Frac water heating system and method for hydraulically fracturing a well

a heating system and hydraulic fracturing technology, applied in the direction of lighting, heating apparatus, wellbore/well accessories, etc., can solve the problems of affecting the effectiveness of the heating facility, the construction of a permanent heating facility at the well site is not cost-effective, and the treatment fluid quantity is large, so as to achieve safe and continuous heating large quantities of treatment fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

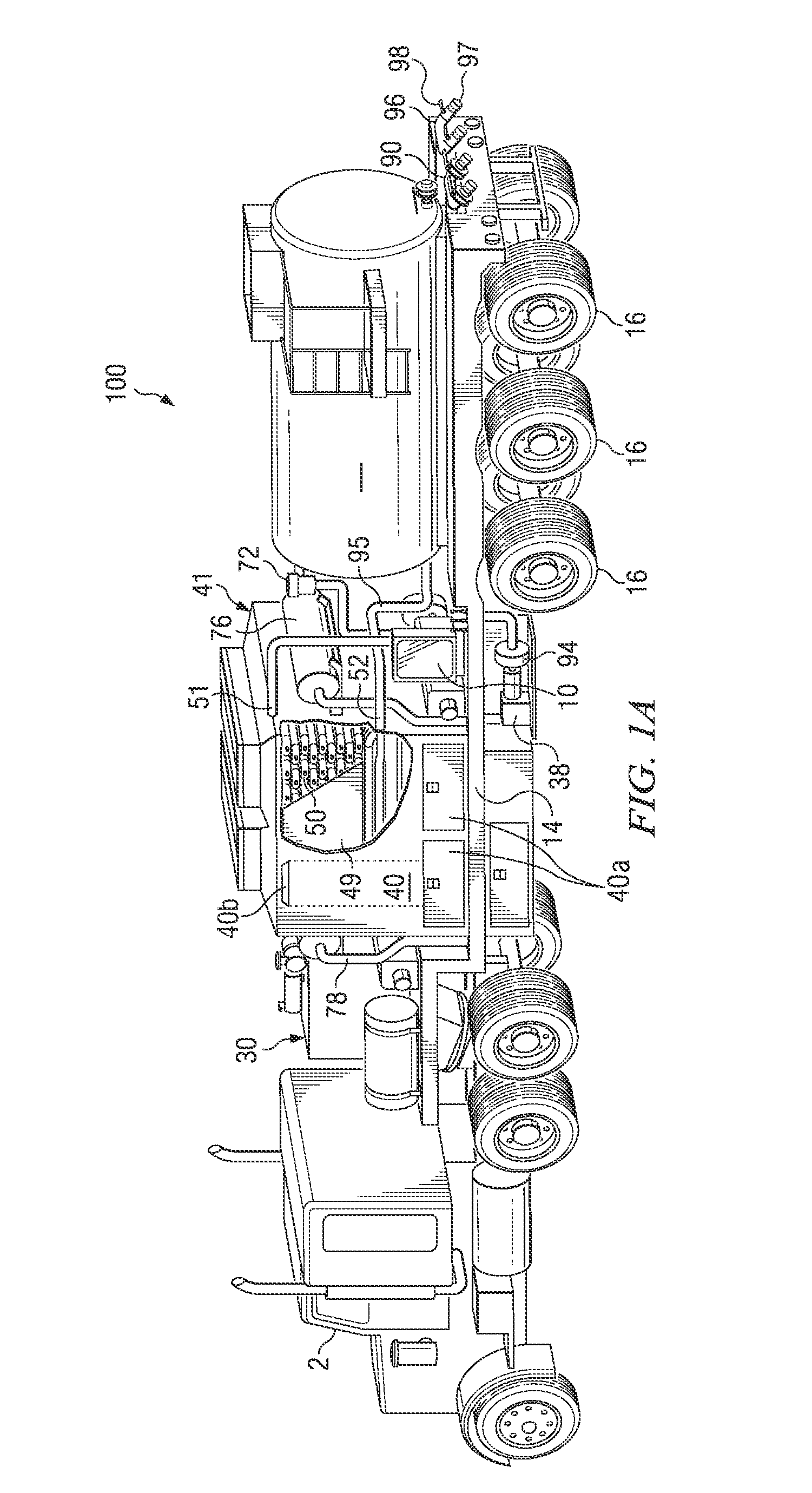

embodiment 100

[0060]As shown in the Figures and schematically depicted in FIGS. 7A and 8A, in one embodiment the fuel system includes a fuel tank 20, which is configured near the rear or back end of the trailer 14. The fuel tank 20 is typically unpressurized and used to store the liquid fuel used by the multiple burner assemblies 60 configured in the firebox 40. In the depicted embodiment 100, the fuel tank 20 is unpressurized and can hold up to 60 bbl. of diesel fuel. The fuel system also includes an unpressurized fuel line 21, which supplies fuel from the fuel tank 20 to the intake of a fuel pump 22. The fuel pump 22 boosts the fuel pressure and directs it to the multiple burner assemblies 60 by means of a pressurized fuel line 26. In one embodiment, the fuel pump 22 boosts the fuel pressure to approximately 50-100 psi, preferably 60 psi.

