Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4446results about "Valve members for absorbing fluid energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

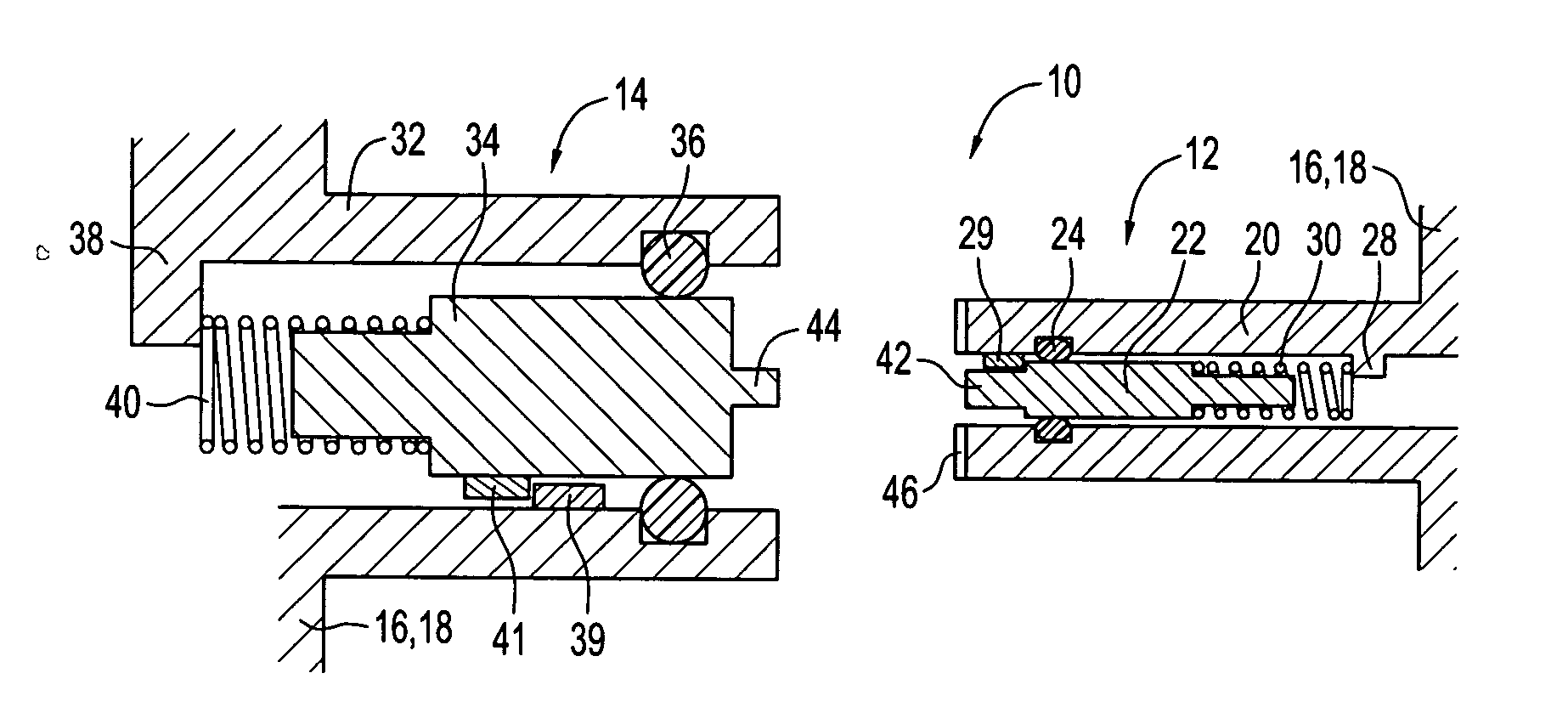

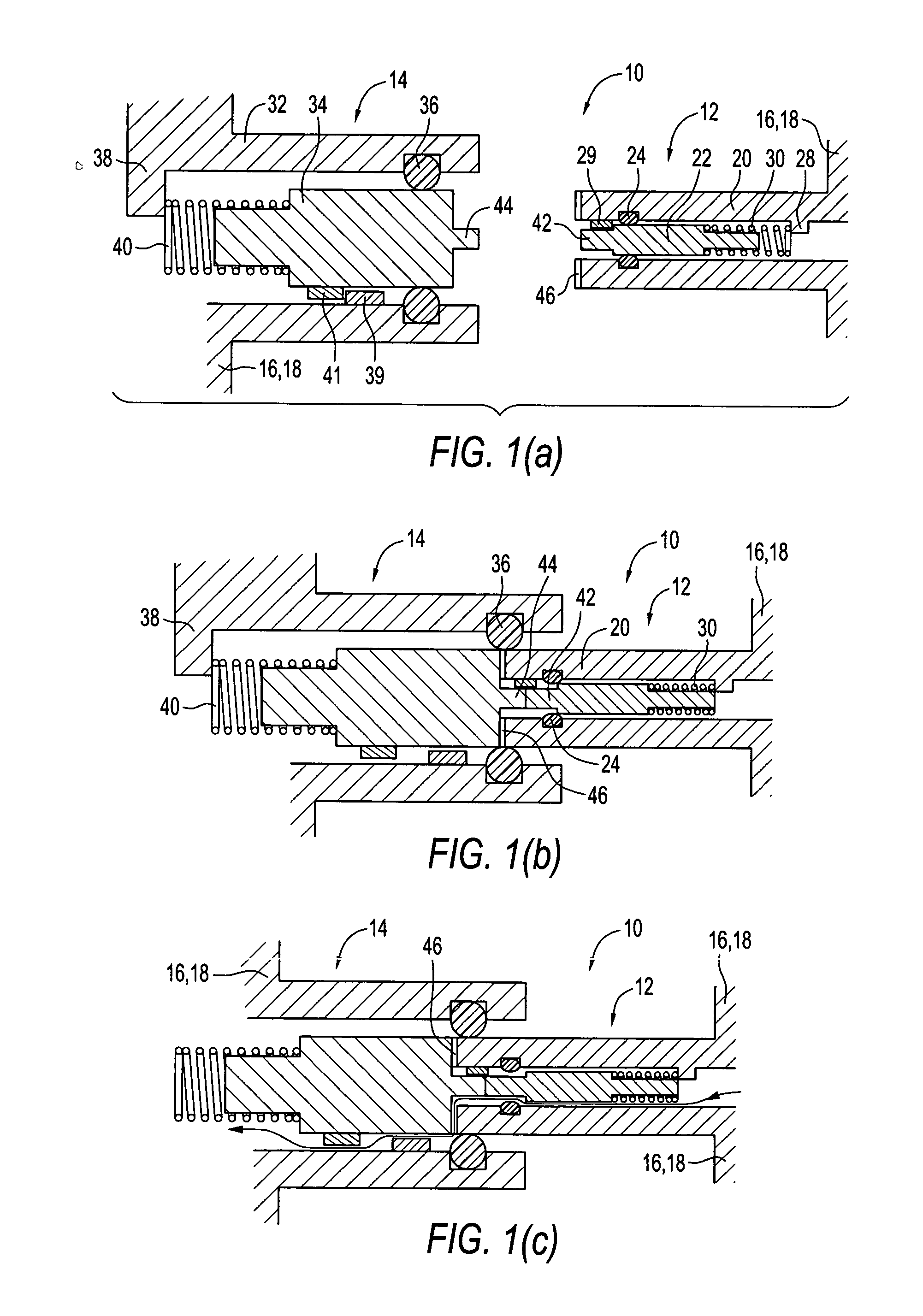

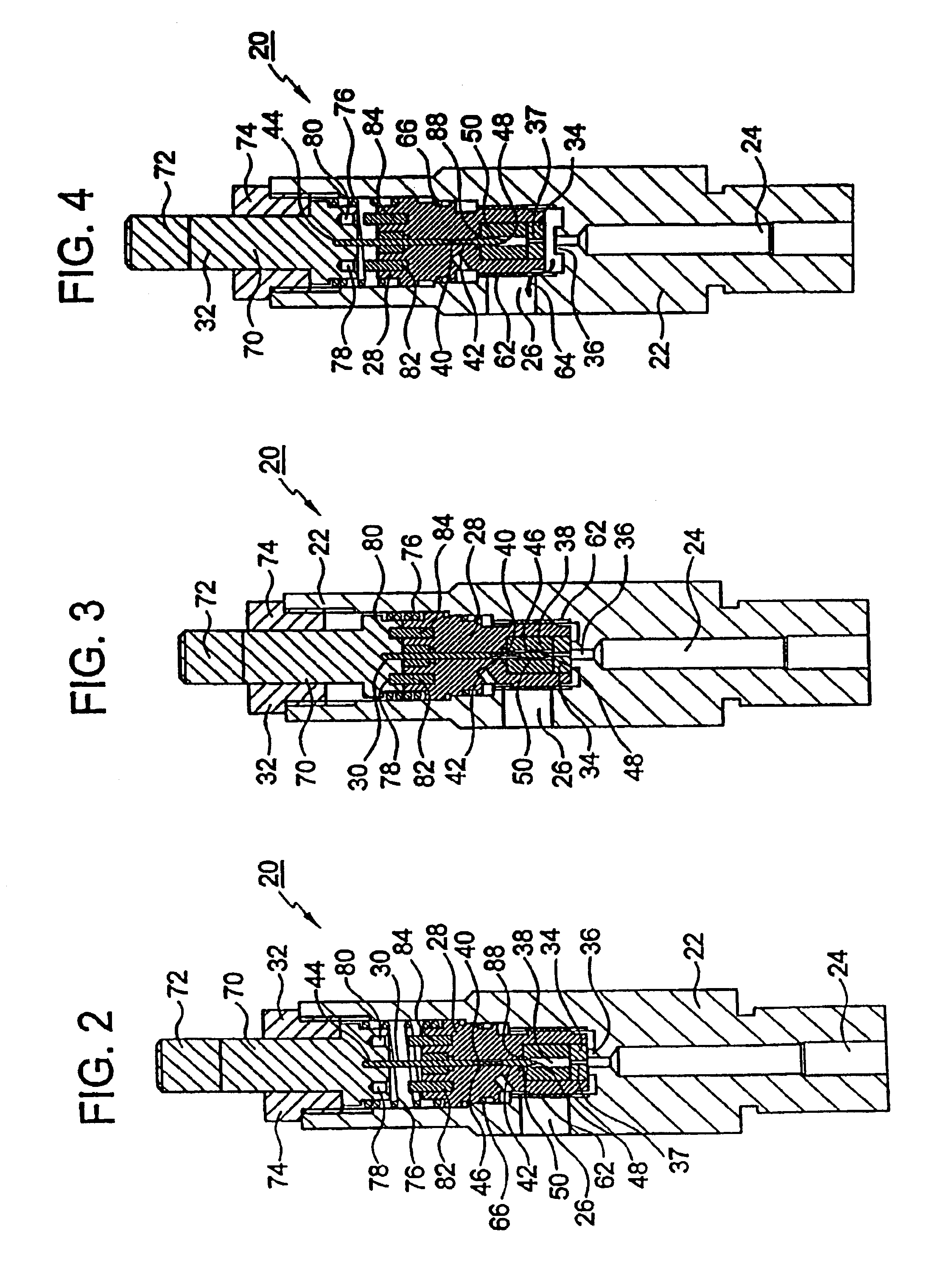

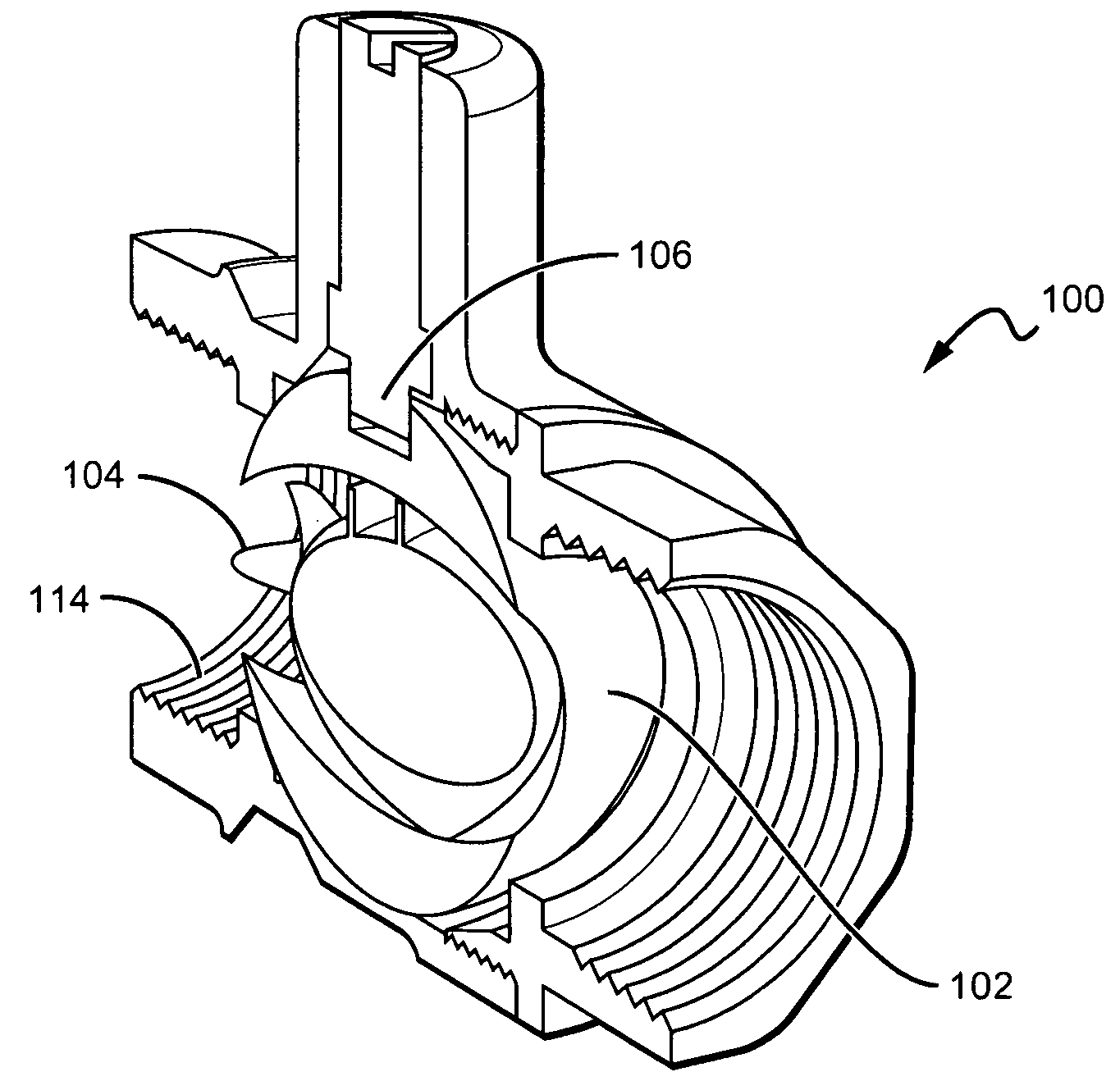

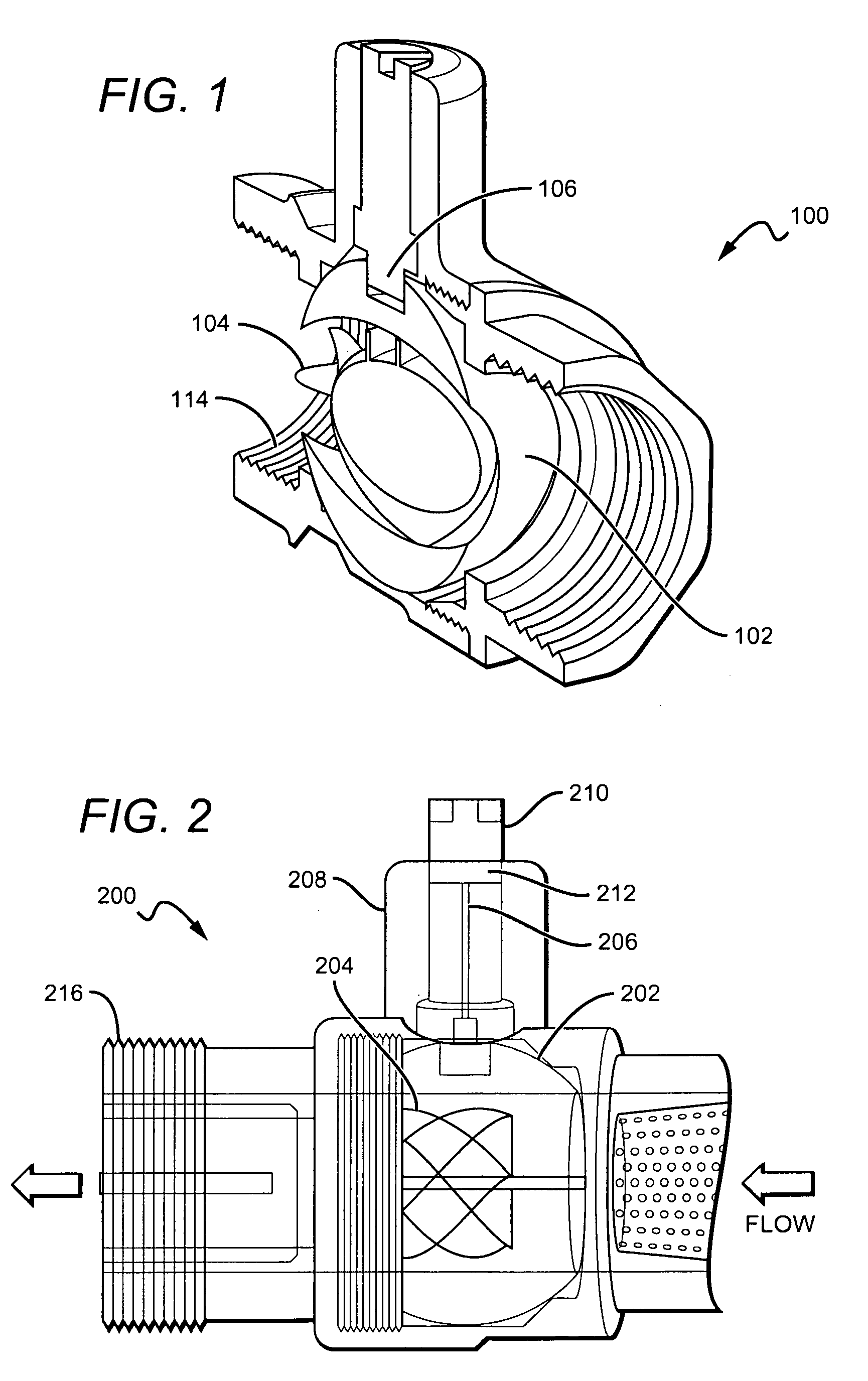

Fuel cartridge with connecting valve

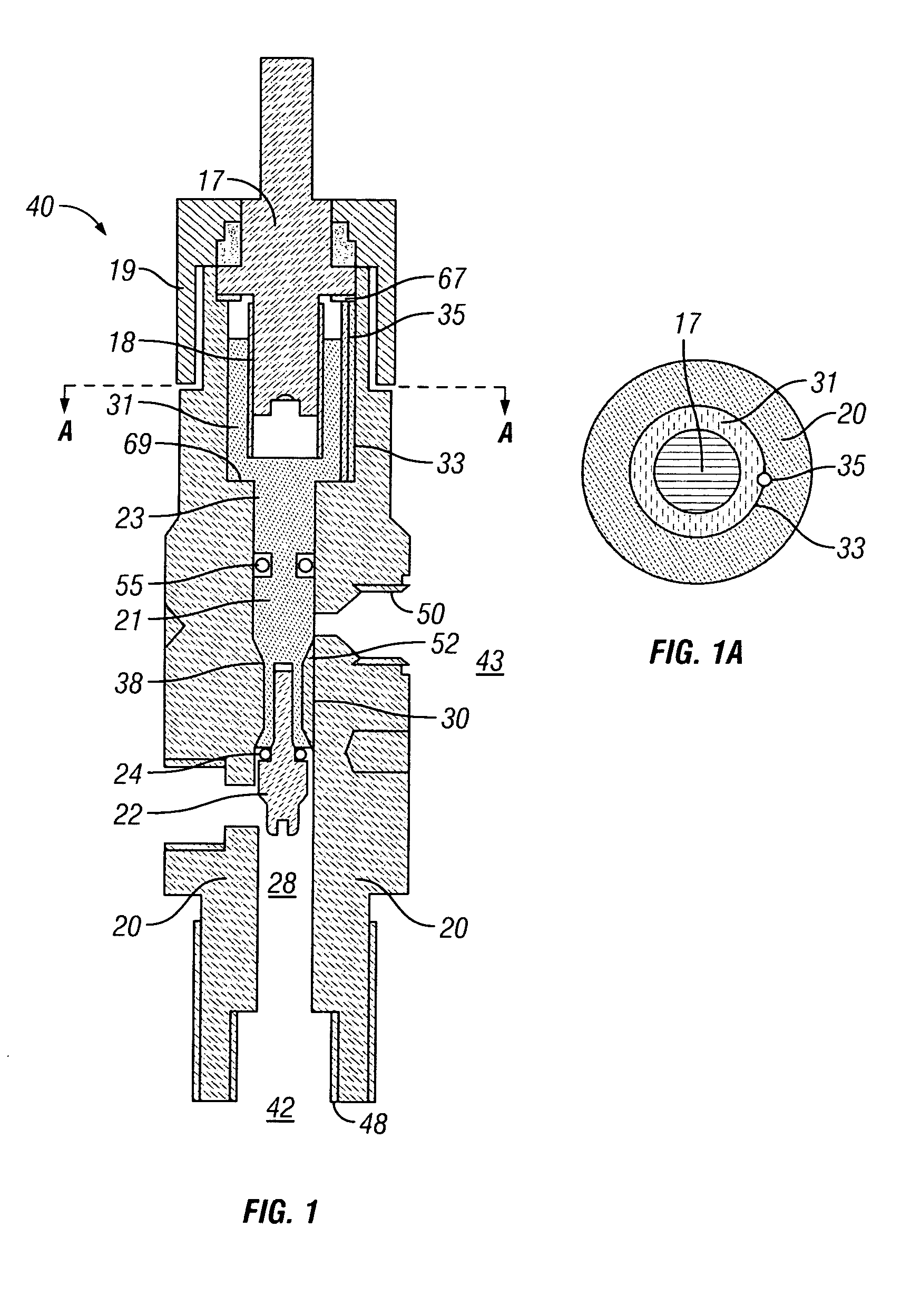

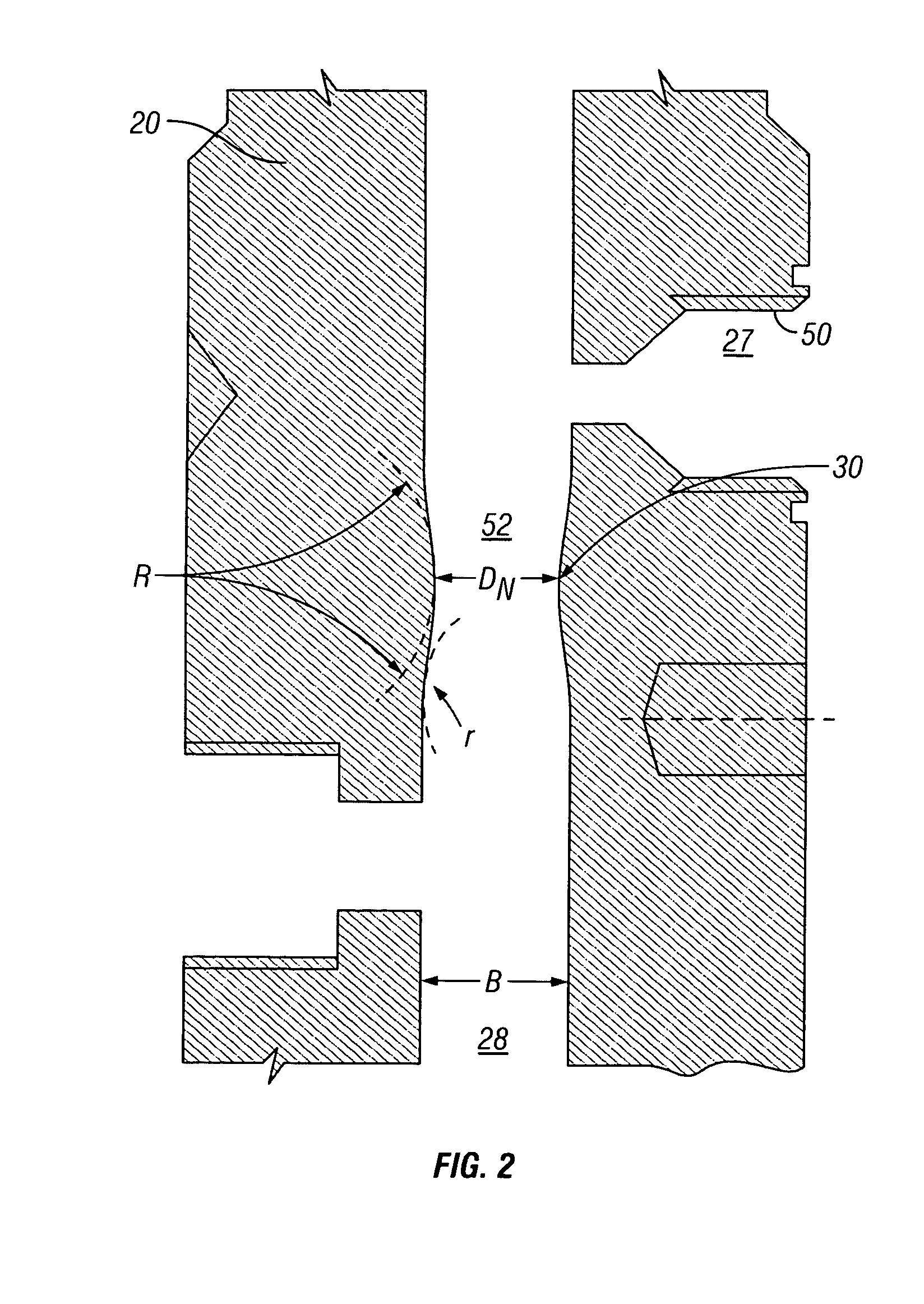

A shut-off valve or connecting valve capable of connecting a fuel supply to a fuel cell is disclosed. The valve comprises a first valve component and a second valve component. Each valve component has an outer housing and a biased slidable member disposed inside the housing forming an internal seal. During the connection process, the two valve components establish an inter-component seal. Afterward, in one suitable embodiment the slidable member moves inward and opens the internal seal in the valve component to establish a flow path. In another embodiment, the slidable member moves inward and exposes a first filler and the first filler abuts a second filler in the other valve component to establish a flow path. In other embodiments, at least one valve component is sized and dimensioned to limit access to the internal seal.

Owner:INTELLIGENT ENERGY LTD

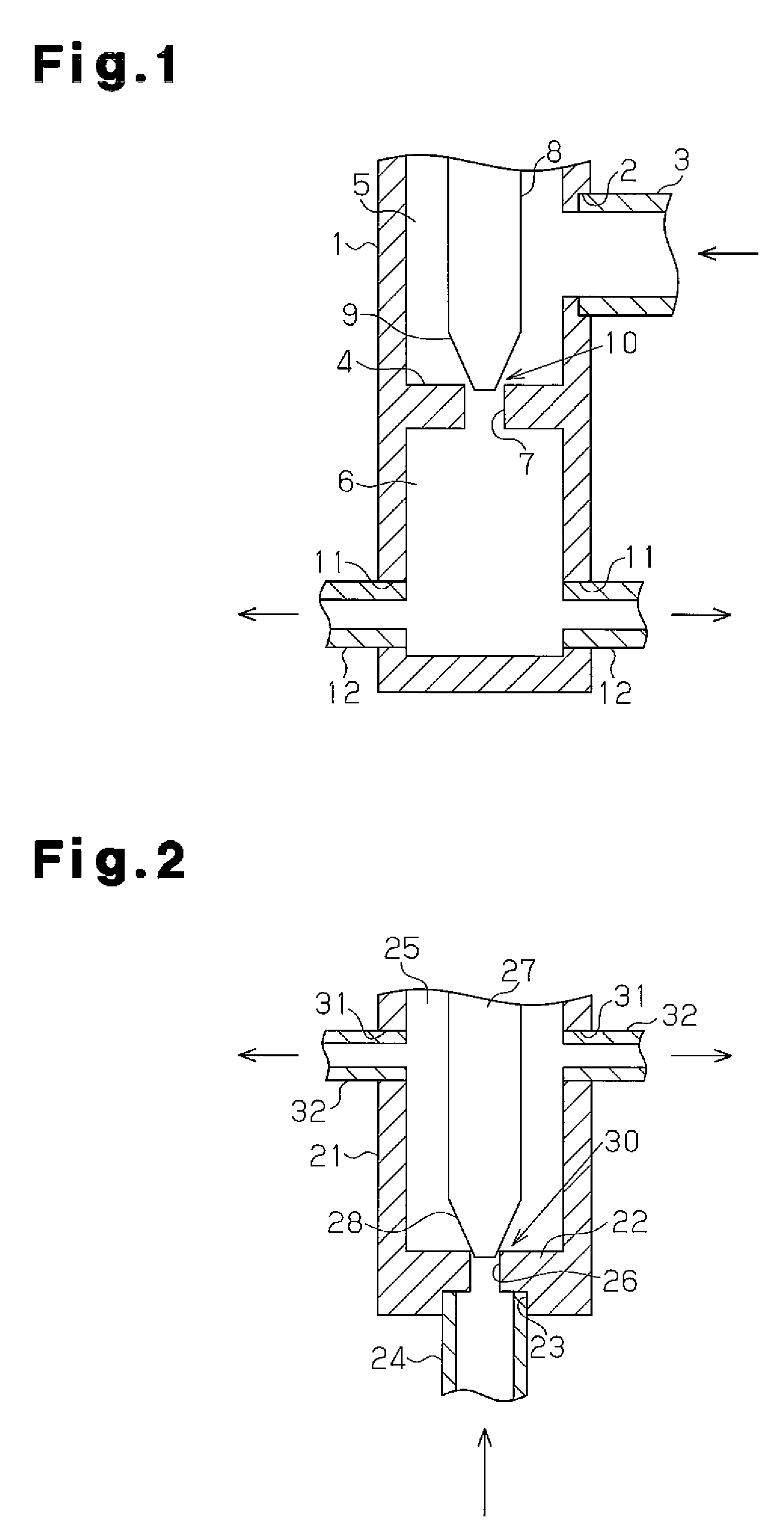

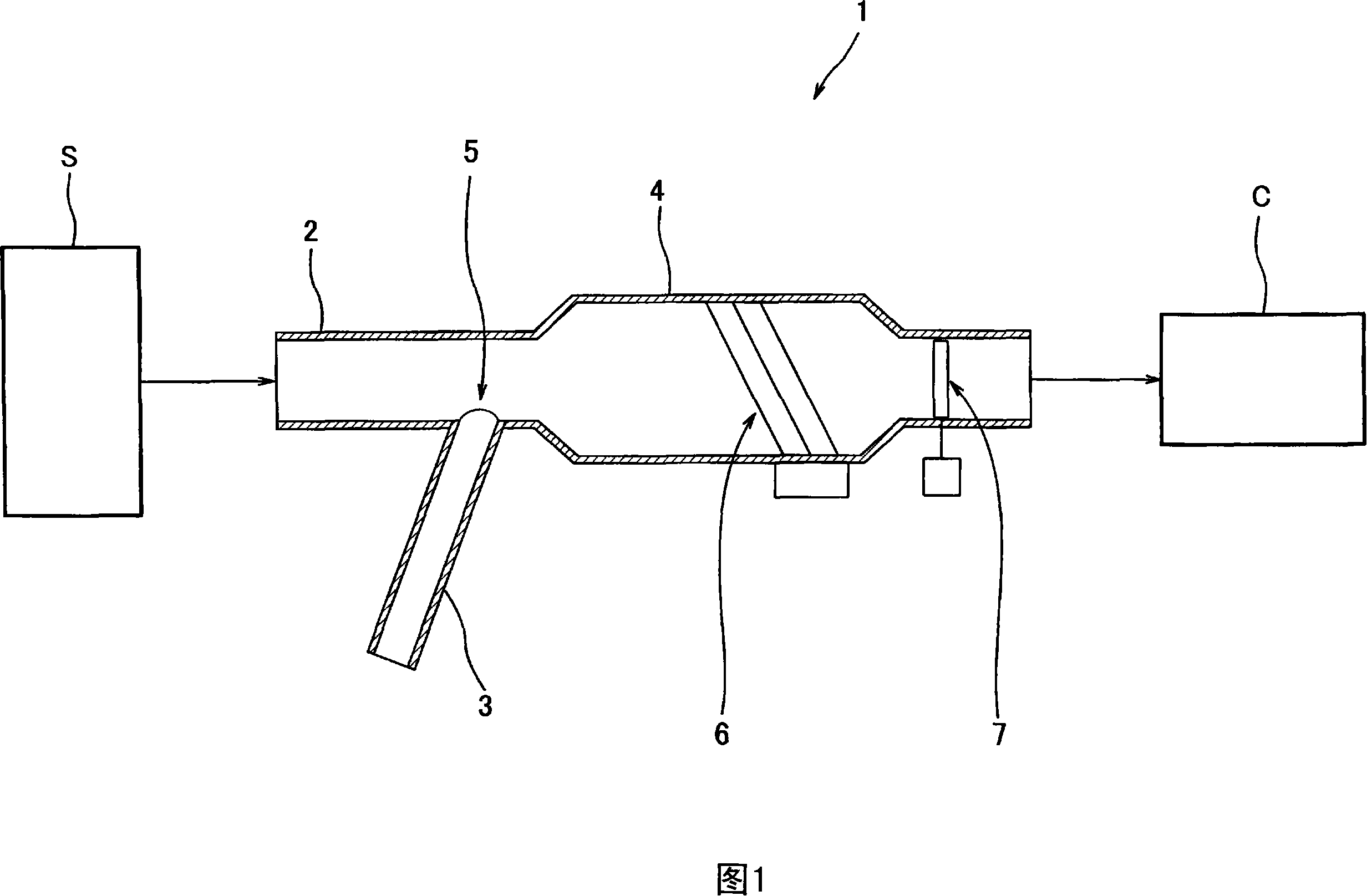

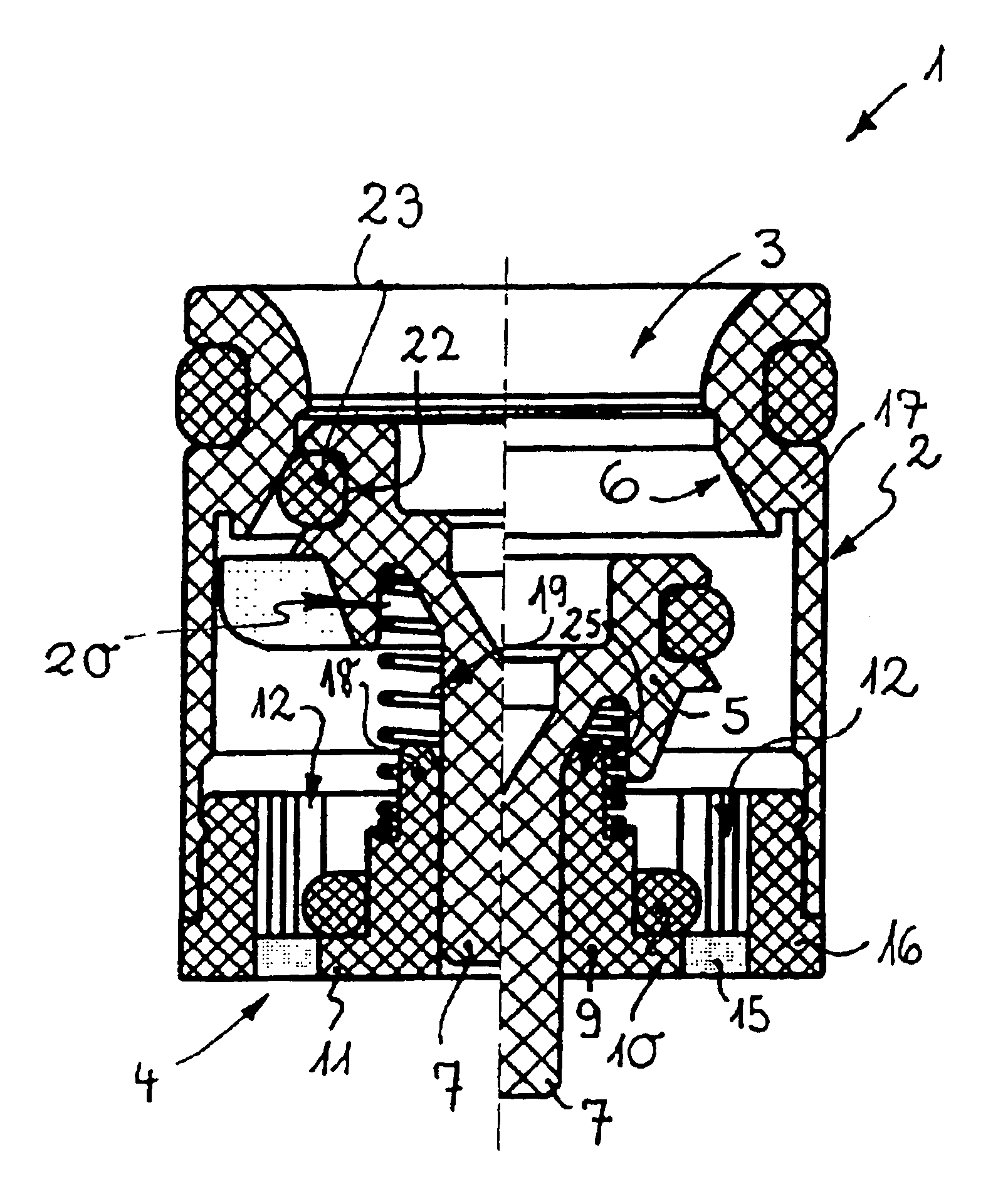

Expansion valve with refrigerant flow dividing structure and refrigeration unit utilizing the same

InactiveUS20090183520A1Reduce noiseShorten speedEvaporators/condensersValve members for absorbing fluid energyEngineeringRefrigeration

