Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

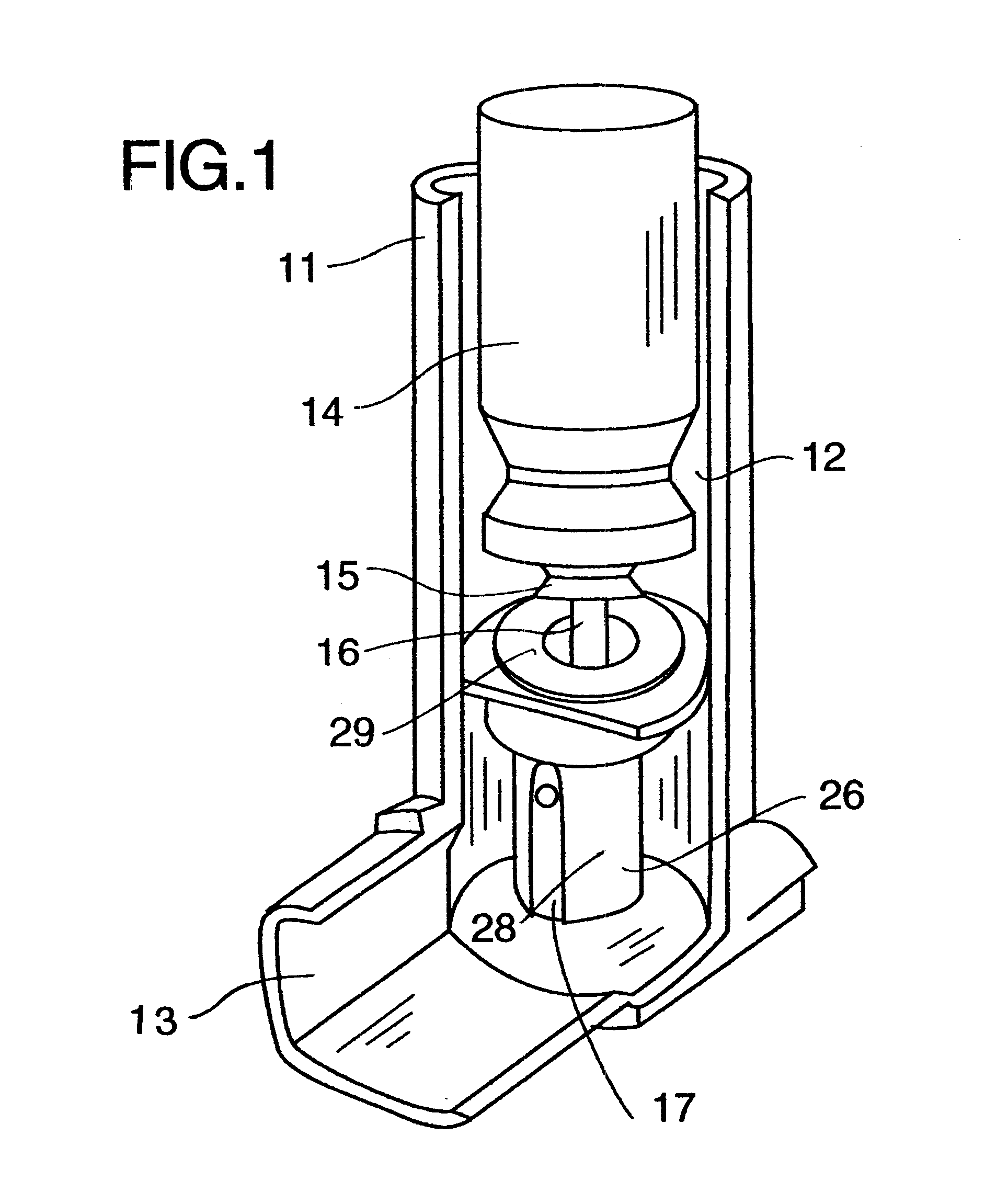

954 results about "Diaphragm valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, an elastomeric diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal, wood or other materials depending on the intended use.

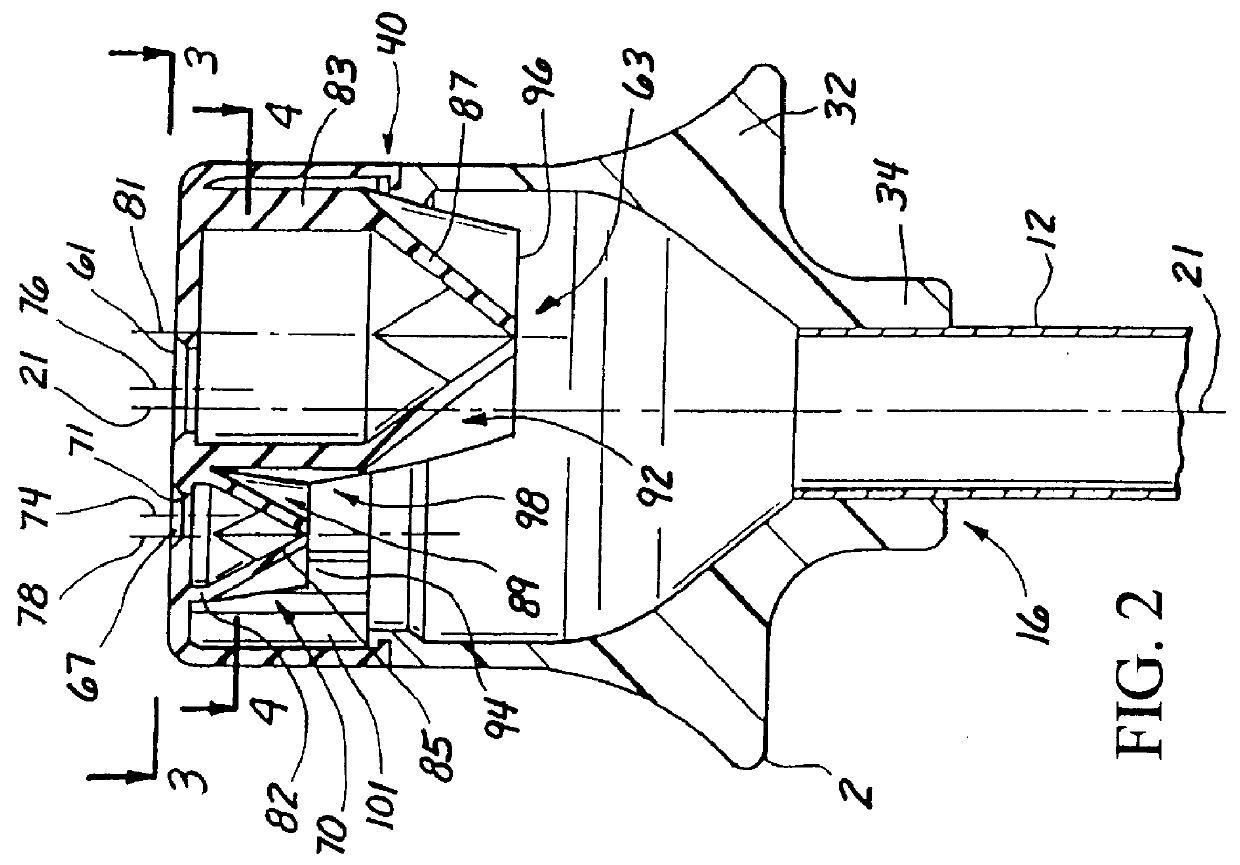

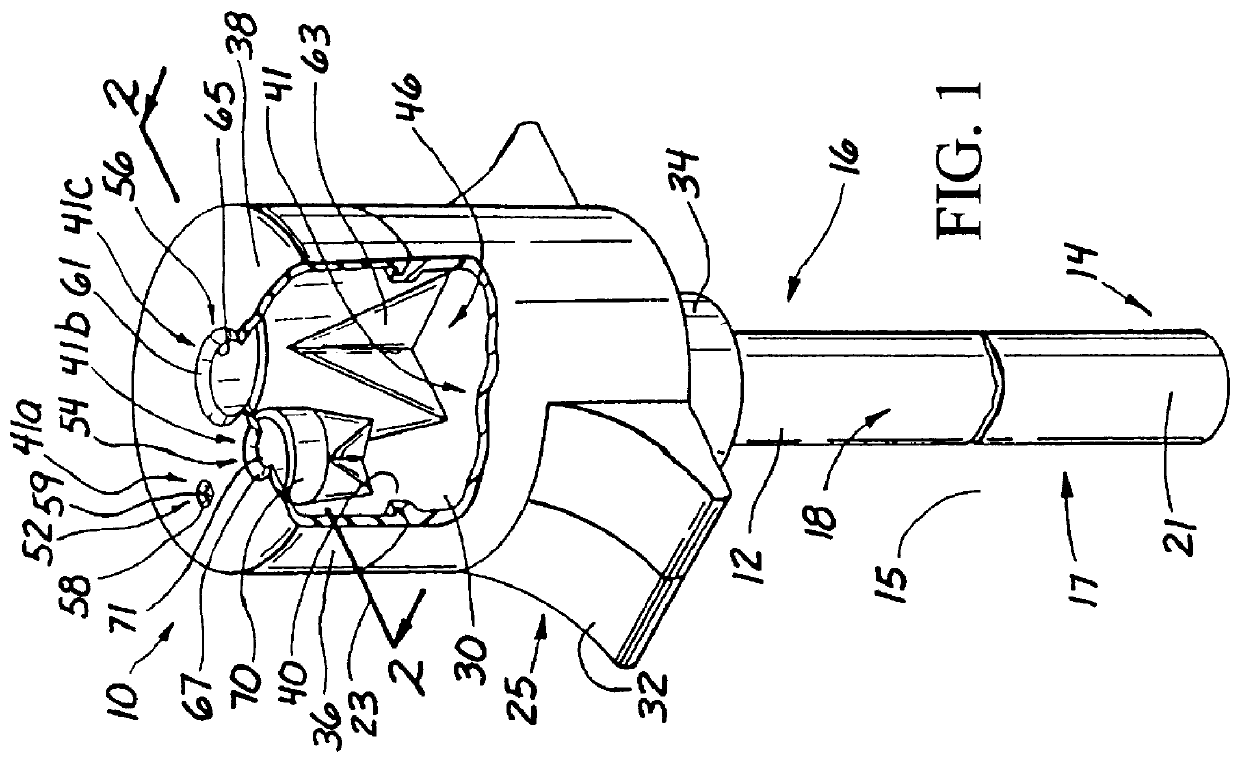

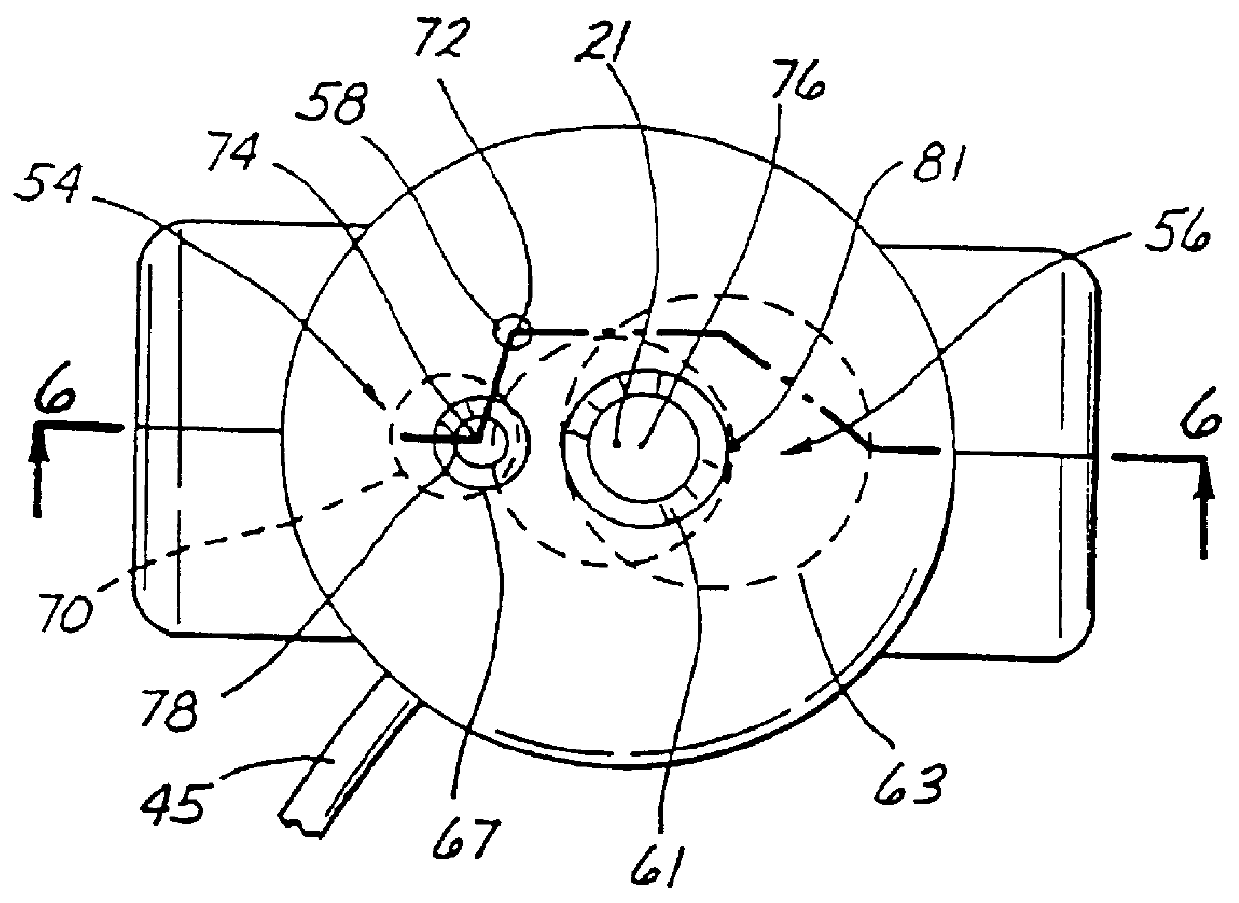

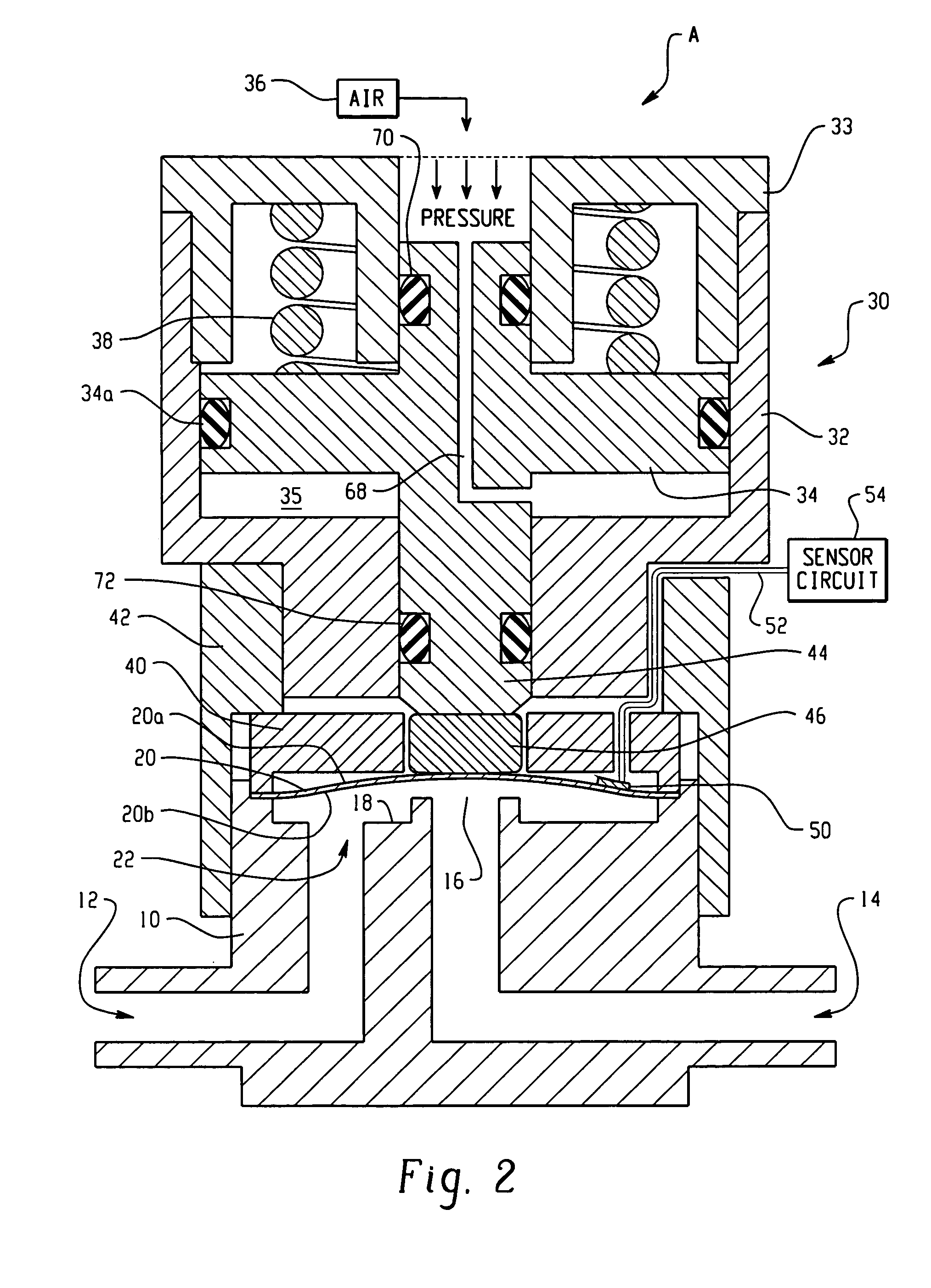

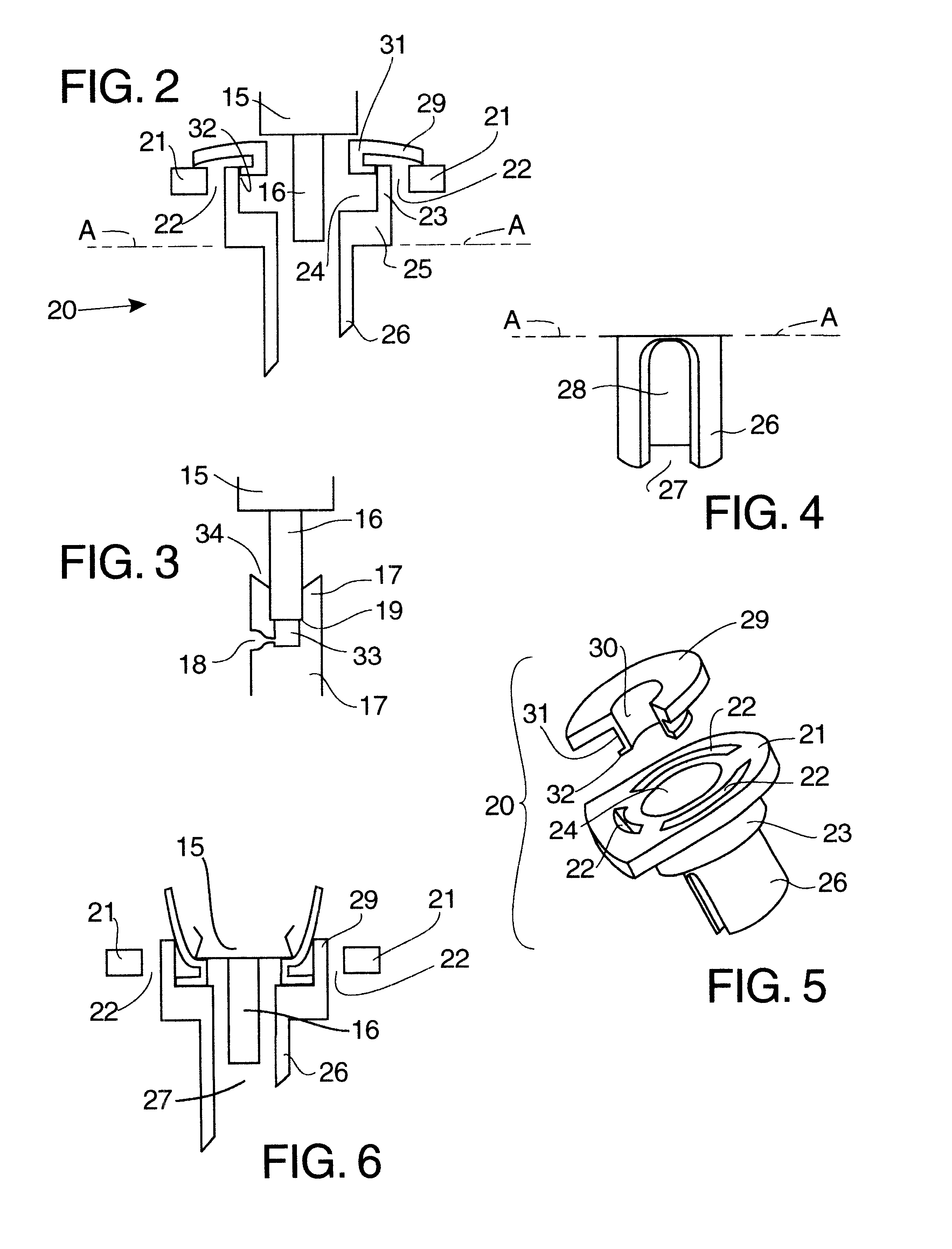

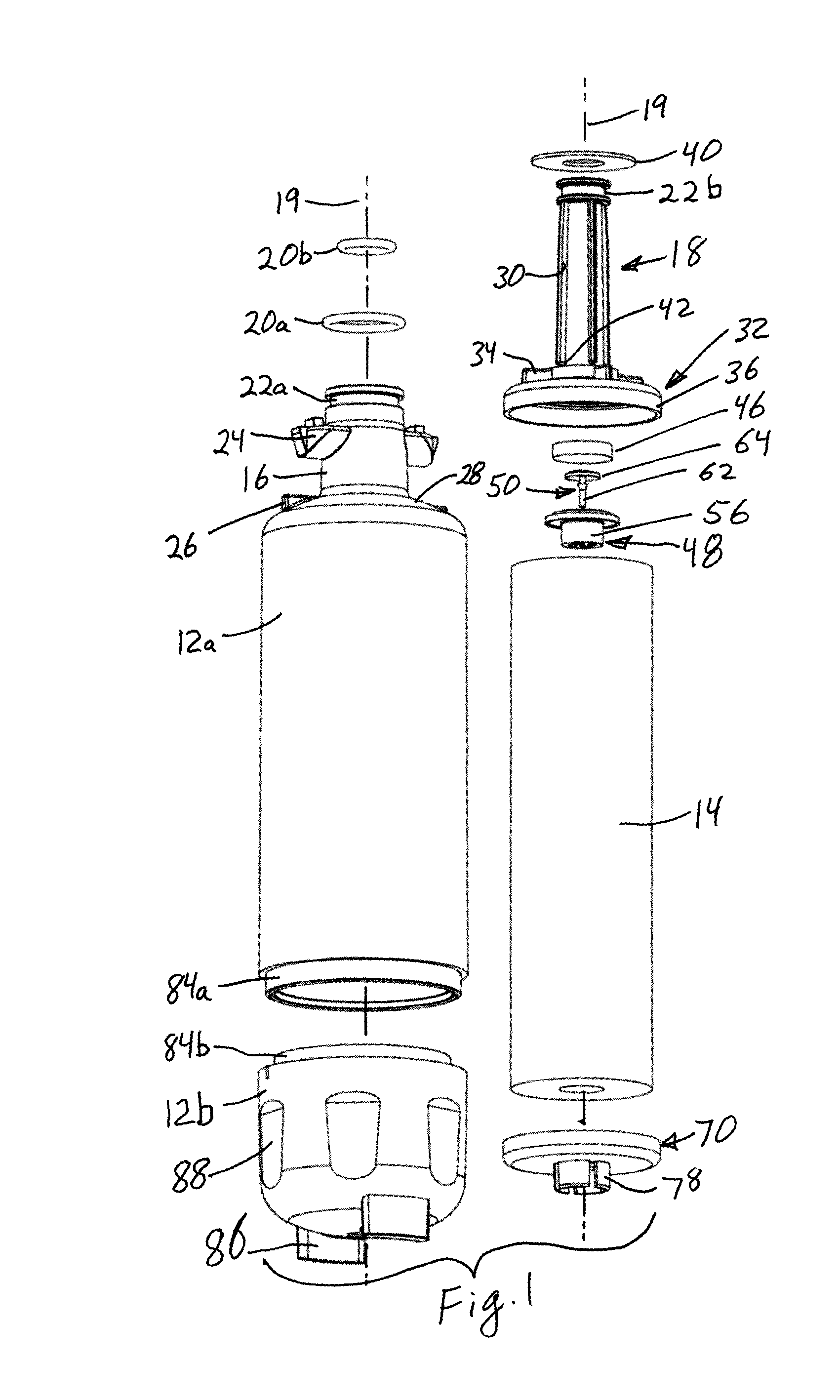

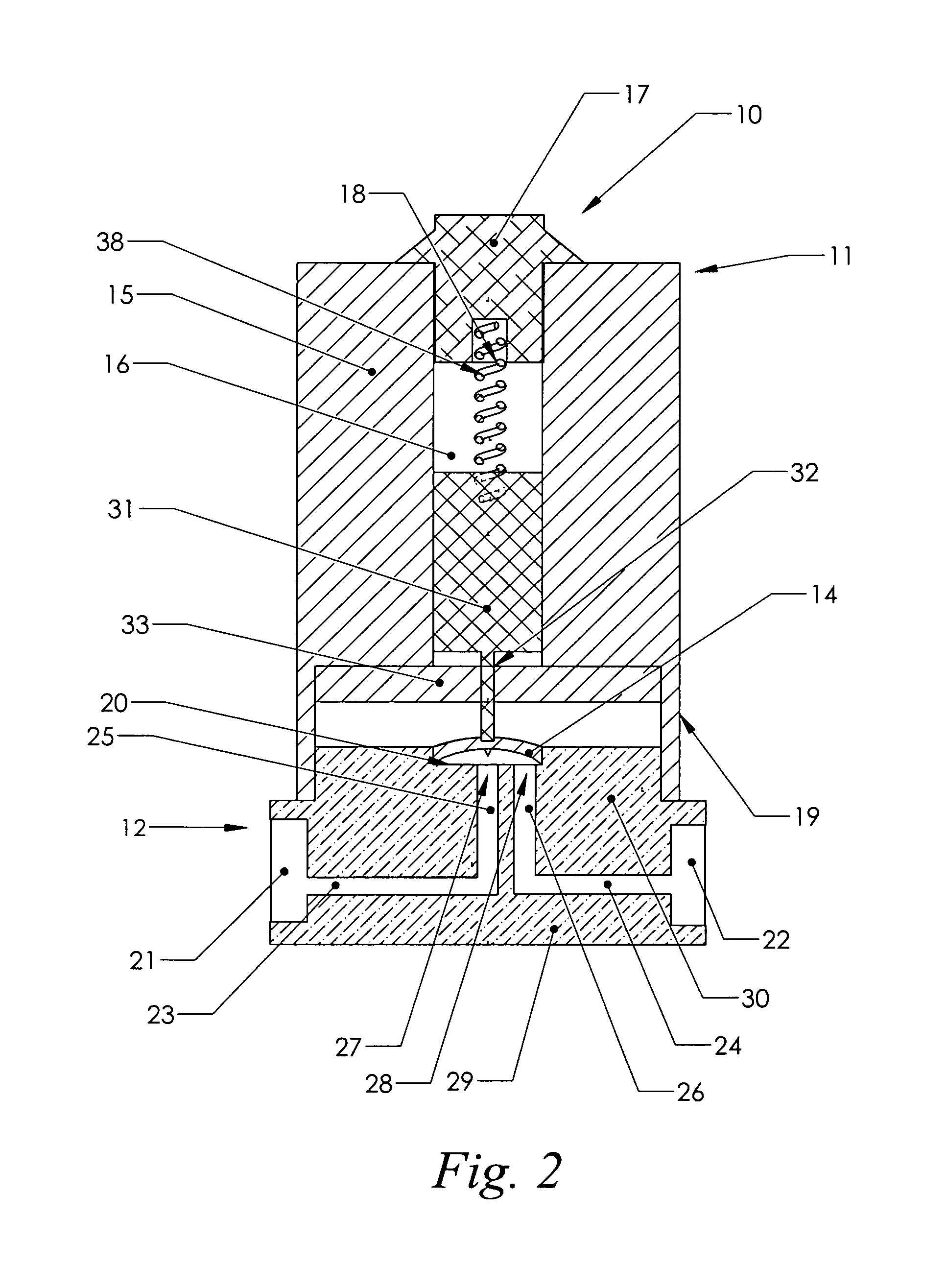

Multiport access device

A trocar having a cannula and a valve housing with a polygonal configuration, provides for a floating septum where the float is encouraged in a first direction and restricted in a second direction. The septum includes multiple septum valves which may function with a comnron zero-closure valve, or individually in a valve assembly with an associated zero-closure valve. Various seals can be configured to prevent blow-back. Cup valves, check valves, and reciprocating valves are contemplated, along with various skirt configurations for maintaining pressurized air within the trocar.

Owner:APPL MEDICAL RESOURCES CORP

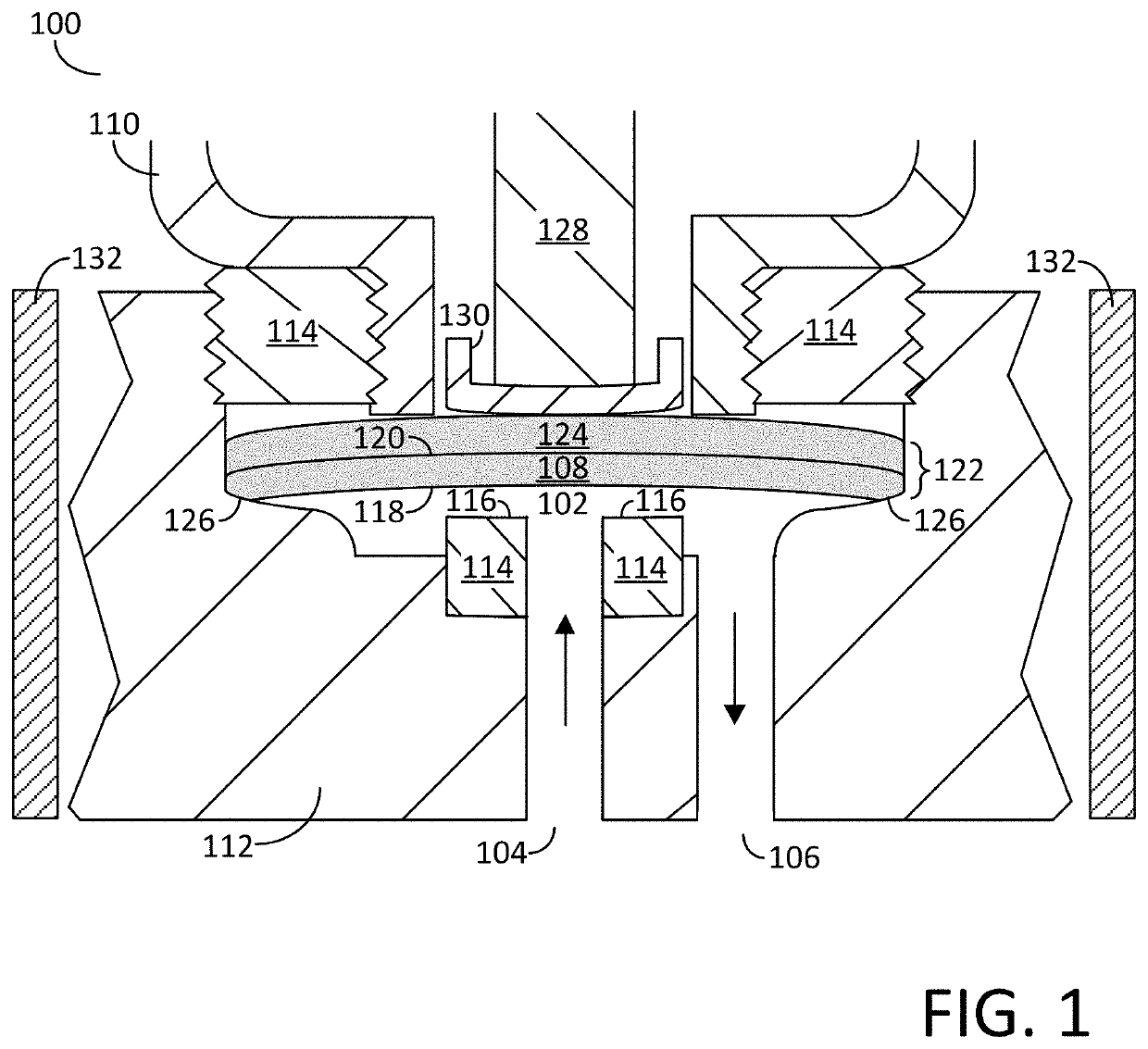

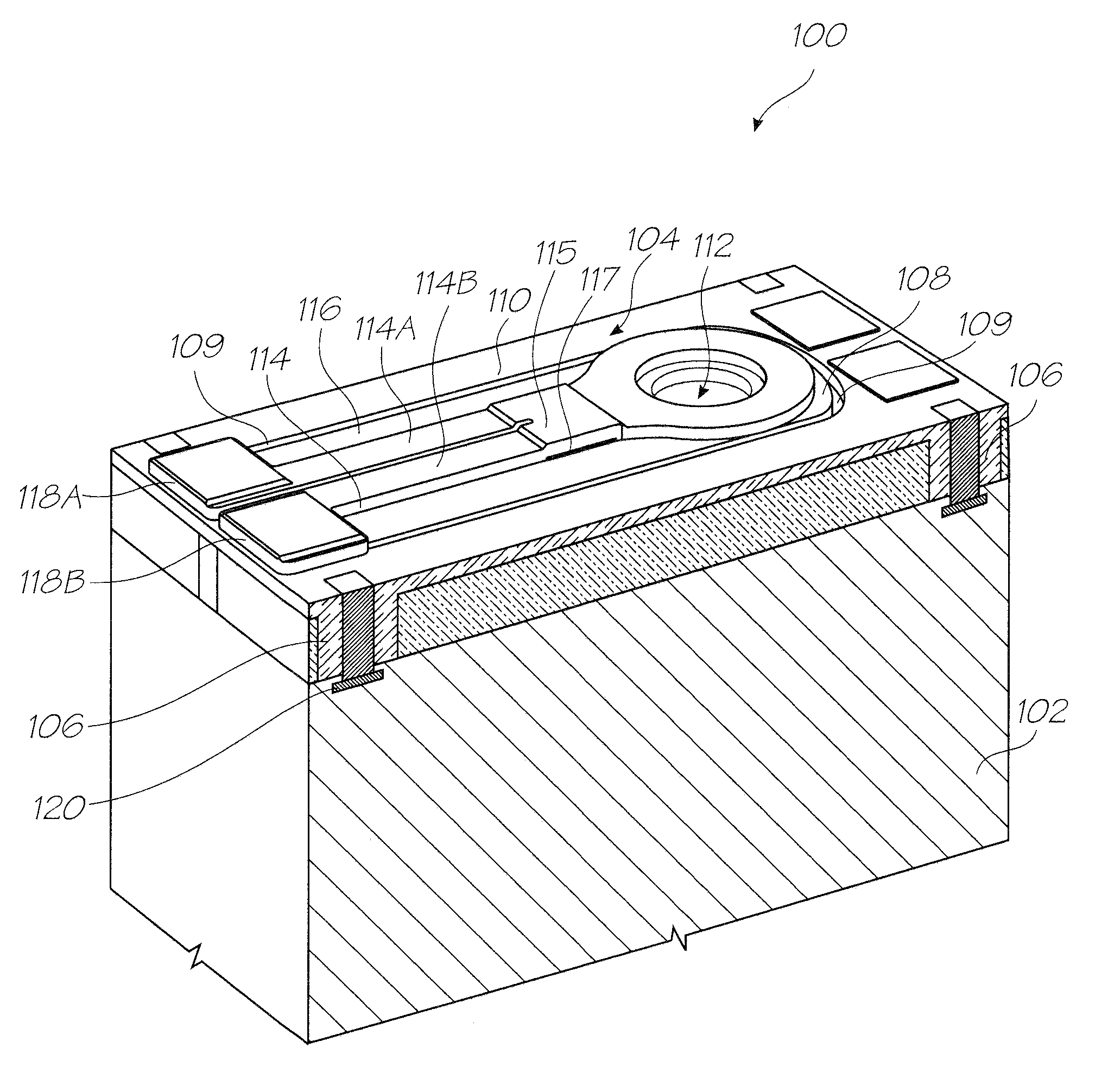

Diaphragm valves, valve components, and methods for forming valve components

ActiveUS20200018421A1Diaphragm valvesOperating means/releasing devices for valvesValve actuatorEngineering

A diaphragm valve is disclosed. The diaphragm valve may include, a valve body comprising a valve channel, the valve channel including an inlet channel and an outlet channel. The diaphragm valve may also include, a valve seat adjacent to the valve channel and a flexible diaphragm comprising a wetted surface and an opposing non-wetted surface, the flexible diaphragm being disposed adjacent to the valve channel. The diaphragm valve may also include, a flexible heater disposed over the non-wetted surface of the flexible diaphragm, and a valve actuator that is operable to operable to move the wetted surface of the flexible diaphragm into and out of contact with the valve seat. Valve components including a flexible heater and methods for forming such valve components are also disclosed.

Owner:ASM IP HLDG BV

Diaphragm valve with reliability enhancements for atomic layer deposition

InactiveUS7021330B2Improve heat transfer performanceInhibiting condensingDiaphragm valvesOperating means/releasing devices for valvesEnhanced heat transferDiaphragm valve

A shut-off type diaphragm valve adapted for use in an atomic layer deposition system includes a valve seat having an annular seating surface that surrounds an inlet of the valve and extends radially therefrom. The seating surface contacts a substantial portion of the first side of a flexible diaphragm when the diaphragm is closed, to facilitate heat transfer and counteract dissipative cooling of the diaphragm, thereby inhibiting condensation of a medium flowing through the valve passage. The seating surface is preferably flat and smooth, to prevent shearing of an elastomeric diaphragm. For a plastic diaphragm, a ring-shaped seating ridge may extend from the seating surface to cause localized permanent deformation of the diaphragm and enhanced sealing, while still allowing a substantial portion of the diaphragm to contact the seating surface for enhanced heat transfer. Valve speed enhancements and other reliability enhancing features are also described.

