Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34071 results about "Exhaust pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

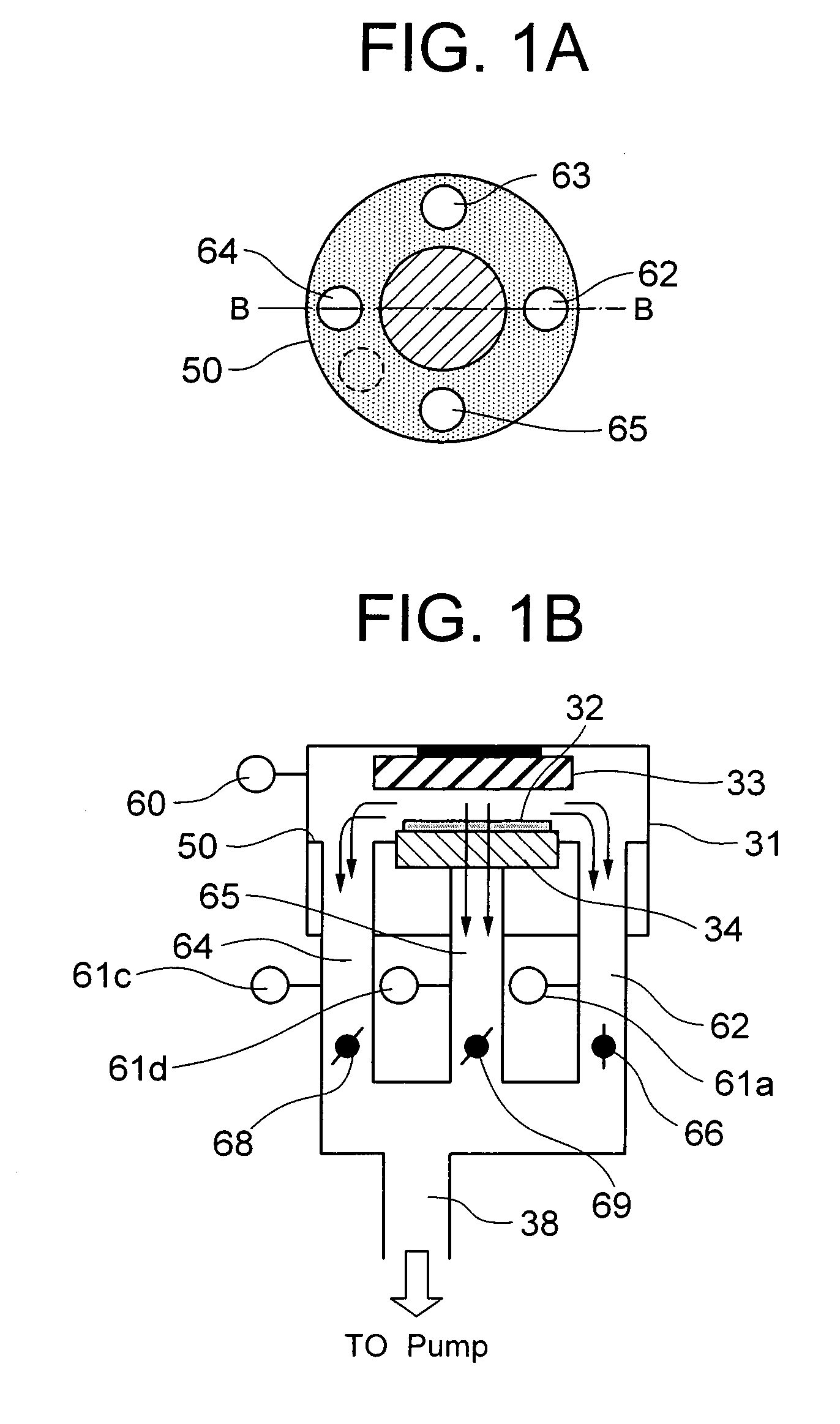

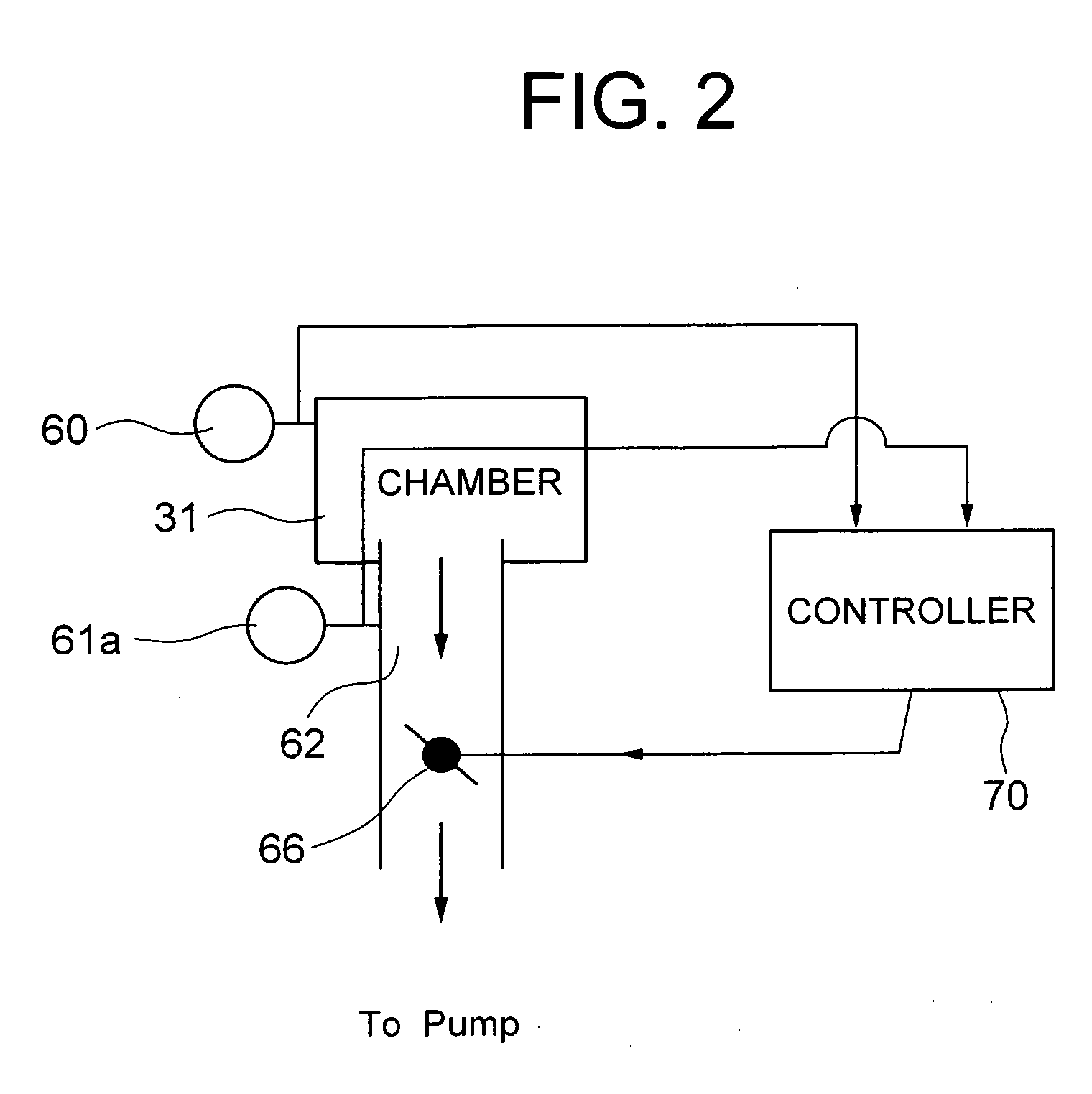

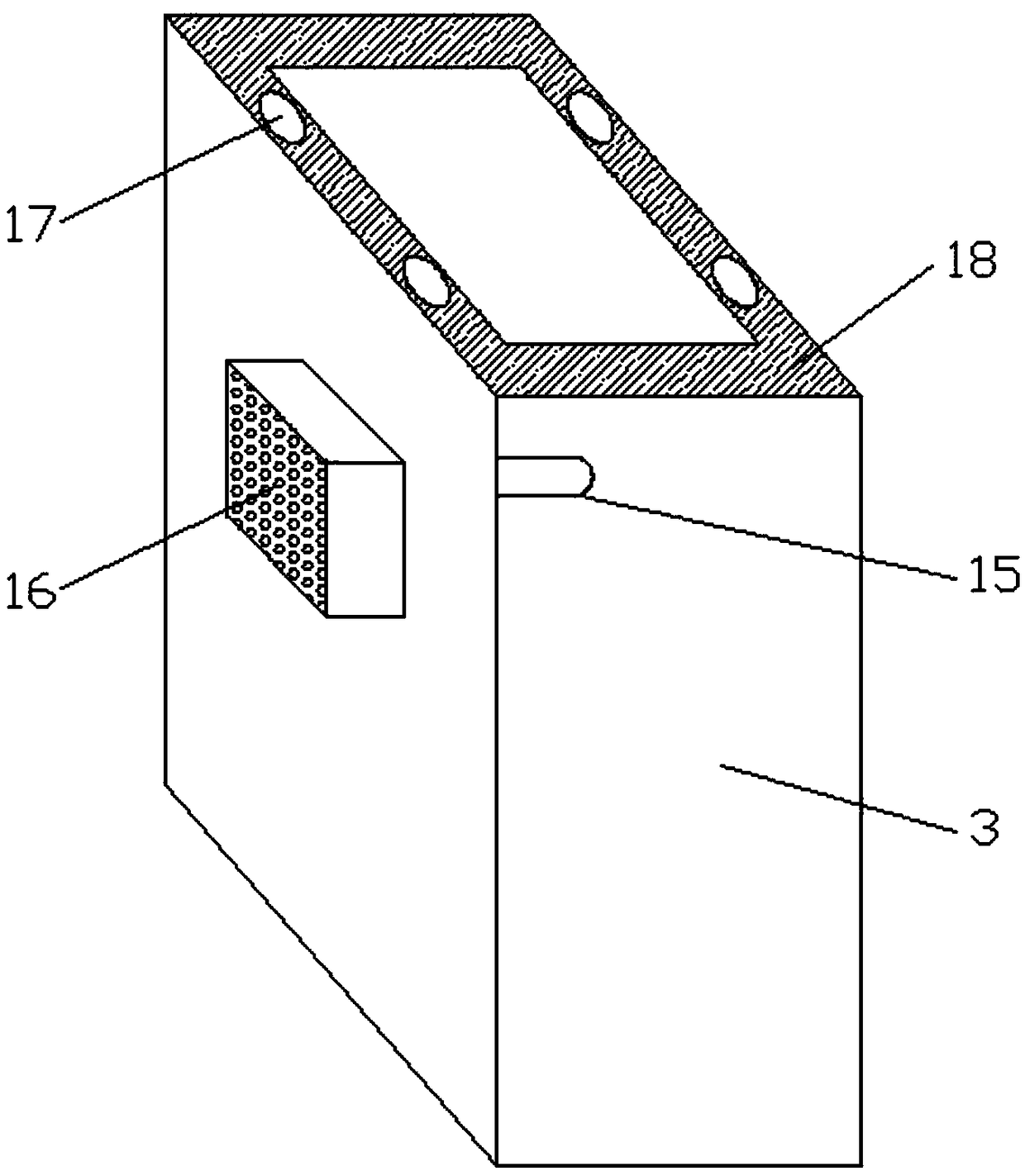

Atomic layer deposition system including a plurality of exhaust tubes

InactiveUS20080176412A1Uniform film qualityHigh aspect ratioLiquid surface applicatorsSemiconductor/solid-state device manufacturingControl valvesVapor phase

An atomic layer deposition system includes a reaction chamber, a plurality of exhaust tubes communicated to the reaction chamber, a plurality of first vacuum gauges for monitoring the degree of vacuum of the respective exhaust tubes, a second vacuum gauge for monitoring the degree of vacuum of the reaction chamber, and control valves for adjusting the exhaust volume of the exhaust tubes independently of one another. The control valves are controlled based on the pressures measured by the first and second control valves for achieving a uniform flow of the vapor phase reactant.

Owner:PS4 LUXCO SARL

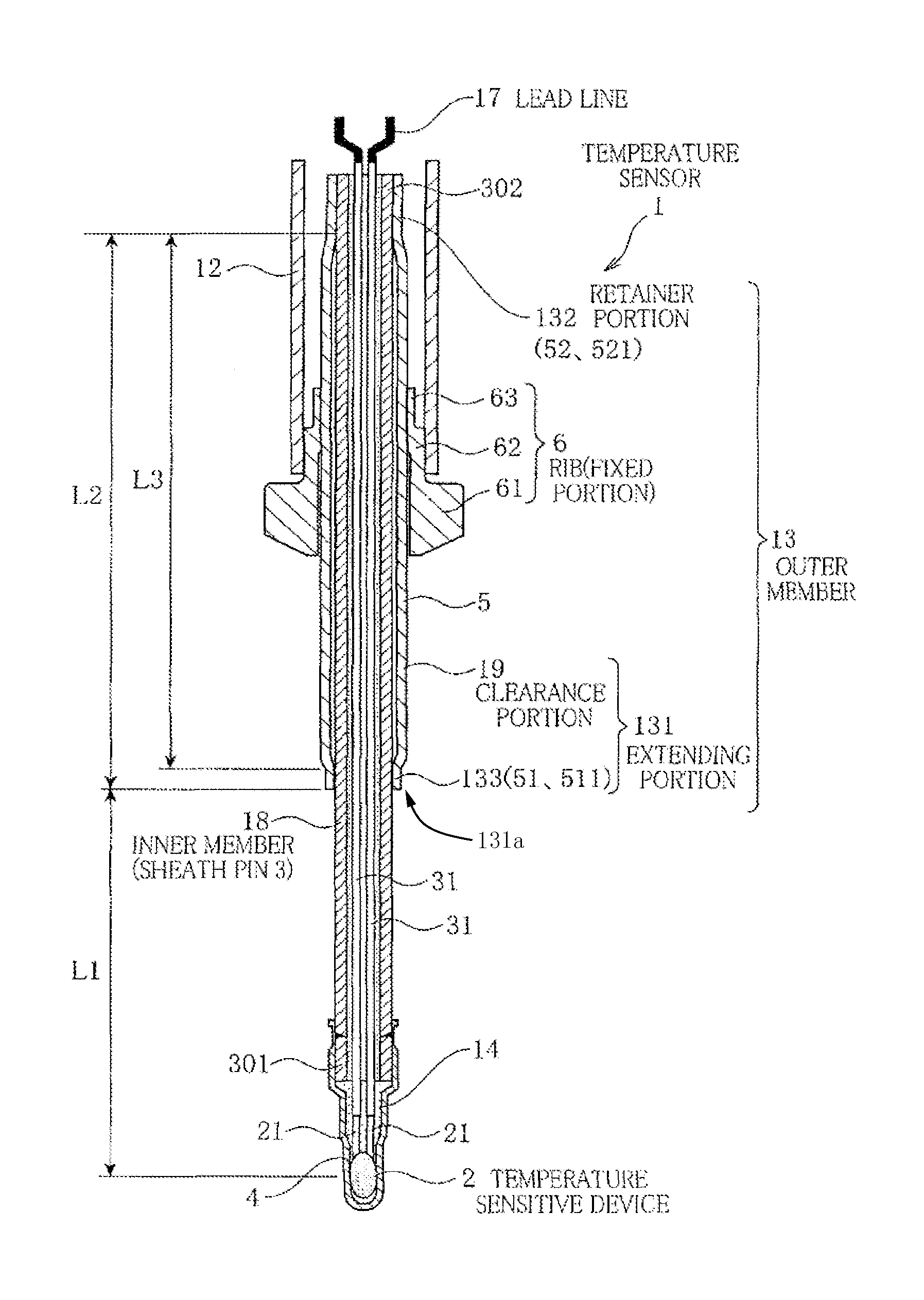

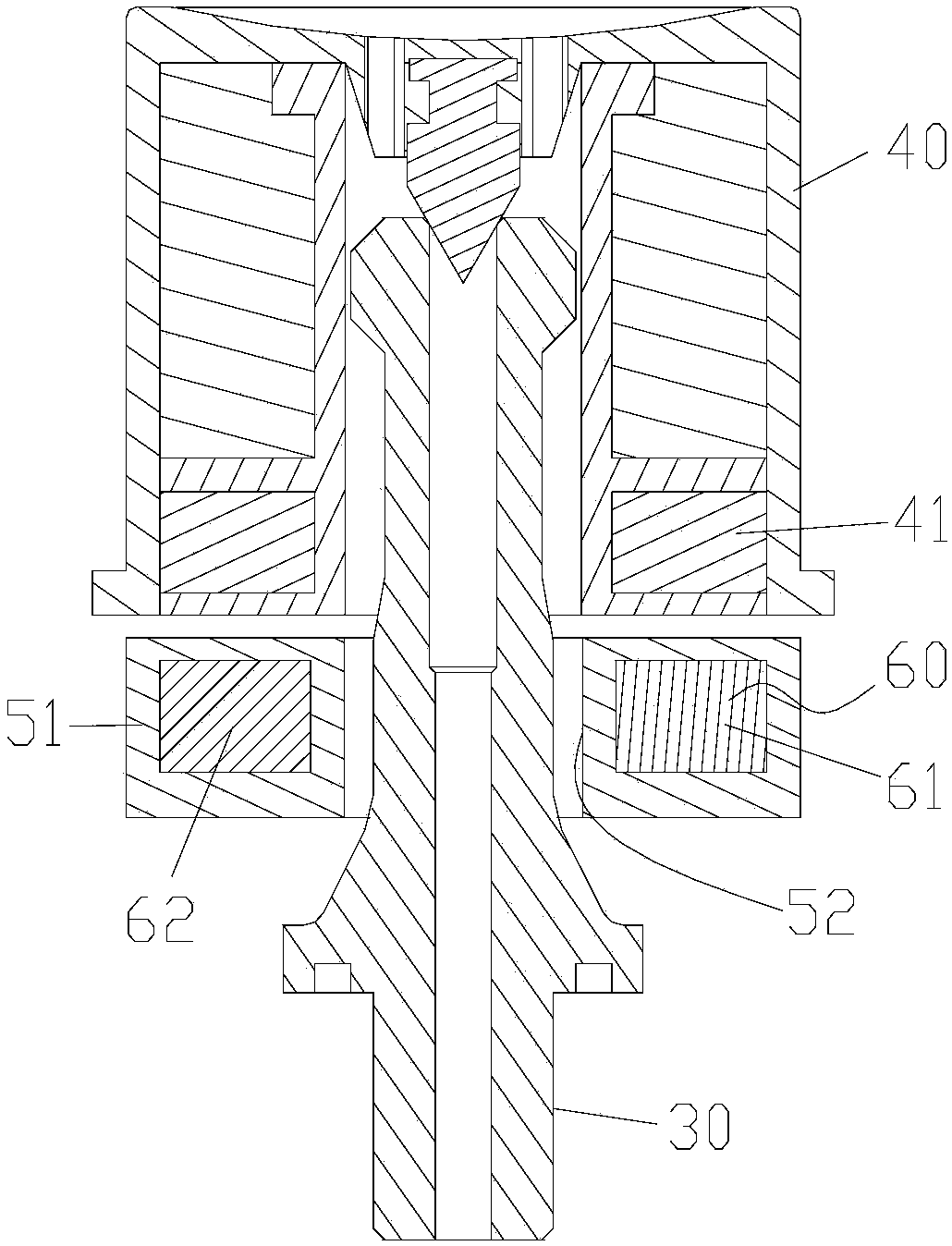

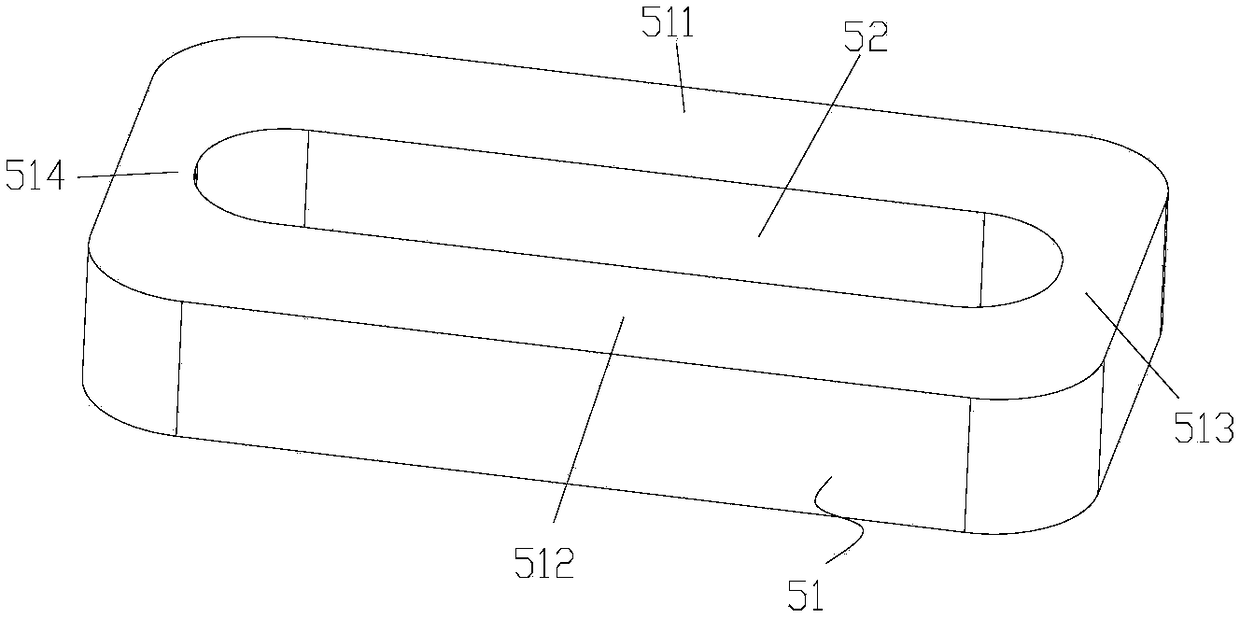

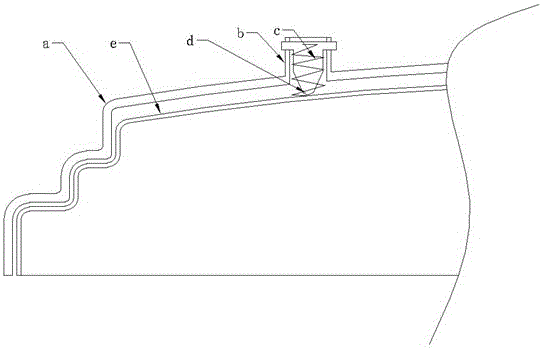

Temperature sensor

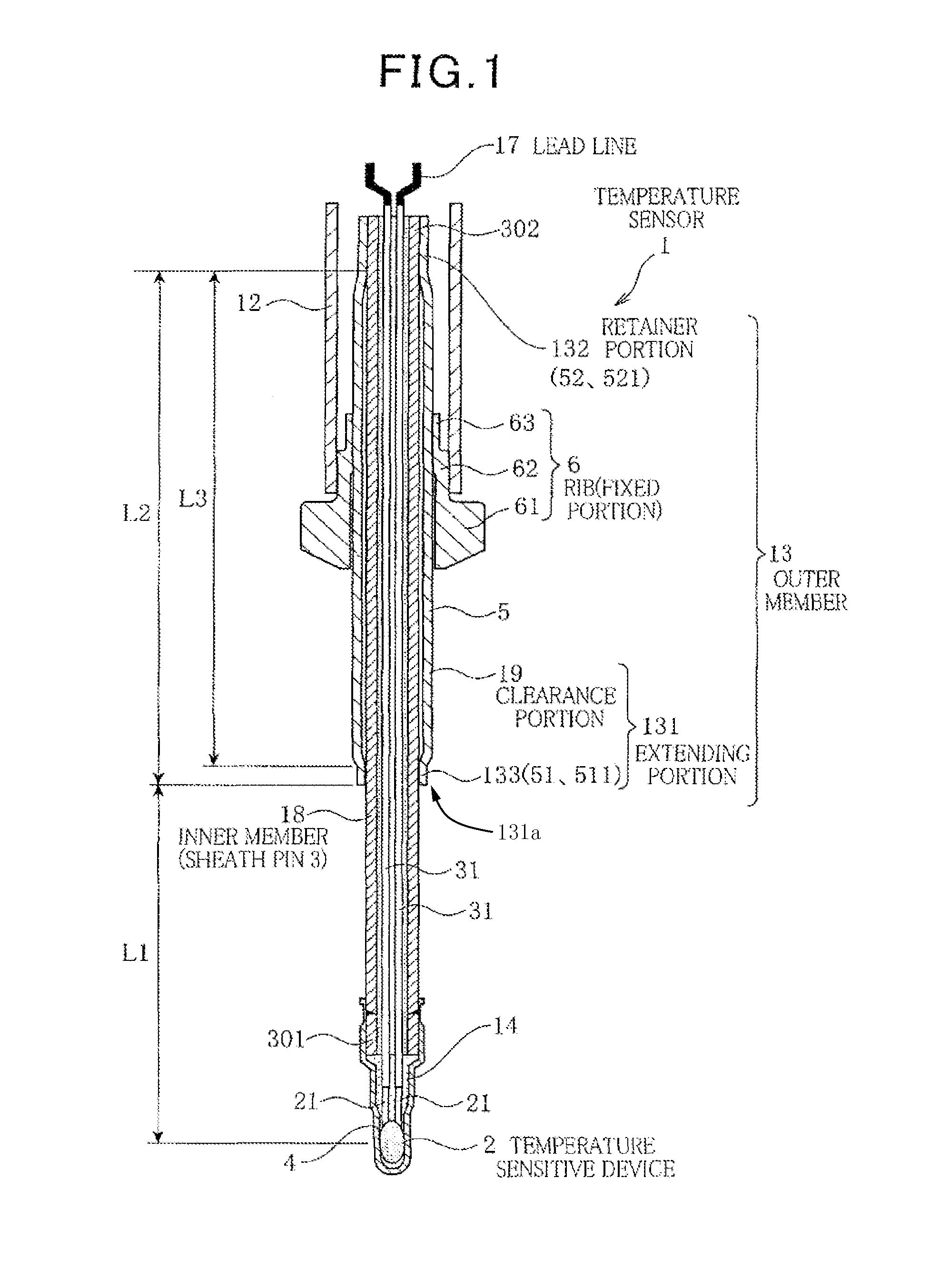

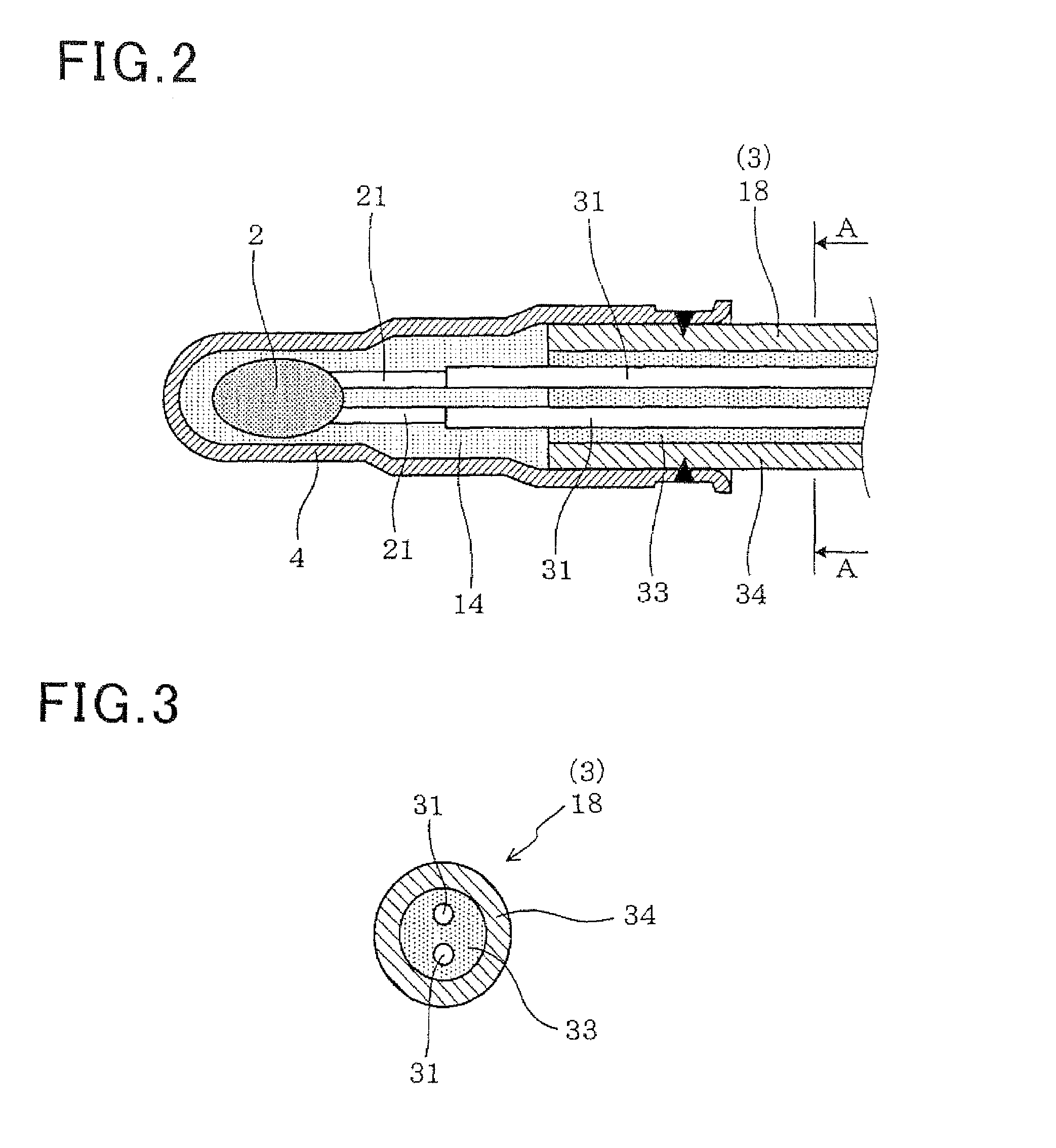

ActiveUS8864375B2Reduce vibrationReduce the overall heightThermometer detailsTemperature measurement in motorsInternal combustion engineExhaust pipe

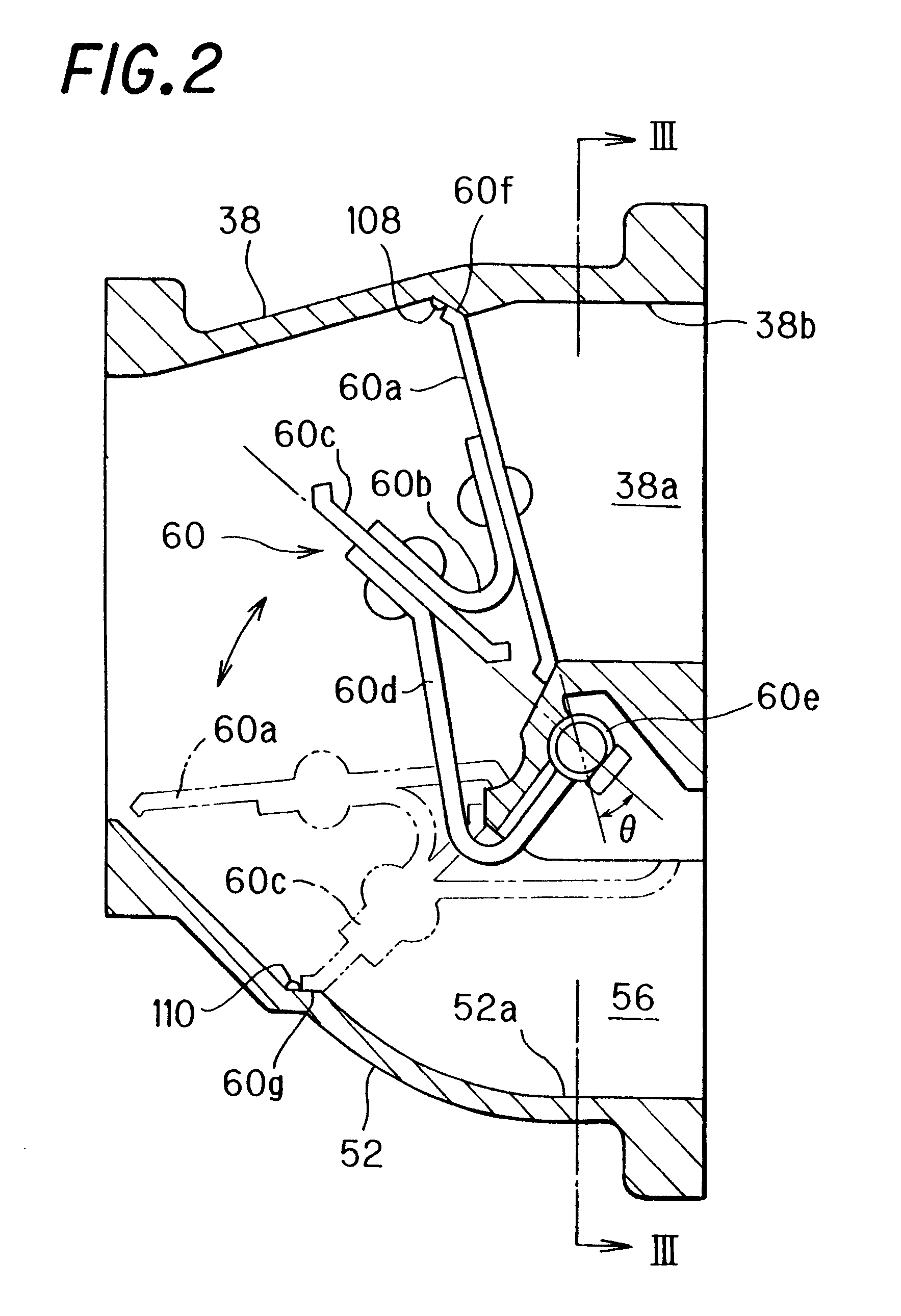

The temperature sensor 1 is equipped with a temperature sensitive device 2 to be disposed inside an exhaust pipe of an internal combustion engine, signal lines 31 connected at a top end side to the temperature sensitive device 2 and at a rear end side to leads for connection with an external circuit, an inner member 18 having a sheath pin 3 in which the signal lines 31 are disposed, and an outer member 13 disposed to cover at least a portion of an outer periphery of the inner member 18. The outer member 13 includes a fixed portion (rib 6) to be fixed to an upper wall of the exhaust pipe, a retainer portion 132 retaining the inner member 18, and an extending portion 131 formed closer to a top end side than the retainer portion 132. The extending portion 131 includes a clearance portion 19 disposed so as to have an air gap between itself and the inner member 18 and a front interference portion 133 disposed in a condition that a maximum air gap between the front interference portion 133 and the inner member 18 in a radius direction is 0.2 mm or less.

