Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

635 results about "Life testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Life Testing and Accelerated Life Testing are methods used to test the reliability of a product in a New Product Development during Design Phase, before the product is released to market. Traditionally Life testing was used to analyze the time to failure under normal conditions.

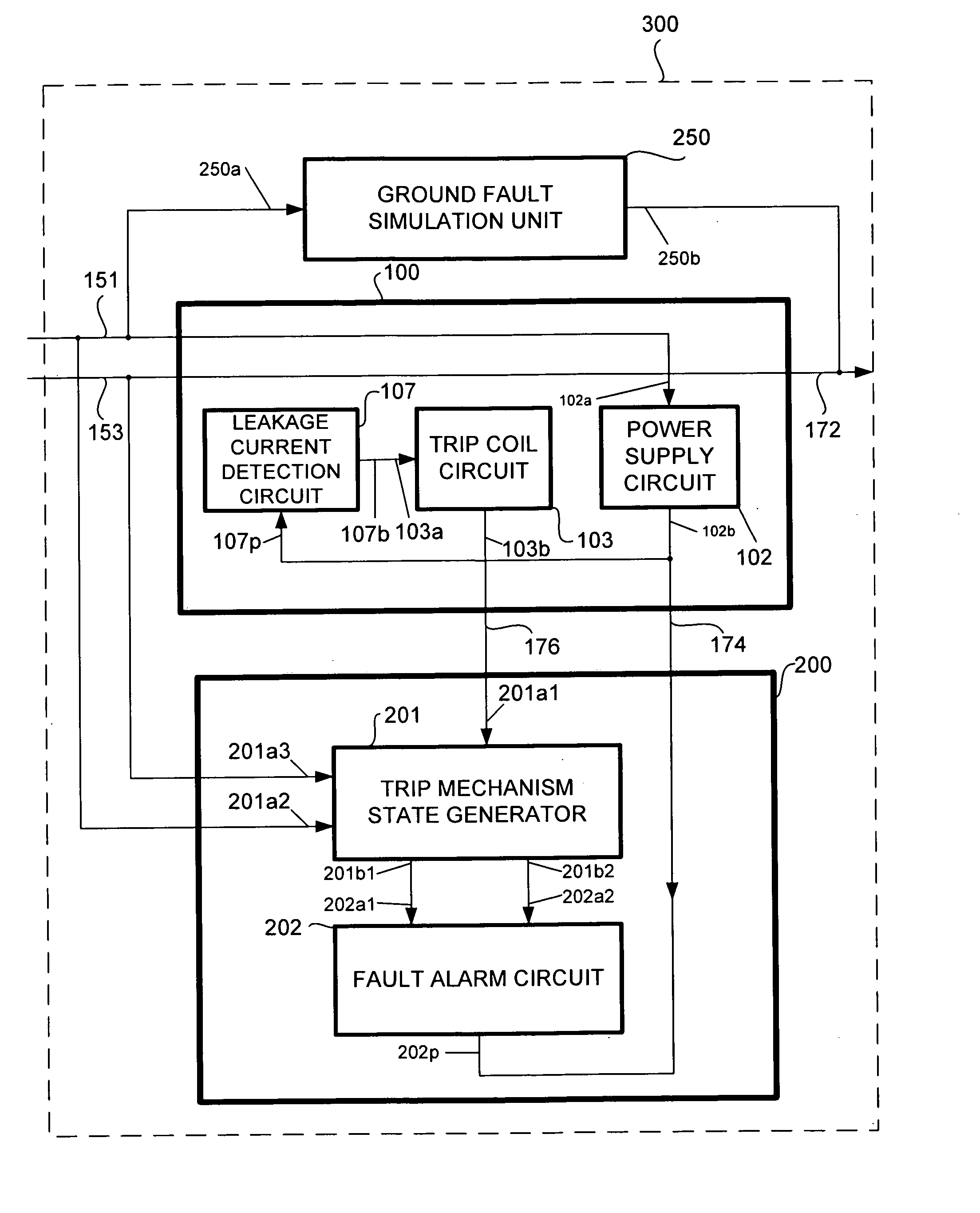

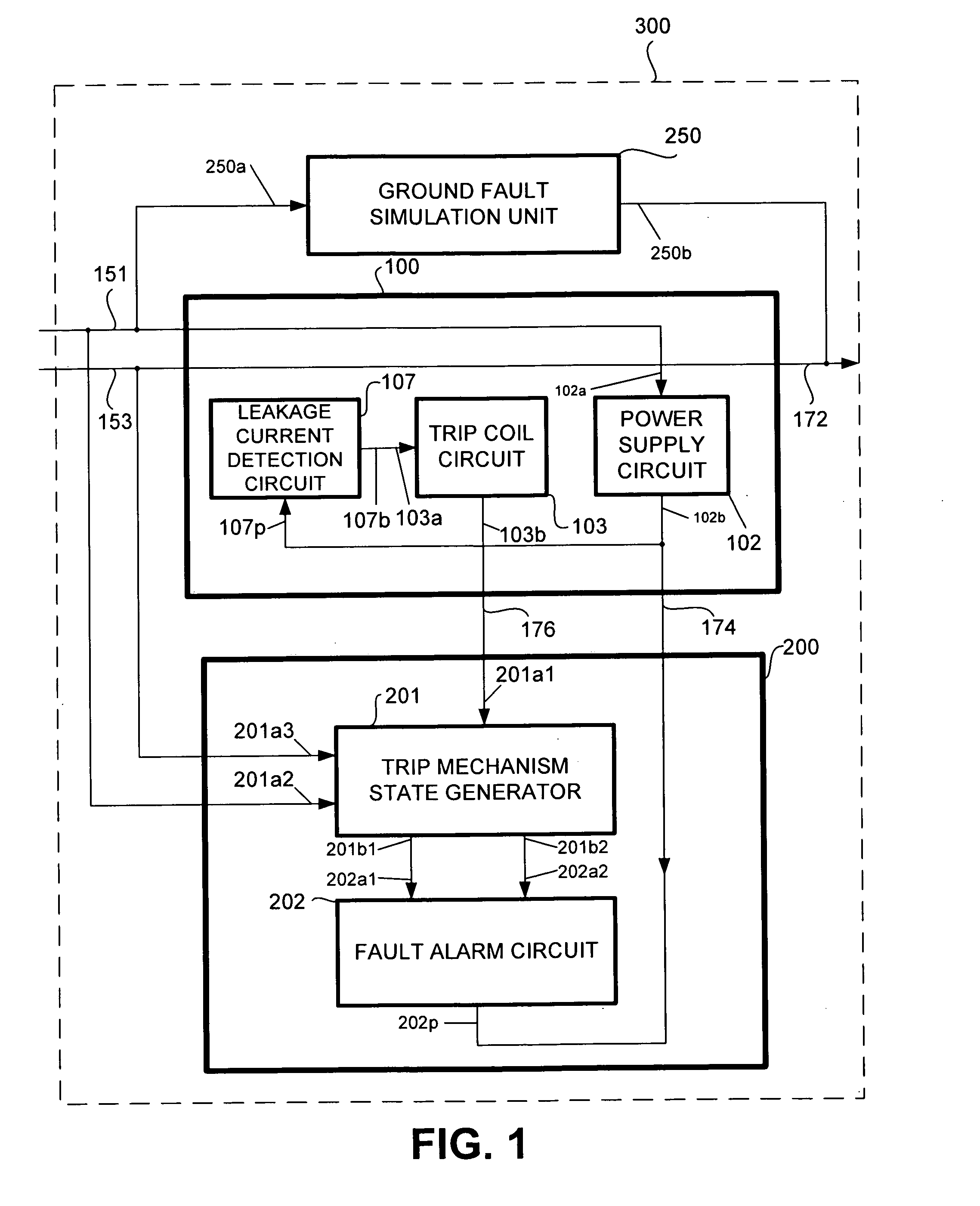

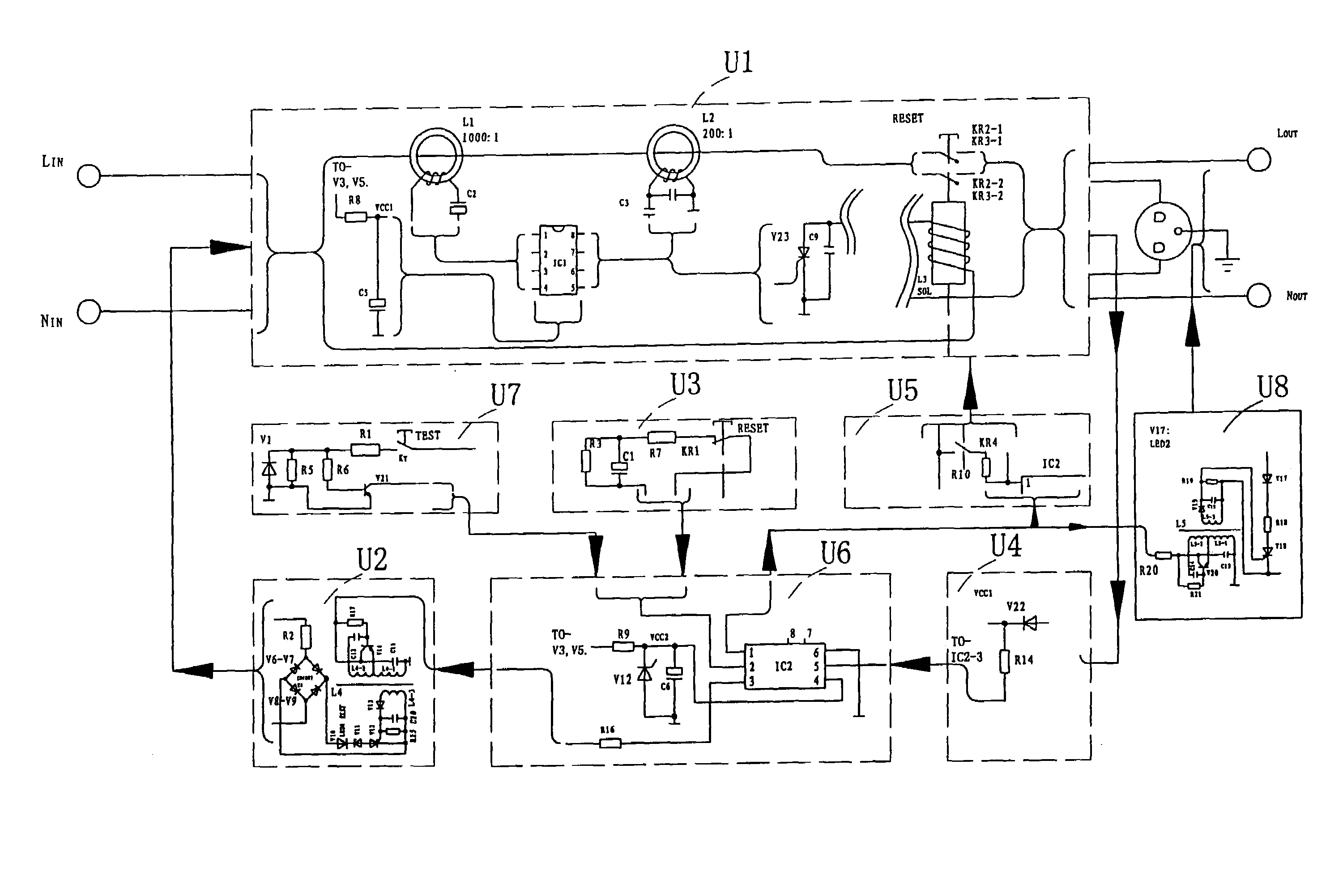

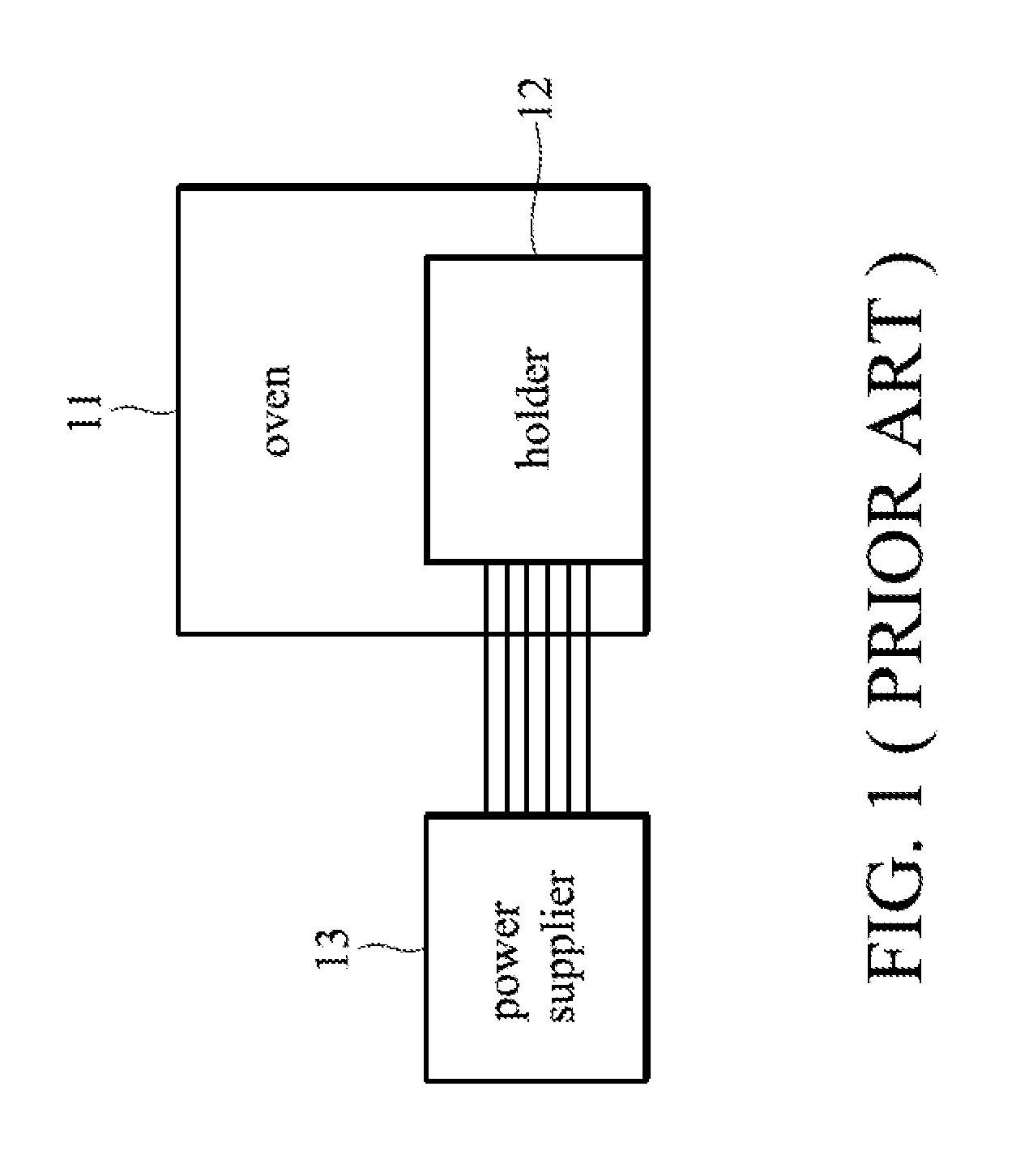

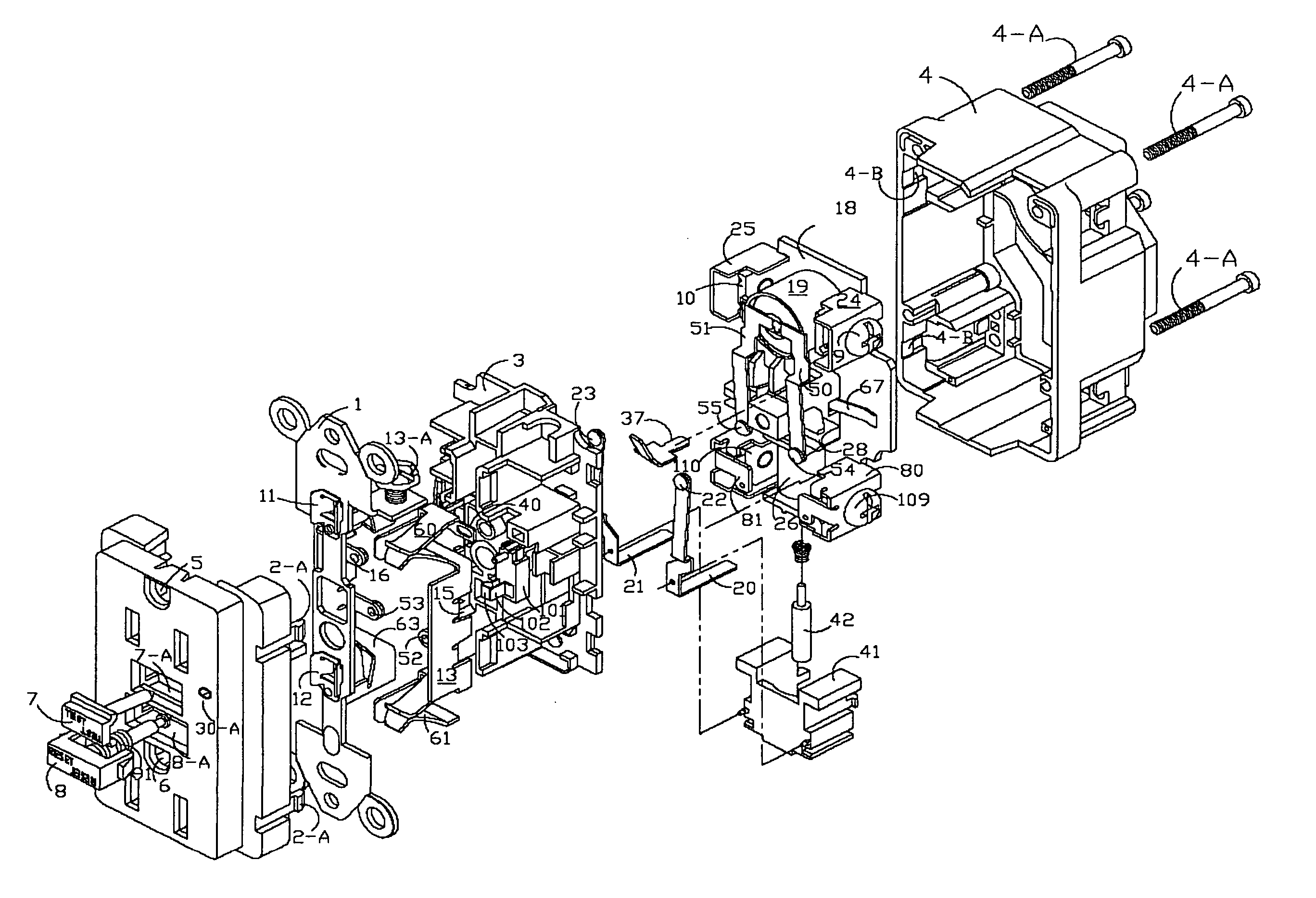

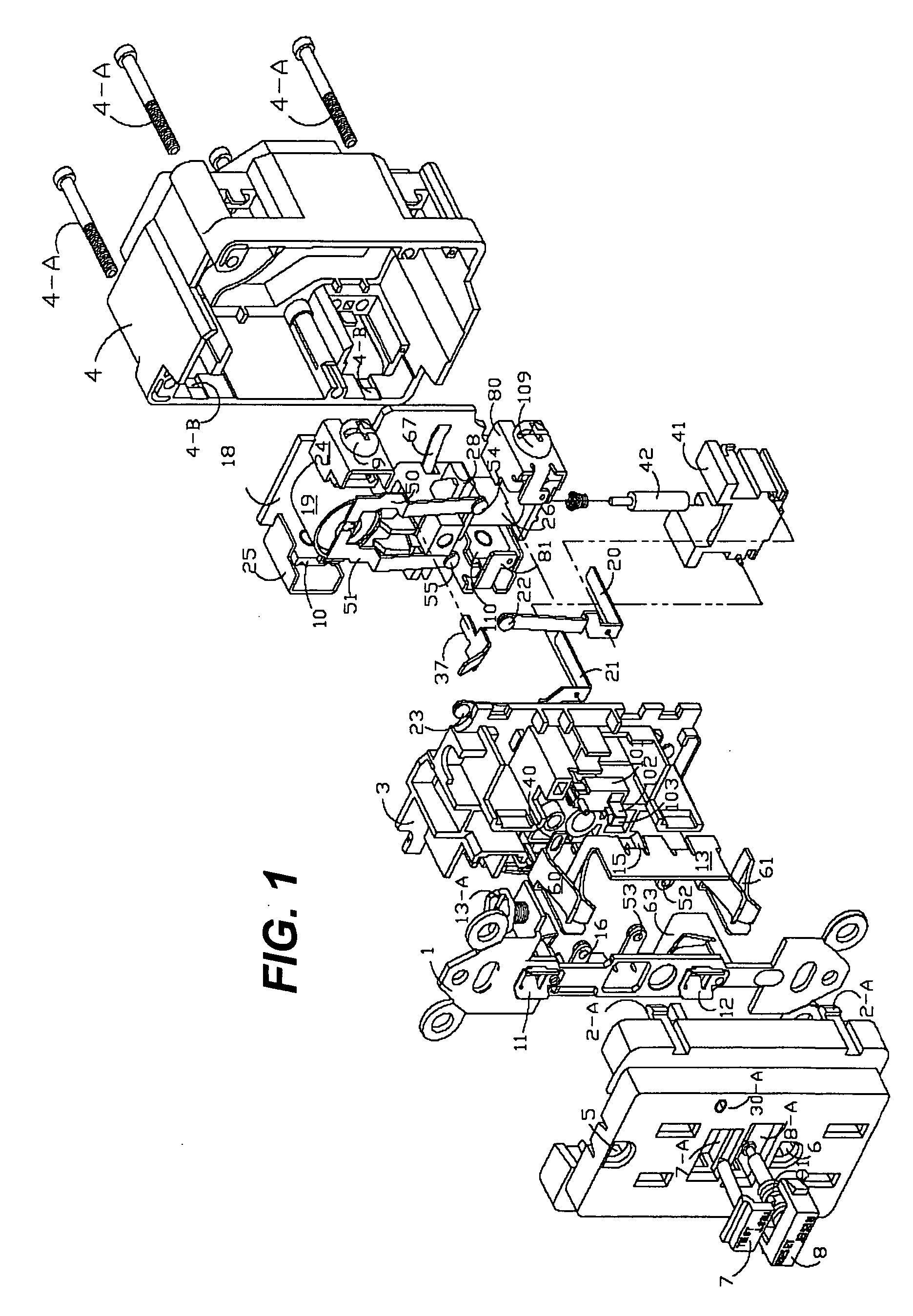

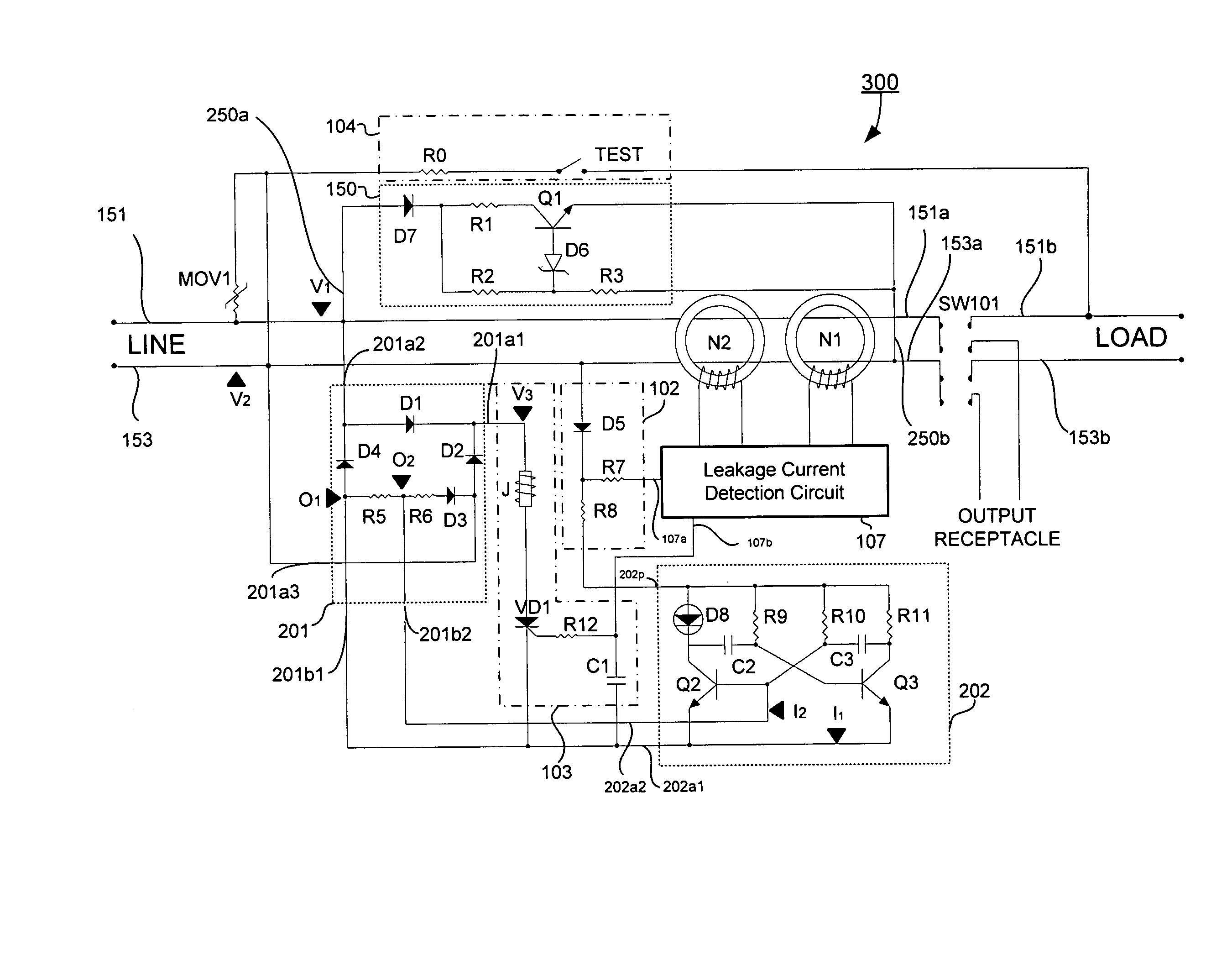

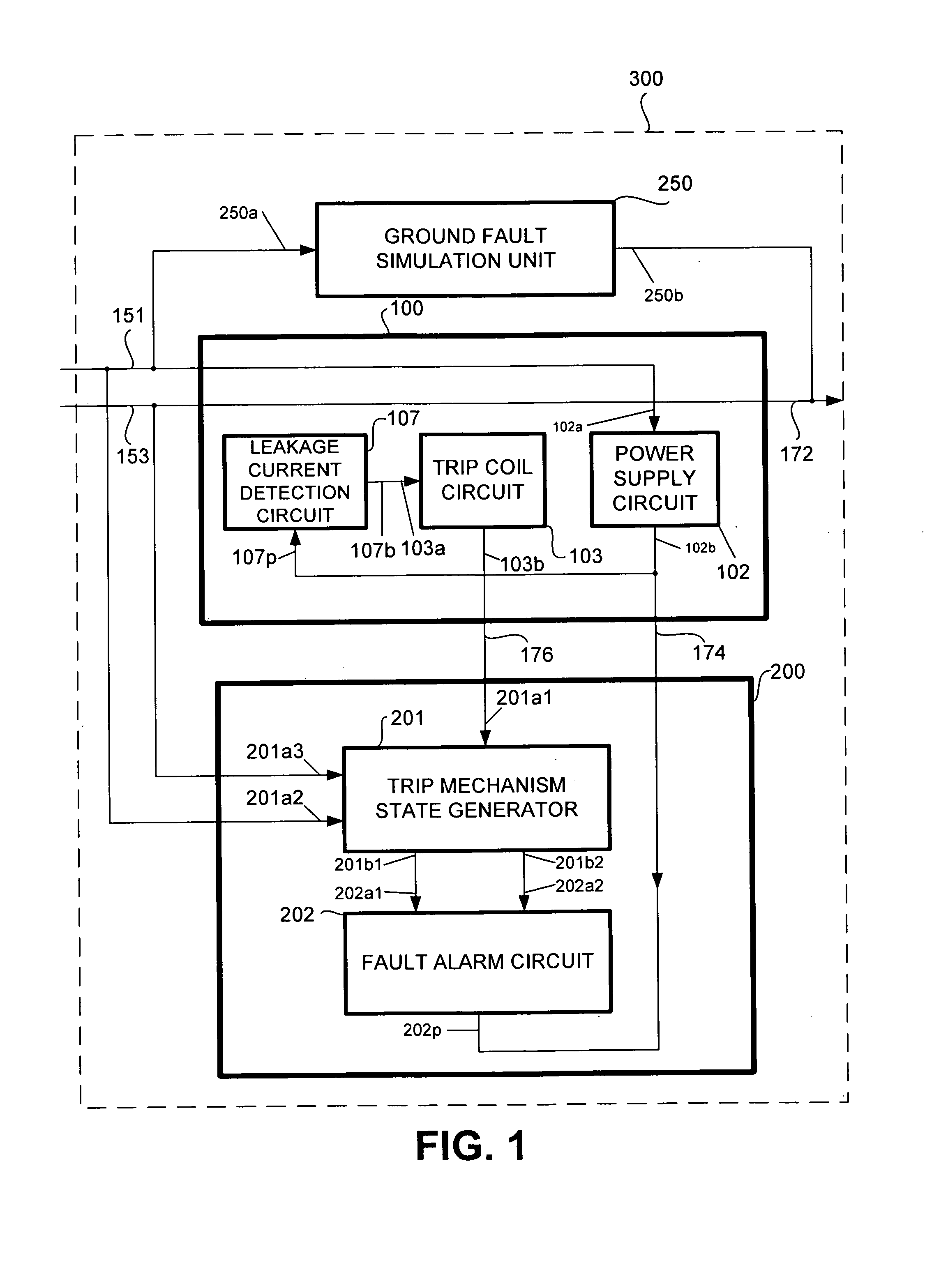

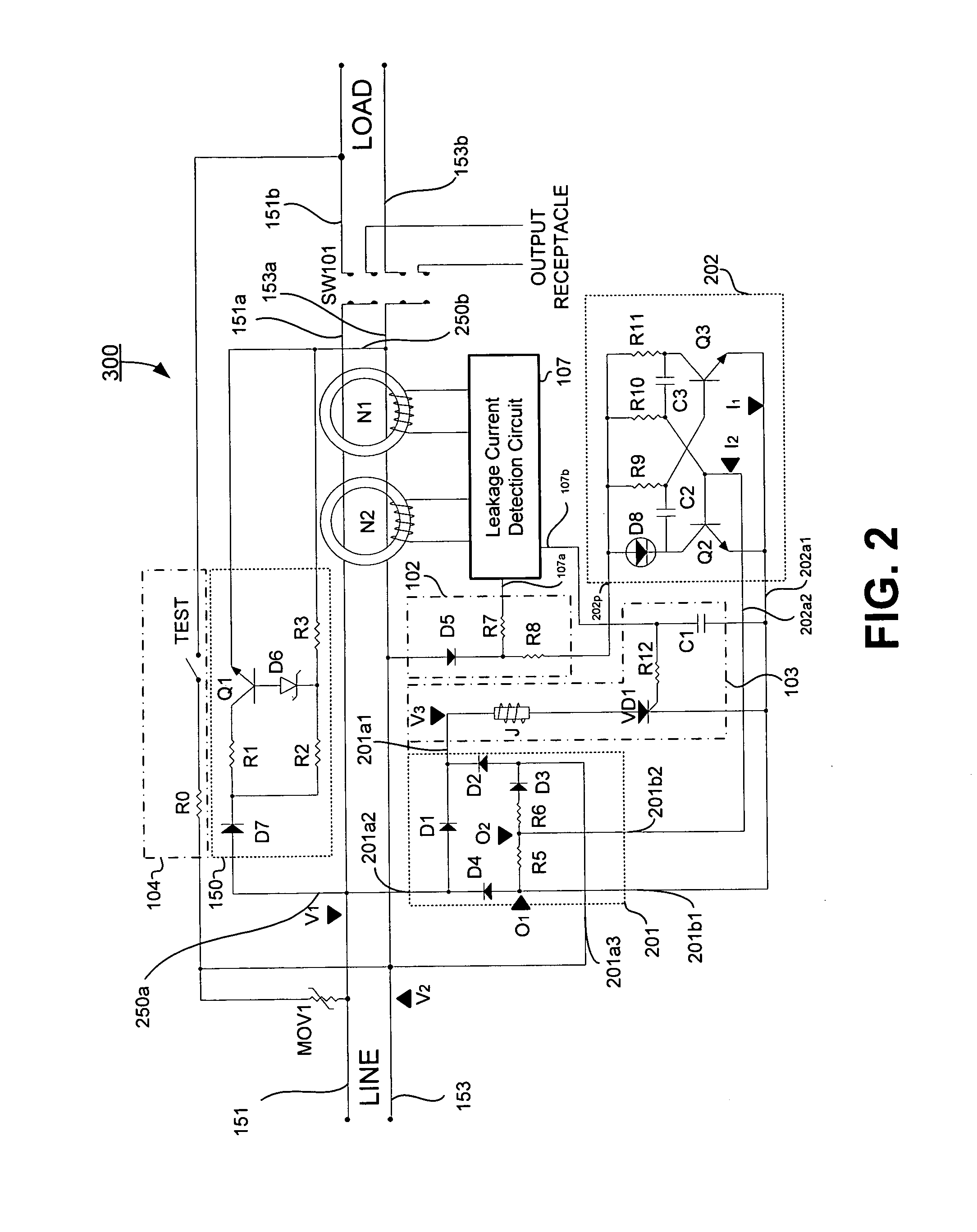

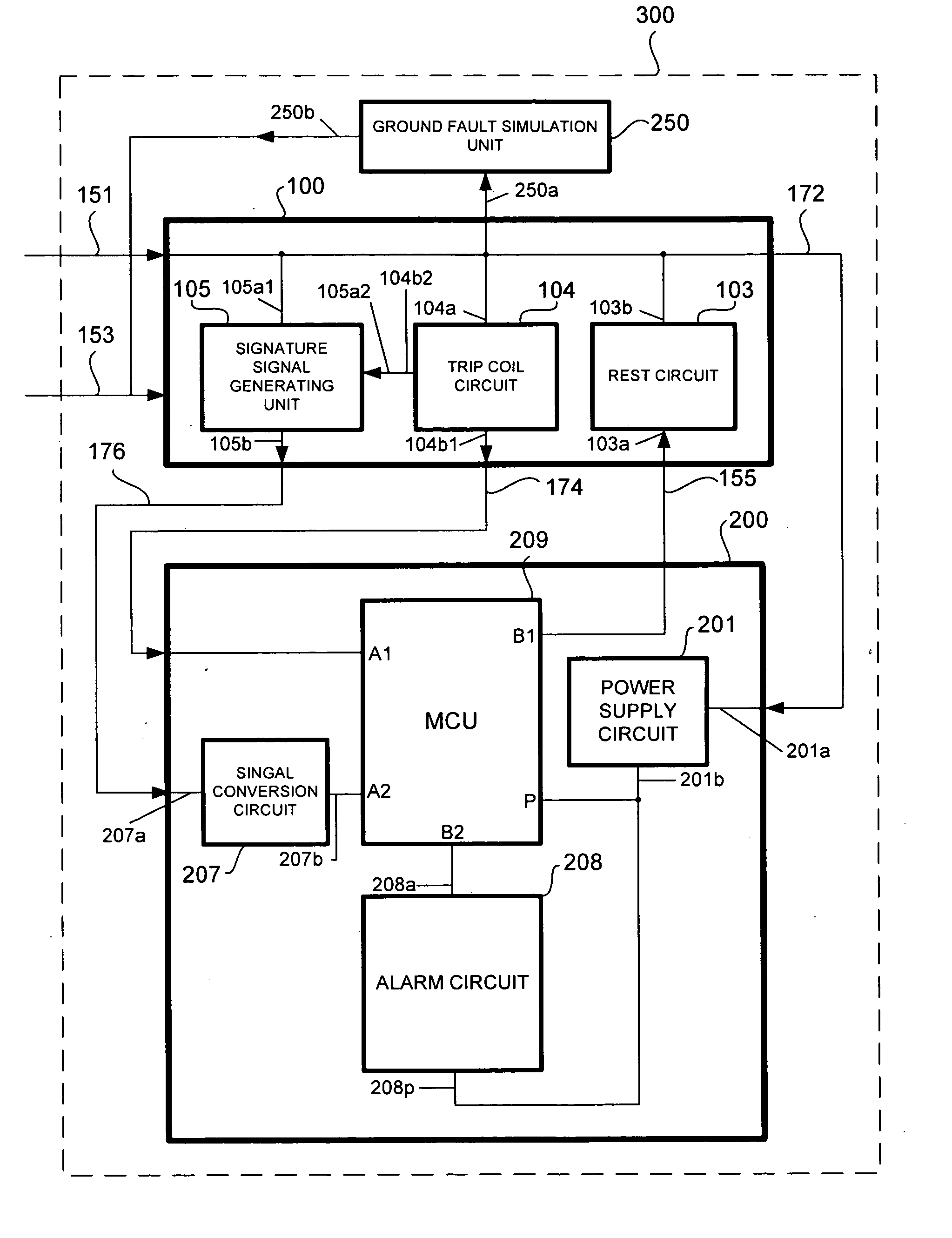

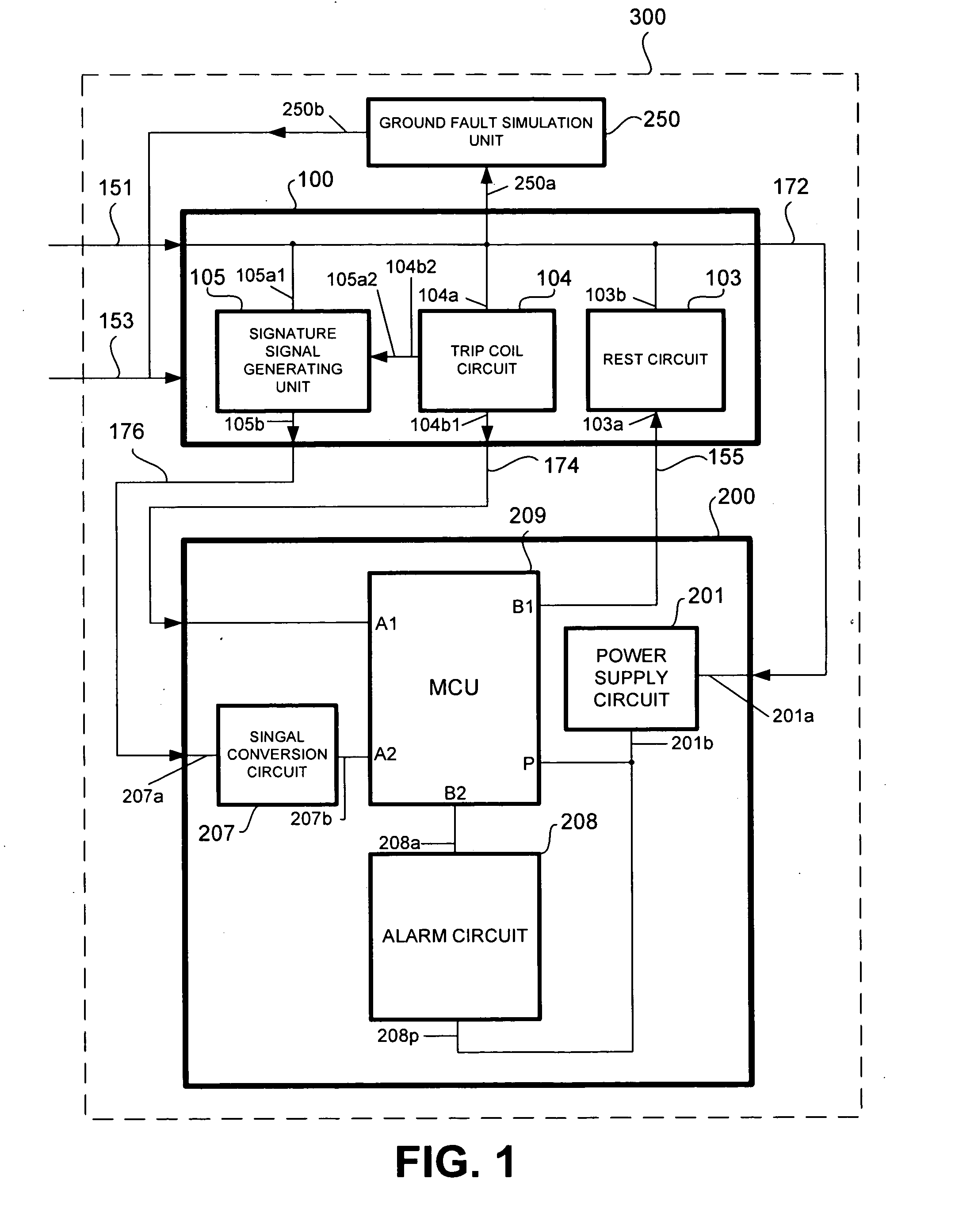

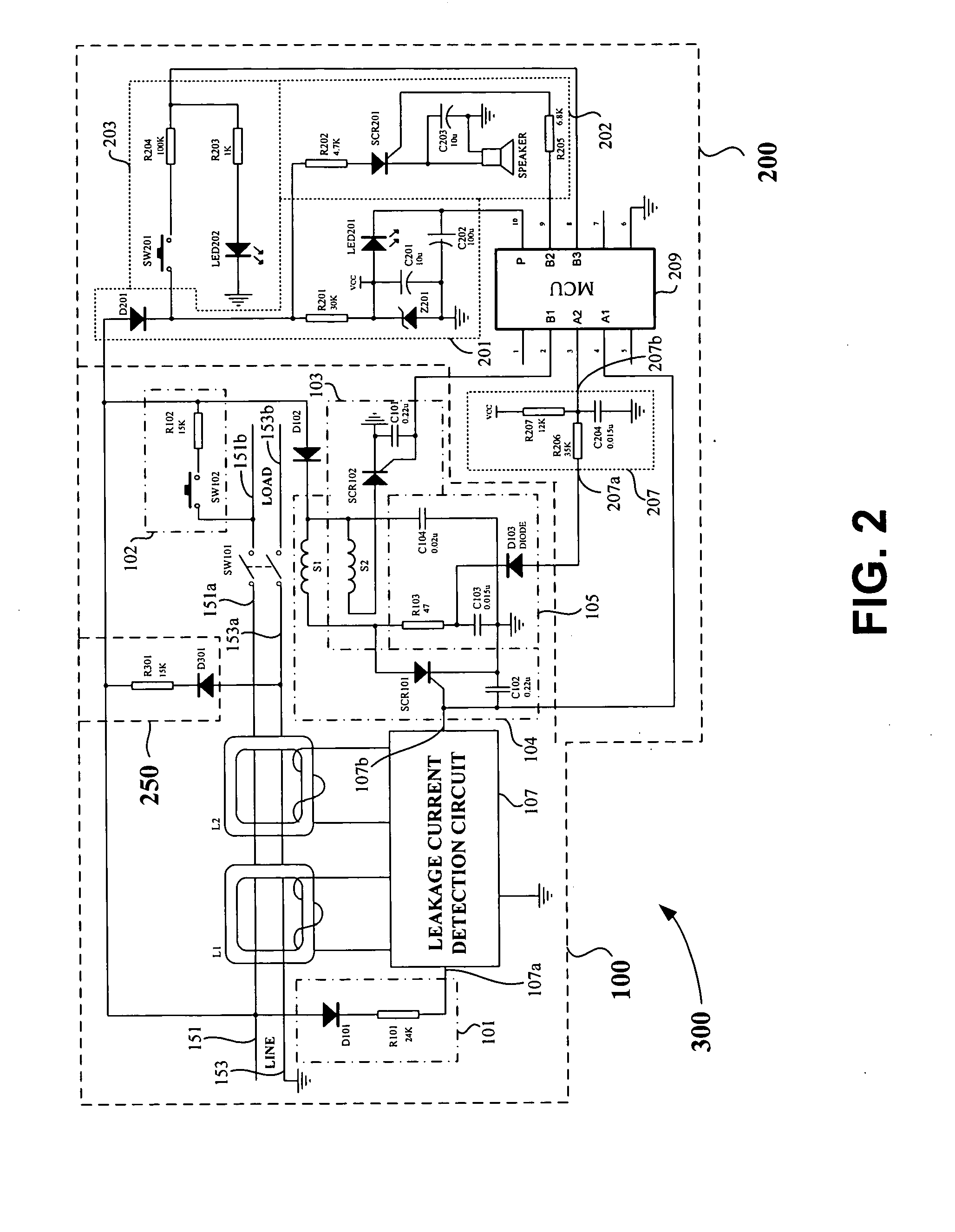

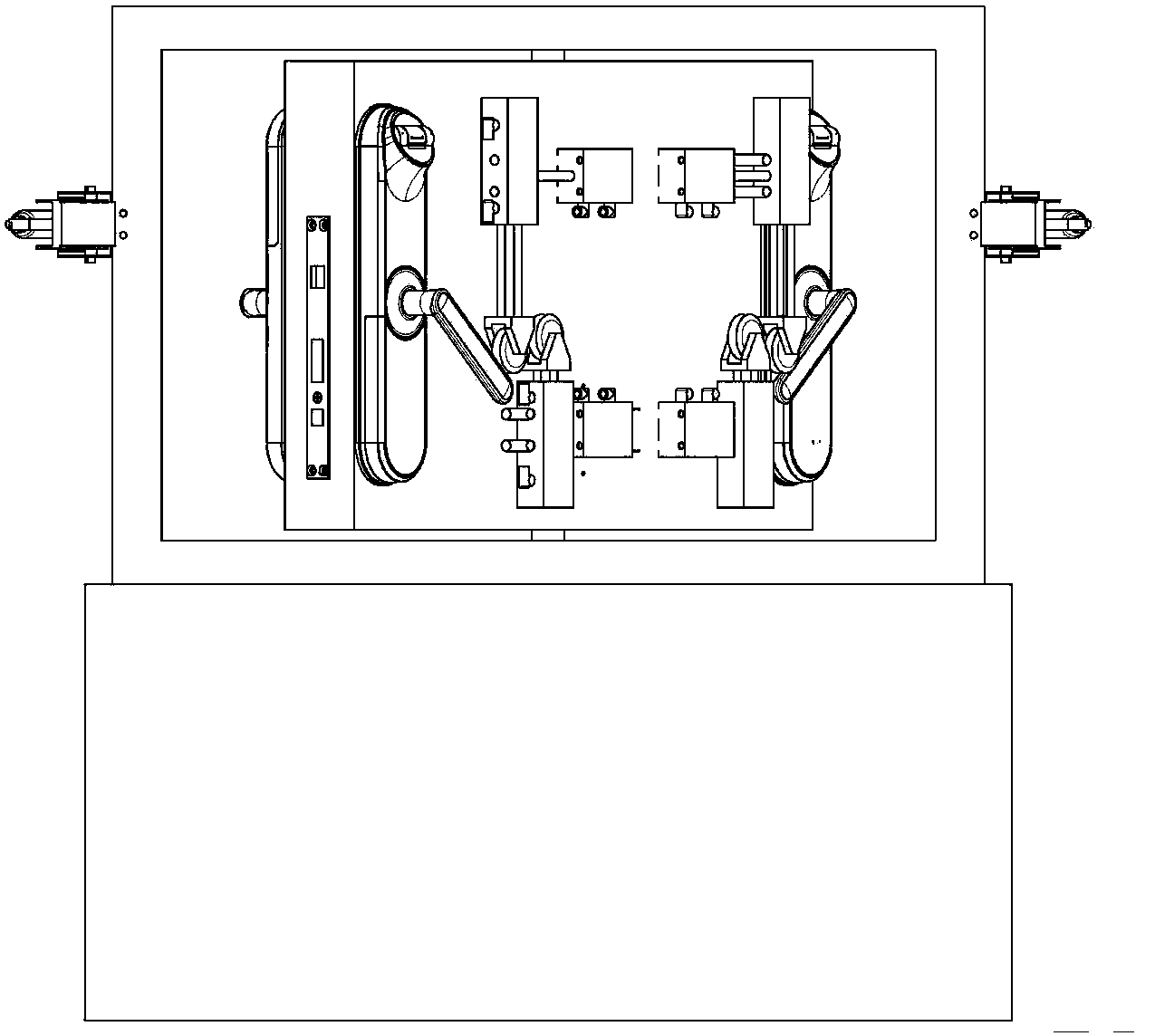

Intelligent life testing methods and apparatus for leakage current protection

ActiveUS20070164750A1Short-circuit testingEmergency protective arrangements for automatic disconnectionEngineeringLife testing

An apparatus for testing the life of a leakage current protection device having a leakage current detection circuit. In one embodiment, the apparatus a trip mechanism state generator, a fault alarm generator, a ground fault simulation unit. In operation, the ground fault simulation unit generates a simulated ground fault signal during every positive half-wave of an AC power, the simulated ground fault signal is detected by the leakage current detection circuit, the leakage current detection circuit responsively generates a signal to turn a switching device into its conductive state so as to allow a current to pass therethrough, the passed current is converted into a DC voltage in accordance with a trip mechanism state generated by the trip mechanism state generator, the fault alarm circuit receives and analyzes the DC voltage and indicates whether a fault exists in the leakage current protection device.