Owner:BENEQ OY

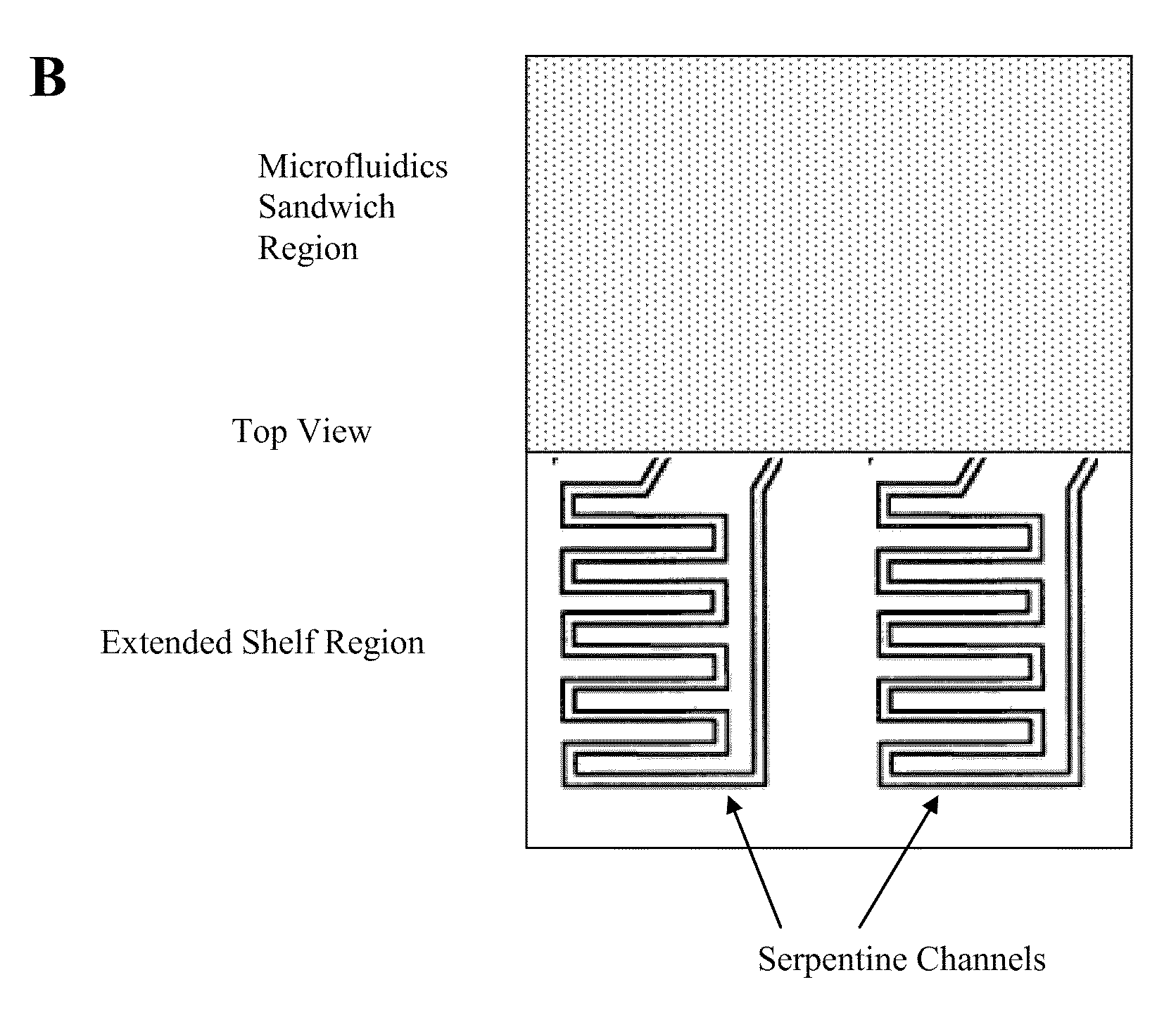

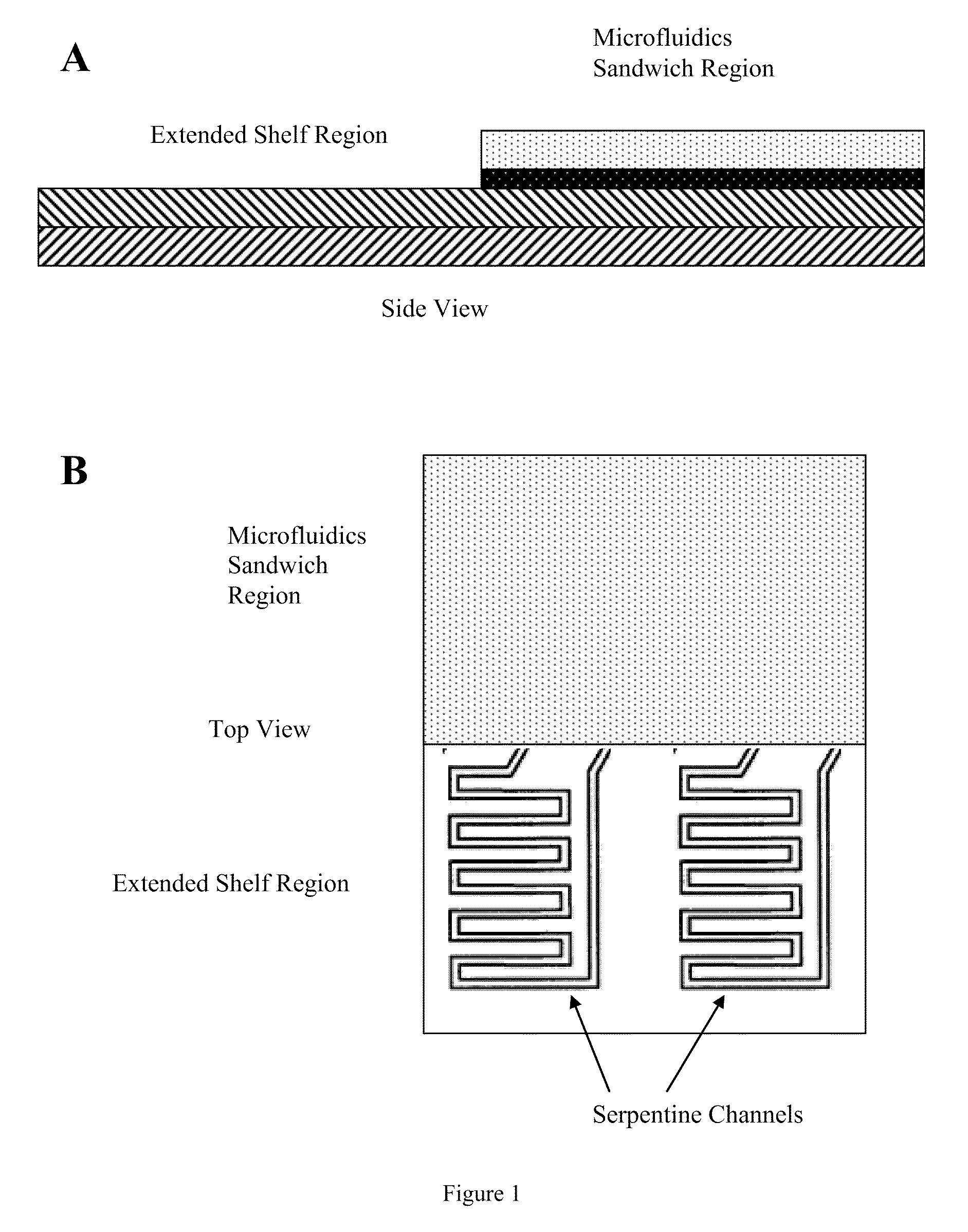

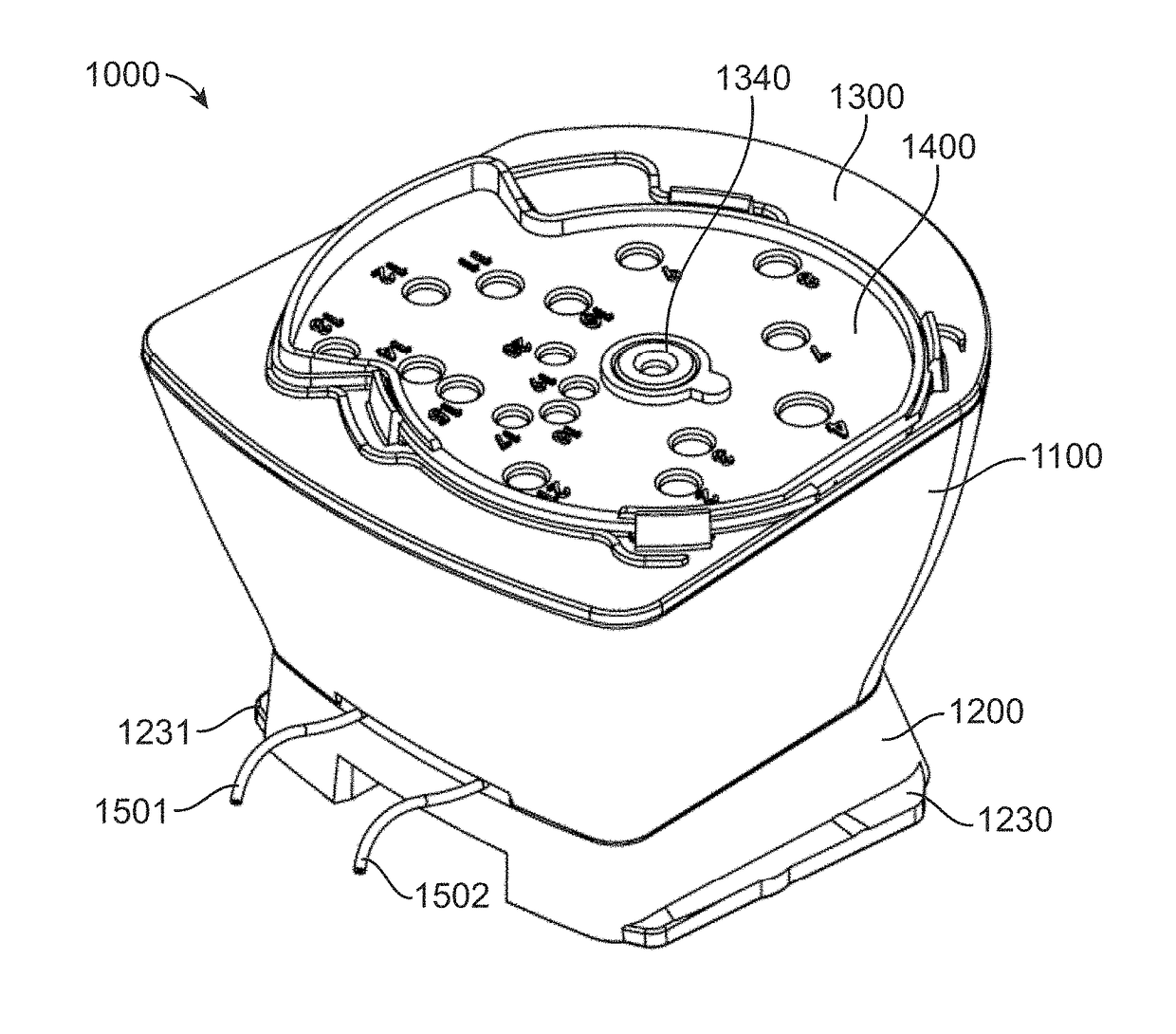

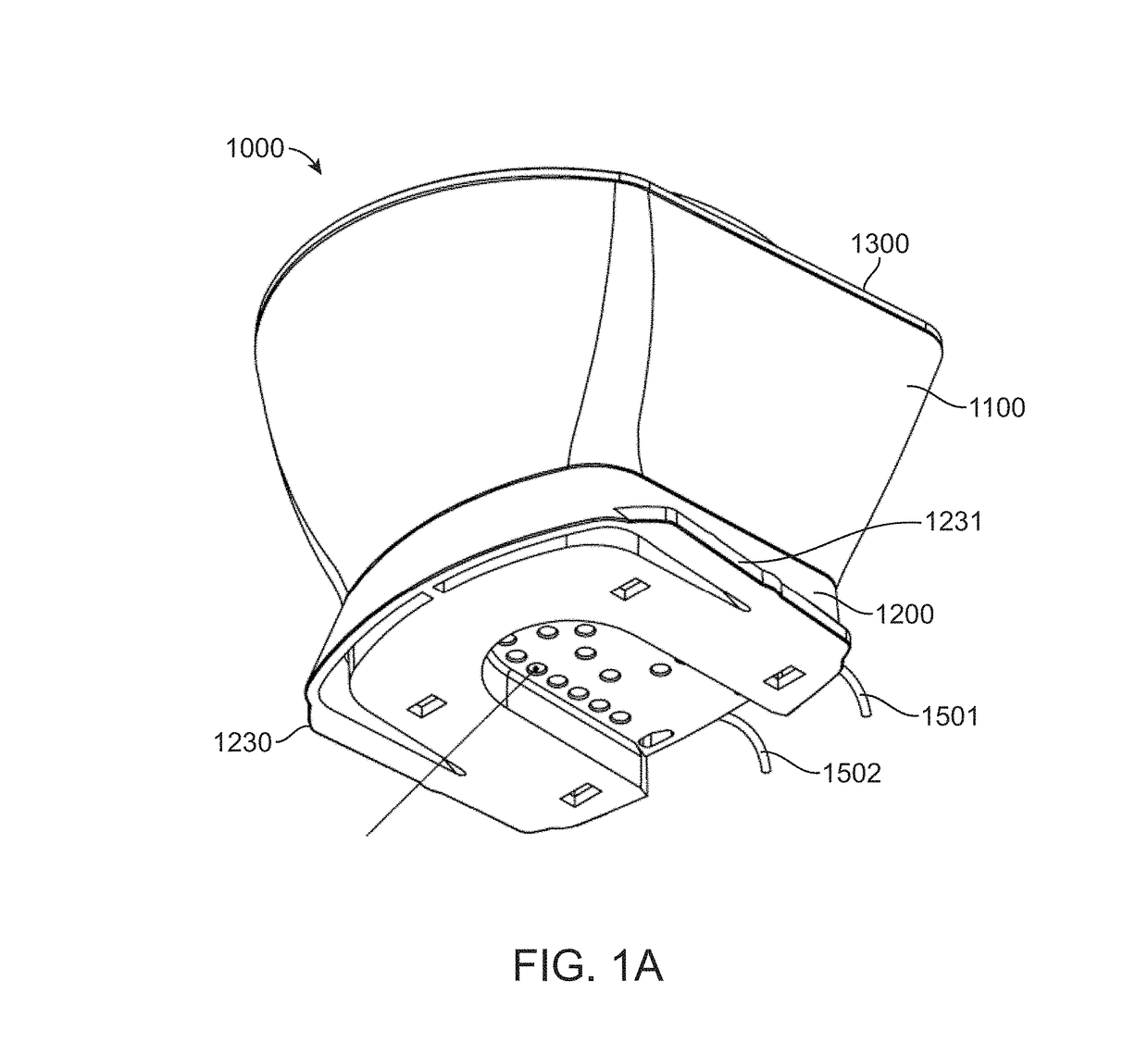

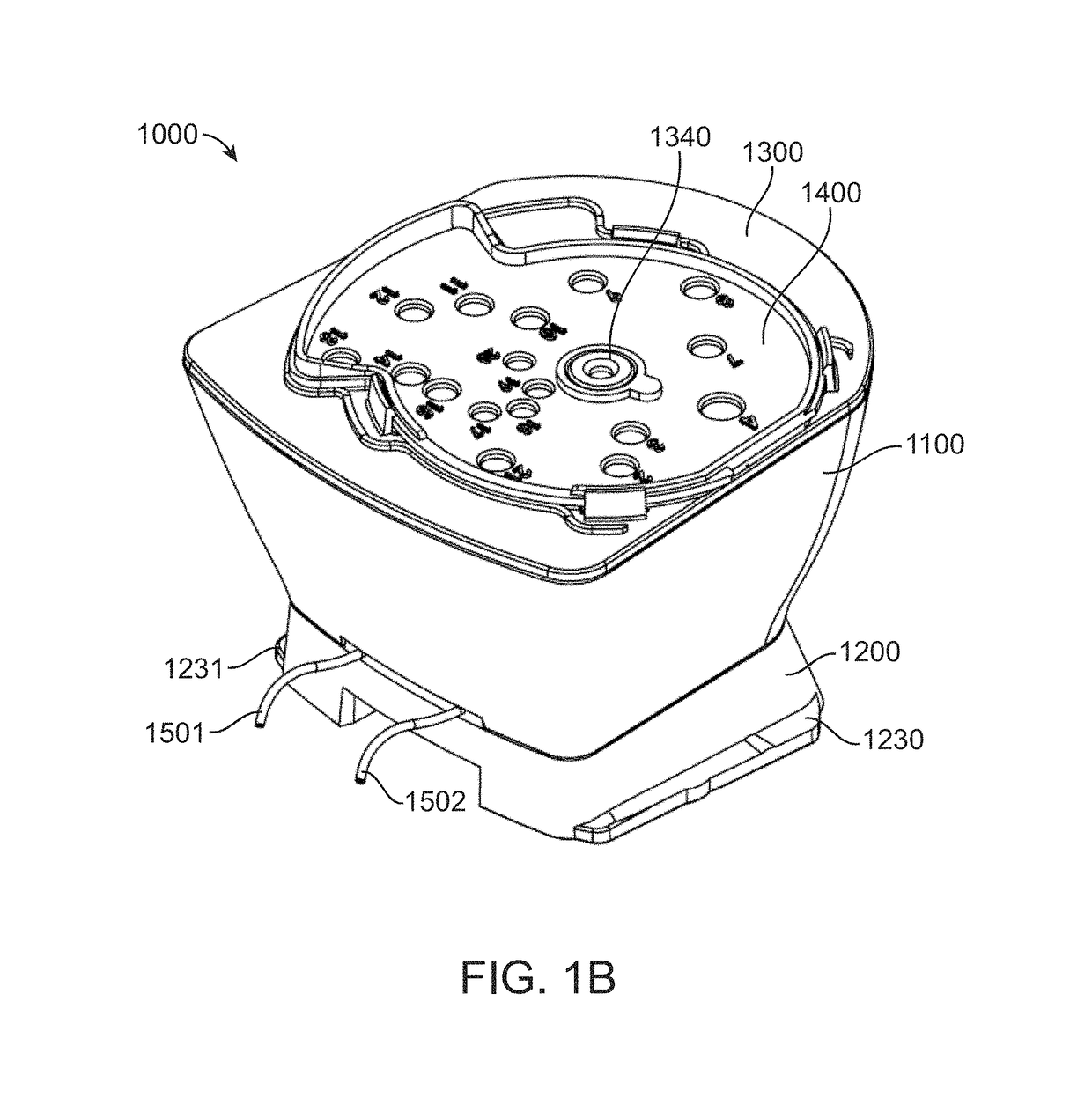

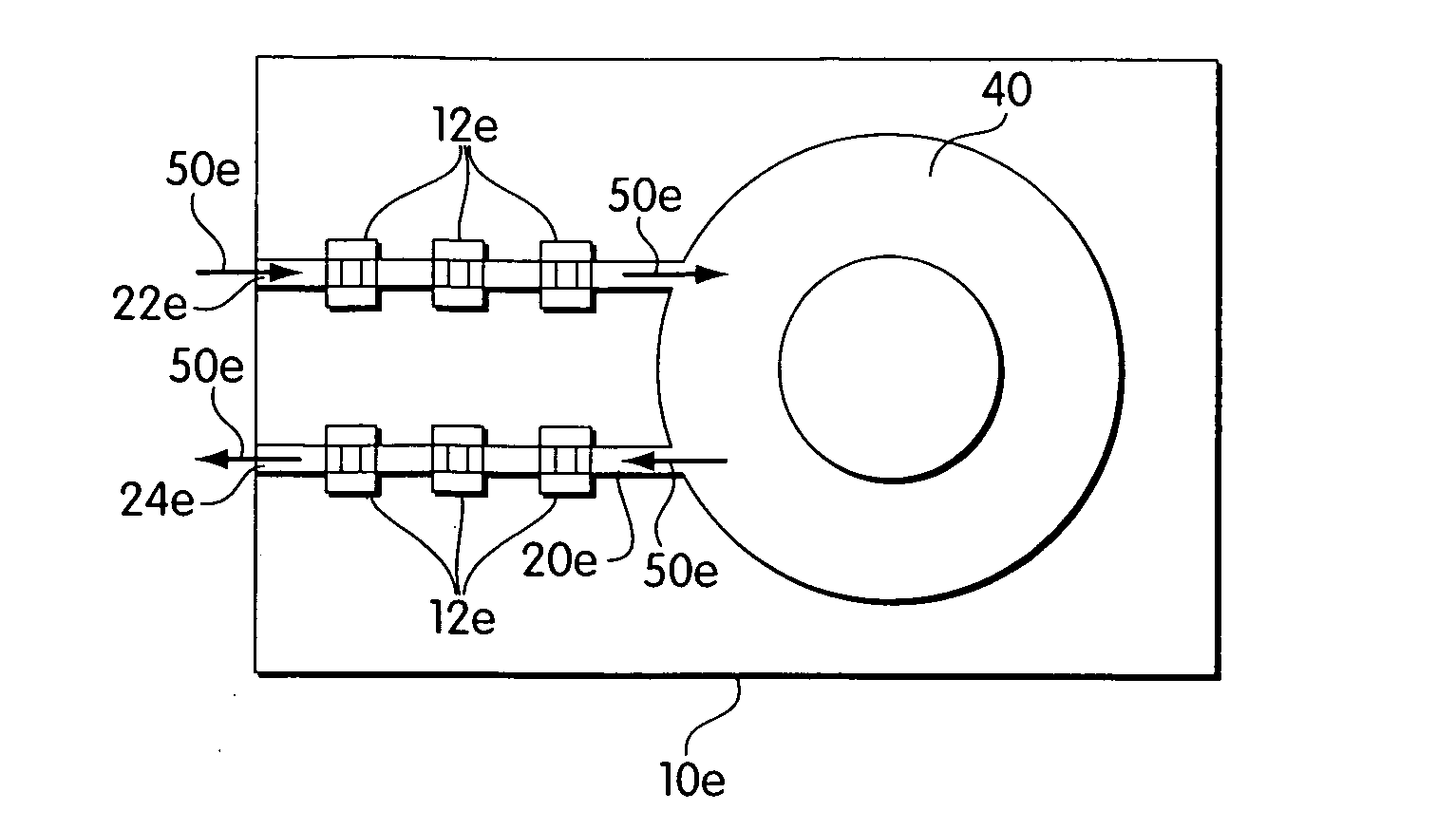

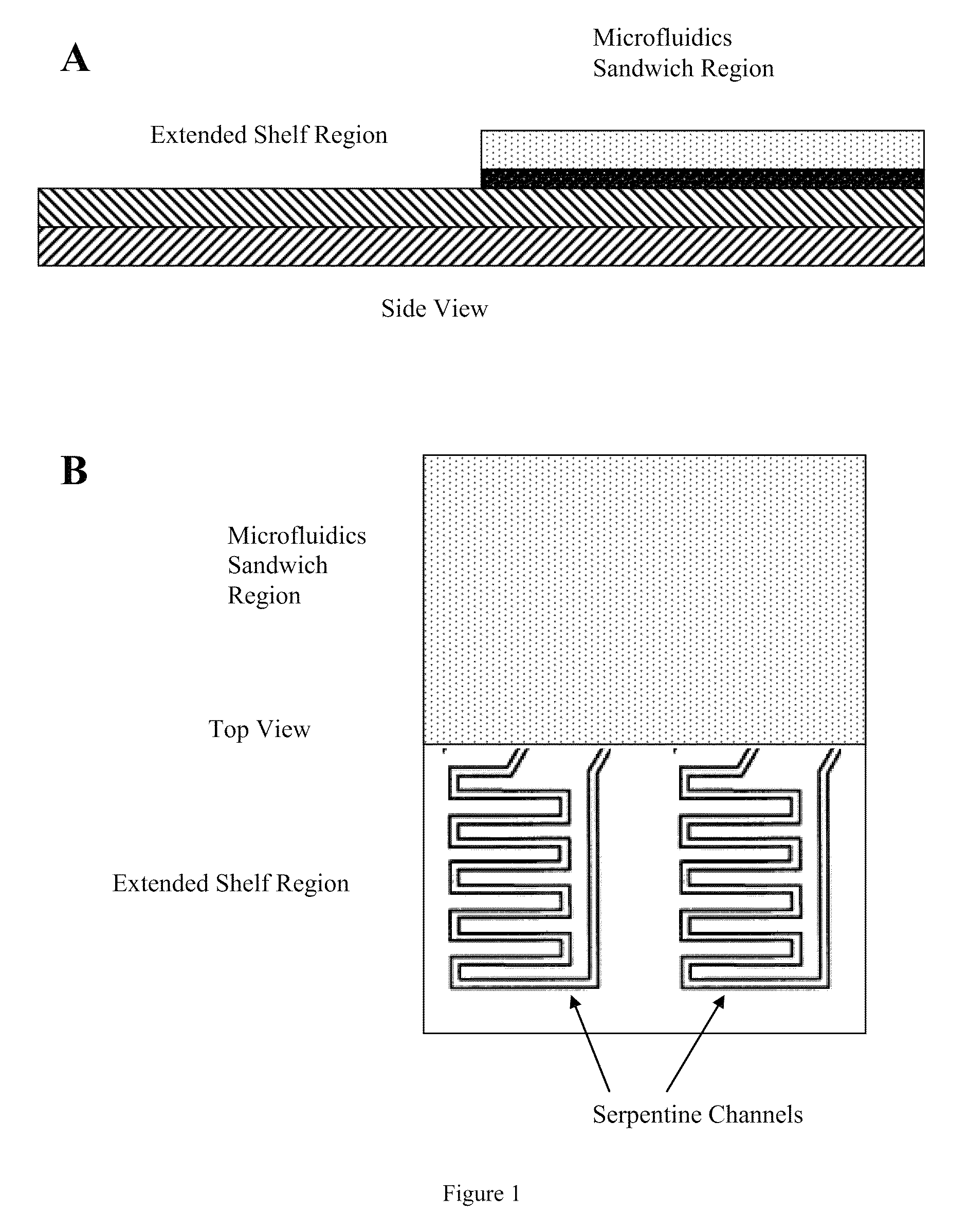

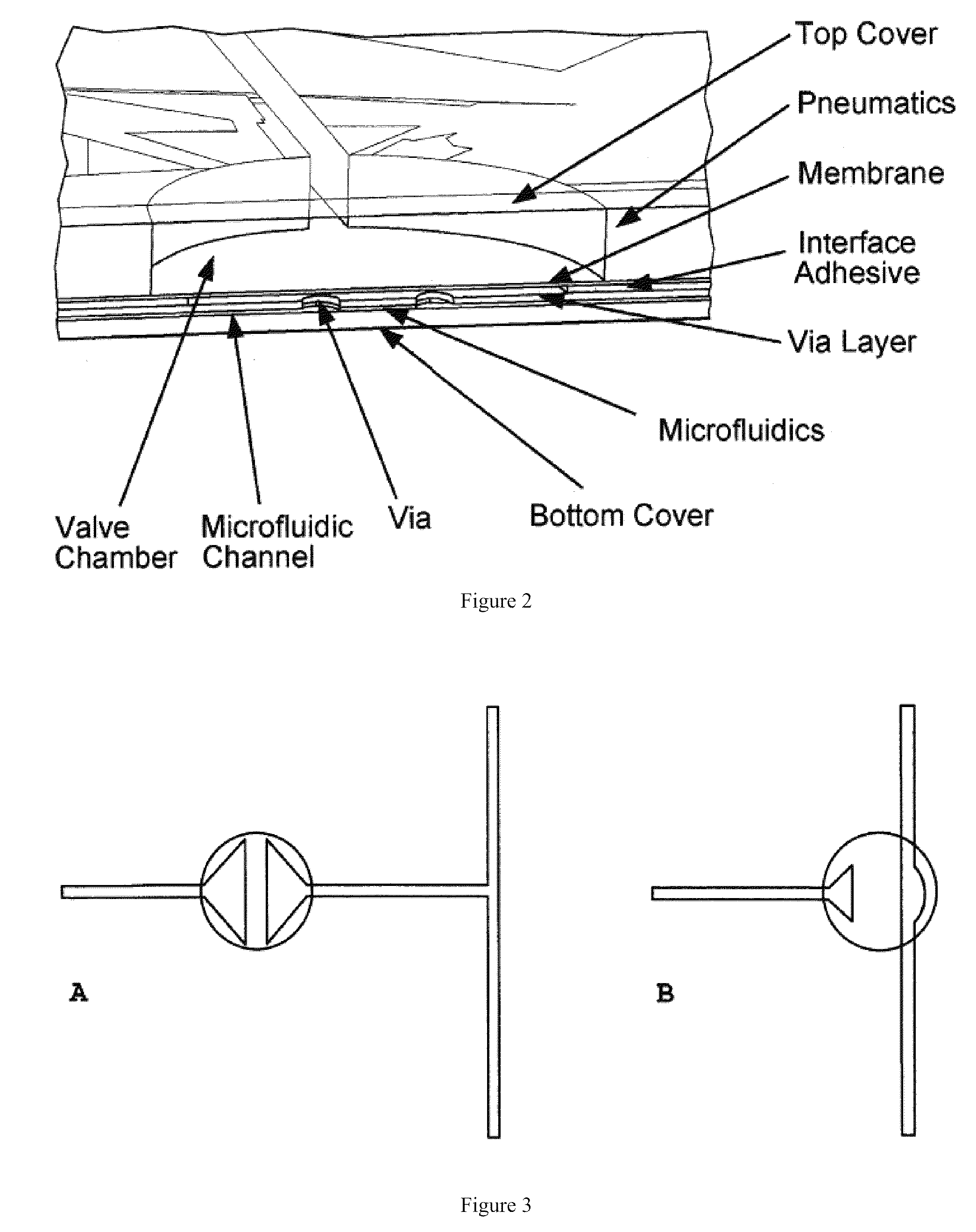

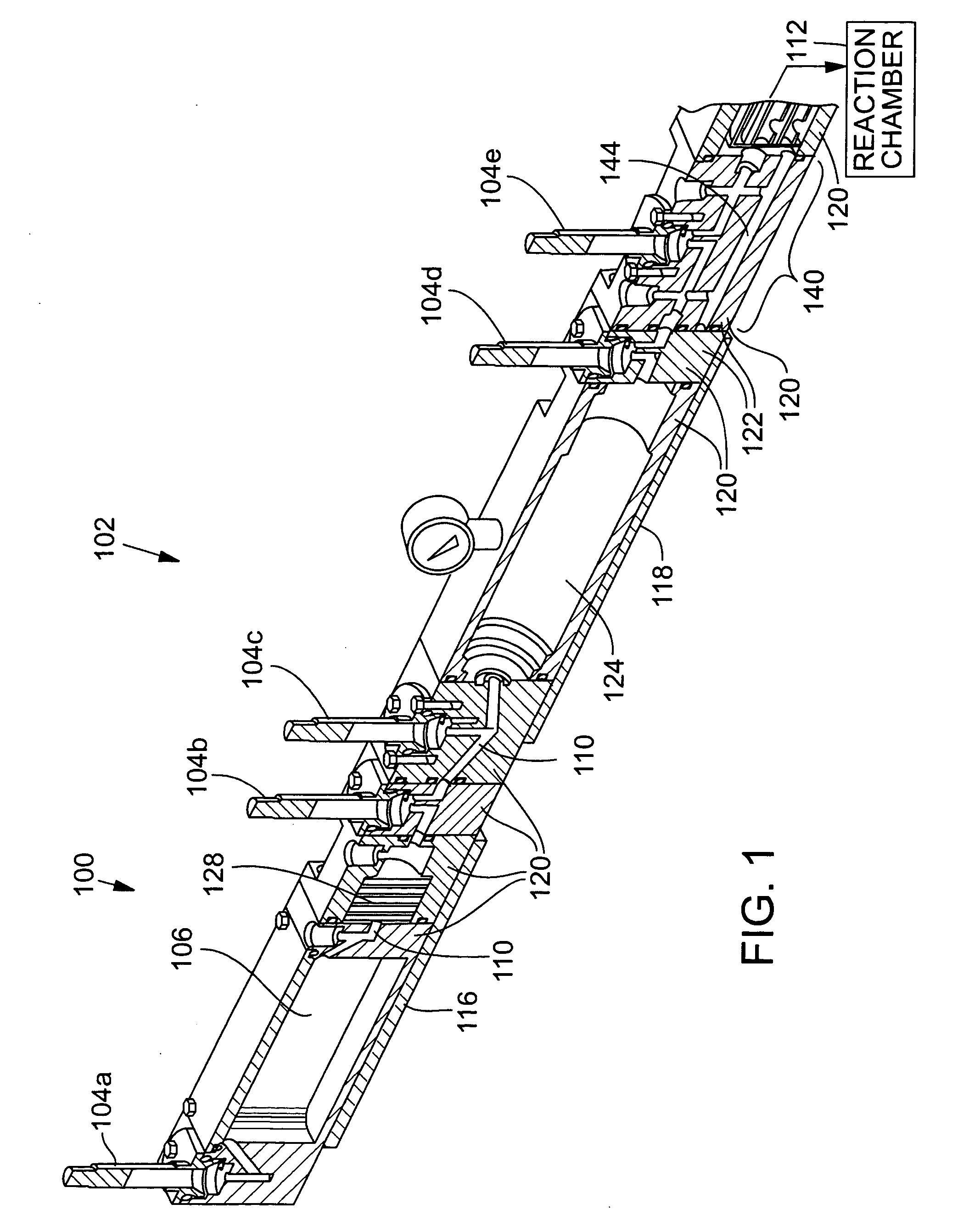

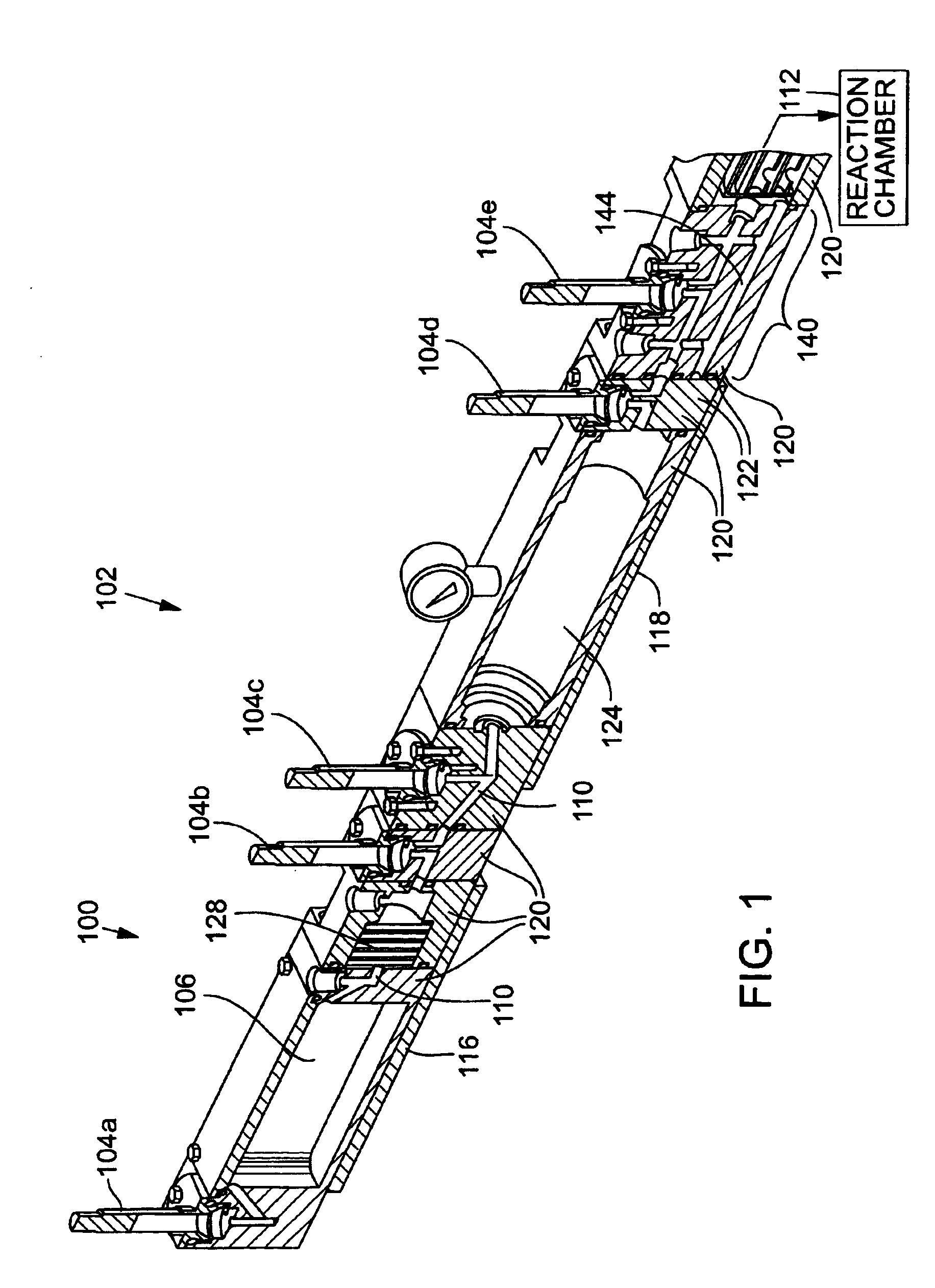

Instrument with microfluidic chip

ActiveUS20100165784A1Well mixedShaking/oscillating/vibrating mixersFlow mixersFluidicsDiaphragm valve

This invention provides microfluidic devices that comprise a fluidics layer having microfluidic channels and one or more regulating layers that regulate the movement of fluid in the channels. The microfluidic devices can be used to mix one or more fluids. At least a portion of the fluidics layer can be isolated from the regulating layer, for example in the form of a shelf. Such isolated portions can be used as areas in which the temperature of liquids is controlled. Also provided are instruments including thermal control devices into which the microfluidic device is engaged so that the thermal control device controls temperature in the isolated portion, and a movable magnetic assembly including magnets with shields so that a focused magnetic field can be applied to or withdrawn from the isolated portion or any other portion of the microfluidic device. Also provided are methods of mixing fluids. The methods include stacking a plurality of alternating boluses of different liquids in a microfluidic channel, and moving the stacked boluses through the channel. In another method, the boluses are moved into a diaphragm valve having a volume able to accommodate several boluses, and then pumping the liquids out of the valve.

