Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29554 results about "Fuel tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fuel tank (or petrol tank) is a safe container for flammable fluids. Though any storage tank for fuel may be so called, the term is typically applied to part of an engine system in which the fuel is stored and propelled (fuel pump) or released (pressurized gas) into an engine. Fuel tanks range in size and complexity from the small plastic tank of a butane lighter to the multi-chambered cryogenic Space Shuttle external tank.

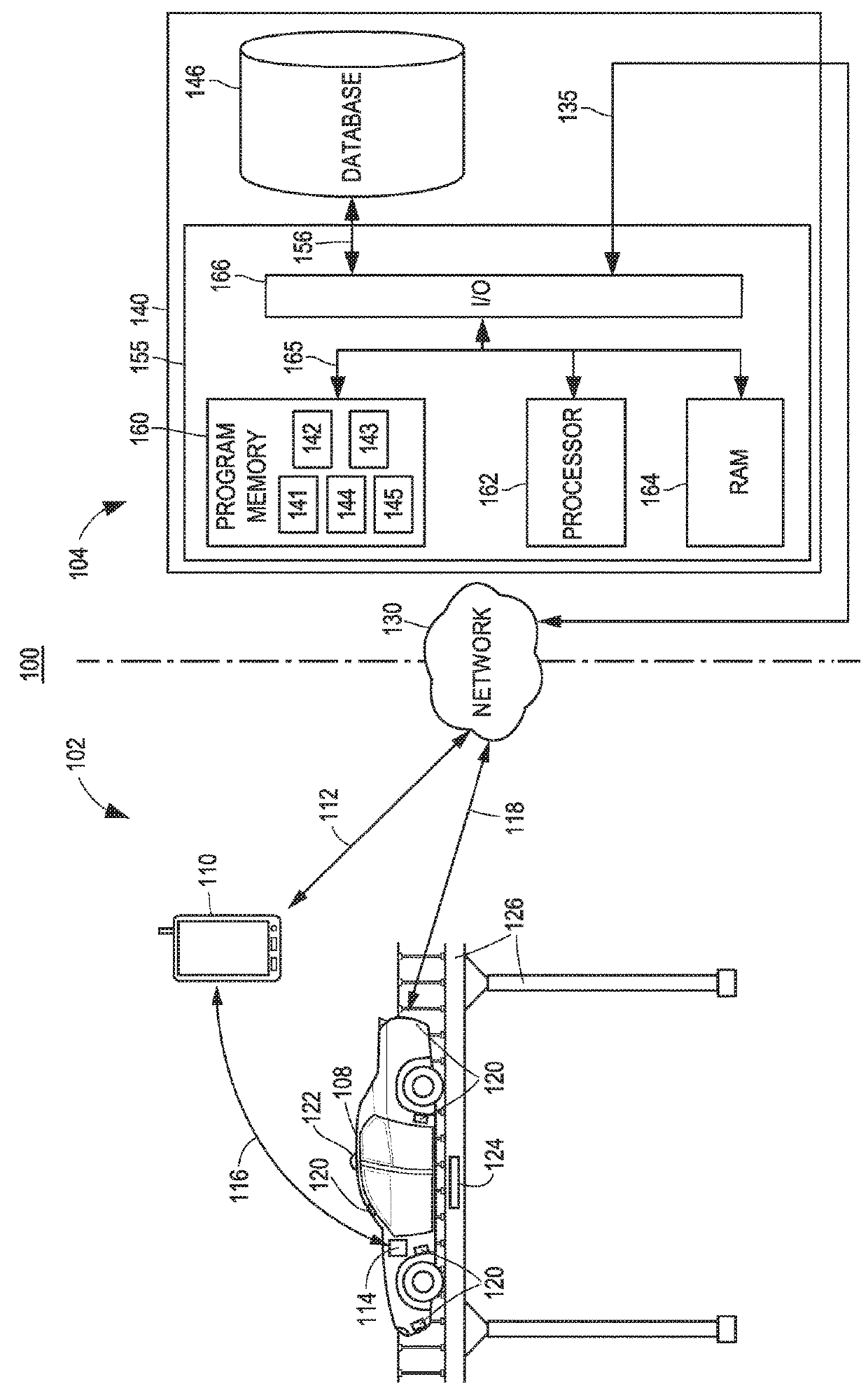

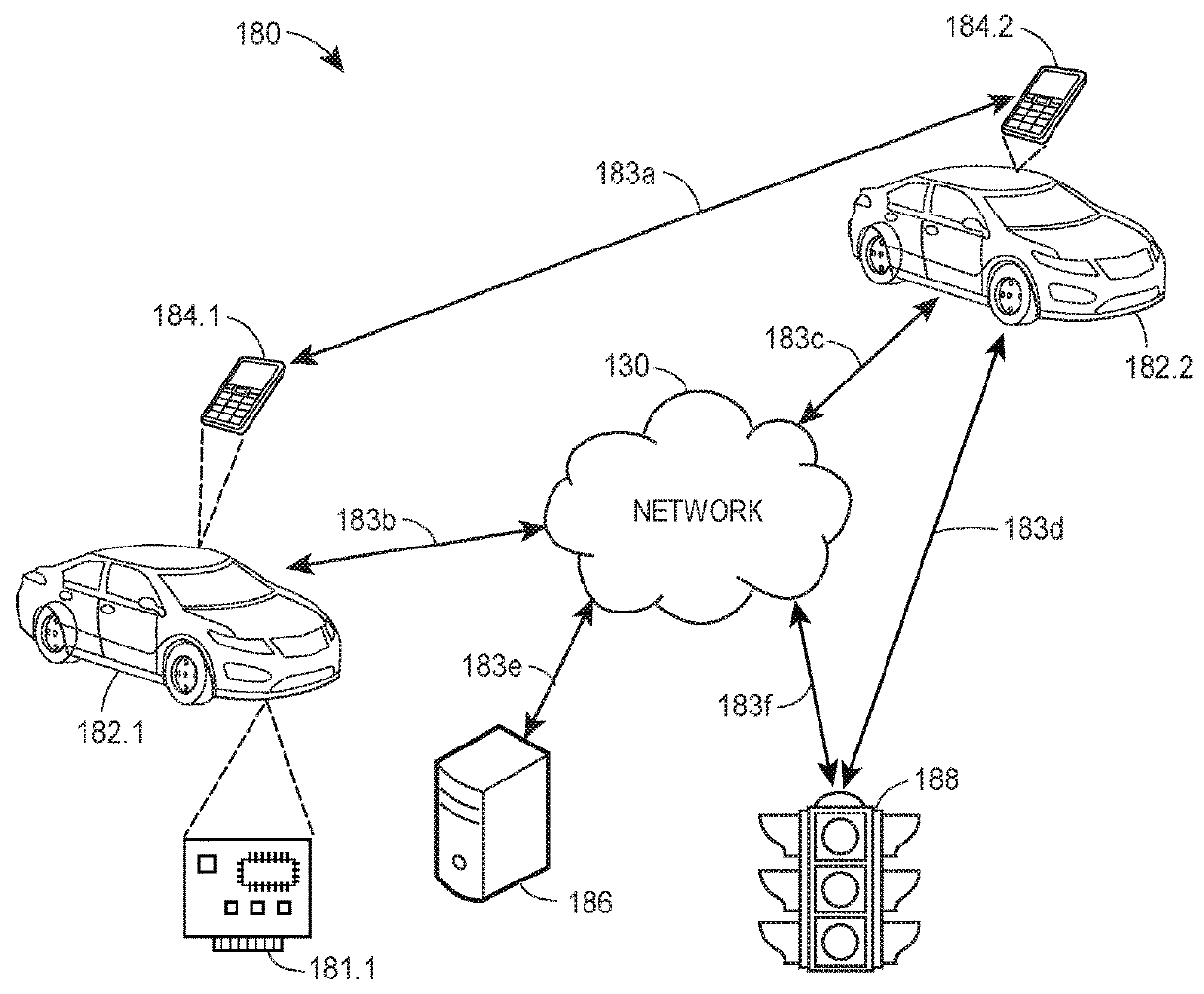

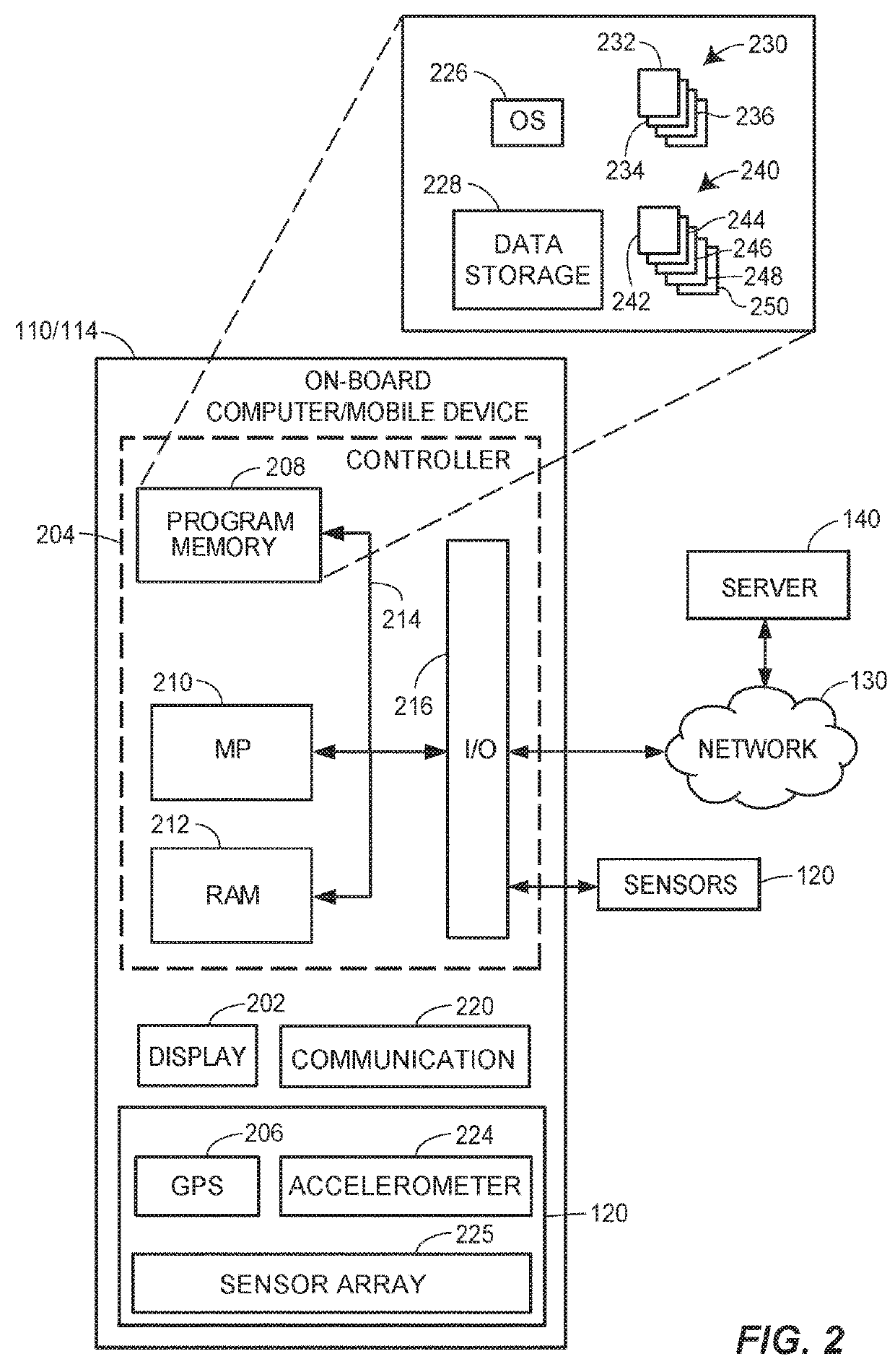

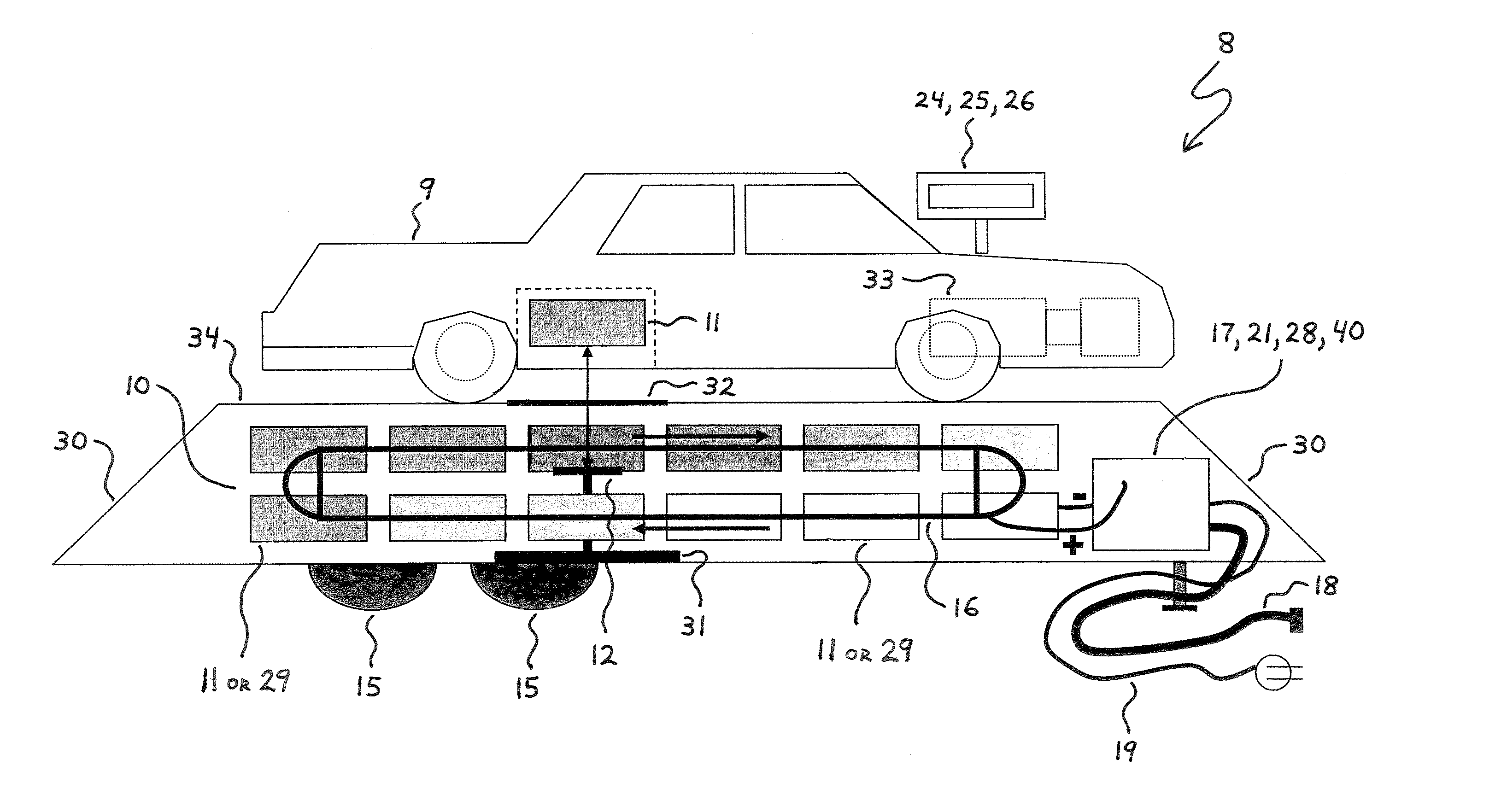

Autonomous vehicle refueling

Methods and systems for autonomous vehicle recharging or refueling are disclosed. Autonomous vehicles may be automatically refueled by routing the vehicles to available fueling stations when not in operation, according to methods described herein. A fuel level within a tank of an autonomous vehicle may be monitored until it reaches a refueling threshold, at which point an on-board computer may generate a predicted use profile for the vehicle. Based upon the predicted use profile, a time and location for the vehicle to refuel the vehicle may be determined. In some embodiments, the vehicle may be controlled to automatically travel to a fueling station, refill a fuel tank, and return to its starting location in order to refuel when not in use.

Owner:HYUNDAI MOTOR CO LTD +1

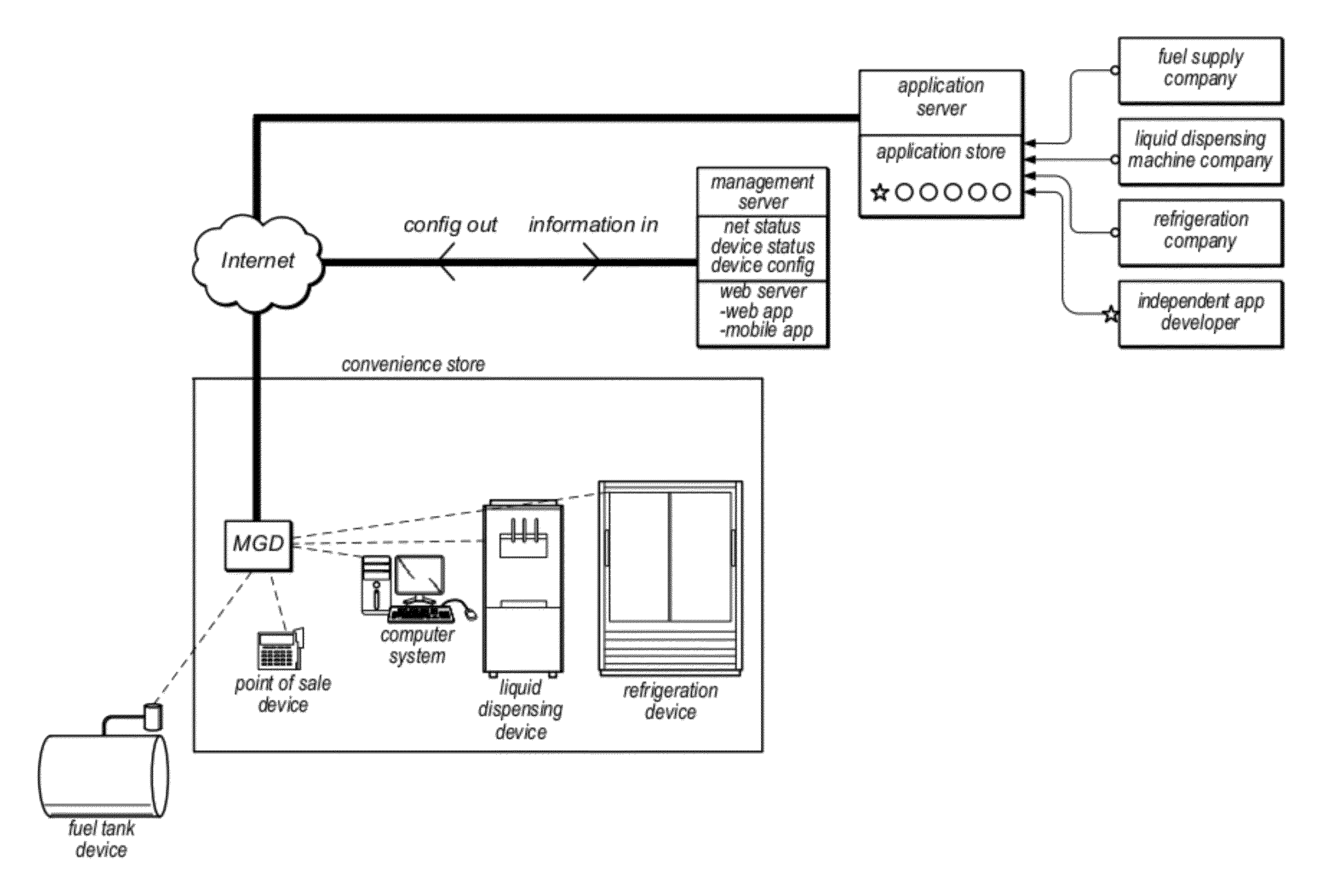

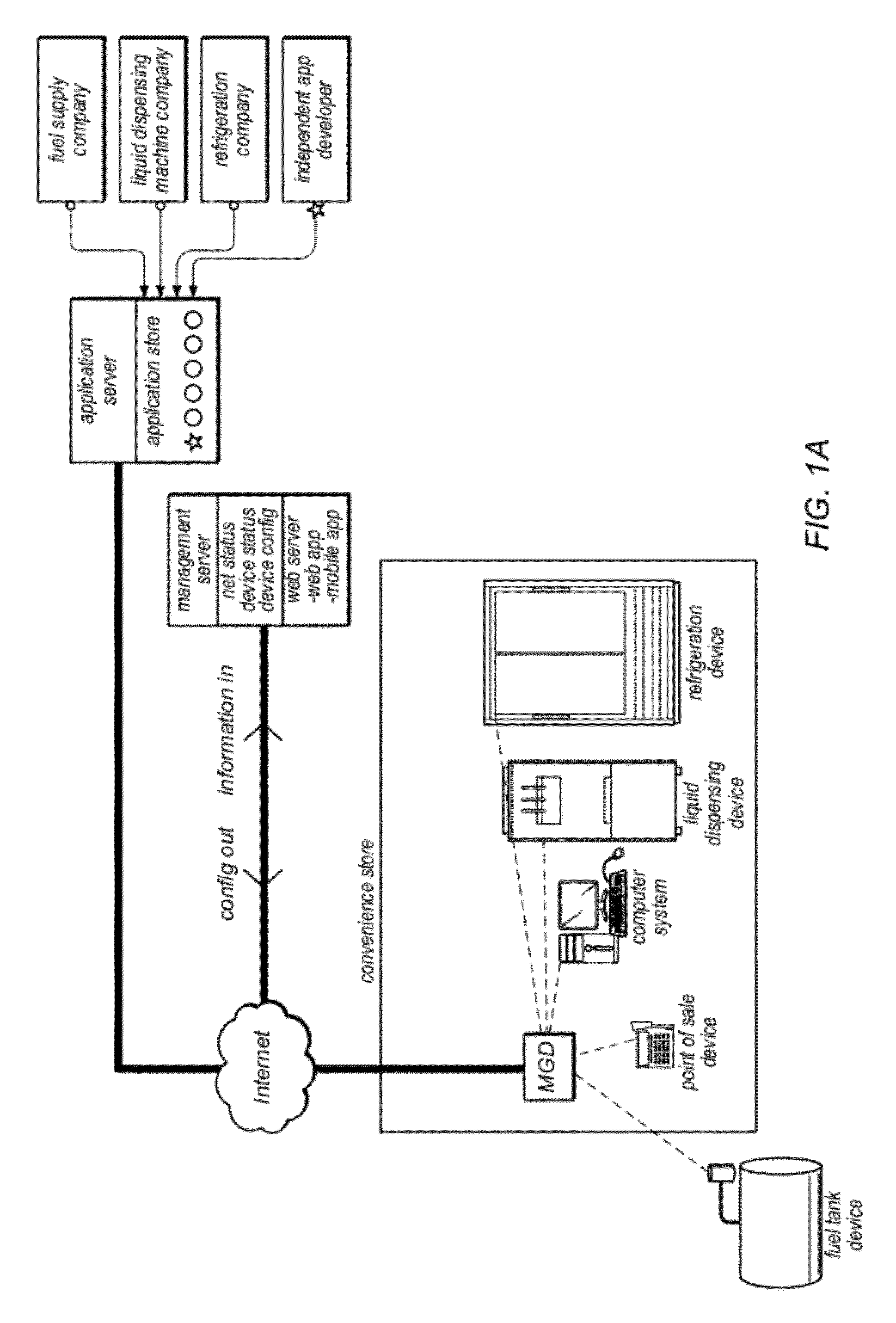

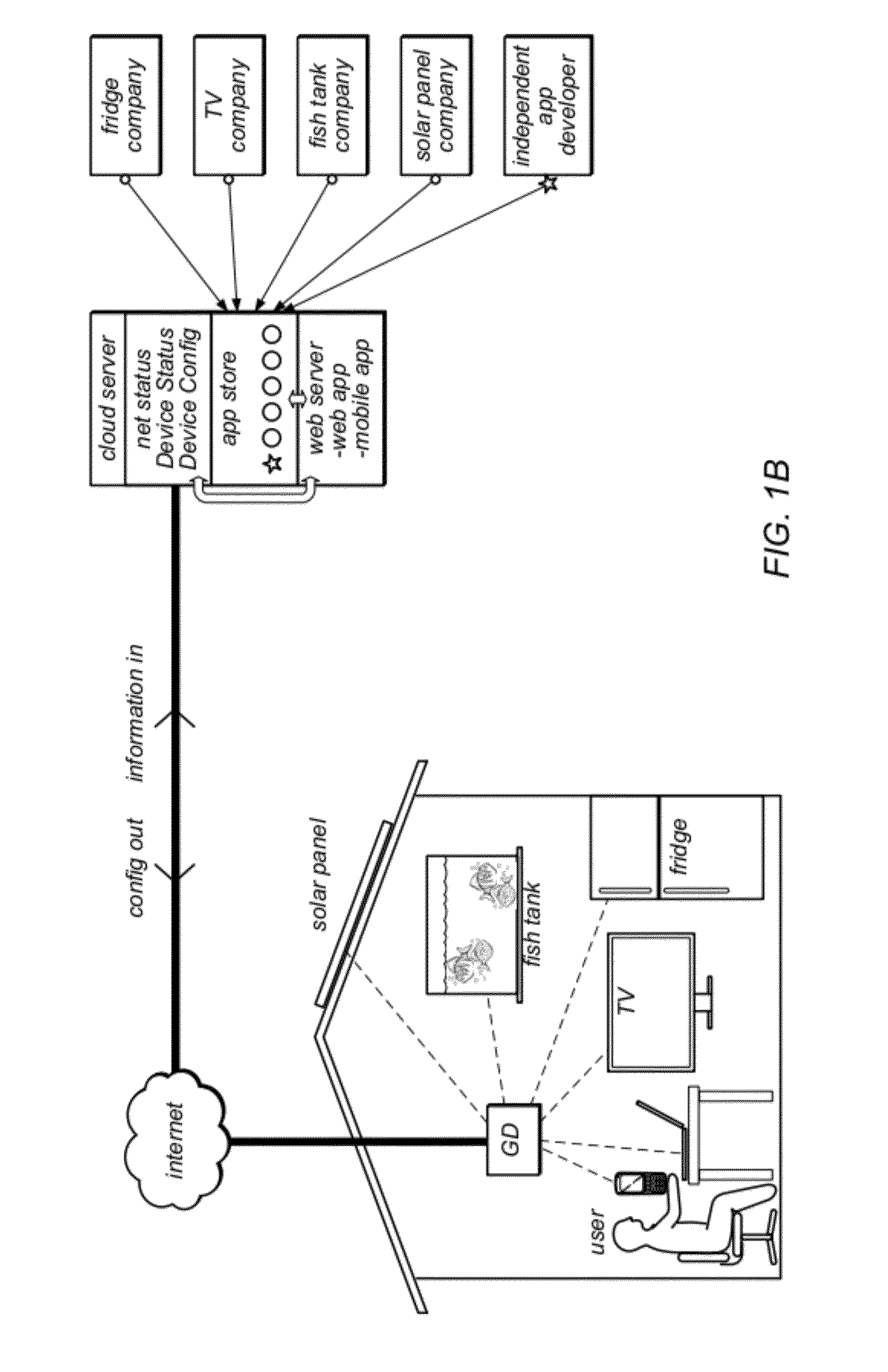

Gateway Device Application Development System

Configuring and managing gateway devices. A gateway device may be installed at a location, such as a merchant location or home. The gateway device may manage (e.g., monitor and / or control) one or more devices at the location. For example, the gateway device may manage various fuel tank devices, point of sale devices, refrigeration devices, liquid dispensing devices, etc., at a convenience store. The gateway device may provide reported information to and receive commands from a cloud server, which may be in communication with other devices which may be used to view reported information of or control the managed devices. The cloud server may also be configured to install applications, e.g., for execution by the cloud server, the gateway device, and / or other devices. For example, the gateway device may install applications provided by the cloud server to manage the devices coupled to the gateway device.

Owner:ACUMERA

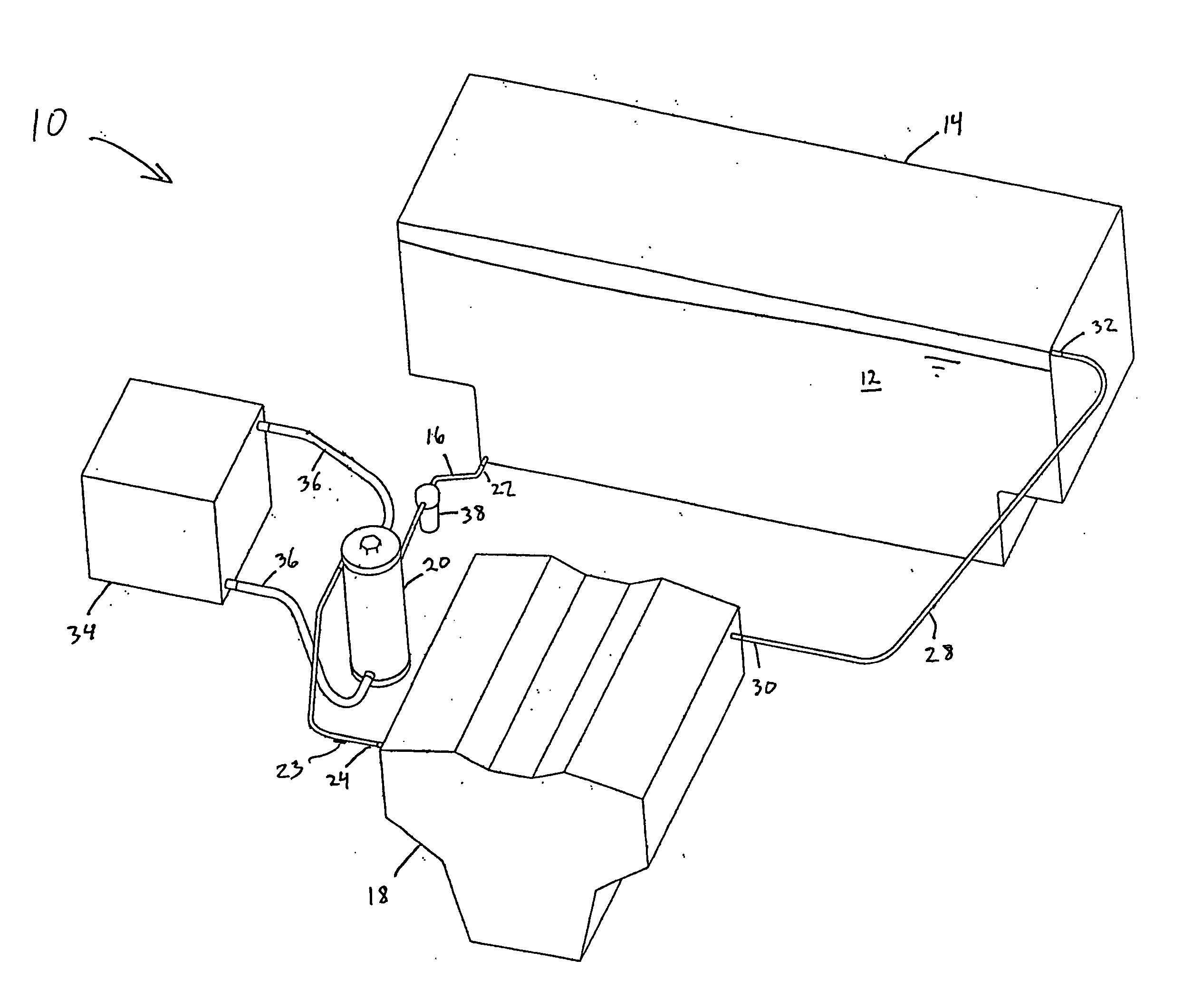

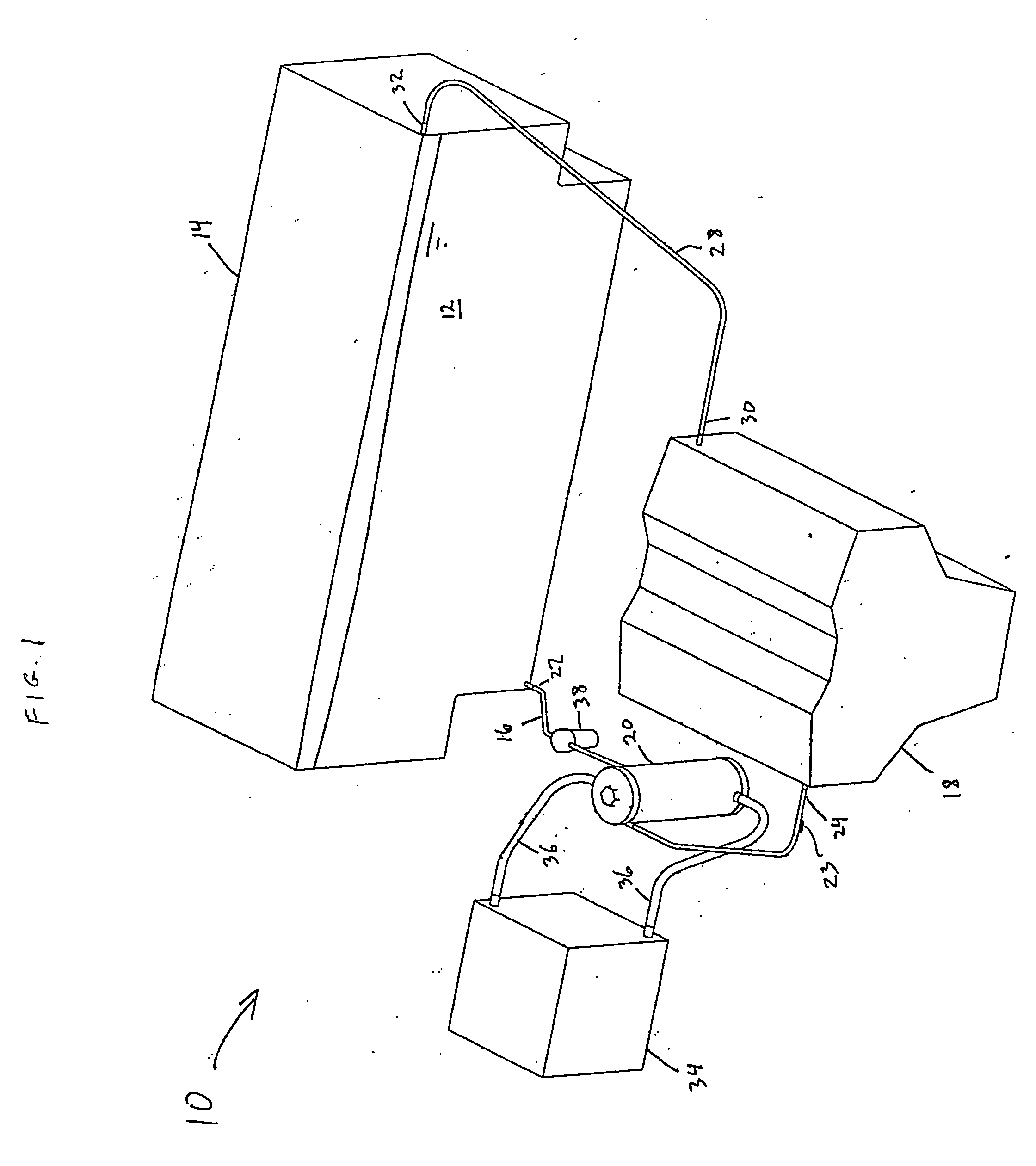

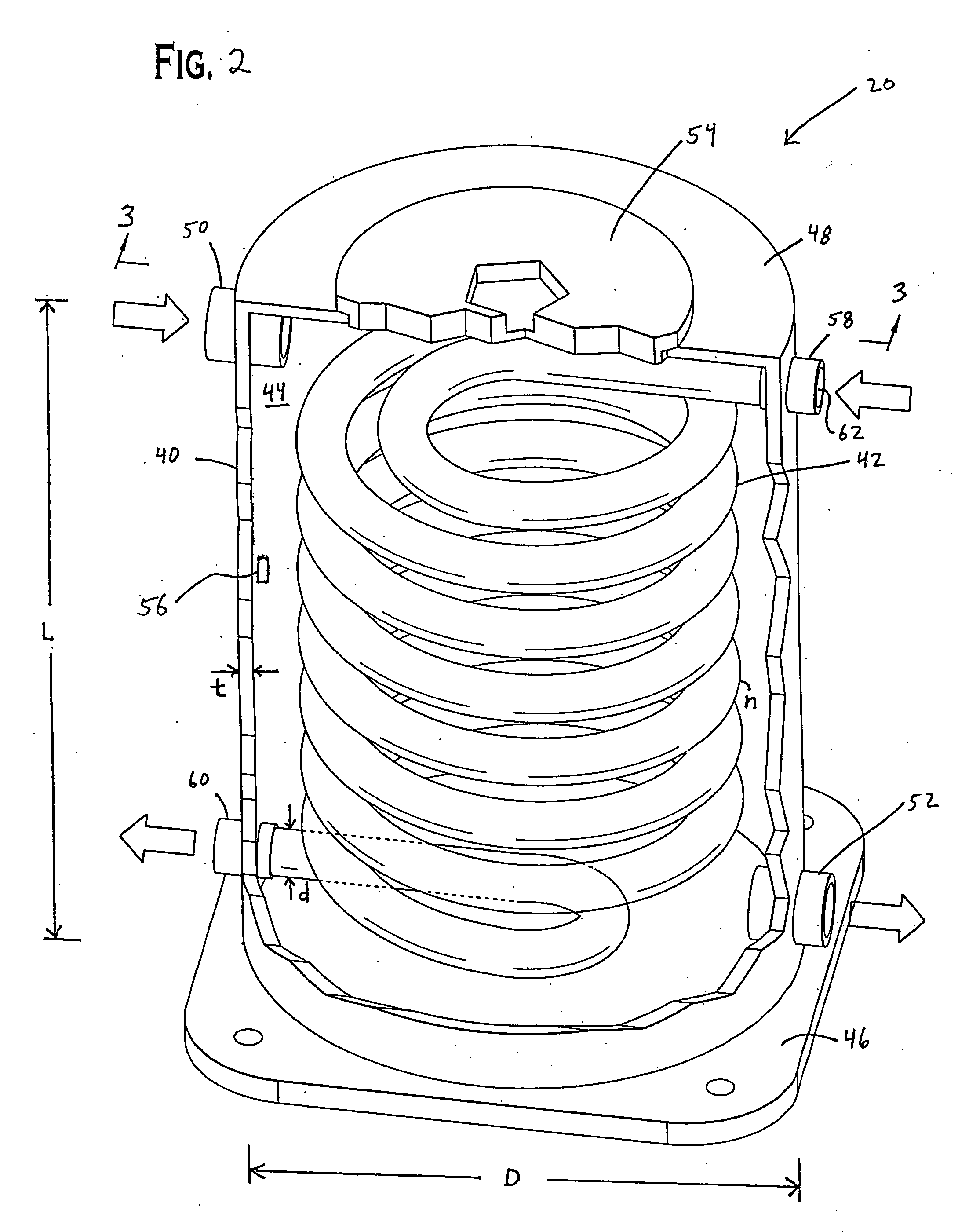

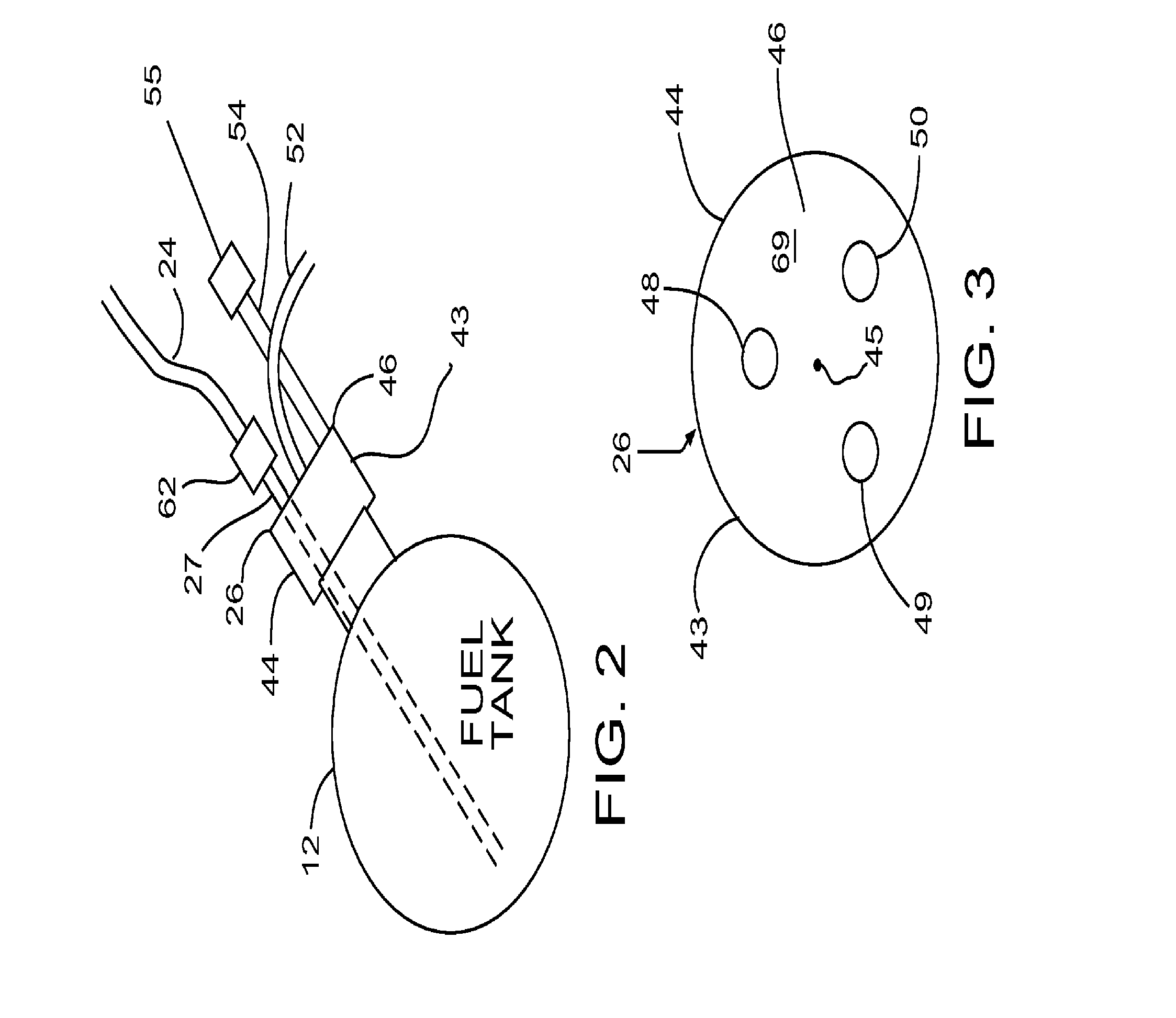

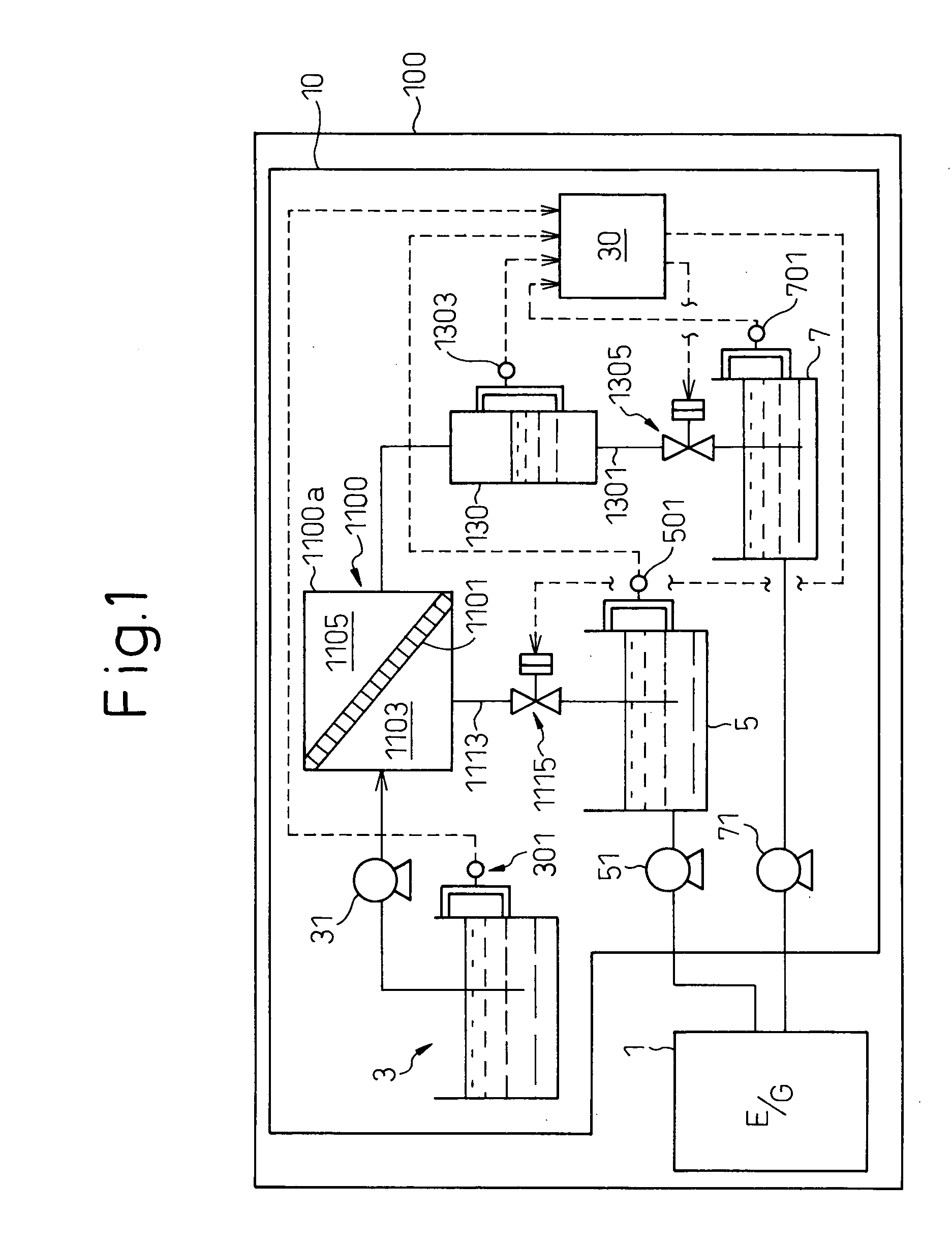

Marine engine fuel cooling system

InactiveUS20060124113A1Internal combustion piston enginesThermal treatment of fuelNuclear engineeringFuel tank

A fuel cooling system for a marine inboard engine, including a fuel tank, a fuel supply conduit, and a heat exchanger. The fuel supply conduit includes first and second ends, and extends between the fuel tank and a fuel injection system for the engine. The heat exchanger is disposed intermediate the first and second ends of the fuel supply conduit, and includes a fuel passage in fluid communication with the fuel supply conduit, and a coolant passage in fluid communication with a coolant side of a closed-loop auxiliary cooling system.

