Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1625results about "Fluid pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

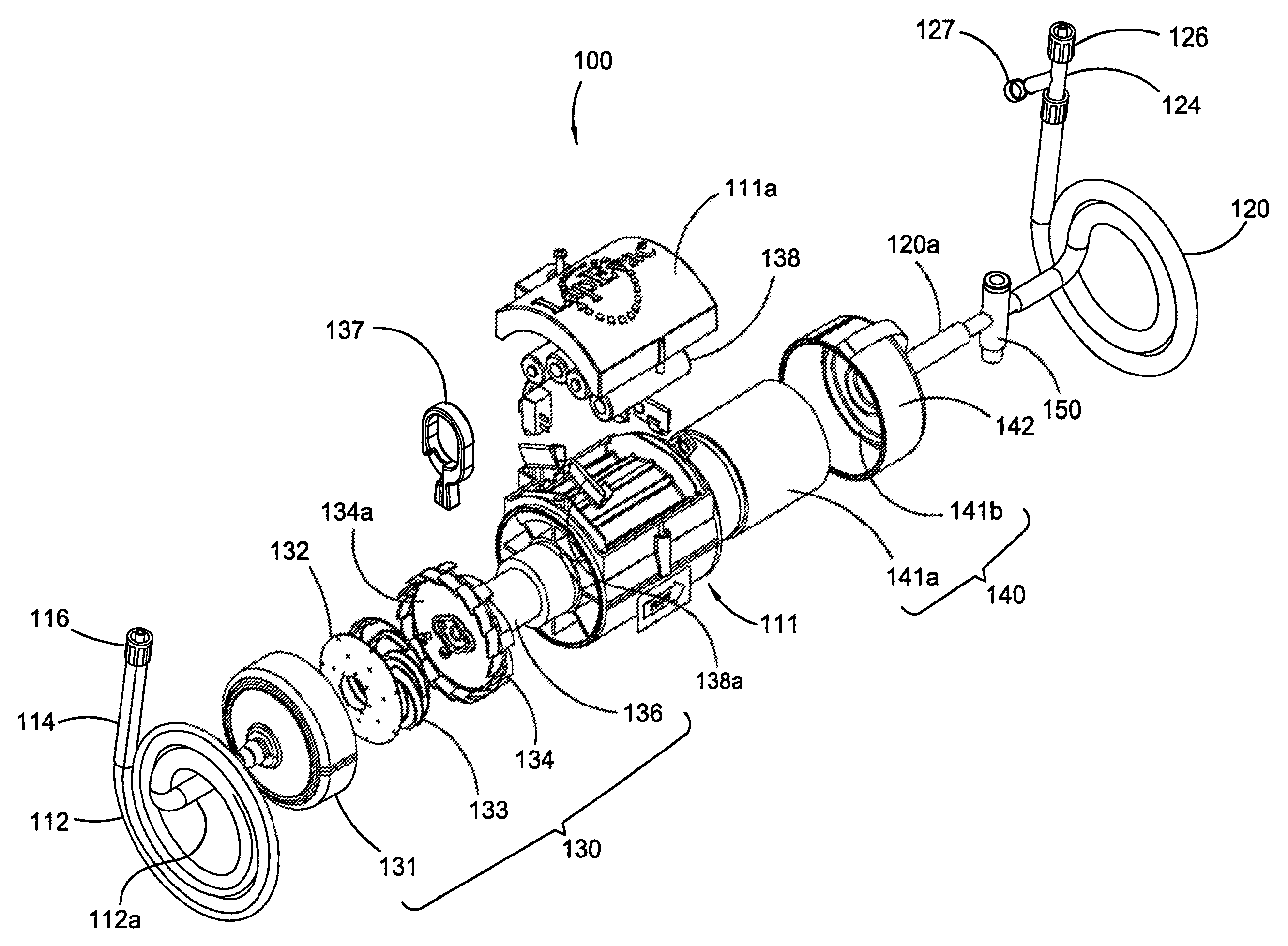

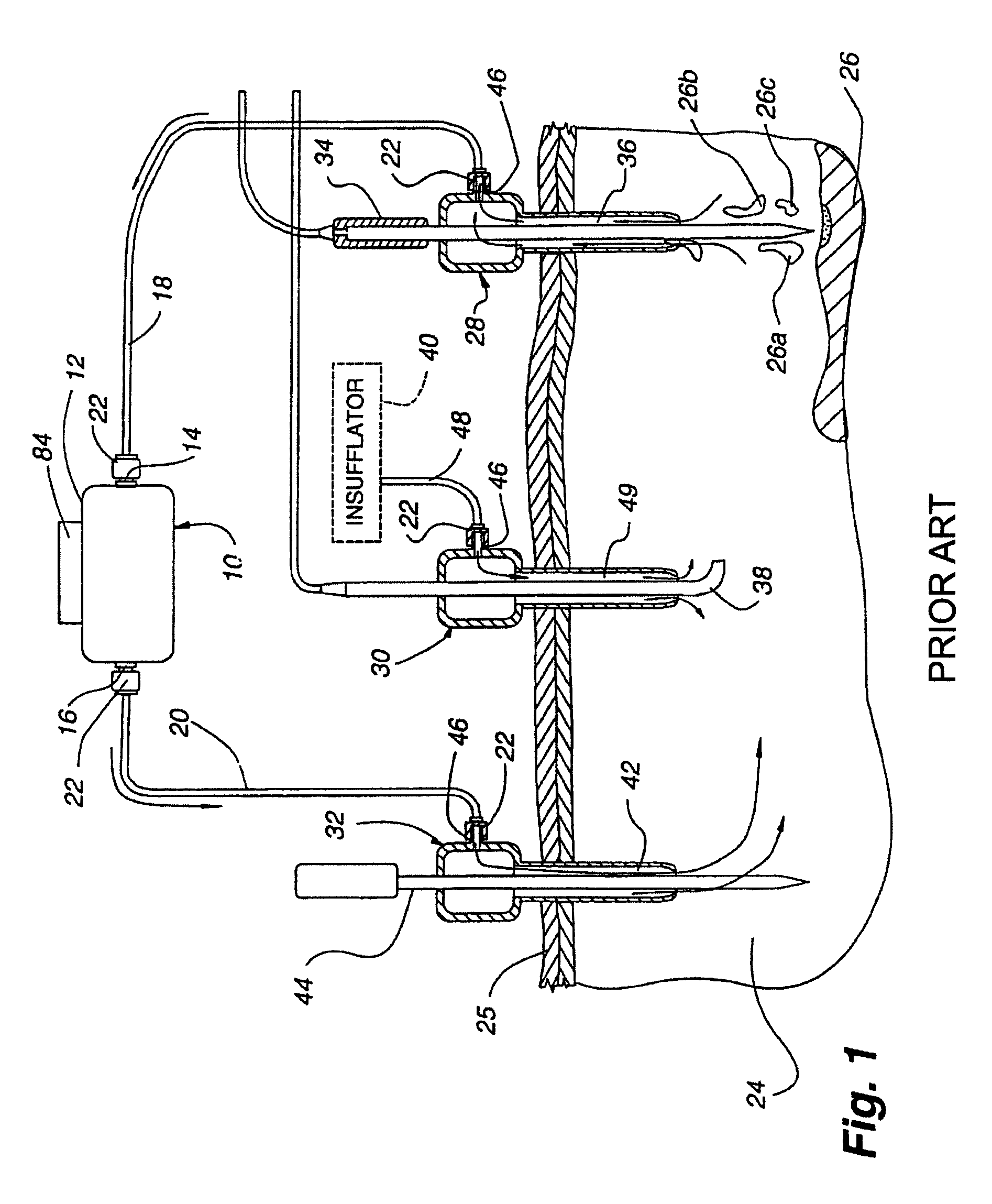

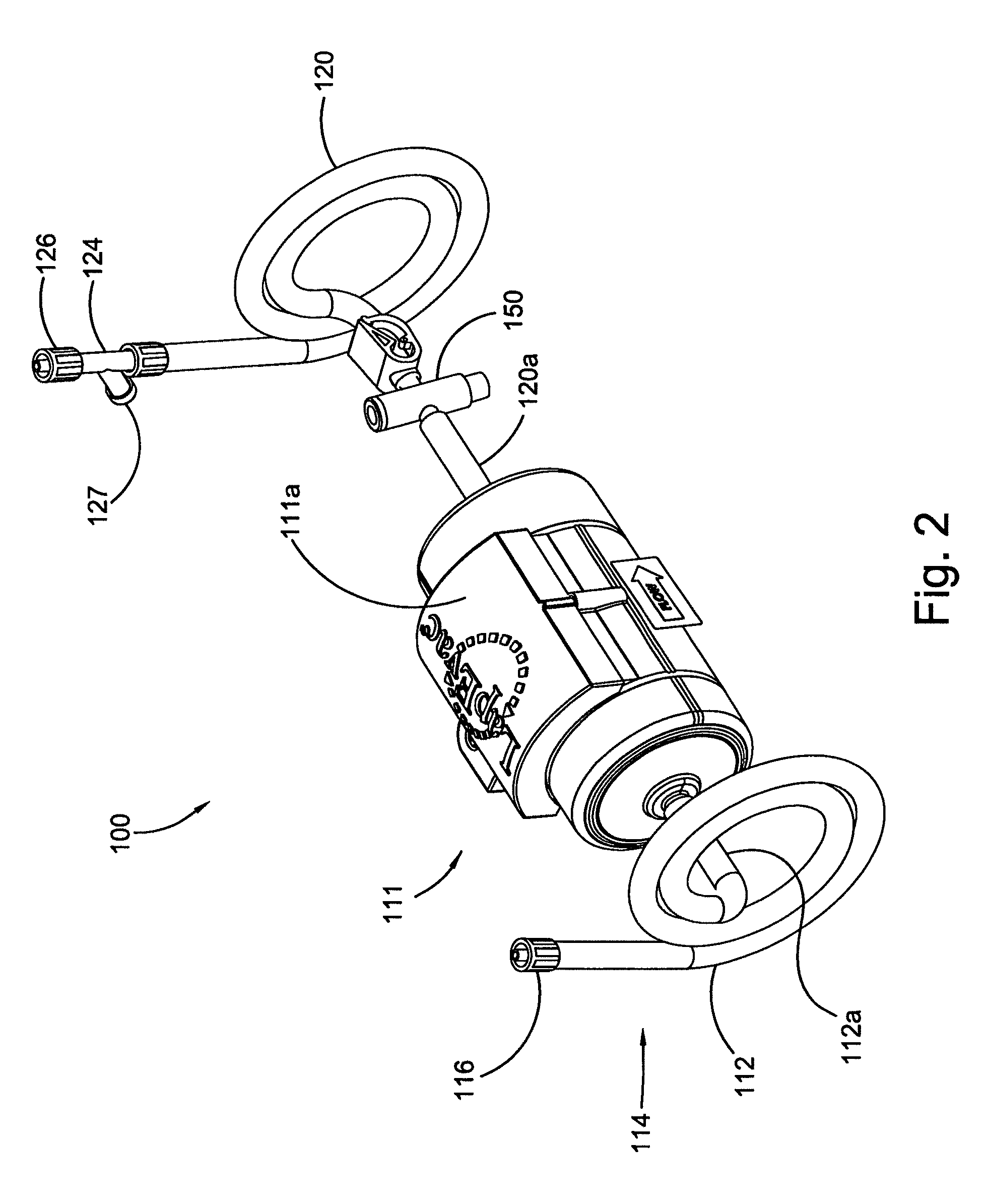

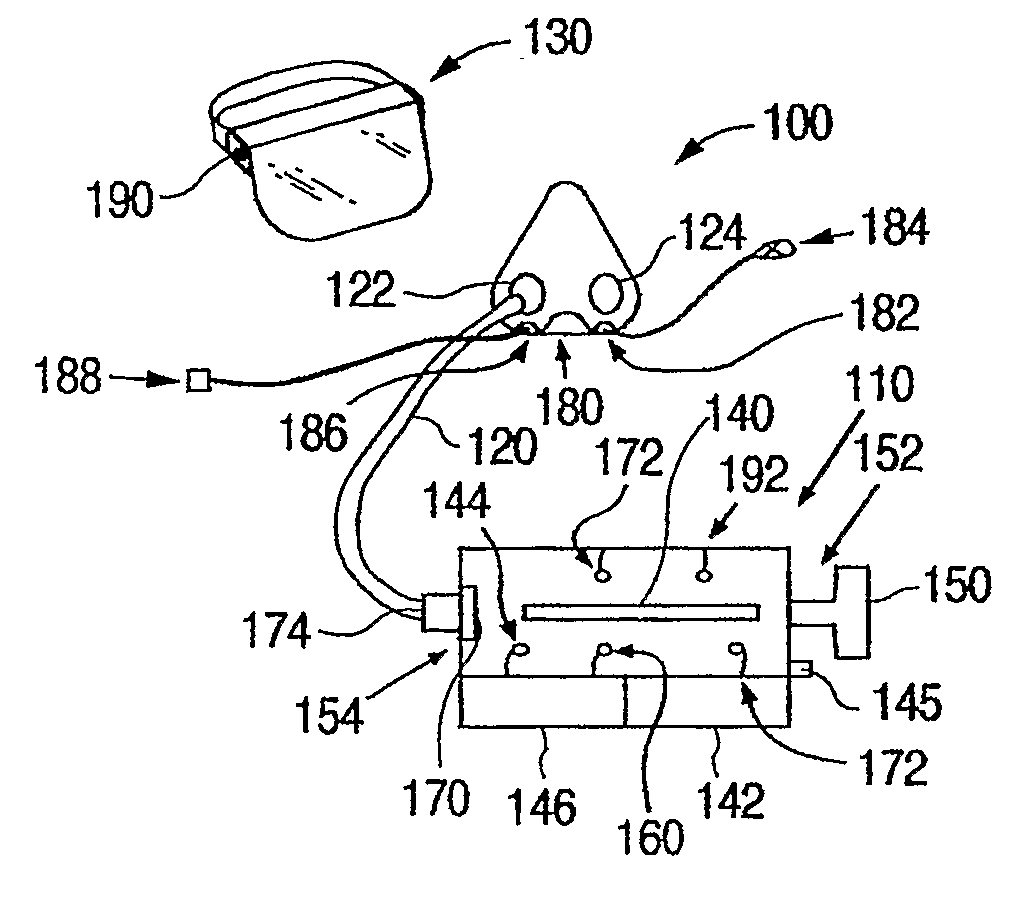

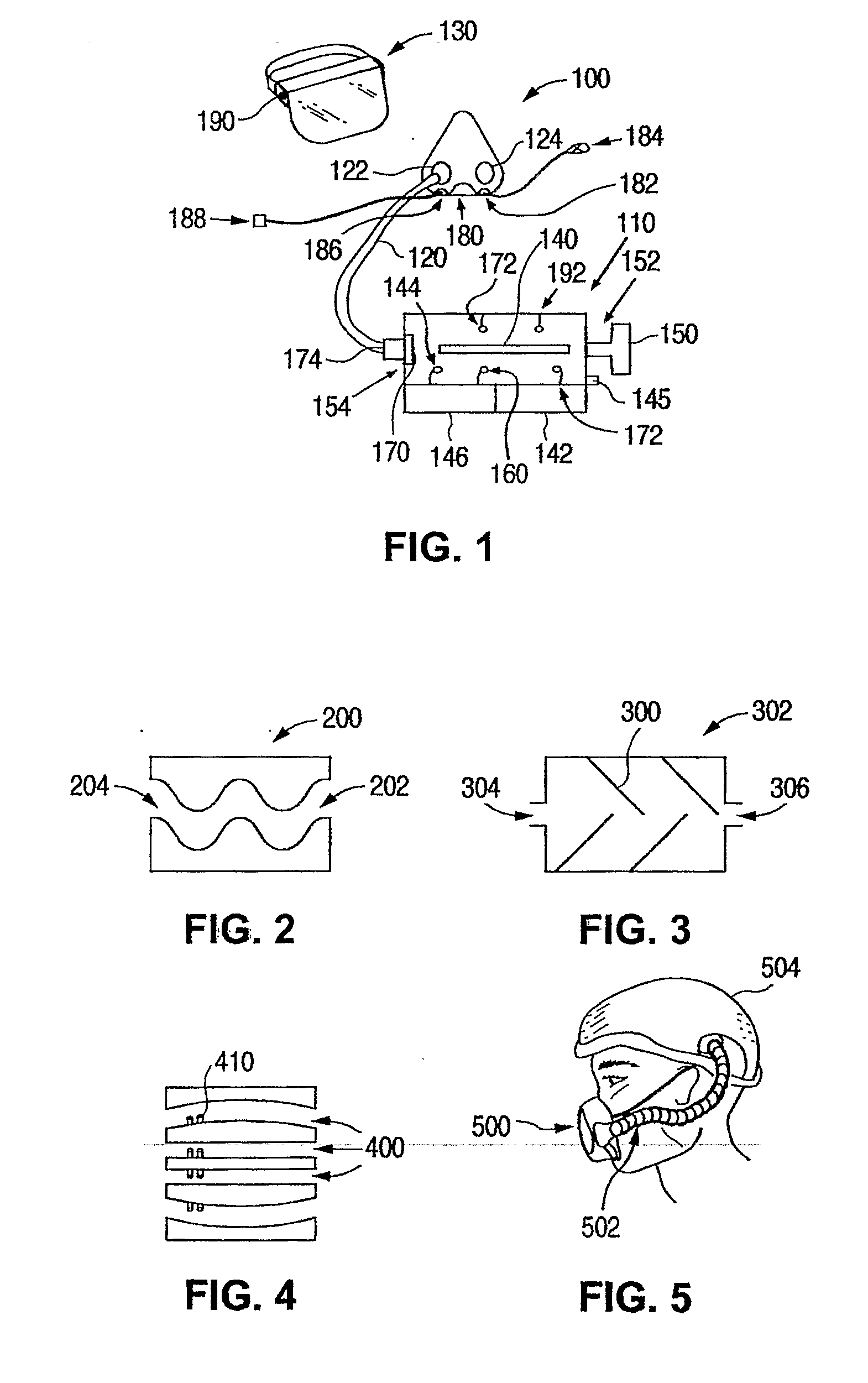

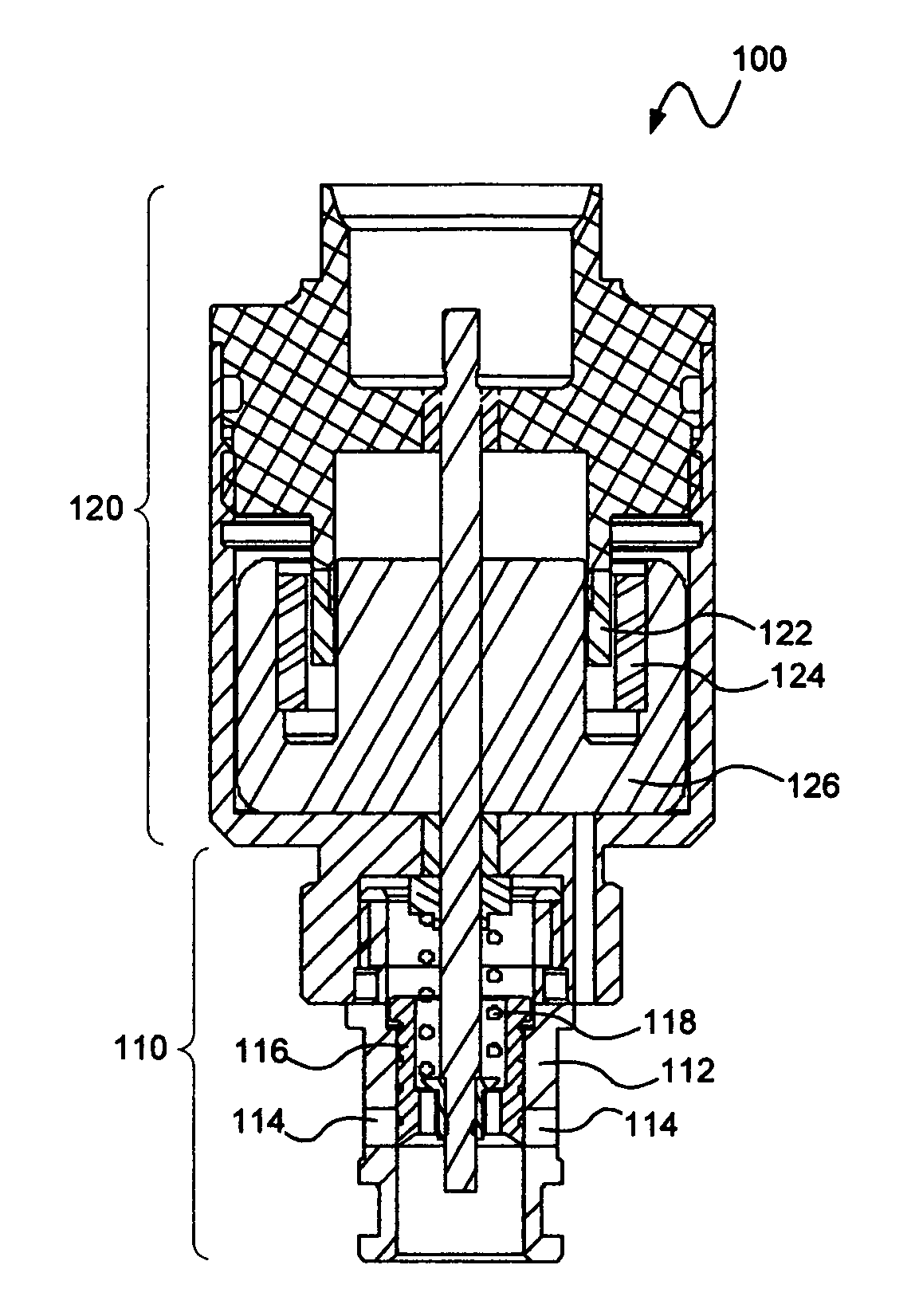

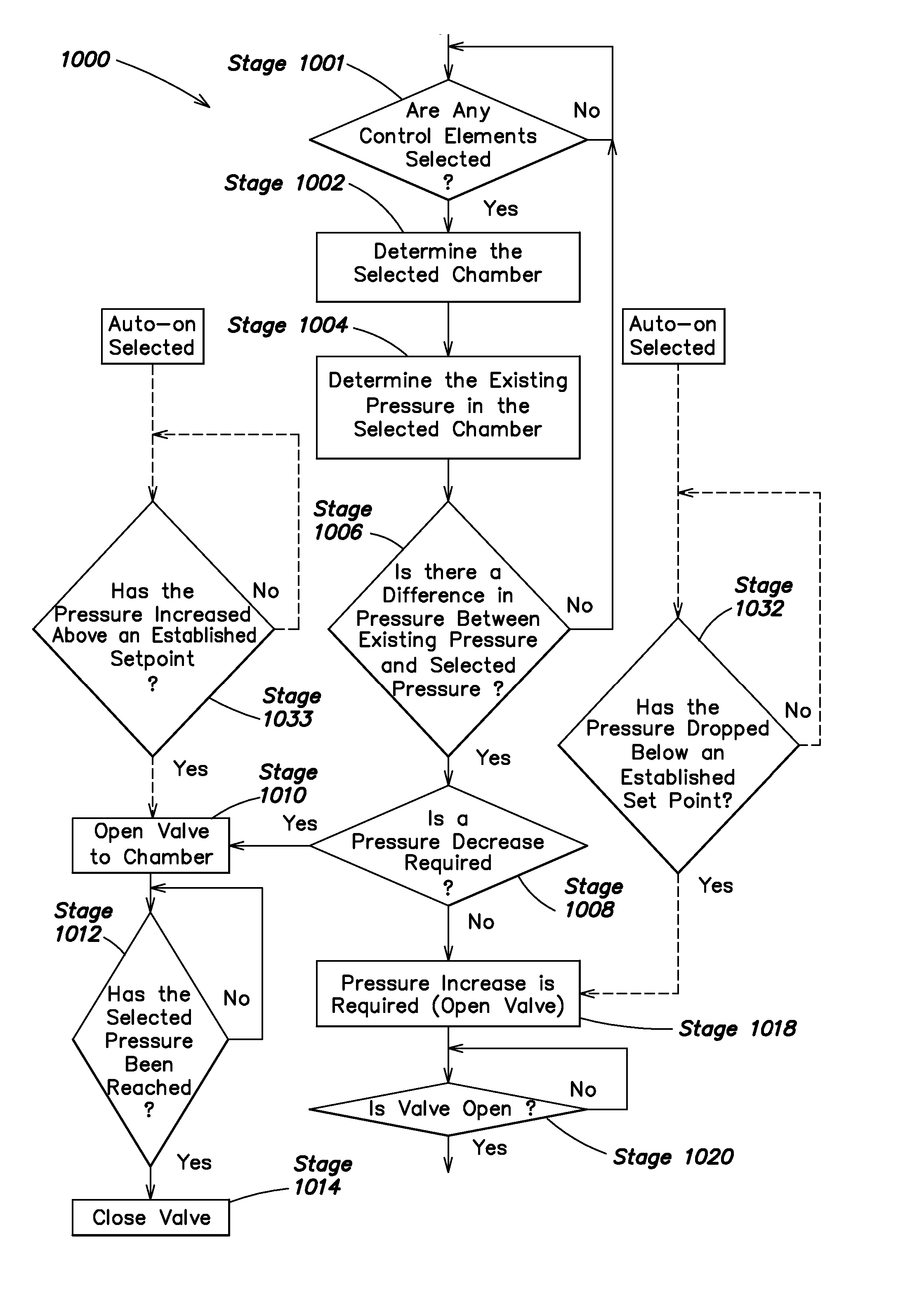

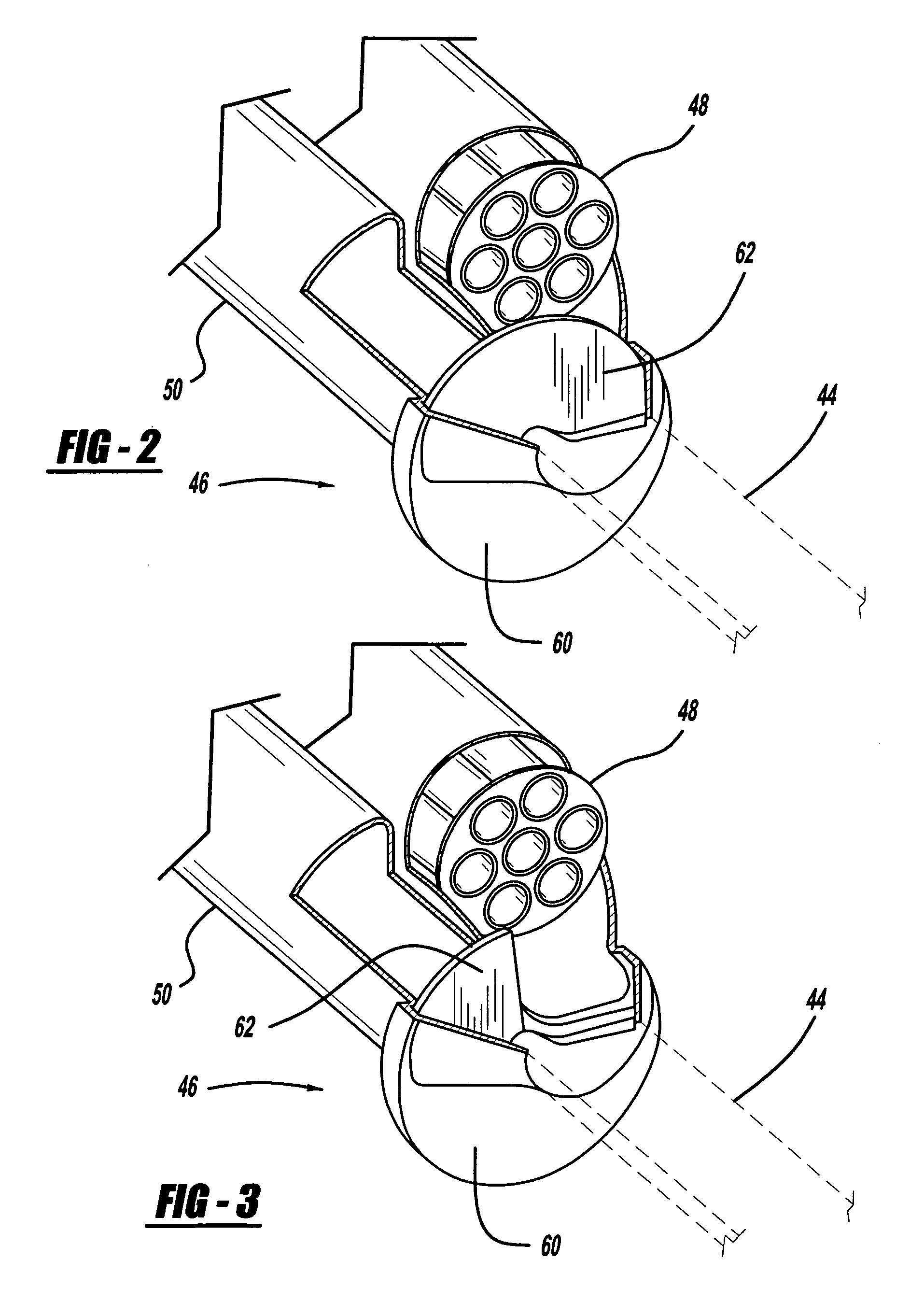

Wick and relief valve for disposable laparoscopic smoke evacuation system

ActiveUS9011366B2Reduce and eliminate blockingReduce eliminate stratificationDispersed particle filtrationMedical devicesPERITONEOSCOPESurgical site

The present invention relates to an improved smoke evacuation device for use in laparoscopic surgeries. One improvement is a hydrophilic wick positioned within the inlet system of the smoke device for absorbing moisture and trapping surgical waste entering the smoke evacuation device. The second improvement is a multi-outlet valve inserted into the outlet system of the smoke evacuation device to enable quick depressurization of the surgical site.

Owner:BUFFALO FILTER

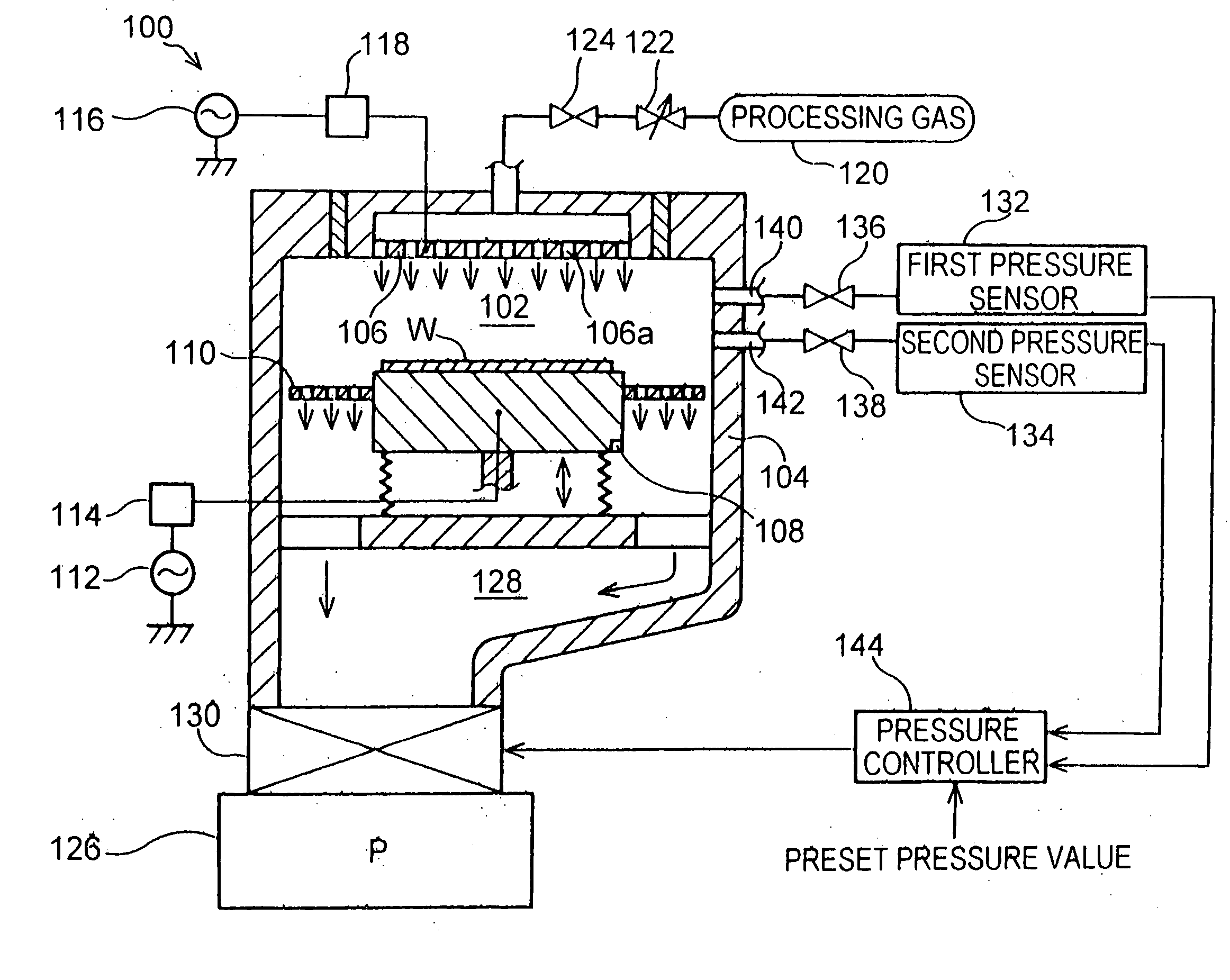

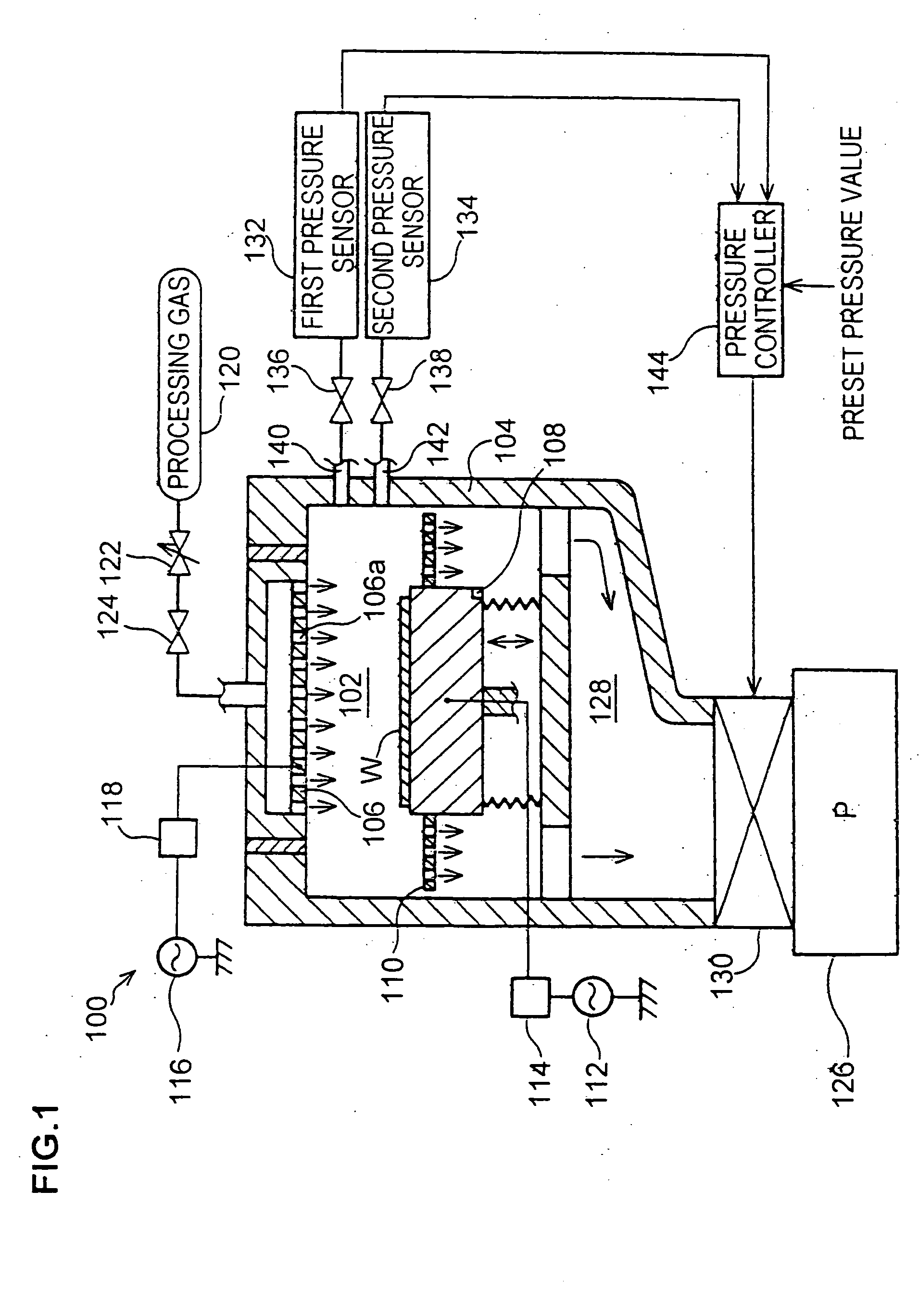

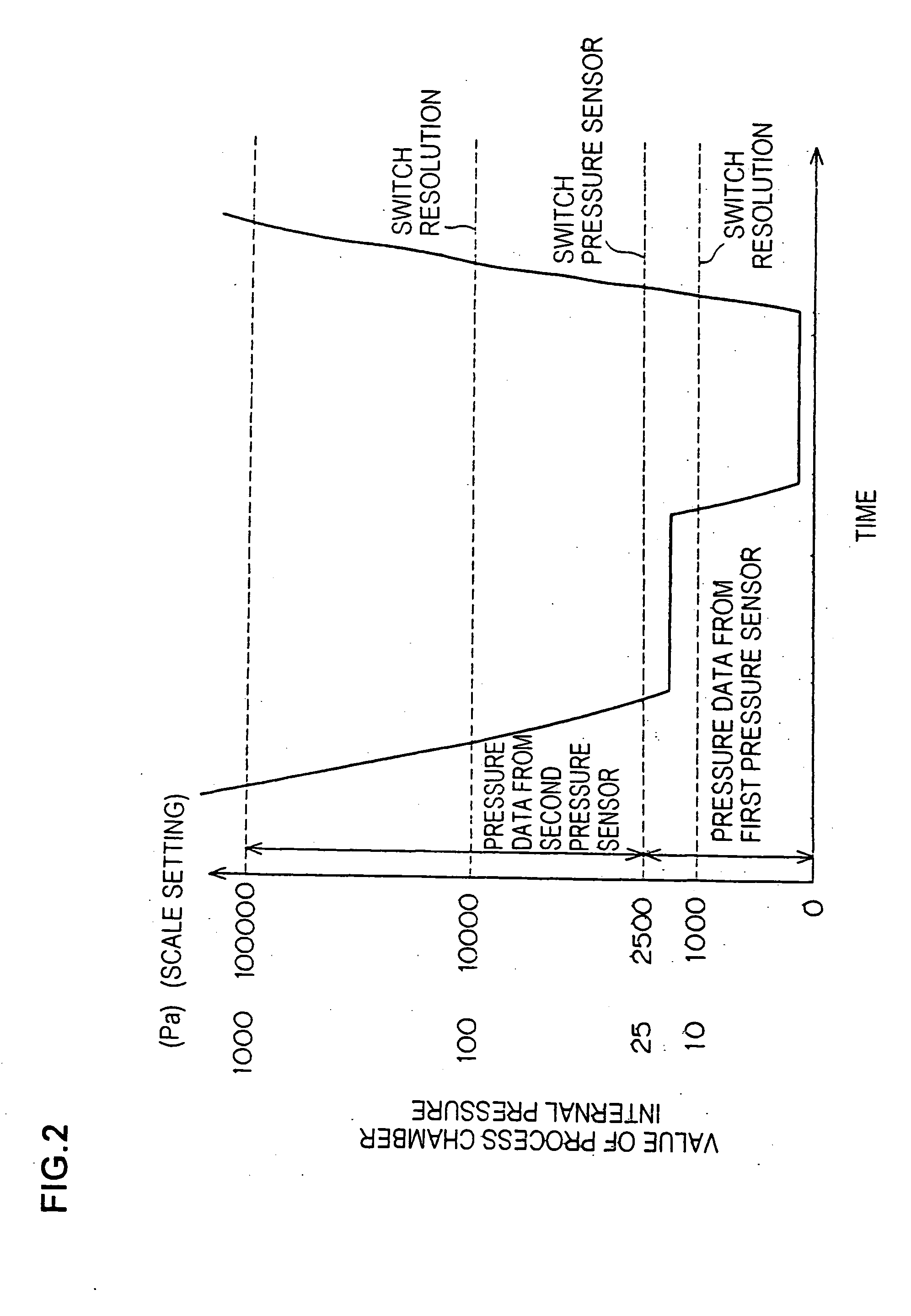

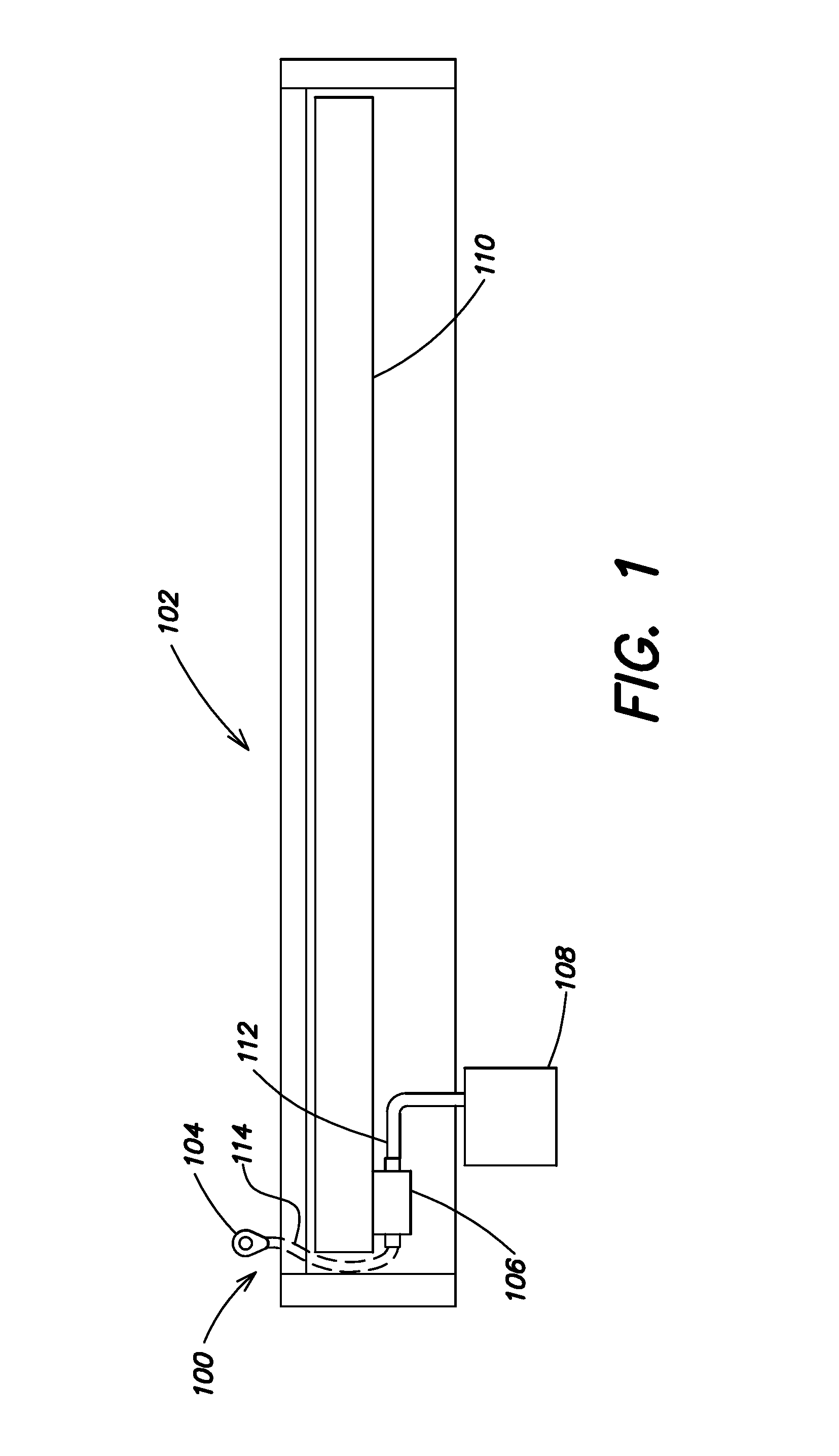

Pressure control method and processing device

InactiveUS20050176258A1Level of control performanceOptimize dataElectric discharge tubesSemiconductor/solid-state device manufacturingImage resolutionEngineering

First and second pressure sensors 132 and 134 that perform pressure detection over different pressure detection ranges from each other detect the pressure within a process chamber 102 of an etching device 100. A pressure controller 144 selects optimal pressure data in correspondence to the pressure inside the process chamber from the pressure data provided by the first and second pressure sensors 132 and 134. It also analyzes the selected pressure data at a resolution selected in correspondence to the pressure inside the process chamber 102 and thus obtains pressure data achieving a predetermined data density. The pressure controller 134 controls a pressure control valve 130 so as to ensure that the pressure data match preset pressure data.

