Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5215results about How to "Avoid deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

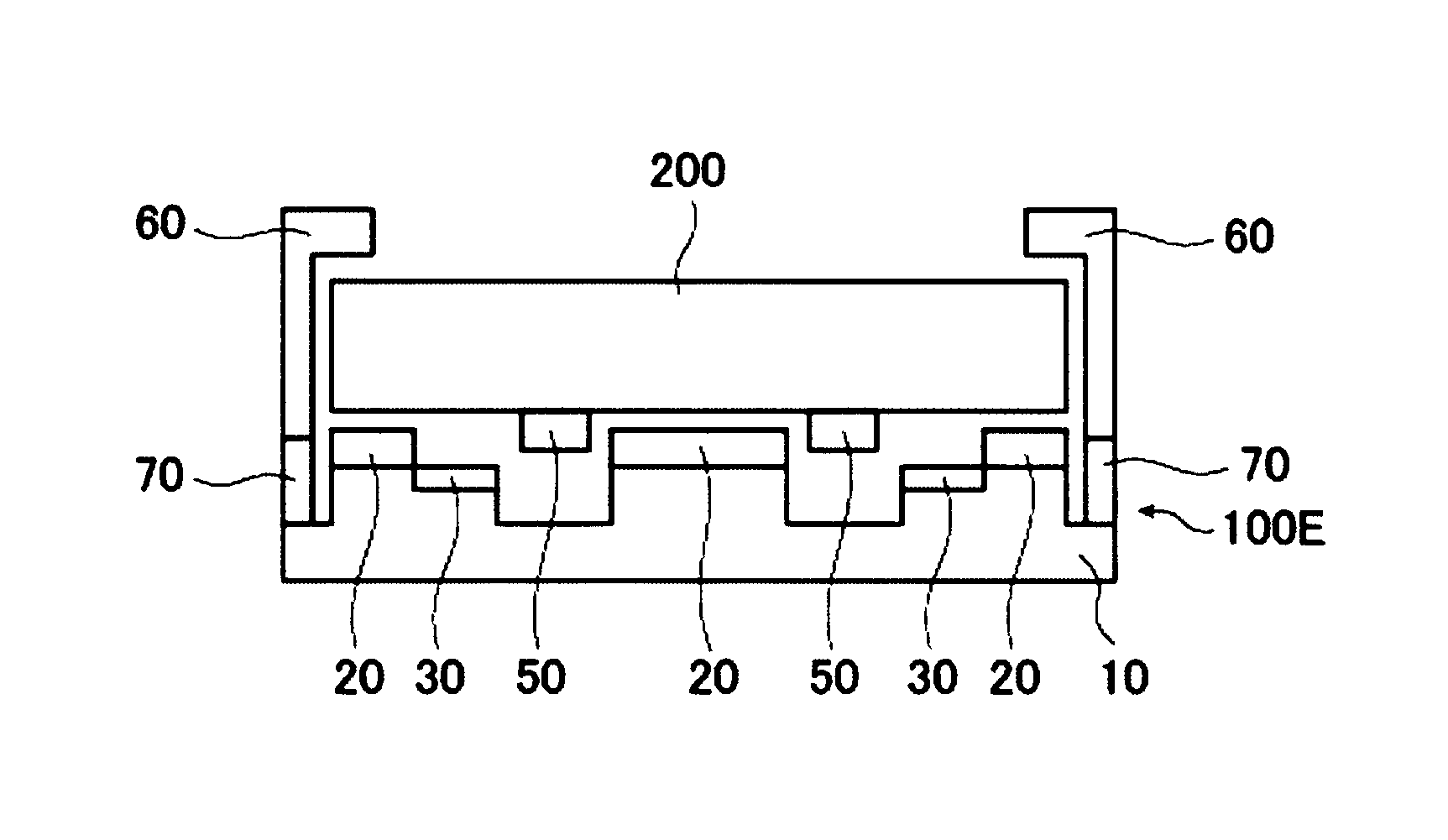

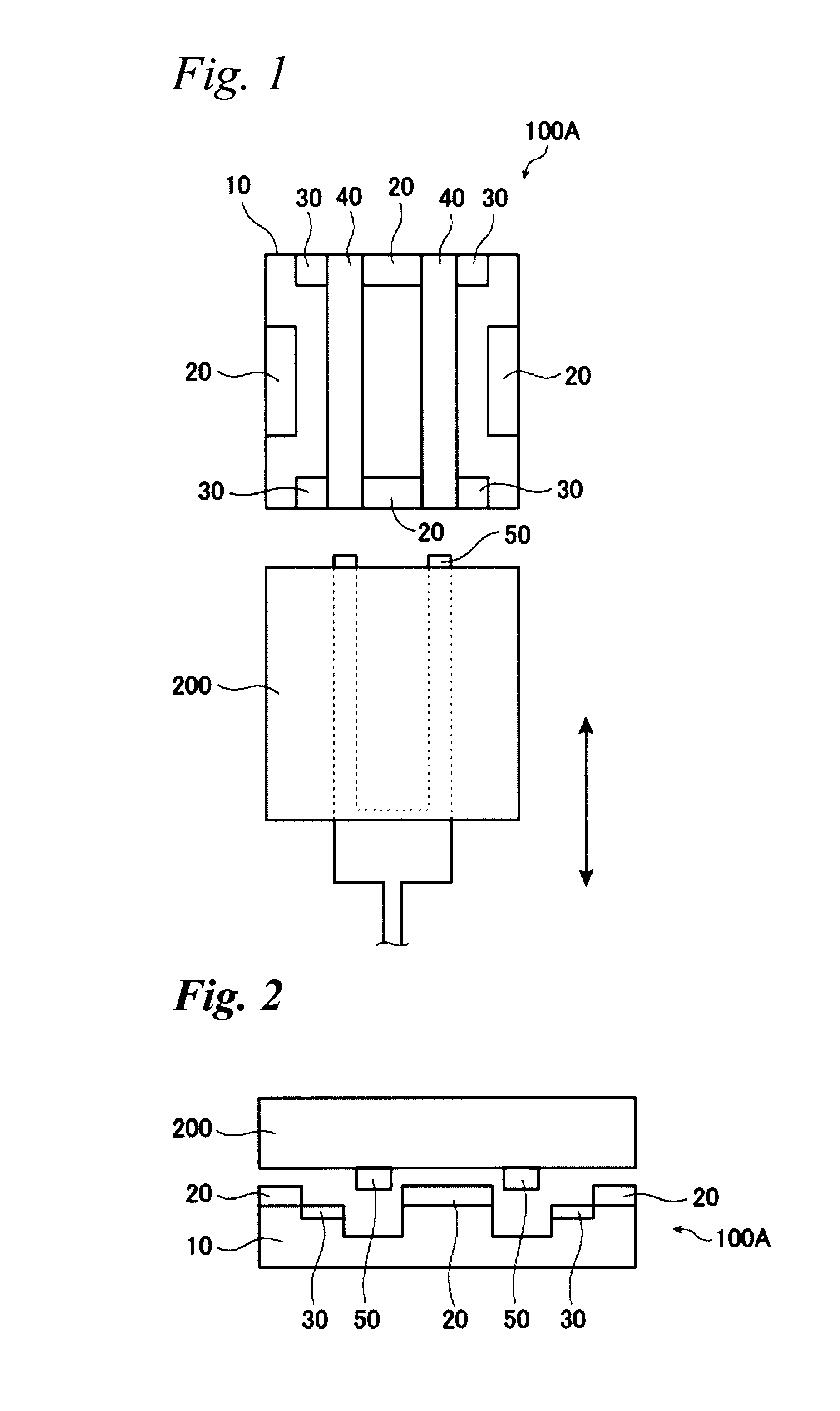

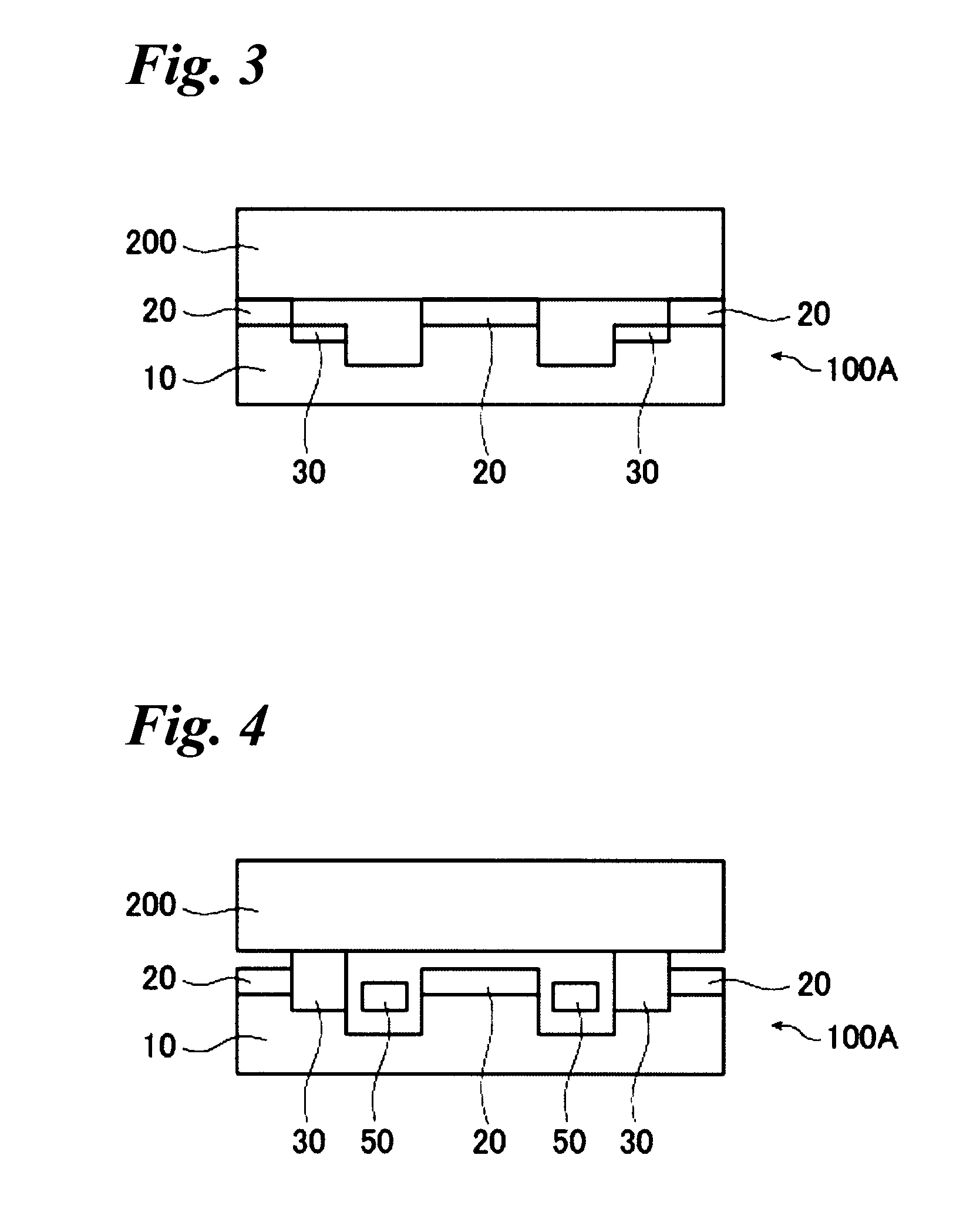

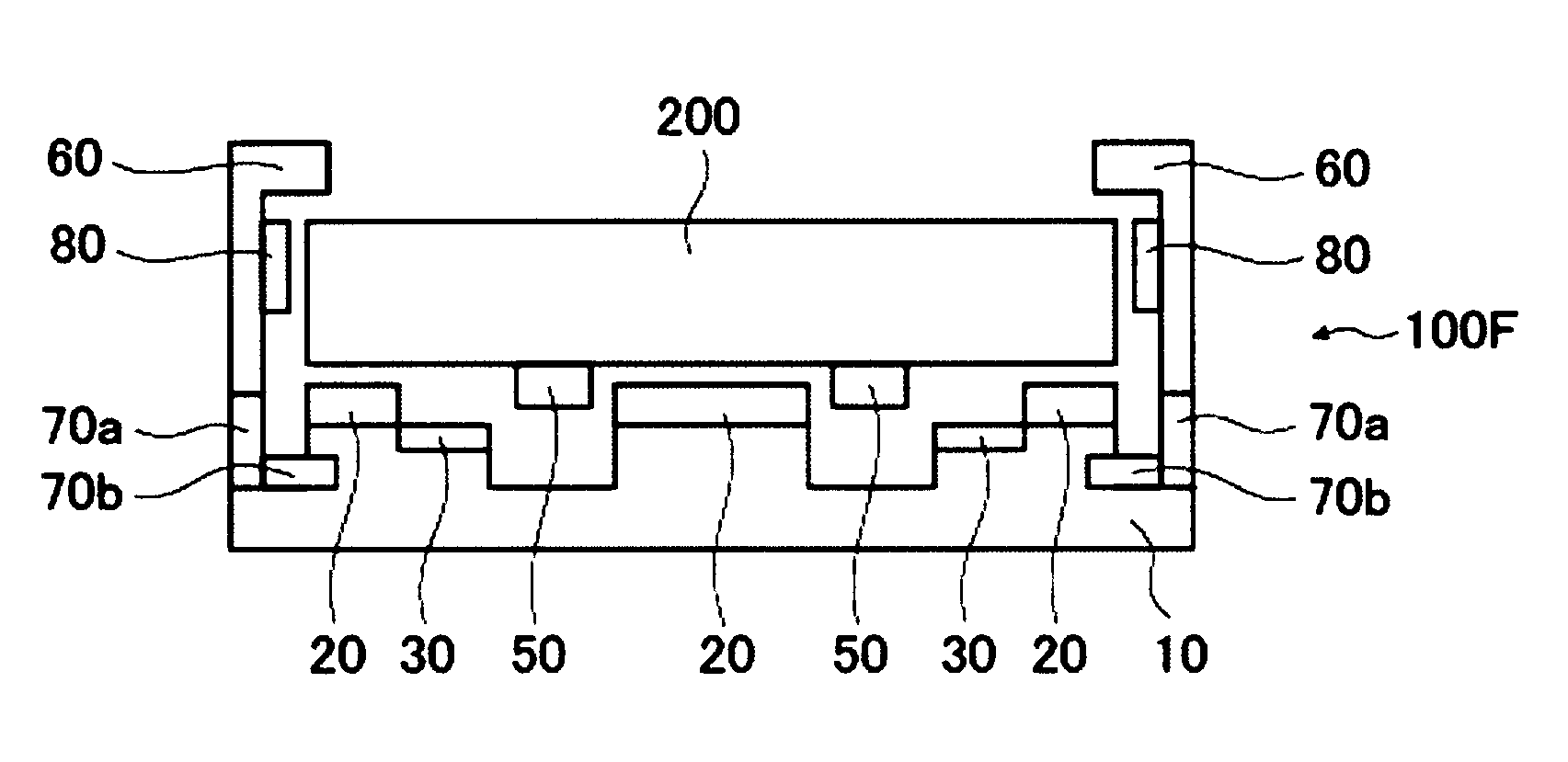

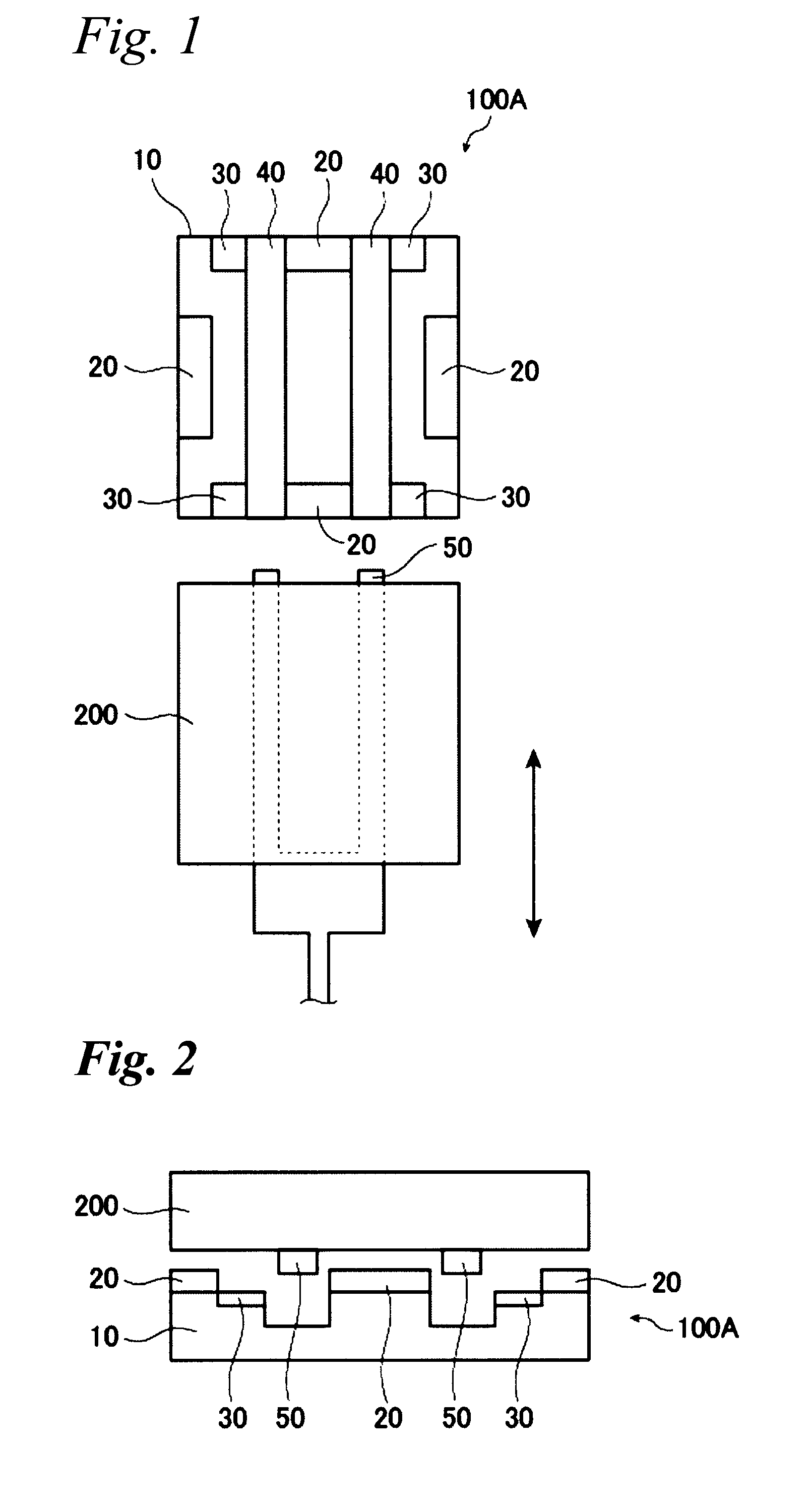

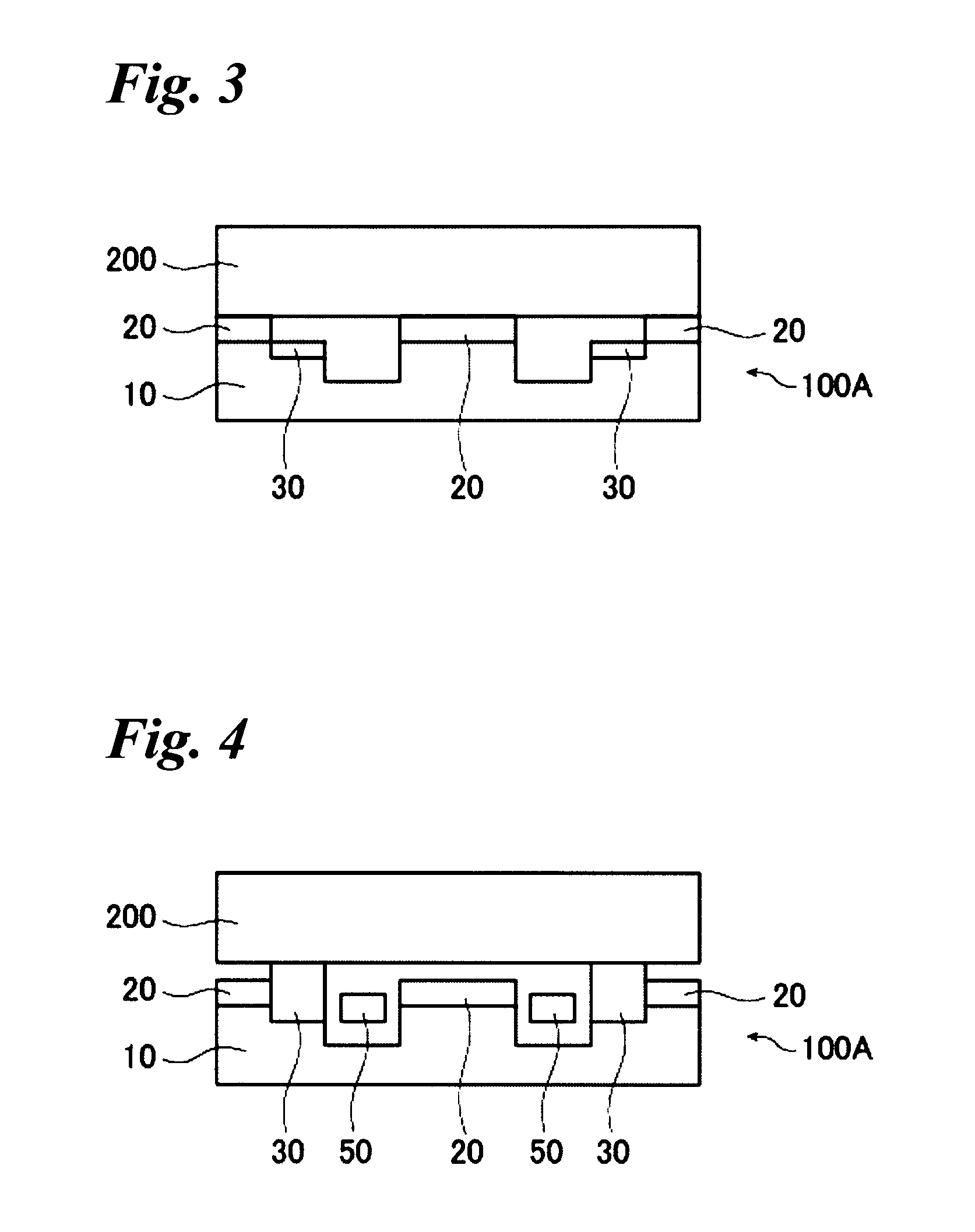

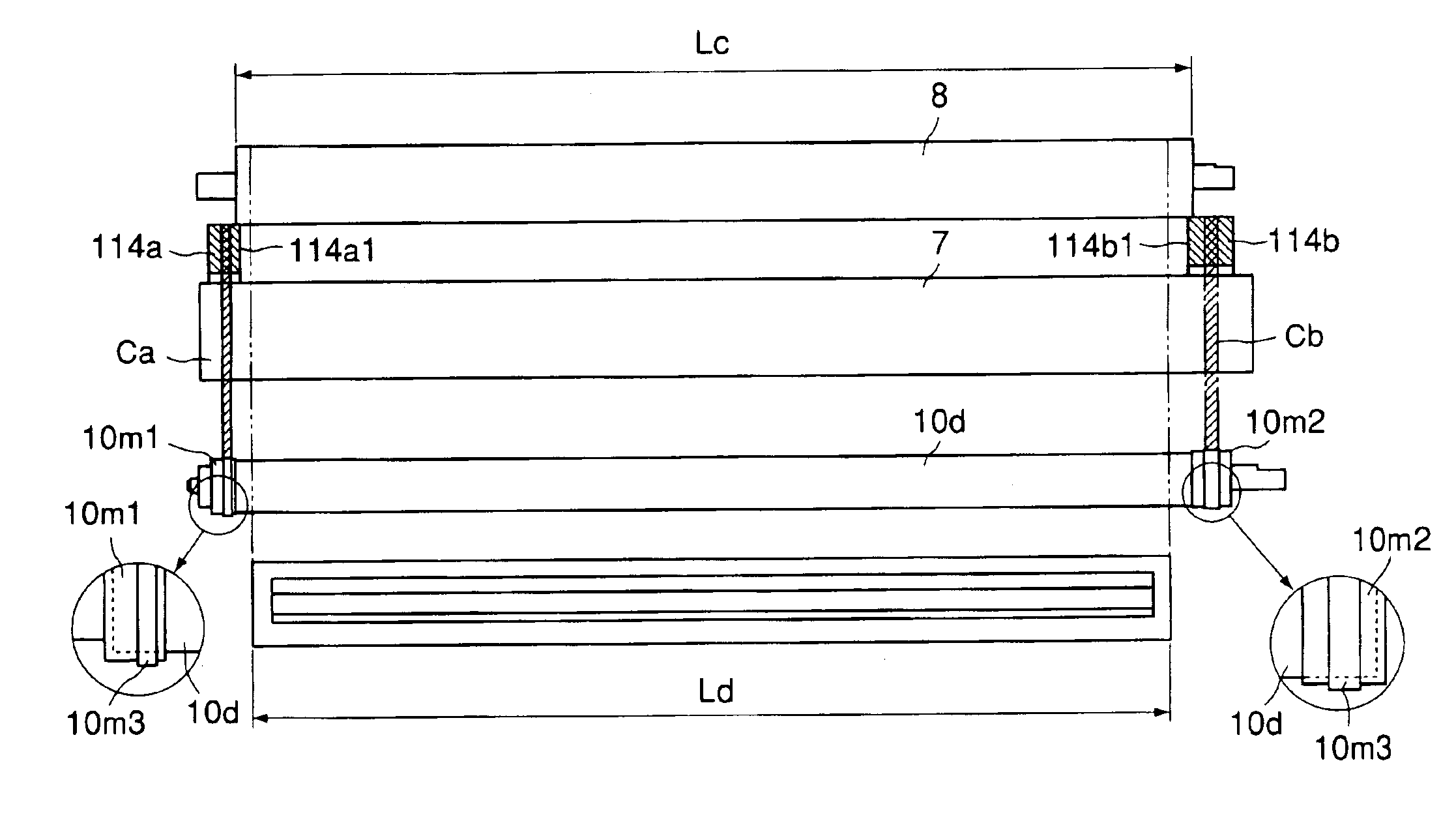

Glass substrate-holding tool

InactiveUS8192901B2Avoid dustAvoid depositionPhotomechanical apparatusSemiconductor/solid-state device manufacturingForeign matterEngineering