Owner:ROBERTS FOREST G SR

Method and system for purifying hydraulic-oil

InactiveCN1546198AEasy to installEasy to operateFiltration circuitsLubricant compositionControl systemFuel tank

The invention refers to a method and system for purifying the hydraulic pressure oil in hydraulic pressure machine. The method includes magnetism absorbing step which absorbs the metal particles in the hydraulic oil through magnetism structure onto the magnetism structure and a filter step blocking the impurities in the sift filter core, and finishes the first grade filter, and the second filter step with a sorption filter; the system includes: forward oil boxes connected in series, oil heater, magnetism filter, oil pump, sorption filter, backwards oil boxes and electric control system. Each device is connected through oil pipes and valves, all of which are set in a mobile machine box, moves the box, the purification to hydraulic pressure oil of different locations can be carried on conveniently.

Owner:邝念曾

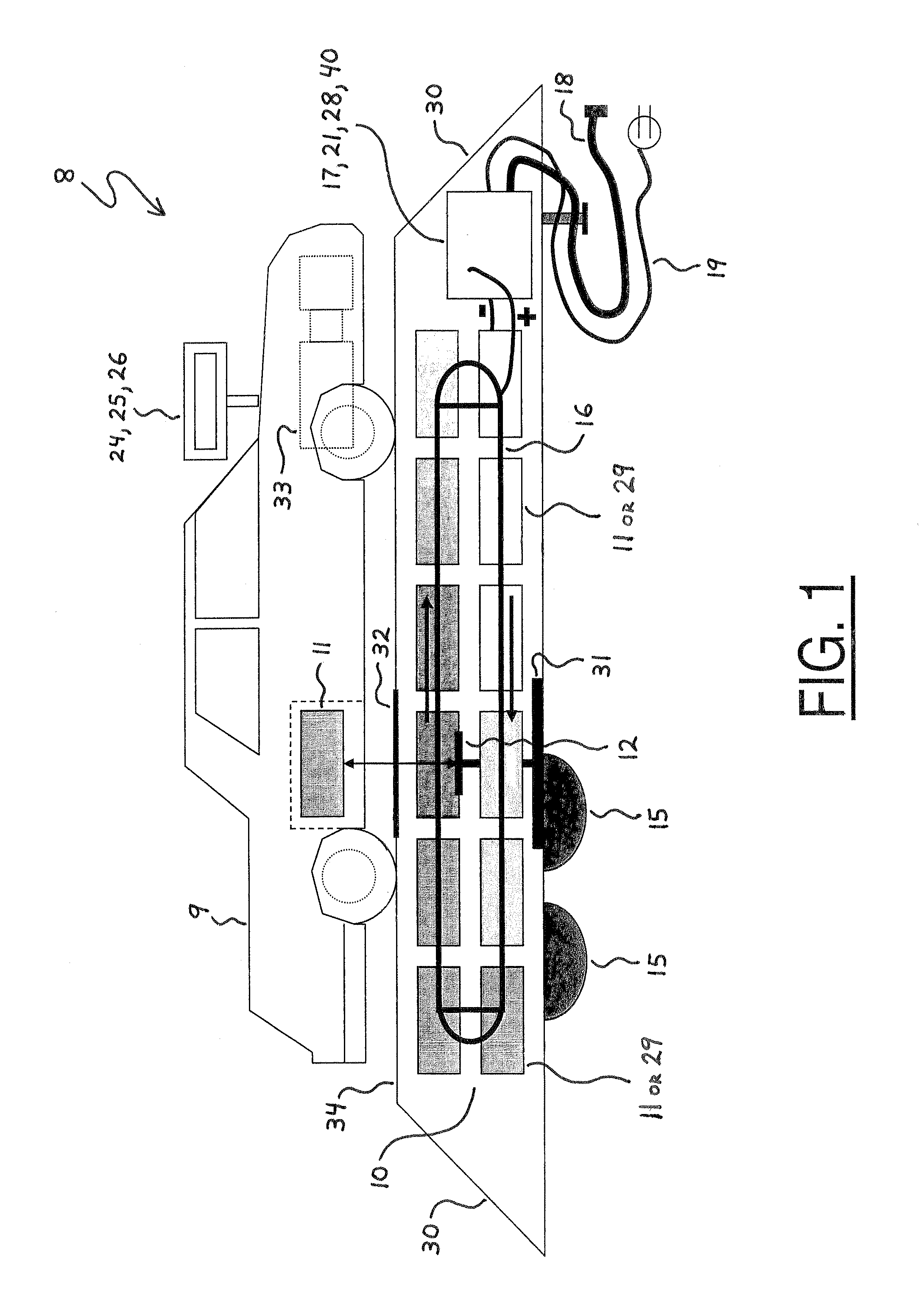

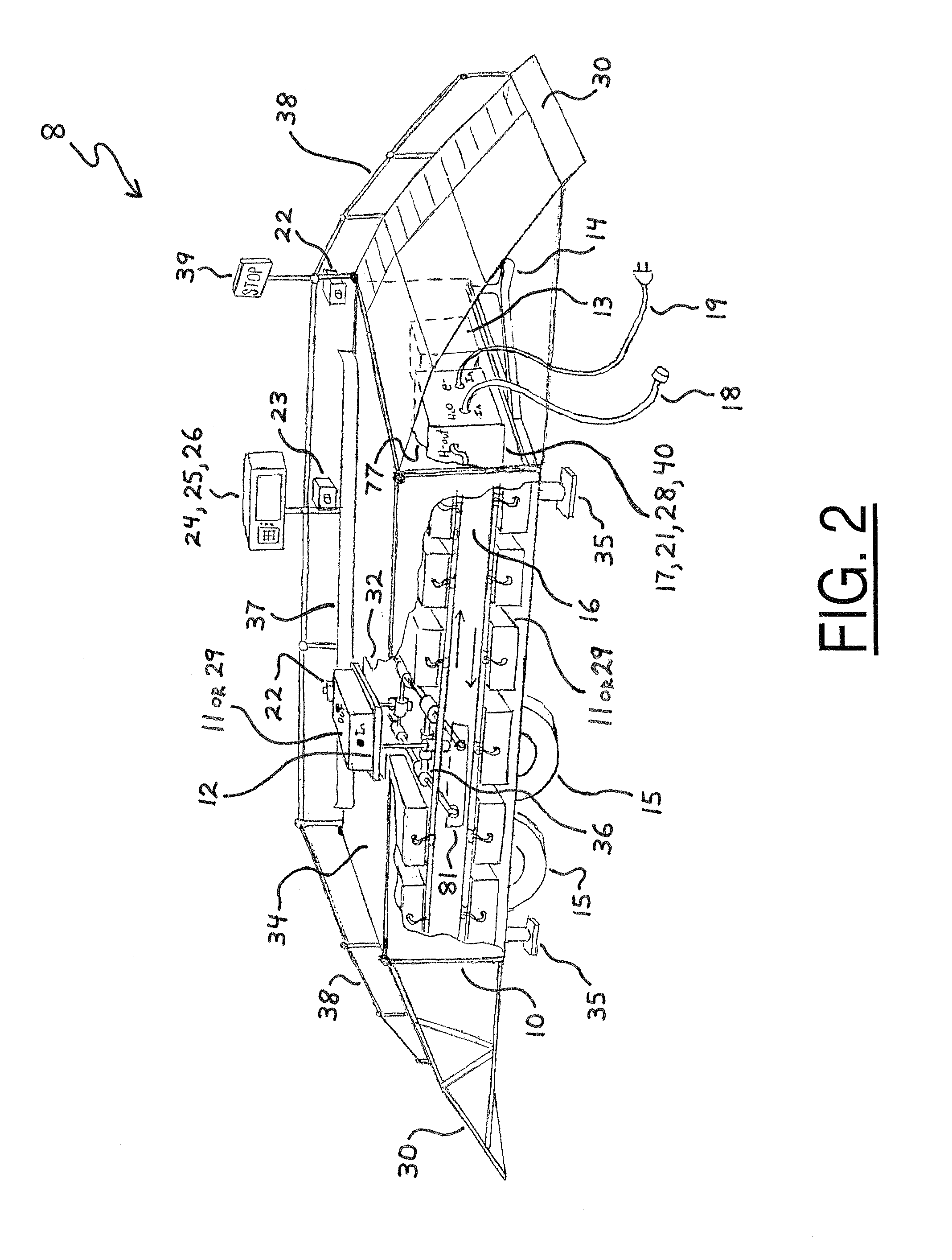

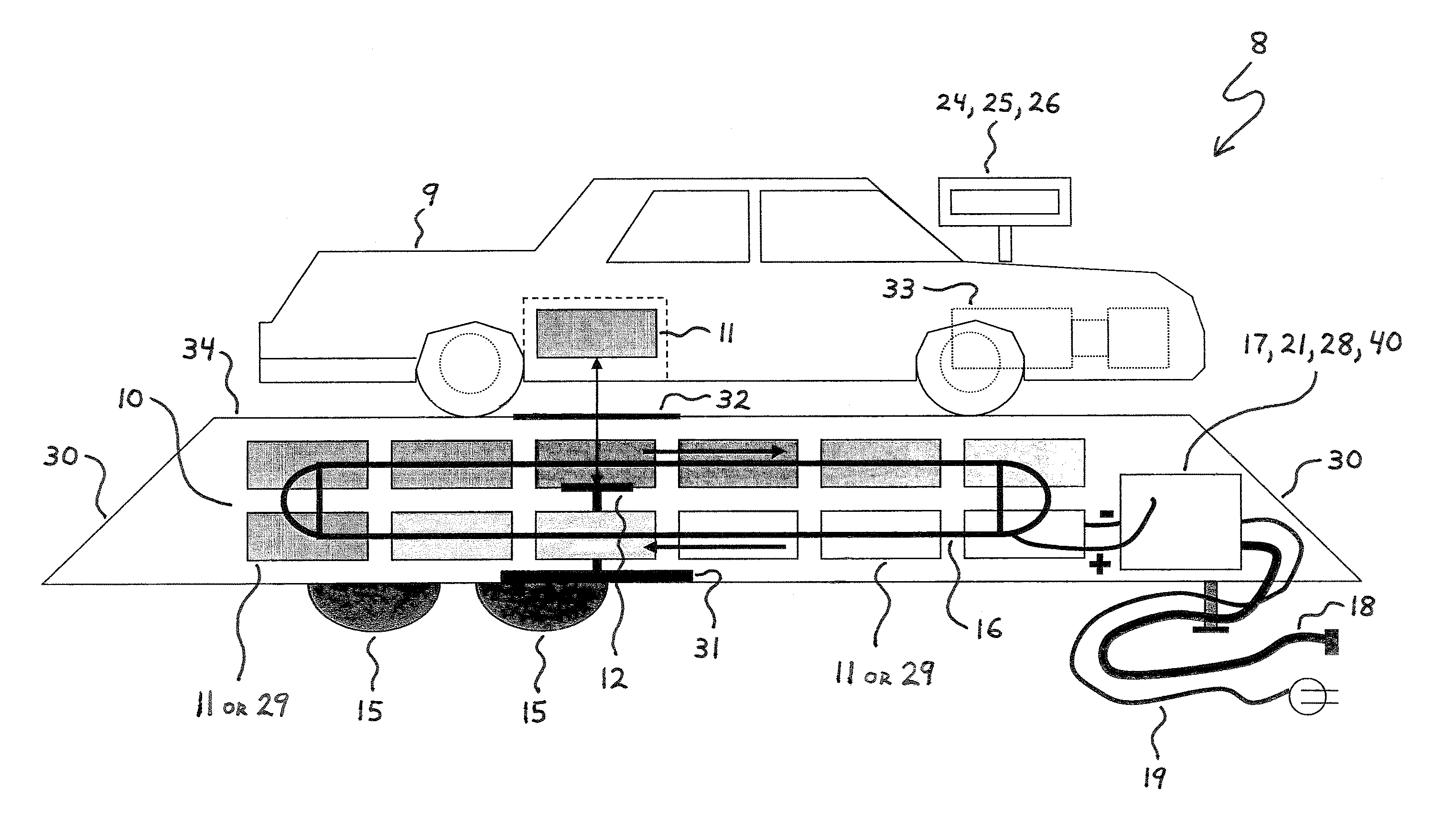

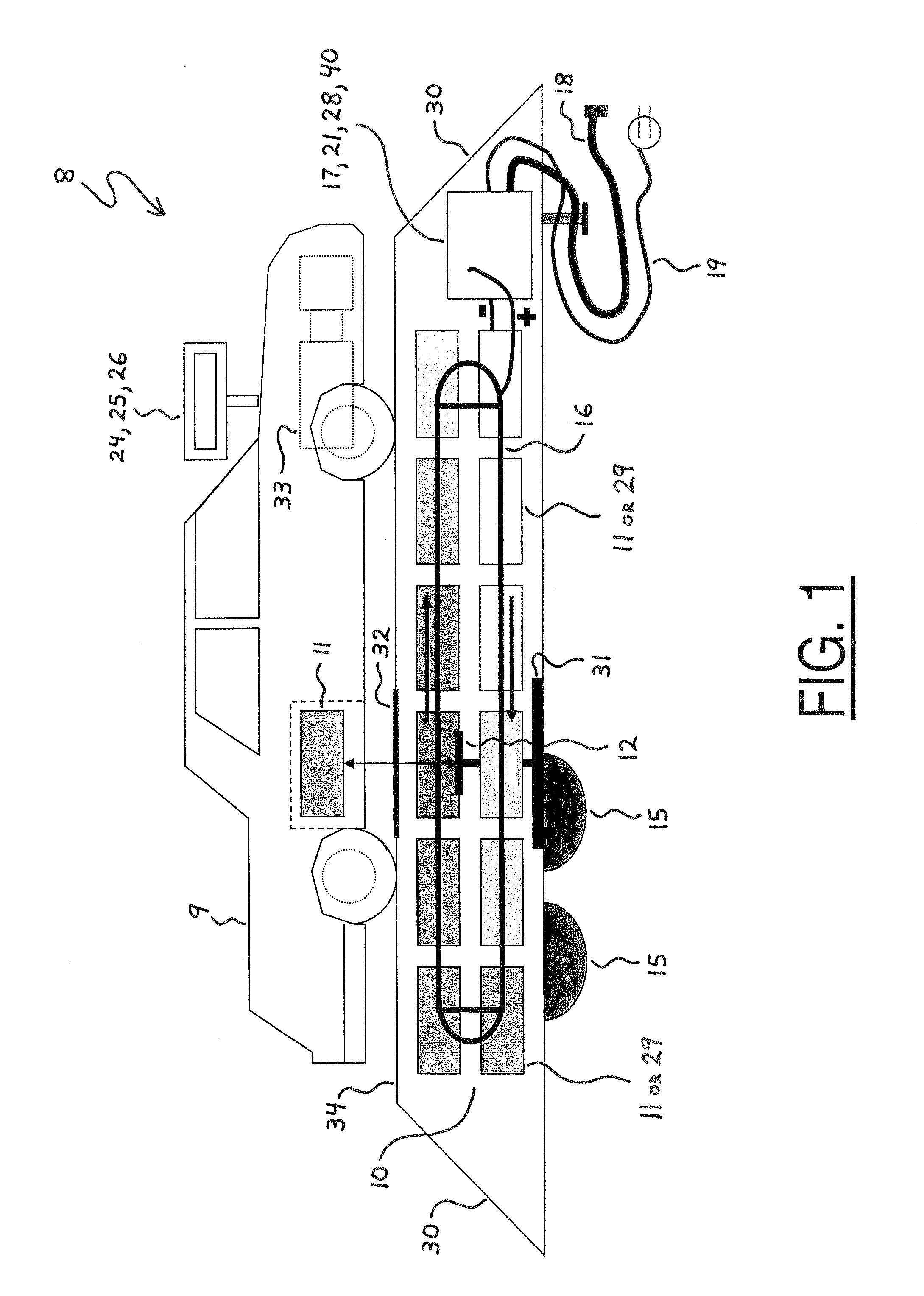

System for replenishing energy sources onboard different types of automotive vehicles

A service station facility for replenishing various motivational energy sources onboard different types of automotive vehicles is disclosed herein. In one embodiment, the service station facility includes a rack, replaceable fuel tanks, a service module, and an electronic computer control system. The replaceable fuel tanks are stocked on the rack and substantially filled with various fluids, such as hydrogen, which are utile as motivational energy sources within fuel-operated automotive vehicles. The service module is mounted on the rack, and the electronic computer control system is connected in electrical communication with the service module. In this configuration, the service module is controllably operable to receive a depleted replaceable fuel tank from a fuel-operated automotive vehicle and also selectively deliver one of the filled replaceable fuel tanks onboard the automotive vehicle. In another embodiment, the service station facility may also stock replaceable batteries for selective delivery onboard battery-operated automotive vehicles.

Owner:CAPIZZO PETER DAVID

System for replenishing energy sources onboard different types of automotive vehicles

Owner:CAPIZZO PETER DAVID

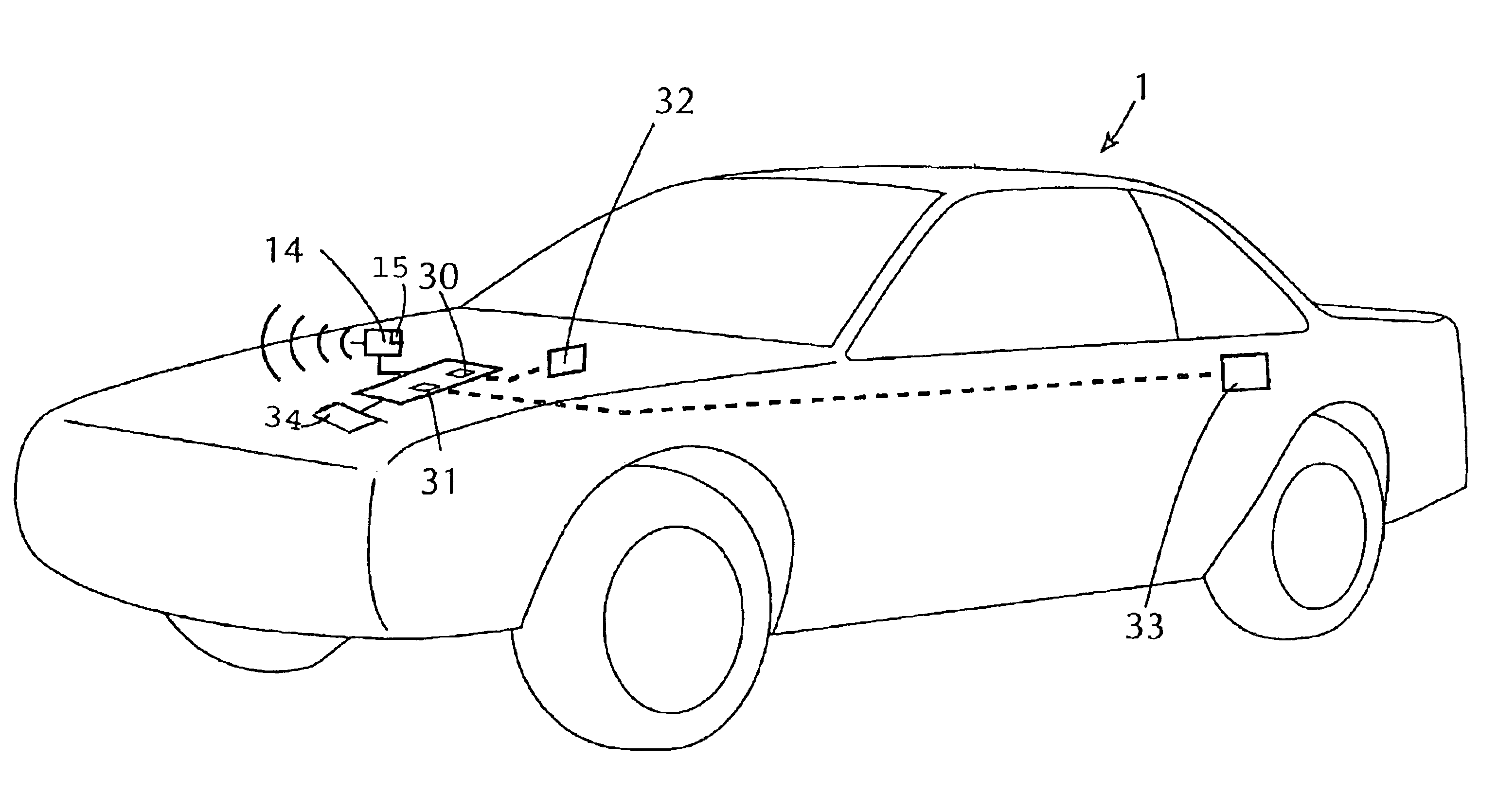

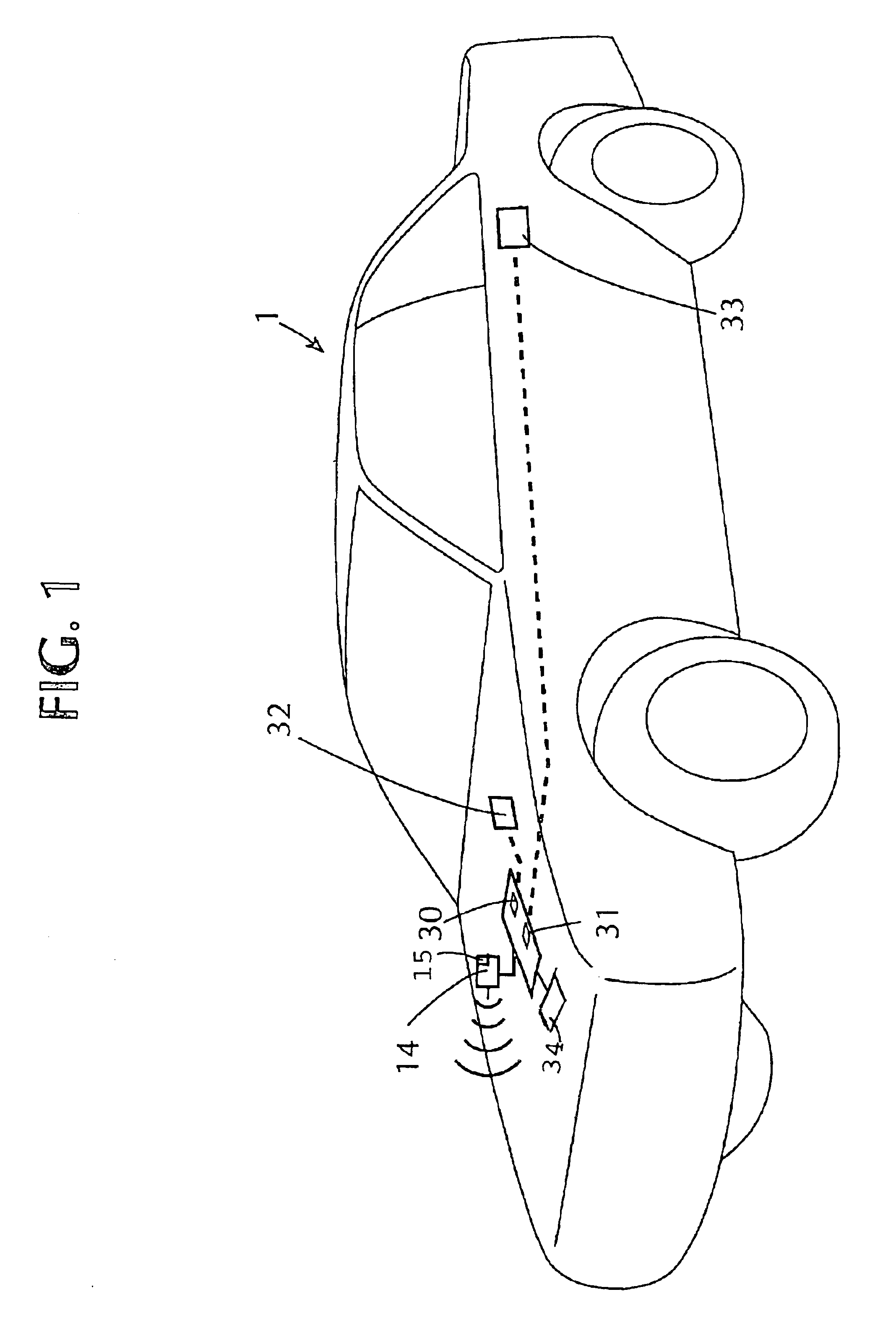

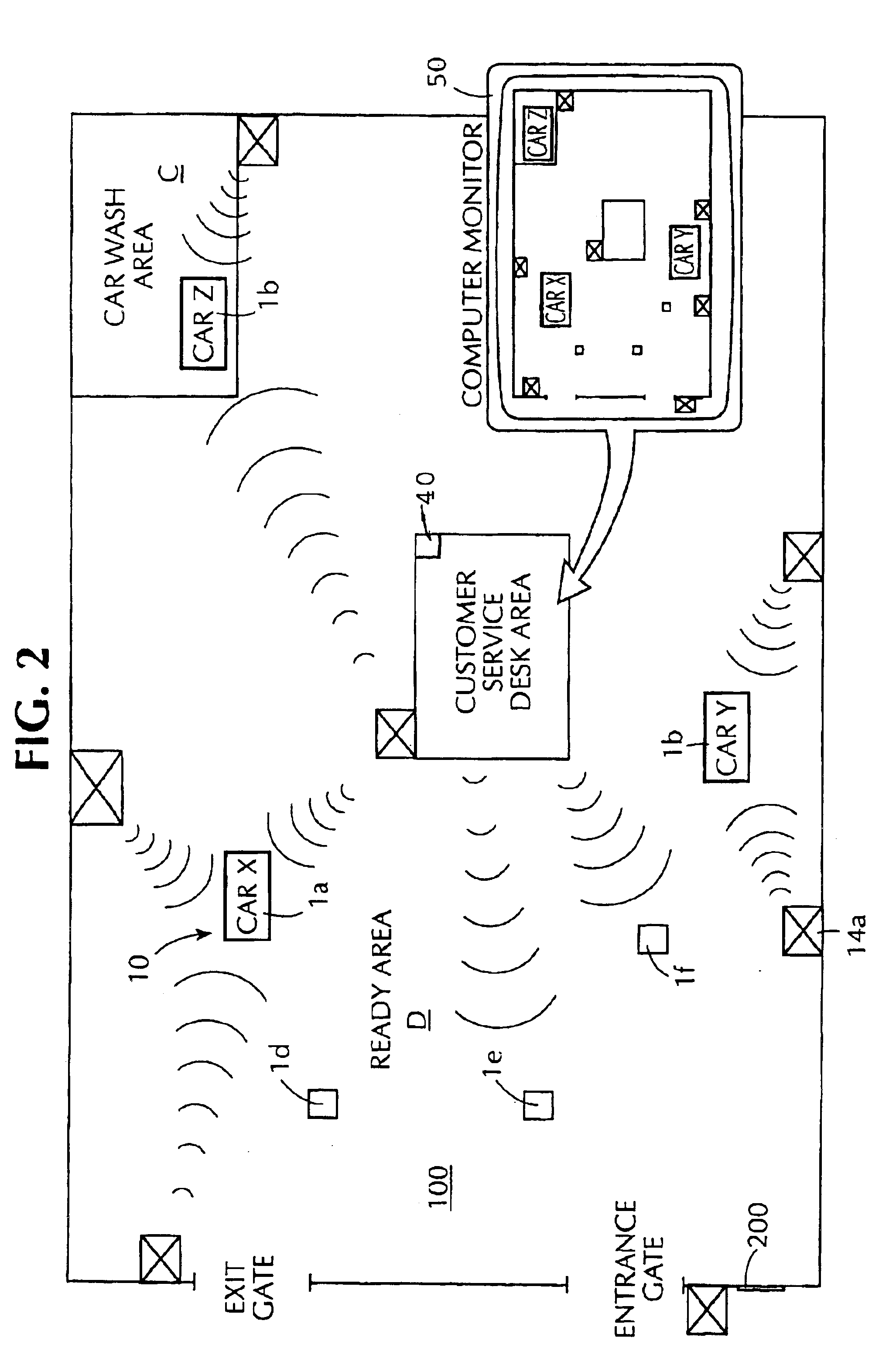

Fully automated vehicle rental system

InactiveUS6898493B2Accurate calculationVehicle testingTicket-issuing apparatusLocation statusIn vehicle

An automated vehicle rental system with individual vehicle transmitting sensors for keeping track of vehicle mileage, fill state of vehicle fuel tank, and localized position status in a rental lot. Sensors are linked to the vehicle odometer reading and to the vehicle fuel tank float sensor with compensation for types of driving and fuel fill-ups which affect float level readings. The sensors are integrated with or are linked with communicating tags operable in a defined site for ultimate communication of stored vehicle related sensor data, vehicle location and type to a central data base for automatically completely effecting check out, charges and state of vehicle readiness for renewed rental. The transmitting sensors are adapted to avoid interference between sensors of other vehicles during multiple transmissions. Also included is an in-vehicle check out and payment device operatively linkable to the transmitting sensor of the vehicle.

