Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27458 results about "Pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

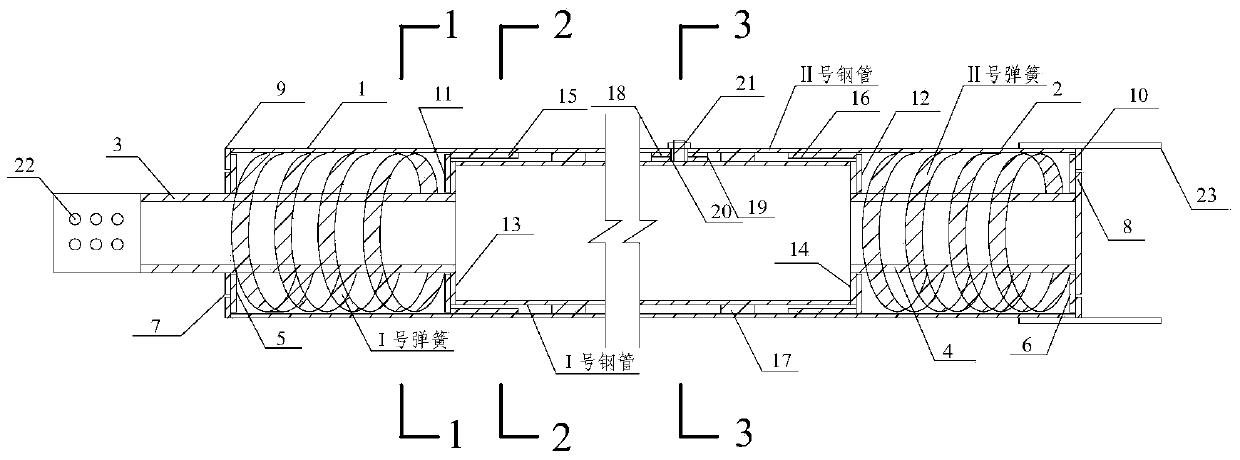

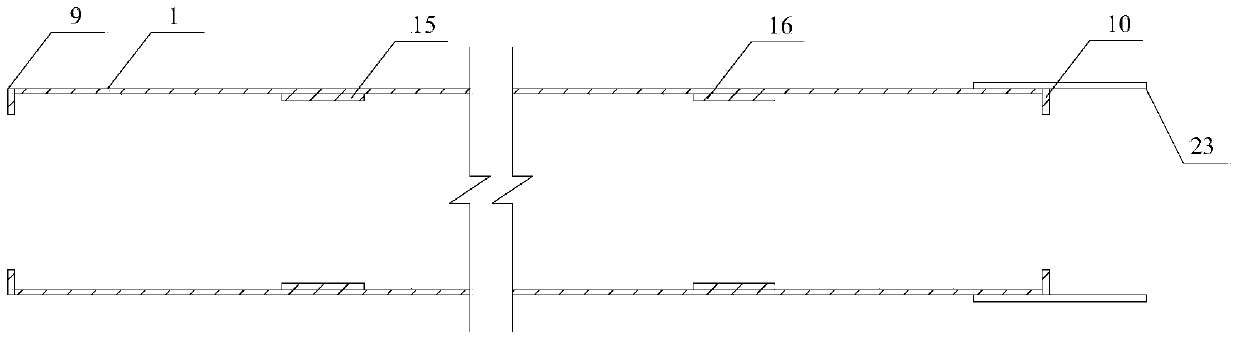

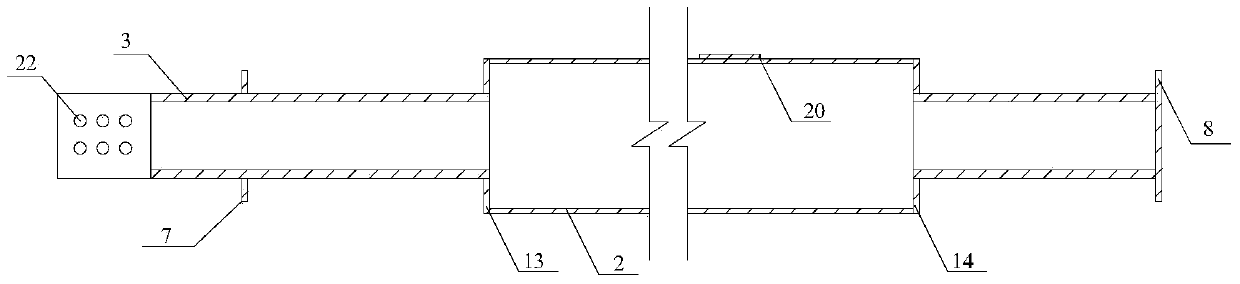

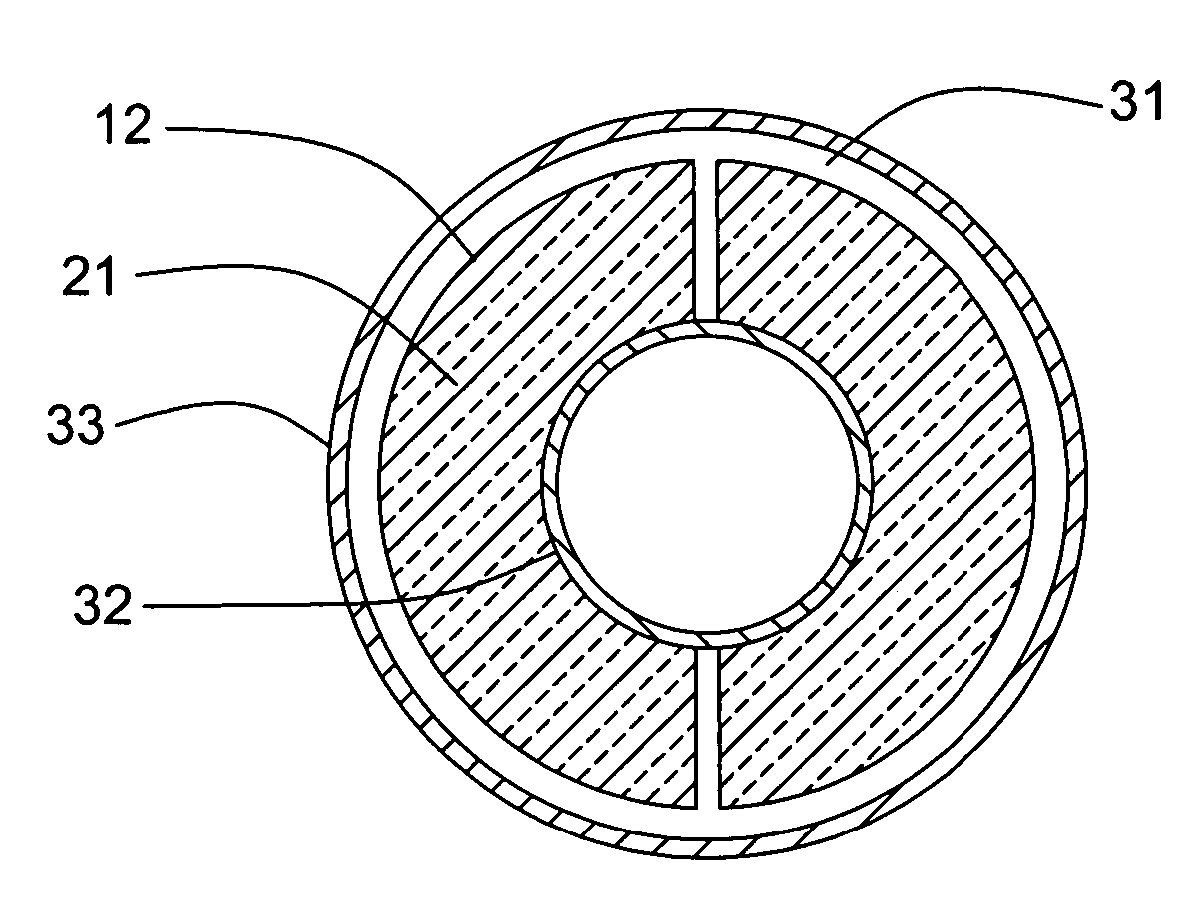

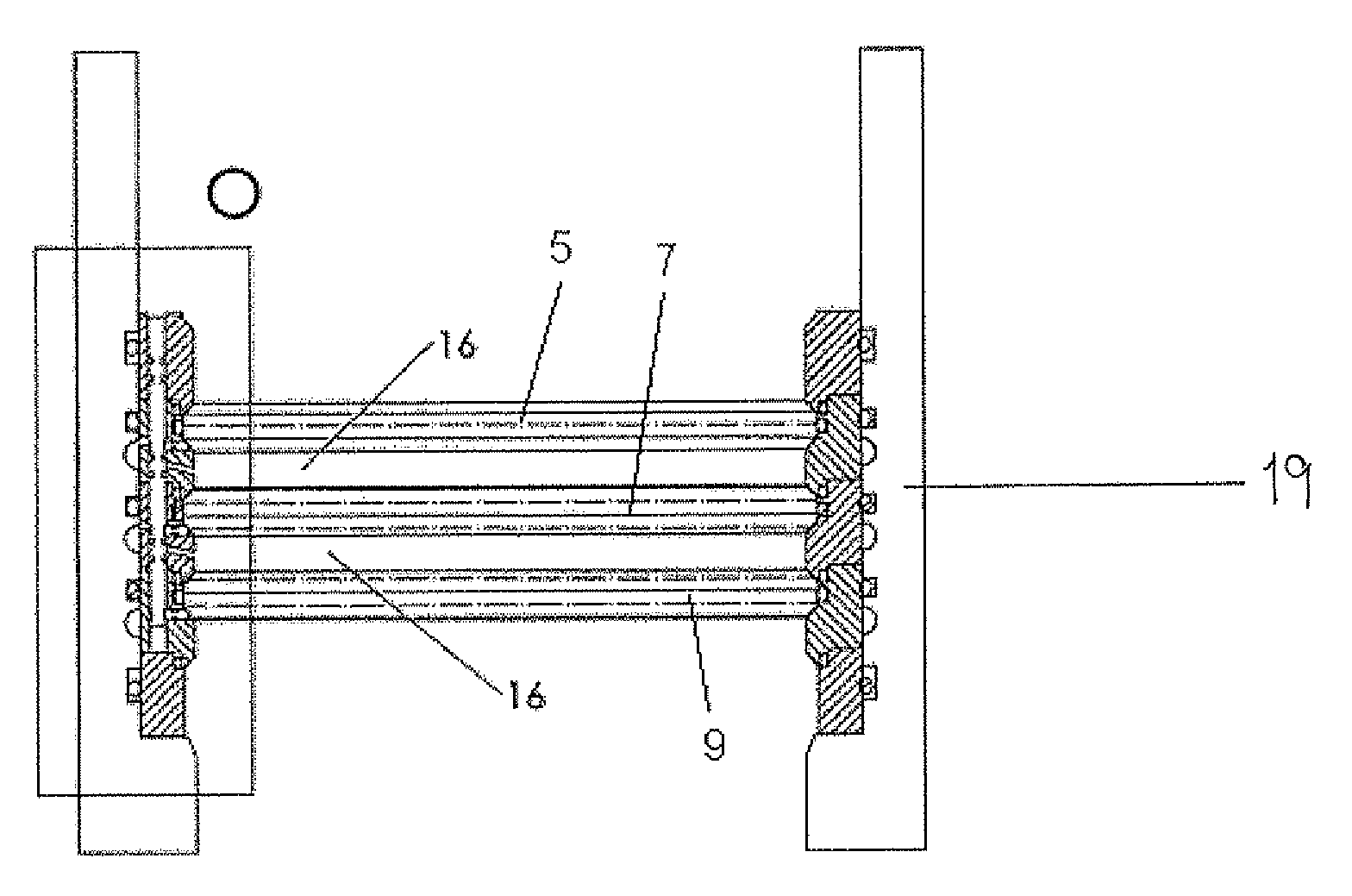

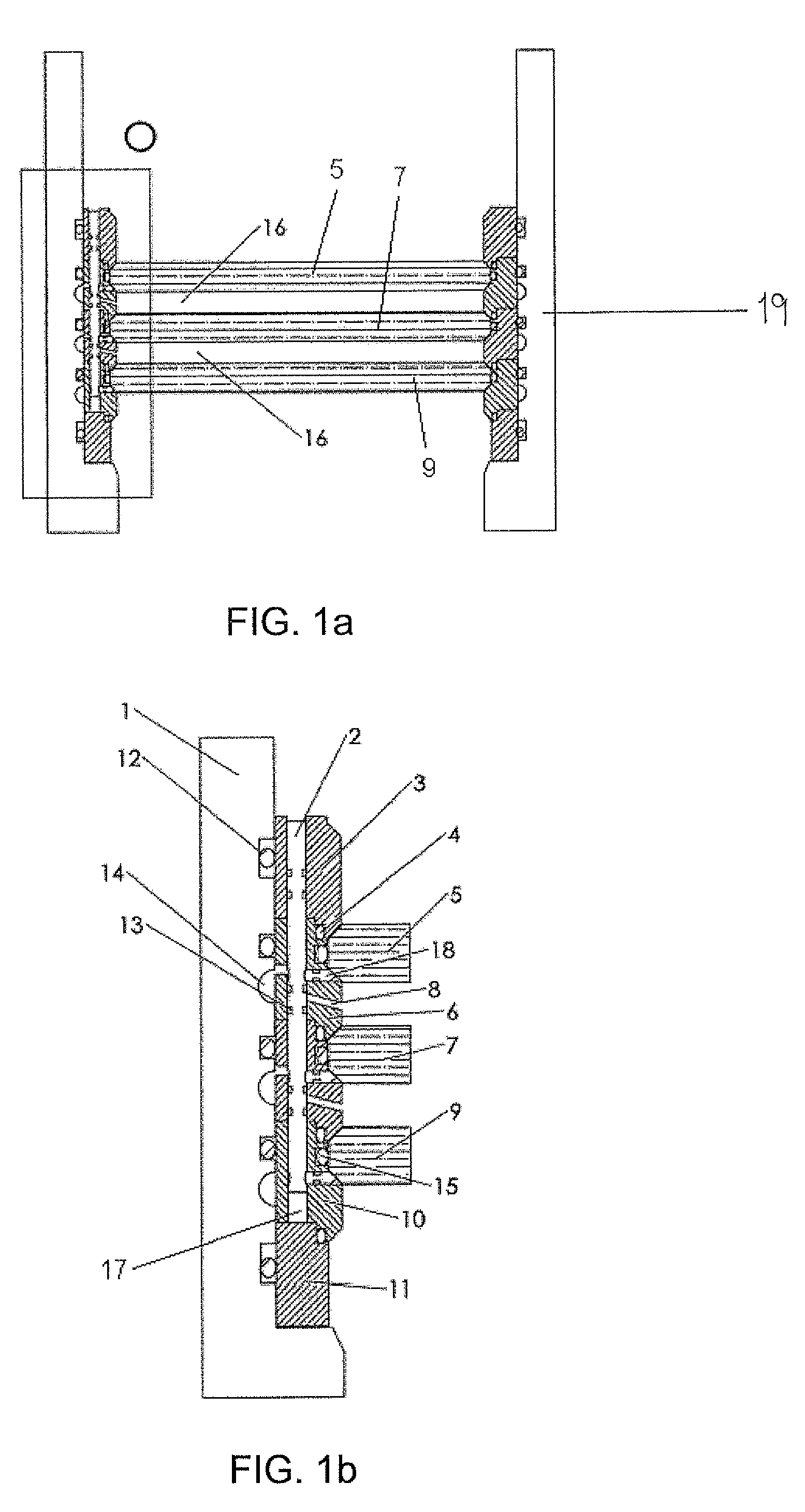

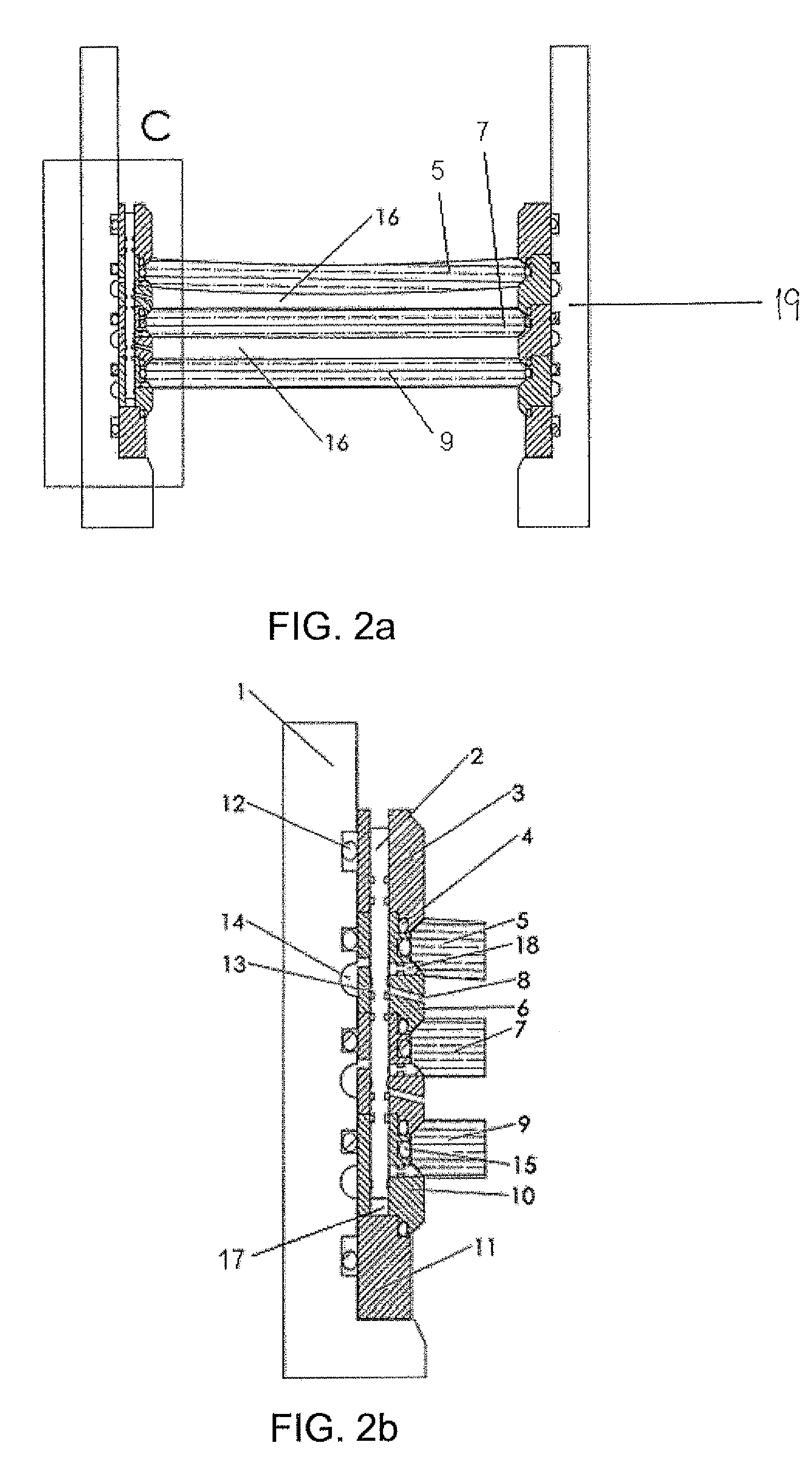

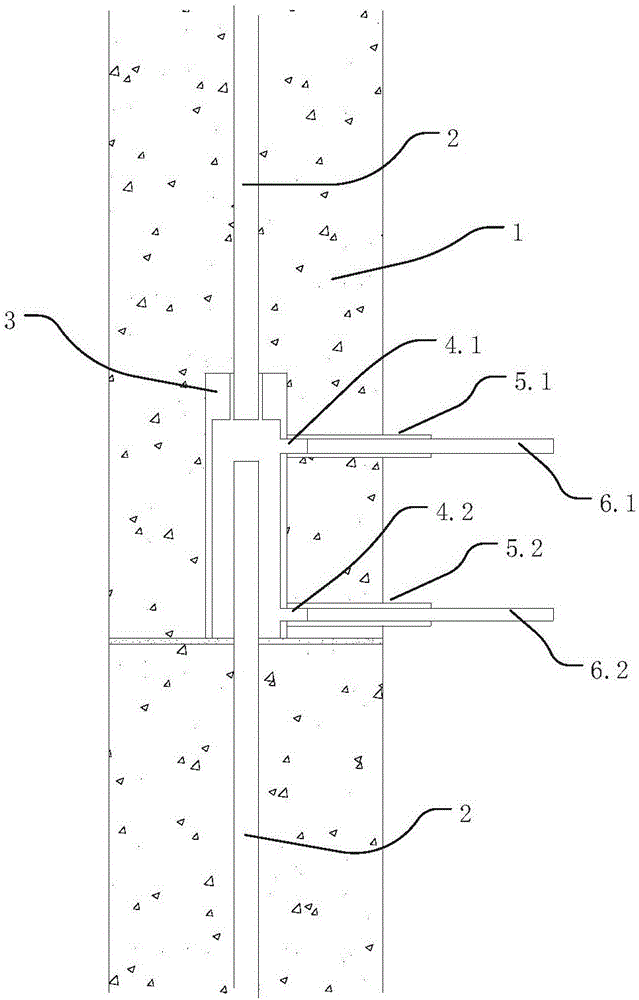

Setup spring self-recovery energy dissipation brace

ActiveCN103469921AReduce residual deformationEasy constructionShock proofingResidual deformationPipe

The invention discloses a setup spring self-recovery energy dissipation brace in the technical field of self-recovery energy dissipation braces. The brace comprises an inner pipe, an outer pipe, a spring, a spring baffle and a guide block; the inner pipe comprises a left inner pipe, a right inner pipe, a first steel pipe, a first steel pipe left baffle, a first steel pipe right baffle, an inner pipe left stopper, an inner pipe right stopper, an inner pipe outer friction plate, a high-strength bolt and an inner pipe connecting plate; the outer pipe comprises a left outer pipe, a right outer pipe, a second steel pipe, an outer pipe left baffle, an outer pipe right baffle, an outer pipe internal left stopper, an outer pipe internal right stopper, an outer pipe inner friction plate and an outer pipe connecting plate; the spring comprises a first spring and a second spring, wherein the first spring is sleeved outside the left inner pipe, and the second spring is sleeved outside the right inner pipe; two ends of the spring are connected with the spring baffle. The brace has the advantages that residual deformation of a structure is decreased, the brace is convenient to construct and easy to maintain and replace after earthquake action, and normal usage state affecting time is shortened.

Owner:BEIJING JIAOTONG UNIV

Insulated pipe and method for preparing same

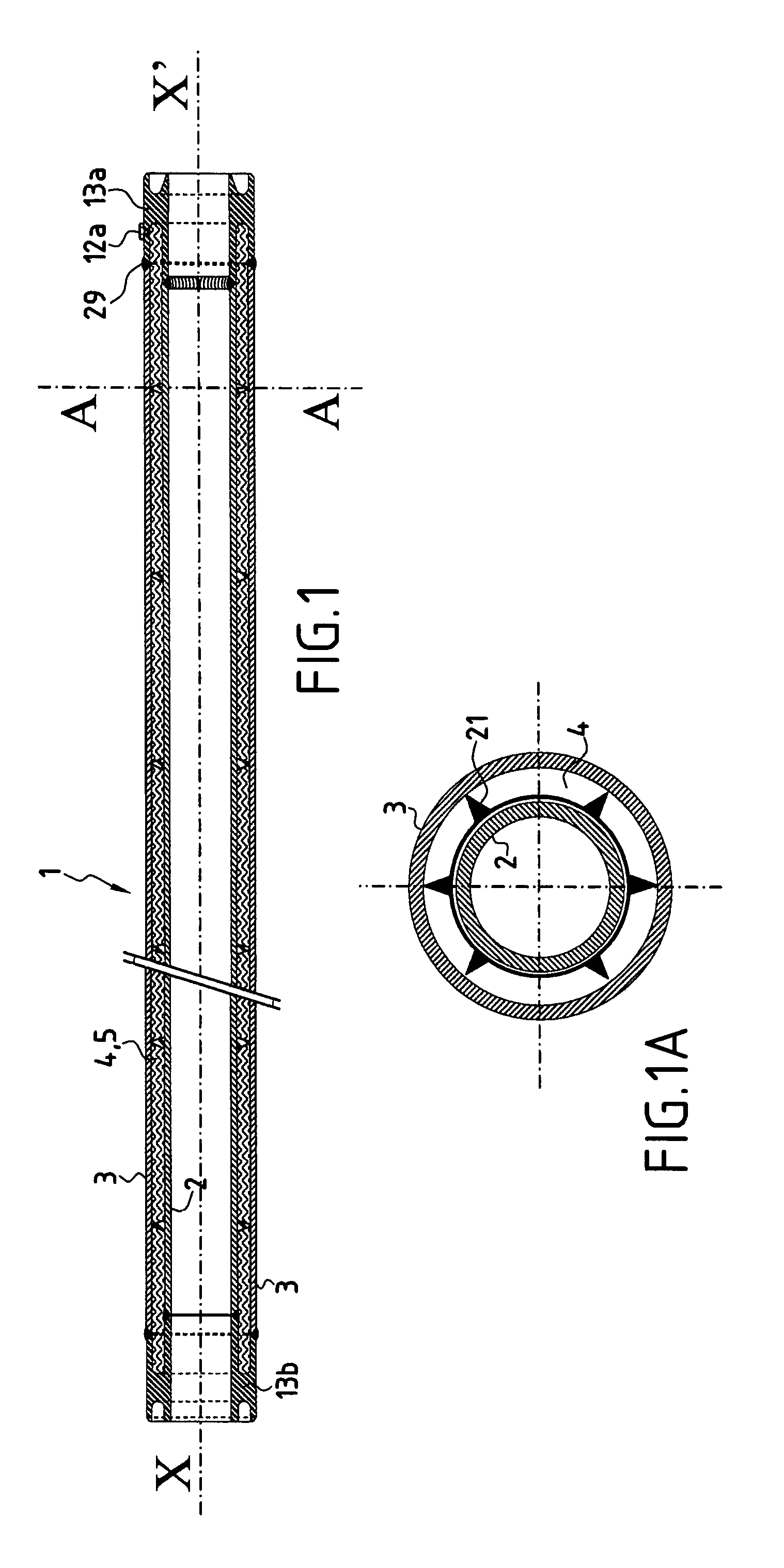

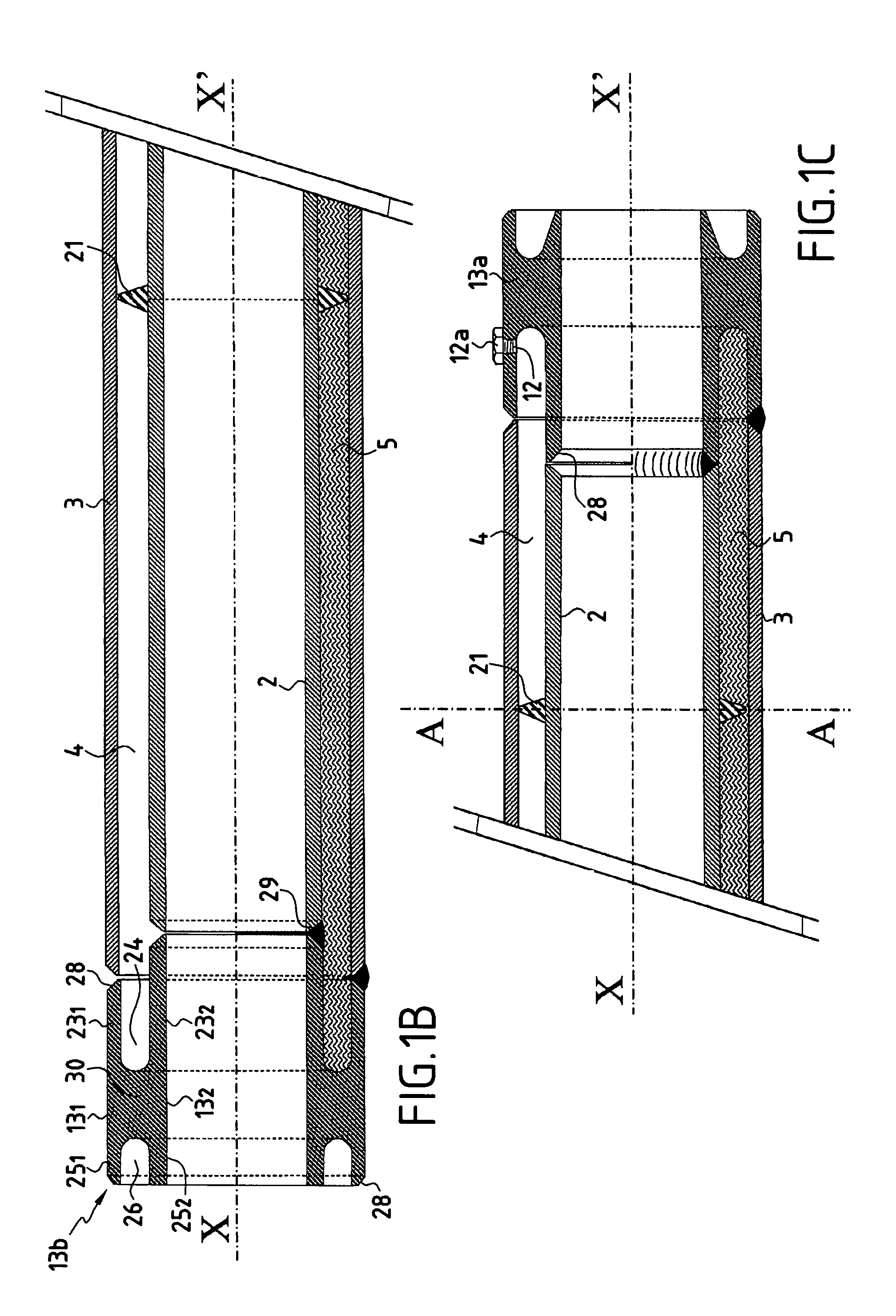

The invention provides an insulated pipe-in-pipe assembly comprising (a) at least one inner pipe, (b) an outer pipe disposed around the at least one inner pipe so as to create an annular space between the outer and inner pipes, (c) porous, resilient, compressible material disposed in the annular space, and (d) a remnant of a container that previously was positioned in the annular space and previously held the compressible material in a volume less than the volume of the compressible material in the annular space. The invention also provides a method for making such an insulated pipe-in-pipe assembly.