Owner:INTEGENX

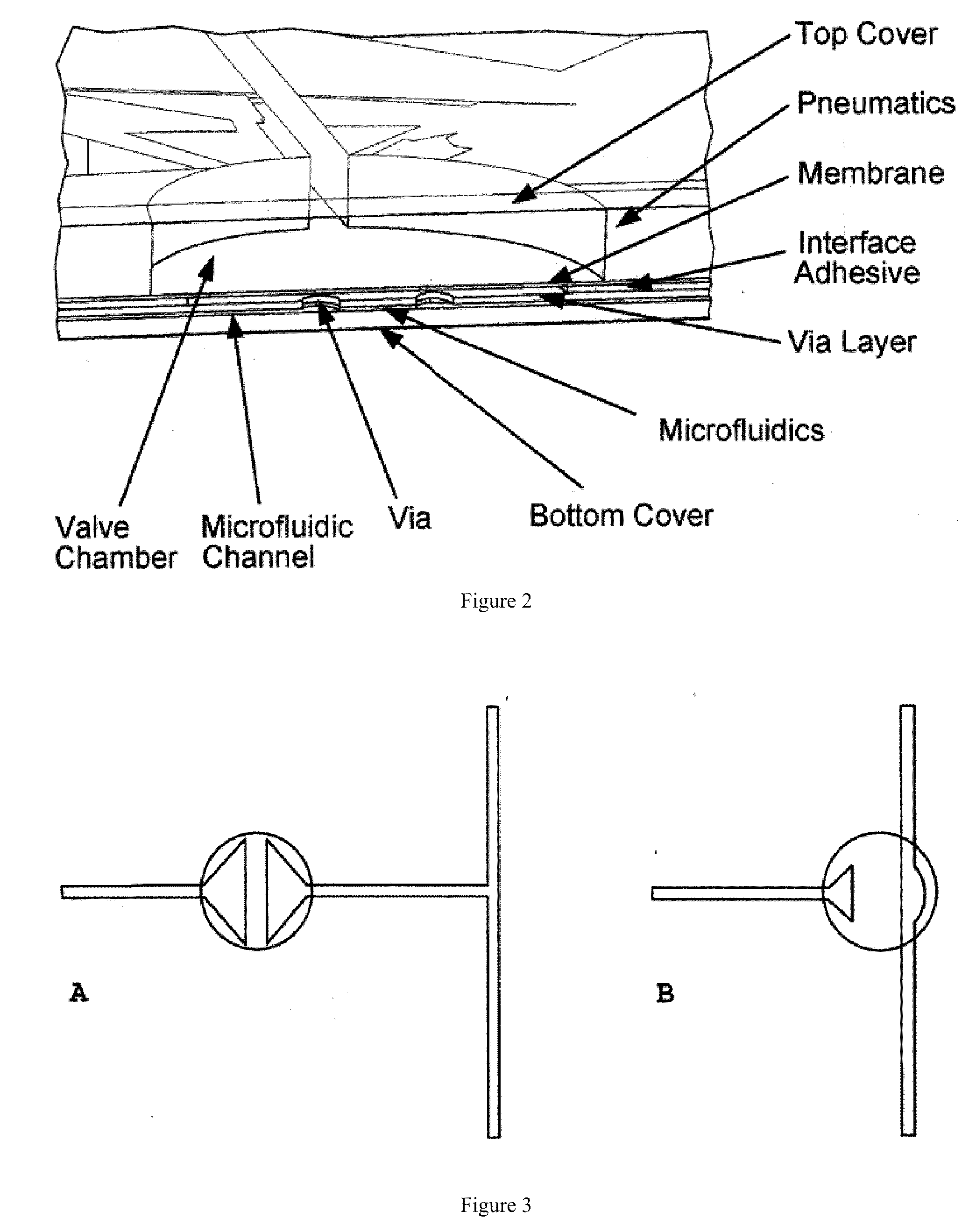

Microfluidic valve mechanism

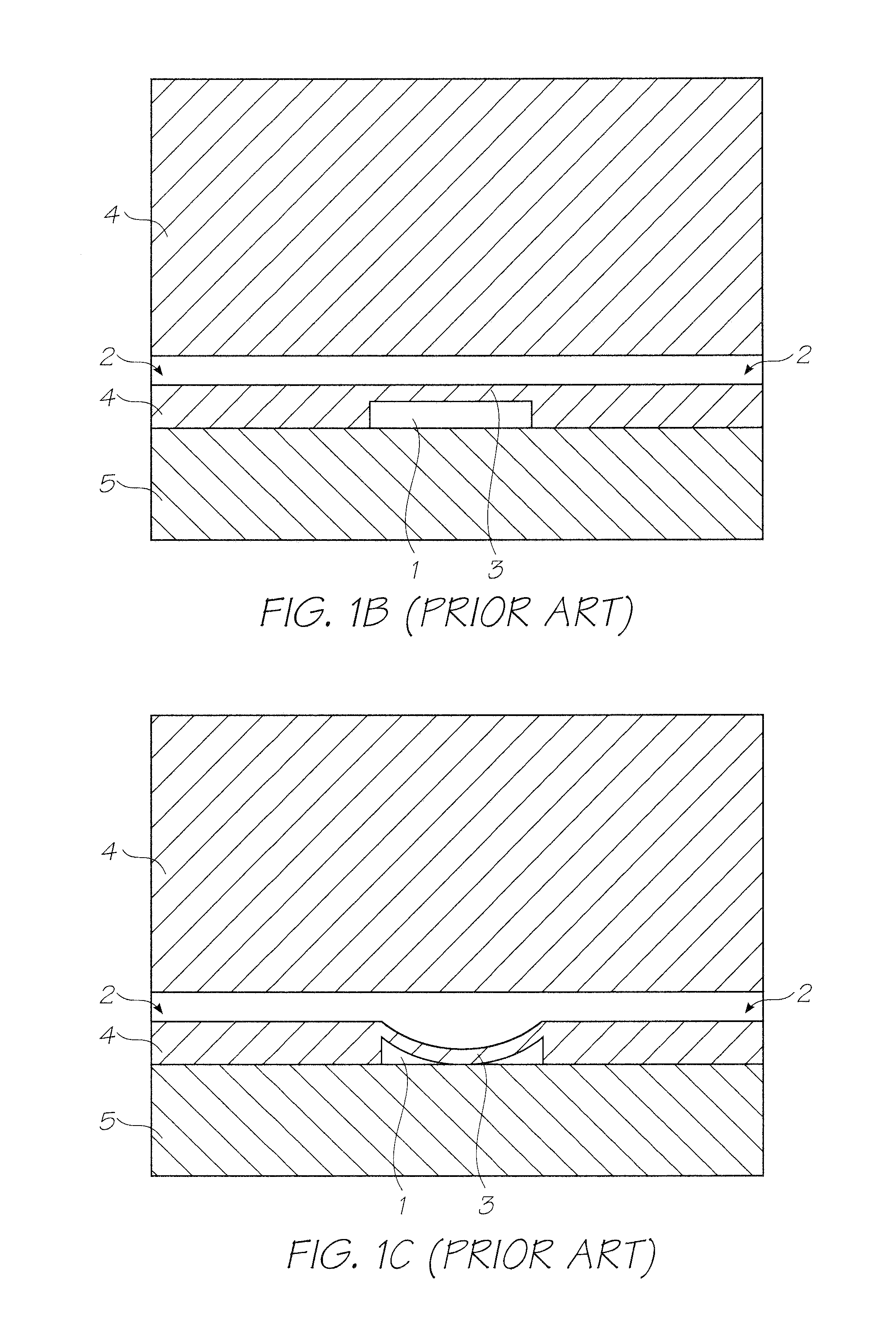

InactiveUS7607641B1Diaphragm valvesOperating means/releasing devices for valvesMagnetic tapeEngineering

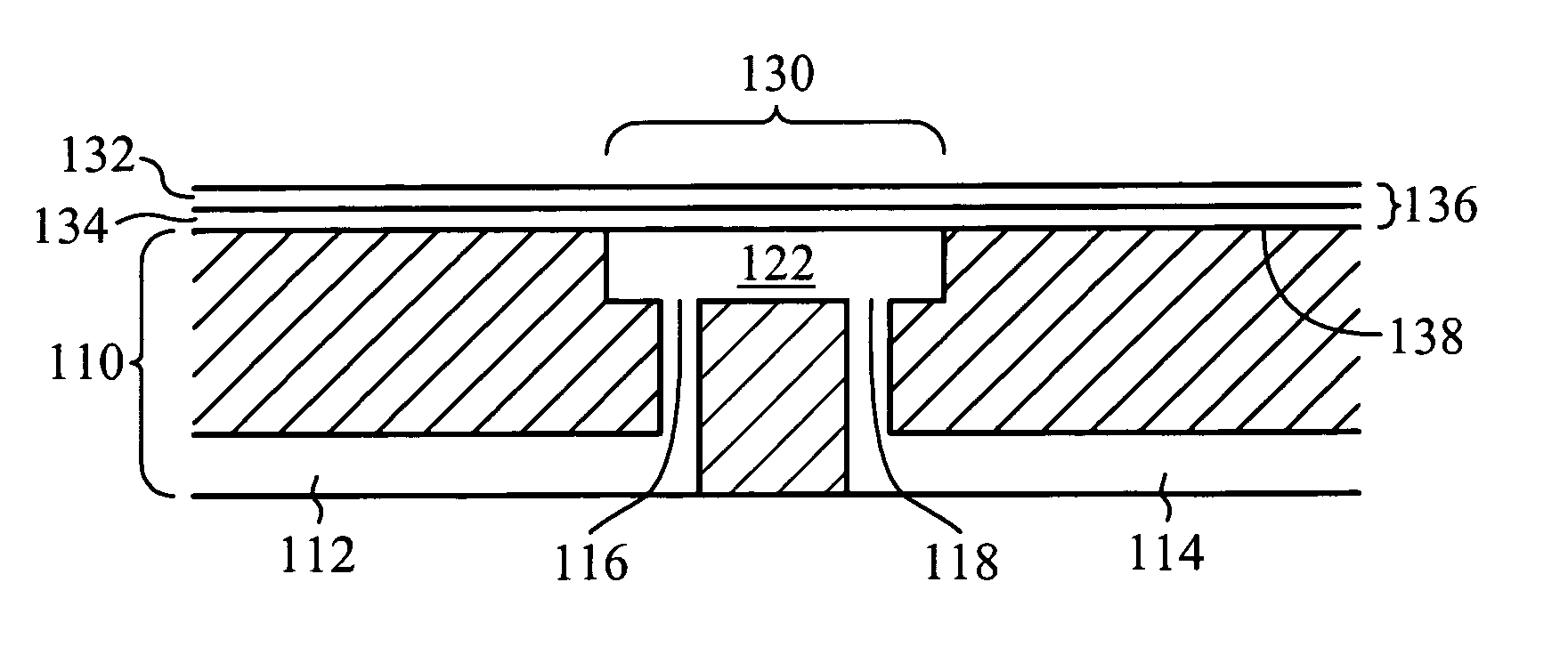

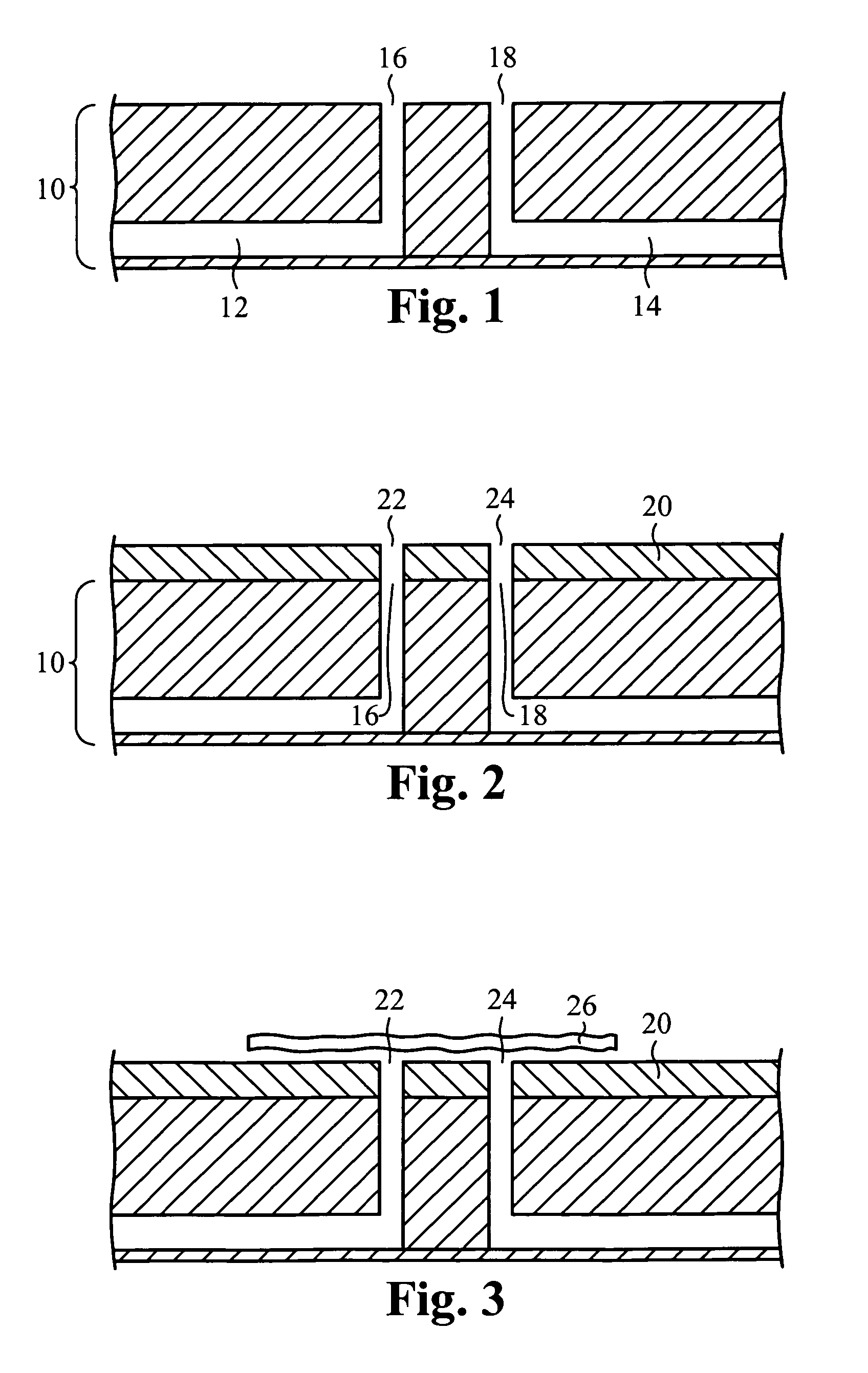

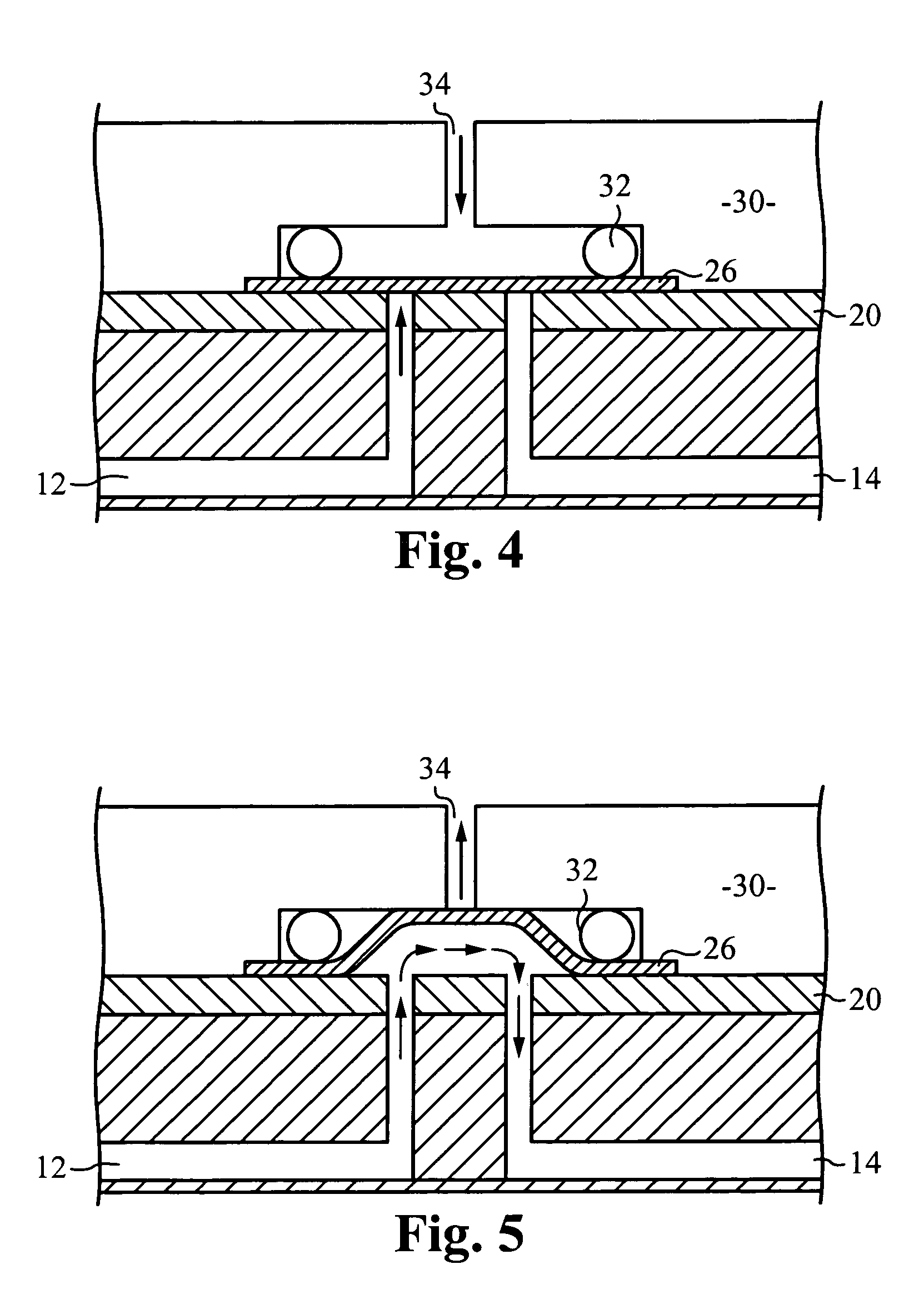

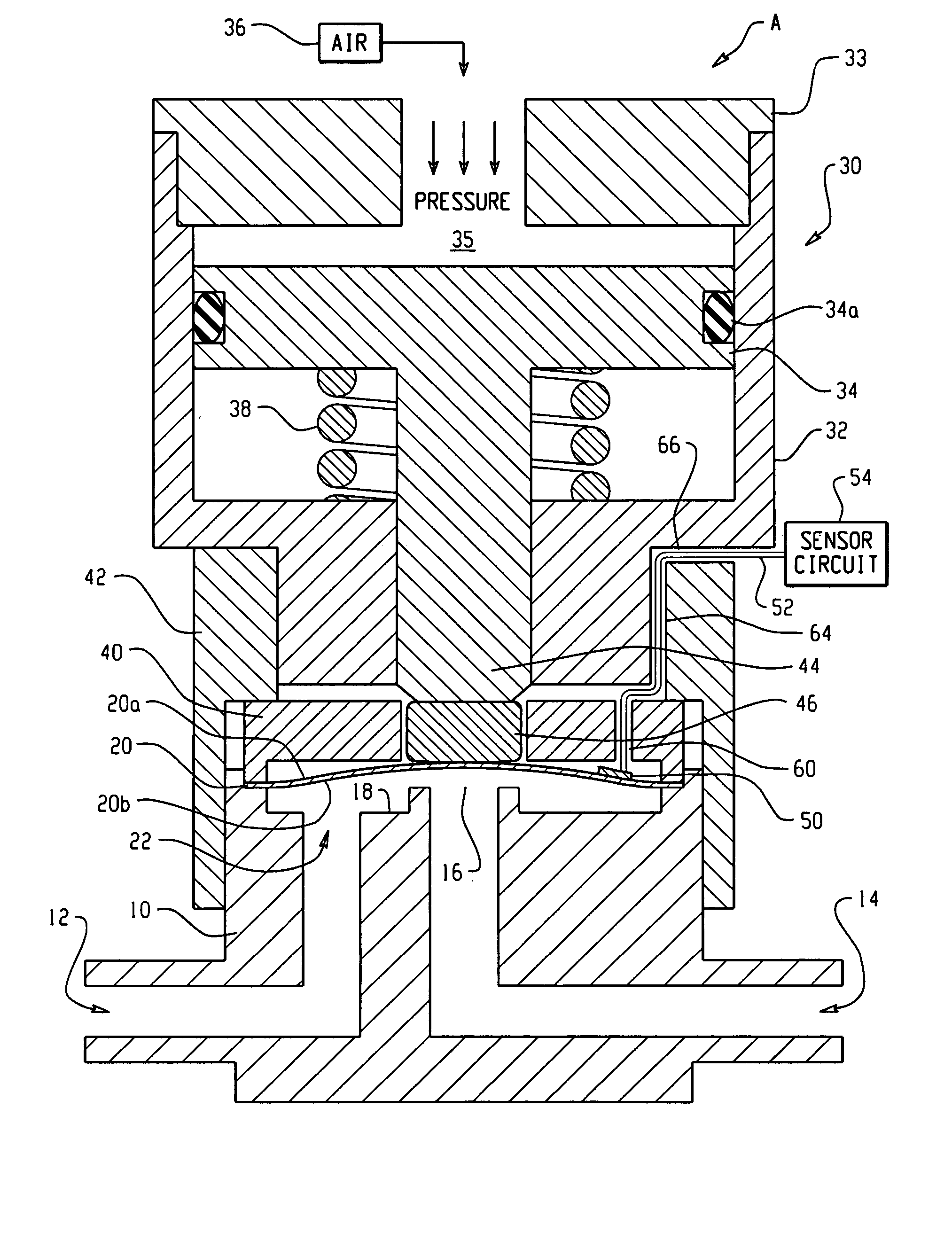

One or more diaphragm valves are integrated as part of a cover of a microfluidic cassette cartridge. A rigid body portion includes one or more recessed valve areas and a plurality of fluid channels. A recessed valve area is disposed along either a bottom surface or a top surface of the rigid body portion. An inlet fluid channel and an outlet fluid channel are formed within the rigid body portion of each recessed valve area. A flexible membrane cover is sealed over the bottom surface of the body portion, and another flexible membrane cover is sealed over the top surface. A portion of the membrane cover that covers a recessed valve area functions as a valve membrane of the diaphragm valve. The flexible membrane functions as both a cover of the cartridge, thereby sealing and enclosing the appropriate channels, and a valve membrane of the diaphragm valve.

Owner:MICROFLUIDIC SYST

Diaphragm monitoring for flow control devices

InactiveUS20050092079A1High sensitivityDiaphragm valvesOperating means/releasing devices for valvesEngineeringDiaphragm valve

Owner:SWAGELOK CO

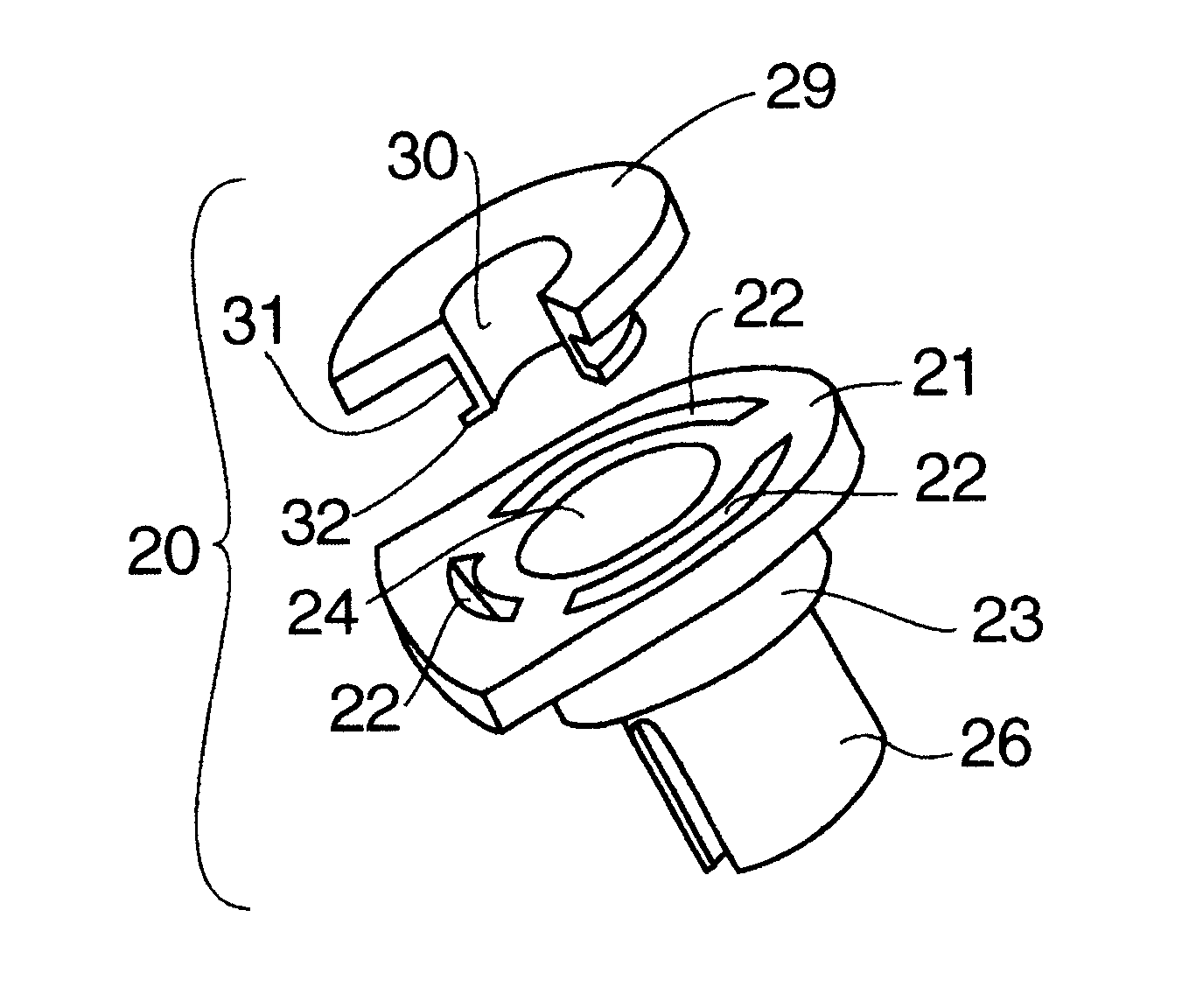

Self closing diaphragm type valve with primary peripheral and secondary central openings

A valve, shaped and sized for metered dose inhalers, consisting of a mount, a central body and top plate with peripheral air passages and central opening for medication delivery. A flexible elastic diaphragm closes the air passages and a central wiper seal on the diaphragm isolates the center opening from the air passageway. Pressure on the rim of the central opening of the diaphragm causes it to open the air passages timed with injection of medication through the central opening.

Owner:STAGE JACK W

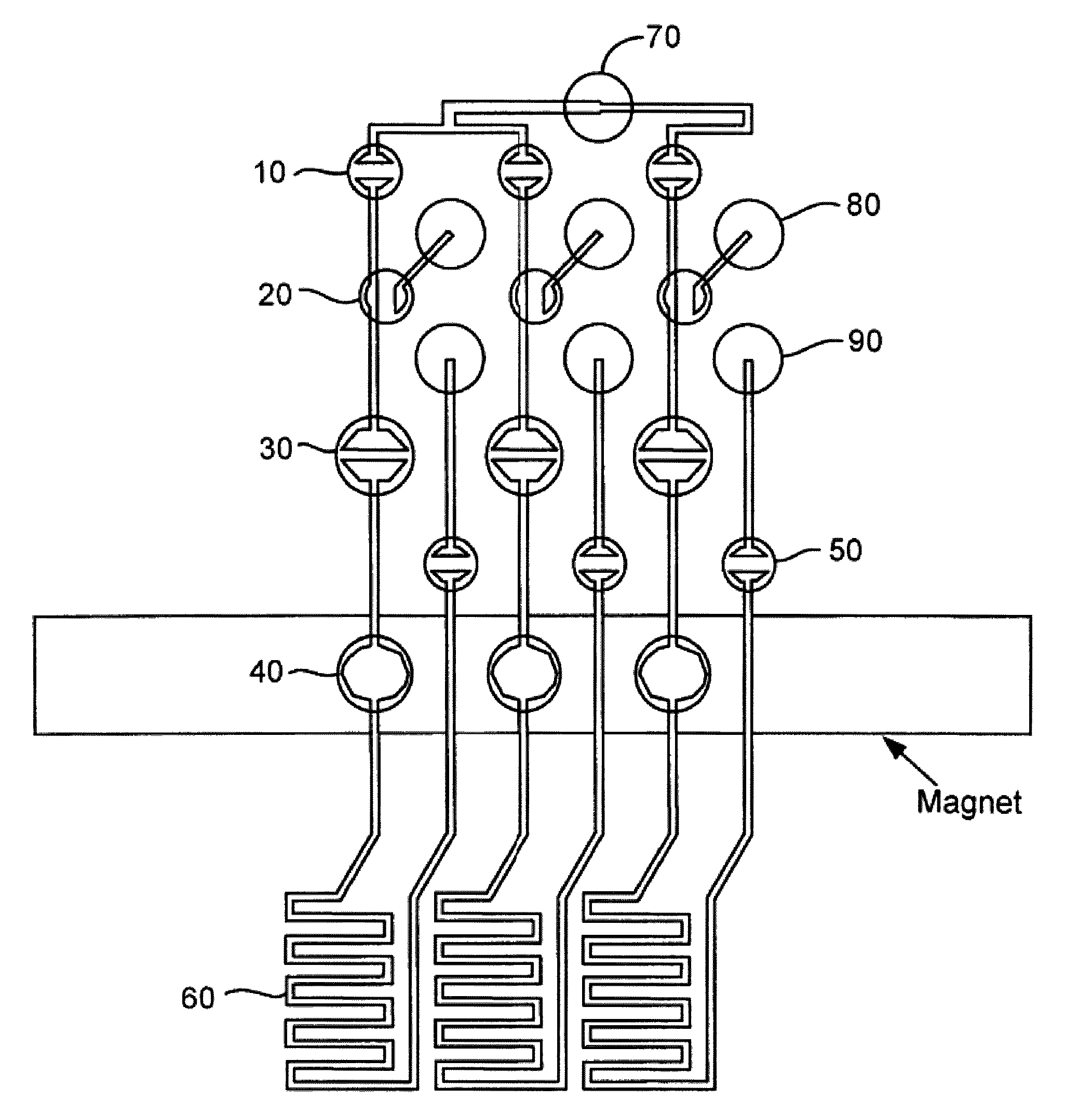

Fluidic apparatus and methods useful for chemical and biological reactions

ActiveUS20180280975A1Improve accuracyMinimize cross contaminationComponent separationMicrobiological testing/measurementElastomerDiaphragm valve

A reagent cartridge including (a) a support having reservoirs; (b) a main channel within the support, the channel having first and second ends exiting the support; (c) a pump channel that connects to the main channel between the first and second ends; (d) a valve manifold in the support, including (i) a first passage at the first end of the main channel, (ii) a second passage at the second end of the main channel, (iii) a first master valve between the pump channel and the first end of the main channel, (iv) a second master valve between the pump channel and the second end of the main channel, and (v) reservoir valves for regulating flow from individual reservoirs to the main channel. The valves can be normally closed diaphragm valves formed by magnetic pistons attached to an elastomeric sheet that is sandwiched in the support.

Owner:PACIFIC BIOSCIENCES

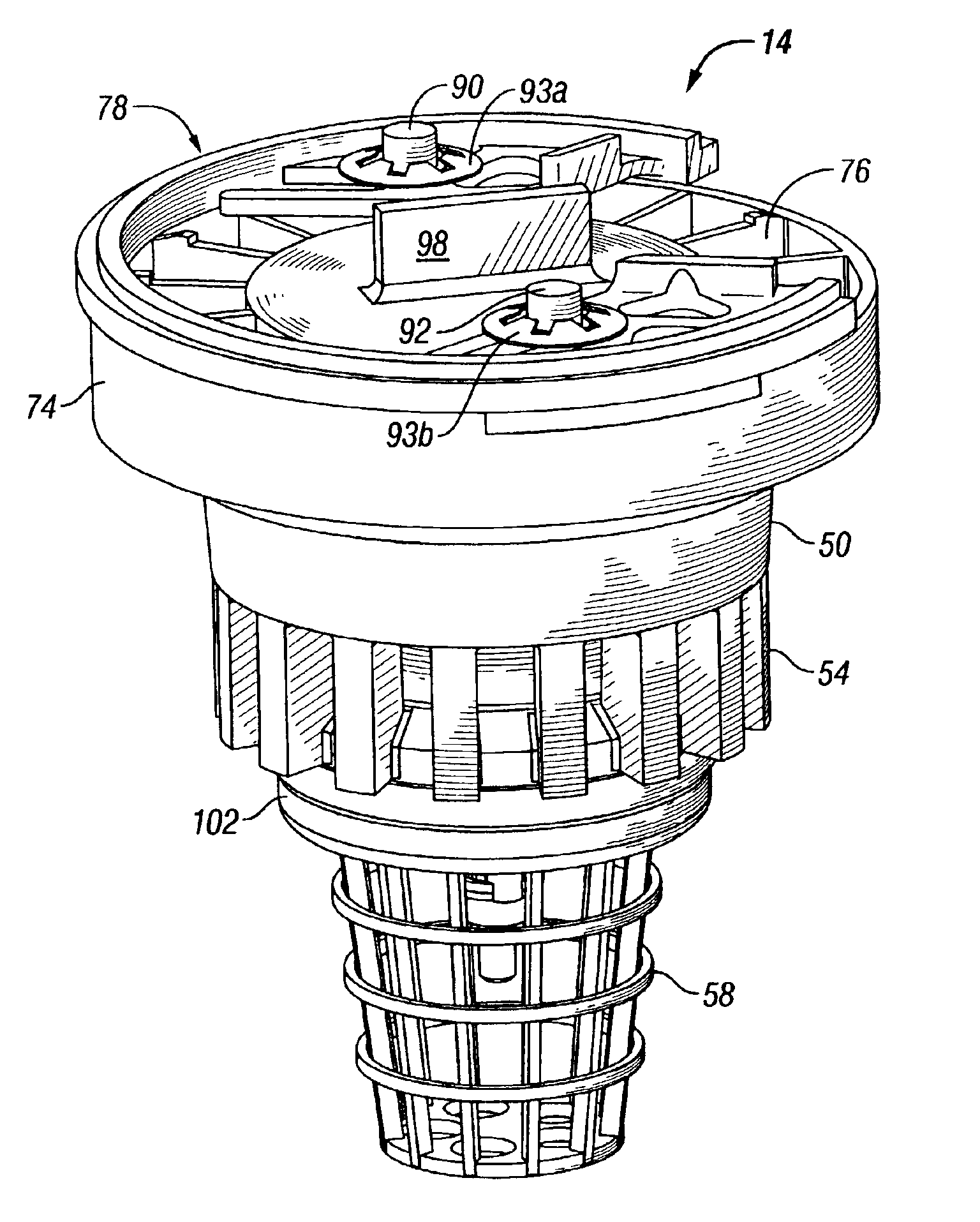

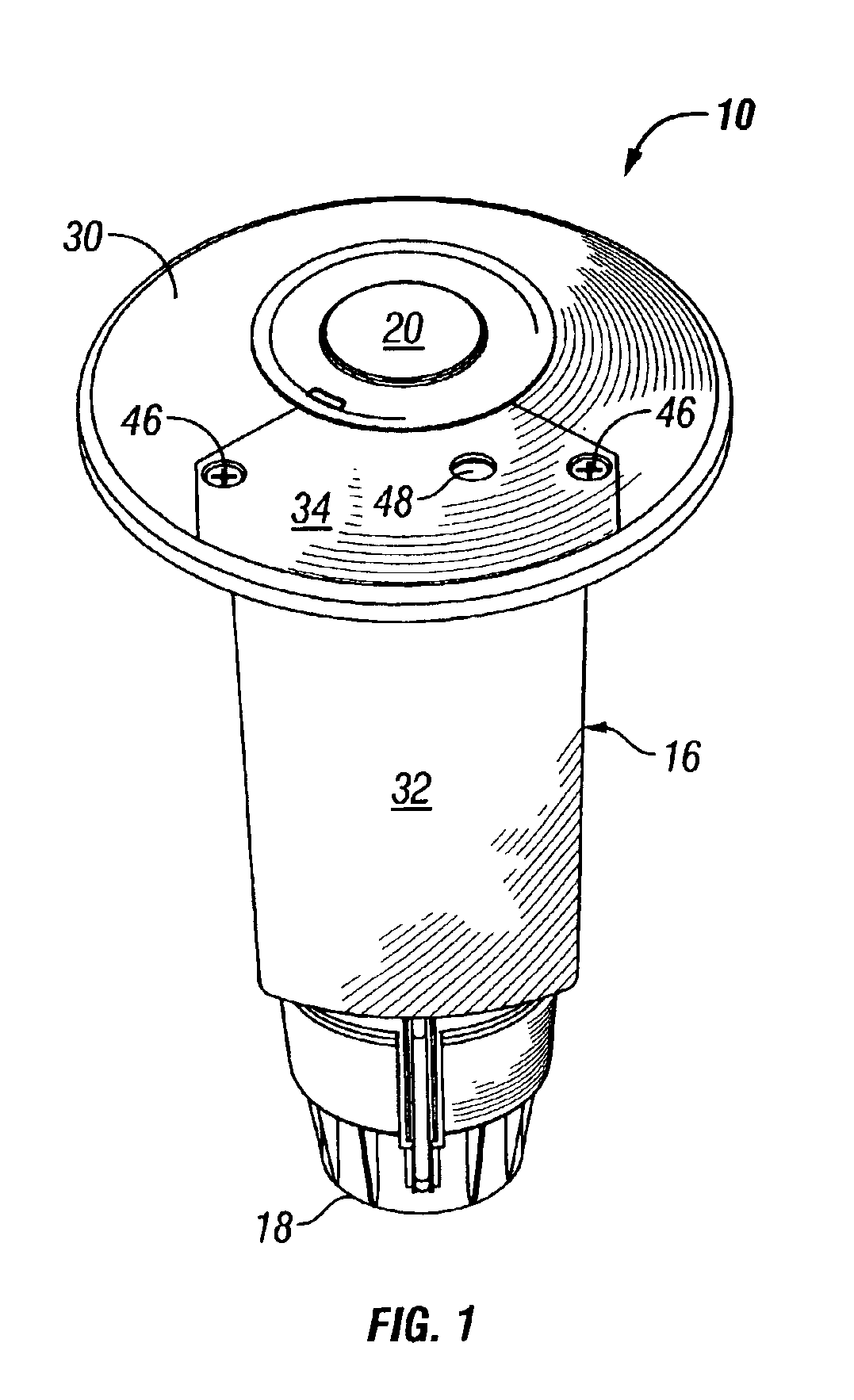

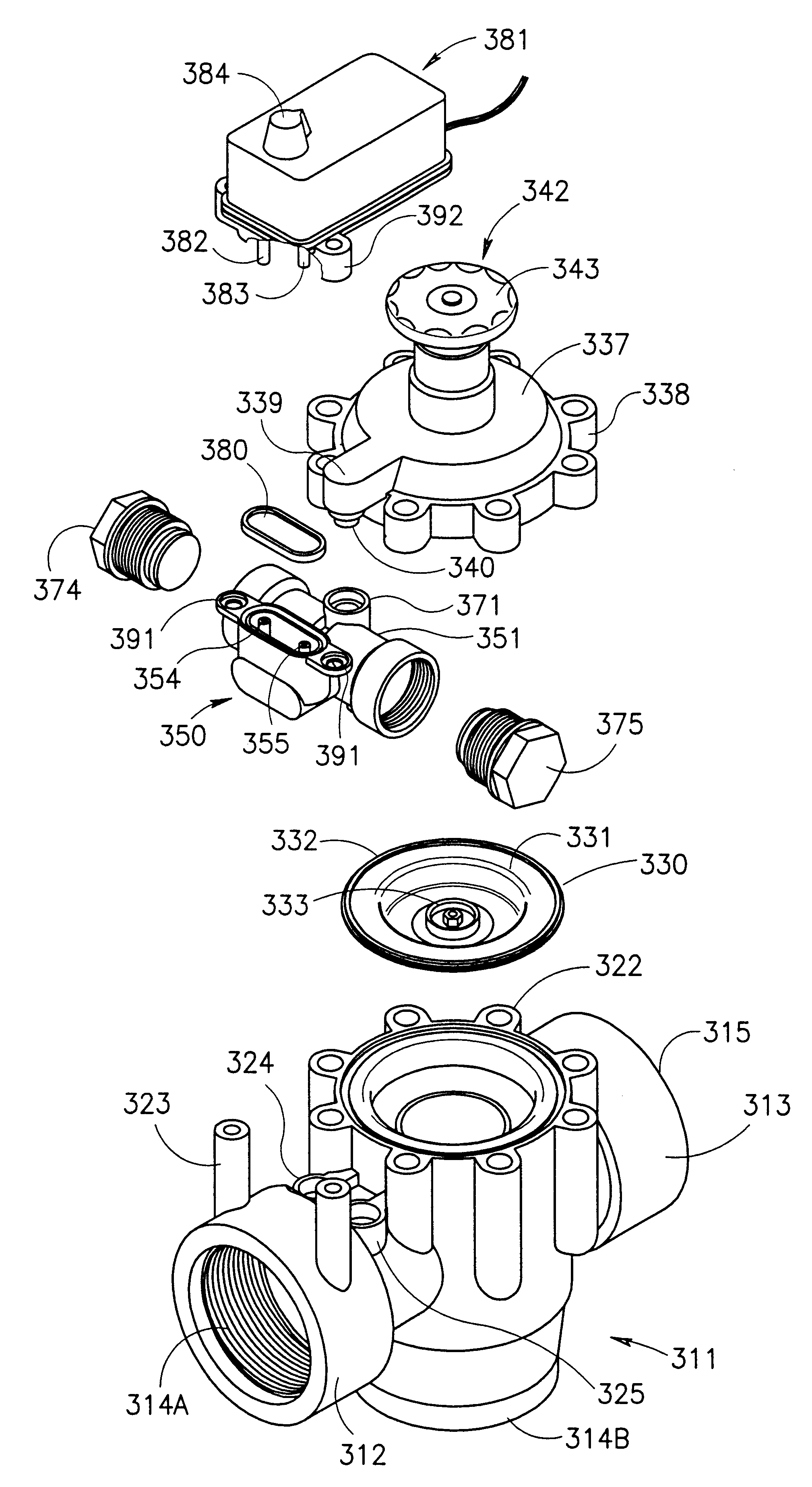

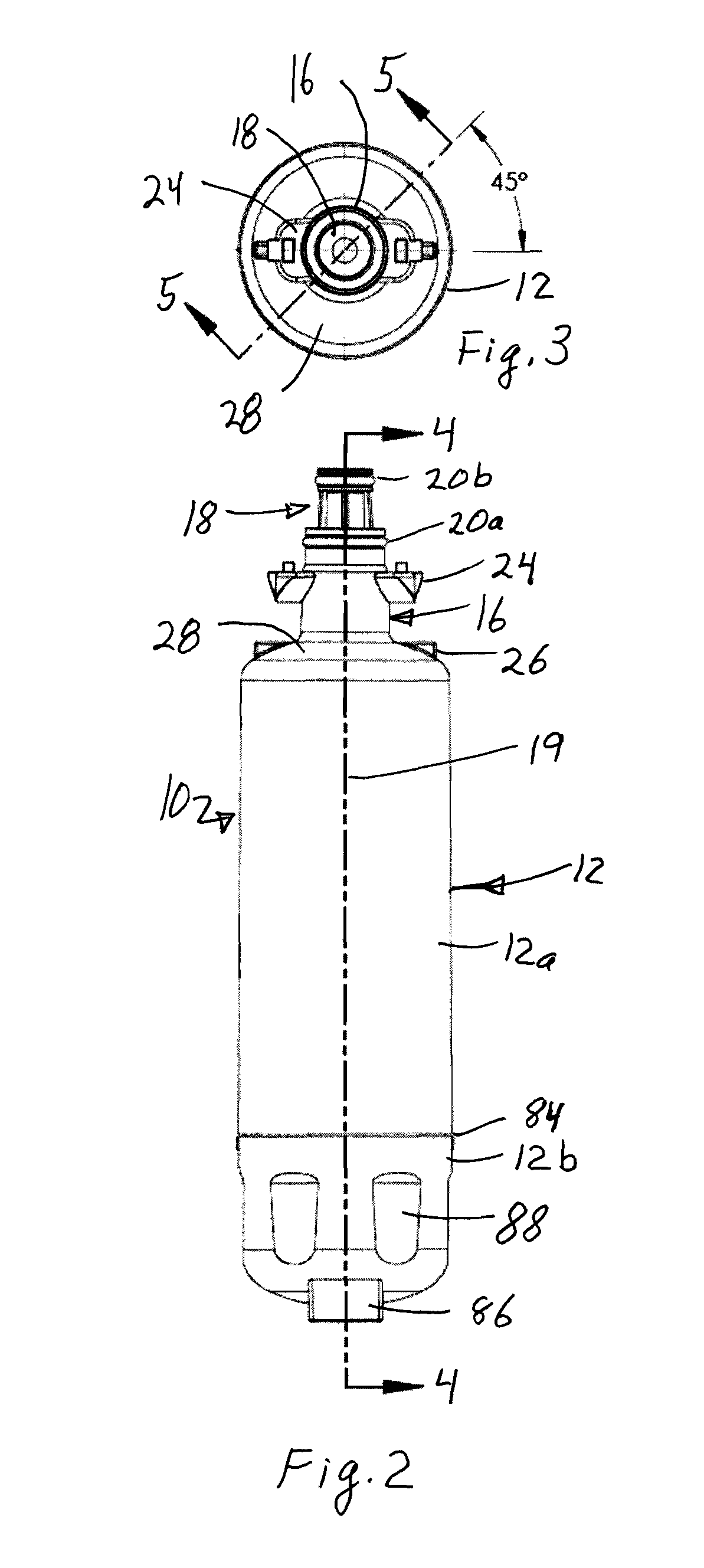

Self-camming snap ring for pop-up sprinkler with top serviceable diaphragm valve module

InactiveUS6854664B2Promote repairEasy to replaceCandle holdersLighting support devicesValve actuatorWater flow