Owner:CHEN HENG

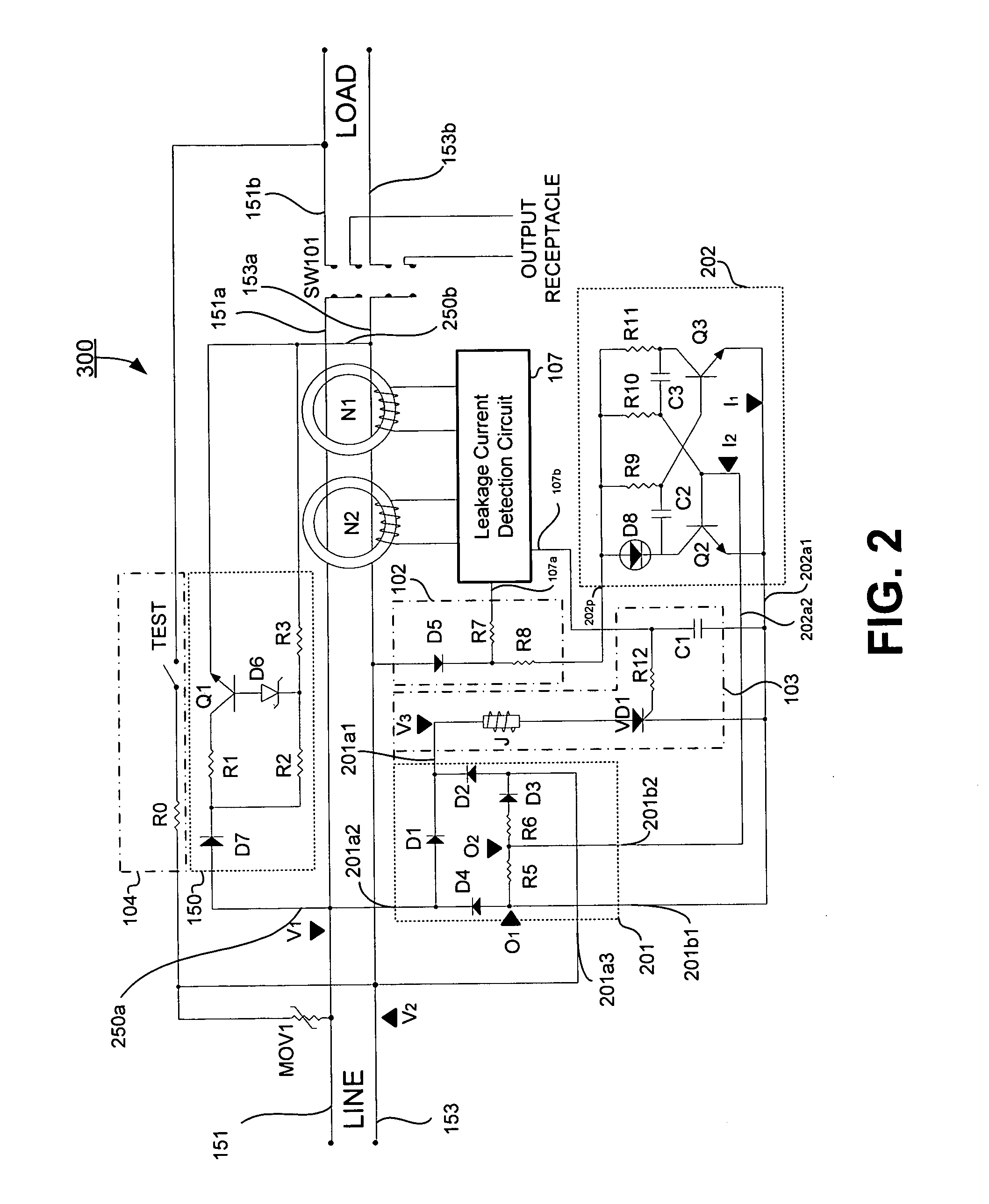

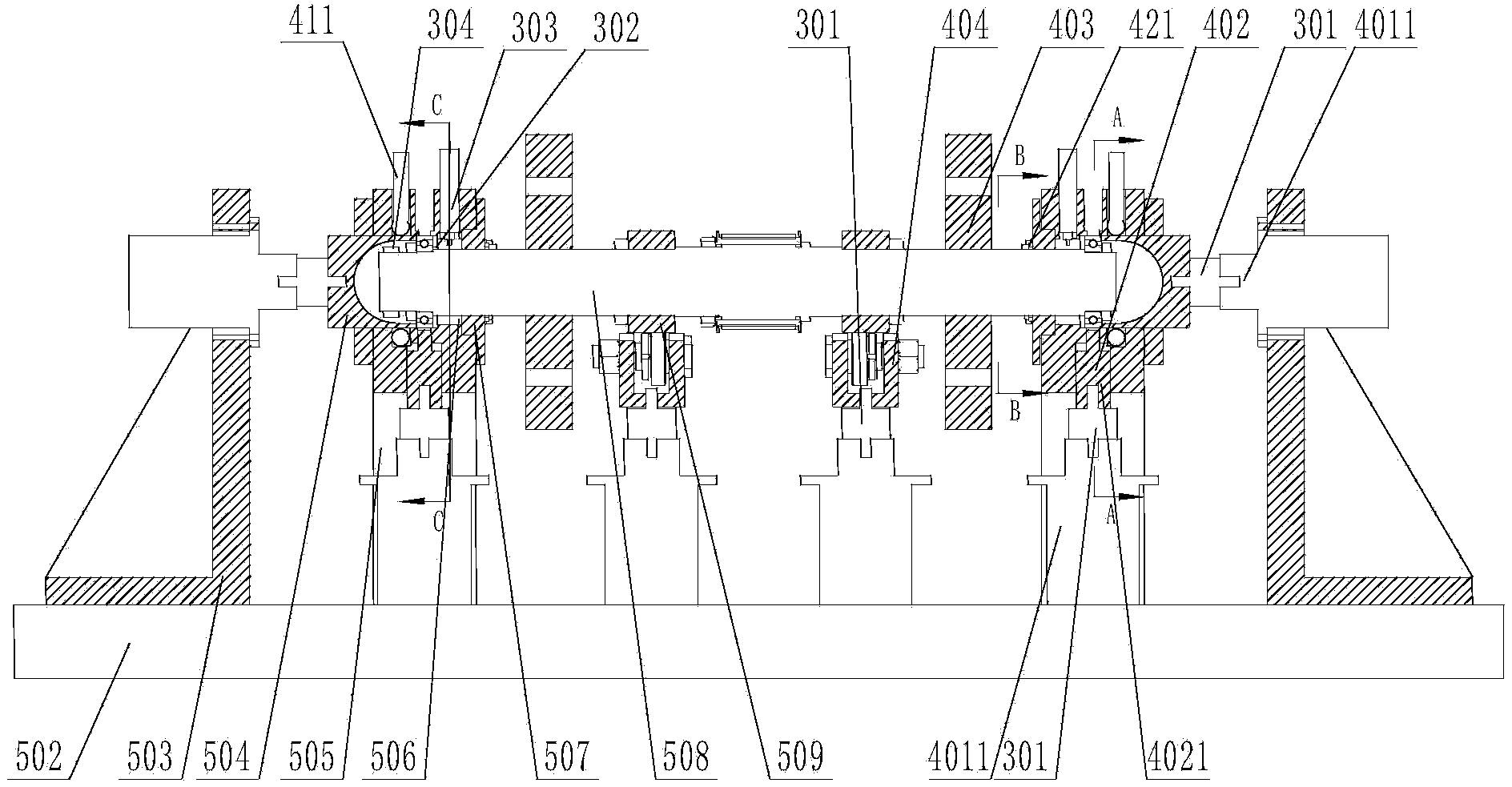

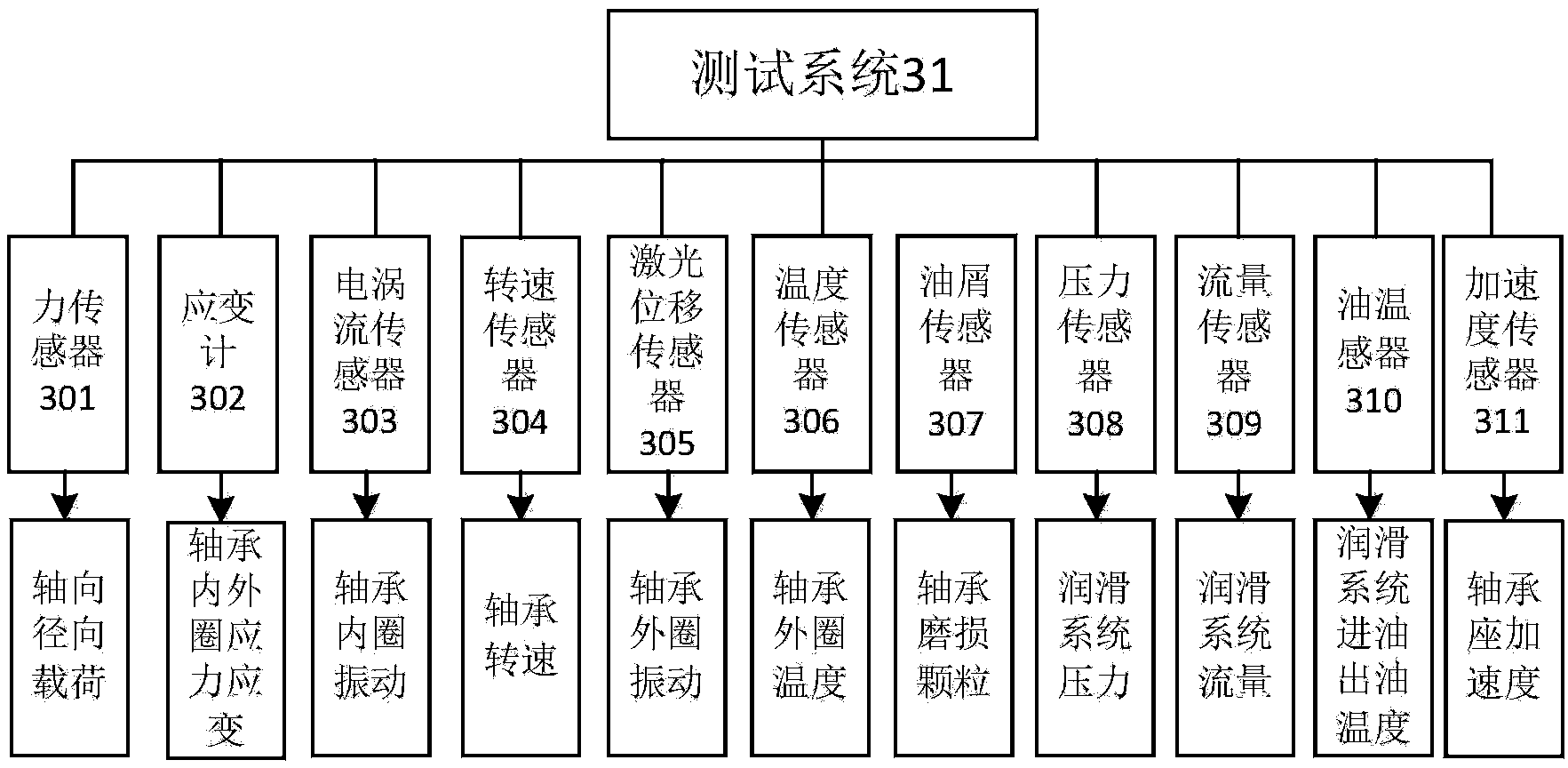

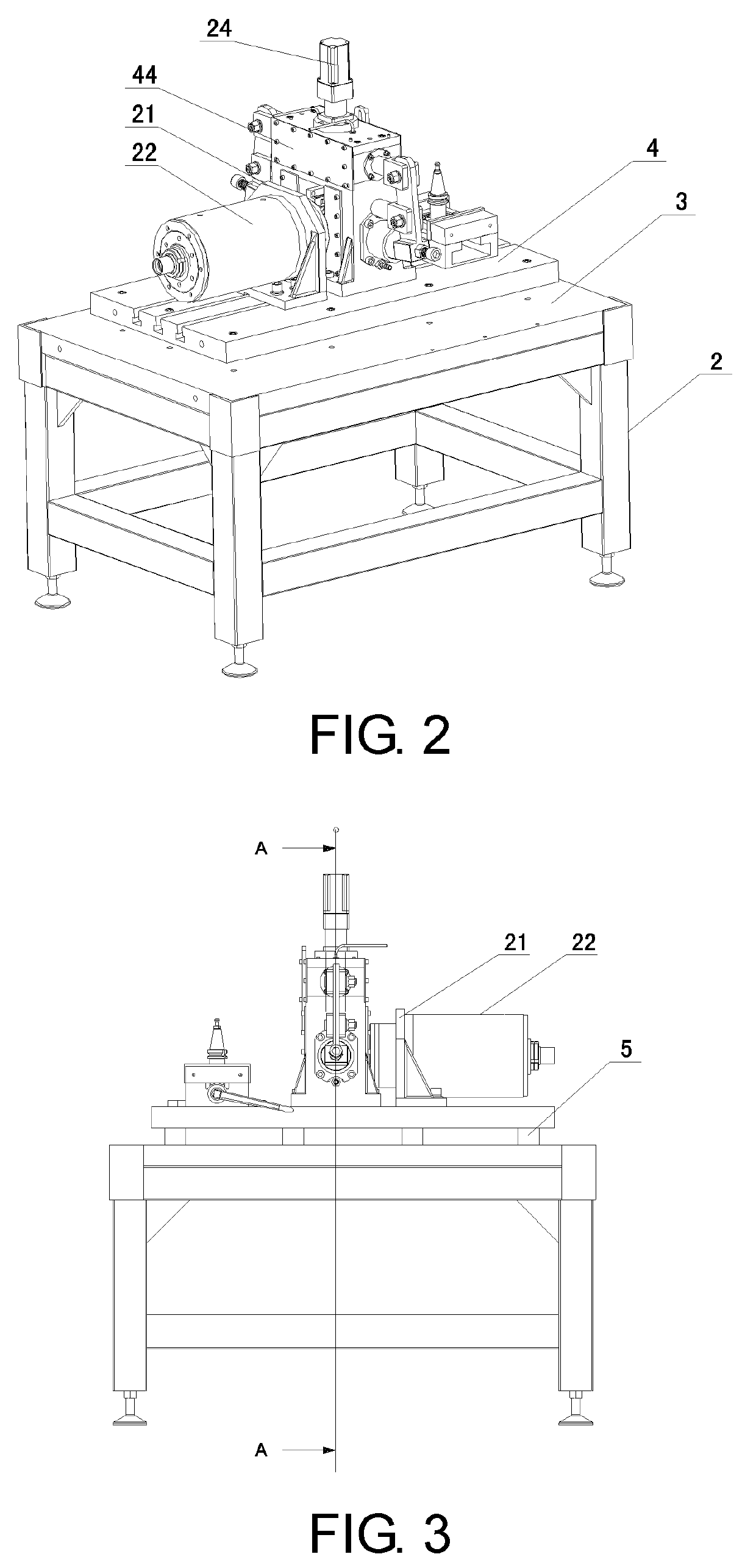

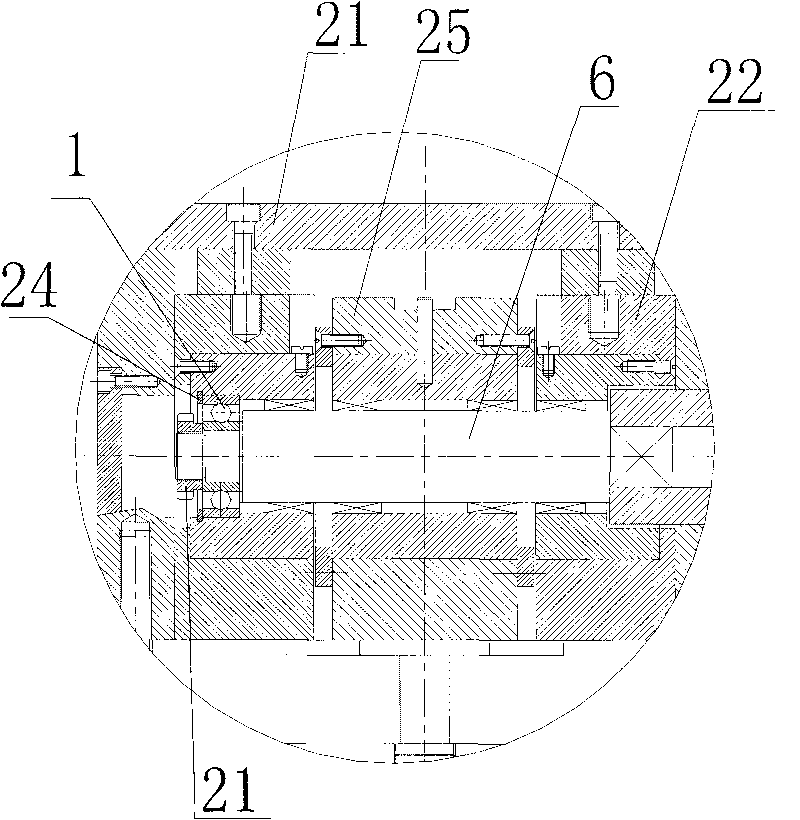

Bearing integrated dynamic performance test device and method

The invention relates to the technical field of bearing testing, in particular to a bearing integrated dynamic performance test device and method. The bearing integrated dynamic performance test device comprises a drive system, a transmission system, a measurement and control system, an environmental simulation system and a mechanical body structure. A motor is adopted by the drive system for driving. The measurement and control system controls the rotation speed of the motor. The transmission system is in a belt transmission mode or a coupler transmission mode. The measurement and control system is provided with a force sensor, a strainmeter, an eddy current transducer, a rotation speed sensor, a laser displacement sensor, a temperature sensor, a magnetic oil residue sensor, a pressure sensor, a flow sensor, an oil temperature sensor, an acceleration sensor and other related sensors used for bearing testing. The control system is driven in a servo mode, and is composed of a frequency converter, a hydraulic solenoid valve, a heating controller, a flow control device and a pressure control device. The environmental simulation system is adopted for simulating a real bearing testing working condition, and the performance and service life testing of the real bearing testing working condition is achieved.

Owner:DALIAN UNIV OF TECH

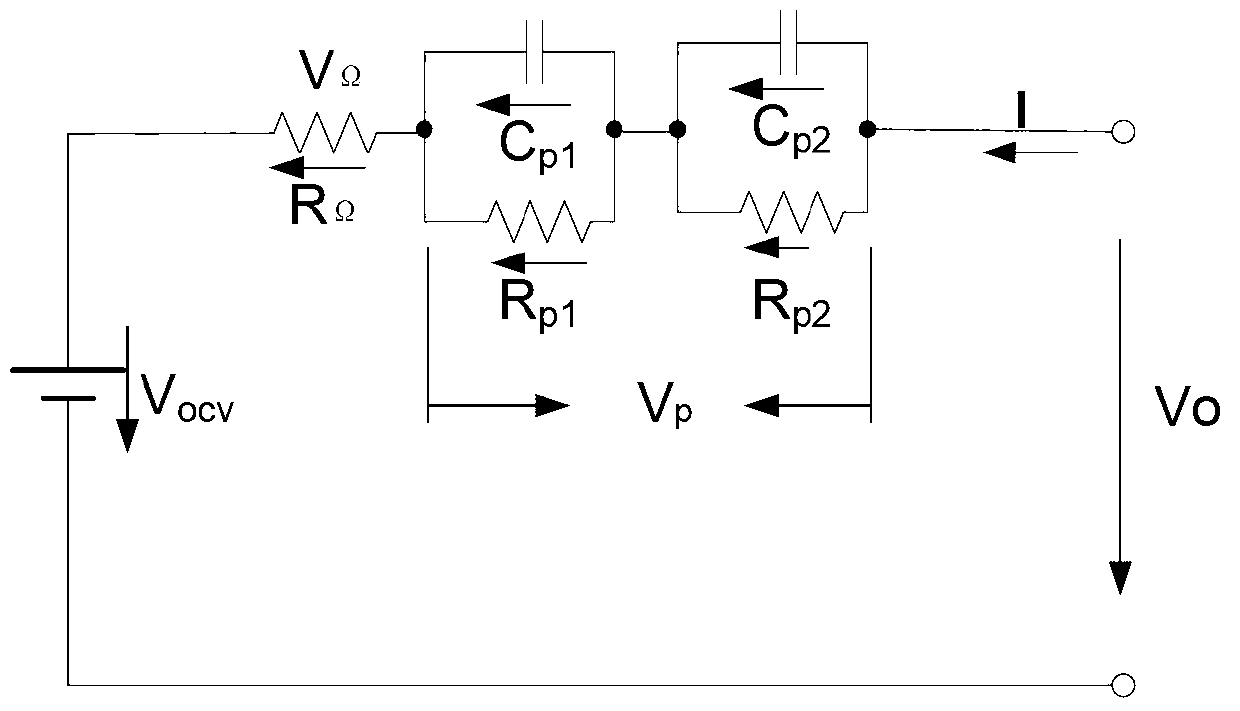

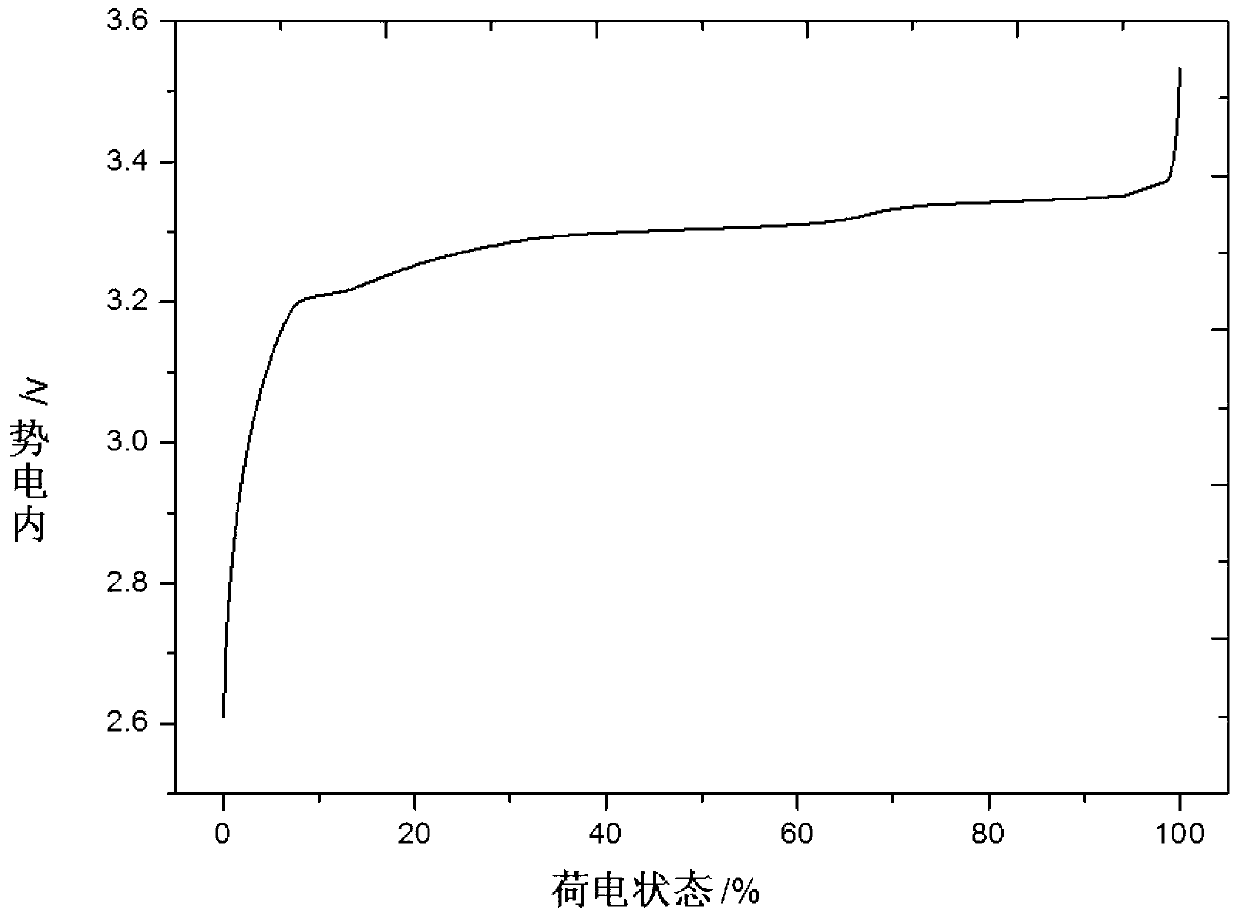

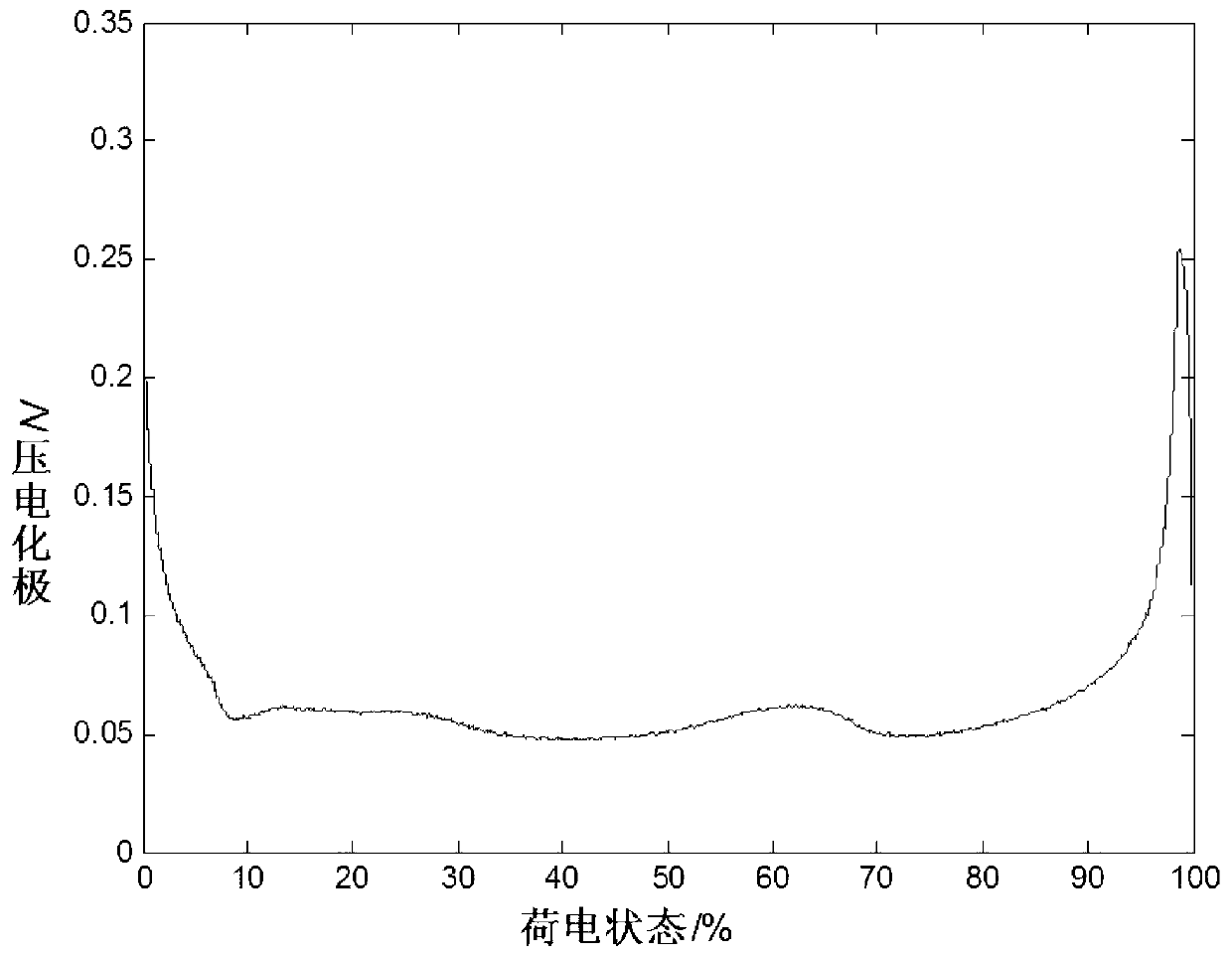

Lithium battery cycle life quick testing method

ActiveCN103344917AReduce designShorten the development cycleElectrical testingElectricityTest battery

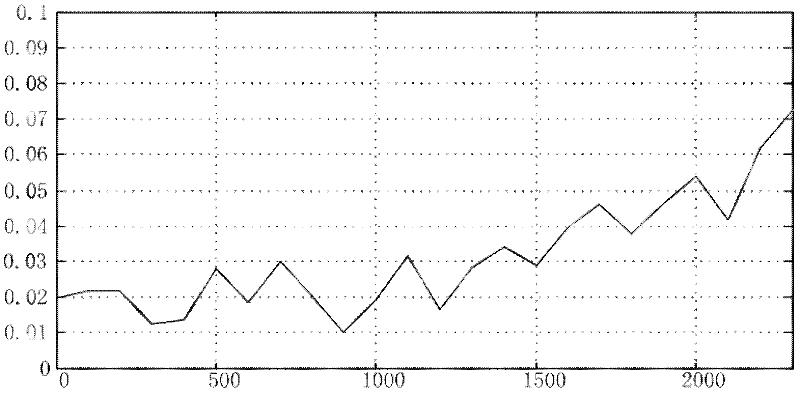

The invention relates to the technical field of lithium battery parameter determination methods, in particular to a lithium battery cycle life quick testing method. The method includes the steps of step 1, determining charge state interval for cycle life quick testing according to polarization voltage characteristics of a battery sample, step 2, carrying out a battery cycle life quick test to obtain cycle life test experimental data, step 3, carrying out cycle life mathematic model deduction in partial charge interval, step 4, establishing cycle life deduction mathematic models in 0-100% charge interval, step 5, obtaining a cycle life formula of a battery in the 0-100% charge interval, and step 6, estimating the cycle life of the tested battery. The lithium battery cycle life quick testing method overcomes the defects that time for conventional testing is long, and difference between an accelerated cycle life testing method and the reality is large, and shortens design, development and testing periods of batteries.

Owner:BEIJING JIAOTONG UNIV +2

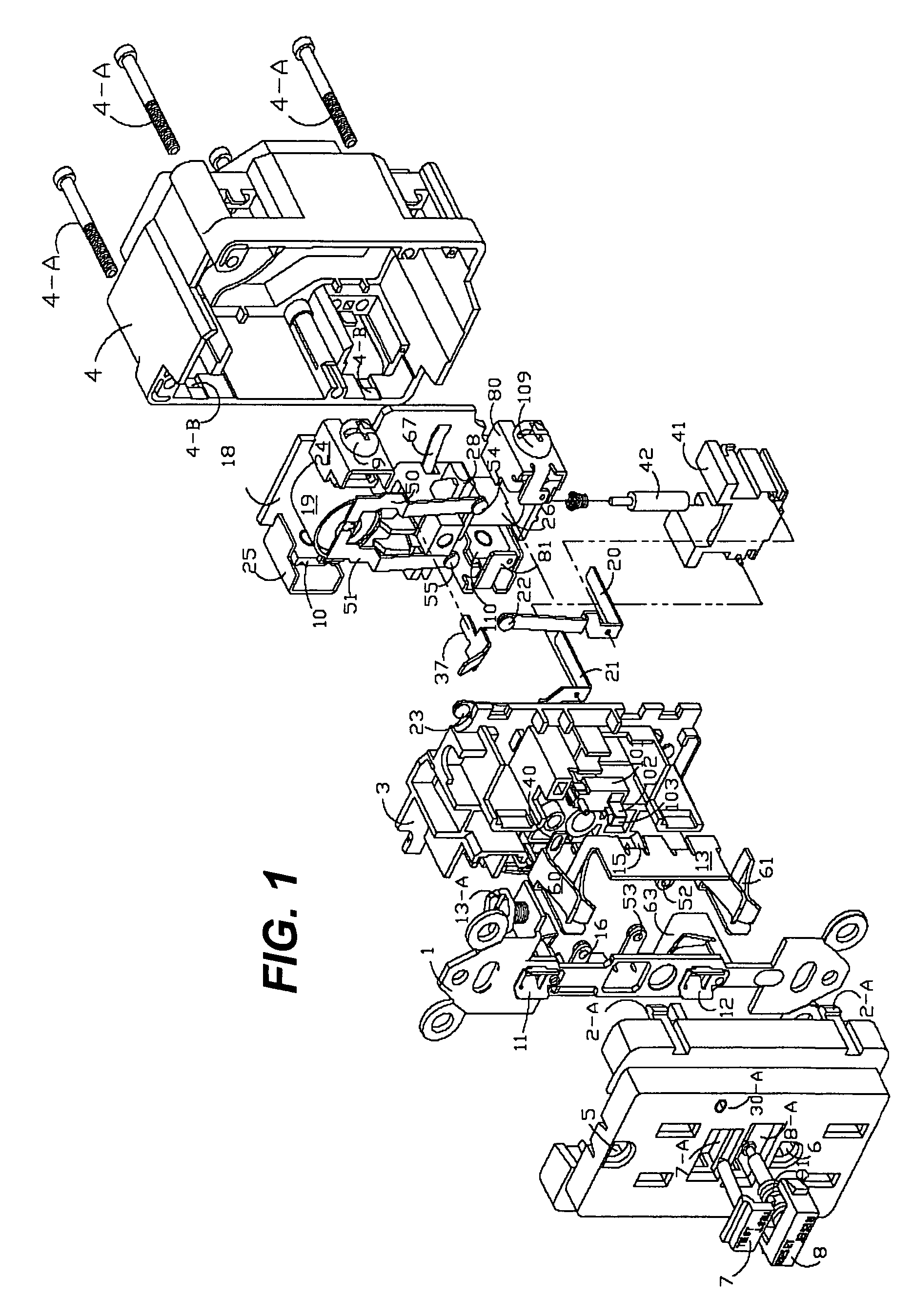

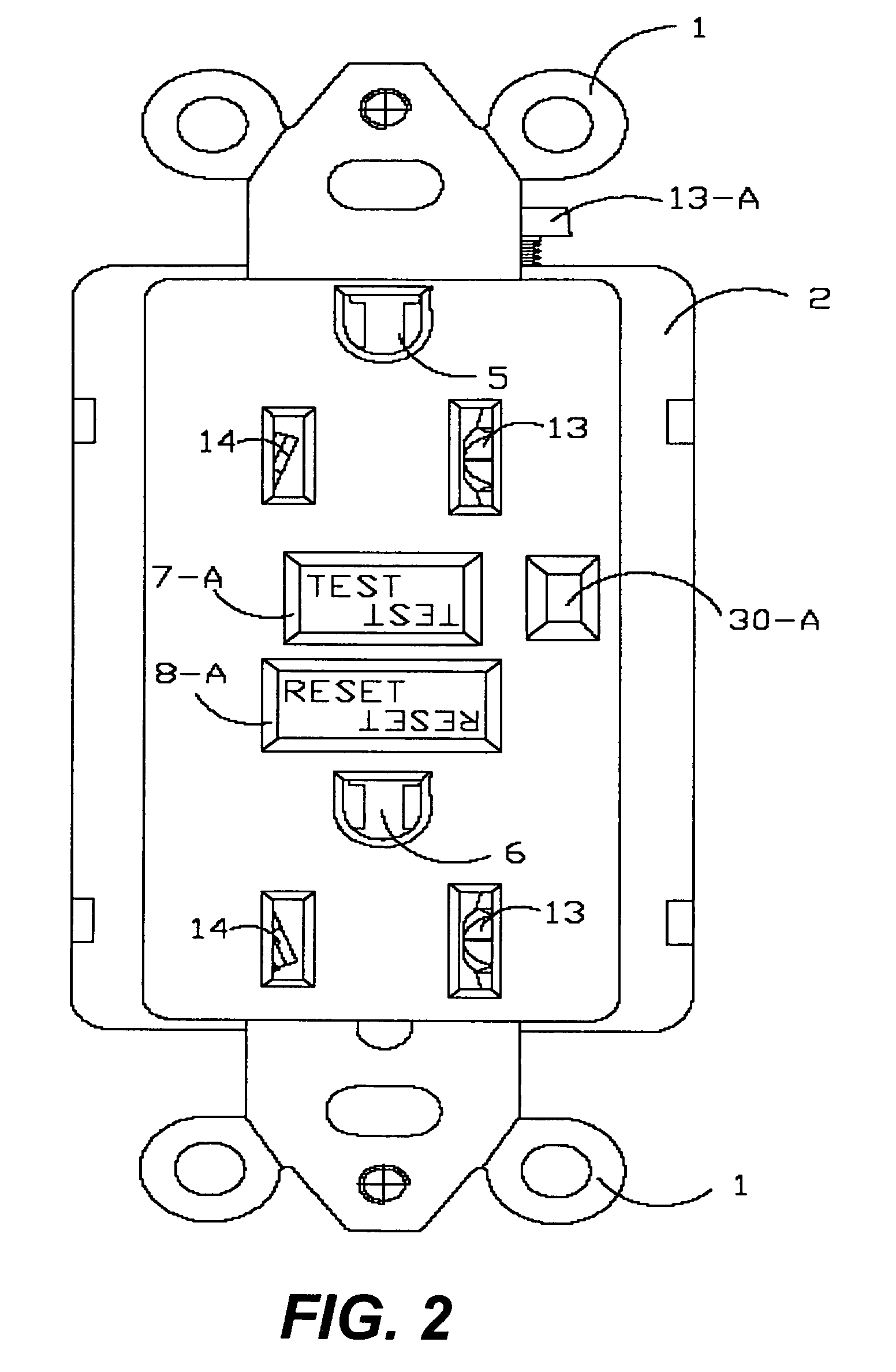

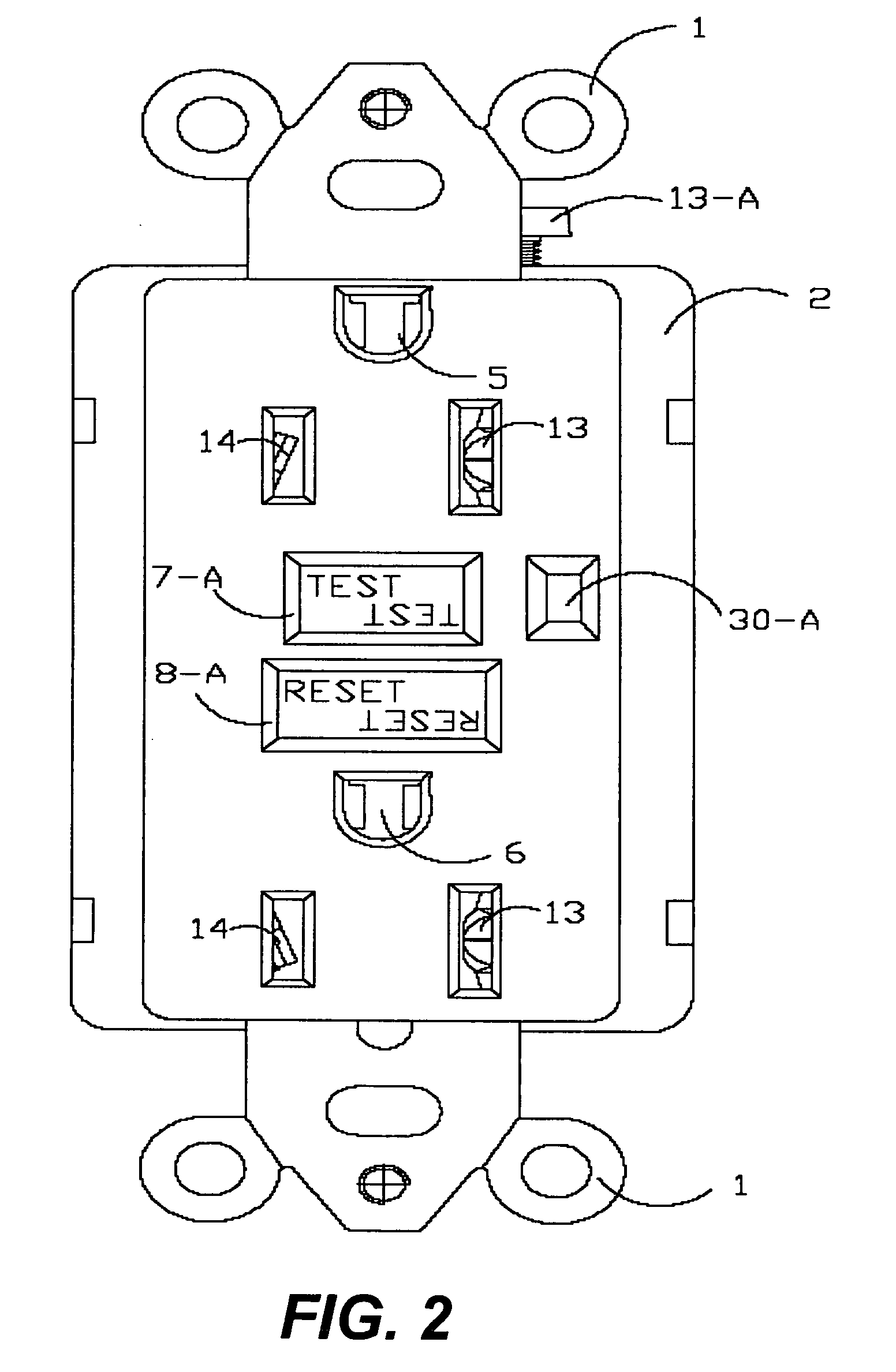

Circuits for circuit interrupting devices having automatic end of life testing function

InactiveUS7295415B2Protective switch detailsCircuit-breaking switches for excess currentsEngineeringLife testing

The present invention provides a set of circuits which is capable of performing an automatic check on main components of a circuit interrupting device when the circuit interrupting device is properly powered and the device is at a tripped state to determine whether these main components function normally. The results of the automatic check can be detected by depressing a reset button in the circuit interrupting device. If the reset button can be depressed, the main components function normally. Alternatively, the results can be automatically displayed by a showing on the face lid of the circuit interrupting device of either a green light, which means that the main components function normally, or a red or yellow light or no light, which means that at least one of the main components in the circuit interrupting device does not function properly. The present invention also provides an end-of-service-life detection integrated circuit chip capable of receiving and transmitting an automatic check signal and determining whether or not the circuit interrupting device can be reset. The preferred circuit interrupting device is a ground fault circuit interrupter (GFCI).

