Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15505results about How to "Avoid wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

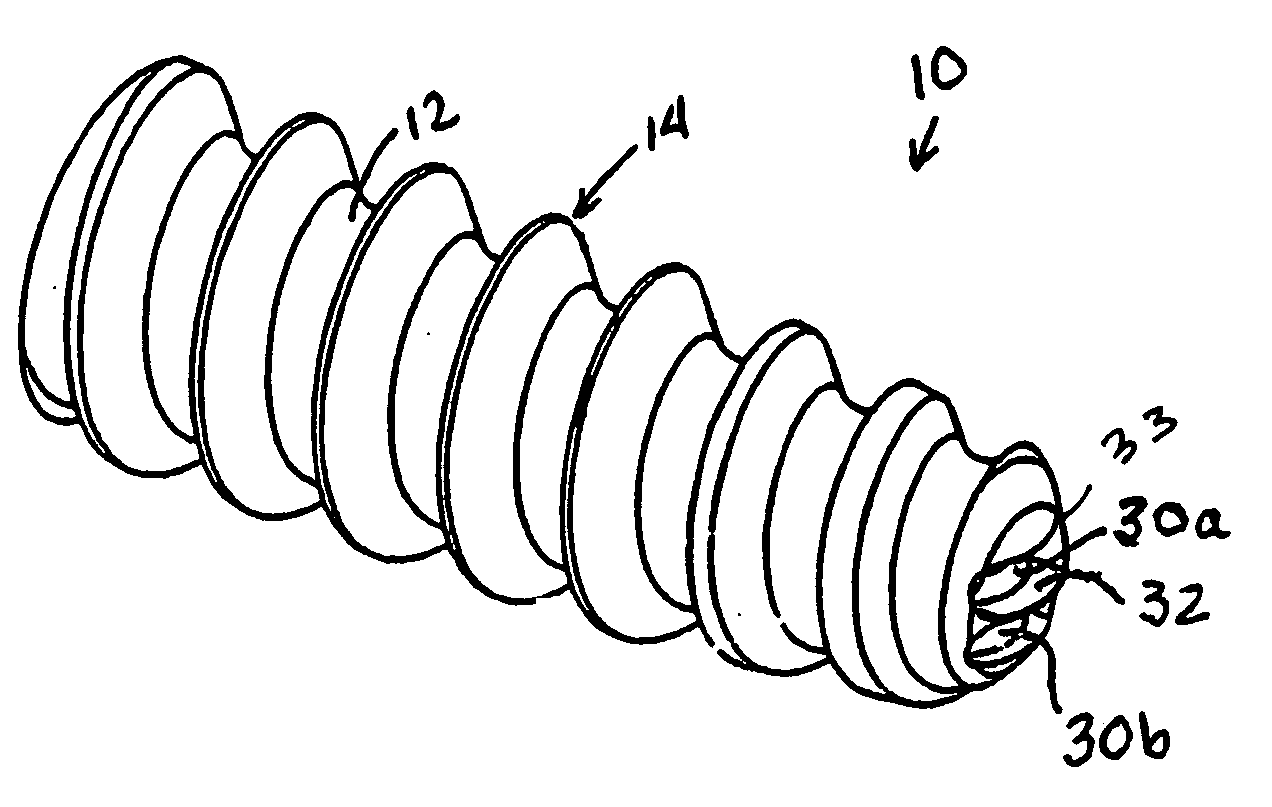

Suture anchor with apertures at tip

A suture anchor includes a threaded anchor body having a bore for receiving a driver, and at least two distal passageways extending from the bore to corresponding apertures at the distal end of the suture anchor. The apertures are provided as pairs with a corresponding groove formed between the apertures of the pair. Suture strands can be inserted into the suture anchor through the apertures, the distal portion of the sutures seated in the grooves between the apertures being protected from abrasion during installation of the suture anchor.

Owner:ARTHREX

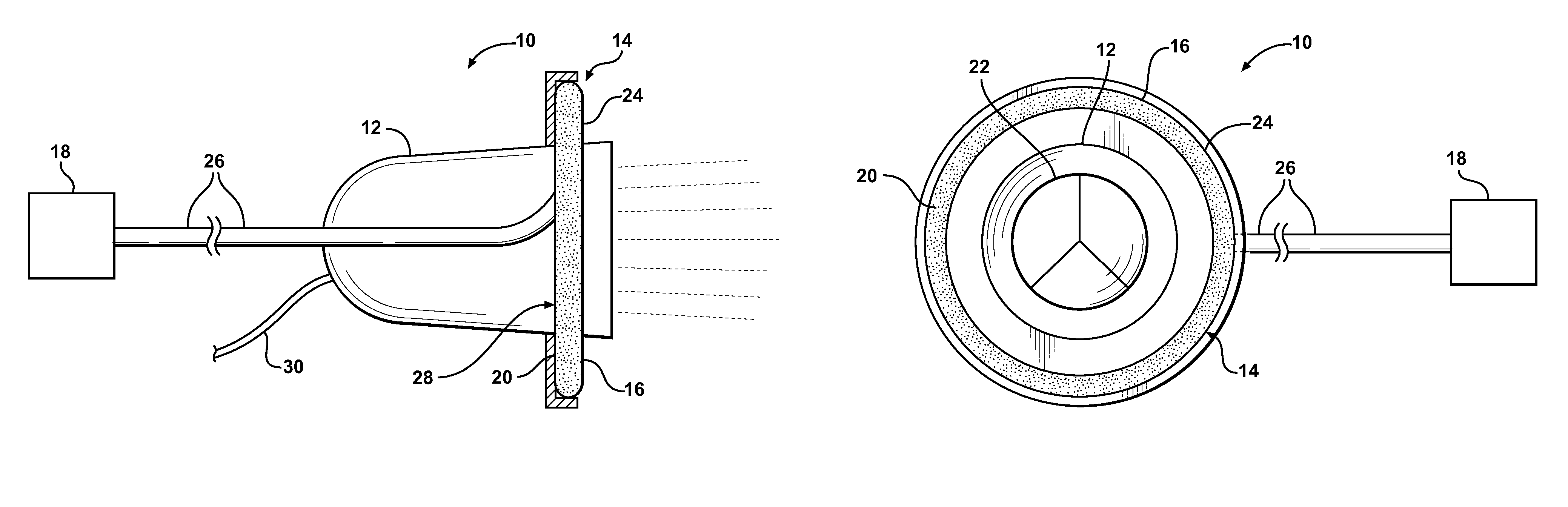

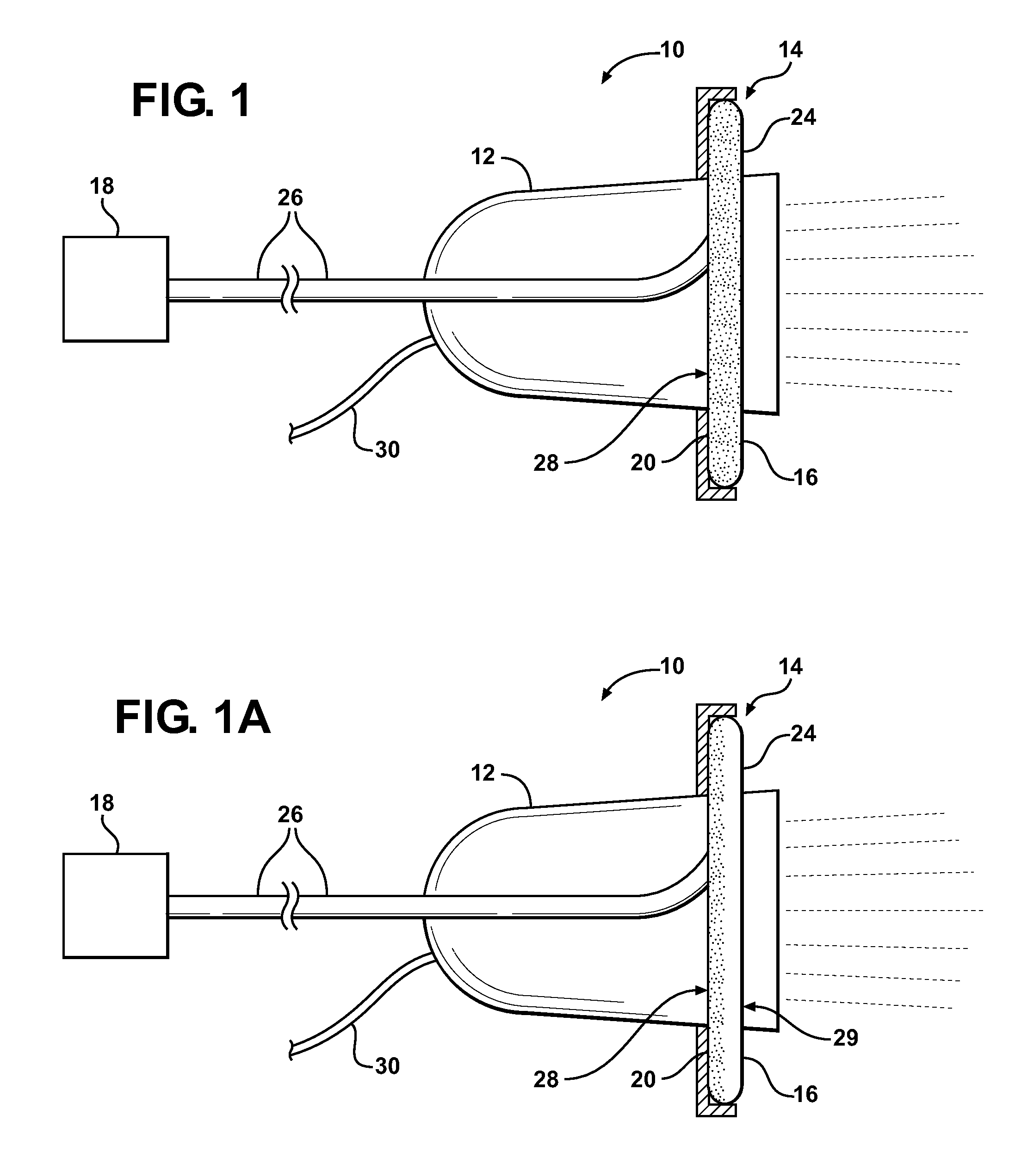

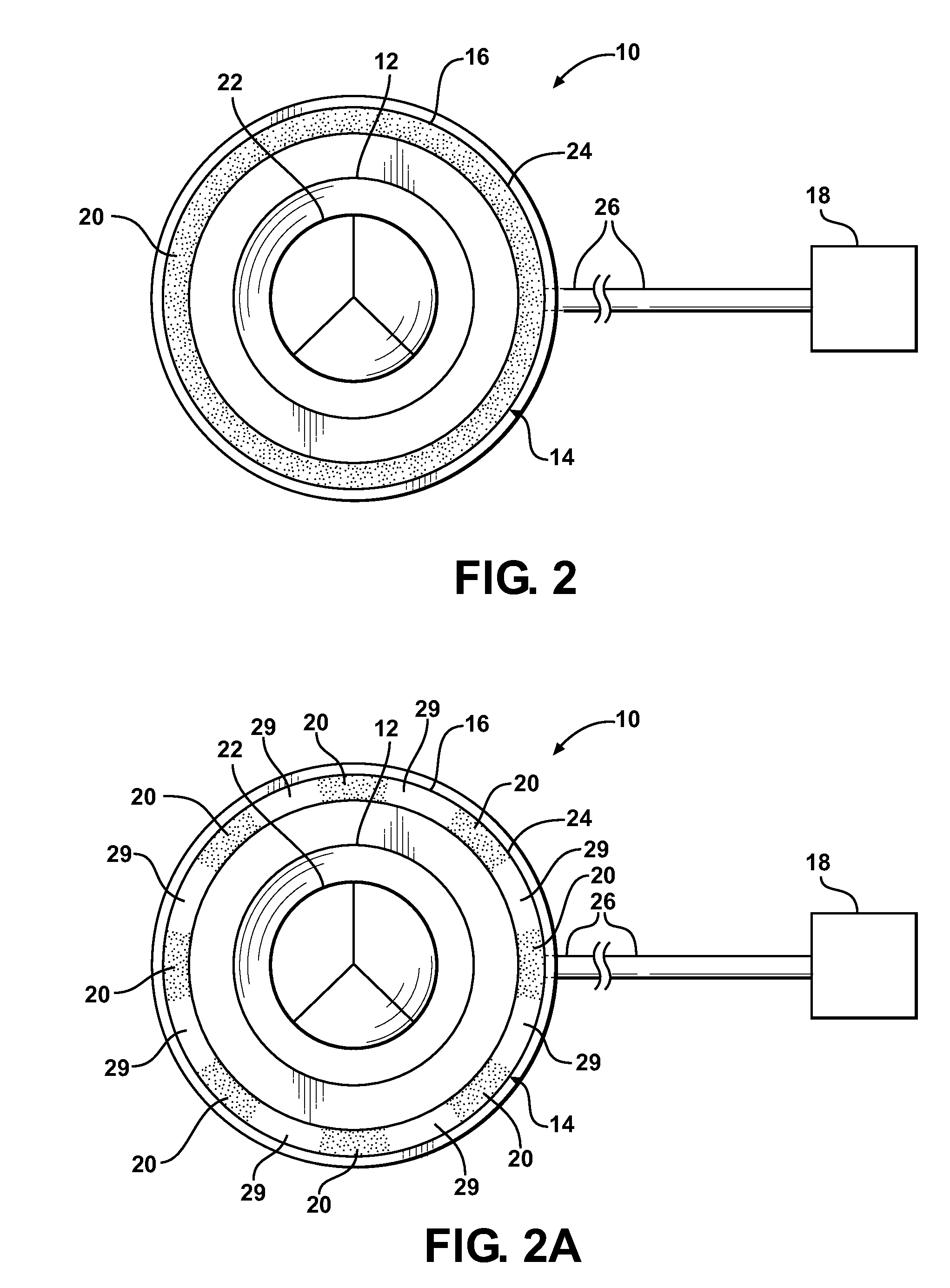

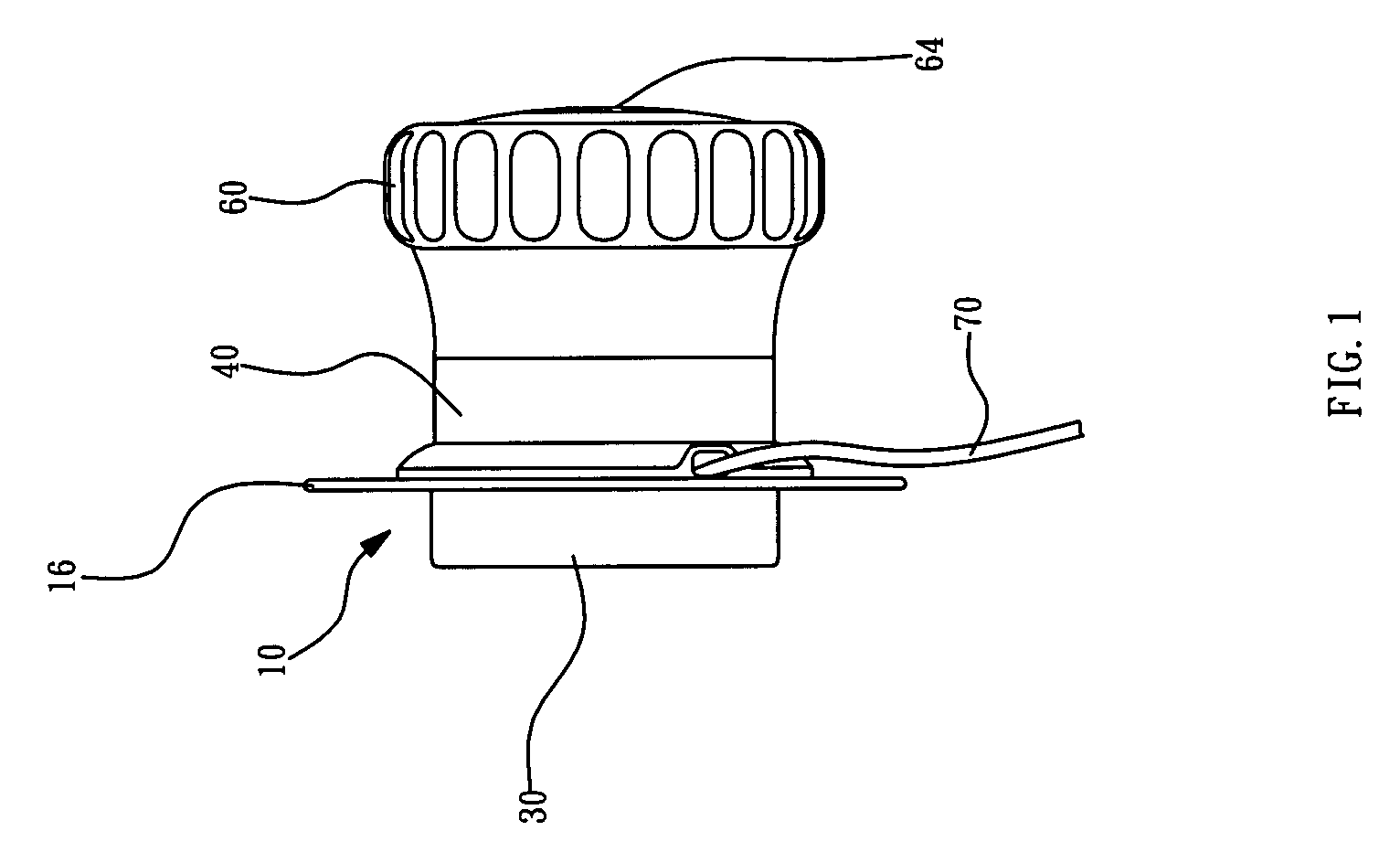

Head lamp assembly and accent lighting therefor

A head lamp assembly having a main functional head lamp and a UV LED light source configured to direct UV light through a decorative accent light pipe is provided. The light pipe extends at least partially about the functional head lamp, wherein the light pipe has a phosphor coated surface to convert the UV light traveling through the light pipe into visible, luminous light. The visible light is emitted from the light pipe to provide the desired decorative appearance about the functional head lamp.

Owner:REBO LIGHTING & ELECTRONICS LLC

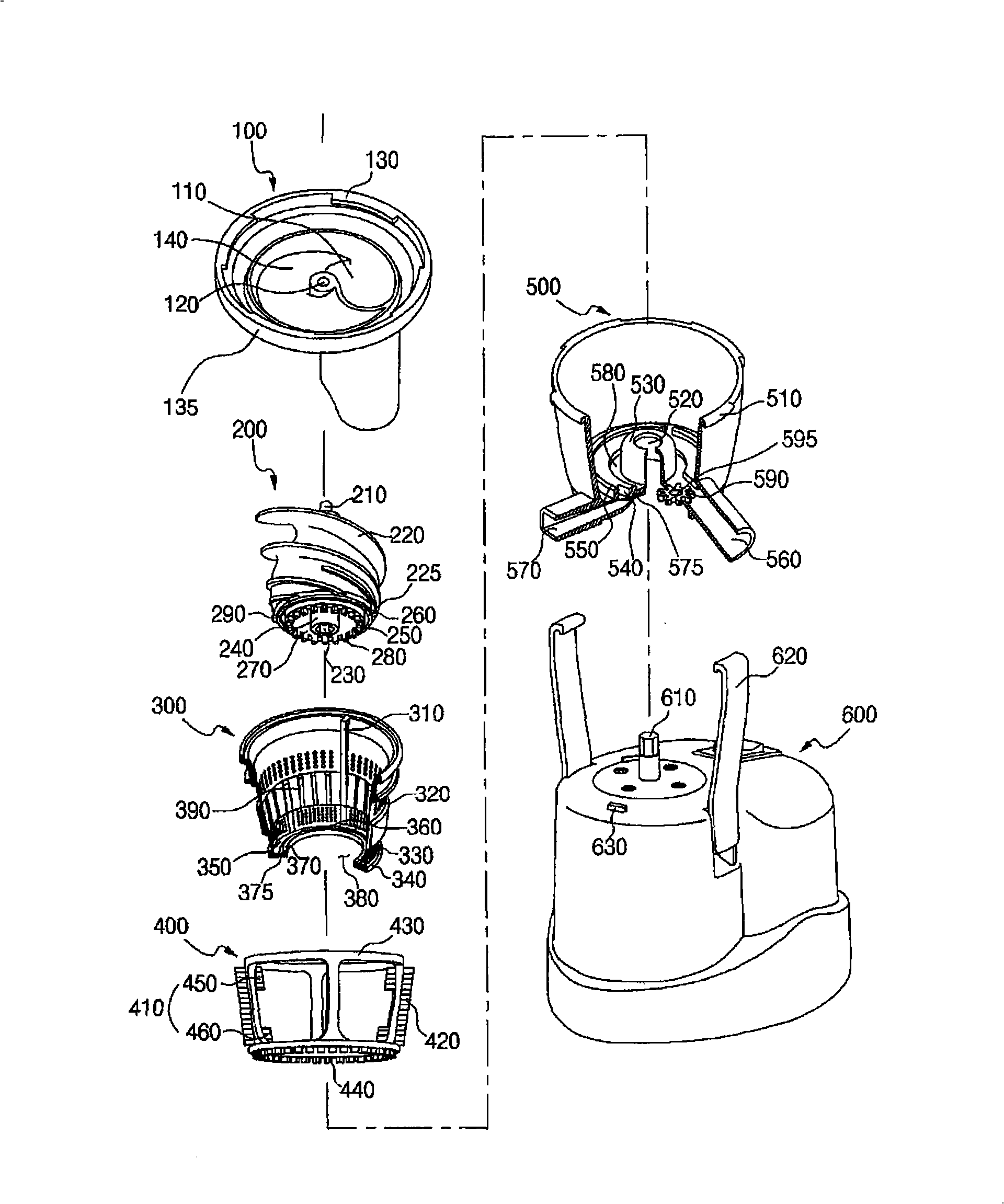

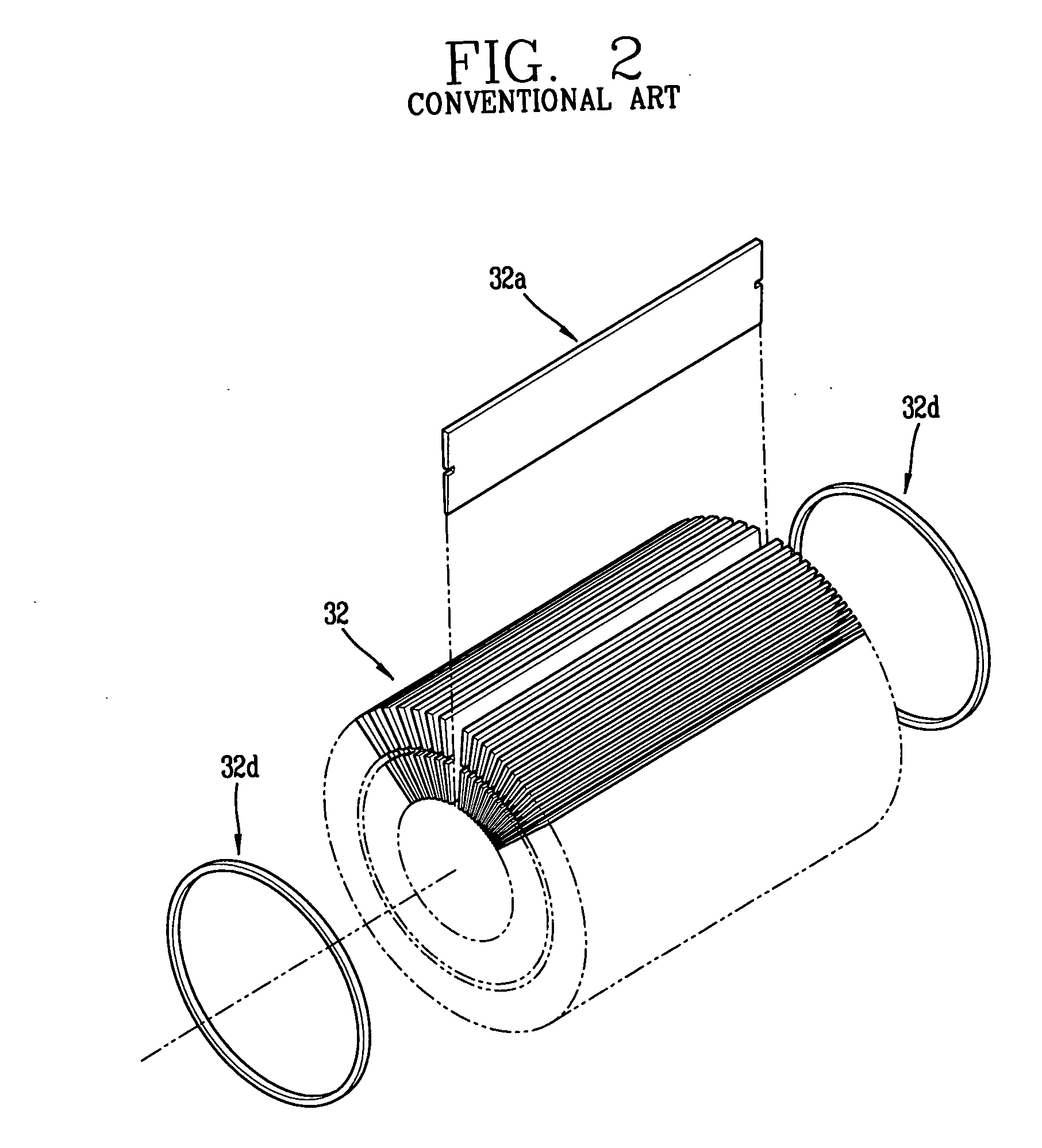

Juice extractor

ActiveCN101355897AKeep to the maximumExtensive extractionBeverage vesselsStrainersLow speedFood flavor

A juice extractor capable of extracting juice from vegetables, fruits or soymilk from beans is disclosed. The extractor includes a housing having a draff outlet port and a juice outlet port, a screw having an upper rotary shaft inserted in a rotary shaft hole of the housing and a lower rotary shaft with a plurality of screw spirals formed on an outer periphery thereof, and a mesh drum for extracting the juice toward the juice outlet port, and a rotary brush mounted between the housing and the mesh drum and having a brush holder. Various nutrients and intrinsic flavor contained in the vegetables or fruits are maintained to the fullest extent by employing a very low speed screw of a squeezing mode. Also, since the housing accommodating the screw is vertically fixed to an upper portion of a drive unit, the material is automatically moved downward without pressing the material down, and the draff is discharged while squeezing and grinding the materials put in an inlet port.

Owner:金煐麒

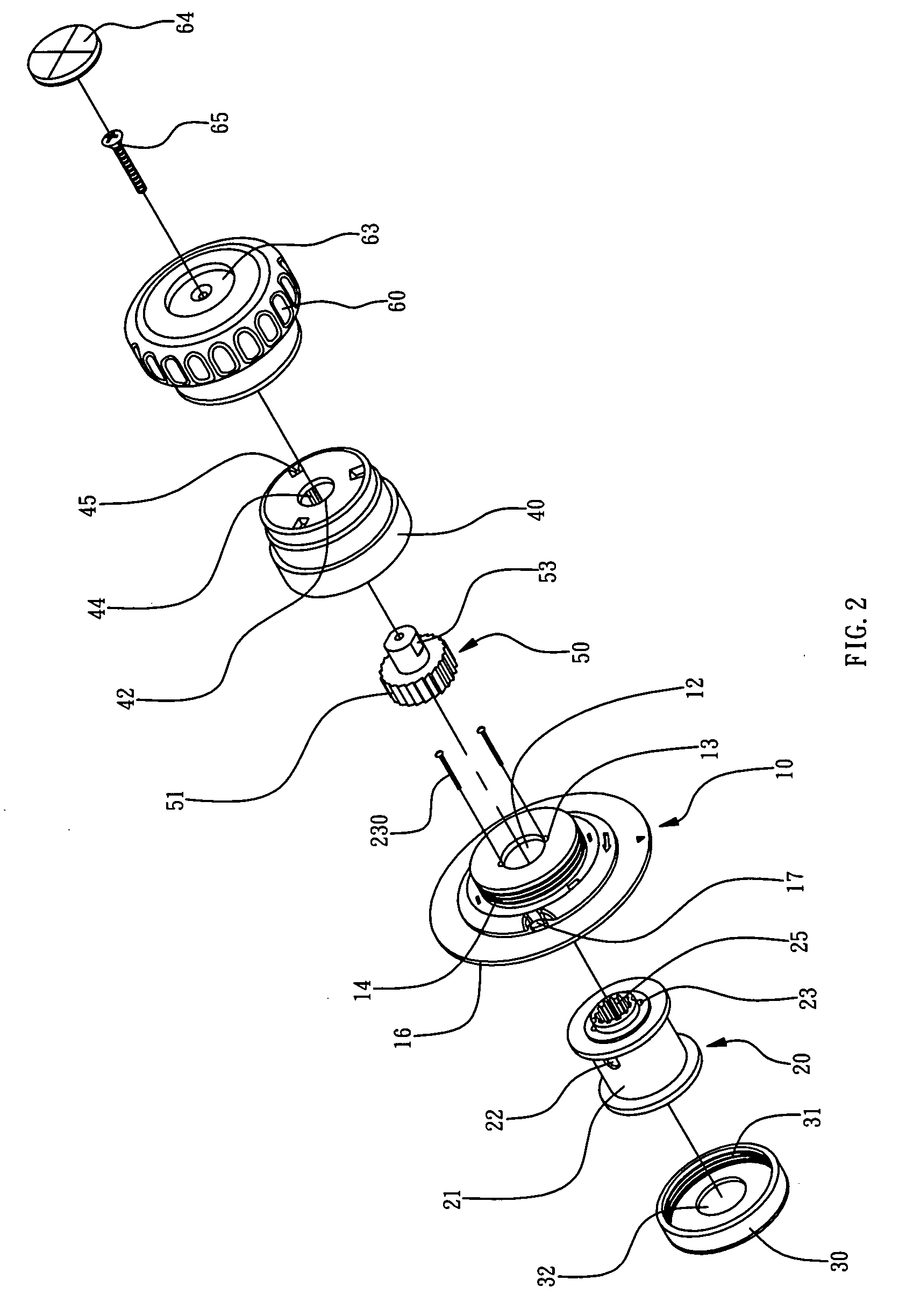

Shoelace reel operated easily and conveniently

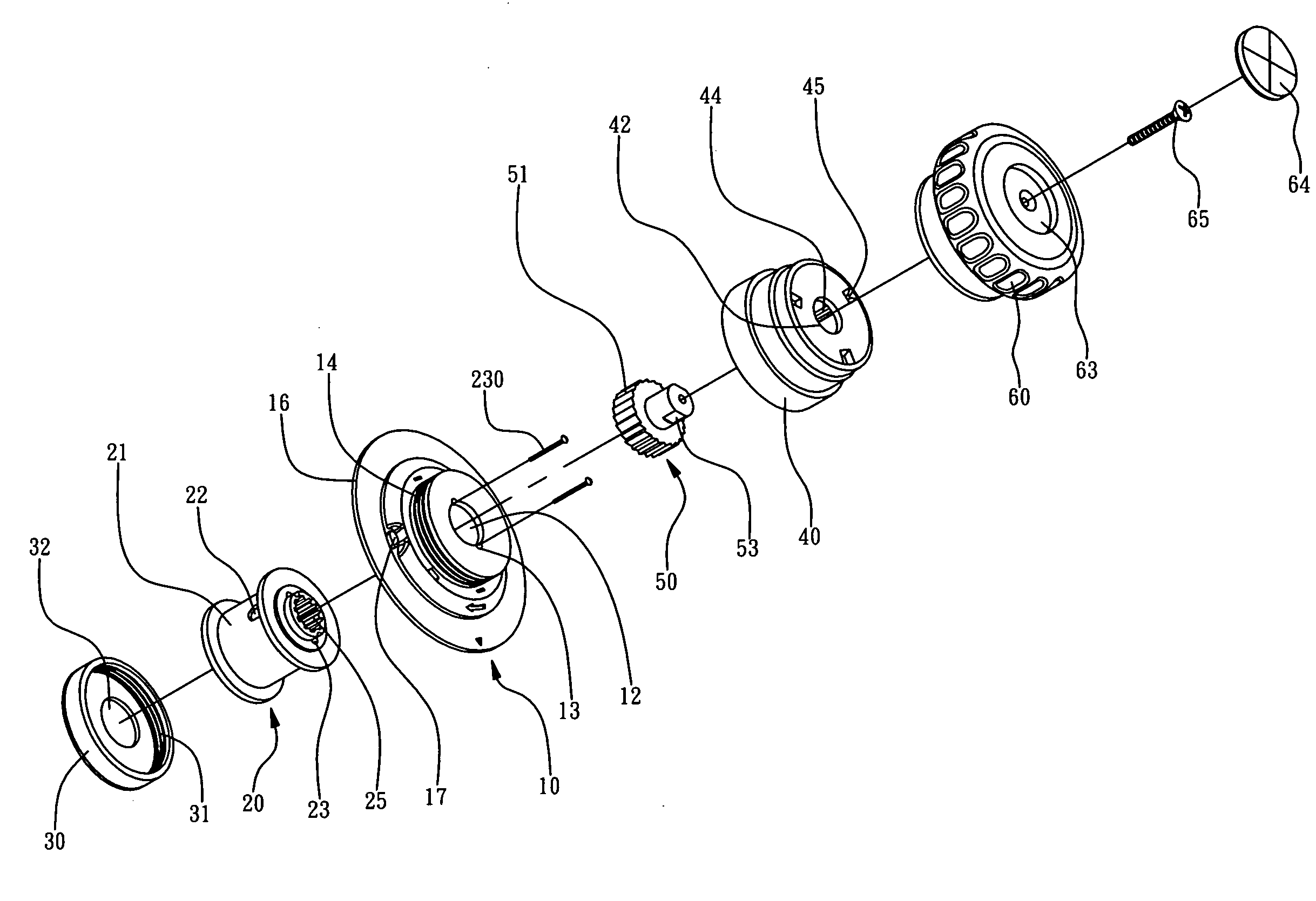

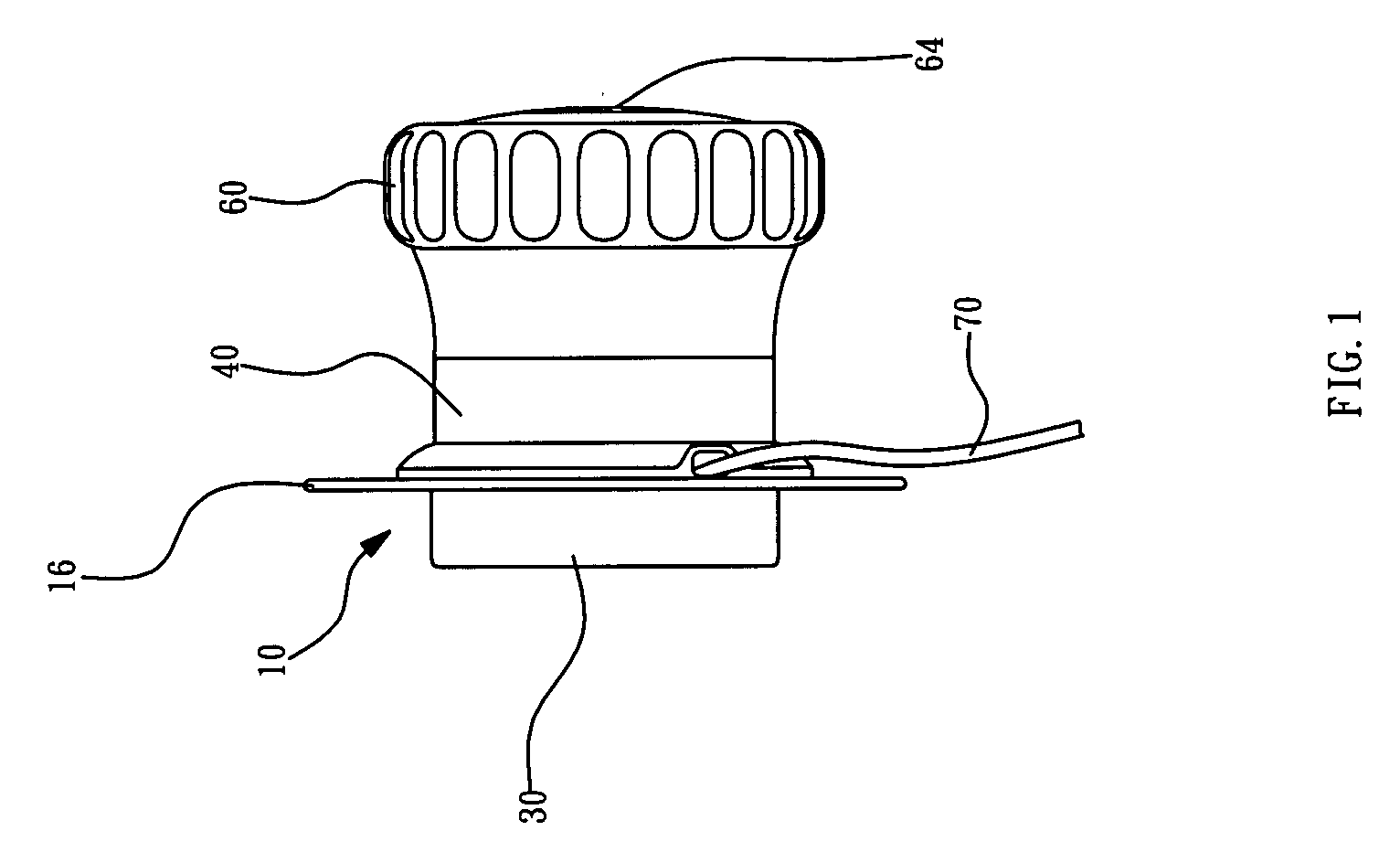

InactiveUS7584528B2Easy to operateThe process is convenient and fastSnap fastenersShoe lace fasteningsMechanical engineeringEngineering