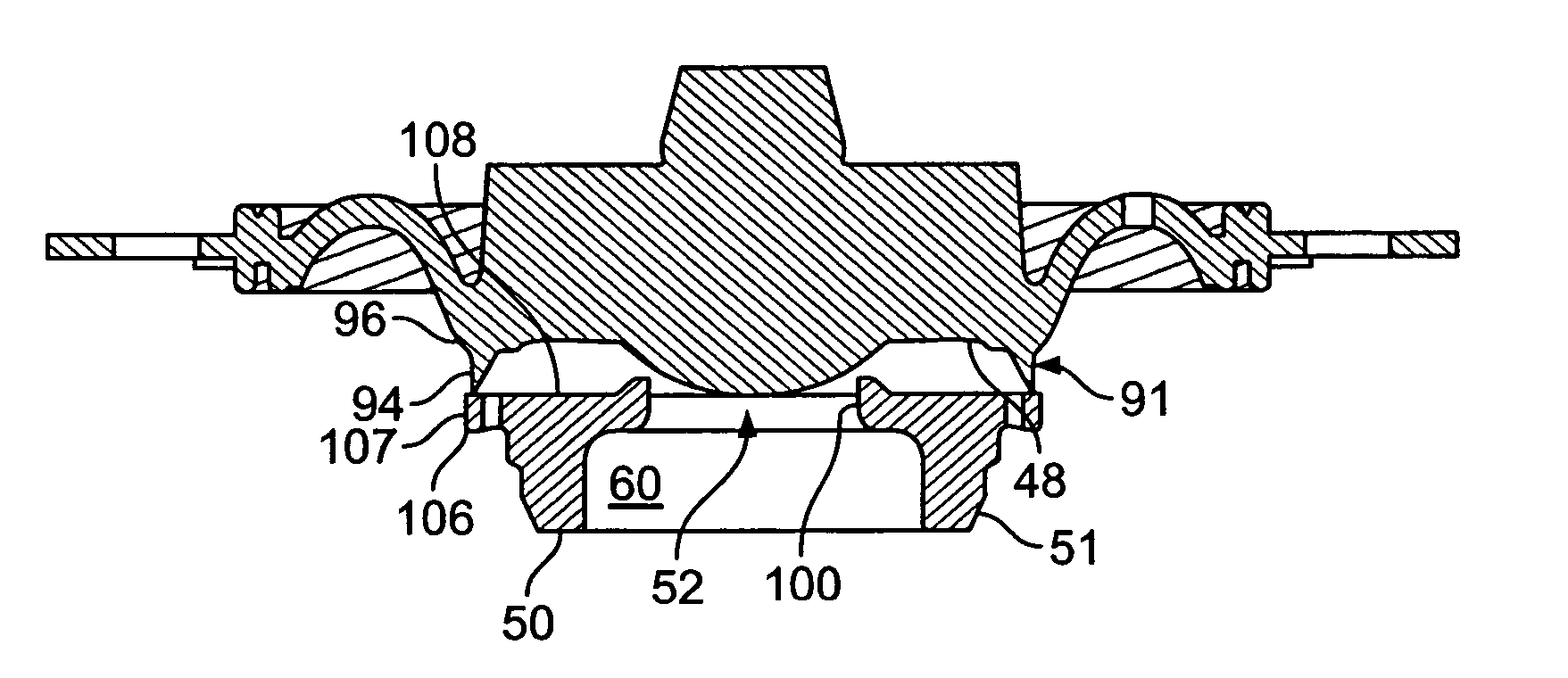

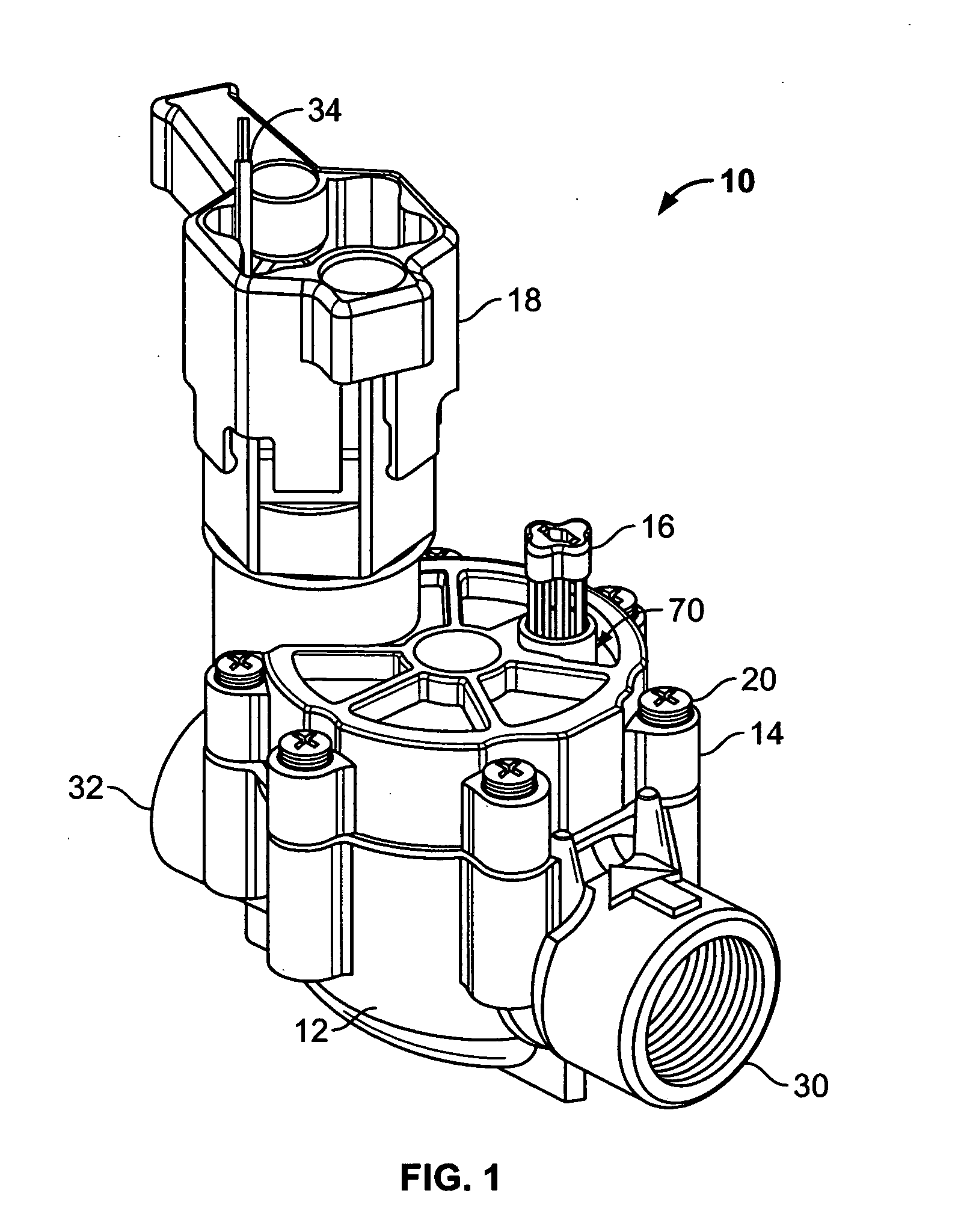

A diaphragm valve module is mounted in the lower end of the outer housing of a pop-up rotor type sprinkler for controlling the flow of water through an inlet in response to actuation of a valve actuator component. A resilient deformable semi-circular snap ring is mounted on top of the module and has a pair of opposing peripheral annular portions. Upon removal of the sprinkler riser, the snap ring can be disengaged from an annular groove formed in the interior wall of the outer housing by manually squeezing the annular portions together. This permits removal of the module for repair or replacement. The annular portions of the snap ring are formed with angled slots that receive projections that extend from the cover of the module to produce a camming movement that uniformly retracts the snap ring out of the annular groove to more readily permit removal of the module.

Owner:HUNTER INDUSTRIES

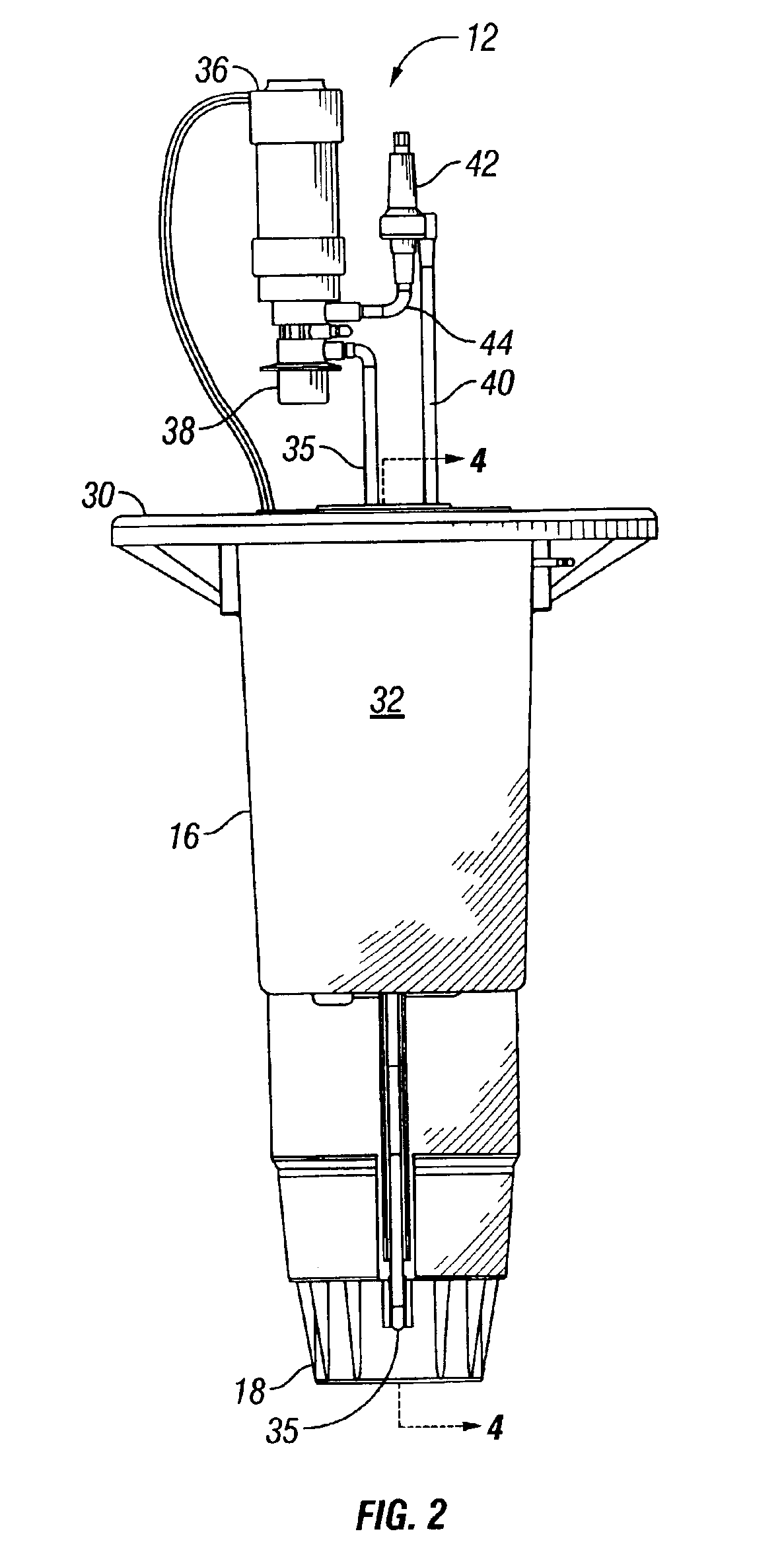

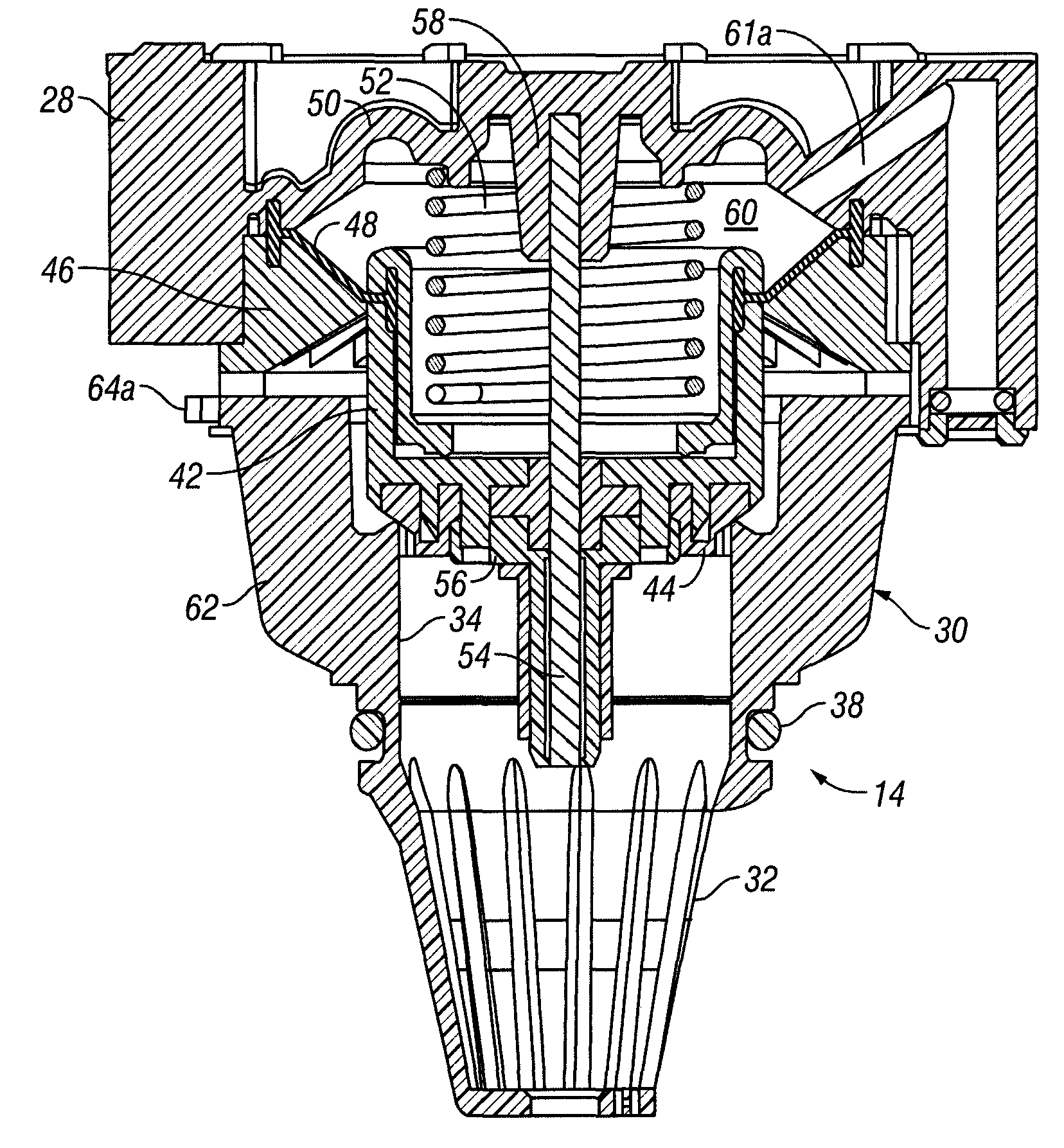

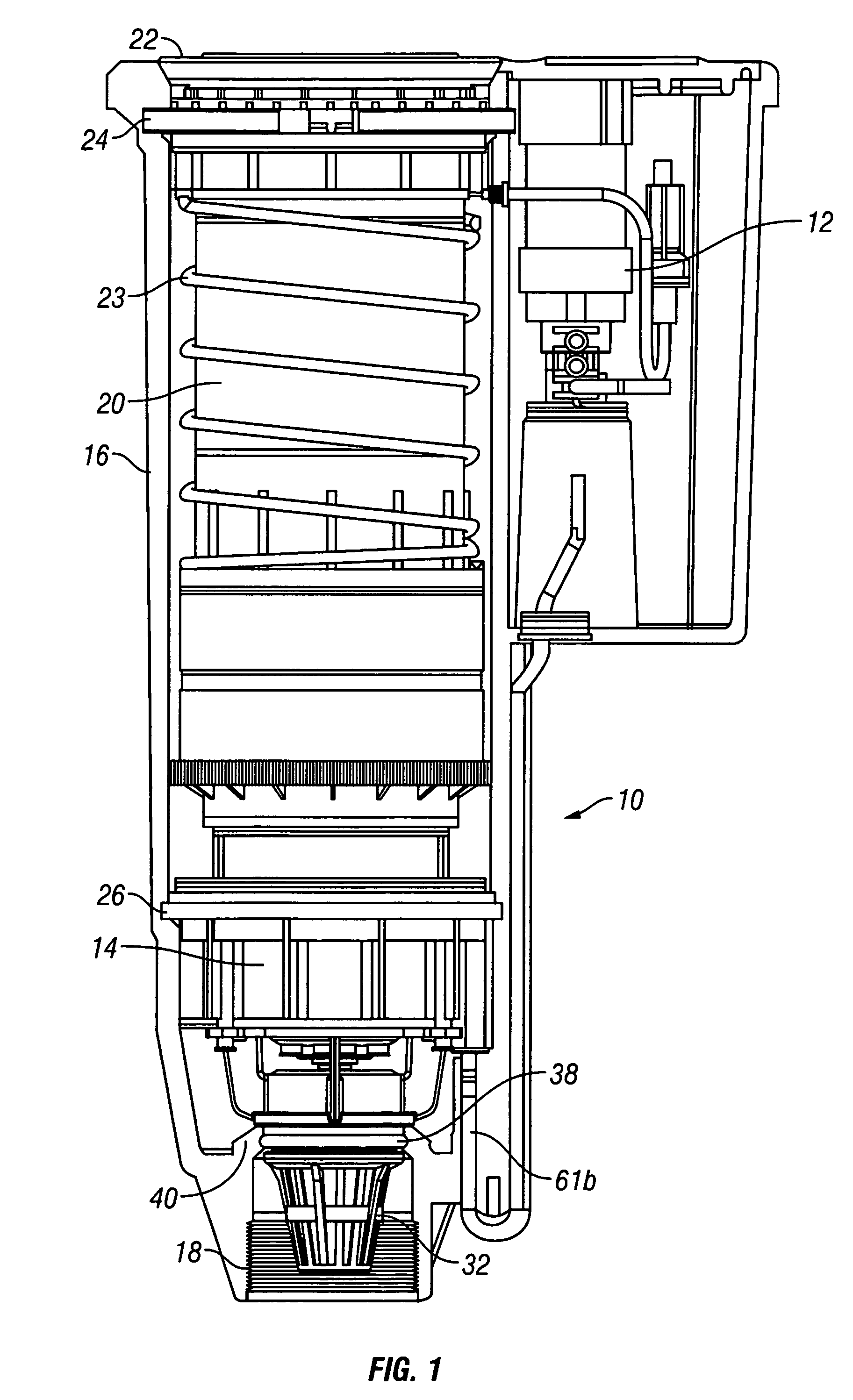

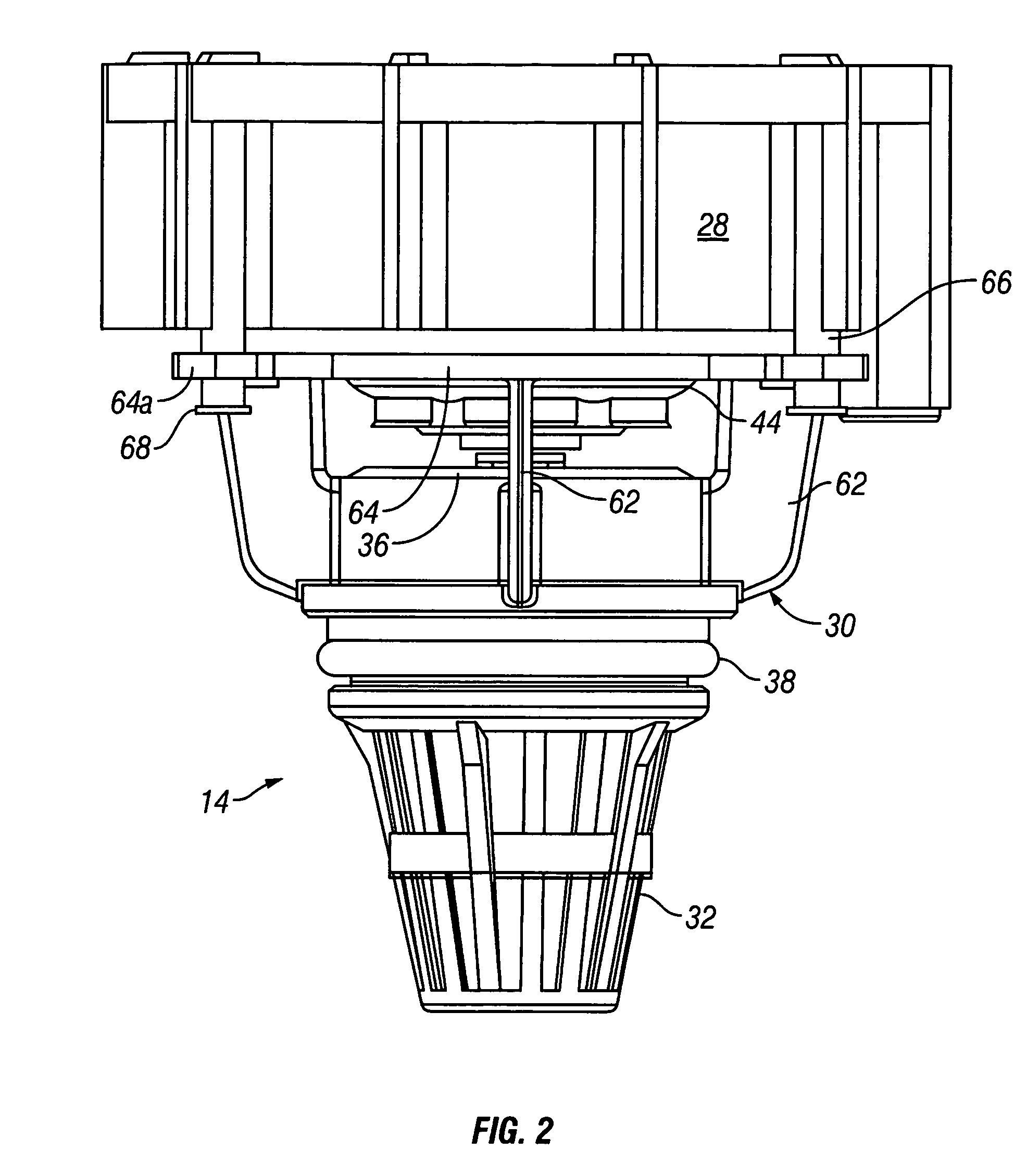

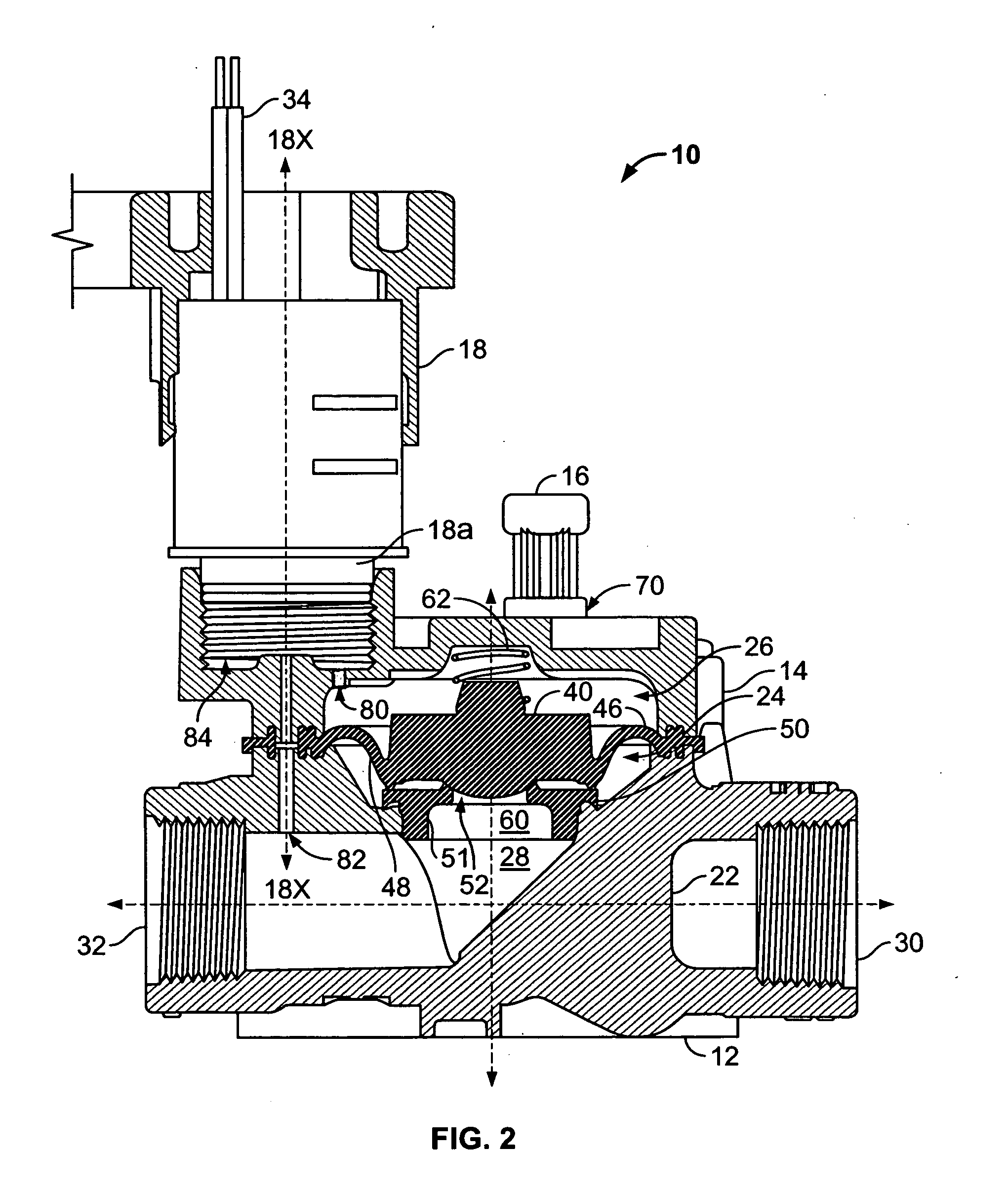

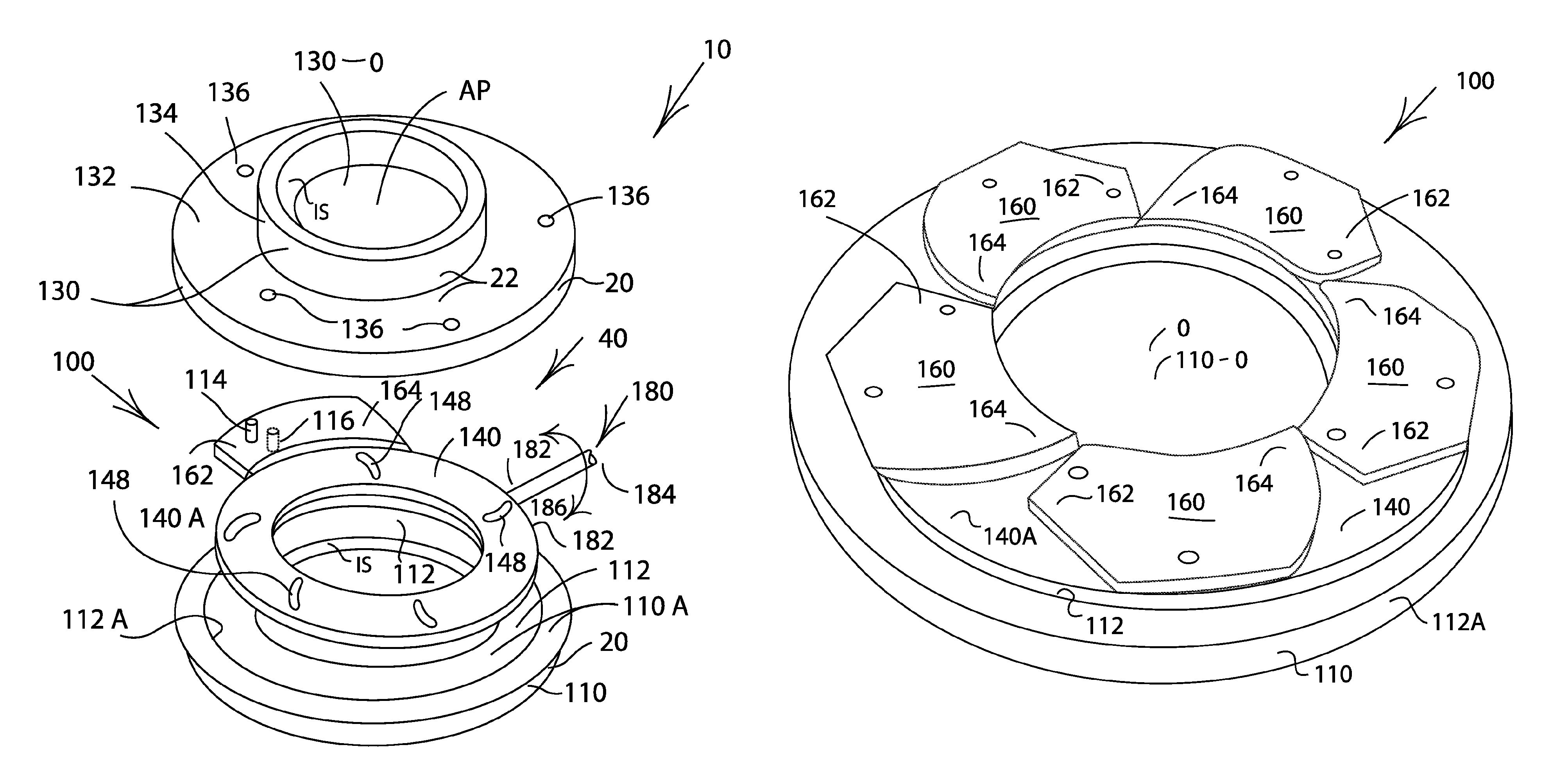

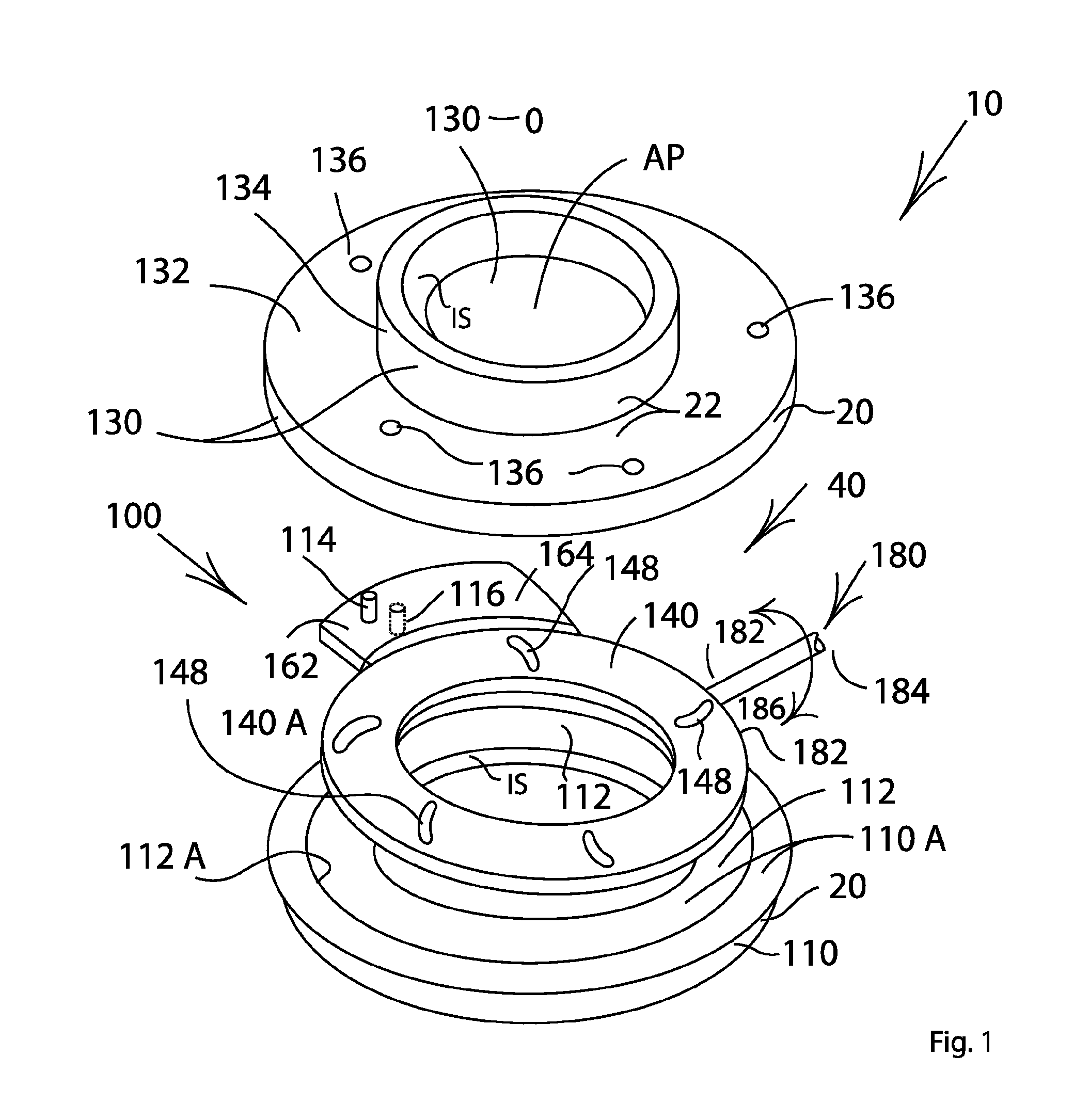

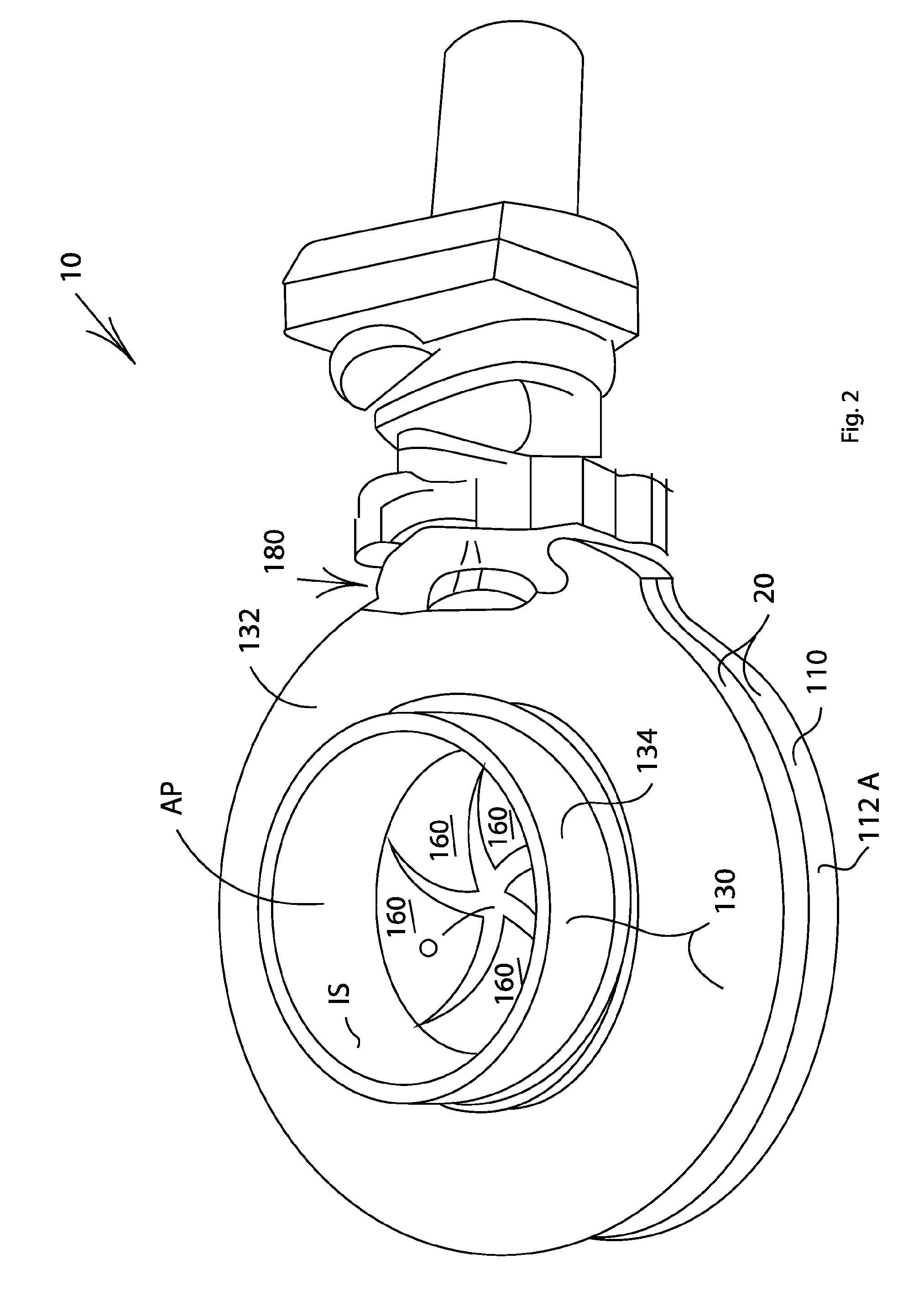

Sprinkler having valve module with reciprocating valve seat

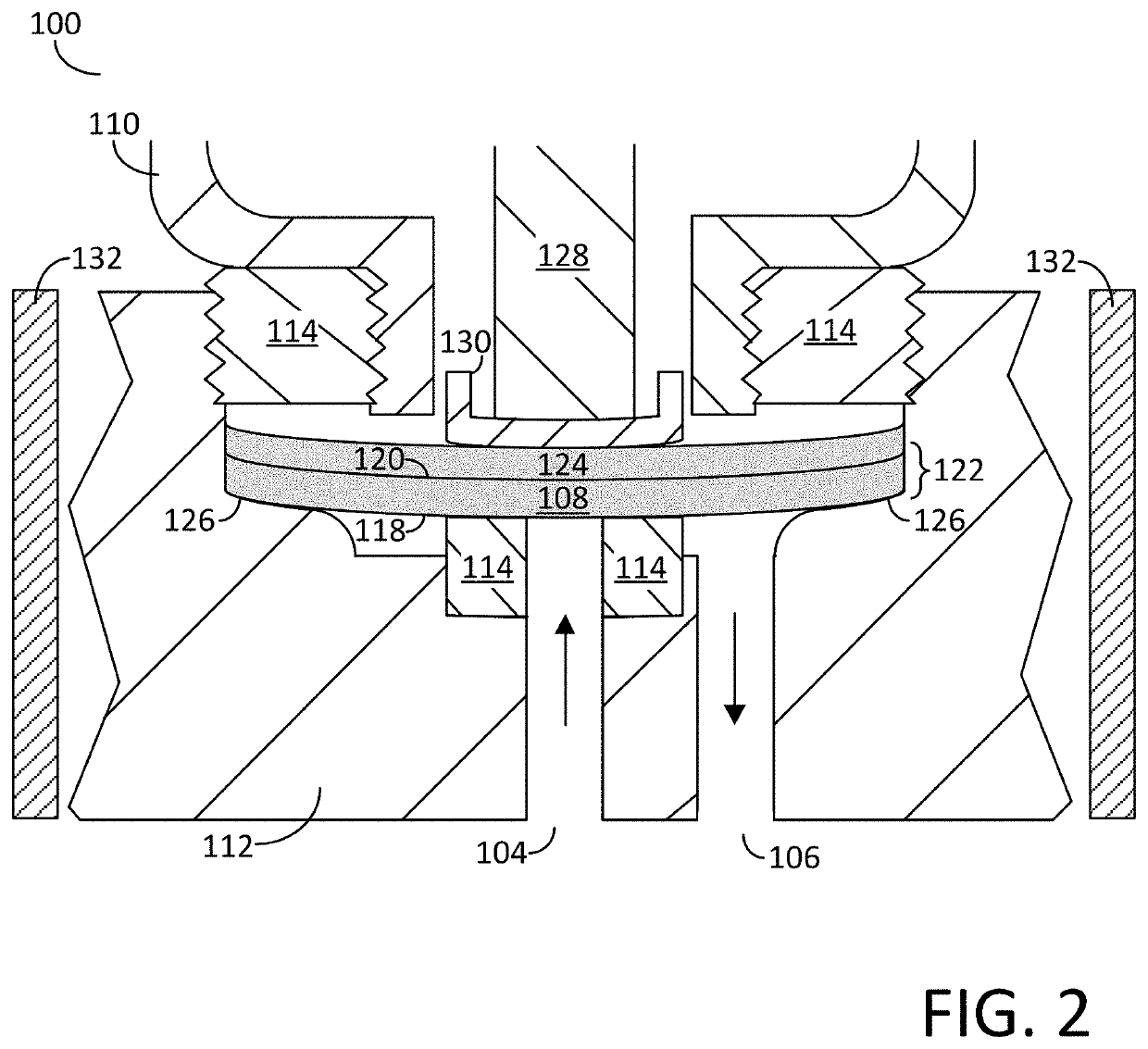

ActiveUS7303147B1Operating means/releasing devices for valvesWatering devicesImpellerReciprocating motion