Owner:HUANG HUADAO

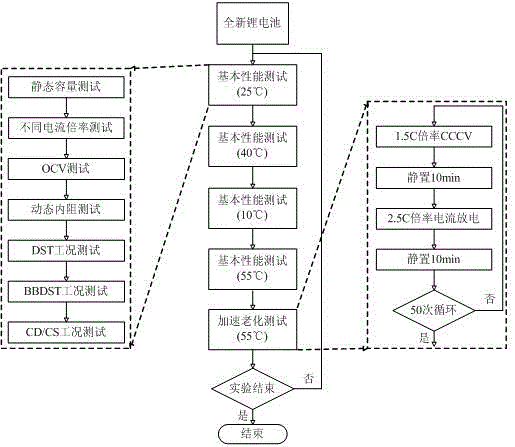

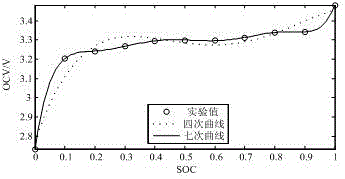

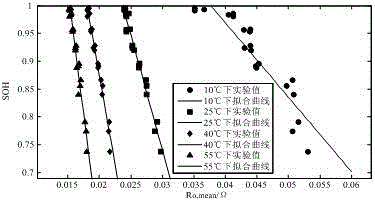

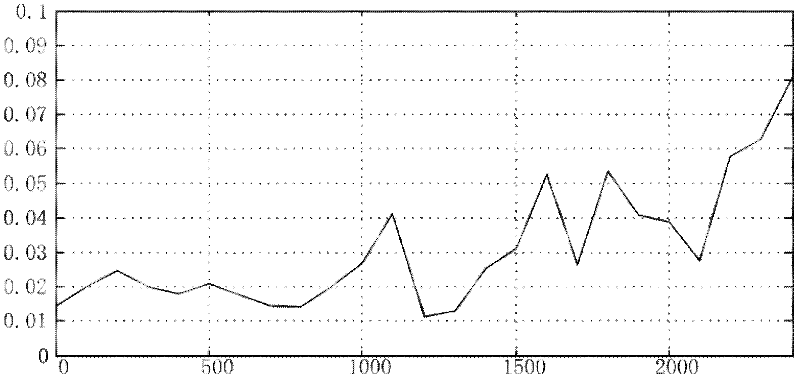

Construction method for lithium battery health life model

The invention discloses a construction method for a lithium battery health life model, and the method is used for the recognition of the aging degree of a lithium battery. The method comprises the steps: firstly carrying out the health lift testing of the lithium battery; secondly constructing the health factor of the lithium battery according to the testing data; thirdly building the lithium battery health life model according to the constructed health factor, thereby achieving the prediction of the health state of the lithium battery; fourthly sequentially carrying out the testing of basic performances at four temperature points (25 DEG C, 40 DEG C, 10 DEG C and 55 DEG C) during the testing of the health life; fifthly carrying out the acceleration aging testing at the degree of 55 DEG C; and finally finishing the testing when the static capacity test value decreases to 75% of a rated capacity. The method carries out the direct obtaining of the performance parameters of the lithium battery based on testing data, carries out the research how to extract the health features to achieve the recognition of the aging degree of the lithium battery, and can be used for achieving the prediction of the health state of the lithium battery.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

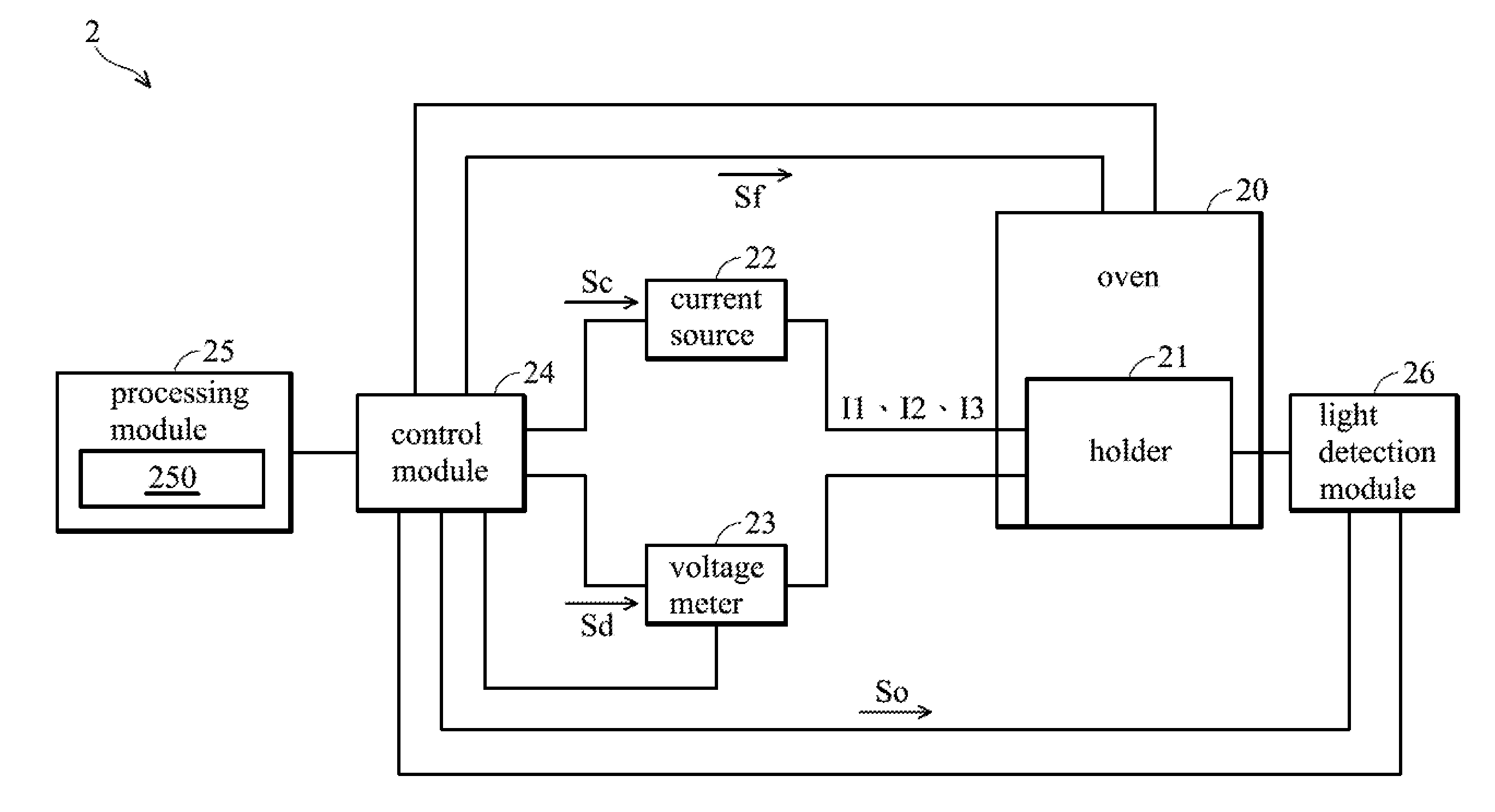

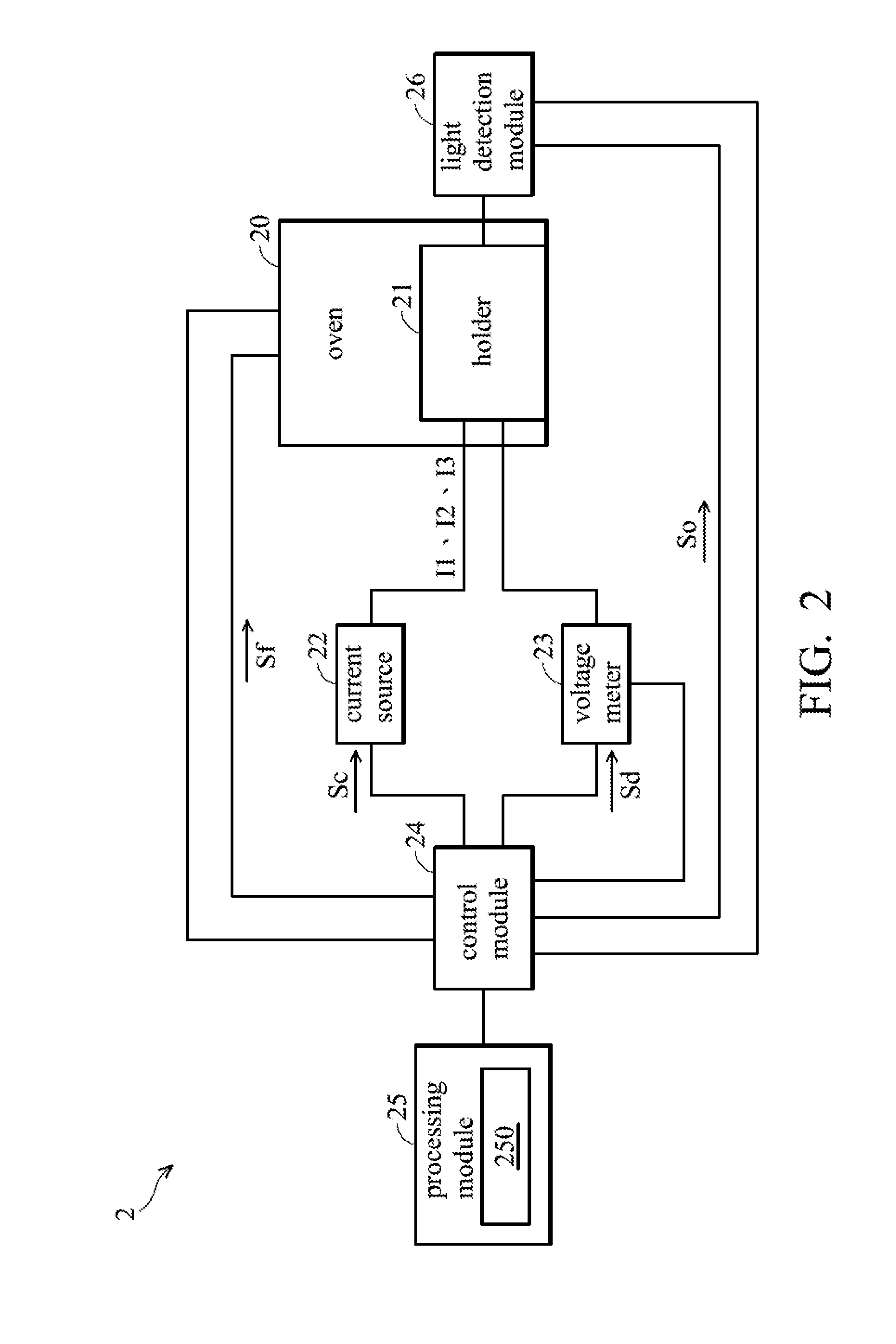

Devices And Methods For LED Life Test

A life test device comprises an oven, a current source, a voltage meter, a control module, and a process module. A light-emitting diode (LED) is disposed in the oven. The temperature of the oven is gradually changed in a first period and remains at a set temperature in a second period. The current source provides a first current and a second current to the LED. The voltage meter measures forward voltages of the LED. The control module controls the current source to output the first or second current to the LED and controls the voltage meter to measure the forward voltages of the LED. The process module calculates a junction temperature of the LED according to the forward voltages and a variation relationship formula between the forward voltages and the temperature of the oven.

Owner:IND TECH RES INST

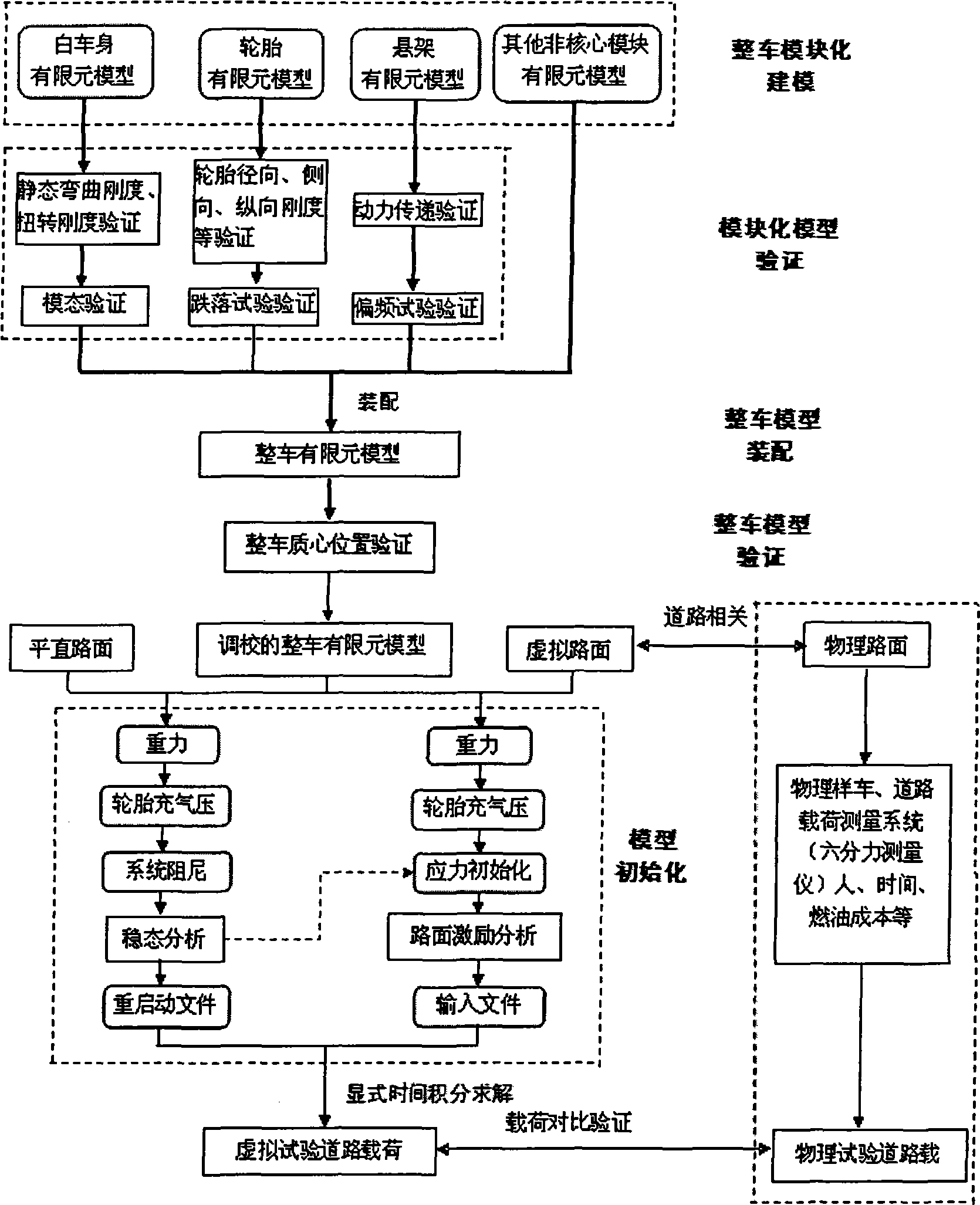

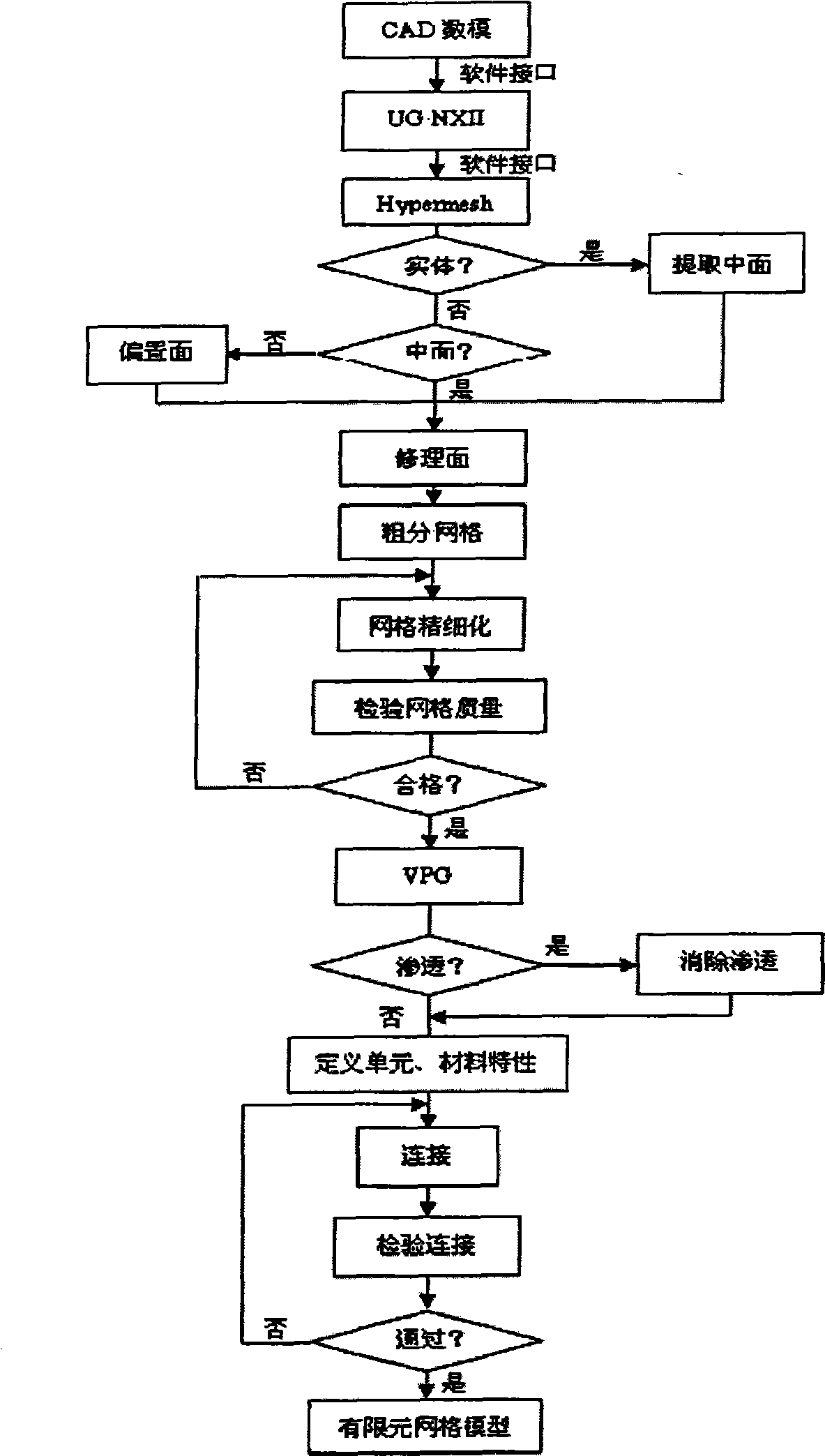

Vehicle road load emulation method

InactiveCN101510230AAvoid the difficulty of determining the force relationshipAvoid undetermined difficultiesSpecial data processing applicationsElement modelModularity

The invention provides a vehicle road load simulation method which comprises the following steps of: 1) complete vehicle modular modeling; 2) complete vehicle modular model validation; 3) complete vehicle model assembly; 4) complete vehicle model validation; 5) establishment of finite element models of enhanced durable roads; 6) model initialization; 7) obtaining of virtual road load result; and 8) comparative validation with physical road load. The invention has the advantages of shortening development time and reducing costs, which is of great significance to vehicle development during the conceptual design phase. During the conceptual design phase of new models, fatigue analysis can be carried out before the design and manufacture process by using a virtual prototype to predict road load so as to truly predict the life of the product, thus greatly reducing great expenses caused by producing prototype machines and testing the fatigue life.

Owner:TONGJI UNIV

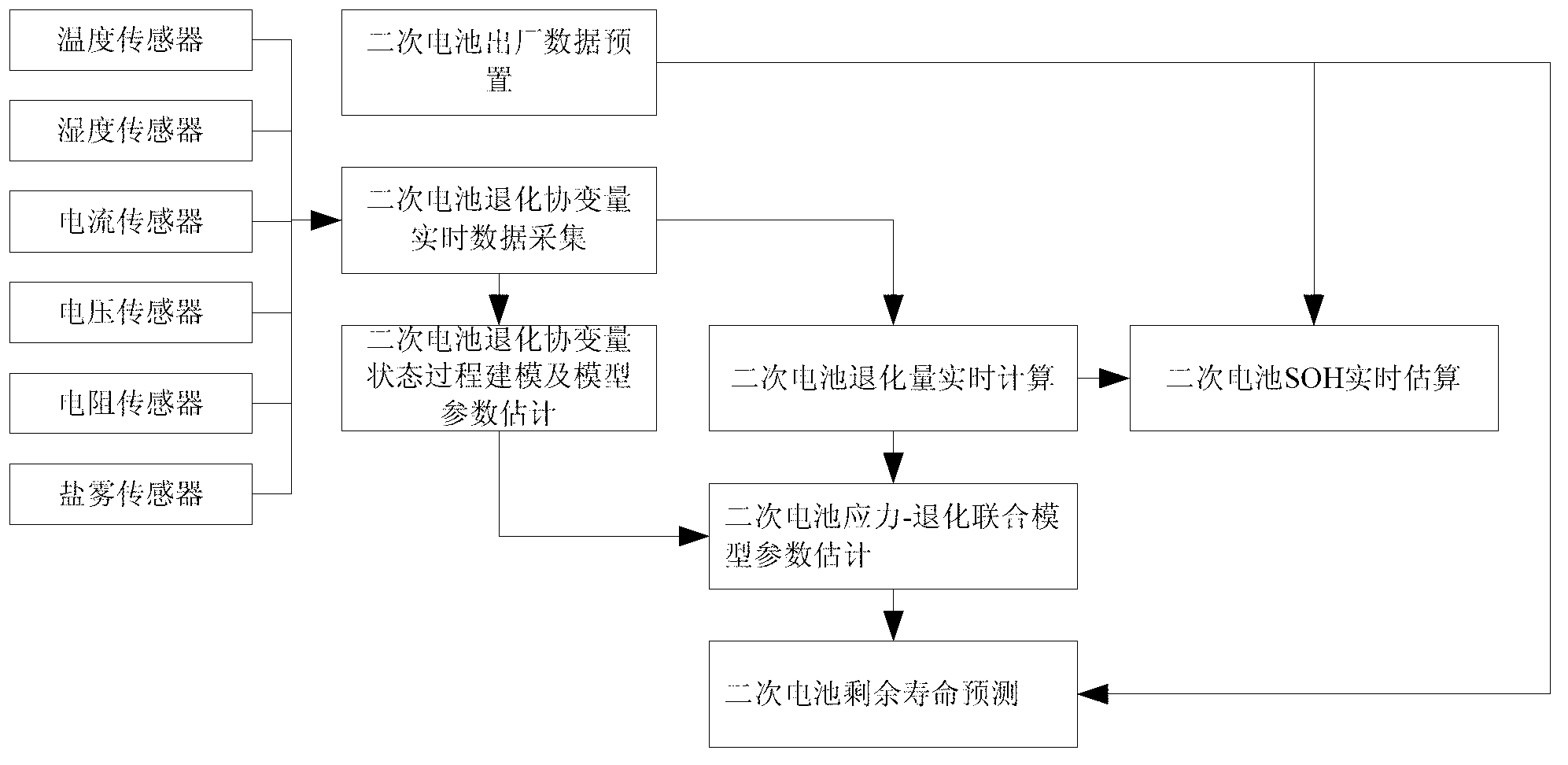

Method for estimating secondary cell SOH value and testing residual service life

InactiveCN103308864AOptimize usage efficiencyEase of maintenanceElectrical testingPredictive methodsModel parameters

The invention provides a method for estimating a secondary cell SOH value and testing the residual service life and relates to a method for predicting the residual service life of a secondary cell. The predicting method comprises the following steps of acquiring performance degradation concomitant variable data of the secondary cell in real time, establishing a secondary cell degradation concomitant variable state process model and estimating model parameters in real time, calculating a degradation quantity value of the secondary cell, calculating a result and cell ex-factory data in real time, estimating a current SOH value of the secondary cell in real time, establishing a secondary cell stress-degradation united model and estimating model parameters, and calculating the residual service life of the secondary cell under different using conditions according to preset using standards of the secondary cell in real time. By means of the method for estimating the secondary cell SOH value and testing the residual service life, the accuracy and the reliability of health status SOH estimation and residual service life prediction of the secondary cell can be improved, the using and maintenance efficiency of the cell is improved, and the service life of the cell is prolonged.

Owner:NAT UNIV OF DEFENSE TECH

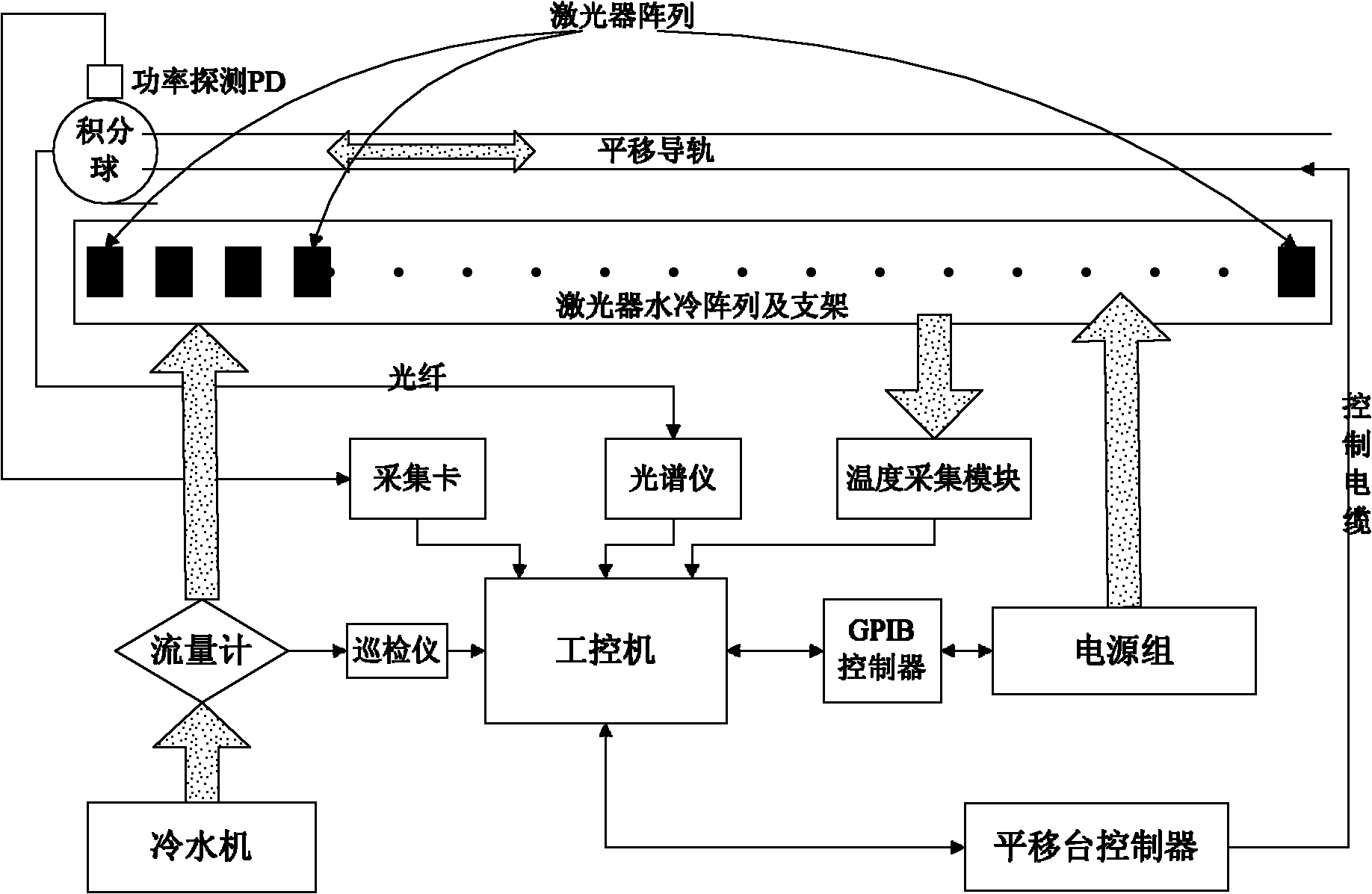

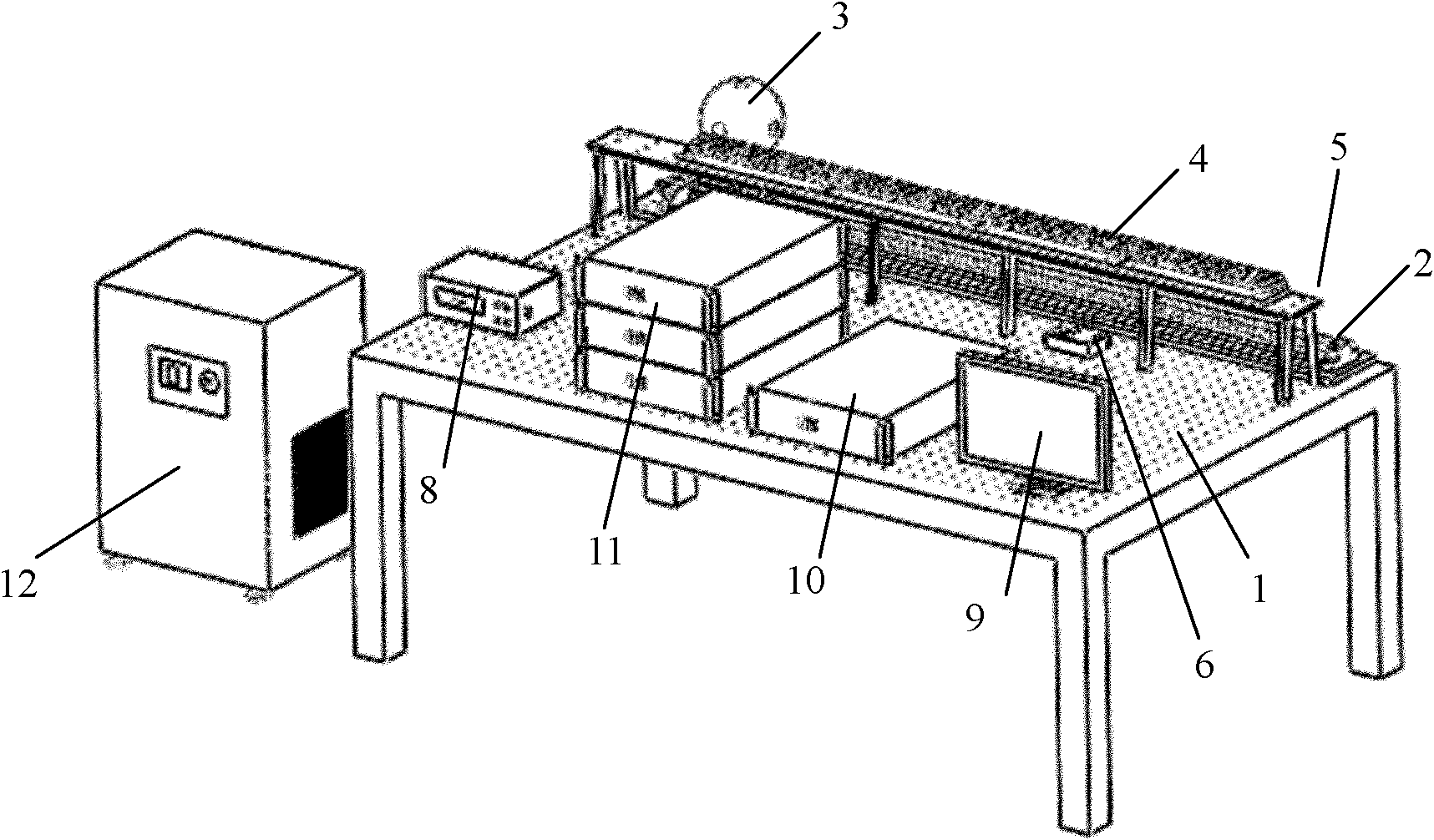

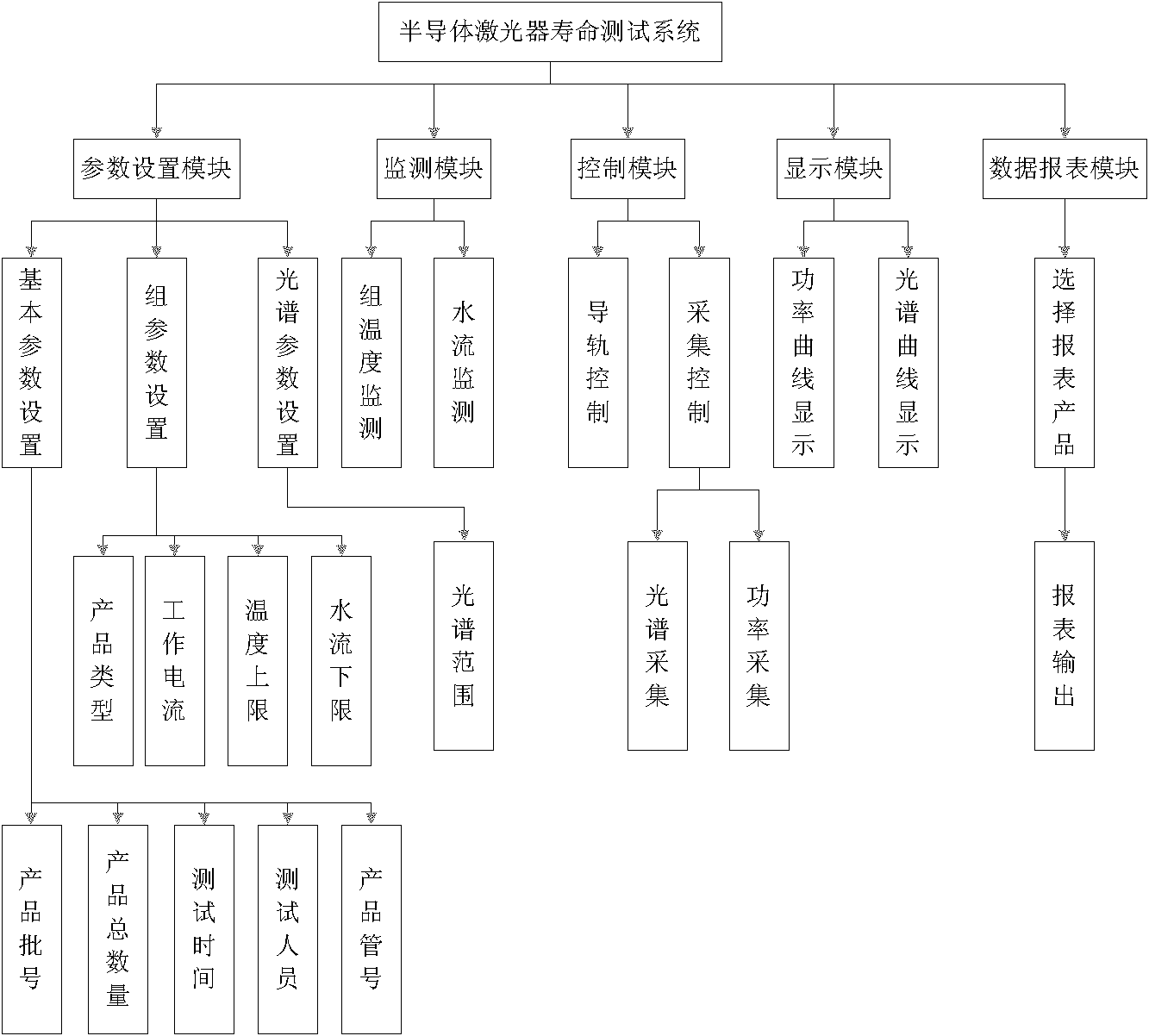

Device for testing life of semiconductor laser

ActiveCN102062675AImprove test efficiencyAchieve multi-functionalitySpectrum investigationPhotometrySpectrographPower detector