Owner:ASAHI GLASS CO LTD

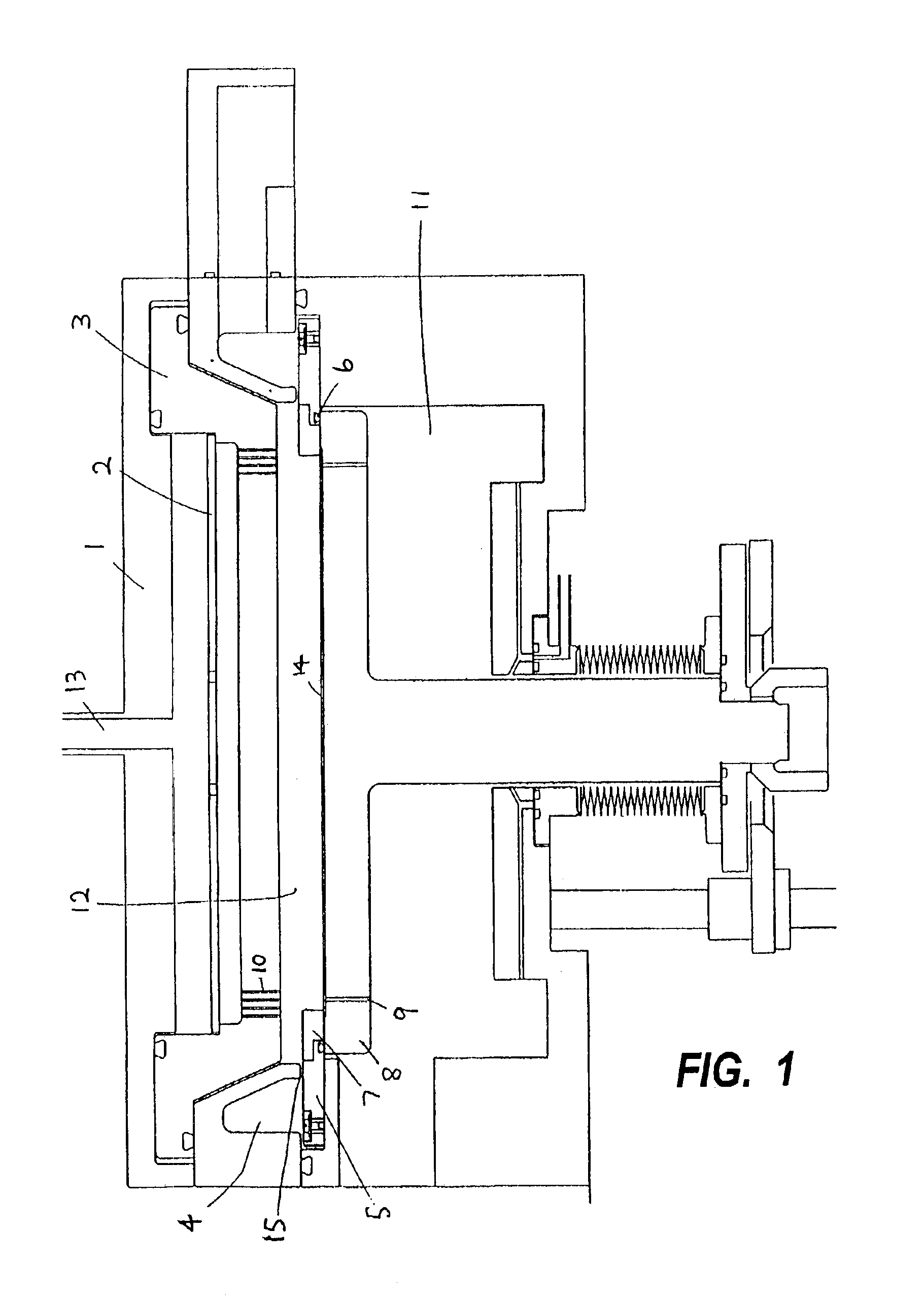

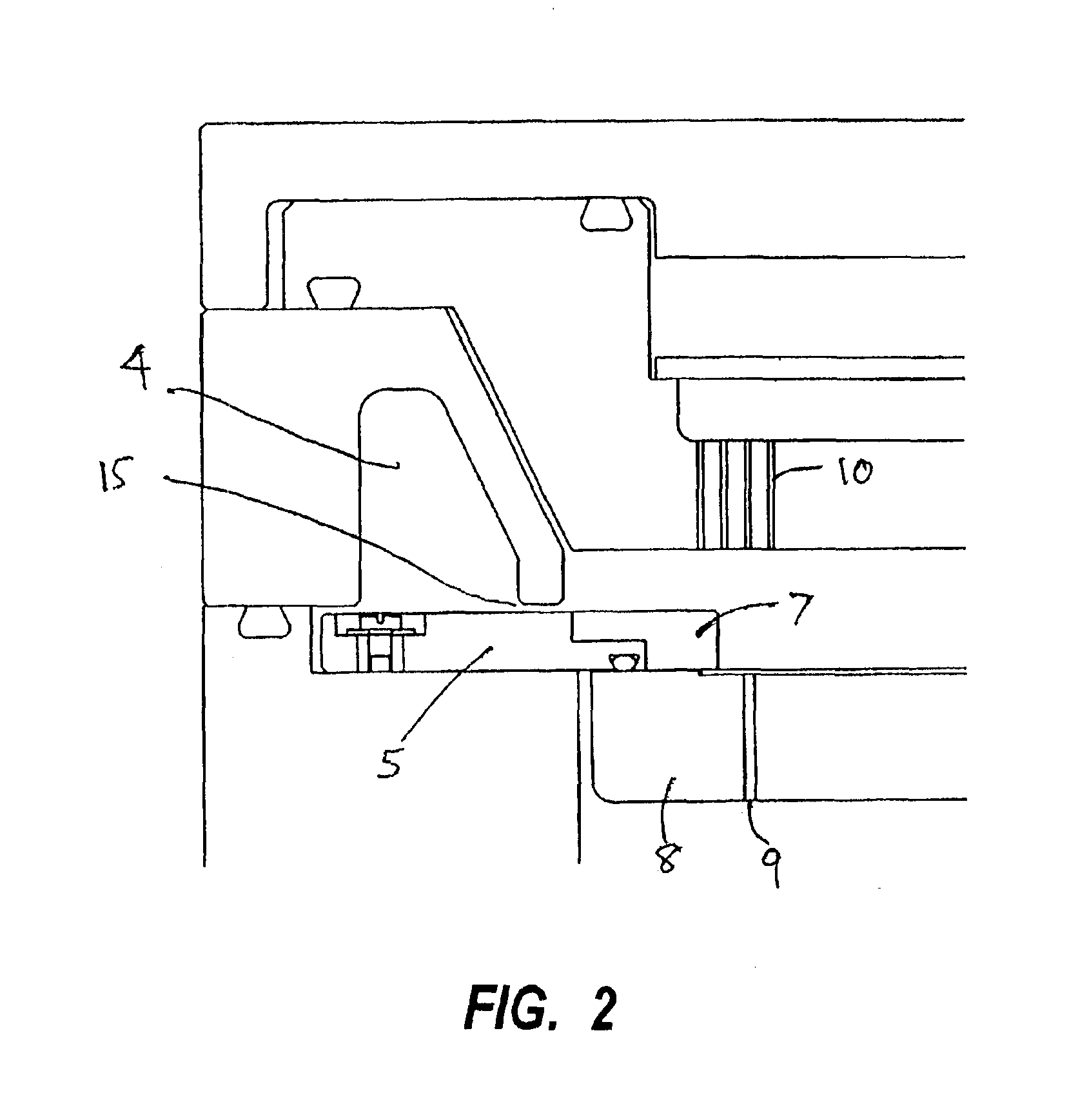

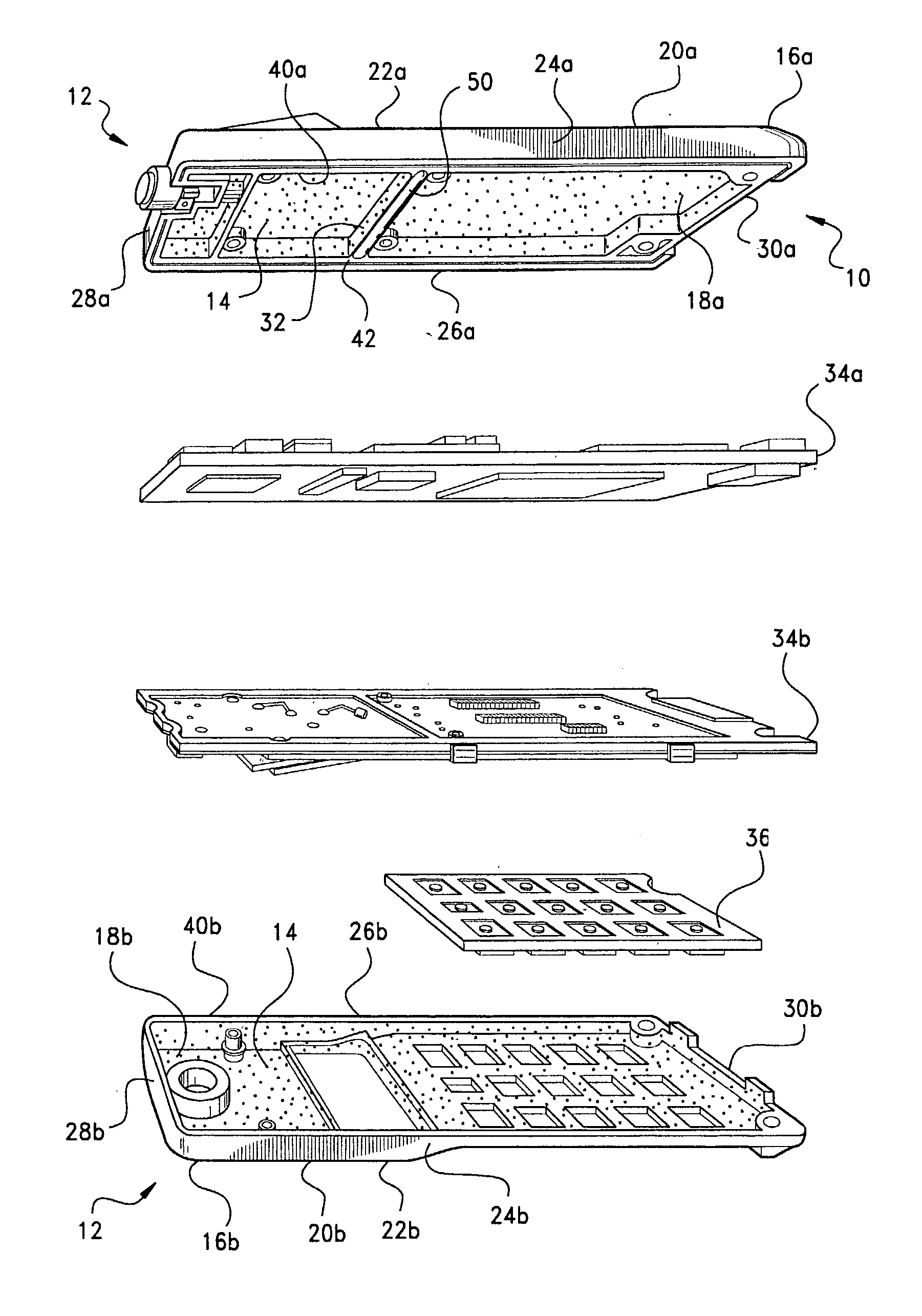

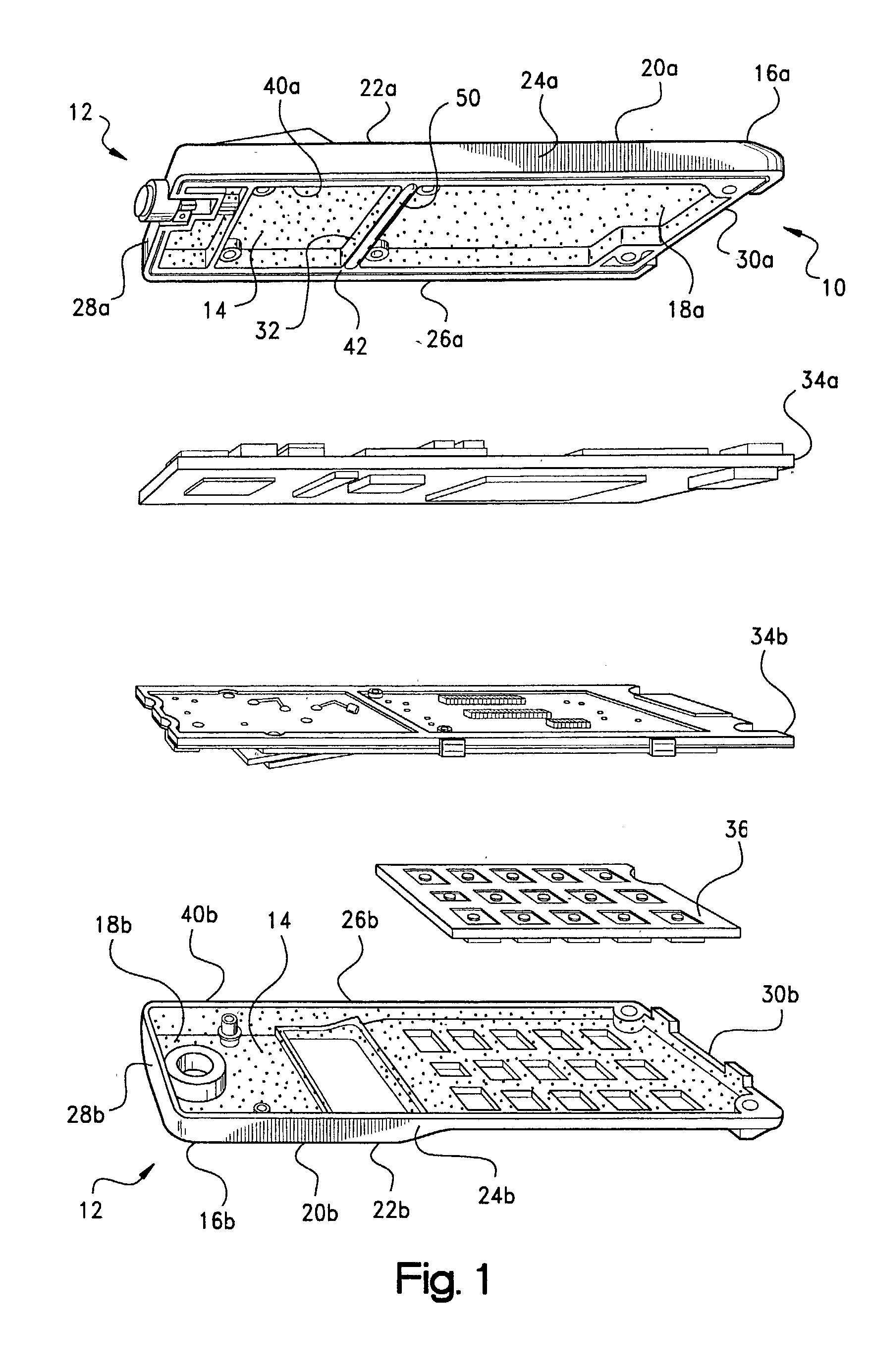

Glass substrate-holding tool

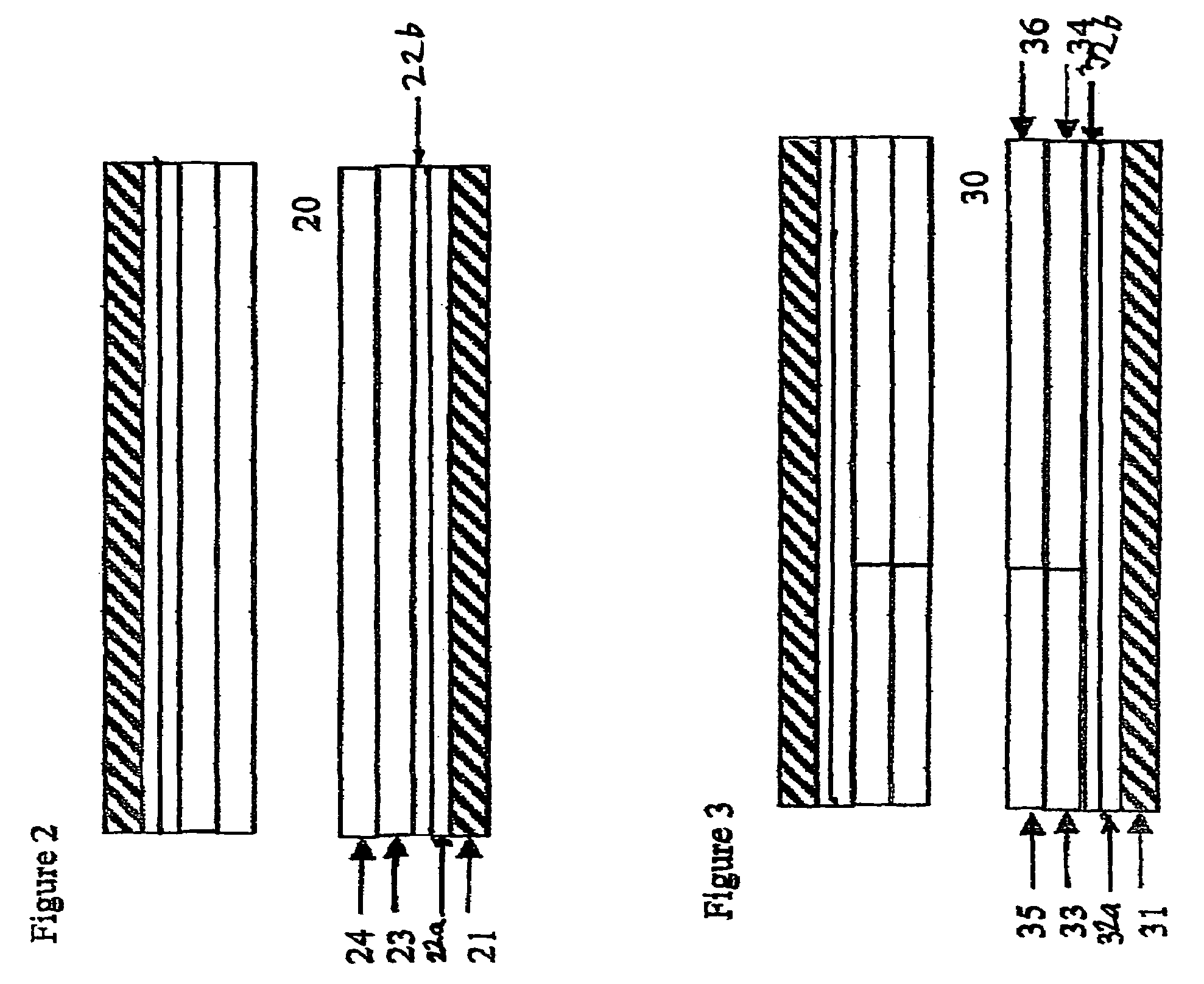

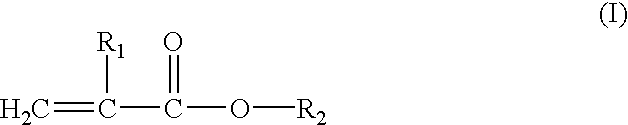

InactiveUS20120100464A1Avoid dustAvoid depositionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringScratching

To provide a glass substrate-holding tool which is capable of avoiding scratching to the deposition surface of a glass substrate and dusting thereby caused as well as scratching and deposition of foreign substances at a center portion of the rear surface of the substrate and which is capable of suppressing dusting from the holding tool itself at the time of forming a multi-layered reflection film and an absorptive layer.A glass substrate-holding tool having, formed on a surface of a flat base, a catching portion for catching and holding by van der Waals forces, wherein the catching portion is in contact with only the periphery of the glass substrate.

Owner:ASAHI GLASS CO LTD

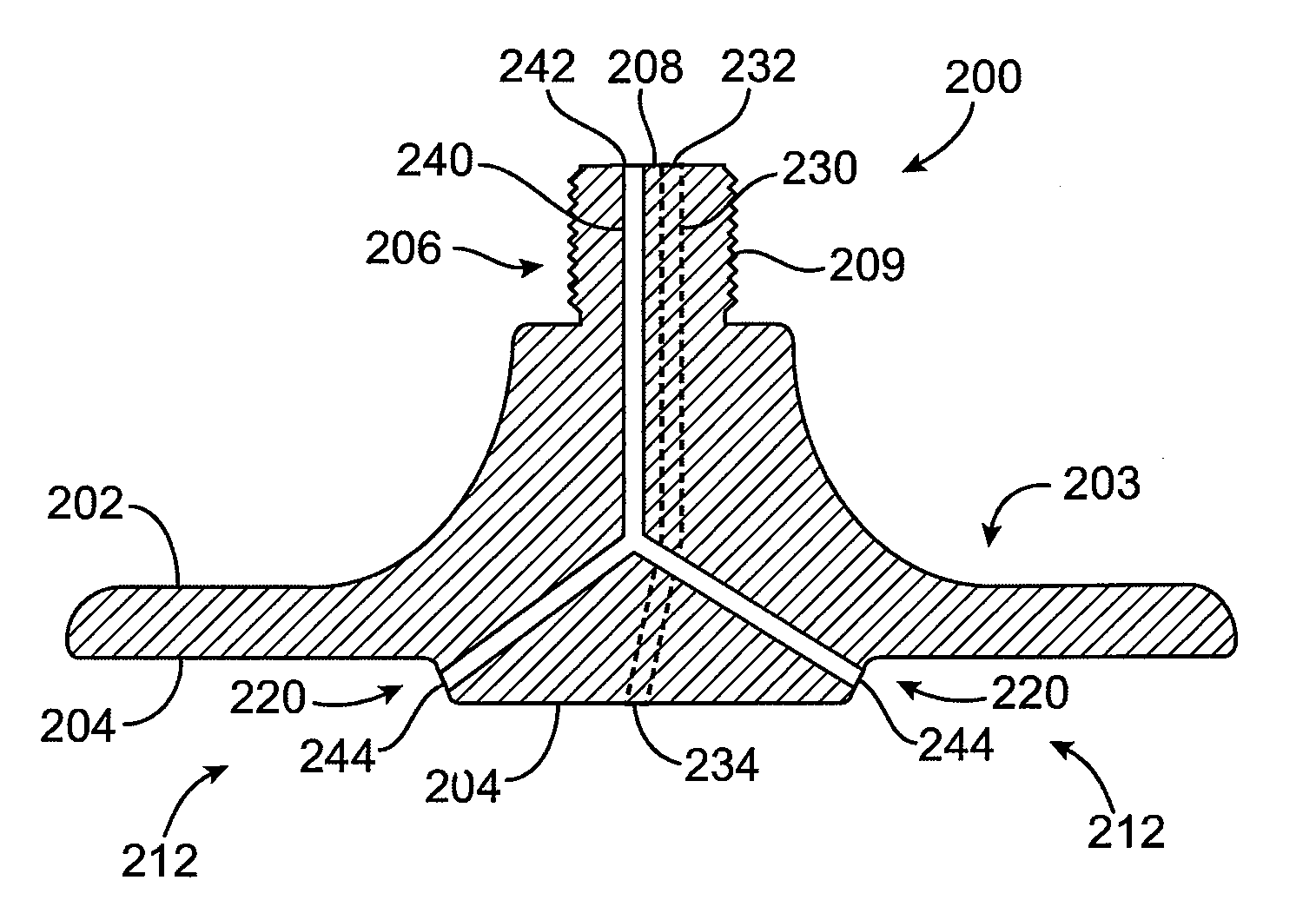

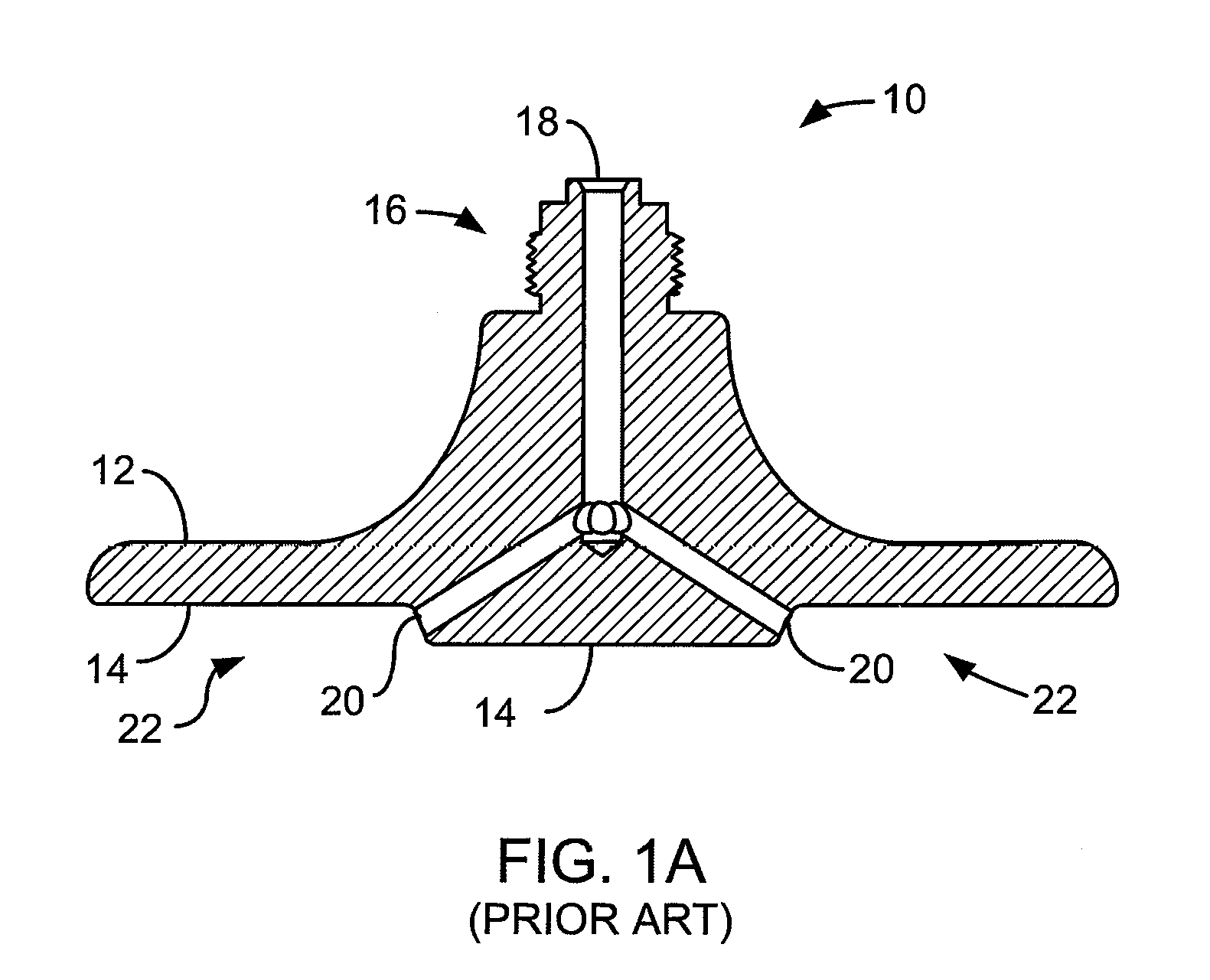

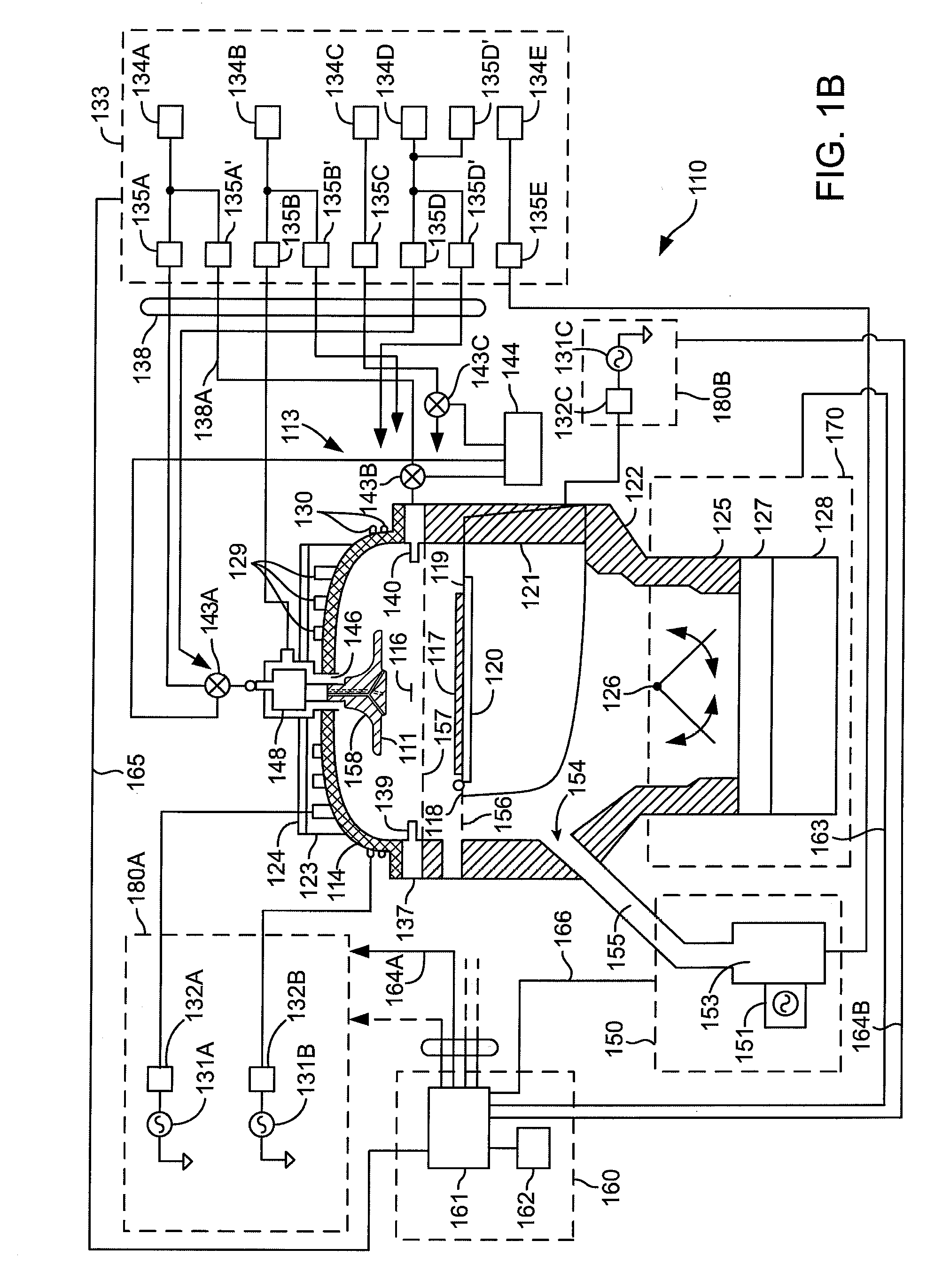

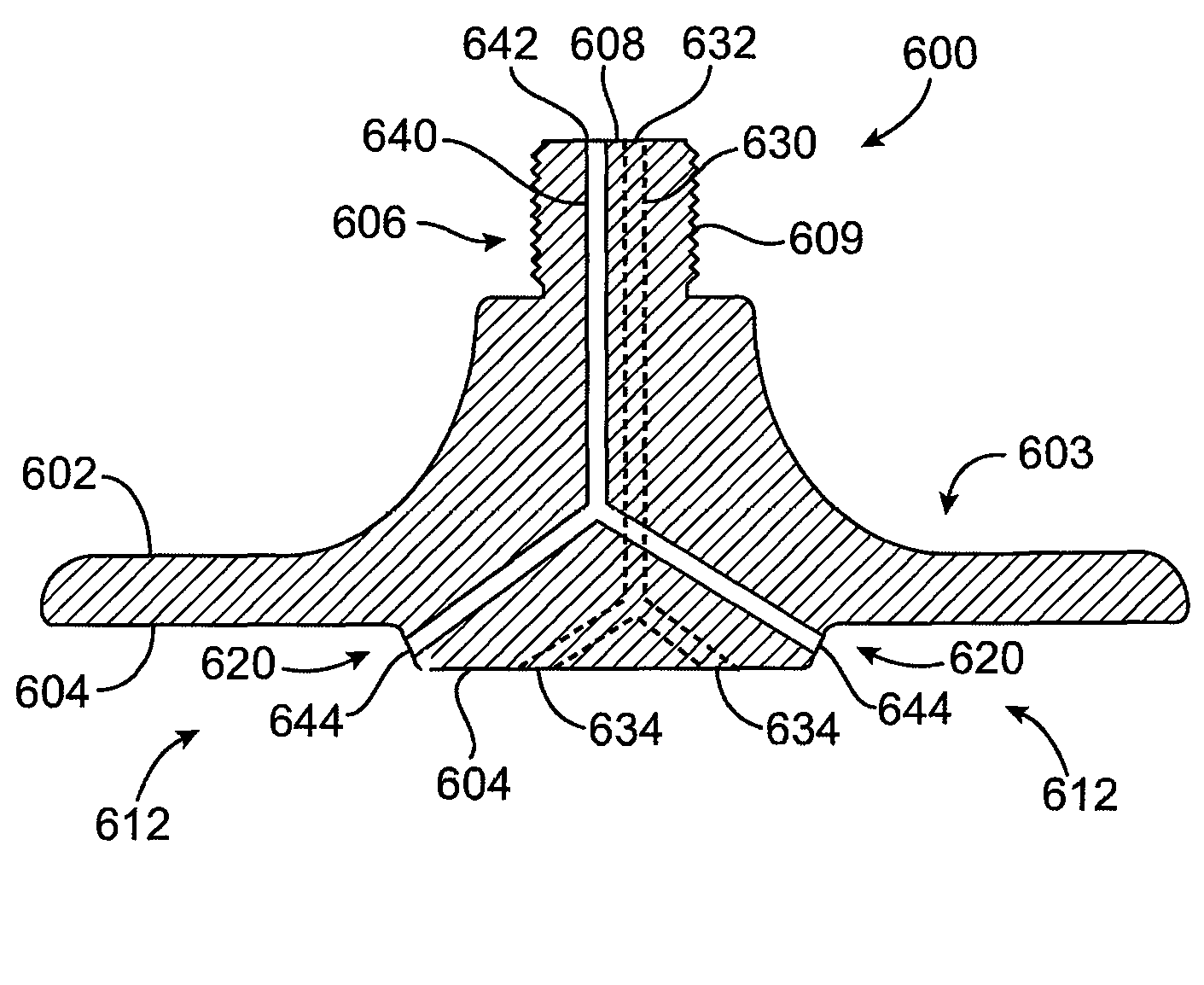

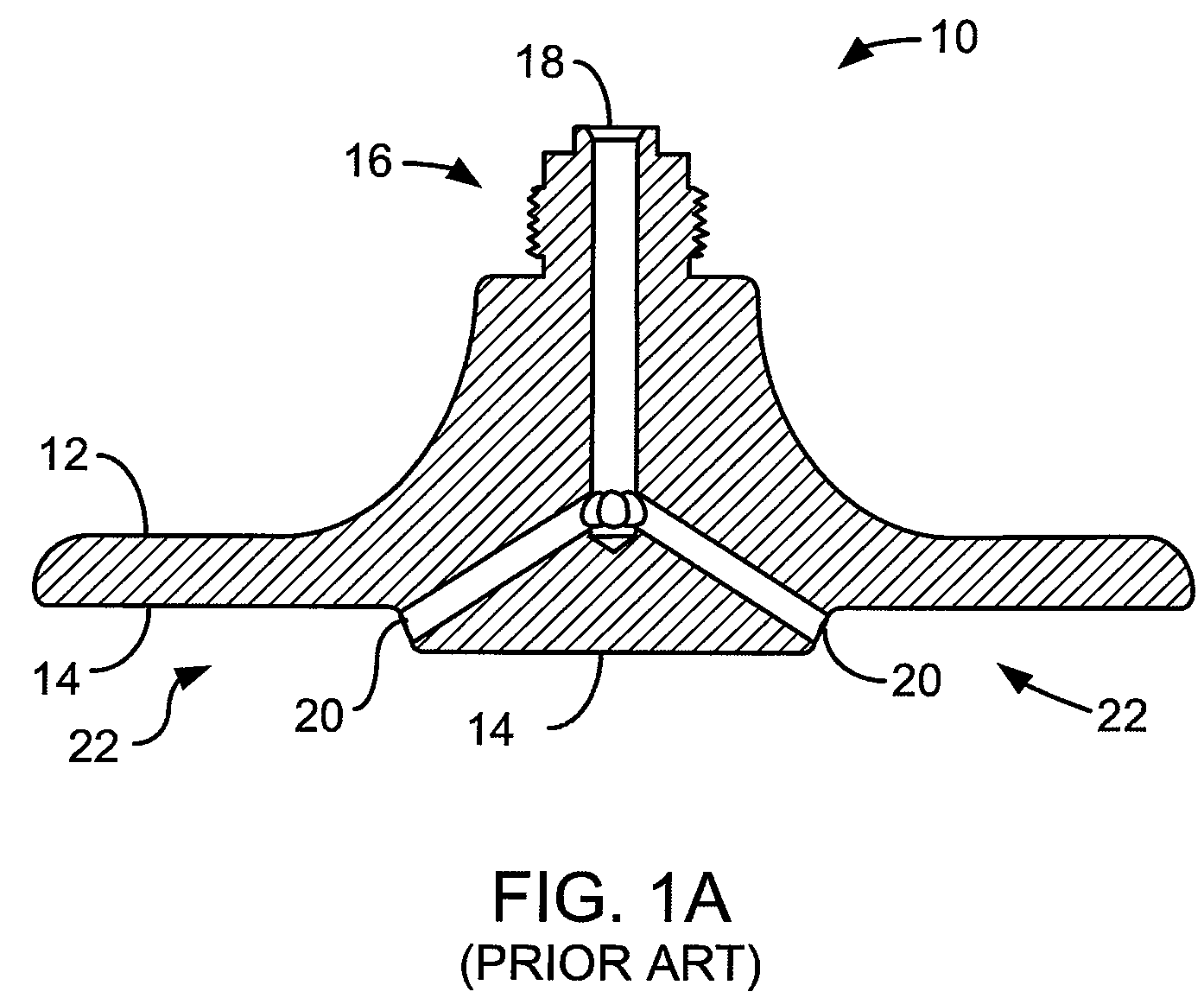

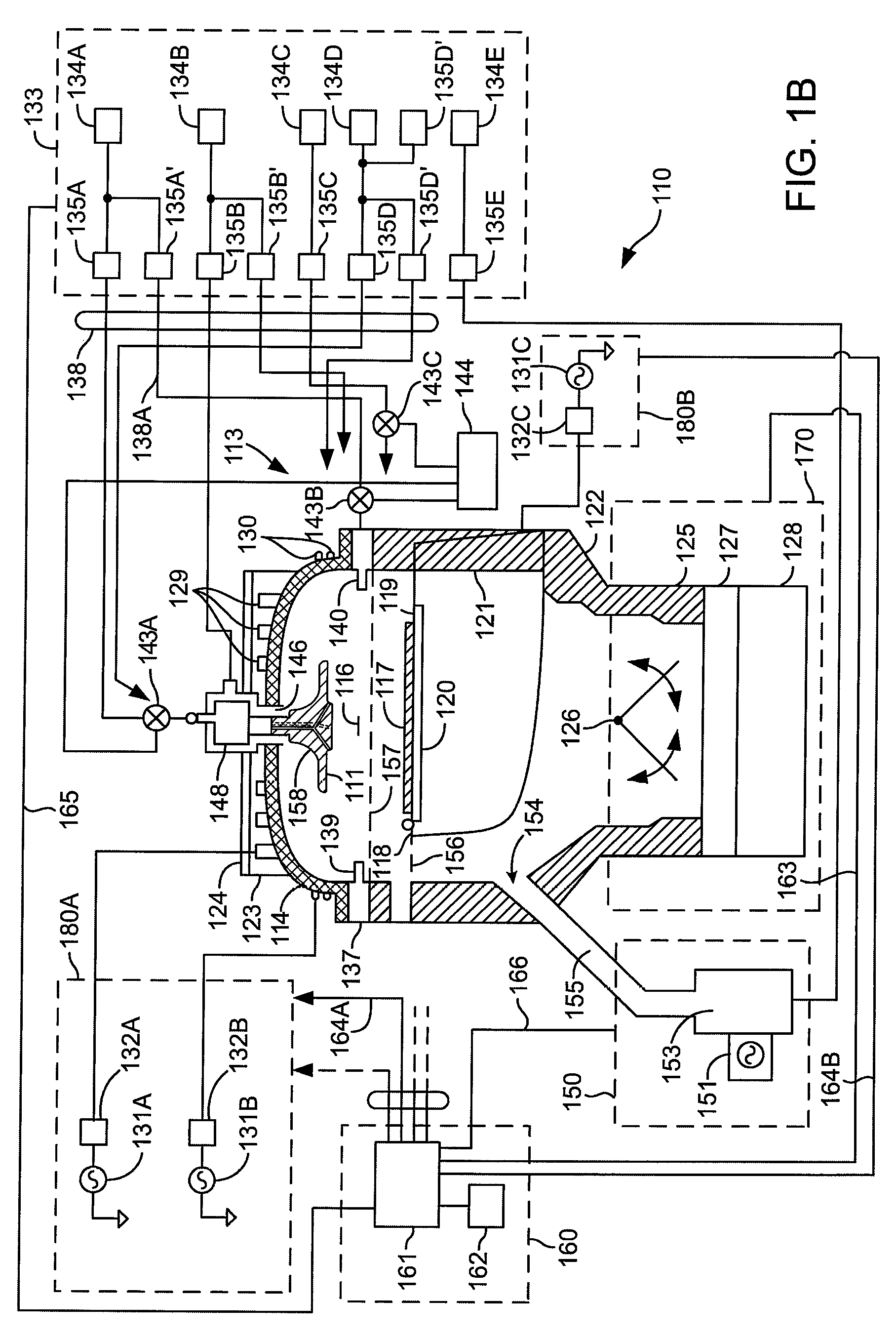

Dual top gas feed through distributor for high density plasma chamber

InactiveUS20080121177A1Improve uniformityUniform layersElectric discharge tubesSemiconductor/solid-state device manufacturingHigh densityProduct gas

A gas distributor for use in a semiconductor process chamber comprises a body. The body includes a first channel formed within the body and adapted to pass a first fluid from a first fluid supply line through the first channel to a first opening. A second channel is formed within the body and adapted to pass a second fluid from a second fluid supply line through the second channel to a second opening. The first and second openings are arranged to mix the fluids outside the body after the fluids pass through the openings.

Owner:APPLIED MATERIALS INC

Dual top gas feed through distributor for high density plasma chamber

InactiveUS7758698B2Improve uniformityAvoid depositionElectric discharge tubesSemiconductor/solid-state device manufacturingHigh densityDistributor

A gas distributor for use in a semiconductor process chamber comprises a body. The body includes a first channel formed within the body and adapted to pass a first fluid from a first fluid supply line through the first channel to a first opening. A second channel is formed within the body and adapted to pass a second fluid from a second fluid supply line through the second channel to a second opening. The first and second openings are arranged to mix the fluids outside the body after the fluids pass through the openings.