Owner:TOKYO ELECTRON LTD

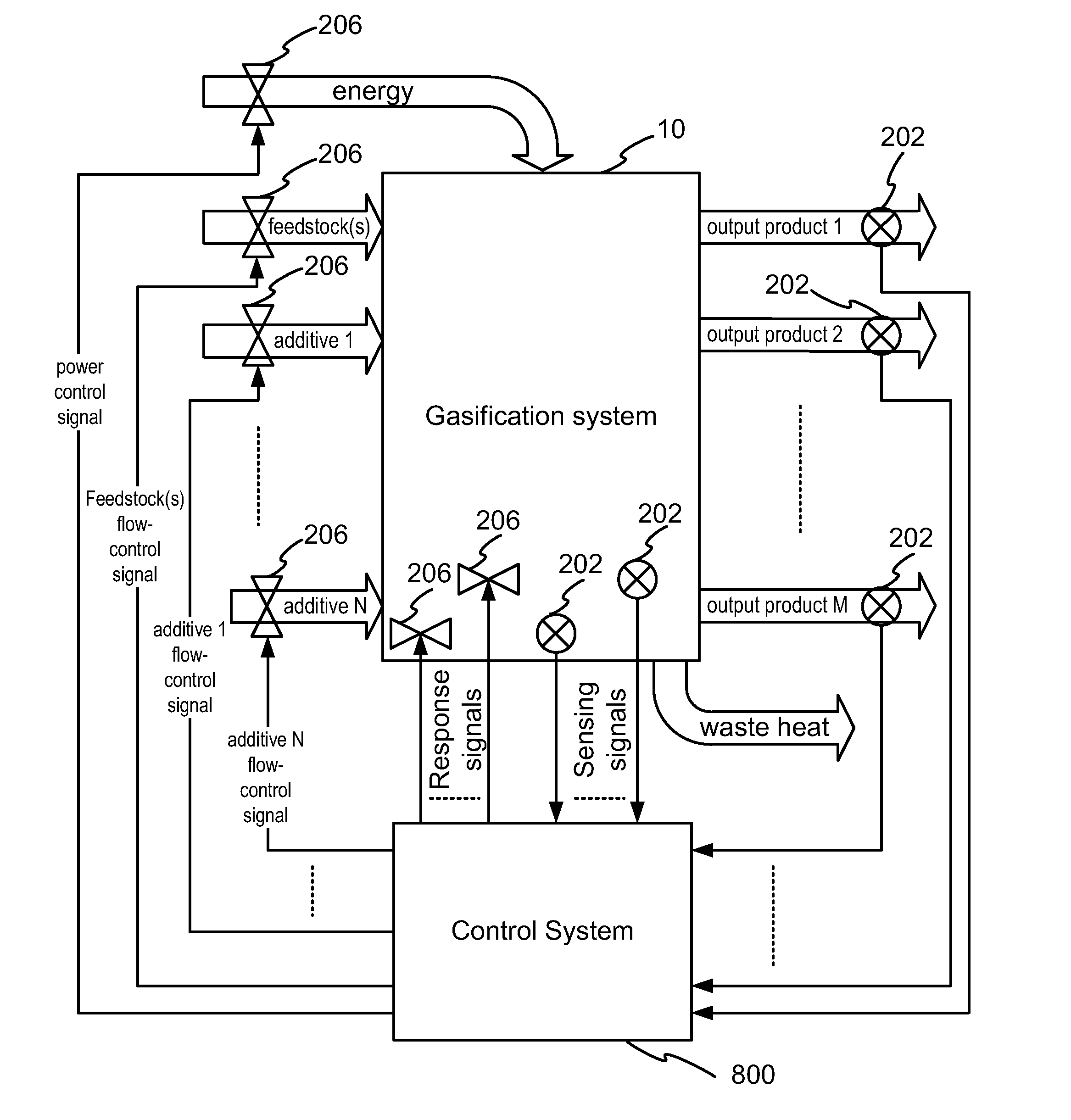

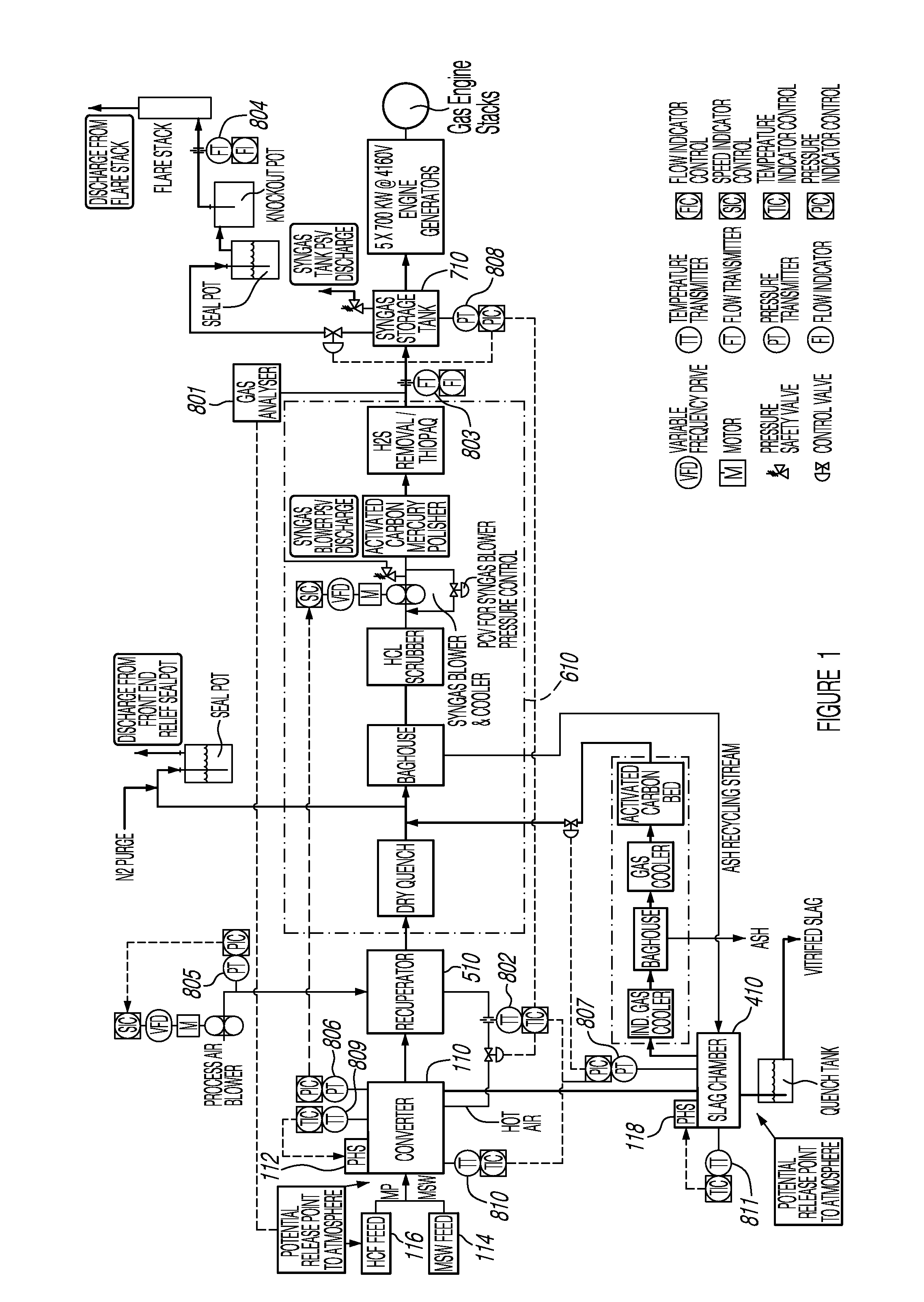

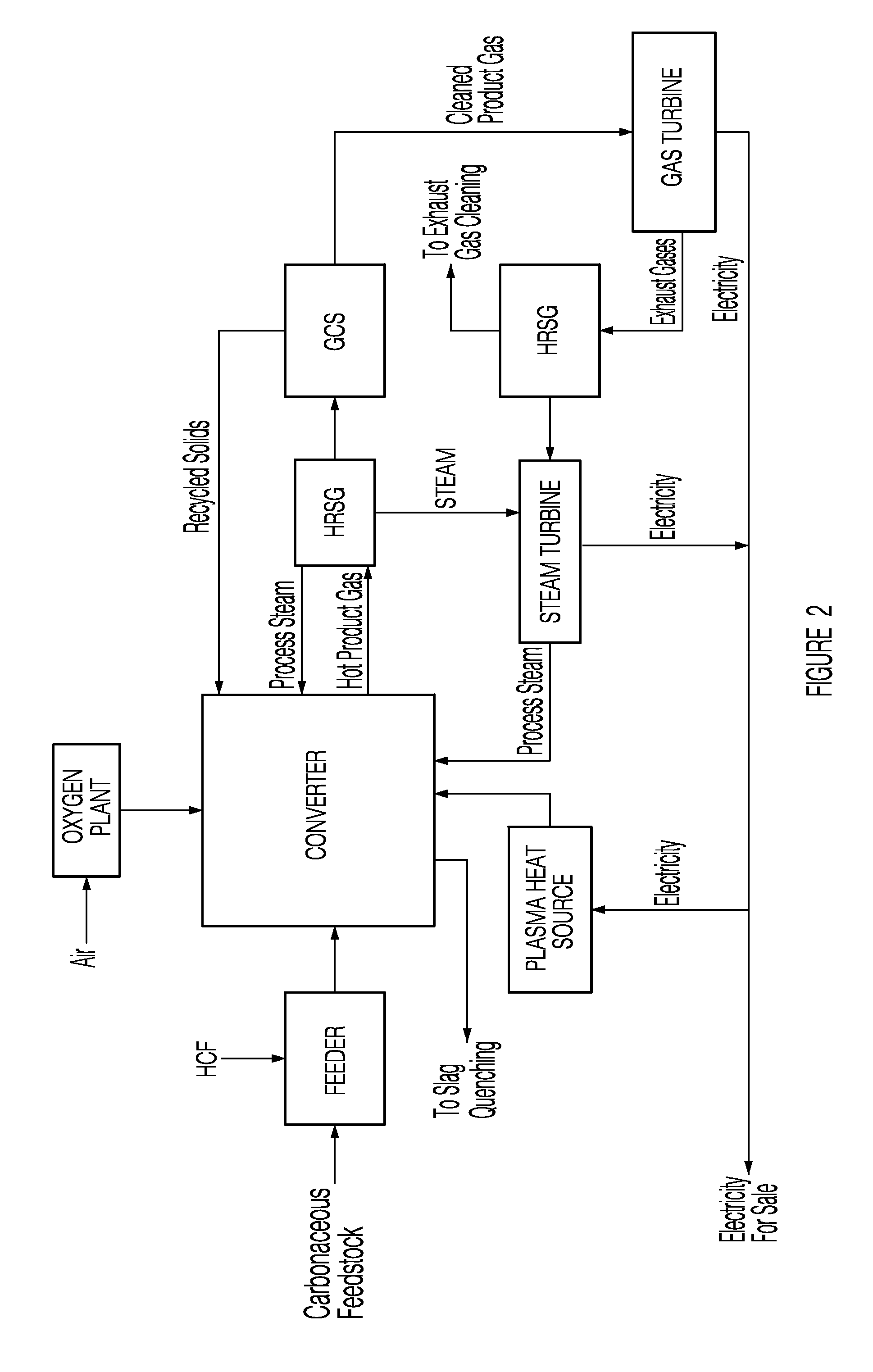

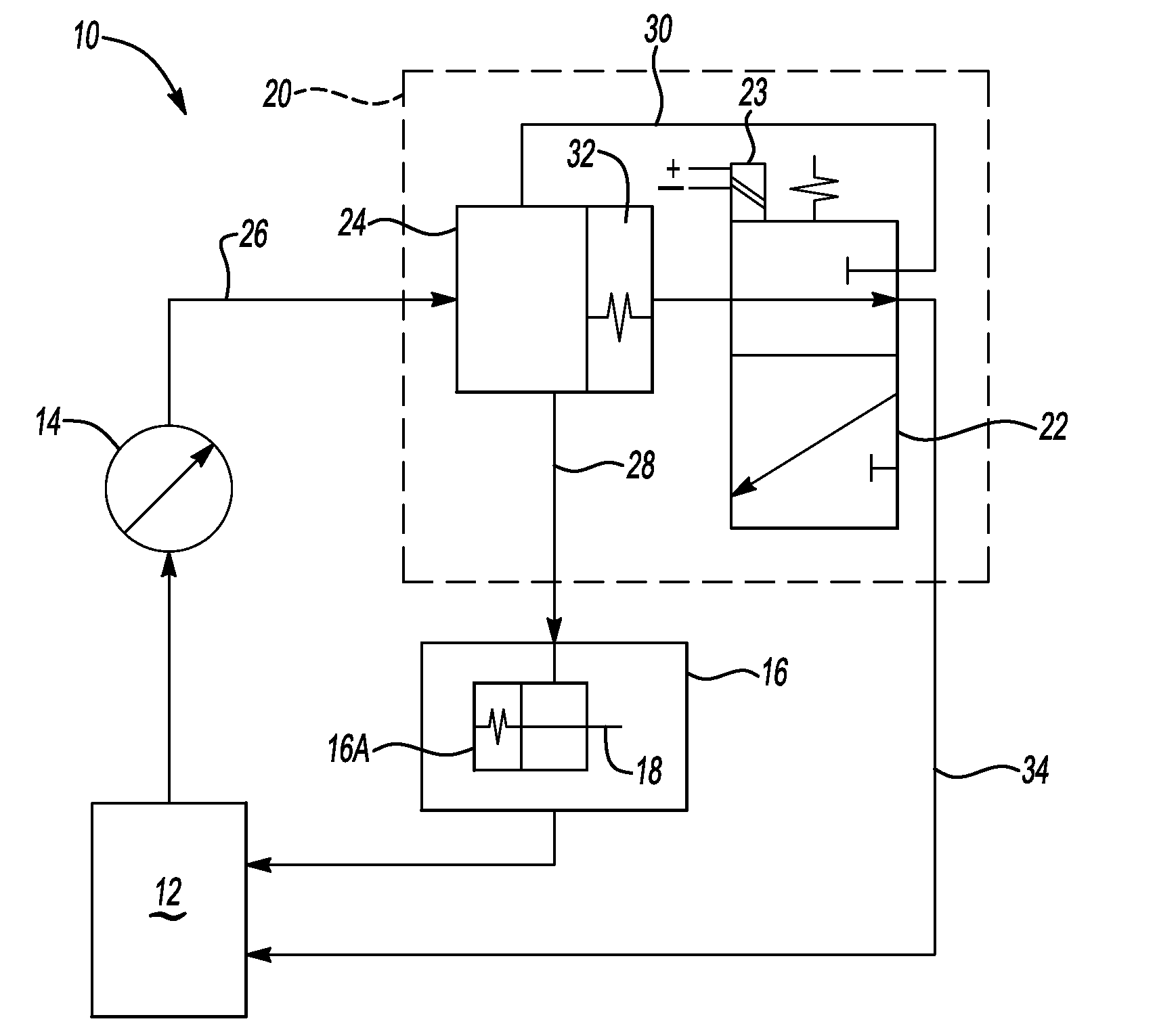

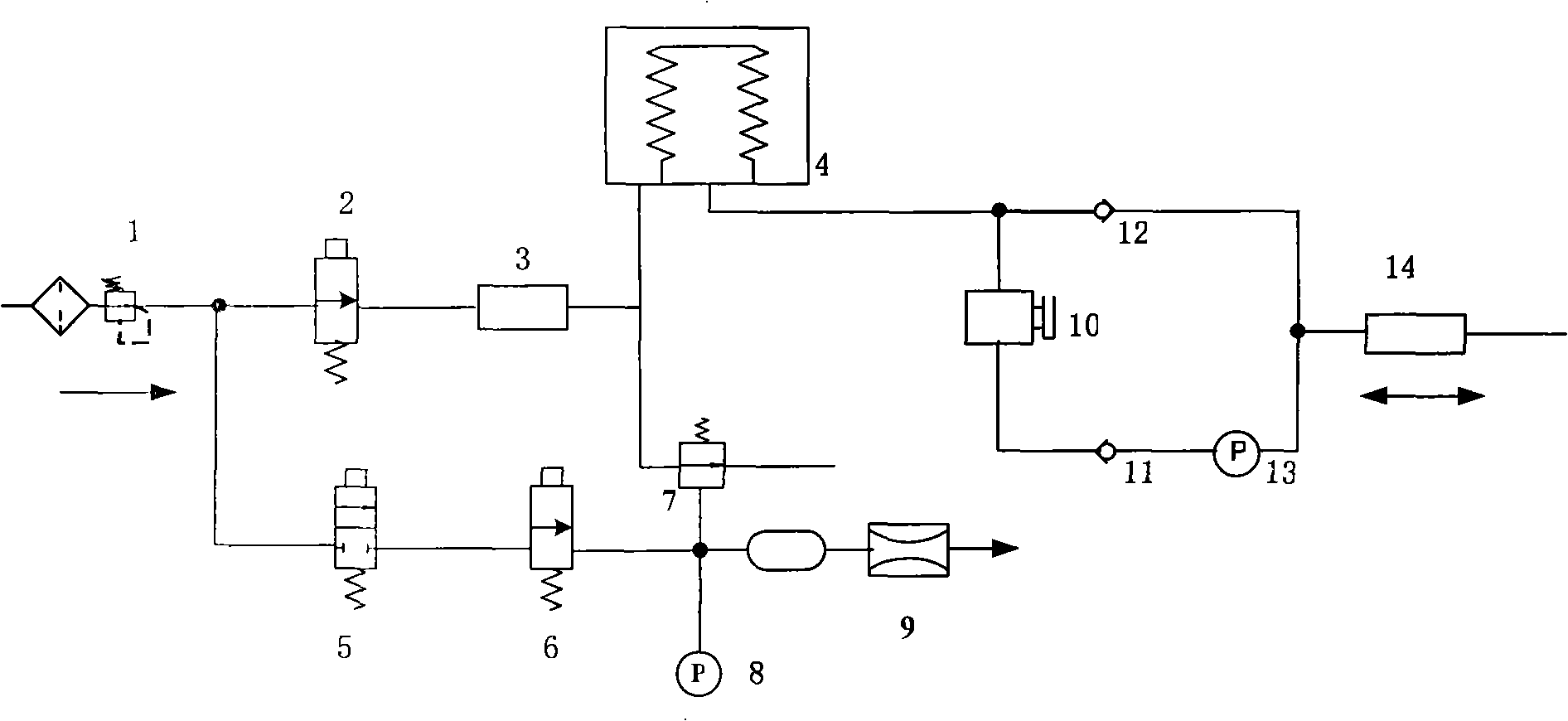

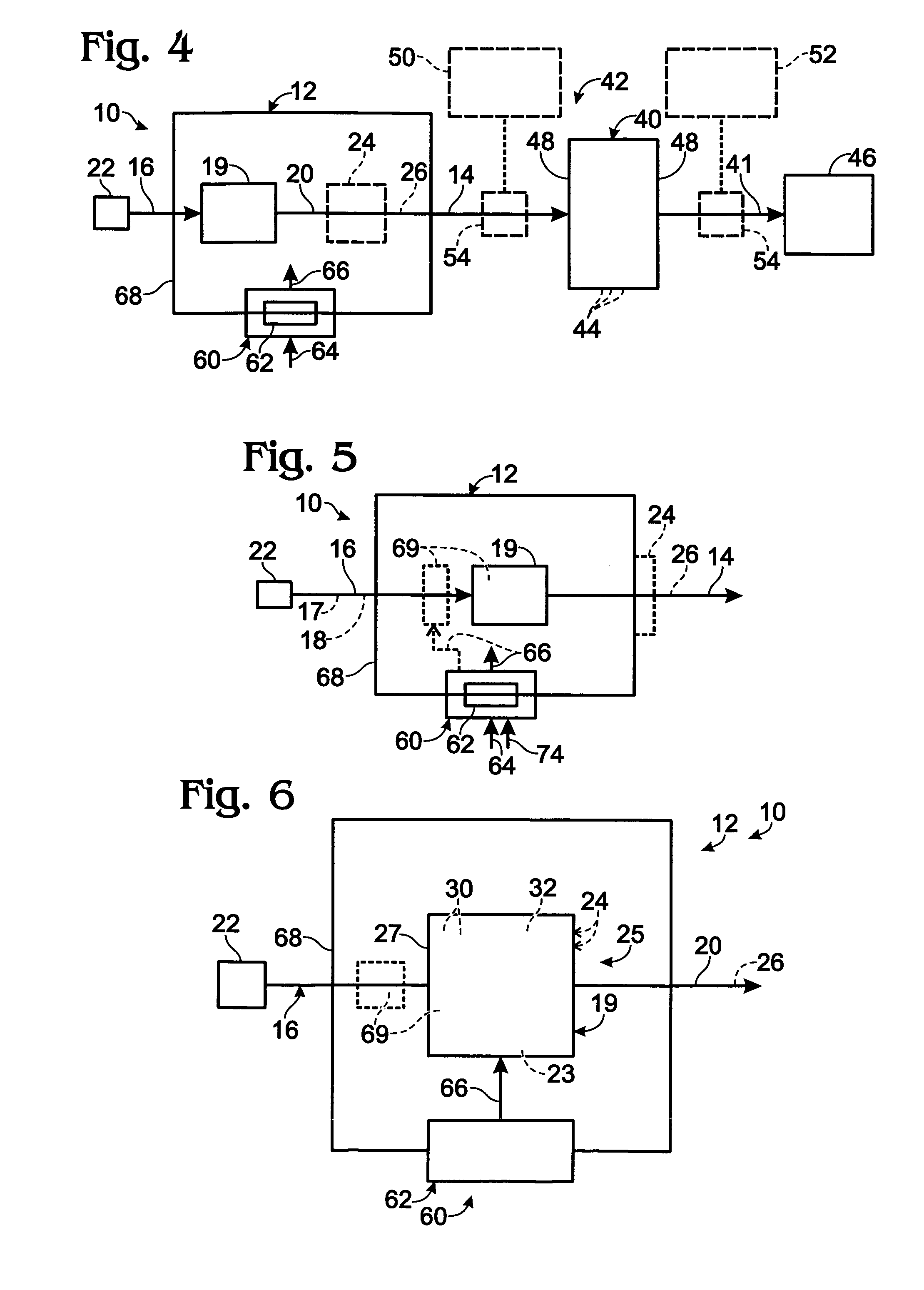

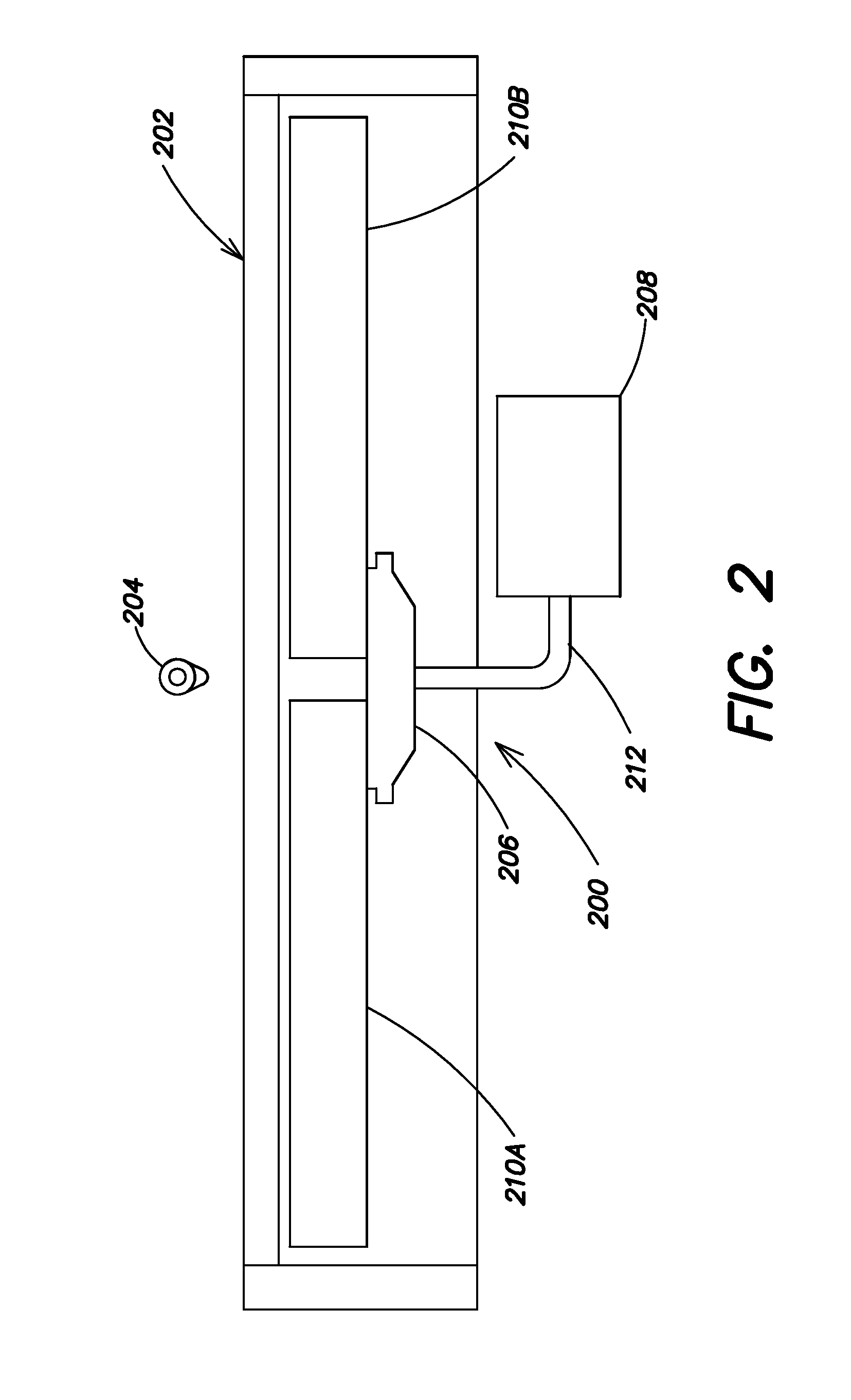

Control System for the Conversion of Carbonaceous Feedstock into Gas

ActiveUS20080147241A1Rapid responseLong responseCombination devicesFunctional valve typesControl systemEngineering

The present invention provides a control system for the conversion of carbonaceous feedstock into a gas. In particular, the control system is designed to be configurable for use in controlling one or more processes implemented in, and / or by, a gasification system for the conversion of such feedstock into a gas, which may be used for one or more downstream applications. Gasification processes controllable by different embodiments of the disclosed control system may include in various combinations, a converter, a residue conditioner, a recuperator and / or heat exchanger system, one or more gas conditioners, a gas homogenization system and one or more downstream applications. The control system operatively controls various local, regional and / or global processes related to the overall gasification process, and thereby adjusts various control parameters thereof adapted to affect these processes for a selected result. Various sensing elements and response elements are therefore distributed throughout the controlled system and used to acquire various process, reactant and / or product characteristics, compare these characteristics to suitable ranges of such characteristics conducive to achieving the desired result, and respond by implementing changes to in one or more of the ongoing processes via one or more controllable process devices.

Owner:PLASCO CONVERSION TECH INC

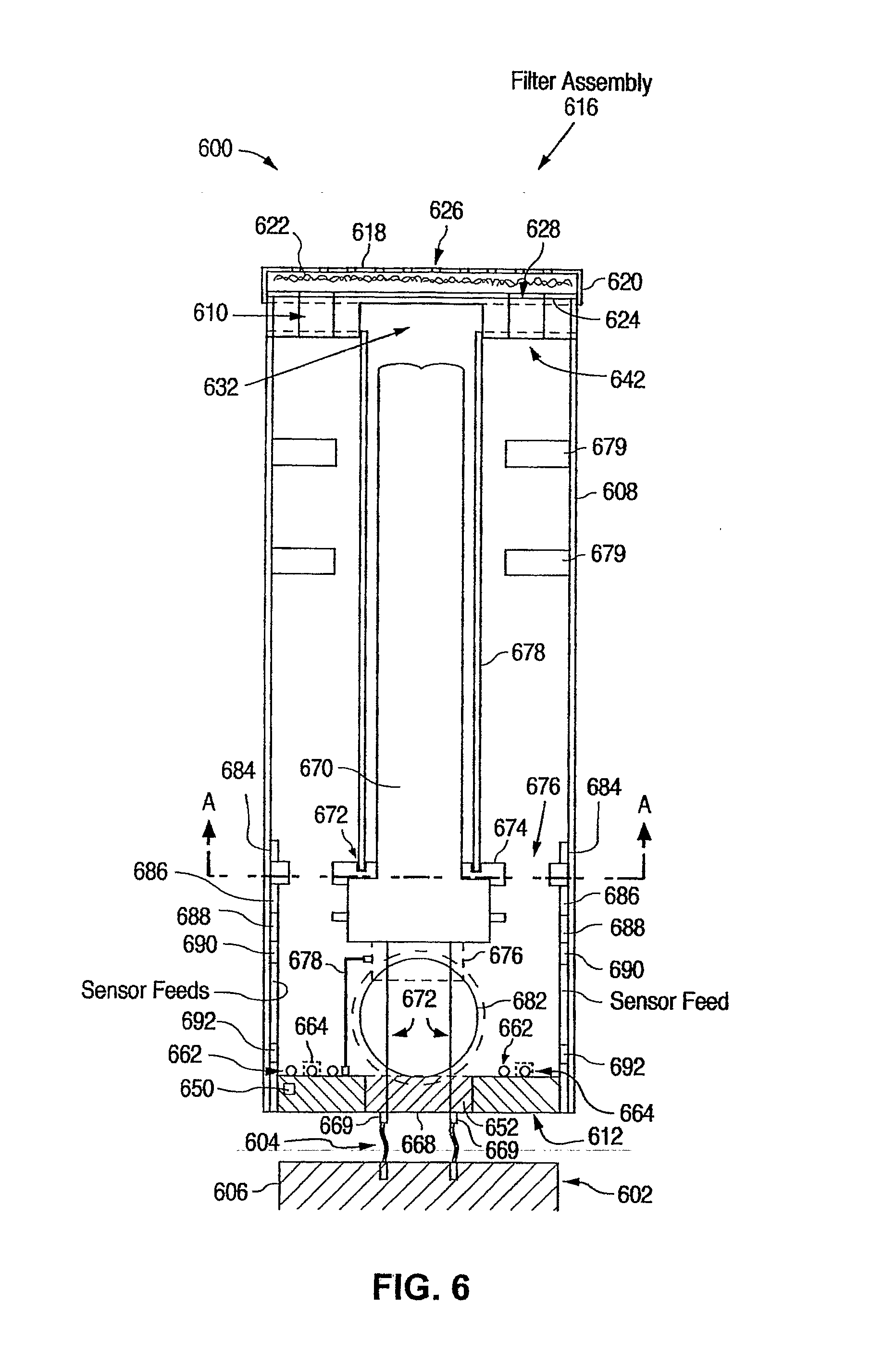

Air Supply Apparatus

InactiveUS20090004047A1Constant pressureDispersed particle filtrationBreathing filtersUltravioletHigh intensity

In an air sterilization system that includes a UV kill chamber for sterilizing air that is to be supplied to users, the effectiveness of killing or neutralizing pathogens is increased by including not only a UV light source of a certain intensity but also including a particle filter and providing short duration high intensity UV radiation. In the case of a user specific system that includes a face mask to supply air to a specific user, exhaled air from the face mask may be sterilized as well, either by using the same kill chamber or by using a separate kill chamber.