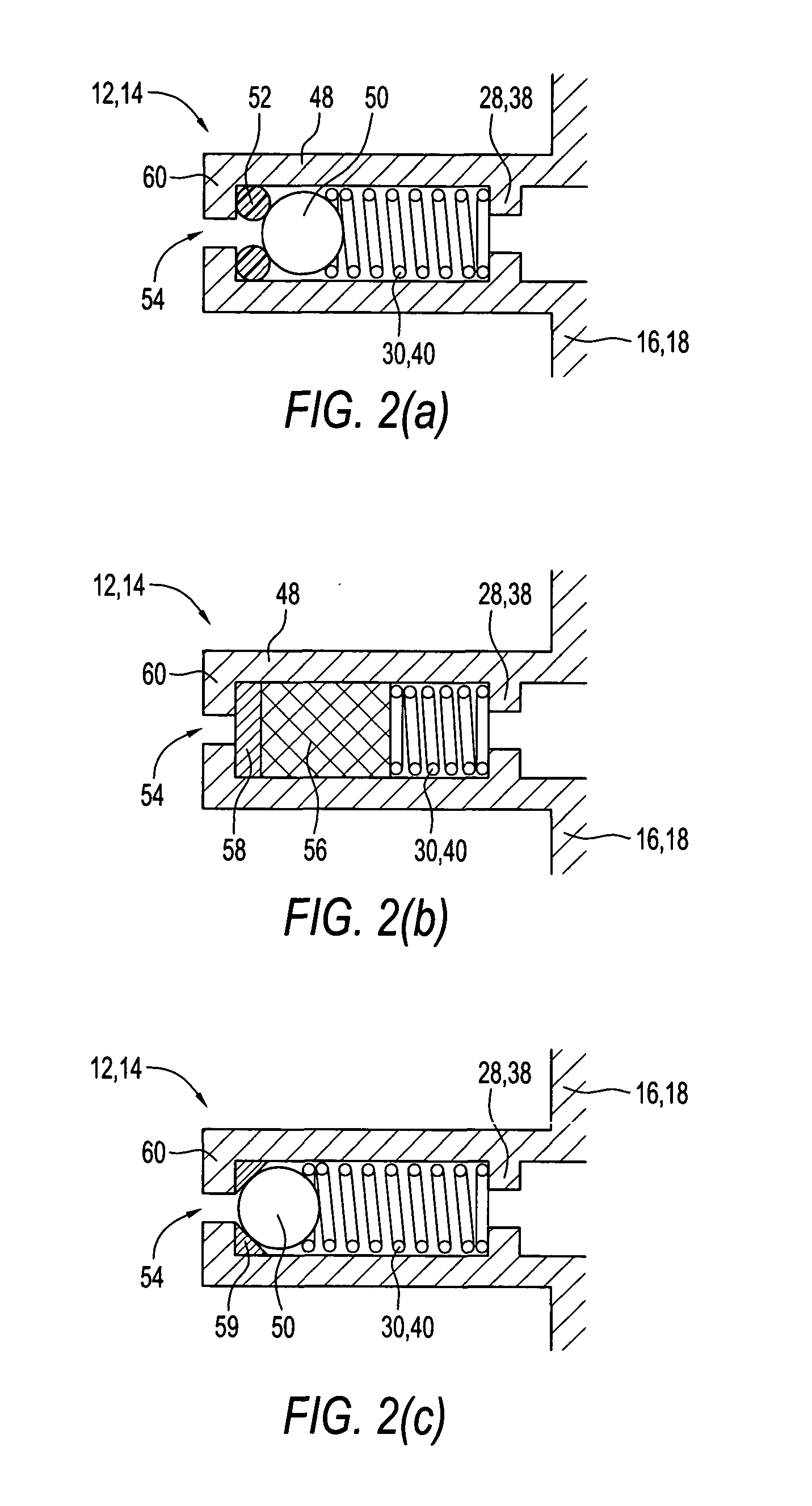

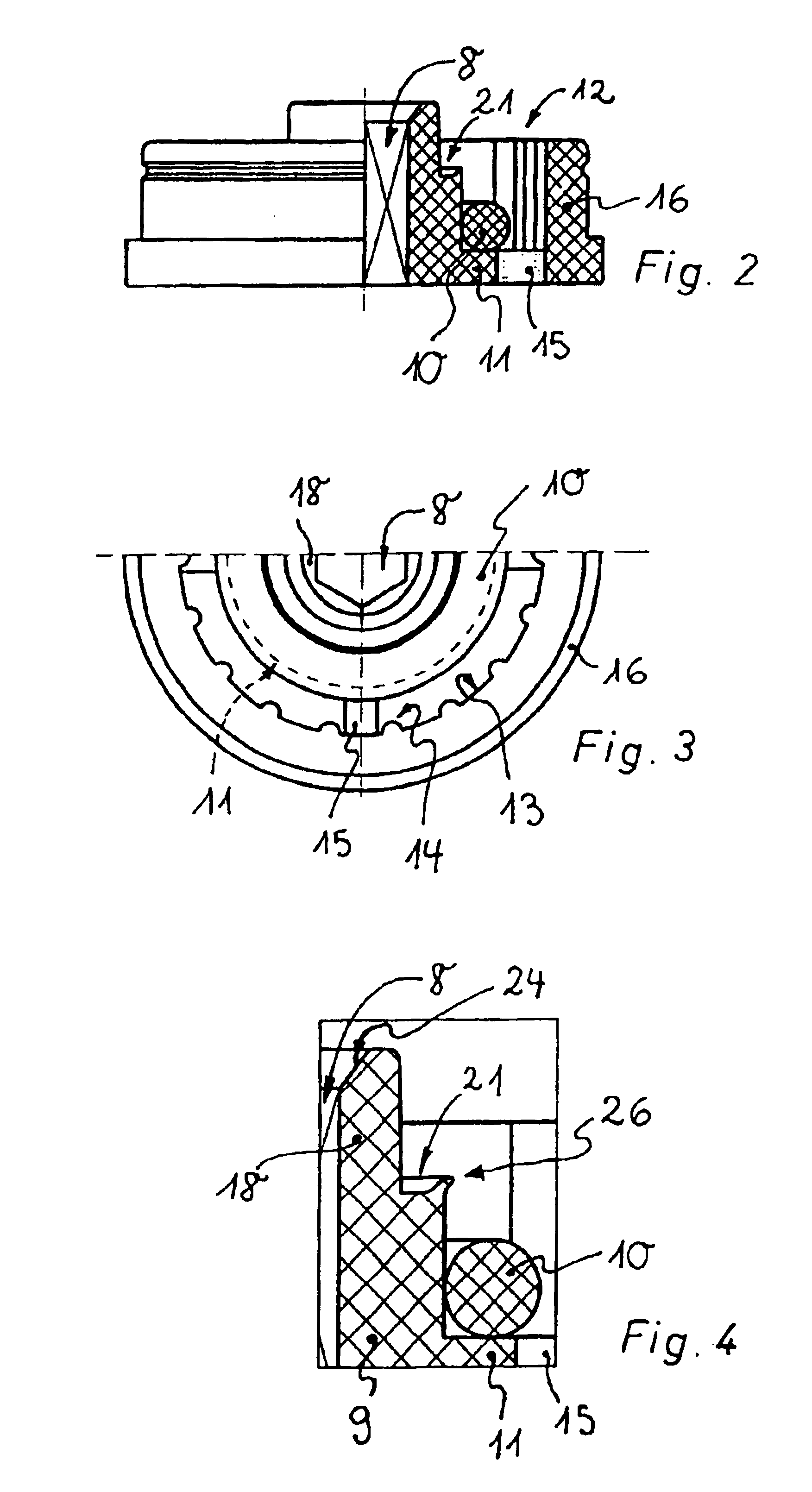

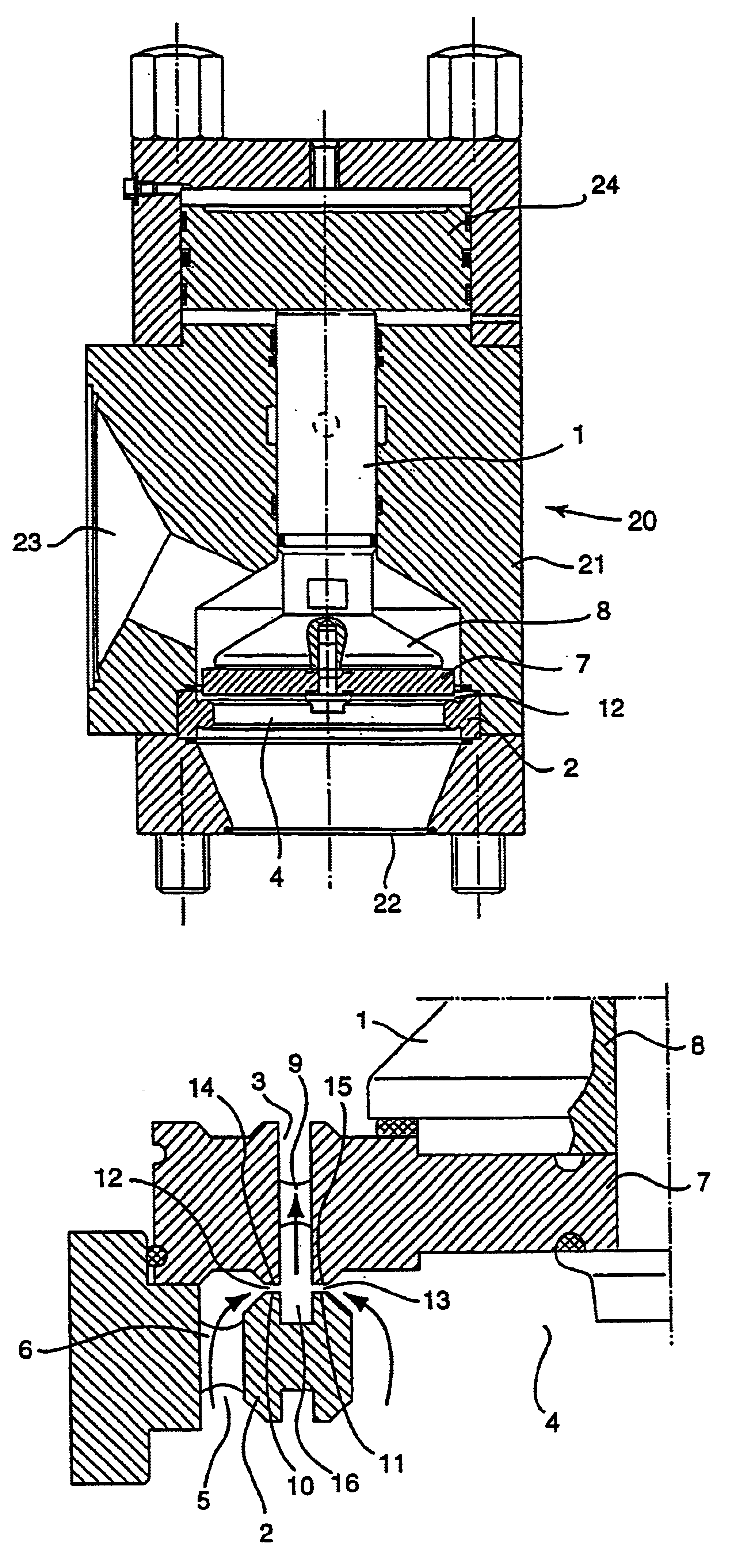

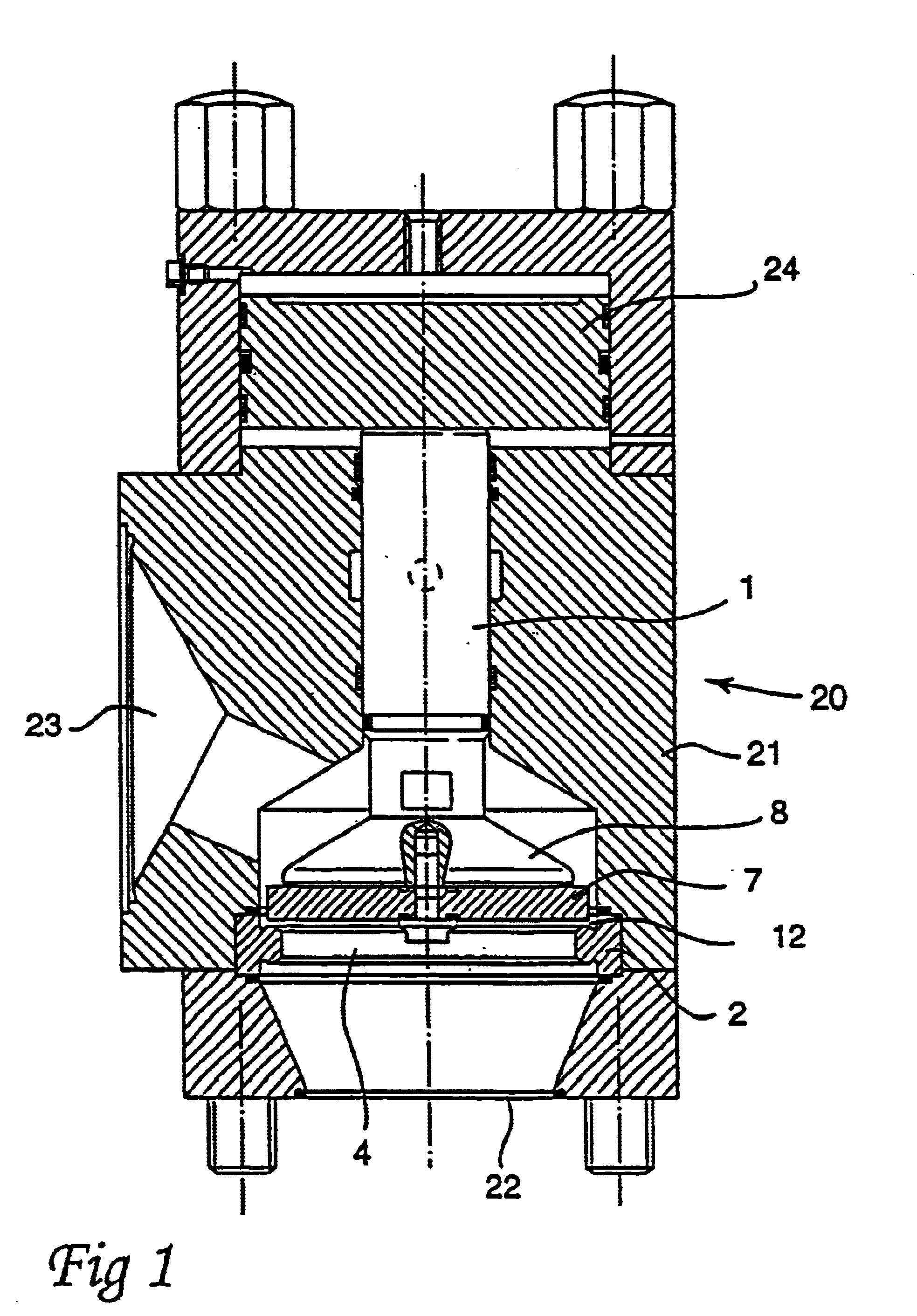

An expansion valve of the present invention has a structure which integrates a refrigerant flow divider. The expansion valve includes a refrigerant flow dividing chamber 6 on the downstream side of a first throttle 10. Flow dividing tubes 12 are connected to the refrigerant flow dividing chamber 6. In the expansion valve, refrigerant which has passed through the first throttle 10 is sprayed into the refrigerant flow dividing chamber 6, so that the flow dividing characteristic of the refrigerant is improved. Also, due to an enlargement of the passage in the refrigerant flow dividing chamber 6, the ejection energy of a flow of the refrigerant ejected from the first throttle 10 is dispersed, whereby a discontinuous refrigerant flow noise is reduced.

Owner:DAIKIN IND LTD

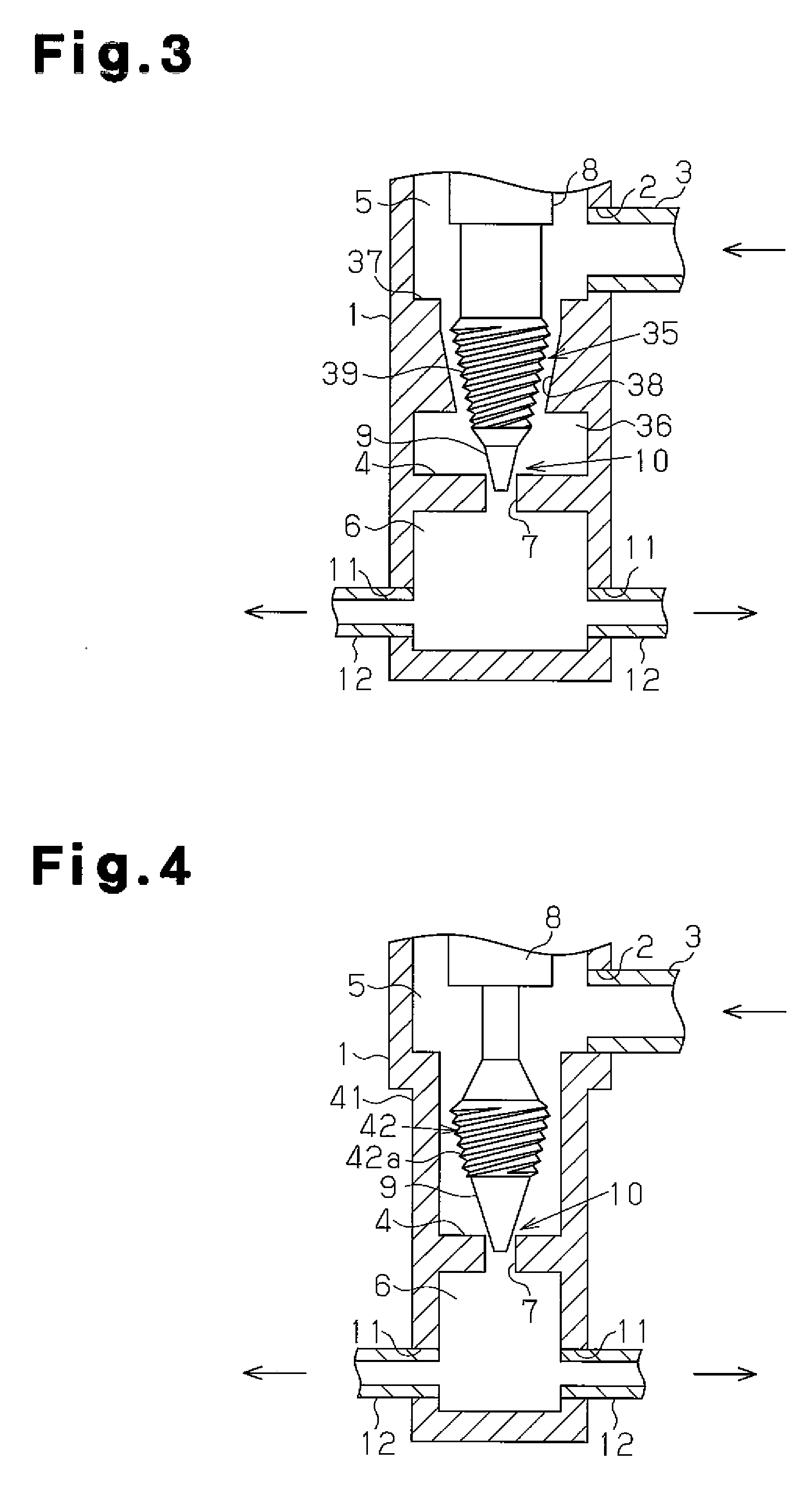

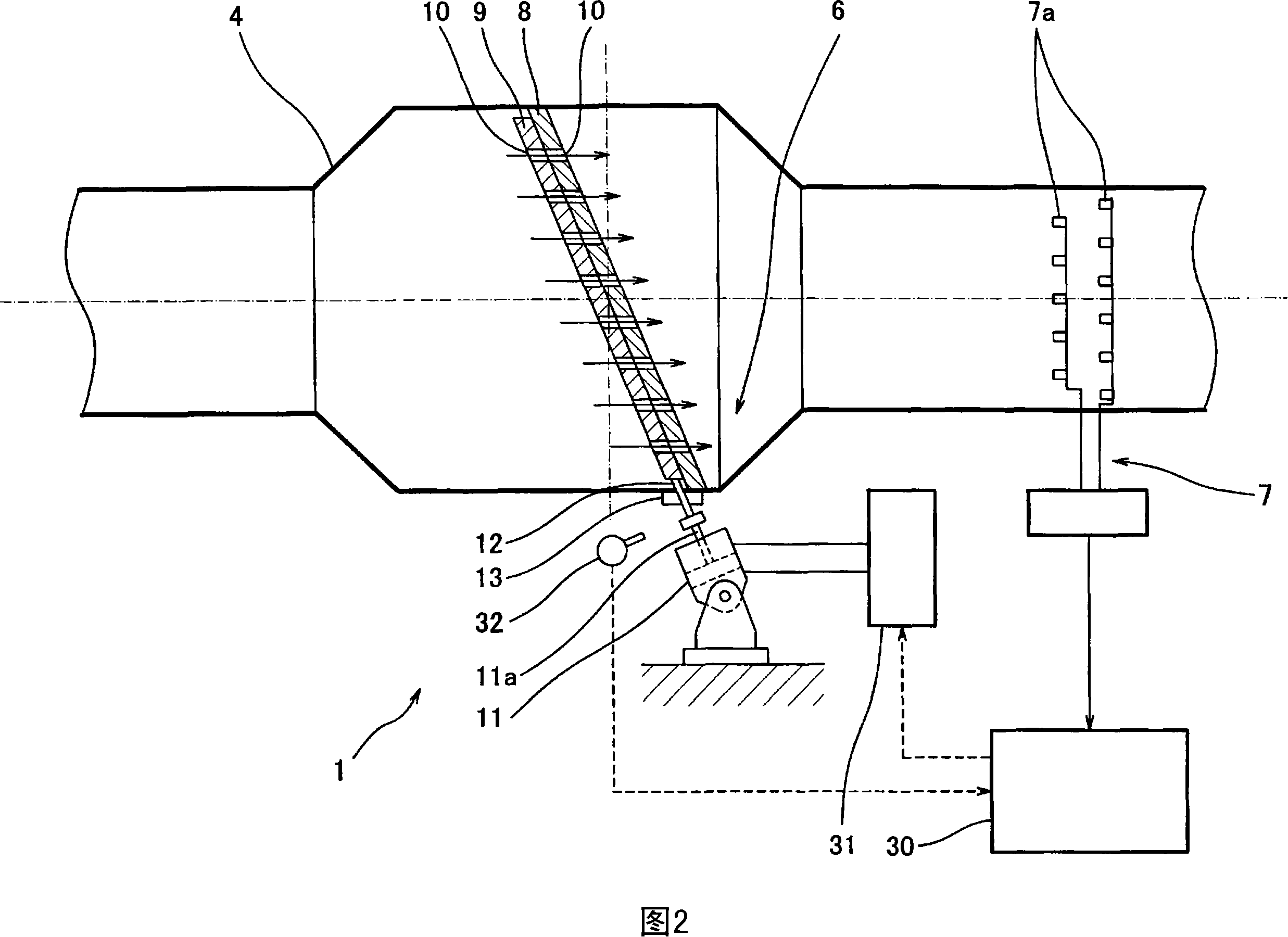

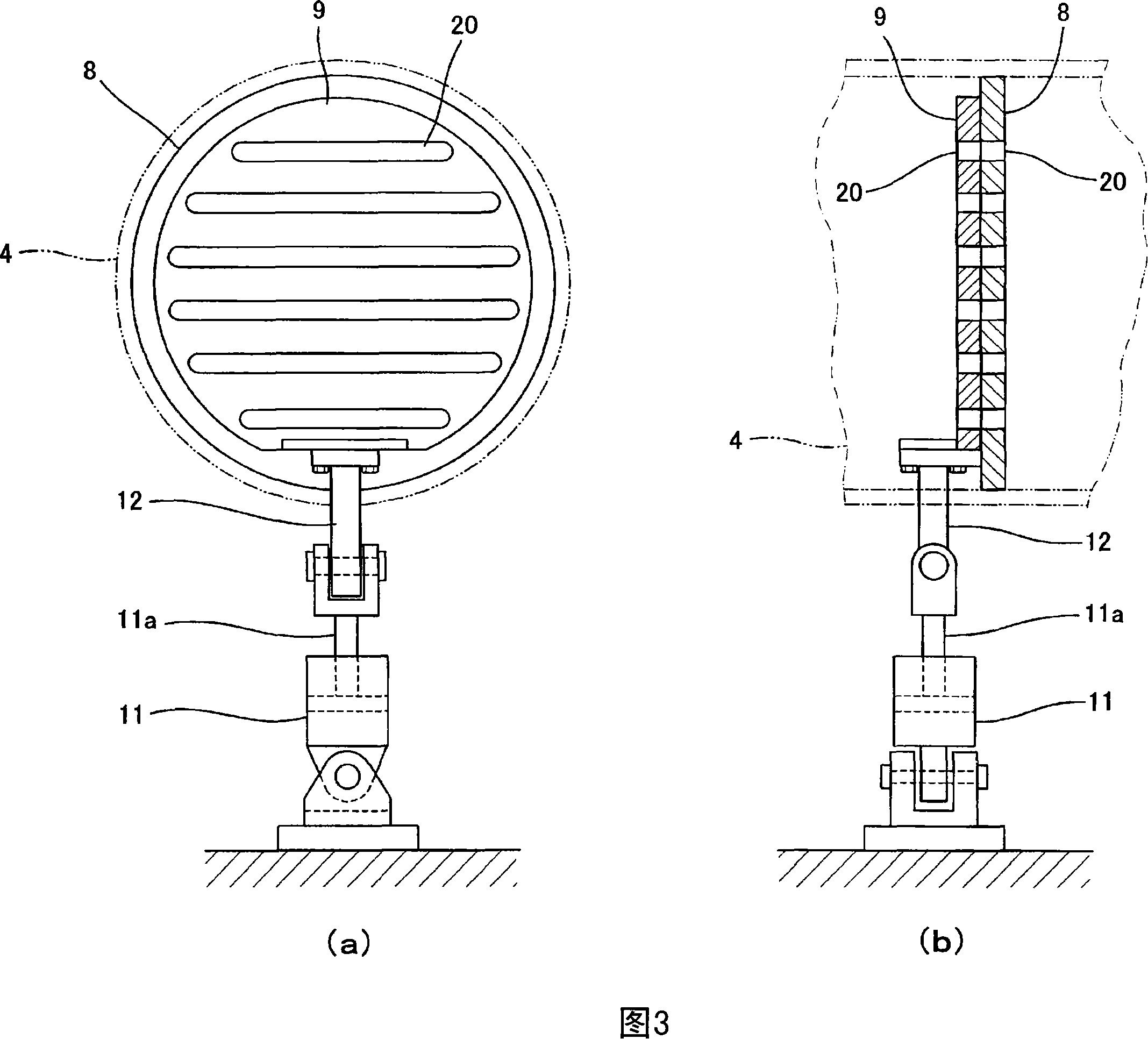

Mixed fluid uniformization device and mixed fluid feeding apparatus

InactiveCN101142012AImprove uniformityFlow mixersTransportation and packagingMixed statesEngineering

