Valve life testing device

A life test and valve technology, applied in the field of machinery, to achieve the effect of small footprint, simple structure, accurate and effective testing

Inactive Publication Date: 2010-08-18

ZHEJIANG WORLD BRASS

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the more common gate valves and globe valves on the market rely on the threaded transmission of the screw or the valve core to drive the movement of the seal to achieve the opening and closing function. The life of this valve is largely determined by the screw or the valve core. Whether it can be sealed at the end, the life test for this type of valve is equivalent to the life test for the screw valve core, but there is no testing equipment for this type of screw valve core in the market

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

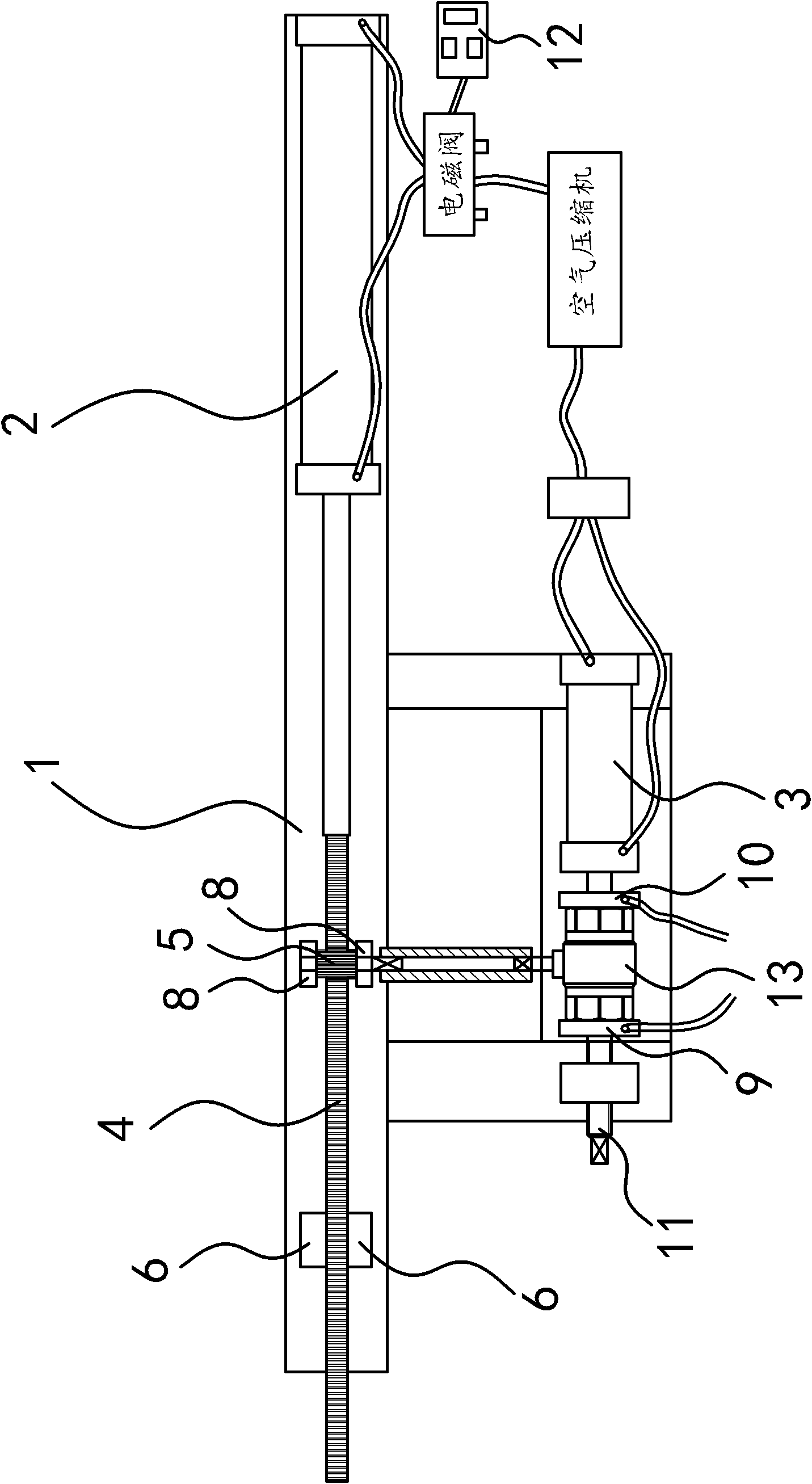

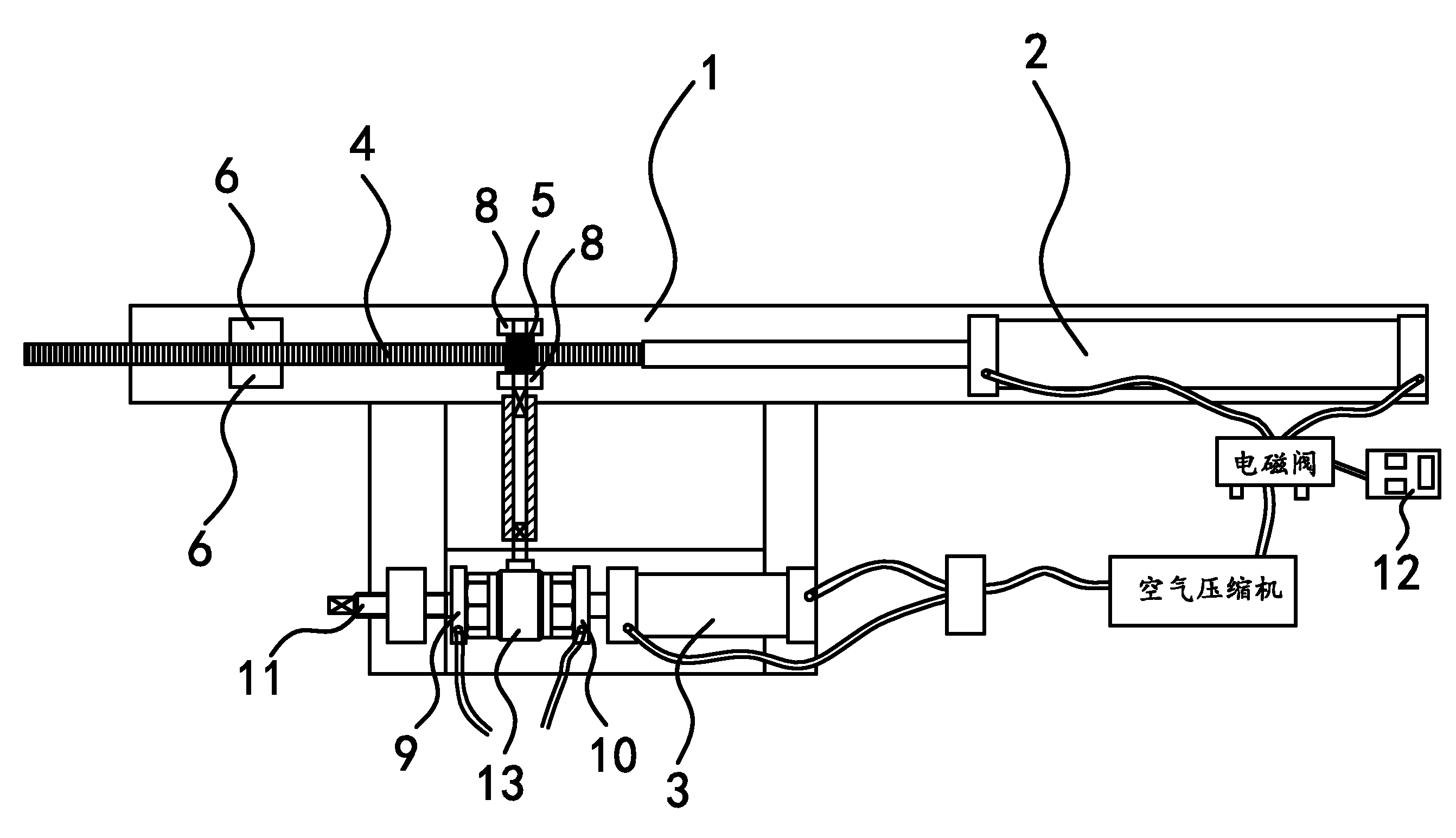

[0029] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the control mechanism includes a solenoid valve connected to the air pipe of cylinder 1 2 and a touch switch arranged on cylinder 1 2, the solenoid valve and the touch switch The switches are all connected with the PLC.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