[0061]The liquid fuel system also includes a pressure relief valve 24 in fluid communication with the pressurized fuel line 26. The pressure relief valve 24 pe...

first embodiment

[0077]The firebox 40 also includes a plurality of burner assemblies 60, which are configured in the lower side of the firebox 40. As will be subsequently described in greater detail, each of the burner assemblies 60 are connected to a fuel system and a pressurized air supply. For example, FIGS. 7A and 8A schematically depicts a first embodiment, which features oil-fired burner assemblies 60 connected to a fuel oil supply system. Liquid fuel is supplied to each burner assembly 60 via the metered pressurized fuel line 28. Similarly, pressurized air for combustion is supplied to each burner assembly 60 via a primary air conduit 78c. The pressurized air and fuel are combined in the burner assembly 60 and directed through an atomizer nozzle 64, which projects an atomized air-fuel spray into the firebox 40 where it is combusted. Each burner assembly 60 is configured in the lower side of firebox 40 so as to initially generate a substantially horizontal combustion flow within the firebox 40...

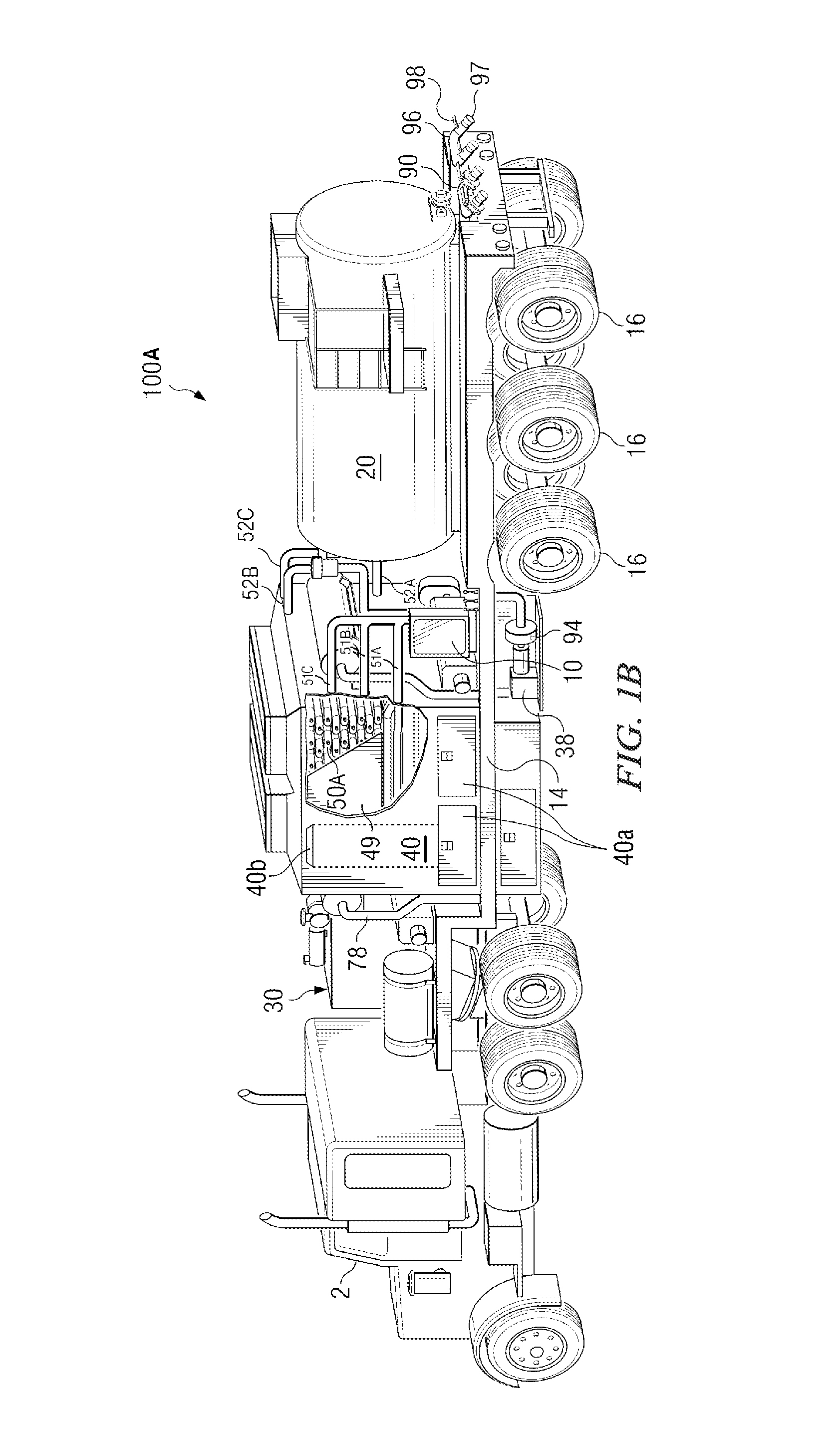

second embodiment

[0078]Similarly, FIGS. 7B and 8B schematically depicts a second embodiment, which features gas-fired burner assemblies 60 connected to a gas fuel supply system. Flammable gas fuel (e.g., LPG or natural gas) is supplied to each gas-fired burner assembly 60 via the metered pressurized gas fuel line 28A. Similarly, pressurized air for combustion is supplied to each gas-fired burner assembly 60 via a primary air conduit 78c. The pressurized air and fuel are combined in the burner assembly 60 and directed through a mixer nozzle 64A, which projects an air-gas fuel spray into the firebox 40 where it is combusted. Each gas-fired burner assembly 60 is configured in the lower side of firebox 40 so as to initially generate a substantially horizontal combustion flow within the firebox 40. Each gas-fired burner assembly 60 includes self-contained controls for adjusting the gas fuel-air mixture and an ignition mechanism for initially igniting the gas fuel-air mixture. In a preferred embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com