Owner:KAWASAKI HEAVY IND LTD

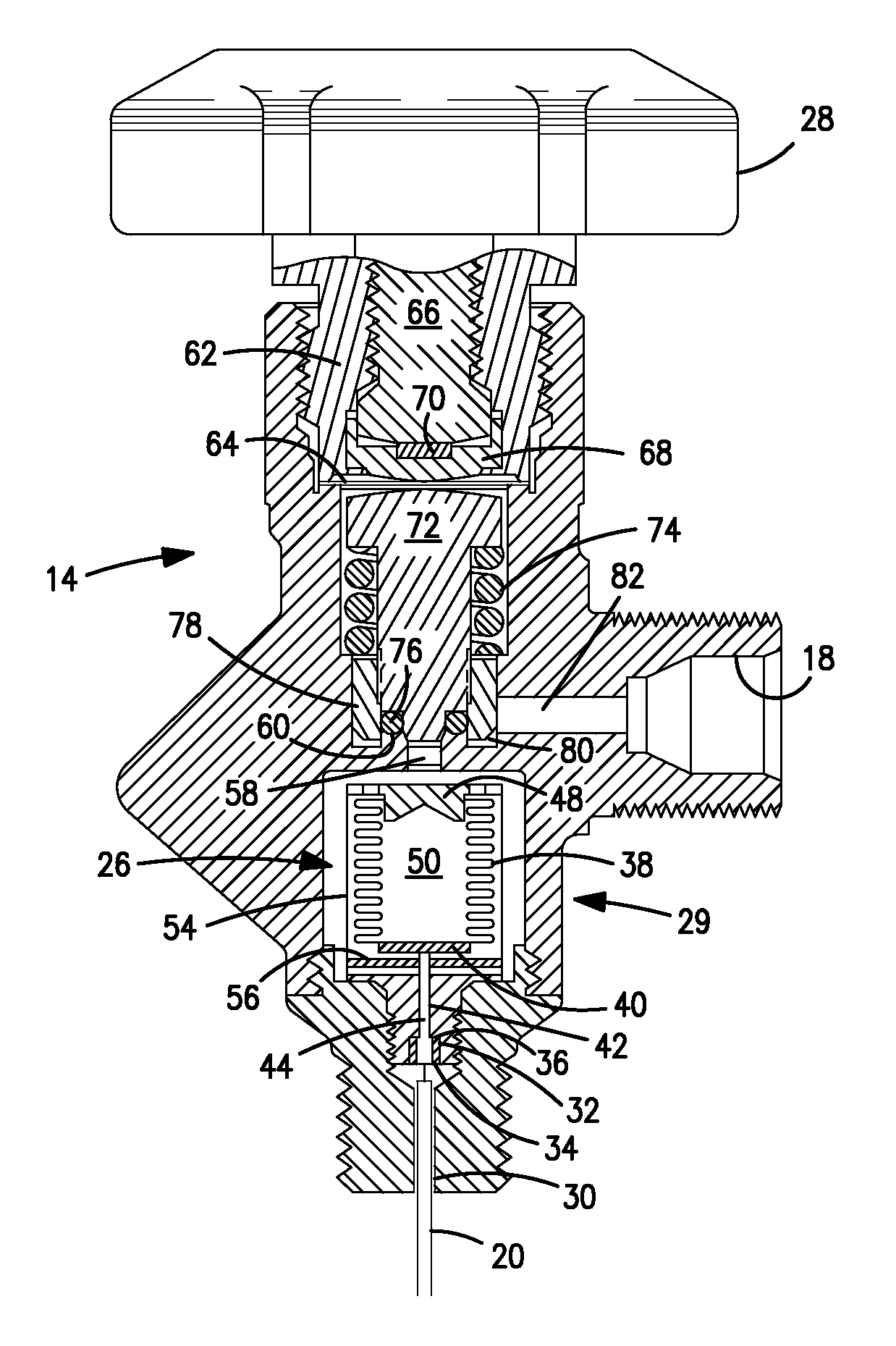

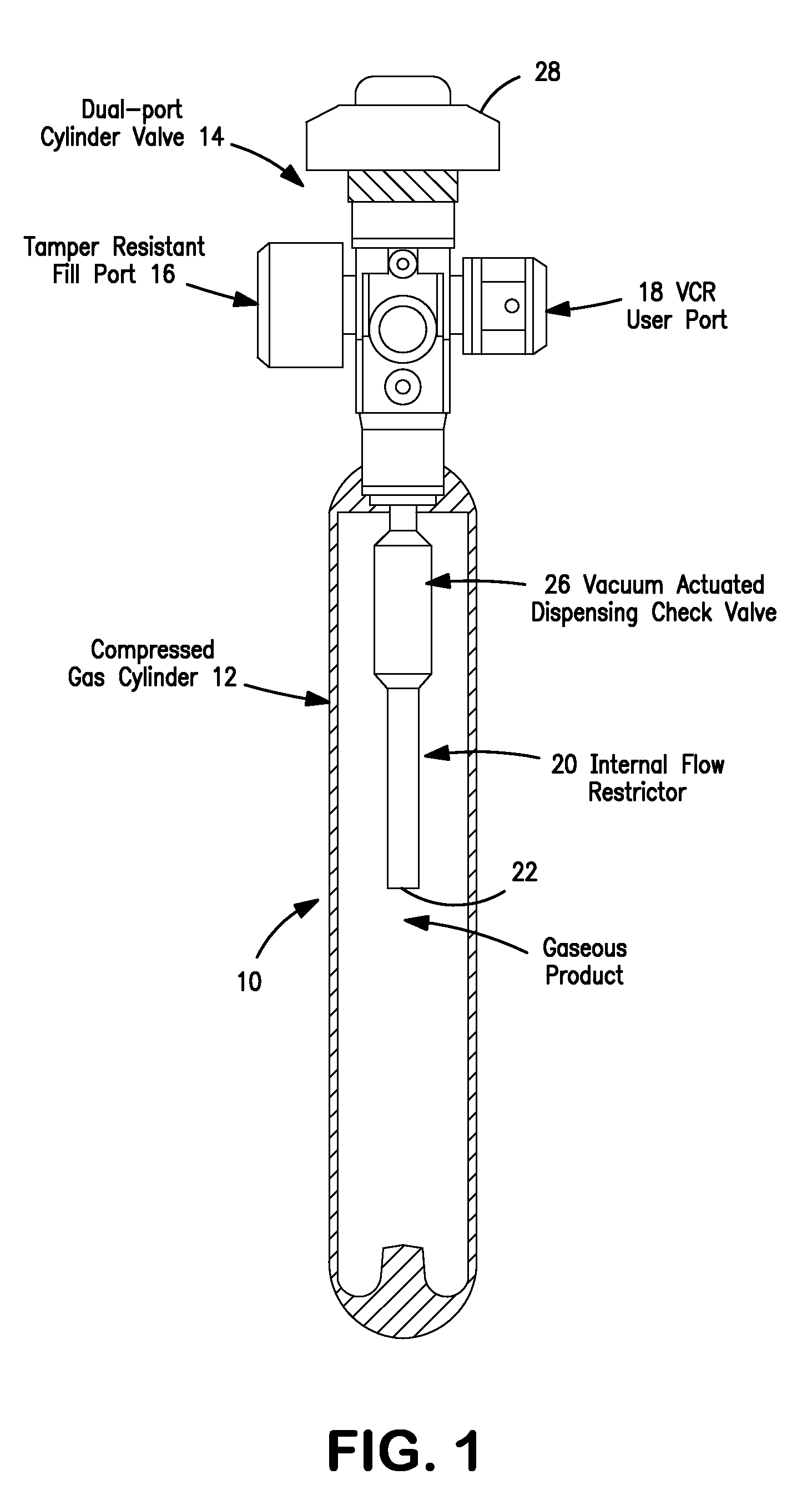

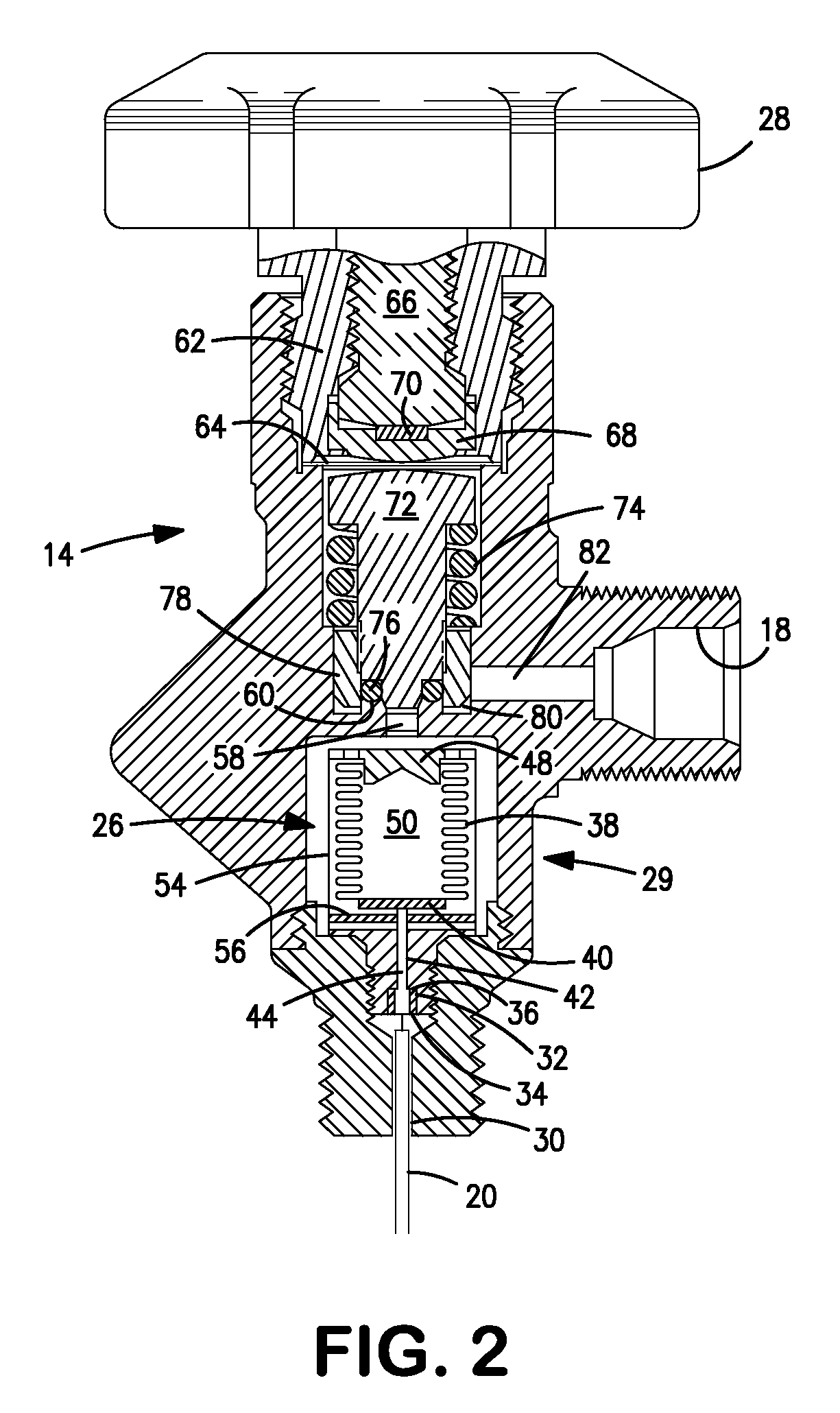

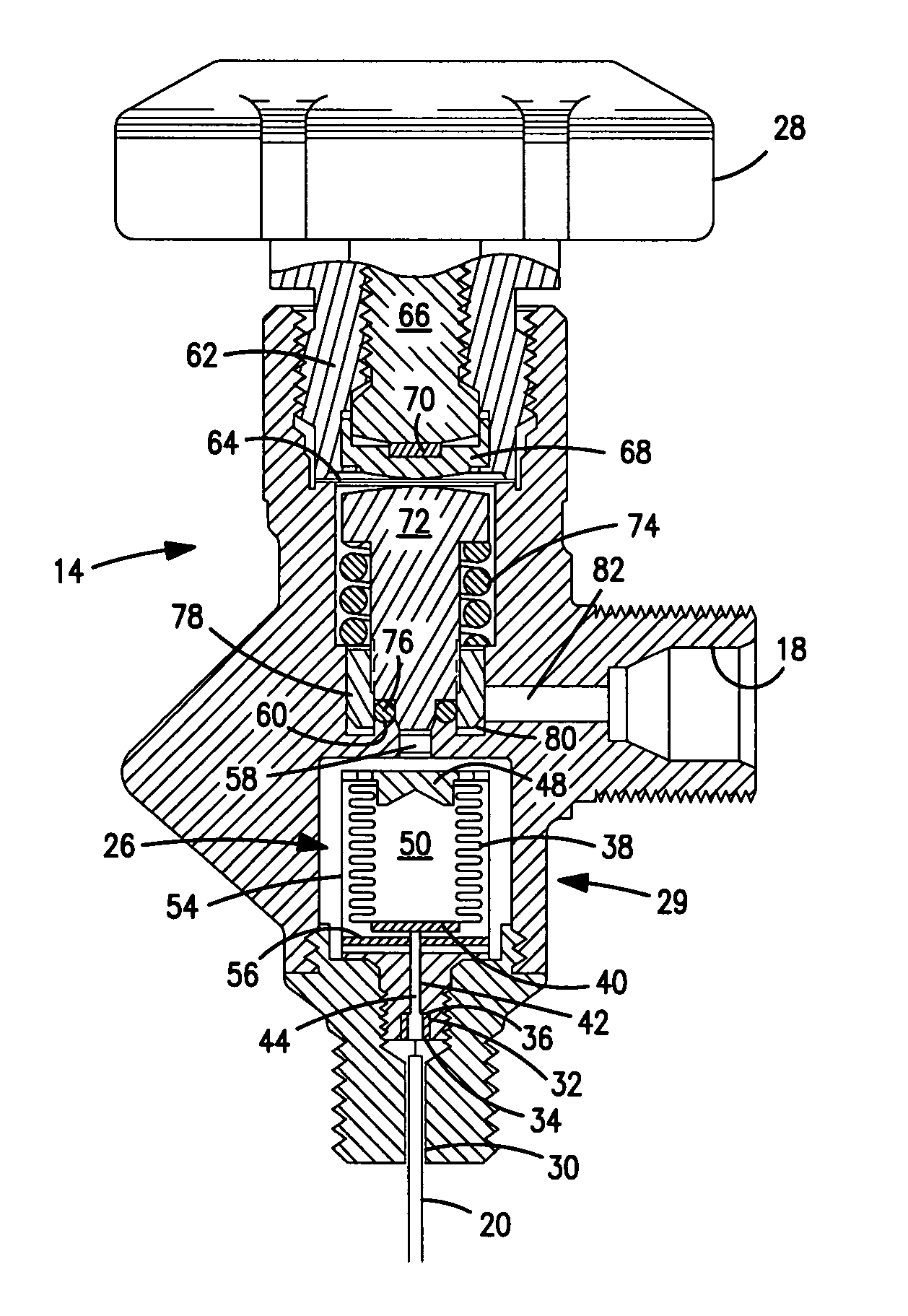

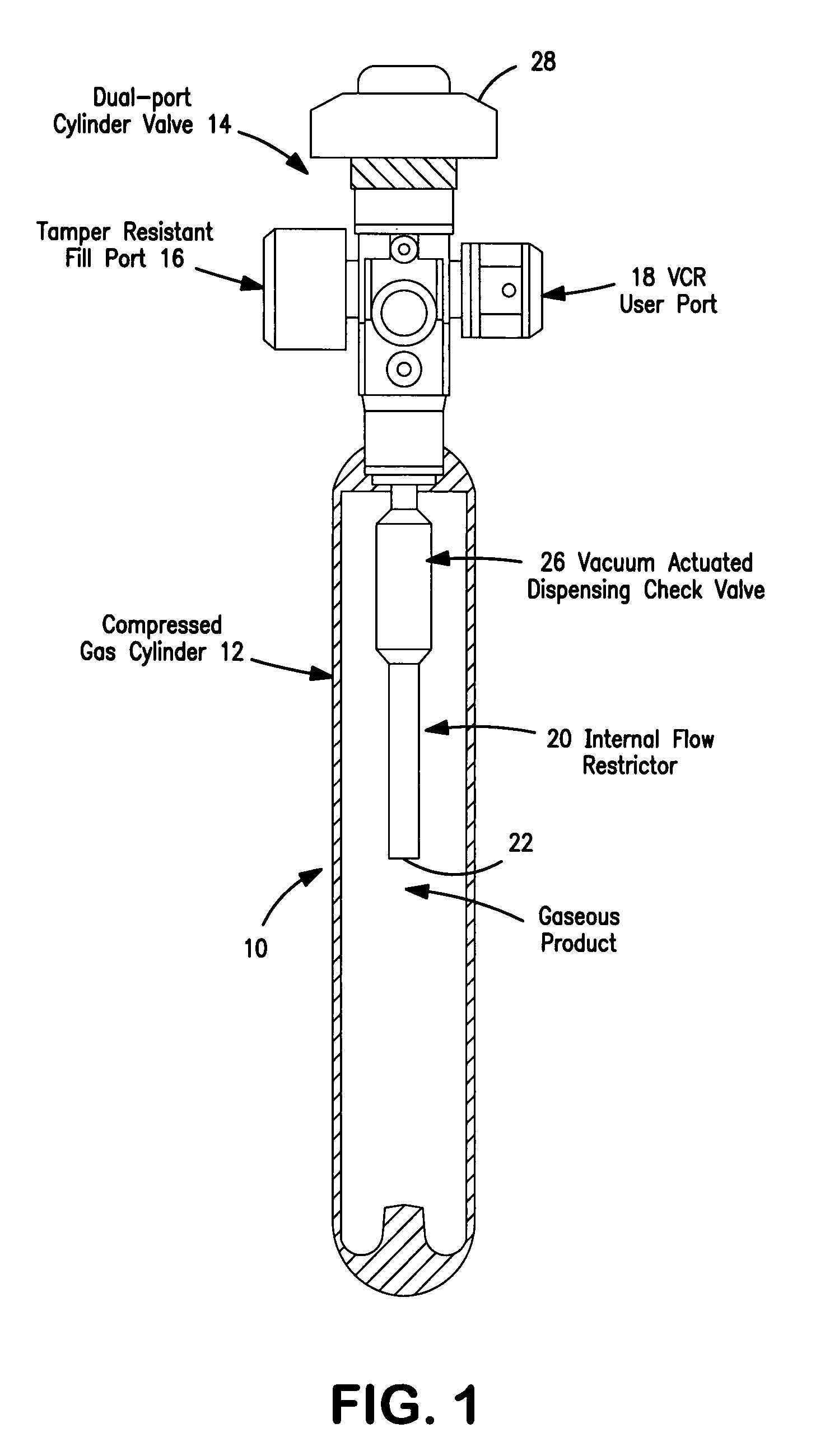

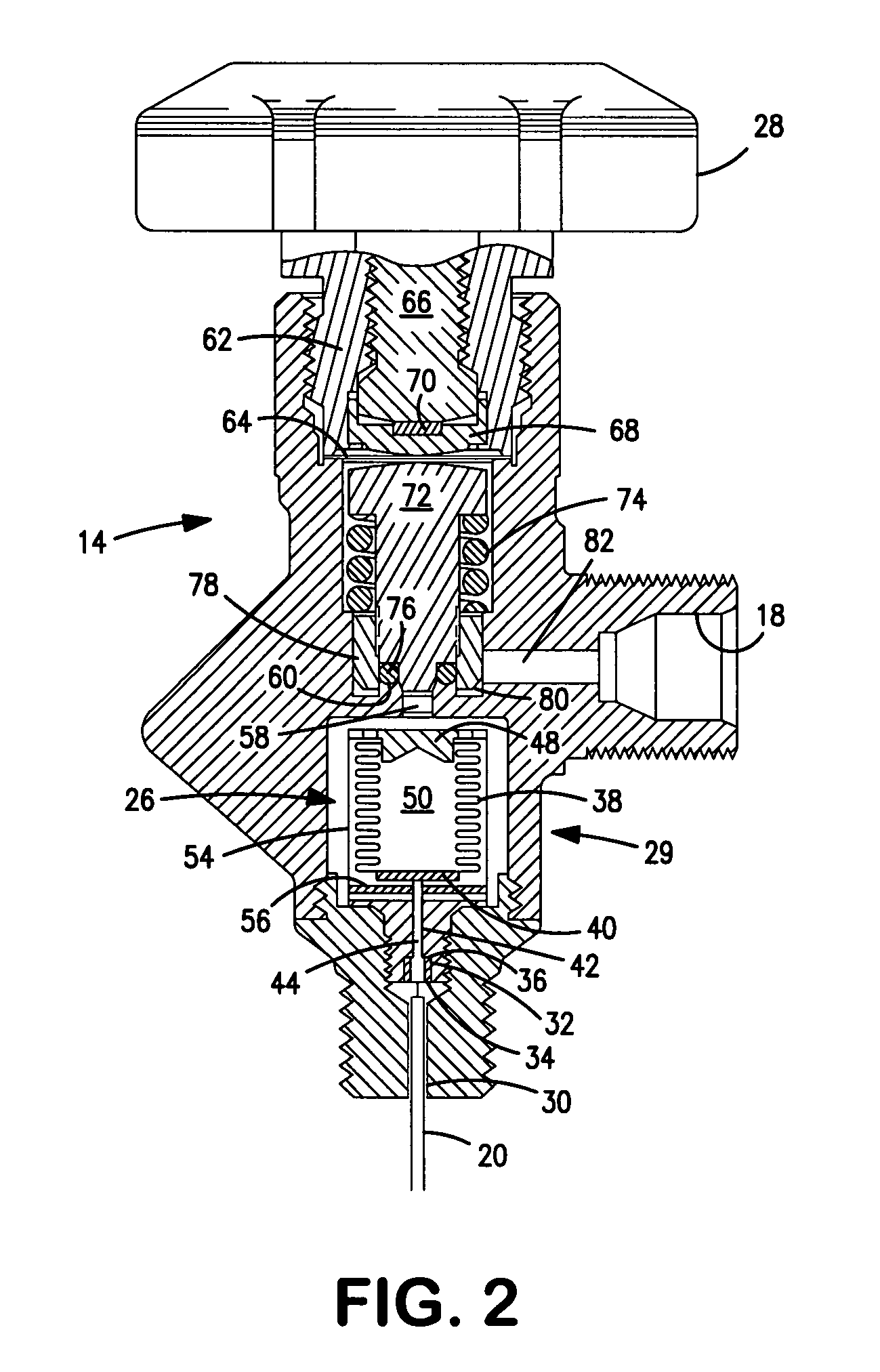

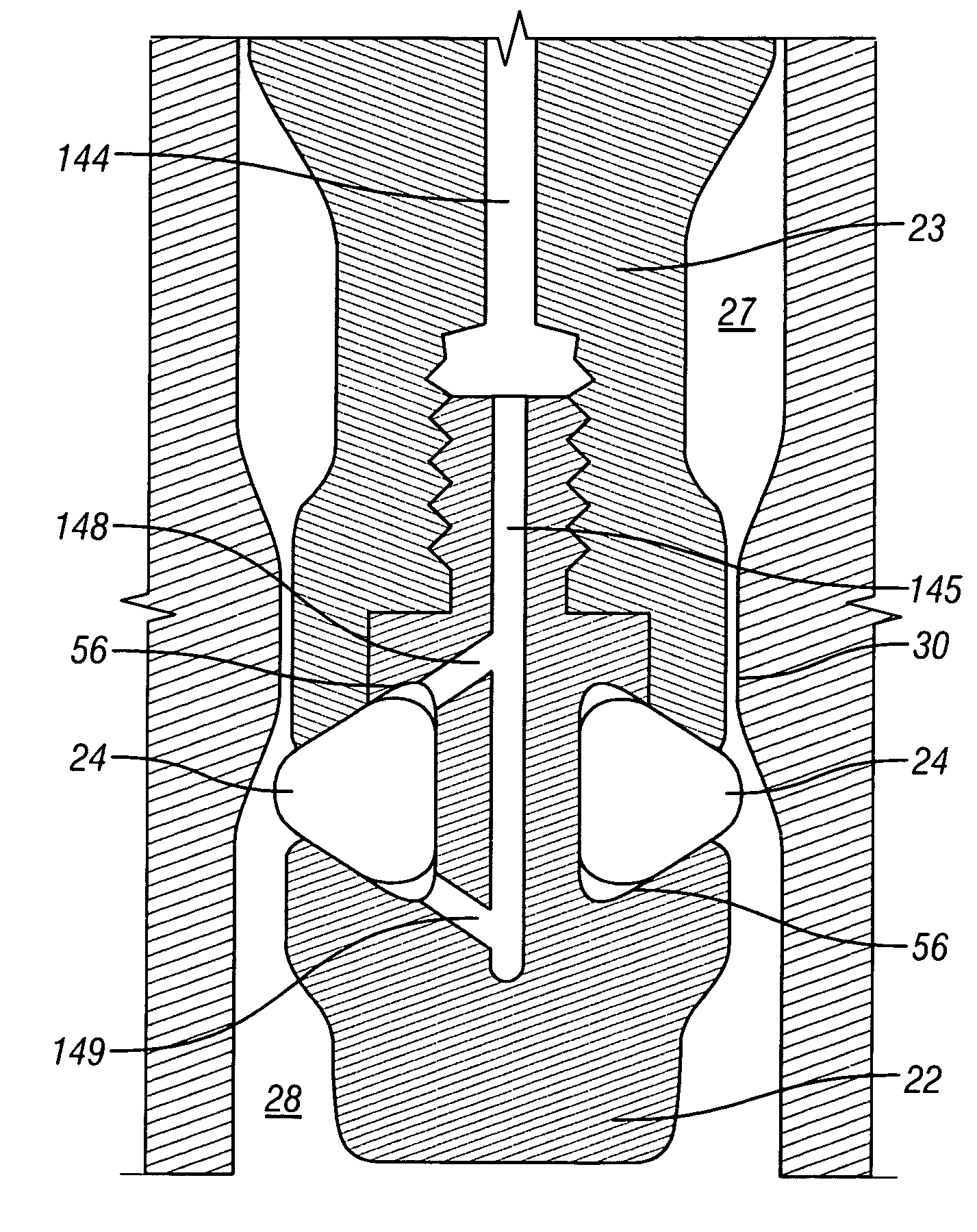

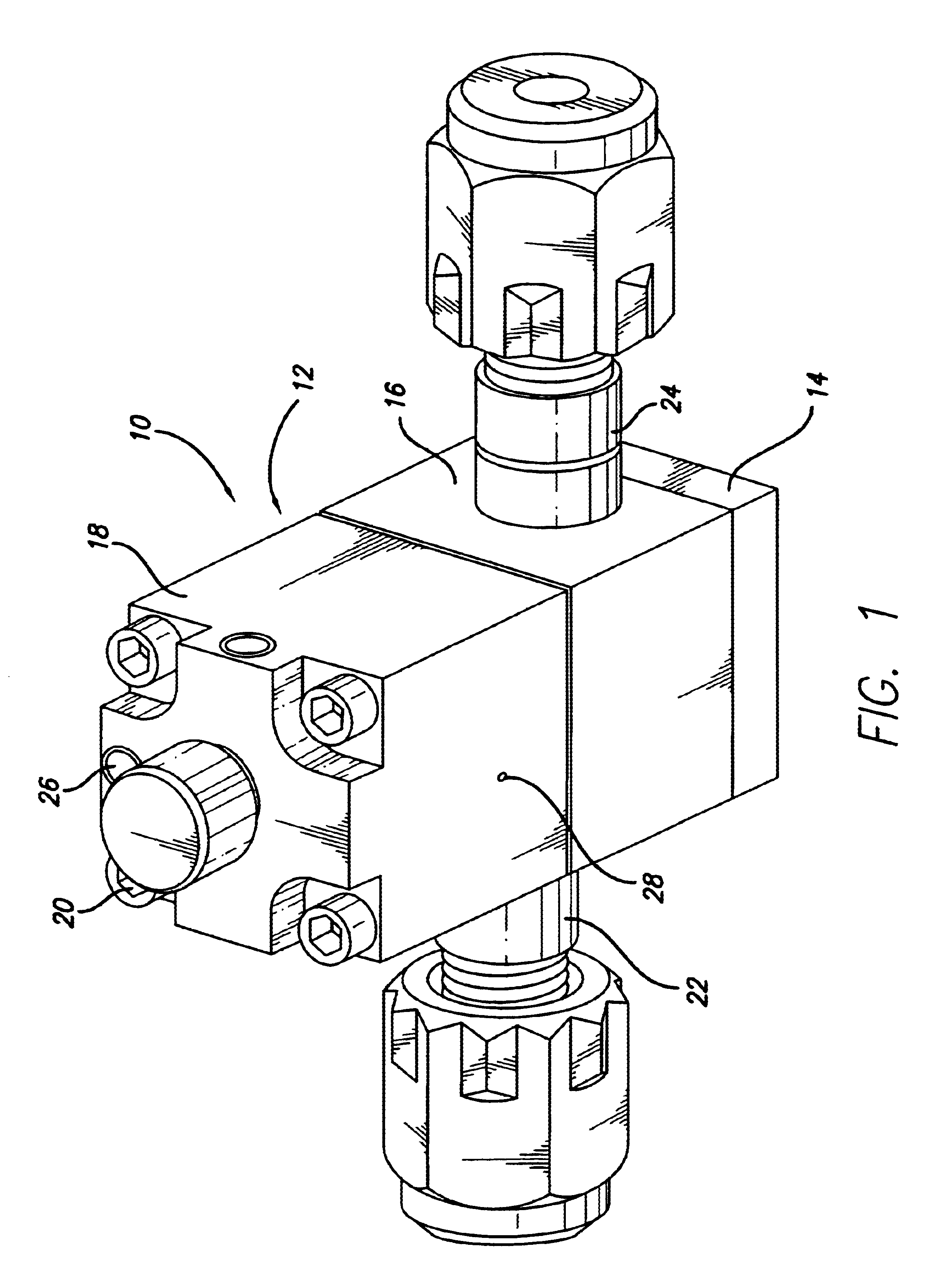

Vacuum actuated valve for high capacity storage and delivery systems

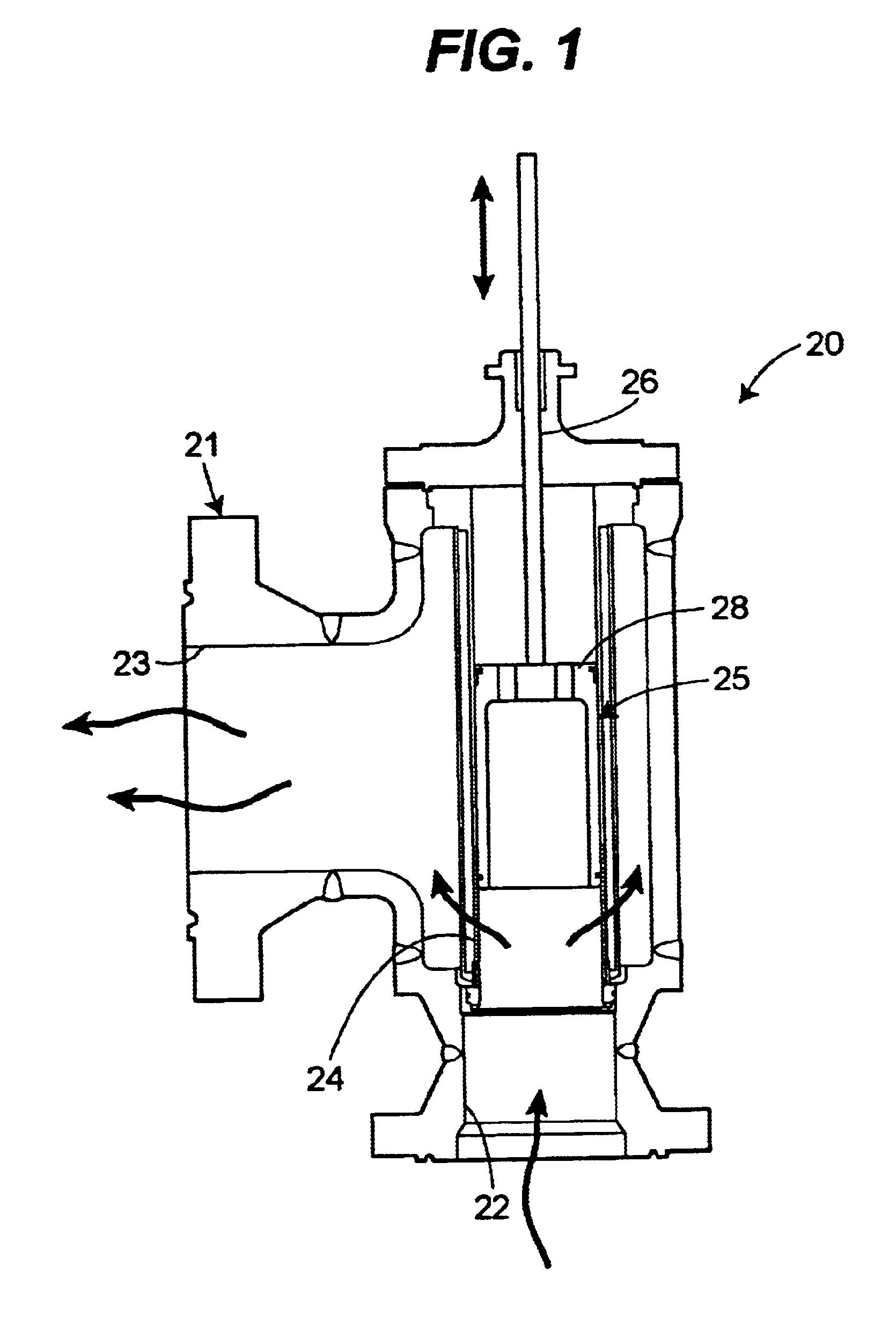

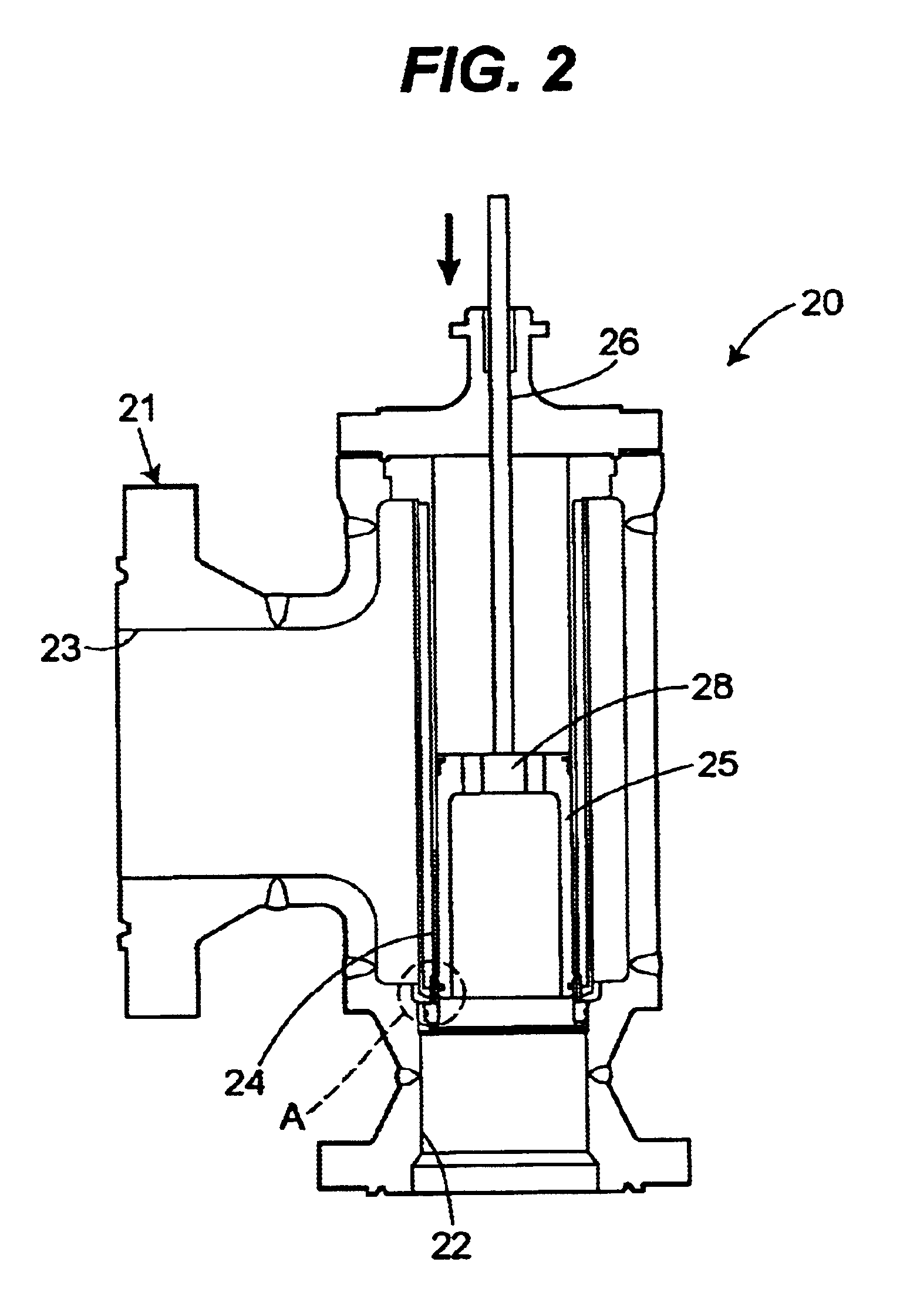

The invention relates to a re-configured valve design to accommodate a high volume of product in the delivery system and the dispensation of product upon the application of a predetermined vacuum condition on the downstream side of the valve.

Owner:PRAXAIR TECH INC

High bandwidth rotary servo valves

InactiveUS20060096644A1Pressure relieving devices on sealing facesValve members for absorbing fluid energyHigh bandwidthEngineering

A valve includes a rotating, substantially pressure-balanced spool that selectively aligns openings within the spool with openings within a sleeve to selectively connect ports of a manifold for gas or liquid routing. A valve may also include a stem, a needle coupled to the stem. a seat configured to receive the needle, a reservoir, an outlet coupled to the reservoir, and a servo motor coupled to the stem. The servo motor rotates the stem to raise or lower the needle relative to the seat to variably restrict or allow matter flowing from the reservoir to the outlet.

Owner:VANDERBILT UNIV

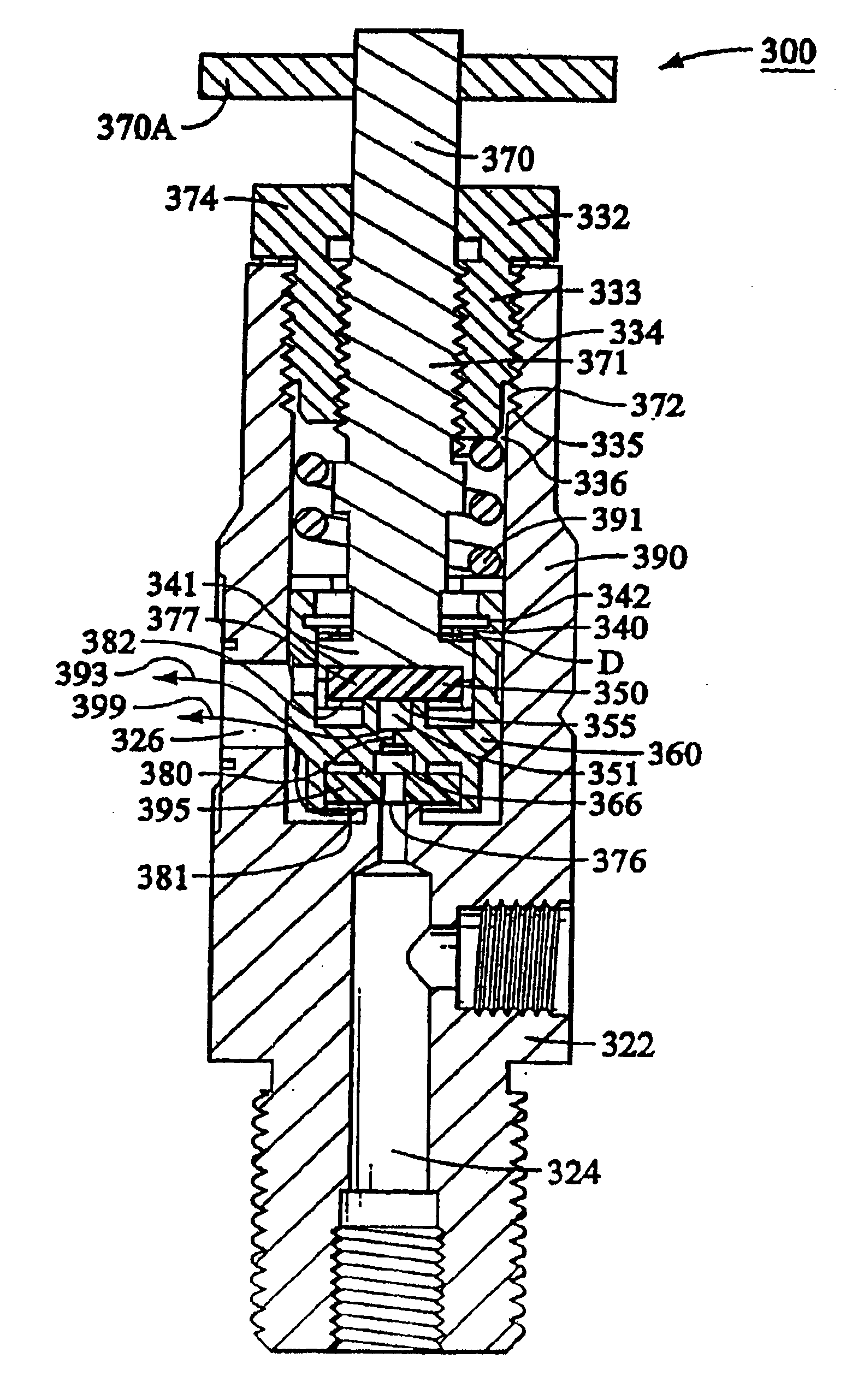

Fail-safe vacuum actuated valve for high pressure delivery systems

A high pressure storage and delivery system having a fail-safe vacuum actuated valve is provided. In particular, through the innovative design of the vacuum actuated check valve, the system can accommodate up to three times the volume of product in similar size cylinders.

Owner:PRAXAIR TECH INC

Combination valve and regulator with vented seat for use with pressurized gas cylinders, particularly oxygen cylinders

Owner:LUXFER INC

Valve with self-cleaning trim

The seal assembly is disclosed for use with a valve having a trim cage with an inner surface extending along in axis and a plug sized to fit inside the trim cage inner surface, wherein the plug is adapted to move along the axis thereof. A seal ring is attached to an upstream portion of the cage to effectuate a seal with the plug. The plug is equipped with a wiper seal that cleans or otherwise removes debris from the seating surface of the seal ring, an interior surface of the seal ring and an interior surface of the cage during both the opening and the closing of the valve. Thus, the valve is self-cleaning. Further, the wiper seal delays throttling action through the valve until the plug has moved a substantial distance away from the seating surface of the seal ring which reduces high pressure abrasive flow against the seating surface of the seal ring to reduce wear on the trim set.

Owner:FISHER CONTROLS INT LLC

Manual gas valve with natural/LP gas conversion capability

ActiveUS7458386B2Reliable supplyEasy to operateVessel mounting detailsPlug valvesTester deviceProcess engineering

Owner:NINGBO WANAN

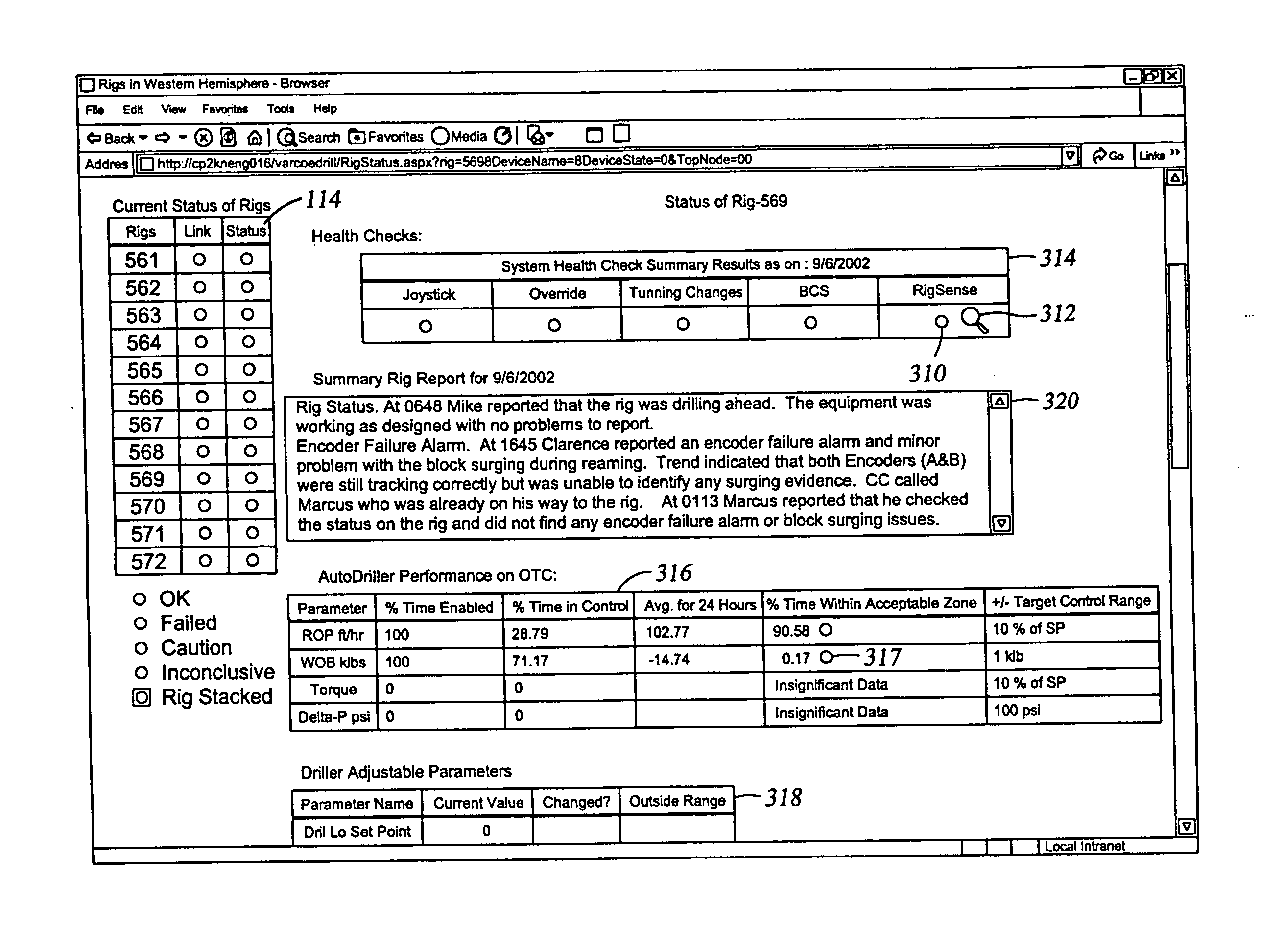

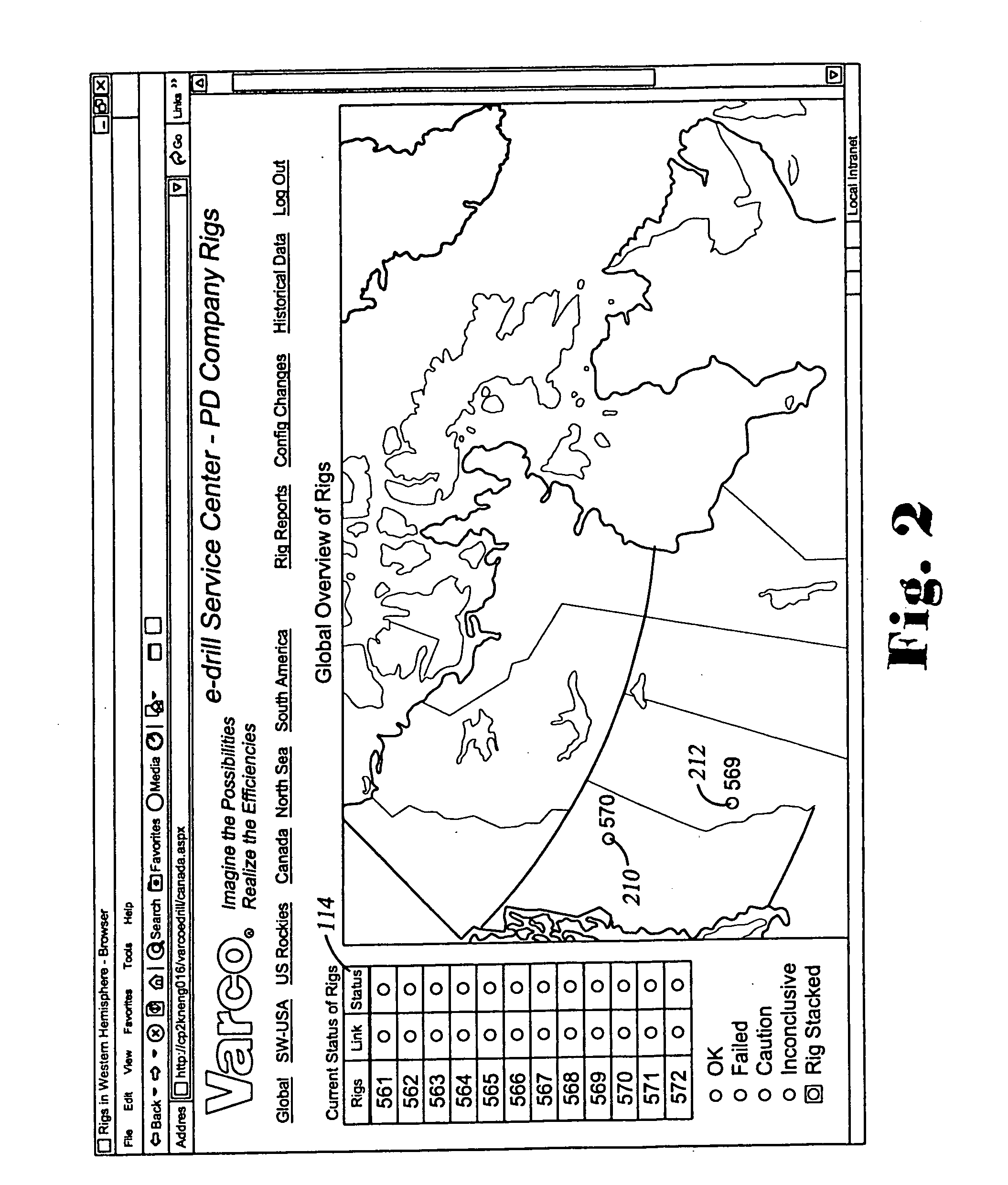

Oil rig choke control systems and methods

InactiveUS20050222772A1Reduce stepsElectric/magnetic detection for well-loggingValve members for absorbing fluid energyIsolation valveControl system

A choke diagnostic system with a positioner for moving a choke mechanism of a choke, a choke isolation valve for placing the choke in standby mode, and a processor controlling the choke and, in certain aspects, the processor for commanding the positioner to move the choke mechanism while the choke is in standby mode.

