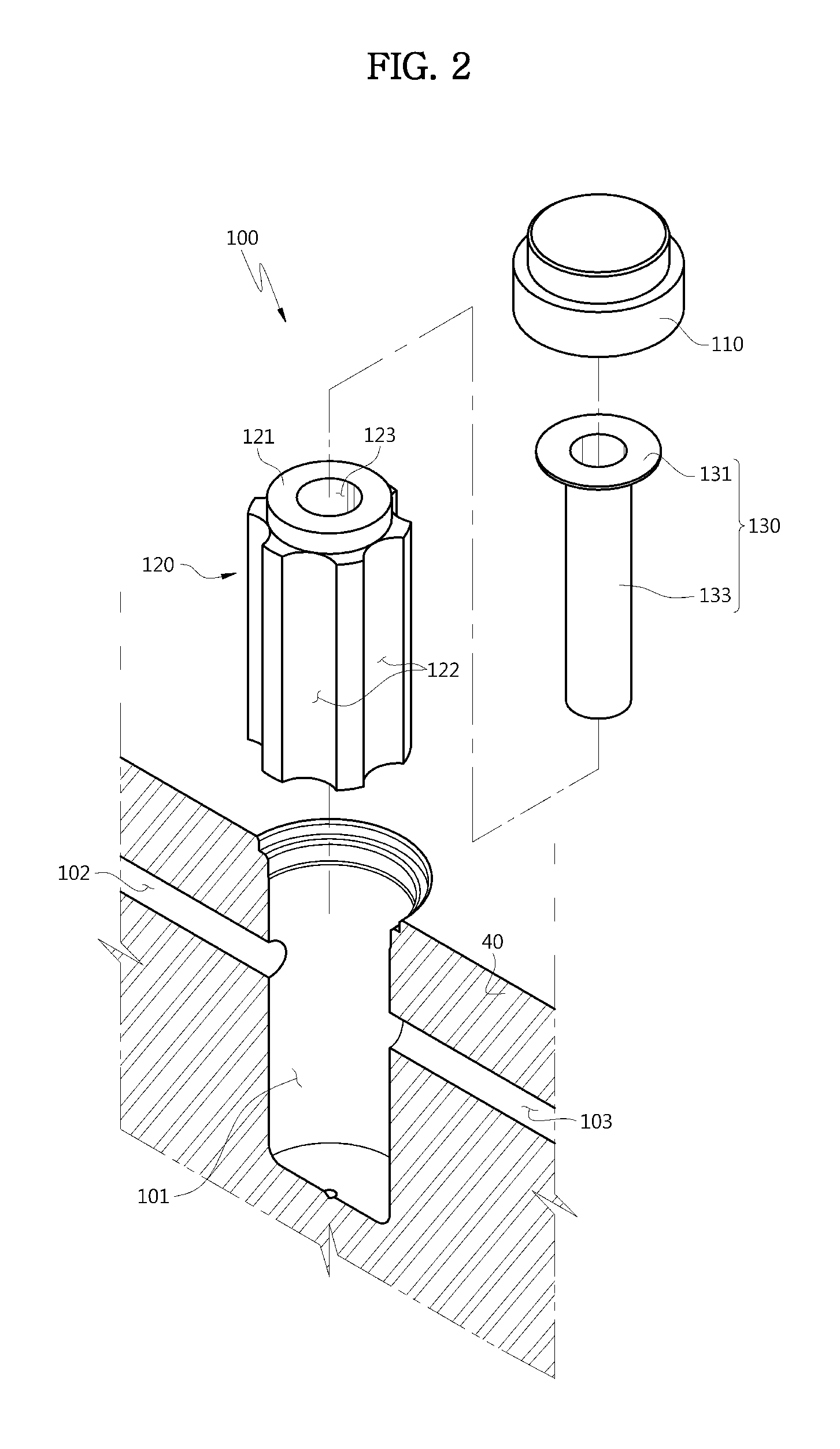

Hydraulic brake system

ActiveUS20150360662A1Effectively reducing pressure pulsationEasy to produceBraking action transmissionPiping arrangementsEngineeringHigh pressure

Disclosed is a hydraulic brake system provided with a high pressure accumulator that reduces a pressure pulsation of brake oil being discharged through operation of a pump. The high pressure accumulator includes a damping member that is provided in a bore communicating with an inlet port and an outlet port of the high pressure accumulator respectively allowing brake oil to be introduced and discharged therethrough, and is provided with a bypass flow passage connecting the inlet port to the outlet port, and a reinforcing member installed at the damping member to improve durability of the damping member.

