Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4625 results about "Open hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

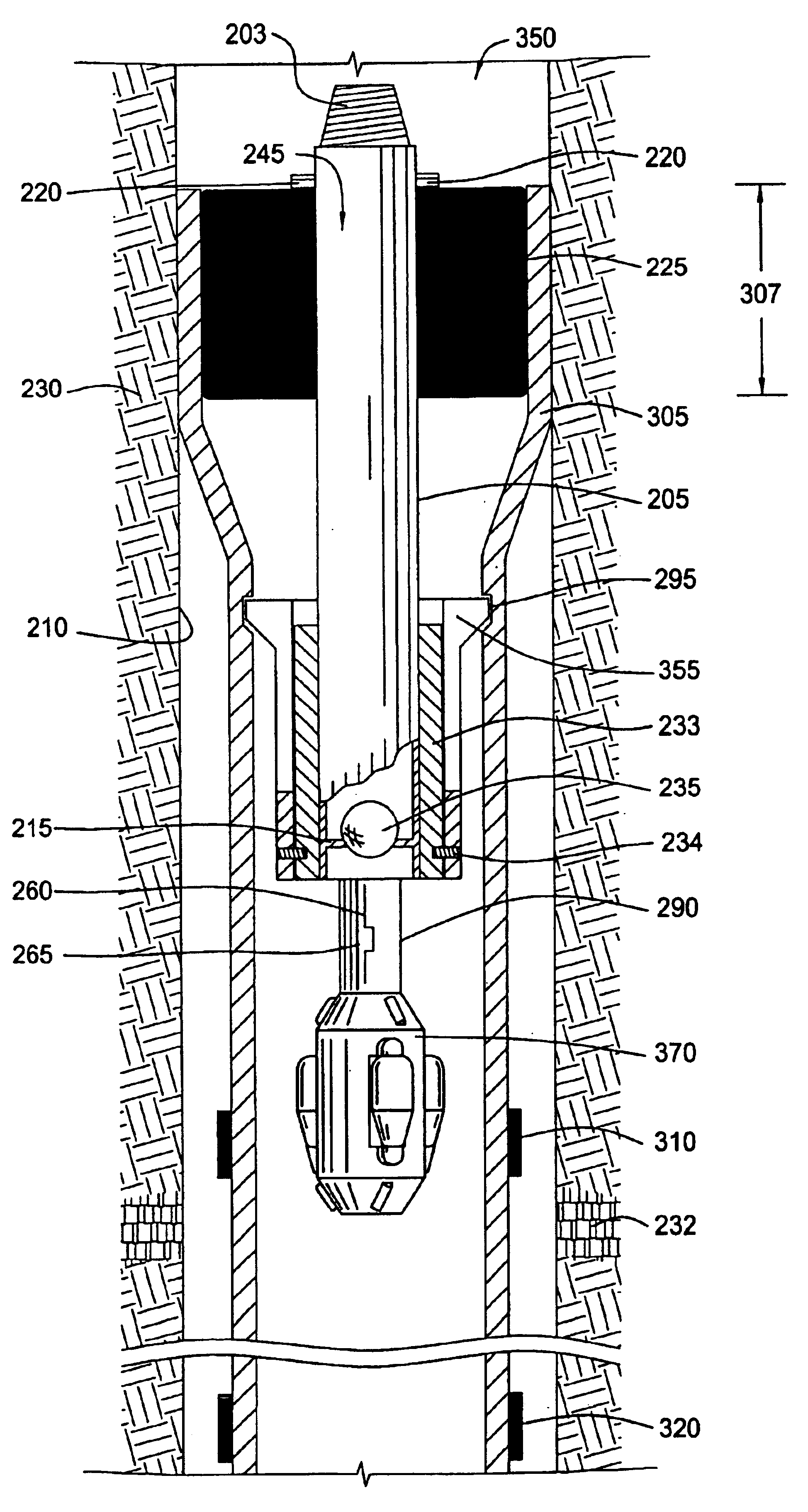

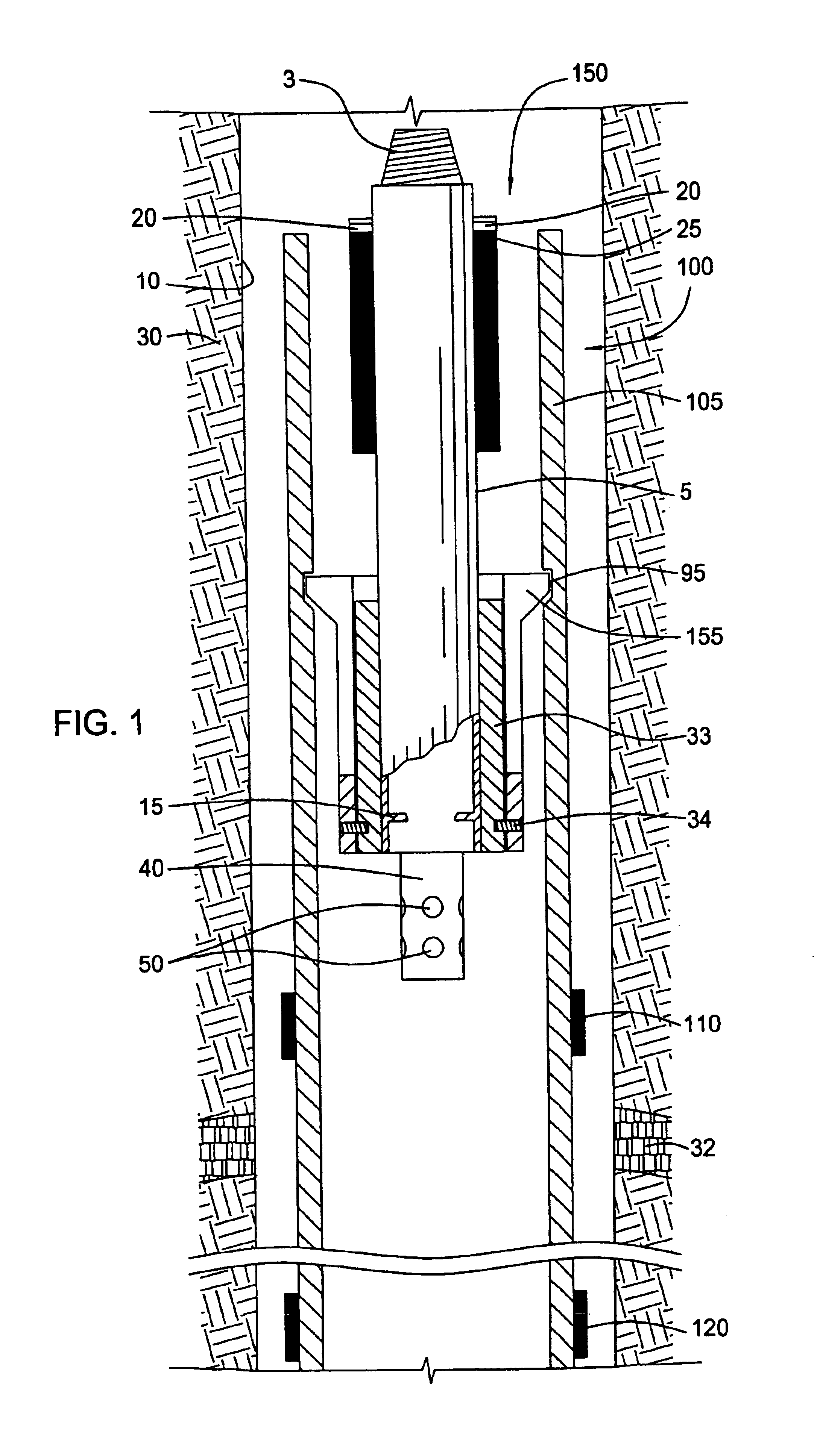

Multi-Position Valve for Fracturing and Sand Control and Associated Completion Methods

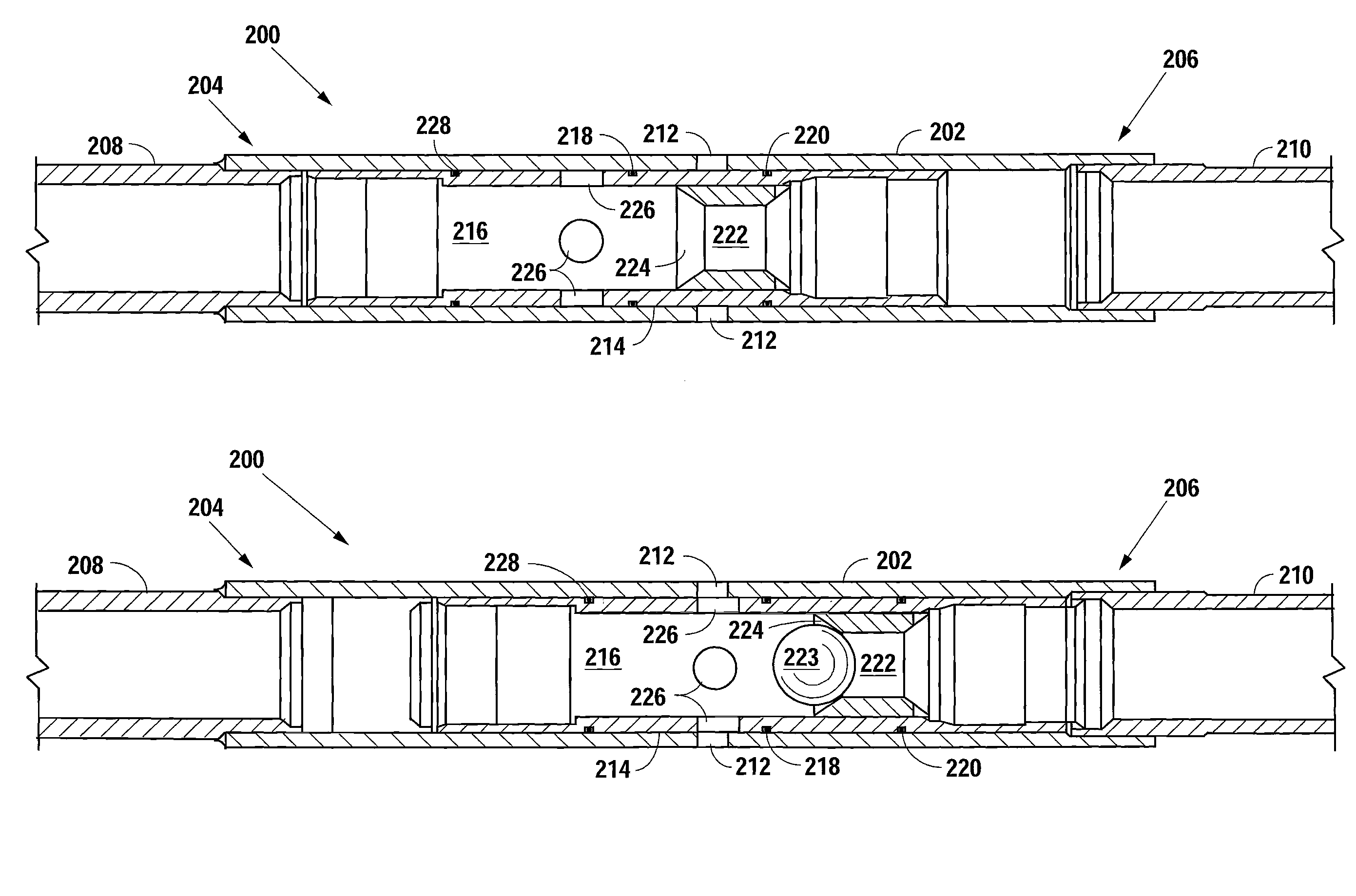

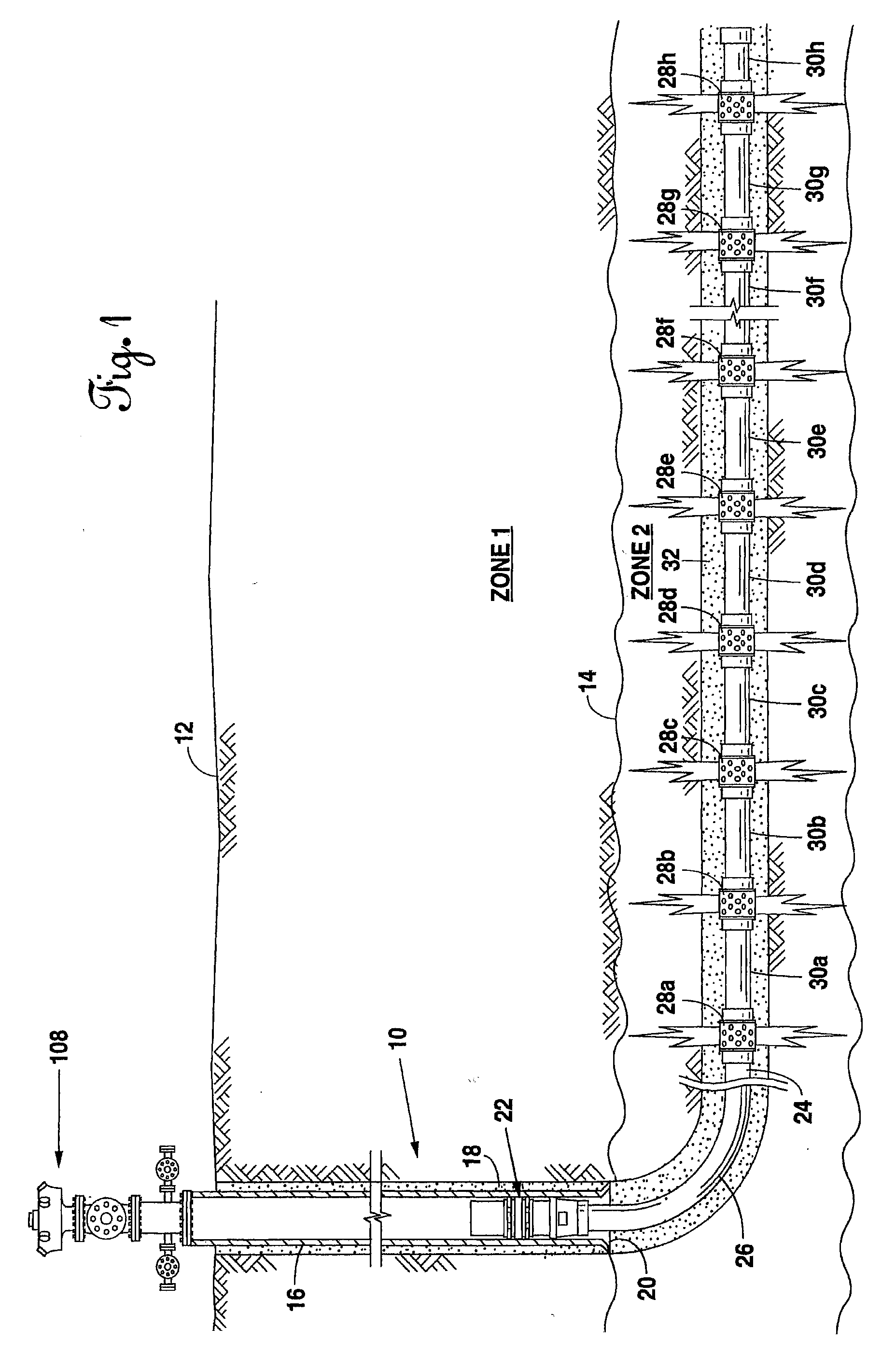

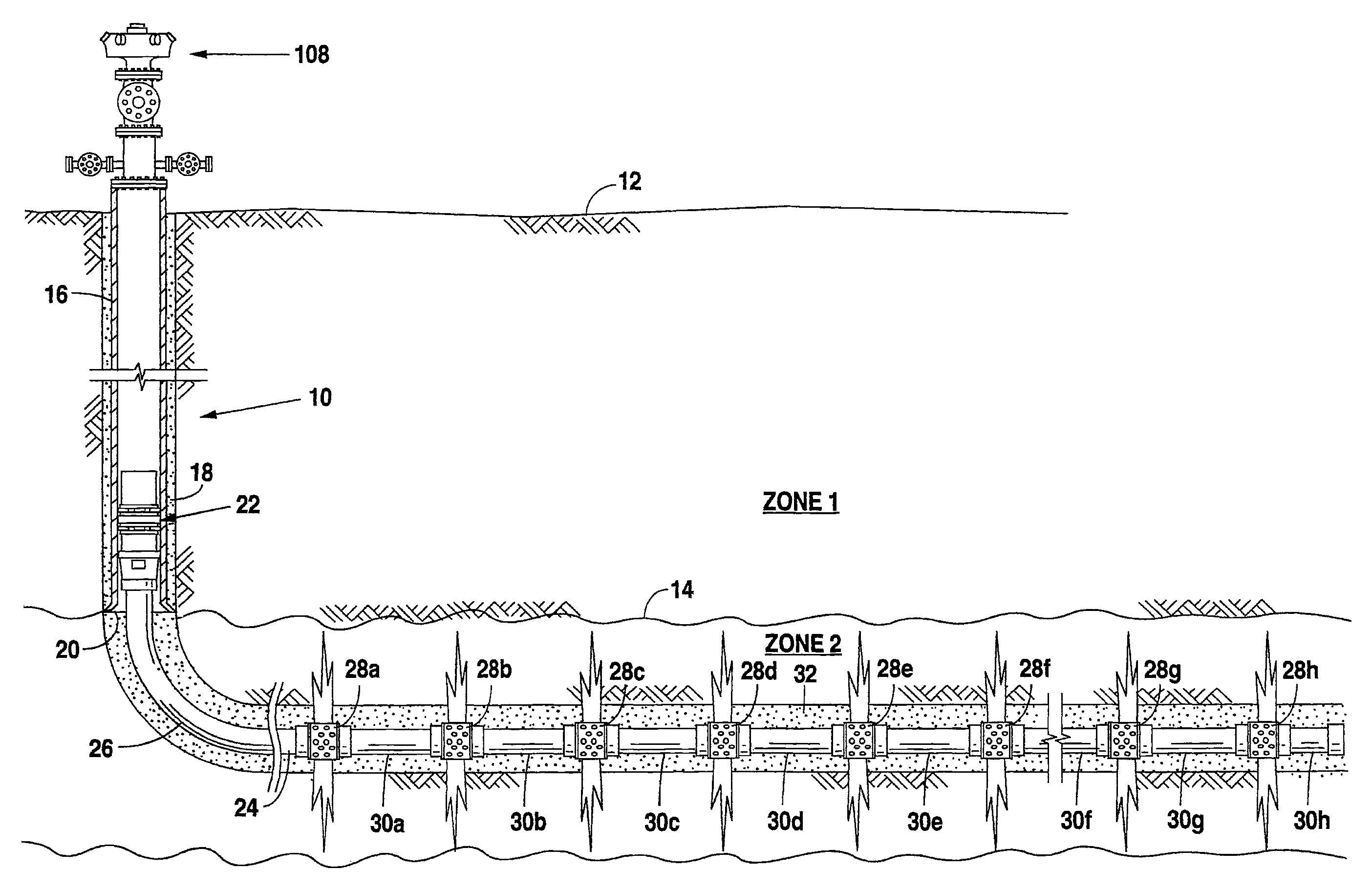

A completion tubular is placed in position adjacent the zone or zones to be fractured and produced. It features preferably sliding sleeve valves that can assume at least two configurations: wide open and open with a screen material juxtaposed in the flow passage. In a preferred embodiment the valve assembly has three positions, adding a fully closed position to the other two mentioned. After run in, the valves can be put in the wide open position in any order desired to fracture. After fracturing, the valves can be closed or selectively be put in filtration position for production from the fractured zones in any desired order. Various ways are described to actuate the valves. The tubular can have telescoping pistons through which the fracturing can take place if the application calls for a cemented tubular. Alternatively, the tubular can be in open hole and simply have openings for passage of fracture fluid and external isolators to allow fracturing in any desired order.

Owner:BAKER HUGHES INC

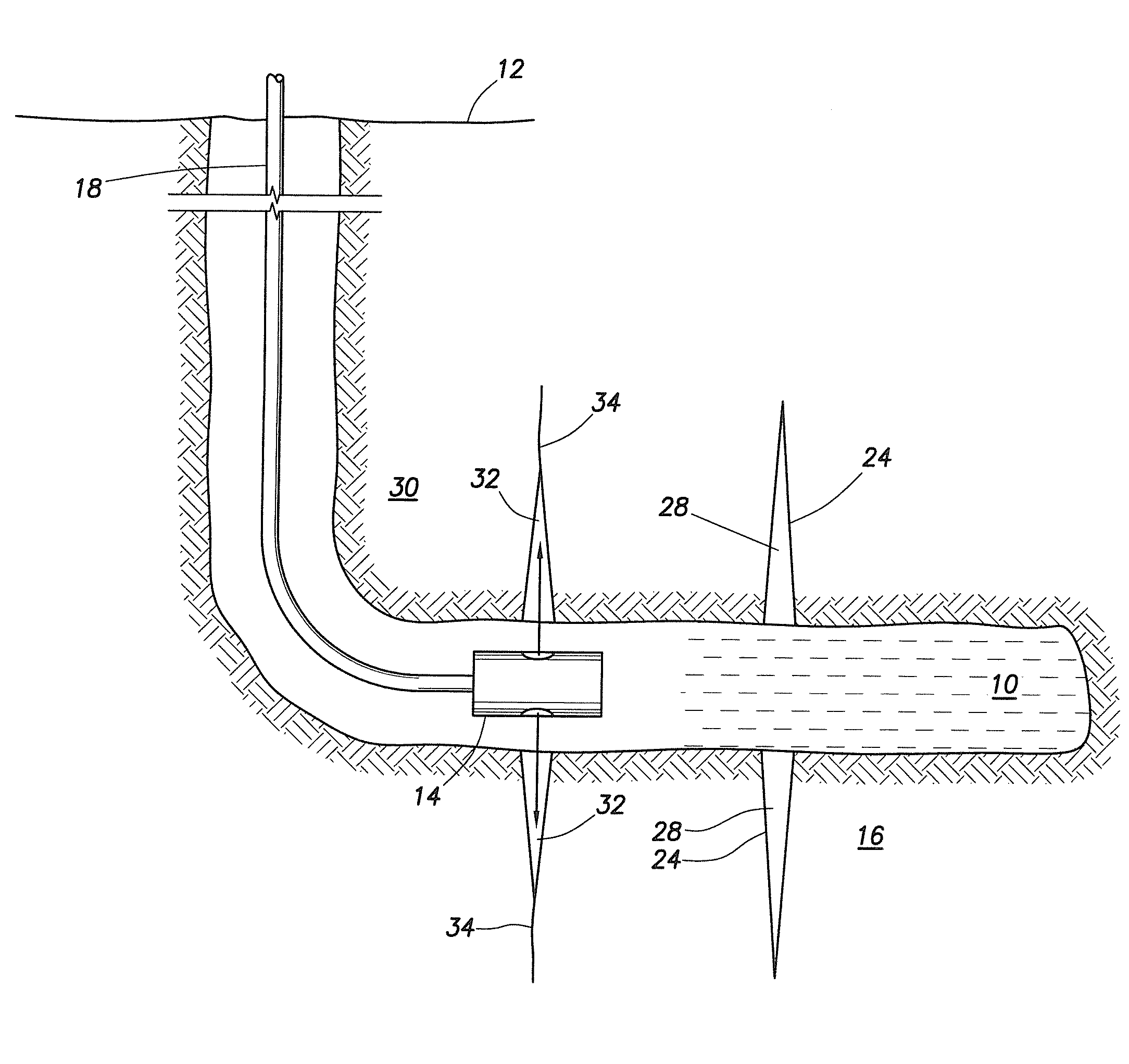

Methods of drilling and completing well bores

Methods of drilling and completing open hole well bores and methods of removing filter cake comprised of a gelling agent and calcium carbonate are provided. A method of the invention for removing filter cake comprised of a gelling agent and calcium carbonate from the walls of an open hole well bore is basically comprised of the steps of contacting the filter cake with a delayed clean-up solution comprised of water and a formate ester and removing the clean-up solution from the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

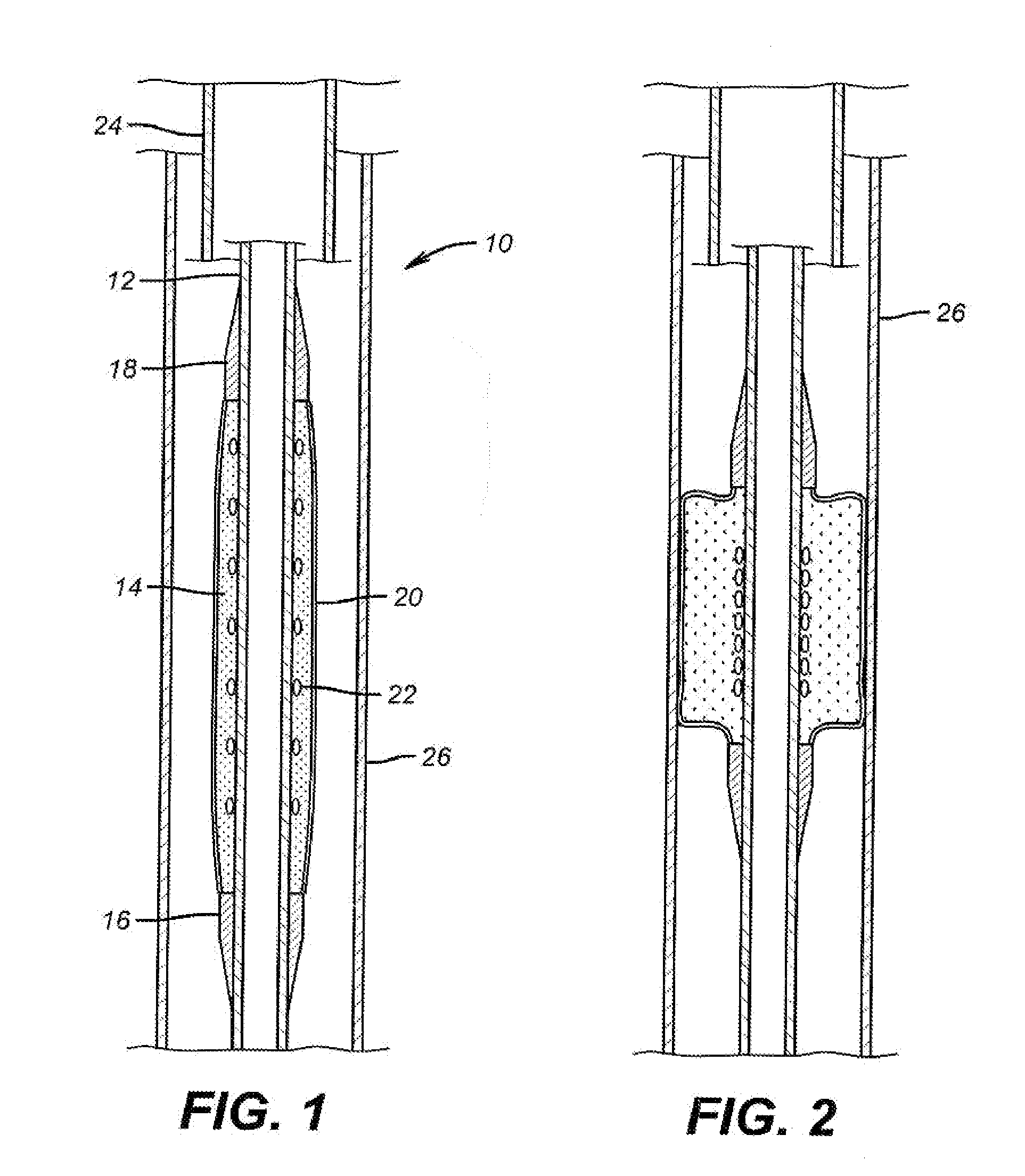

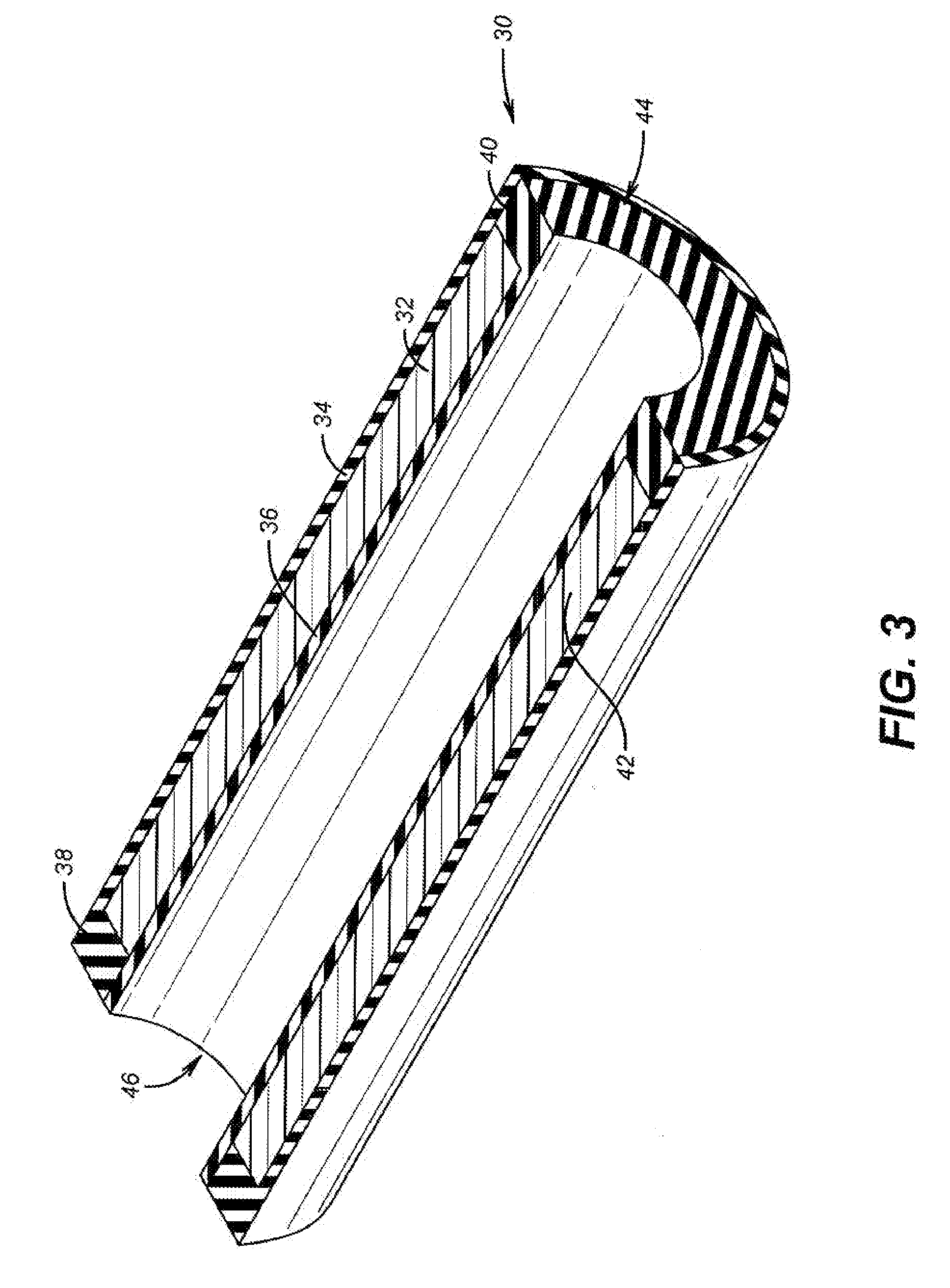

Packer sealing element with shape memory material

A packer or bridge plug uses a sealing element made from a shape memory polymer (SMP). The packer element receives heat or other stimulus to soften the SMP while the element is compressed and retained. While so retained, the heat or other stimulus is removed to allow the SMP to get stiff so that it effectively seals a surrounding tubular. High expansion rates are possible as the softness of the material under thermal input allows it to be reshaped to the surrounding tubular or to the surrounding open hole from a smaller size during run in and to effectively retain a sealed configuration after getting stiff on reduction in its core temperature while longitudinally compressed. The SMP or equivalent material whose modulus is changeable can be covered on the outside, the inside or both with an elastic material that protects the SMP and enhances the seal in the wellbore and against the mandrel.