Owner:MENG HANN PLASTIC

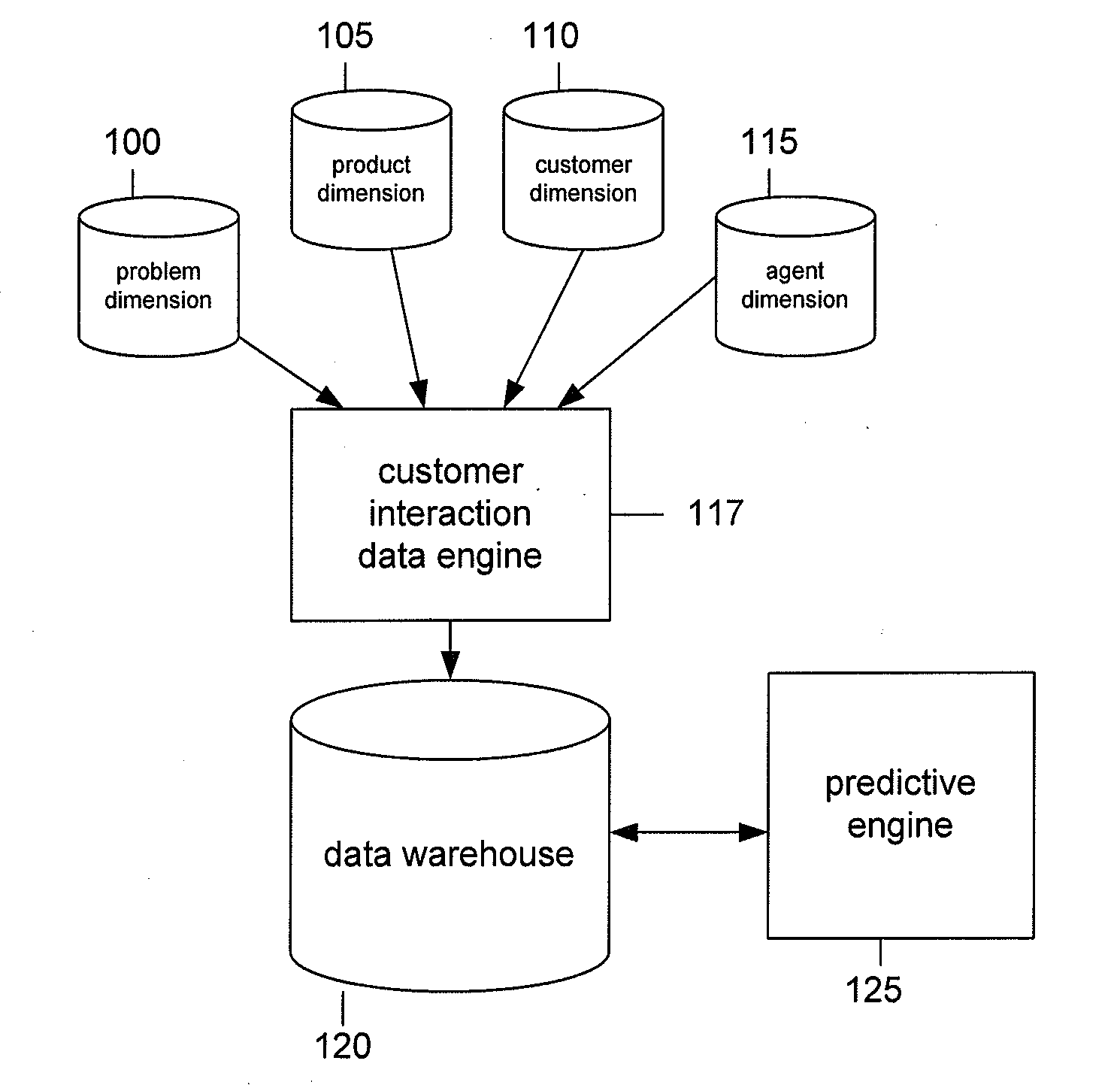

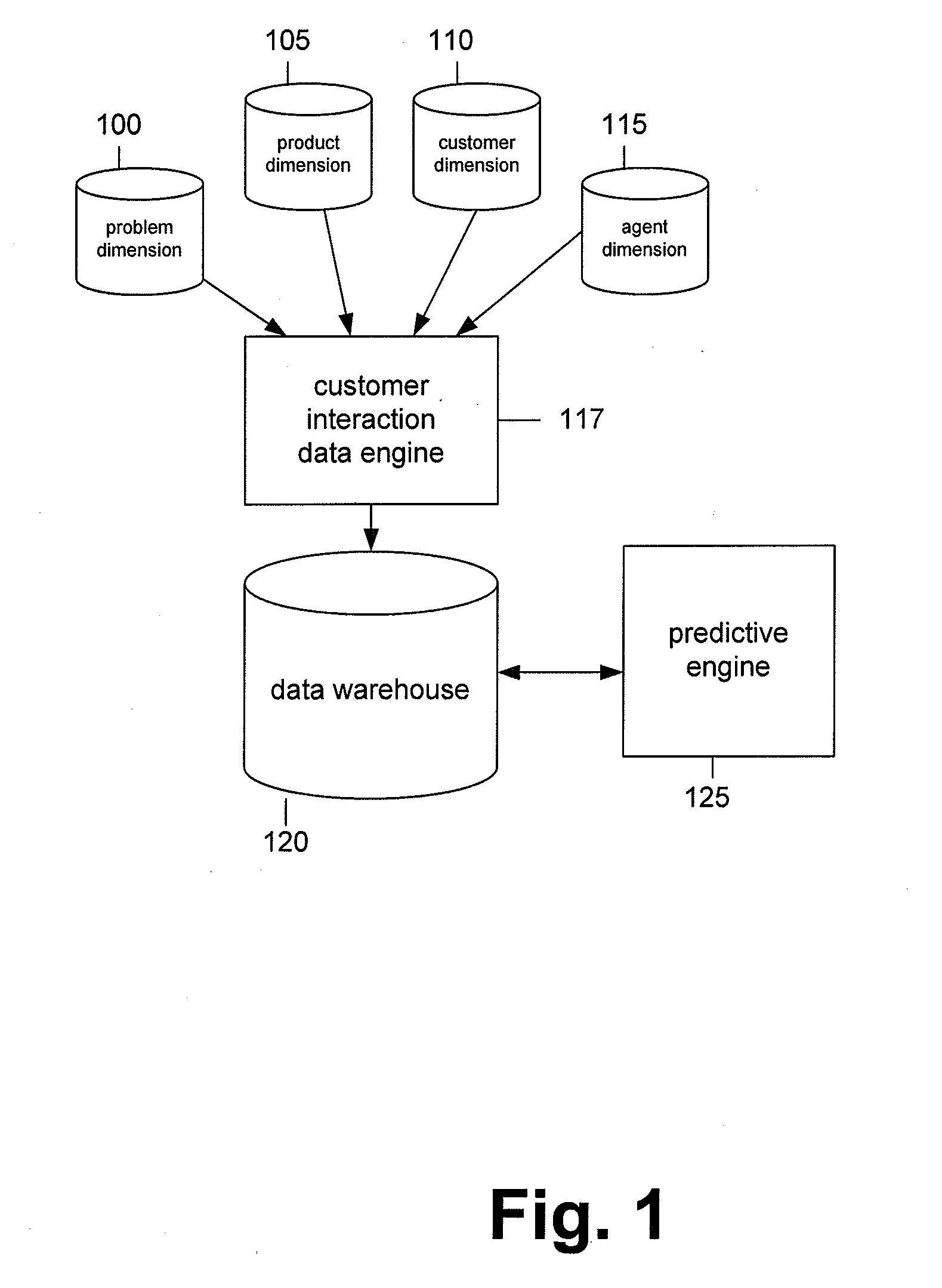

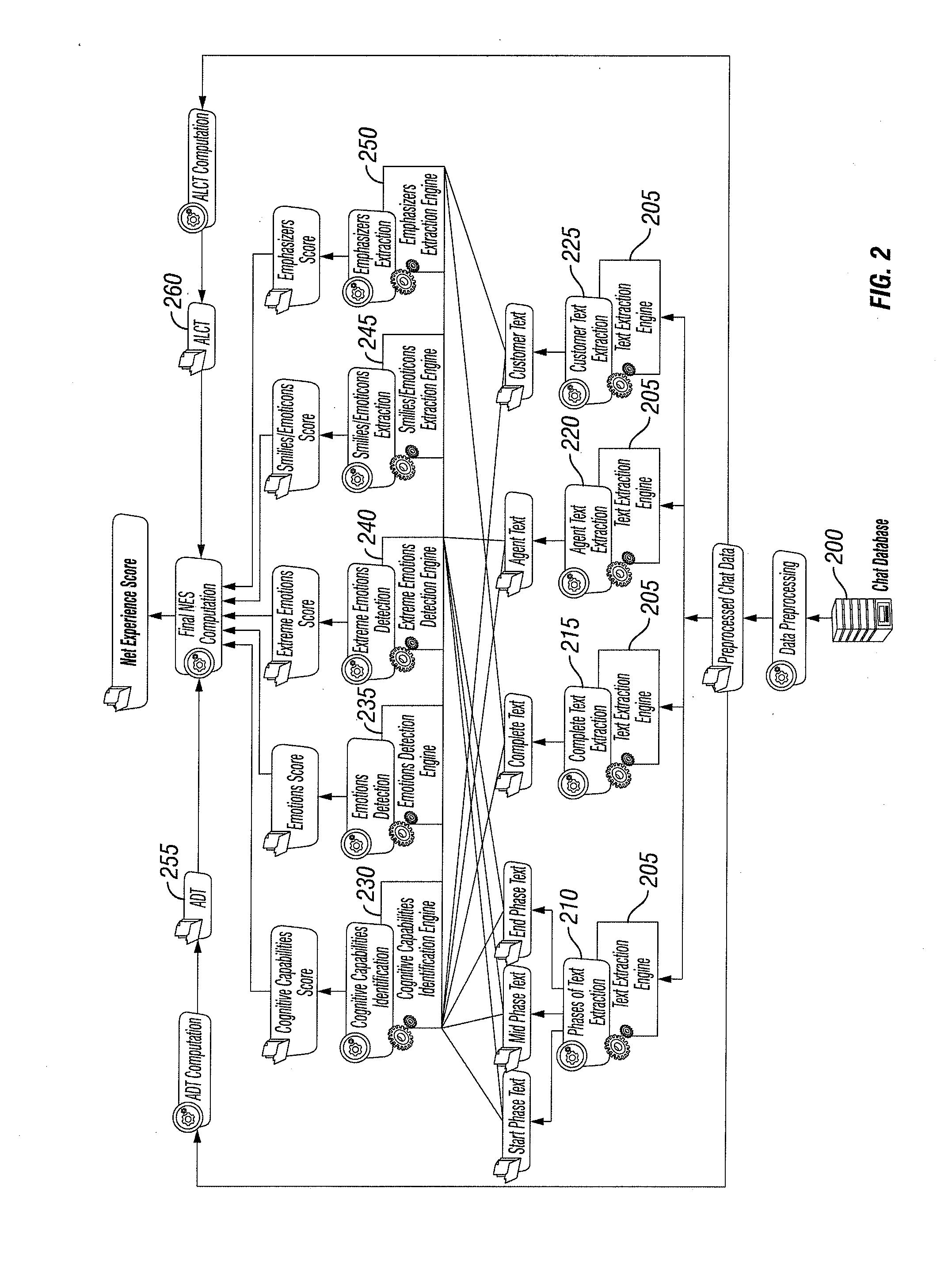

Apparatus and method for predicting customer behavior

ActiveUS20090222313A1Enhanced customer experienceCost reductionFuzzy logic based systemsKnowledge representationData conversionAnalysis data

A predictive model generator that enhances customer experience, reduces the cost of servicing a customer, and prevents customer attrition by predicting the appropriate interaction channel through analysis of different types of data and filtering of irrelevant data. The model includes a customer interaction data engine for transforming data into a proper format for storage, data warehouse for receiving data from a variety of sources, and a predictive engine for analyzing the data and building models.

Owner:24 7 AI INC

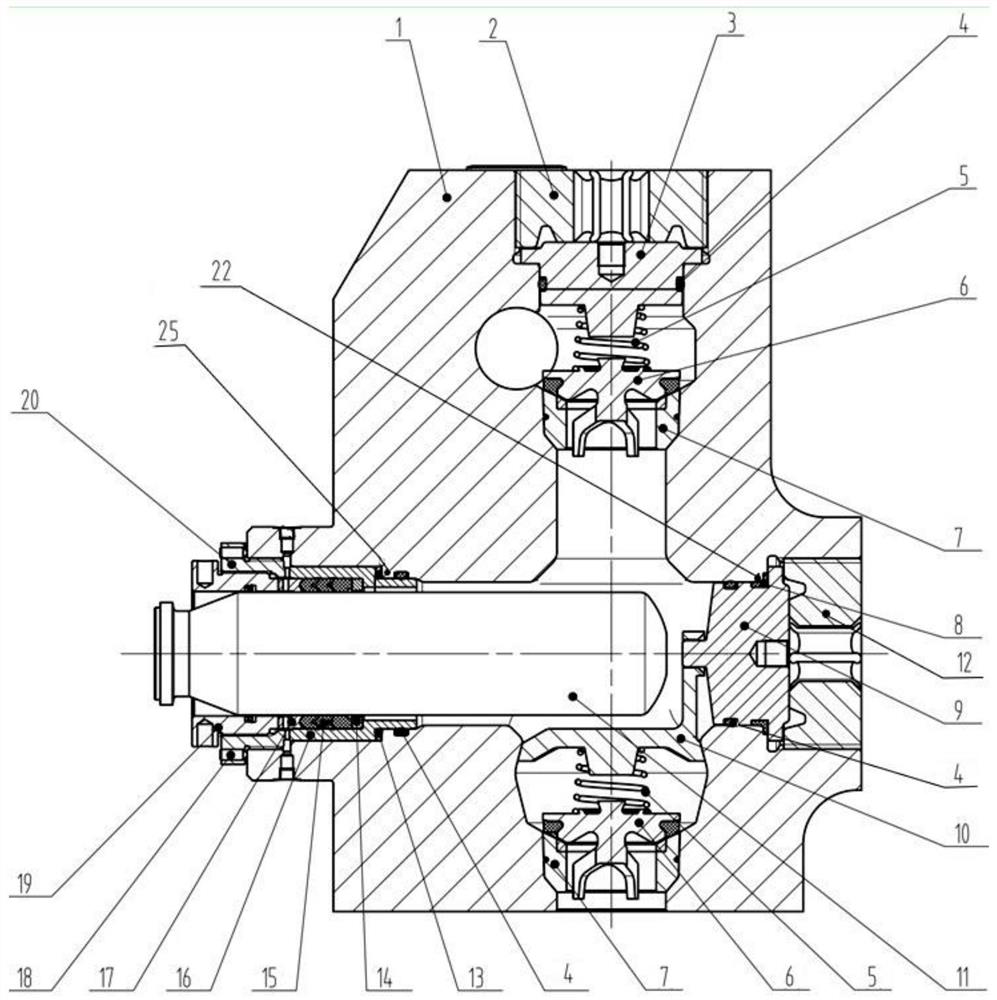

Plunger pump hydraulic end with long service life

PendingCN111692064AExtended service lifeReduced reversibilityPositive displacement pump componentsFluid removalStructural engineeringMechanical engineering

The invention discloses a plunger pump hydraulic end with long service life. The plunger pump hydraulic end comprises a valve box, a plunger, and a packing assembly; the valve box serves as a container for liquid conveying; the plunger is connected to the valve box through the packing assembly; the packing assembly comprises a packing component, a packing sleeve, a packing pressing cap, and a packing sleeve pressing cap; the packing sleeve is connected to the valve box in a sealed manner; the packing component used for sealing fills between the packing sleeve and the plunger; the packing sleeve pressing cap is used for fixing the packing sleeve; and the packing pressing cap is used for fixing the packing component. The plunger pump hydraulic end with the long service life has the beneficial effects that the service lives of the valve box, a suction pressing cover, a suction pressing cap, and a discharging pressing cap are prolonged through optimization design of each of the plunger, the suction pressing cover, and the suction pressing cap, thereby prolonging the service life of the plunger pump hydraulic end.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