Owner:DENSO CORP

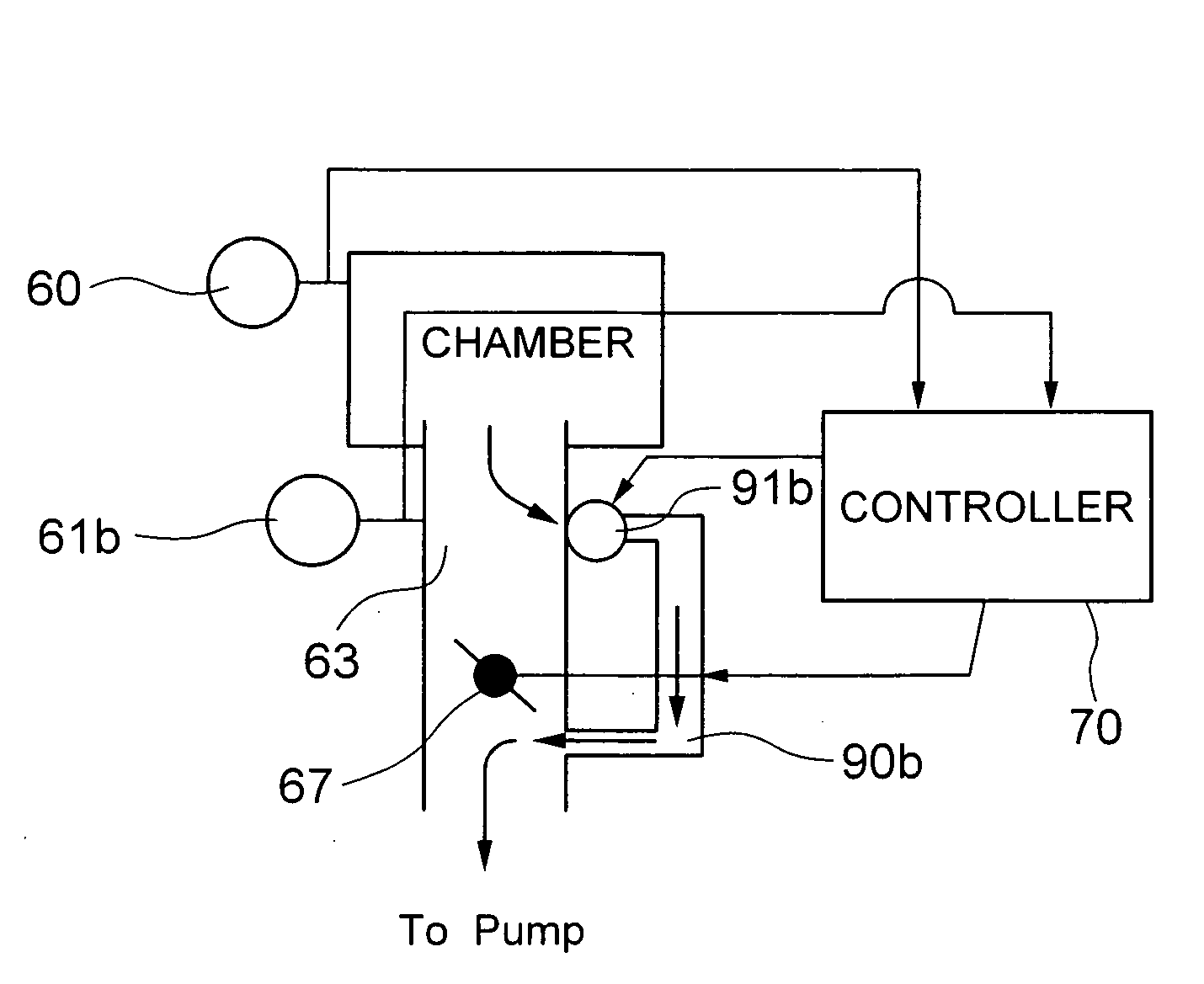

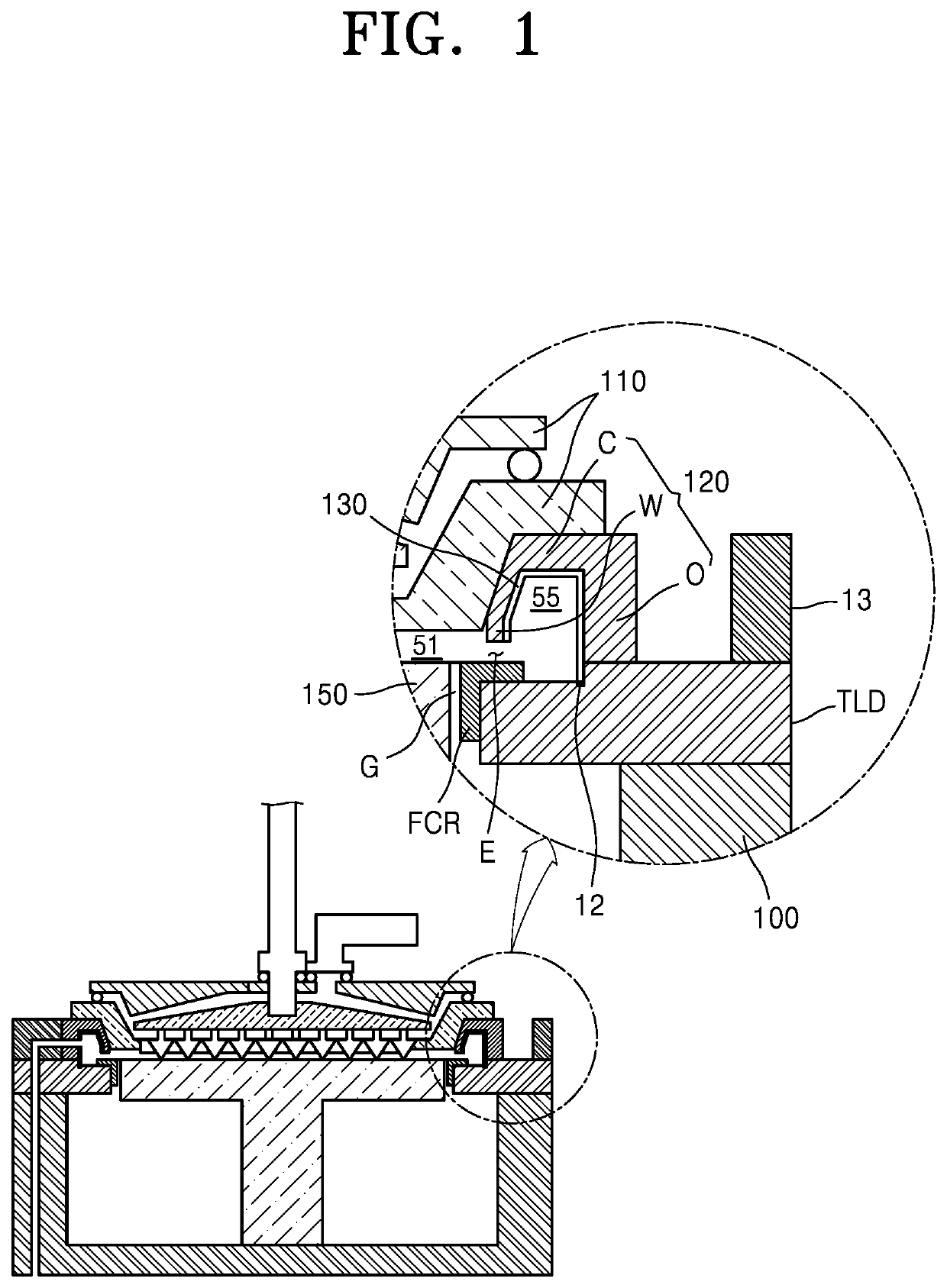

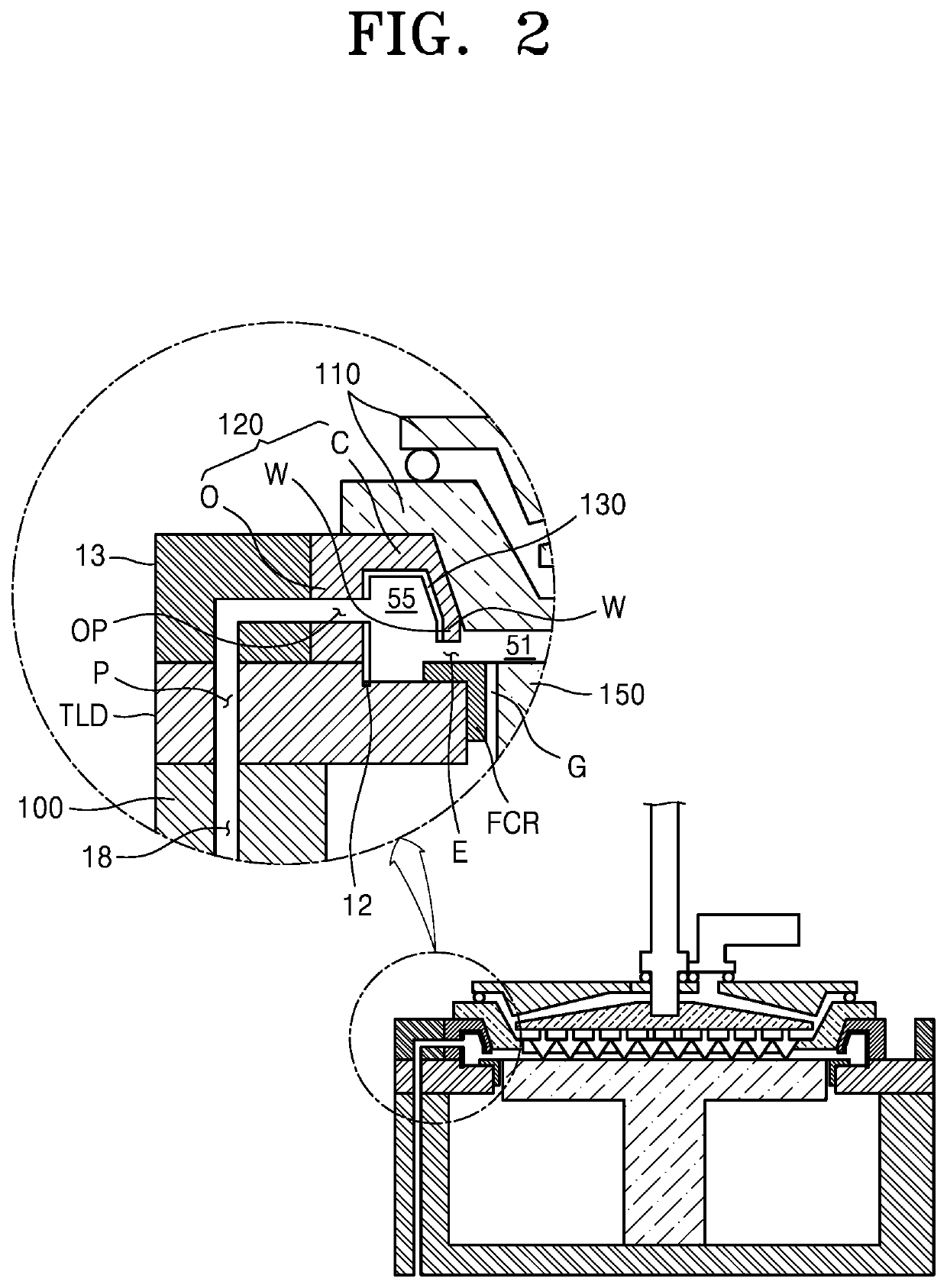

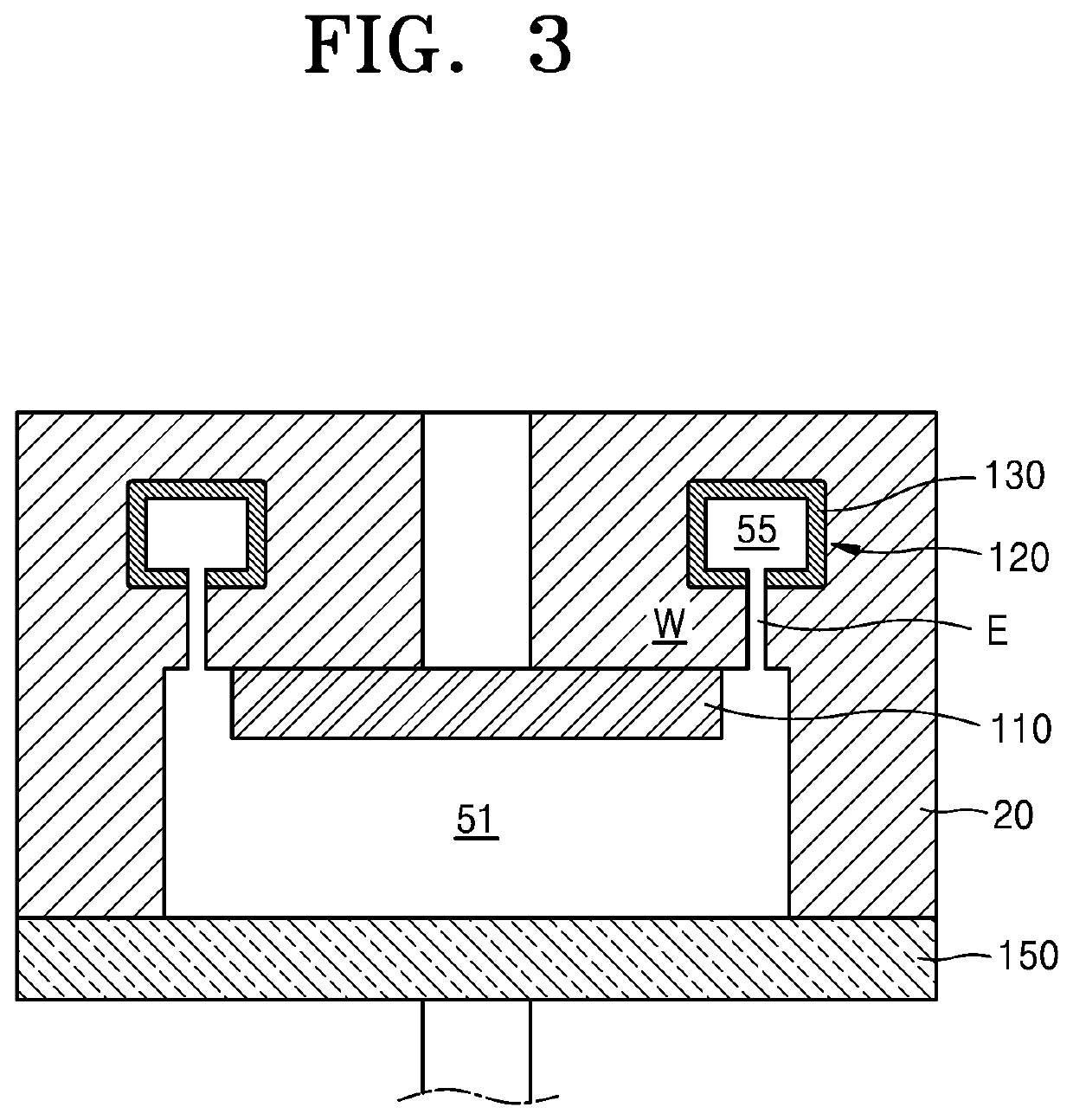

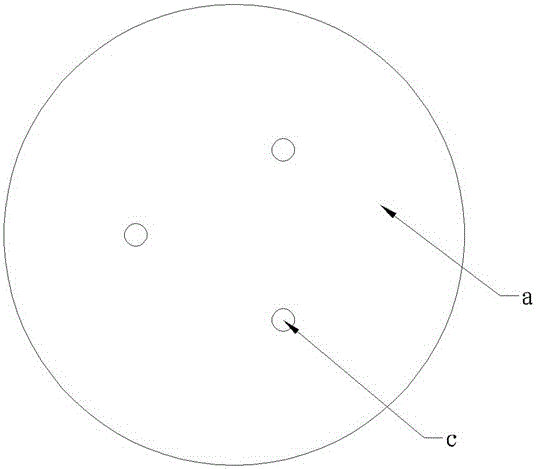

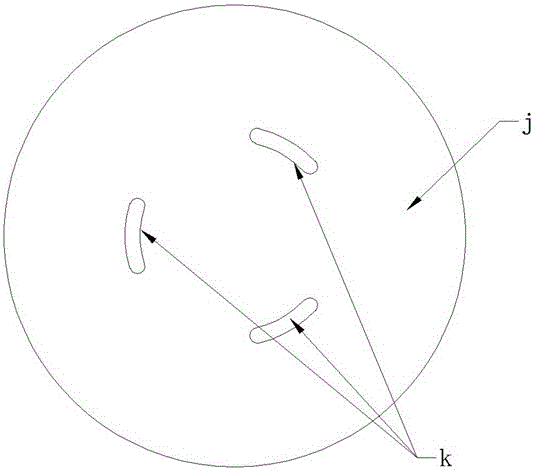

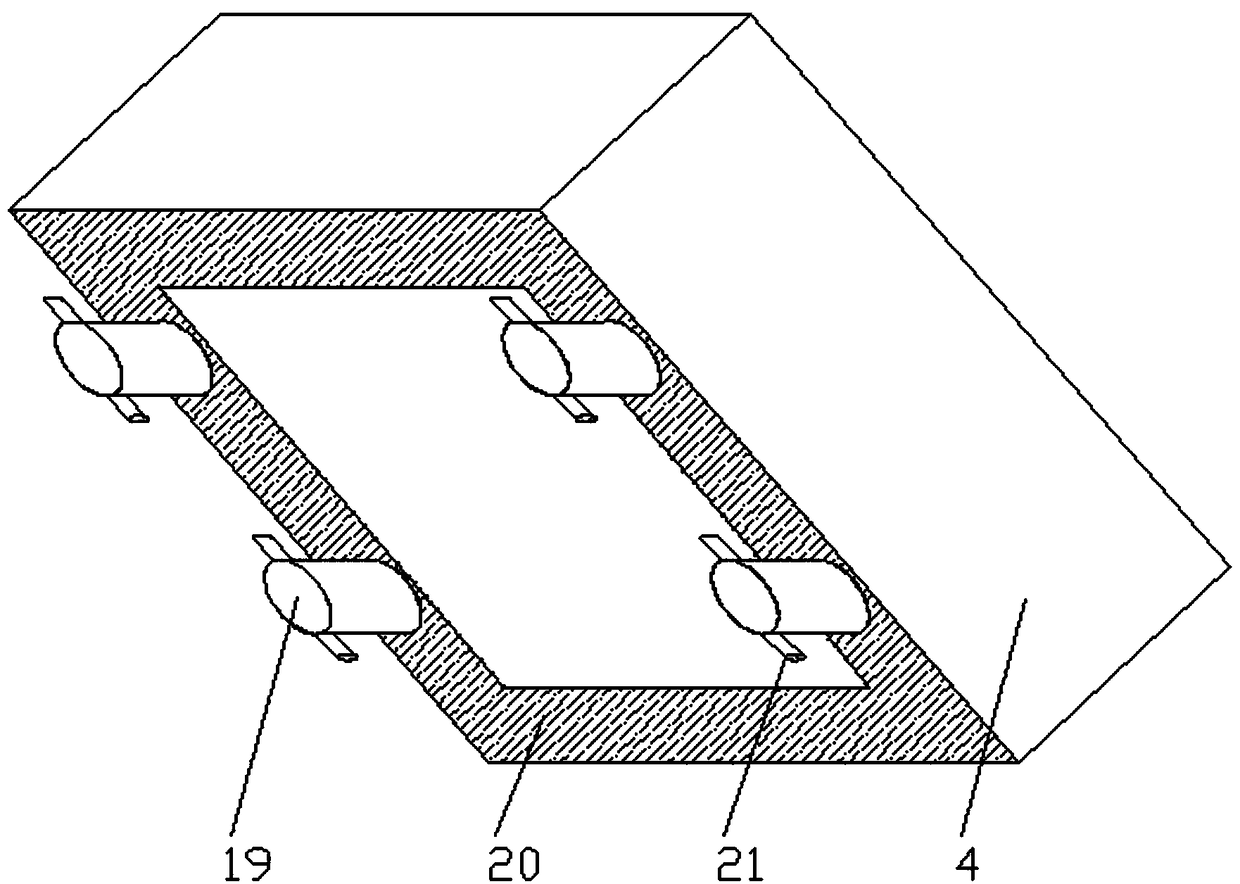

Substrate processing apparatus

ActiveUS20210035786A1Avoid it happening againReduce volumeElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringMechanical engineering

A substrate processing apparatus having an improved exhaust structure includes a reaction space formed between a processing unit and a substrate support unit, an exhaust unit surrounding the reaction space, an exhaust port with a channel inside, a partition wall with an exhaust line inside, wherein the channel of the exhaust port connects the exhaust unit and the exhaust line.

Owner:ASM IP HLDG BV

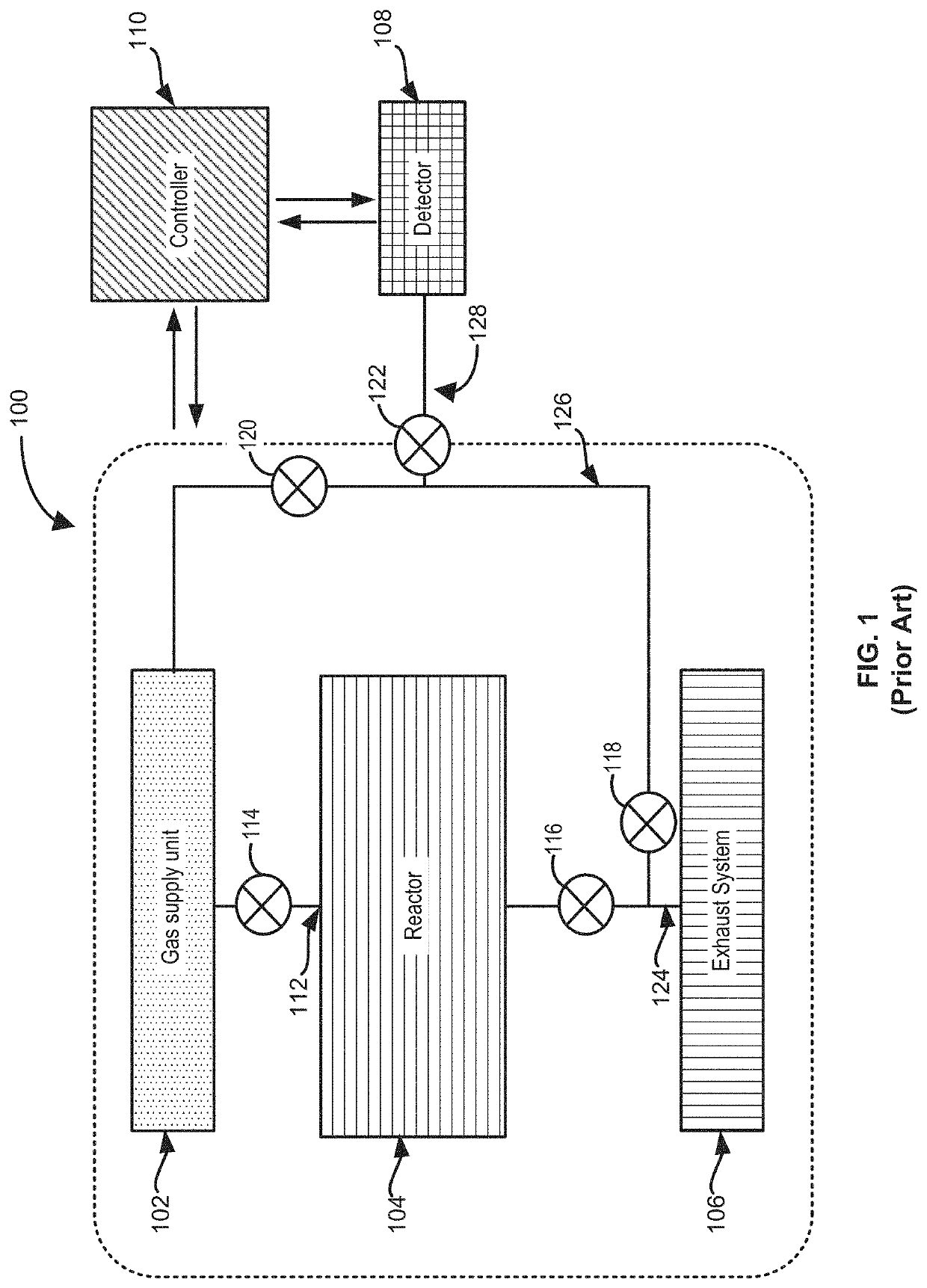

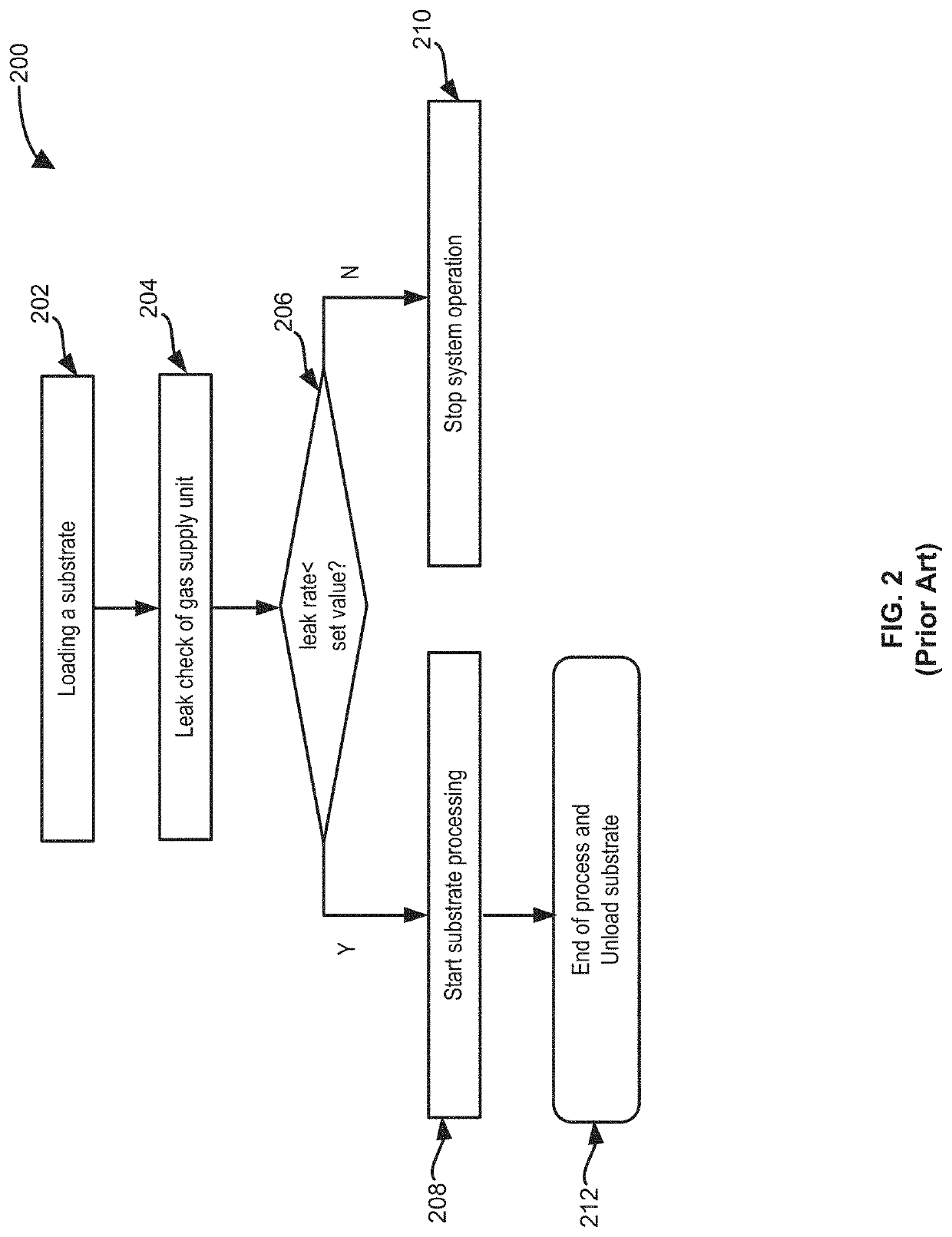

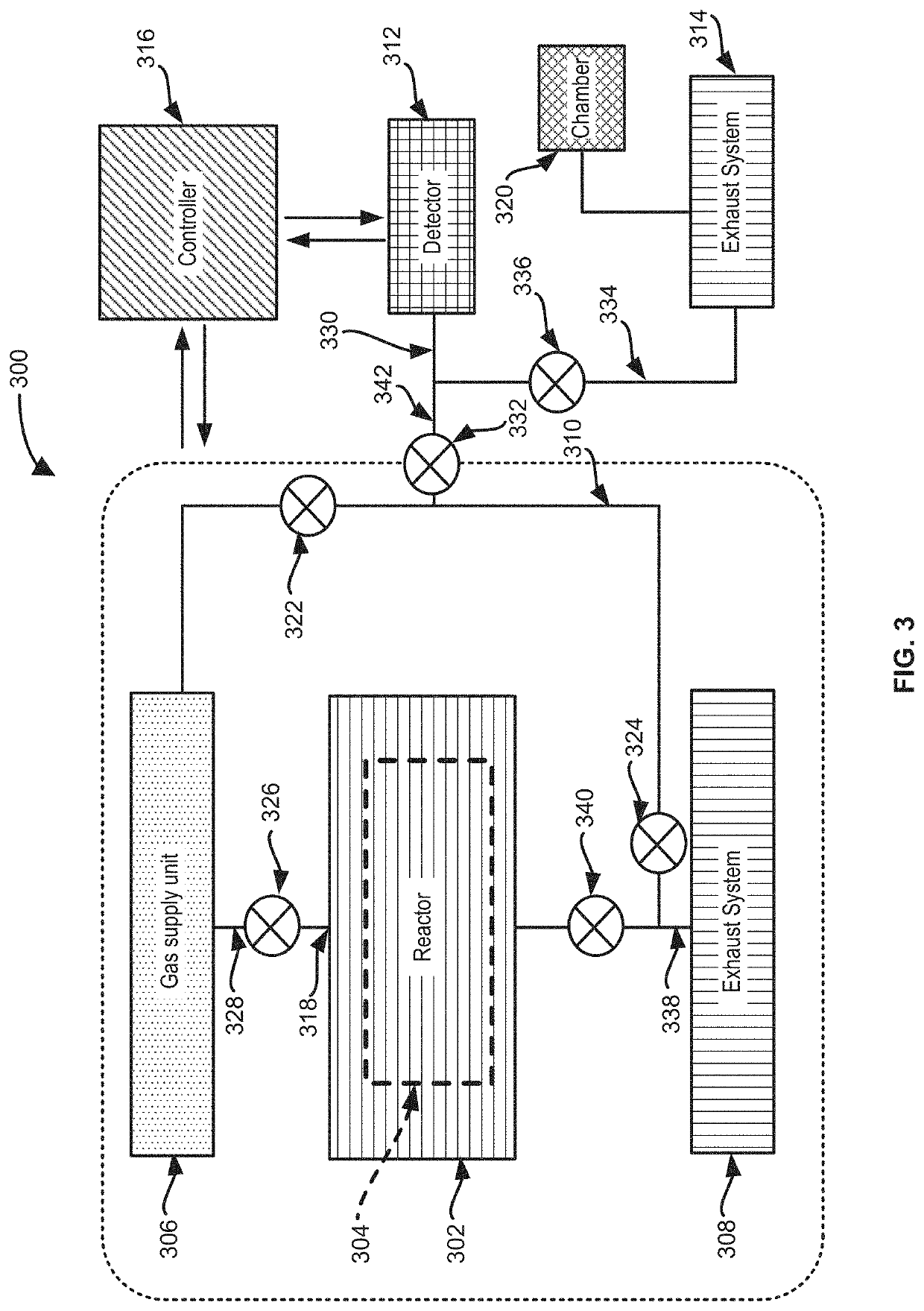

Method of using a gas-phase reactor system including analyzing exhausted gas

ActiveUS20200385868A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateThermodynamicsReactor system

Methods of and systems for performing leak checks of gas-phase reactor systems are disclosed. Exemplary systems include a first exhaust system coupled to a reaction chamber via a first exhaust line, a bypass line coupled to a gas supply unit and to the first exhaust system, a gas detector coupled to the bypass line via a connecting line, a connecting line valve coupled to the connecting line, and a second exhaust system coupled to the connecting line. Methods include using the second exhaust system to exhaust the connecting line to thereby remove residual gas in the connecting line that may otherwise affect the accuracy of the gas detector.

Owner:ASM IP HLDG BV

Method And Apparatus For Delivering Two Fuels To A Direct Injection Internal Combustion Engine

ActiveUS20070199539A1Saving operating costIncrease energy densityInternal combustion piston enginesFuel supply apparatusCombustion chamberLiquid fuel

An apparatus for delivering two fuels to a direct injection internal combustion engine comprises a liquid-fuel supply rail, a gaseous-fuel supply rail, a drain system with a shared drain rail for collecting both liquid fuel and gaseous fuel, and a venting device for venting gaseous fuel collected by the drain rail. The method comprises separately delivering a liquid fuel at injection pressure to an injection valve through a liquid-fuel rail, and actuating the liquid-fuel injection valve to introduce liquid fuel directly into the combustion chamber. The method further comprises delivering a gaseous fuel at injection pressure to an injection valve through a gaseous-fuel rail and actuating the gaseous-fuel injection valve to introduce gaseous fuel directly into the combustion chamber. The method further comprises collecting in a drain rail liquid fuel and gaseous fuel from the liquid-fuel injection valve and the gaseous-fuel injection valve, directing liquid fuel to a storage vessel, and directing gaseous fuel to a vent pipe.

Owner:WESTPORT FUEL SYST CANADA INC

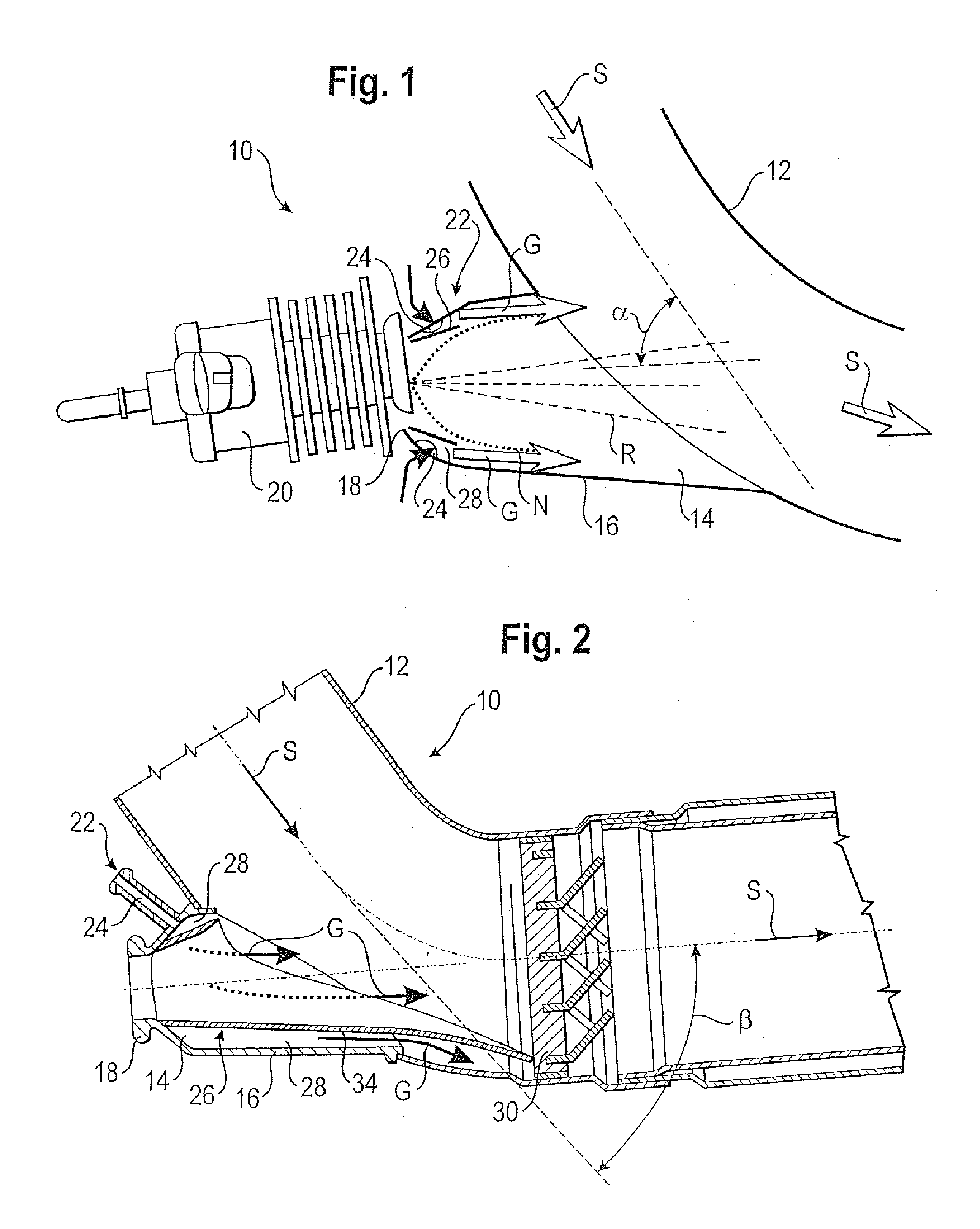

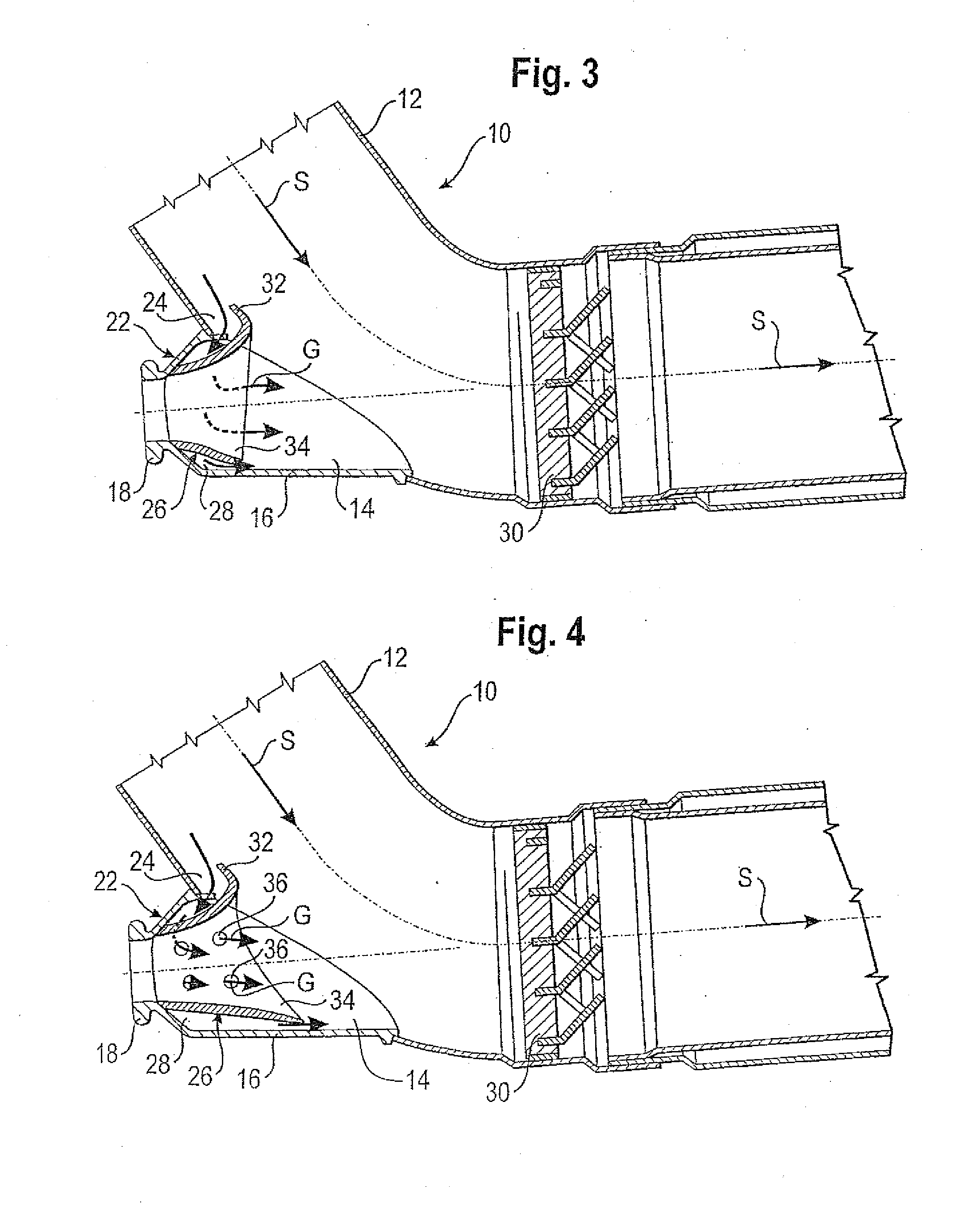

Assembly and Method for Introducing a Reducing Agent into the Exhaust Pipe of an Exhaust System of an Internal Combustion Engine

InactiveUS20100212292A1Avoid depositionWell mixedGas treatmentInternal combustion piston enginesMobile vehicleExternal combustion engine

An assembly and method for introducing a reducing agent into an exhaust pipe of an exhaust system of an internal combustion engine, in particular of a motor vehicle includes a feed connector which opens into the exhaust pipe and has a wall; a feed device for reducing agents which opens into the feed connector; and a device that generates a gas flow which is additional to the reducing agent flow and lines the wall of the feed connector.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