Owner:HL MANDO CORP

Burner comprising a fluidic oscillator, for a gas turbine, and a gas turbine comprising at least one such burner

InactiveUS20170254541A1Reduce pollutionReduce pressure pulsationBurnersContinuous combustion chamberCombustorFluidic oscillator

A burner having a pre-mixing passage delimited radially outwardly by a wall, a burner lance and a plurality of fuel injectors arranged in the pre-mixing passage, the injectors extending from the burner lance in the direction of the wall and having fuel nozzles. The fuel supply arrangement has at least one fluidic oscillator that has an interaction chamber, an inlet to the interaction chamber connected to a fuel channel of the fuel supply arrangement, a first outlet channel of the interaction chamber extending at least to a first fuel nozzle and a second outlet channel extending at least to a second fuel nozzle, the fluidic oscillator has one feedback line for each outlet channel, one end of the feedback line terminating into the respective outlet channel downstream of the at least one fuel nozzle, and the other end thereof terminating into an inlet region of the interaction chamber.

Owner:SIEMENS AG

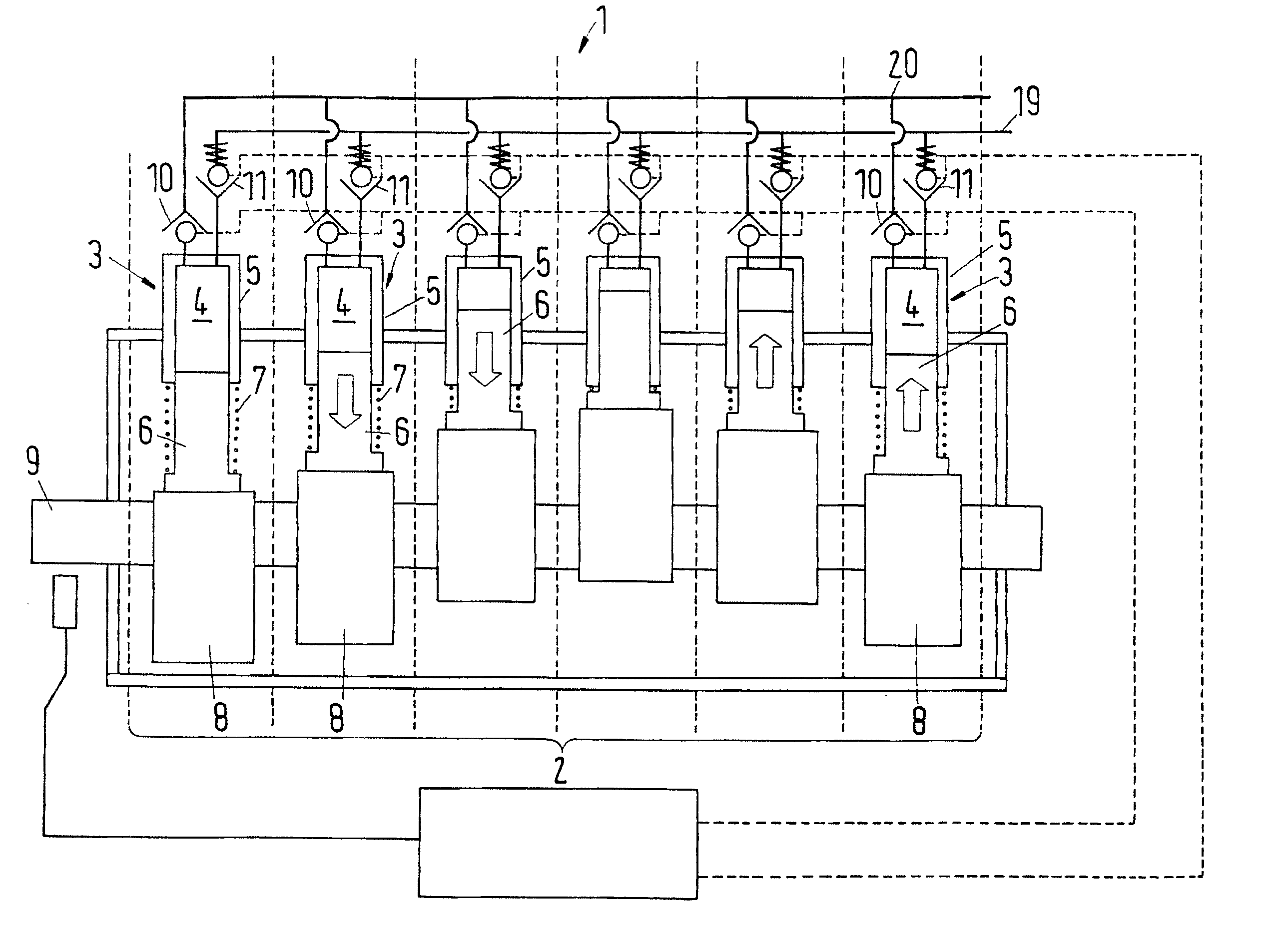

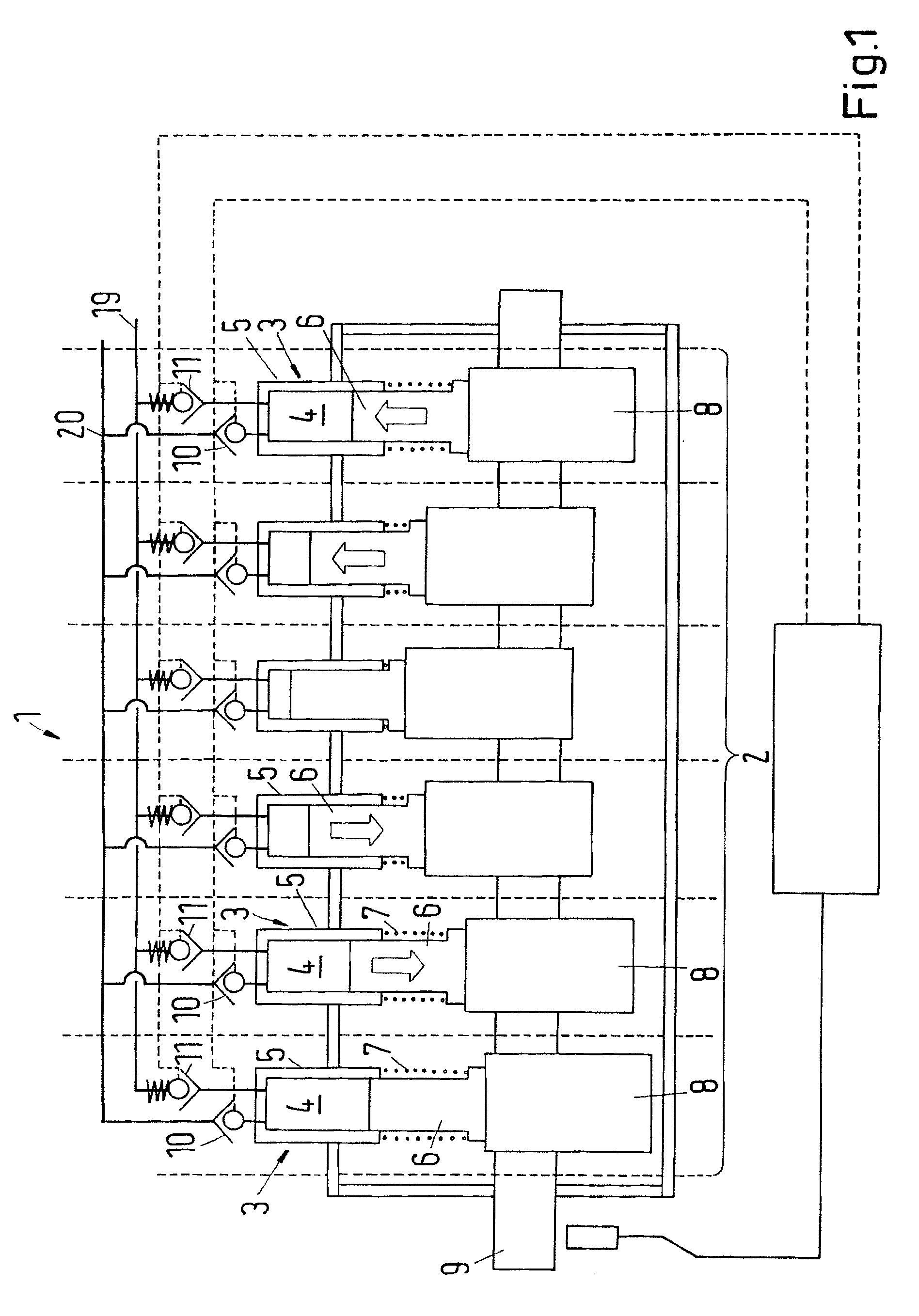