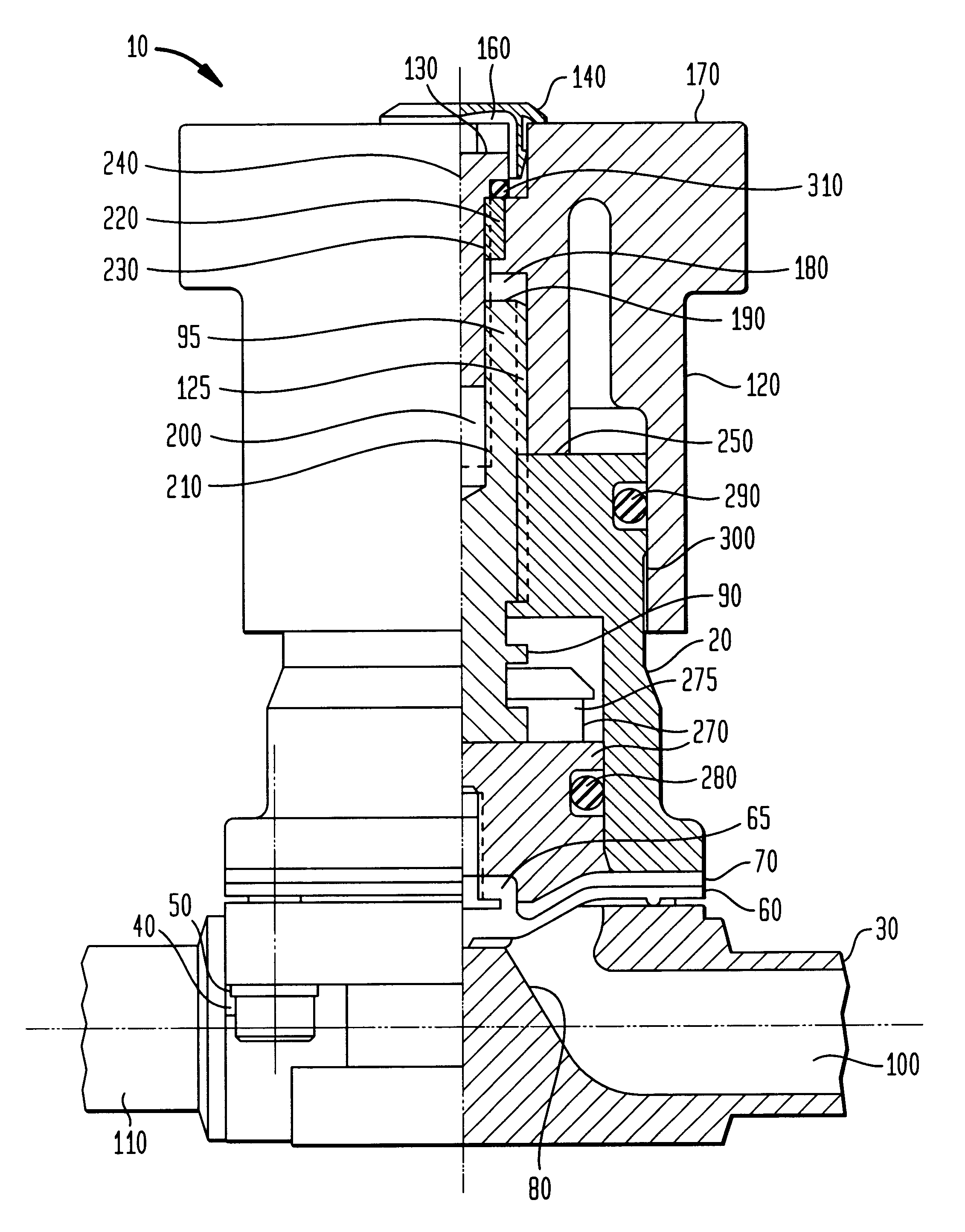

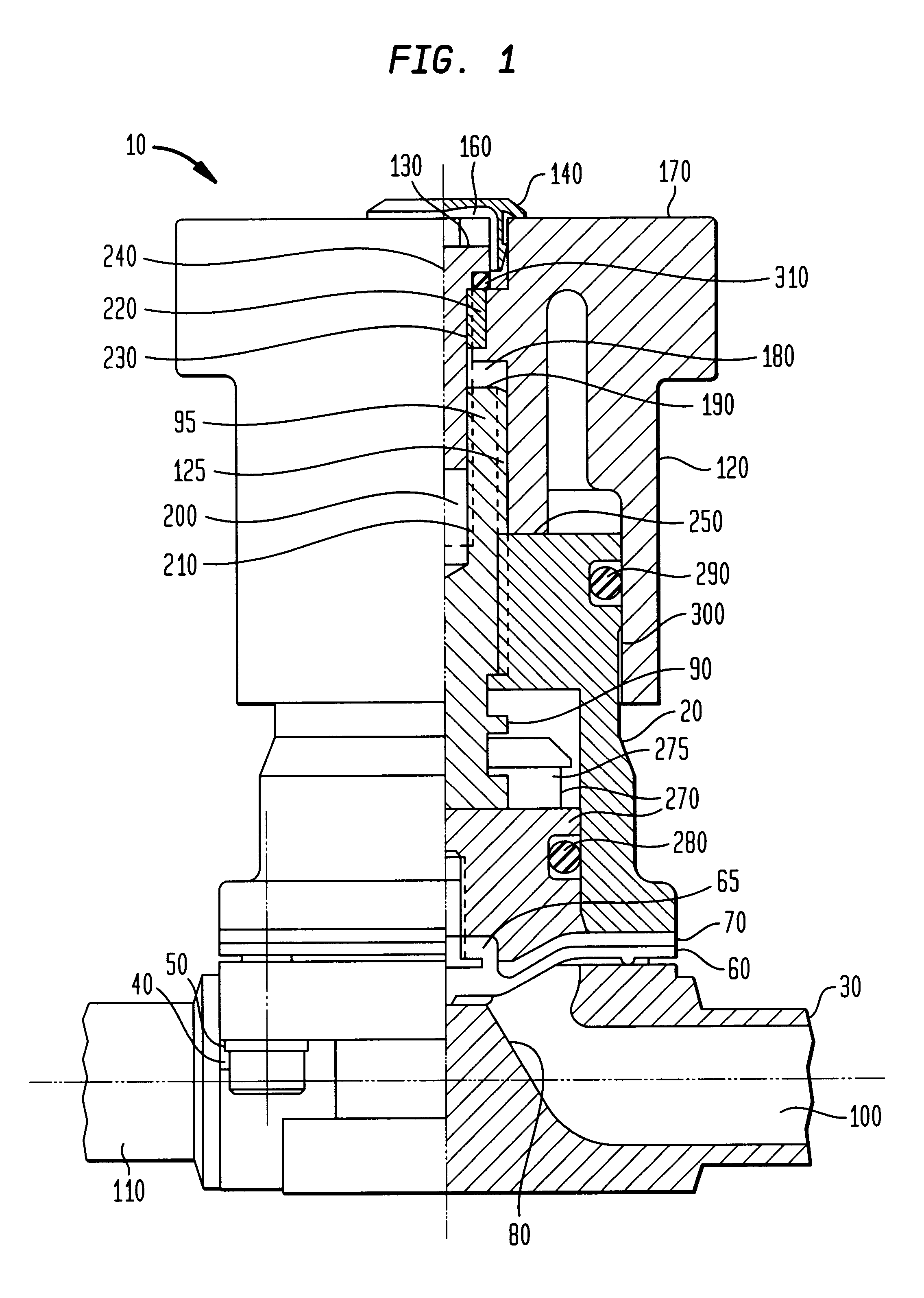

A sprinkler includes an outer case and a riser mounted for reciprocation within the case. The riser supports a nozzle, an impeller, and a drive linkage connecting the nozzle and the impeller. A diaphragm valve is mounted in outer case beneath the riser and includes a valve member vertically reciprocable within a valve support housing to engage and disengage a valve seat. The valve seat can reciprocate relative to the valve support housing to reduce mechanical loading.

Owner:HUNTER INDUSTRIES

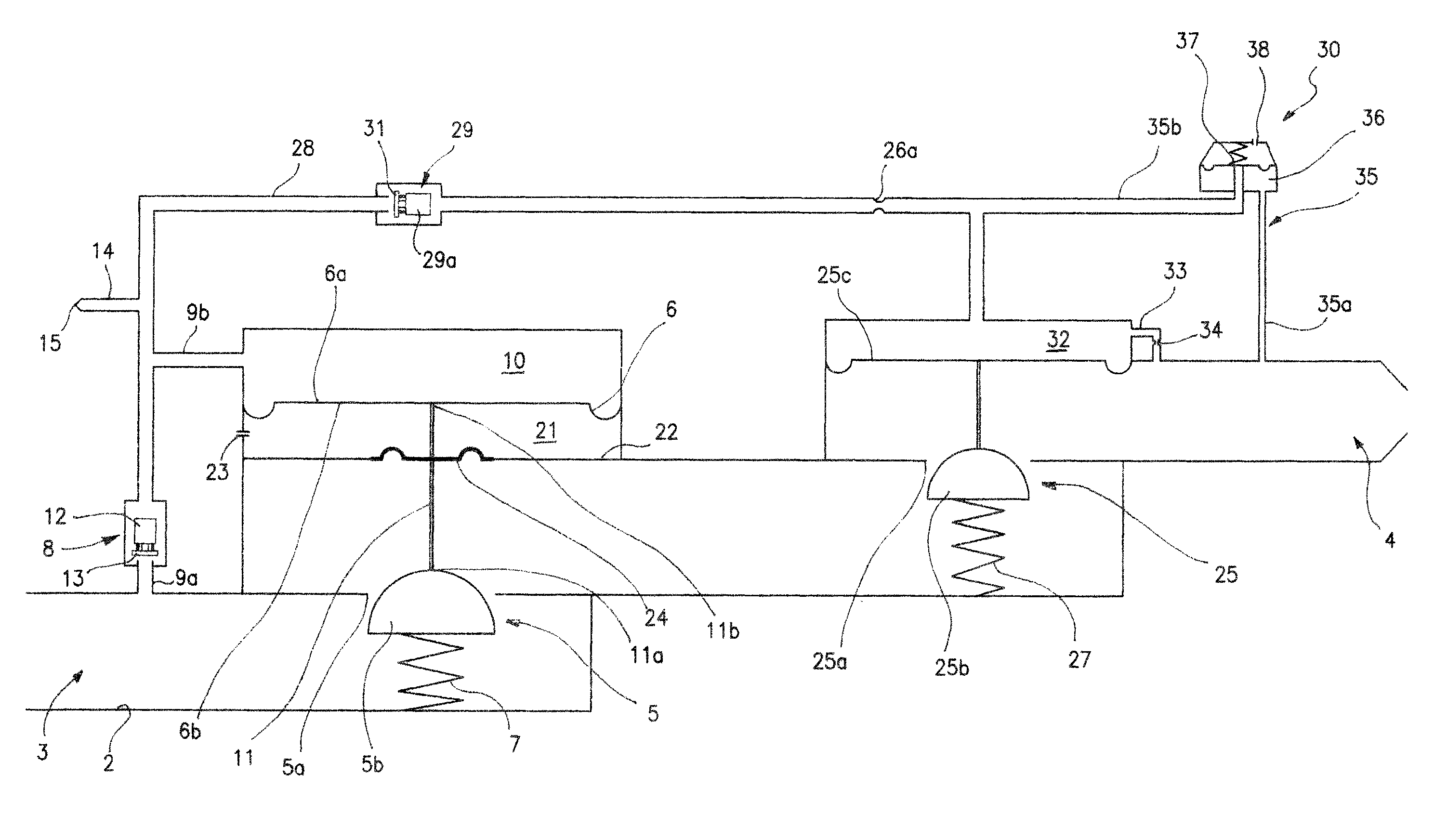

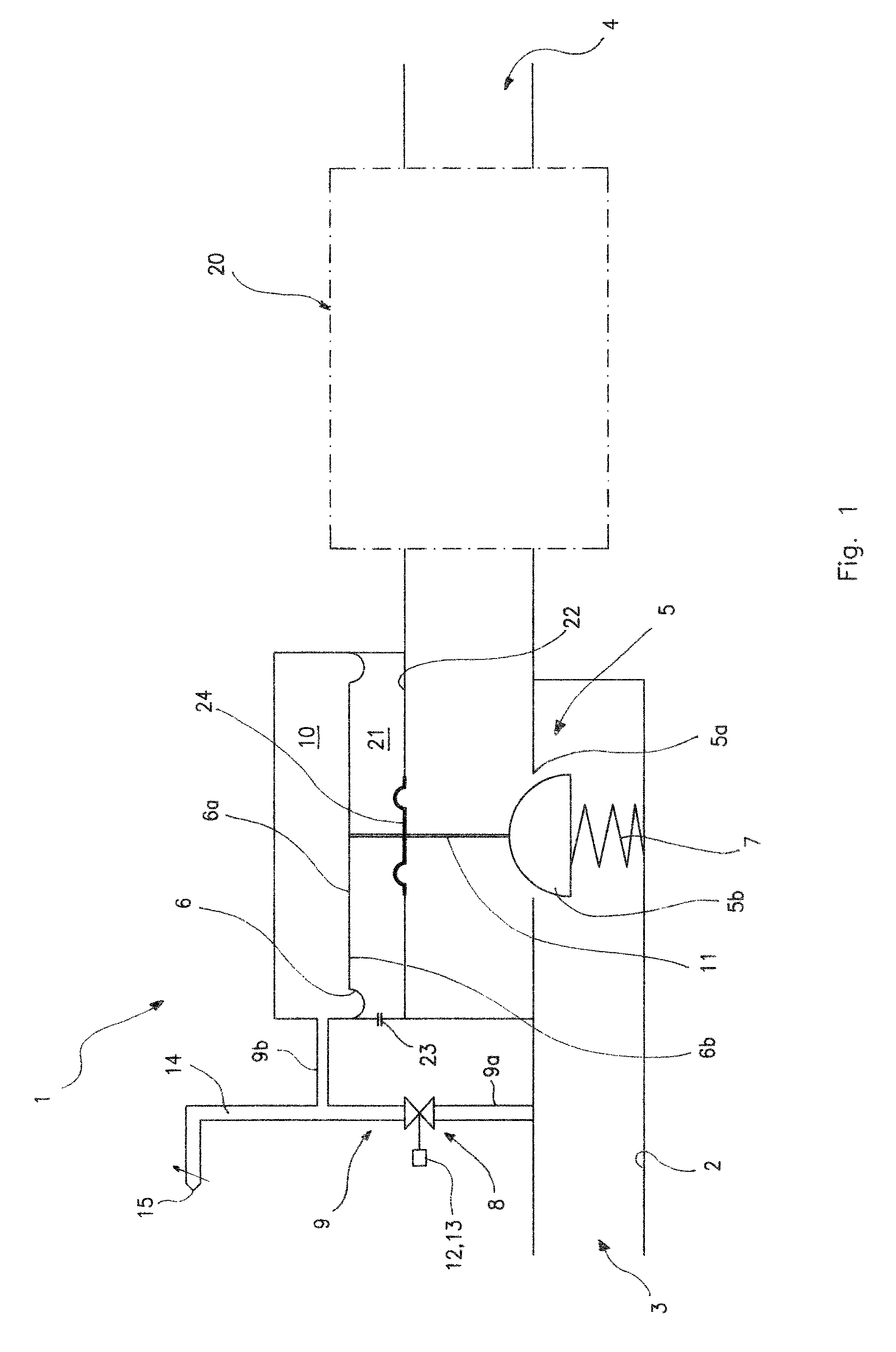

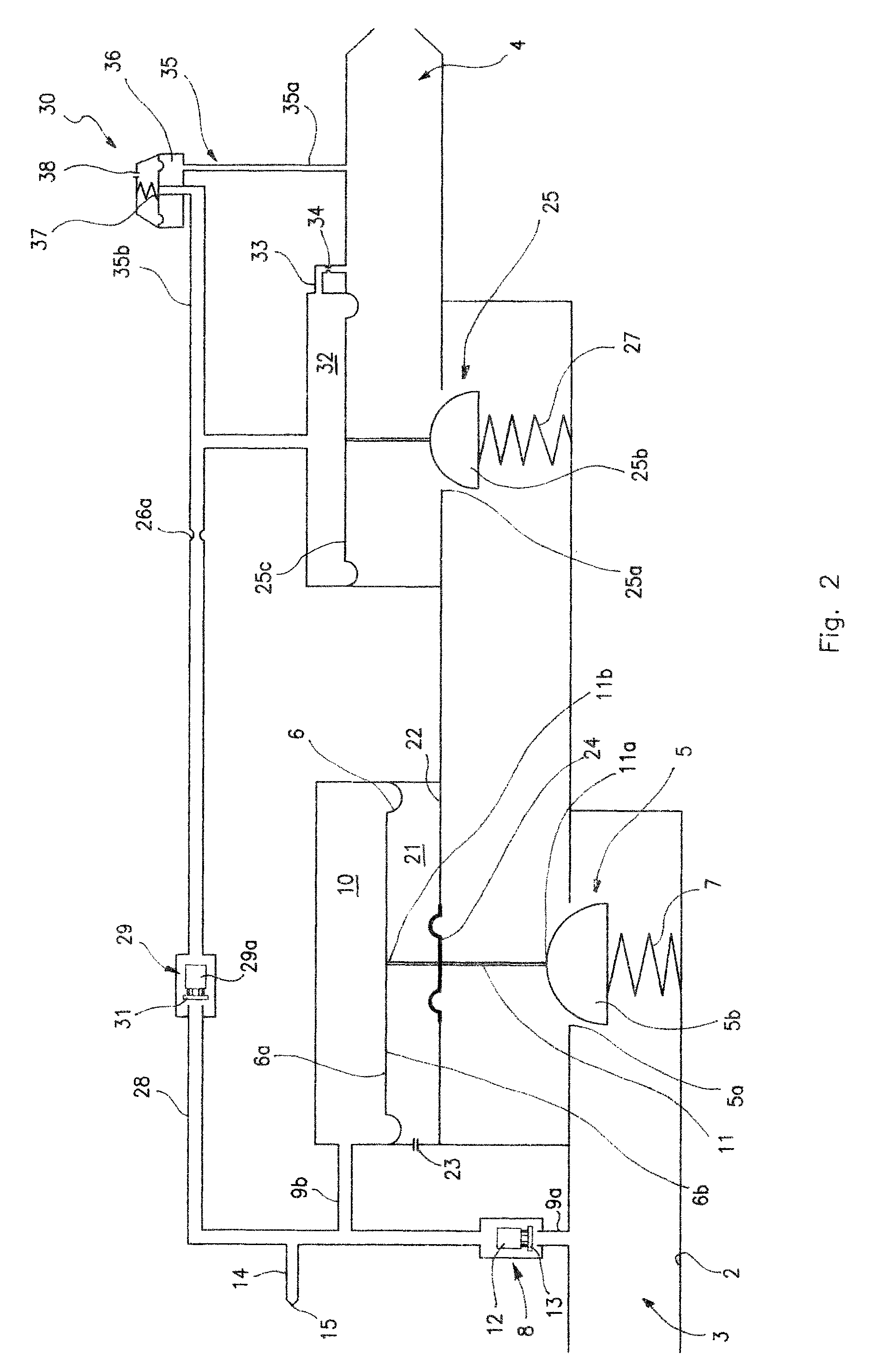

Device for controlling the delivery of a combustible gas to a burner apparatus

ActiveUS8162002B2Fuel supply regulationOperating means/releasing devices for valvesCombustorSolenoid valve

A device for controlling the delivery of a combustible gas to a burner apparatus is provided including a main gas-delivery duct in which there is at least one servo-assisted diaphragm valve including a valve seat associated with a corresponding closure member with diaphragm control for opening the seat against the action of a resilient biasing member. The diaphragm valve includes a respective control solenoid valve with an electromagnetic operator for controlling the corresponding valve, the solenoid valve being arranged to bring about the opening / closure of a duct of a respective servo-assisted control circuit so as to operate the closure member of the valve indirectly, by the diaphragm control. The duct of the control circuit putting a portion of the main duct that is disposed upstream of the valve seat with respect to the direction of the gas-flow into flow communication with a respective control chamber of the diaphragm valve.

Owner:SOC ITALANA TECNOMECCANICA

Hydraulic diaphragm

InactiveUS6394412B2Constant pressureOperating means/releasing devices for valvesValve members for absorbing fluid energyControl roomEngineering

A hydraulic diaphragm valve comprising a housing, an inlet, an outlet, a diaphragm valve seating between the inlet and the outlet, a sealing diaphragm mounted in the housing and displaceable about the diaphragm valve seating, so as to close and open a flow path between the inlet and outlet, a valve control chamber and a command valve comprising a first duct communicating a one end thereof with the valve inlet, and at an opposite end thereof with a first command valve seating, a second duct communicating into one end with the valve outlet, and at an opposite end thereof, with a second command valve seating. A third duct communicates at one end with the valve control chamber and at its opposite end it selectively communicates with the first and second command valve seatings. A flexible command diaphragm is selectively biased into sealing engagement with one or other of the command valve seatings to effect communication between the third duct and the command valve seating not in seating engagement with the command diaphragm.

Owner:NETAFIM LTD

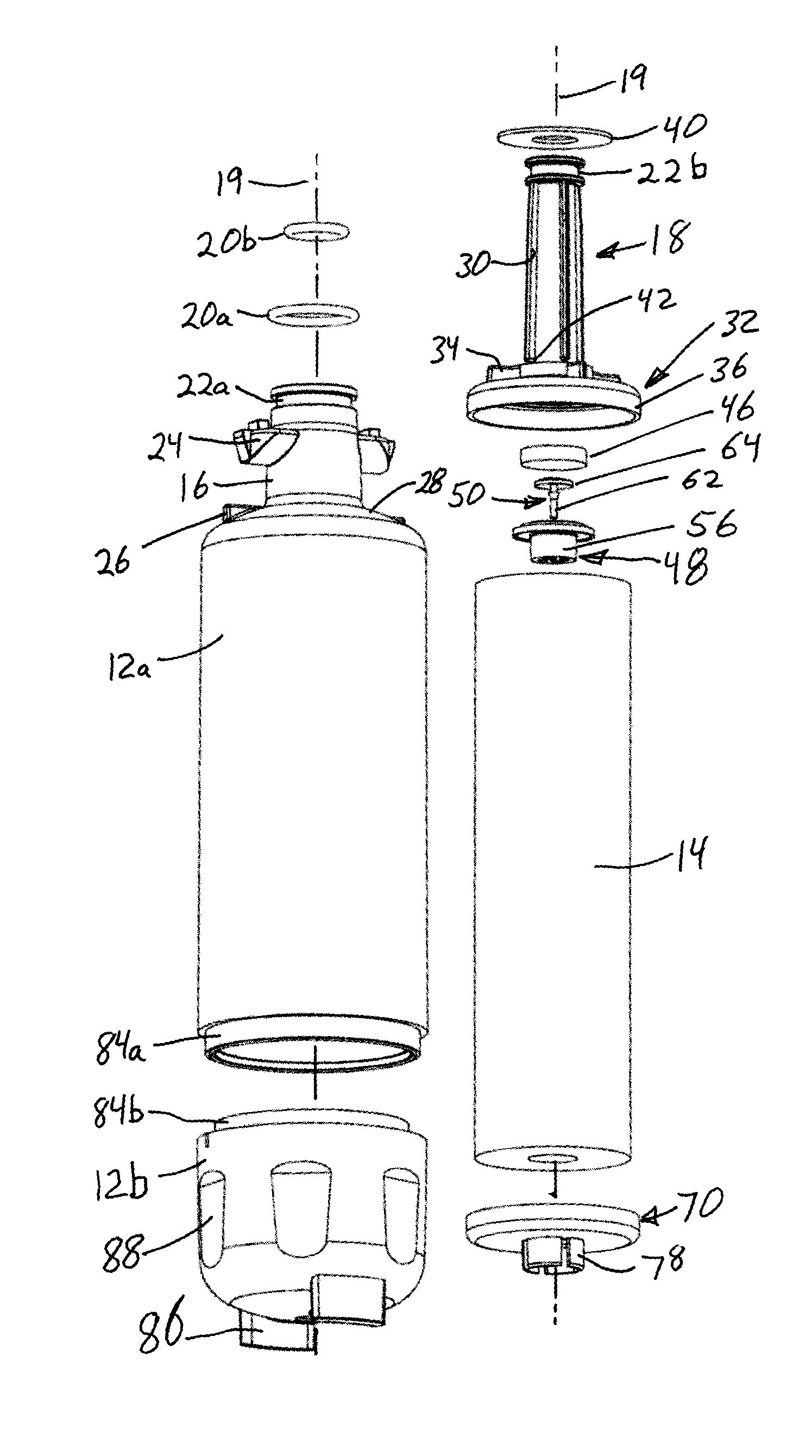

Valves and pumps for microfluidic systems and method for making microfluidic systems

ActiveUS7942160B2Avoid flowFunctional valve typesFixed microstructural devicesEngineeringDiaphragm valve

The present invention relates to microfluidic systems, including valves and pumps for microfluidic systems. The valves of the invention include check valves such as diaphragm valves and flap valves. Other valves of the invention include one-use valves. The pumps of the present invention include a reservoir and at least two check valves. The reservoir may be of variable volume. The present invention also relates to a flexible microfluidic system. The present invention additionally relates to a method of making microfluidic systems including those of the present invention. The method includes forming a microfluidic system on a master, connecting a support to the microfluidic system and removing the microfluidic system from the master. The support may remain connected to the microfluidic system or the microfluidic system may be transferred to another substrate. The present invention further relates to a method of manipulating a flow of a fluid in a microfluidic system. This method includes initiating fluid flow in a first direction and inhibiting fluid flow in a second direction and may be practiced with the valves of the present invention.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Microfluidic methods

This invention provides microfluidic devices that comprise a fluidics layer having microfluidic channels and one or more regulating layers that regulate the movement of fluid in the channels. The microfluidic devices can be used to mix one or more fluids. At least a portion of the fluidics layer can be isolated from the regulating layer, for example in the form of a shelf. Such isolated portions can be used as areas in which the temperature of liquids is controlled. Also provided are instruments including thermal control devices into which the microfluidic device is engaged so that the thermal control device controls temperature in the isolated portion, and a movable magnetic assembly including magnets with shields so that a focused magnetic field can be applied to or withdrawn from the isolated portion or any other portion of the microfluidic device. Also provided are methods of mixing fluids. The methods include stacking a plurality of alternating boluses of different liquids in a microfluidic channel, and moving the stacked boluses through the channel. In another method, the boluses are moved into a diaphragm valve having a volume able to accommodate several boluses, and then pumping the liquids out of the valve.

Owner:INTEGENX

Water filter cartridge with valves

InactiveUS20140110331A1Reduce leakageChange flexibilityTreatment involving filtrationMembrane filtersWater filterEngineering

A water filter cartridge having a housing with an inlet nozzle with a concentric, smaller outlet nozzle extending through the inlet nozzle with a space therebetween defining an inlet to a flow path passing through a filter and through the outlet nozzle. A diaphragm valve mounted to the outlet nozzle blocks upstream flow out of the inlet when the cartridge is not in use. An umbrella valve mounted on the end of the filter blocks downstream flow out of the outlet nozzle when the cartridge is not in use, thus reducing leakage when the cartridge is removed from the appliance.

Owner:BAIRD MICHAEL T

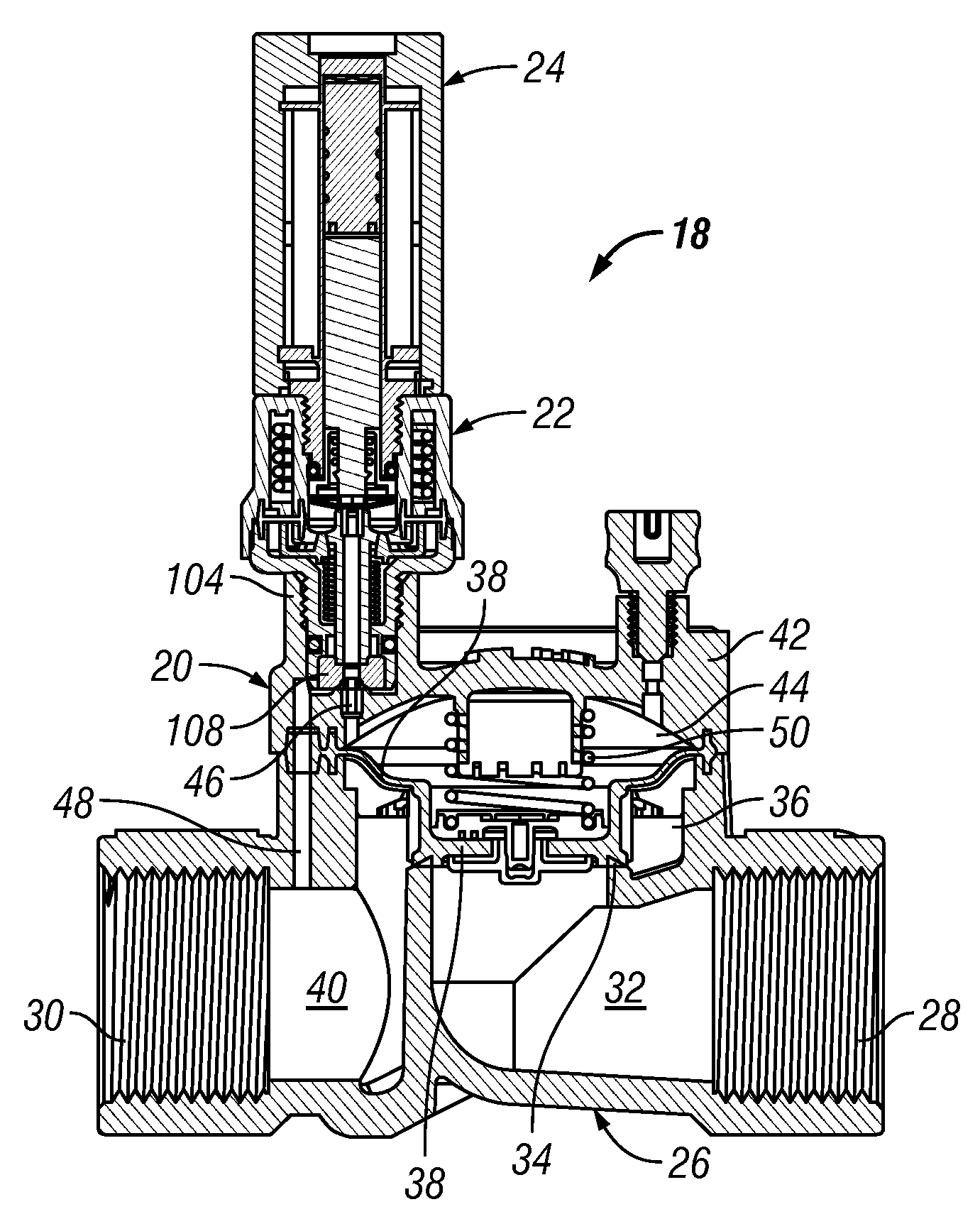

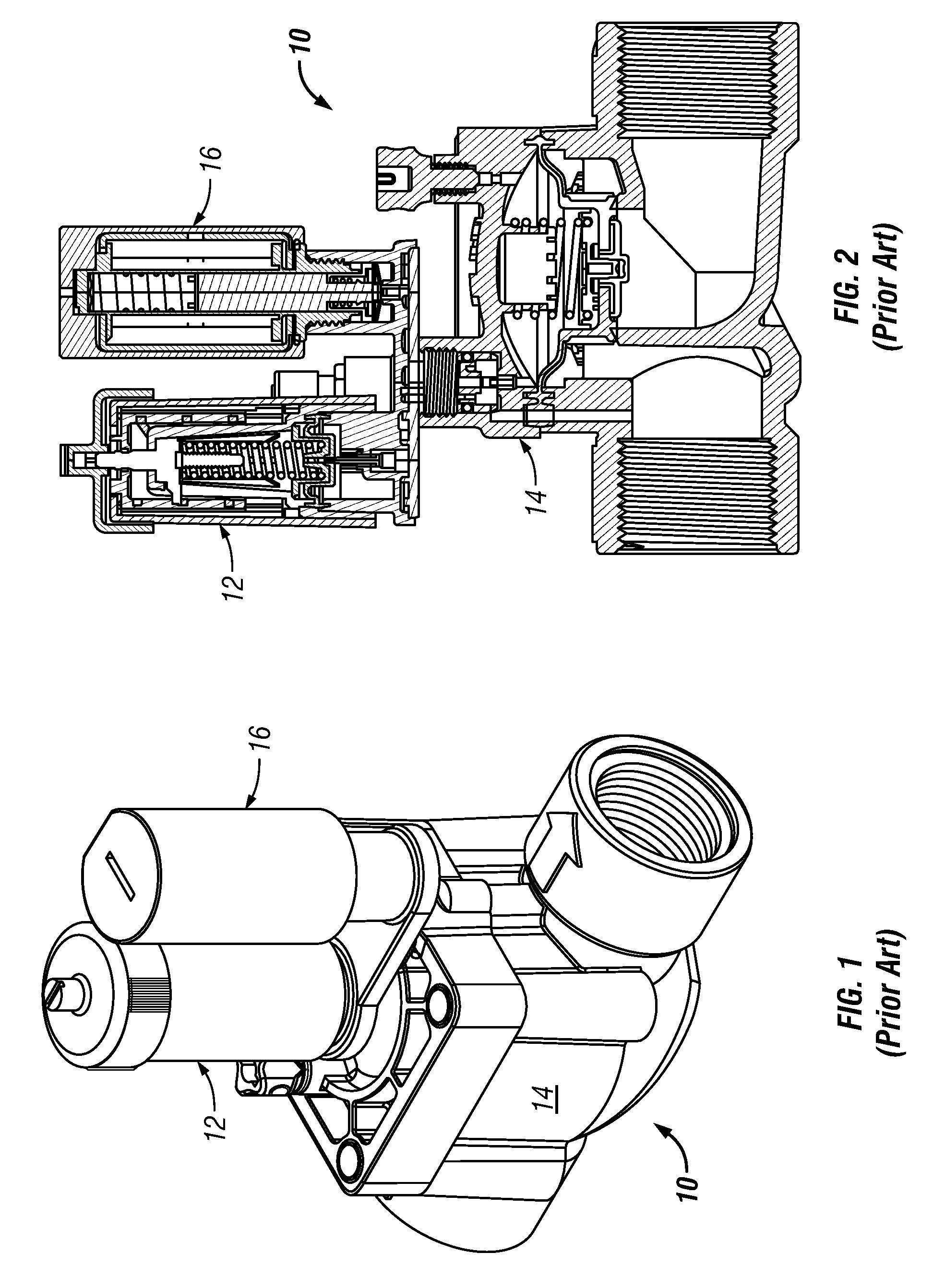

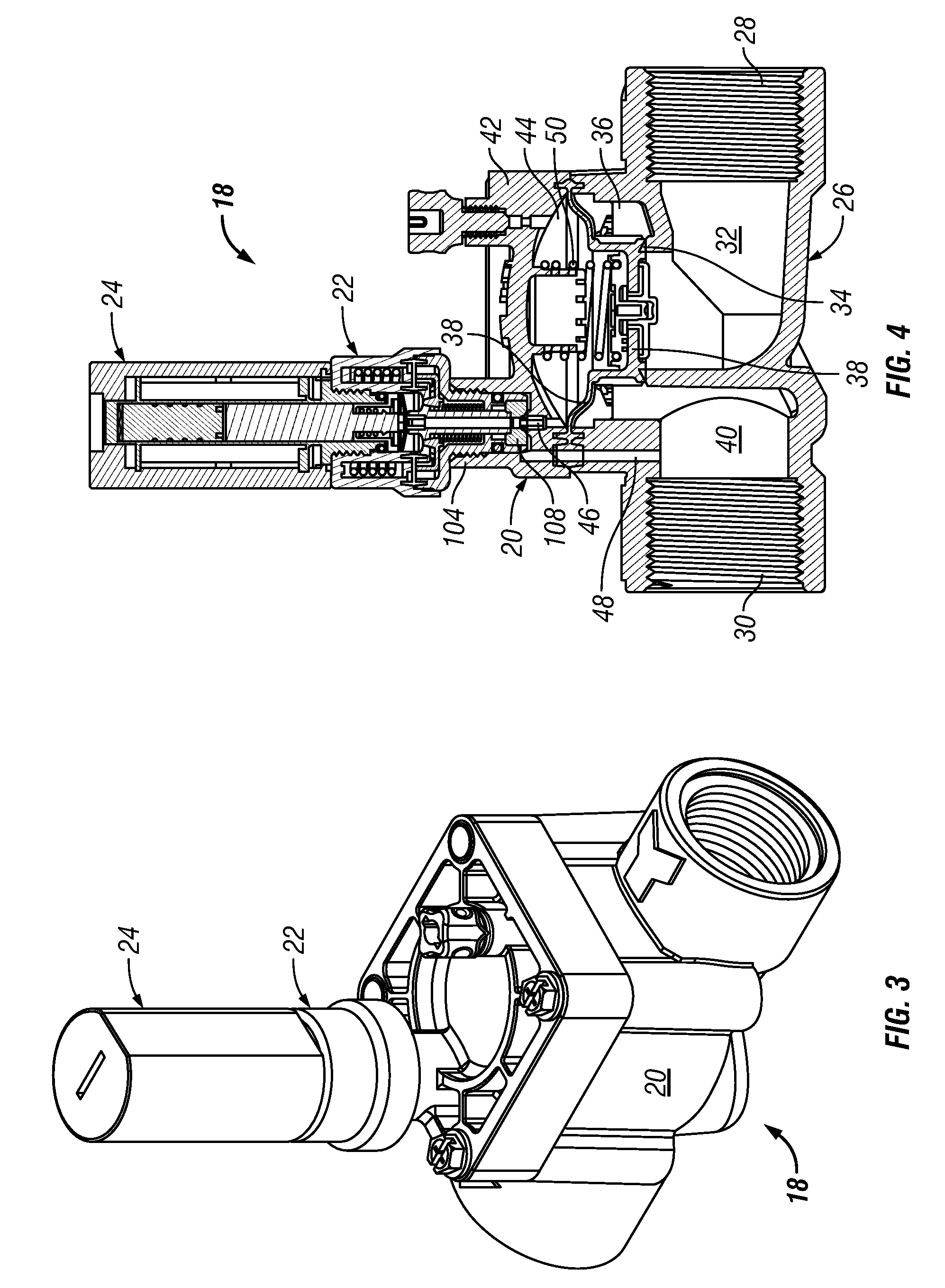

Co-axial solenoid and pressure regulator for diaphragm valve

ActiveUS7806382B1Operating means/releasing devices for valvesFluid pressure controlCoil springEngineering

A valve assembly comprises a diaphragm valve, a pressure regulator and a solenoid. The pressure regulator is operatively coupled to the diaphragm valve for maintaining a predetermined pressure in water exiting the diaphragm valve despite fluctuations in the pressure of water entering the diaphragm valve. The solenoid is mounted on the pressure regulator so that a plunger axis of the solenoid extends through a coil spring of the pressure regulator. The solenoid is operatively coupled to the diaphragm valve through the pressure regulator for opening and closing the diaphragm valve.