Owner:HUNTER ERIC C +4

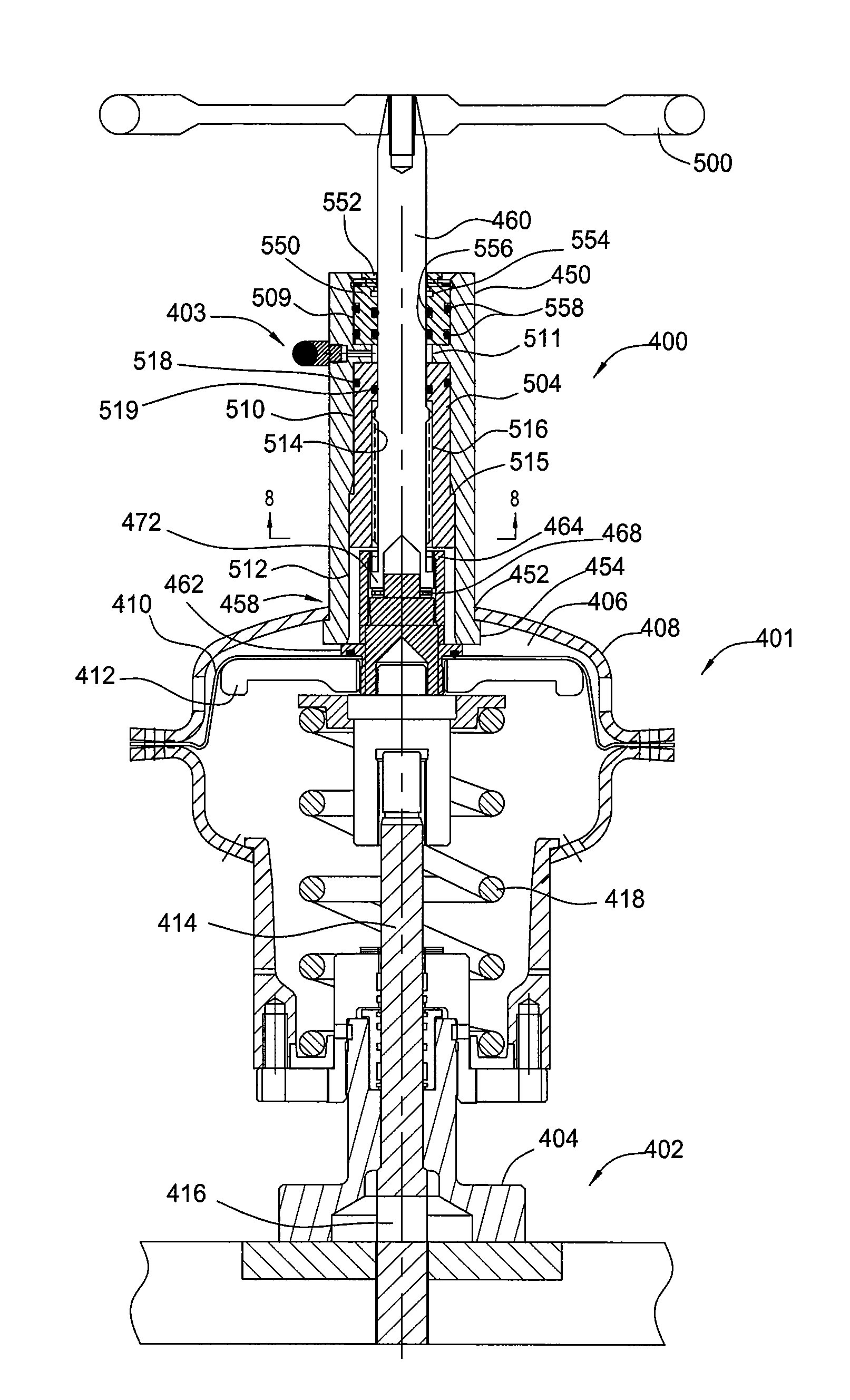

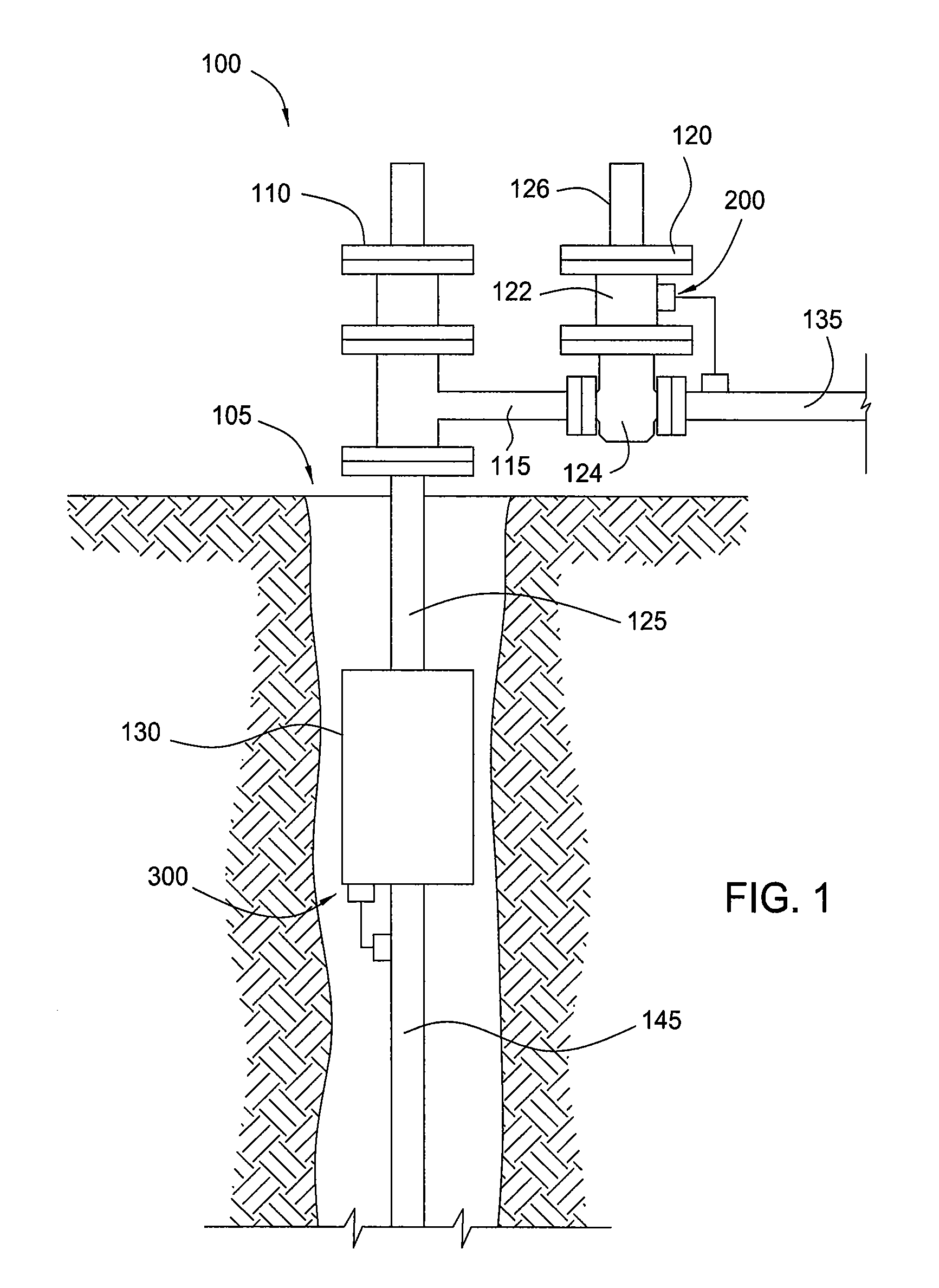

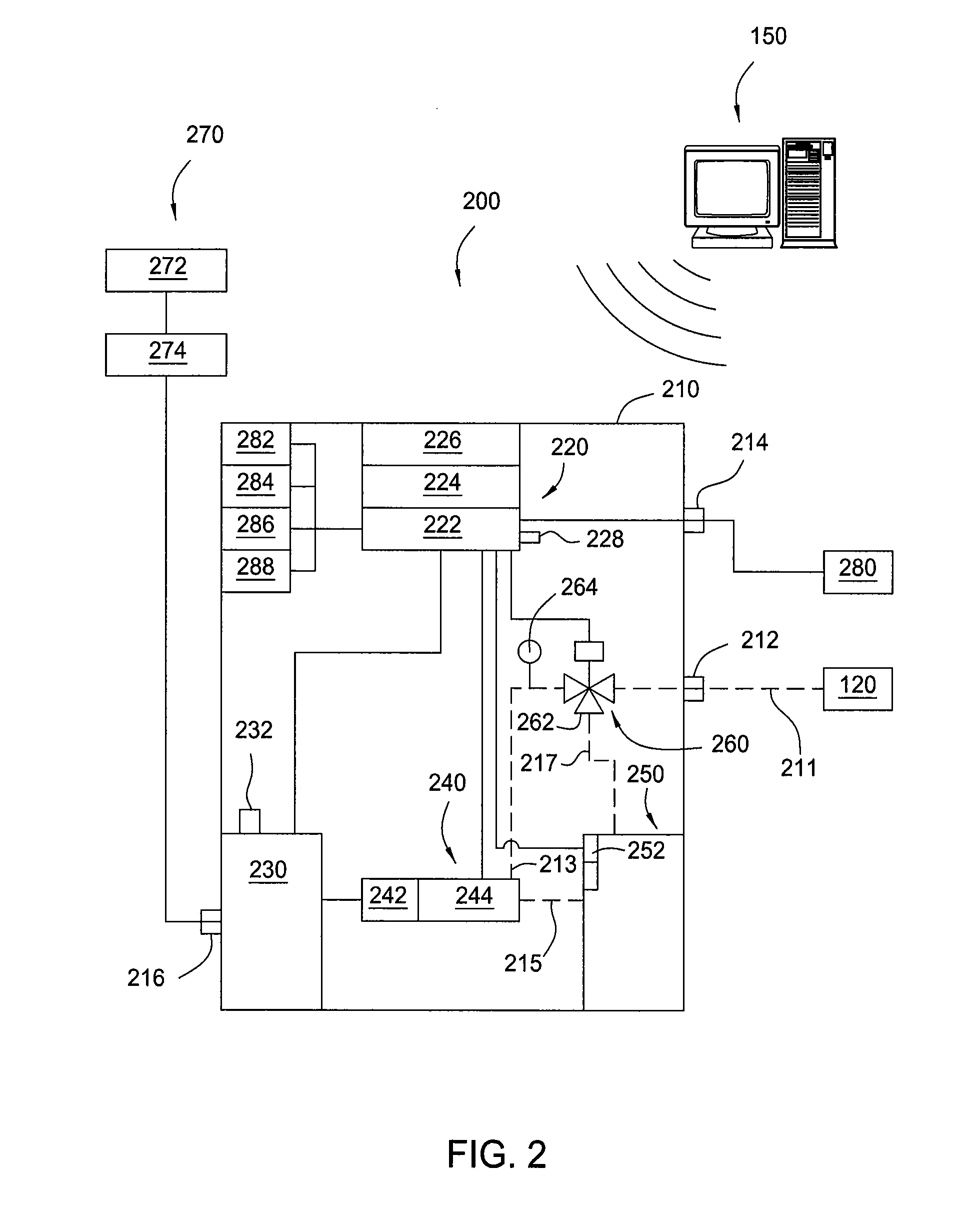

Safety valve control system and method of use

ActiveUS20120227983A1Reduce fluid pressureFluid-pressure actuator safetyEqualizing valvesControl systemTransducer

A safety valve control system may include a remotely operable control assembly, a first transducer, a valve assembly, and a compressor assembly in communication with the control assembly. The control assembly is operable to actuate the pump and valve assemblies to supply fluid to actuate the safety valve into open and closed positions, in response to one or more signals received from the first transducer. A method of operation may include maintaining the safety valve in an open or closed position while sensing a physical property with the control system; communicating a signal corresponding to the sensed physical property to the control system; and automatically closing or opening the safety valve in response to a comparison of the sensed physical property to a pre-set condition.

Owner:SAFOCO

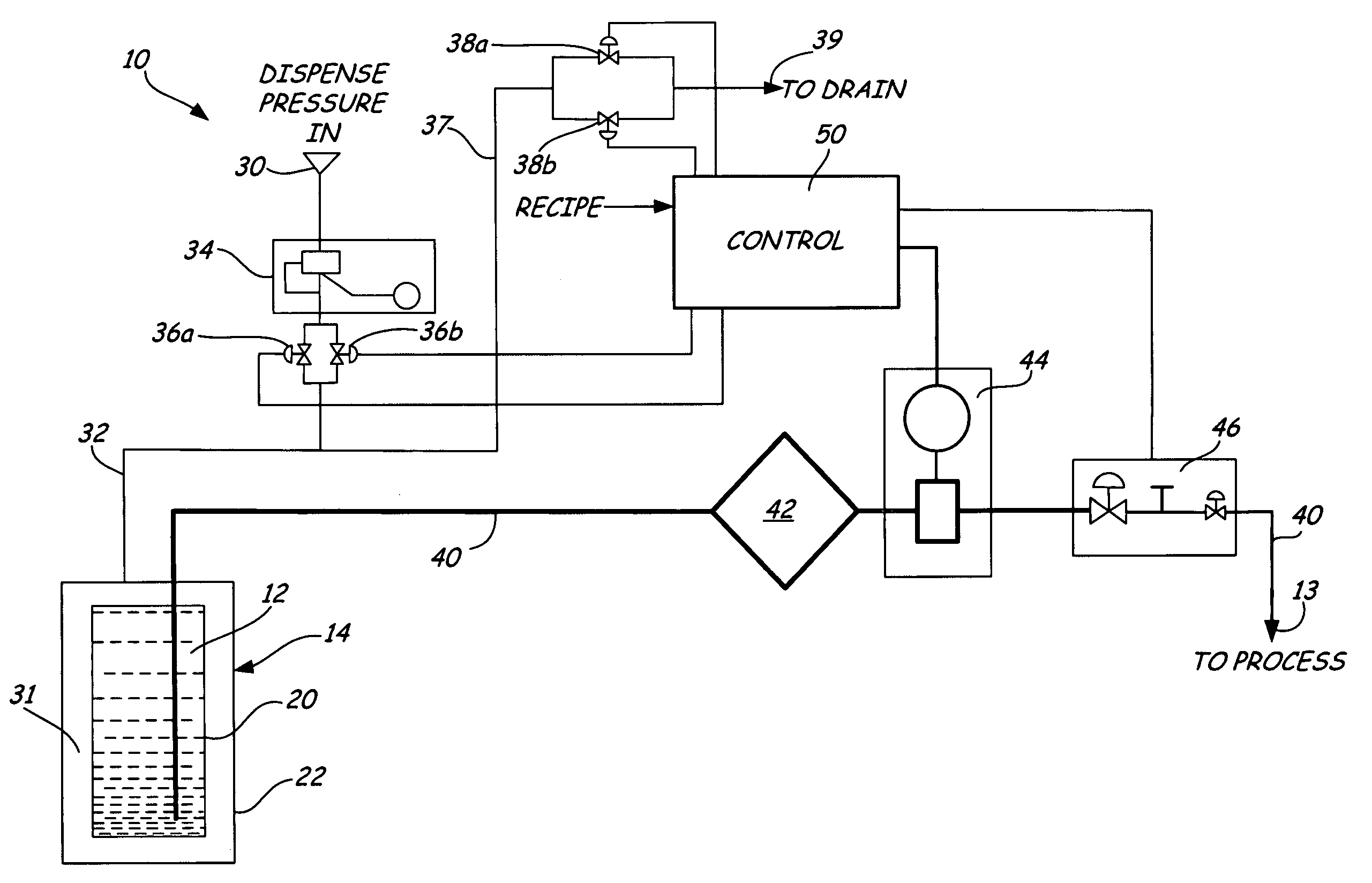

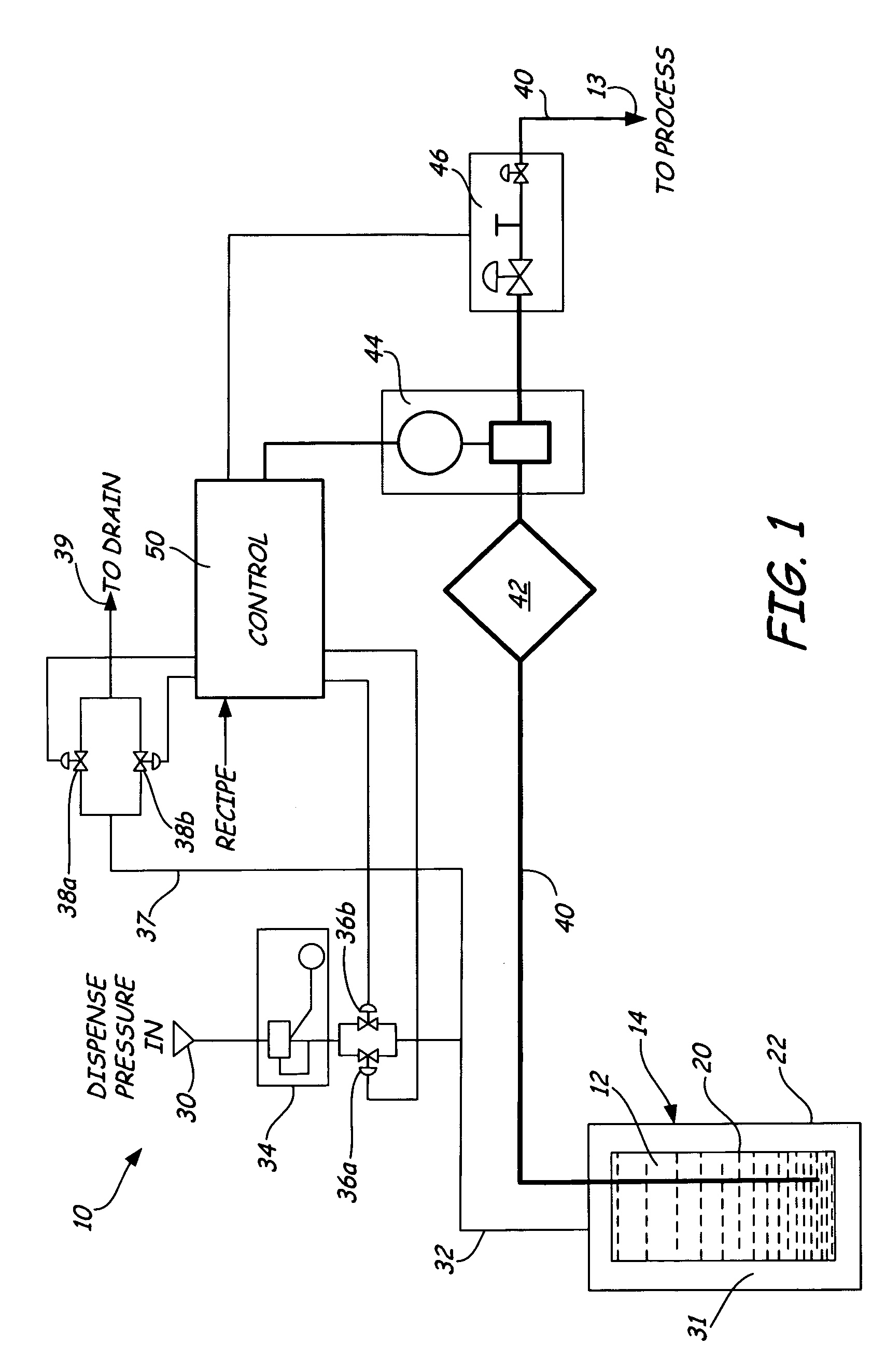

Liquid dispensing system

ActiveUS7172096B2Low costFirmly connectedOpening closed containersBottle/container closureEngineeringForce sensor

Owner:ADVANCED TECH MATERIALS INC

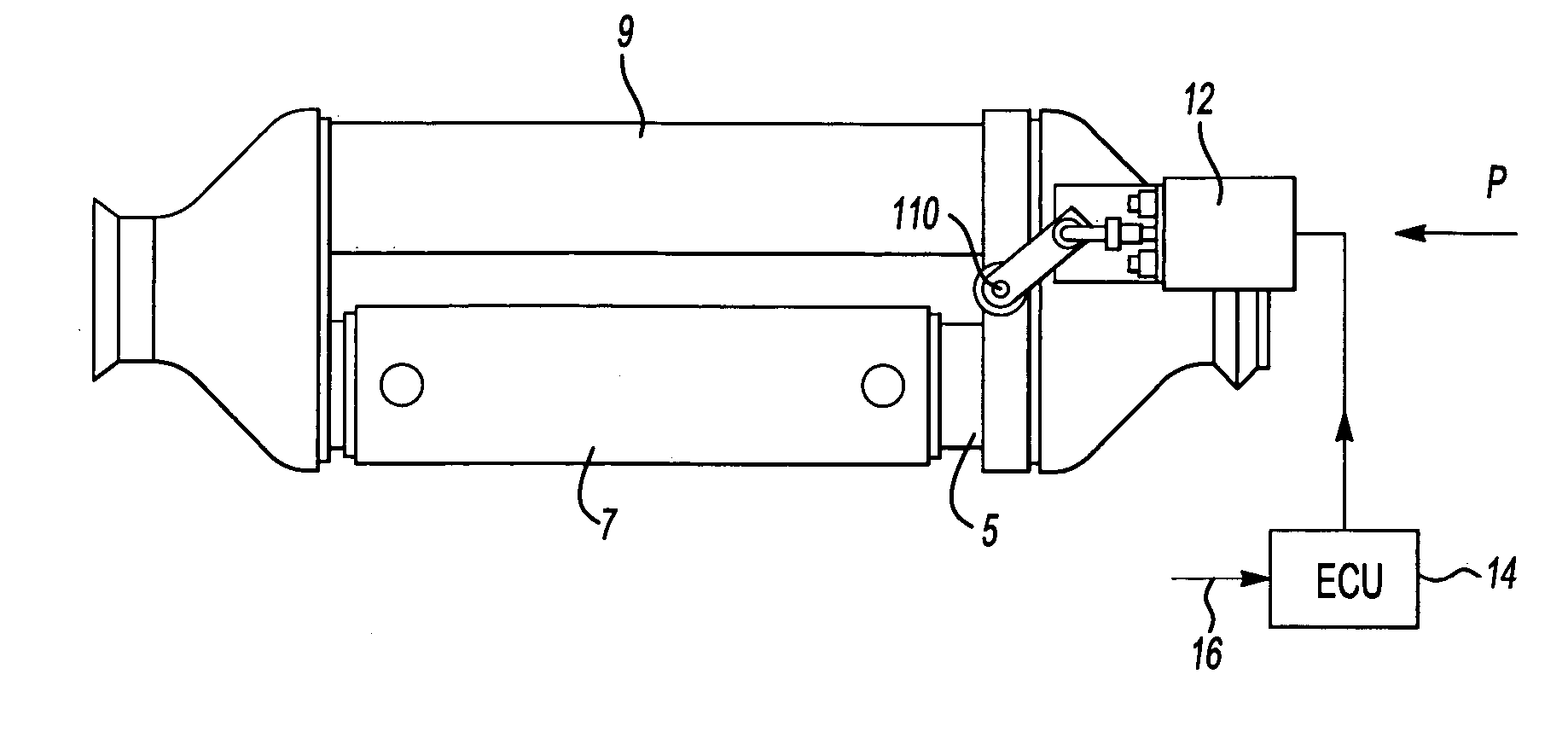

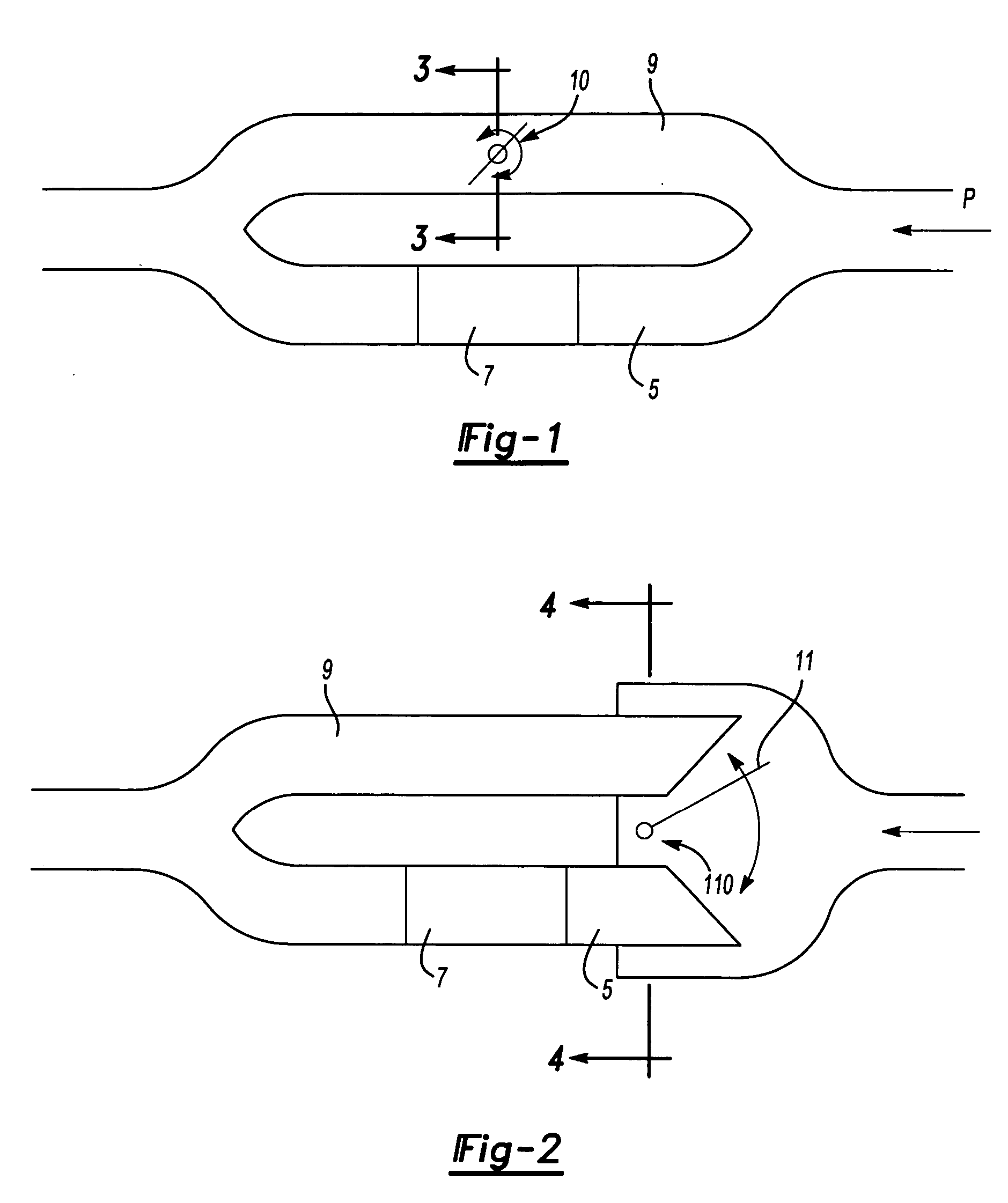

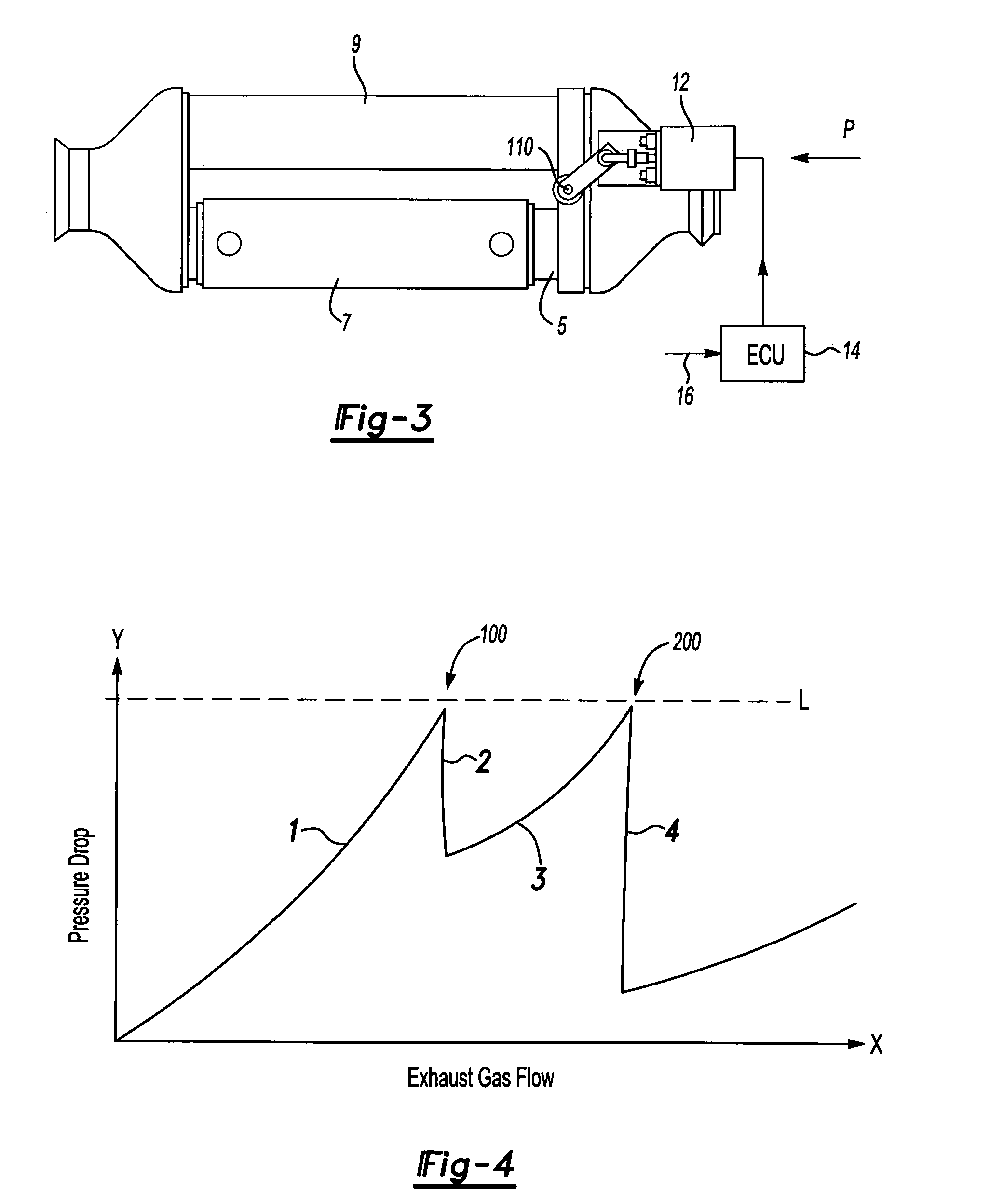

Method for controlling a valve for an exhaust system

ActiveUS20050051322A1Lower overall pressure dropAir-treating devicesInternal combustion piston enginesCombustionExhaust fumes

An exhaust gas heat exchanger system of a combustion engine has a bypass duct and a heat exchanger duct with a heat exchanger. A valve is controlled by determining when heat is to be transferred from exhaust gas flowing through the exhaust system to the heat exchanger. When heat is to be transferred, the valve is switched into a first position in which all of the exhaust gas flows through the heat exchanger duct. A pressure drop across the heat exchanger system is monitored either directly or indirectly. If the pressure drop reaches a predefined limit, the valve is switched into an intermediate position, resulting in a smaller portion of the exhaust gas flowing through the heat exchanger duct than when the valve is in the first position and a remaining portion flowing through the bypass duct, thereby reducing the pressure drop across the heat exchanger system. If the pressure drop again reaches a predefined limit, the valve is switched into a second position, resulting in an even smaller portion of the exhaust gas flowing through the heat exchanger duct, thereby further reducing the pressure drop across the heat exchanger system.

Owner:ET US HLDG

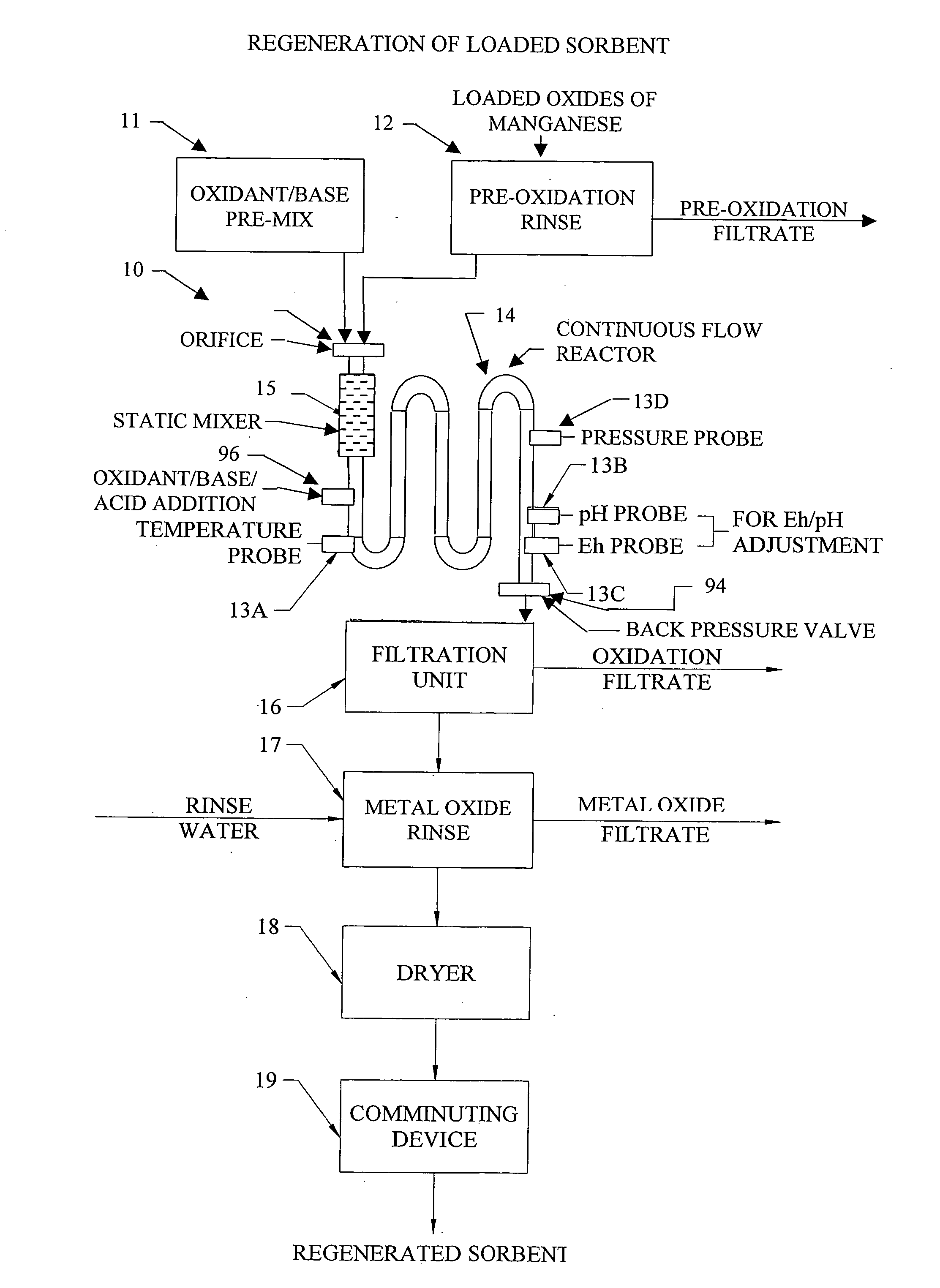

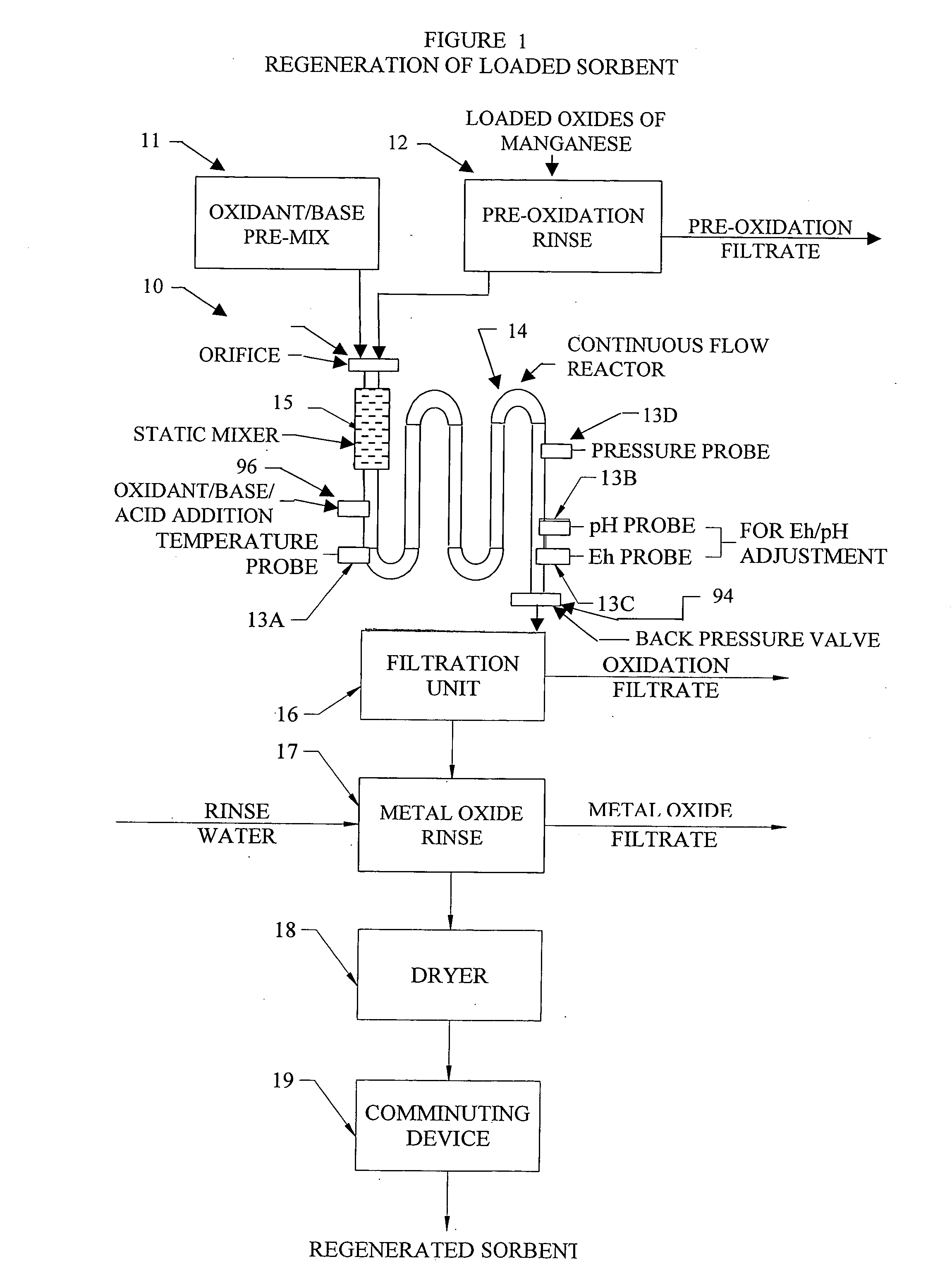

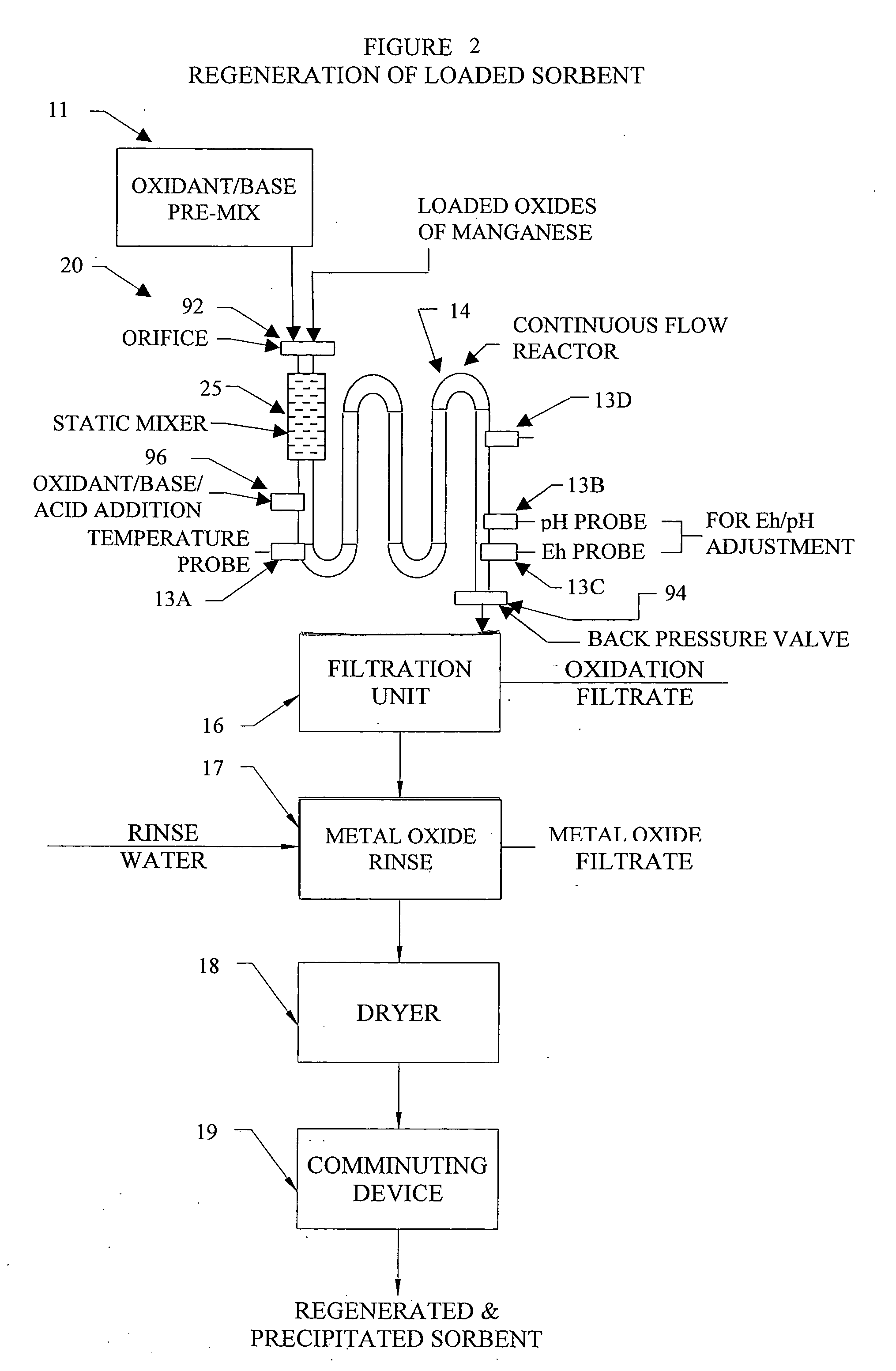

Metal oxide processing methods and systems

InactiveUS20050074380A1Move quicklyIncrease load capacityCombination devicesTemperatue controlIndustrial gasBatch processing

Methods and systems for processing metal oxides from metal containing solutions. Metal containing solutions are mixed with heated aqueous oxidizing solutions and processed in a continuous process reactor or batch processing system. Combinations of temperature, pressure, molarity, Eh value, and pH value of the mixed solution are monitored and adjusted so as to maintain solution conditions within a desired stability area during processing. This results in metal oxides having high or increased pollutant loading capacities and / or oxidation states. These metal oxides may be processed according to the invention to produce co-precipitated oxides of two or more metals, metal oxides incorporating foreign cations, metal oxides precipitated on active and inactive substrates, or combinations of any or all of these forms. Metal oxides thus produced are, amongst other uses; suitable for use as a sorbent for capturing or removing target pollutants from industrial gas streams or drinking water or aqueous streams or for personal protective respirators.