Owner:BAKER HUGHES INC

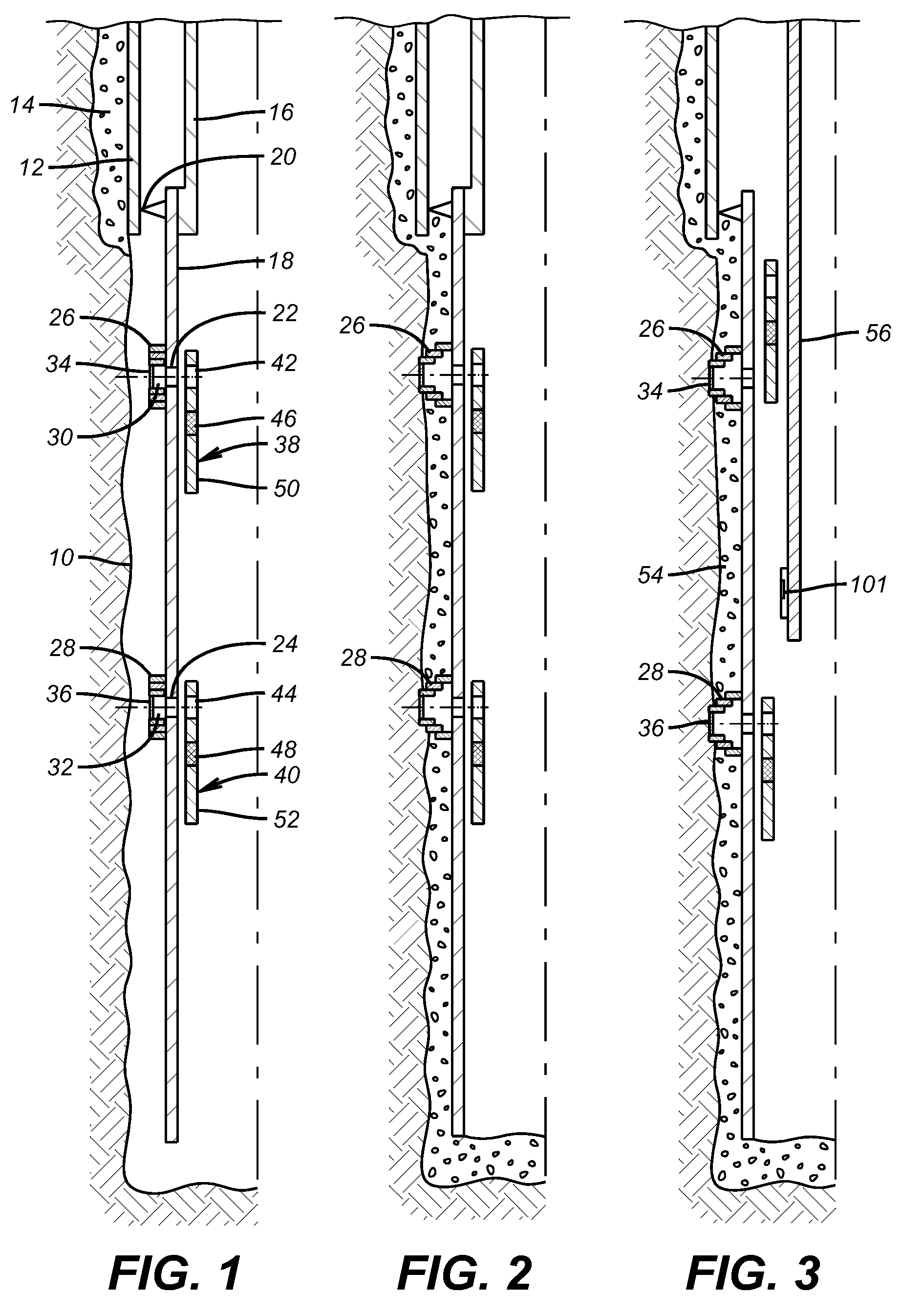

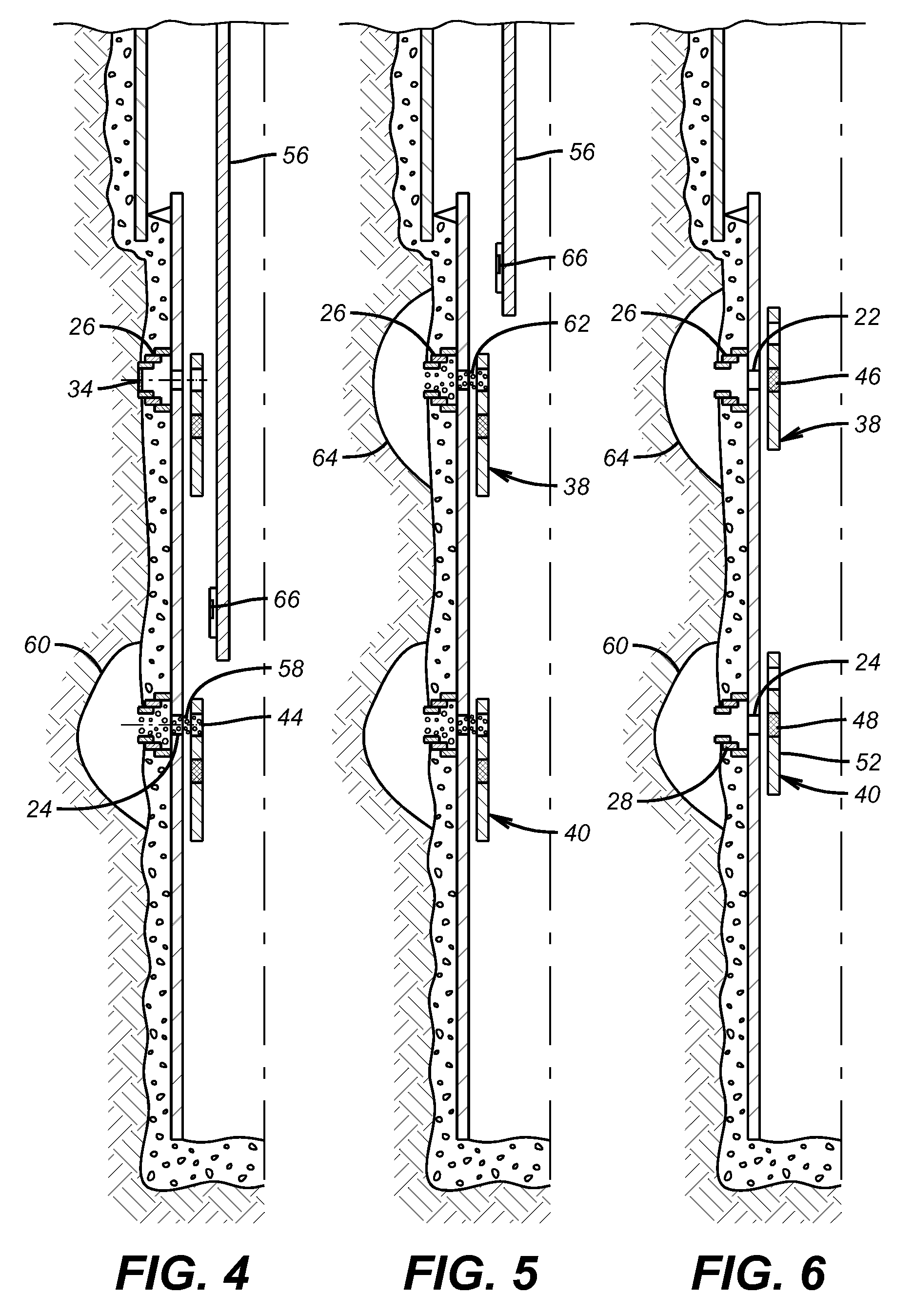

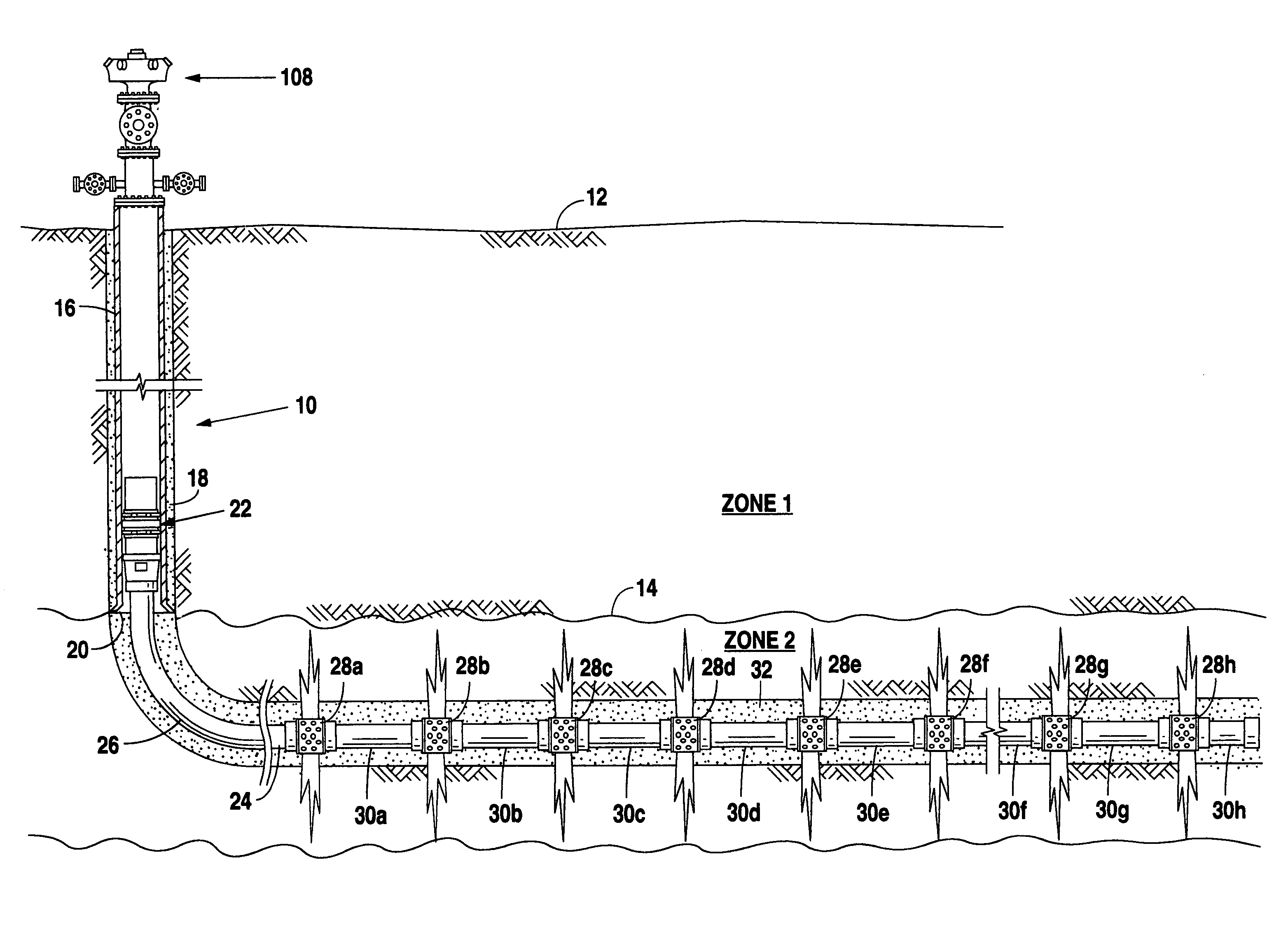

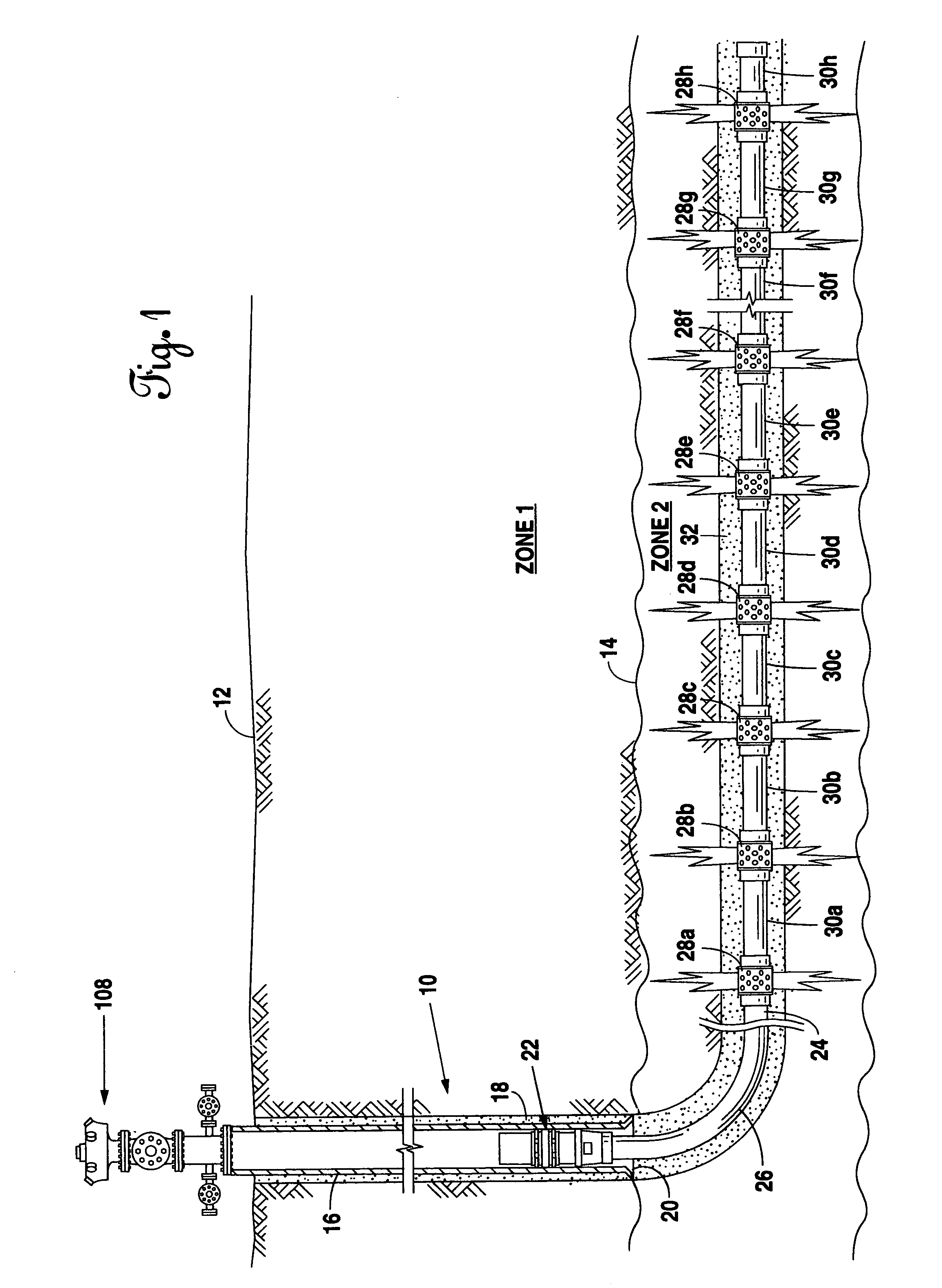

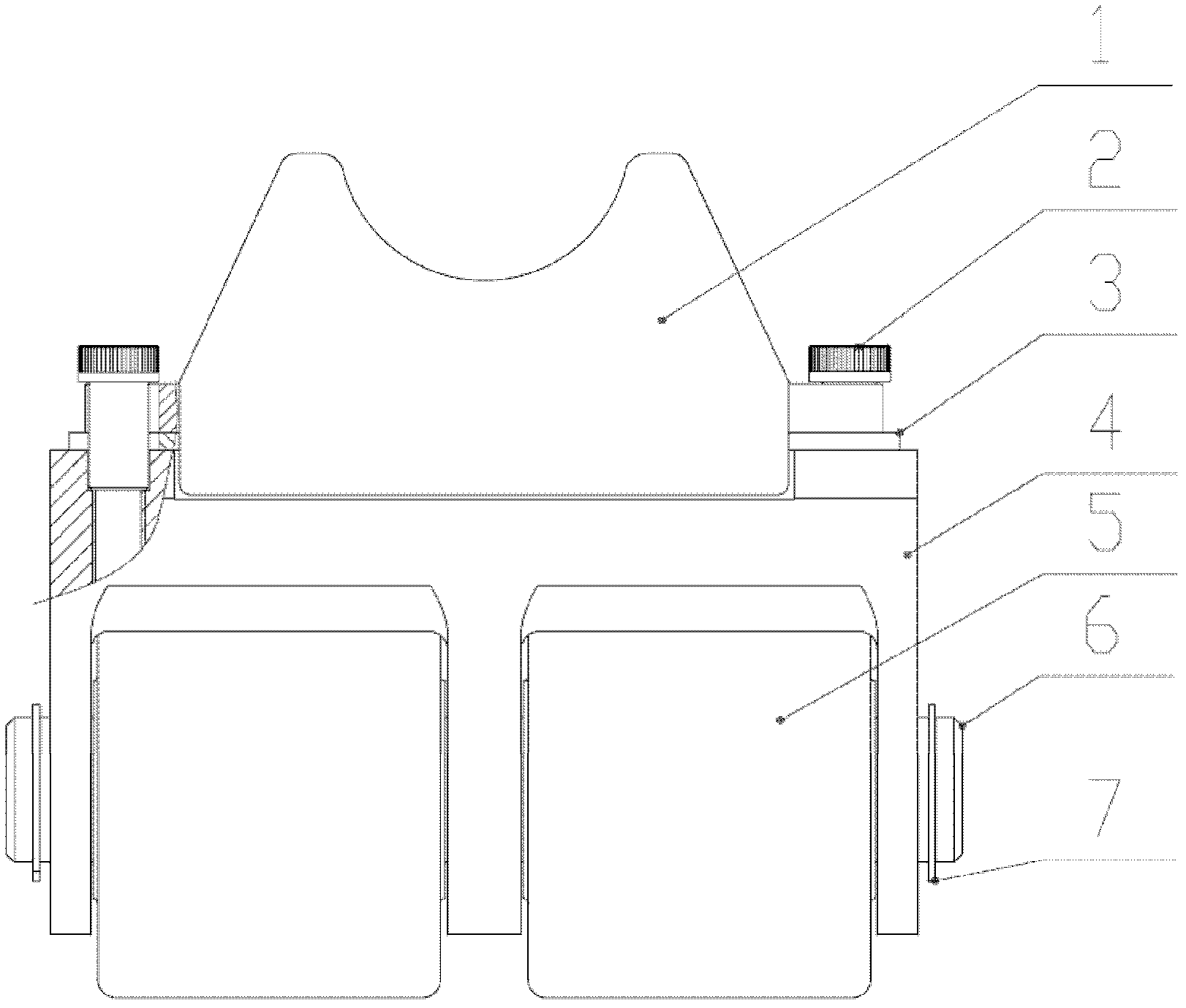

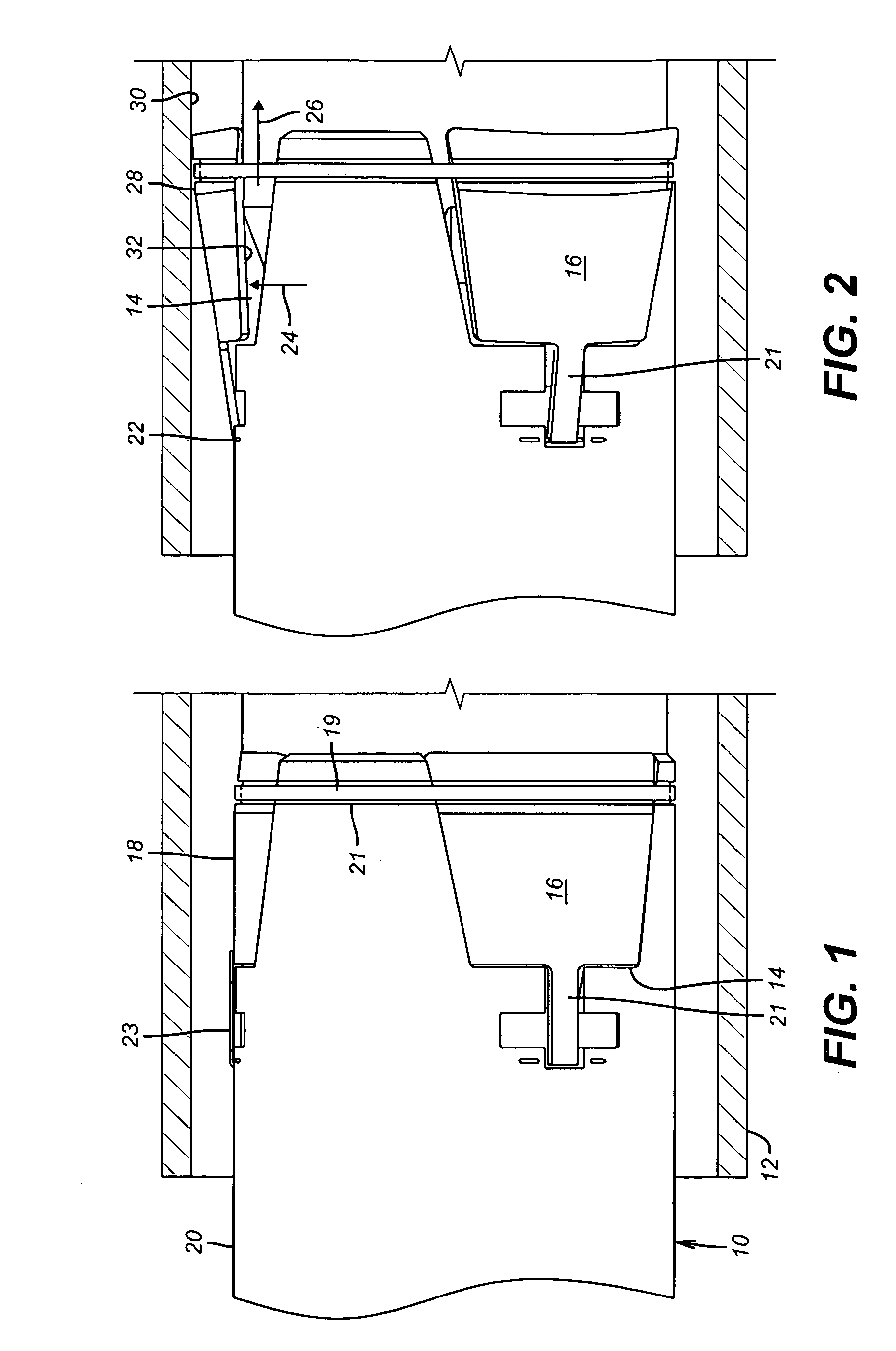

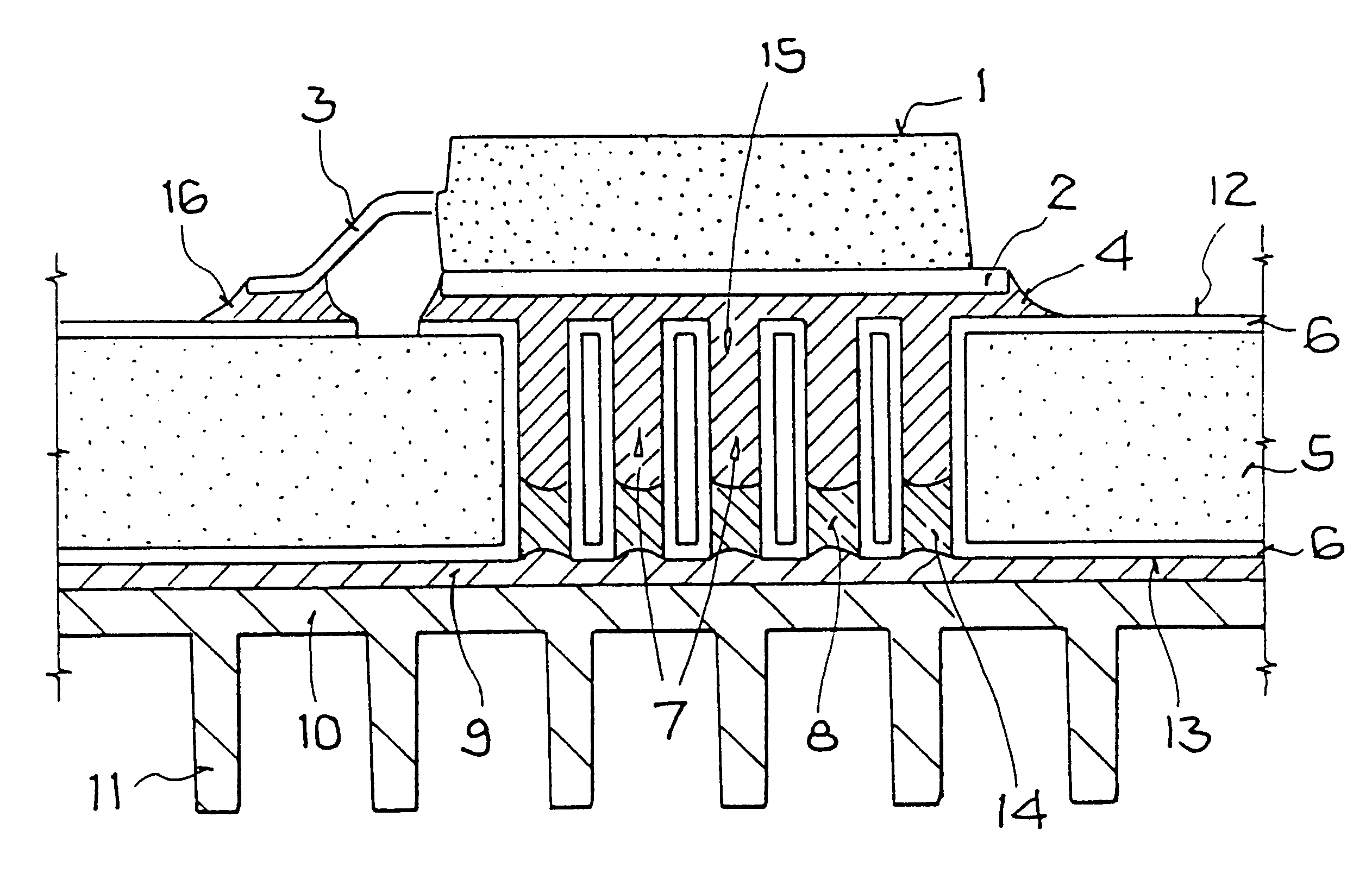

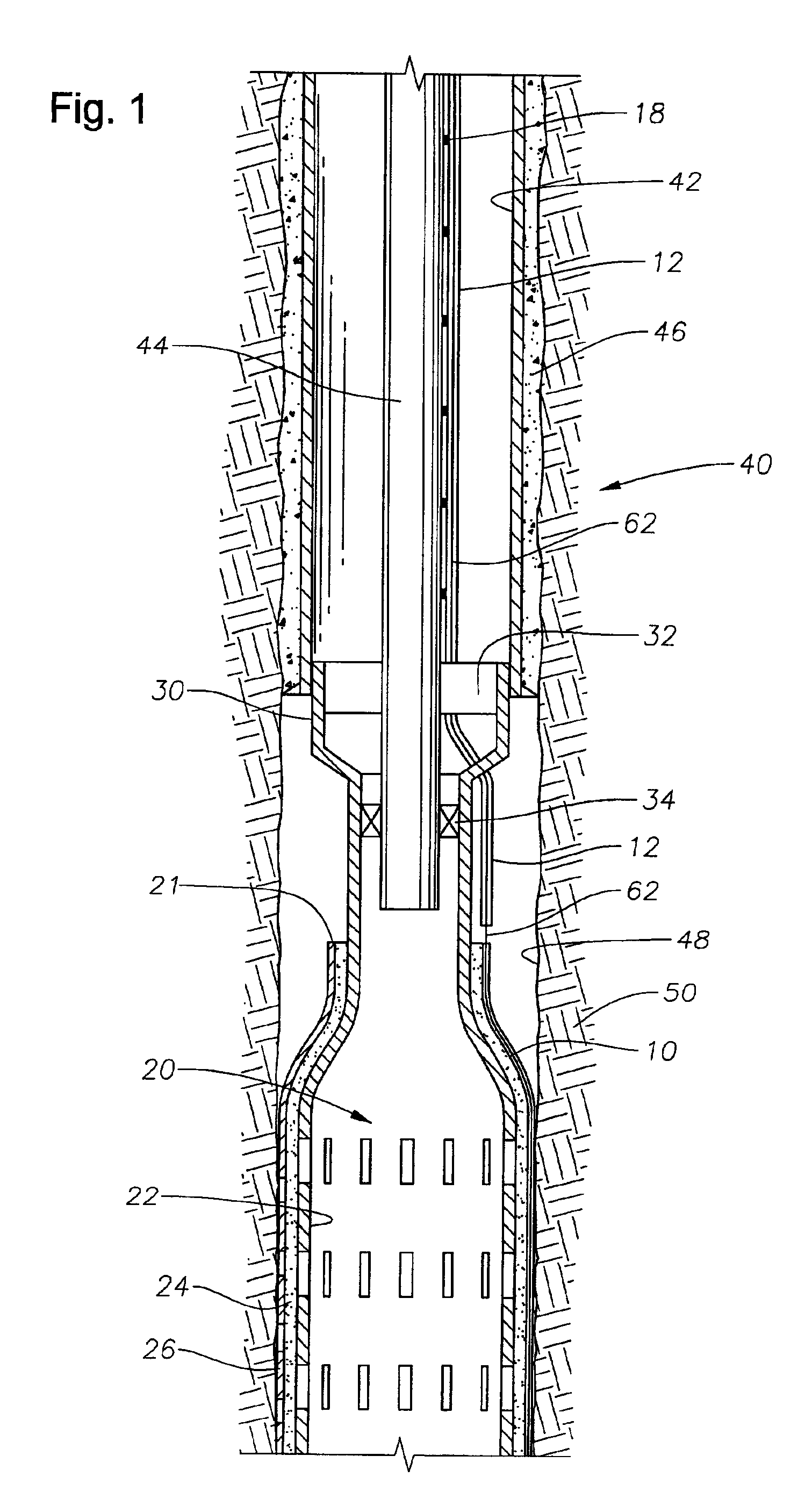

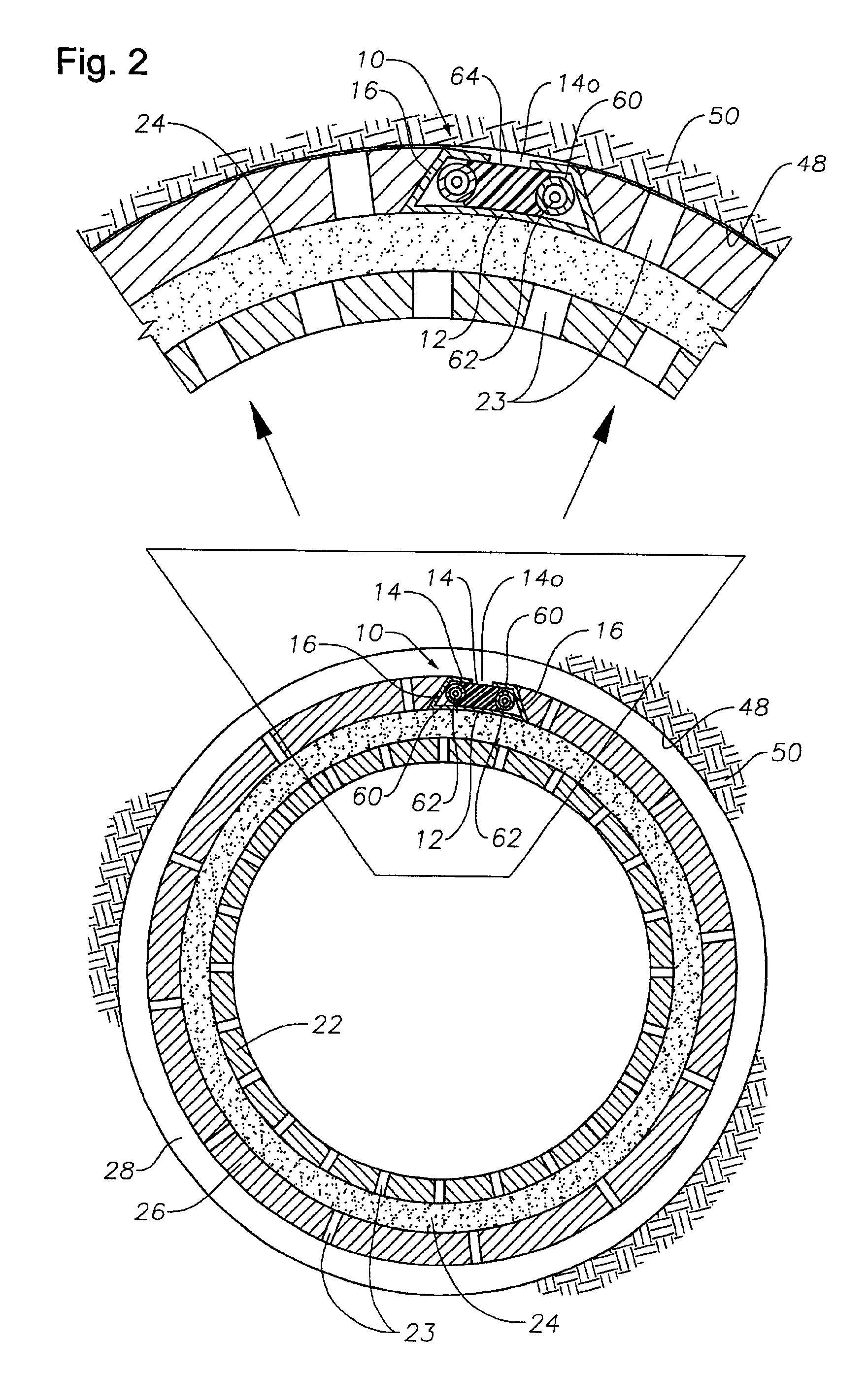

Cemented open hole selective fracing system

A cemented open hole selective fracing system is shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened by a shifting tool, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened with a switching tool, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETIONS TECH INC

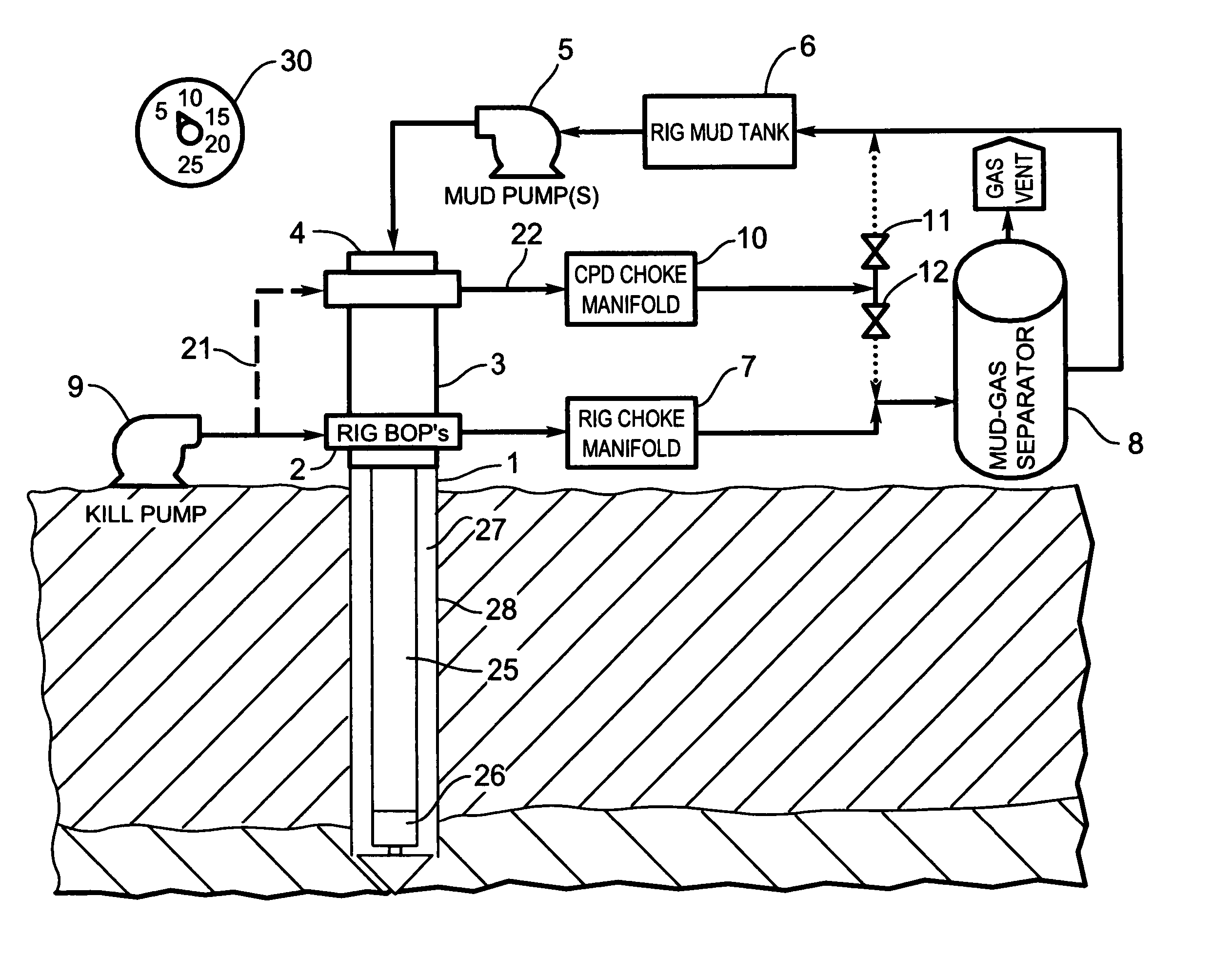

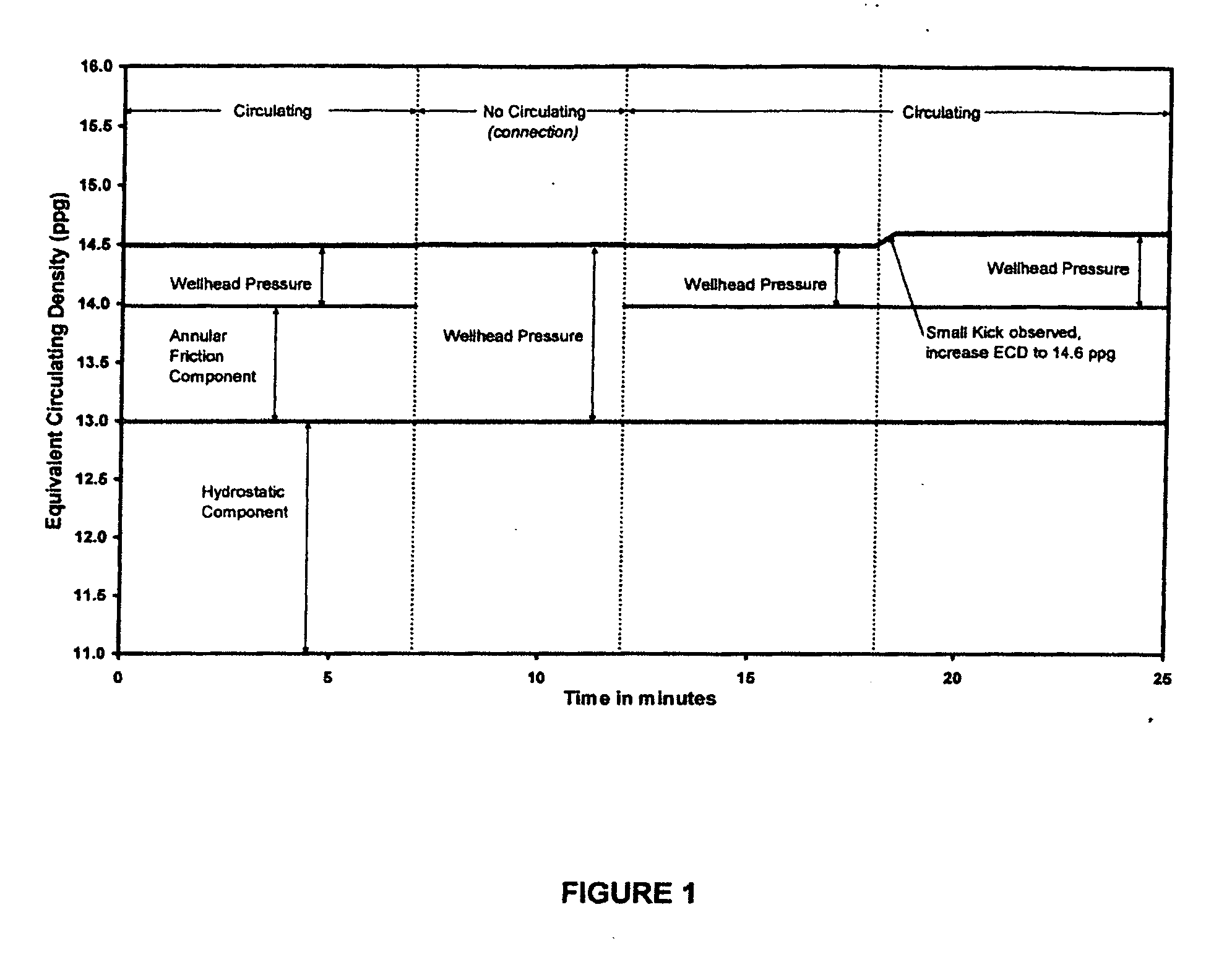

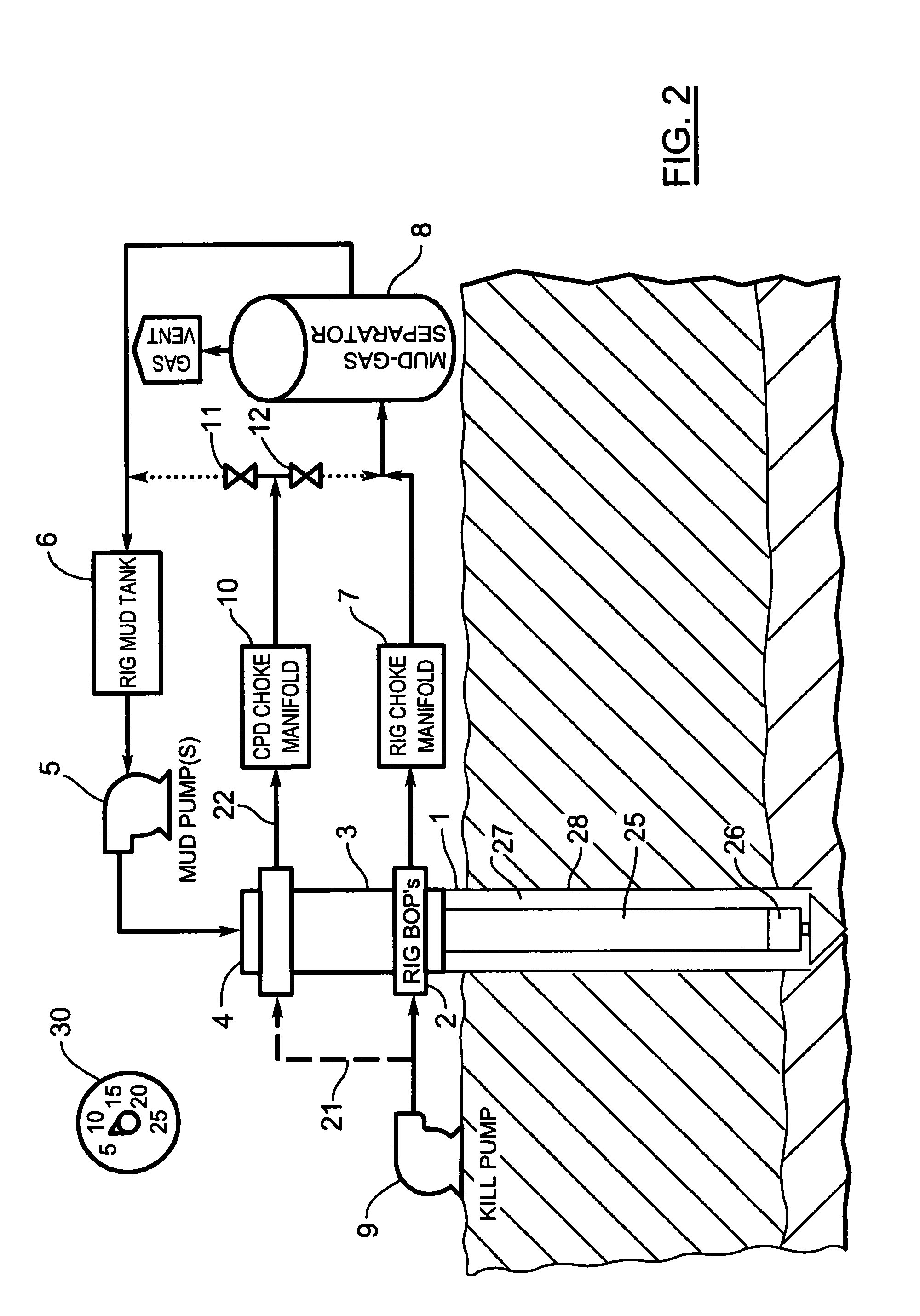

Method of dynamically controlling open hole pressure in a wellbore using wellhead pressure control

ActiveUS20060207795A1Simplified and efficient and relatively inexpensiveIncrease pumping rateFlushingDrilling compositionPressure controlled ventilationThrottle