Owner:CABOT CORP

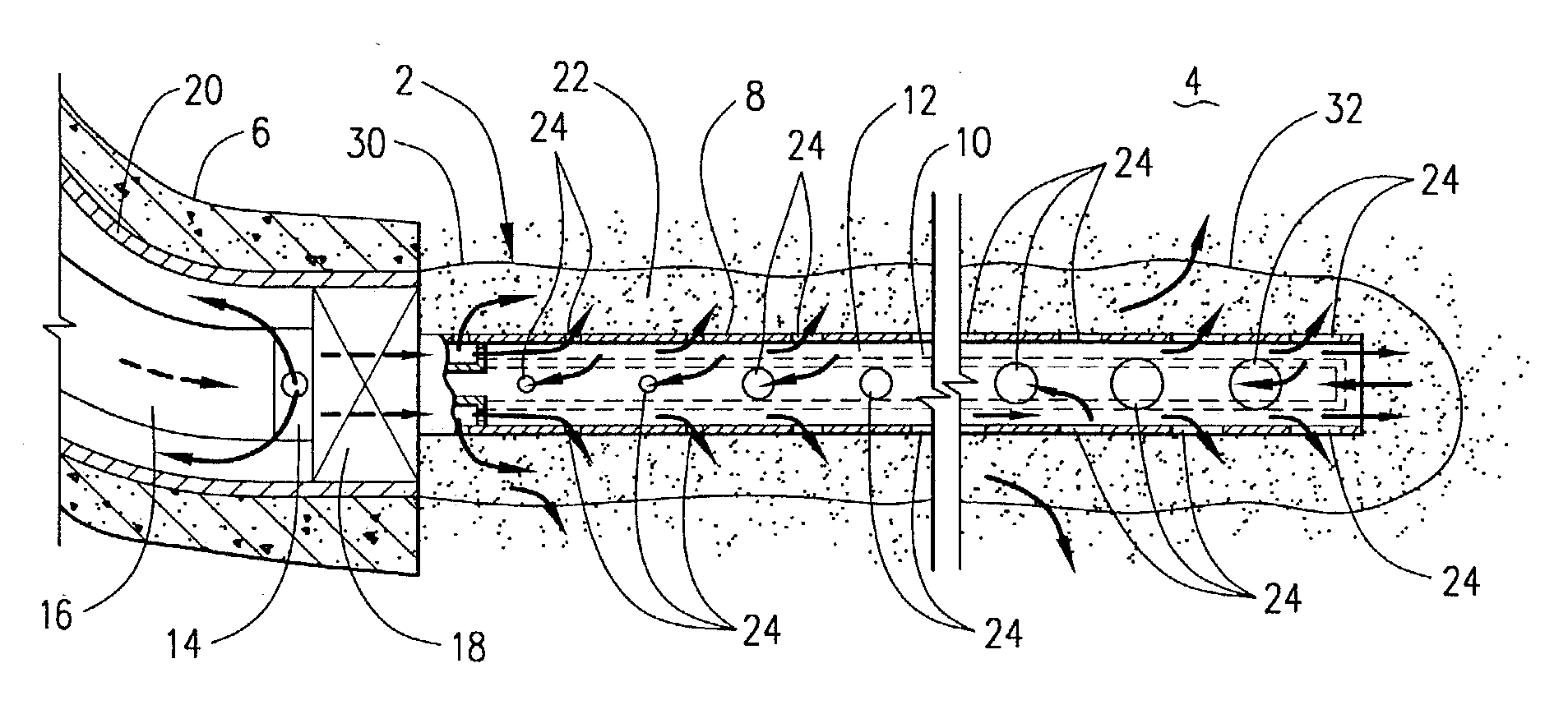

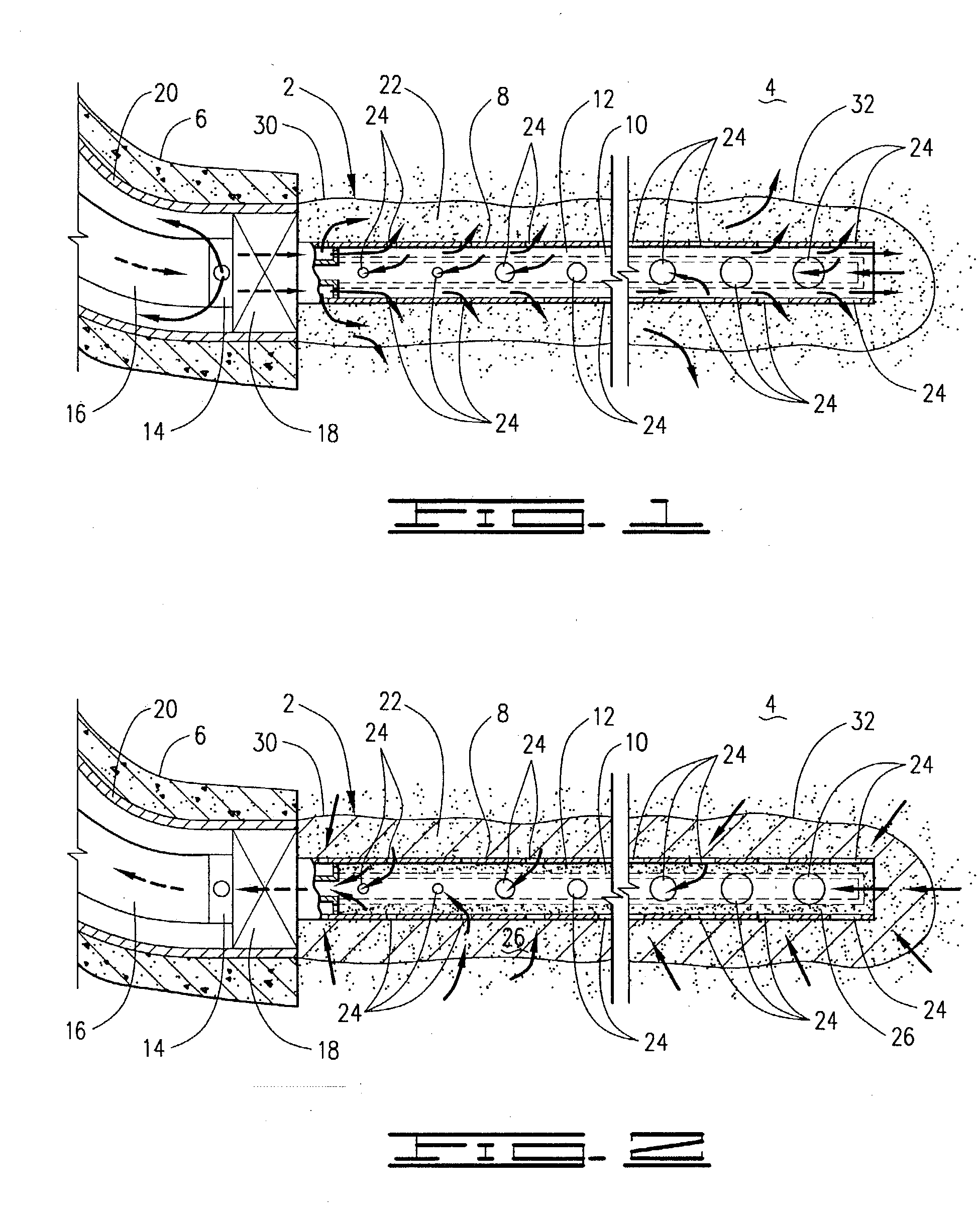

Methods and apparatus for completing unconsolidated lateral well bores

InactiveUS20040211559A1Inhibit migrationDrilling rodsFluid removalImproved methodMechanical engineering

Improved methods and apparatus for completing unconsolidated subterranean zones penetrated by well bores are provided. The methods basically comprise the steps of placing a slotted pipe having openings formed therein which vary in size or in the number of openings along the length of the slotted pipe or both in the subterranean zone, isolating the annulus between the slotted pipe and the well bore and injecting particulate material into the annulus whereby the particulate material is uniformly packed therein.

Owner:HALLIBURTON ENERGY SERVICES INC

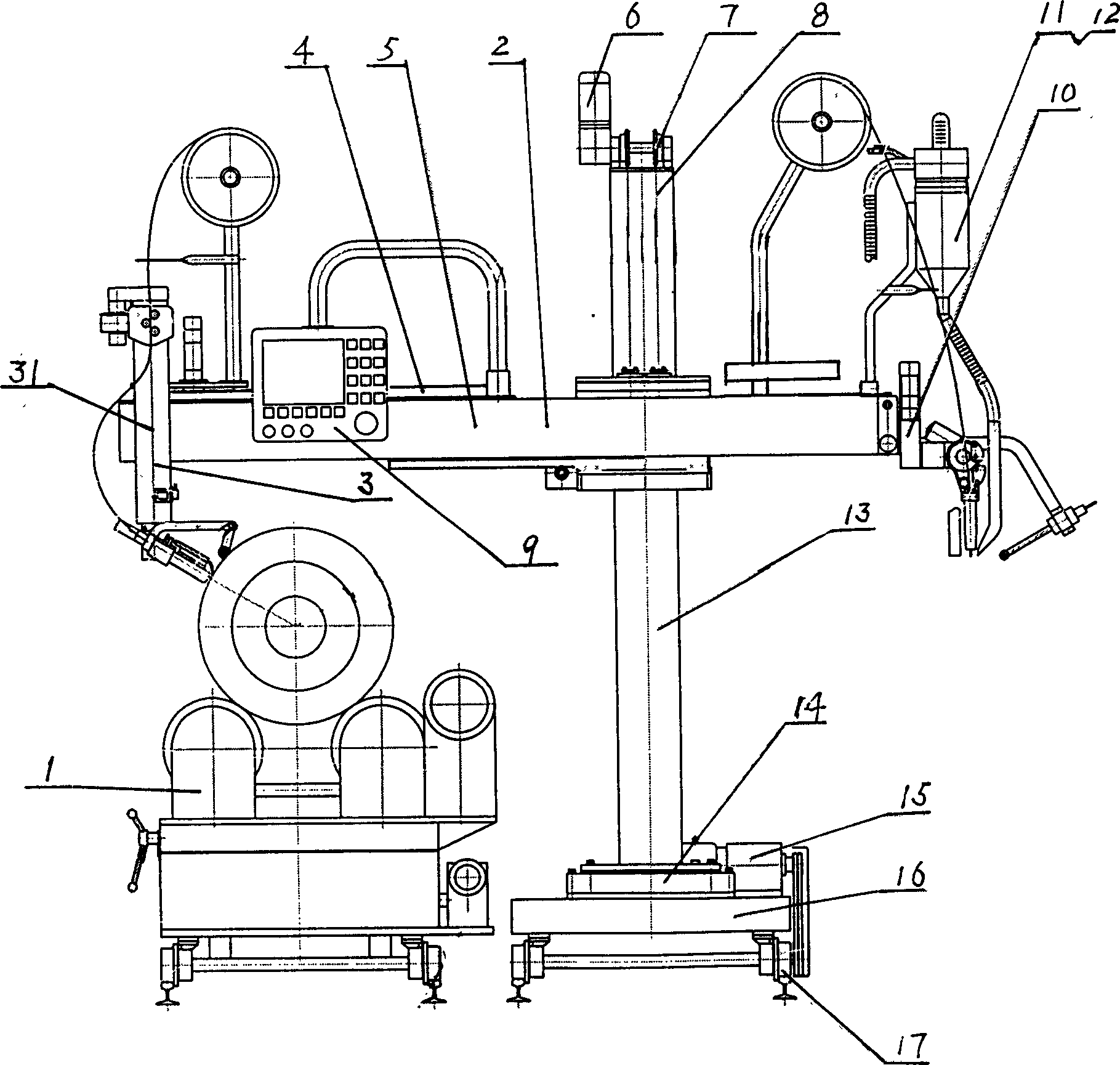

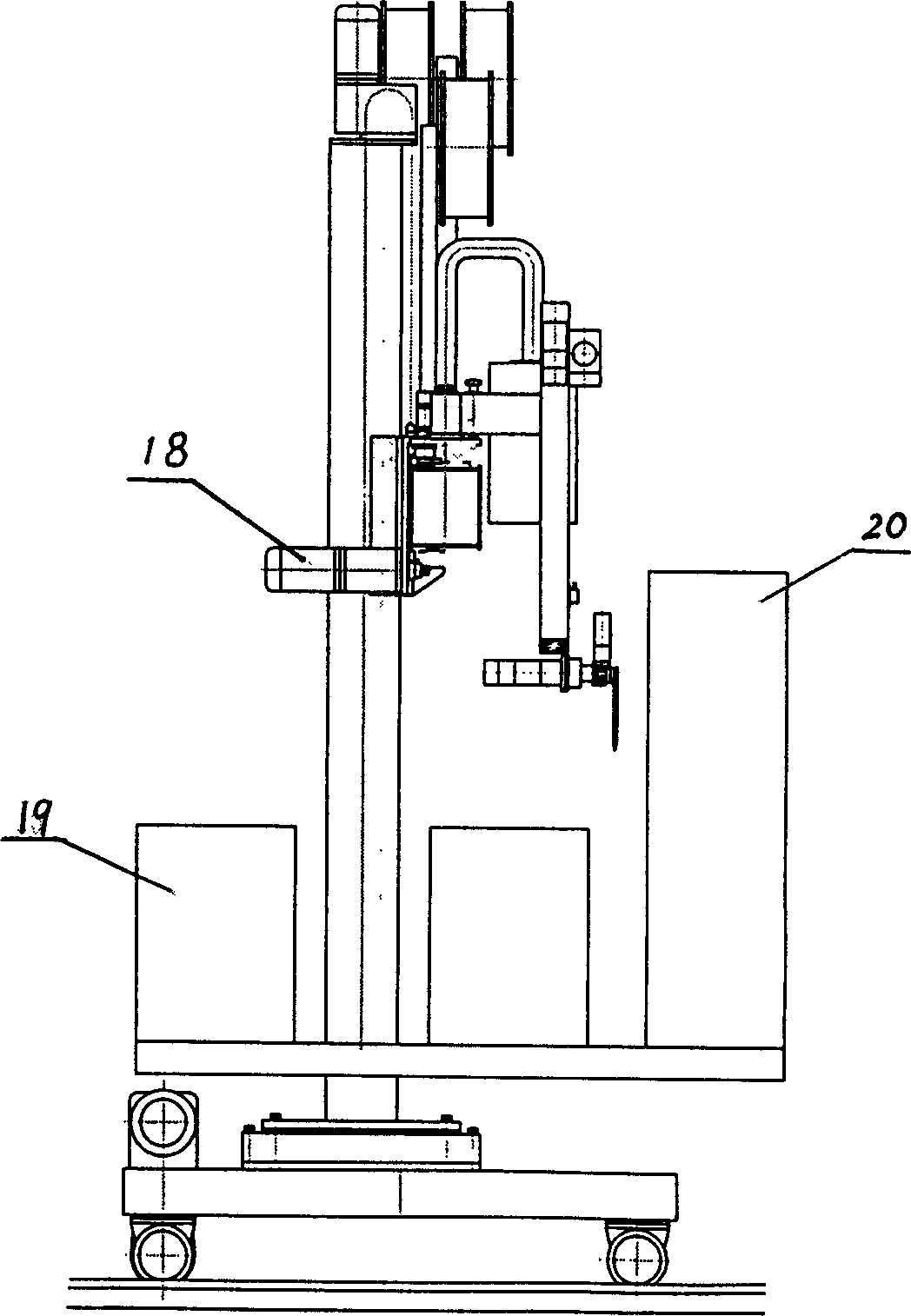

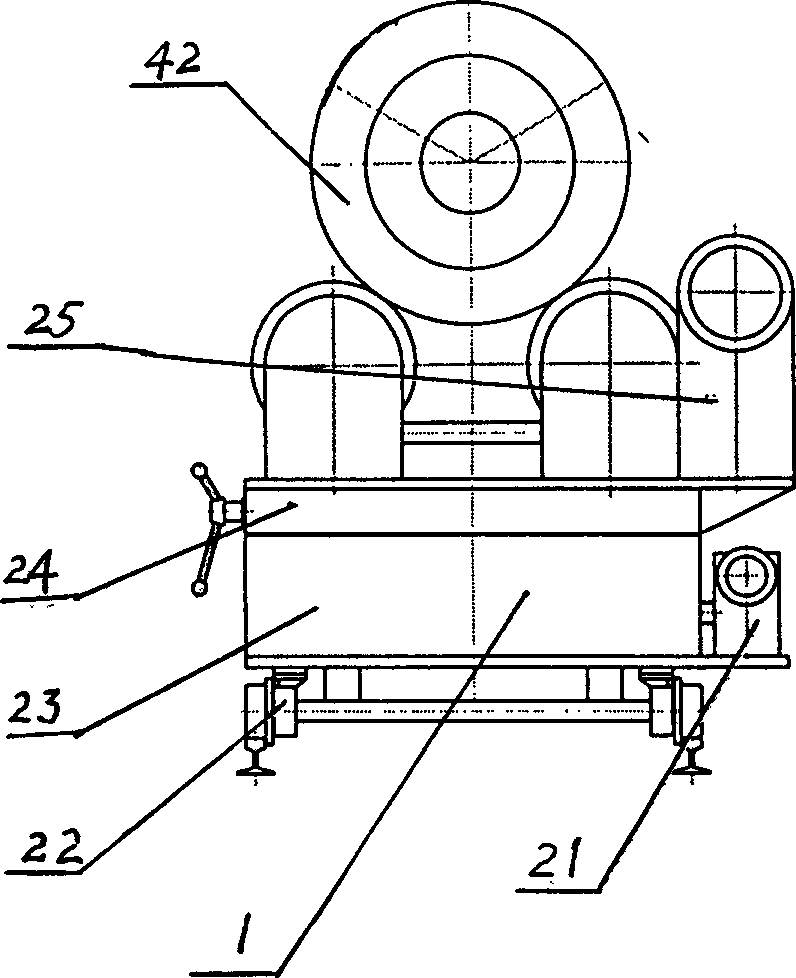

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN1714978AAutomatically calculate relative coordinate origin positionEnsure shapeArc welding apparatusBogieEngineering

The automatic argon arc welding and narrow gas submerged arc welding process for circular pipe header seam features the first horizontal and vertical welding with immobile workpiece and using automatic cold welding TIG wire until completing over one third of circle; the subsequent welding in the other two thirds of circle with automatically rotating welding roller frame; and the performing in the identical site of the annular seam assembling and the welding. The welding apparatus for the said technological process consists of roller device and welding frame bogie, and the welding frame bogie on some tracks parallel to roller frame tracks is movable. The present invention has the advantages of automatic operation, raised welding quality, etc.

Owner:SHANGHAI BOILER WORKS

Method for testing undercut on the inner diameter of pipe welds

InactiveUS20070278196A1Reduce and eliminate needArc welding apparatusMetal working apparatusEngineeringElectrical and Electronics engineering

Owner:LINCOLN GLOBAL INC

Sealing device

Owner:BJRGUM MEKANISKE

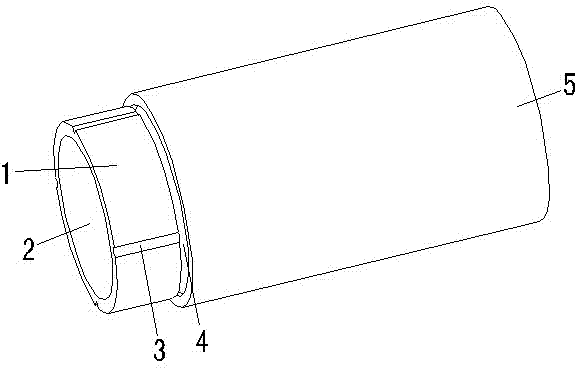

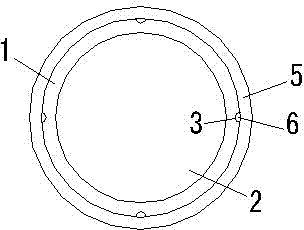

Telescopic copper pipe component

InactiveCN103591096AAchieve lockingSimple structureRod connectionsStructural engineeringOuter Cannula

The invention discloses a telescopic copper pipe component which comprises an inner pipe and an outer sleeve. The outer sleeve is sleeved on the inner pipe. A inner pipe through hole is formed in the center of the inner pipe. A plurality of linear grooves parallel with the central line of the inner tube are evenly distributed on the outer periphery of the inner pipe. Protrusions are disposed on the inner wall of the inner hole of the outer sleeve. The protrusions are disposed in the grooves. By the structure, when the outer sleeve is sleeved on the inner pipe, the protrusions can move linearly along the grooves, and the outer sleeve can move along the inner pipe. In addition, annular grooves are evenly formed in the outer periphery of the inner pipe, and the central line of each annular groove coincides with that of the inner pipe. When the protrusions enter the annular grooves, the outer sleeve can be relatively locked with the inner pipe by rotating the outer sleeve. The telescopic copper pipe is simple in structure and practical.