Owner:APPLIED MATERIALS INC

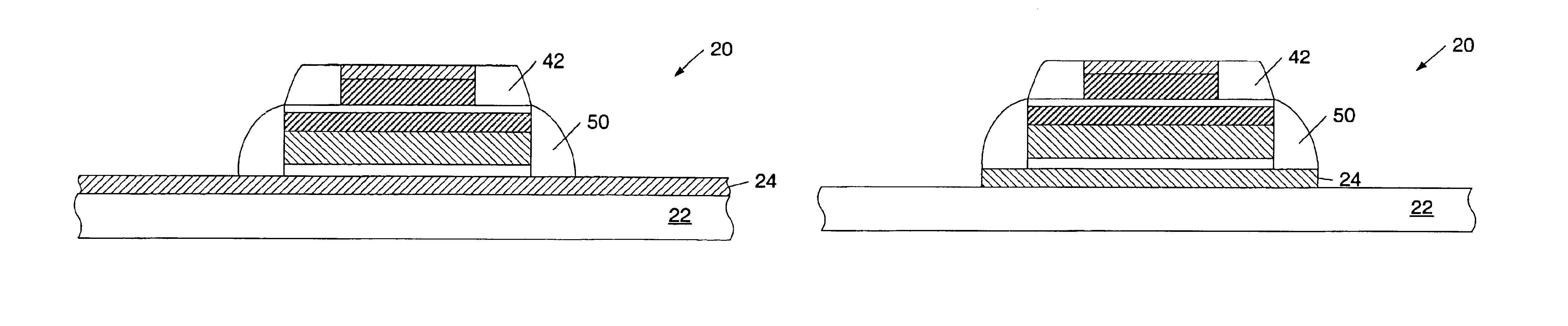

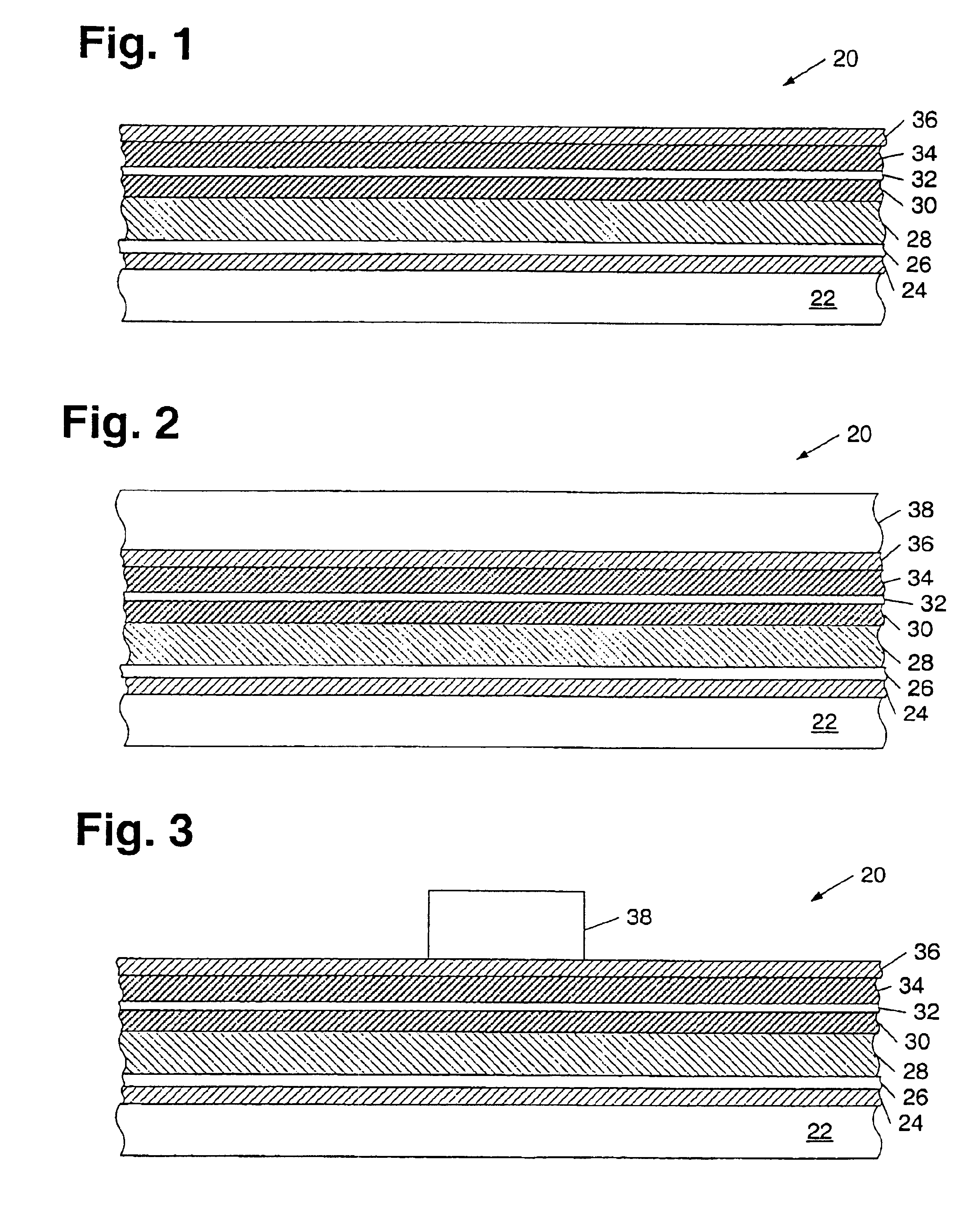

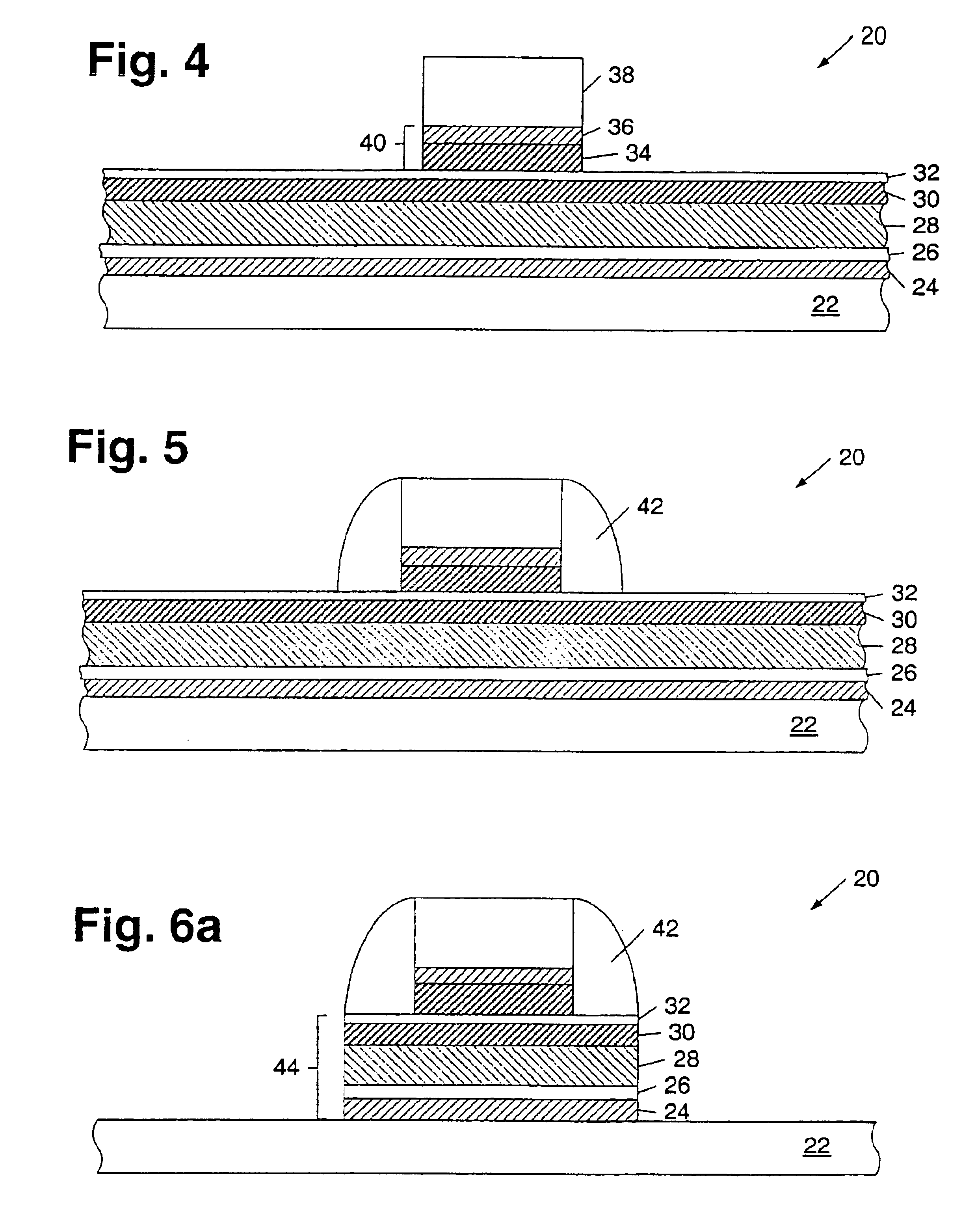

Magnetic tunneling junction configuration and a method for making the same

InactiveUS6897532B1Reduce the temperatureAvoid depositionTransistorNanomagnetismEngineeringGobio gobio obtusirostris

A method for forming a magnetic tunneling junction (MJT) is provided. In some embodiments, the method may include patterning one or more magnetic layers to form an upper portion of a MTJ. The method may further include patterning one or more additional layers to form a lower portion of the MTJ. In some cases, the lower portion may include a tunneling layer of the MTJ having a width greater than the upper portion. In addition, in some embodiments the method may further include patterning an electrode below the lower portion. In some cases, the electrode may include a lowermost layer with a thickness equal to or less than approximately 100 angstroms. In addition or alternatively, the electrode may have a width greater than the width of the tunneling layer. In yet other embodiments, the method may include forming spacers along the sidewalls of the upper and / or lower portions.

Owner:CENT NAT DE LA RECHERCHE SCI

Method of film deposition using single-wafer-processing type CVD

InactiveUS6921556B2Avoid depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcessing typeSusceptor

Owner:ASM JAPAN

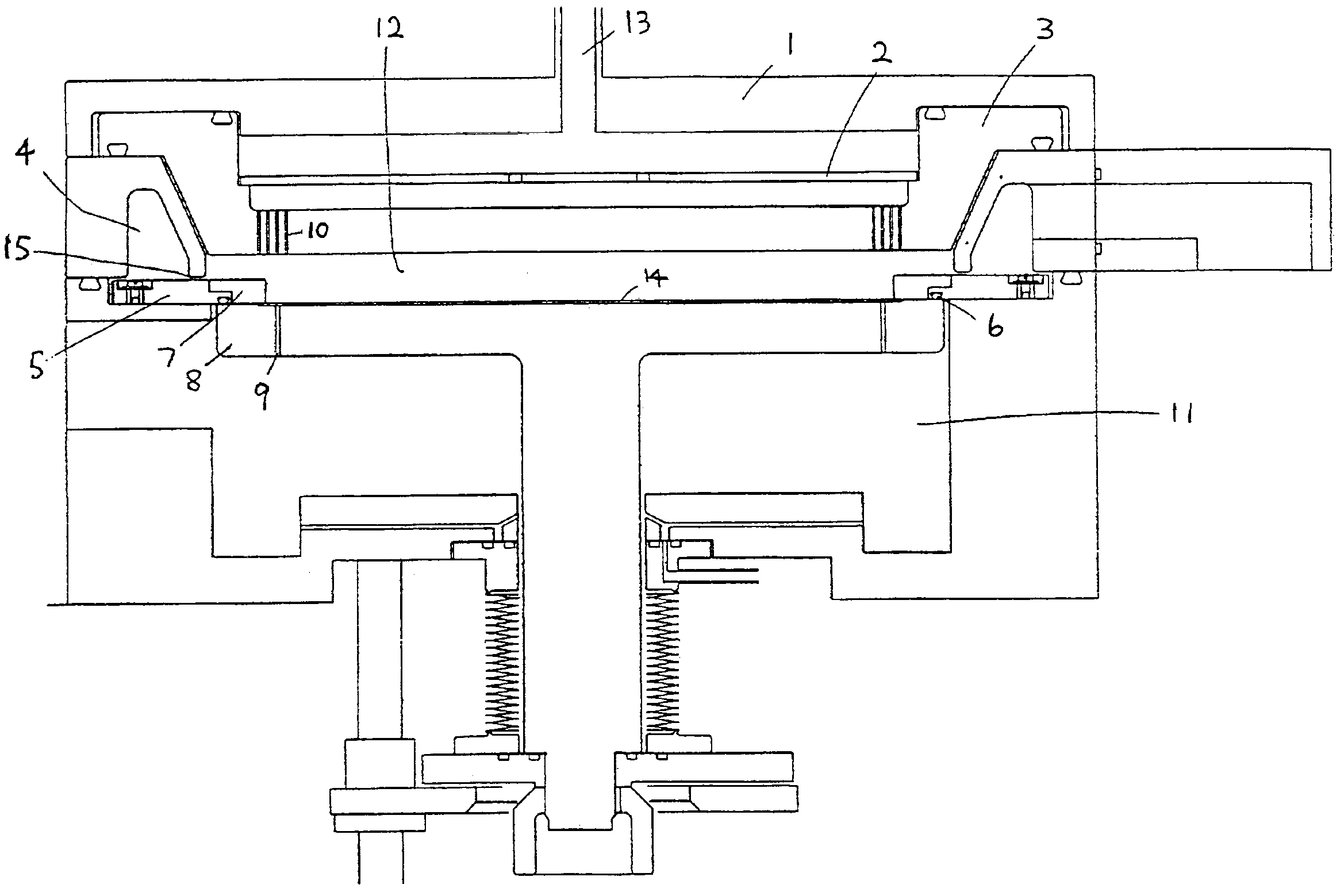

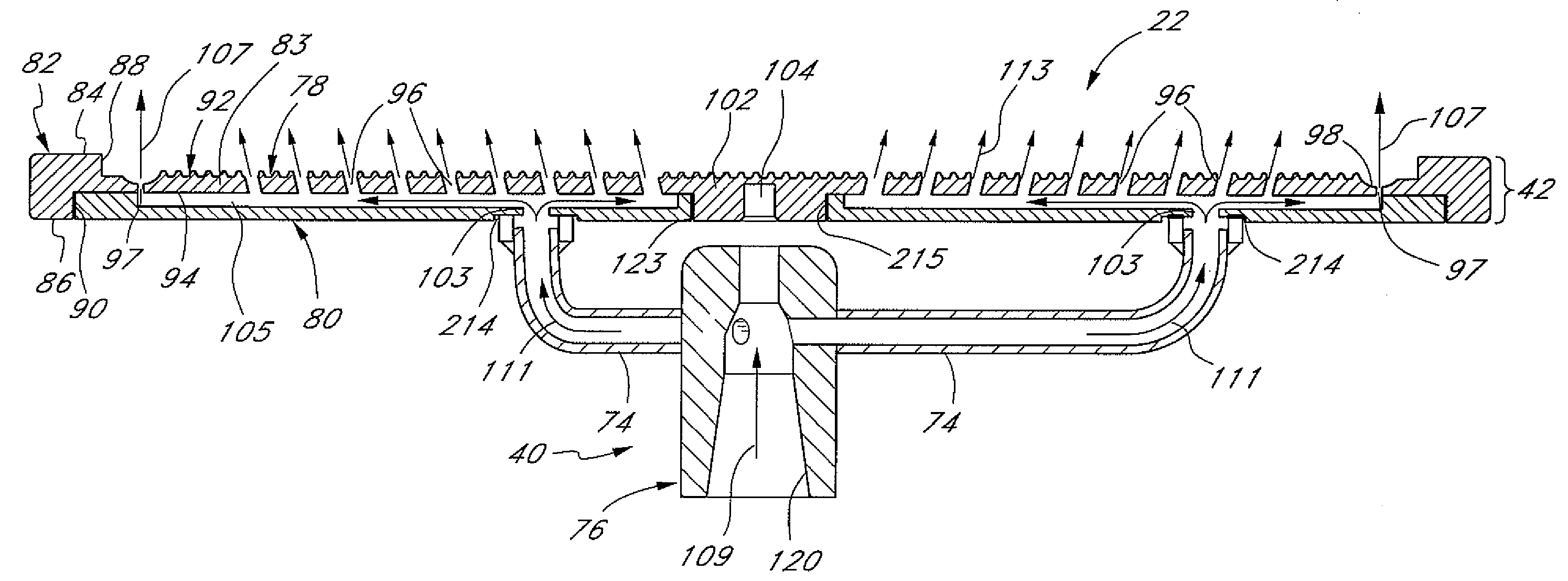

Method of supporting a substrate in a gas cushion susceptor system

ActiveUS20060222481A1Slow its descentReduce temperature differenceSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorEngineering

An apparatus and method to position a wafer onto a wafer holder and to maintain a uniform wafer temperature is disclosed. The wafer holder or susceptor comprises a recess or pocket whose surface includes a grid containing a plurality of grid grooves that separate protrusions. A plurality of gas passages is provided in the susceptor to enable an upward flow of gas toward the bottom surface of the substrate. During drop-off of the substrate, a cushion gas flow is provided to substantially slow the rate of descent of the substrate onto the susceptor and to gradually heat the substrate before it makes contact with the susceptor. Optionally, a trickle gas flow may be provided through the aforementioned passages during processing of the substrate to prevent deposition of reactant gases onto the bottom surface of the substrate. A liftoff gas flow may then be provided through the passages to help lift the substrate off of the susceptor after processing is completed and thus aid in removing the substrate from the process chamber. These features help to achieve temperature uniformity and thus quality of deposited films onto the substrate.

Owner:ASM IP HLDG BV

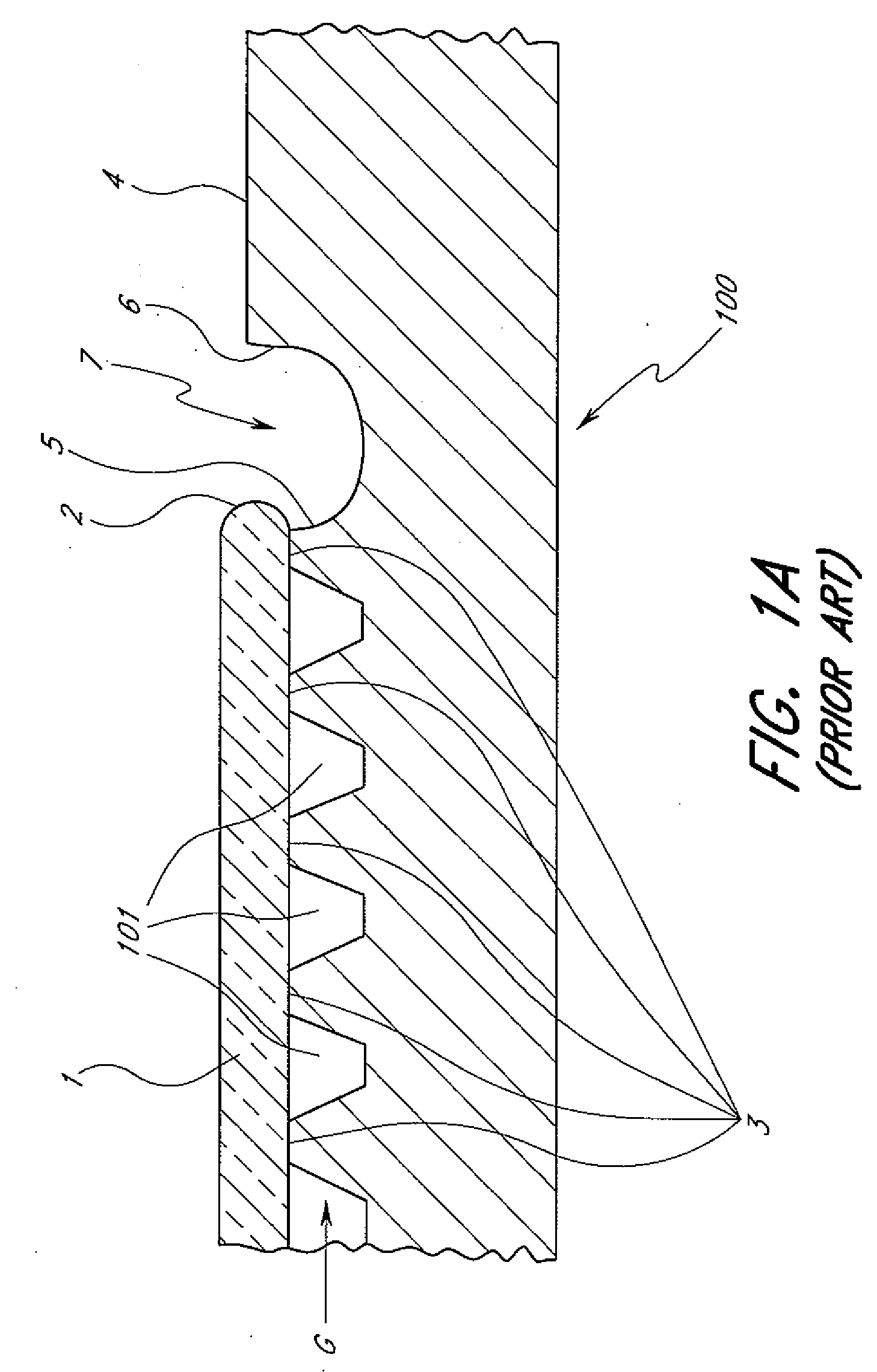

Process of manufacturing Trench gate semiconductor device having gate oxide layer with multiple thicknesses

InactiveUS6291298B1Reduced strengthReduce capacitanceSemiconductor/solid-state device manufacturingDiodePhysicsPhotoresist

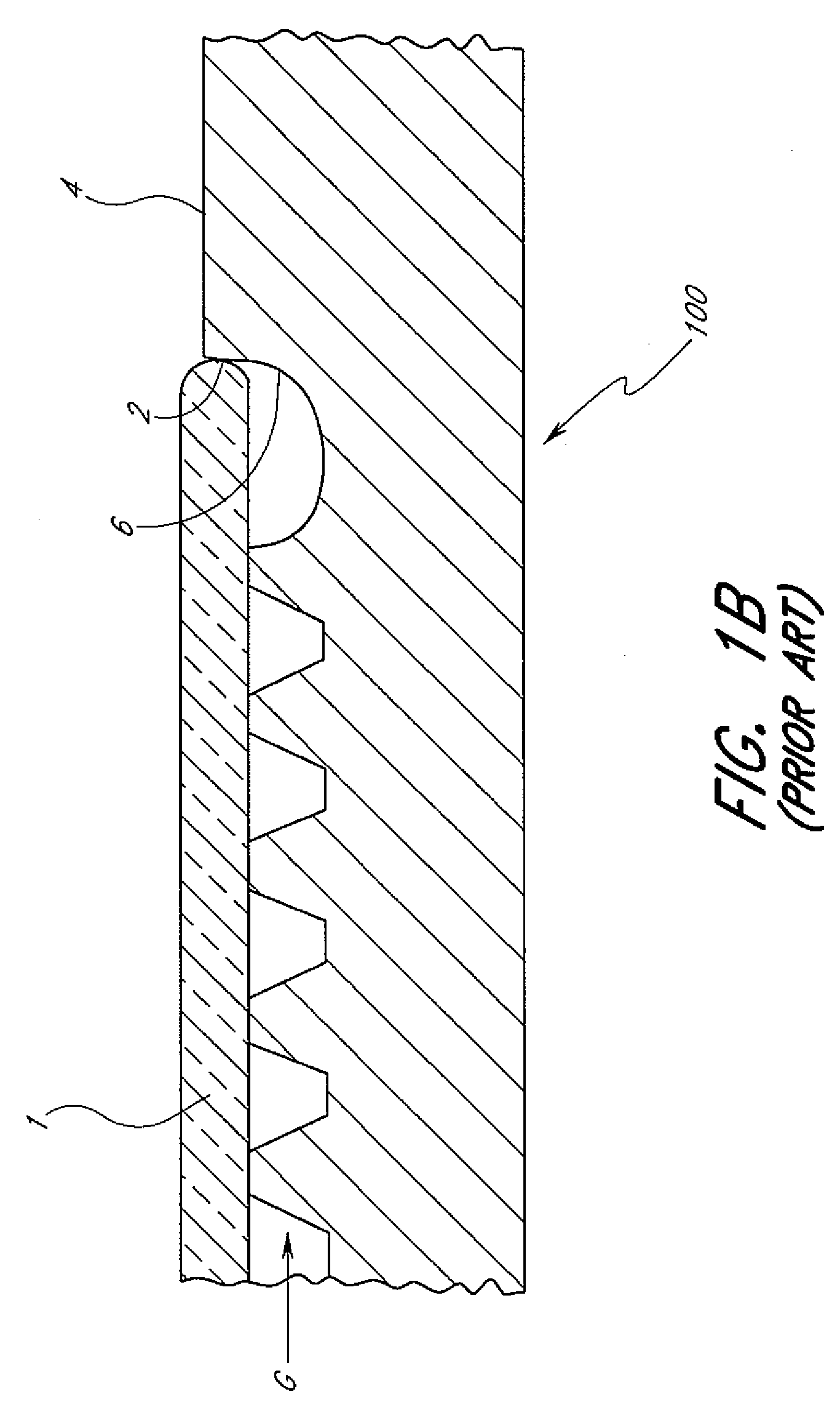

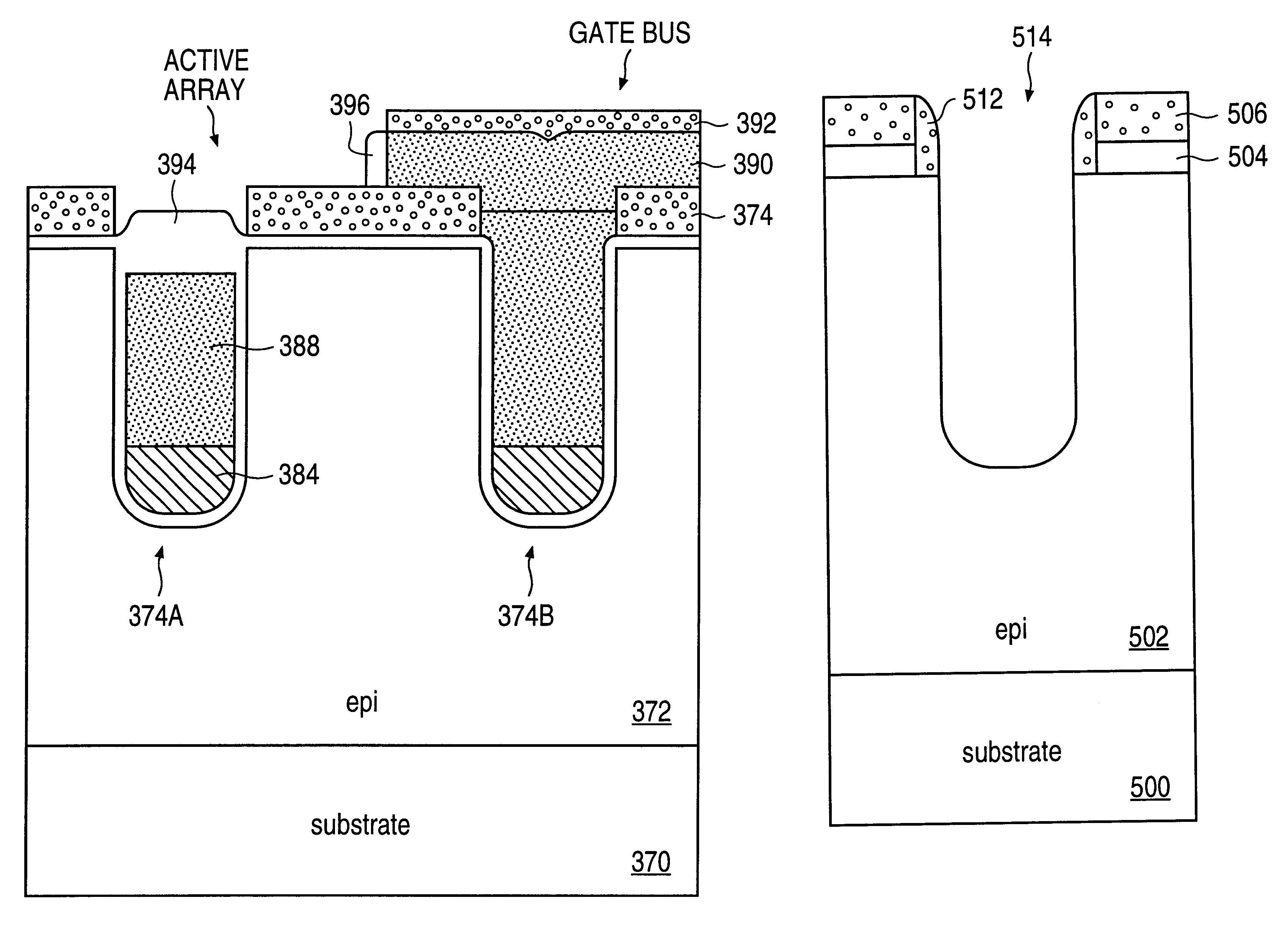

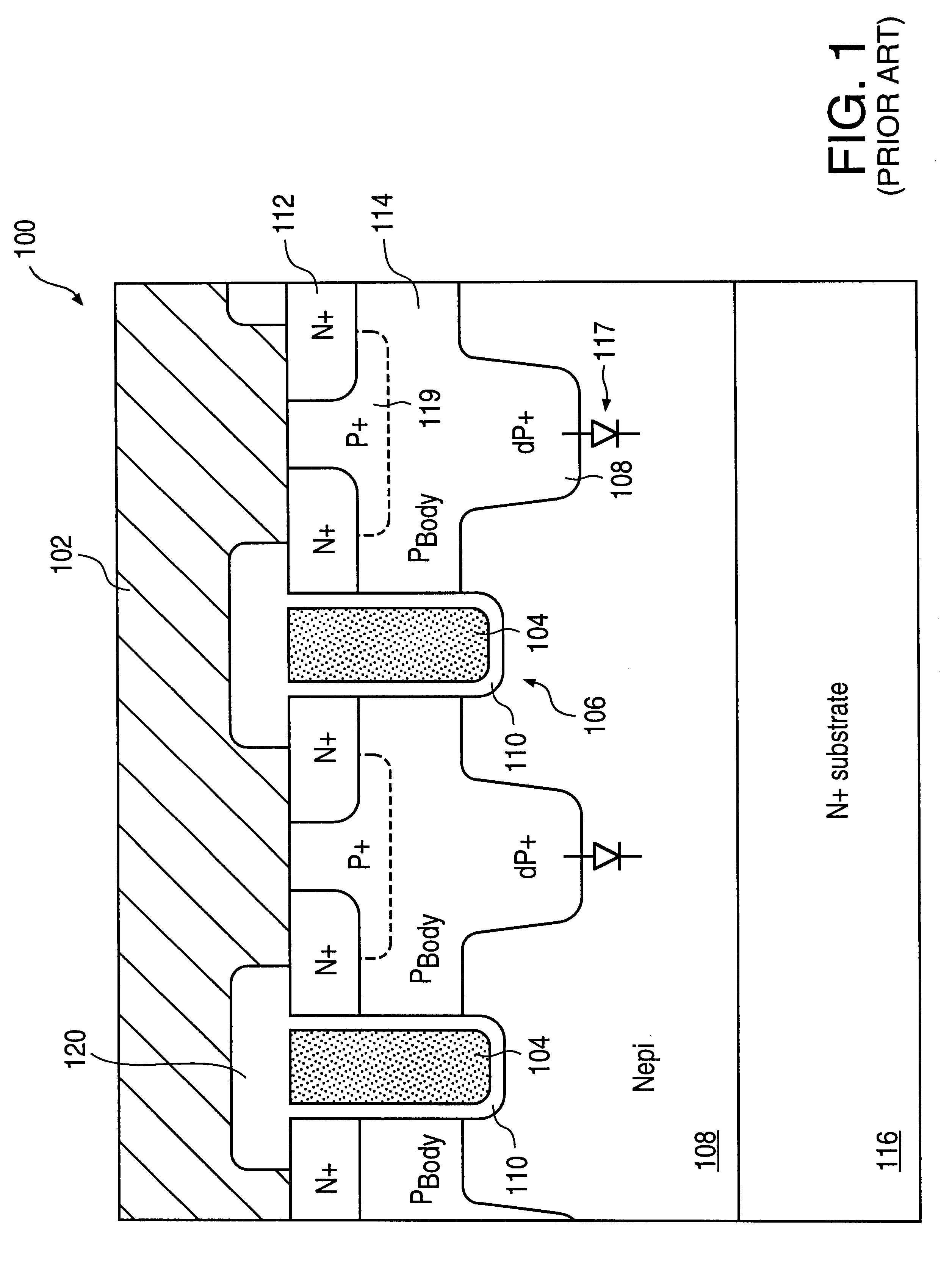

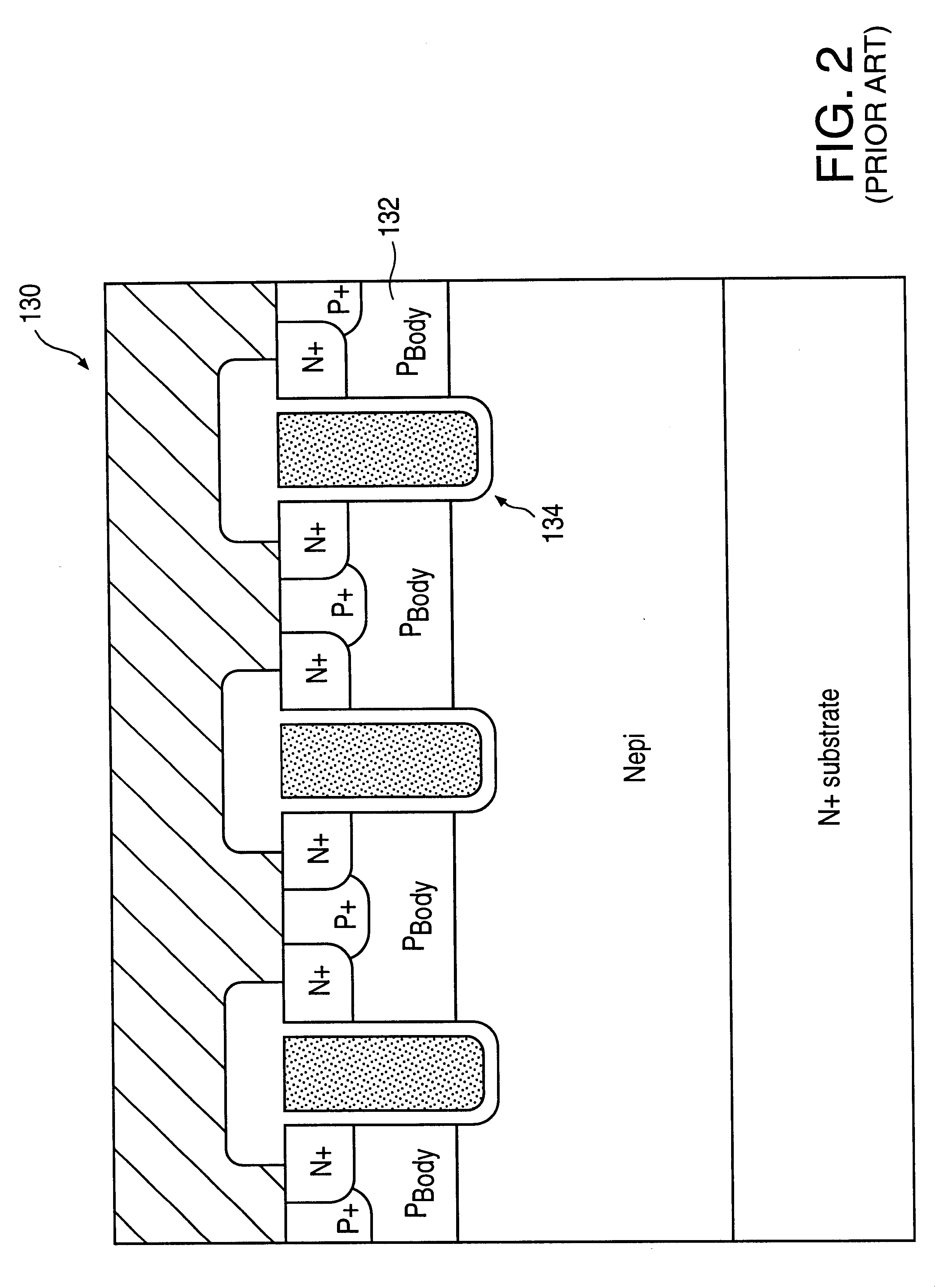

The a trench semiconductor device such as a power MOSFET the high electric field at the corner of the trench is diminished by increasing the thickness of the gate oxide layer at the bottom of the trench. Several processes for manufacturing such devices are described. In one group of processes a directional deposition of silicon oxide is performed after the trench has been etched, yielding a thick oxide layer at the bottom of the trench. Any oxide which deposits on the walls of the trench is removed before a thin gate oxide layer is grown on the walls. The trench is then filled with polysilicon in or more stages. In a variation of the process a small amount of photoresist is deposited on the oxide at the bottom of the trench before the walls of the trench are etched. Alternatively, polysilicon can be deposited in the trench and etched back until only a portion remains at the bottom of the trench. The polysilicon is then oxidized and the trench is refilled with polysilicon. The processes can be combined, with a directional deposition of oxide being followed by a filling and oxidation of polysilicon. A process of forming a "keyhole" shaped gate electrode includes depositing polysilicon at the bottom of the trench, oxidizing the top surface of the polysilicon, etching the oxidized polysilicon, and filling the trench with polysilicon.