A method of dynamically controlling open hole pressure within a wellbore having a drill string positioned therein. The method comprising the steps of pumping a fluid down the drill string, into an annulus formed by the drill string and the interior of the wellbore, and then subsequently up the annulus to the surface of the ground; selectively applying wellhead pressure to the annulus through selectively pumping an additional quantity of the fluid or a quantity of a secondary fluid across the annulus; and, controlling the application of wellhead pressure applied to the annulus by controlling one, or both, of (a) the operation of a wellhead pressure control choke, and (b) the flow rate of the additional quantity of fluid or the secondary fluid pumped across the annulus, to thereby maintain open hole pressure within a desired range.

Owner:WEATHERFORD CANADA

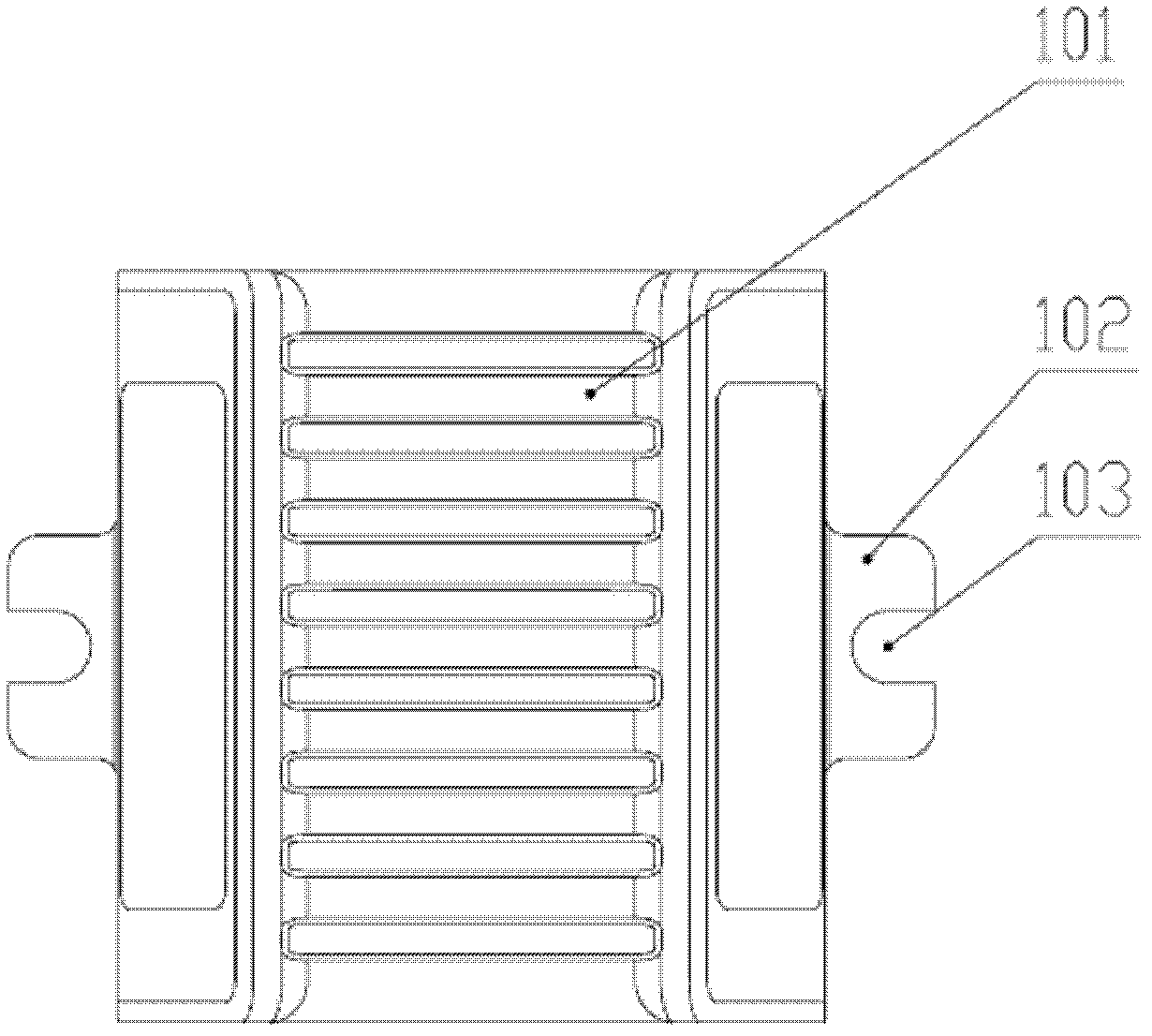

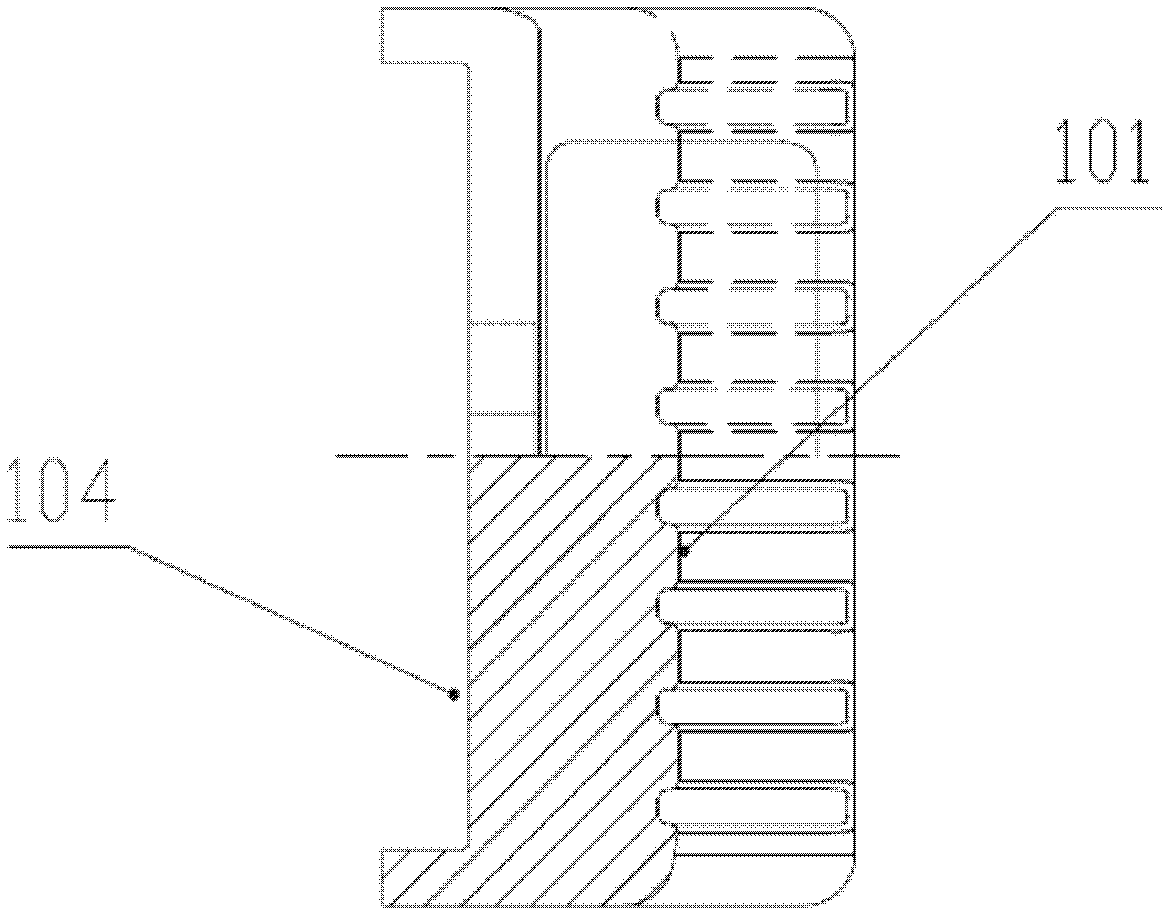

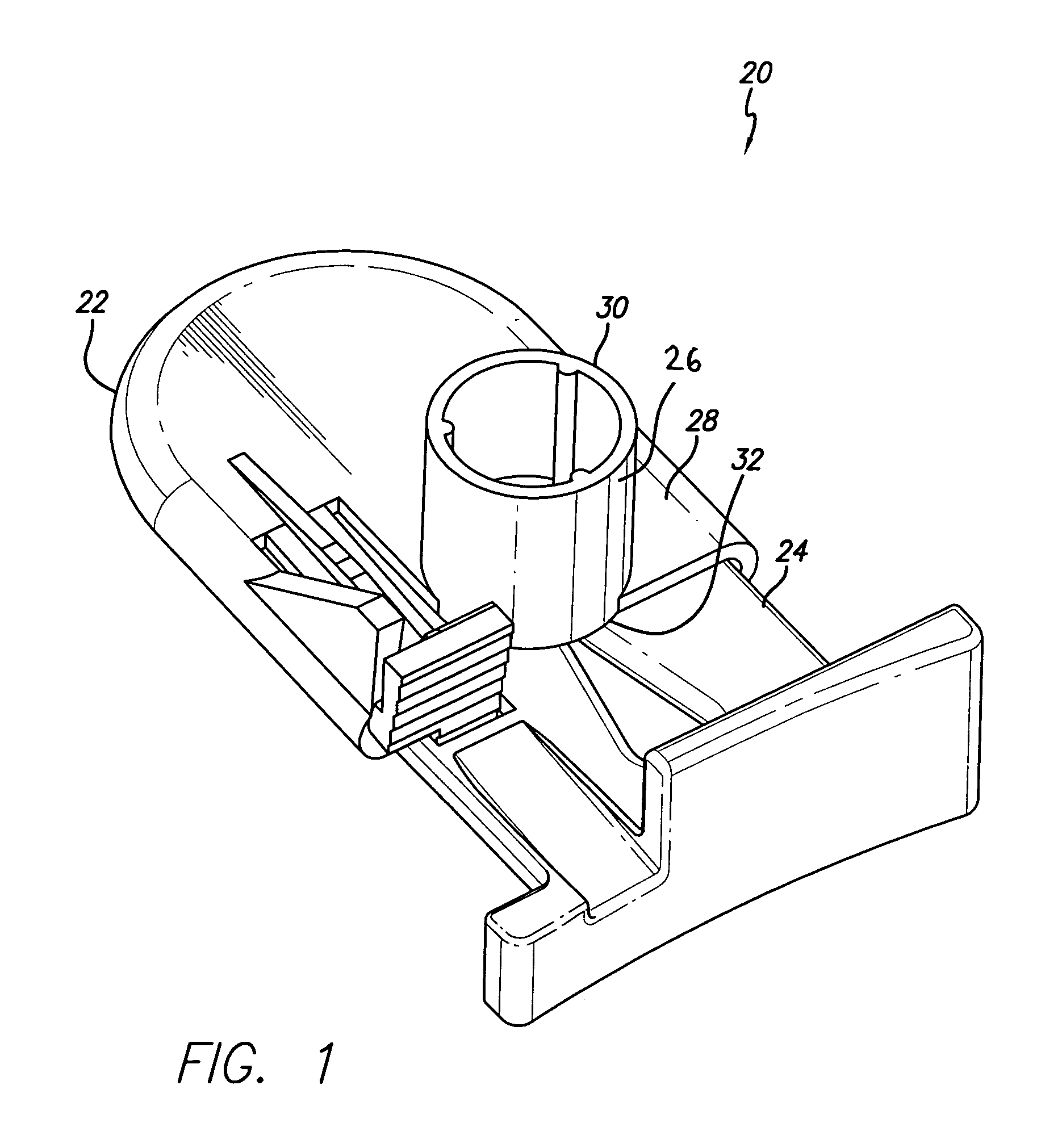

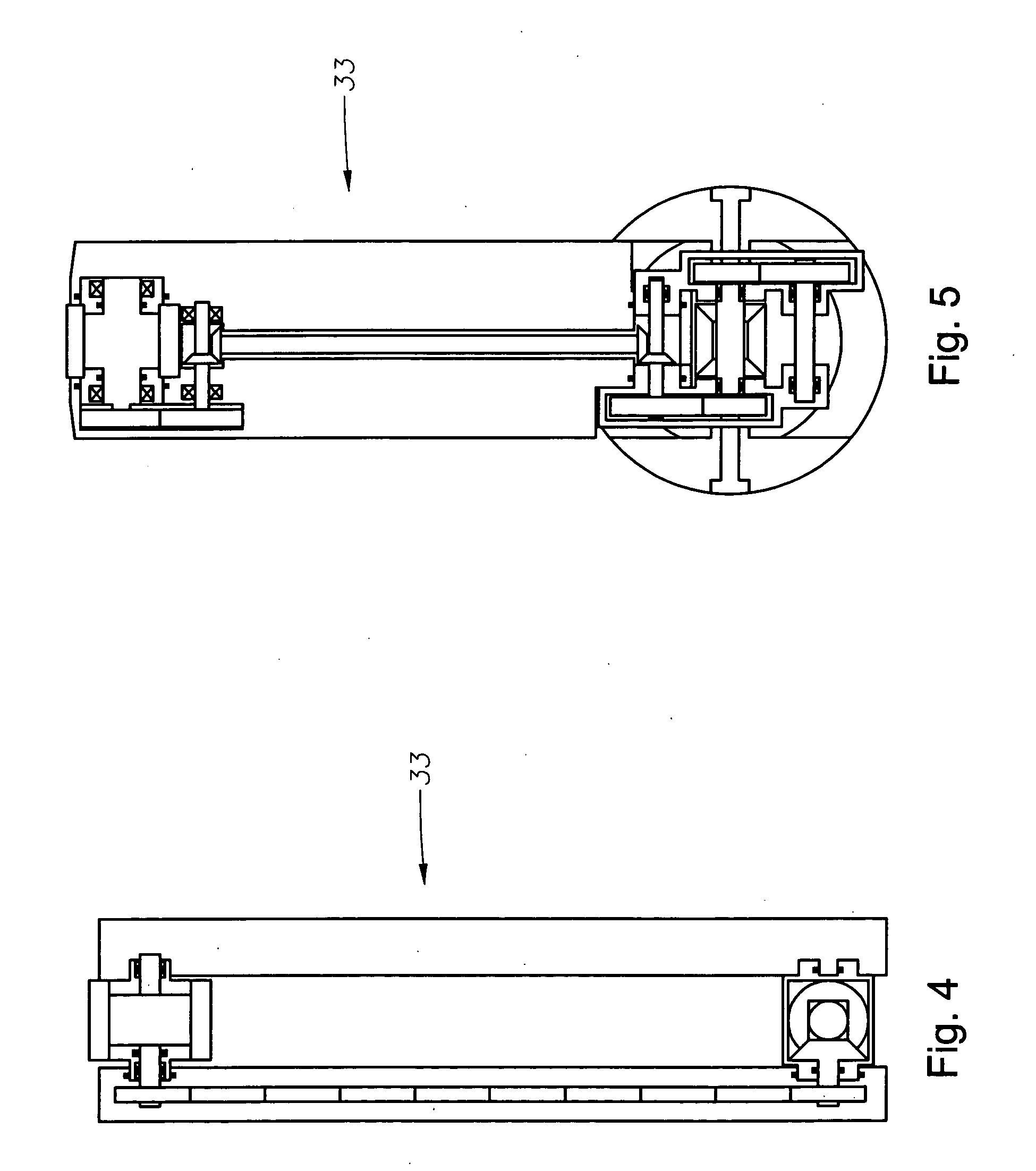

Coiled tubing clamping device and injection head using same

ActiveCN102704870BAvoid wear and tearImprove reliabilityDrilling rodsDrilling casingsCoiled tubingEngineering