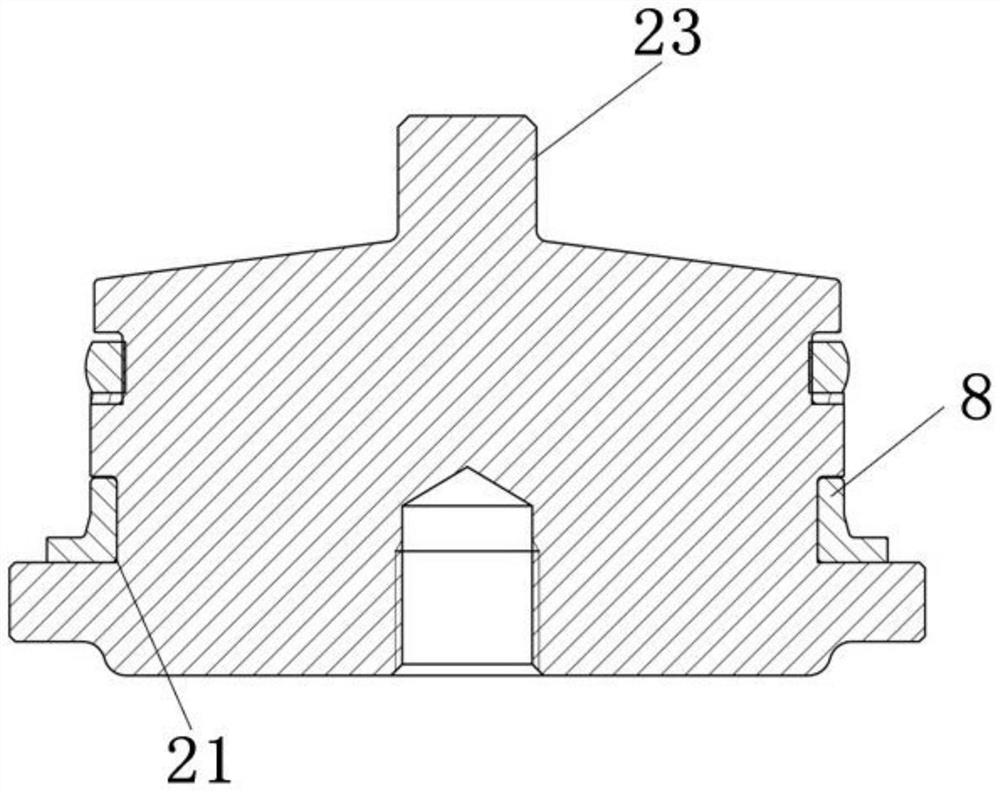

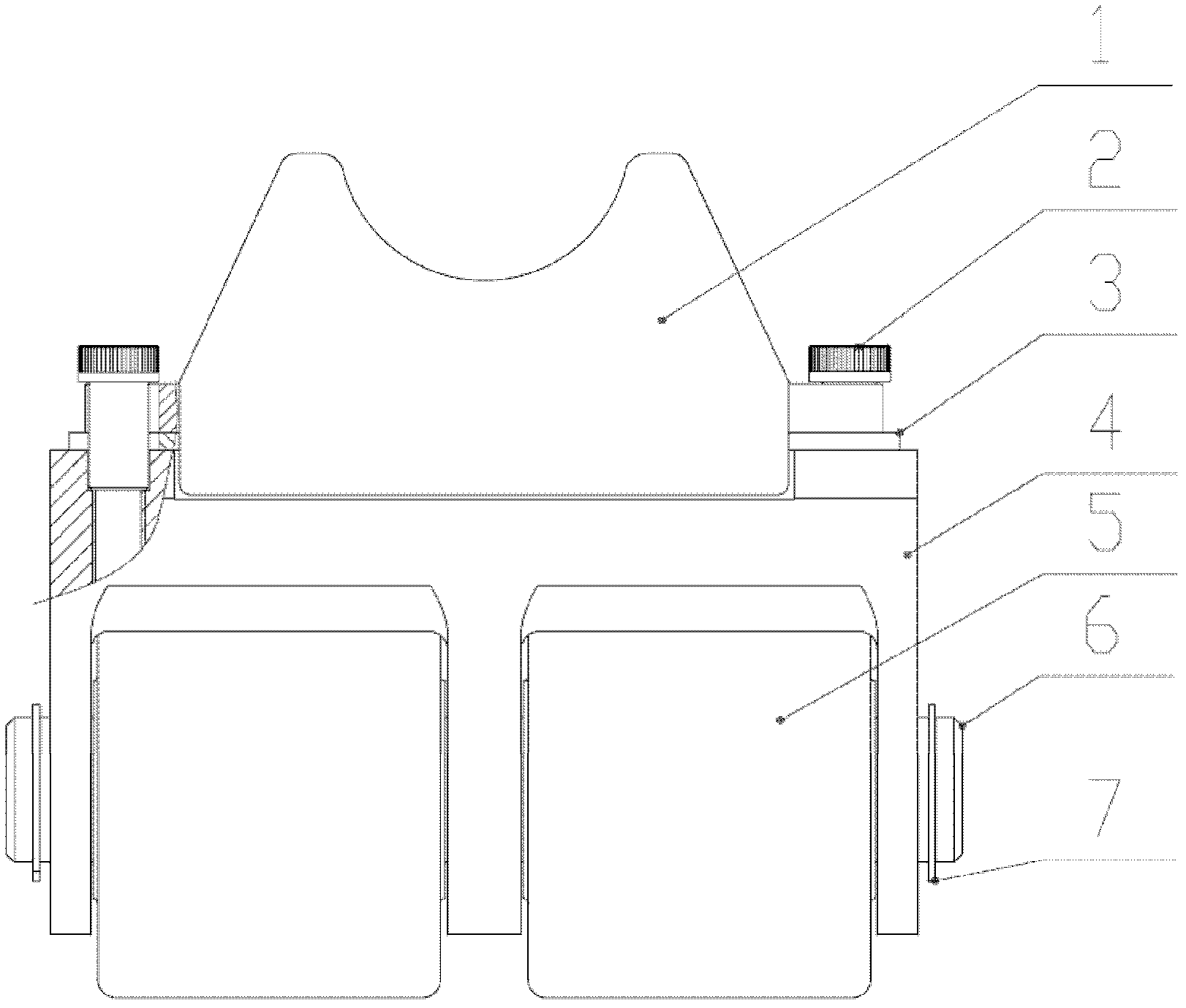

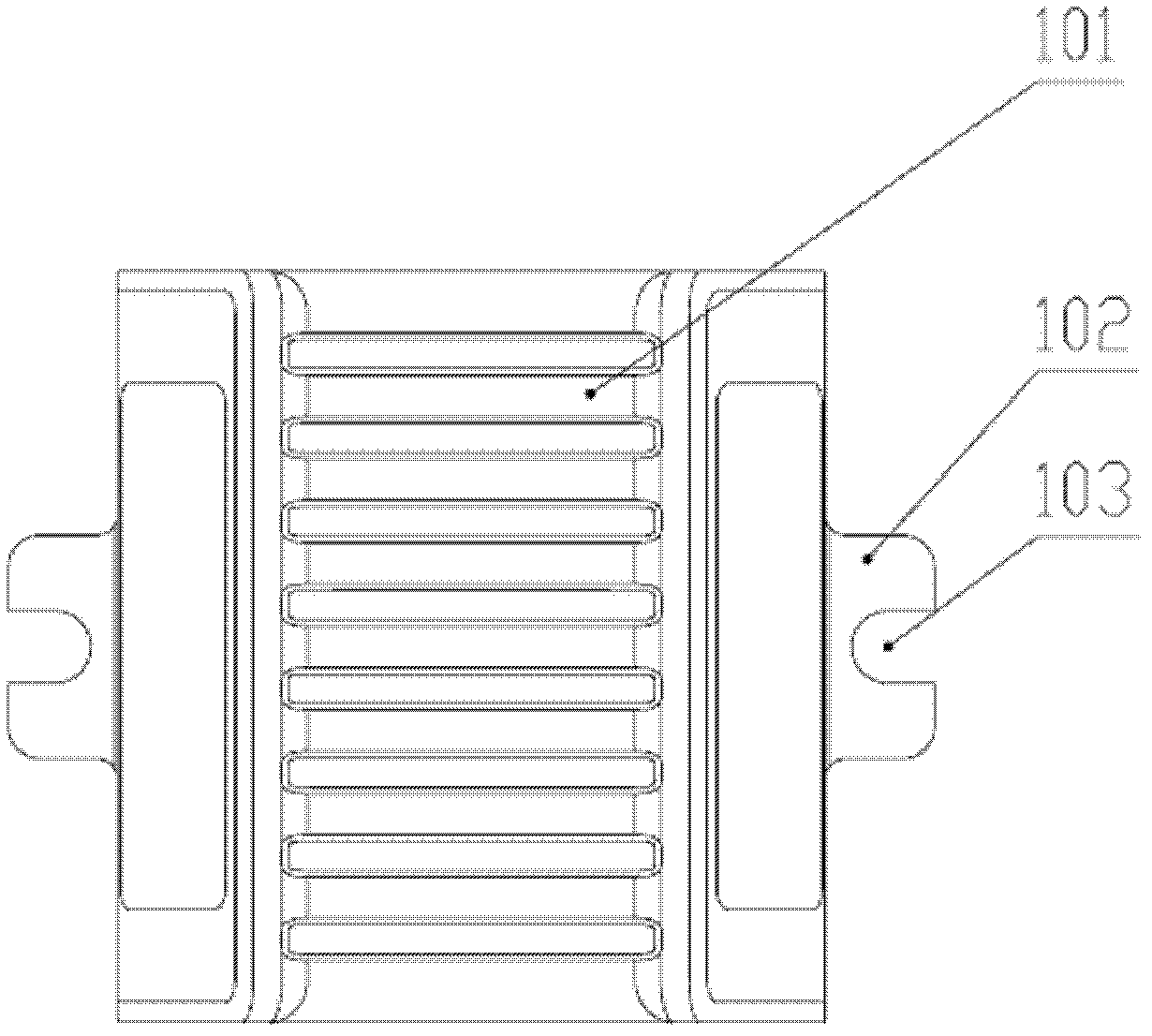

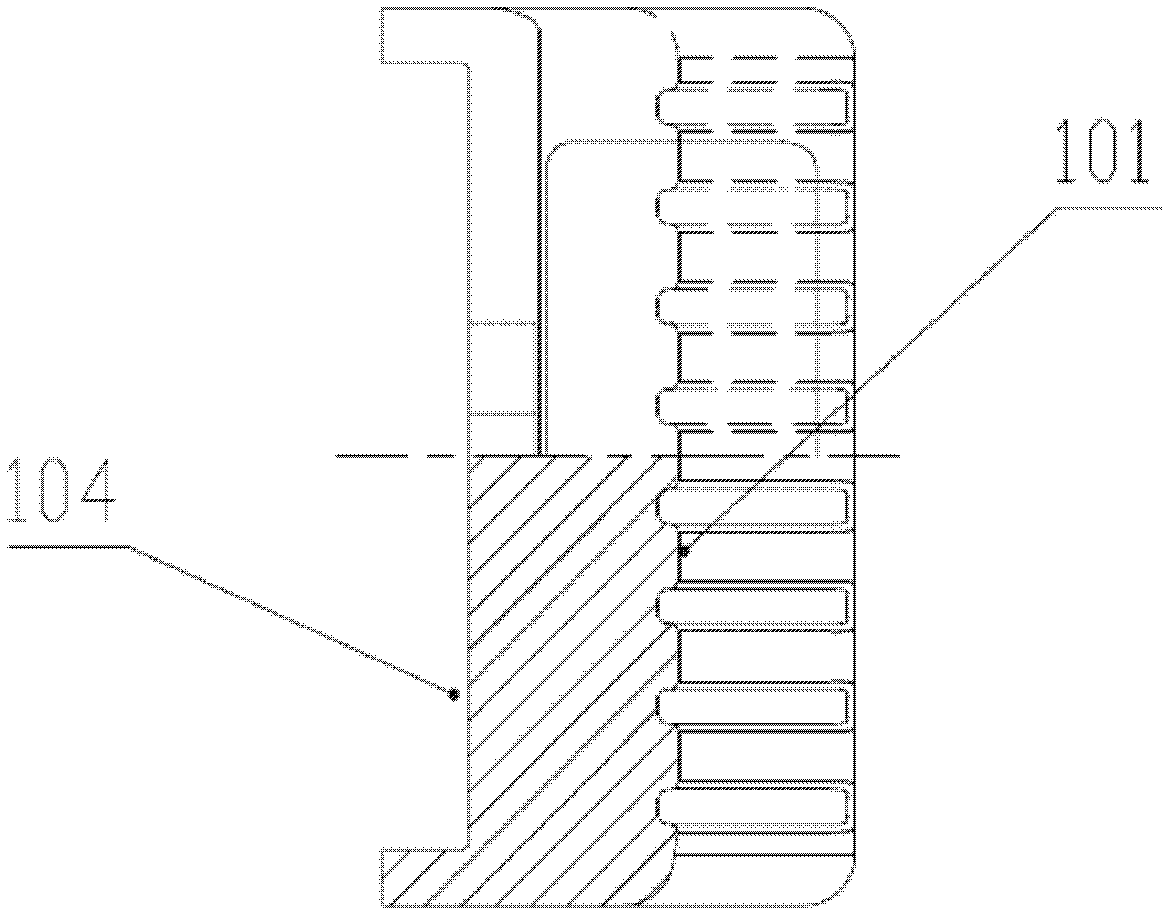

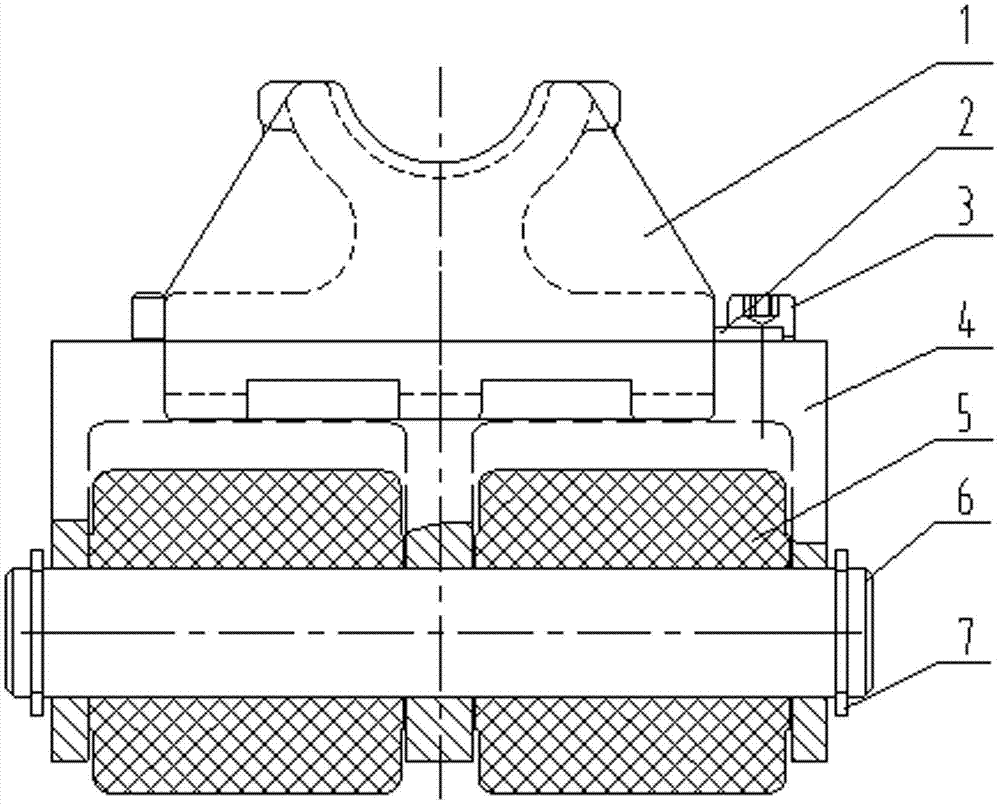

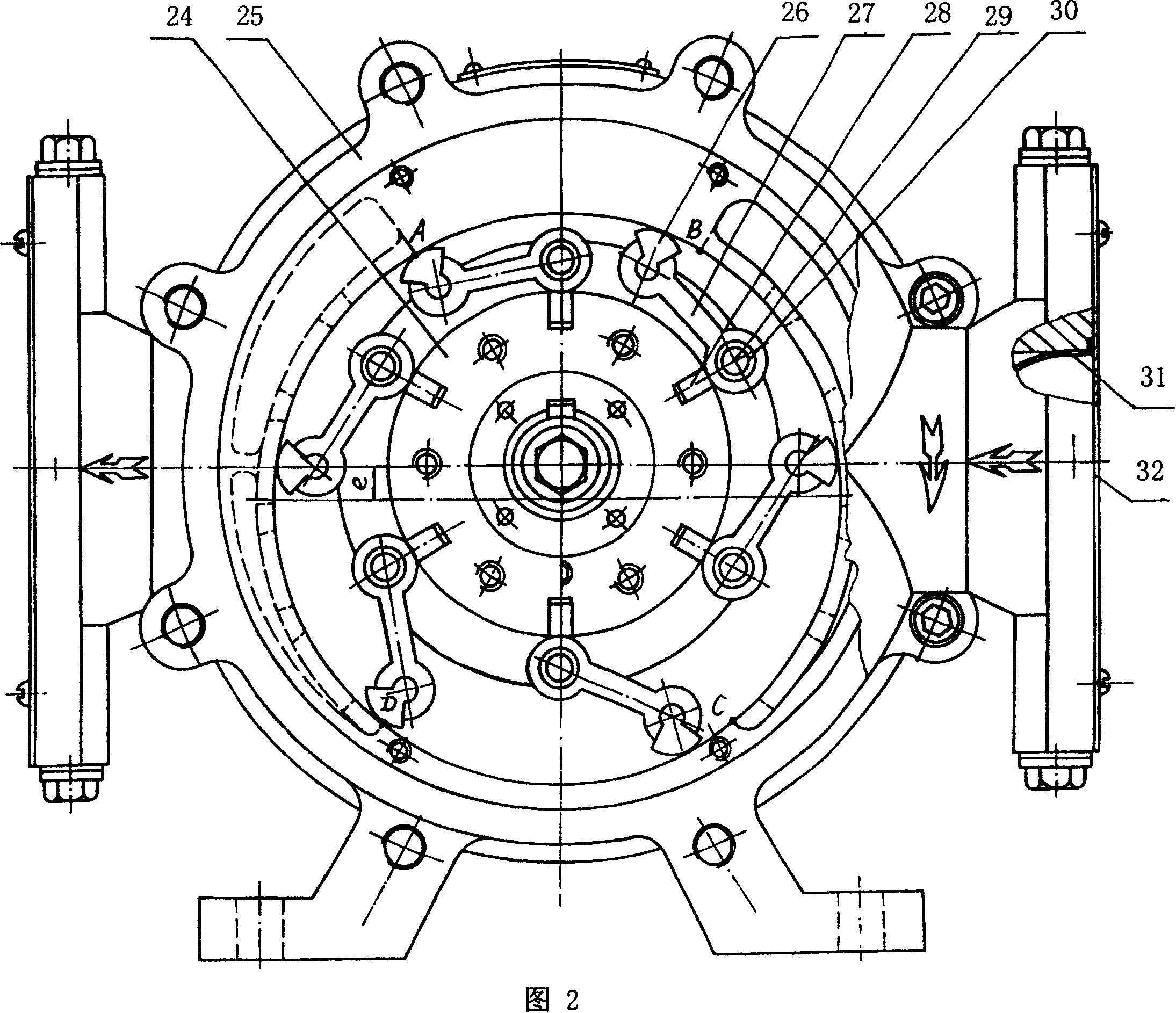

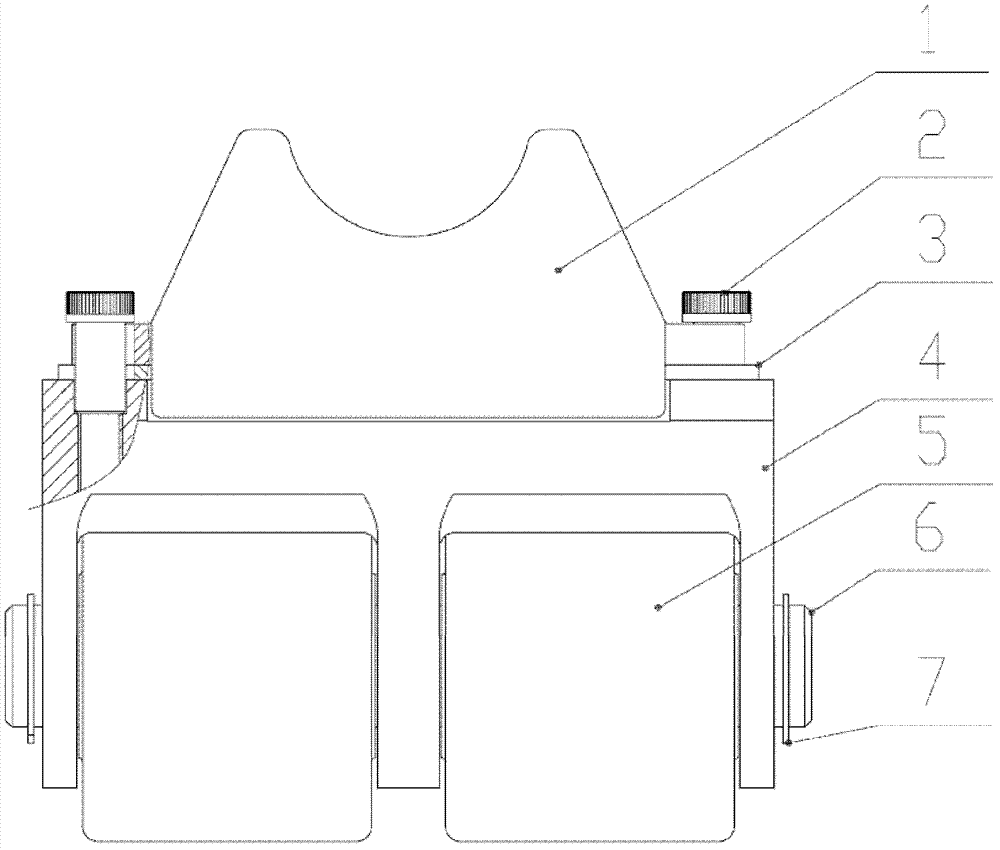

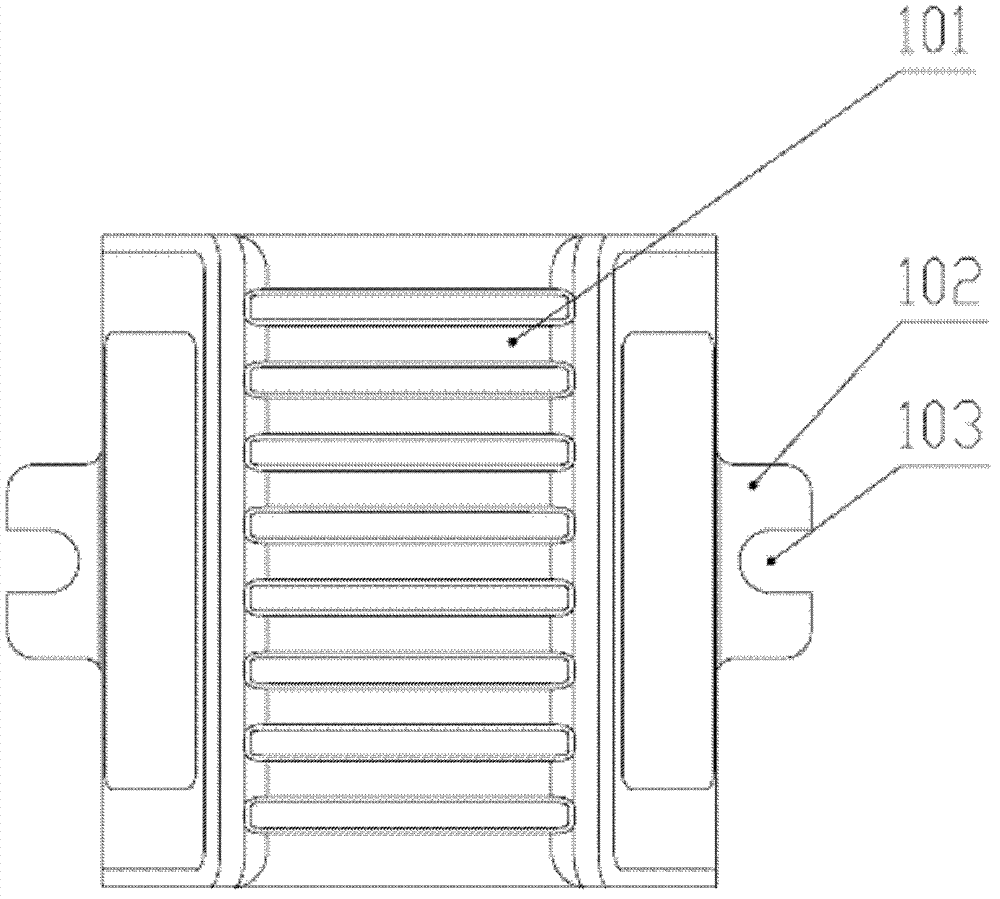

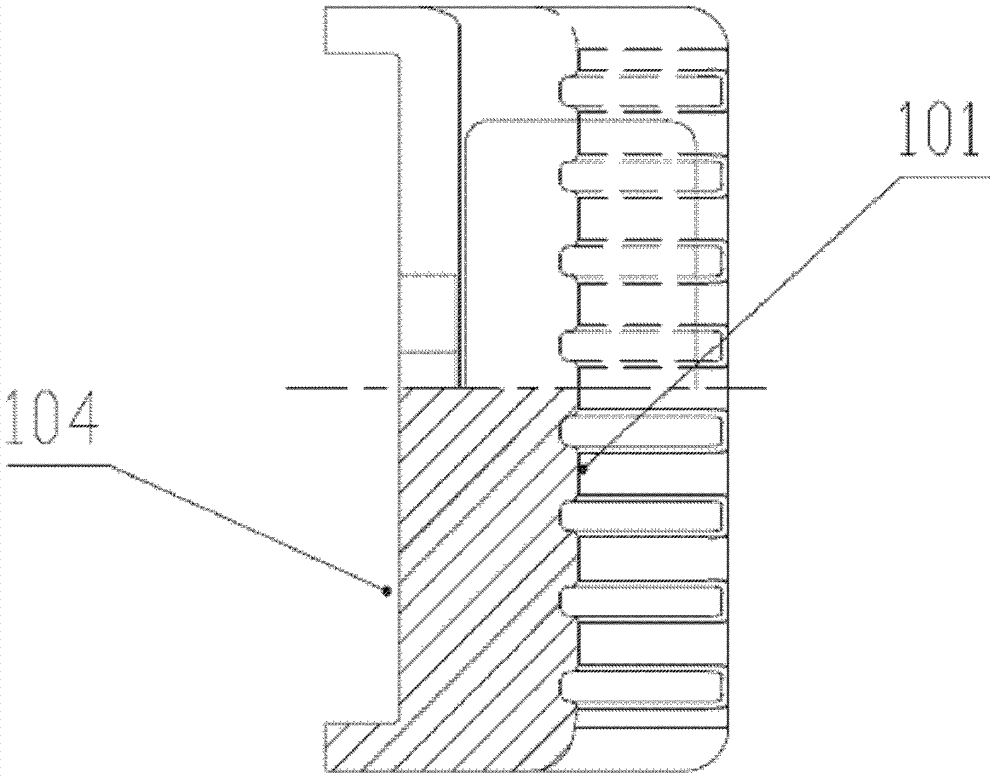

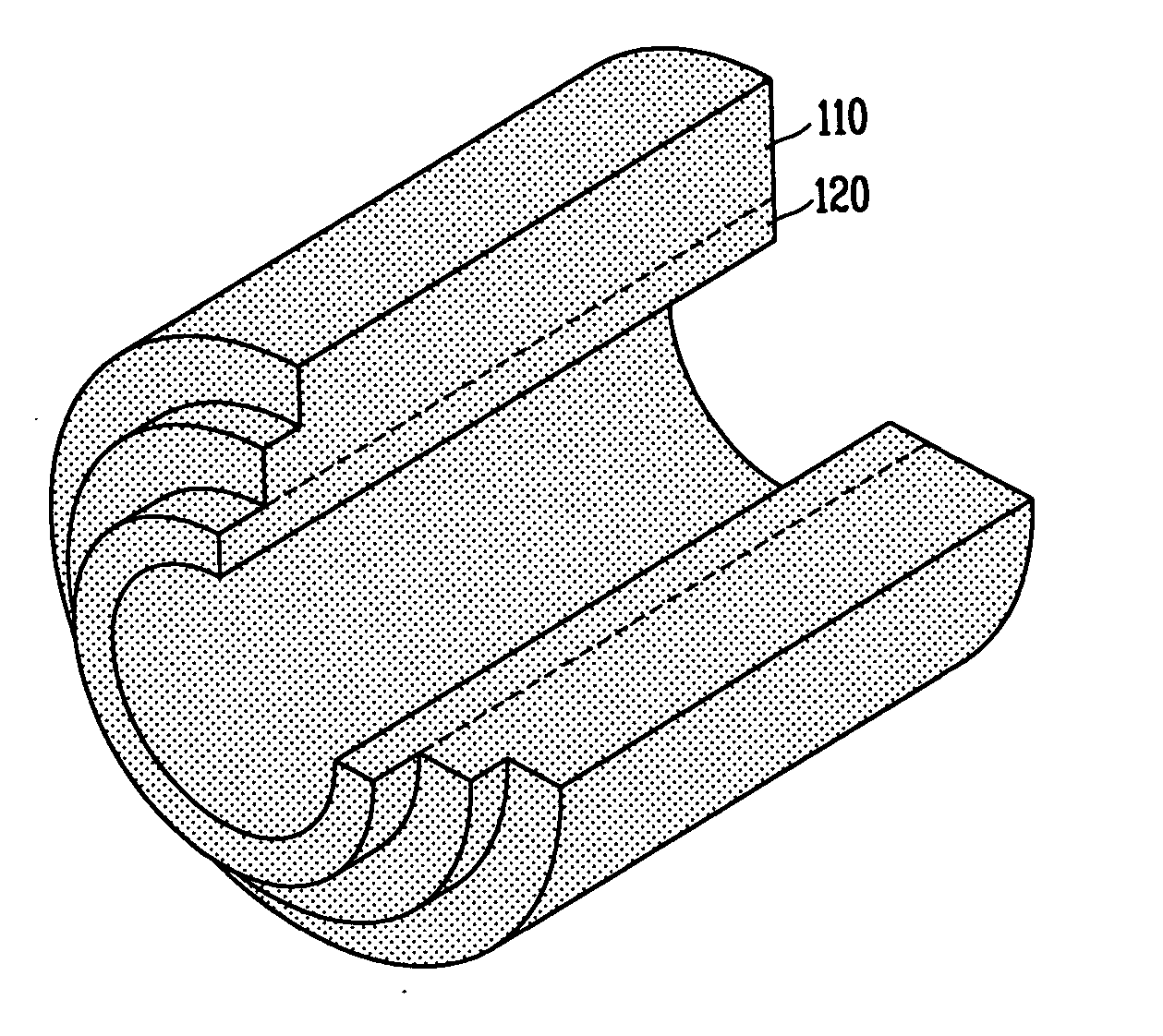

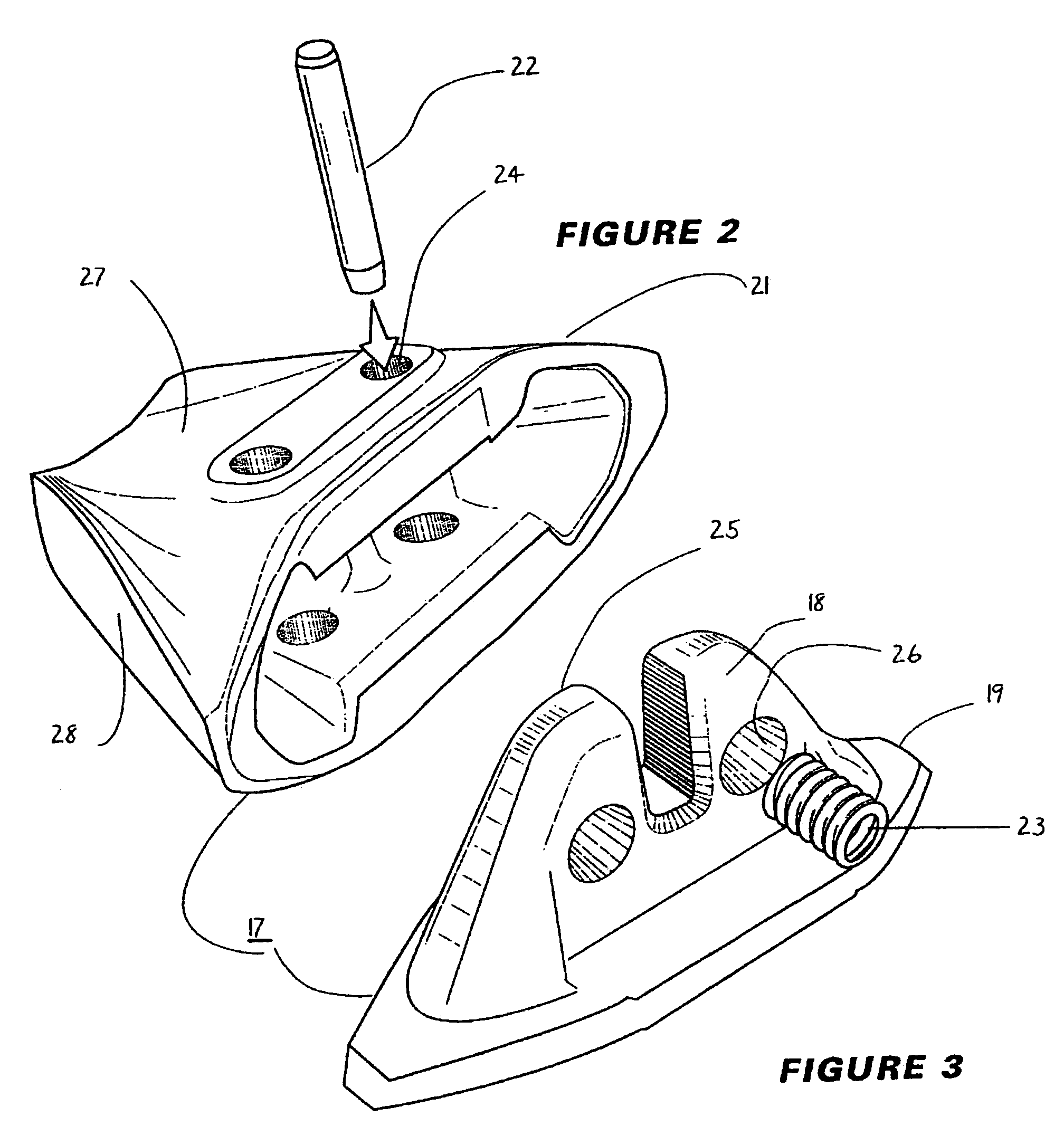

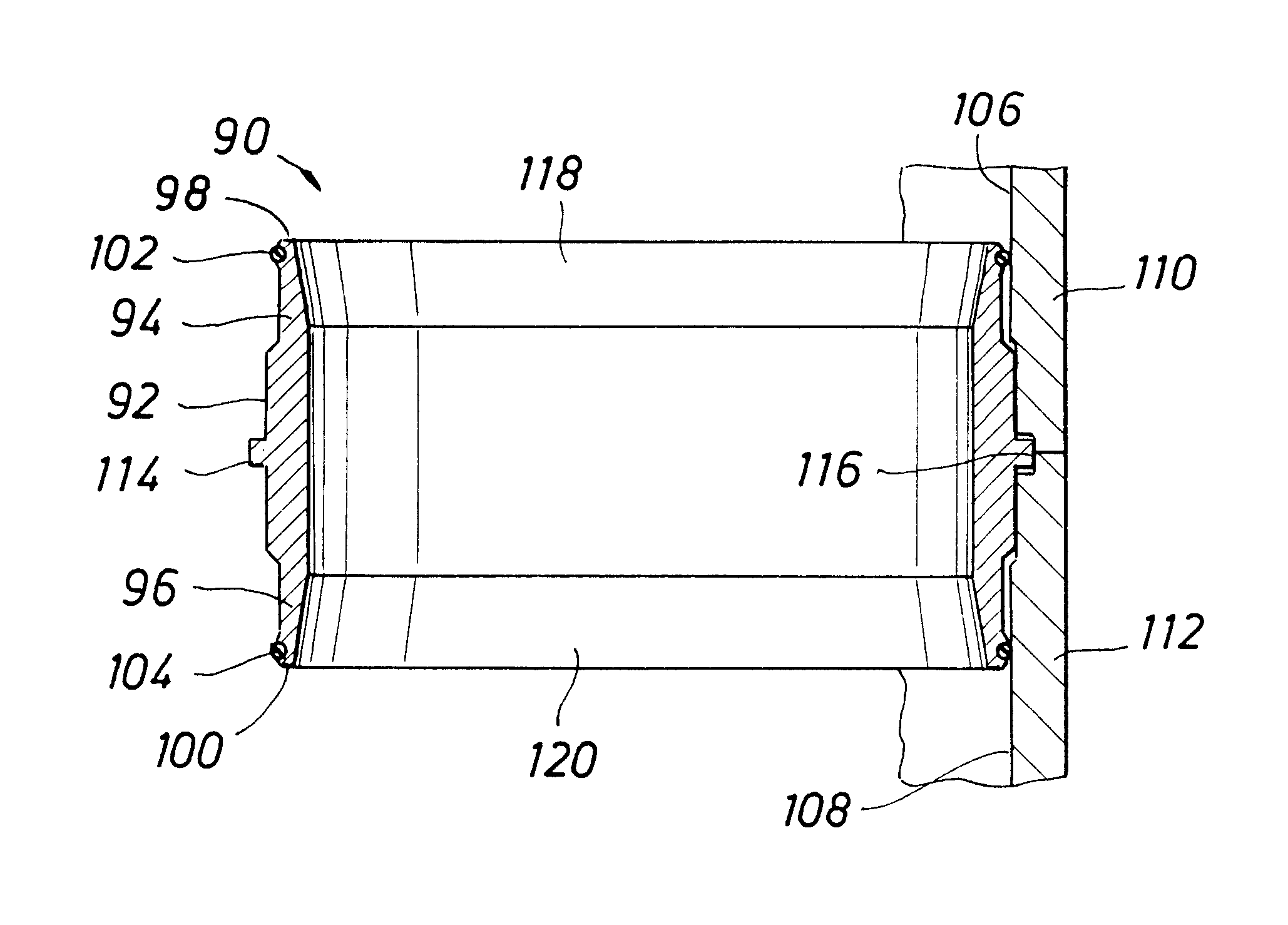

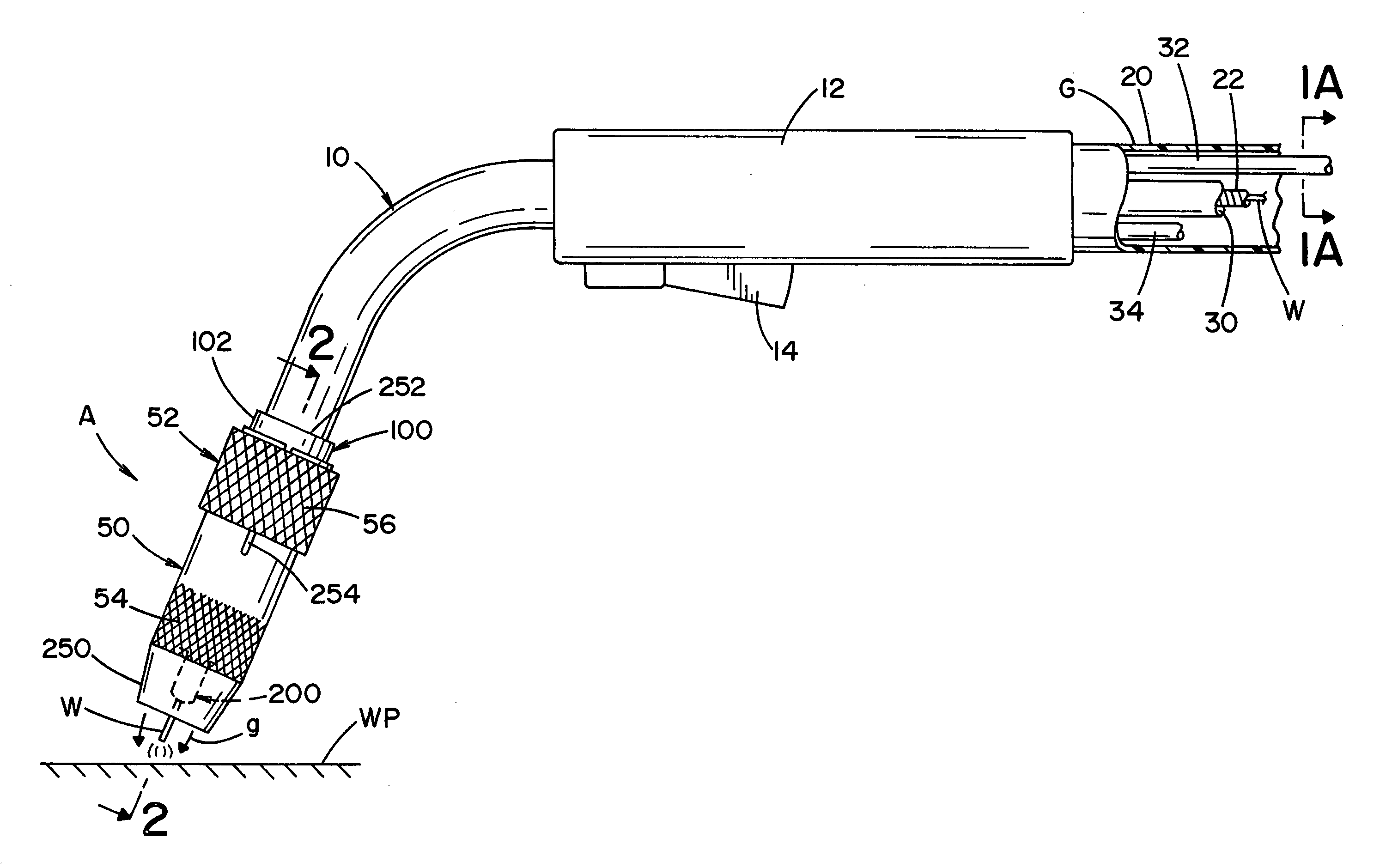

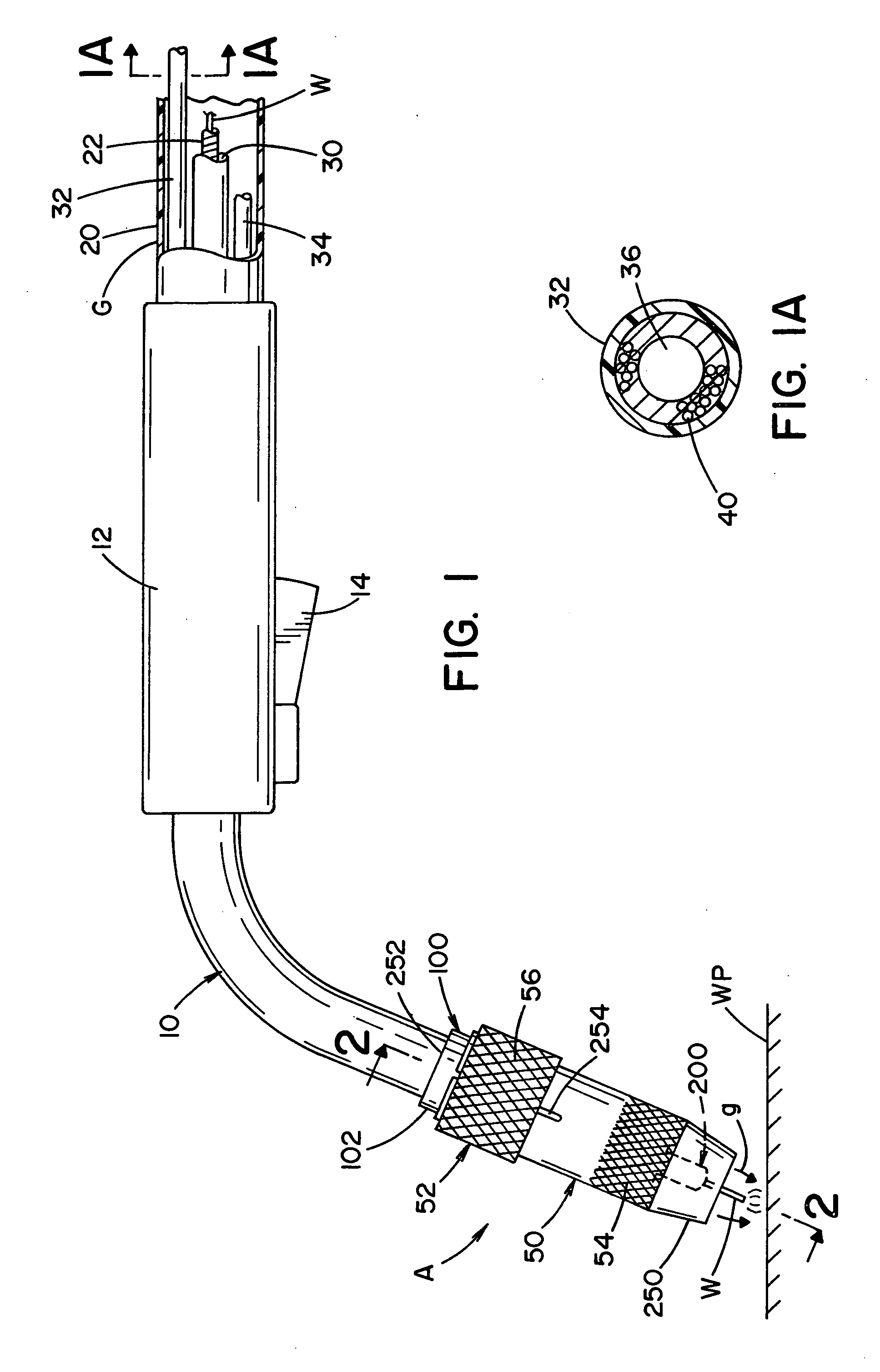

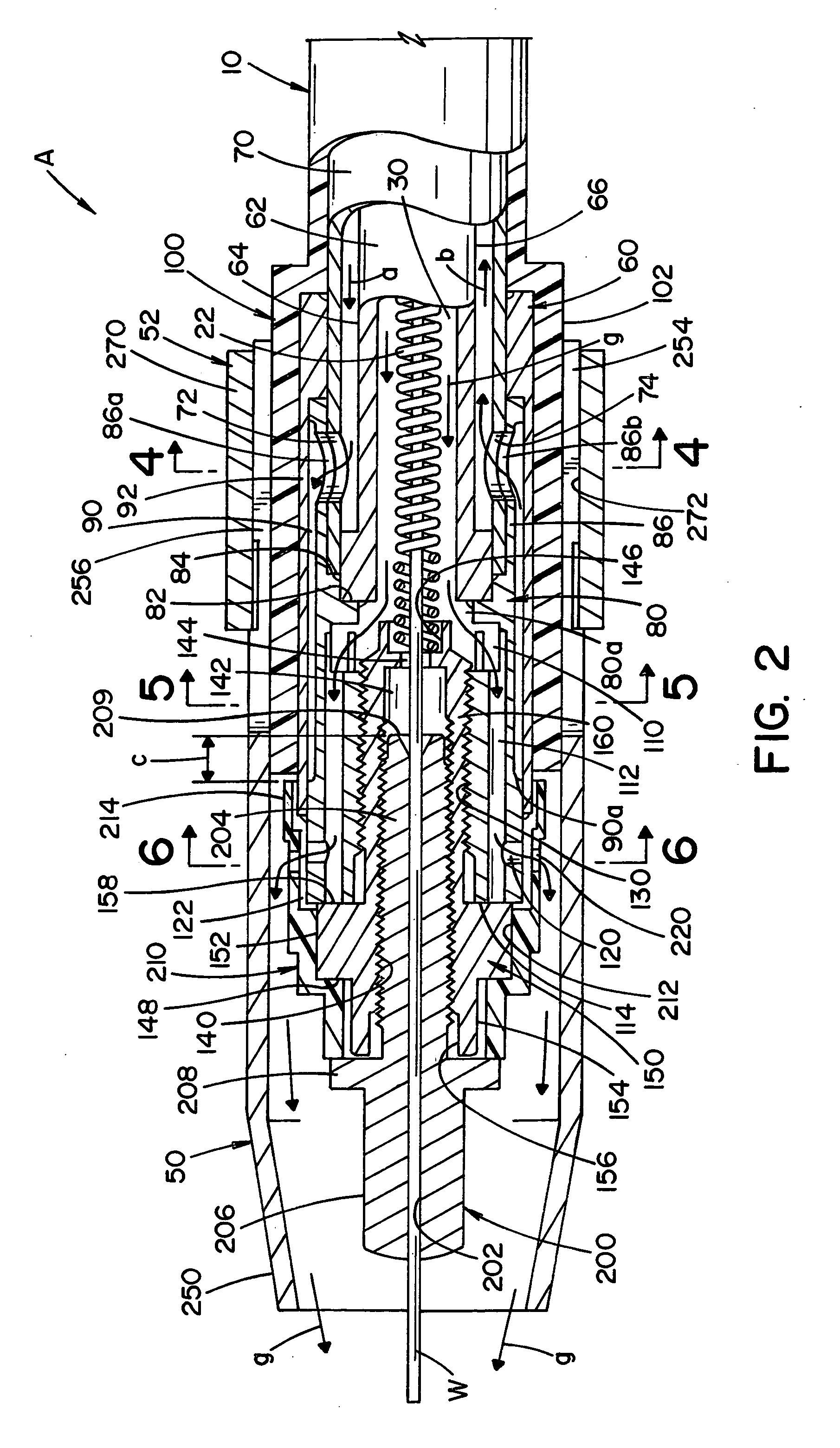

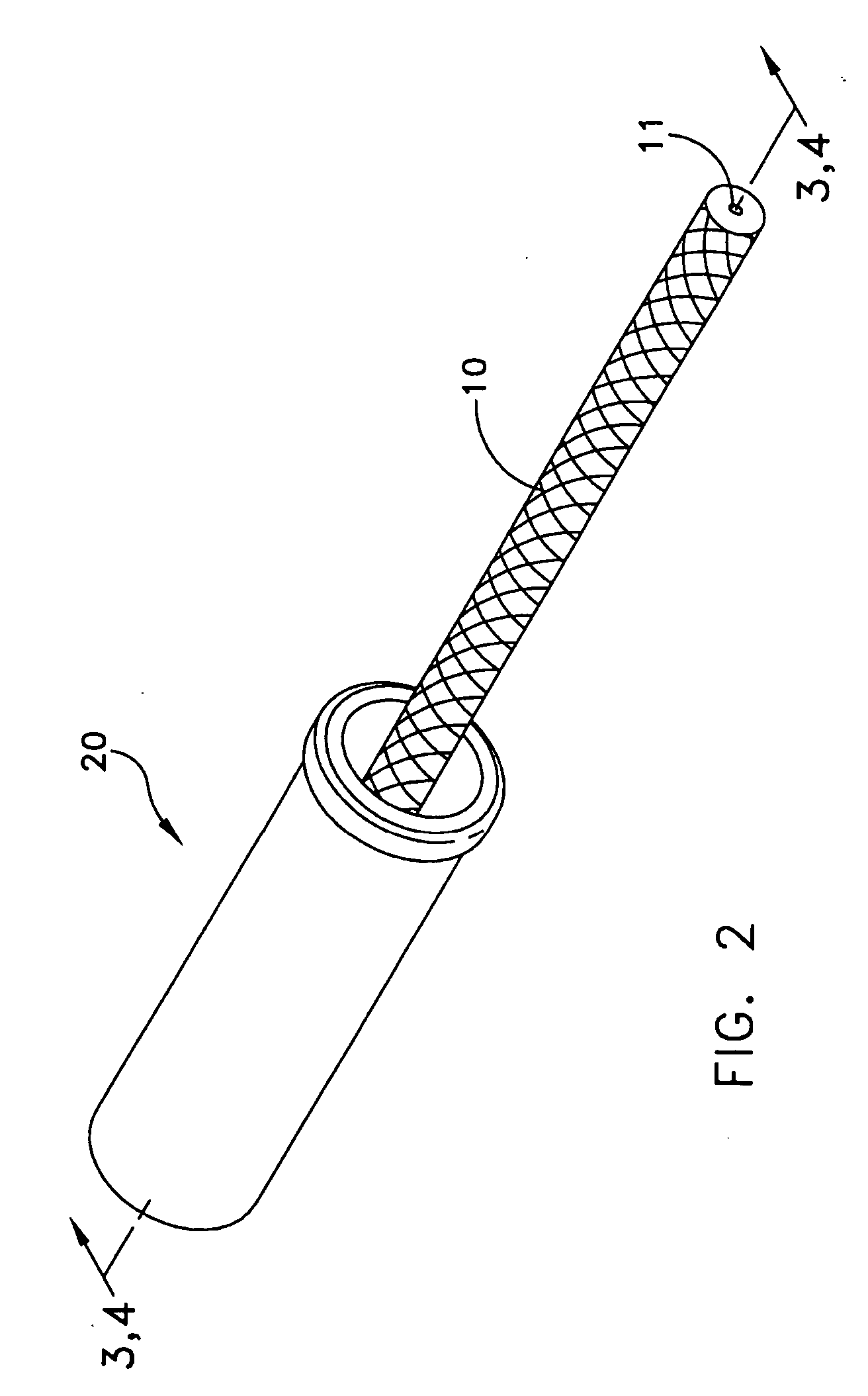

Coiled tubing clamping device and injection head using same

ActiveCN102704870BAvoid wear and tearImprove reliabilityDrilling rodsDrilling casingsCoiled tubingEngineering