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED

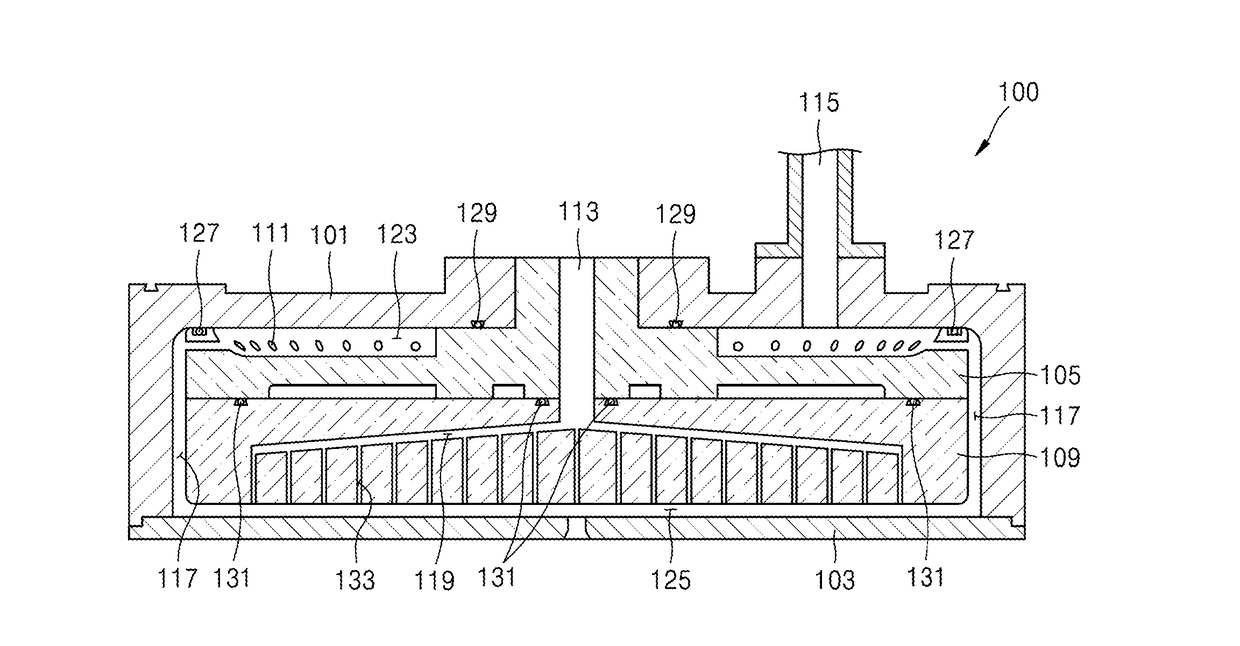

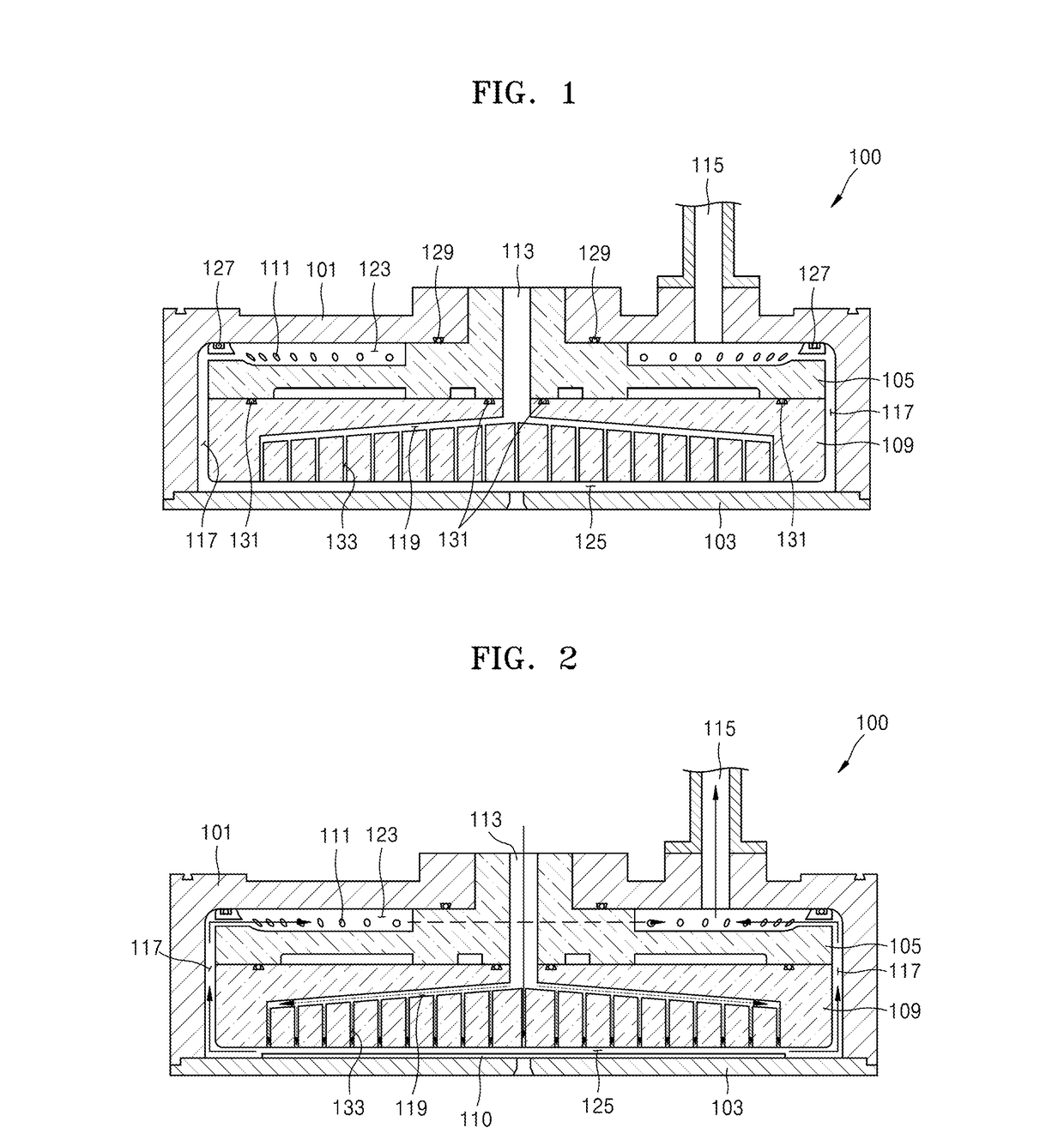

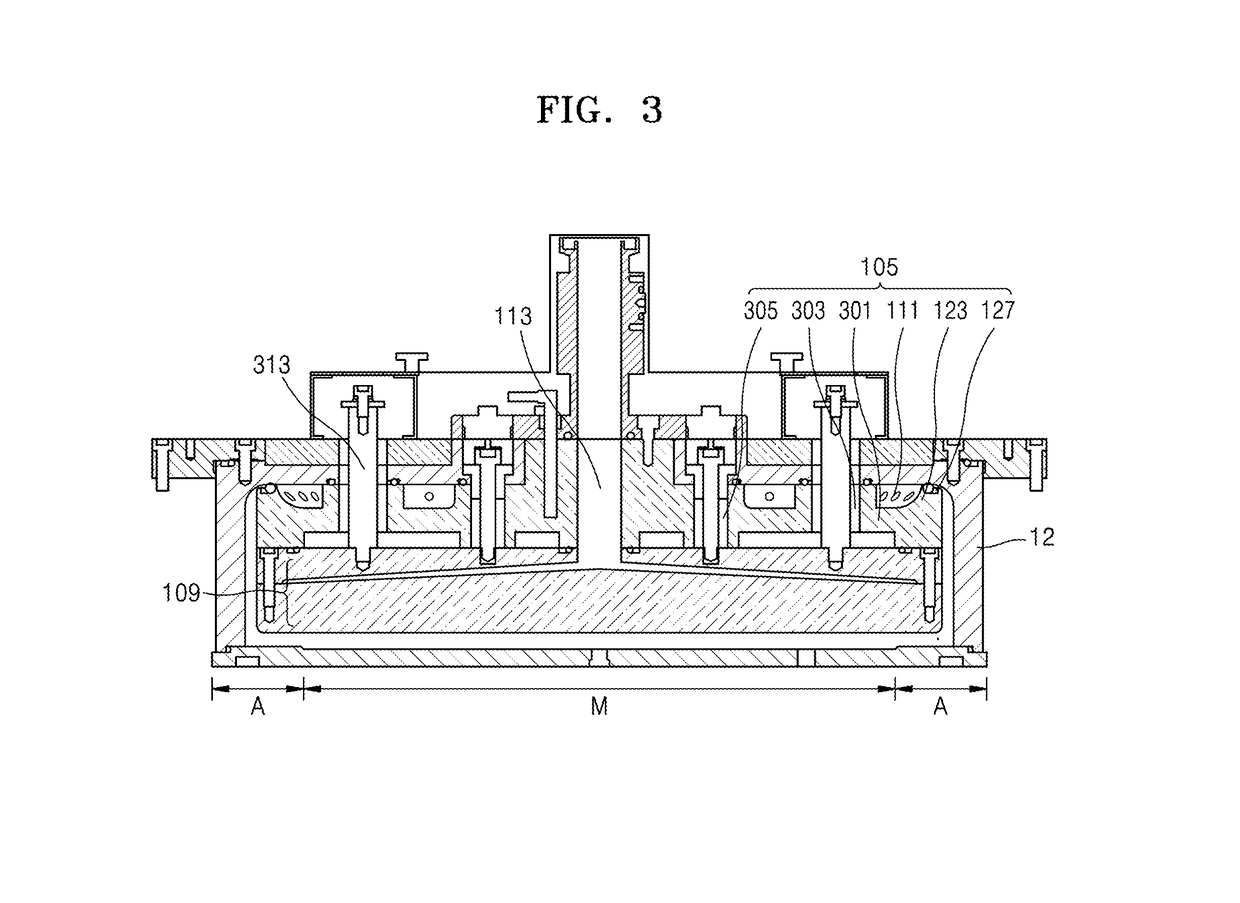

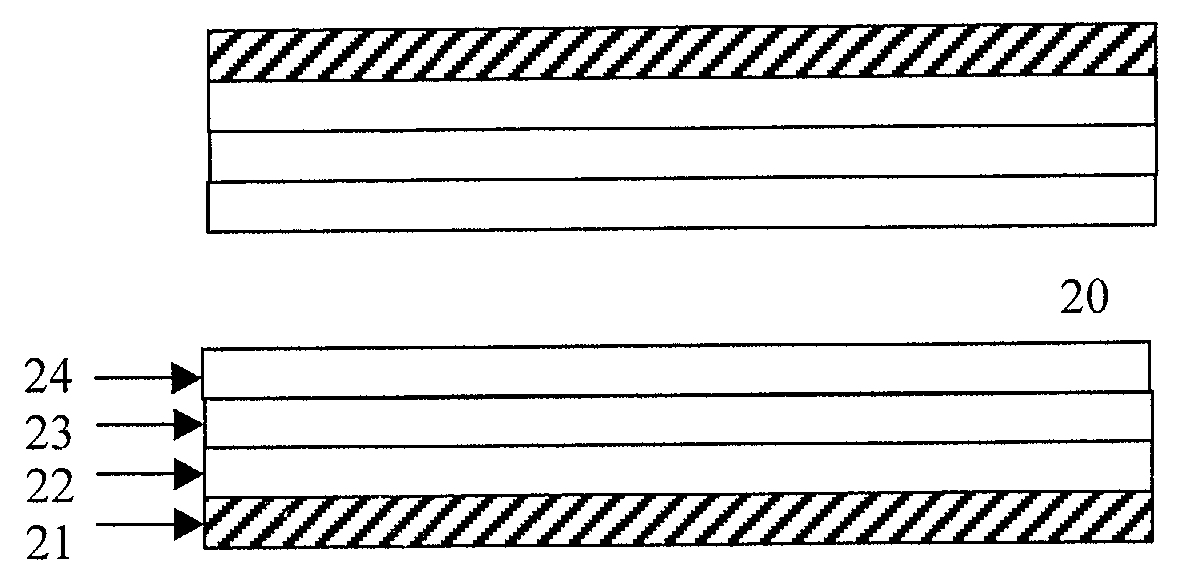

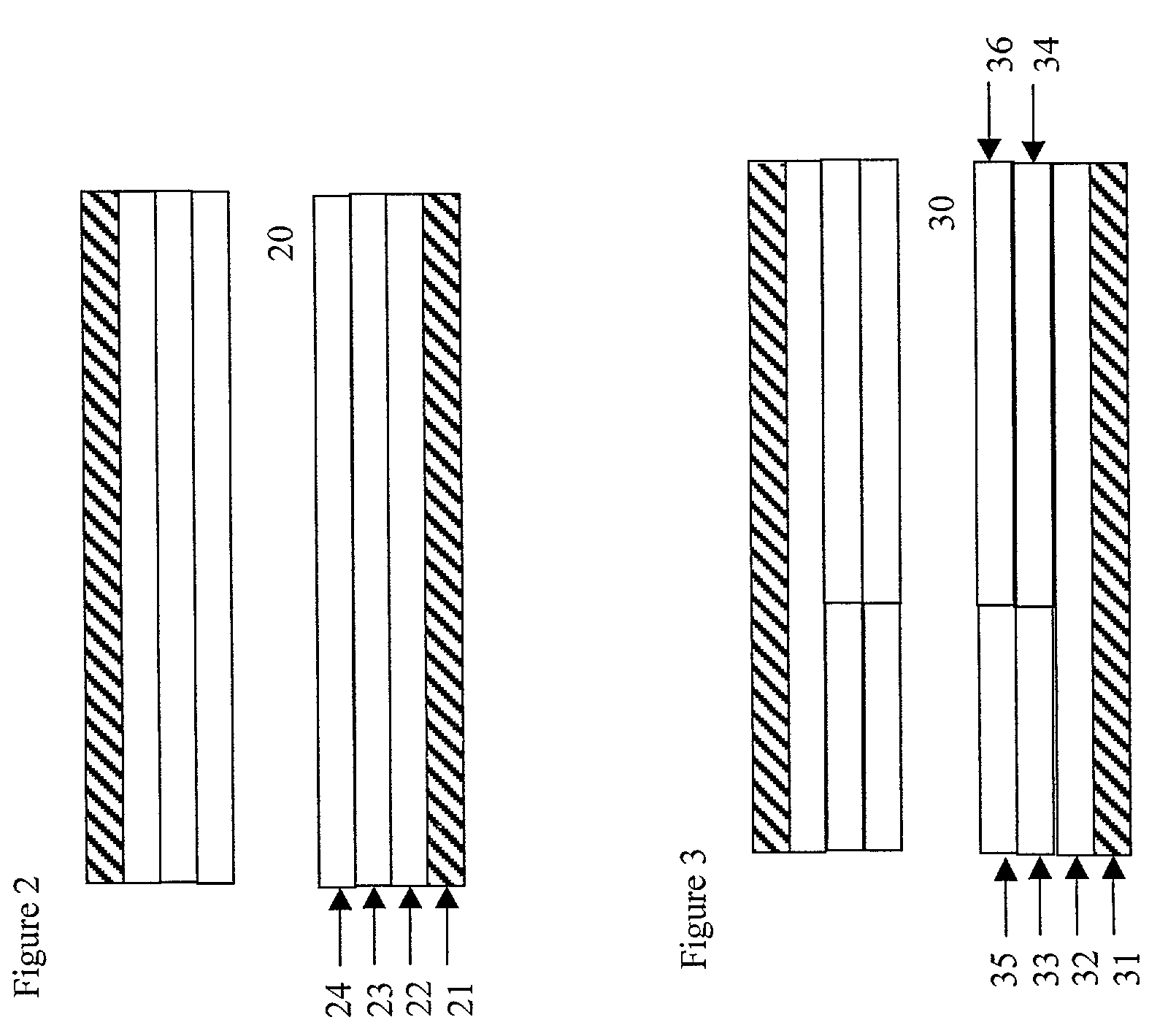

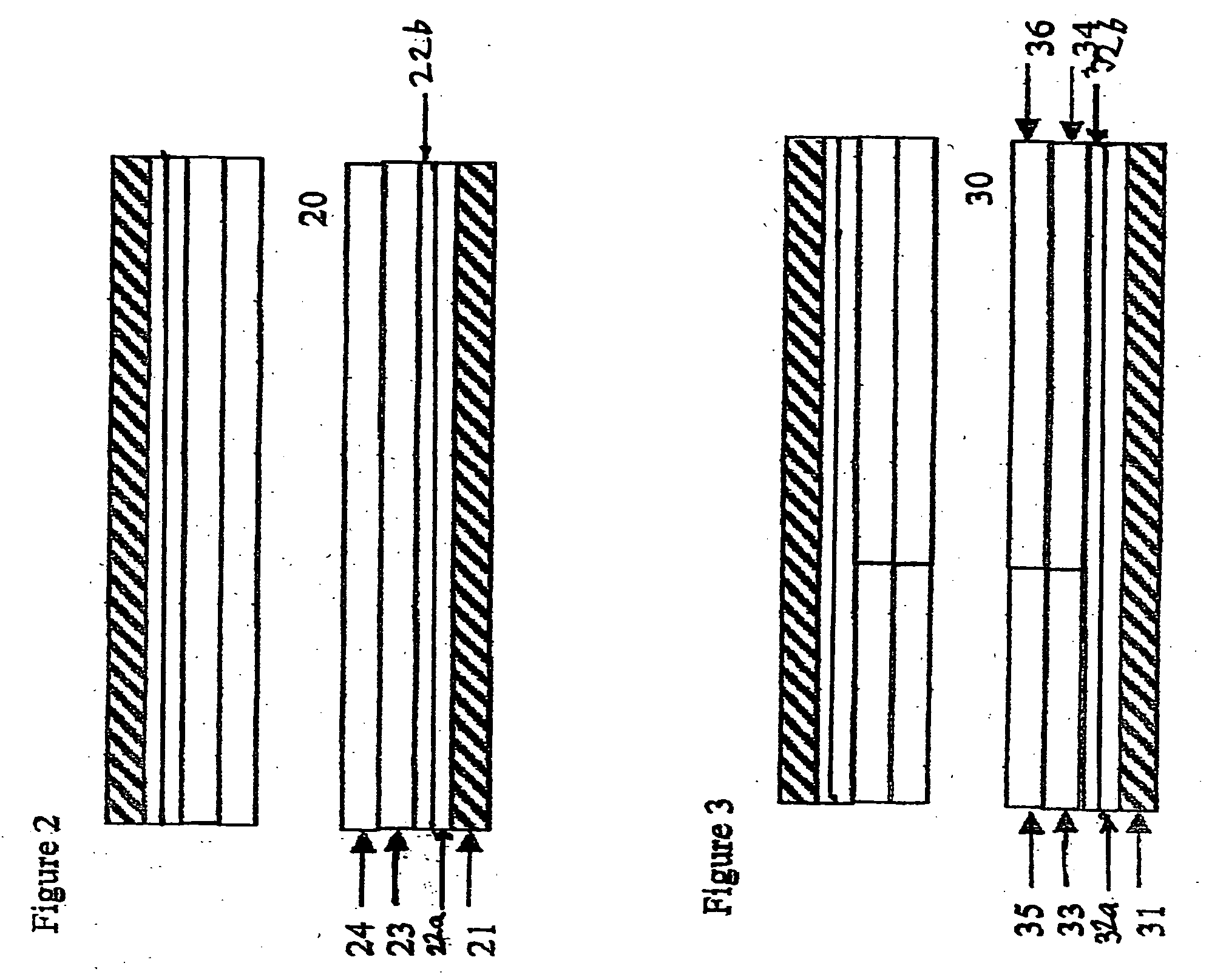

Substrate supporting plate, thin film deposition apparatus including the same, and thin film deposition method

A substrate supporting plate that may prevent deposition on a rear surface of a substrate and may easily unload the substrate. The substrate supporting plate may include a substrate mounting portion and a peripheral portion surrounding the substrate mounting portion. An edge portion of a top surface of the substrate mounting portion may be anodized. A central portion of the top surface of the substrate mounting portion may not be anodized.

Owner:ASM IP HLDG BV

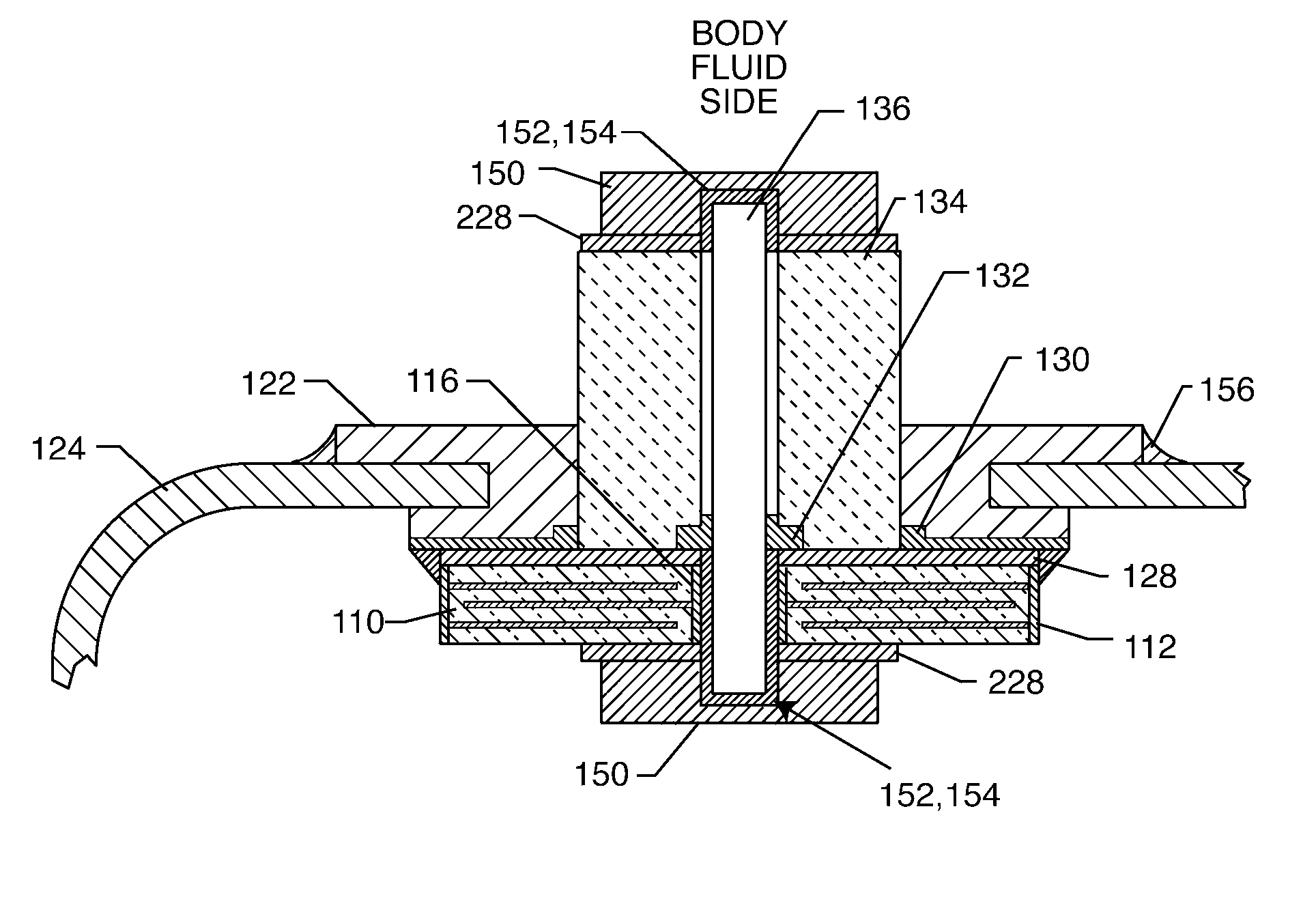

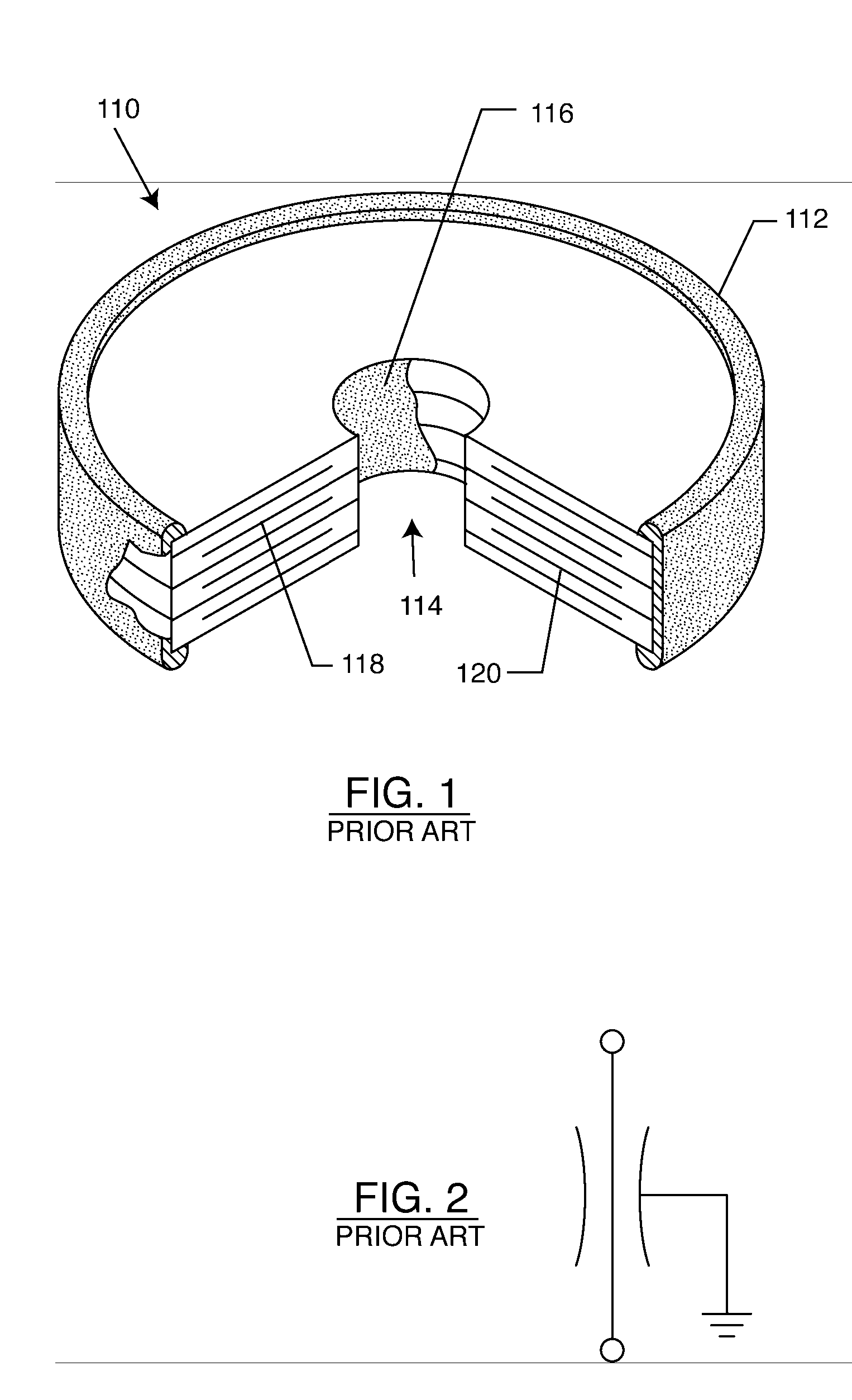

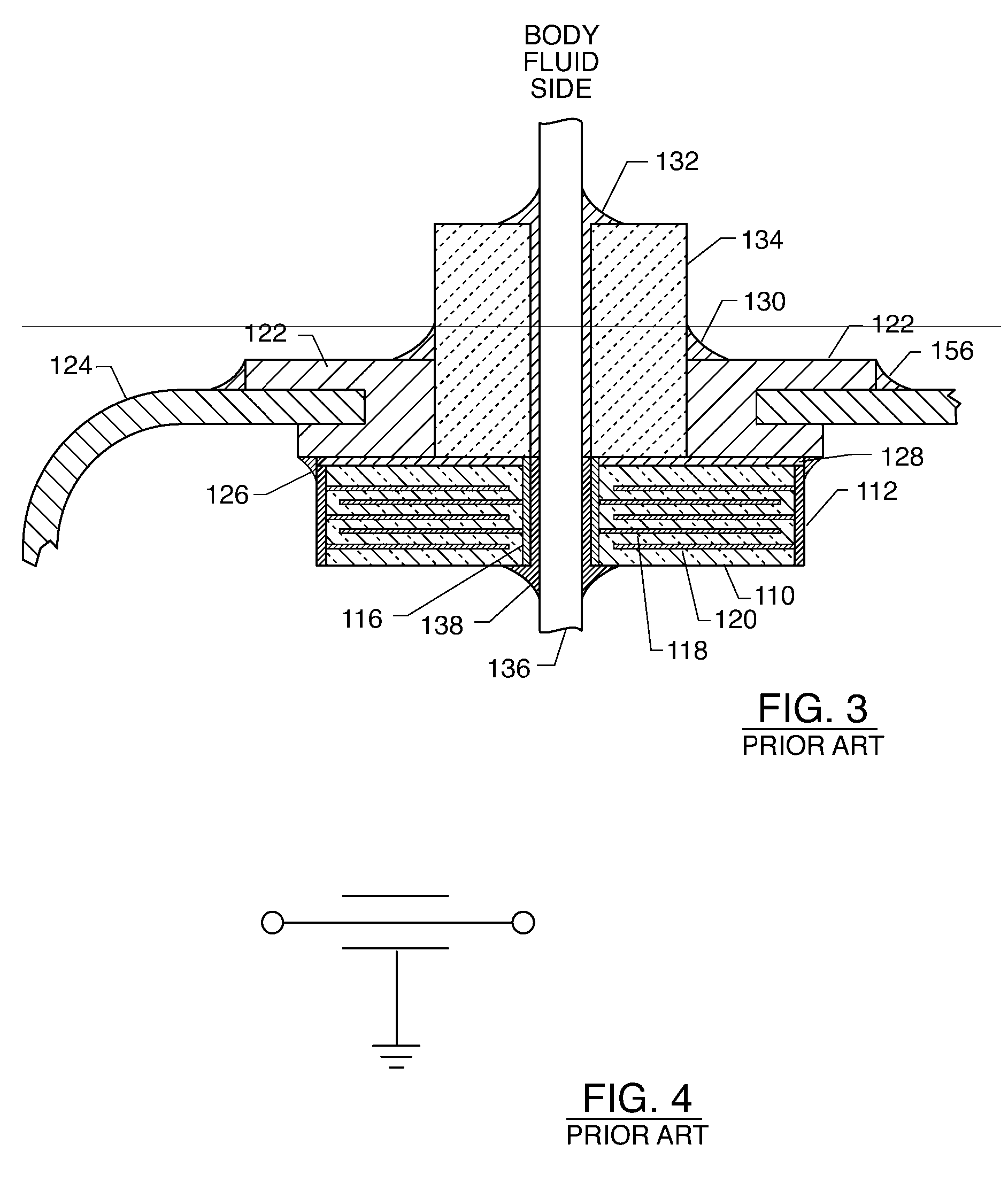

Hermetic feedthrough terminal assembly with wire bond pads for human implant applications

ActiveUS20060259093A1Consume energyReduce tensionMultiple-port networksAnti-noise capacitorsUltrasonic bondingMedical device

A feedthrough terminal assembly for active implantable medical devices includes a structural wire bond pad for a convenient attachment of wires from either the circuitry inside the implantable medical device or wires external to the device. Direct attachment of wire bond pads to terminal pins enables thermal or ultrasonic bonding of lead wires, while shielding the capacitor or other delicate components from the forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