Owner:HUNTER INDUSTRIES

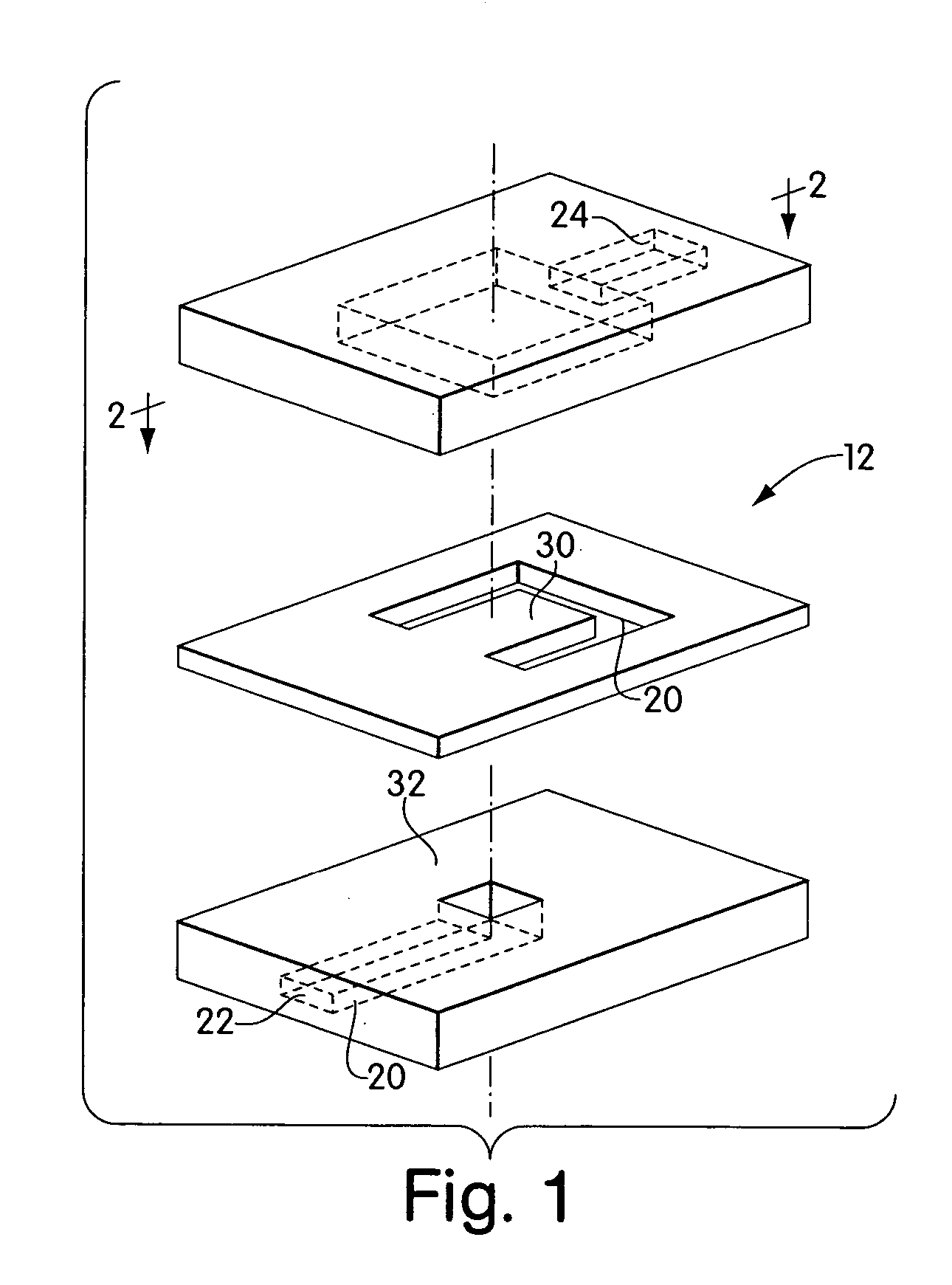

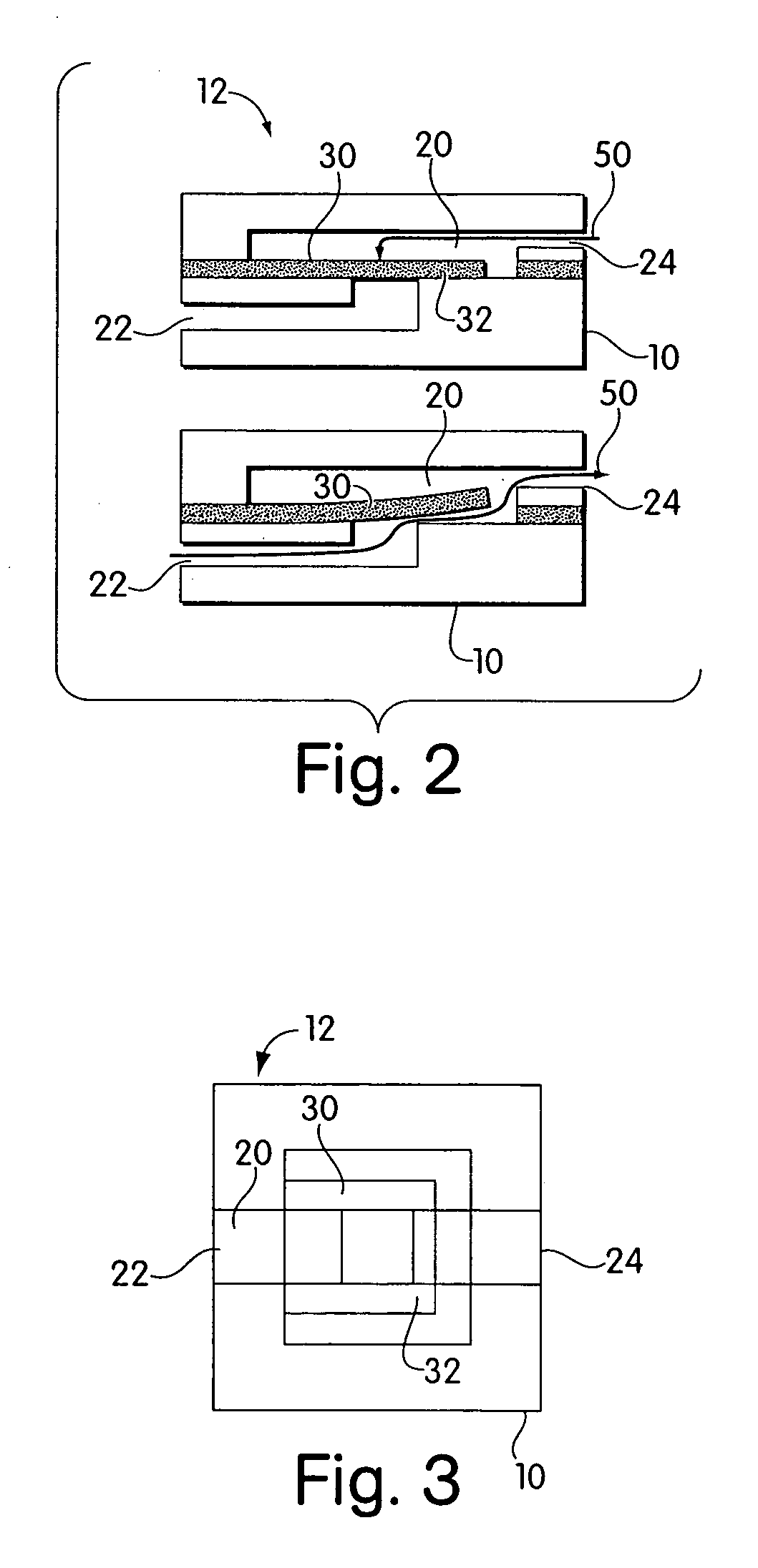

Microdevice having multilayer structure and method for fabricating the same

InactiveUS20030175162A1Well formedGood reproducibilityFixed microstructural devicesVolume/mass flow measurementProduction rateThin layer

The present invention provides a method of manufacturing a microdevice having a fine capillary cavity formed as a cut portion of a very thin layer which is likely to be broken, particularly a method of manufacturing a microdevice having complicated passages formed in three dimensions with high productivity. Also, the present invention provides a multi-functional microdevice which has a fine capillary passage formed by laminating plural resin layers, fine capillary cavities piercing through the respective layers to communicate and intersect three-dimensionally with each other, a space which should serve as a reaction chamber, a diaphragm valve, and a stopper structure. The method includes the steps of forming a semi-cured coating film having a cut portion made of an active energy ray curable composition on a coating substrate, laminating the semi-cured coating film with another member and removing the substrate, irradiating the semi-cured coating film again with an active energy ray before and / or after the removal of the substrate, thereby curing the coating film and bonding with said another member. The microdevice has a multi-layered structure wherein a member (J') {selected from a member having a cut portion piercing through the member, a member having a recessed cut portion on the surface, and a member having a cut portion piercing through the member and a recessed cut portion on the surface}, a member (K') and one or more active energy ray curable resin layers (X') having a cut portion at a portion of the layer, the cut portion having a minimum width within a range from 1 to 1000 mum, are laminated and two or more cut portions in the members are connected to form a cavity.

Owner:KAWAMURA INST OF CHEM RES

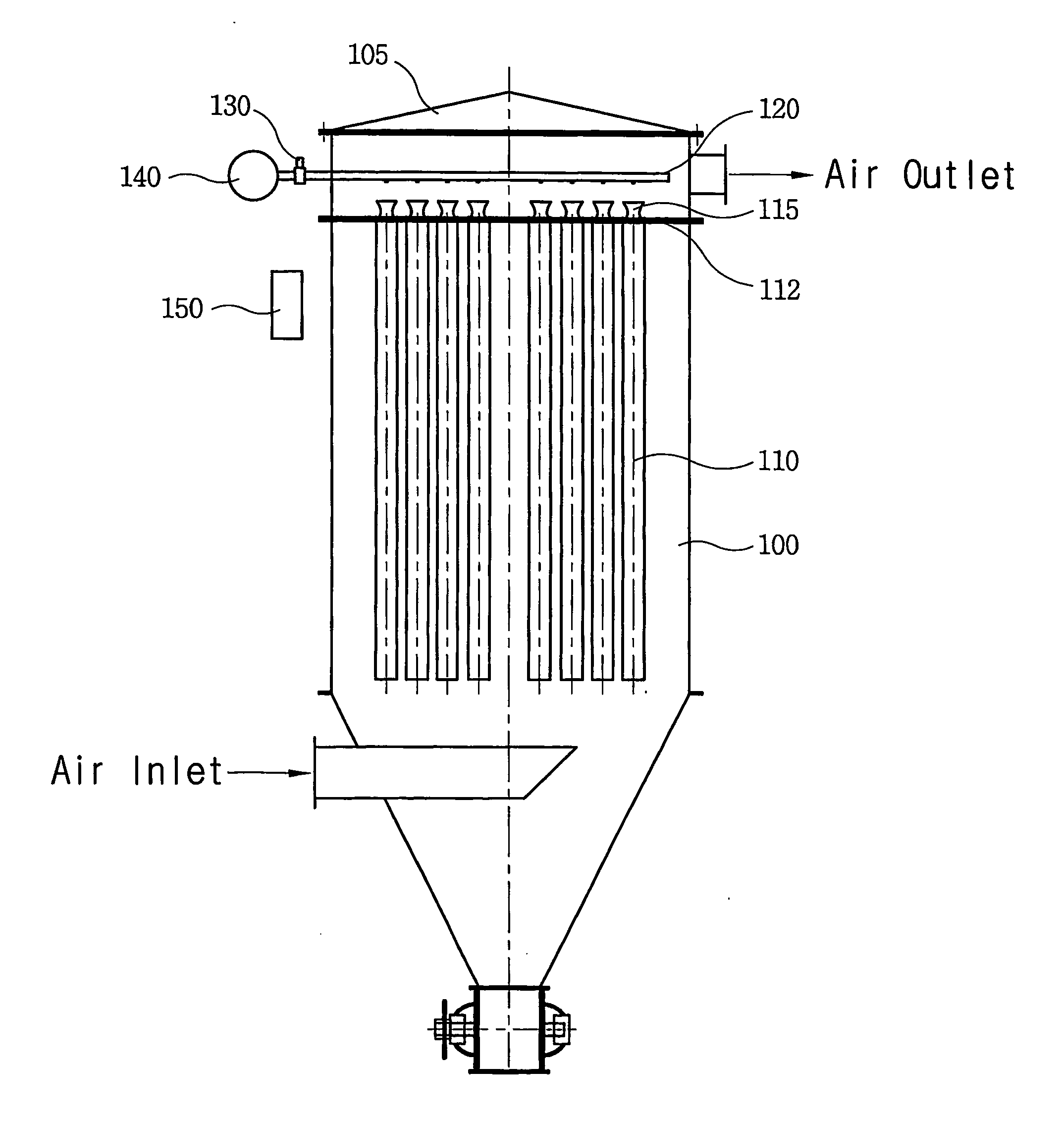

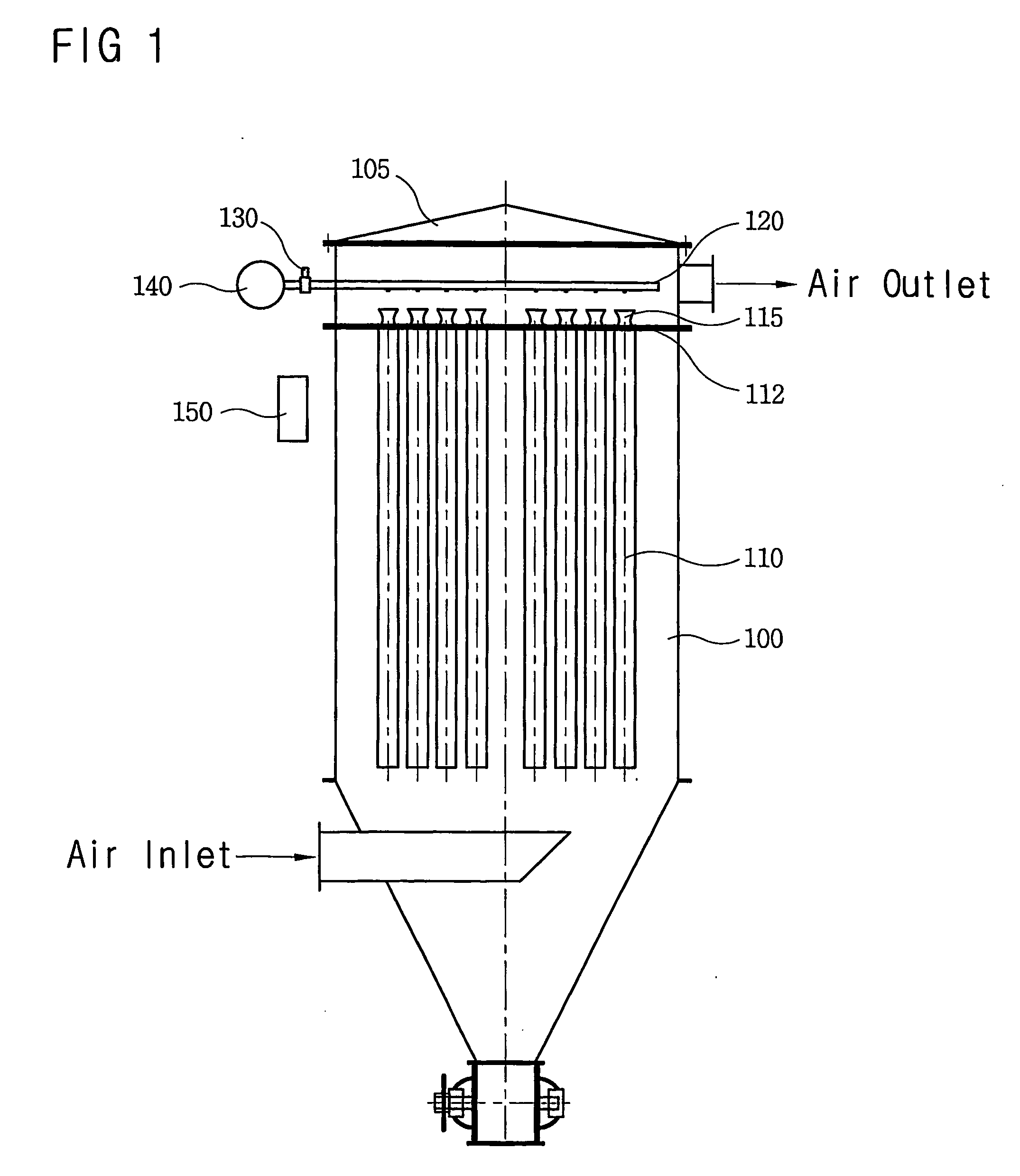

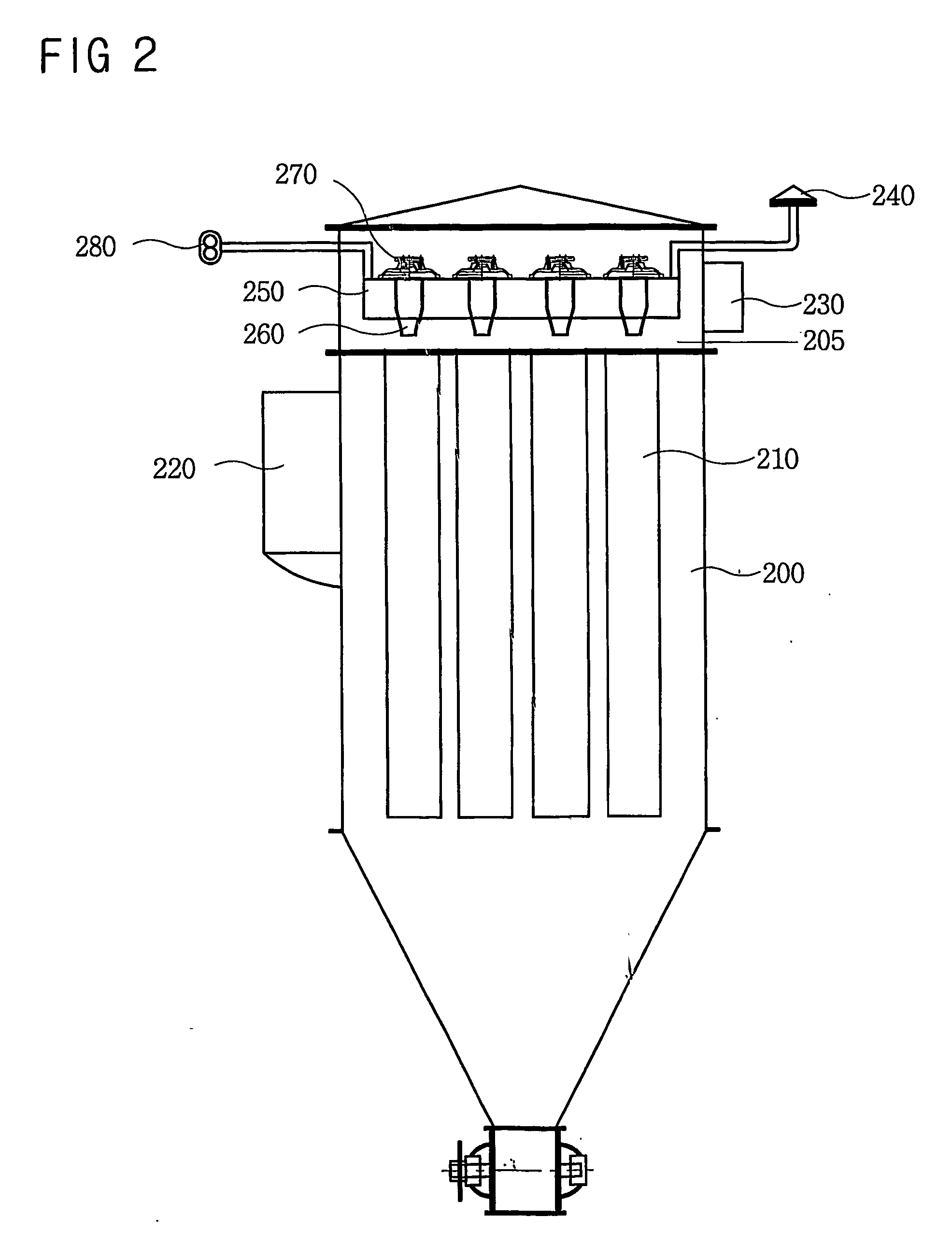

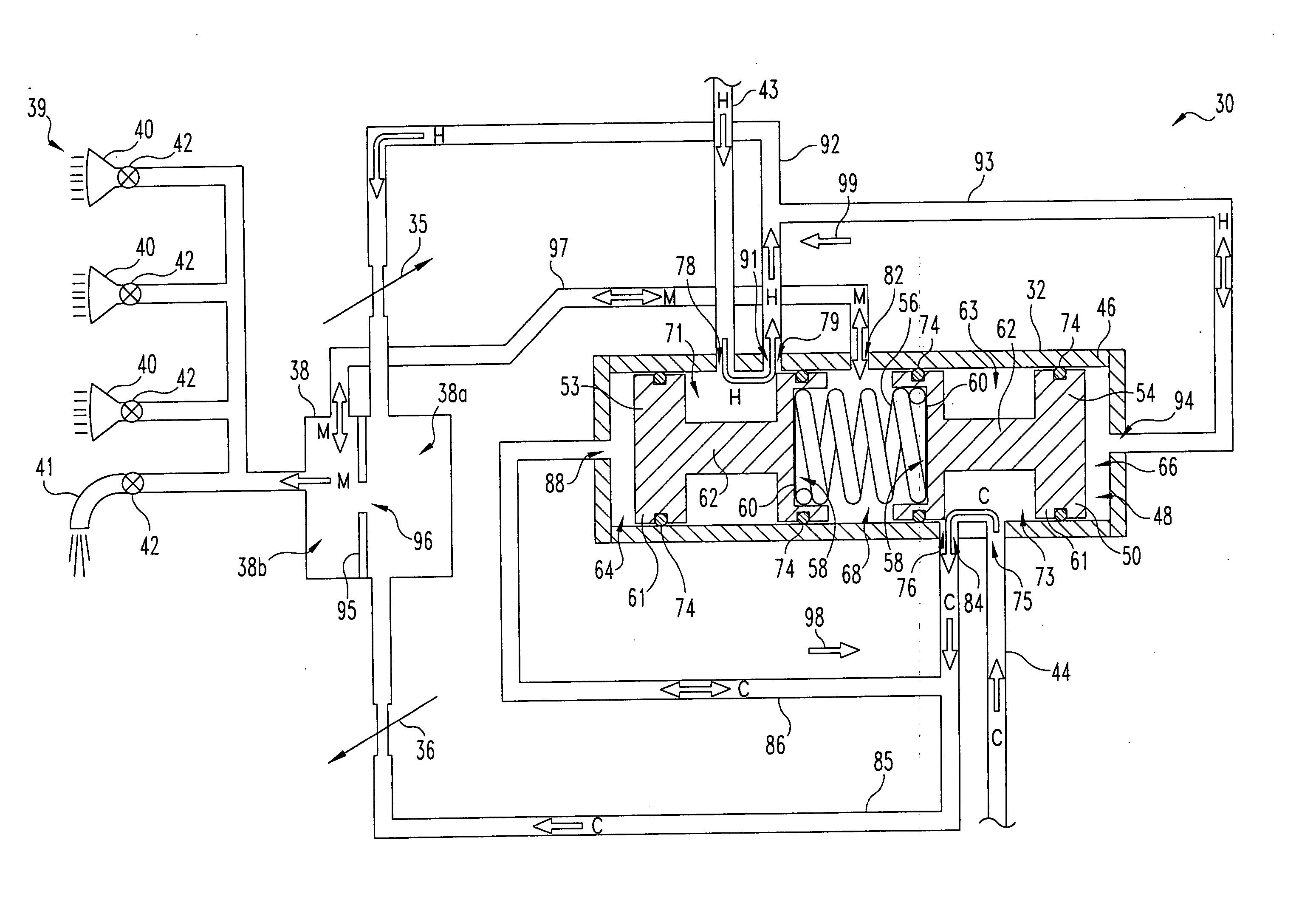

Rotary pulse type filter dust collector

InactiveUS20070039290A1Reducing maintenance feeReduce manufacturing costCombination devicesAuxillary pretreatmentManufacturing cost reductionDiaphragm valve

The present invention discloses a rotary pulse type filter dust collector, which can maintain excellent de-dusting efficiency of a low pressure pulse type filter dust collector, reduce the number of required components in order to reduce manufacturing costs, maintenance fees, and lower defect factors to provide higher reliability. The dust collector includes: a dust collector body, a number of filter bags, a moving compressed air tank, nozzles, diaphragm valves, mechanical 3-way valves, protrusions, a reduction motor and a mechanical device for driving the compressed air tank, and an inverter controller.

Owner:LEE IN OK

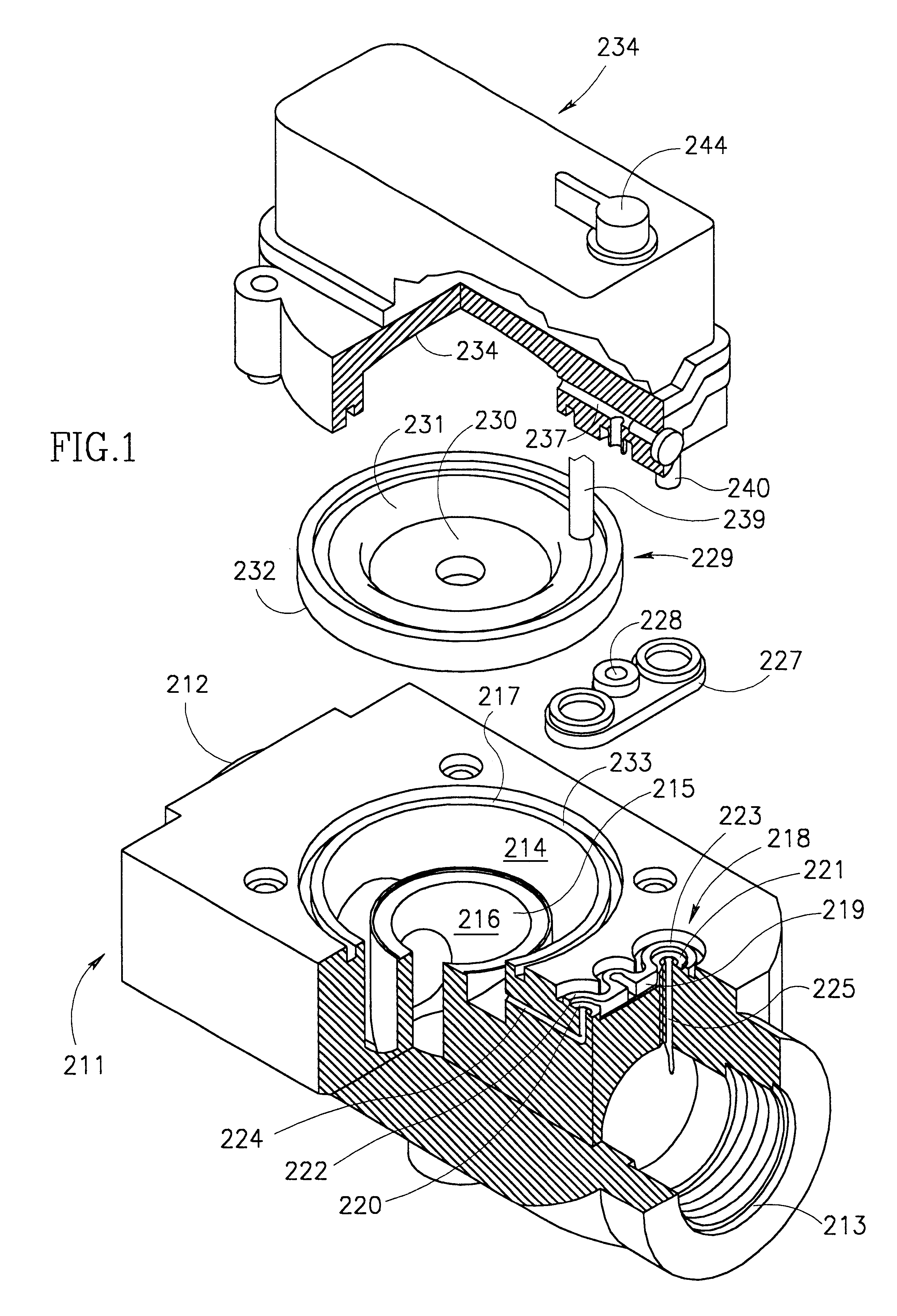

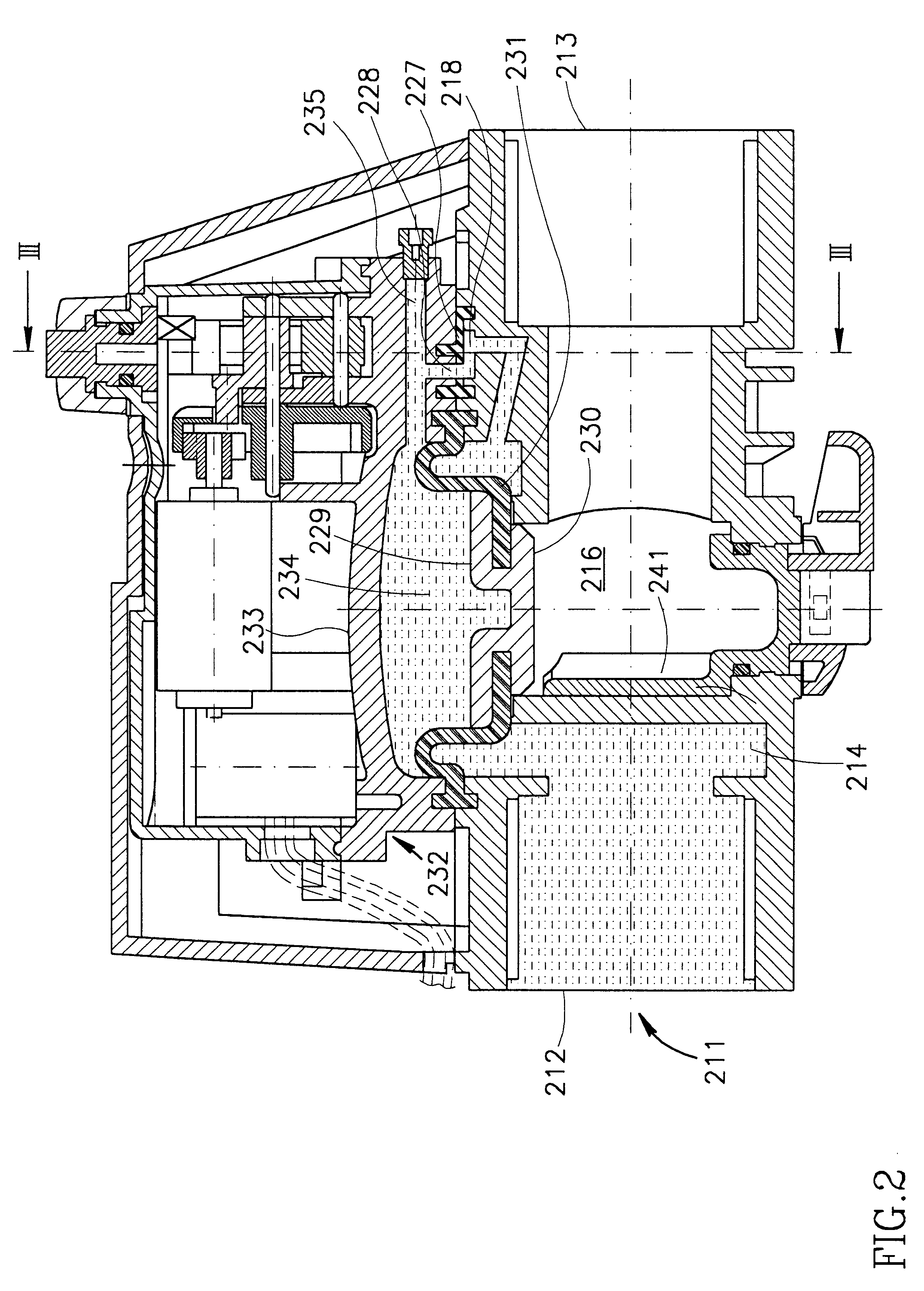

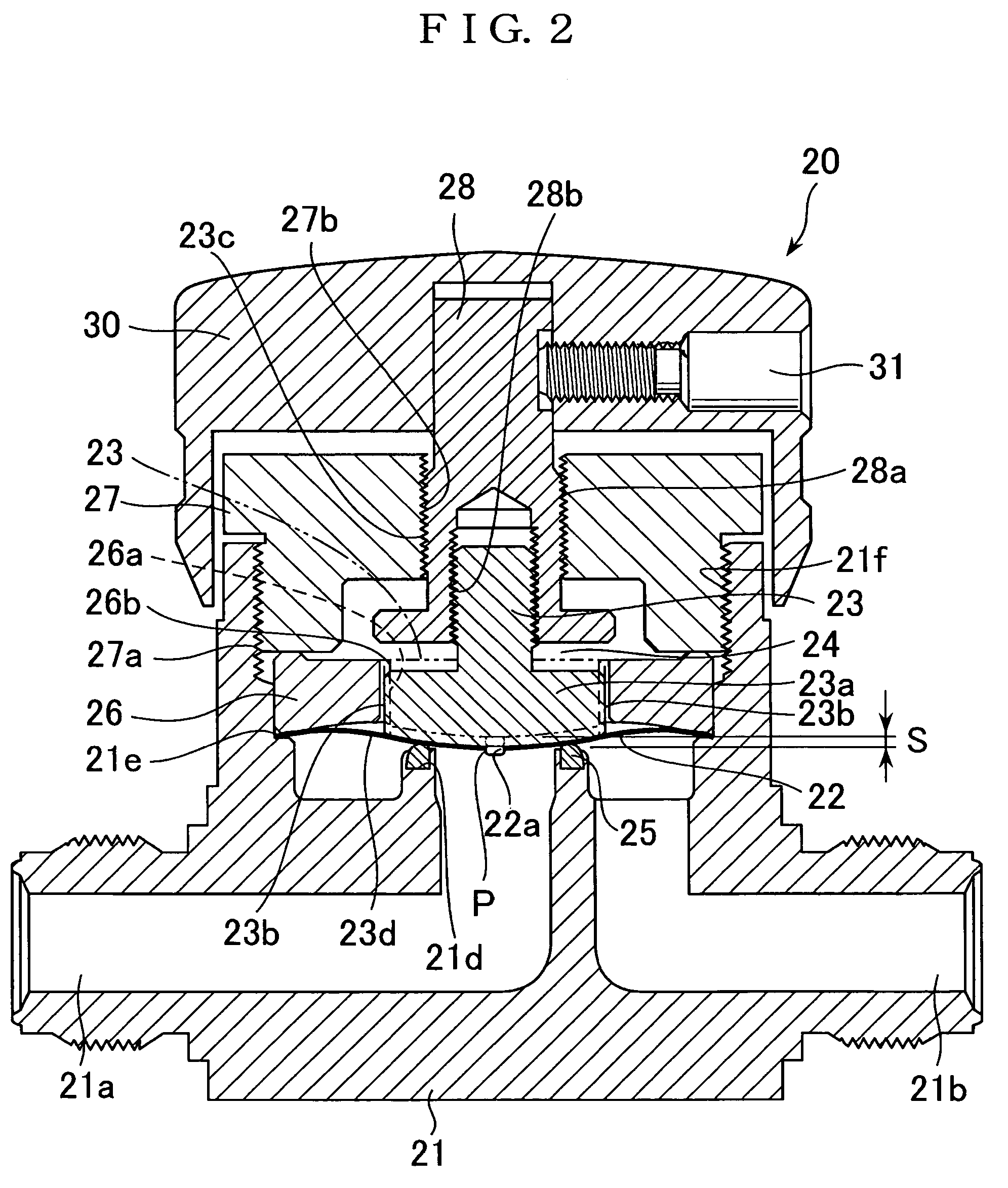

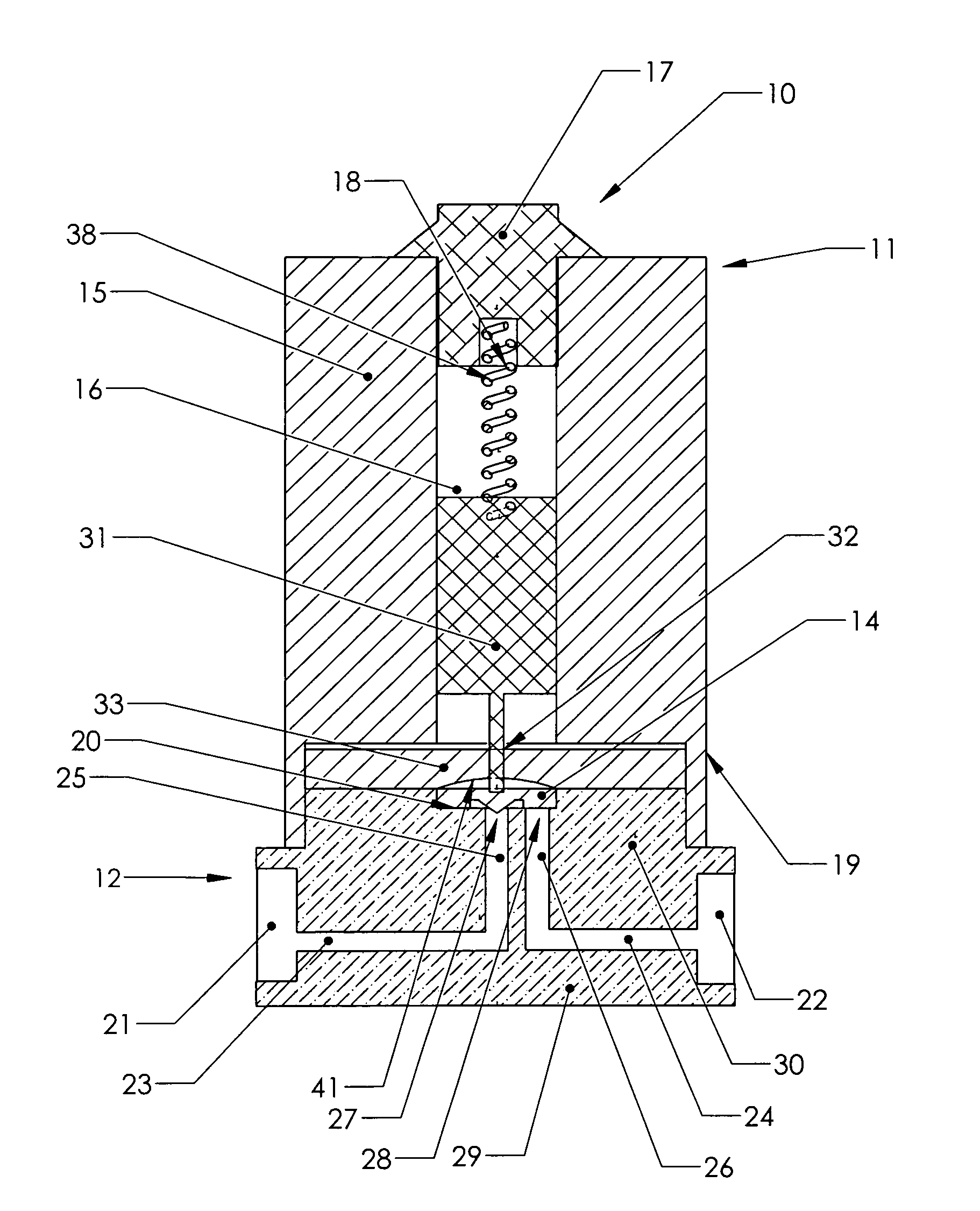

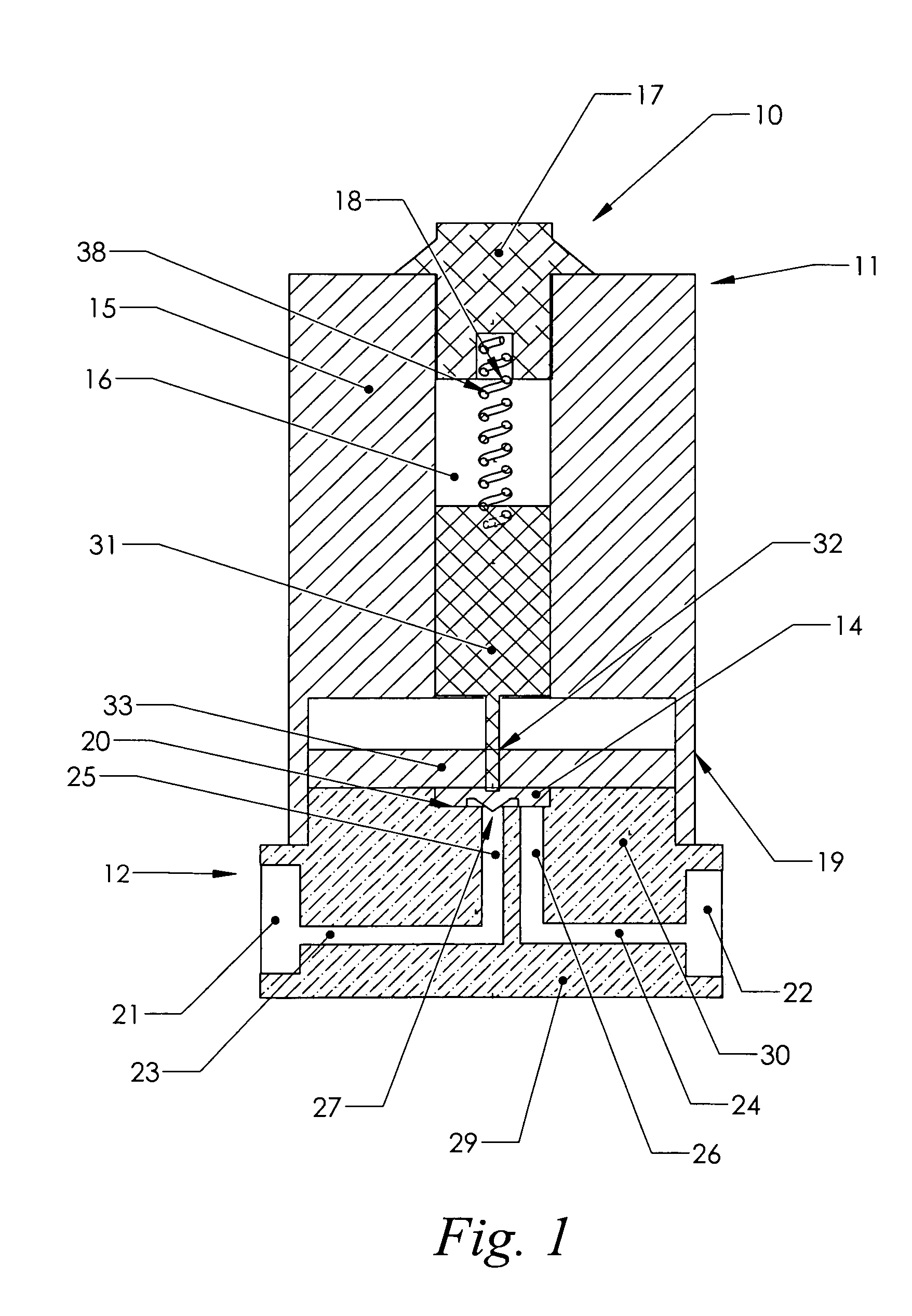

Direct touch type metal diaphragm valve

ActiveUS20100090151A1Reduce replacement timeAchieve stabilityDiaphragm valvesOperating means/releasing devices for valvesDirect touchEngineering