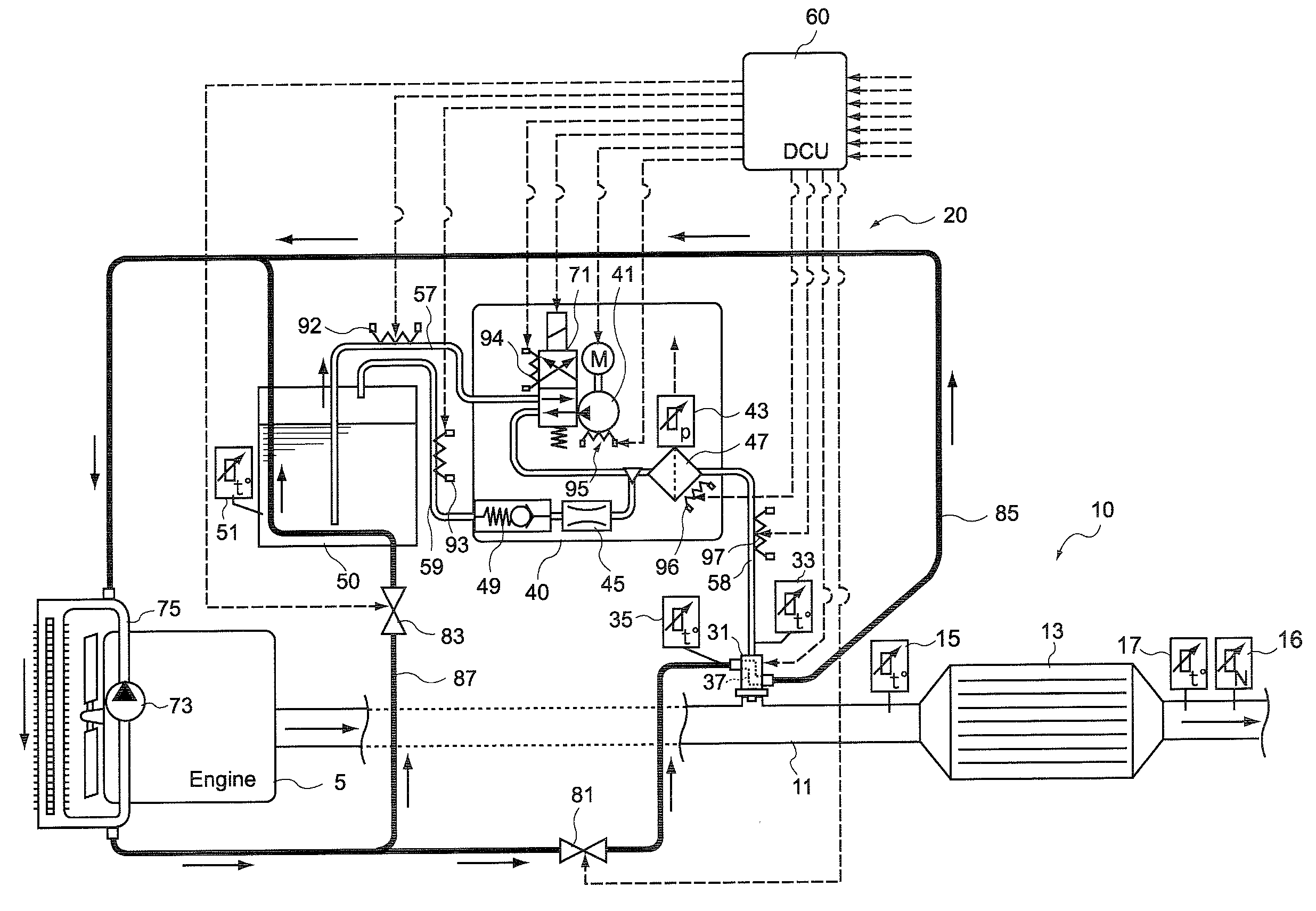

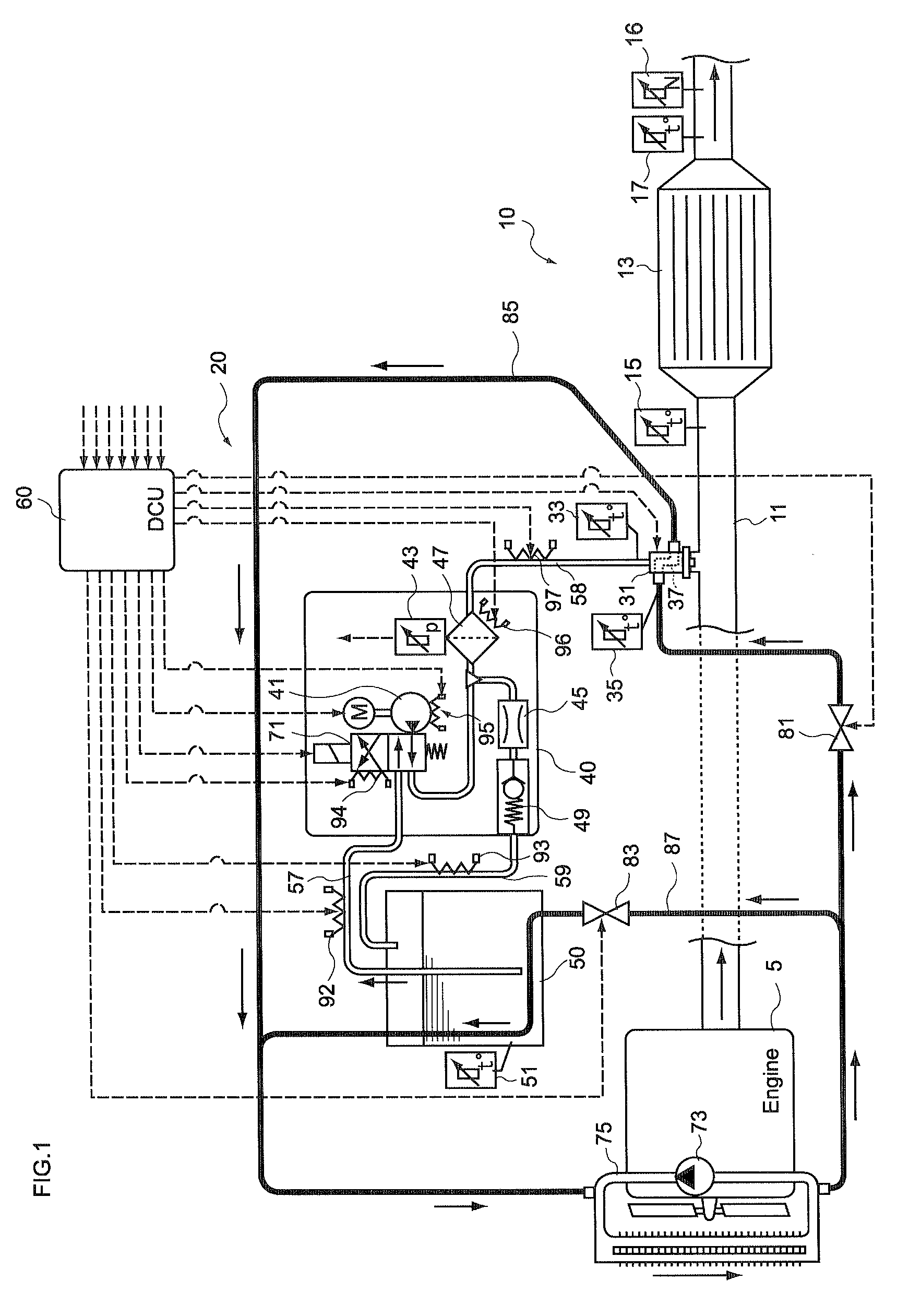

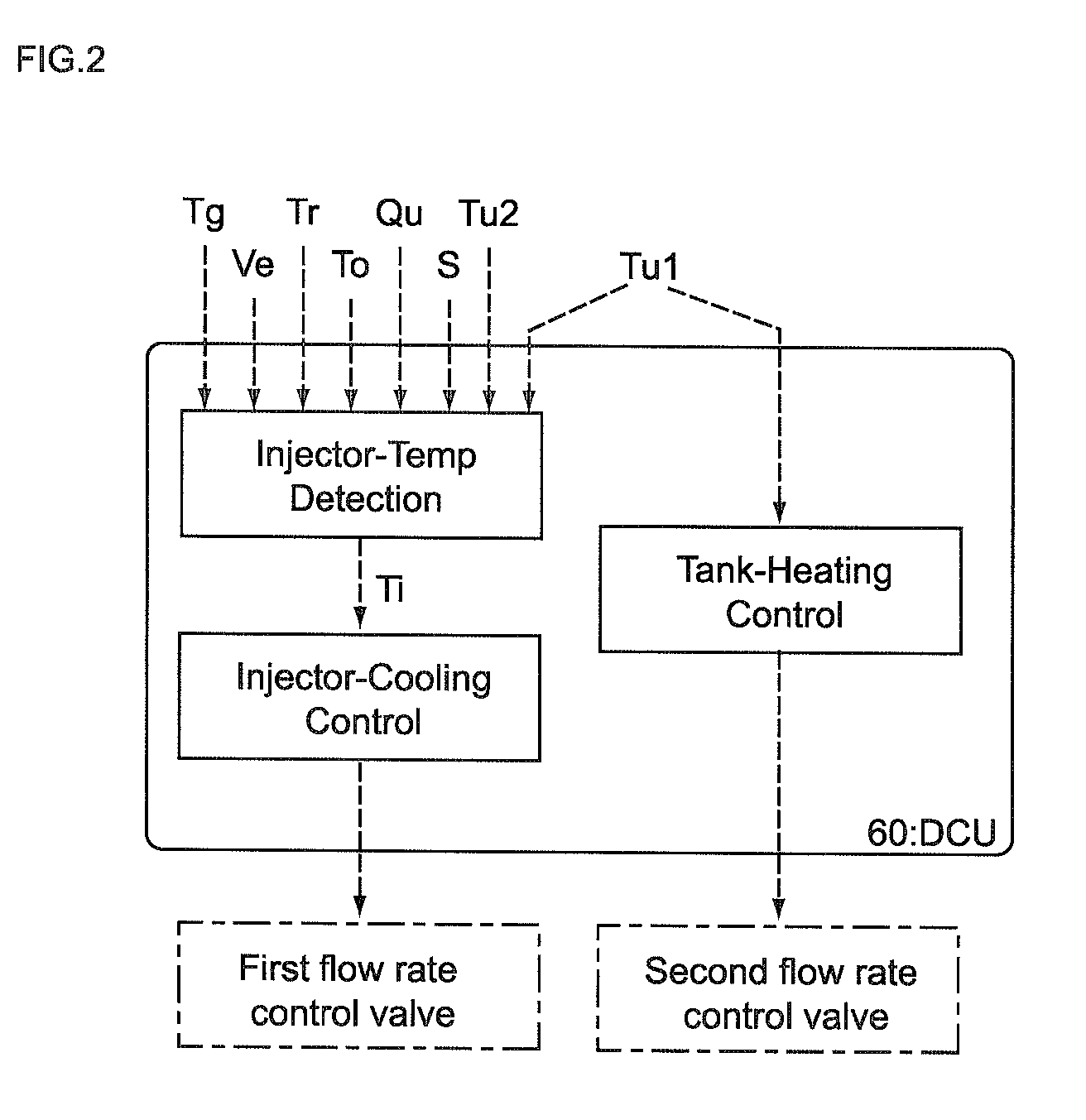

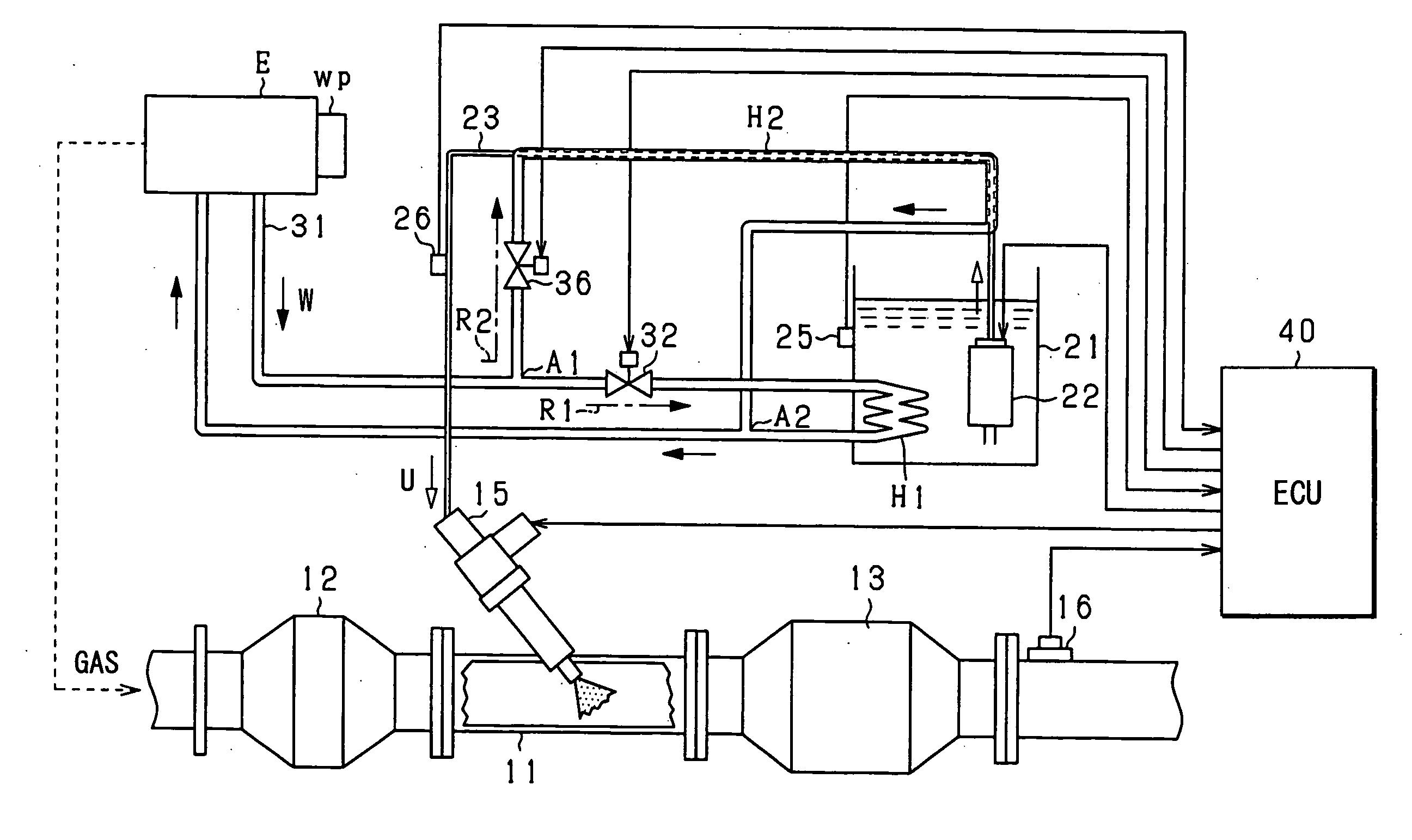

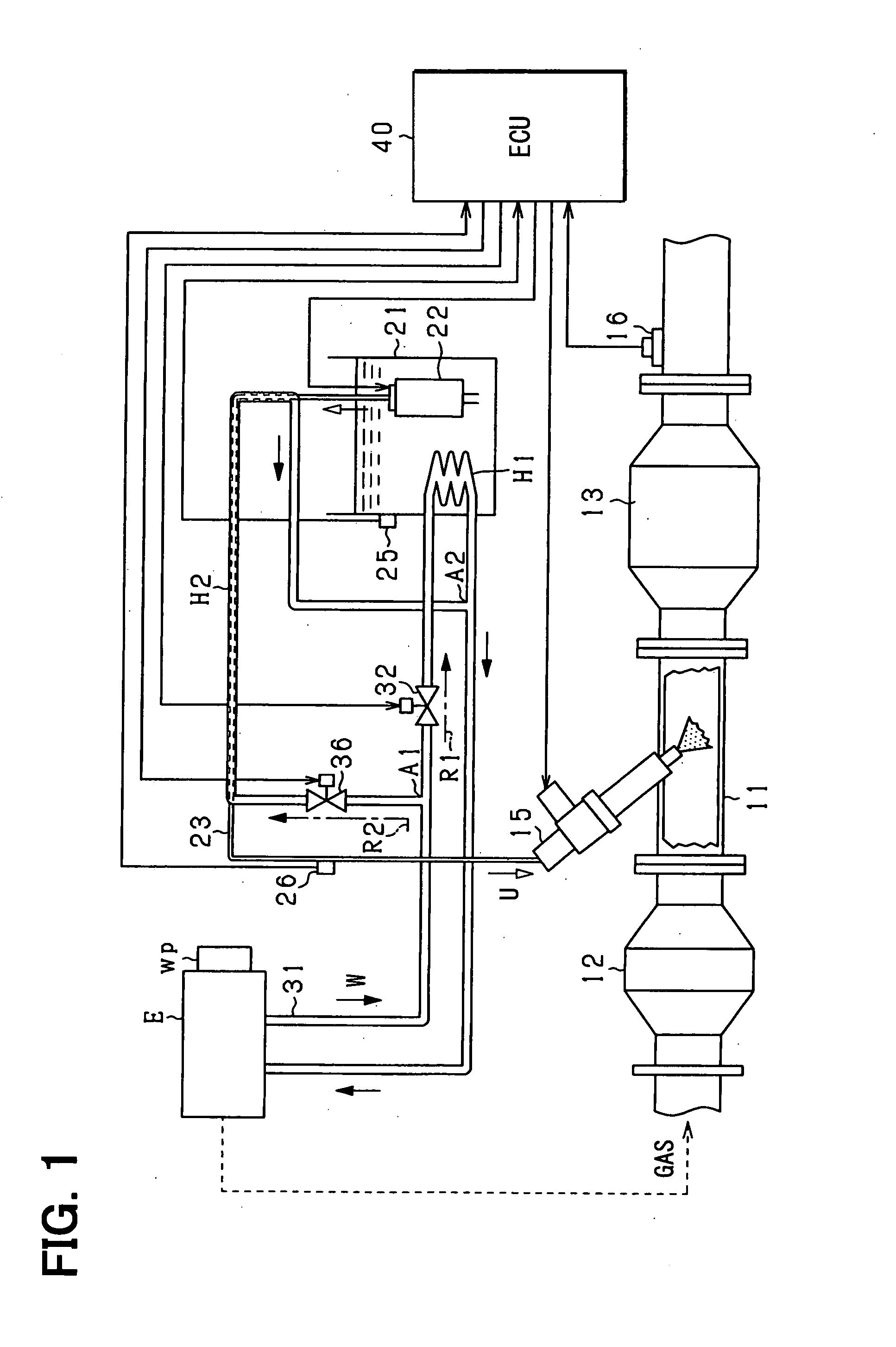

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

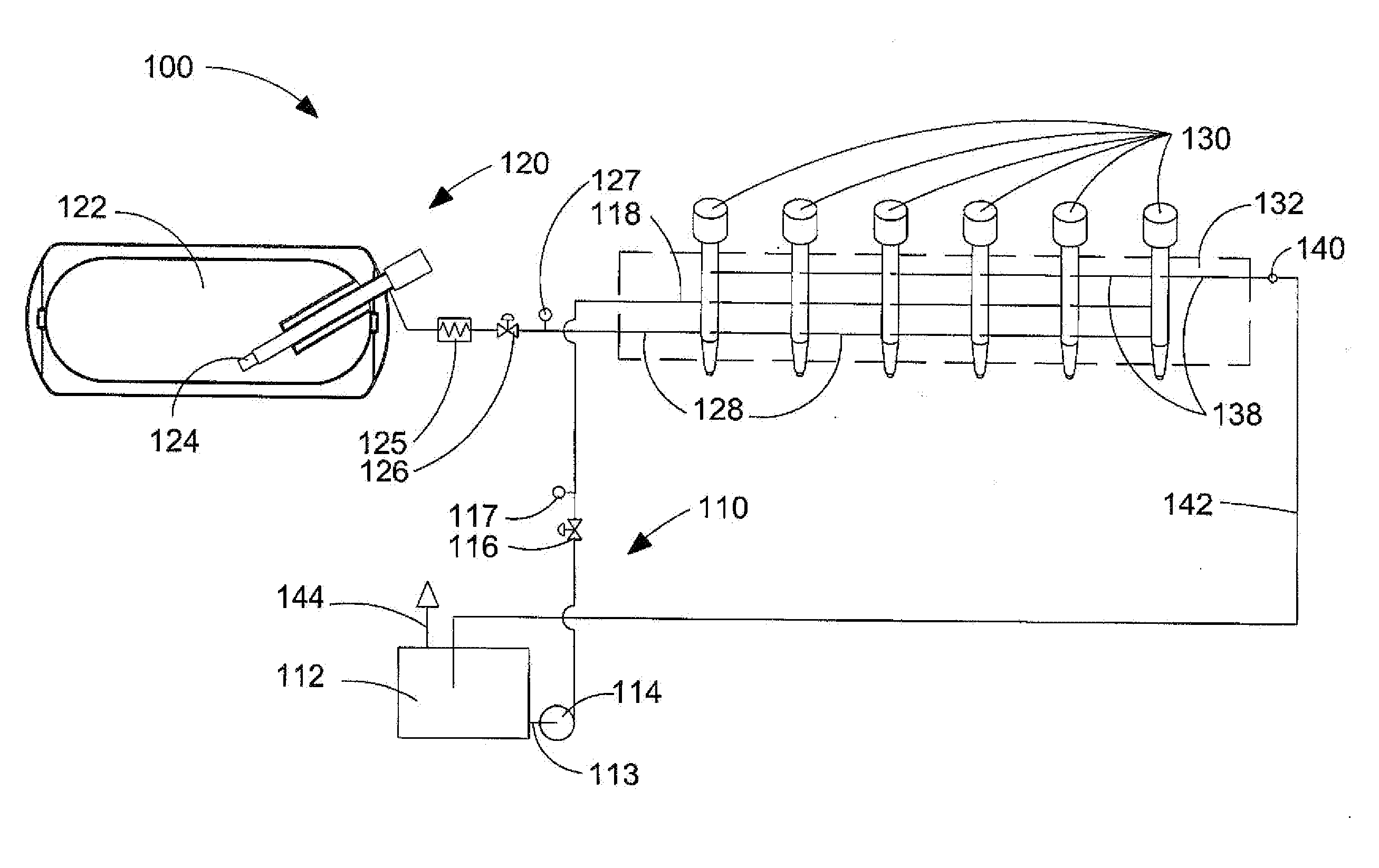

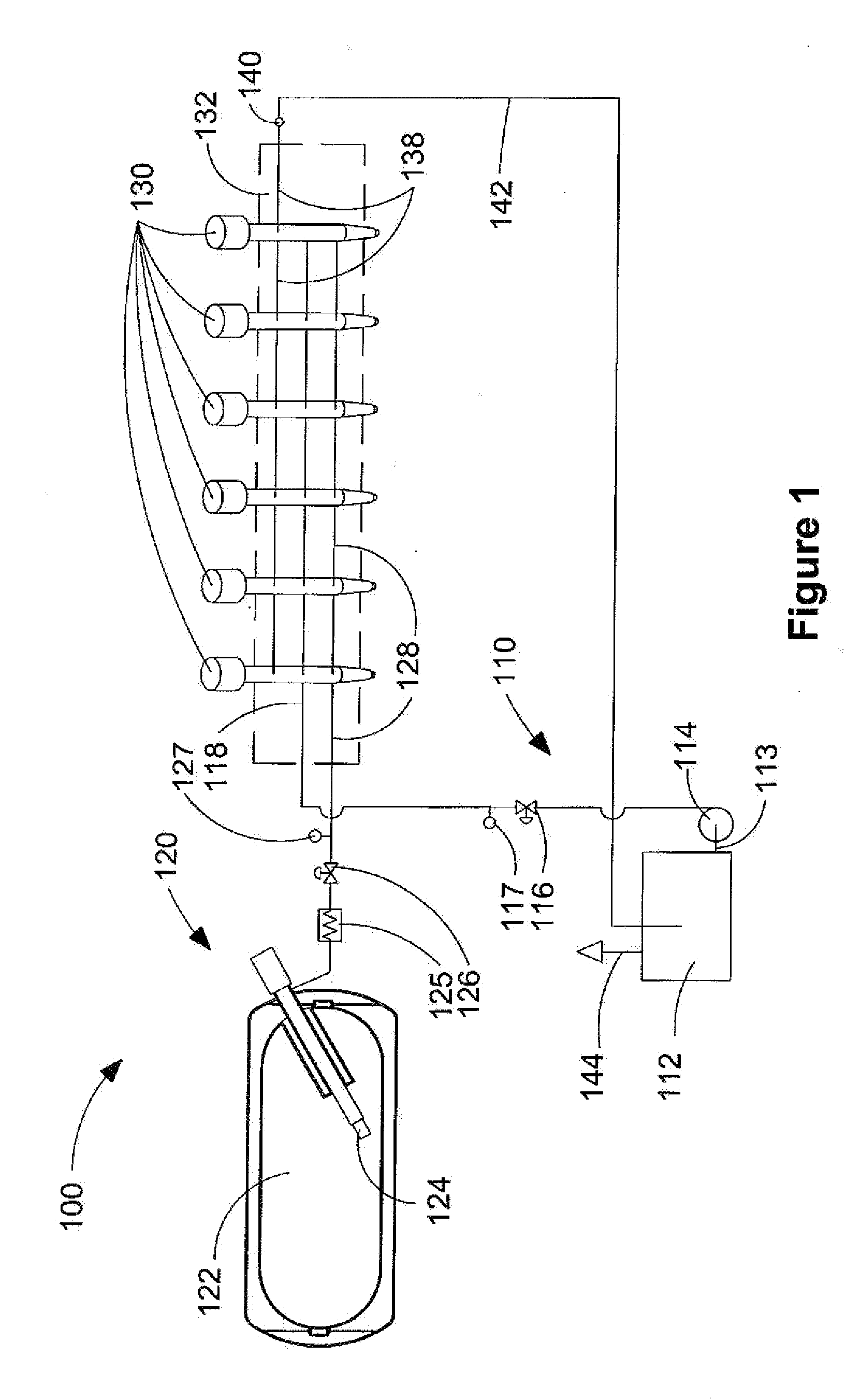

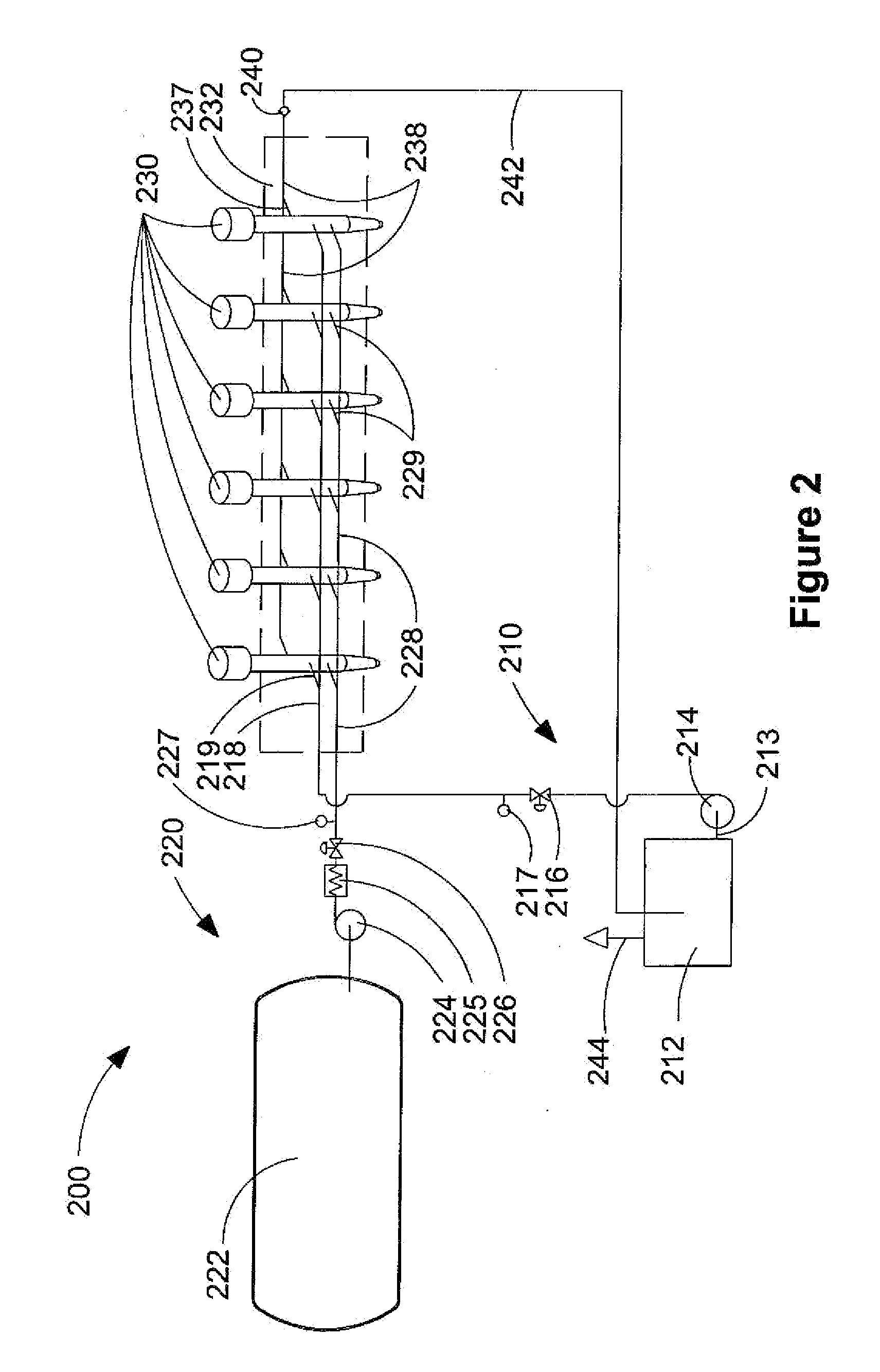

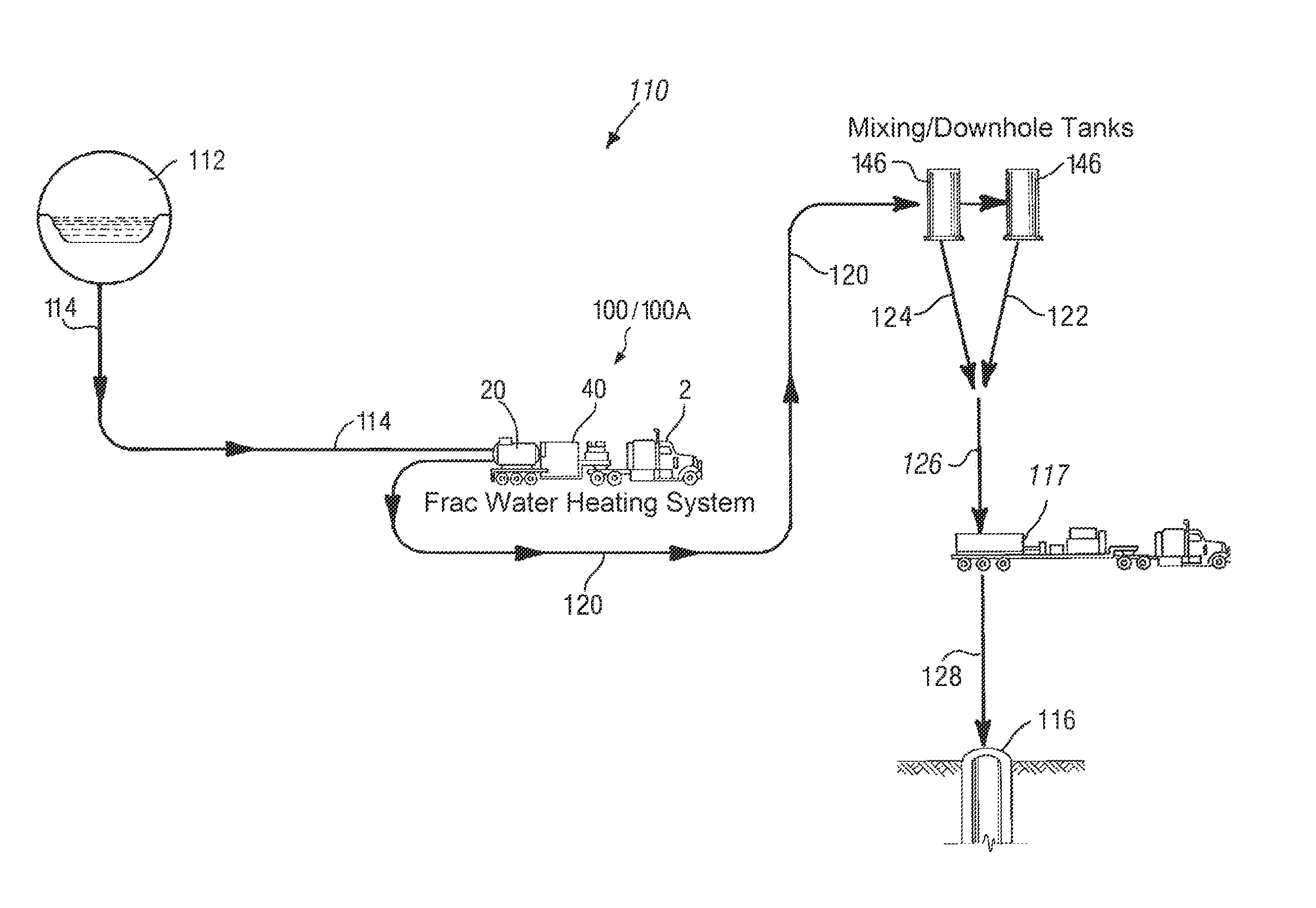

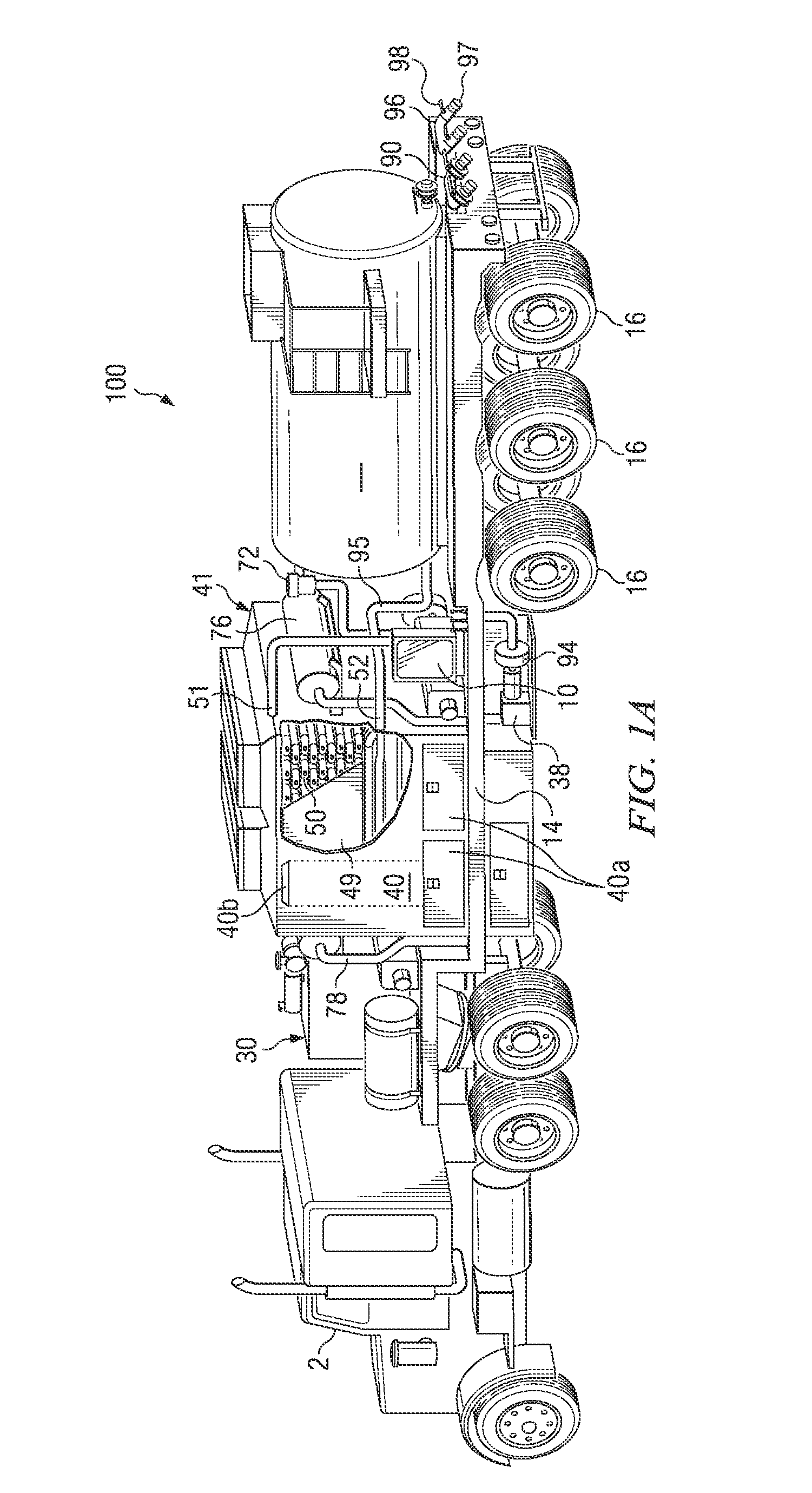

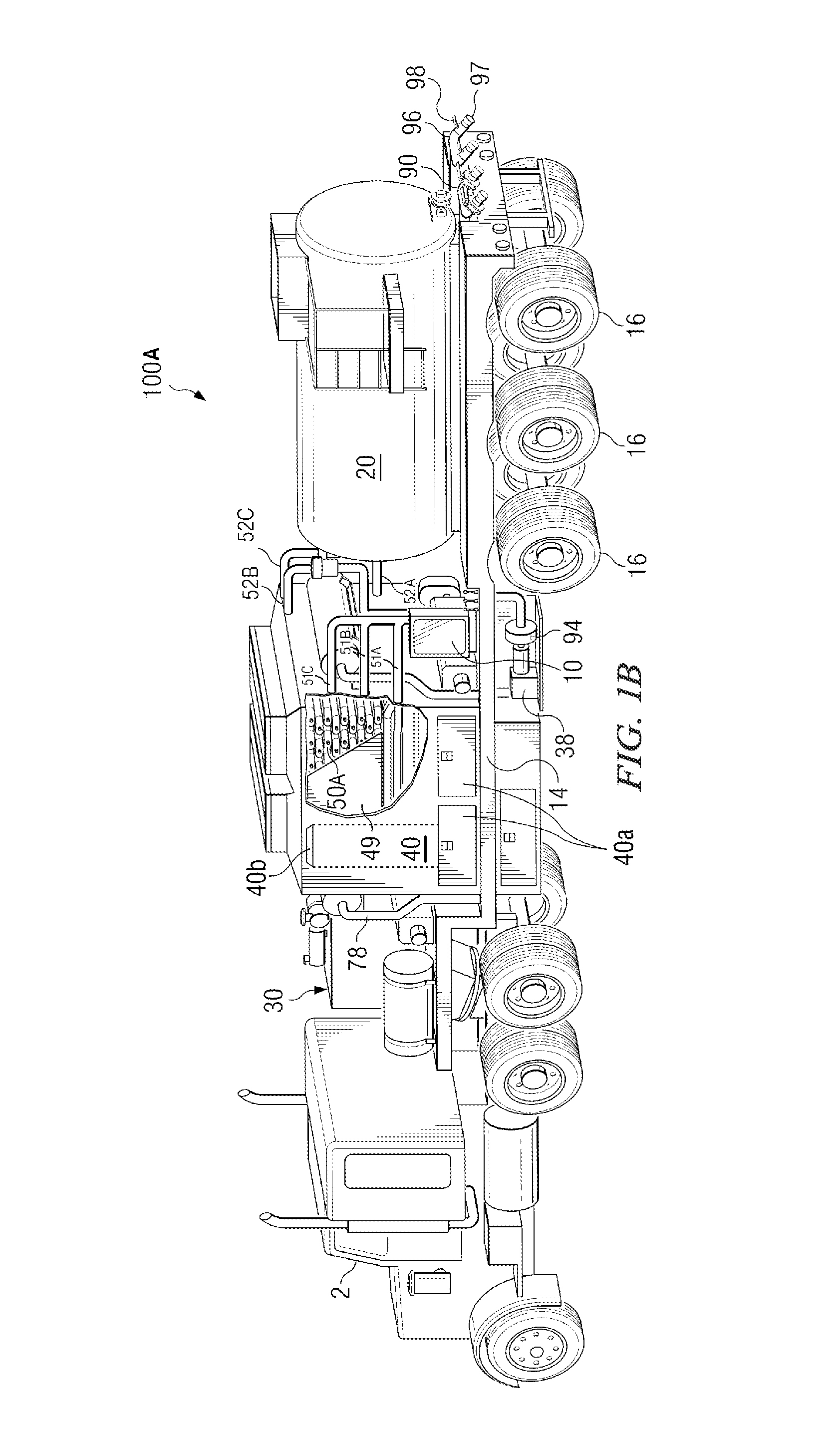

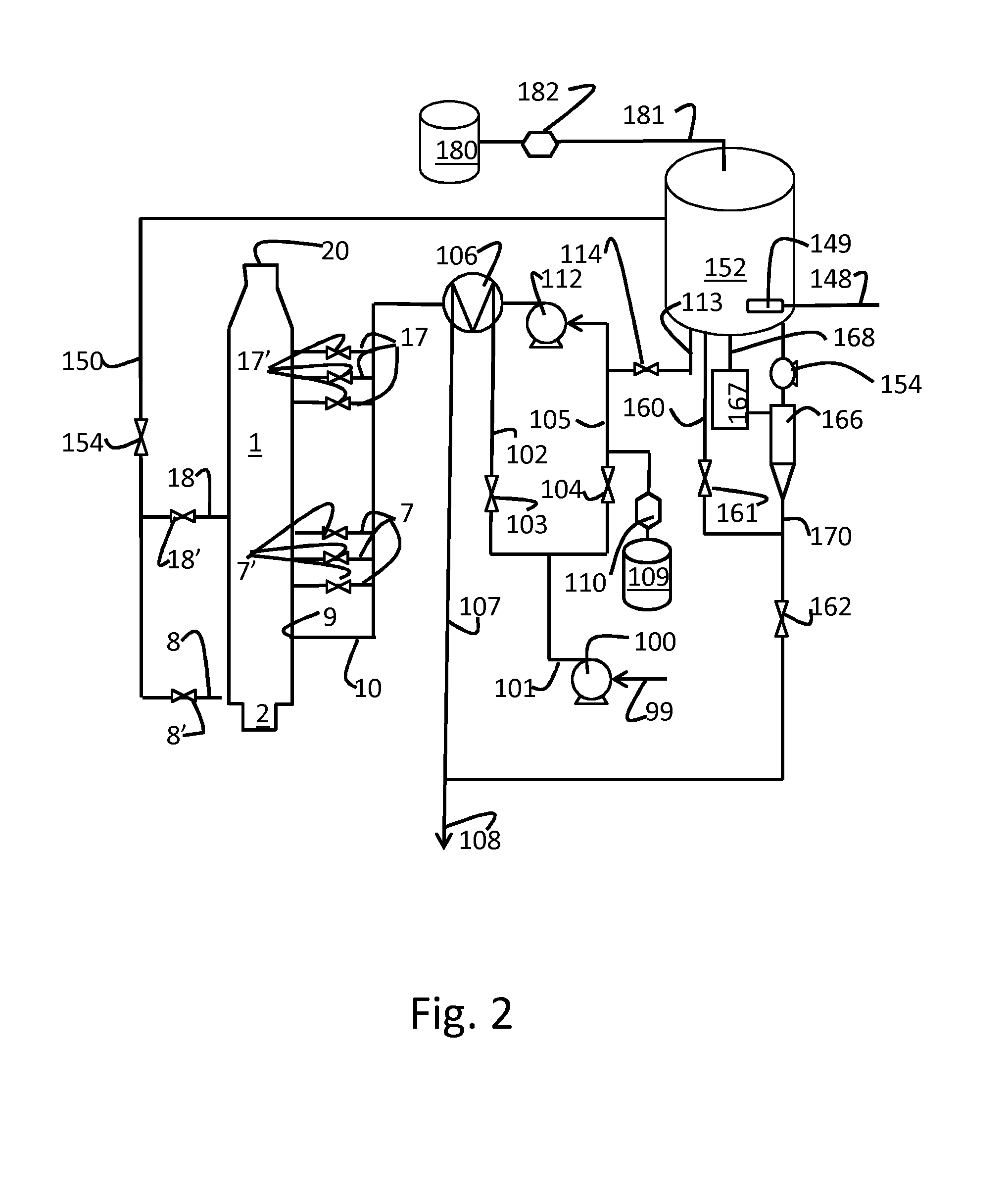

Frac water heating system and method for hydraulically fracturing a well

InactiveUS20140144641A1Safely and continuously heatingMaximize atomization and combustionInsulationFluid removalCombustion chamberFuel tank