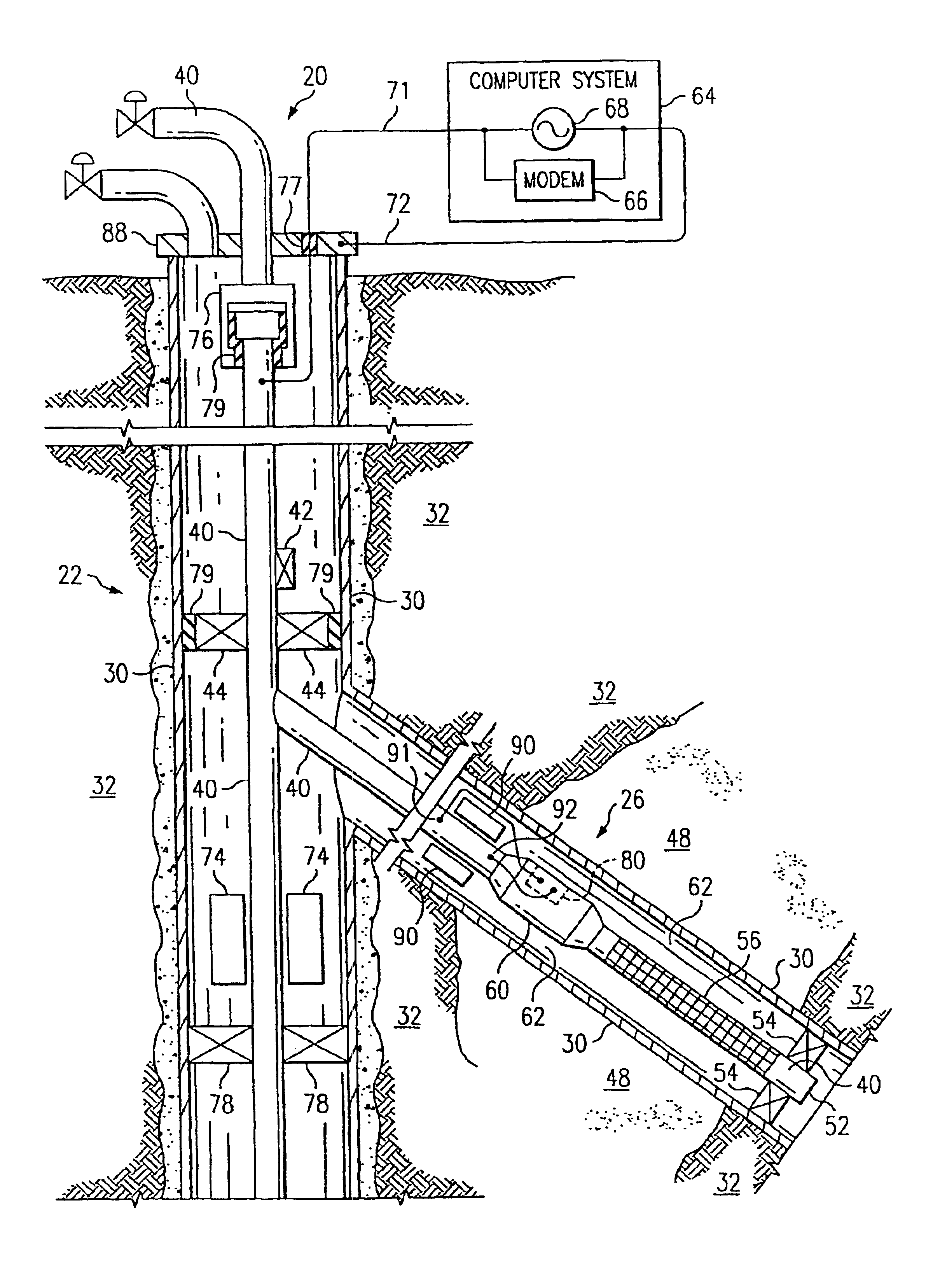

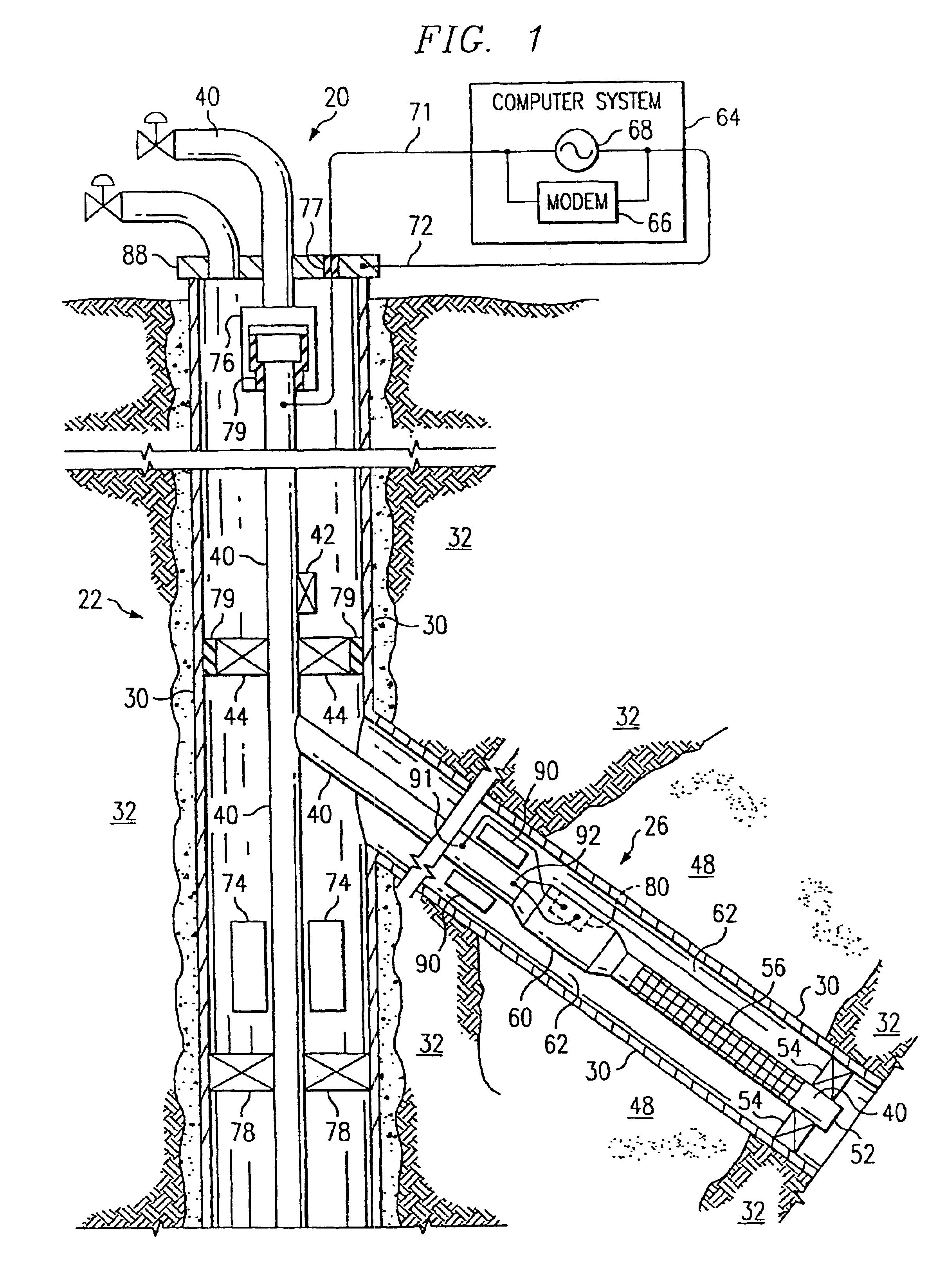

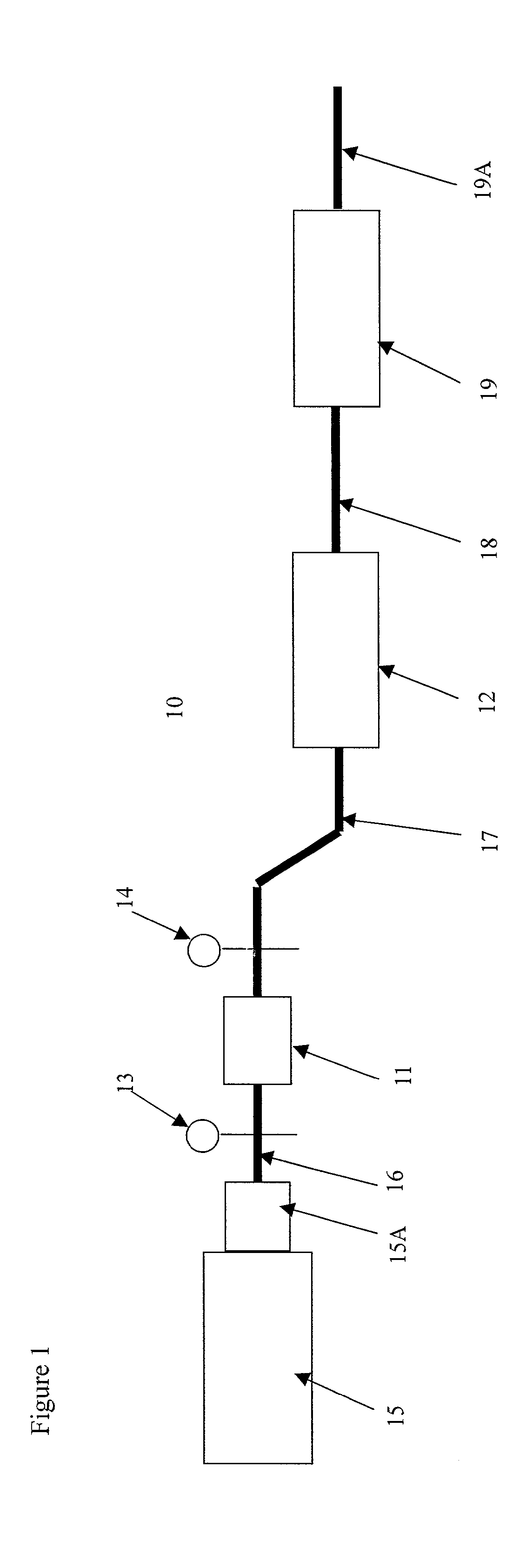

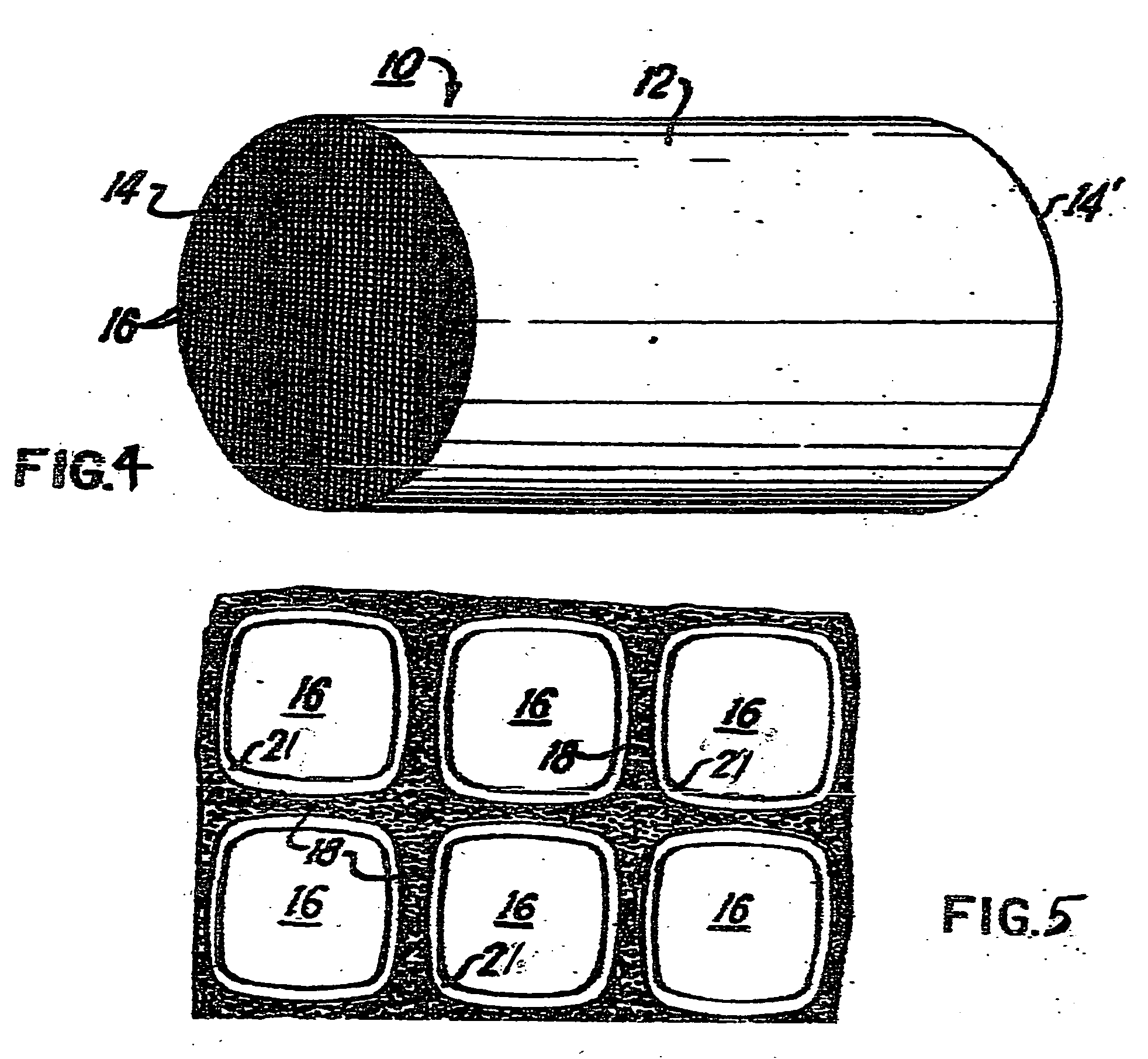

Controlled downhole chemical injection

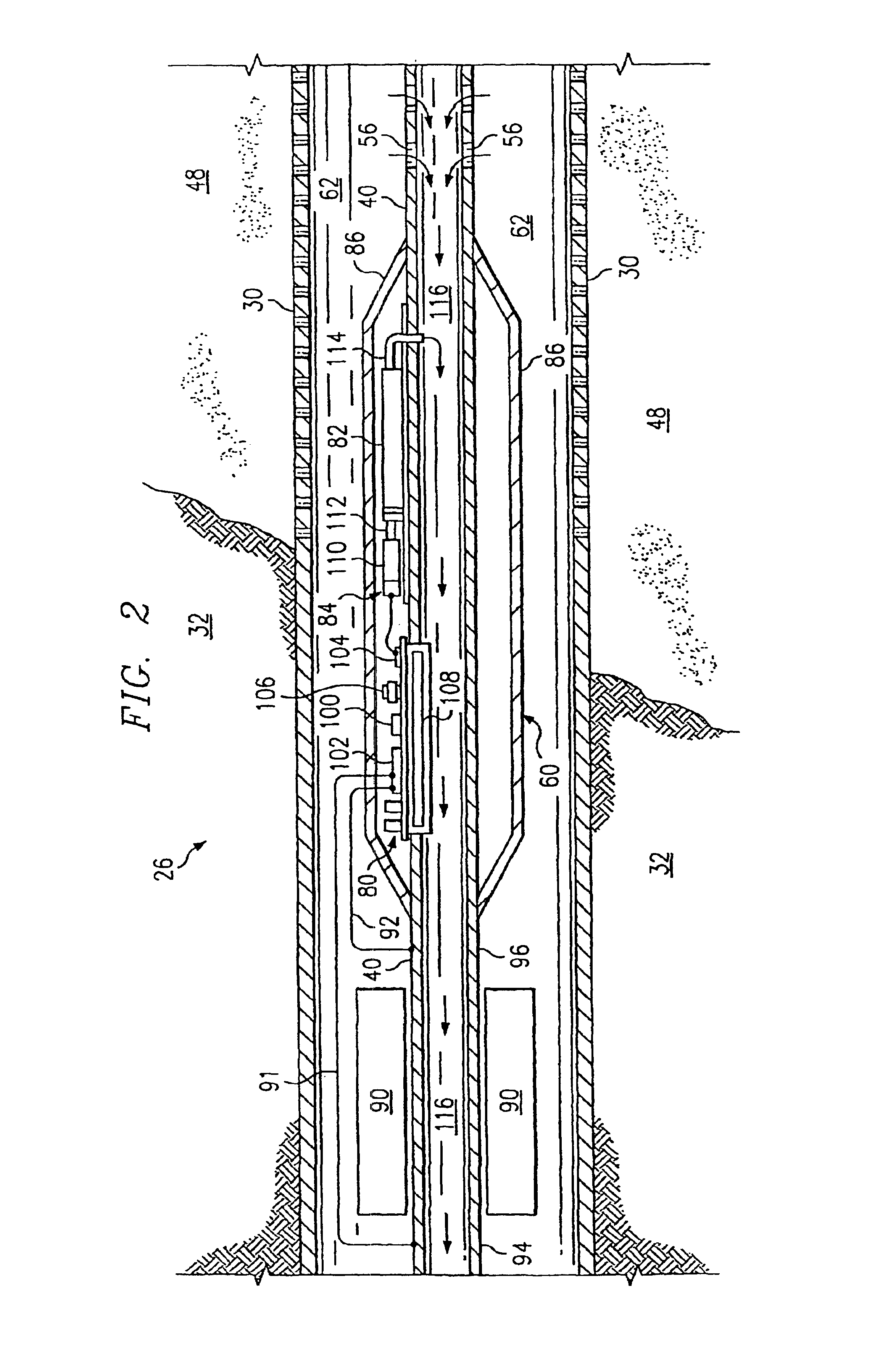

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

Plasma processing method and plasma processing apparatus

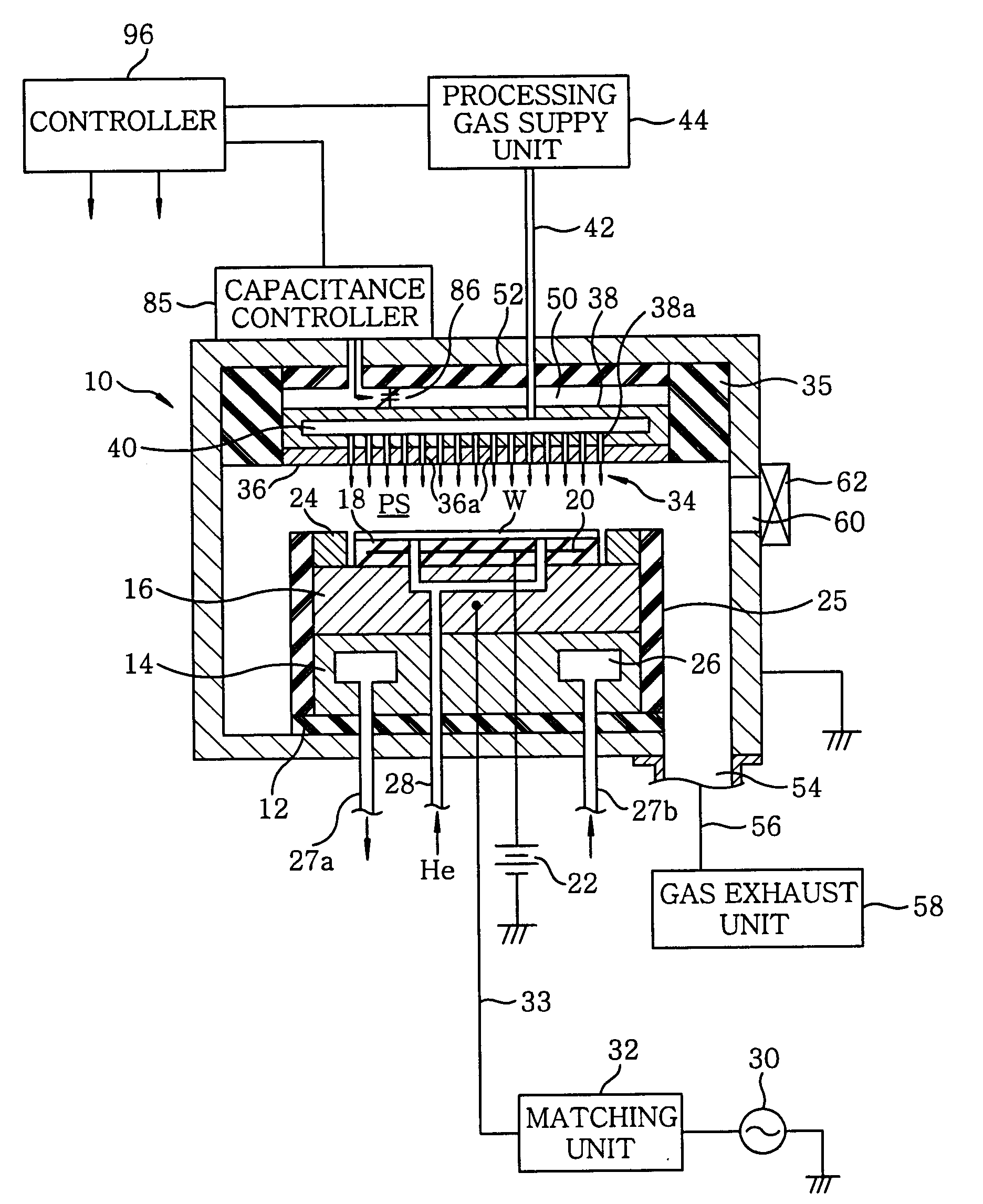

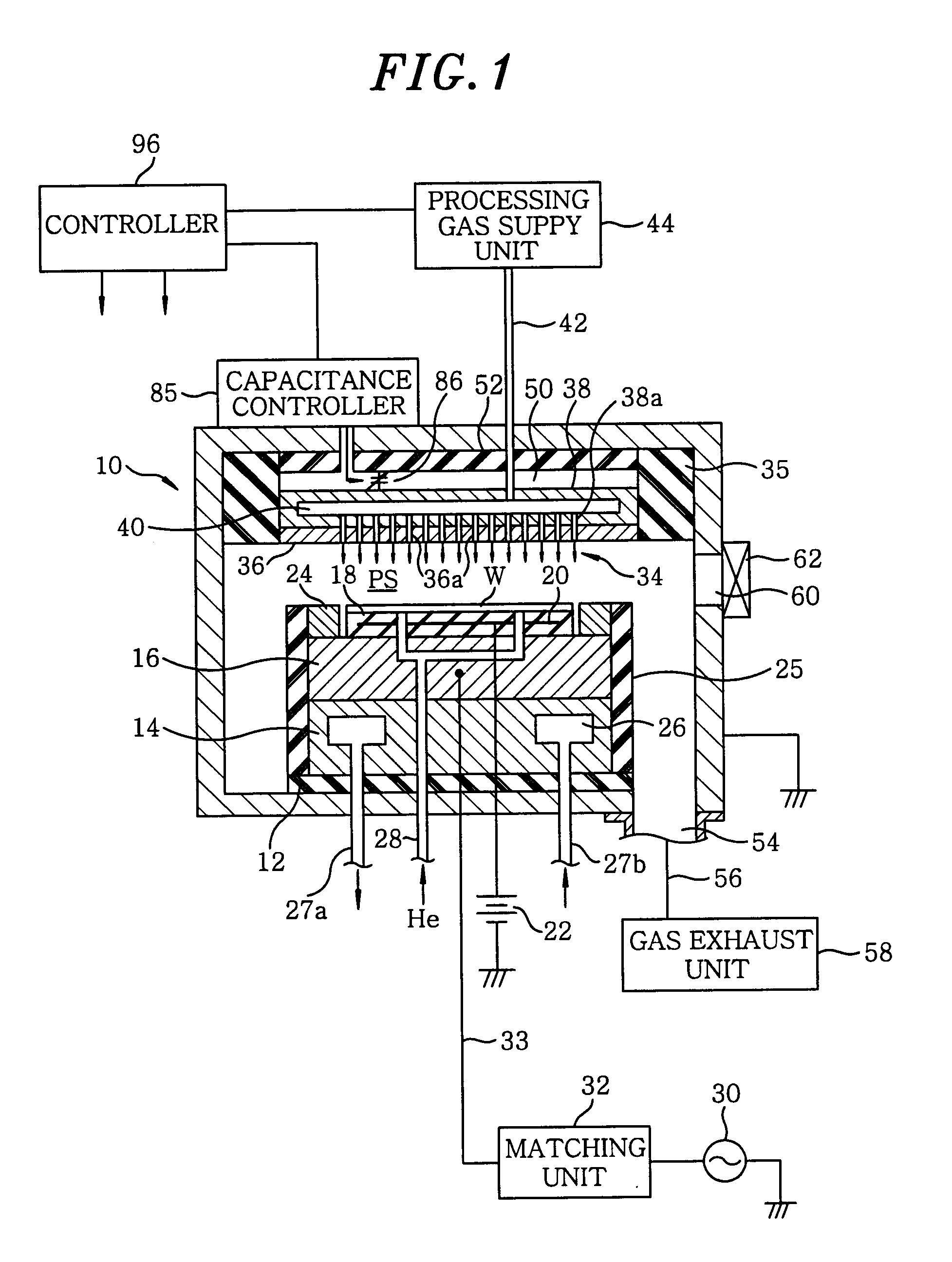

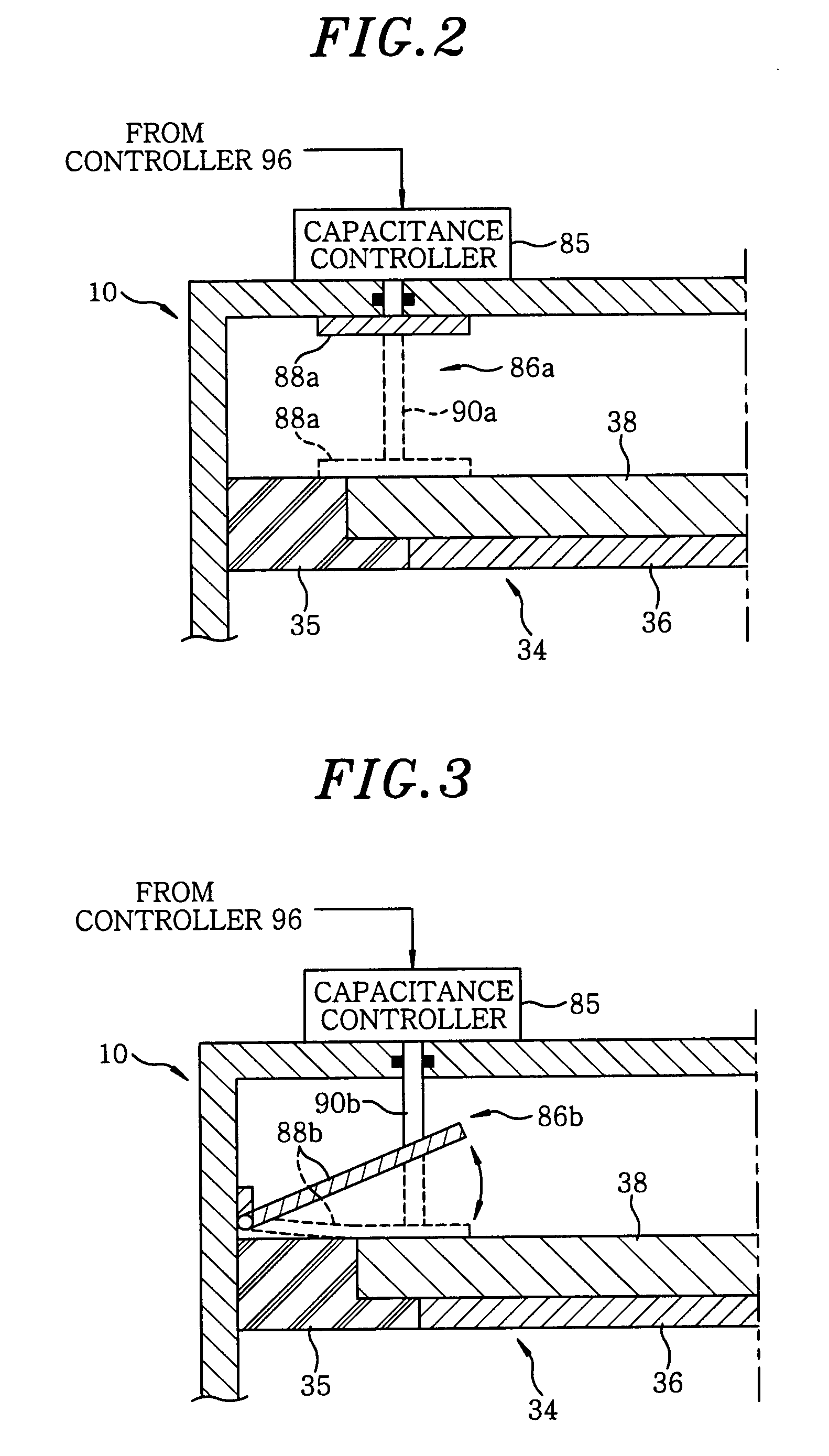

ActiveUS20070227665A1Uniform processingSecuring uniformityLiquid surface applicatorsElectric discharge tubesCapacitanceEngineering

A plasma processing method performs a desired plasma process on substrates by using a plasma generated in a processing space. A first and a second electrode are disposed in parallel in a processing vessel that is grounded, the substrate is supported on the second electrode to face the first electrode, the processing vessel is vacuum evacuated, a desired processing gas is supplied into the processing space formed between the first electrode, the second electrode and a sidewall of the processing vessel, and a first radio frequency power is supplied to the second electrode. The first electrode is connected to the processing vessel via an insulator or a space, and is electrically coupled to a ground potential via a capacitance varying unit whose electrostatic capacitance is varied based on a process condition of the plasma process performed on the substrate.

Owner:TOKYO ELECTRON LTD

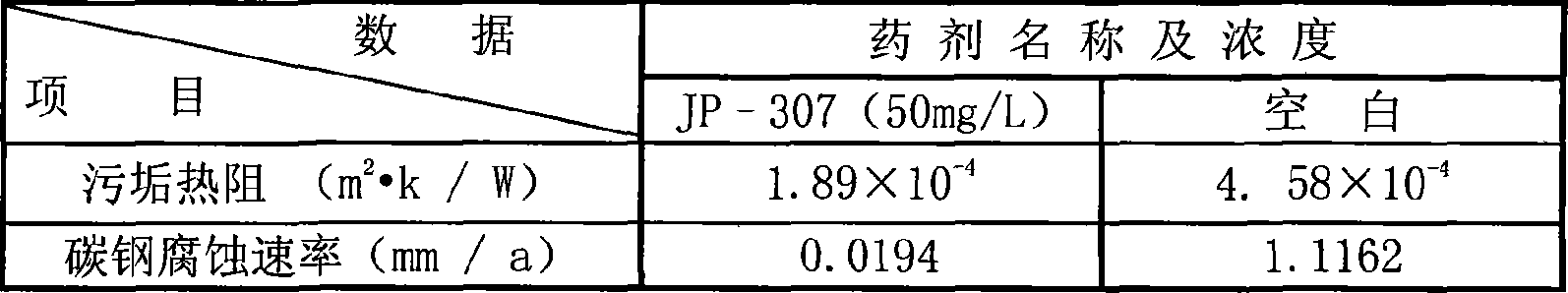

No-phosphate corrosion and scale inhibitor and its application

InactiveCN101066811AExcellent corrosion inhibition performanceIncrease polarityScale removal and water softeningNon-contaminated water treatmentPolyaspartic acidPhosphate

The present invention relates to no-phosphate corrosion and scale inhibitor and its application. The no-phosphate corrosion and scale inhibitor consists of polyaspartic acid and / or polyepoxy succinic acid 10-20 wt%, polymaleic anhydride 20-30 wt%, copolymer of acrylic acid and 2-acrylamido-2-methyl propenyl sulfonic acid 15-20 wt%, zinc salt 3-5 wt%, natural organic high molecular compound 5-12 wt%, molybdate 5-8 wt%, and other components 5-20 wt%. It has excellent corrosion retarding performance, high scale inhibiting performance and environment friendship.