Owner:VARCO I P INC

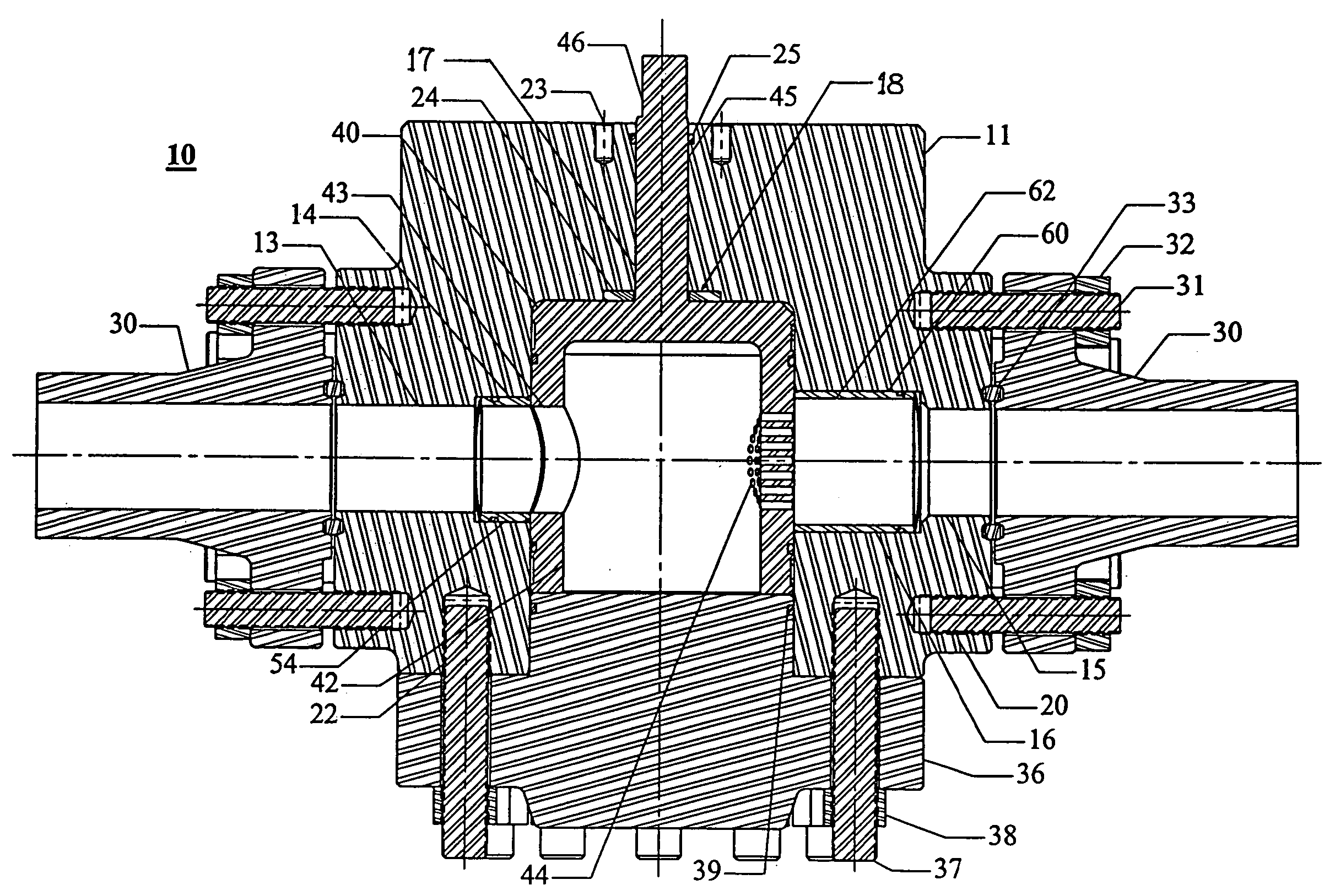

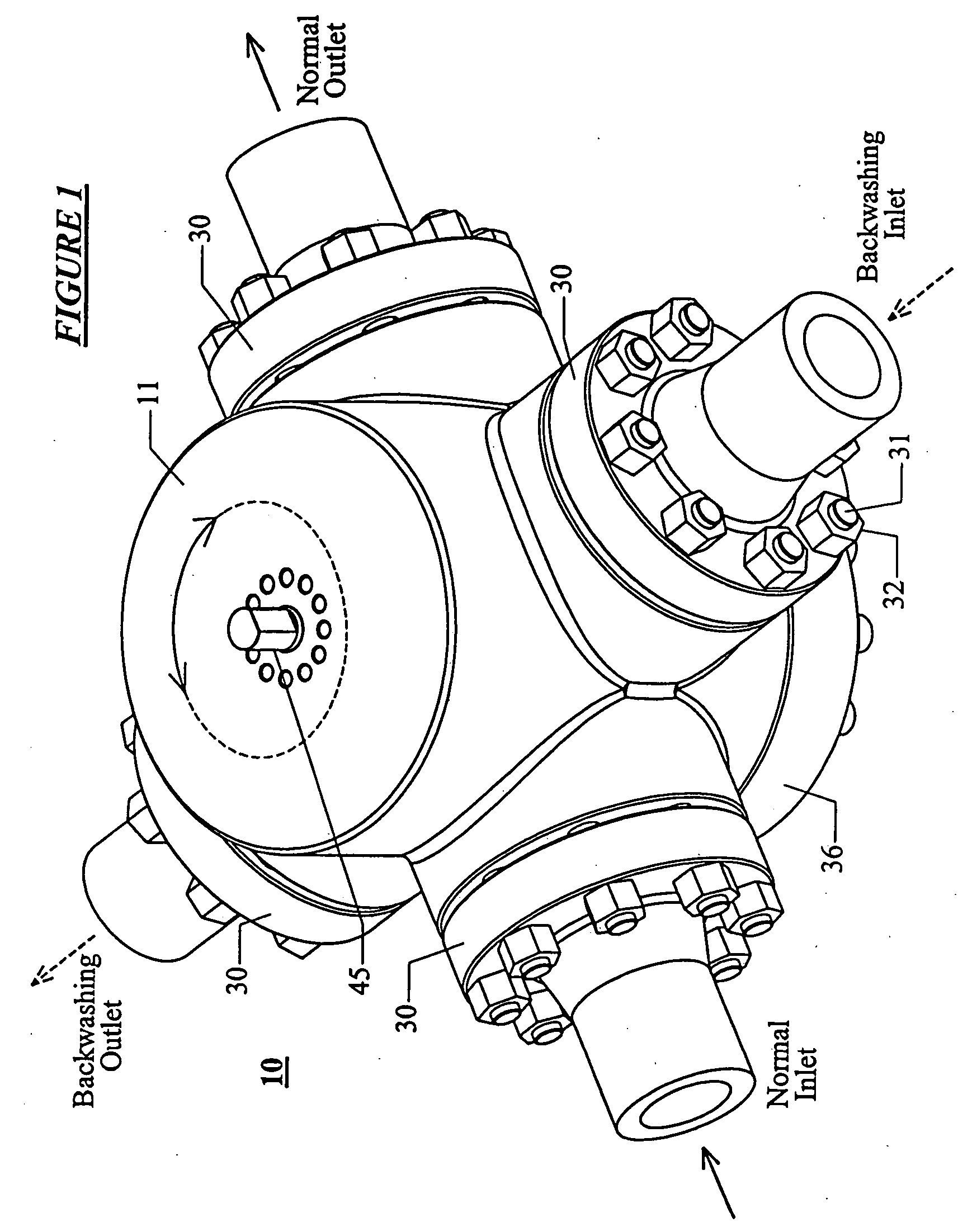

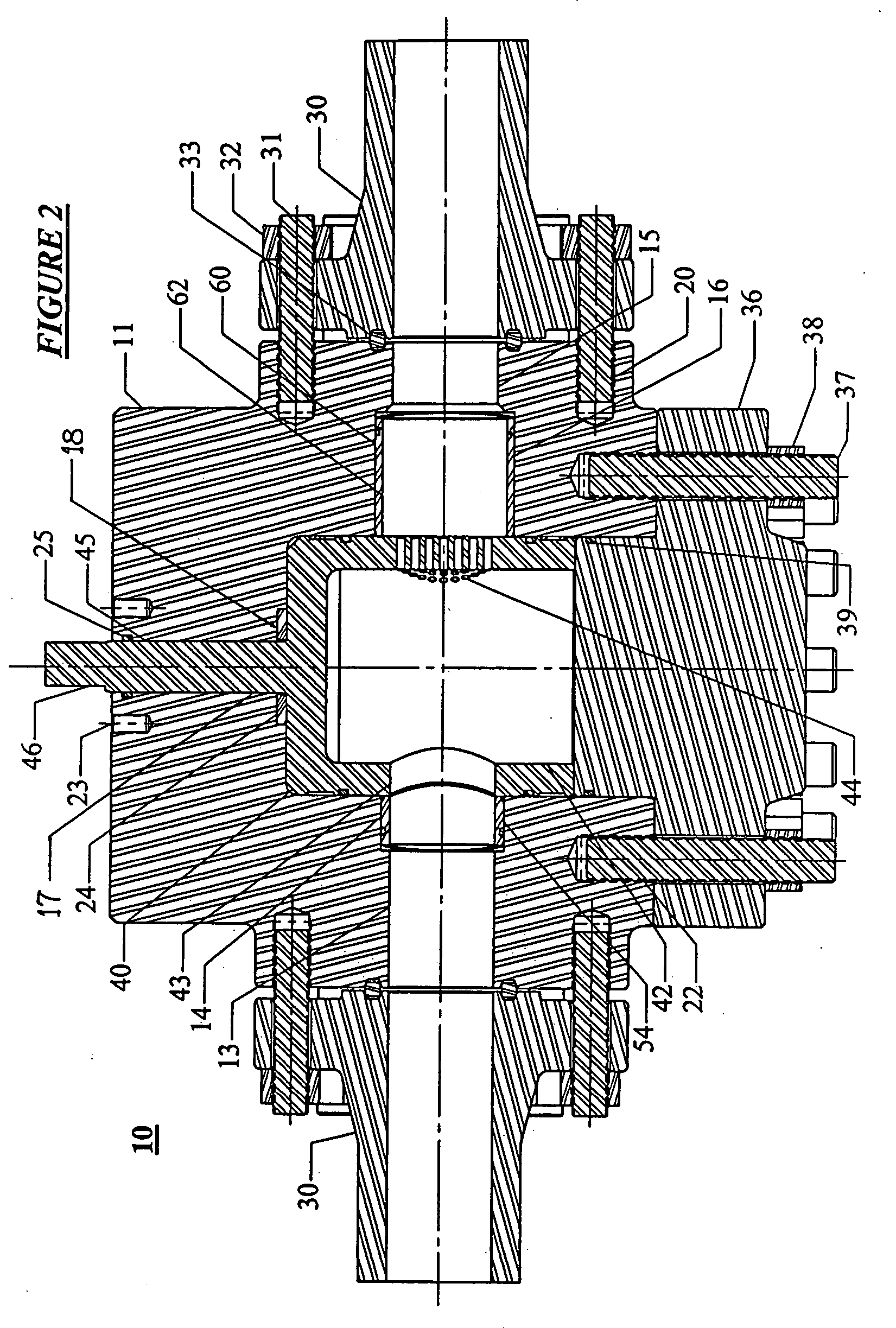

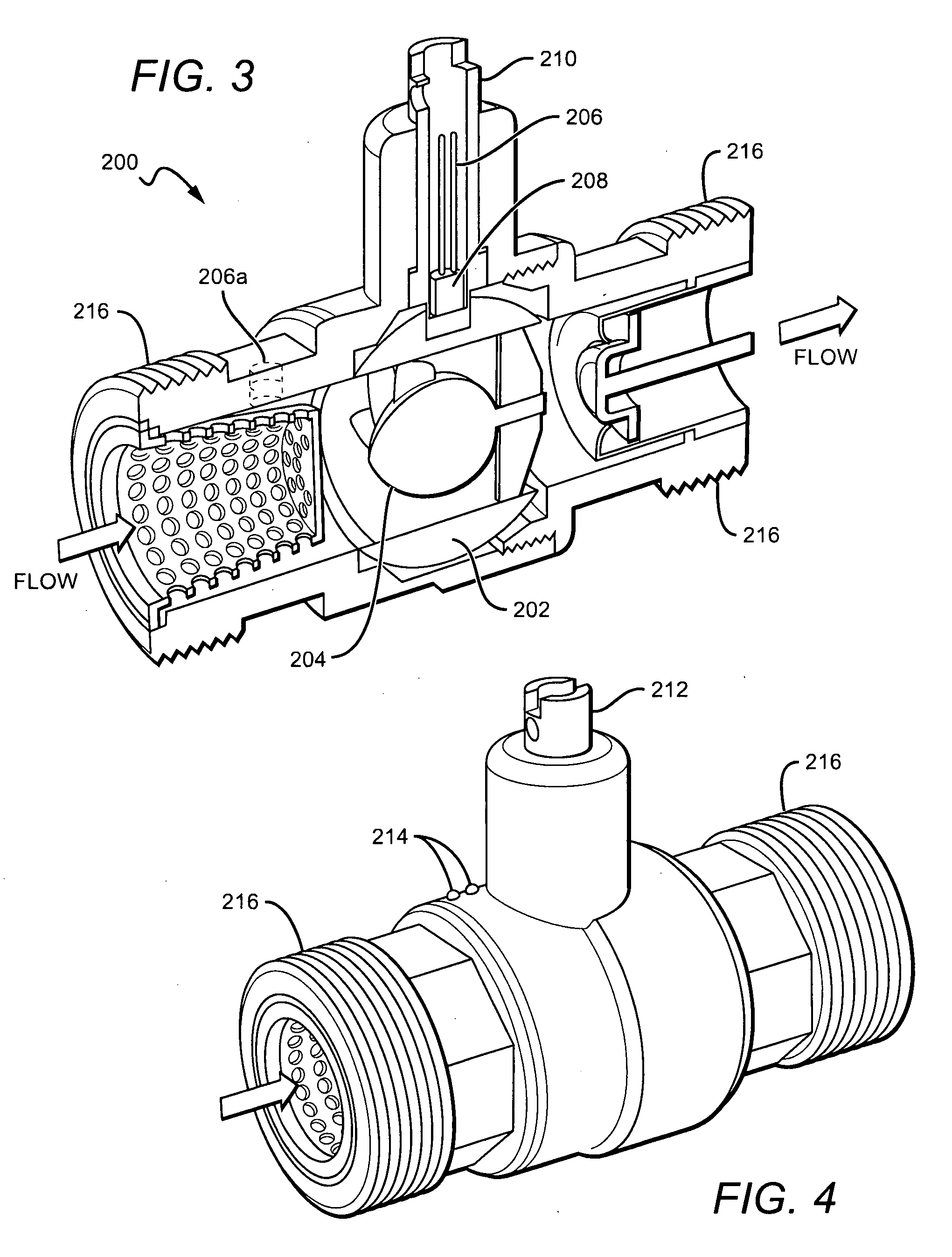

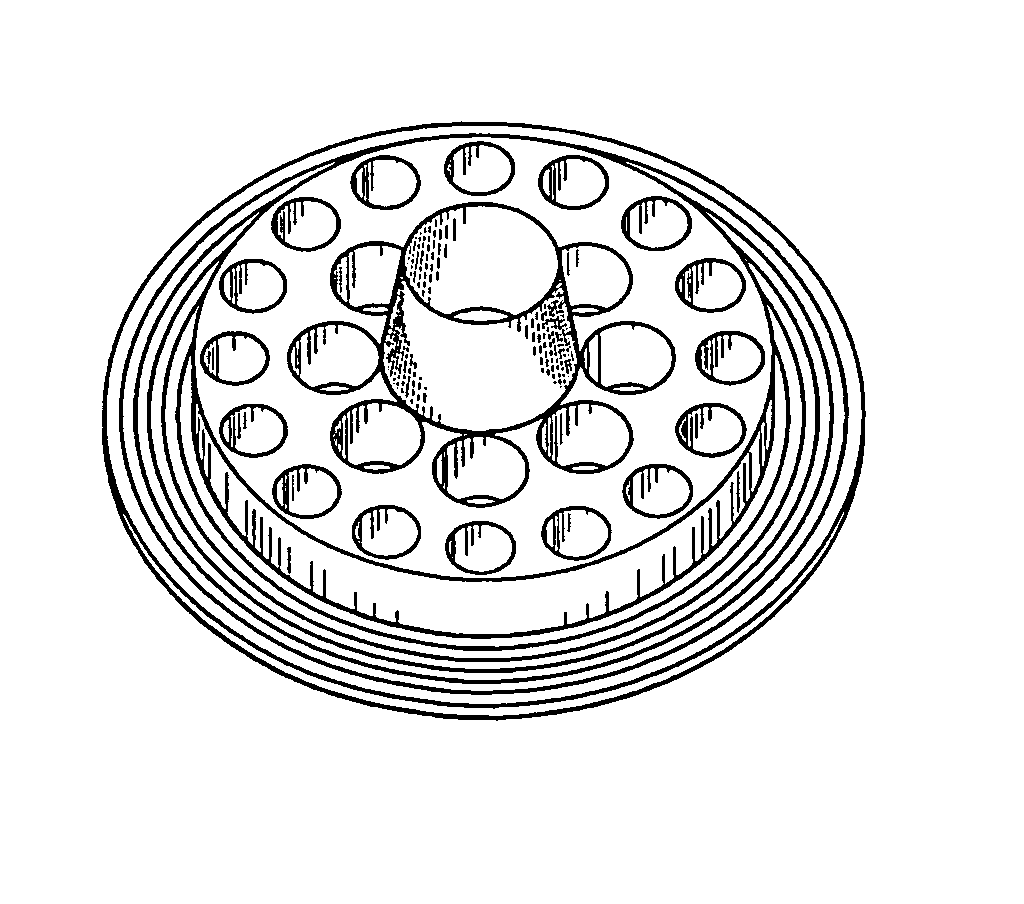

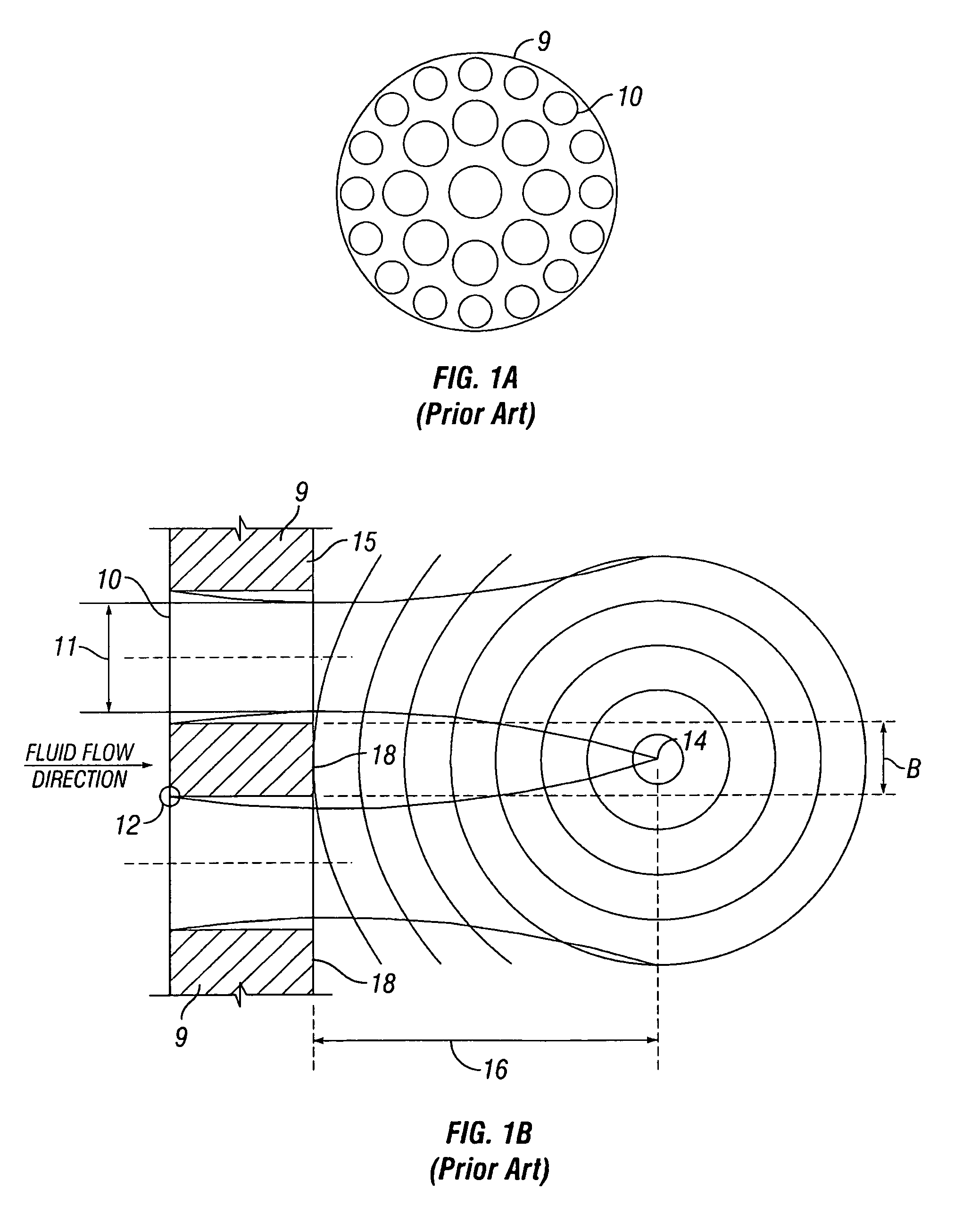

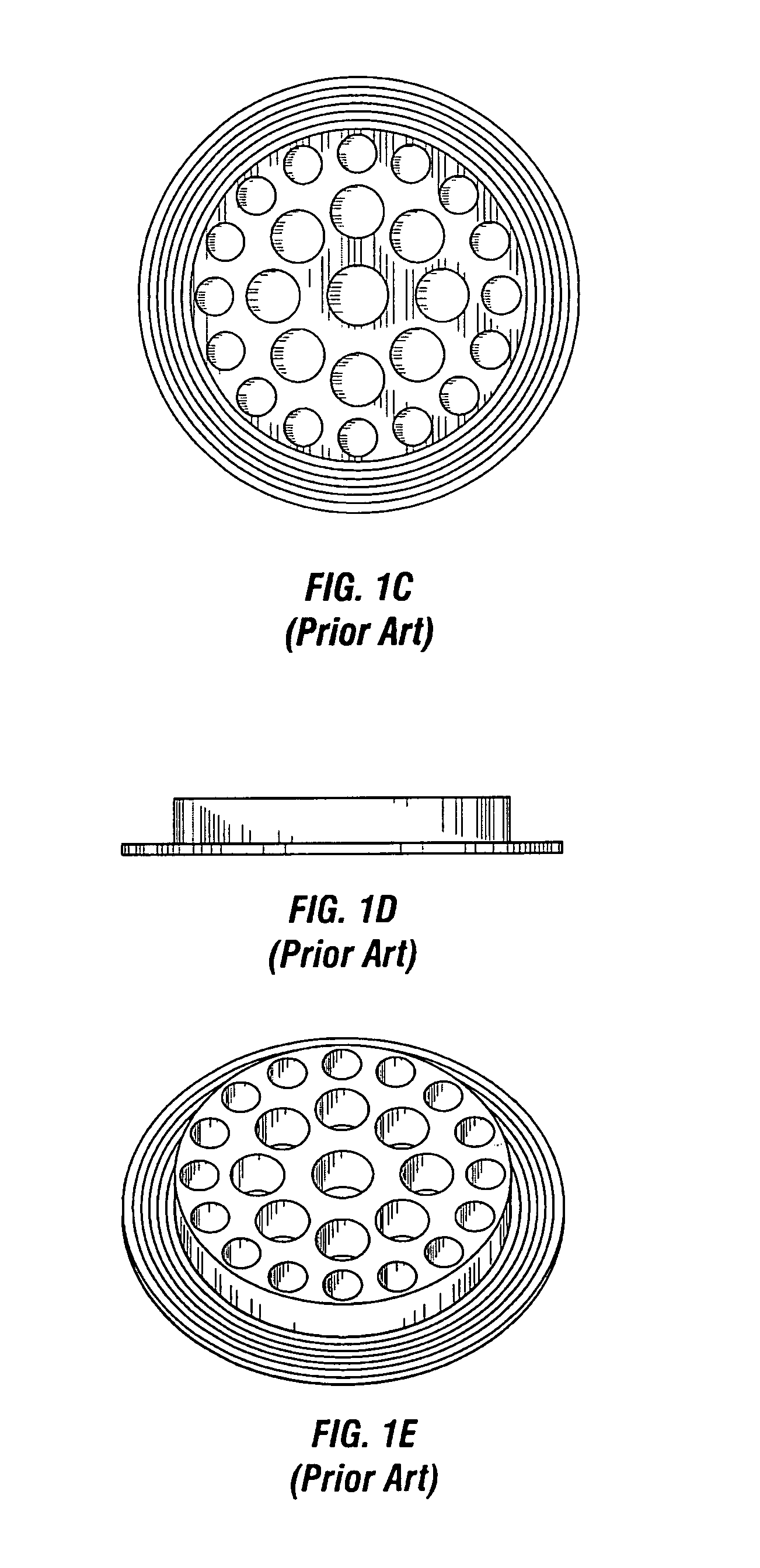

Solids strainer system for a hydraulic choke

InactiveUS20050006150A1Improve liquidityDrilling rodsValve members for absorbing fluid energyTransverse planeEngineering

The invention contemplates a strainer based upon a four-way, two-position rotary cylindrical plug valve having a hollow plug. The normal entry port for the sealing plug of the plug valve is a circular radial hole passing from the exterior of the plug into the interior cavity of the plug. The normal exit port for the sealing plug is a regular array of small holes across from and coaxial with the normal entry hole. The ports for the valve body are in two pairs positioned at 90° from each other, with the axes of the ports lying in the same transverse plane as the ports of the valve plug.

Owner:EXPRO AMERICAS

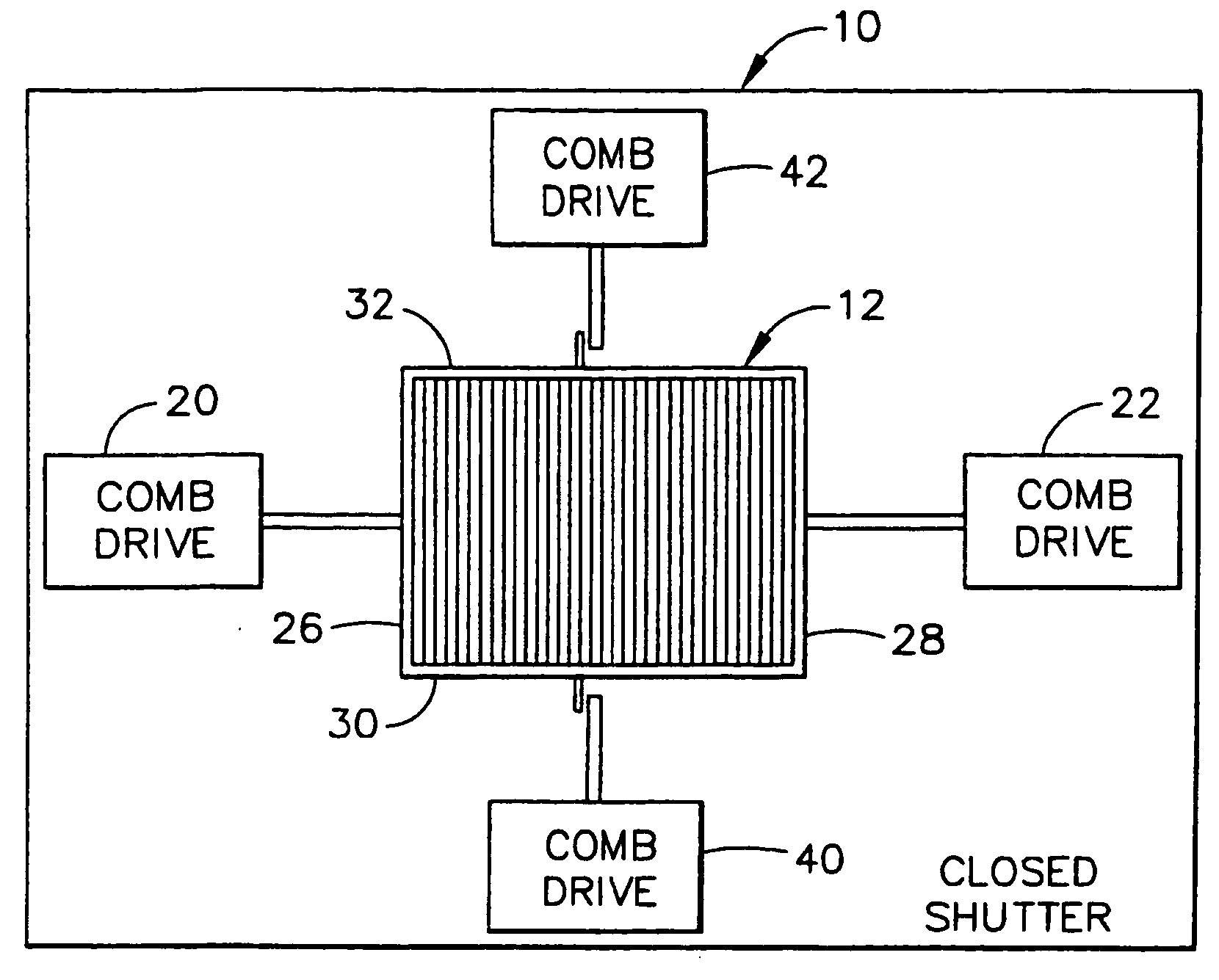

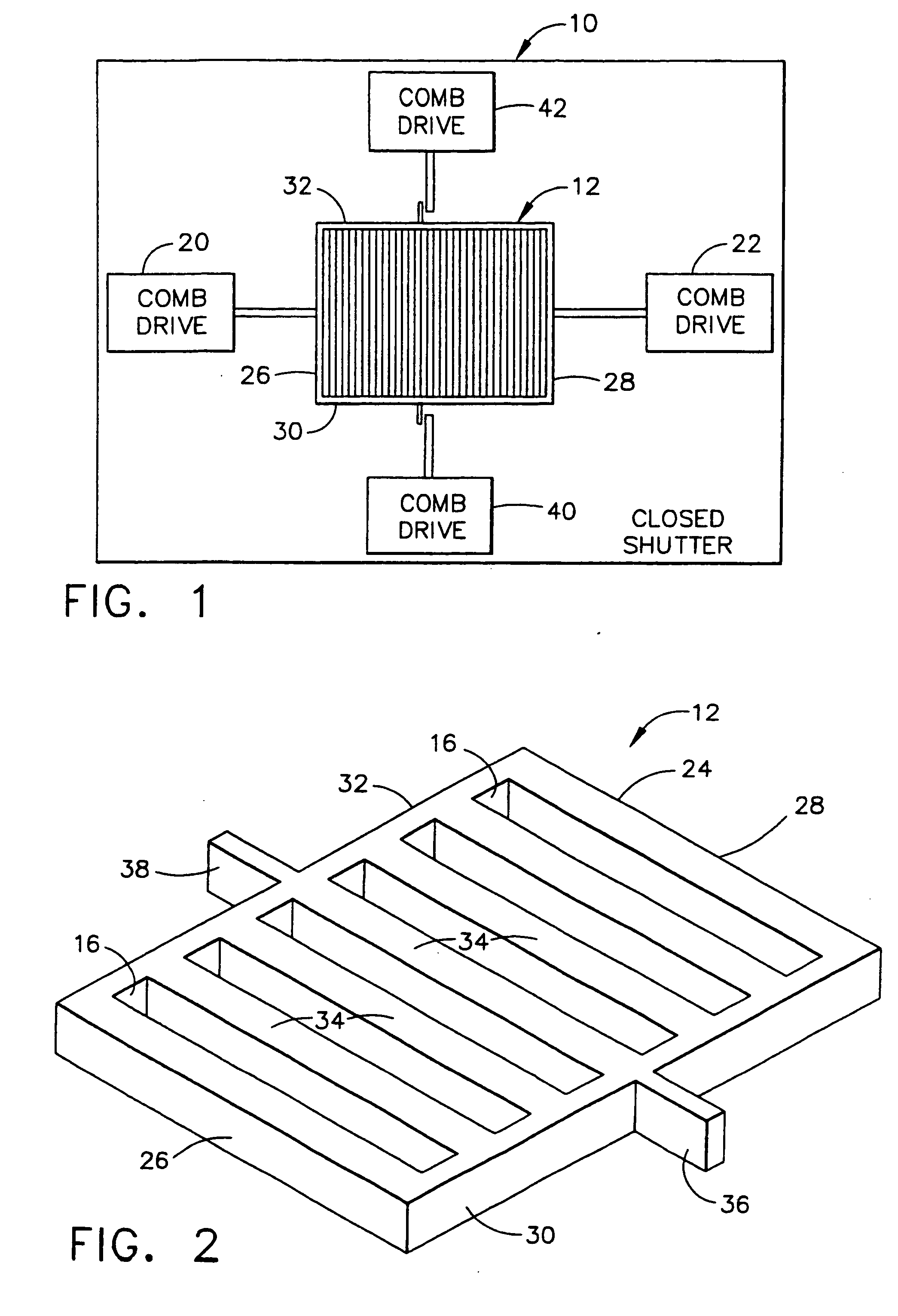

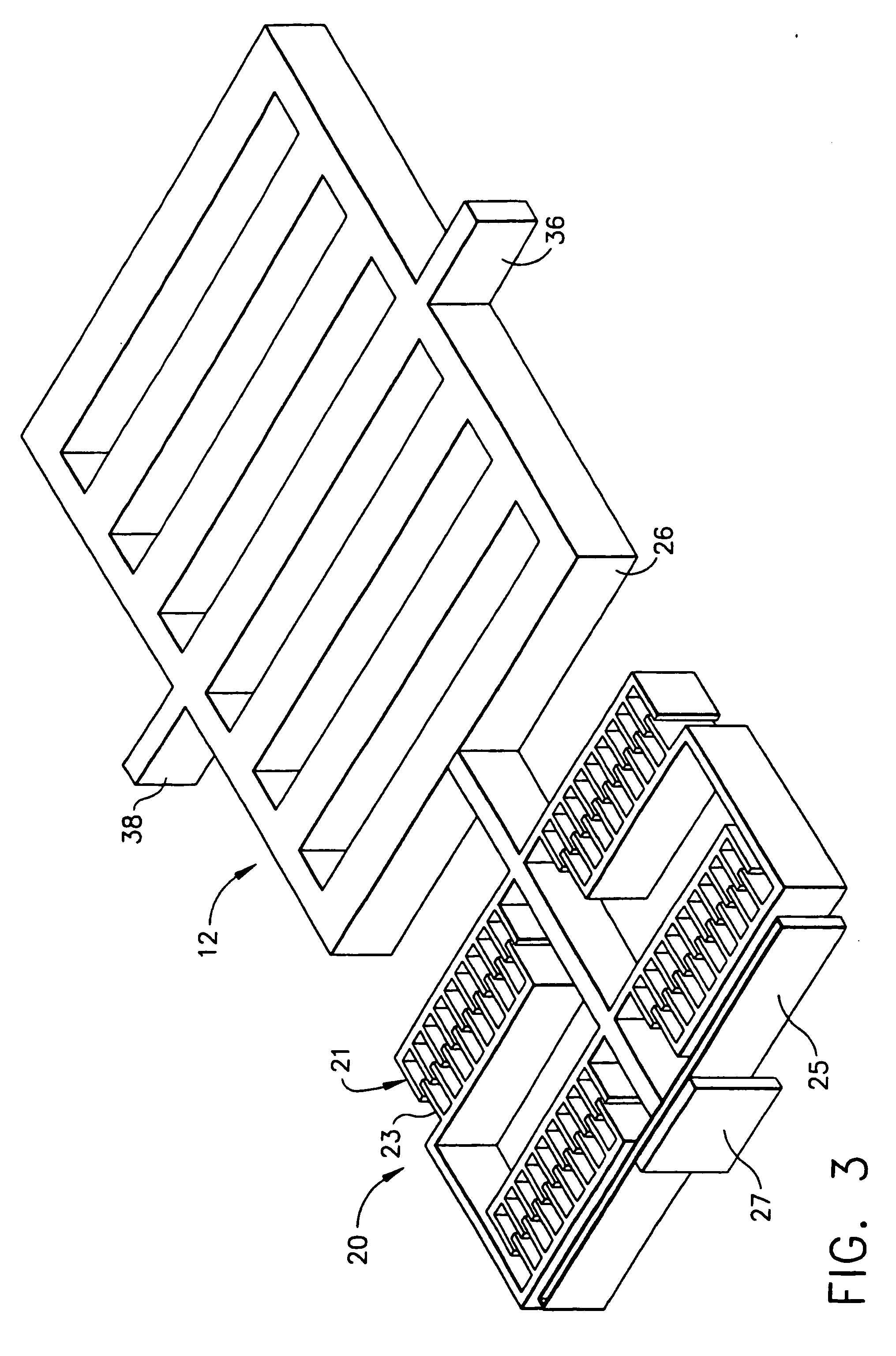

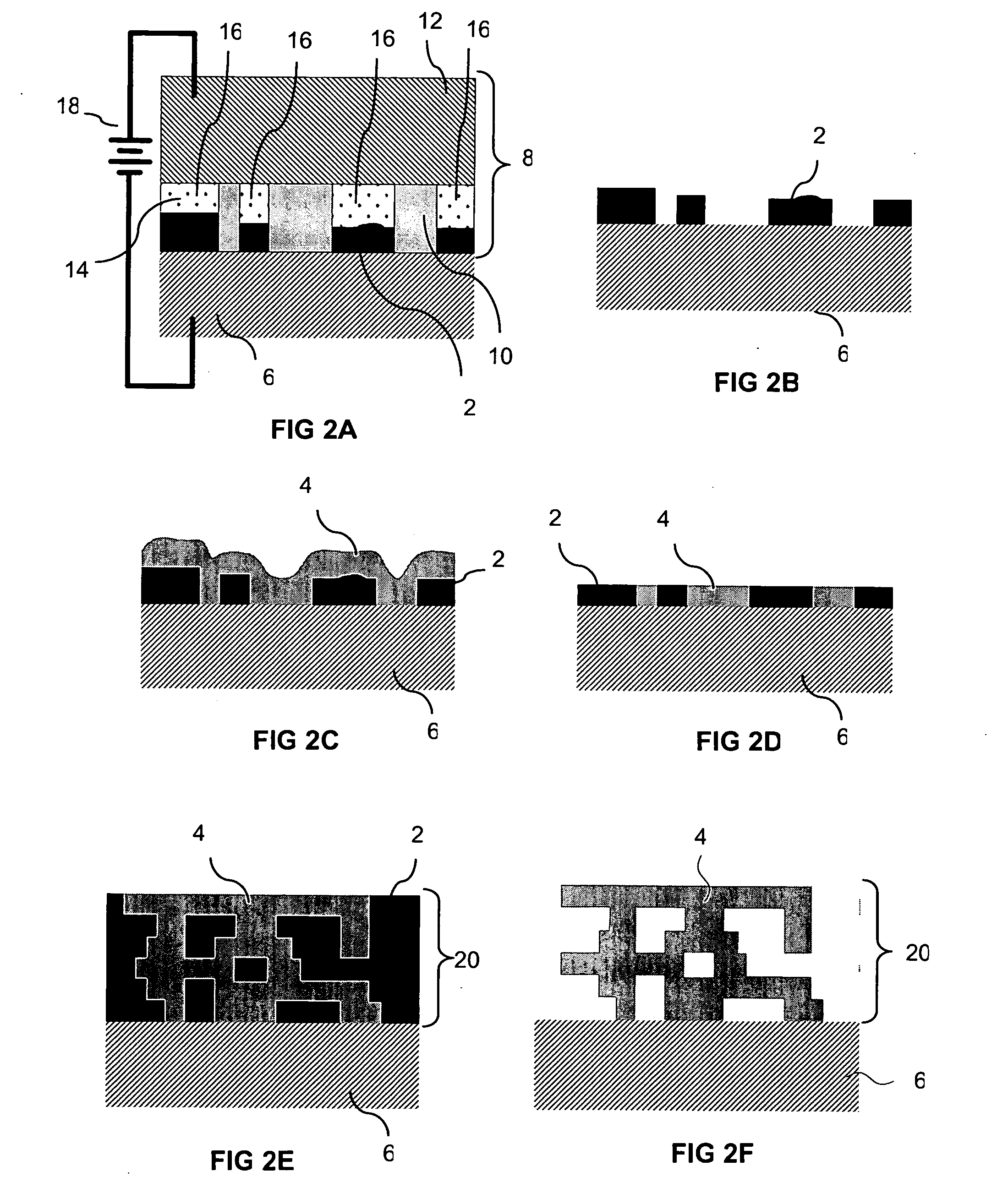

Microvalve for controlling fluid flow

InactiveUS20050016605A1Prevent movementAvoid flowFuel and primary cellsOperating means/releasing devices for valvesEngineeringMechanical engineering

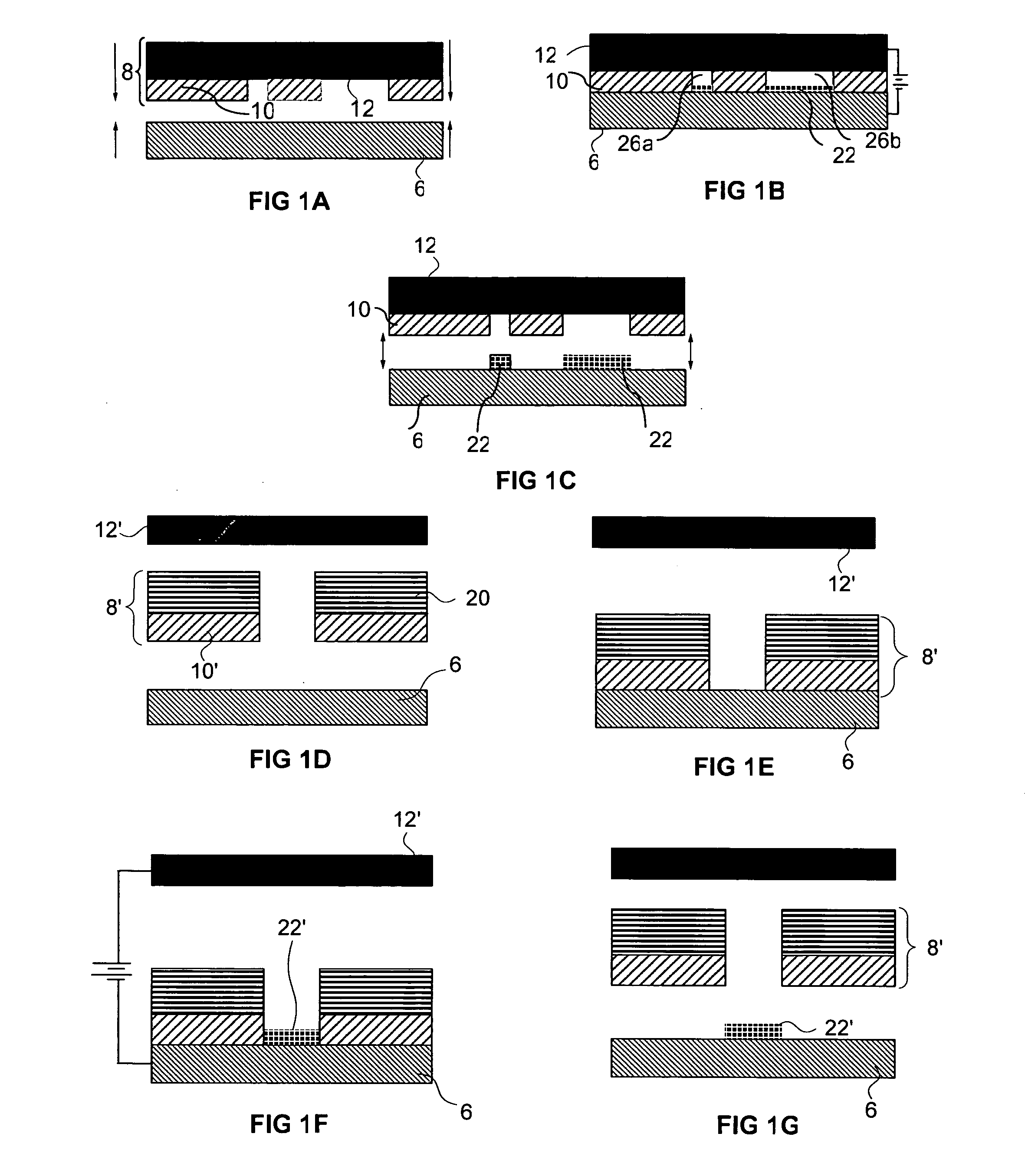

A microvalve for controlling fluid flow, including a body portion having a plurality of spaced openings formed therein, a shutter located adjacent to and substantially parallel with the body portion having a plurality of spaced openings formed therein, a drive mechanism for causing the shutter to move laterally with respect to the body portion so that the spaced openings of the shutter are brought into and out of alignment with the spaced openings of the body portion, wherein the microvalve is in an open position and a closed position, respectively, and, a latching mechanism for preventing the shutter from moving laterally with respect to the body portion.