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

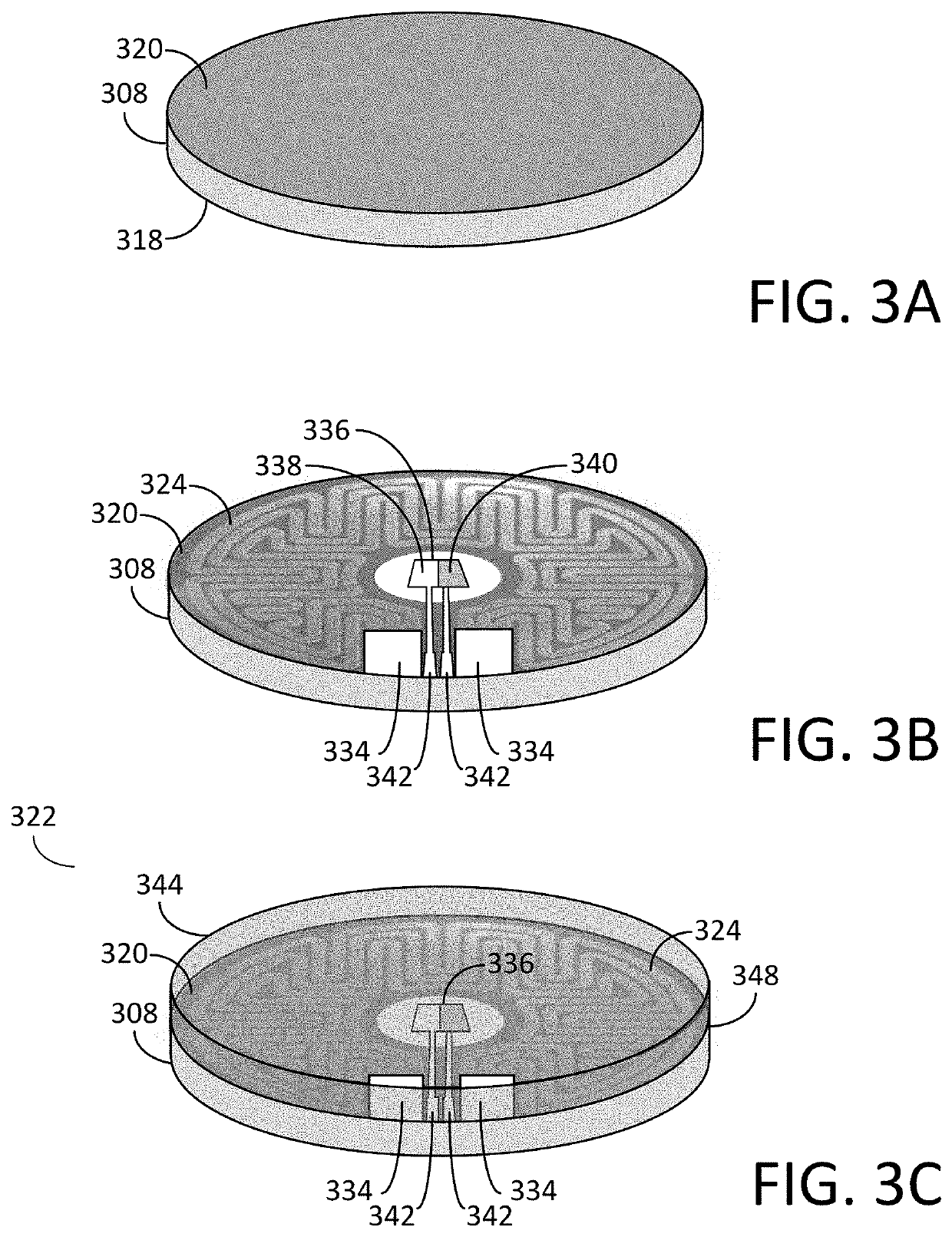

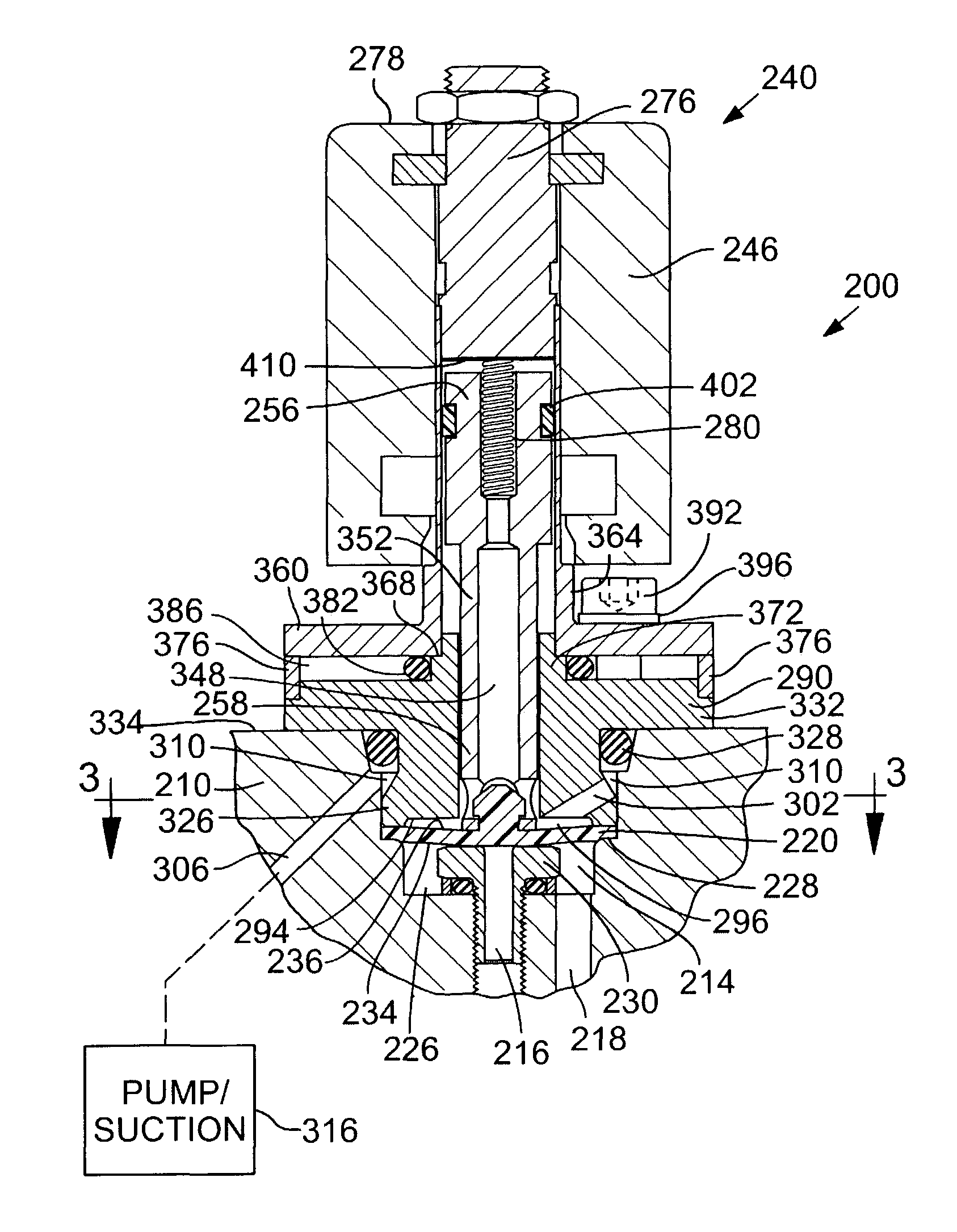

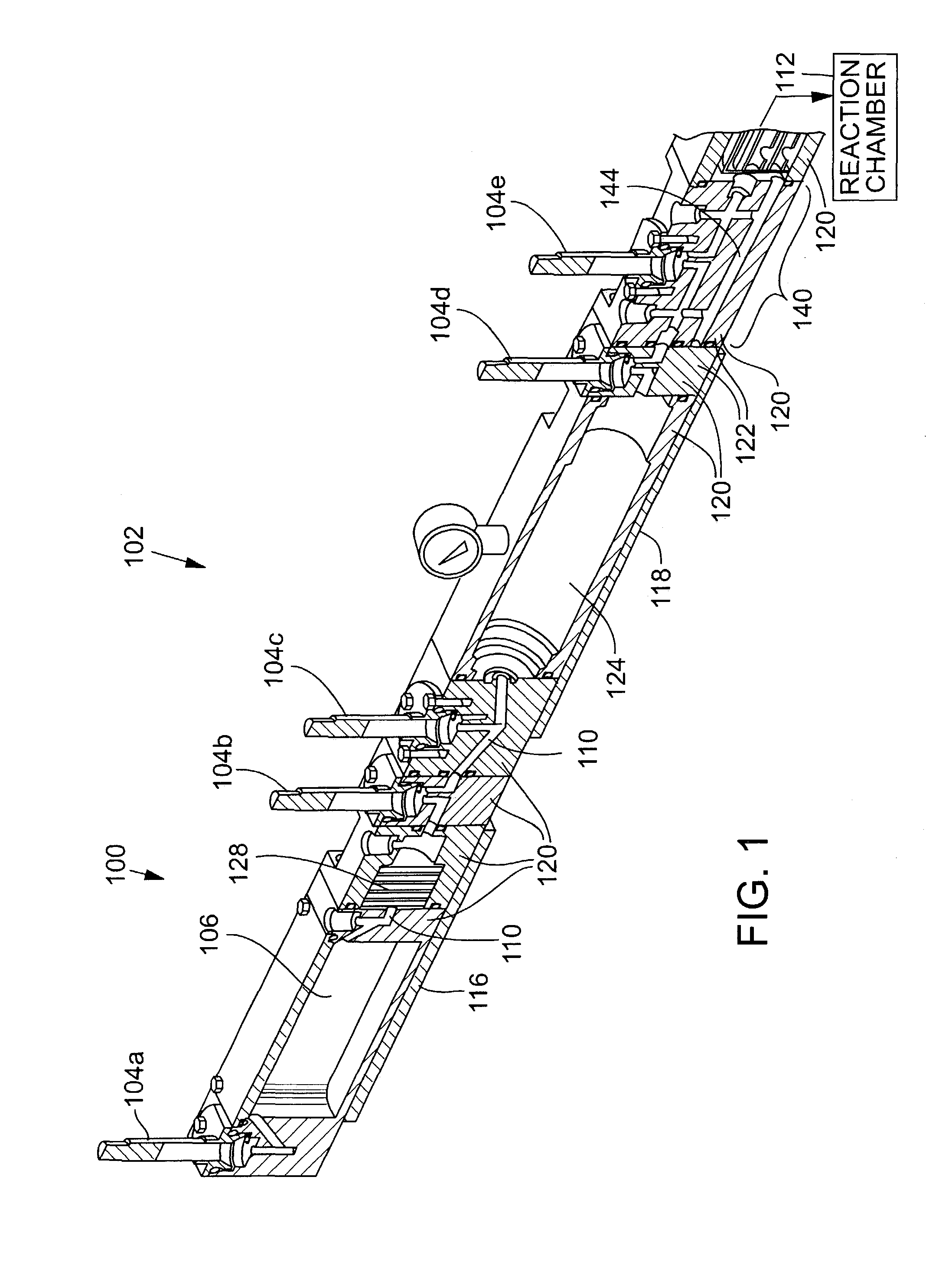

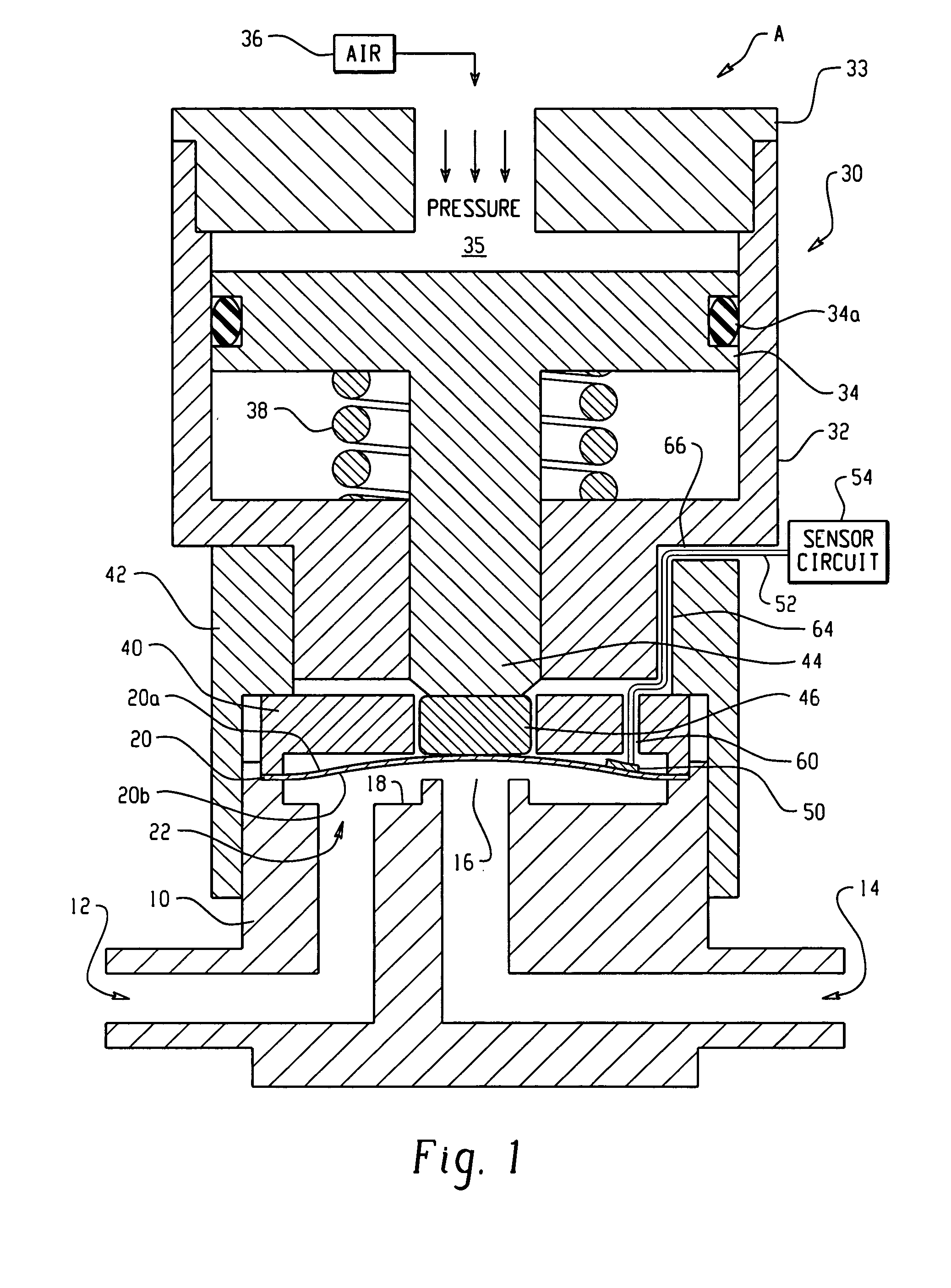

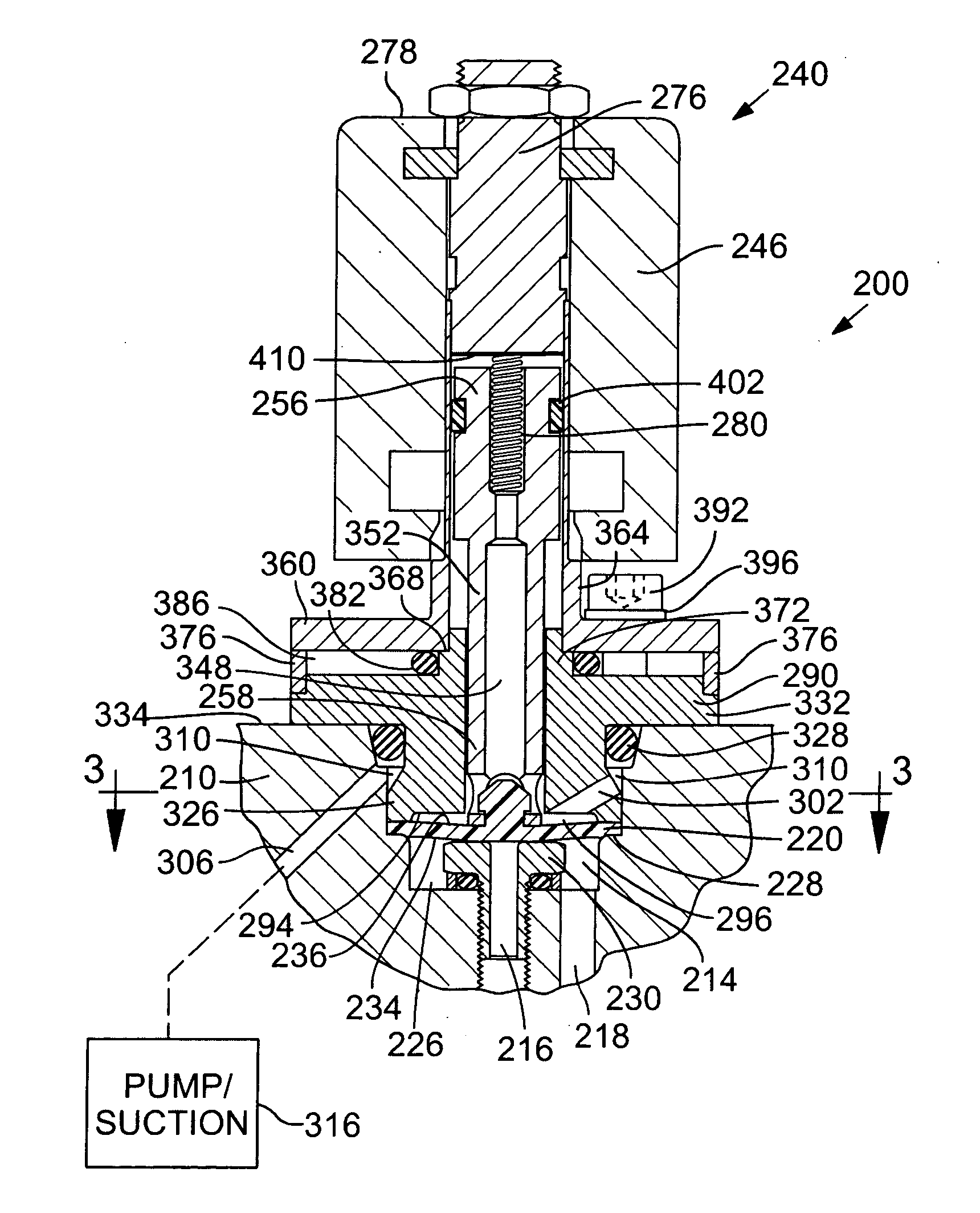

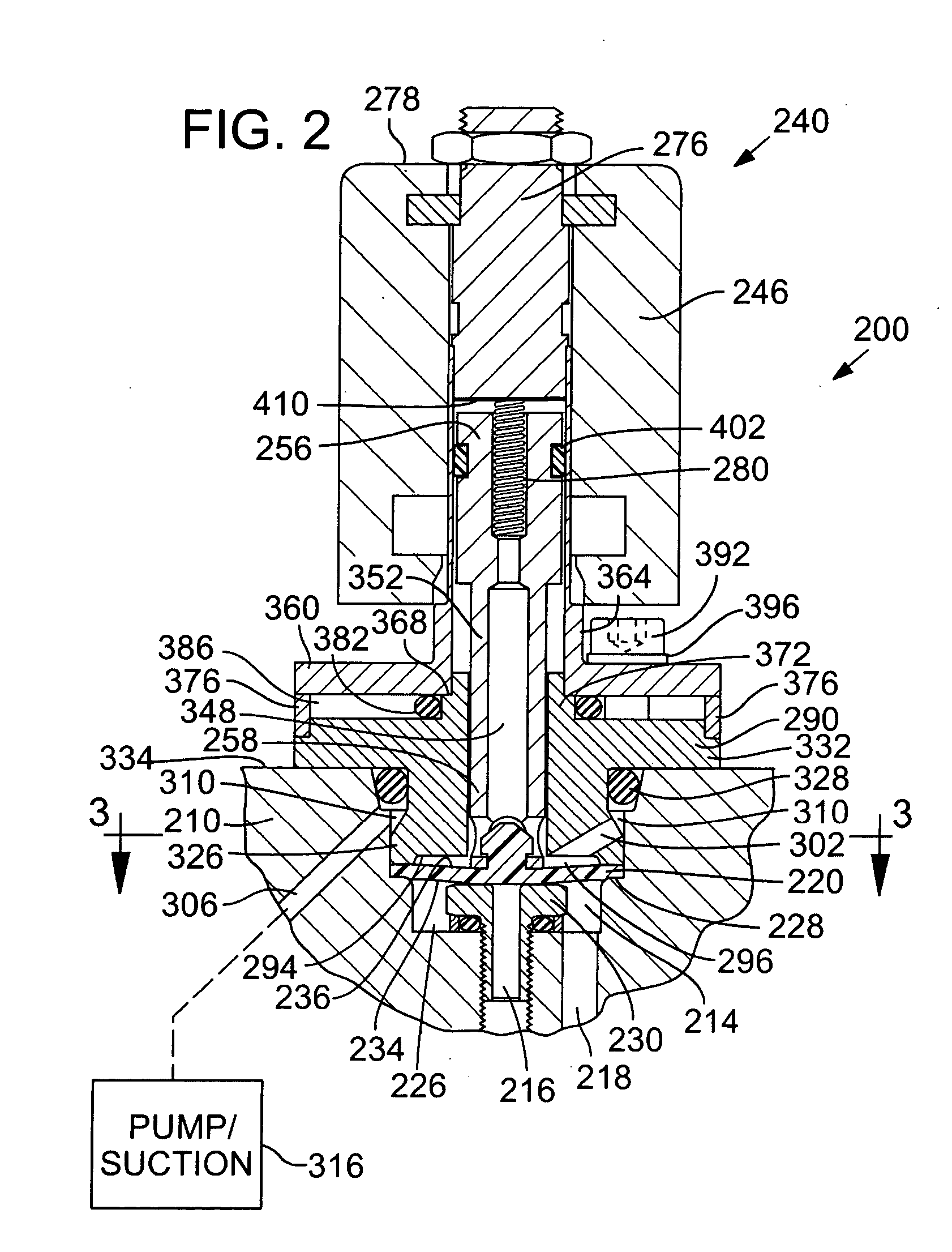

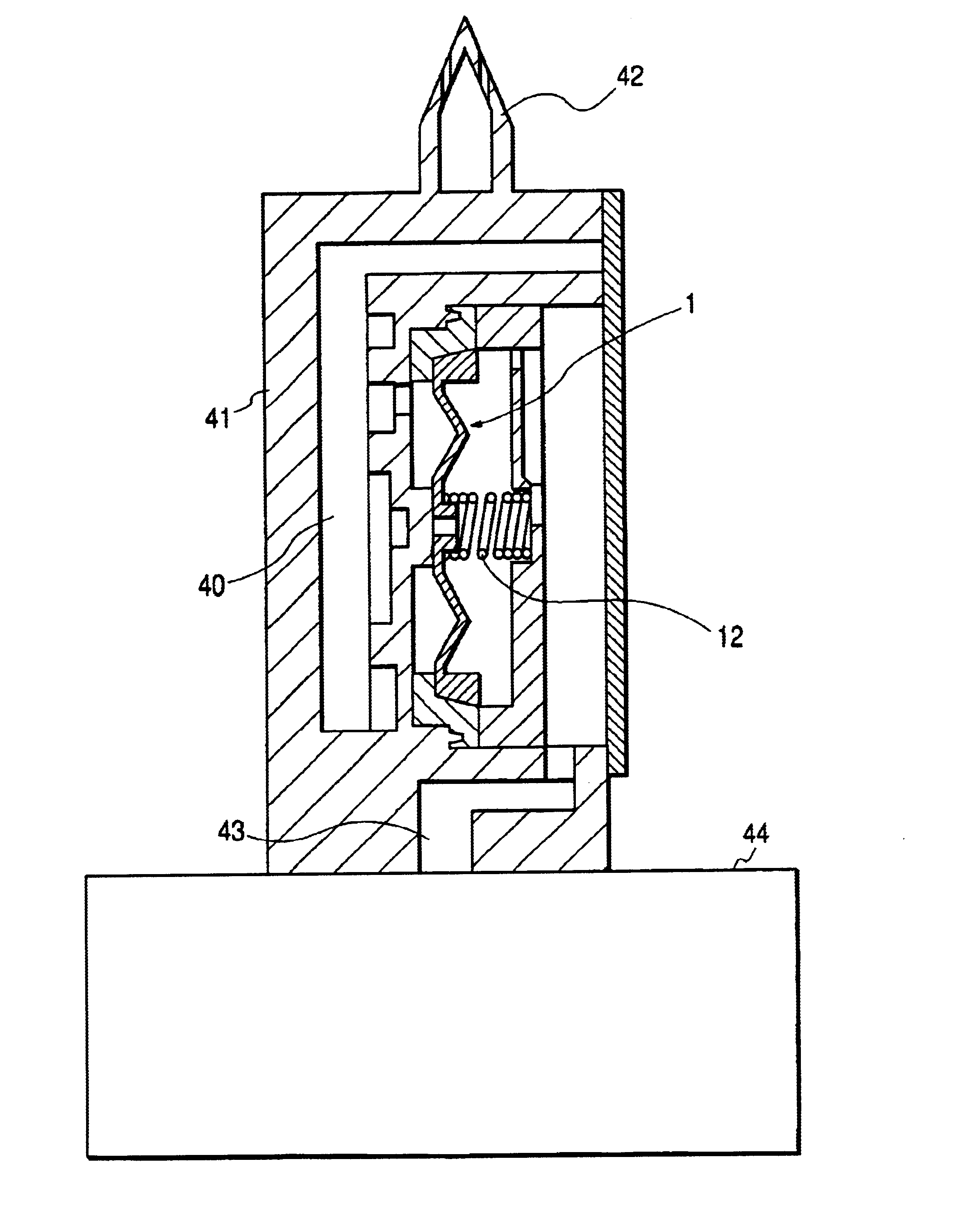

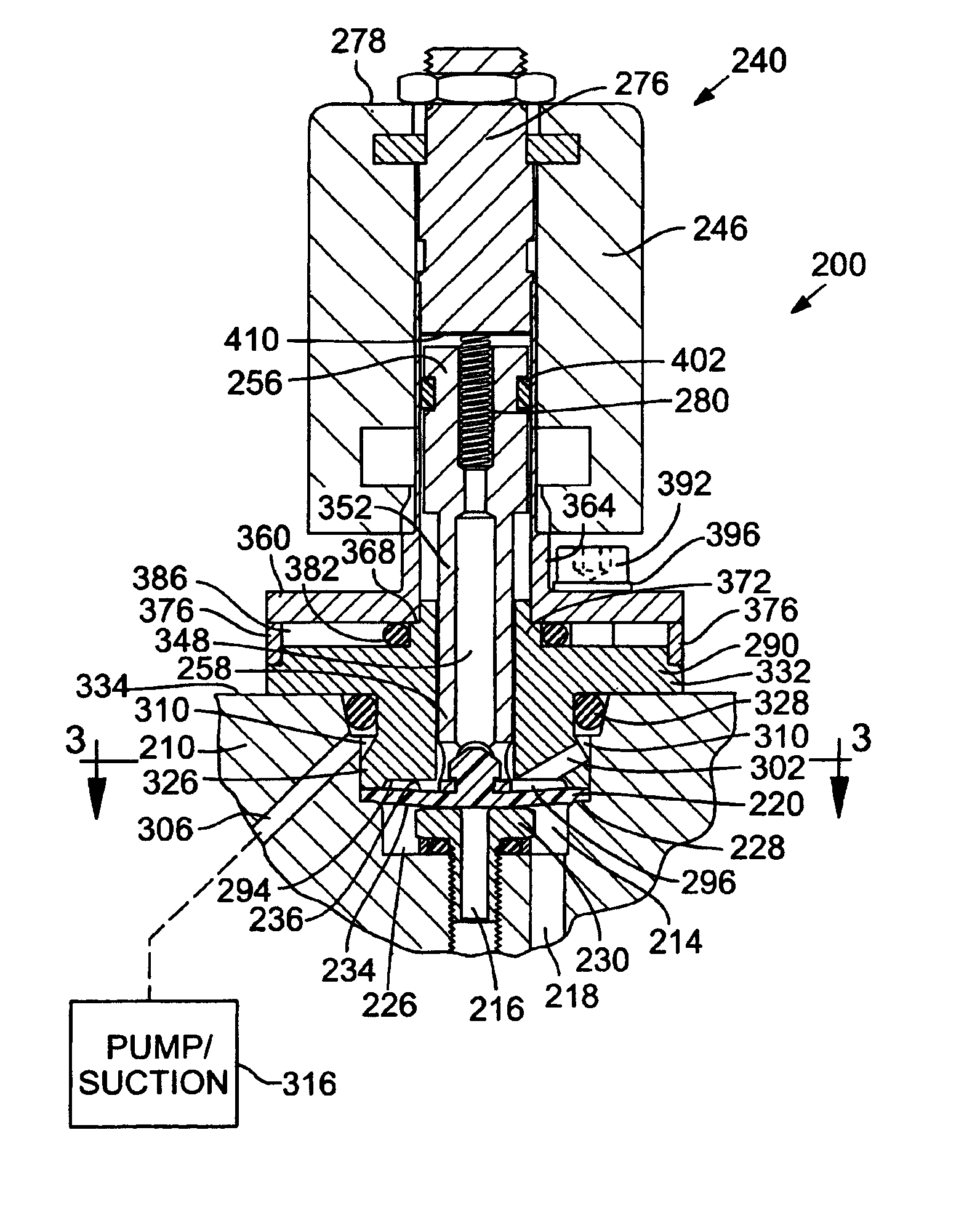

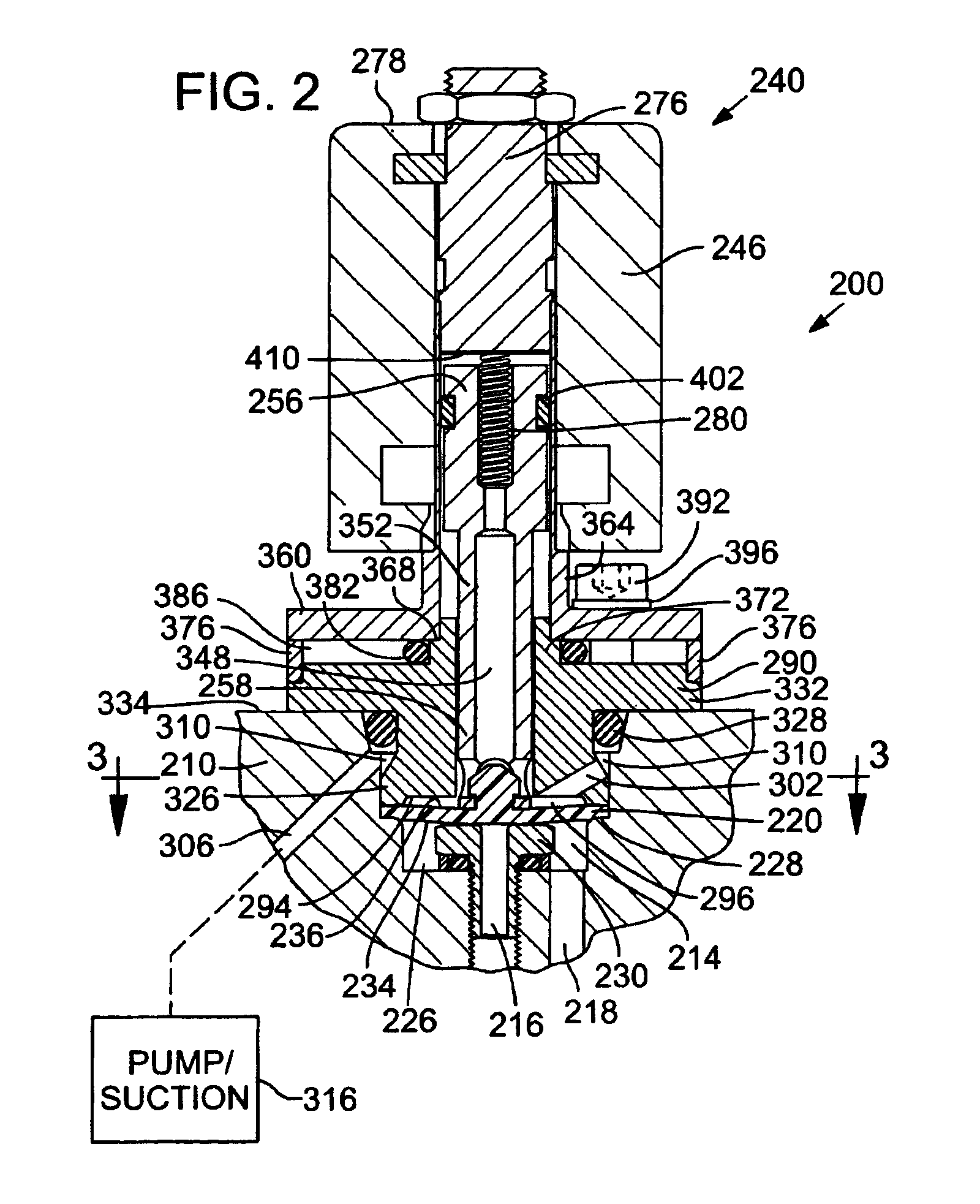

High-speed diaphragm valve for atomic layer deposition

InactiveUS20050011555A1Easy to moveLow efficiencyDiaphragm valvesOperating means/releasing devices for valvesEngineeringDiaphragm valve

A diaphragm valve includes a pressure vent communicating with an enclosed space behind the diaphragm for reducing resistance to transitioning of the diaphragm between the open and closed positions. In some implementations, a pump or other source of suction is coupled to the pressure vent to reduce fluid pressure in the enclosed space. When used in an atomic layer deposition (ALD) system, the venting and suction improves the thin film deposition process and prevents leakage through the valve of potentially toxic ALD precursor vapors. Features for thermal management and reliability enhancement are also described.

Owner:BENEQ OY

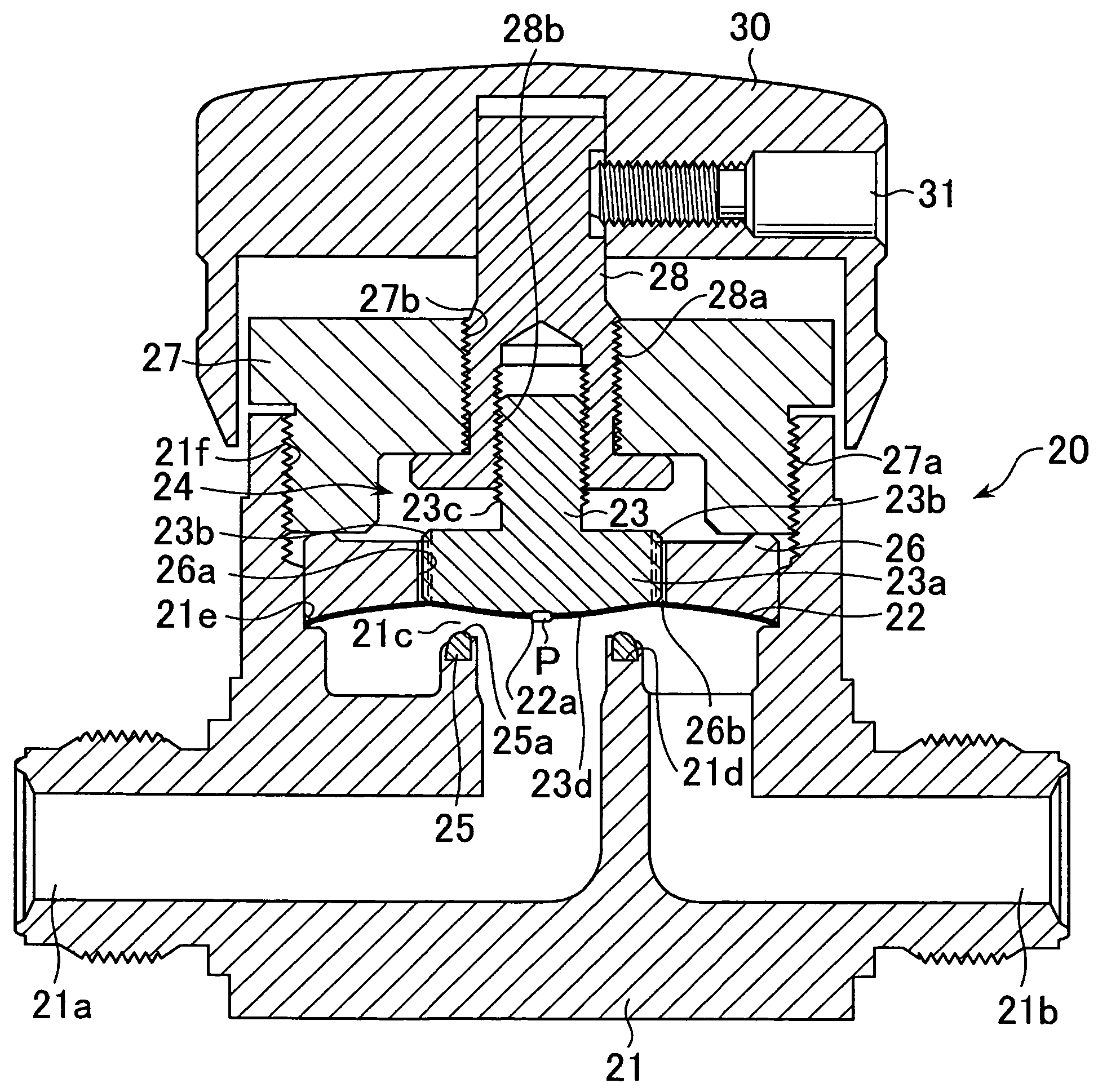

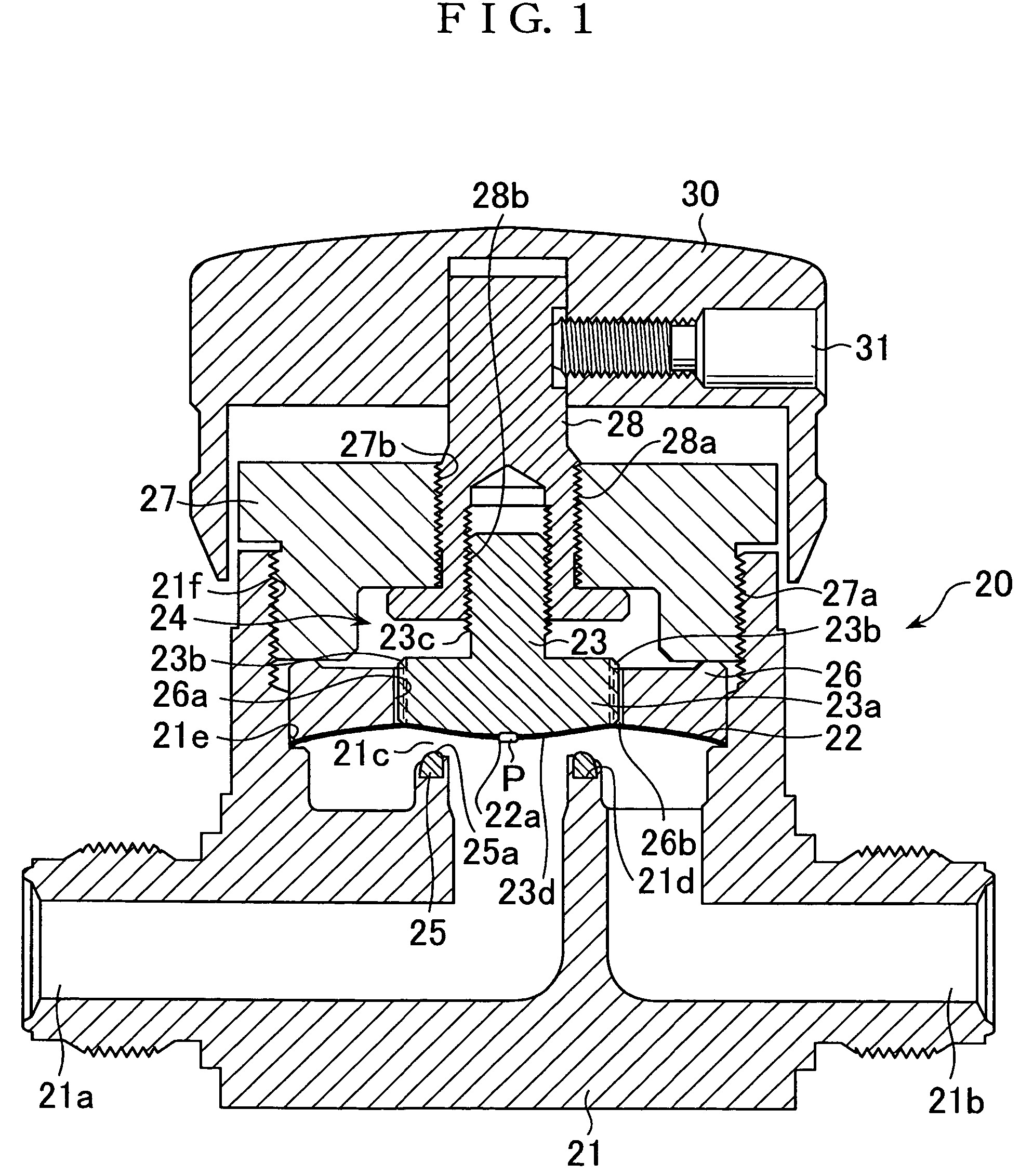

Diaphragm valve

ActiveUS7377483B2Speed up the flowSuppress generationDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveEngineering

A diaphragm valve for opening or closing itself through making direct contact of or through breaking the direct contract of a metal diaphragm with a valve seat disposed inside a body provided with an inlet port and an outlet port. The diaphragm valve includes an elevating member which serves to make or break the direct contact of the metal diaphragm with the valve seat and which is fusion-bonded to the metal diaphragm.