Owner:苏州市吴中区曙光铜管厂

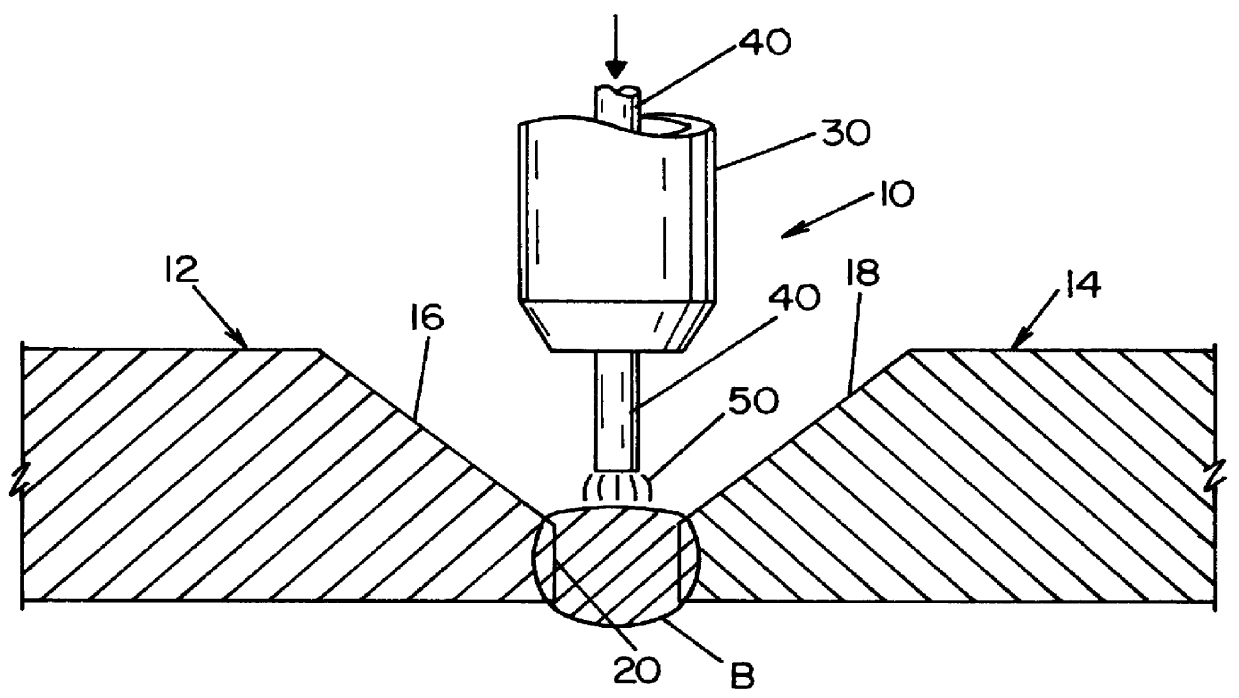

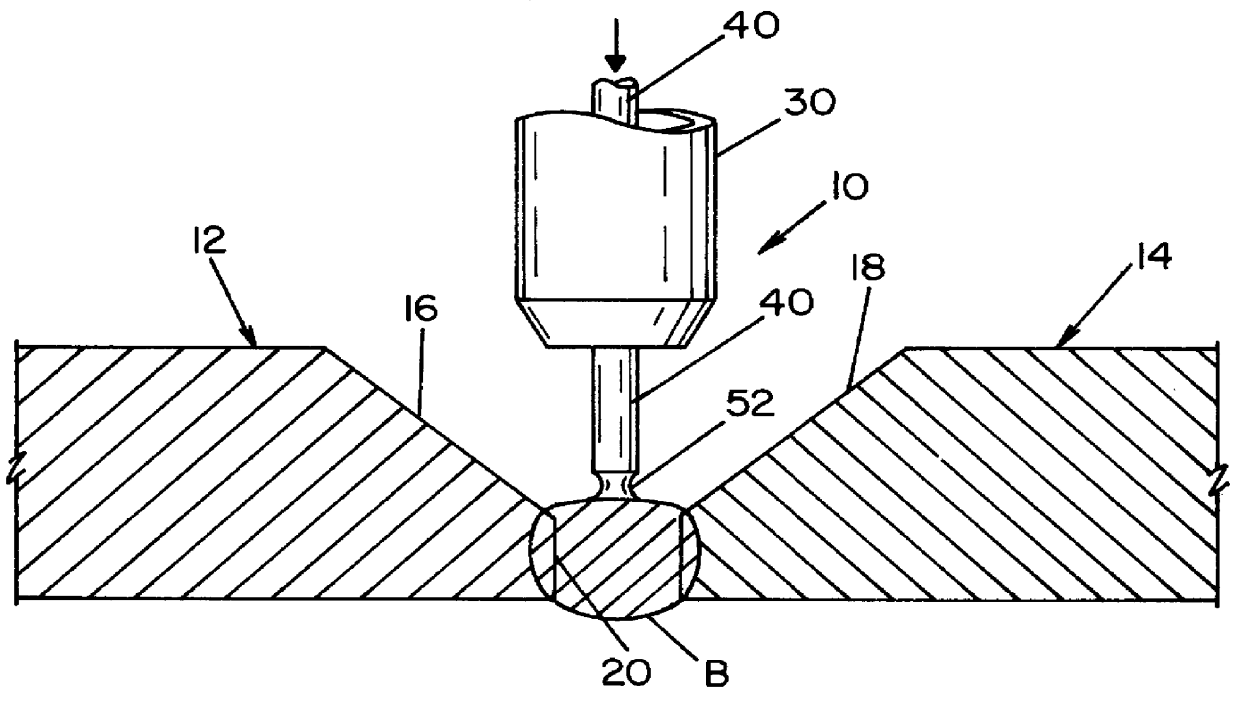

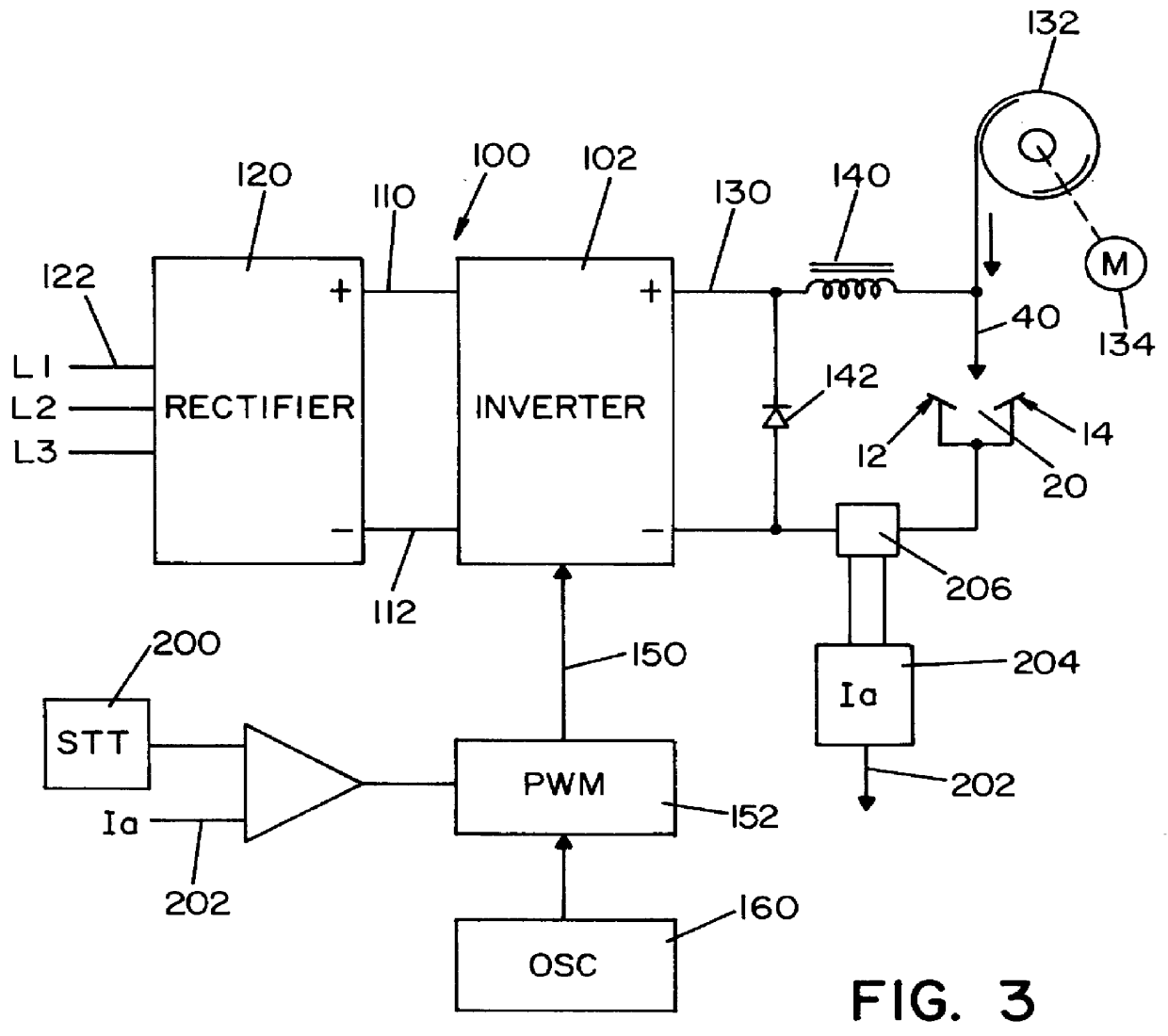

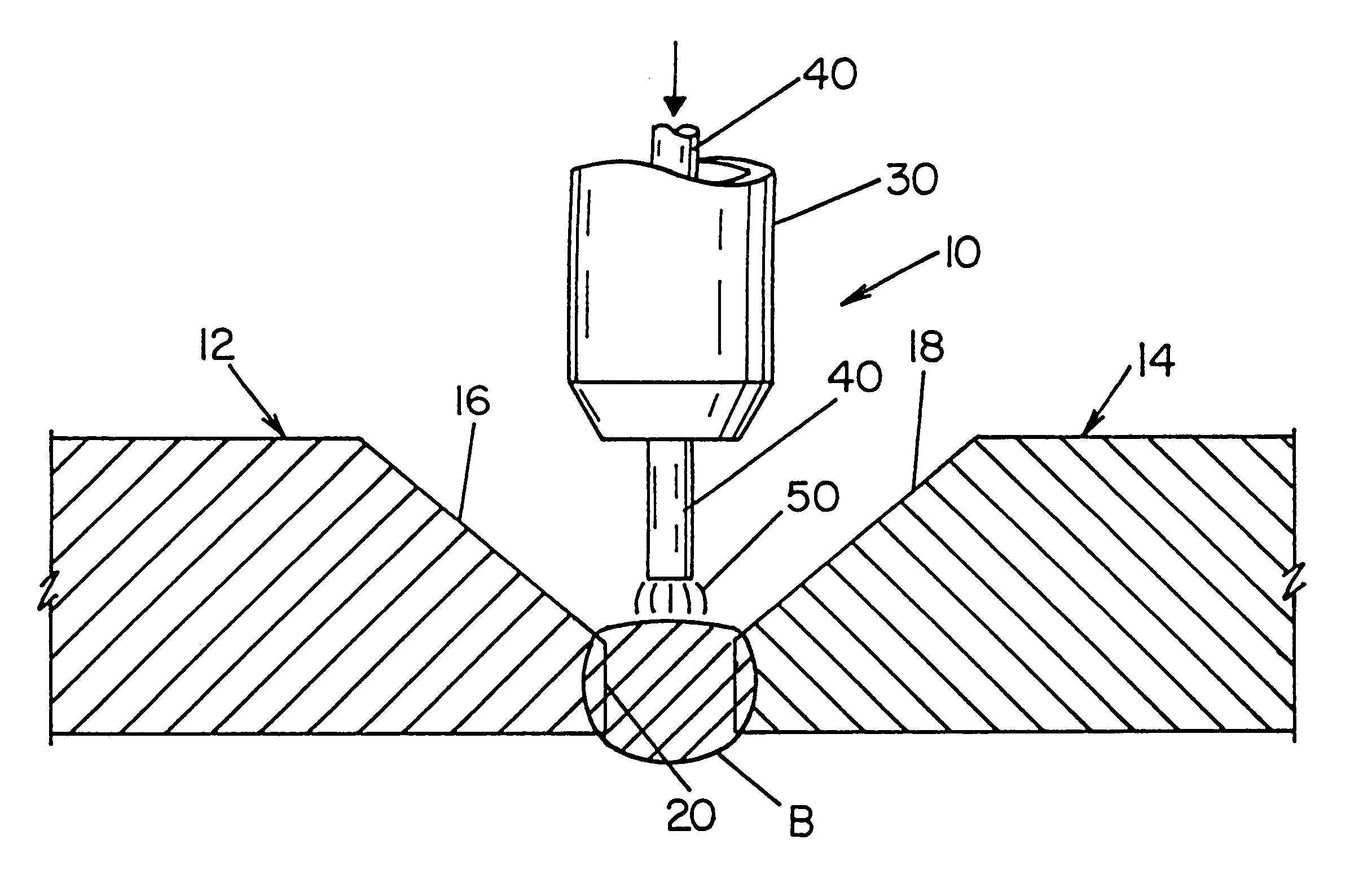

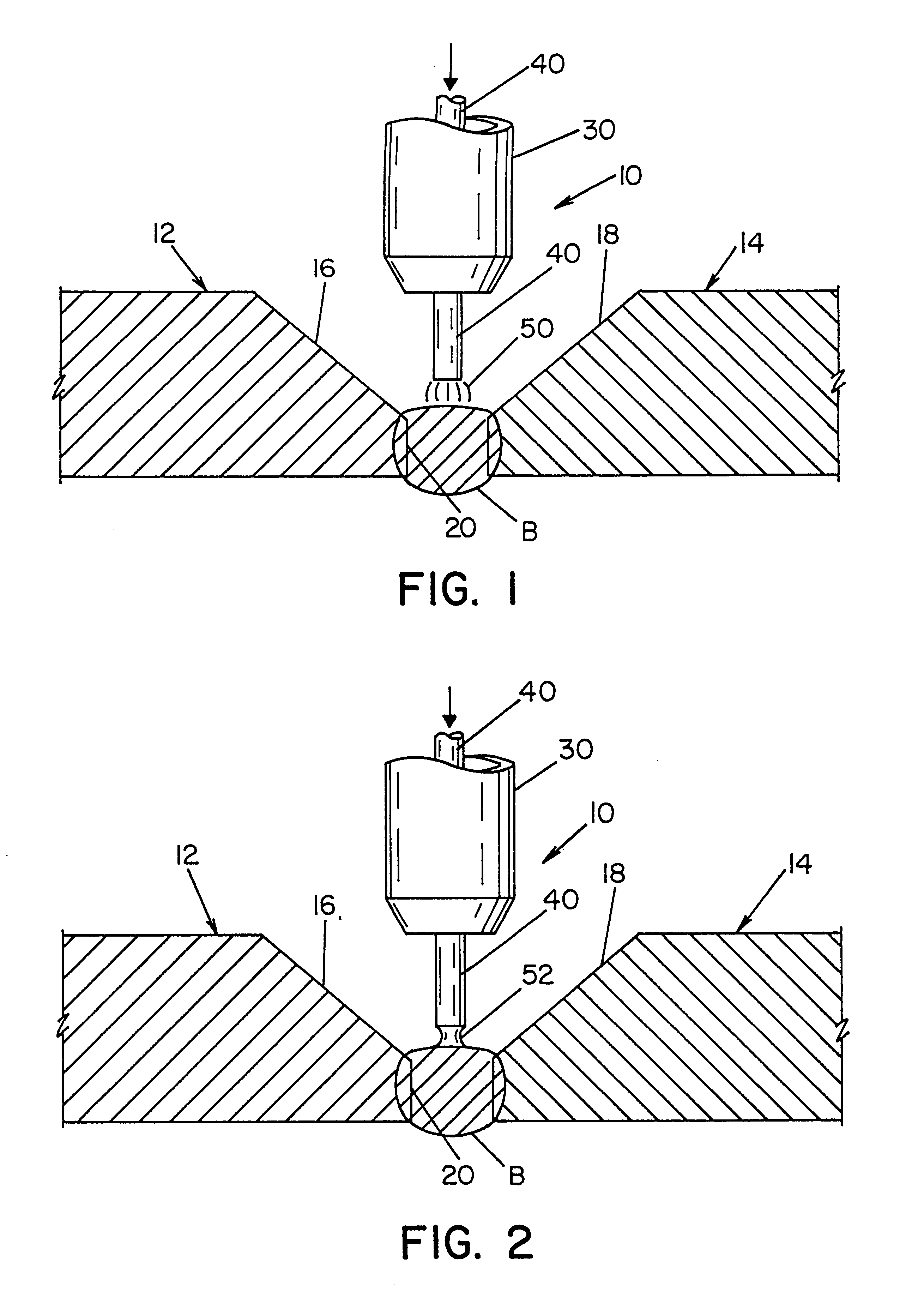

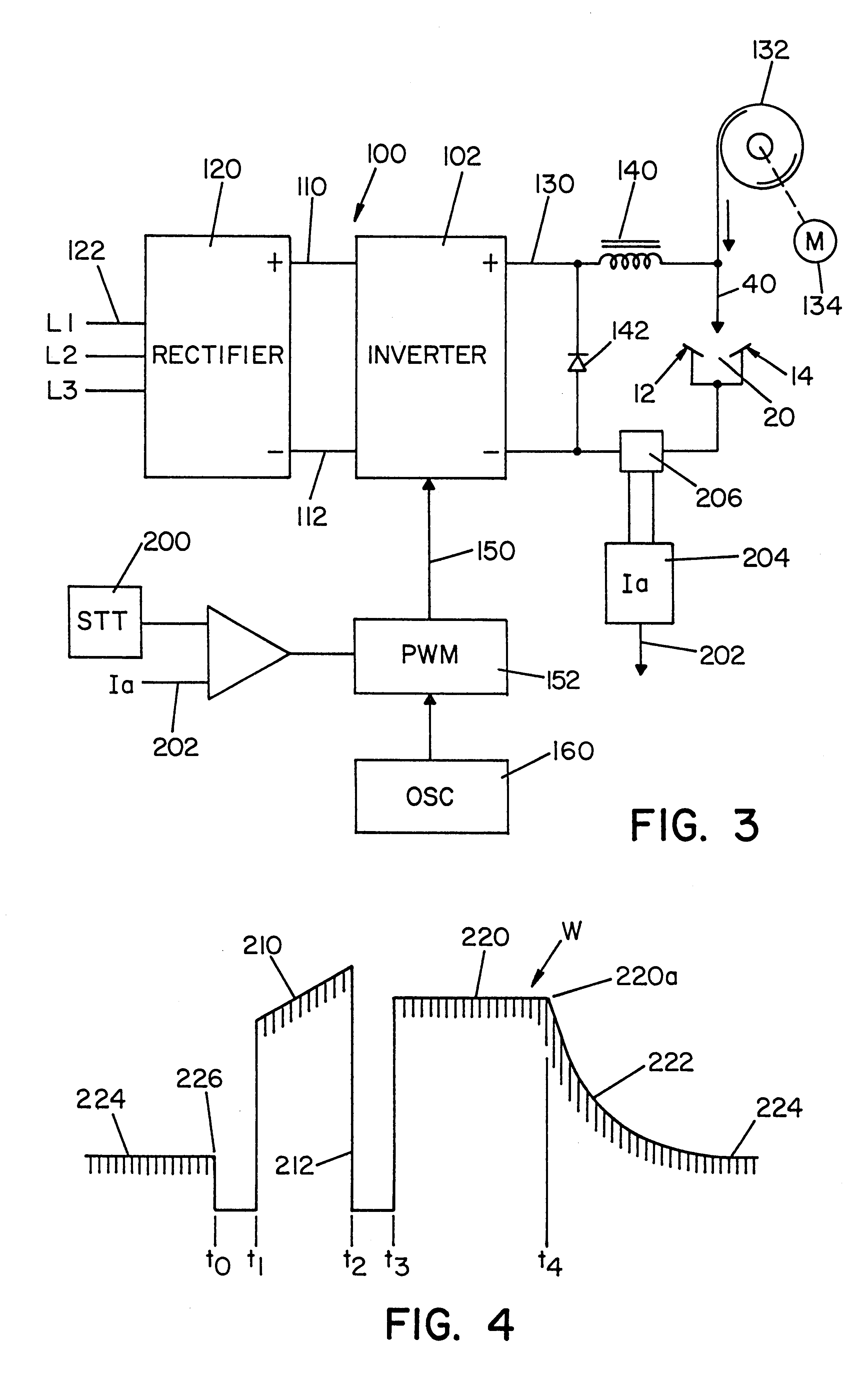

Method of pipe welding

InactiveUS6093906AGood lookingIncrease driving speedArc welding apparatusWelding/cutting media/materialsSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

Method of pipe welding

InactiveUS6204478B1Good lookingIncrease driving speedMeasurement of fluid loss/gain rateArc welding apparatusSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

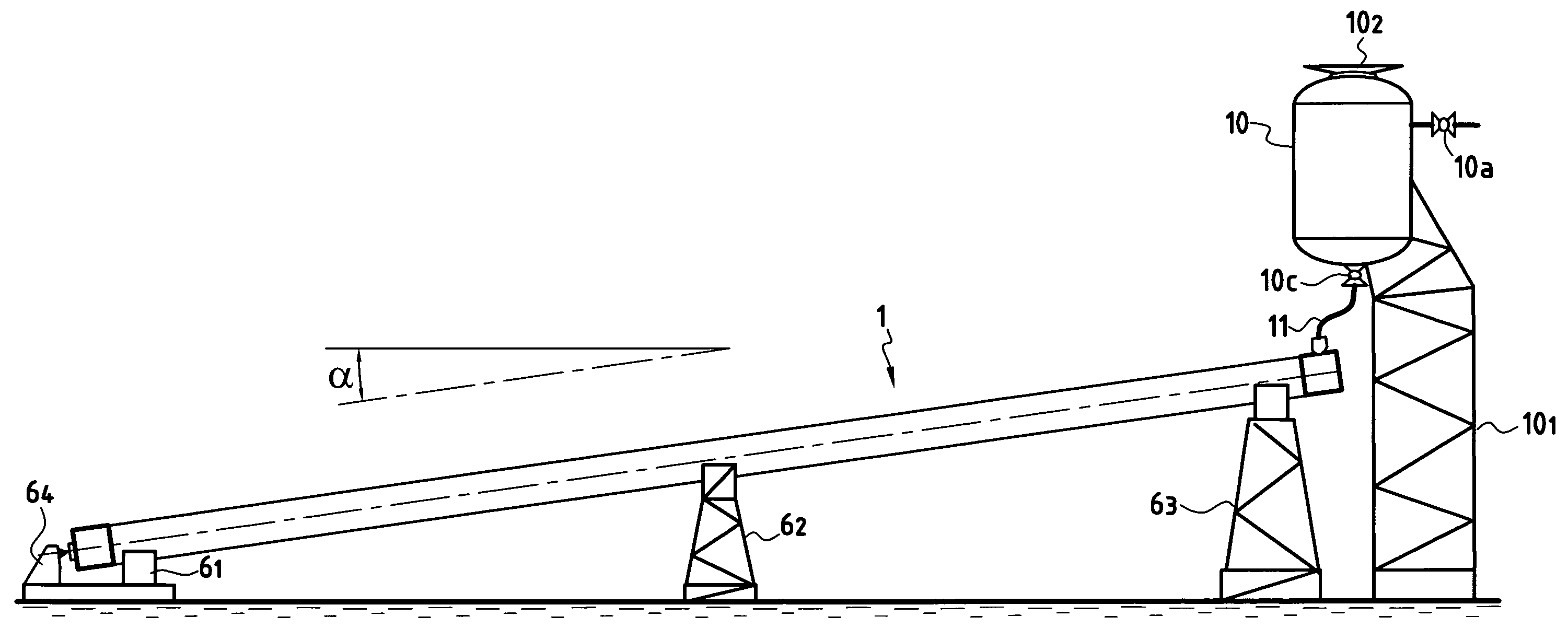

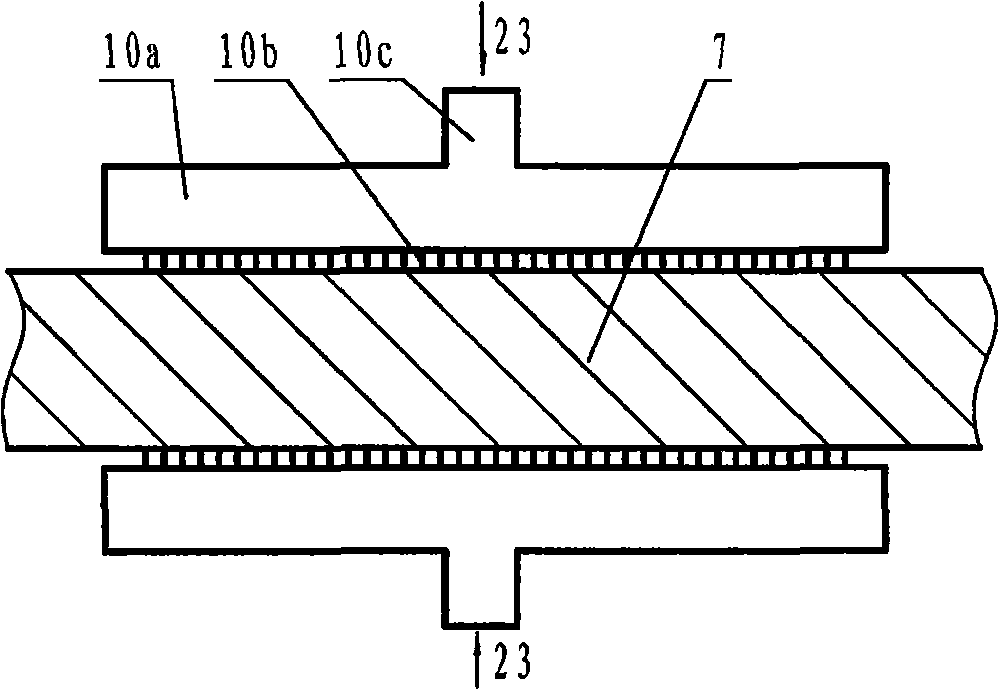

Method of thermally insulating coaxial pipes with a particulate insulating material

InactiveUS7938148B2Raise the level of performancePerformed easily and quicklyLiquid fillingThermal insulationParticulatesEngineering

A method of thermally insulating the annular space in an element of an assembly of two coaxial pipes, the space being filled with a porous thermally insulating material, under low absolute gas pressure in which method the following steps are performed: a) the pipe element is inclined, preferably at an angle α of 5° to 30°, the annular space being closed at each end by respective closure pieces; and b) substantially all of the annular space is filled with the insulating material in the form of particles in bulk; and c) preferably said particles of insulating material are shaken, at least intermittently, as the annular space is filled in order to compact the insulating material, the annular space being maintained under high vacuum during filling.

Owner:SAIPEM SA

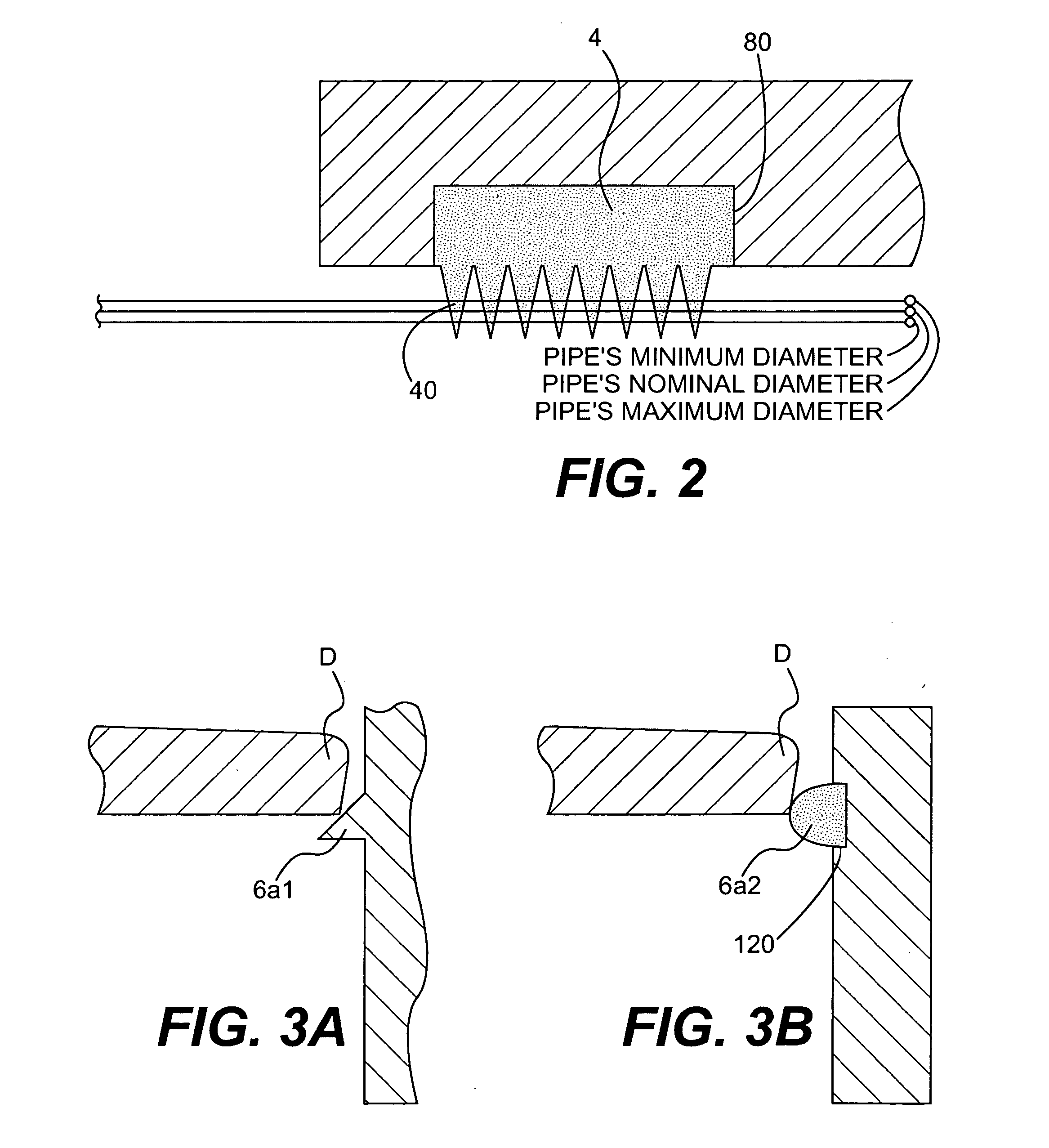

Thread protector for tubular members

A pipe thread protector includes a case, a first seal member, and a second seal member. The case is attachable to an end of a pipe to protect a threaded region of the pipe. The case has a cylindrical or frustoconical portion having threads over at least a portion of its length to engage the threaded region of the pipe, and an annular end portion configured to abut a distal end of the pipe. A first seal member is disposed at the cylindrical portion of the case, and a second seal member is disposed at the annular end portion of the case. At least one of the first and second seal members (i) is detachable from the case, and (ii) comprises a material different than a material of the case.