Owner:ENVIROSCRUB TECH CORP

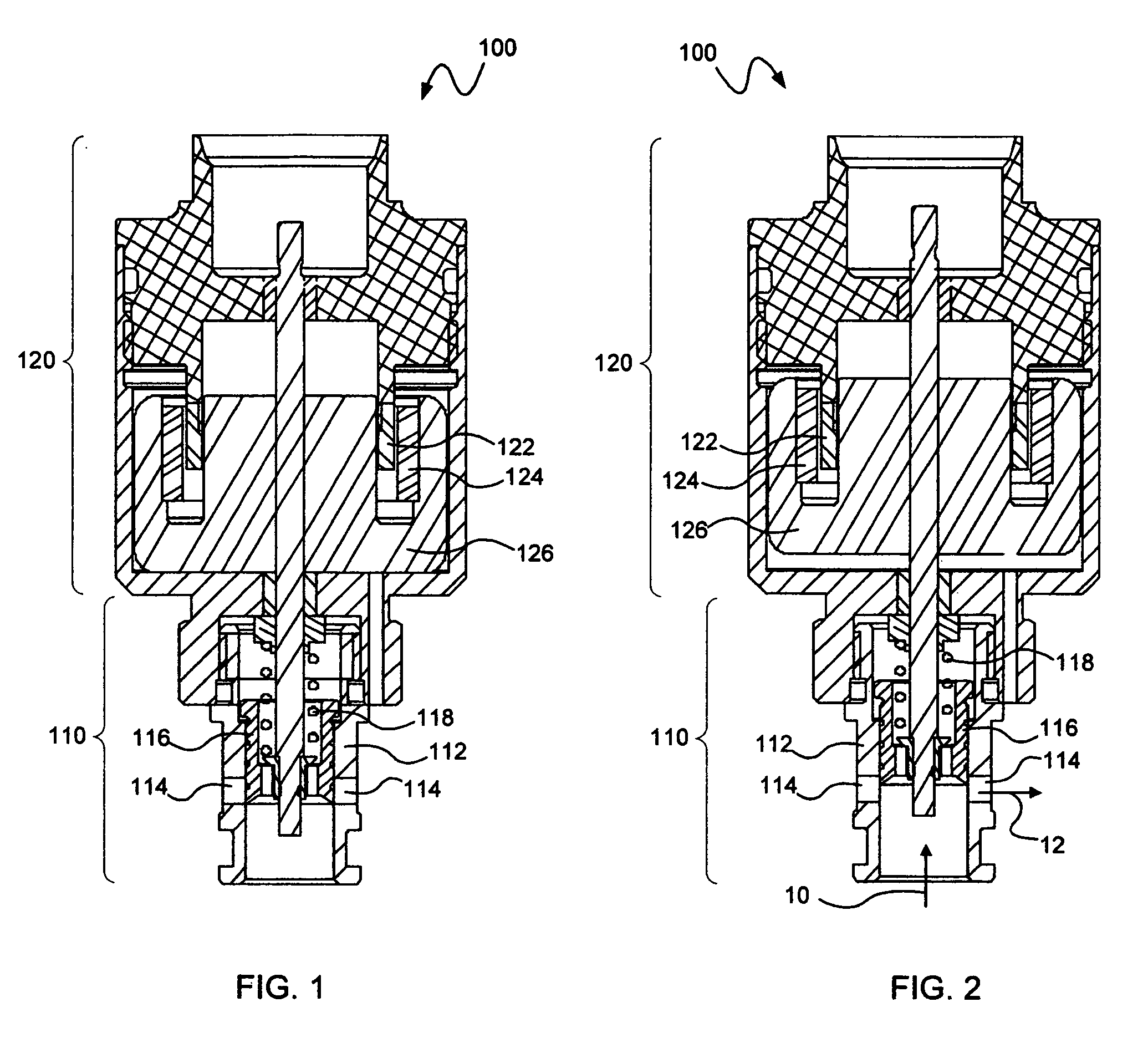

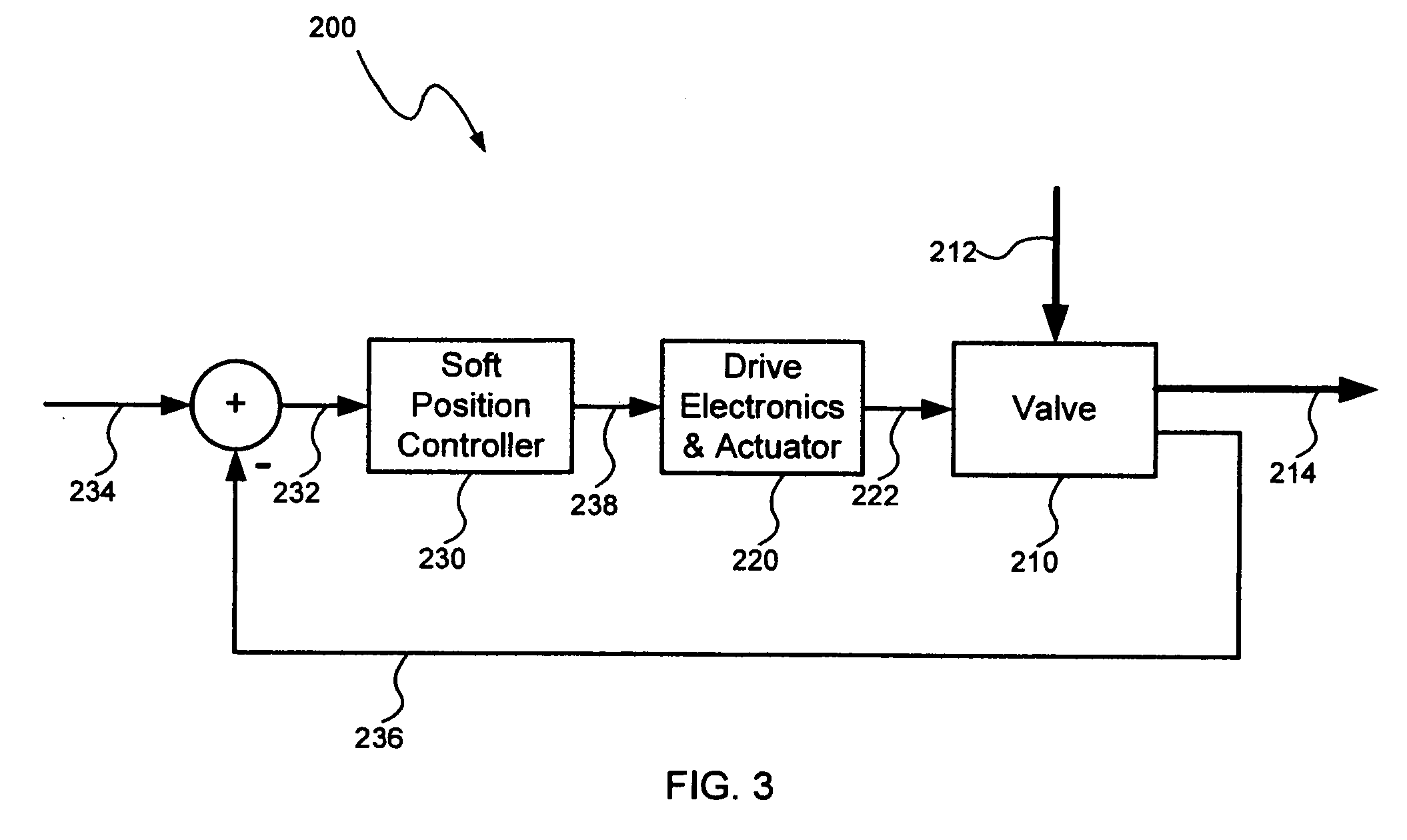

Electrically controlled pressure relief valve and system and method for controlling same

ActiveUS7299112B2Operating means/releasing devices for valvesLevel controlControl systemControl valves

A system and method for controlling an electrically controlled pressure relief valve may use a soft position control loop to control the position of the valve. A pressure relief valve may also include a modified orifice shape to improve stability, to uniformly distribute the effective bandwidth over the valve operating range, and to provide a tunable default mode.

Owner:GENERAL KINETICS ENG CORP

Valvetrain oil control system and oil control valve

InactiveUS20100018482A1Reduce fuel consumptionOperating means/releasing devices for valvesPipeline systemsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

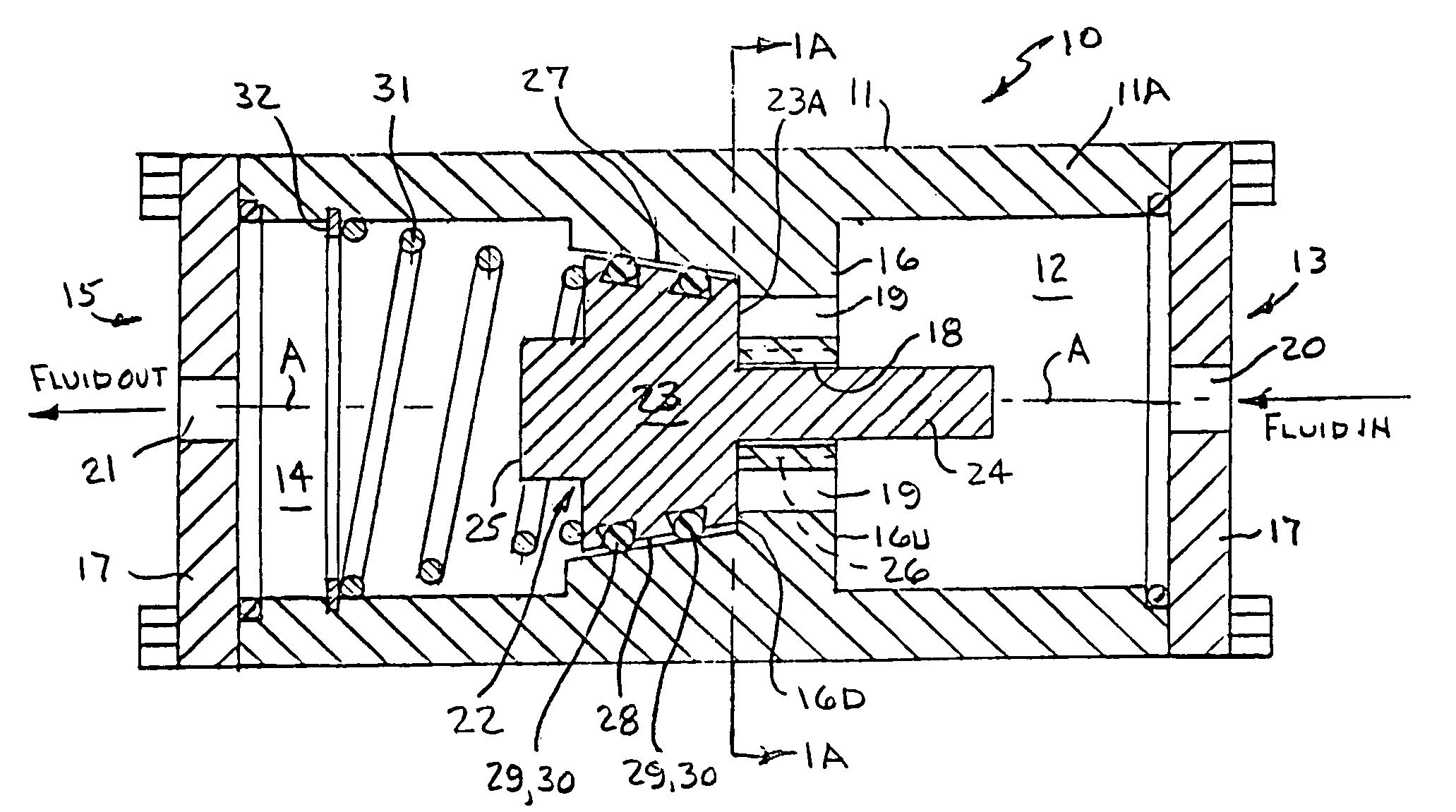

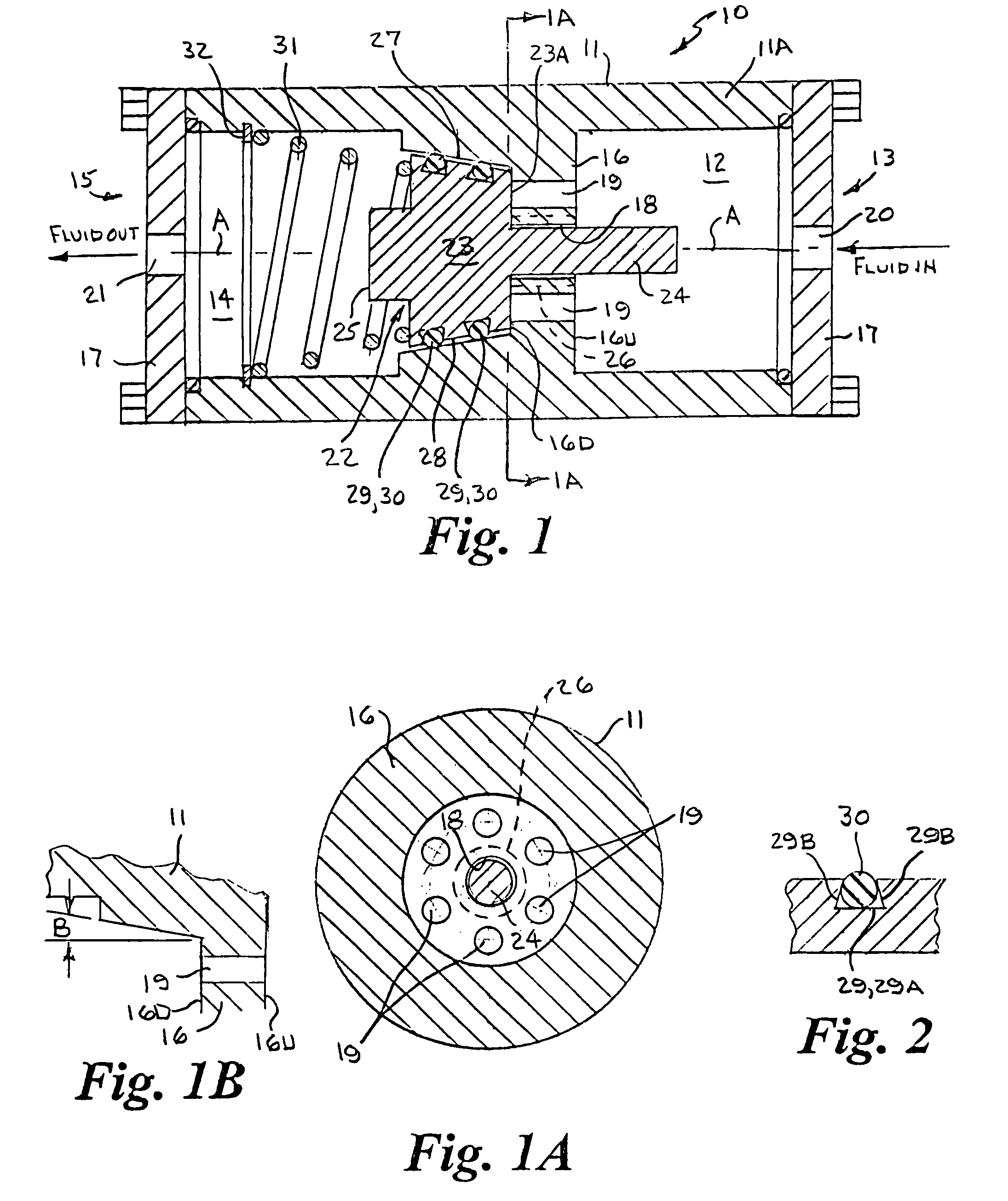

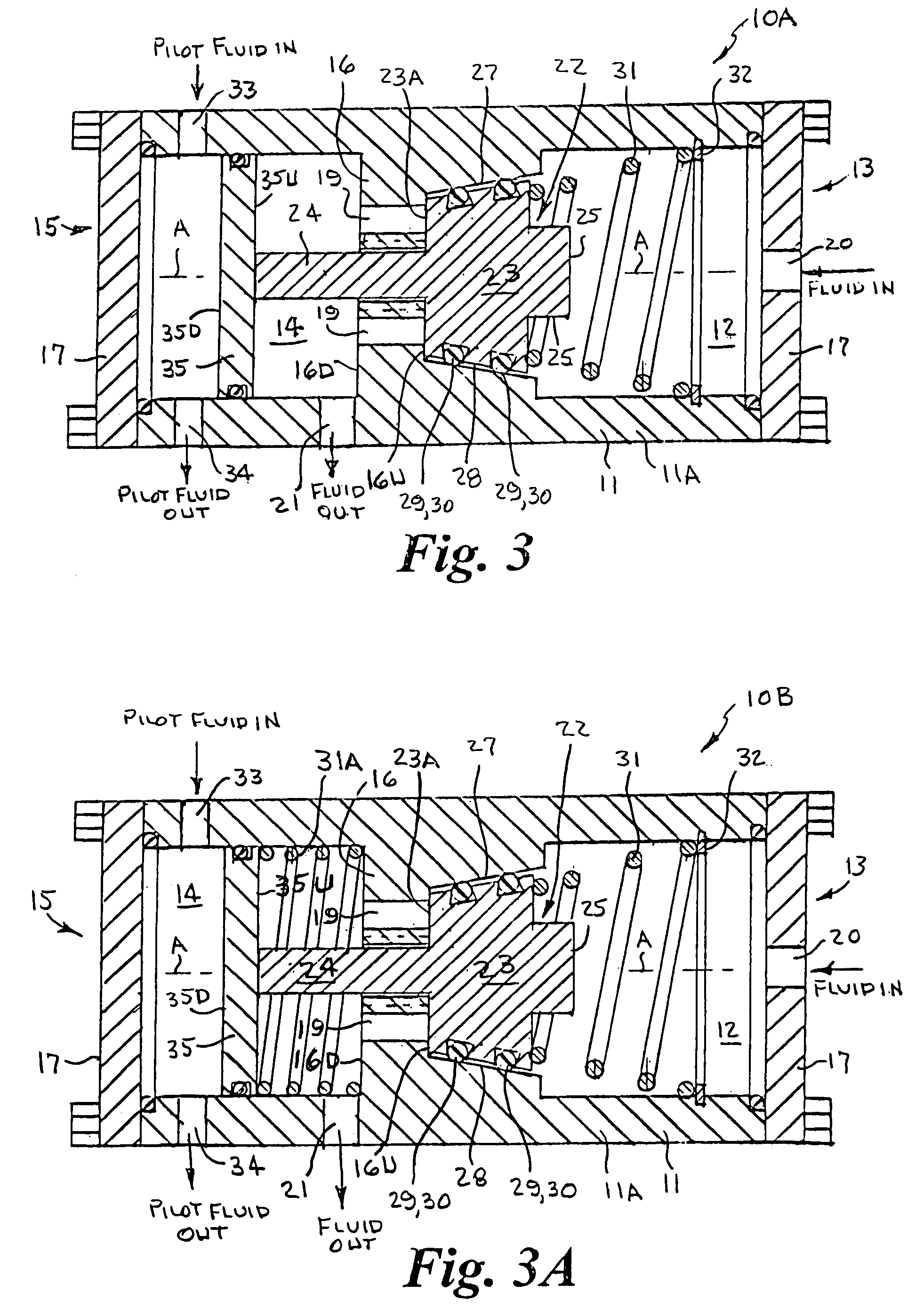

Fluid control valve

InactiveUS7225830B1Easy constructionFew partsOperating means/releasing devices for valvesCheck valvesFluid controlDifferential pressure

A fluid control valve having a spring biased shuttle plunger member which opens or closes fluid flow through a plurality of radially spaced apart fluid passageways disposed between an upstream chamber and downstream chamber in the valve body responsive to a fluid pressure greater than the spring force and any differential pressure between the upstream and downstream chambers to prevent fluid from being supplied at a pressure higher than a desired operating pressure and prevent high dynamic differential pressures, such as a “water hammer” or explosive pressure. Alternatively, in a normally closed embodiment, pilot fluid at a pressure greater than the spring force and any differential pressure in the upstream chamber is utilized to open the valve, which is then closed by the spring force.

Owner:KERSHAW CHARLES H

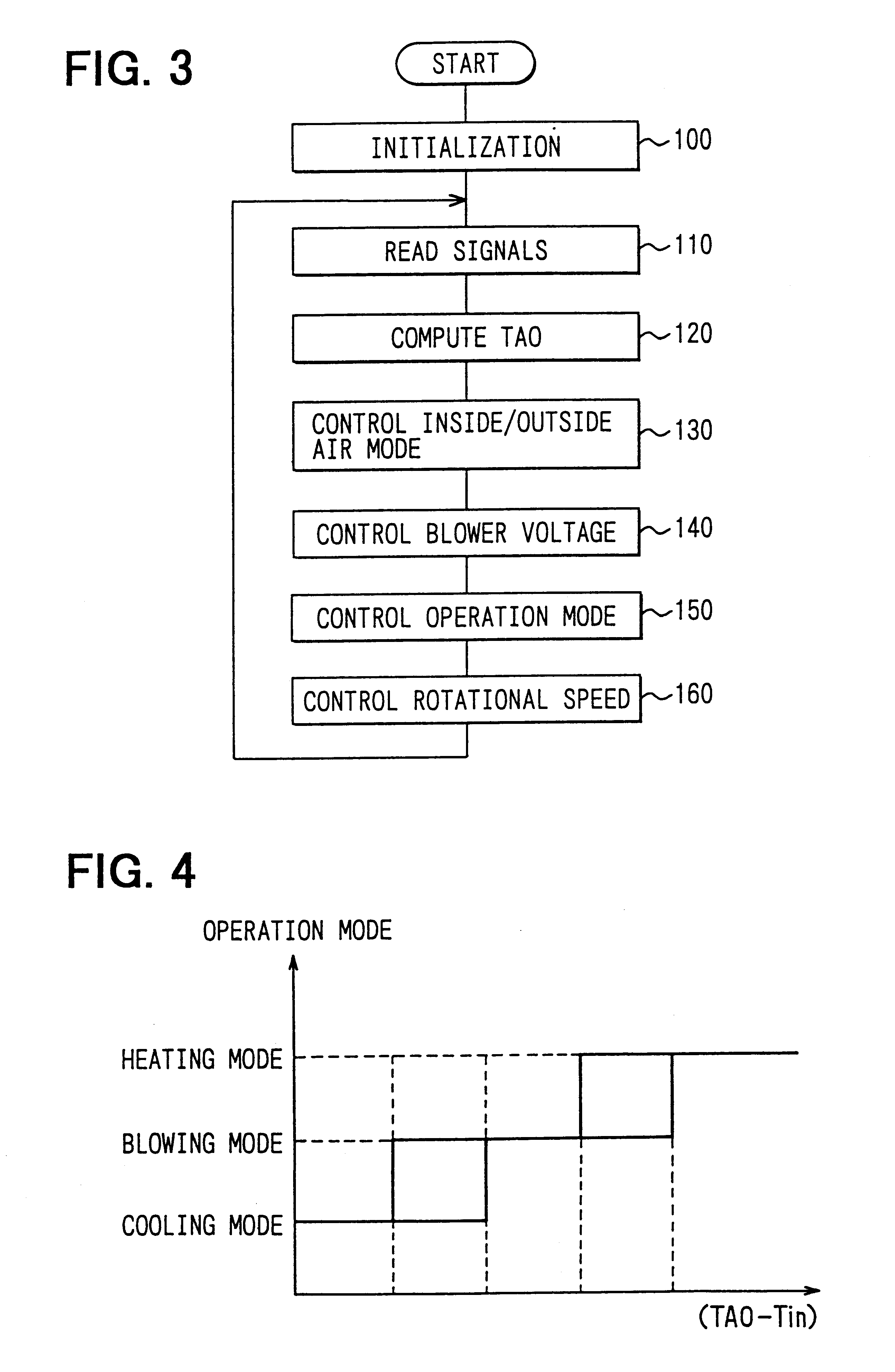

Method and apparatus for monitoring and controlling pressure in an inflatable device

A system includes a fluid controller coupled to an inflatable bladder and configured to add fluid to and remove fluid from the inflatable bladder, a control unit configured to provide information used by the fluid controller to adjust the pressurization of the inflatable bladder, the control unit including a user interface configured to constantly display a plurality of indicia corresponding to a range of pressure levels in which the inflatable bladder is employed by a user, where each of the plurality of indicia is associated with a different level of pressure of the inflatable bladder, respectively. In one embodiment, the fluid controller is configured to adjust the pressurization, in response to a user input at the user interface, to a pressure level selected by the user based on a current pressure level of the inflatable bladder, the pressure level selected by the user and an operating time of the fluid controller. In a further embodiment, a first indicia included in the plurality of indicia is associated with the current pressure level and a second indicia included in the plurality of indicia is associated with the pressure level selected by the user.

Owner:CHAFFEE ROBERT B

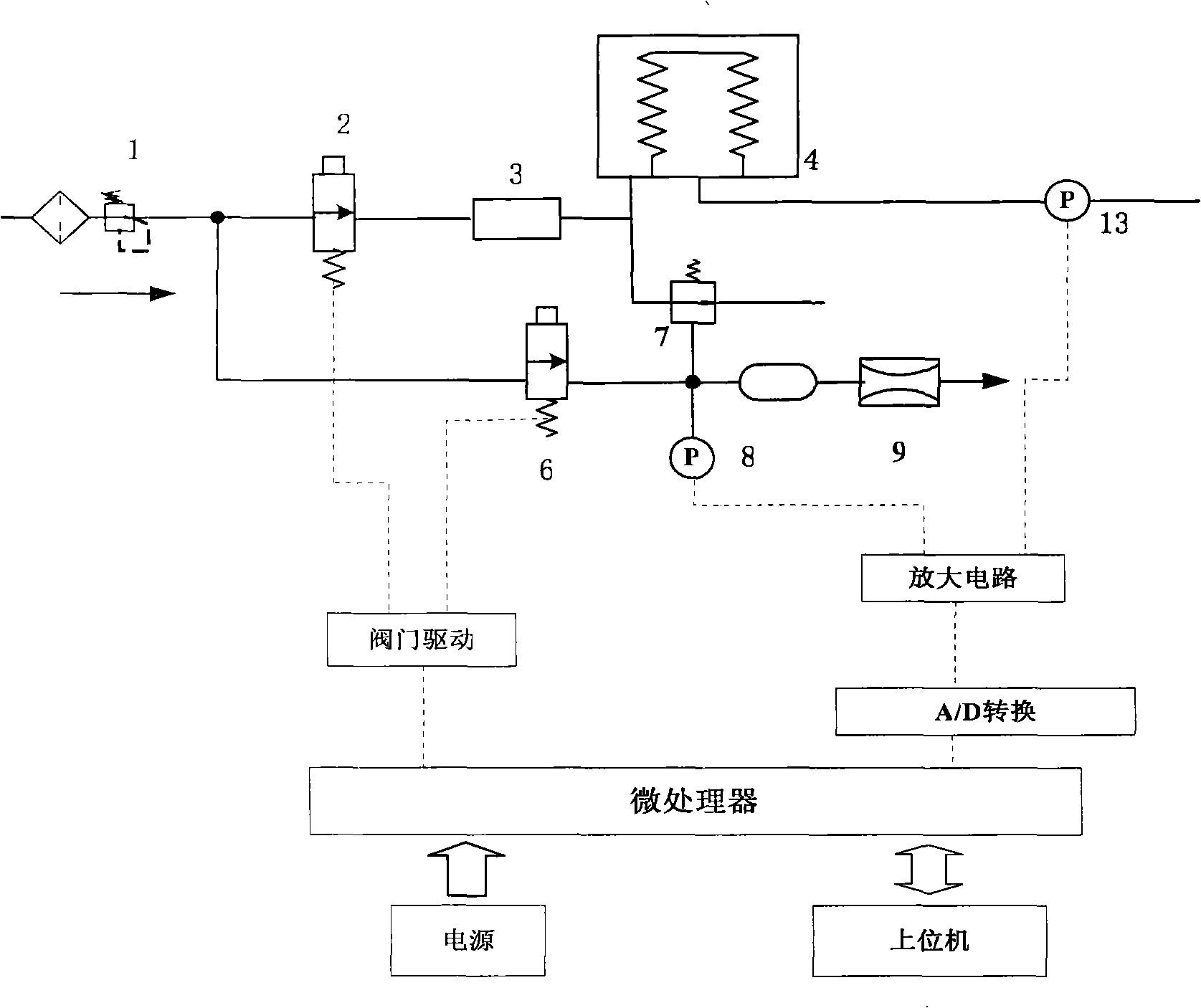

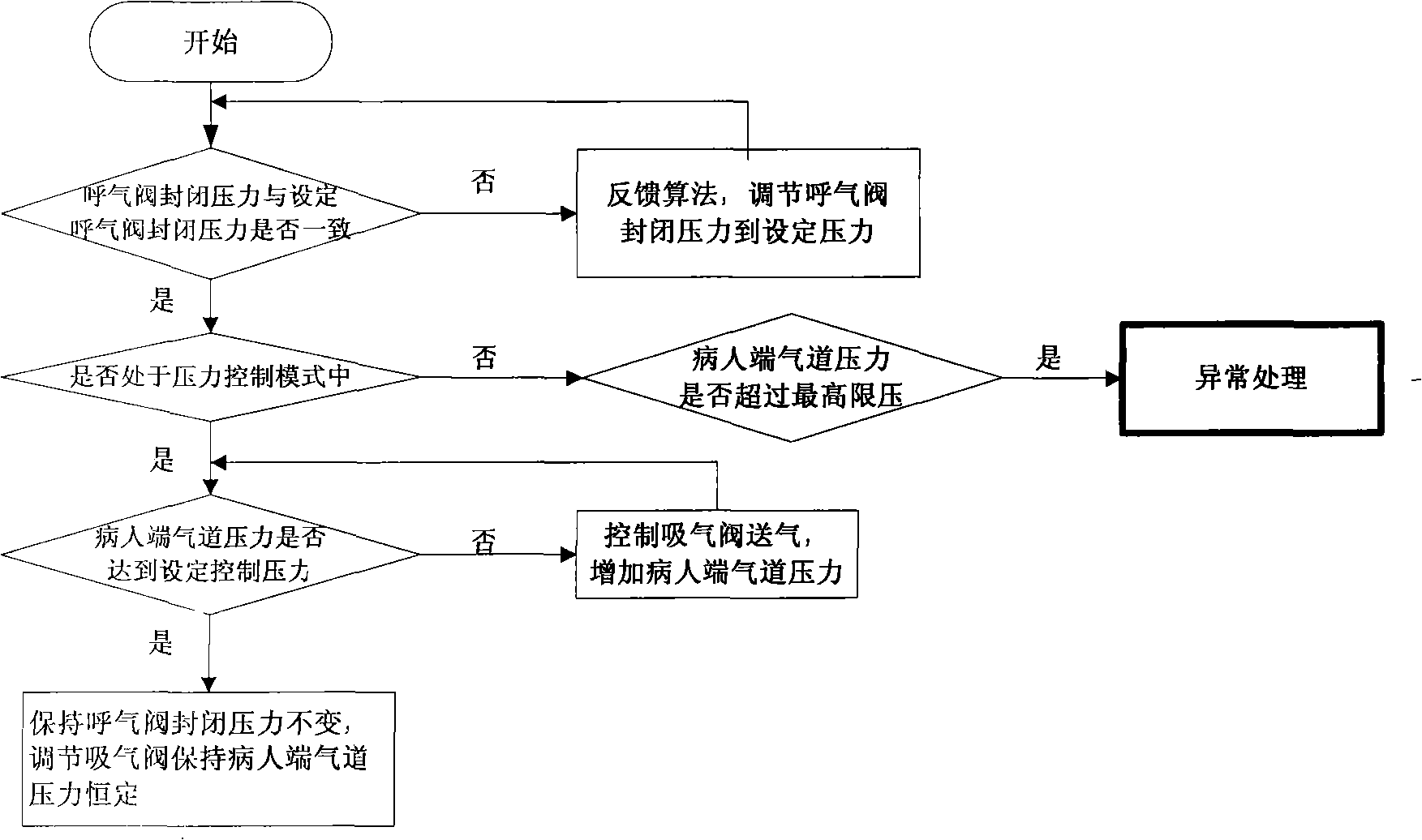

Aerating system of anesthesia apparatus and respirator and pressure monitoring method

ActiveCN101337101AAvoid interferenceStable and reliable pressure monitoringRespiratorsFluid pressure controlEmergency medicineFeedback control

The invention discloses a pressure monitoring and controlling method used in an aerating system of a medical device. The pressure monitoring and controlling method comprises monitoring the confining pressure of an expiratory valve on a real-time basis, and regulating and maintaining the pressure and the set confining pressure of the expiratory valve at the same value; and monitoring the pressure of a patient terminal gas channel on a real-time basis, and regulating and maintaining the pressure to reach a set control pressure. The aerating system used in the medical facility comprises a gas path system and a pressure monitoring and controlling device. The pressure monitoring and controlling device comprises a parameter monitoring and controlling unit, a valve control unit and a master controller, wherein the parameter monitoring and controlling unit includes a first pressure detecting device placed in to the patient terminal gas channel in the gas path system, and a second pressure detecting device for monitoring and controlling the confining pressure of the expiratory valve in the gas path system. A breathing machine and an anaesthetic machine using the aerating system in the technical proposal monitor the pressure of a control branch of the expiratory valve therein and employ the pressure as the basis of the feedback control to effectively avoid the external disturbance, thereby realizing stable and reliable pressure control.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

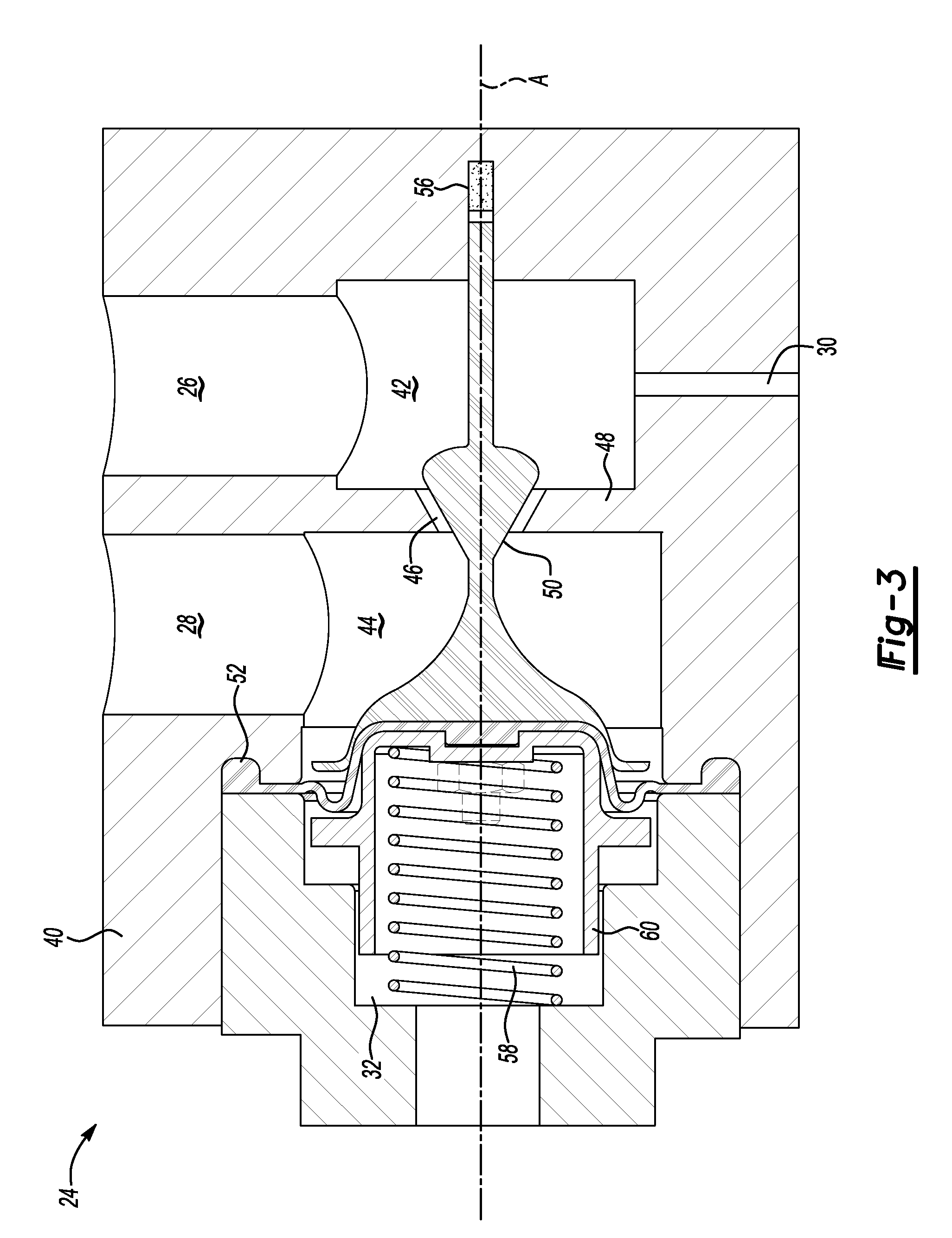

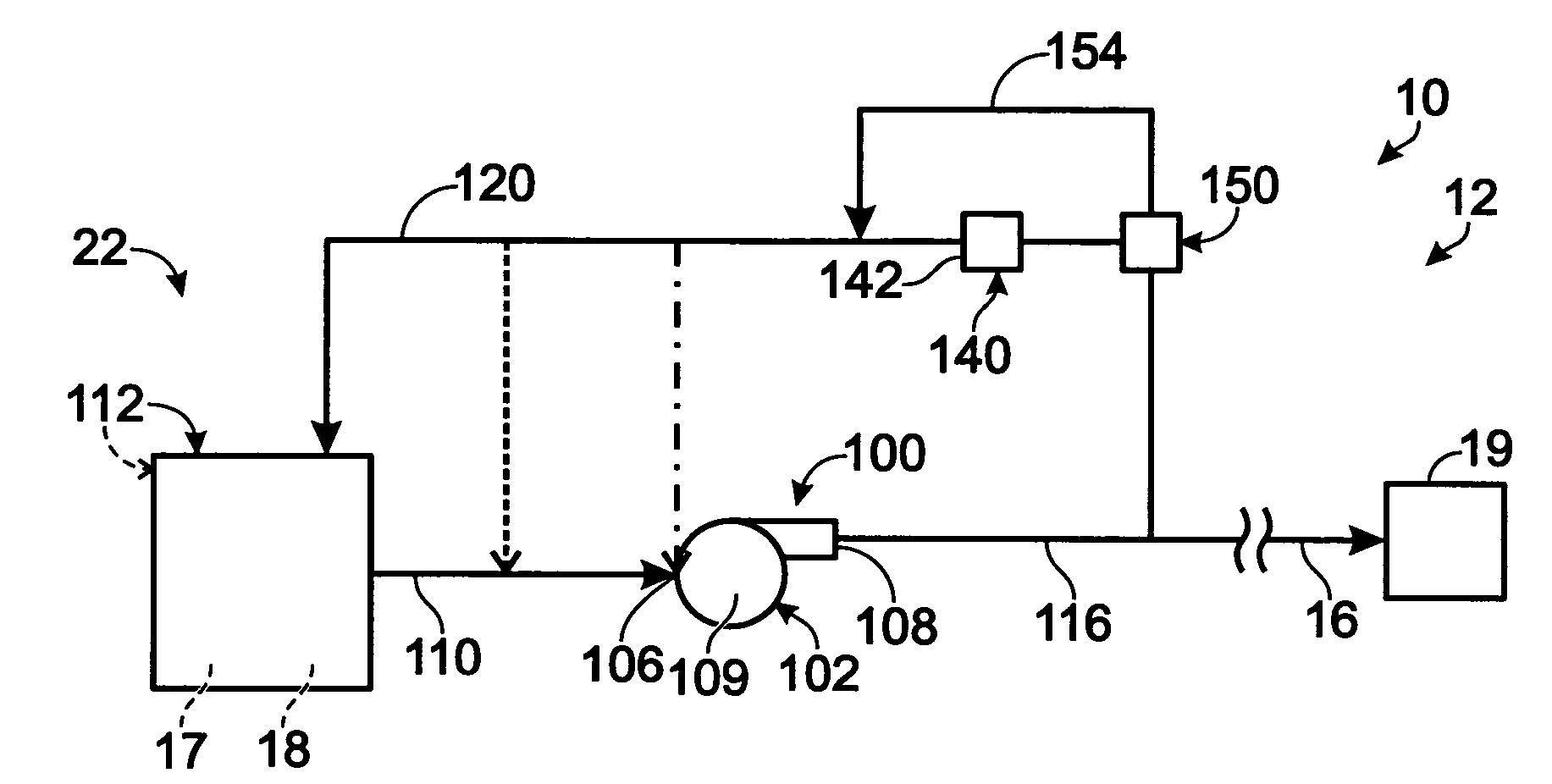

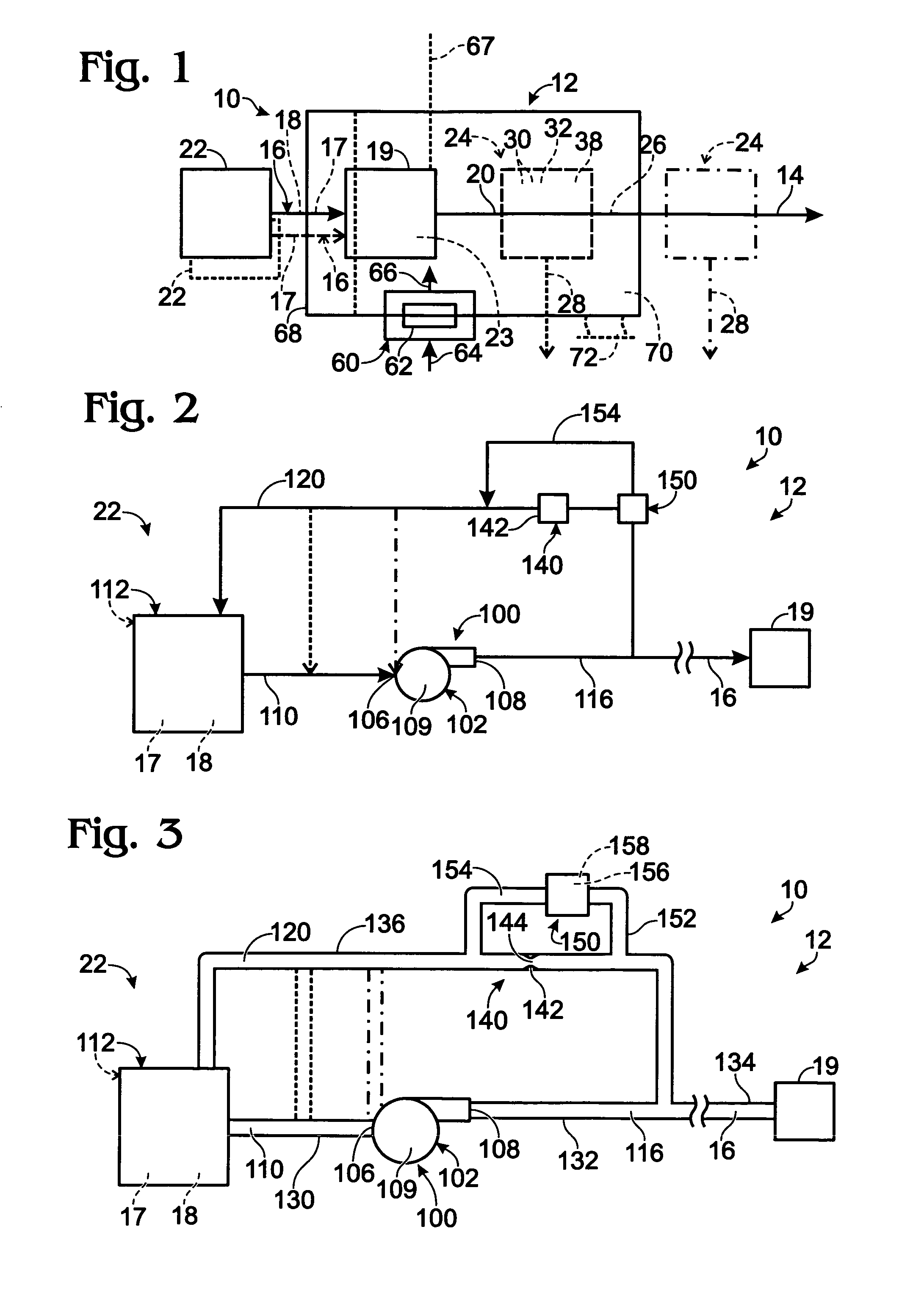

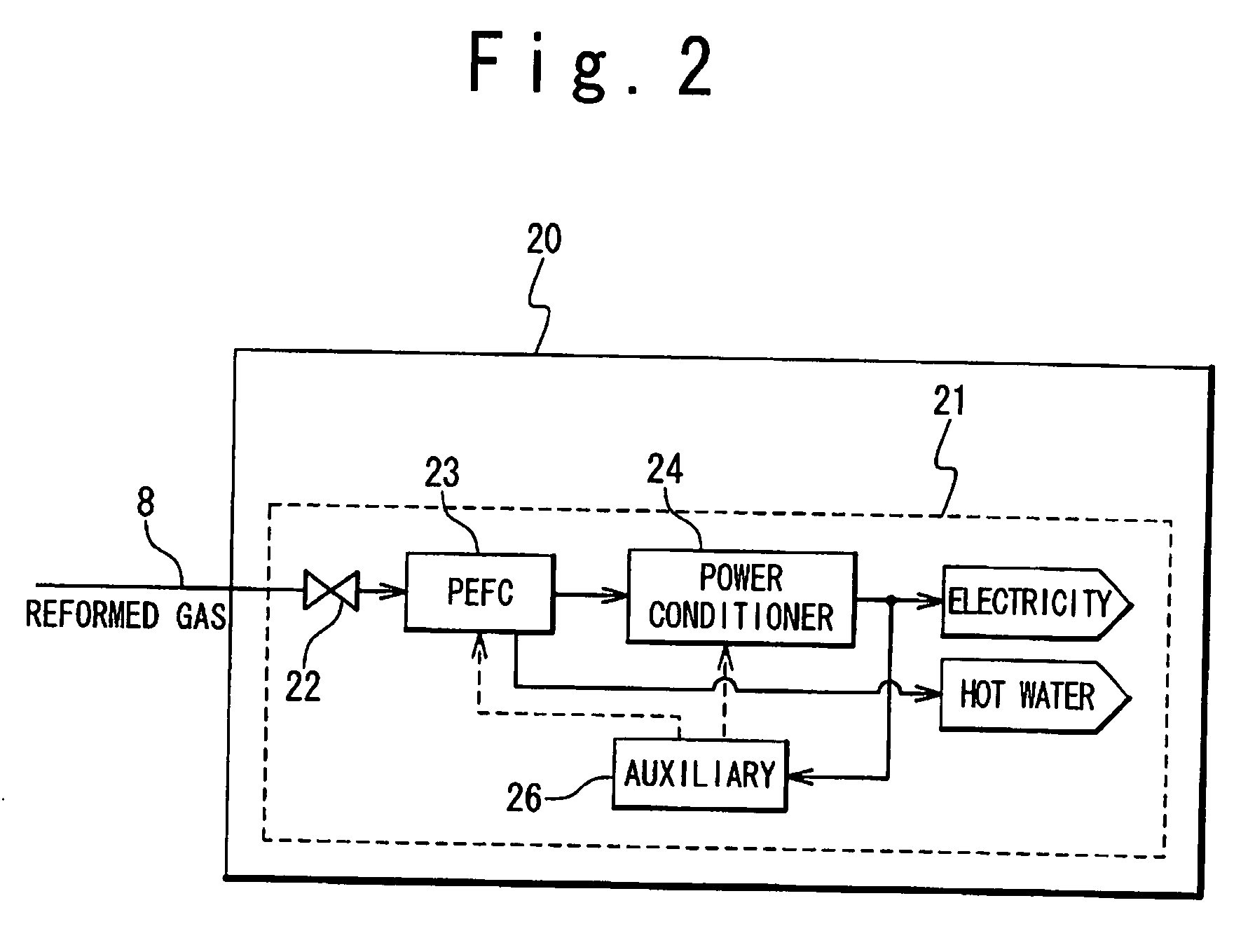

Self-regulating feedstock delivery systems and hydrogen-generating fuel processing assemblies and fuel cell systems incorporating the same

Feedstock delivery systems and hydrogen-producing fuel processing assemblies and fuel cell systems containing the same. The feedstock delivery systems include a liquid pump that draws at least one liquid feedstock from a supply and delivers at least one feed stream containing the feedstock(s) to a fuel processor, such as to the hydrogen-producing region thereof. The feedstock delivery system further includes a recycle conduit that establishes a fluid flow path for the liquid feedstock(s) from a location downstream of the pump back to a location upstream of the pump. In some embodiments, the feedstock delivery system further includes a flow restrictor associated with the recycle conduit and a pressure-actuated valve that selectively permits the recycled feedstock to bypass the flow restrictor. In some embodiments, the pump is configured to draw a greater flow rate of the feed stream from the supply than is delivered to the fuel processor.