Owner:DURACELL U S OPERATIONS

Cartridge insert for a fluid line

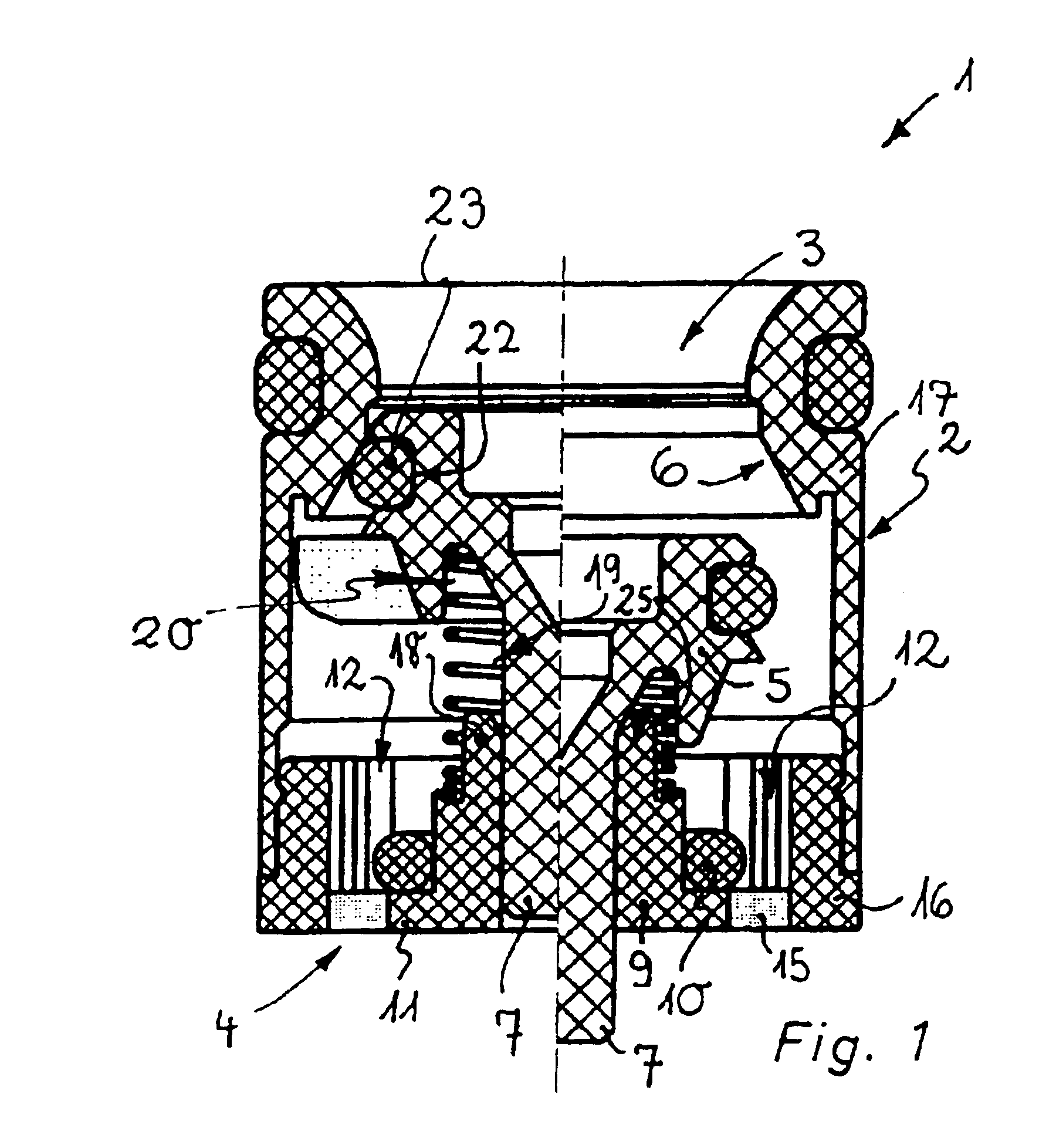

InactiveUS6837267B2Small space requirementEconomically manufacturedServomotor componentsCheck valvesValve seatCentral governor

A cartridge insert for insertion in a fluid line is provided having a cartridge housing within which is located at least one backflow inhibitor and downstream at least one flow regulator. The backflow inhibitor has a closing element, which, in a closed position thereof, lies tightly sealed on a valve seat of the cartridge housing and which may be displaced from the closed position against a return force into an open position. A downstream guide pin projects from the closing element, and extends into a guide opening of a central regulator core of the flow regulator, and the flow regulator is formed from a regulator element made from an elastic material that surrounds the regulator core, which rests on an annular shoulder and defines a control gap, which changes with pressure between the above and an opposing enclosing wall. The cartridge insert is compact and space saving in that the flow regulator terminates generally flush with the downstream side of the cartridge and the annular shoulder projects from the regulator core and the control gap is provided between the regulating element and an inside of the cartridge housing which forms the enclosing wall.

Owner:NEOPERL

Three-dimensional structures having feature sizes smaller than a minimum feature size and methods for fabricating

ActiveUS20050126916A1Small feature sizeImprove efficiencyAdditive manufacturing apparatusDuplicating/marking methodsFeature DimensionComputer science

Owner:MICROFAB

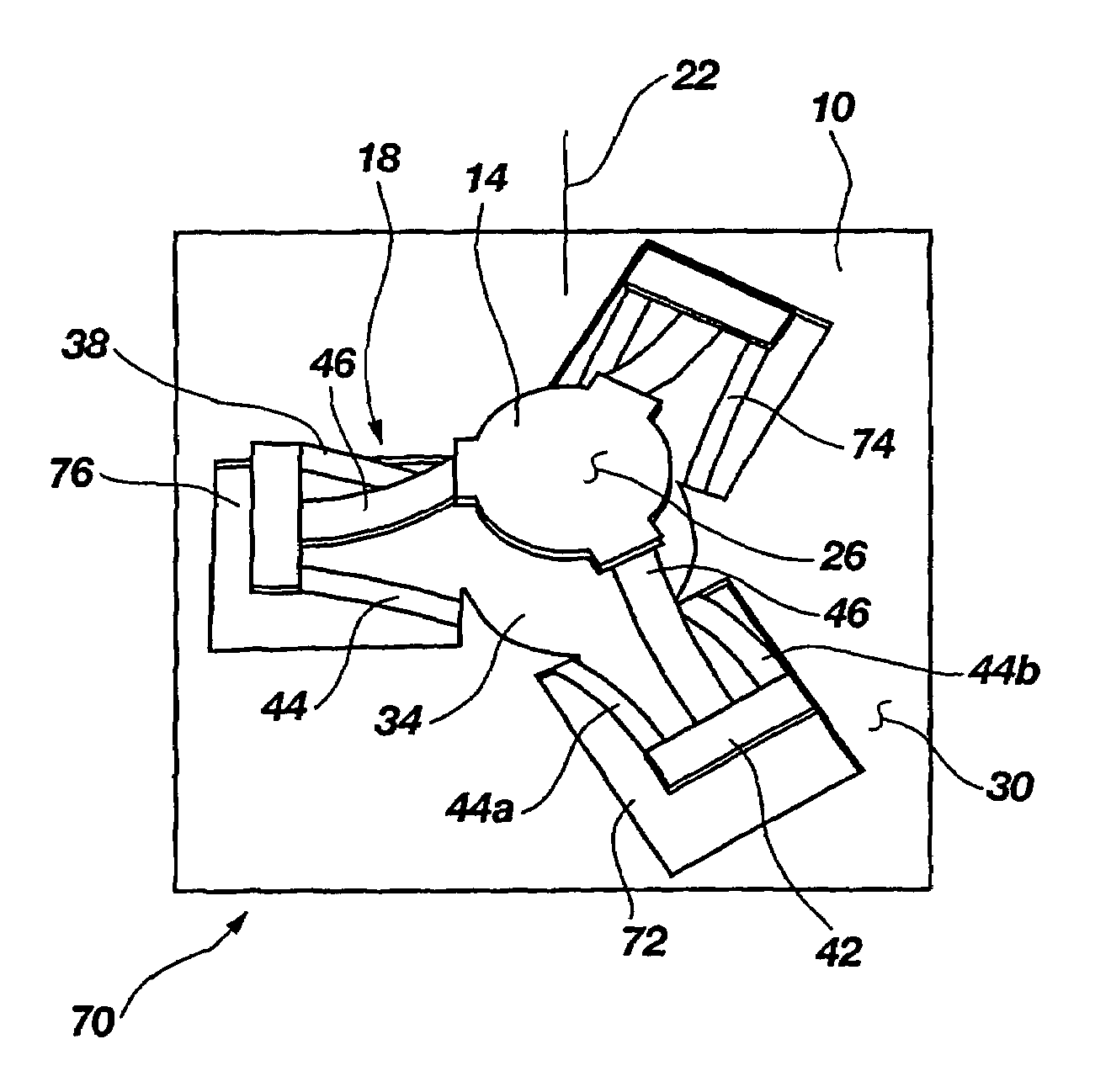

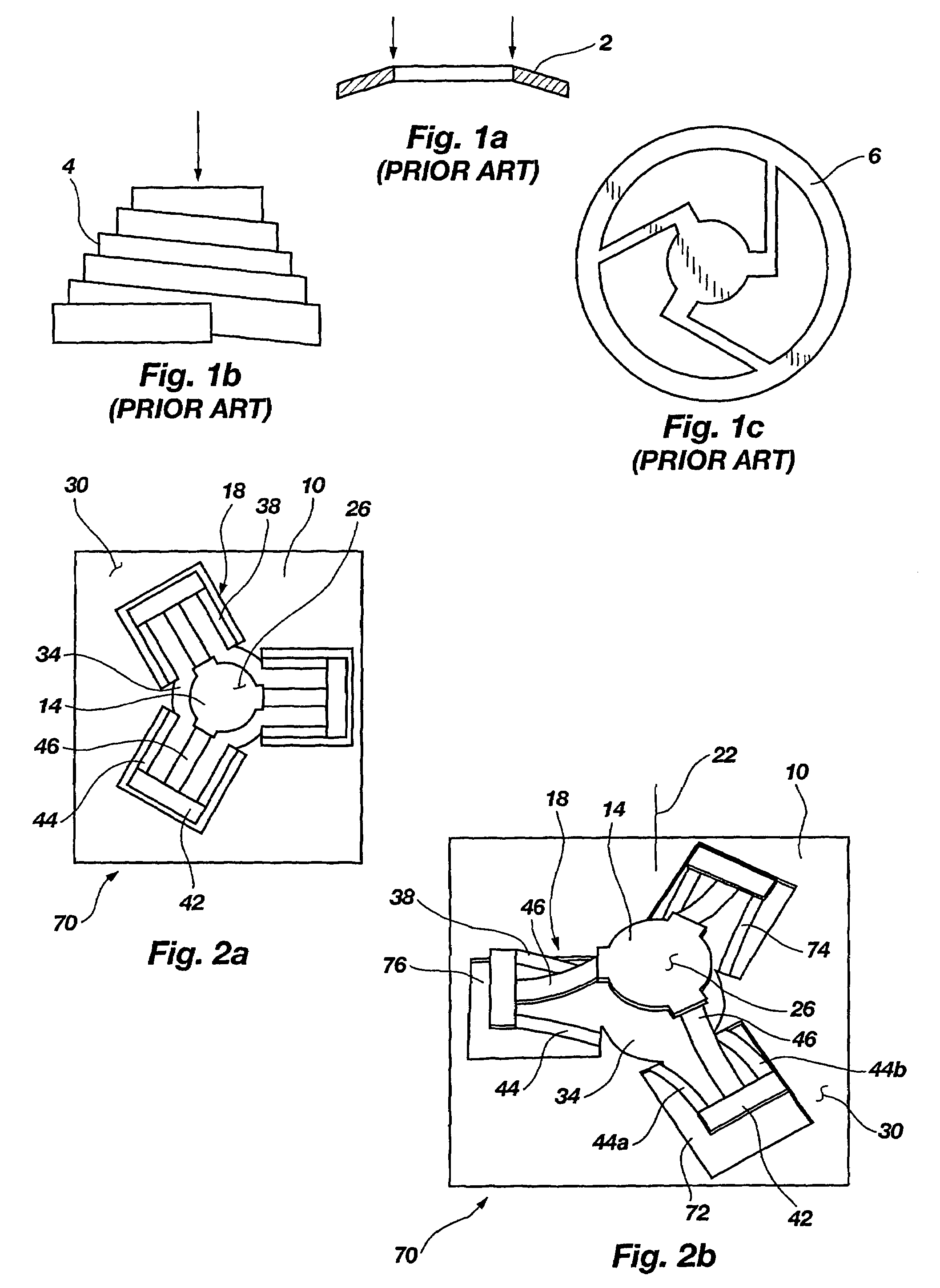

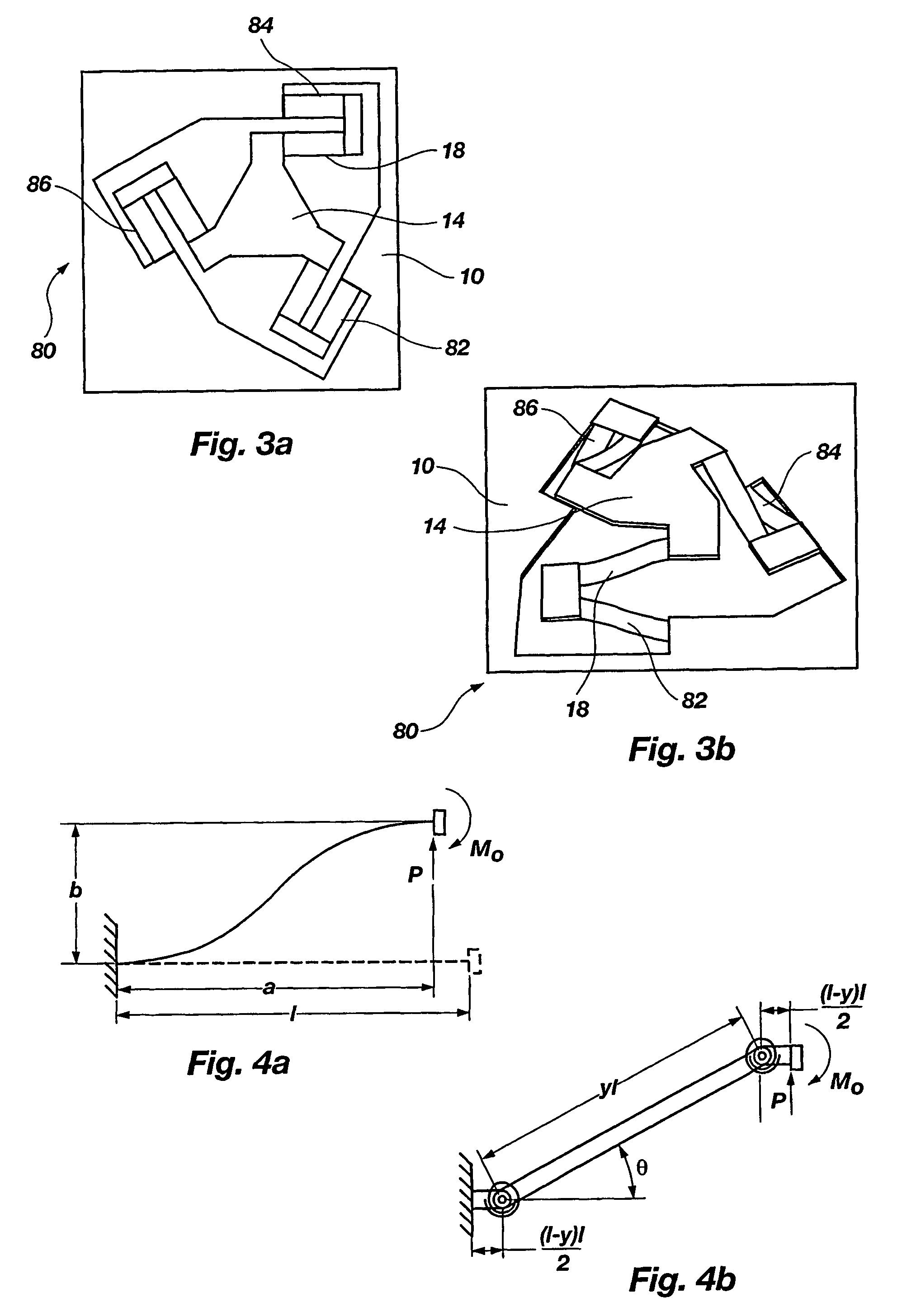

Compliant, ortho-planar, linear motion spring

An ortho-planar spring has a platform movably coupled to a base and being movable linearly with respect to the base along at least a portion of an axial direction perpendicular to both a base surface and a platform surface. A resilient and flexible connecting structure is connected to and between the base and platform. The connecting structure is bendable to develop (i) an axial force along the axial direction to bias the platform in a stable position with respect to the base, and (ii) non-axial forces which substantially sum to zero to preserve the orientation of the platform with respect to the base. Thus, the spring is very compact and does not have rotation between the deflecting ends. The spring may be associated with a valve opening, and a button for restricting flow through the valve opening, to bias the button at a position with respect to the valve opening.

Owner:BRIGHAM YOUNG UNIV

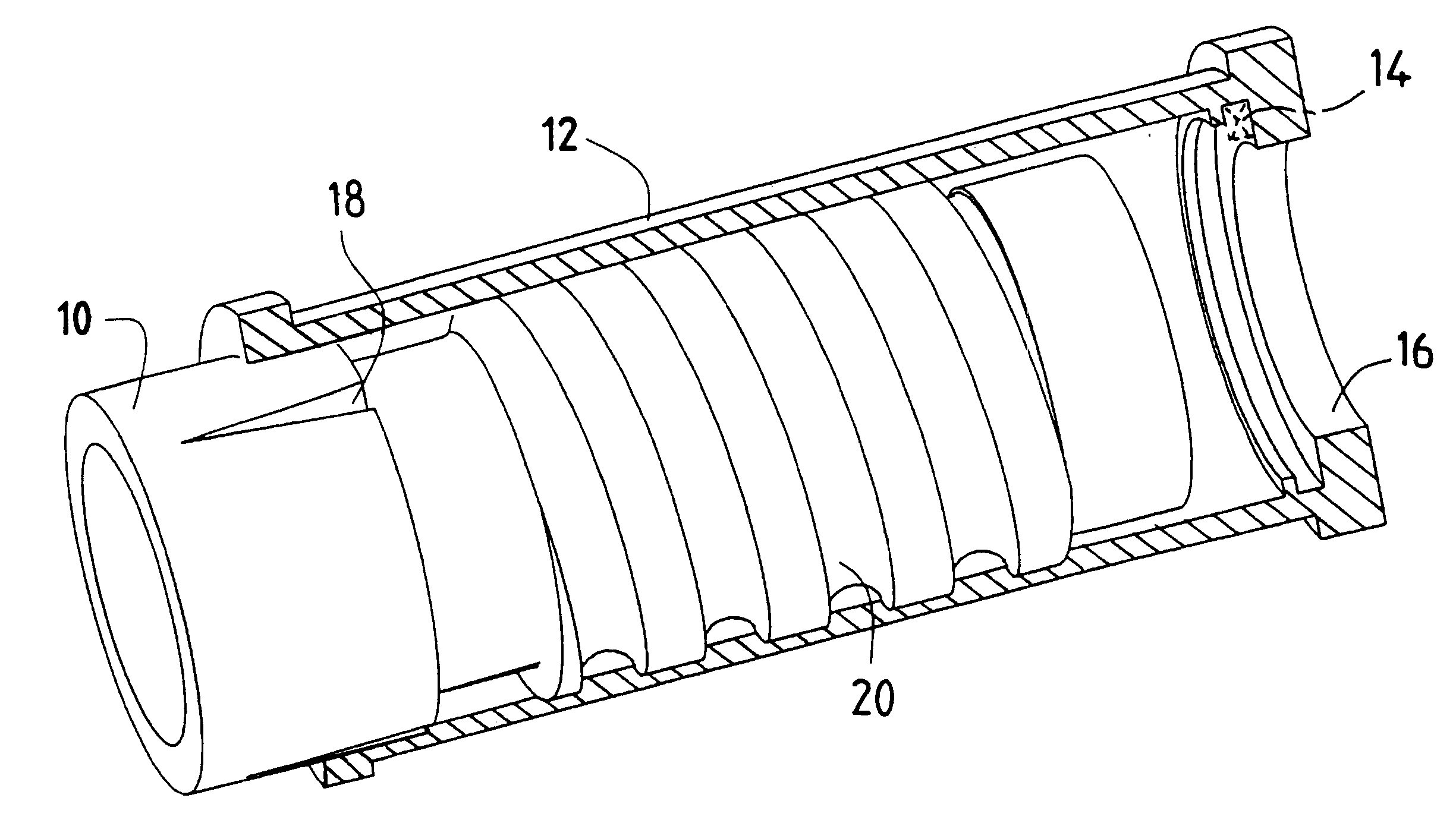

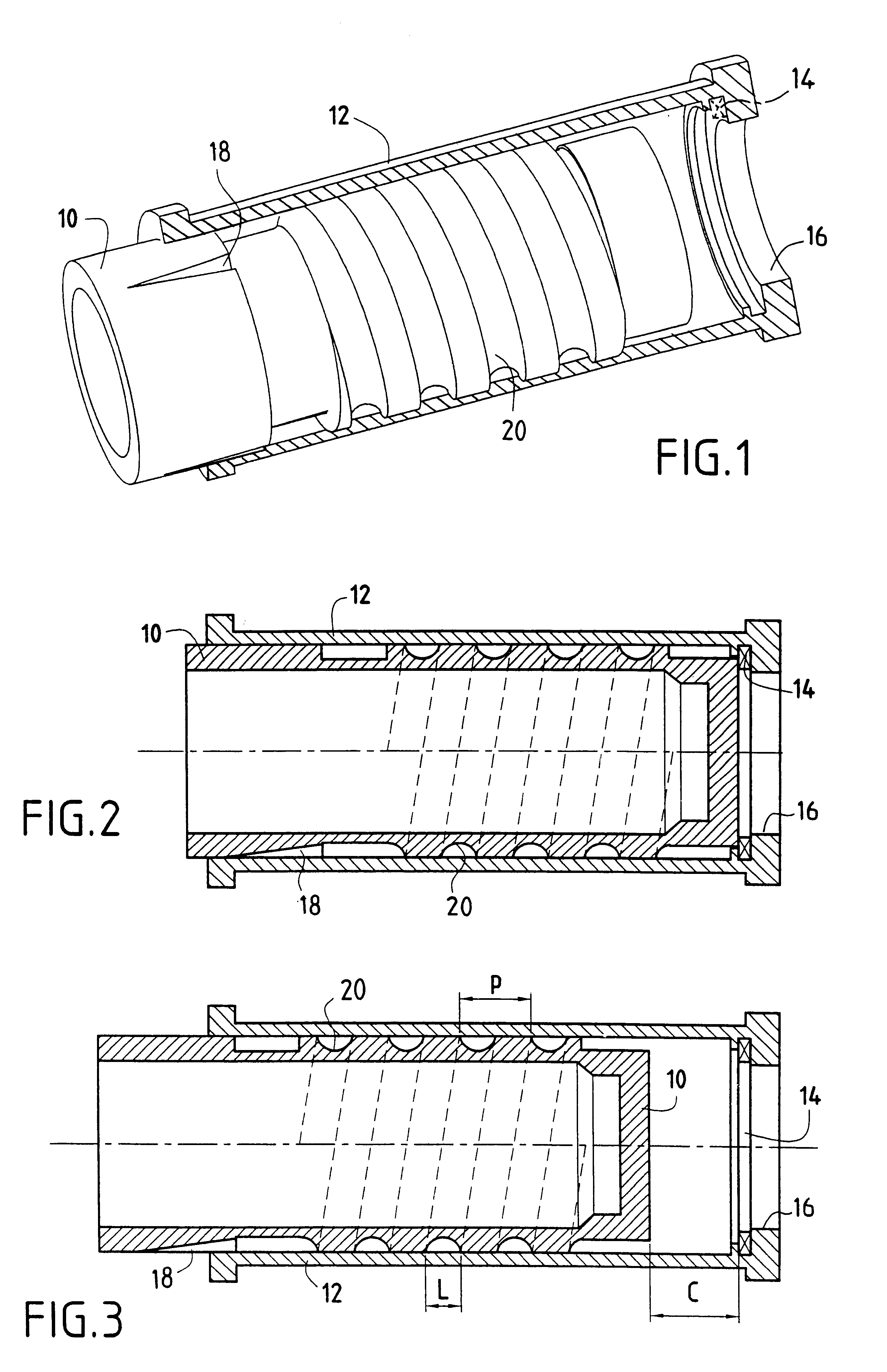

Method of homogenization

InactiveUS6705755B1Efficient and improved homogenizationSimple designFlow mixersMilk treatmentEmulsionEngineering

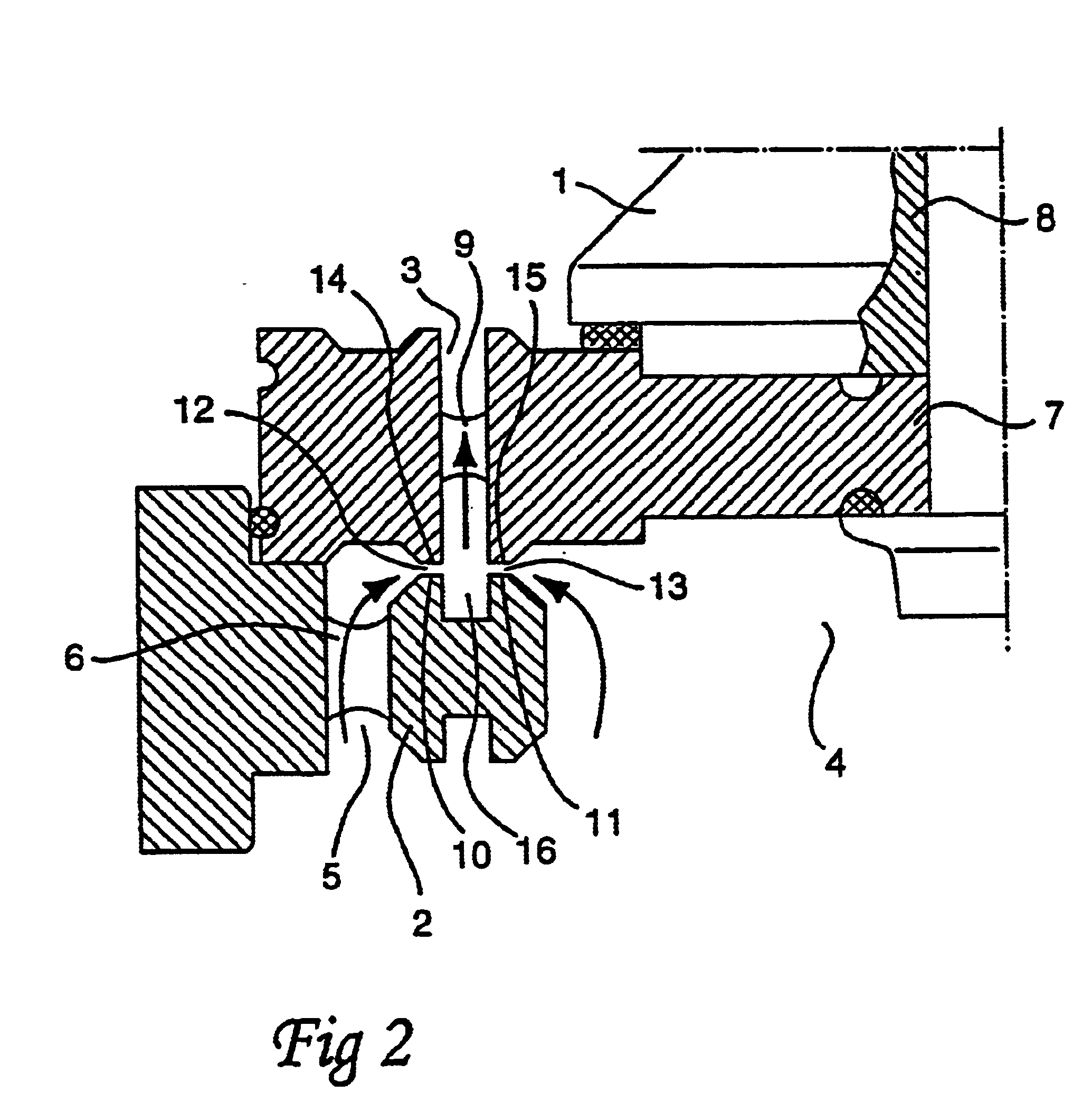

The invention relates to a method of homogenization of a pressured liqueform emulsion, such as milk. The liquid is caused to pass at least two concentrically placed homogenization gaps (12, 13) which are form in the space between two narrow surface (10, 11)on a fixed valve seat (2) and two narrow surfaces (14, 15) on a movable valve cone (1). When the liquid passes out the homogenization gaps (12, 13) a first homogenization takes place. The homogenization is rendered more efficient in that the liquid, when it passes out from one of the homogenization gaps (12) at high speed and in a restricted space meets the liquid out from one or more of the other homogenization gaps (13).

Owner:TETRA LAVAL HLDG & FINANCE SA

Anti-pumping dispense valve

Anti-pumping dispense valves, constructed according to principles of this invention, comprise a fluid transport housing having a fluid inlet passage extending into the housing, a fluid outlet passage extending out of the housing, and a fluid transport chamber disposed within the housing. The fluid transport chamber includes an valve seat. An actuator housing is attached to the fluid transport housing and includes an actuator chamber that is in contact with the fluid transport chambers. A diaphragm / poppet assembly is disposed within the fluid transport chamber and comprises a poppet positioned downstream of the seat for placement against the seat to stop fluid flow through the first fluid transport chamber. An actuator is disposed within the actuator chamber for moving the diaphragm / poppet assembly. Dispense valves of this invention operate to provide a slight vacuum within the fluid flow passageway in the valve to retain or pull back into the valve any nondispensed liquid, thereby eliminating and / or greatly reducing the possibility product contamination via unwanted excess liquid dispensement or dried residual liquid dispensement.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

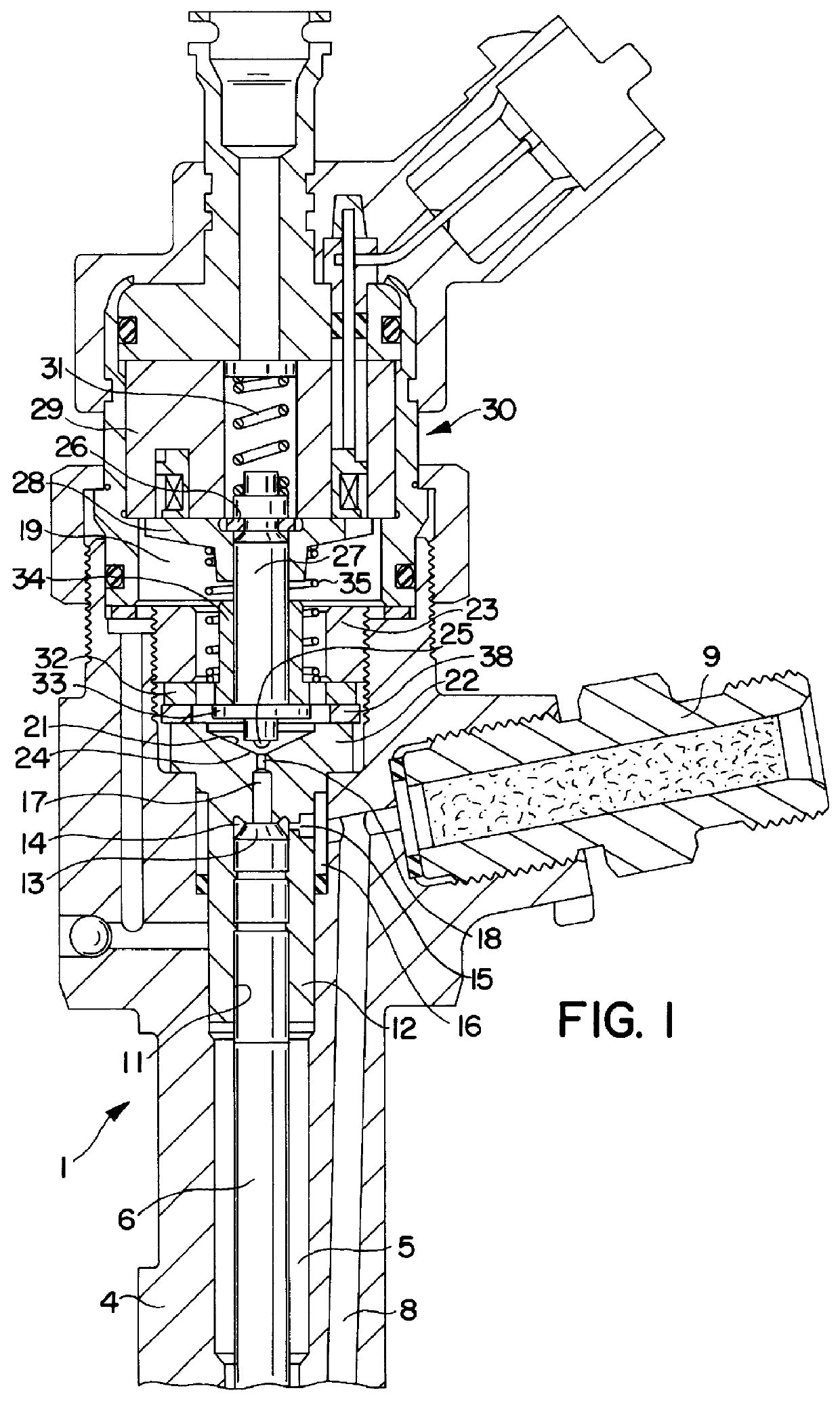

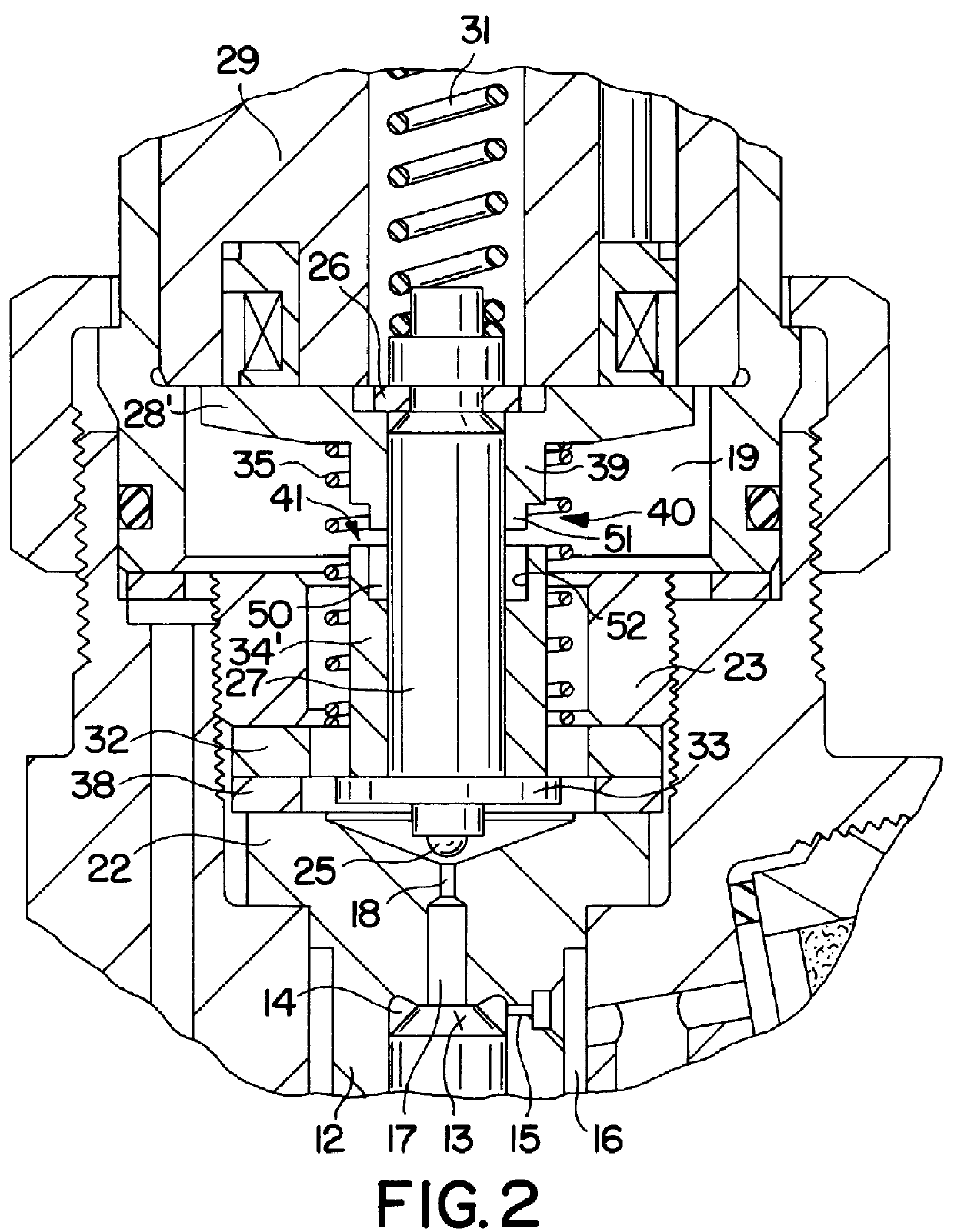

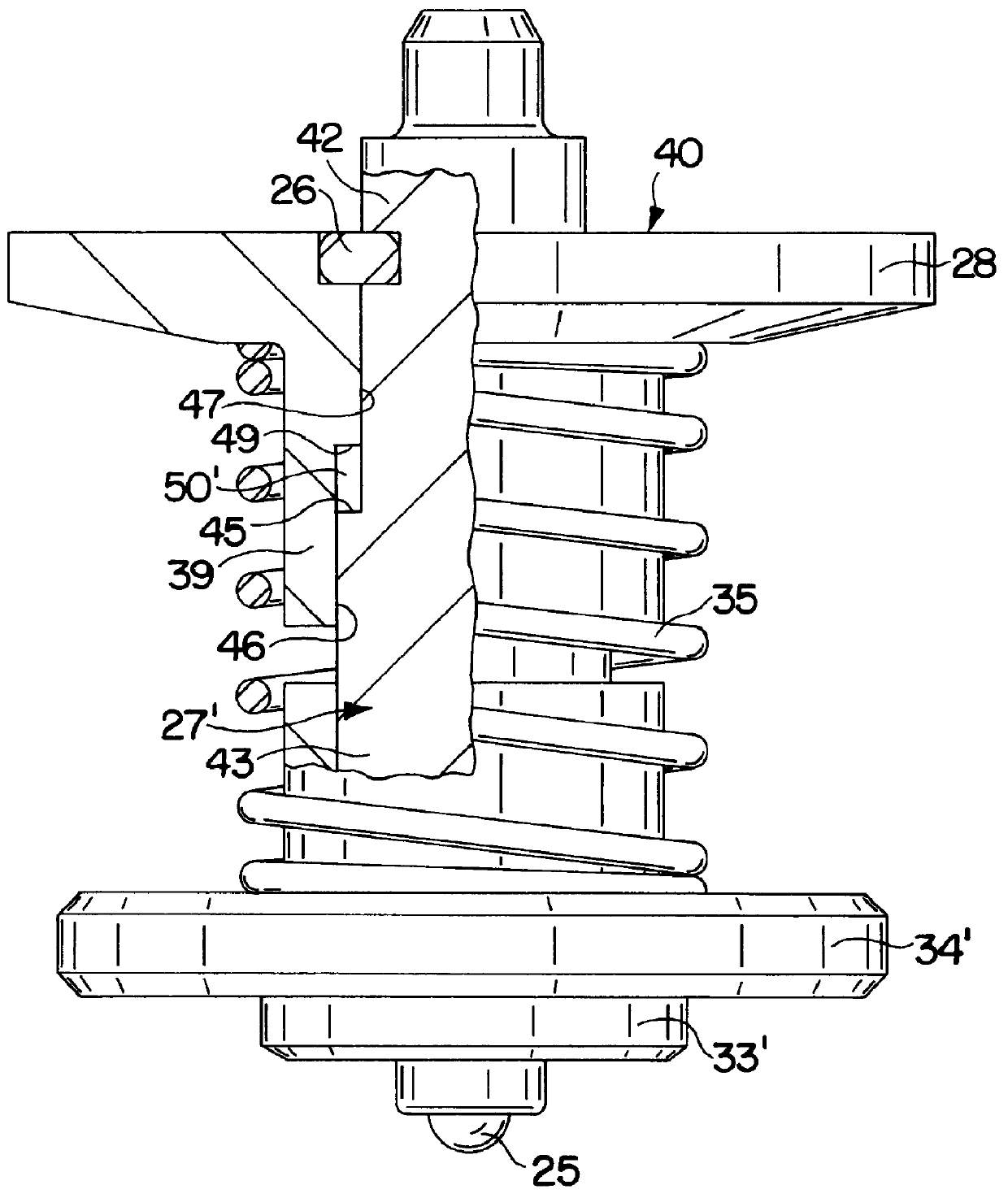

Solenoid valve for controlling an electrically controlled fuel ignition valve

InactiveUS6062531AAchieve dampingOperating means/releasing devices for valvesValve members for absorbing fluid energyMagnetEngineering

PCT No. PCT / DE97 / 01887 Sec. 371 Date Aug. 7, 1998 Sec. 102(e) Date Aug. 7, 1998 PCT Filed Aug. 29, 1997 PCT Pub. No. WO98 / 25025 PCT Pub. Date Jun. 11, 1998A solenoid valve including a magnet armature having an armature disk and an armature bolt that is guided in a sliding part. In order to prevent a postoscillation of the armature disk after a closing of the solenoid valve, a damping device is provided on the magnet armature. With a device of this kind, a required short switching time of the solenoid valve can be precisely maintained. The solenoid valve (30) is designated for use in fuel injection systems with a common rail.