Owner:TENARIS CONNECTIONS

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

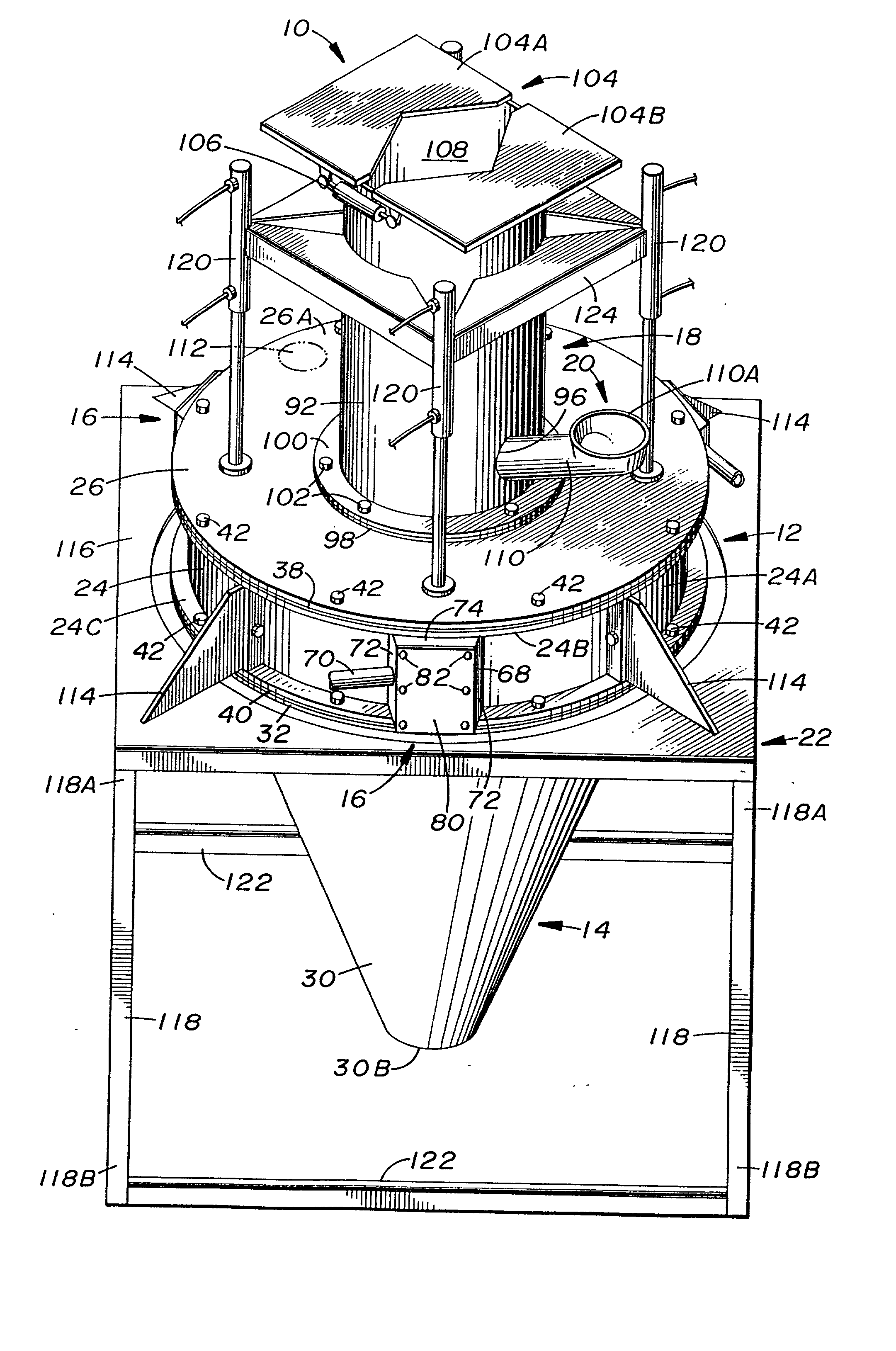

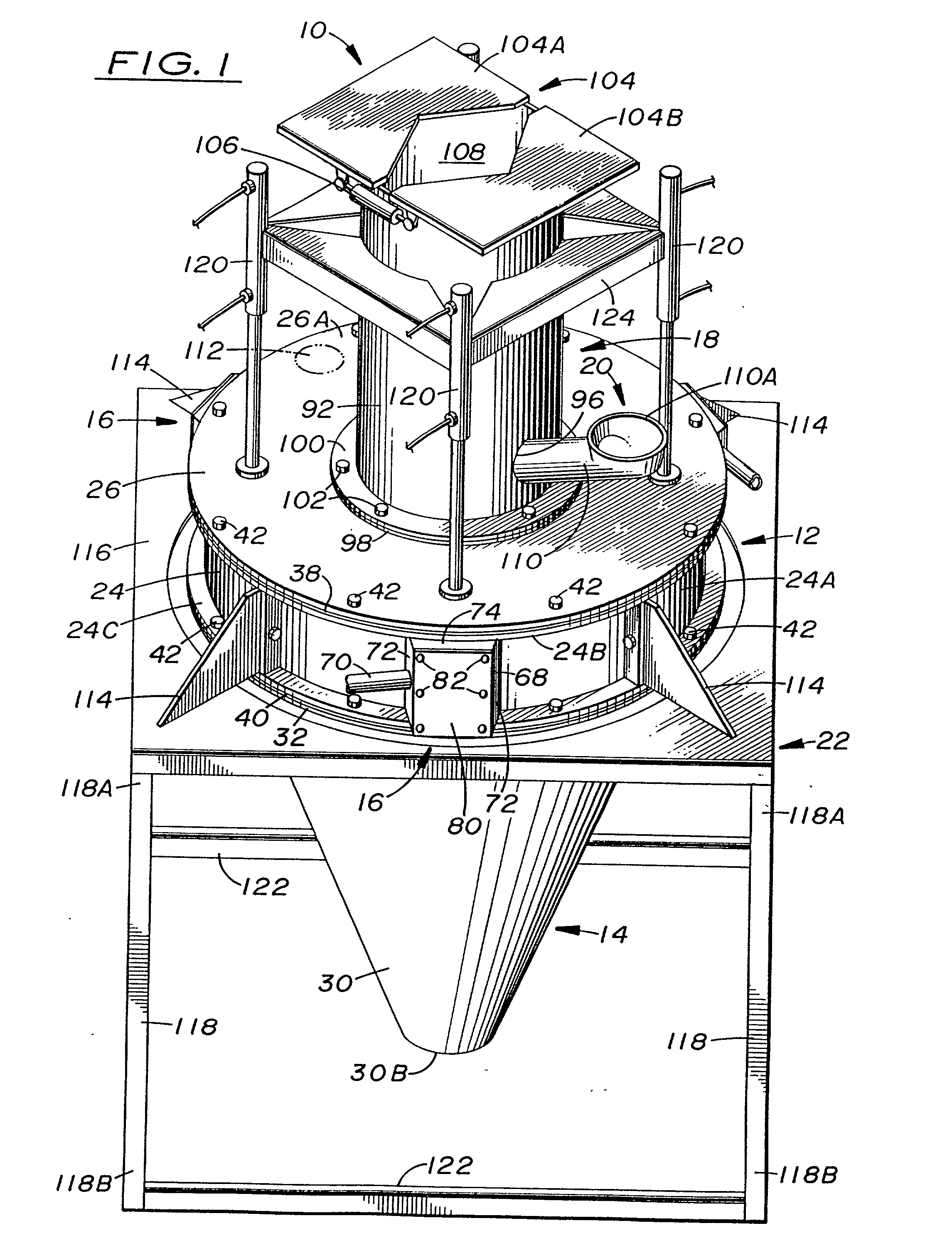

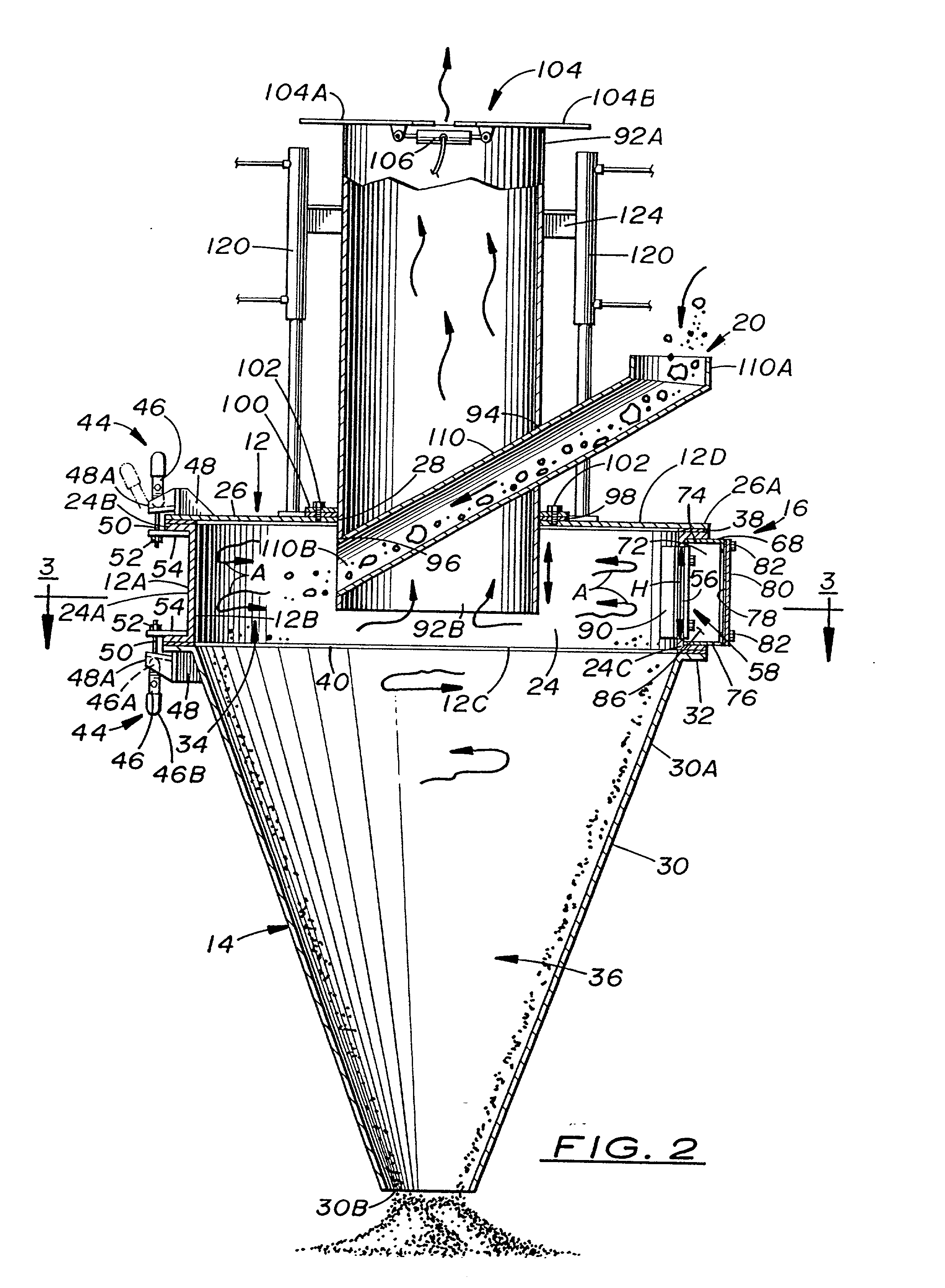

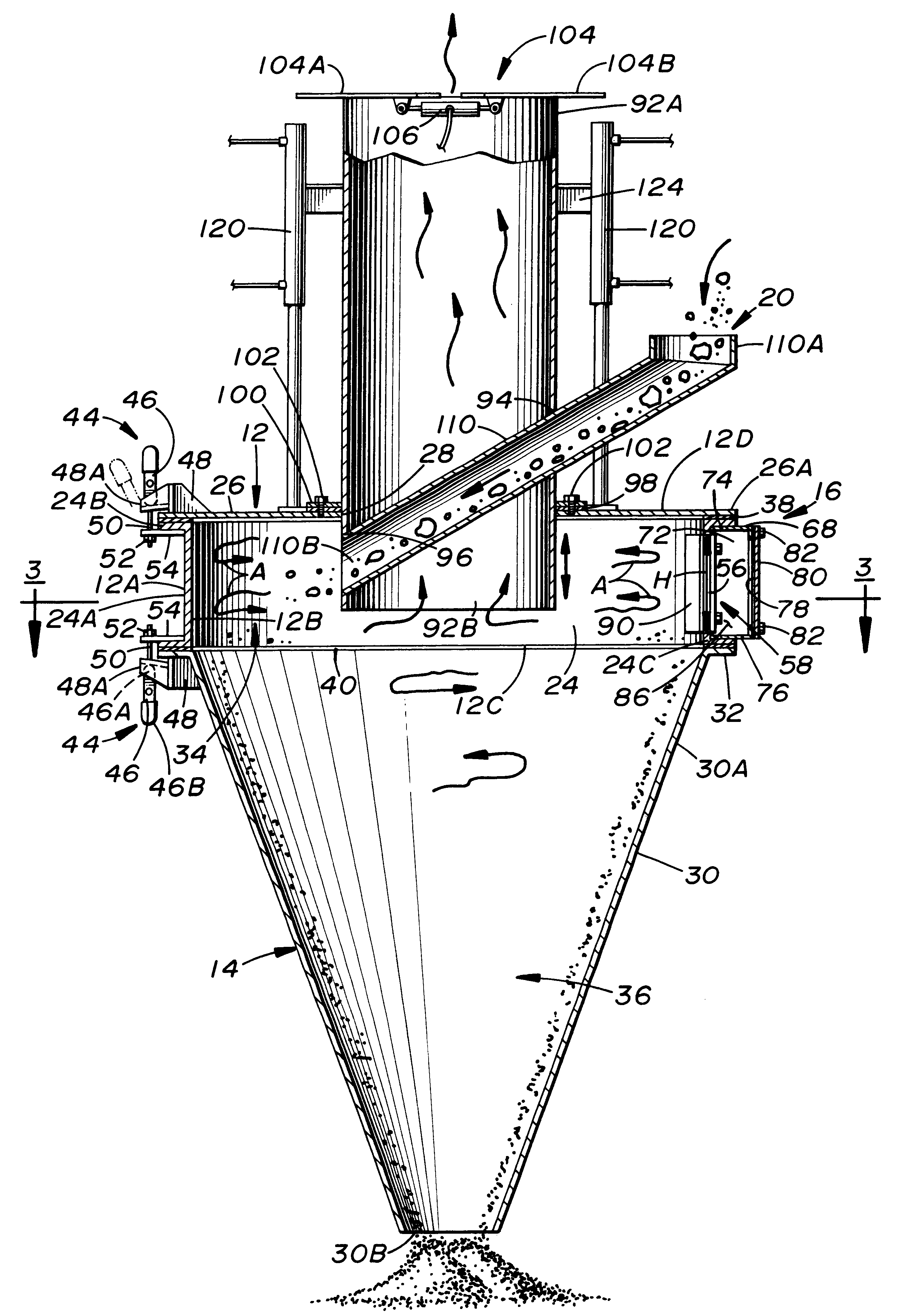

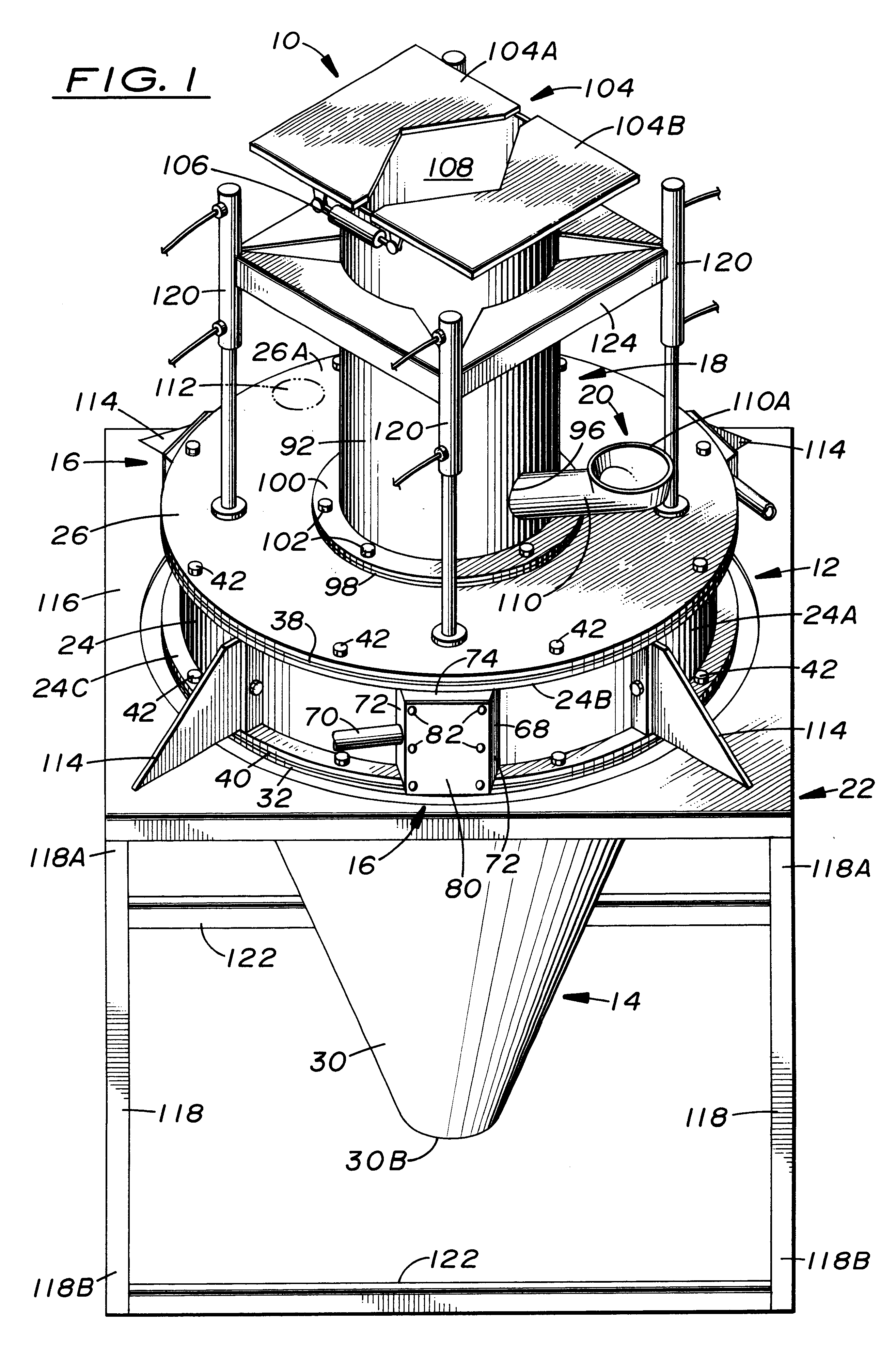

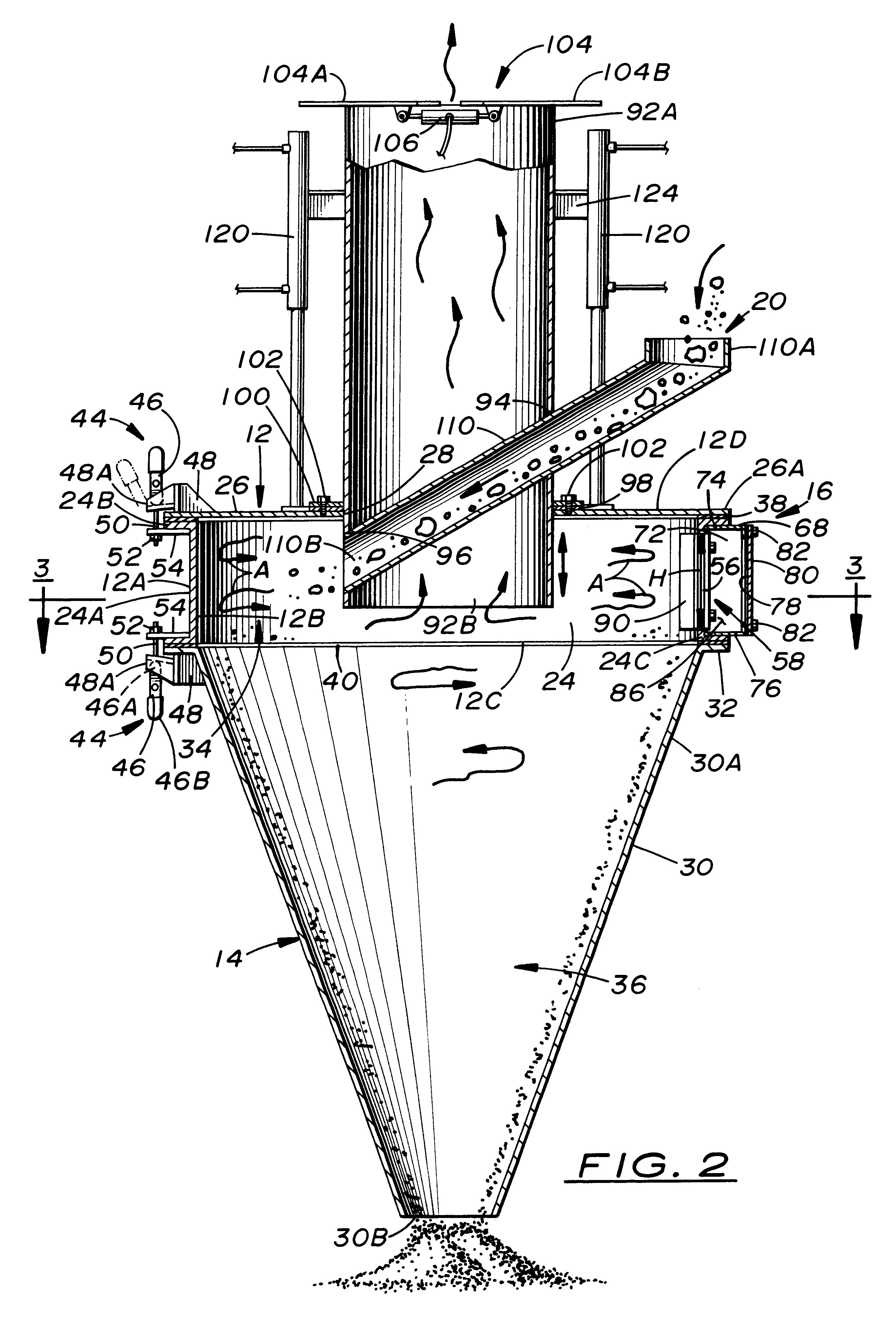

Apparatus and method for circular vortex air flow material grinding

InactiveUS20020027173A1Easy constructionEliminate needGas current separationGrain millingEngineeringAirflow

A material grinding apparatus (10) includes an annular upper enclosure (12) defining an upper chamber (34) into which material to be ground is introduced from above, a conical lower enclosure (14) defining a lower chamber (36) and supported in tandem with the upper enclosure (12), and one or more angled slots (56) defined in the sidewall of the upper enclosure (12) through which compressed air is introduced relatively circumferentially into the upper chamber (34) so as to generate a circular vortex flow of air and material in the upper enclosure (12) for grinding and drying to take place. The air flow is exhausted by a pipe (92) through an upper end of the upper enclosure (12) and the dried ground material is discharged through an open lower end of the lower enclosure (14). The lower enclosure (14) is a downward continuation and extension of the upper enclosure (12) so as not to extend upwardly into nor past the upper chamber (34) thereof.

Owner:VORTEX DEHYDRATION TECH

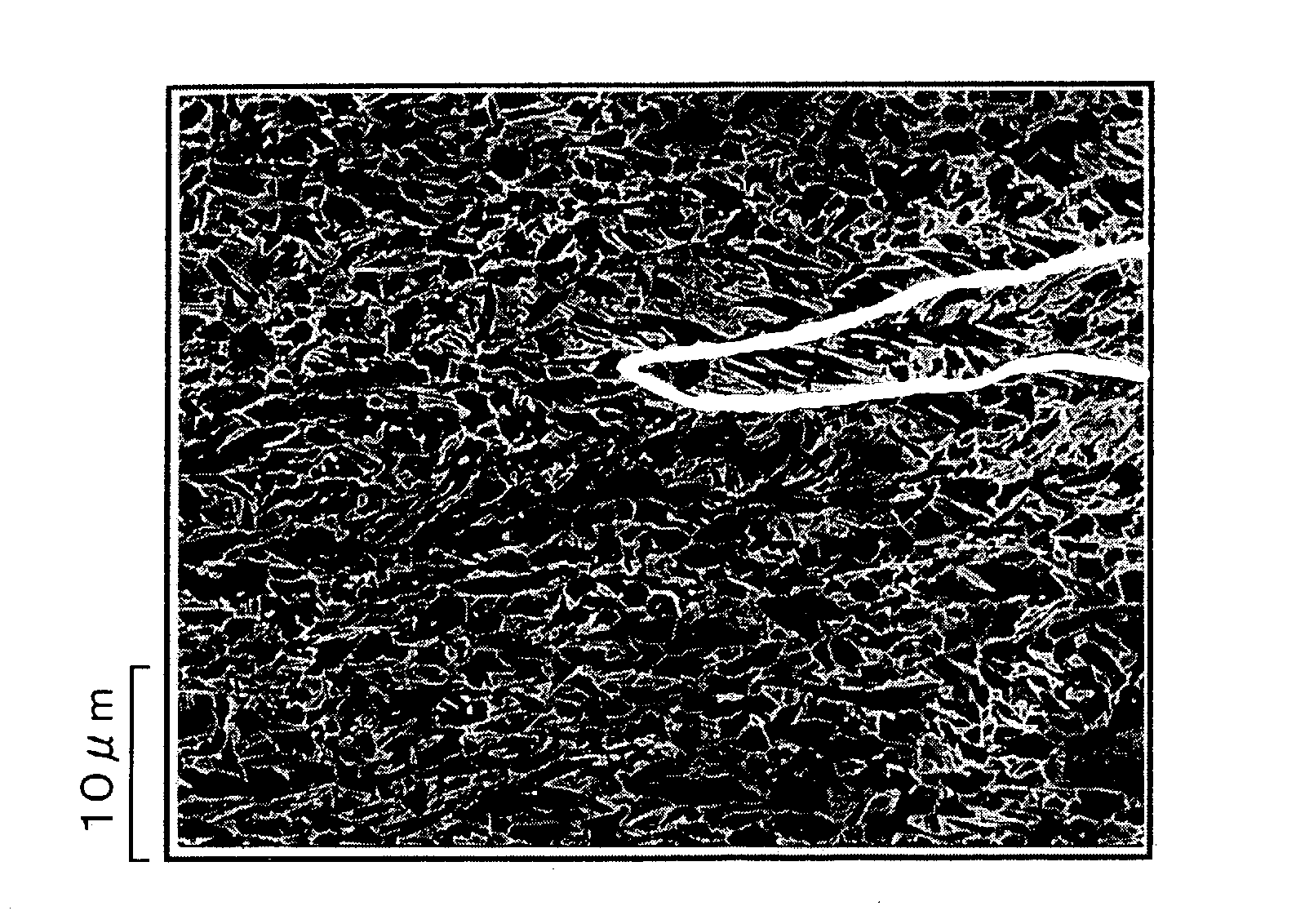

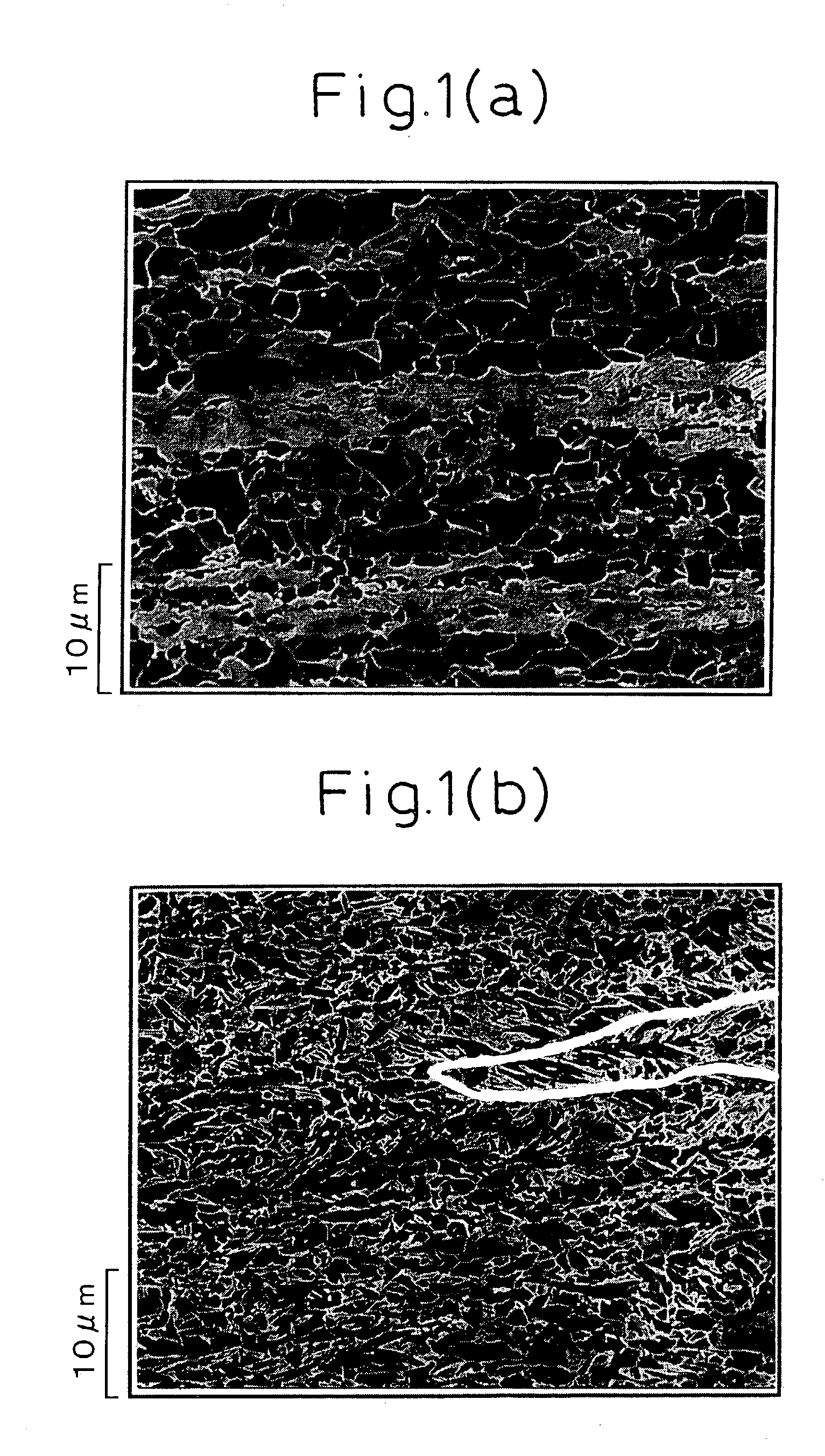

High-strength steel sheet and high-strength steel pipe excellent in deformability and method for producing the same

The present invention provides a line pipe of, e.g., the API standard X60 to X100 class. The line pipe has an excellent deformability, as well as excellent low temperature toughness and high productivity, a steel plate used as the material of the steel pipe. Methods for producing the steel pipe and the steel plate are also provided. In particular, a high-strength steel plate excellent in the deformability has a ferrite phase is dispersed finely, and accounts for 5% to 40% in area percentage in a low temperature transformation structure mainly composed of a bainite phase. For example, most grain sizes of the ferrite phase are smaller than the average grain size of the bainite phase. A high-strength steel pipe excellent in deformability is also provided, in which a large diameter steel pipe is produced through forming the steel plate into a pipe shape. The steel pipe has the above-referenced structure, and satisfies the conditions that YS / TS is 0.95 or less and YSxuEL is 5,000 or more. Methods for producing such steel plate and steel pipe are also provided.