A coiled tubing clamping mechanism comprises a saddle-shaped clamping block (1) and a clamping block seat (4). The saddle-shaped clamping block (1) is connected to the clamping block seat (4). Two sides of the saddle-shaped clamping block (1) are provided with a tongue platform (102). The tongue platform (102) is provided with an open hole (103). The back of the saddle-shaped clamping block (1) is provided with a groove (104). Two sides of the clamping block seat (4) are provided with a pair of bosses (406) respectively. The groove (104) of the saddle-shaped clamping block (1) is inserted in a holding slot (405) formed by the bosses (406) of the clamping block seat. A traverse gap is kept between the groove (104) and the holding slot (405). The clamping block seat (4) is provided with a positioning screw (2) for limiting the position of the saddle-shaped clamping block (1). Also disclosed is an injector head using the coiled tubing clamping mechanism, comprising a tubing clamping mechanism (11) and a drive chain (13). The tubing clamping mechanism (11) is mounted on the drive chain (13) through two pin holes (401) in the clamping block seat (4). The present invention can effectively prevent the tubing from being worn, is reliable in use, and makes it convenient to replace the clamping block.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

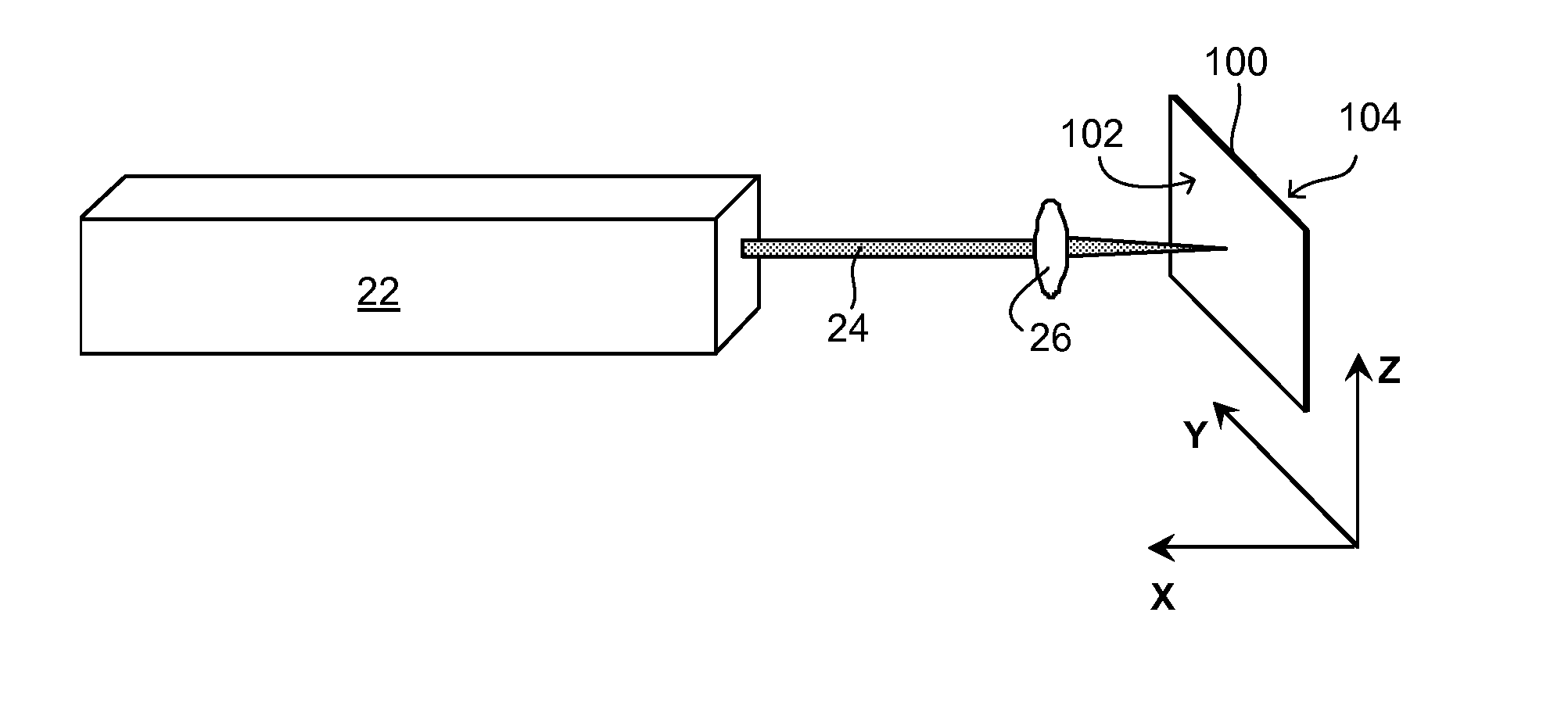

Methods of forming high-density arrays of holes in glass

ActiveUS20130247615A1High positioning accuracyReliable and low-costGlass furnace apparatusSemiconductor/solid-state device detailsUv laserEtching

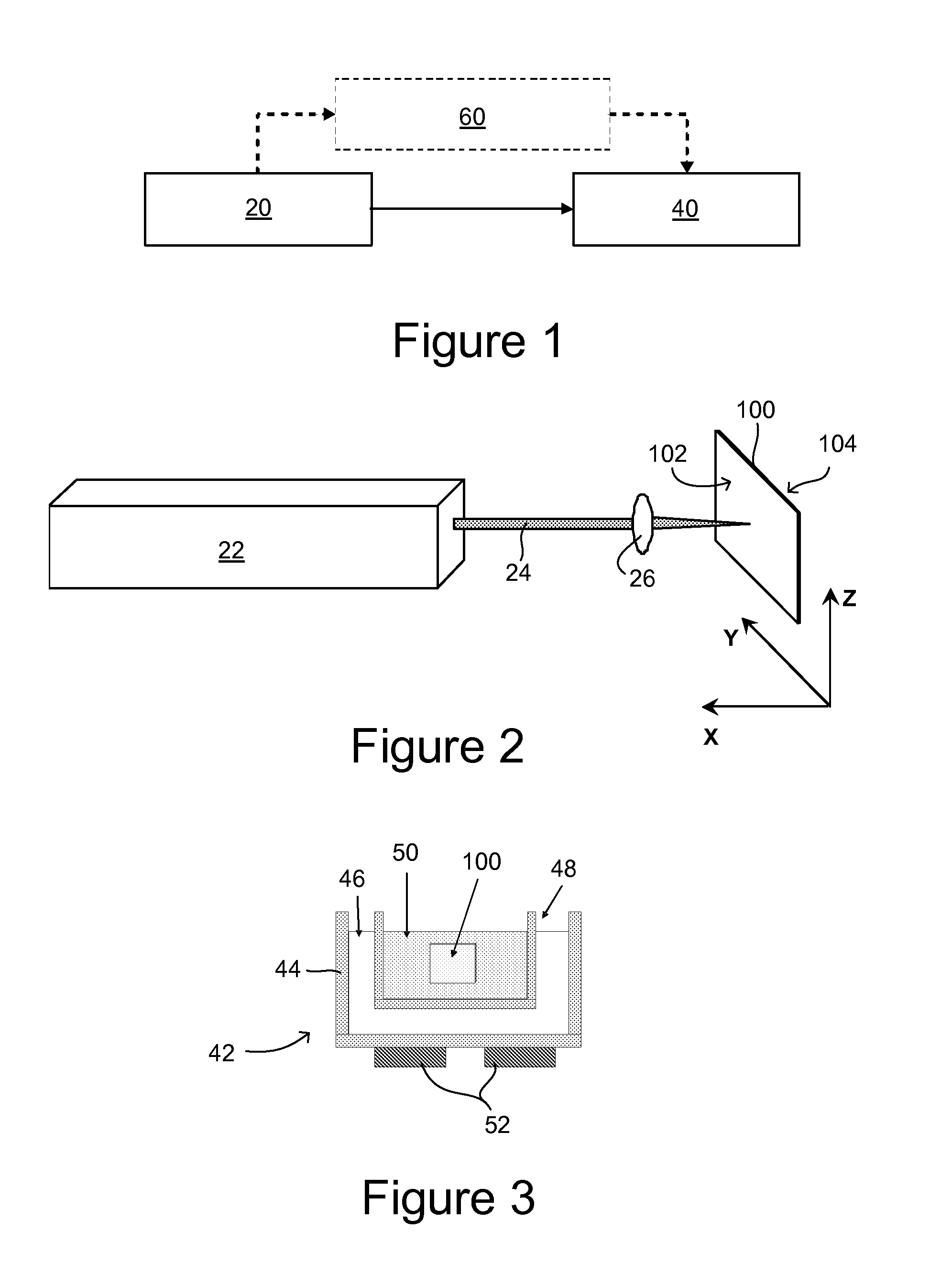

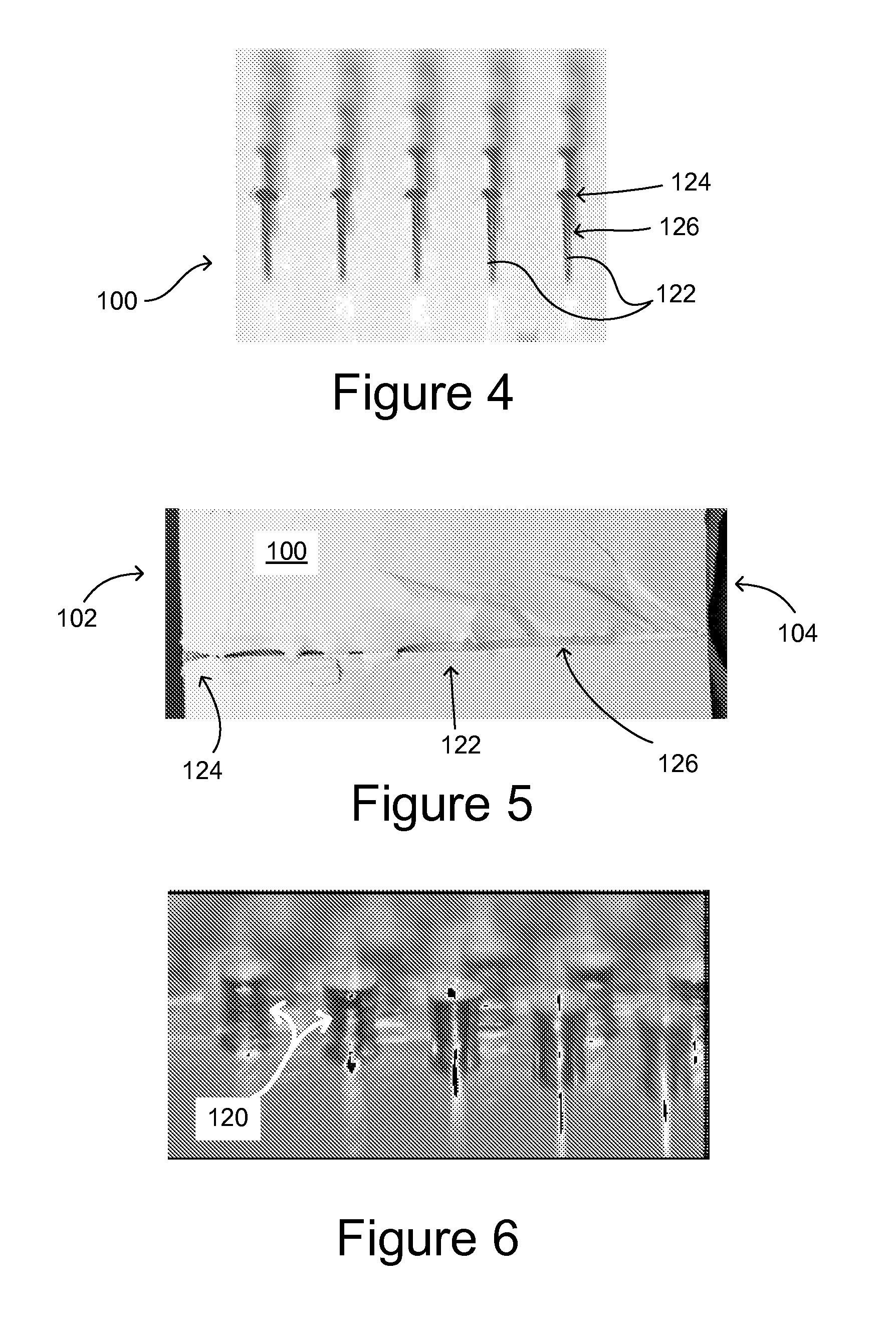

A method of fabricating a high-density array of holes in glass is provided, comprising providing a glass piece having a front surface, then irradiating the front surface of the glass piece with a UV laser beam focused to a focal point within + / −100 μm of the front surface of the glass piece most desirably within + / −50 μm of the front surface. The lens focusing the laser has a numerical aperture desirably in the range of from 0.1 to 0.4, more desirably in the range of from 0.1 to 0.15 for glass thickness between 0.3 mm and 0.63 mm, even more desirably in the range of from 0.12 to 0.13, so as to produce open holes extending into the glass piece 100 from the front surface 102 of the glass piece, the holes having an diameter the in range of from 5 to 15 μm, and an aspect ratio of at least 20:1. For thinner glass, in the range of from 0.1-0.3 mm, the numerical aperture is desirably from 0.25 to 0.4, more desirably from 0.25 to 0.3, and the beam is preferably focused to within + / −30 μm of the front surface of the glass. The laser is desirable operated at a repetition rate of about 15 kHz or below. An array of holes thus produced may then be enlarged by etching. The front surface may be polished prior to etching, if desired.