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an improved frac water heating system. The present invention is a self-contained unit which is easily transported to remote locations. In one embodiment, the present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. In another embodiment, the present invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in all weather environments. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

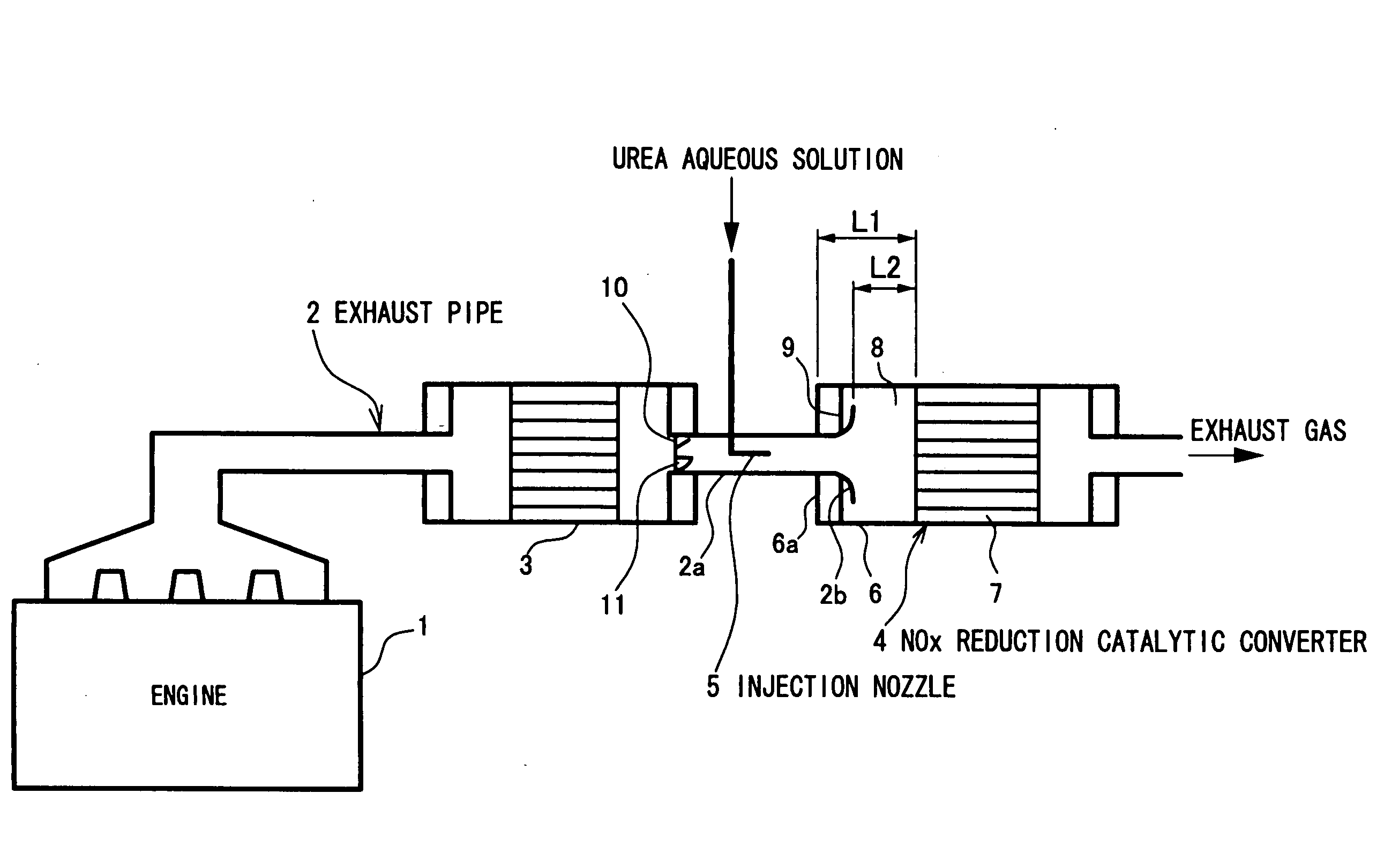

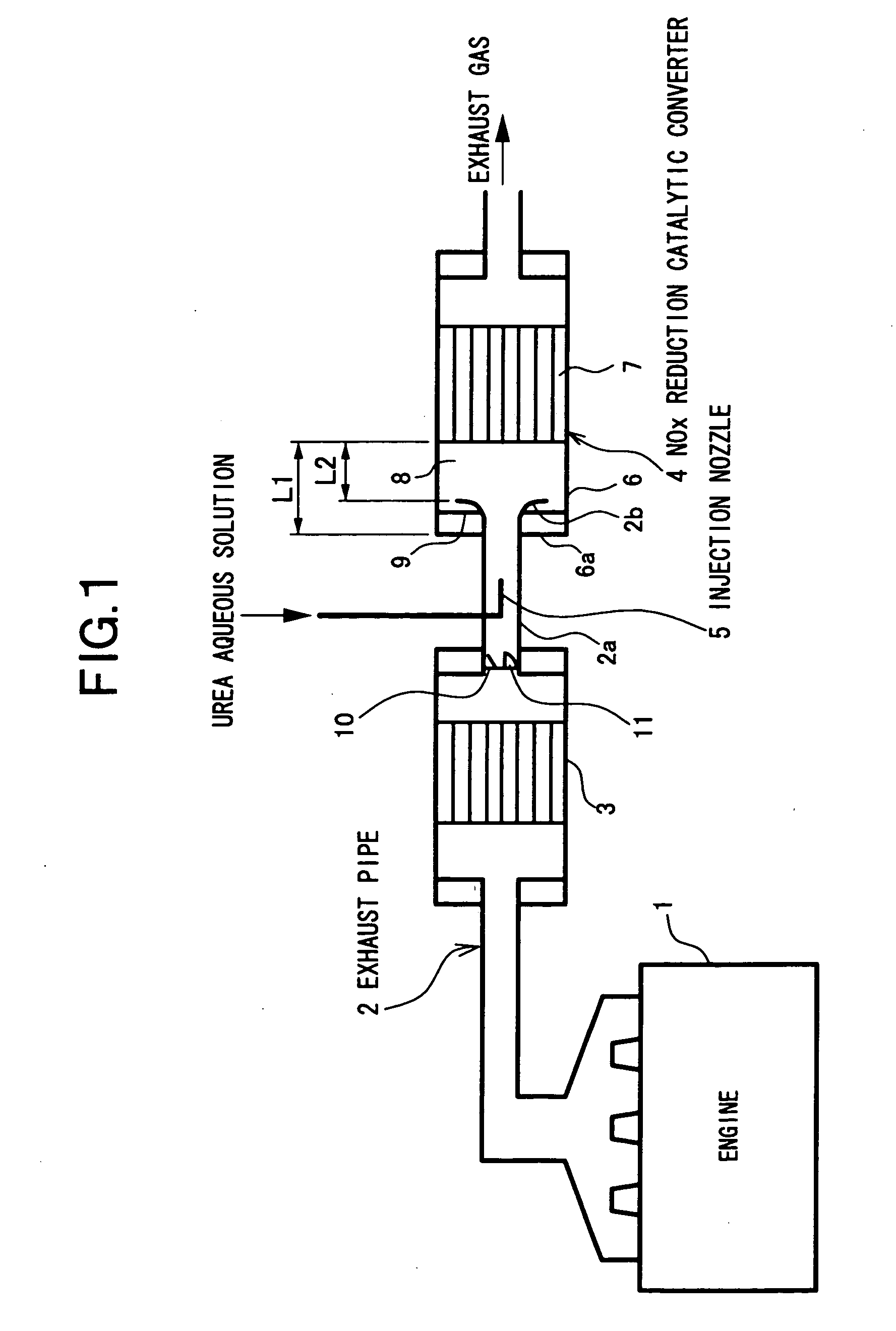

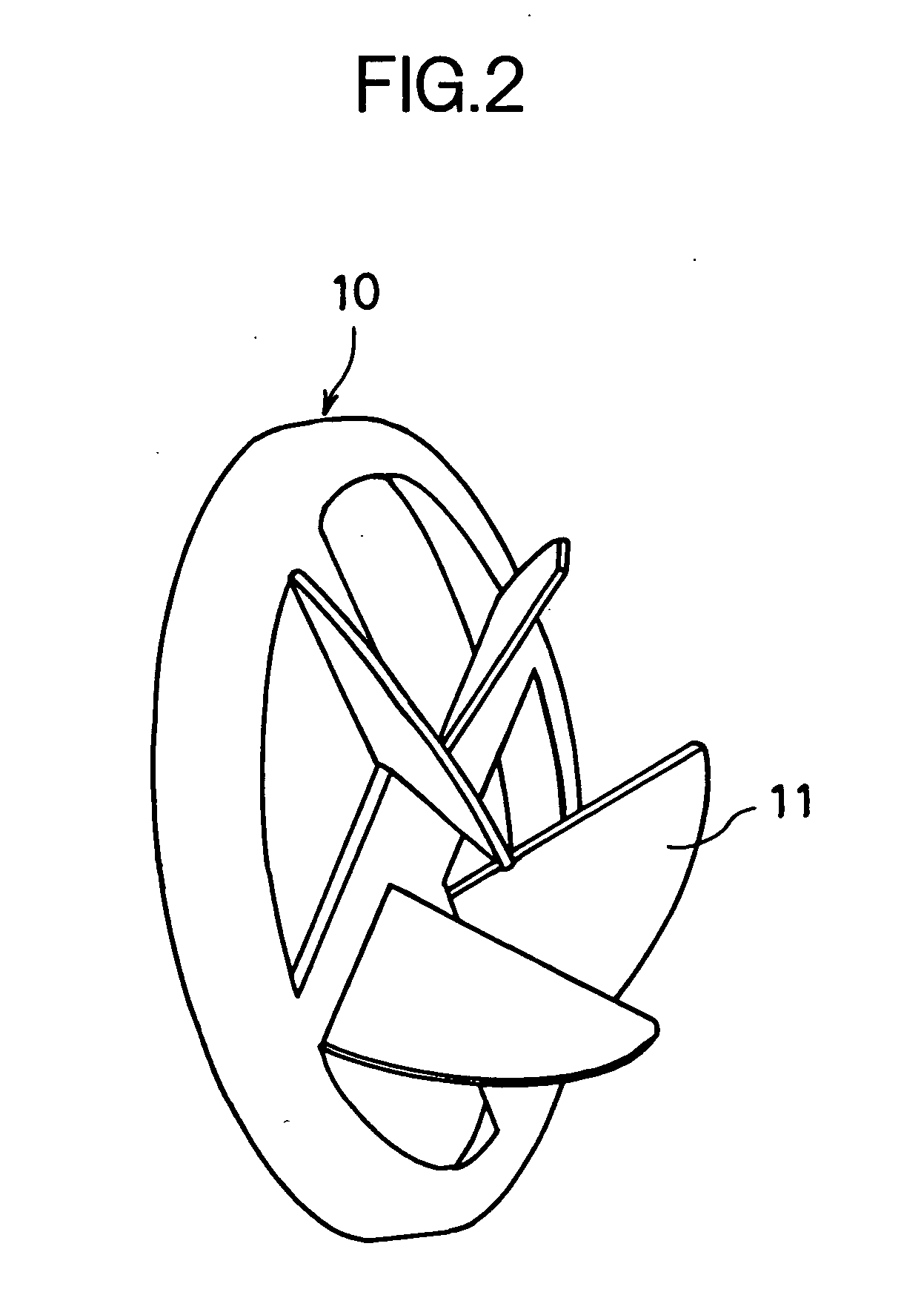

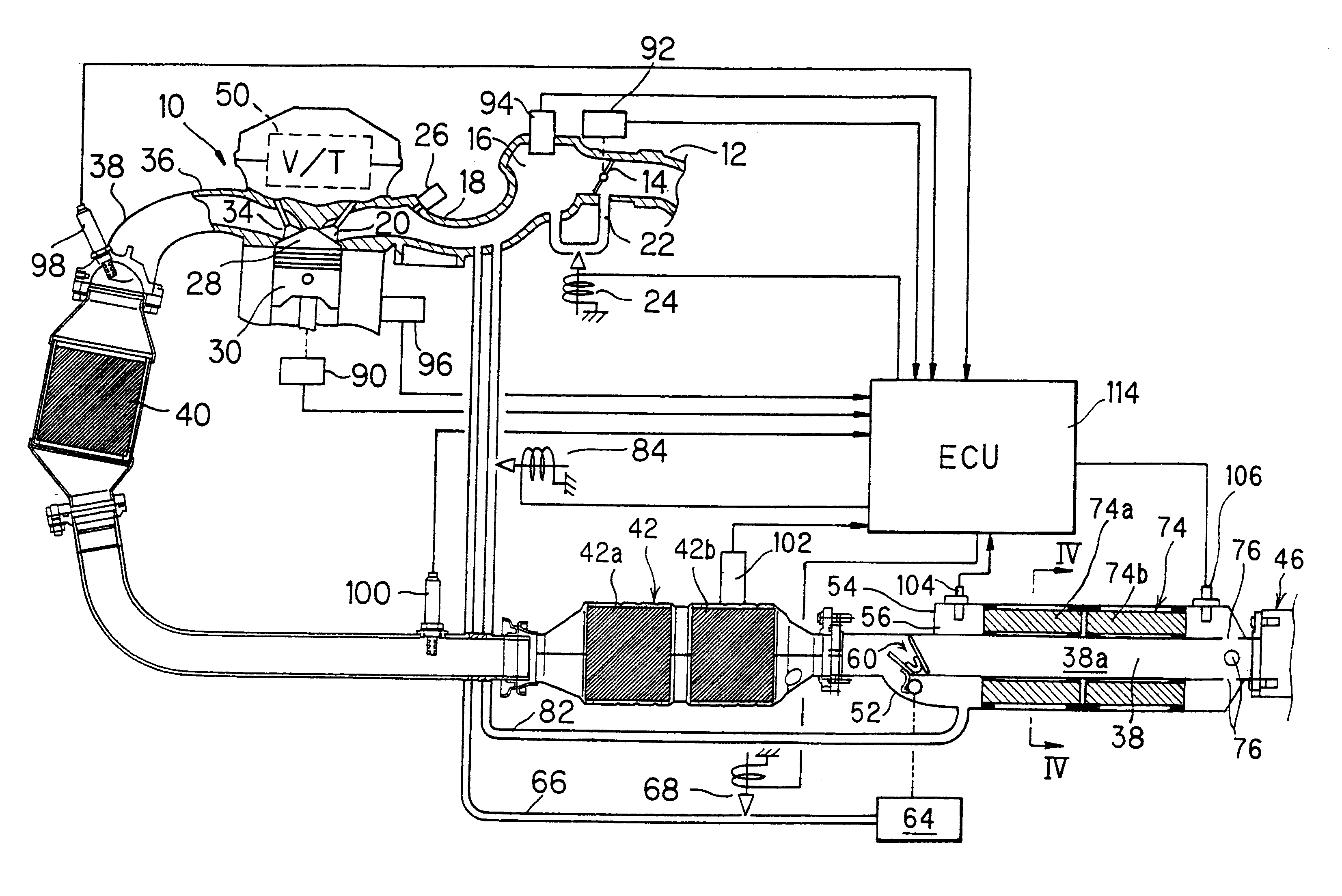

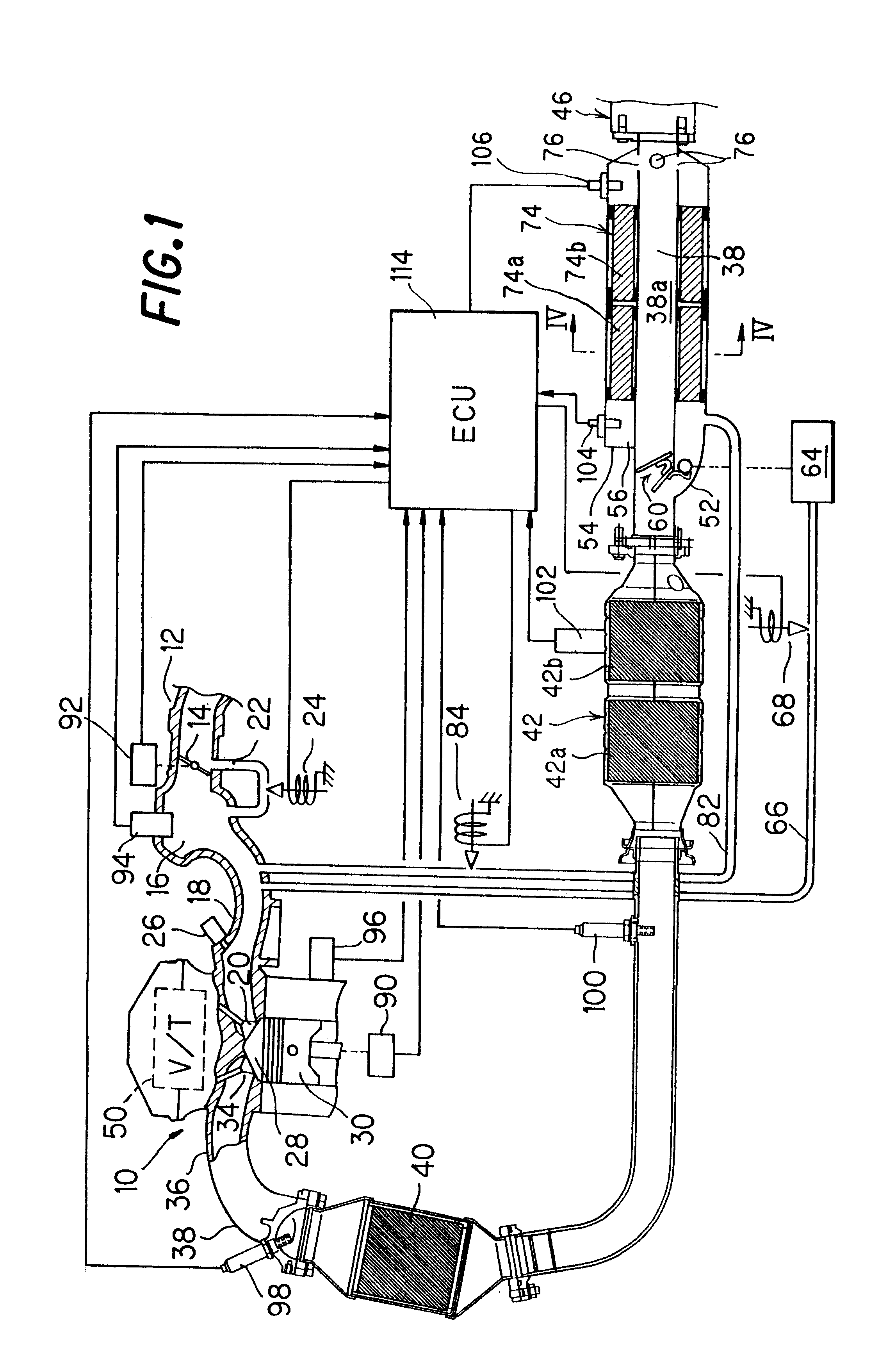

Exhaust emission purifying apparatus for engine

ActiveUS20070101703A1Easy to produceEasily swirling flowInternal combustion piston enginesFlow mixersNitrogen oxidesExhaust fumes

An exhaust emission purifying apparatus has a NOx reduction catalytic converter in an exhaust passage of an engine, for purifying nitrogen oxides in the exhaust gas by reduction with urea aqueous solution; an injection nozzle injecting the urea solution toward an exhaust upstream side of the converter in the exhaust passage; and fins disposed on an exhaust upstream side of an injection position of the urea solution in the injection nozzle, for generating a spiral swirling flow of the gas swirling about a center corresponding to the central axis of an exhaust pipe. The swirling flow generated in the exhaust gas prior to the injection-supply of the urea aqueous solution promotes mixing of the solution with the gas to thereby promote the hydrolysis of the urea solution. And the exhaust gas and ammonia generated from the urea solution are uniformly mixed together.

Owner:TOKYO ROKI +2

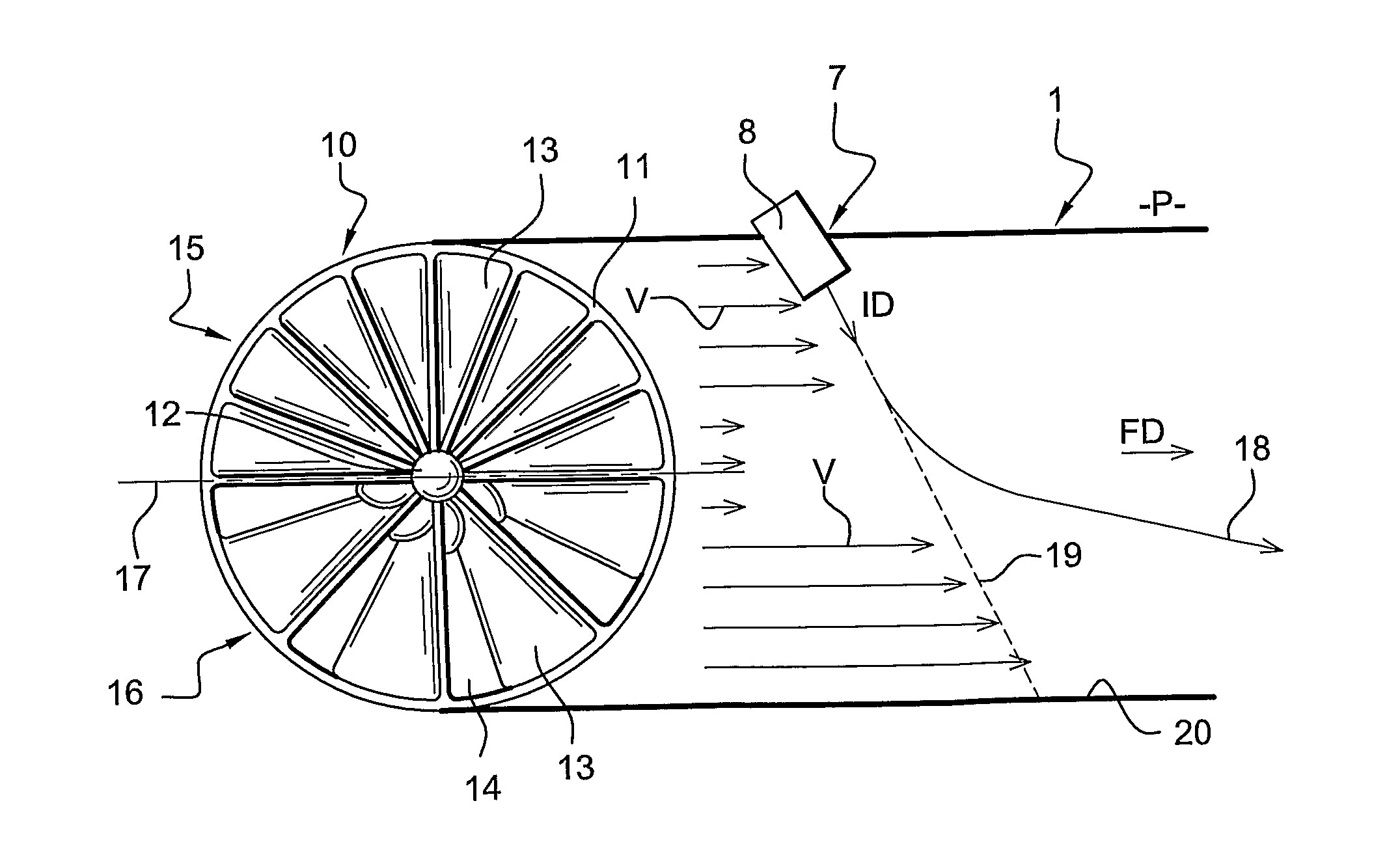

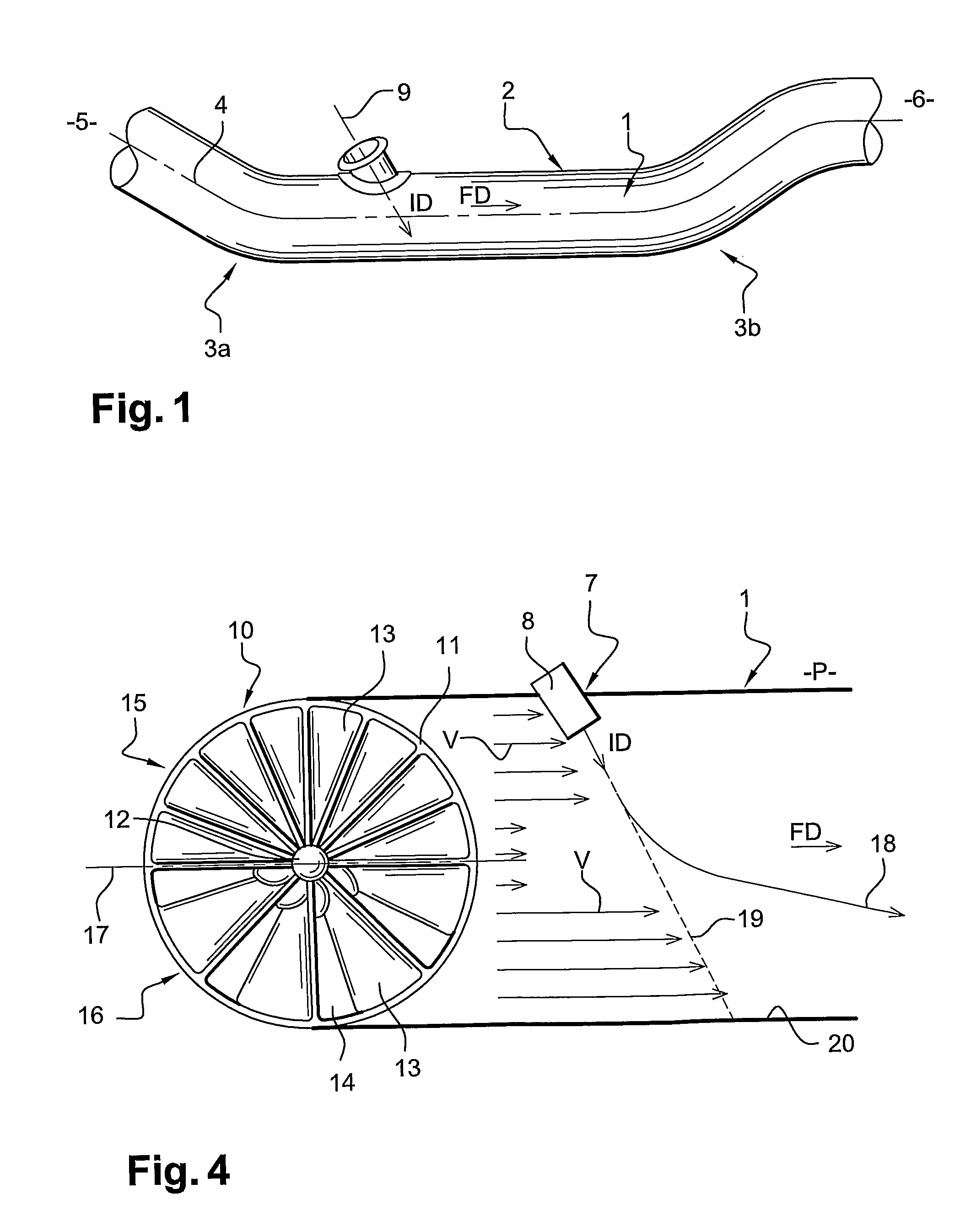

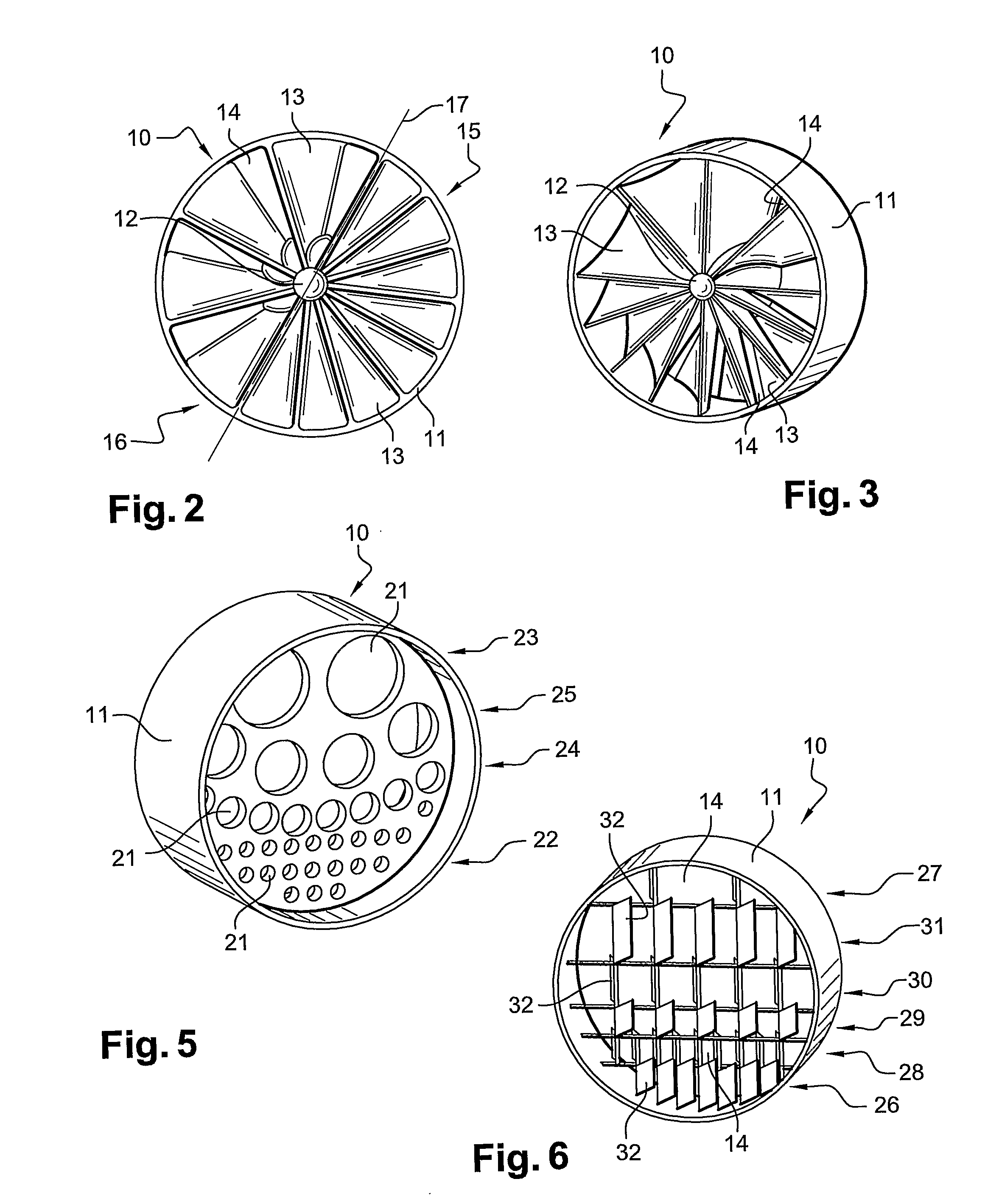

Mixing device in an exhaust gas pipe

ActiveUS20110162353A1Flow fastBetter mixing of fluidGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust gas pipe, a first fluid flows in a flow direction in the pipe, and a second fluid is injected inside the pipe by a nozzle, from an injection inlet arranged in the pipe wall, according to an injection direction. A mixing device fastened inside the pipe upstream from the injection inlet creates turbulence that helps the mixing of the fluids. The mixing device has a first portion located on the injection inlet side of the pipe and a second portion located opposite the injection inlet side of the pipe, the portions being designed so that the fluid velocity is higher downstream from the mixing device second portion than downstream from the mixing device first portion. An aqueous solution of urea can be injected inside an exhaust pipe of a diesel engine.

Owner:VOLVO LASTVAGNAR AB

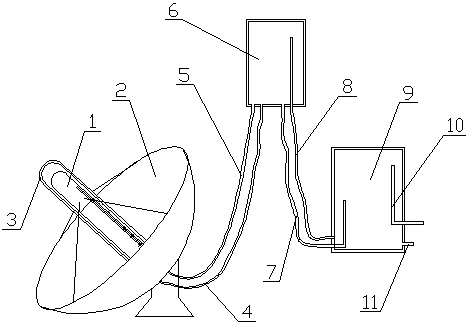

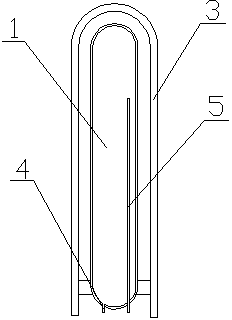

Solar energy storage and utilization device

InactiveCN104165347AAvoid lossImprove utilization efficiencySolar heating energySteam generation heating methodsWater storage tankHigh pressure water

A solar energy storage and utilization device comprises a metal inner container, a collecting lens, an energy storage tank and a water storage tank. A transparent vacuum tube is arranged outside the metal inner container; the bottom of the water storage tank and the bottom of the metal inner container are communicated through a water pipe I, the upper portion in the metal inner container and the bottom of the water storage tank are connected through a steam pipe I, and an exhaust pipe and a water supplementing pipe are arranged on the energy storage tank. According to the solar energy storage and utilization device, the transparent vacuum tube layer is arranged outside the metal inner container, received solar energy is stopped from being lost and thus the utilization rate of solar energy is substantially increased; meanwhile, the water storage tank and the energy storage tank are arranged so that solar energy received in good weather is stored in the energy storage tank in the form of high temperature and high pressure water and utilized in bad weather, the situation that an existing solar energy utilization device depends a lot on weather conditions is eliminated, and the application range of the solar energy utilization device is widened.