Owner:NIPPON STEEL CORP

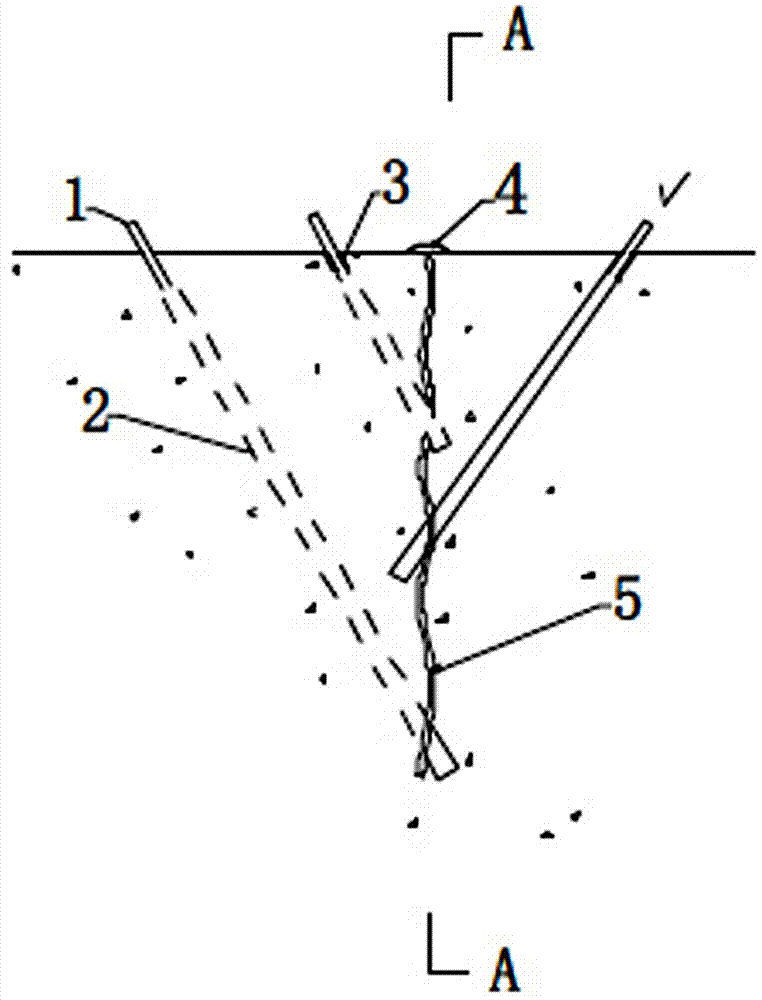

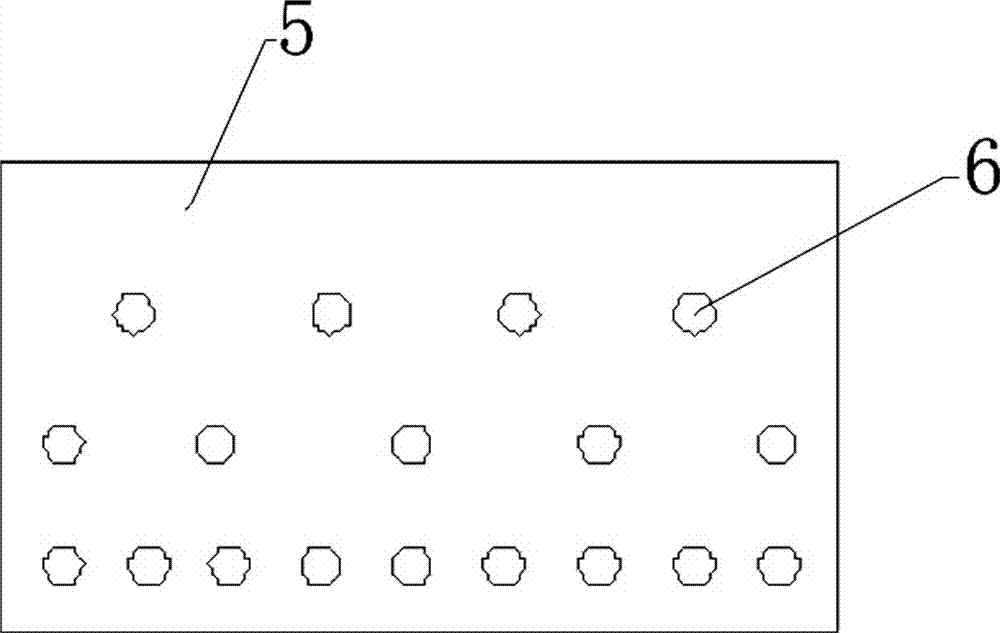

Grouting method of penetrability concrete cracks

InactiveCN103174112AChange the idea of grouting technologyIncreased durabilityFoundation engineeringMarine site engineeringChiselCement grout

The invention discloses a grouting method of penetrability concrete cracks. The grouting method of the penetrability concrete cracks comprises the steps of drilling holes, burying pipes, sealing cracks and grouting. The drilled holes comprise inclined holes and roulettes. The inclined holes are preferably distributed in the same side or two sides of the cracks. The roulettes are distributed along the cracks to the bottom portions of the cracks. The pipes are buried by gelatinization materials. The cracks are sealed through the chisel groove method and the surface crack sealing method. With regard to stable and unexpanded penetrability concrete cracks (dead cracks) or compressive zone penetrability cracks, the grouting method of the penetrability concrete cracks adopts cement grout to conduct a grouting process, not only is the grouting method environment-friendly, economical and convenient to construct, but also quality effects meet engineering requirements. Besides, durability of materials is good, and strength of the materials is high.

Owner:HUBEI GEZHOUBA TESTING

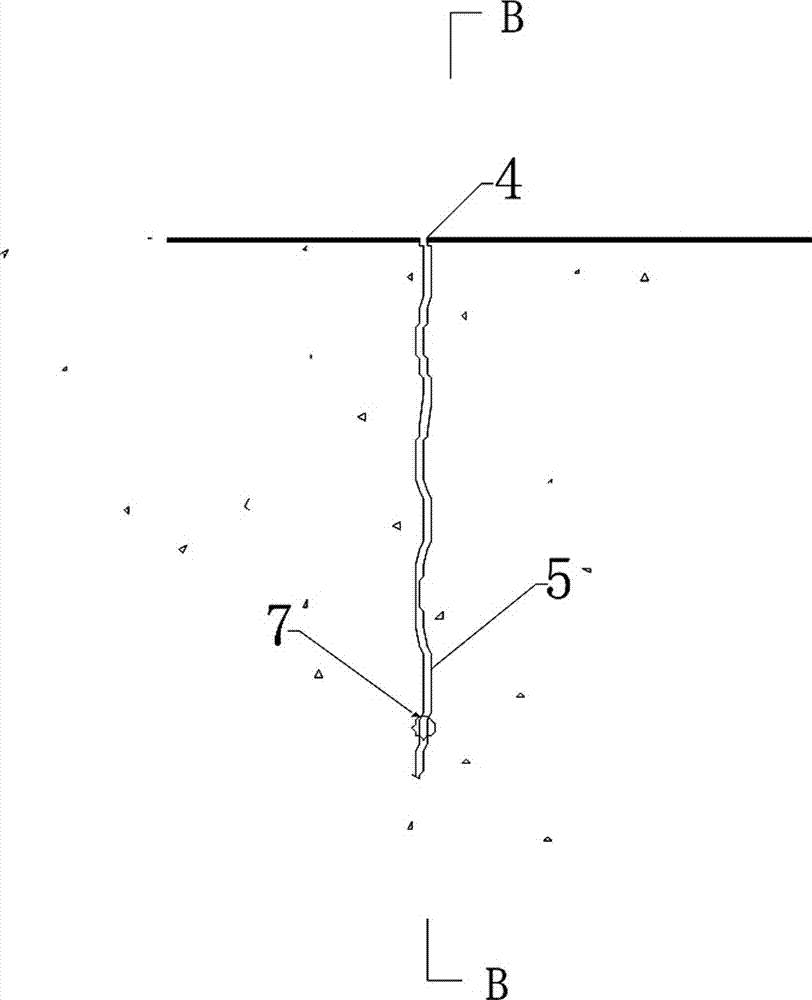

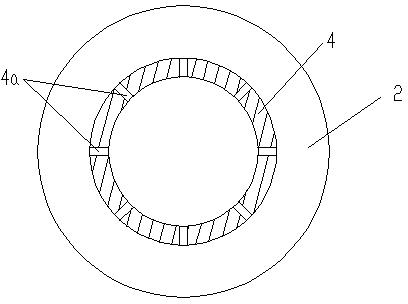

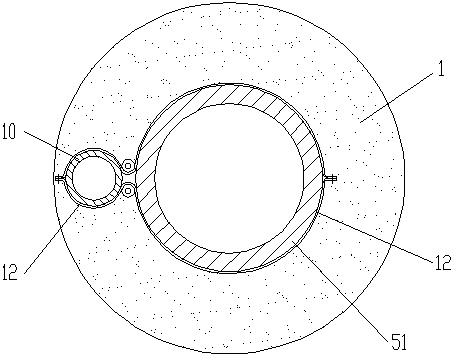

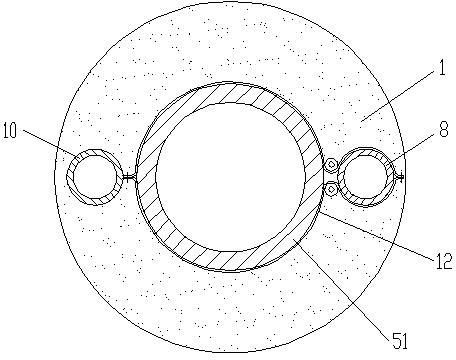

Drilling and sealing method and sealing device for ultra-high pressure fracturing holes in underground coal mines

The invention discloses a drilling-sealing method and a sealing device of a coal mine underground ultrahigh pressure fracturing hole. The drilling-sealing method comprises the following steps: drilling a plugging hole on coal rock body; going on drilling a fracturing hole forward in the plugging hole; transmitting the sealing device into the plugging hole, enabling a water outlet hole of a fracturing pipe to stretch into the fracturing hole and enabling a taper sleeve sleeved on the fracturing pipe and made of soft material to plug on a hole opening of the fracturing hole; sealing by using polyurethane and solidifying for 30 minutes for 1 m length section at the hole opening of the plugging hole; and grouting cement slurry greater than 425 into the plugging hole with pressure by a grouting pipe, and solidifying for 48 hours after finishing grouting. The device comprises a grouting pipe and a slurry returning pipe and a fracturing pipe. The grouting pipe and the slurry returning pipe are arranged in the plugging hole. The grouting pipe, the slurry returning pipe and the fracturing pipe are connected integrally. A soft taper sleeve is arranged on the fracturing pipe. The soft taper sleeve is plugged at the hole opening of the fracturing hole. The invention has the advantages that the sealing method has high sealing success rate, good effect and wide application range; and the sealing device has simple structure and convenient operation.

Owner:重庆市能源投资集团科技有限责任公司 +1

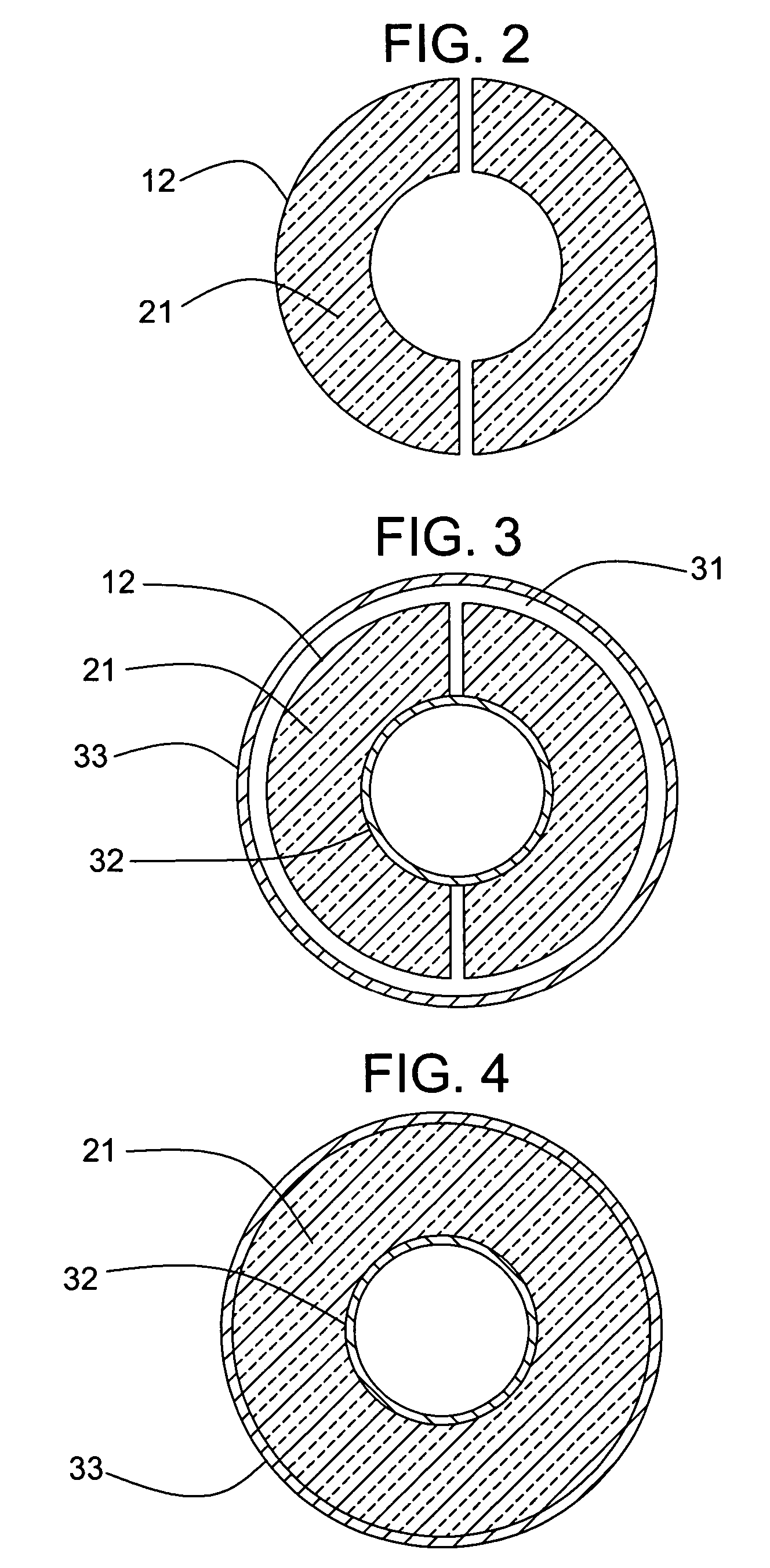

Universal support and vibration isolator

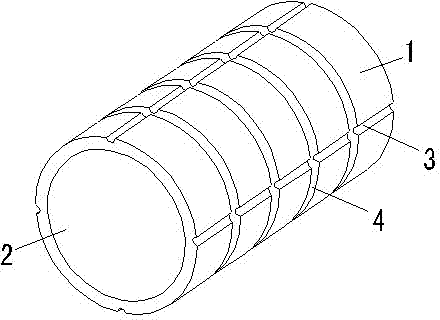

InactiveUS7500642B2Decrease stockGood adhesionNon-rotating vibration suppressionPipe elementsEngineeringVibration isolation

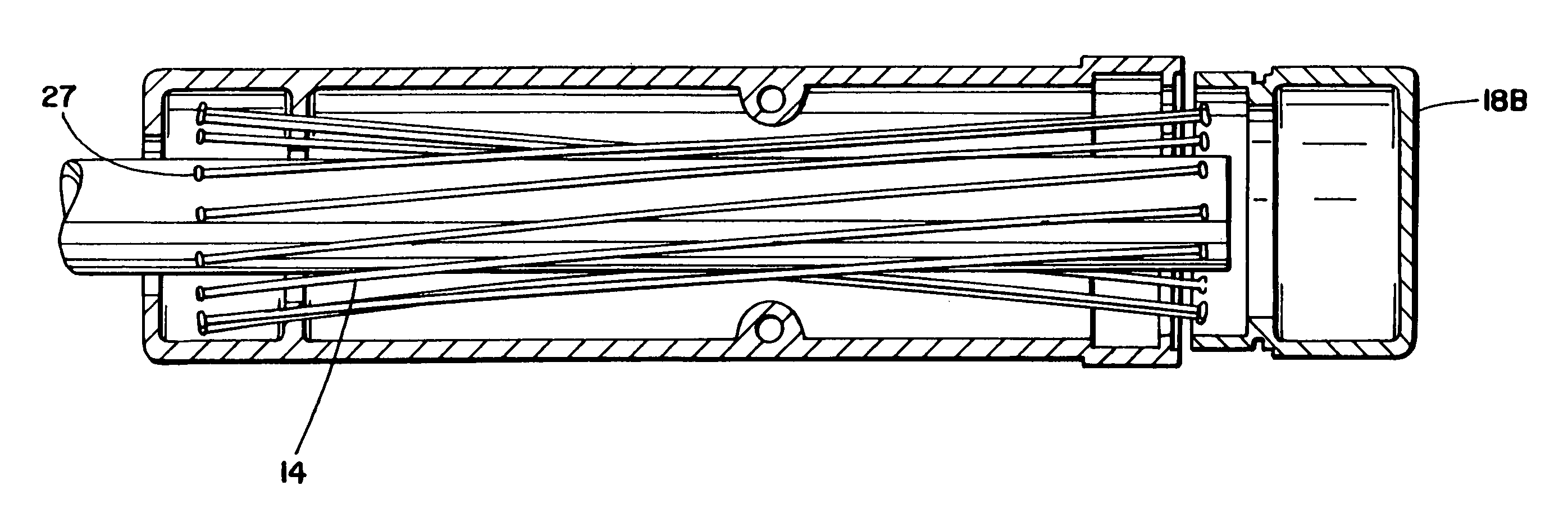

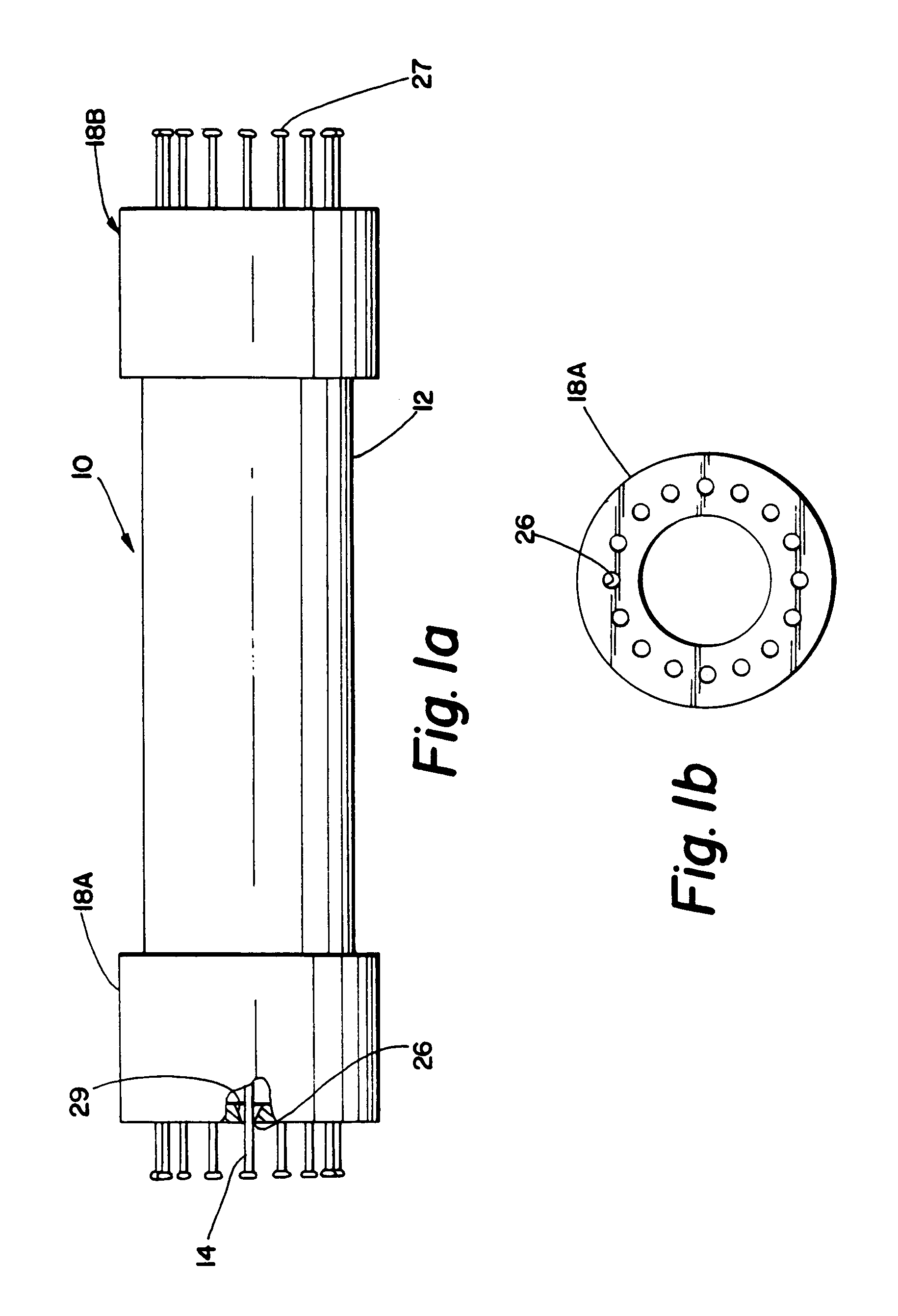

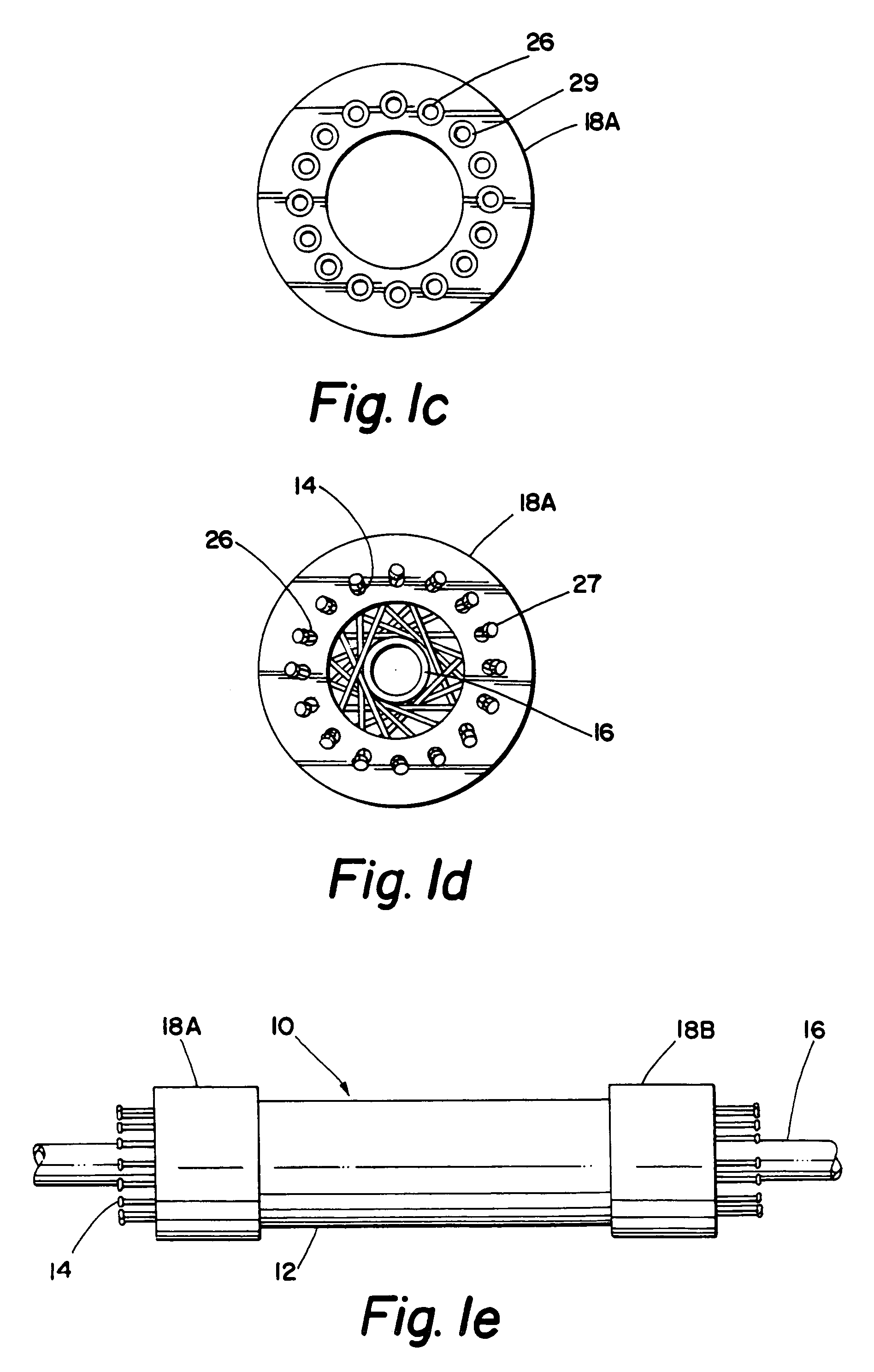

A pipe support is provided that includes a frame capable of being placed around an existing pipe and a plurality of support members within the frame. The frame is a hollow cylinder that includes two connectable halves divided along the diameter of the hollow cylinder. The pipe support includes two bearing rings connected to the frame for supporting each of the plurality of members at a minimum of two contact points. Each of the two bearing rings include bearing points for each support member arranged in a cylindrical pattern concentric with the hollow cylinder frame. The pipe support includes means for rotating each of the support members at a first contact point with respect to a second contact point so that the support members engage a pipe placed within the pipe support. The support members are rods that provide vibration isolation to a pipe placed within the pipe support.

Owner:SEICON

Overflow downdrawn glass forming method and apparatus

InactiveUS6895782B2Reduce unevennessGlass furnace apparatusGlass drawing apparatusFlat glassThermal creep

The present invention alters the flow path at the inlet of the sheet glass forming apparatus to improve quality. The bottom of the downcomer pipe is preferably shaped to alter the character of the vortex flow in the quiescent flow zone between the pipes. In another embodiment, a bead guide provides hydraulic stresses that are in opposition to the surface tension stress and thus reduces the influence of surface tension on the formation of thick beads on the edges of the sheet. The present invention also measures the temperature of the glass by immersing thermocouples in the glass, at locations where any defects caused by the immersion are in the glass that forms the unusable edges of the sheet. In another embodiment, the support structure for the trough is altered to substantially reduce the aging of the trough due to thermal creep.