The invention discloses a device for testing life of a semiconductor laser, comprising an optical platform, wherein the optical platform is provided with parallel guide rails and a laser water cooling array; the parallel guide rails are provided with electric translation tables; an integrating sphere and a PD (Power Detector) are fixed on the electric translation tables; the integrating sphere isconnected with a spectrograph through an optical fiber; the spectrograph is connected to an industrial personal computer; the PD is connected with the industrial personal computer through a collecting card; a temperature collecting module is arranged at the side of the laser water cooling array and connected with the industrial personal computer; the electric translation tables are connected witha translation table controller through controlling a cable; and the translation table controller is connected to the industrial personal computer. By the system, automatic parameter tests can be carried out on laser products with different packaging types, powers and numbers. The power and the spectral information of the laser products are automatically collected and recorded in the processing ofworking, the report printing data can be automatically carried out to form a test report, and therefore, the basis for failure analysis and research of the laser products is provided.

Owner:FOCUSLIGHT TECH

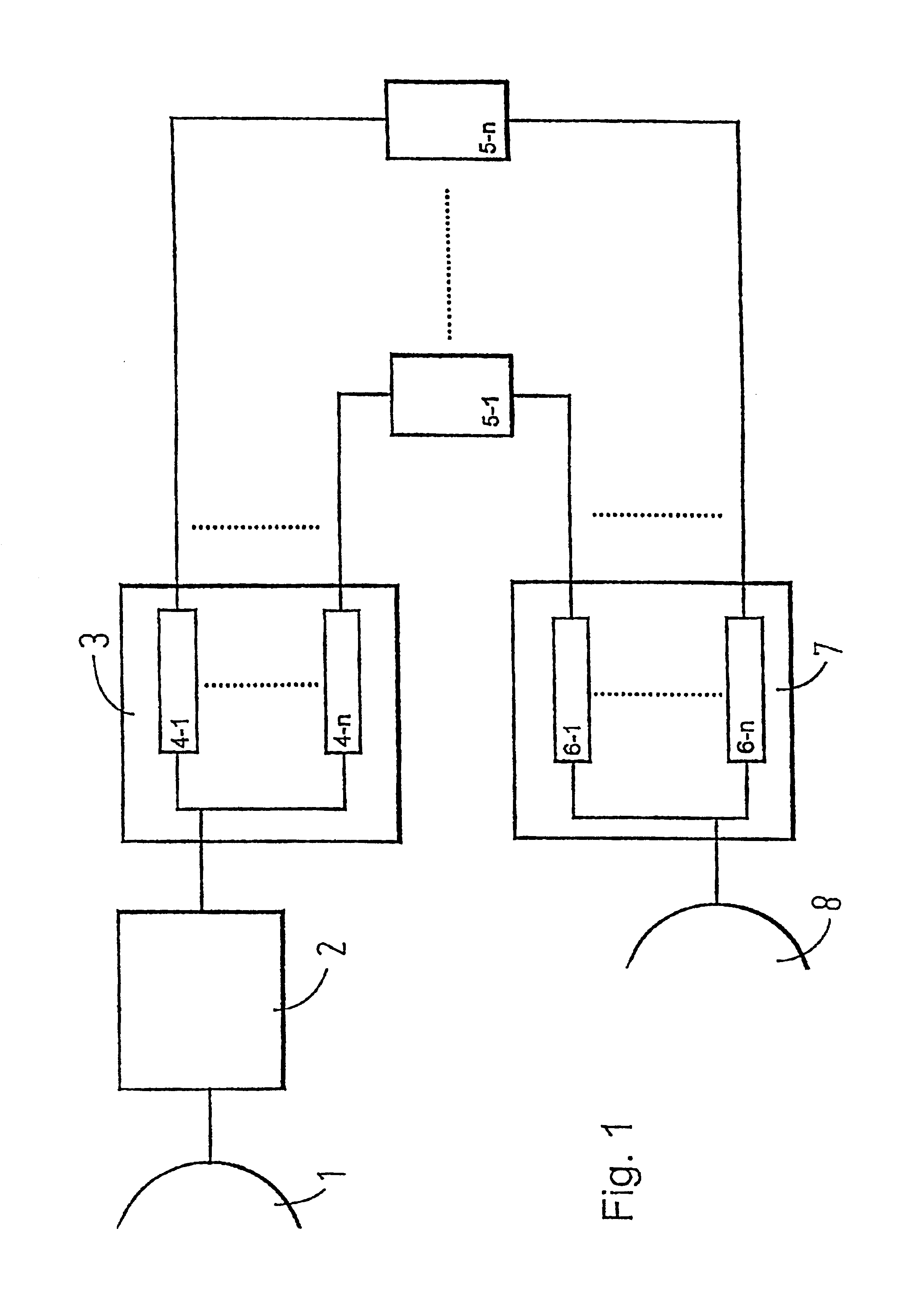

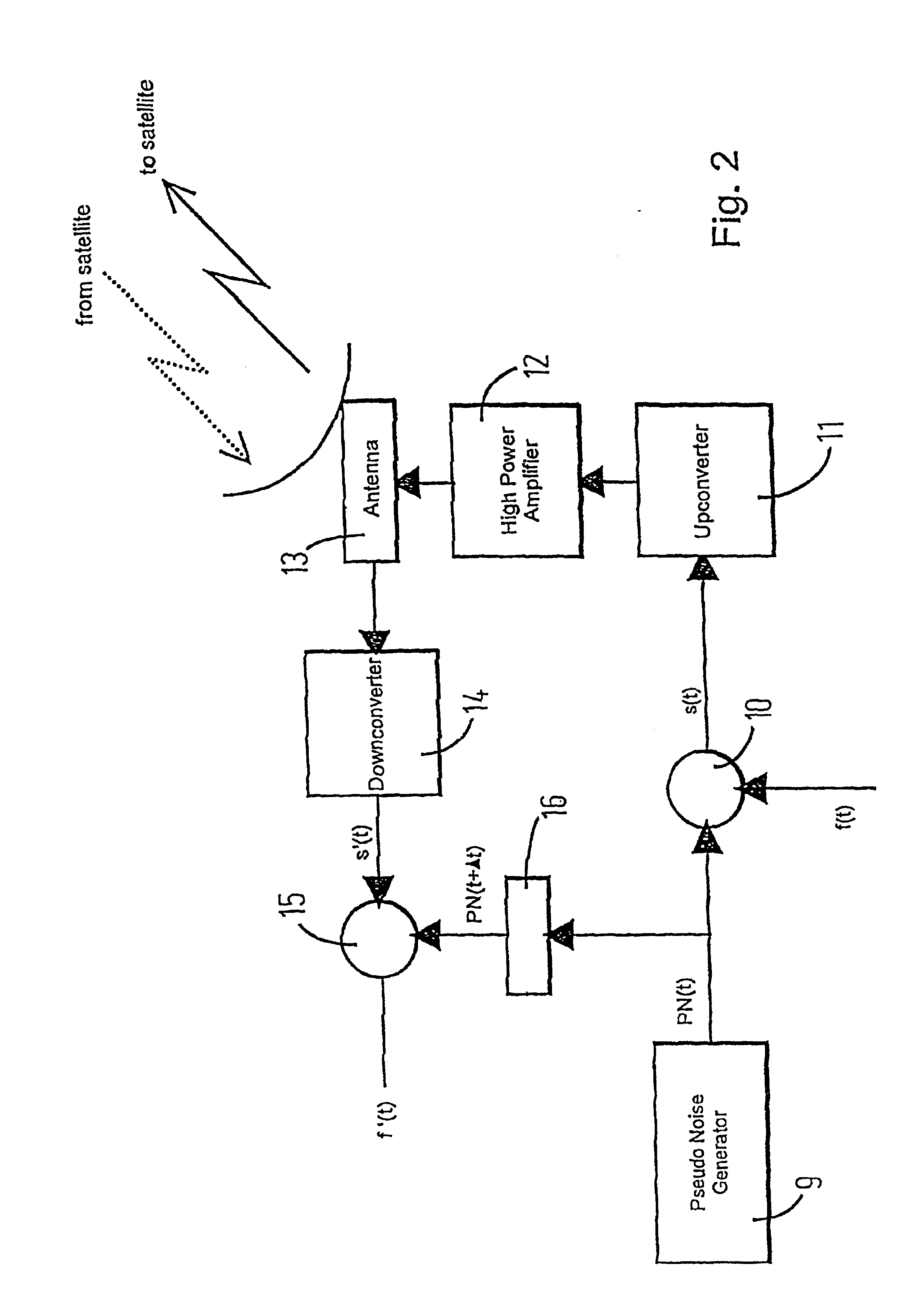

Method and apparatus for determining characteristics of components of a communication channel

InactiveUS6934314B2Simplify intersystem coordinationAvoid interferenceTransmission monitoringRadio relay systemsCarrier signalLife time

The invention refers to a method and an apparatus for determining characteristics of components of a communication channel. In order to simplify the intersystem coordination in a beginning of life test of a satellite communication channel and avoiding the interference of adjacent satellite systems the method according to the invention comprises the following steps: modulating a clean carrier signal f(t) by spread spectrum modulation to generate a spreaded clean carrier signal s(t); transmitting said spreaded clean carrier signal s(t) through said communication channel at a first predetermined level; receiving a receive signal s′(t) corresponding to said spreaded clean carrier signal s(t) after having traveled through said communication channel; demodulating said receive signal s′(t) by spread spectrum demodulation to generate a despreaded carrier signal f′(t); determining characteristics of components of the communication channel on the basis of a comparison of said clean carrier signal f(t) and said despreaded carrier signal f′(t).

Owner:SES ASTRA SA

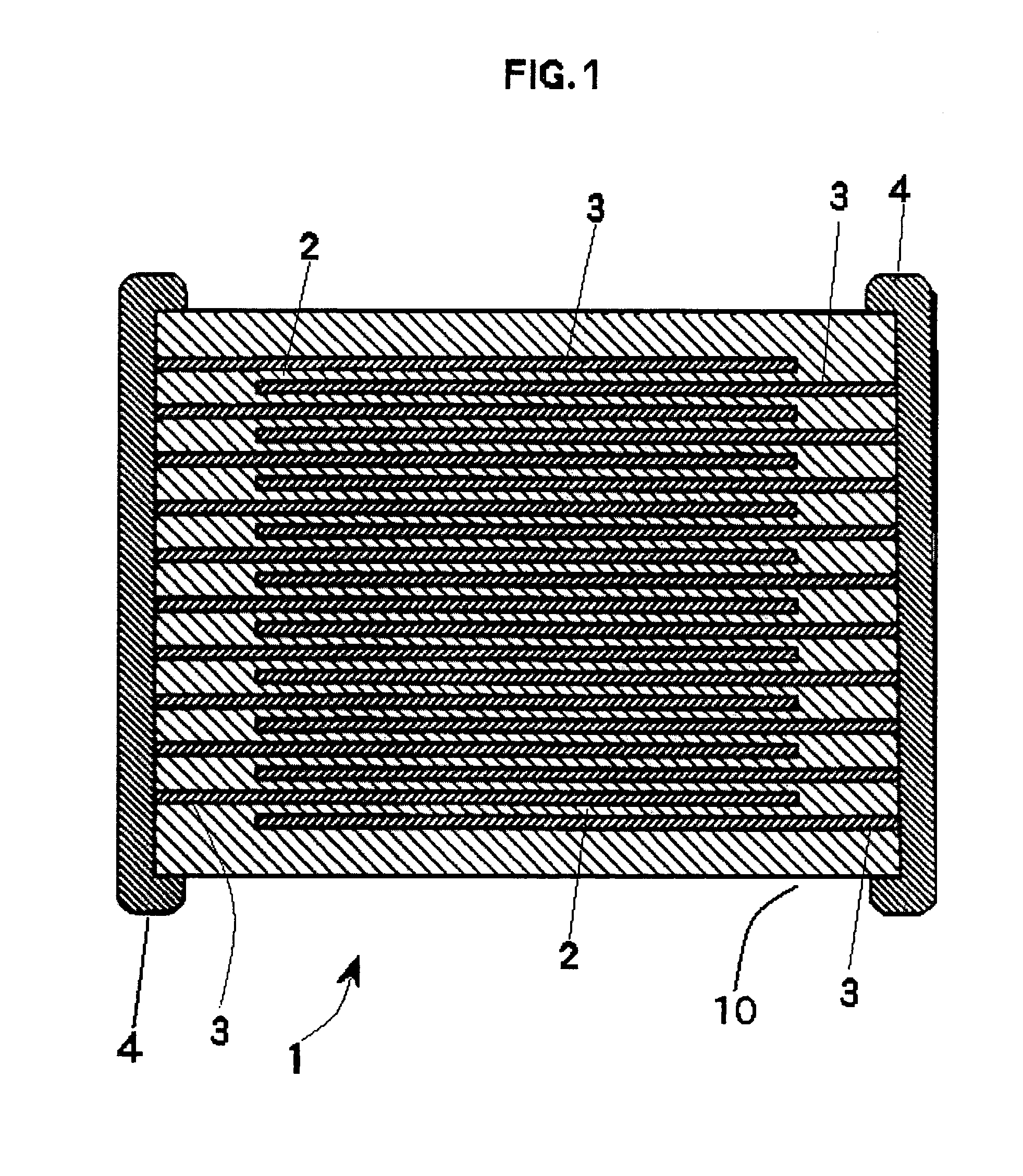

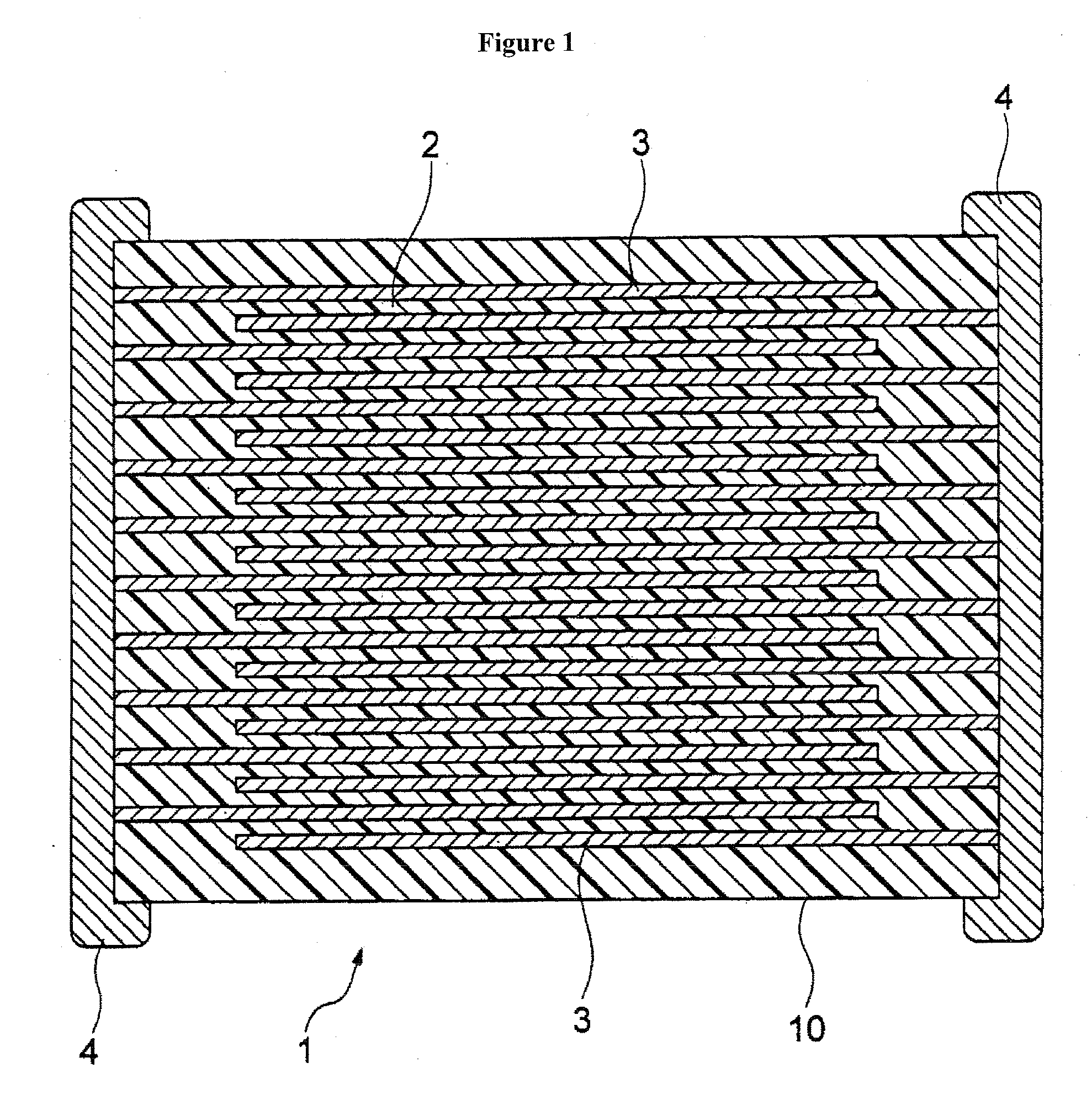

COG dielectric composition for use with copper electrodes

ActiveUS7161795B1Small dielectric lossImprove reliabilityFixed capacitor dielectricStacked capacitorsLow dissipationBarium titanate

Multilayer ceramic chip capacitors which satisfy COG requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as copper and copper alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a composite oxide formed by calcining rare earth titanates, barium titanate, together with other metal oxides such as MgO, CaO, ZnO, MnO2, ZrO2, SiO2, Ga2O3, Nd2O3, Nb2O5, and Y2O3.

Owner:FERRO CORP

Circuits for circuit interrupting devices having automatic end of life testing function

InactiveUS20070014068A1Circuit-breaking switches for excess currentsProtective switch detailsEngineeringLife testing

The present invention provides a set of circuits which is capable of performing an automatic check on main components of a circuit interrupting device when the circuit interrupting device is properly powered and the device is at a tripped state to determine whether these main components function normally. The results of the automatic check can be detected by depressing a reset button in the circuit interrupting device. If the reset button can be depressed, the main components function normally. Alternatively, the results can be automatically displayed by a showing on the face lid of the circuit interrupting device of either a green light, which means that the main components function normally, or a red or yellow light or no light, which means that at least one of the main components in the circuit interrupting device does not function properly. The present invention also provides an end-of-service-life detection integrated circuit chip capable of receiving and transmitting an automatic check signal and determining whether or not the circuit interrupting device can be reset. The preferred circuit interrupting device is a ground fault circuit interrupter (GFCI).

Owner:HUANG HUADAO

Lead And Cadmium Free, Low Temperature Fired X7R Dielectric Ceramic Composition And Method Of Making

ActiveUS20100220427A1Stable dielectric constantSmall dielectric lossFixed capacitor dielectricStacked capacitorsCeriumCadmium Cation

Multilayer ceramic chip capacitors (MLCC's) which satisfy X7R TCC requirements and which are compatible with silver-palladium internal electrodes. The MLCC's exhibit desirable dielectric properties—high capacitance, low dissipation factor, high insulation resistance, stable TCC—and excellent performance on highly accelerated life testing, and good resistance to dielectric breakdown. The dielectric layers comprise a lead-free and cadmium-free barium titanate base material doped with other metal oxides such oxides of zinc, boron, bismuth, barium, titanium, praseodymium, cerium, tungsten, neodymium, tungsten, tin, niobium, copper, and / or manganese in various combinations. The dielectric ceramic materials herein can be fired at less than 1150° C. with an inner electrode having 70 wt % or more Ag and 30 wt % or less Pd to form an MLCC.

Owner:FERRO CORP

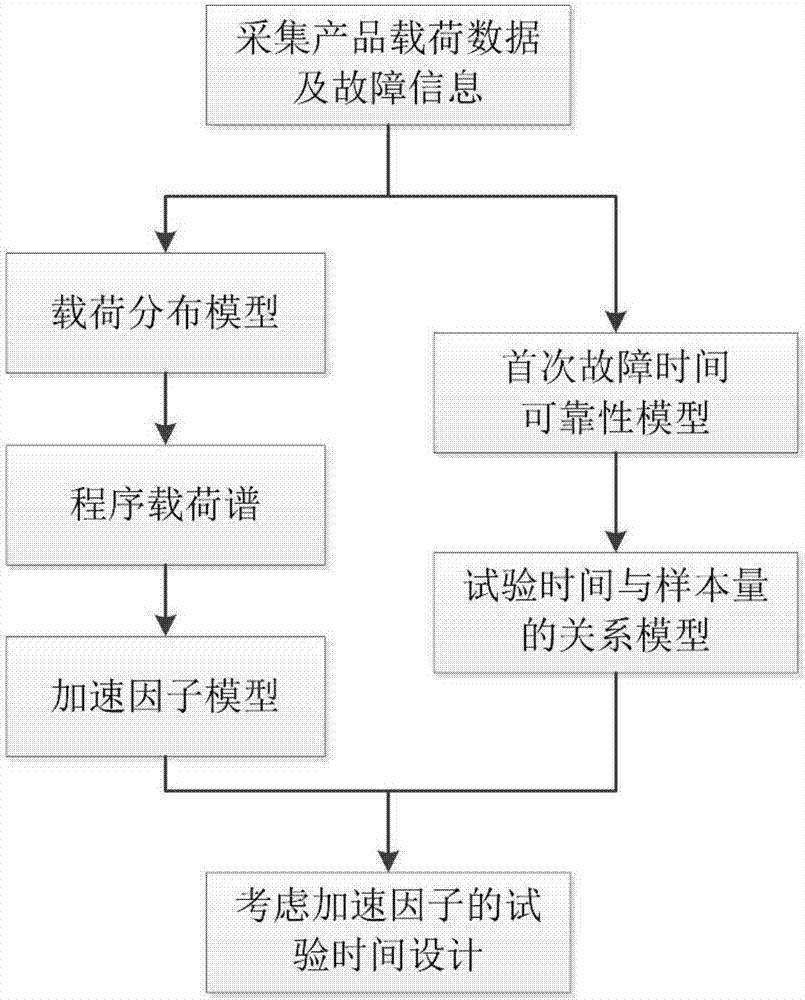

Motorized spindle accelerated life testing time design method

InactiveCN106874582AImprove accuracyGeometric CADSpecial data processing applicationsNumerical controlRelational model

The invention belongs to the technical field of numerical control machine tool and relates to a motorized spindle accelerated life testing time design method. The method includes the steps that firstly, product load data and fault information are collected; secondly, a load distribution model is established; thirdly, a program load spectrum is designed; fourthly, a product service life estimated formula is determined on the basis of the Miner fatigue accumulation damage theory, and an accelerated life testing accelerating factor model is built on the basis of the formula; fifthly, based on the fault information, a first fault time reliability mode is built through model hypothesis, parameter estimation and hypothesis testing; sixthly, testing time design is conducted on the basis of the first fault time, the first fault time corresponding to an acceptable reliability degree serves as a standard, and a relational model of motorized spindle testing time and the sample capacity is established; seventhly, an accelerating factor is considered for testing time design, and the creditability of the testing time design is verified. The relational model of the testing time and the sample capacity is considered, the accelerating factor model is established on the basis of the modification Miner theory, the modeling accuracy is improved, and the method better conforms to actual conditions.