Owner:CORNING INC

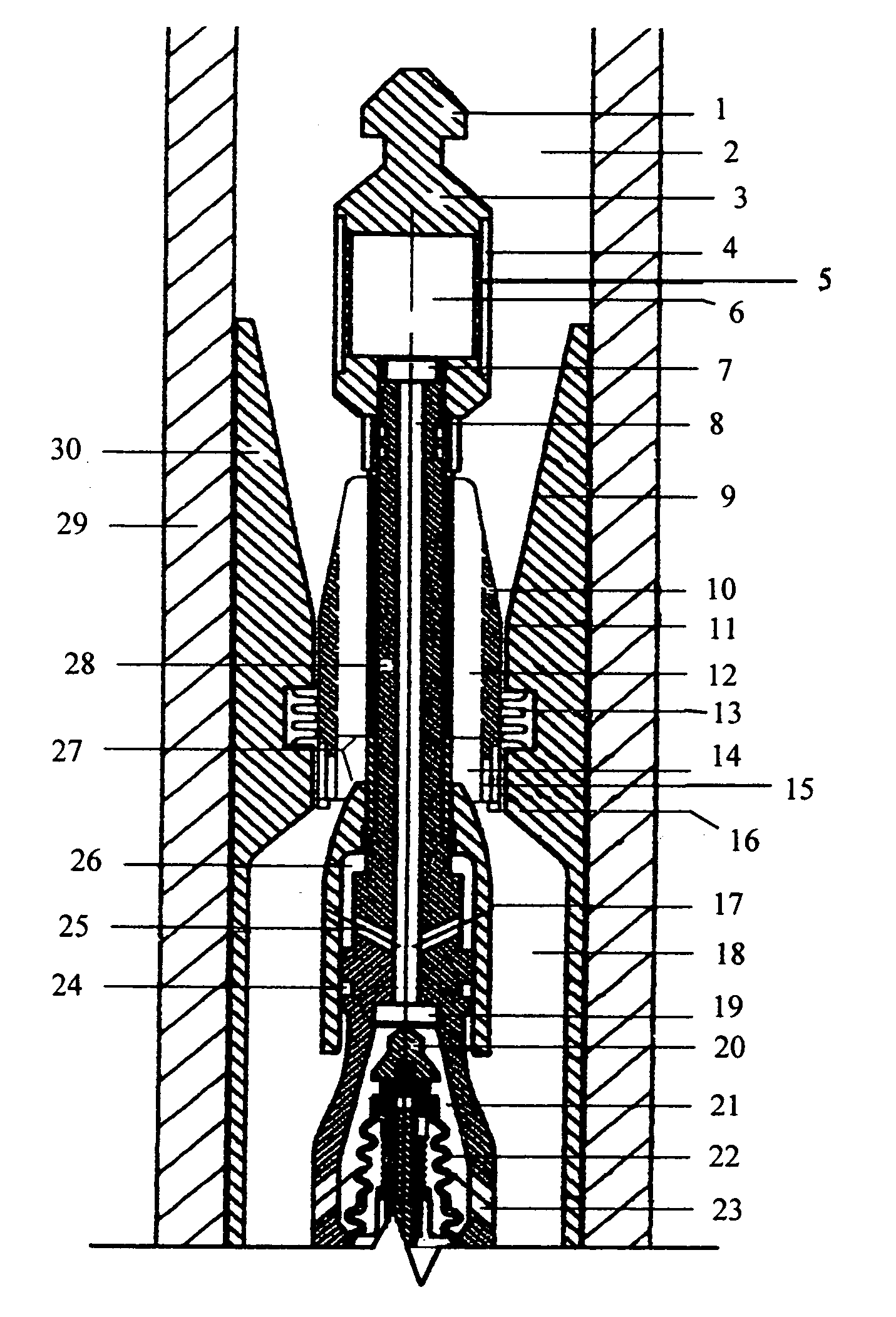

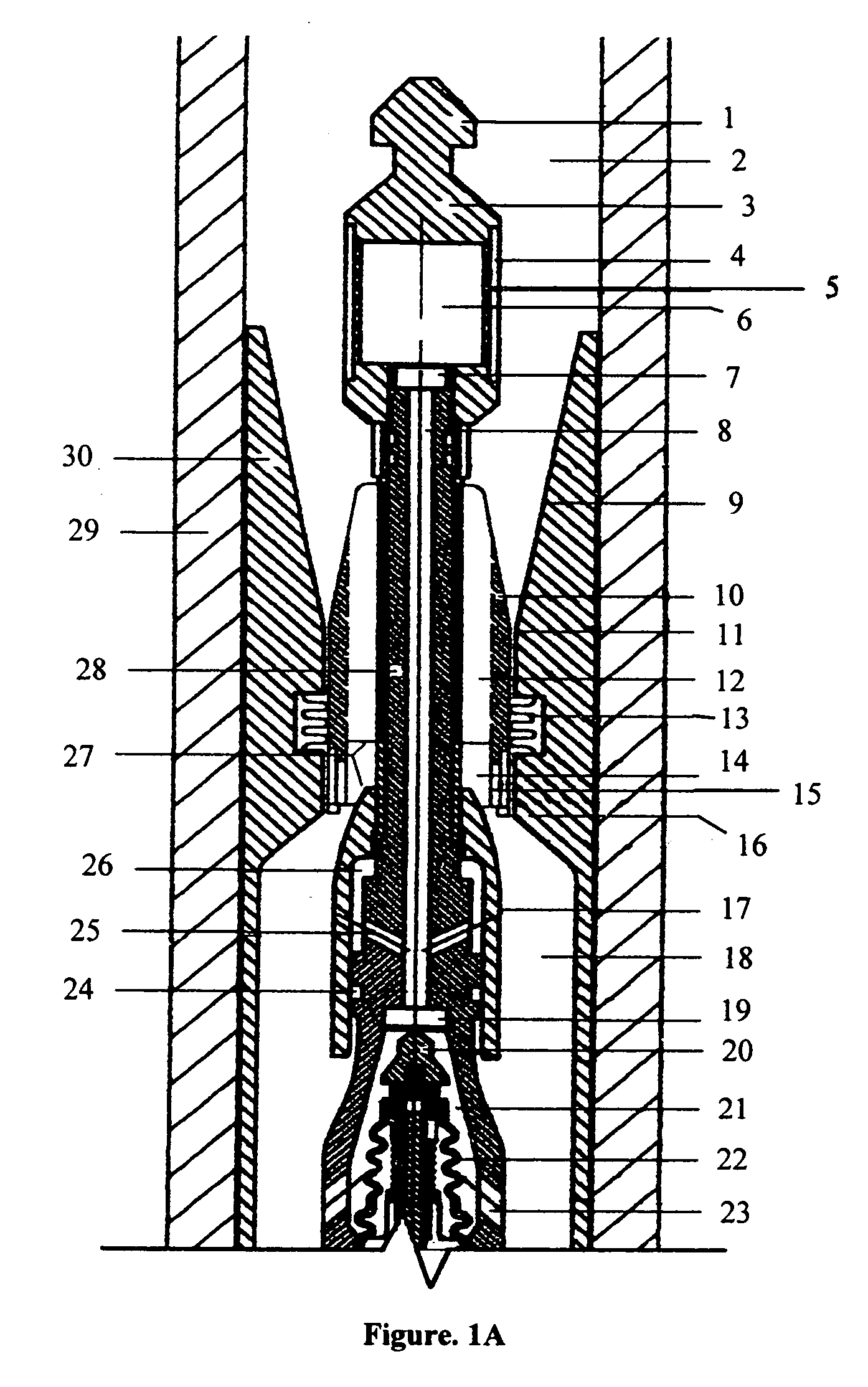

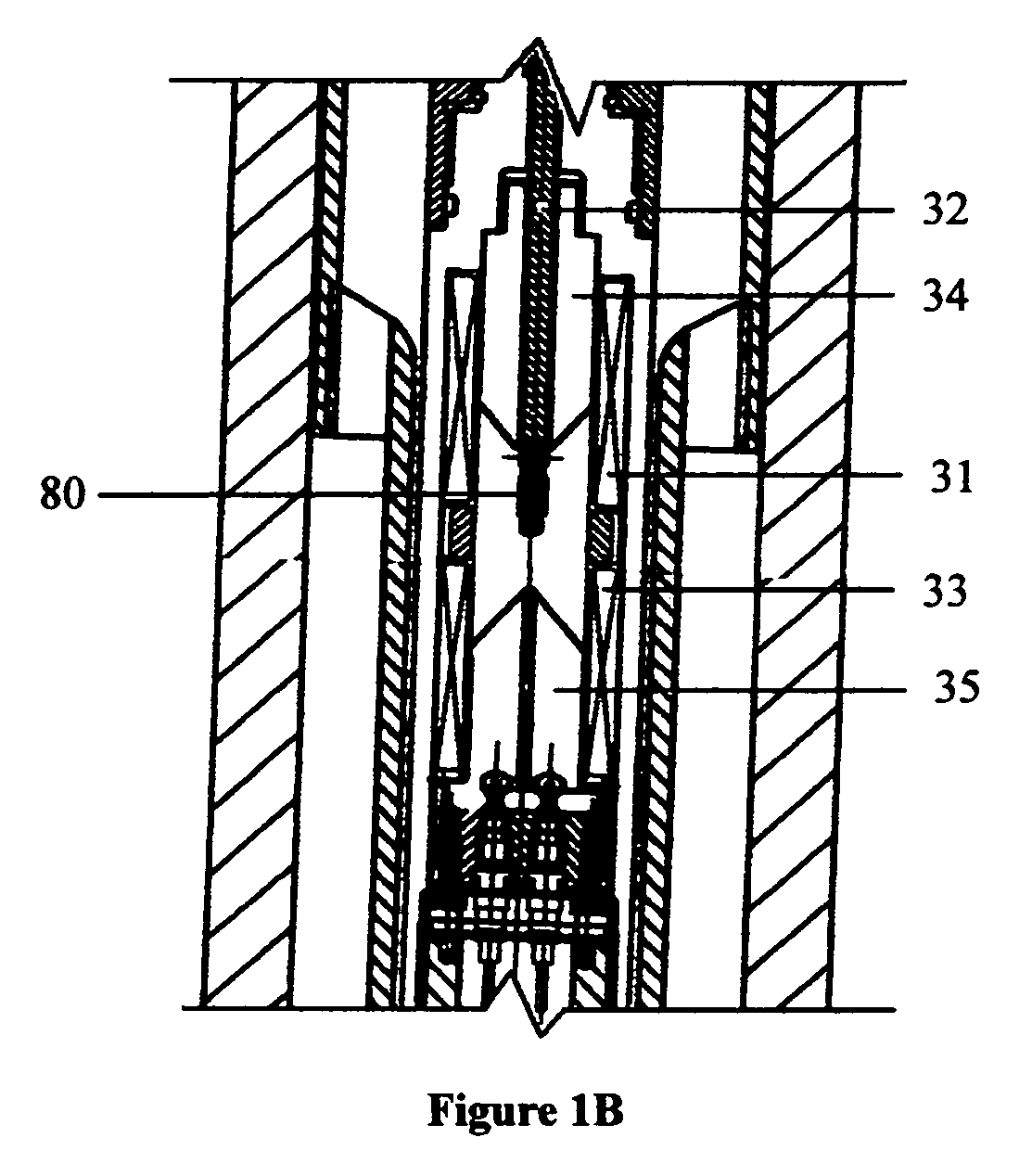

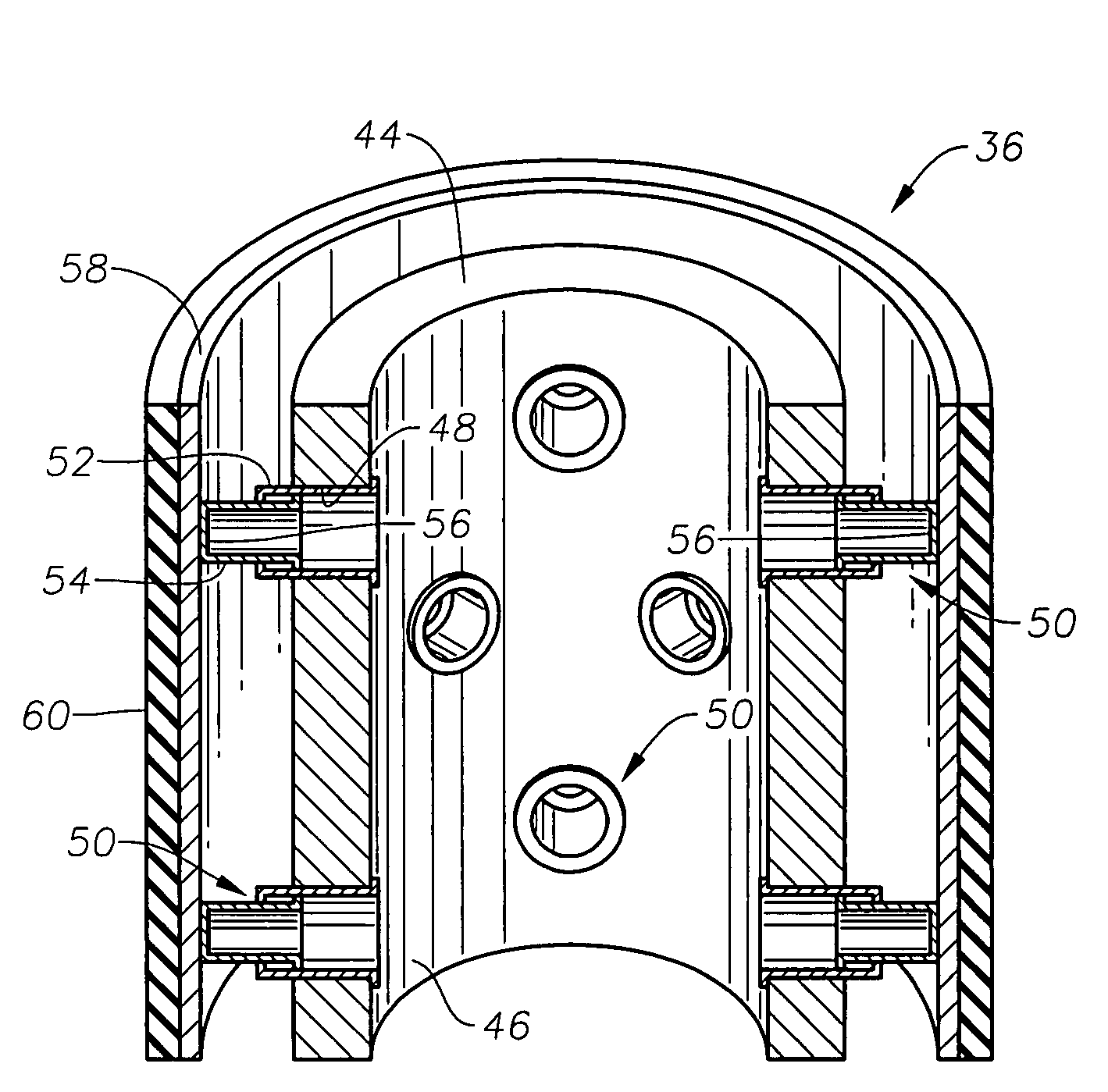

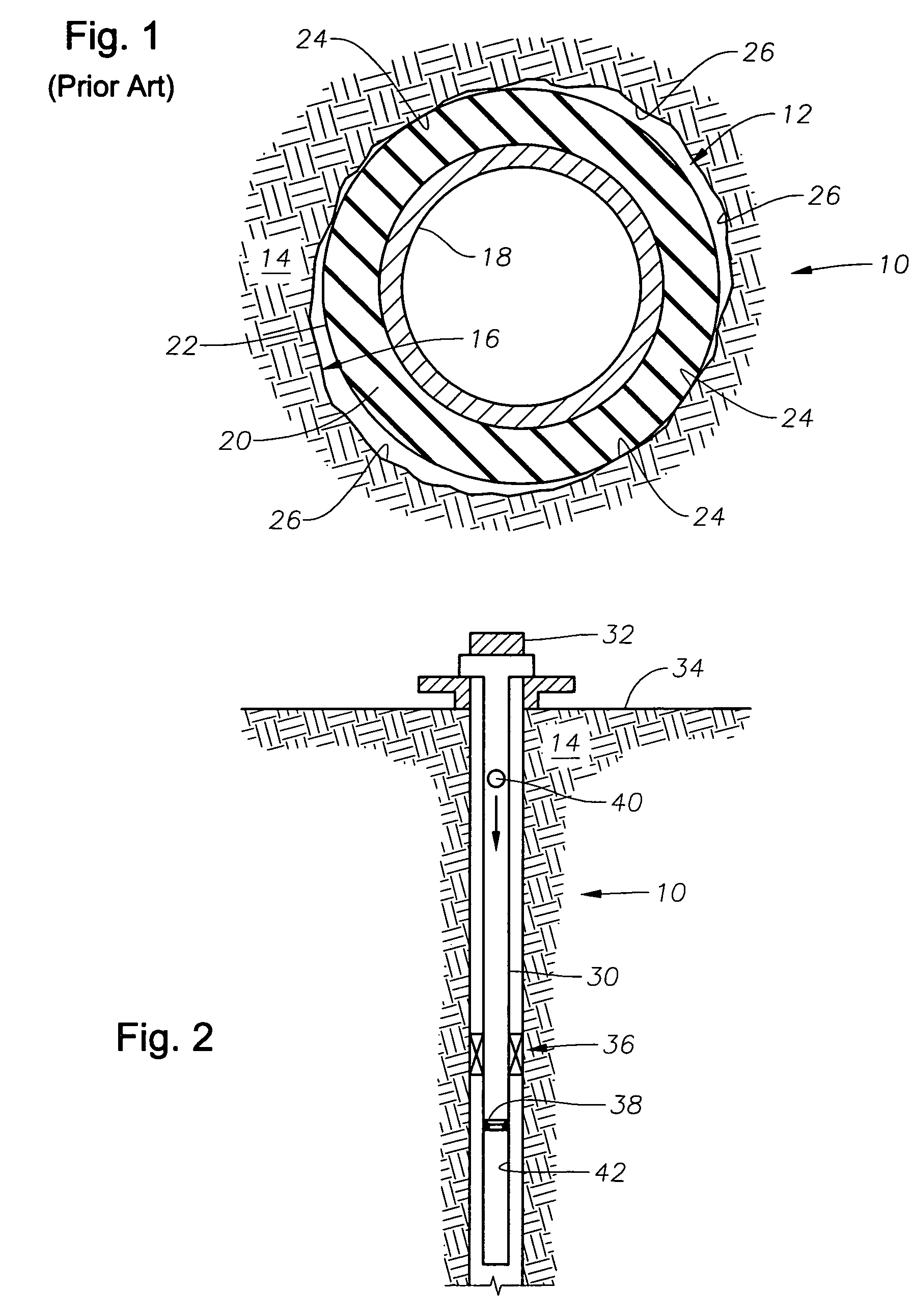

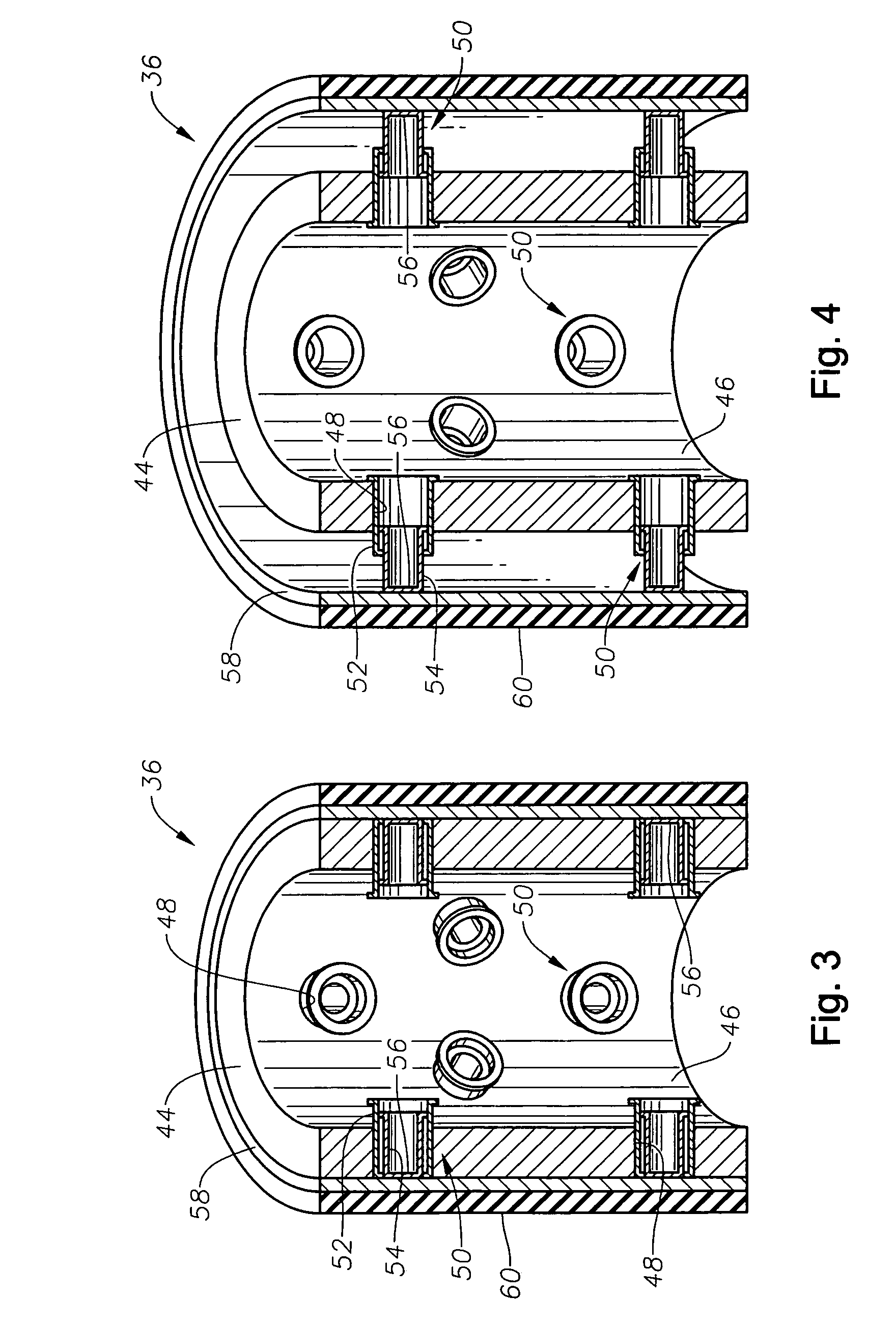

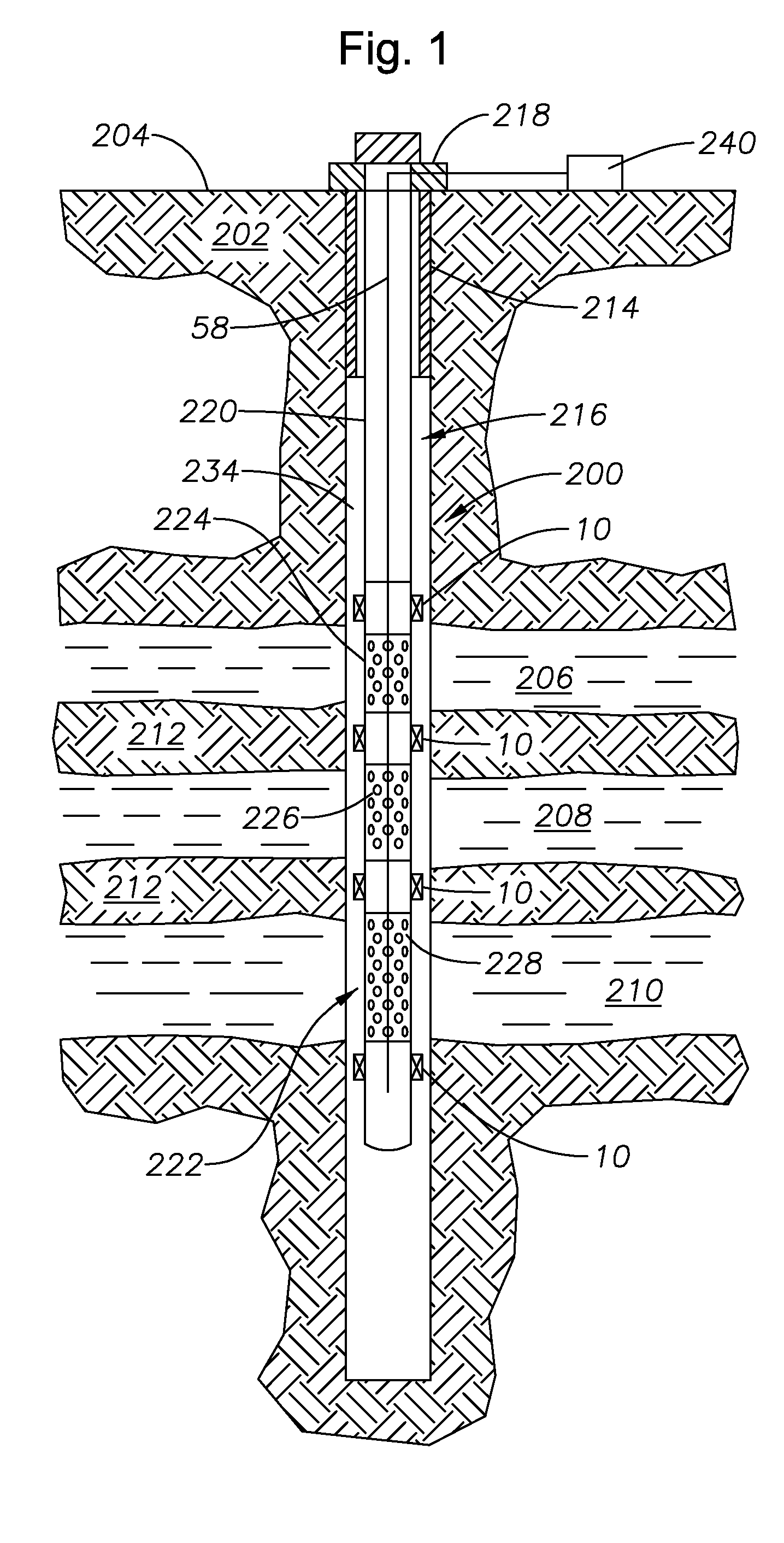

Cemented Open Hole Selective Fracing System

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

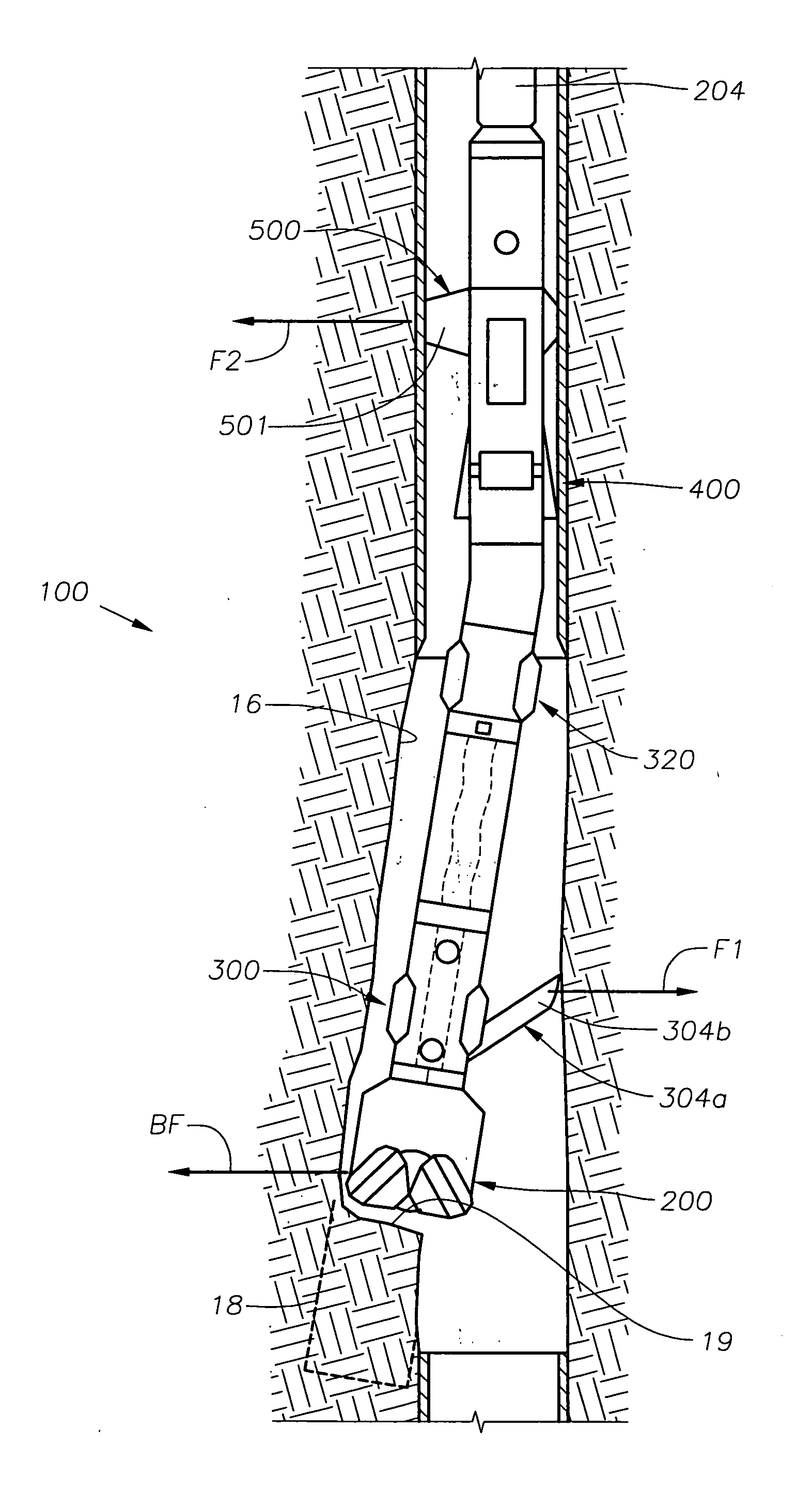

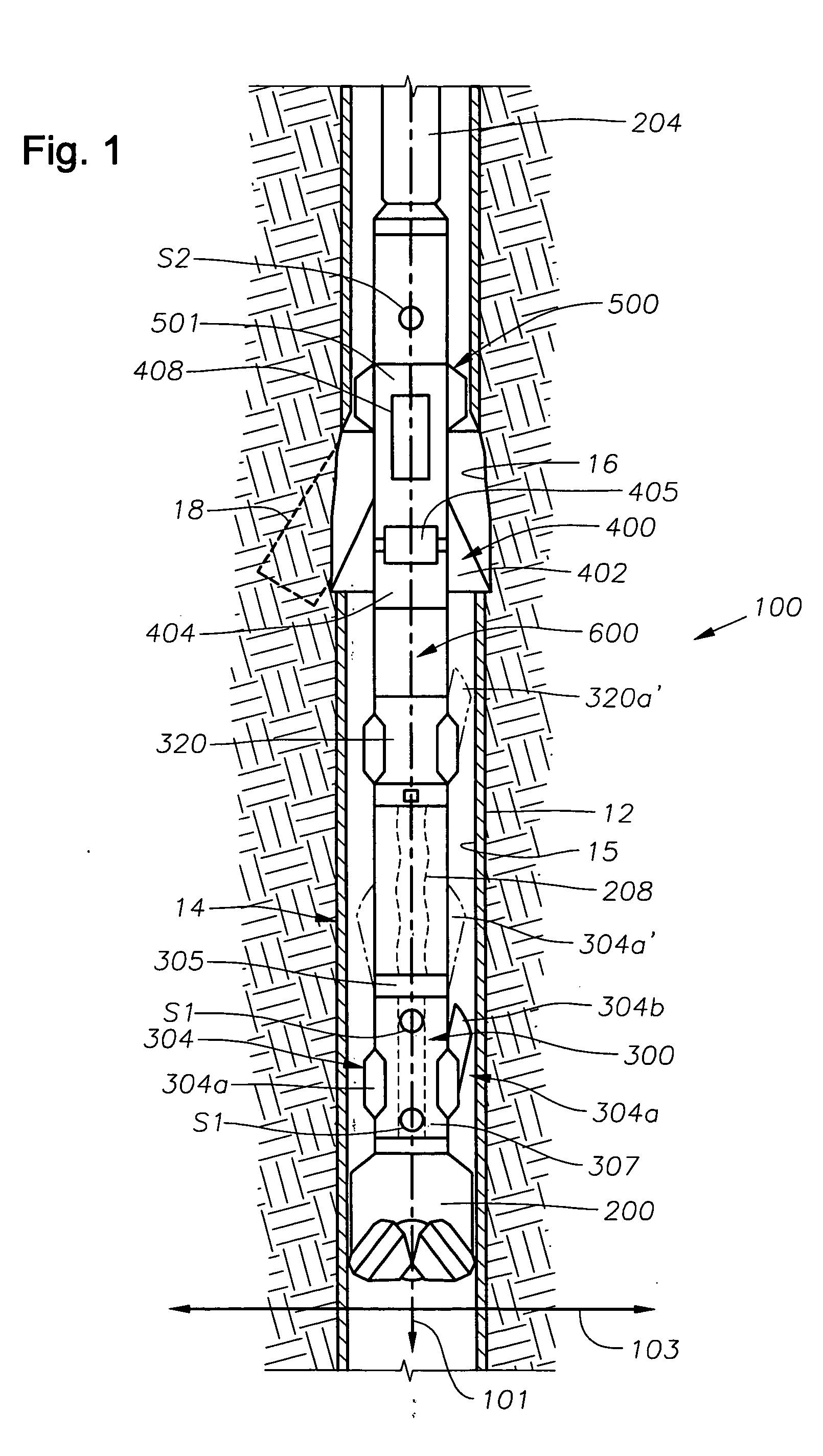

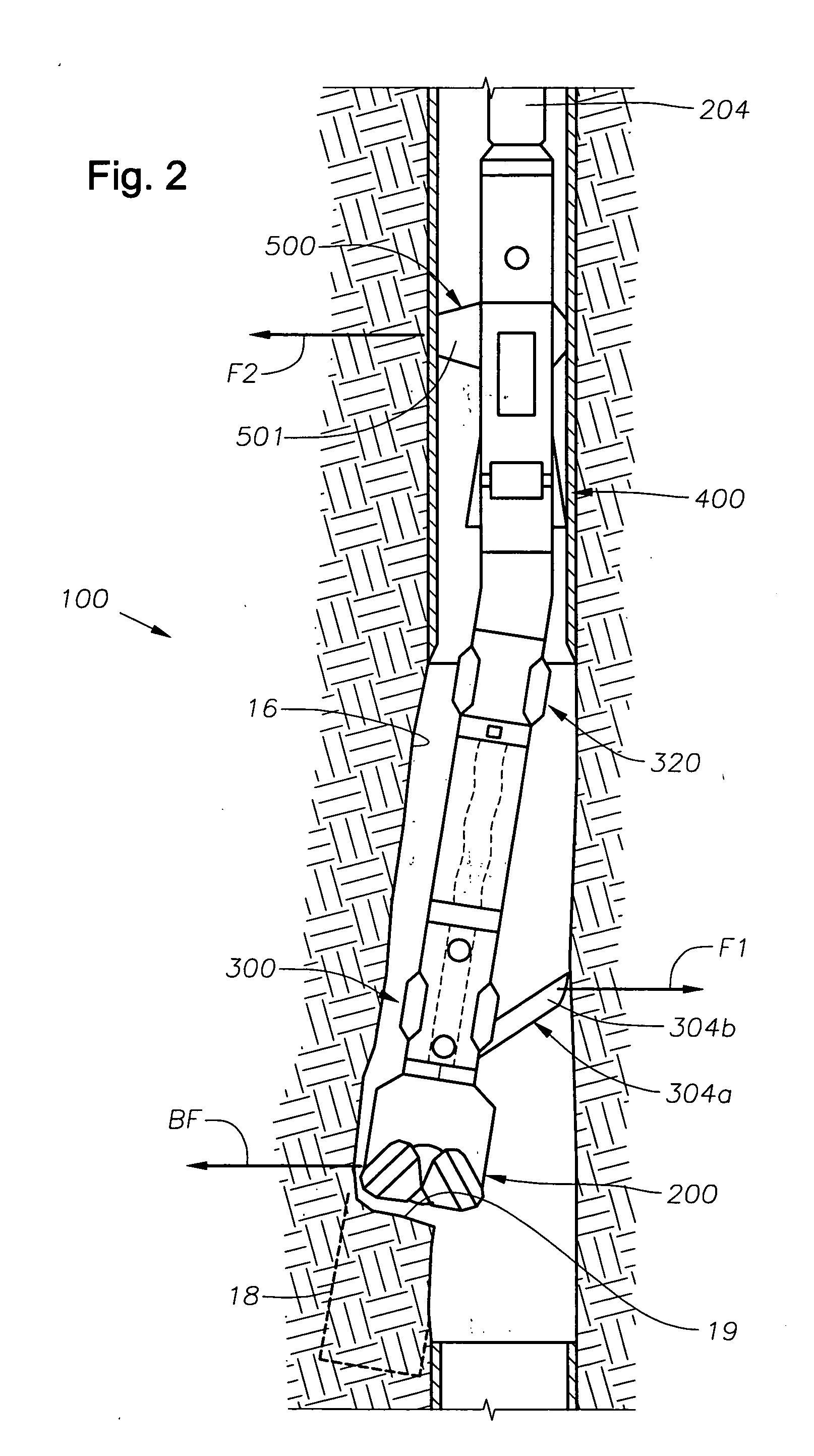

Directional cased hole side track method applying rotary closed loop system and casing mill

InactiveUS20050150692A1Easy to operateEasy to controlDrill bitsDrilling rodsWell drillingClosed loop

A bottomhole assembly (BHA) for single trip sidetracking operations has a mill for forming an open hole section in a cased wellbore and a steering unit for controlling drill bit orientation. During use, the drilling system is assembled at the surface and tripped into the wellbore. The mill is positioned adjacent a kick-off point and operated to form an open hole section. Thereafter, the drill bit is positioned adjacent the open hole section. An exemplary steering unit includes one or more force application members that, when energized, displace the drill bit such that the bit is pointed in a specified direction into the open hole section. The steering unit also includes one or more force application members that facilitate directional drilling through the open hole section. Other suitable steering units can employ devices that alter the BHA centerline geometry.

Owner:BAKER HUGHES INC

Method for removing filter cake from injection wells

InactiveUS6978838B2Eliminate needReduce capacity requirementsCleaning apparatusFluid removalBridge materialHigh rate

A method is given for completing an interval of an open-hole injection well penetrating a subterranean formation when the interface between the wellbore and the formation includes a zone invaded by a filter cake that includes bridging materials and other embedded solid materials. The method includes the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loosen some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid containing suspending additives; and then injecting a dissolving fluid containing a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

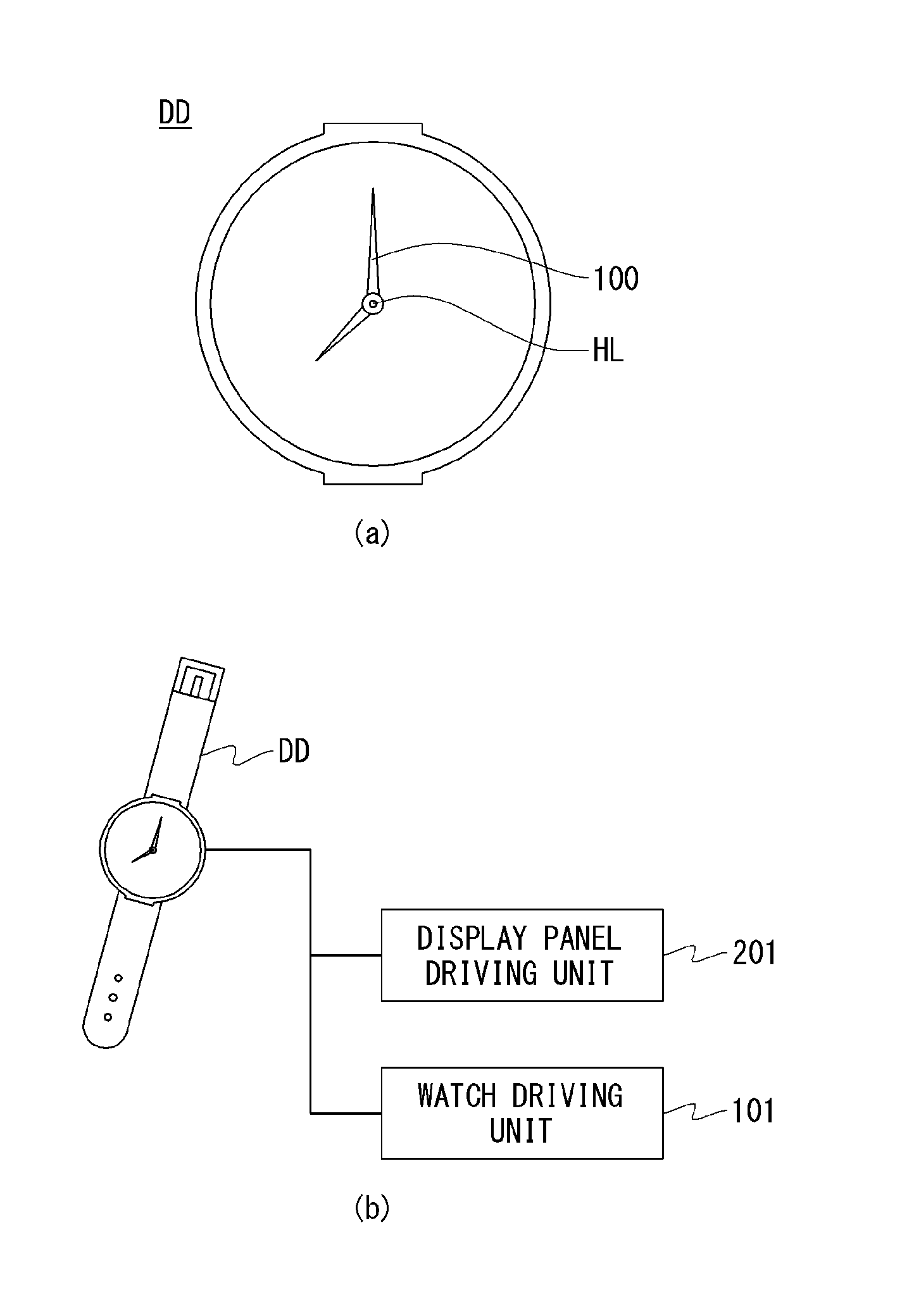

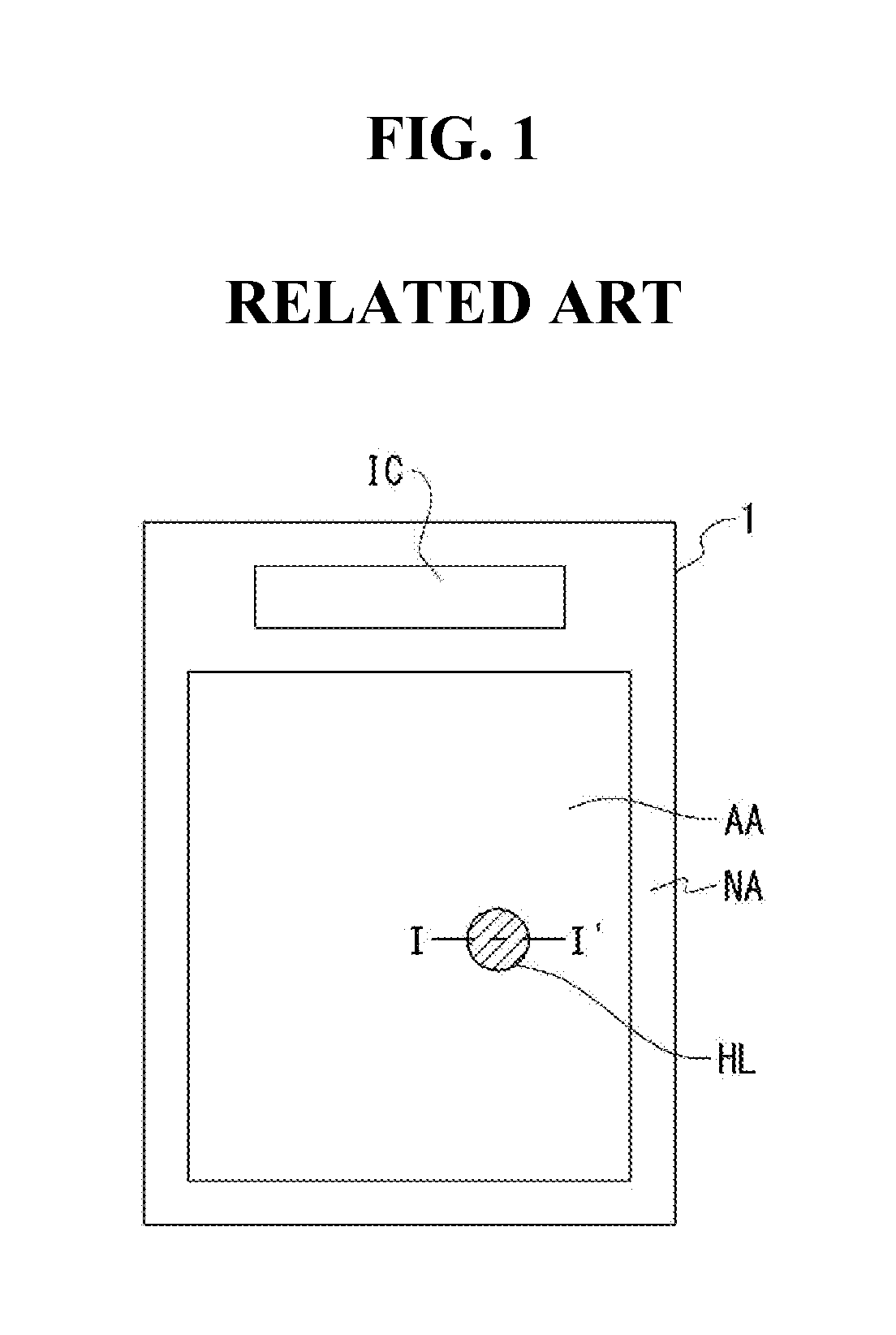

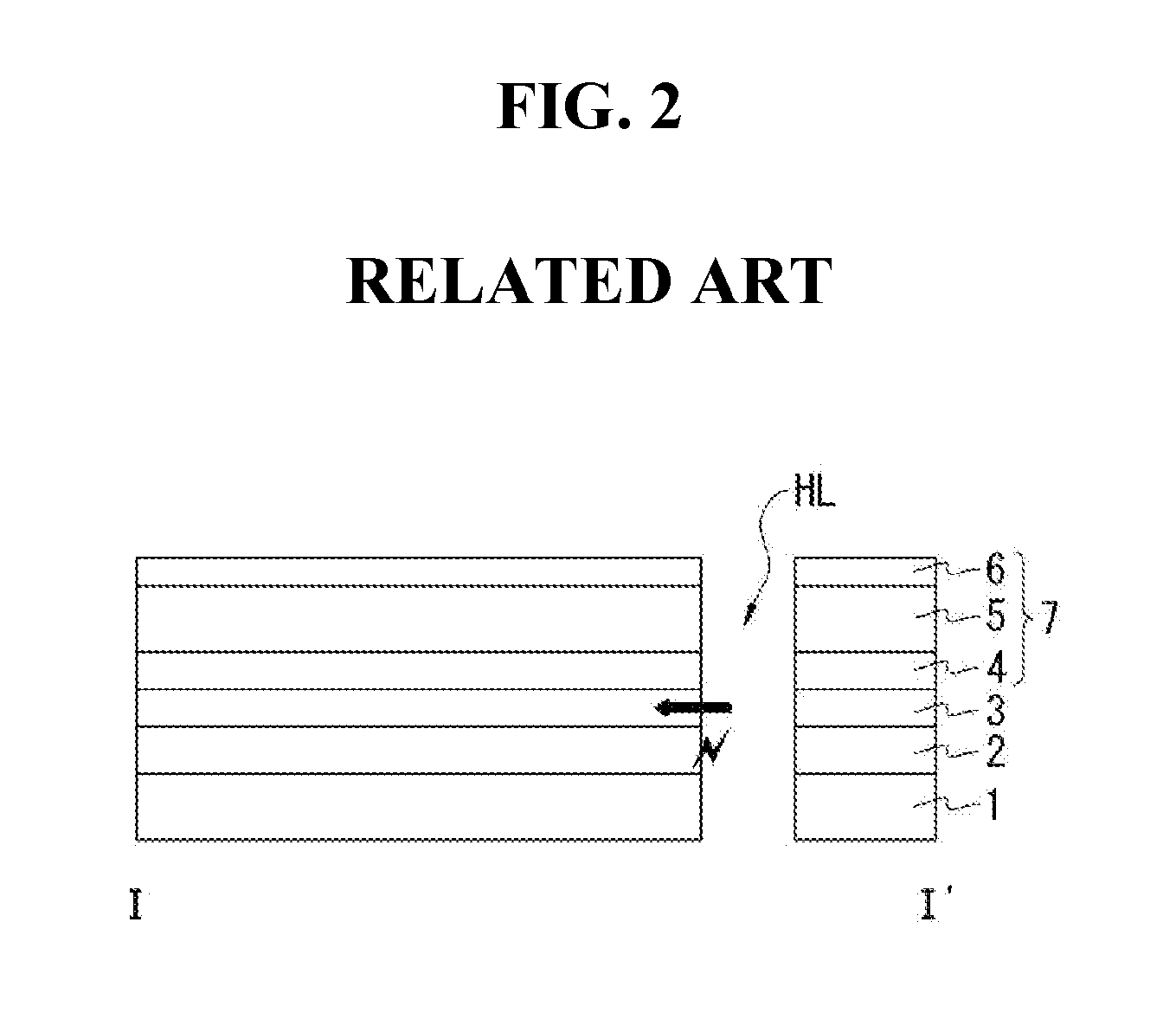

Organic light emitting display device

ActiveUS20170031323A1Improve stability and reliabilityHinders its propagationVisual indicationsSolid-state devicesOrganic layerDisplay device

Discussed is an organic light emitting display device including a substrate having a display area in which a plurality of plurality pixels are disposed, a non-display area outside of the display area, and at least one open hole area defined between the plurality of pixels, and a stacked layer structure disposed on the substrate and defining the plurality of pixels in the display area, the stacked layer structure including at least one organic layer, wherein the at least one open hole area includes at least one open hole penetrating through the substrate and at least one partition disposed along a circumference of the at least one open hole between the at least one open hole and the plurality of pixels adjacent thereto to separate the at least one organic layer from a corresponding layer that extends to the at least one open hole.