Owner:I D SYST

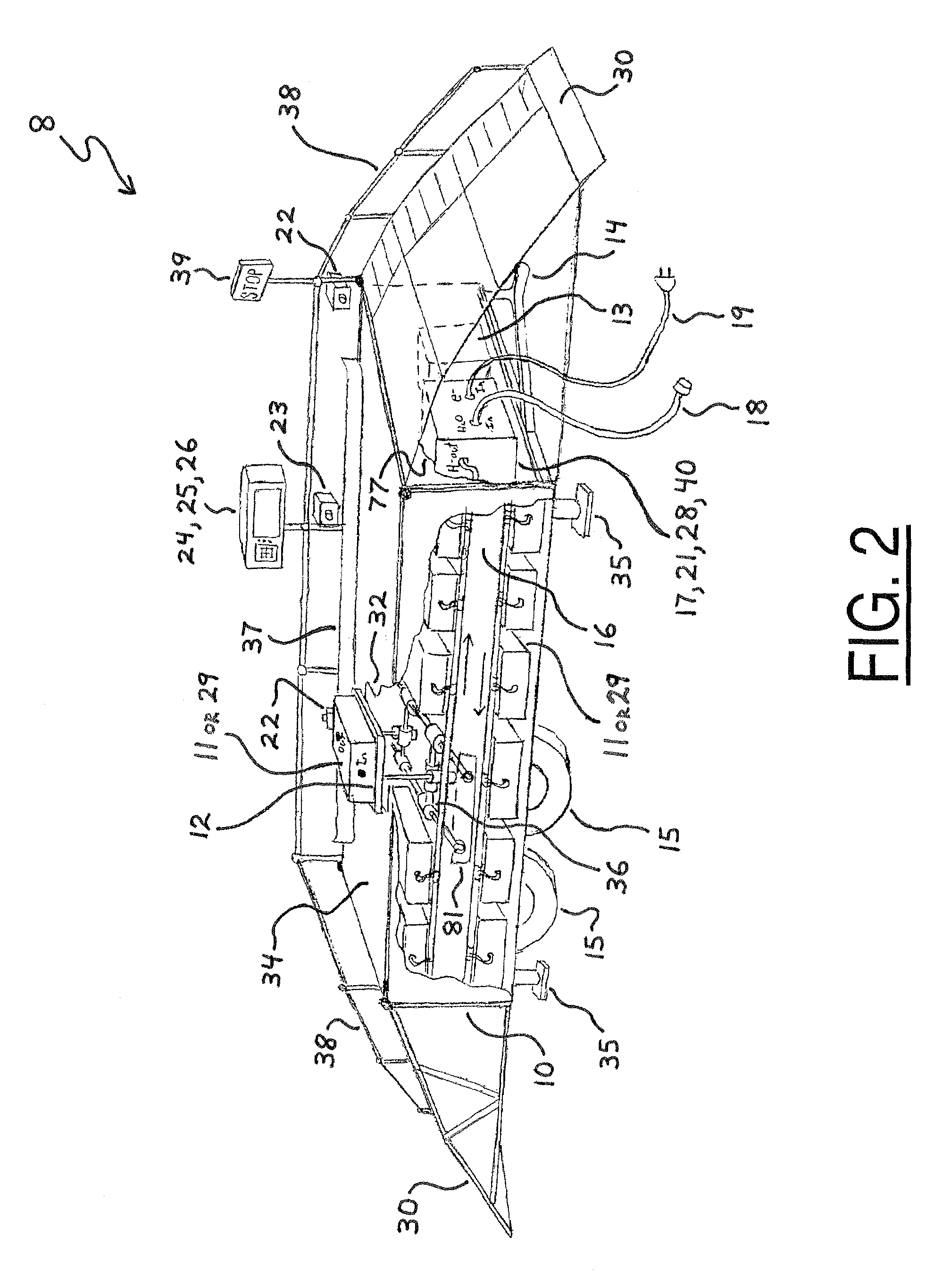

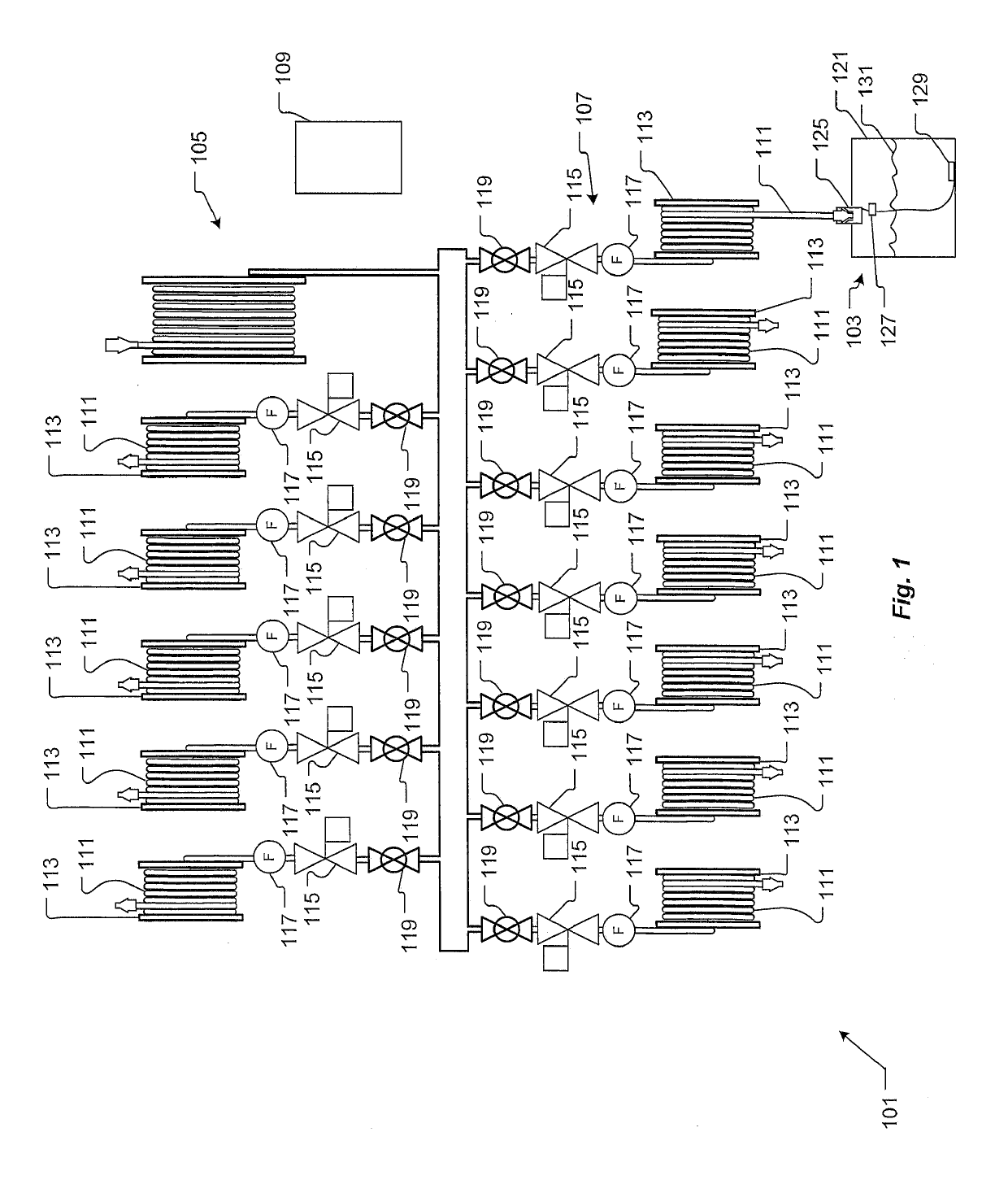

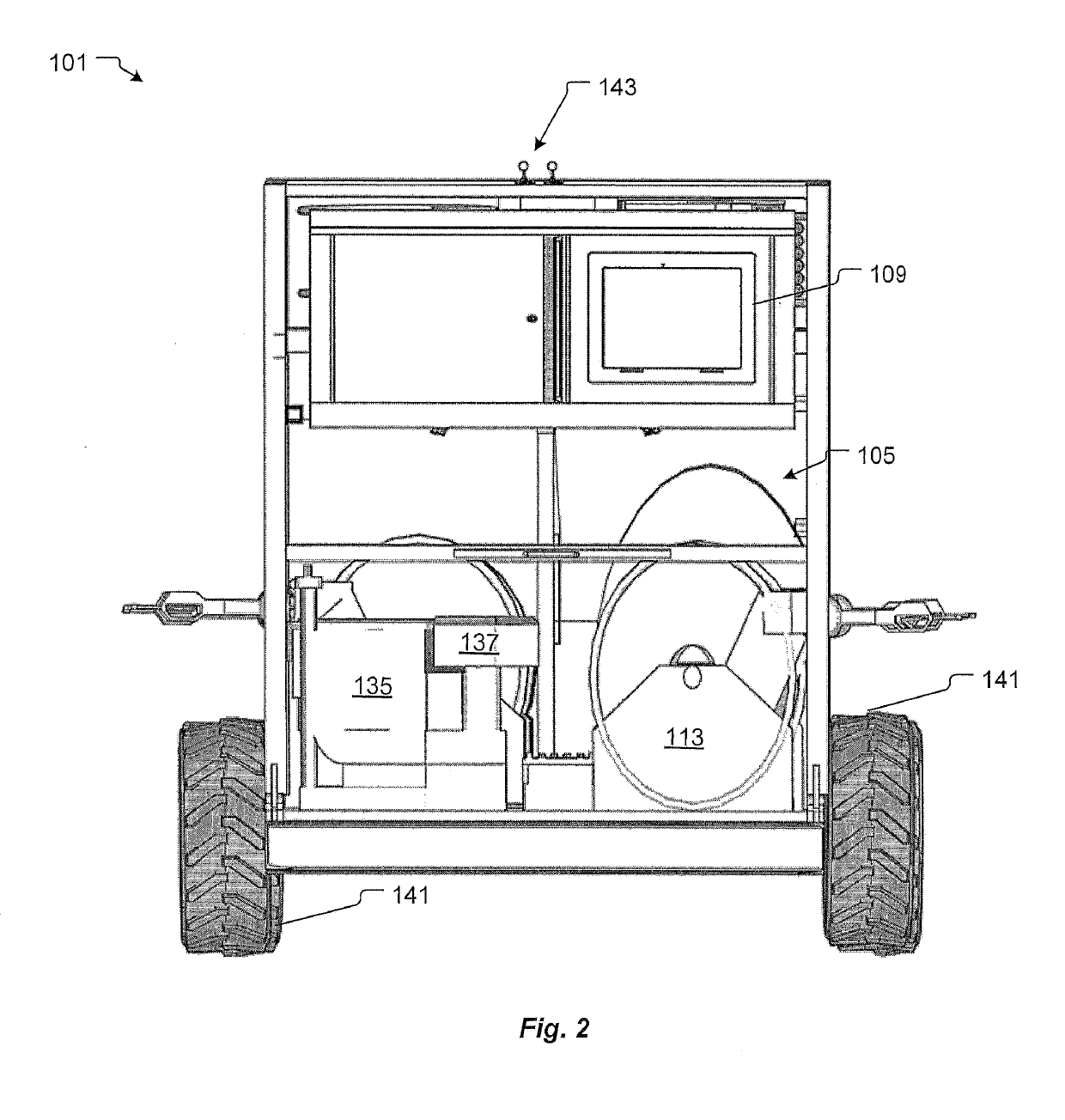

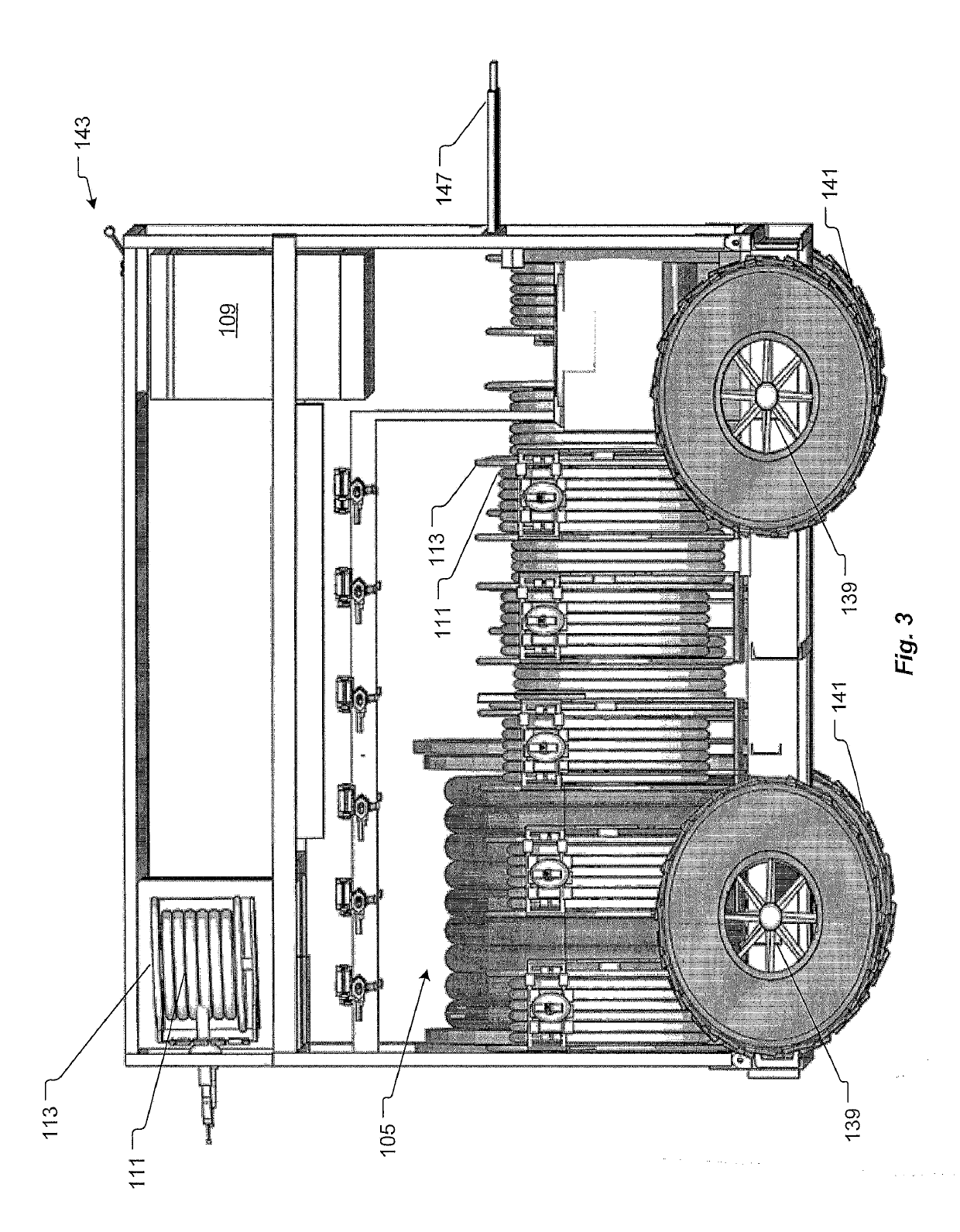

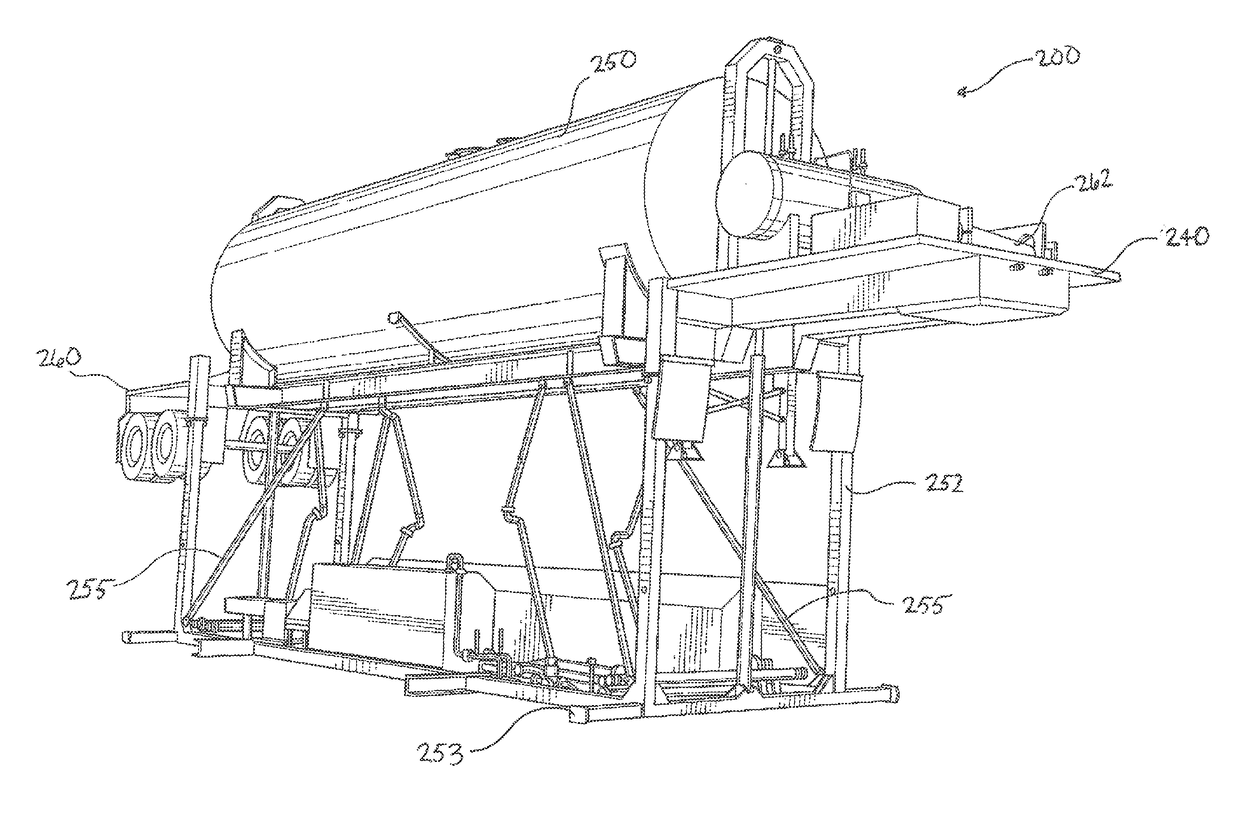

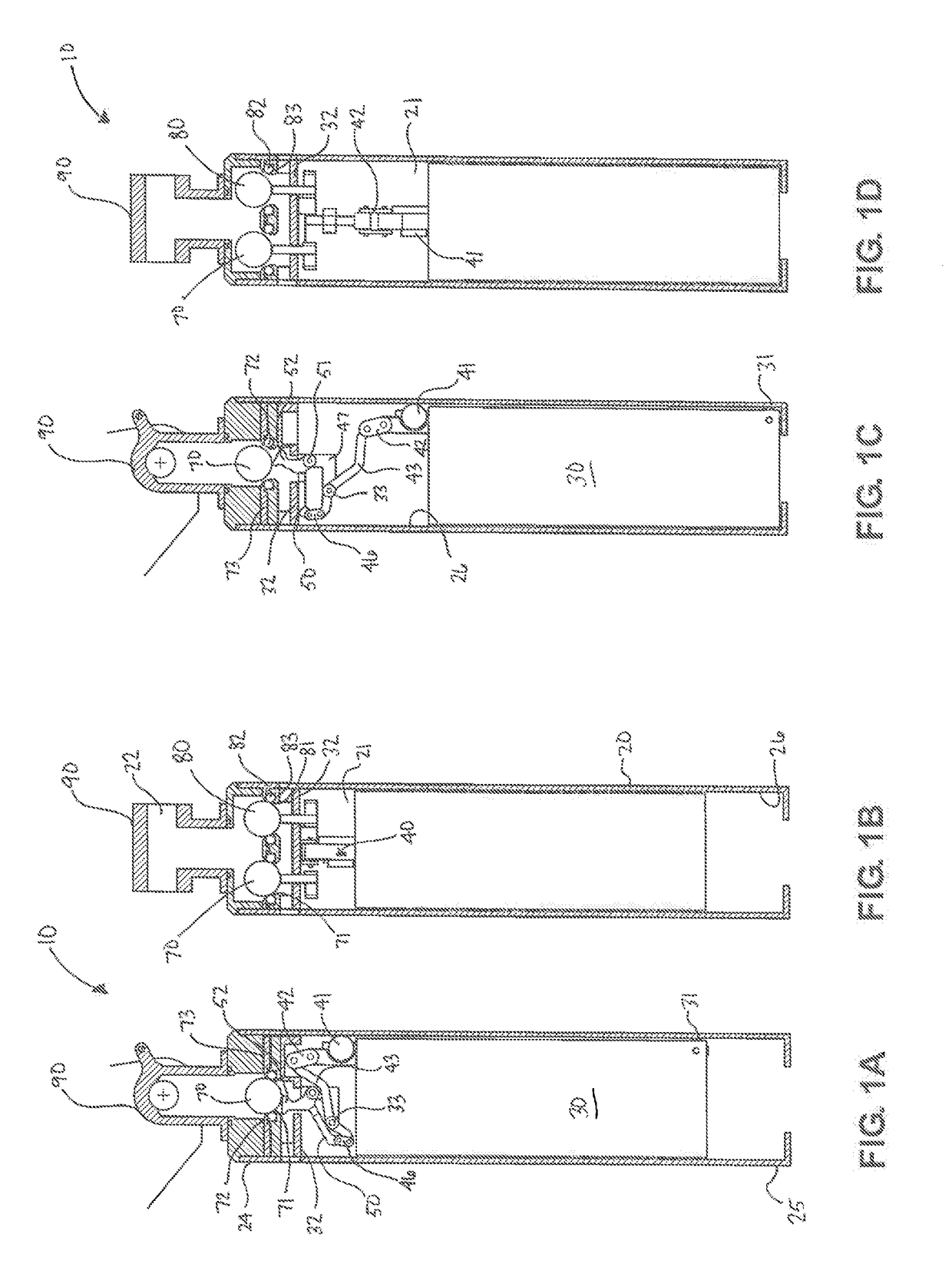

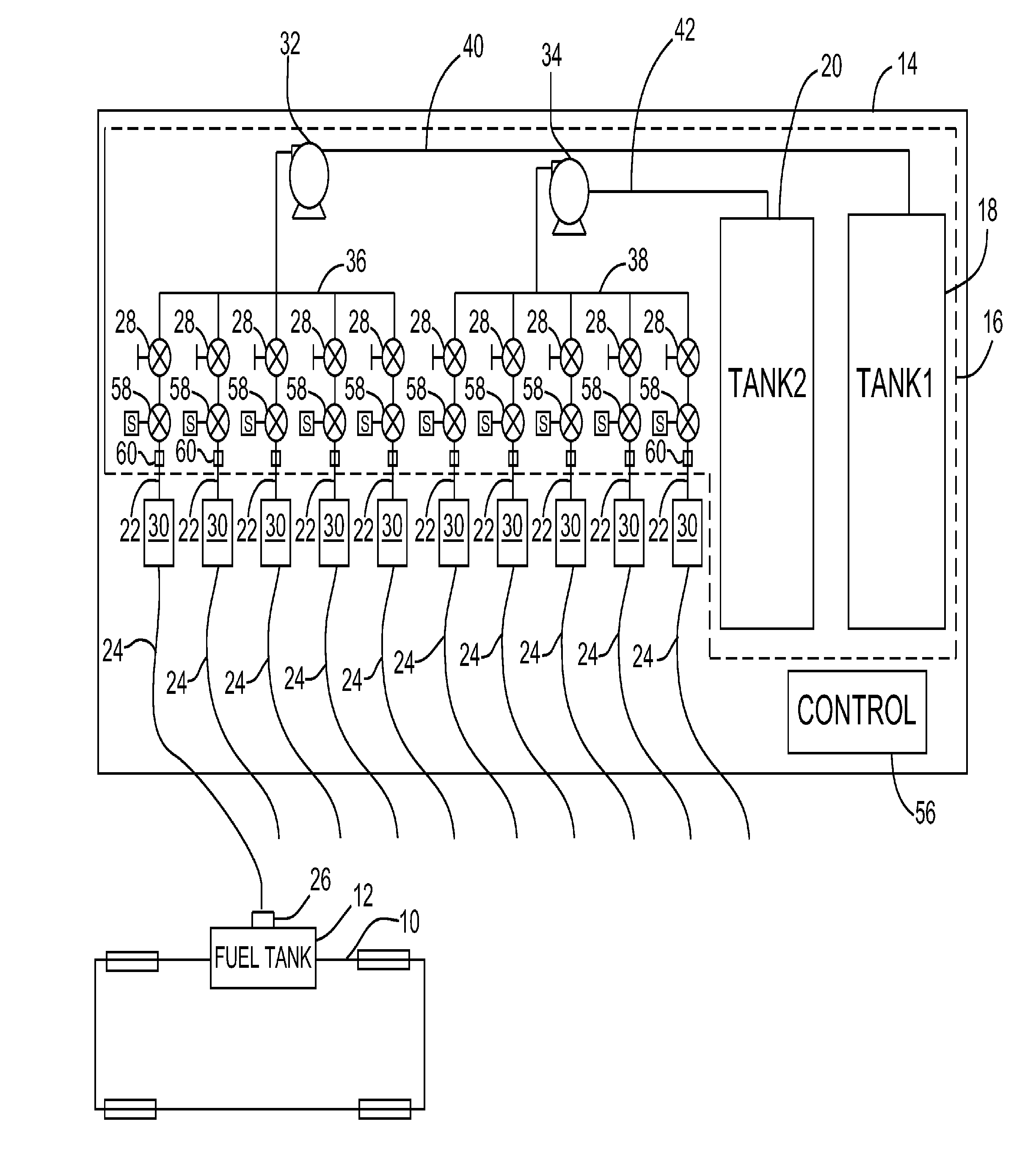

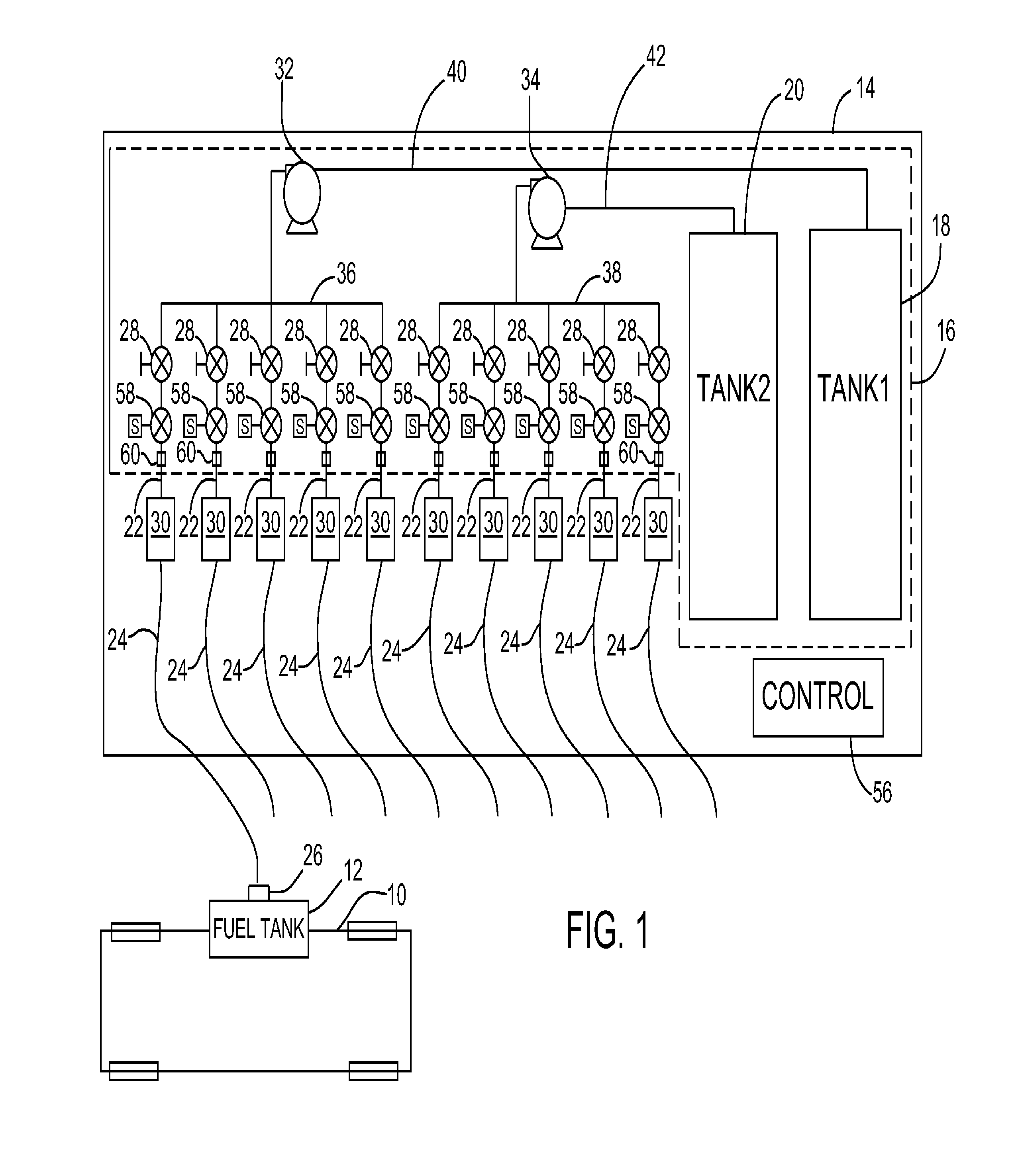

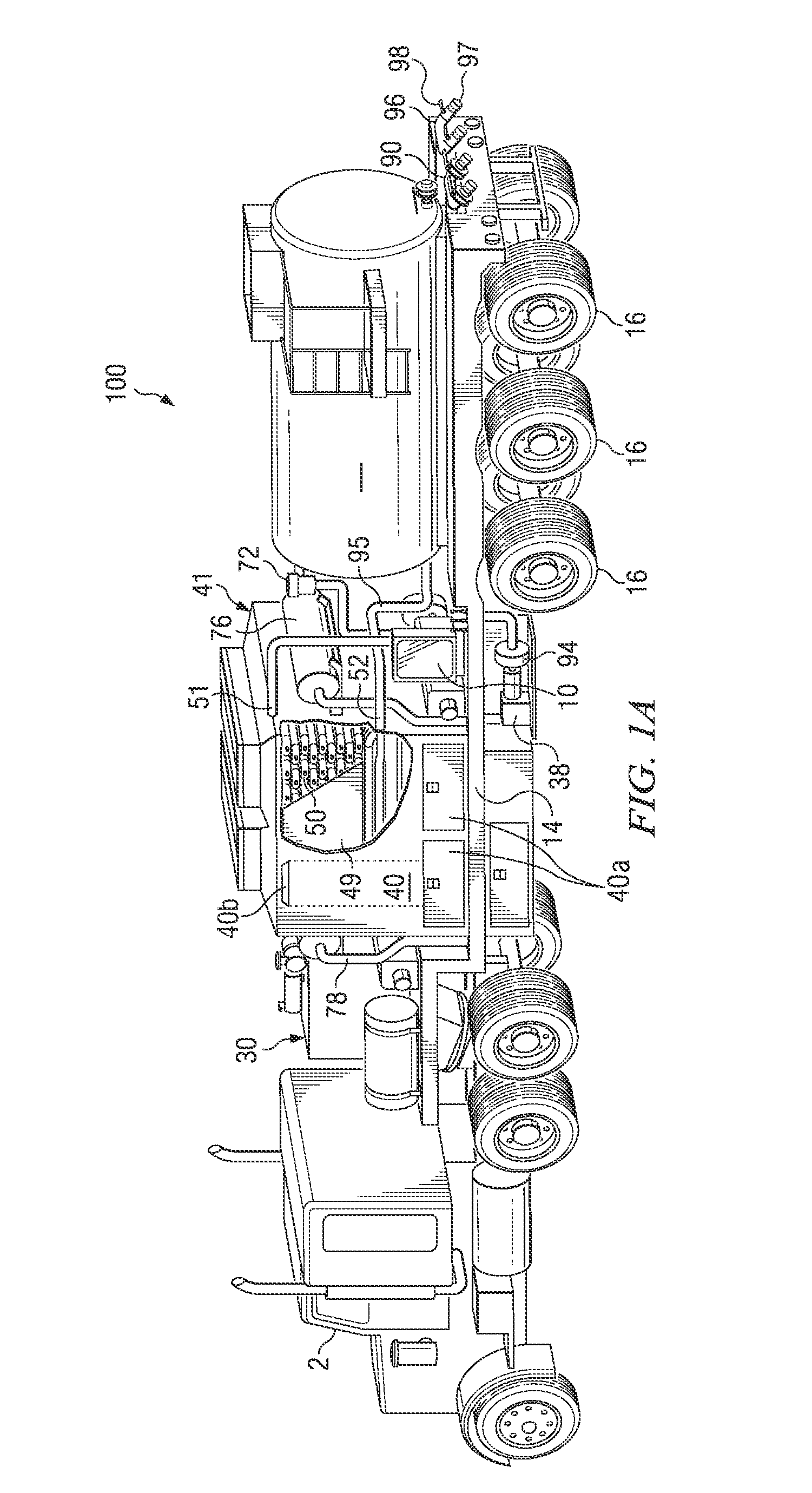

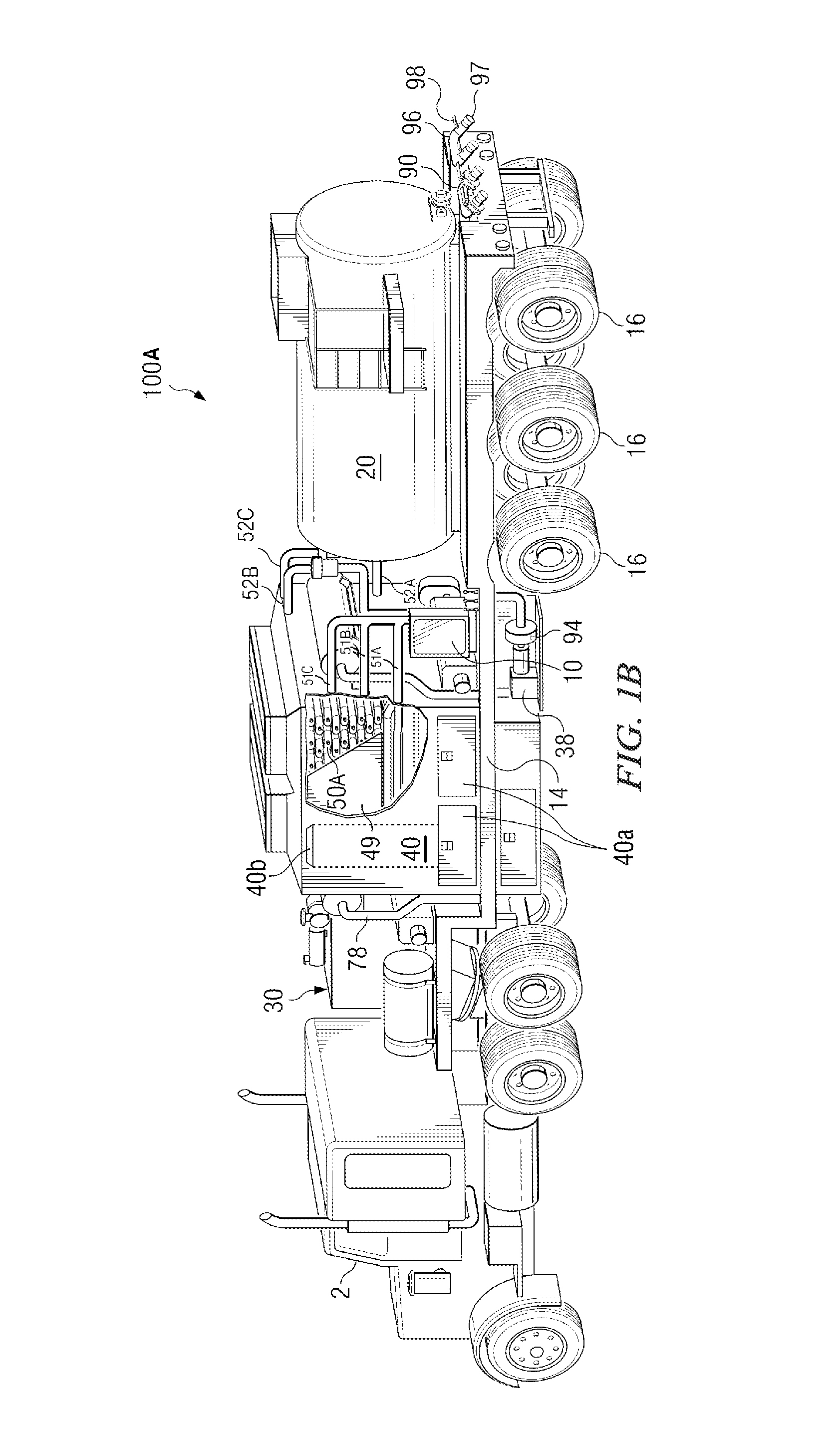

System and Method for Automatic Fueling of Hydraulic Fracturing and Other Oilfield Equipment

A system and method for fueling multiple saddle tanks of hydraulic fracturing equipment from a single self-propelled cart. The cart having multiple retractable fuel lines for providing and obtaining fuel. Each retractable fuel supply line uses a flowmeter, a ball valve, and an electrically actuated valve to provide remote control to a controller based on a user's selected fueling requirements. An electronic reporting system provides fuel data to operators and users. Fuel data such as fuel tank status, an amount of fuel usage over a stage level, a daily level, or job level along with a fill level of the fuel tank.

Owner:AMERICAN ENERGY INNOVATIONS LLC

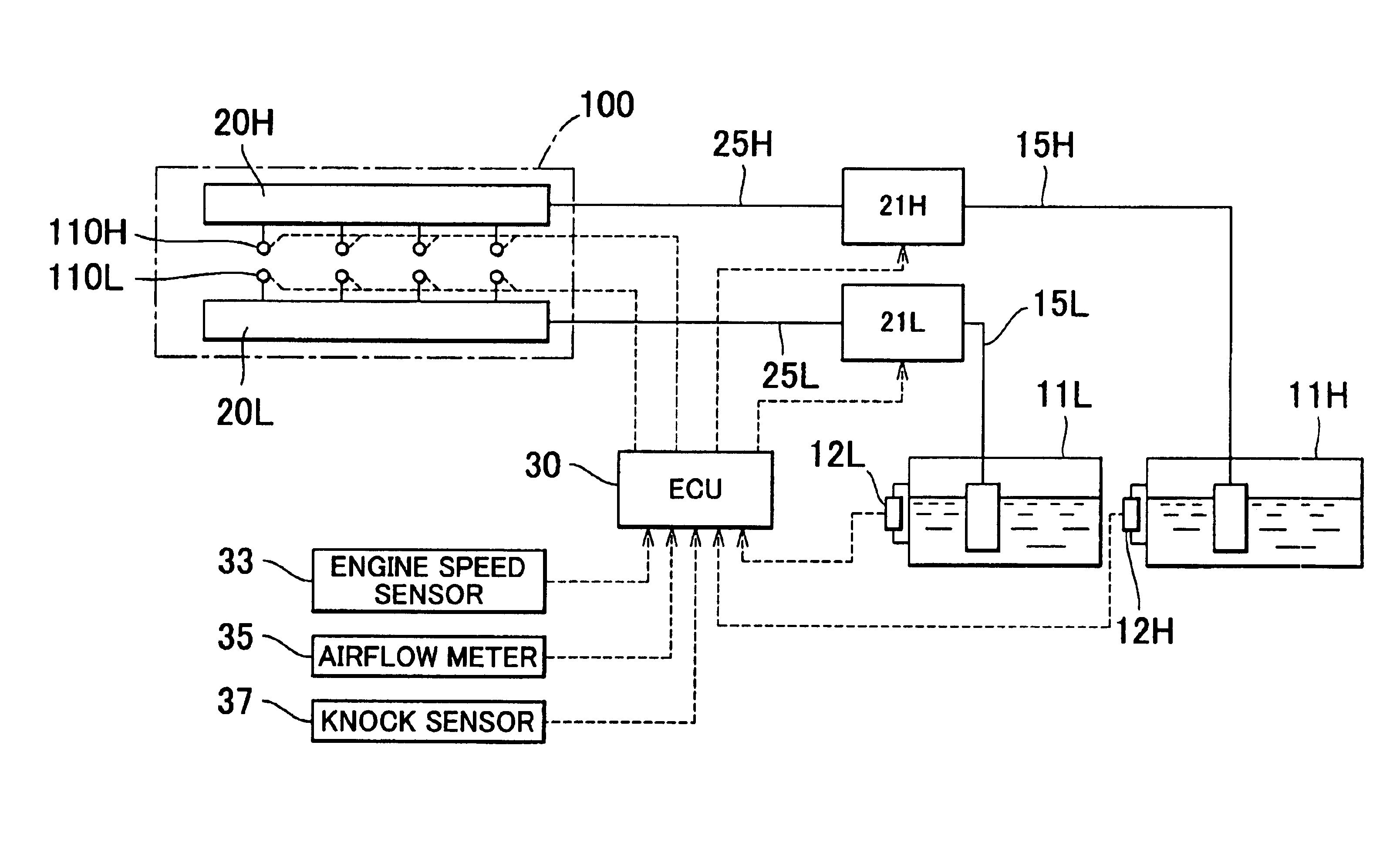

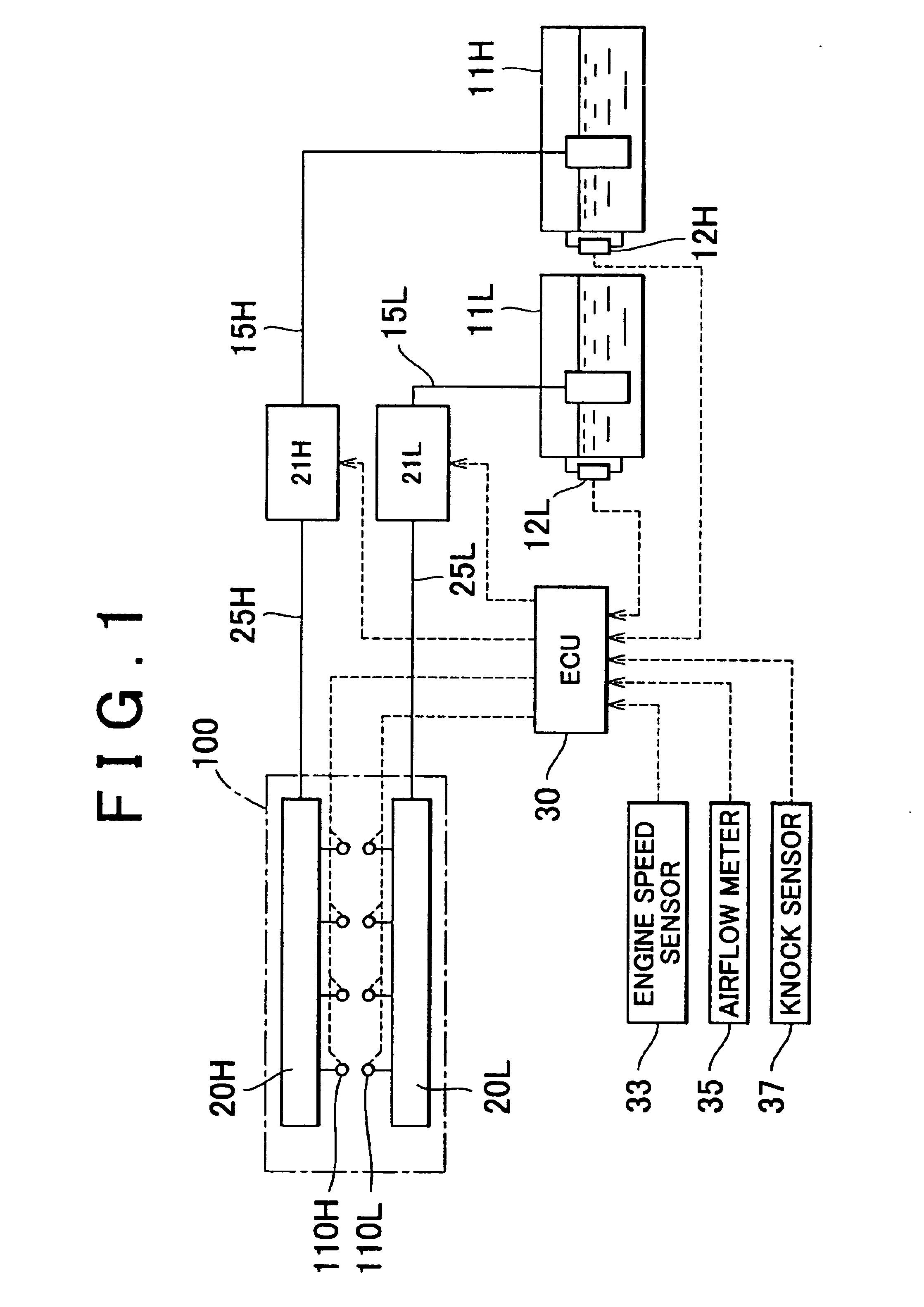

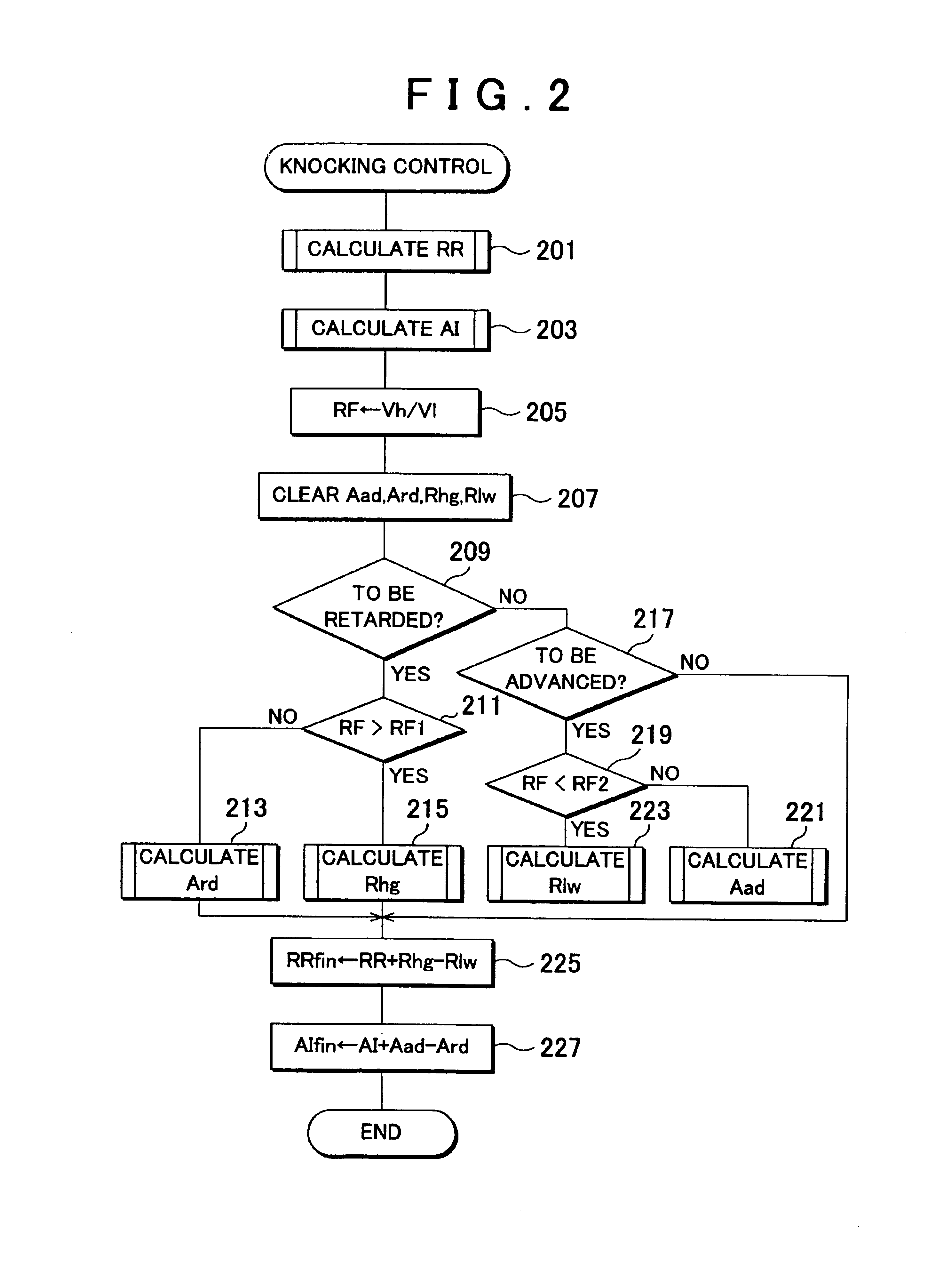

Knocking control system and method for internal combustion engine using multiple fuels

InactiveUS6951202B2Maintain balanceImprove balanceElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

High octane fuel and low octane fuel are supplied into the combustion chamber of an engine from high-octane fuel tank and low octane fuel tank via a high octane fuel injector and a low octane fuel injector. During a knocking control, if the quantity of high and low octane fuels in the respective tanks has been unbalanced, the supply ratio between high octane fuel and low octane fuel is changed 1 to control a knocking occurring in the engine without changing the ignition timing.