Owner:DCNS SA

Ambient air backflushed filter vacuum

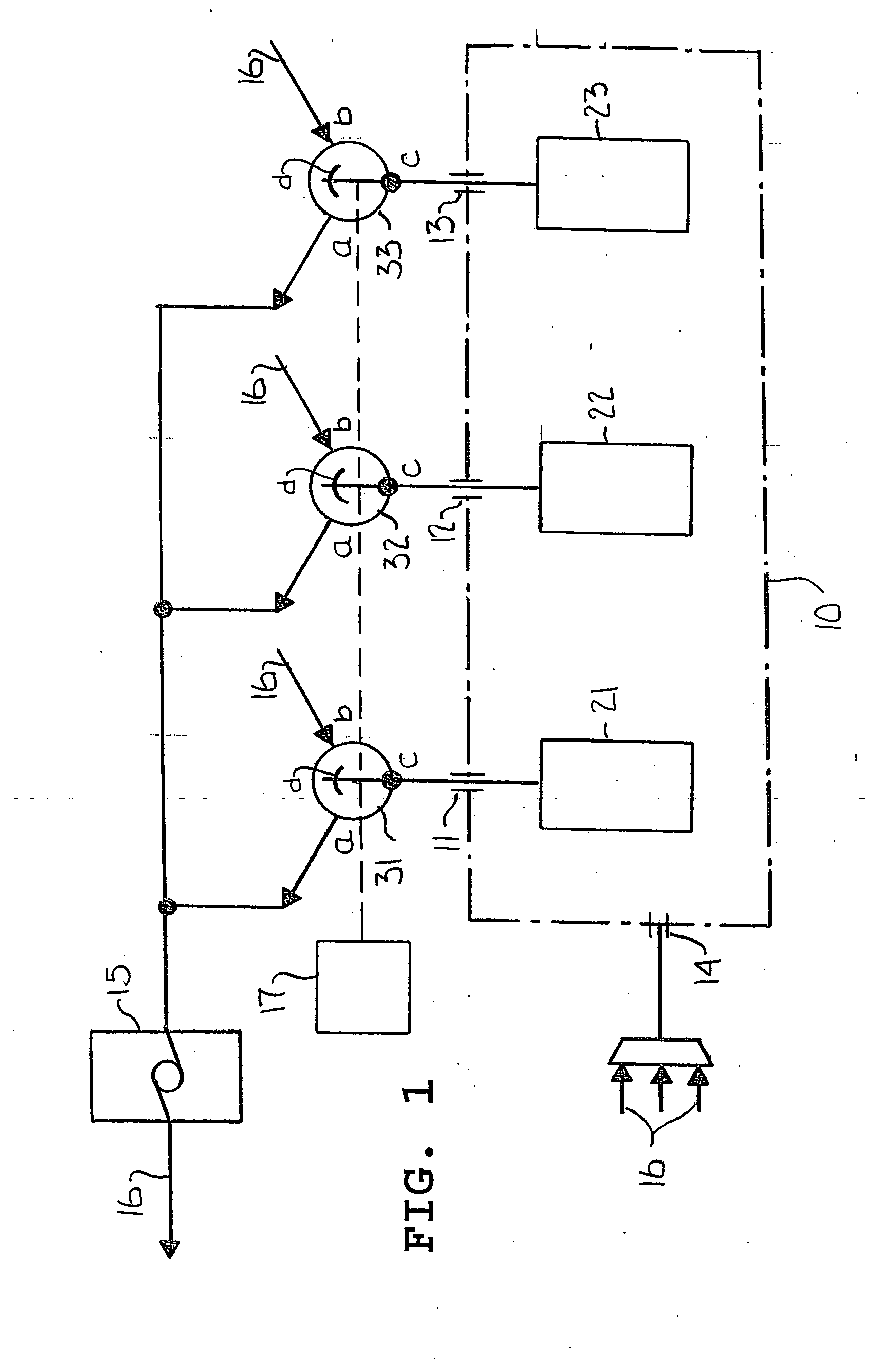

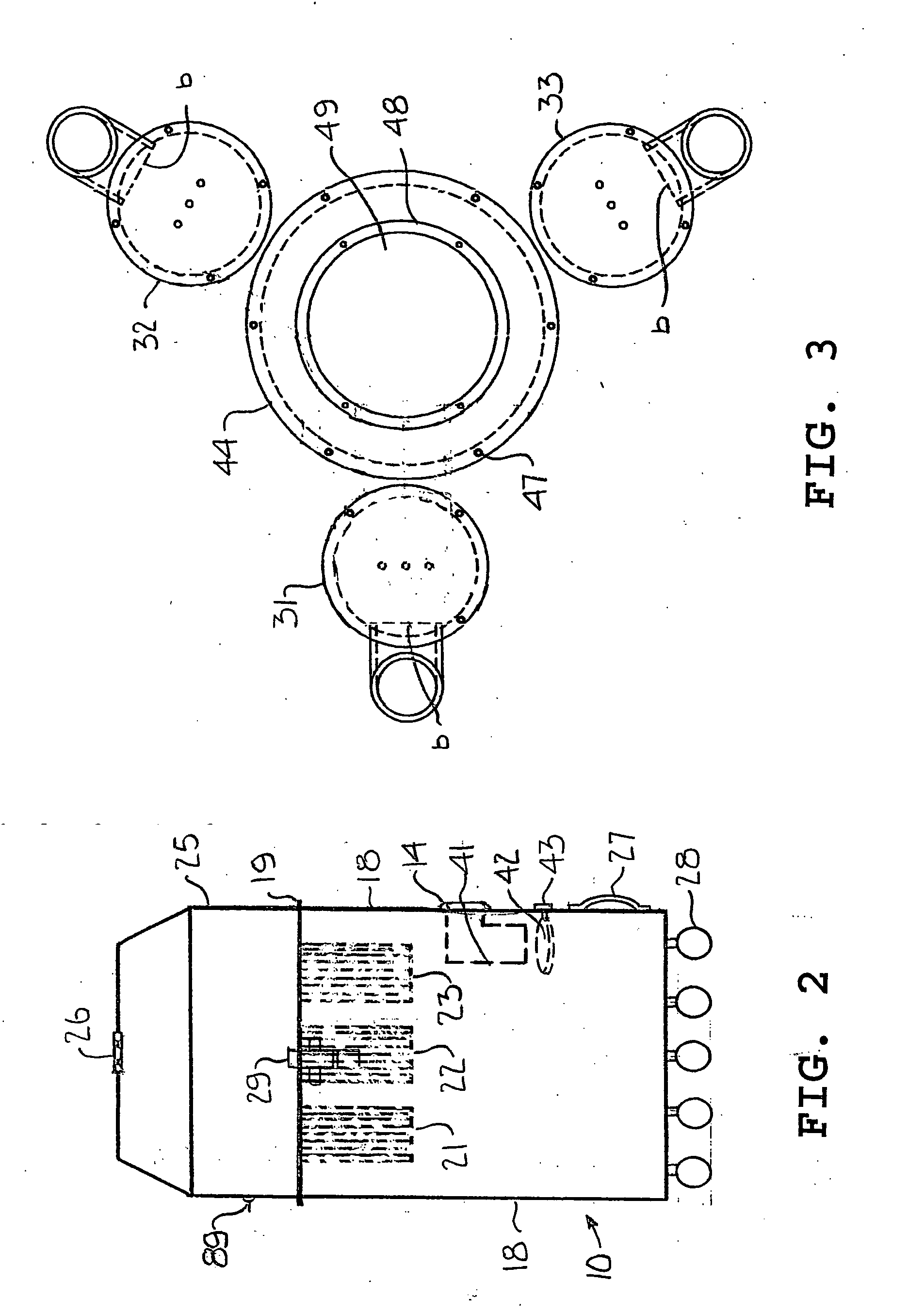

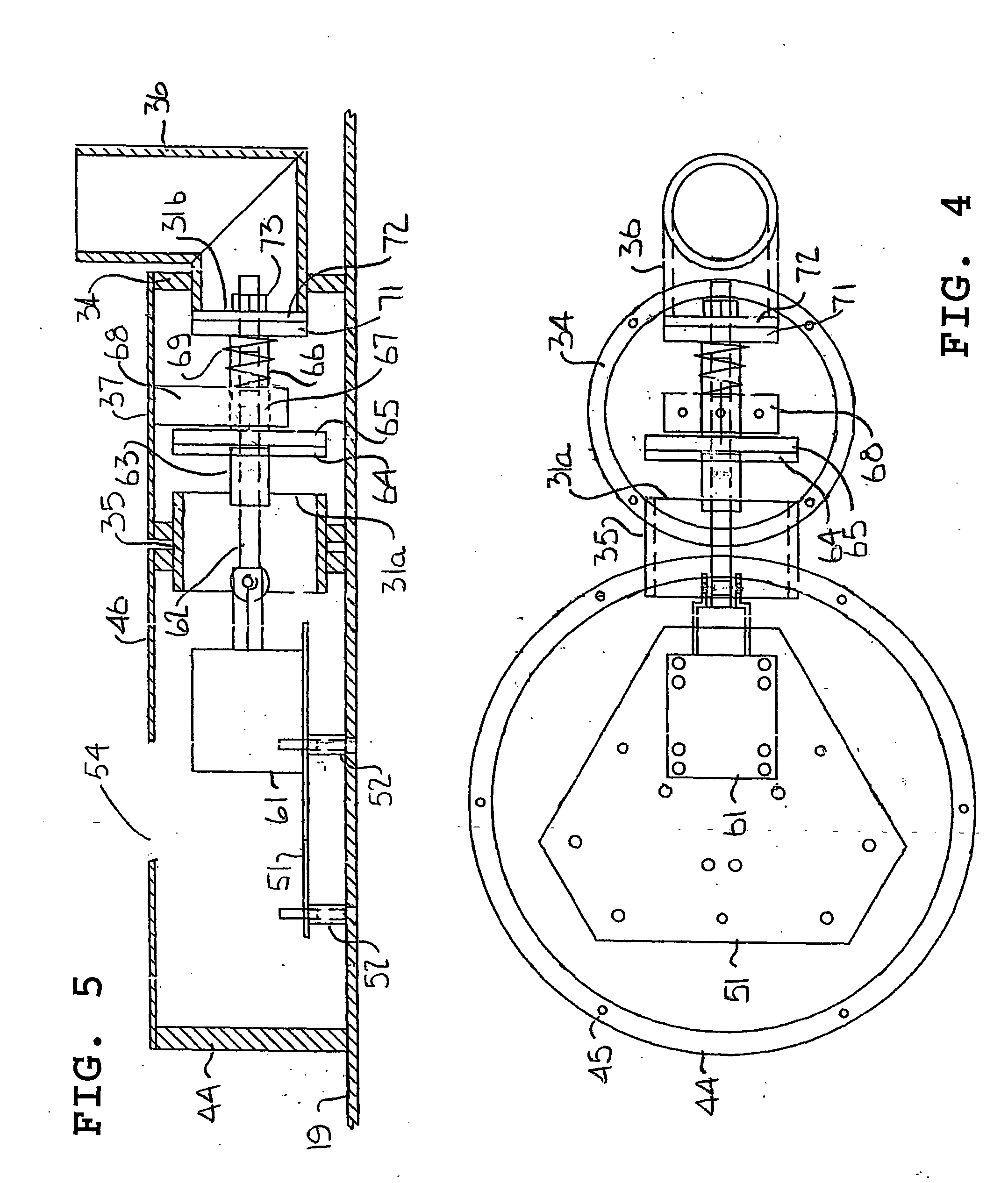

ActiveUS20050011036A1Reduce the possibilityCleaning filter meansCombination devicesDelayed timeEngineering

A vacuum cleaning machine has a cannister with an inlet port and at least two outlet ports. At least two filters are disposed inside of the cannister, one in pneumatic communication through each of the outlet ports. At least two valves are disposed outside of the cannister. Each valve is in pneumatic communication between a vacuum source and an outlet port so as to permit air to be drawn by the vacuum source from the inlet port simultaneously through the filters. A controller operates the valves to switch the filters from the vacuum source to ambient air so as to permit ambient air to be sequentially intermittently drawn through corresponding valves and filters into the cannister. Preferably, the controller includes a timing mechanism for setting the delay time of the sequential valve operation and a timing mechanism for setting the intermittent time of connection of each filter to ambient air.

Owner:CHRISTY

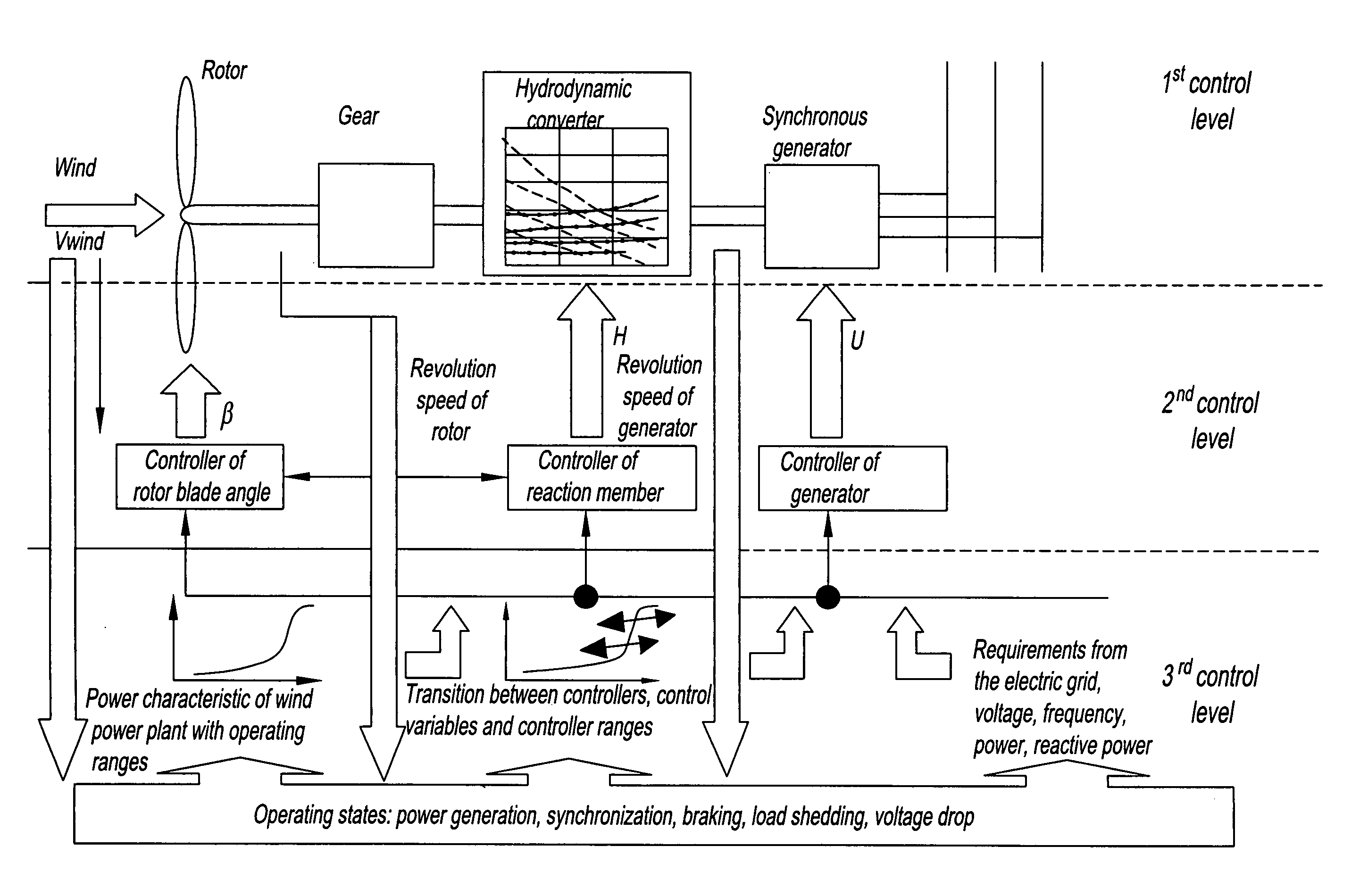

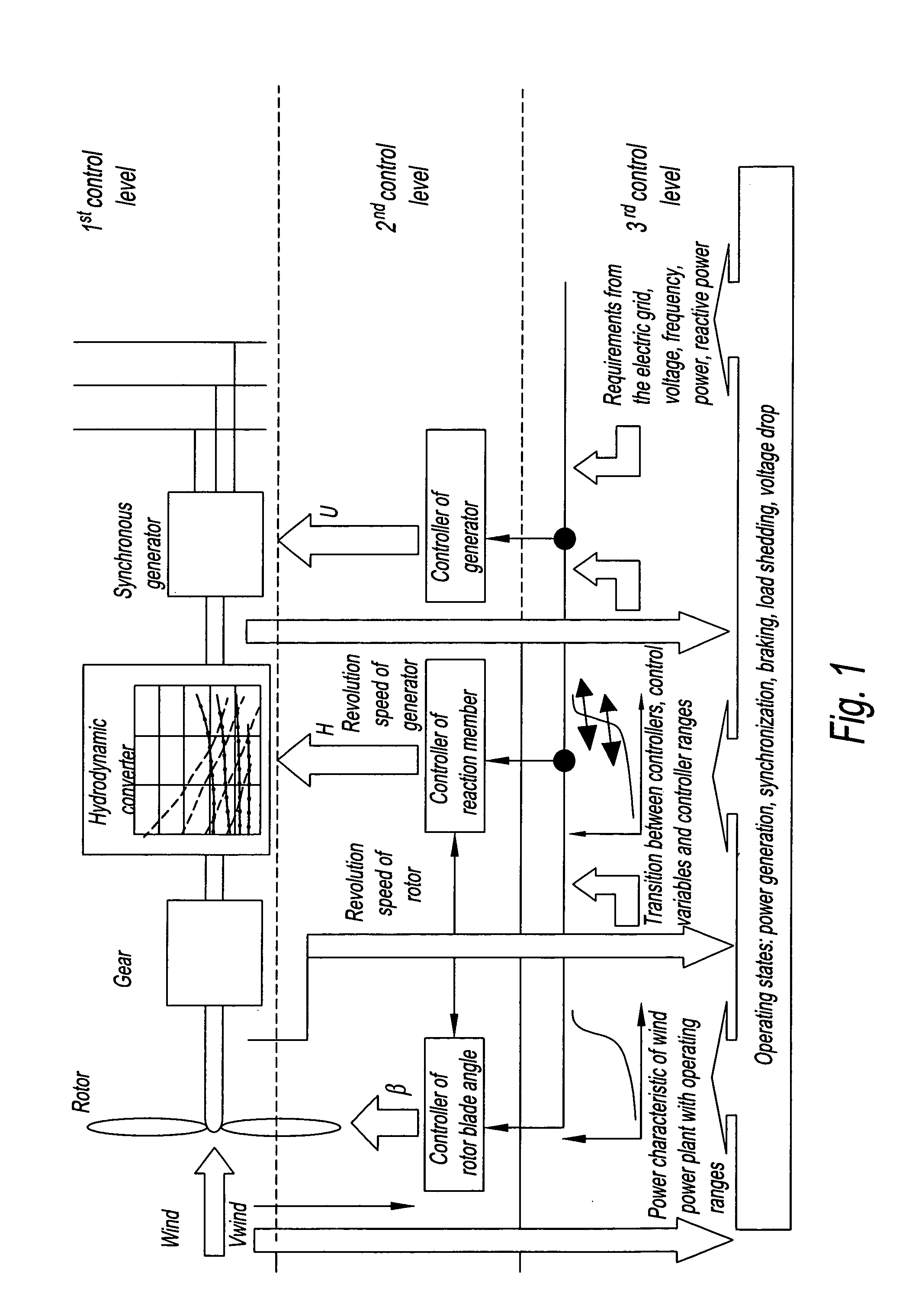

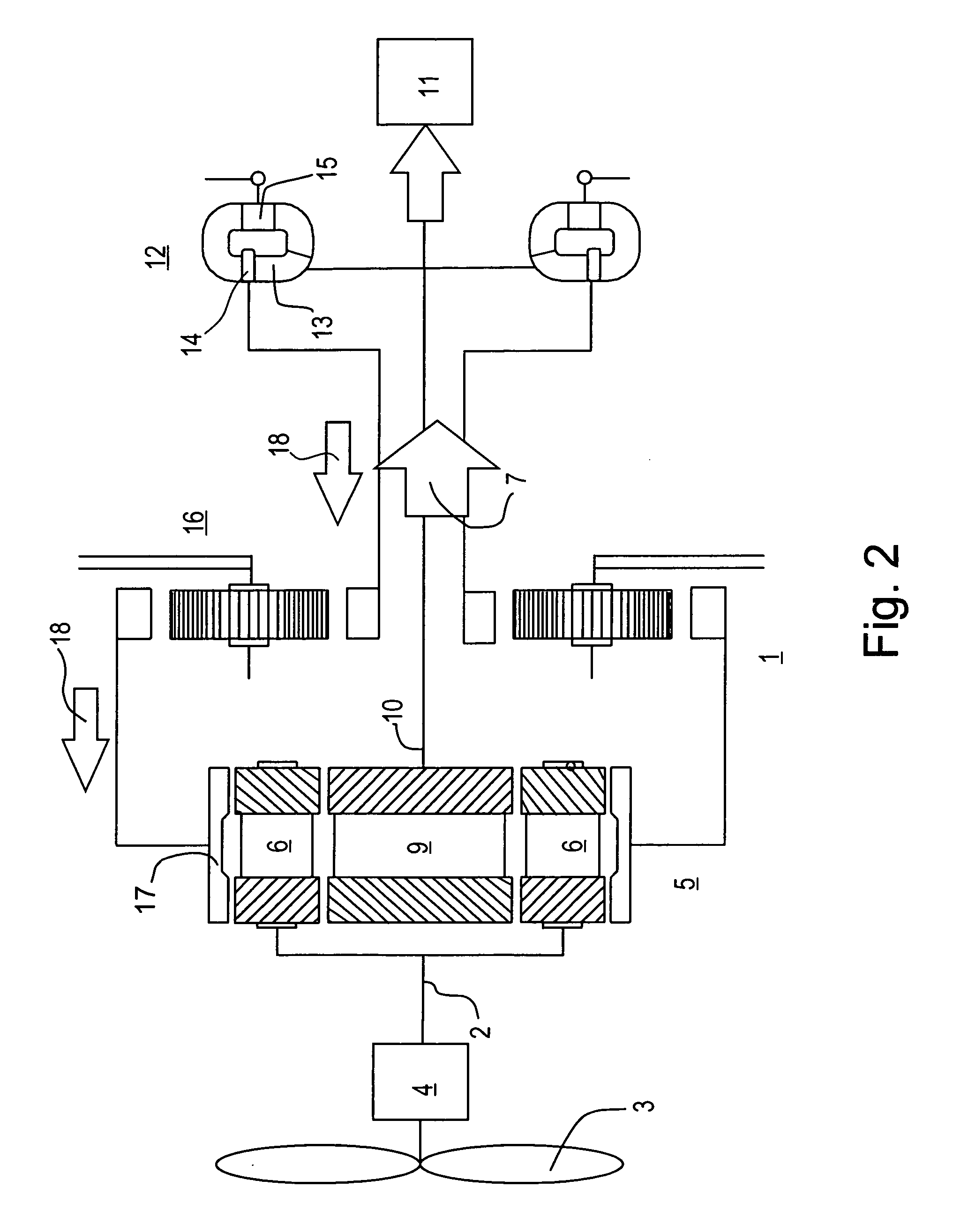

Control system for a wind power plant with hydrodynamic gear

A wind power plant connectable to an electric grid is provided that has at least three control levels. A controller controls an angular position of the rotor blades and / or controls a setting of the reaction member of the hydrodynamic speed transformer and / or controls the power electronics of the generator. The controller is provided with predetermined setpoint characteristics depending on operating states of the wind power plant and / or the electric grid or characteristics of the wind.

Owner:VOITH PATENT GMBH

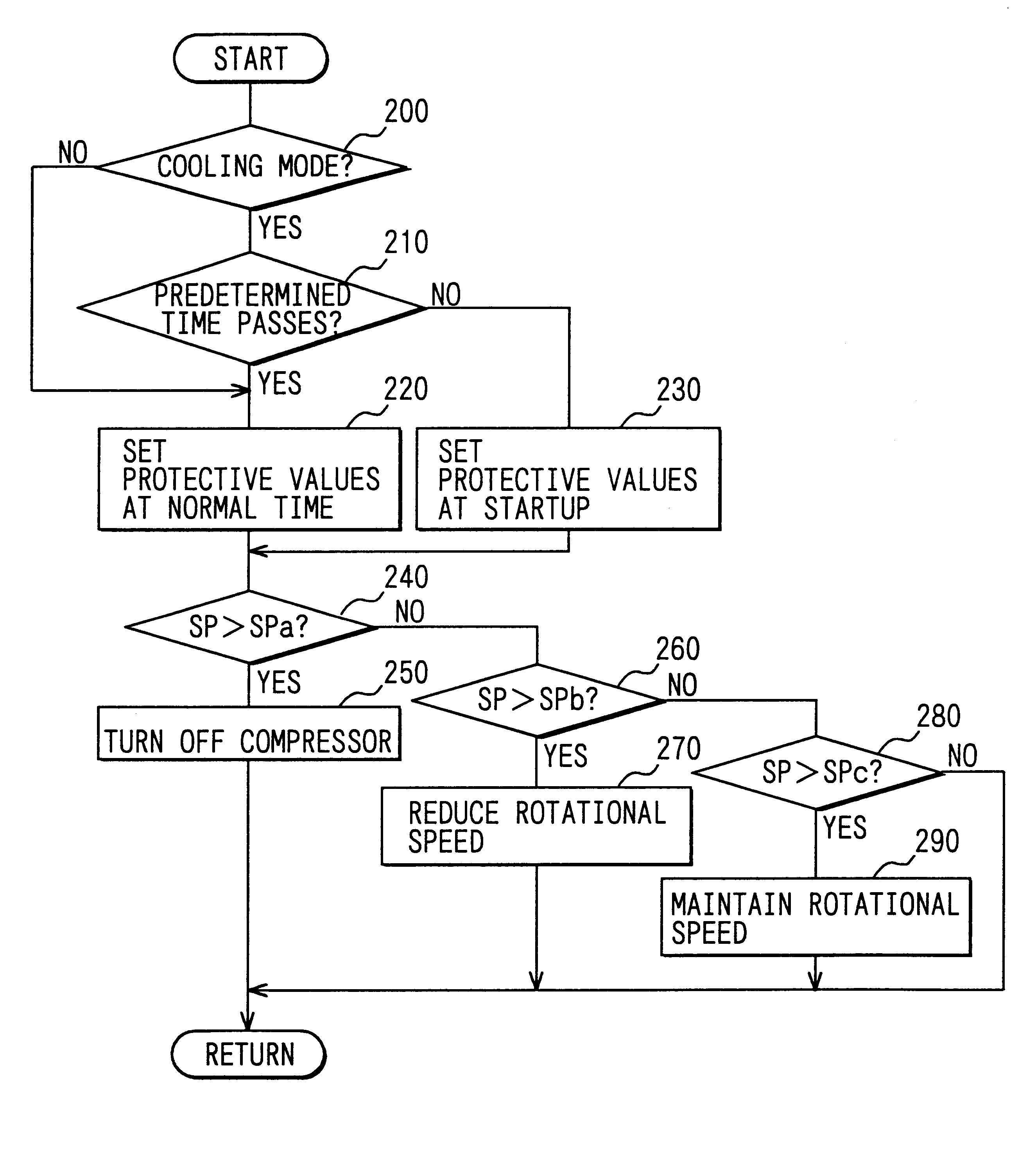

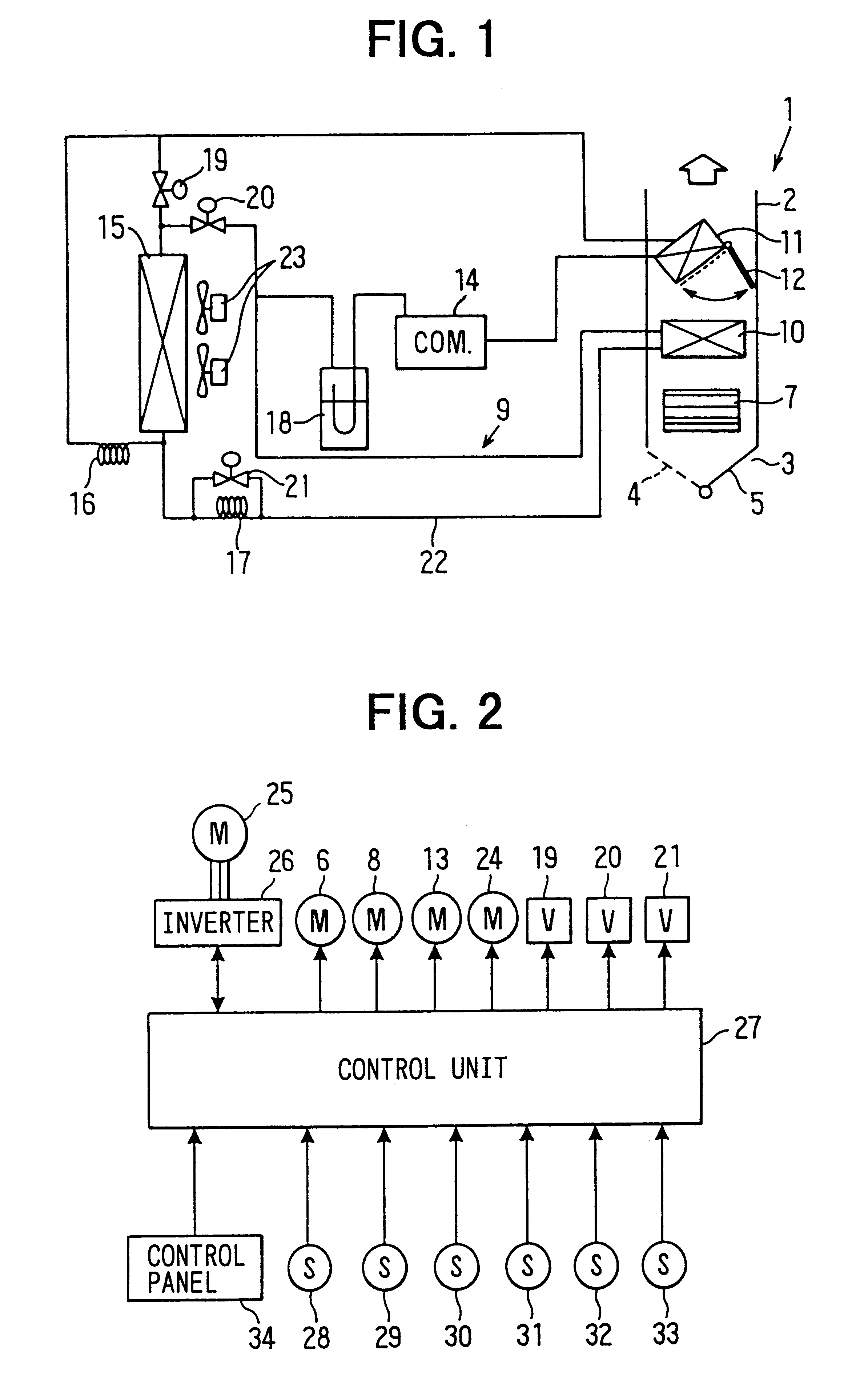

Air conditioning system with compressor protection

InactiveUS6381971B2Air-treating devicesSpace heating and ventilation safety systemsHigh pressureAir conditioning

An air conditioning system includes compressor protective means for protecting a compressor. The compressor protective means includes first and second protective values. The first protective value is set for preventing a failure of a compressor. The second protective value is lower than the first protective value in order to prevent a high pressure in a refrigerant cycle system from reaching the first protective value. The compressor protective means sets the second protective value such that the second protective value used before an elapse of a predetermined time period from startup of the compressor is lower than the second protective value used after the elapse of the predetermined time period.

Owner:DENSO CORP

Method and apparatus for monitoring and controlling pressure in an inflatable device

A method for a user to adjust a pressure in an inflatable device. The method includes acts of adjusting the pressure in the inflatable device with a control device to a pressure preferred by the user, where the pressure preferred by the user has a first value, and establishing a first setting corresponding to the pressure preferred by the user with the control device, and automatically establishing a second setting corresponding to a second pressure having a second value once the first setting is established, where the second value differs from the first value by a predetermined amount.