Owner:LG DISPLAY CO LTD

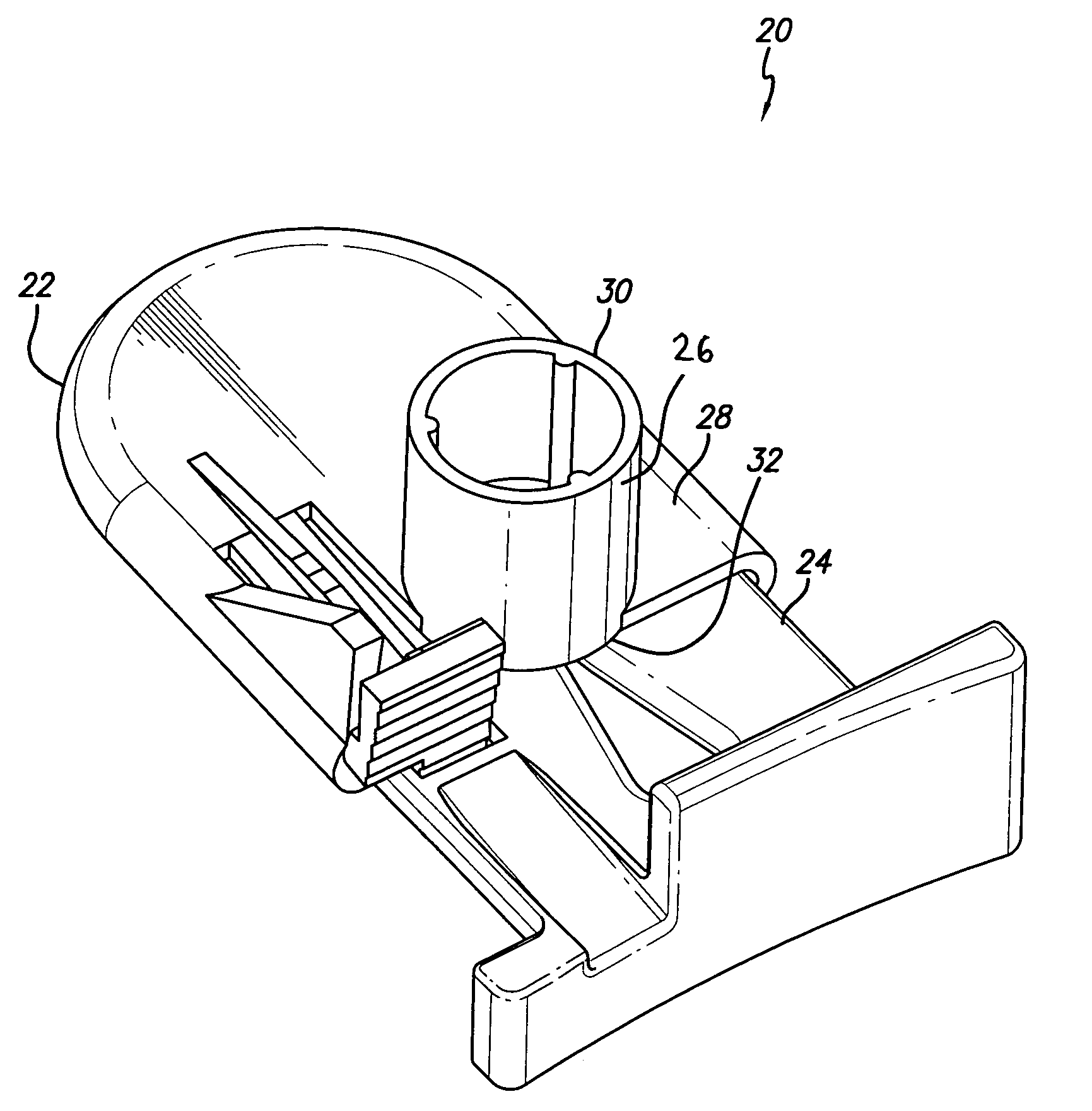

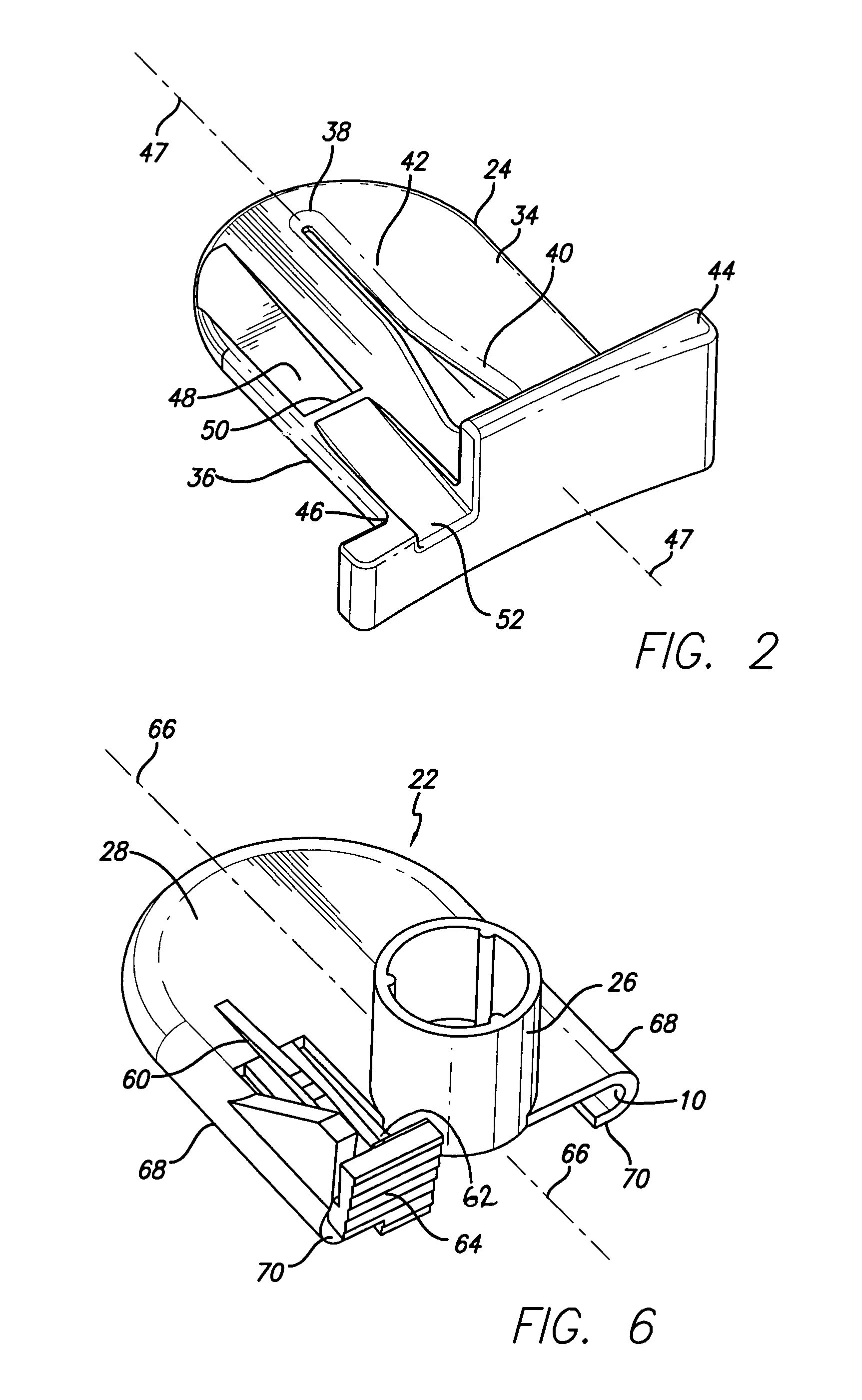

Automatic clamp apparatus for IV infusion sets used in pump devices

A clamp apparatus for selectively occluding a resilient tube to prevent free flow of fluid in the tube. The device comprises a base member to which the resilient IV tube is attached or through which it passes, and a slide clamp that slides relative to the base member and relative to the tube. The aperture in the slide clamp has a relatively open hole at one end, through which the tube passes when the slide clamp is an open position, allowing fluid to flow through the tube. The aperture also has a relatively constricted slot at the other end, through which the tube passes when the slide clamp is in the occluding position, preventing fluid flow through the tube. A deflectable cantilevered locking arm on the base interlocks with a detent on the slide clamp to lock the slide clamp at the occluding position to avoid inadvertent free flow. A release tab that is used to release the locking arm from the slide clamp is located off center to avoid inadvertent activation. The deflectable arm is unstressed when the slide clamp is in either the occluding or the open positions. A stop device prevents over-stressing the release tab when it is moved. In one embodiment, the clamp apparatus may be slid along the IV tube to a desired location.

Owner:CAREFUSION 303 INC

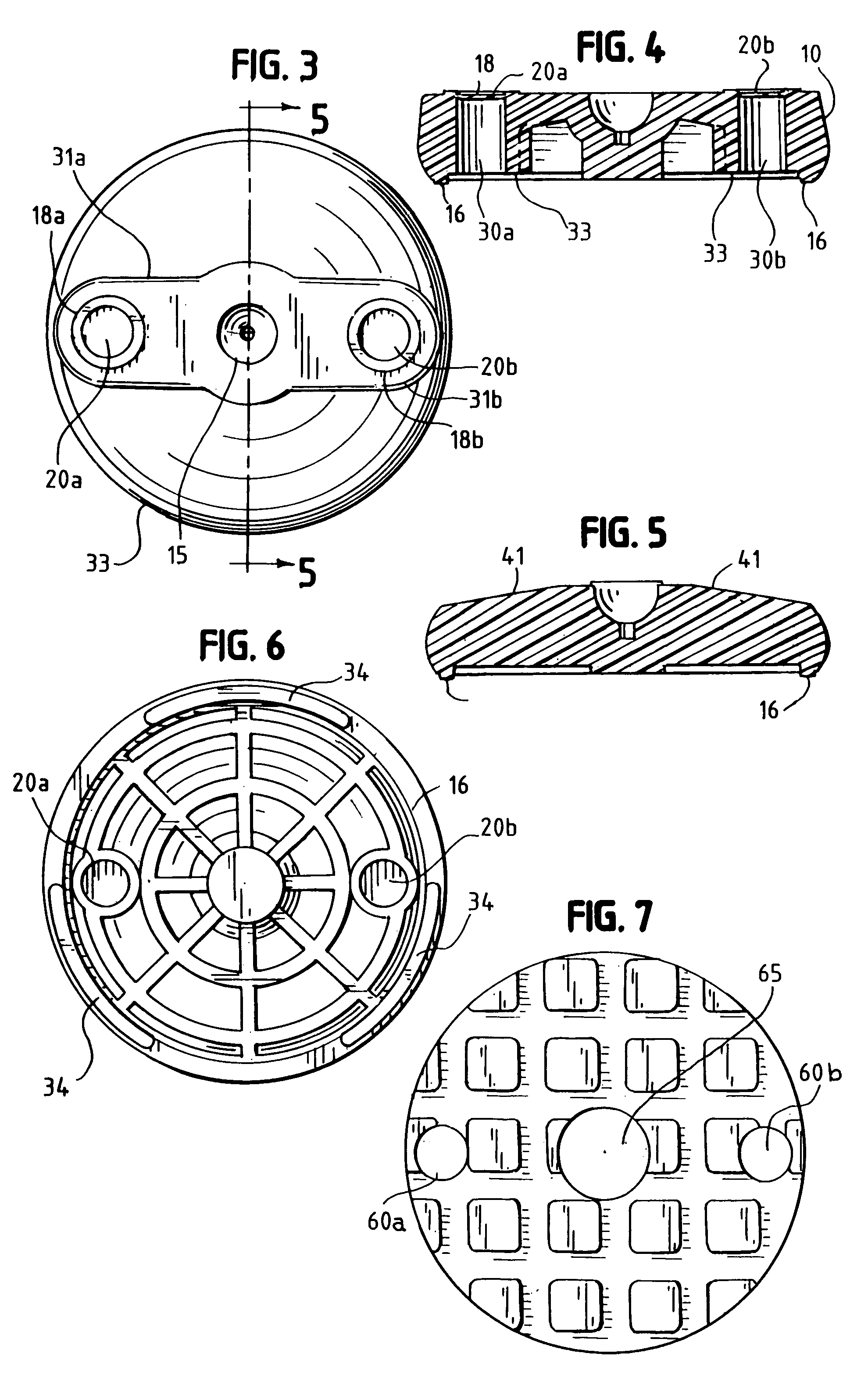

Frac-pack casing saver

InactiveUS7559357B2Prevent and minimize direct impingementSimply replacedFluid removalHigh velocityWellbore

Owner:BAKER HUGHES HLDG LLC

Method of fabricating a circuit arrangement with thermal vias

InactiveUS6190941B1Prevent penetrationThe method is simple and reliablePrinted circuit assemblingFinal product manufactureScreen printingEngineering

An electronic component is mounted on a substrate such as a circuit board by means of a soldering process such as reflow soldering. The circuit board has a thermal via hole therethrough to provide a heat dissipation path from the top surface to the bottom surface of the circuit board, for dissipating heat from the electronic component. To prevent molten solder from penetrating through the via hole during the soldering process, the via hole is sealed prior to the soldering process. The via hole is sealed from the bottom surface of the substrate by carrying out a screen printing process including at least two printing passes to print a sealing material into the open hole of the thermal via.