Owner:TOYOTA JIDOSHA KK

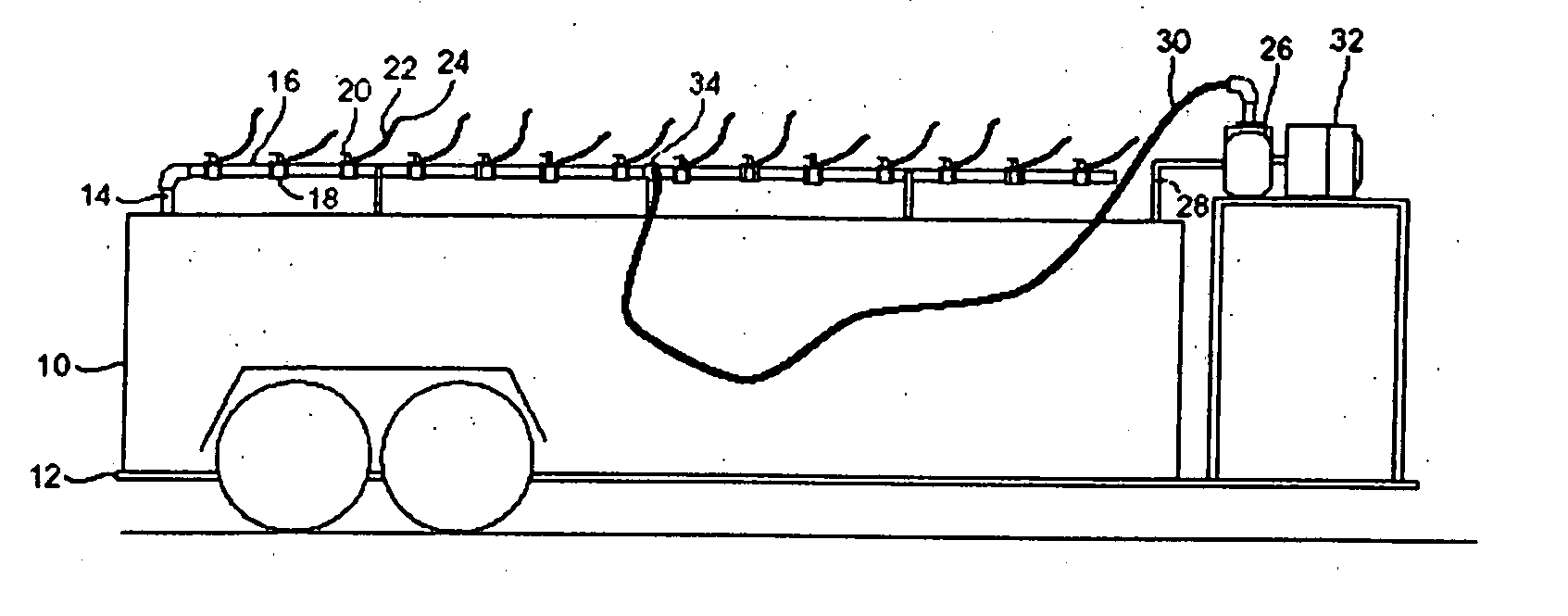

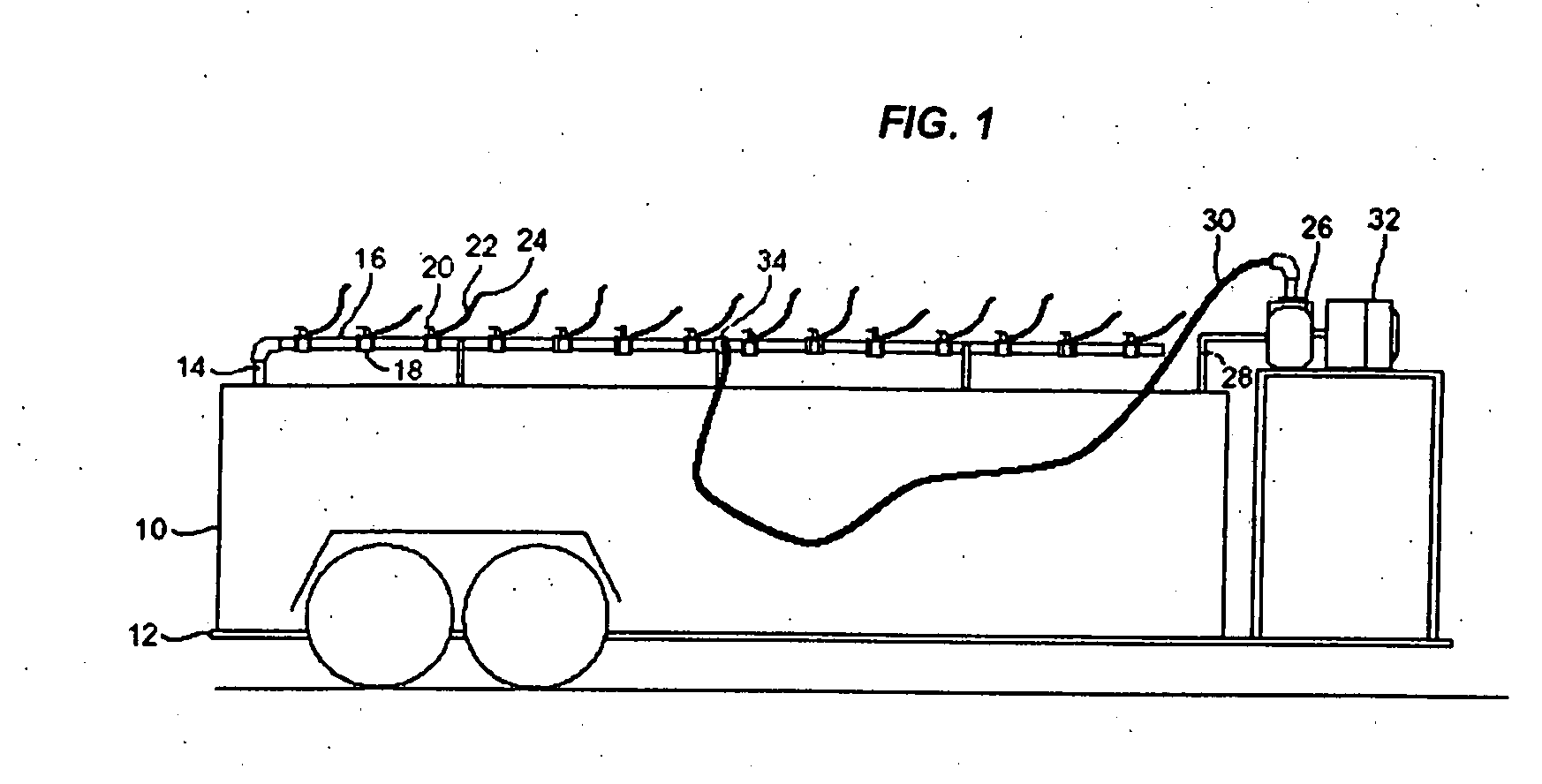

Method and apparatus for refueling multiple vehicles

InactiveUS20070181212A1Easy accessReduces time and expenseSolid materialItem transportation vehiclesFuel tankTruck

A refueling dock for refueling multiple vehicles at one time is disclosed. The dock has a manifold that has an inlet that can be connected to a fuel tanker truck and a plurality of outlet openings. Each outlet opening has a valve that controls the flow of fuel through the hose. A nozzle is fitted to the hose and is located at the end of the hose distant from the outlet opening. Two or more hoses can be simultaneously connected to different equipment in need of refueling. A valved fuel tank inlet line enables fuel to flow from the manifold to a fuel tank on the dock. When needed, fuel from the tank can then be pumped to the manifold through a fuel tank outlet line,.which can be connected to the same inlet on the manifold that is used to receive fuel from the tanker trick.

Owner:RYAN CENT

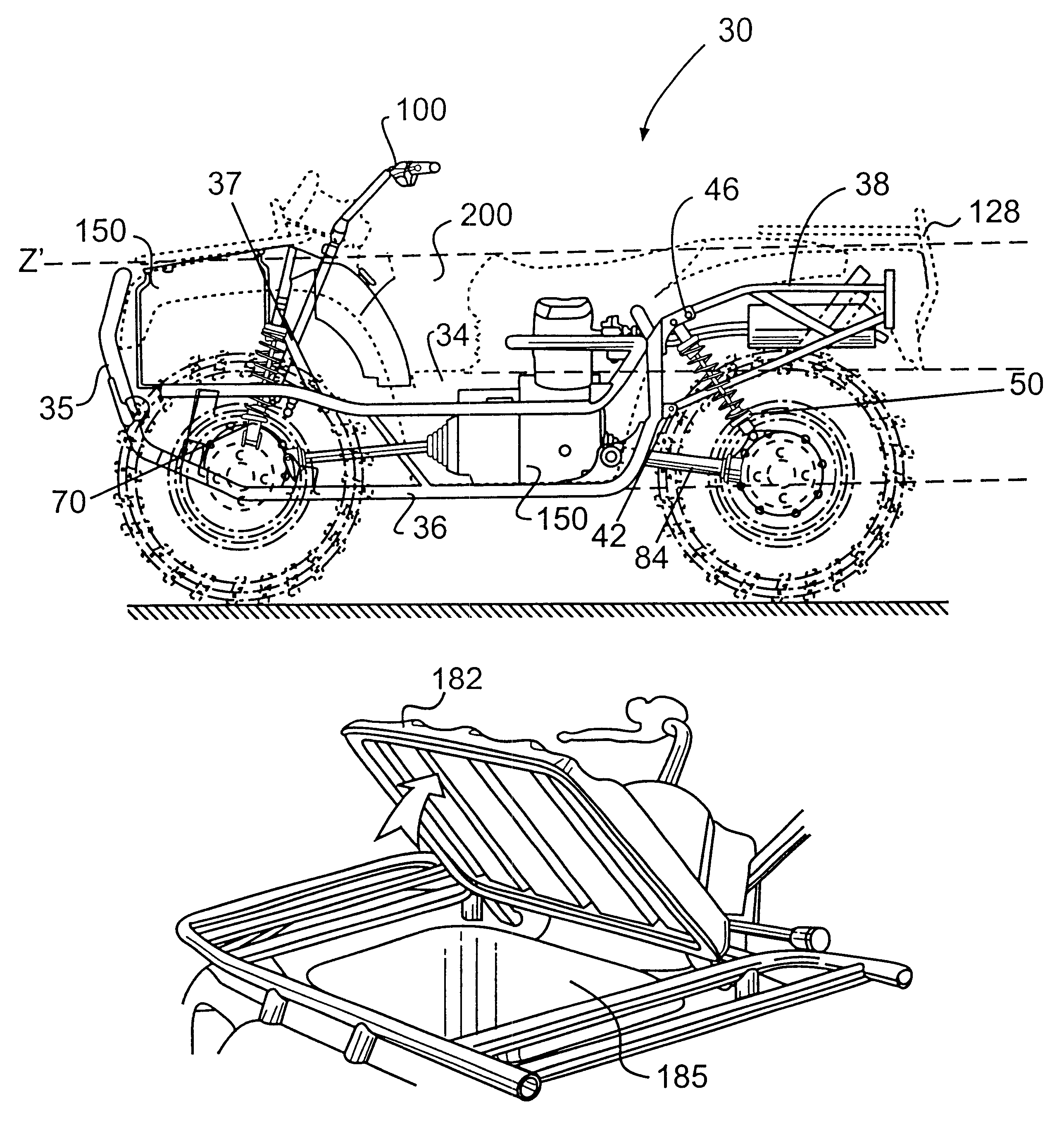

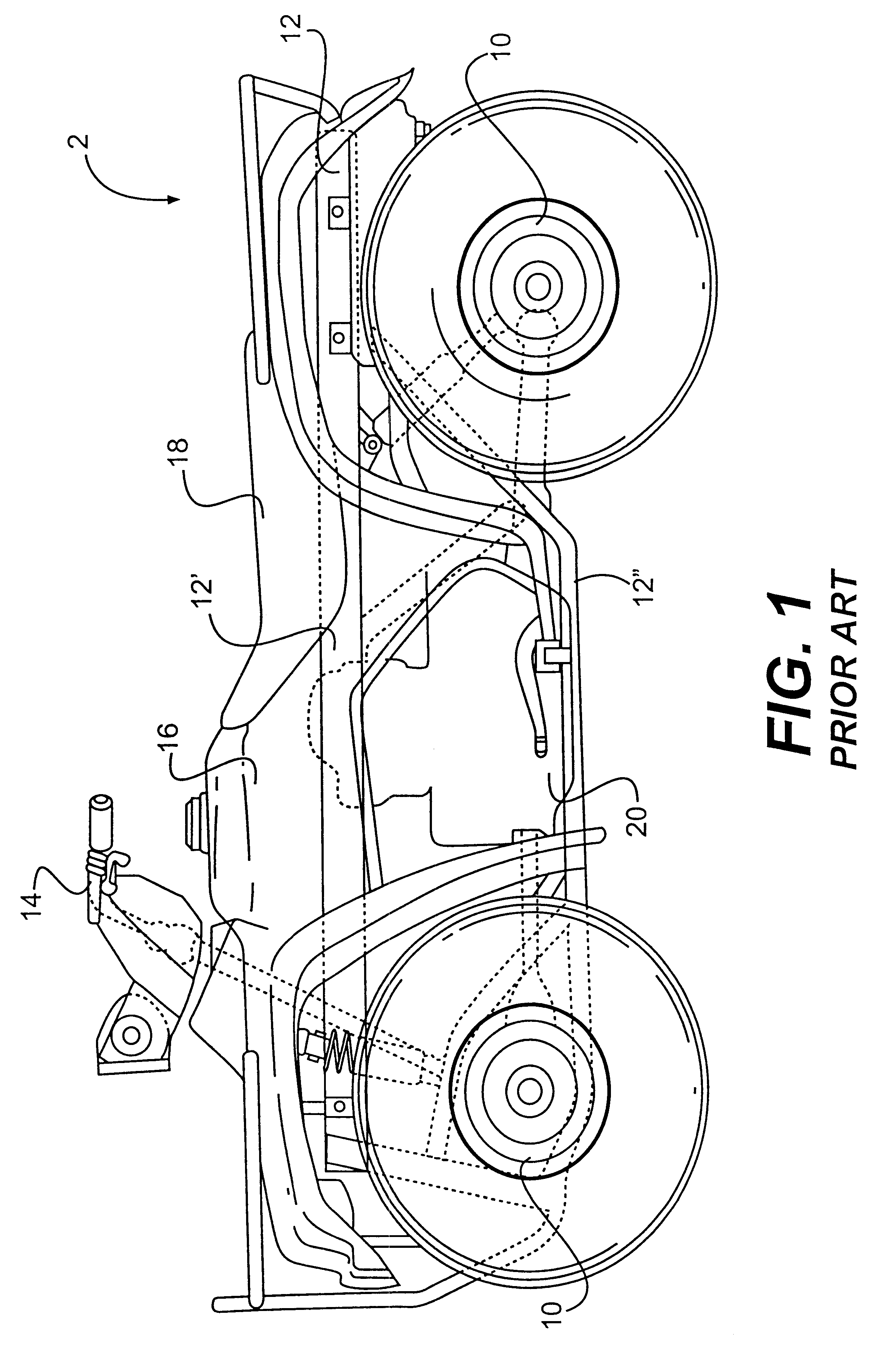

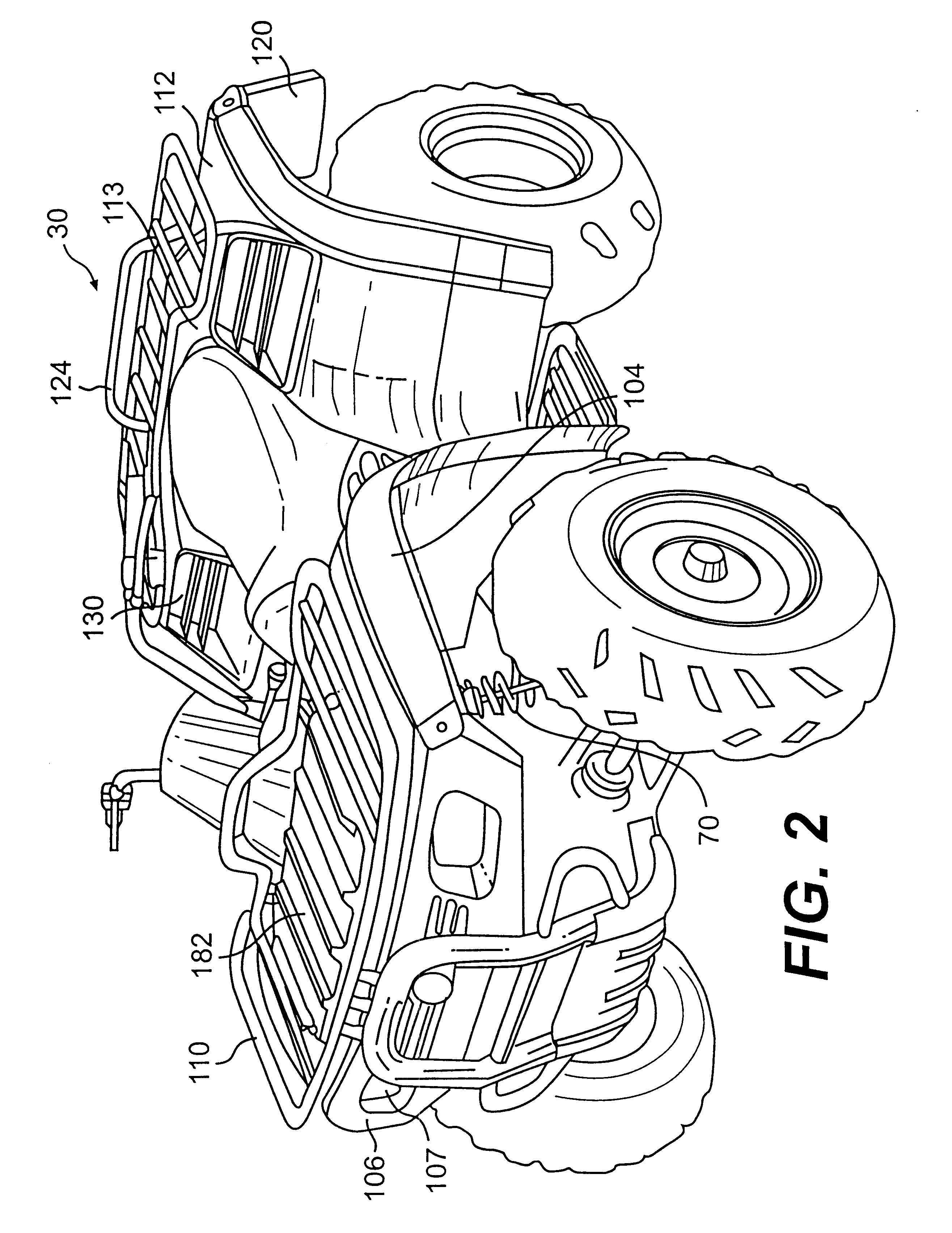

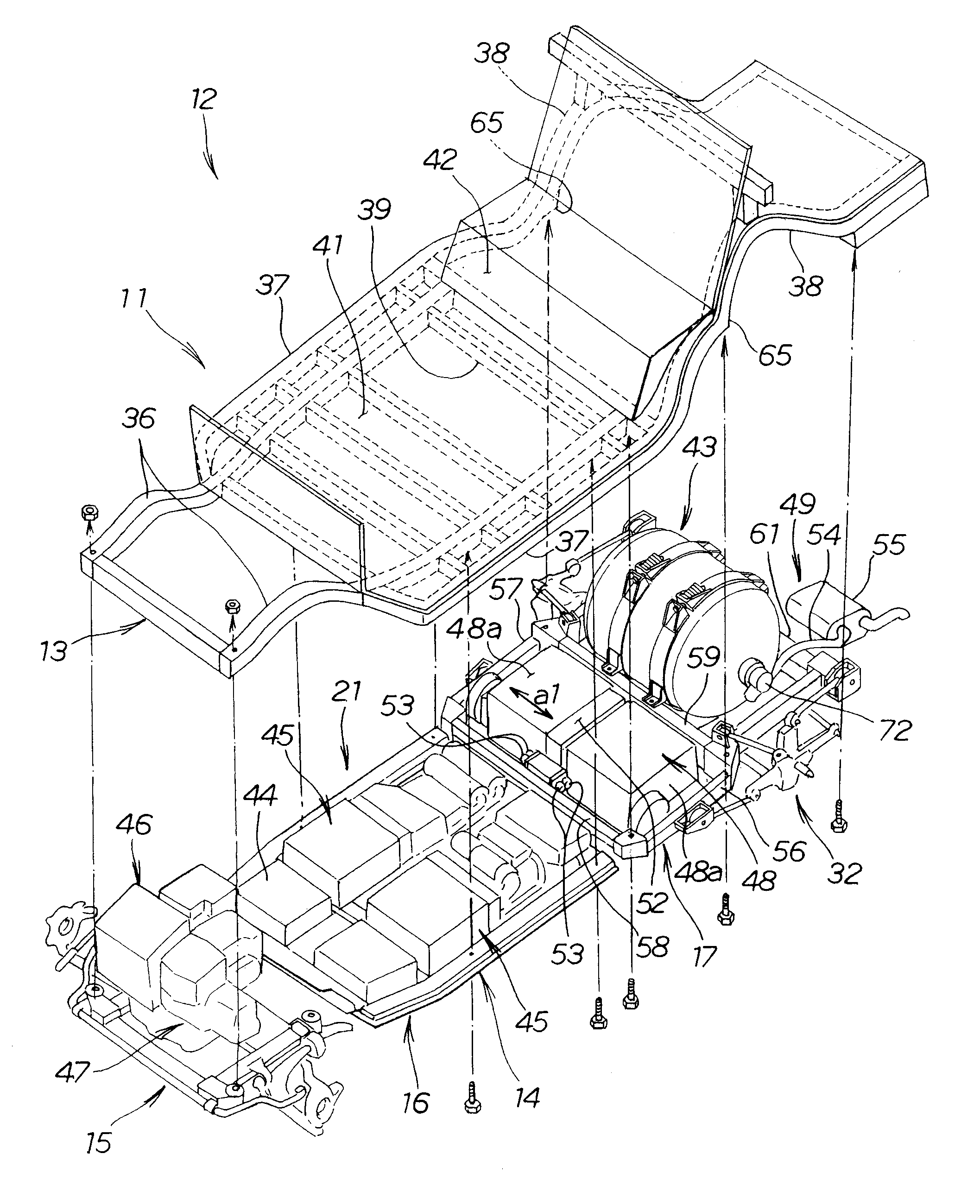

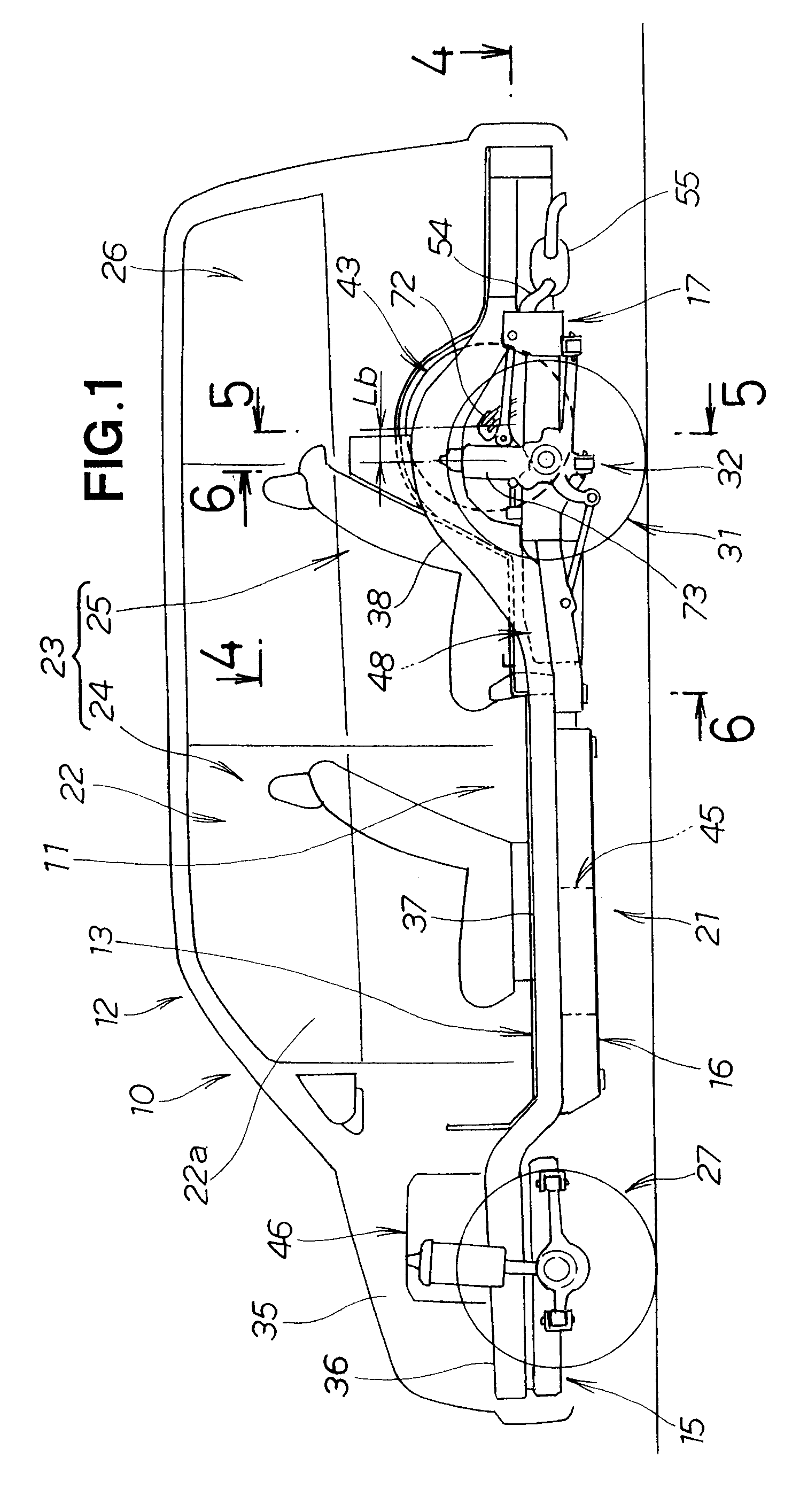

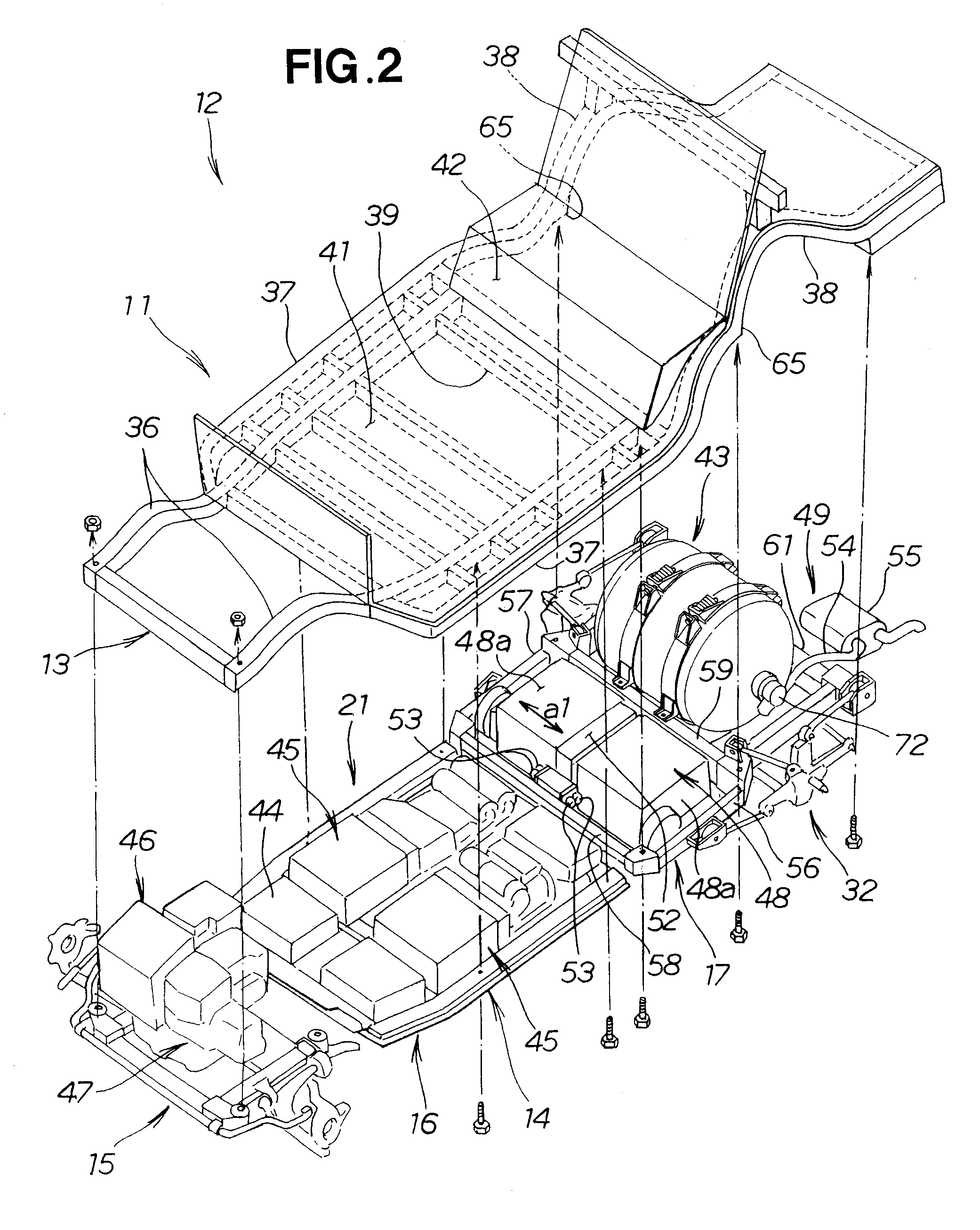

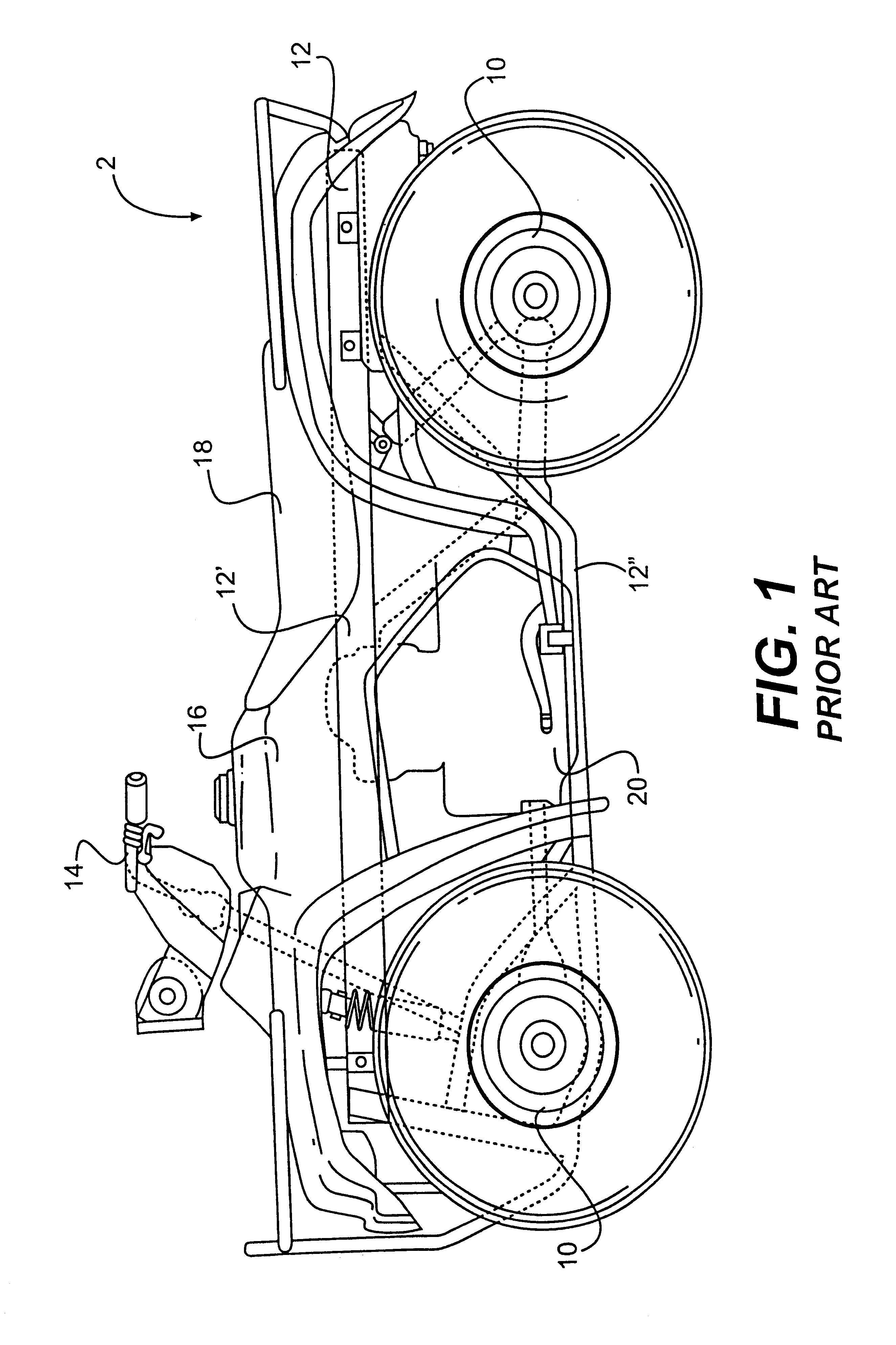

All terrain vehicle

InactiveUS6523634B1Convenient framingAdd featureTank vehiclesMachines/enginesDriver/operatorFuel tank

A straddle-type vehicle, or all terrain vehicle, has an engine located towards the rear of the vehicle such that a main portion of the engine, or power unit, is disposed beneath the seat. The fuel tank extends generally vertically beneath the steering member. The radiator is located at a rear portion of the vehicle rearwardly of the engine where it is protected from collisions and objects striking the front grille. A front storage compartment is also provided in the front portion of the vehicle. The vehicle also has a pivotally connected and removable seat for easy access to the engine. There is also a gap between the seat and the front wheel well through which the driver can pass his feet or where an optional container or auxiliary fuel tank can be secured.

Owner:BOMBARDIER RECREATIONAL PROD INC

Vehicle body structure

InactiveUS20060289224A1Easy to useLower center of gravityTank vehiclesUnderstructuresVehicle frameFuel tank

A vehicle body structure includes a body frame with a subframe mounted to a lower part of the body frame. The subframe is formed into a rectangular shape and has front, intermediate and rear cross members. A storage battery is designed to be mounted astride the front cross member and the intermediate cross member. A fuel tank is designed to be mounted astride the intermediate cross member and the rear cross member.