Owner:CHAFFEE ROBERT B

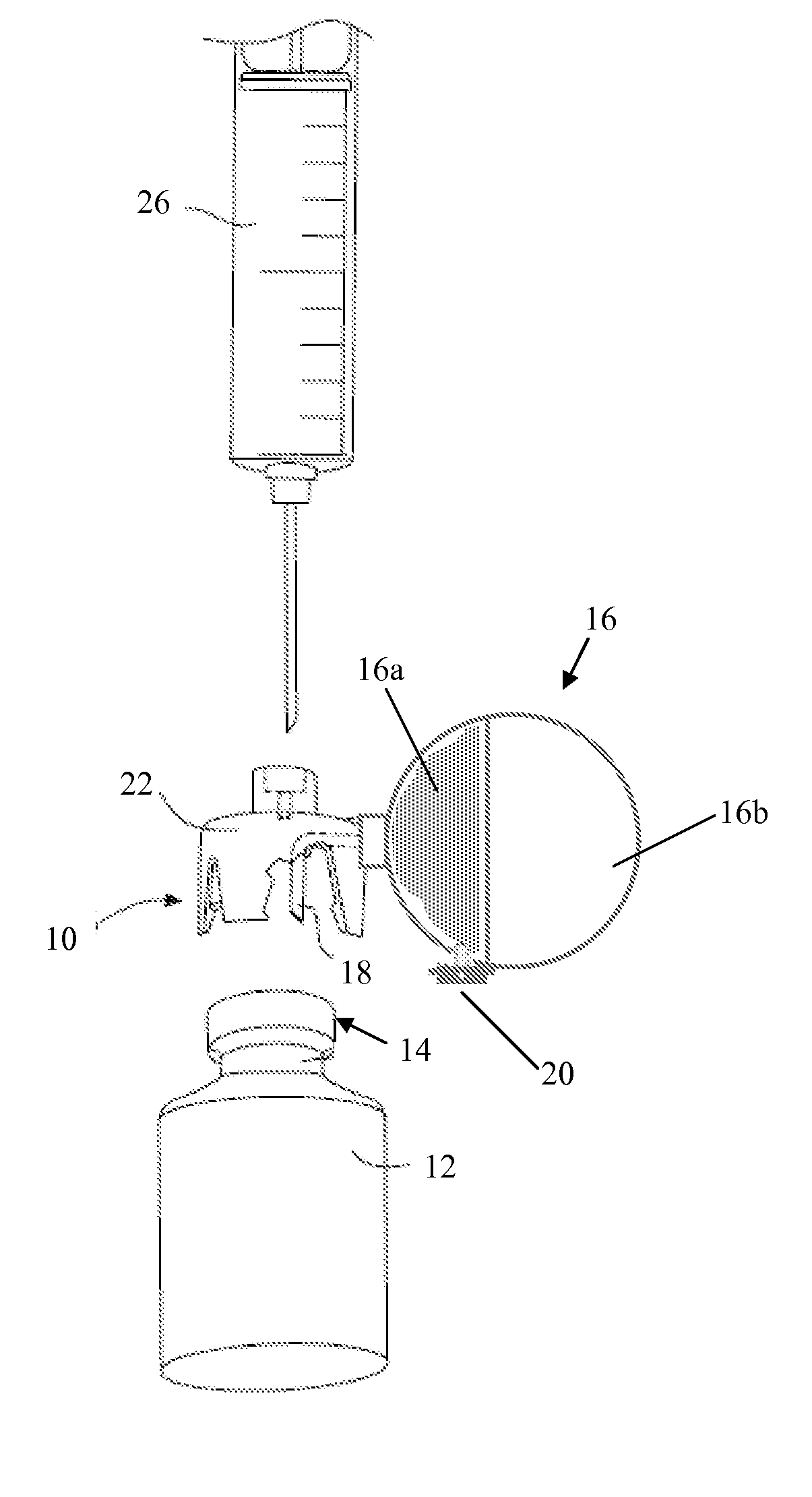

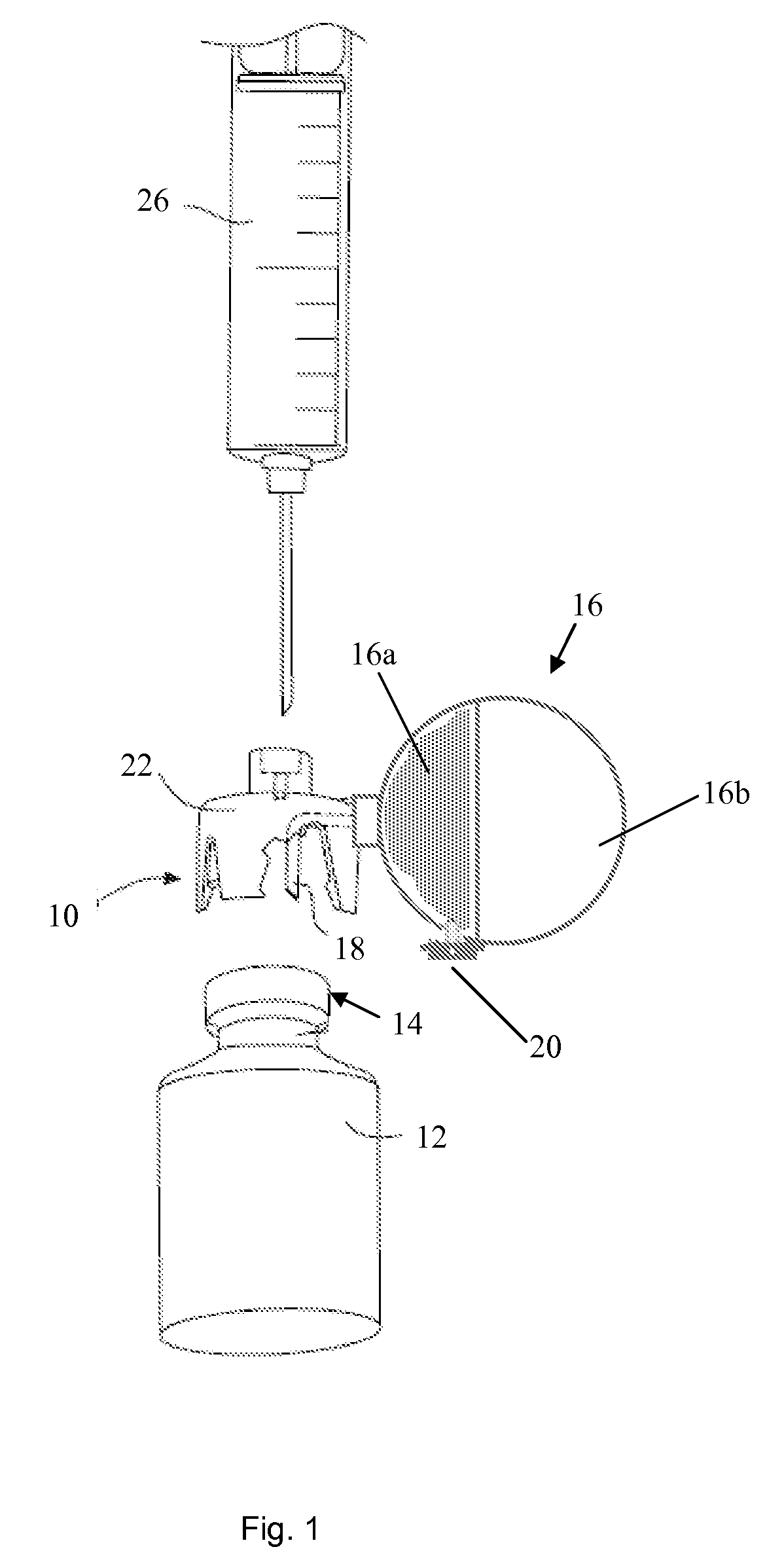

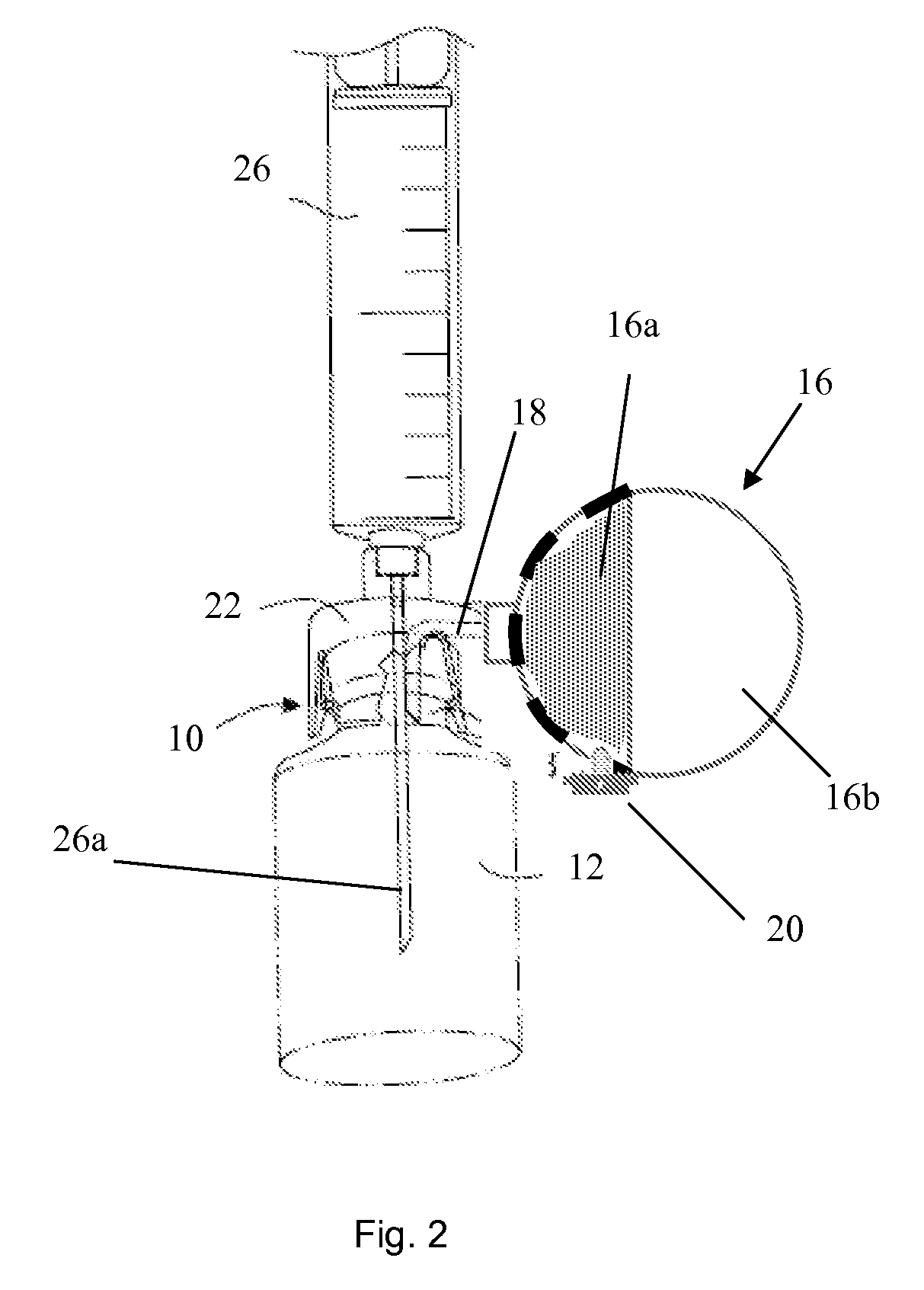

Pressure equalizing device, receptacle and method

ActiveUS8029747B2Eliminate riskSimple wayDiagnosticsPharmaceutical containersEqualizationBiomedical engineering

Pressure equalizing device comprising a fluid container for attachment to a receptacle such as a vial to permit pressure equalization between the fluid container and the receptacle. The pressure equalizing device comprises a flow channel that is arranged to provide fluid communication into or out of the fluid container when the pressure equalizing device is attached to the receptacle. The pressure equalizing device also comprises a fluid inlet that contains a one-way valve that permits fluid to flow into the fluid container via said fluid inlet and that prevents fluid from flowing out of the fluid container via said fluid inlet and filter-receiving means that are arranged to permit fluid flowing into or out of the fluid container to be filtered when the filter-receiving means comprises a filter.

Owner:CARMEL PHARMA

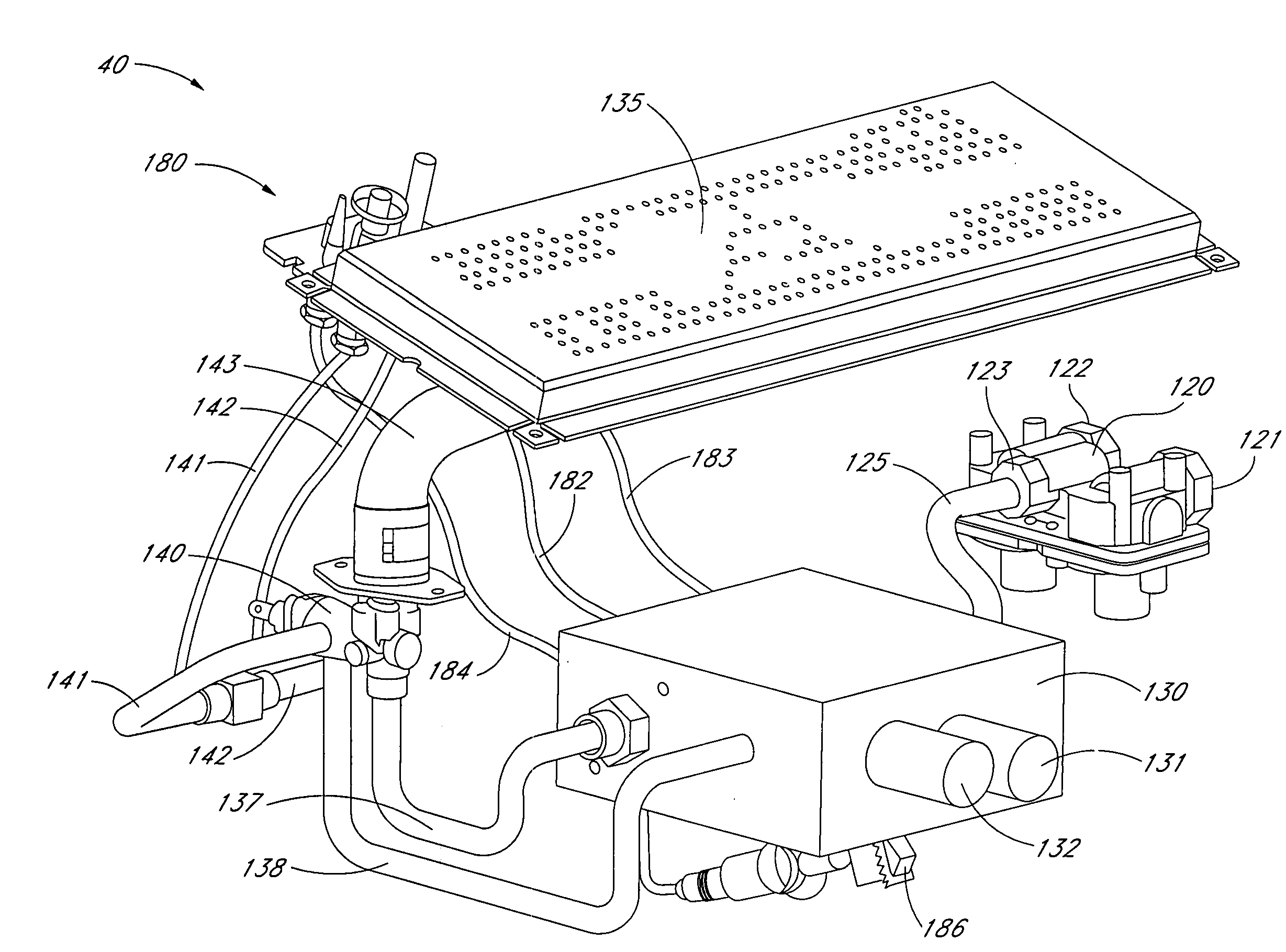

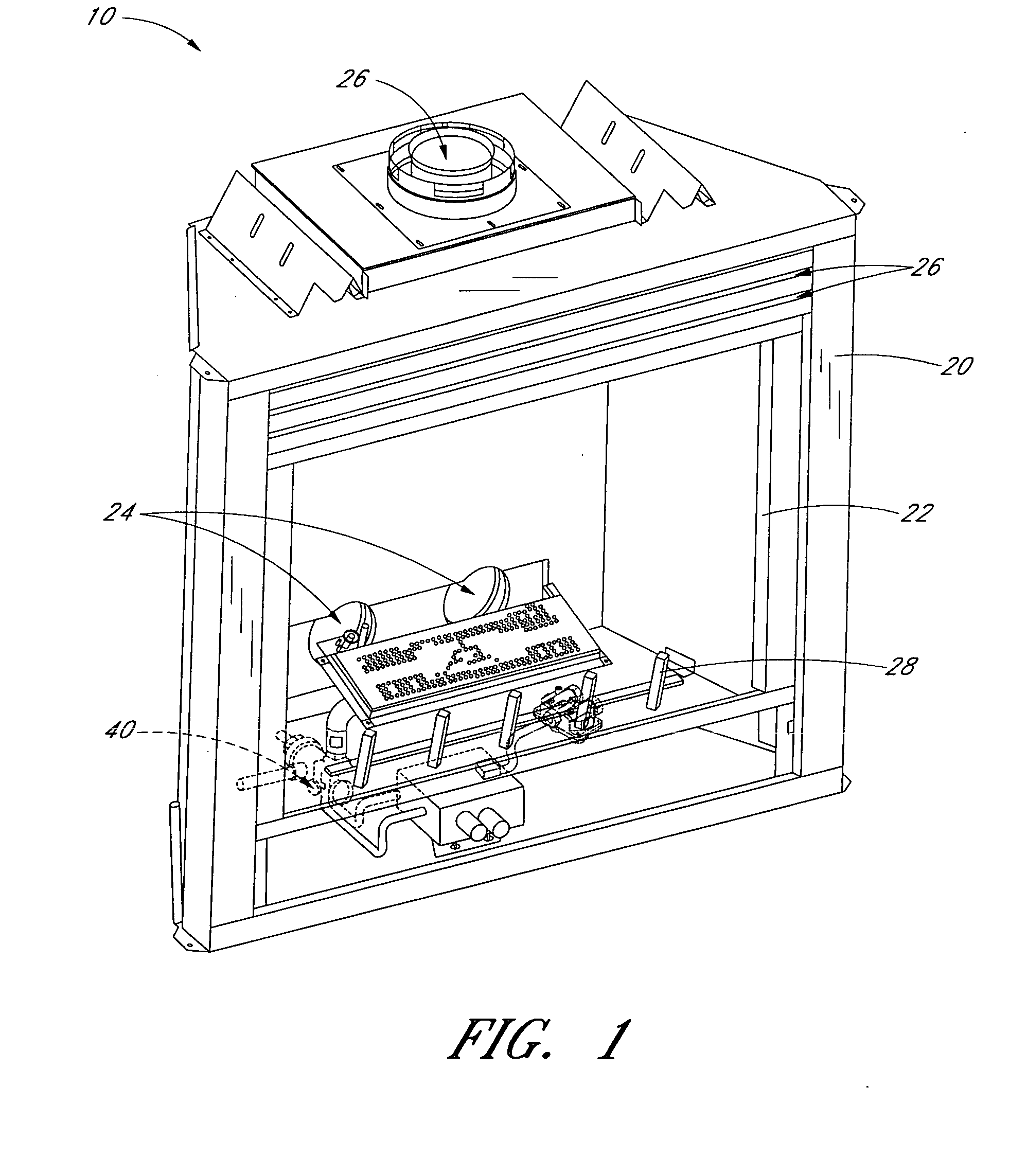

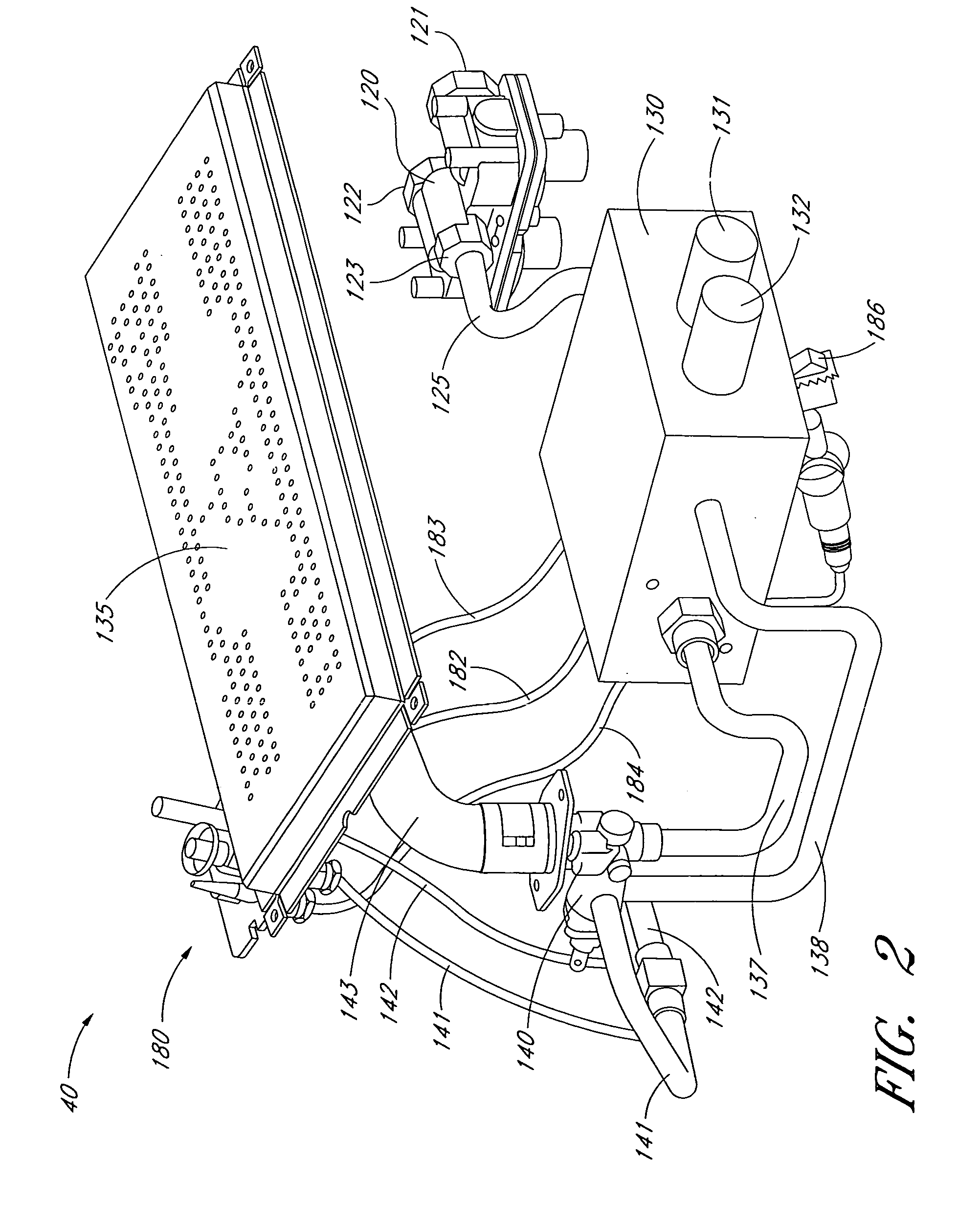

Valve assemblies for heating devices

In certain embodiments, a valve assembly includes a housing. The housing can define a first fuel intake, a first fuel output, and a second fuel output. The assembly can include a valve member configured to direct fuel from the first fuel intake to either the first fuel output or the second fuel output. The assembly can further include a nozzle having a first portion and a second portion. The first portion of the nozzle can be in communication with the first fuel output, and the second portion of the nozzle can be in communication with the second fuel output. The assembly can include a compartment in communication with the nozzle, and can include one or more air intakes.

Owner:PROCOM HEATING

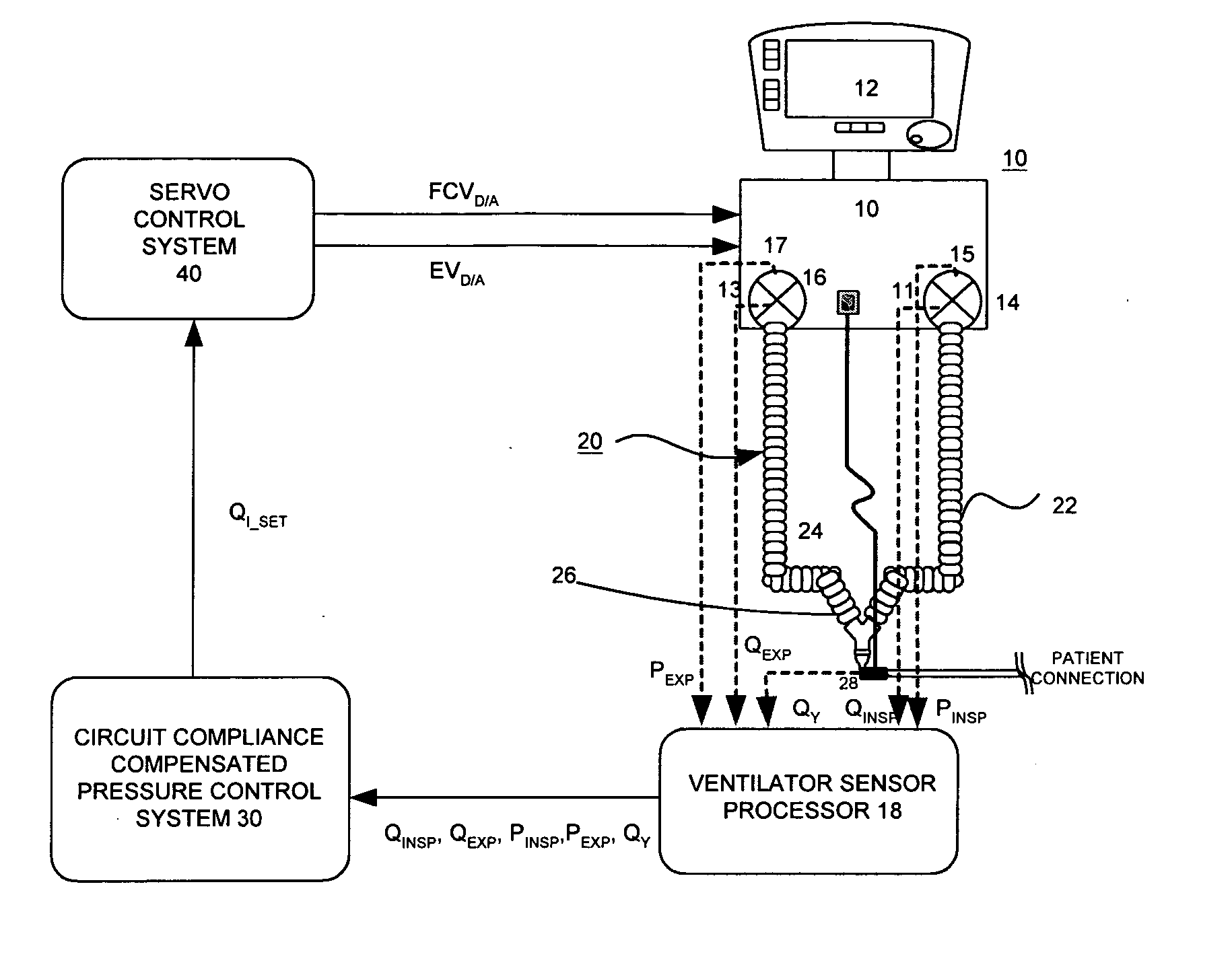

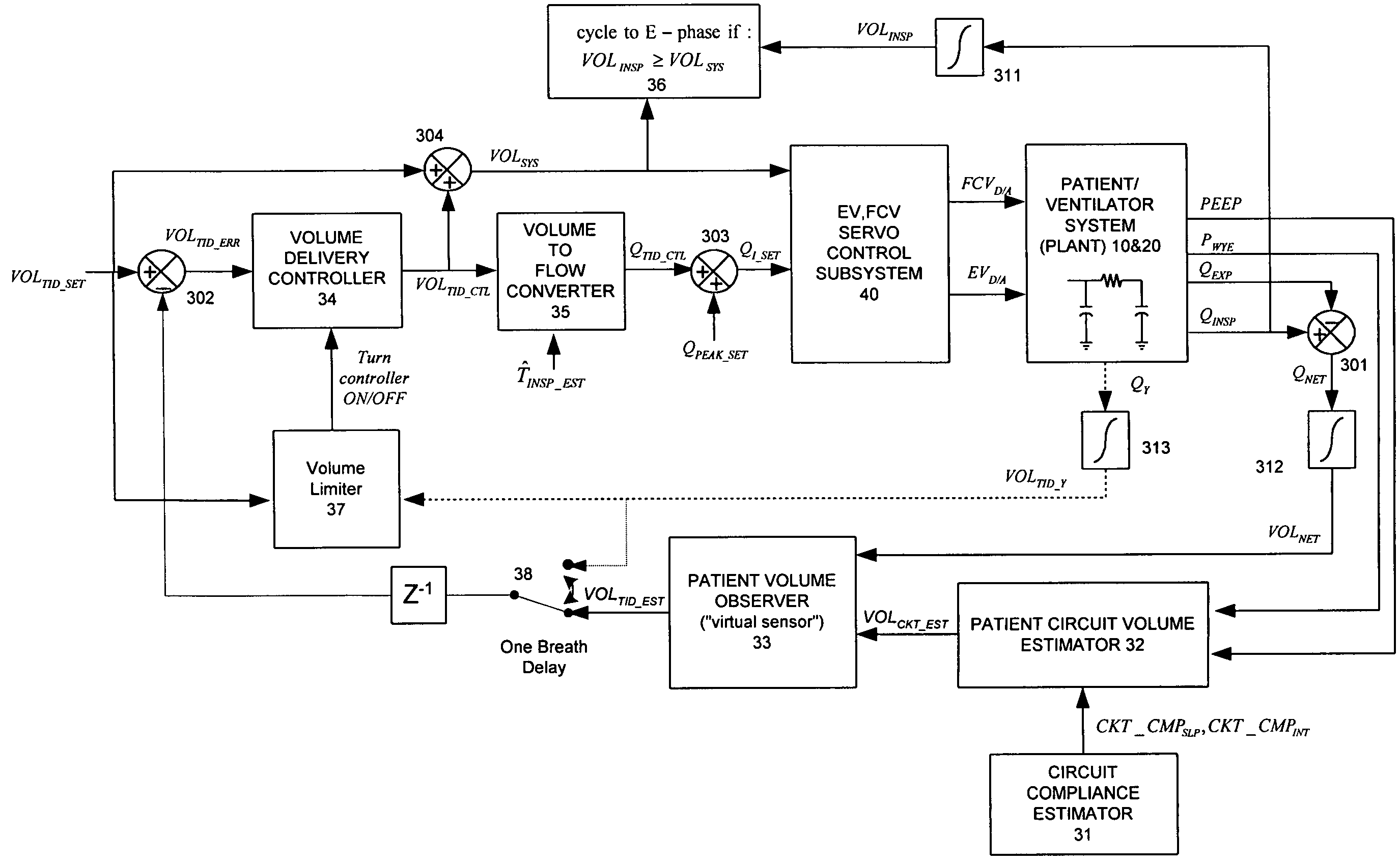

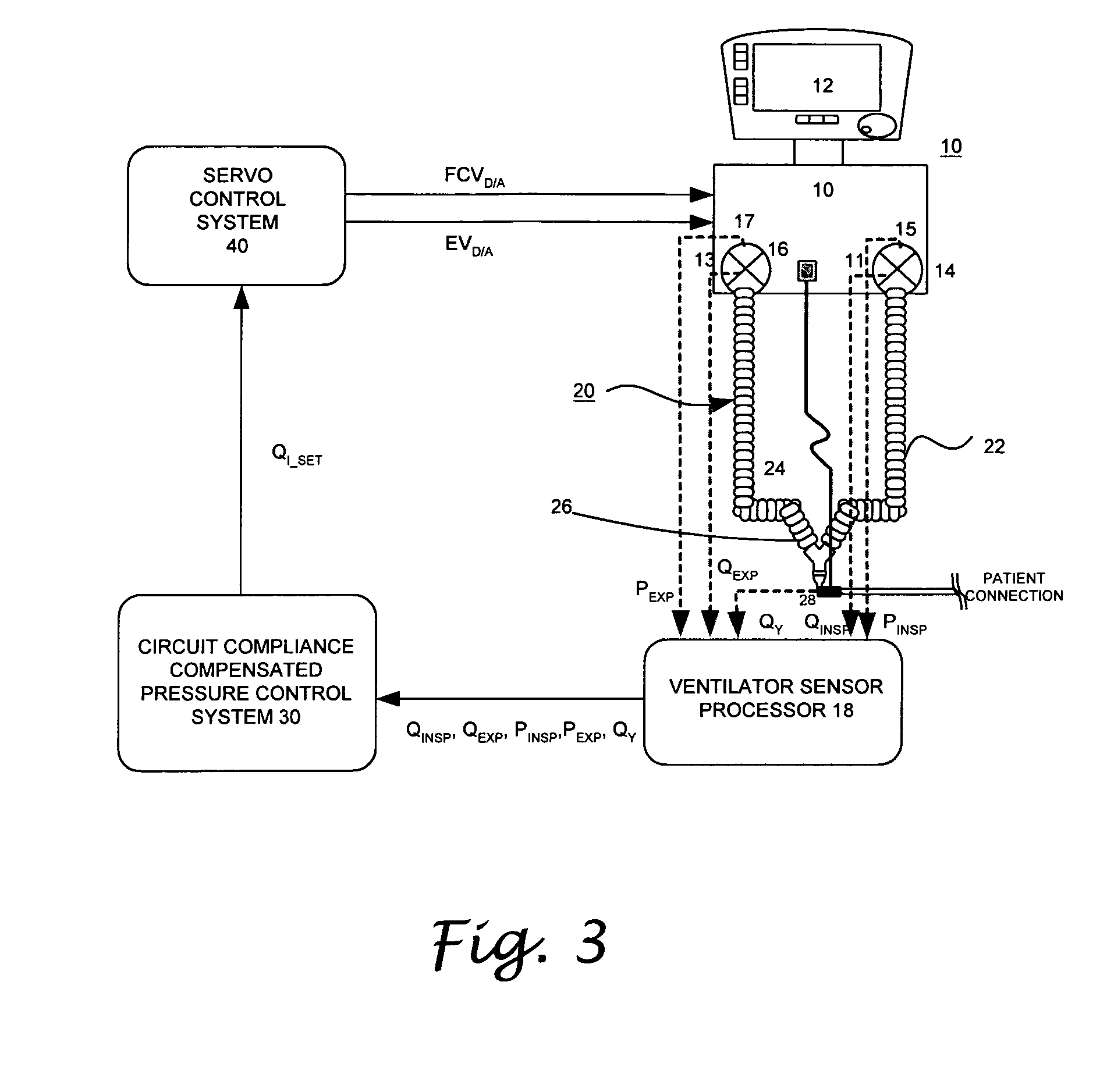

System and method for circuit compliance compensated volume control in a patient respiratory ventilator

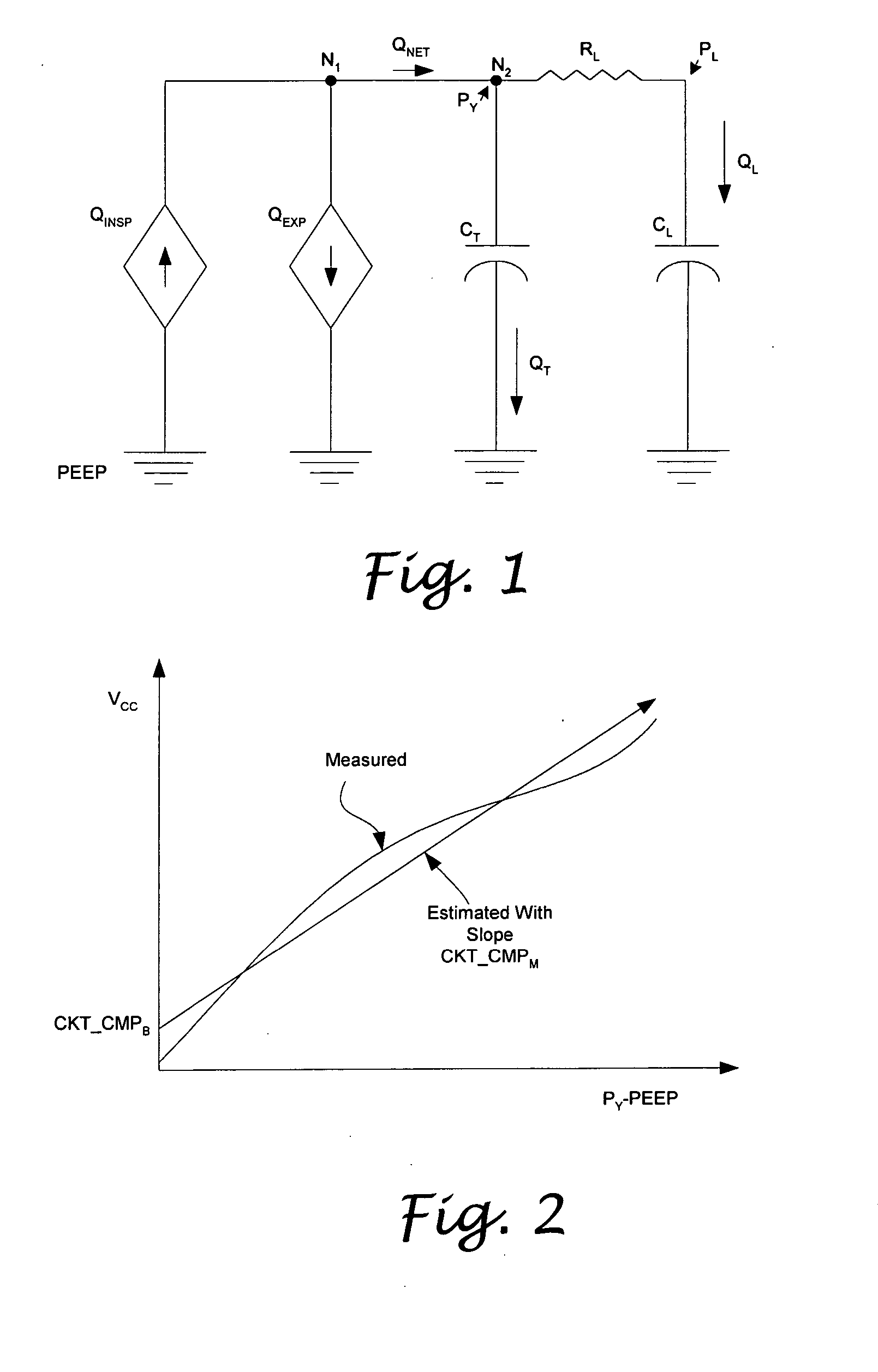

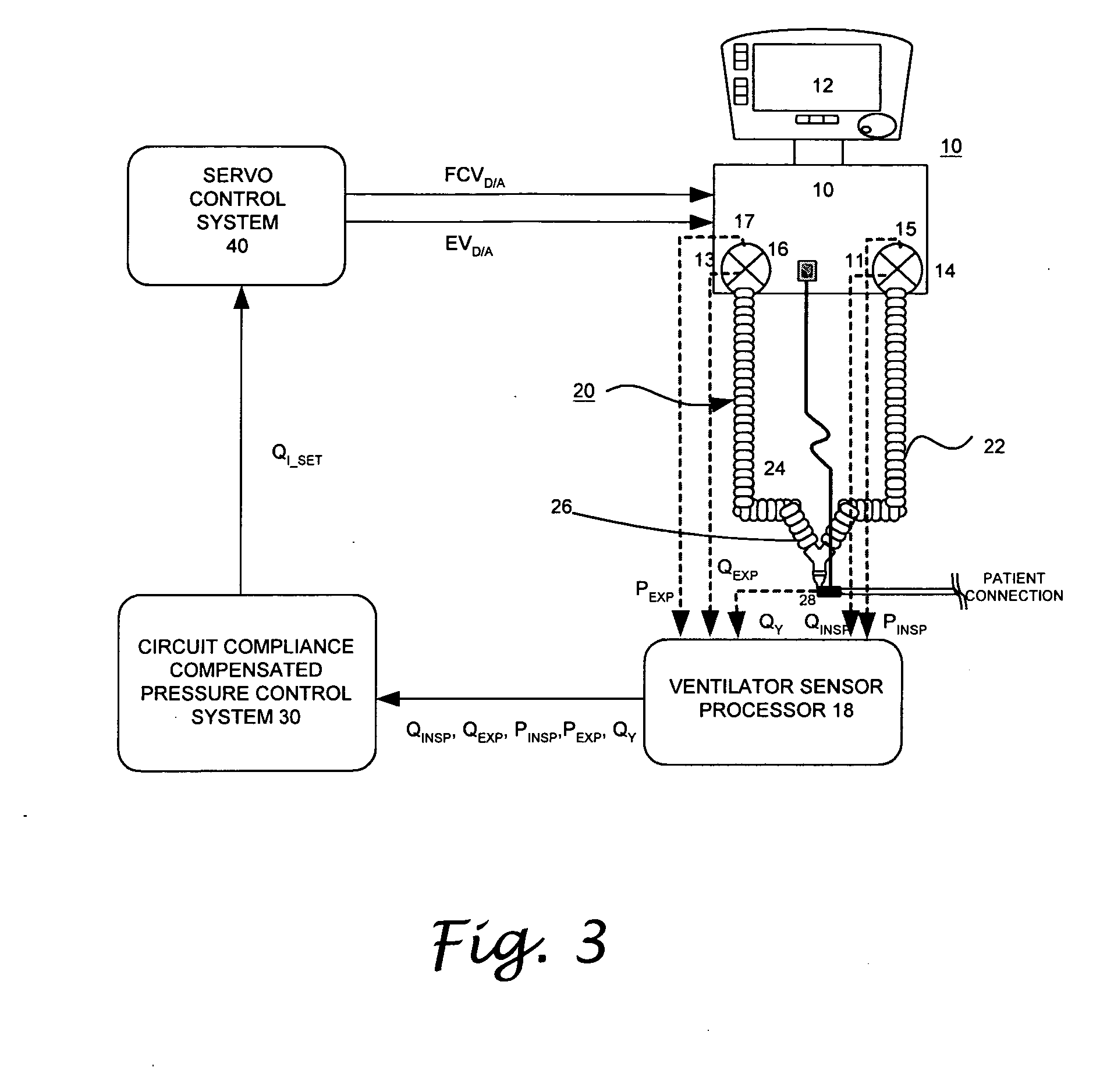

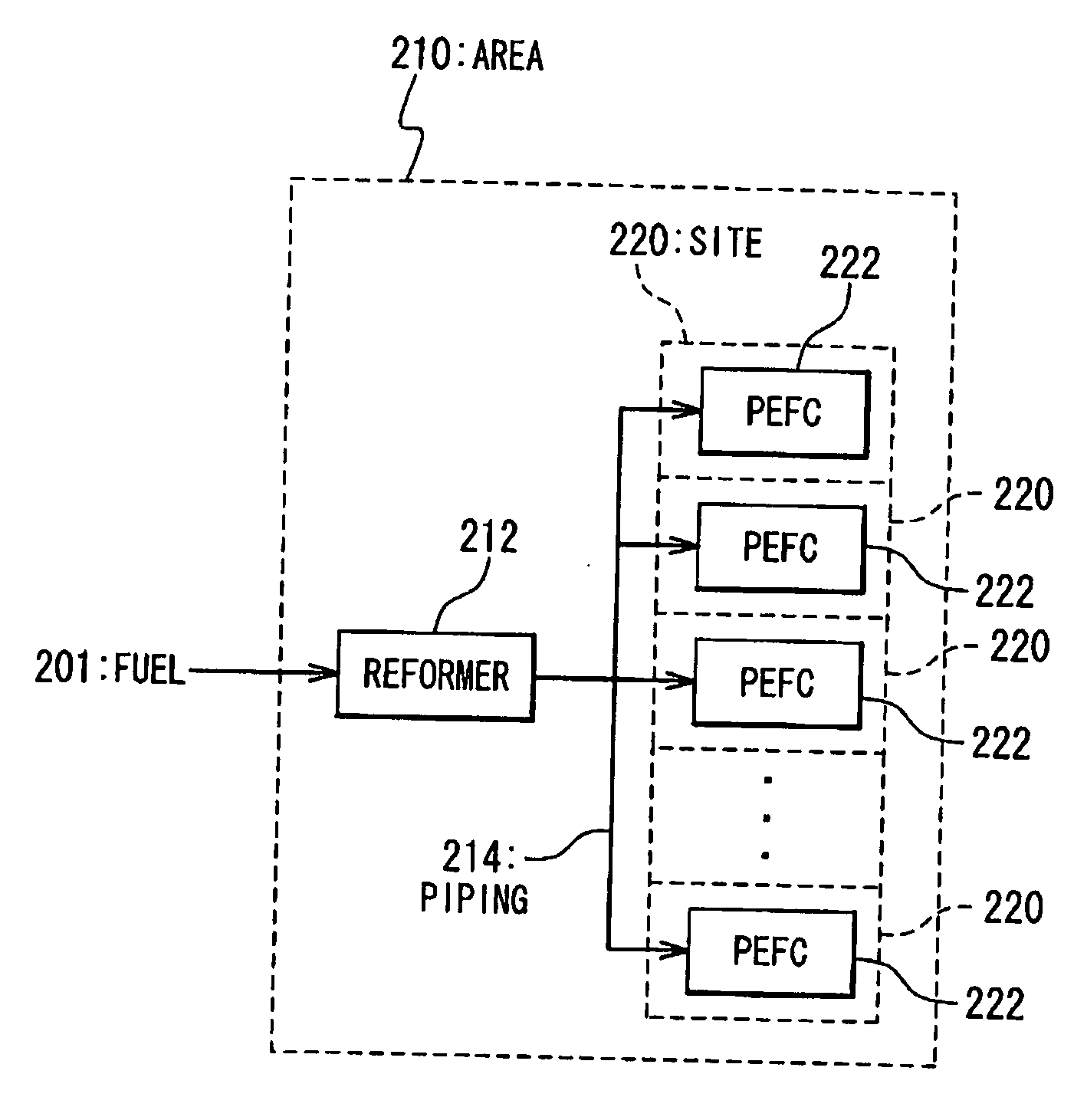

ActiveUS20070089738A1Accurate flowGas trapping and auto PEEP is preventedLevel controlInflated body pressure measurementMedicinePeak inspiratory flow

A system and a method for circuit compliance compensated volume control in a patient respiratory ventilation system having a flow regulated feedback servo control loop, a volume delivery controller, and a patient volume observer. In the flow regulated feedback servo control loop, an estimate of patient volume is used for feedback control, such that a tidal volume is achieved upon servo regulation, and the peak inspiratory flow is modulated based on volume error between the set tidal volume and the estimated patient volume. Thereby, a constant inspiratory time and a constant I:E ratio can be maintained. In the volume delivery control, the feedback volume error is normalized to a volume error percentage, and the gain of the controller is dynamically changed based on the volume error percentage, such that the controller effort can be minimized when the volume target is approached. The patient volume observer is operative to estimate the patient delivered volume based on the estimated circuit volume and the measured net delivered volume, while the measured net delivered volume includes effects of leaks and valve dynamics and is synchronously captured with true patient breathing.