Owner:深圳市新浩建筑装饰工程有限公司

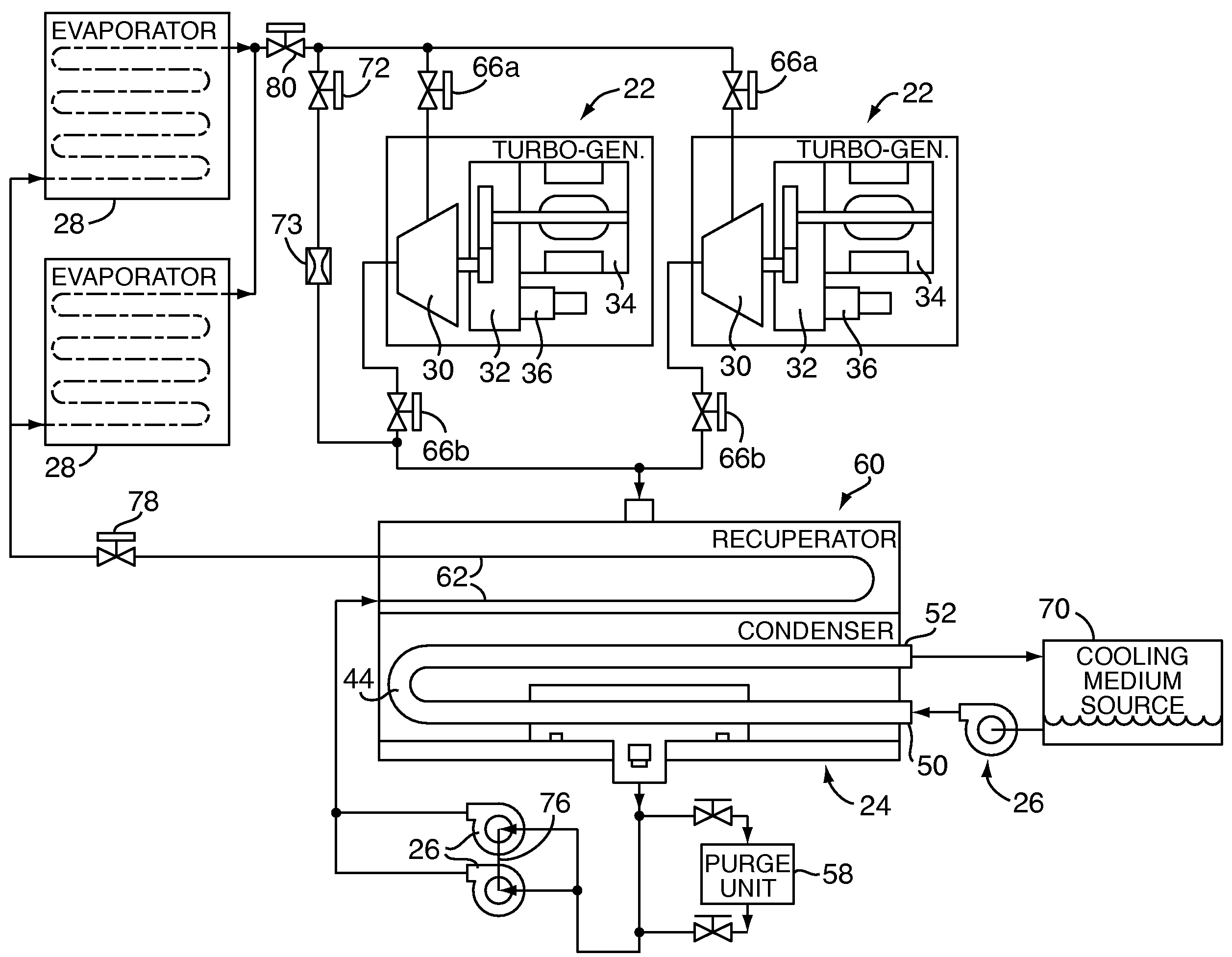

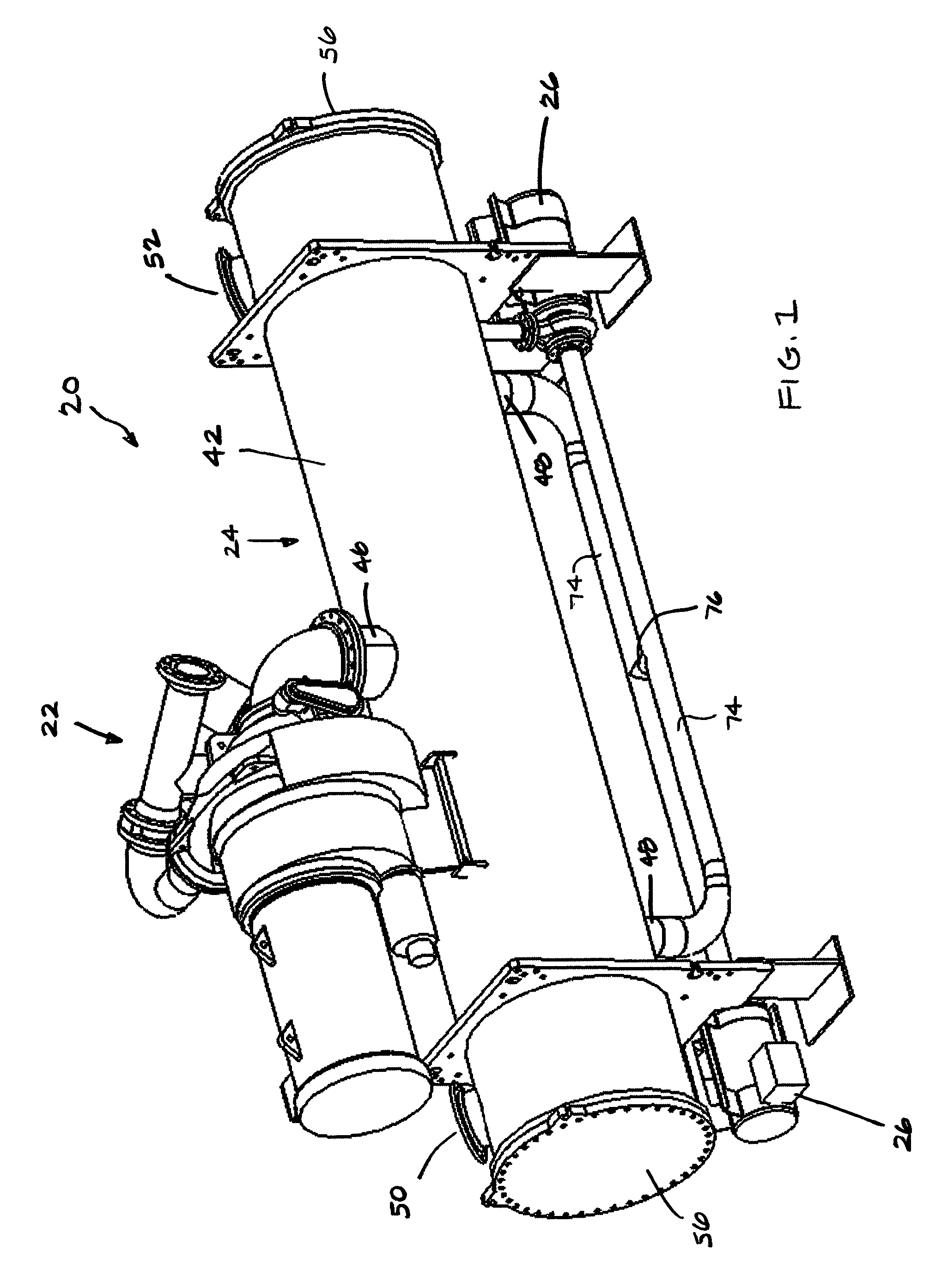

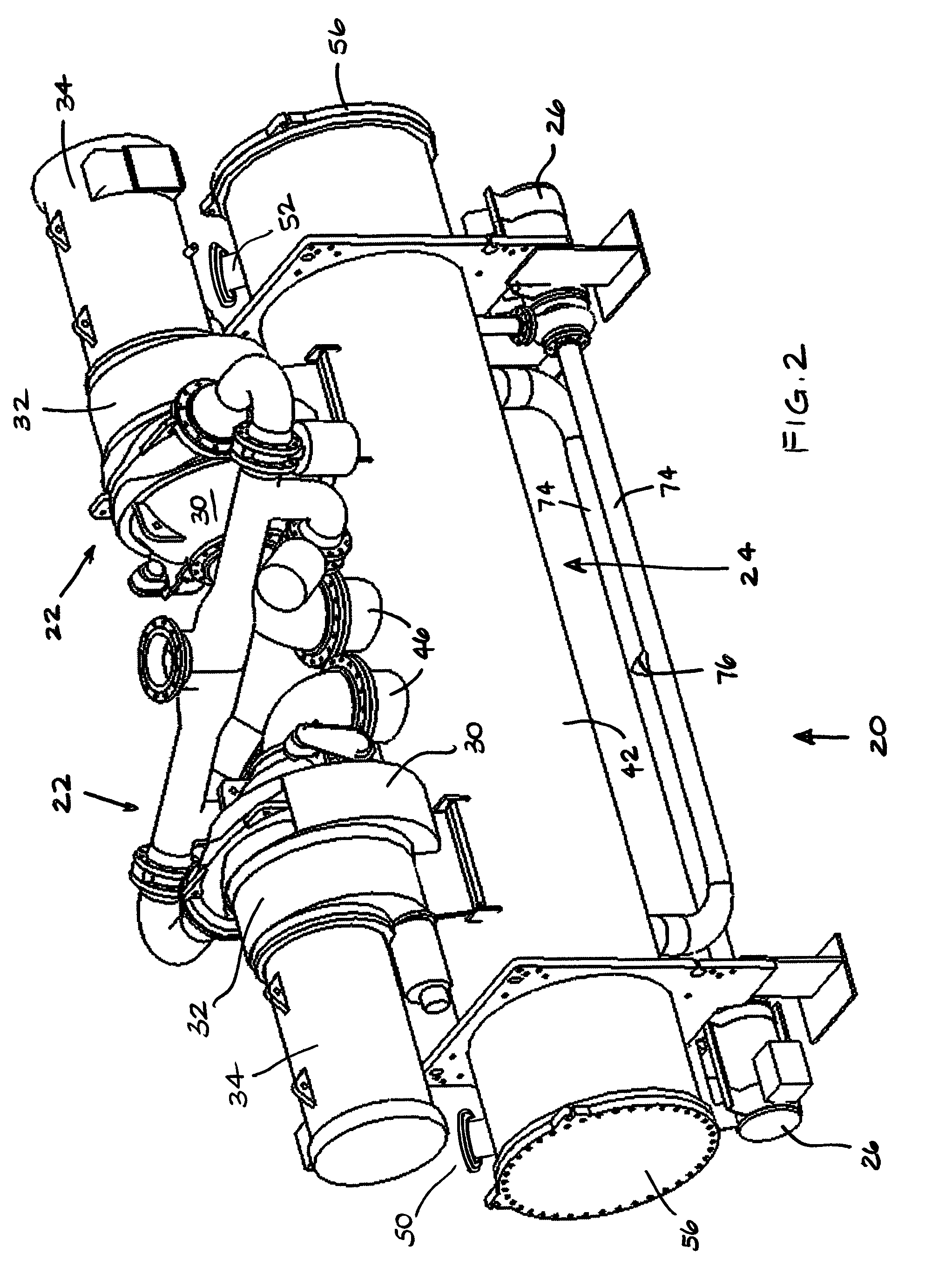

Rankine cycle device having multiple turbo-generators

A method for generating power, comprising the steps of: a) providing a Rankine Cycle device that includes a plurality of turbo-generators, each including a turbine coupled with an electrical generator, and at least one of each of an evaporator, a condenser, and a refrigerant feed pump; b) disposing the one or more evaporators within an exhaust duct of a power plant of a marine vessel; c) operating the power plant; and d) selectively pumping refrigerant through the Rankine Cycle device.

Owner:NANJING TICA AIR CONDITIONING CO LTD +1

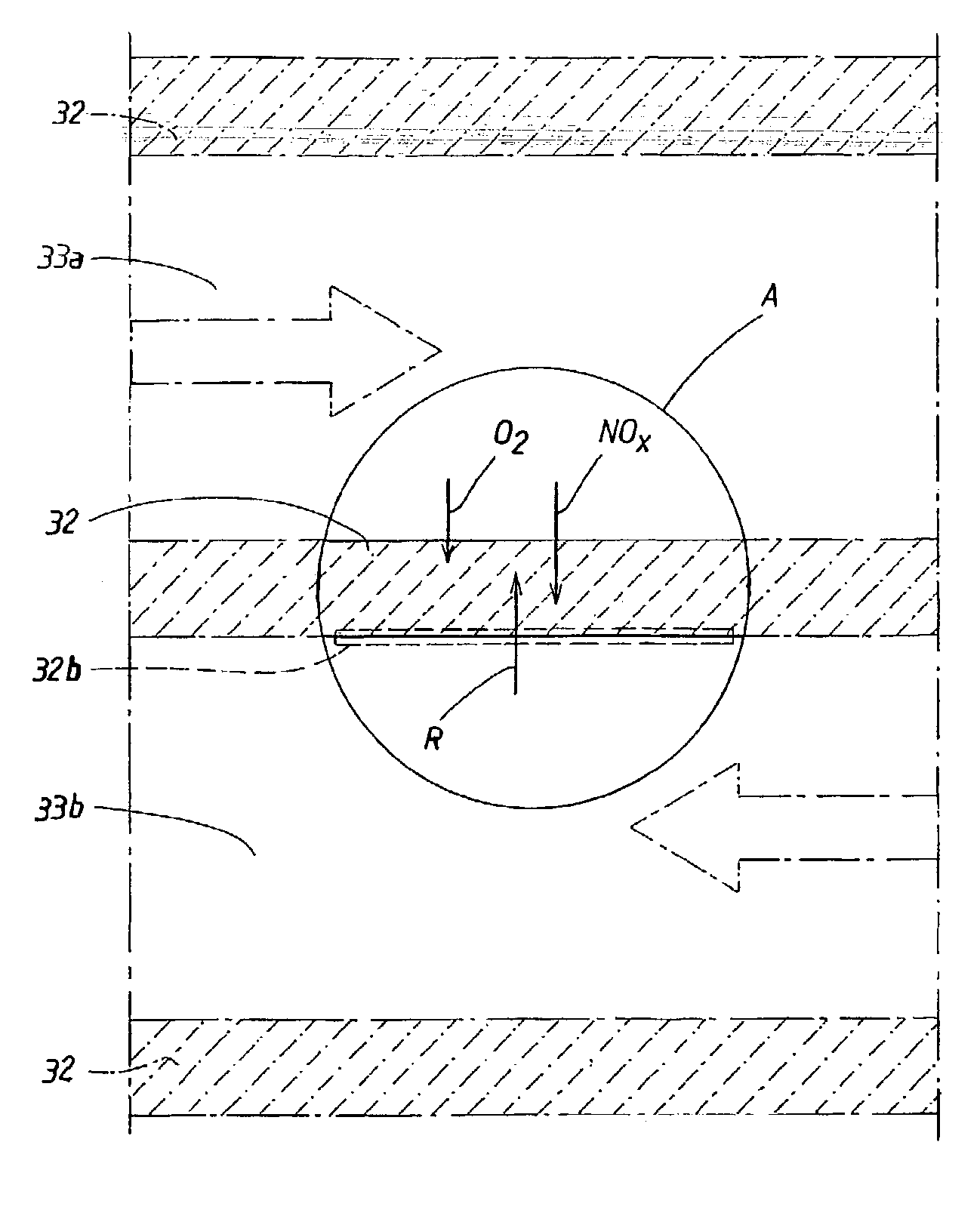

Device and method for reduction of a gas component in an exhaust gas flow of a combustion engine

InactiveUS8065870B2Reduce the amount requiredEasy dischargeCombination devicesElectrical controlCombustionProcess engineering

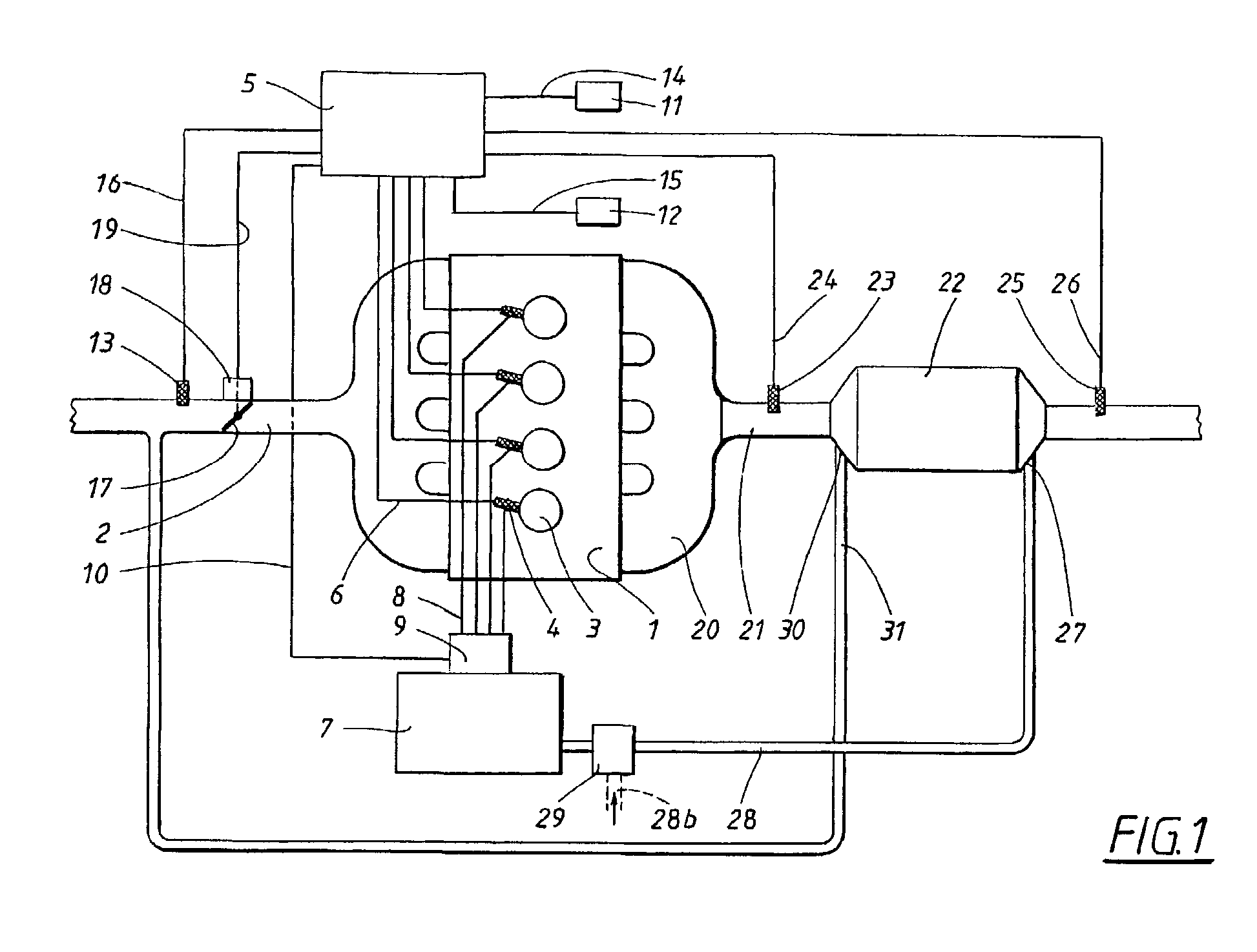

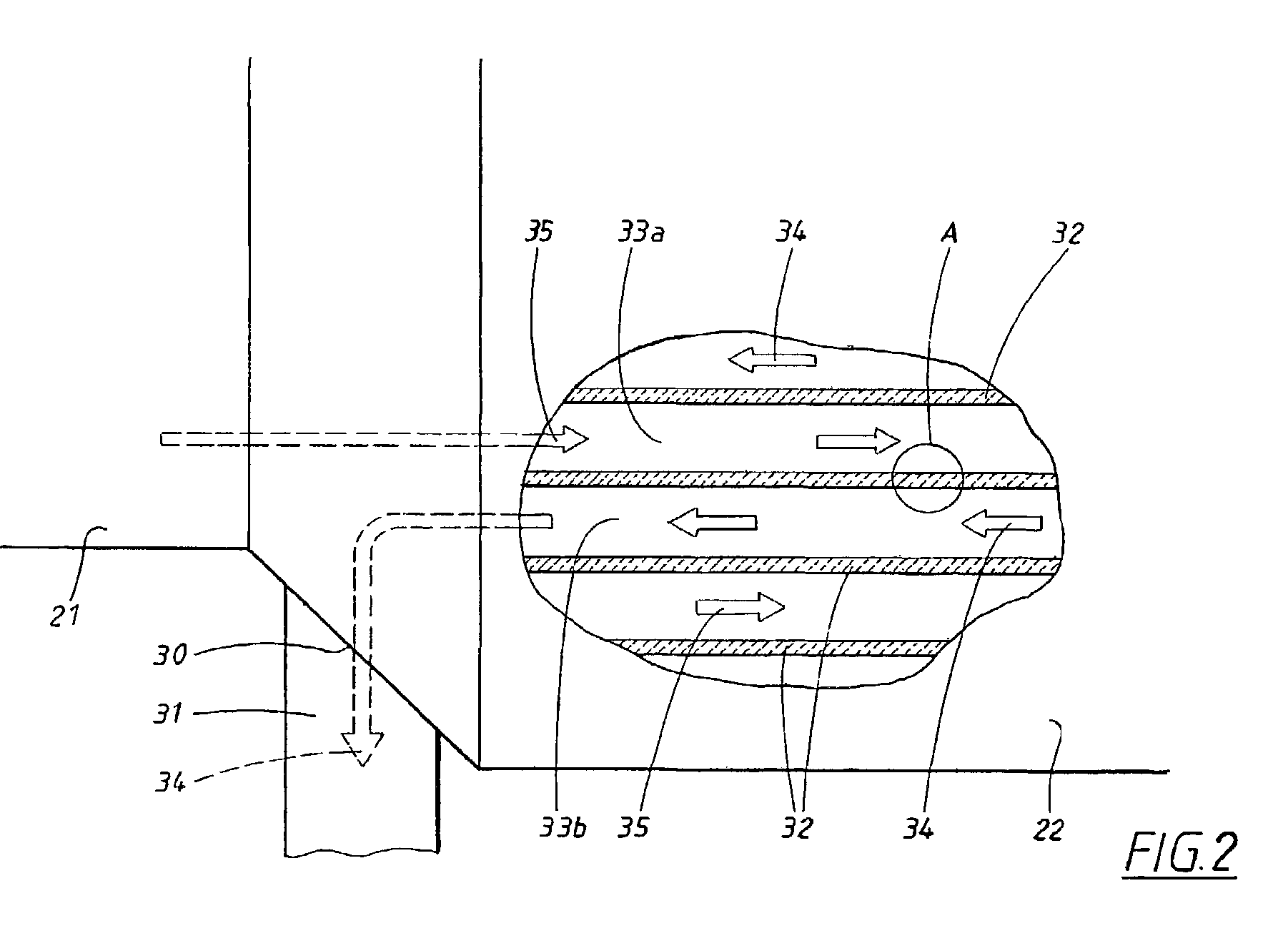

Method and device for reduction of a gas component in an exhaust gas flow of a combustion engine (1) that is adapted for operation by a lean air / fuel mixture. An exhaust pipe (21) is included for transport of the exhaust gas flow from the engine (1). A separation unit (22) is also included that is arranged along the exhaust pipe (21), which separation unit (22) has a wall structure (32) of a material which provides separation of the gas component from the exhaust gas flow by means of a selective passage of the gas component before other gas components in the exhaust gas flow. The method provides for a reduction and a separation unit that is intended to be utilized during such a reduction. An improved reduction of in particular NOx compounds from a so-called “lean-burn” engine is also provided.

Owner:VOLVO TECH

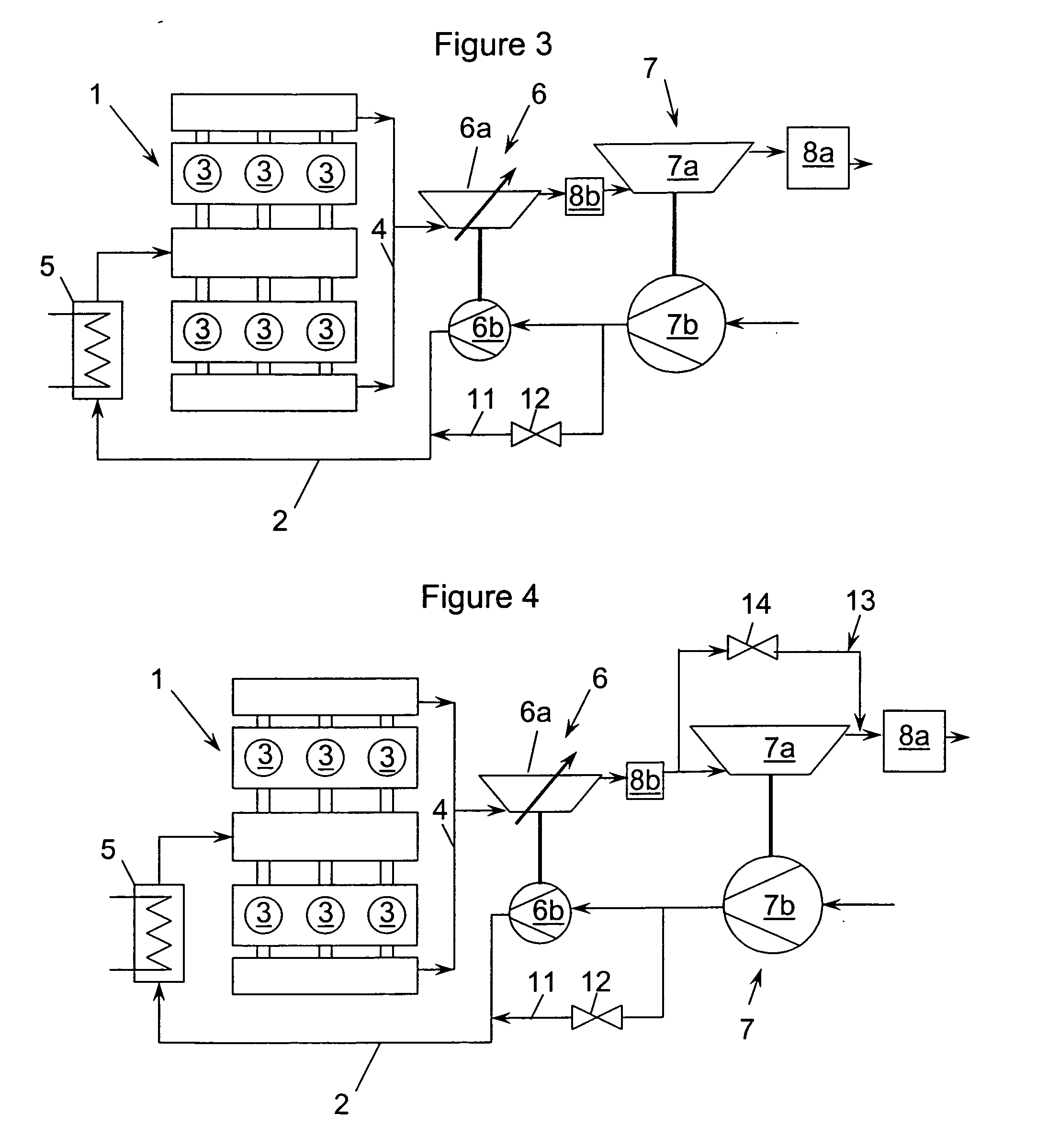

Pressure-charged internal combustion engine

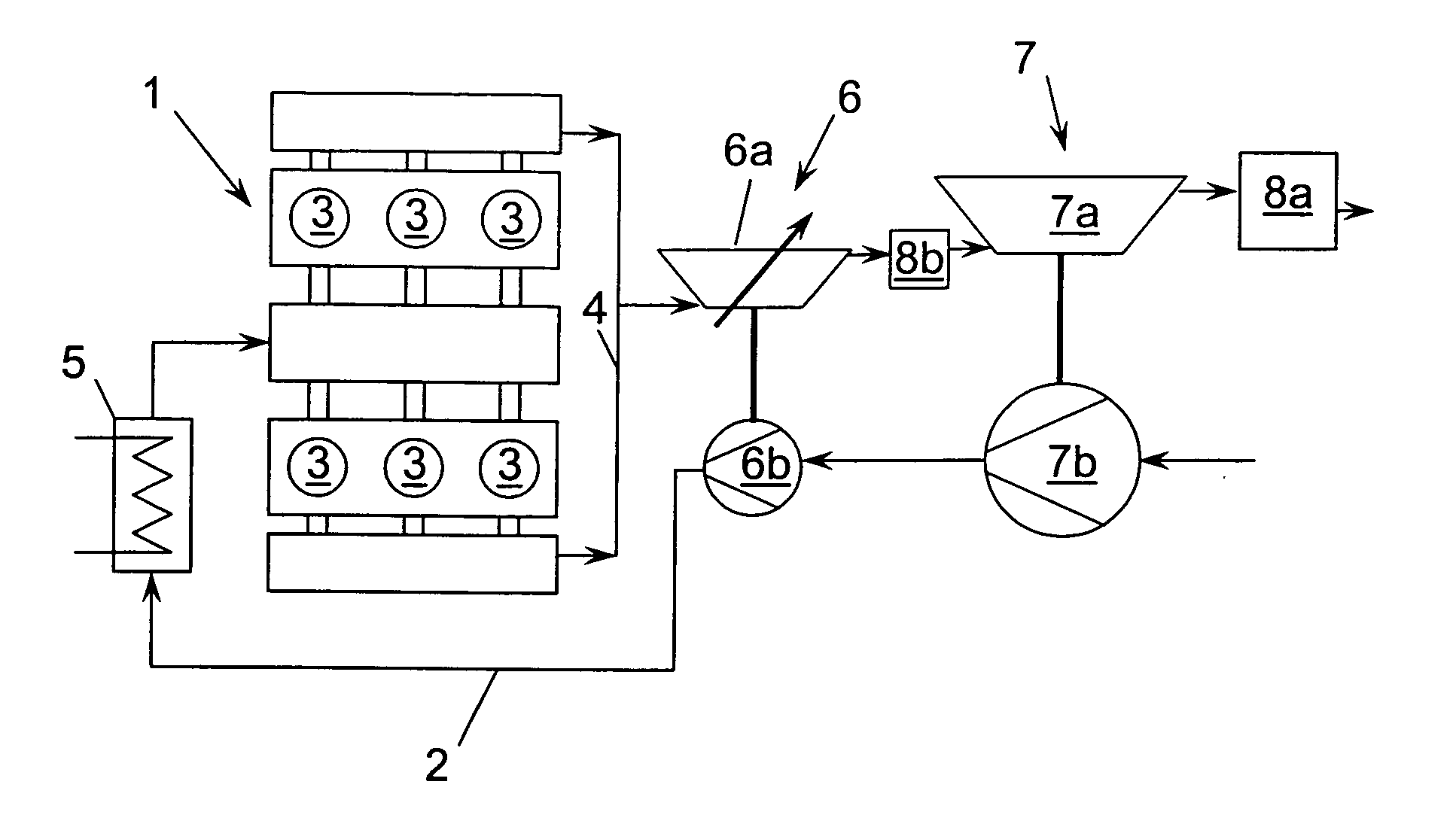

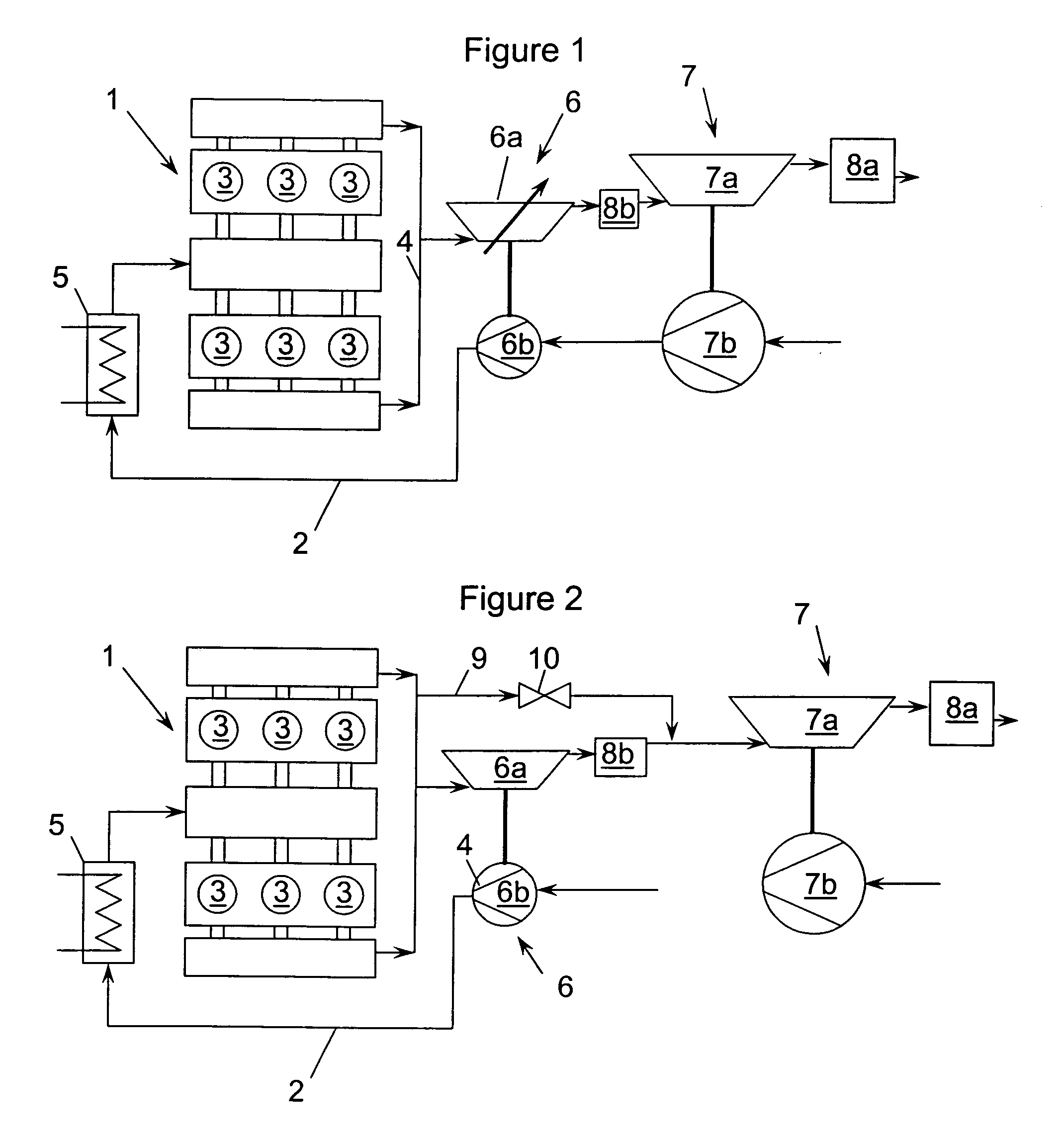

InactiveUS20060059910A1Improve emission characteristicsImproved emission behaviorInternal combustion piston enginesExhaust apparatusTurbochargerHigh pressure

The invention relates to a system and method for improving the emission characteristics of a pressure-charged internal combustion engine. The engine (1) has an intake line (2) and an exhaust-gas line (4) and at least two exhaust-gas turbochargers (6, 7) connected in series. Each turbocharger has a turbine (6a, 7a) in the exhaust-gas line (4) and a compressor (6b, 7b) in the intake line (2). The first exhaust-gas turbocharger (6) serves as high-pressure stage (6). The second exhaust-gas turbocharger (7) serves as low-pressure stage (7). Two exhaust-gas aftertreatment systems are located in between and after the turbines.

Owner:FORD GLOBAL TECH LLC

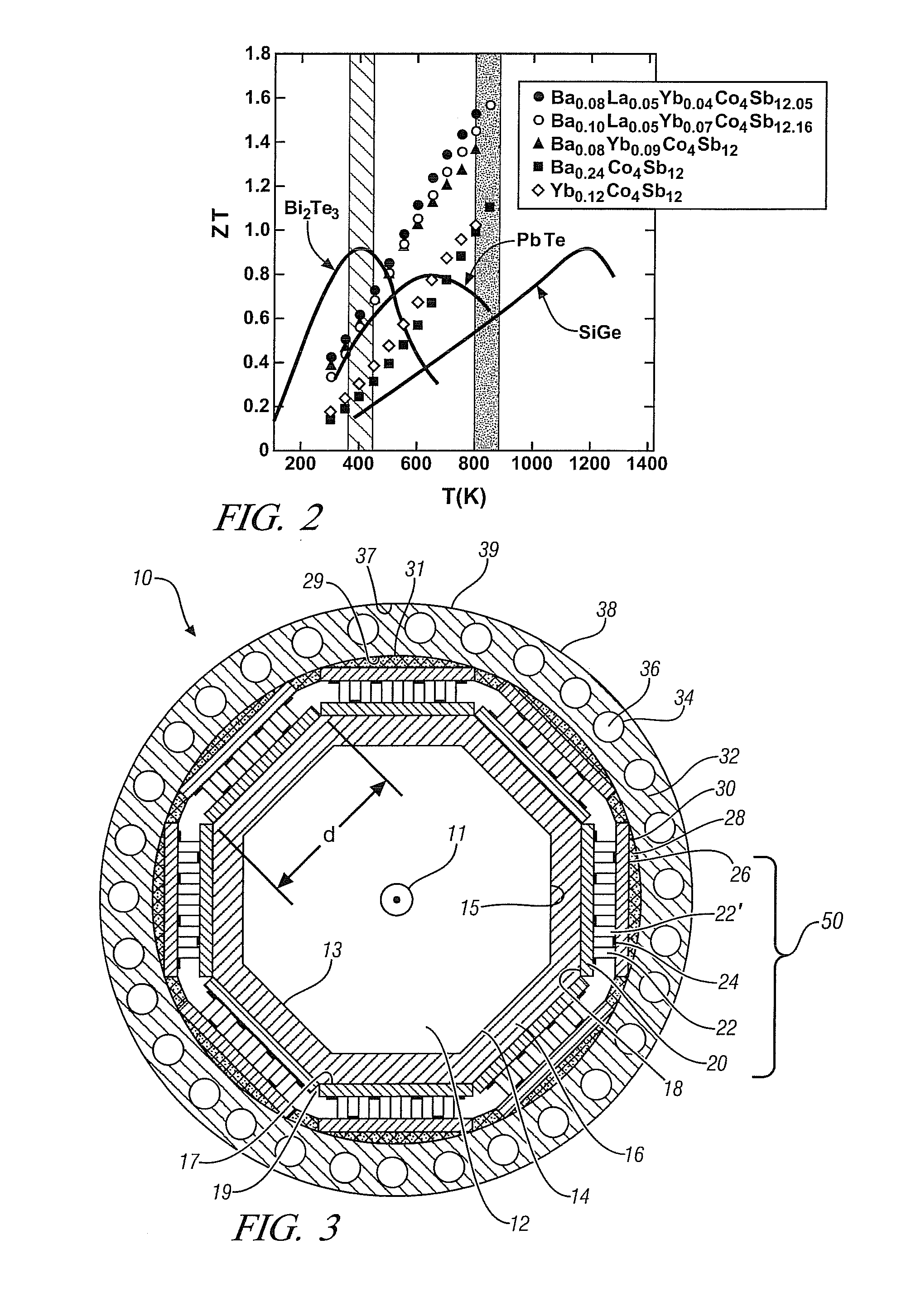

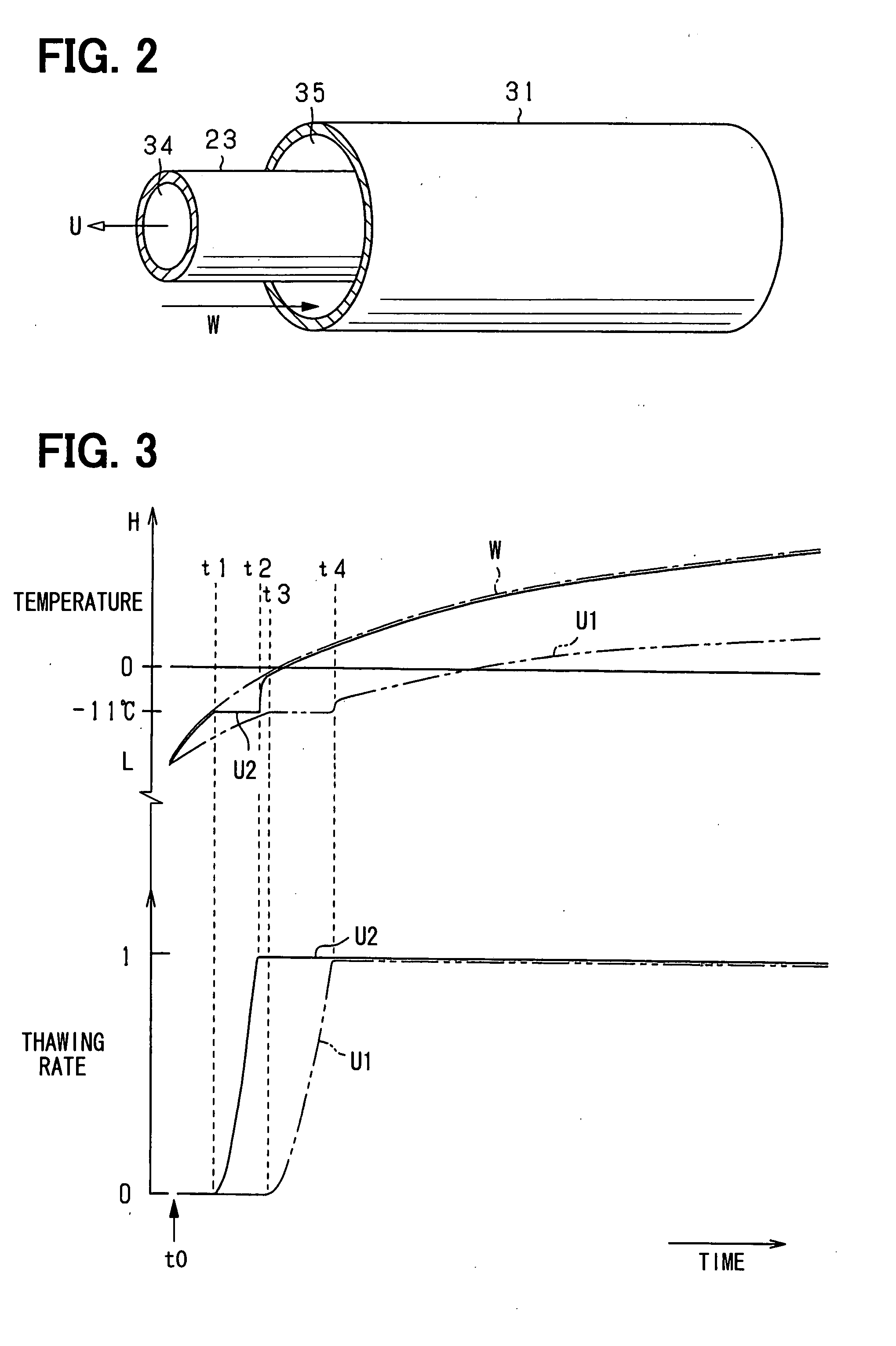

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

ActiveUS20120073276A1Efficient extractionThermoelectric device with peltier/seeback effectExhaust apparatusEngineeringInternal combustion engine

Thermoelectric devices, intended for placement in the exhaust of a hydrocarbon fuelled combustion device and particularly suited for use in the exhaust gas stream of an internal combustion engine propelling a vehicle, are described. Exhaust gas passing through the device is in thermal communication with one side of a thermoelectric module while the other side of the thermoelectric module is in thermal communication with a lower temperature environment. The heat extracted from the exhaust gasses is converted to electrical energy by the thermoelectric module. The performance of the generator is enhanced by thermally coupling the hot and cold junctions of the thermoelectric modules to phase-change materials which transform at a temperature compatible with the preferred operating temperatures of the thermoelectric modules. In a second embodiment, a plurality of thermoelectric modules, each with a preferred operating temperature and each with a uniquely-matched phase-change material may be used to compensate for the progressive lowering of the exhaust gas temperature as it traverses the length of the exhaust pipe.