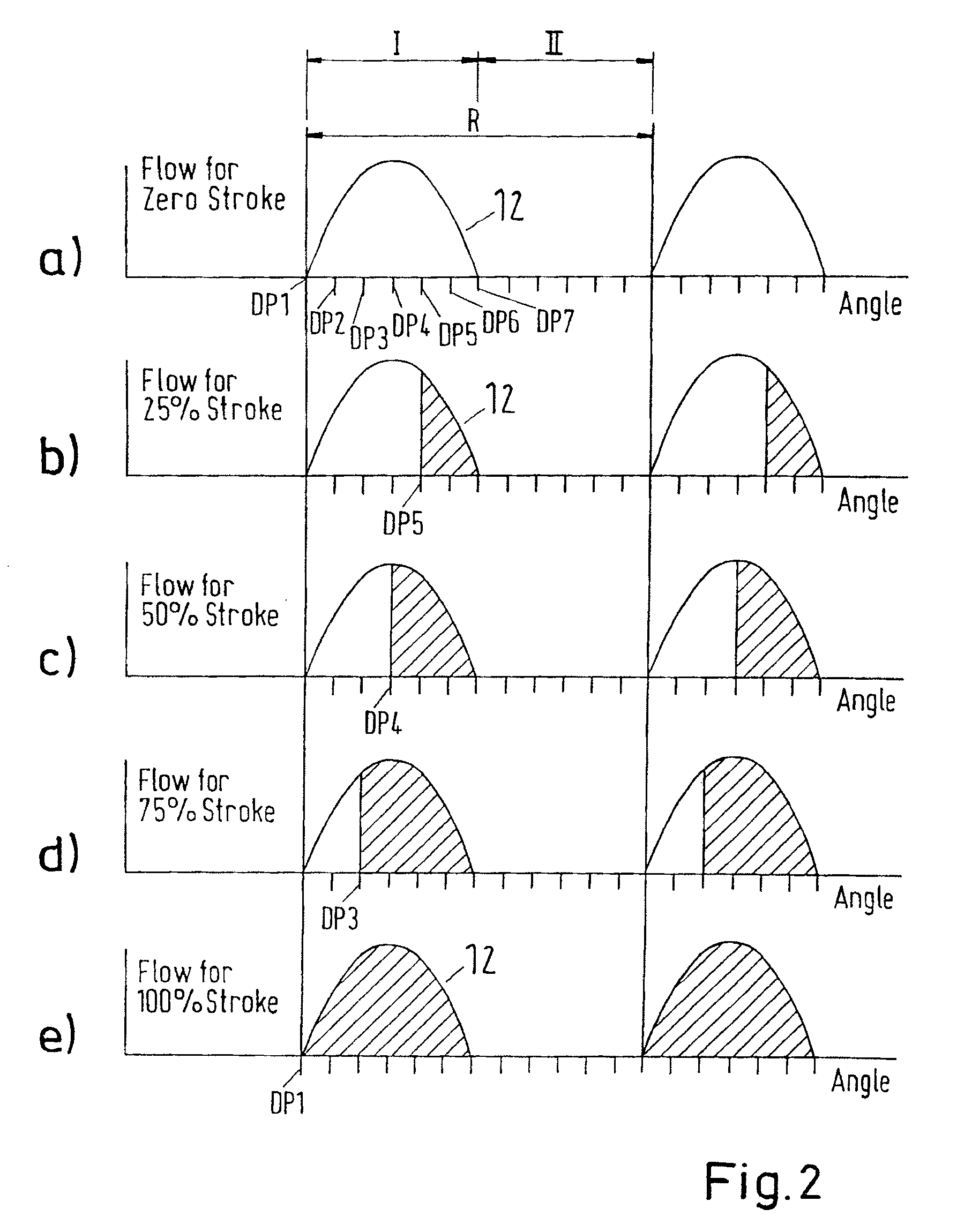

Method of controlling a cyclically commutated hydraulic pump

ActiveUS8192175B2Reduce pressure pulsationImprove responsivenessFluid couplingsPump controlTime delaysHydraulic pump

When employing synthetically commutated hydraulic pumps (1), a time delay between a change in fluid flow demand (15) and the resulting fluid flow output (13) can be observed. It is suggested to use a time evolvement function, taking into account the time evolvement of the fluid flow demand and / or the time evolvement of the pumping strokes, to modify the actuation of the electrically commutated valves.

