Self-cleaning device of full-automatic washing machine

A fully automatic washing machine and washing machine technology, applied in the control device of washing machine, washing device, other washing machines, etc., can solve the problems of secondary pollution of clothes, bad, easy to jam cleaning effect of cleaner dirt, achieve comprehensive cleaning, The effect of eliminating pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

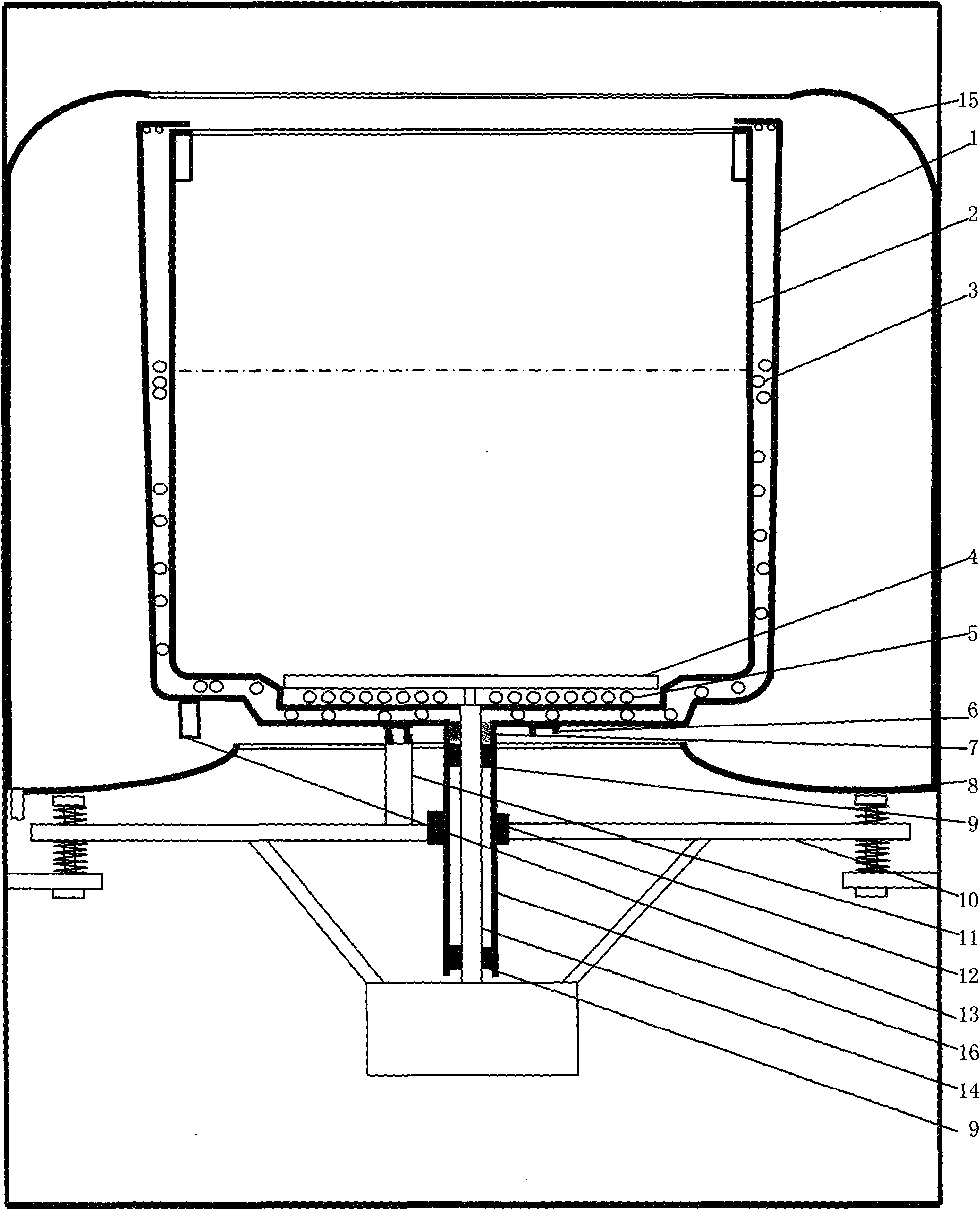

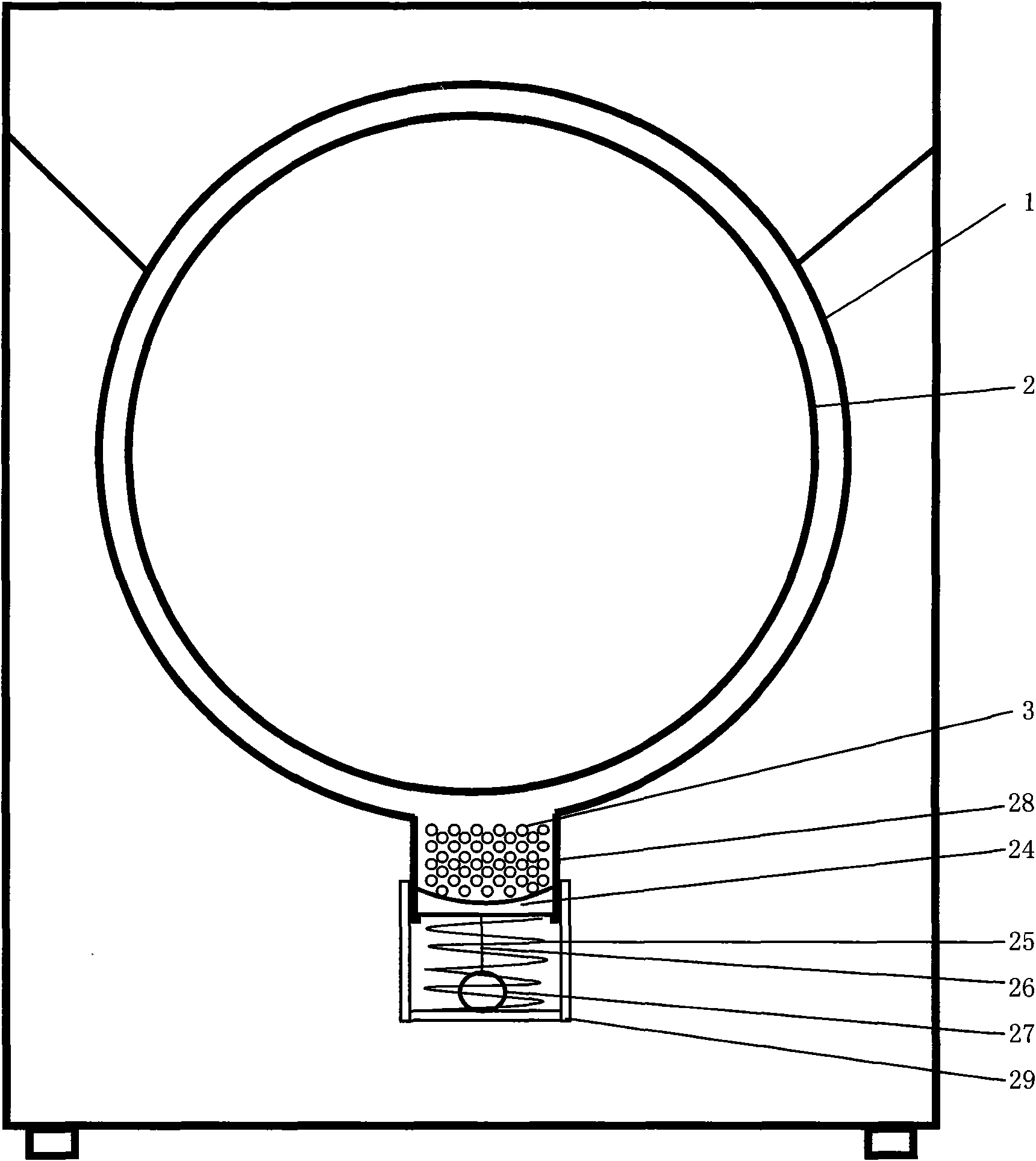

[0013] exist figure 1 , figure 2 with image 3 Middle cleaning ball (3) and (5) are approximate spheres such as sphere or ellipsoid or polyhedral sphere, and cleaning ball (3) and (5) adopt wear-resistant ductile plastics or rubber to make, and its hardness is less than water storage bucket (1) and material hardness such as dehydration barrel (2), pulsator (4).

[0014] exist figure 1In the shown first embodiment, the water storage bucket (1) is enclosed within the dehydration bucket (2), and many cleaning balls (3) are arranged in the interlayer between the water storage bucket (1) and the dehydration bucket (2), cleaning The height of the balls (3) piled up in the interlayer does not exceed the lowest washing water level so as not to rub the cleaning balls (3) in the absence of water during washing; a lot of cleaning is arranged between the bottom of the dehydration bucket (2) and the bottom of the pulsator (4). Ball (5), its quantity accounts for 2 / 3 of interlayer spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com