Owner:GM GLOBAL TECH OPERATIONS LLC

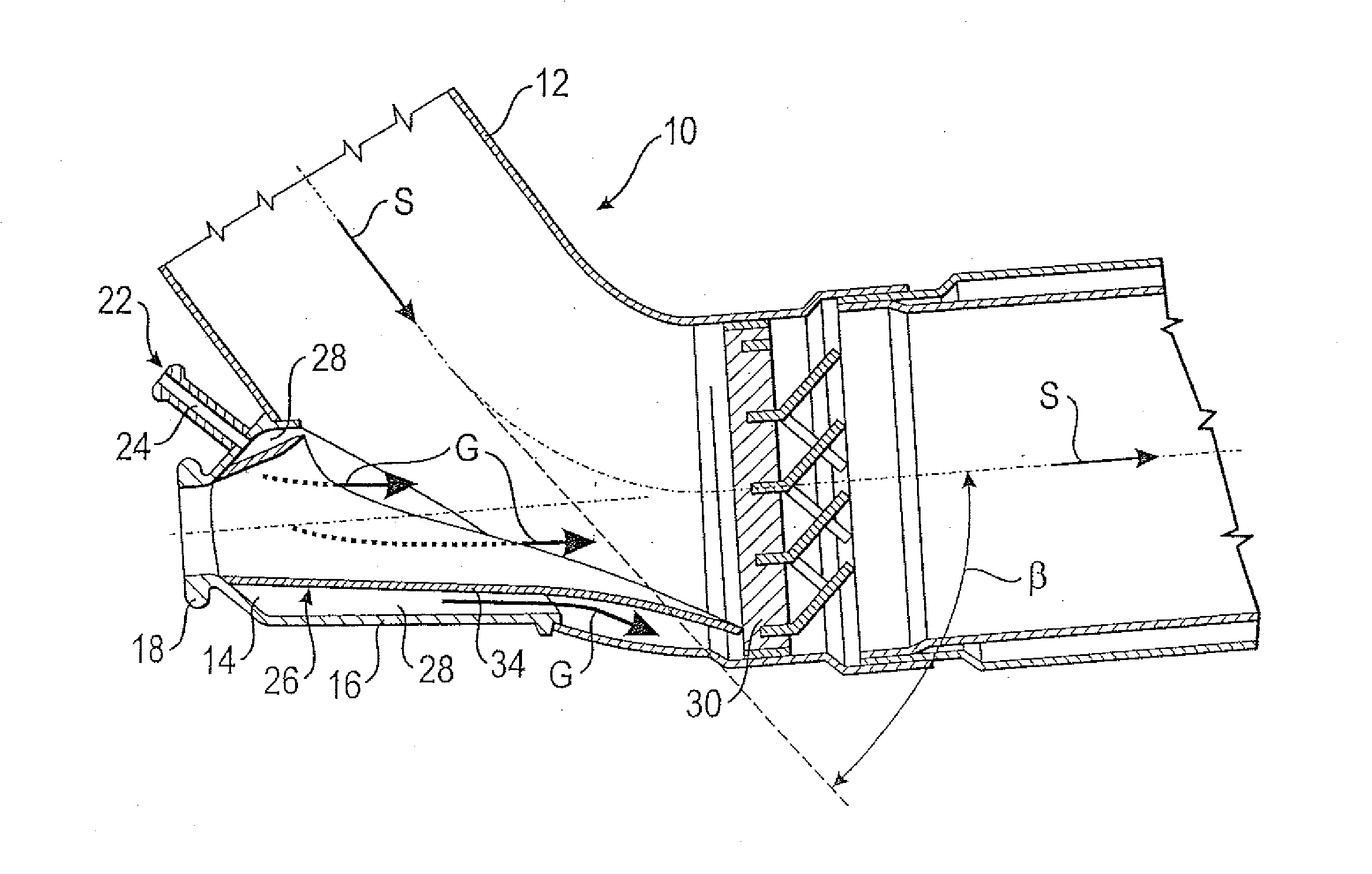

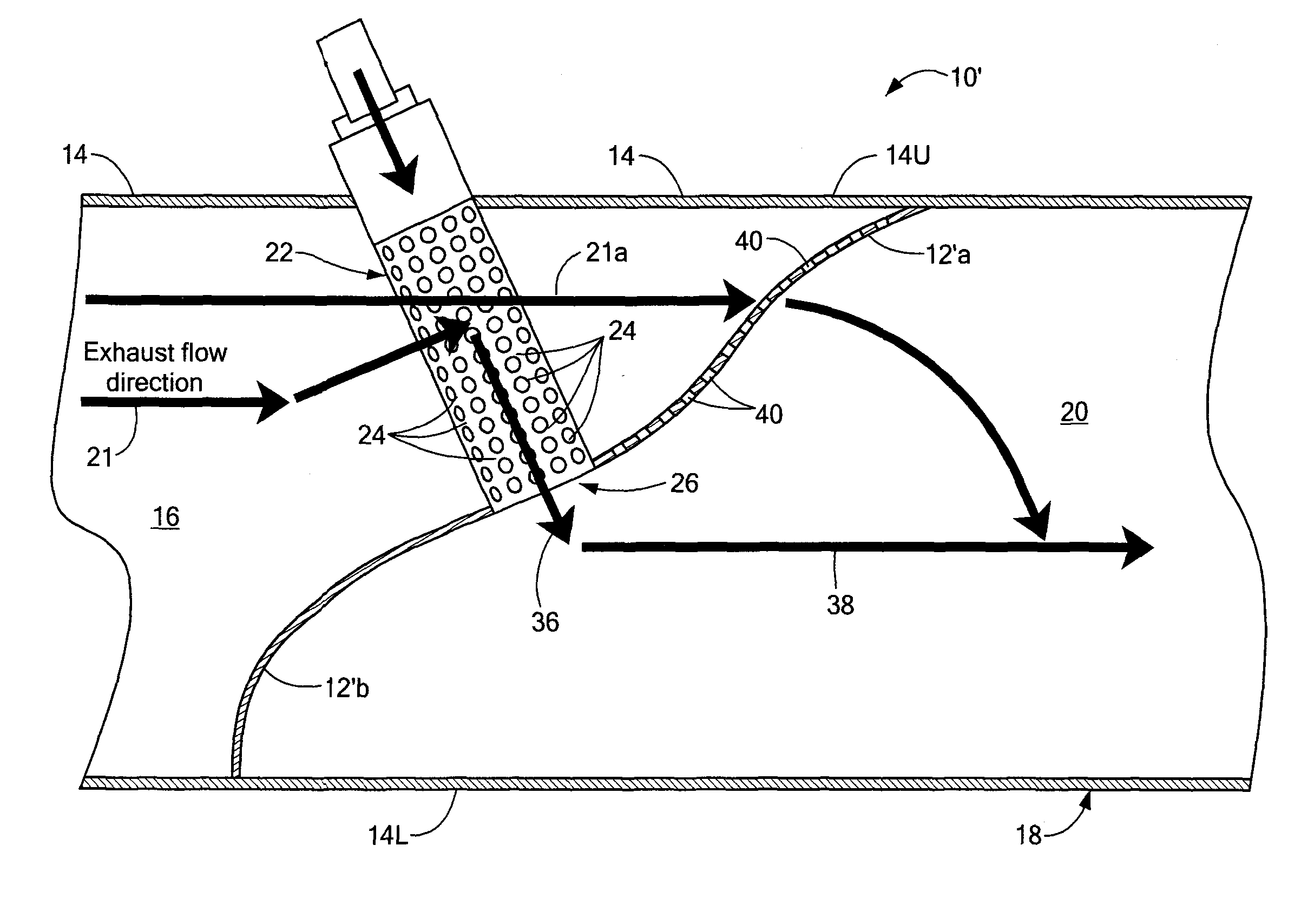

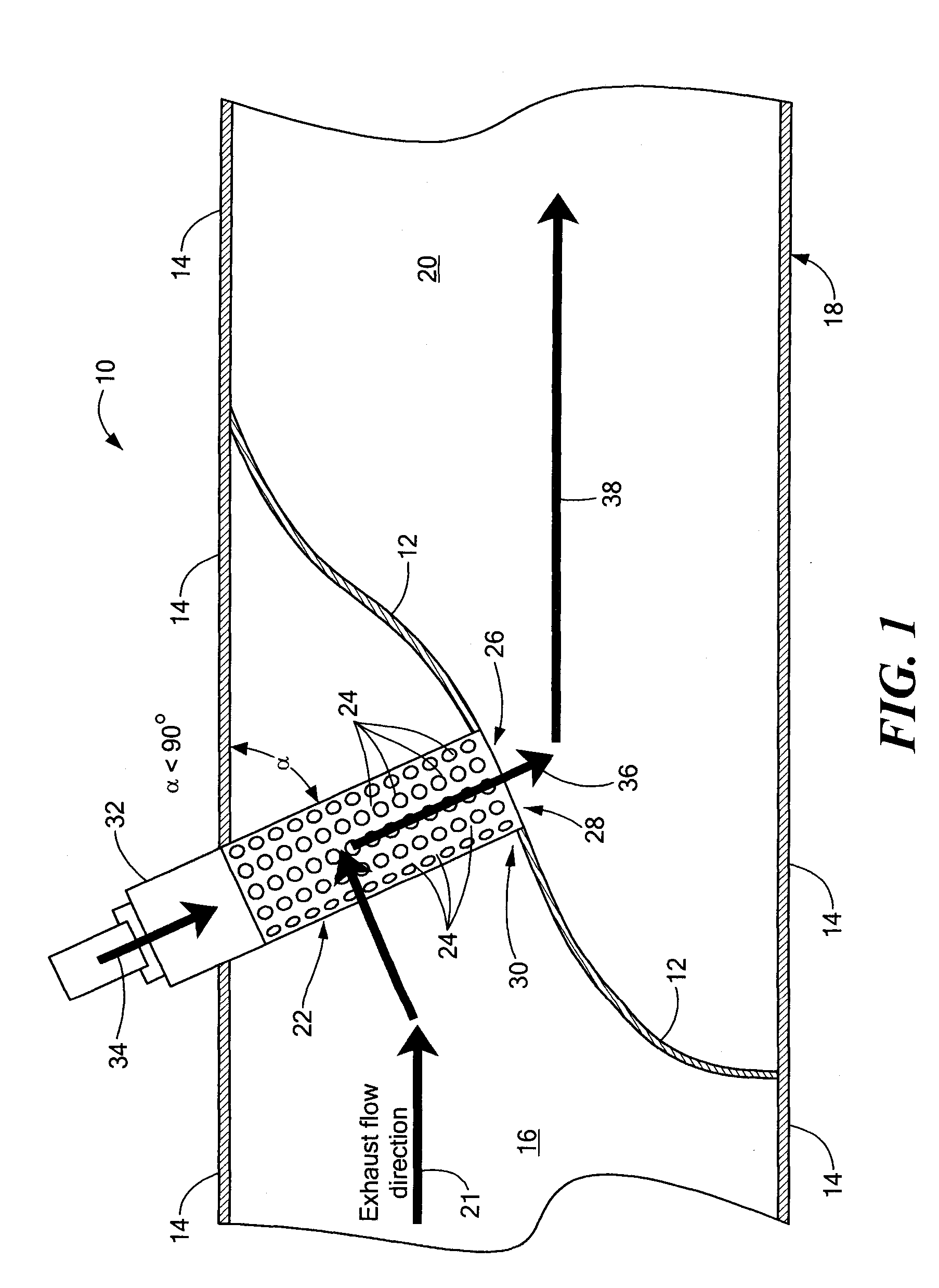

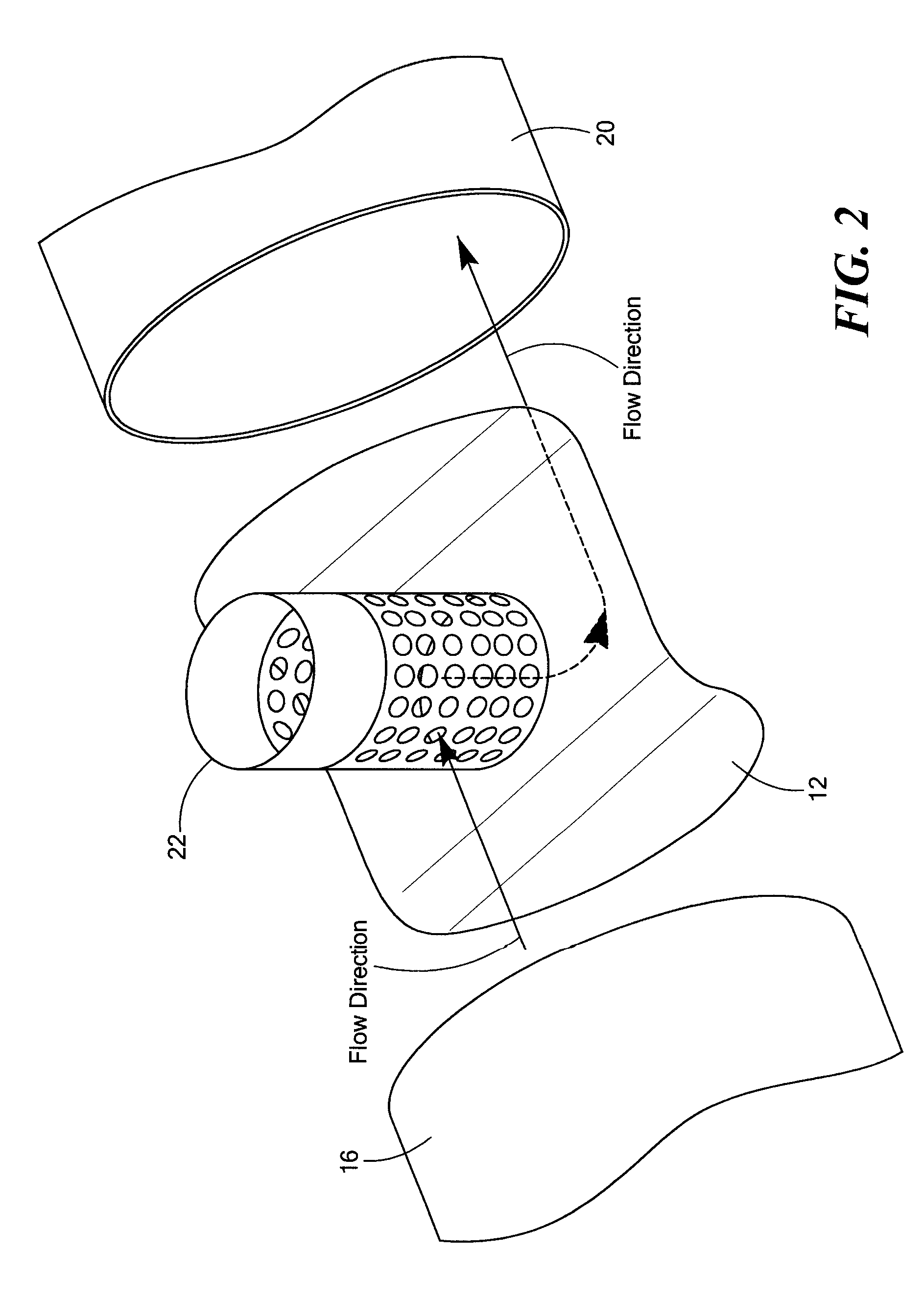

Selective catalytic reduction (SCR) catalyst injection systems

ActiveUS8033104B2Speed up the flowPromote atomizationInternal combustion piston enginesSilencing apparatusExhaust fumesExhaust pipe

A Selective Catalytic Reduction (SCR) injection system for mixing reductant with exhaust gasses. The system includes a plate disposed between walls of an entrance portion and an egress section of the exhaust pipe. The plate intercepts exhaust gasses entering the entrance section of the exhaust pipe and directs such exhaust gasses through apertures in a wall of a reductant-introducing conduit. The conduit has an outlet disposed in the egress section of the exhaust pipe. The wherein dimensions of the apertures in the wall and dimensions in the outlet of the conduit being selected to increase the velocity of the exhaust leaving the outlet of the conduit into the egress section of the exhaust pipe relative to the velocity of the exhaust gases in the entrance section.