Owner:CORNING INC

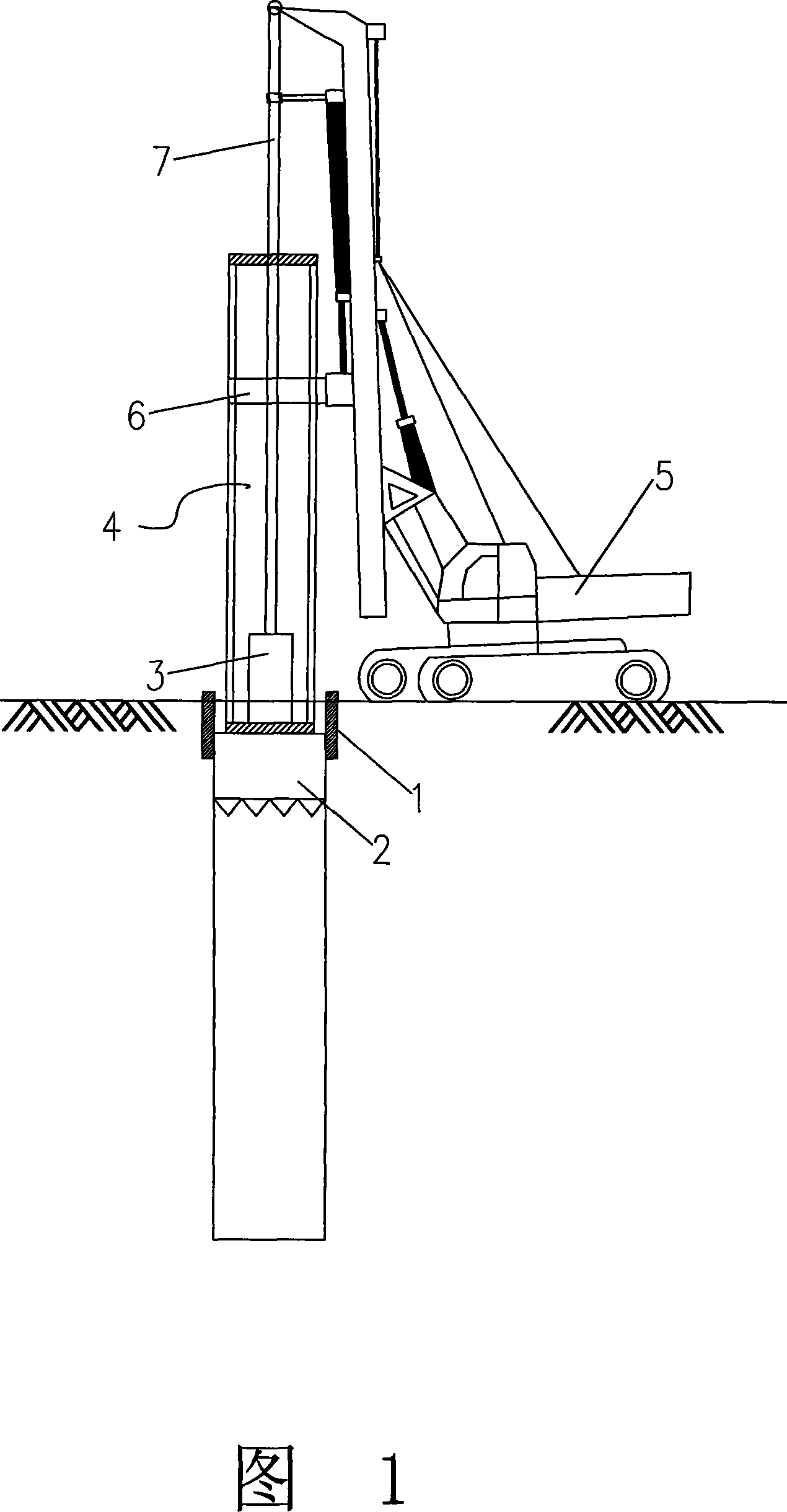

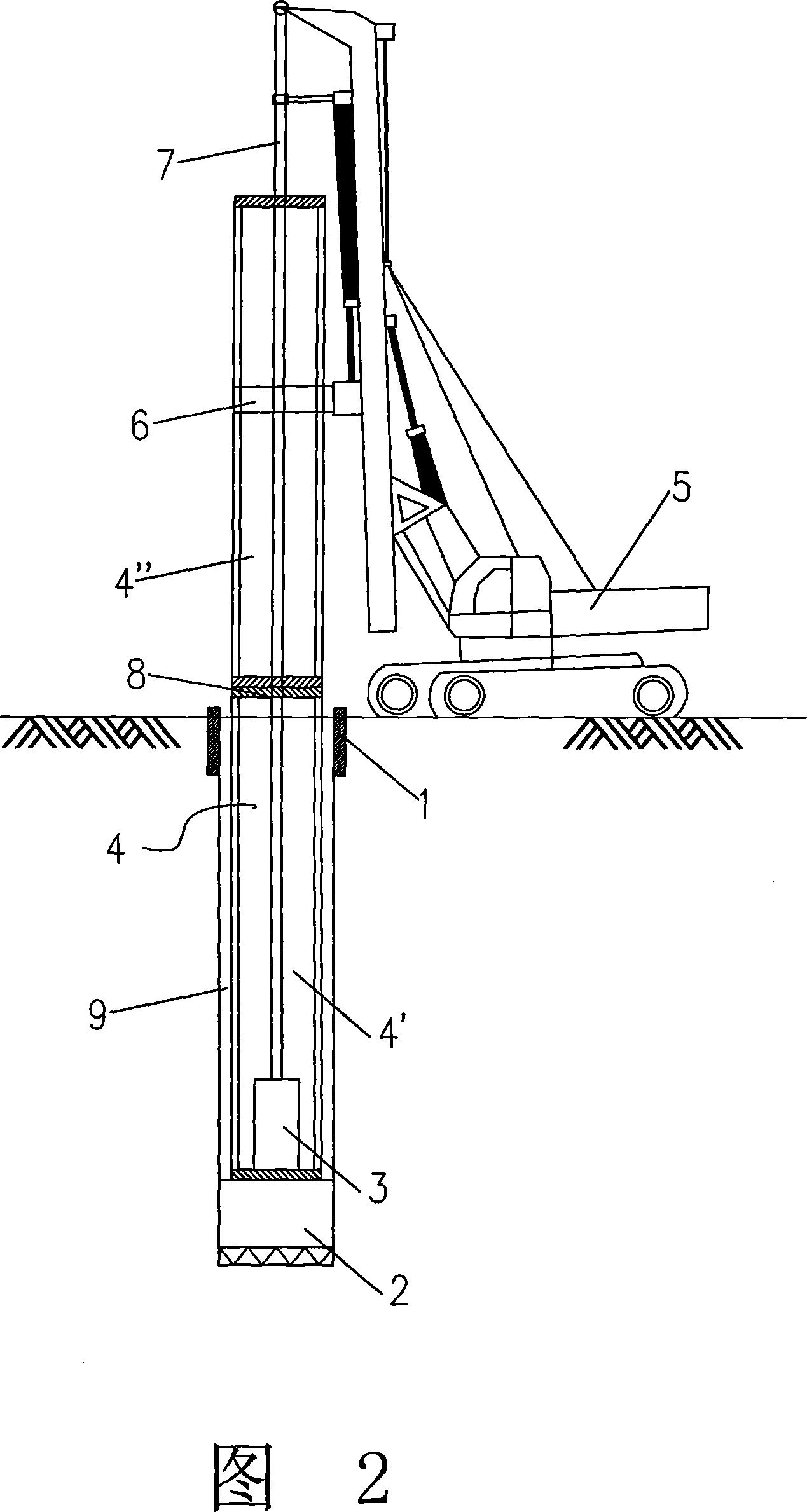

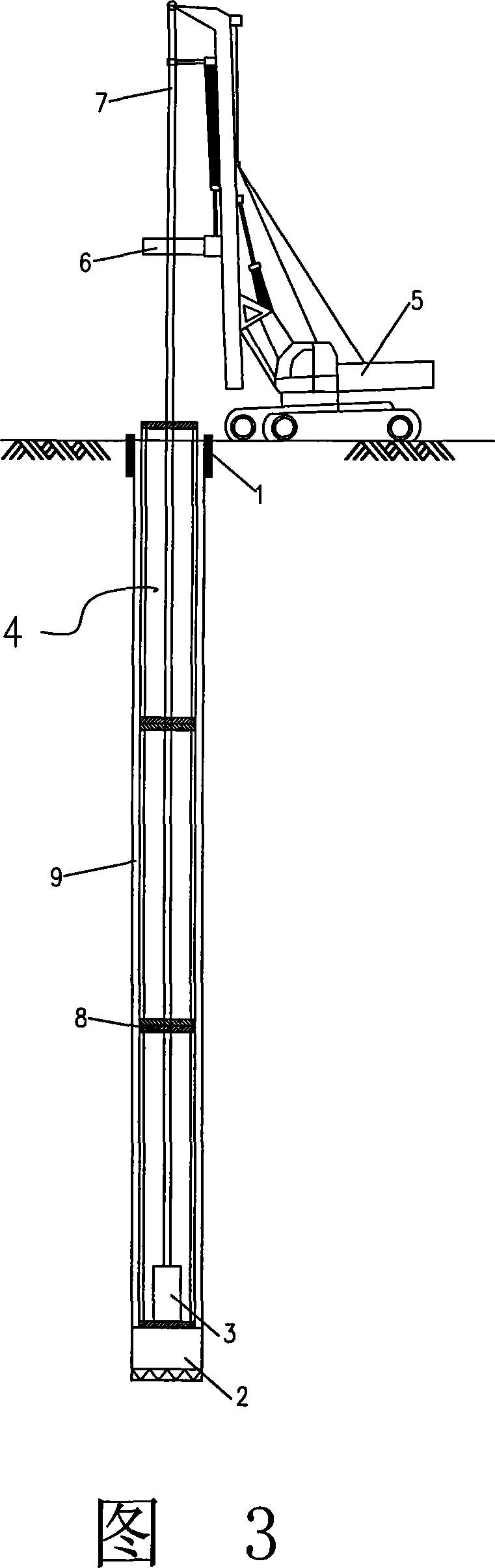

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

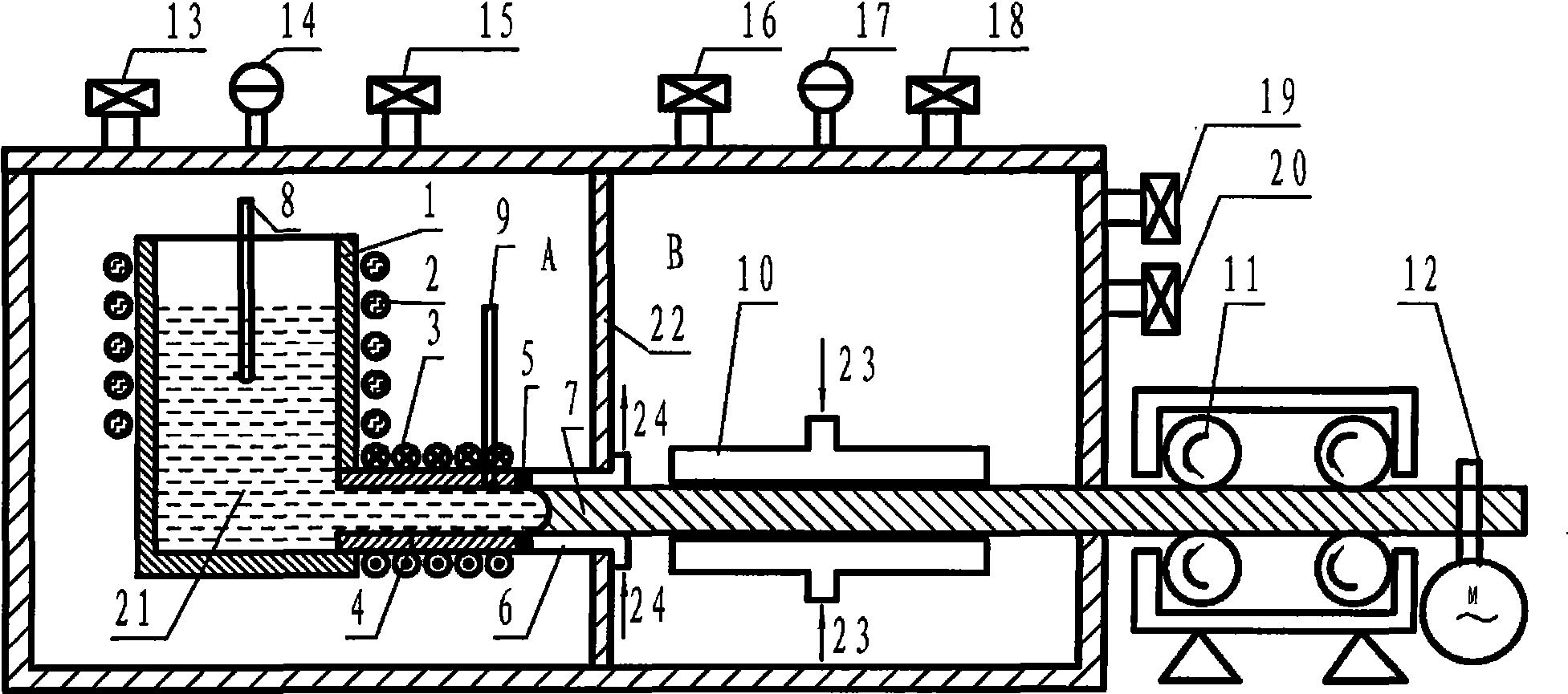

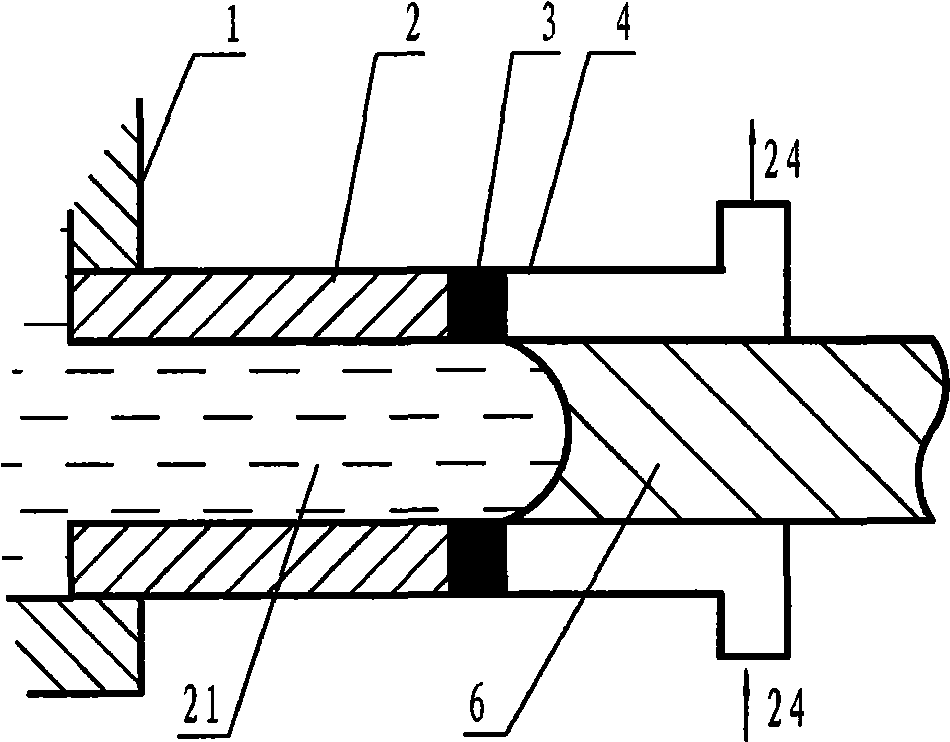

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

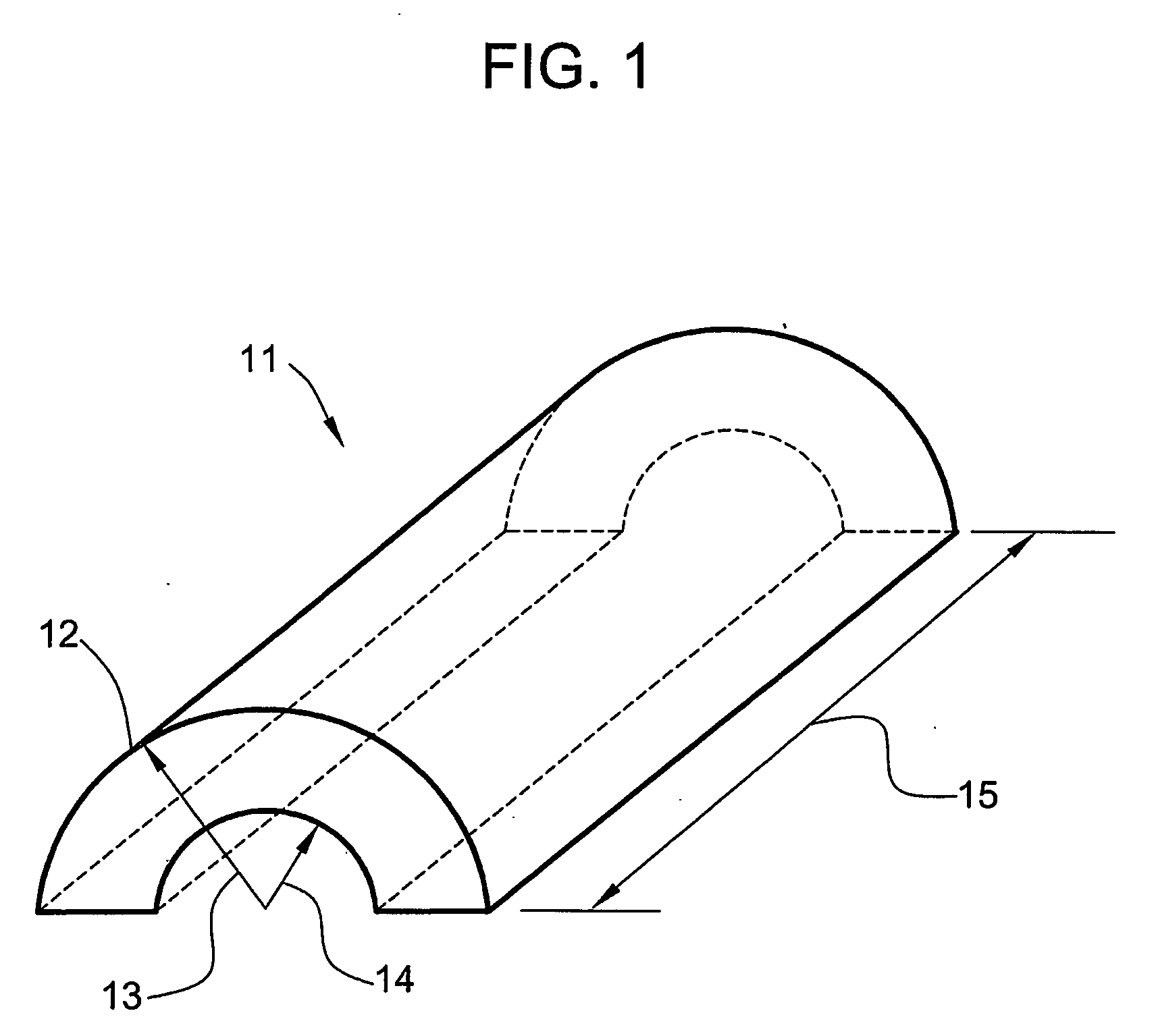

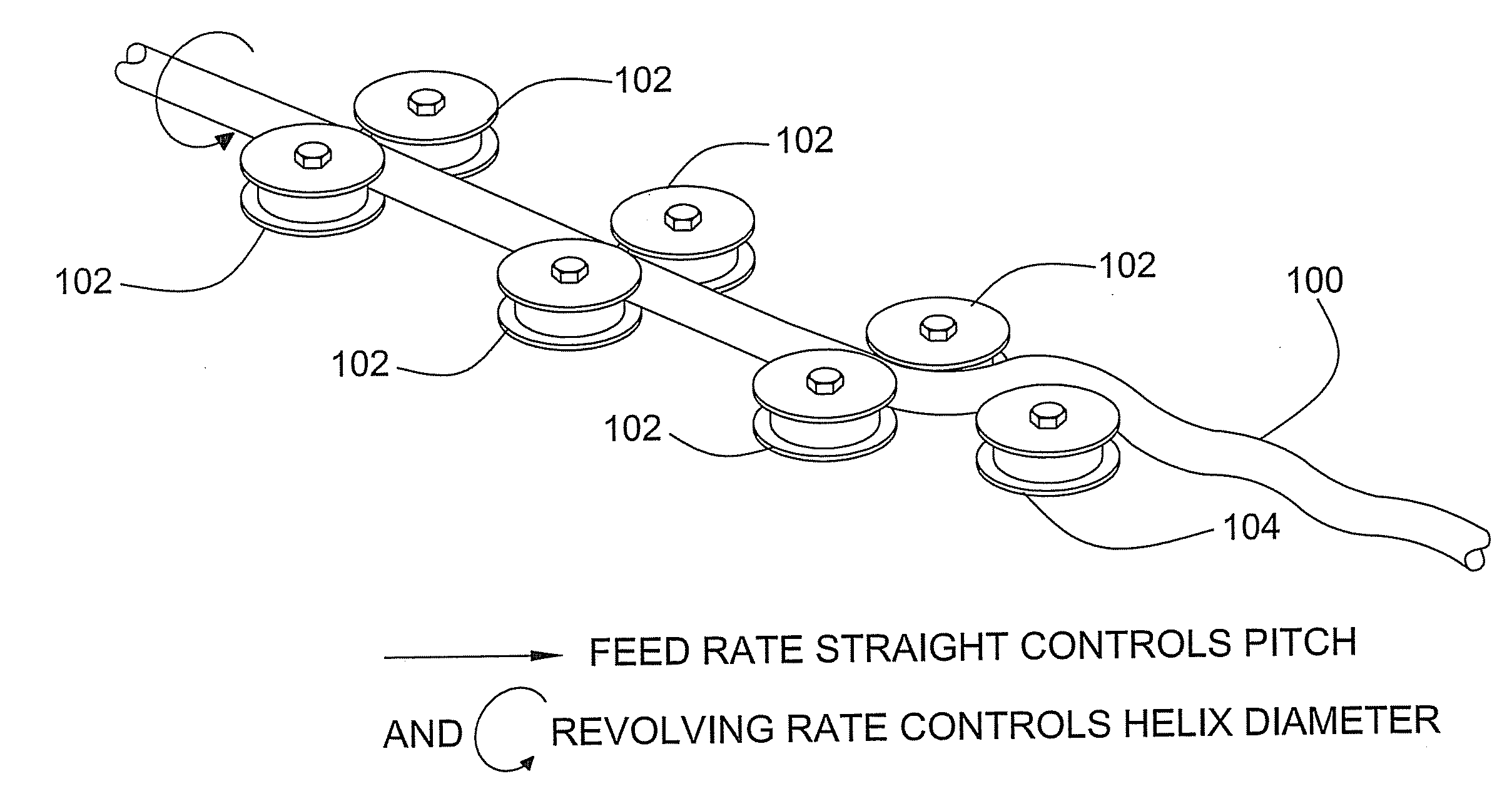

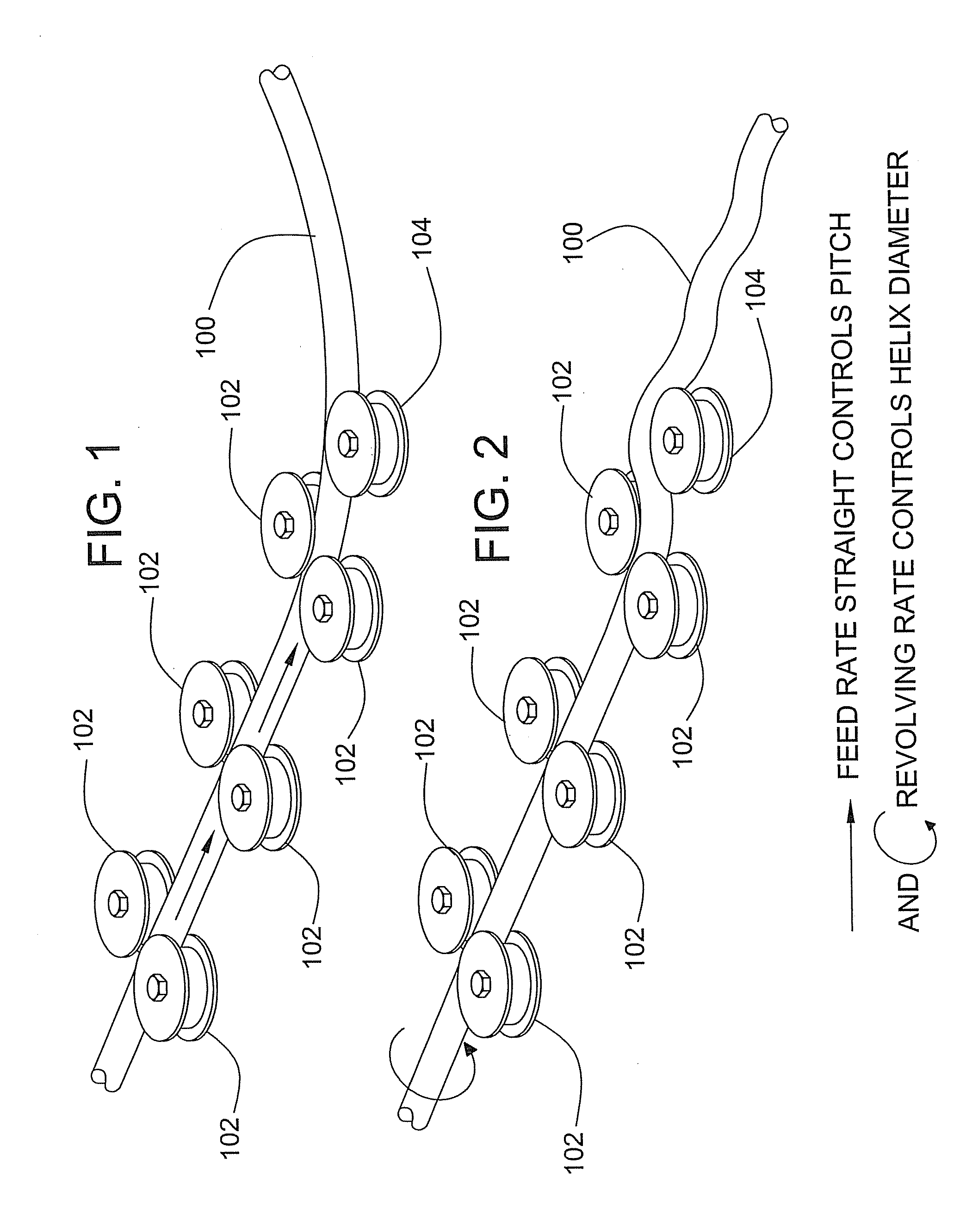

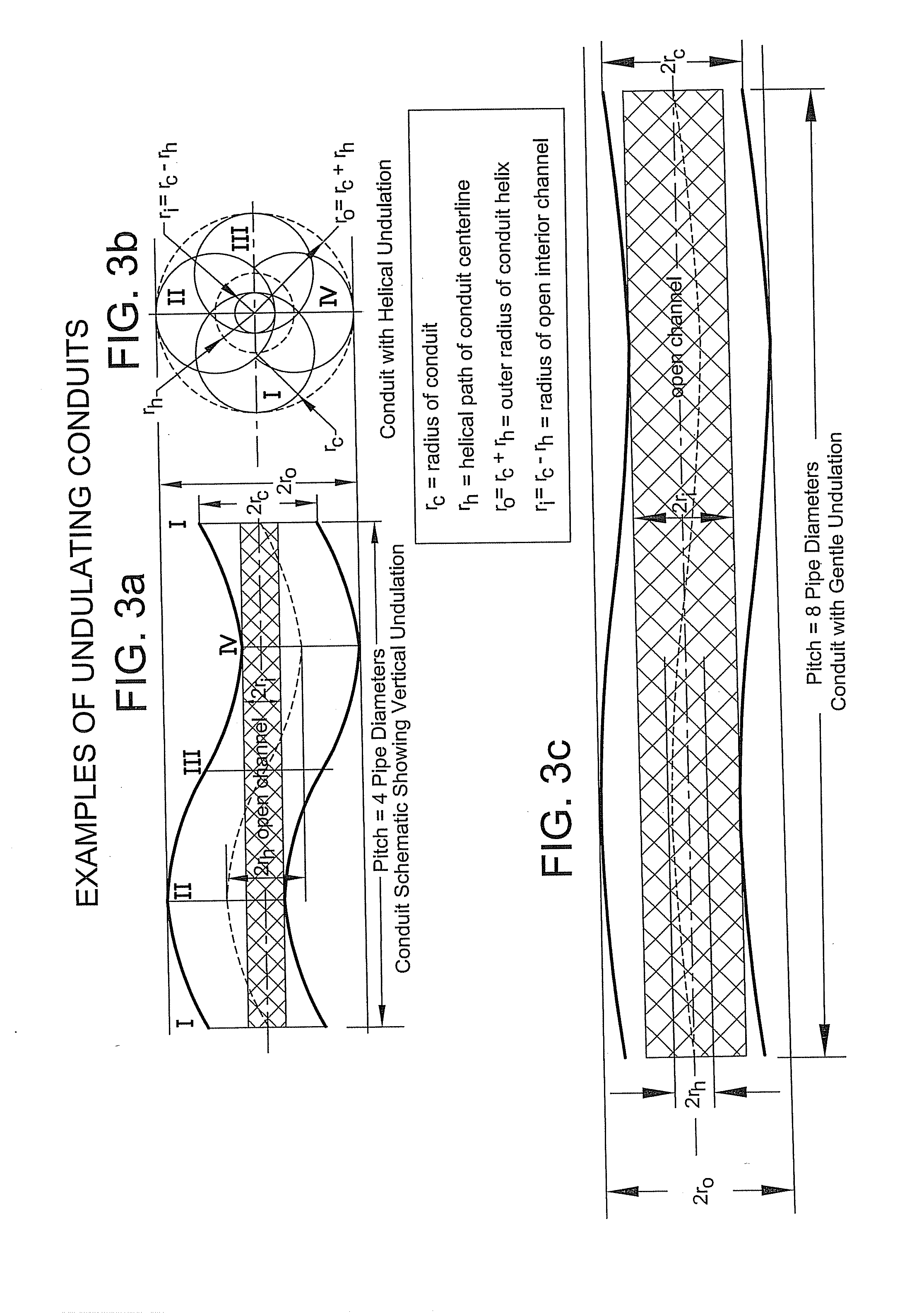

Method and apparatus for forming undulating conduit

Method and apparatus for forming conduit or pipe of various sizes into undulating, helical pipe by feeding a length of conduit at a controlled rate through a bending mechanism while also continuously rotating the pipe at a controlled rate so that bending occurs in multiple axis directions and the diameter of the helical path of the conduit centerline of the coil is less than the conduit diameter, the pitch is greater than the pipe diameter, and a straight open channel is retained through the pipe coil.