Owner:DAIMLER AG

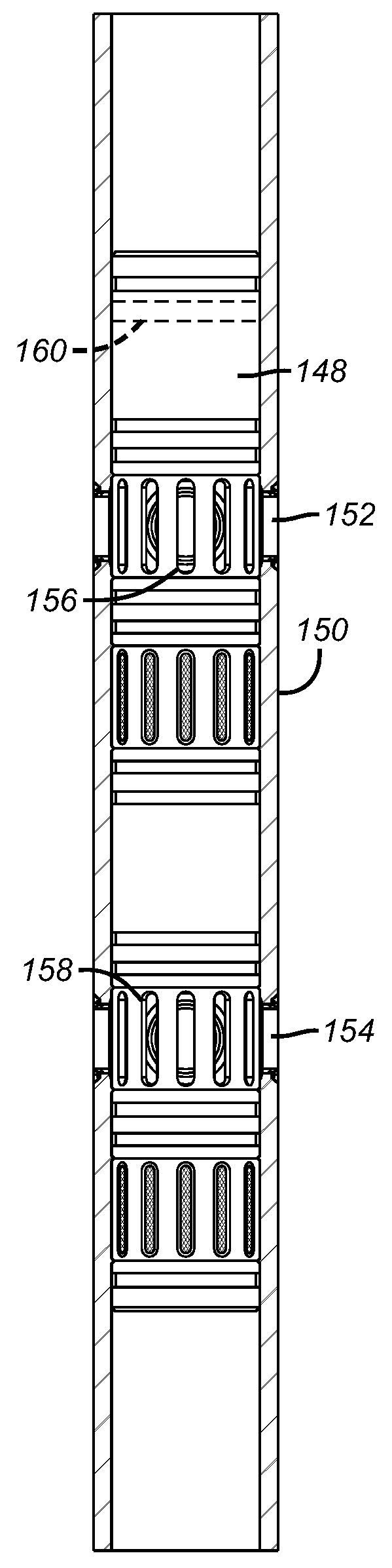

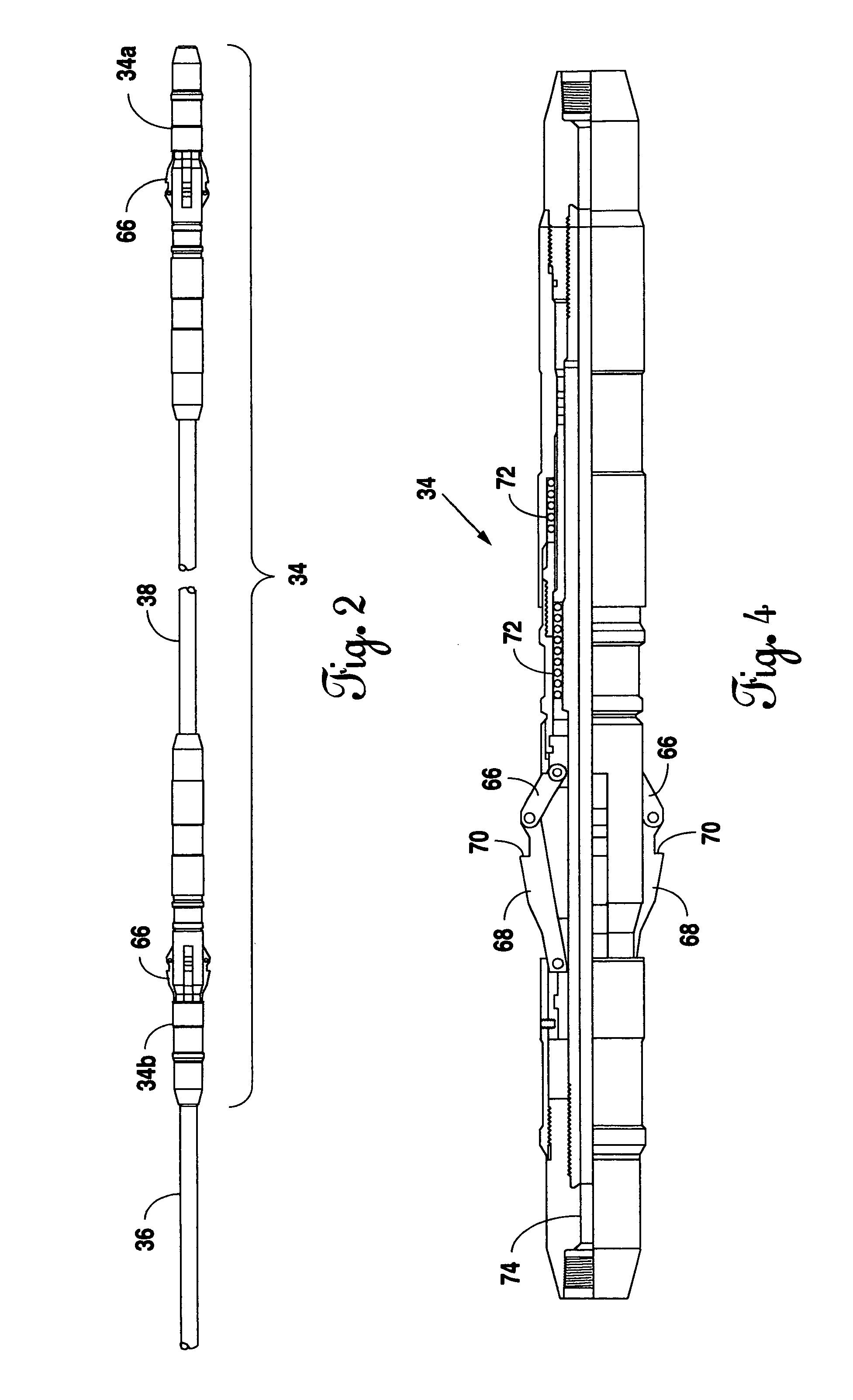

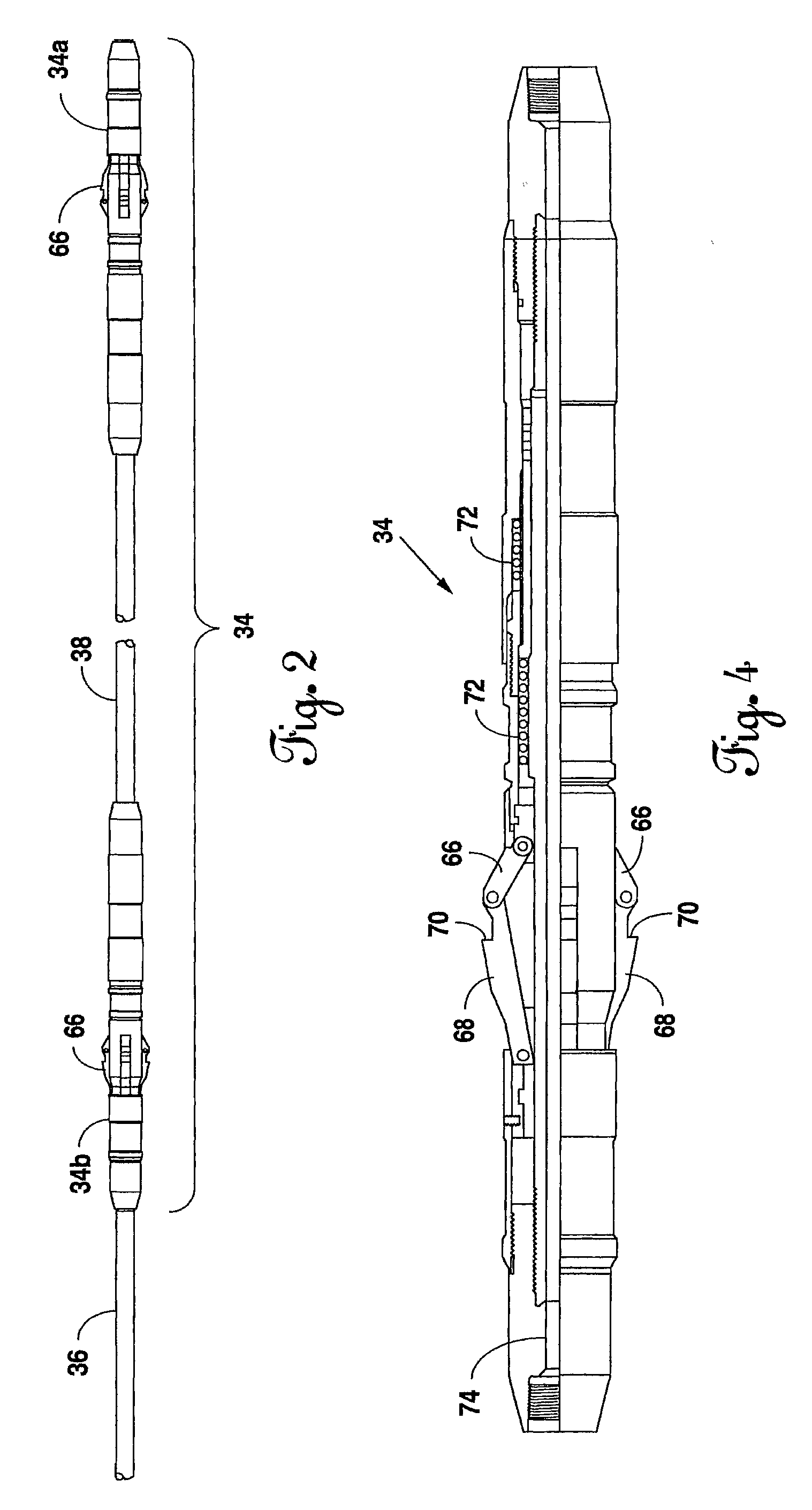

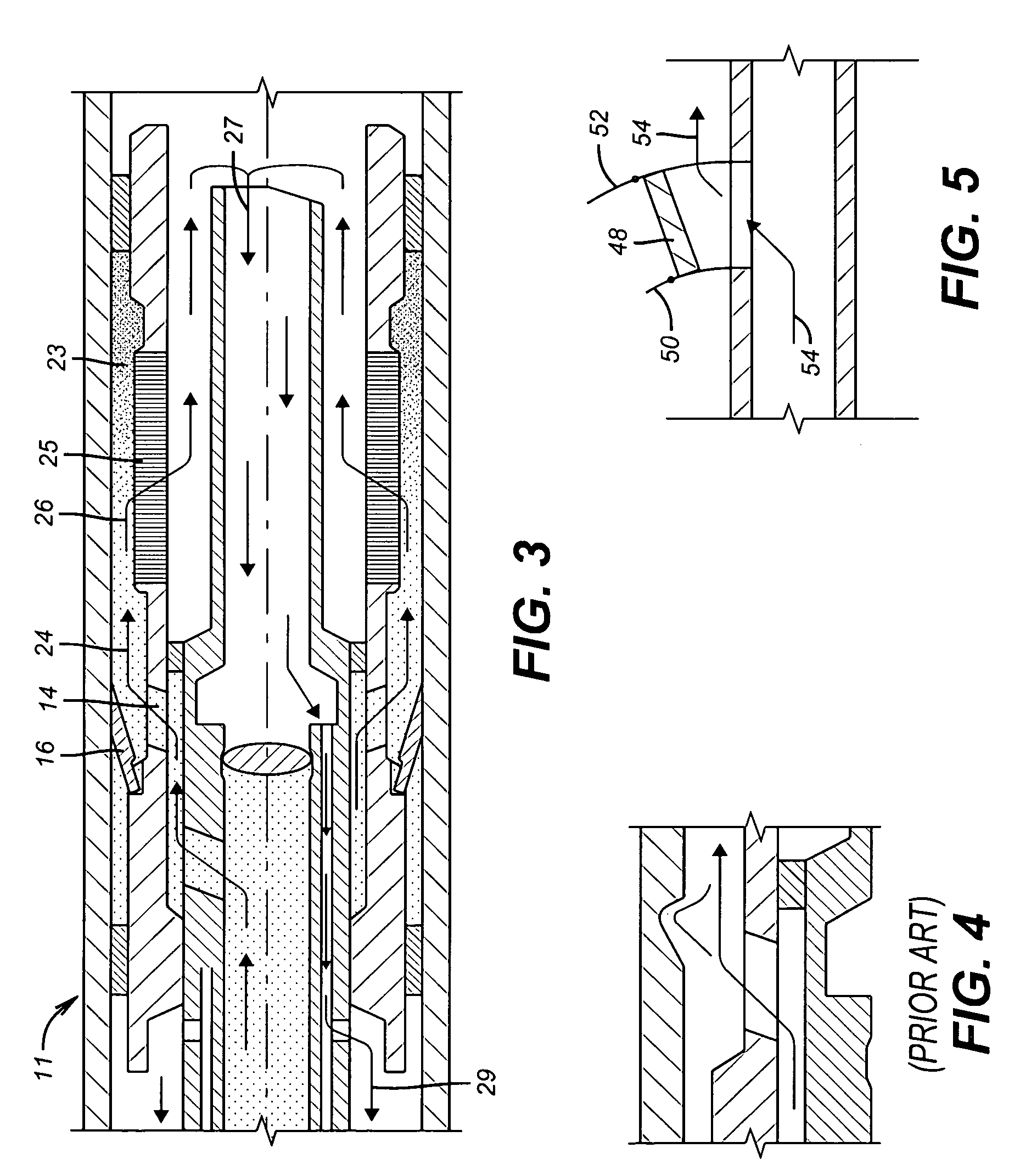

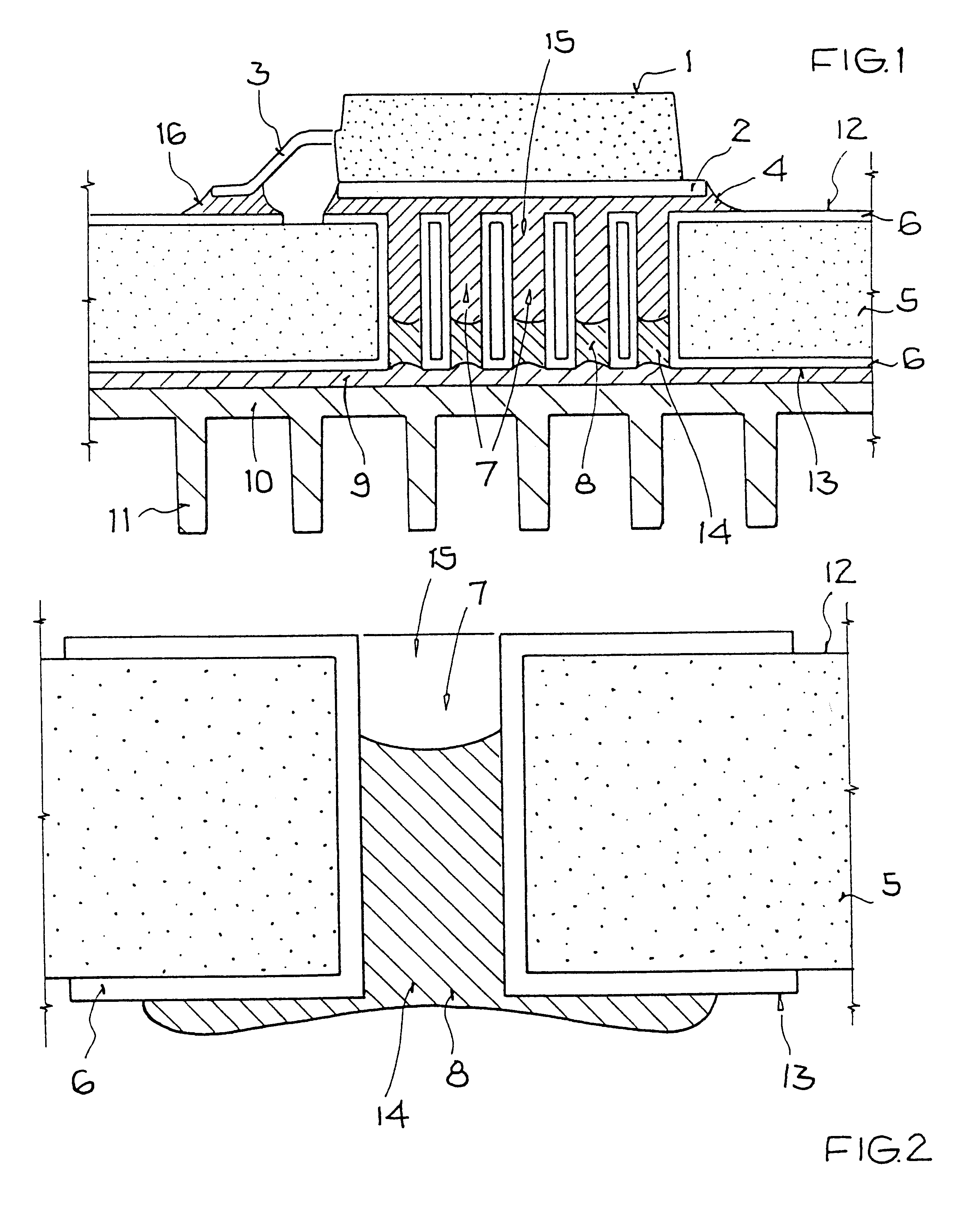

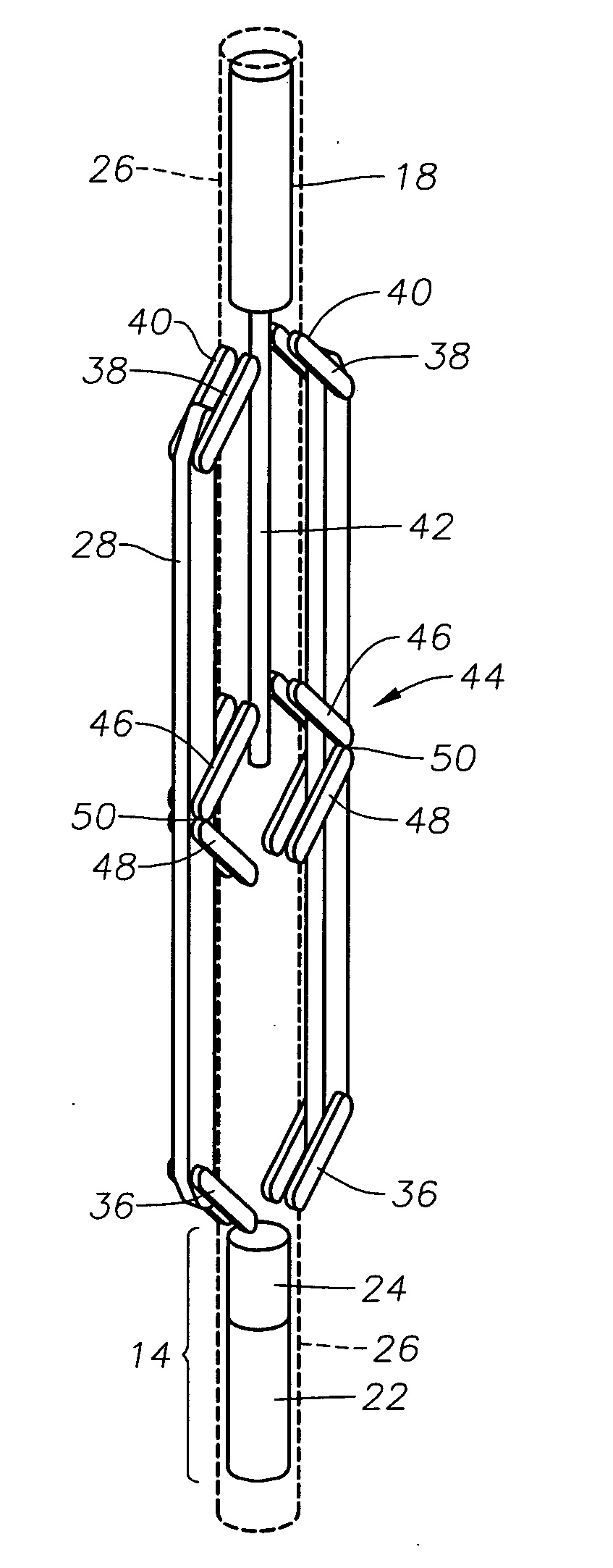

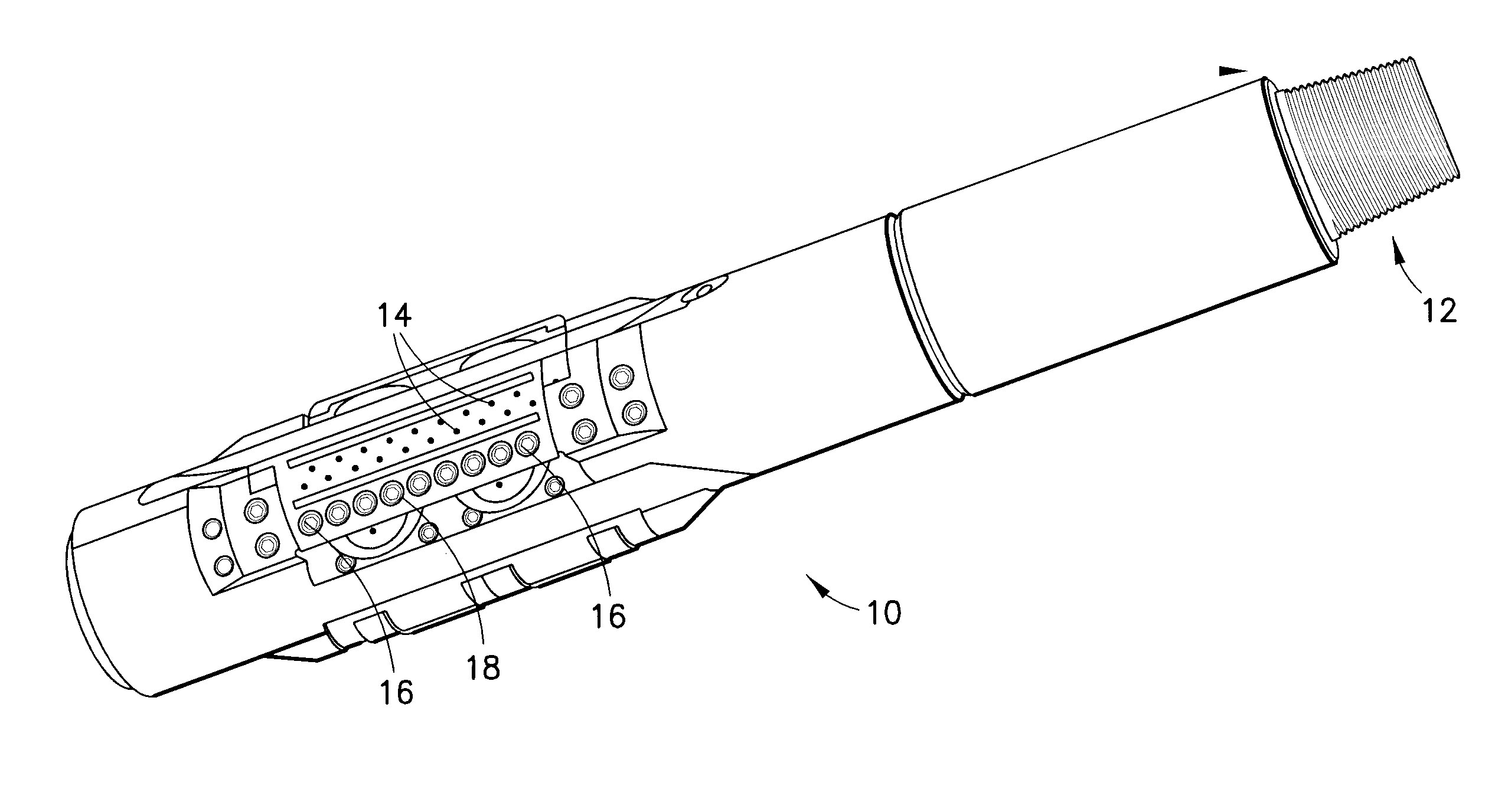

Open hole tractor with tracks

A downhole tractor is provided that may be used in open or cased wells, and is also designed for use in open holes having a variety of soil / formation consistencies (e.g., soft, firm, rigid, etc.), varying diameters and non-uniform and irregular bore profiles. The tractor may include a track assembly including a plurality of idler wheels and a continuous track rotatably disposed around the idler wheels. A motor may be adapted to rotate the track around the idler wheels. Upper and lower arms may be pivotally connected to opposite ends of the track assembly and pivotally connected to a tractor housing. An actuator arm or link assembly may be provided to impart an outward force to the track assembly to move the track assembly outwardly into an open position and a retracting force to retract the track assembly into a closed position. A rotatable screw may be connected to a second motor, or a rod may be connected to a hydraulic system, to actuate the actuator arm or link assembly.

Owner:SCHLUMBERGER TECH CORP

Measurement while drilling bi-directional pulser operating in a near laminar annular flow channel

A device, method, and system for creating a pressure pulse from drilling fluid within a drill string in a down hole drill collar for enabling measurement-while drilling. The device and system are designed such that primarily laminar flow exists in the area surrounding the pulser apparatus. The method associated with the reproducible and essentially noise-free pulses occurs when a pulser bell is manipulated in an upward and downward direction by a combination of the solenoid activation of a bi-directional poppet to redirect the fluid flow from the pressure reservoir to and from a sliding pressure chamber and associated upper and lower flow connecting channels. The pulse or non-pulse is converted into a digital signal uphole by a pressure transducer in conjunction with a decoding algorithm. It is then displayed to the driller and oilfield operators as useful directional and formation information that help the oilfield operator for uphole decision making regarding directional drilling. Additional pulsers can be added to the tool so that higher data bit rates can be accomplished. These higher data bit rates will provide for more comprehensive data collection thereby reducing drilling costs and optimizing oil field yields. The higher bit rate allows for more sensors that can send additional and improved information uphole without the use of open hole wire line logging which is impossible to accommodate while drilling horizontally.

Owner:TELEDRILL

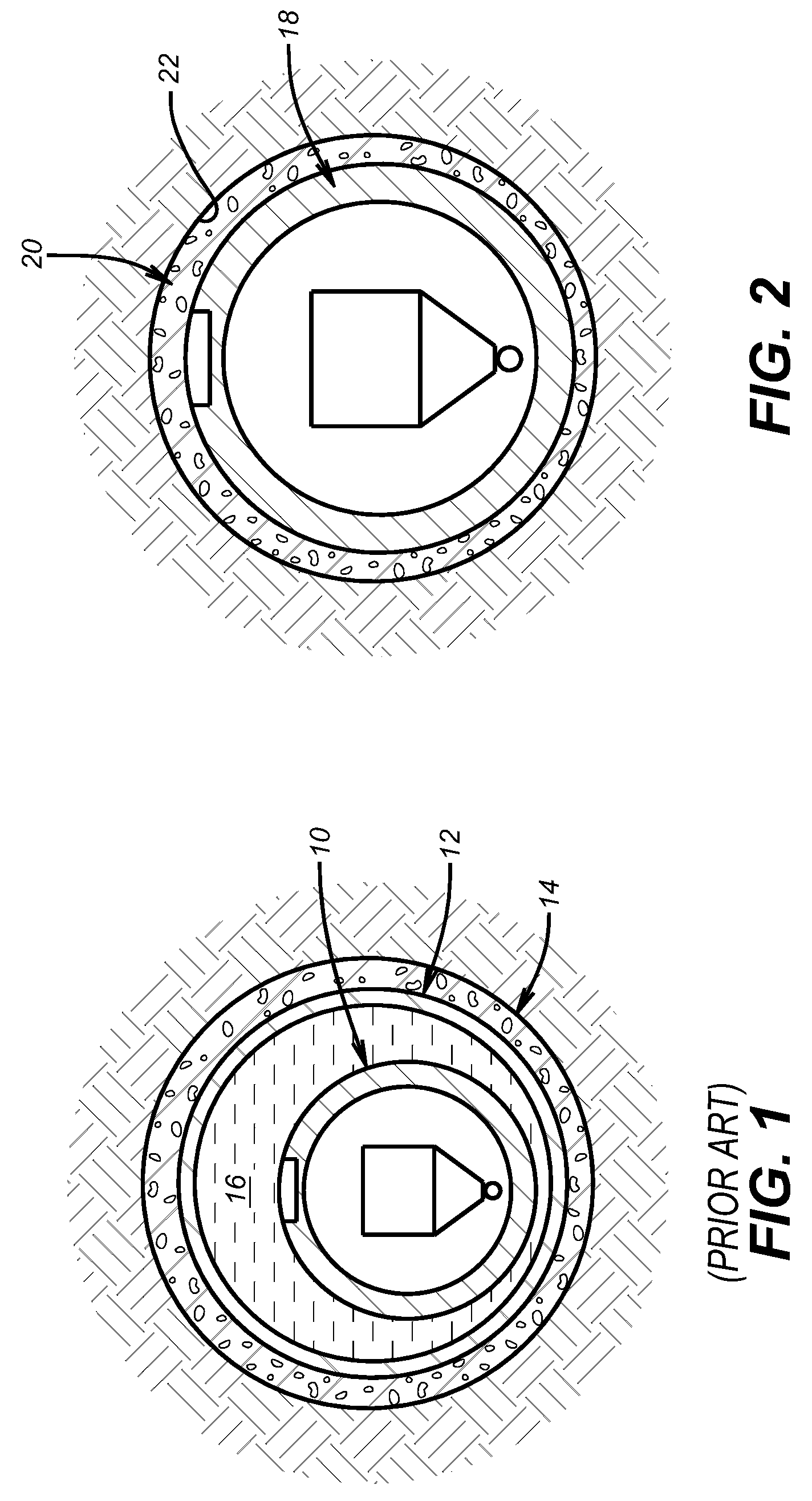

Profiled recess for instrumented expandable components

The present invention provides a recess within an expandable downhole tubular, such as an expandable sand screen. The recess resides within the wall, such as the outer shroud of an expandable sand screen. The recess serves as a housing for instrumentation lines, fiber optics, control lines, or downhole instrumentation. By placing the lines and instrumentation within a wall of the expandable downhole tool, the tool can be expanded into the wall of the wellbore without leaving a channel outside of the tool through which formation fluids might vertically migrate. The recess is useful in both cased hole and open hole completions. In one embodiment, the recess serves as a housing for an encapsulation which itself may house instrumentation lines, control lines, and downhole instrumentation.

Owner:WEATHERFORD TECH HLDG LLC

Epoxy compositions with improved mechanical performance

Polymer compositions capable of a high degree of curing at relatively low temperatures, and prepregs, adhesives, films and composites formed therefrom are discussed. The polymer compositions include epoxy resin systems and a dual curing system including one or more curing agents containing one or more hydrazine-based curing agents having hydrazine functional groups and one or more amine-based curing agents containing one or more amine functional groups. The hydrazine-amine curing systems enable the polymer composition to achieve elevated levels of gelation or degree of cure at lower temperatures than are achievable with amine functional curing agents alone. Furthermore, this elevated degree of curing of the polymer composition may be achieved with substantially no reduction in tack life and / or out life of the prepreg, adhesive or film or cured state mechanical properties of composites, adhesives or other products fabricated therefrom, such as open hole compression strength and compressive strength after impact. The glass transition temperature of the cured polymer compositions is similarly unaffected.

Owner:CYTEC TECH CORP

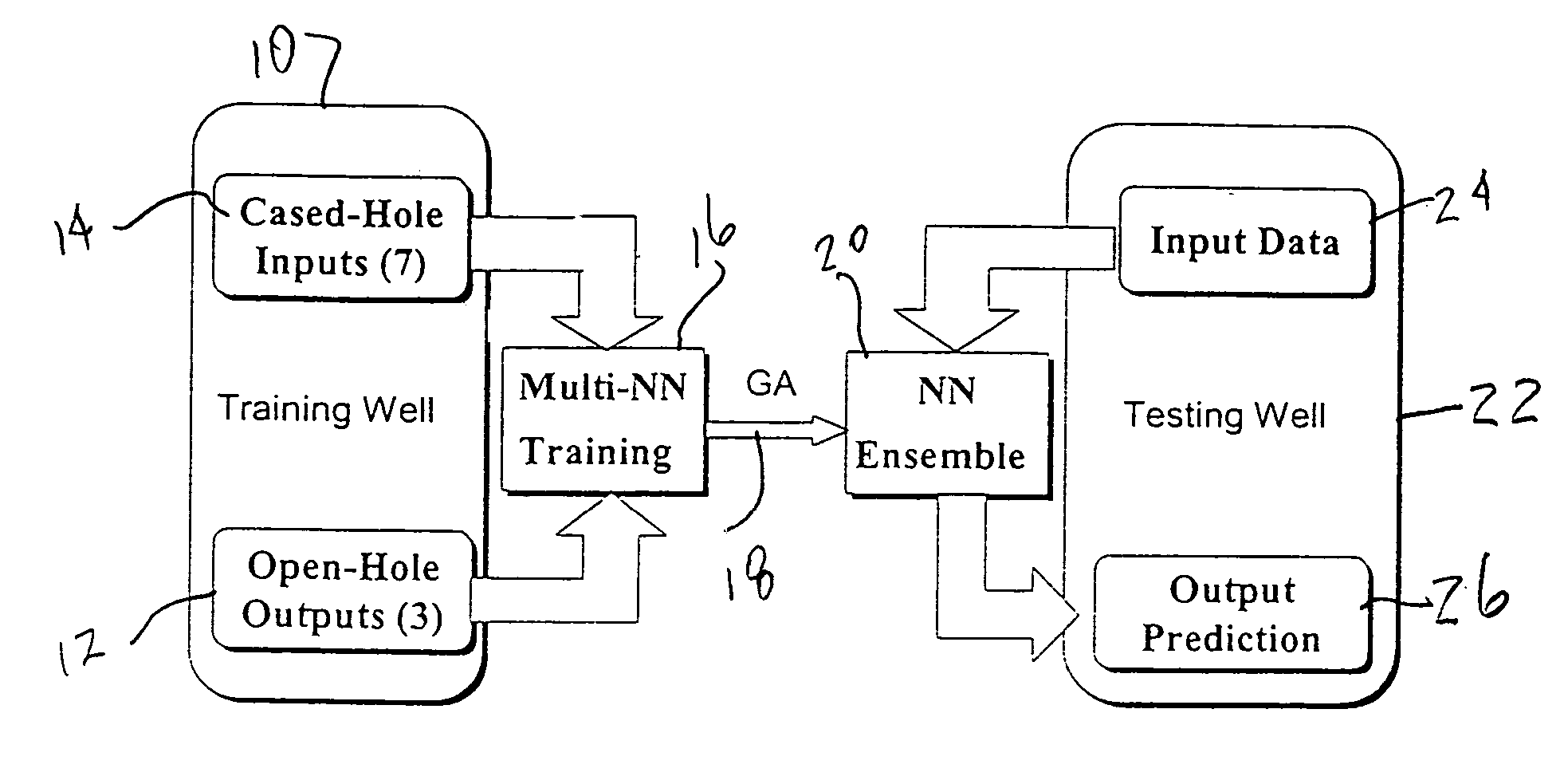

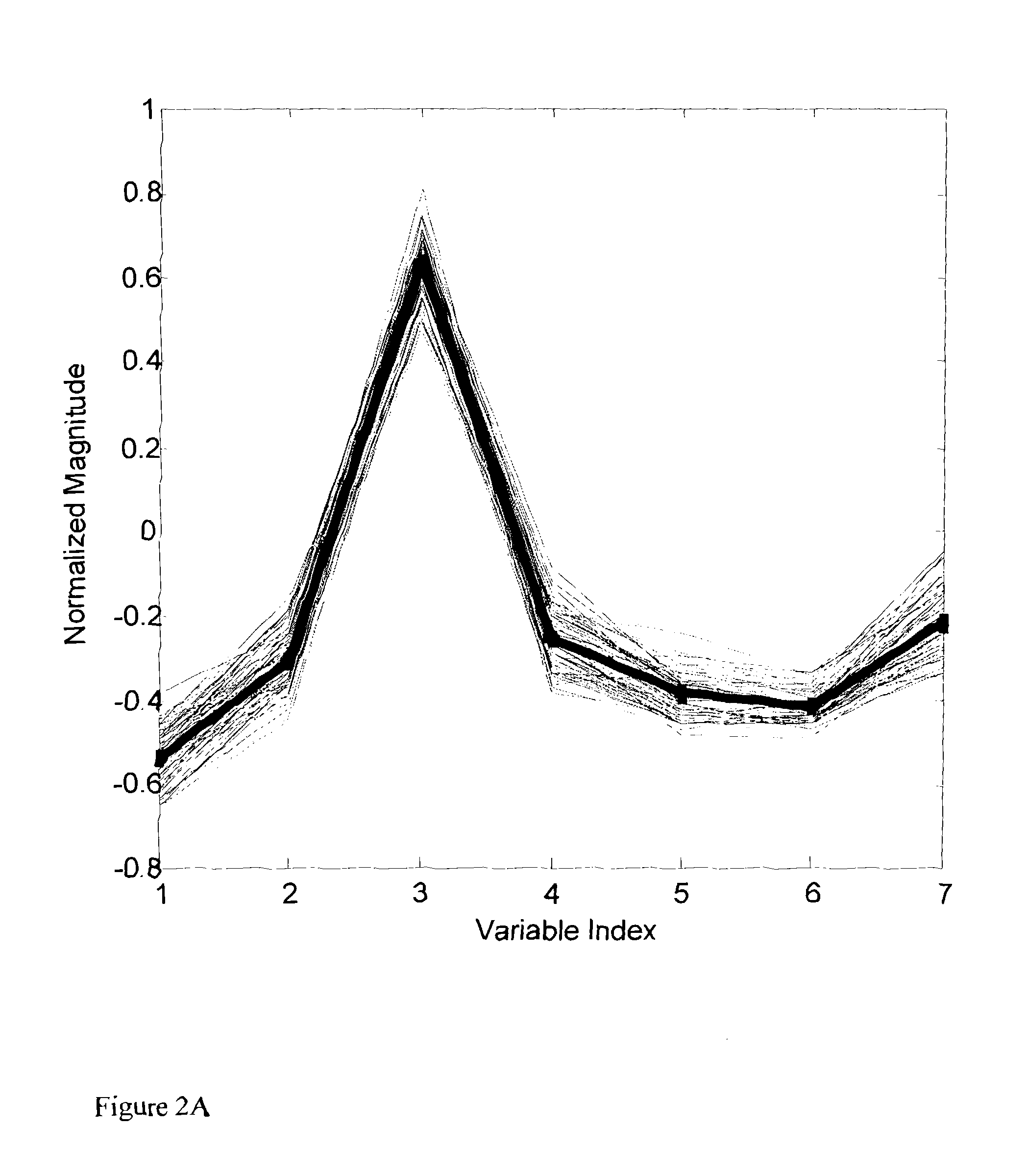

Genetic algorithm based selection of neural network ensemble for processing well logging data

ActiveUS20050246297A1Improve generalization abilityElectric/magnetic detection for well-loggingDigital computer detailsNegative errorNerve network

A system and method for generating a neural network ensemble. Conventional algorithms are used to train a number of neural networks having error diversity, for example by having a different number of hidden nodes in each network. A genetic algorithm having a multi-objective fitness function is used to select one or more ensembles. The fitness function includes a negative error correlation objective to insure diversity among the ensemble members. A genetic algorithm may be used to select weighting factors for the multi-objective function. In one application, a trained model may be used to produce synthetic open hole logs in response to inputs of cased hole log data.

Owner:HALLIBURTON ENERGY SERVICES INC

Full bore cementable gun system

A completion method delivers cement to an open hole below a cemented casing. A gun or guns are run below a liner and a hanger and advanced into the cement before it sets up. With the gun and the liner surrounded in cement up to close to the hanger that supports the liner to the already cemented casing, the cement is allowed to set around the gun with no tubular surrounding the gun. The gun carries extra shot to enhance the perforation and can be fluid filled with clean fluid. Prior well cleaning such as with brine circulation is now limited to the region of the hanger and above. Production flow is through the perforations into the gun body allowing any residue of the explosive charge used to perforate to flow to surface.

Owner:BAKER HUGHES INC

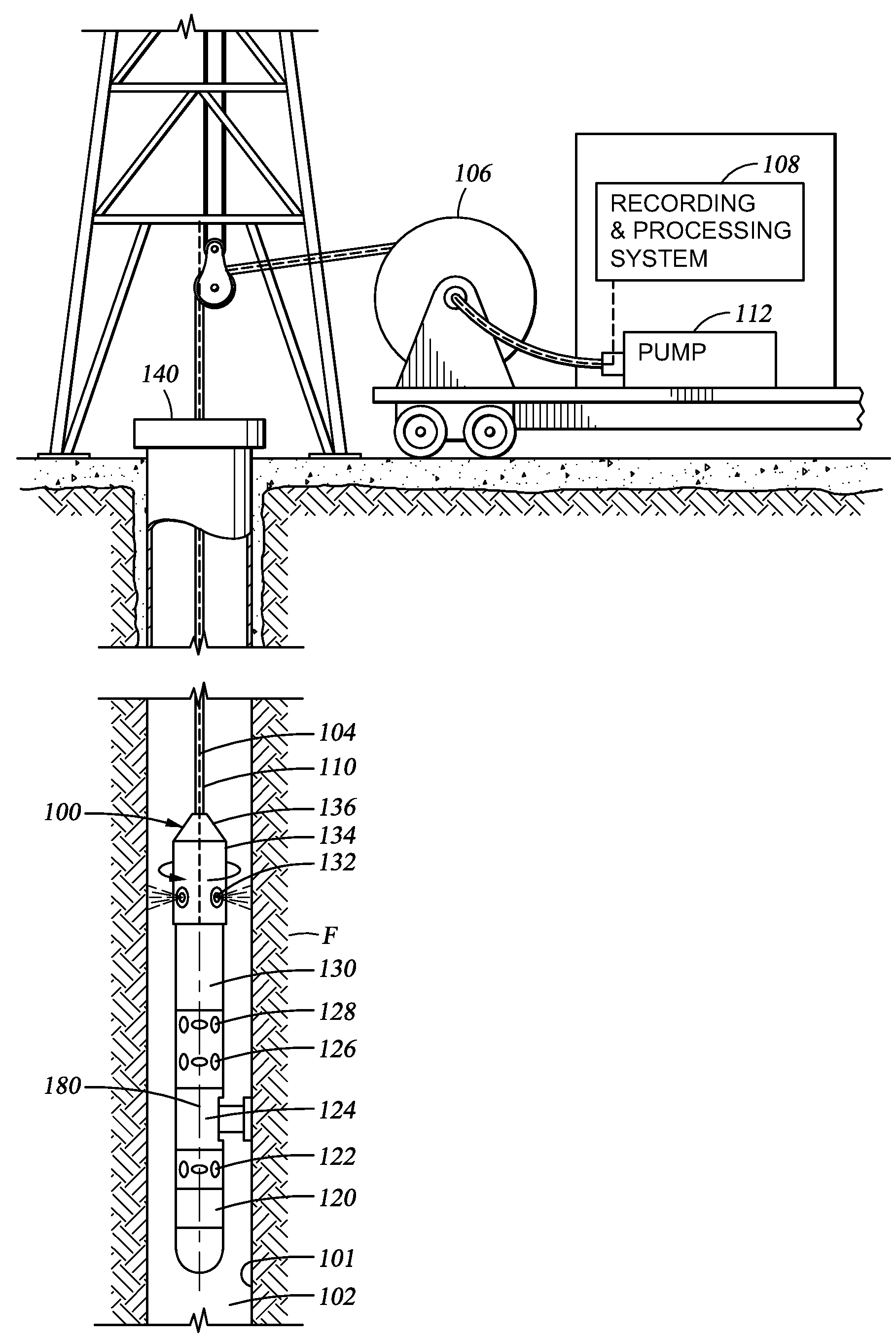

Instrumented formation tester for injecting and monitoring of fluids

An example instrumented formation tester for injecting fluids and monitoring of fluids described herein includes a downhole tool which can be deployed in a wellbore via a wireline or a drill string. The downhole tool may facilitate the injection of fluids into an underground formation, and the monitoring of the directions in which the injected fluids flow in the formation in an open hole environment. In particular, the downhole tool may be configured for removing the mud cake from a portion of the wellbore wall for facilitating a fluid communication with the formation to be tested.