Owner:HONDA MOTOR CO LTD

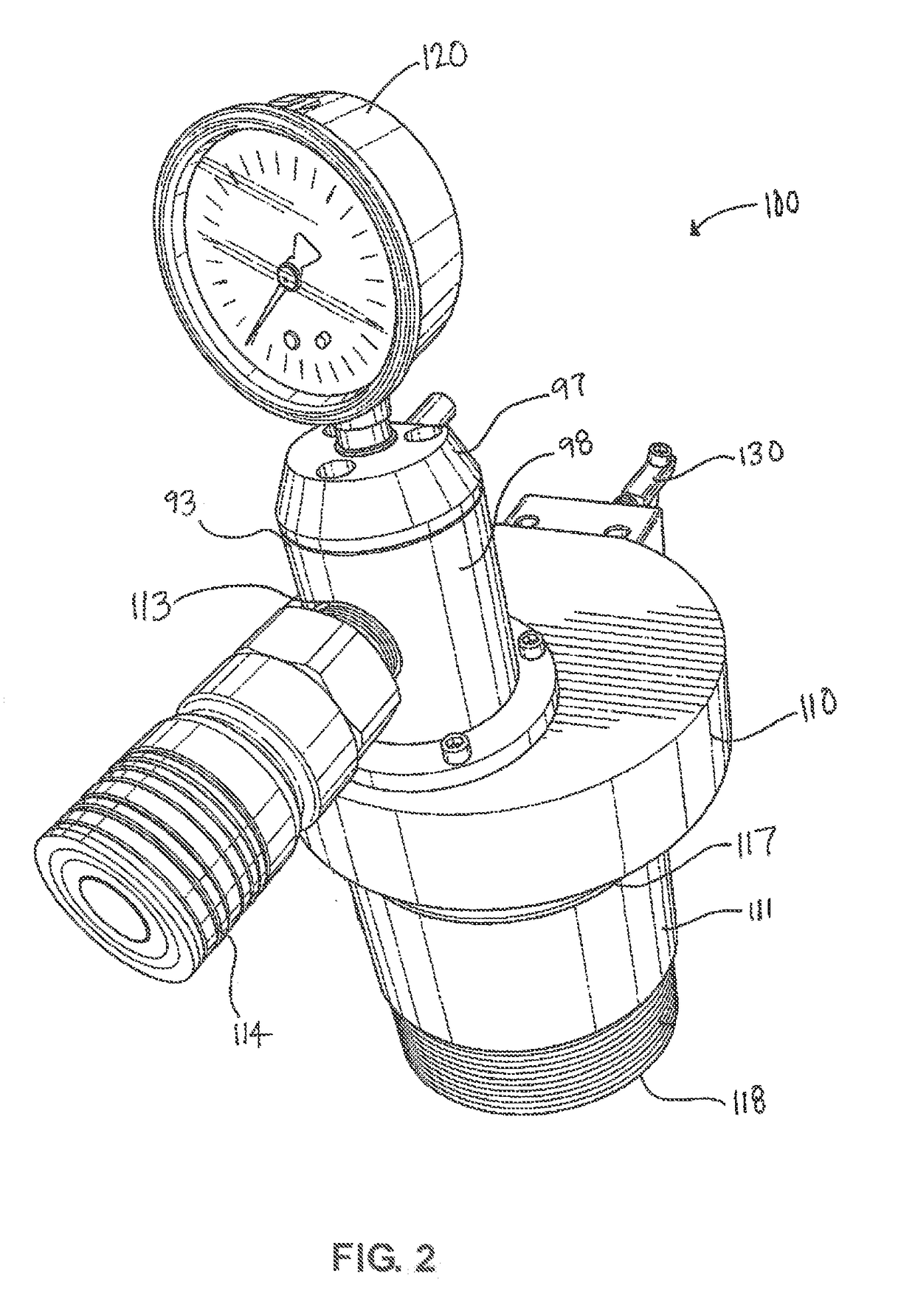

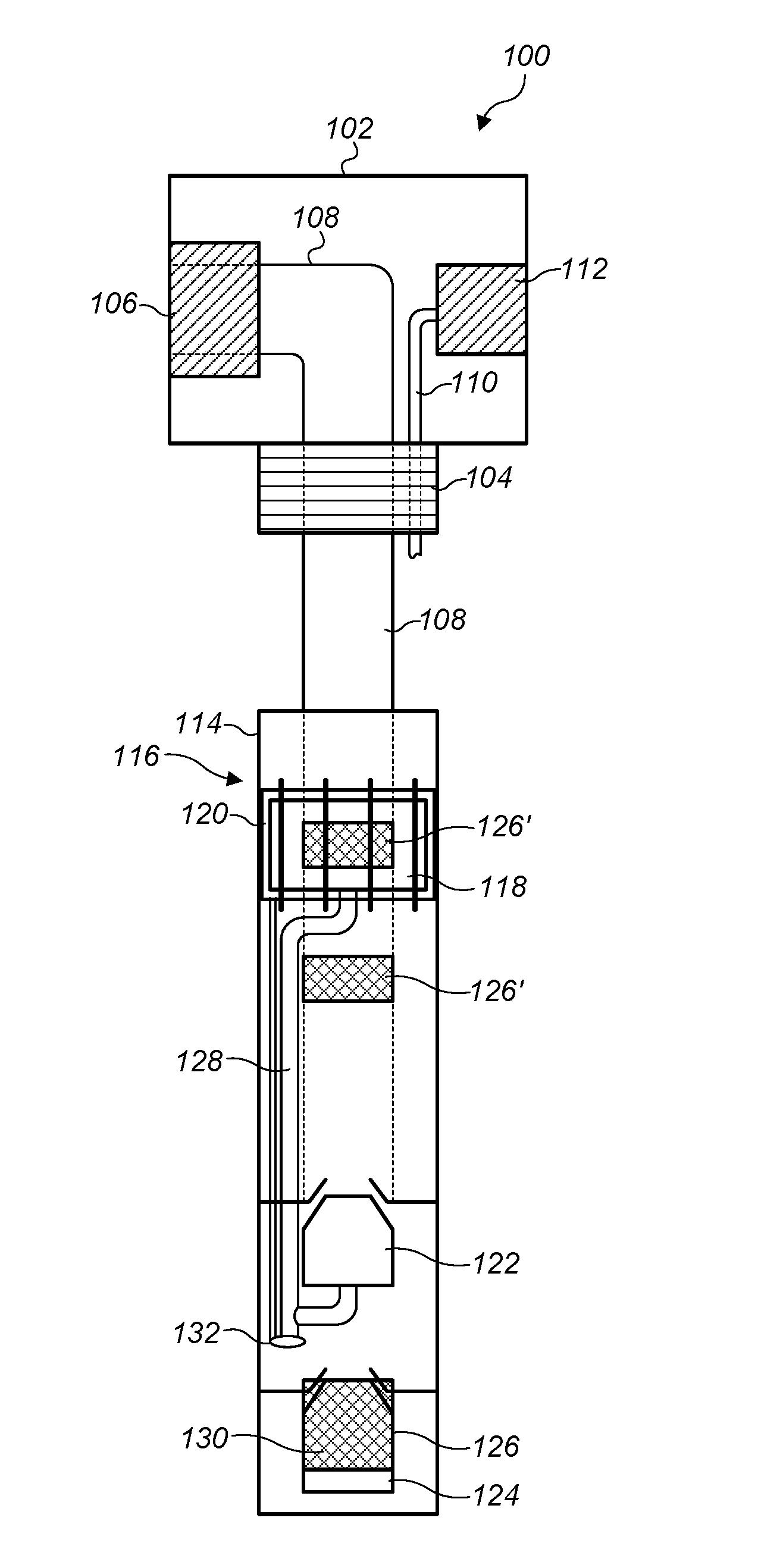

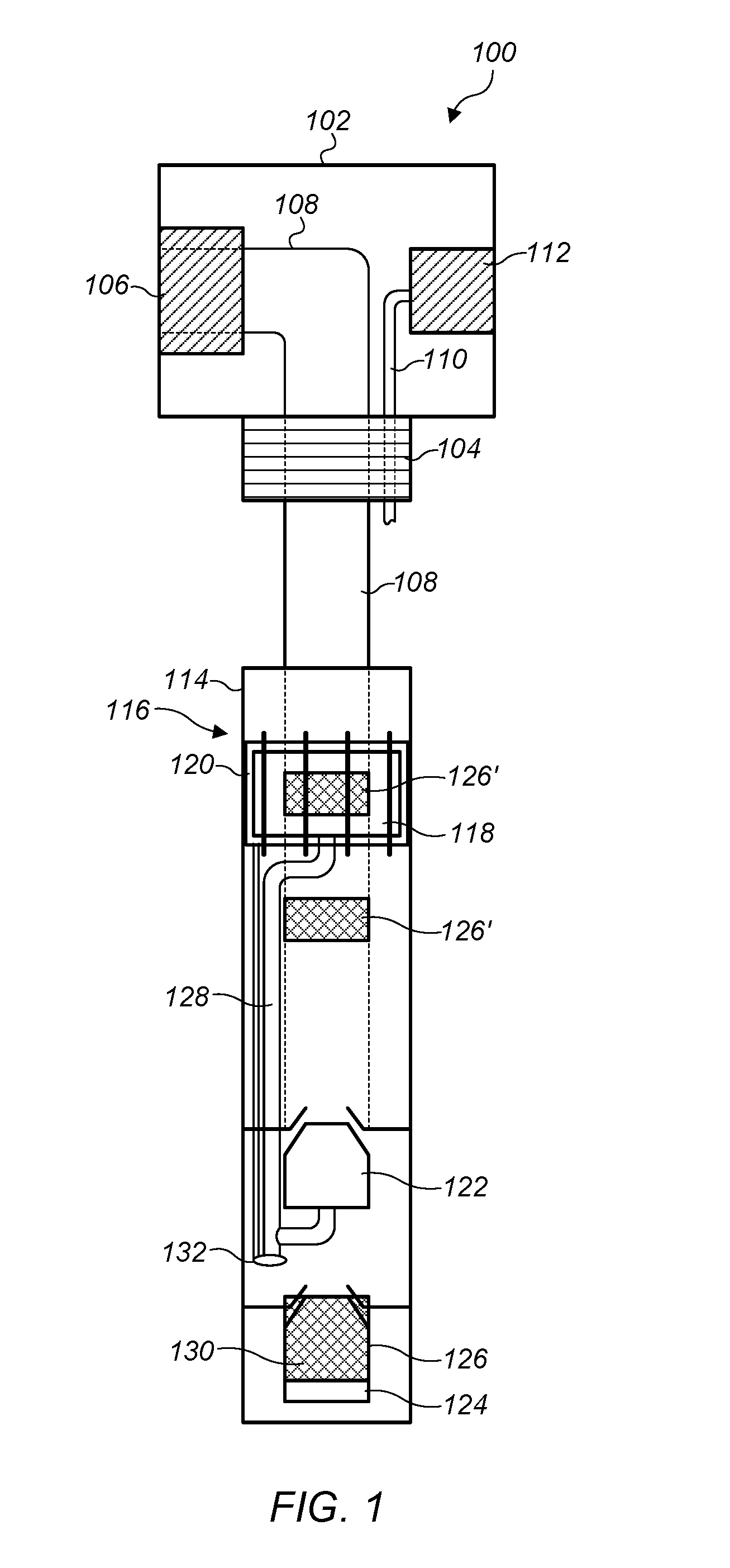

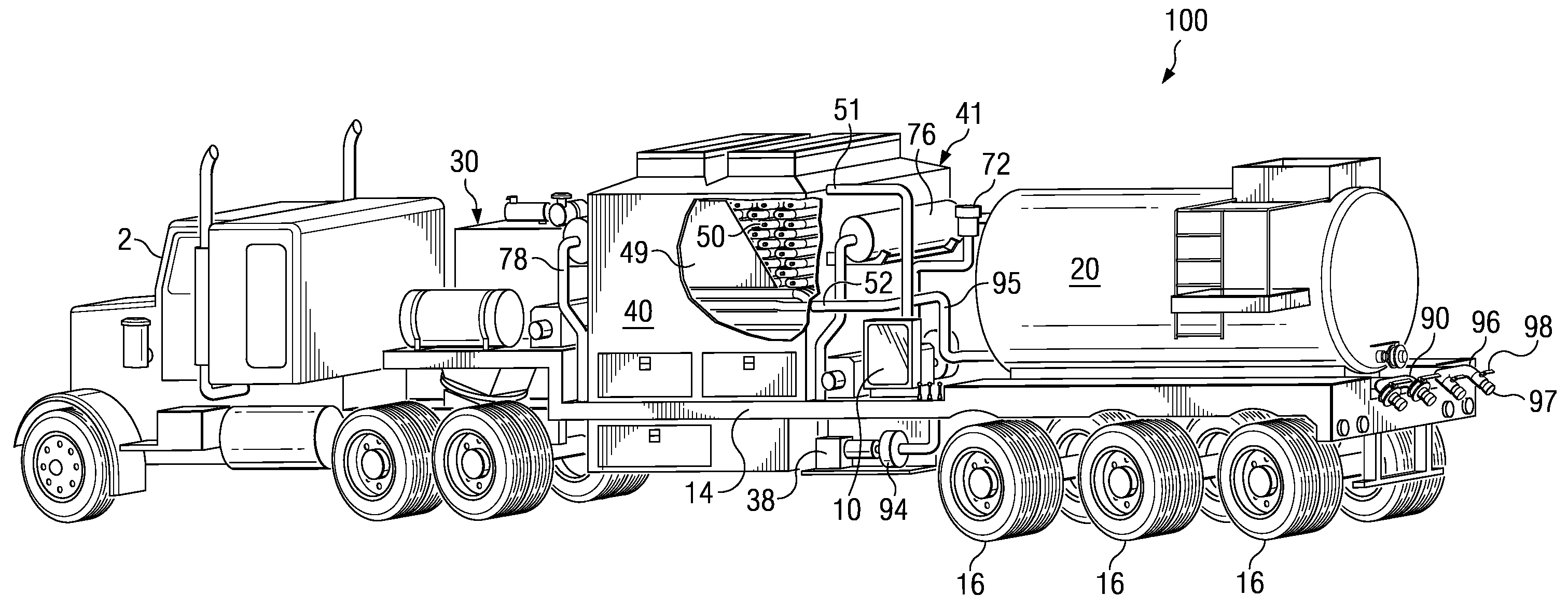

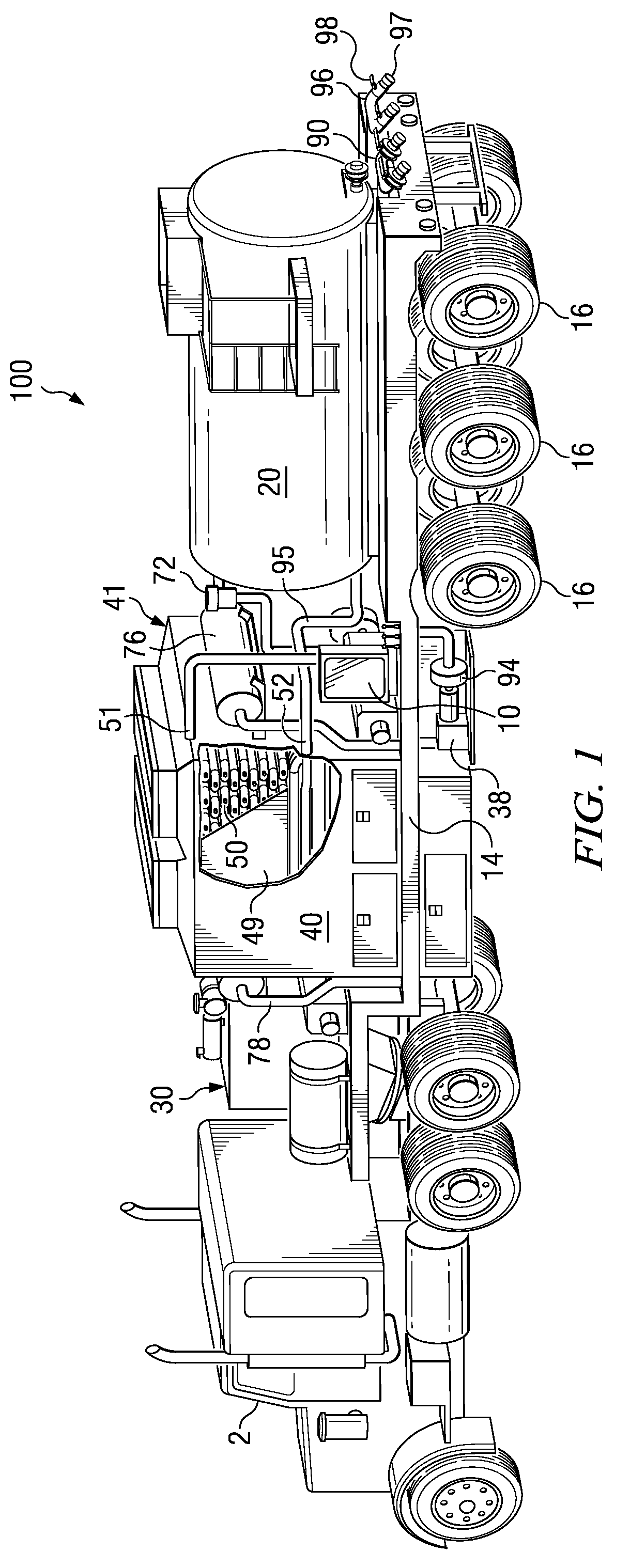

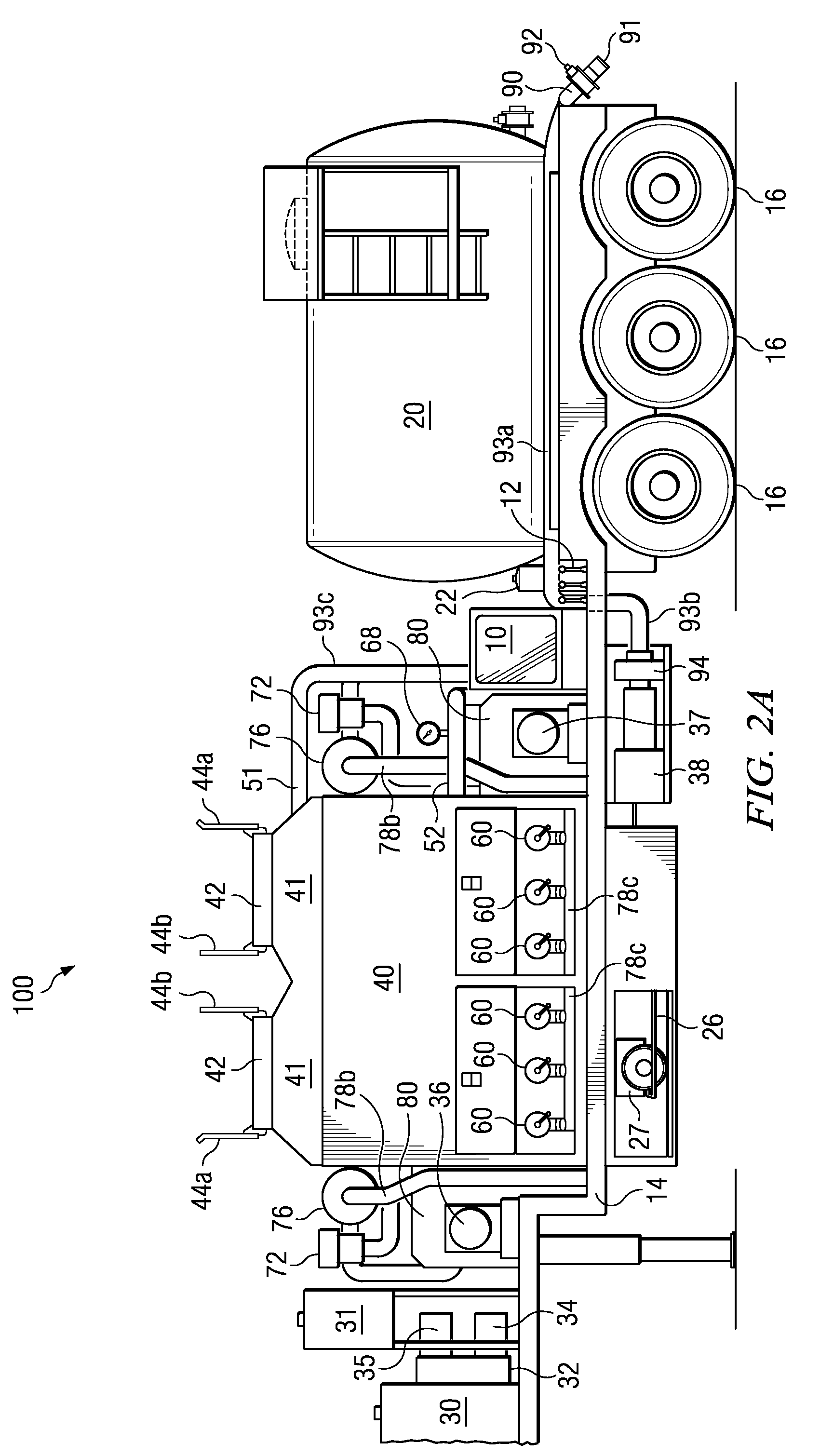

Method and Apparatus for Multi-Line Fuel Delivery

ActiveUS20170275149A1Prevent overflowMechanically operatedOperating means/releasing devices for valvesFluid removalFuel tankEngineering

A gravity-fed fuel delivery system is provided. A central storage tank holds fuel to re-supply a number of pump trucks or other mechanized equipment, such as on a hydraulic fracturing location, and can be selectively raised or lowered. Hoses or other conduits extend from the central storage tank to individual fuel tanks of the equipment to be refueled. Adapters allow connection of the distal end of each hose or conduit to an inlet opening of a fuel tank. A float valve assembly senses when fuel inside an individual fuel tank is below a predetermined level, thereby mechanically opening a valve assembly to permit fluid to flow from the central storage tank, through a conduit, through the float valve assembly and into the fuel tank.

Owner:GRAVITY FUEL SYST LLC

Fuel delivery system and method

A fuel delivery system and method for reducing the likelihood that a fuel tank of equipment at a well site during fracturing of a well will run out of fuel. A fuel source has plural fuel outlets, a hose on each fuel outlet of the plural fuel outlets, each hose being connected to a fuel cap on a respective one of the fuel tanks for delivery of fuel to the fuel tank. At least a manually controlled valve at each fuel outlet controls fluid flow through the hose at the respective fuel outlet.

Owner:ENERGERA INC +2

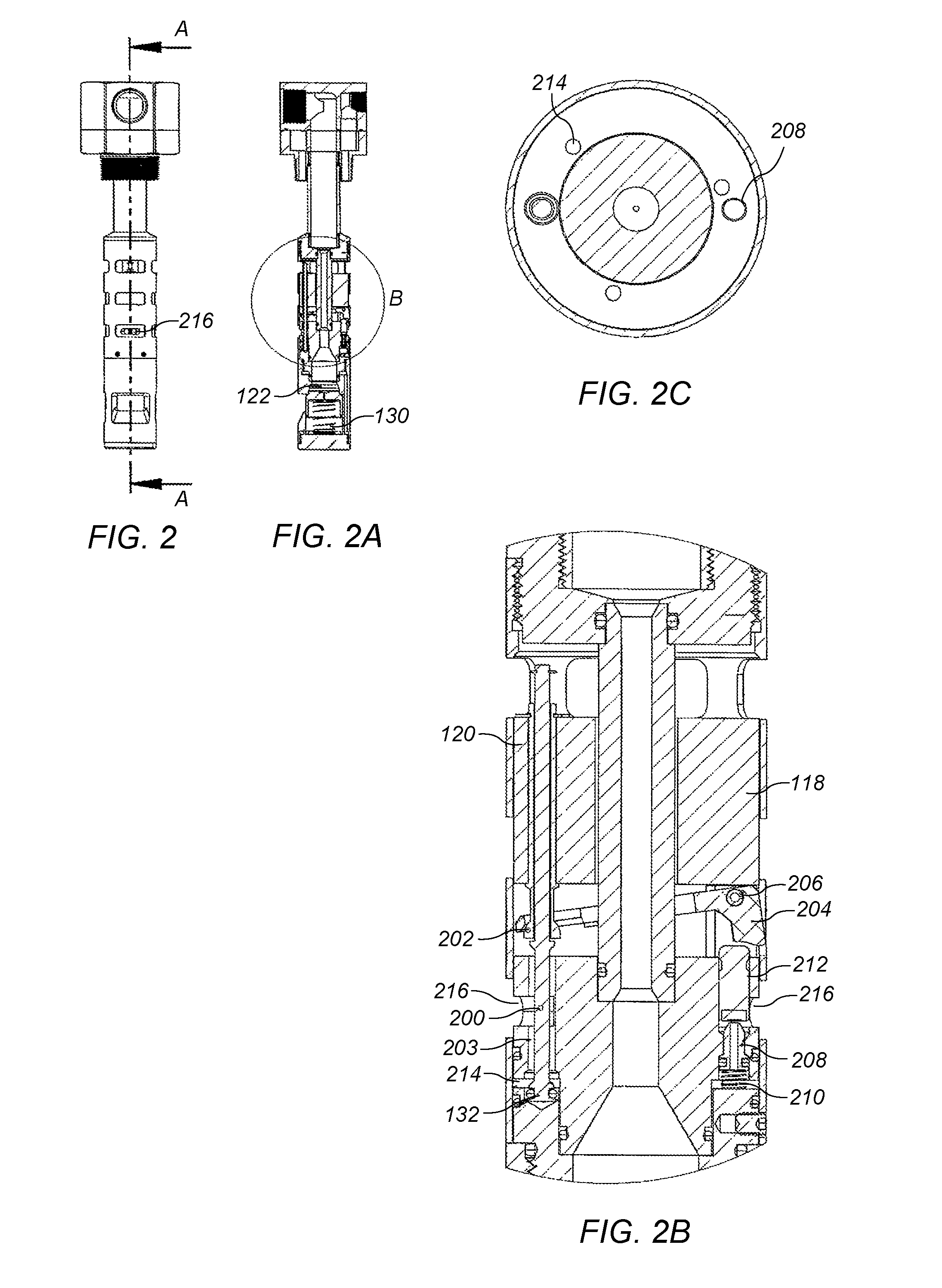

Device for automatically filling fracking pump fuel tanks

InactiveUS20170009905A1Avoid flowOperating means/releasing devices for valvesFluid removalFuel tankAutomotive engineering

A system for automatically filling a fuel tank coupled to a fracking pump is described. The filling system includes a device that automatically opens and closes fuel flow to the fuel tank based on a level of fuel in the fuel tank. The device may close fuel flow to the fuel tank when a fill capacity of the fuel tank is reached. The device may open fuel flow to the fuel tank when a fuel level in the fuel tank drops below a selected level (e.g., below 1 / 4 of the fill capacity of the fuel tank). The device may be used to substantially continuously supply fuel to the fuel tank.

Owner:ARNOLD OIL CO OF AUSTIN LP

Method of operating a wormgear drive at high energy efficiency

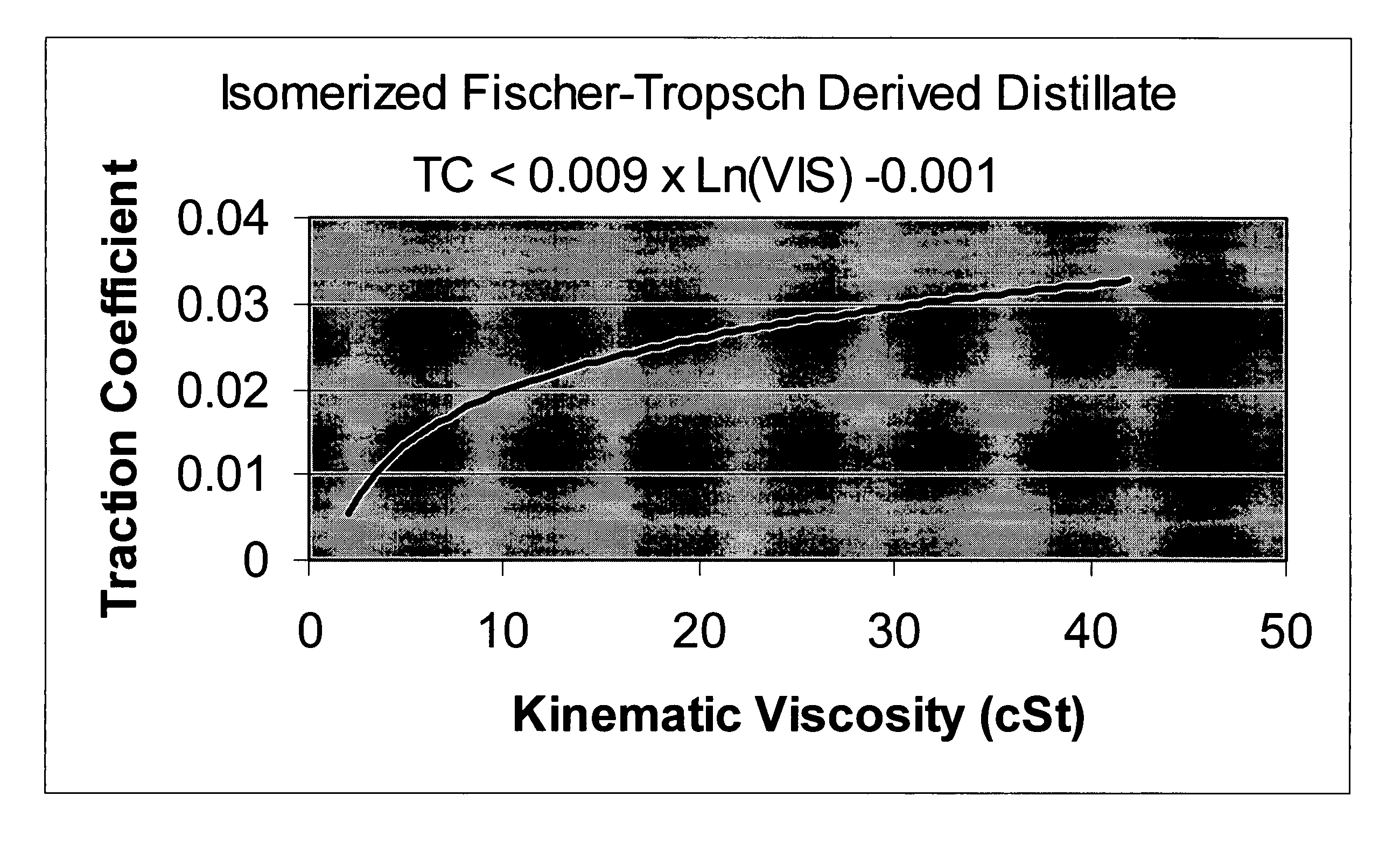

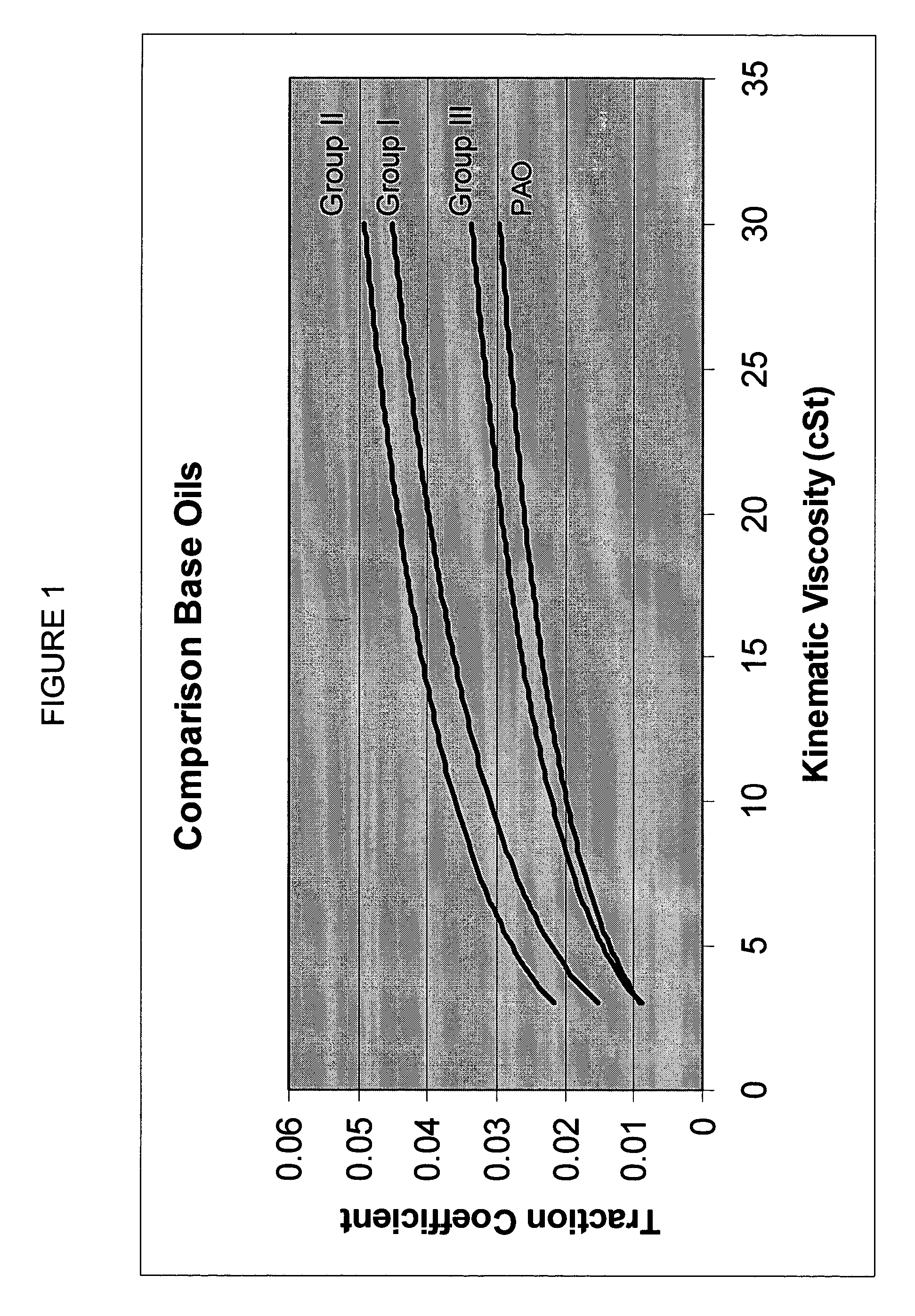

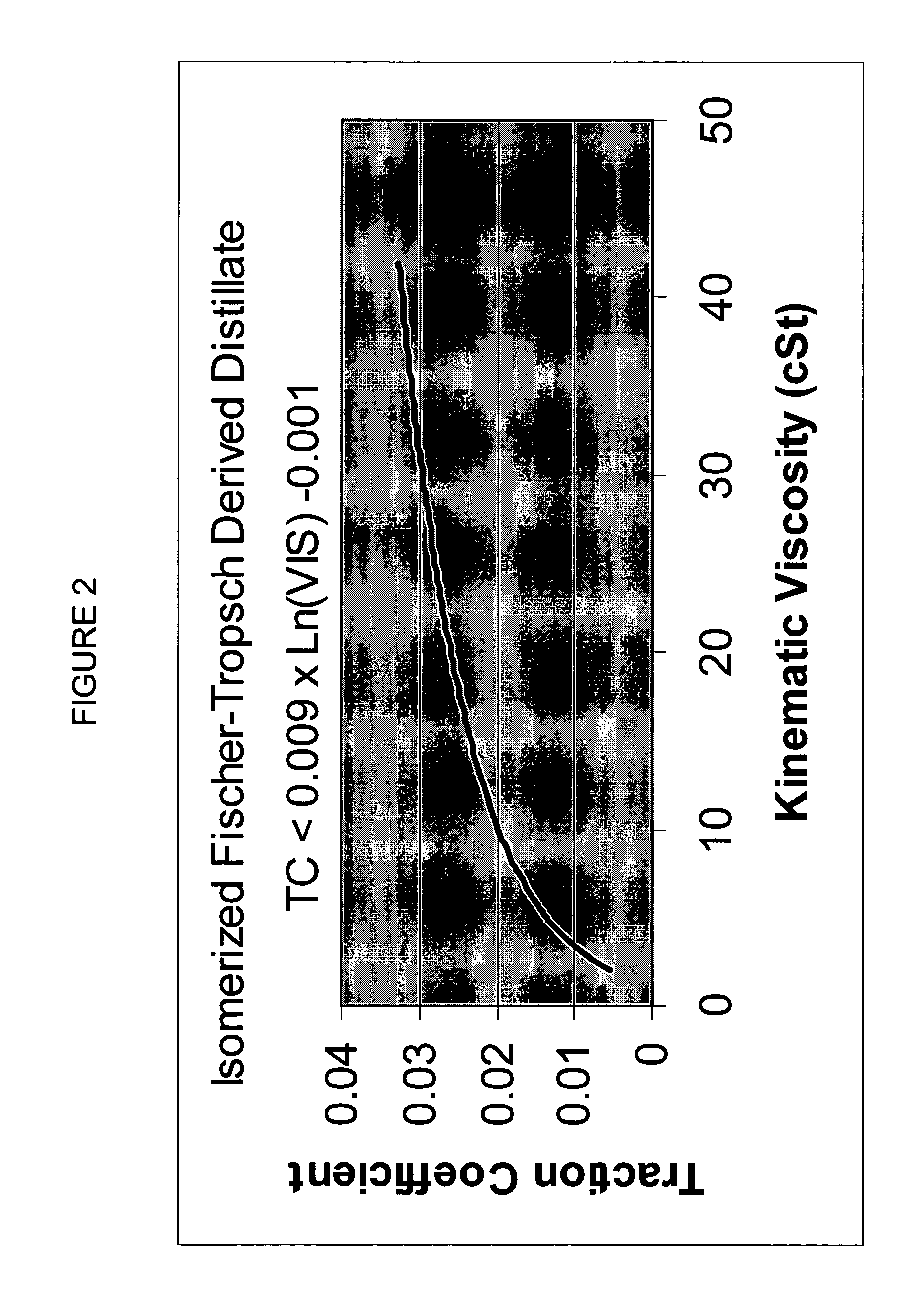

InactiveUS7045055B2Reducing traction coefficientGear lubrication/coolingToothed gearingsHigh energyFuel tank

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

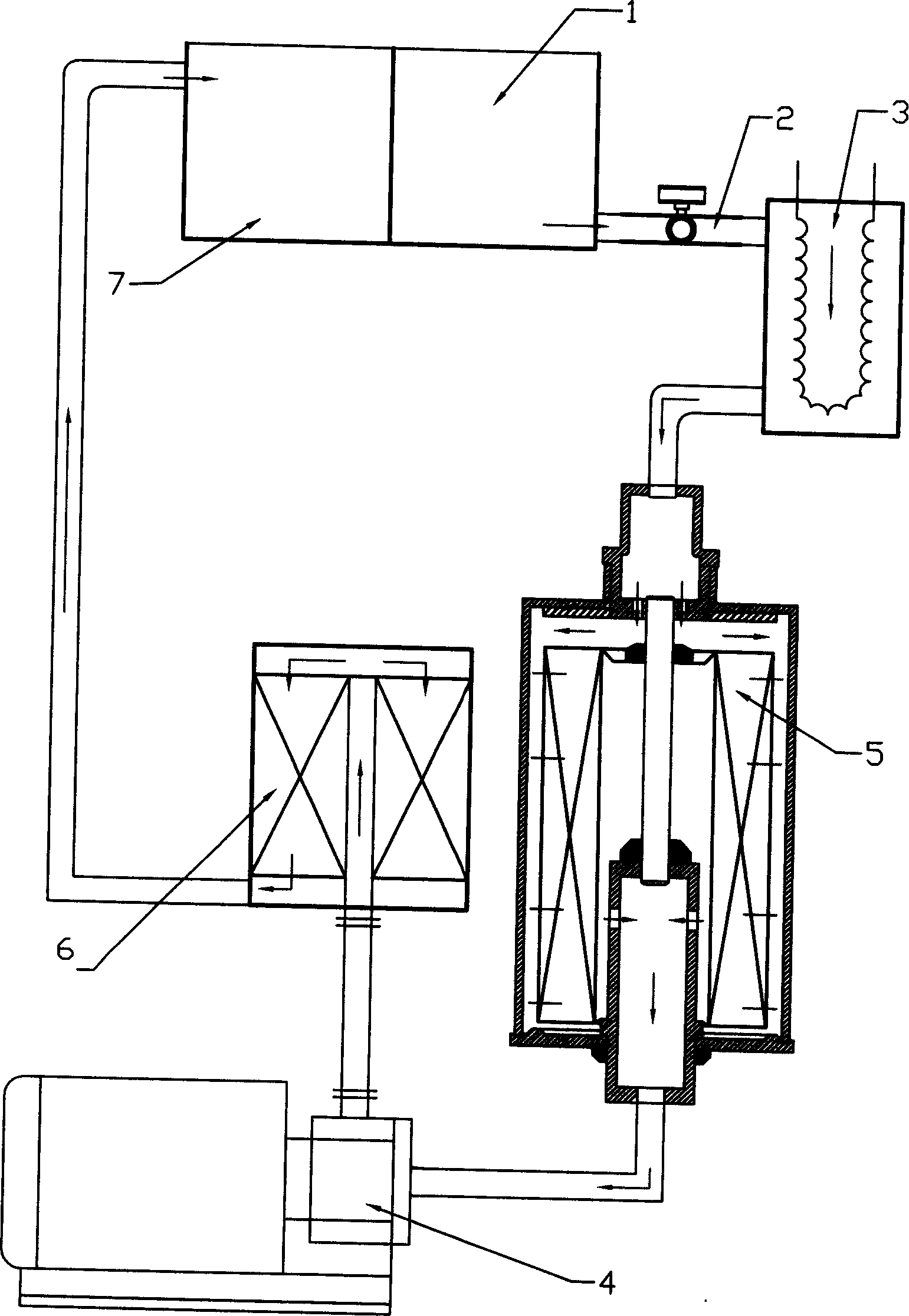

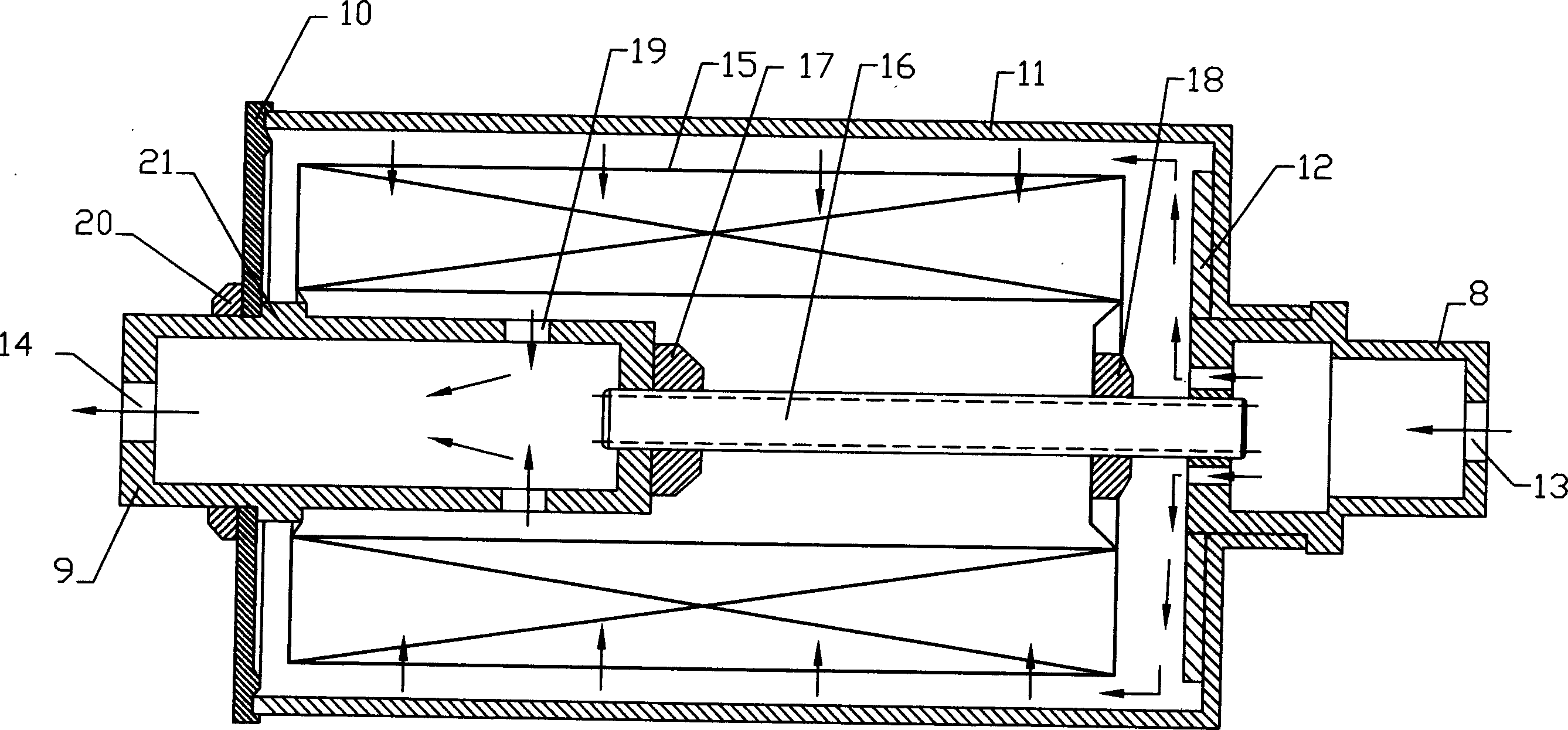

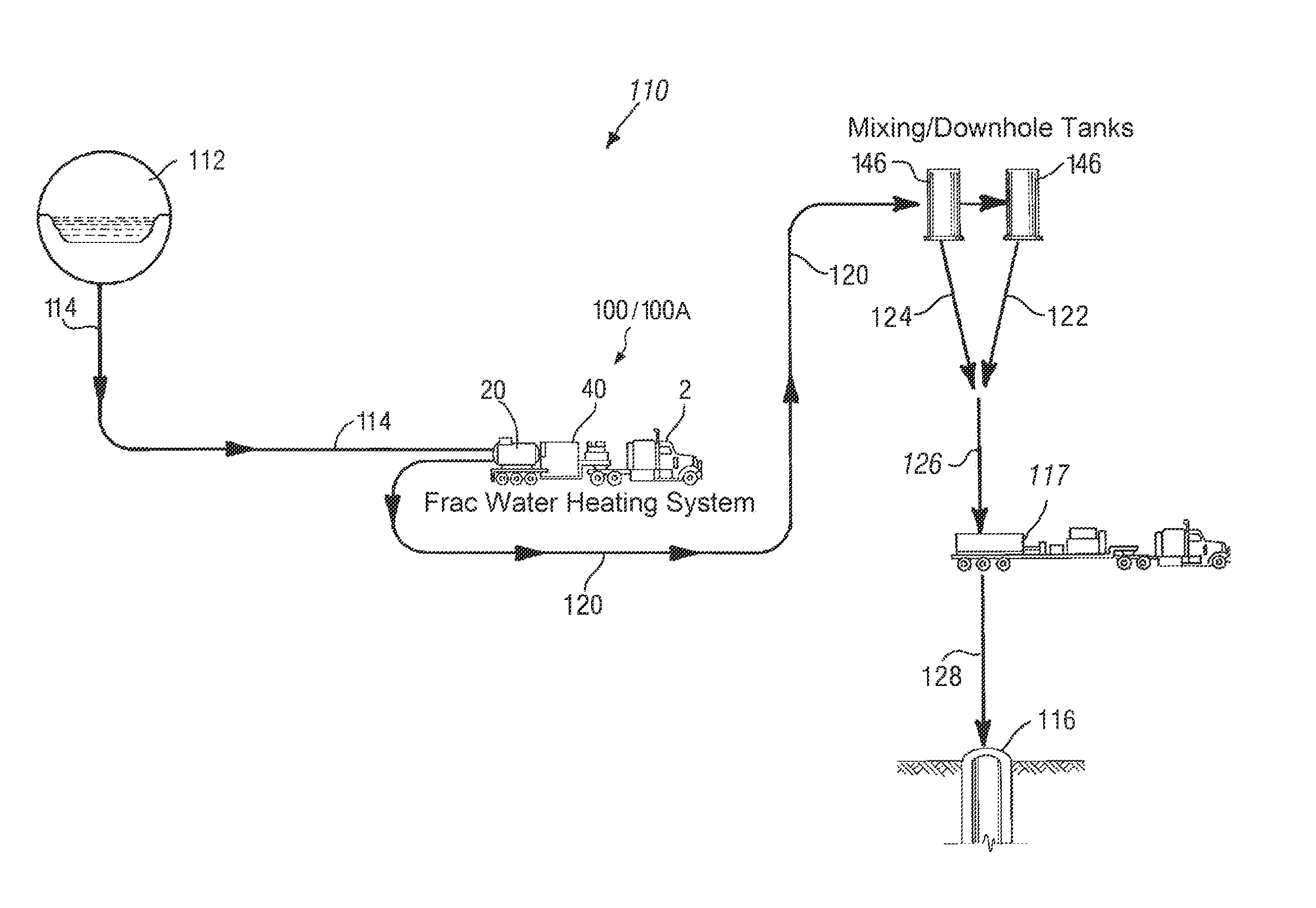

Frac water heating system and method for hydraulically fracturing a well

InactiveUS20140144641A1Safely and continuously heatingMaximize atomization and combustionInsulationFluid removalCombustion chamberFuel tank