Owner:UNDULTEC

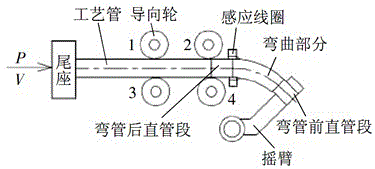

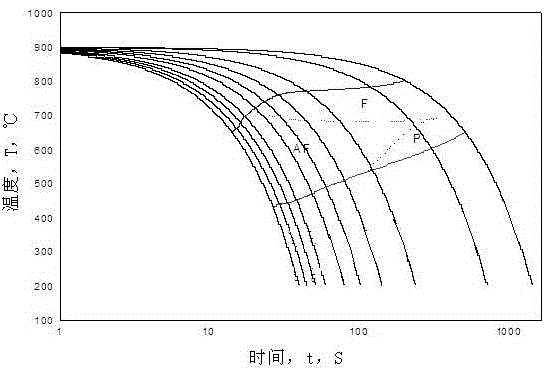

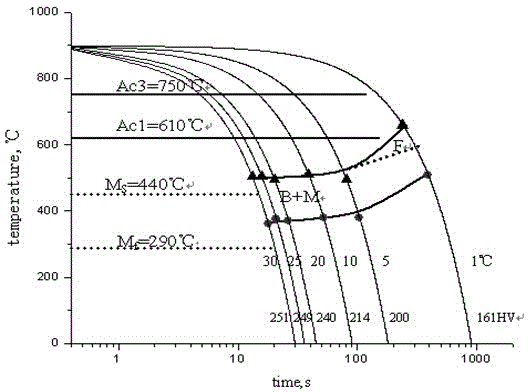

Wide and thick steel plate for hot-bent elbow pipes at X65-X80 levels and manufacturing method of wide and thick steel plate

InactiveCN104404378AGuaranteed StrengthGuaranteed tissue homogeneityLine tubingStructural engineering

The invention relates to a wide and thick steel plate for hot-bent elbow pipes at X65-X80 levels and a manufacturing method of the wide and thick steel plate. Especially, proper ingredients, structures and technologies for the steel plate for the elbow pipes at X65, X70 and X80 levels are designed respectively according to different pipe bending technologies of pipe bending factories, and the pipeline steel performance requirement for reaching the related strength levels after hot bending of the pipes is met. The steel plate is 20-40 mm thick and 2,500-4,000 mm wide, the hot-rolled steel plate with excellent toughness, thermal formability and thermal stability is obtained, a solution is provided for steel plates for high-pressure elbow pipes in long delivery pipeline projects, and the usage security of the high-level pipeline steel plate is improved.

Owner:SHANDONG IRON & STEEL CO LTD

Apparatus and method for circular vortex air flow material grinding

Owner:POLIFKA RUTH

Method for detecting solid strength of grouting material for grouting connection of rebar sleeve and method for detecting grouting material construction quality

ActiveCN106769441AAccurate and fast detectionTo fill the technical gap in the means of solid strength inspectionMaterial strength using tensile/compressive forcesRebarGrout

The invention relates to a method for detecting solid strength of a grouting material for grouting connection of a rebar sleeve in a prefabricated concrete structure and a method for detecting grouting material construction quality. The method for detecting the solid strength of the grouting material comprises the following steps: during production of a precast concrete unit, casing pipes extending out of concrete surface by predetermined lengths are mounted at a grouting hole and a grout outlet hole of the grouting sleeve respectively and are not bonded with concrete; the casing pipes fully filled with a hardened grouting material are taken out of the concrete unit after grouting connection construction is finished and a specified age is reached; the hardened grouting material is taken out of the casing pipes and processed into a sample; compressive strength of the sample is tested, and the solid strength of the grouting material is obtained. Besides, the grouting material filling condition at the top in a chamber of the grouting sleeve can be observed by an interior peeping device, and whether missing grouting exists and the grouting fullness are checked; the method overcome the defect that the solid strength and fullness of the grouting material in the grouting sleeve cannot be detected directly in the prior art, so that the quality of actual grouting construction can be detected.

Owner:CHINA ACAD OF BUILDING RES

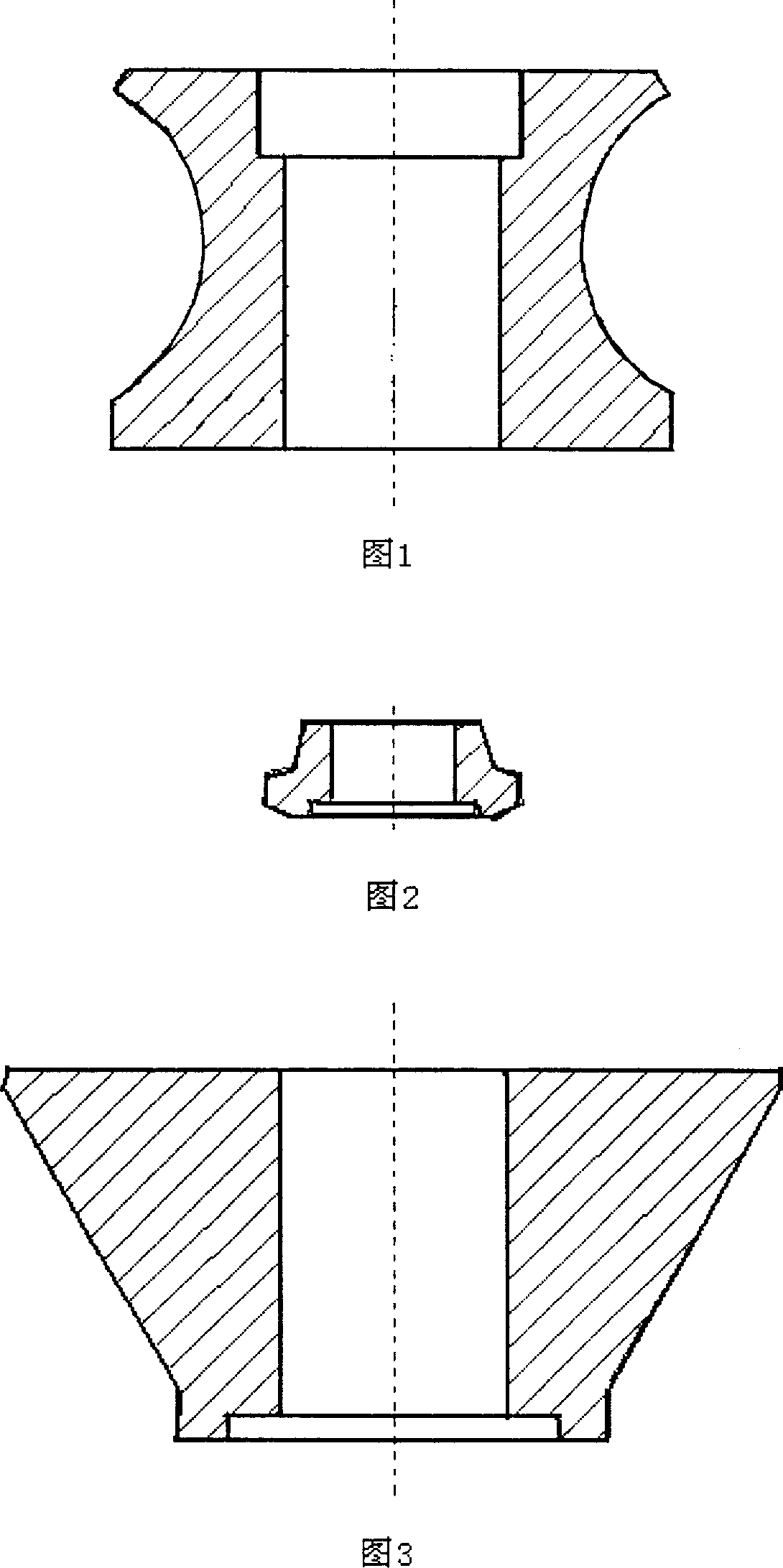

Casting high ferrochrome or casting high chromium steel roll for welding steel pipe

ActiveCN101015836AReduce the amount of processingHigh material utilizationRollsMetal rolling arrangementsSteel tubeFerrochrome

The invention provides a cast high chrome iron or cast high chrome steel roller used to roll weld steel tube and on straight-slim welding steel tube roller, or the like, wherein the cast high chrome iron roller comprises C in 1.8-2.8%, Si <=1.0%, Mn <=1.0%, P<=0.05%, S<=0.05%, Cr in 12-22%, Ni in 0.5-3.0%, Mo in 0. 0%, Ti in 0-0.3%, V in 0-1.0%, Cu in 0-1.0%, RE in 0.01-0.5%, and the left is Fe. The inventive roller has uniform organism, high abrasion resistance and flexibility, while its service life is 2-5 times of general product and material utilization can reach 70% or 80%, with low cost.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

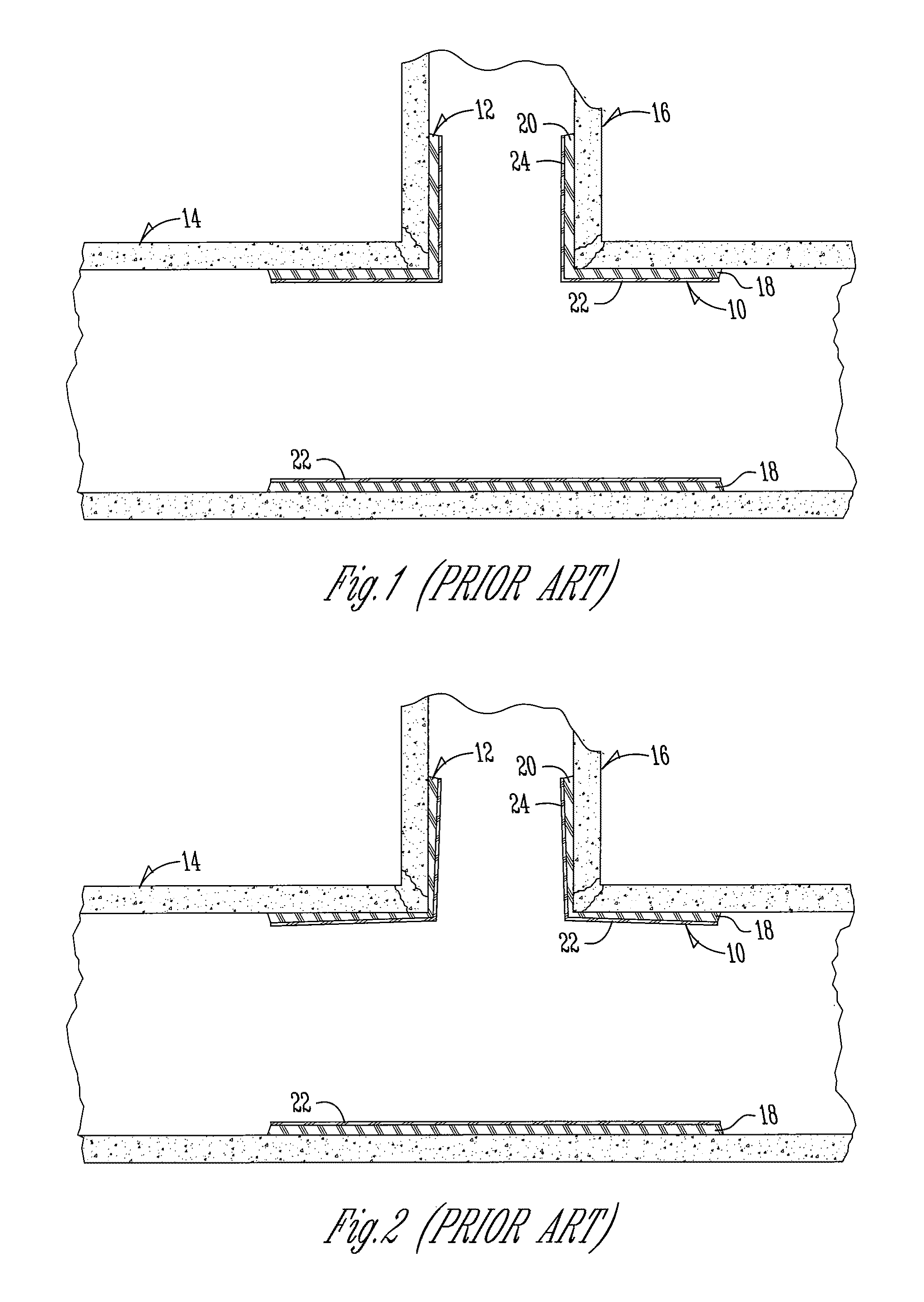

Device and method for repairing pipe

ActiveUS7987873B2Improves over and solvesSacrificing wall thicknessUnderground chambersPipe elementsAbsorbent materialMechanical engineering

The present invention relates to a new liner for repairing a damaged portion of a pipe. A lining tube formed from a non-resin absorbent material has an exterior surface adapted to receive a curable resin and contact an interior wall of the pipe. The present invention also includes a main / lateral liner assembly for repairing the junction between main and lateral pipes using a non-resin absorbent liner for at least a portion of the lining.