Owner:SCHLUMBERGER TECH CORP

Reinforced open-hole zonal isolation packer and method of use

Owner:BAKER HUGHES HLDG LLC

Methods of fracturing a subterranean formation using a jetting tool and a viscoelastic surfactant fluid to minimize formation damage

Owner:HALLIBURTON ENERGY SERVICES INC

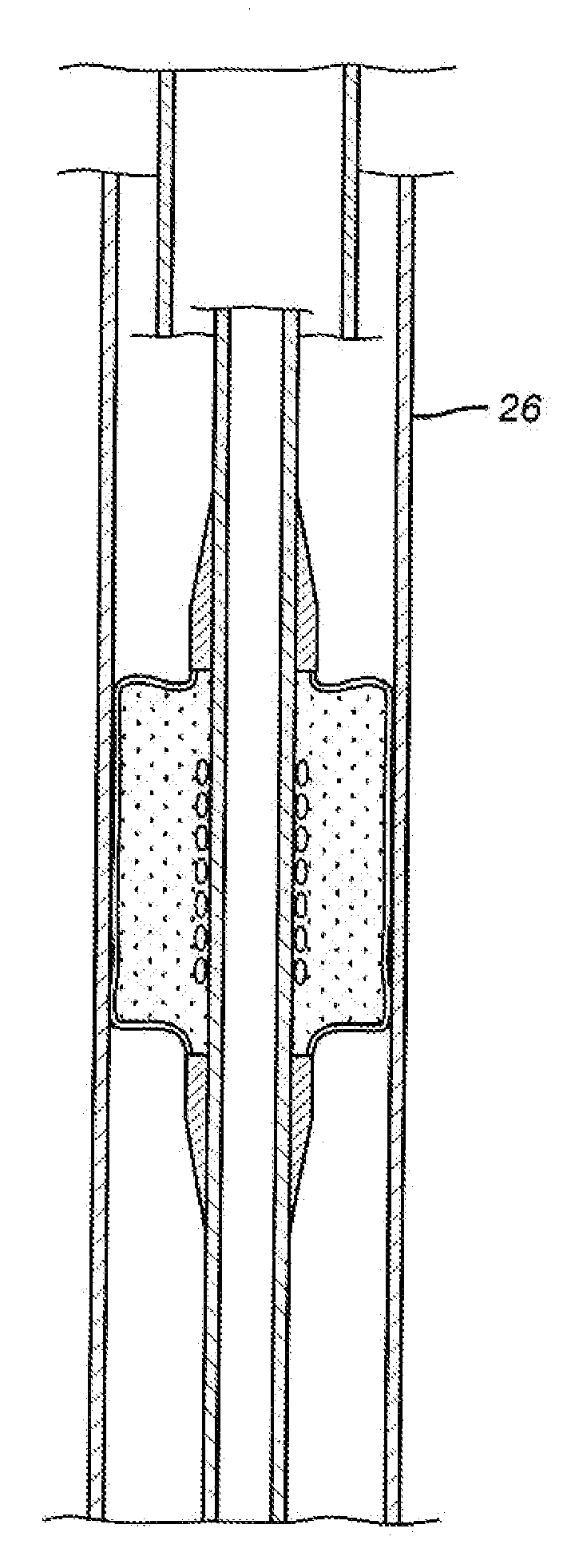

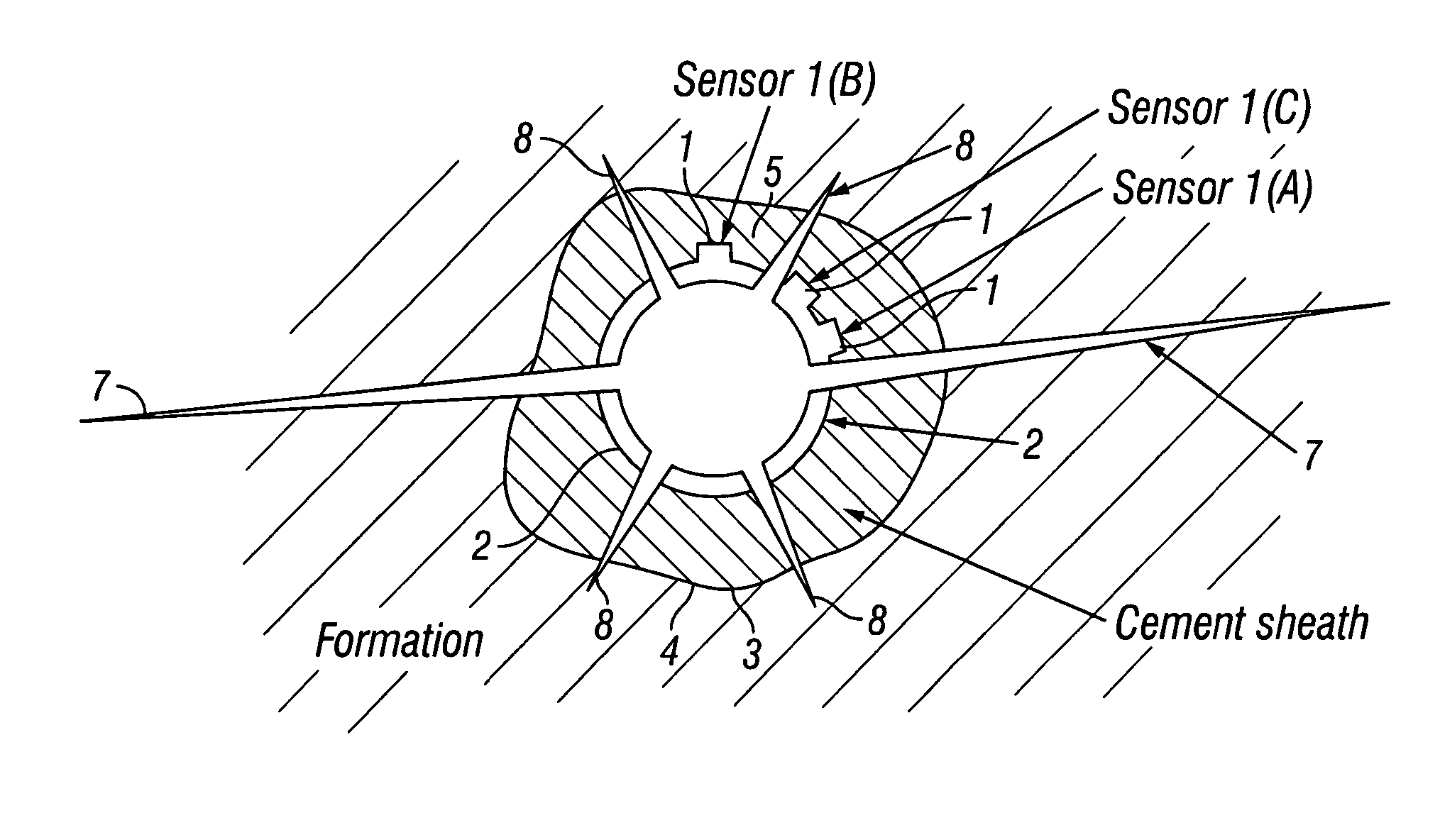

Optical sensor use in alternate path gravel packing with integral zonal isolation

Devices and methods for monitoring wellbore conditions while conducting hydrocarbon production within a wellbore, particularly an open-hole wellbore, having multiple zones within. A production tubing string assembly is made up having a plurality of packers for sealing within an open-hole wellbore having multiple individual zones. The production tubing string includes production nipples and one or more fiber optic sensor lines disposed upon the outside of the production tubing string. The sensor line or lines are disposed through the packers using a pass-through system so as to provide unbroken sensing line(s) to the surface of the wellbore. This allows temperature, pressure or other wellbore conditions to be monitored at the surface in each of the individual zones of interest.

Owner:BAKER HUGHES HLDG LLC

Open hole anchor and associated method

The present invention relates to a method and apparatus for anchoring an expandable tubular within a wellbore prior to expanding the length of the expandable tubular into contact with the wellbore. An expandable system comprises the expandable tubular and a deployment tool, wherein the deployment tool exerts radial force against the expandable tubular to expand at least a portion of the expandable tubular into contact with the wellbore to anchor the expandable tubular prior to the expansion process. A method for anchoring an expandable tubular within a wellbore prior to the expansion process is also provided, wherein radial force expands the expandable tubular into contact with the wellbore to initially anchor the expandable tubular. A method for altering the shape of the anchor is also provided.

Owner:WEATHERFORD TECH HLDG LLC

Cemented open hole selective fracing system

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

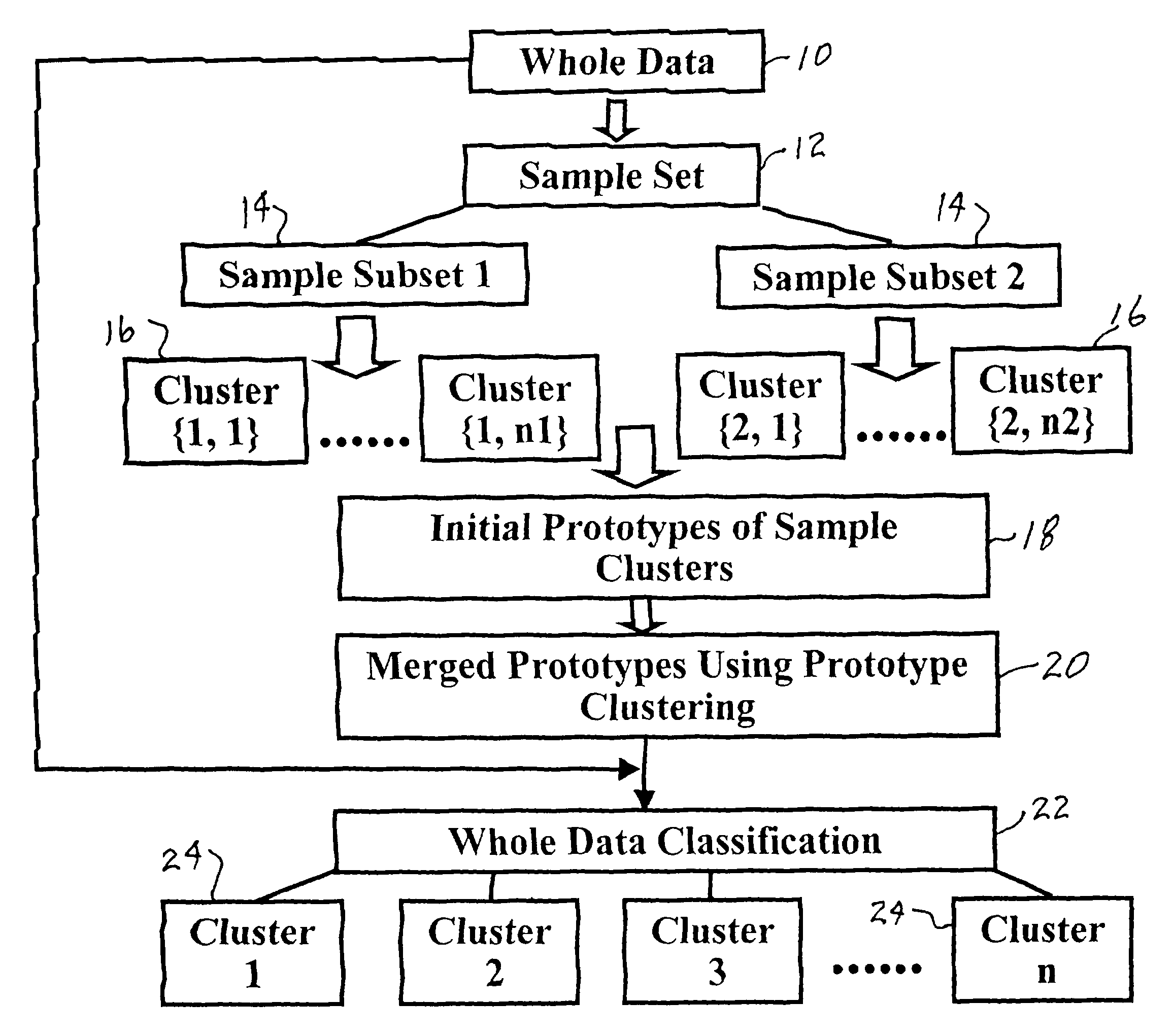

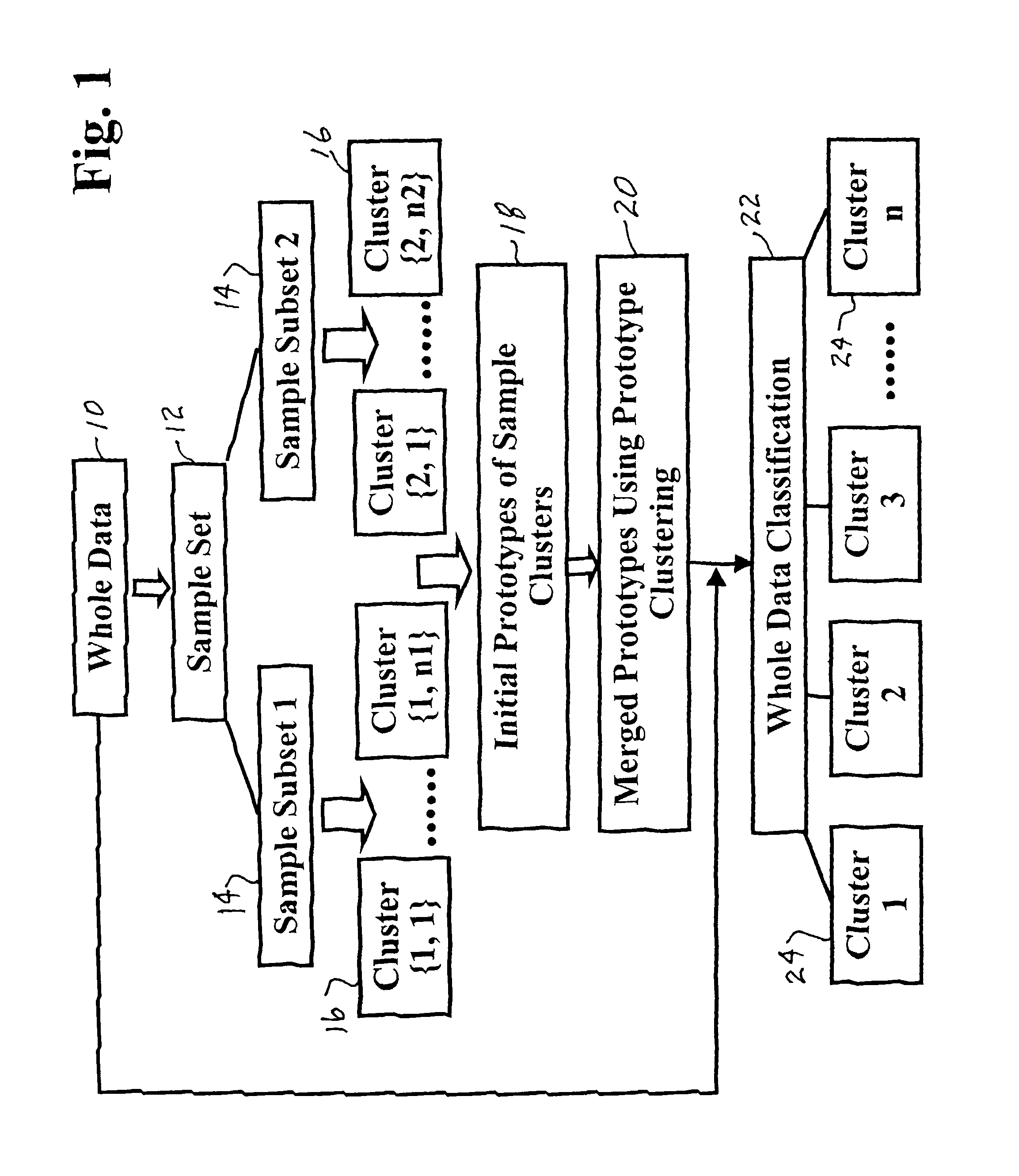

Neural network training data selection using memory reduced cluster analysis for field model development

InactiveUS8374974B2Digital computer detailsCharacter and pattern recognitionFuzzy inferenceNerve network

A system and method for selecting a training data set from a set of multidimensional geophysical input data samples for training a model to predict target data. The input data may be data sets produced by a pulsed neutron logging tool at multiple depth points in a cases well. Target data may be responses of an open hole logging tool. The input data is divided into clusters. Actual target data from the training well is linked to the clusters. The linked clusters are analyzed for variance, etc. and fuzzy inference is used to select a portion of each cluster to include in a training set. The reduced set is used to train a model, such as an artificial neural network. The trained model may then be used to produce synthetic open hole logs in response to inputs of cased hole log data.

Owner:HALLIBURTON ENERGY SERVICES INC

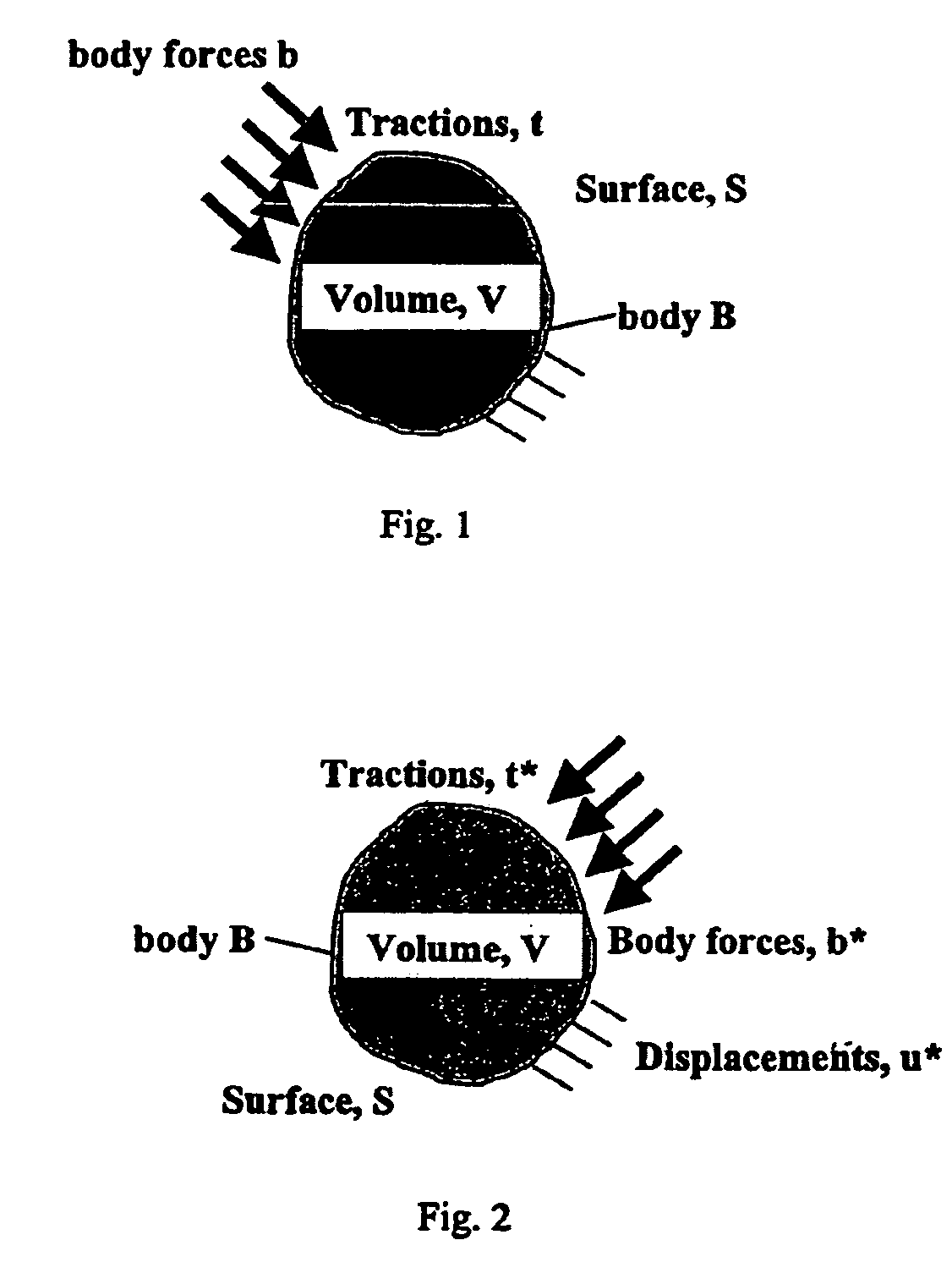

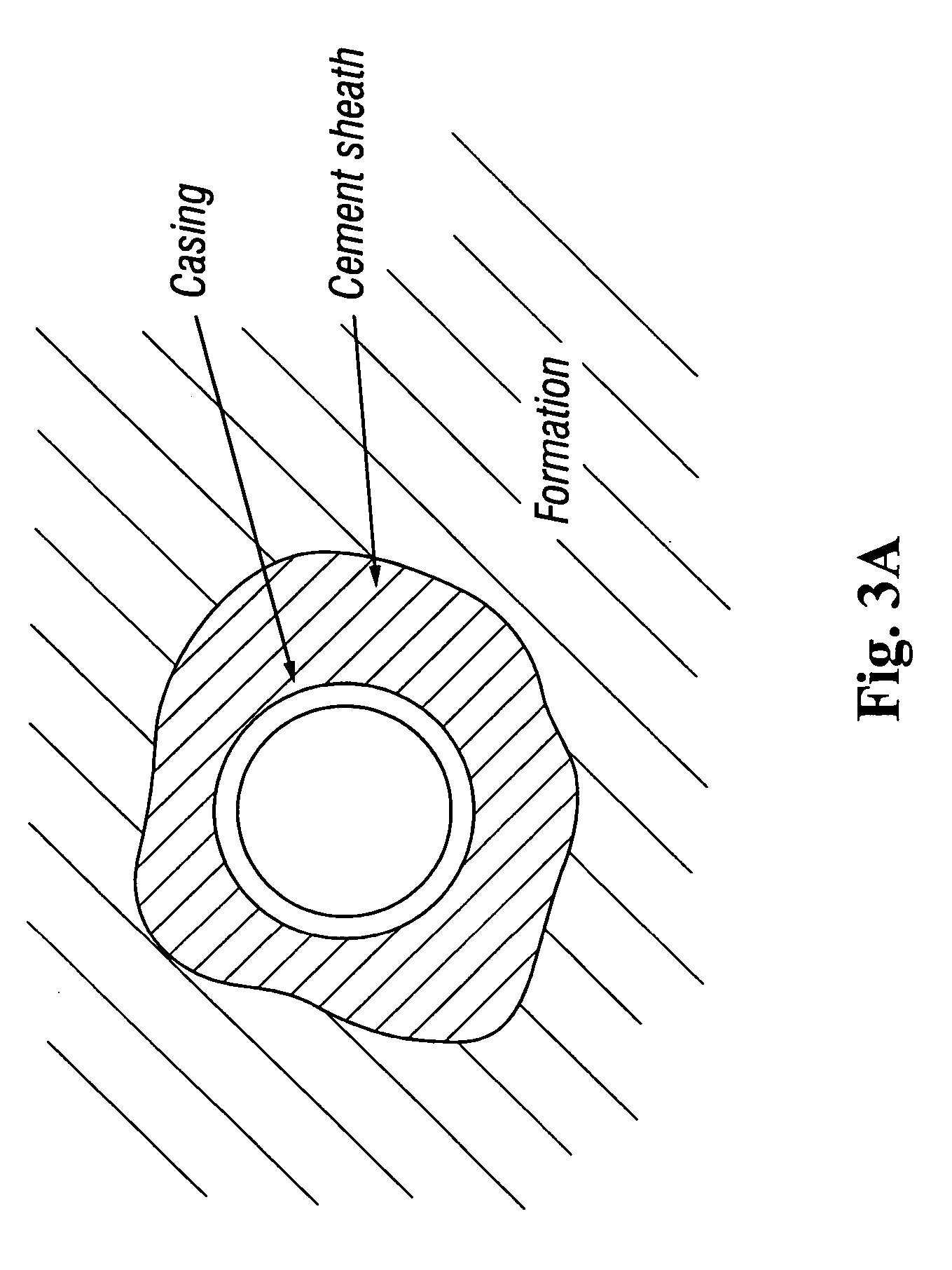

Method for stress and stability related measurements in boreholes

InactiveUS7006918B2Good choiceSurveySpecial data processing applicationsStress boneHydraulic fracturing

A method for the measurement of the stresses and pressure perturbations surrounding a well, and a system for computing the optimum location for initiating a hydraulic stress fracture. The technique includes using sensors attached to the wellbore casing connected to a data analyzer. The analyzer is capable of analyzing the stresses on the well system. Using an inverse problem framework for an open-hole situation, the far field stresses and well departure angle are determined once the pressure perturbations and stresses are measured on the wellbore casing. The number of wellbore measurements needed for the inverse problem solution also is determined. The technique is also capable of determining the optimal location for inducing a hydraulic fracture, the effect of noisy measurements on the accuracy of the results, and assessing the quality of a bond between a casing and a sealant.

Owner:UNIV HOUSTON SYST

Open-hole wellbore lining

InactiveUS20090090514A1Control moreLiquid spraying plantsLiquid surface applicatorsLength waveFluid composition

Embodiments of the present invention provide systems and methods for lining a wellbore. In certain aspects, the systems and methods comprise providing a fluid composition that is solidifiable or gellable on exposure to actinic radiation of a predetermined wavelength at the wall of open-hole wellbore and providing actinic radiation at the predetermined wavelength to solidify or gel the composition.

Owner:SCHLUMBERGER TECH CORP

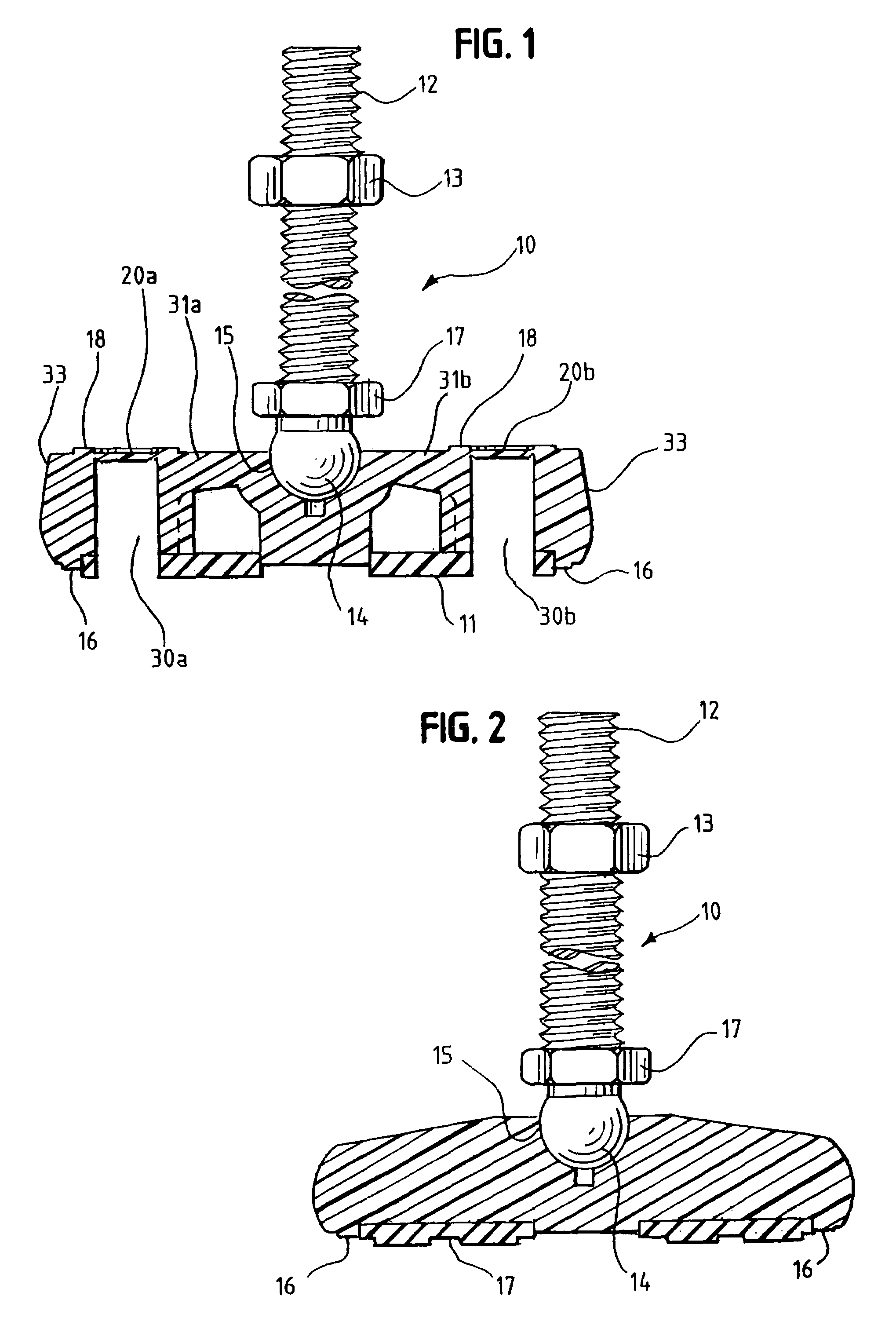

Adjustable leveling mount

InactiveUS6910666B2Opportunities decreaseMinimal obstructionMachine framesStands/trestlesEngineeringSupport surface

A leveling mount is disclosed for equipment in temporary or permanent installations wherein the supporting surface can be a non-level planar surface. A ball and socket support stud provides a self-leveling adjustment of support. An elastomeric removable mount base pad provides non-skid means. Swivel and radial movement of the ball and socket support stud are maintained to about 15° from the vertical and 360° rotary movement of the leveling mount base. The leveling mount base can engage a threaded support stud affixed to the supported equipment. A suitable number of lag holes with knock-out covers over said lag holes are provided. The lag holes are in perpendicular alignment with parallel top and bottom configured surfaces of the leveling mount base to permit secure attachment of the leveling mount base to support surfaces to reduce to a minimum the presence of open holes, crevices, recesses and cavities in the juncture of the leveling device with the support surface. Additionally, the surface design of the leveling device base element is configured to present a clean unencumbered surface for cleaning procedures after the leveling device is secured in place by employment of securing elements including bolts, screws and washers.

Owner:S & W MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com