Owner:FORD GLOBAL TECH LLC

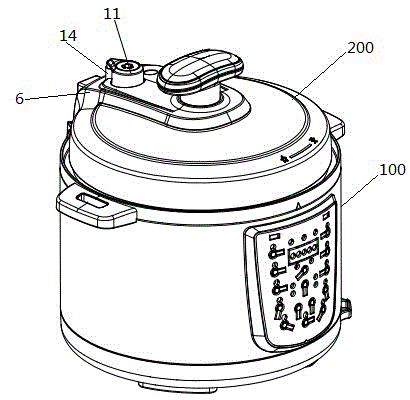

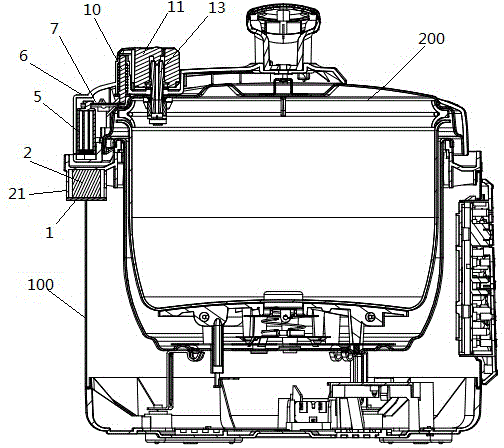

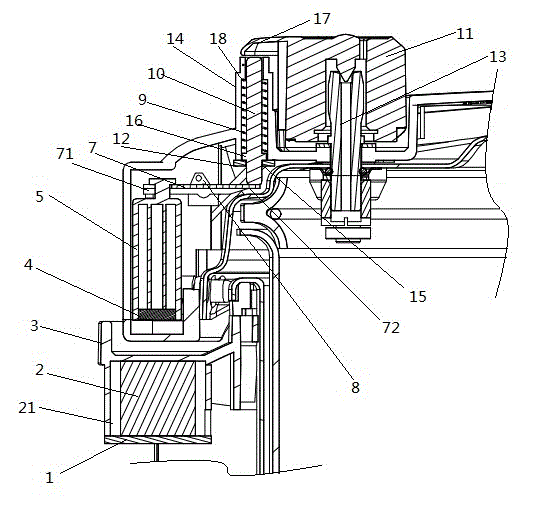

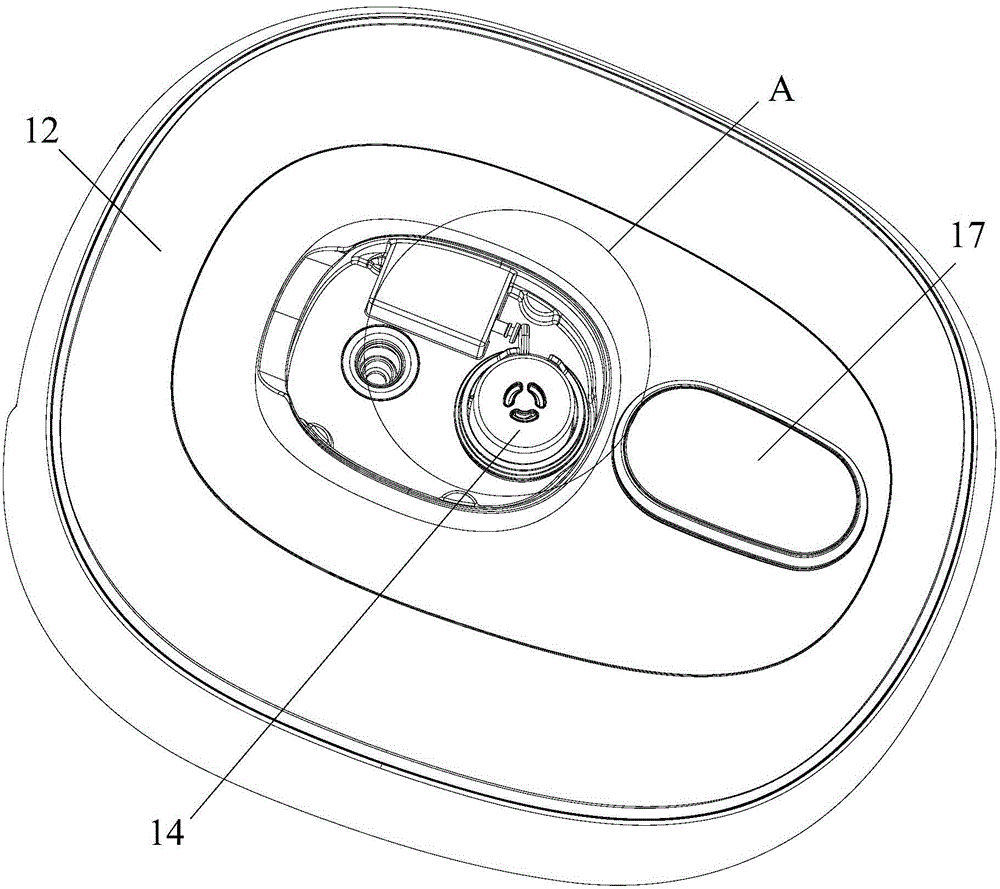

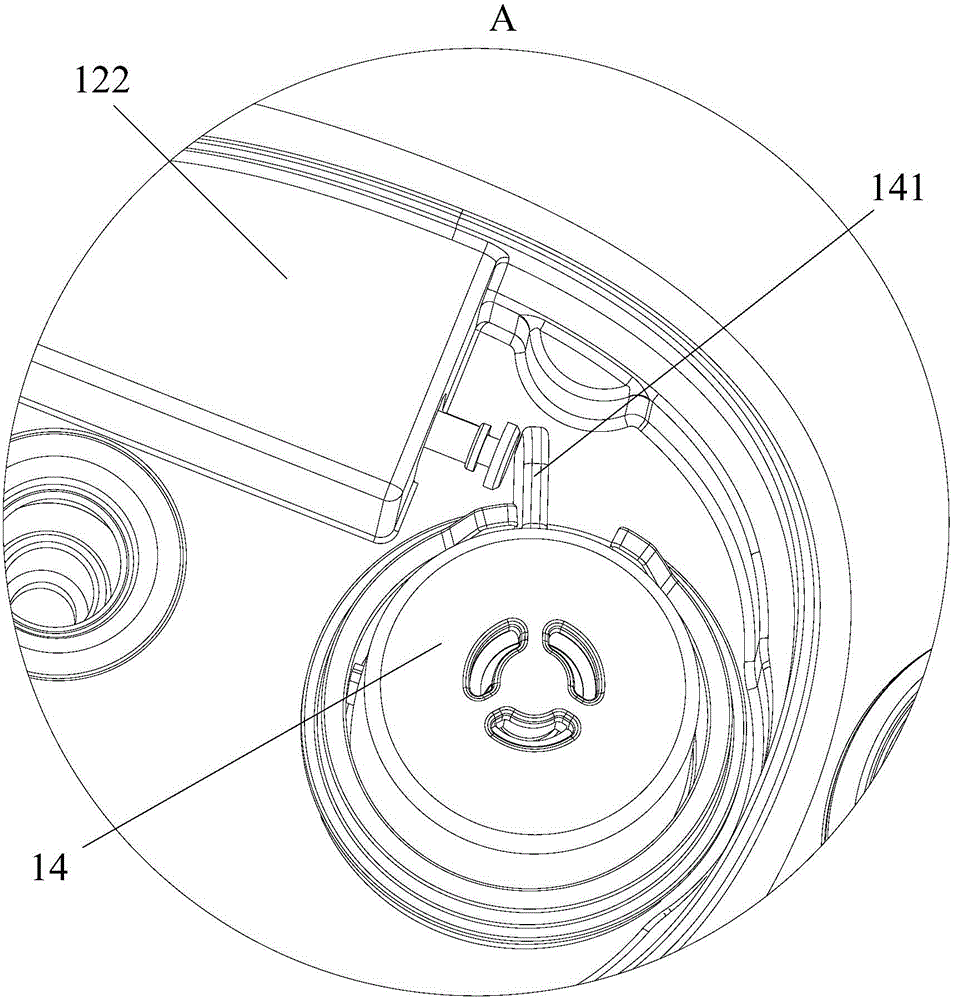

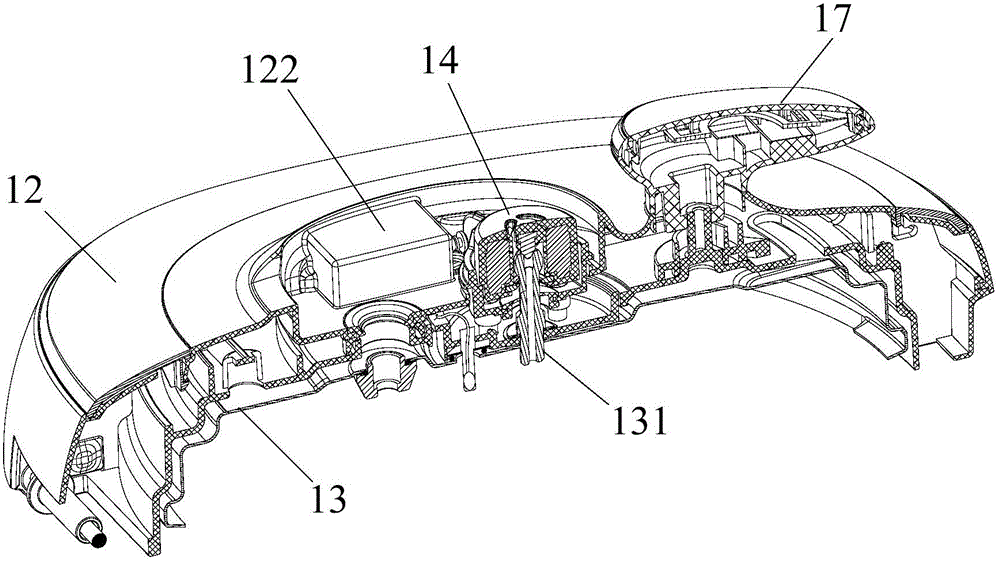

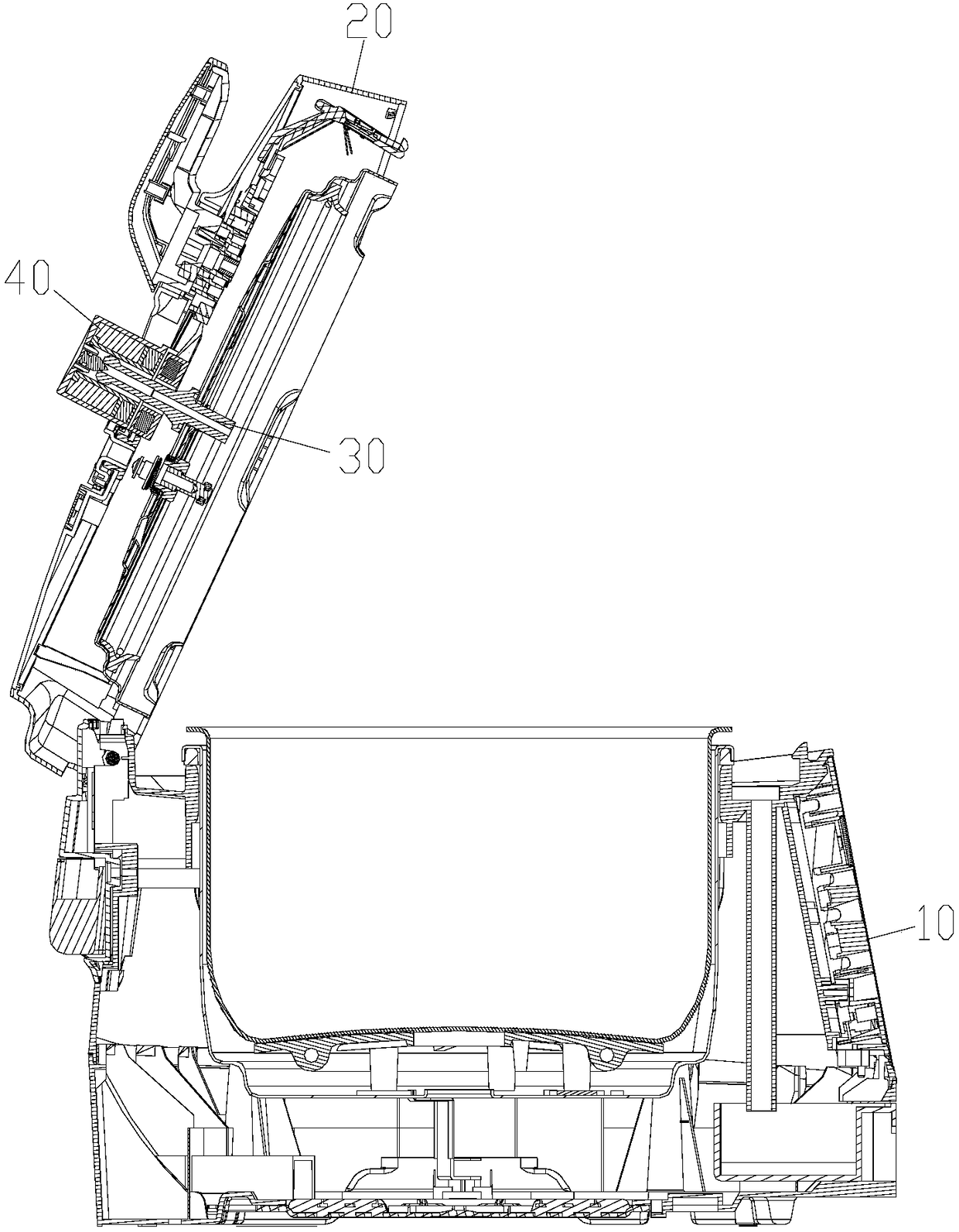

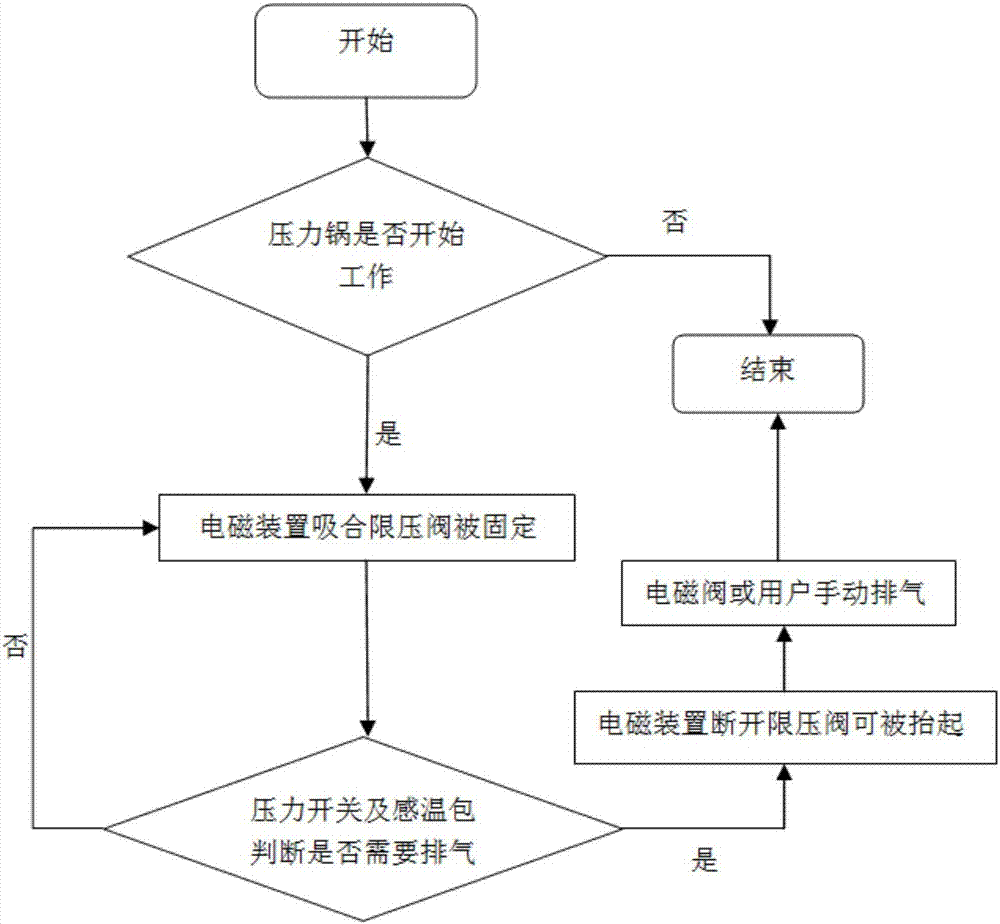

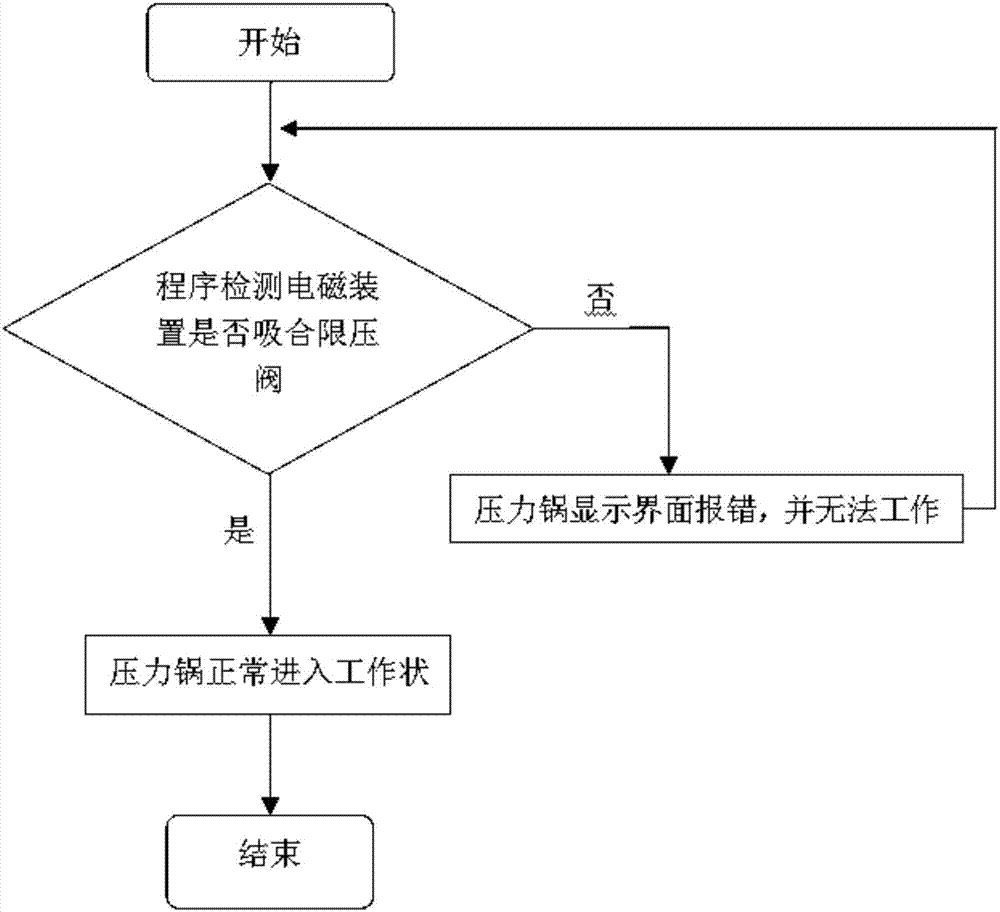

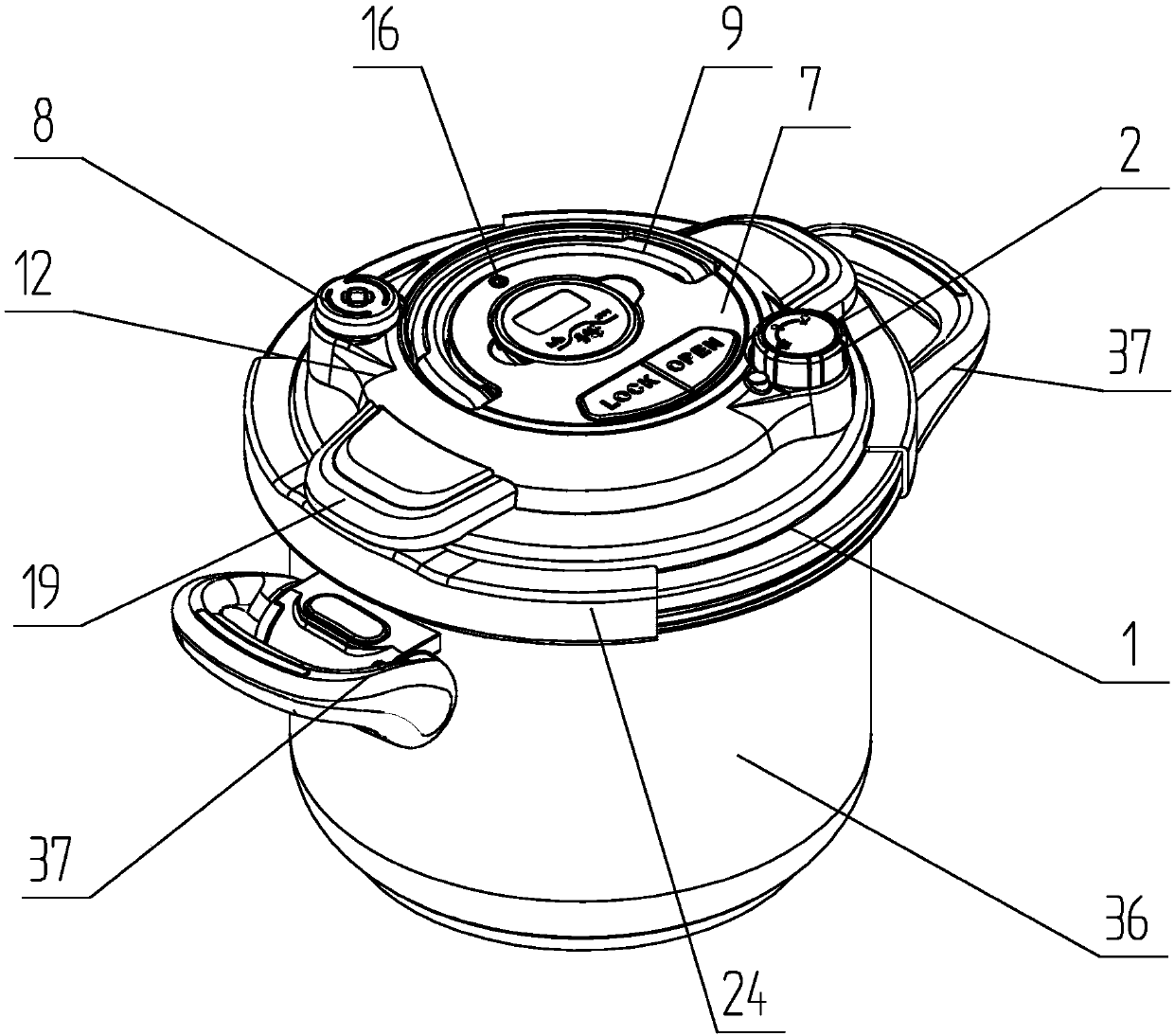

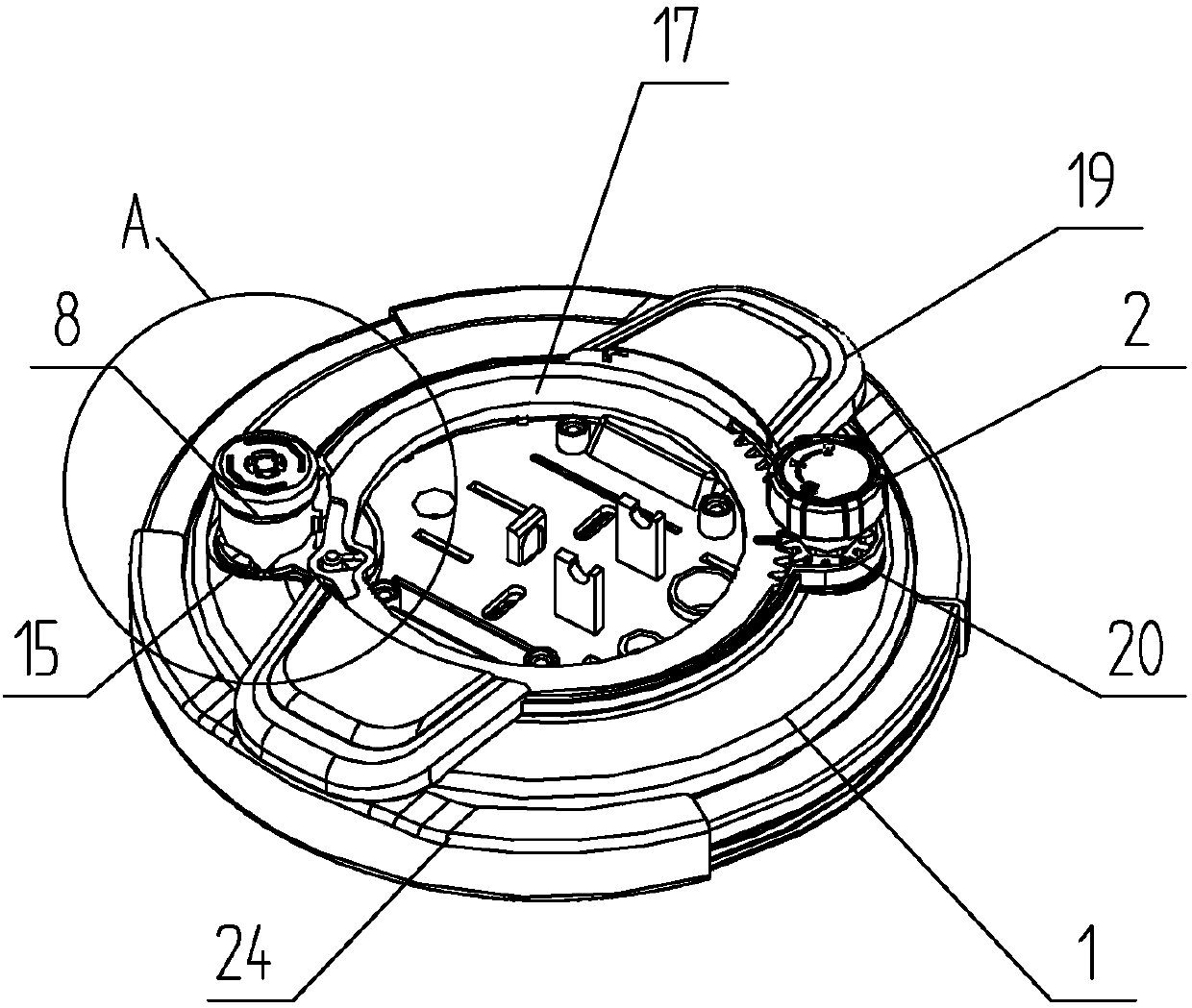

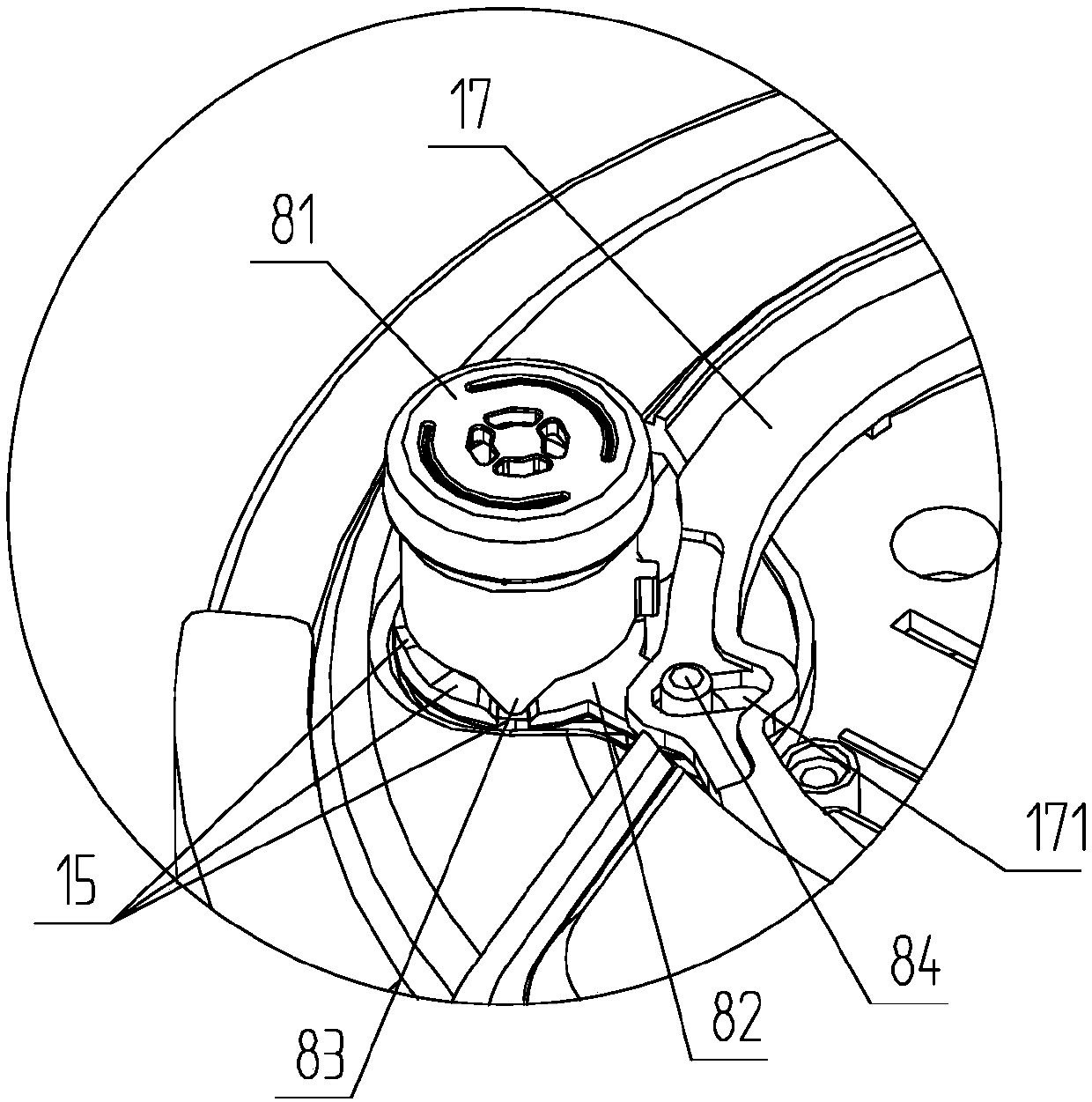

Electric pressure cooker capable of automatically exhausting

InactiveCN105768859ASimplify the automatic exhaust structureShorter drivelinesPressure-cookersMagnetic effectEngineering

The invention provides an electric pressure cooker capable of automatically exhausting. The electric pressure cooker comprises a cooker body, a cooker cover and a control circuit, wherein an exhaust pipe and a gravity hammer which is in sealed contact with the exhaust pipe are arranged on the cooker cover; a first connecting rod is additionally arranged on the cooker cover; a ferromagnetic material is arranged at the first end of the first connecting rod; the position, corresponding to the ferromagnetic material, of the cooker body, is provided with an electromagnet which can take a magnetic effect on the ferromagnetic material; the electromagnetic is electrically connected to the control circuit; the second end of the first connecting rod is in transmitted connection to the gravity hammer; and the gravity hammer is displaced directly or indirectly when the second end of the first connecting rod displaces upwards, and the gravity hammer is separated away from the port of the exhaust pipe. By virtue of the electromagnet and a lever linkage device which are mutually matched, the electric pressure cooker can simplify an automatically exhausting structure, shorten a power transmission route, reduce a probability of a jamming phenomenon in a power transmission process and improve product quality.

Owner:ZHONGSHAN YALESI ELECTRIC CO LTD

Exhaust purification device of engine

A DPF and a SCR catalyst are provided in an exhaust pipe, and a urea solution addition valve is provided between the DPF and the SCR catalyst for performing addition supply of urea solution into the exhaust pipe. In a urea solution supply system, the urea solution of prescribed concentration is stored in a urea solution tank, and a urea solution pump is provided in the tank. A urea solution supply pipe is connected to the urea solution pump. A part of the urea solution supply pipe is structured as a compound pipe structure defining two passages. One of the two passages serves as a urea solution passage, and the other one serves as an engine coolant passage.

Owner:DENSO CORP

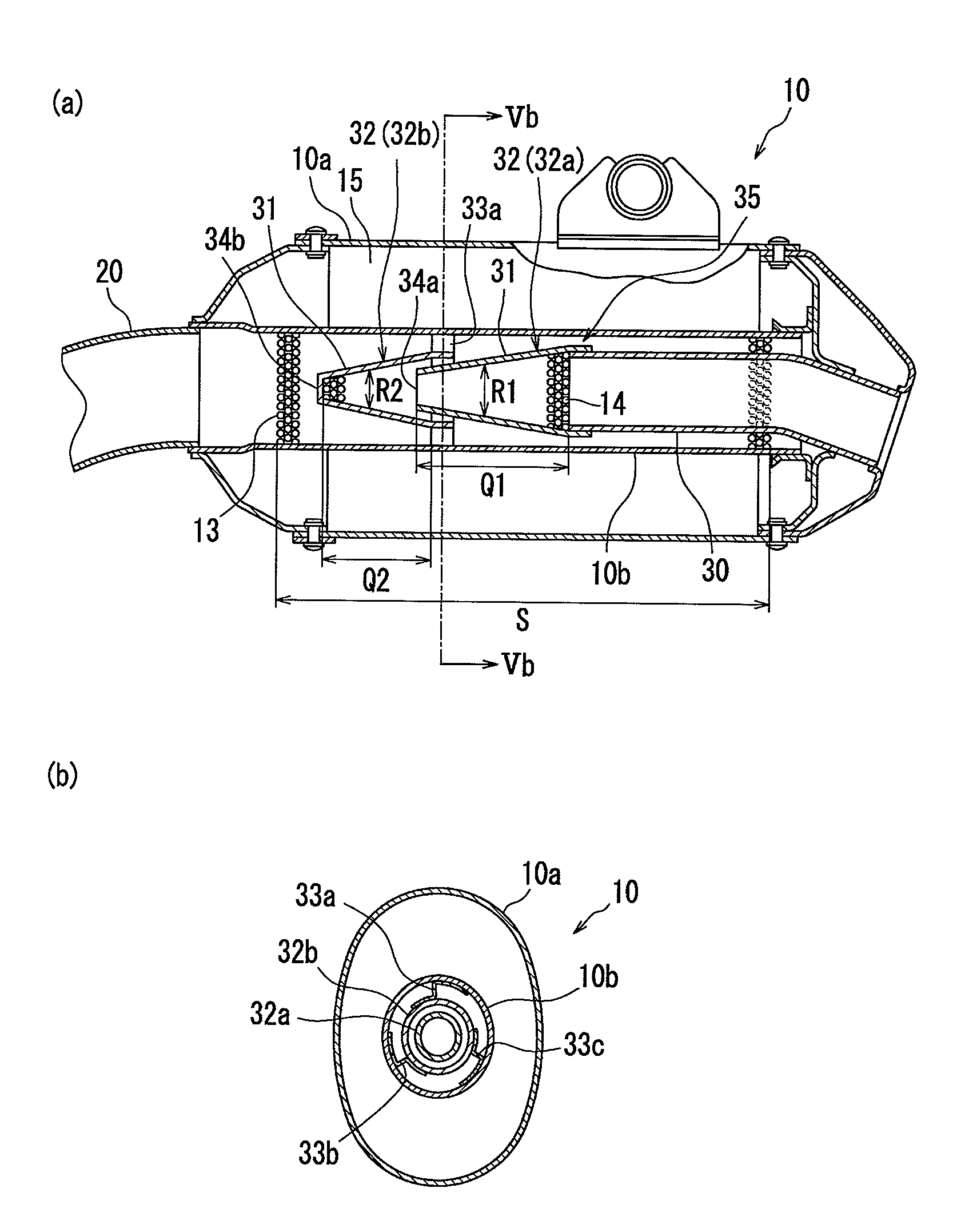

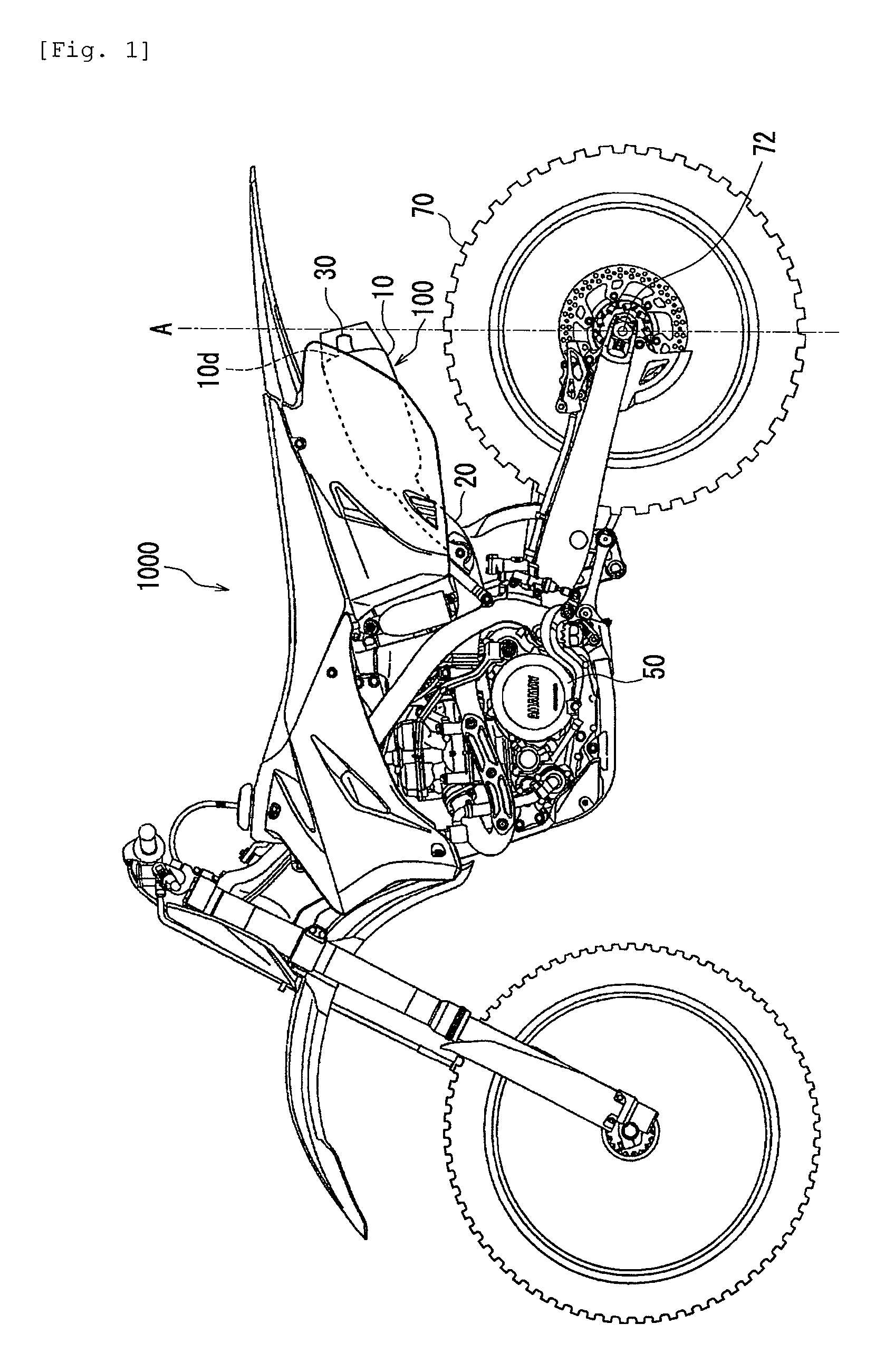

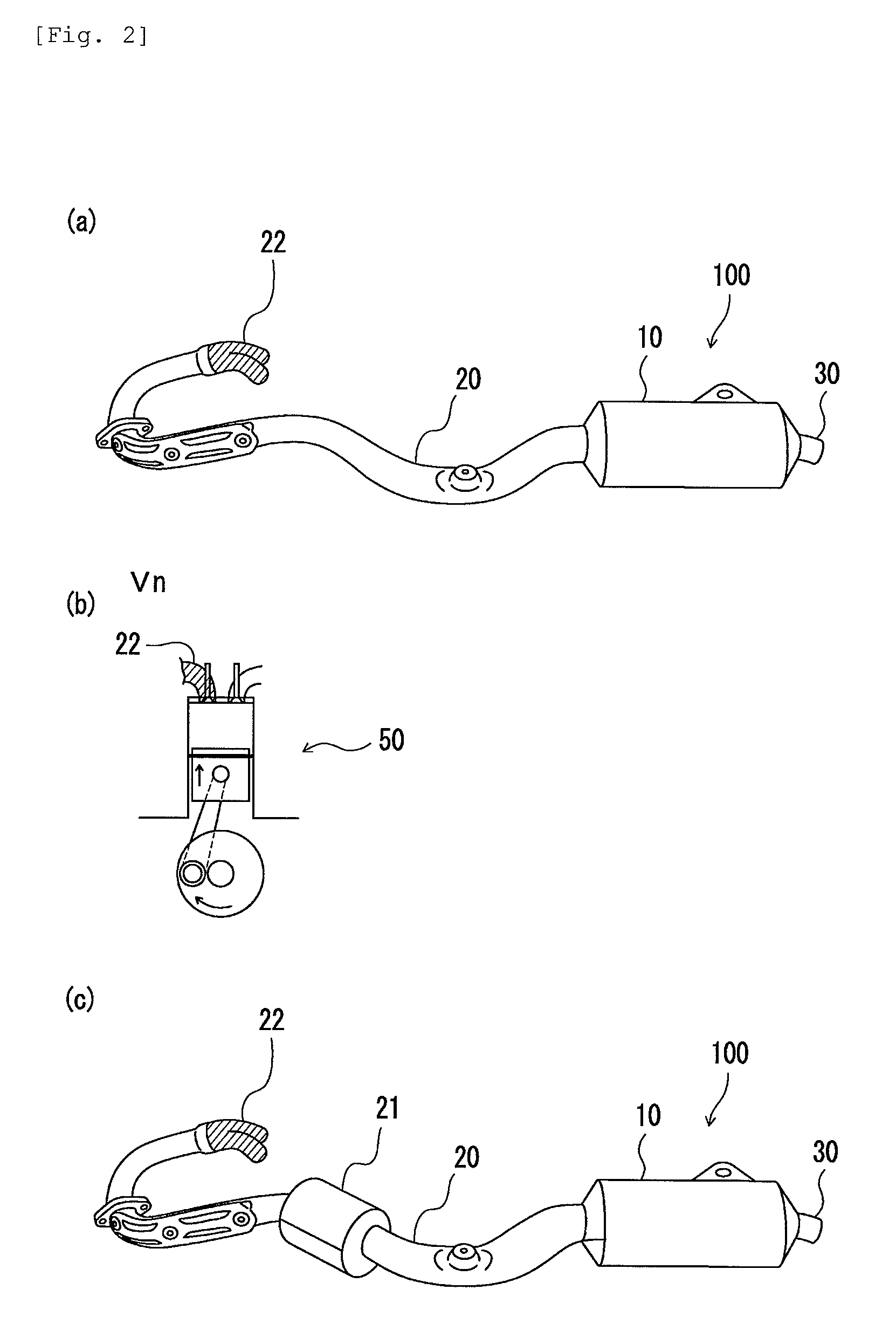

Vehicle exhaust system

InactiveUS7766123B2Improve featuresAbsorb noiseSilencing apparatusMachines/enginesMiniaturizationEngineering

An exhaust system for a vehicle, such as a motorcycle or other straddle-type vehicle, that achieves miniaturization while providing advantageous noise reduction characteristics. The exhaust system is associated with an engine of a vehicle and includes an exhaust pipe connected to the engine and a silencer. A conical member is positioned within the silencer and includes an upstream end and a downstream end. At least a portion of a side wall of the conical member includes a plurality of through-holes. The conical member is oriented such that a radial dimension of the conical member increases in a direction from the upstream end to the downstream end.

Owner:YAMAHA MOTOR CO LTD

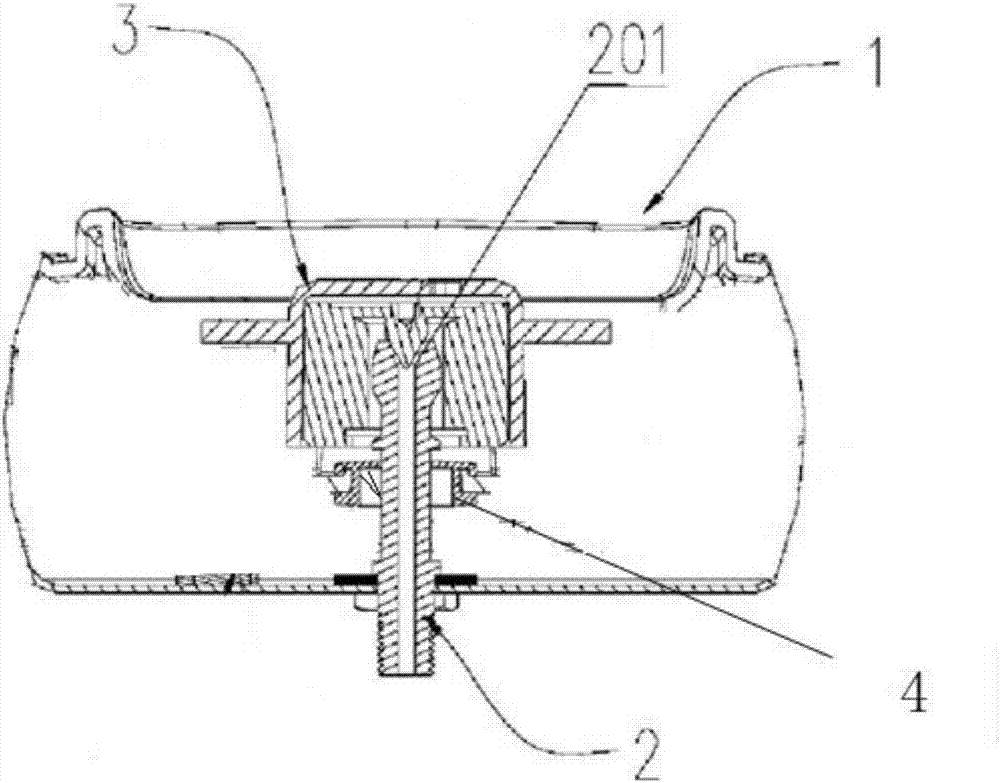

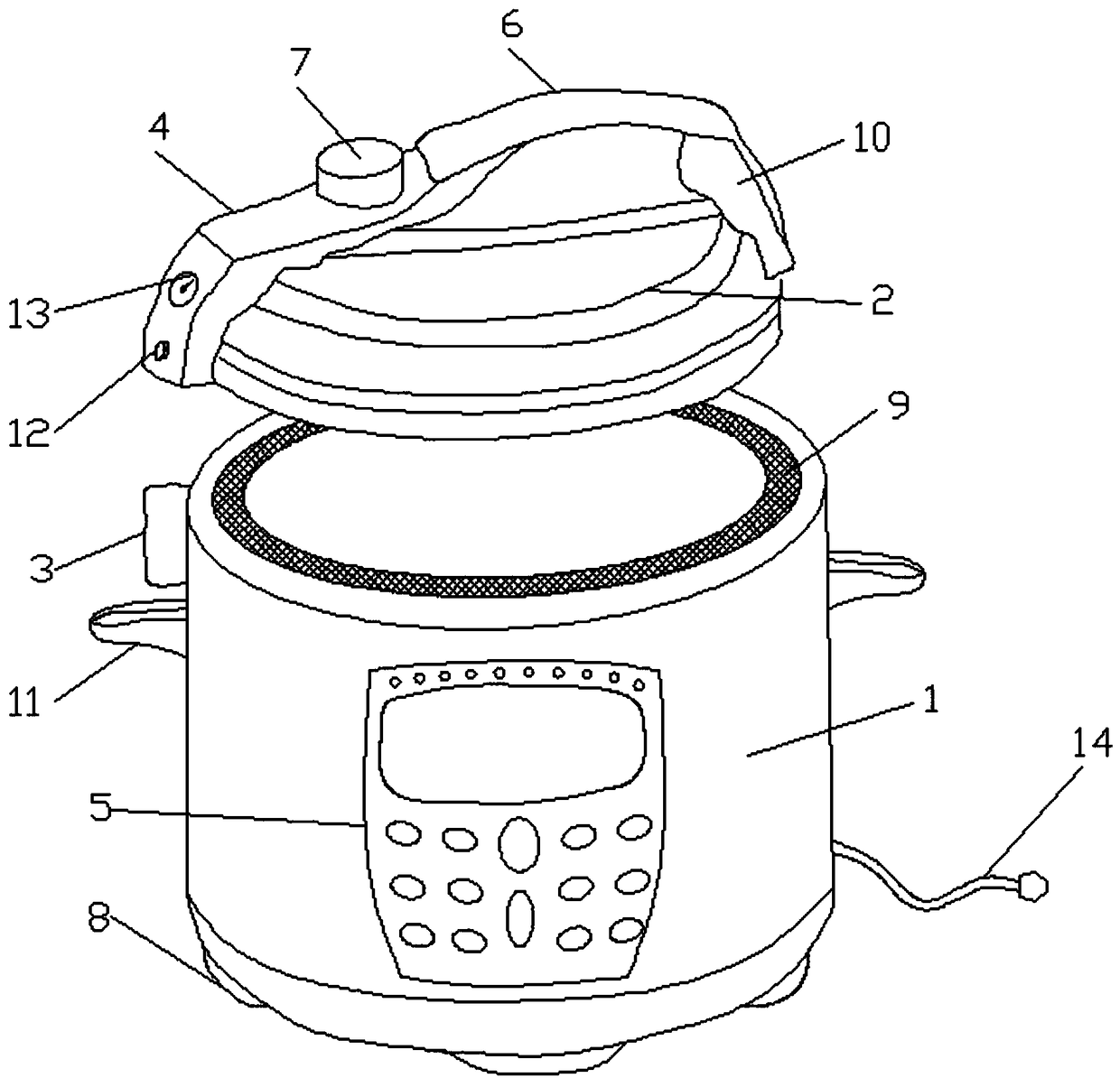

Electric pressure cooker

ActiveCN105476461AEasy to closeReduce differential pressurePressure-cookersInternal pressureElectricity

The invention provides an electric pressure cooker which comprises a control circuit, a cooker, an upper lid, a lid, a pressure limiting valve and a driving component. The upper lid is positioned on the upper side of the cooker and is mounted on the cooker in such a manner that the upper lid can be opened and closed; the lid is positioned between the upper lid and the cooker, is rotatably mounted on the upper lid and is rotationally fastened and connected with the cooker; a through hole is formed in the upper lid, an exhaust pipe on the lid extends out of the through hole, and the pressure limiting valve sleeves the exhaust pipe; the driving component is positioned on a side of the exhaust pipe, is mounted on the upper lid and is electrically connected with the control circuit; a slip lift structure is arranged between the pressure limiting valve and the lid, and a matching portion is arranged on the pressure limiting valve. Compared with the traditional electric pressure cooker, the electric pressure cooker has the advantages that the lid is easy to open and close, the problem of difficulty in closing an existing lid due to the fact that internal pressures of an existing electric pressure cooker are higher than external pressures can be solved, and problems of cooker sucking and difficulty in opening the existing lid due to the fact that the internal pressures of the existing electric pressure cooker are lower than the external pressures also can be solved, and the electric pressure cooker can have functions of automatically exhausting air and releasing pressures in cooking procedures.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Electric pressure cooker

PendingCN108245000AManufacturing precision requirements are lowAssembly accuracy is lowPressure-cookersCooked foodExhaust pipe

The invention provides an electric pressure cooker. The electric pressure cooker comprises a cooker body, a cooker lid, an exhaust pipe, a relief valve and a switching device; the cooker body is usedfor containing cooked food, the cooker lid is arranged on the cooker body, the exhaust pipe is arranged on the cooker lid and communicated with the cooker body, the relief valve is arranged on the exhaust pipe, and a first magnetic part is arranged on the relief valve; the switching device is arranged in the cooker lid and movably arranged relative to the relief valve, multiple second magnetic parts different in magnetism are arranged on the switching mechanism, the second magnetic parts and the first magnetic part cooperate with each other and apply magnetic force to the relief valve, the switching device has multiple switching positions, and when the switching device moves between the different switching positions, the magnetic force applied to the relief valve is changed. According to the technical scheme, the problem that in the prior art, a magnetic drive structure of the relief valve of the electric pressure cooker needs high manufacturing precision and installation precision issolved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

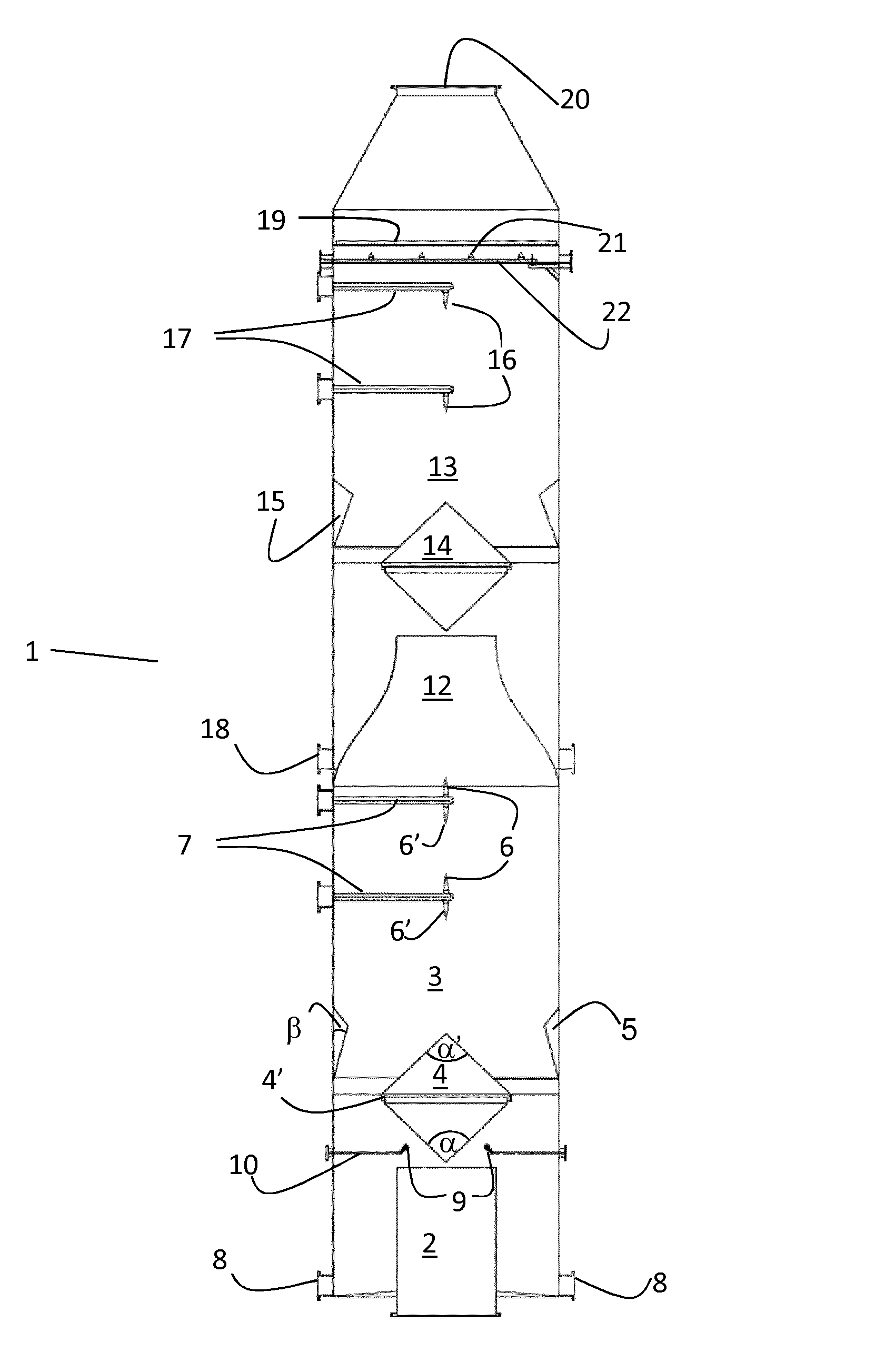

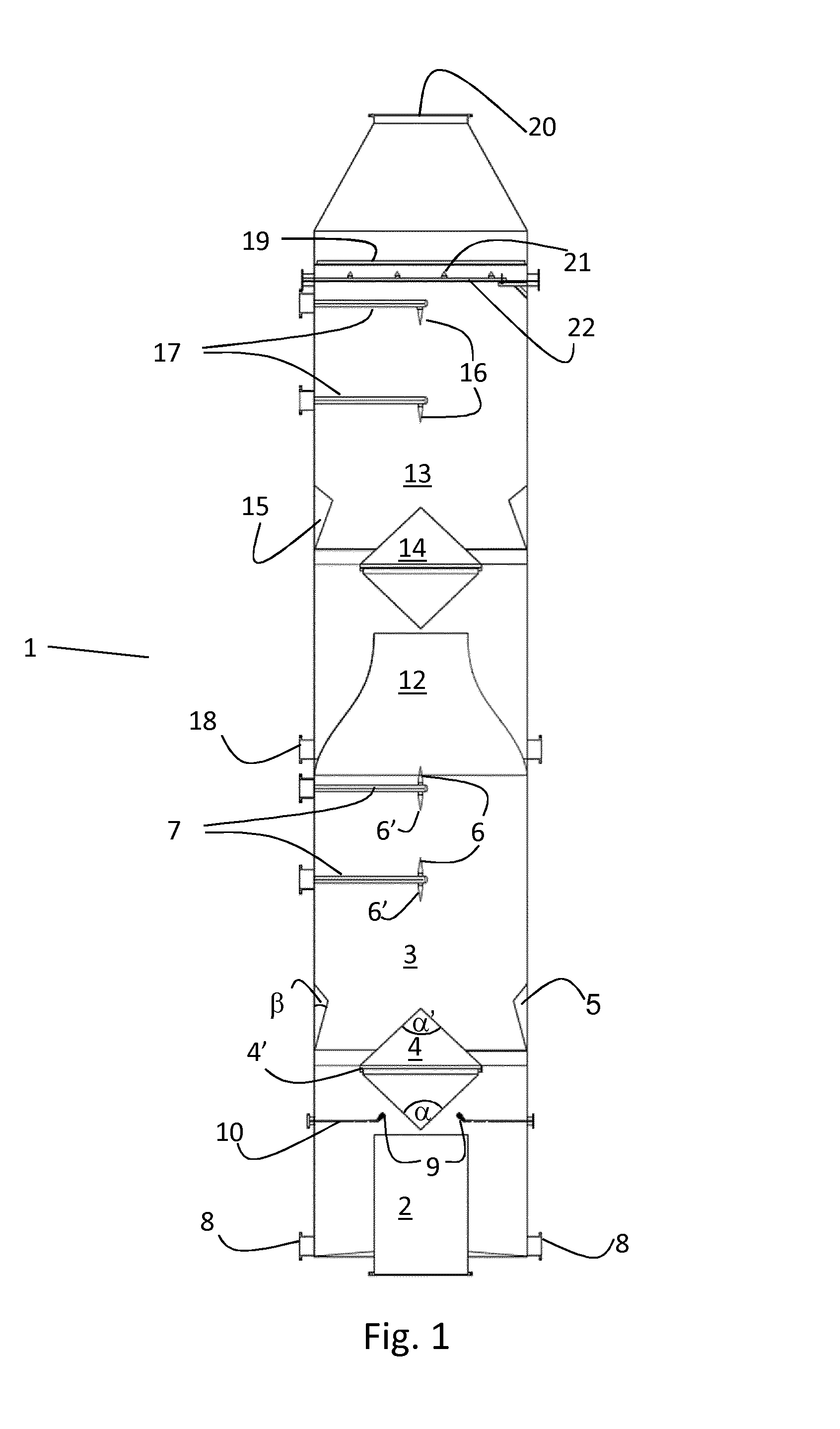

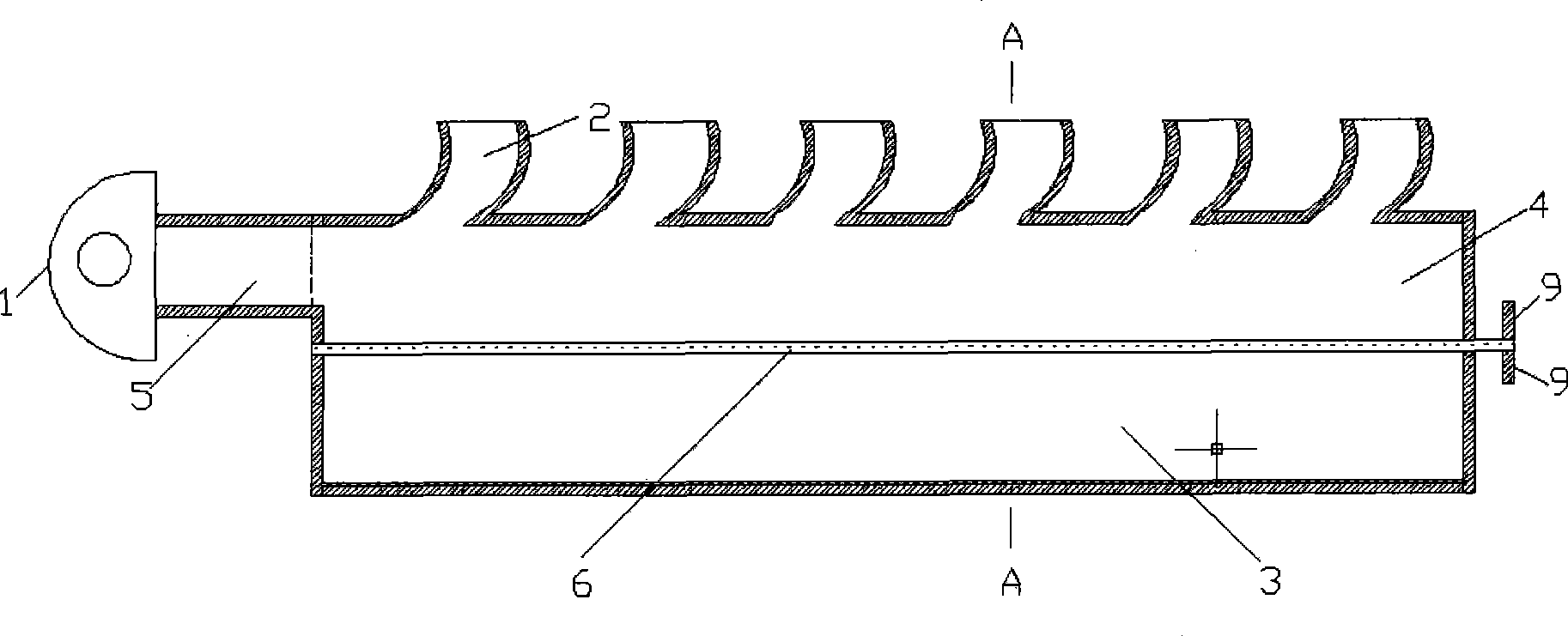

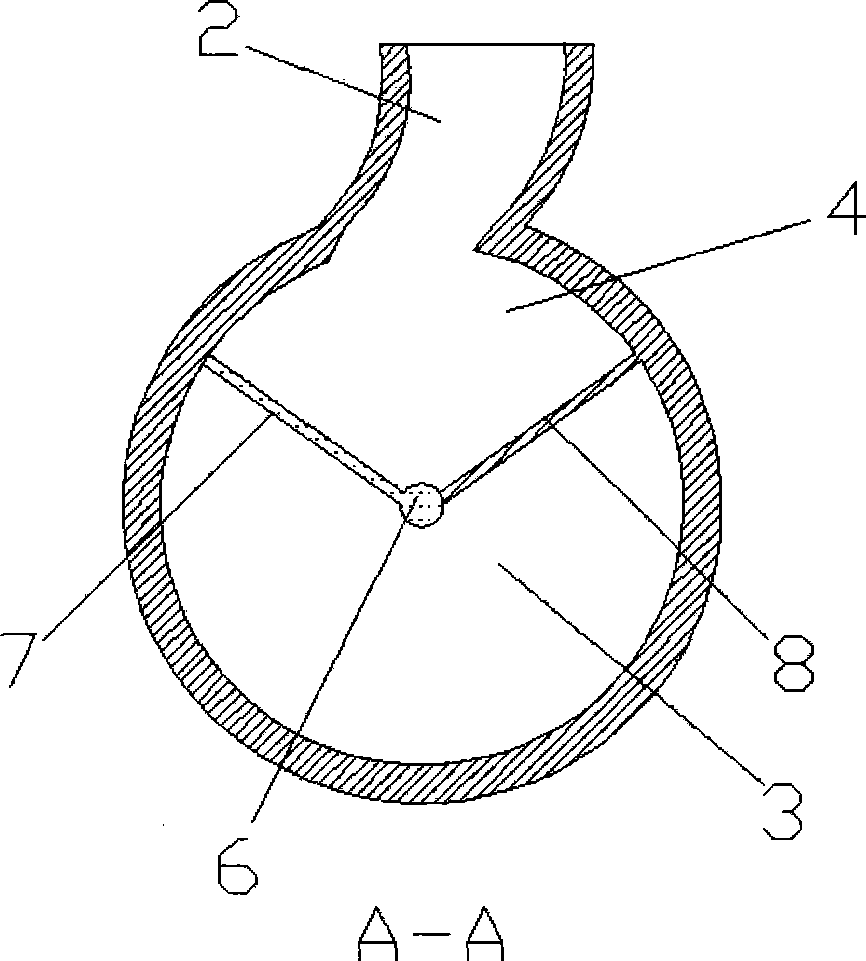

Marine exhaust gas scrubber

ActiveUS20160016109A1Easy constructionEffective dissolutionCombination devicesGas treatmentExhaust fumesEnvironmental engineering

A vertical scrubber (1) for exhaust gas from a marine vessel is described. An exhaust gas tube (2) is substantially coaxially arranged through the bottom of a lower scrubbing chamber (3) and is released though an exhaust gas outlet (20) being coaxially arranged through the top of an upper scrubbing chamber (13). A lower scrubbing chamber deflection body (4) is arranged above the opening of the exhaust gas tube (2) for redirecting the exhaust gas towards the walls of the scrubber and create turbulent gas flow, where one or more lower chamber water injector(s) (6, 6′) is (are) arranged above the lower scrubbing chamber deflection body (4), to introduce scrubbing water, and where a lower chamber exhaust gas outlet (12) is arranged at the top of the lower scrubbing chamber (3) as a coaxial constriction, for withdrawing the partly scrubbed exhaust gas from the first scrubbing chamber and introducing the gas into the upper scrubbing chamber (13).