Owner:WUHAN JINPO CHEM TECH

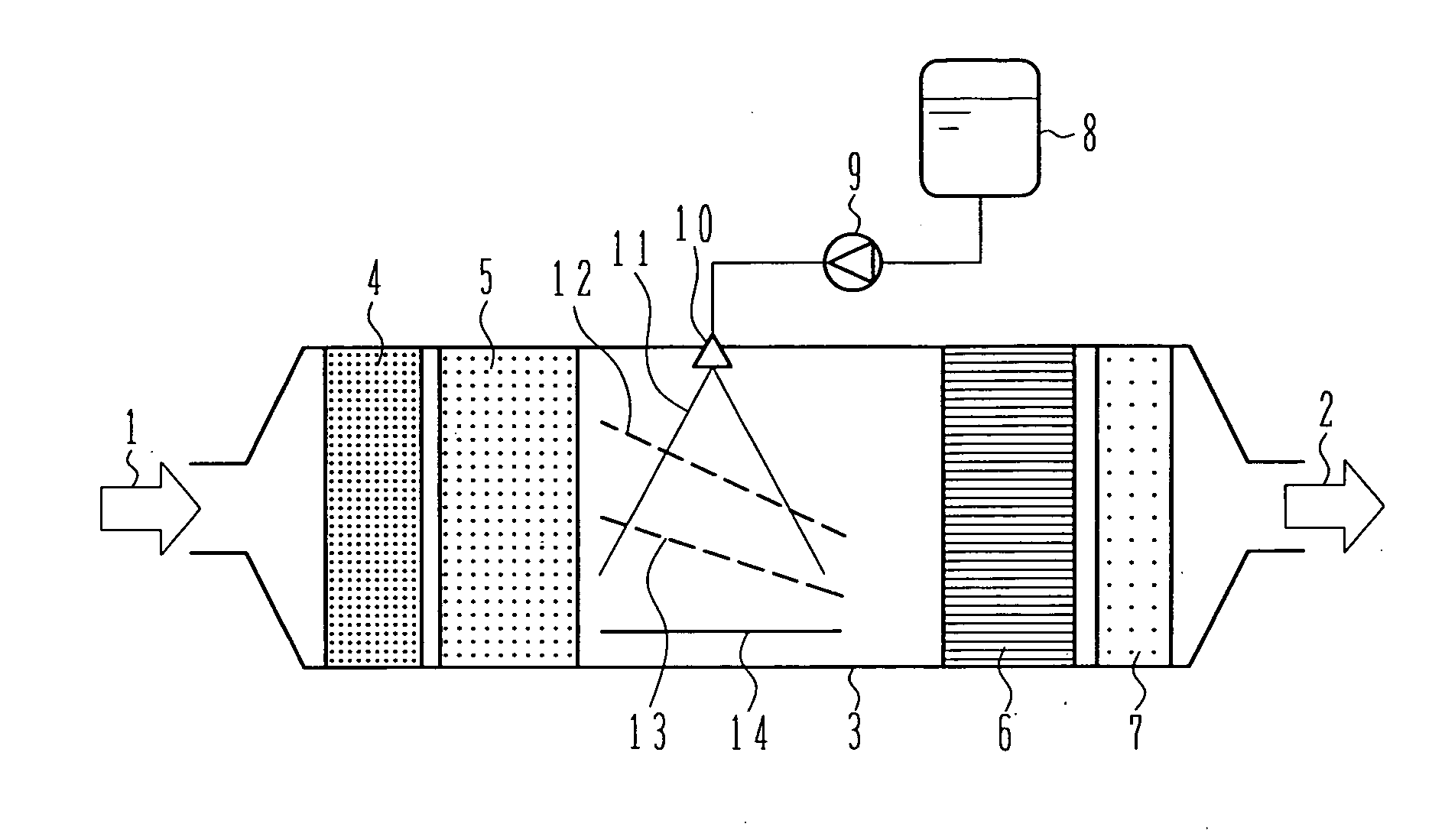

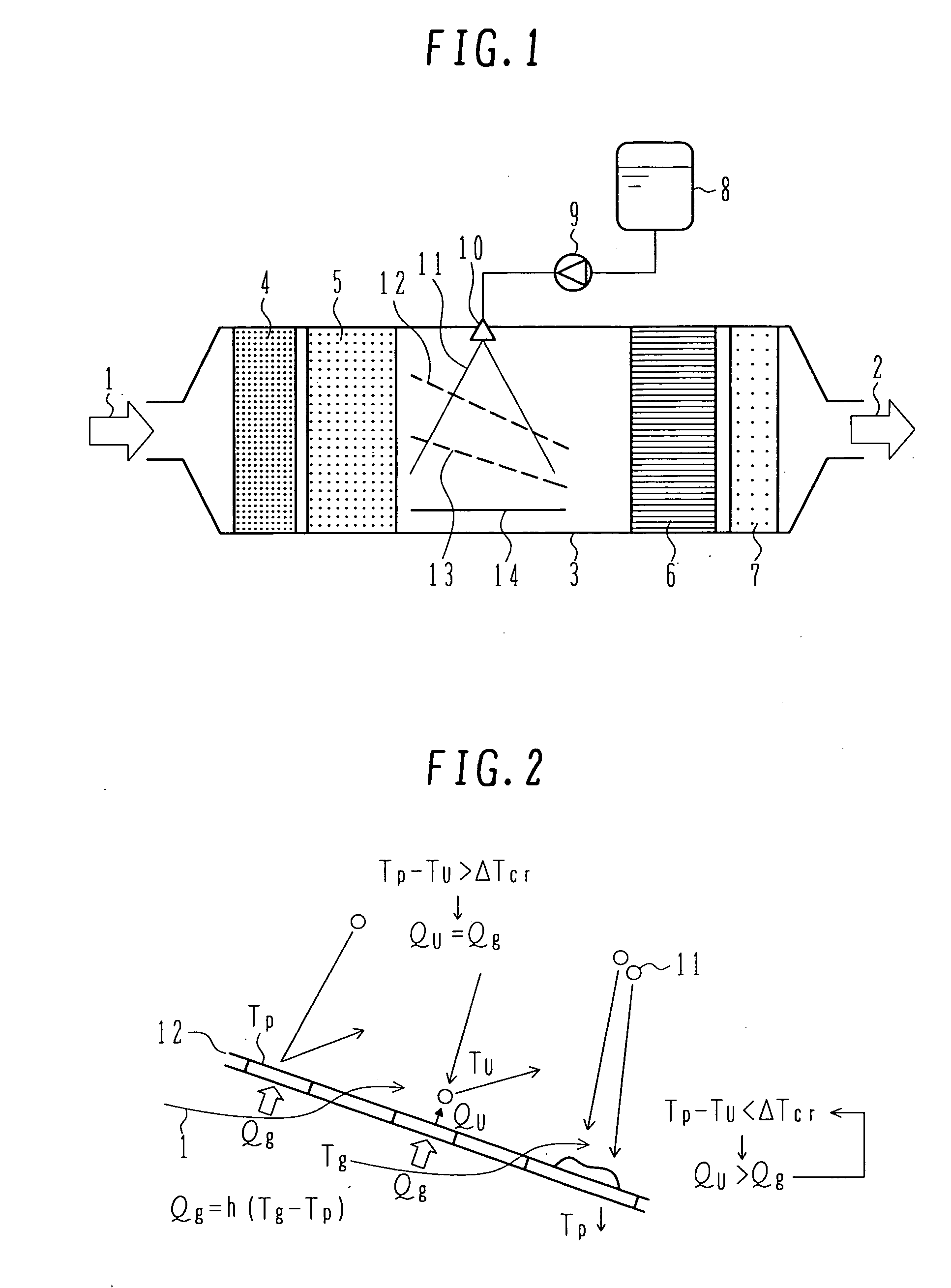

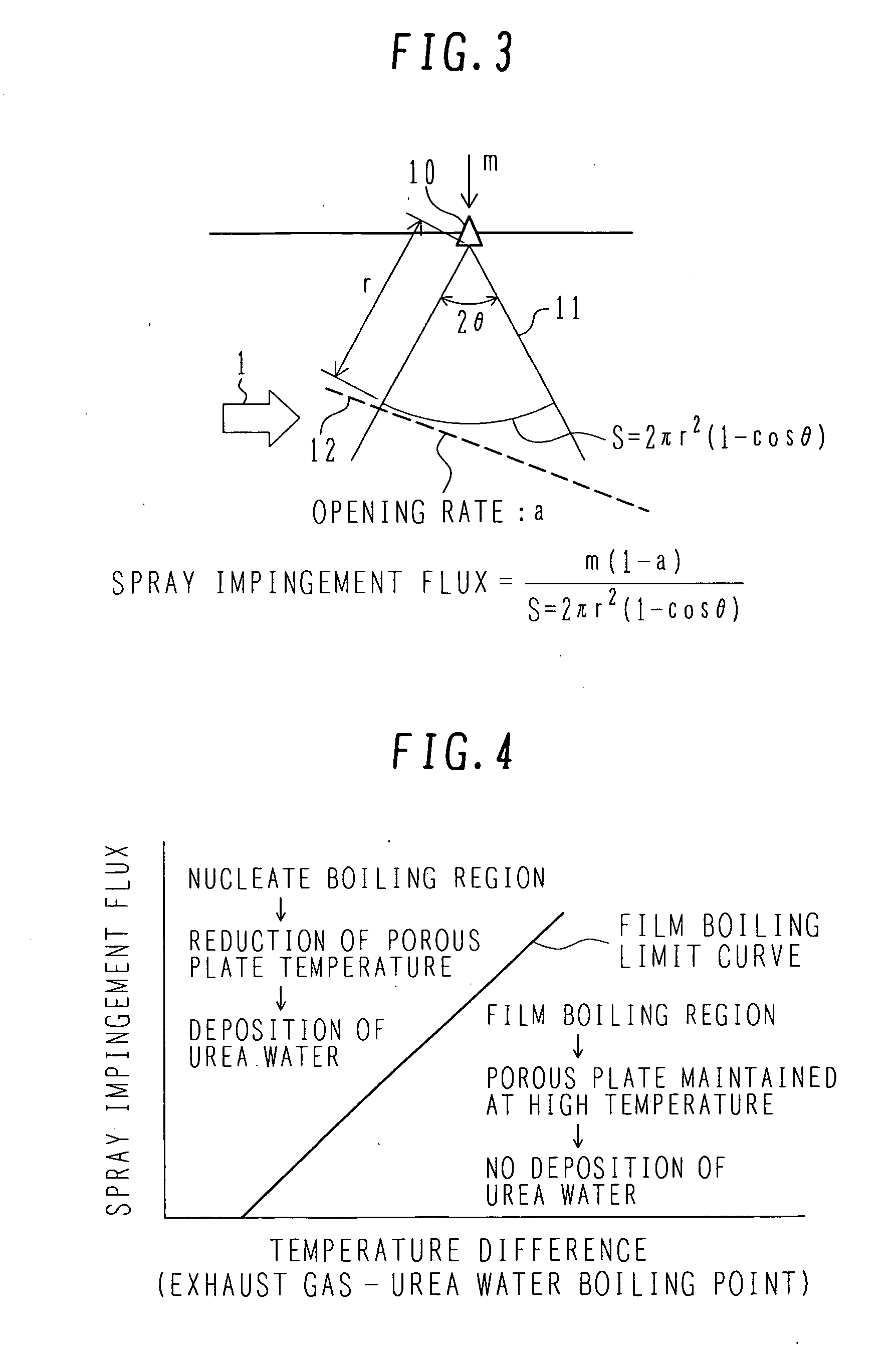

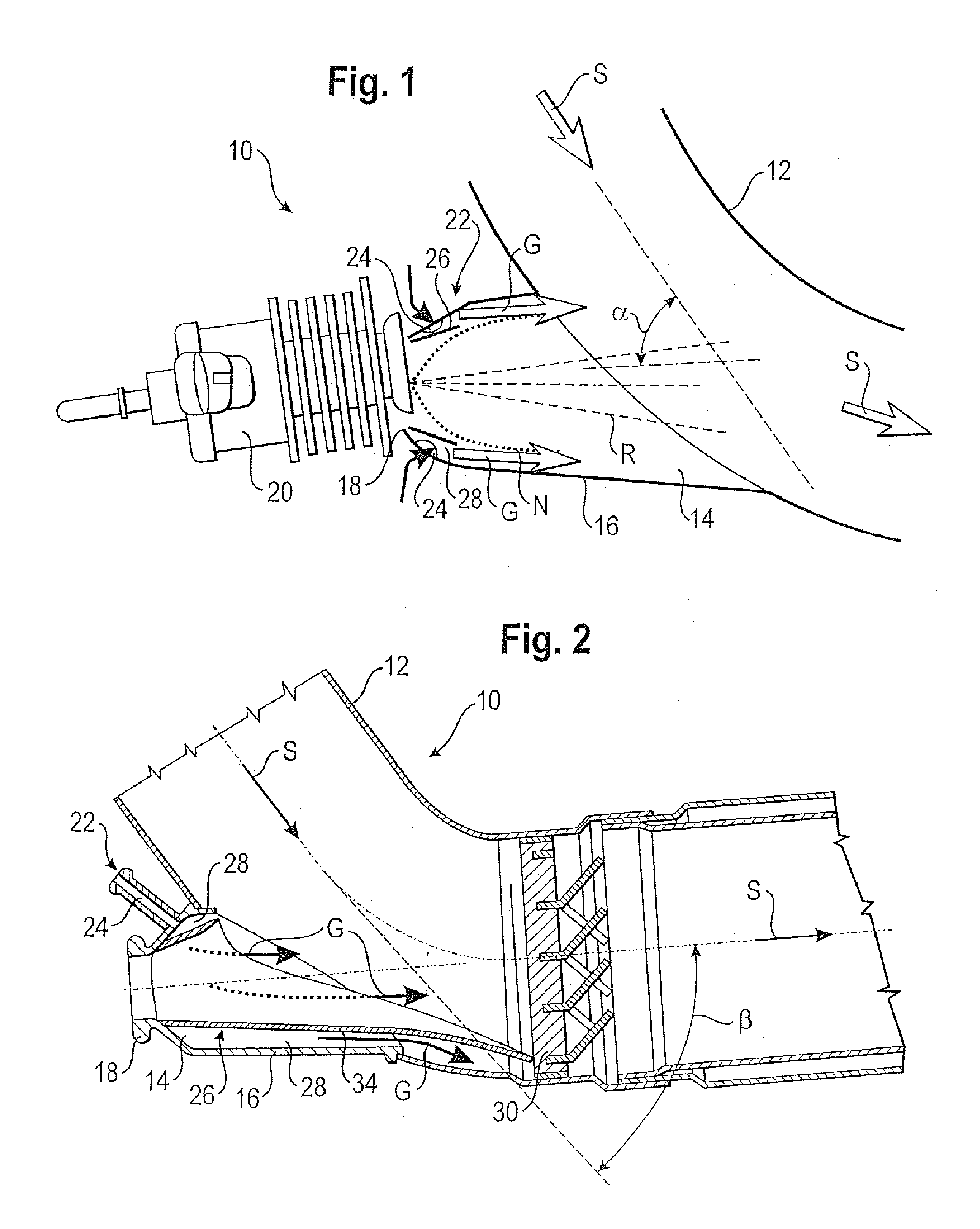

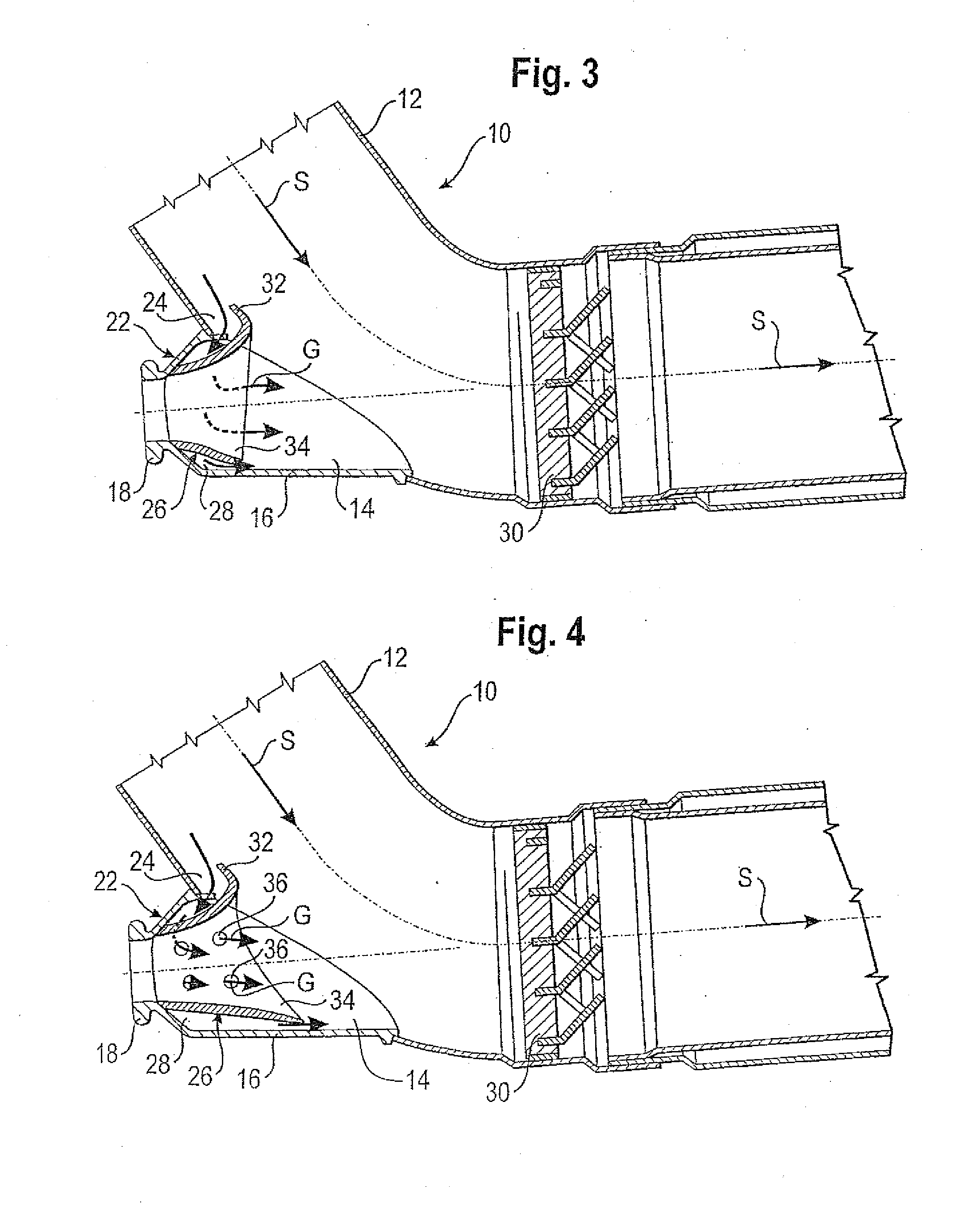

Exhaust aftertreatment system using urea water

InactiveUS20070036694A1Avoid depositionReduced responseCombination devicesInternal combustion piston enginesHandling systemMultiple stages

An exhaust aftertreatment system comprises an injector for injecting urea water into an exhaust duct, and a denitration catalyst disposed downstream of the injector with respect to a flow of exhaust gas. The exhaust aftertreatment system reduces nitrogen oxides in the exhaust gas by the denitration catalyst while using ammonia produced from the urea water injected from the injector. The urea water is injected along a direction of the flow of the exhaust gas within the exhaust duct, and a porous plate is disposed in multiple stages in a space of the exhaust duct such that droplets of the injected urea water impinge against the porous plate before reaching a wall surface of the exhaust duct. A surface of the porous plate subjected to the impingement of the droplets is arranged to face downstream with respect to the flow of the exhaust gas. Deposition of the urea water is prevented by causing film boiling when the droplets impinge against the porous plate, and the urea water reflected by the porous plate is uniformly dispersed into the exhaust gas. Thus, the urea water is uniformly dispersed into the exhaust gas without increasing a pressure loss of the exhaust gas. The urea water is prevented from depositing on the wall surface and producing a precipitate in the form of a solid.

Owner:HITACHI HIGH-TECH CORP +2

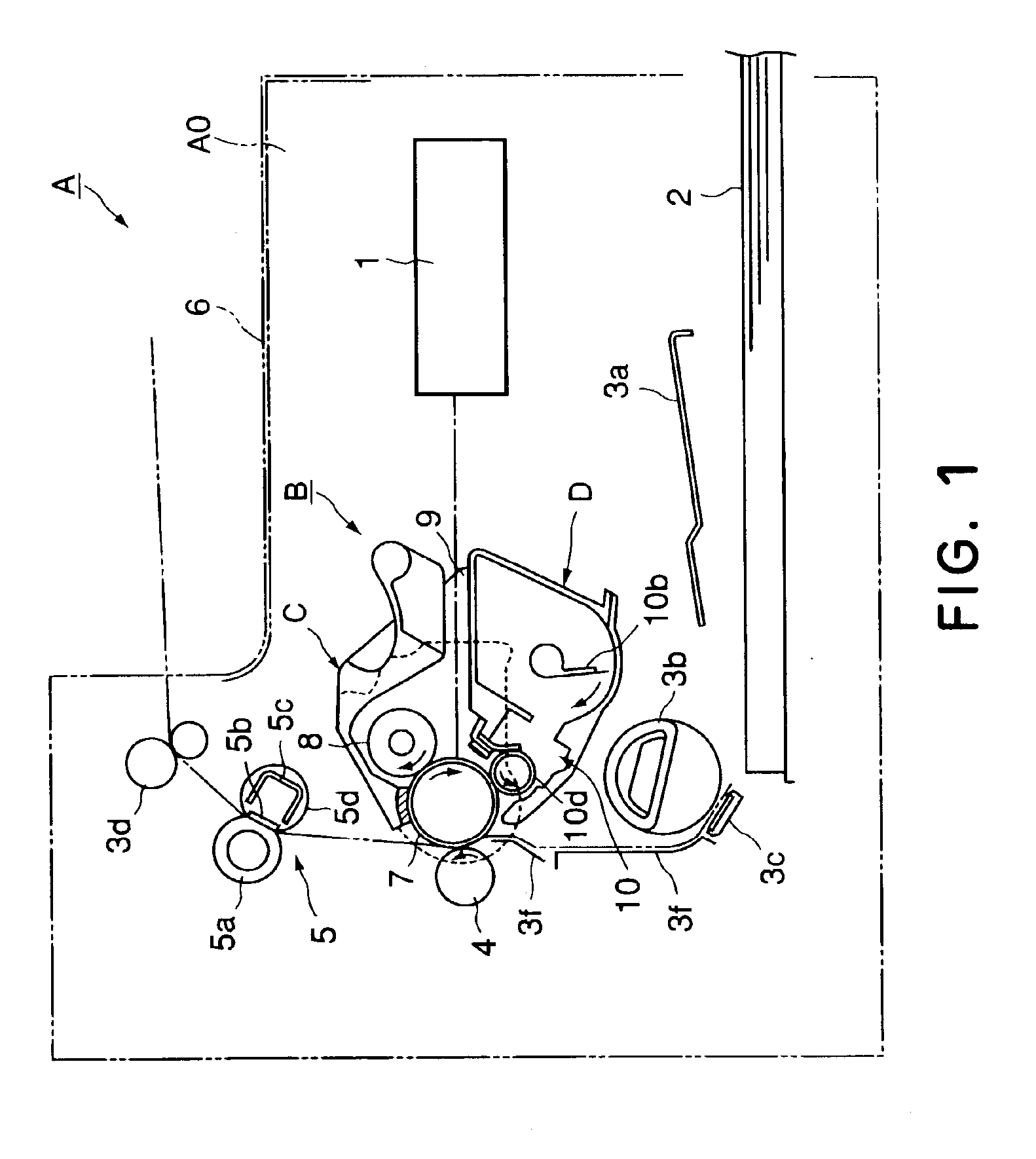

Process cartridge and electrophotographic image forming apparatus

InactiveUS6963706B2Avoid depositionElectrographic process apparatusCorona dischargeEngineeringImaging equipment

A process cartridge detachably mountable to a main assembly of an electrophotographic image forming apparatus, includes a photosensitive drum; a developing roller rotatable in the drum-rotating direction when the cartridge is mounted to the apparatus; first and second separation members disposed at one and the other end of the roller so as to provide a gap between the roller and the drum and contacting the drum surface adjacent one and the other end thereof; a charging roller, contacting and charging the drum, which is rotatable with a peripheral speed difference relative to the drum; and a cleaning member contacting the drum adjacent one end thereof, the cleaning member having an effective area outside a developing-roller developing zone and inside a charging-roller-and drum contact region and which is in a region where the first separation member contacts the drum.

Owner:CANON KK

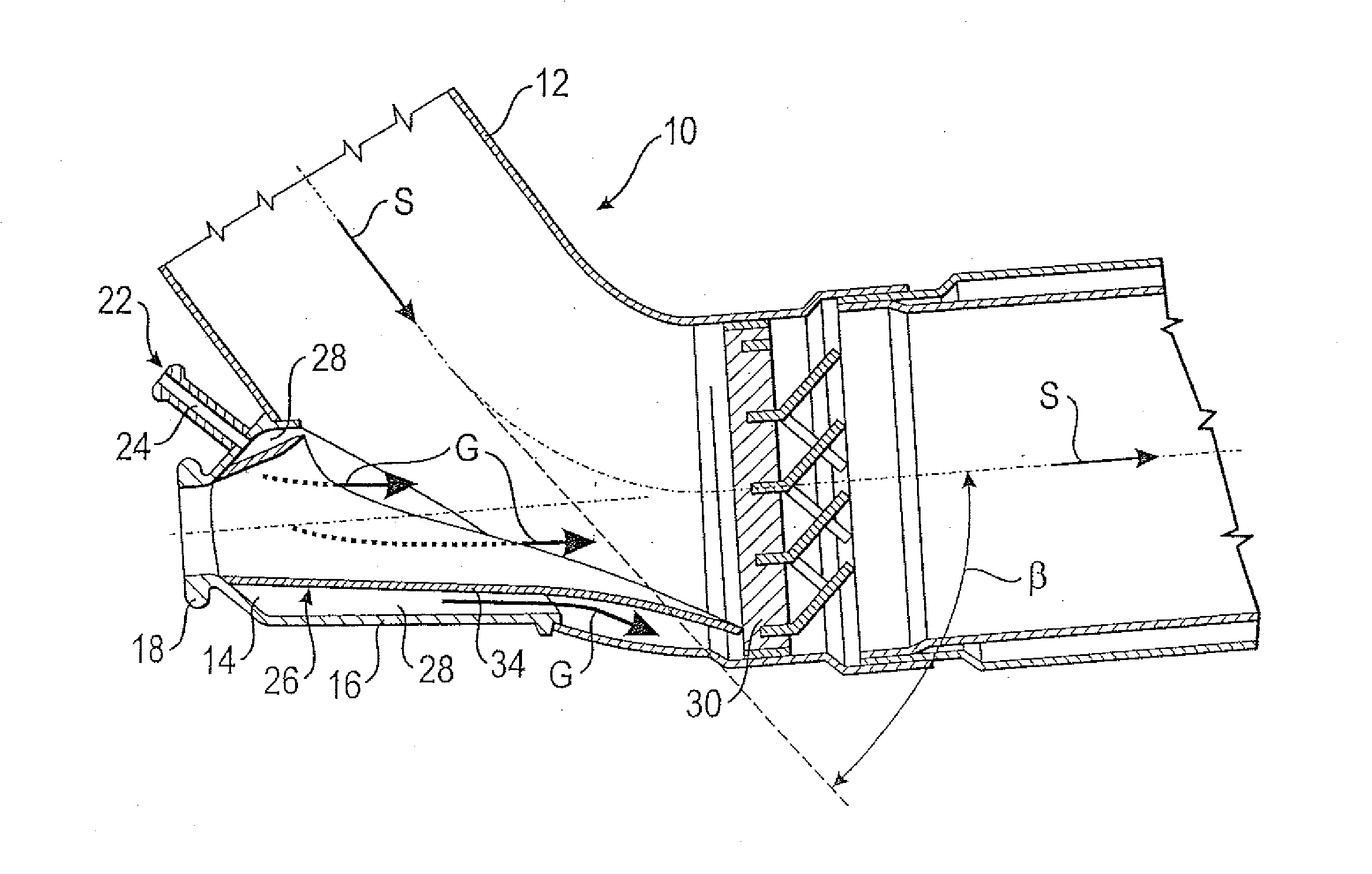

Assembly and Method for Introducing a Reducing Agent into the Exhaust Pipe of an Exhaust System of an Internal Combustion Engine

InactiveUS20100212292A1Avoid depositionWell mixedGas treatmentInternal combustion piston enginesMobile vehicleExternal combustion engine

An assembly and method for introducing a reducing agent into an exhaust pipe of an exhaust system of an internal combustion engine, in particular of a motor vehicle includes a feed connector which opens into the exhaust pipe and has a wall; a feed device for reducing agents which opens into the feed connector; and a device that generates a gas flow which is additional to the reducing agent flow and lines the wall of the feed connector.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

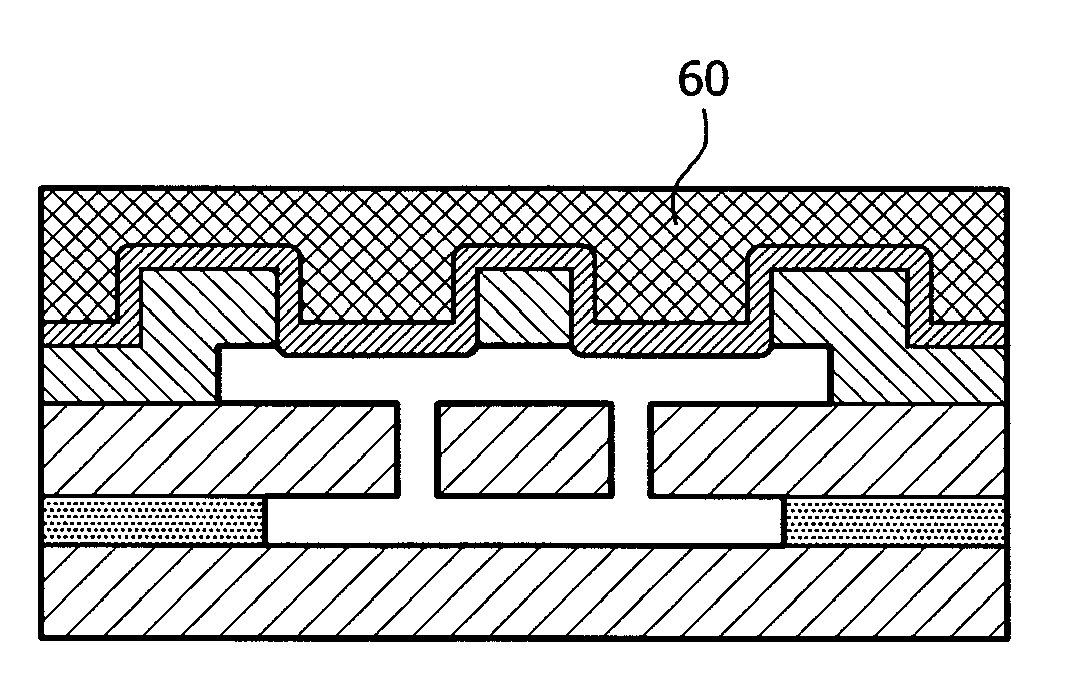

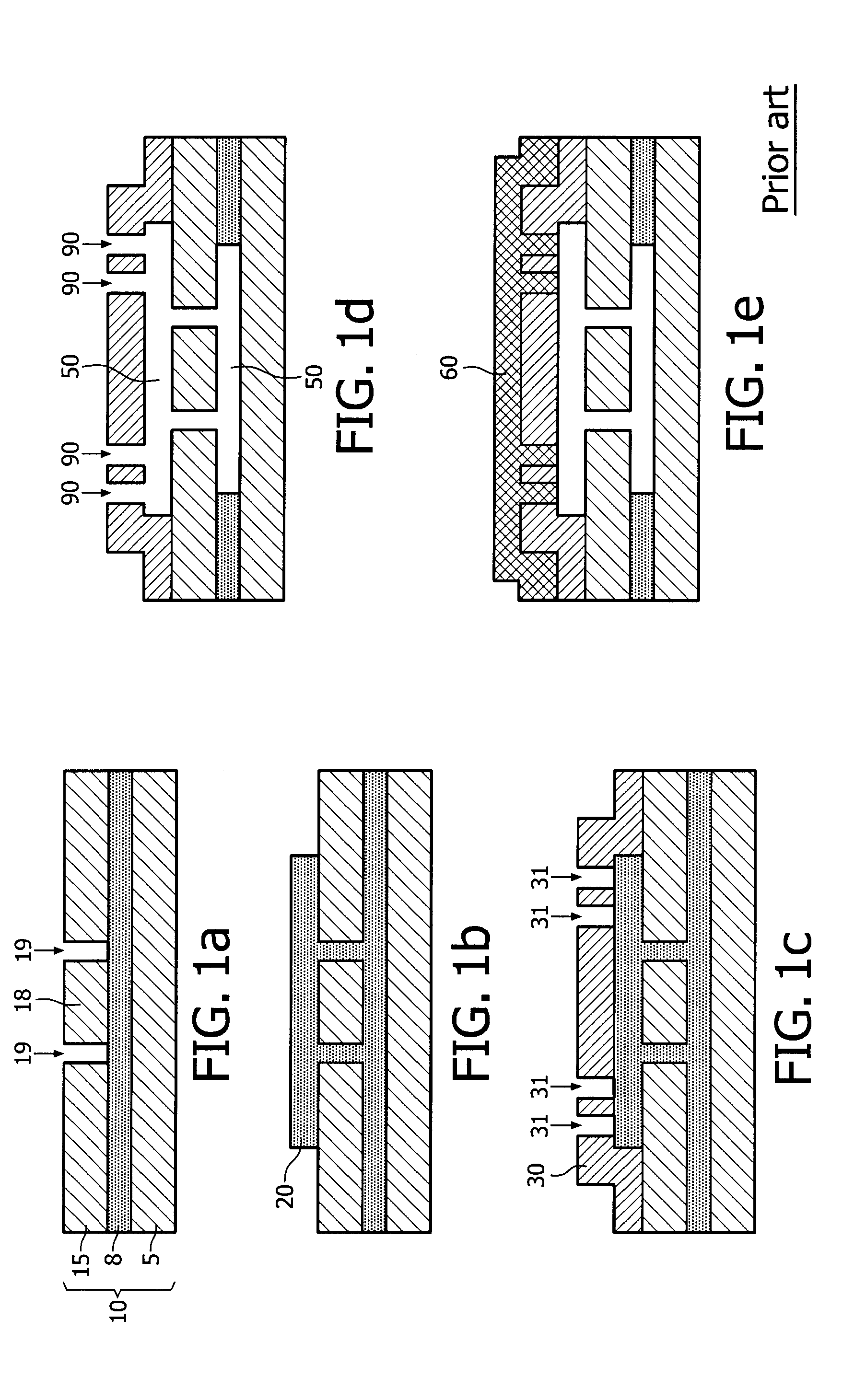

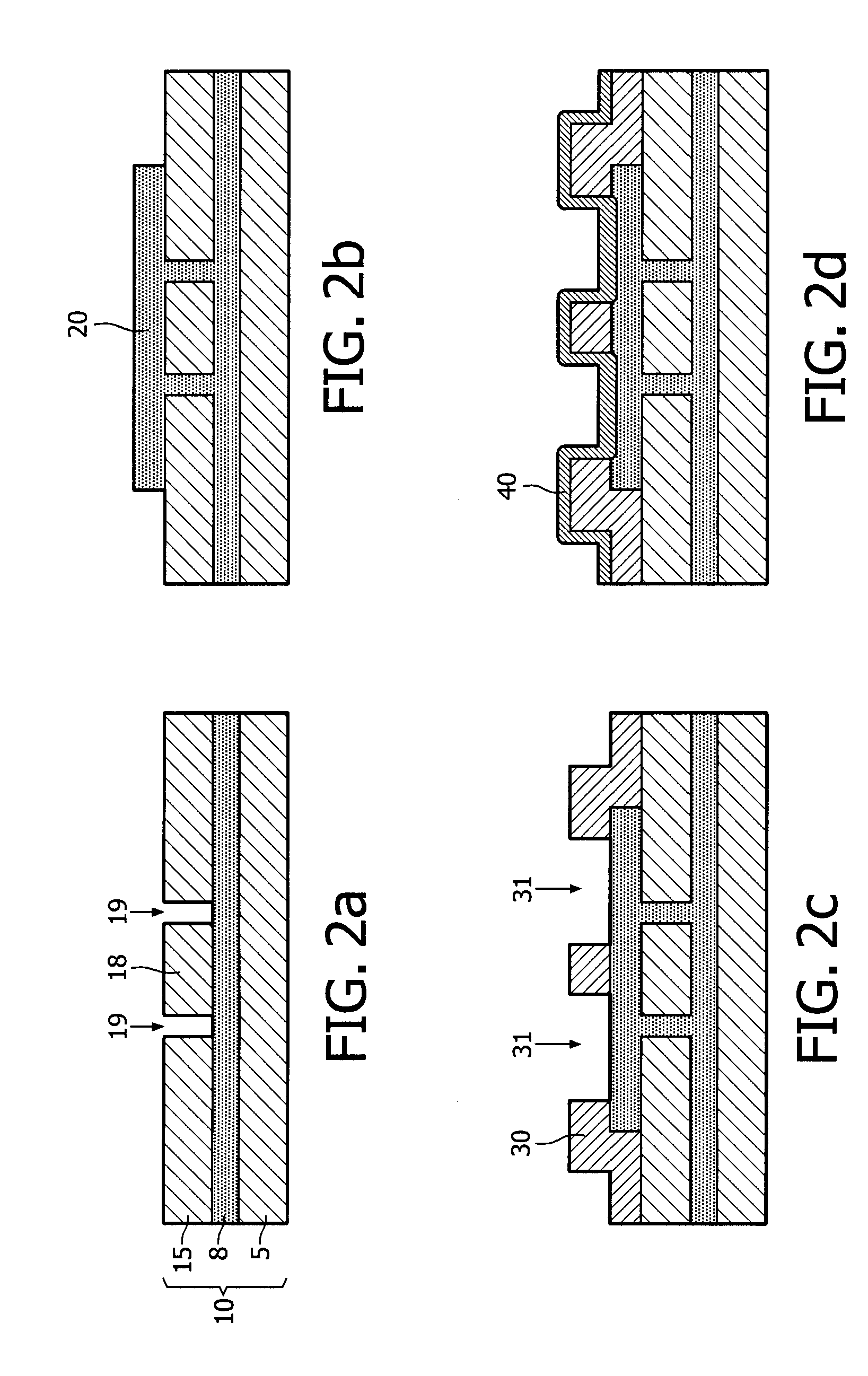

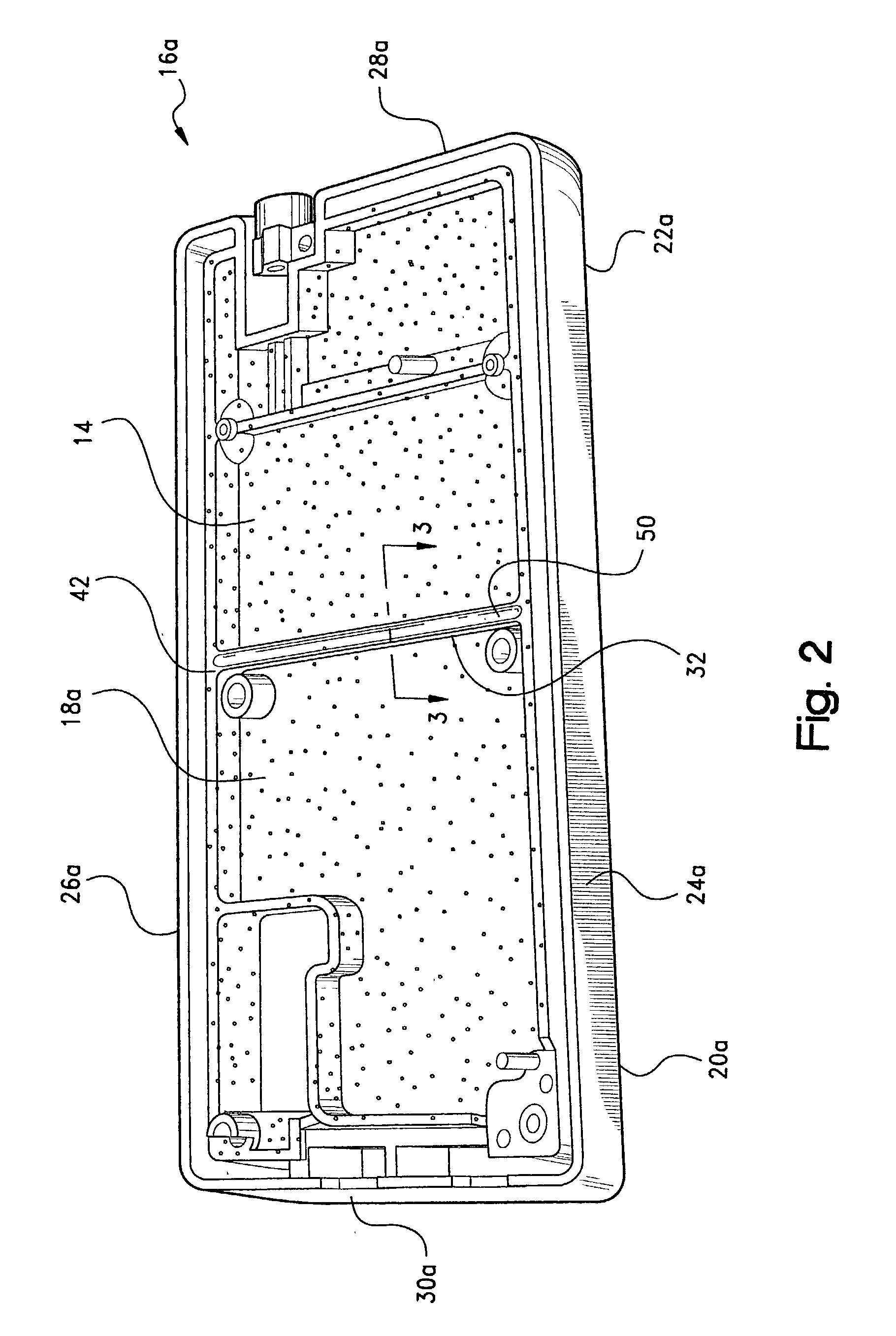

Method of manufacturing a device with a cavity

ActiveUS20090267166A1More BEOL-processing compatibleReduce the temperatureSemiconductor/solid-state device detailsSolid-state devicesPorous layerDevice material

The invention relates to a micro-device with a cavity (50), the micro-device comprising a substrate (10, 110), the method comprising steps of: A) providing the substrate (10, 110), having a surface and comprising a sacrificial oxide region (20, 107, 115) at the surface ( ); B) covering the sacrificial oxide region (20, 107, 115) with a porous layer (40, 114, 124) being permeable to a vapor HF etchant (100), and C) selectively etching the sacrificial oxide region (20, 107, 115) through the porous layer (40, 114, 124) using the vapor HF etchant (100) to obtain the cavity (50). This method may be used in the manufacture of various micro-devices with a cavity (50), i.e. MEMS devices, and in particular in the encapsulation part thereof, and semiconductor devices, and in particular the BEOL-part thereof.

Owner:TAIWAN SEMICON MFG CO LTD

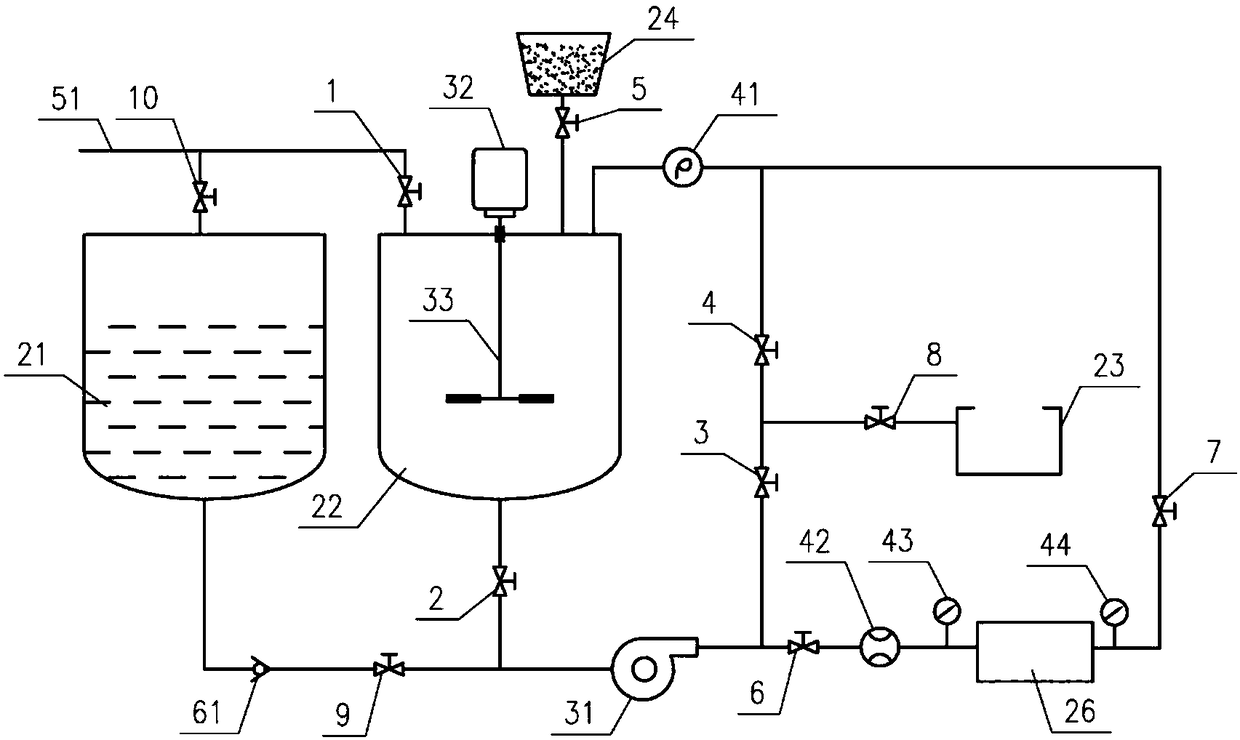

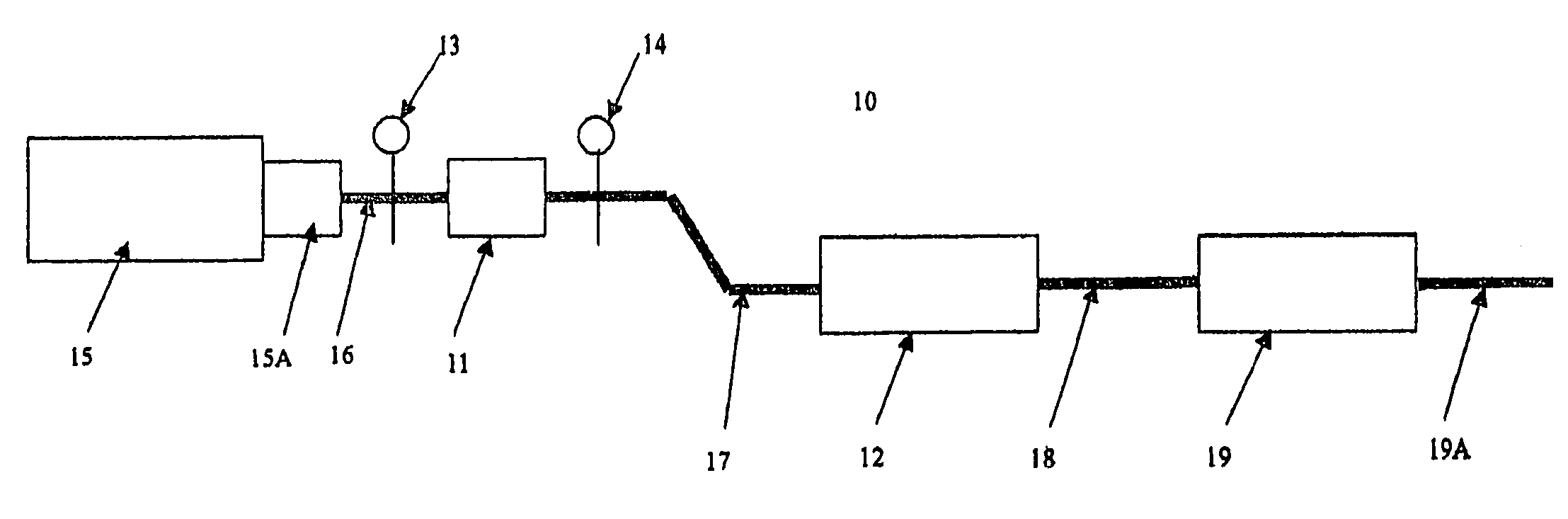

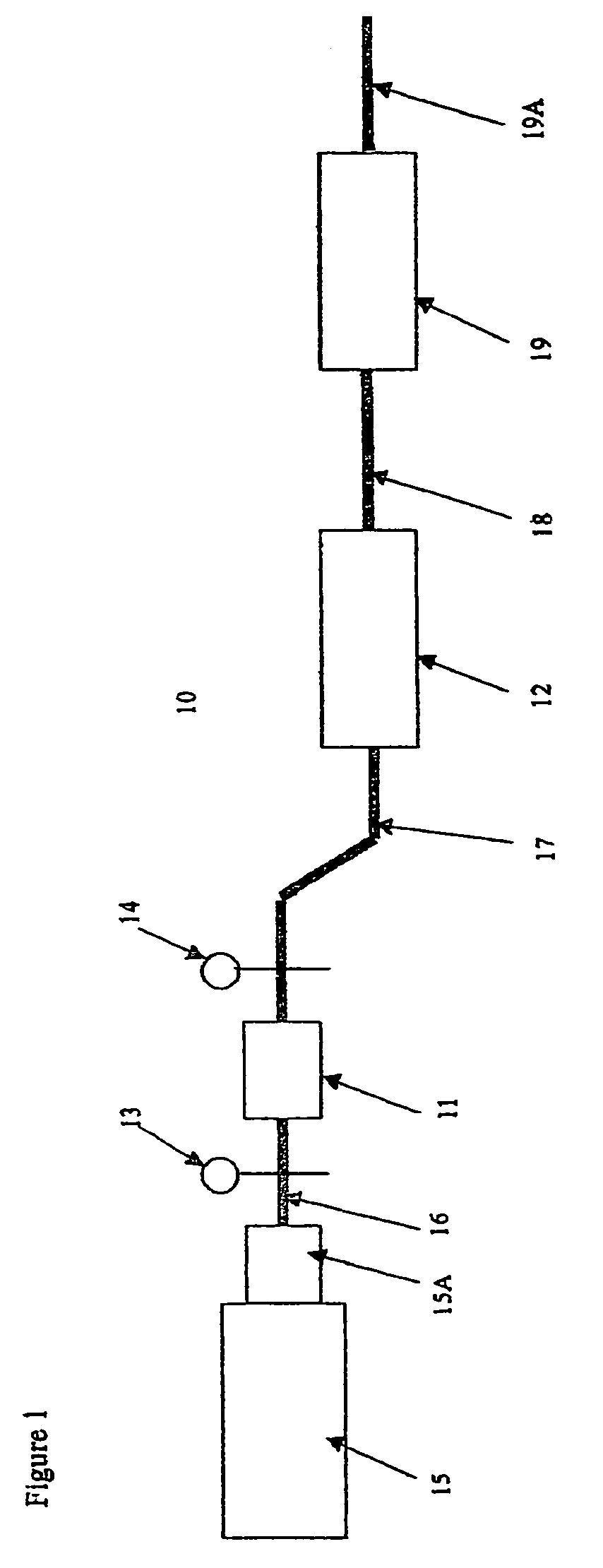

Fluid product service life testing device and testing method

PendingCN108254276AImprove work efficiencyPrevent sinkingInvestigating abrasion/wear resistanceProduct testingBiomedical engineering