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an improved frac water heating system. The present invention is a self-contained unit which is easily transported to remote locations. In one embodiment, the present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. In another embodiment, the present invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in all weather environments. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

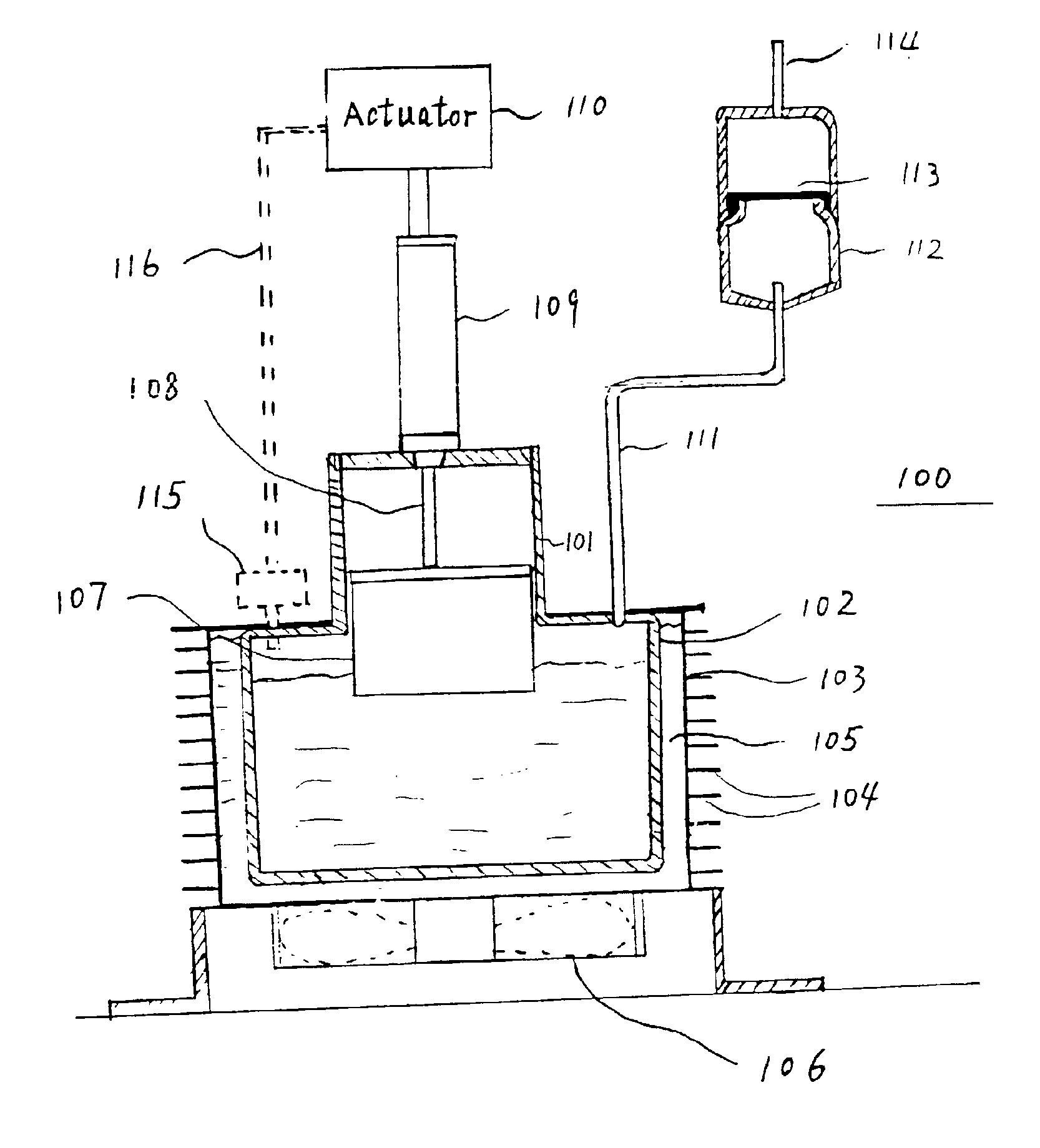

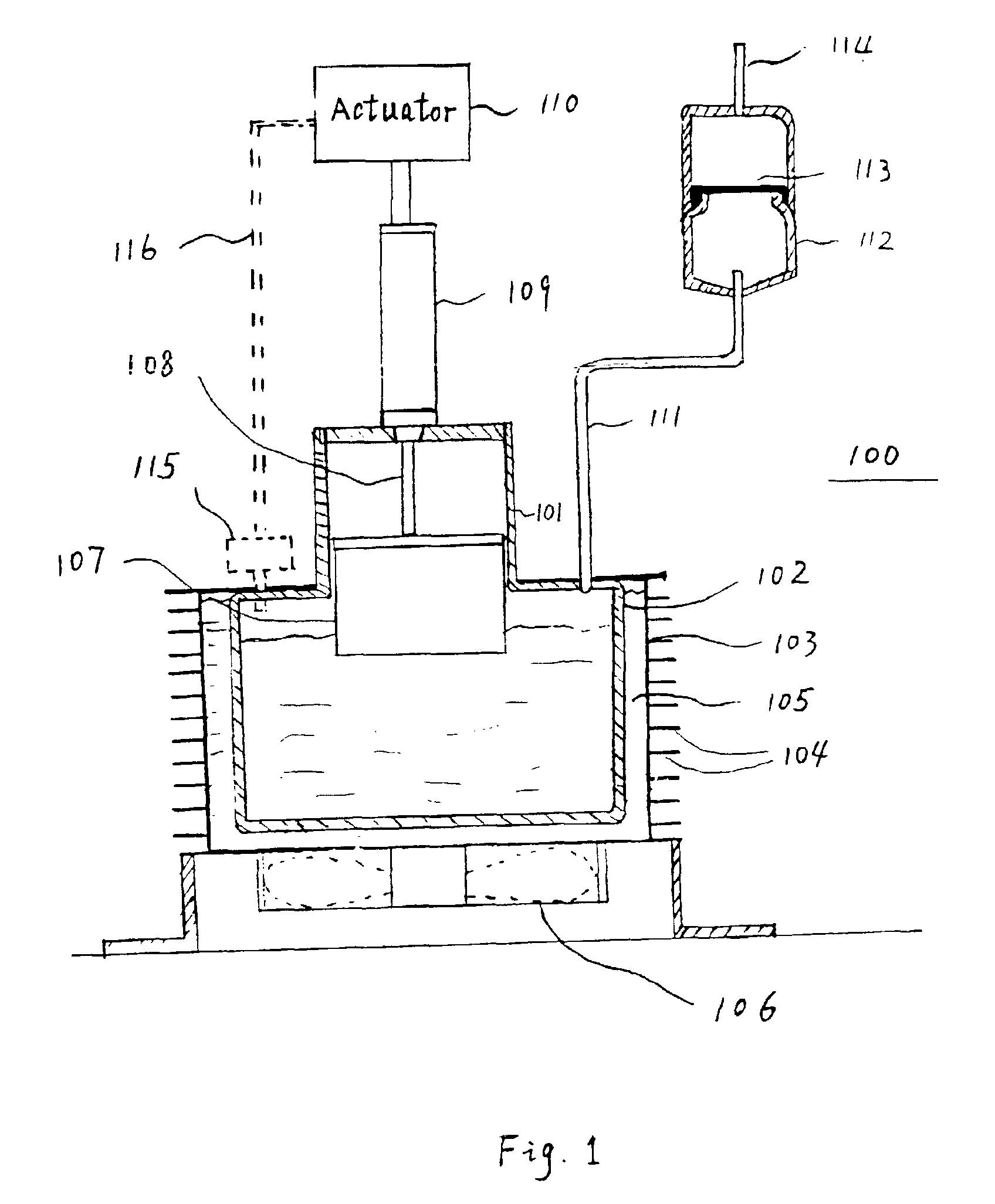

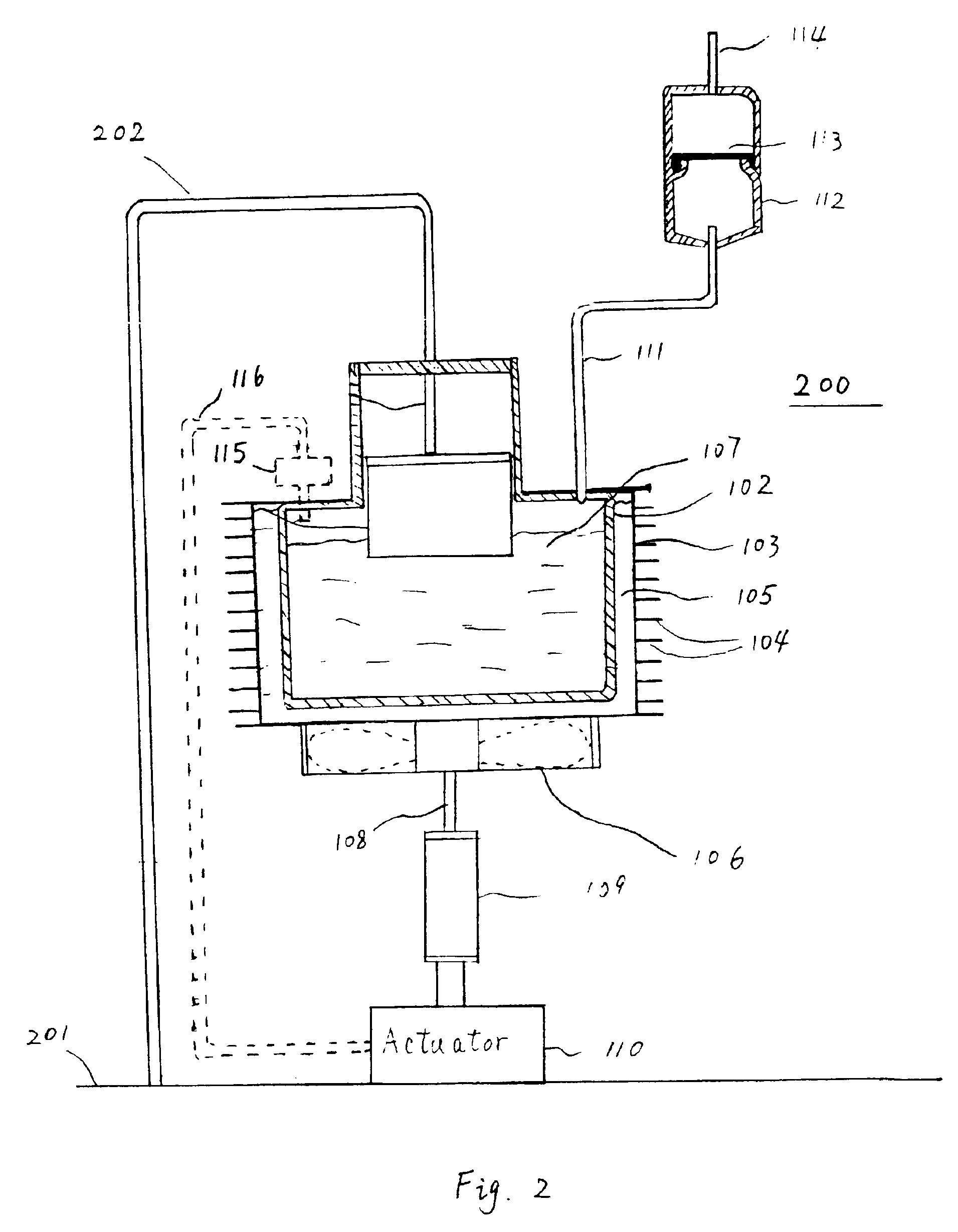

Self-regulating hydrogen generator

InactiveUS6939529B2Increase and decrease hydrogen generation rateIncrease rate of hydrogen generationPhysical/chemical process catalystsHydrogen productionGeneration processGeneration rate

A hydrogen generating system regulates its rate of hydrogen generation by monitoring one or more parameters of the hydrogen generation process and then providing relative movement between the fuel tank and the catalyst chamber so as to increase or decrease the rate of hydrogen generation.In the disclosed embodiments, the catalyst chamber is disposed in a tank containing the fuel. The relative movement provided moves the catalyst chamber toward the fuel solution so as to increase the rate of hydrogen generation and moves the catalyst chamber away from the fuel solution to decrease such generation. Advantageously, such self-regulation can be provided without an external power source and can be varied to meet the requirements of different commercial applications. The overall system can be readily fabricated using commercially available parts.

Owner:PROTONEX TECH CORP

Oil-fired frac water heater

ActiveUS20100000508A1Maximize atomization and combustionMaximize combustionAir-treatment apparatus arrangementsAir heatersFuel tankEngineering

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an oil-fired heat exchange system. The present invention is a self-contained unit which is easily transported to remote locations. The present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in ail weather environments. In a preferred embodiment, the oil-fired heat exchanger system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

All terrain vehicle

InactiveUS6732830B2Convenient framingAdd featureElectric propulsion mountingGas pressure propulsion mountingFuel tankLandform

Various embodiments of a saddle type vehicle are described. Configurations are shown in which the engine is located more towards the rear of the vehicle and in which the fuel tank extends generally vertically beneath the steering member. A radiator may also be located at a rear portion of the vehicle, rearwardly of the engine. A front storage compartment is also provided in the front portion of the vehicle. The resulting vehicle has improved access and storage capabilities and also has a lower center of gravity.

Owner:BOMBARDIER RECREATIONAL PROD INC

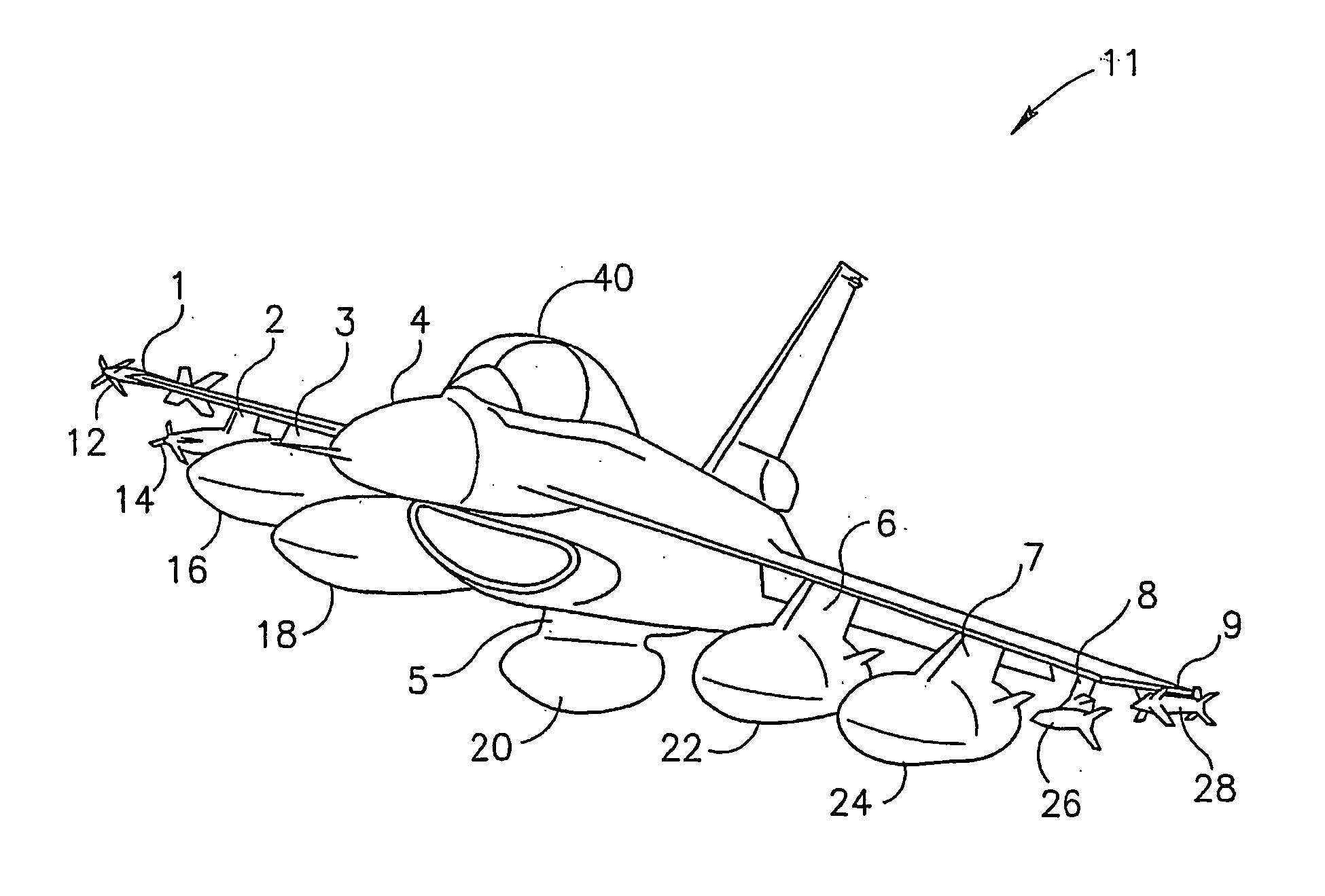

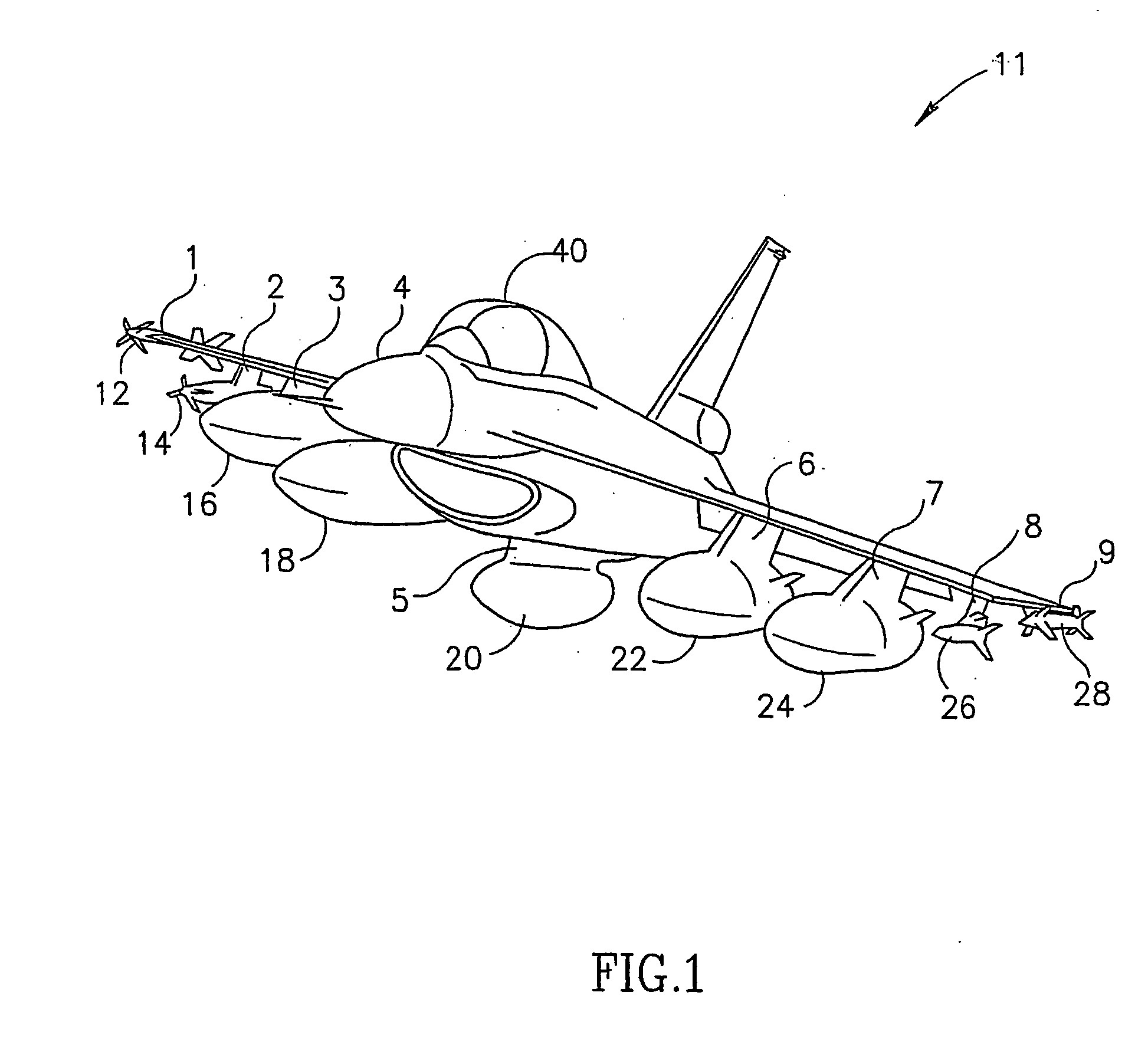

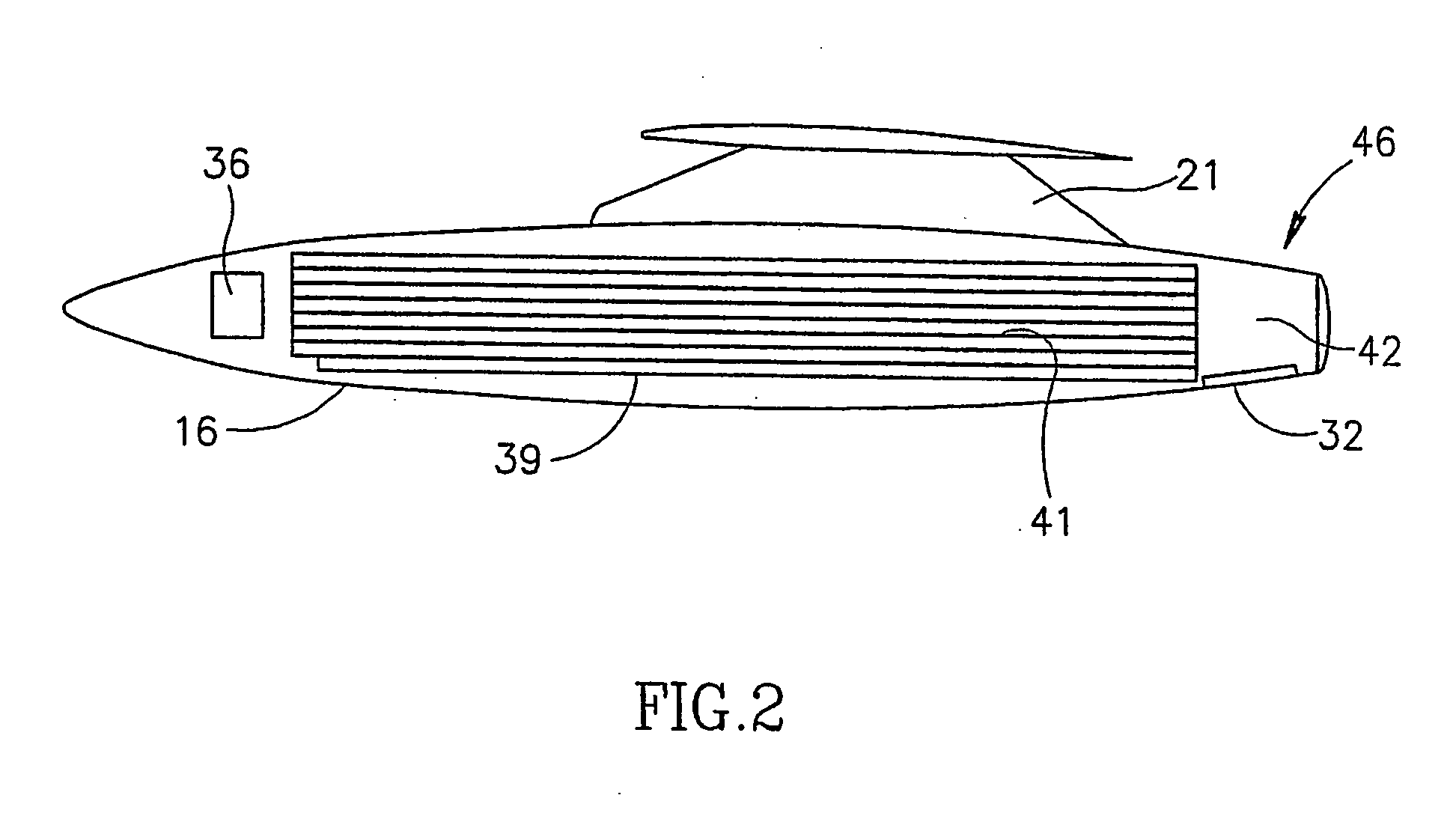

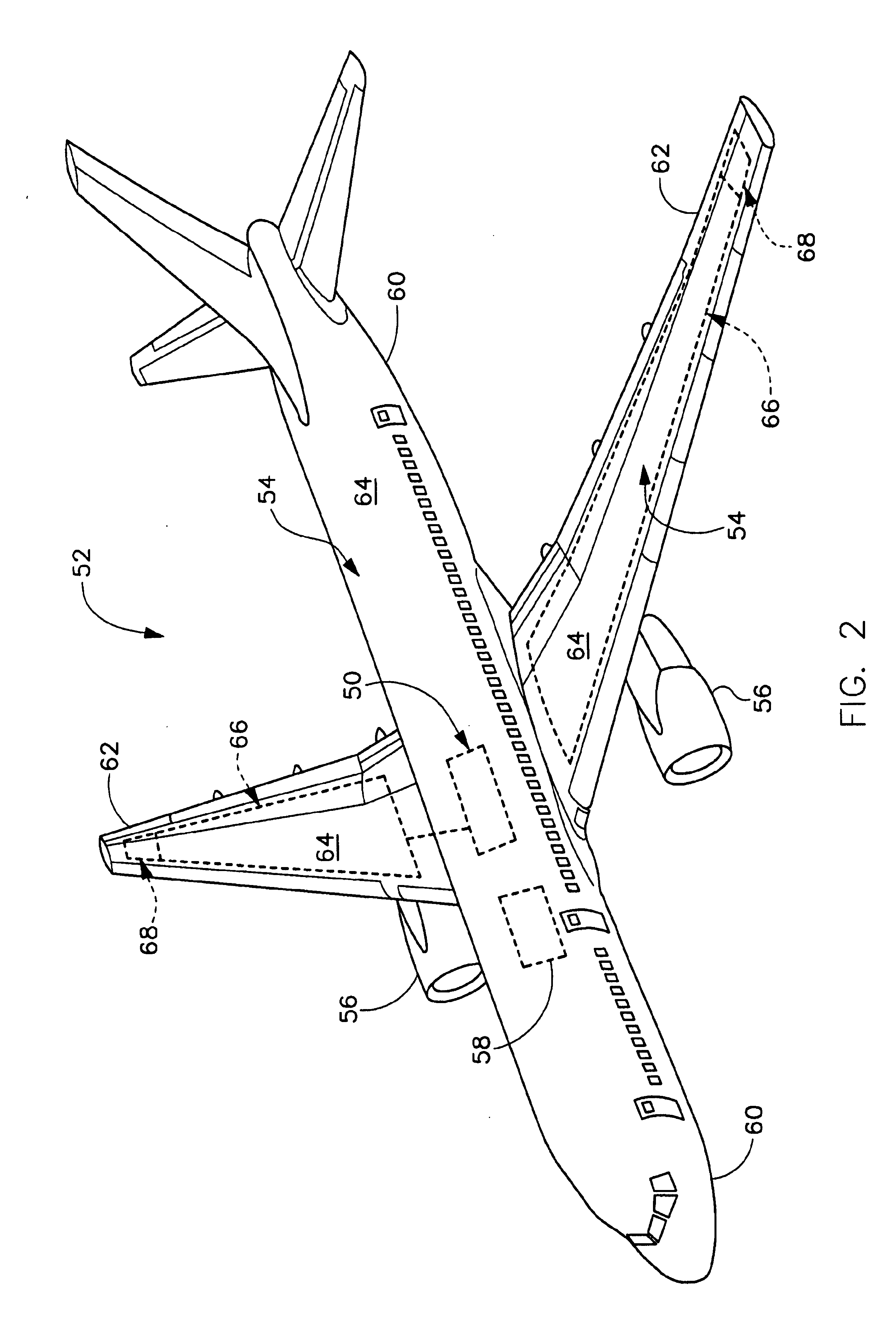

System and method for enhancing the payload capacity, carriage efficiency, and adaptive flexibility of external stores mounted on an aerial vehicle

InactiveUS20050204910A1Enhanced volumetric efficiency storeIncreased payload capacityRocket launchersPower plant fuel tanksFuel tankSelf adaptive

A system and method for the conversion of fuel tanks, detachably mountable on the exterior of an aerial vehicle, into high volume, high capacity, diverse functionality and aerodynamically efficient airborne stores is disclosed. A conventional external fuel drop tank is modified such that the exterior shape of the tank is substantially retained while the interior of the tank is suitable restructured to allow for the introduction of diverse airborne stores, associated airborne store mounting means, control and monitoring means and support means therein, which replace the fuel store. The airborne store is suitably interfaced to the stores control and management system of the aerial vehicle. The airborne store is integrated into a new external stores configuration The enhanced airborne store will have aerodynamic characteristics substantially similar to the original external fuel tank while its payload capacity is substantially improved.

Owner:PADAN NIR

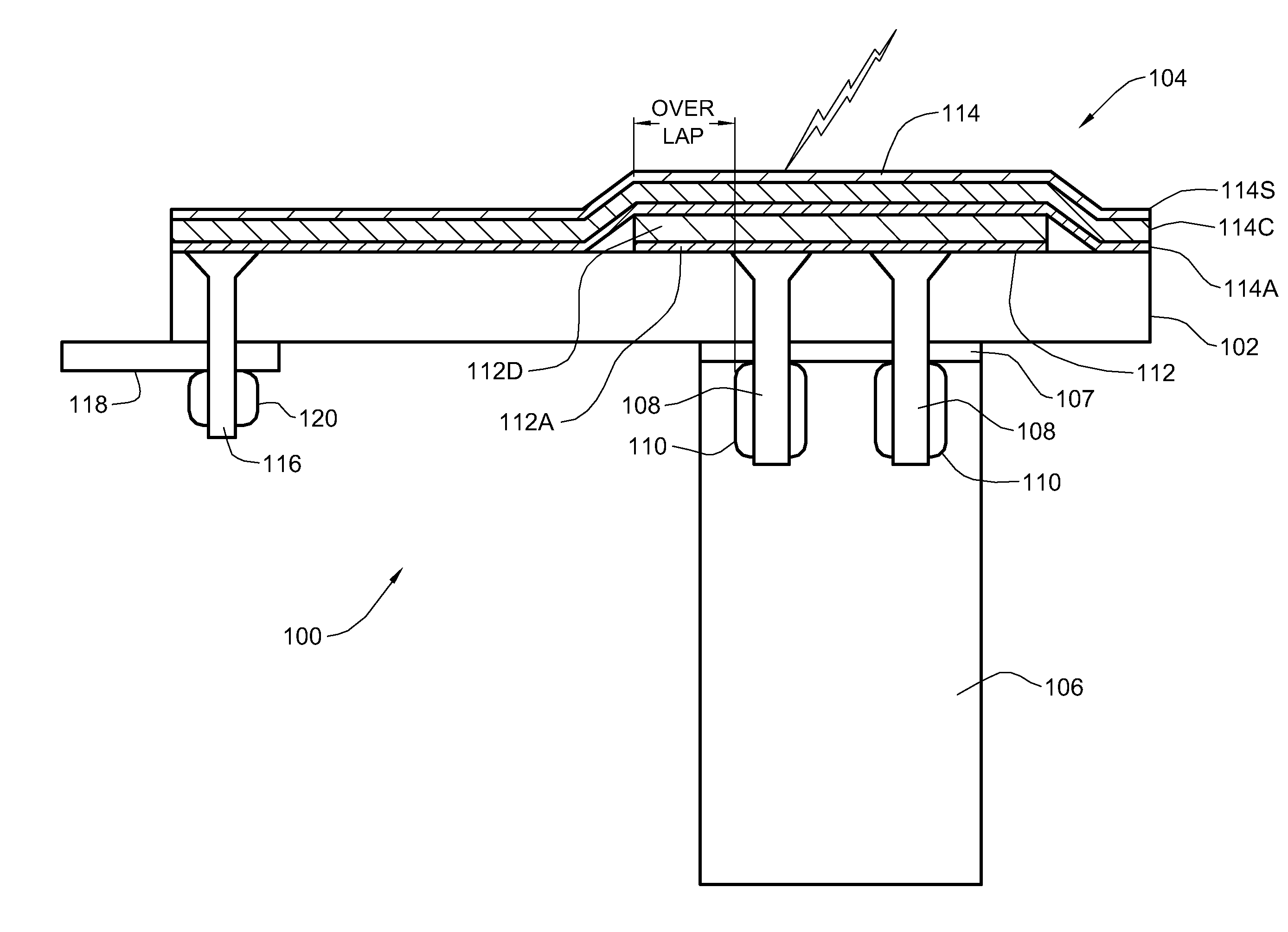

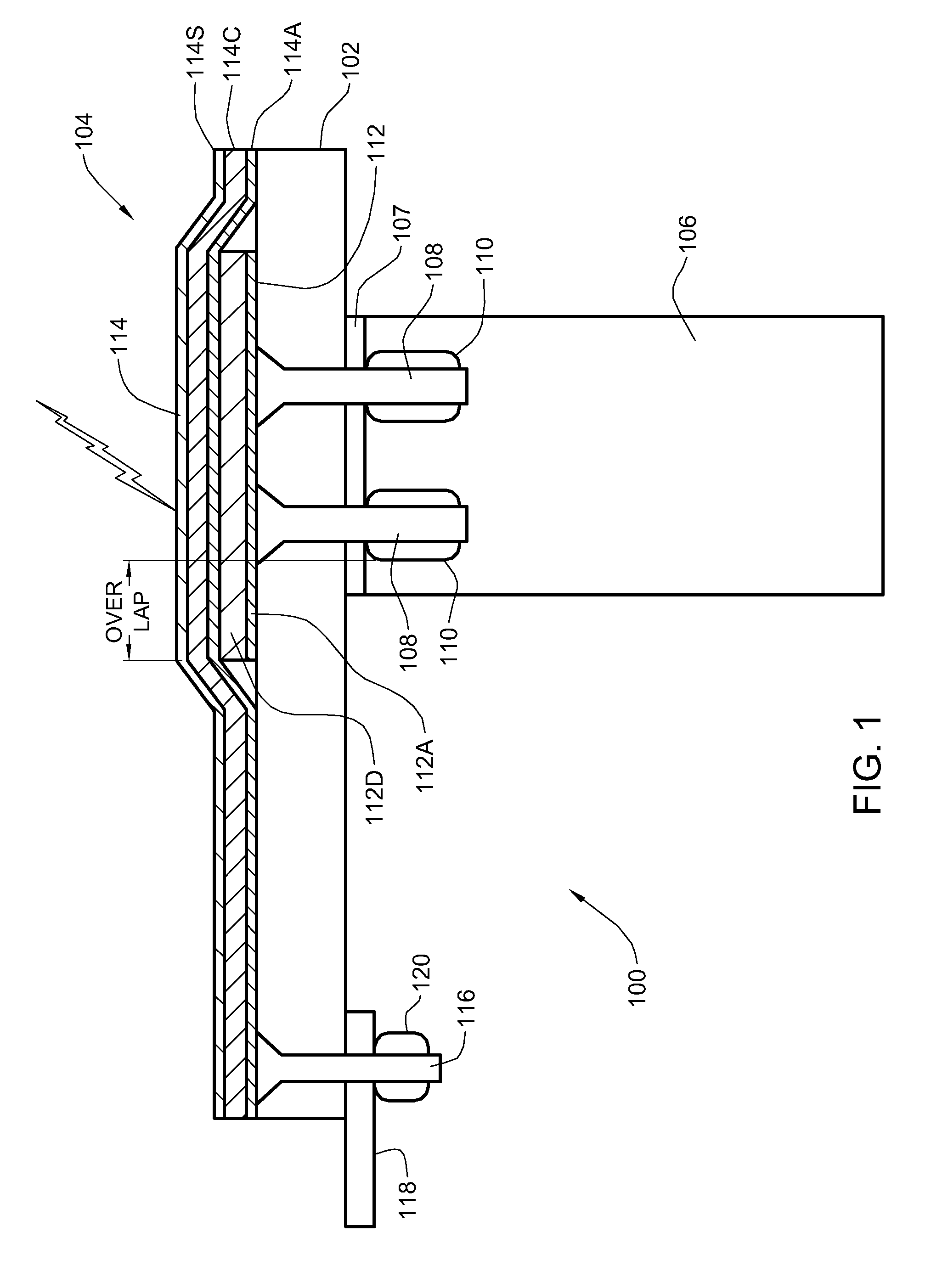

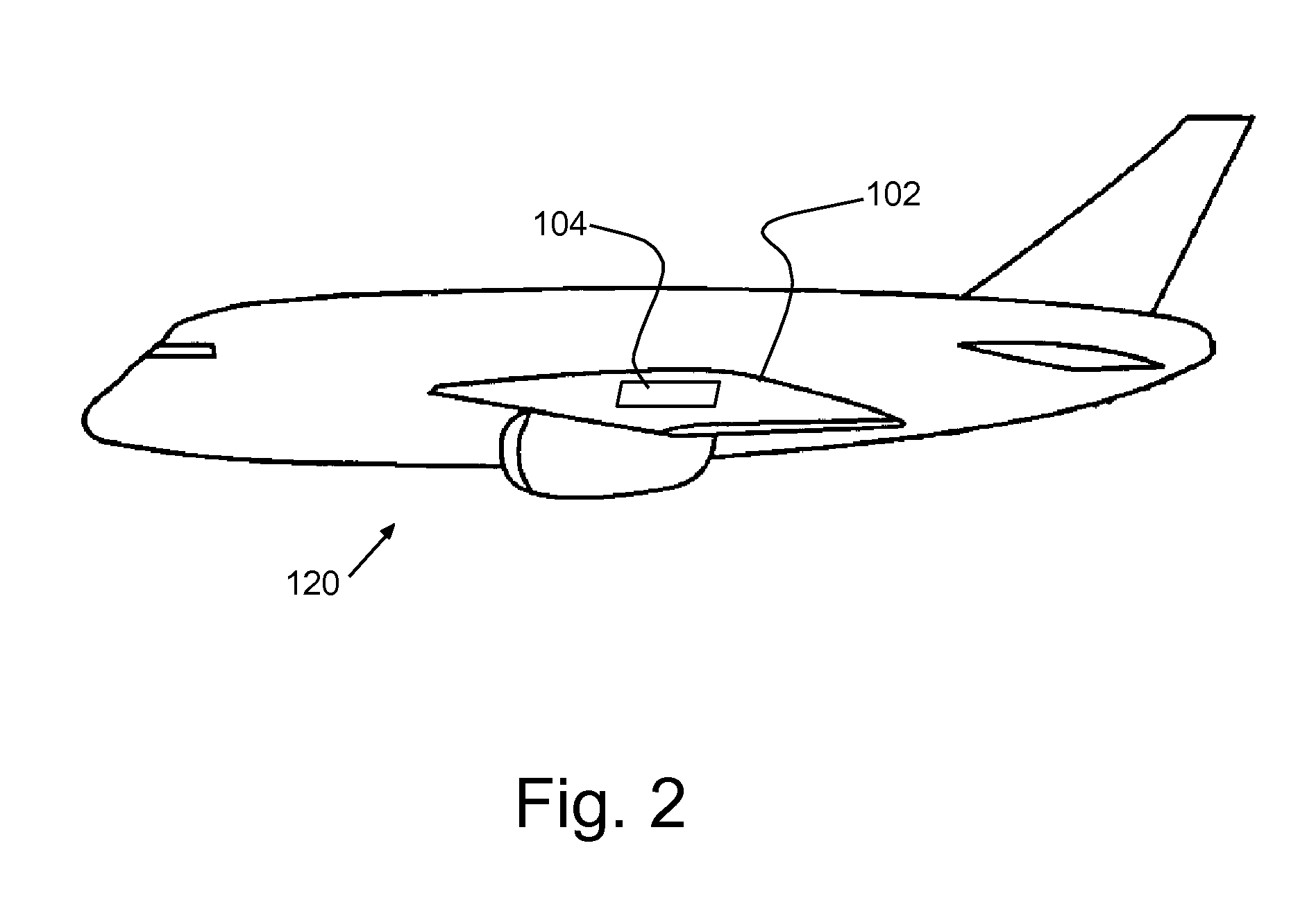

Lightning protection system for composite structure

ActiveUS7277266B1Flexibility in lightning protection designIncreasing aircraft weightAircraft lighting protectorsEmergency protective arrangement detailsElectricityLightning strike

A lightning protection system for protecting composite structures and a method of protecting composite structures from lightning strikes. A dielectric ply is fixed above and completely covers metal surface features, e.g., skin fasteners through a composite skin to a wing fuel tank. A conductive ply is fixed above and completely covers the dielectric ply and extends to an external connection to a platform ground. The conductive ply directs current from lightning strikes away from metal surface features, e.g., to the platform ground. Both plies may be adhesively backed and sequentially pressed into place.