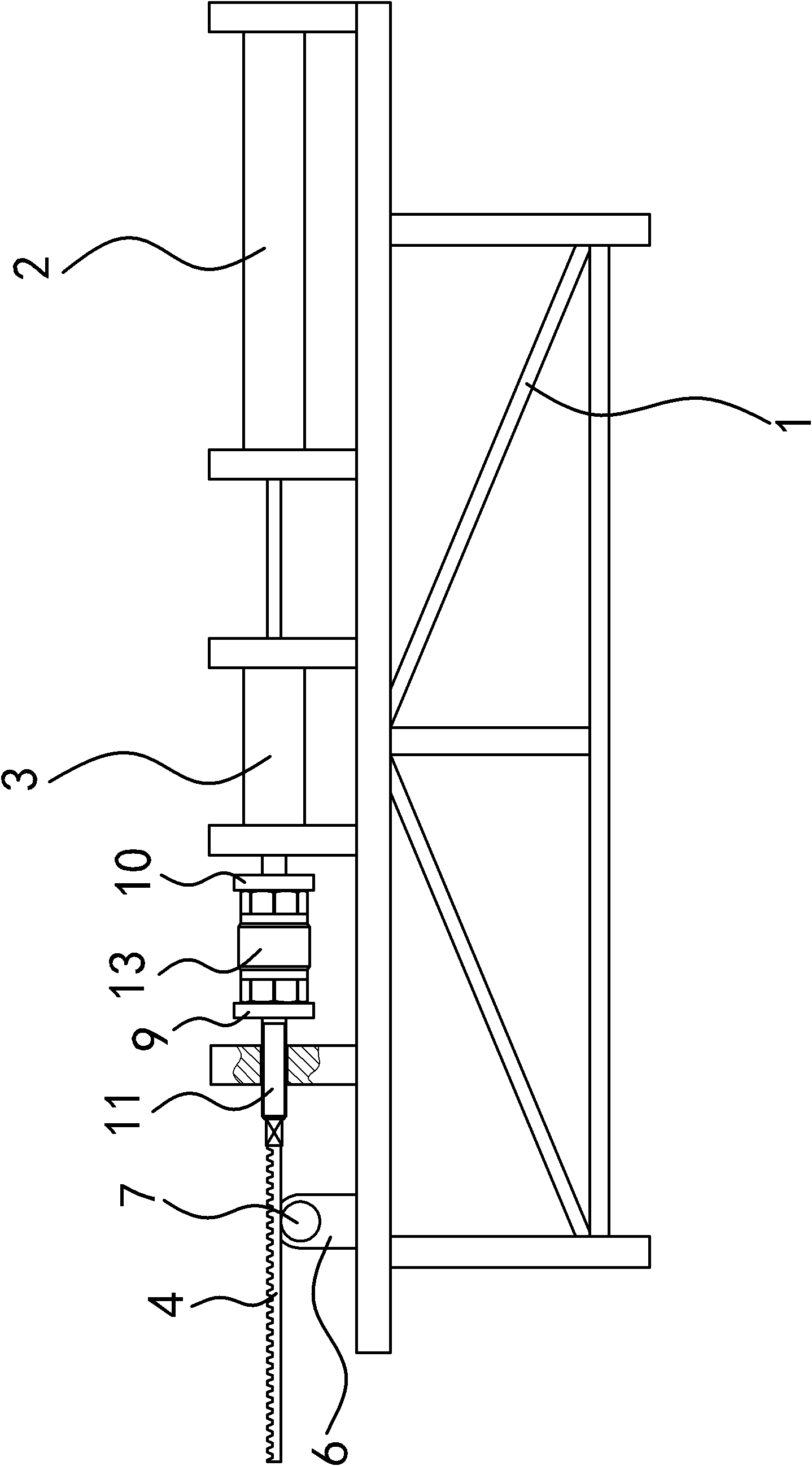

The invention provides a valve life testing device which belongs to the technical field of machinery and solves the problem that no testing equipment for a lead screw valve core exists on a traditional market. The valve life testing device comprises a stand, wherein the stand is provided with a clamping mechanism which can fix the valve body of a valve on the stand, the stand is provided with a cylinder 1 and a rotating sleeve which can be connected with the lead screw of the valve, a rack is connected to the piston rod of the cylinder 1, and the rotating sleeve is connected with a gear engaged with the rack; when the piston rod of the cylinder 1 extends and shrinks, the rotating sleeve can rotate; and the cylinder 1 is connected with a control mechanism which can control the sliding stroke of the piston rod. The valve life testing device has the advantages of simple structure, convenient use, capability of on-line pressurized testing, small occupied area and accurate and effective testing.

Description

technical field [0001] The invention belongs to the technical field of machinery, in particular to a valve life testing device. Background technique [0002] There are more and more types of existing valves. According to their different designs and operating principles, their testing equipment and methods also need to be adjusted in time. At present, the more common gate valves and globe valves on the market rely on the threaded transmission of the screw or the valve core to drive the movement of the seal to achieve the opening and closing function. The life of this valve is largely determined by the screw or the valve core. Finally, it can be determined whether it can be sealed. The life test for this type of valve is equivalent to the life test for the screw valve core, but there is no testing equipment for this type of screw valve core on the market. Contents of the invention [0003] The object of the present invention is to solve the above-mentioned problems in the e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M19/00G01M99/00

Inventor 卓旦春

Owner ZHEJIANG WORLD BRASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com