Owner:VYAIRE MEDICAL 211 INC

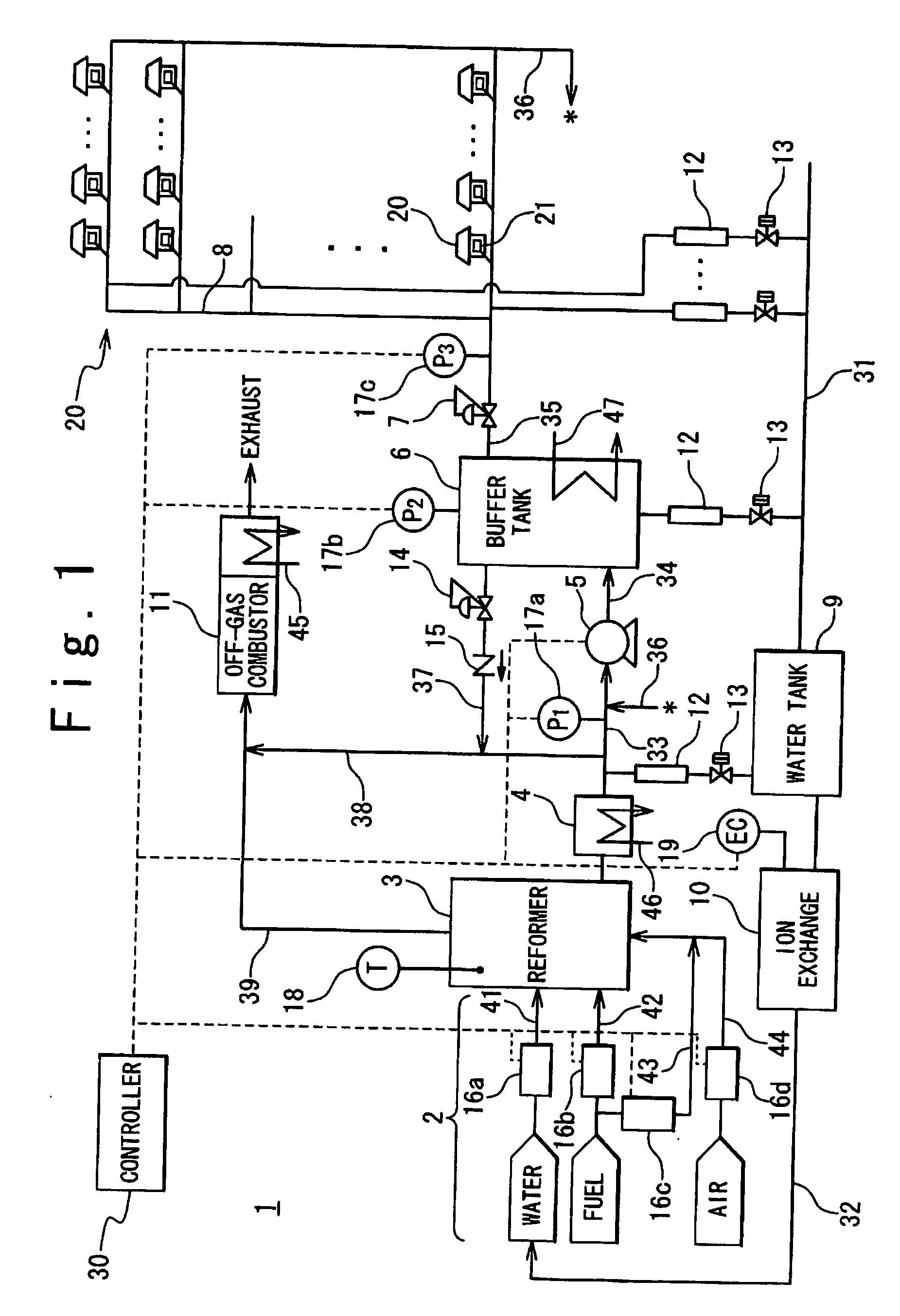

Gas supplying system and gas supplying method

A gas supplying system for fuel cell includes a reformer generating a reformed gas by reforming a mixed raw material including a fuel and a first water, a piping network distributing the reformed gas to fuel cell systems each of which is installed in different rooms or buildings, a drain recovery unit recovering a water condensed from the reformed gas in the piping network. The piping network has a circulating route. By the circulation route, the reformed gas does not stay in the piping network so that the water condensation in the piping is suppressed. The water in the piping is removed by the drain recovery unit. According to this configuration, the clogging and corrosion of the piping caused by the condensed water is avoided.

Owner:MITSUBISHI HEAVY IND LTD

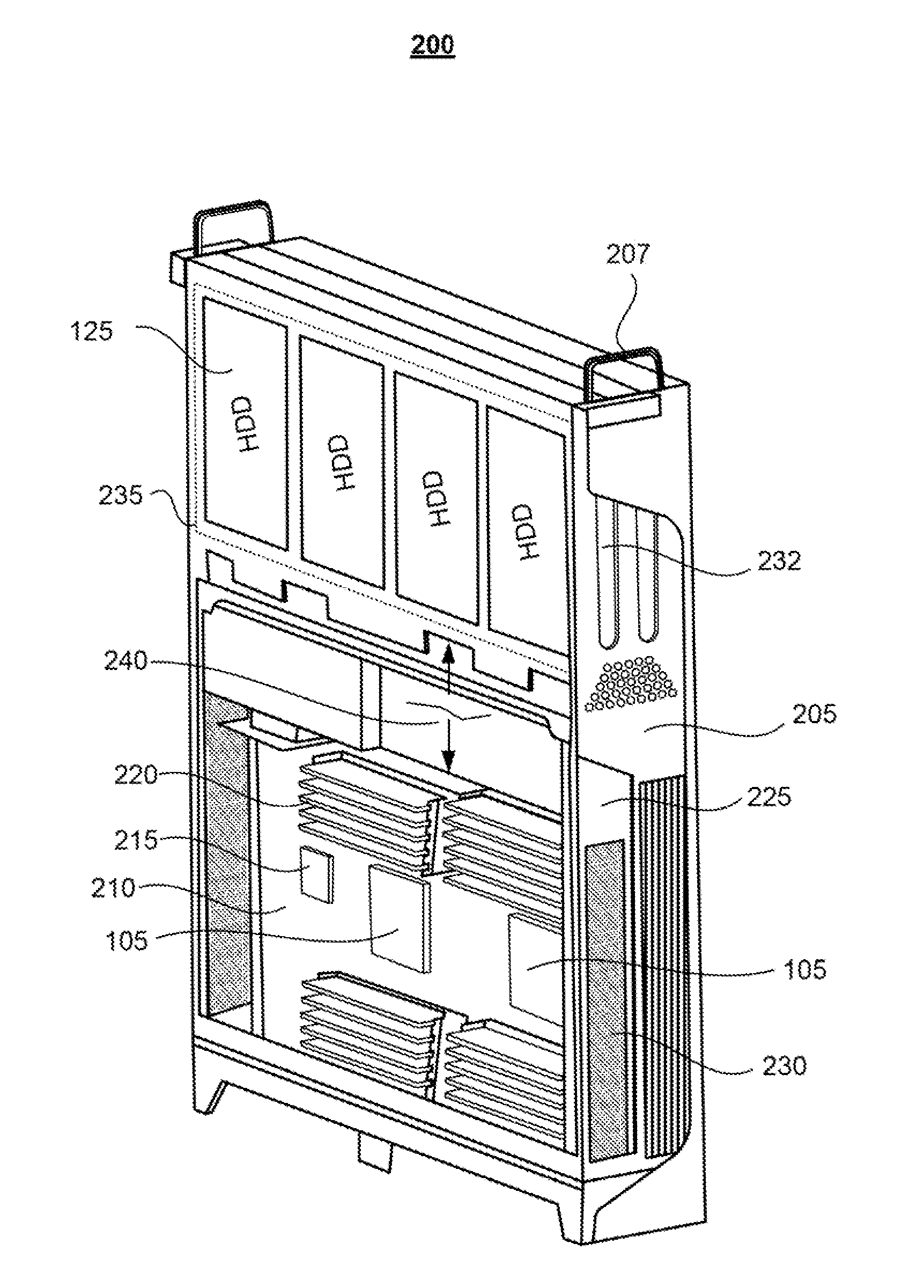

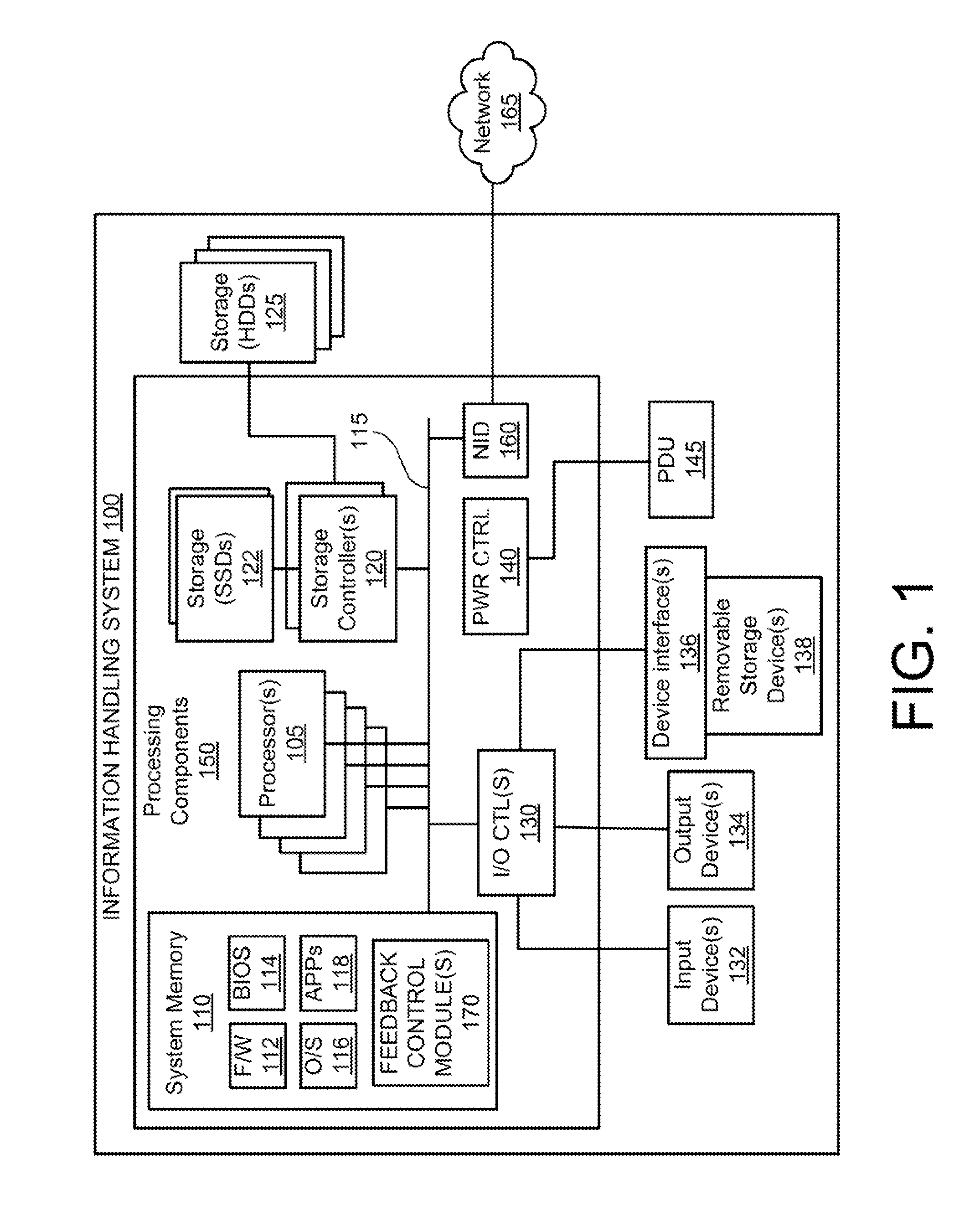

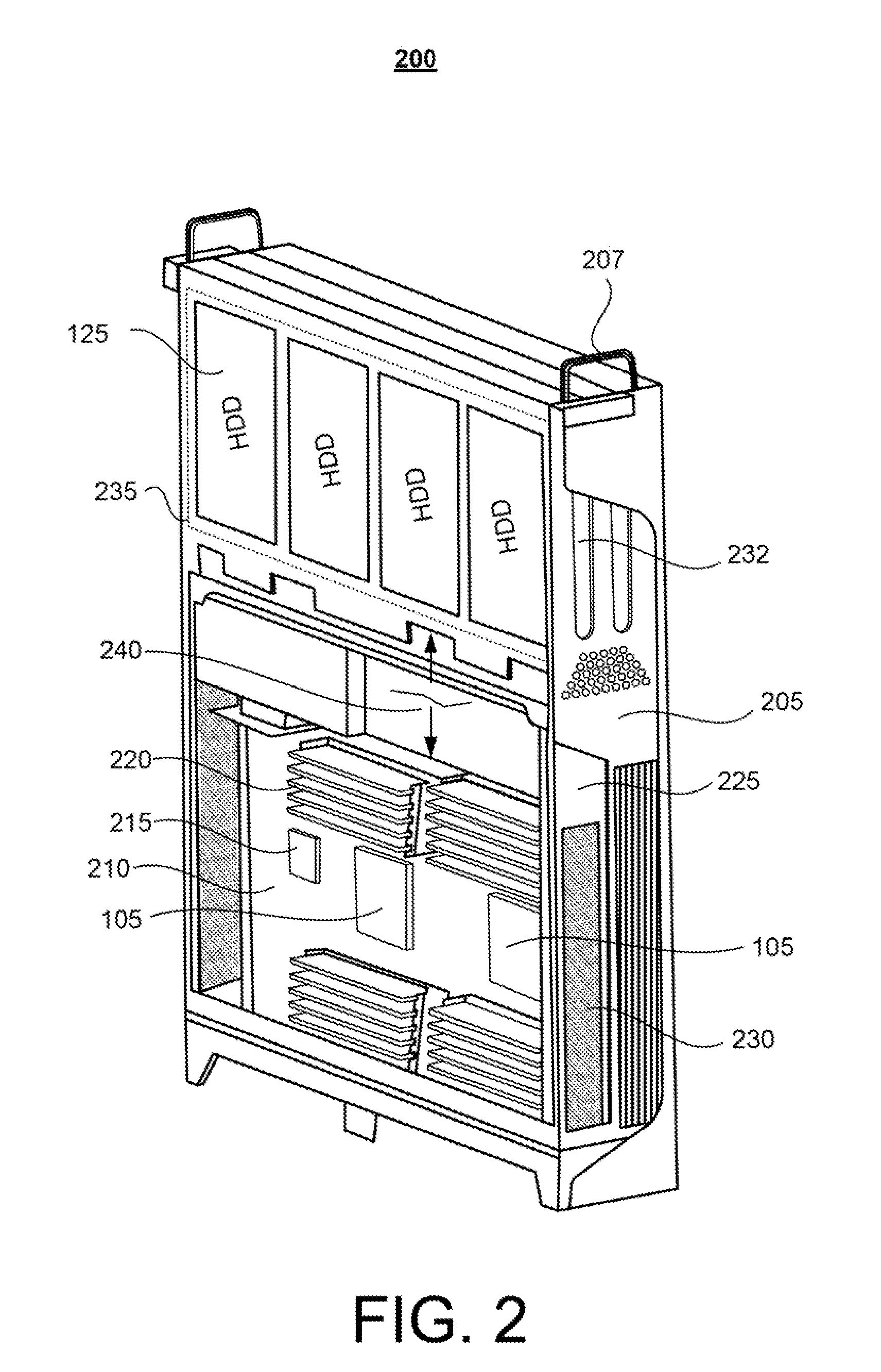

Techniques for Controlling Vapor Pressure in an Immersion Cooling Tank

ActiveUS20150060009A1Eliminate increase in pressureMaximize the effectAir-treating devicesTemperatue controlDifferential pressureTransducer

A method that controls pressure within an immersion cooling tank having condensation fluid flowing through a condenser, includes: a controller receiving a signal that indicates a current level of vapor pressure within the tank; determining from the signal when the current level of vapor pressure exceeds or is below a first preset threshold pressure level; and in response to the current level of vapor pressure exceeding or being below the first preset threshold pressure level, signaling a flow control mechanism that modulates a flow rate of the condensation fluid through the condenser to increase or decrease the rate of flow from a current rate of flow. The controller receives the signal by a pressure sensor within the immersion cooling tank detecting the current vapor pressure, generating the signal and forwarding the signal to the controller. The pressure sensor can be a differential pressure transducer that measures a differential pressure internal to and outside of the immersion tank.

Owner:DELL PROD LP

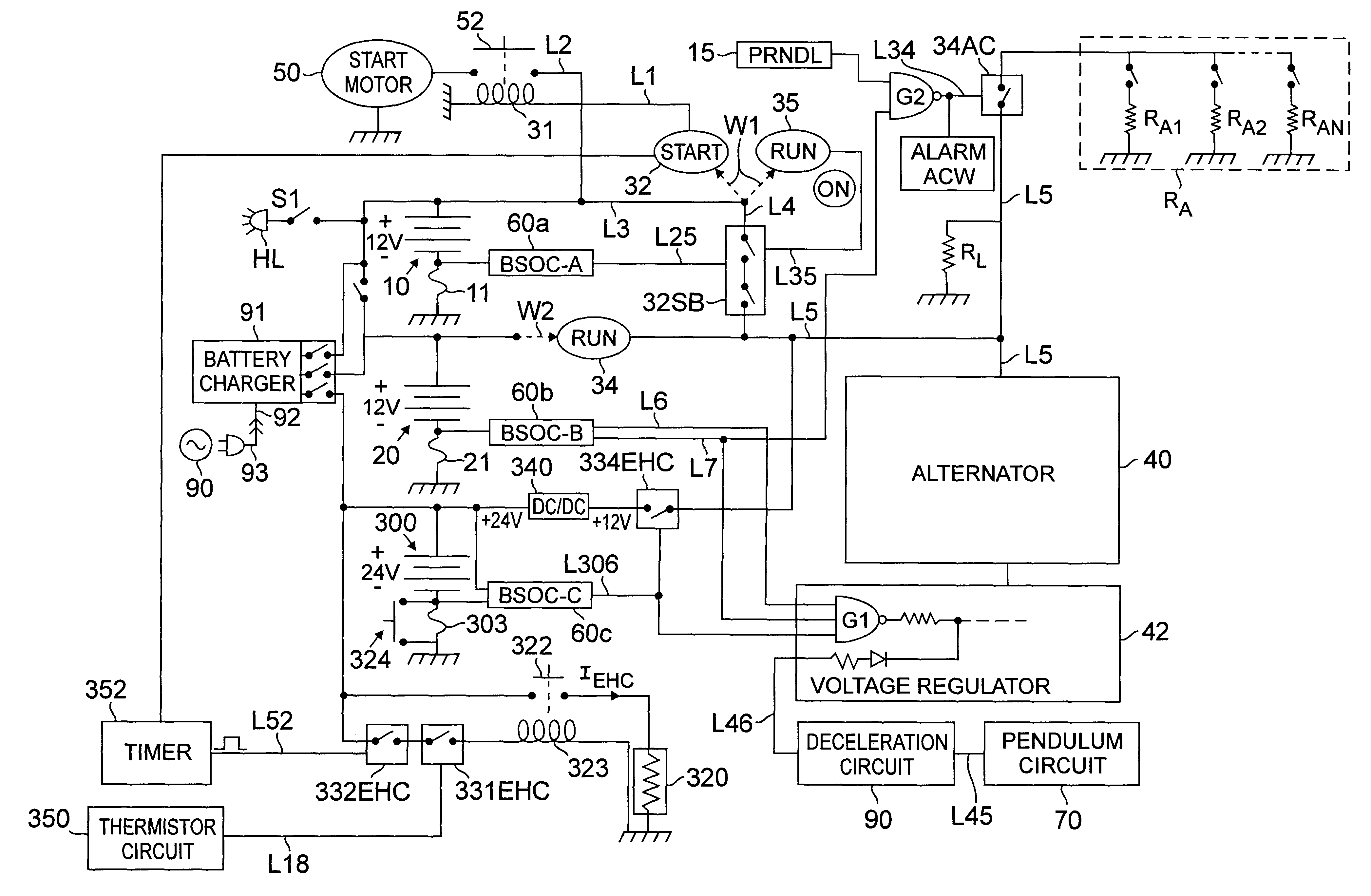

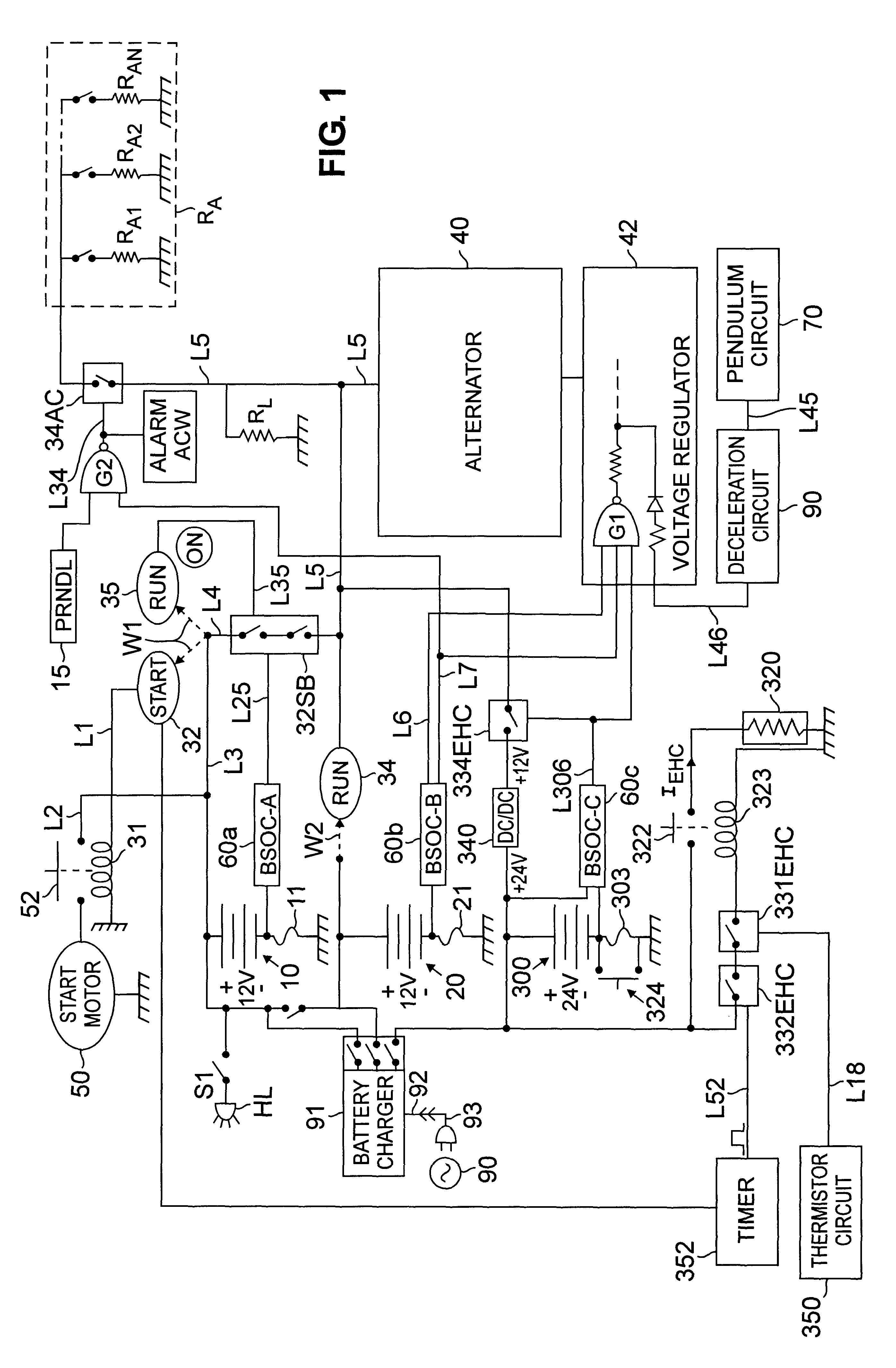

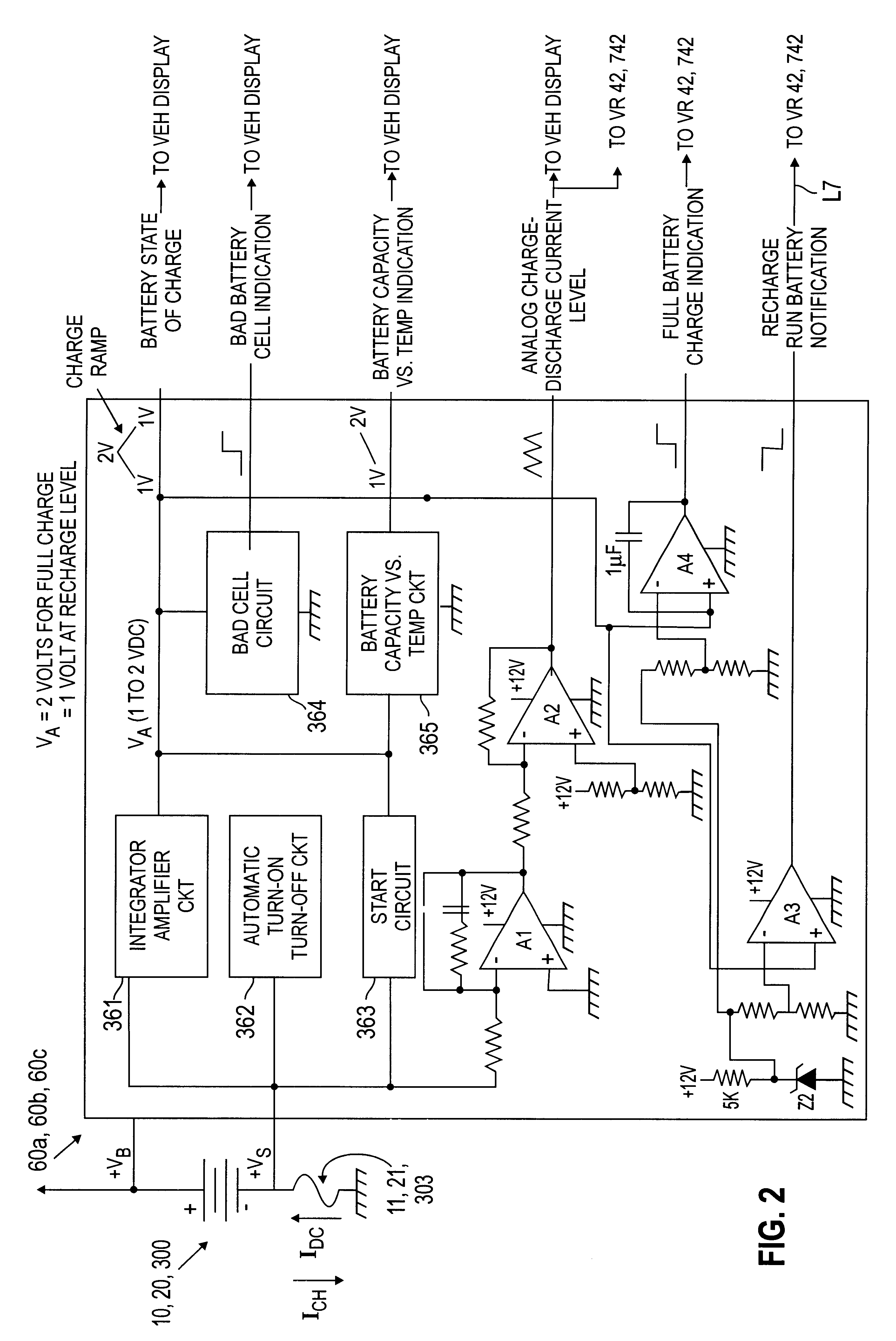

Multi-battery fuel saving and emission reduction system for automotive vehicles

InactiveUS6466024B1Easy to controlImprove the immunityCircuit monitoring/indicationExhaust apparatusAlternatorBattery charge

A multi-battery charging system for reduced fuel consumption and emissions for an automotive vehicle. The system starts the vehicle with a start battery in a fuel savings manner, removing electrical torque from the alternator shaft, and allows a second (run) battery to provide all or some of the current required by the vehicle loads as a fuel savings measure. The system also utilizes an electrically heated catalytic converter (EHC) and a third (EHC or storage) battery to provide a 3 to 15 second preheat and / or a 20 second current, during vehicle start, to the EHC heater coil, e.g., of a small EHC located in series with a standard catalytic converter for emissions reduction to reduce emissions during start. The start battery is recharged after start and switched out of the system fully charged for future vehicle starts. The run battery is recharged when its charge level drops below a predetermined level with an on board battery charging device powered from a 115 volt or 220 volt ac power line source external to the vehicle.

Owner:BRADLEY CHARLES W

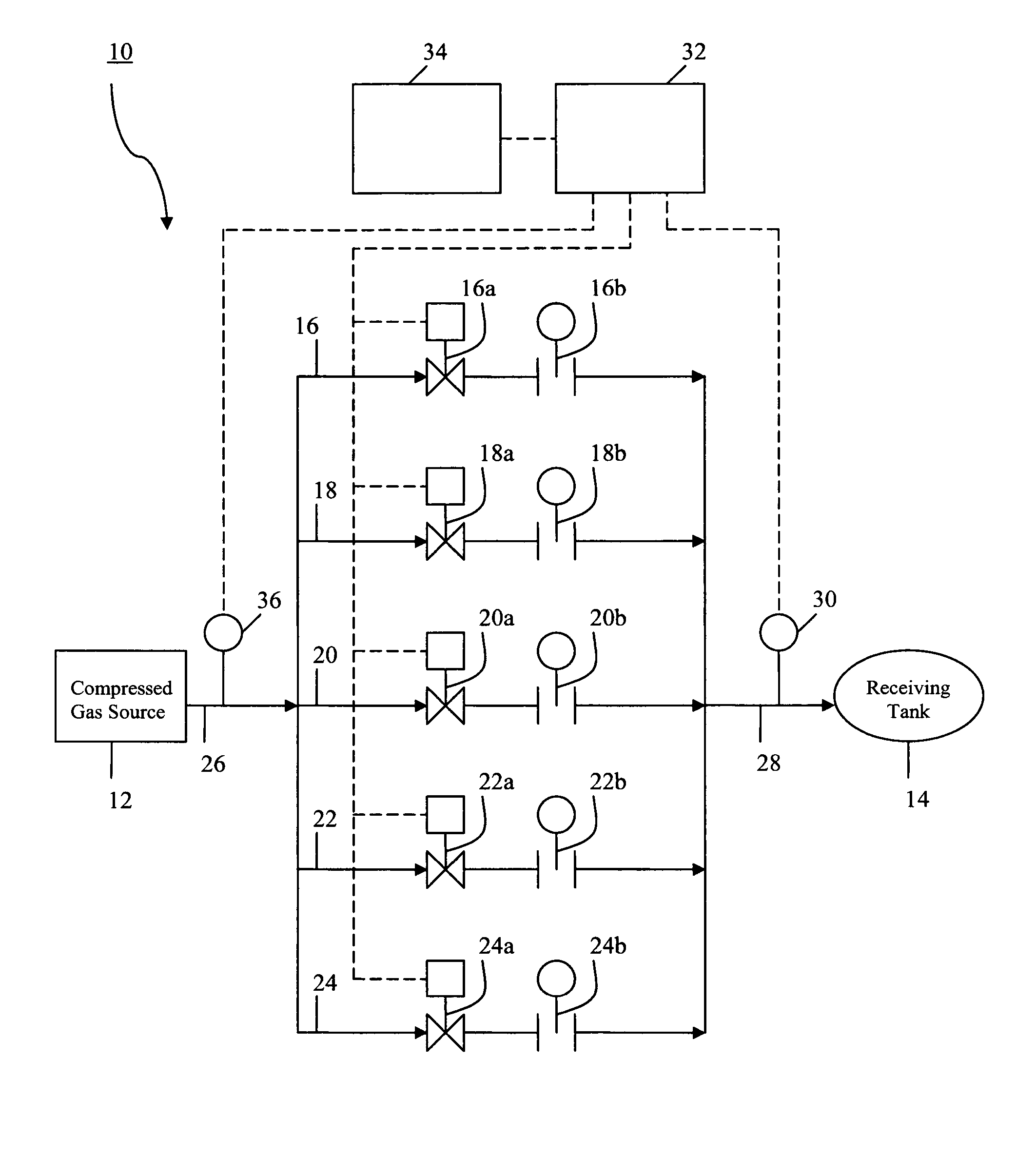

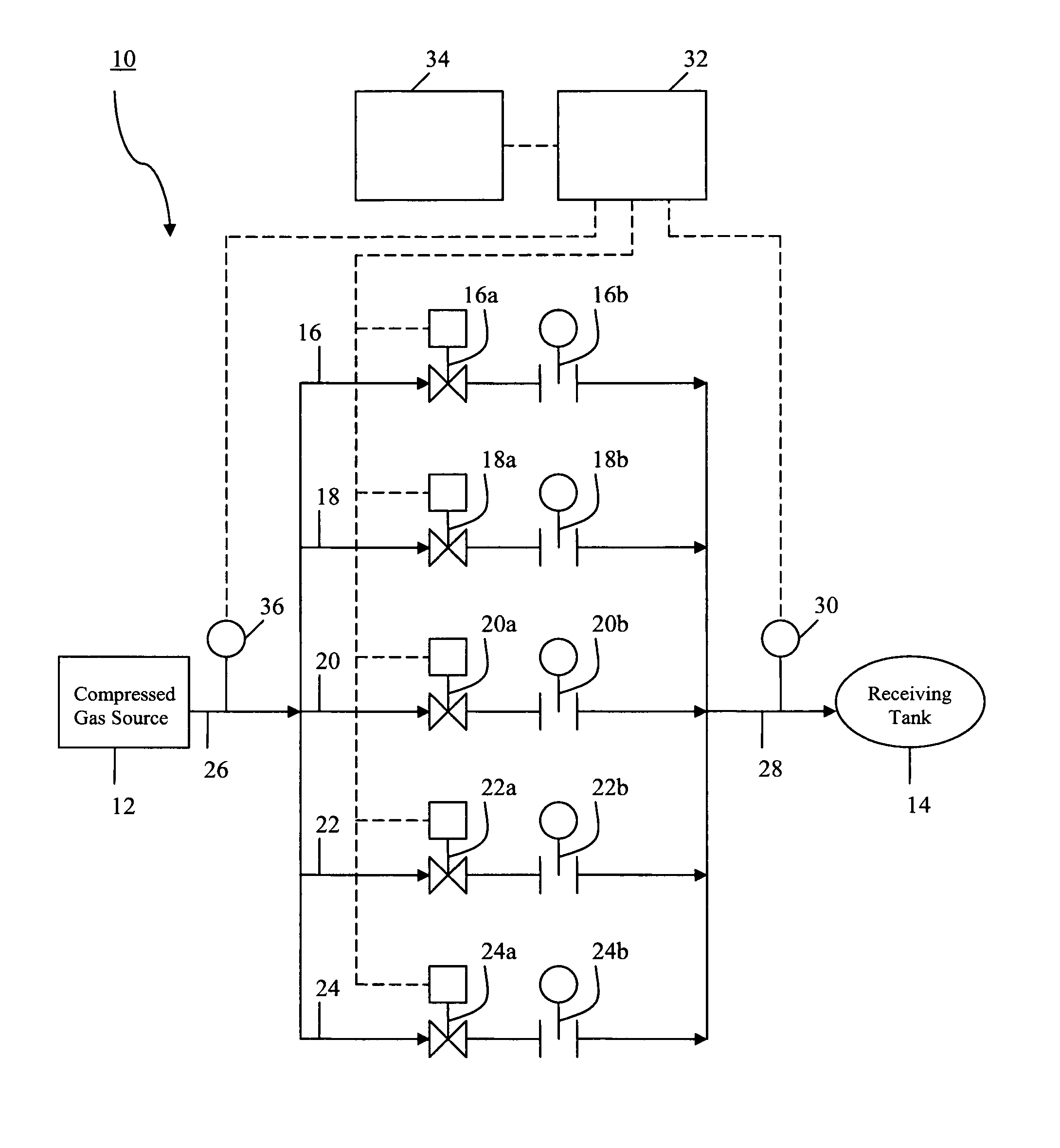

Gas filling system

InactiveUS20070079892A1Increase flow rateReduce flow rateLiquid fillingGas handling applicationsEngineeringTraffic volume

A system and method for supplying a gas from a supply of compressed gas to a receiving vessel by measuring the pressure of gas being directed into the receiving vessel in successive selected time intervals to determine the actual ramp rate of gas being directed into the receiving vessel and providing means for comparing the actual ramp rate with a desired ramp rate and controlling the gas flow rate in response to that comparison. In a preferred embodiment the pressure of the gas at an upstream end of the system is monitored and directed into a controller and this latter pressure is employed in determining the mass flow of gas into the receiving vessel.