Owner:JILIN UNIV

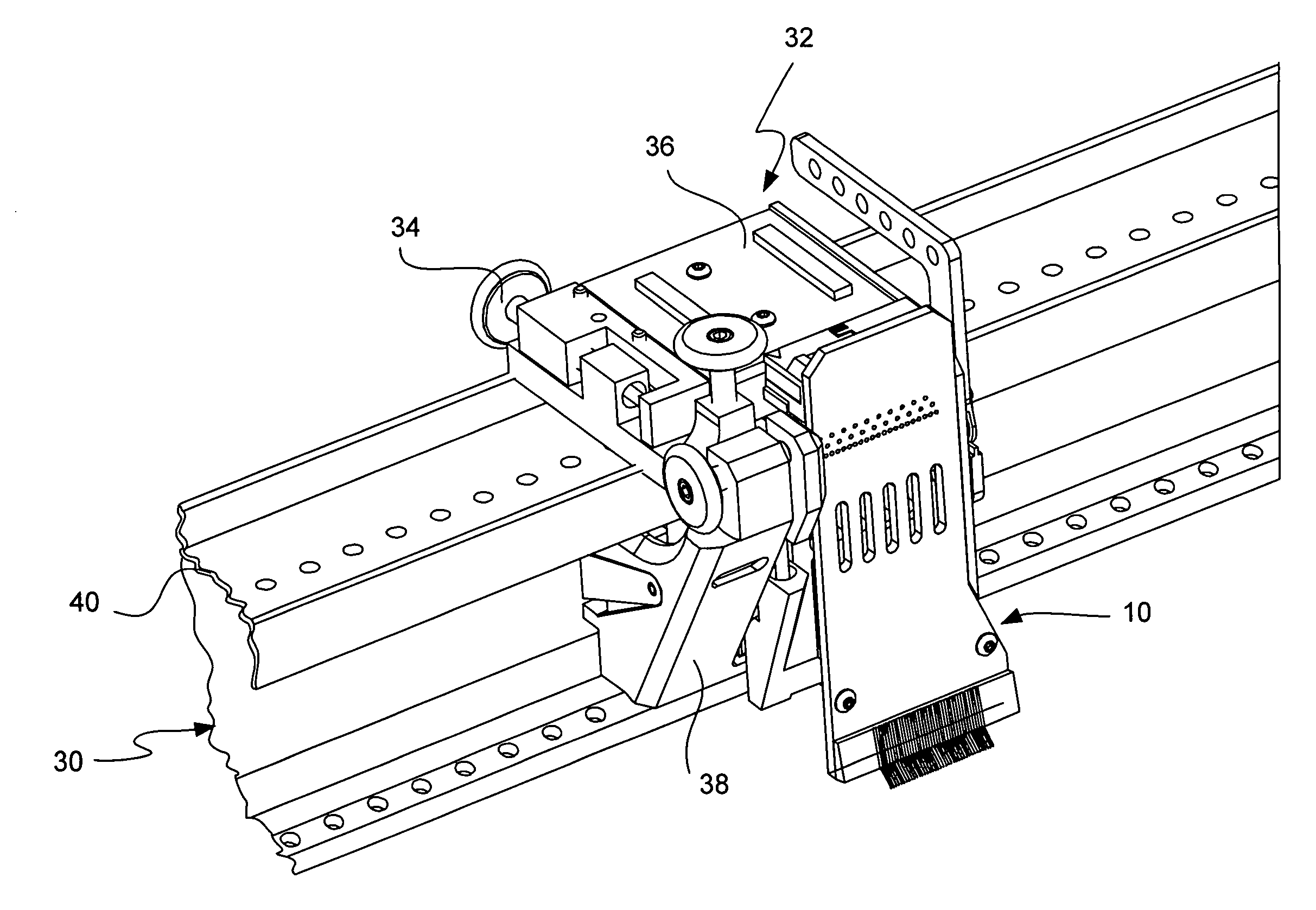

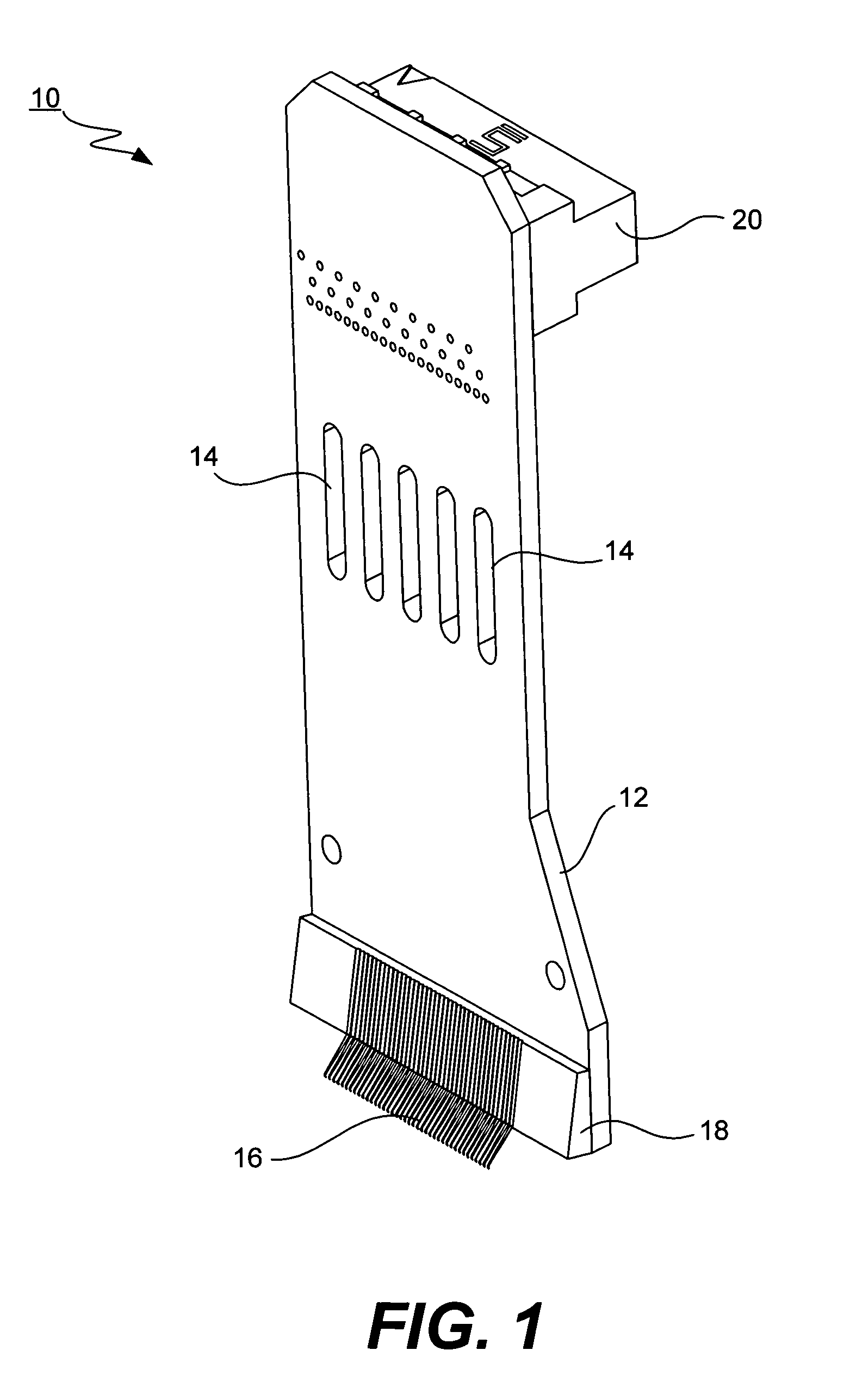

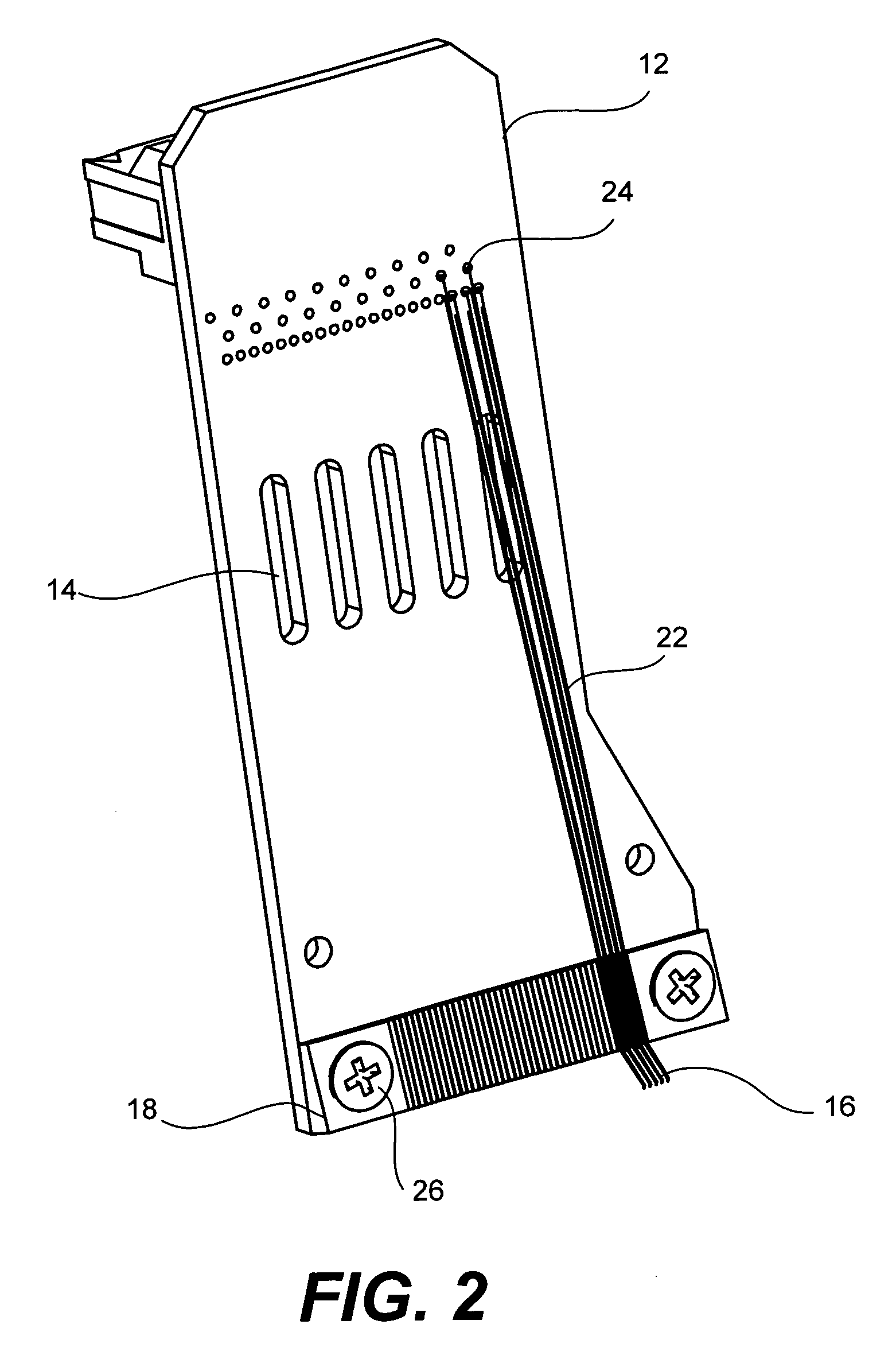

Vertical probe card and air cooled probe head system

ActiveUS7126361B1Exposure was also limitedSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardLife testing

A probe card is vertically mounted generally perpendicular to a wafer undergoing life tests in a heated environment to limit exposure of the probe card to heat from the wafer chuck. The probe card and probe head assembly are mounted on a support rail which has one or more channels for the flow of cool air to a probe head assembly and the probe card, while it shields the flex cable from the hot chuck. The cool air flow disrupts convective hot air flow upwards from the heated chuck to the probe card and probe head and facilitates cooling of the probe card and probe head.

Owner:QUALITAU

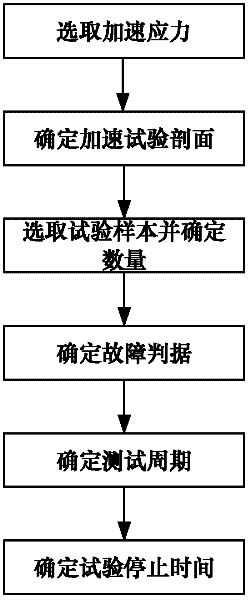

Combined stress acceleration life test method of spaceflight drive assembly

The invention, which belongs to the spaceflight drive assembly reliability and life evaluation field, relates to a combined stress acceleration life test method of a spaceflight drive assembly. According to the method, an acceleration stress is selected; an acceleration testing profile is determined and as a result, a combined stress acceleration life testing profile is employed; testing samples are selected and the number of samples is determined; fault determination and a testing period are determined; testing stop time is determined; and according to data obtained by the above-mentioned testing process, a life characteristic value of the spaceflight drive assembly is evaluated. According to the method, a combined stress is employed to carry out acceleration life testing and an acceleration effect is obvious; therefore, rapid evaluation on reliability and life of the spaceflight drive assembly is realized.

Owner:BEIHANG UNIV

Intelligent life testing methods and apparatus for leakage current protection

ActiveUS7268559B1Short-circuit testingEmergency protective arrangements for automatic disconnectionLife testingDrain current

An apparatus for testing the life of a leakage current protection device having a leakage current detection circuit. In one embodiment, the apparatus a trip mechanism state generator, a fault alarm generator, a ground fault simulation unit. In operation, the ground fault simulation unit generates a simulated ground fault signal during every positive half-wave of an AC power, the simulated ground fault signal is detected by the leakage current detection circuit, the leakage current detection circuit responsively generates a signal to turn a switching device into its conductive state so as to allow a current to pass therethrough, the passed current is converted into a DC voltage in accordance with a trip mechanism state generated by the trip mechanism state generator, the fault alarm circuit receives and analyzes the DC voltage and indicates whether a fault exists in the leakage current protection device.

Owner:CHEN HENG

Intelligent life testing methods and apparatus for leakage current protection device with indicating means

ActiveUS20070146945A1Electrical testingEmergency protective arrangements for automatic disconnectionMicrocontrollerLife testing

An apparatus for testing the life of a leakage current protection device having a leakage current detection circuit and a trip mechanism. In one embodiment, the apparatus includes a ground fault simulation circuit for generating a simulated ground fault during every negative half-wave of an AC power, a signature signal generating circuit for generating a signature signal reflecting the characteristic of the leakage current detection circuit and the trip mechanism, when the simulated ground fault is generated, and a life testing detection control circuit having a microcontroller and an alarm circuit. In operation, the life testing detection control circuit receives the signature signal from the signature signal generating circuit, analyzes the received signature signal to determine whether at least one fault exists in the leakage current detection circuit and the trip mechanism, and activates the alarm circuit if the at least one fault exists.

Owner:CHEN HENG

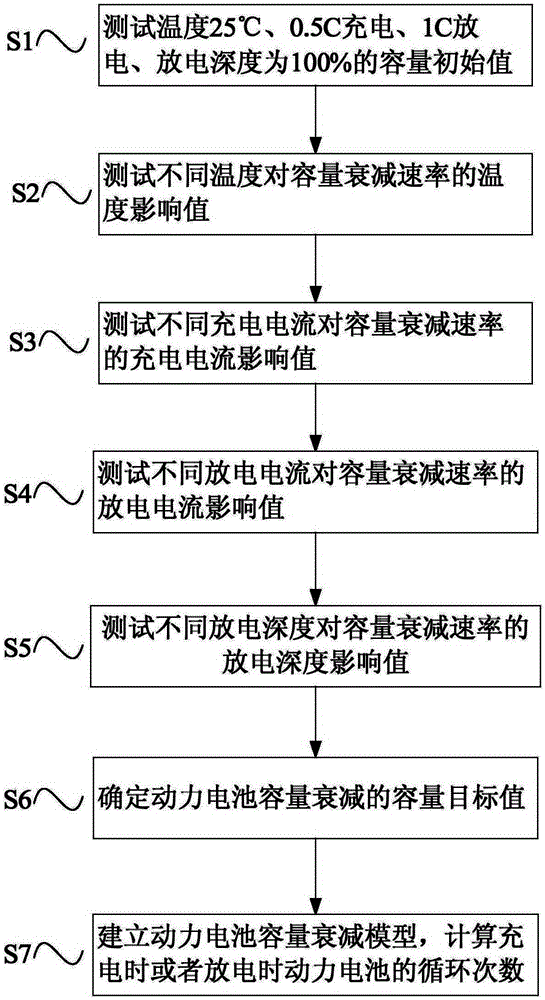

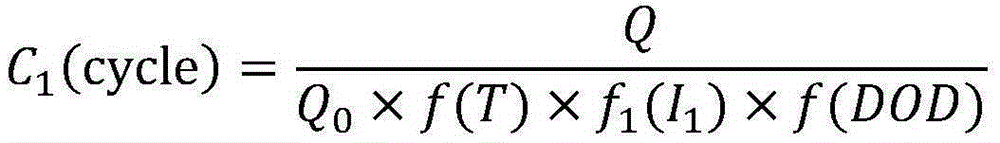

Cycle life testing method for power battery

The invention belongs to the technical field of automobile testing, and provides a cycle testing method for a power battery. The method comprises the steps: testing capacity initial values Q0 during the temperature 25 DEG C, 0.5C charging, 1C discharge and the discharge depth of 100%; testing a temperature impact value on a capacity attenuation rate from different temperatures, the charging current impact value on the capacity attenuation rate from different charging currents, the discharge current impact on the capacity attenuation rate from different discharging currents, and the discharge depth impact value on the capacity attenuation rate from different discharge depths; determining the capacity target value of the capacity attenuation of the power battery; building a model of the capacity attenuation of the power battery; and calculating the cycle number of the power battery during charging and the cycle number of the power battery during discharging. The method can accurately calculate the cycle life of the power battery of an electric car during operation through building power battery capacity attenuation rate models of different temperatures, charging currents, discharge currents, and discharge depths, and is high in testing effectiveness.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

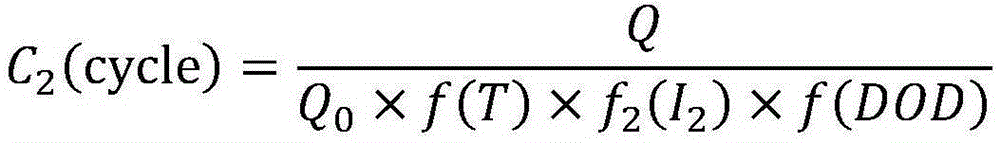

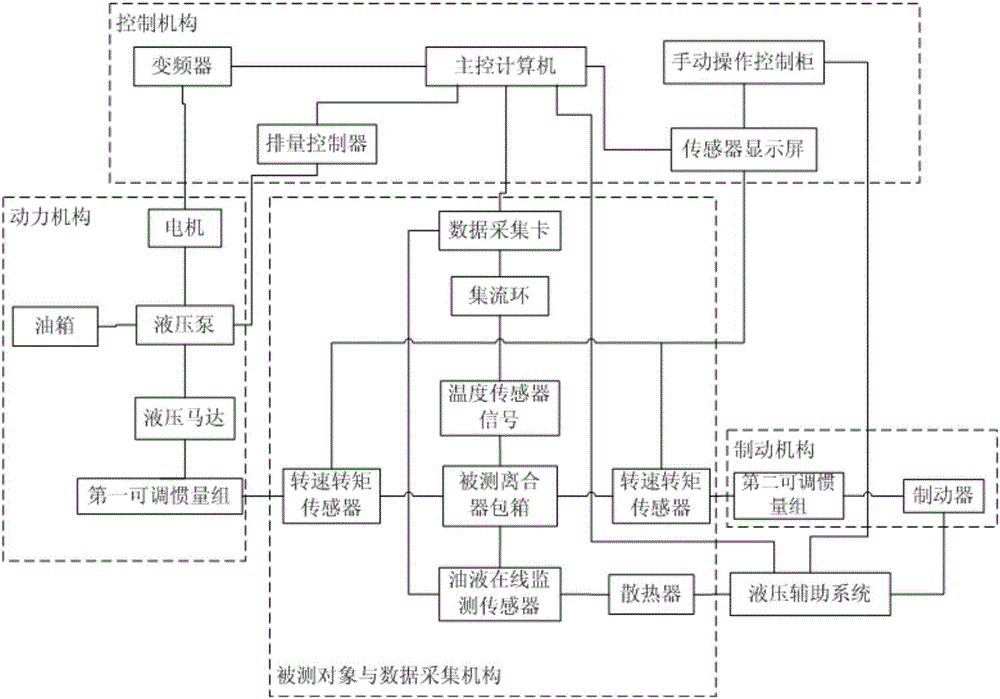

Wet-clutch friction plate's wear extent testing method and testing stand

ActiveCN105021483ASafe and reliable operationAvoid damageUsing mechanical meansInvestigating abrasion/wear resistanceStatic friction coefficientFriction torque

Owner:BEIJING INFORMATION SCI & TECH UNIV

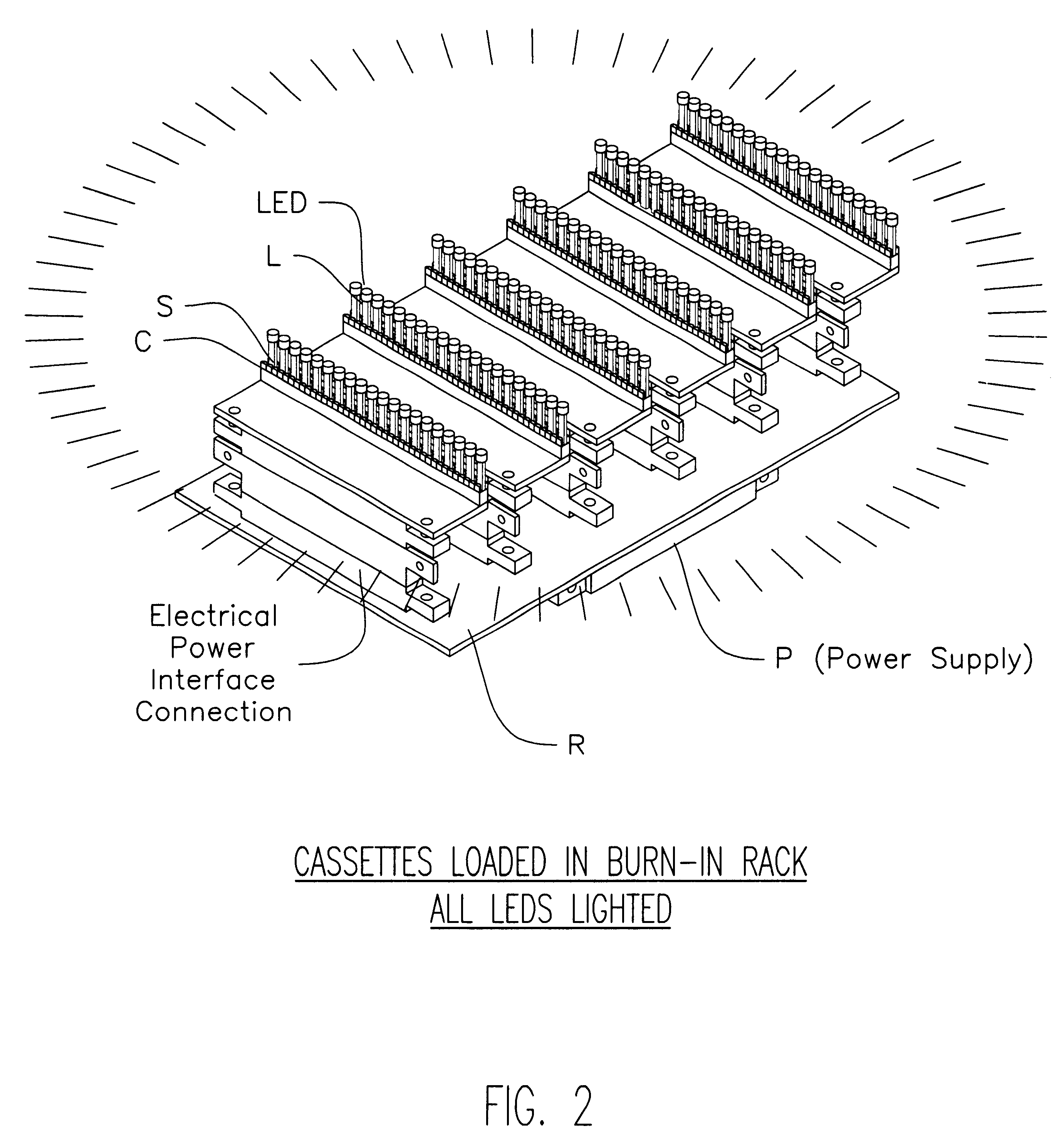

Method of and cassette structure for burn-in and life testing of multiple LEDs and the like

InactiveUS6597195B1Address limitationsPhotometryFault location by increasing destruction at faultEngineeringLife testing

A novel cassette structure technique for enabling simultaneous burn-in of pluralities of LEDs plugged into the cassettes, and then, with the cassettes mounted within a light integrating sphere system, separately measuring the spectral flux emitted by each successive individual LED plugged into the cassette to determine optical and electrical characteristics of each LED separately from the others.

Owner:LABSPHERE

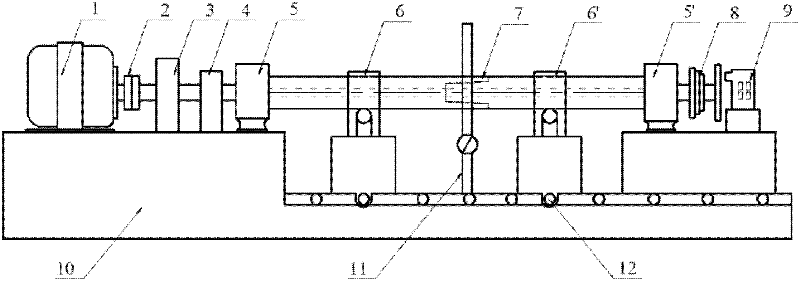

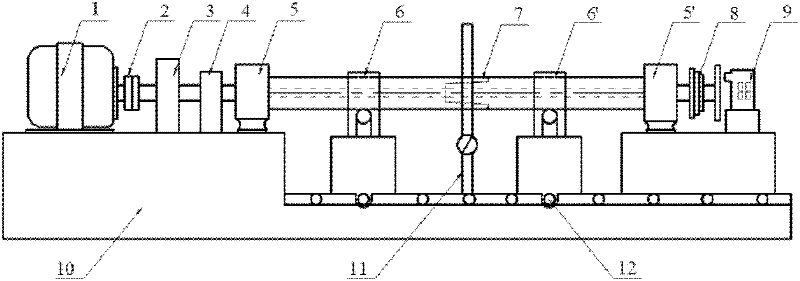

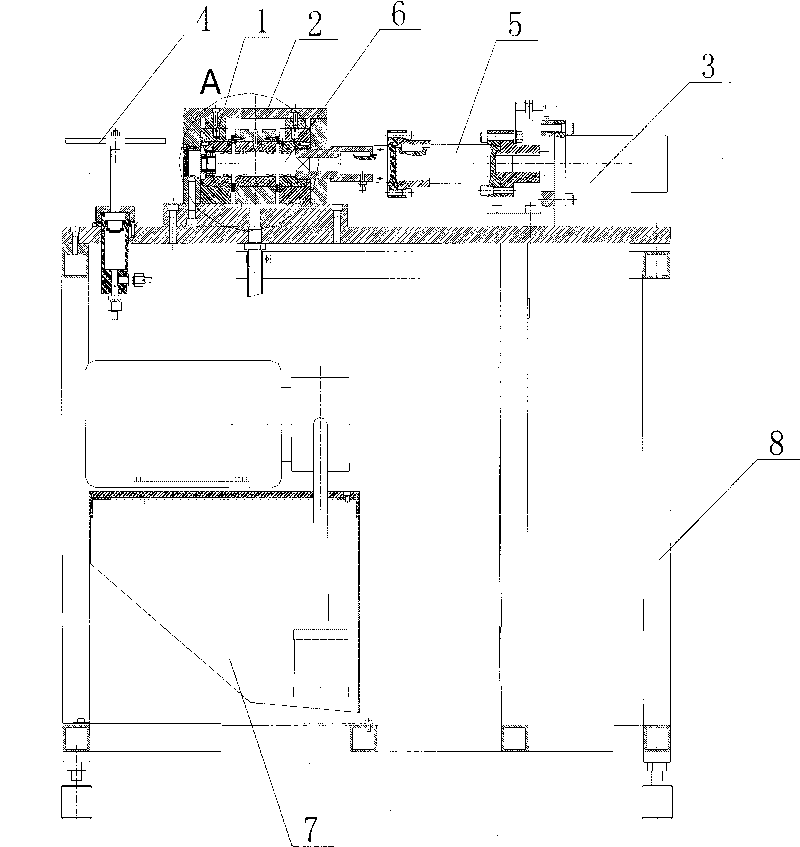

Experiment device for testing fatigue life of threading connector of petroleum drill

InactiveCN102410963AOvercoming the Insufficiency of Fatigue Life TestingMaterial strength using repeated/pulsating forcesStress workingMeasuring instrument

The invention provides an experiment device for testing fatigue life of threading connector of petroleum drill, which comprises a base, a guide rail, a motor, a coupler, a floating bearing, an aligning roller bearing, a fixing end spring clamp, a bending moment applying device, a flexivity measuring instrument, a tail seat and a counter. Bending stress can be applied to the threading connector of the drill by the bending moment applying device based on four-point bending principle. The fixing end spring clamp is driven by the motor to rotate, so the threading connector of the drill can be rotated under certain torsion moment. Therefore, composite alternating stress working conditions of drill under well can be truly simulated. The experiment device is suitable for test research on fatigue life of full-size drill.

Owner:SOUTHWEST PETROLEUM UNIV

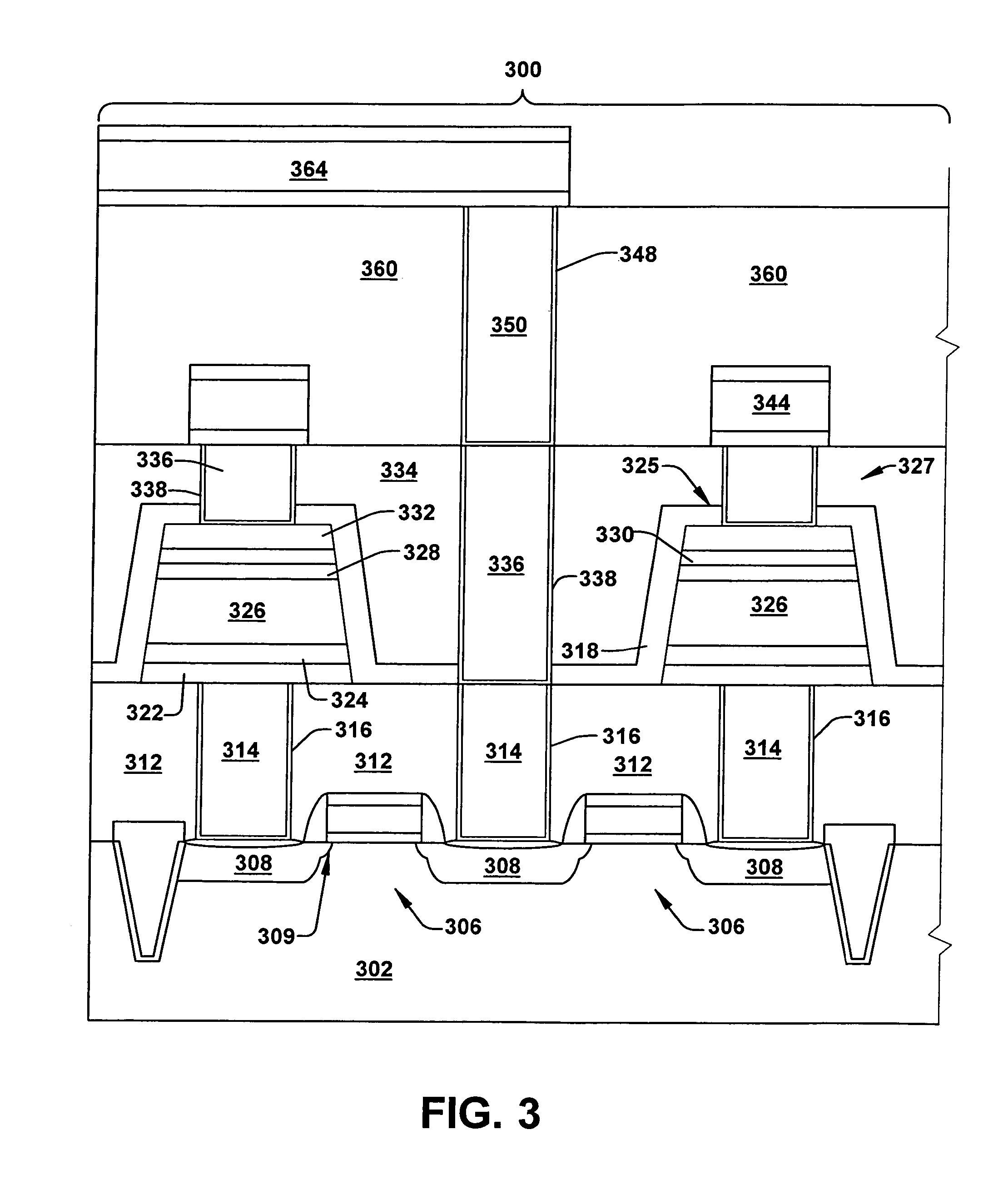

Process monitoring for ferroelectric memory devices with in-line retention test

The present invention facilitates evaluation of ferroelectric memory devices. A ferroelectric memory device is fabricated that comprises memory cells comprising ferroelectric capacitors (802). A short delay polarization value is obtained (804) by writing a data value, performing a short delay, and reading the data value. A long delay polarization value is obtained (806) by again writing the data value, performing a long delay, and again reading the data value. The short delay and long delay polarization values are compared (808) to obtain a data retention lifetime for the ferroelectric memory device. The obtained data retention lifetime is compared with acceptable values (810) and, if deemed unacceptable, avoids unnecessary performance of thermal bake data retention lifetime testing.