Owner:KITZ SCT

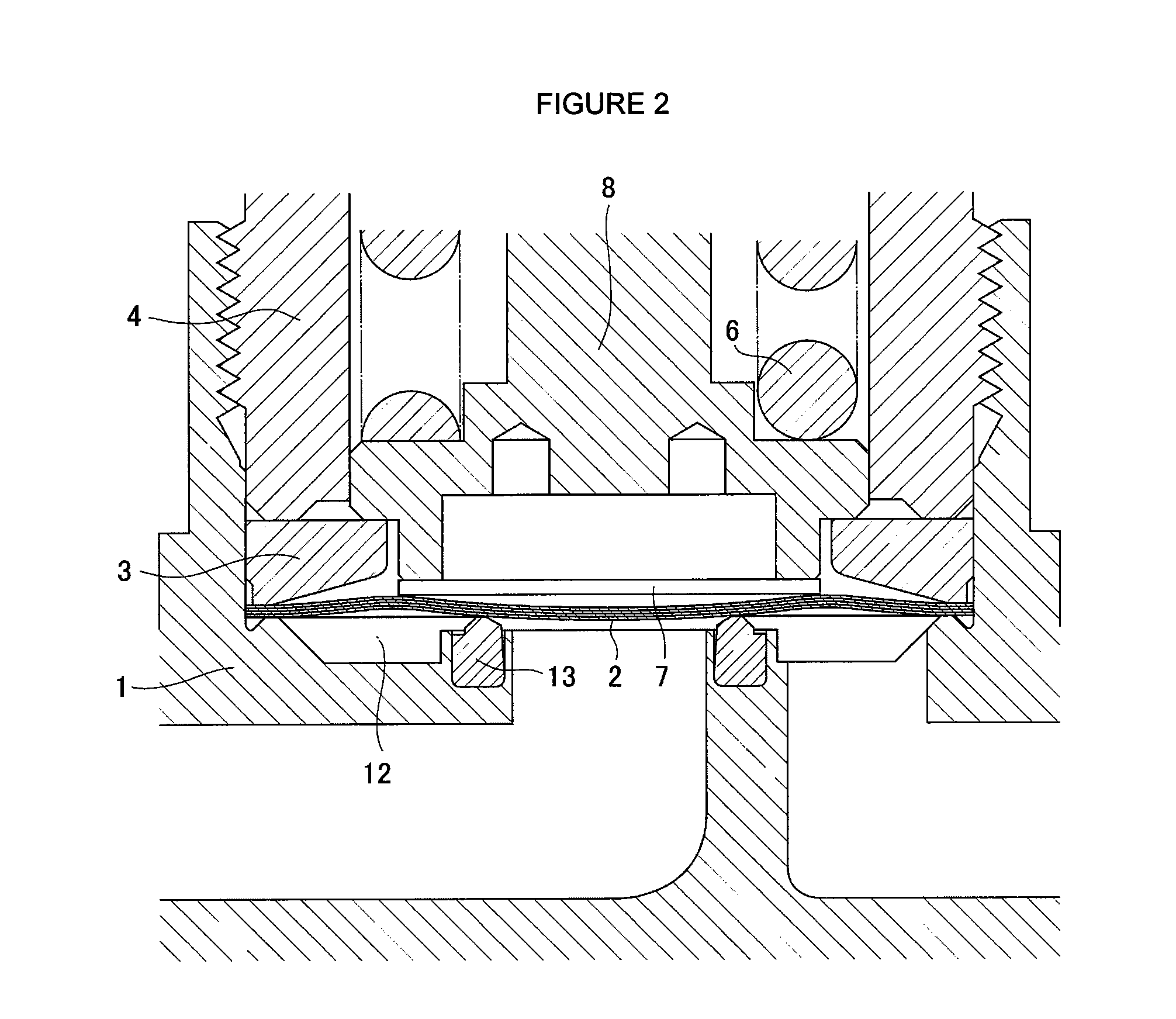

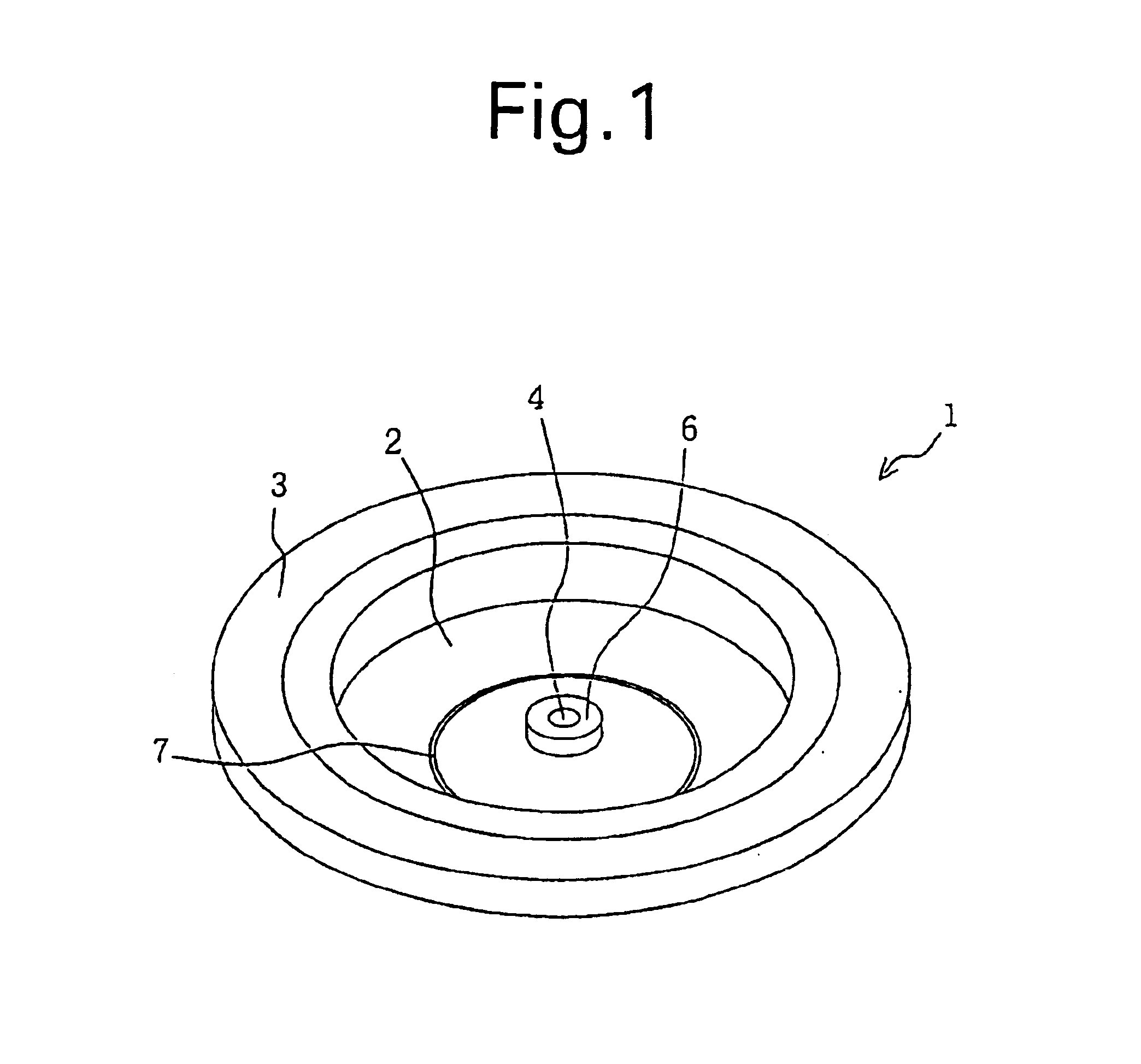

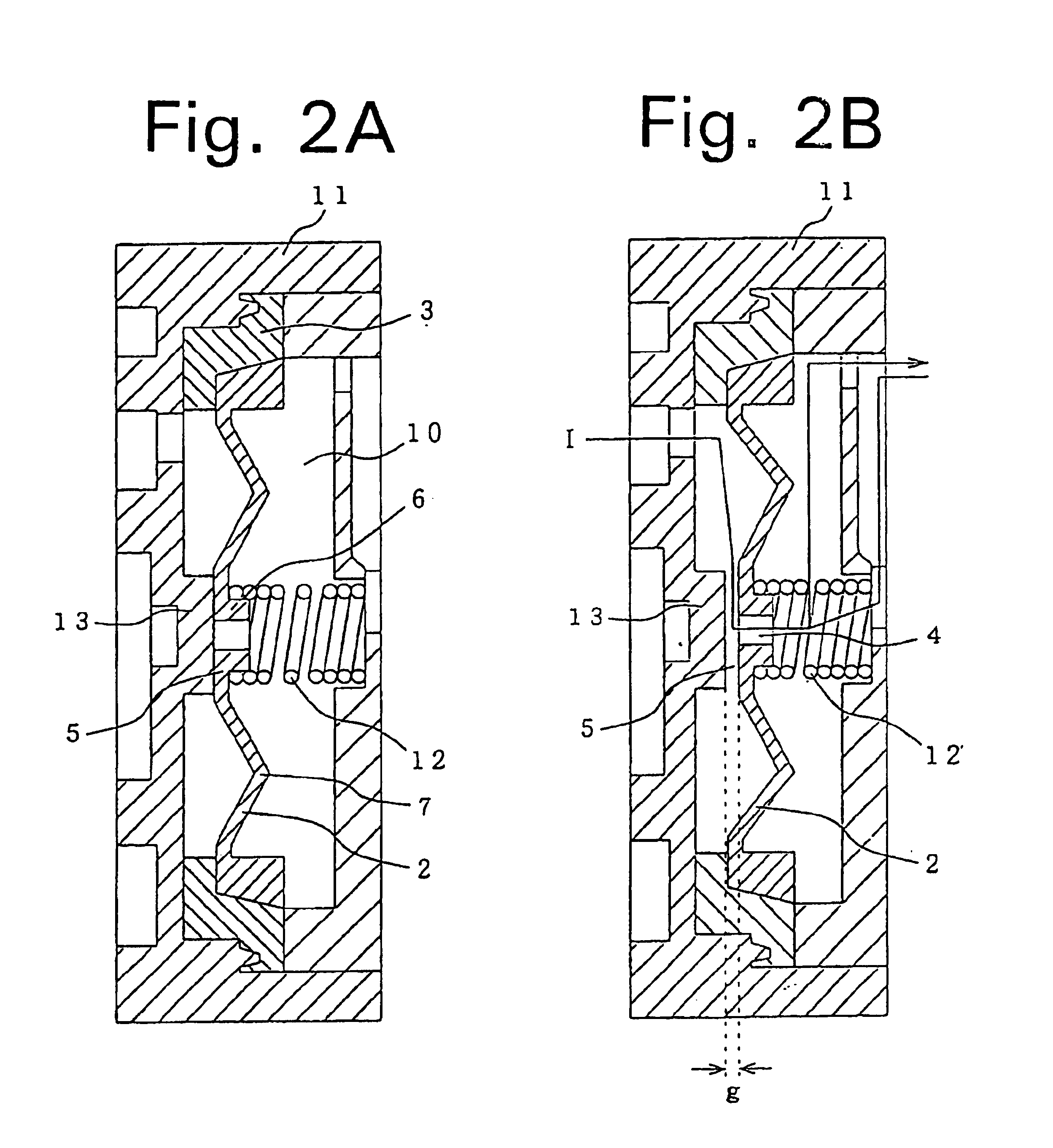

Ink feed unit for ink jet recorder and diaphragm valve

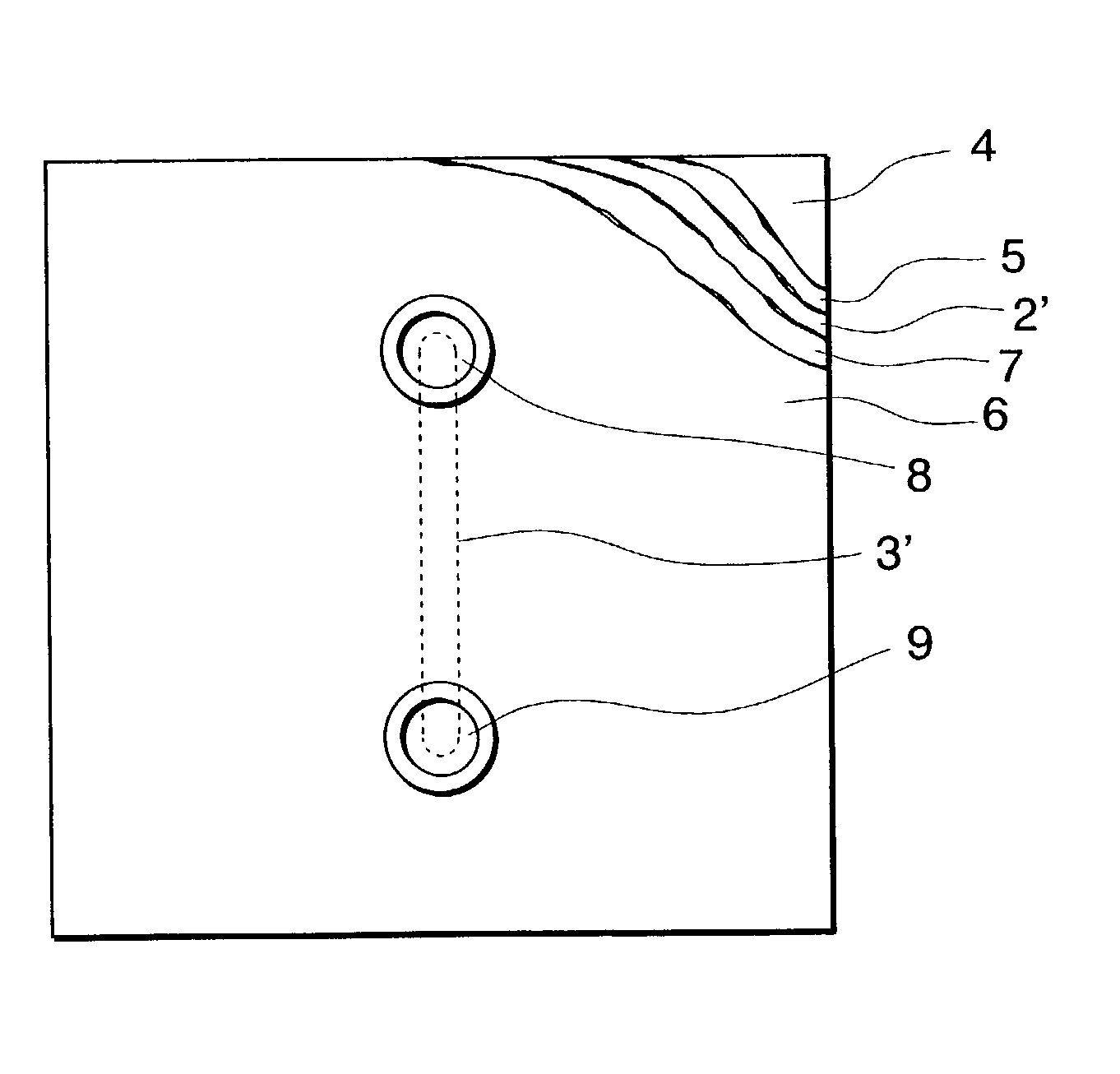

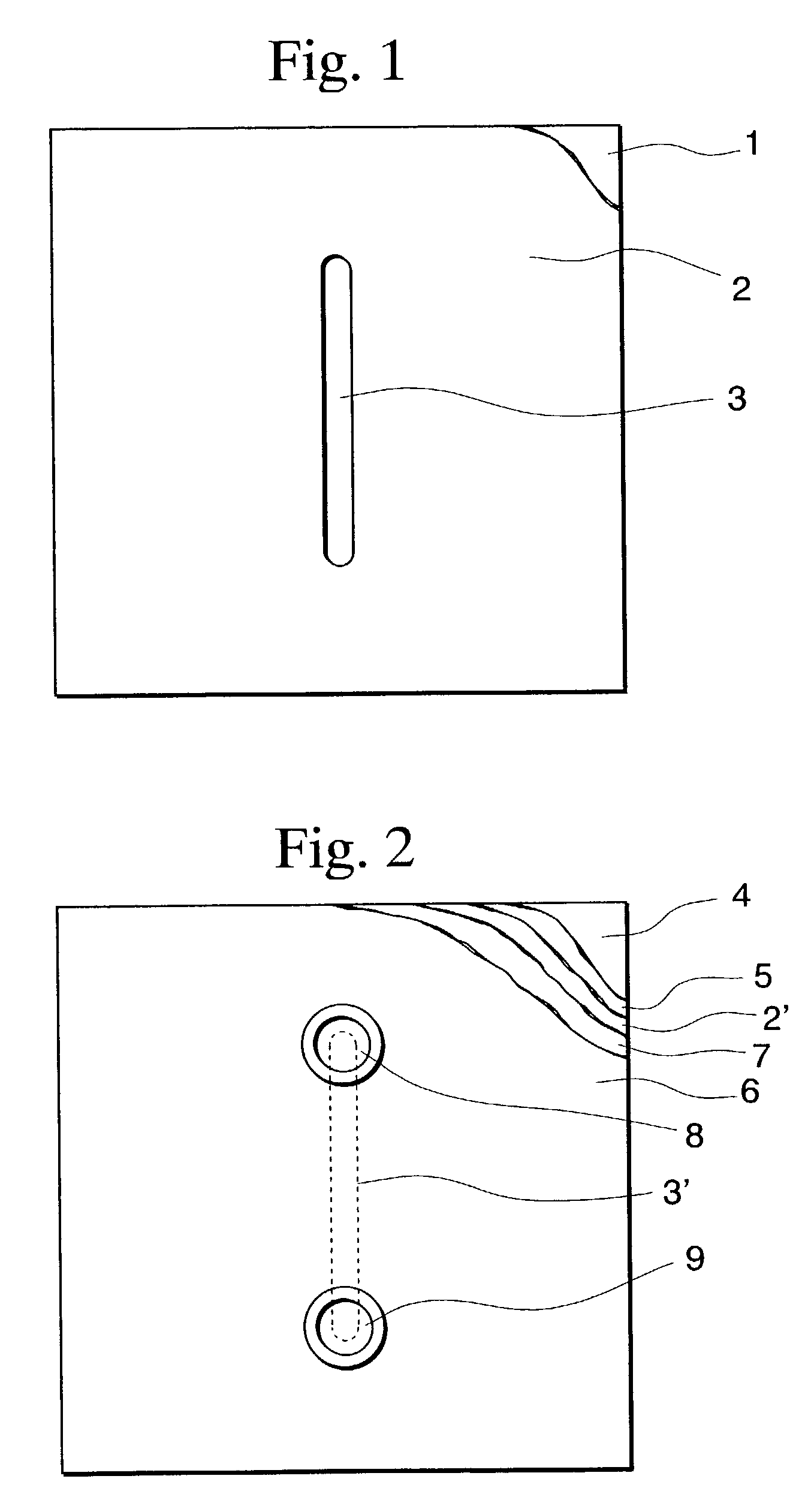

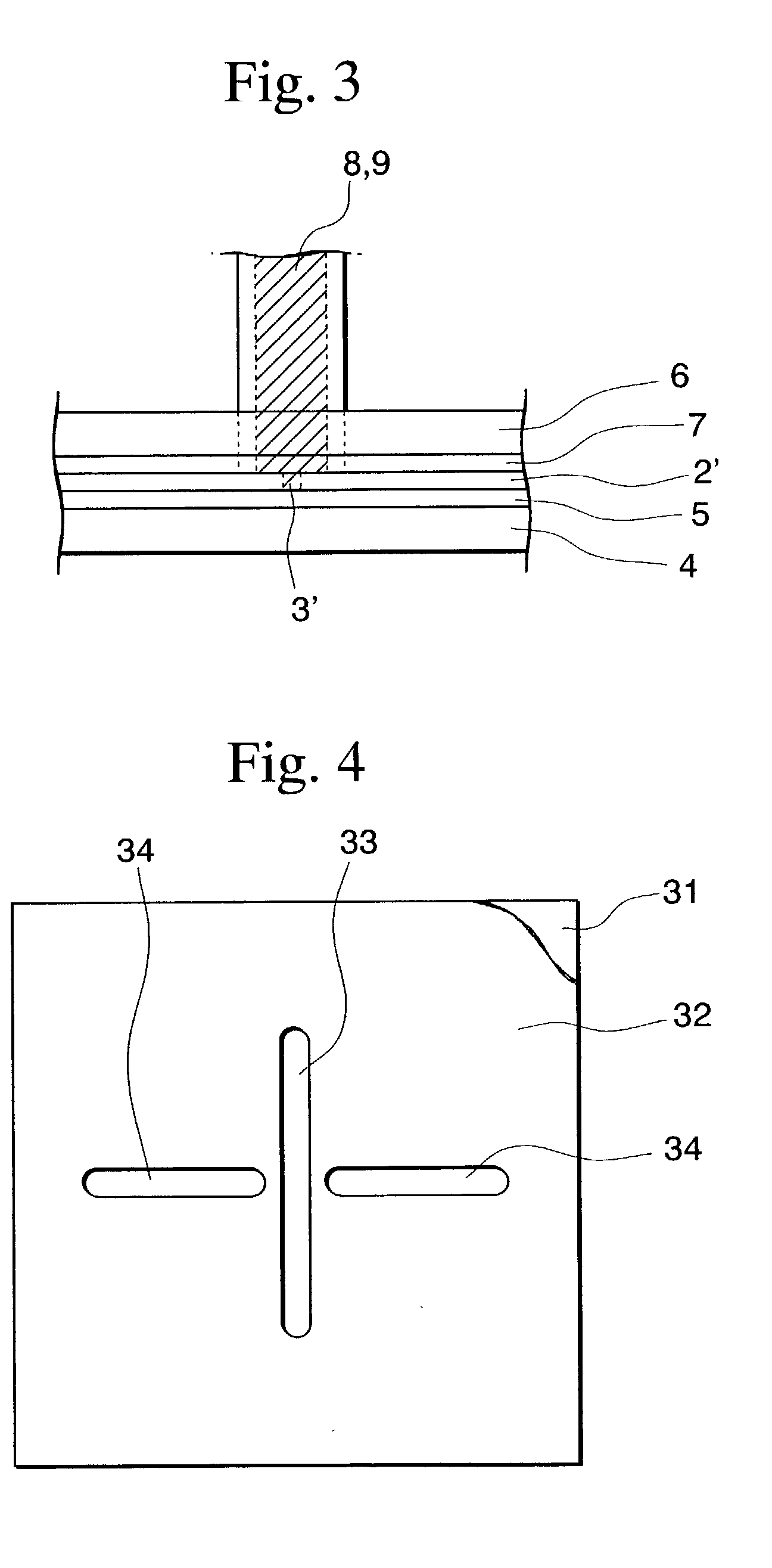

An angled portion that is concentric with respect to an ink passing port (4) is formed in a central region (7) of a membrane portion (2) to function as an elasticity providing portion, whereby the influence produced when a thick portion is injection molded at the periphery is removed from affecting elasticity of a membrane valve.

Owner:SEIKO EPSON CORP

Diaphragm valve

InactiveUS6241213B1Diaphragm valvesOperating means/releasing devices for valvesEngineeringDiaphragm valve

A valve including: a bonnet; a body secured to the bonnet and including at least two ports and at least one weir positioned between the ports; a valve stem being movably coupled with the bonnet, the valve stem including first and second longitudinal ends, and a recess in the first longitudinal end; a diaphragm positioned substantially adjacent to the second end of the valve stem so as to be deflectable towards the weir by the valve stem to restrict a flow between the ports; a handwheel rotatably secured to the valve stem so as to enable a torque to be applied to the valve stem, the handwheel including a longitudinal aperture; and, a screw directed through and engaged with the handwheel aperture and being selectively engagable within the recess of the valve stem, such that the valve stem and handwheel remain in a constant relative longitudinal position with respect to one another, and when the diaphragm sets against the weir the handwheel abuts the bonnet to serve as a closing lift valve stop.

Owner:ITT MFG ENTERPRISES LLC

Low-flow valve

ActiveUS20060016494A1Diaphragm valvesOperating means/releasing devices for valvesParticulatesDiaphragm valve

A low-flow diaphragm valve is disclosed having a flexible diaphragm that cooperates with a portion of the valve body to open and close the valve. The diaphragm may have a dome for seating in a passage between the inlet and outlet of the valve, and the passage may be surrounded by an annular ridge for contacting the dome. The diaphragm may have one or more ribs for seating against other portions of the body located around the passage. The valve body may include openings or interruptions to permit fluid to flow through the valve, as well as to permit relatively small particulate matter to flow through. The diaphragm may have a first open position and / or a second open position such that the ribs and openings may perform screening functions to block or restrict particulate matter of relatively large size from flowing to the passage between the dome and the valve body. The ribs and the openings or interruptions may cooperate to perform the blocking function and to prevent an undesirable amount of liquid from passing through the valve even when particulate matter is trapped between one or more of the dome and ribs, on the one hand, and the body on the other hand.

Owner:RAIN BIRD CORP

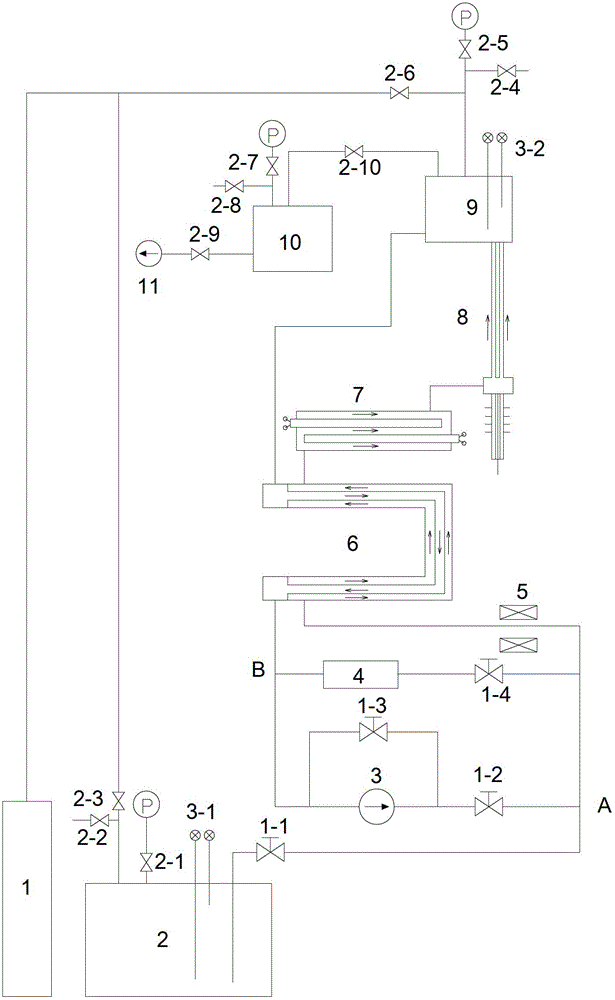

Liquid metal sodium boiling two-phase thermal-hydraulic test loop system and test method thereof

InactiveCN102915777AMeet the requirement of boiling two-phase testGuaranteed tightnessNuclear energy generationNuclear monitoringData acquisitionLiquid metal

The invention discloses a liquid metal sodium boiling two-phase thermal-hydraulic test loop system and a test method thereof. The loop system is divided into three parts comprising a high temperature part, a low temperature part and an argon branch, wherein the low temperature part comprises a sodium storage tank, an electromagnetic pump, an electromagnetic flowmeter, a purification cold trap, four sodium valves and corresponding connecting pipelines; the low temperature part is made of 316L stainless steel; the high temperature part comprises a regeneration heater, a preheater, a test section, an upper expansion box and corresponding connecting pipelines; the high temperature part is made of Incoloy 800 and allows the operating temperature to reach 1,200 DEG C; and the argon branch comprises an argon bottle, an expansion pressure stabilizing box, a vacuum pump, three pressure gauges, ten vacuum diaphragm valves and corresponding connecting pipelines. The system is suitable for operating at high temperature, has a good sealing property and can realize analysis and research on the liquid metal sodium boiling two-phase heat exchange flow characteristic by adding different test sections and a data acquisition system.

Owner:XI AN JIAOTONG UNIV

Mechanically-Actuated Microfluidic Diaphragm Valve

InactiveUS20090314972A1Operating means/releasing devices for valvesCircuit elementsDiaphragm valveEngineering

A microfluidic diaphragm valve. The valve comprises: an inlet port; an outlet port; a weir positioned between the inlet and outlet ports, the weir having a sealing surface; a diaphragm membrane for sealing engagement with the sealing surface; and a thermal bend actuator for moving the diaphragm membrane between a closed position in which the membrane is sealingly engaged with the sealing surface and an open position in which the membrane is disengaged from said sealing surface.

Owner:SILVERBROOK RES PTY LTD

Throttle providing unobstructed air flow path when fully open and vortex generating configuration when partly open

InactiveUS8316820B1Increase the diameterIncrease or decrease areaPlug valvesEngine controllersDiaphragm valveControl theory

A throttle includes a throttle body having a generally tubular throttle body side wall with a throttle body side wall interior surface defining a throttle body interior for containing an air flow path for delivering air into at least one cylinder of an engine; and a flow regulating mechanism including an diaphragm valve secured to the throttle body and extending diametrically across the throttle body interior for progressively reducing and progressively increasing the diameter of an air flow passing valve opening defined within the diaphragm valve, and thereby regulating air flow through the throttle body.

Owner:CAMMARATA EDWARD

Flow compensated control valve

InactiveUS20050258258A1Reduce trafficHigh trafficTemperature control without auxillary powerDiaphragm valvesFluid controlControl system

A fluid control system includes a valve and a restrictor. The valve is configured to regulate the proportion at which a first fluid and a second fluid are mixed together. Based on the pressure drop across the restrictor, the valve further regulates the overall flow rate of the mixed first and second fluids. In one form, the valve includes a pair of spools that regulate the proportion and flow rate of the fluids. In another form, the valve includes a thermostatic element that regulate the proportion at which the first and second fluids are mixed together so as to control the temperature of the mixed fluids. The valve in a further form incorporates a pair of diaphragm valves.

Owner:MASCO CORP

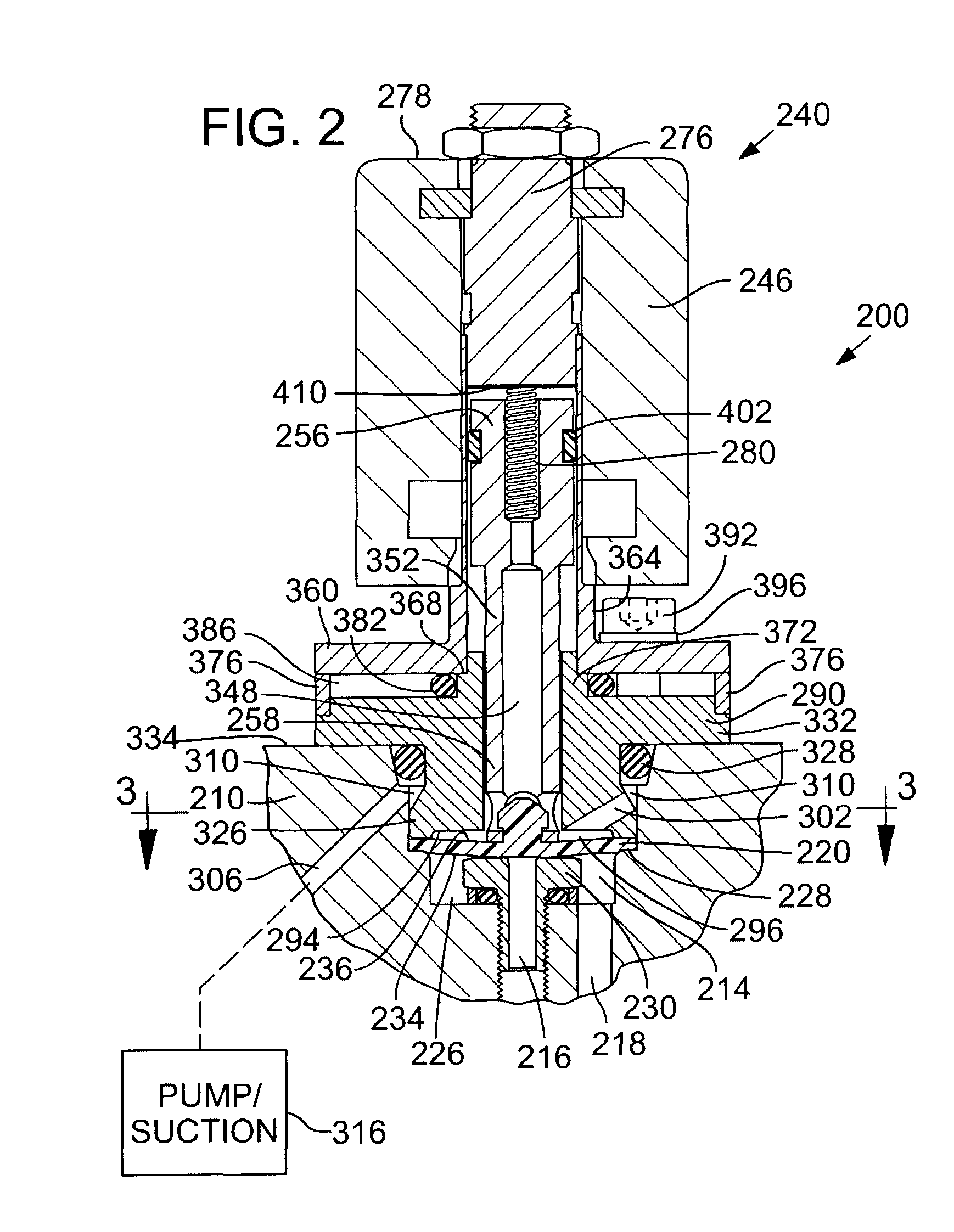

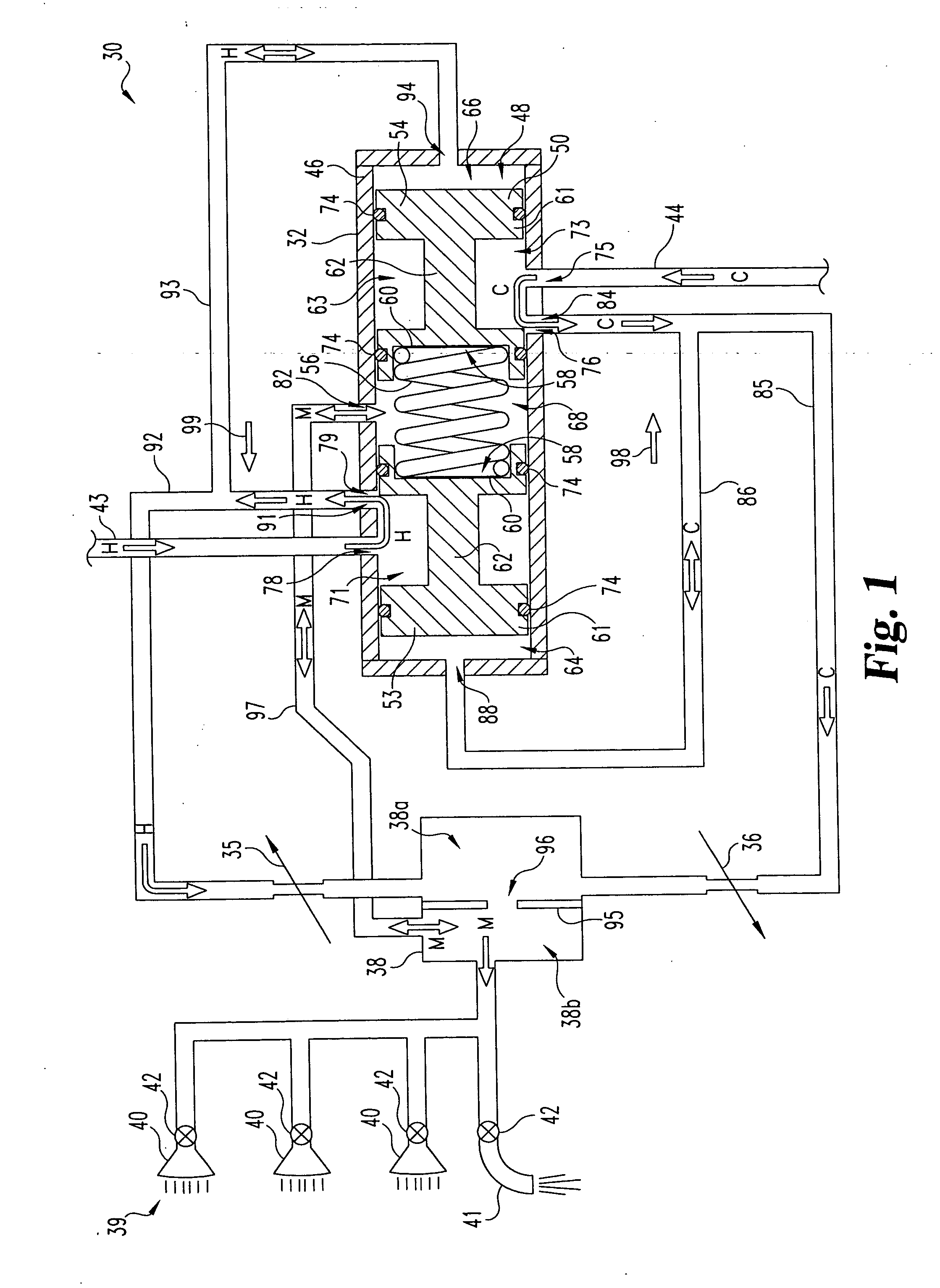

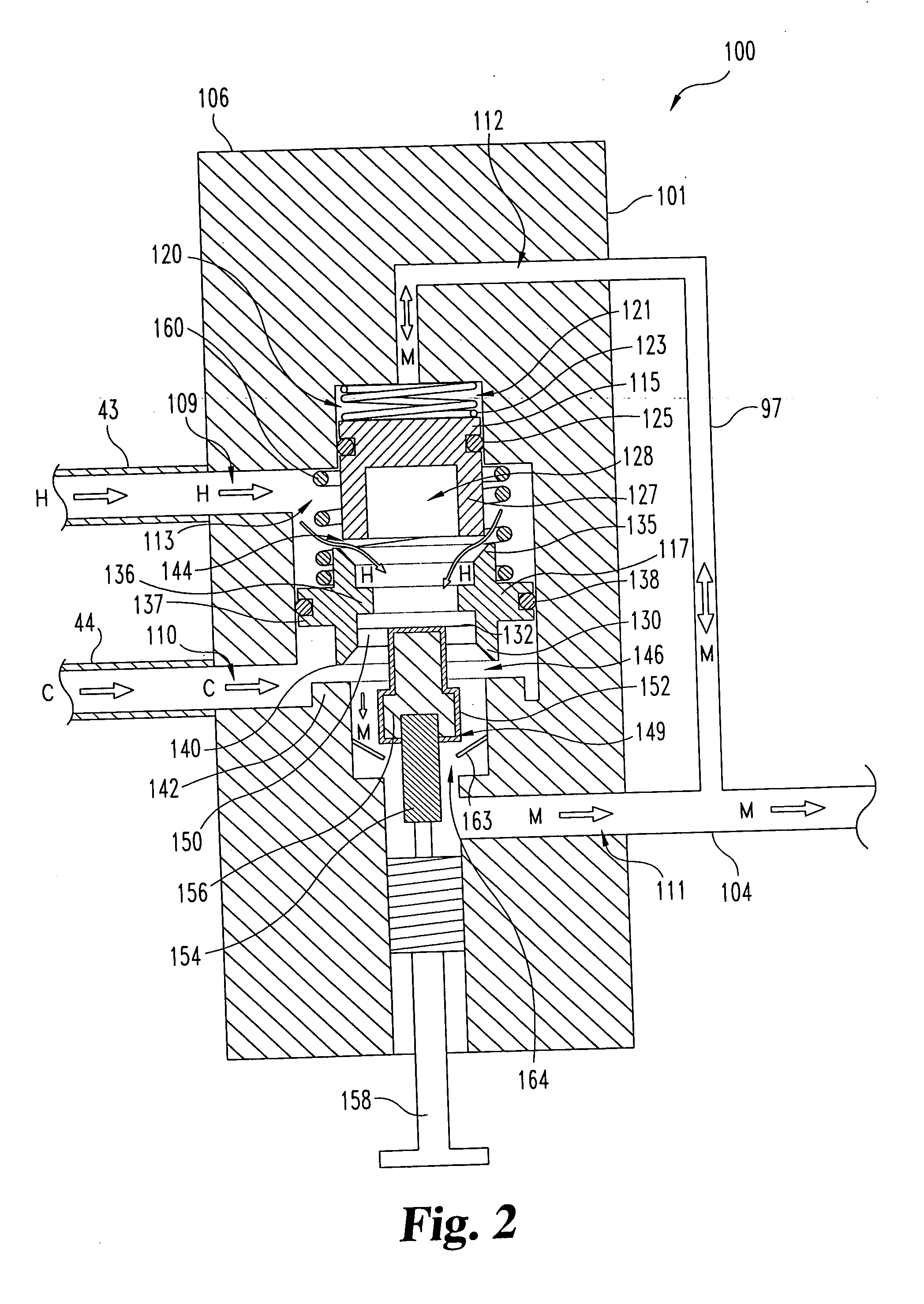

High-speed diaphragm valve for atomic layer deposition

InactiveUS6941963B2Easy to moveLow efficiencyDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveEngineering

A diaphragm valve includes a pressure vent communicating with an enclosed space behind the diaphragm for reducing resistance to transitioning of the diaphragm between the open and closed positions. In some implementations, a pump or other source of suction is coupled to the pressure vent to reduce fluid pressure in the enclosed space. When used in an atomic layer deposition (ALD) system, the venting and suction improves the thin film deposition process and prevents leakage through the valve of potentially toxic ALD precursor vapors. Features for thermal management and reliability enhancement are also described.

Owner:BENEQ OY

Solenoid-actuated diaphragm valve

InactiveUS20090212248A1Increase fluid pressureRelieve pressureOperating means/releasing devices for valvesSolenoid valveDead volume

A solenoid-actuated diaphragm valve achieves minimal dead volume, tolerance of high pressures, prolonged diaphragm life, and energy conservation using a three-sector multi-seal diaphragm combined with a three-component plunger, which automatically switches from bilateral to unilateral circumferential diaphragm restraint between the closed and open positions.

Owner:KOZAK EUGENIUSZ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com