Owner:ARTEMIS INTELLIGENT POWER

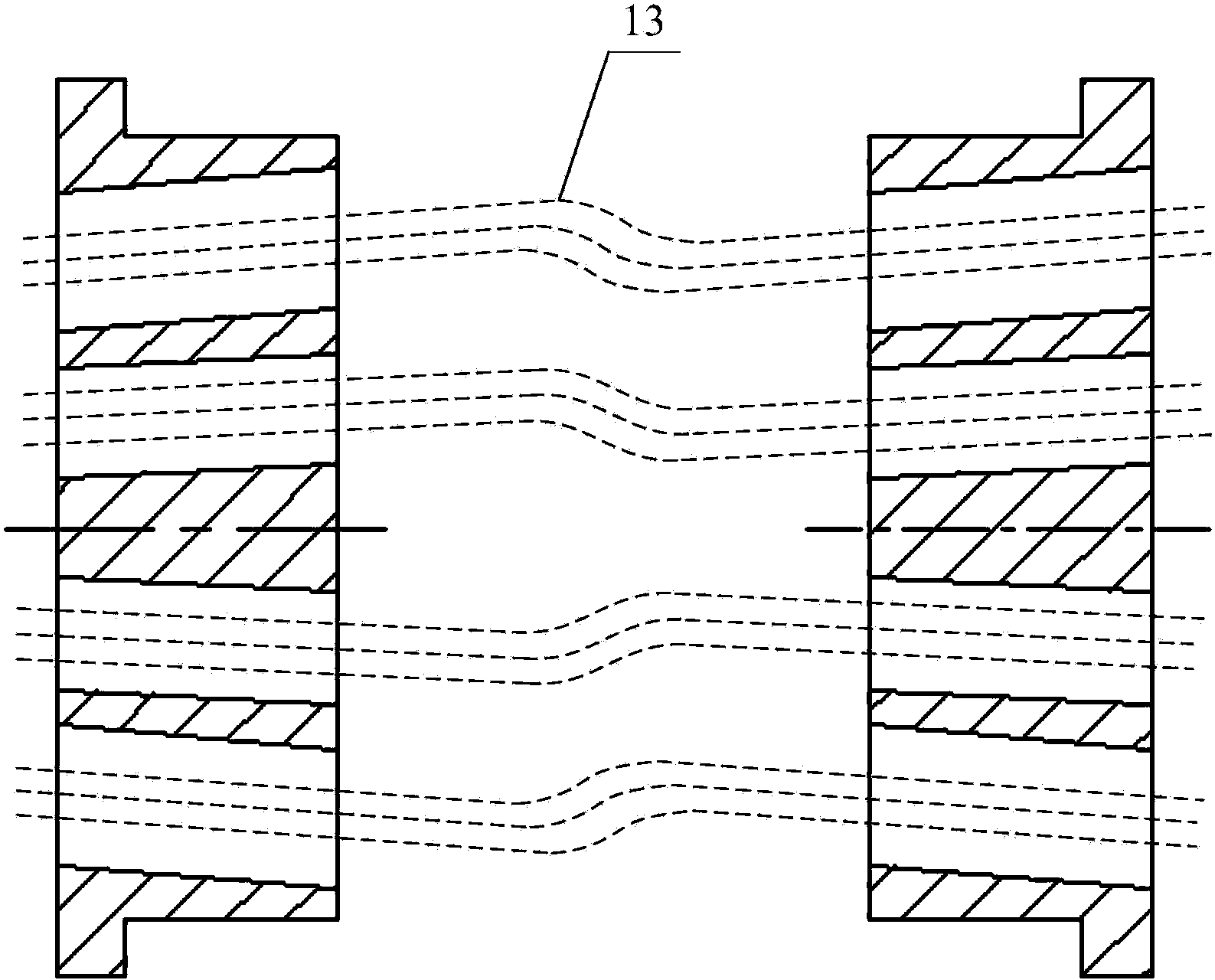

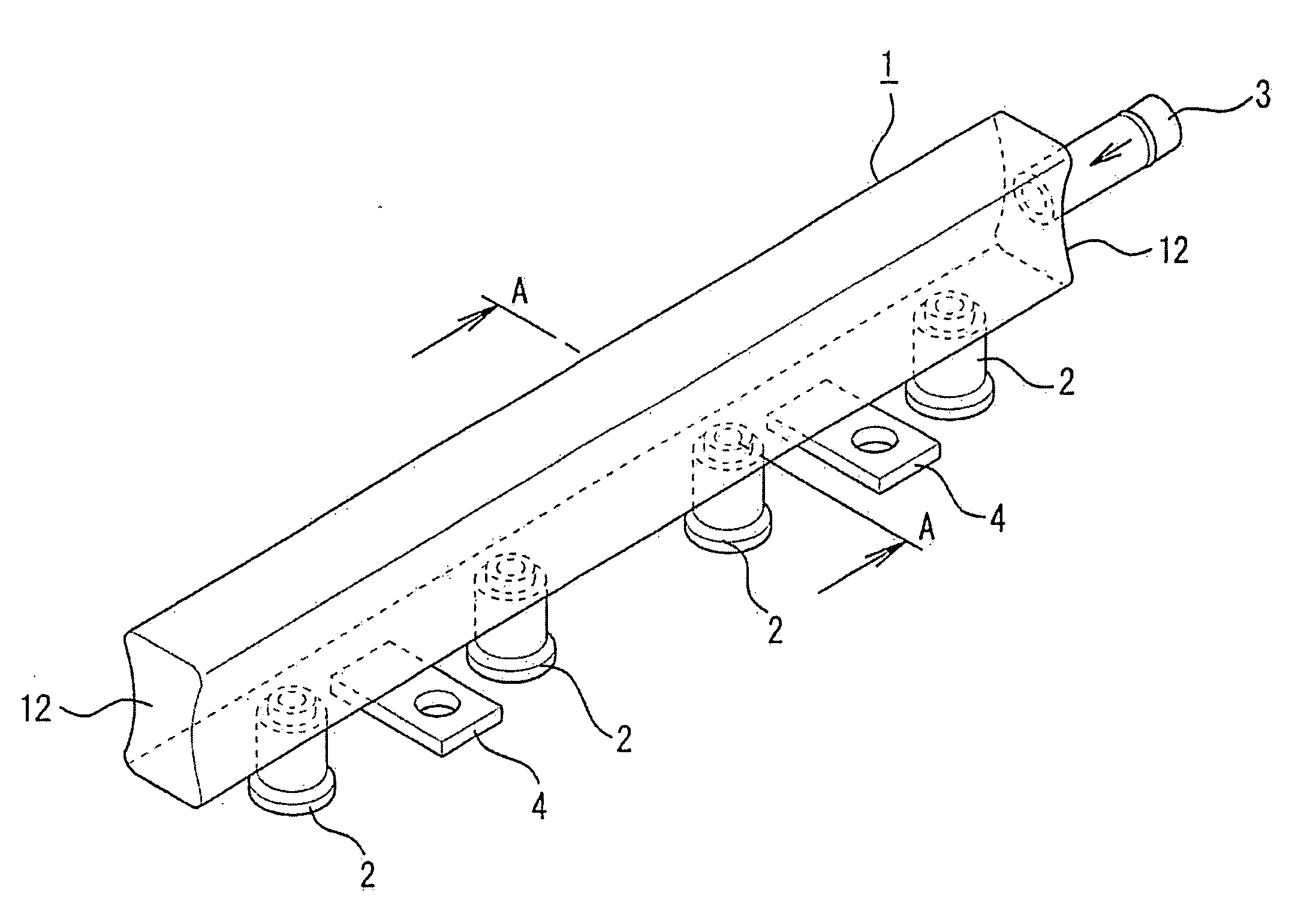

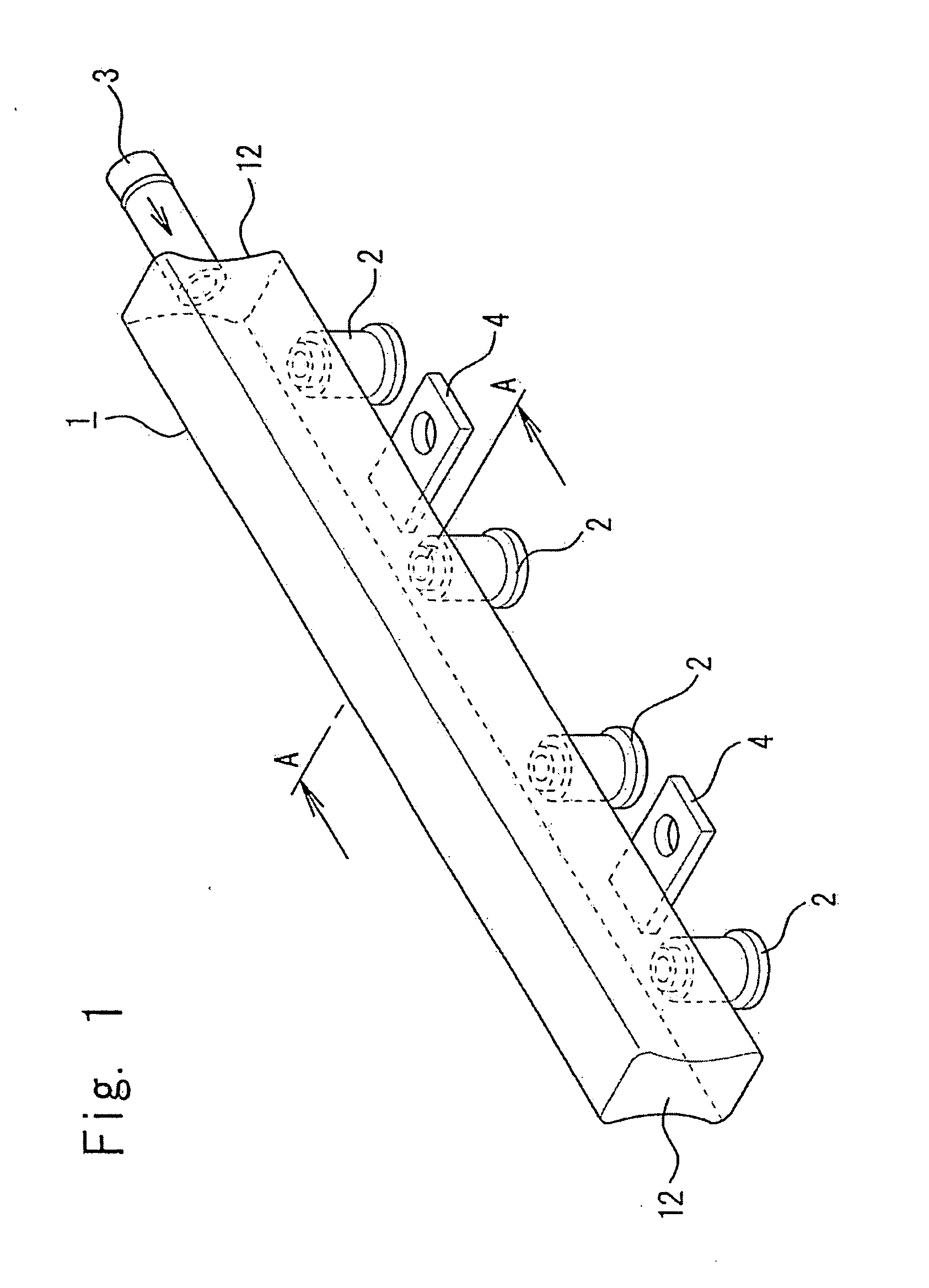

Fuel delivery pipe

ActiveUS20050257774A1Maintain interchangeabilityReduce pressure pulsationLow pressure fuel injectionMachines/enginesInternal pressureEngineering

A fuel delivery pipe capable of reducing a pressure pulsation at the time of a fuel injection due to injection nozzles, preventing vibrations and noises at an underfloor pipe arrangement, and turning down a radiate sound from the fuel delivery pipe, wherein a flexible absorbing wall surface 10 formed on a wall surface of a fuel delivery body 1 is loosened due to internal pressure changes to render internal volume of the fuel delivery body 1 increasable, αL / {square root}{square root over ( )}V determined by sonic speed αL of fuel flowing through the fuel delivery body 1 and the internal volume V of the fuel delivery body 1 is set as 20×103(m−0.5·sec−1)≦αL / {square root}{square root over ( )}V≦85×103(m−0.5·sec−1) while a ratio αL / αH of equivalent sonic speed αH in a high frequency area to the sonic speed αL of the fuel is set as αL / αH≦0.7, and the cross section shape in a perpendicular direction to an axis of the fuel delivery body 1 is formed in a substantially double side concaved shape, a substantially flask shape, a substantially trapezoid shape, a substantially key shape, and a substantially goggles shape.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com