Owner:TEXAS INSTR INC

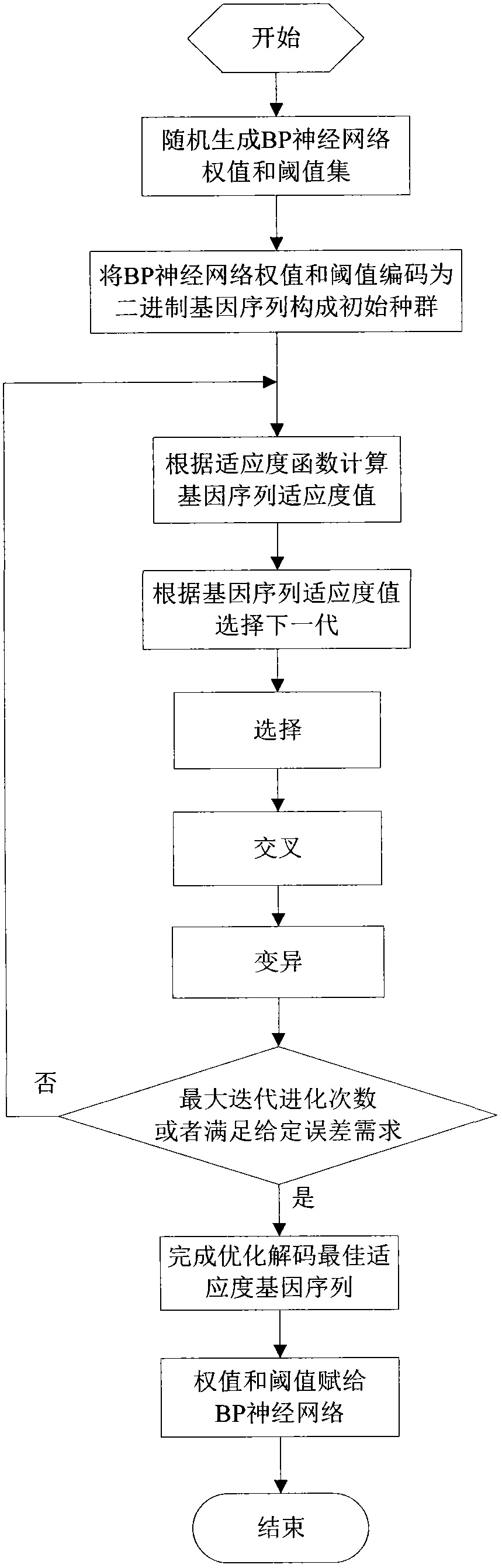

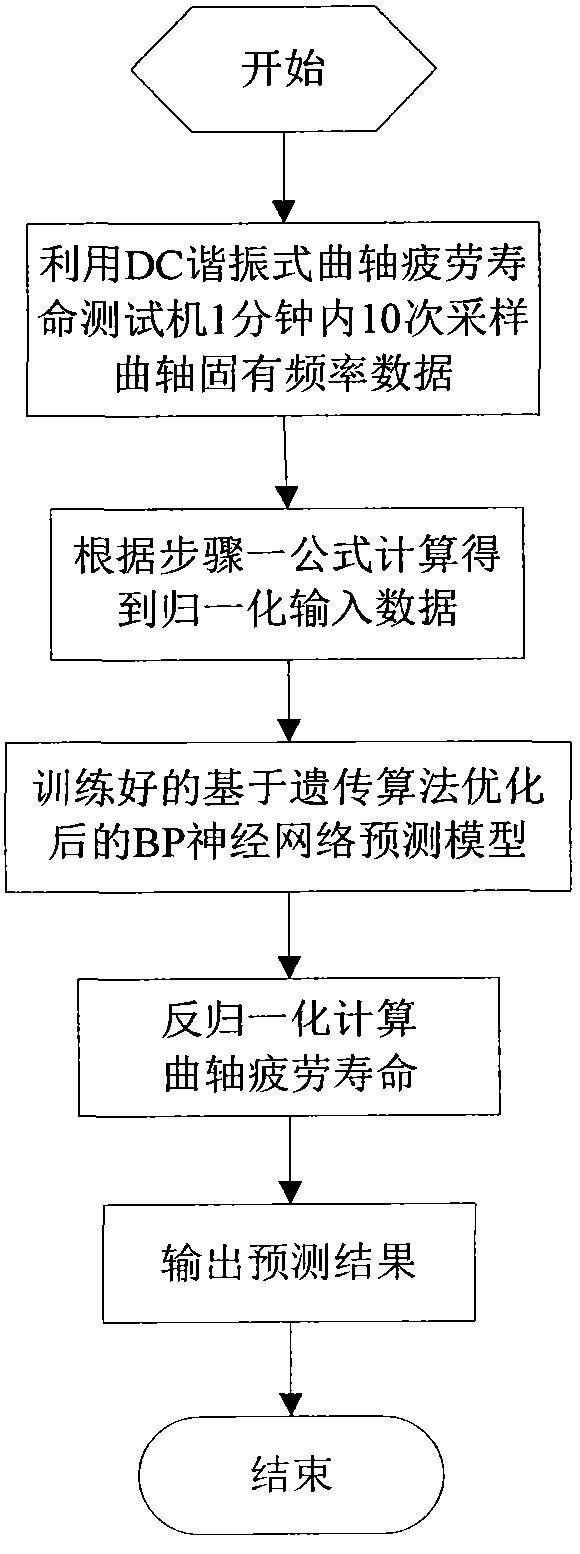

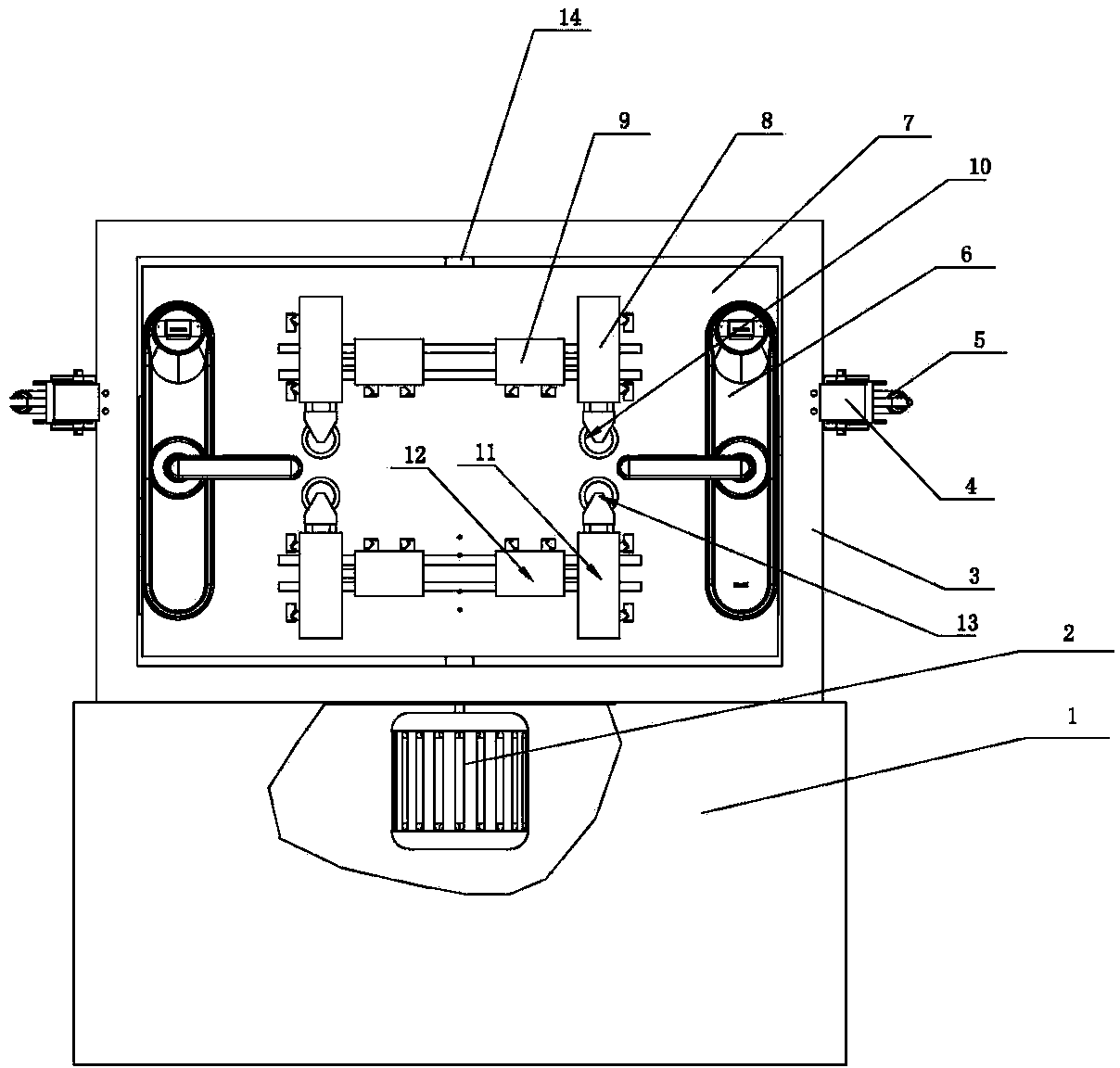

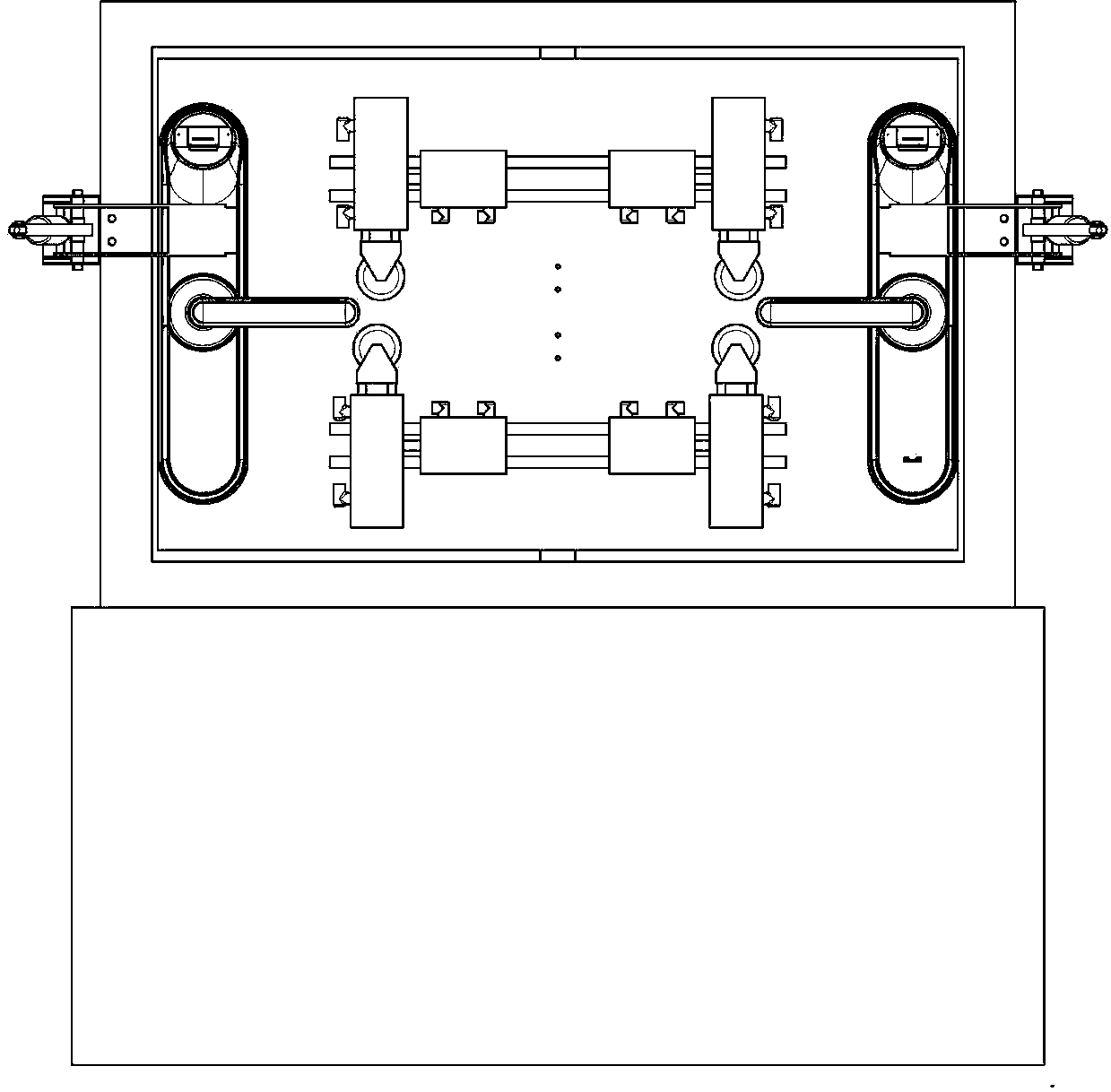

A prediction method for crankshaft fatigue life based on genetic nerve network

InactiveCN102693450APrevent overfittingImprove forecast accuracyGenetic modelsBiological neural network modelsNerve networkEngineering

The invention discloses a prediction method for crankshaft fatigue life based on a genetic nerve network, belongs to the field of crankshaft fatigue life testing of an internal combustion engine. The purpose of the method is to solve the deficiency of a DC resonant-type crankshaft fatigue life testing machine for possessing destructiveness to the crankshaft testing and having long testing time. The principle of the method is to normalize the historical data of the crankshaft testing by utilizing the conventional DC resonant-type crankshaft fatigue life testing machine to obtain a training sample set; to optimize a BP artificial nerve network model through genetic algorithm; to carry out iteration training to the genetic algorithm-based and optimized BP artificial nerve network by utilizing the training sample set to obtain a trained BP artificial nerve network prediction model; to use the prediction model to carry out rapid prediction for the crankshaft fatigue life. The method optimizes the BP artificial nerve network based on the genetic algorithm, avoids the "over fitting" problem of the single BP nerve network, improves the training speed and prediction precision effectively; rapidly predicts the crankshaft fatigue life in a short time without destroying the crankshaft quality, is capable of carrying out a batch testing for the crankshafts of a whole production batch.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Intelligent lock comprehensive performance tester and testing method thereof

InactiveCN103411768AImprove efficiencyGood effectMachine part testingProgramme control in sequence/logic controllersTorsion testControl system

The invention relates to a detection device, in particular to an intelligent lock comprehensive performance tester. The intelligent lock comprehensive performance tester comprises a device body, a door hinge capable of rotating around the device body, a central control system, a sound and light alarm and a plurality of detecting units arranged on the door hinge, wherein the a lock mounting area is arranged at the edge of the door hinge, and the detecting units correspond to the lock mounting area in position; each detecting unit comprises an outer dock detecting unit installed on the front face of the door hinge and an inner lock detecting unit installed on the back face of the door hinge. According to the tester, the testing range of performance of a lock is wide, and the tester is capable of performing a service life test on a lock body, a stretching in-place test on a spring bolt, a torsion test on a lever handle, a continuous card swiping test, a service life test on the lever handle, a service life test on a battery and a service life test on the whole lock, meanwhile reduces labor intensity of operators and improves the efficiency and the effect of testing of the performance of the lock, and therefore the testing period is shortened.

Owner:ZHEJIANG BADA HARDWARE

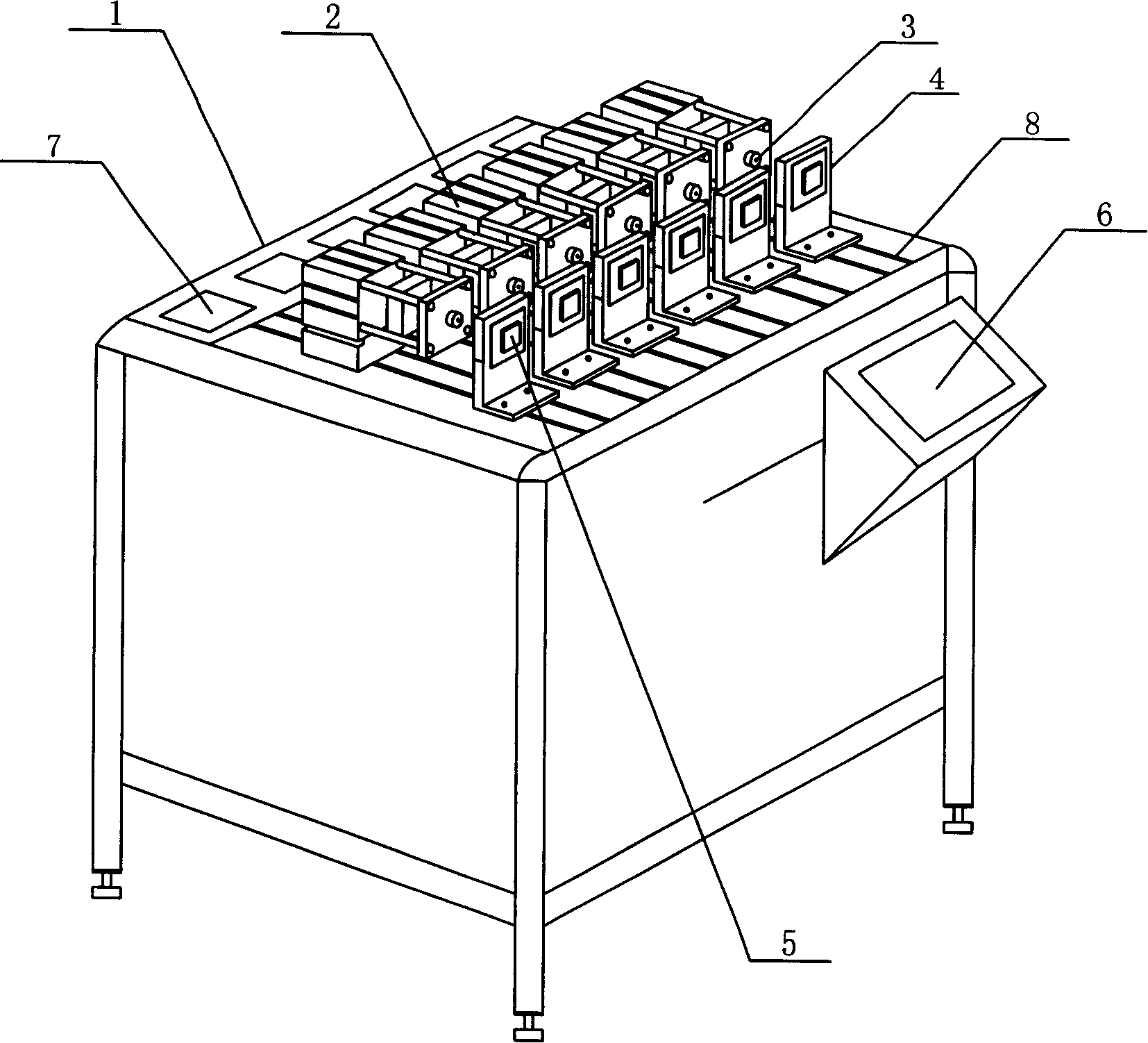

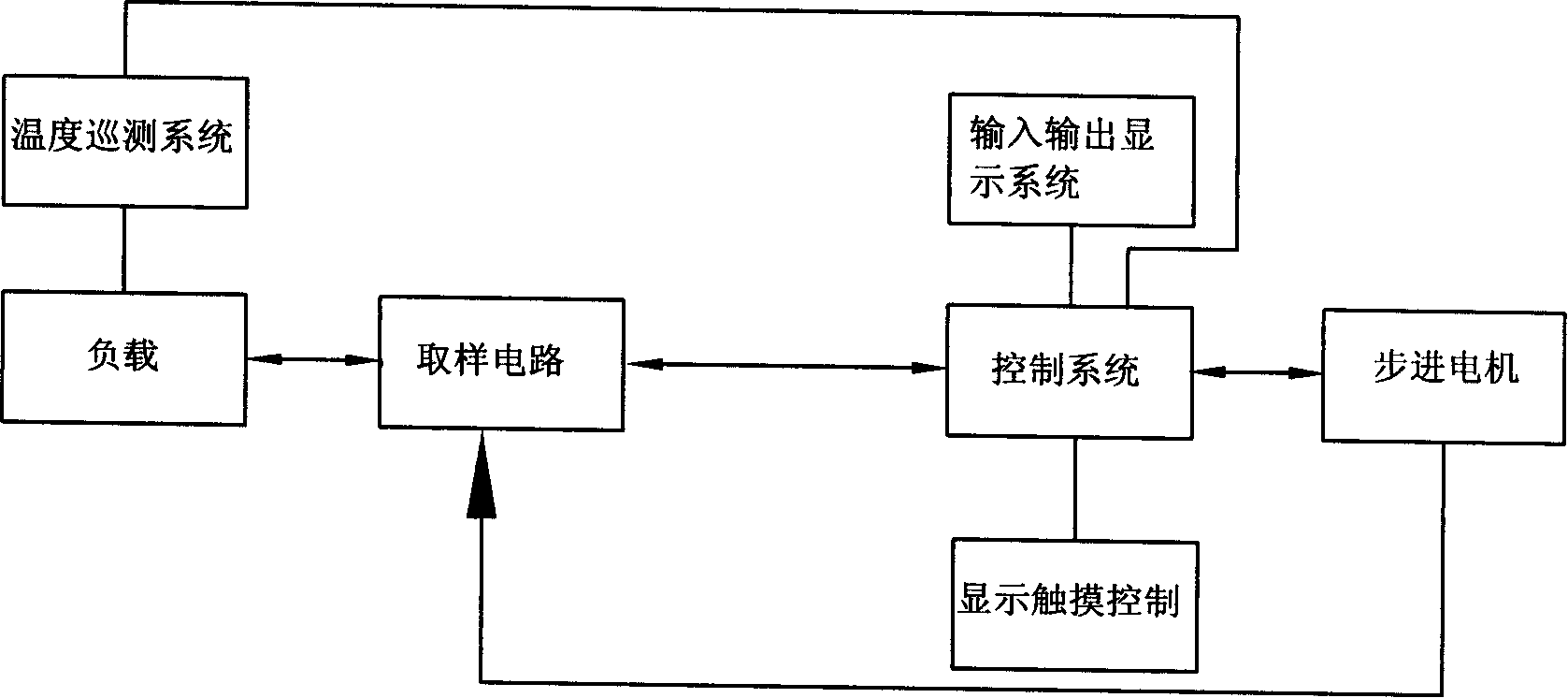

Multifunctional rotating switch test machine

The invention discloses a multifunctional rotary switch tester, which comprises a machine frame, a test bed, a display screen, an input device, a control system and a load, wherein, the test bed comprises a plurality of test units; each test unit is provided with a switch fixture which is correspondingly provided with a stepper motor and a switch rotating shaft grip holder which is driven to rotate by the stepper motor; the control system comprises a controller, a motor driver, a counter, a sampling circuit and a temperature controller; control software is arranged inside the controller; the display screen ,the input device, various stepper motors and the load are accessed into the control system. The tester of the invention is a device which integrates a plurality of test functions like service life test, temperature rise test, on-off capacity test and so on into a whole and completely improves the defects of the prior tester which are respectively bulkiness, non-tunable detect, small capacity, inconvenient assembly, high cost and so on.