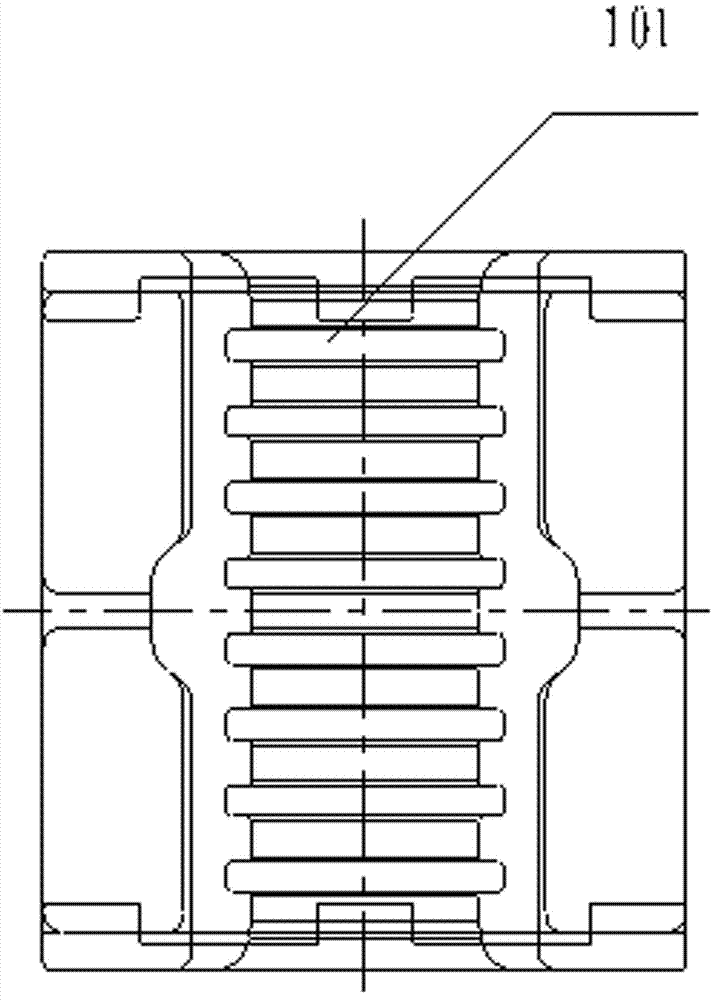

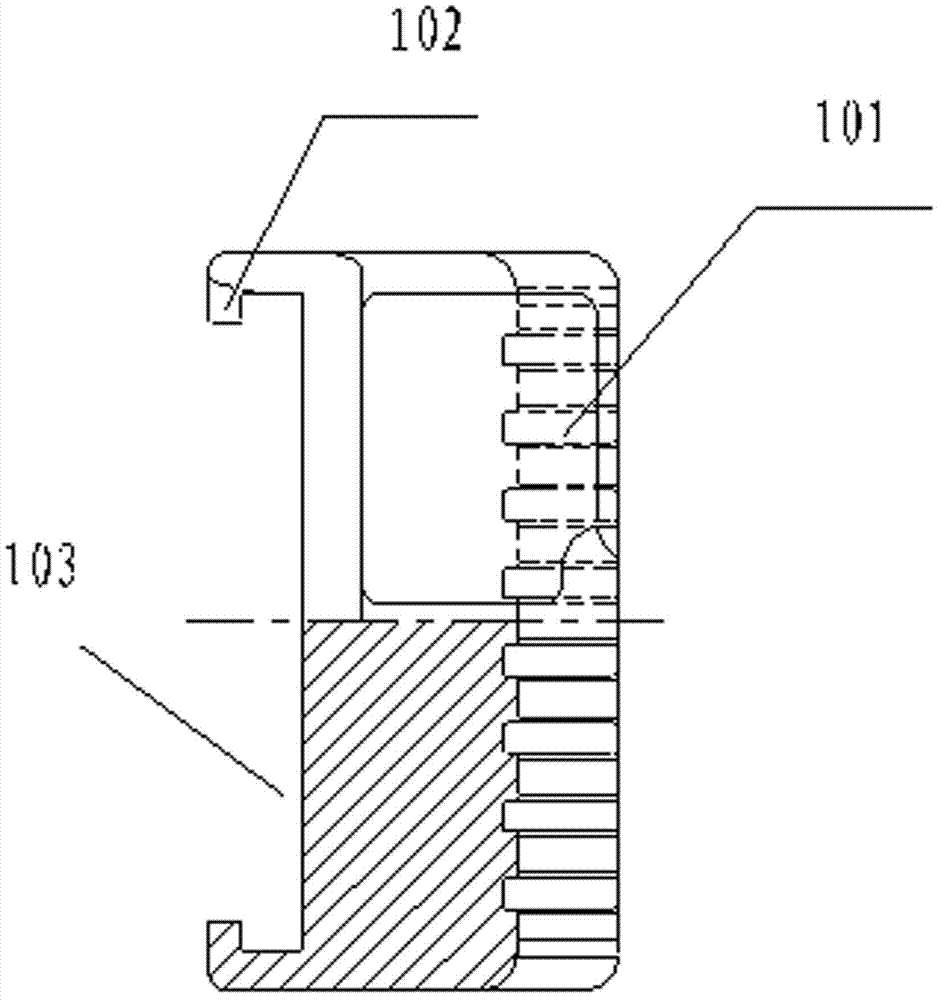

A coiled tubing clamping mechanism comprises a saddle-shaped clamping block (1) and a clamping block seat (4). The saddle-shaped clamping block (1) is connected to the clamping block seat (4). Two sides of the saddle-shaped clamping block (1) are provided with a tongue platform (102). The tongue platform (102) is provided with an open hole (103). The back of the saddle-shaped clamping block (1) is provided with a groove (104). Two sides of the clamping block seat (4) are provided with a pair of bosses (406) respectively. The groove (104) of the saddle-shaped clamping block (1) is inserted in a holding slot (405) formed by the bosses (406) of the clamping block seat. A traverse gap is kept between the groove (104) and the holding slot (405). The clamping block seat (4) is provided with a positioning screw (2) for limiting the position of the saddle-shaped clamping block (1). Also disclosed is an injector head using the coiled tubing clamping mechanism, comprising a tubing clamping mechanism (11) and a drive chain (13). The tubing clamping mechanism (11) is mounted on the drive chain (13) through two pin holes (401) in the clamping block seat (4). The present invention can effectively prevent the tubing from being worn, is reliable in use, and makes it convenient to replace the clamping block.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

Coiled tubing clamping device and injection head using same

ActiveCN102140898BEasy to replaceAvoid hard squeezeDrilling rodsDrilling casingsCoiled tubingInjector

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

Shoelace reel operated easily and conveniently

InactiveUS20080196224A1Easy to operateThe process is convenient and fastSnap fastenersShoe lace fasteningsEngineeringMechanical engineering

Owner:MENG HANN PLASTIC

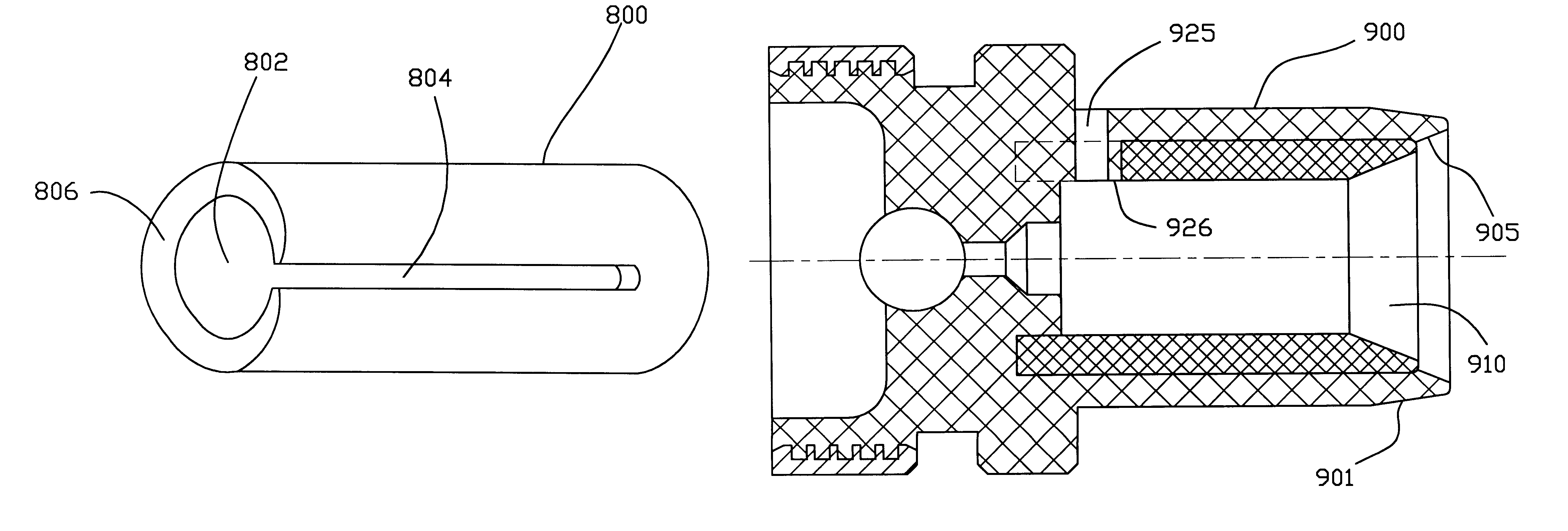

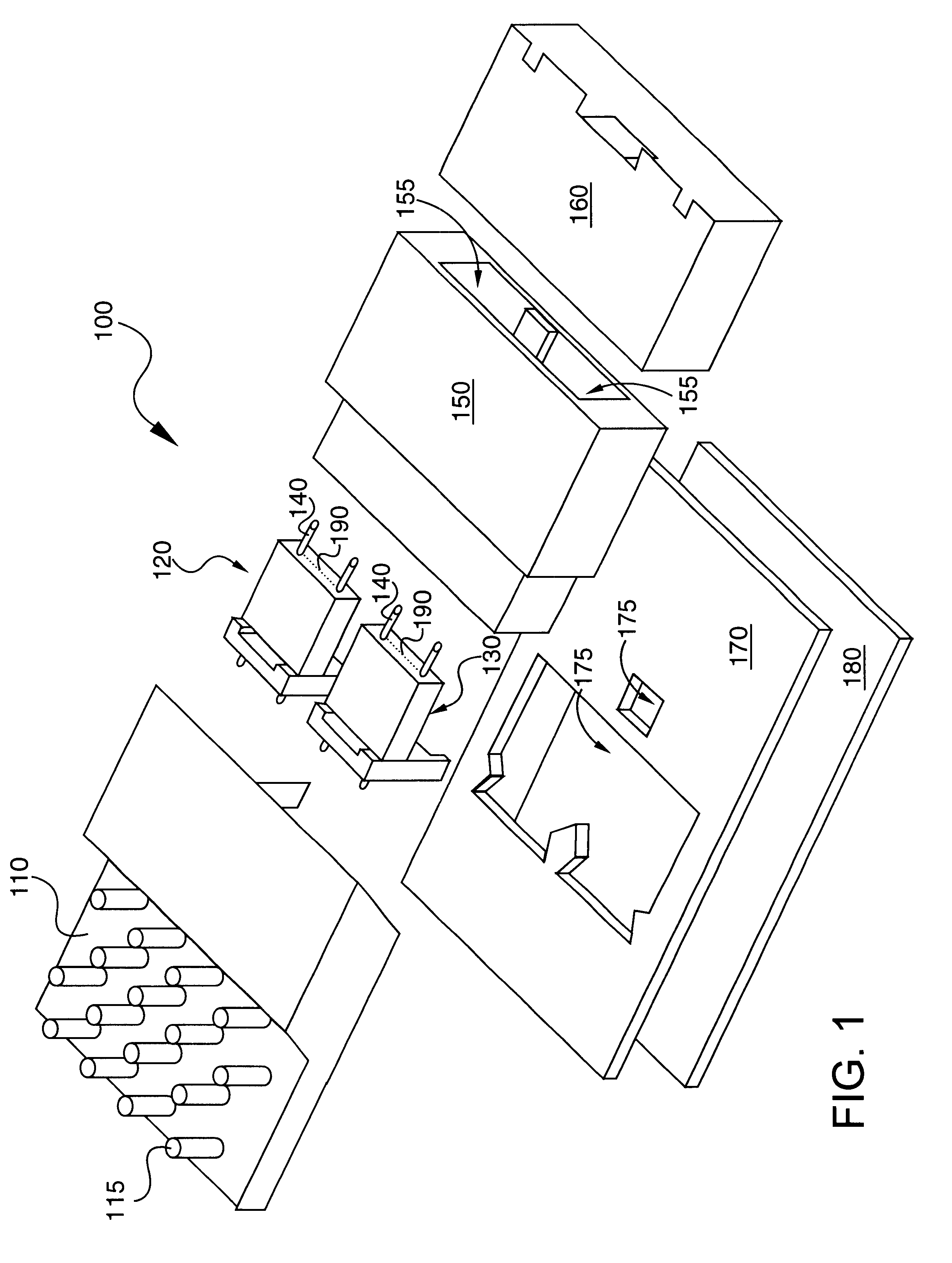

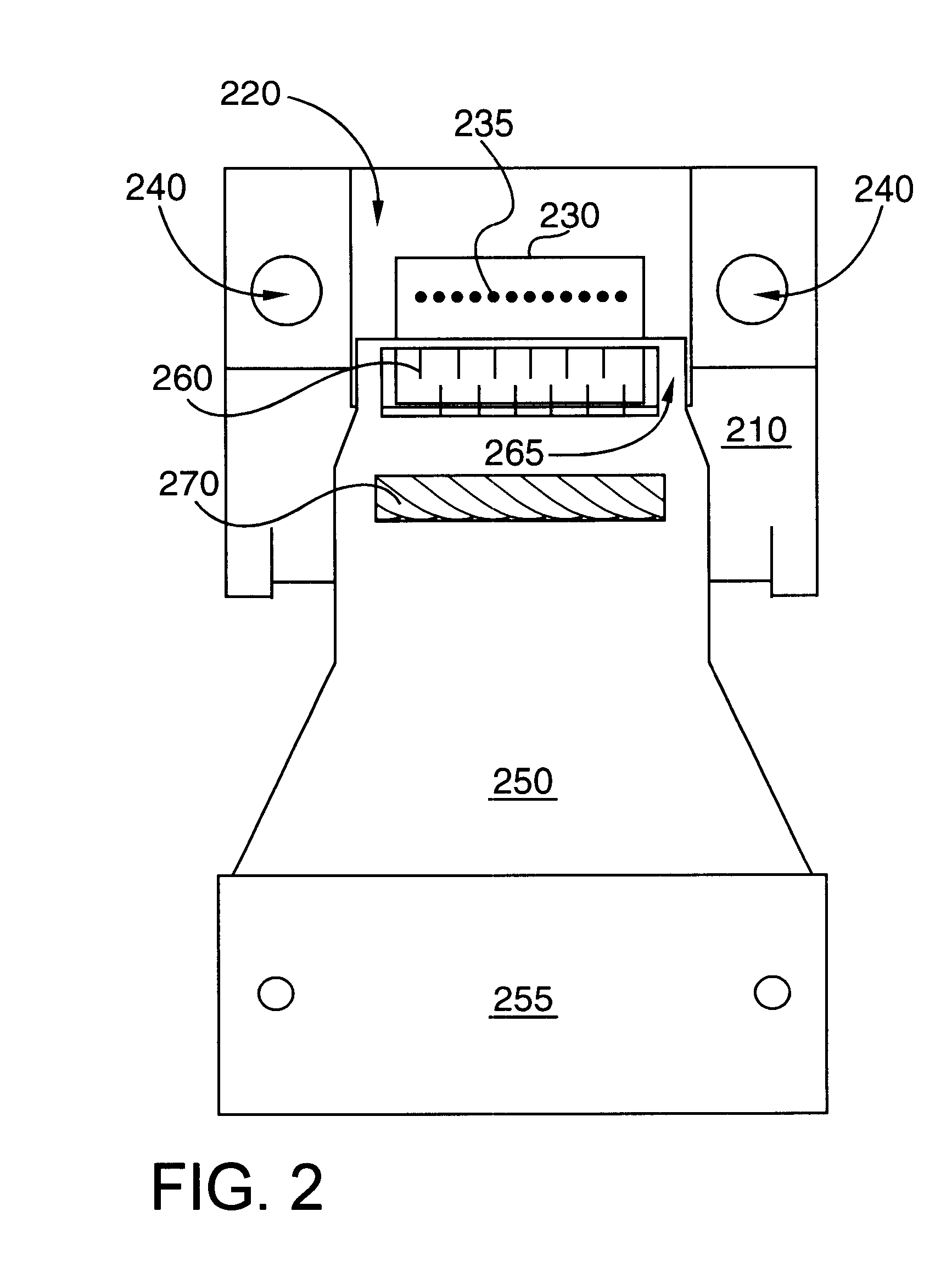

Optical package with alignment means and method of assembling an optical package

InactiveUS6283644B1Easy alignmentQuickly and inexpensively manufacturedSolid-state devicesCoupling light guidesFiberAdhesive

An optical package is provided including a housing having first and second ends. A ferrule receiving bore is formed in the first end, and an optics cavity is formed in the second end. The optics cavity and the ferrule receiving bore are axially aligned with one another along an optical axis defined by the package. A mounting cap is inserted over the optics cavity and frictionally engages an outer surface of the housing. The end cap includes an endplate and a substrate having an optical device mounted thereon. The ferrule receiving bore includes a longitudinal slot extending generally parallel to the axis of the bore providing radial flexibility to the outer wall. Additionally, a split sleeve is provided for accepting a fiber optic connector ferrule. The split sleeve being insertable and expandable in a ferrule receiving bore of an optical package housing. The split sleeve being retained in the ferrule receiving bore with an adhesive.

Owner:STRATOS INT

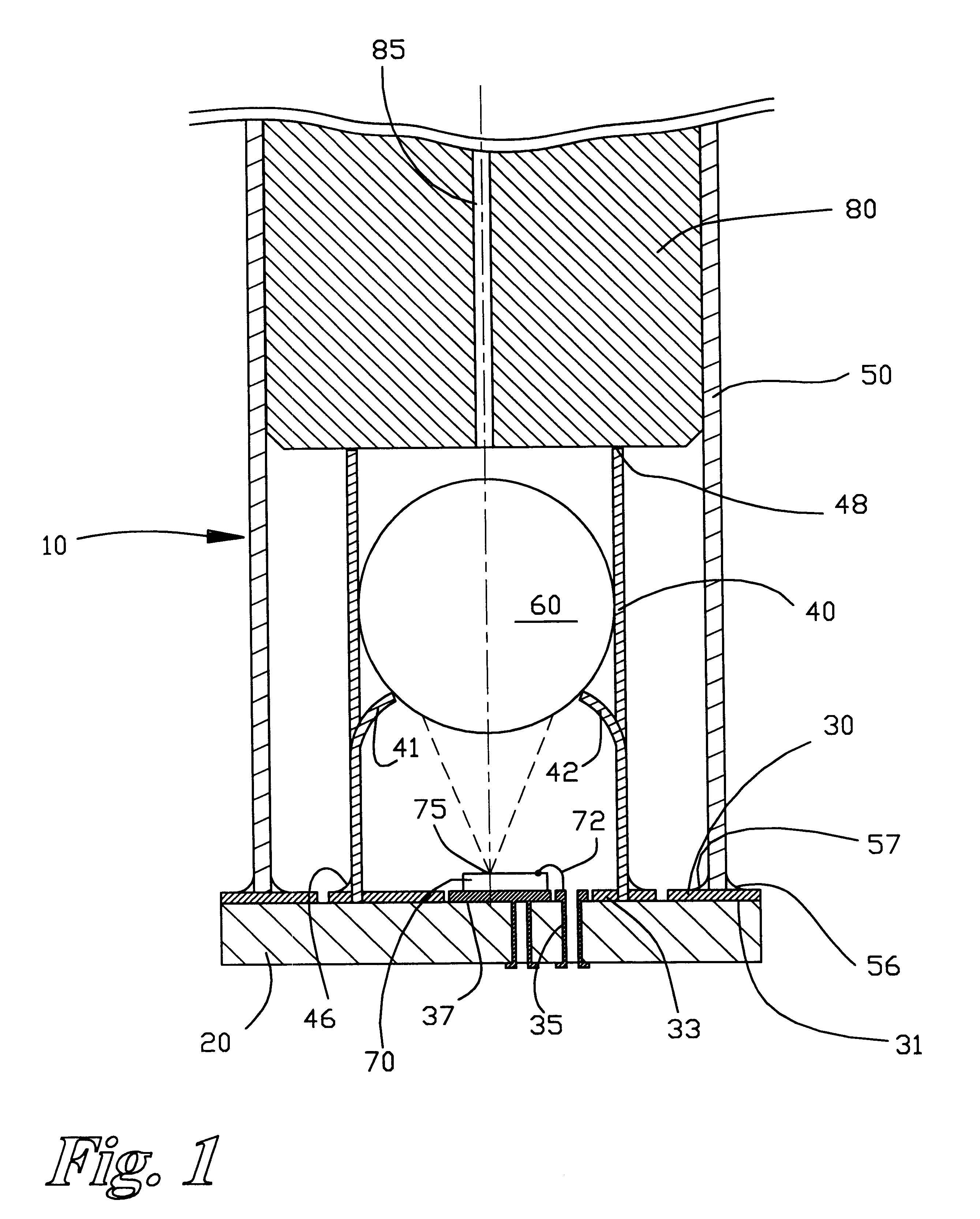

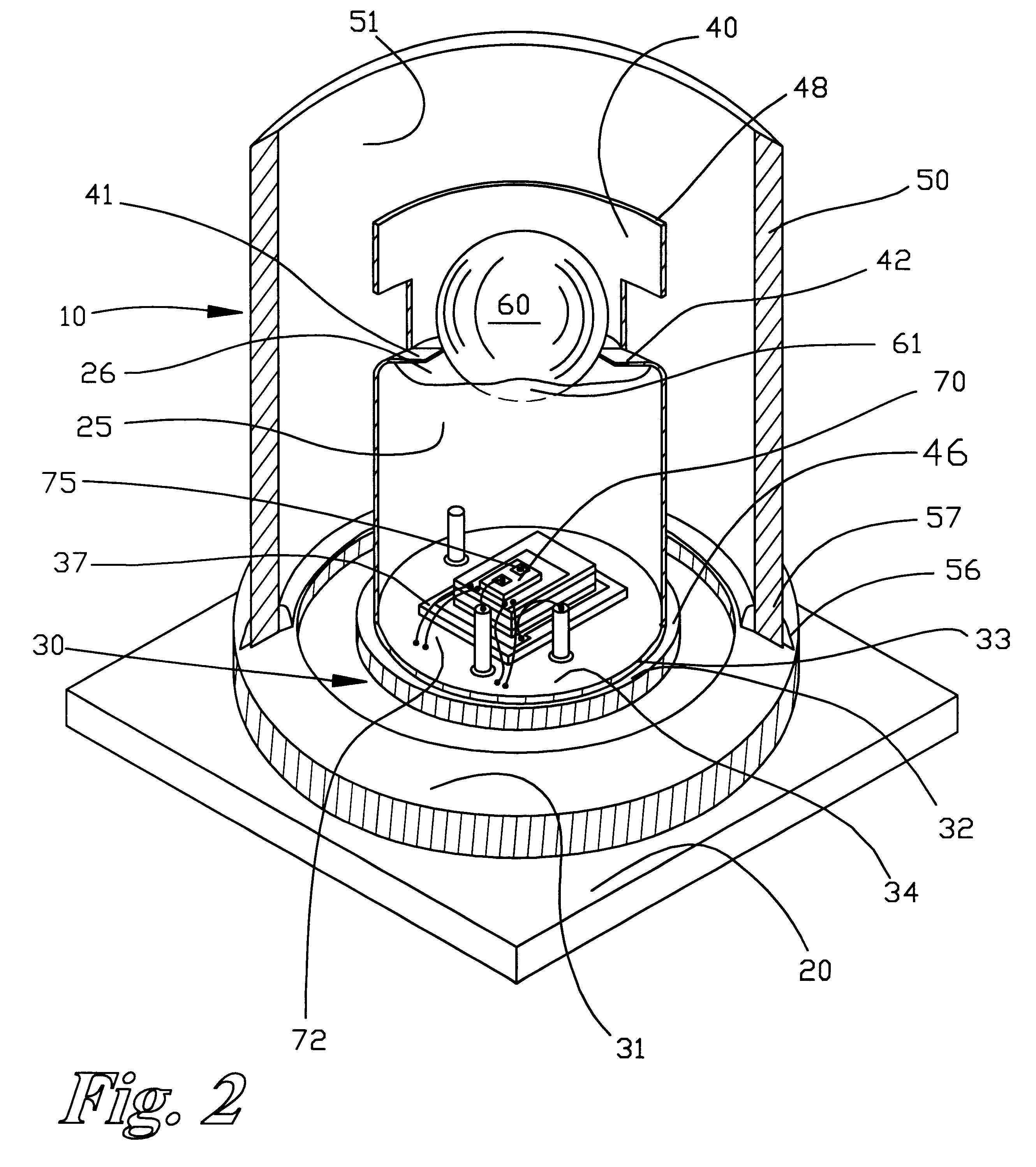

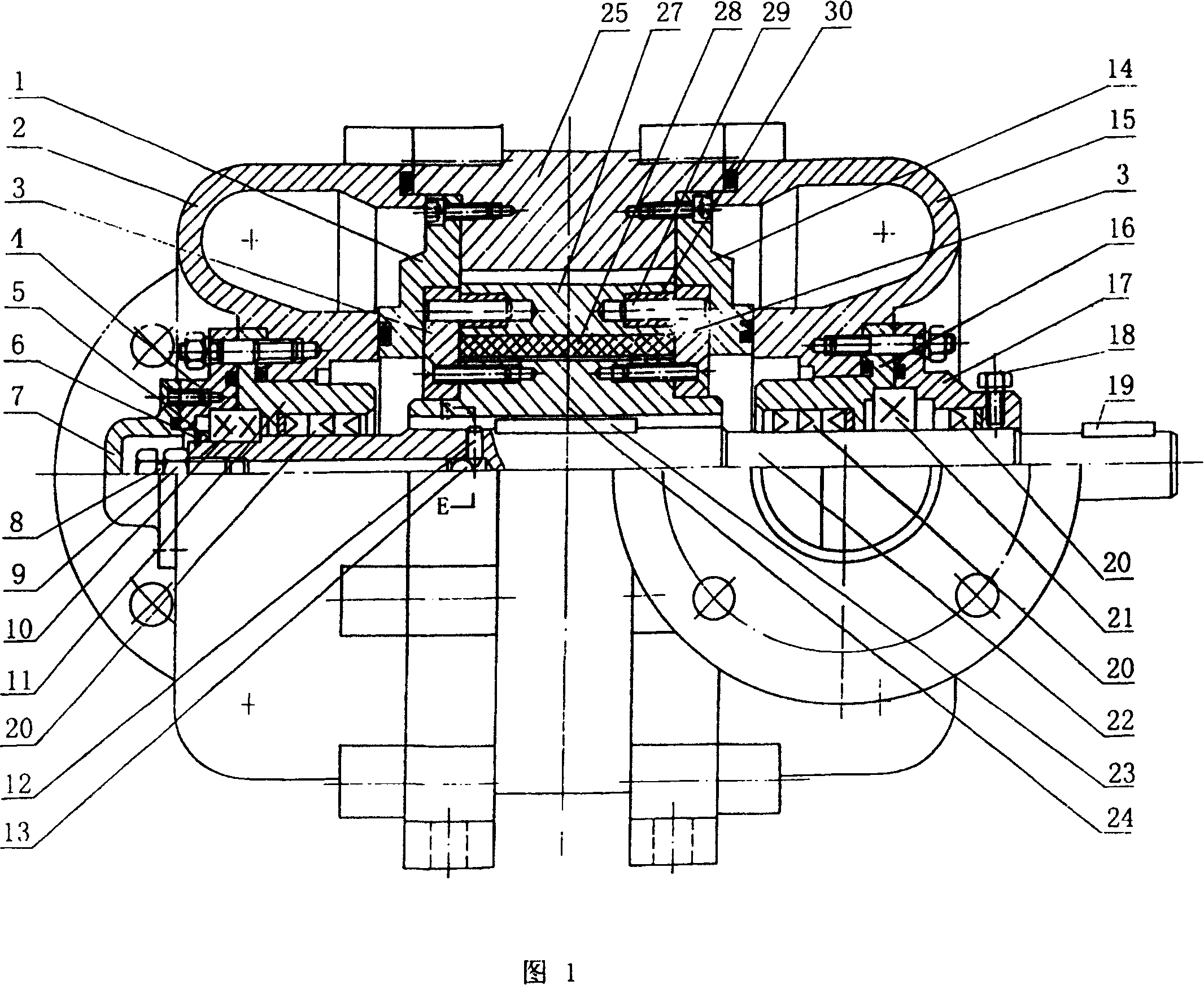

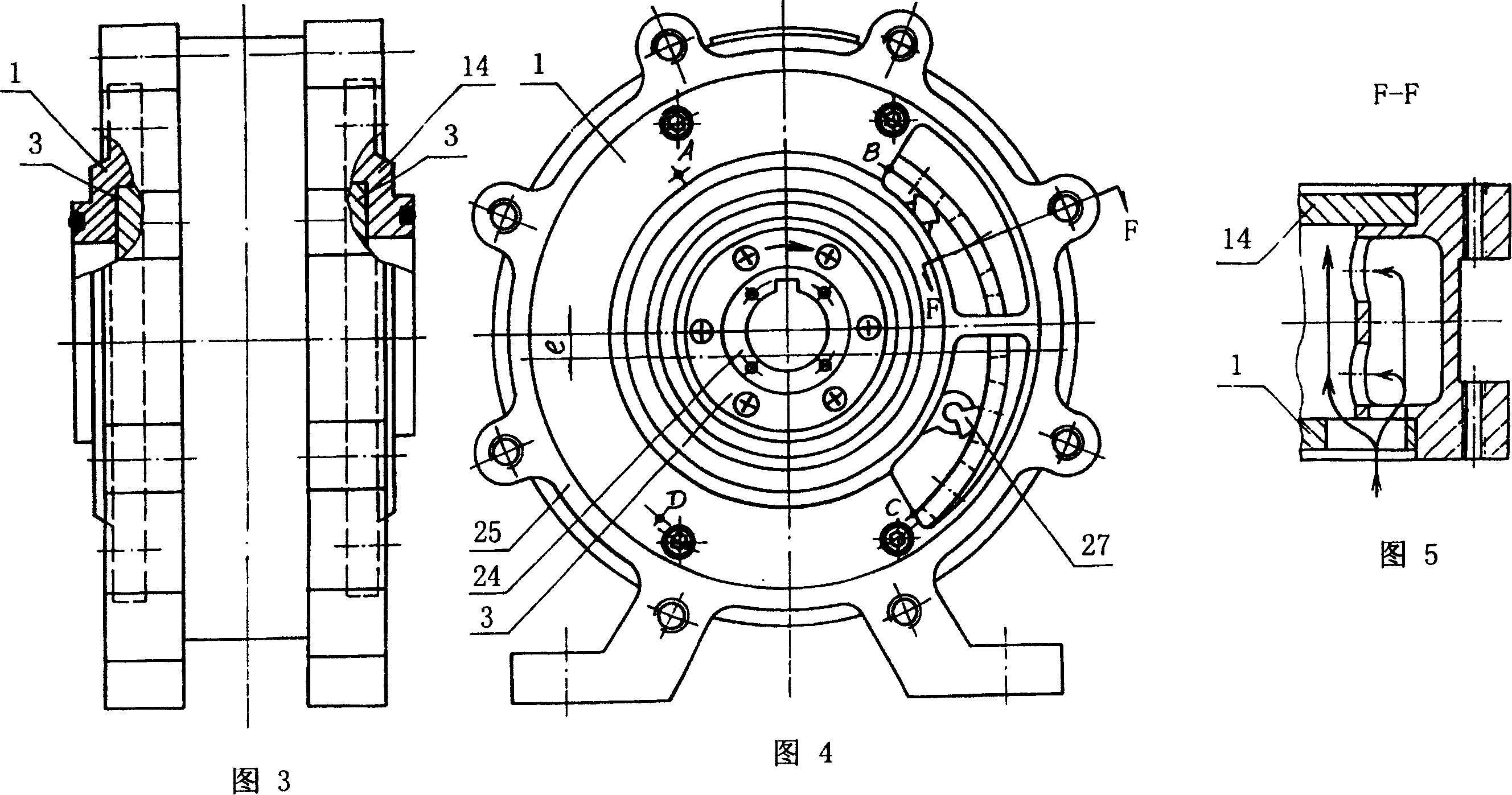

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

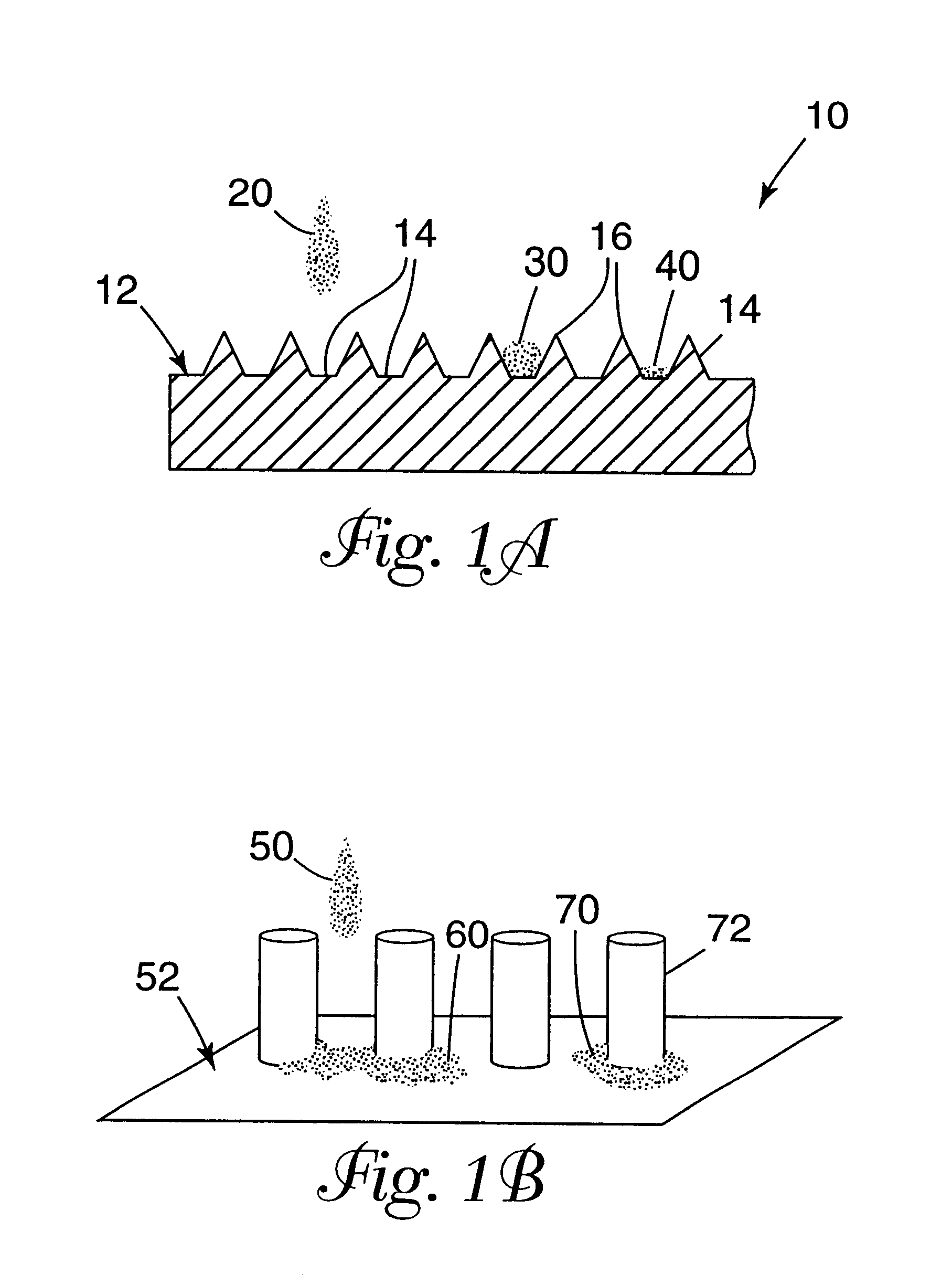

Random microembossed receptor media

InactiveUS6649249B1Form with easePrevention of feathering and bleedingAdditive manufacturing apparatusDecorative surface effectsWaxBiological fluid