Owner:THE BOEING CO

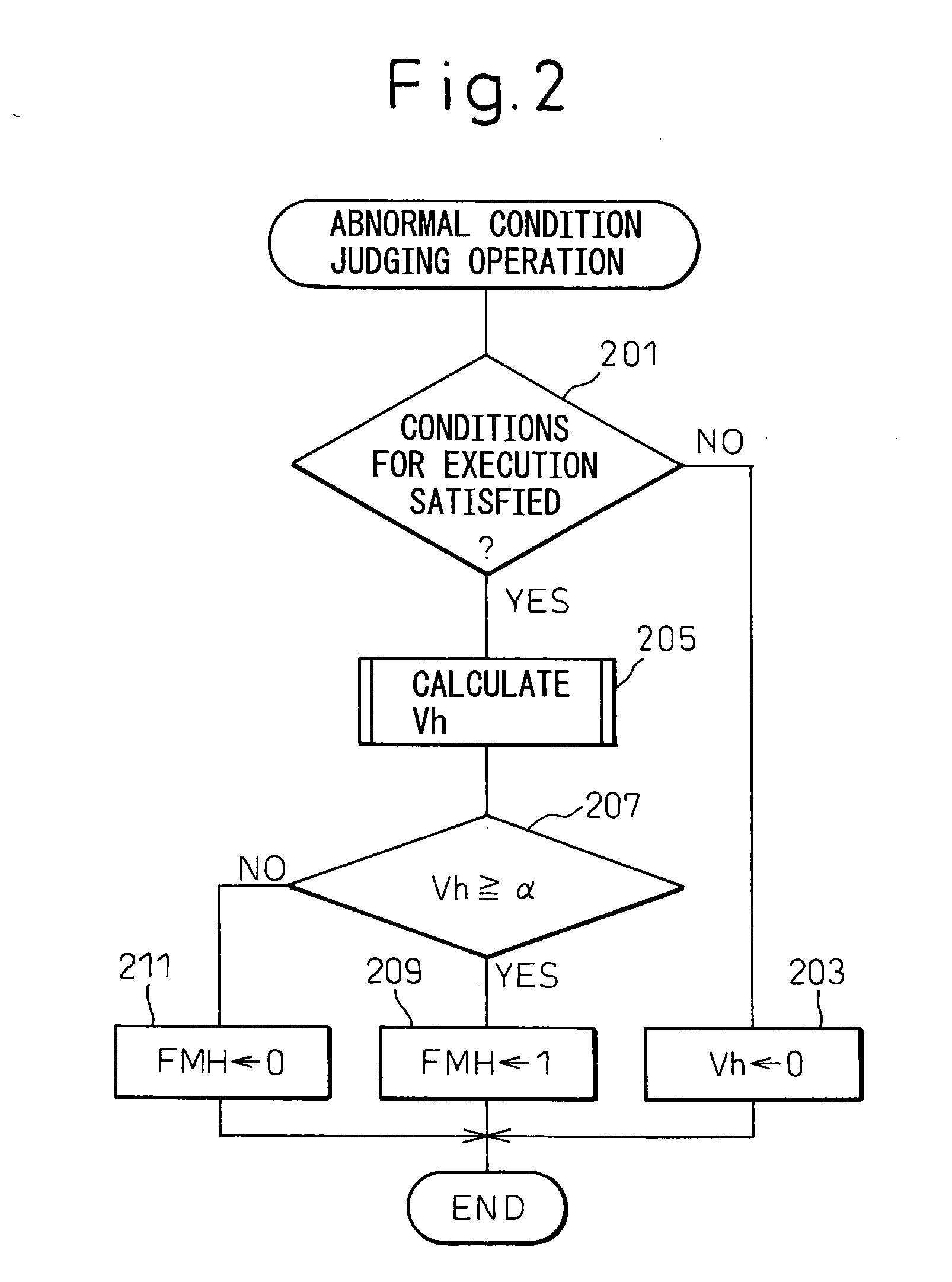

Onboard fuel separation apparatus for an automobile

A fuel separation apparatus includes a fuel tank storing the material fuel fed to a separation membrane, a fuel tank storing a separated low-octane fuel, and a fuel tank storing a separated high-octane fuel. An electronic control unit of the separation apparatus calculates the flow rate (amount of formation) of the high-octane fuel flowing into the high-octane fuel tank based on a change in the liquid level in the tank and on the amount of fuel fed to an engine from the tank, and so judges that an abnormal condition is occurring due to the breakage of the separation membrane when the amount of forming the high-octane fuel is larger than a predetermined upper limit value and that an abnormal condition is occurring due to a drop in the function of the separation membrane when the amount of formation is smaller than a predetermined lower limit value.

Owner:TOYOTA JIDOSHA KK

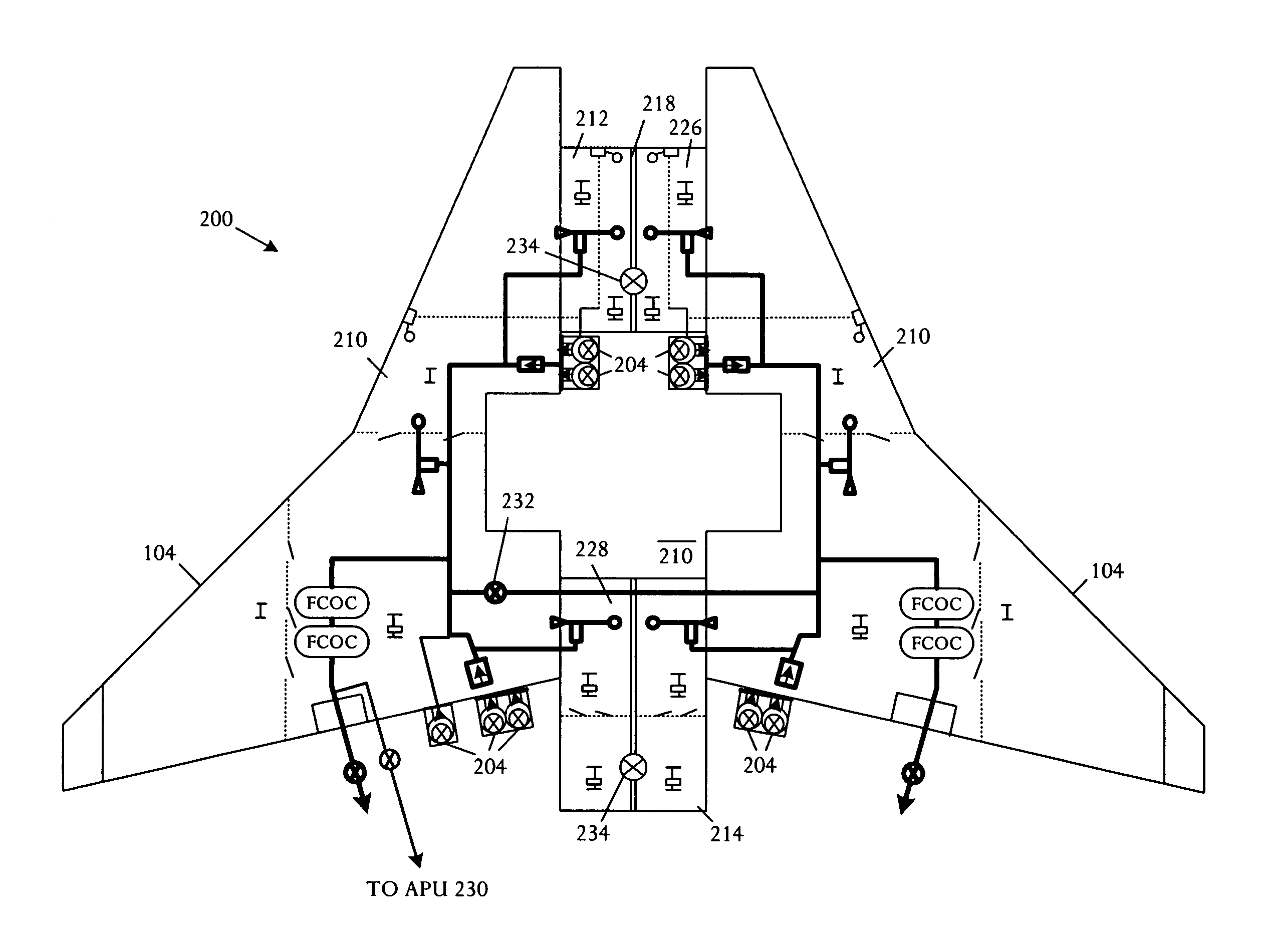

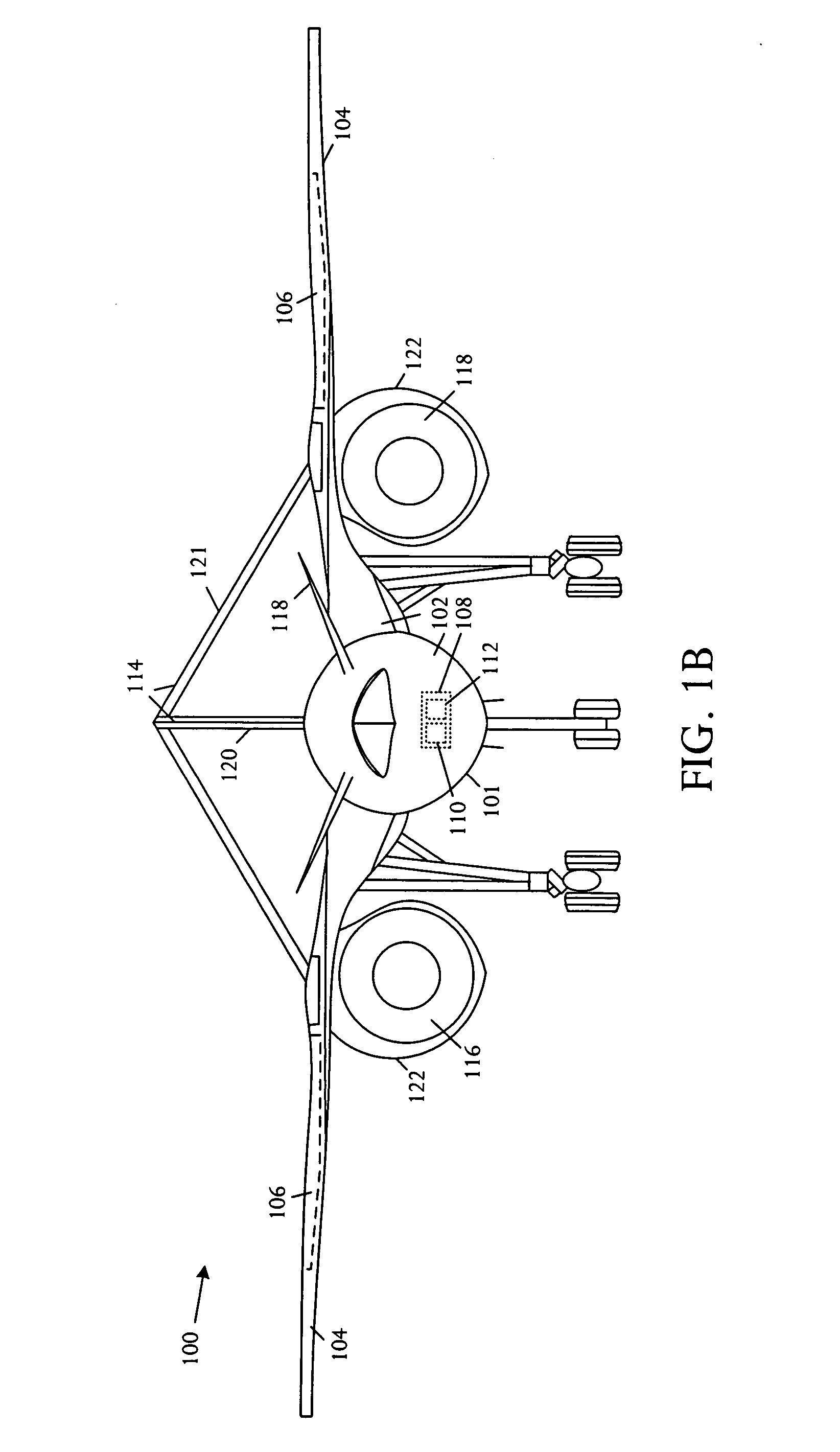

Aircraft with active center of gravity control

InactiveUS20050051666A1Reduce travel timeIncrease the voyageAircraft stabilisationDigital data processing detailsTransfer systemFlight vehicle

A supersonic aircraft comprises a wing, a fuselage, a plurality of fuel tanks contained within the wing and / or fuselage, and a fuel transfer system communicatively coupled to the plurality of fuel tanks and capable of transferring fuel among the plurality of fuel tanks. The aircraft further comprises at least one sensor capable of indicating a flight parameter and a controller. The controller is coupled to the one or more sensors and to the fuel transfer system. The controller can transfer fuel among the plurality of fuel tanks and adjust the aircraft center of gravity to reduce trim drag and increase aircraft range.

Owner:SUPERSONIC AEROSPACE INT

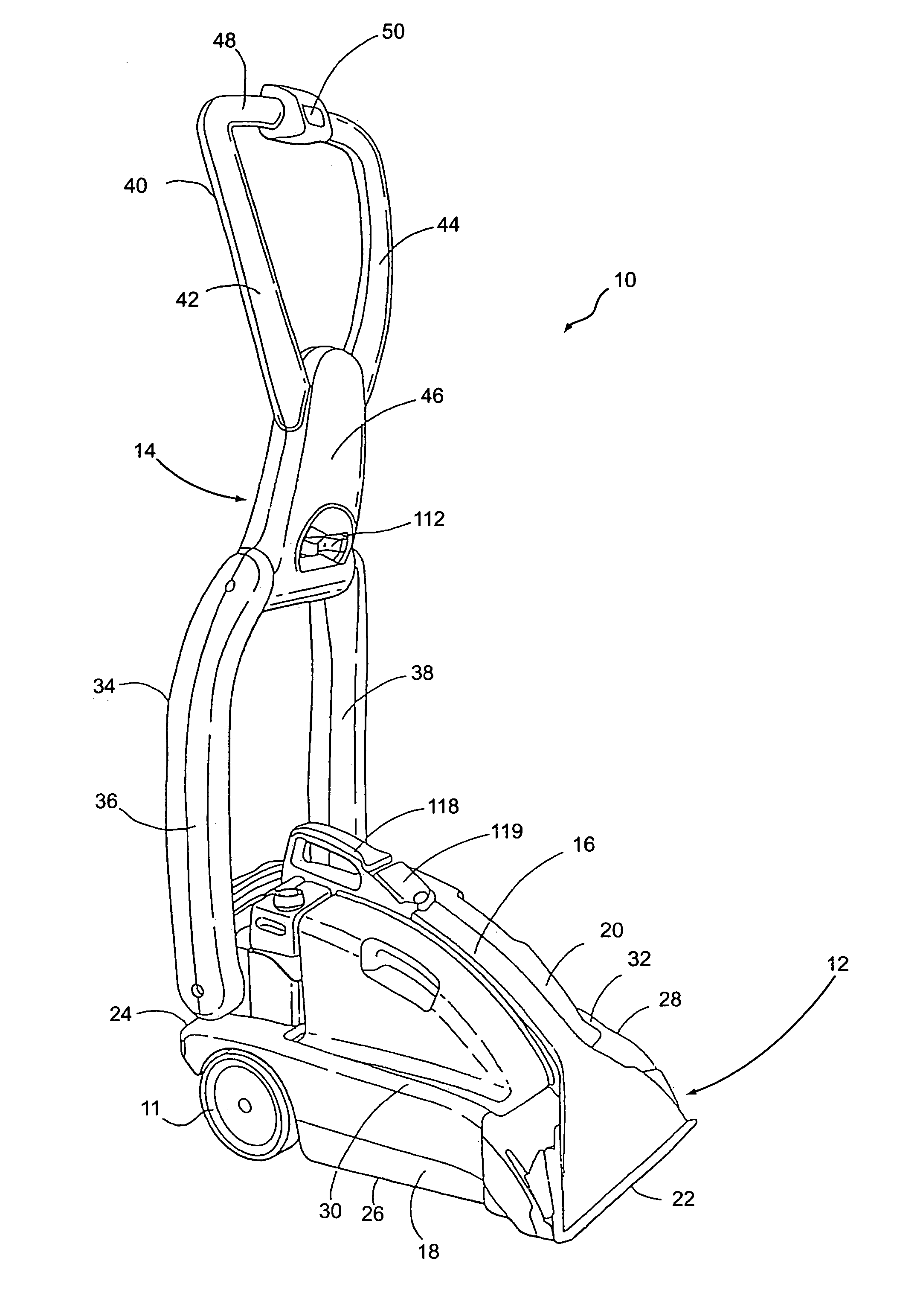

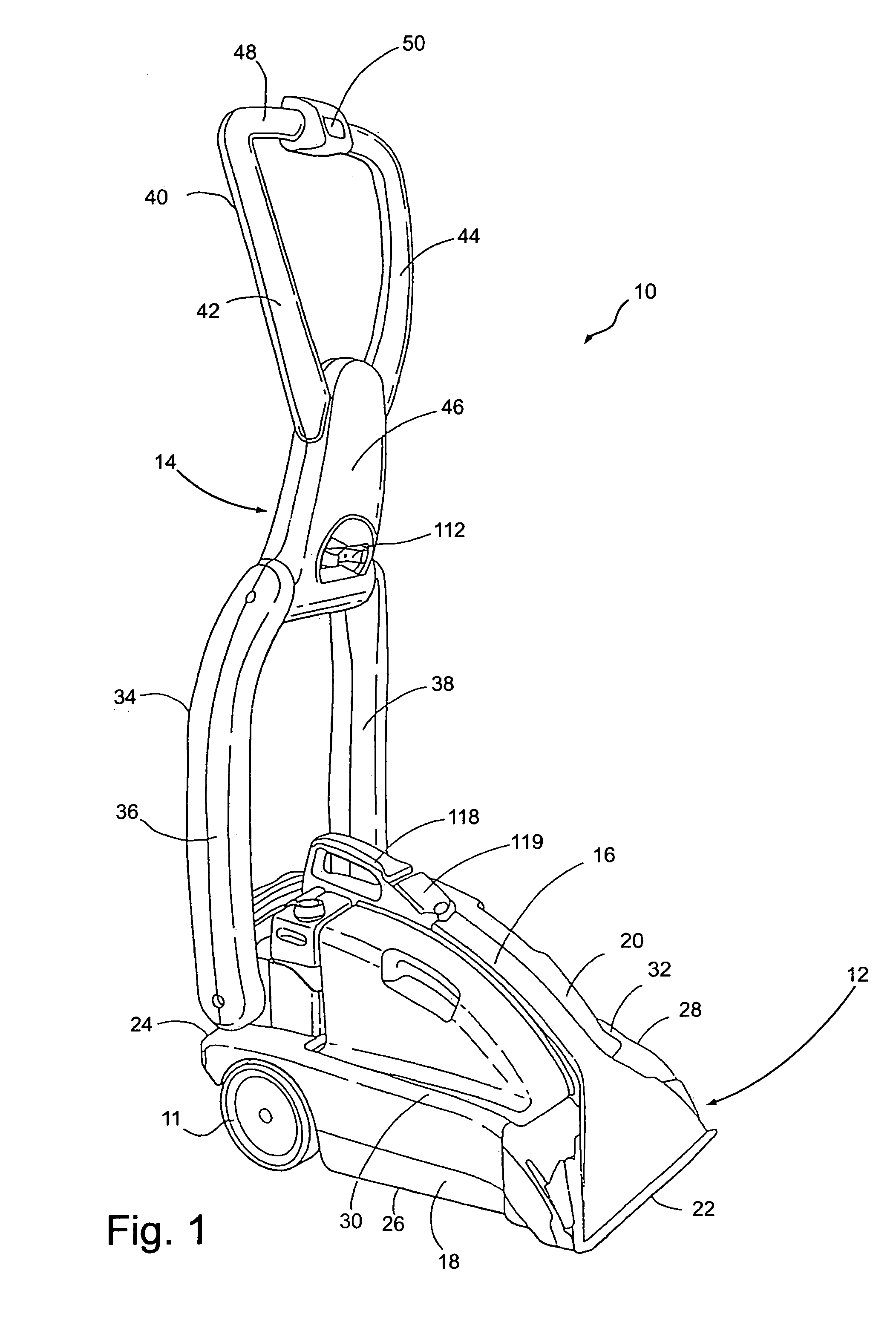

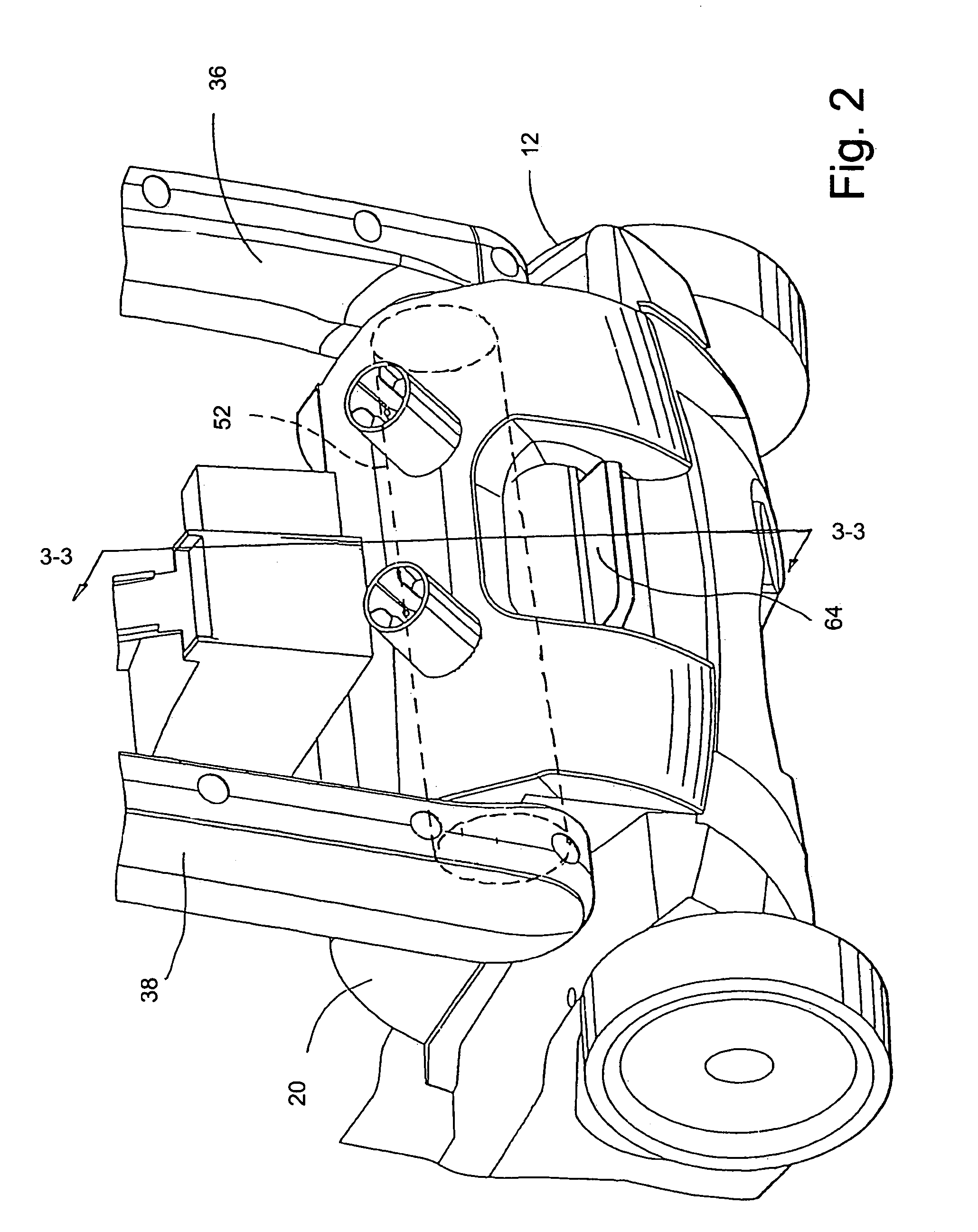

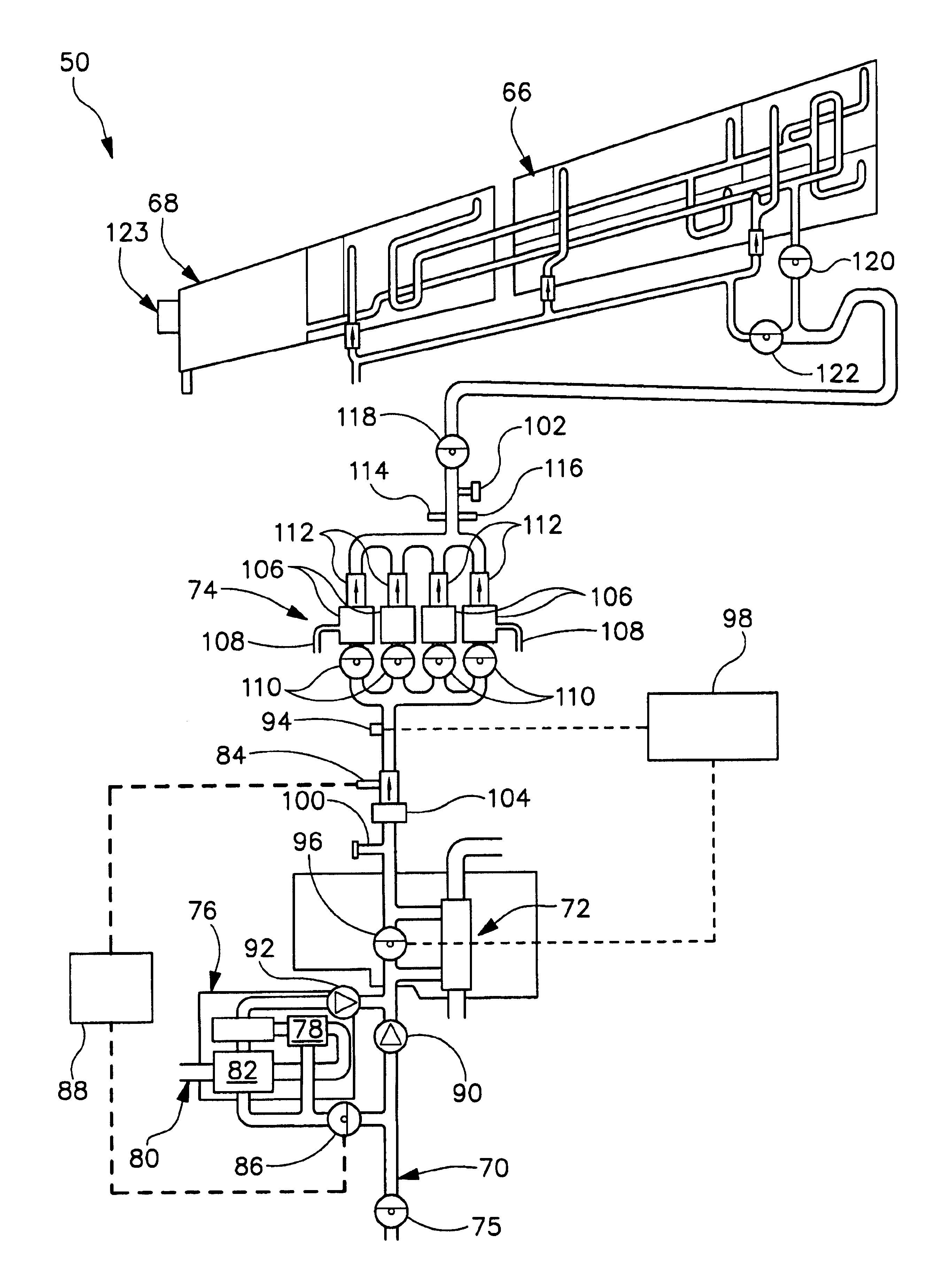

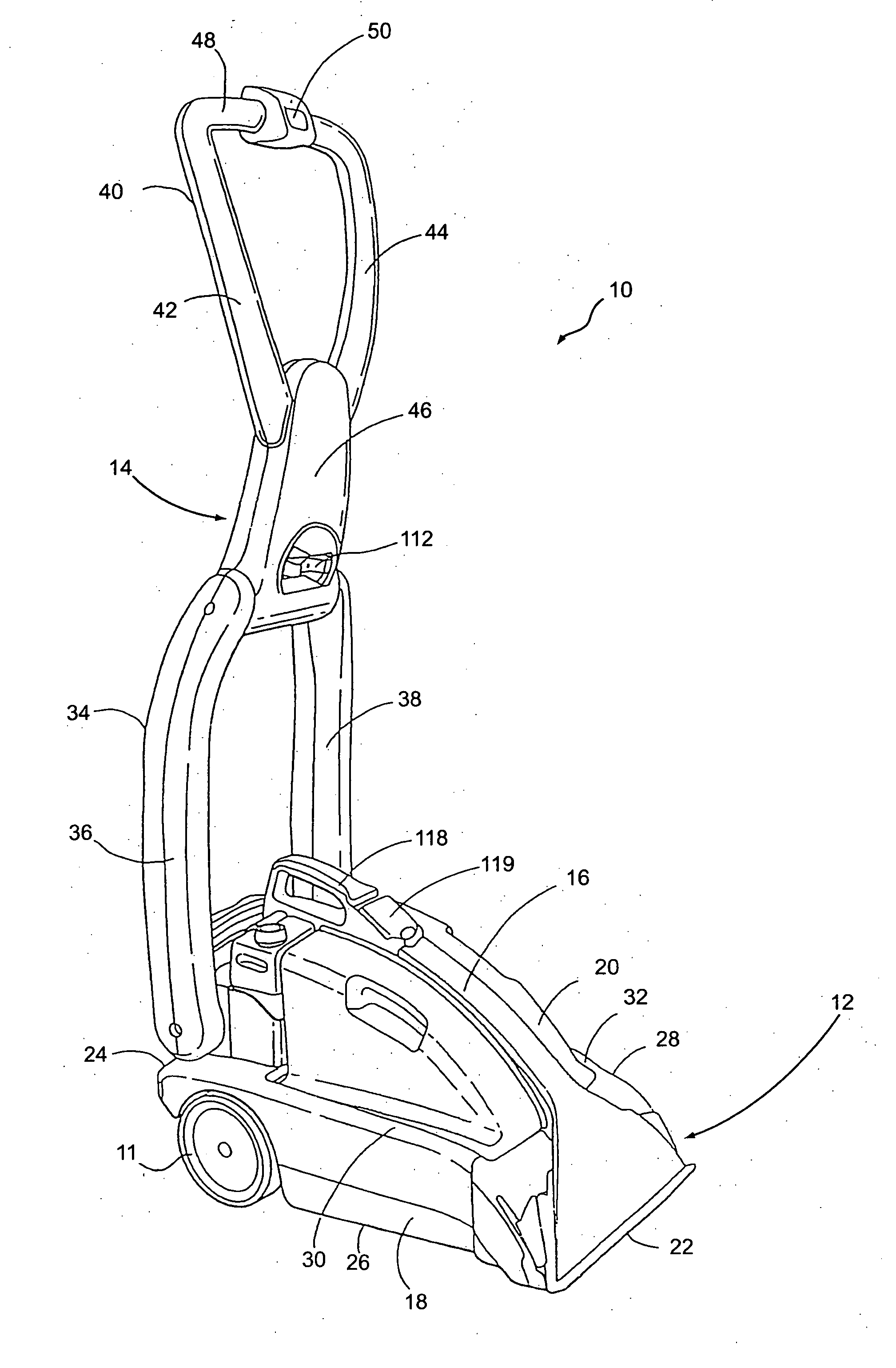

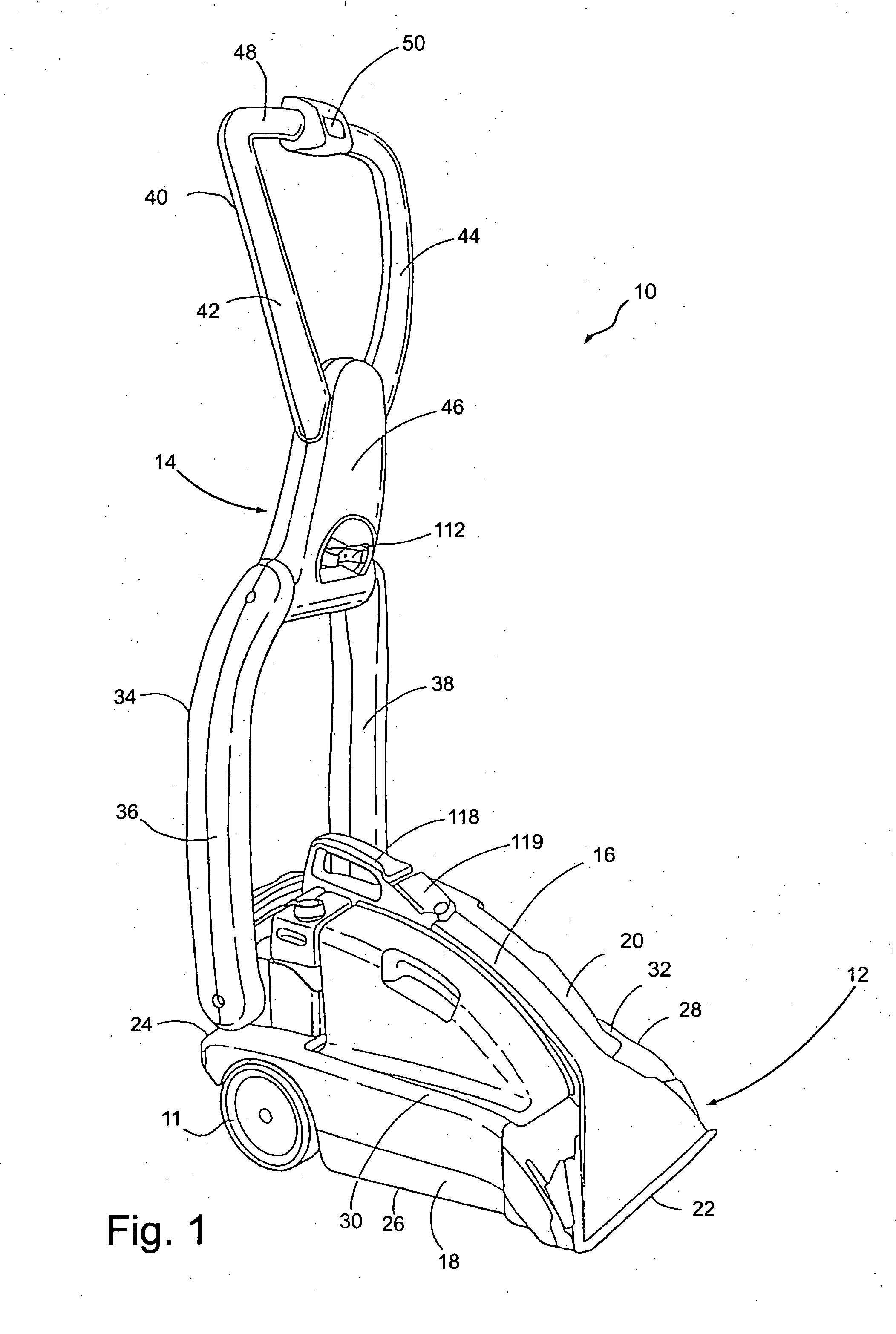

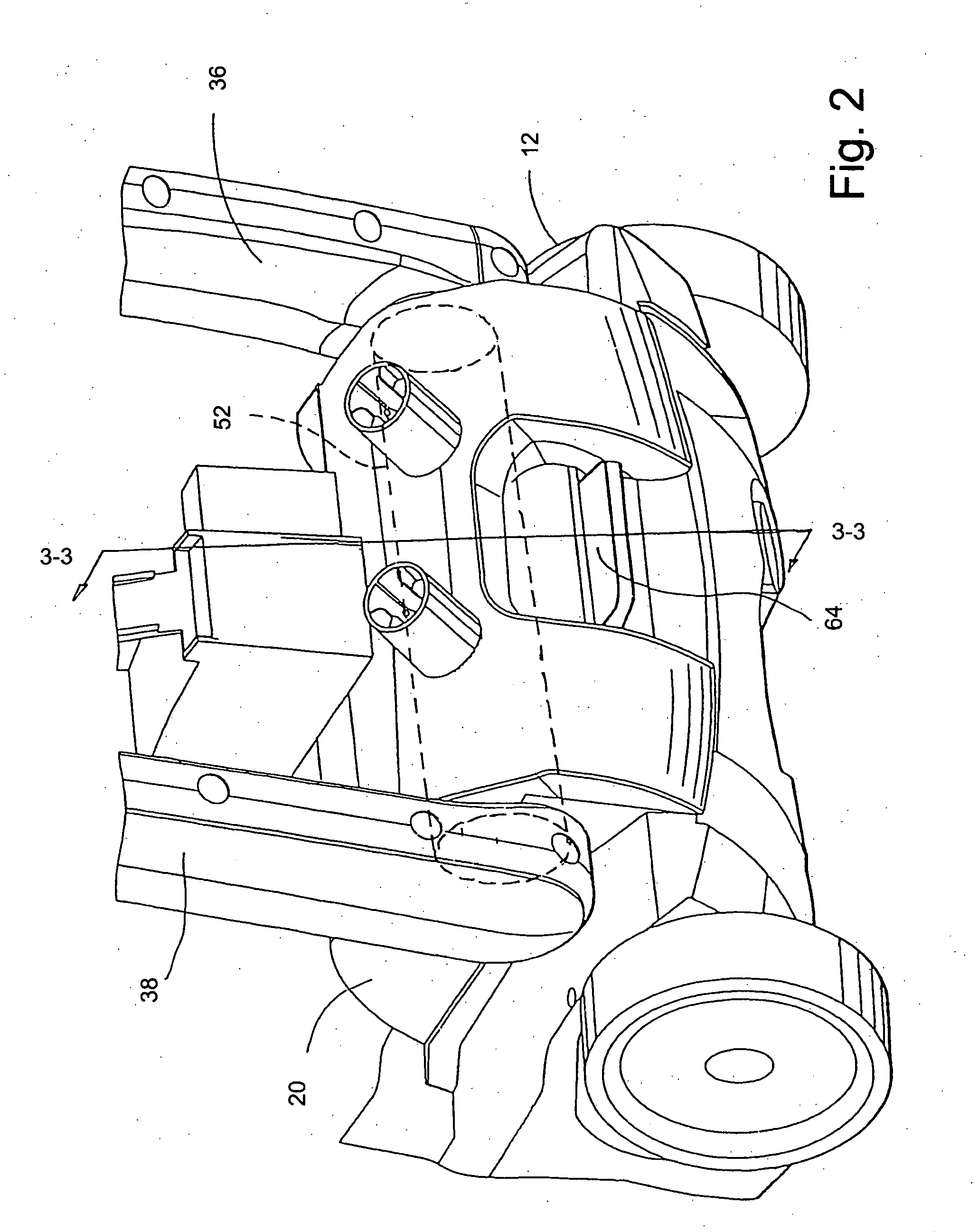

Wet extractor cleaning device fluid tank arrangement

A wet extraction floor cleaning device having a base assembly adapted for movement on a surface being cleaned, an operating handle pivotally attached to the base assembly, a supply tank having a supply tank outlet, and a recovery tank having a recovery tank inlet and a recovery tank outlet. The base assembly has an inlet nozzle that extends from an inlet slit proximal the surface being cleaned to a nozzle outlet. The device further includes a fluid deposition assembly that can be selectively placed in fluid communication with the supply tank outlet, a vacuum source, and first and second external pockets. The supply and recovery tanks are adapted to be selectively placed in the first and second external pockets, thereby placing the supply tank outlet in fluid communication with the fluid deposition system, the recovery tank inlet in fluid communication with the nozzle outlet, and the recovery tank outlet in fluid communication with the vacuum source inlet.