The invention provides a fluid product service life testing device. The fluid product service life testing device comprises a fluid generation device, a fluid product testing region and a washing device, wherein a fluid circulating pipeline is formed between the fluid generation device and the fluid product testing region; fluid flows into the fluid product testing region from the fluid generationdevice and then continually flows back into the fluid generation device; the washing device is communicated with the fluid circulating pipeline; the washing device is communicated with the fluid product testing region and then is communicated with the fluid generation device through the fluid circulating pipeline; the fluid generation device is connected with a sediment recycling device. The fluid product service life testing device can be used for testing the service life of a product through simulating fluid flowing of production conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

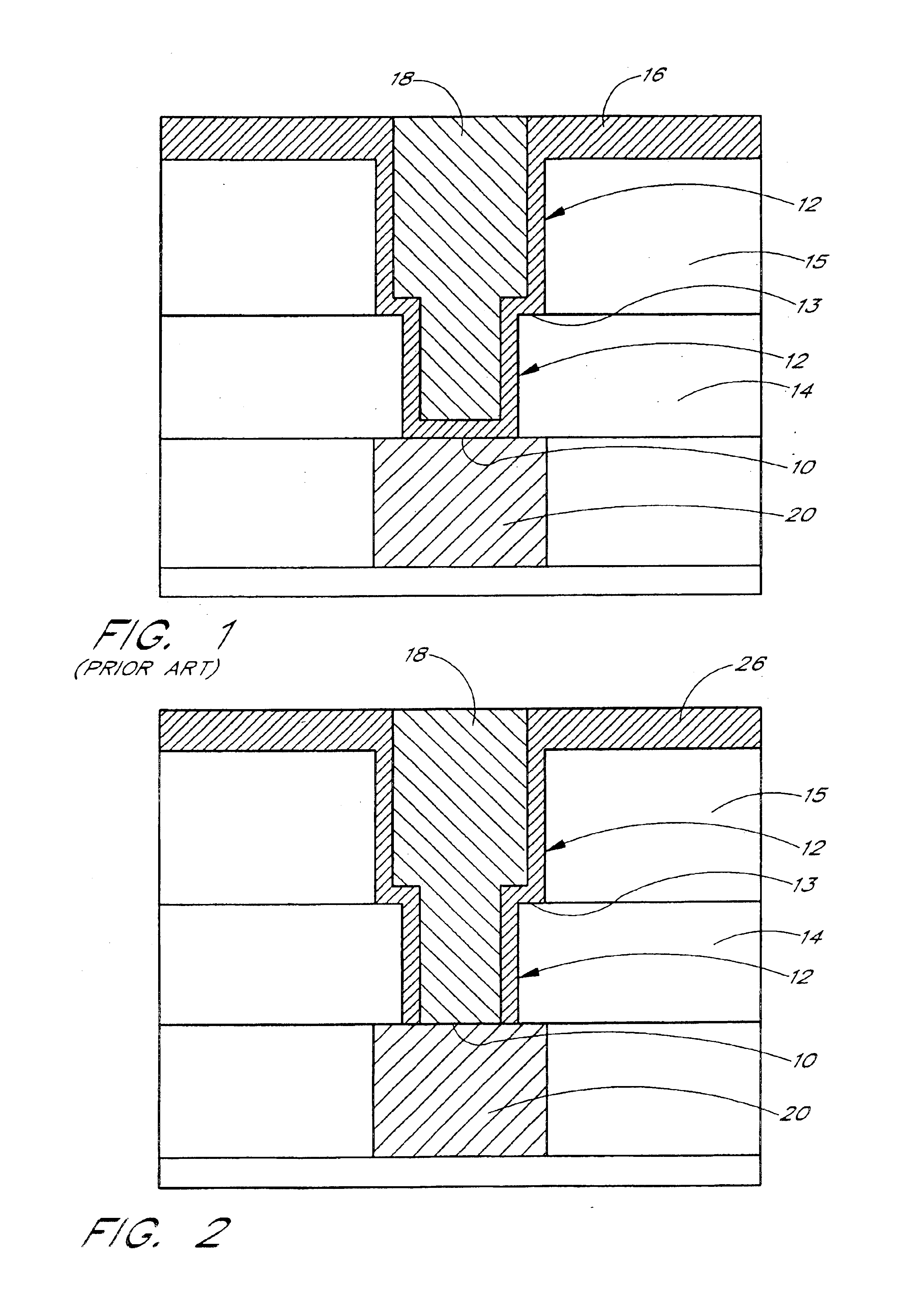

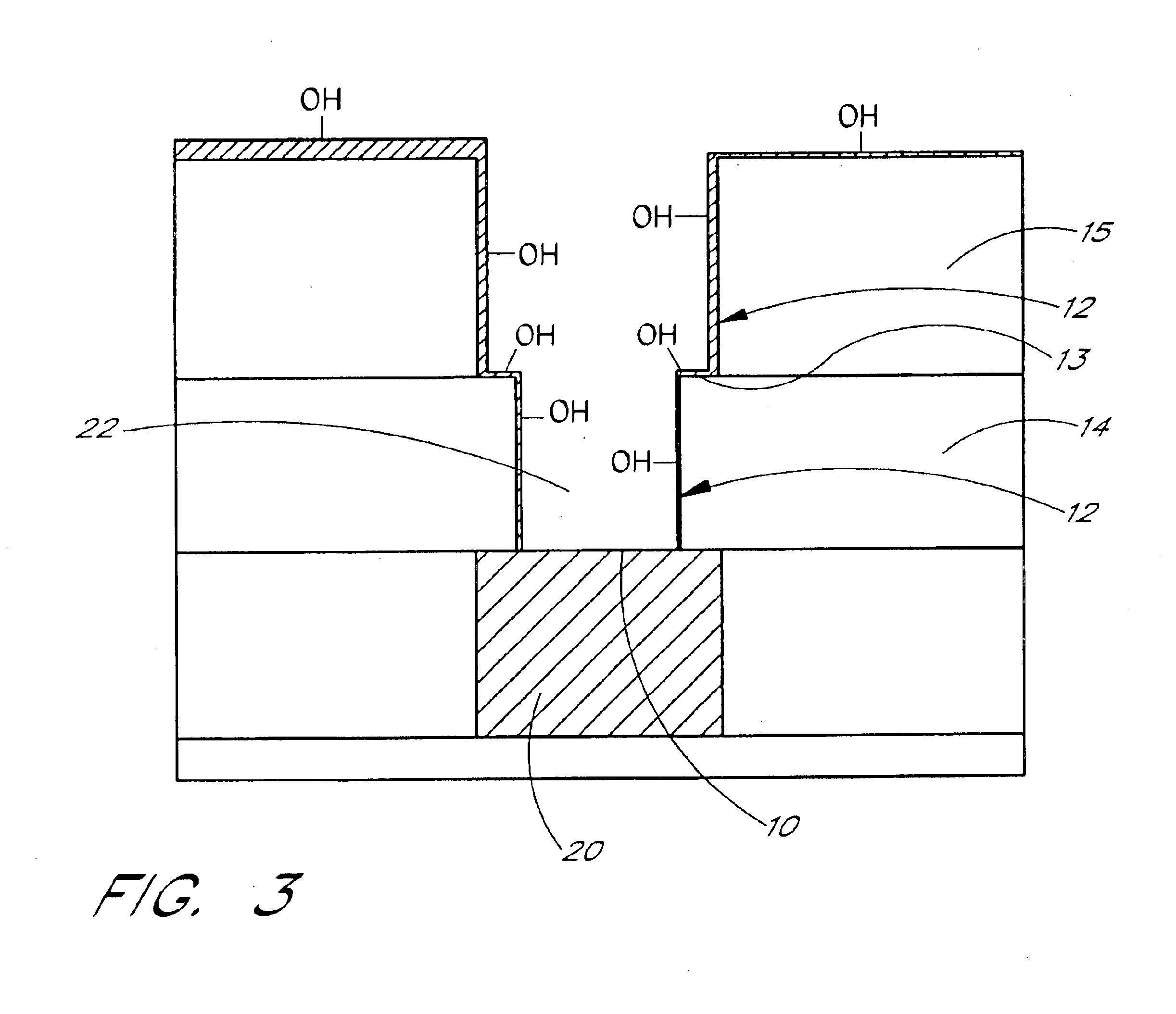

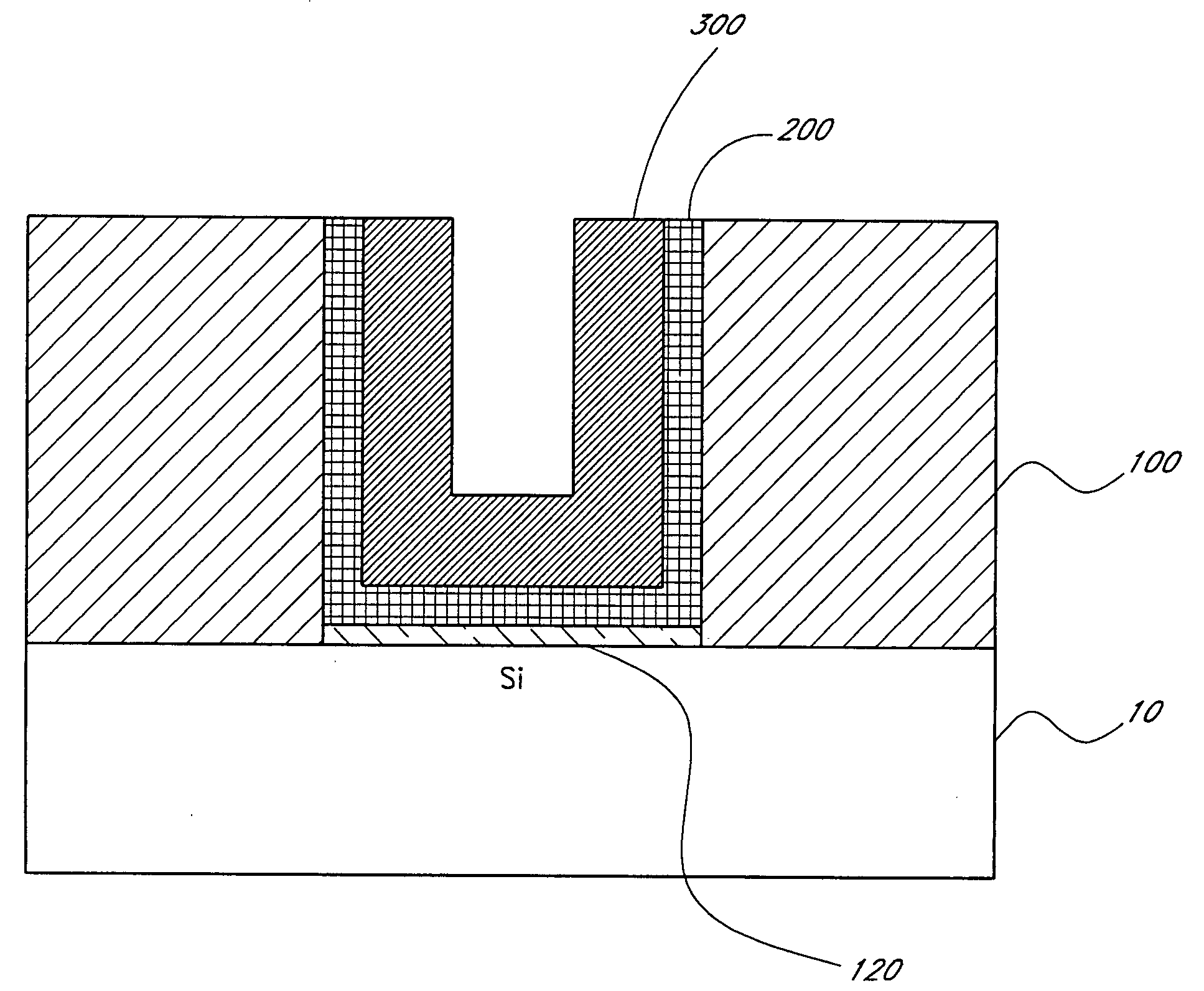

Method for bottomless deposition of barrier layers in integrated circuit metallization schemes

InactiveUS6852635B2Avoid depositionPolycrystalline material growthSemiconductor/solid-state device detailsContact formationEngineering

Methods are disclosed for selective deposition on desired materials. In particular, barrier materials are selectively formed on insulating surfaces, as compared to conductive surfaces. In the context of contact formation and trench fill, particularly damascene and dual damascene metallization, the method advantageously lines insulating surfaces with a barrier material. The selective formation allows the deposition to be “bottomless,” thus leaving the conductive material at a via bottom exposed for direct metal-to-metal contact when further conductive material is deposited into the opening after barrier formation on the insulating surfaces. Desirably, the selective deposition is accomplished by atomic layer deposition (ALD), resulting in highly conformal coverage of the insulating sidewalls in the opening.

Owner:INTERUNIVERSITAIR MICROELECTRONICA CENT VZW (IMEC) +2

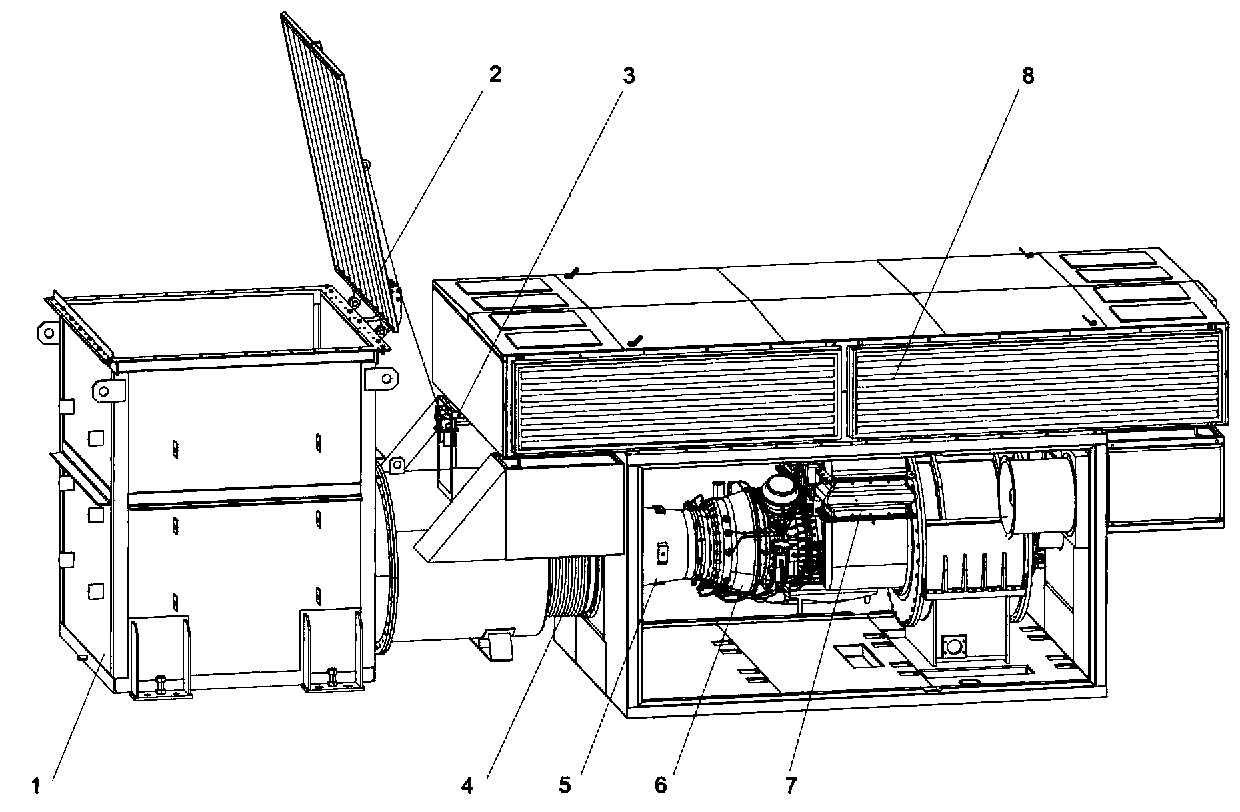

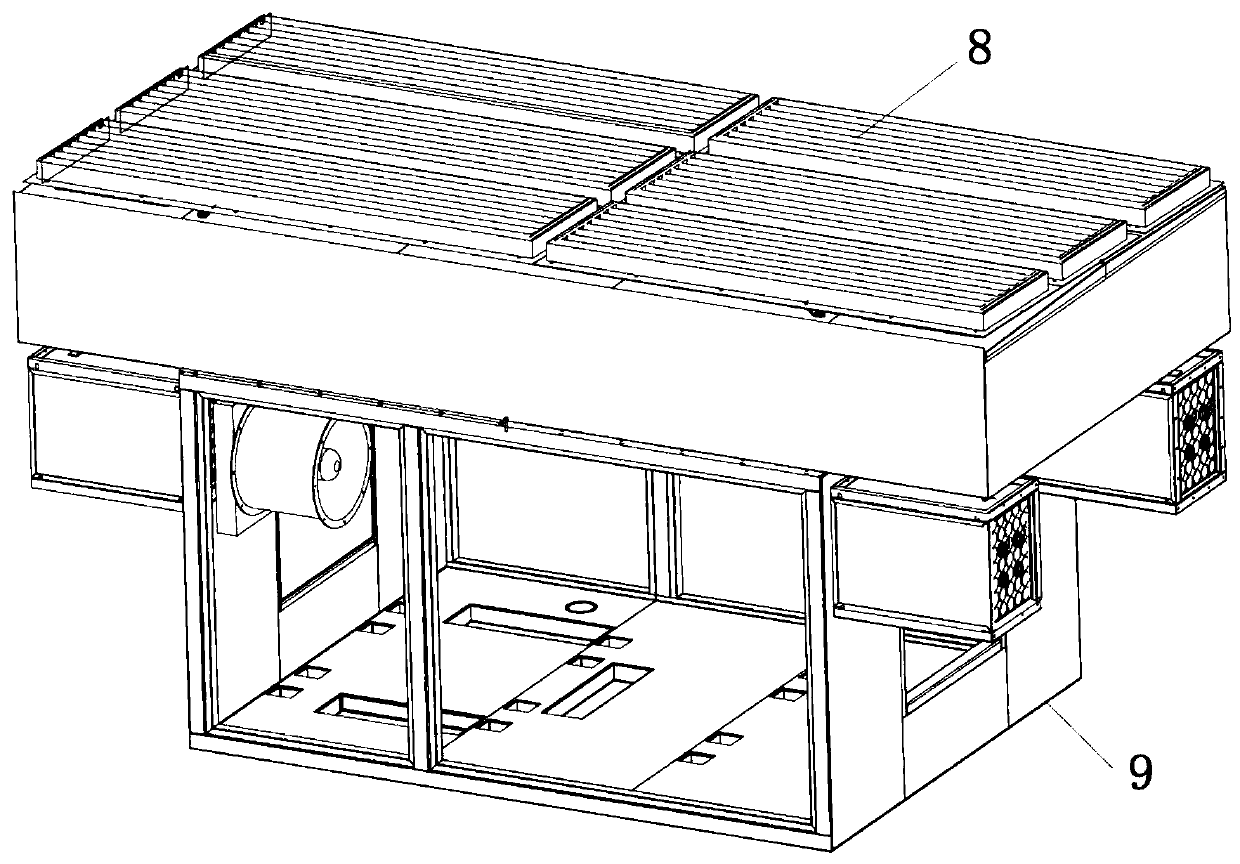

Intake and exhaust system of turbine engine

PendingCN111206994AMeet air intake needsAvoid damageGas turbine plantsTurbine/propulsion air intakesAir filterExhaust fumes

The invention discloses an intake and exhaust system of a turbine engine. The intake and exhaust system of the turbine engine comprises an intake system and an exhaust system, wherein the intake system is connected with an intake port of the turbine engine, the exhaust system is connected with an exhaust port of the turbine engine, the intake system comprises an intake filter and an intake pipeline, the intake filter is connected with the intake pipeline, the intake filter adopts a V-shaped structure, and a rain shielding cap is arranged at the exhaust tail end of the exhaust system. The intake and exhaust system of the turbine engine has the beneficial effects that the air inlet area is large, the air inlet flow speed is lower, the service life of an air filter is long, the rain shieldingcap additionally arranged at the exhaust port avoids the rainwater deposition in an exhaust silencer, the condition that rainwater possibly flows backwards is avoided and damages the turbine engine,and an opening of the rain shielding cap is away from the intake port, so that exhausted waste gas is prevented from being sucked by the intake port, and the quality of inlet air is ensured.

Owner:美国杰瑞国际有限公司

Exhaust gas treatment catalyst

InactiveUS7374729B2Improved coating architectureSacrificing TWC catalyst performanceCombination devicesInternal combustion piston enginesSorbentMetal

Provided are an exhaust treatment catalyst and an exhaust article containing the catalyst. The catalyst comprises:(a) a carrier;(b) a first layer deposited on the carrier, said first layer comprising substantially only at least one refractive metal oxide;(c) a second layer deposited on the first layer, said second layer comprising substantially only at least one oxygen storage component and at least one binder therefor; and(d) a third layer deposited on the second layer, said third layer comprising at least one layer of one or more platinum group metal components supported on a refractory metal oxide support.Optionally, a fourth layer is deposited on the third layer wherein the fourth layer comprises one or more platinum group metal components supported on a refractory metal oxide support. As a further option, an overcoat layer may be deposited on the third or fourth layer wherein the overcoat layer comprises a catalyst poison sorbent. Also provided are methods for preparing the catalyst and methods for monitoring the exhaust storage capacity of an exhaust article containing the catalyst.

Owner:BASF CATALYSTS LLC

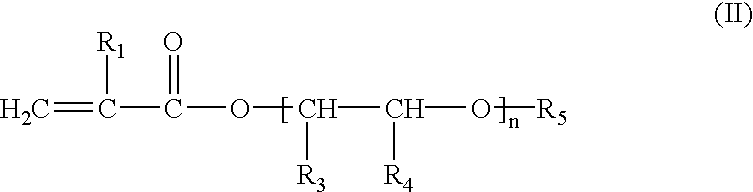

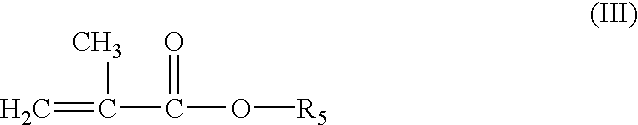

Additive for biodiesel and biofuel oils

InactiveUS6409778B1Improve featuresAvoid depositionBiofuelsLiquid carbonaceous fuelsAcrylateBiofuel Oils

The invention relates to a copolymer consisting of the following monomer components: a) 48-98 wt. % of compounds of formula (I), b) 2-30 wt. % of one or several oxygen-containing methacrylates of formula (II) and c) 0-30 wt. % of a methacrylate of formula (III) of styrol, the quantities a)-c) totalling 100 wt. %. The inventive copolymer is suitable as a an additive for diesel fuels and biodiesel.

Owner:EVONIK ROHMAX ADDITIVES

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS20030066672A1Eliminate needHeat dissipationMolten spray coatingScreening gaskets/sealsMolten stateThermal spraying

Heat dissipation and electromagnetic interference (EMI) shielding for an electronic device having an enclosure. An interior surface of the enclosure is covered with a conformal metallic layer which, as disposed in thermal adjacency with one or more heat-generating electronic components or other sources contained within the enclosure, may provide both thermal dissipation and EMI shielding for the device. The layer may be sprayed onto the interior surface in a molten state and solidified to form a self-adherent coating.

Owner:PARKER INTANGIBLES LLC

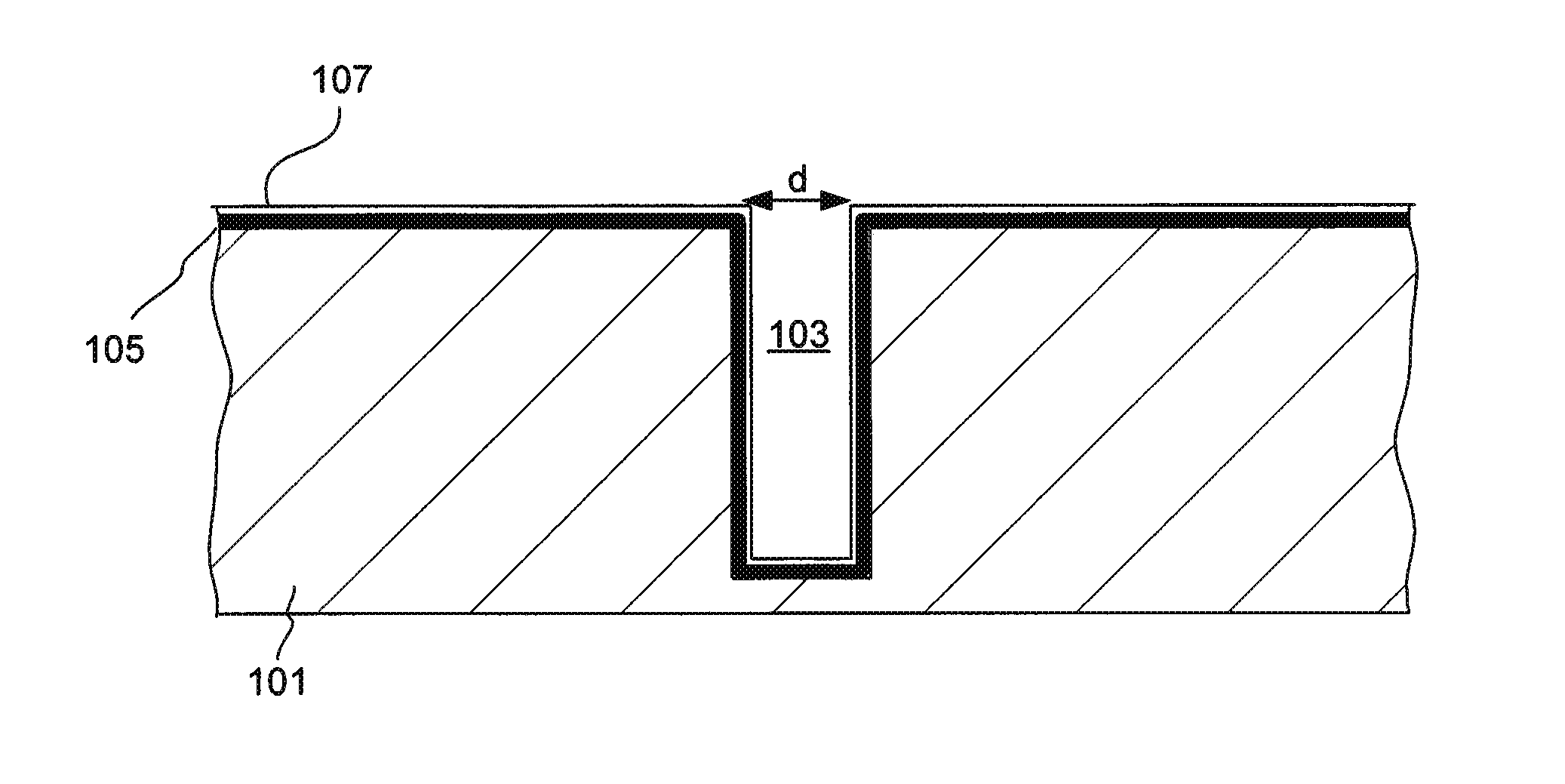

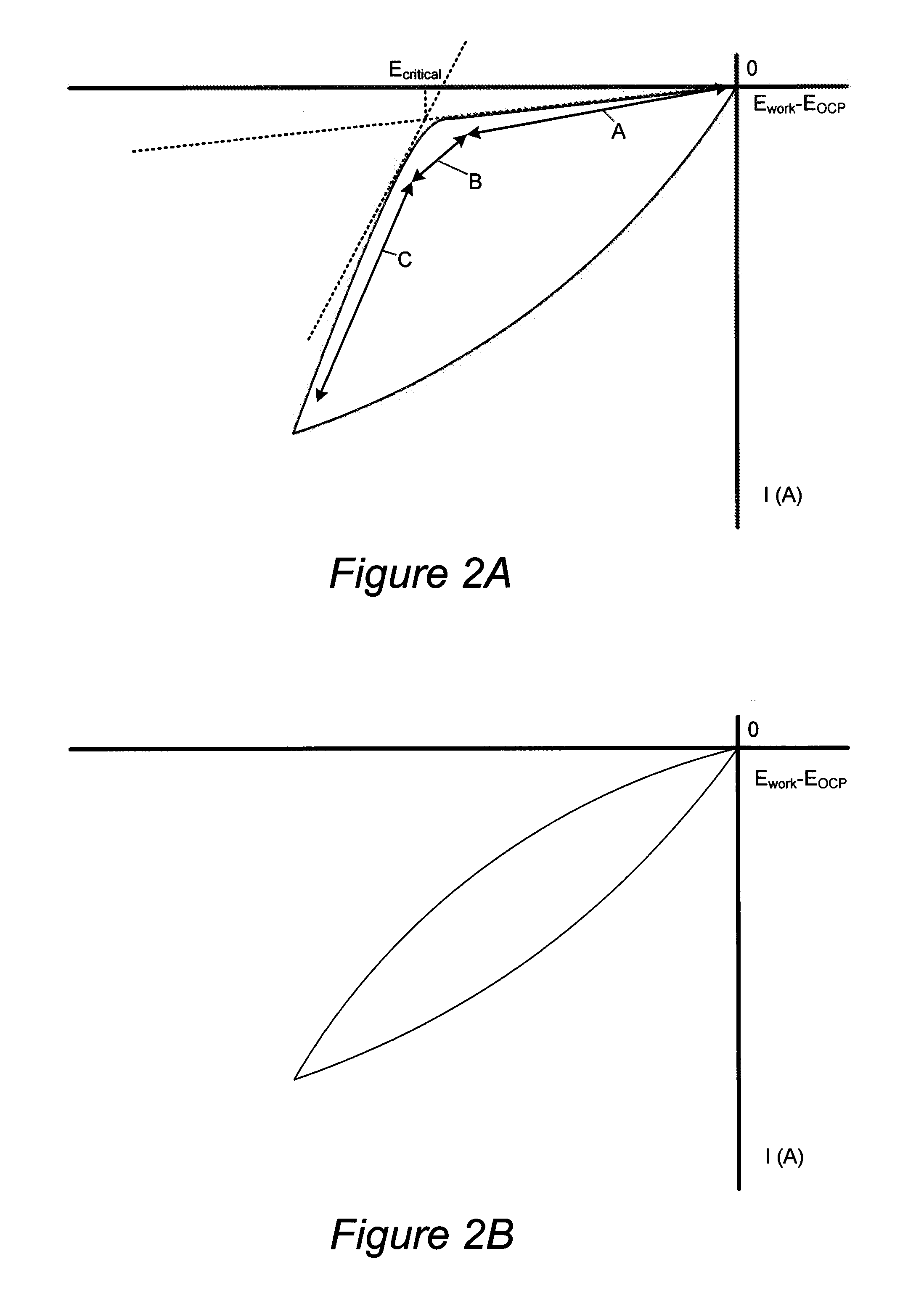

Through silicon via filling using an electrolyte with a dual state inhibitor

ActiveUS20110284386A1Faster rateLittle and depositionCellsMachining electric circuitsElectricityElectroplating

A method for electrofilling large, high aspect ratio recessed features with copper without depositing substantial amounts of copper in the field region is provided. The method allows completely filling recessed features having aspect ratios of at least about 5:1 such as at least about 10:1, and widths of at least about 1 μm in a substantially void-free manner without depositing more than 5% of copper in the field region (relative to the thickness deposited in the recessed feature). The method involves contacting the substrate having one or more large, high aspect ratio recessed features (such as a TSVs) with an electrolyte comprising copper ions and an organic dual state inhibitor (DSI) configured for inhibiting copper deposition in the field region, and electrodepositing copper under potential-controlled conditions, where the potential is controlled not exceed the critical potential of the DSI.

Owner:NOVELLUS SYSTEMS

Exhaust articles for internal combustion engines

InactiveUS7276212B2Improved coating architectureSacrificing TWC catalyst performanceCombination devicesInternal combustion piston enginesCombustionInternal combustion engine

Provided is a base metal undercoat containing catalyst and an exhaust article containing the catalyst. The catalyst contains a base metal undercoat with an oxygen storage component, and at least one catalytic layer. Also provided are methods for preparing the catalyst and methods for monitoring the oxygen storage capacity of an exhaust article containing the catalyst.

Owner:ENGELHARD CORP

Enhanced deposition of noble metals

ActiveUS20070036892A1Deposition process be enhanceEnhance film growthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentMetalloorganic Compounds

The invention relates generally to processes for enhancing the deposition of noble metal thin films on a substrate by atomic layer deposition. Treatment with gaseous halides or metalorganic compounds reduces the incubation time for deposition of noble metals on particular surfaces. The methods may be utilized to facilitate selective deposition. For example, selective deposition of noble metals on high-k materials relative to insulators can be enhanced by pretreatment with halide reactants. In addition, halide treatment can be used to avoid deposition on the quartz walls of the reaction chamber.