A receptor medium with a sheet having a random microembossed imaging surface as one major surface thereof. The receptor medium can receive jettable materials, which include inks, adhesives, biological fluids, chemical assay reagents, particulate dispersions, waxes, electrically, thermally, or magnetically modifiable materials, and combinations thereof. The random microembossed medium unexpectedly solves such common inkjet printing problems as feathering, banding, and mudcracking in inkjet printing systems by controlling how an inkjet drop contacts and dries on an inkjet receptor medium and also Moire' effects. Clear lines of demarcation between adjoining colors of a pigmented inkjet image graphic can be obtained without creation of the Moire' effects. Methods of making and using the inkjet receptor medium are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

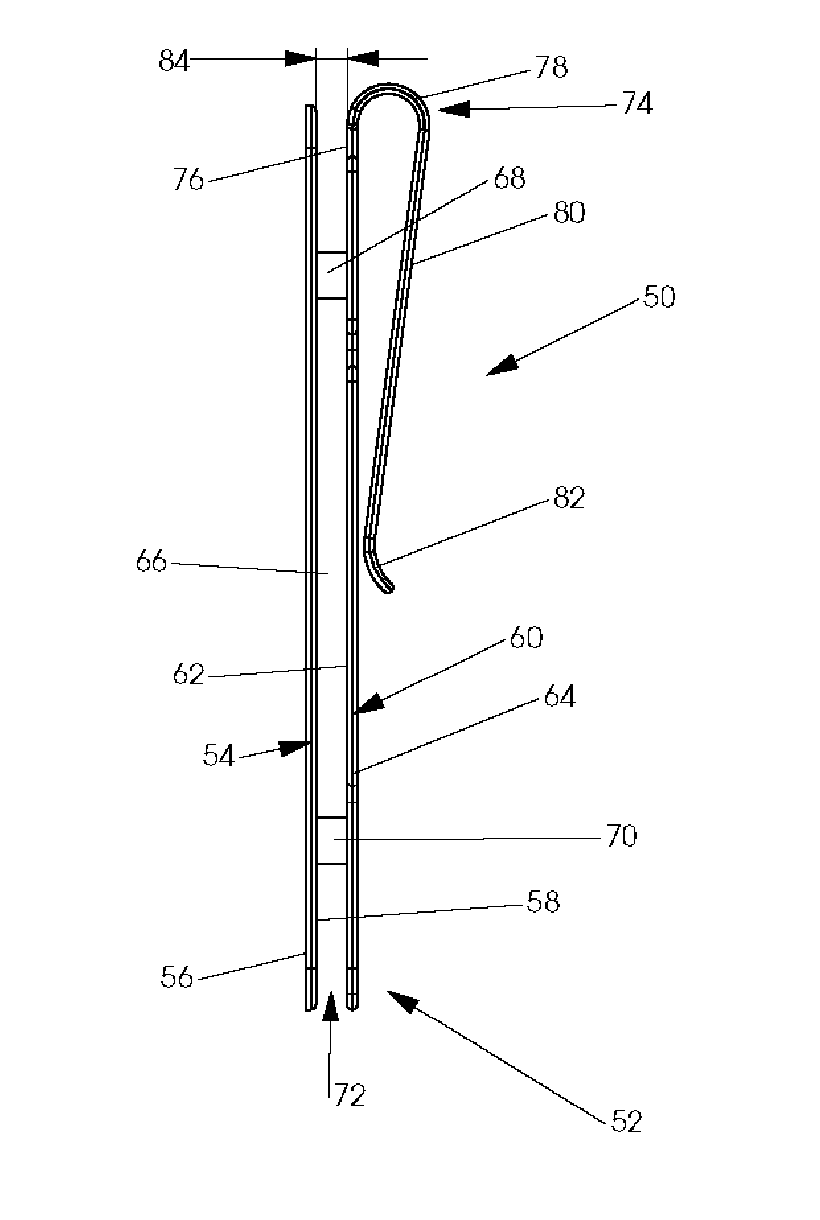

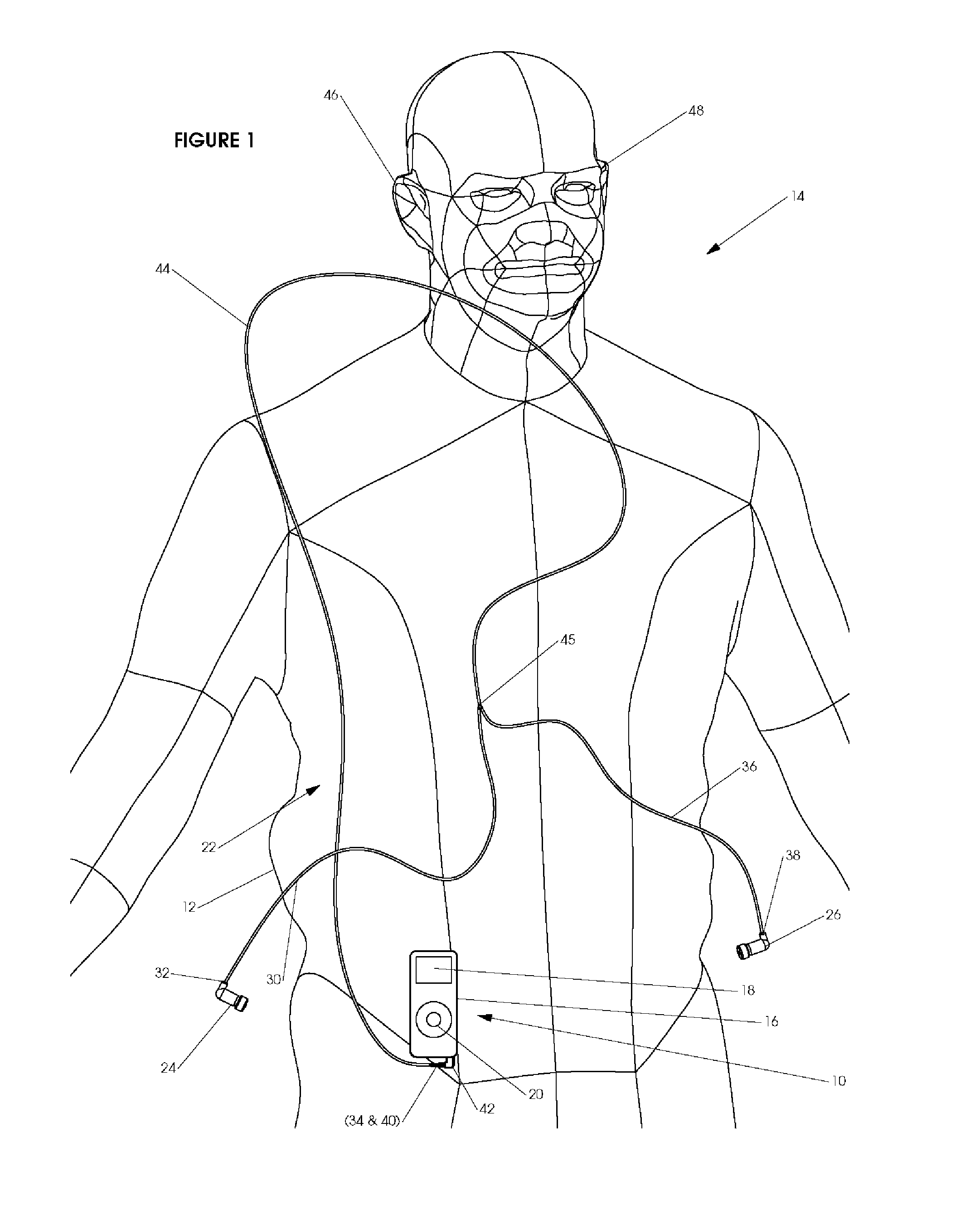

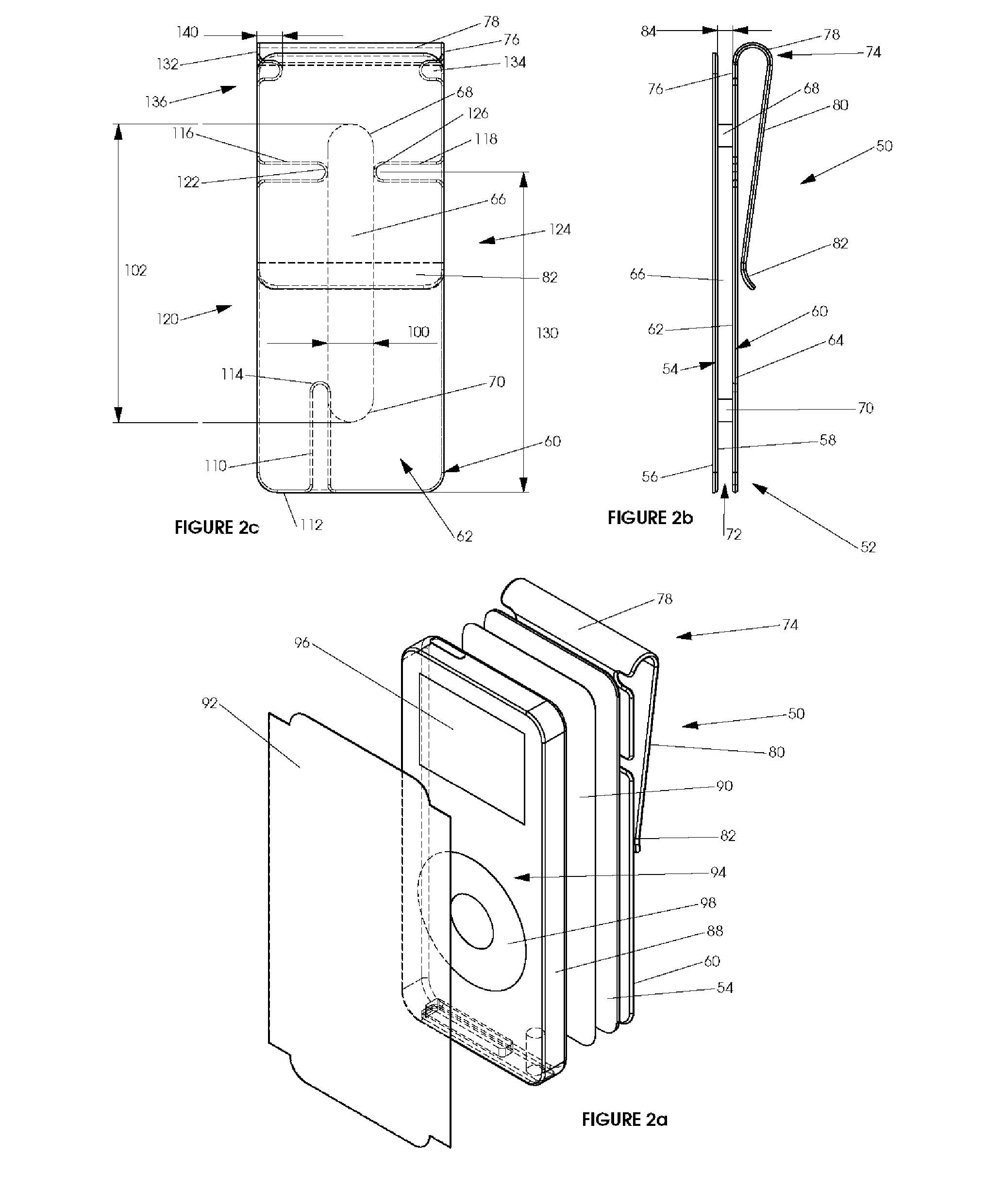

Wearable caddy for a personal audio device having integrated cord storage

InactiveUS20070099681A1Easy to storeConvenient and wearable deviceTravelling carriersHoldersEngineeringHeadphones

A wearable caddy for a personal audio device (PAD) adapted to mount at least one PAD and store excess earphone cord. The caddy comprises a front plate and a back plate joined by a plate separating member that creates a space between the plates adapted to store the excess cod by spooling the excess cord around the separating member. The PAD is mounted to the front surface of the front plate using a double-sided adhesive pad. A clear self-adhesive plastic cover is placed over the face of the PAD. More than one pad may be mounted to the same caddy. The caddy clips to the belt of the wearer and can be used to store earphone cord or heavier head-set cord.

Owner:KIELLAND PETER

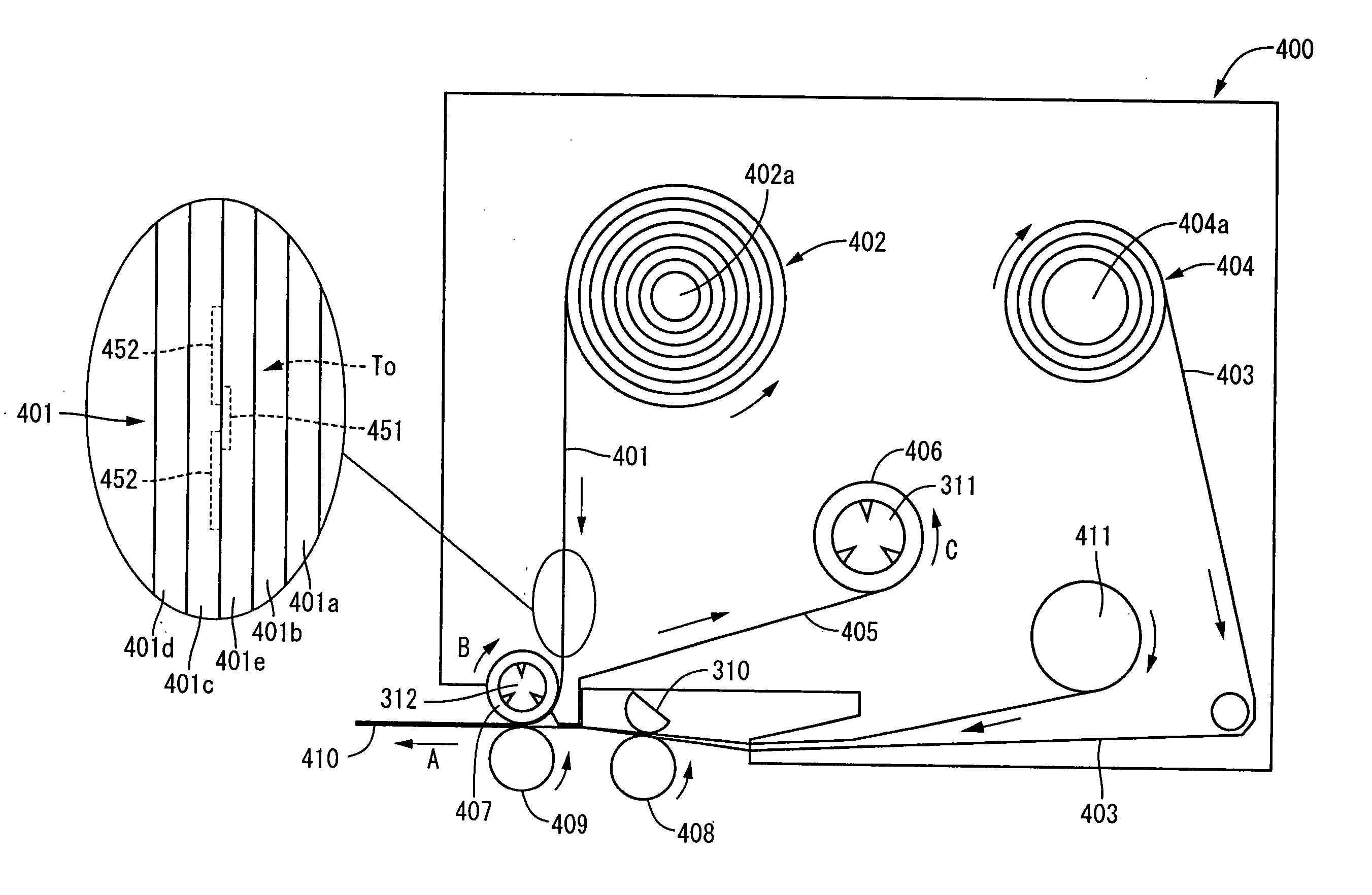

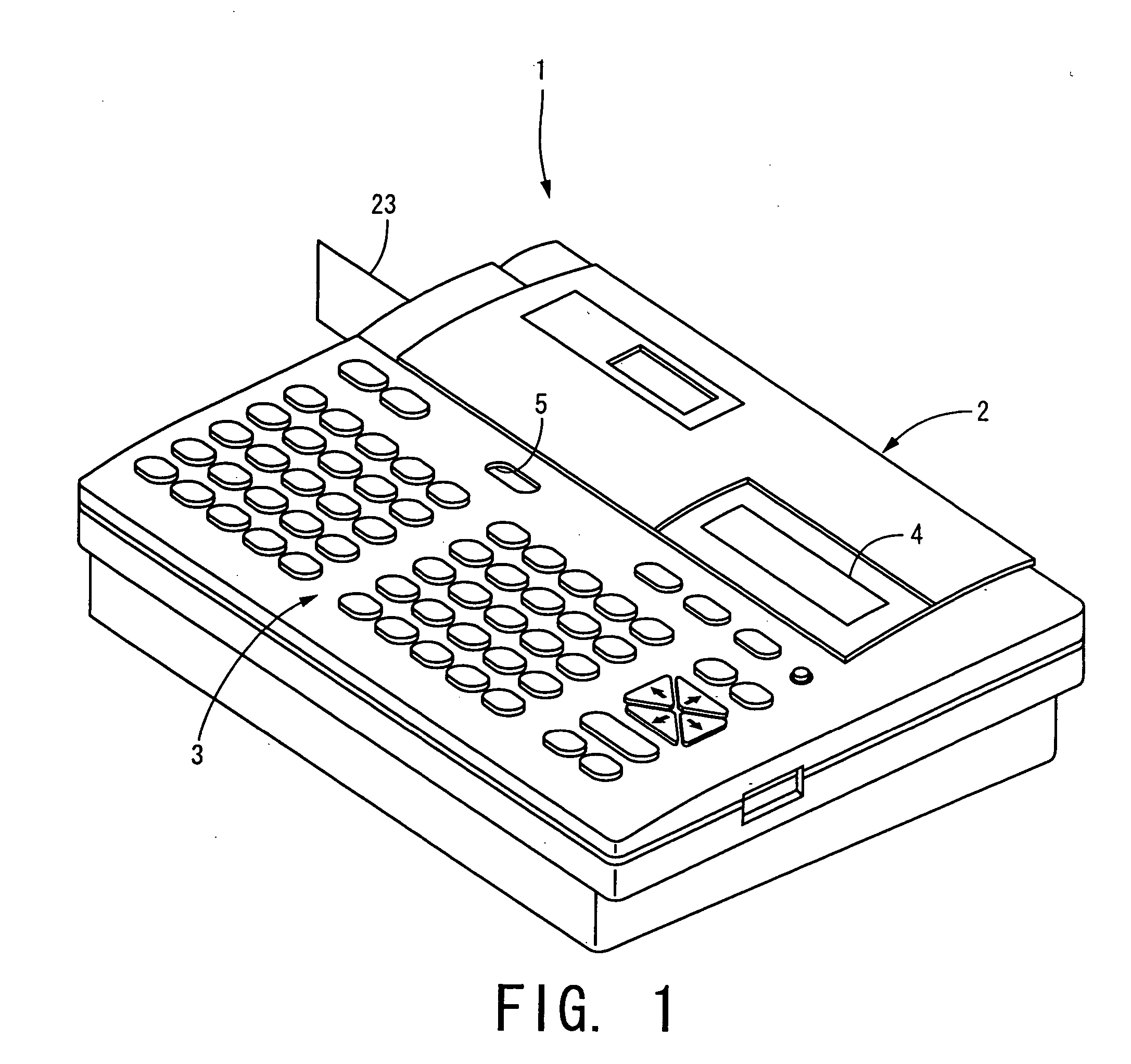

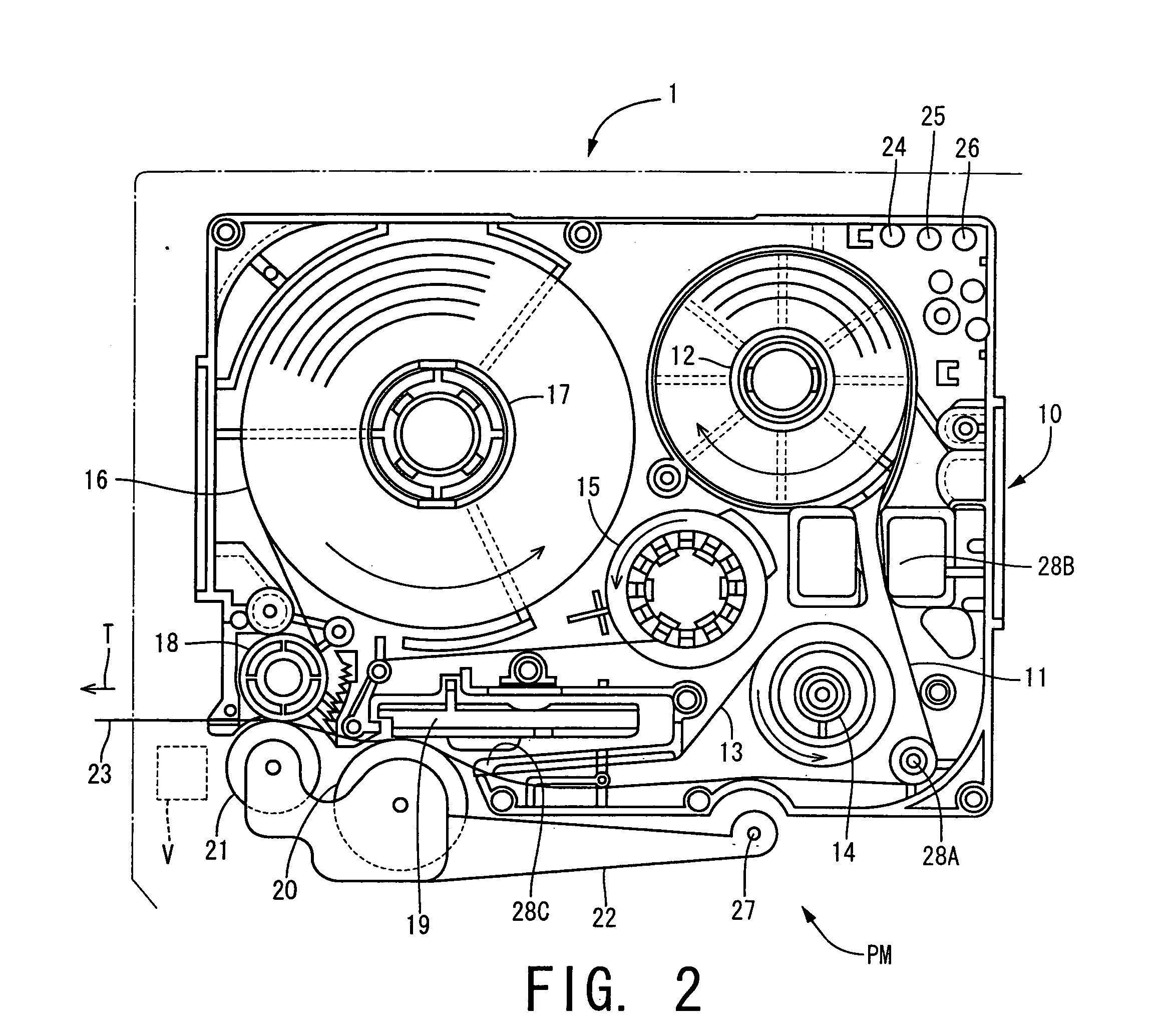

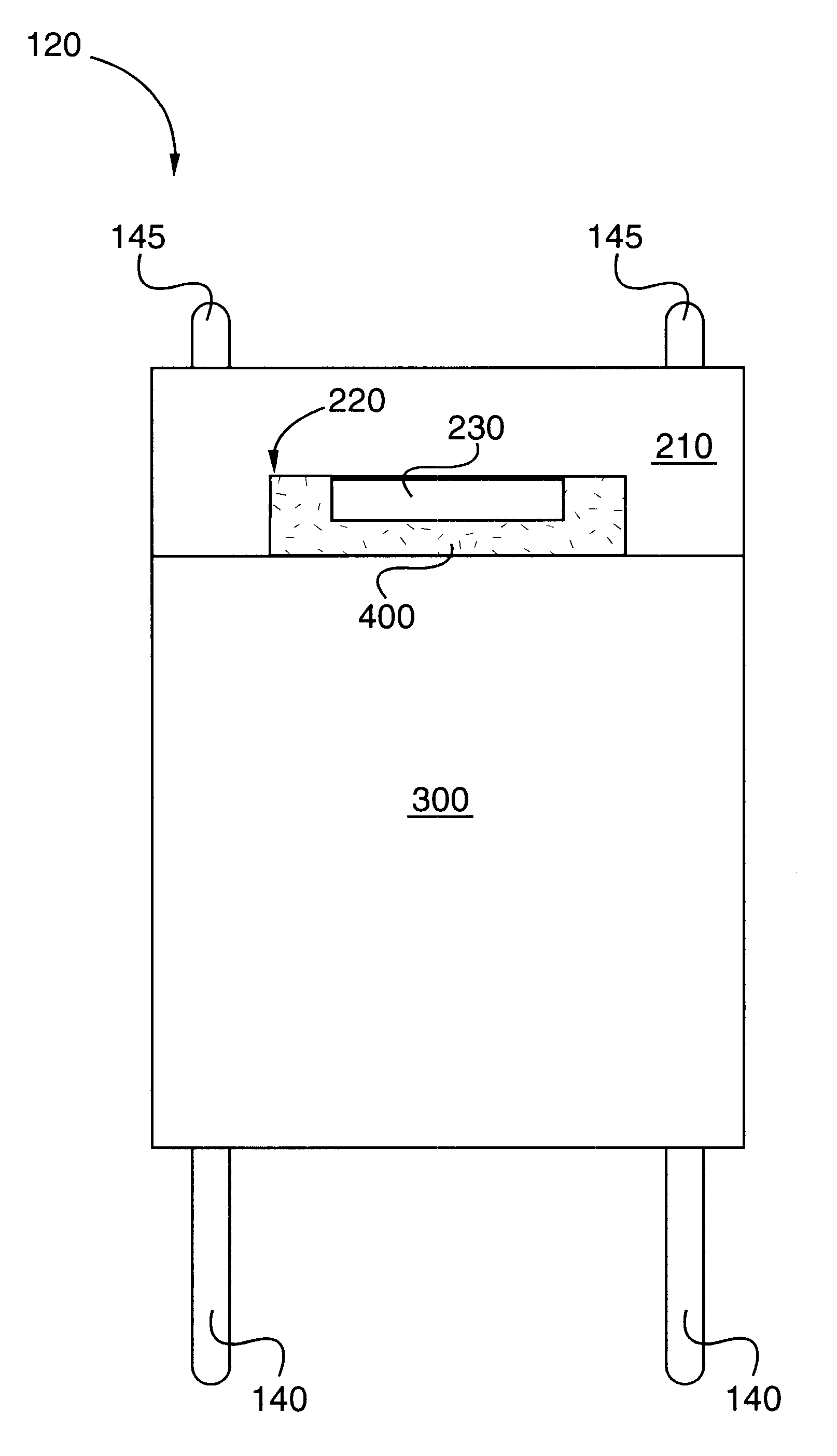

RFID label, method for producing the RFID label, device for producing the RFID label, sheet member (tag sheet) used for the RFID label, and cartridge attached to the device for producing the RFID label

ActiveUS20060118229A1Avoid wear and tearExcellent statePaper/cardboard articlesAntenna supports/mountingsElectrical conductorEngineering

A method for producing a RFID label comprises conveying a first label base material which is transparent from a first holding portion holding the first label base material, forming an image on a surface of the first label base material, conveying a second label base material including at least one of a RFID antenna conductor and an IC chip from a second holding portion holding the second label base material and joining the second label base material and the first label base material on which an image has been formed together, wherein, when an image is formed on the first label base material, the image is formed on a surface of the first label base material, the surface being joined to the second label base material.

Owner:BROTHER KOGYO KK

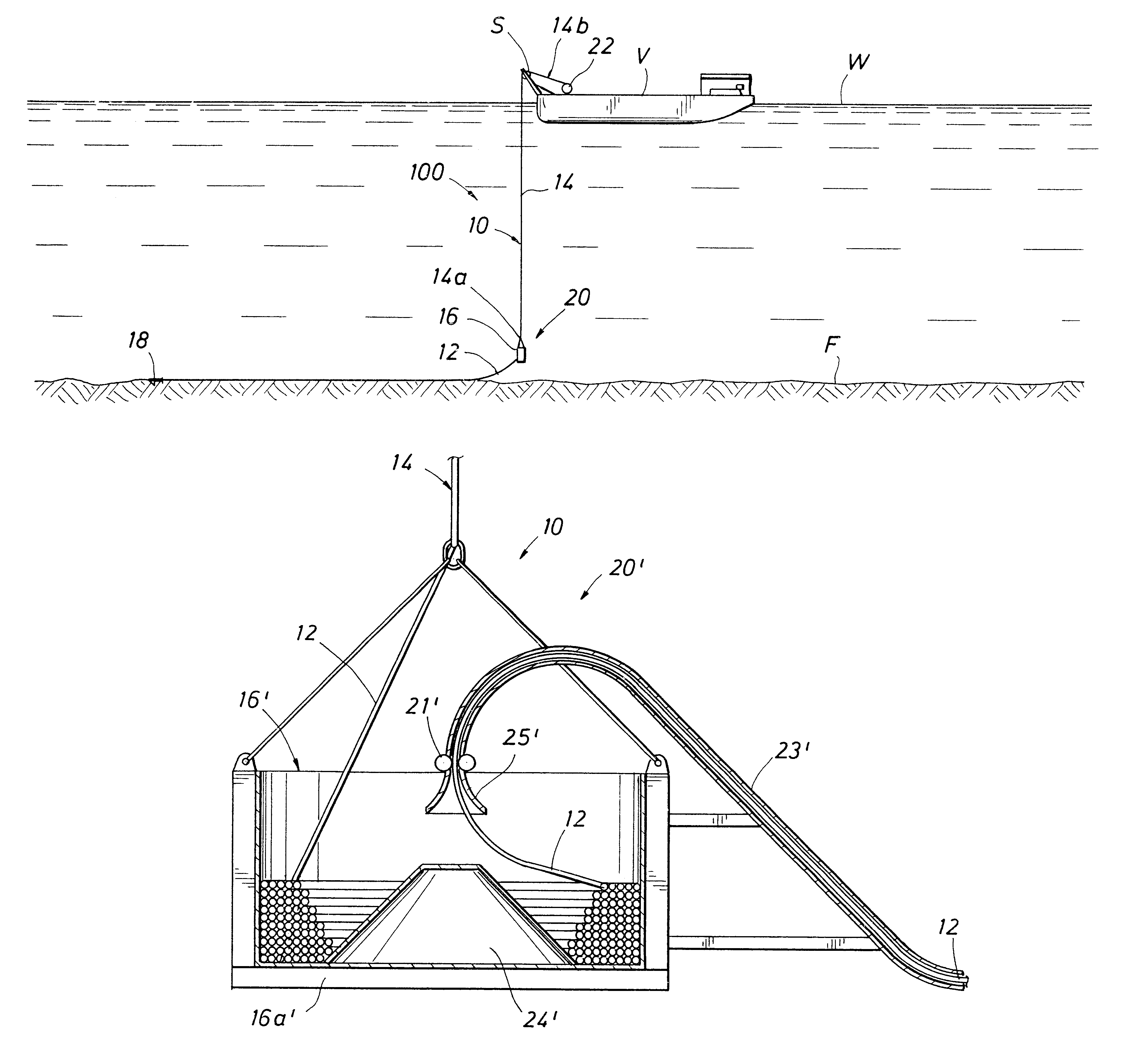

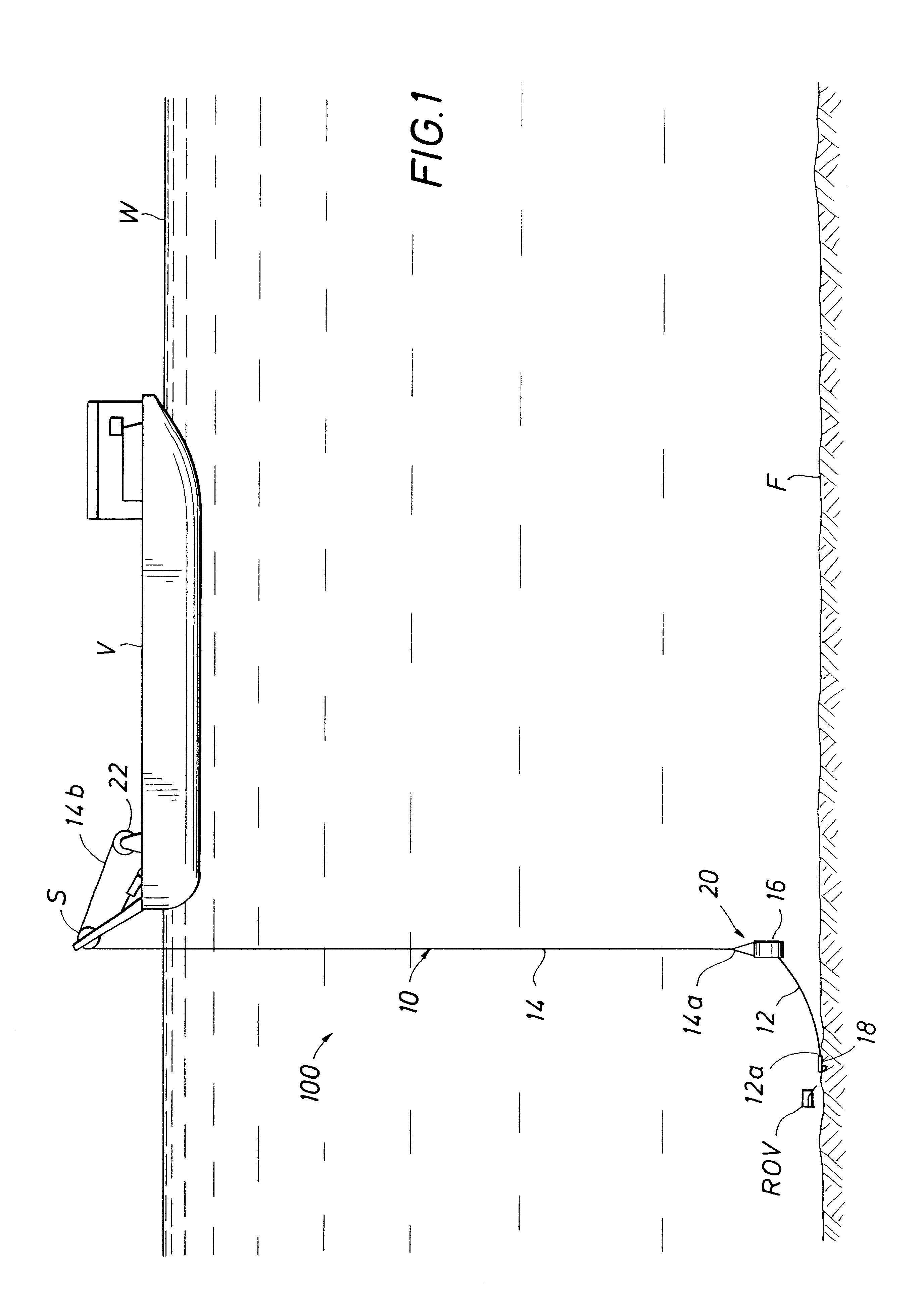

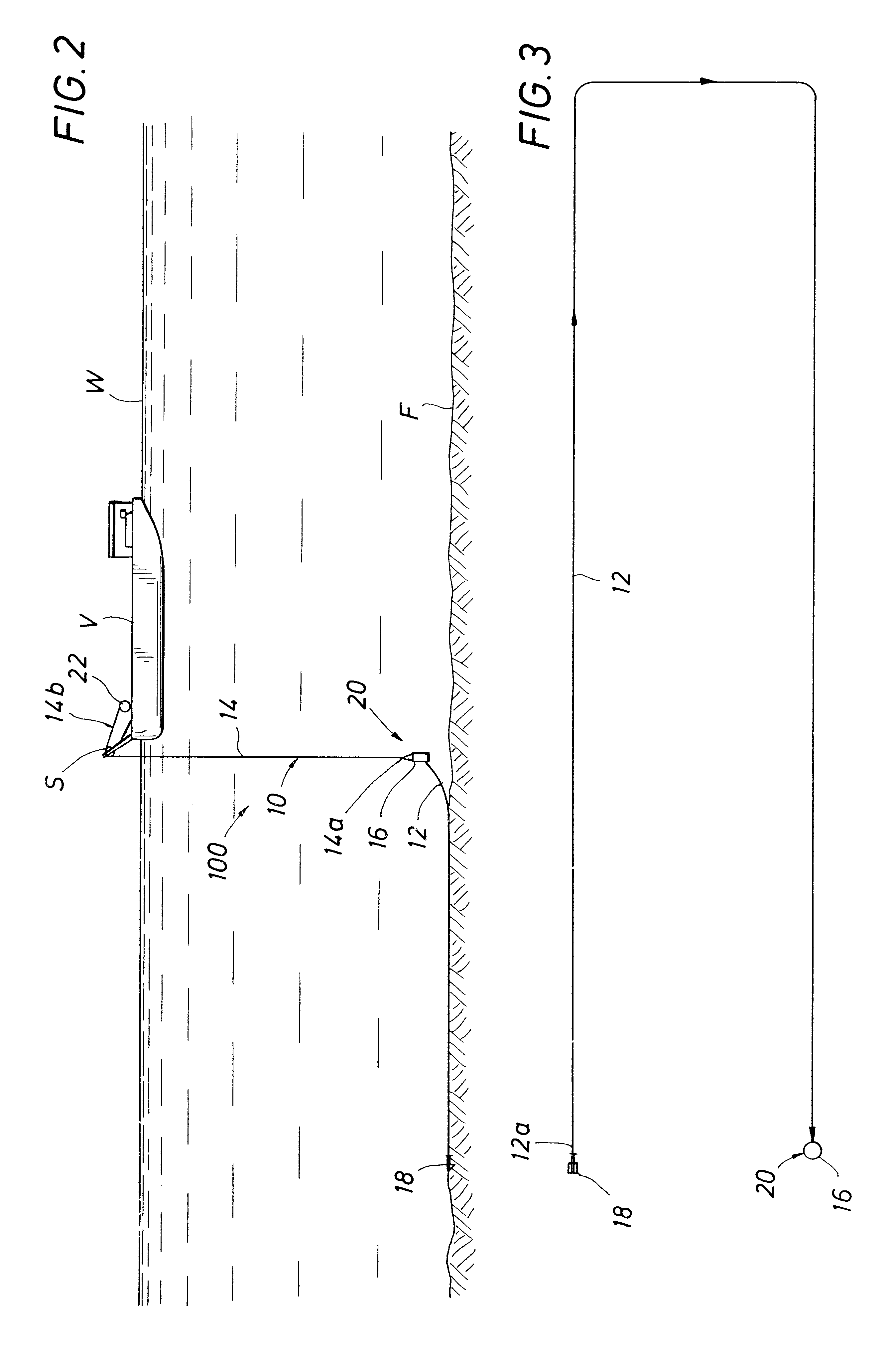

Cable deployment system and method of using same

A cable deployment system and method for laying a cable on the sea floor. The cable deployment system includes a cable having a first cable section connected to a riser cable section. The riser cable section includes an armor that is connected to a drum capable of containing a required length of the first cable section. A stinger is attached to the drum and shaped to allow the first cable section to exit the drum. The cable deployment system also includes a tensioning device attached to the drum. The tensioning device is capable of maintaining a tension in the first cable section during deployment of the first cable section from the drum. The method of deploying the cable in deep water from a surface vessel includes the steps of containing the first cable section within the drum and lowering the drum from the surface vessel. An end of the first cable section is secured to the sea floor and the first cable section is deployed from the drum onto the sea floor.