Owner:ELECTROLUX HOME CARE PRODS NORTH AMERICA A DIV OF ELECTROLUX HOME CARE PRODS

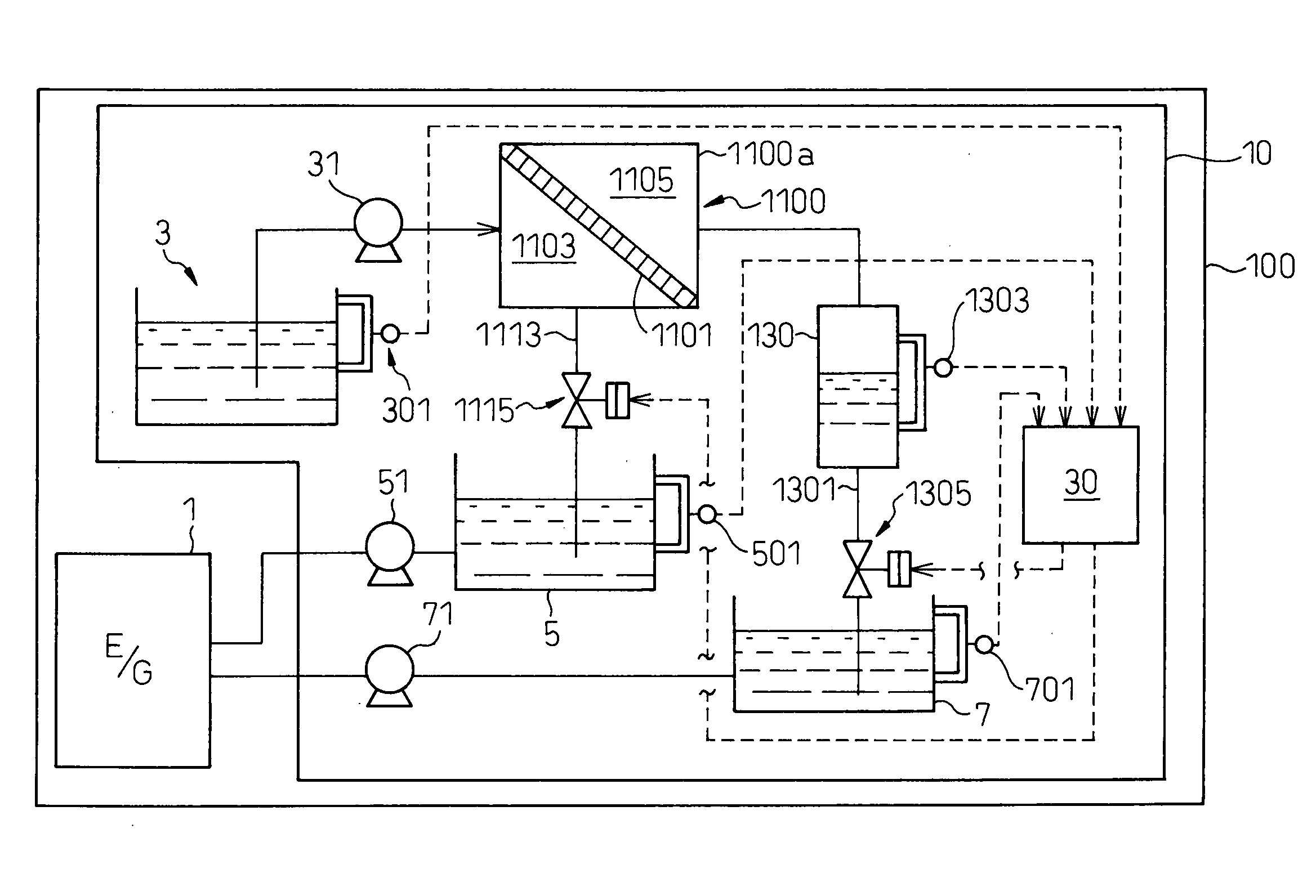

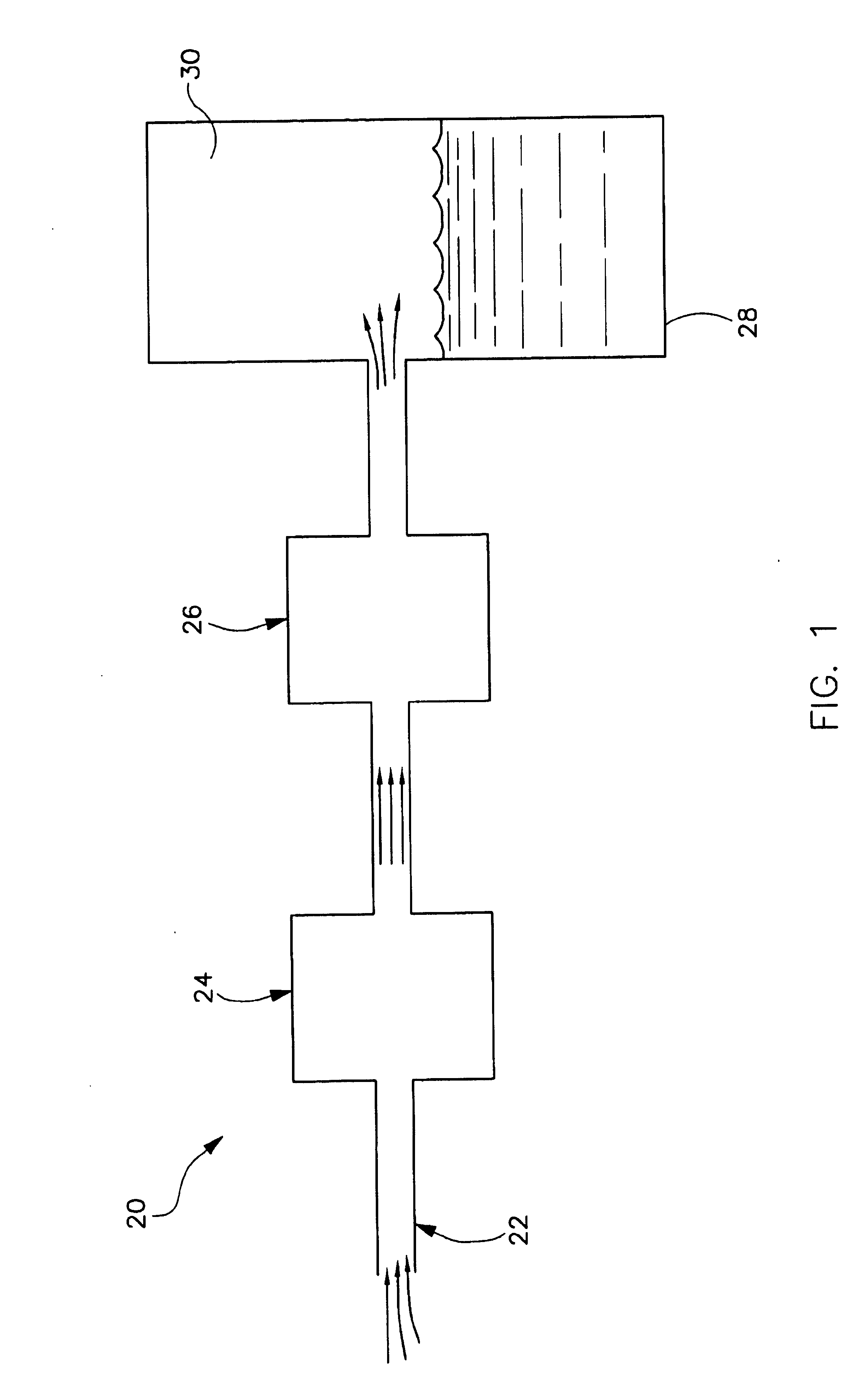

Method and apparatus for generating an inert gas on a vehicle

An inert gas generating system for generating inert gas on a vehicle having a fuel tank and a fuel tank vent. The system includes an inlet for receiving a flow of gas having a nitrogen component and an oxygen component from a gas source, a heat exchanger downstream from the inlet and in fluid communication with the inlet for cooling gas received from the inlet, and a gas separation module downstream from the heat exchanger and in fluid communication with the heat exchanger for separating gas received from the heat exchanger into a nitrogen-enriched gas flow and an oxygen-enriched gas flow. The gas separation module is adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank without delivering the nitrogen-enriched gas through the fuel tank vent. The gas separation module is also adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank vent.

Owner:THE BOEING CO

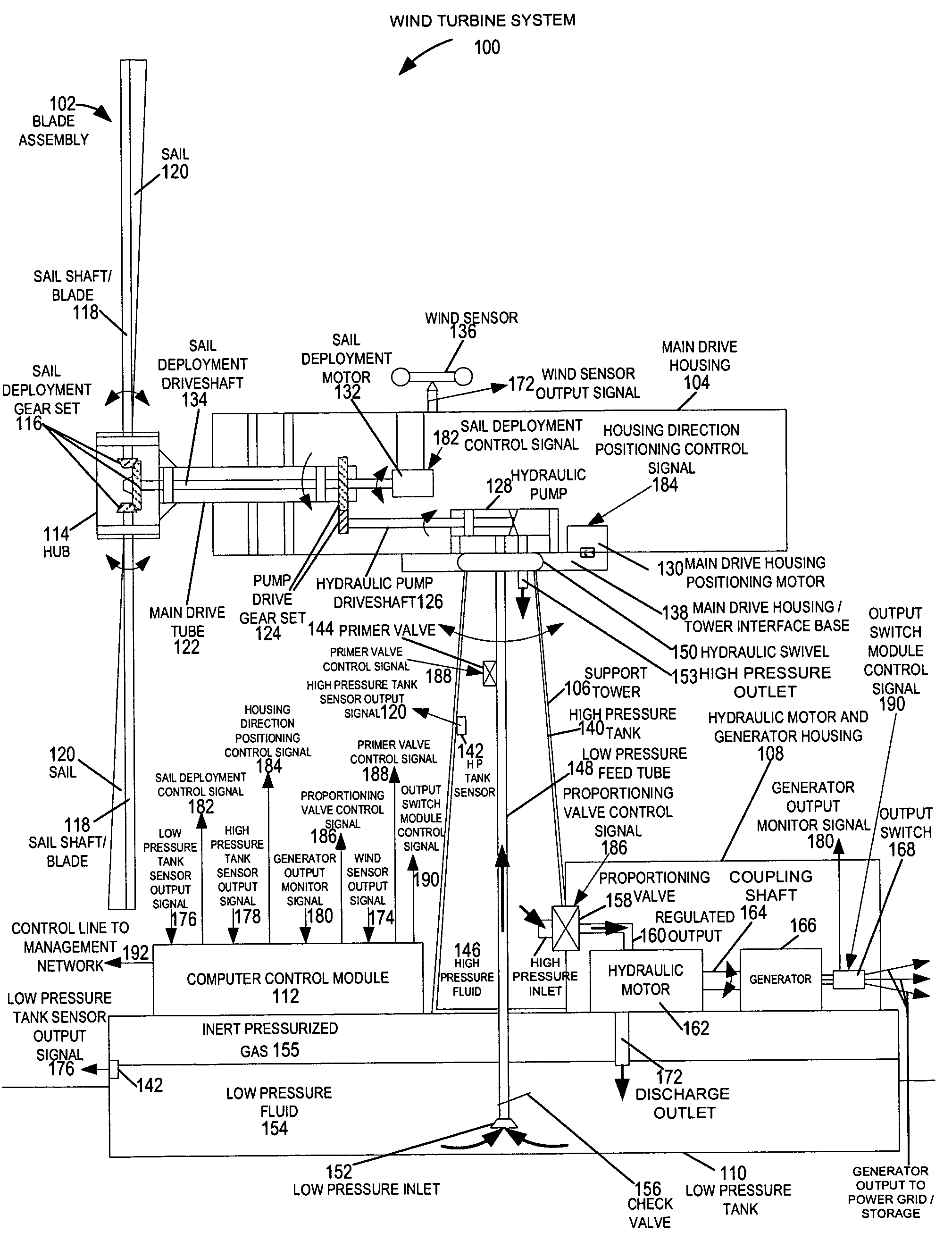

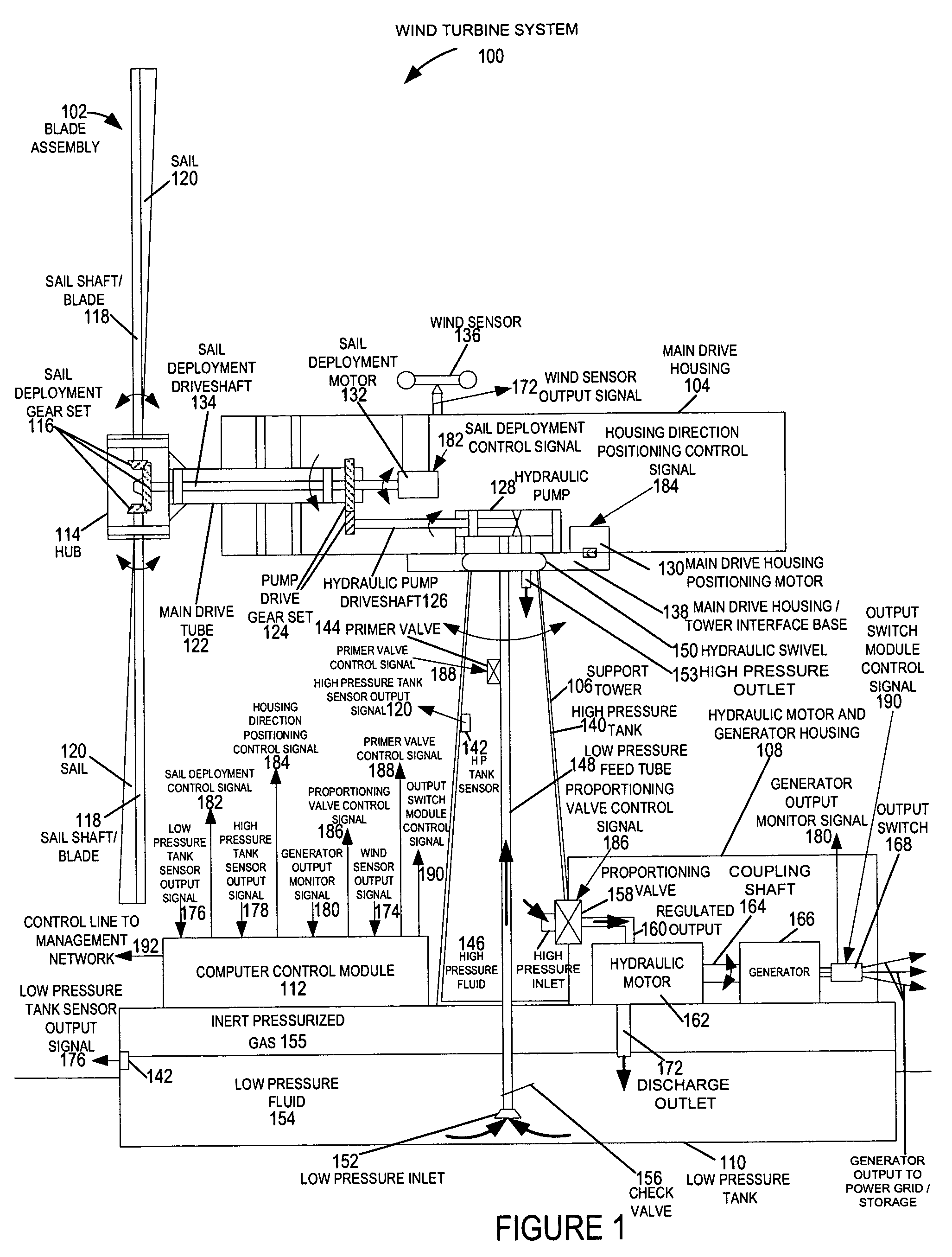

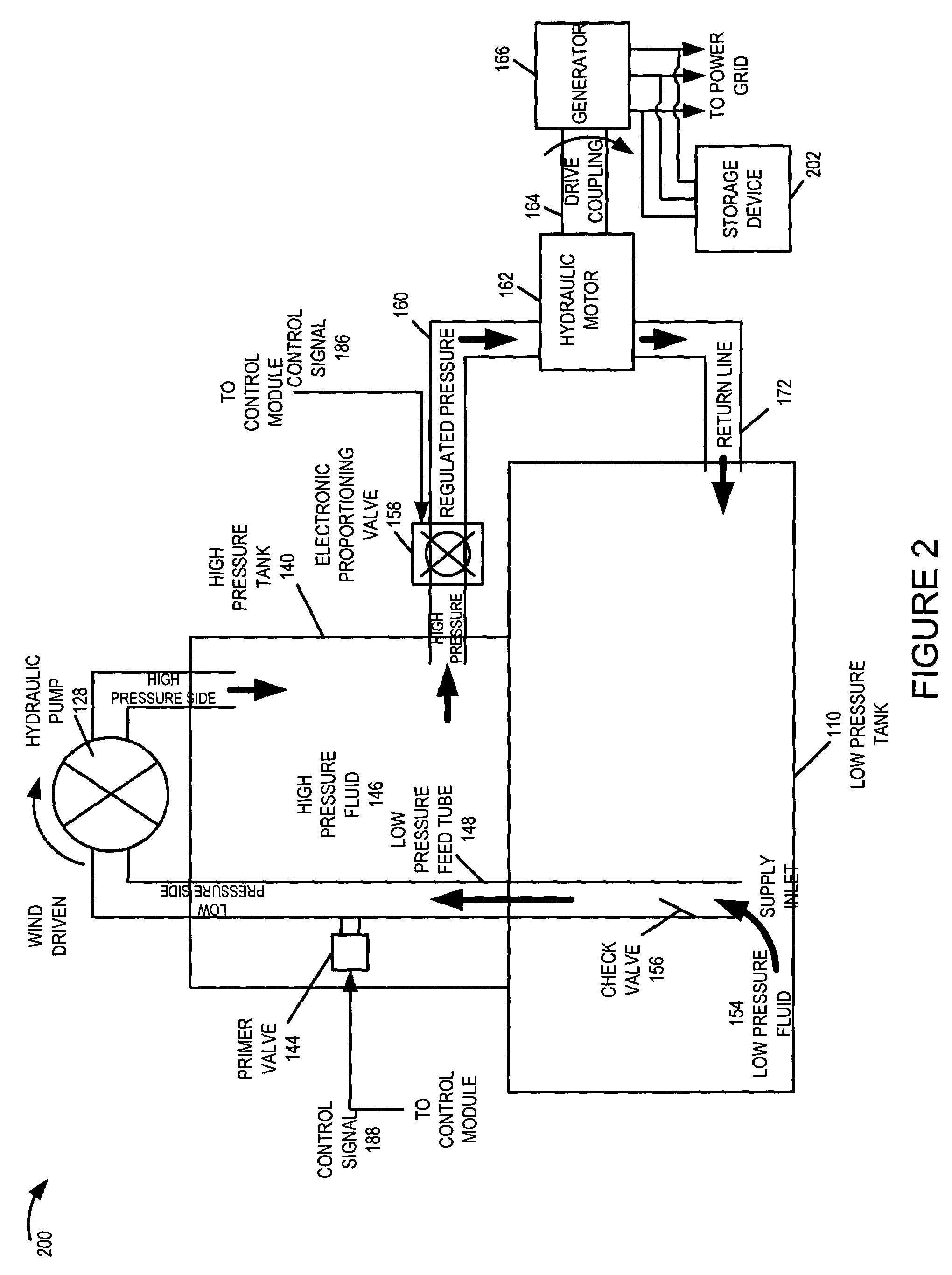

Methods and apparatus for advanced wind turbine design

ActiveUS7183664B2Eliminate needReduce pressureWind motor controlEngine fuctionsHigh energyHydraulic pump

A wind turbine system includes a variable blade assembly including adjustable sails and wing shaped masts expanding the wind velocity capture envelope. The blade assembly turns a hydraulic pump, which pressurizes fluid and stores the pressurized fluid in a chamber in the support tower. Pressurized fluid is directed via an electronically controllable proportioning valve to a hydraulic motor which is coupled to an electric generator. A computer control module operates the proportioning valve regulating pressure to the hydraulic motor, maintaining generator rotational speed, and providing consistent output frequency to the power grid. Stored energy in the high pressure tank is used to continue generator operation after the winds cease, allowing early warning notification to the power management system of impending power loss. Residual pressure maintained in the high pressure tank allows restart operations via hydraulic pressure rather than power grid energy drain. On site high energy capacitors store additional energy.

Owner:MCCLINTIC FRANK

Floor cleaning device

A wet extraction floor cleaning device having a base assembly adapted for movement on a surface being cleaned, an operating handle pivotally attached to the base assembly, a supply tank having a supply tank outlet, and a recovery tank having a recovery tank inlet and a recovery tank outlet. The base assembly has an inlet nozzle that extends from an inlet slit proximal the surface being cleaned to a nozzle outlet. The device further includes a fluid deposition assembly that can be selectively placed in fluid communication with the supply tank outlet, a vacuum source, and first and second external pockets. The supply and recovery tanks are adapted to be selectively placed in the first and second external pockets, thereby placing the supply tank outlet in fluid communication with the fluid deposition system, the recovery tank inlet in fluid communication with the nozzle outlet, and the recovery tank outlet in fluid communication with the vacuum source inlet.

Owner:ELECTROLUX HOME CARE PRODS NORTH AMERICA A DIV OF ELECTROLUX HOME CARE PRODS

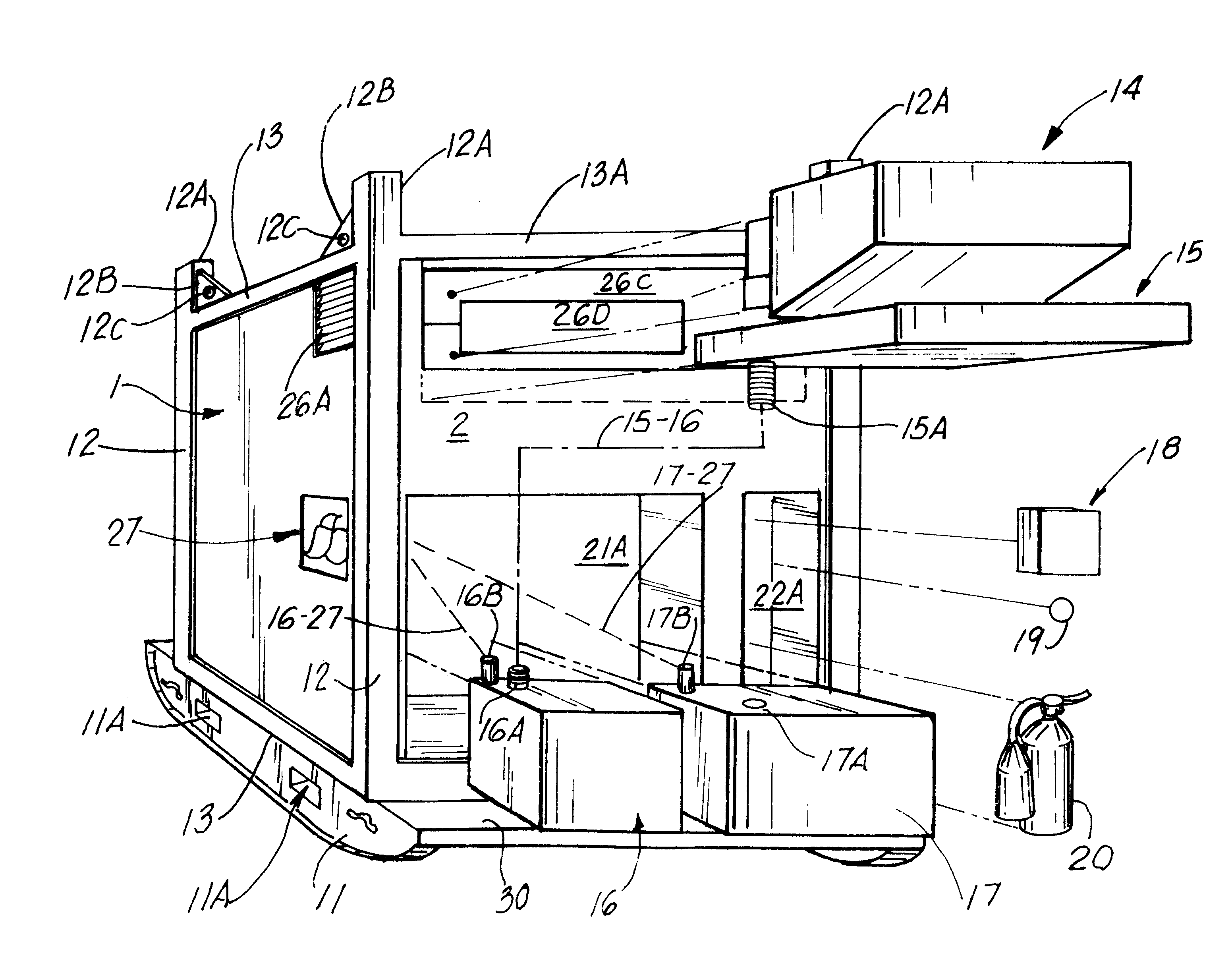

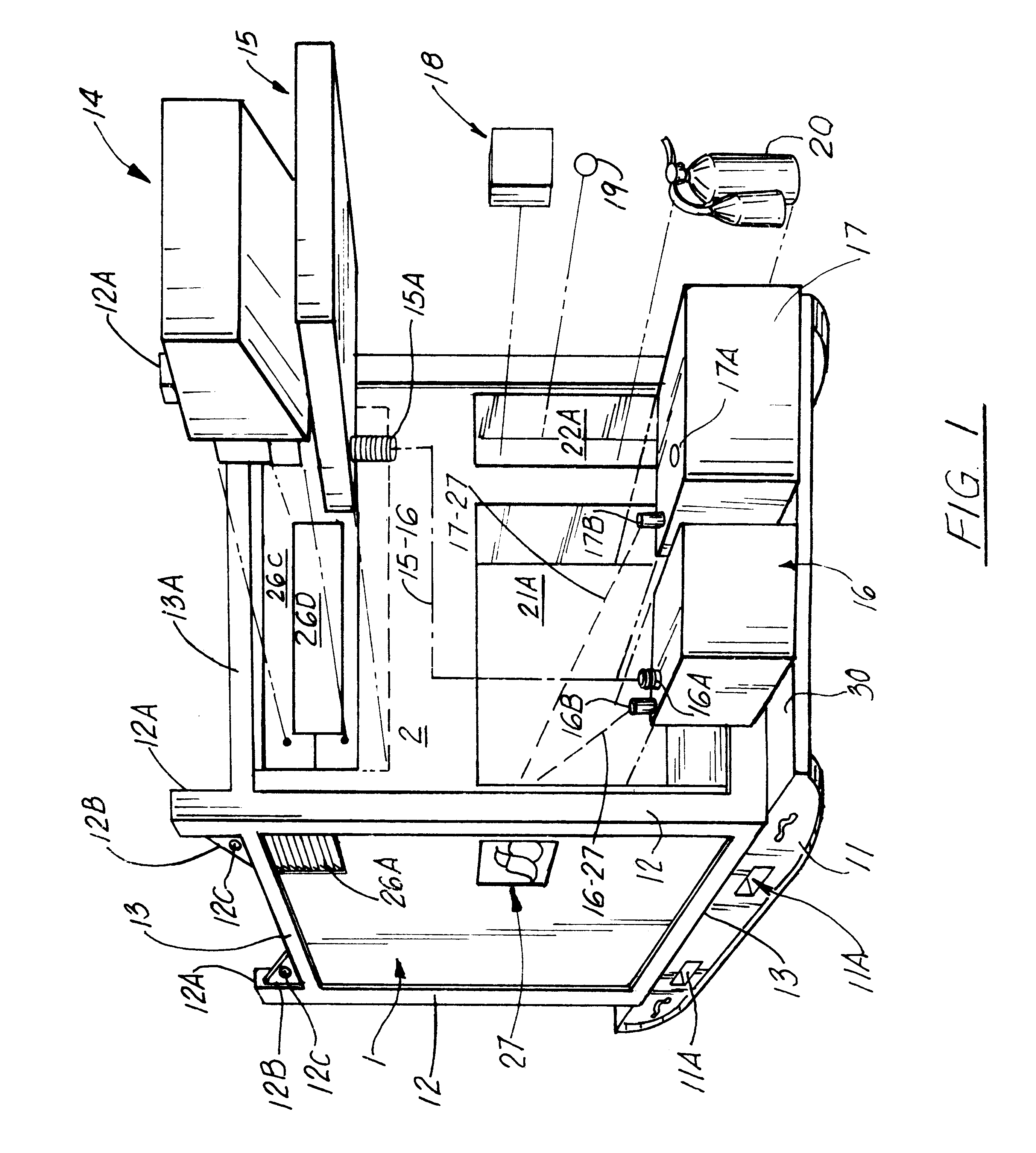

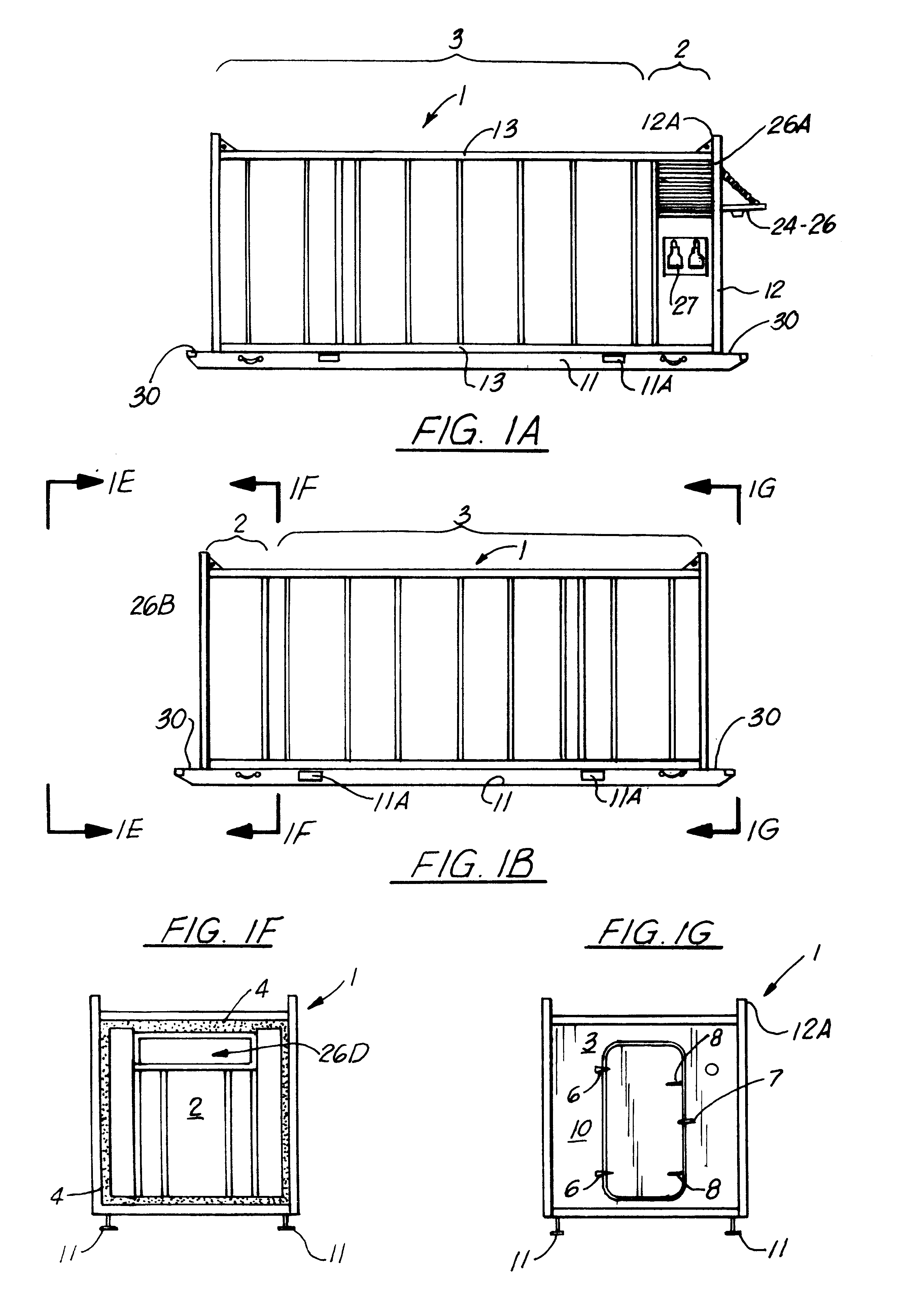

Transportable, self-contained, refrigeration system

InactiveUS6289684B1Easy to transportEasy to moveAir-treating devicesCompression machines with non-reversible cycleMetals industryMarine engineering

An extended, box-like, metal, industrial size, insulated container (1 / 101, two embodiments disclosed, FIGS. 1-1G & FIGS. 2A-2D) including a rigid, structural framework (12 / 13) for safely and reliably transporting and / or storing relatively large quantities of temperature sensitive items (food, medical supplies, ice, human corpses, etc.) over a long distance (e.g., from an on-shore food center to an offshore platform) and / or for a substantial period of time (7+days), useful for such delivery / storage and in emergencies, disasters, etc. The container includes at its ends a structurally protected, enclosed equipment section (2 / 102), which includes all operating machinery (e.g. compressor, motor, fuel tank, control mechanisms, etc., in isolated sub-compartments) and associated equipment, and a freezer / cooler section (3 / 103A-103B) for the temperature sensitive items. The second embodiment includes two, separate, freezer and cooler sections (103A / 103B) with separate, side doors (105A / 105B). An escape structure (FIGS. 3A & 3B) on the lock latch is included on the access door(s) for escape of an occupant who becomes locked in. Many other, innovative safety features are disclosed, along with innovative use methodologies (FIGS. 4 & 5).

Owner:GUIDRY & MORALES HLDG

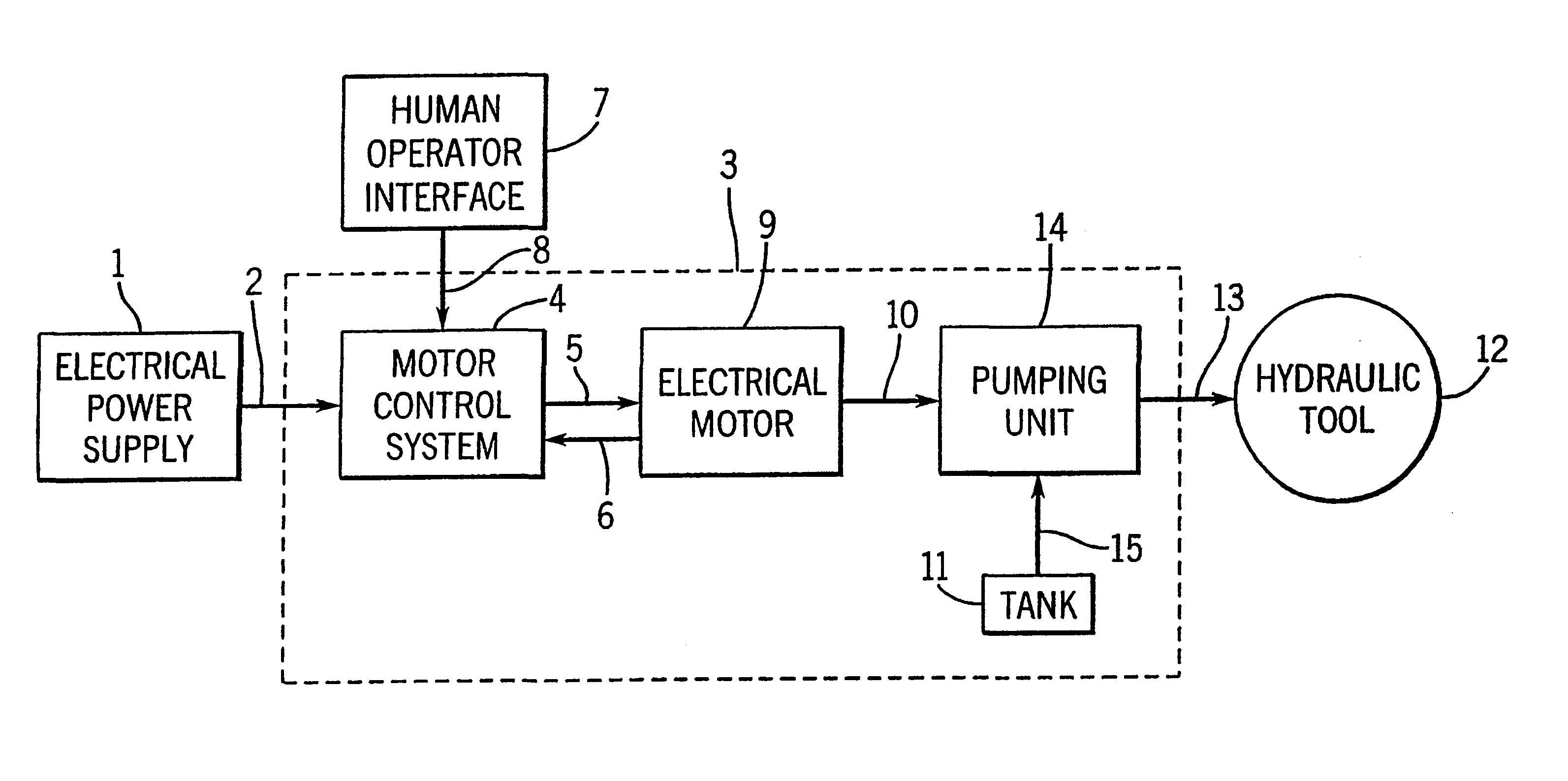

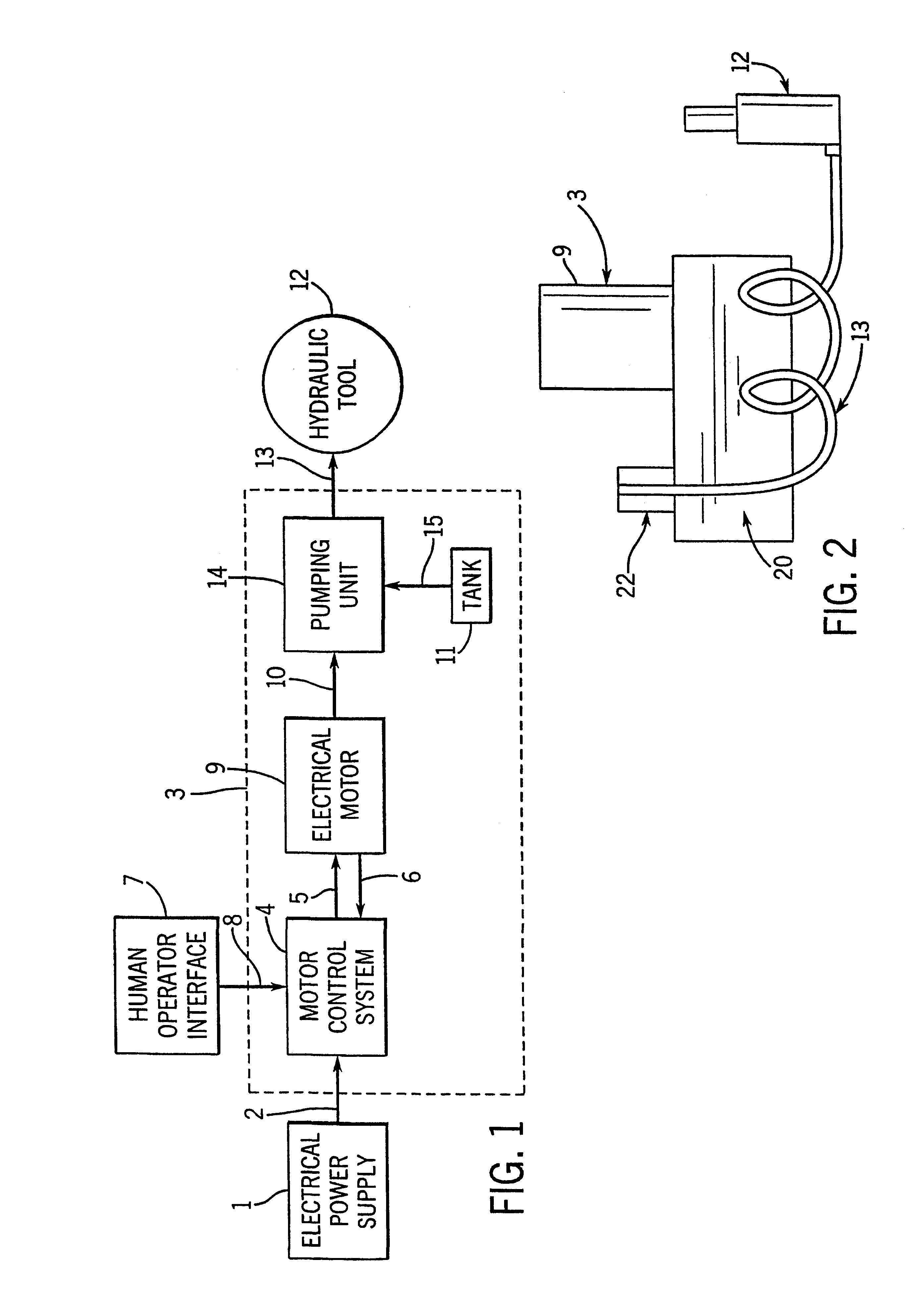

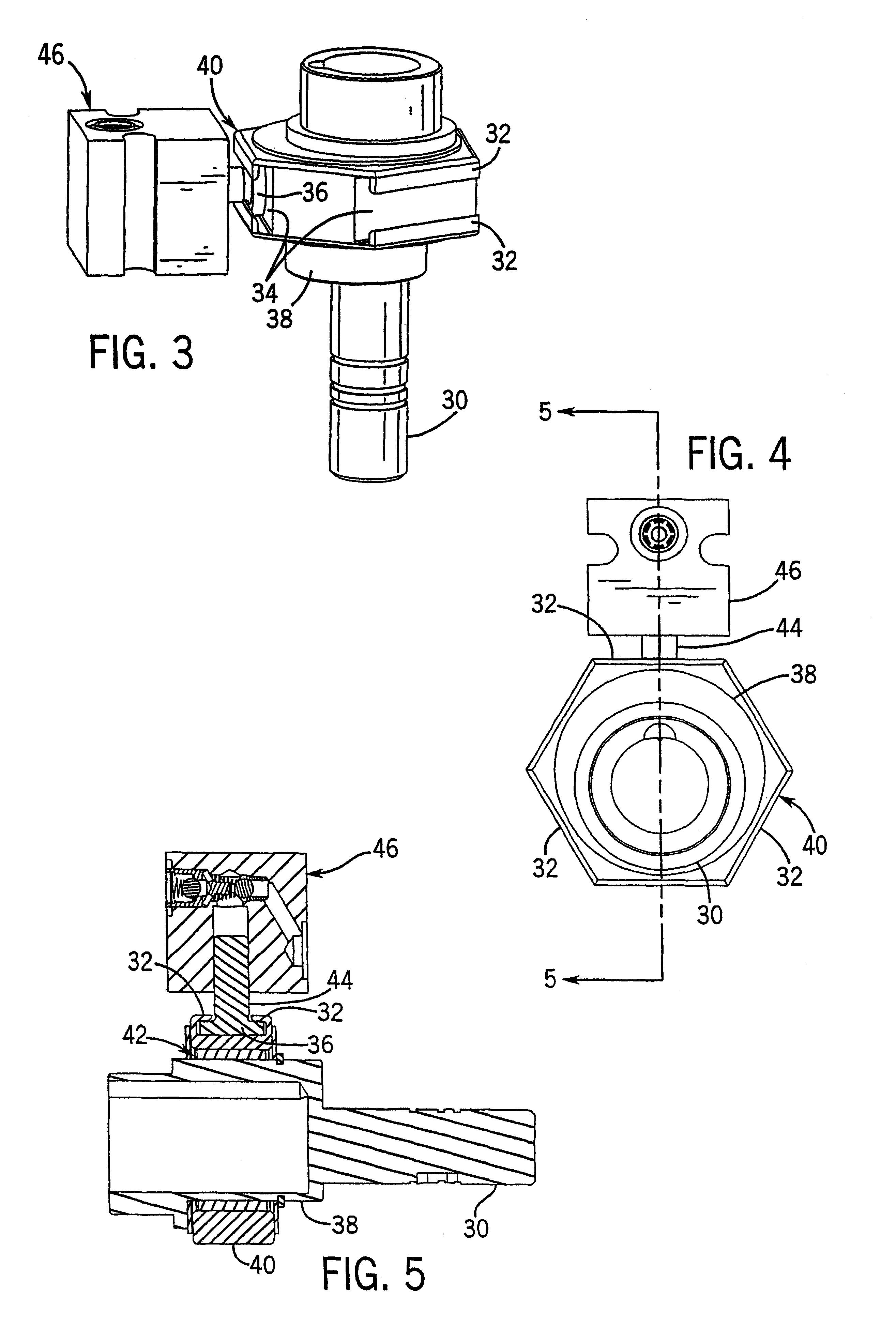

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com