Methods and apparatus for completing unconsolidated lateral well bores

a technology of lateral wells and wells, which is applied in the direction of wellbore/well accessories, drilling pipes, sealing/packing, etc., can solve the problems of gravel bridges, fines and sand in the produced fluids, and reduce the fluid production capacity of formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

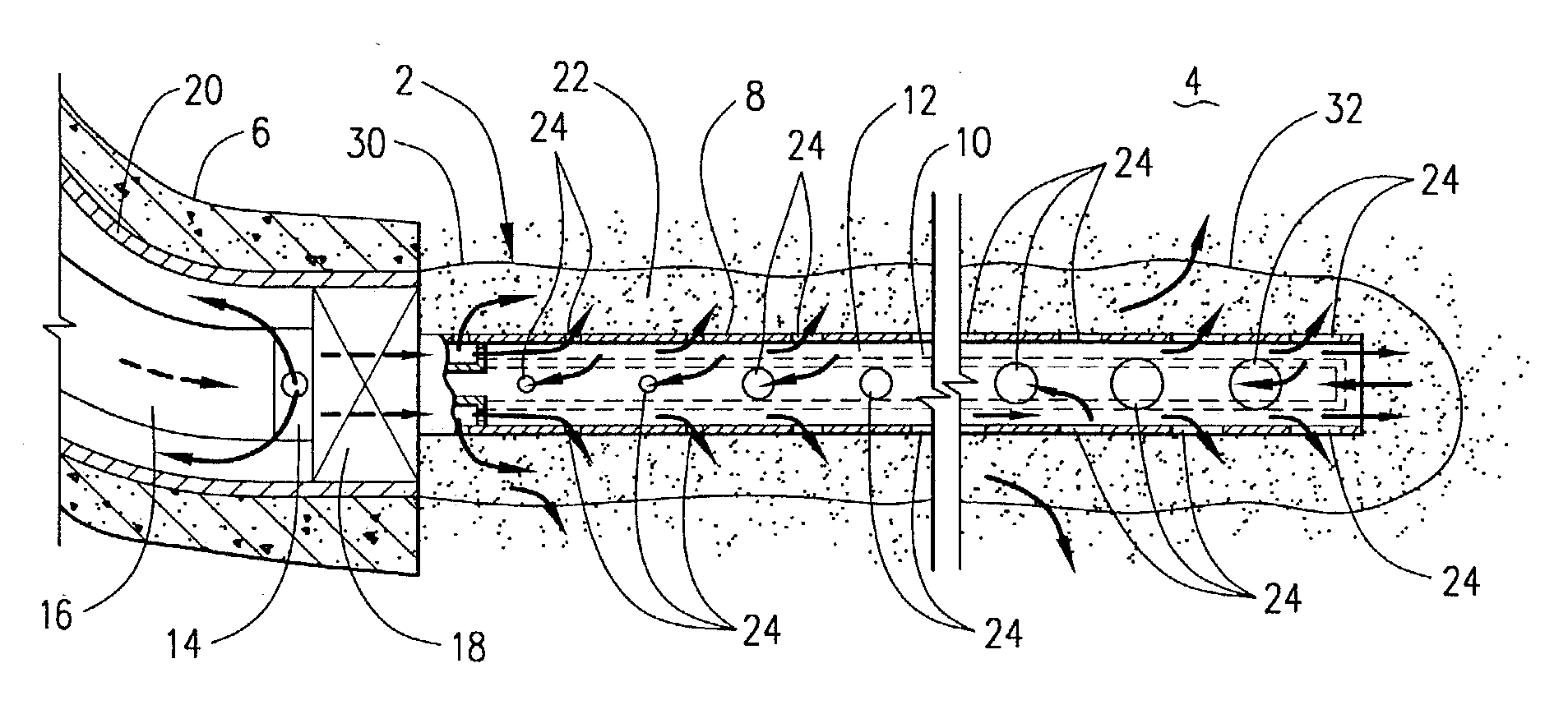

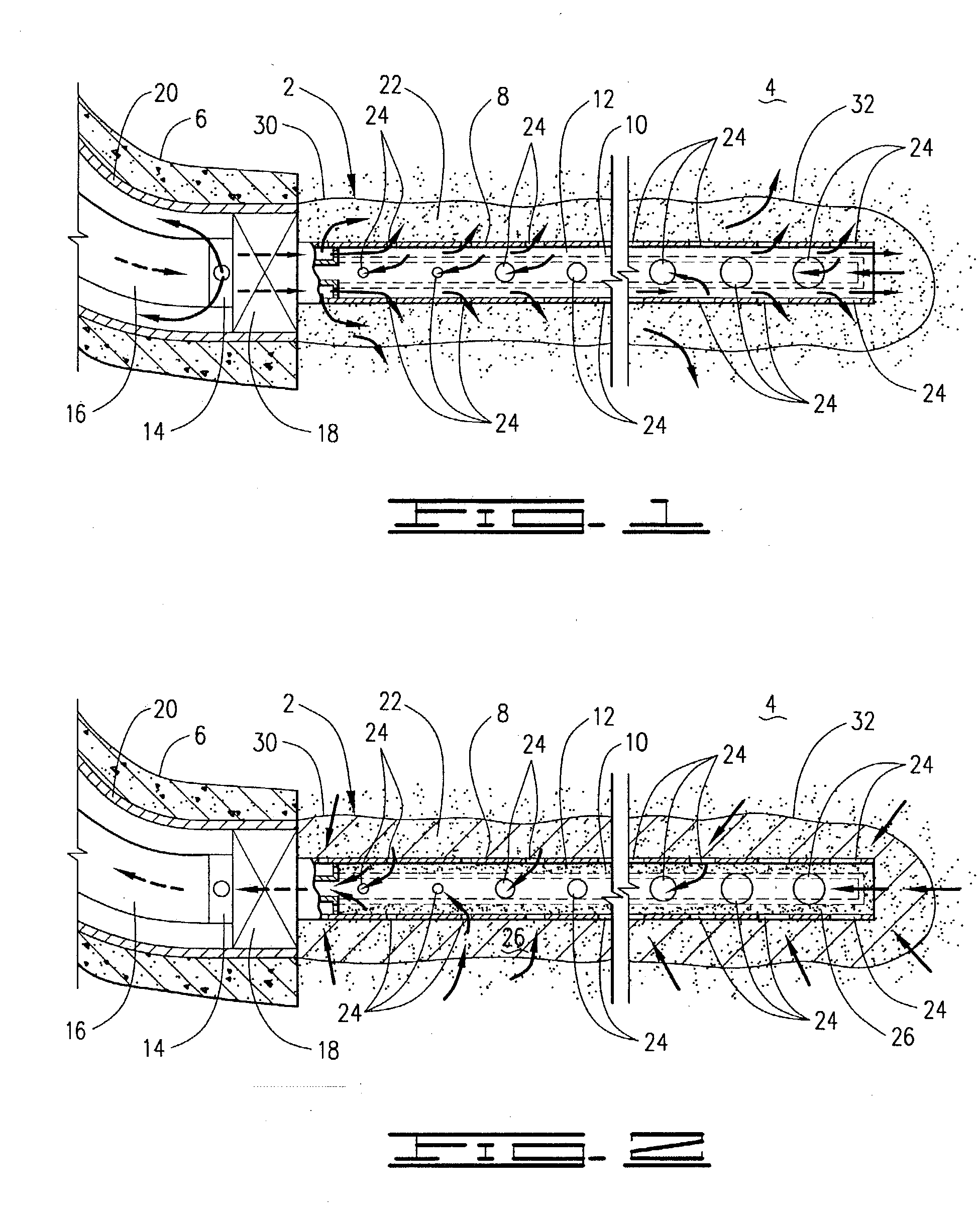

[0017] The present invention provides improved methods and apparatus for completing an unconsolidated subterranean zone subject to the migration of formation fines and sand penetrated by a lateral well bore having unequal produced formation fluid flow rates over the length of the well bore. The term "lateral well bore" is used herein to mean the portion of a well bore in an unconsolidated subterranean producing zone to be completed which is substantially horizontal or at an angle from vertical in the range of from about 65.degree. to about 105.degree.. The term "slotted pipe" is used herein to mean pipe which includes slots, holes or other shaped openings therein.

[0018] Referring now to the drawings, the improved apparatus of the present invention is illustrated disposed in an open hole lateral well bore 2. The lateral well bore 2 is illustrated extending into an unconsolidated subterranean zone 4 from a cased and cemented well bore 6 which extends to the surface. A slotted pipe 8 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com