Owner:SAIPEM AMERICA

Coiled tubing clamping device and injection head using same

ActiveCN102704870AAvoid wear and tearImprove reliabilityDrilling rodsDrilling casingsOil productionCoiled tubing

The invention provides a coiled tubing clamping device and an injection head using the same, belonging to the field of oil production and drilling equipment. The clamping device includes a saddle-type clamping block and a clamping block seat, wherein the saddle-type clamping block is connected to the clamping block seat. The clamping device is characterized in that two sides of the saddle-type clamping block are provided with tongue-like platforms, the tongue-like platform is provided with an opening hole, the back part of the saddle-type clamping block is provided with a recess, two sides of the clamping block seat are respectively provided with a pair of bosses, the recess of the saddle-type clamping block is inserted into a slot formed by the clamping block seat bosses, a running clearance is left between the recess and the slot, and the clamping block seat is provided with a positioning screw for limiting the position of the saddle-type clamping block. The injection head comprises an oil pipe clamping mechanism and a transmission chain, wherein the oil pipe clamping mechanism is mounted on the transmission chain through two hinge pin holes on the clamping block seat. The technical proposal has the advantages that the abrasion of the oil pipe can be effectively reduced, the clamping device has operational reliability, and the clamping blocks are convenient in replacement.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

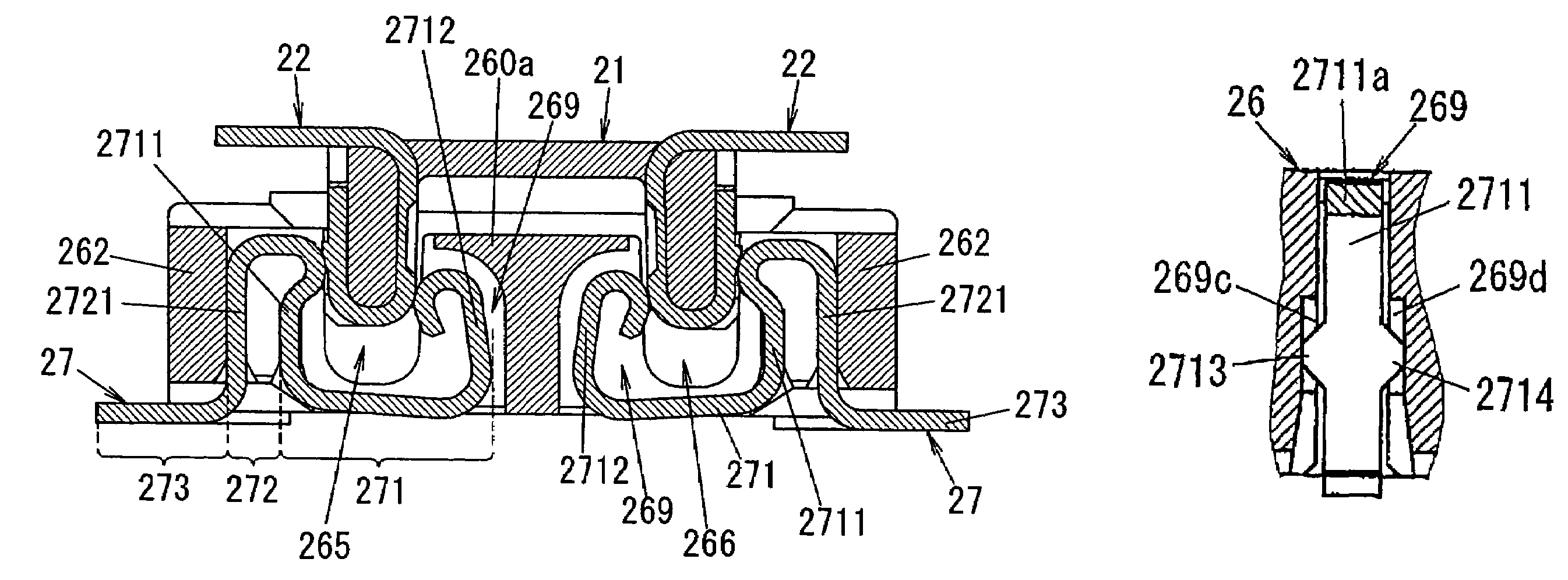

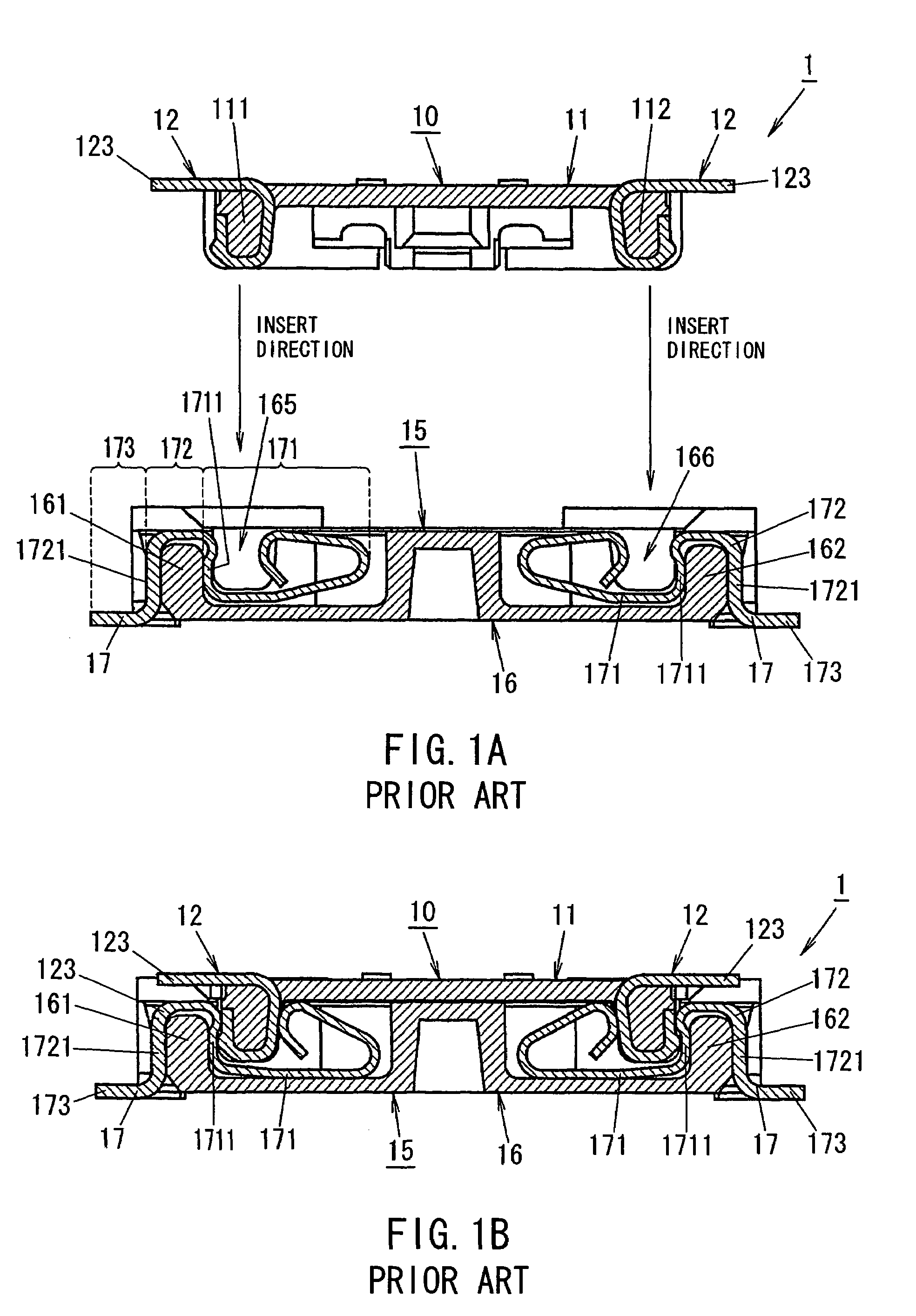

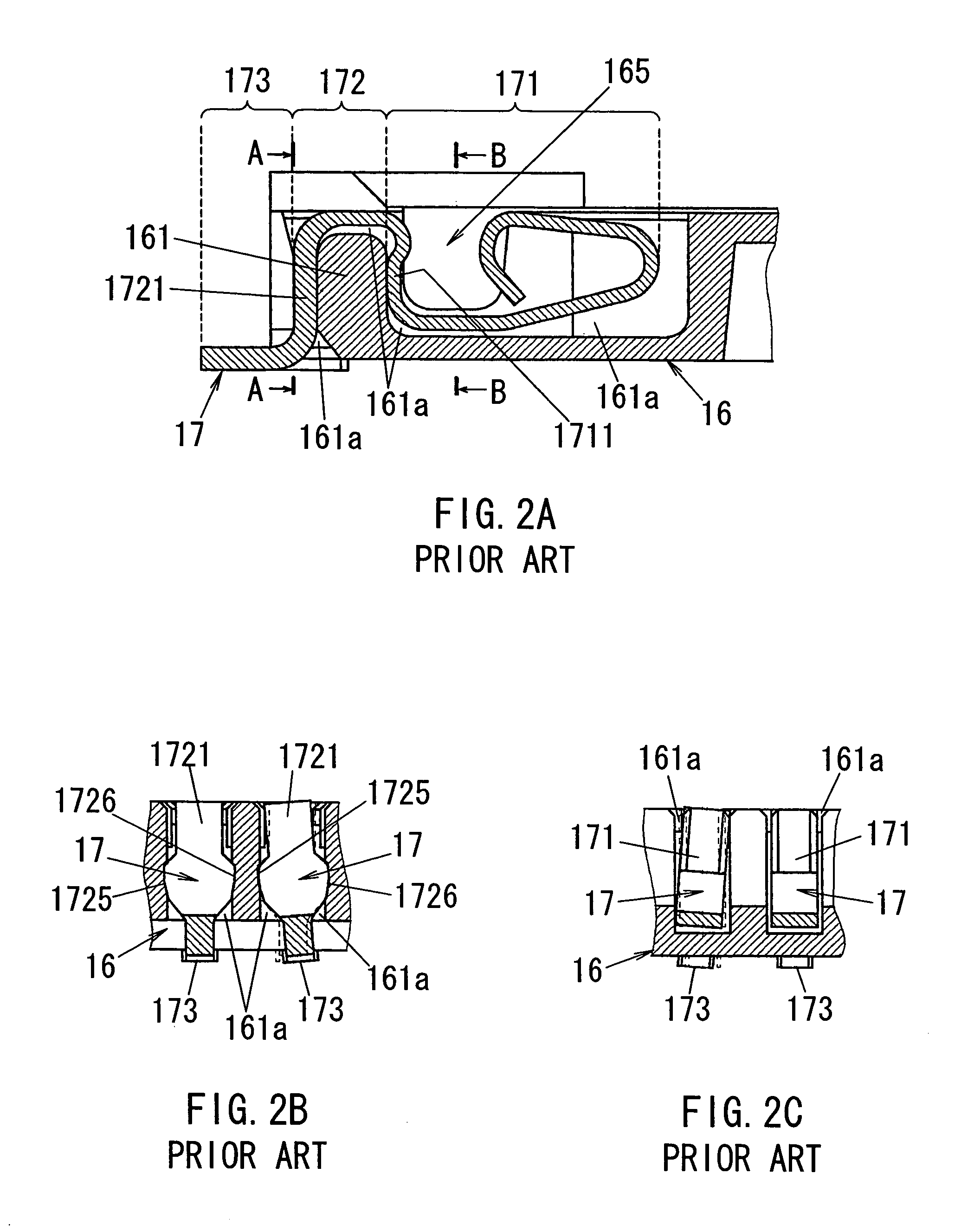

Connector with header connector and socket connector that are mechanically and electrically connected with each other

ActiveUS7410364B2Increase in sizeIncrease the lengthSubstation/switching arrangement detailsElectric discharge tubesEngineeringMechanical engineering

Owner:MATSUSHITA ELECTRIC WORKS LTD

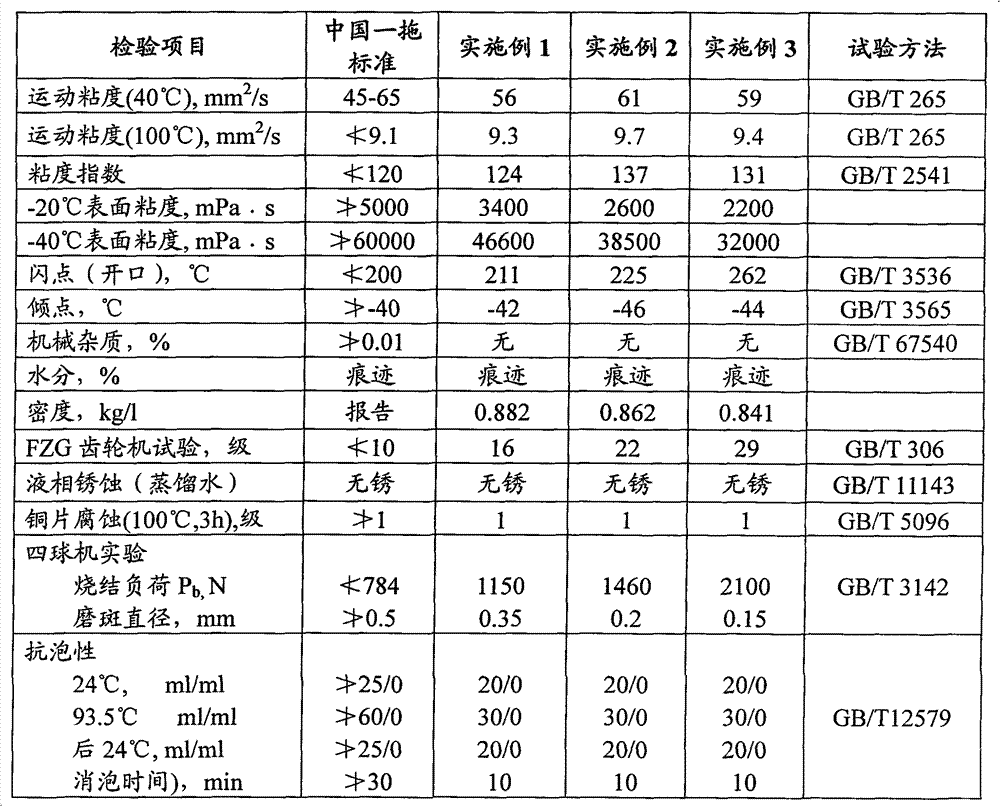

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

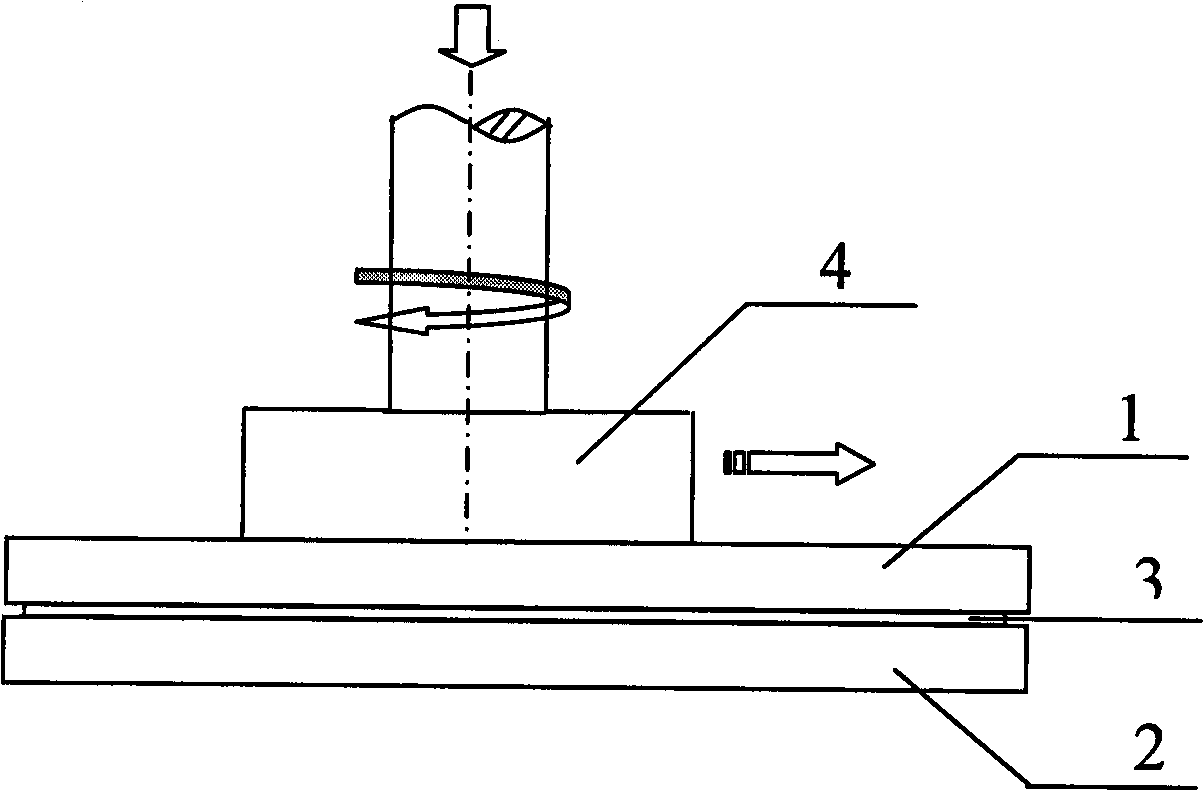

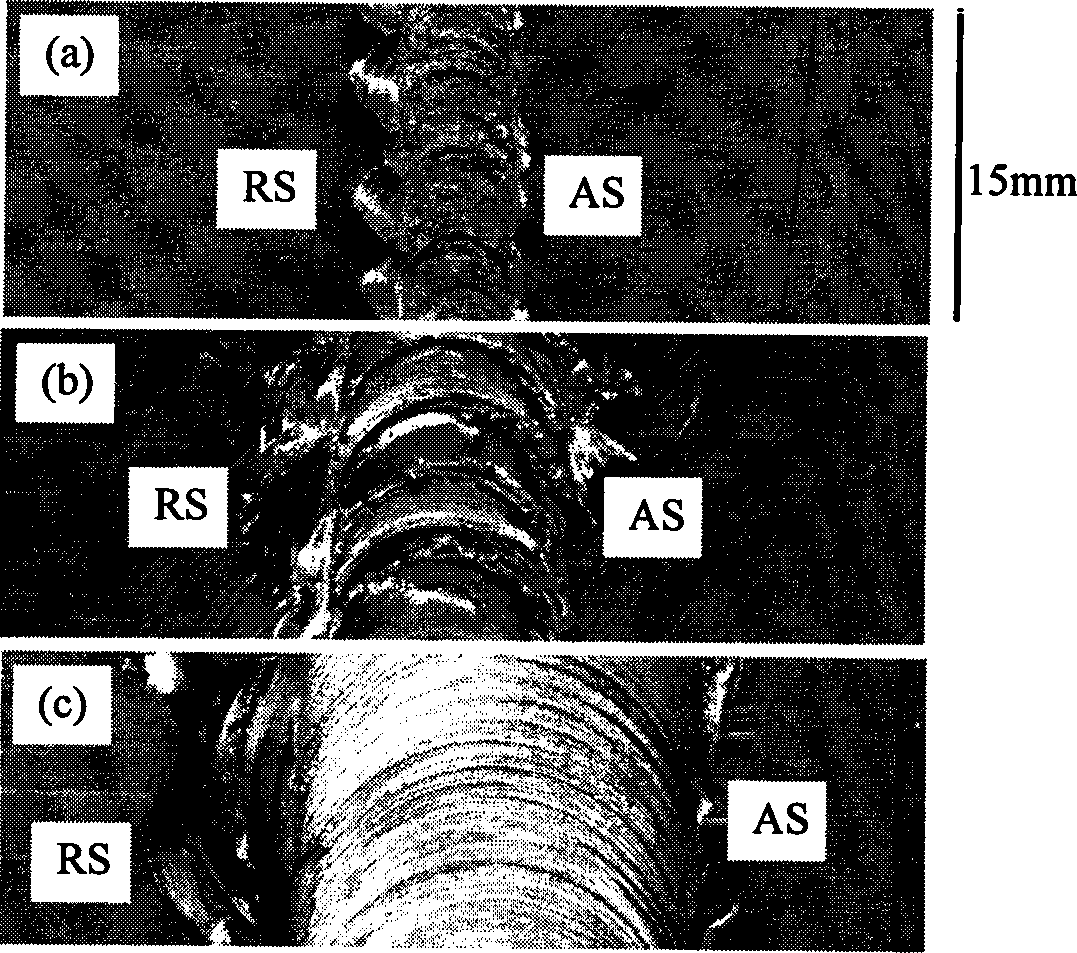

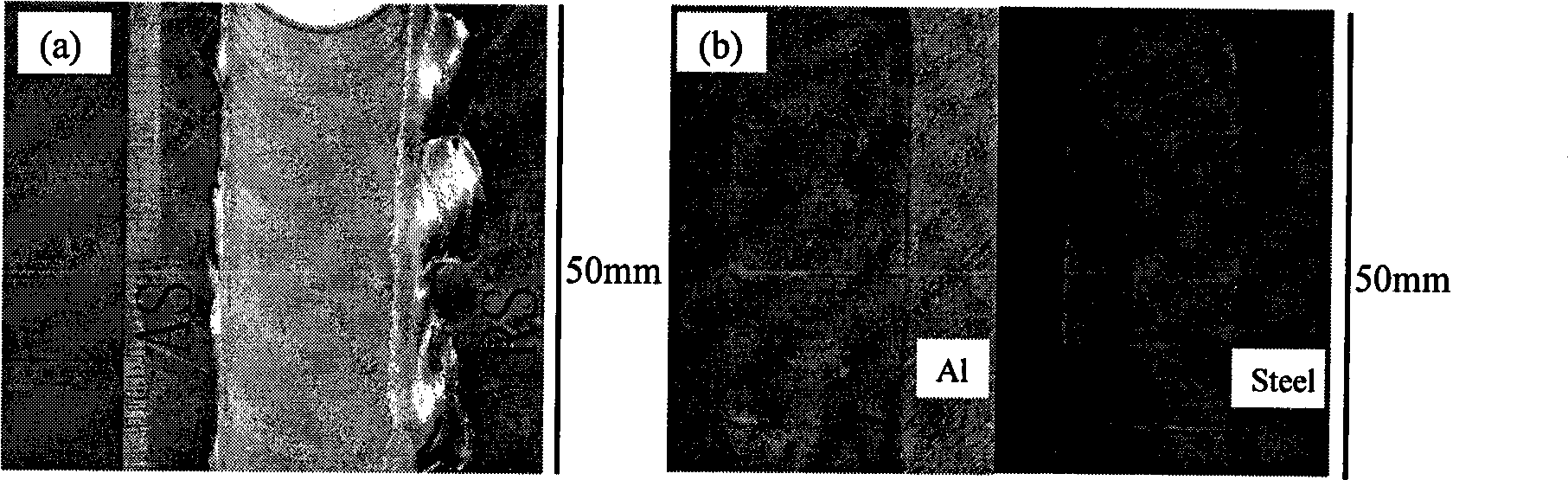

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

Reciprocating compressor and manufacturing method thereof

InactiveUS20060024181A1Easily manufacturePrevent abrasionReciprocating/oscillating/vibrating magnetic circuit partsEngine manufacturePowder metallurgyStator

The present invention discloses a reciprocating compressor and a manufacturing method thereof. The reciprocating compressor includes a frame installed in a casing, an outer stator having a winding coil and being fixed to the frame, an inner stator disposed in the outer stator with a predetermined gap, and sintered by a powder metallurgy process using metal powder, a rotor having a permanent magnet between the outer stator and the inner stator, a cylinder disposed inside the inner stator of the reciprocating motor for forming a compression chamber, and sintered by a powder metallurgy process using metal powder, a piston slidably inserted into the inner circumference of the cylinder, for sucking and compressing gas by linear reciprocation, and a plurality of resonance springs for elastically supporting the connection part of the piston and the rotor, and inducing resonance of the piston. Accordingly, the cylinder is not deformed by the inner stator, and thus abrasion of the piston and the cylinder by deformation of the cylinder is prevented in advance. Moreover, the reciprocating compressor is easily manufactured by considerably simplifying the manufacturing process.

Owner:LG ELECTRONICS INC

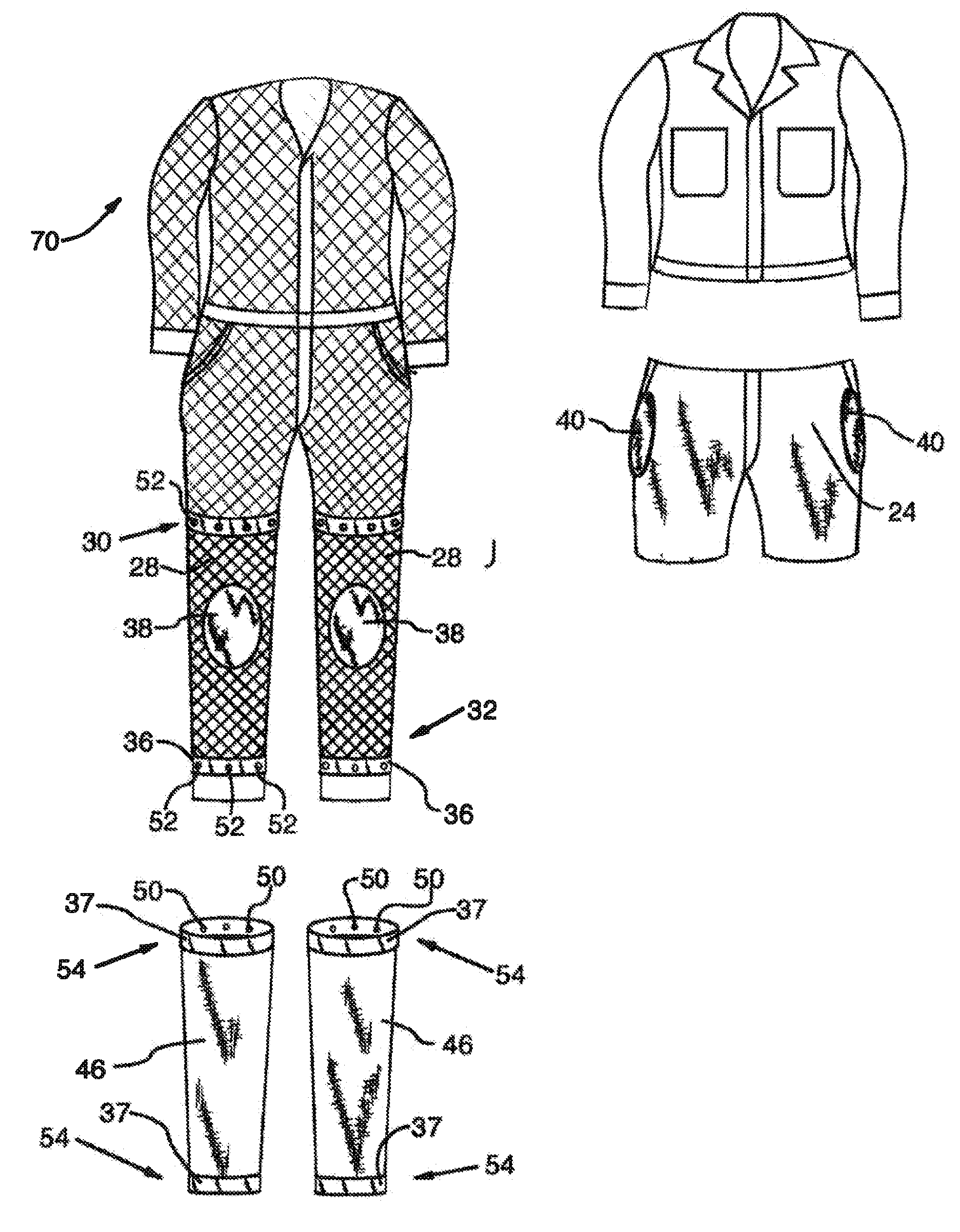

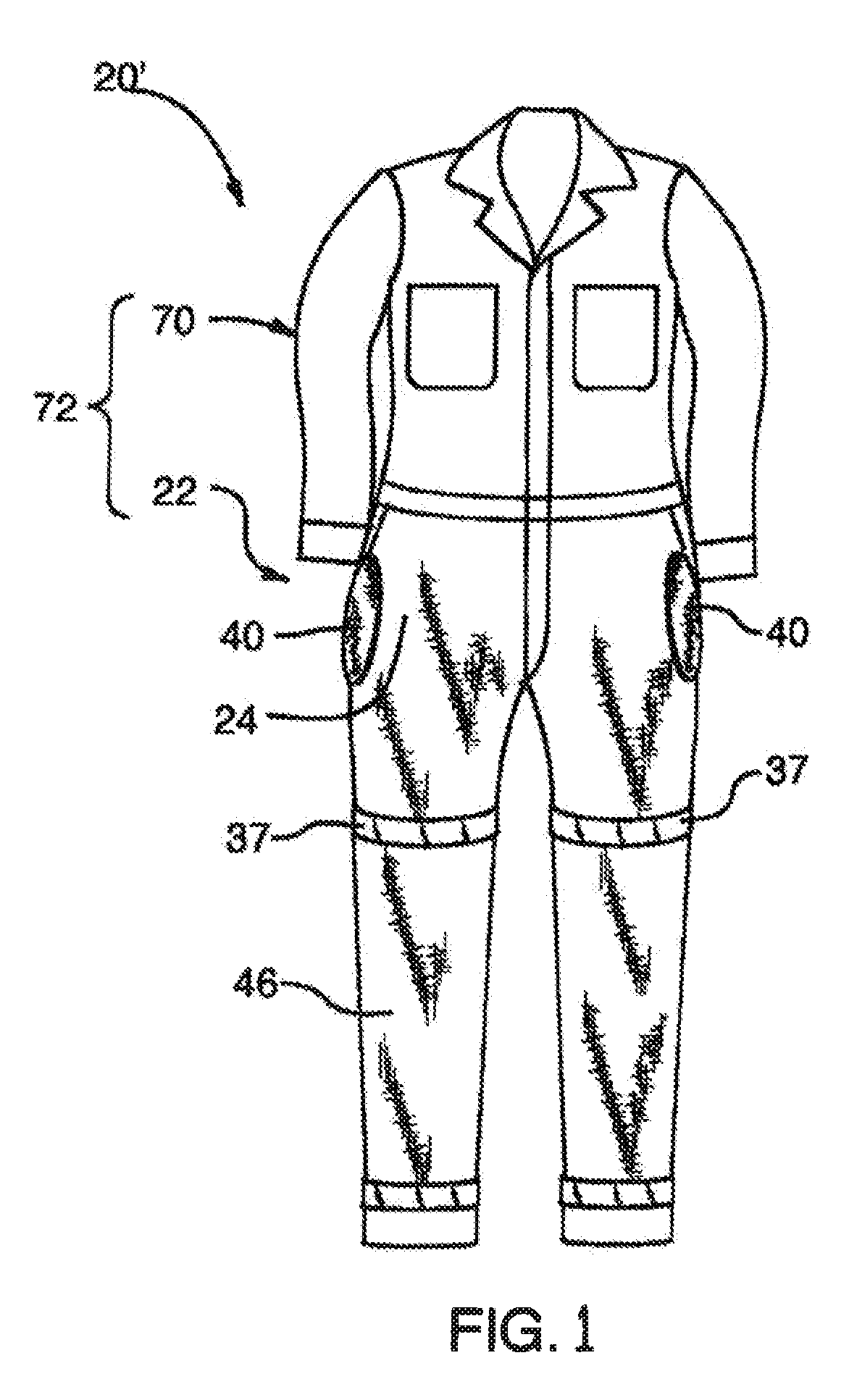

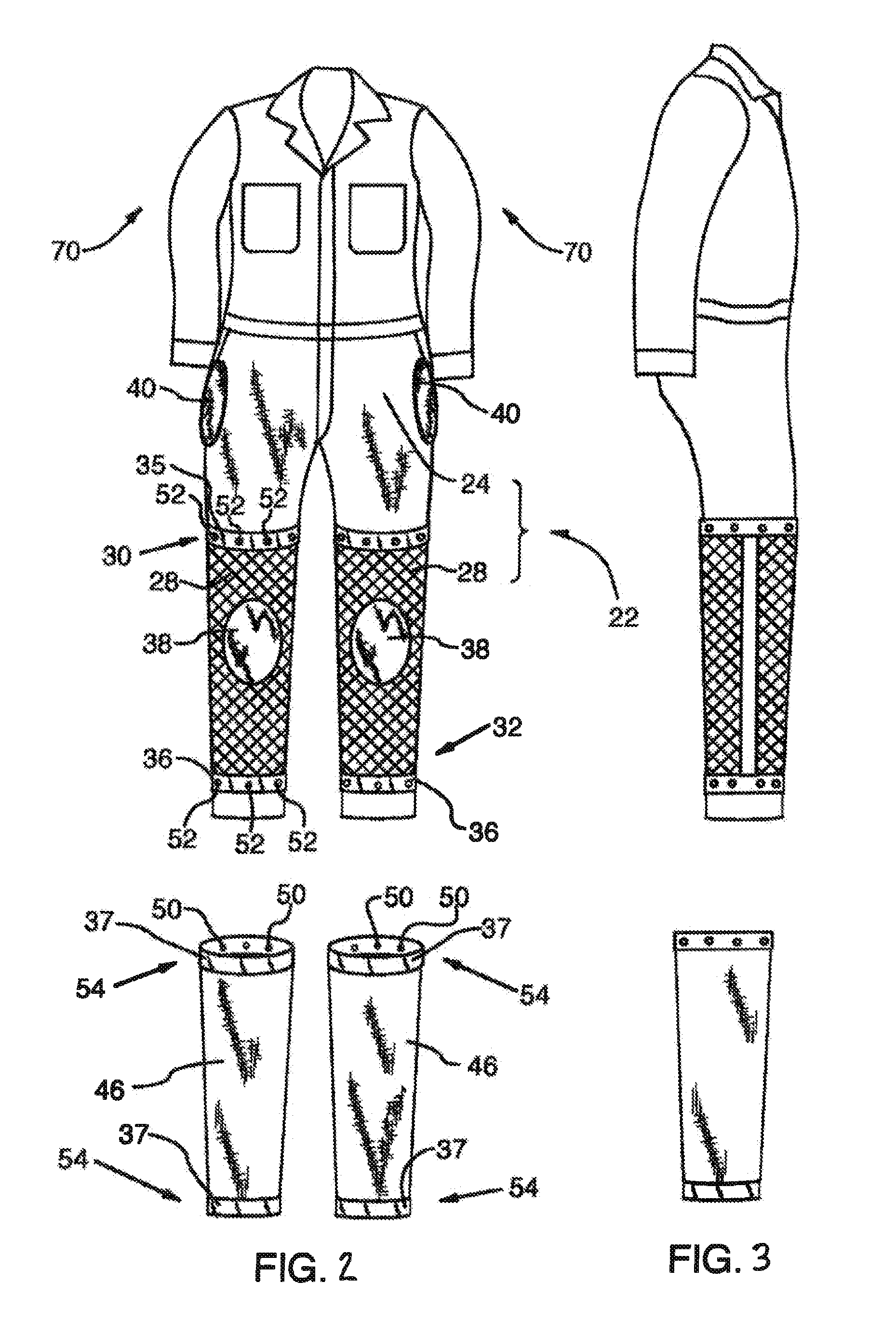

Safety outerwear with fire resistant mesh

InactiveUS20070094763A1Avoid wear and tearConstant exposureChemical protectionHeat protectionEngineeringStructural engineering

An article of safety outerwear has a main body piece that receives a portion of the body of a wearer in use. The main body piece includes a garment wall that defines inside and outside wall portions. The inside wall portion presents a smooth surface to the body of the wearer in use. The outside wall portion is adapted for constant exposure to environmental conditions and to protect against abrasion during working and / or athletic activity. The garment wall is formed at least in part from a vent portion, such that at least a portion of each of the inside and outside wall portions is defined thereby. The vent portion is constructed solely from one or more layers of a mesh material, and is safety rated with a flame resistant rating qualifying same for flame resistant use in hazardous environments. The mesh material operatively has an open texture for high breathability.