Owner:LMK TECH LLC

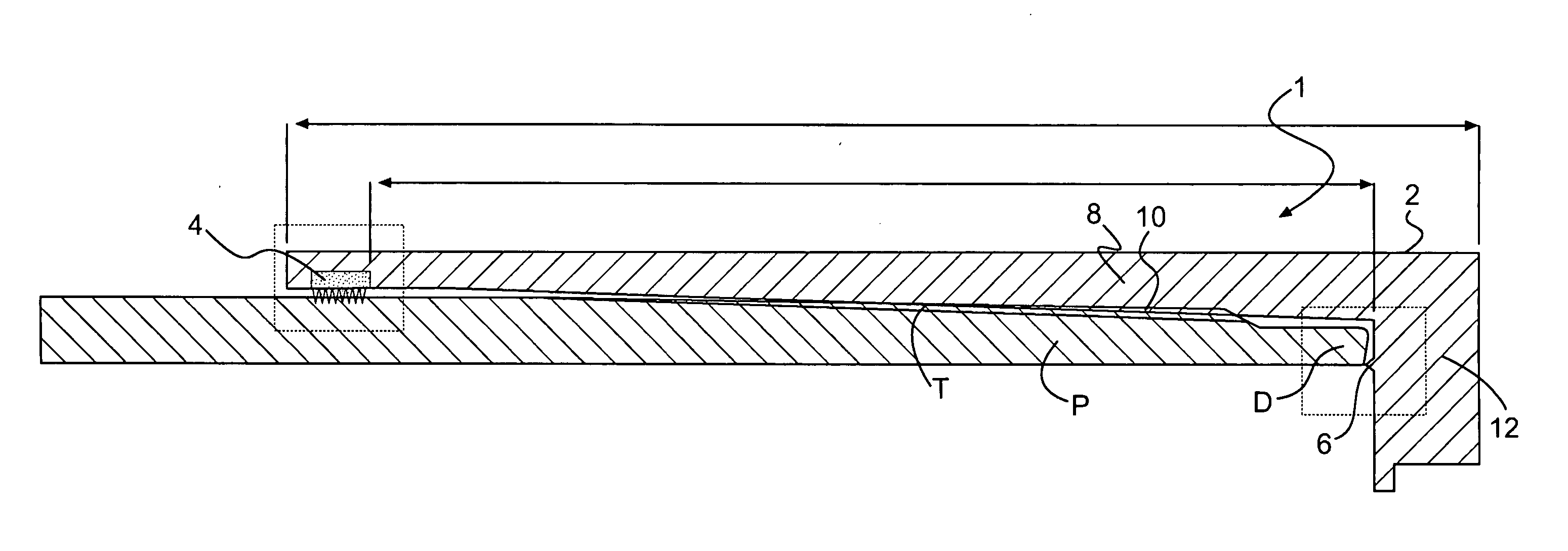

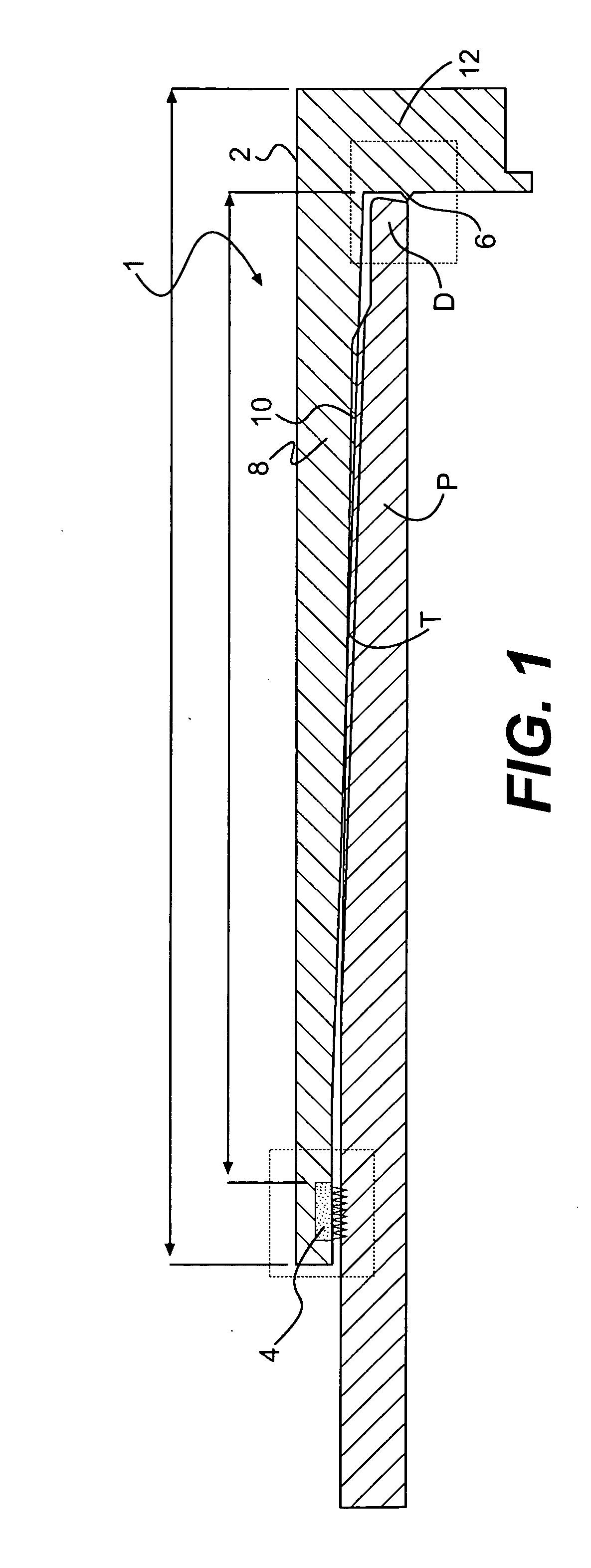

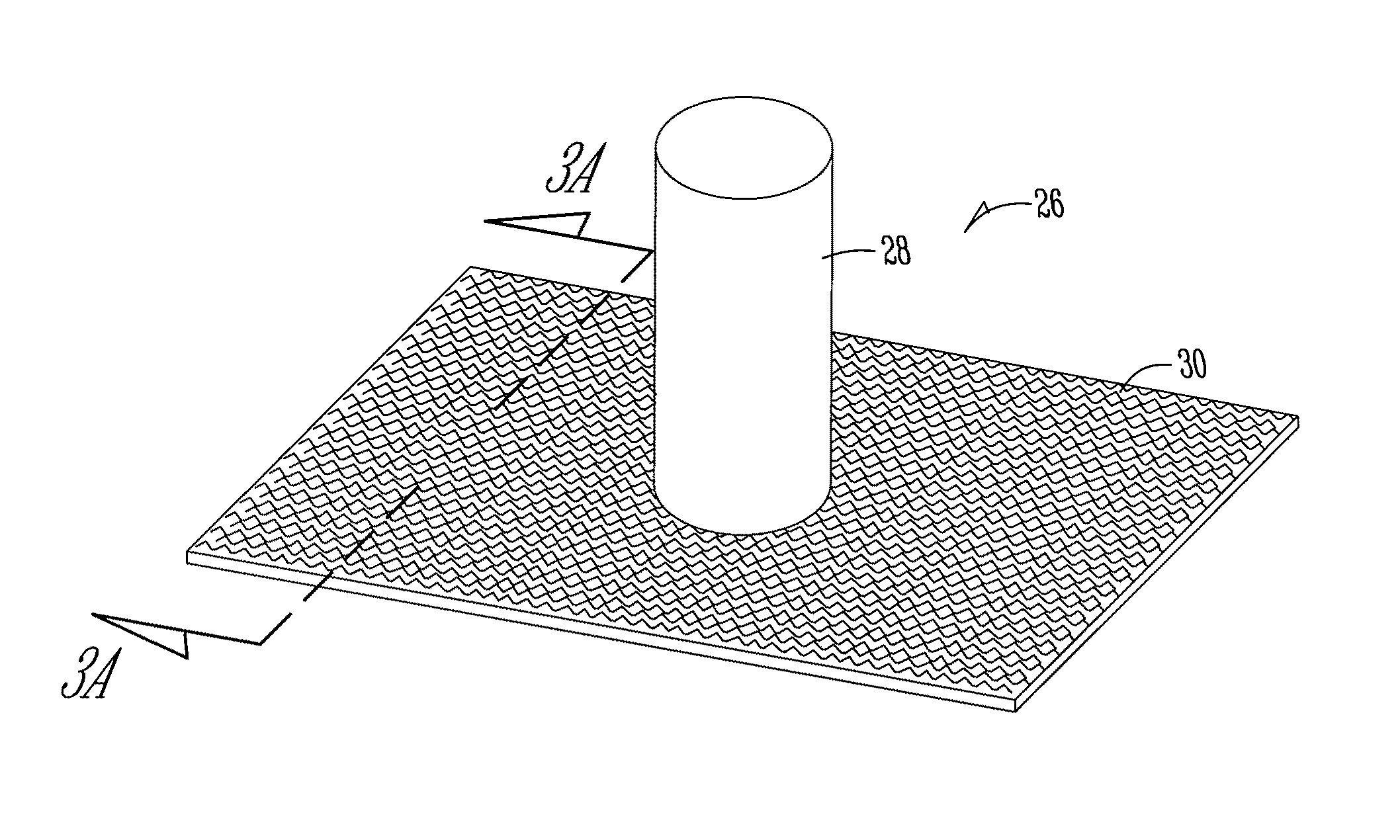

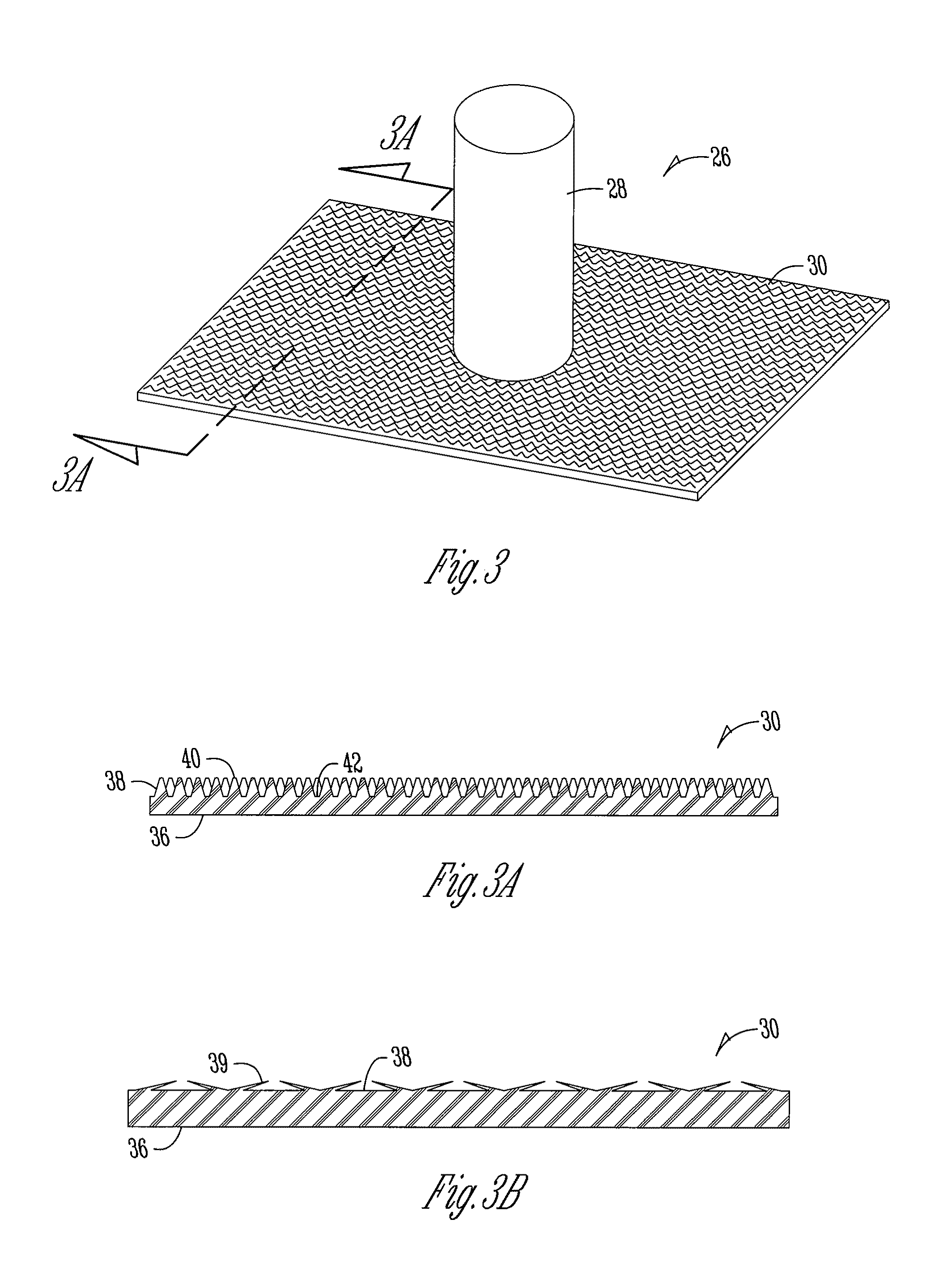

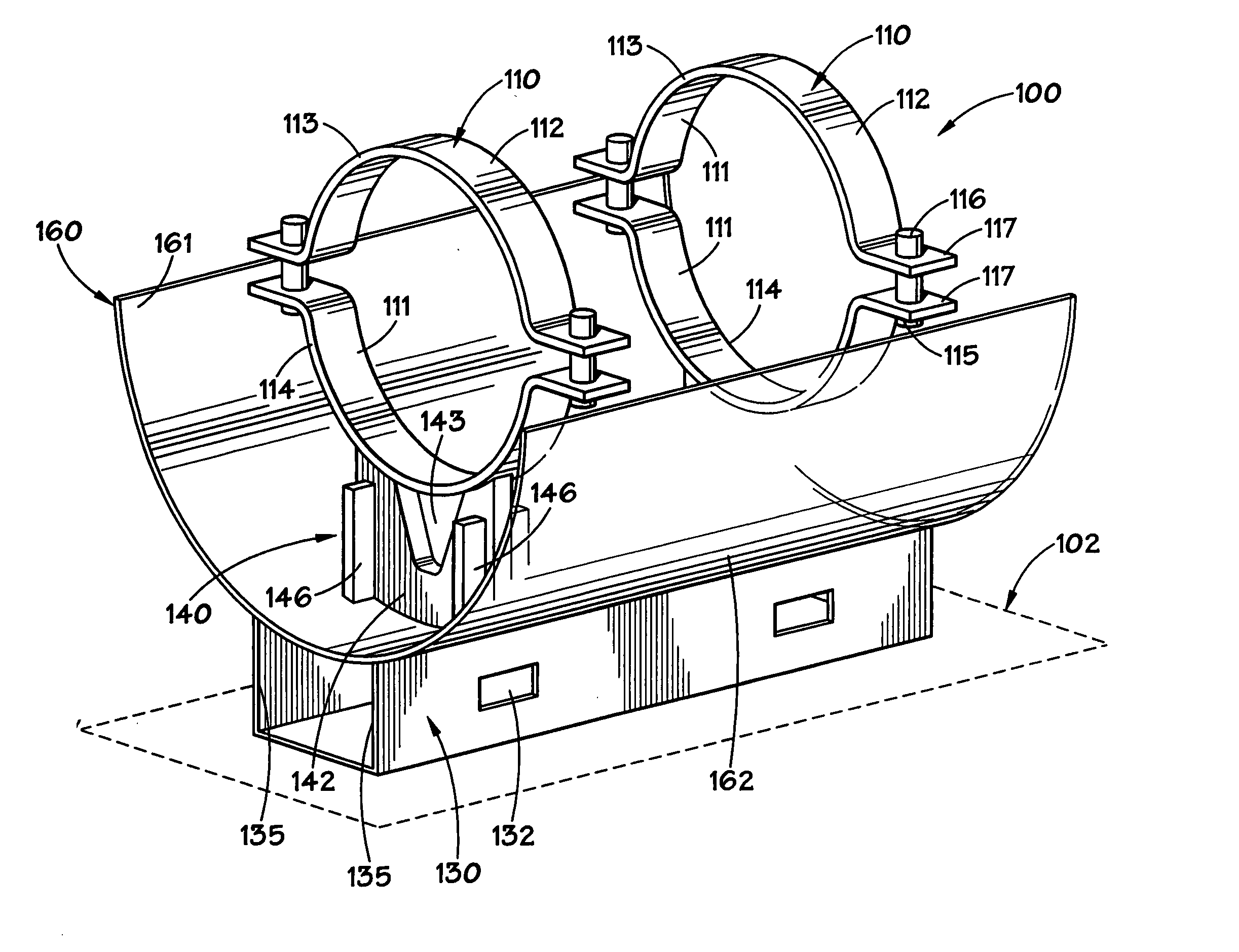

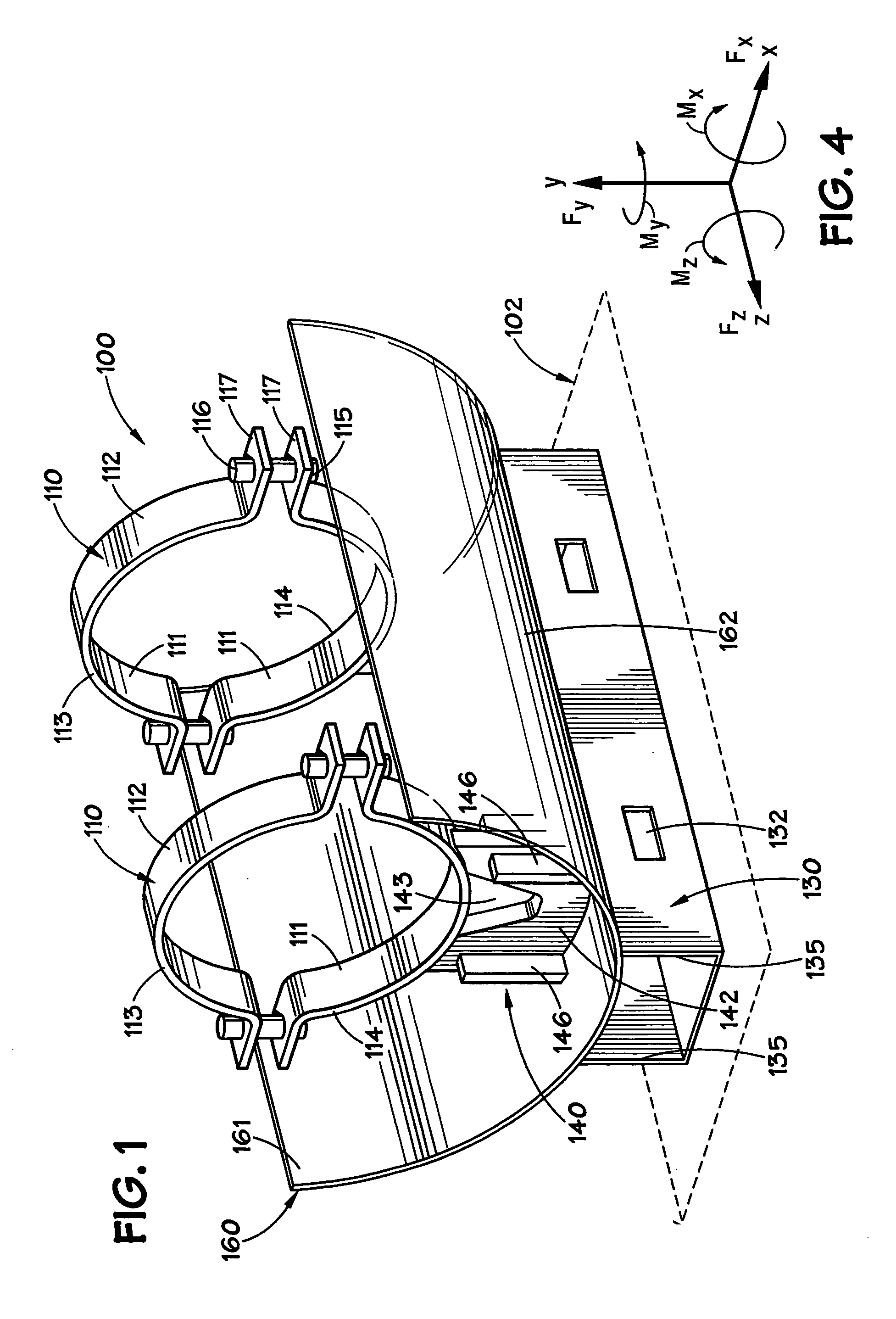

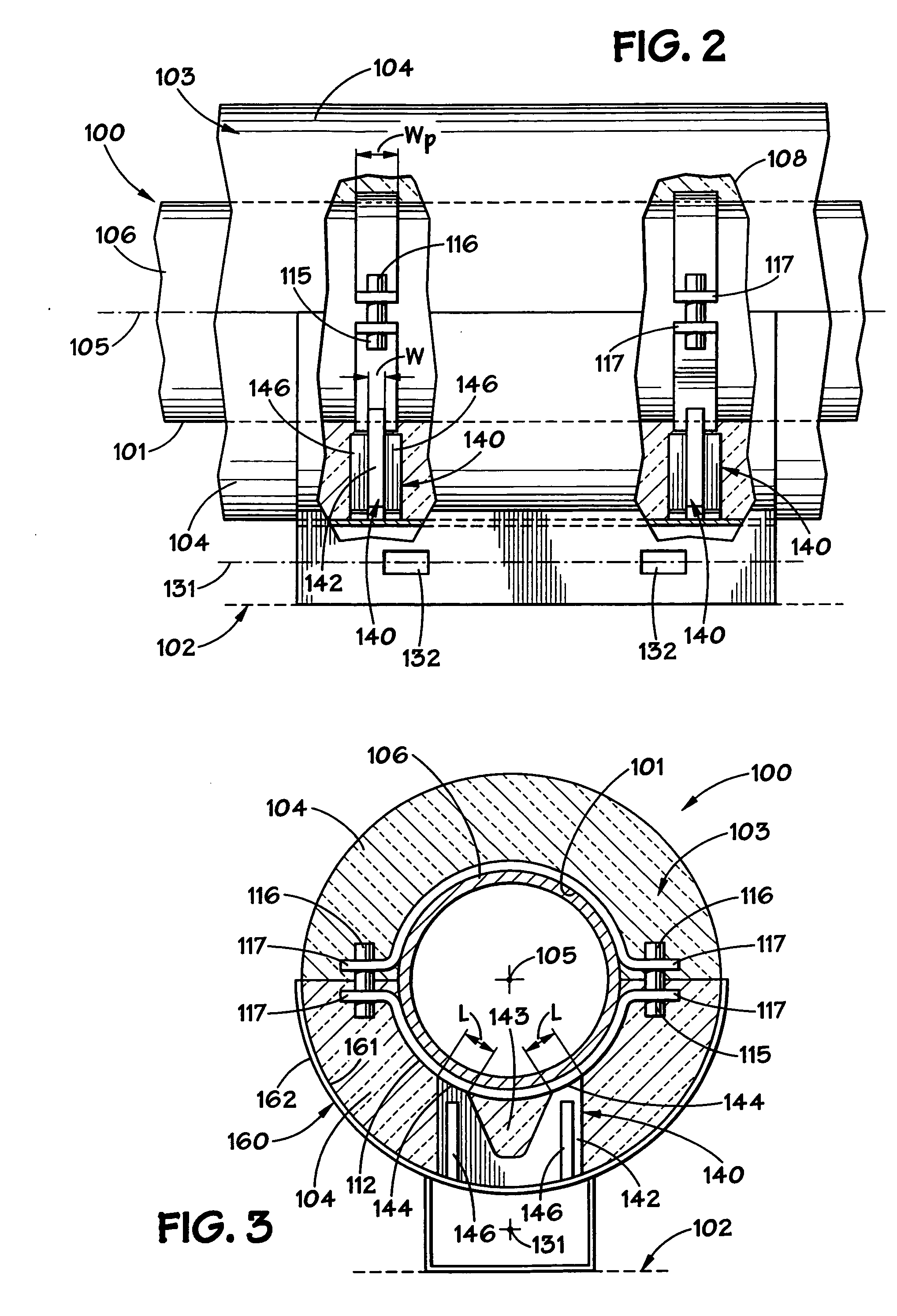

Method and apparatus for supporting an insulated pipe

ActiveUS20050116123A1Easy and economical to and installEasy and economical to manufacturePipe supportsThermal insulationEngineeringInsulated pipe

A method and apparatus for supporting a portion of a length of insulated pipe by a girder or other support structure, includes at least two pipe clamps, a base member, and a load transfer member attached to each of the at least two pipe clamps, wherein substantially none of the load, or forces and moments, exerted by the pipe, are carried, or transmitted, by the insulation disposed about the pipe.

Owner:PIPING TECHNOLOGY AND PRODUCTS

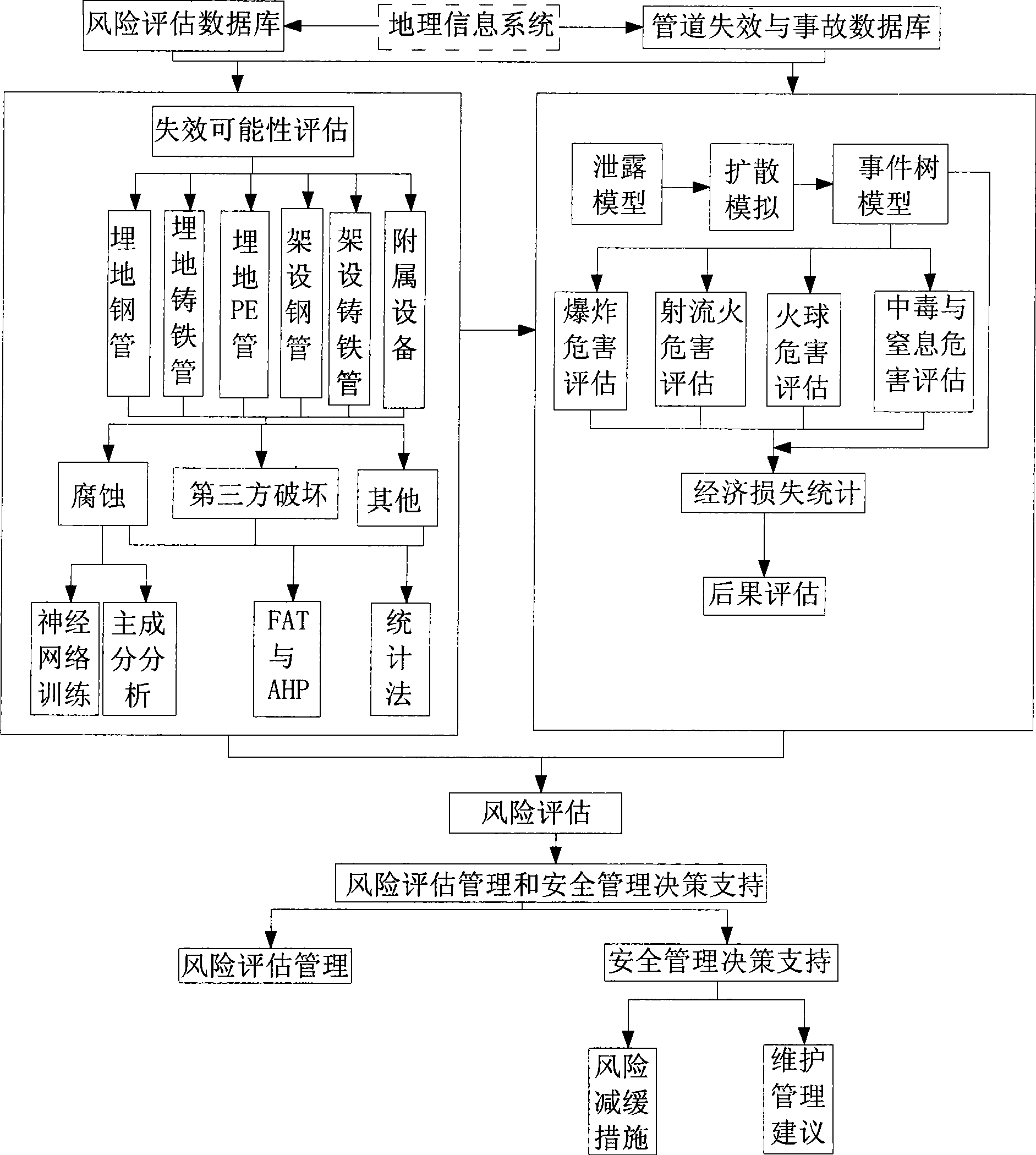

Risk evaluation and security management decision support system for town gas pipe

InactiveCN101488213AQuick Pipeline MaintenanceWide applicabilityData processing applicationsModularityCast iron

The invention provides a decision support system for risk assessment and safety management of quantitative / semi-quantitative town gas pipelines with a modularized component type structure. The system comprises an invalidation and failure database module, a risk assessment database module, a dynamic segmentation module, a risk assessment module and a decision support module. Assessment objects comprise pipeline auxiliary equipment such as steel pipes, cast iron pipes, PE pipes, valves, condenser cylinders, compensators and the like in two laying modes of burying and erection. The invalidation, failure and risk assessment database modules provide data support for risk computation; the dynamic segmentation module dynamically divides a pipe network into pipe sections convenient for management; the risk assessment module comprises a plurality of sub modules, and a user can selectively carry out risk computation; and the decision support module provides a decision reference basis for a manager. Based on investigating multiple gas companies, each module is established by combining scientific analysis, and can achieve active and dynamic management for the gas pipelines.

Owner:新奥(廊坊)燃气技术研究发展有限公司

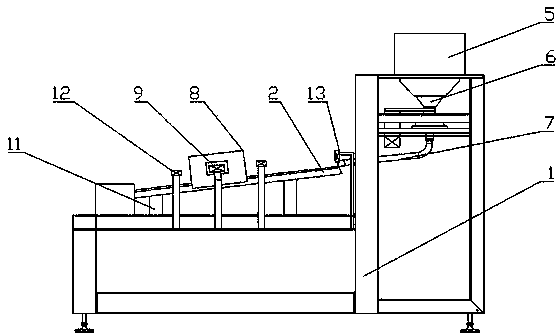

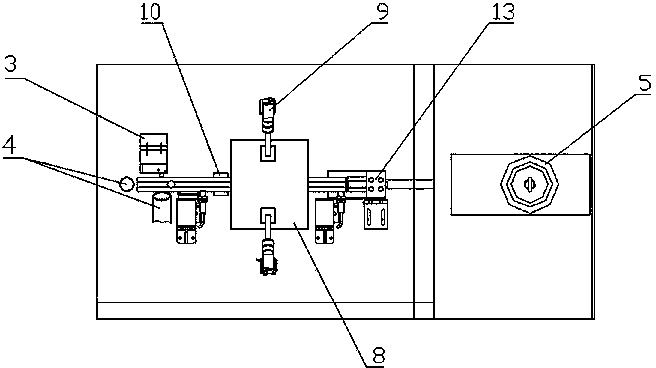

Detection sorting device for steel balls

ActiveCN104043596ARealize automatic feeding processEasy to detectOptically investigating flaws/contaminationSortingEngineeringStructural engineering

The invention relates to a detection sorting device for steel balls The detection sorting device comprises a rack, a feed mechanism, an unfolding mechanism, a stock stop, a detecting mechanism, a sorting mechanism and a material collecting mechanism, wherein the feed mechanism comprises a material storing box, a material discharging hopper and a material discharging pipe; the unfolding mechanism comprises a material transporting guide rail, the material transporting guide rail is a V-shaped linear guide rail, the material discharging hopper is connected with an initiating end of the material transporting guide rail through the material discharging pipe, and the detecting mechanism comprises a light source assembly and a camera assembly; the light source assembly is arranged on the material transporting guide rail in a sleeved mode, the sorting mechanism and the material collecting mechanism are arranged on the tail end of the material transporting guide rail, and the separate collection of defect steel balls and qualified steel balls are realized through the sorting mechanism and the material collecting mechanism. The detection sorting device provided by the invention has the advantages that the automatic feed, detection and sorting of the steel balls are realized, a detection process is that two-dimensional motion of a traditional unfolding disc is changed into single one-dimensional rolling of one-sided steel balls, the detection efficiency is high, a false drop ratio and an omission ratio are low, and the steel balls are not magnetized or the surfaces of the steel balls are not damaged in a detection process.

Owner:LUOYANG FANGZHI MEASUREMENT & CONTROL

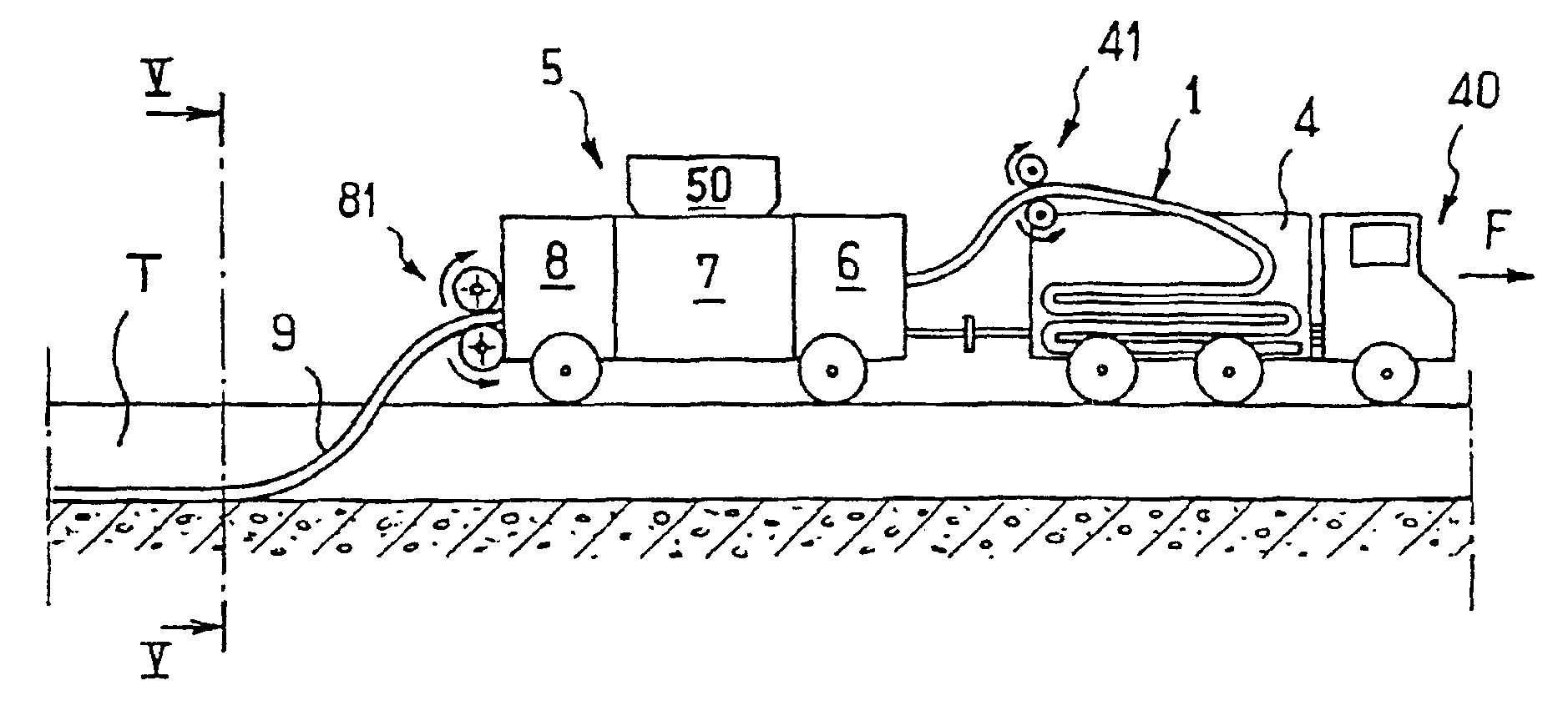

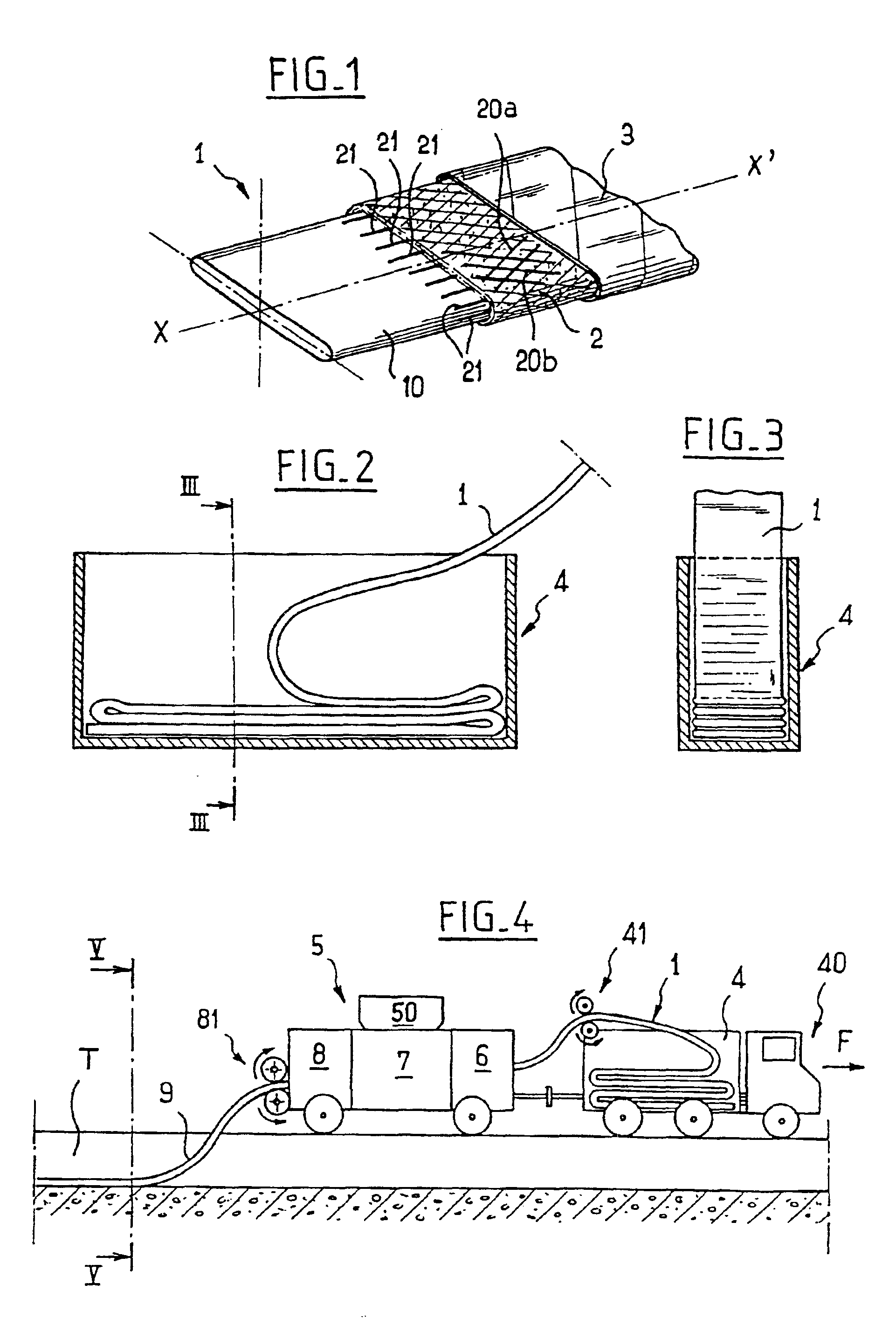

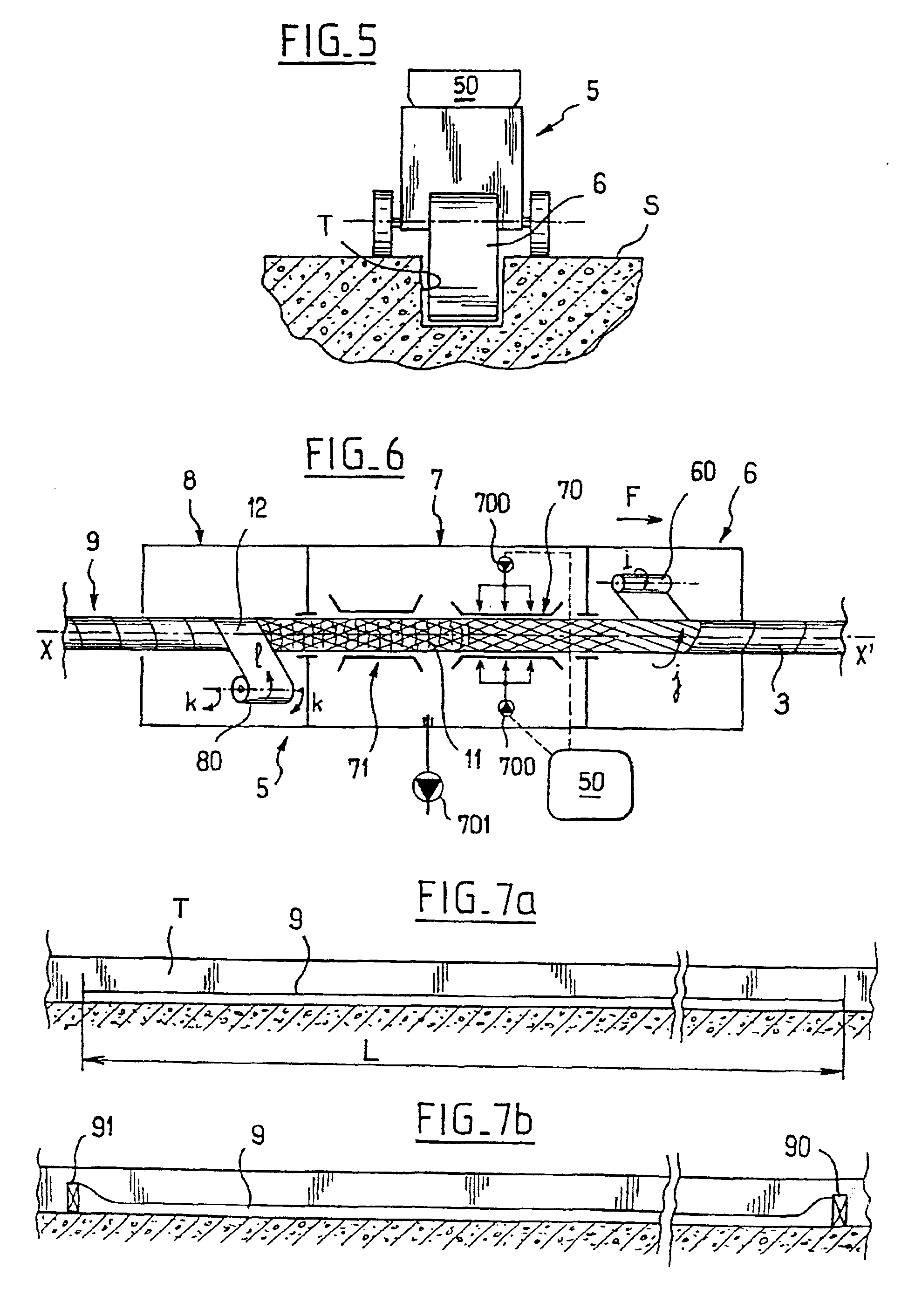

Method and installation for laying a cylindrical pipe on a support

InactiveUS6899842B1Simple and inexpensive implementationAvoid radial expansionUnderground chambersButter manufactureWaste managementStructural engineering

Owner:SERVICES PETROLIERS SCHLUMBERGER SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com