Owner:ROBERT BOSCH GMBH

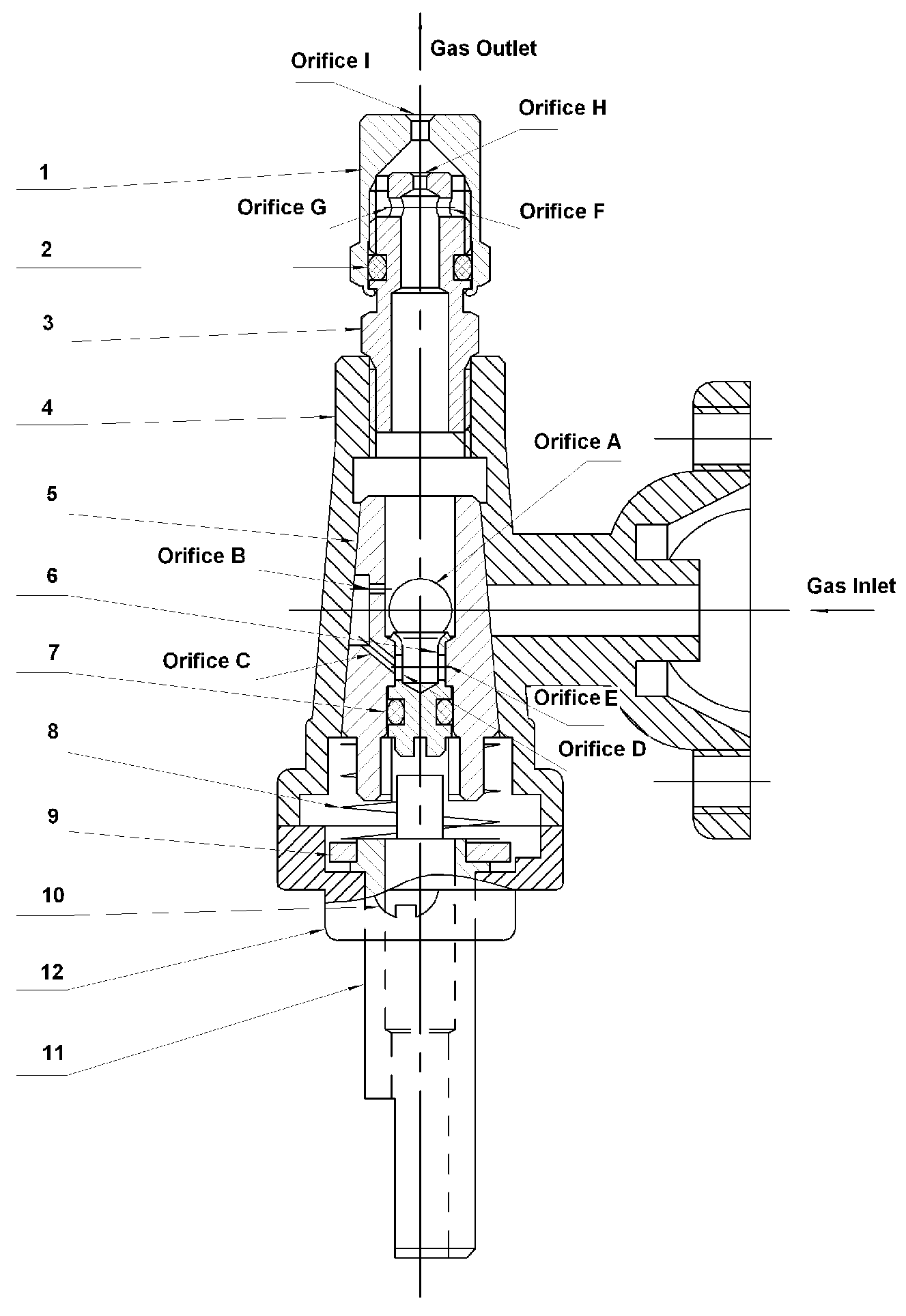

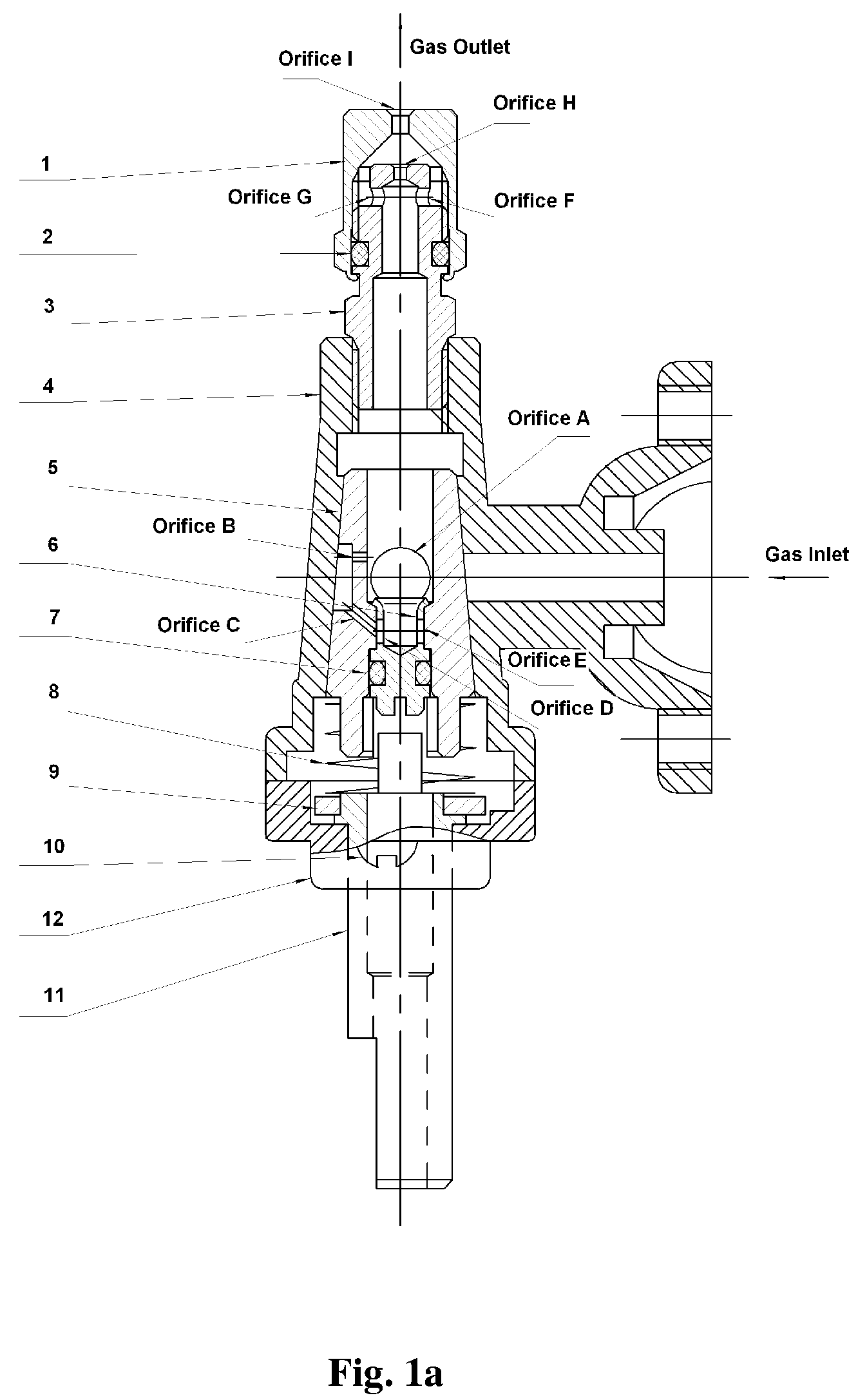

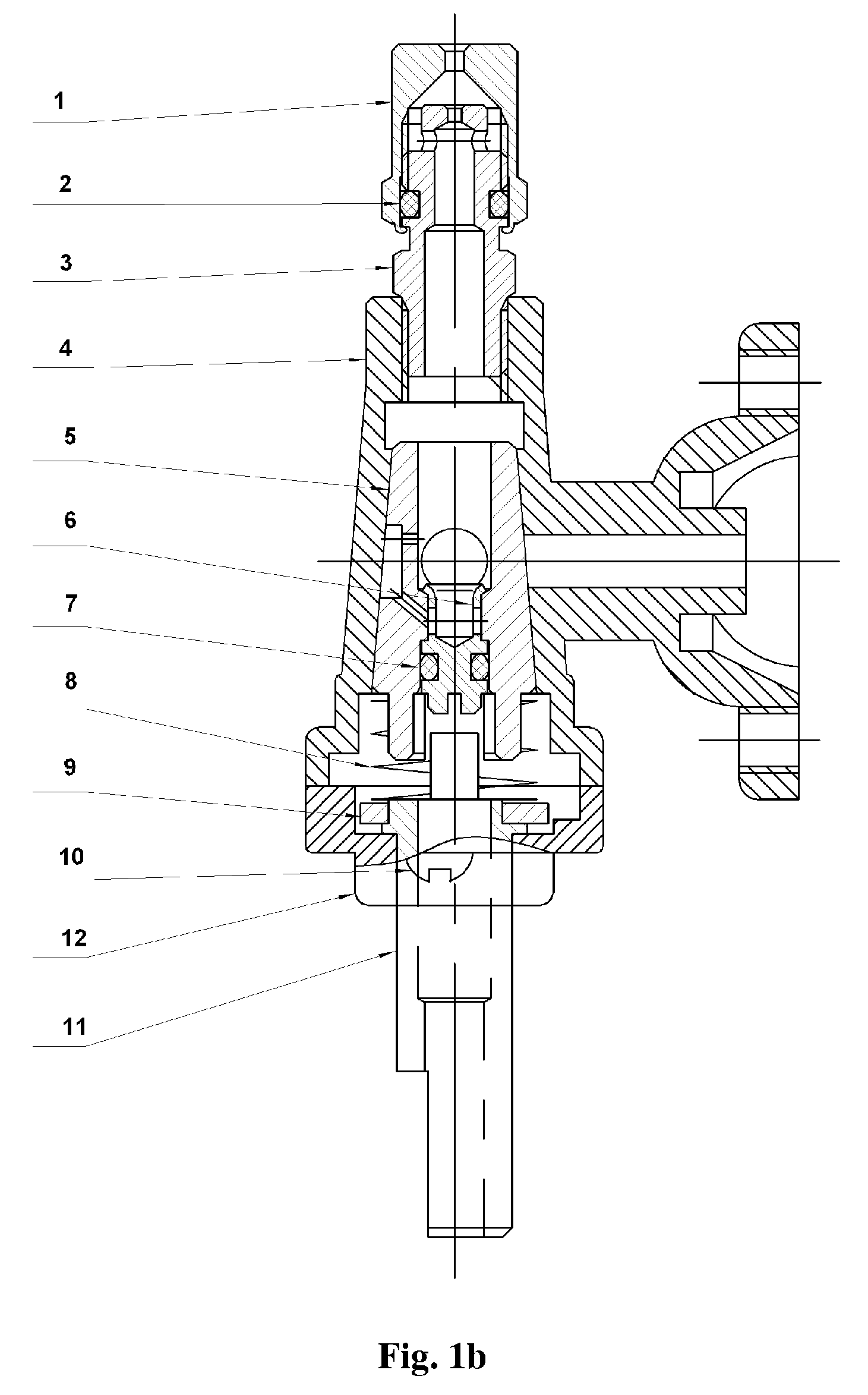

Surge prevention device

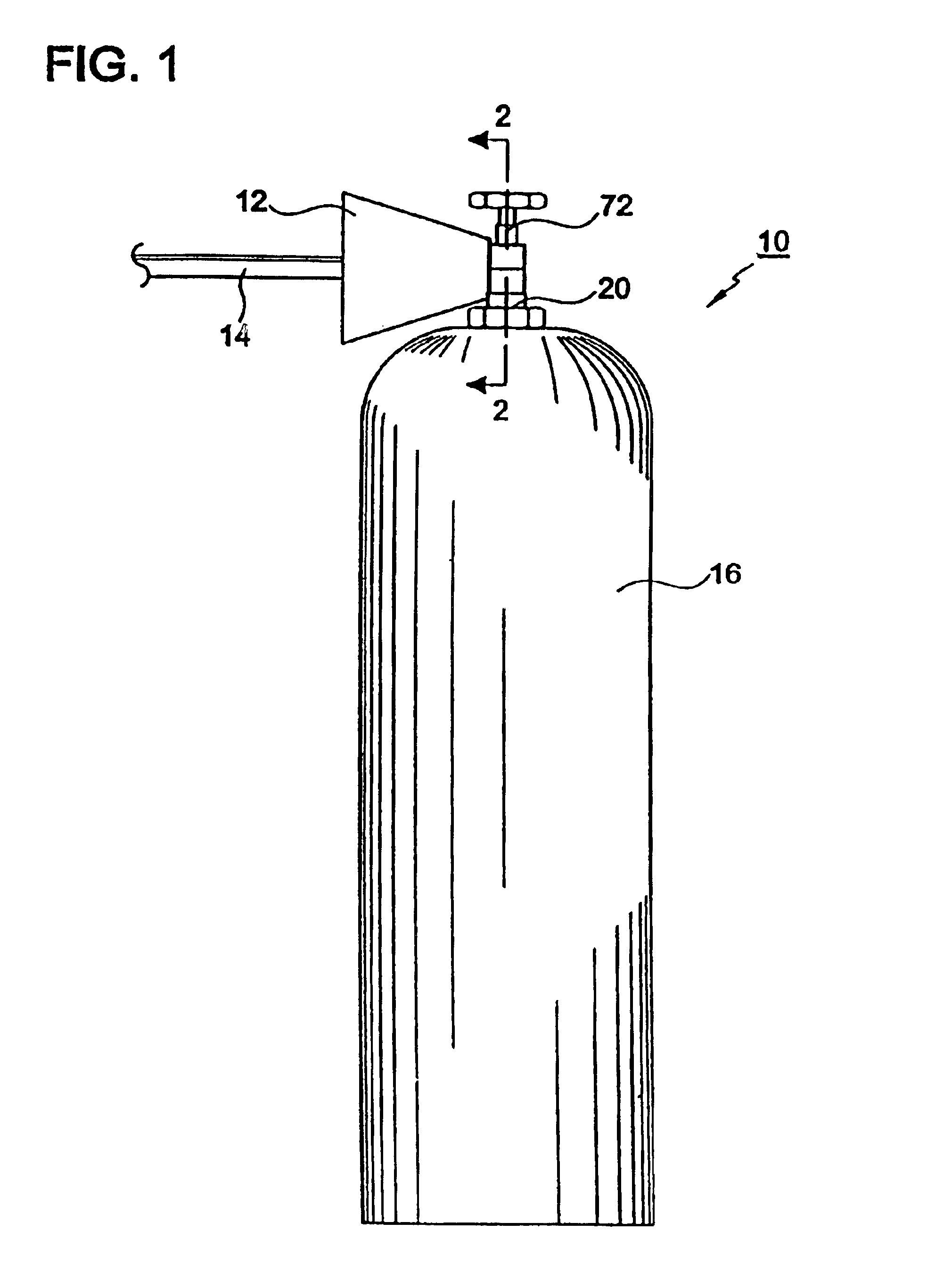

InactiveUS6901962B2High trafficIncrease flow rateCircuit elementsContainer filling methodsGas cylinderHigh pressure

A surge prevention valve may be used to prevent the formation of an initial surge of high pressure. The valve may be located, for example, between a high pressure gas cylinder and a medical pressure regulator. The valve is provided with first and second valves located within a housing and integrating a pressurization orifice. The initial opening of the valve in an axial direction enables gas to flow through the pressurization orifice at a first flow rate. The full opening of the valve in the axial direction enables the gas to flow through the second valve at a second flow rate, which is much higher than the first flow rate. The controlled pressurization of the gas through the orifice delays the time during which the gas reaches full recompression.

Owner:ALLIED HEALTHCARE PROD INC

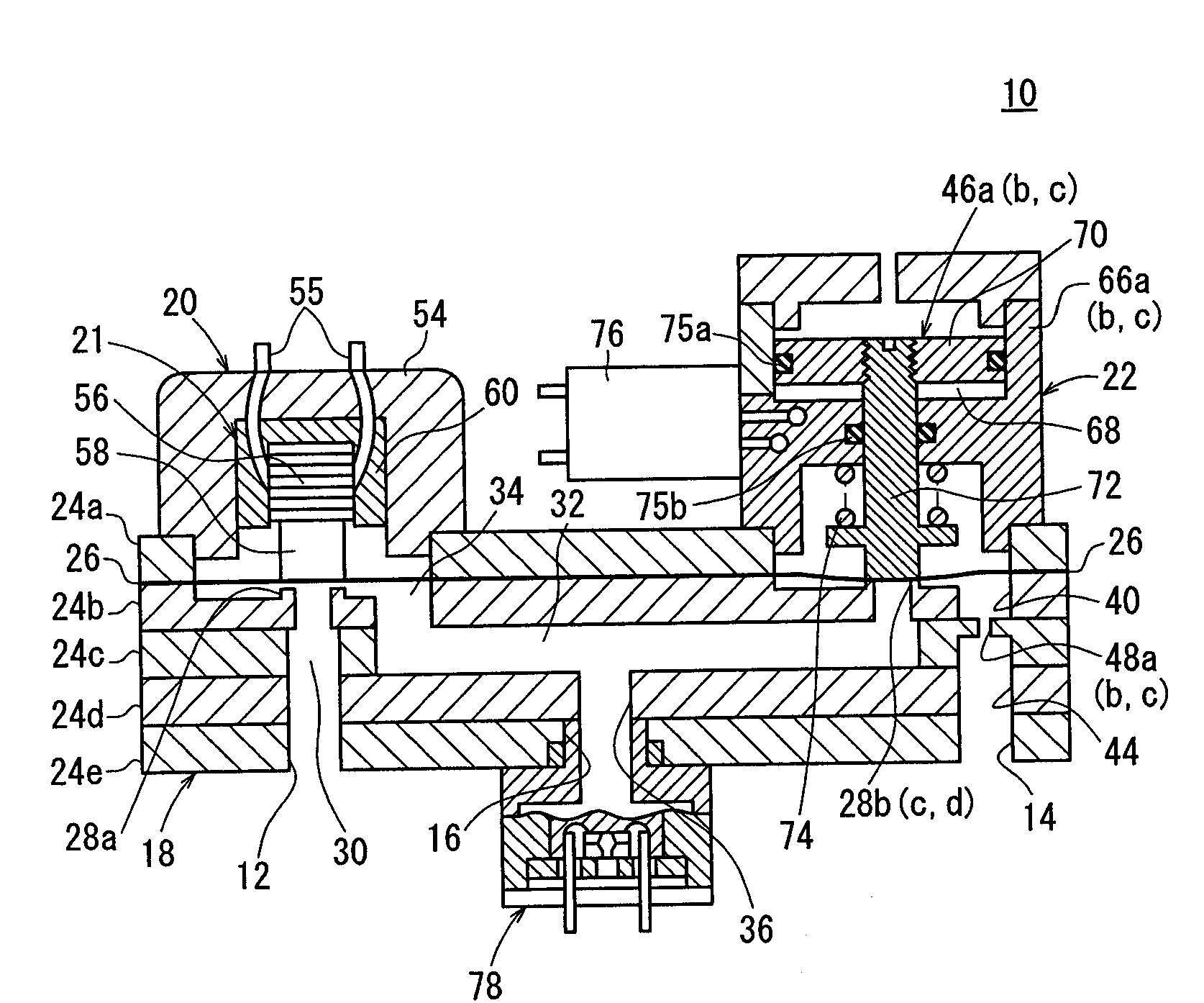

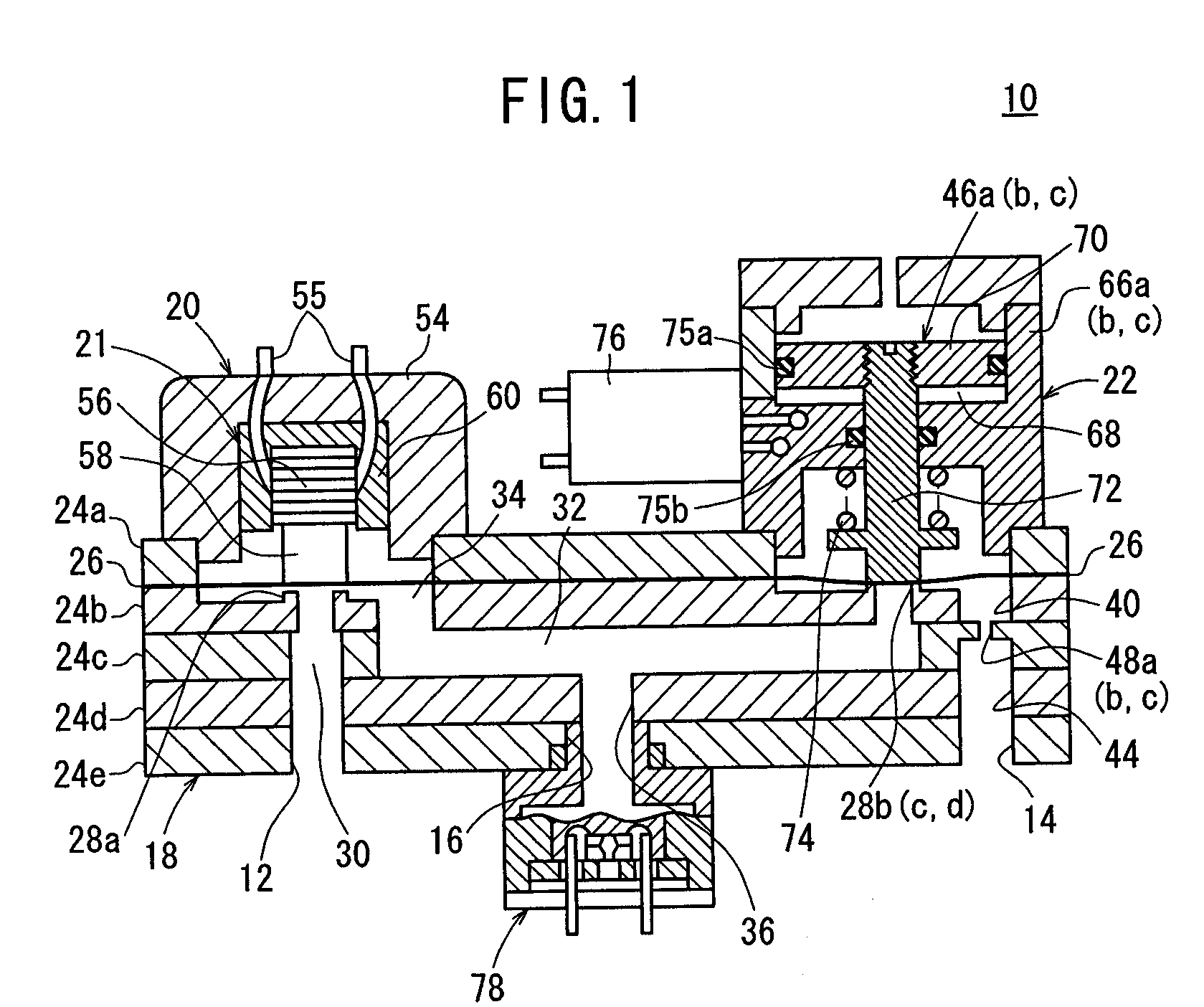

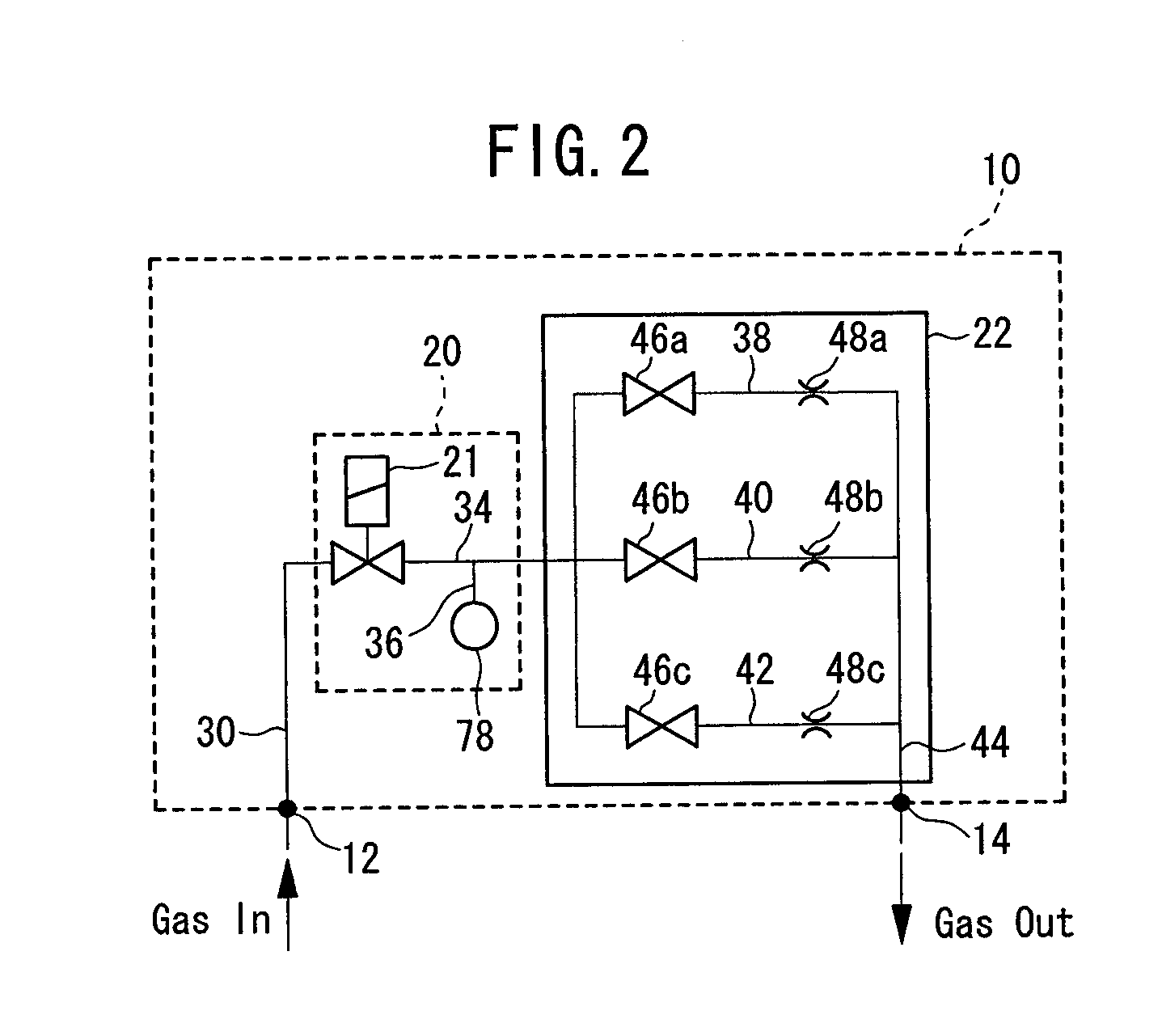

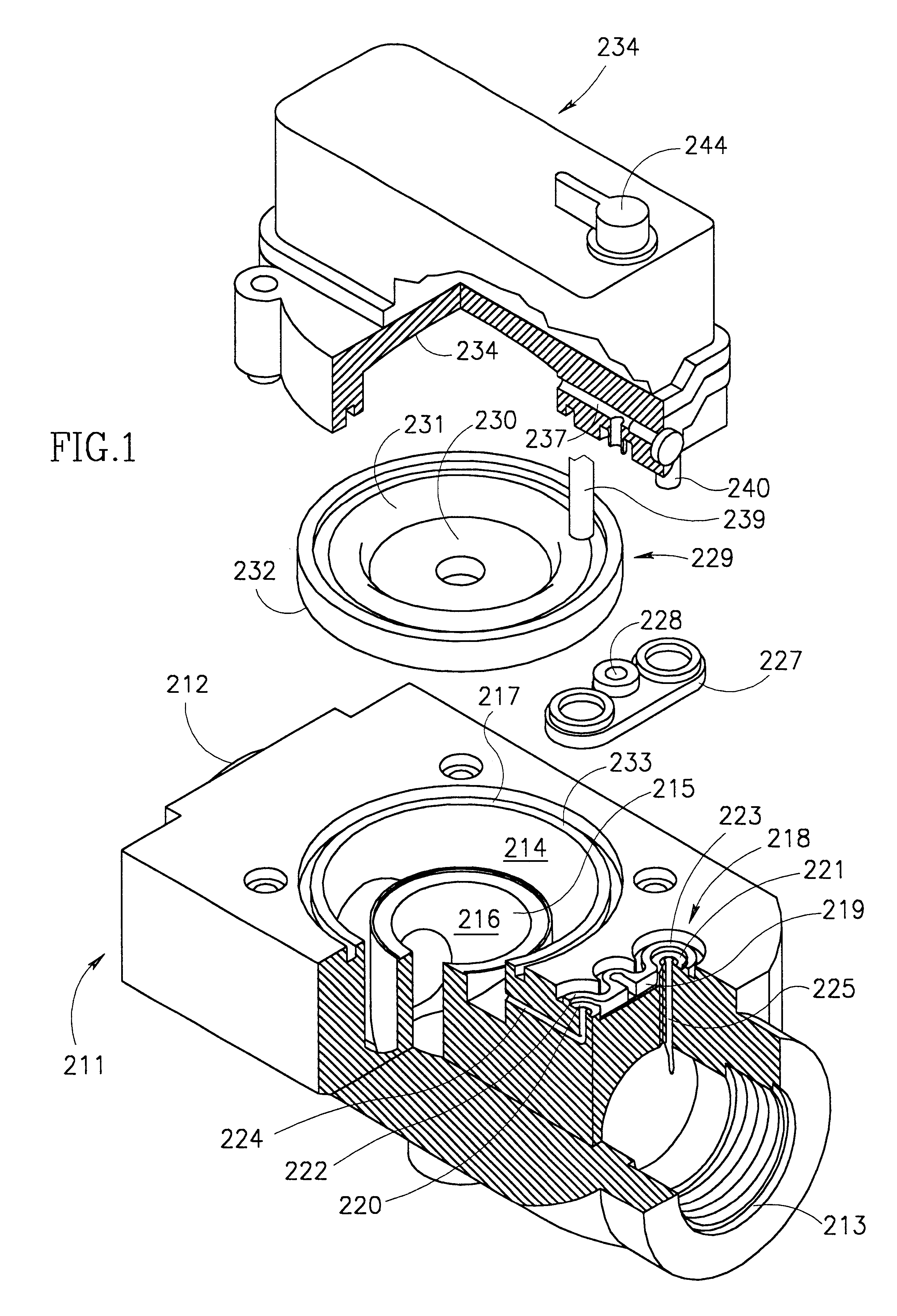

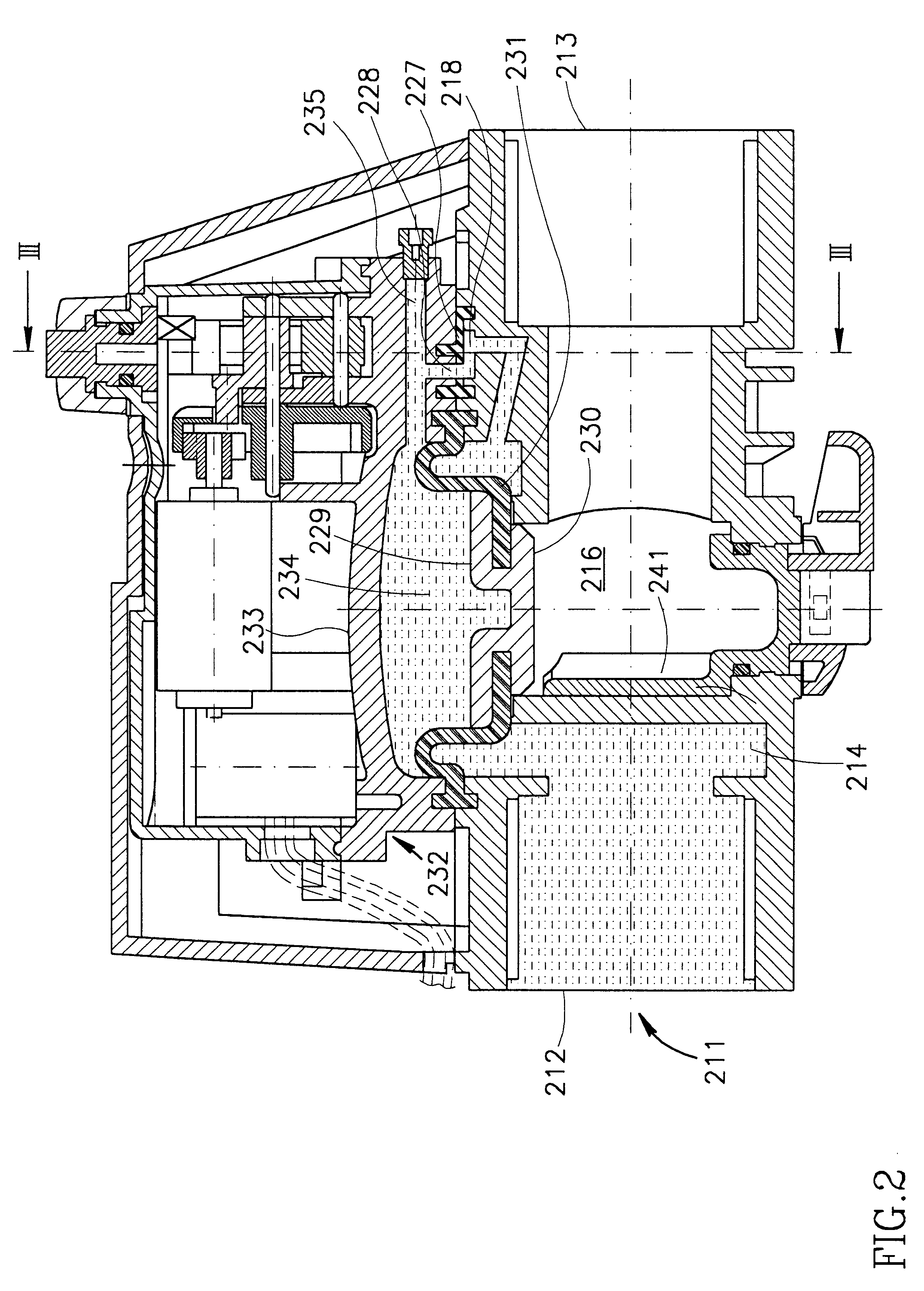

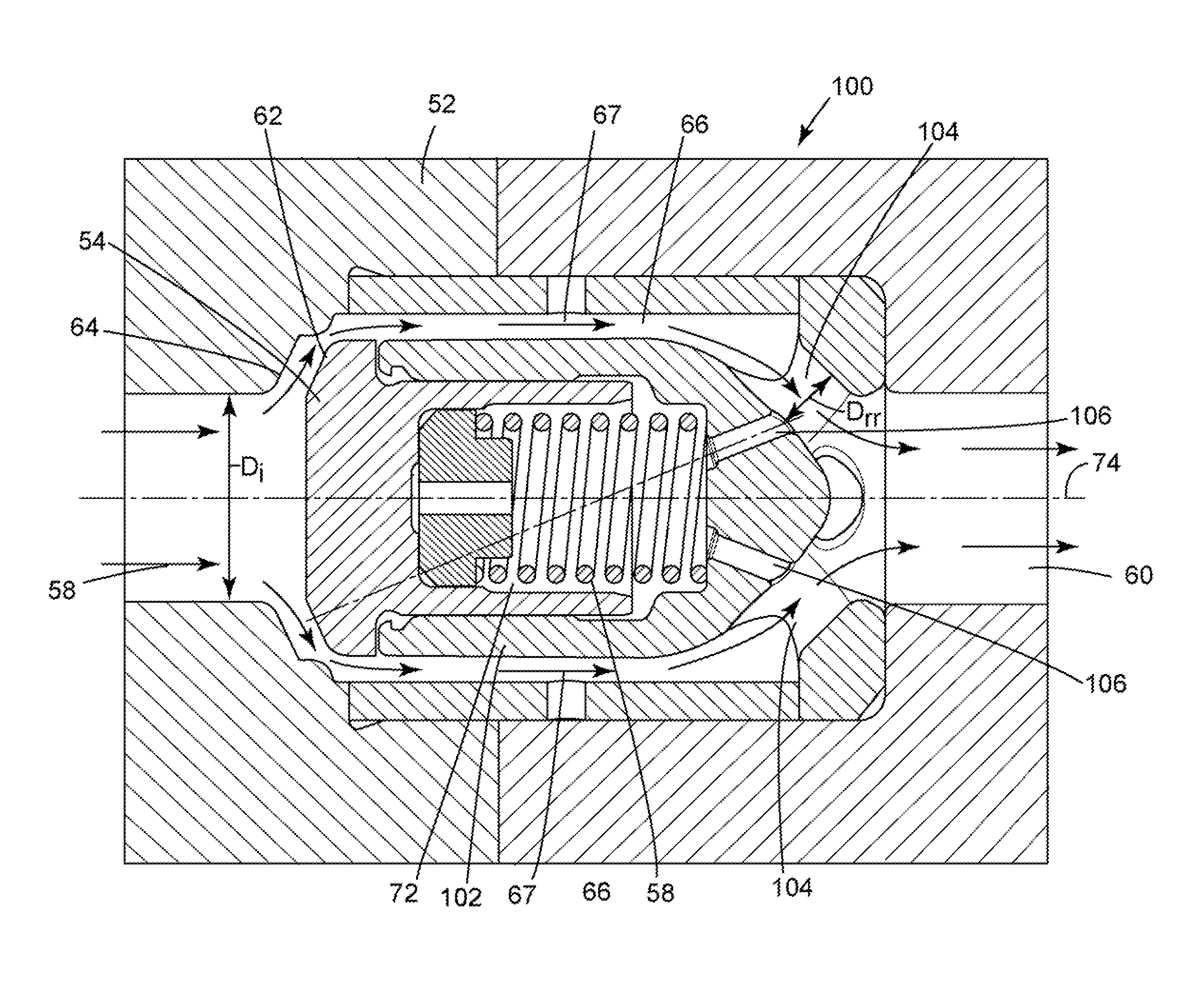

Flow Rate Control Apparatus

InactiveUS20070205384A1Controlled stably and highlyStable controlServomotor componentsCircuit elementsEngineeringPressure controlled ventilation