Owner:MESHWEAR TECH

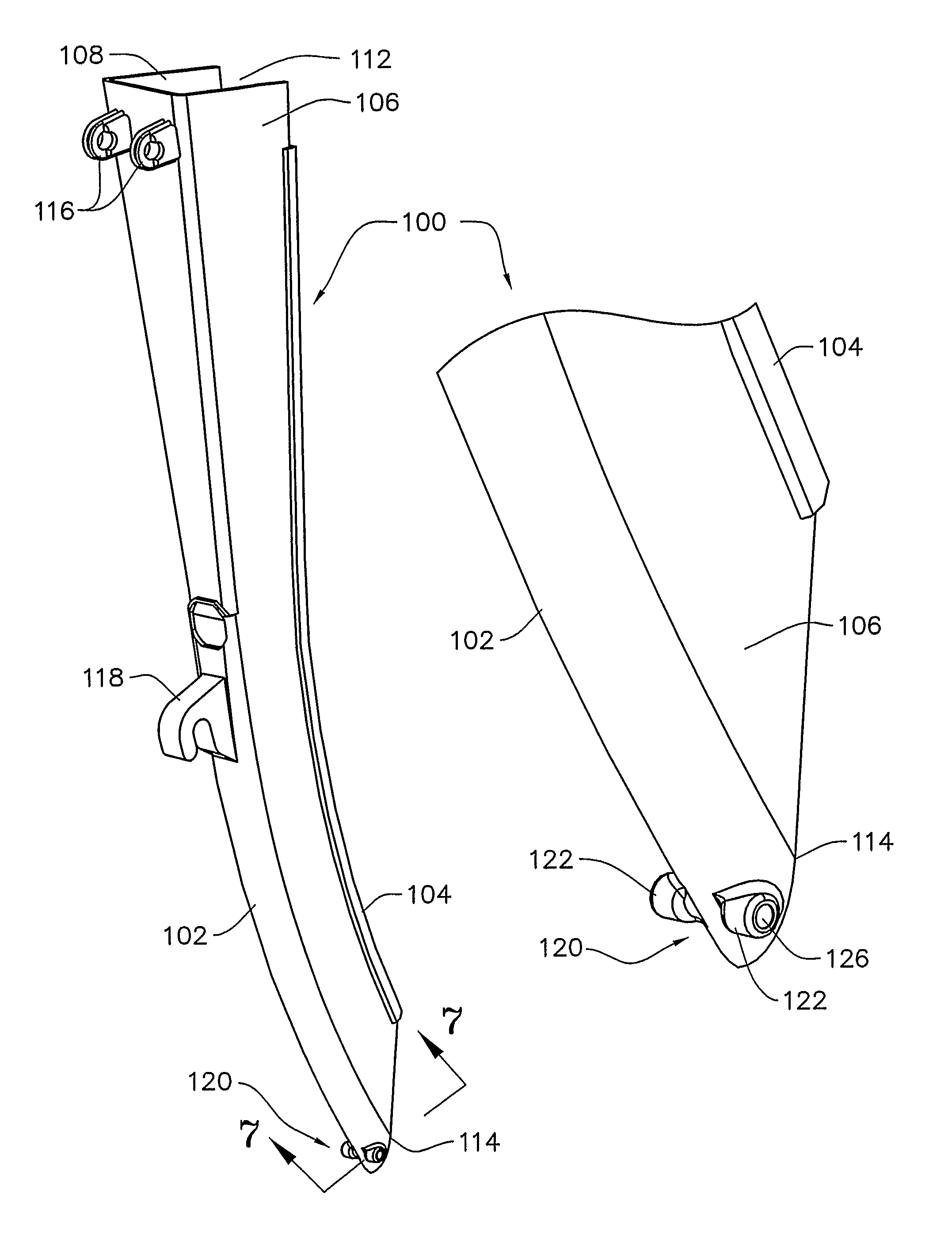

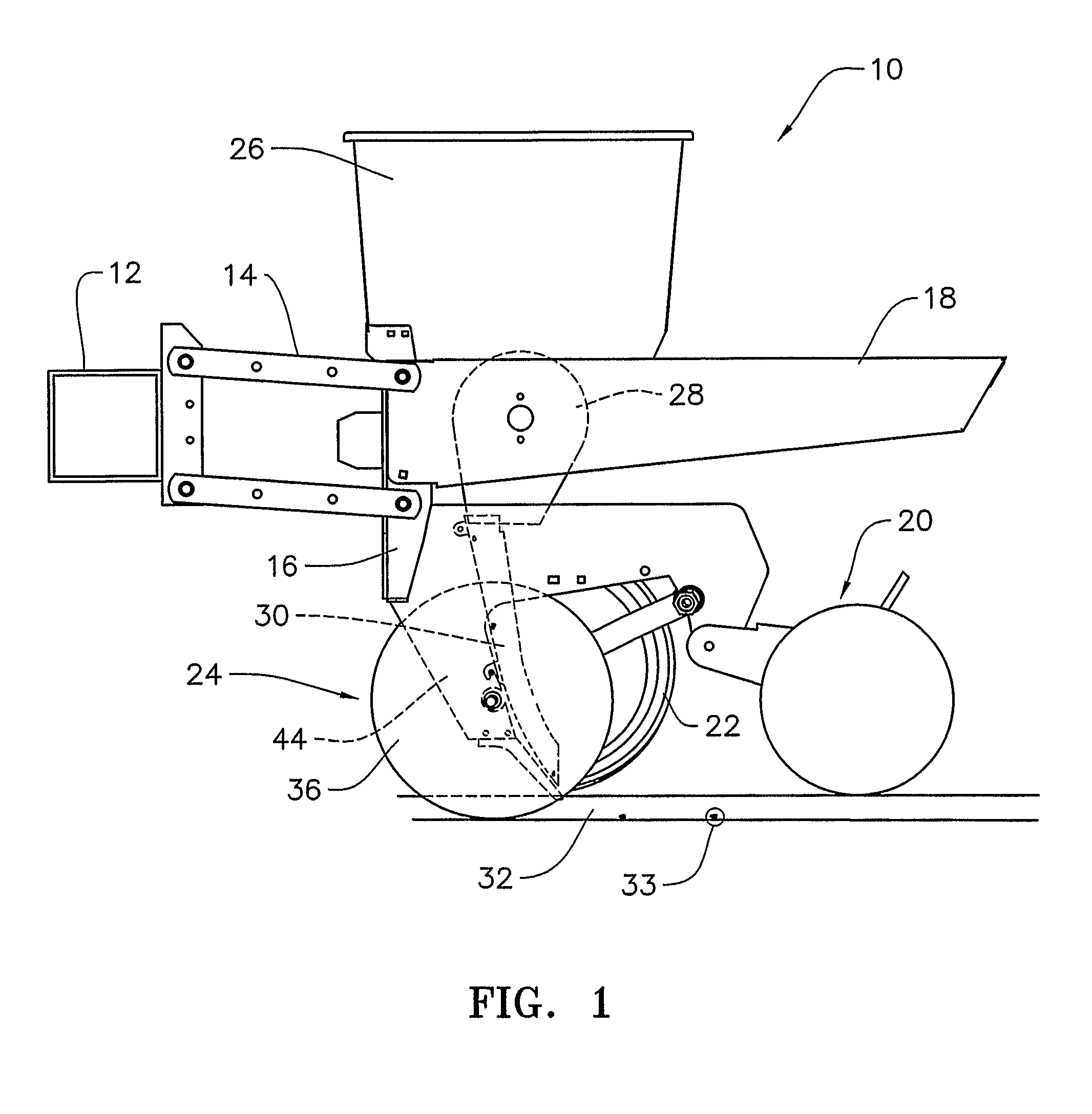

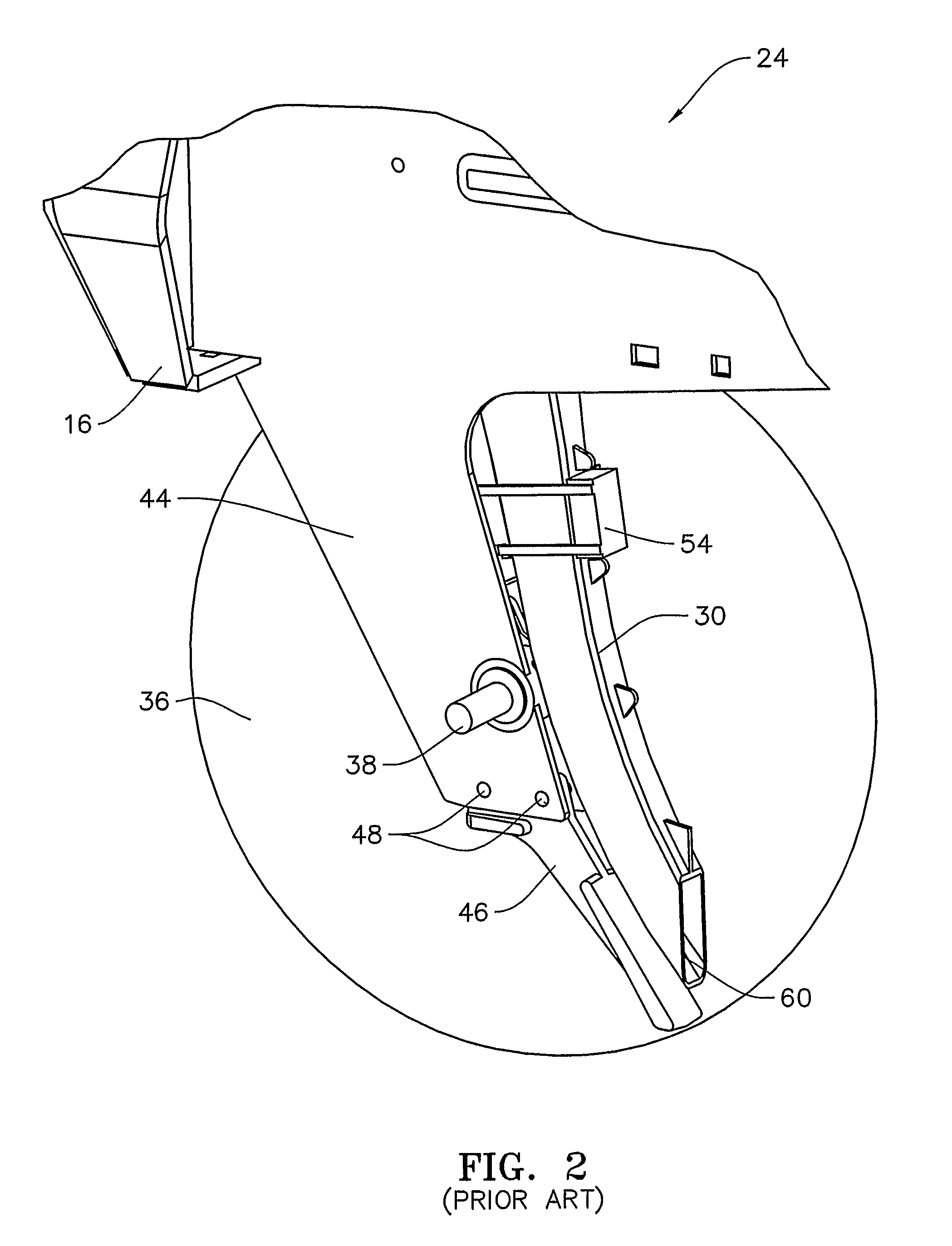

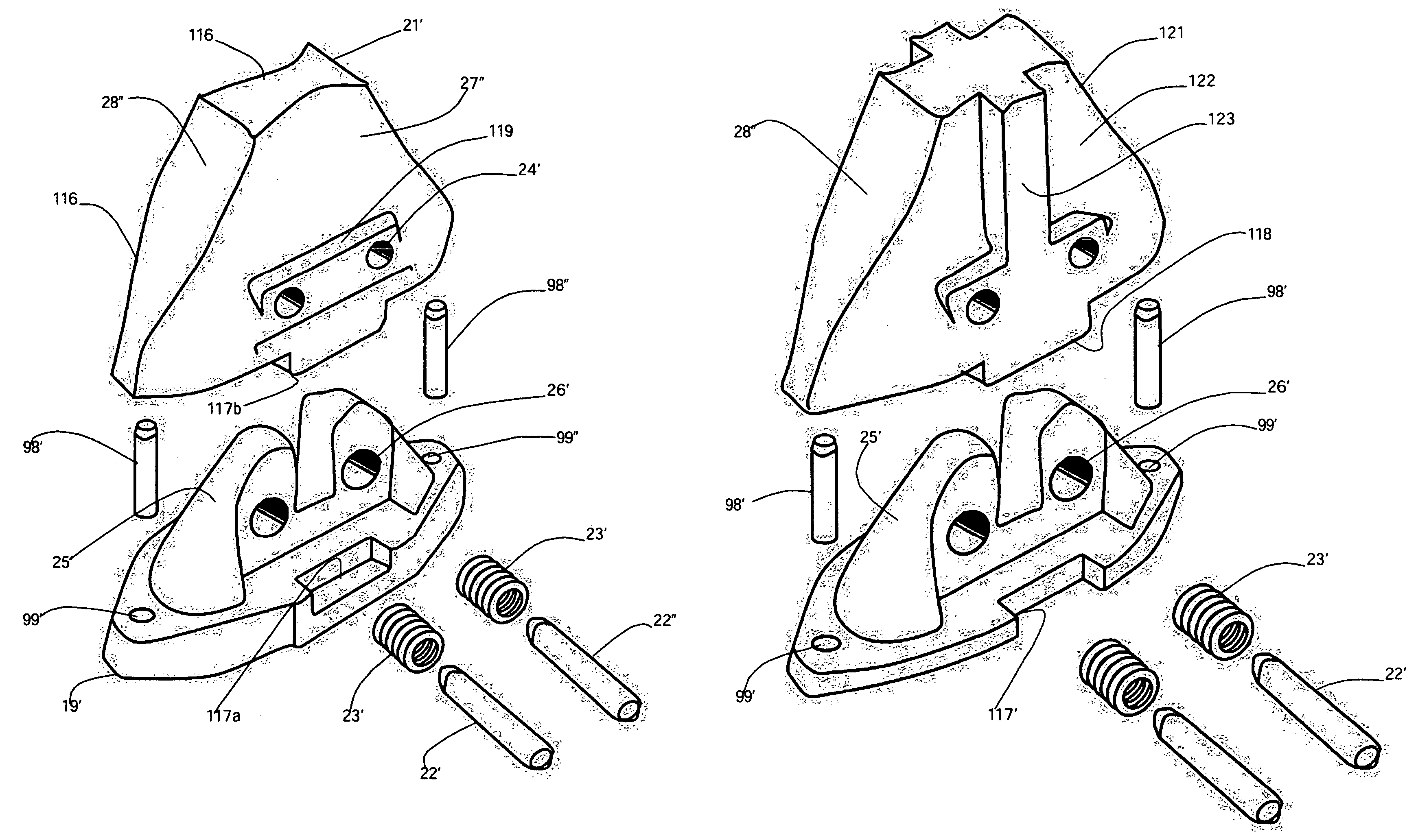

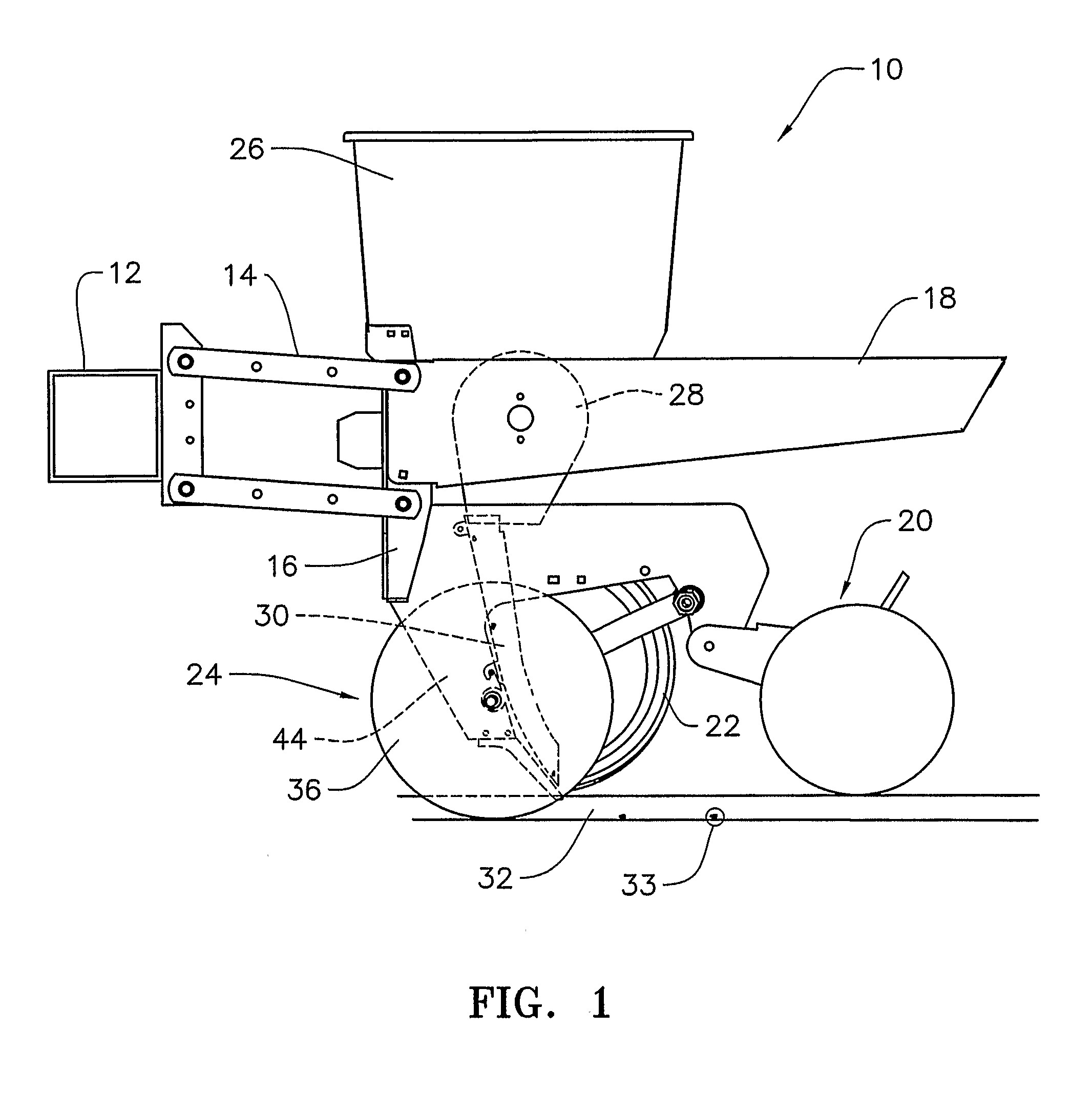

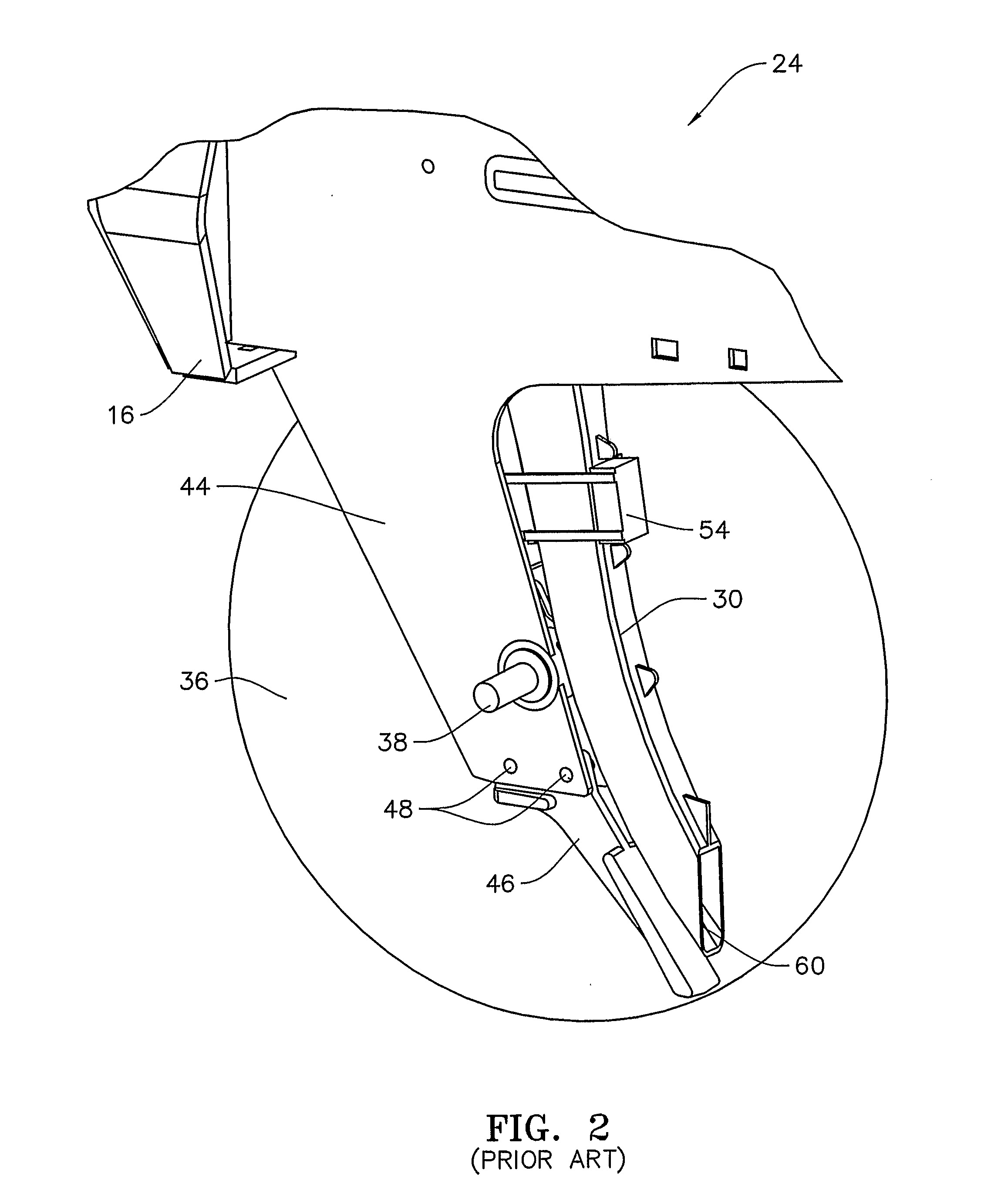

Wear resistant seed tube for an agricultural planter

ActiveUS7584707B2Avoid wear and tearSpadesSoil-working equipmentsWear resistantAgricultural engineering

A seed tube for an agricultural planter having a rearwardly curving forward wall, a rearwardly curving rearward wall and opposing sidewalls defining a seed passageway which curves rearwardly from an upper ingress end toward a lower egress end. Wear resistant material is disposed proximate the egress end which provides a point of first contact with the opener disks thereby preventing appreciable wear of the egress end of the seed tube.

Owner:PRECISION PLANTING LLC

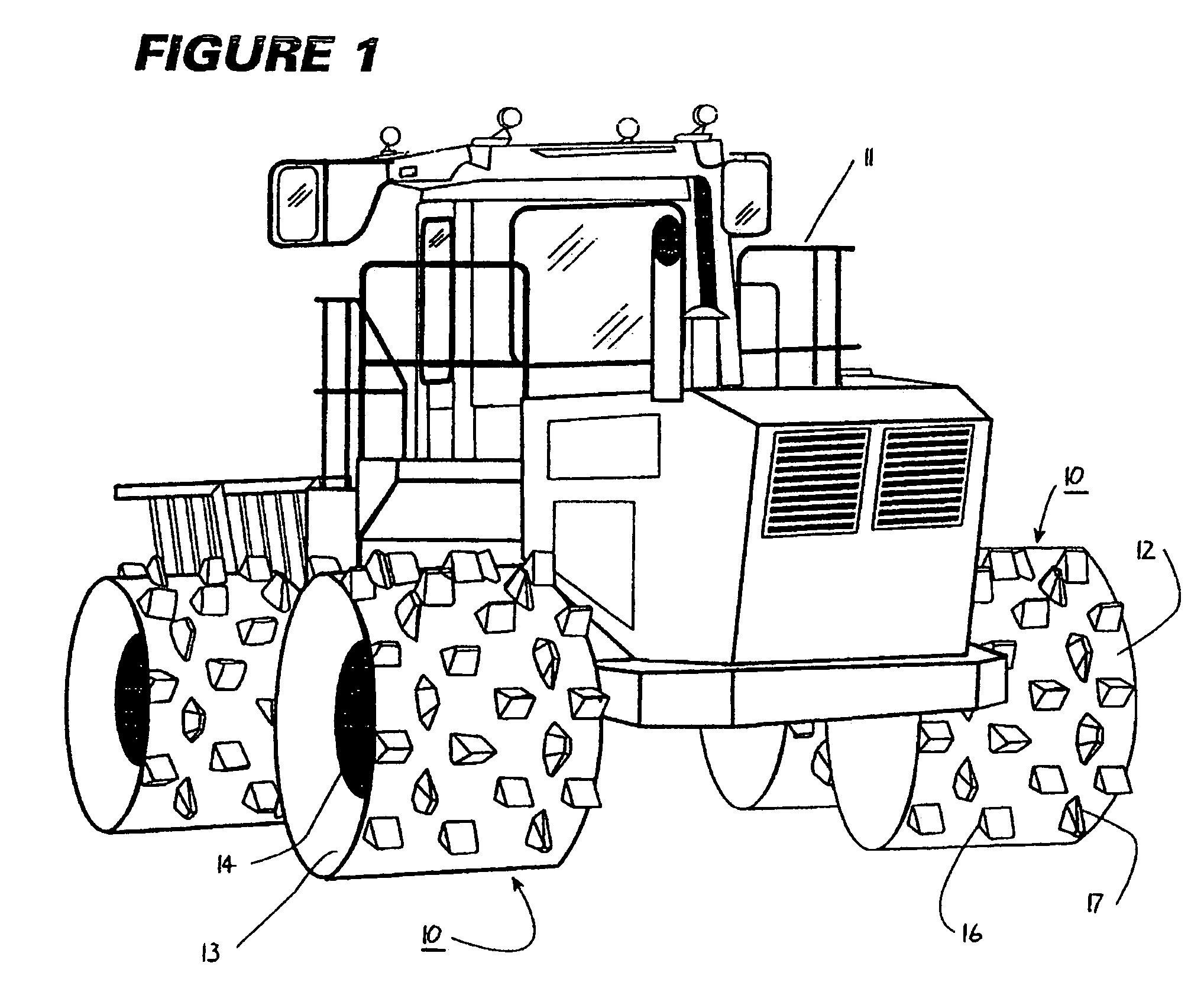

Fill and compaction roller using replaceable cleat assemblies with extended service life

InactiveUS7108452B2Easy to replaceAvoid wear and tearRoads maintainenceSoil preservationMortise and tenonWear resistant

A compaction roller for mounting on a driven compaction vehicle is equipped with both destructive and tractive, highly wear-resistant cleat assemblies. These include readily removable wear caps and supporting bases which have continuous side walls across the parting lines between the parts. Inset in the outer sidewalls are exposed mortise and tenon Jock joints serving to reduce relative movements between the parts under sever working forces. Pins extending radially between the wear caps and supporting bases further enhance the anti-twist resistance between the parts.