Owner:AIR PROD & CHEM INC

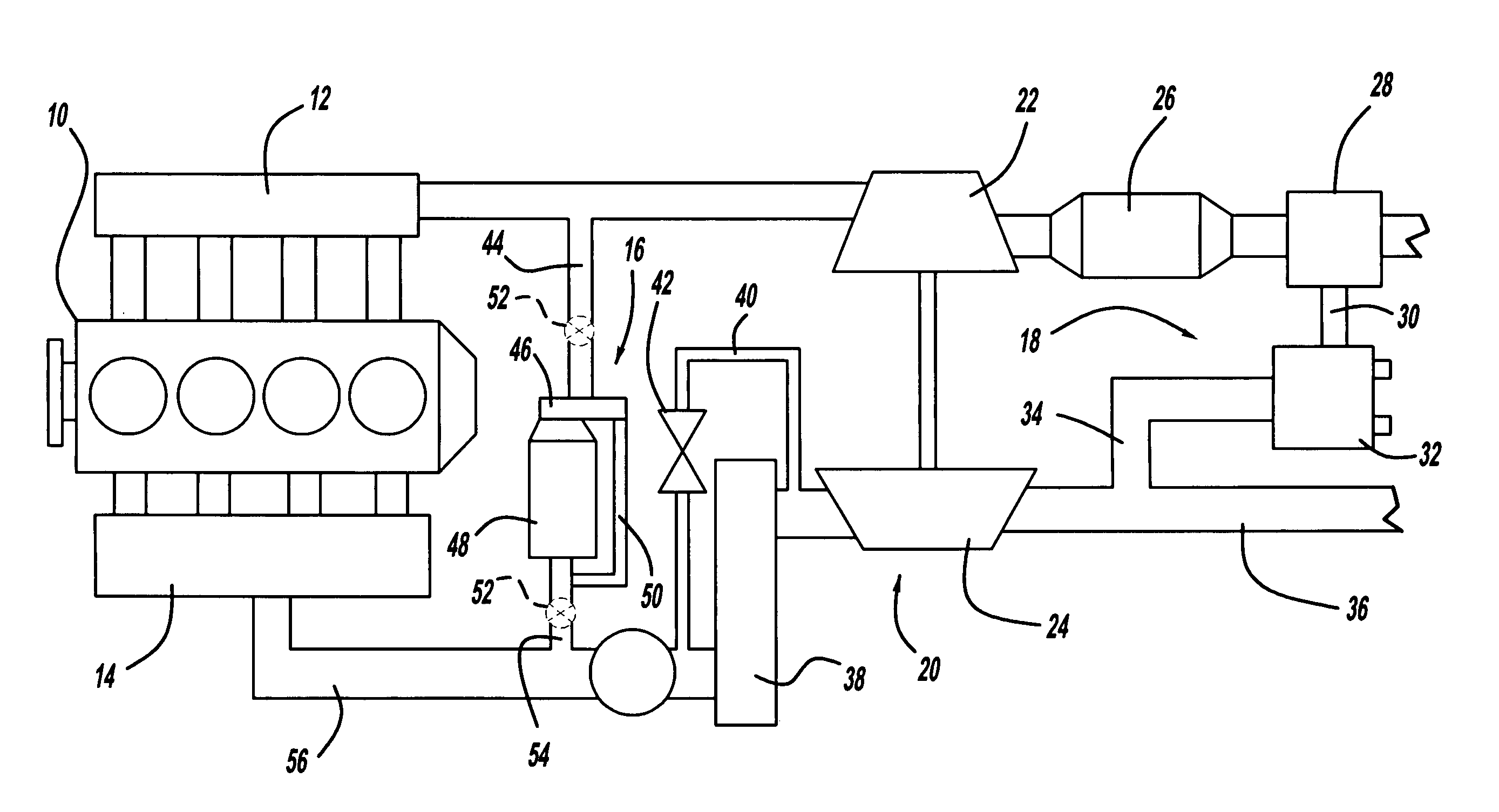

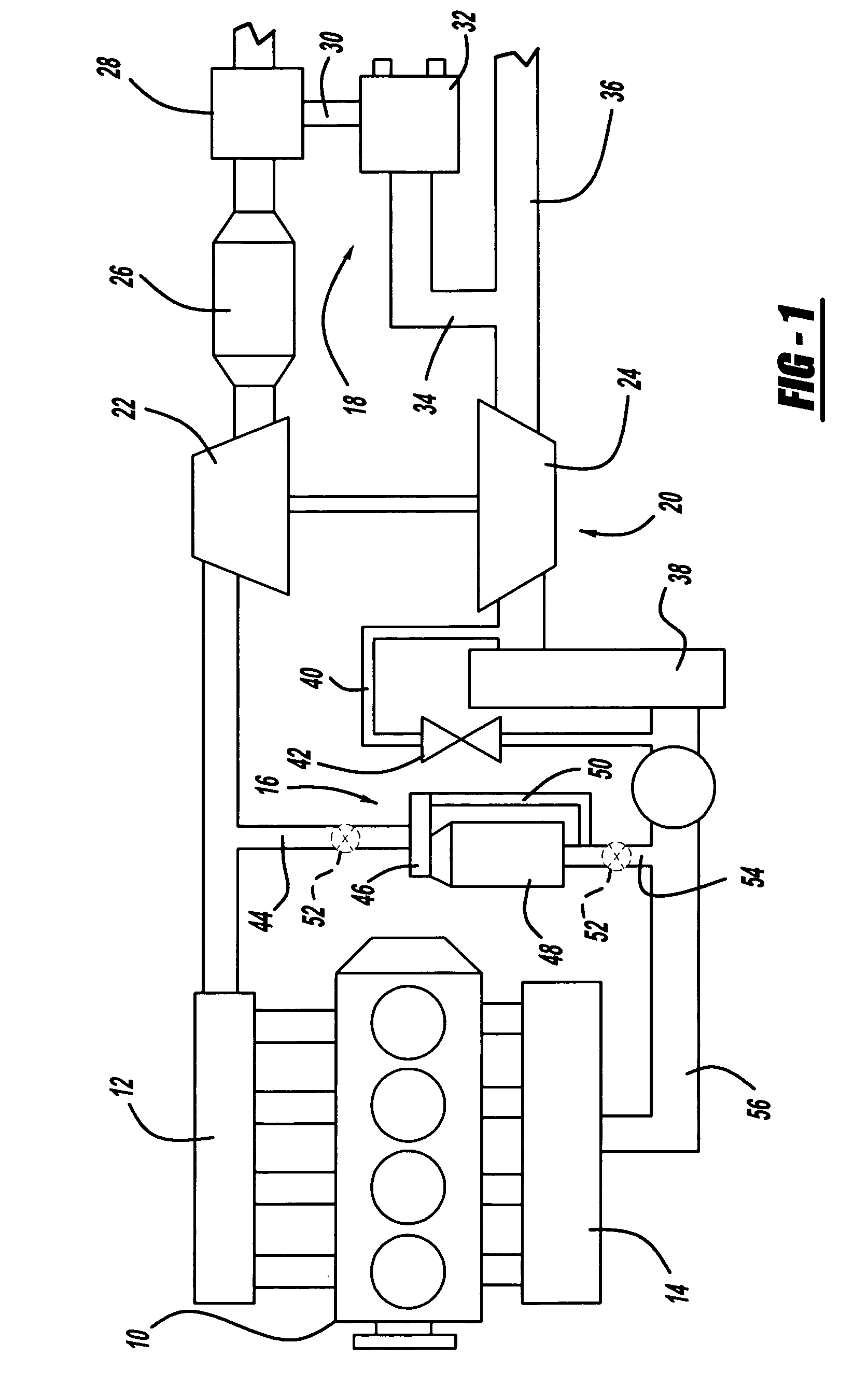

Combined EGR valve and cooler by-pass

InactiveUS20070125081A1Internal combustion piston enginesExhaust apparatusExhaust fumesExhaust gas recirculation

The present invention is an exhaust gas recirculation (EGR) valve for an engine having an exhaust gas recirculation cooler operable for receiving exhaust gas from an exhaust, and delivering the exhaust gas to an intake. The present invention also includes an exhaust gas recirculation bypass passage operable for receiving exhaust gas from an exhaust, bypassing the exhaust gas recirculation cooler, and delivering the exhaust gas to an intake, as well as a single valve operably associated with the exhaust gas recirculation cooler and the exhaust gas recirculation bypass passage. The single valve is selectively operable for opening or closing flow from the exhaust to the exhaust gas recirculation cooler, the exhaust gas recirculation bypass passage, or both, the single valve also operable for metering flow therebetween.

Owner:BORGWARNER INC

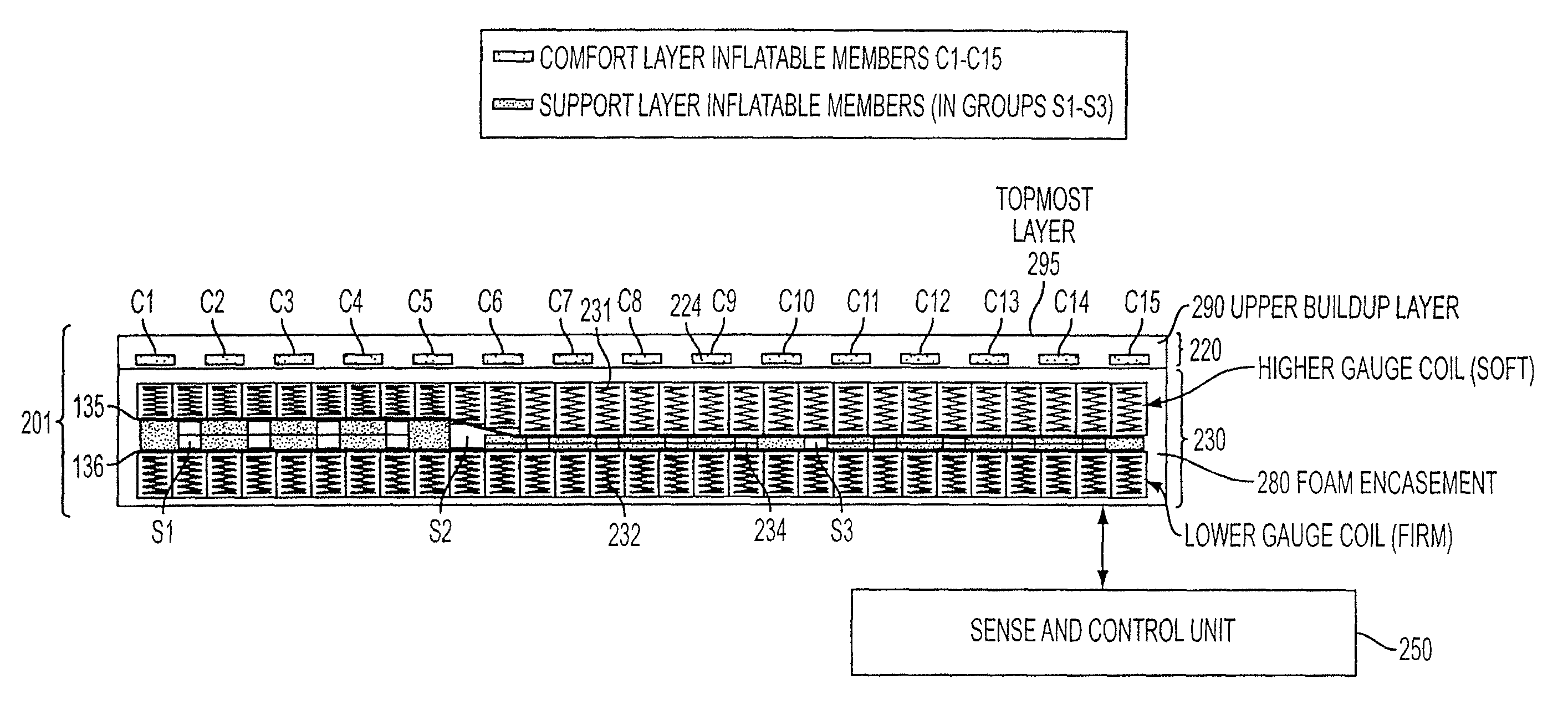

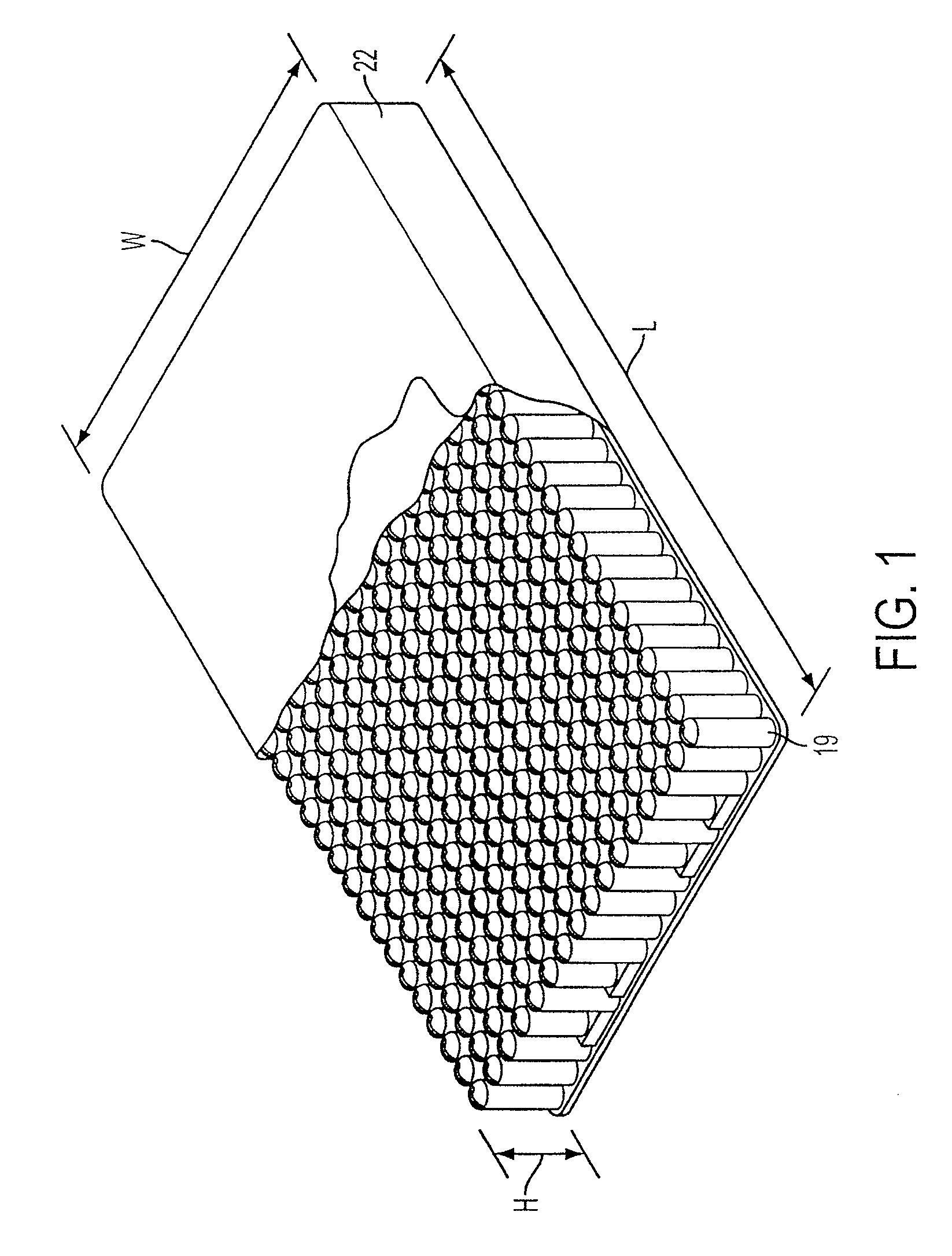

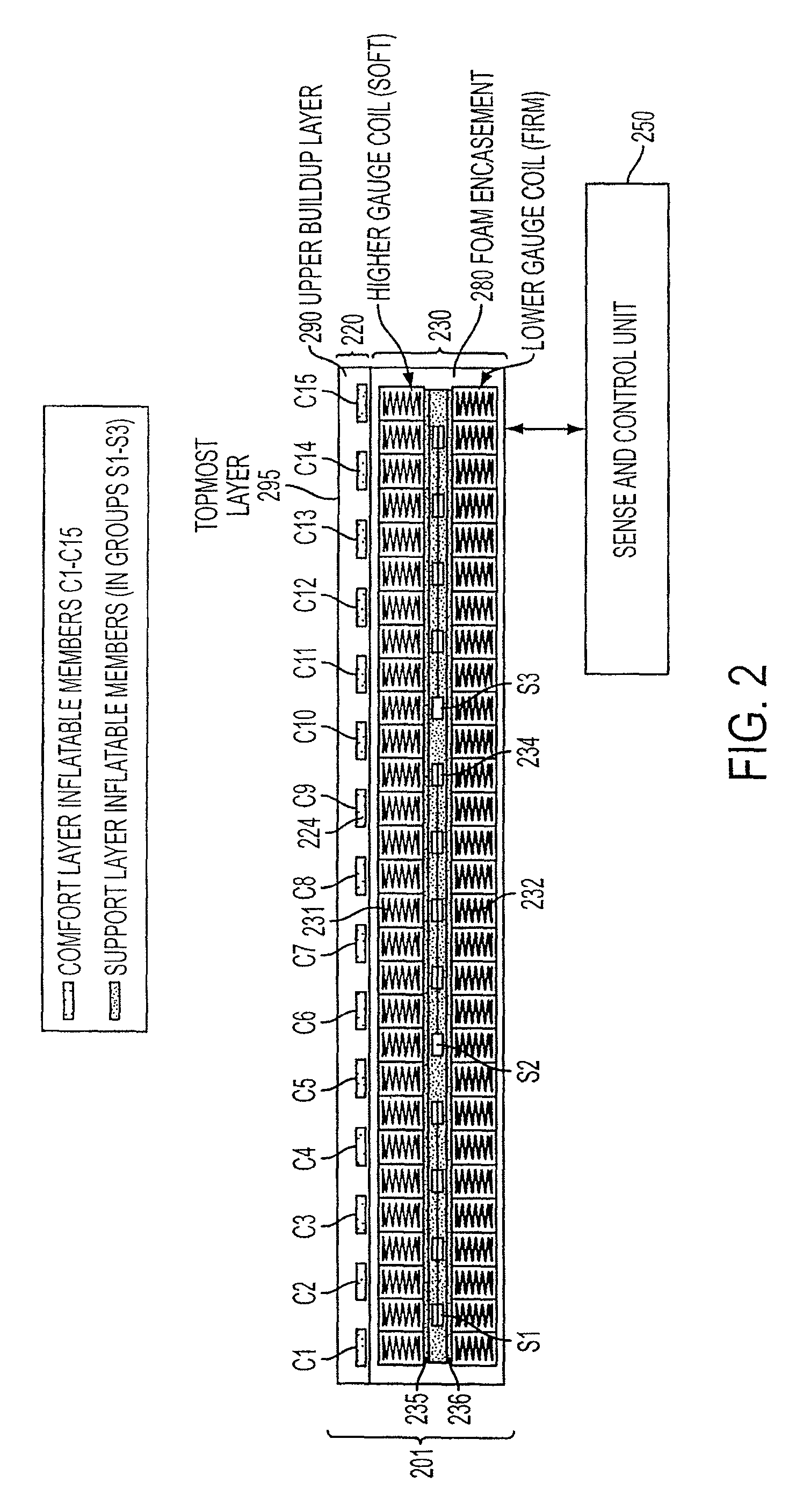

Apparatuses and methods providing variable support and variable comfort control of a sleep system and automatic adjustment thereof

An apparatus and method providing variable support and variable comfort control of a sleep system, the apparatus including a sleep support member including: a comfort layer including: a plurality of comfort layer inflatable members; and a comfort layer sensor configured to provide data relating to respective pressures of the comfort layer inflatable members; a data analysis unit configured to analyze data provided by the comfort layer sensor and to generate analyzed comfort layer data; and a control unit configured to control a pressure within each of the respective comfort layer inflatable members using the analyzed comfort layer data.

Owner:KINGSDOWN INC

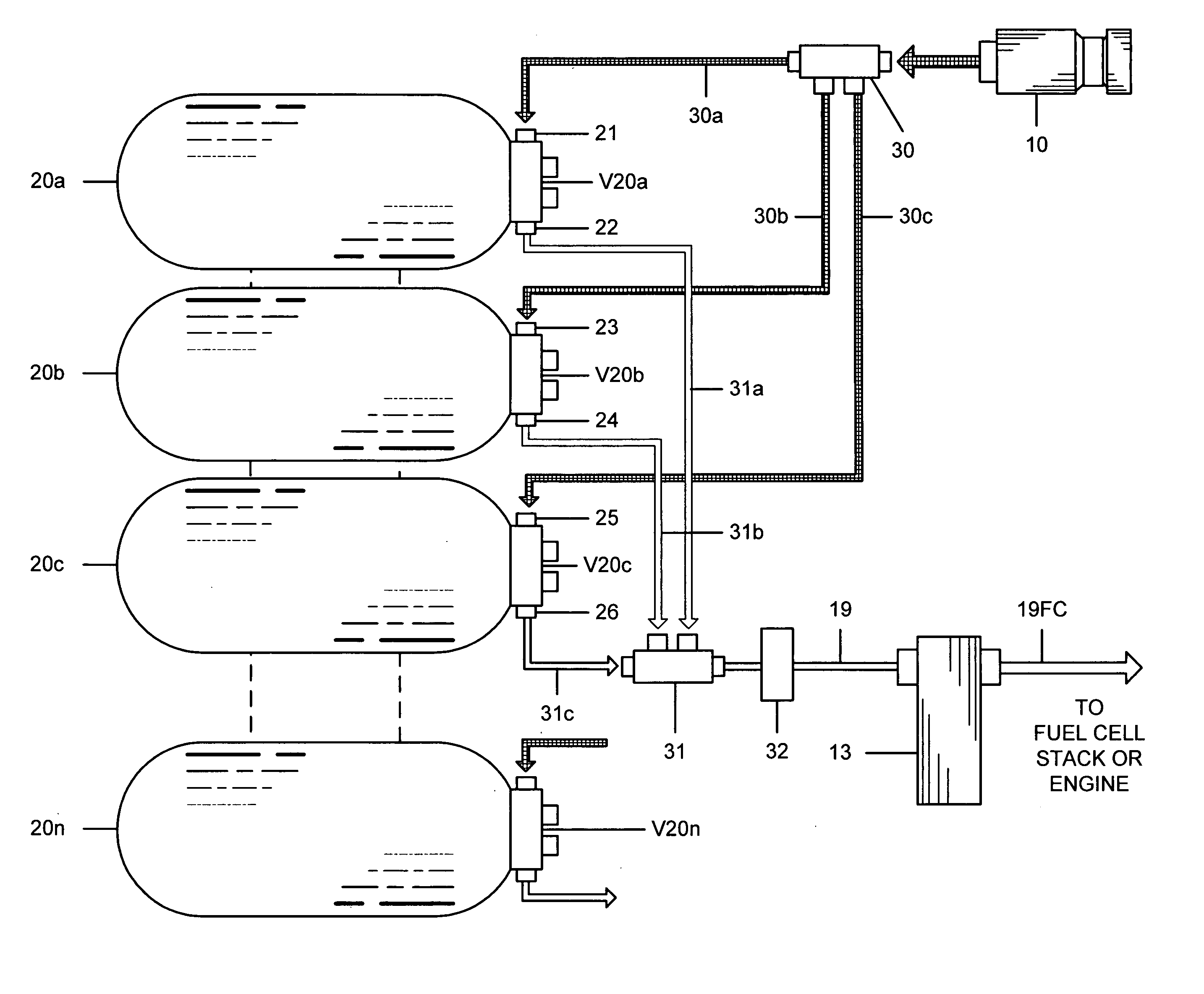

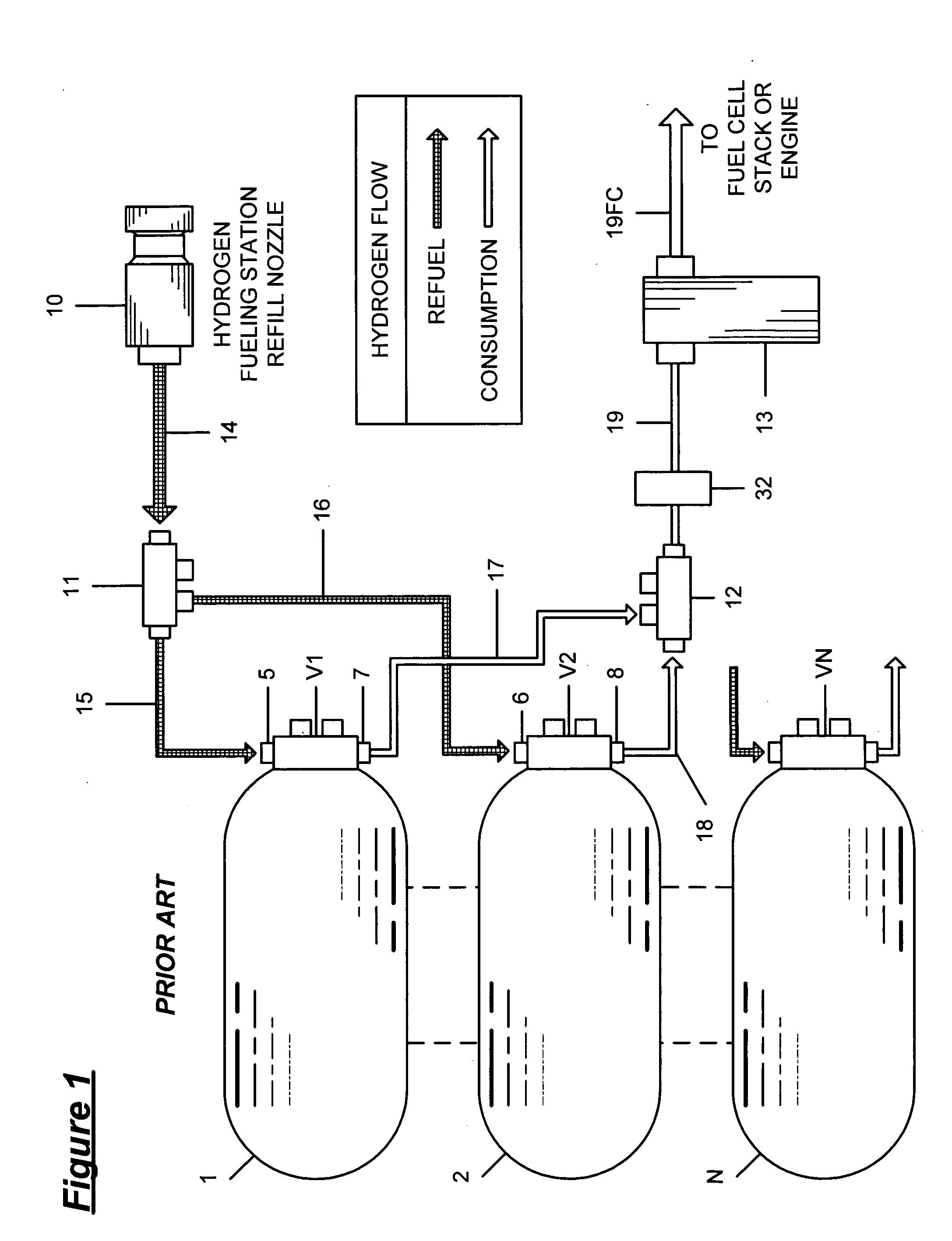

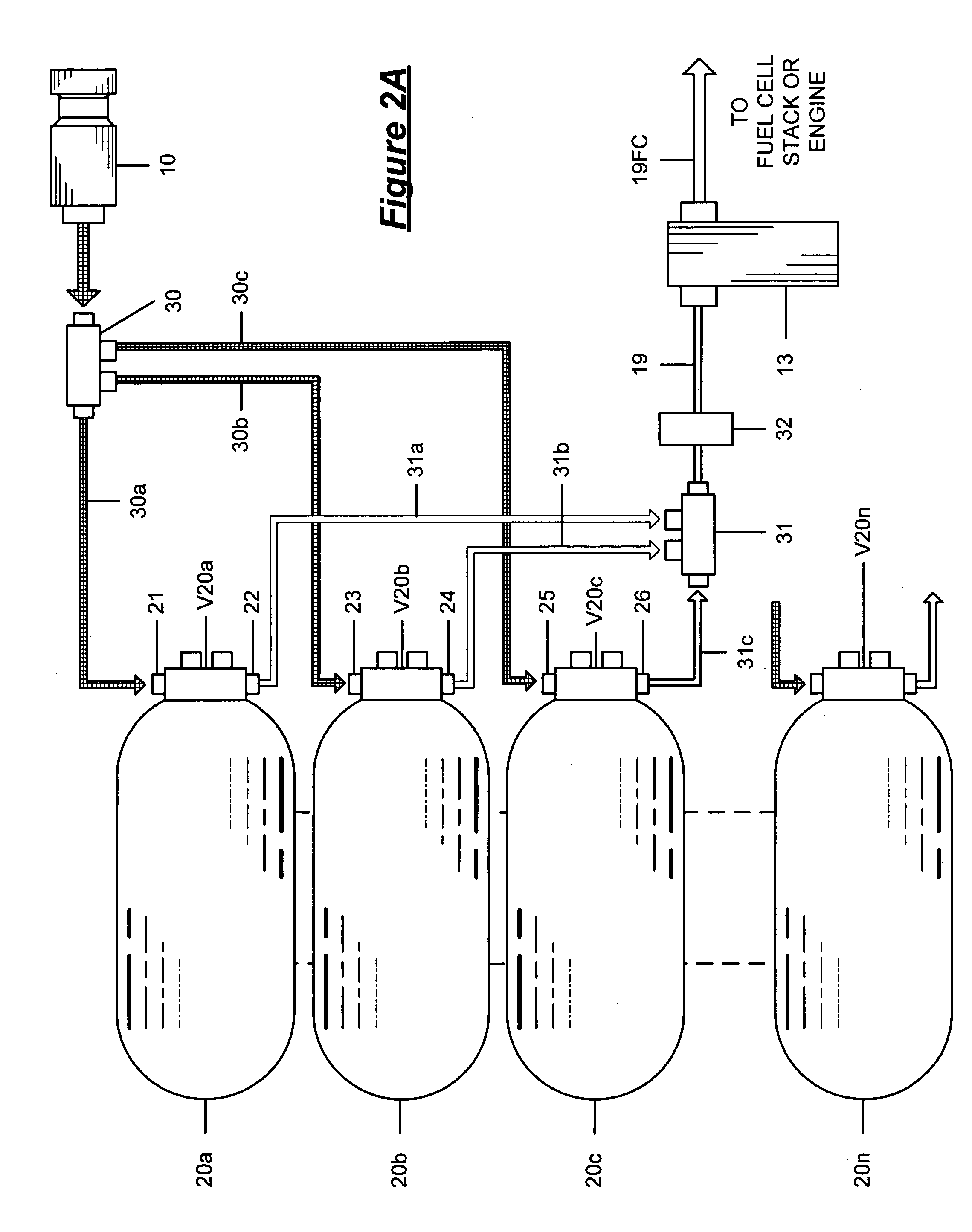

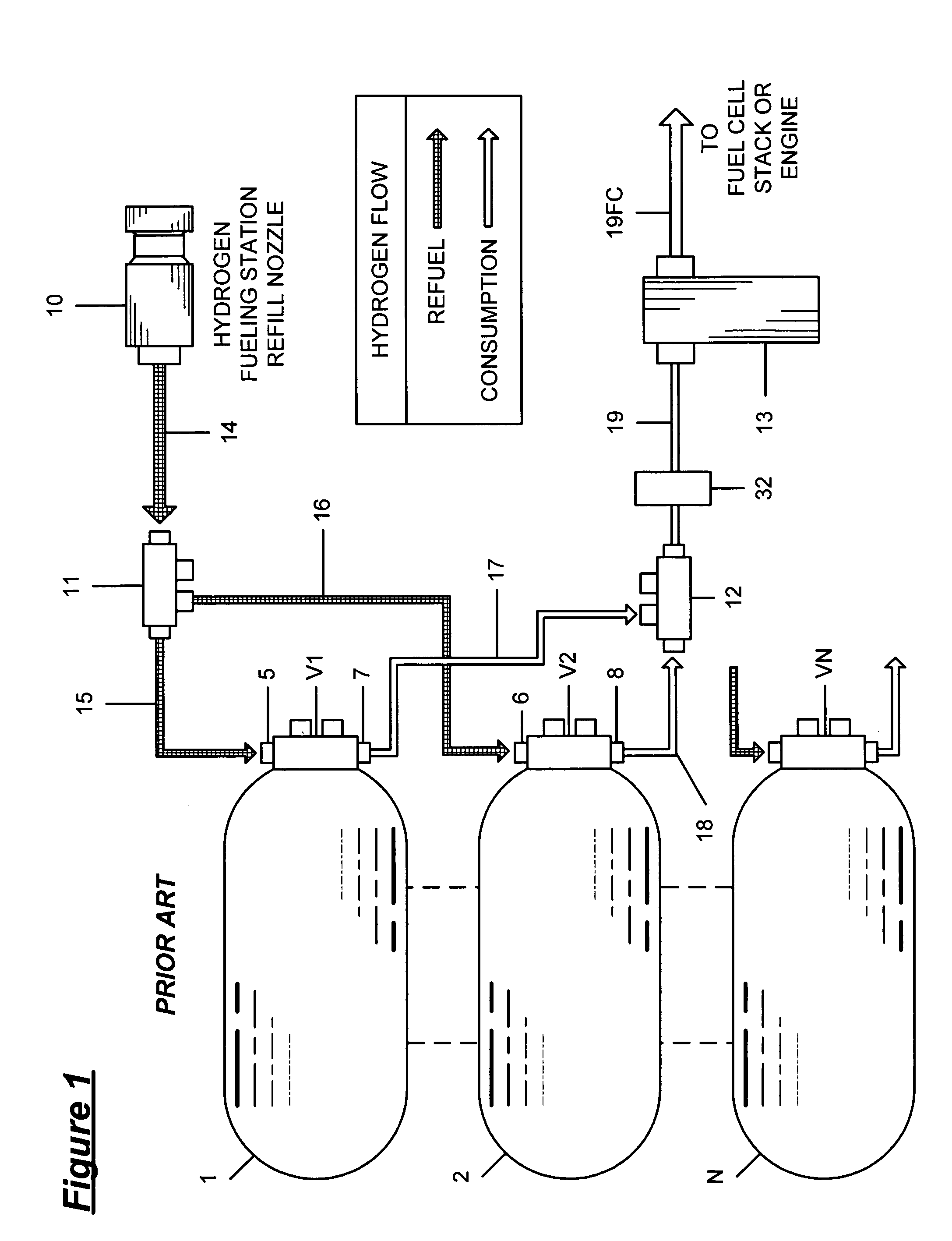

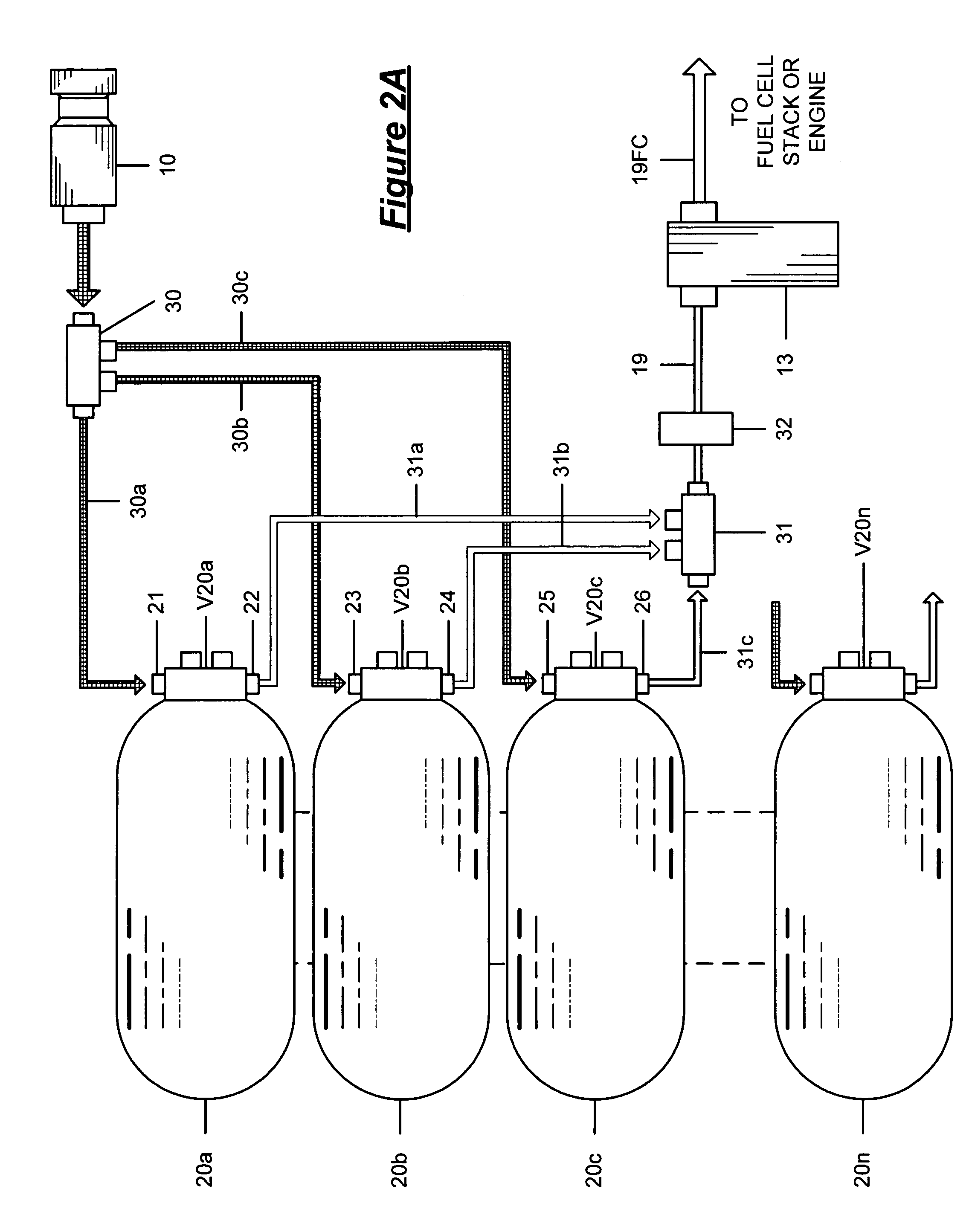

Hydrogen vehicle gas utilization and refueling system

InactiveUS20060118175A1Minimize mechanical energy lossMinimize compression energyGas handling applicationsBottling operationsMobile vehicleOn board

A system for increasing the overall efficiency of a hydrogen fueled vehicle and refilling station infrastructure wherein the process of (1) consuming pressurized hydrogen gas that is stored in on board tanks used to power hydrogen fueled motor vehicles and (2) refueling the vehicle tanks at a hydrogen refilling station after the available on board fuel supply in the tanks is consumed is controlled according to a predetermined sequence involving the utilization of the hydrogen in the on board tanks.

Owner:HONDA MOTOR CO LTD

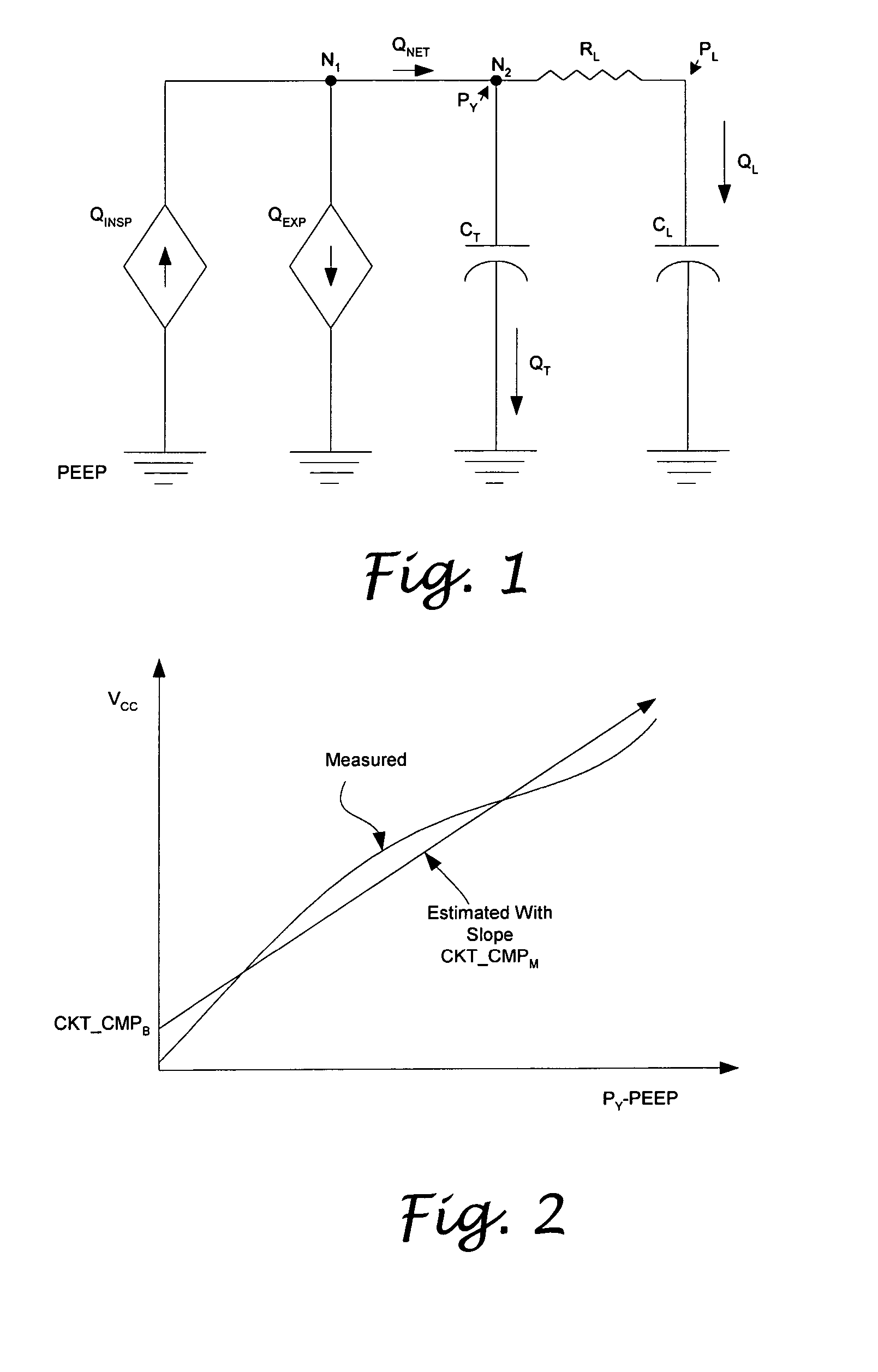

System and method for circuit compliance compensated volume control in a patient respiratory ventilator

ActiveUS7886739B2Accurate flowGas trapping and auto PEEP is preventedLevel controlInflated body pressure measurementDifferential pressureControl system

A circuit compliance compensated volume control system in a patient respiratory ventilation system and method, including: a circuit compliance estimator, to provide a relationship between a circuit volume and a differential pressure between a circuit pressure and a positive end-expiratory pressure (PEEP) of the respiratory circuit, a circuit volume estimator, operative to provide an estimated circuit volume based on the relationship between the circuit volume and the differential pressure, a patient volume observer, operative to provide an estimated patient volume by subtracting the estimated circuit volume from a measured machine delivered net volume, and a volume delivery controller, operative to update the machine delivered net volume based on the estimated patient volume and a set tidal volume.

Owner:VYAIRE MEDICAL 211 INC

Hydrogen vehicle gas utilization and refueling system

InactiveUS7325561B2Minimize mechanical energy lossMinimize compression energyGas handling applicationsBottling operationsMobile vehicleOn board

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com