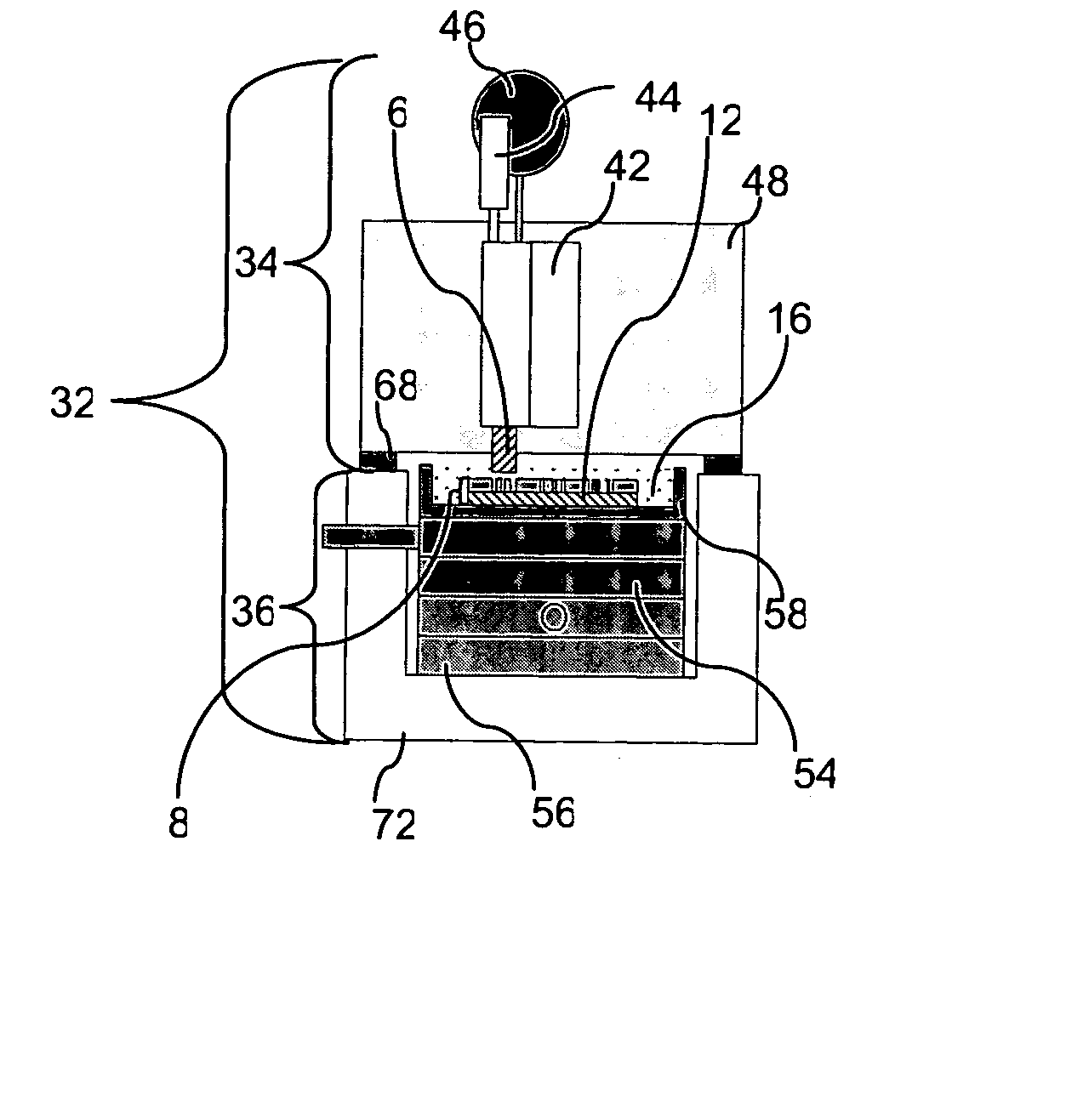

A flow rate control apparatus includes a base section, wherein the base section is composed of a plurality of stacked metal plates. The flow rate control apparatus further includes a pressure control section, which regulates pressure of a pressure fluid (gas) that flows through a first passage in the base section, a pressure sensor that detects pressure of the pressure fluid flowing through a second passage, and a flow passage-switching section, including first to third orifices, for throttling the fluid pressure-regulated by the pressure control section so as to have a predetermined flow rate, and which has first to third ON / OFF valves for switching fourth to sixth passages for respectively directing the pressure fluid toward a pressure fluid output port.

Owner:SMC CORP

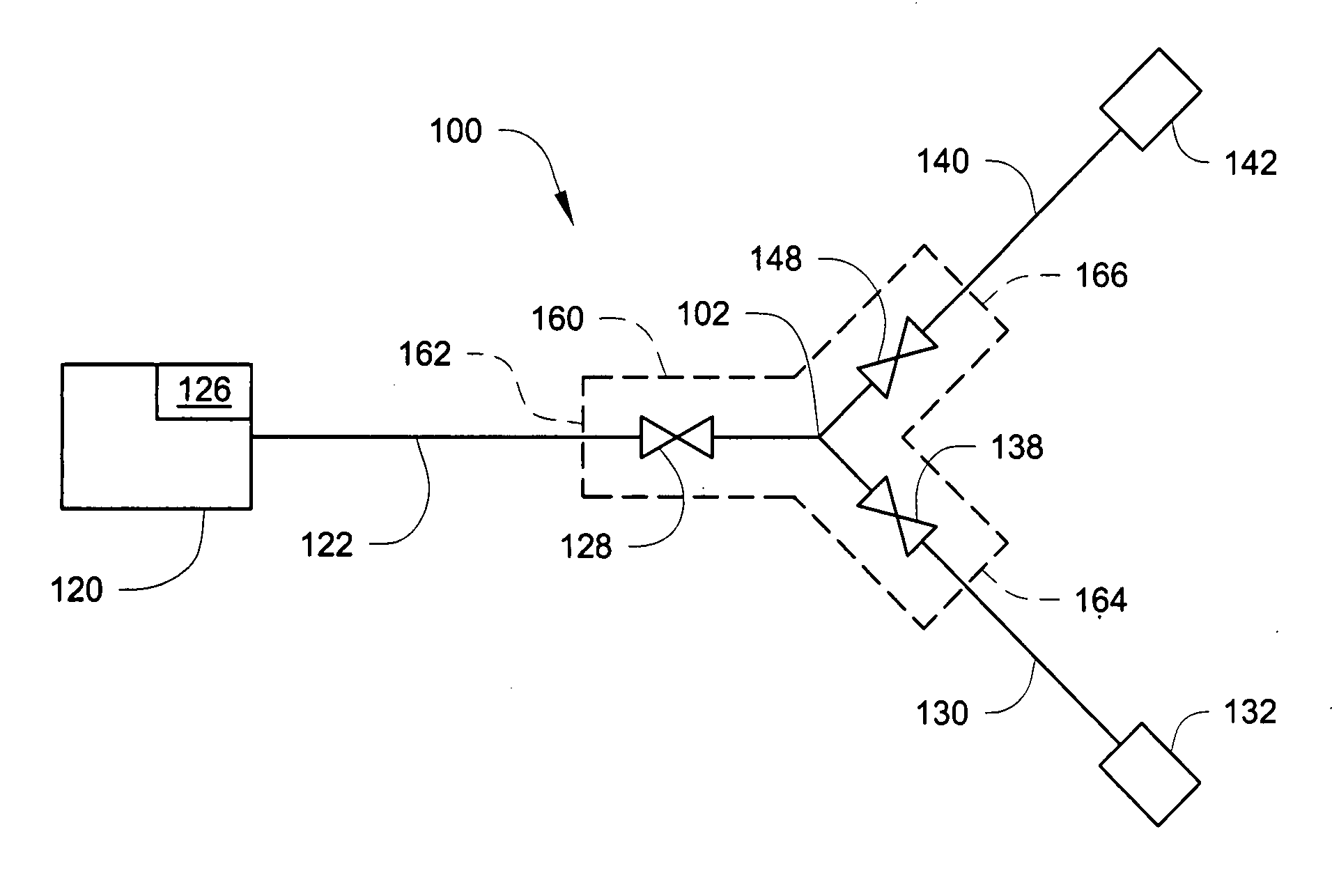

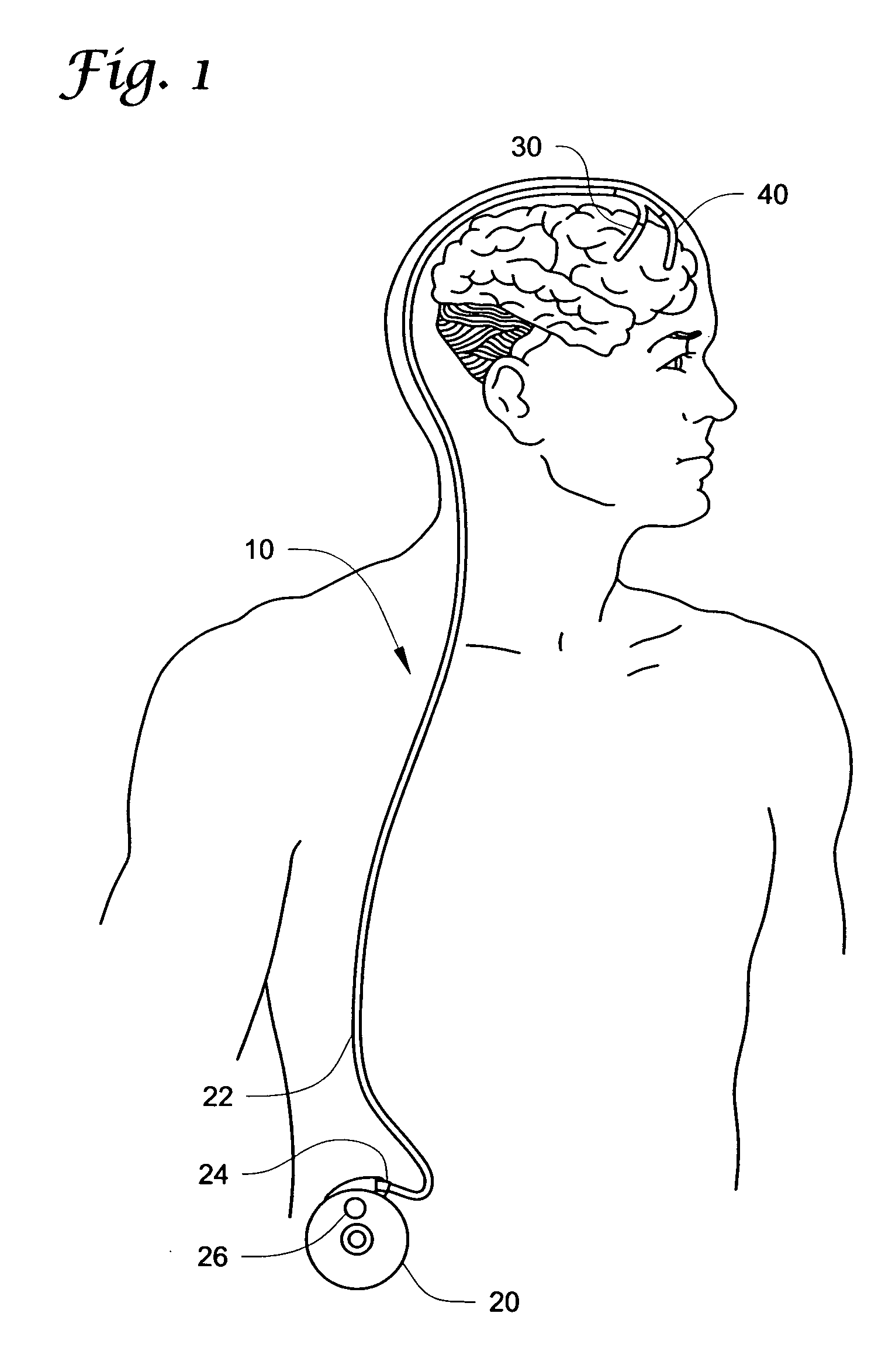

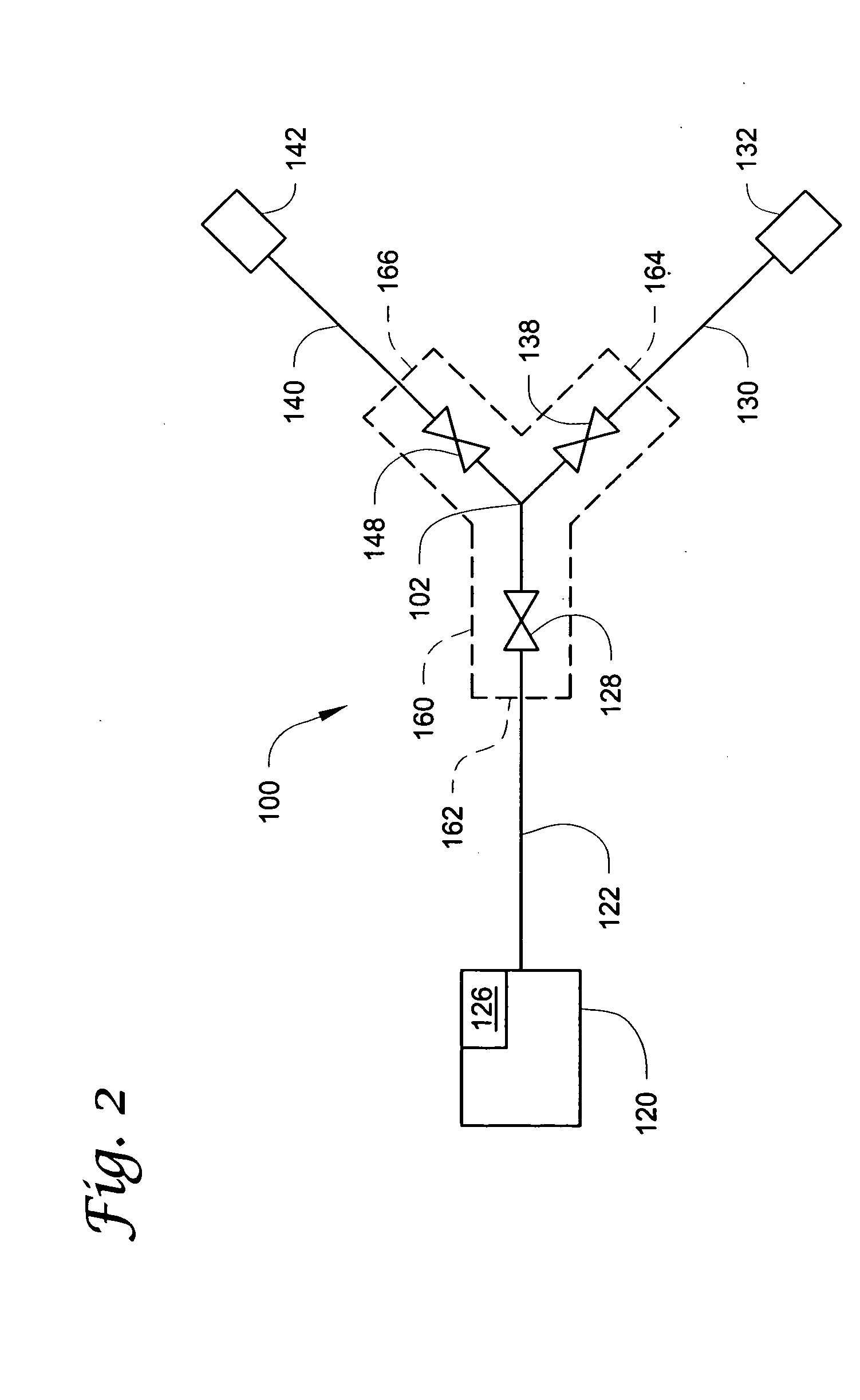

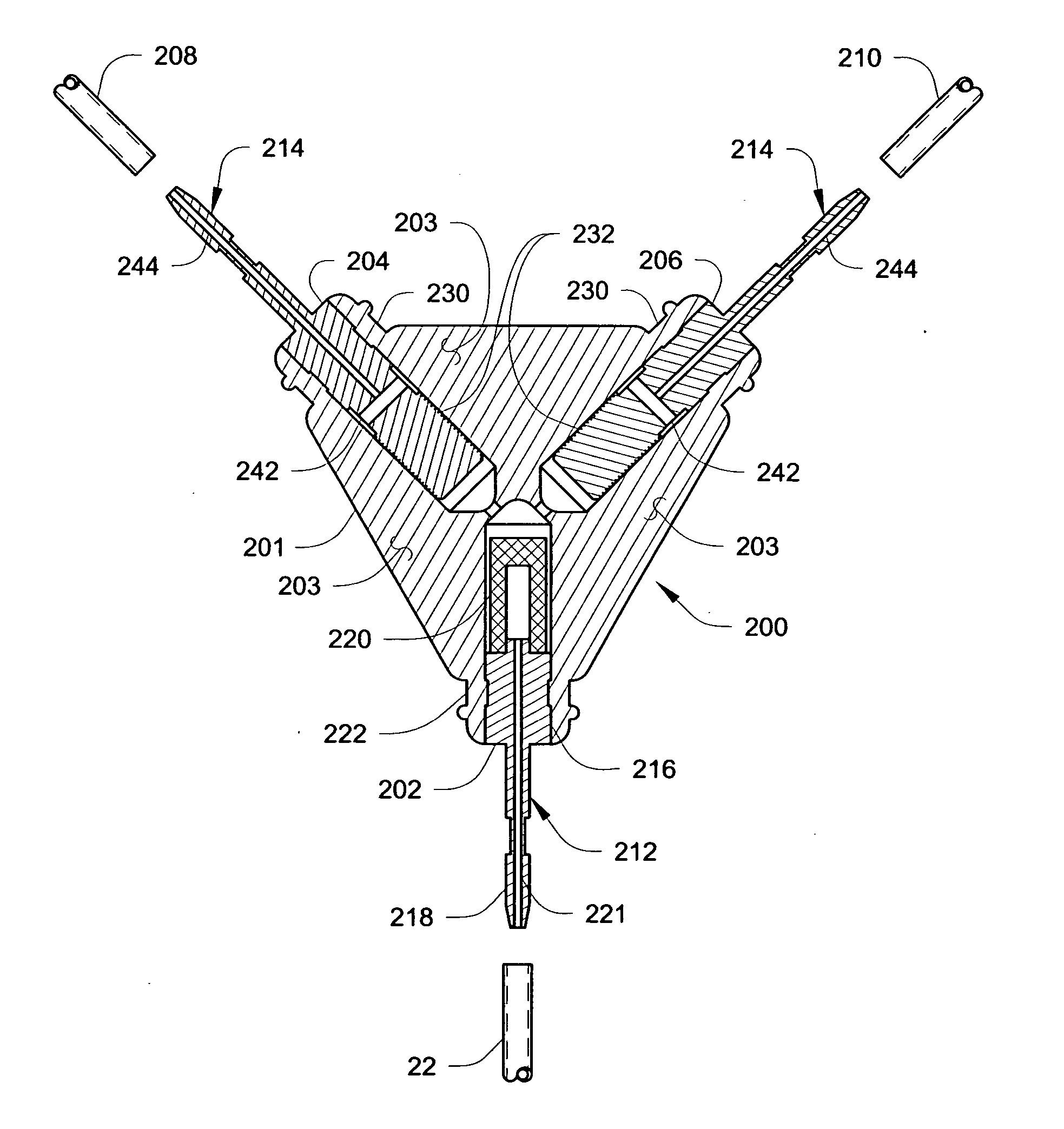

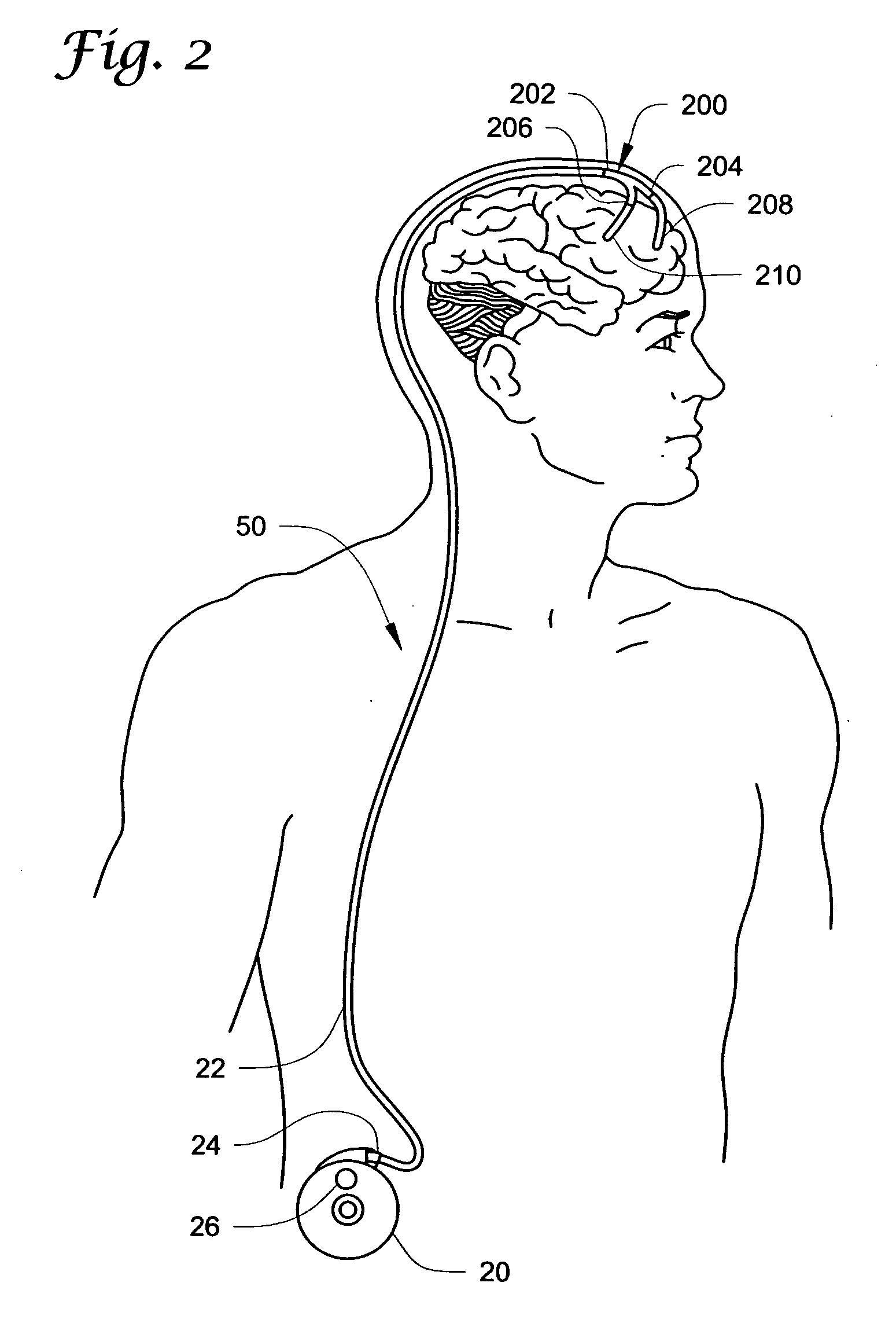

Branching catheter systems with diagnostic components

InactiveUS20050245858A1Less invasiveLess time consumingMulti-lumen catheterVolume/mass flow by thermal effectsControl systemDiagnostic system

Branching catheter systems with diagnostic components for detecting and isolating fluid flow problems (e.g., leaks, occlusions, etc.) and methods for detecting and isolating fluid flow problems are disclosed. Among the fluid flow problems that may potentially be detected are leaks in the branching catheter systems (e.g., cuts, disconnected components, etc.). Another fluid flow problem that may be detected using the diagnostic systems of the present invention is the presence of occlusions or other blockages that prevent fluid flow within the catheter systems. In addition to identifying that a problem exists, the diagnostic components may preferably also be used to identify the location of the fluid flow problem as discussed herein. Connectors for use in the branching catheter systems are also disclosed. Among the diagnostic components that may be used in branching catheter systems of the present are valves to control fluid flow through the various sections of the branching catheter system, fluid flow detectors to detect flow through the one or more sections of the branching catheter system and a control system for operating the diagnostic components.

Owner:MEDTRONIC INC

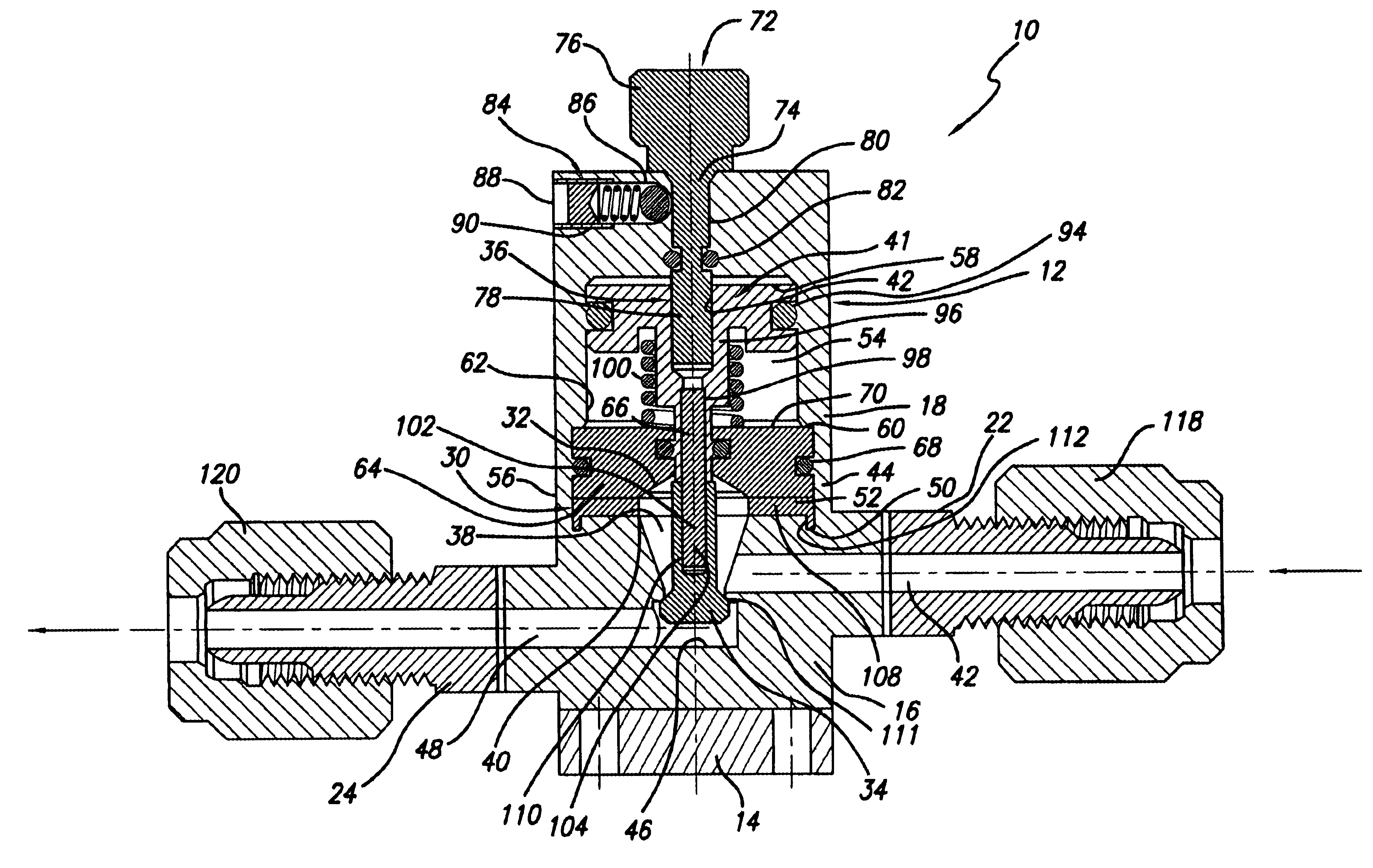

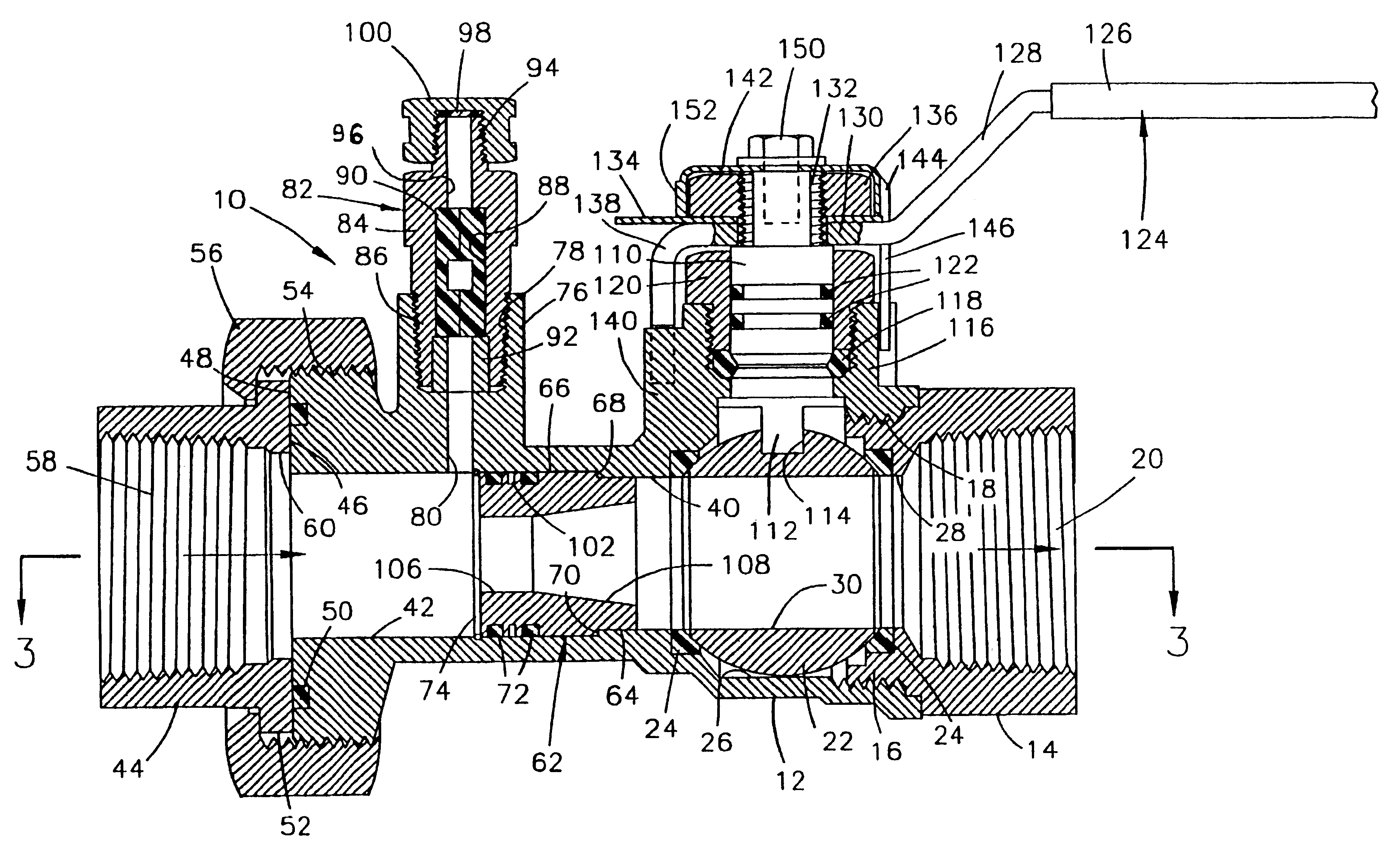

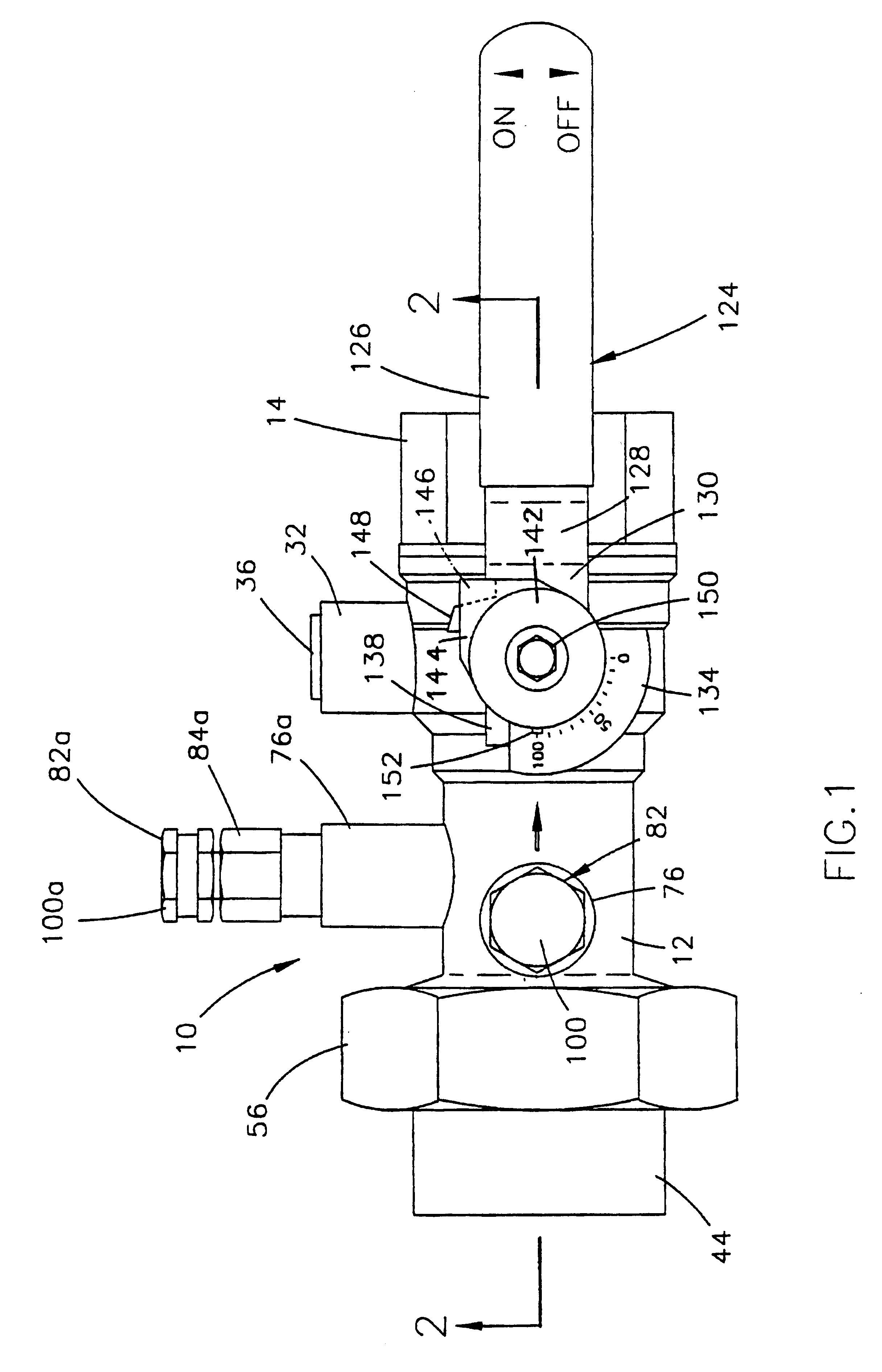

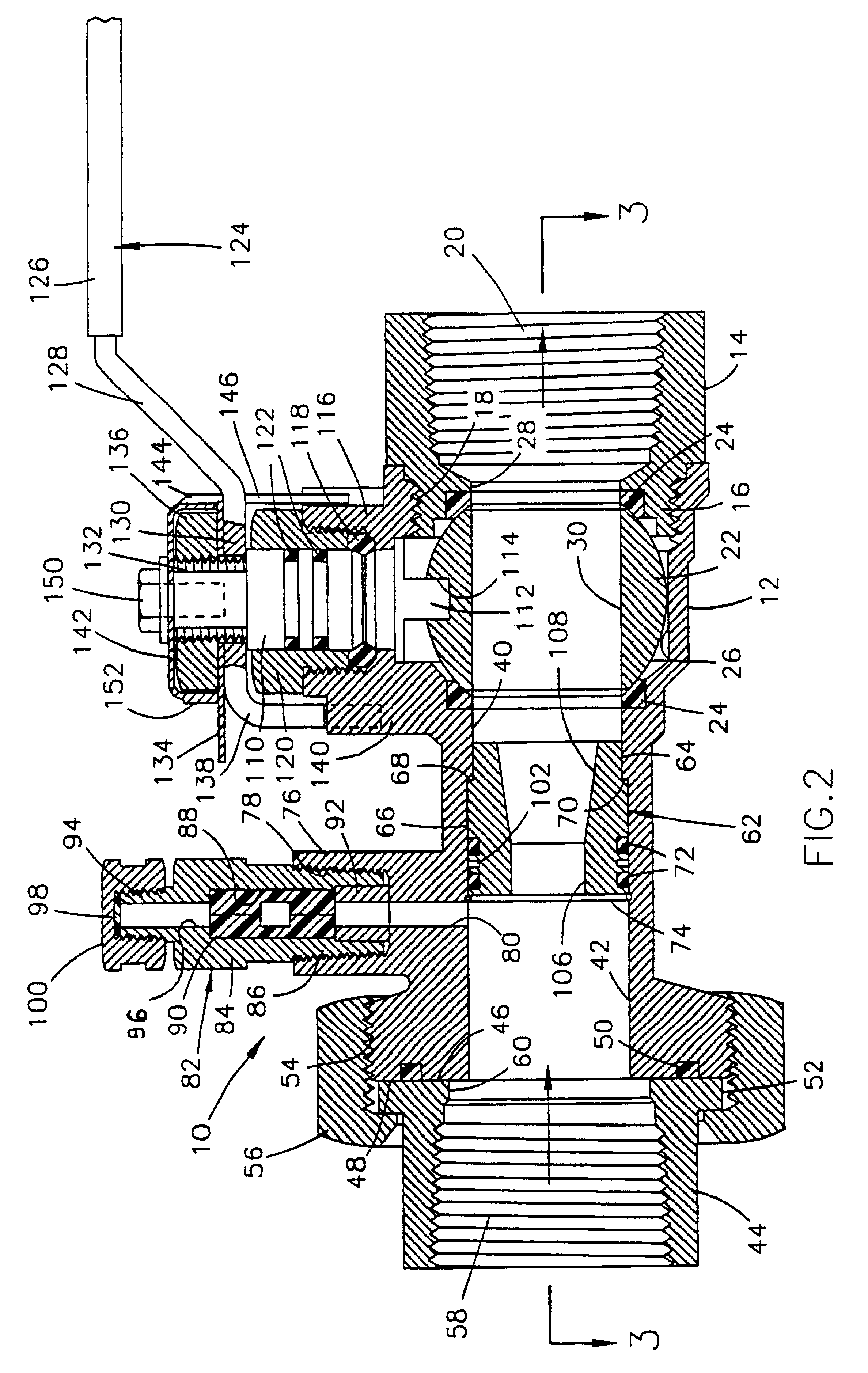

Ball valve with integrated removable flow venturi, flow balancing means, and pipe union means

InactiveUSRE37617E1Considerable timeEasy to installPlug valvesValve members for absorbing fluid energyEngineeringAir conditioning

A valve assembly for use in heating, ventilating and air conditioning systems. The valve assembly includes a valve body having a chamber in which is rotatably mounted a quarter-turn flow control ball valve. A valve body nut having an outlet port is threadably mounted on the valve body adjacent the outlet end of the valve body chamber. A flow venturi is removably mounted in the inlet end of the valve body. A pipe union tailpiece is detachably mounted on the inlet end of the valve body. A pair of pressure / temperature readout ports are mounted on the valve body for use in determining the rate of fluid flow through the venturi. A vent plug is mounted on the valve body for venting air from the ball valve chamber.