Owner:CARON COMPACTOR

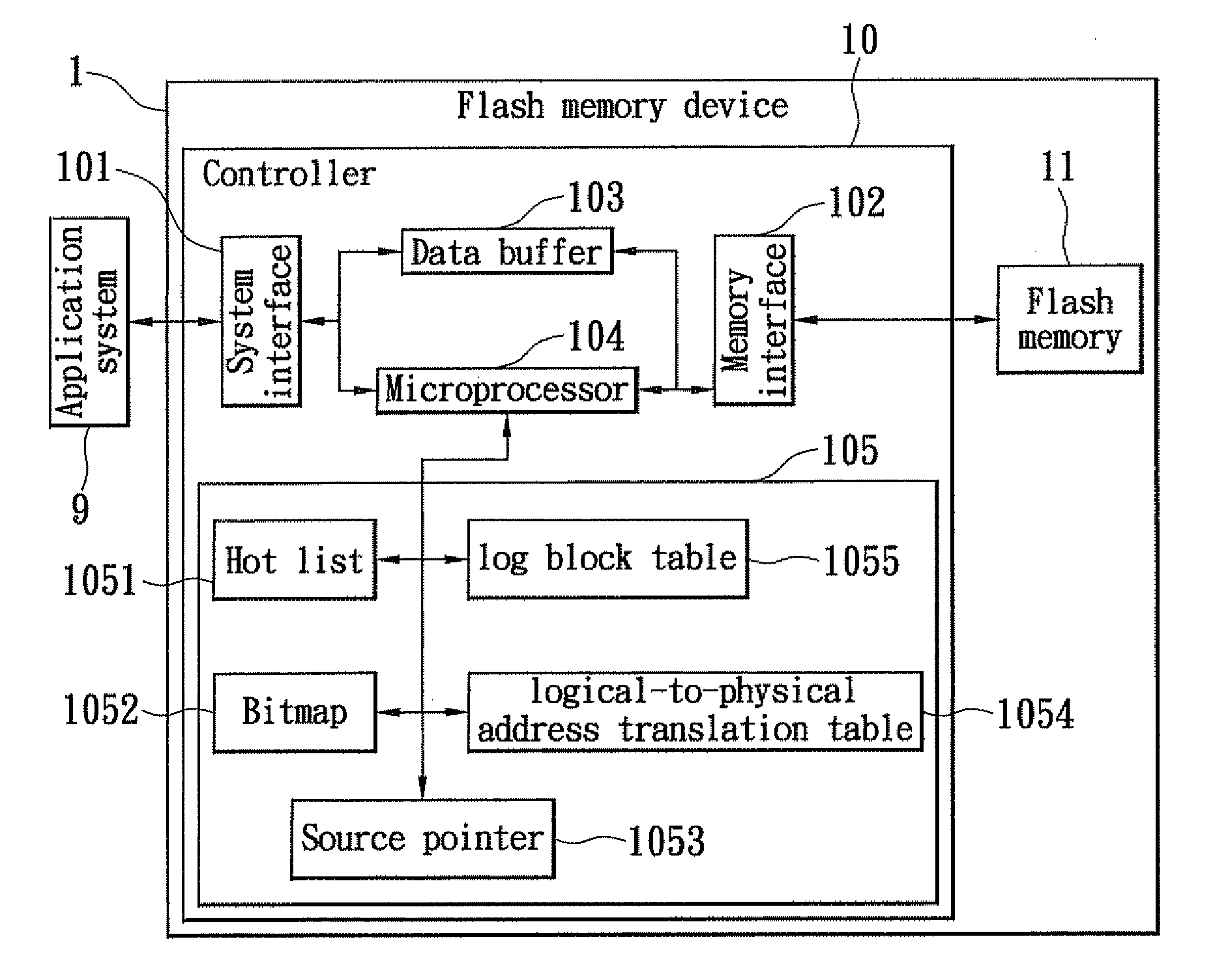

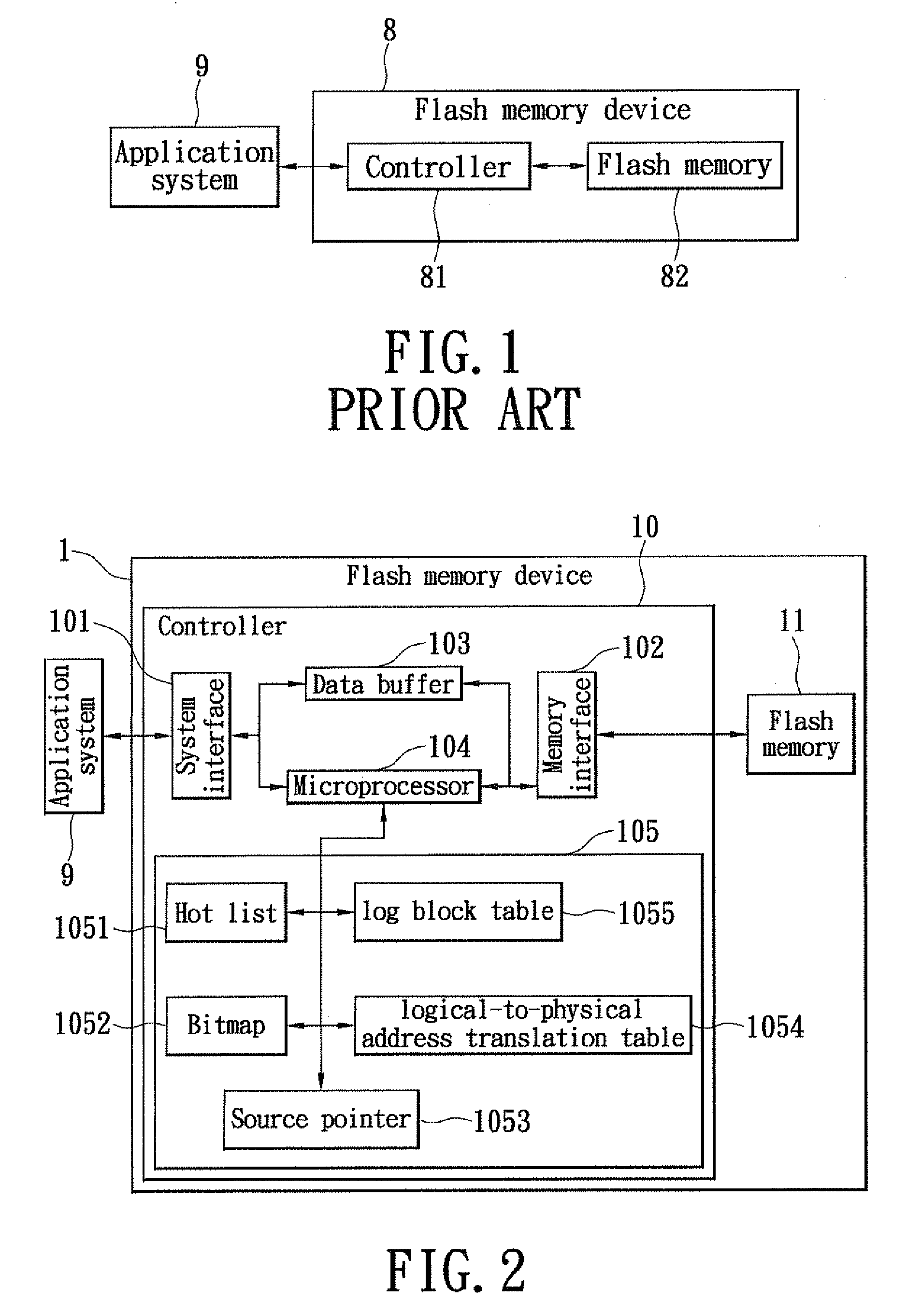

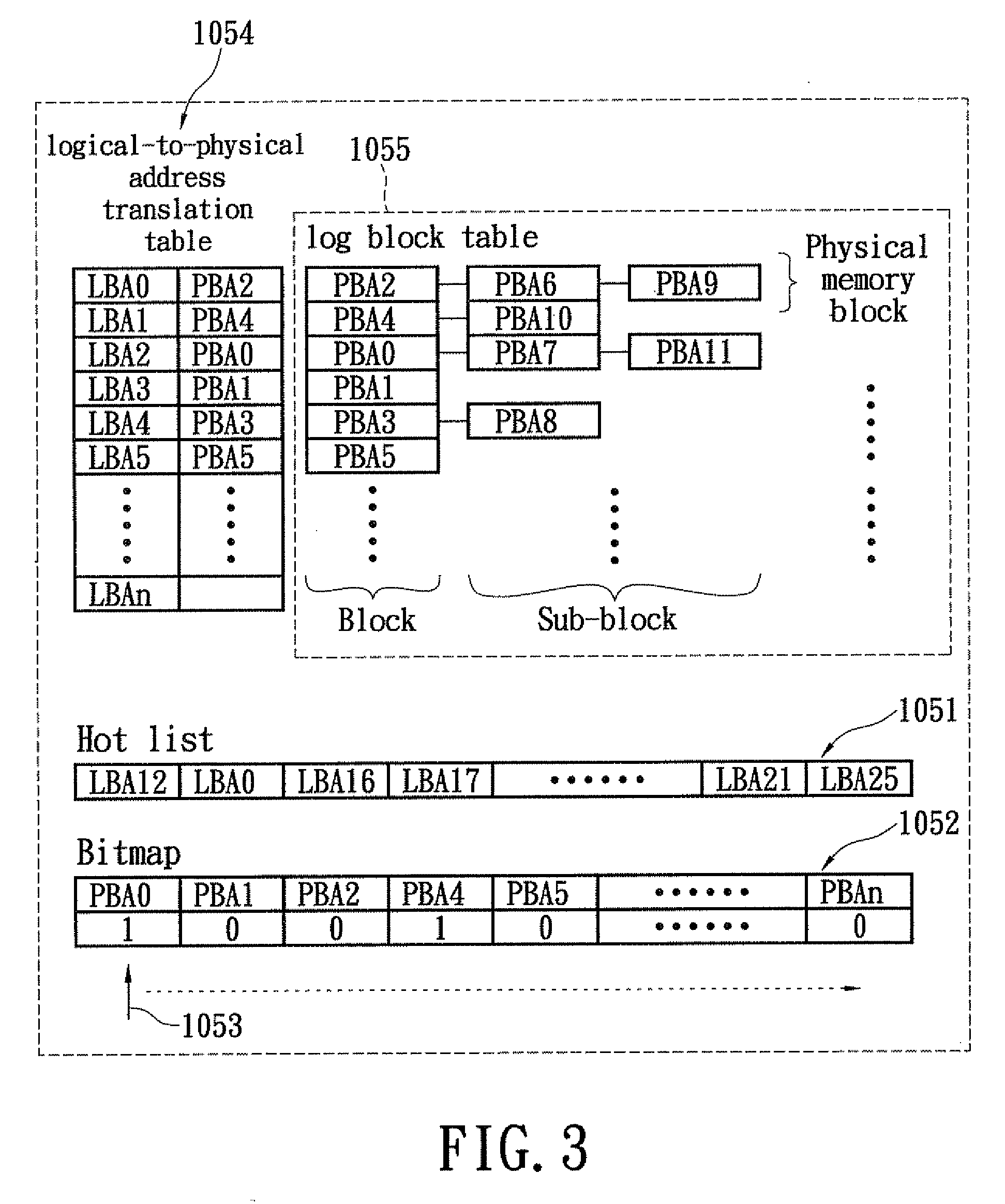

Flash memory device with wear-leveling mechanism and controlling method thereof

ActiveUS20100115186A1Raise countImprove performanceMemory architecture accessing/allocationMemory adressing/allocation/relocationBitmapWear leveling

A flash memory device with a wear-levelining mechanism includes at least one flash memory, a hot list, a bitmap, a source pointer, and a controller. The controller obtains a physical memory block with high erase count through the hot list, an erase count of the physical memory block, and an overall average erase count of the flash memory device. The controller further finds out a physical memory block which stores static data through managing the bitmap and the source pointer. The controller moves the static data to the physical memory block with high erase count, and releases the physical memory block which stores the static data to avoid the physical memory block with high erase count being worn down increasingly more seriously.

Owner:ADATA

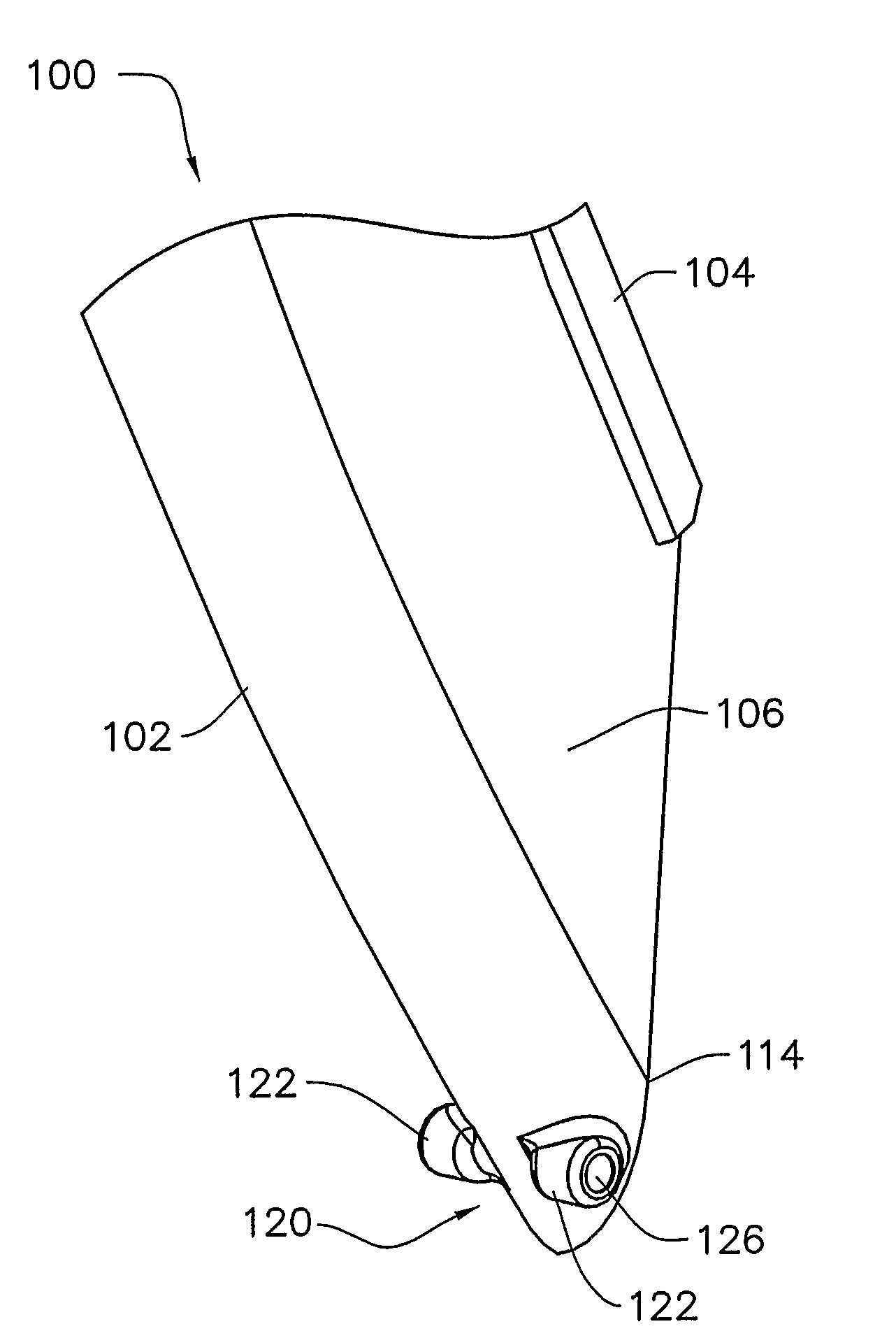

Wear Resistant Seed Tube for an Agricultural Planter

ActiveUS20080236461A1Avoid wear and tearSpadesSoil-working equipmentsWear resistantAgricultural engineering

A seed tube for an agricultural planter having a rearwardly curving forward wall, a rearwardly curving rearward wall and opposing sidewalls defining a seed passageway which curves rearwardly from an upper ingress end toward a lower egress end. Wear resistant material is disposed proximate the egress end which provides a point of first contact with the opener disks thereby preventing appreciable wear of the egress end of the seed tube.

Owner:PRECISION PLANTING LLC

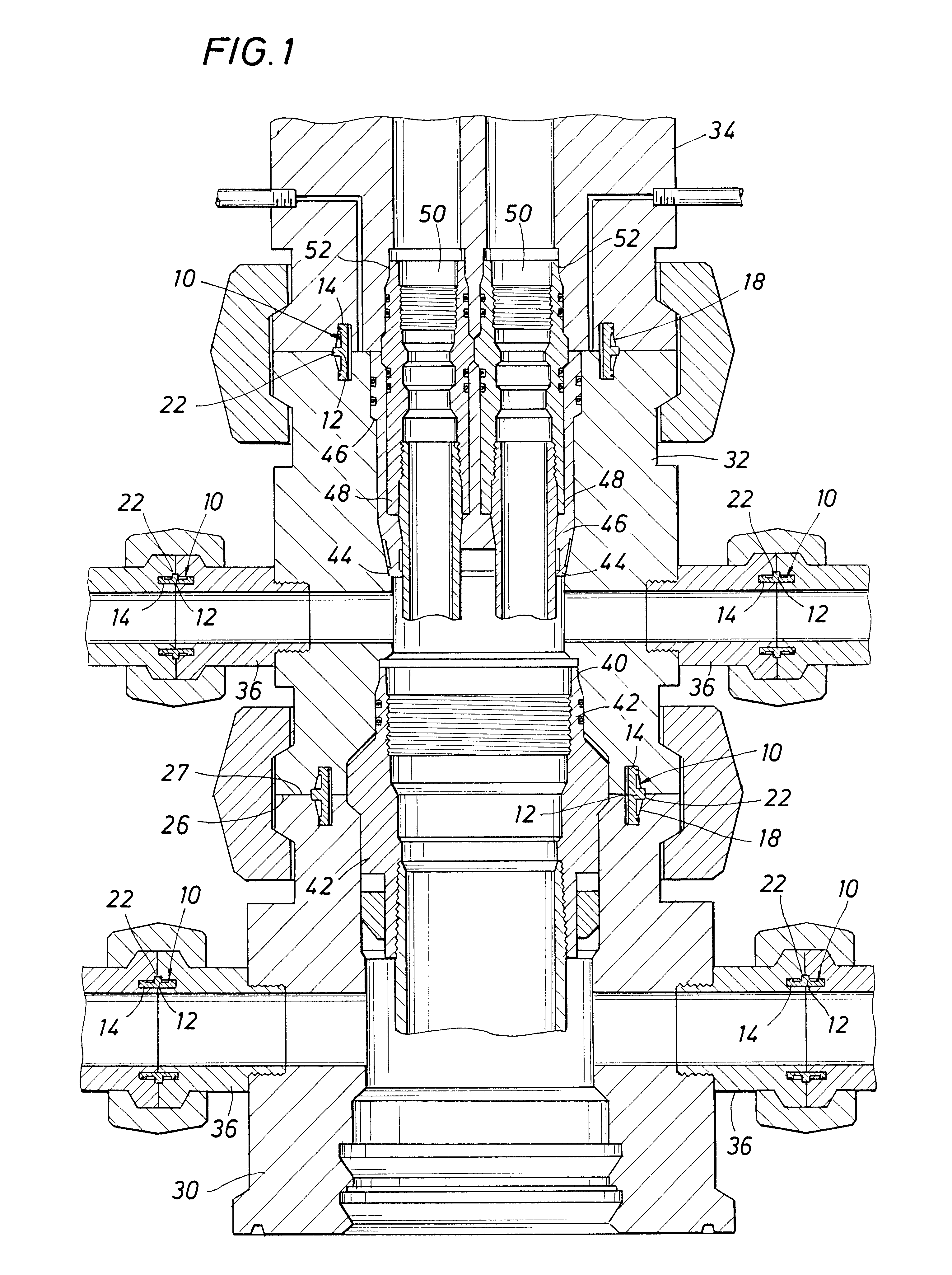

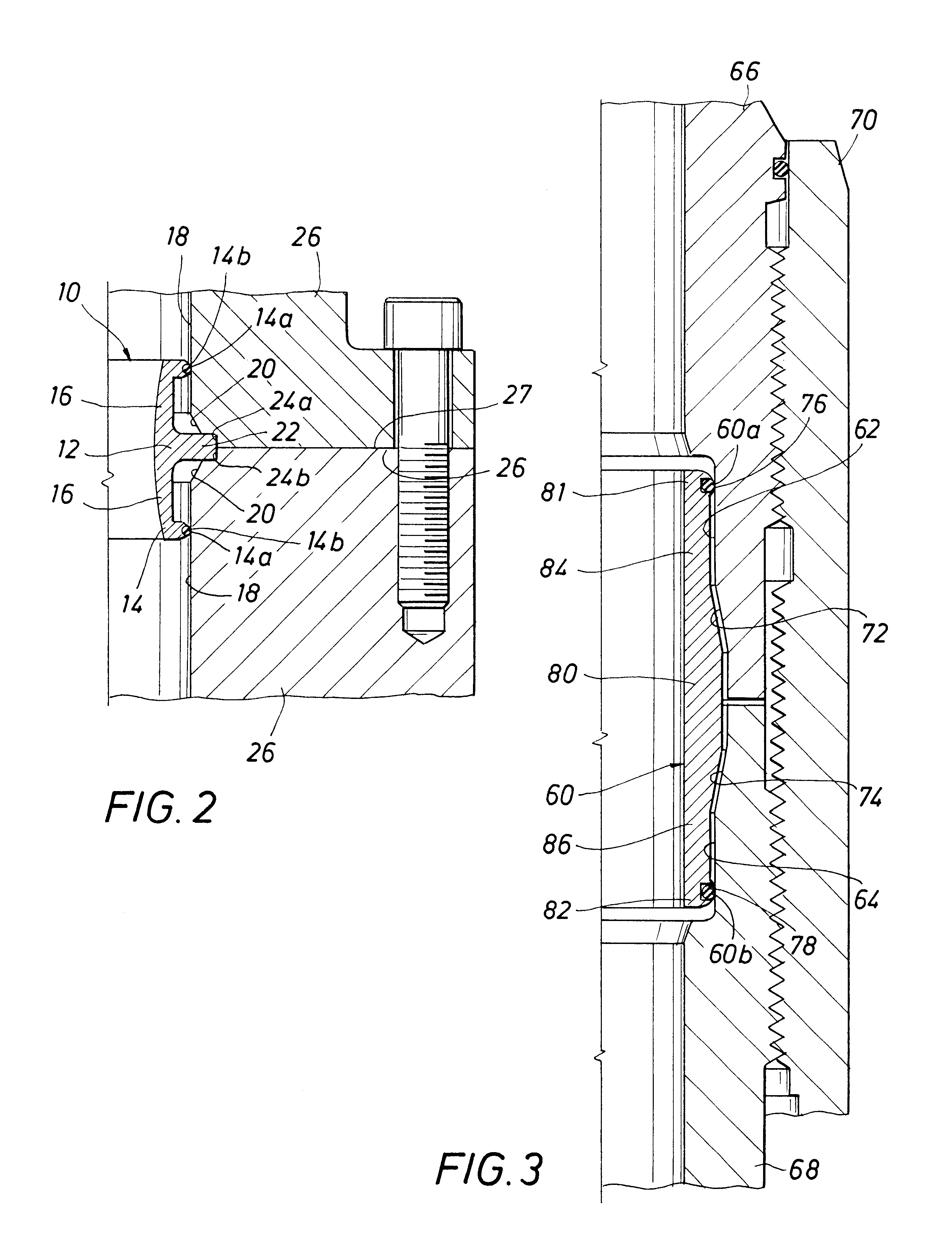

Metal-to-metal seal with soft metal insert

An annular metal-to-metal sealing system, for use in wellhead systems and having many other uses, has a metal member defining an annular internal or external sealing surface for which sealing is intended. An annular seal body composed of high strength metal material is positioned in concentric relation with the annular sealing surface and is sufficient flexible to become spring loaded, typically during assembly, for continuous application of a spring force. The annular seal body defines one or more annular seal retainer grooves each having an annular soft metal sealing insert therein, with a portion thereof exposed for sealing engagement with the annular sealing surface. The spring loaded characteristic of the annular seal body applies constant force to maintain the soft metal seal insert in constantly energized sealing relation with the annular sealing surface and maintains effective sealing even when dimensional changes to the sealing surface occur due to temperature or pressure changes.

Owner:FMC CORP

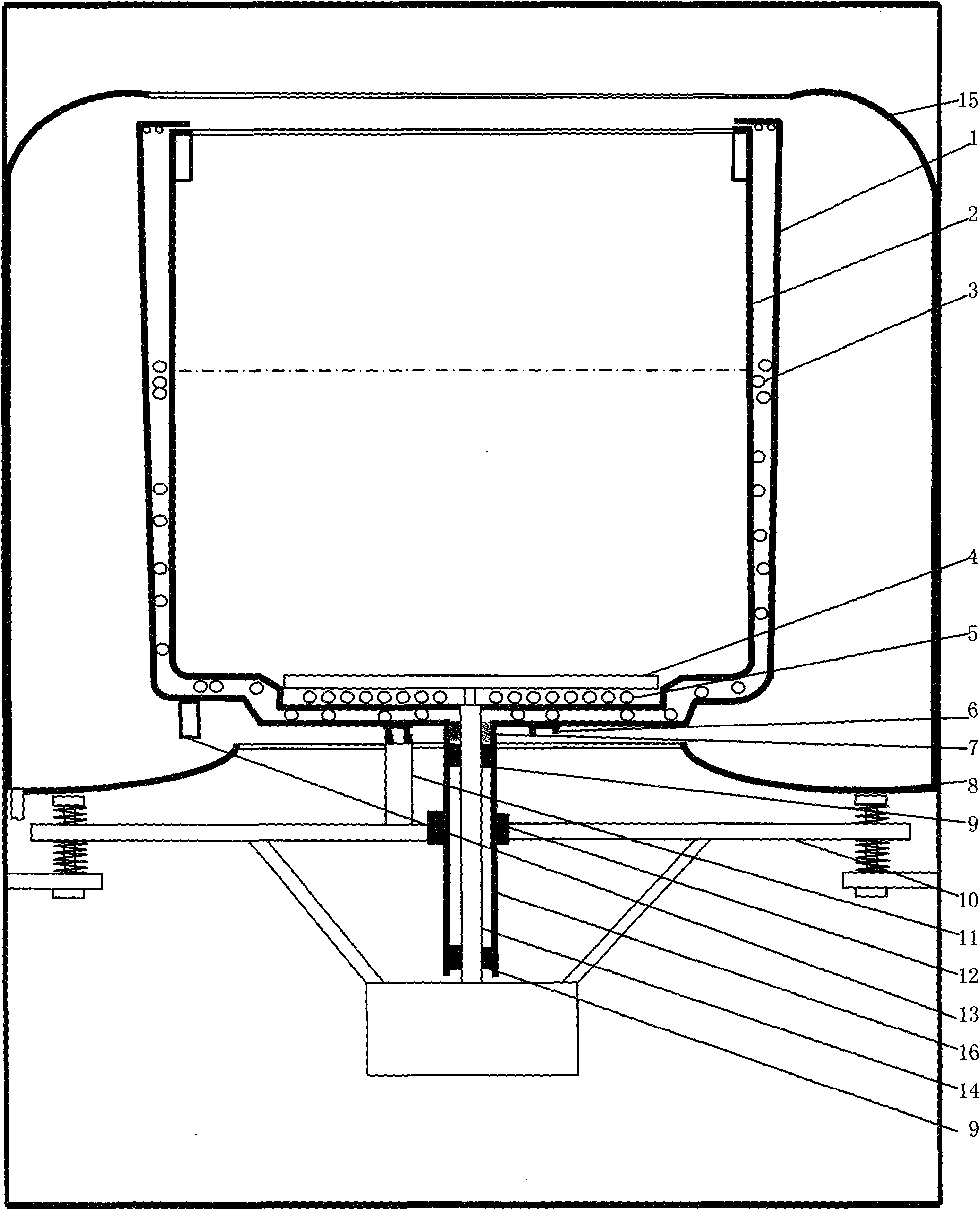

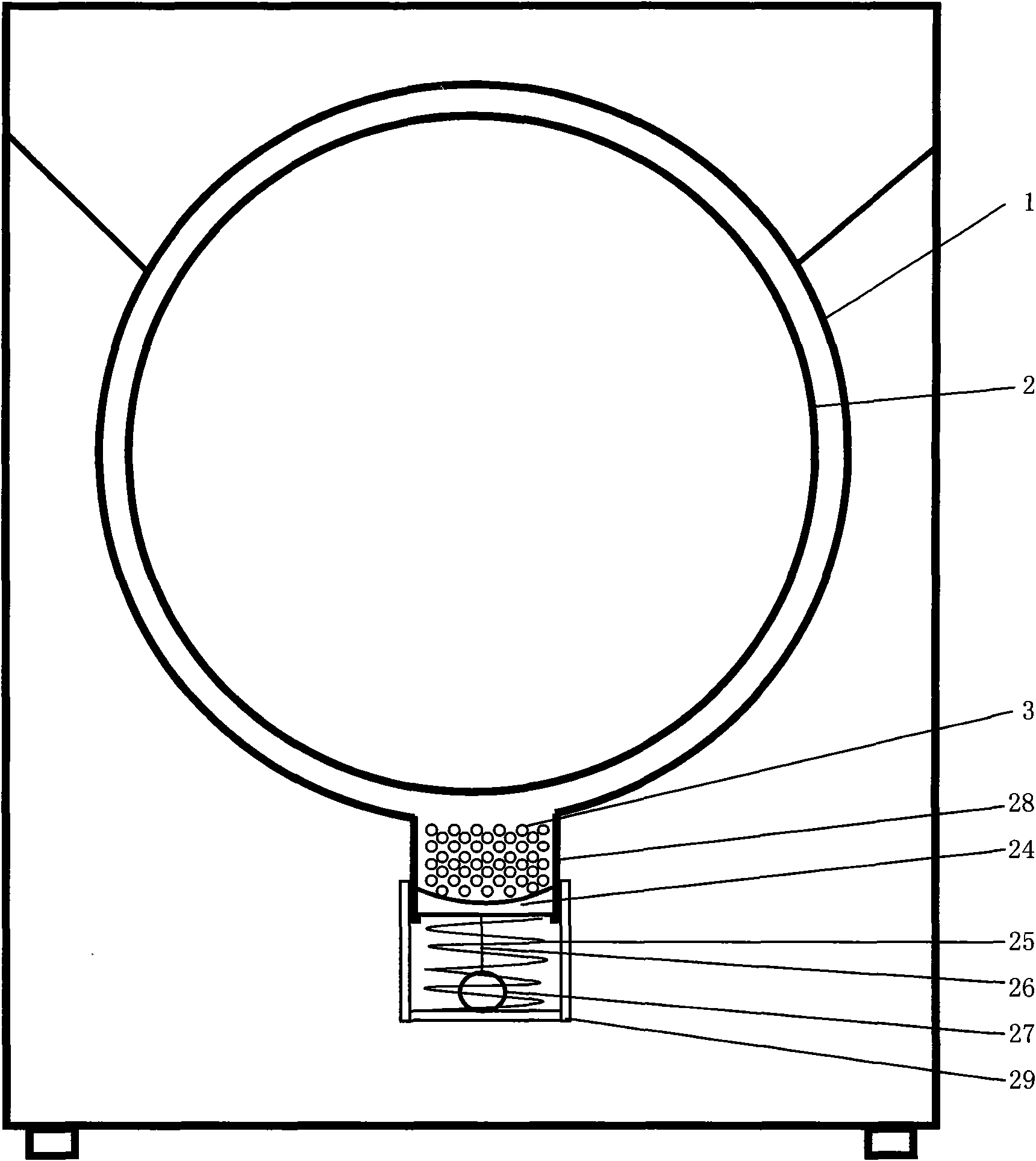

Self-cleaning device of full-automatic washing machine

InactiveCN101643994AEliminate sources of pollutionClean and comprehensiveOther washing machinesControl devices for washing apparatusPistonImpeller

The invention provides a self-cleaning device of a full-automatic washing machine, which is used for solving the problem of secondary contamination on clothes caused by clustered dirt in the interlayer between the water storage tank and the dehydration tank, and in the interlayer between the dehydration tank bottom and the impeller bottom of the washing machine. The interlayer between the water storage tank and the dehydration tank is provided with a plurality of clean balls 3, and a plurality of clean balls 5 are arranged between the dehydration tank bottom and the impeller bottom. When the washing machine washes or rinses, the clean balls perform friction with the water storage tank wall, the dehydration tank wall, the impeller bottom and the dehydration tank bottom to clean the dirt inthe positions, and simultaneously the clean balls are self cleaned through mutual collision and friction. By adopting the way in which the water storage tank rotates along with the dehydration tank when dehydrating and the storage tank wall or bottom is provided with a groove or a piston cylinder (to lead the clean balls to drop into the groove or the piston cylinder when dehydrating), the clean balls do not generate friction with the dehydration tank, thus prolonging the service life of the clean balls and saving energy; and the adoption of the way in which the water storage tank rotates along with the dehydration tank when dehydrating can decrease the width of the interlayer between the water storage tank and the dehydration tank to save water.

Owner:任文涛

Torch for arc welding gun

InactiveUS20070062922A1Reduce exposurePrevent spatter abrasionNon-shielding electrode holdersCooled electrode holdersEngineeringFlange

A welding torch comprising: a main cylindrical conductive assembly with a front diffuser section having a plurality of circumferentially spaced shielding gas diffuser orifices for directing shielding gas radially outwardly from the assembly, a forwardly facing threaded bore extending through a cylindrical support nose and an elongated wire passageway coaxial with the threaded bore and opening at the rear end of the assembly. An insulated, cylindrical protective sleeve fitted around both the support nose and the diffuser orifices where the sleeve has a front clearance opening and circumferentially spaced openings communicated with the diffuser orifices and a contact tip having a central wire guide bore with a diameter only slightly larger than the diameter of the welding wire, a threaded rear body, a front extension passing through the front clearance opening and a radially extending flange between the rear body and the front extension to hold the protective sleeve around the nose when the body is screwed into the threaded bore of the main assembly.

Owner:LINCOLN GLOBAL INC

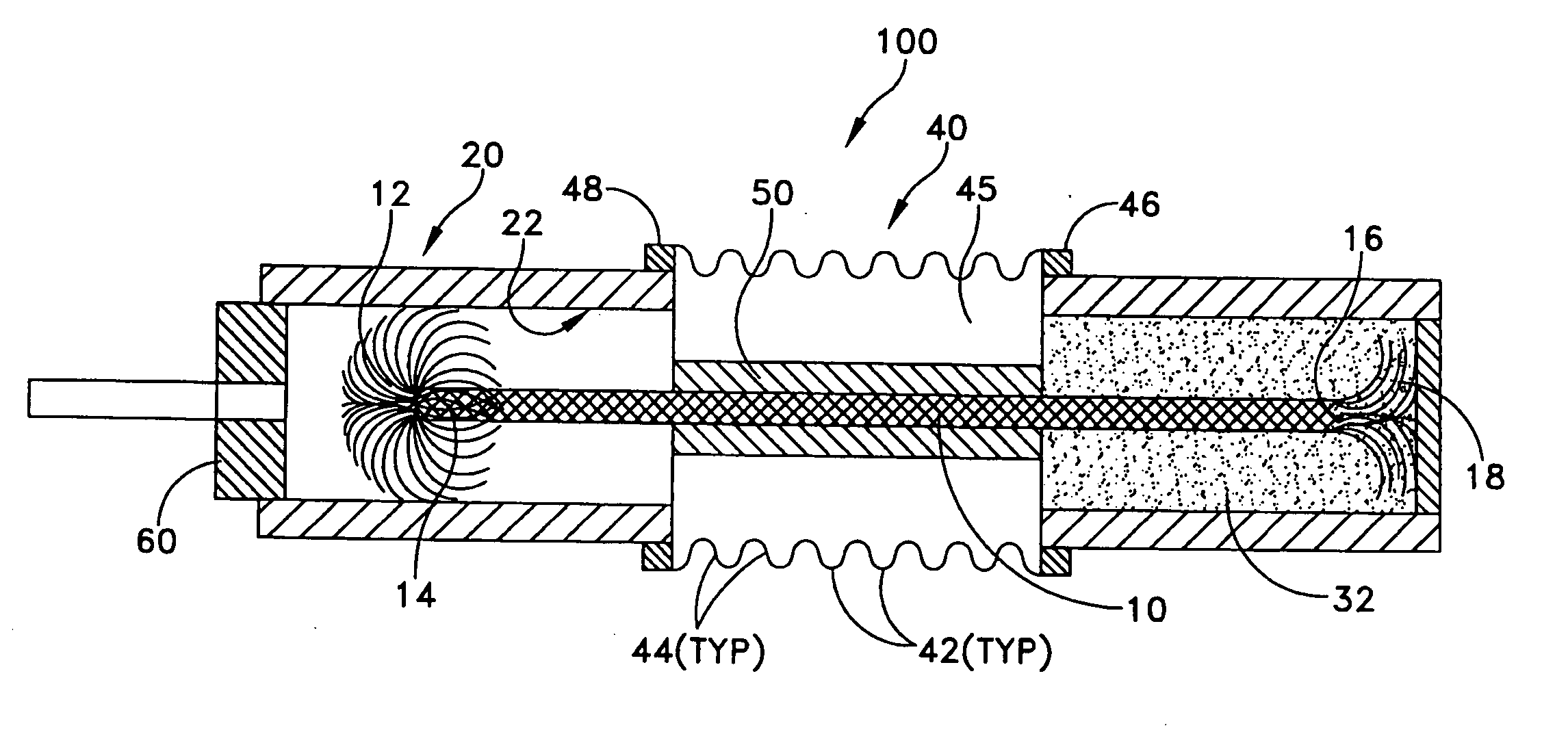

Optoelectronic device encapsulant

InactiveUS6356686B1Preventing interfering accumulationAvoid wear and tearCoupling light guidesOptical waveguide light guideEpoxyParticulates

An optically clear encapsulant for optoelectronic packages exhibits a suitably high viscosity both to replace a silicon nitride passivation layer required on a VCSEL die and to fill a gap between the die and an optical coupler, preventing light signal degradation. The encapsulant exhibits optical transparency to light having a wavelength of about 850 nanometers (nm) with substantially no Mie scattering since particulate fillers are not required to modulate viscosity in the encapsulant. Also, the encapsulant further seals wire bonds between the die and a cable header to prevent abrasive wear. The gap-filling encapsulant is particularly suitable for use with vertical cavity surface emitting laser (VCSEL) technology. The encapsulant includes prior to curing, a difunctional acrylate epoxy resin exhibiting pseudoplastic flow and a viscosity of greater than about 0.7x106 centipoise. Accordingly, a method of manufacturing an optical subassembly may eliminate a separate passivation step and instead fill the gap between the die and optical coupler with an optically clear encapsulant.

Owner:IBM CORP

Heat pipe with axial and lateral flexibility

InactiveUS20060086482A1Avoid wear and tearSmall sizeIndirect heat exchangersCooling/ventilation/heating modificationsWorking fluidPliability

A flexible heat pipe is disclosed for use with evaporator and condenser elements for removing heat from electronic components. The flexible heat pipe comprises a bellows member fixed at one end to a condenser member and at an opposite end to an evaporator member. A cable artery is disposed within the bellows and is fixed at one end to the evaporator, and slidingly engages the condenser at the opposite end. The bellows acts as a flexible vapor envelope, and the cable artery acts as a flexible wick for directing condensed working fluid from the condenser back to the evaporator. The sliding connection between the cable artery and the condenser allows relative axial movement, and the inherent flexibility of the cable artery allows relative lateral movement. Thus, the condenser and evaporator can move in all directions with respect to each other, which can provide desired vibration isolation of the two components.

Owner:THERMAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com