Owner:MARINE GLOBAL HLDG

Pressure cooker

ActiveCN107048993AImprove securityPrevent togglePressure-cookersTime-controlled ignitorsEngineeringExhaust pipe

The invention provides a pressure cooker. The pressure cooker comprises a cover body, an exhaust pipe arranged on the cover body and a pressure limiting valve. The pressure limiting valve is arranged at the air exhaust opening of the exhaust pipe in a sleeving manner. The pressure cooker further comprises a limiting device used for attracting or disconnecting with the pressure limiting valve and a controller used for attracting or disconnecting with the pressure limiting valve according to the current working parameters of the pressure cooker. The pressure cooker has the following beneficial effects: a problem in the prior art is solved so that the pressure limiting valve of the pressure cooker is not wrongly operated, thereby avoiding potential safety hazards; safety of the pressure cooker is improved; and a user does not get burned during operation of the pressure cooker due to mal-operation by the user.

Owner:GREE ELECTRIC APPLIANCES INC

Electric pressure cooker with lid applying side suspension support

The invention purports to provides an electric pressure cooker which has a simple structure, offers stable support, and which can effectively prevent the horizontal and vertical lid shaking and is provided with a sidely suspended lid. The cooker comprises a seat (1), an outer pot (2), an inner liner (3), a heating disk (4) and a lid. The lid comprises a surface lid (6), a liner lid (7) and a steel lid (8) which are all connected by an exhaust pipe (5) from the outside to the inside. The liner lid is placed with three suspending supports (9) device. The underneath end of the suspending support device (9) is provided with a suspended pressure blocking ball (91). The pressure blocking ball (91) presses tightly on a support arc groove (81) located on the steel lid (8). Therefore the pressure blocking ball (91) exerts a force upon the support arc groove, and the direction of the pressing force bears an acute angle with the axial direction of the exhaust pipe (5). The cooker lid mechanism can be used in the field of cooking equipment.

Owner:ZHUHAI DOUBLE HAPPINESS ELECTRIC APPLIANCE

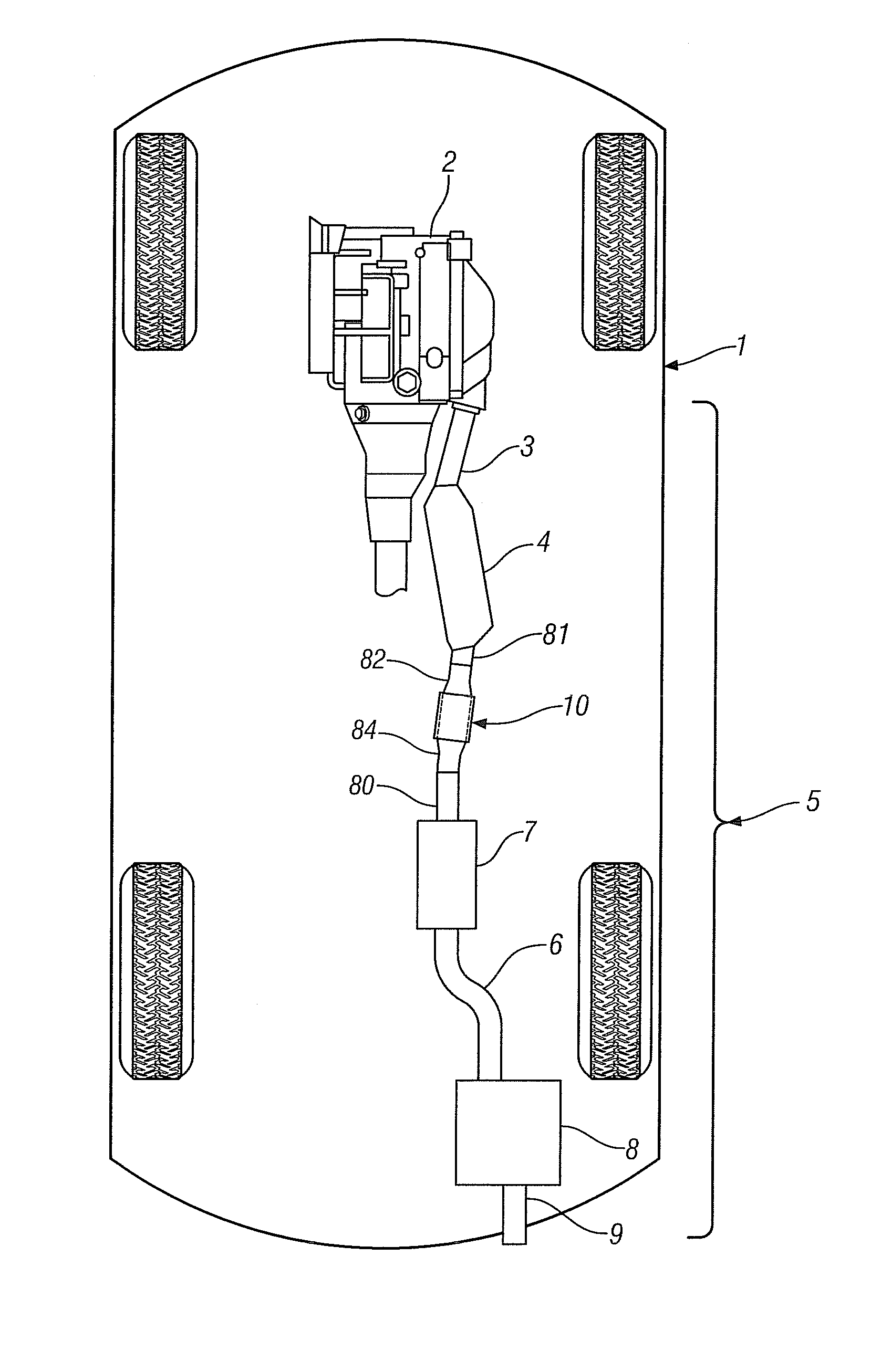

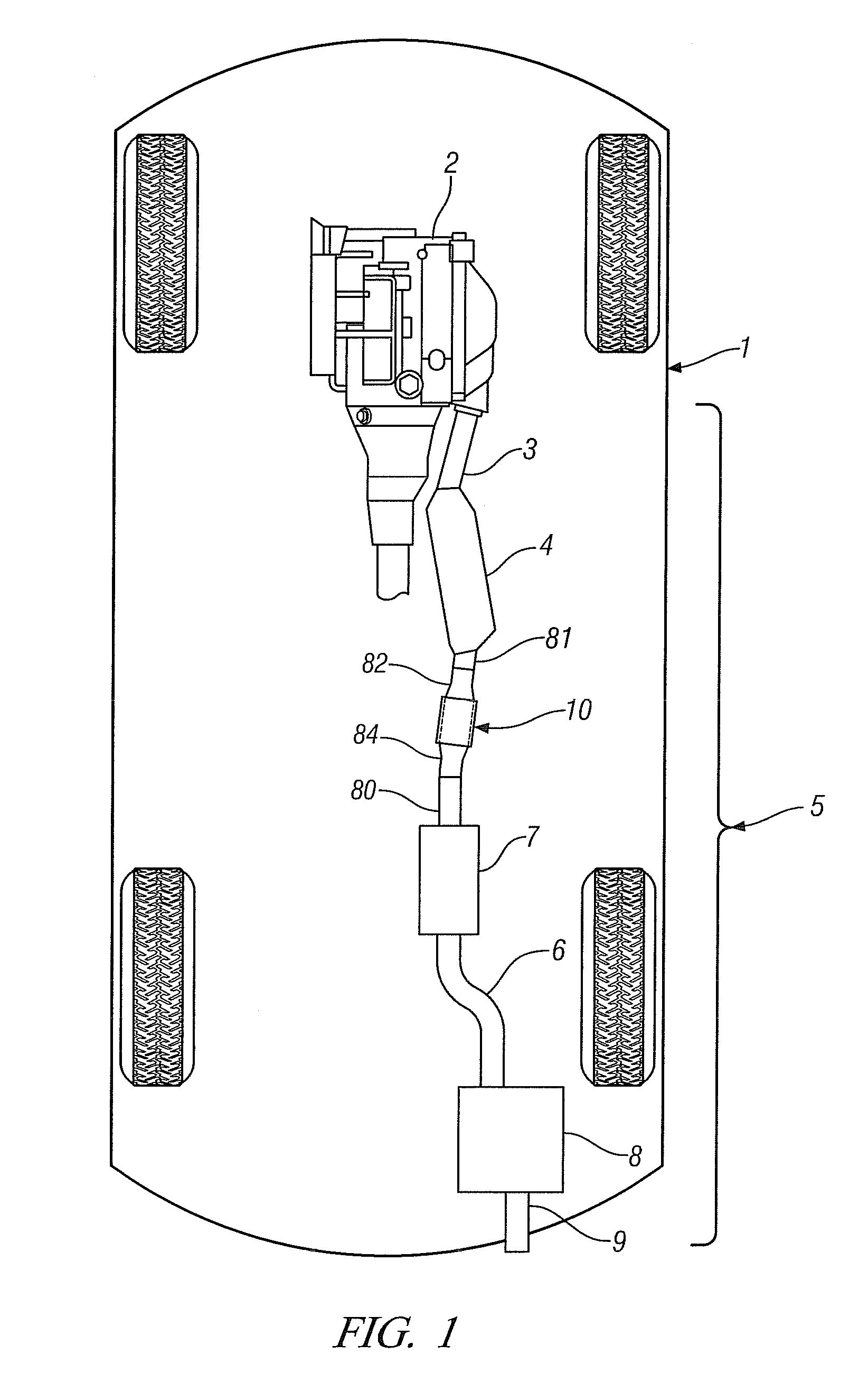

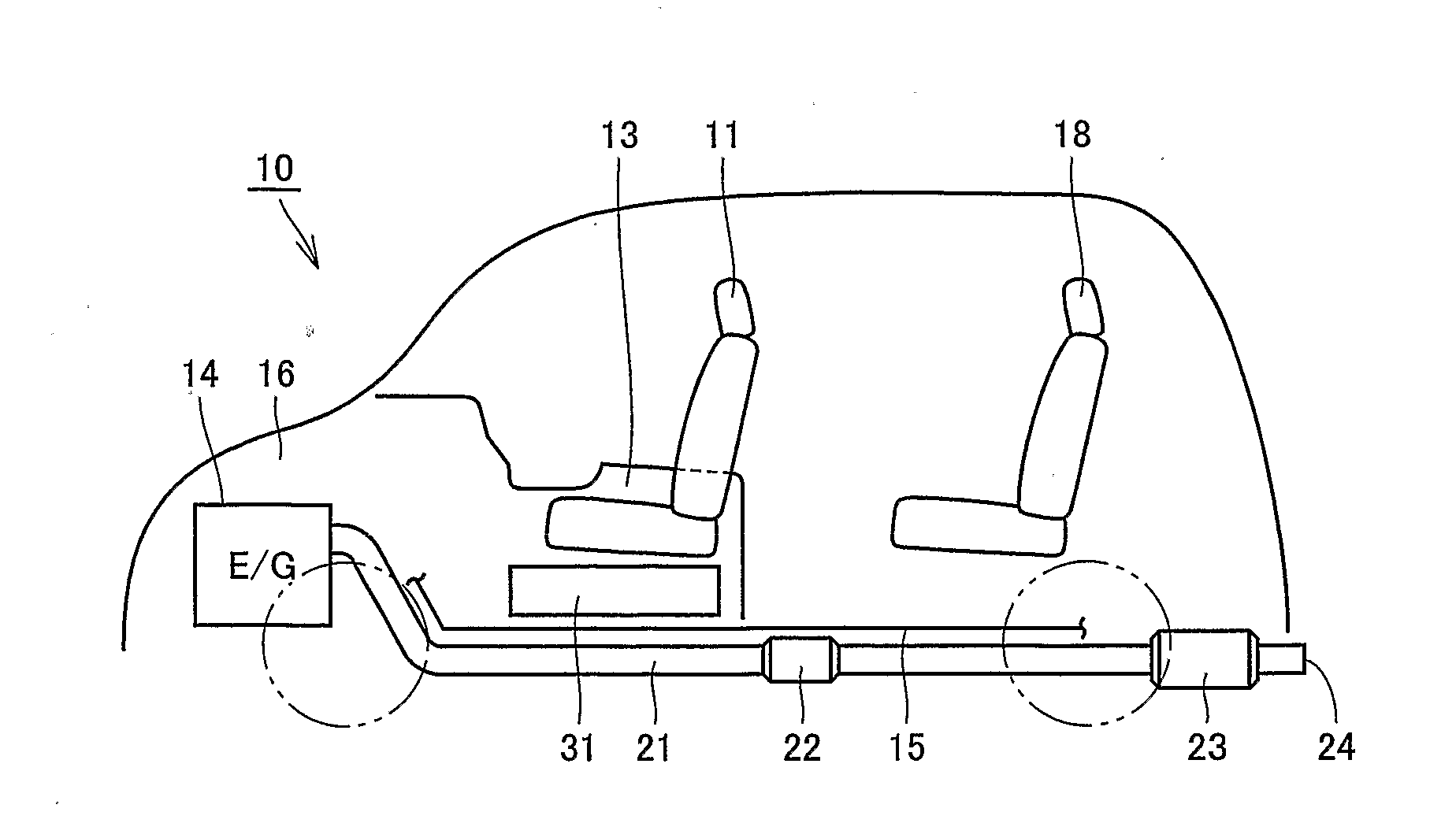

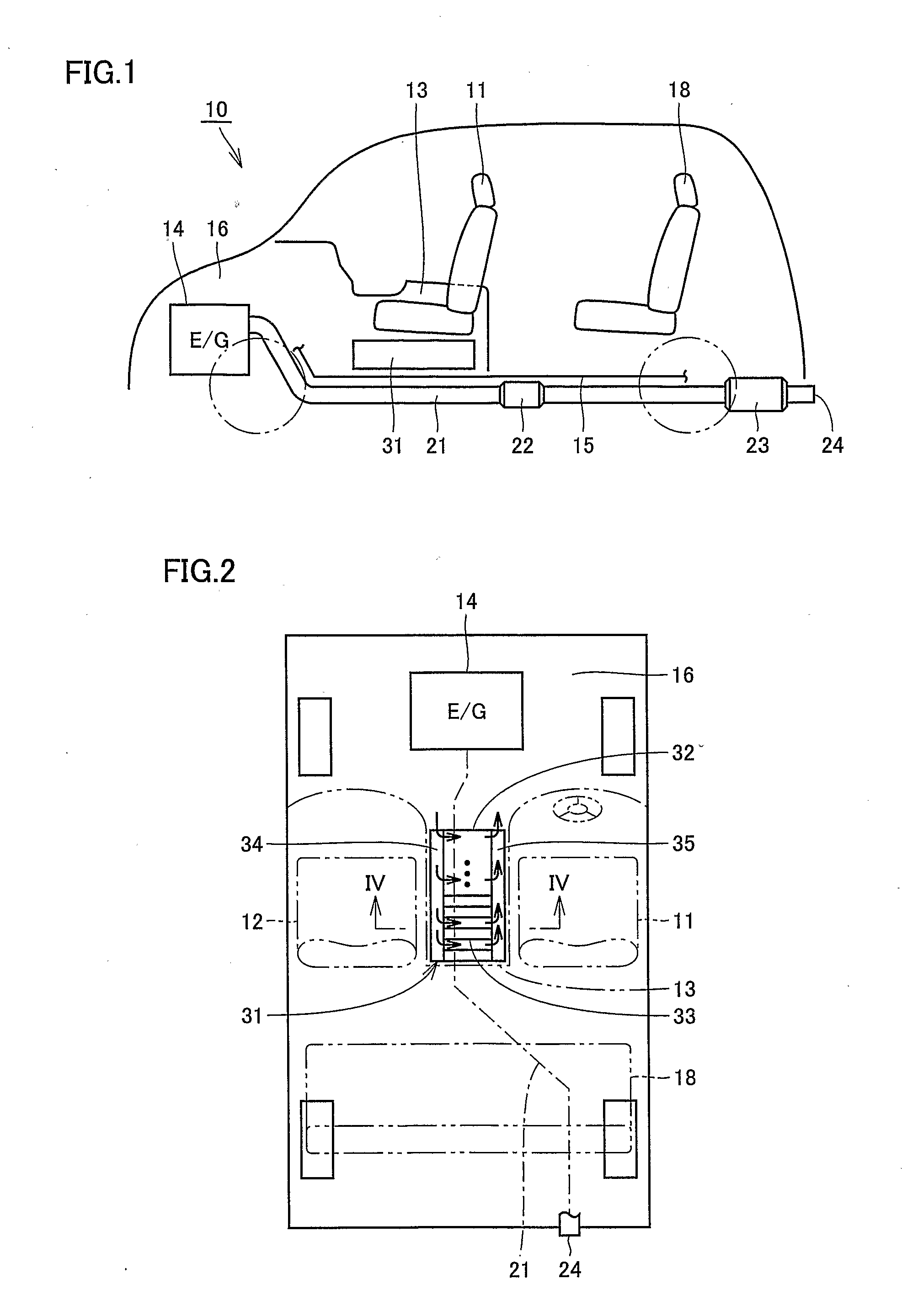

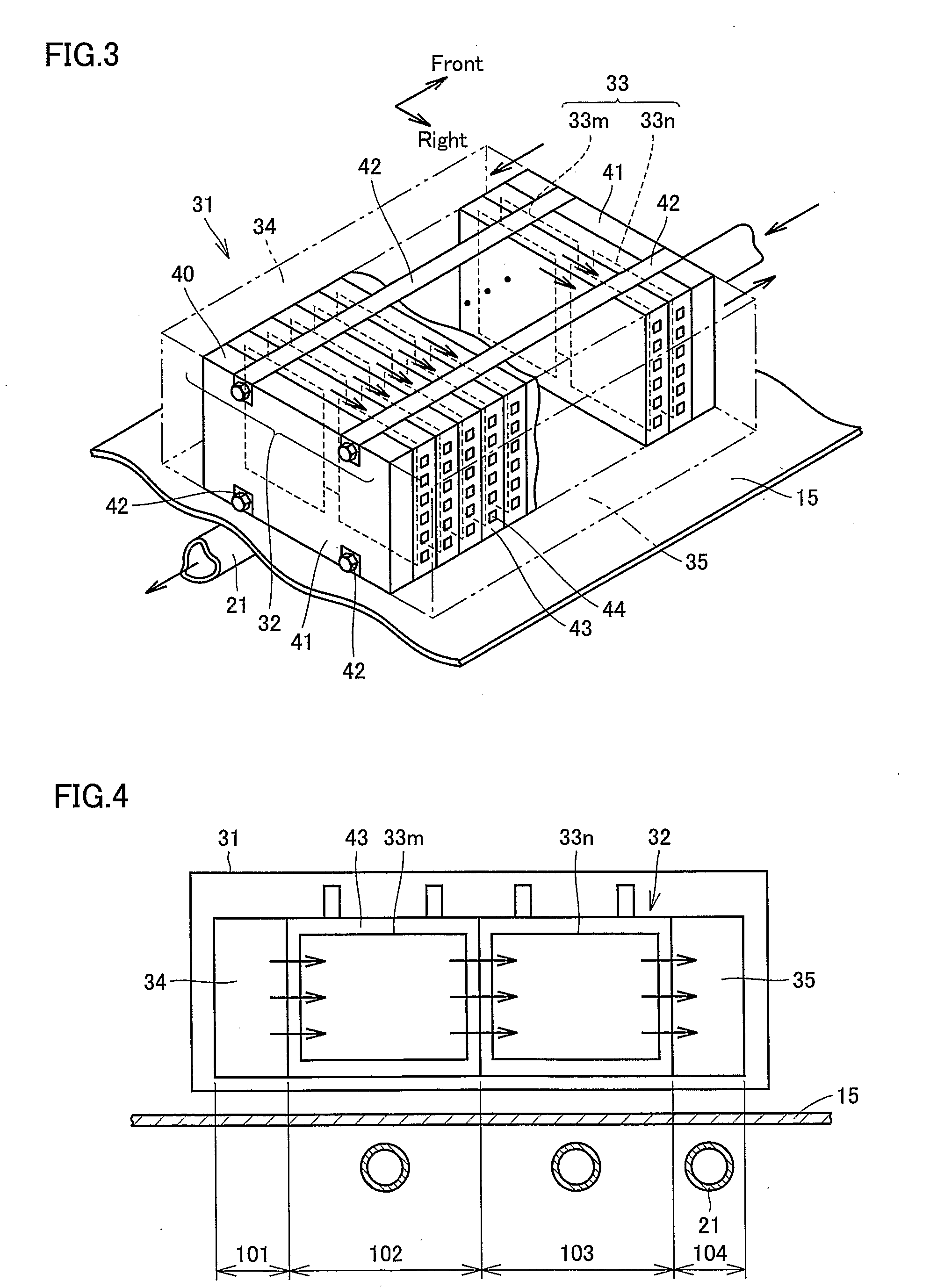

Structure of Hybrid Vehicle

InactiveUS20080164081A1Suppresses reduction efficiencyReduction efficiency can be preventedBatteries circuit arrangementsExhaust apparatusElectrical batteryHybrid vehicle

A structure of a hybrid vehicle includes a battery pack arranged on a floor panel and an exhaust pipe extending from an engine, passing below the floor panel, to an exhaust port. The battery pack has a secondary battery constituted by a plurality of battery cells stacked in a vehicle traveling direction for supplying electric power to a motor, and an intake chamber provided adjacent to the secondary battery in a substantially horizontal direction perpendicular to the direction along which the plurality of battery cells are stacked for supplying cooling air between each of the plurality of battery cells. The exhaust pipe is provided so that it passes immediately below the battery pack and passes a position displaced from a position immediately below the intake chamber. With such a configuration, a structure of a hybrid vehicle that suppresses reduction in the efficiency of cooling a secondary battery without placing a great limit on routing of an exhaust pipe is provided.

Owner:TOYOTA JIDOSHA KK

Turbocharging system for adjusting exhausting pipe volume by rotating baffle

InactiveCN101413429AMeet the requirements of variable working conditionsImprove performanceInternal combustion piston enginesGas turbine plantsInternal combustion engineTurbine

The invention relates to a turbocharging system through utilizing the rotation of a clapboard to adjust the cubage of an exhaust pipe and belongs to the technical field of internal combustion engine. The turbocharging system comprises an exhaust branch pipe, the exhaust pipe, a connecting pipe, a cubage adjusting pipe, a turbine, a clapboard shaft and clapboards; the clapboard shaft is arranged between the center of the front end face of the cubage adjusting pipe and the center of the rear end face of the cubage adjusting pipe; a first clapboard and a second clapboard are arranged between the clapboard shaft and the inner sidewall of the cubage adjusting pipe; and the cubage of the exhaust pipe is adjusted through rotating the clapboards. When the working condition is lowered, the clapboards rotate so as to lessen the cubage of the exhaust pipe; and when the working condition is heightened, the clapboards rotate so as to enlarge the cubage of the exhaust pipe. The turbocharging system has the advantages that the turbocharging system has reasonable design, meets the operation requirement of variable working conditions of the engine, is not limited by the number of cylinders and is suitable for the turbocharging system the turbine of which is provided with a single inlet and laterally arranged.

Owner:SHANGHAI JIAO TONG UNIV

Pressure cooker with pressure-limiting valve control structure

The invention discloses a pressure cooker with a pressure-limiting valve control structure. The pressure cooker comprises a cover. A pressure-limiting valve component is arranged on the lateral side of the cover, and comprises an exhaust hole communicated with the cover in the thickness direction. A gravity-type pressure-limiting valve is arranged in an upper end gap of the exhaust hole in a sleeved mode, can only ascend and descend on an exhaust pipe axially and cannot rotate circumferentially. A pressure-limiting valve height adjusting step is arranged at the root of the exhaust hole rotationally in an encircling mode, and encircles the circumferential outer side of the exhaust pipe. Three pressure-limiting valve steps with different heights are arranged in the thickness direction of thecover sequentially, and the adjacent steps are in smooth transition. A step contact is arranged at the lower end of the pressure-limiting valve in a protruded mode, and can contact one of the pressure-limiting valve steps correspondingly. The pressure cooker has the advantages that the pressure-limiting valve is arranged on the lateral side of the cover, the center of the cover can be reserved for arrangement of a lifting-type handle, and the function of accurately controlling ascending and descending of the pressure-limiting valve is provided.

Owner:浙江凯达工贸有限公司

Electric pressure cooker vapor exhausting device

InactiveCN108577514AEasy to install and disassembleEasy to usePressure-cookersWater vaporEngineering

The invention discloses an electric pressure cooker vapor exhausting device which structurally comprises an electric pressure cooker, a pot cover, a water collecting tank, an exhausting device and a control panel. The control panel is arranged at the front portion of the electric pressure cooker. A power line is arranged at the rear portion of the electric pressure cooker. The left side of the electric pressure cooker is connected with the water collecting tank through a buckle. A silica gel seal ring is arranged on the top of the electric pressure cooker by a circle. The pot cover is arrangedon the top of the electric pressure cooker. The right portion of the pot cover is in threaded connection with a fixed base. A handle is arranged on the top of the fixed base. The left portion of thehandle is connected with the exhausting device. The water collecting tank is composed of a liquid level sensor, an alarm device, a concave hole and a natural rubber seal ring. The exhausting device comprises a fixed column, a synthesized rubber seal ring, a telescopic elastic head, a vapor inlet, a vapor guide pipe, a liquefied device and an exhaust pipe. The electric pressure cooker vapor exhausting device is convenient to install and detach, high in sealing performance and high in intelligence and efficiently senses the vapor liquid level.

Owner:黄文才

Exhaust switch-over valve malfunction detection system of internal combustion engine

A system for detecting malfunctions of an exhaust switch-over valve of an internal combustion engine, which opens / closes a bypass exhaust gas passage branched from an exhaust pipe of the engine and storing an adsorbent that adsorbs unburned components of the exhaust gas generated by the engine when the engine is started. In the system, the entrance temperature and the exit temperature in the bypass exhaust gas passage are detected and compared with each other in a first detection period when the passage is opened and in a second detection period when the passage is closed. Based on this comparison, it is determined whether the valve malfunctions. Alternatively, the valve malfunction is determined by comparing the valve opening / closing state with an instruction to operate the valve. With this, little time lag exists in the detection, thereby improving malfunction detection accuracy.

Owner:HONDA MOTOR CO LTD

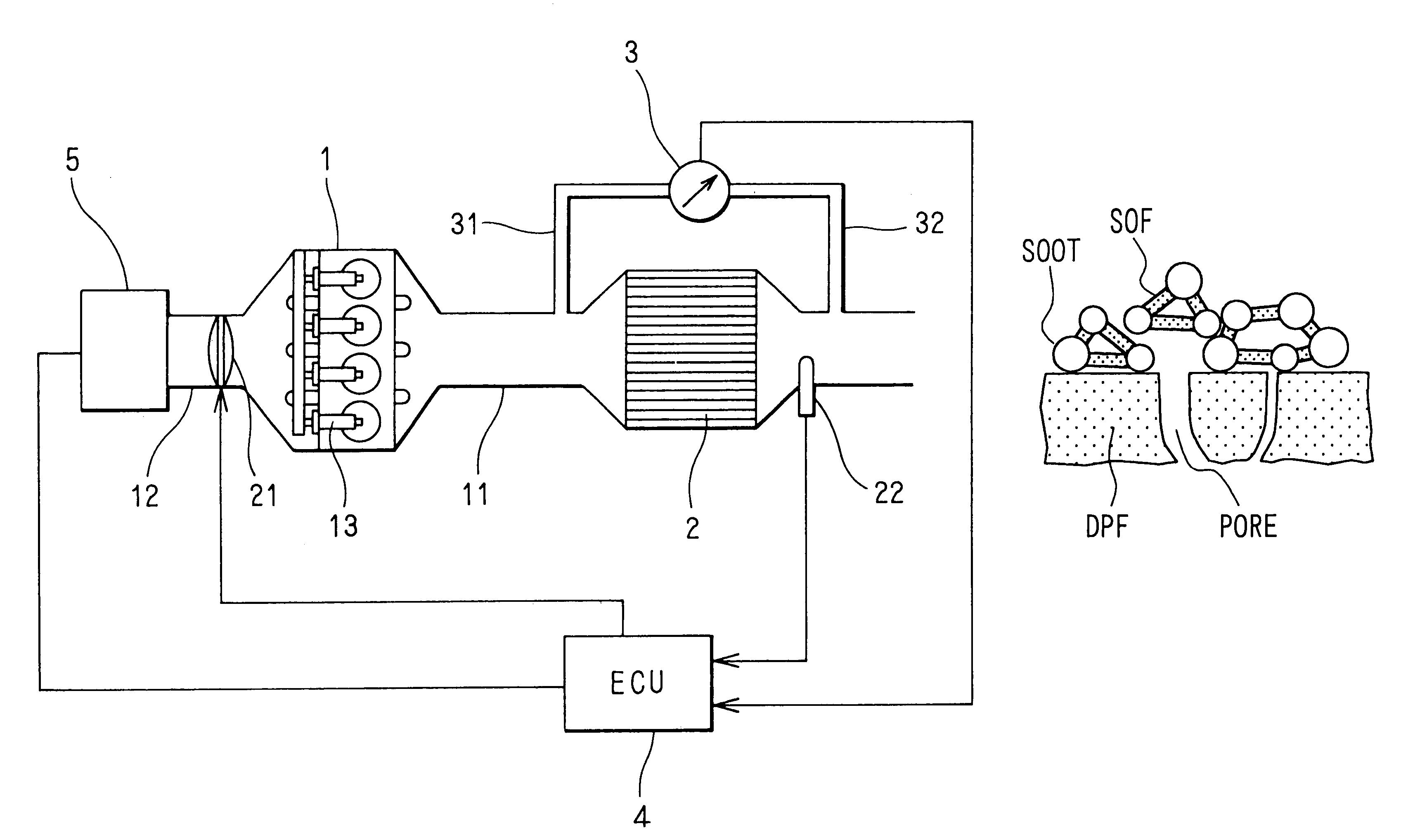

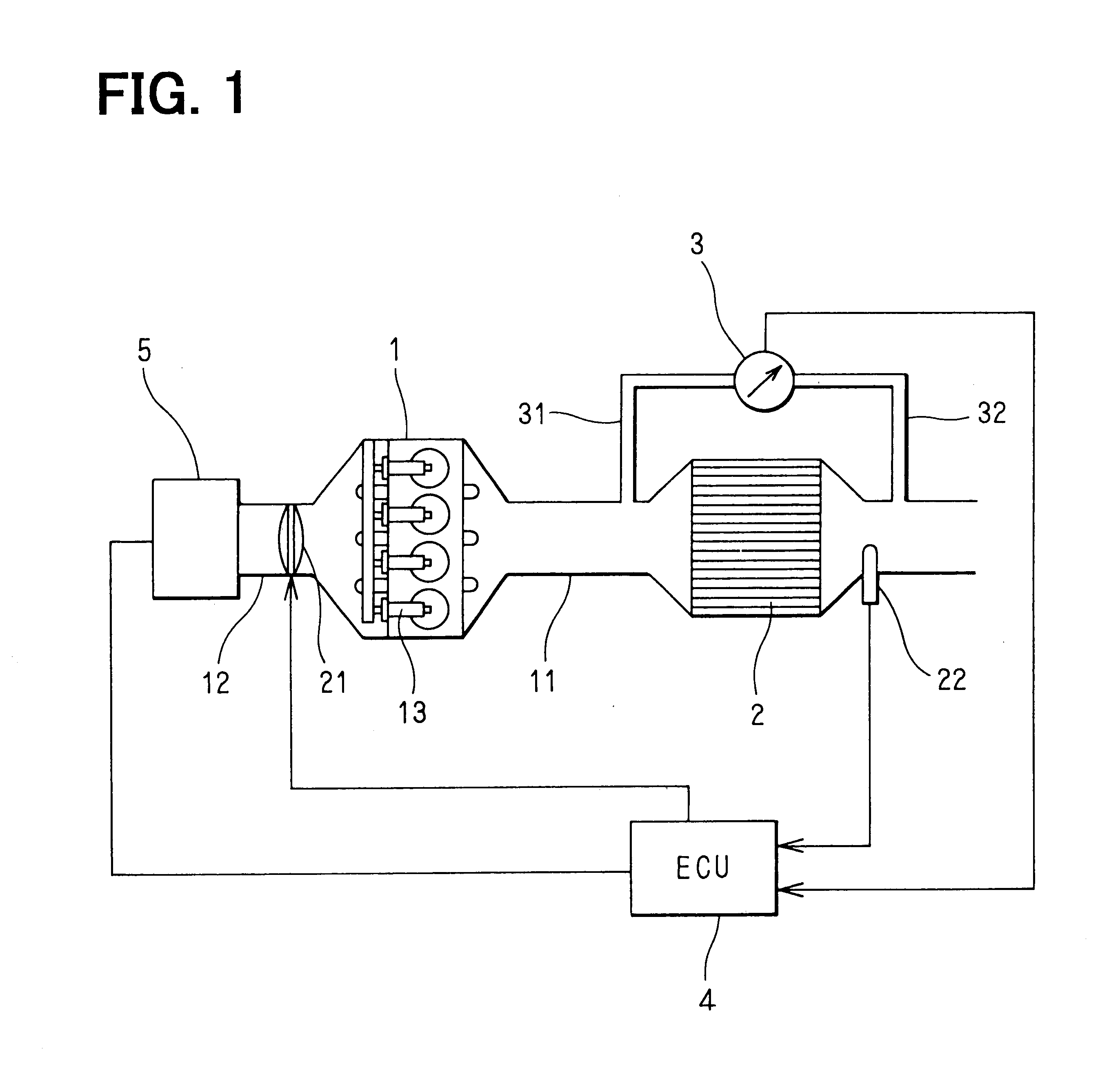

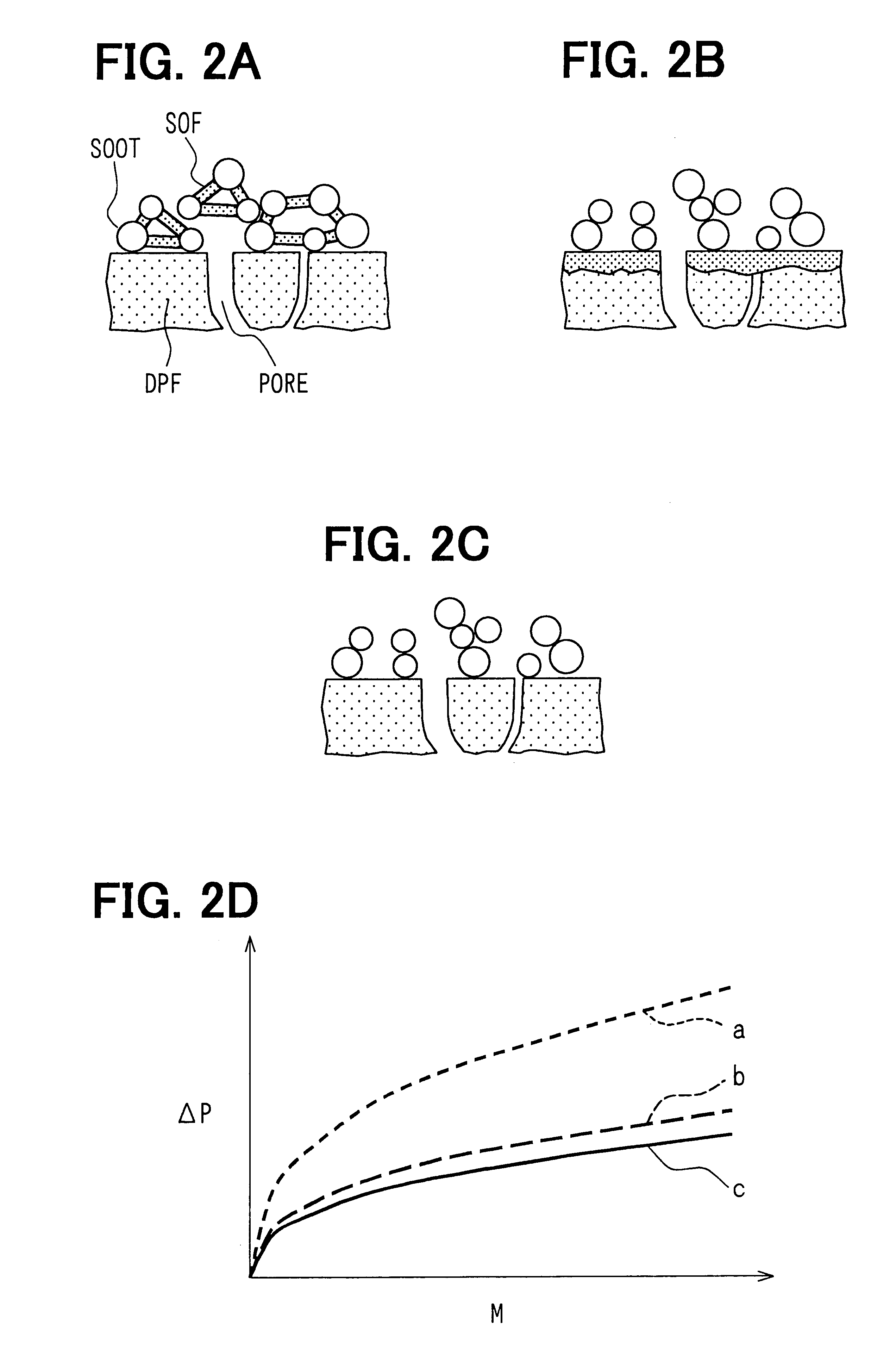

Exhaust gas purification system having particulate filter

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com