Owner:SHERMAN JOHN C

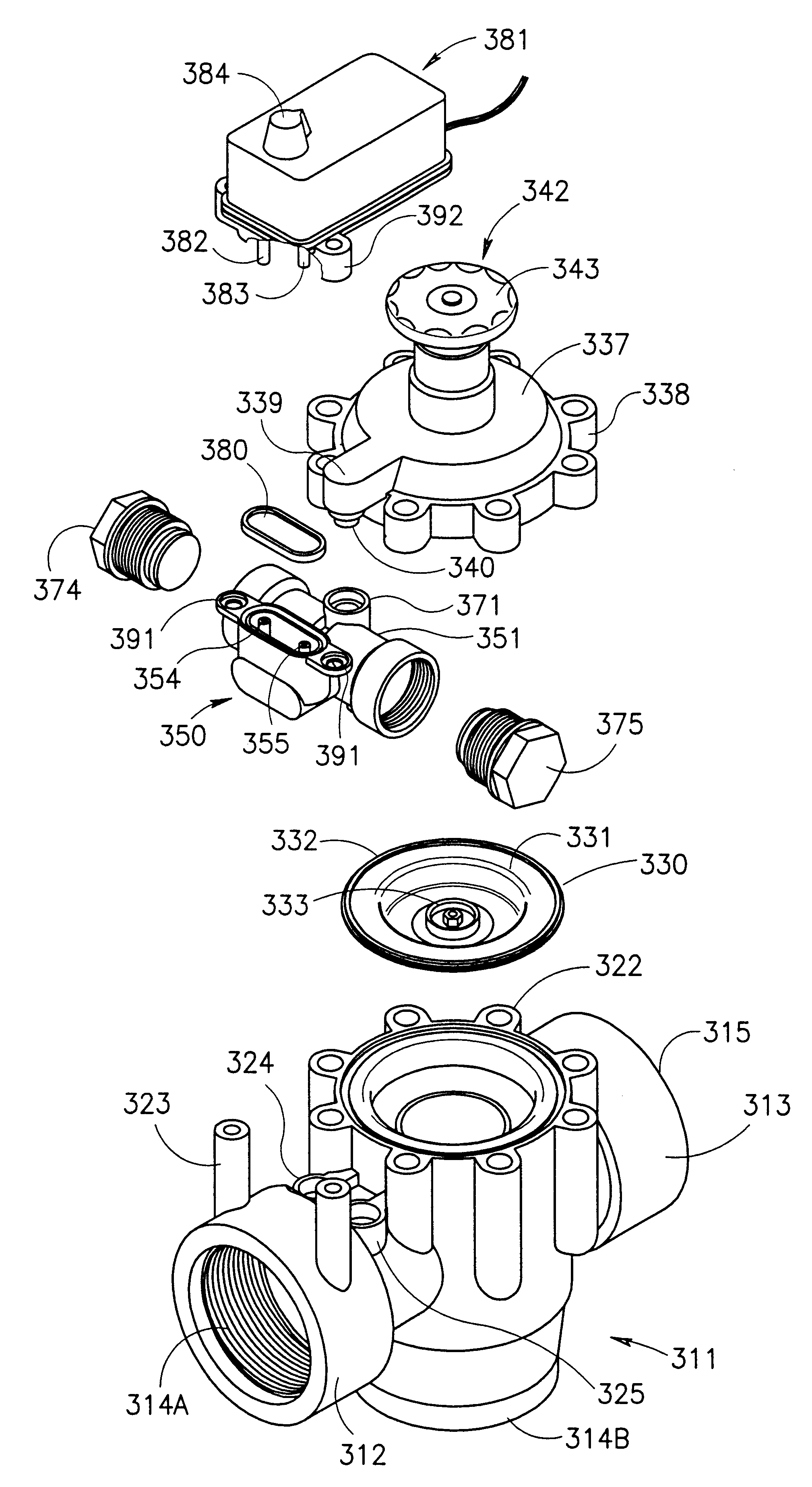

Hydraulic diaphragm

InactiveUS6394412B2Constant pressureOperating means/releasing devices for valvesValve members for absorbing fluid energyControl roomEngineering

A hydraulic diaphragm valve comprising a housing, an inlet, an outlet, a diaphragm valve seating between the inlet and the outlet, a sealing diaphragm mounted in the housing and displaceable about the diaphragm valve seating, so as to close and open a flow path between the inlet and outlet, a valve control chamber and a command valve comprising a first duct communicating a one end thereof with the valve inlet, and at an opposite end thereof with a first command valve seating, a second duct communicating into one end with the valve outlet, and at an opposite end thereof, with a second command valve seating. A third duct communicates at one end with the valve control chamber and at its opposite end it selectively communicates with the first and second command valve seatings. A flexible command diaphragm is selectively biased into sealing engagement with one or other of the command valve seatings to effect communication between the third duct and the command valve seating not in seating engagement with the command diaphragm.

Owner:NETAFIM LTD

Valve With Built-In Sensor

InactiveUS20090165866A1Reduce riskPlug valvesVolume/mass flow measurementDistribution systemEngineering

A valve is disclosed that has a control ball. The control ball has a passageway within which a sensor is disposed. The sensor measures a characteristic of the fluid passing through the control ball. The control ball can be controlled either manually or with an electronic actuator. A method is disclosed of retrofitting an existing fluid distribution system by replacing a valve that lacks sensing capabilities with a new valve having a sensor. The sensor measures the flow, temperature, or pressure of the fluid, and provides a signal that can be remotely monitored and corresponds to the measured characteristic.

Owner:FIMA GIOVANNI

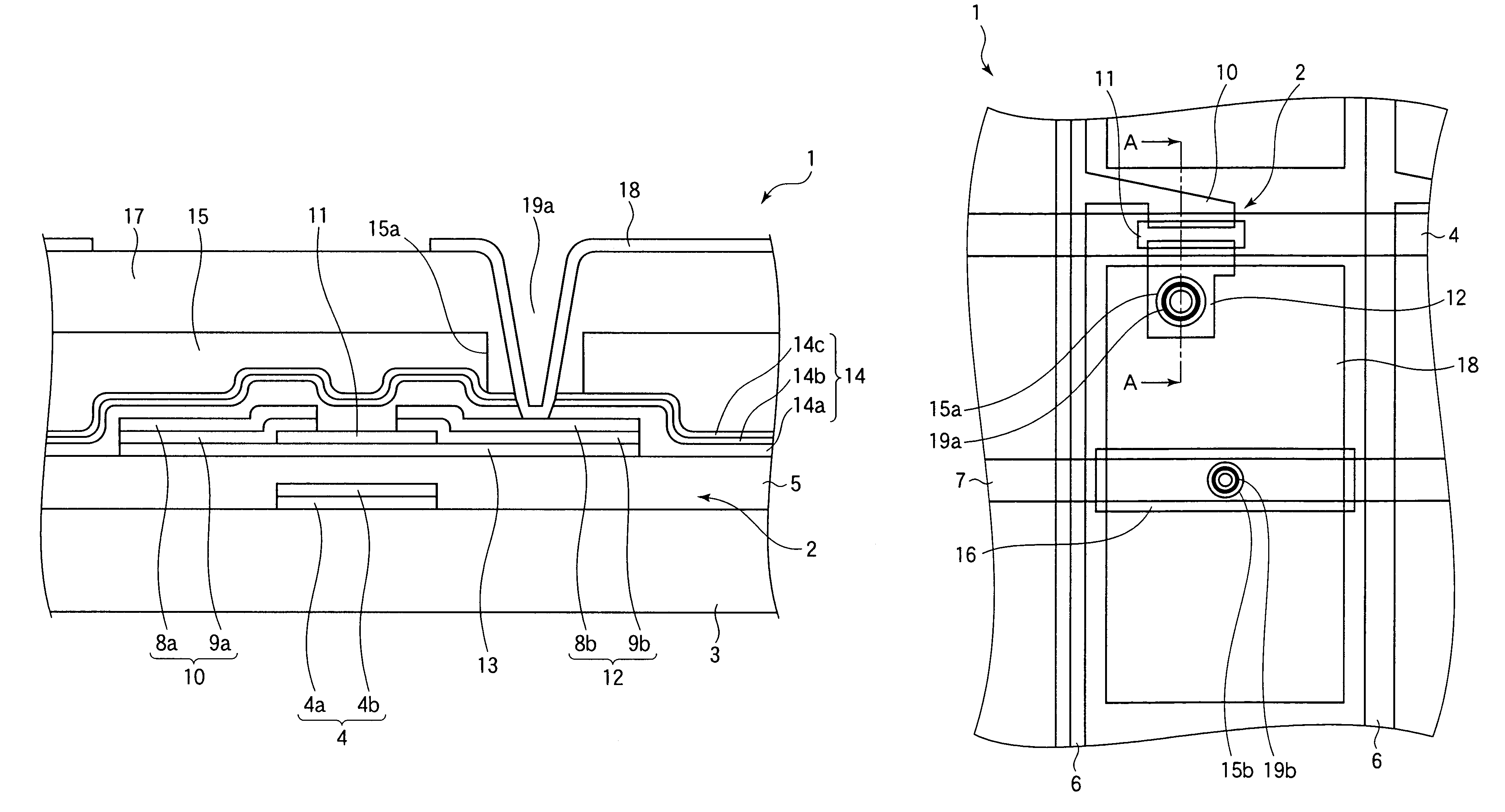

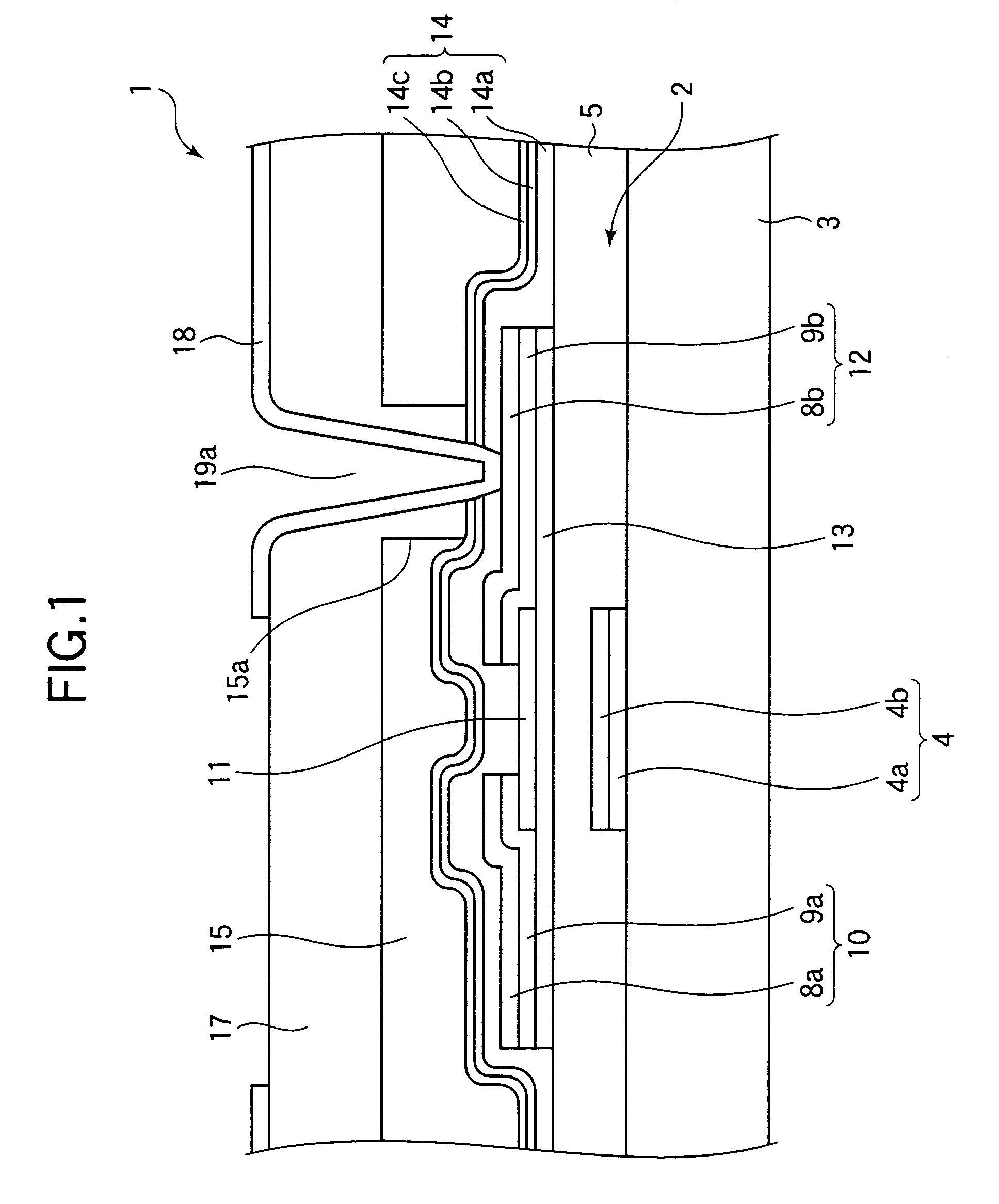

Substrate for liquid crystal display and liquid crystal display utilizing the same

ActiveUS7012658B2Occurrence of failureExcellent characteristicsTransistorOperating means/releasing devices for valvesLiquid-crystal displayPhysics

The generation of residues or flakes of a color filter is suppressed to eliminate conduction failures on an LCD substrate having a color filter on an array substrate. A passivation film formed between a pixel electrode formed in each of a plurality of pixel regions and a TFT for driving the pixel electrode has a multi-layer structure constituted by SiN layers and a SiO layers, and the SiO layer is located at the top of the film. A resin CF layer is formed on the passivation film having such a multi-layer structure. Since the resin CF layer is formed directly on the SiO layer, reduction of the adhesion of the same is suppressed. As a result, the color filter is unlikely to come off when the resin CF layer is formed, and residues of the color filter is unlikely to be generated when a contact hole is formed in the resin CF layer. This suppresses conduction failures and makes it possible to provide a reliable TFT substrate and LCD having high display characteristics.

Owner:UNIFIED INNOVATIVE TECH

Silencer for perforated plate flow conditioner

Owner:SAWCHUK BLAINE DARREN +1

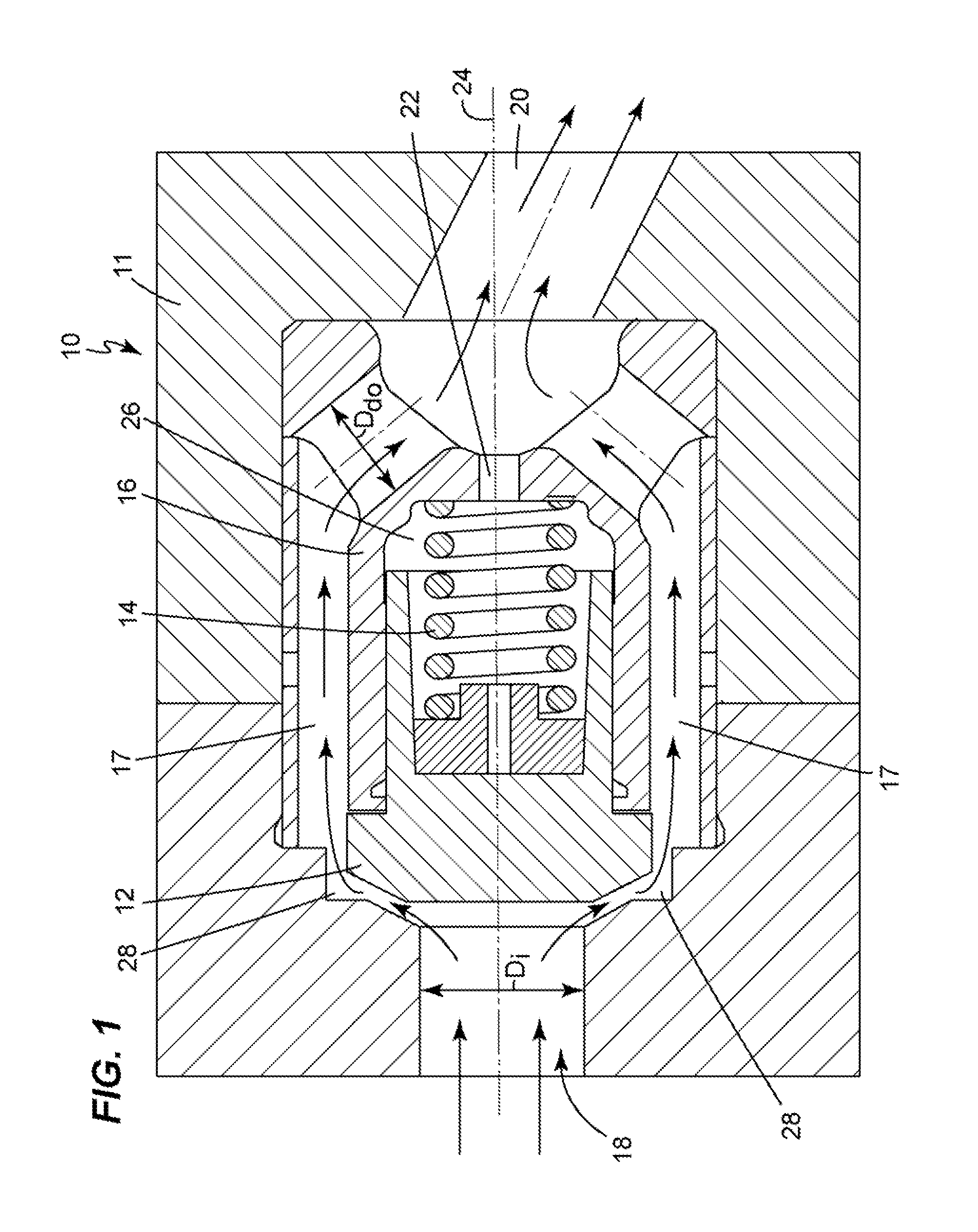

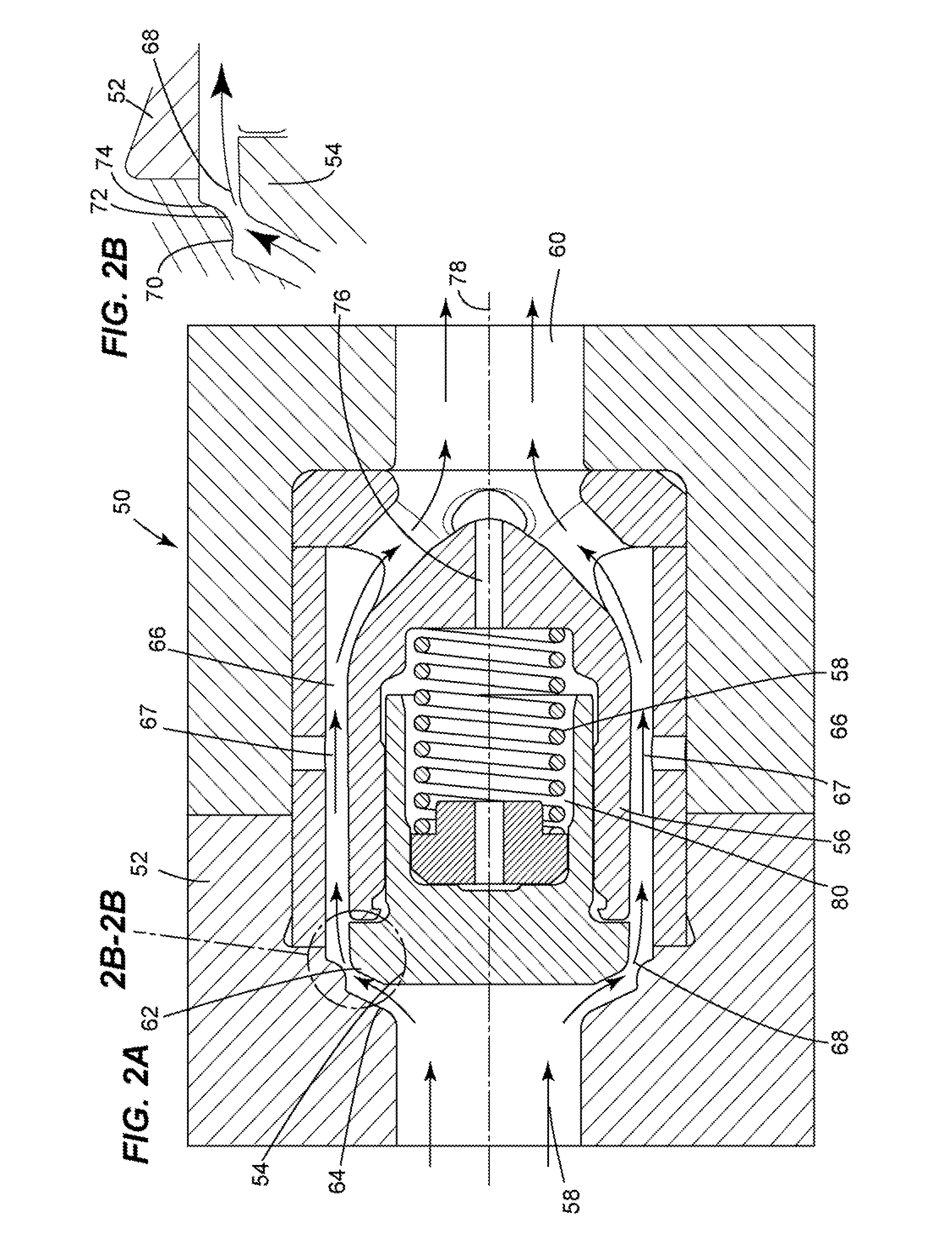

Poppet valve with diverging-converging flow passage and method to reduce total pressure loss

ActiveUS20100024891A1Stabilizing dynamic openingImprove performanceCheck valvesValve members for absorbing fluid energyEngineeringMechanical engineering

A poppet valve is disclosed that include a valve body, a poppet guide disposed inside the valve body so as to form a a flow passage from a flow inlet to a flow outlet of the valve, a poppet shutter disposed inside the poppet guide, and a converging-diverging flow passage formed by a portion of an outer surface of the poppet shutter and a corresponding portion of an inner surface of valve body. A method for reducing a closing pressure force acting on a poppet shutter of a poppet valve is also disclosed.

Owner:NUOVO PIGNONE TECH SRL

Self-cleaning metering device

InactiveUS6581902B2Reduce and even to eliminate any build-upMitigate such drawbackValve members for absorbing fluid energyPipe elementsEngineeringSelf cleaning

Owner:HISPANO SUIZA SA

Catheter systems having flow restrictors

ActiveUS20050245887A1Reduce frequencyMulti-lumen catheterVolume/mass flow by thermal effectsCatheter device

Catheter systems including one or more flow restrictors are disclosed. The catheter systems may include two or more delivery branches. The delivery branches may be connected to a supply catheter section using a branching catheter connector that may include one or more flow restrictors. The flow restrictors may include a restrictor body located within a lumen with a channel located between the restrictor body and interior surface of the lumen, the channel restricting flow through the lumen past the flow restrictor. The channel may be defined by a groove formed in the restrictor body and / or the interior surface of the lumen. Methods of providing pressure relief by flowing fluid past a flow restrictor are also disclosed.

Owner:MEDTRONIC INC

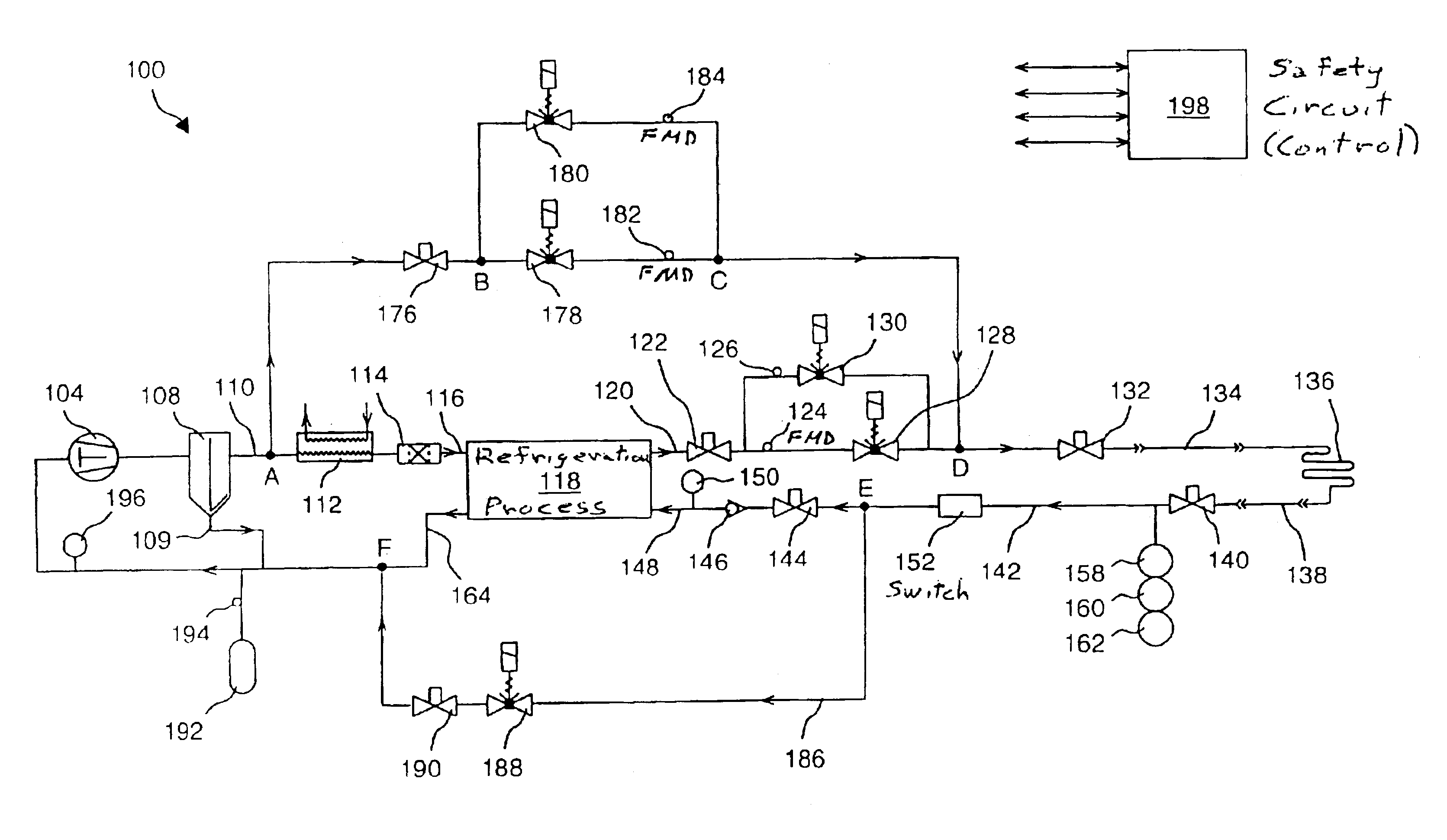

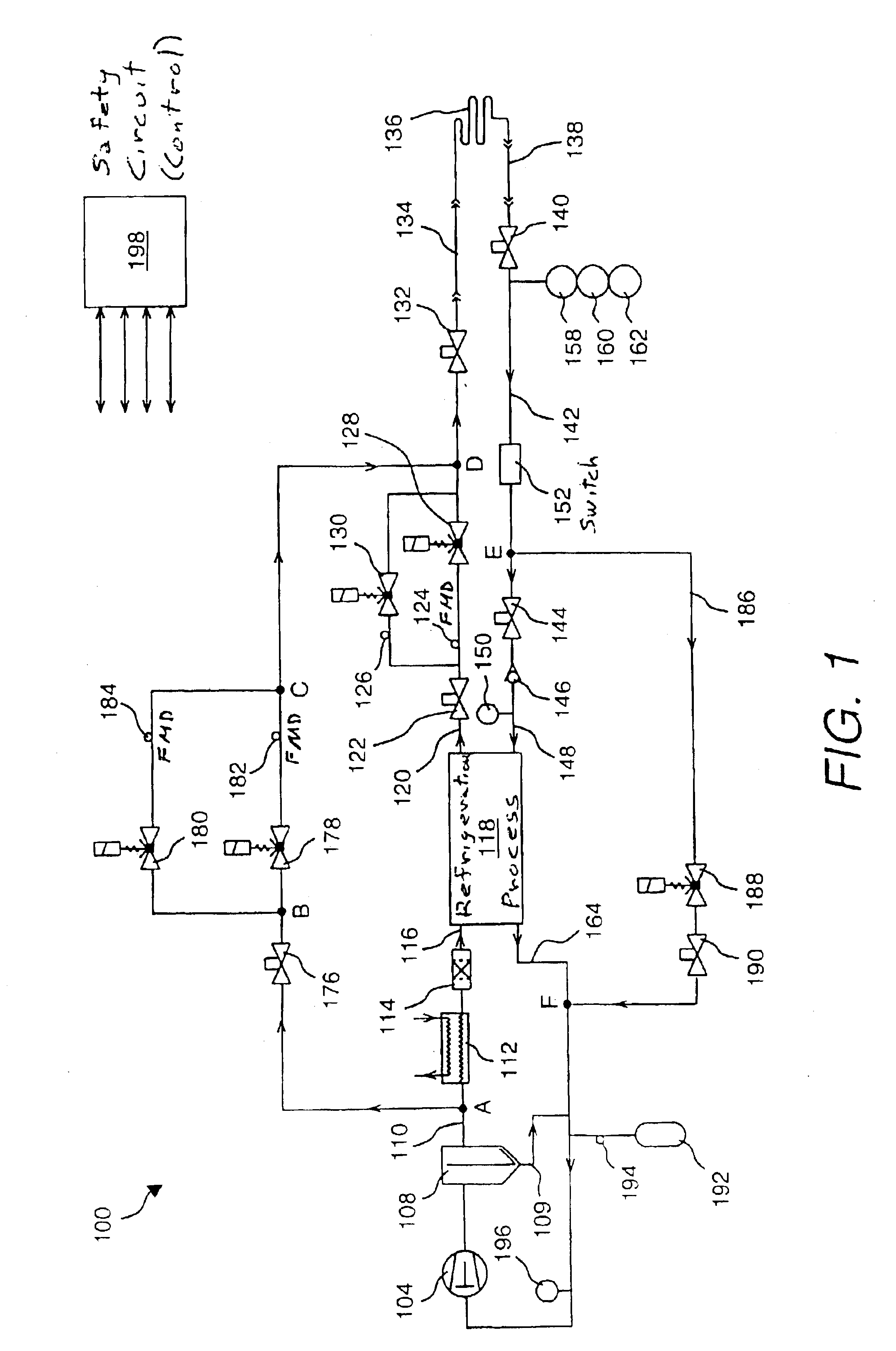

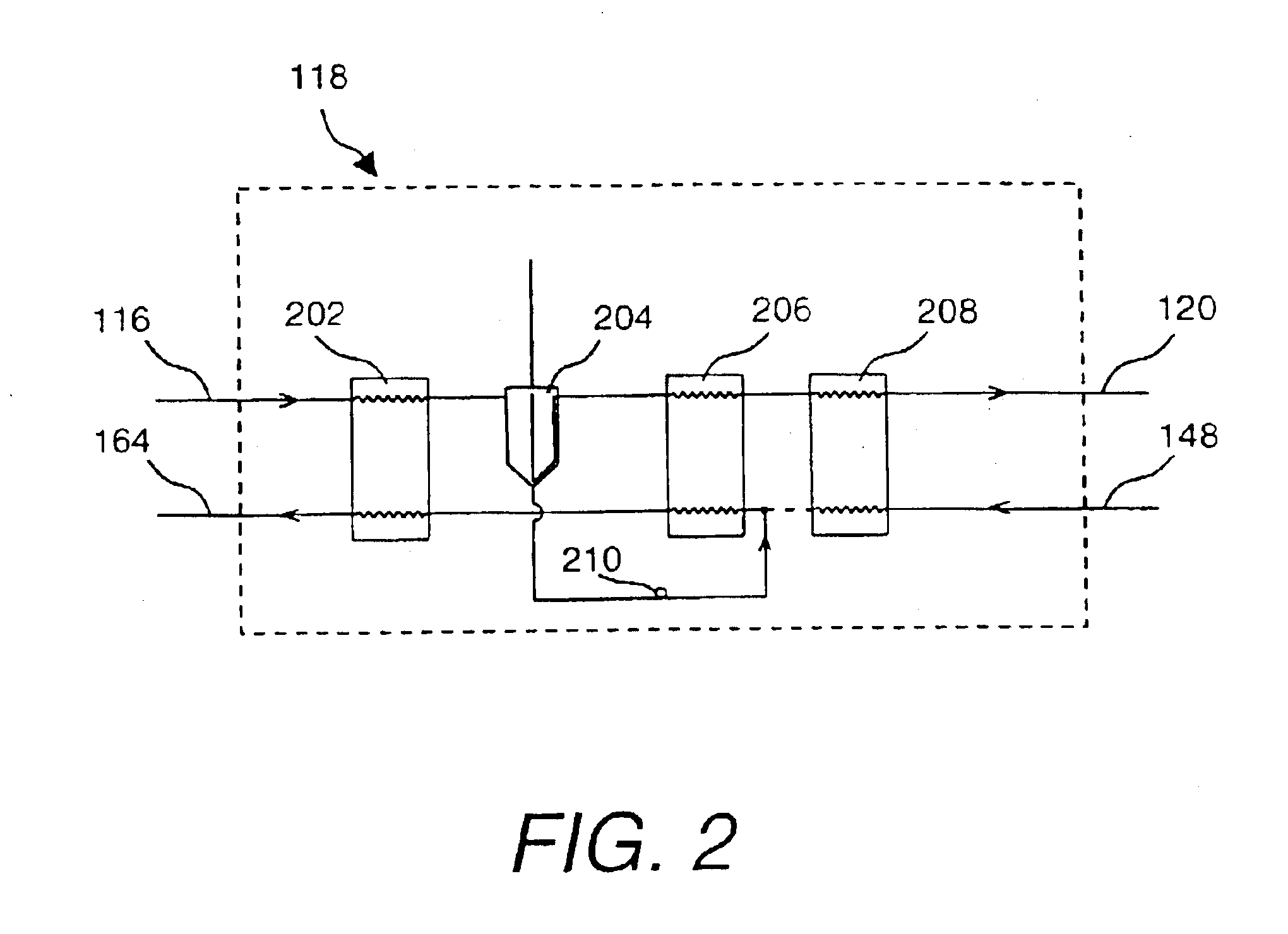

Very low temperature refrigeration system with controlled cool down and warm up rates and long term heating capabilities

InactiveUS6843065B2Continuous operationSmall temperature rangeCompression machinesValve members for absorbing fluid energyRecovery periodEngineering

Heating / defrost constructions of a very low temperature refrigeration system having a defrost supply circuit and a defrost return bypass circuit optimizing the heating / defrost cycle, preventing overload (excessive pressure) of its refrigeration process and protecting components from damaging temperatures. The defrost cycle operates continuously, when required, and provides a shorter recovery period between heating / defrost and cooling operating modes. The rate of the temperature change during cool down or warm up is controlled in an open loop fashion by controlled refrigerant flow in bypass circuits.

Owner:EDWARDS VACUUM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com