Owner:ASM INTERNATIONAL

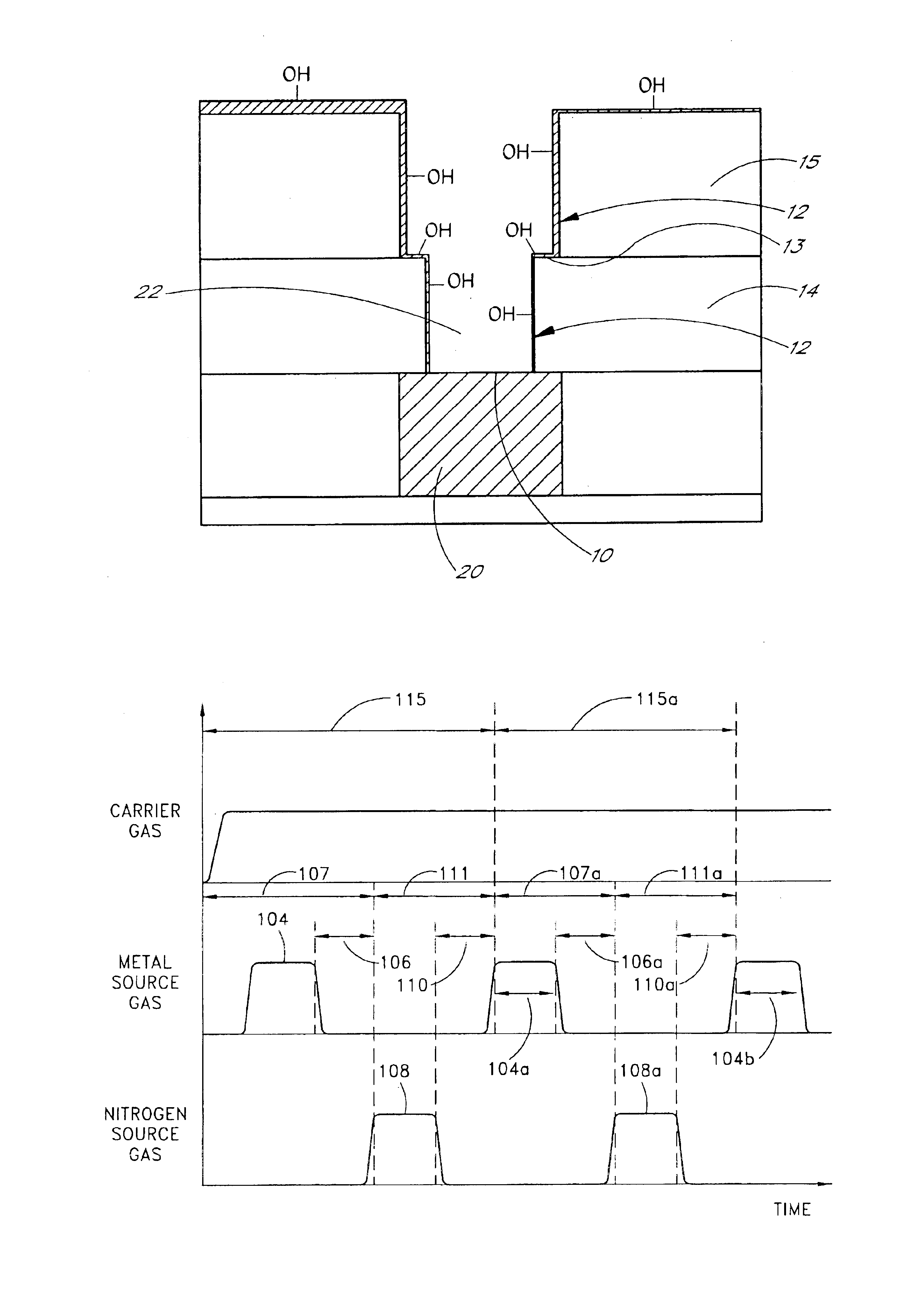

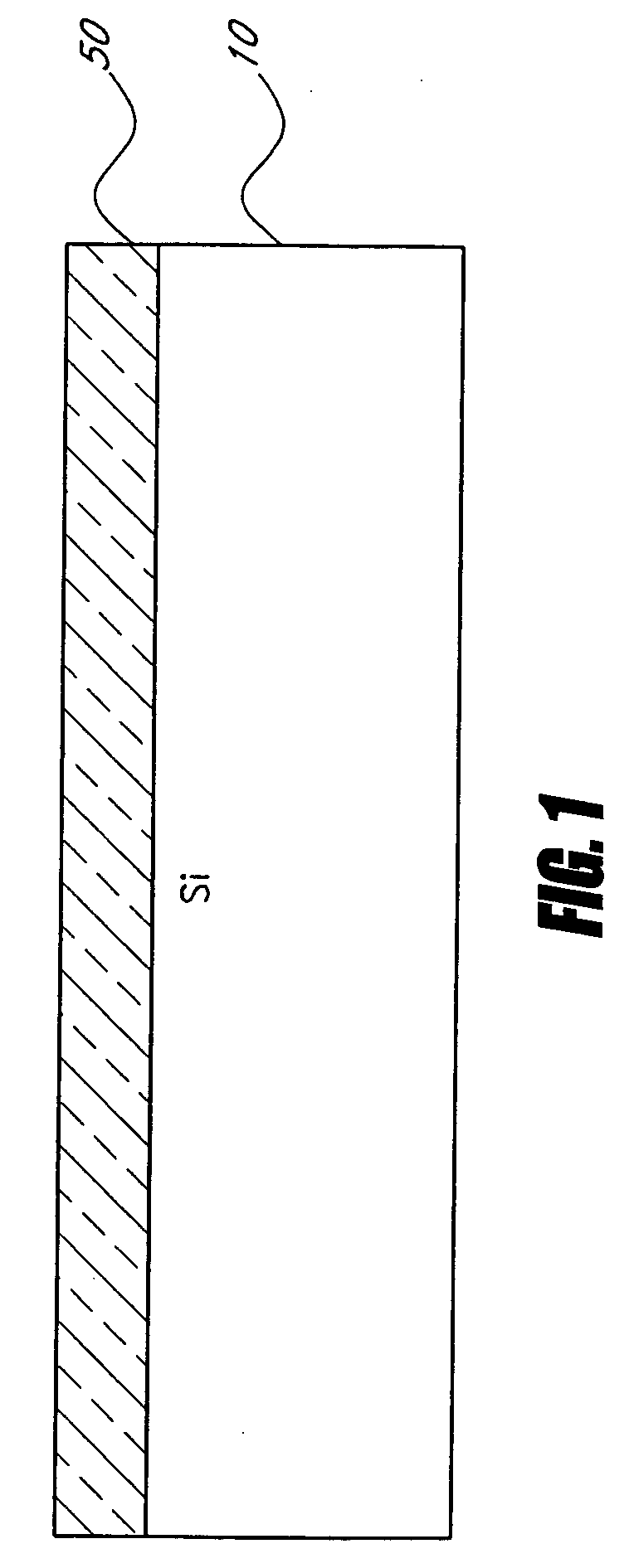

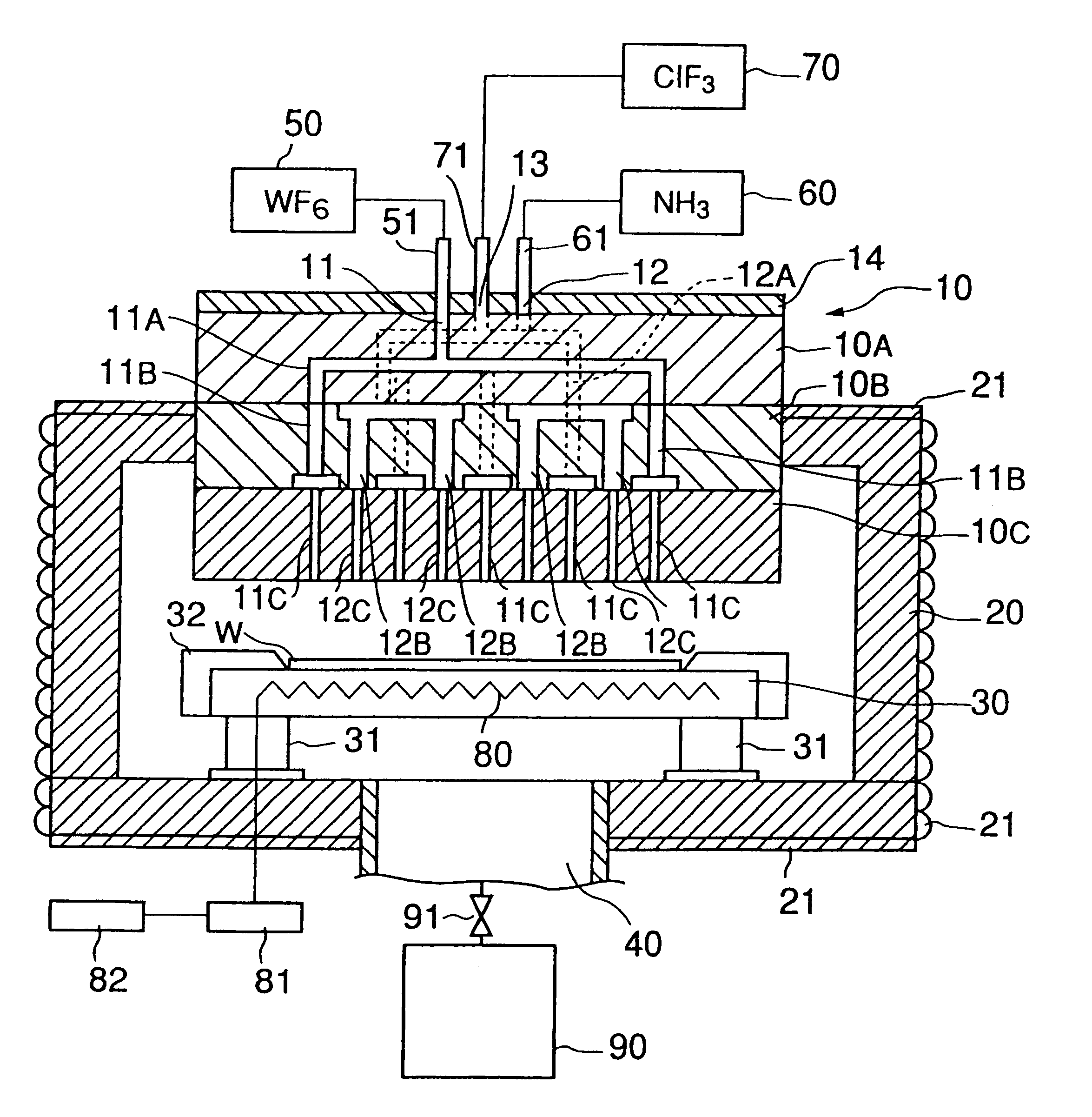

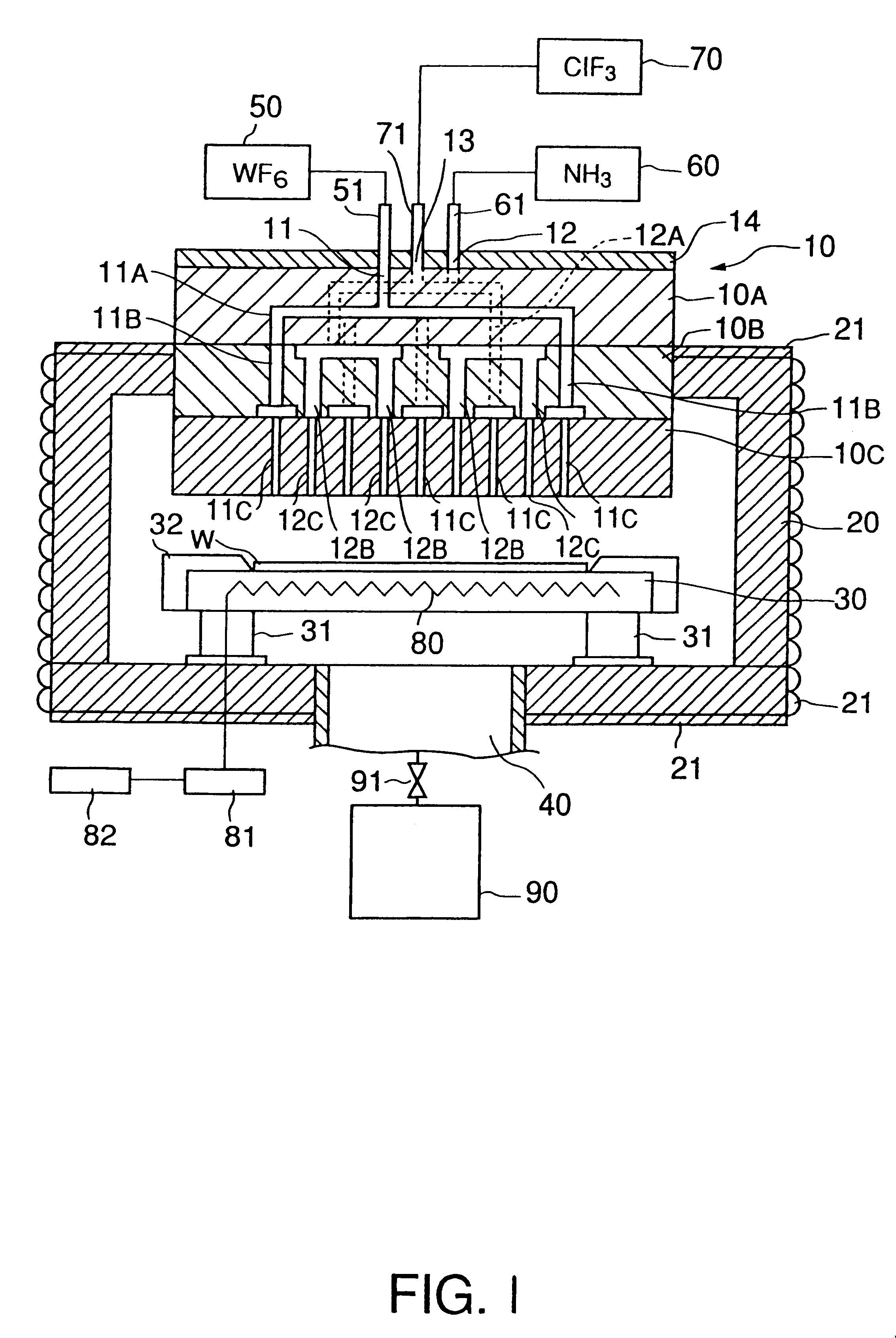

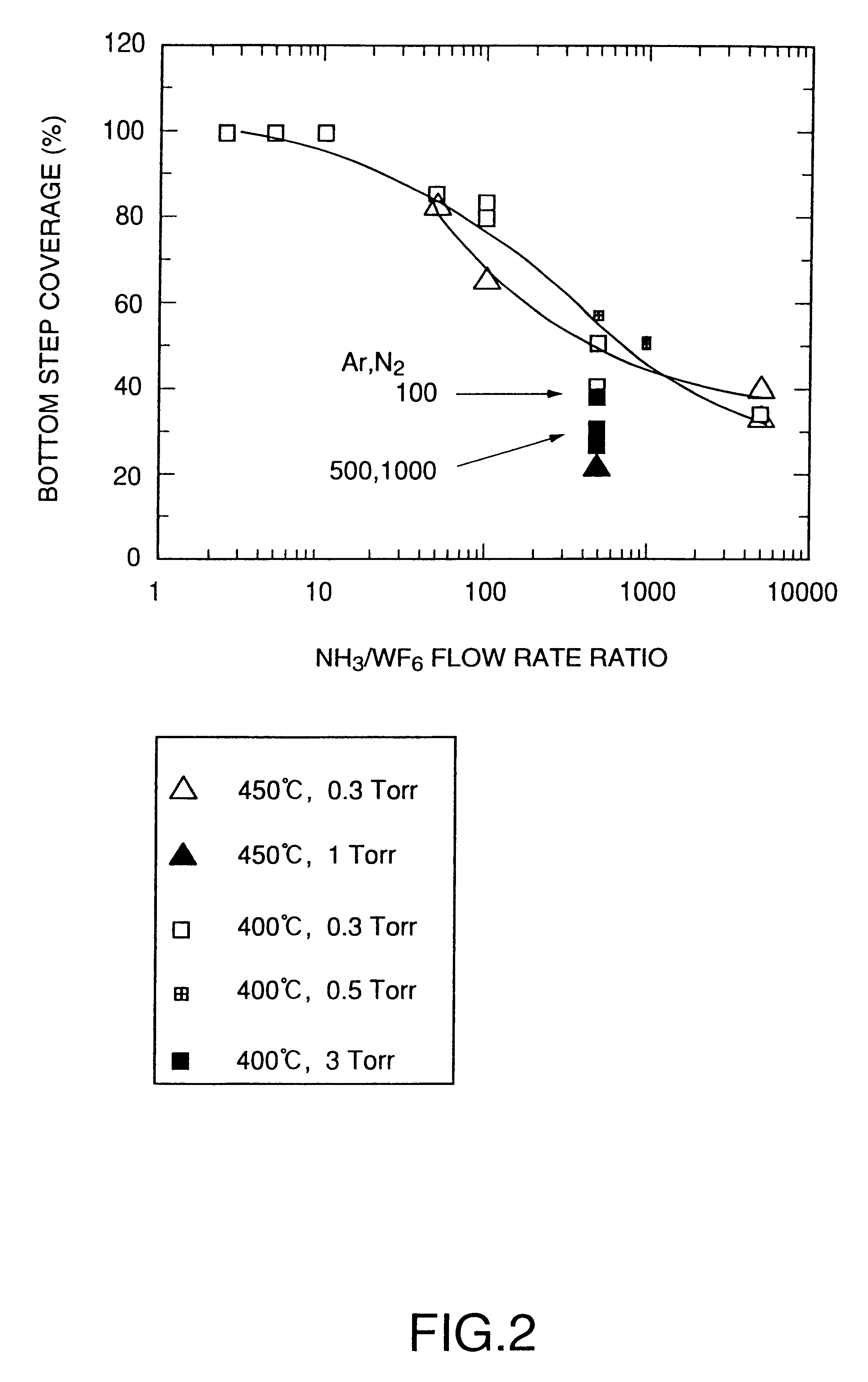

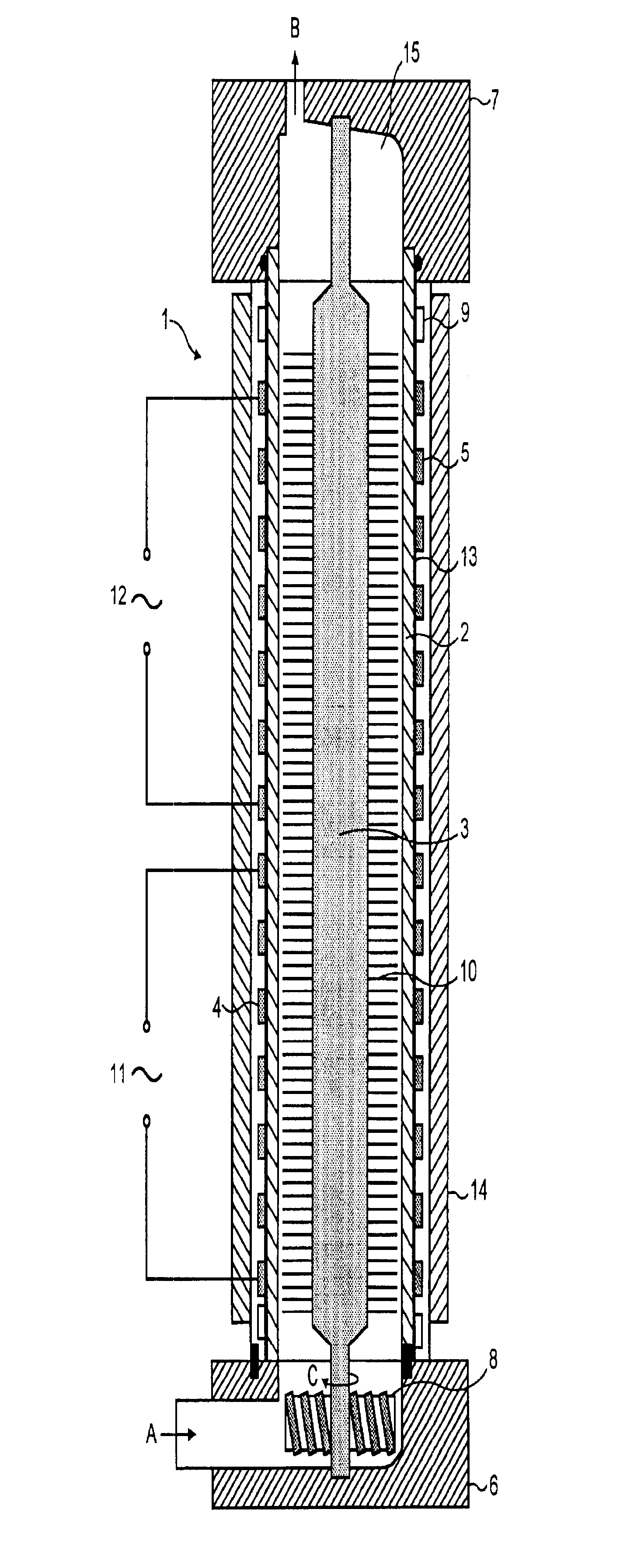

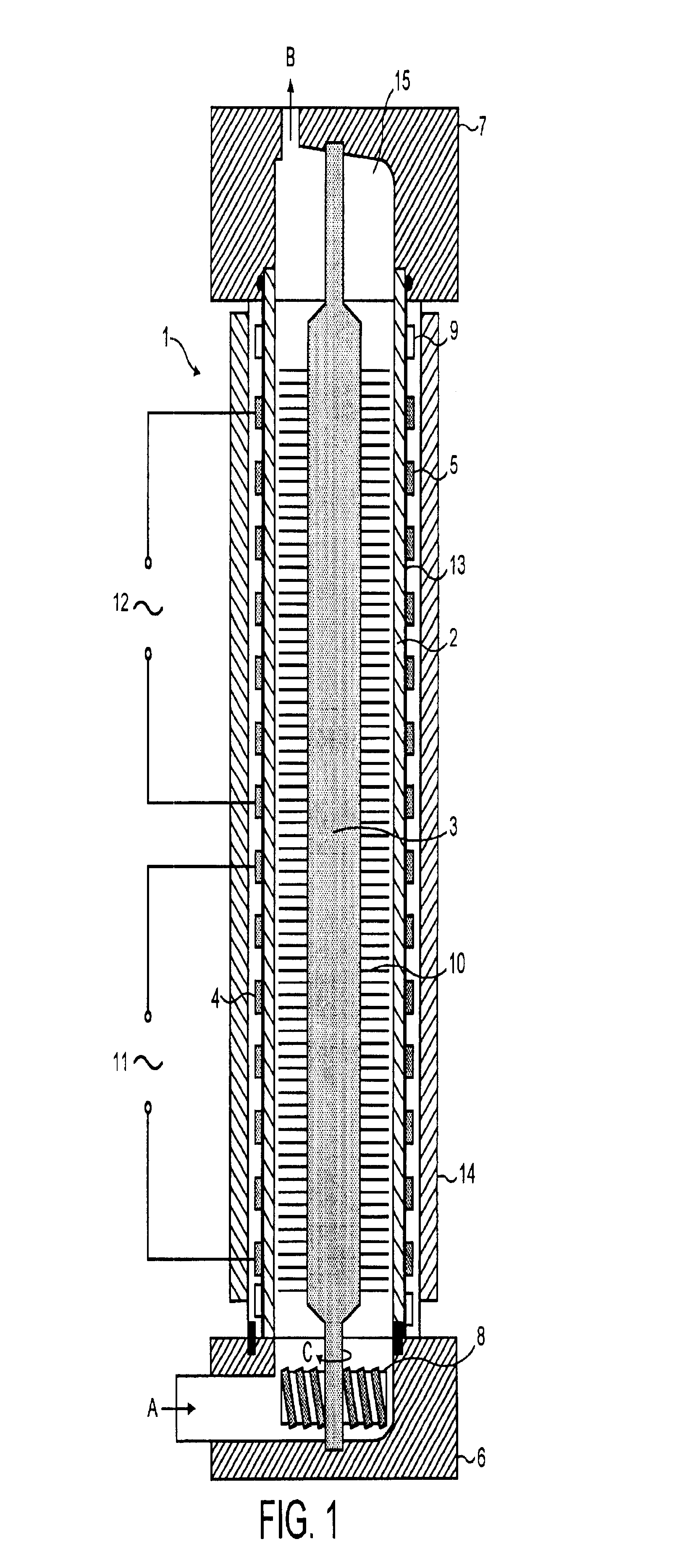

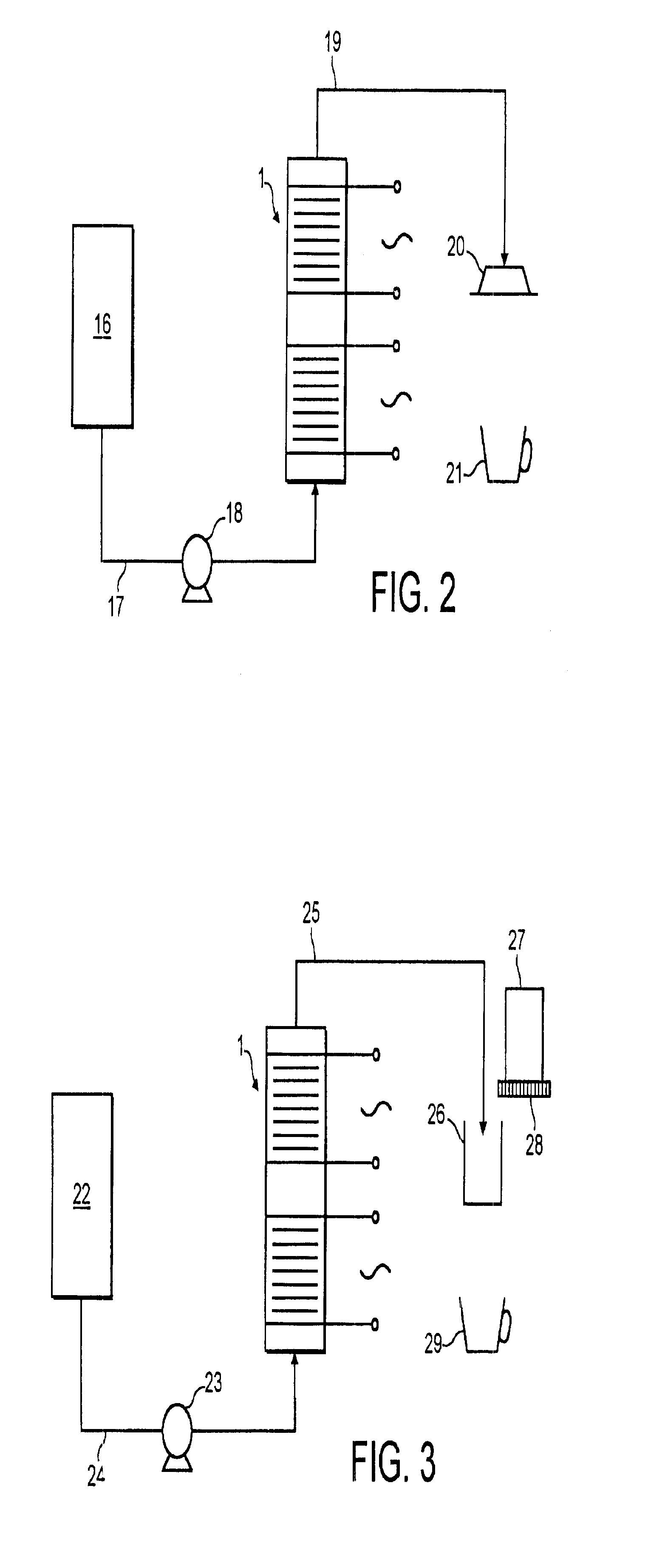

Semiconductor device fabricating method and system for carrying out the same

InactiveUS6399484B1Reduced form requirementsAvoid depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTungsten nitrideNitrogen

A semiconductor device fabricating method includes a preparatory process that brings a first source gas containing tungsten atoms into contact with a workpiece and that does not bring a second source gas containing nitrogen atoms into contact with the workpiece, and a film forming process that forms a tungsten nitride film on the workpiece by using the first and the second source gases so as to fabricate a semiconductor device. The semiconductor device fabricating method is capable of preventing the tungsten nitride film from peeling off from a layer underlying the same when the tungsten nitride film is subjected to heat treatment.

Owner:TOKYO ELECTRON LTD

Process and module for heating liquid

InactiveUS6459854B1Accurate temperature rangeImprove heat transfer performanceImmersion heating arrangementsLiquid transferring devicesAxis of symmetryEngineering

A liquid heating module for use in a hot beverage machine, a beverage forming system that includes the module, and a process for heating liquid for forming beverages. The liquid heating module includes a hollow metal tube, a cylindrical insert which is disposed inside the hollow tube along its entire length and substantially along its axis of symmetry, at least one electrical resistor on a first outer part of the tube for preheating liquid flowing through the tube, and at least one additional electrical resistor on a second outer part of the tube for temperature adjustment of the liquid flowing through the tube.

Owner:NESTEC SA

Exhaust gas treatment catalyst

InactiveUS20050227867A1Improved coating architectureSacrificing TWC catalyst performanceCombination devicesInternal combustion piston enginesSorbentPlatinum group

Provided are an exhaust treatment catalyst and an exhaust article containing the catalyst. The catalyst comprises: (a) a carrier; (b) a first layer deposited on the carrier, said first layer comprising substantially only at least one refractive metal oxide; (c) a second layer deposited on the first layer, said second layer comprising substantially only at least one oxygen storage component and at least one binder therefor; and (d) a third layer deposited on the second layer, said third layer comprising at least one layer of one or more platinum group metal components supported on a refractory metal oxide support. Optionally, a fourth layer is deposited on the third layer wherein the fourth layer comprises one or more platinum group metal components supported on a refractory metal oxide support. As a further option, an overcoat layer may be deposited on the third or fourth layer wherein the overcoat layer comprises a catalyst poison sorbent. Also provided are methods for preparing the catalyst and methods for monitoring the exhaust storage capacity of an exhaust article containing the catalyst.

Owner:BASF CATALYSTS LLC

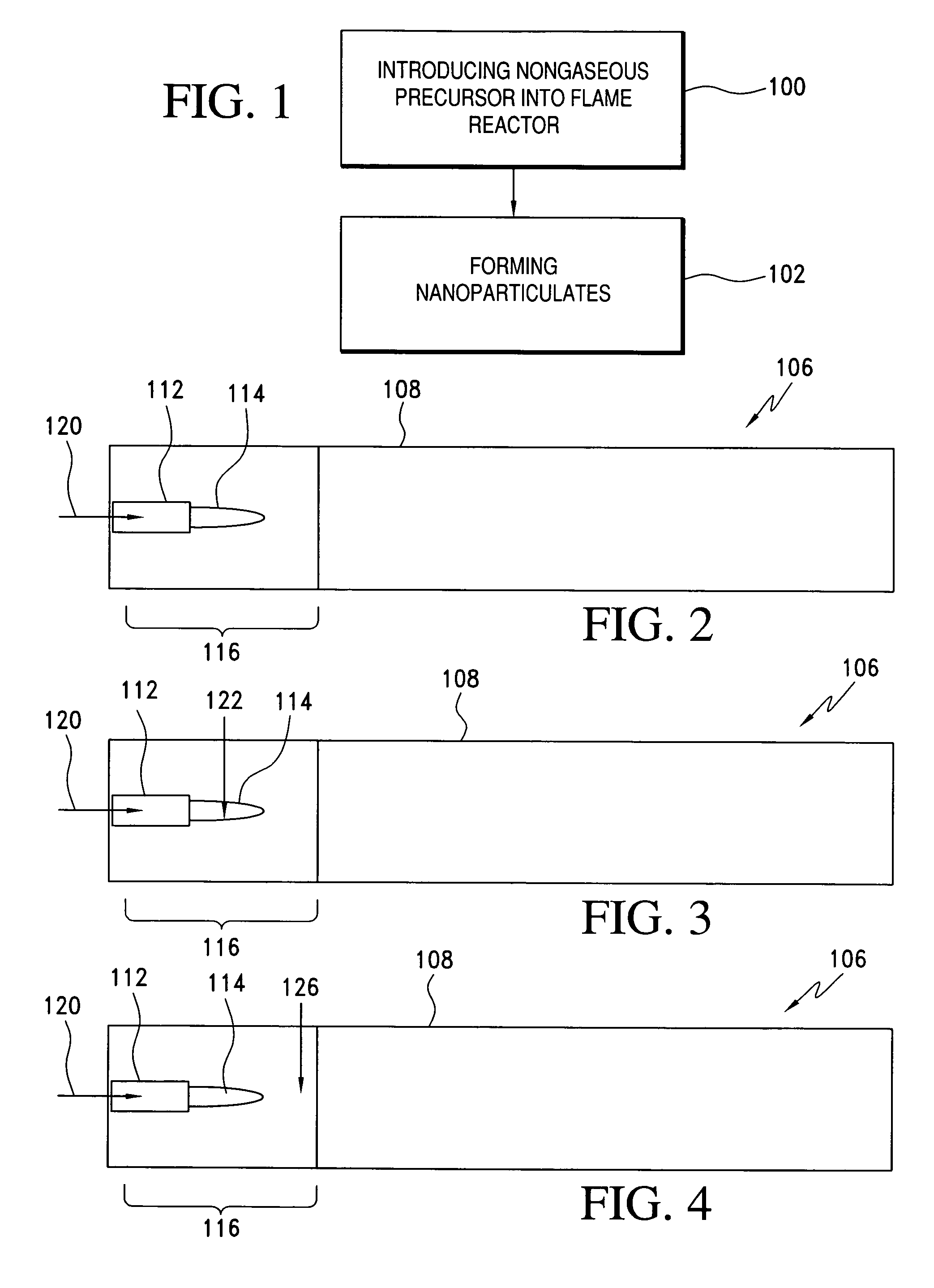

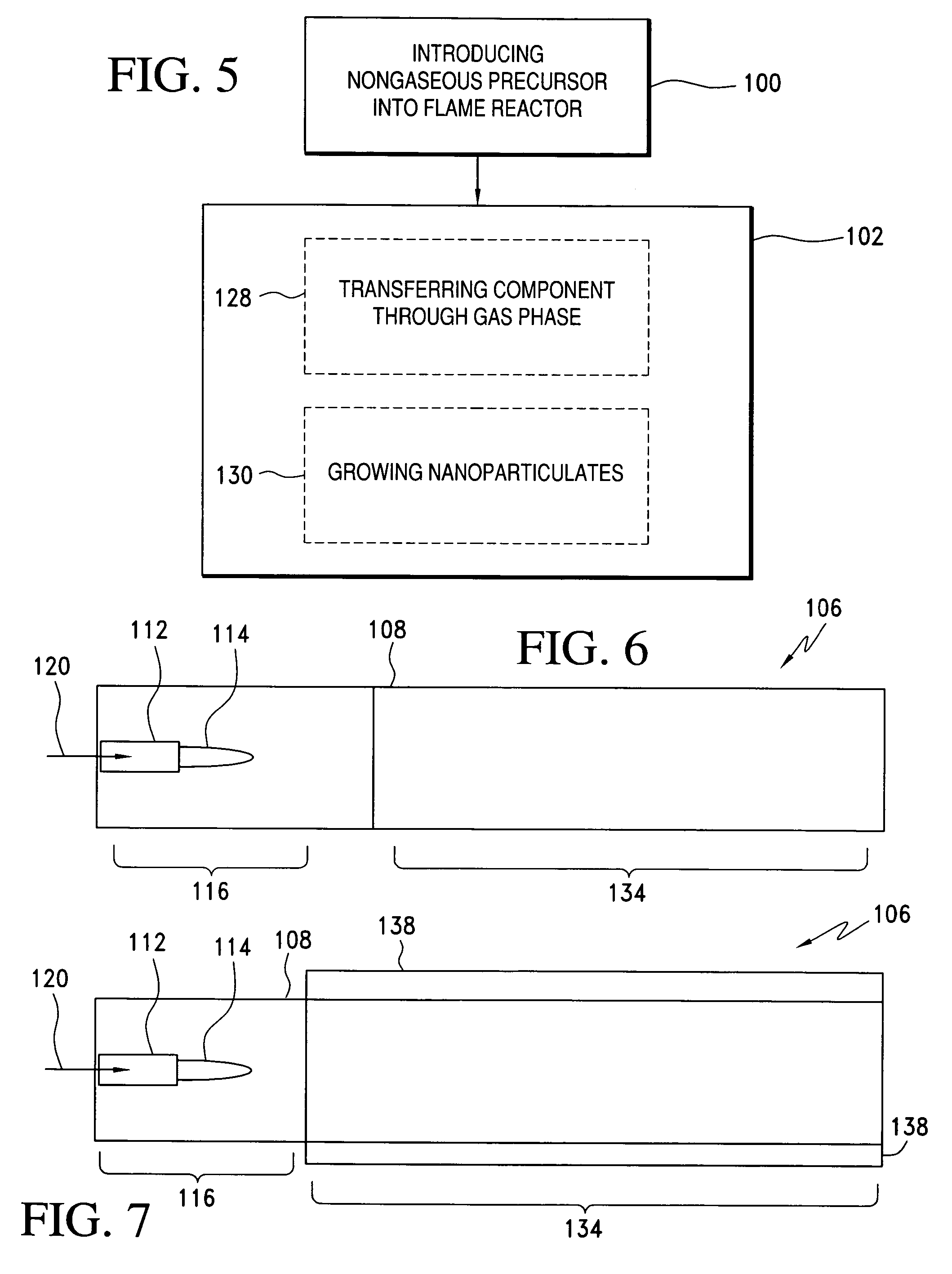

Method of making nanoparticulates and use of the nanoparticulates to make products using a flame reactor

InactiveUS20060166057A1Easy to joinLower melting temperatureMaterial nanotechnologyBurnersMulti materialNanoparticle

The present invention relates to a method of making nanoparticulates in a flame reactor, the nanoparticulates having controlled properties such as weight average particle size, composition and morphology. The nanoparticulates made with the method of present invention may be tailored to a specific weight average particle size range, such as from about 1 nm to about 500 nm. In addition to weight average particle size, the nanoparticulates made with the method of the present invention may include a variety of materials including metals, ceramics, organic materials, and combinations thereof. Moreover, the method of the present invention allows control over the morphology of the nanoparticulates, which allows the production of nanoparticulates with any desired morphology including spheroidal and unagglomerated; and agglomerated (aggregated) into larger units of hard aggregates.

Owner:CABOT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com