Owner:HANGZHOUSNGOOSE ELECTRICAL

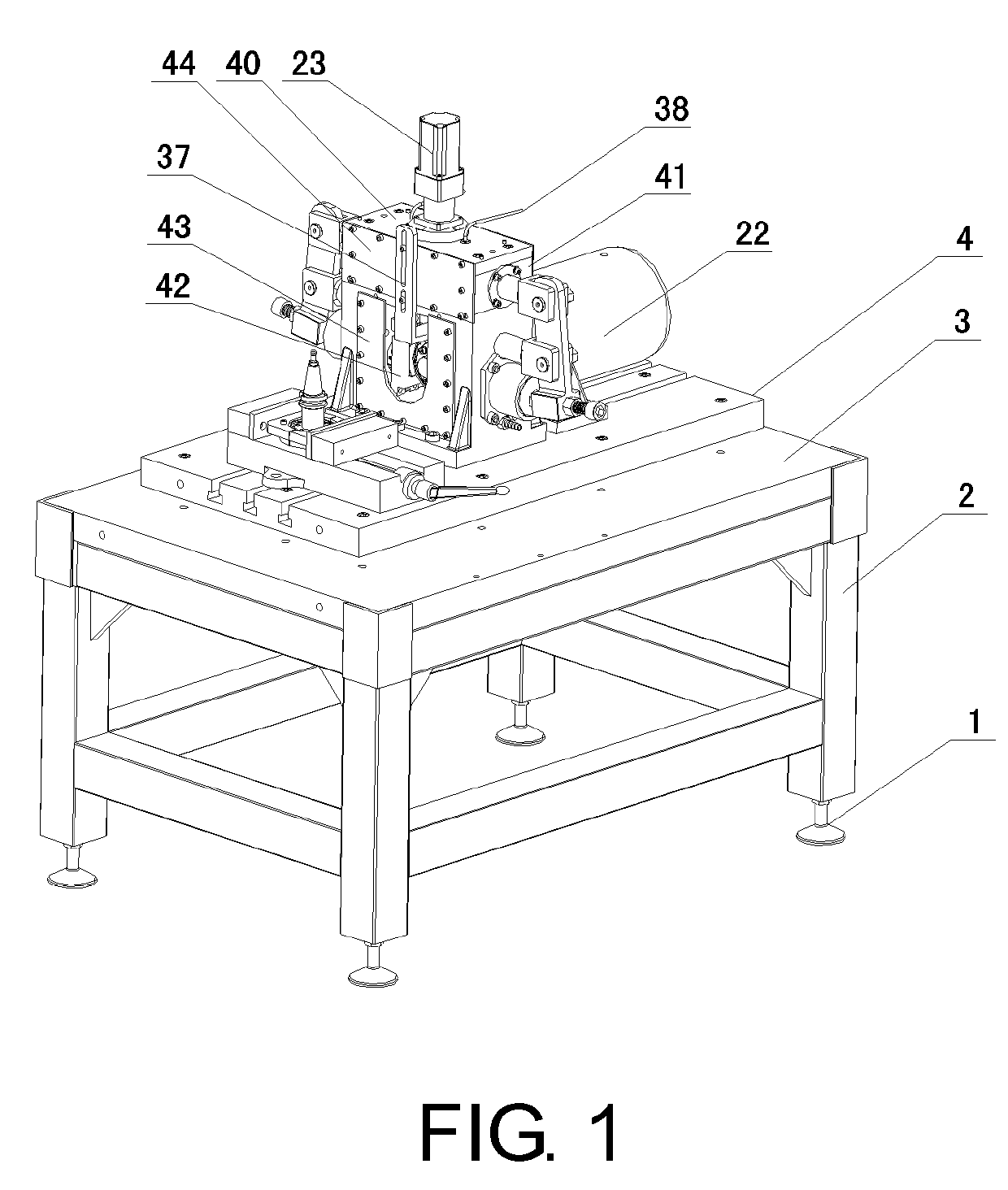

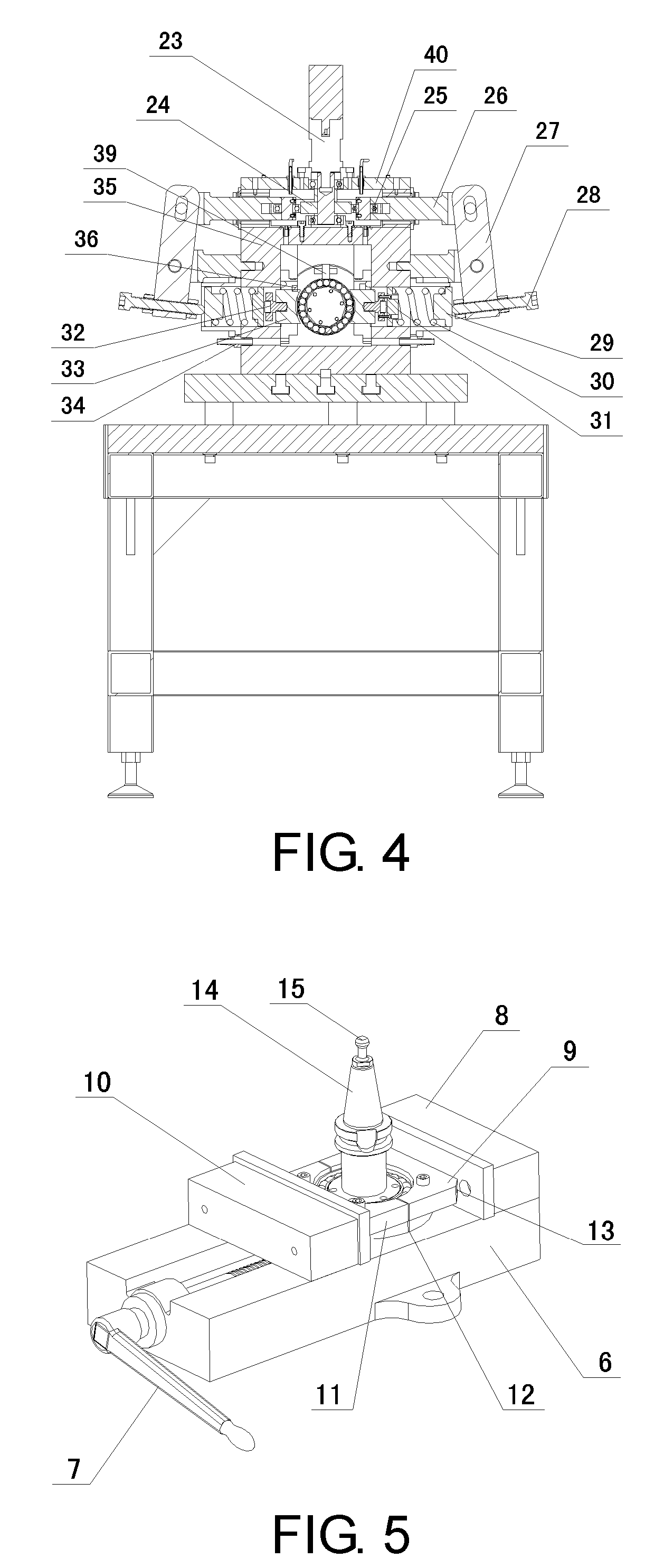

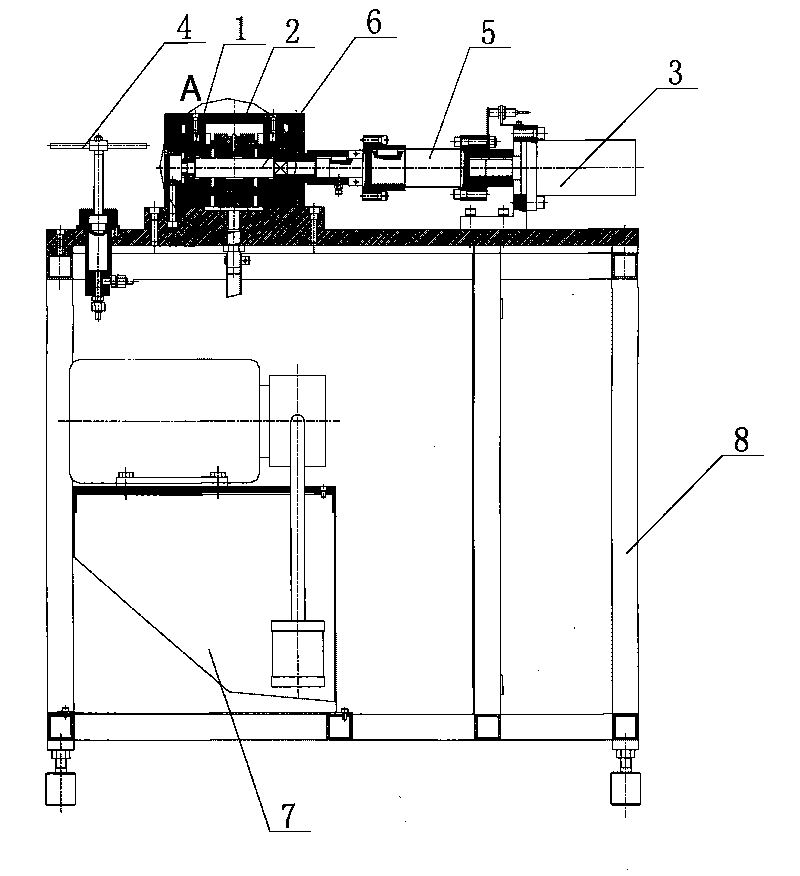

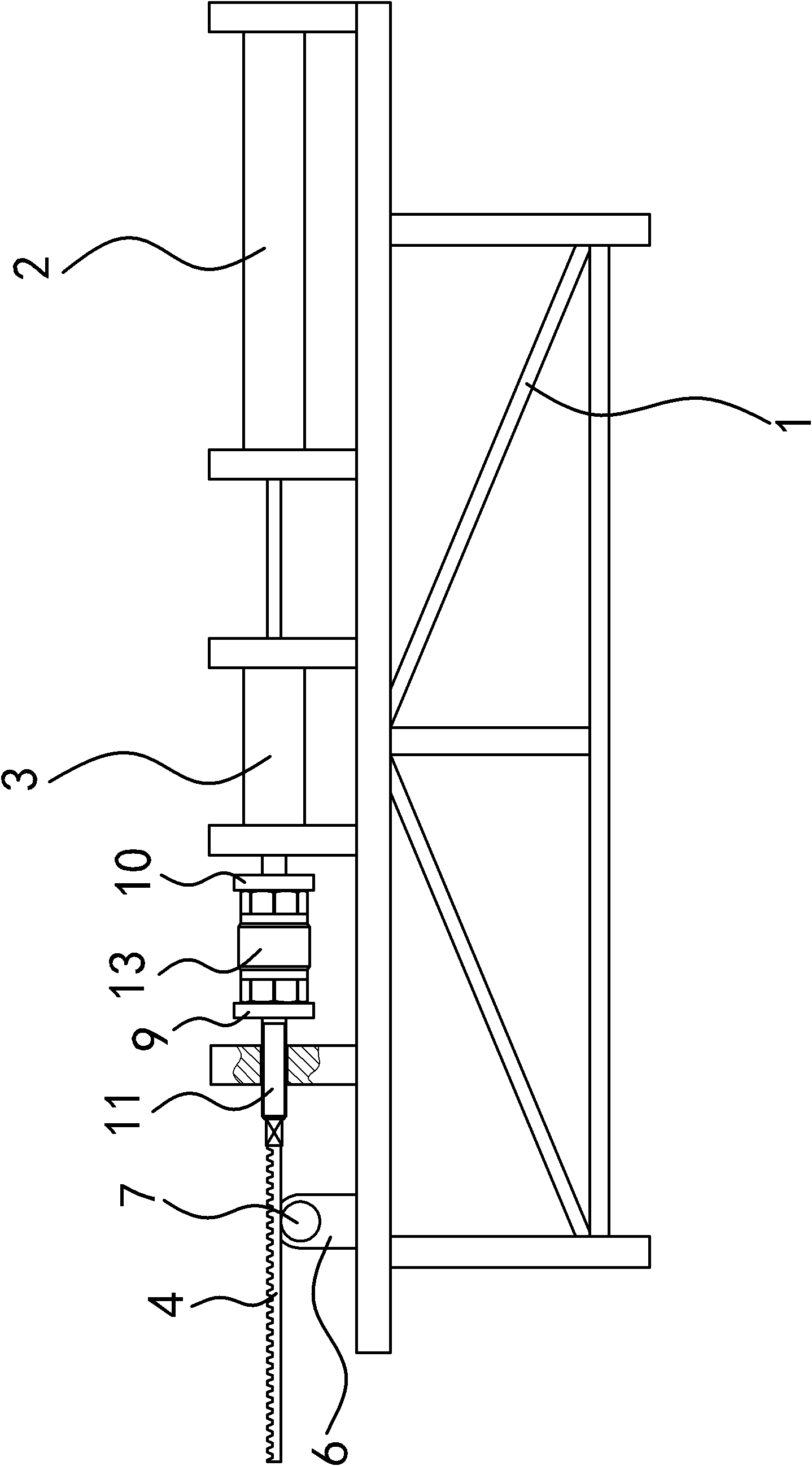

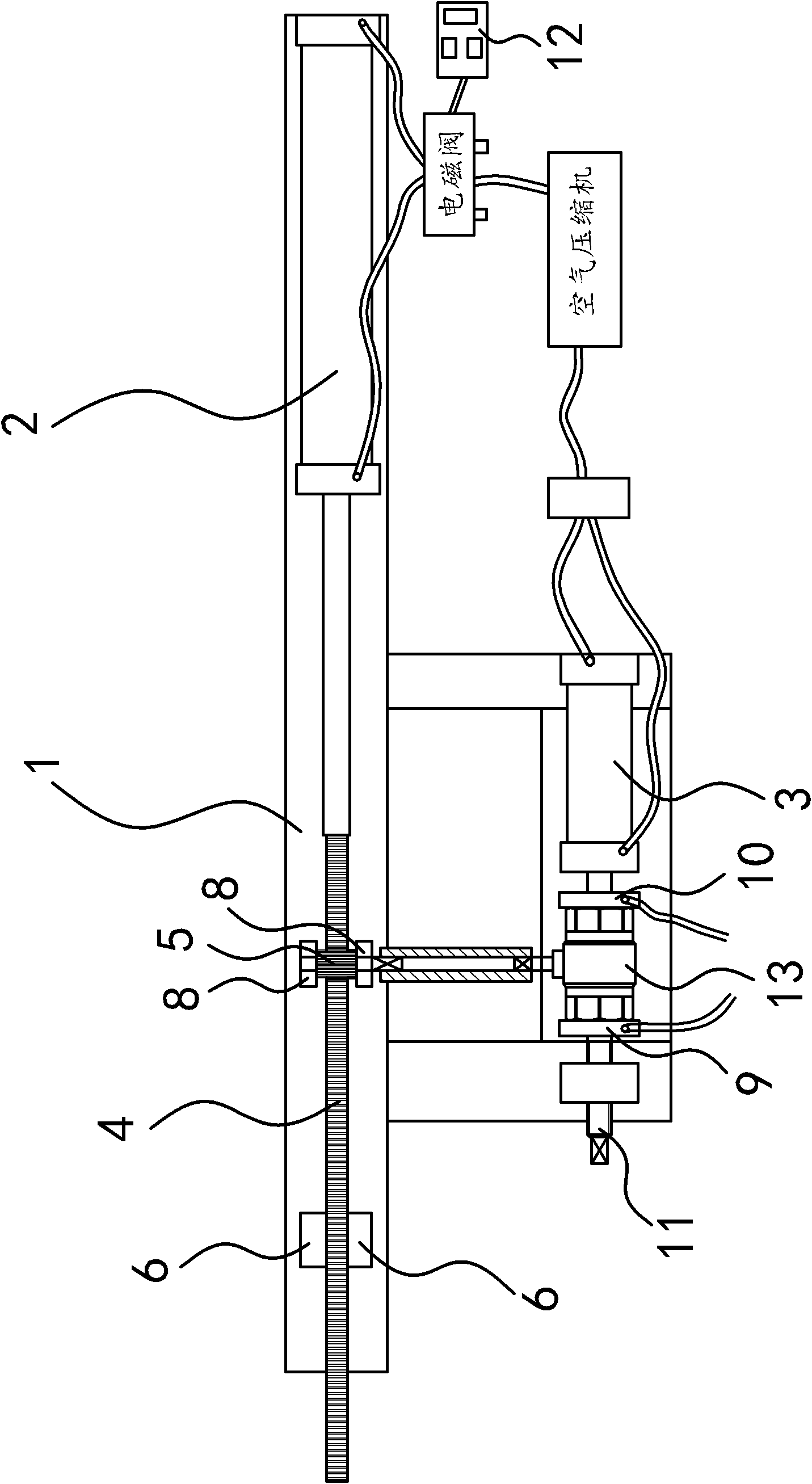

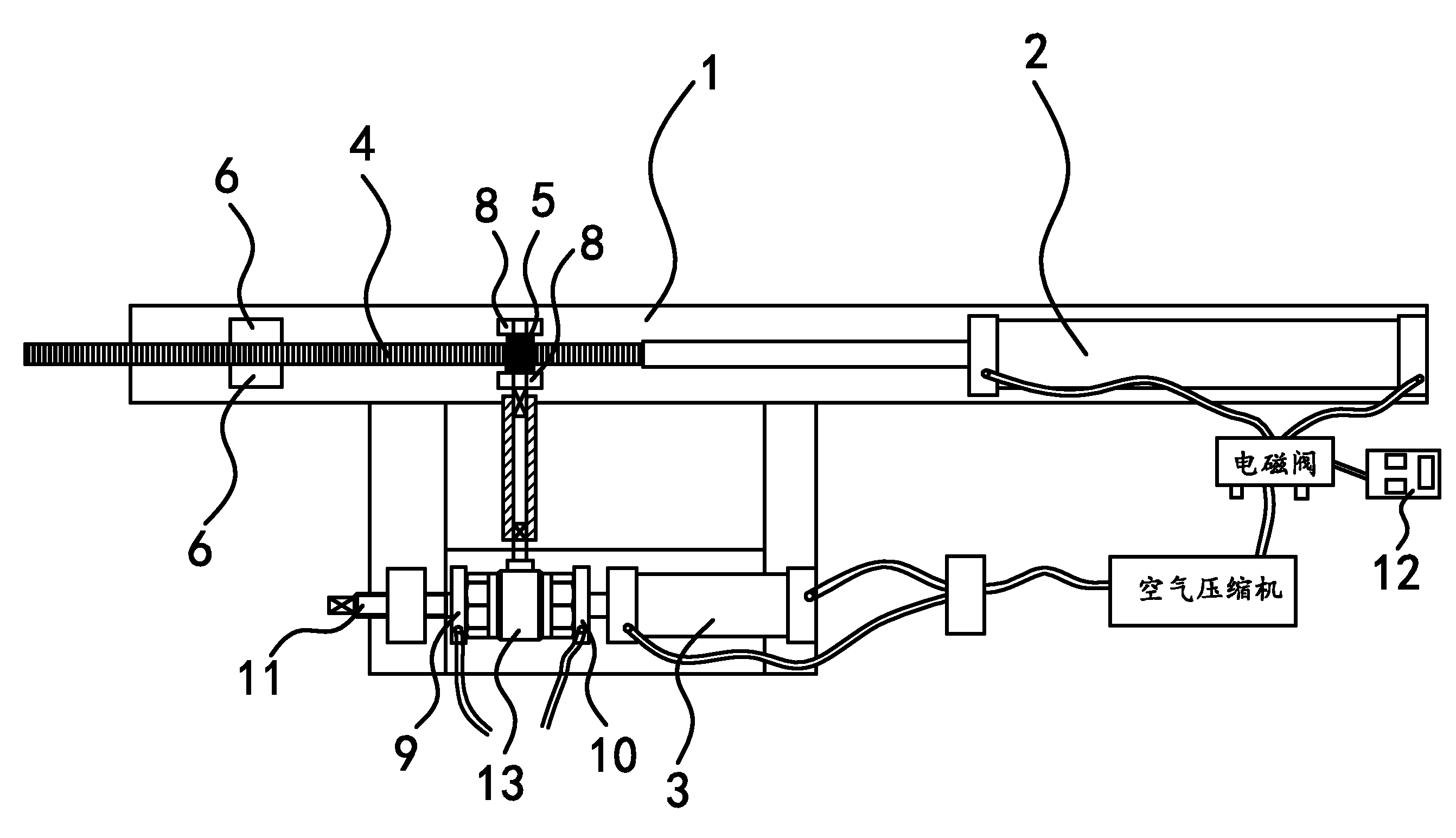

Fault diagnosis and life testing machine for flexible precision thin-wall bearing

ActiveUS20190250067A1Ingenious structureComprehensive test functionMachine part testingData acquisitionEngineering

The present invention discloses a fault diagnosis and life testing machine for a flexible precision thin-wall bearing (16), including a rack, and an axial loading device, a main driving device, a bearing mounting device, a clamping tooling, a data acquisition device, a hydraulic and a pneumatic auxiliary device which are provided on the rack. The main driving device is connected to a rear side of the axial loading device, and the clamping tooling is arranged at a front side of the axial loading device, for clamping the thin-wall bearing (16) onto the bearing mounting device. The data acquisition device is arranged in the axial loading device and at a side of the rack, the hydraulic and pneumatic auxiliary device is arranged at a side of the rack, and the axial loading device and the main driving device are connected by a pipeline. This testing machine can apply dynamic and static loads to the precision flexible thin-wall bearing (16), can realize measurement of a bearing vibration, a bearing temperature, a bearing rotation progress and a rotation speed, and has advantages such as clever structure, perfect test function and relatively high test accuracy, safe and reliable detection process, and highly feedback results.

Owner:SOUTH CHINA UNIV OF TECH

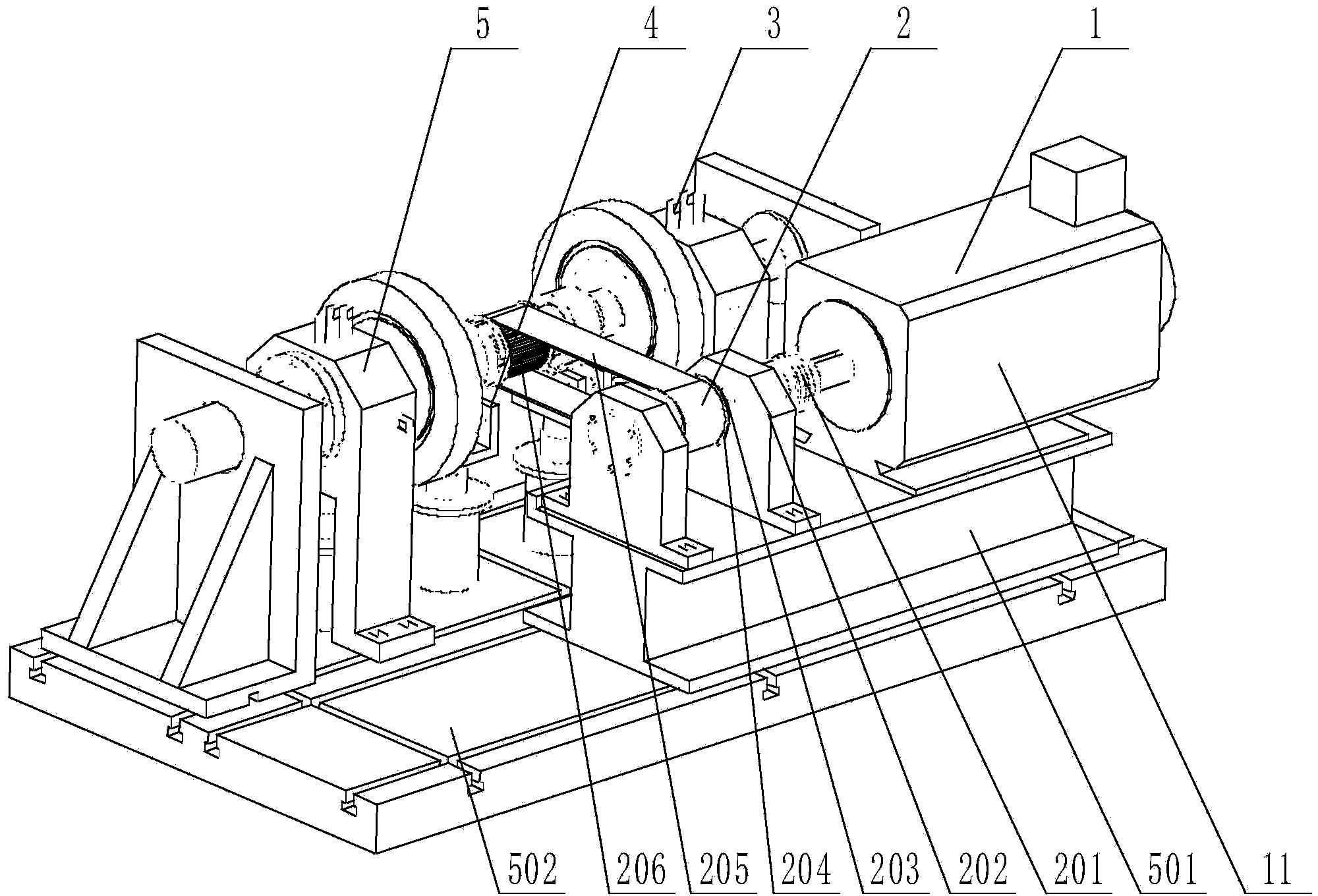

Accelerated rolling bearing fatigue life tester

ActiveCN101699242AEmbodied stateReliable test resultsMachine bearings testingHydraulic motorRolling-element bearing

The invention discloses an accelerated rolling bearing fatigue life tester, which comprises a test head part (2), of which the inside is provided with a test bearing (1), a transmission gear (3), a loading mechanism (4) and a control system, wherein the transmission gear (3), the loading mechanism (4) and the control system are arranged outside the test head part (2); and the loading mechanism (4) is connected with the test head part (2) through a hydraulic piping to load the test bearing. The tester is characterized in that: the transmission gear is a reversible hydraulic motor; the transmission gear (3) is connected with the test bearing (1) to drive the test bearing to rotate reciprocally; and the outside of the test head part (2) is provided with a torque sensor (5) for monitoring the torque of the test bearing, and the control system receives information of the torque sensor and controls the loading mechanism (4) and the transmission gear (3) to stop according to the information. The tester has high testing accuracy and more reliable life testing result.

Owner:SUZHOU BEARING FACTORY CO LTD

Valve life testing device

InactiveCN101806672ASimple structureEasy to useStructural/machines measurementEngineeringSmall footprint

The invention provides a valve life testing device which belongs to the technical field of machinery and solves the problem that no testing equipment for a lead screw valve core exists on a traditional market. The valve life testing device comprises a stand, wherein the stand is provided with a clamping mechanism which can fix the valve body of a valve on the stand, the stand is provided with a cylinder 1 and a rotating sleeve which can be connected with the lead screw of the valve, a rack is connected to the piston rod of the cylinder 1, and the rotating sleeve is connected with a gear engaged with the rack; when the piston rod of the cylinder 1 extends and shrinks, the rotating sleeve can rotate; and the cylinder 1 is connected with a control mechanism which can control the sliding stroke of the piston rod. The valve life testing device has the advantages of simple structure, convenient use, capability of on-line pressurized testing, small occupied area and accurate and effective testing.

Owner:ZHEJIANG WORLD BRASS

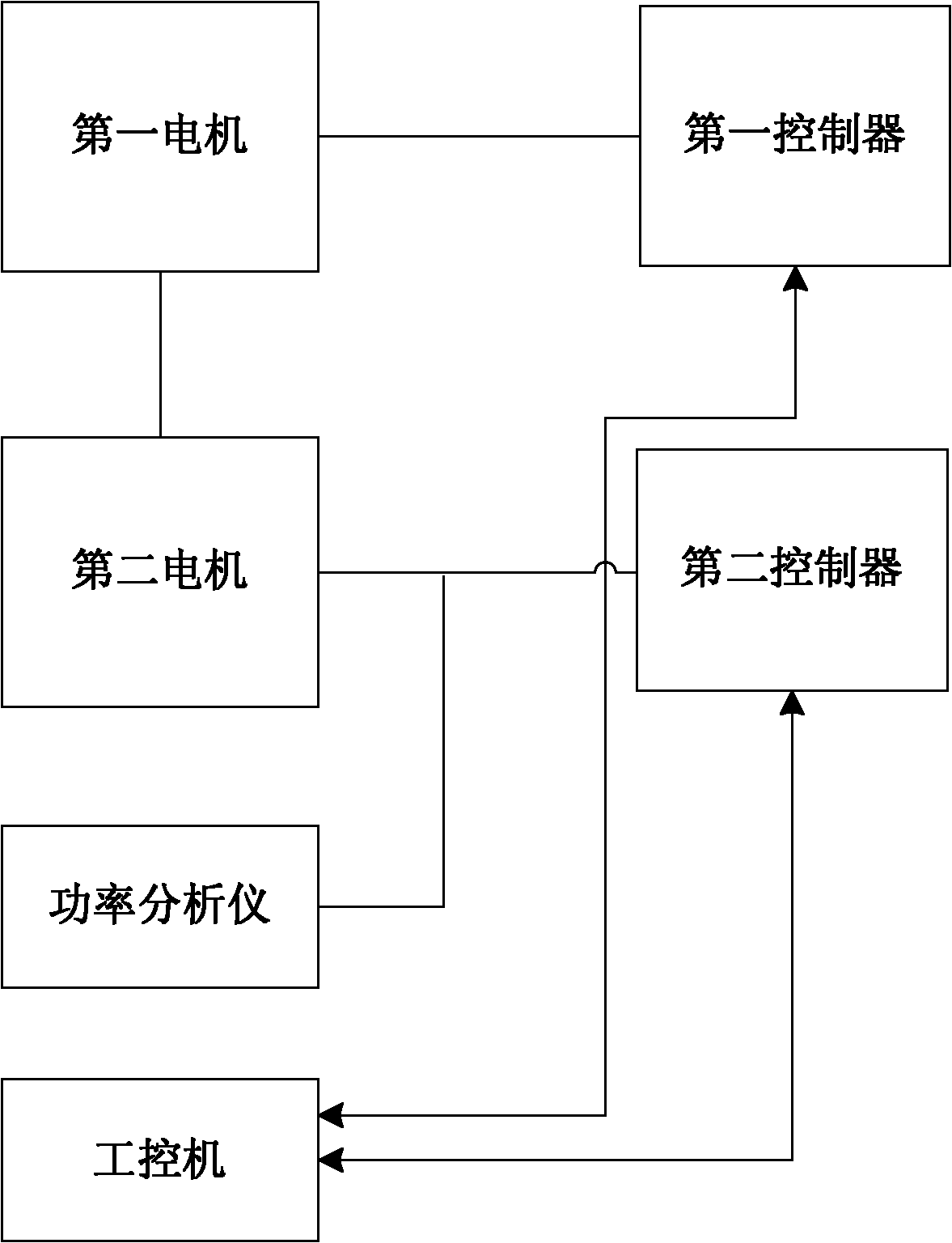

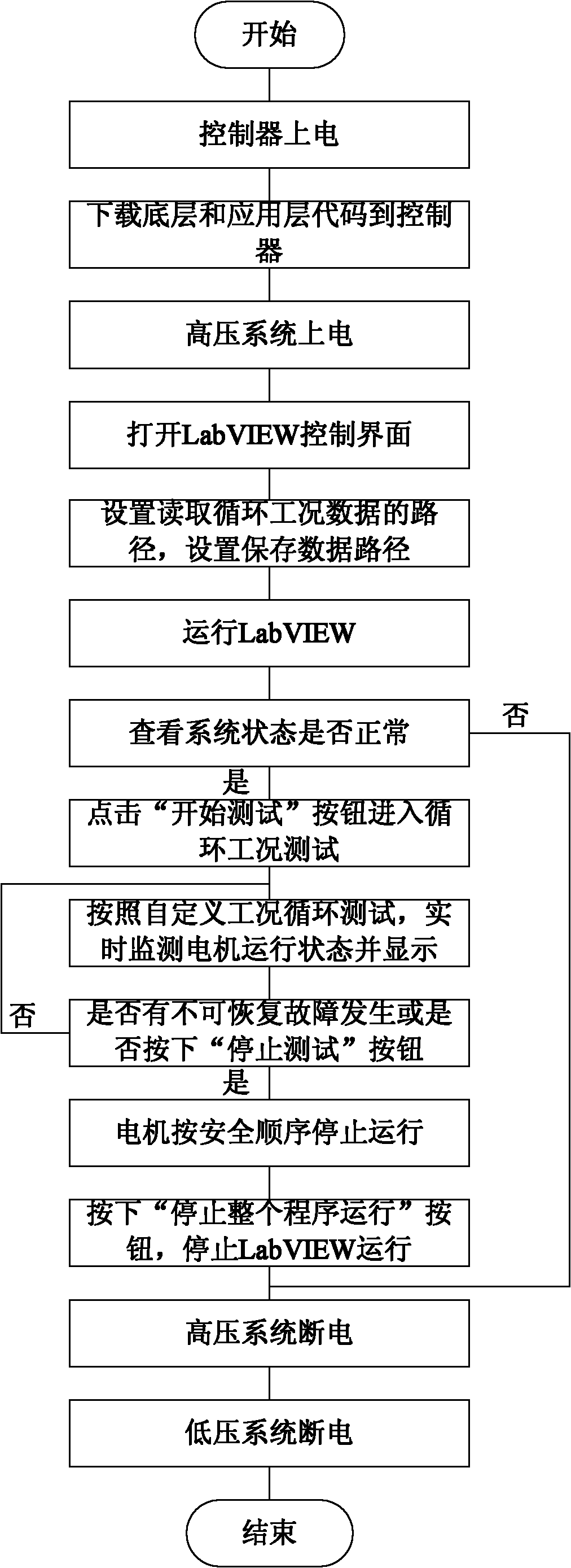

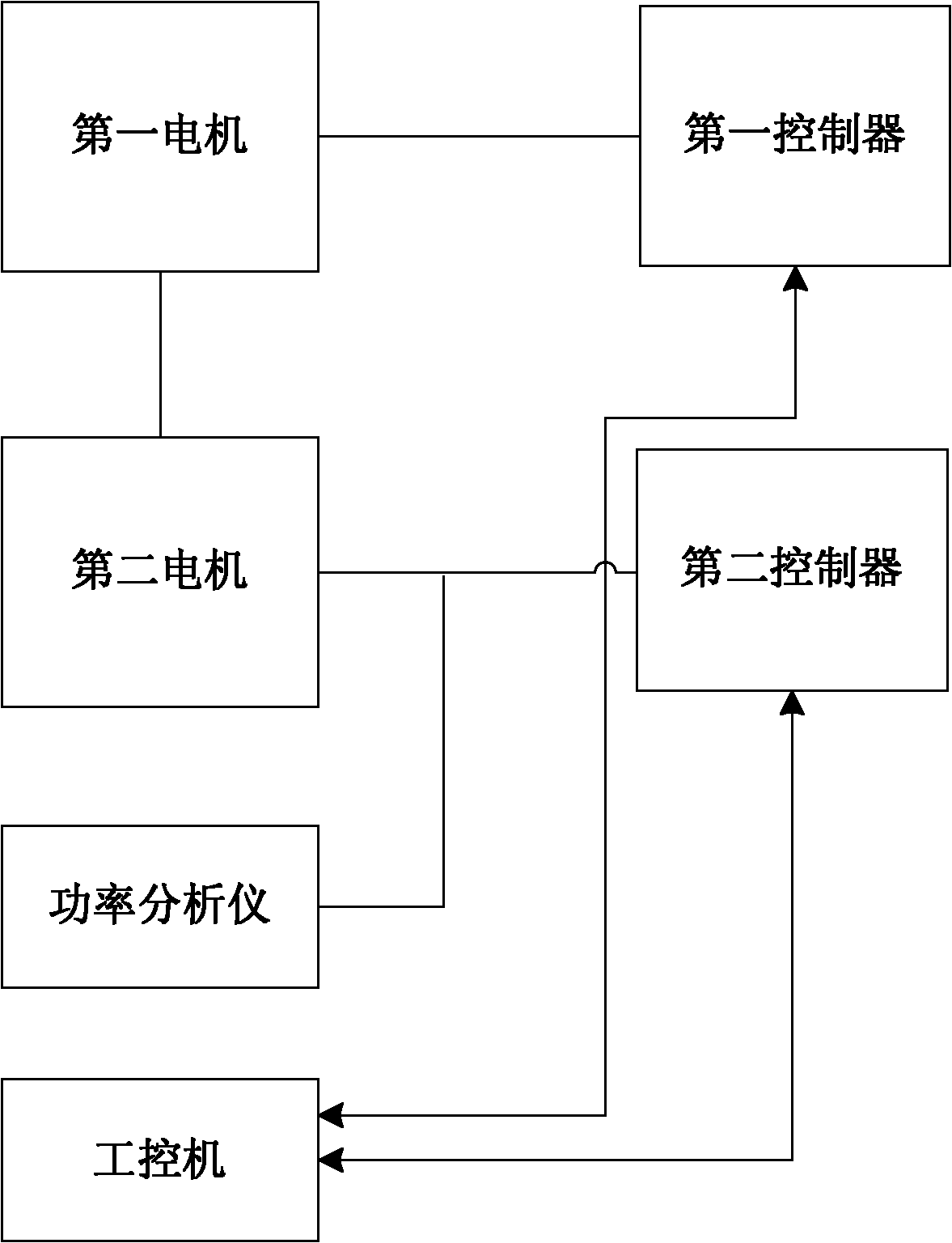

Platform and method for testing life of motors

ActiveCN102096043ASimple structureSimple methodDynamo-electric machine testingArea networkControl store

The invention discloses a platform and a method for testing the life of motors, which are used for testing the life of a first motor and a second motor. The platform comprises an industrial control computer, a first controller for controlling the work of the first motor, a second controller for controlling the work of the second motor, a torque rotating speed measurer and a power analyzer; the first motor is coaxially connected with the second motor oppositely; the industrial control computer comprises two serial ports; the industrial control computer communicates with the first controller and the second controller through the two serial ports via a controller area network (CAN) bus; and the torque rotating speed measurer is arranged on a connecting shaft of the two motors, and a measuring result of the torque rotating speed measurer is output to the power analyzer. The platform capable of simultaneously testing the life of the two coaxially and oppositely connected motors by using the industrial control computer, automatically sending a test command to the controllers of the motors through the industrial control computer during testing, receiving, displaying and storing real-time tested information sent from the controllers is provided. The device has a simple structure and the method is easy, the test capability is enhanced greatly, and the labor intensity during testing is lowered.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com